Patents

Literature

348results about How to "Convenient temperature control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

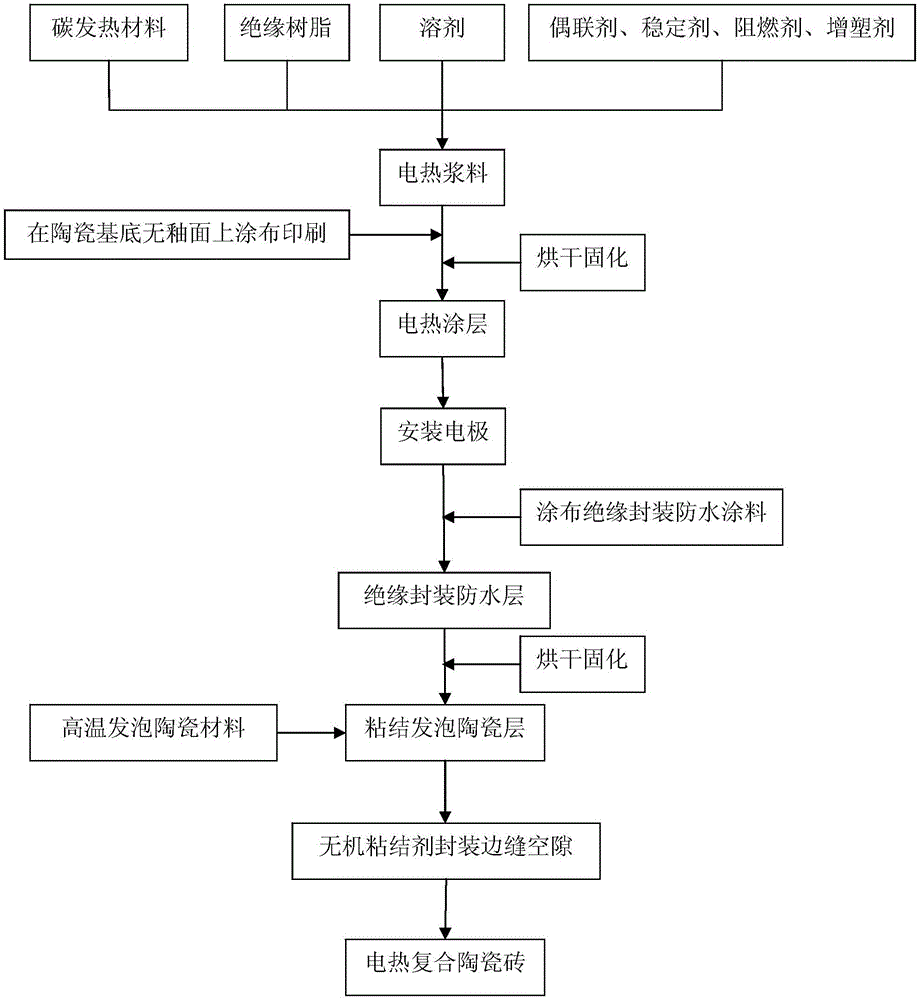

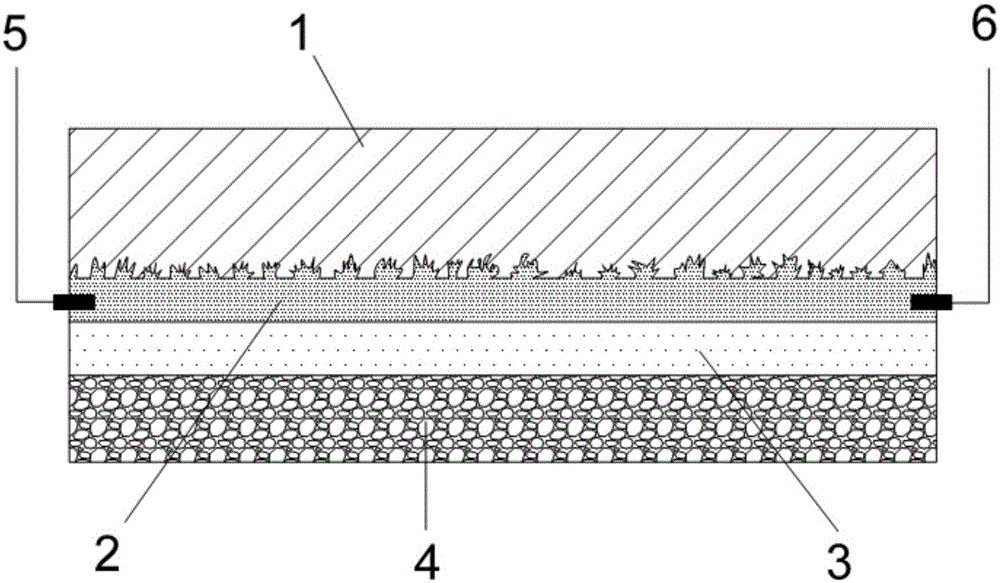

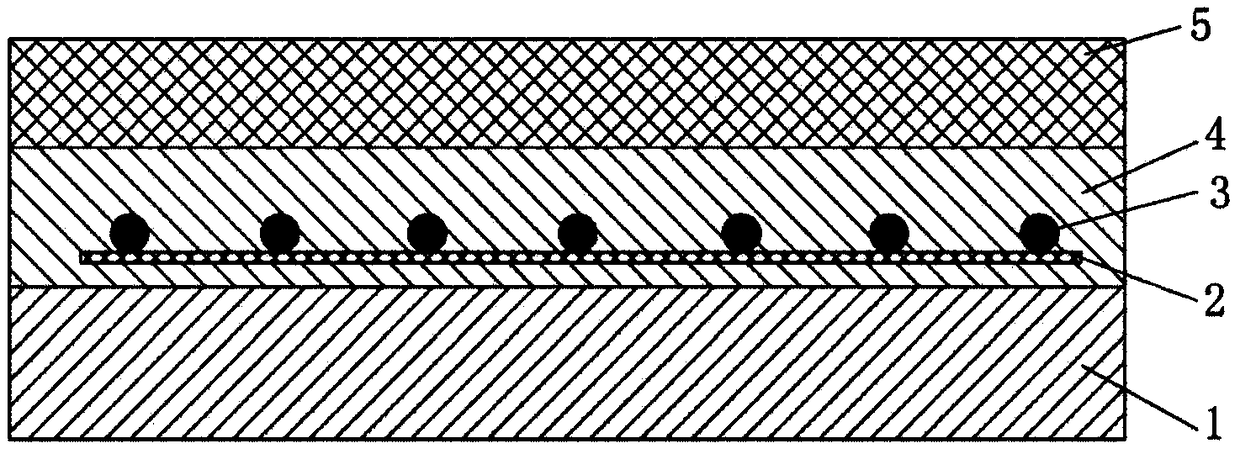

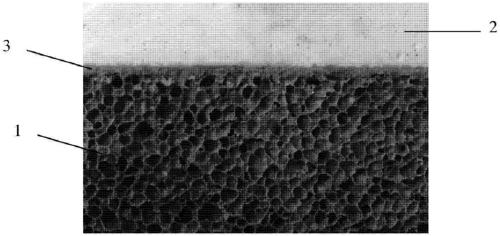

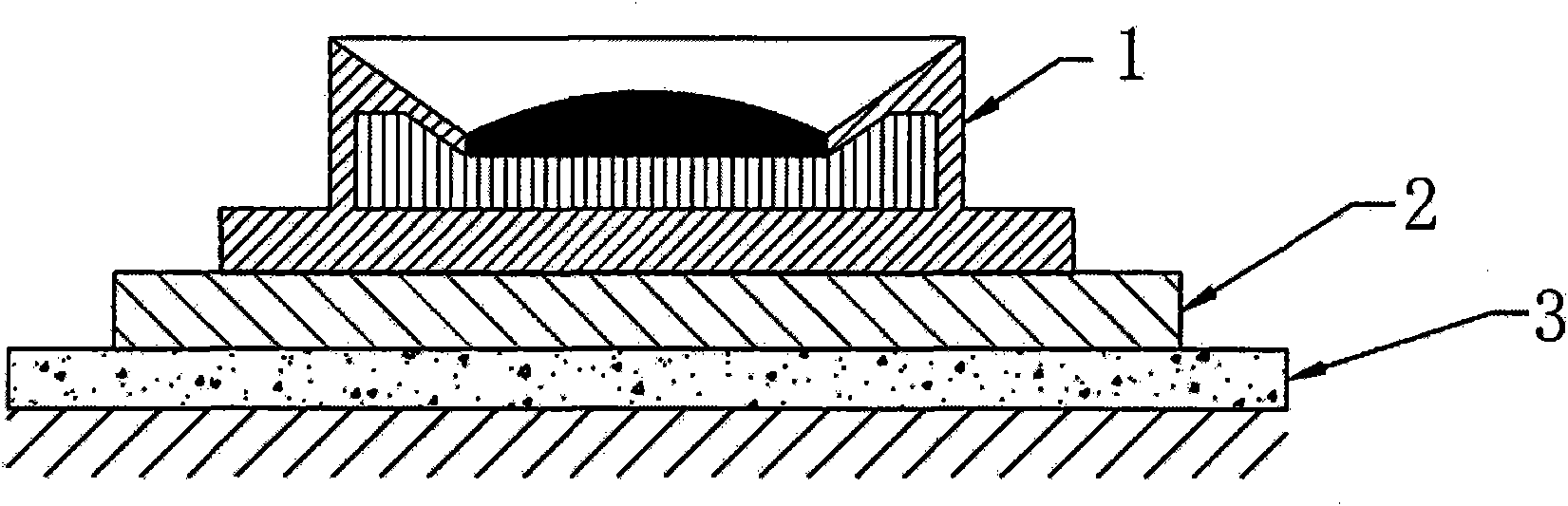

Electrothermal composite ceramic brick and preparation method thereof

The invention discloses an electrothermal composite ceramic brick and a preparation method thereof. An electrothermal coating layer, a guiding-out wiring electrode, a coating insulation packaging waterproof layer and an application foaming ceramic layer coat an unglazed surface of a ceramics substrate in order. The electrothermal coating layer coats the unglazed surface of the ceramics substrate in an electrothermal slurry form, the electrothermal slurry permeates the green body of the ceramics substrate, and the penetration depth is less than the thickness of the ceramics substrate and more than 0.5mm. Because of the penetration, the electrothermal coating layer of the electrothermal composite ceramic brick is combined with the ceramics substrate tightly, a surface heating mode is achieved, the thermal efficiency is high, normal and safe usage can be achieved under a voltage of 24-380V, the heating power is 90-120w / m<2>, and the temperature of the ceramics substrate can reach 18-50 DEG C through a temperature control device. The insulation packaging waterproof layer and the foaming ceramic layer outside the electrothermal coating layer can prevent heat from outward transmission effectively, heat loss is lowered, and the whole safety and reliability of the ceramic brick are raised.

Owner:GUANGDONG TIANBI CERAMICS

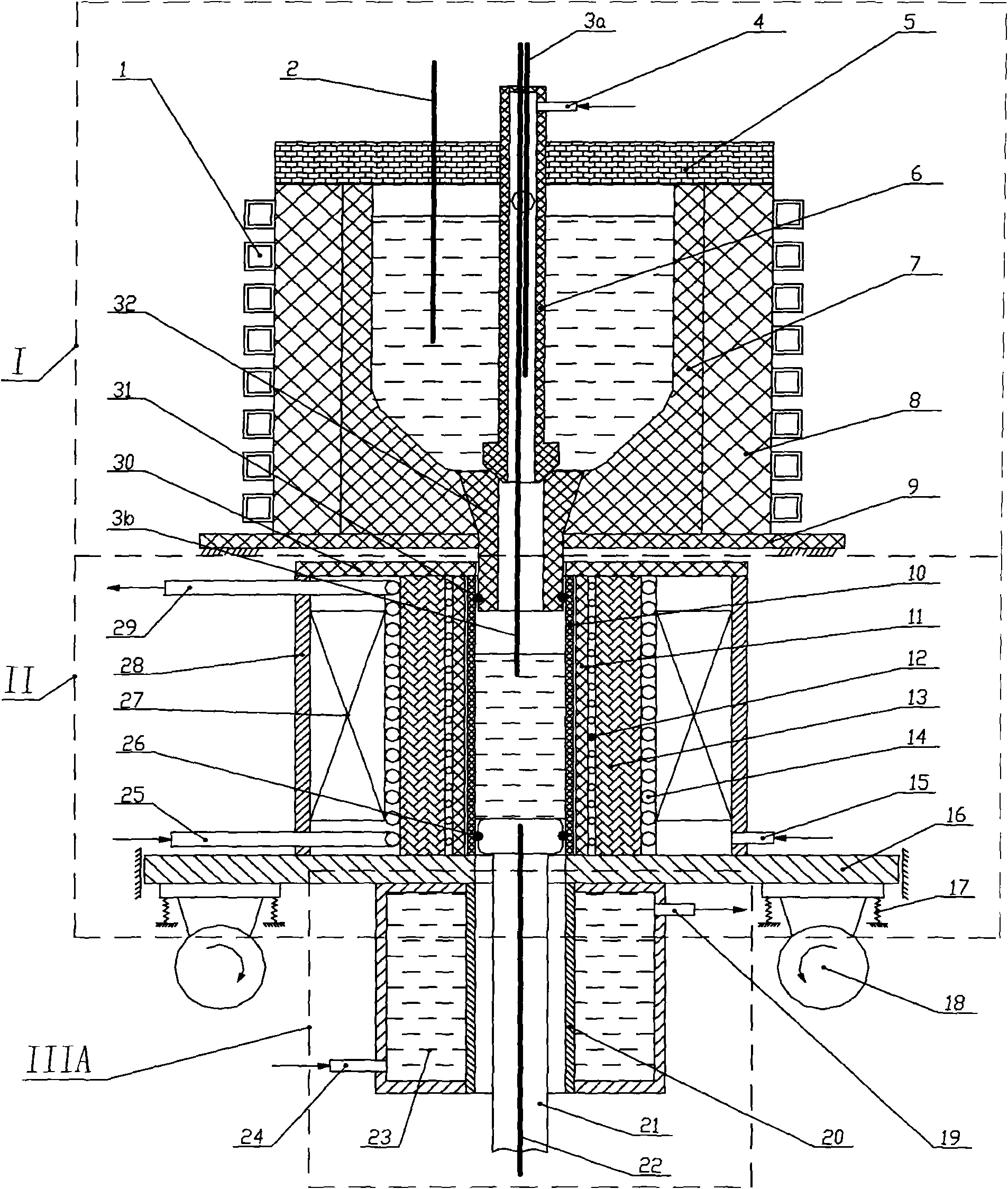

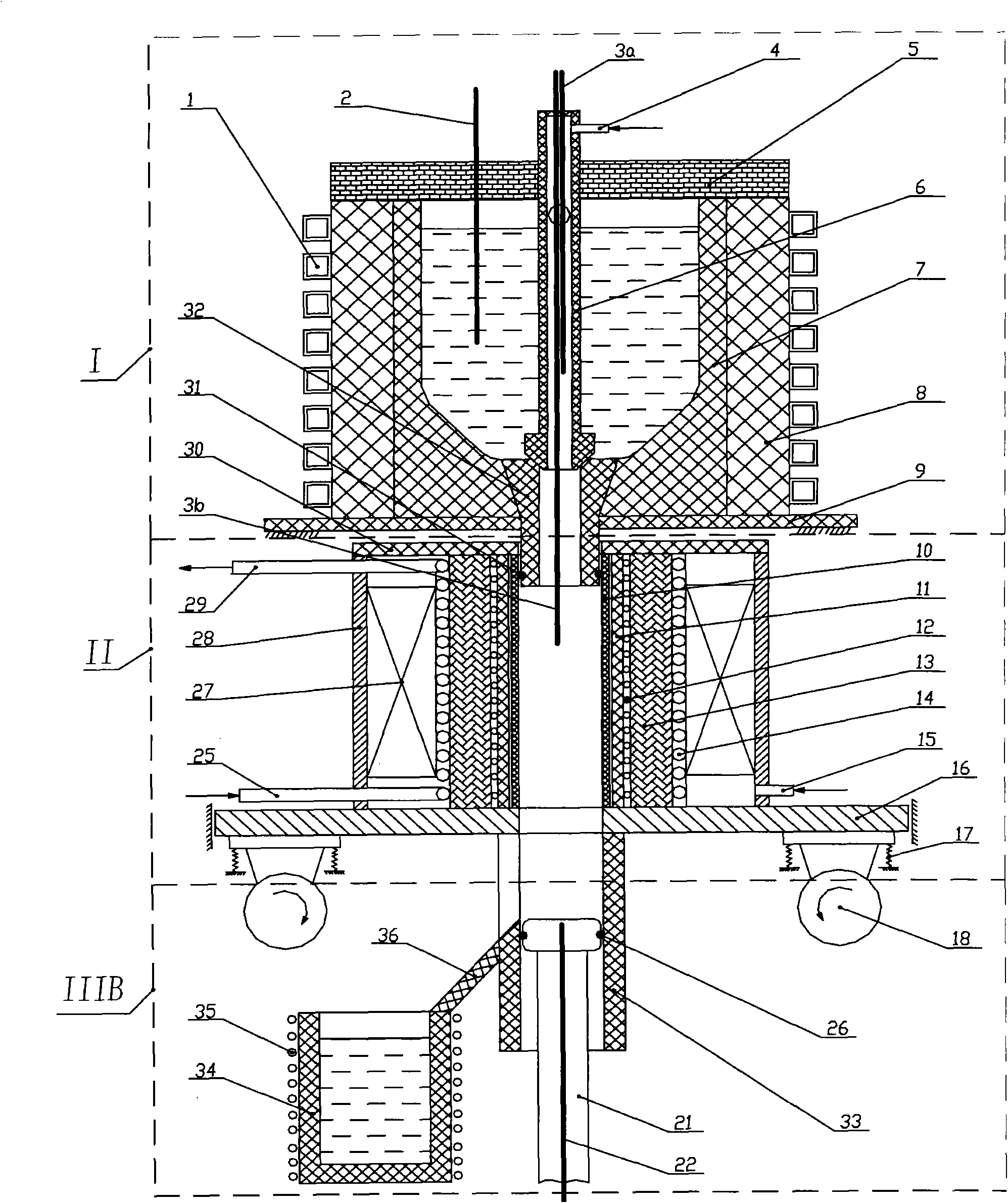

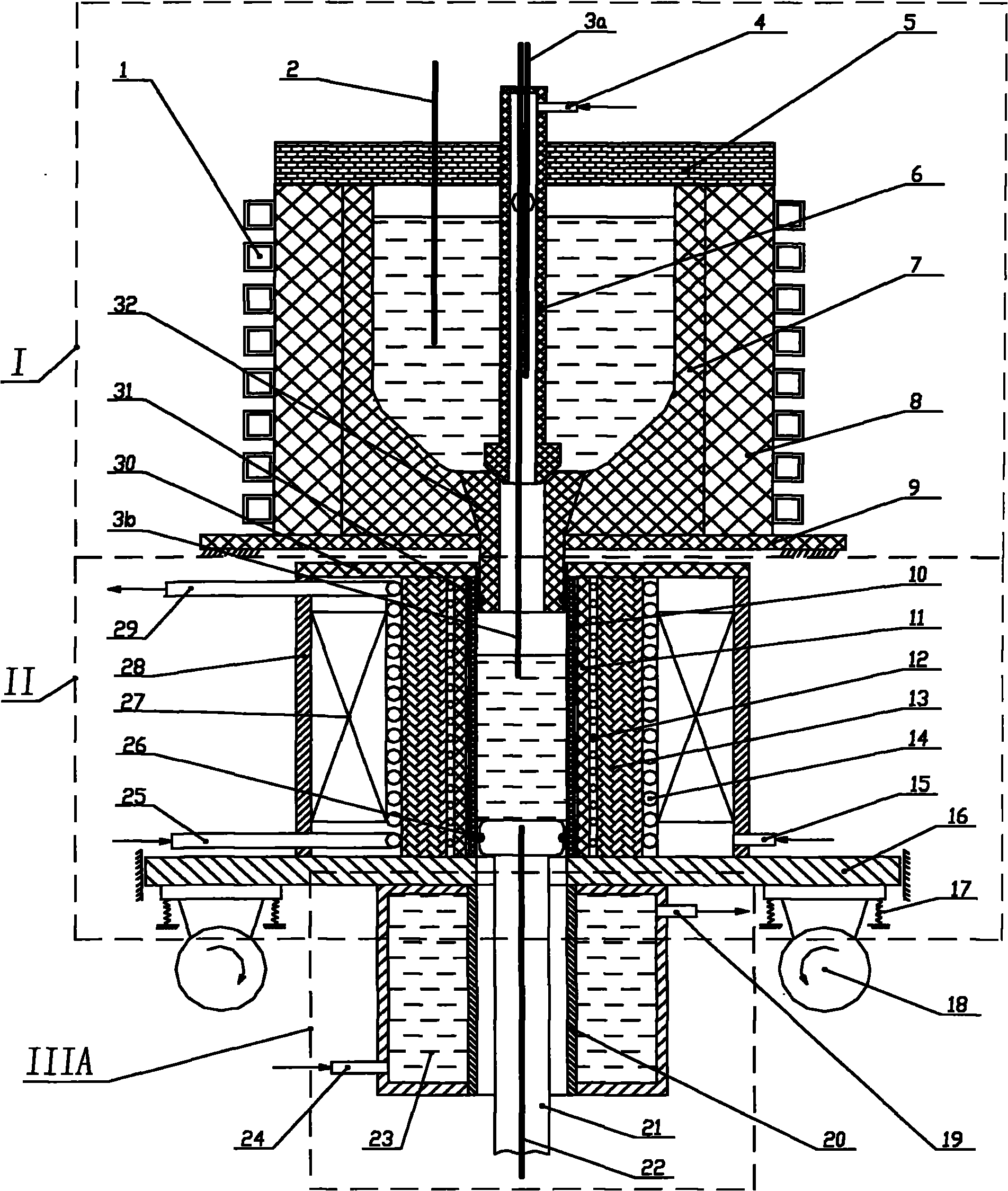

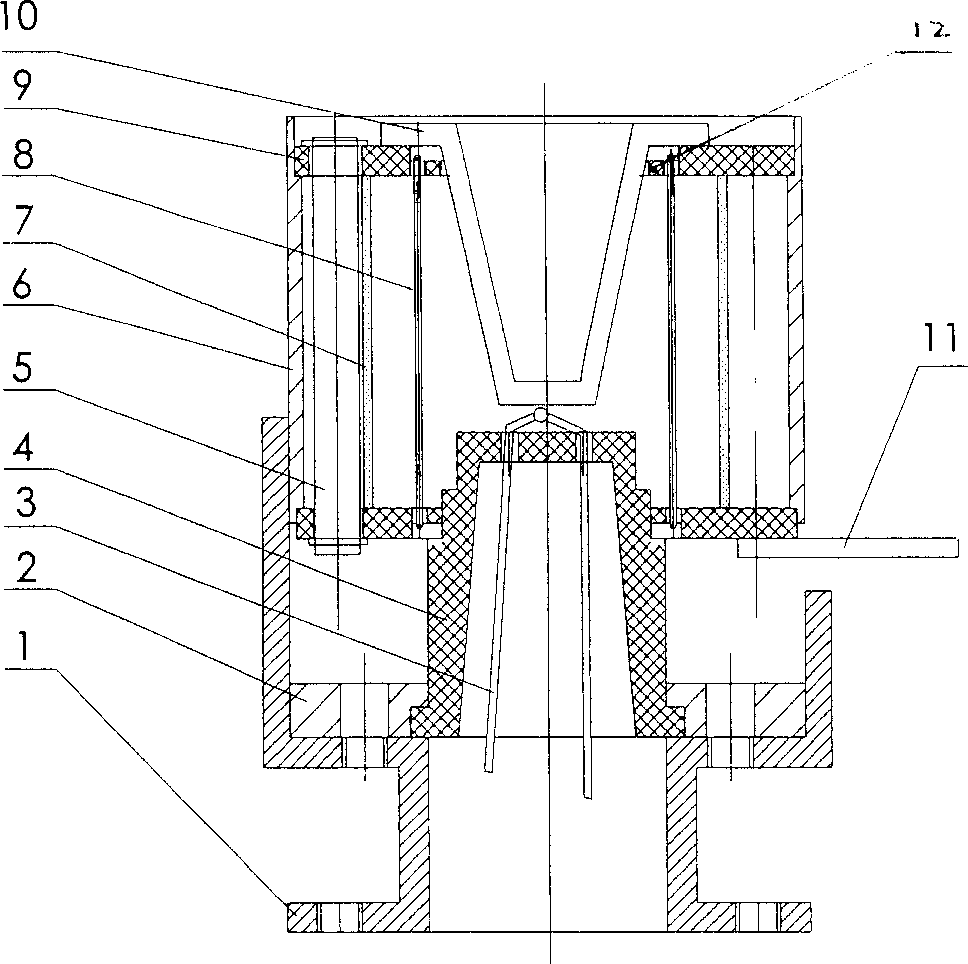

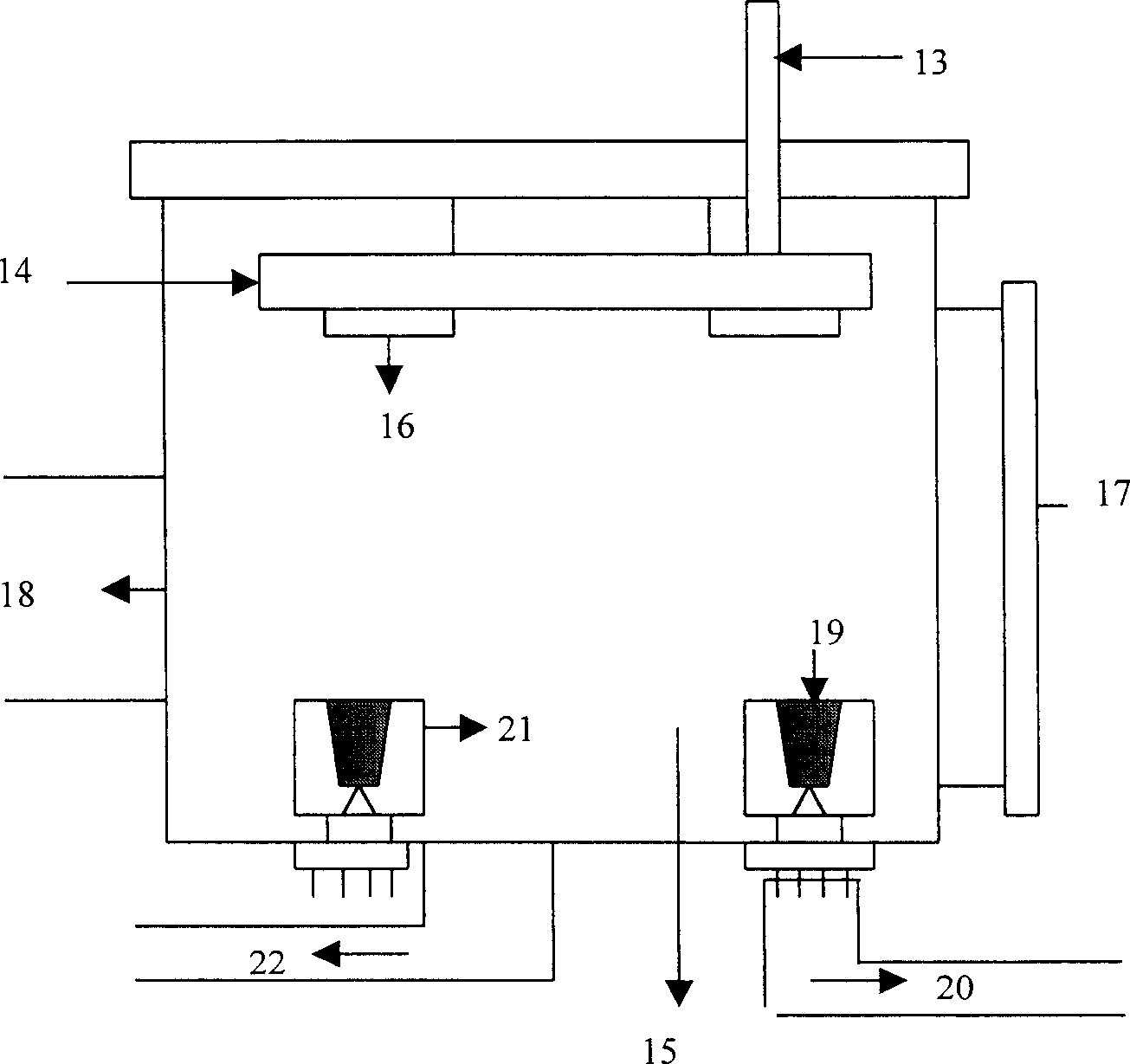

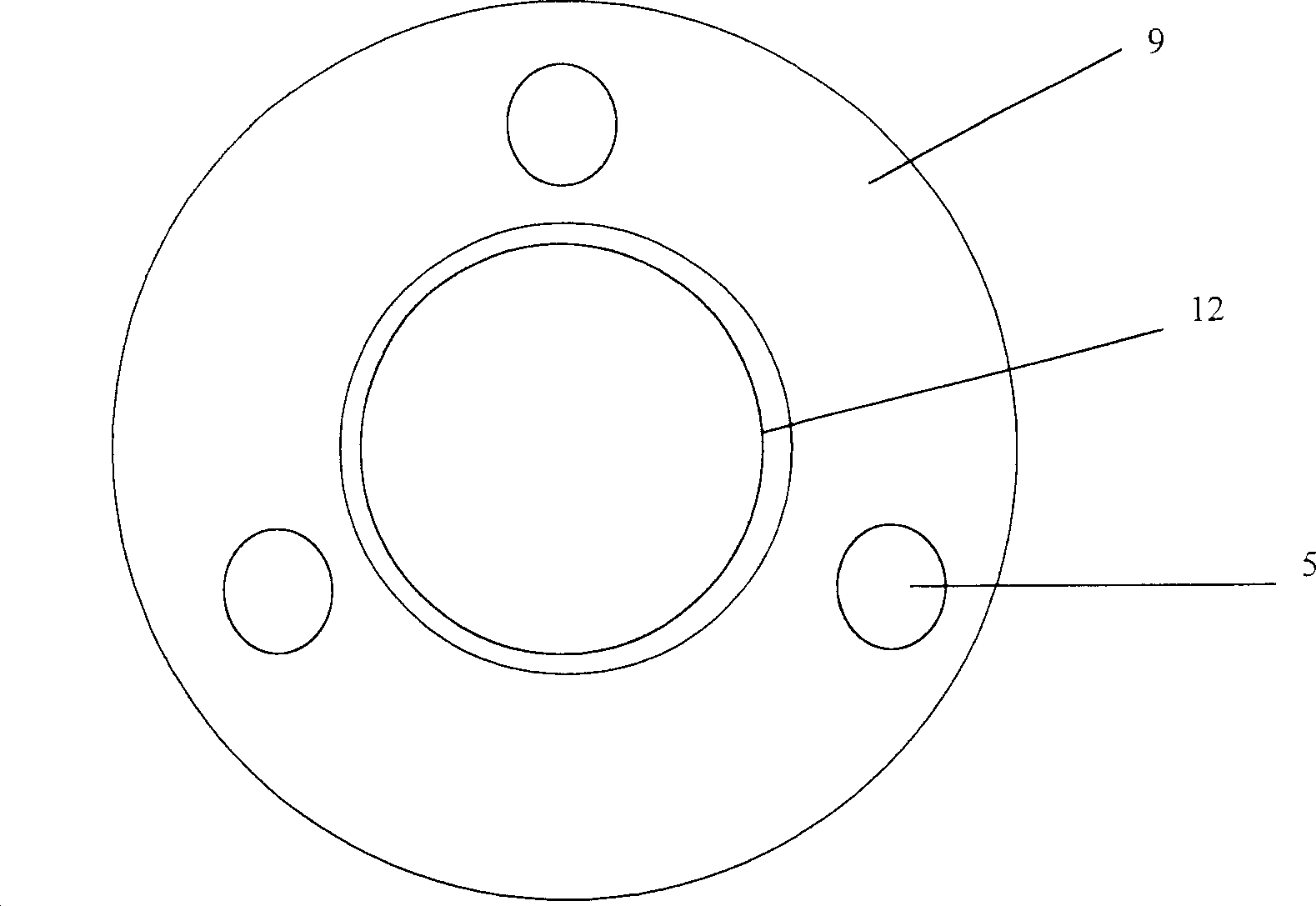

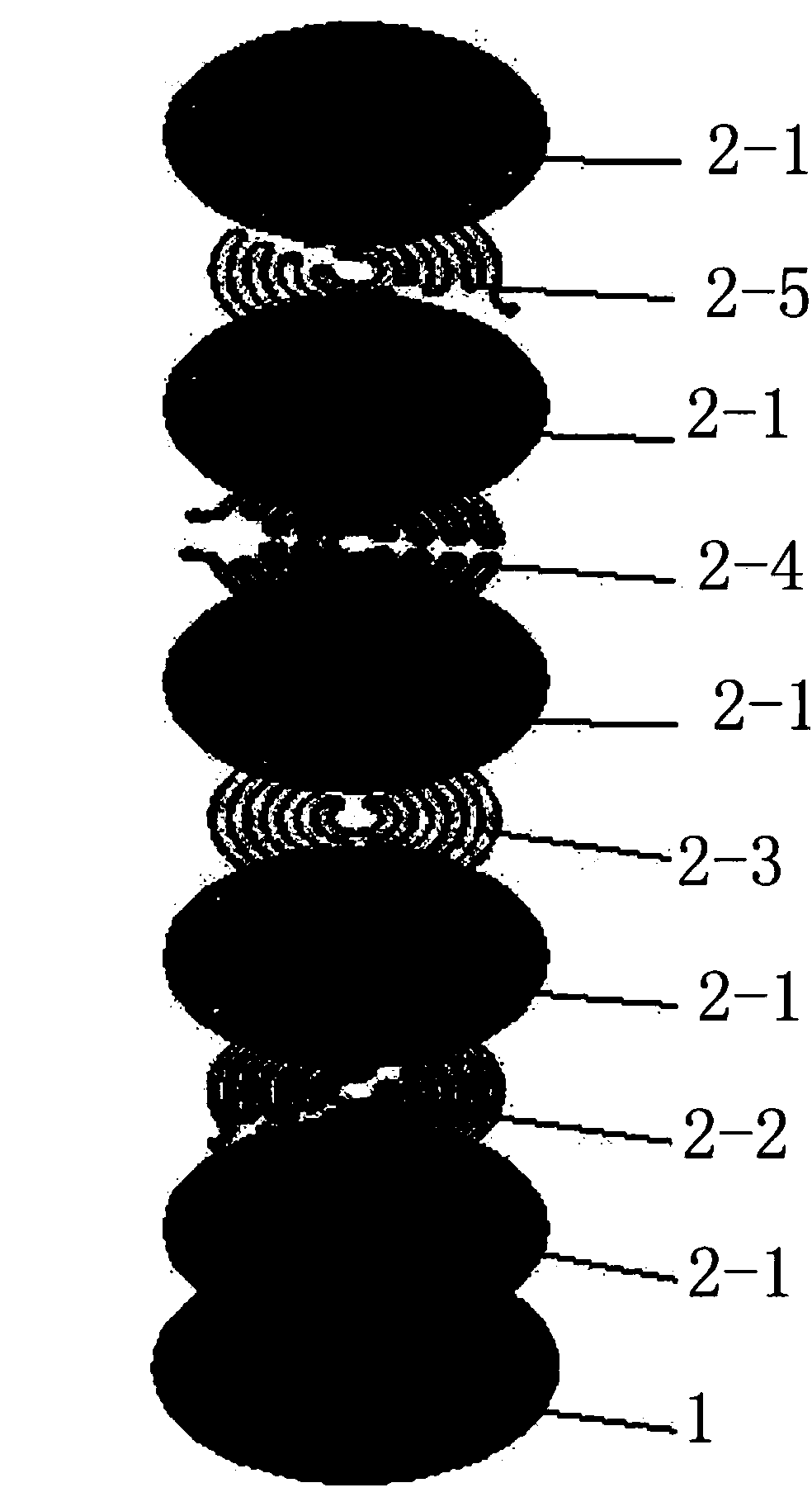

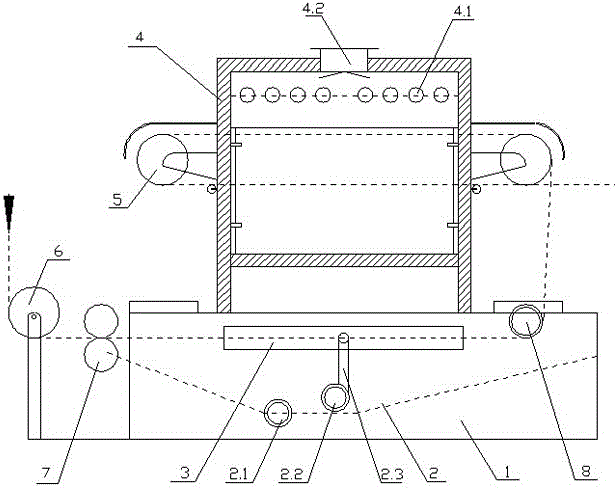

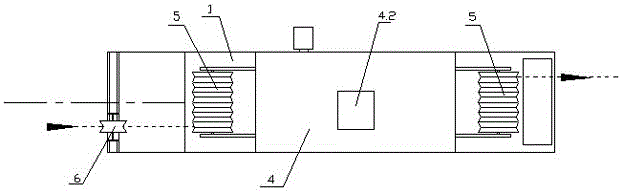

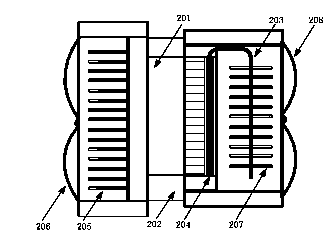

Electromagnetic stirring and vibration combined device for preparing semi-solid slurry of black metal

The invention relates to an electromagnetic stirring and vibration combined device for preparing semi-solid slurry of a black metal. The device comprises three main sections: a melting furnace, a stirring chamber, and a crystallizer or a rheologic conveyor, wherein the melting furnace is arranged at the upper part of the stirring chamber, and the crystallizer or the rheologic conveyor is arranged at the lower part of the stirring chamber. When molten metal is poured into the melting furnace, a medium-frequency induction heater is used for maintaining temperature and uniformly heating; when the temperature of the molten metal is within the liquidus temperature range, the molten metal is poured into a stirring crucible in a quantitative amount, and a non-dendritic fine equiaxial spherical or nearly spherical microstructure is obtained by electromagnetically stirring and mechanically vibrating the molten metal; and the prepared fine nearly spherical semi-solid slurry is poured into the crystallizer, then cooled and solidified into a blank, or the slurry is poured into the rheologic conveyor and then is rapidly conveyed to a forming mold for rheoforming. The device can be used for preparing semi-solid slurry of a black metal and nonferrous metal, which improves the efficiency and the quality for preparing metal semi-solid slurry and shortens the preparation time. The device is especially suitable for rheoforming.

Owner:XI AN JIAOTONG UNIV

Method for preparing graphene oxide modified composite phase-change microcapsule

ActiveCN107417867AImprove thermal effectGood compatibilityHeat-exchange elementsMicroballoon preparationWater bathsCross-link

The invention discloses a method for preparing graphene oxide modified composite phase-change microcapsules. The method specifically comprises the following steps: preparing a graphene oxide solid from graphite powder, concentrated sulfuric acid, sodium nitrate, potassium permanganate and deionized water; mixing the obtained graphene oxide solid with absolute ethyl alcohol and a silane coupling agent, and performing a reaction so as to obtain a double-bond modified functional graphene oxide solid; uniformly mixing the obtained functional graphene oxide solid with a phase-change material, a reaction monomer, a cross-linking agent, a reactive emulsifier and deionized water, and performing ultrasonic dispersion so as to form an oil-in-water type pre-emulsion; and putting the obtained oil-in-water type pre-emulsion into a hot water bath, continuously stirring, further adding an initiator solution, and performing a heat-preservation reaction, thereby obtaining the graphene oxide modified composite phase-change microcapsules. By adopting the method disclosed by the invention, composite phase-change microcapsules which are high in encapsulation efficiency, stable in property, good in heat conductivity, appropriate in phase-change temperature and relatively high in phase-change latent heat enthalpy can be prepared.

Owner:SHAANXI UNIV OF SCI & TECH

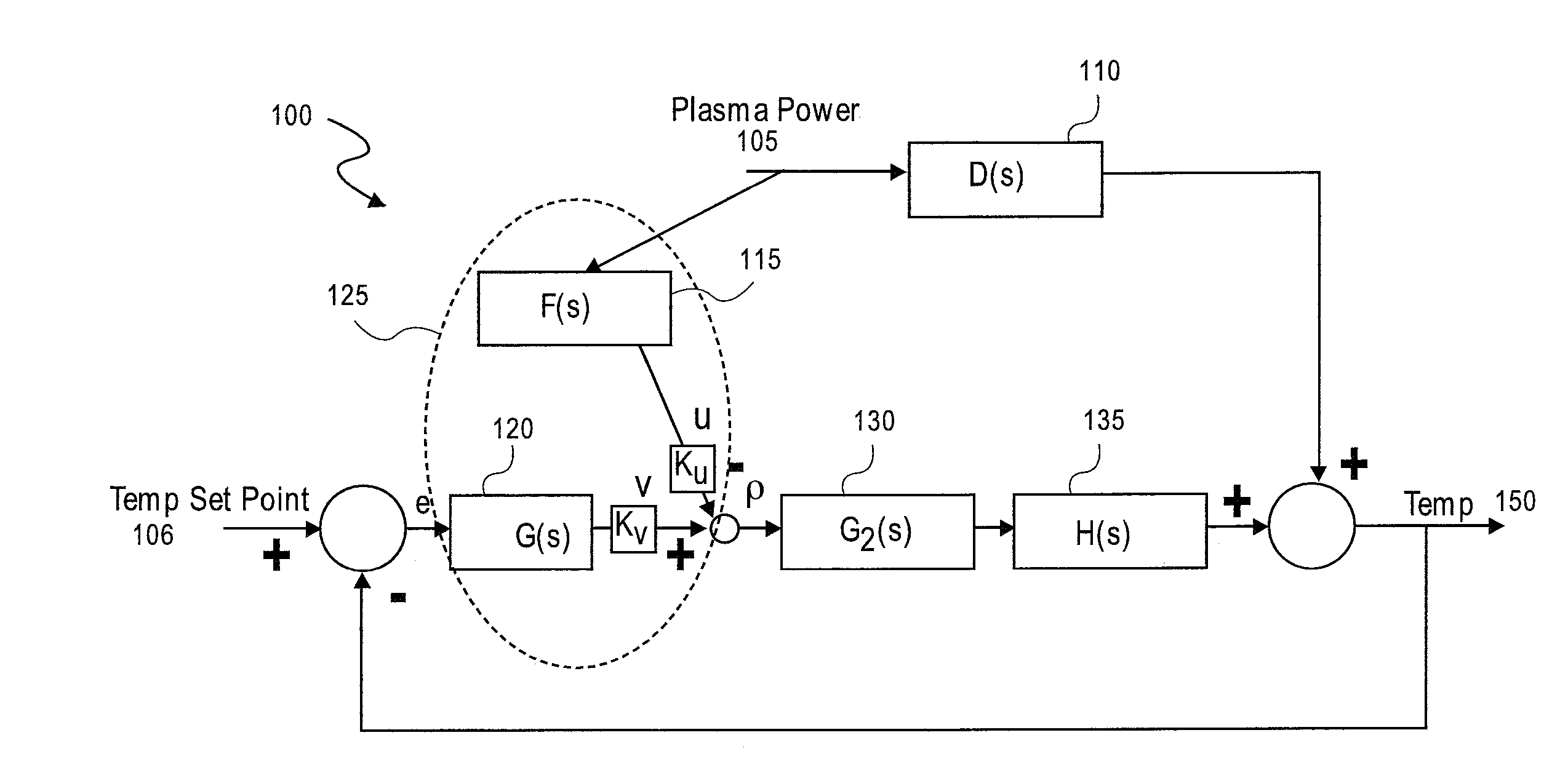

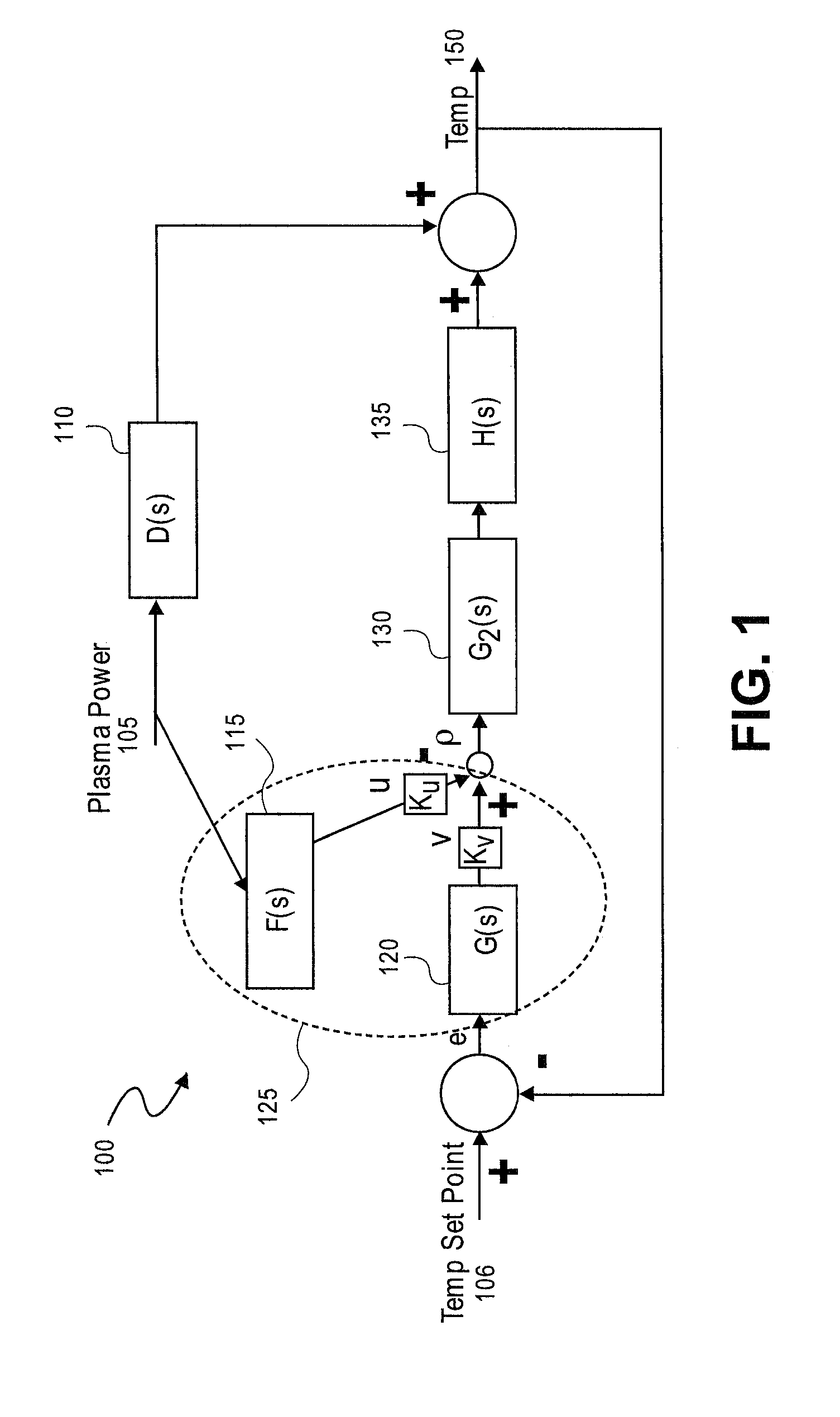

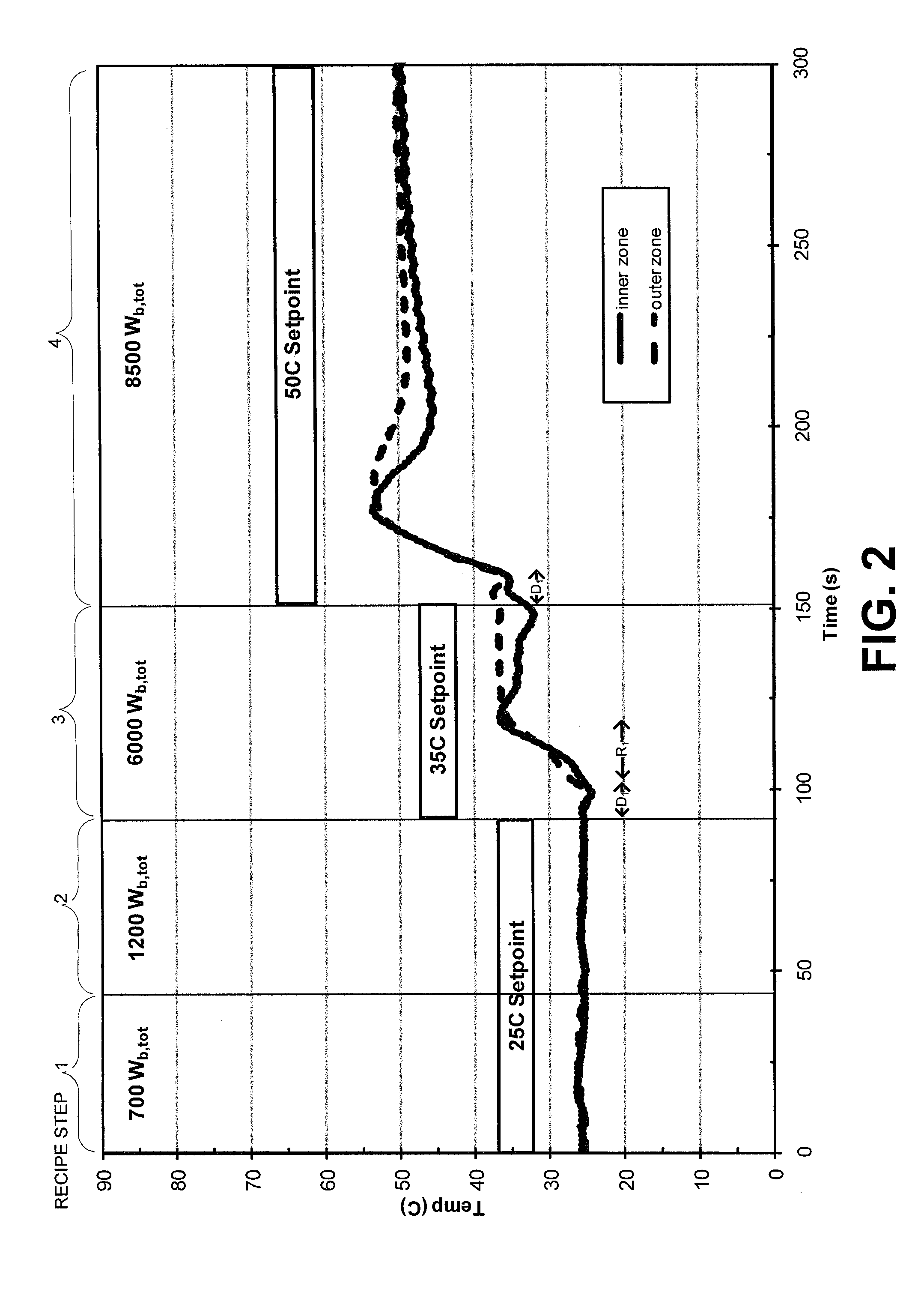

Temperature control in plasma processing apparatus using pulsed heat transfer fluid flow

ActiveUS20120132397A1Convenient temperature controlFast control response timeLiquid surface applicatorsElectric discharge tubesTemperature controlControl signal

Methods and systems for controlling temperatures in plasma processing chamber via pulsed application of heating power and pulsed application of cooling power. In an embodiment, temperature control is based at least in part on a feedforward control signal derived from a plasma power input into the processing chamber. In further embodiments, fluid levels in each of a hot and cold reservoir coupled to the temperature controlled component are maintained in part by a passive leveling pipe coupling the two reservoirs. In another embodiment, digital heat transfer fluid flow control valves are opened with pulse widths dependent on a heating / cooling duty cycle value and a proportioning cycle having a duration that has been found to provide good temperature control performance.

Owner:APPLIED MATERIALS INC

Carbon series electric heating coating

InactiveCN101148551AHigh electrothermal conversion efficiencyEasy to makePolyurea/polyurethane coatingsHeating element materialsLight energyGraphite

The electrothermal carbon paint includes inorganic conducting material 30-80 wt%, adhesive 20-70 wt% and assistant 1-8 wt%. The inorganic conducting material is one or several kinds of scale graphite, silicon carbide, artificial graphite and conductive carbon black. The electrothermal carbon paint has electrothermal efficiency as high as 93 %, no light energy consumption and wide application.

Owner:HUNAN UNIV +1

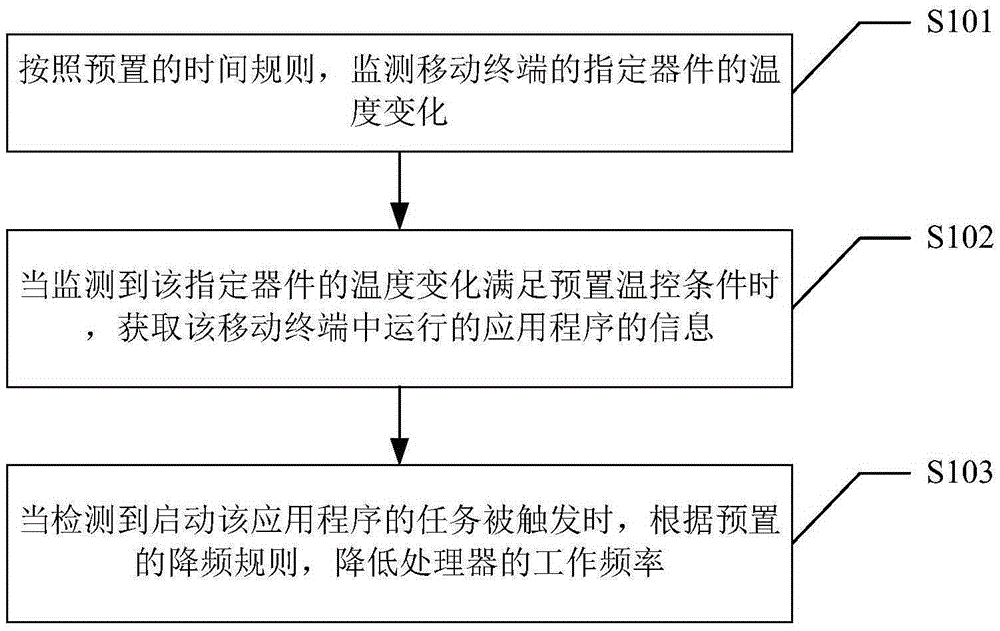

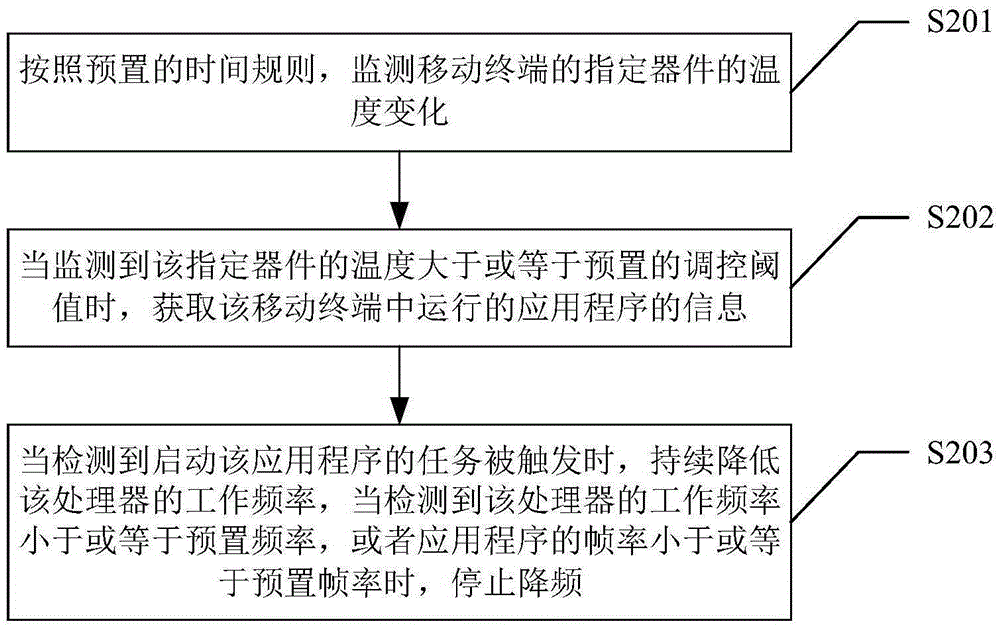

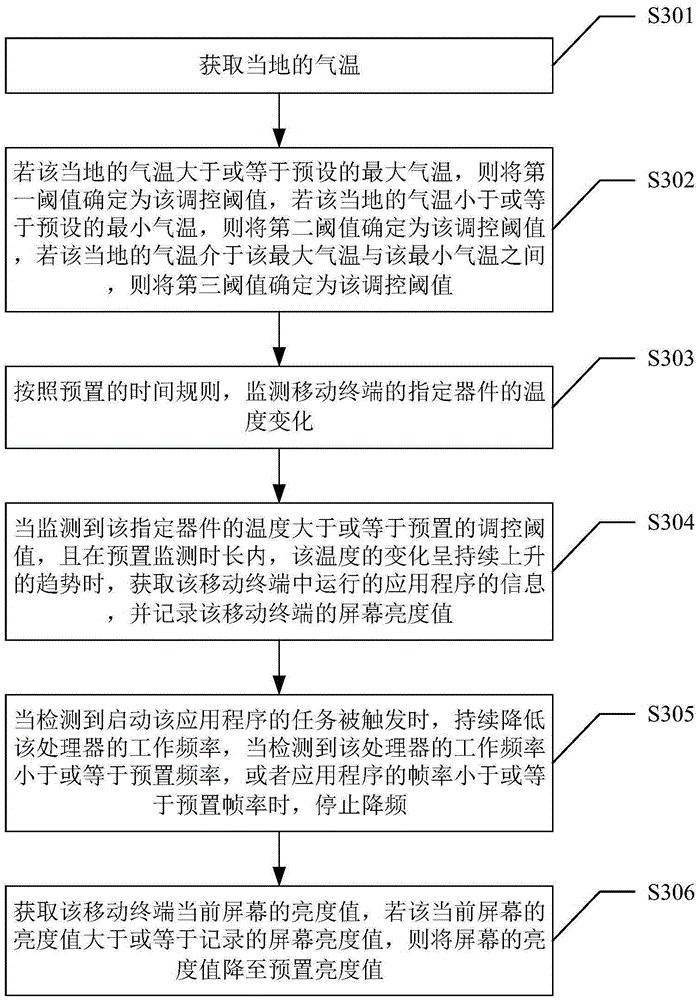

Processor temperature regulation method and apparatus

ActiveCN106557135AIncrease temperatureEffective temperature controlDigital data processing detailsAuxillary controllers with auxillary heating devicesTemperature controlOperating frequency

The present invention provides a processor temperature regulation method and apparatus. The method comprises: according to a preset time rule, monitoring a temperature change of a specified device of a mobile terminal; when it is monitored that the temperature change of the specified device meets a preset temperature control condition, acquiring information of an application that runs in the mobile terminal; and when it is detected that a task for starting the application is triggered, decreasing an operating frequency of a processor according to a preset down-conversion rule, so as to regulate a temperature of the processor. According to the method and apparatus provided by the present invention, before the application that can cause increase of the temperature of the processor is started, down-conversion processing is performed on the processor, so that the temperature of the processor can be effectively controlled.

Owner:BEIJING ERENEBEN INFORMATION TECH

Preparation method for nanometer TiO2 modified composite phase change microcapsule

ActiveCN105056854AHigh phase change enthalpyConstant phase transition temperatureMicroballoon preparationMicrocapsule preparationAlkaneCross-link

The invention discloses a preparation method for a nanometer TiO2 modified composite phase change microcapsule. The preparation method comprises the following steps: preparing a core material from n-alkane and alkyl stearate, preparing a wall material from methyl methacrylate, butyl acrylate, ethyl acrylate, a cross-linking agent and nanometer TiO2 and mixing the core material with the wall material so as to obtain an oil phase A; dissolving a reactive emulsifier in deionized water so as to prepare a water phase B; adding the oil phase A into the water phase B and carrying out ultrasonic dispersion so as to form an O / W pre-emulsion; heating the O / W pre-emulsion and adding an initiator into the O / W pre-emulsion so as to prepare a nanometer TiO2 modified composite phase change microcapsule emulsion; and subjecting the nanometer TiO2 modified composite phase change microcapsule emulsion to standing and carrying out filtering, washing and drying so as to obtain the nanometer TiO2 modified composite phase change microcapsule. According to the preparation method, under the condition of usage of reactive emulsifier, nanometer TiO2 is used to modify the wall material, so the phase change microcapsule with a small and uniform size is prepared.

Owner:SHAANXI UNIV OF SCI & TECH

Reduction method for copper-radic catalyst for reforming methanol vapour to produce hydrogen

The present invention discloses a reduction method of catalyst for reforming hydrogen production by using methyl alcohol aqueous vapour. Said method includes the following several stages: a, dehydration stage of catalyst; b, initiation stage of catalyst reduction; and c, reduction stage of catalyst. Said invention also provides the concrete steps of the above-mentioned every stage and its concrete requirements.

Owner:HAO HUA CHENGDU TECH

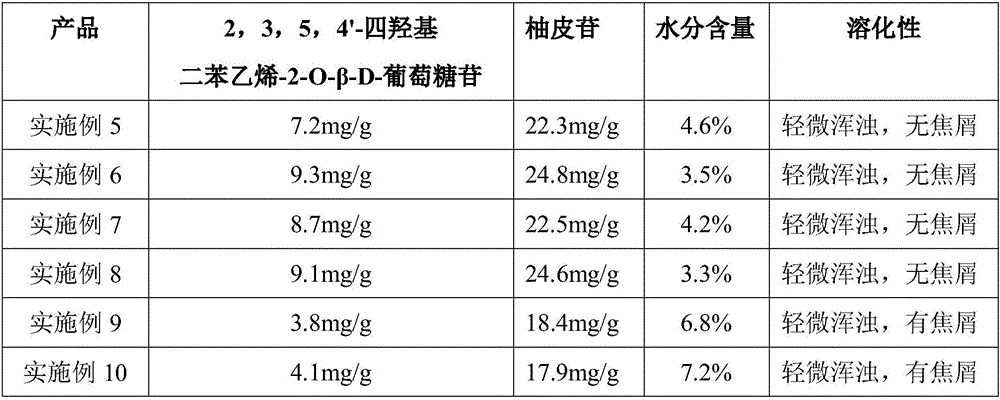

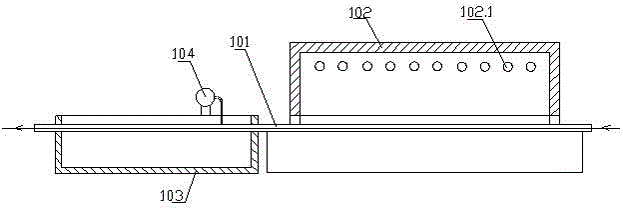

Drying method for Chinese medical extract

InactiveCN106123496AKeep the fragranceModerate colorDrying solid materials with heatDrying solid materials without heatMedicinal herbsMedicine

The invention relates to a drying method for Chinese medical extract, in particular to a vacuum drying method for Shouhui cathartic extract. The vacuum drying method adopts circulating hot water with the temperature being controlled automatically to serve as a medium for heating of the Chinese medical extract, and the purpose of low-temperature drying of the Chinese medical extract is achieved. Through the method, the defects, occurring to traditional vacuum drying and the like, that thermosensitive components of extract are decomposed due to high temperature, the energy consumption is high, the heat efficiency is low, the extract is dried and burnt, drying is insufficient can be overcome. According to the dried Chinese medical extract obtained through the drying method, the content of effective components is high, the quality of finished products is good, the water content is low, and preparation processing and storage of the finished products are facilitated; fresh scent of medicinal materials is maintained, the color and lustre are natural, the texture is loose and uniform, the extract is easy to crush; and continuous and automatic production can be achieved, and the method has quite high operability and practicability.

Owner:LUNAN PHARMA GROUP CORPORATION

Crucible type evaporator source used for film plating machines in organic electrofluorescence type

InactiveCN1431339AImprove insulation effectEasy to take outVacuum evaporation coatingSputtering coatingOrganic filmHeating furnace

A crucible-type evaporator for the machine used to plate electroluminescent organic film is composed of supporting base, temp-measuring thermocuple system, crucible, and heating furnace which consists of upper and lower No.95 ceramic rings, cylindrical quartz glass as internal shielding layer, cylindrical stainless steel as external shielding layer, and Mo wire embedded in the inner surfaces of two ceramic rings. Its advantages are long service life, good temp control, stable evaporating speed, and high thermal insulating performance.

Owner:JILIN UNIV

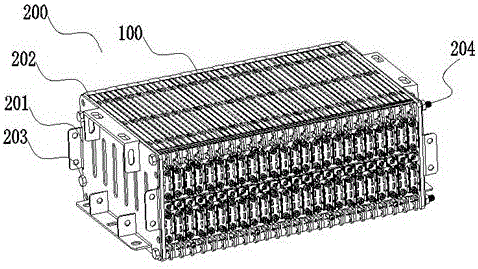

New energy power batter

PendingCN106356587AExquisite structureEasy to installFinal product manufactureCurrent conducting connectionsAluminiumGraphite

The invention discloses a new energy power battery. The new energy power battery comprises a battery box upper cover, a power battery module and a battery box lower casing, wherein the power battery module comprises an electric core bracket, more than two electric cores and an aluminum casing clamp plate; the electric cores are arranged in the electric core bracket, and the two outermost sides of each electric core are tightly attached to the aluminum casing clamp plate. The new energy power battery is characterized in that Lvte cotton is adhered to one surface of each electric core, and a silica gel sheet is adhered onto an electrode lug of each electric core; after the two electric cores are adhered with the Lvte cottons and the silicon rubber sheets, a heat conduction graphite sheet is adhered onto the surface, adhering with the Lvte cotton, of one electric core, a heating plate is arranged between the two electric cores, and the two side surfaces of the heating plate are respectively adhered with the Lvte cotton surfaces; a temperature sensor is connected with the heat conduction graphite sheet; a water cooling system is arranged at the exterior of the battery box lower casing, and a connecting structure of positive and negative electrode lugs of each electric core adopts laser welding or riveting type. The new energy power battery has the advantage that the water cooling heat radiating and heating functions are simultaneously realized.

Owner:JIANGXI DIBIKE

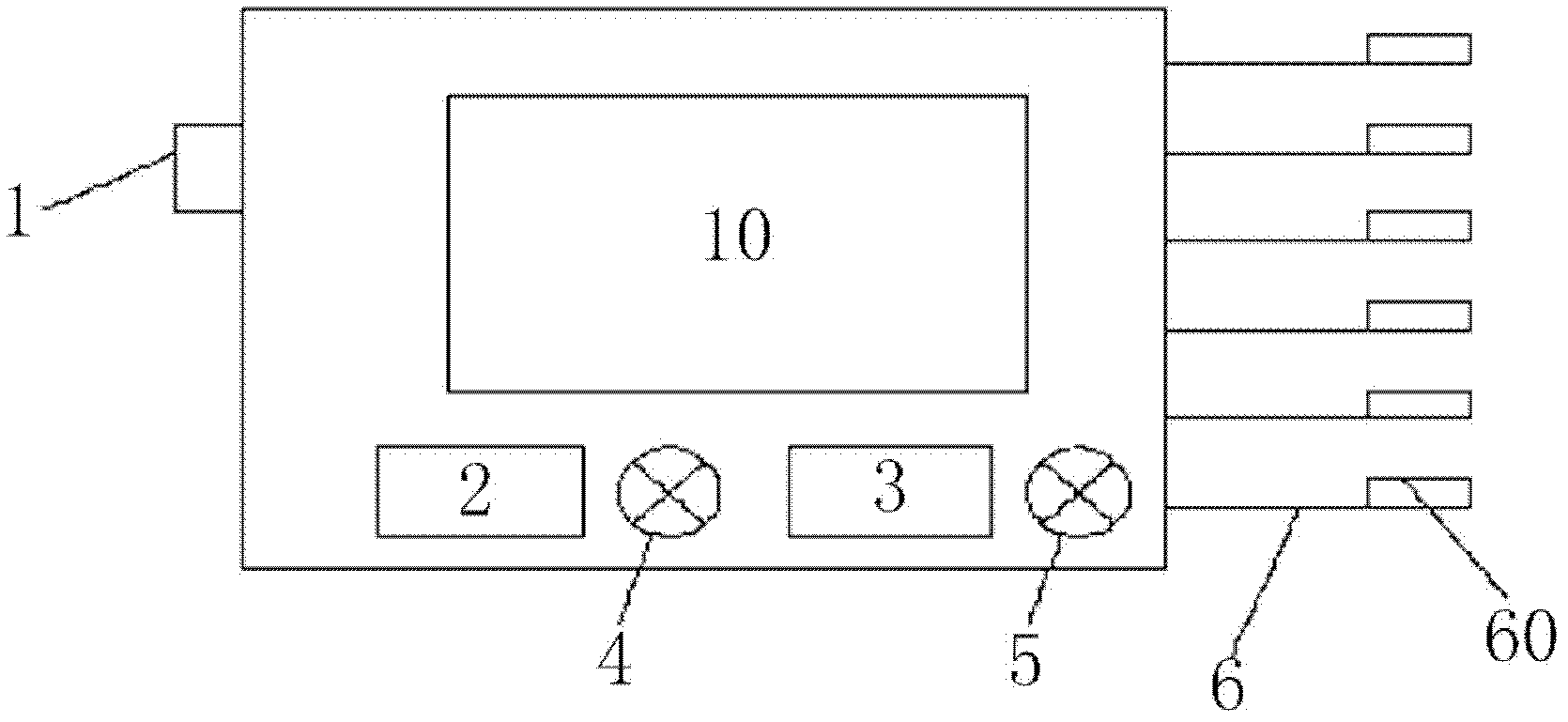

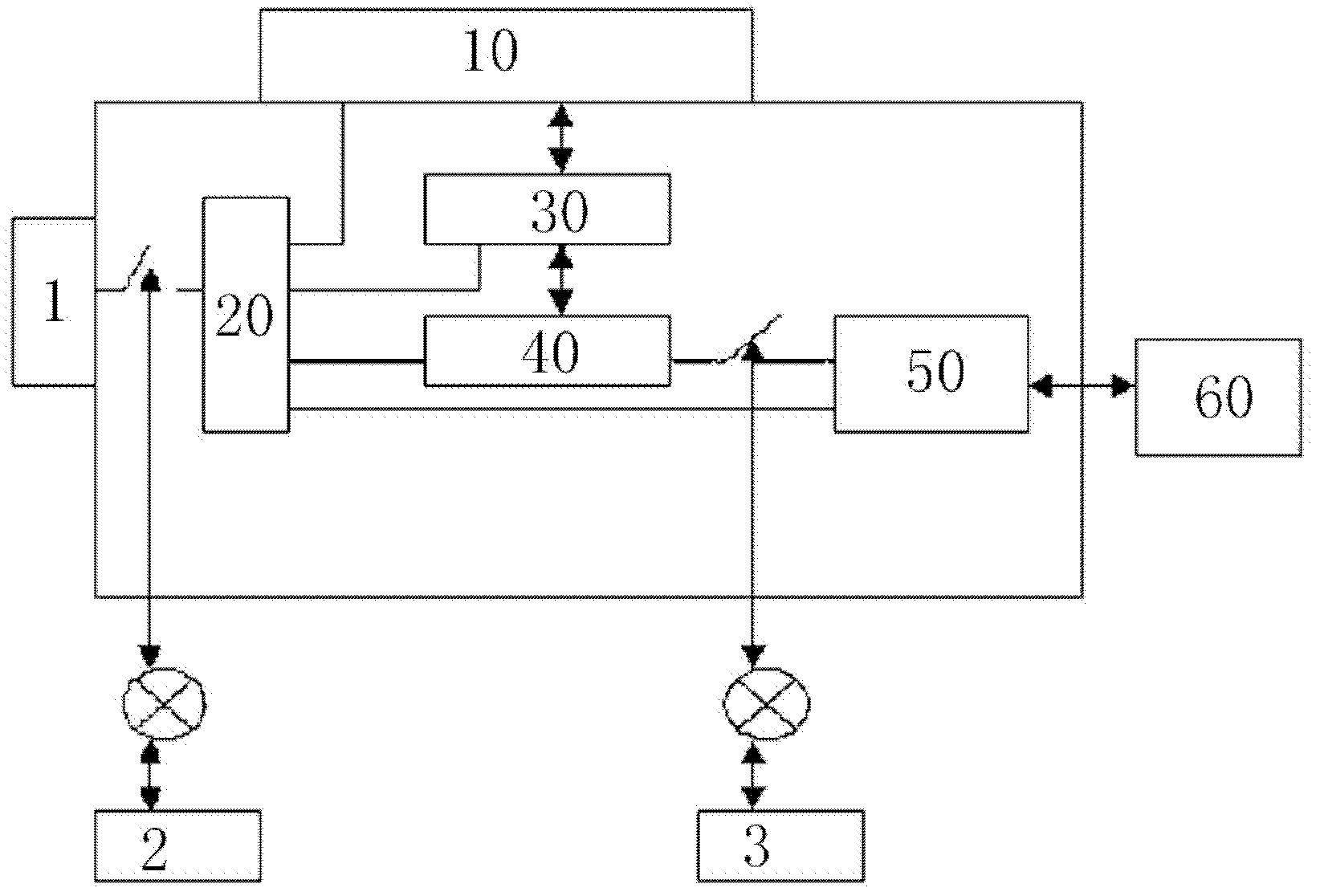

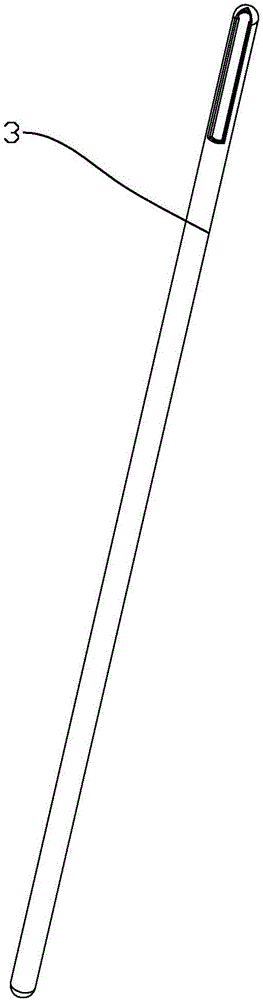

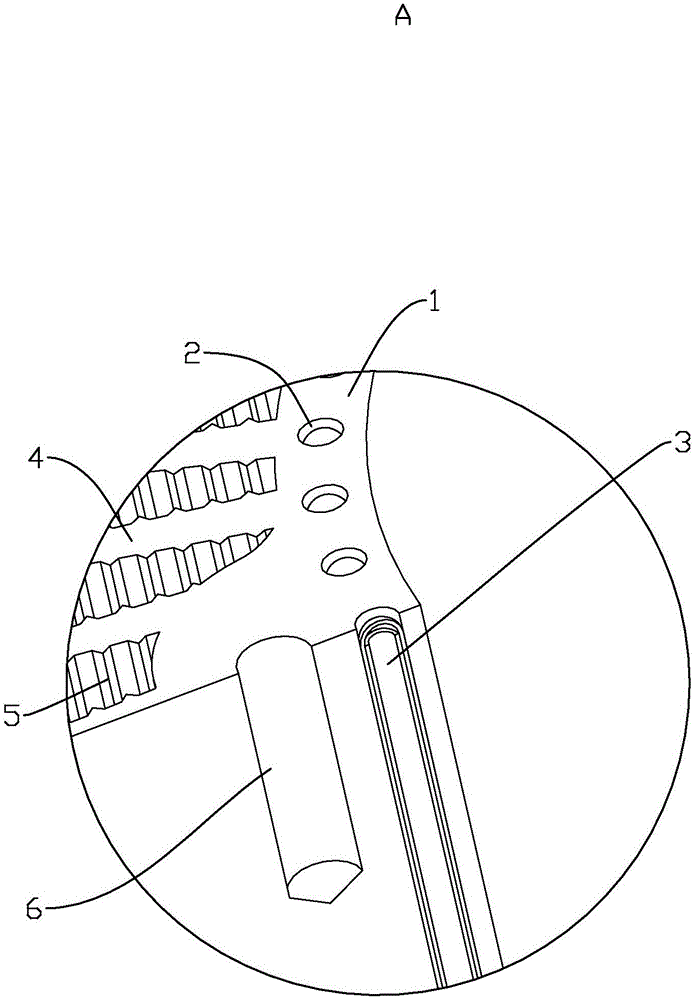

Intelligent temperature control acupuncture therapeutic apparatus

ActiveCN103126881AAccurate temperature controlHeating fastDevices for heating/cooling reflex pointsAcupunctureEngineeringElectrical and Electronics engineering

The invention discloses an intelligent temperature control acupuncture therapeutic apparatus. The intelligent temperature control acupuncture therapeutic apparatus comprises a power module, a liquid touch screen, a touch-screen controller, an electronic temperature control component used for simulating moxibustion temperature curve and a heating head used for being inserted into the handle portion of an acupuncture pin to conduct heating, wherein the electronic temperature control component is composed of a system control module and a heating driving module, the system control module is connected with the heating driving module in a communication mode, the system control module is connected with the power module and the touch-screen controller in a communication mode, the liquid touch screen is connected with the touch-screen controller in a communication mode and used for setting the heating time and the temperature cycle period of the heating head and displaying the temperature change and the heating time of the heating head in work, the heating head is connected with the heating driving module through a guide line, and the system control module and the heating driving module control the temperature change range of the heating head from 30 DEG C to 59 DEG C. According to the intelligent temperature control acupuncture therapeutic apparatus, moxibustion technique change and moxa-cone temperature change are effectively simulated, a continuous and variational thermal stimulus state is kept, fast - slow adaptation phenomenon caused when a human body experiences the apparatus is avoided, and clinical effect is improved.

Owner:上海中医药大学附属龙华医院浦东分院 +2

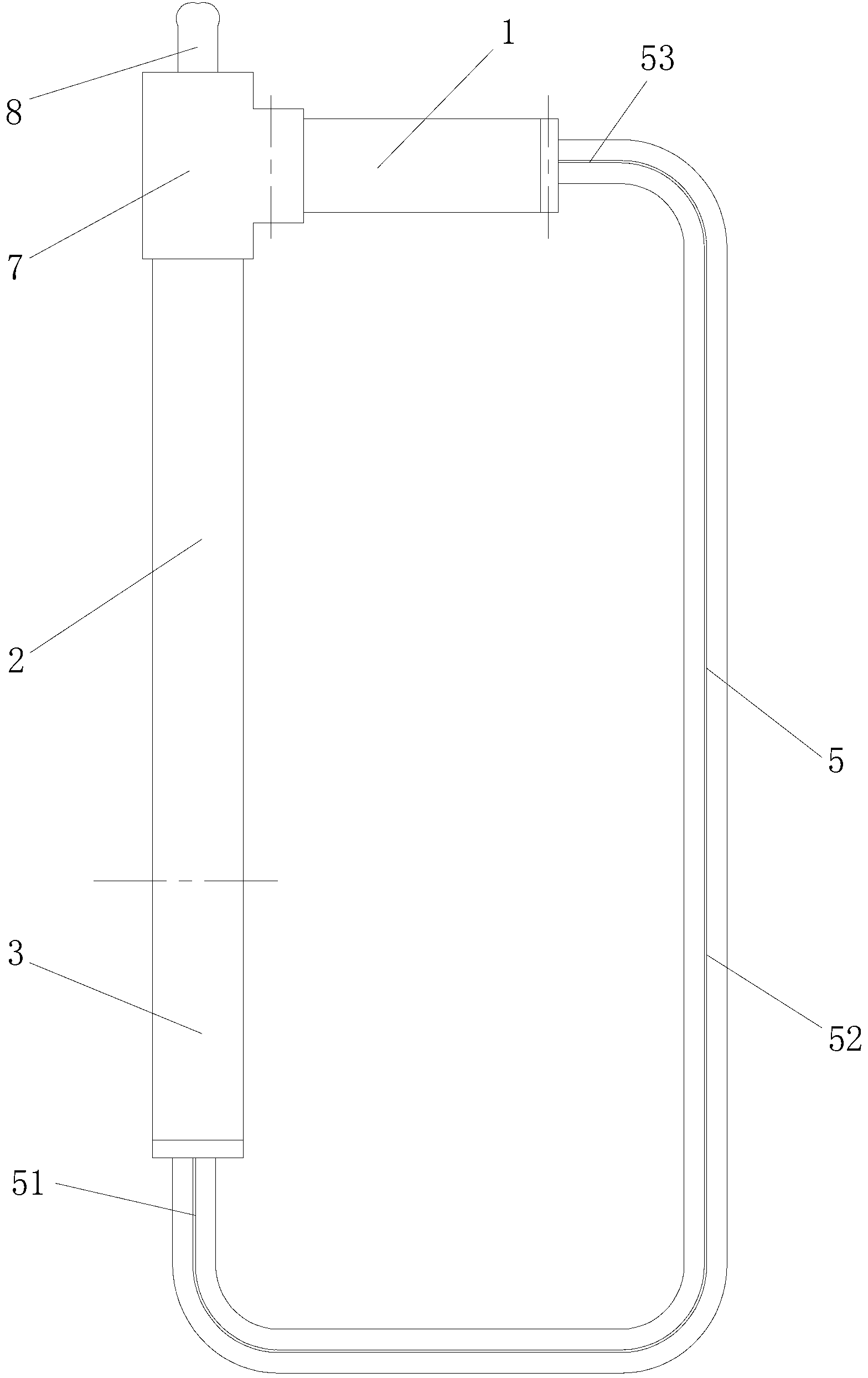

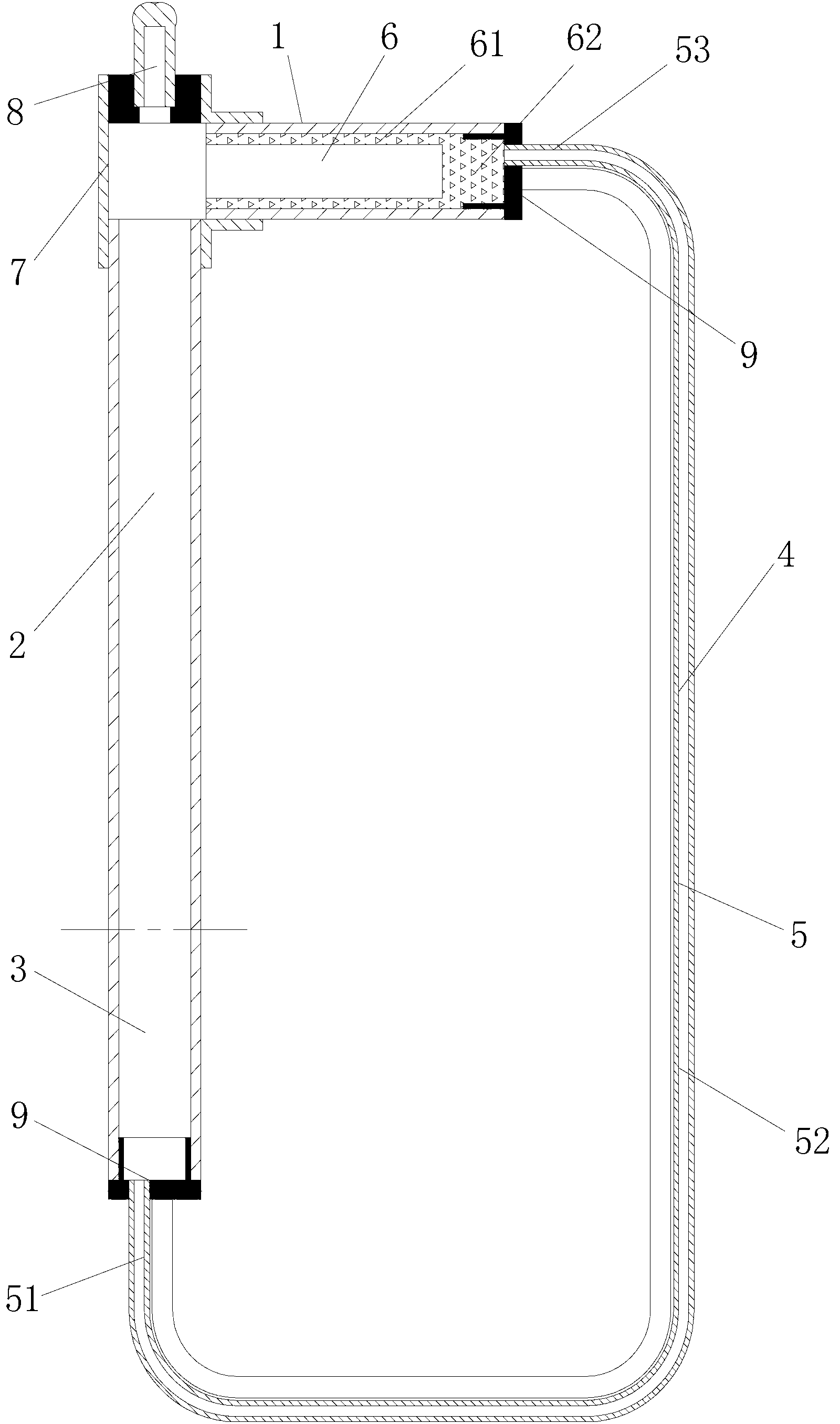

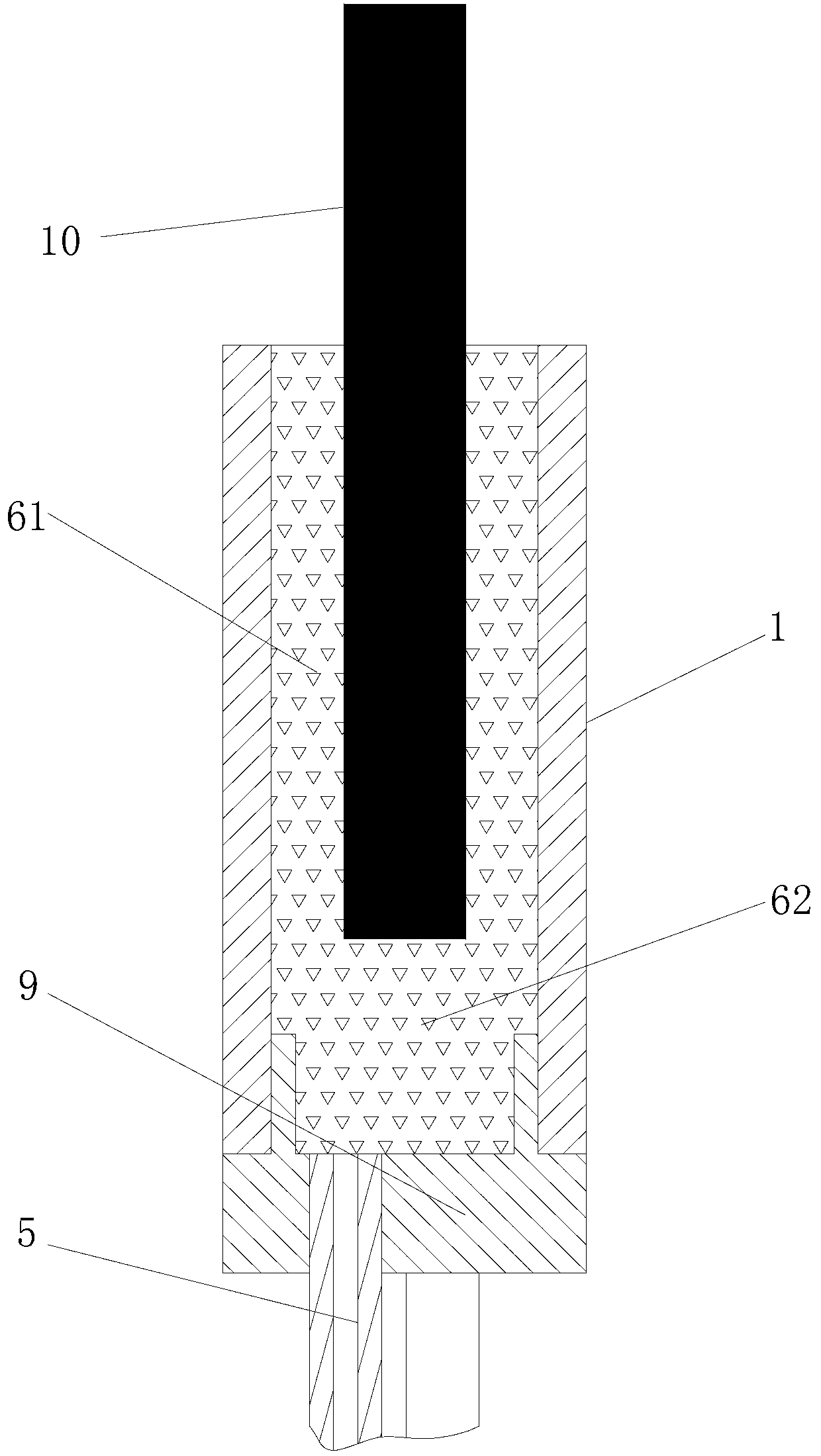

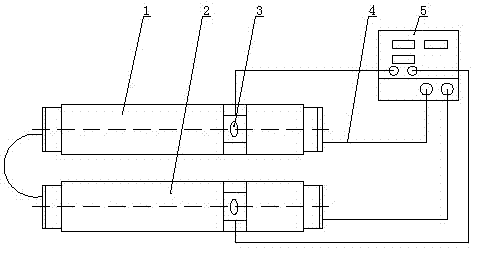

Anti-gravity loop heat pipe and production method thereof

InactiveCN103322843AStable return speedLow temperature fluctuationChemical industryIndirect heat exchangersChemical industryHeat transfer efficiency

The invention discloses an anti-gravity loop heat pipe. The anti-gravity loop heat pipe comprises an evaporation segment, an insulating segment, a condensation segment and a liquid conveying segment, which are connected end to end to form a loop. The liquid conveying segment comprises at least one capillary tube, and two ends of every capillary tube are connected with the evaporation segment and the condensation segment respectively; the inner diameter of the capillary tubes is smaller than that of the pipe body of the evaporation segment and the pipe body of the condensation segment; a liquid-absorbing core passage is formed in the evaporation segment. The anti-gravity loop heat pipe drives liquid working medium to quickly move in the pipe by capillary force, has fine return speed stability and higher heat transfer efficiency, and is applicable to the complex fields having high radiating condition requirements, such as aerospace, photoelectrons, chemical industry and power engineering. The invention further provides a production method of the anti-gravity loop heat pipe.

Owner:SOUTH CHINA UNIV OF TECH

Phase change energy storage temperature-adjusting internal wall coating and preparing method thereof

ActiveCN105062241AHigh phase change enthalpyImprove energy storage performanceCoatingsBalance waterDefoaming Agents

The invention provides a phase change energy storage temperature-adjusting internal wall coating and a preparing method thereof. The phase change energy storage temperature-adjusting internal wall coating comprises, by mass, 30%-50% of emulsion, 0.5%-1.5% of dispersing agents, 0.5%-2% of antifreezing agents, 1%-3% of coalescing agents, 1%-2% of thickening agents, 0.5%-1% of defoaming agents, 5%-15% of titanium dioxide, 5%-10% of functional padding, 15%-30% of composite phase change materials and the balance water. According to the phase change energy storage temperature-adjusting internal wall coating and the preparing method, the attapulgite-based paraffin composite phase change materials serve as temperature-control base materials, the obtained phase change coating has good energy storage performance, cheap in price and excellent in weather resistance, energy consumption is saved, the indoor comfort is improved, the phase change coating is not limited by the territory and weather in use due to the adjustable phase change temperature, the application field of the phase change coating is broadened, and the coating has the good economic benefits and environment benefits and wide application prospects.

Owner:盱眙凹土能源环保材料研发中心 +1

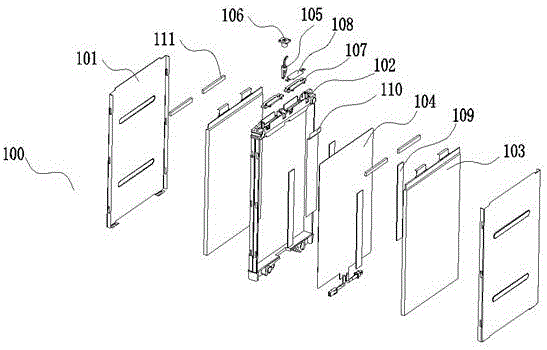

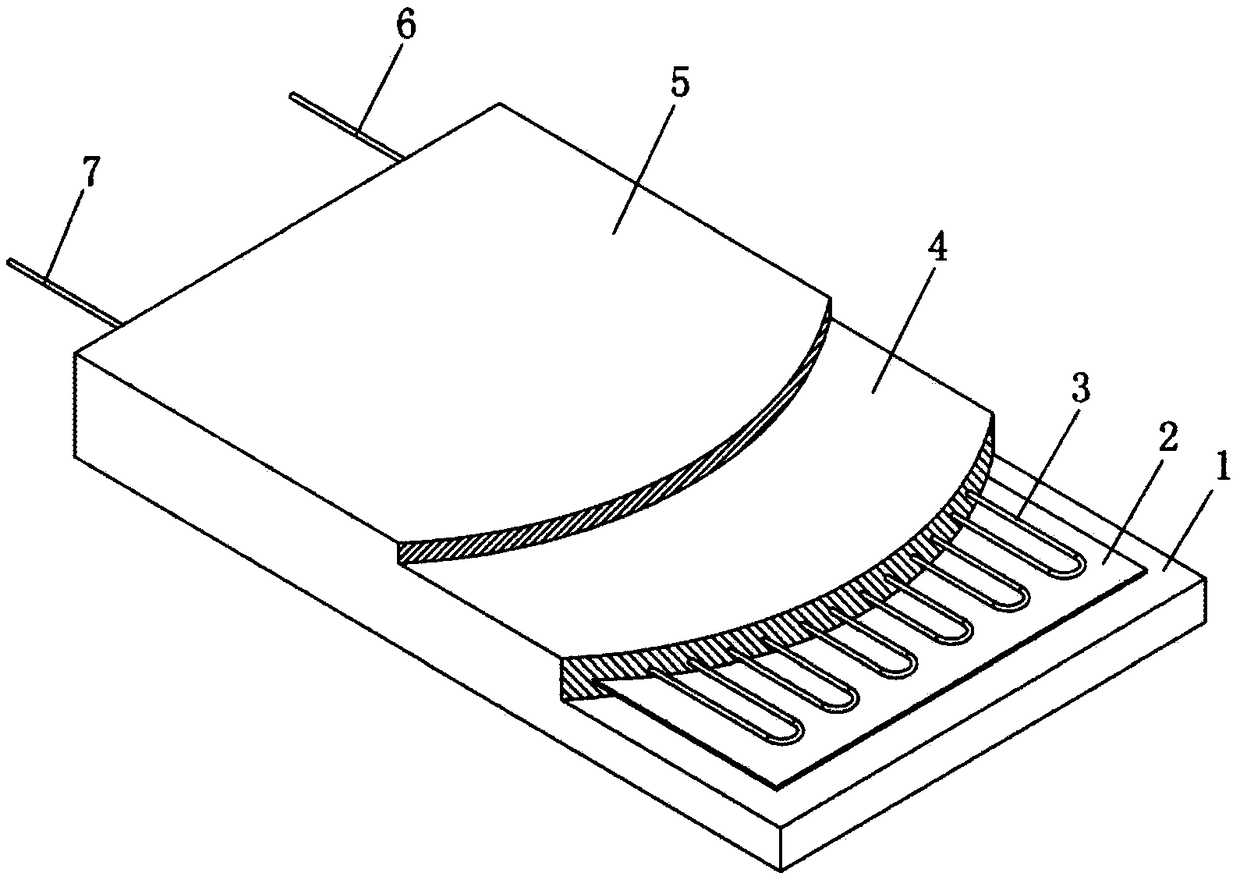

Electrothermal insulation and decoration integrated wall and floor tiles and preparation method thereof

ActiveCN109053136ARealize transmissionReduce heat lossCovering/liningsCeramic shaping apparatusFoaming agentBrick

The invention discloses electrothermal insulation and decoration integrated wall and floor tiles and a preparation method thereof. The method comprises the steps of sequentially distributing a tile matrix layer mixture (prepared from the following components: clay, quartz, feldspar and pigment), a non-metallic conductive layer mixture (prepared from the following components: a carbonaceous material, clay, an iron material and feldspar), and a foamed ceramic insulating layer mixture (prepared from the following components: solid wastes, feldspar, clay and a foaming agent); pressing into green bodies by using a press, drying the green bodies, and then firing the dried green bodies in a kiln at the high temperature. The wall and floor tiles have the advantages of being low in thermal loss energy consumption, having an electrothermal efficiency reaching up to 99%, and being convenient in construction, and can lower the construction and use costs to a certain extent.

Owner:山东晟世达科技有限公司

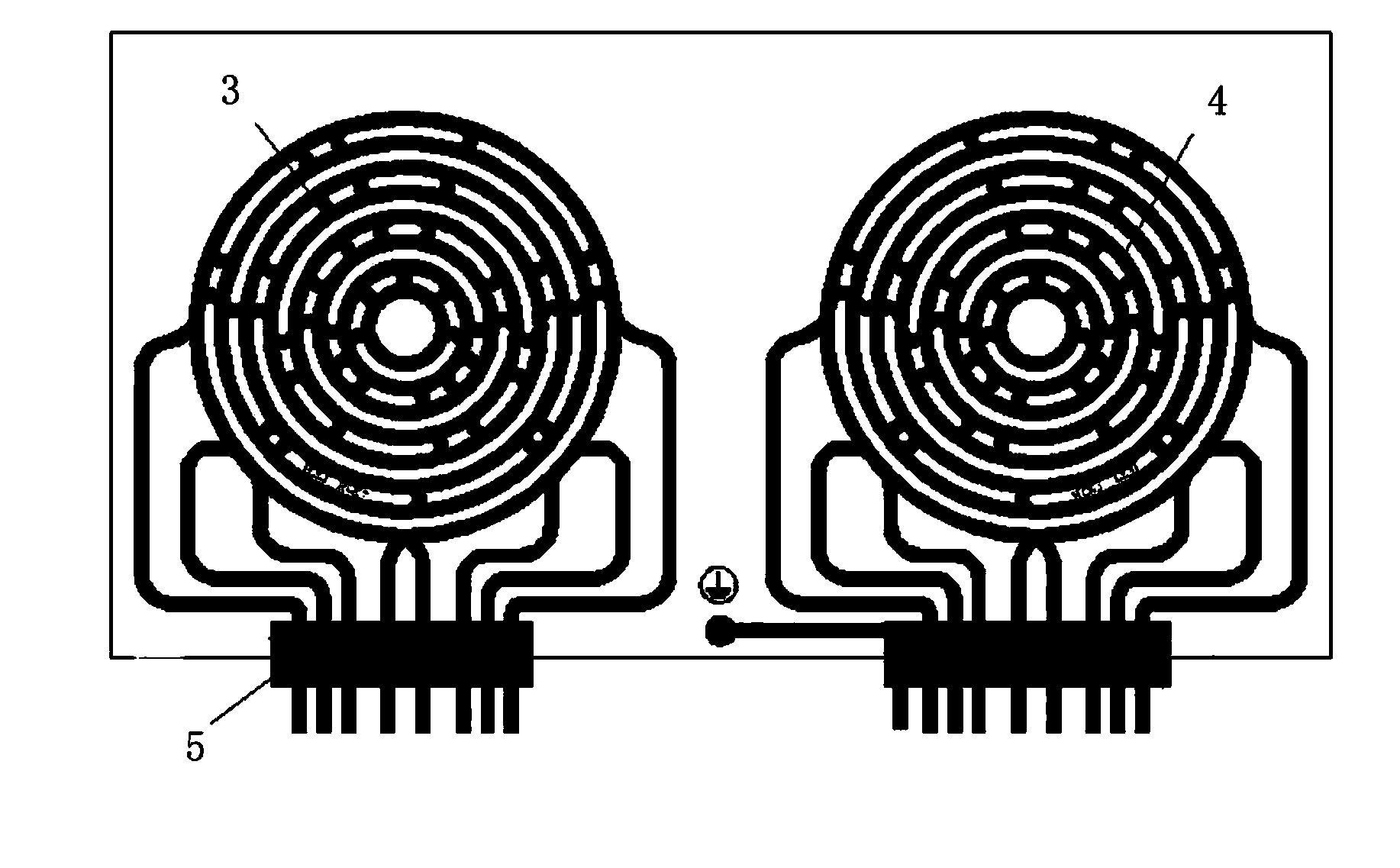

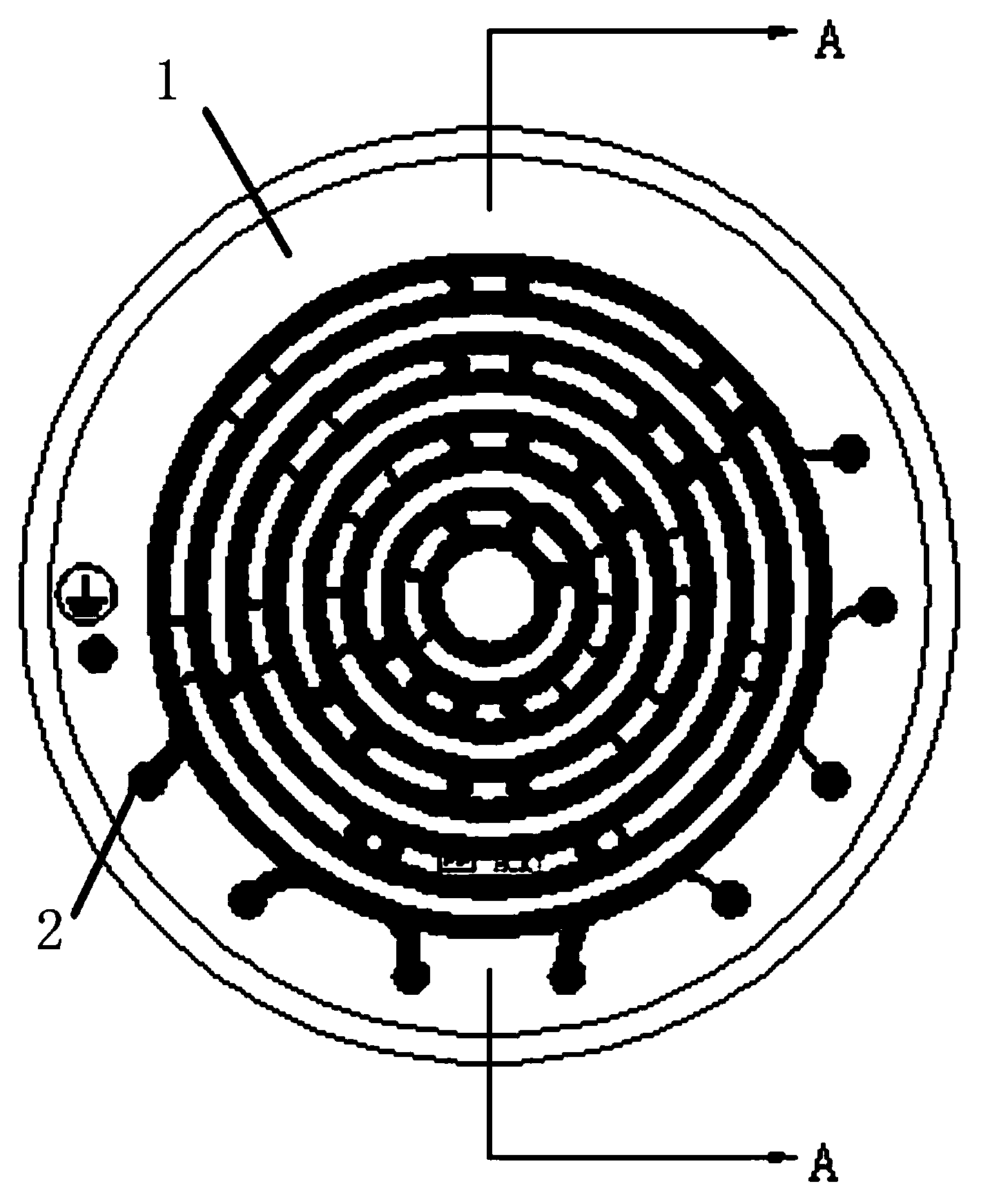

Rare earth thick film circuit electric heating chip and manufacturing technology thereof

ActiveCN103716924AGood compatibilityImprove wettabilityHeating element materialsManufacturing technologyRare earth

The invention discloses a rare earth thick film circuit electric heating chip and a manufacturing technology of the chip. The rare earth thick film circuit electric heating chip is characterized in that the chip comprises a bacteriostatic copper and aluminum composite metal substrate and a rare earth thick film circuit manufactured on the composite metal substrate, the rare earth thick film circuit comprises a rare earth thick film dielectric layer, a rare earth thick film resistor circuit, a rare earth thick film control circuit, a rare earth thick film electrode connection circuit and a rare earth thick film function circuit, the rare earth thick film resistor circuit, the rare earth thick film control circuit, the rare earth thick film electrode connection circuit and the rare earth thick film function circuit are curved, wound and superposed in multiple layers, and the rare earth thick film function circuit integrates and is connected with the output port of a split electronic component and the output port of a temperature control component in a combined mode. The rare earth thick film circuit electric heating chip has the advantages of being high in film compactness, good in uniformity, excellent in performance, short in production period, few in work procedures, low in energy consumption, little in material loss and the like.

Owner:GUANGDONGSHENG YUCHEN ELECTRONICS & TECH CO LTD

Automatic temperature control cable material resin composition and preparation method thereof

InactiveCN101608044AHigh strengthConvenient temperature controlPlastic/resin/waxes insulatorsTemperature controlEngineering

The invention relates to an automatic temperature control cable material resin composition comprising the following main components by weight percent: 85 to 90% of modified PVC, 5 to 10% of PVC stabilizing agent, 1 to 5% of filler, 0.1 to 0.3% of BaTiO3, 0.1 to 0.2% of SrTiO3, 0.1 to 0.3% of Y2O3, 0.1 to 0.3% of Nb2O5, 0.1 to 0.2% of SiO5 and 0.1 to 0.2% of MnO2. The invention also relates to a preparation method of the automatic temperature control cable material resin composition. The invention has the advantages of high PTC strength, good temperature-control performance, convenient use, energy saving and environmental protection.

Owner:JIANGYIN NANFANG GRANULATION FACTORY

Preparation process for stainless steel wire

ActiveCN106755836AShorten the lengthSmall sizePretreated surfacesFurnace typesWire rodProduction line

The invention discloses a preparation process for a stainless steel wire. The process comprises the following steps that firstly, an online coating drying device is used for coating a wire rod with a coating agent and drying the coating agent; secondly, the wire rod is guided into a thick straight wire-drawing machine to be continuously drawn 3-5 times; thirdly, surface heat treatment is carried out, the drawn wire rod is guided into a heat treatment furnace to be subjected to surface brightening treatment, and after heat treatment is completed, water cooling, water washing and drying are carried out; fourthly, the online coating drying device is used for coating the wire rod with the coating and drying the coating agent; fifthly, the wire is guided into a thin straight wire-drawing machine to be continuously drawn 3-5 times; sixthly, surface heat treatment is carried out, the drawn wire rod is guided into the heat treatment furnace to be subjected to surface brightening treatment, and after heat treatment is carried out, water cooling, water washing and drying are carried out; seventhly, the online coating drying device is used for coating the wire rod with the coating agent and drying the coating agent; eighthly, the wire rod is guided into a straight wire-drawing machine to be continuously drawn 12-13 times; and ninthly, wire taking is carried out. According to the preparation process for the stainless steel wire, the floor space of a production line is small, the quality of produced products is high, and the wire taking efficiency is high.

Owner:江阴祥瑞不锈钢精线有限公司

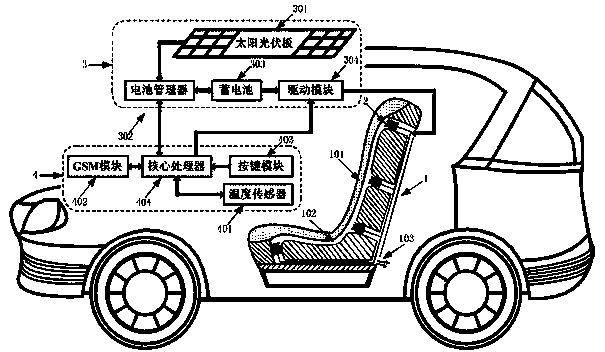

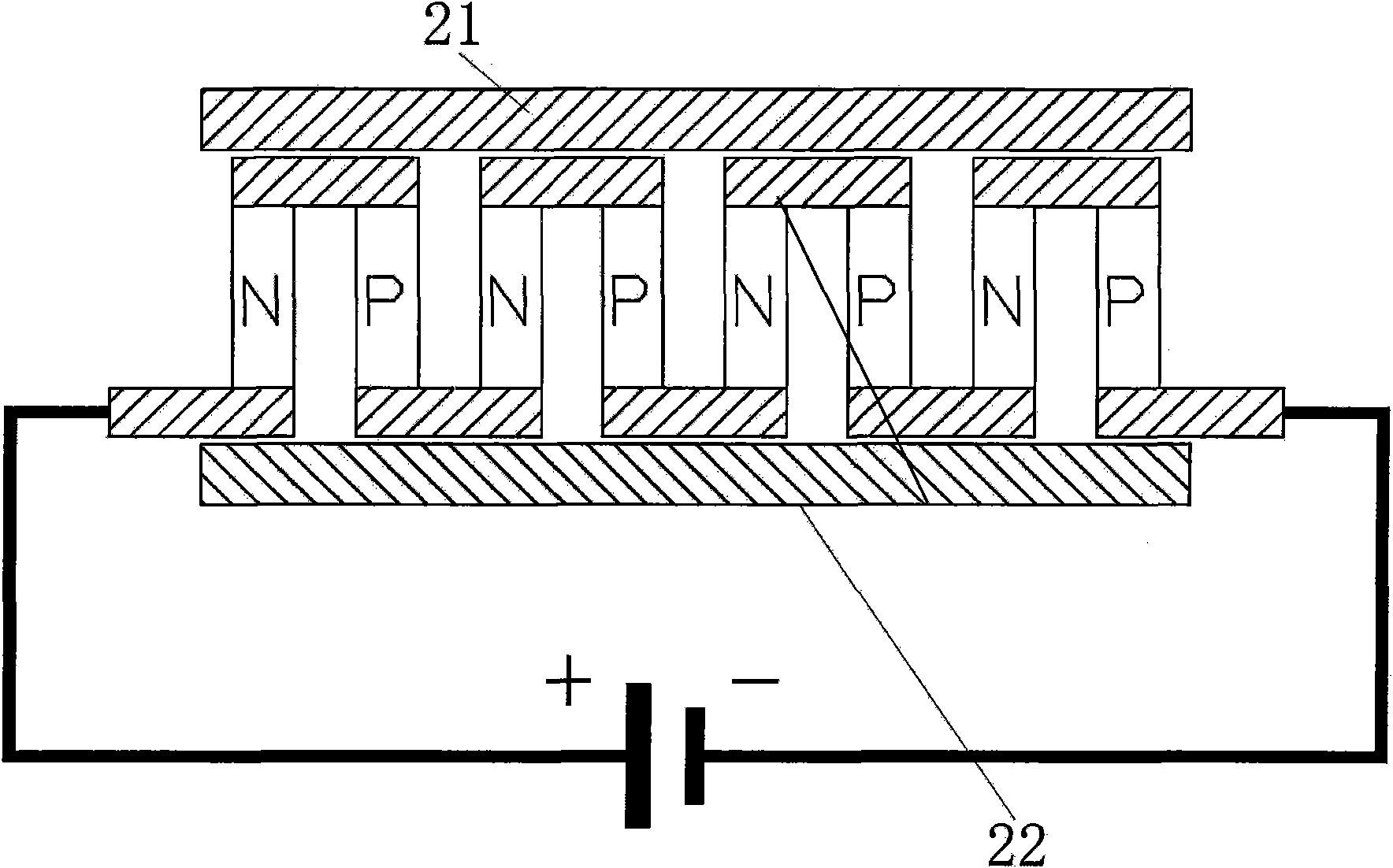

Remotely-controllable automobile cooling seat

InactiveCN104108332ASolve the problem of hot car seatsImprove the environment in the carSeat heating/ventillating devicesElectric/fluid circuitHeat sinkSupply energy

The invention discloses a remotely-controllable automobile cooling seat which is composed of an automobile seat body, a refrigeration device, an energy supply device and a control device. A cushion with air holes is arranged on the surface of the automobile seat body. The automobile seat body is internally provided with a ventilation pipeline and a ventilation opening. According to the refrigeration device, the semiconductor refrigeration technology is adopted, a radiation system composed of a bendable heat pipe, a fin-type radiating fin and an axial flow fan is arranged at the hot end of a semiconductor refrigeration chip, and the radiation strength is enhanced. The energy supply device is composed of a solar photovoltaic panel, a battery manager, a storage battery and a driving module, and absorbed solar energy is converted into electric energy to the maximum extent. Meanwhile, a temperature sensor is adopted to conduct real-time temperature sampling, a GSM module is adopted to be communicated with a core processor, and the functions of rapid remote control over the automobile seat temperature and short message reminding through mobile phone short messages are achieved. The remotely-controllable automobile cooling seat is simple in structure, efficient in operation and environmentally friendly and saves energy, the problem that the automobile seat is burning due to parking for a long time when it is hot is solved, and the riding comfort is improved.

Owner:HOHAI UNIV CHANGZHOU

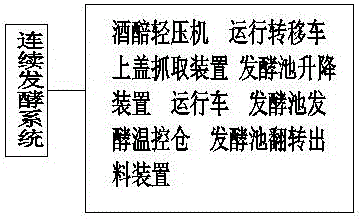

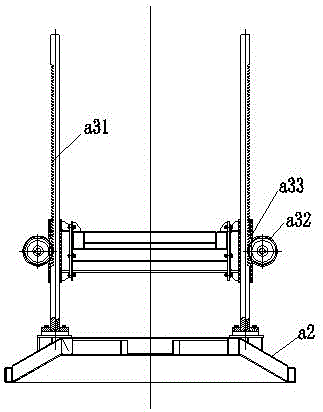

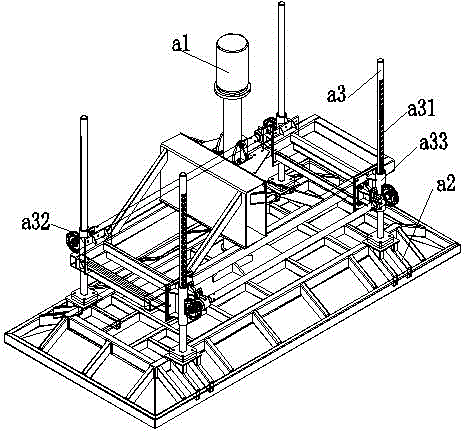

Intelligent continuous fermentation system for solid-state Baijiu

PendingCN106479815AAchieve continuous fermentationHigh yieldAlcoholic beverage preparationContinuous fermentationTemperature control

The invention relates to an intelligent continuous fermentation system for solid-state Baijiu. The intelligent continuous fermentation system comprises a fermented-grain mild compression machine, an operation transfer vehicle, an upper cover grabbing device, a fermentation tank lifting device, an operation vehicle, a fermentation tank, a fermentation temperature control bin and a turnover discharge device. Fermented grains are fed into the fermentation tank, the fermentation tank is stopped below the fermented-grain mild compression machine, and the fermented-grain mild compression machine performs compaction by an electric-hydraulic pusher pushing down a compression panel; after the compaction, the fermentation tank is transferred to the fermentation tank lifting device through the operation vehicle and just stopped above the upper cover grabbing device in a position-limited manner, and the upper cover grabbing device stably places an upper cover on the fermentation tank through lifting and unhooking; the fermentation tank is placed into the fermentation temperature control bin, the fermentation tank is moved through the operation transfer vehicle, the fermentation tank is moved out of the temperature control bin after the fermentation, and discharging is performed through the turnover discharge device to complete the whole fermentation process. The intelligent continuous fermentation system for the solid-state Baijiu is reasonable in structure and capable of achieving mechanical brewing.

Owner:YANGZHOU XIANYE GRP

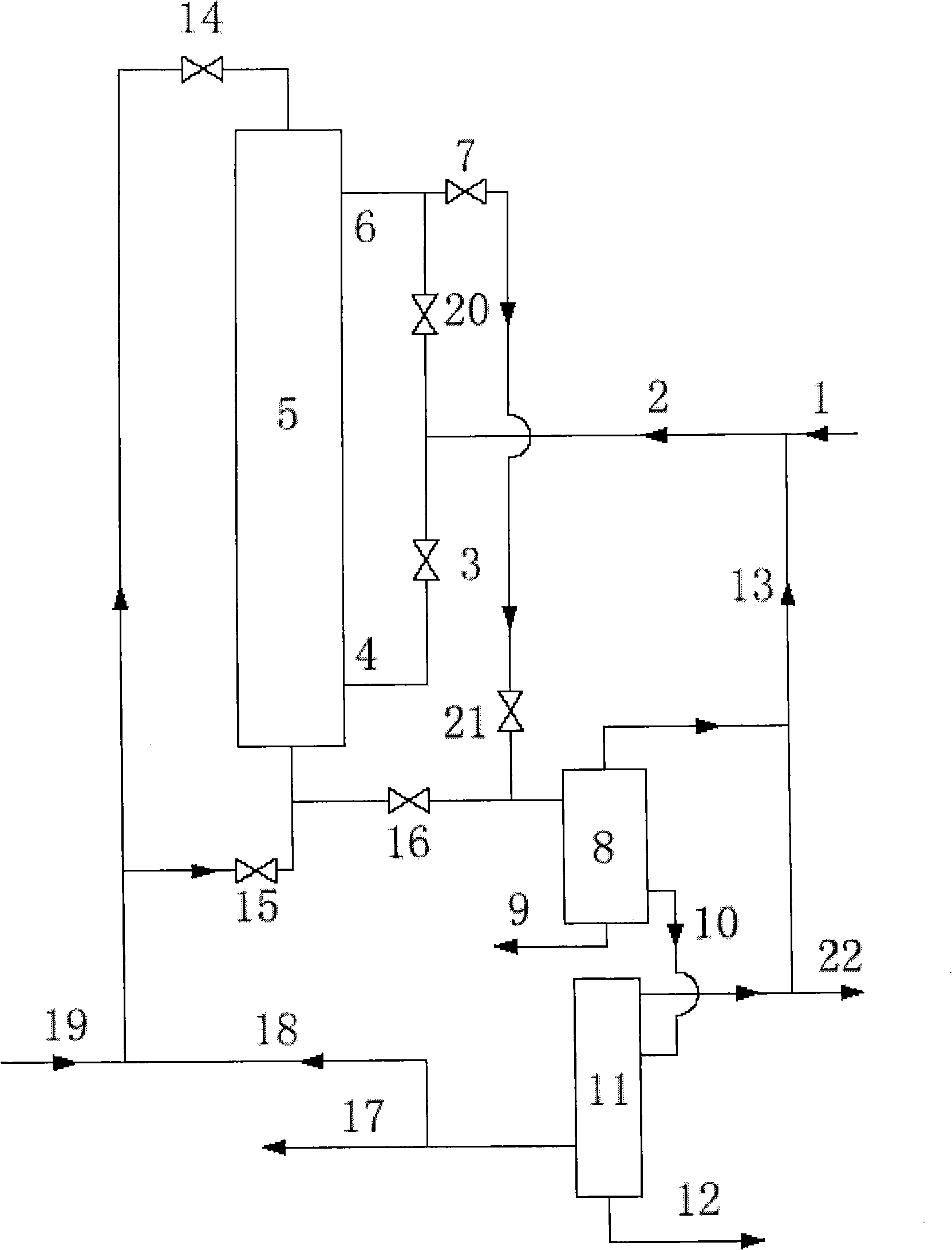

Fischer-Tropsch synthesis process based on fixed bed reactor

ActiveCN101275080AImprove heat transfer phenomenonEliminate hot spotsHydrocarbon from carbon oxidesLiquid hydrocarbon mixture productionSyngasExhaust gas

The present invention provides a ft synthesis reaction process based on the fixed bed reactor is that the cycling medium enters from the top of the fixed bed reactor after preheated, the feed gas formed by mixing the syngas with the tail gas enters from the lower of the fixed bed reactor to contact with the catalyst to process ft synthesis , the product is fully collected to process the separation of water, a long chain hydrocarbon and a gas phase component; the long chain hydrocarbon processes C5-C18 middle distillate, the separation of C18+hydrocarbon and gaseous low carbon hydrocarbon, one part C5-C18 middle distillate is mixed with the cycling liquid medium, the other part is processed oil product process, C18+hydrocarbon fully enters in the oil product process, the gaseous low carbon hydrocarbon mixing with the gas phase component forms the tail gas, the water component is used as a gas agent to return in the gasification system. The invention has high heat exchange efficiency, high syngas throughput, lower cycling gas quantity, lower energy consumption, stable operation.

Owner:中科潞安能源技术有限公司

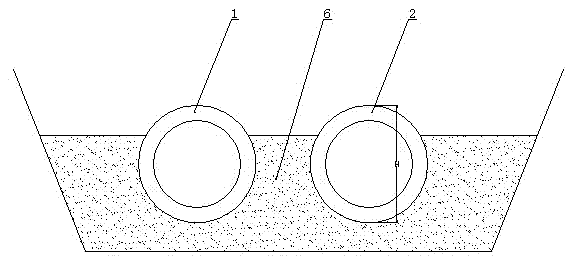

Construction method for prefabricating directly-buried uncompensated centralized heat supply pipeline by electrically preheating

InactiveCN102444750AImprove running stabilityGuaranteed elongationPipe laying and repairElectricityEngineering

The invention relates to a construction method for prefabricating a directly-buried uncompensated centralized heat supply pipeline by electrically preheating. The method comprises the following steps of: (1) grooving, adjusting the coordinate and scale height of the heat supply pipeline, and computing the preheating temperature and the designed elongation of the heat supply pipeline; (2) controlling the sand refilling height at a half to three quarters of the pipeline height H; (3) connecting the same-side end of the heat supply pipeline with preheating equipment through a cable respectively, and short-circuiting the other side of the heat supply pipeline through a cable; (4) arranging temperature sensors on the heat supply pipeline respectively; (5) recording the initial temperature of the heat supply pipeline and the initial position of a measuring point, starting temperature raising, controlling the temperature raising gradient within 1 DEG C per hour, and preserving heat after a preheating temperature is reached; (6) refilling sand into both sides of the heat supply pipeline, tamping, and controlling the preheating temperature within the range of + / -2 DEG C; (7) after the designed elongation is reached, shutting down the preheating equipment; and (8) performing subsequent construction according to the steps (1)-(7). The construction method disclosed by the invention is safe, reliable, easy and practical, is easy for accurately controlling construction equipment, and is consistent with the national policy of energy saving and emission reduction.

Owner:MCC TIANGONG GROUP

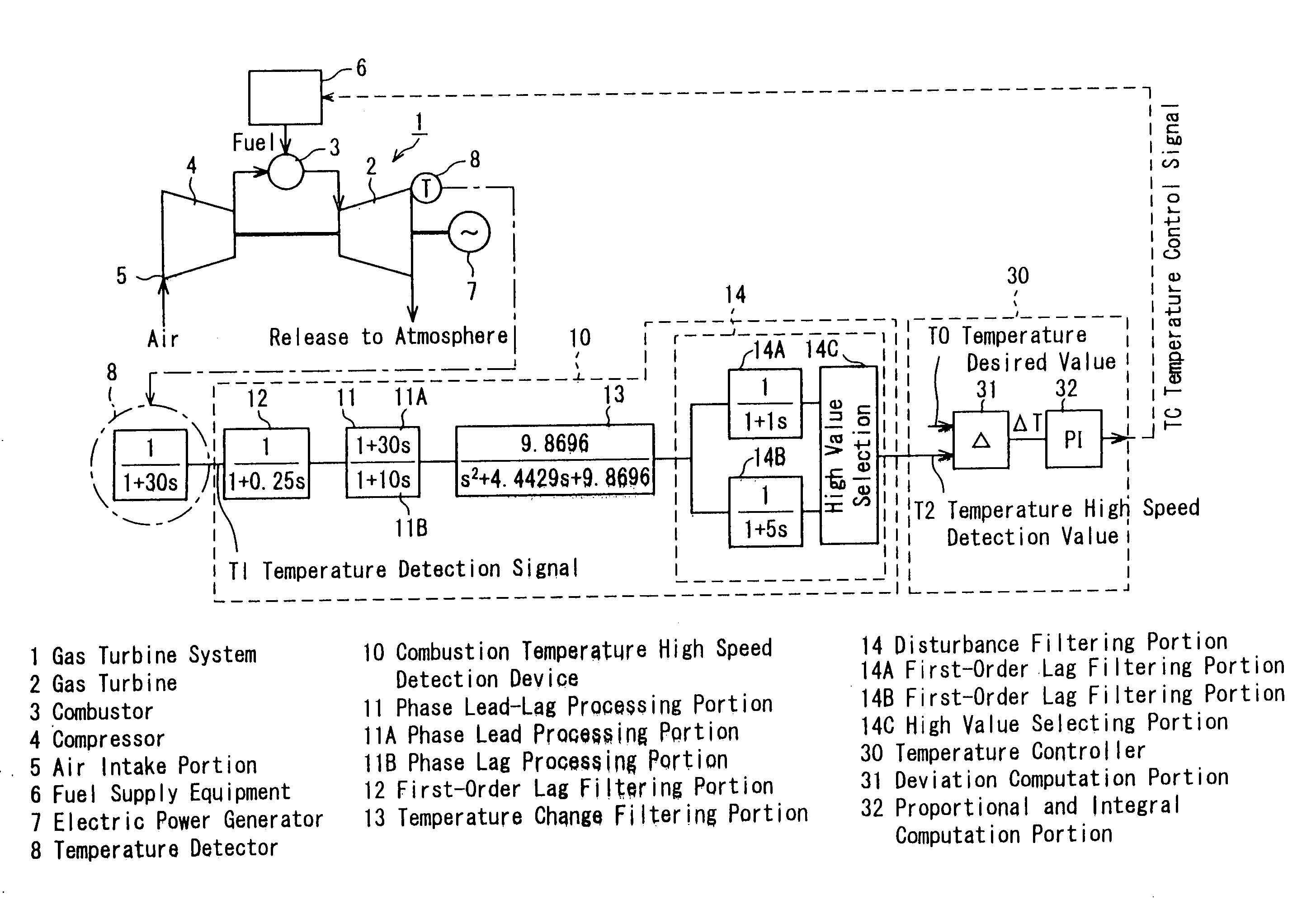

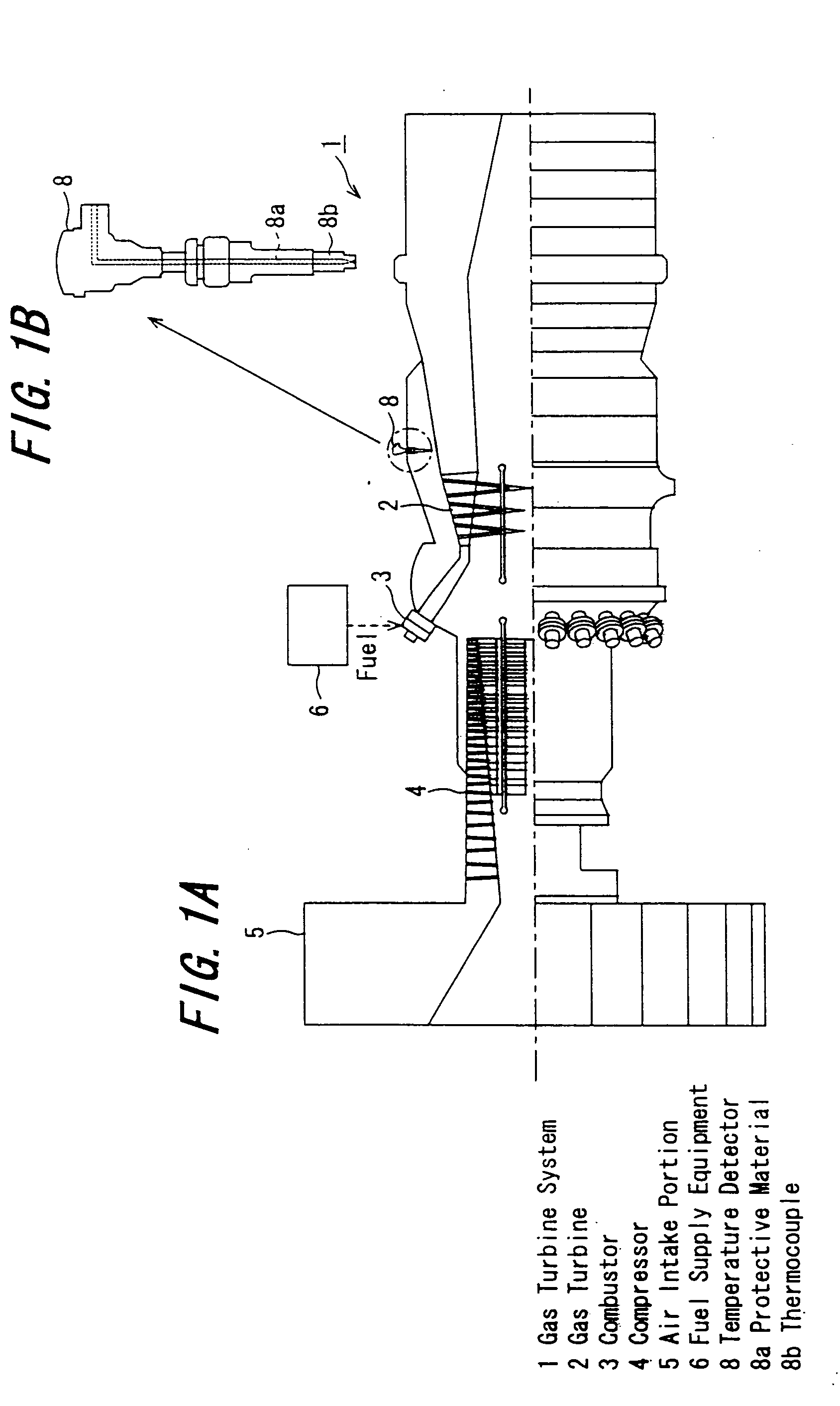

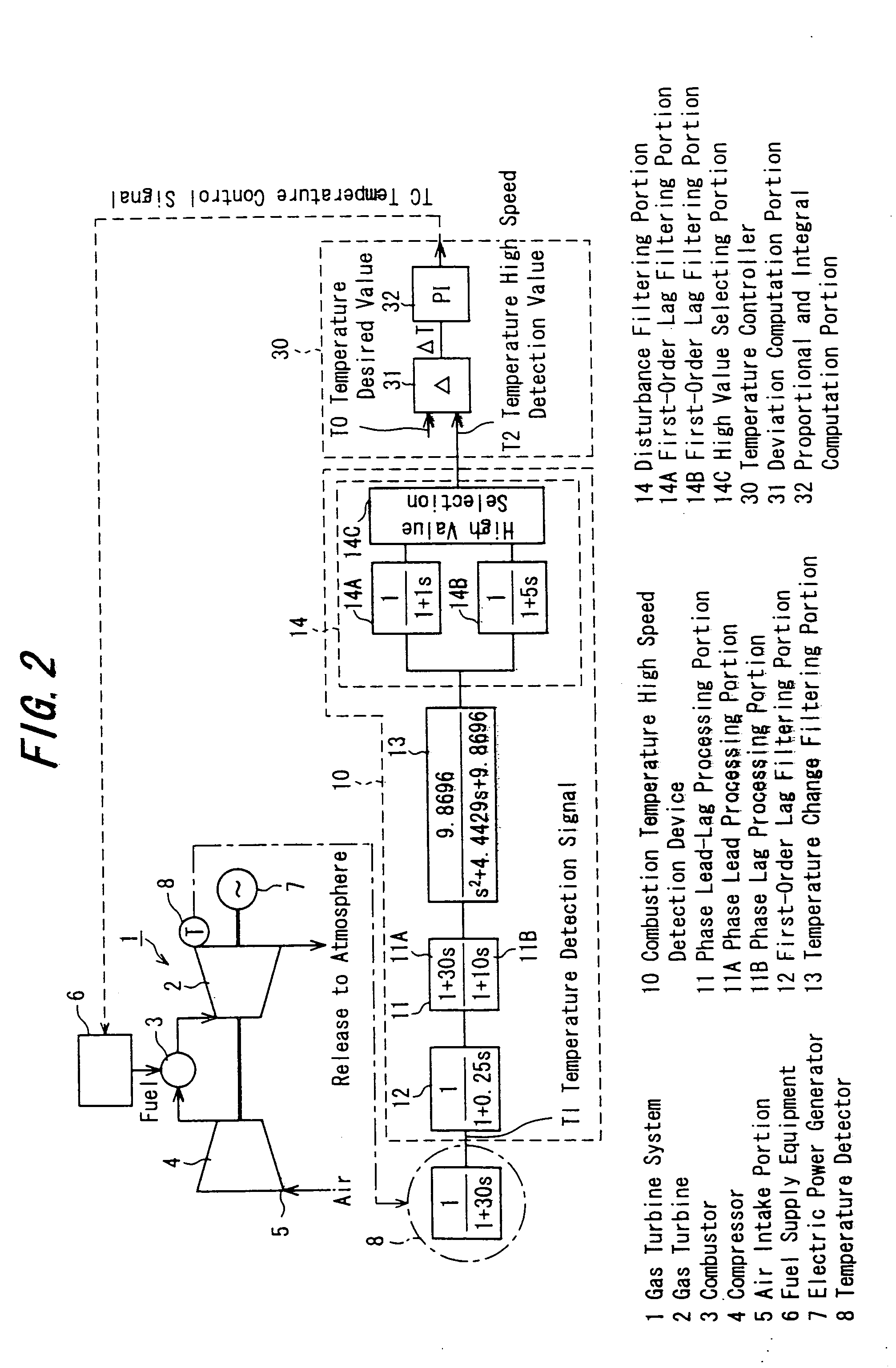

Combustion temperature high speed detection device

ActiveUS20050126183A1Convenient temperature controlHigh speed detectionTemperature measurement in motorsThermometers using electric/magnetic elementsTime delaysPhase lead

A combustion temperature high speed detection device is provided with a phase lead processing portion, thereby canceling out a detection lag of a temperature detector, and detecting the combustion gas temperature of a combustor at a high speed. The combustion temperature high speed detection device is also provided with a first-order lag filtering portion with a time constant of 0.25 second, a phase lag processing portion with a time constant of 10 seconds, a temperature change filtering portion with a cutoff frequency of 2 to 3 Hz, and a disturbance filtering portion including first-order lag filtering portions with different time constants and a high value selecting portion. Thus, high speed detection of the combustion gas temperature more suitable for a gas turbine system can be performed.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

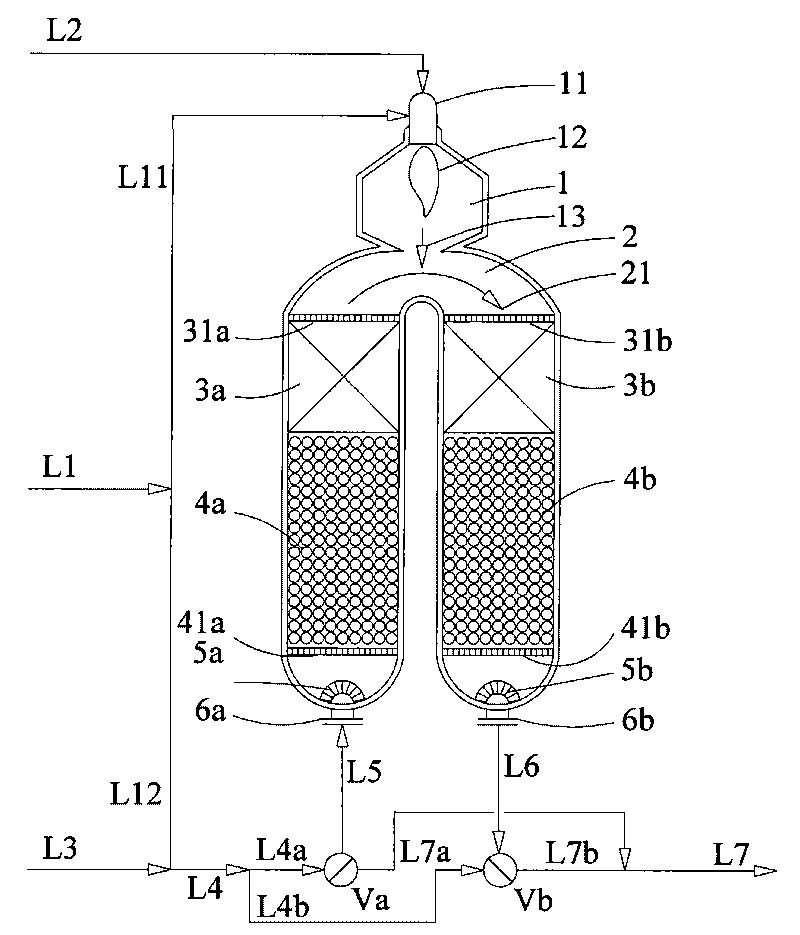

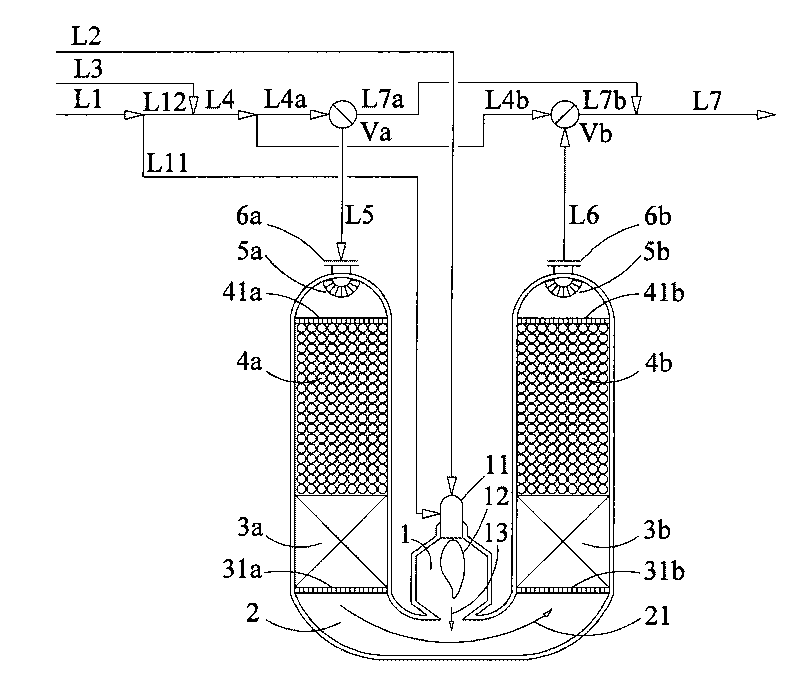

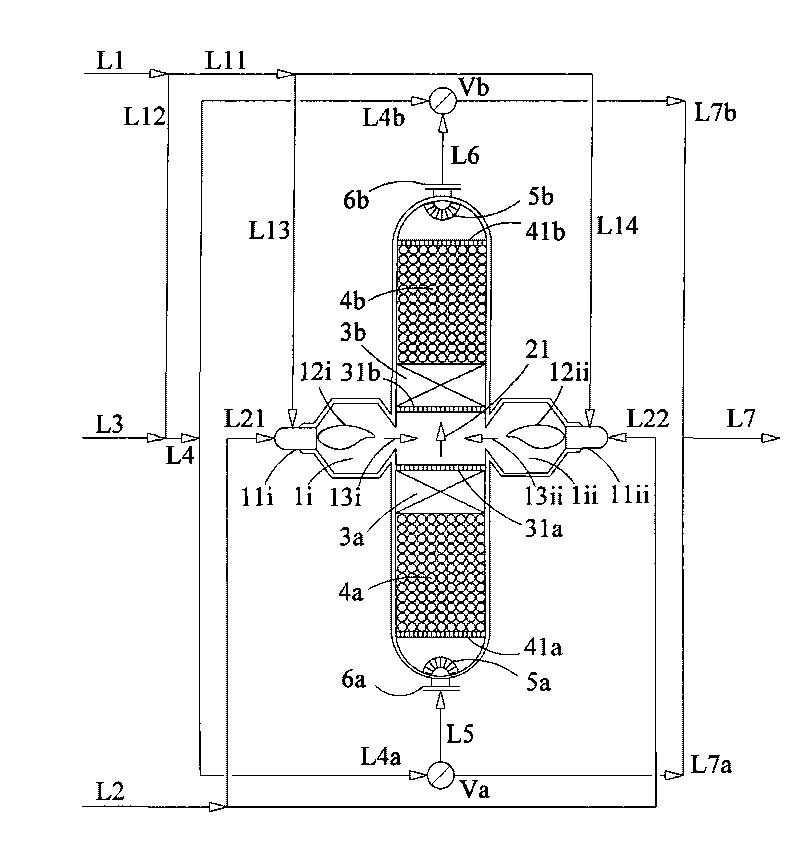

Non-steady state reactor and method for producing synthesis gas

ActiveCN101735872AAvoid the danger of burning out the catalystConvenient temperature controlGaseous fuelsCombustion chamberWater vapor

The invention discloses a reactor device and method for producing synthesis gas by using gaseous hydrocarbon as a raw material for carrying out heat accumulating type self-heating conversion. The reactor mainly comprises a combustion chamber, a mixing chamber, two reforming sections and two heat accumulating sections. The feeding raw gas of the reactor is divided into two paths of gas, wherein one path of raw gas and oxygen gas enter the combustion chamber from a middle combustion nozzle to carry out heat generating reaction; and after the other path of raw gas is mixed with water vapor, the mixed gas laterally enters the reactor through a gas inlet at one end, the mixed gas carries out pre-reforming reaction in one reforming section after being preheated in one heat accumulating section,the gas after reaction is mixed with the high-temperature gas at the outlet of the combustion chamber, then the mixed gas enters the other reforming section to carry out reforming reaction, and products are discharged after being cooled by the other heat accumulating section. The reactor of the invention is matched with a flow direction switching valve capable of periodically changing the flow direction of the gas in the reactor, thus the purposes of preheating feed materials, carrying out reaction and cooling products in one reactor can be realized. The reactor of the invention can reduce the oxygen consumption in the process, improve the yield and the quality of the synthesis gas and improve the heat efficiency of the overall process.

Owner:SYNFUELS CHINA TECH CO LTD

LED light source with semiconductor heat dissipation device

InactiveCN101619846ALight attenuation is smallExtended service lifePoint-like light sourceSemiconductor/solid-state device detailsEngineeringRefrigeration

The invention discloses an LED light source with a semiconductor heat dissipation device, comprising the LED light source and a semiconductor refrigeration sheet, wherein the cold end of the semiconductor refrigeration sheet is closely connected with the back surface of the LED light source, and the hot end of the semiconductor refrigeration sheet is closely connected with a heat dissipater; when the LED light source works, the cold end of the semiconductor refrigeration sheet absorbs heat generated by the LED light source and conducts the heat to the hot end, and then the hot end discharges the heat to surrounding environment through the heat dissipater connected with the hot end, thus, an LED is kept to work under environment with lower temperature.

Owner:SHENZHEN HOYOL OPTO ELECTRONICS

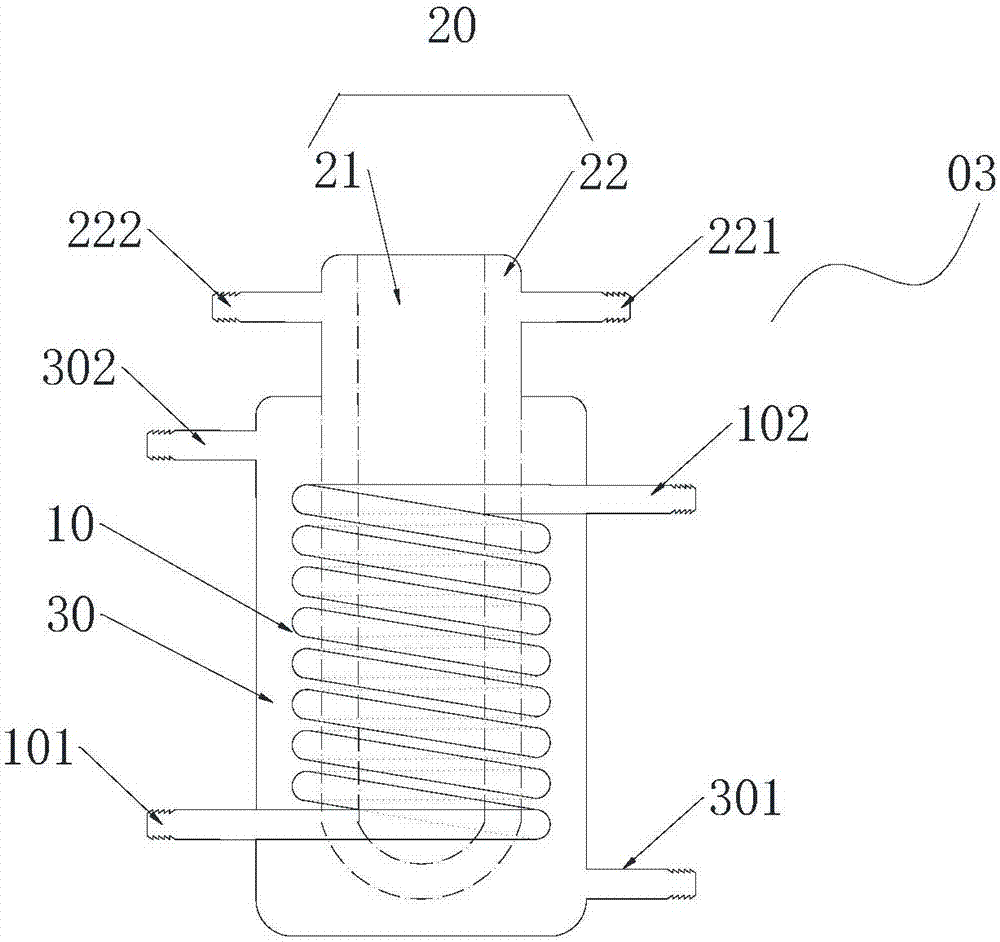

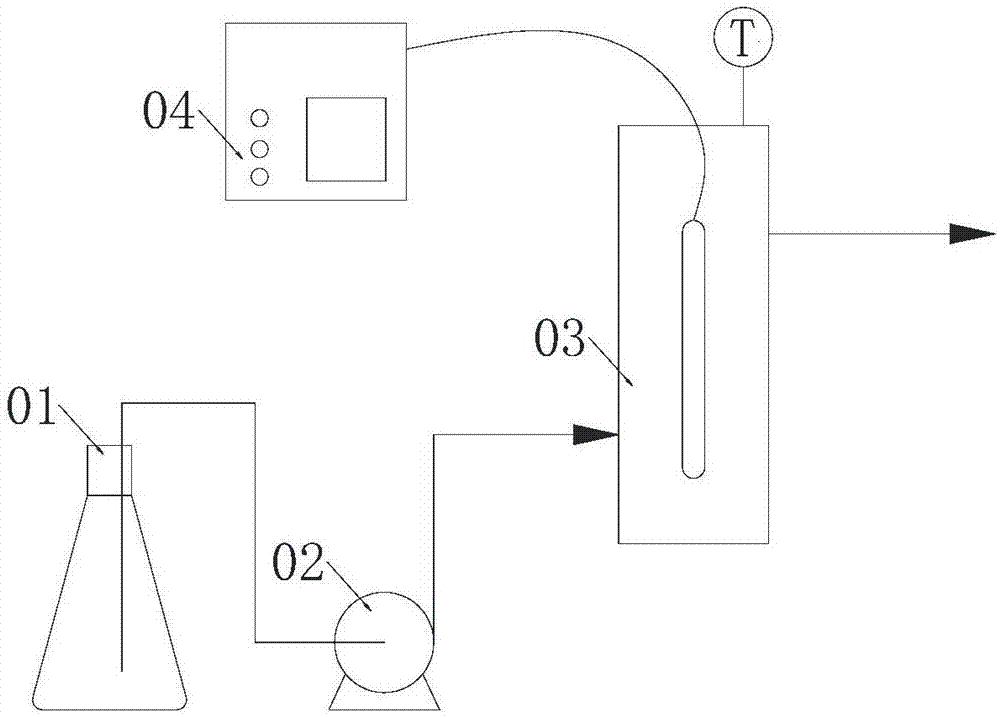

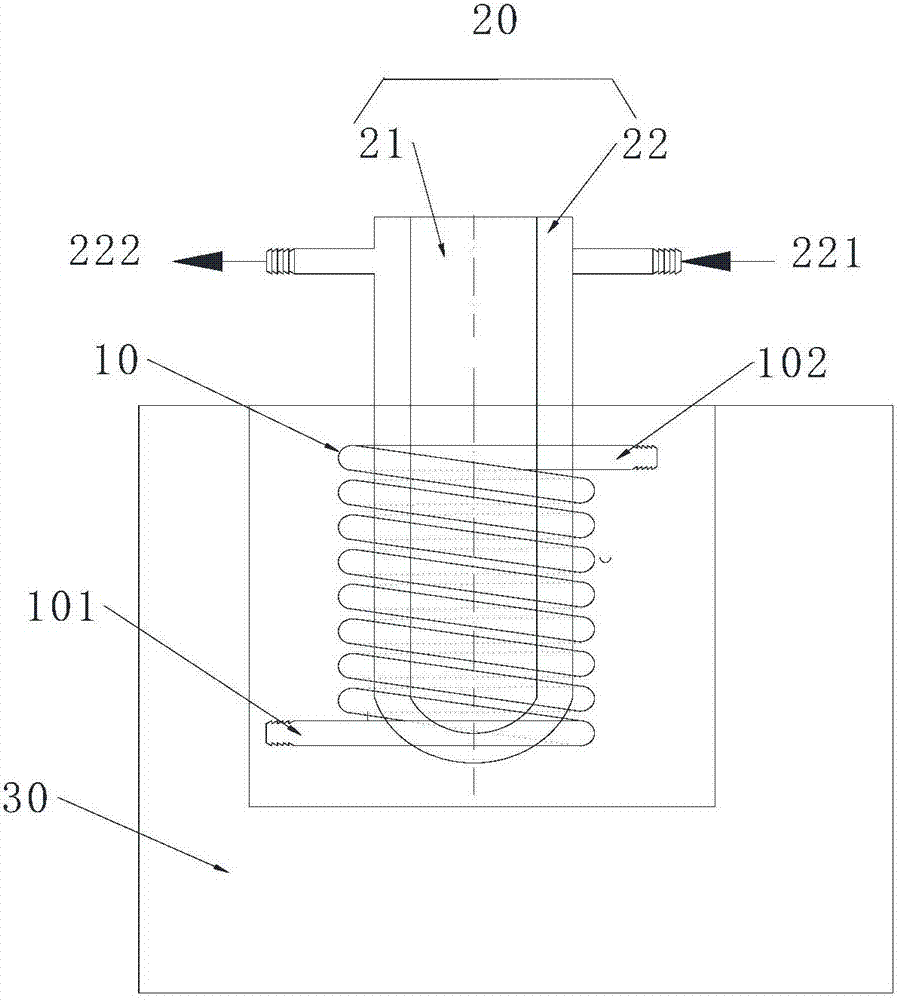

Continuous light chemical reaction apparatus, system and continuous preparation method of propellane carbonylation reaction

PendingCN107486115AImprove transfer efficiencyShort reaction timeOrganic compound preparationCarbonyl compound preparationContinuous lightOptical radiation

The invention provides a continuous light chemical reaction apparatus, a system and a continuous preparation method of a propellane carbonylation reaction. The continuous light chemical reaction apparatus comprises a continuous reactor, an irradiation light source used for providing illumination to a continuous reactor for performing the continuous light chemical reaction, and a temperature control apparatus, the continuous reactor of the temperature control apparatus and the irradiation light source are positioned in the temperature control apparatus, by arranging the continuous reactor, the light chemical reaction can be continuously generated, the reaction raw materials are continuously introduced into the reactor, the reaction products are continuously discharged from the reactor, the continuous reaction can effectively improve the transmission efficiency of optical radiation in a reaction mixture, so that the reaction time is shortened, the reaction efficiency is increased, and side reaction is reduced. The batch reaction is stable, the temperature control operation is convenient, the continuous light chemical reaction apparatus is benefit for amplification of the light chemical reactions from a laboratory scale to a factory grade, and the amplification effect is smaller.

Owner:ASYMCHEM LAB FUXIN

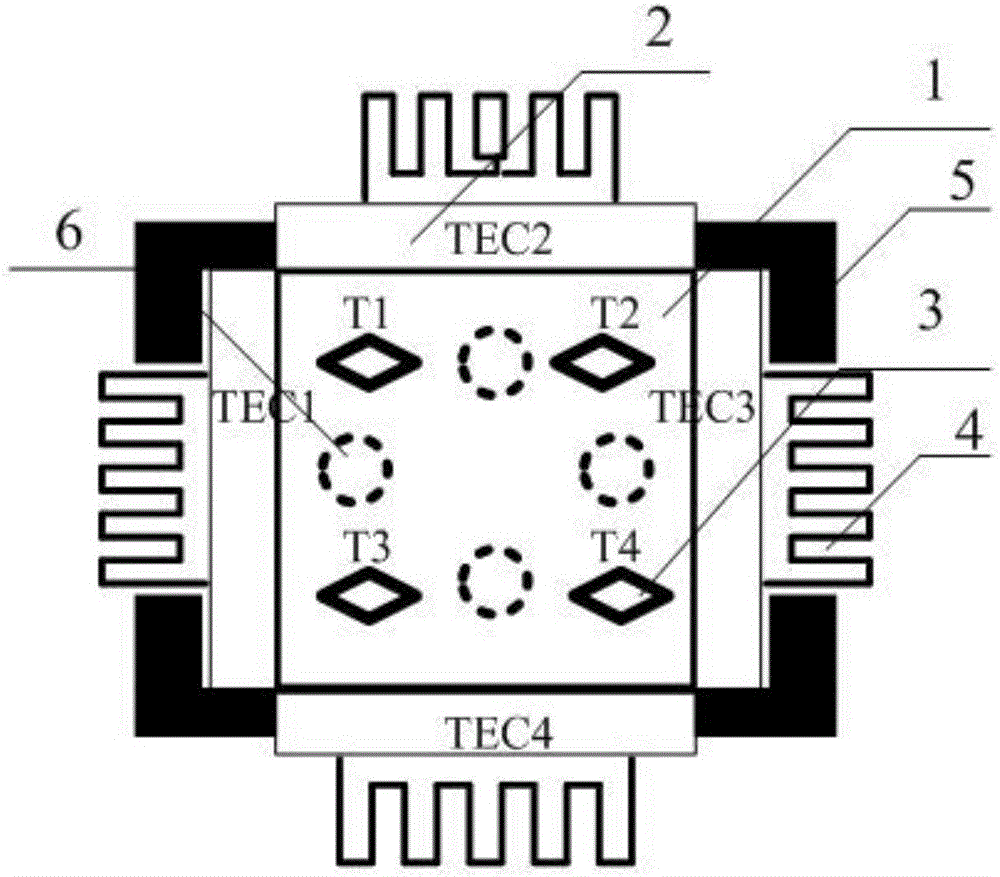

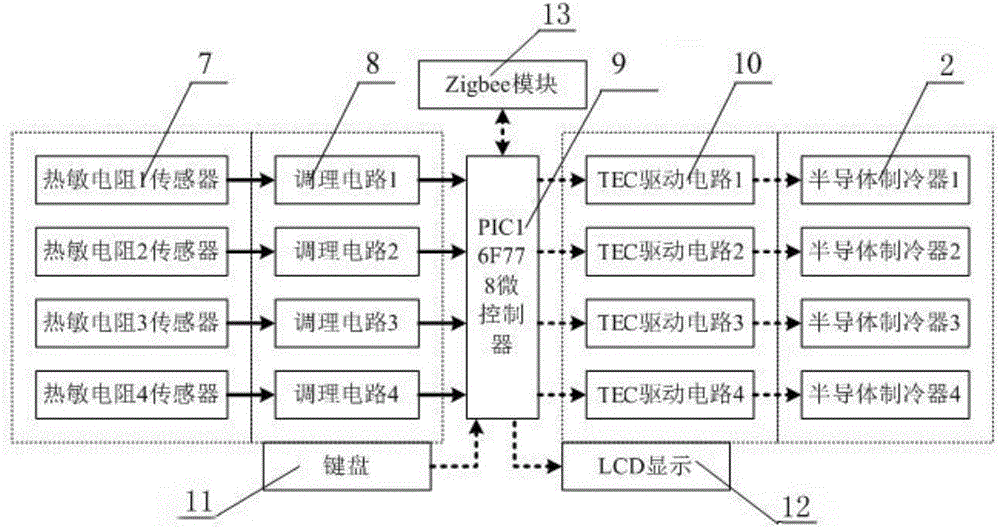

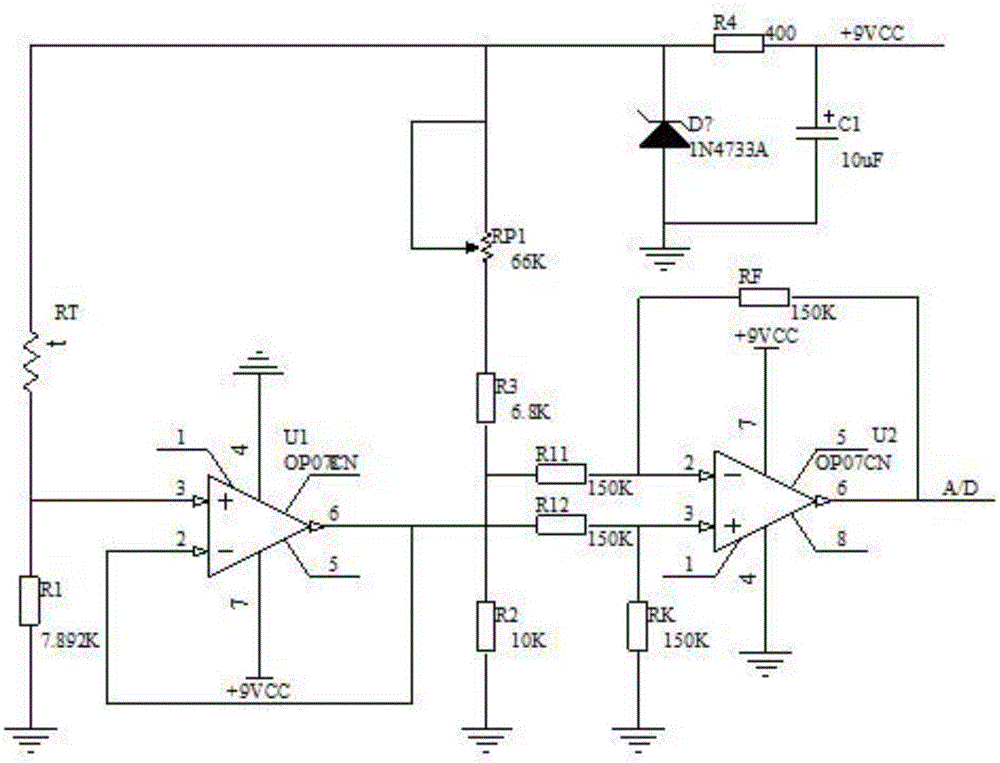

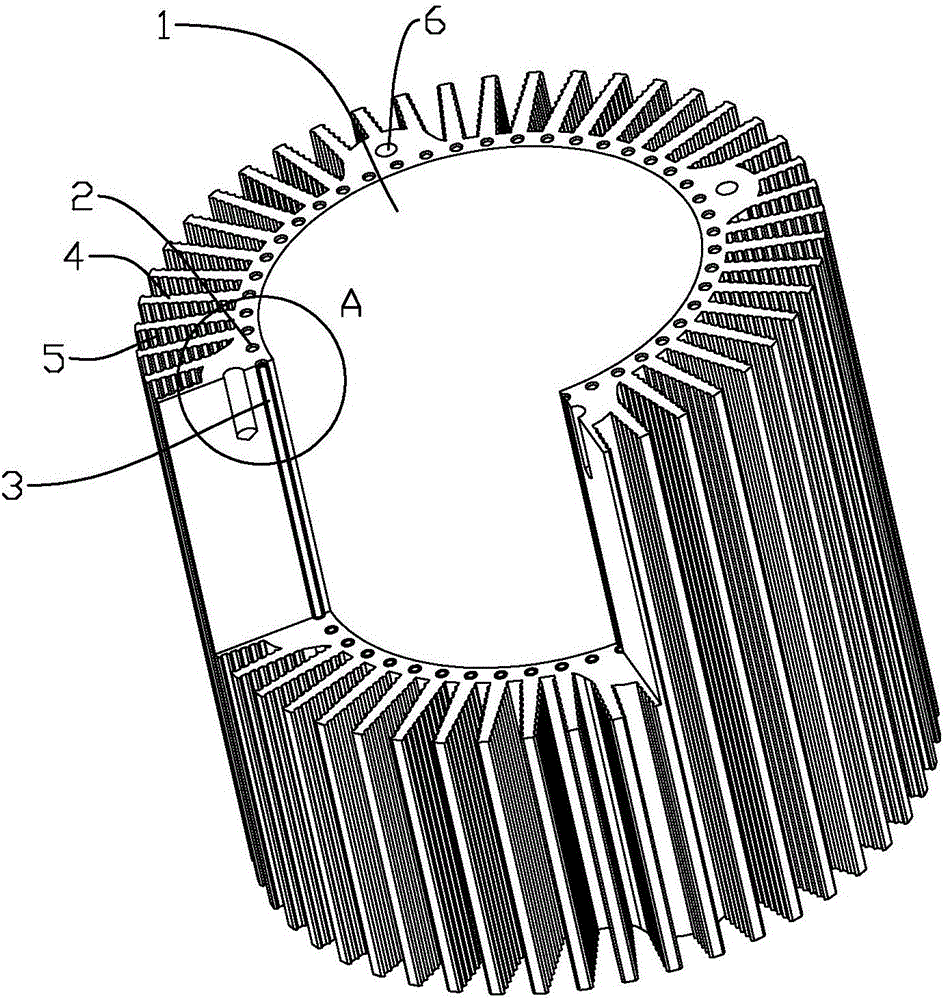

Thermocouple cold-end thermostat device for portable field calibration and control method thereof

InactiveCN106644172AMeet temperature field requirementsNovel structureAuxillary controllers with auxillary heating devicesThermometer testing/calibrationMicrocontrollerElectrical resistance and conductance

The invention relates to a thermocouple cold-end thermostat device for portable field calibration and a control method thereof, and belongs to the technical field of thermocouple cold-end constant temperature control. The thermocouple cold-end thermostat device includes a 0-degree-centigrade thermostat and a control system. The 0-degree-centigrade thermostat includes a temperature equalizer, a semiconductor cooler, a thermistor and a semiconductor cooler radiator-cooler. The control system comprises four thermistor temperature sensors, a conditioning circuit, a microcontroller, four TEC driving circuits, a keyboard circuit, an LCD display circuit and a ZigBee module. The thermocouple cold-end thermostat method sets eight modes for the operation of the semiconductor cooler. The control system has high temperature uniformity and stability, completely meets the temperature field requirements of a thermocouple calibration reference-end thermostat, and is small in size, easy to carry, and suitable for field calibration because of the temperature equalizer and modular design,.

Owner:YANGZHOU UNIV

Motor air-cooled casing based on integrated extrusion molding and phase-change heat pipe technology

PendingCN106602774AEfficient heat transfer capabilityAchieve lightweightSupports/enclosures/casingsDrive motorEngineering

The invention discloses a motor air-cooled casing based on integrated extrusion molding and phase-change heat pipe technology. The casing comprises a pipe shaped casing; the side wall of the casing is provided with at least four installation holes; the installation holes are provided with phase-change heat pipes and the outer side wall of the casing is provided with heat radiating fins. According to the invention, the casing utilizes phase-change heat pipes as heat conduction and soaking components; the phase-change heat pipes possess extremely high efficient heat conduction capability and the heat conduction coefficient is ten thousand times as that of the known metal and could achieve the rapid re-organization of the distributed heat energy inside a drive motor. As the phase-change heat pipes are installed in the installation holes, the large amount of heat concentrated in the stator core and the casing contact part can be spread rapidly to the entire casing, therefore, eliminating the problem with the over-heat in some parts of the casing and reducing the temperature difference of the casing substantially. In this way, the heat distribution can be re-organized so that more heat can be transmitted from the stator windings and the stator core to the fins on the casing for heat radiation and more excellent temperature control performance can be achieved for the drive motor.

Owner:ZHONGSHAN INST OF MODERN IND TECH SOUTH CHINA UNIV OF TECH

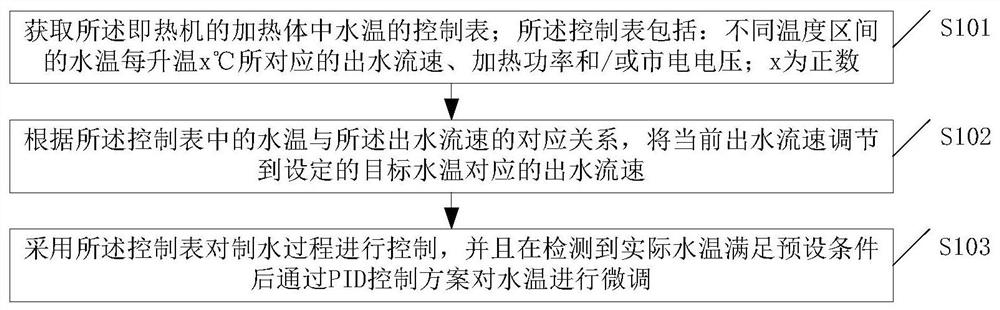

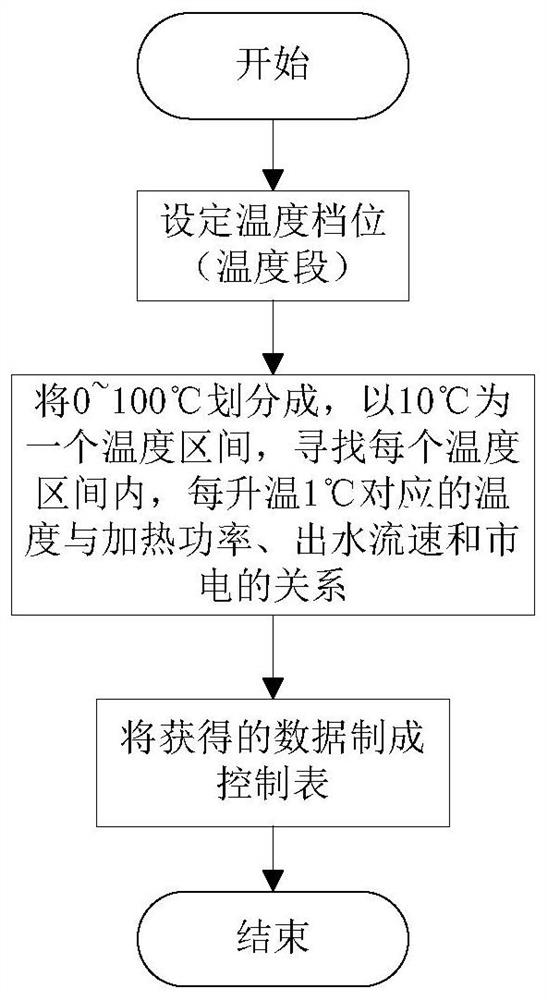

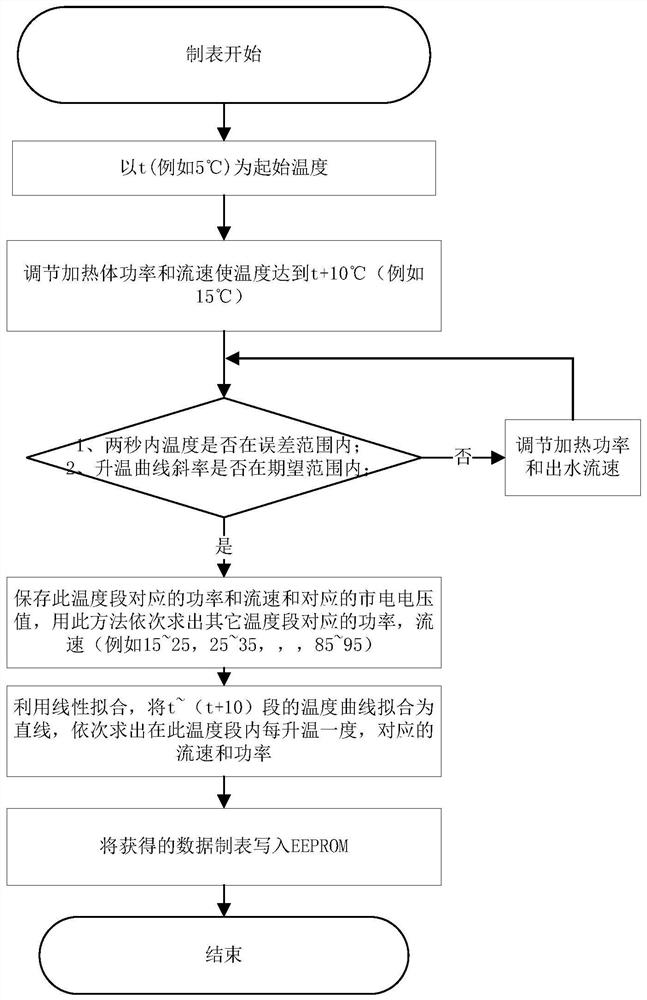

Instant heating machine and water production control method thereof

PendingCN114246472AImprove experienceGood temperature control effectBeverage vesselsTemperature controlWater production

The embodiment of the invention discloses an instant heating machine and a water production control method thereof. The method comprises the steps that a control table of water temperature in a heating body of the instant heating machine is obtained; the control meter comprises the water outlet flow speed, the heating power and / or the mains supply voltage corresponding to the condition that the water temperature in different temperature intervals is increased by x DEG C every time; x is a positive number; according to the corresponding relation between the water temperature and the water outlet flow speed in the control table, the current water outlet flow speed is adjusted to the water outlet flow speed corresponding to the set target water temperature; a control table is adopted to control the water production process, and after it is detected that the actual water temperature meets the preset condition, the water temperature is finely adjusted through a PID control scheme. According to the scheme of the embodiment, the instant heating machine is controlled based on the control table and the PID control scheme in a fine adjustment mode, the control table is mainly used, a good temperature control effect is achieved, fine adjustment is carried out through the PID control scheme, temperature deviation caused by the inconsistency problem of accessory batch is solved, the whole machine achieves an ideal temperature control effect, and user experience is improved.

Owner:HANGZHOU JIUYANG WATER PURIFICATION SYST

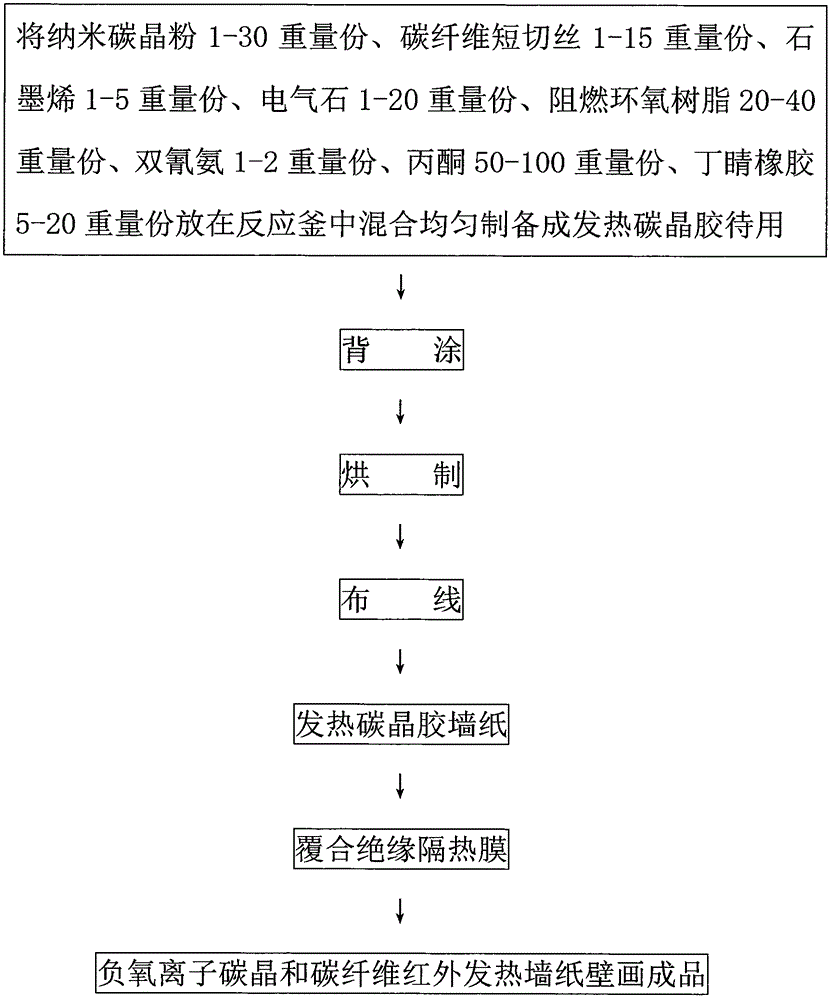

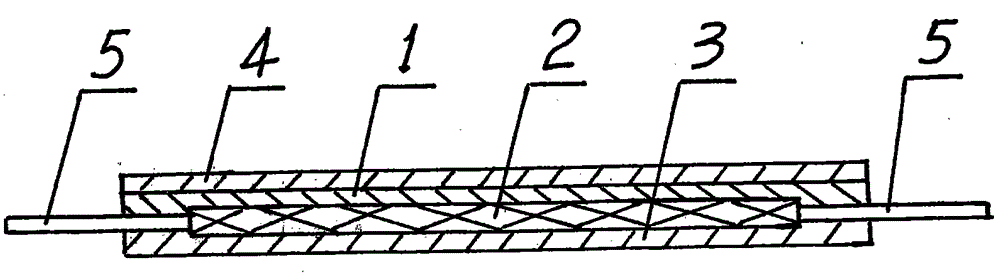

Manufacturing method of negative oxygen ion carbon crystal and carbon fiber infrared heating wallpaper mural

ActiveCN104896558AComplete specificationsEvenly heatedLighting and heating apparatusElectric heating systemEpoxyFiber

The invention discloses a manufacturing method of a negative oxygen ion carbon crystal and carbon fiber infrared heating wallpaper mural, and relates to the technical field of heating of heating paper (film). A key technology of setting a heating carbon crystal layer is adopted, the negative oxygen ion carbon crystal and carbon fiber infrared heating wallpaper mural used as a mural layer, a wallpaper layer, a heating carbon crystal layer and an insulating layer are adhered in sequence; the two sides of the heating carbon crystal layer are electrically connected with wires; the method comprises the following steps: back-coating and drying heating carbon crystal colloid prepared from 1-30 parts by weight of nanometer carbon crystal powder, 1-15 parts by weight of carbon fiber chopped fiber, 1-5 parts by weight of graphene, 1-20 parts by weight of tourmaline, 20-40 parts by weight of flame-retardant epoxy resin, 1-2 parts by weight of dicyandiamide, 50-100 parts by weight of acetone and 5-20 parts by weight of nitrile butadiene rubber; wiring; covering with the insulating film. The wallpaper mural is used for indoor heating and decoration. The method has the advantages of simple process, good effect, low cost and contribution to generalization.

Owner:深圳市长奇节能环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com