New energy power batter

A power battery and new energy technology, which is applied in the field of new energy power batteries, can solve the problems of complex group heat dissipation and heating integration in the lithium-ion pouch battery assembly process, and achieve the effect of high riveting pressure, stable current and exquisite structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

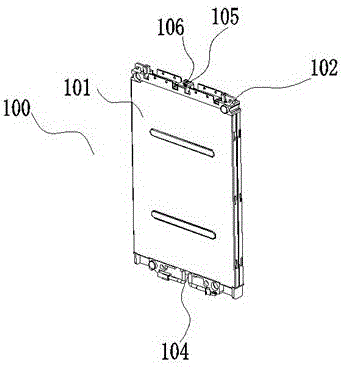

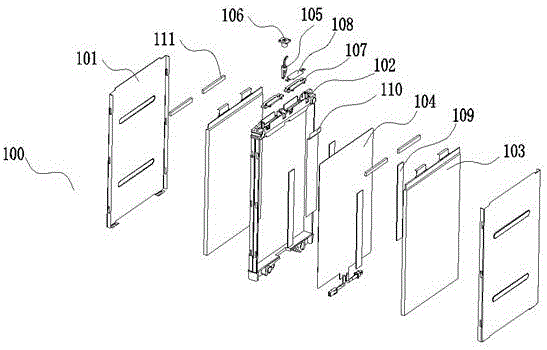

[0065] Depend on figure 1 , figure 2 As shown, the battery module includes:

[0066] The aluminum shell splint 101 is first assembled with the cell support 102 on one side;

[0067] The square polymer lithium-ion battery cell is the designated side of the battery cell 103, which is pasted with green special cotton 109 and the ear of the battery cell 103 is pasted with a silicone sheet 111;

[0068] Select two (or three or more) battery cells 103 pasted with green special cotton 109 and silica gel sheet 111, and then paste a heat-conducting graphite sheet 110 in one of the battery cells 103 (the same side as the green special cotton 109) , and then, the heating sheet 104 is placed between the two electric cores 103 (adhere to the surface of the pasted green special cotton 109), and is wound and fixed with a high-temperature adhesive tape;

[0069] Then place the fixed cell 103 in the inner cavity of the cell bracket 102 where the aluminum shell splint 101 has been combined,...

Embodiment 2

[0094] refer to Figure 5 with 7 , the second cold water plate 315 is the second implementation method, which is to process the curved path of the shape and size of the cooling copper pipe 315a from the aluminum alloy sheet; The two ends of the cooling copper pipe 315a are welded with internal threaded joints, and are threadedly connected with the L-shaped joint 315b; the L-shaped joint 315b is an external threaded joint at one end, and a ferrule-type water pipe joint at one end, and the two ends are connected at a right angle of 90 degrees; The countersunk head screw 313 fixes the second cold water plate 315 to the cavity at the bottom of the battery box lower case 307, and then connects one end of the connecting pipeline 308 to the L-shaped joint 315b of the second cold water plate 315, and the adapter 309 is connected to the vehicle. The connection of the cooling water circuit can form a complete water circuit cooling cycle device, which can realize the external liquid coo...

Embodiment 3

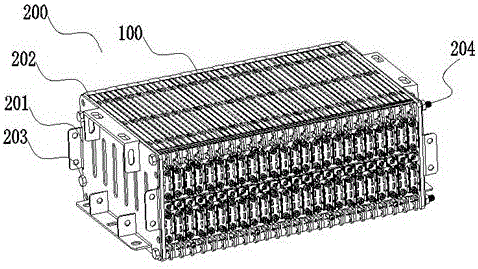

[0096] More than two battery cells 103 are placed in the battery cell holder 102. When the battery cells 103 adopt two or more multi-winding cores to continuously wind the battery cores 411, the two or more continuous winding battery cores 411 are bundled together to form a parallel The battery core electrode group is continuously wound, and the installation structure of the tabs is riveted.

[0097] Two or more multi-roll core continuous winding battery cores 411 are bundled together to form a parallel battery core. The outer layer is covered with an insulating bag 409 (PE insulating bag). The insulating bag 409 is installed in the battery support 102 or fixed In the cell casing 416, the cell casing 416 is installed in the cell support 102. The connection between the cell casing 416 and the casing cover 403 is provided with an insulating bracket 413 (PE insulating bracket), and the cell casing 416 and the casing cover The plate 403 is sealed by laser welding; each multi-roll ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com