Fischer-Tropsch synthesis process based on fixed bed reactor

A technology of fixed bed reactor and Fischer-Tropsch synthesis, which is applied in the petroleum industry, the preparation of liquid hydrocarbon mixtures, and the production of hydrocarbons from carbon oxides. Solve problems such as low conversion rate in one pass, achieve sufficient heat transfer, good temperature control, and improve the effect of heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

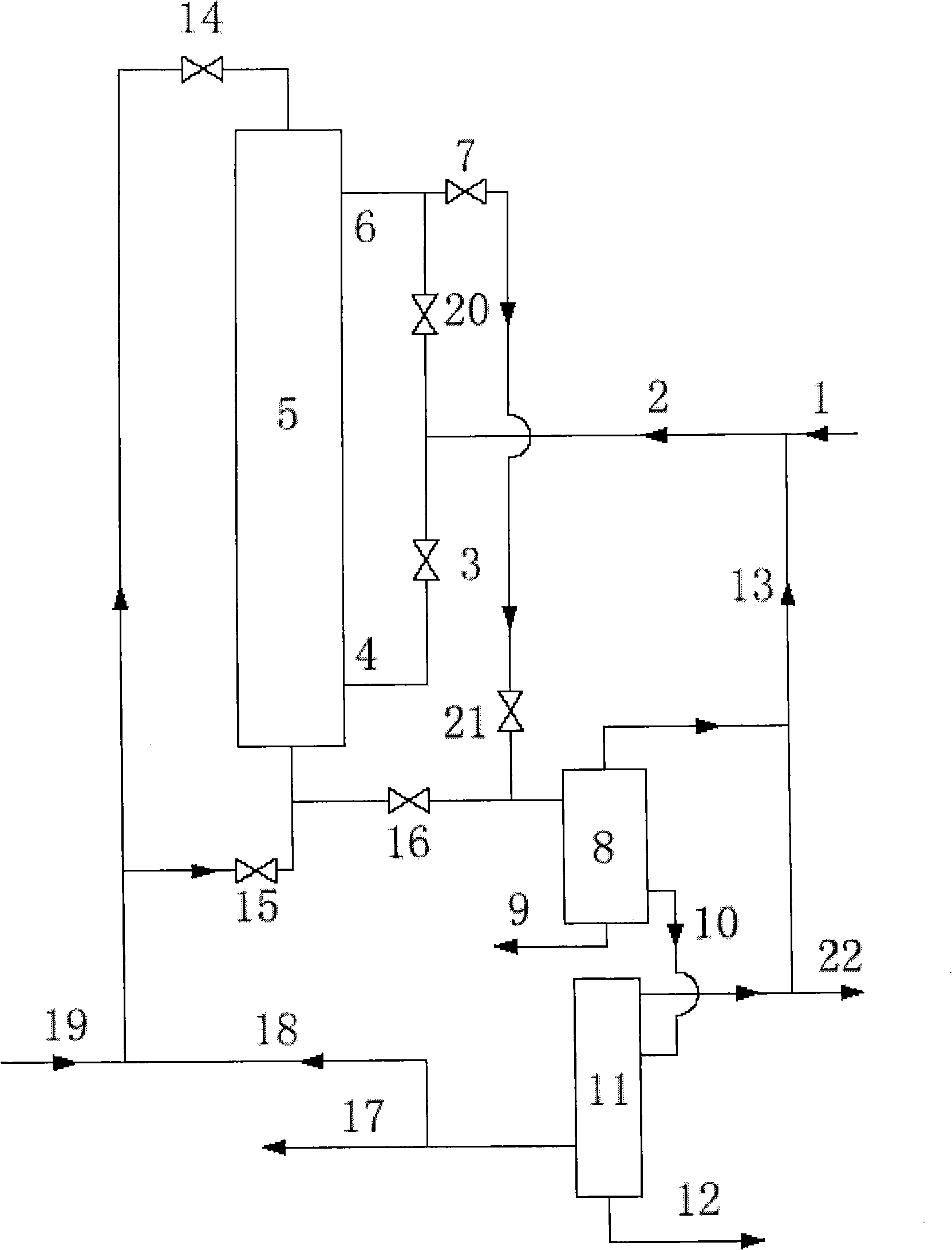

Embodiment 1

[0031] Prepare Co / ZrO according to the method described in Chinese patent CN1398669 2 catalyst. Prepare a concentration of 0.8M Co(NO 3 ) 2 , ZrOCl 2 and Mn(NO 3 ) 2 The mixed solution, wherein the content of Co in the mixed solution is 10wt%, ZrO 2 The content is 89.8wt%, the content of MnO is 0.2wt%, the preparation concentration is 0.2M Na 2 CO 3 solution. Under continuous heating and stirring, the above mixed solution and lye were added dropwise into the beaker for precipitation. The temperature of the precipitation was controlled at 70°C, and the pH value of the precipitation was controlled at 7. The precipitation was aged for 2 hours, and the precipitation was washed repeatedly until there was no chloride ion. The precipitate was baked at 100°C for 8 hours, and then burned in a muffle furnace at 500°C for 2 hours to prepare the catalyst. Grind the catalyst to 10-20 mesh and fill it in the fixed bed reactor 5 with a catalyst bed volume of 15L. Catalyst at 400°C,...

Embodiment 2

[0036] A Fischer-Tropsch synthesis catalyst was prepared according to Example 1. The raw material gas flows through the fixed bed reactor 5 from the upper inlet 6 of the fixed bed reactor and the circulating liquid medium entering from the top of the fixed bed reactor, and all the products flow out from the bottom of the fixed bed reactor 5 and enter the three-phase separator for separation. 8. Realize the separation of water, long-chain hydrocarbons and gas phase components. Others are the same as in Example 1.

Embodiment 3

[0038] Catalyst preparation: The catalyst was prepared according to the method described in Chinese patent CN1303738. Prepare a mixed solution of absolute ethanol, distilled water and glacial acetic acid in a volume ratio of 350:175:1 in a beaker. Add tetraethyl orthosilicate in the same amount as absolute ethanol while stirring. After standing for 3 hours, it becomes a gel, and the temperature in the preparation process is kept constant at 40°C. The gel was dried at 110°C, then calcined at 200°C for 1 h, at 250°C for 1 h, and at 350°C for 5 h to obtain SiO 2 carrier. A catalyst with a cobalt content of 20% was prepared by the equal volume impregnation method, and the mass ratio of the carrier to the water required for the incipient wetness of the carrier was 1:2. Prepare the cobalt nitrate solution according to the amount of water needed for the initial moistening of the carrier, and drop all the solution onto the carrier, let it stand for 5 hours, then dry it at 120°C, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com