Patents

Literature

547results about How to "Uniform heating effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

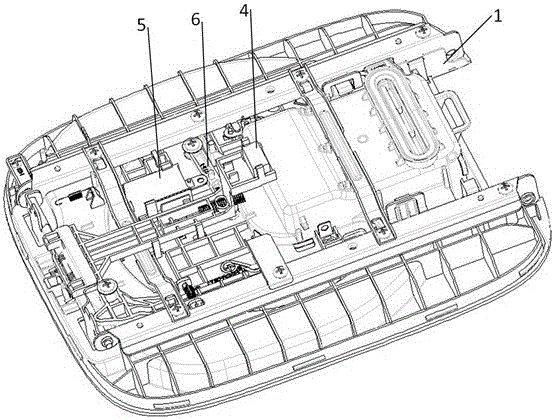

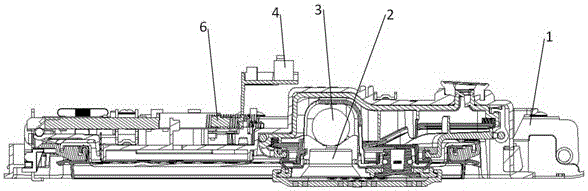

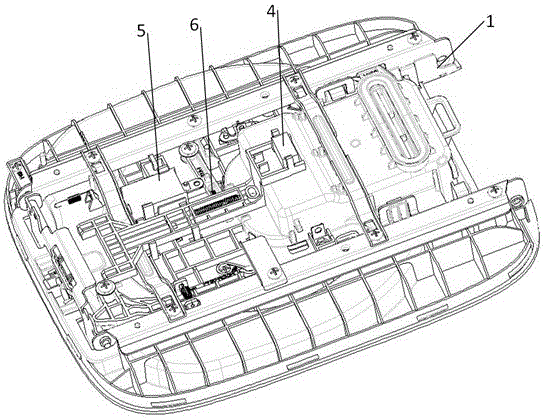

A pressure type electric cooker and a control method therefor

The invention provides a pressure type electric cooker and a control method therefor. The pressure type electric cooker comprises an upper cover which is snapped to a cooker body and used for sealing the cooker body; a temperature control device used for collecting the temperature at the bottom of an inner pot is arranged in the cooker body; the upper cover is inside provided with a pressure valve used for blocking an exhaust passage and an execution component used for pressure rise and pressure relief; the execution component gets away from or close to the top of the pressure valve. The control method for the pressure type electric cooker comprises the steps that the pressure of the electric cooker rises, the stress of the pressure valve is balanced, rice and water boil, and the execution component gets away from the pressure valve. The pressure rise and pressure relief of the cooker body of the electric cooker are realized through the positional relationship between the pressure valve and the execution component and the drive mode of the pressure valve; through the self-weight of the pressure valve, the magnetic attraction magnitude of the execution component, the air pressure of the exhaust passage and the change from a closed state to an open state of the pressure valve, the pressure state in the electric cooker can be detected without high-precision sensors; the pressure type electric cooker is simple in structure and high in reliability and the scheme cost can be effectively controlled by reducing unnecessary sensors; the pressure type electric cooker can guarantee that all rice in the cooker can be heated and gelatinated uniformly.

Owner:SHANGHAI CHUNMI ELECTRONICS TECH CO LTD +1

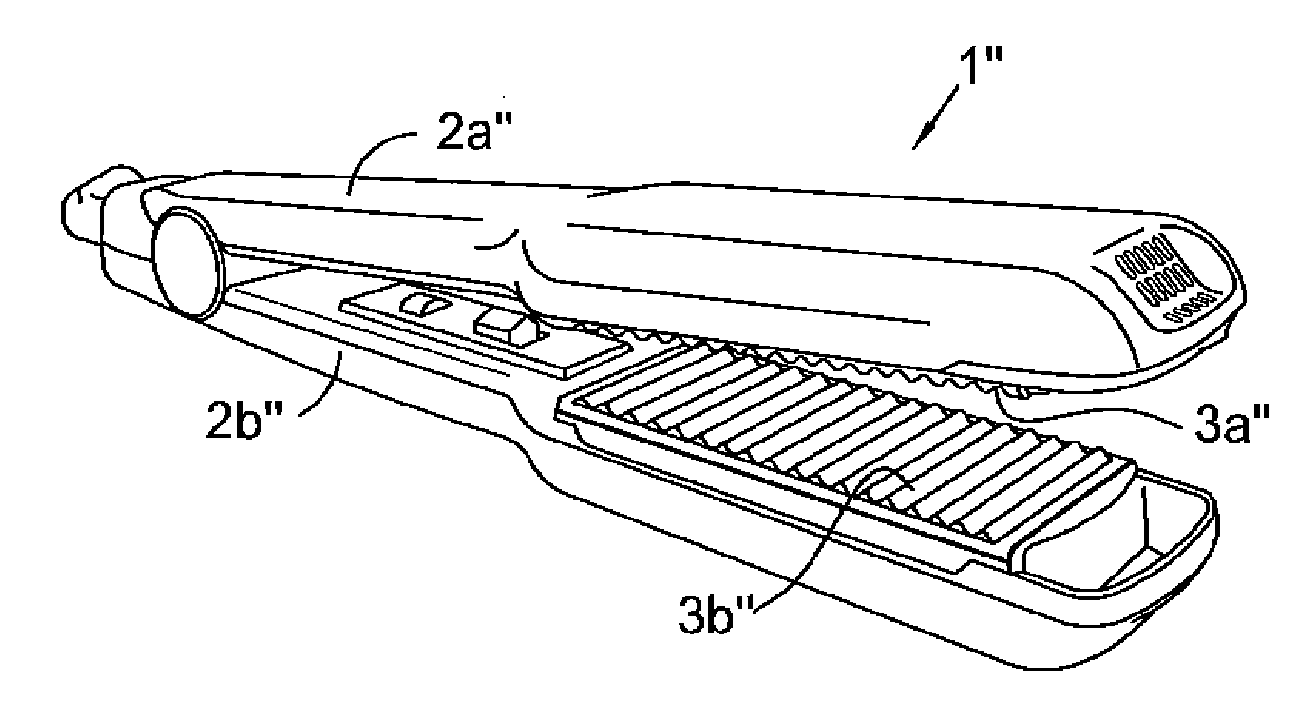

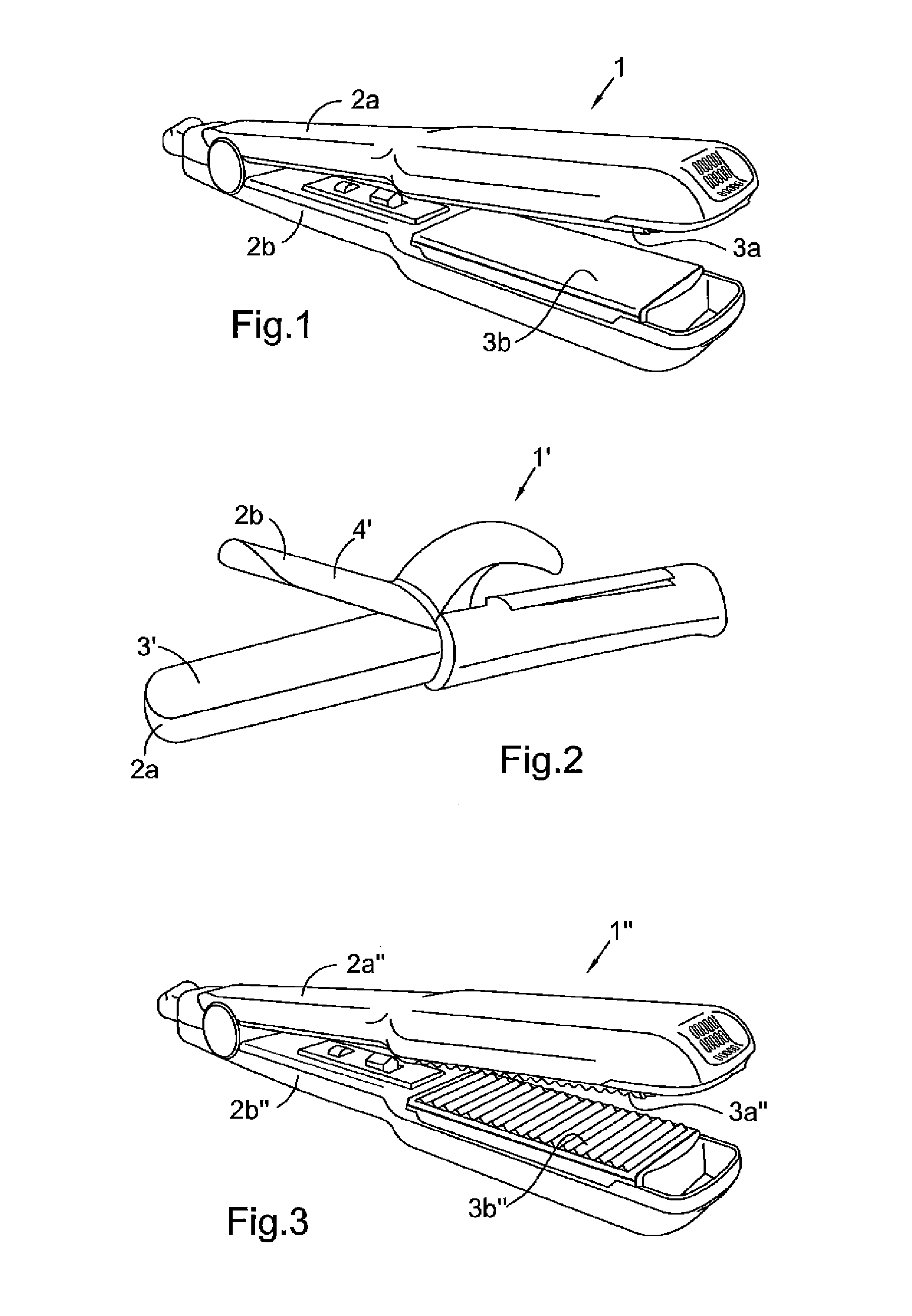

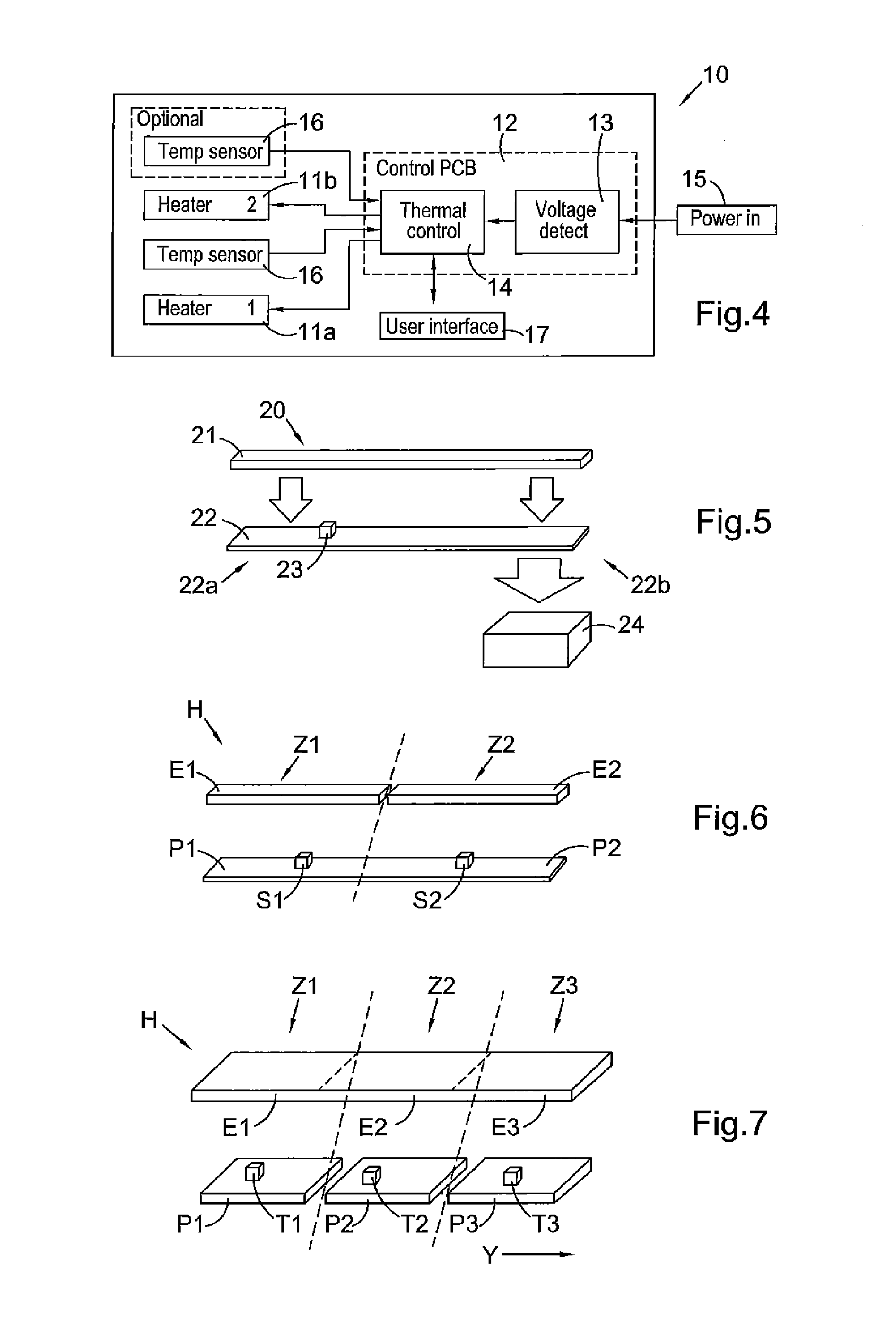

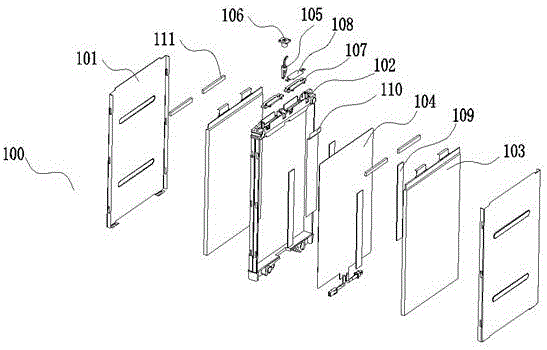

Hair styling appliance

ActiveUS20120227758A1Improve thermal controlUniform heating effectCurling-ironsCurling-tongsEngineeringThermal control

The invention relates to a hair styling appliance (100, 100′, 100″) comprising at least one heater (103, 104) having plurality of heating zones (Z1-Z5). The heating zones are independently operable arranged along the length of the heater. The sequential arrangement of the independently operable heating zones helps to improve the thermal control of the hair styling appliance. The hair styling appliance may be a hair straightener, curling tong, curling wand or a crimping iron.

Owner:JEMELLA

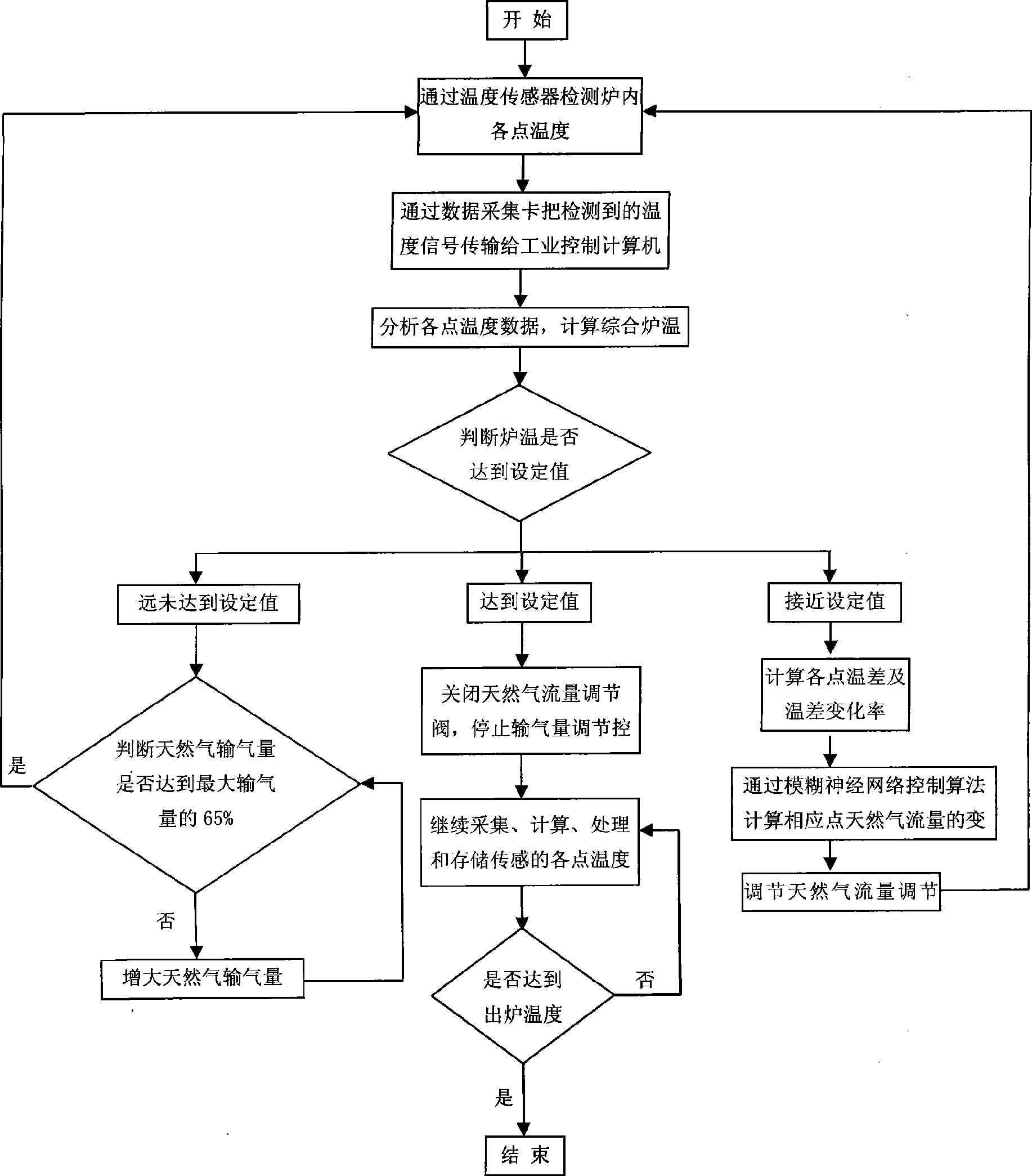

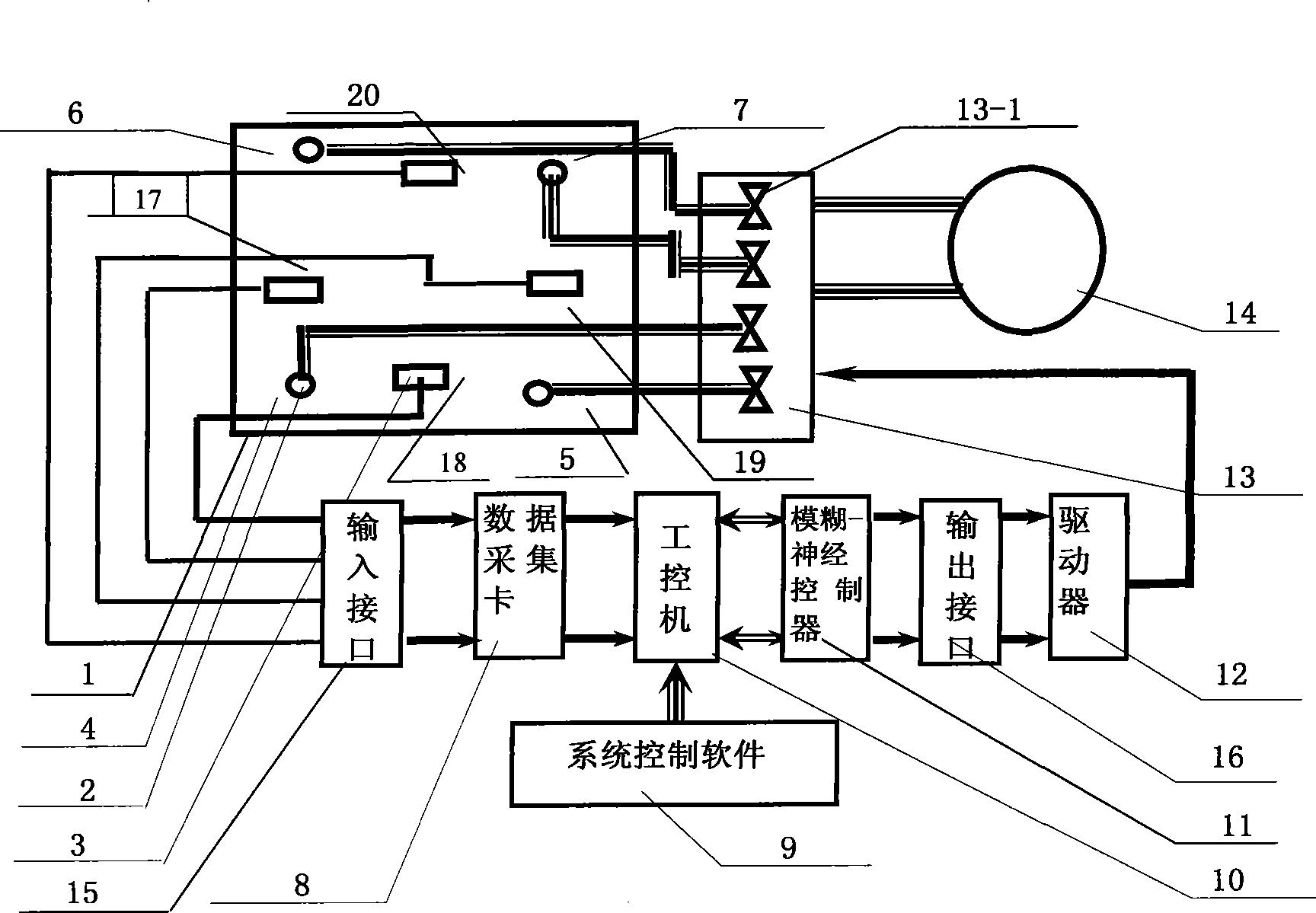

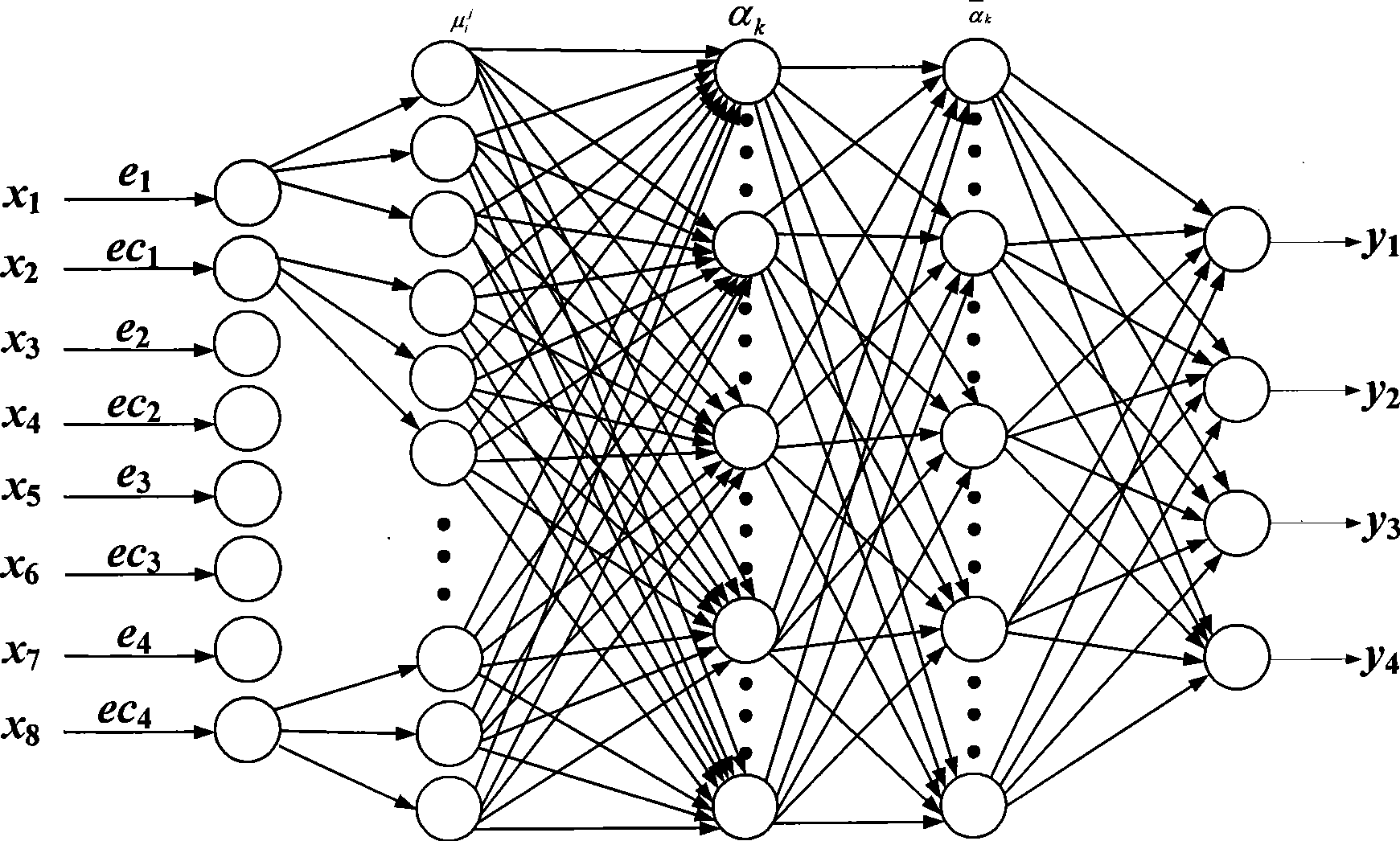

Multi-point sensing and intelligent control method for temperature of gas heating stove

ActiveCN101464096AGuaranteed temperatureGuaranteed uniformThermometer applicationsGas emission reductionControl softwareNatural gas

The invention discloses a method for multi-point sensing and intelligent controlling of the temperature of a gas heating furnace. The method comprises the following steps: firstly, temperature sensors evenly distributed in a natural gas heating furnace detects the temperature of each point in the heating furnace in a synchronous, real-time and continuous manner; then, an input interface and a data acquisition card transmit the detected temperature signals to an industrial control computer; the industrial control computer calculates, analyzes, and stores the temperature difference between each point and the change rate of the temperature differences through a system control software on a real-time basis, and calculates the integrated temperature in the heating furnace on a real-time basis; finally, whether the temperature of the furnace reaches the set value is judged, and treatment is carried out according to three conditions including reaching the set value, falling short of the set value, and approaching the set value, respectively. The invention can synchronously sense multi-point temperatures in a natural gas heating furnace, display furnace temperature change curves and temperature differences among areas on a real-time basis, and store the temperature change curves of each area in a database on a continuous and real-time basis. The invention adopts a fuzzy-neural network method to adjust each area temperature intelligently, thereby improving the quality of heavy forgings.

Owner:JIANGSU JINYUAN FORGE +1

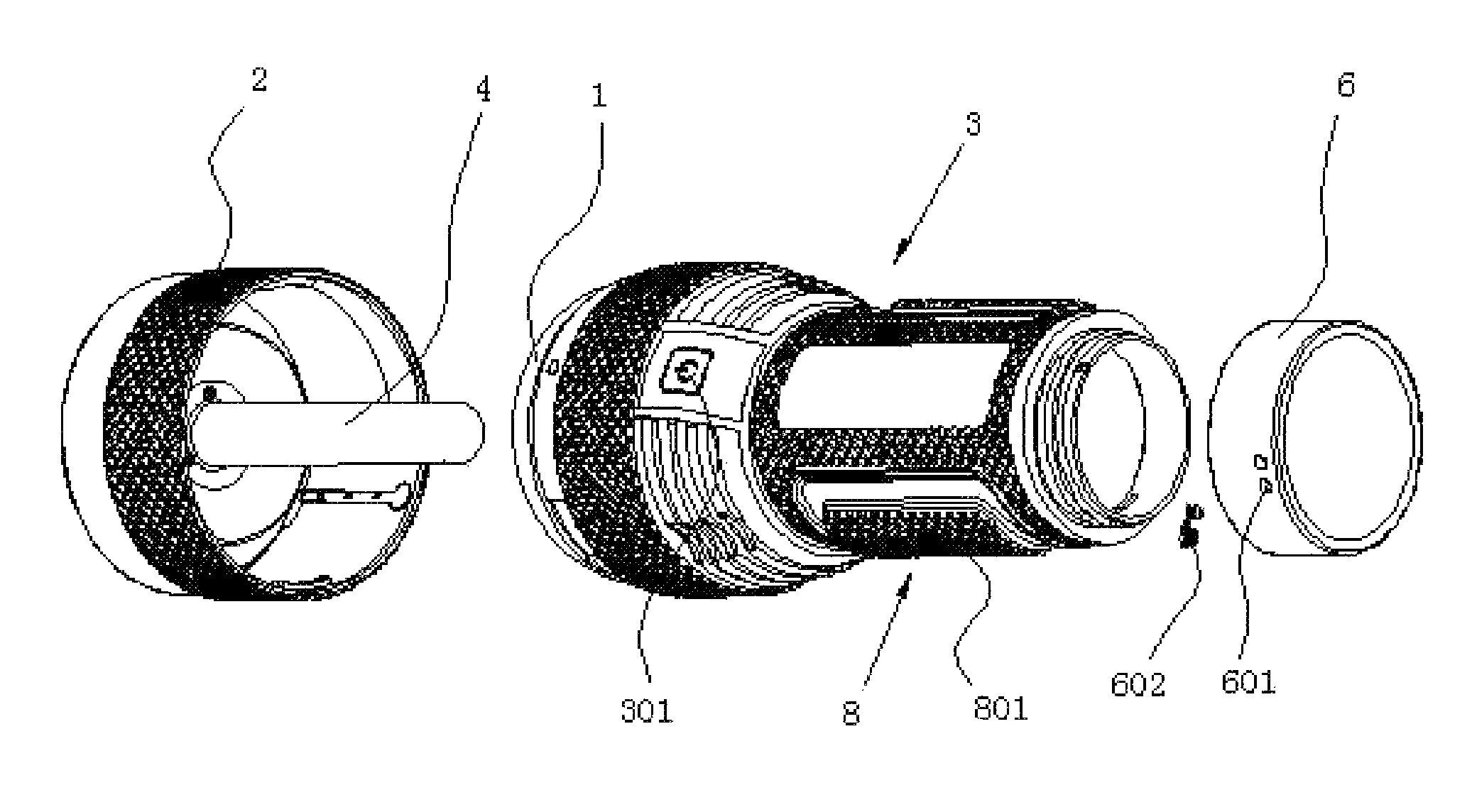

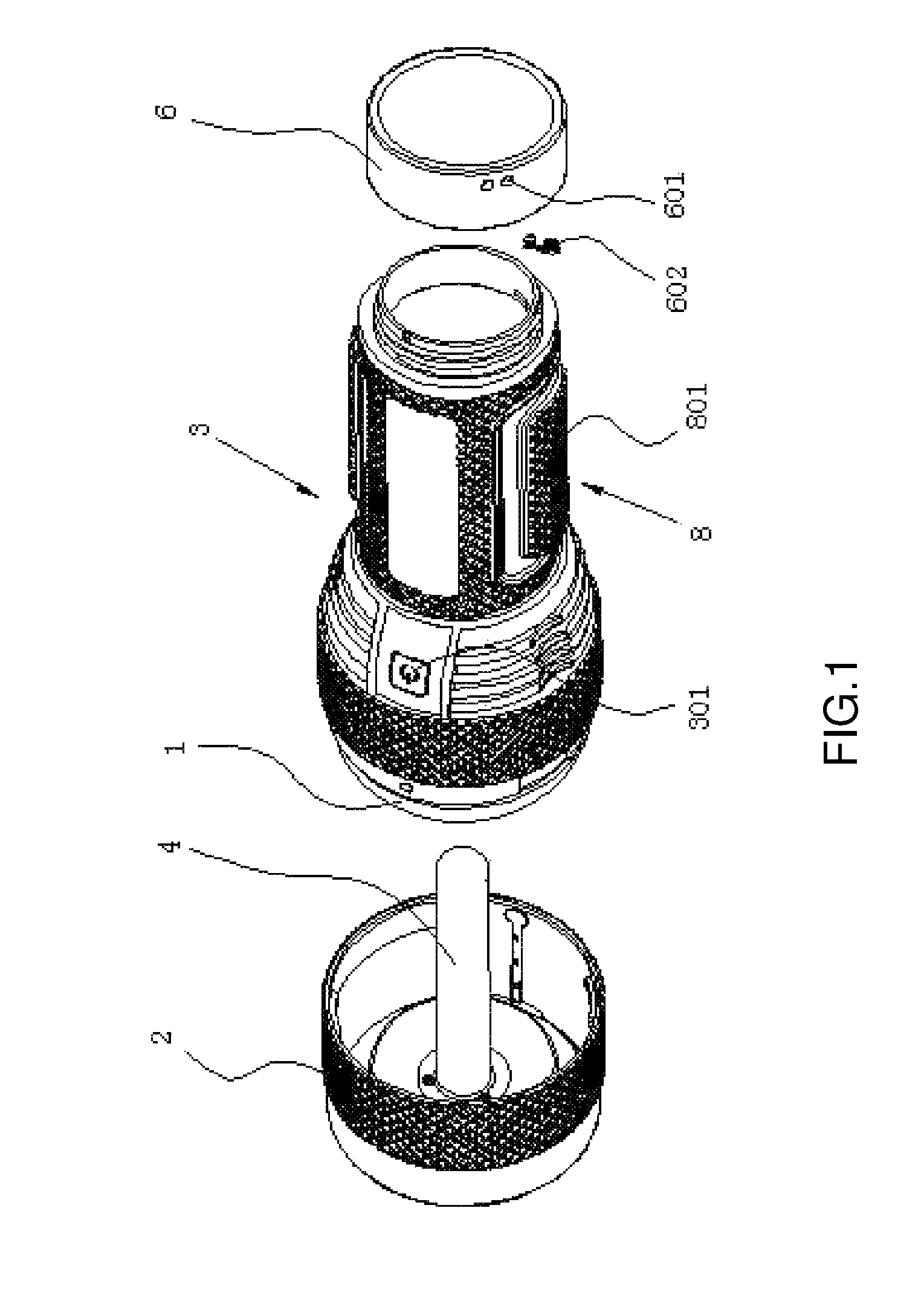

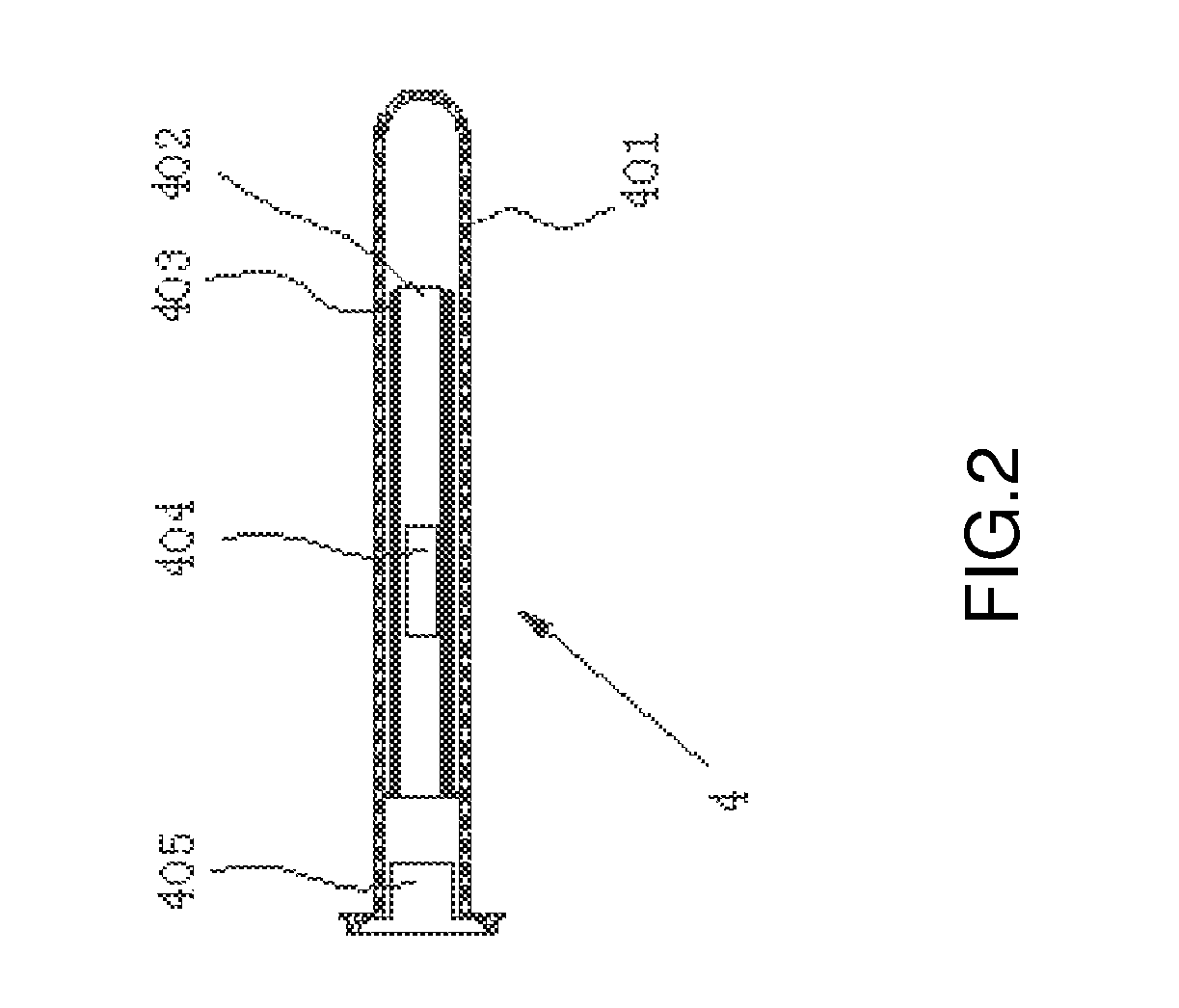

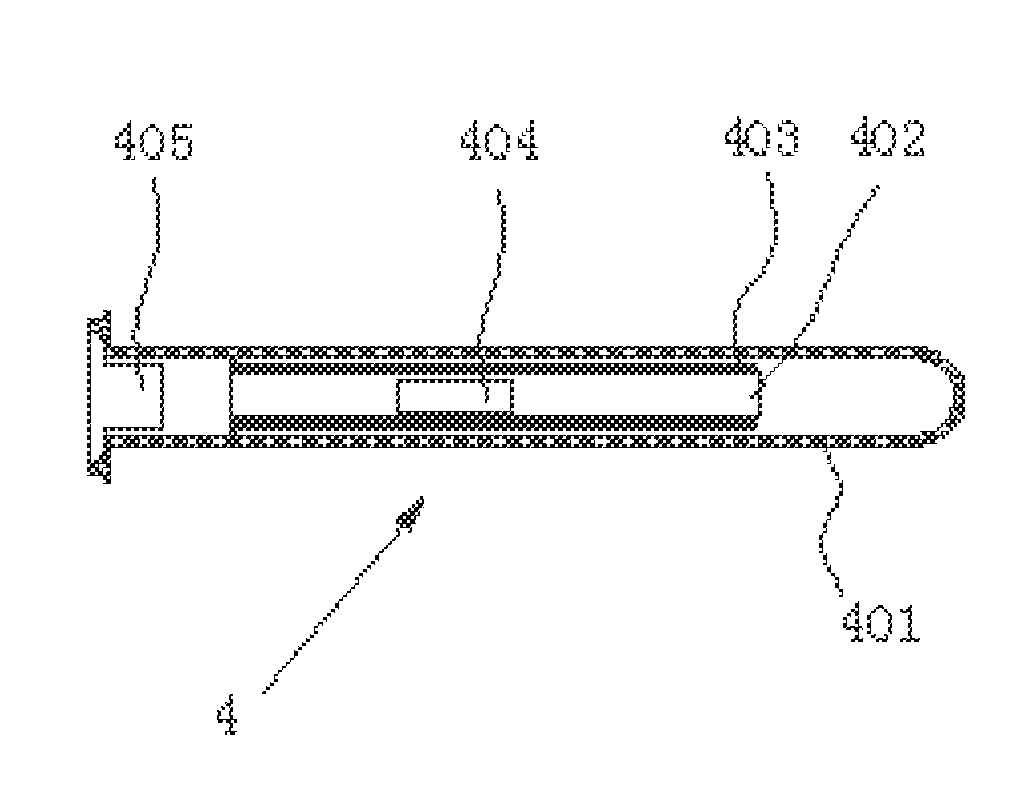

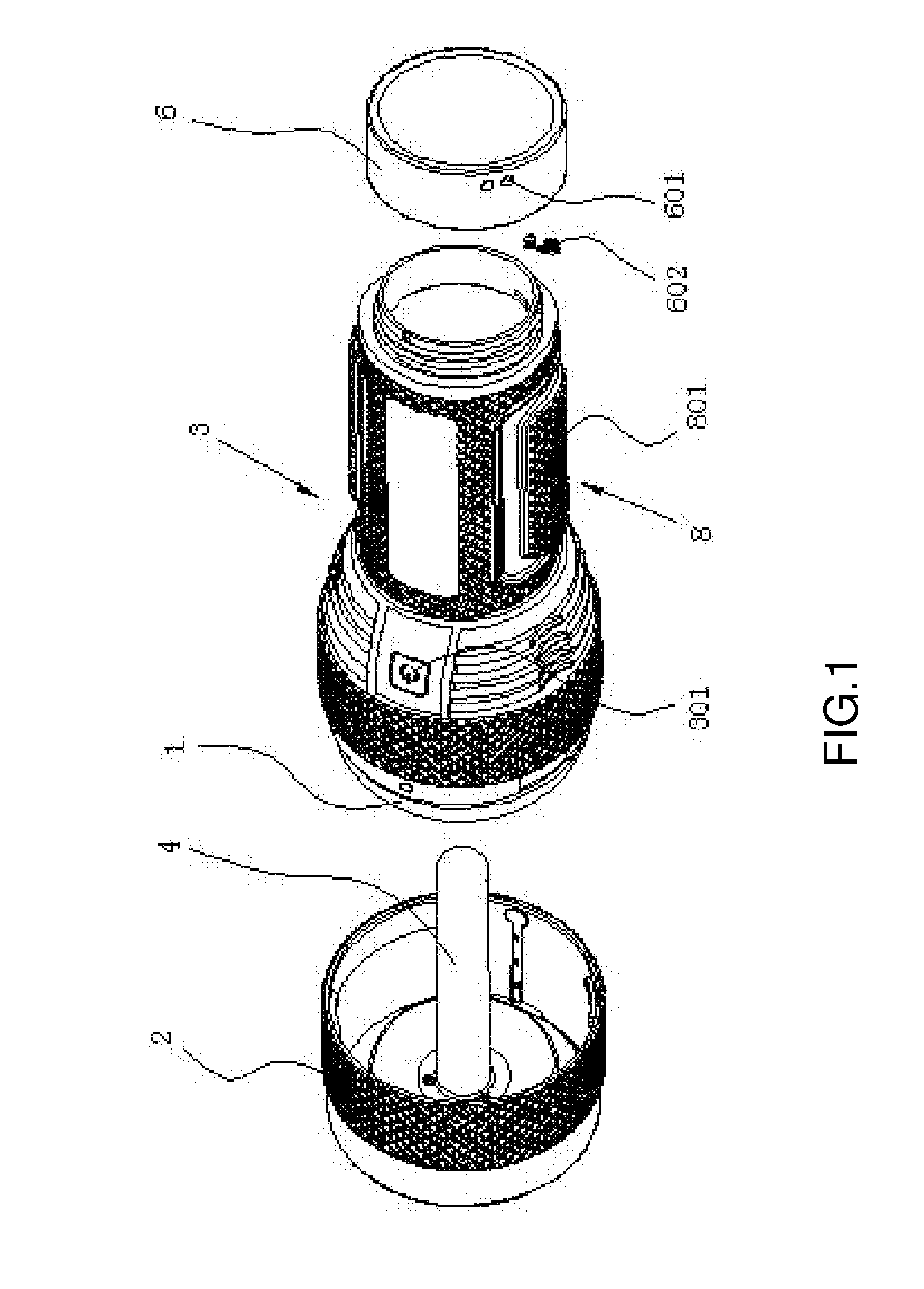

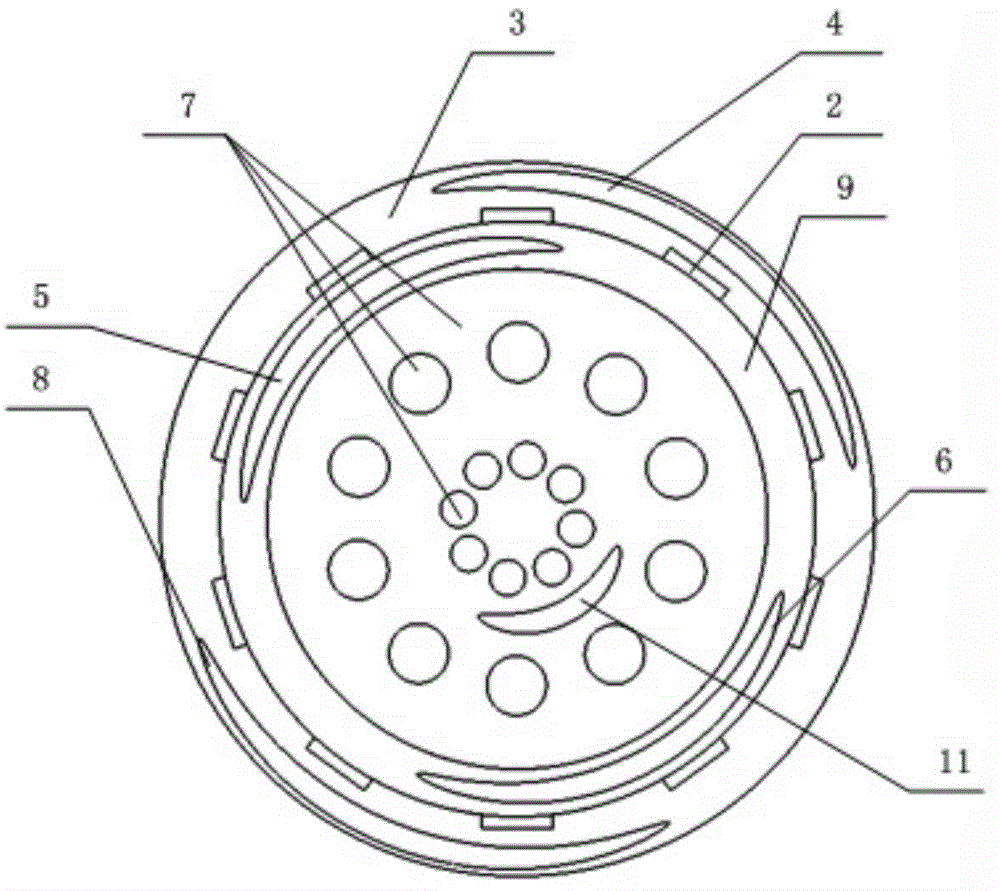

Sperm collector with squeezing function

InactiveUS8475422B2Good effectFast and convenient insertionVaccination/ovulation diagnosticsNon-surgical orthopedic devicesPenisHeater Rod

The present invention is a sperm collector with squeezing function. It includes a soft rubber body provided with a penis insertion passage and a container body provided with at least a top end cover and receives the soft rubber body. When the top end cover and the container body are engaged, the soft rubber body is confined within a cavity formed by the top end cover and the container body. When the top end cover is disengaged, a front end portion of the soft rubber body protrudes out of an opening of the container body. A pressing means is provided at a middle lower portion of the container body. When using the present invention, the user could press the pressing means to squeeze the penis insertion passage of the sperm collector. Accordingly, stimulation to penis is increased and better effect of sperm collection is achieved. In particular, since the present invention is also provided with a heating rod, lubricant pockets and electrical vibrators, which enable the user to reach a climax as quick as possible, thereby further enhancing the effect of sperm collection.

Owner:AILV HEALTH TECH

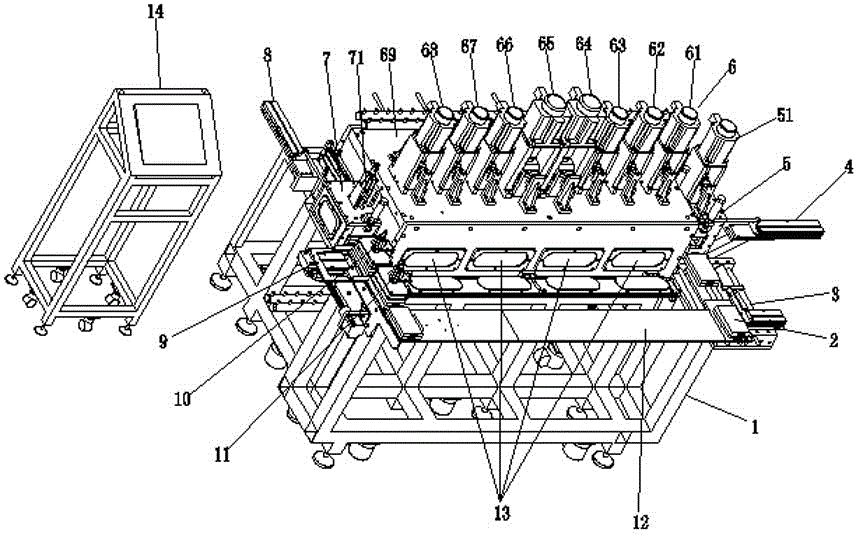

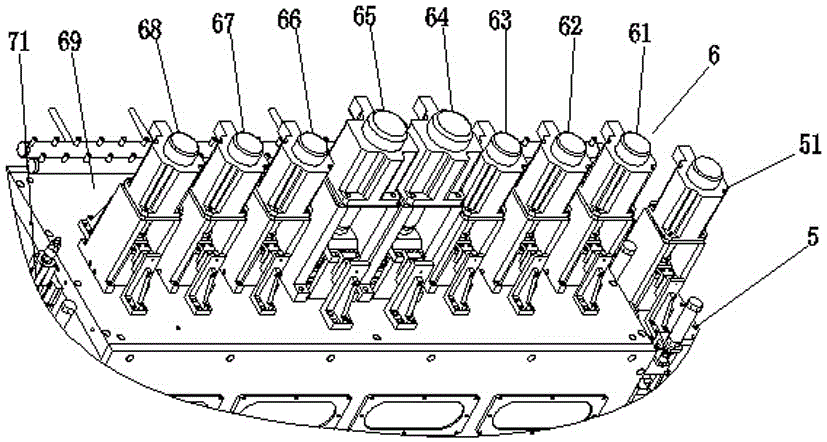

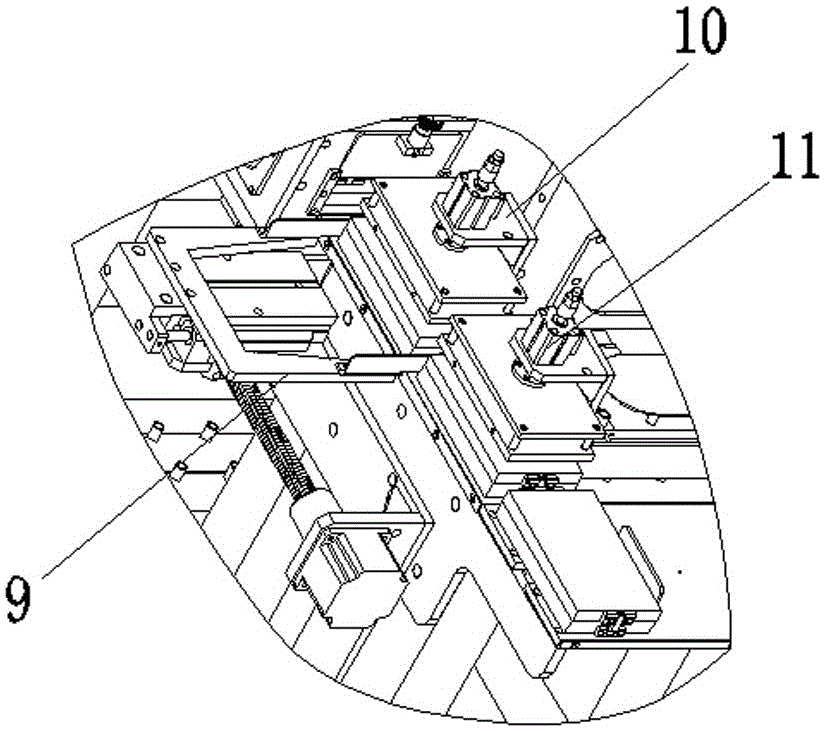

Hot-bending forming machine for mobile phone glass and watch surface covers

InactiveCN106316081AUniform heating effectImprove production continuityGlass reforming apparatusEngineeringHeating effect

The invention discloses a hot-bending forming machine for mobile phone glass and watch surface covers. The hot-bending forming machine comprises a rack and an operation console, wherein a forming part is arranged on the rack and comprises a forming bin, mold preheating mechanisms, a forming mechanism, a shaping mechanism, mold precooling mechanisms and a mold first cooling mechanism are sequentially arranged from an inlet end to an outlet end in the forming bin, and a forking and conveying mechanism for conveying a mold to each mechanism is arranged on the back side of the forming bin; a transition bin is arranged outside the inlet end of the forming bin, a mold feeding mechanism is arranged in front of the transition bin, a mold pushing mechanism is arranged on the outer side of the transition bin, and a first mold preheating mechanism is arranged in the transition bin; a discharging bin is arranged outside the outlet end of the forming bin, a second mold cooling mechanism is arranged in the discharging bin, a discharged material pushing mechanism is arranged on the back side of the discharging bin, a secondary cooling mechanism is arranged in front of the discharging bin, and a discharging cooling and conveying mechanism is arranged on the outer side of the secondary cooling mechanism. The hot-bending forming machine for the mobile phone glass and the watch surface covers has the advantages of uniform heating effect, good production continuity, high production efficiency and the like.

Owner:饶武良

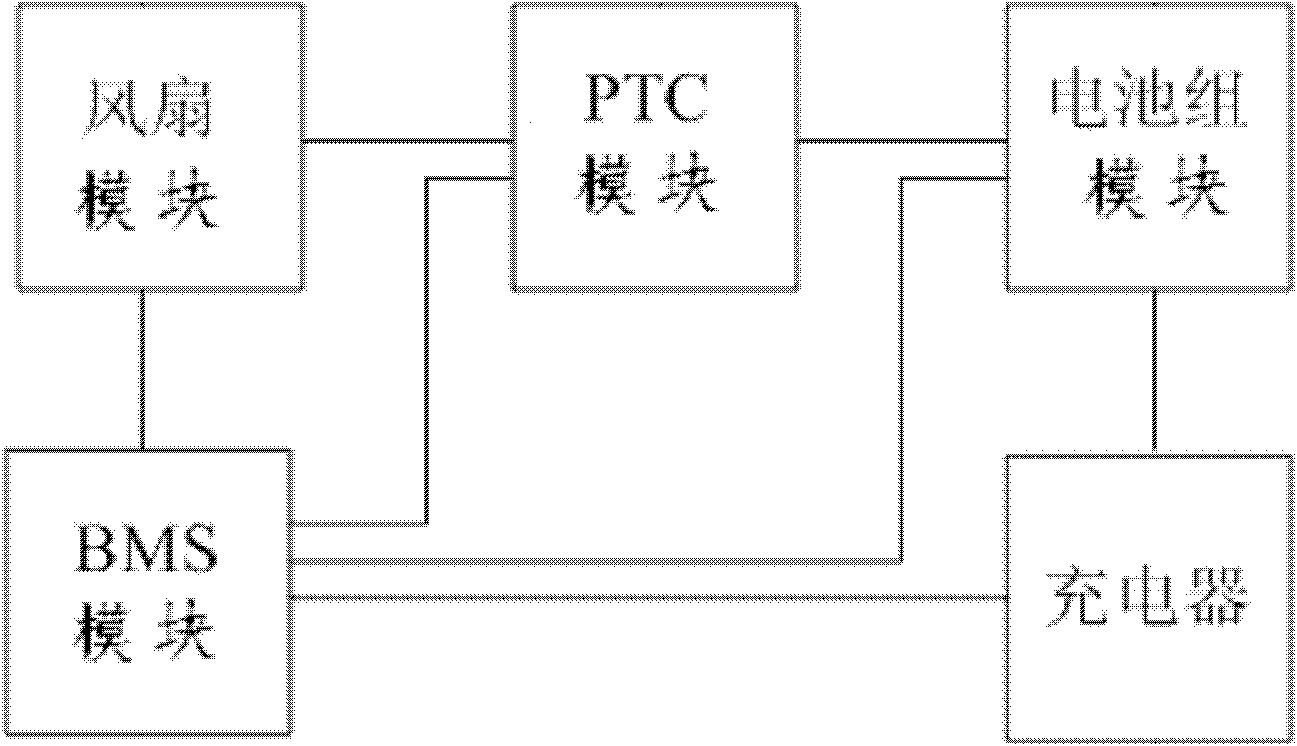

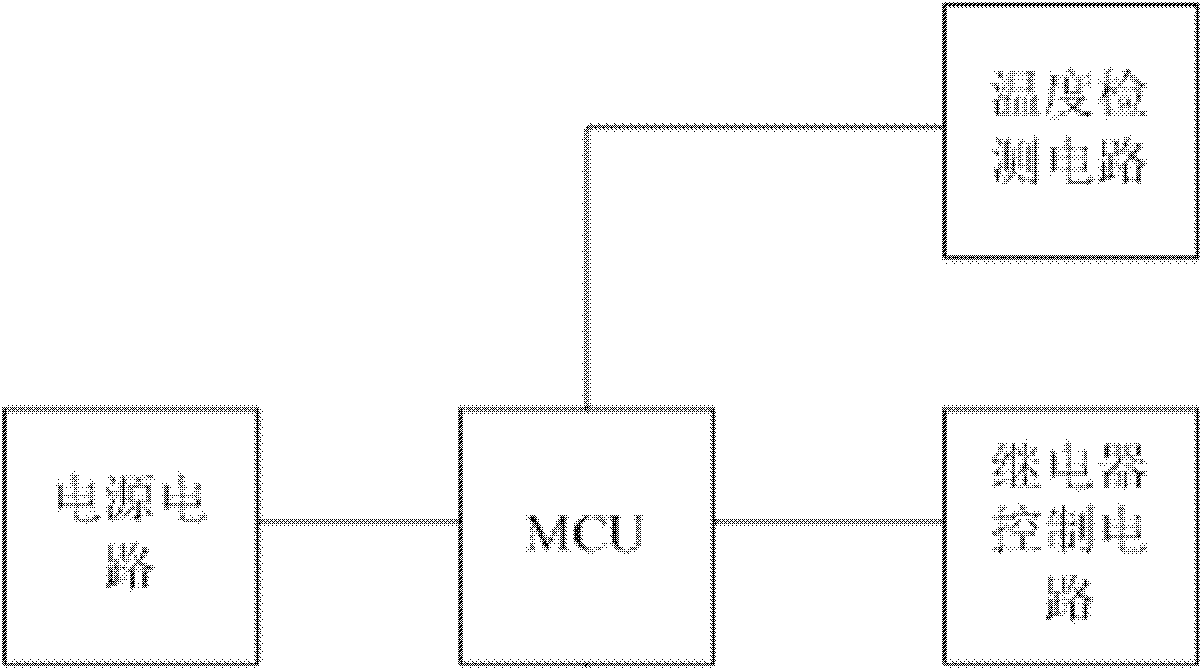

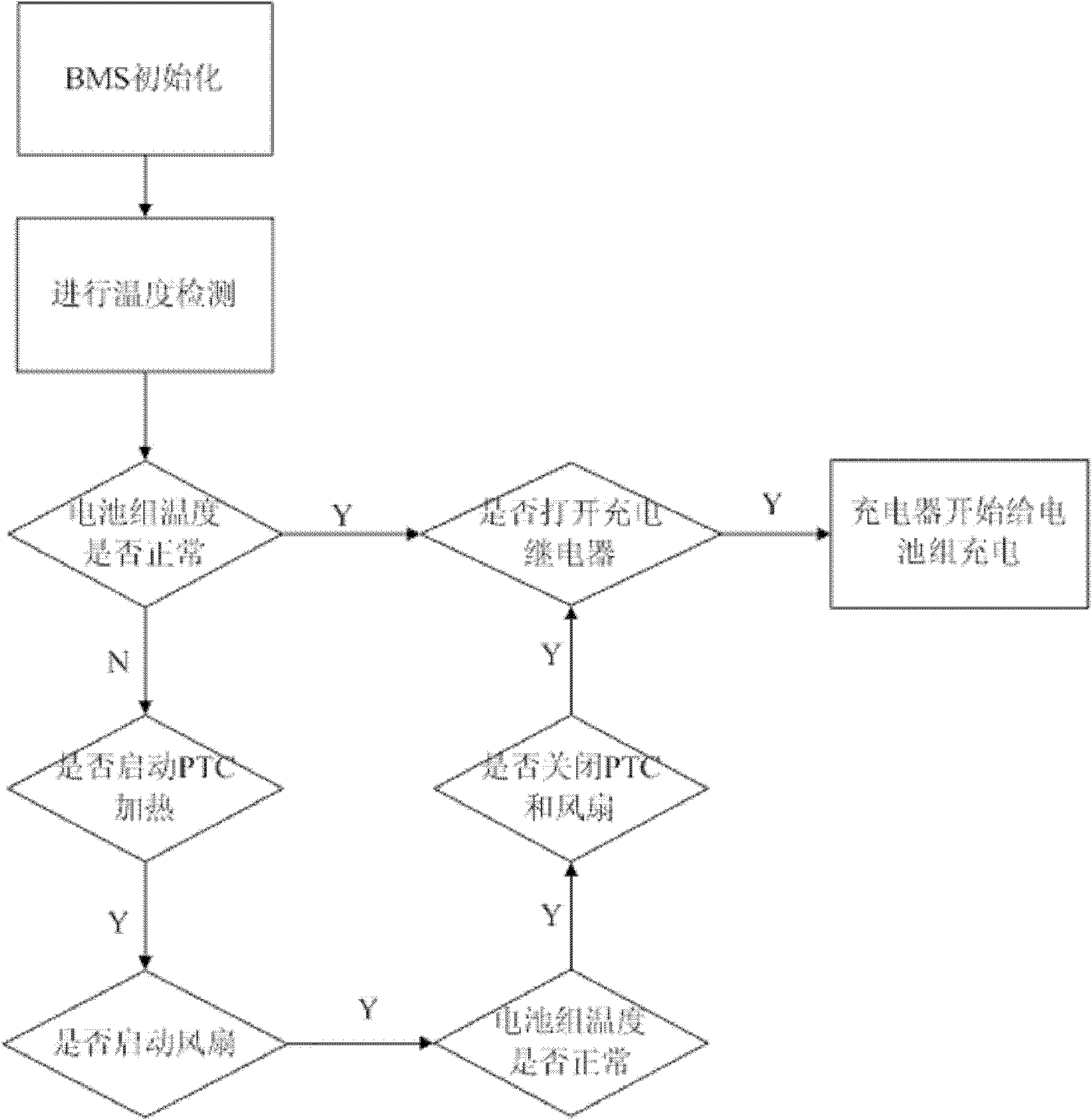

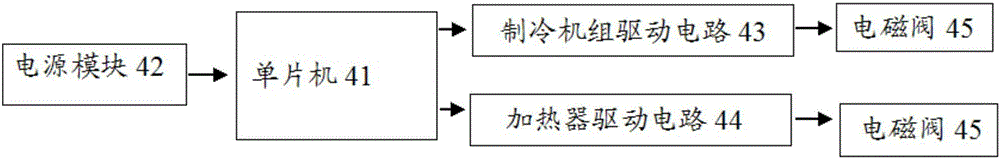

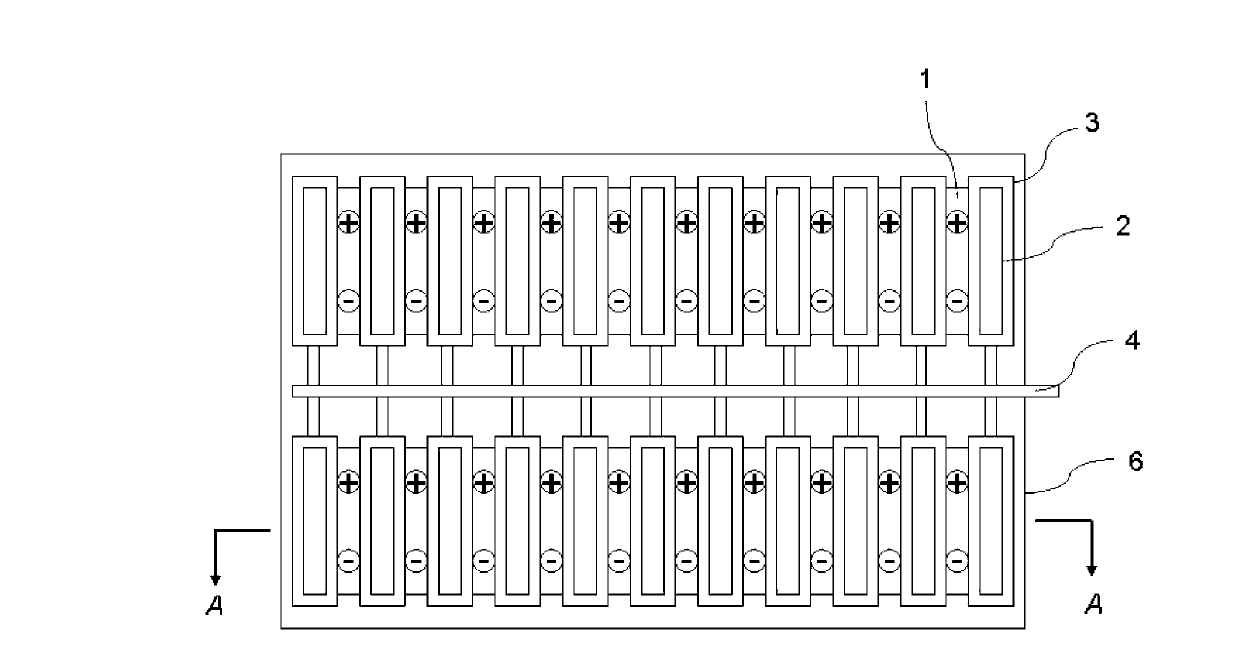

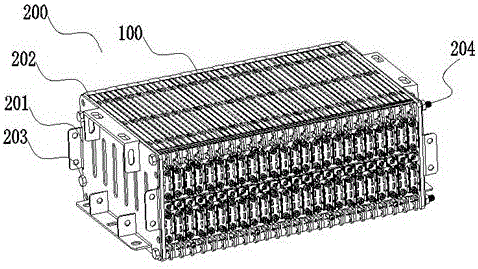

Automatic heating system of lithium-ion power battery for electric vehicle

InactiveCN102208700AAutomatic temperature controlFacilitate automatic adjustment controlSecondary cells charging/dischargingPower batteryElectrical battery

The invention discloses an automatic heating system of a lithium-ion power battery for an electric vehicle, comprising a battery pack module, a charger, a PTC module, a BMS (battery management system) module and a fan module, wherein the charger is connected with the battery pack module; the BMS module is respectively connected with the charger, the battery pack module, the PTC module and the fan module; the battery pack module is internally provided with a temperature sensor; and a temperature detection circuit in the BMS module is connected with the temperature sensor in the battery pack module. The system is used for solving the problems that the temperature is not regulated and controlled automatically, the even heating for the whole battery is difficult to realize and the use is fussy when an existing heating system heats a lithium-ion power battery.

Owner:奇瑞新能源汽车股份有限公司

Mold heating and cooling rod and mold capable of realizing rapid cooling and rapid heating

The invention relates to a mold heating and cooling rod which comprises a heating and cooling rod body and a heating element, a cooling thermal insulation hole for introducing a cooling medium when a mold needs to be cooled and discharging the cooling medium when the mold needs to be heated and a heating element accommodating hole are arranged in the heating and cooling rod body along the axial direction, and the heating element is mounted in the heating element accommodating hole; the mold capable of realizing rapid cooling and rapid heating comprises a mold core and the heating and cooling rod, and the heating and cooling rod is in contact with the mold core; and one side of the heating and cooling rod which is provided with the heating element is near to a molding surface of the mold core. The advantages are that, as the molding surface can be rapidly and evenly heated and cooled and rapidly heated to the temperature which is near to or equal to that of melting materials, a molded product has the advantages of good quality, difficult production of weld marks, flow marks, surface bubbles and the like, even color and luster, even density of the product, small shrinkage and ability of reducing the injection pressure and the product deformation caused by residual stress after consolidating and molding the molten materials.

Owner:杨东佐

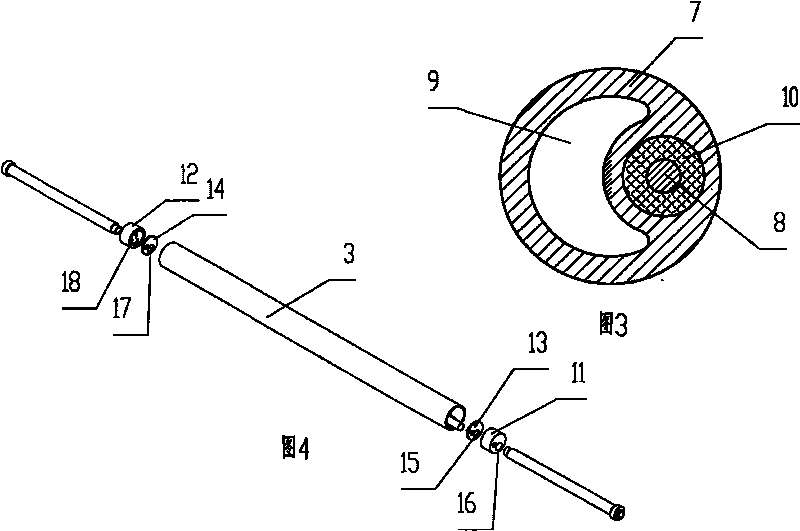

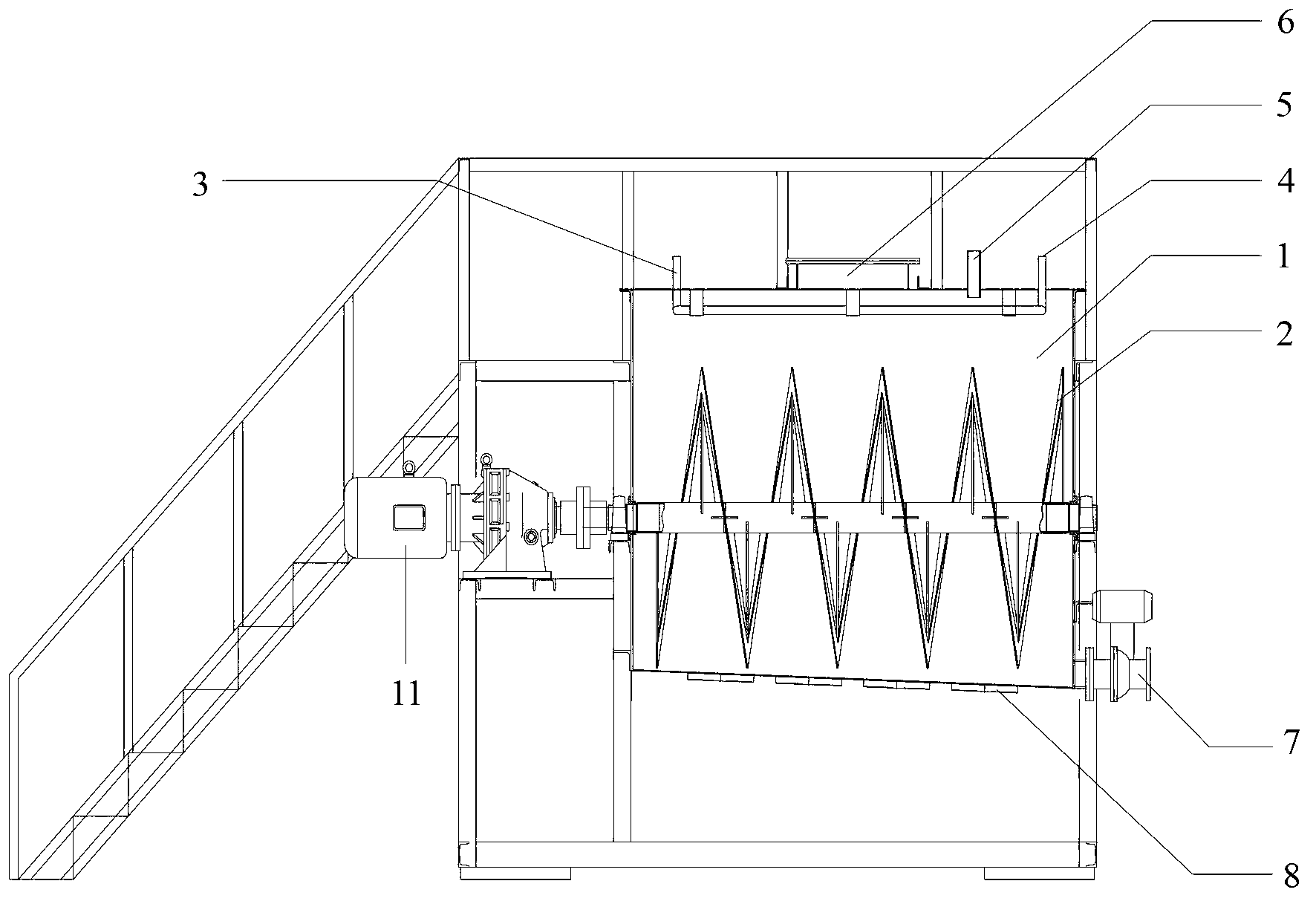

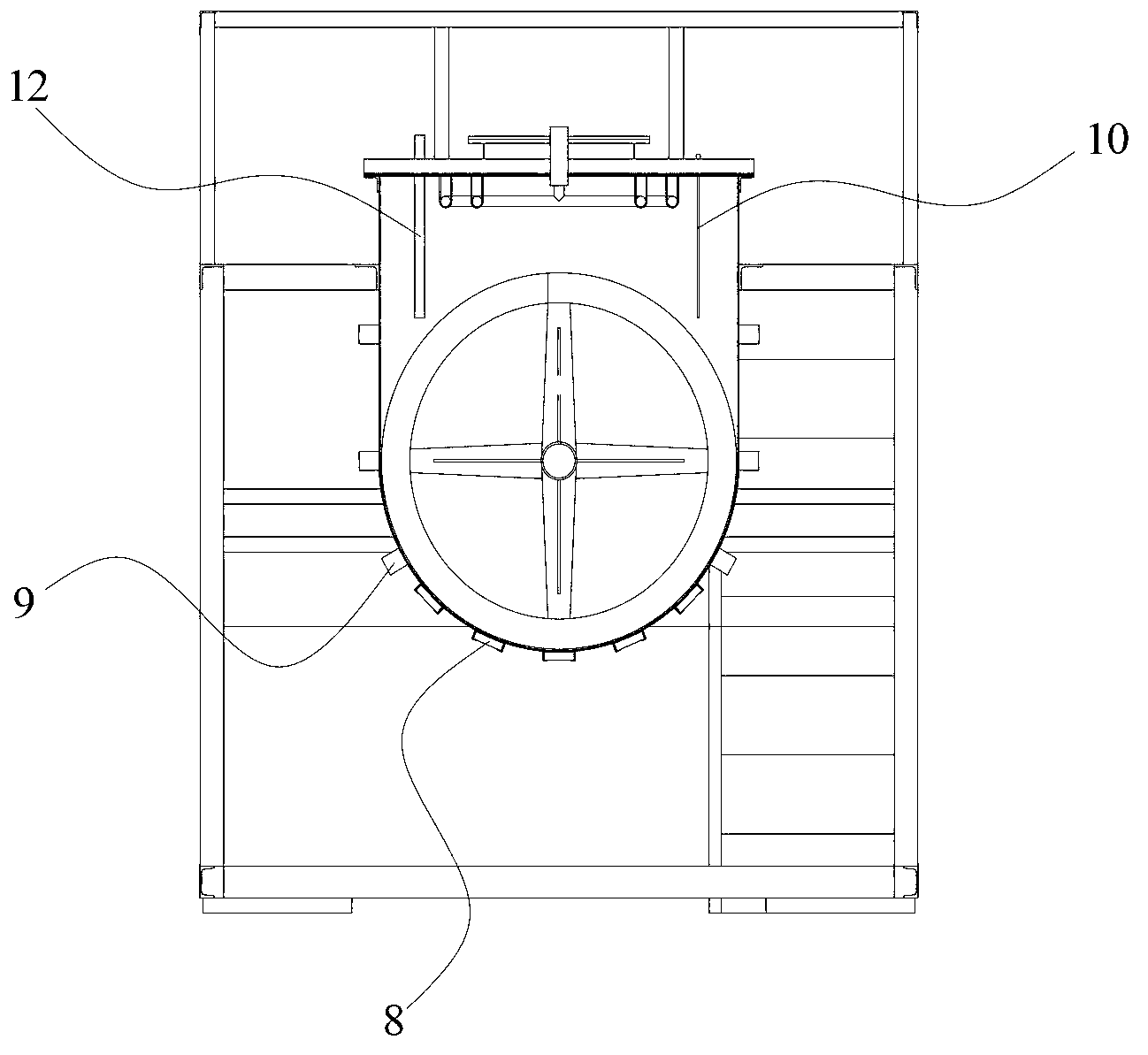

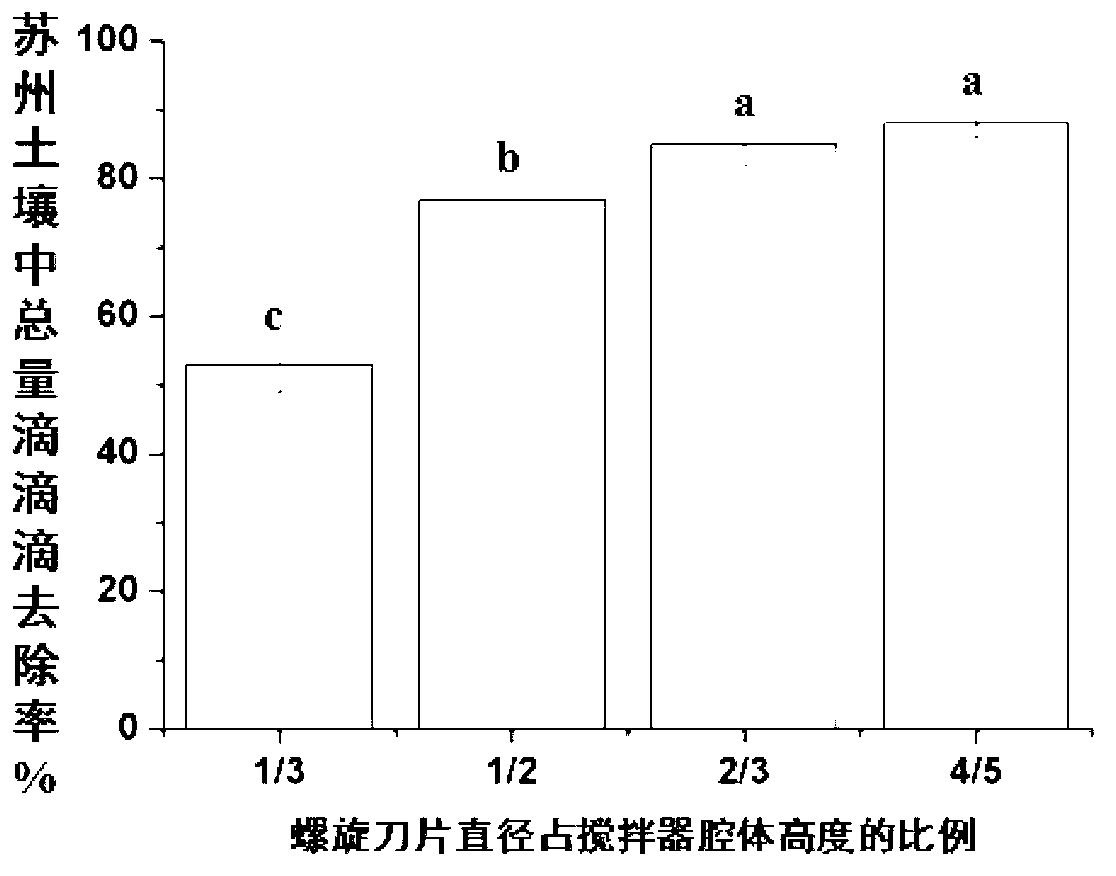

Multielement ex-situ remediation equipment and method used for organo-chlorine pesticide contaminated soil

InactiveCN103182394AWell mixedUniform heating effectContaminated soil reclamationSoil organic matterElution

The invention discloses multielement ex-situ remediation equipment and method used for organo-chlorine pesticide contaminated soil, belongs to the technical field of materializing remediation equipment for contaminated sites. The equipment comprises a stirring device, an eluent injecting device, an eluent recovery device, an ultrasonic generator and a heater. The equipment has extremely strong remediation broad-spectrum performance for organo-chlorine pesticide site soil with different characteristics such as organo-chlorine pesticide substance types, soil contamination incidents, soil contamination concentration, soil organic matter content, soil texture and the like, and a removal rate by single or repeated continuous elution is higher (larger than or equal to 85%); the equipment can form a good matching technology with a patent eluent (ZL201010547630.2), and is developed specially aiming at solving actual contamination situation of organo-chlorine pesticide sites in our country; and during a process of manufacturing the equipment, on the basis of synergistic effects generated by multielement strengthening components such as stirring, ultrasonic, heating and the like, the parameter condition design is optimized, the distribution is scientific and reasonable, and the optimal integration of multielement strengthening components is reflected.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

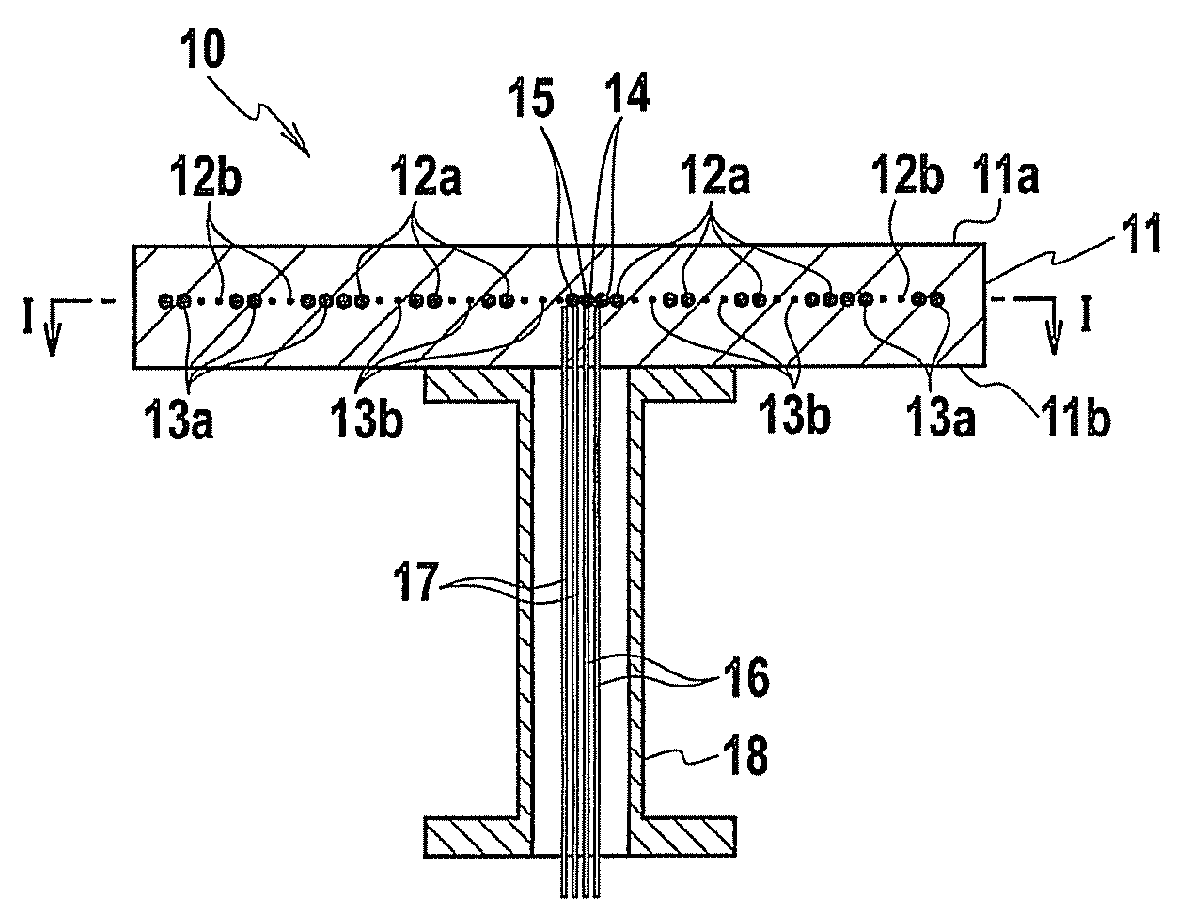

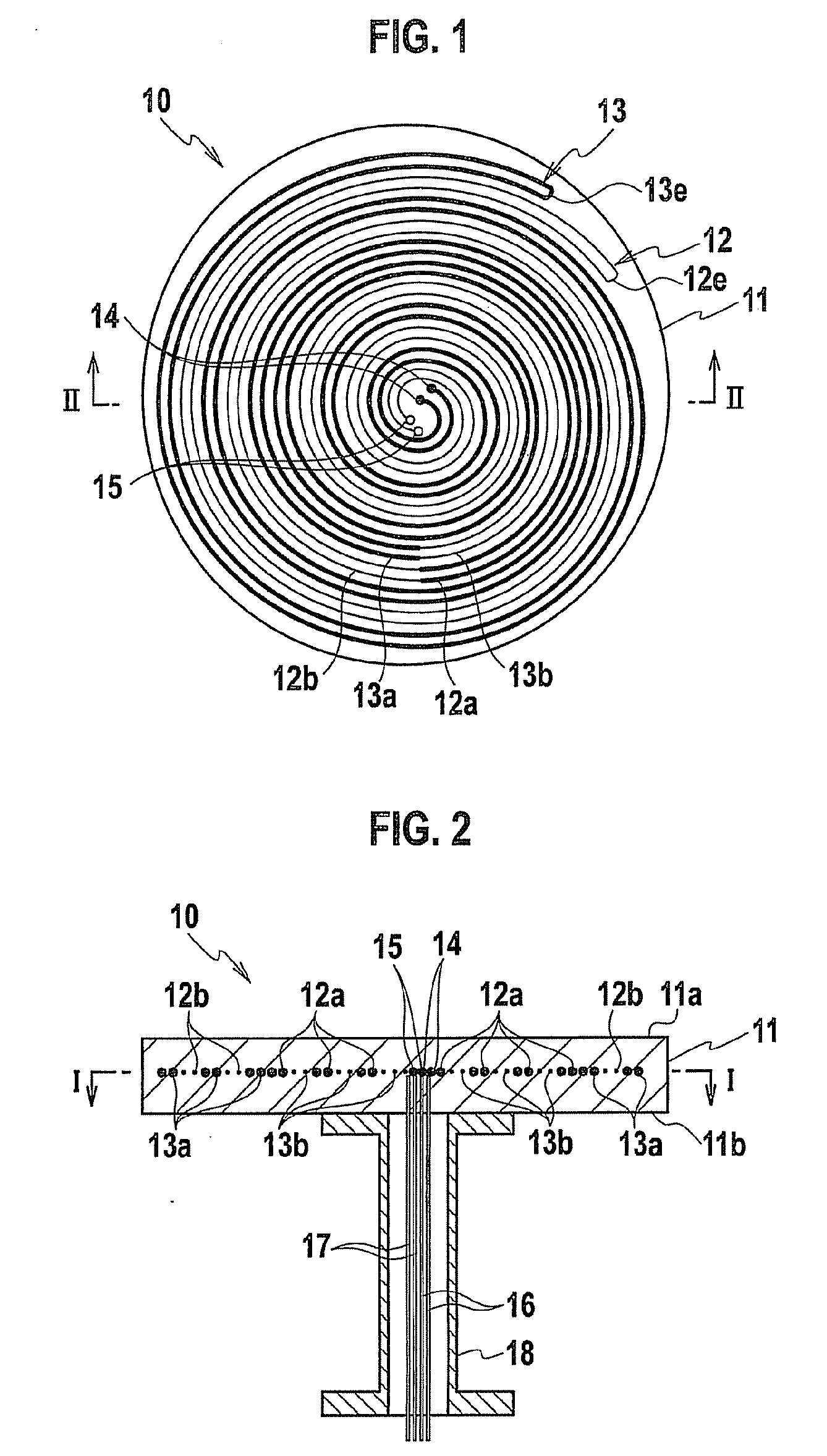

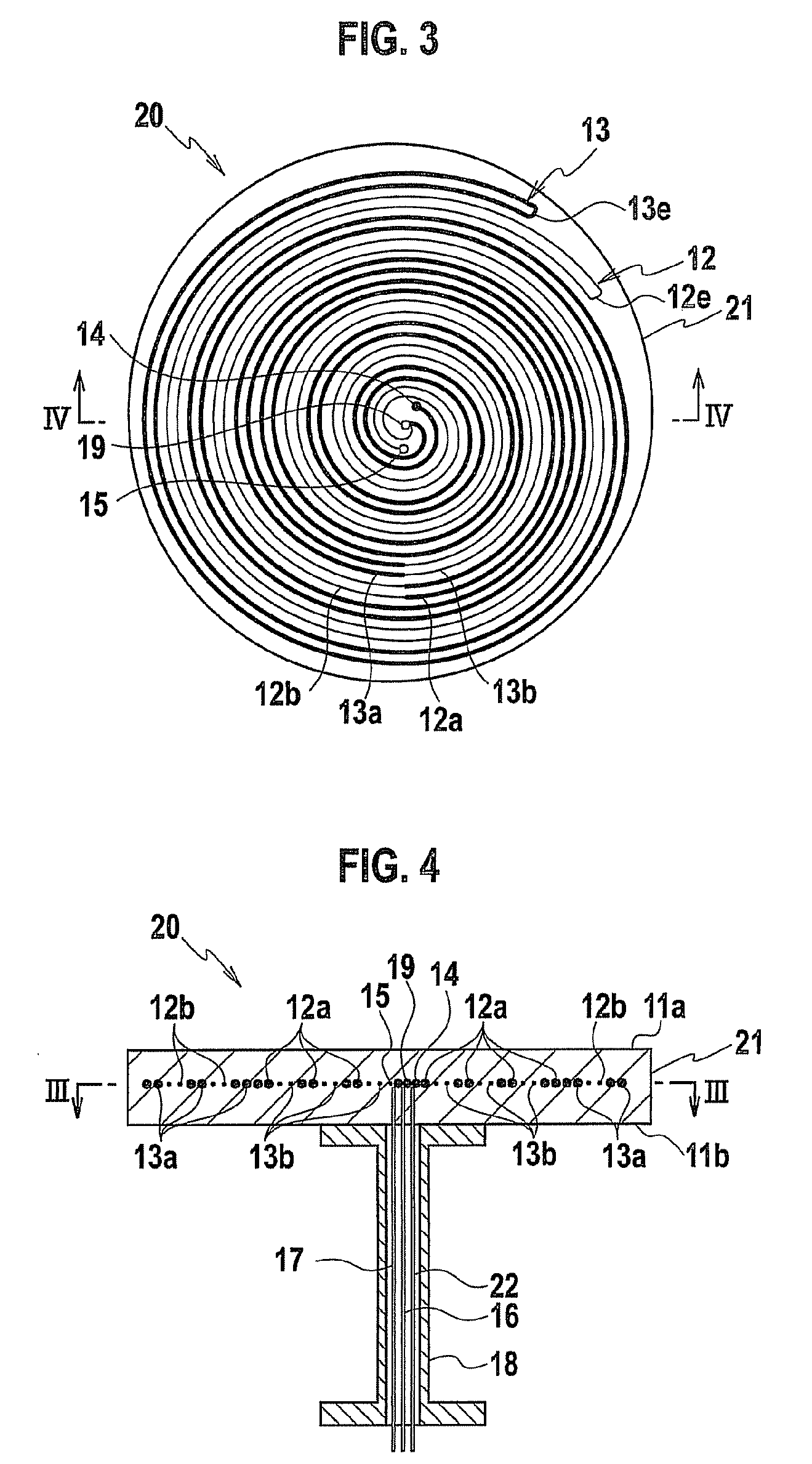

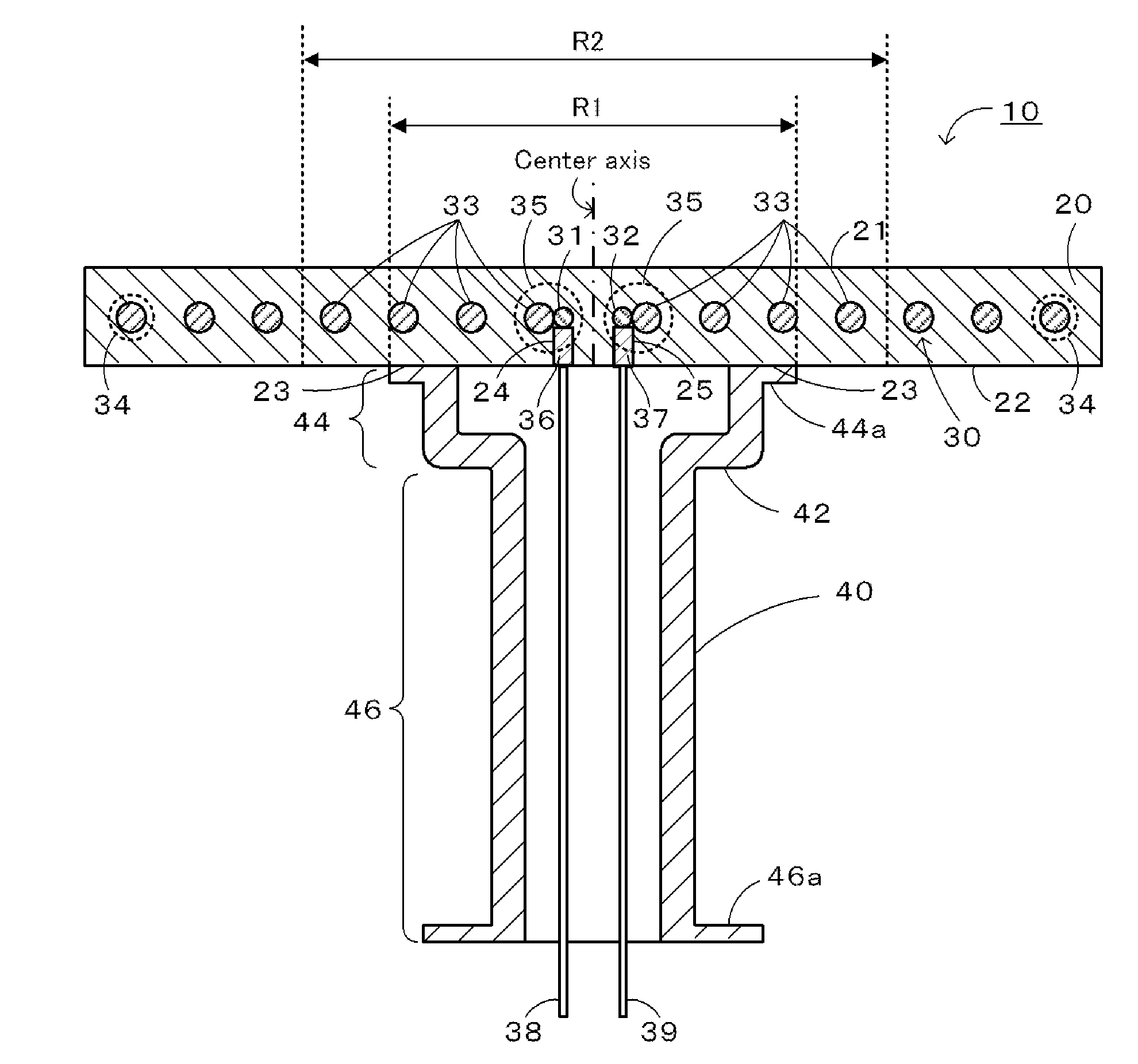

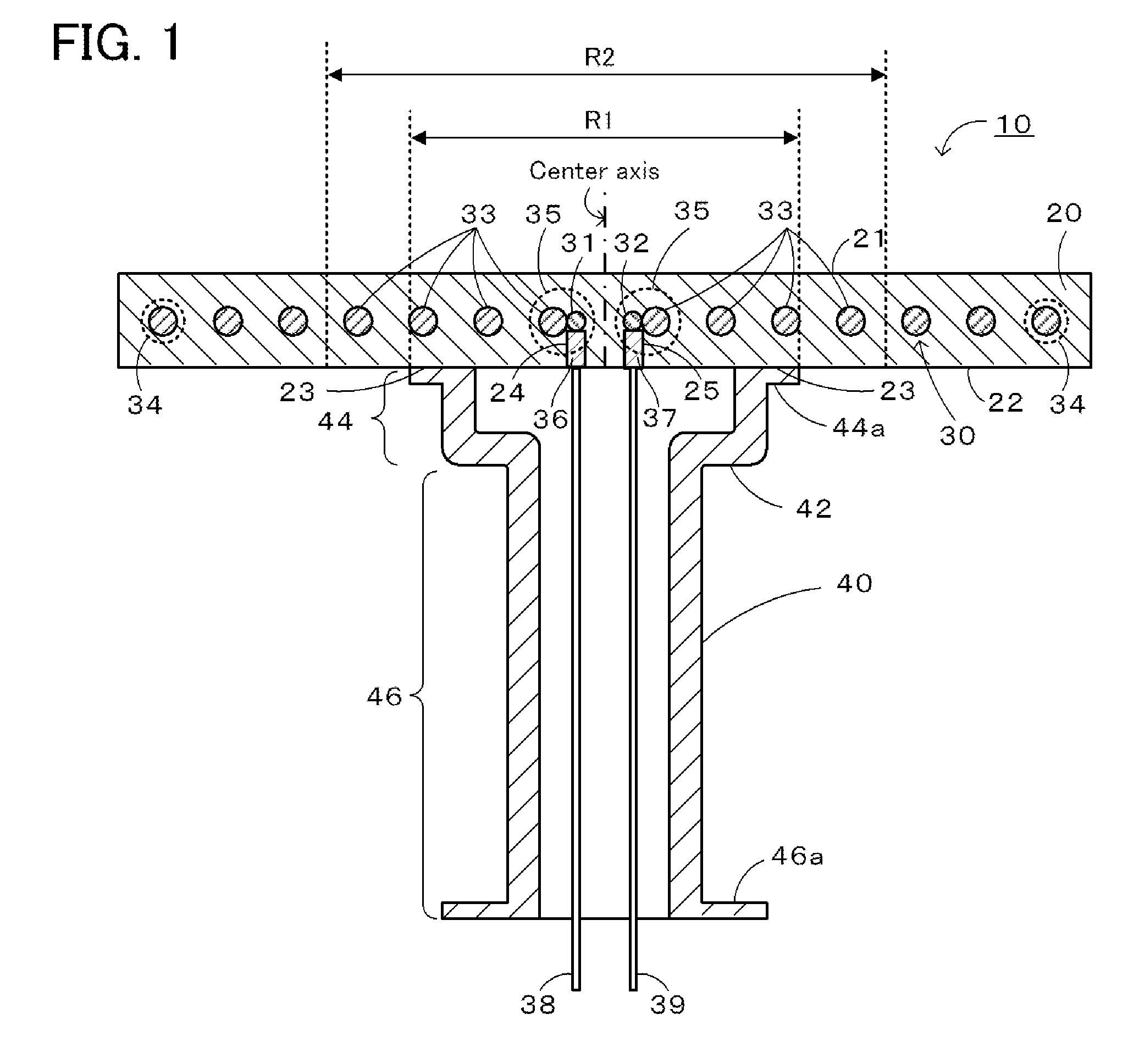

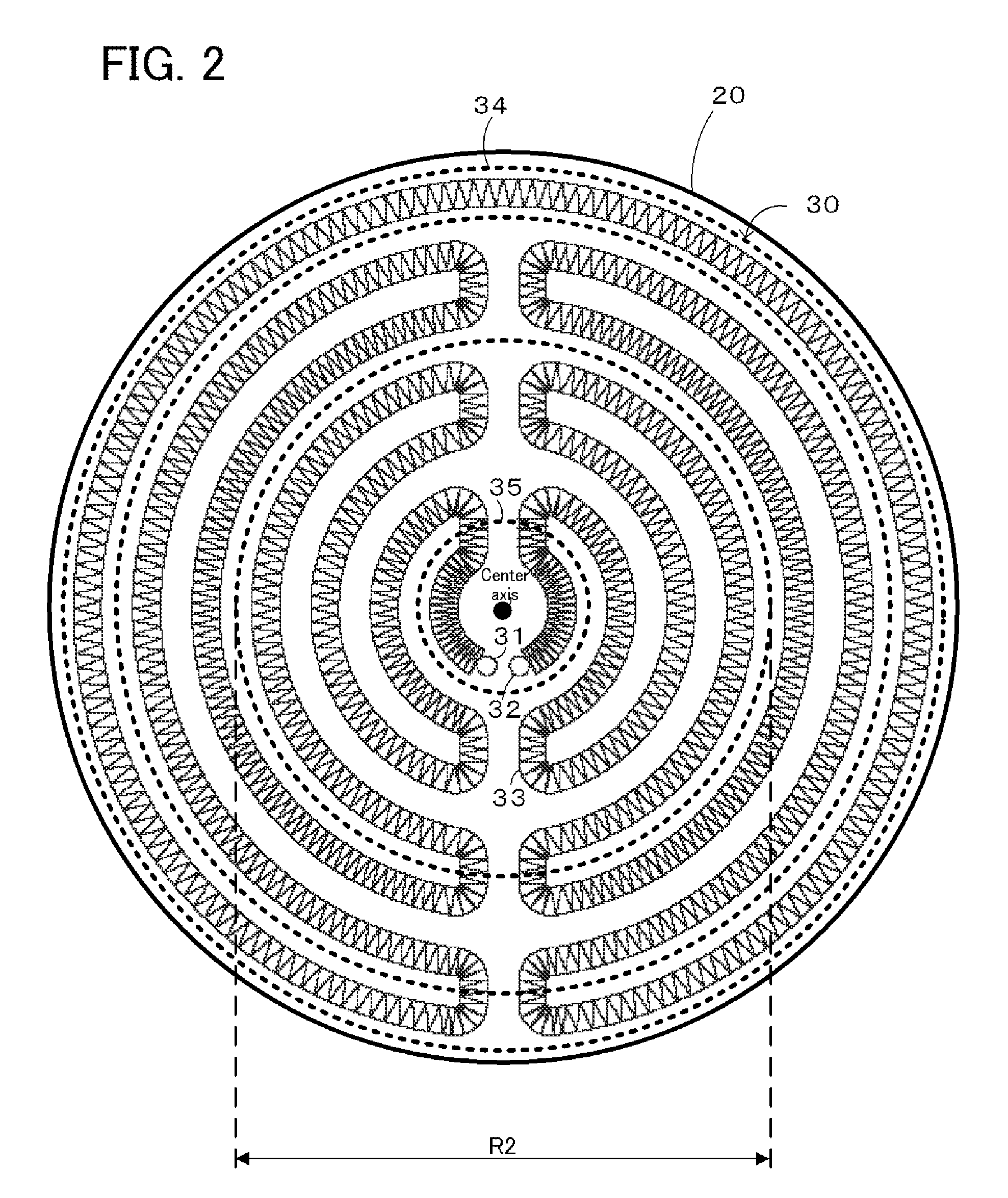

Heating device

ActiveUS20080237216A1Thickness of base can be reducedUniform heating effectSemiconductor/solid-state device manufacturingHot plates heating arrangementsEngineeringHeating element

A first heating element and a second heating element, which are capable of individually controlling temperatures thereof, are embedded in a ceramic base. Each of the first heating element and the second heating element is formed into a spiral shape so as not to contact the other from a central portion of the base to an outer circumferential portion thereof in substantially the same plane parallel to a heating surface of the base. One of the first and second heating elements includes a high heating density portion on the central portion side of the base, and a low heating density portion on the peripheral portion side of the base, and the other of the first and second heating elements includes a low heating density portion on the central portion side of the base, and a high heating density portion on the peripheral portion side of the base.

Owner:NGK INSULATORS LTD

Vacuum freeze drying method and vacuum freeze dryer

ActiveCN104949473AImprove qualityReduce process stepsDrying solid materials without heatSmall footprintFreeze dry

The invention provides a vacuum freeze dryer which comprises a material box, a water catching bin, a refrigerating unit, a heater, a vacuum pump and a control device. The material box is communicated with the water catching bin. The water catching bin is connected with the vacuum pump. The refrigerating unit and the heater are arranged outside the material box. The control device controls the refrigerating unit, the heater and the vacuum pump. The material box is internally provided with a refrigerating pipe and a heating pipe at the same time, and the refrigerating pipe and the heating pipe are used for freezing and drying materials respectively. The inner wall of a material frame and the inner wall of the material box are each provided with a temperature sensor, and the temperature sensors monitor the temperature of the material frame and the temperature of the material box. Materials inside a material bottle are frozen in advance to reach the eutectic point approximately, then the temperature is decreased rapidly, and the materials pass through the eutectic point within the short time as little as possible, so that the grain size of crystals is effectively controlled, the fine freeze-drying powder is obtained, and the freeze-dried powder product quality is improved. The freezing cavity and the drying cavity are integrated, the technological steps are simplified, the occupied space is small, and refrigerating and heating are uniform.

Owner:BEIJING HAIHETIAN TECH DEV

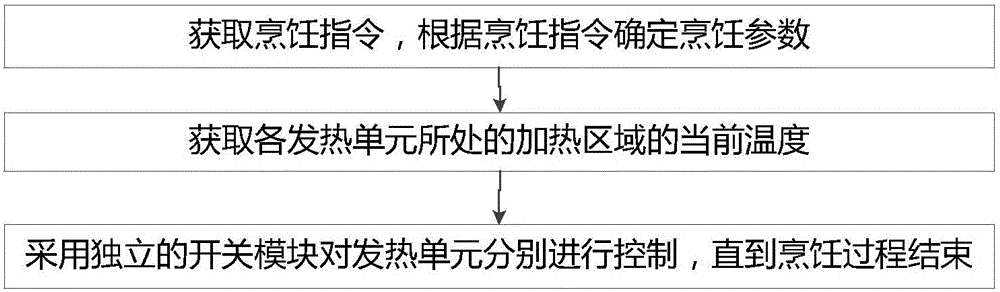

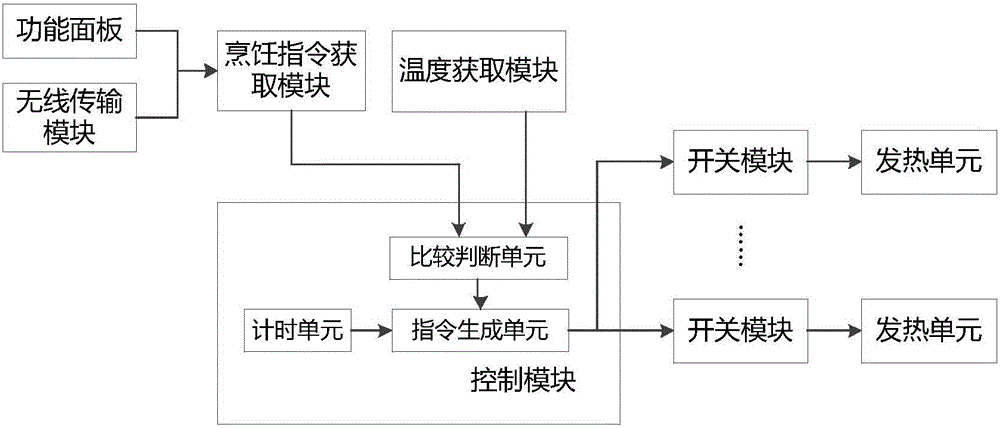

Cooking method, cooking system and cooking device

InactiveCN105942880AMeet diverse cooking needsSimple and accurate cooking methodRoasters/grillsProgramme control in sequence/logic controllersProcess engineeringCooking methods

The invention relates to the field of household appliance control, in particular to a cooking method, a cooking system and a cooking device. The cooking method includes steps of acquiring cooking instructions and determining cooking parameters according to the cooking instructions; acquiring current temperatures of heating regions where various heating units of the cooking device are located; generating control commands according to the current temperatures of the various heating regions and the cooking parameters and respectively controlling the various heating units until cooking procedures are completed. The cooking method, the cooking system and the cooking device have the advantages that the actual temperatures of the different heating regions of the cooking device can be accurately acquired by the aid of the cooking method, independent on-off control can be carried out the heating units of the different heating regions according to the actual temperatures and cooking requirements, accordingly, cooking effects under the condition of real identical temperatures of all the heating regions can be realized, cooking effects under the condition of different temperatures of the different cooking regions also can be realized, and the diversified cooking requirements of users can be met; the cooking method which is a control method is simple and accurate, and the good cooking effects can be realized.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

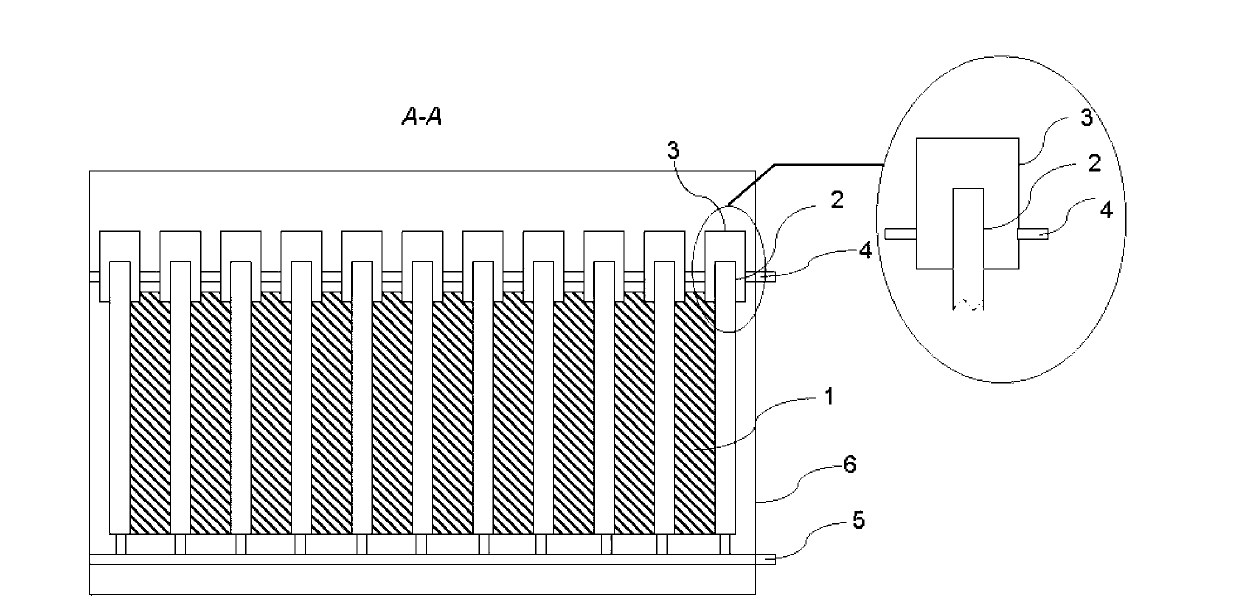

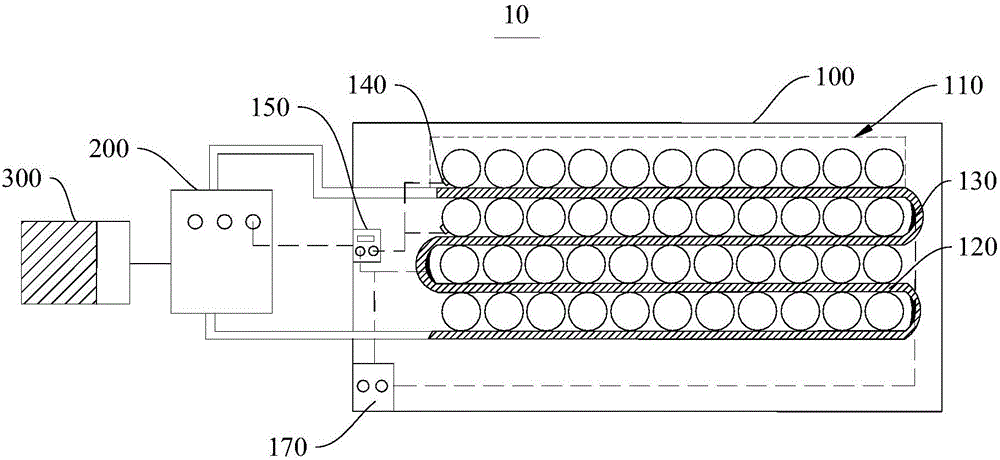

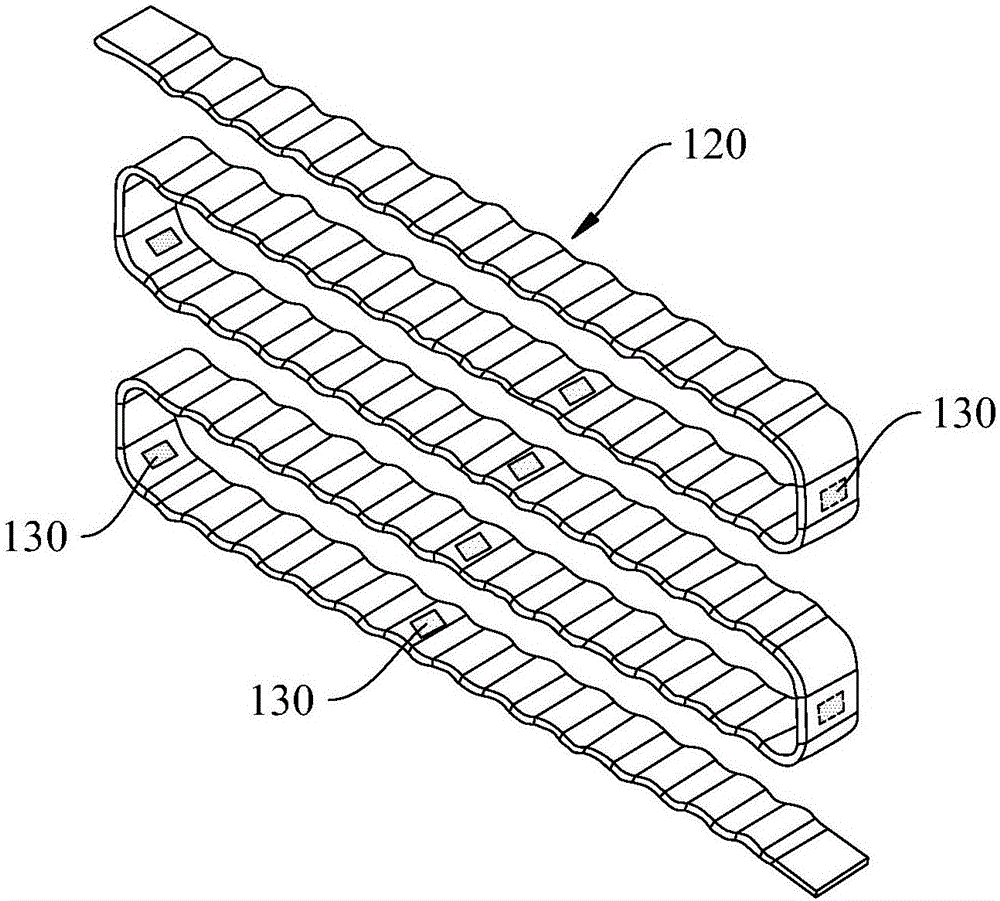

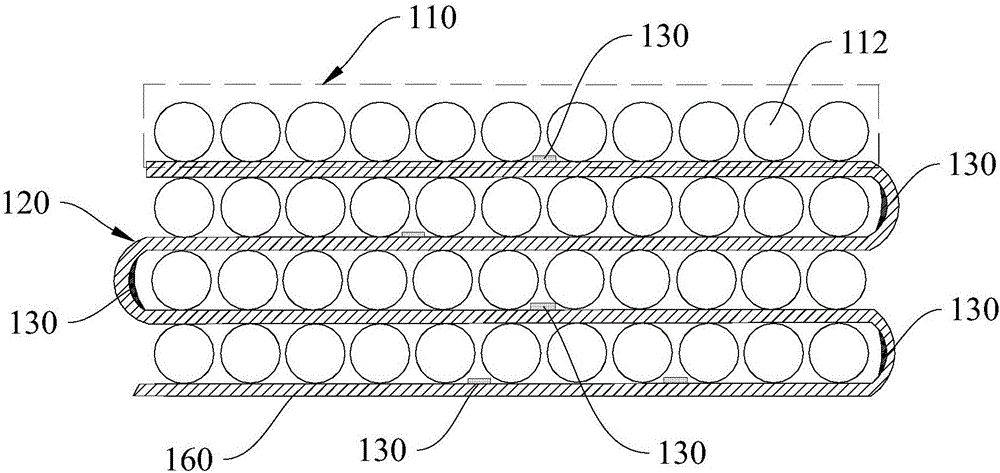

Battery pack

ActiveCN103107385AReduce quality problemsSimple structureSecondary cellsPower stationElectrical battery

The invention discloses a battery pack. The battery pack comprises a plurality of cells and a temperature regulating module, wherein the temperature regulating module comprises a first flow channel, a second flow channel, and a third flow channel communicated with each other; and the third flow channel is vertically arranged between adjacent cells. The battery pack provided by the invention has the advantages of low energy consumption, good internal thermal balance, uniform overall heat dissipation, simple structure, and the like, and can be widely used in the related fields of electric vehicles, energy storage power stations and the like.

Owner:CONTEMPORARY AMPEREX TECH CO

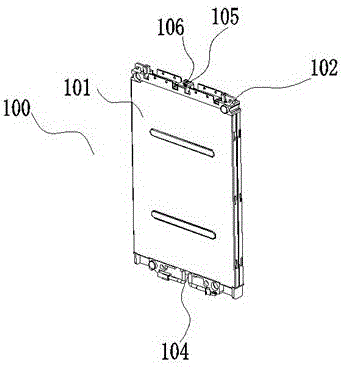

New energy power batter

PendingCN106356587AExquisite structureEasy to installFinal product manufactureCurrent conducting connectionsAluminiumGraphite

The invention discloses a new energy power battery. The new energy power battery comprises a battery box upper cover, a power battery module and a battery box lower casing, wherein the power battery module comprises an electric core bracket, more than two electric cores and an aluminum casing clamp plate; the electric cores are arranged in the electric core bracket, and the two outermost sides of each electric core are tightly attached to the aluminum casing clamp plate. The new energy power battery is characterized in that Lvte cotton is adhered to one surface of each electric core, and a silica gel sheet is adhered onto an electrode lug of each electric core; after the two electric cores are adhered with the Lvte cottons and the silicon rubber sheets, a heat conduction graphite sheet is adhered onto the surface, adhering with the Lvte cotton, of one electric core, a heating plate is arranged between the two electric cores, and the two side surfaces of the heating plate are respectively adhered with the Lvte cotton surfaces; a temperature sensor is connected with the heat conduction graphite sheet; a water cooling system is arranged at the exterior of the battery box lower casing, and a connecting structure of positive and negative electrode lugs of each electric core adopts laser welding or riveting type. The new energy power battery has the advantage that the water cooling heat radiating and heating functions are simultaneously realized.

Owner:JIANGXI DIBIKE

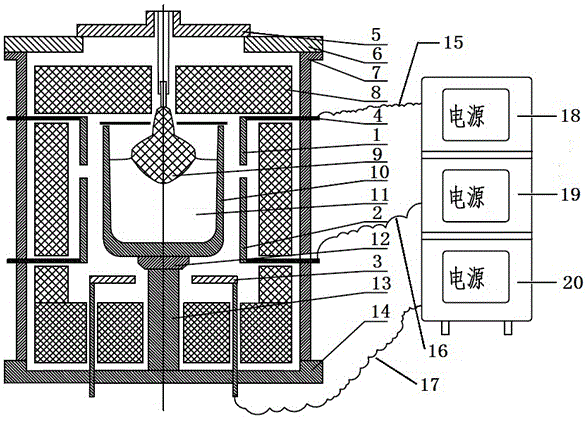

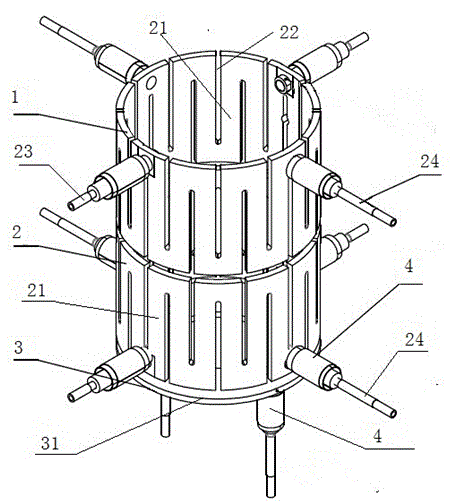

Multistage graphite heating system of sapphire crystal growth equipment and using method of multistage graphite heating system

InactiveCN104451892AImprove product qualityChange the temperature distributionAfter-treatment apparatusPolycrystalline material growthGraphite electrodeControl power

The invention belongs to the technical field of sapphire crystal growth furnace equipment, and provides a multistage graphite heating system of the sapphire crystal growth equipment and a using method of the multistage graphite heating system. The multistage graphite heating system comprises an upper heater, a middle heater, a bottom heater, three power supply devices, a growth furnace cavity, a crucible device and a heat preservation layer, wherein the growth furnace cavity comprises a small furnace cover, a large furnace cover, a furnace cylinder and a furnace base plate; the crucible device comprises a crucible, a crucible tray and a crucible supporting column; each of the upper heater and the middle heater comprise a continuous S-shaped fence-shaped graphite cylinder, four graphite round columns, two long water cooling copper electrodes and two short water cooling copper columns; the bottom heater comprises an S-shaped fence-shaped graphite disc, two graphite electrodes and a water cooling copper electrode; the three individually controlled power supplies are connected with water cooling cables of the upper heater, the middle heater and the bottom heater. The multistage graphite heating system of the sapphire crystal growth equipment and the using method of the multistage graphite heating system have the advantages that the temperature gradient requirement for the growth of large-sized sapphire crystals at each stage can be met, the cost can be reduced, and the quality can be improved.

Owner:SHANGHAI HUICUI OPTICAL TECH

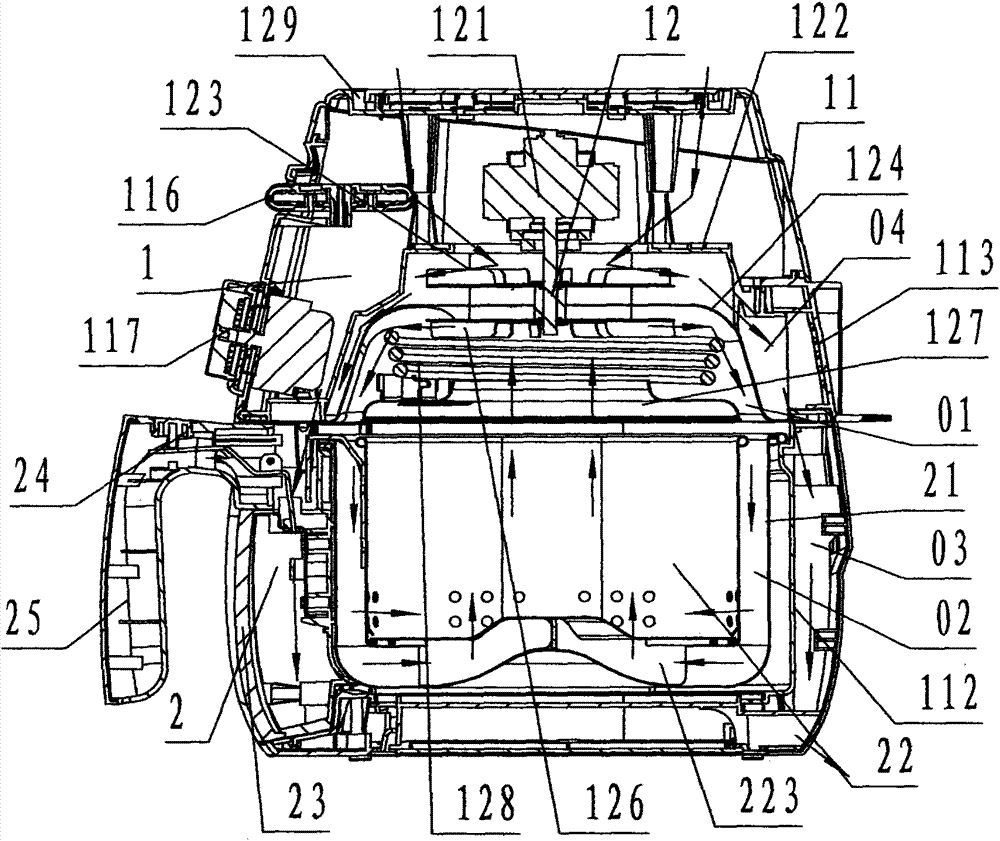

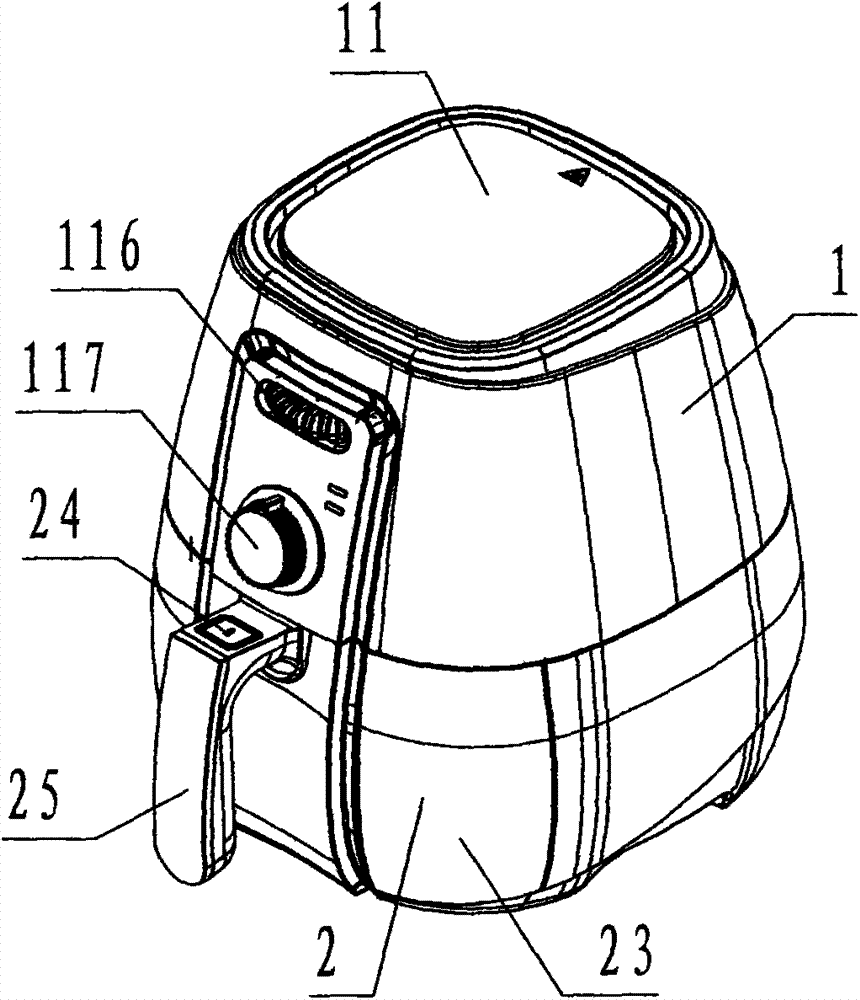

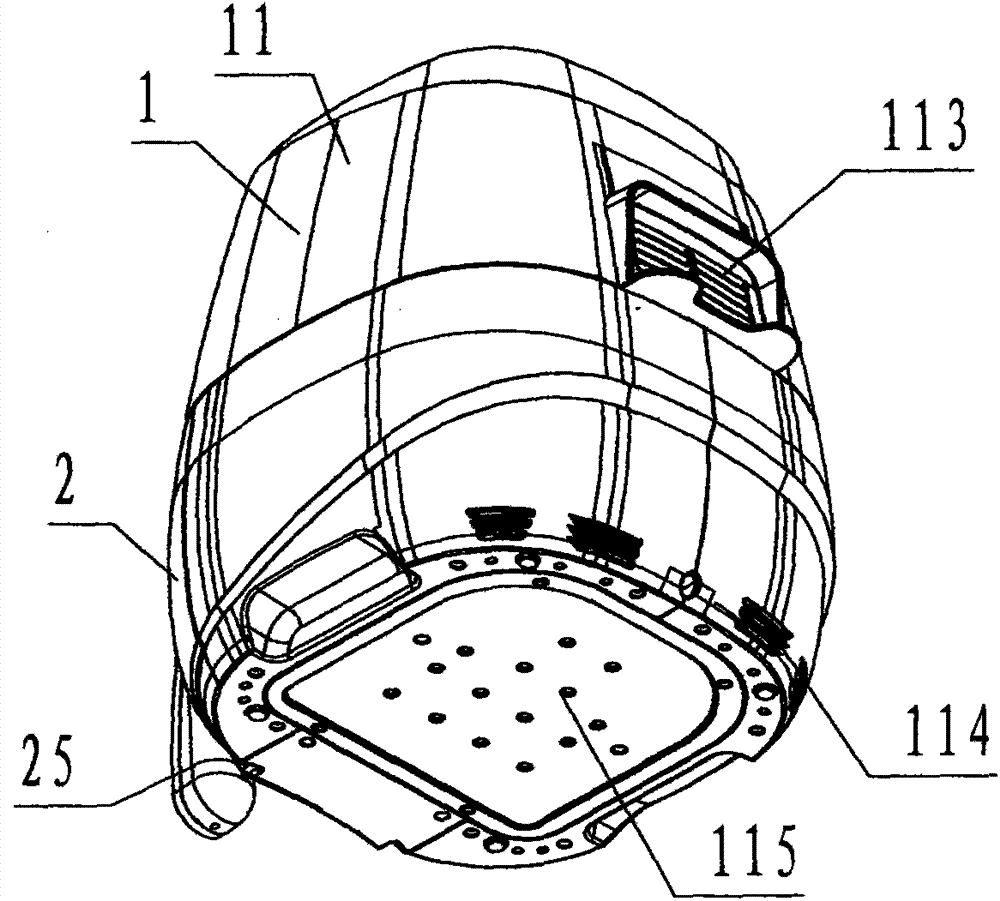

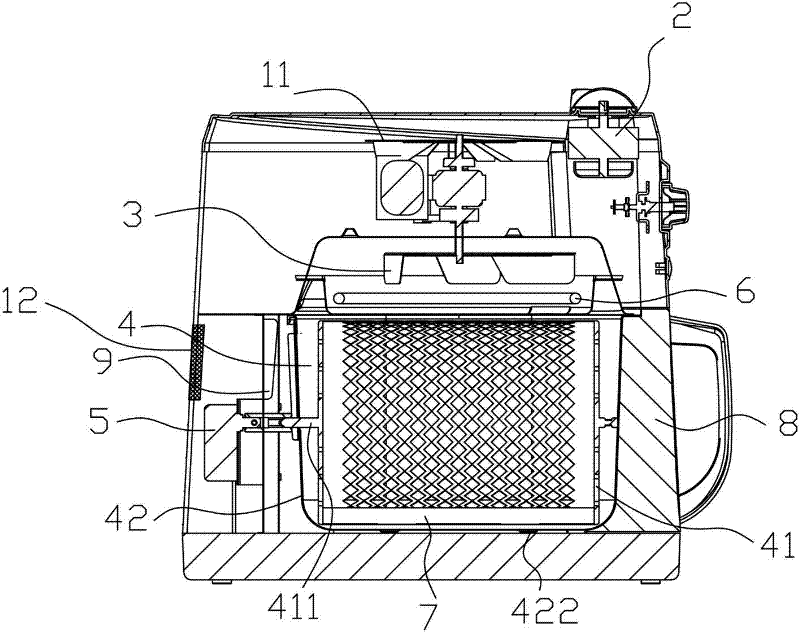

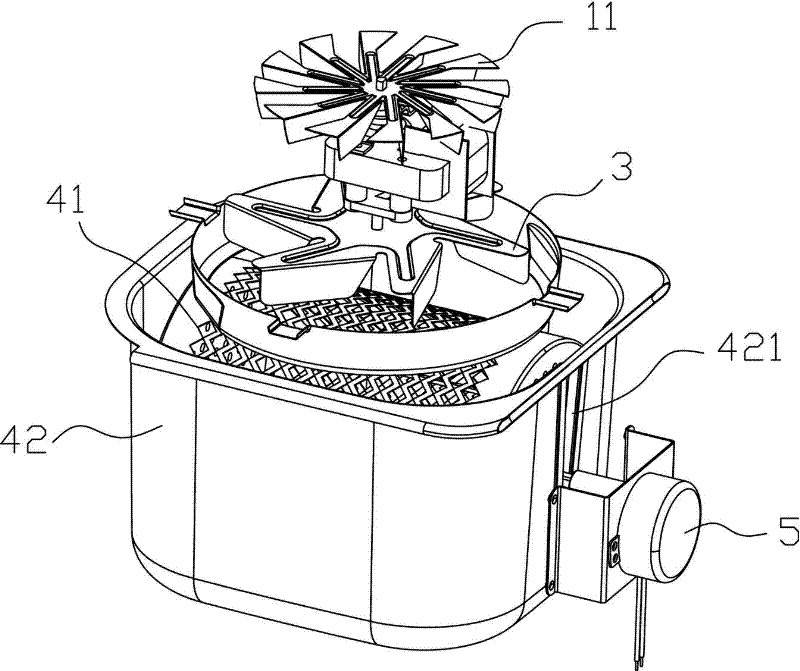

Household electric-heating air heat baking pot

The invention discloses a household electric-heating air heat baking pot which comprises a hot air generating portion (1) and a drawer pot (2). A device composed of the hot air generating portion and the drawer pot is adopted, a drawer pot socket used for inserting of the drawer pot is arrange on the lower portion of the hot air generating portion, a fan and electrical heated tubes are arranged on the upper portion of the hot air generating portion, the fan is downwardly provided with a fan cover, an upper blade, a hot air guiding hood, a lower blade and a hot air suction hood, a motor is located above the fan cover, and a gap formed between side walls of the hot air guiding hood and the hot air suction hood is called as an upper hot air channel; the drawer pot is internally provided with a hot air pot and a net basket, and a gap formed between the hot air pot and the net basket is called as a lower hot air channel. The technical scheme includes that when in use of the baking pot, the drawer pot is located in the drawer pot socket, food is placed in the net basket, the fan and the electrical heated tubes are started, and the lower blade drives hot air to enter the net basket via the lower hot air channel form the upper hot air channel to have the food cyclically heated, so that requirements of a household kitchen on hot air cookers are met.

Owner:NINGBO FENGYA ELECTRICAL APPLIANCES

Hot whirlwind type multifunctional cooker

InactiveCN102342761AAvoid Process Safety IssuesImprove the heating effectRoasters/grillsDeep fat fryersBiochemical engineeringHeating effect

The invention discloses a hot whirlwind type multifunctional cooker. The hot whirlwind type multifunctional cooker comprises a main body, a control assembly, a heating assembly, an air blowing assembly and a containing assembly, wherein the containing assembly comprises a rotating type containing basket, a motor assembly is arranged on the main body, the air blowing assembly is arranged above the containing basket, and is used for blowing air towards the top of the containing basket, and the heating assembly comprises a plurality of heating pieces which are arranged between the air blowing assembly and the containing basket. In the invention, heat produced by the heating pieces can be driven by cyclonic eddy to flow into the whole heating space, so that a good and uniform heating effect can be achieved; and food to be processed can be overturned at the same time to achieve a good and uniform baking effect, so that the problem on the safety of food processing due to the excessive application and recycling of oil caused by immersing and frying the food in oil is solved. When an oil scoop is further provided to pour shoveled oil above the food, the oil can rotate together with the food, and can be uniformly mixed with the food, so that fried food is more uniform and healthy after being heated by high-temperature cyclonic eddy.

Owner:黄朝龙

Sperm collector with squeezing function

InactiveUS20120215189A1Good effectIncrease stimulationVaccination/ovulation diagnosticsNon-surgical orthopedic devicesHeater RodEngineering

The present invention is a sperm collector with squeezing function. It includes a soft rubber body provided with a penis insertion passage and a container body provided with at least a top end cover and receives the soft rubber body. When the top end cover and the container body are engaged, the soft rubber body is confined within a cavity formed by the top end cover and the container body. When the top end cover is disengaged, a front end portion of the soft rubber body protrudes out of an opening of the container body. A pressing means is provided at a middle lower portion of the container body. When using the present invention, the user could press the pressing means to squeeze the penis insertion passage of the sperm collector. Accordingly, stimulation to penis is increased and better effect of sperm collection is achieved. In particular, since the present invention is also provided with a heating rod, lubricant pockets and electrical vibrators, which enable the user to reach a climax as quick as possible, thereby further enhancing the effect of sperm collection.

Owner:AILV HEALTH TECH

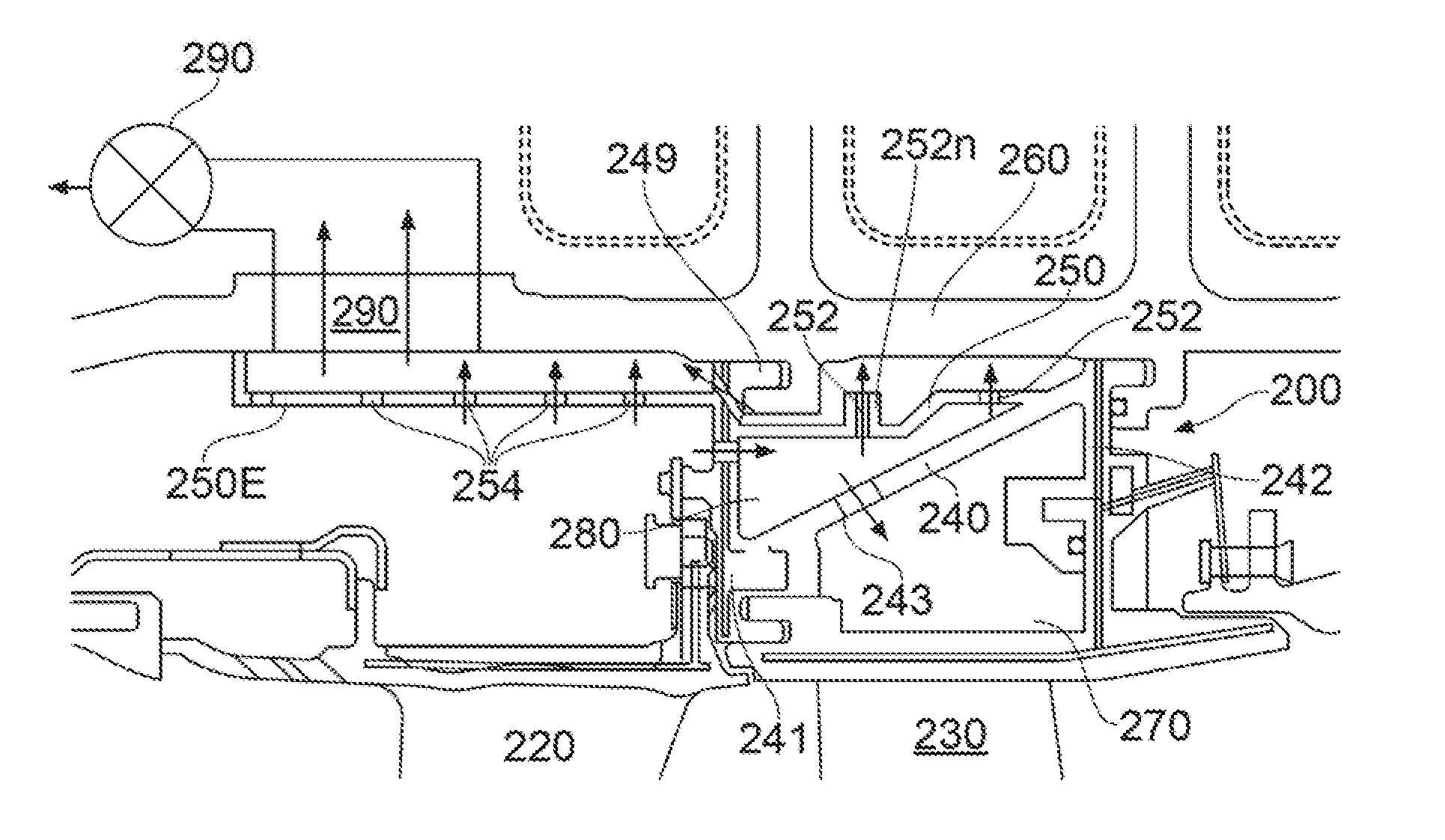

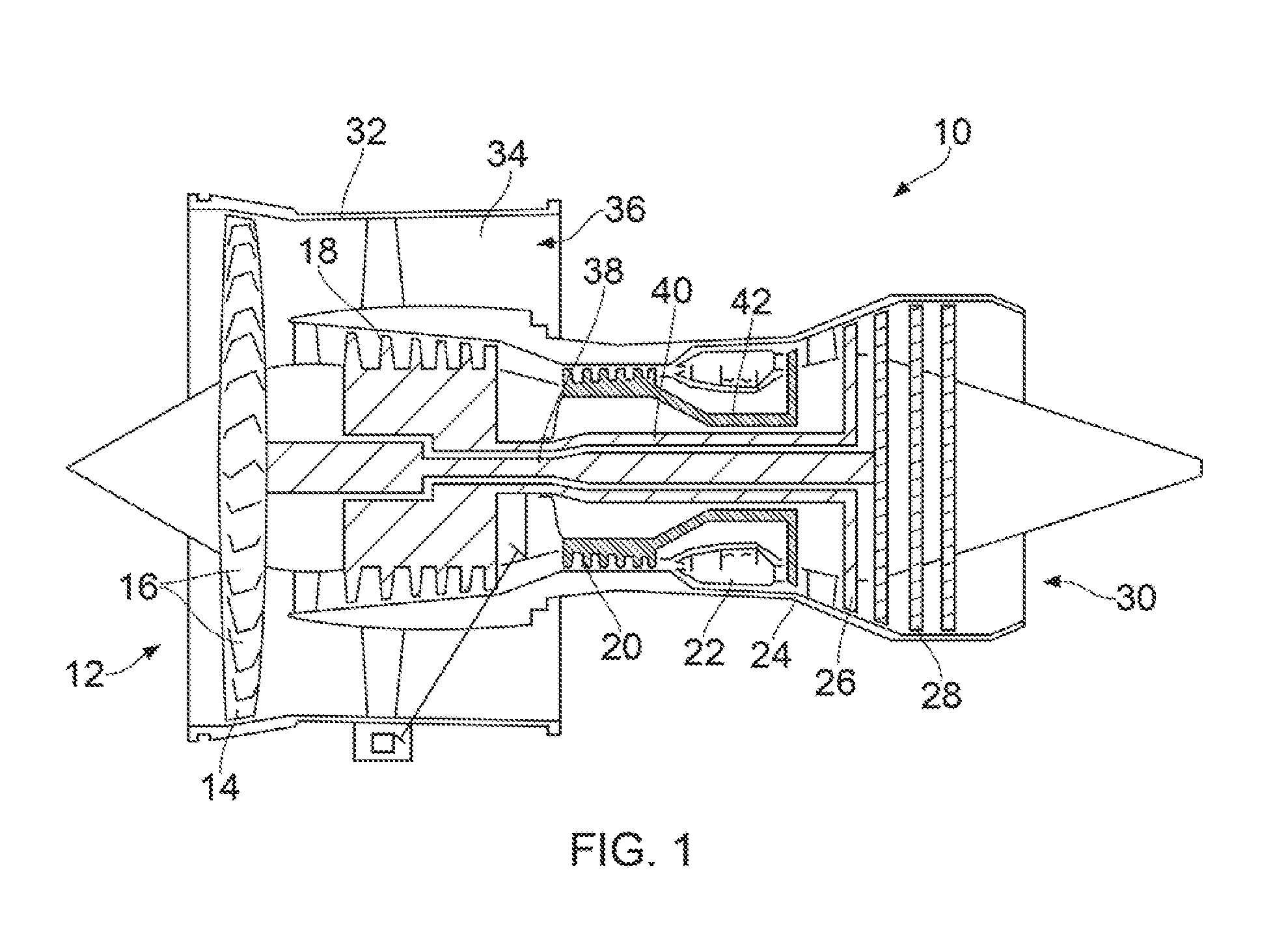

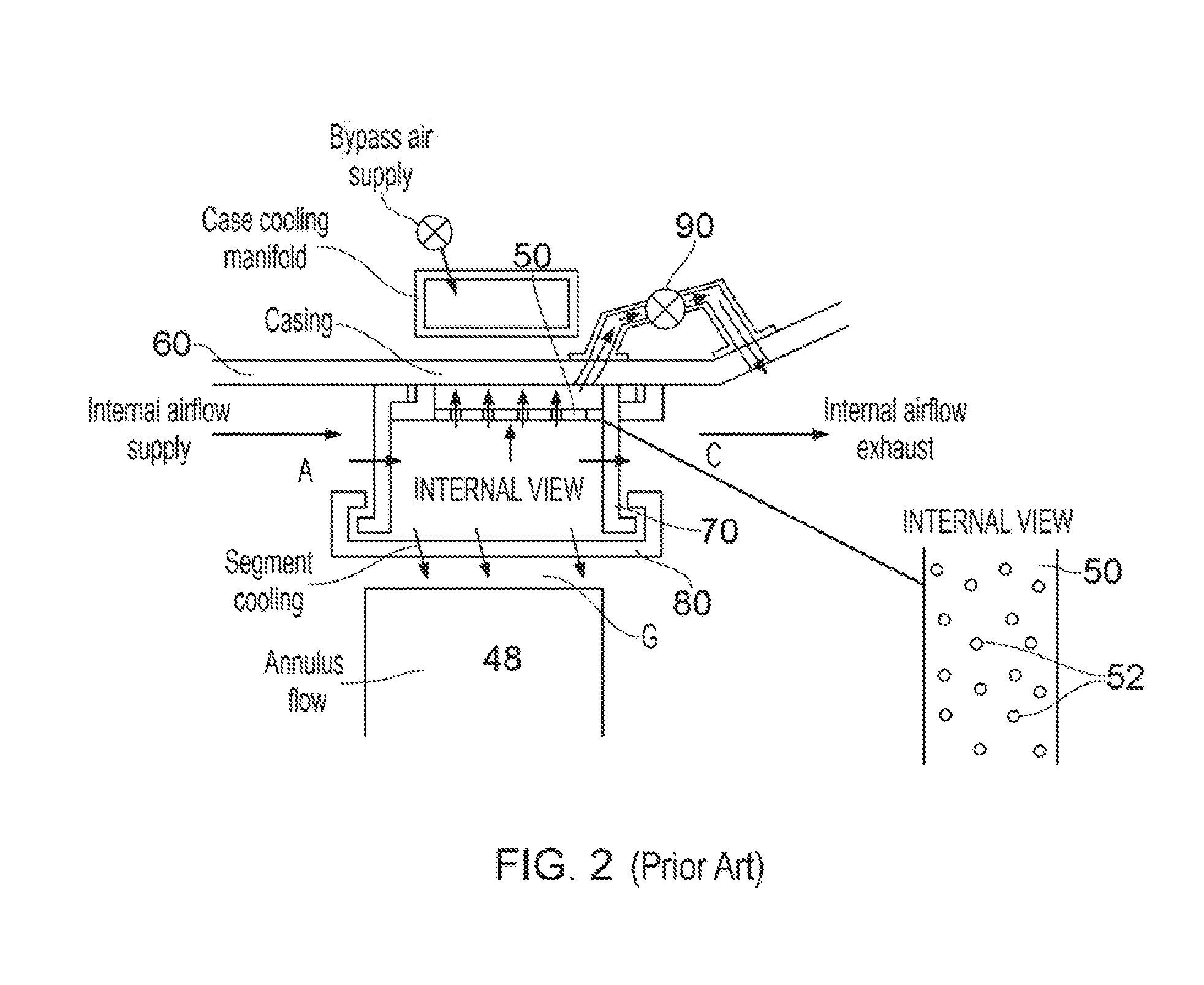

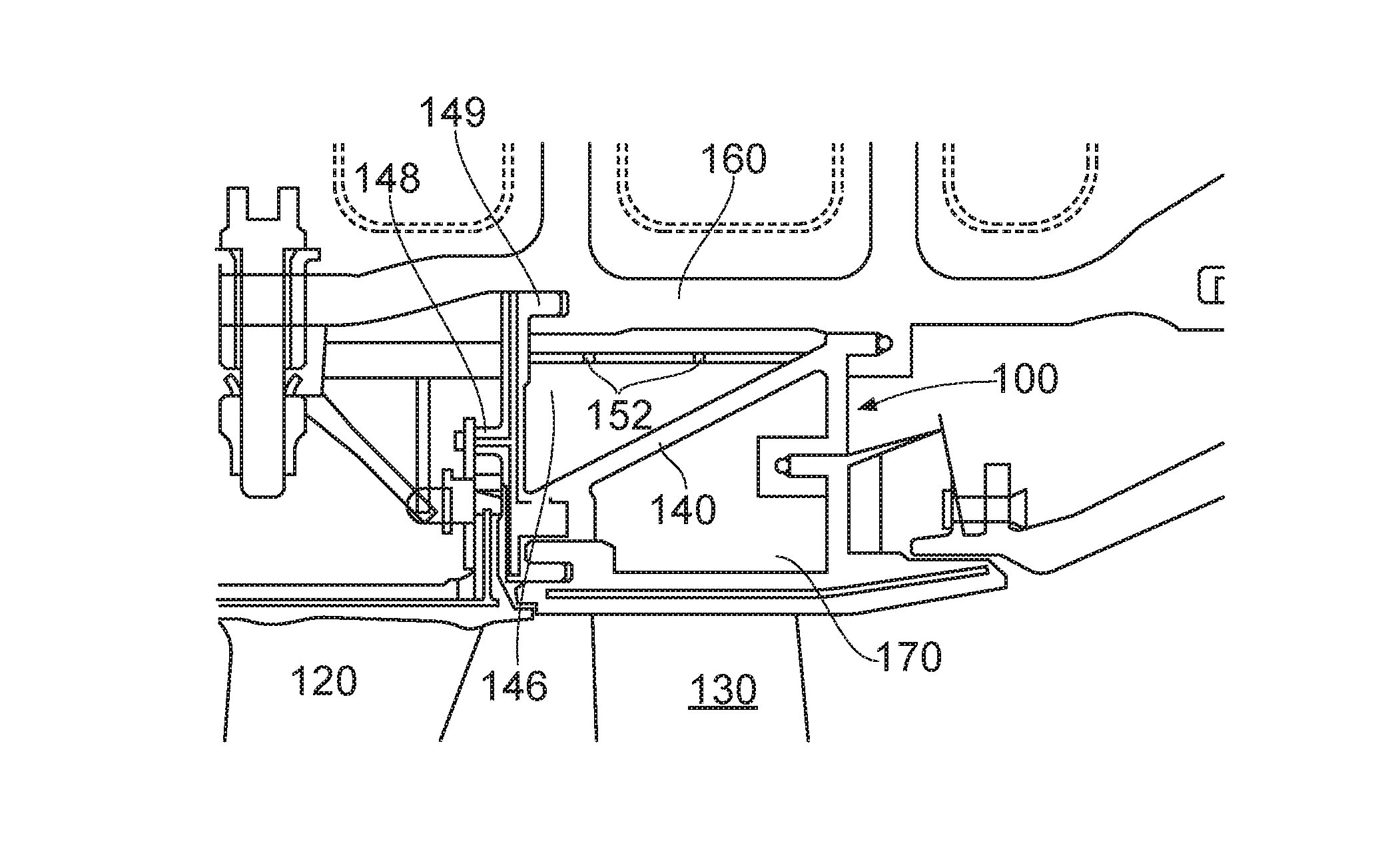

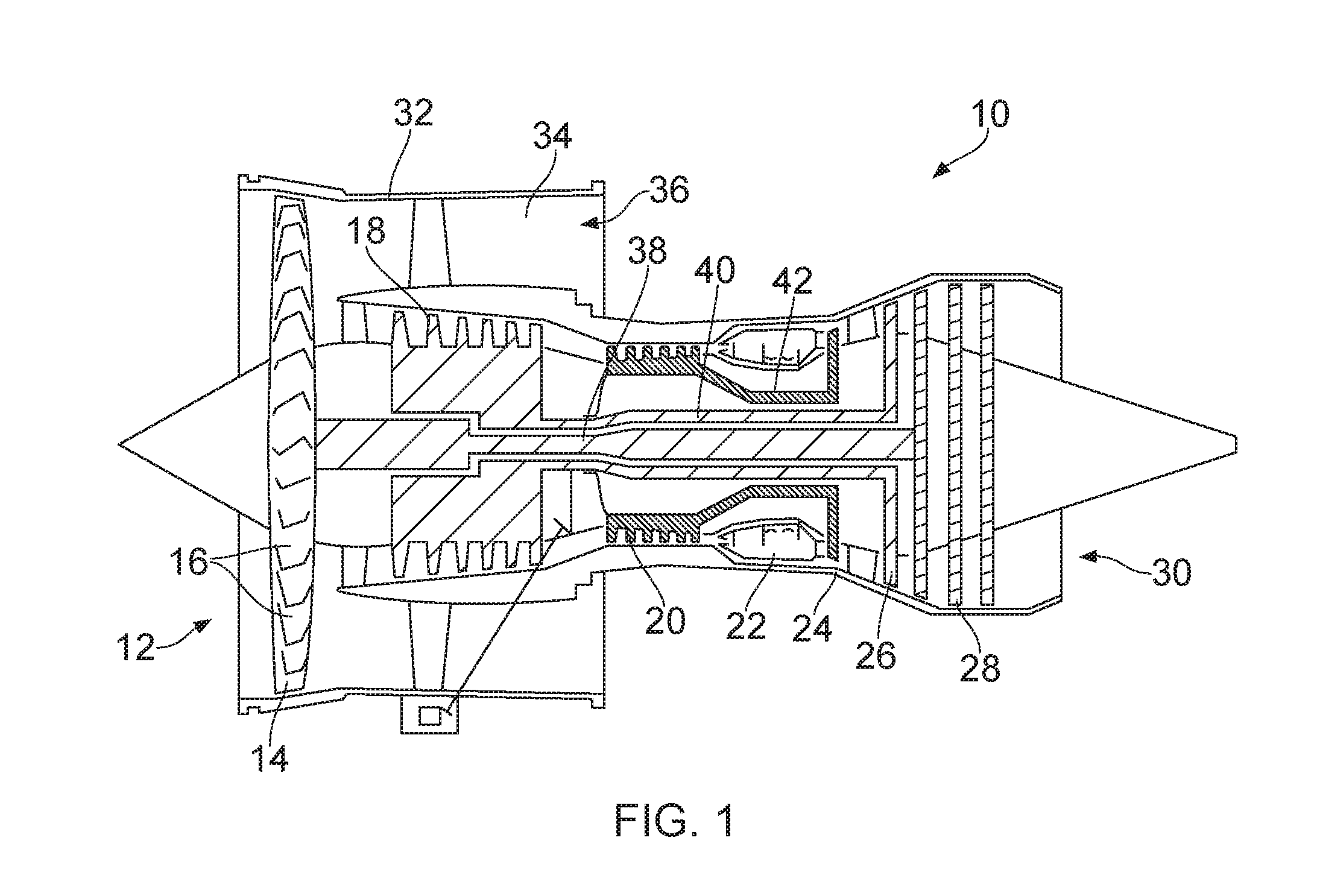

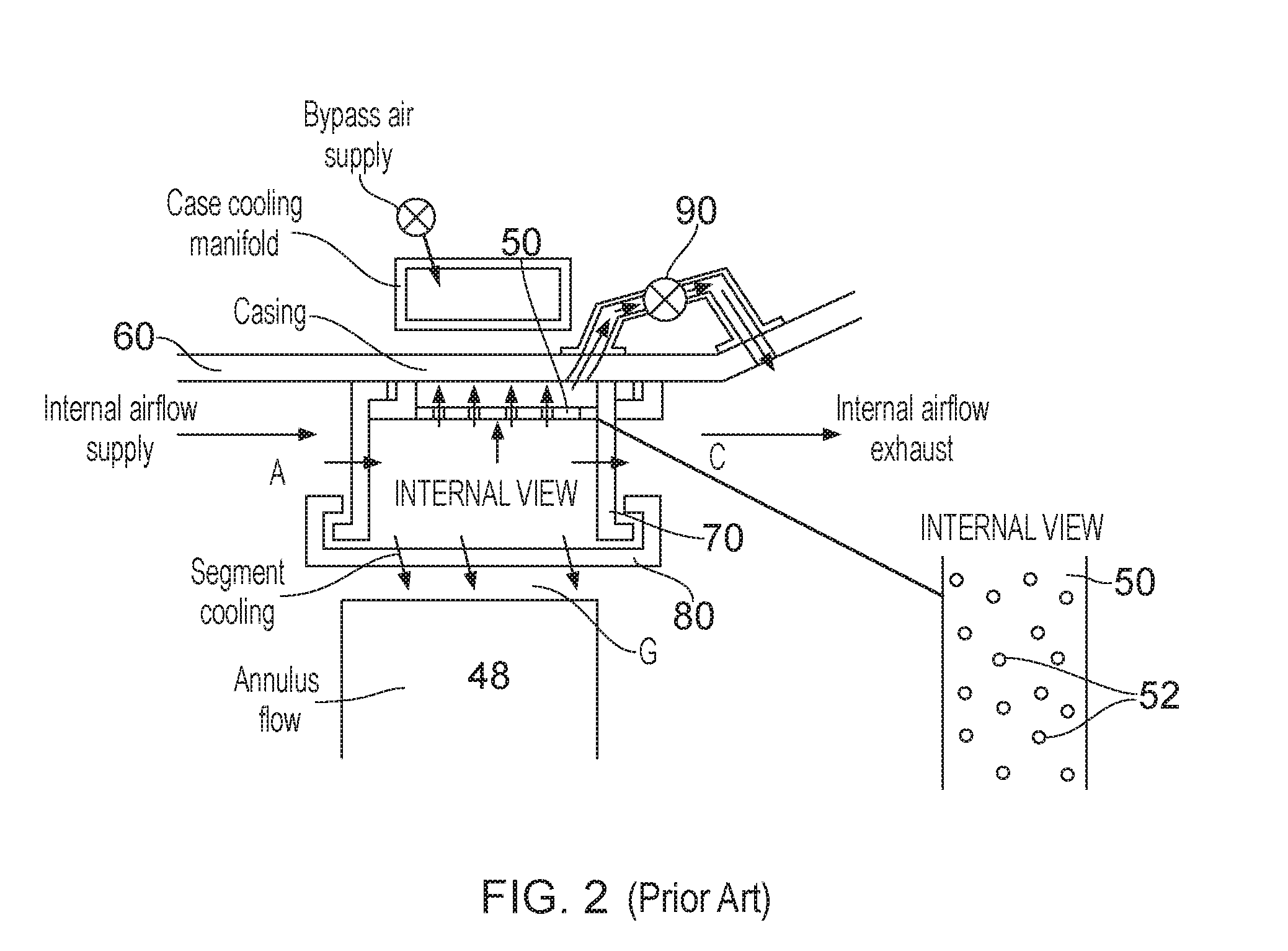

Tip clearance control for turbine blades

ActiveUS20160169026A1Increase powerOptimise thermal responsiveness of systemEngine fuctionsBlade accessoriesTurbine bladeGas turbines

An engine includes circumferentially spaced turbine blades radially inward a casing and circumscribed by a carrier section having segments, each having a carrier wall radially inward the casing and radially outward the turbine blades. The wall has one or more portions facing the casing. At least one of the portions has one or more impingement apertures for air passage of a predetermined temperature from a feed source into impingement onto the casing. The segments are radially inward the casing and radially outward the turbine blades, with the portions of their respective walls facing the casing. A method of controlling the gas turbine engine turbine casing temperature includes: passing air of a predetermined temperature from a feed source through the apertures in the one or more portions and into impingement on the casing; and optionally exhausting the air impinged onto the casing from a space between the segment and the casing.

Owner:ROLLS ROYCE PLC

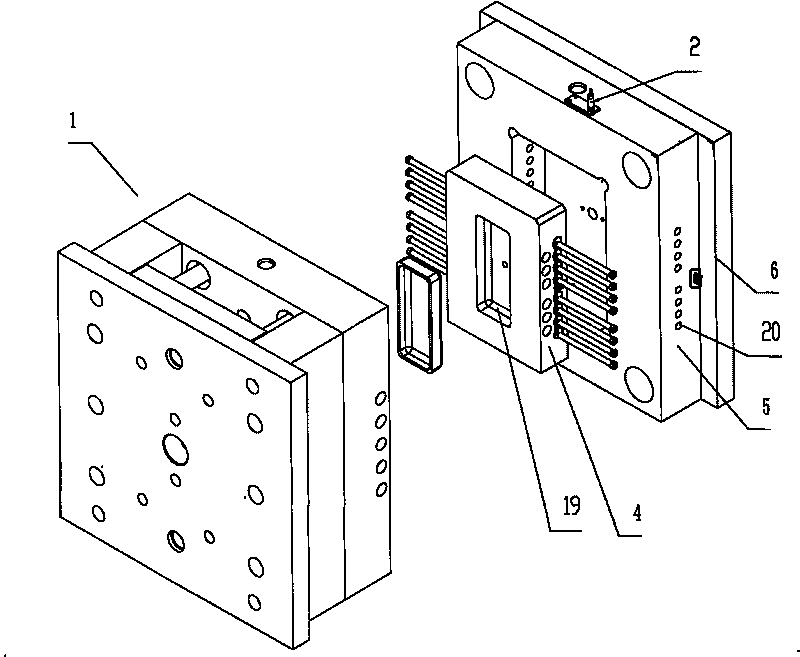

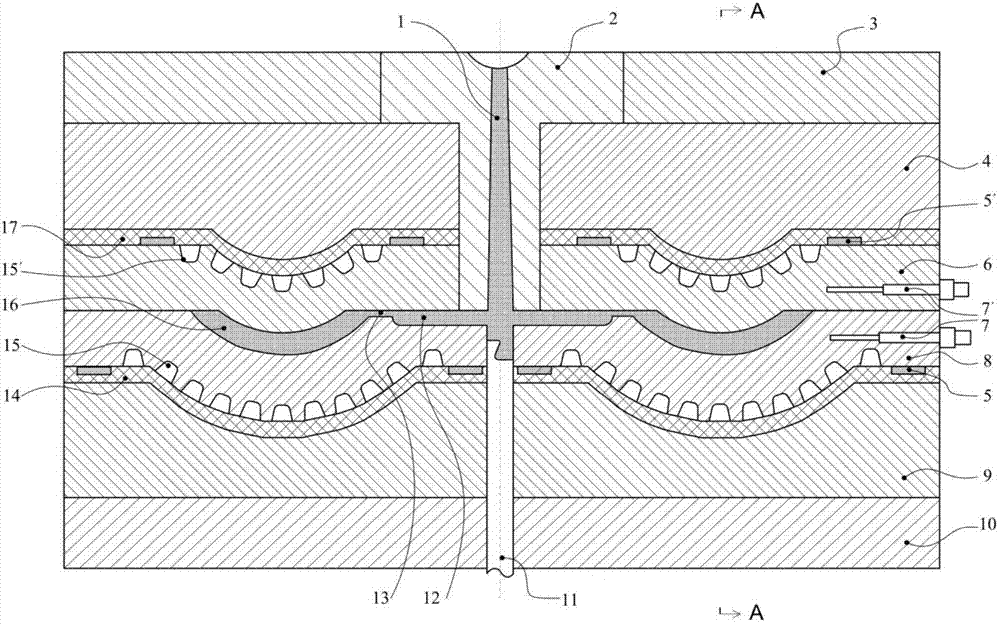

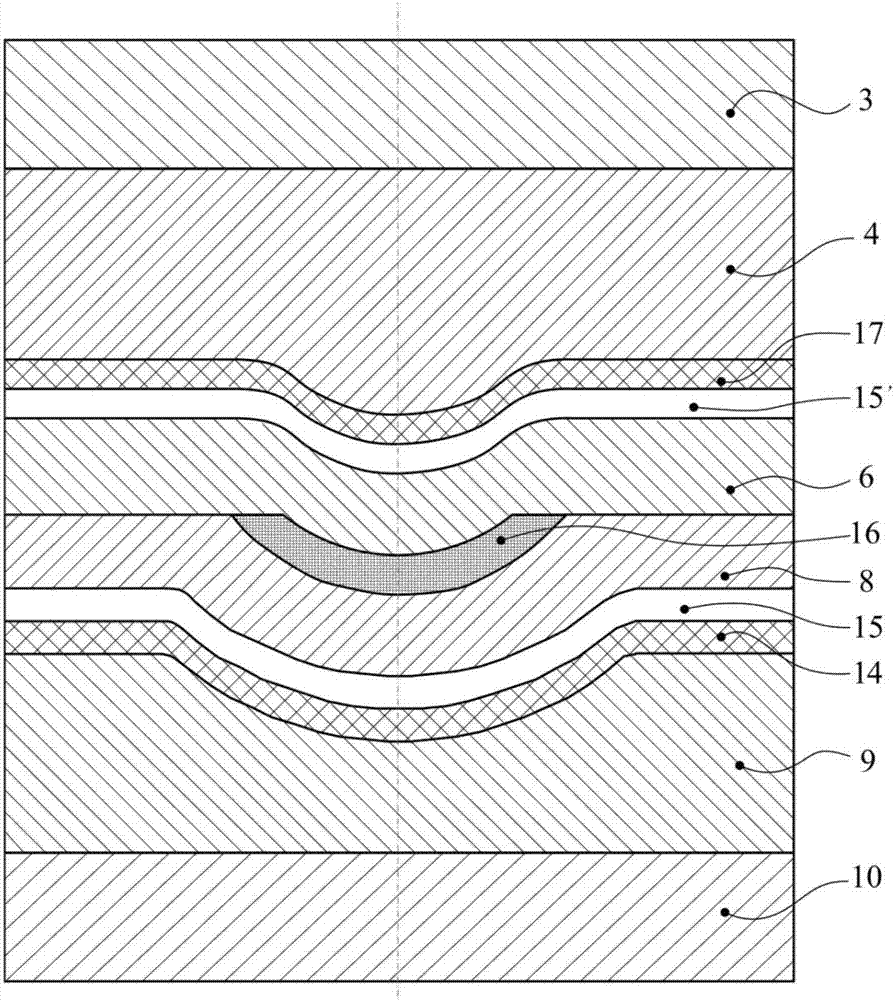

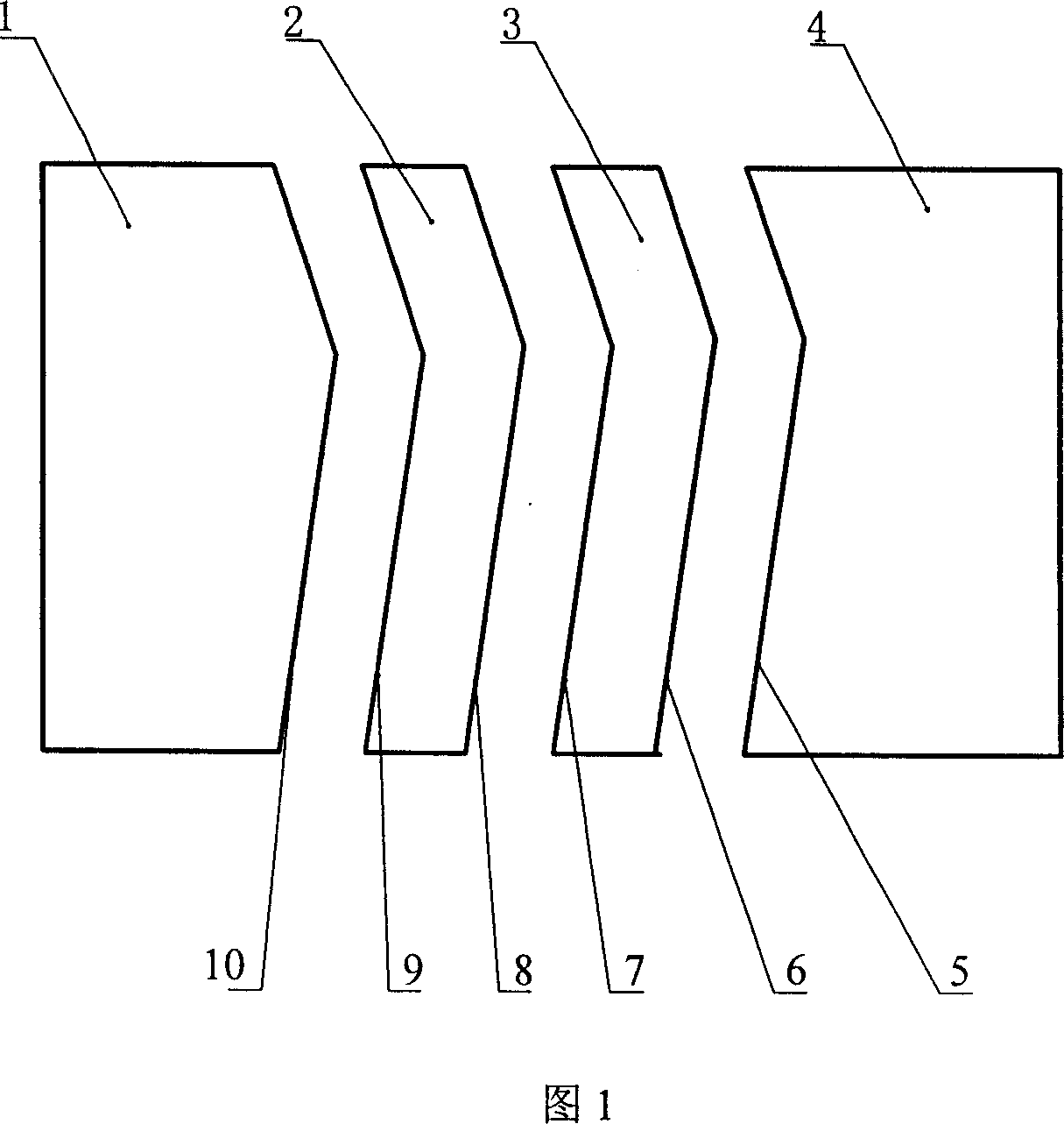

Steam heating type fast heat-circulation injection mould

The invention relates to a steam heating type fast heat-circulation injection mould which comprises a steam heating type sectional cavity plate and an electric heating type sectional core plate, wherein the fast heat-circulation injection mould further comprises a thermal insulation device and a support device which are respectively matched with the steam heating type sectional cavity plate and a steam heating type sectional core plate. The back surfaces of the steam heating type sectional cavity plate and the steam heating type sectional core plate are provided with grooves, the grooves are matched with the surface of the thermal insulation device to form a sealed pipe hole, so as to be used as a heating device and a cooling device. Sealing devices are respectively arranged between the steam heating type sectional cavity plate and the corresponding thermal insulation device and between the steam heating type sectional core plate and the corresponding thermal insulation device. Temperature measurement devices are respectively installed on the steam heating type sectional cavity plate and the steam heating type sectional core plate. The temperature measurement devices, the heating device and the cooling device are connected with a temperature control device. The steam heating type fast heat-circulation injection mould has the outstanding advantages of high heating and cooling efficiency and heating uniformity, so that the surface of a sectional cavity of a three-dimensional complex-shape mould can be uniformly and quickly heated or cooled.

Owner:SHANDONG UNIV

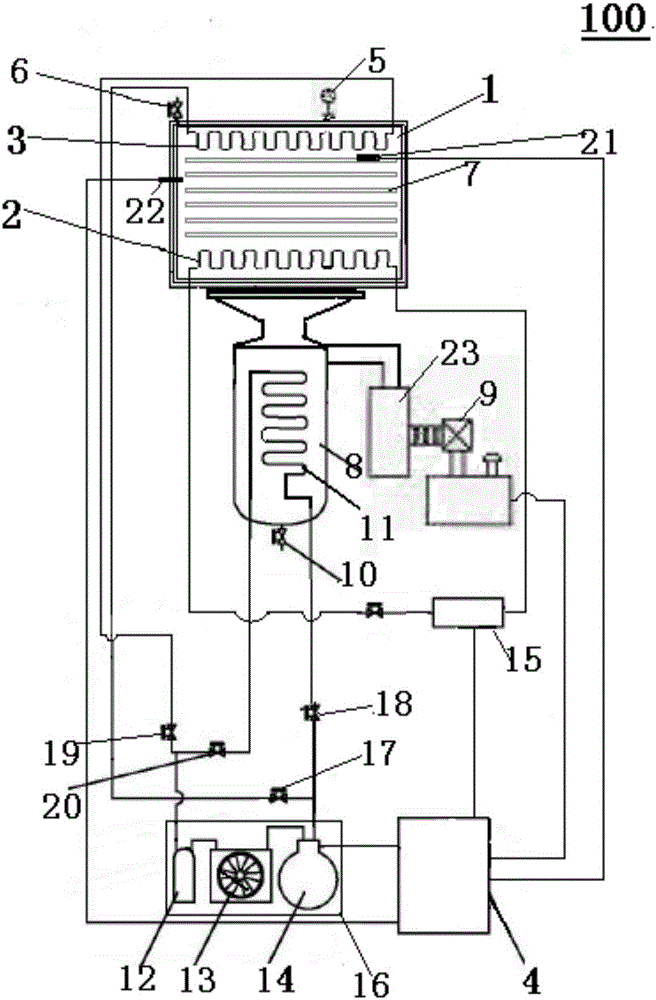

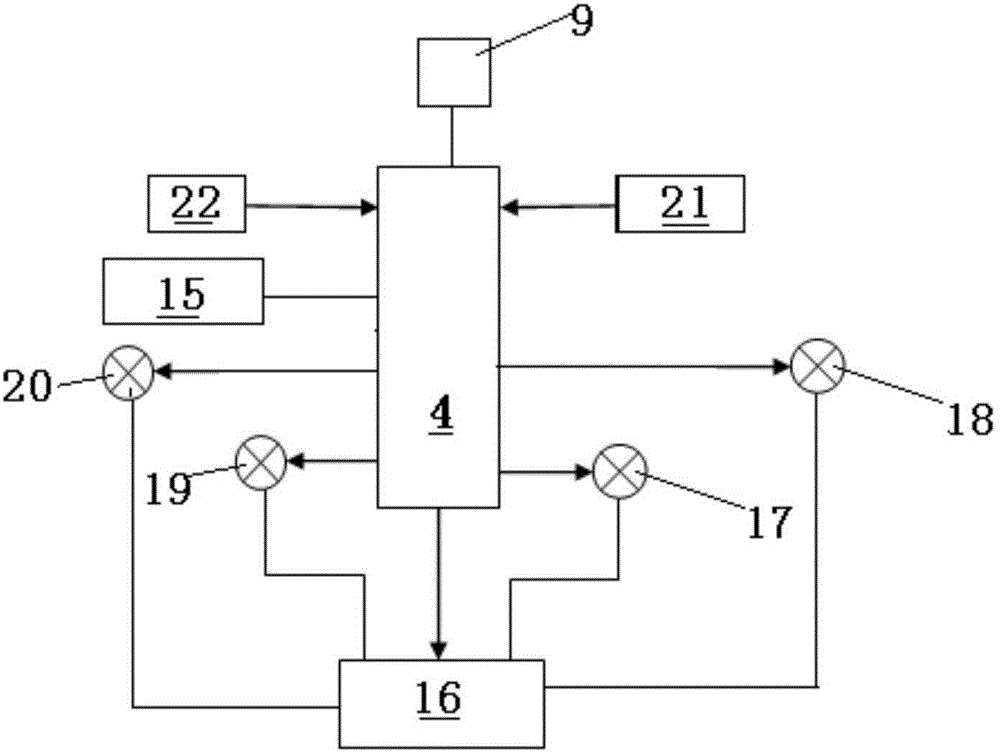

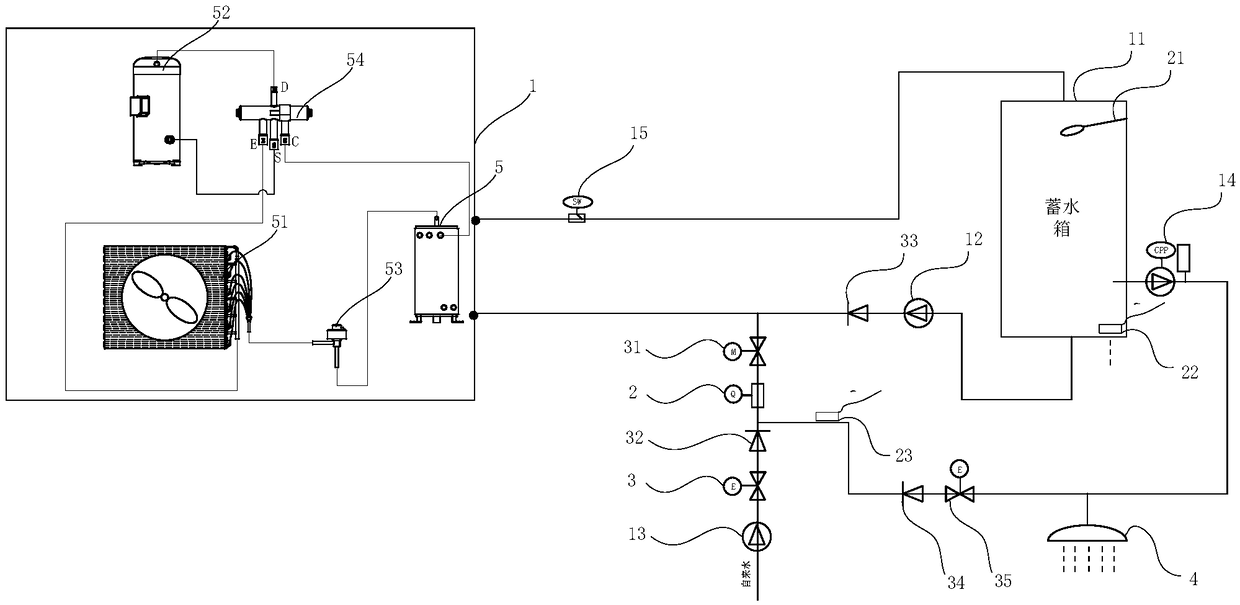

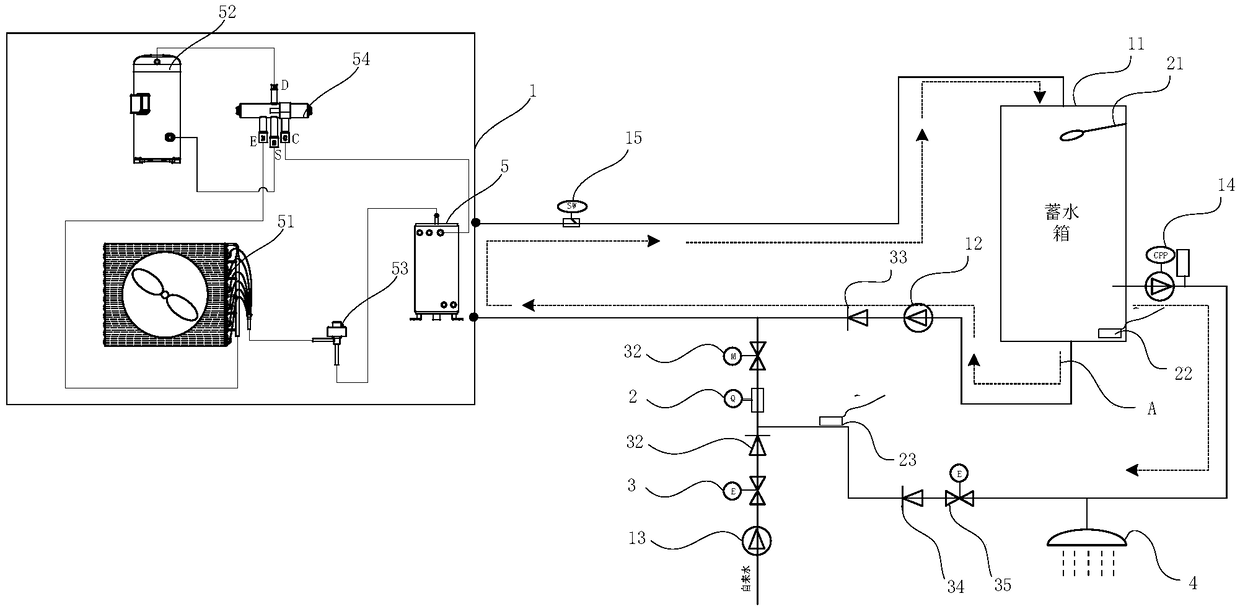

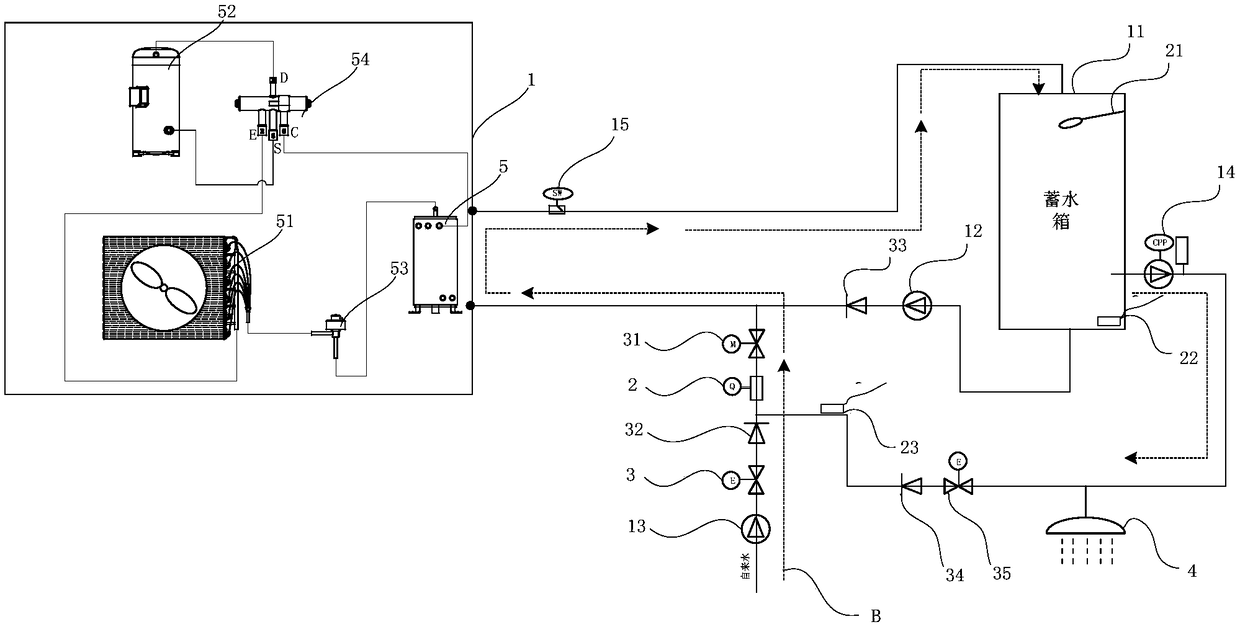

Heat pump hot water system and control method thereof

ActiveCN109059280ARealize the heating function of circulation-direct heating integrationEnhance hot water supply capacityFluid heatersElectricityWater storage tank

The invention discloses a heat pump hot water system and a control method of the heat pump hot water system. The system comprises a controller, a heat pump unit, a water storage tank and a water supply pipeline. The first water outlet end of the water storage tank is communicated with the water inlet end of the heat pump unit to form a first pipeline, and the water storage tank is communicated with the water outlet end of the heat pump unit to form a second pipeline. The water storage tank, the first pipeline, the heat pump unit and the second pipeline are sequentially connected to form a circulating heating loop, and the water supply pipeline, the first pipeline, the heat pump unit and the water storage tank are sequentially connected to form a direct heating loop. The water supply pipeline is provided with a water supply pump, a first electromagnetic two-way valve, a flow sensor and a second electromagnetic two-way valve which are sequentially connected in series, and the first pipeline is provided with a circulating water pump which is electrically connected with the controller. By the adoption of the heat pump hot water system and the control method, the integration of a circulating heating mode and a direct-heating heating mode of a heat pump water heater can be effectively achieved, and the hot water supply capacity of the heat pump water heater is improved, so that improvement of the use comfort of users is facilitated.

Owner:GUANGDONG PHNIX ECO ENERGY SOLUTION

Power supply device and automobile

PendingCN106684501AExtended service lifeUniform heating effectSecondary cellsBatteriesHeat managementElectrical battery

The invention provides a power supply device and an automobile. The power supply device comprises a plurality of parallel battery modules, a liquid cooling flat tube bypassing the plurality of battery modules, processing controllers, a plurality of heating pieces and temperature transducers, wherein the heating pieces are arranged on the liquid cooling flat tube and make contact with the battery modules; the temperature transducers are arranged on the battery modules and used for measuring temperature of the battery modules; the temperature transducers and the heating pieces are electrically connected with the processing controllers; the processing controllers control the heating pieces to work to heat the battery modules when the temperature, detected by the temperature transducers, of the battery modules is lower than a first preset temperature value. Therefore, heating management of the battery modules can be subjected to independent control (namely, distributed control), the temperature of the battery modules can be adjusted flexibly and dynamically according to the actual temperature conditions of the battery modules, more uniform heating effect is realized, and the service life of each battery module can be prolonged effectively.

Owner:HUATING HEFEI POWER TECH

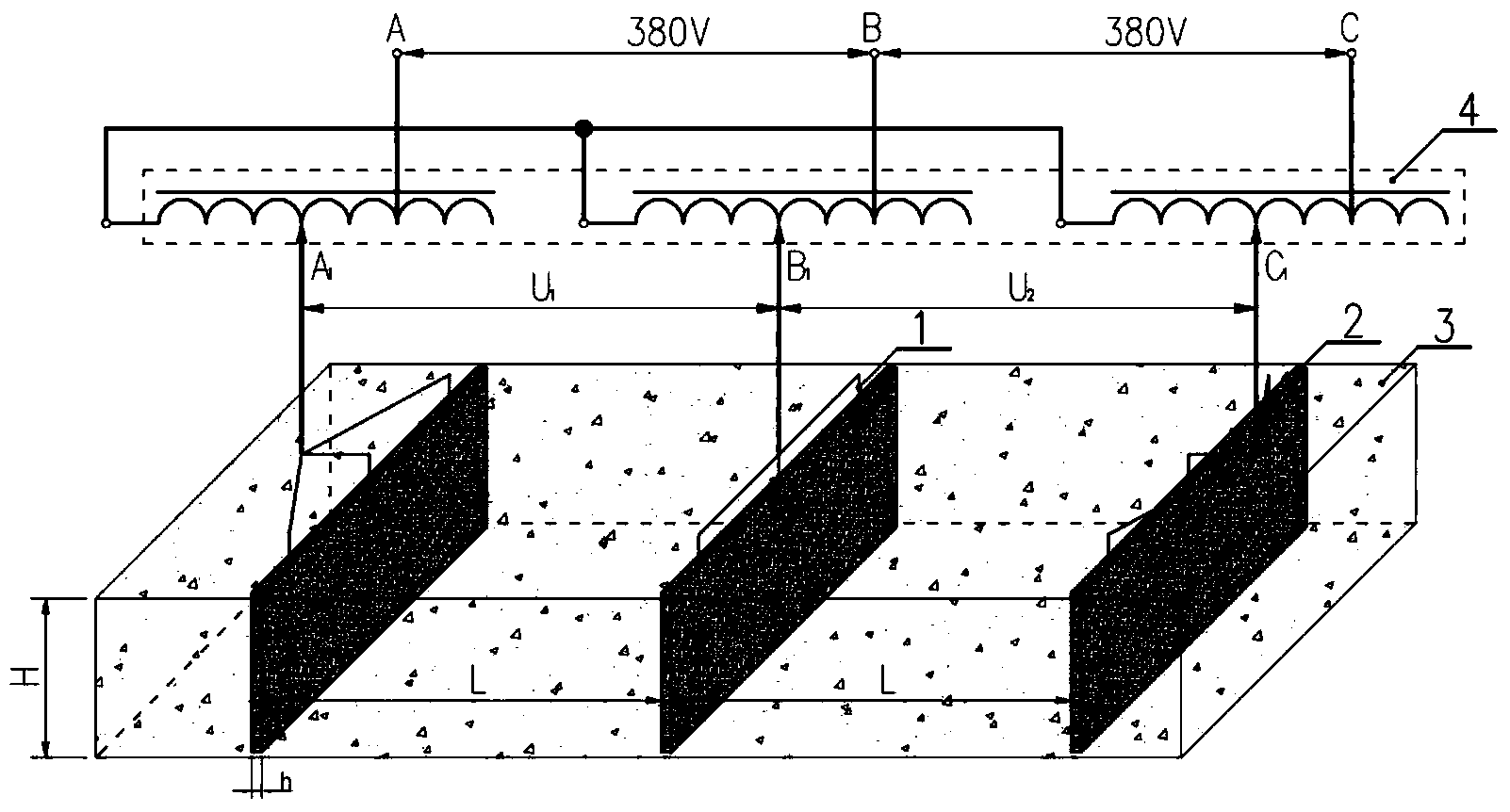

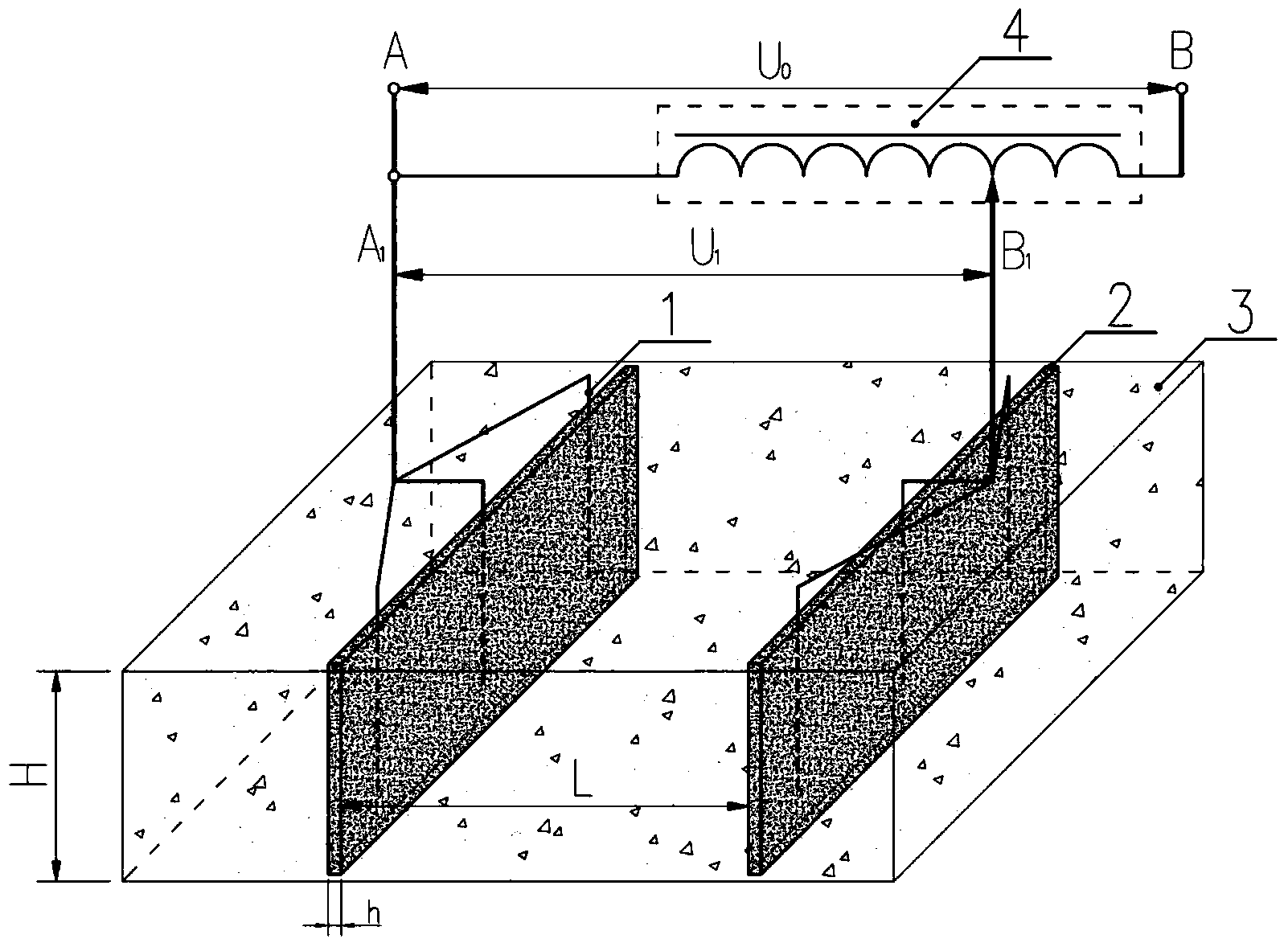

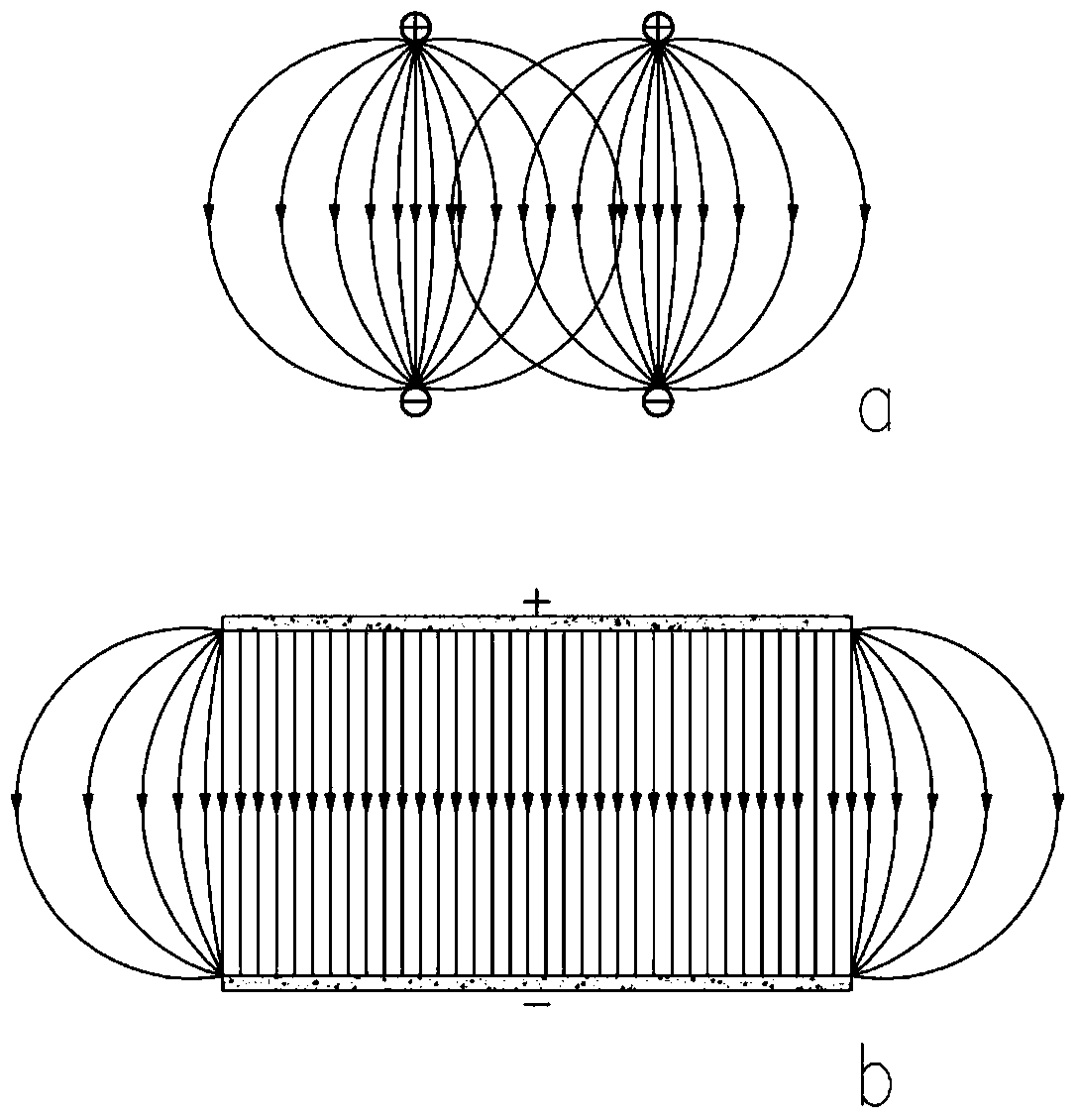

Method and device for obtaining uniform electric field for electrically repairing polluted soil

ActiveCN103706622ALow costUniform heating effectContaminated soil reclamationCarbon particleElectric field

The invention discloses a method for obtaining a uniform electric field for electrically repairing polluted soil. The method comprises the following steps: digging grouped channels or grooves of certain widths and depths at certain intervals in a field needing soil repair; filling current-conducting carbon particles being phi1.5-phi5 millimeters in particle sizes into the grouped channels or grooves; placing leading-in terminals of a power supply into the current-conducting carbon particles in the grouped channels or grooves to form parallel electrodes, wherein the number of the electrodes is 2*N or 3*N, and N is a positive integer. By adopting the method, a uniform soil repair electric field can be provided, spindle type electric field distribution is eliminated, and the problems of the need of repairing microorganism-polluted soil with a completely symmetrical electric field and the like are particularly solved. Compared with the distribution of linear electrodes or matrix electrodes, the method has the advantages of simplicity and easiness in making electrodes, low cost and higher efficiency.

Owner:JIANGSU DDBS ENVIRONMENT REMEDIATION

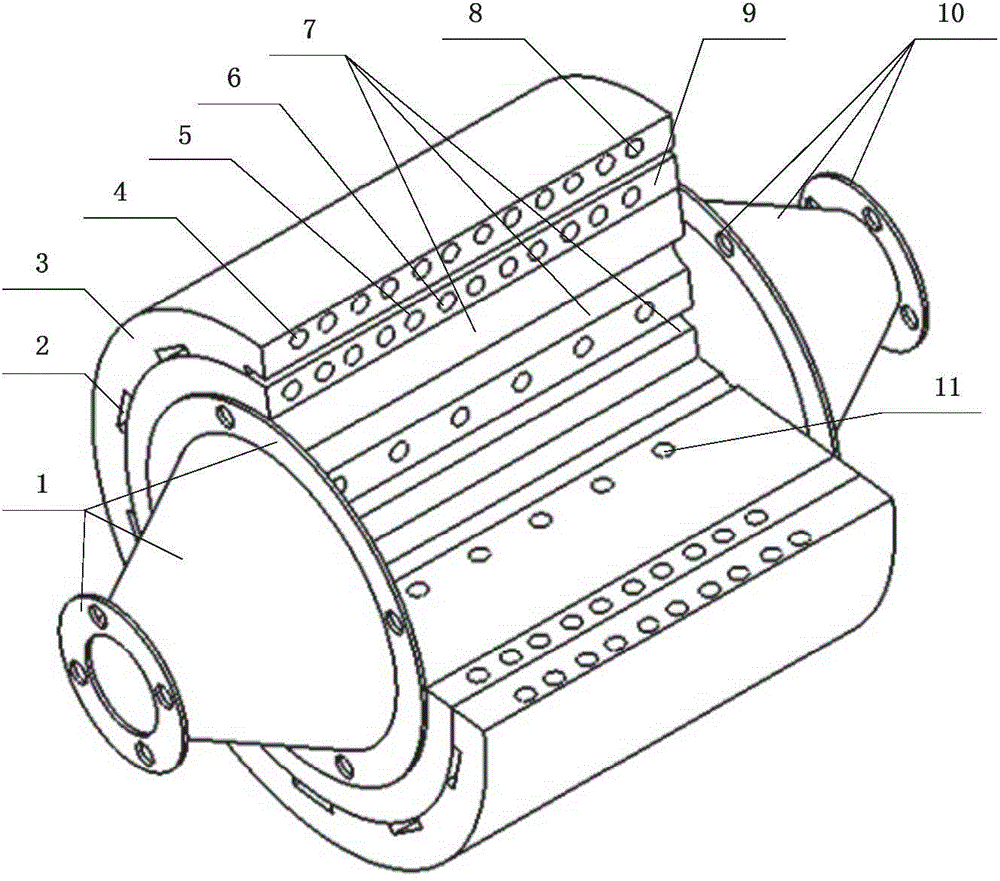

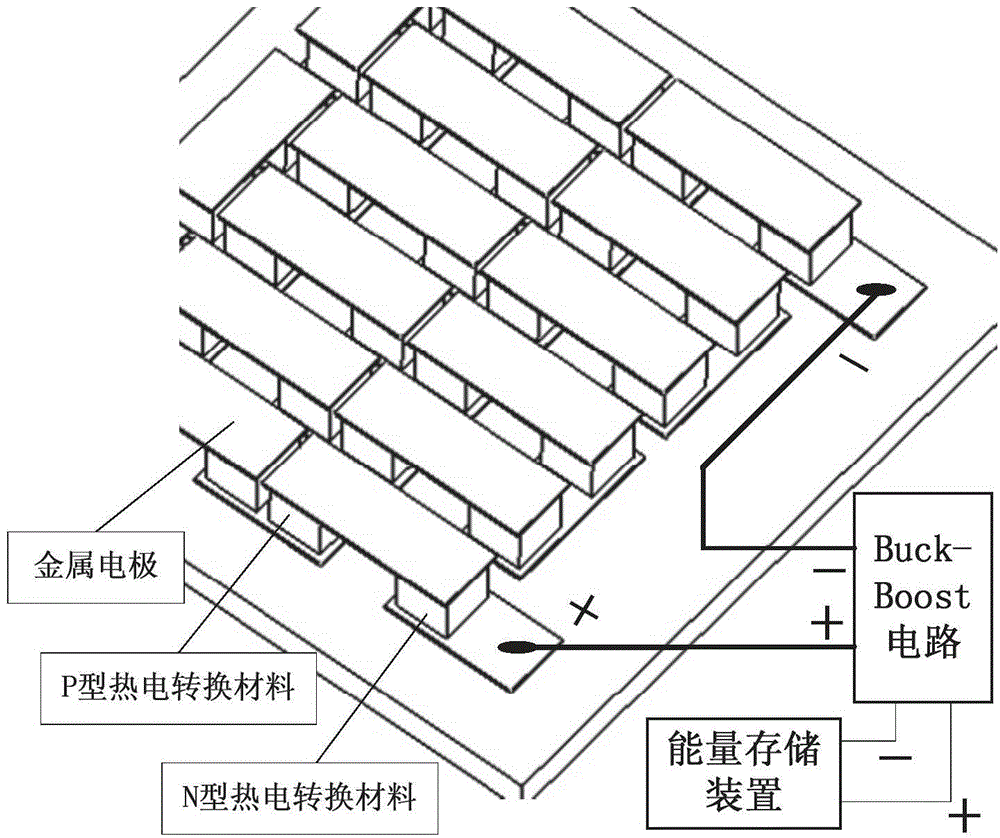

Cellular cylinder type vehicle engine waste heat power generator

ActiveCN104935210AEasy to assembleOptimize layoutInternal combustion piston enginesExhaust apparatusRecuperatorEngineering

The invention discloses a cellular cylinder type vehicle engine waste heat power generator comprising an air inlet flange connection assembly, a thermoelectric generation assembly, a water cooling plate, a water cooling plate cold water pipe A, a water cooling plate cold water pipe B, a high temperature heat transfer medium channel A, a high temperature heat transfer medium channel B, a cellular heat exchanger, a high temperature plate, an air outlet flange connection assembly, and a heat transfer medium cycle channel. Waste gas generated by an engine enters the cellular cylinder type vehicle engine waste heat power generator through the air inlet flange connection assembly; partial heat in the waste gas is collected by a heat absorb coating on an inner wall of the pipe and transferred to the heat transfer medium; the heat transfer medium transfers the heat to the high temperature plate through double helix channels in the high temperature plate. One side of the thermoelectric generation assembly is tightly attached to the high temperature plate, and the other side is cooled by the water cooling plate with flowing cold water, thus generating power under a Seebeck effect.

Owner:JIANGSU UNIV

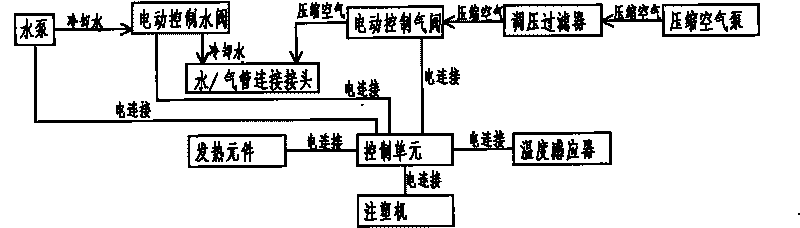

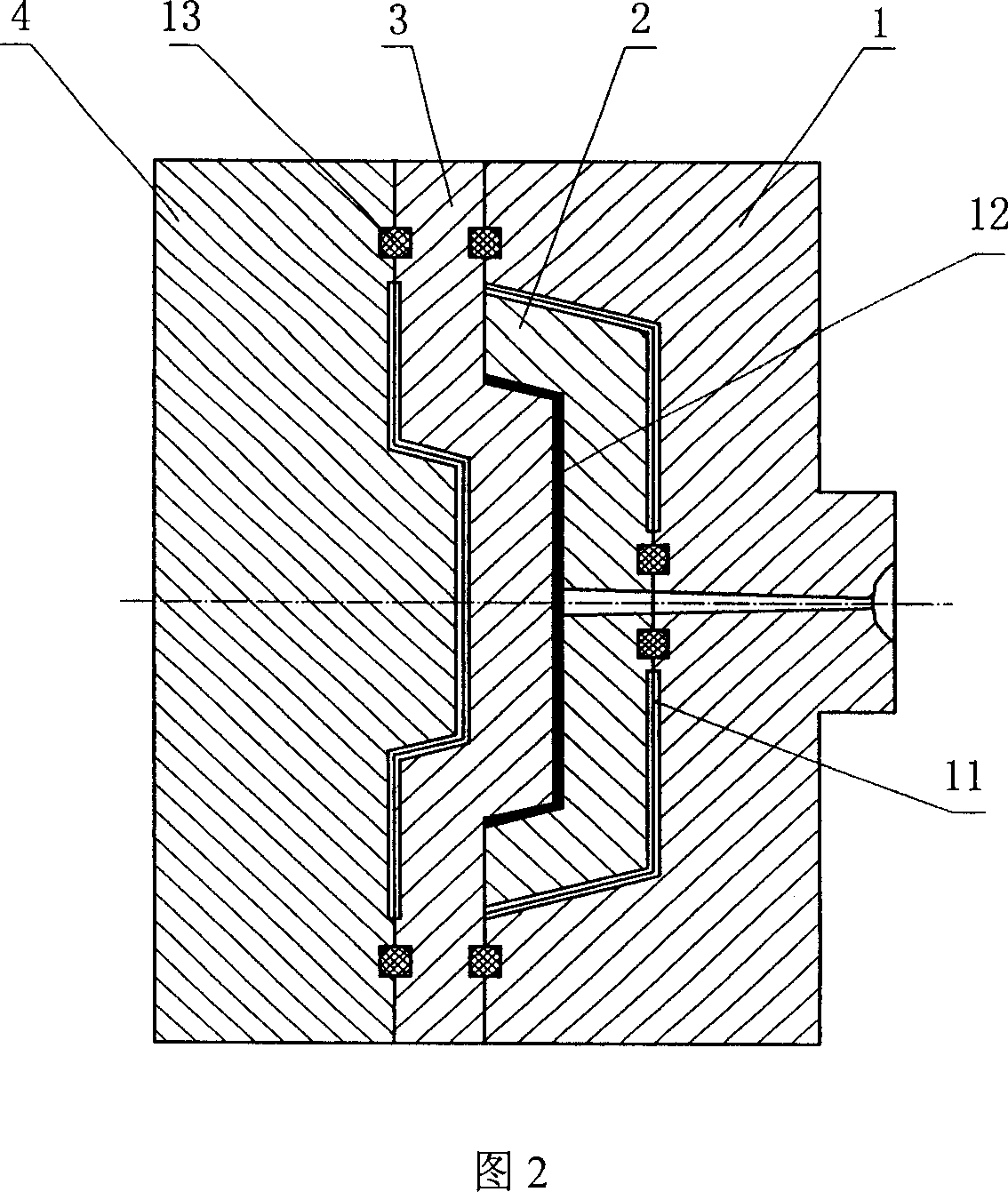

Method for realizing uniform heating and cooling of plastic injection mould

The present invention provides one kind of method of heating and cooling plastic injecting mold. The method includes splitting each of the movable mold and the fixed mold into two parts, one inner part and one outer part, assembled together; making the split movable mold and the fixed mold possess the required profile, and machining water / air channels in the split movable mold and the fixed mold for both heating and cooling. The present invention has water / air channels for both heating and cooling in the same distance to the profile of the mold cavity, so that it has homogeneous heating and cooling and capacity of obtaining high quality plastic injecting formation product.

Owner:SHANDONG UNIV

Tip clearance control for turbine blades

ActiveUS20160169027A1Increase powerOptimise thermal responsiveness of systemEngine fuctionsBlade accessoriesTurbine bladeEngine power

A carrier segment of a carrier section for circumscribing an array of circumferentially spaced turbine blades of a gas turbine engine, the blades being disposed radially inwardly of a turbine casing, the carrier segment including a carrier wall disposed radially inwardly of the casing and radially outwardly of the turbine blades, and the carrier wall including one or more portions facing the casing, wherein at least one of the one or more portions of the carrier wall is provided with one or more impingement apertures therein for passage therethrough of air of a predetermined temperature, heating air, from a feed source into impingement onto the turbine casing. The application of heating air onto the casing during transient stages of enhanced engine power, e.g. during step climbs, results in better matching of radial expansion of the casing relative to the turbine blades, thereby enabling improved blade tip clearance control.

Owner:ROLLS ROYCE PLC

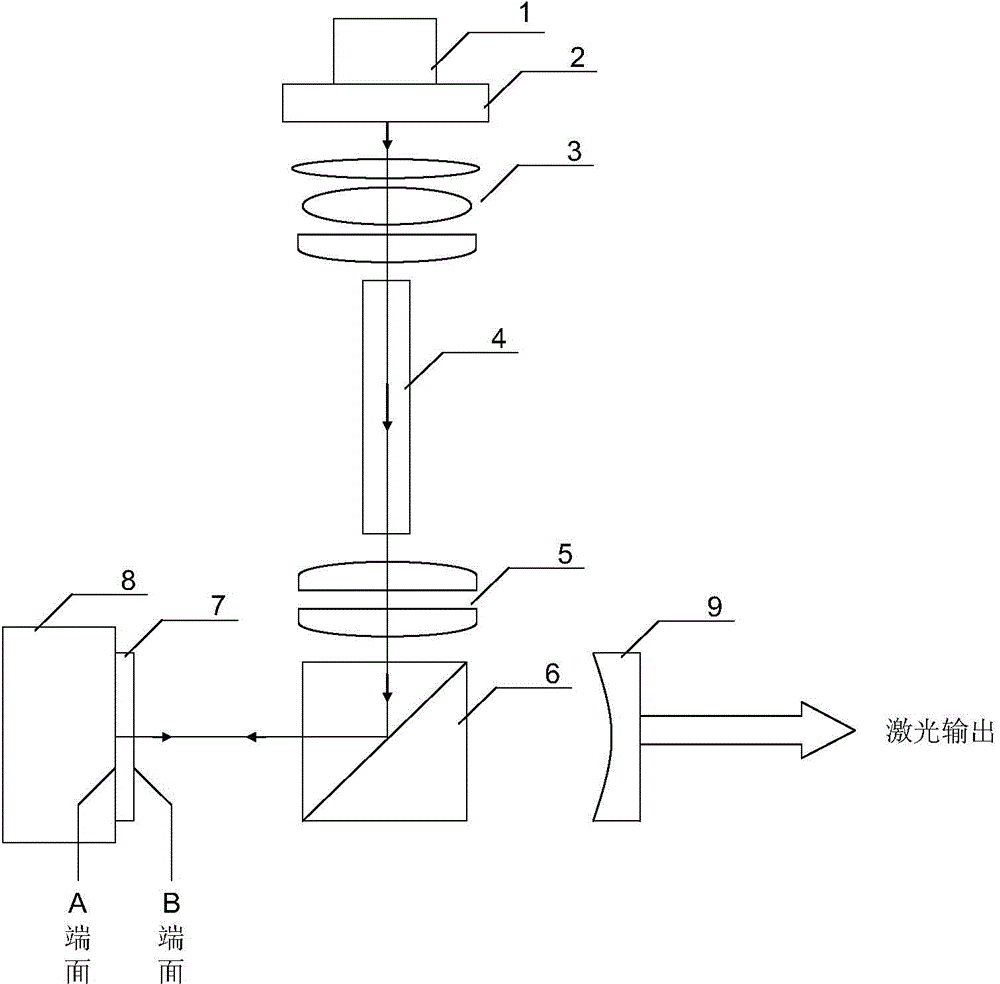

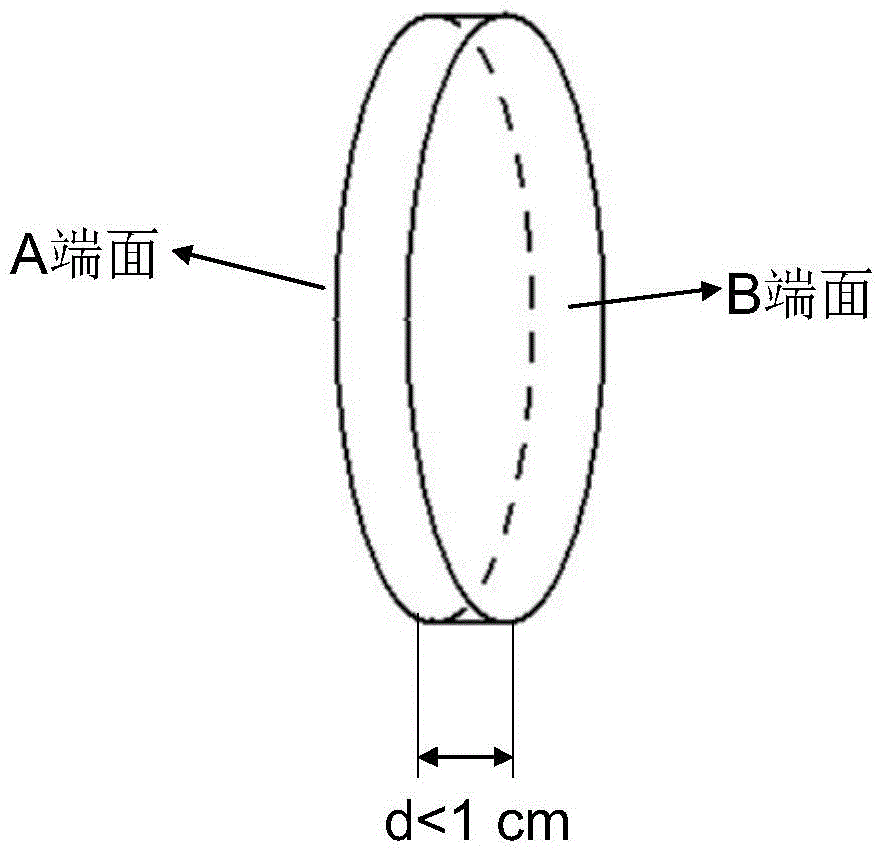

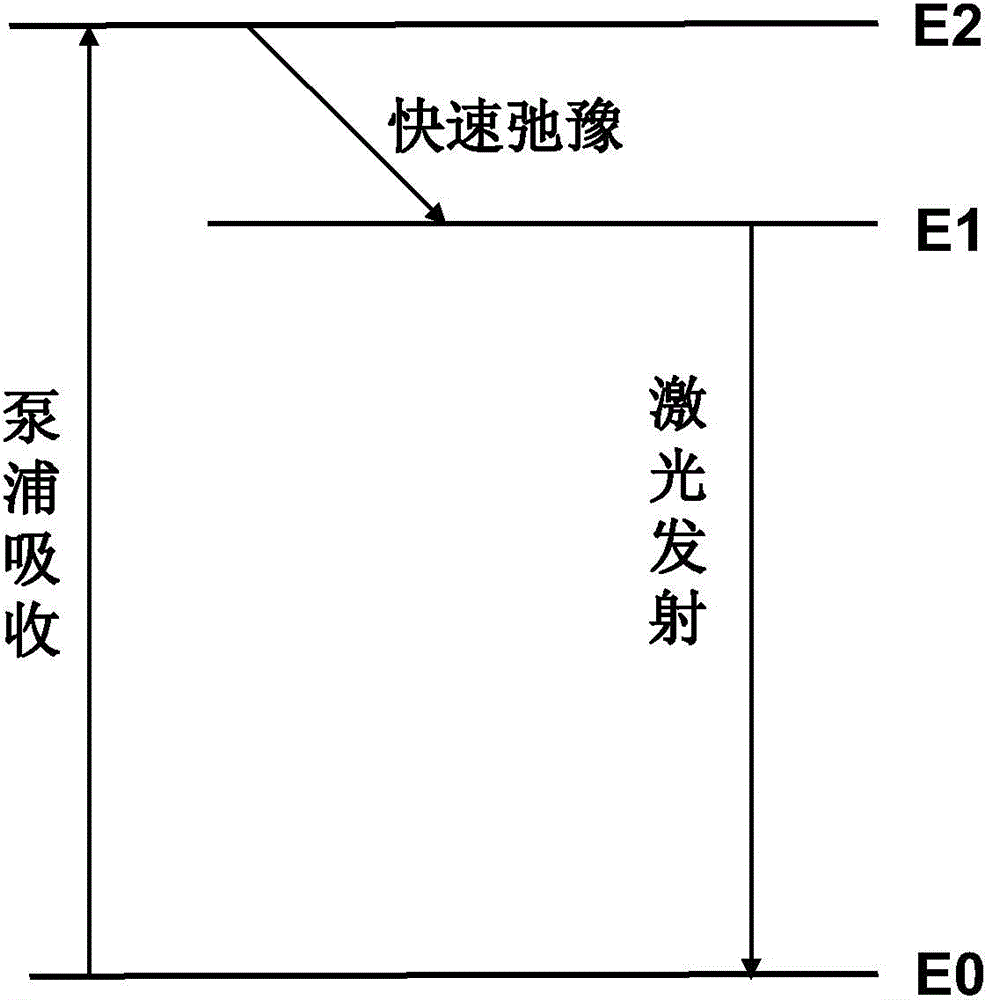

Flake type semiconductor laser pumping alkali metal laser system

InactiveCN104617481AReduce thermal effectsReduce the temperatureActive medium materialLine widthLaser light

The invention provides a flake type semiconductor laser pumping alkali metal laser system. The laser system is able to speed up steam medium radiating speed and further lighten the temperature gradient distribution of a steam cavity. The flake type semiconductor laser pumping alkali metal laser system is realized through the following technical scheme: a semiconductor laser light source is narrowed through a pumping light line-width narrowing system, and then coupled by a pumping light beam homogenizing collimating system to enter an alkali metal steam cavity filled with alkali metal medium and buffer gas, so as to match up with the pumping line-width and absorbing line-width of an alkali metal atom; the pumping light beam homogenizing collimating system homogenizes and absorbs the pumping light; a pumping light reflecting system reflects the unabsorbed pumping light for many times to the alkali metal steam cavity; an alkali metal steam temperature control system is closed to a back end face of the alkali metal steam cavity; a planar and large-area temperature control method is applied to speed up the heat transmission in axial direction and reduces the temperature gradient distribution of the steam cavity in cross direction; a laser is oscillated in a laser resonate cavity to output.

Owner:SOUTH WEST INST OF TECHN PHYSICS

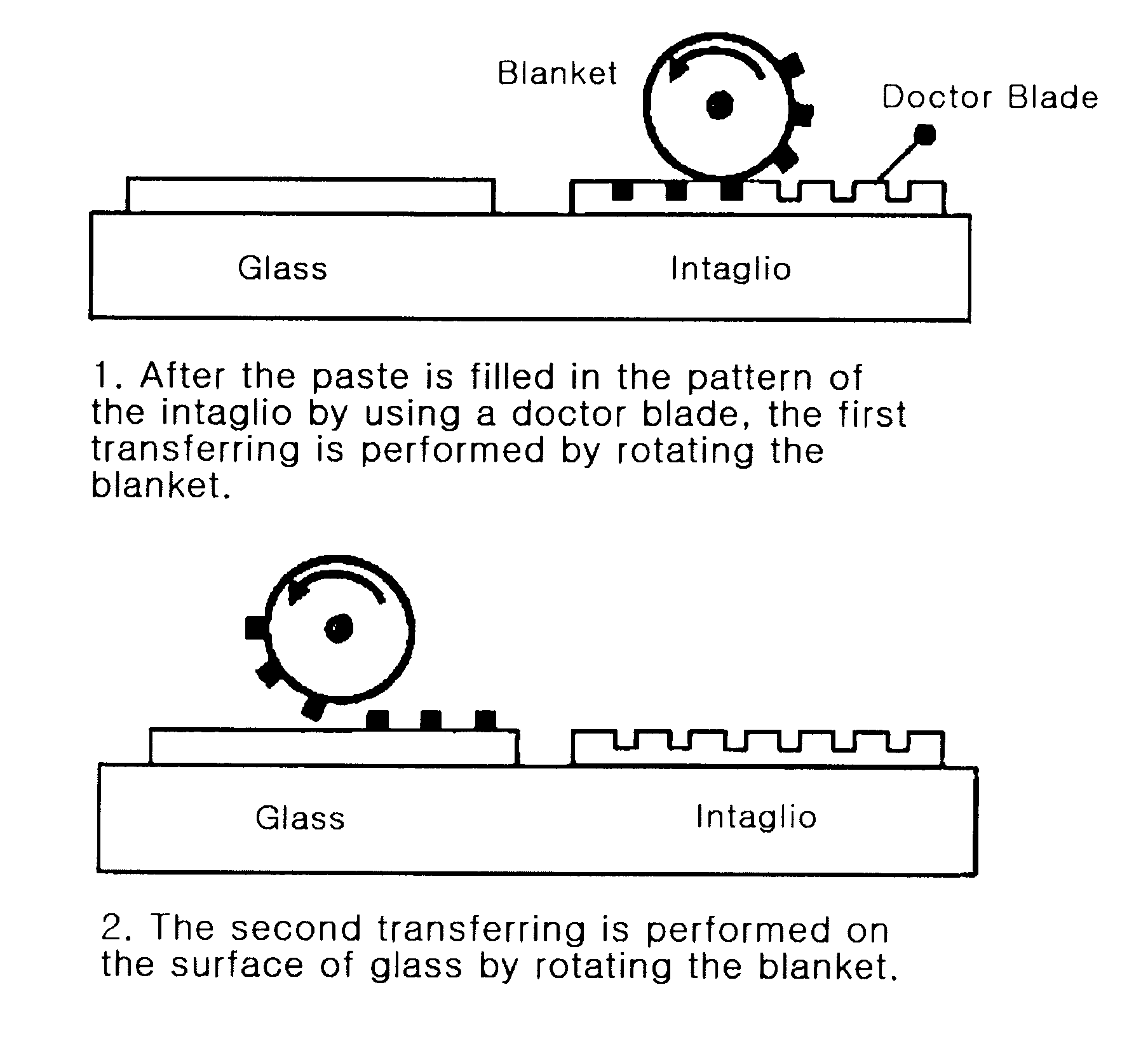

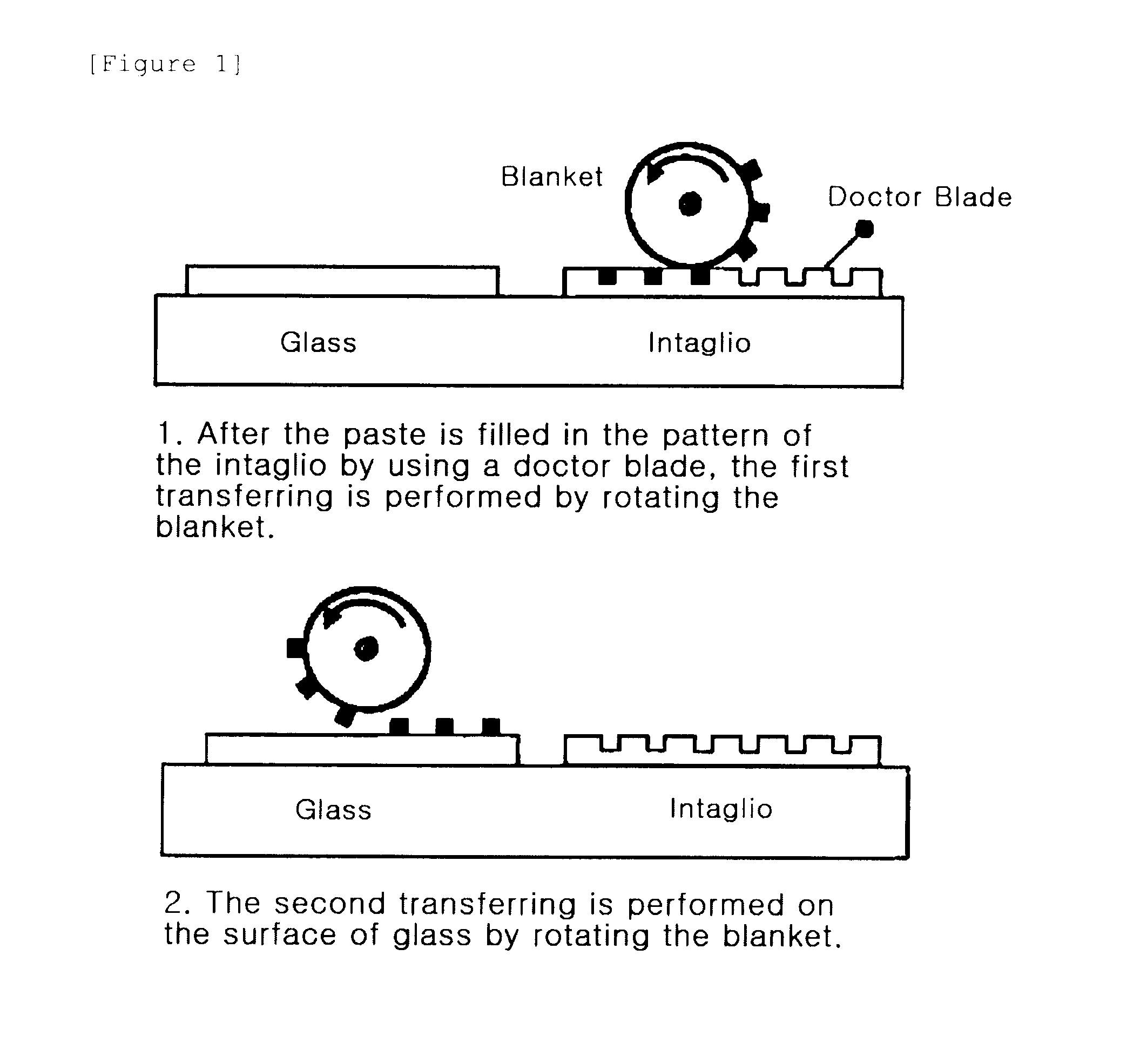

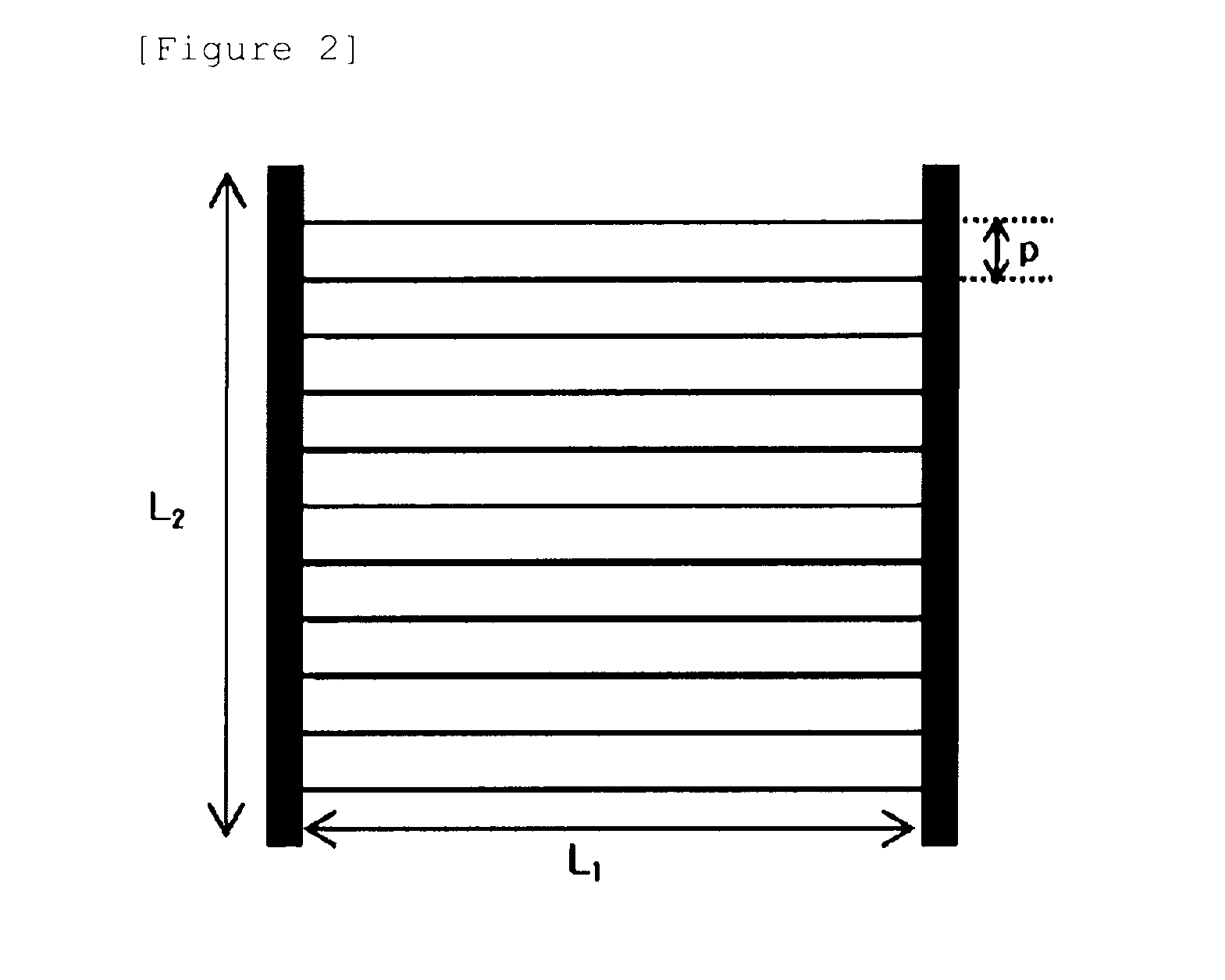

Heating glass and manufacturing method thereof

ActiveUS20120292307A1Improve the heating effectUniform heating effectHeater elementsTransparent/reflecting heating arrangementsOptoelectronicsConductive oxide

The present invention provides a heating glass including a glass; a transparent conductive oxide (TCO) layer formed on one surface of the glass; and a thermal conductive pattern formed on the transparent conductive oxide layer, and a method of manufacturing the same.

Owner:LG CHEM LTD

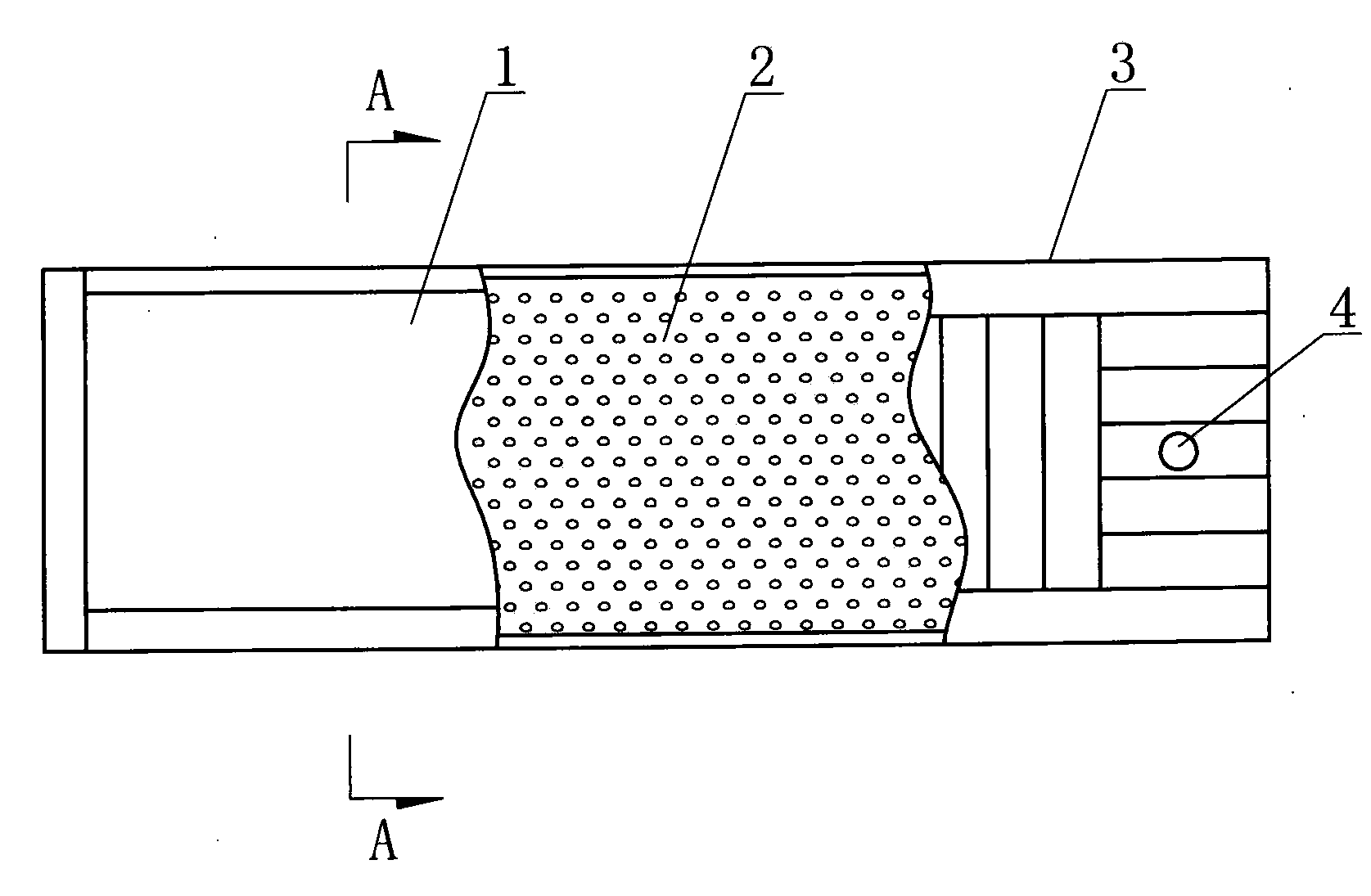

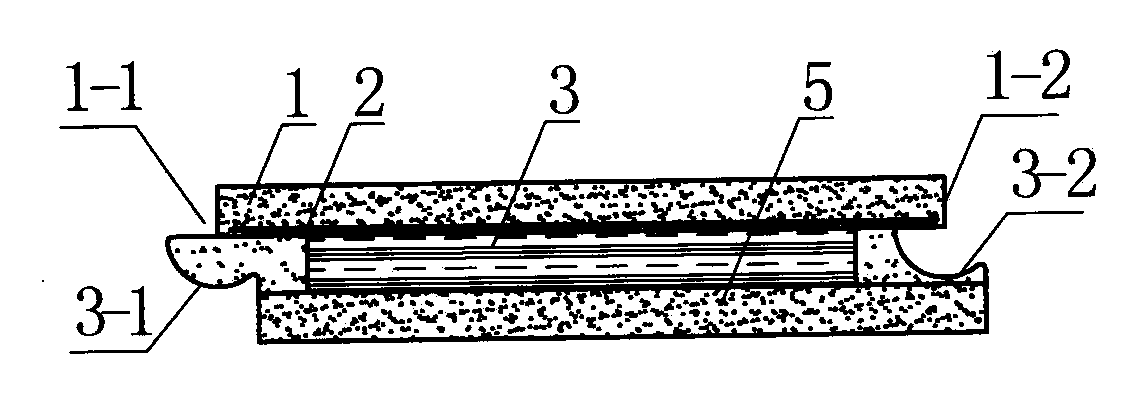

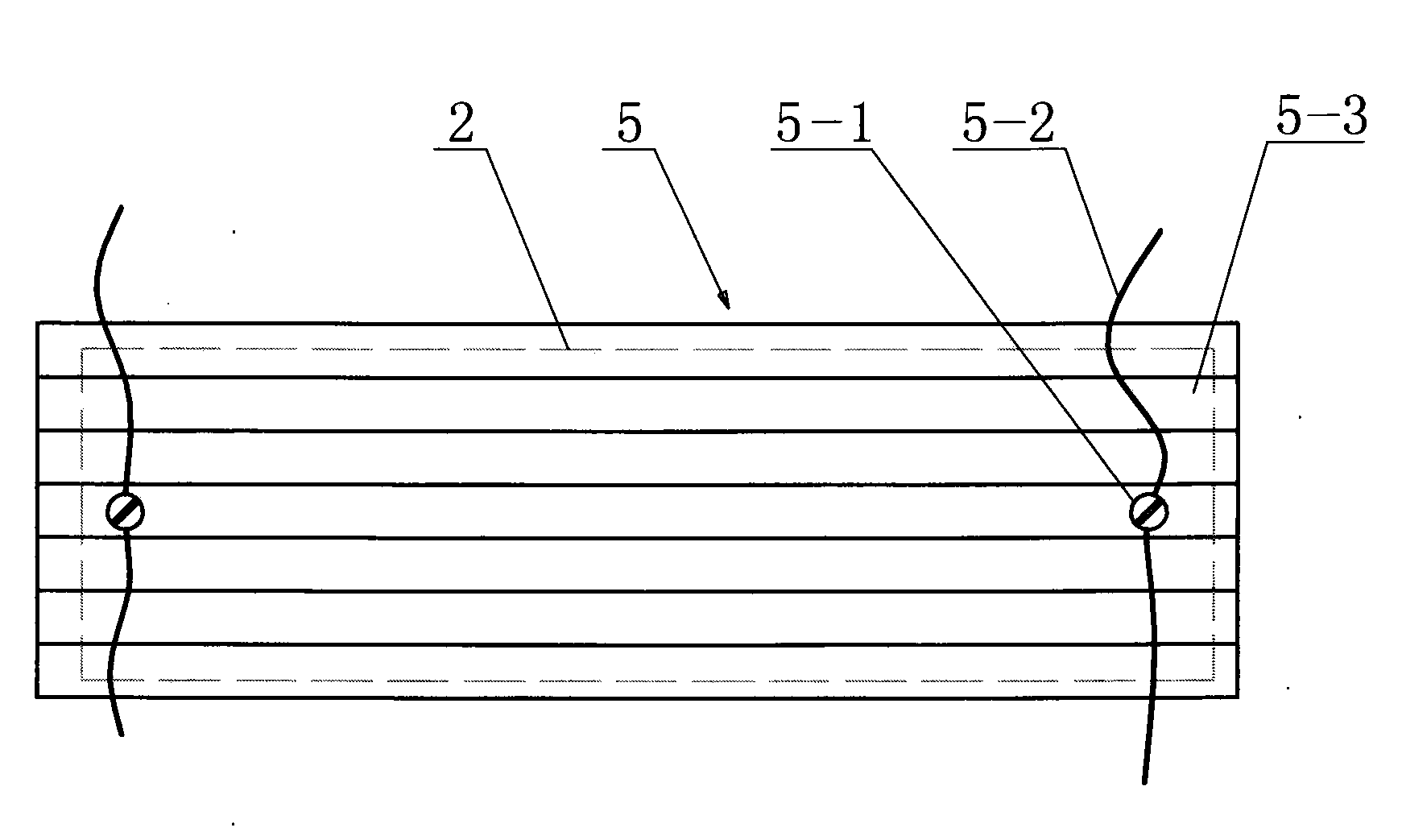

Electric heating bamboo floor

InactiveCN103423802ADoes not occupy thickness spaceEasy to installLighting and heating apparatusElectric heating systemSolid woodElectricity

The invention discloses an electric heating bamboo floor which comprises a heat conducting face plate, an electric heating body layer, a middle plate and a bottom plate. The electric heating body layer is disposed between the adhesive faces of the middle plate and heat conducting face plate and is electrically connected with electrode connecting screws through conductive holes. Every two forming blocks are matched through a corresponding lock type inserting mechanism. The heat conducting face plate is made by using reorganized bamboo structures as base material. The electric heating body layer comprises a thin paper body, conductive copper foil sticks, a connecting electrode A port, electric heating pieces and a connecting electrode B port. The middle plate comprises elongated straight-side bamboo chip blocks, transverse short bamboo chip sections and longitudinal short bamboo chip sections which are crisscross staggered and spliced, and the conductive holes are formed at two ends of the middle plate. The bottom plate is flatly spliced by elongated bamboo chips along the fiber direction, and the electrode connecting screws are disposed at two ends of the bottom plate. The middle plate and the bottom plate can also be made of multi-layer solid wood plates. The electric heating bamboo floor is small in space occupation, simple in structure, convenient to use and mount, high in safety, and the like.

Owner:刘国兴

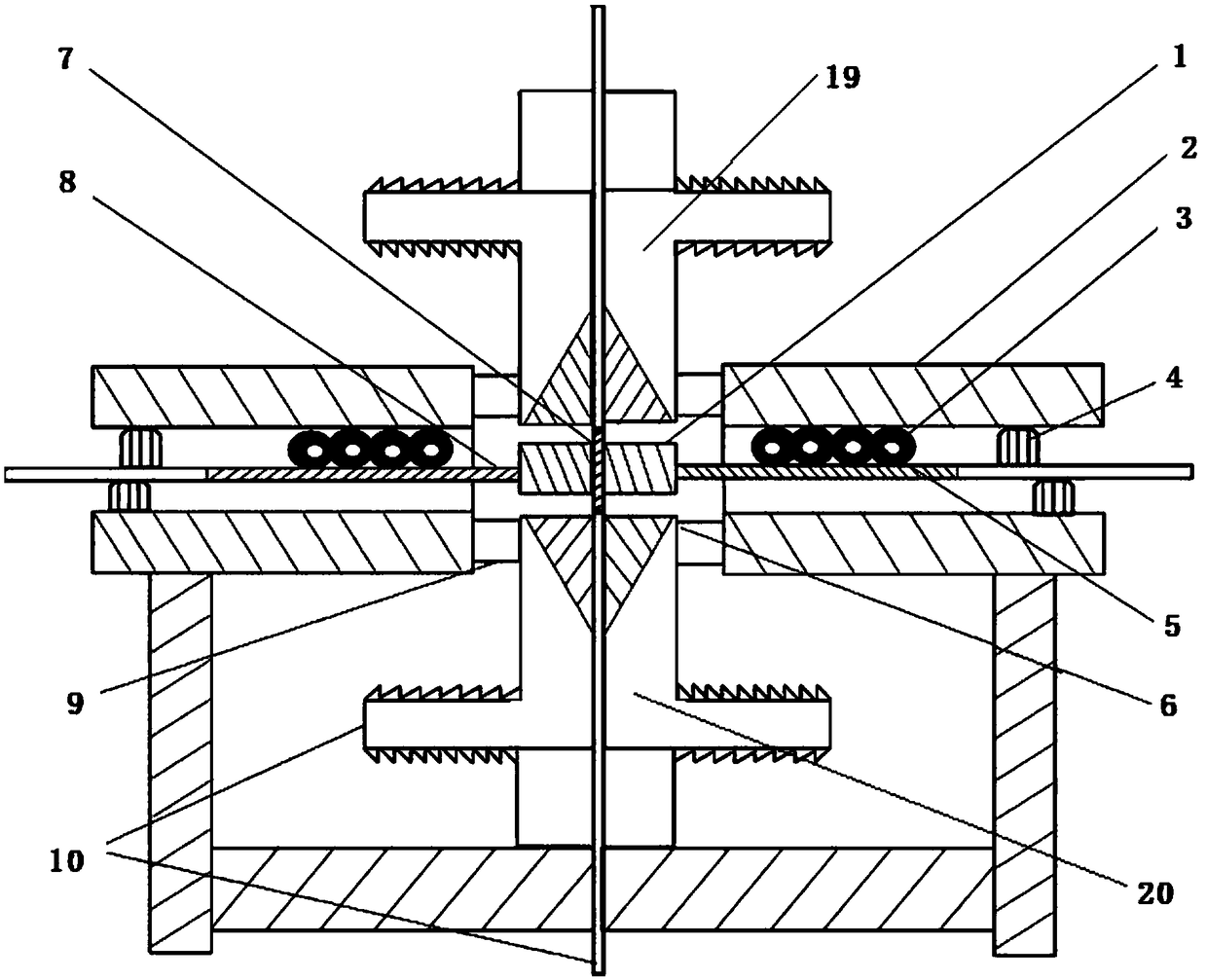

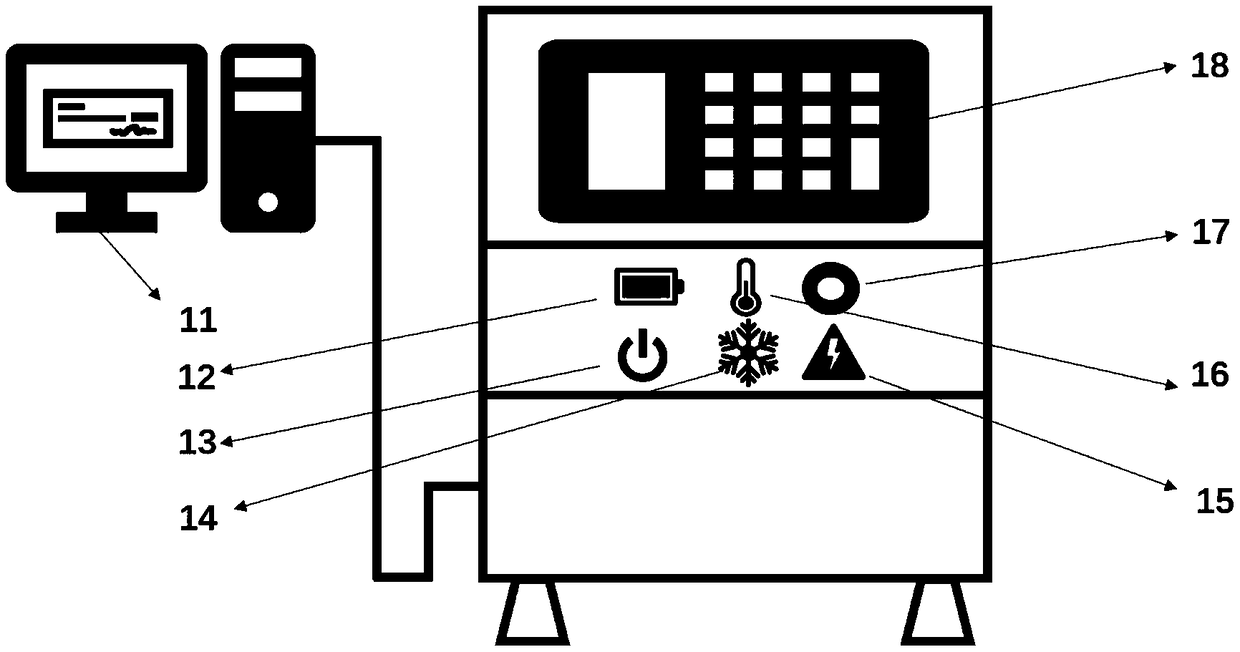

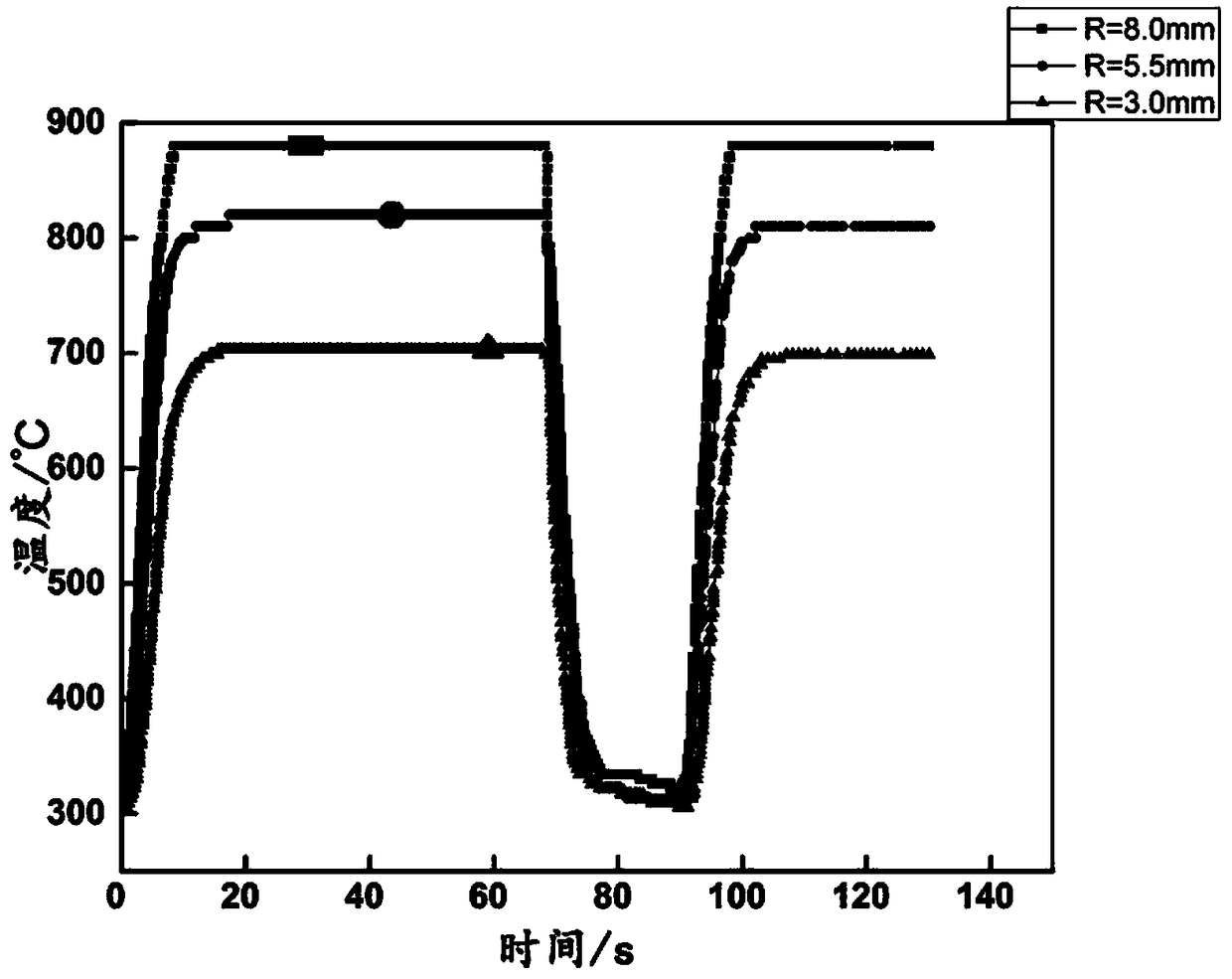

Experimental device used for thermal fatigue of turbine blade material

The invention discloses an experimental device used for the thermal fatigue of a turbine blade material. The device comprises an experiment test bench, an induction coil heating system, a temperaturetesting and collecting system, a cooling system and an experiment control platform, wherein the induction coil heating system, the temperature testing and collecting system, the cooling system and theexperiment control platform are independently connected with the experiment test bench; a specimen is fixed on a fixture; cooling gas passes through a first cooling gas channel and a second cooling gas channel to cool the surface, the end part and the inner side of the specimen; a thermocouple is independently arranged on a position with a surface radius of 3.5mm, a position with a surface radiusof 6.5mm, a position with a surface radius of 8.5mm and a specimen inner ring; the thermocouple is connected with a temperature display instrument and a computer host; and the inner ring of the induction coil is provided with an induction coil cooling water channel, cooling water flows in from one side of the induction coil and flows out from the other side. The device has the advantages that thermal fatigue working environment, where the turbine blade is positioned, with alternating circulation under different working states can be simulated, and in addition, important experiment data can beprovided for the thermal fatigue failure mechanism and the reliability of the turbine blade material.

Owner:NANCHANG HANGKONG UNIVERSITY

Ceramic heater and method for making the same

ActiveUS20110062144A1Amount heat escapingNot perishableLiquid surface applicatorsEnvelope/housing resistor manufactureMolybdenum carbideOperation temperature

A resistive heating element 30 has a higher molybdenum carbide content in a central portion 35 than in a peripheral portion 34. Since molybdenum carbides have a low temperature coefficient of resistance compared to molybdenum, the amount of heat generated in the central portion 35 of the resistive heating element 30 does not increase as much as in the peripheral portion 34 even when the temperature is increased, and the increase in difference in temperature between the peripheral portion 34 and the central portion 35 can be suppressed. In other words, generation of hot spots near the center can be suppressed and a good uniform heating property in a wide range of operation temperatures can be obtained.

Owner:NGK INSULATORS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com