Patents

Literature

42results about How to "Wide process adaptability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for recycling heavy metal pollution wastes

InactiveCN101871046AWide process adaptabilityRealize the purpose of resource utilizationProcess efficiency improvementChemistryCopper

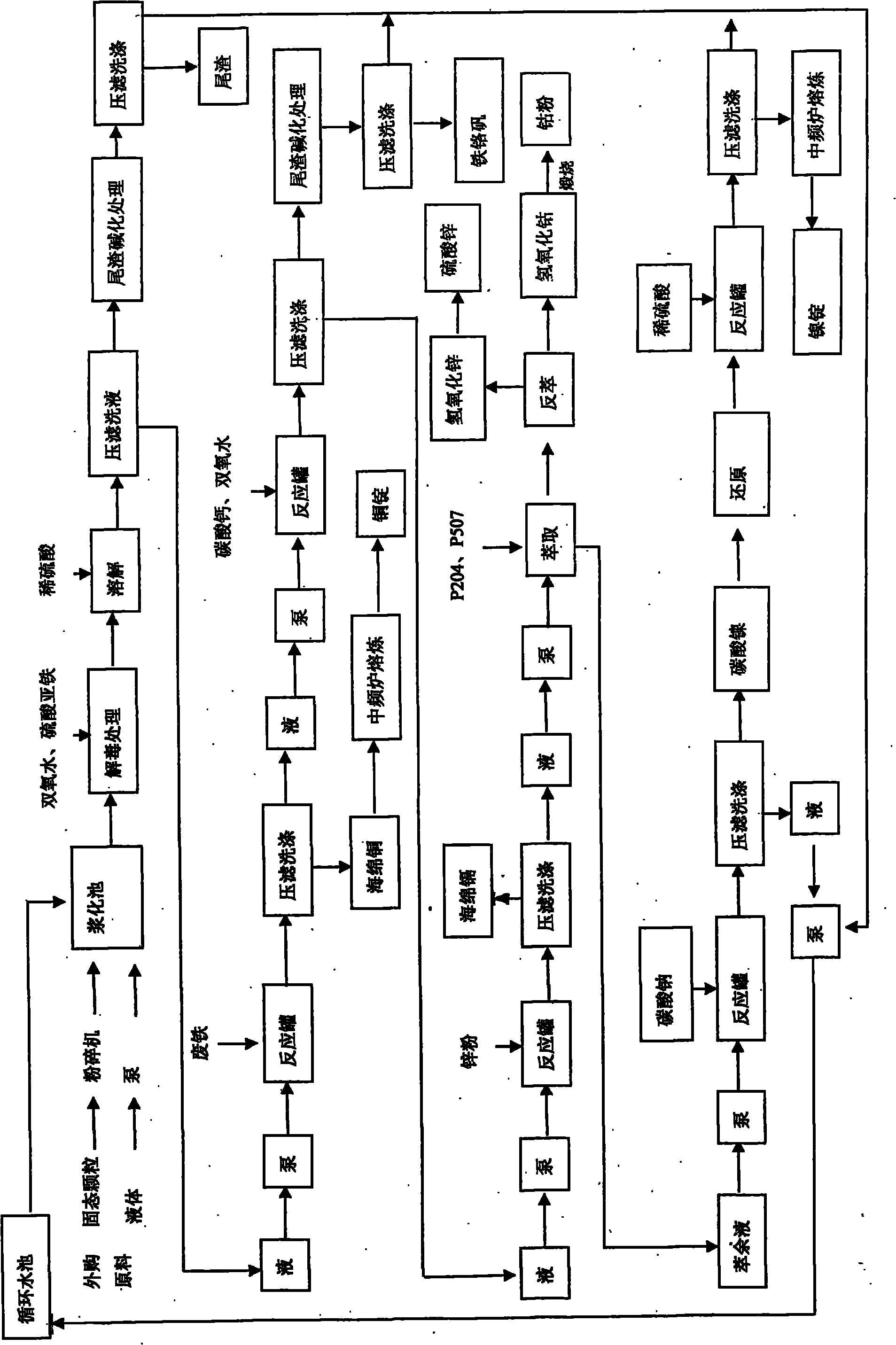

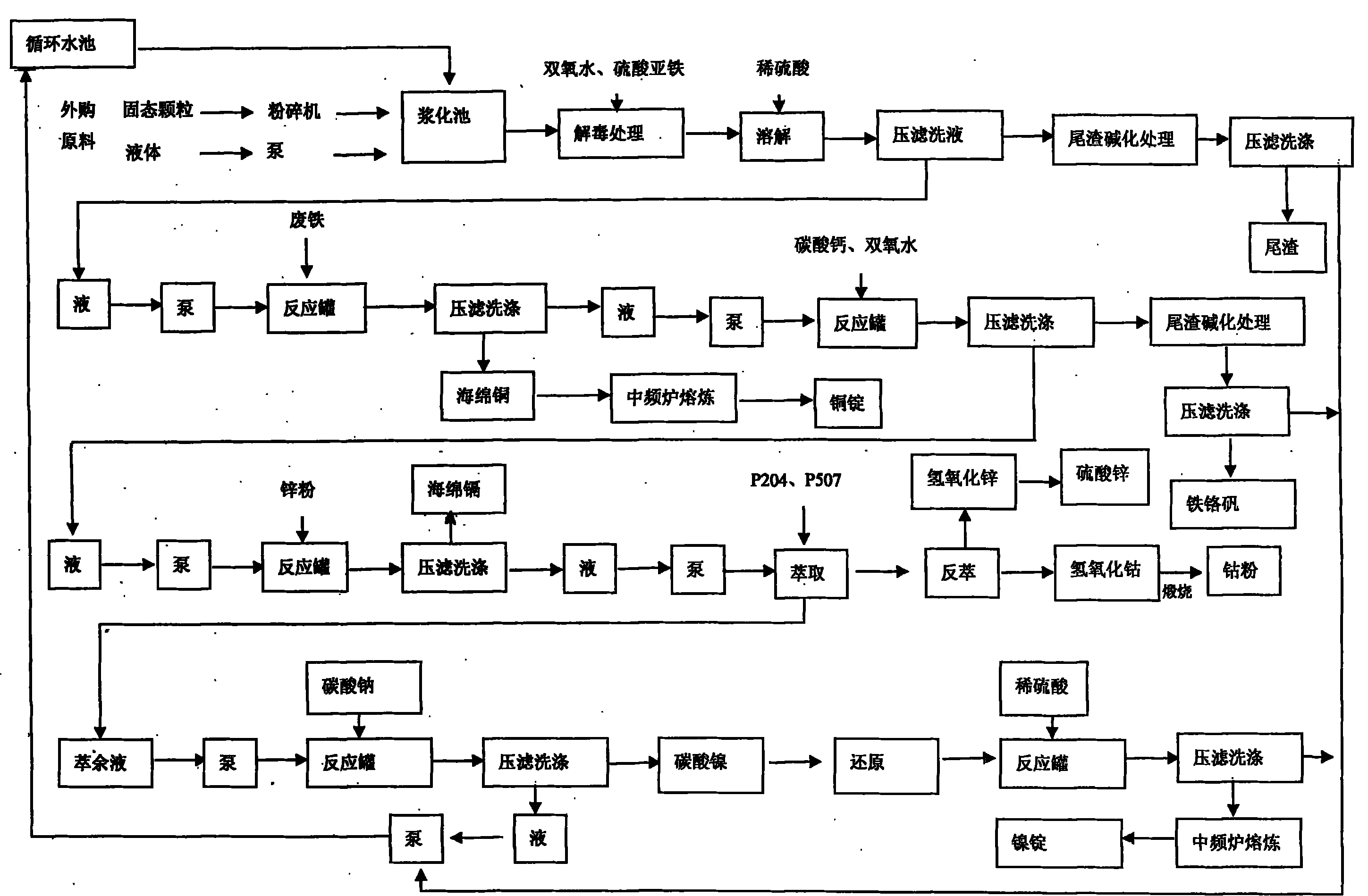

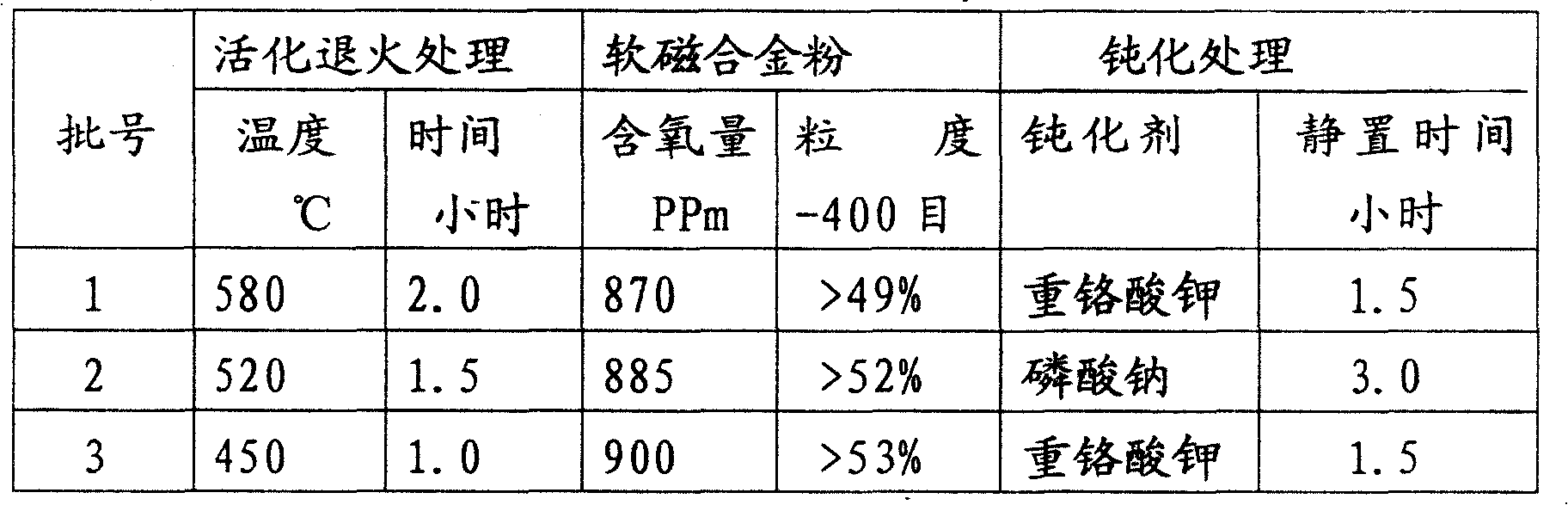

The invention discloses a method for recycling heavy metal pollution wastes, which comprises the following steps of: 1) the pulping of raw materials; 2) acid leaching, namely, adding pulp obtained in the step 1 into a dilute sulphuric acid for filtration, and taking filter residues as the raw materials of bricks or cement; 3) copper displacement, namely, displacing copper out of filtrate in the step 2 with iron; 4) the preparation of ferrum-chrome-alum, namely, adding alkaline substances and an oxidant into the filtrate obtained in the step 3, adjusting a PH value, and precipitating and filter-pressing the mixed solution to obtain the ferrum-chrome-alum; and 5) the preparation of sponge cadmium, namely, displacing cadmium out of the filtrate obtained in the step 4 with zinc. The process has the advantages of suitability for the treatment of waste residues and waste liquor in a plurality of industries of electroplating, surface treatment, heavy metal smelting, chemical engineering and the like, no need of heating liquid-phase materials, the realization of closed cycle, and the capacity of extracting a plurality of valuable metals, such as Cu, Cr, Cd, Ni, Co, Zn and the like, directly taking the wastes obtained after the metal separation as the raw materials of the bricks or cement, and saving coal and electricity amounting to 20,000 T standard coal and 40,000-ton water per year for enterprises recycling 5,000-ton metals per year.

Owner:青川县天运金属开发有限公司

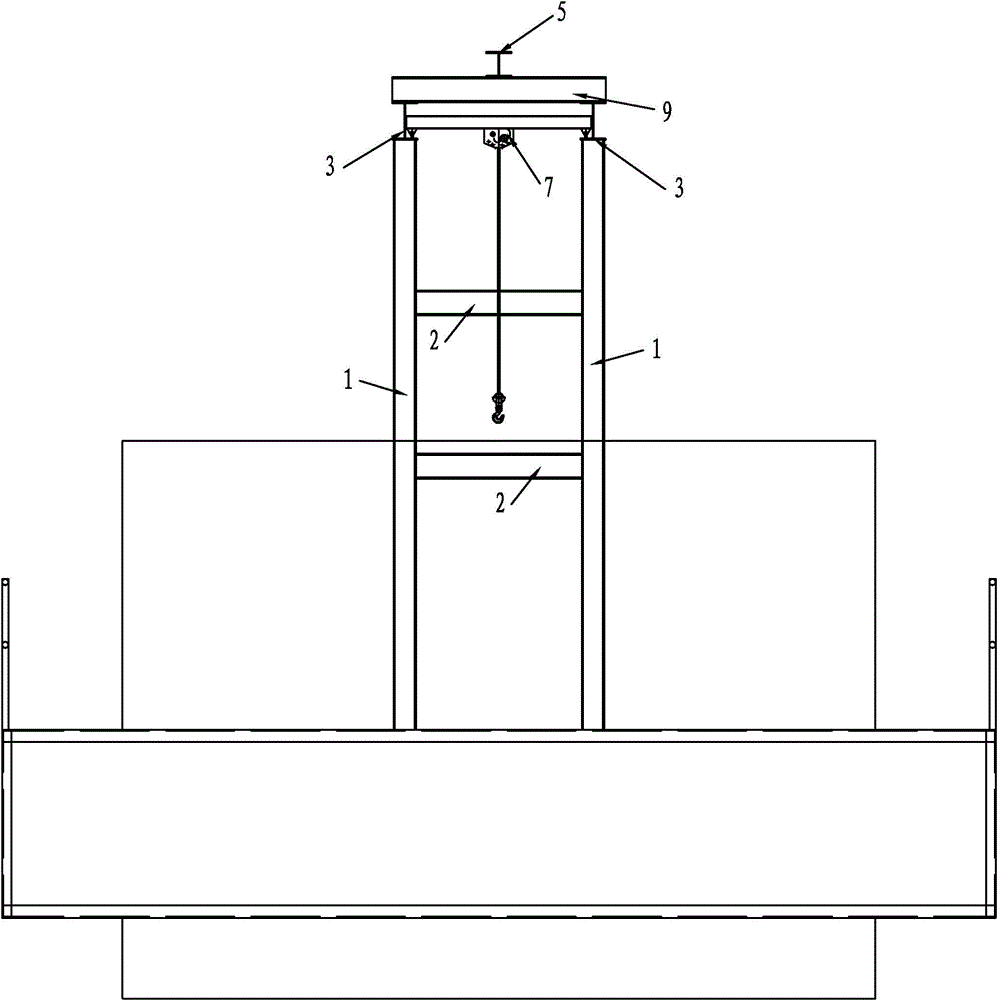

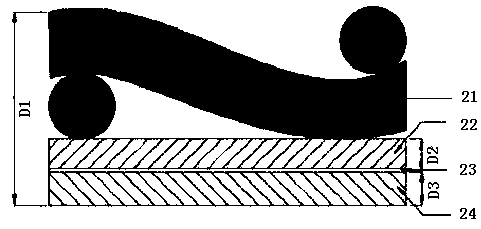

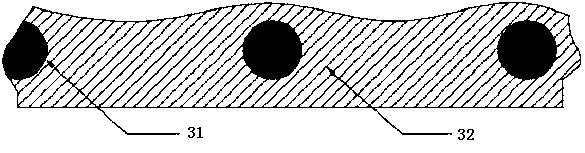

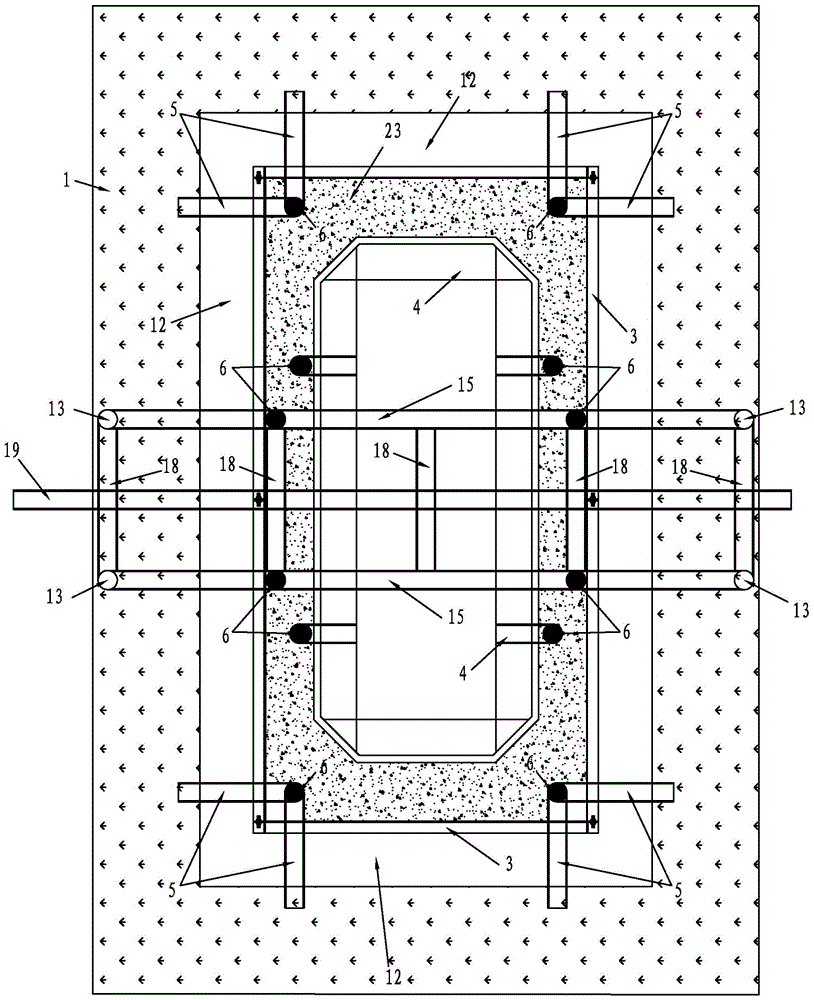

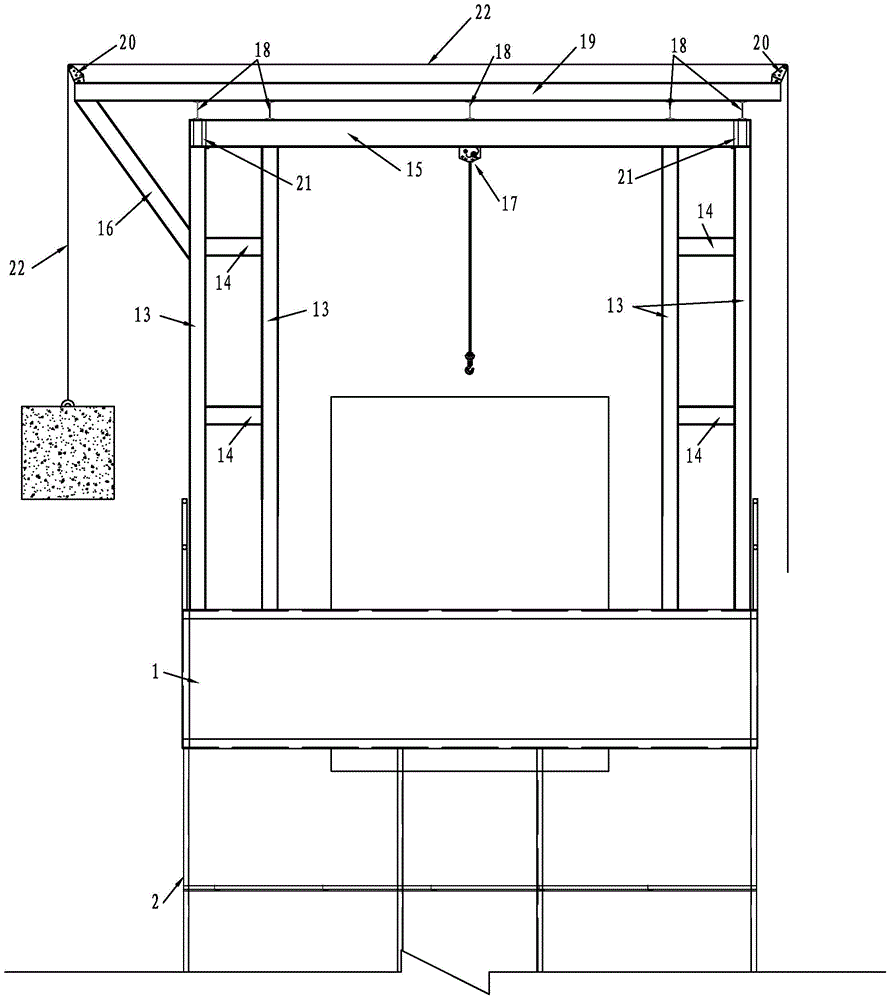

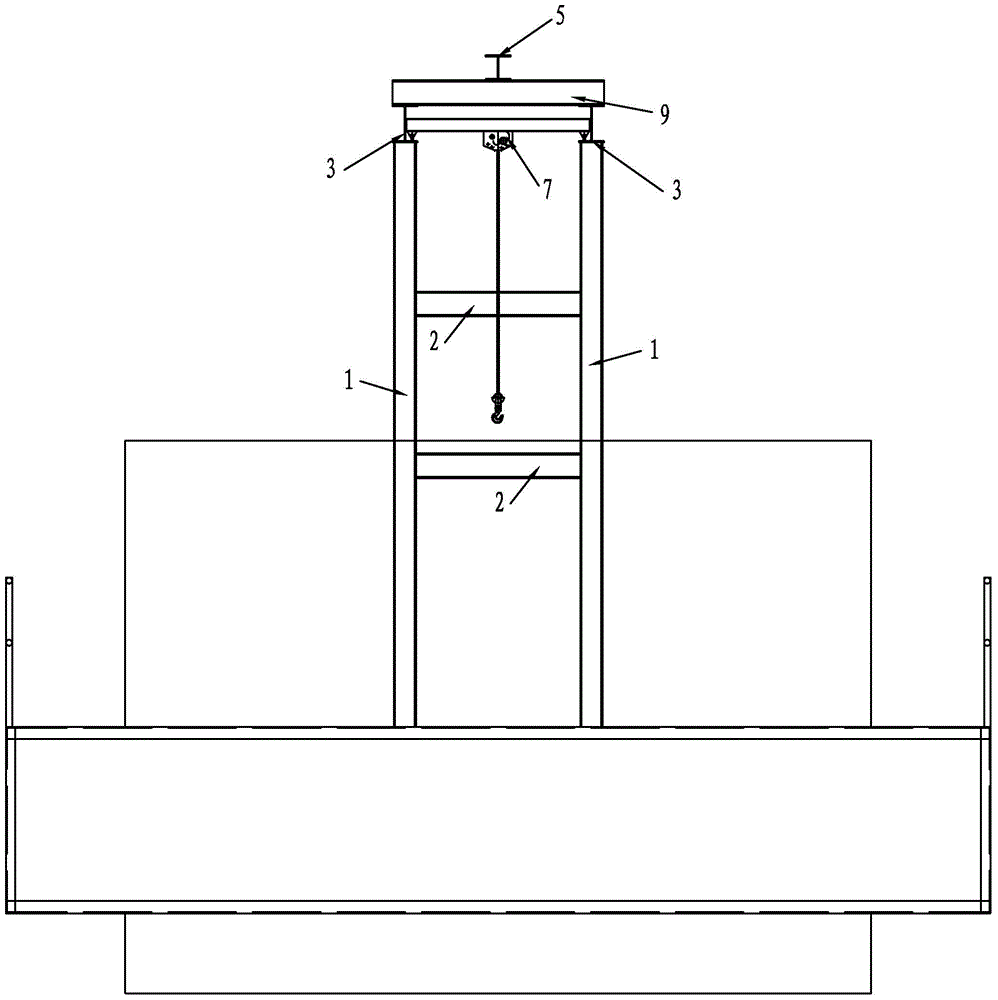

Self-lifting sliding and turnover construction system and construction method

ActiveCN104695337AReduce manual labor intensityReduce the risk of manual overmoldingBridge erection/assemblyTruckRebar

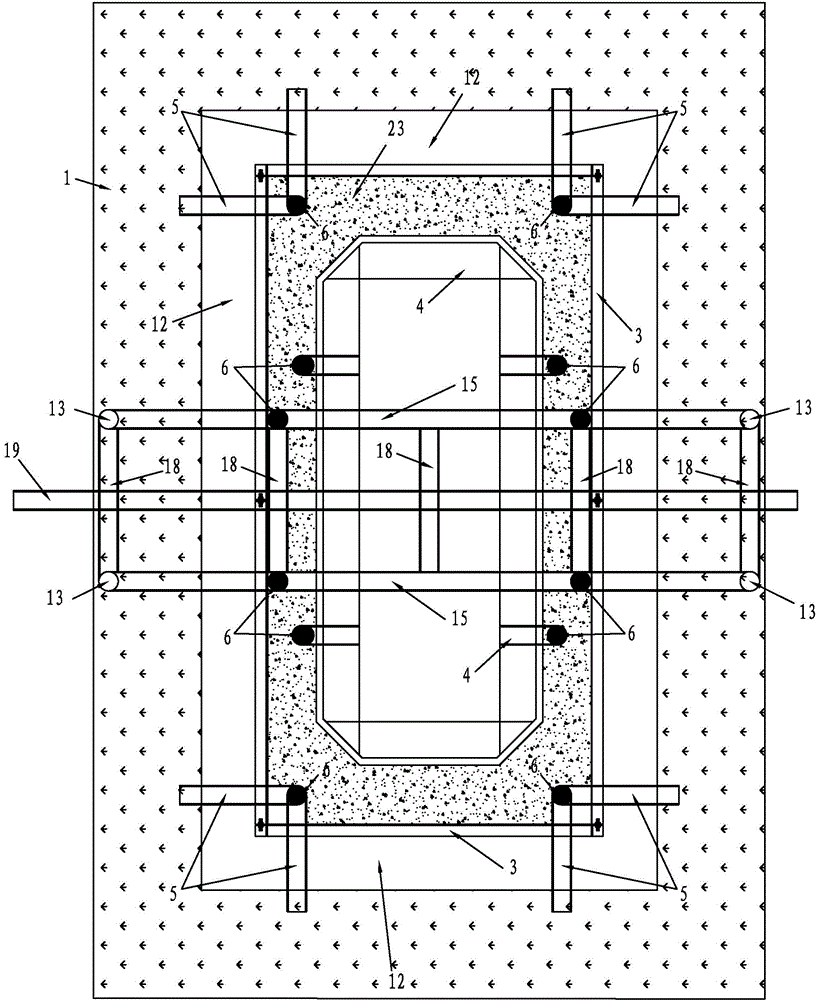

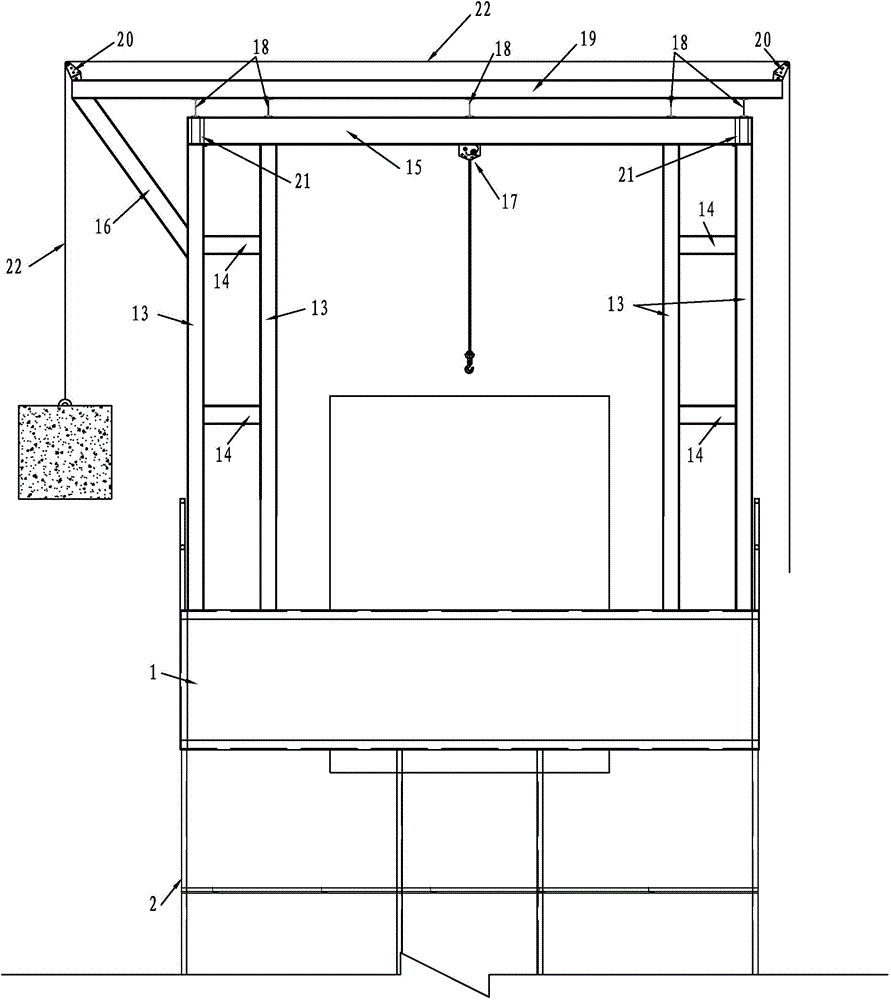

The invention discloses a self-lifting sliding and turnover construction system and a construction method. The system comprises a framework type combination crown block hanging bracket device and a semi-automatic turnover device. The construction method comprises steps as follows: construction of reinforcing steel bars of a pier body, large-area formwork bracket splicing, sliding formwork bracket splicing, self-lifting hanging bracket splicing, concrete pouring, sliding formwork bracket sliding rising, large-area formwork turnover and next stage of reinforcing steel bar construction. A self-lifting technique can be adopted, auxiliary construction by mechanical equipment such as a tower crane, a truck crane and the like can be omitted, high-pier construction is realized with the self-lifting technique, and the method guarantees the construction speed of a sliding formwork and the appearance quality of a turnover formwork without relying on external machines.

Owner:CCCC FIRST HIGHWAY XIAMEN ENG +1

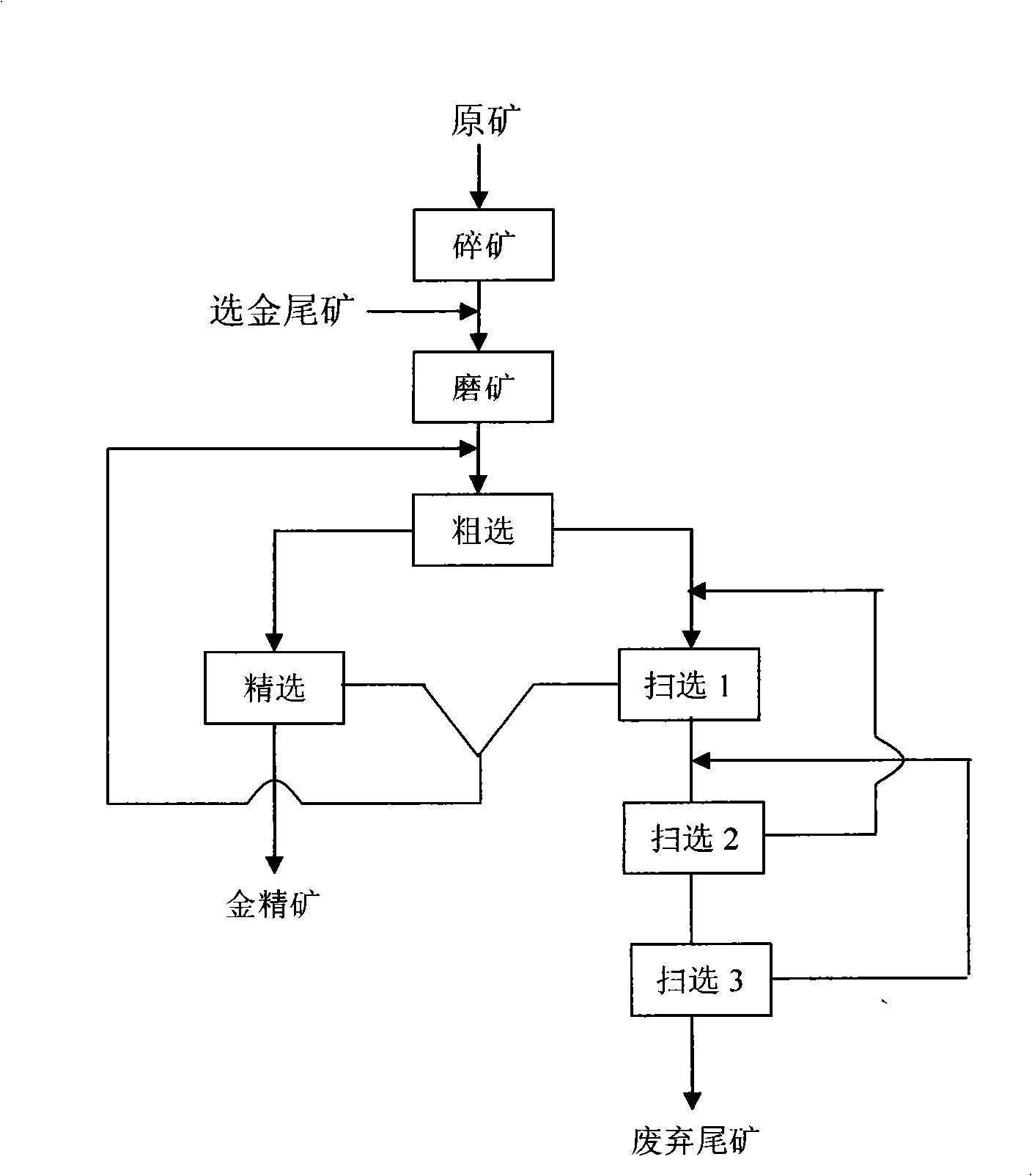

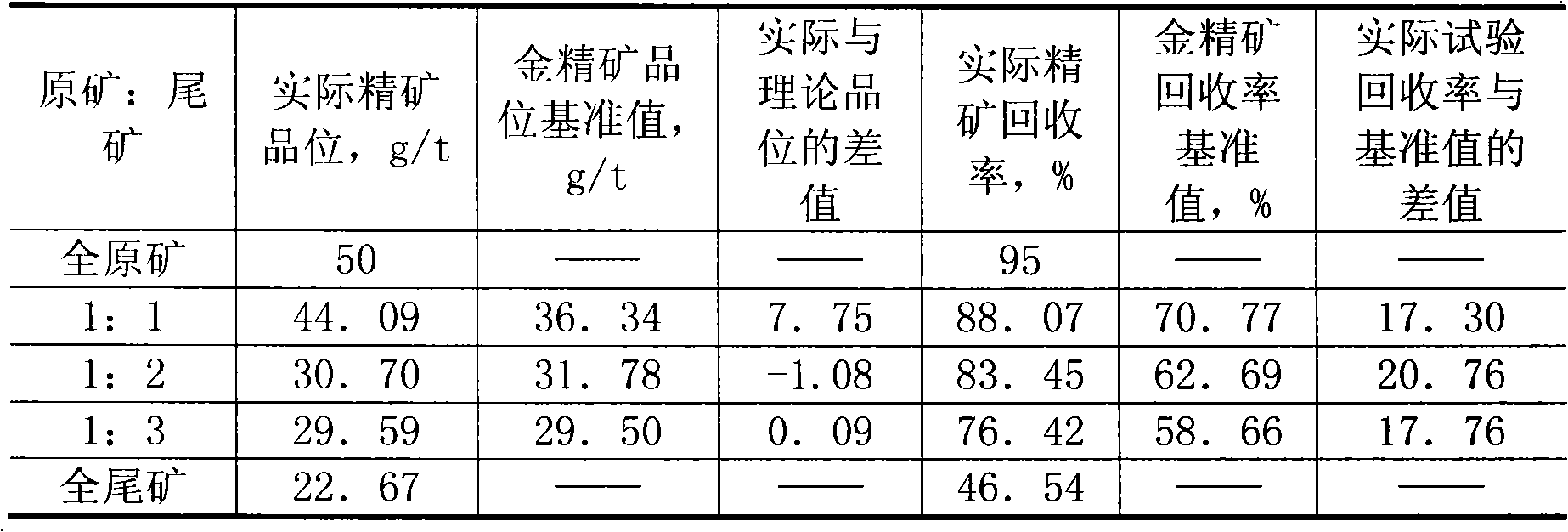

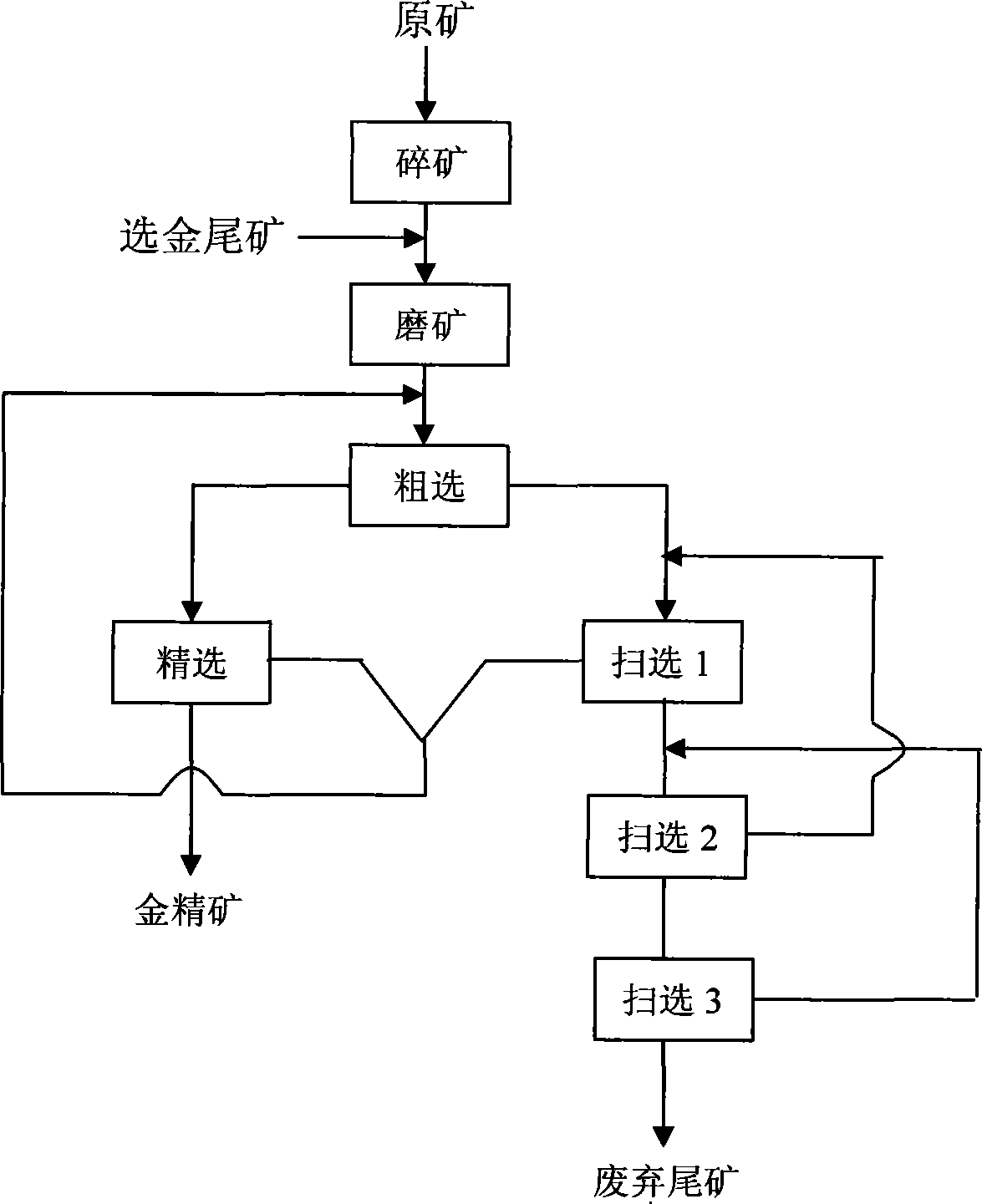

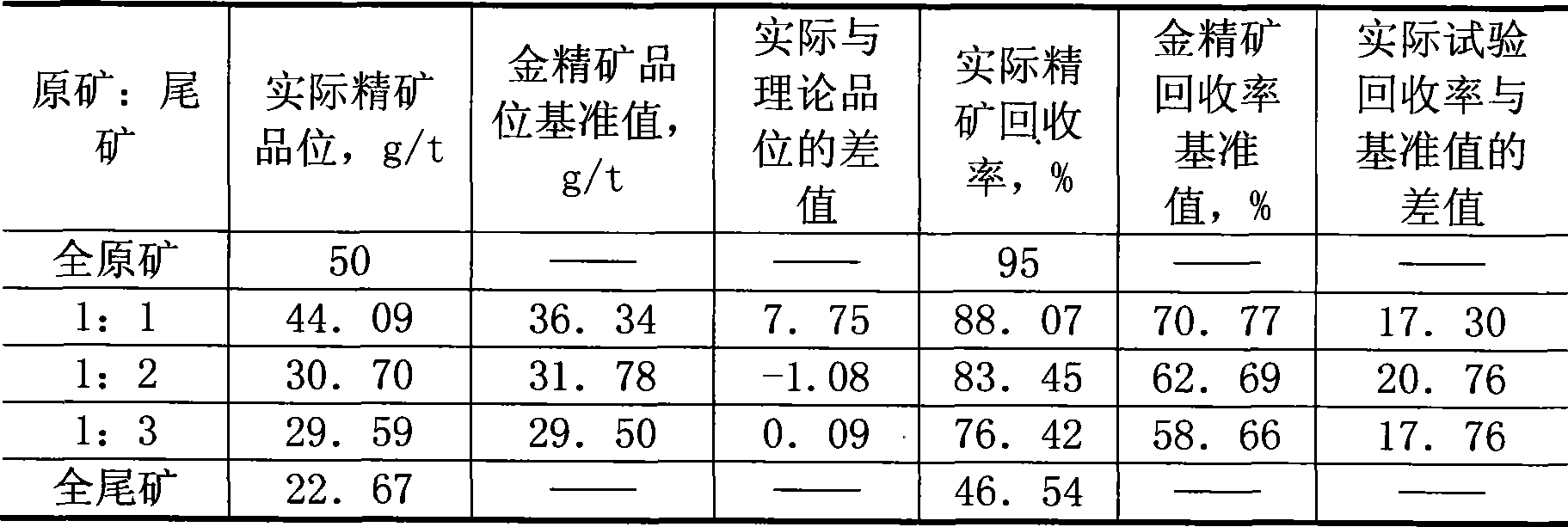

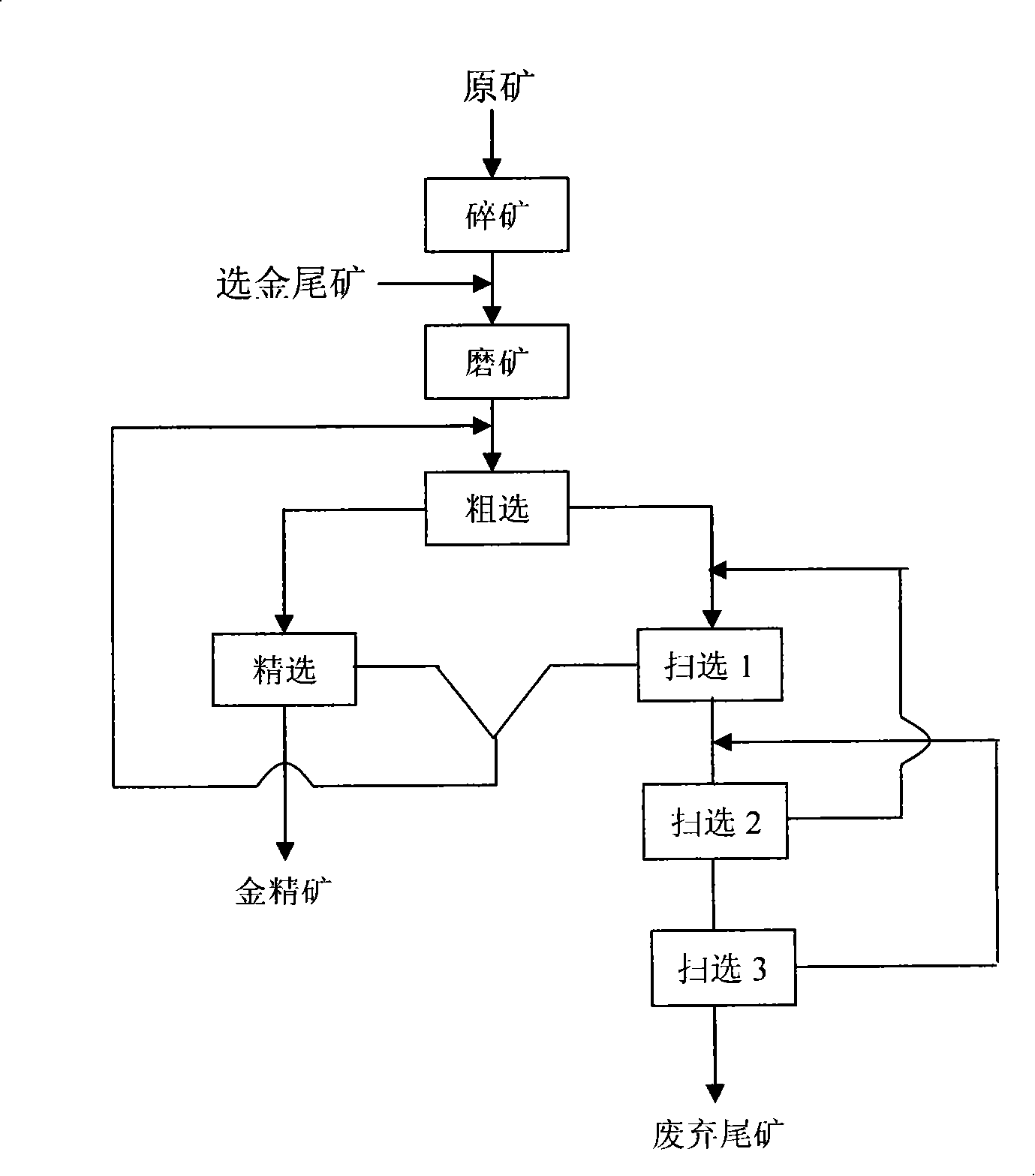

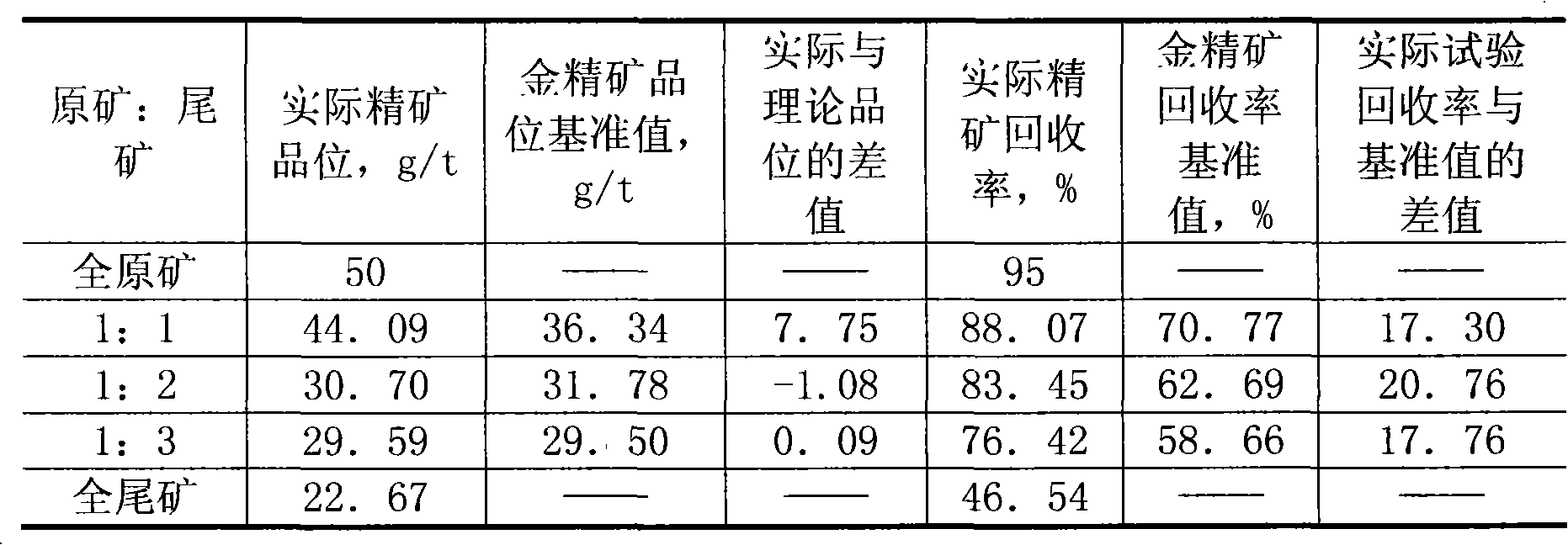

Mineral separation process capable of increasing gold recovery in gold tailings

The invention relates to a beneficiation method for improving the recovery ratio of gold in gold tailings, wherein, raw ore is chosen as a carrier, connected with gold tailings and is applied with a reagent for beneficiation. The method comprises the following process steps: a. ore crushing: the raw ore is crushed; b, grinding: the crushed raw ore is added with the gold tailings with the ratio of the raw ore to the gold tailings being 1:1-1:3 for grinding until the fineness of minus 0.074mm and 60-70% is obtained; c. roughly selecting: the finely ground mixed ore is added with 20-100g / t of butyl xanthogenate, 1-30g / t of ammonium butyl aerofloat and 5-20g / t of 2# oil for roughly selecting; d. cleaning: rough concentrate obtained from roughly selecting is added with 20-100g / t of sodium silicate for cleaning, thus selecting gold concentrate. The beneficiation method has the advantages of wide process versatility, simple flow, convenient operation, no pollution, being environment-friendly, low manufacturing cost, high recovery ratio, etc.

Owner:ZIJIN MINING GROUP

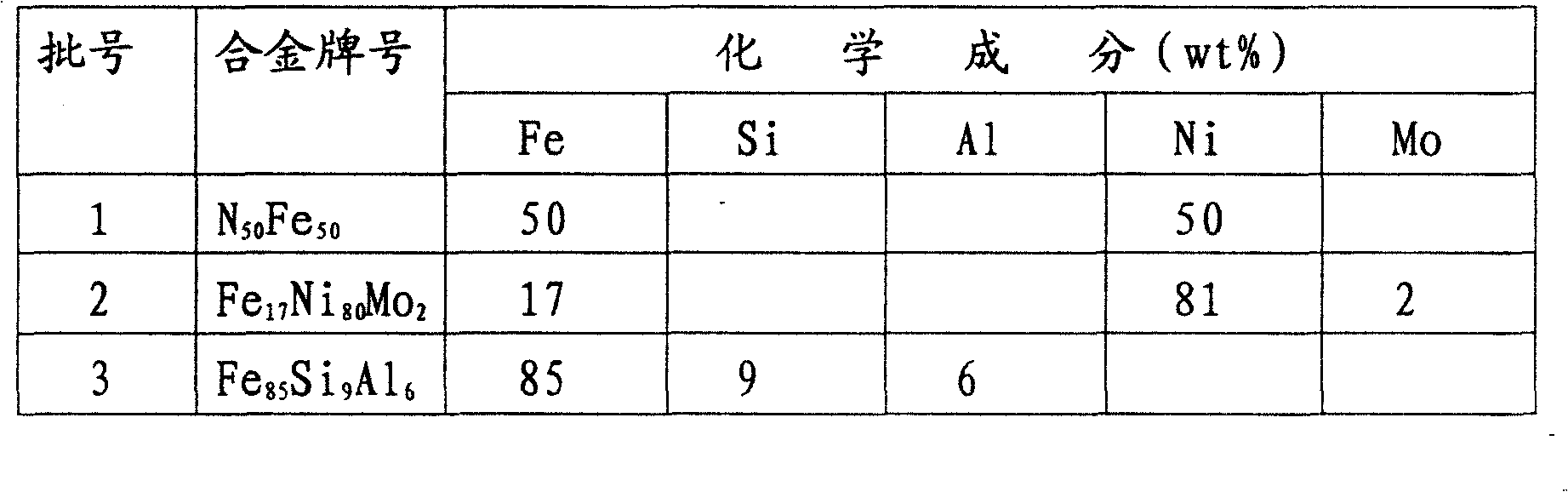

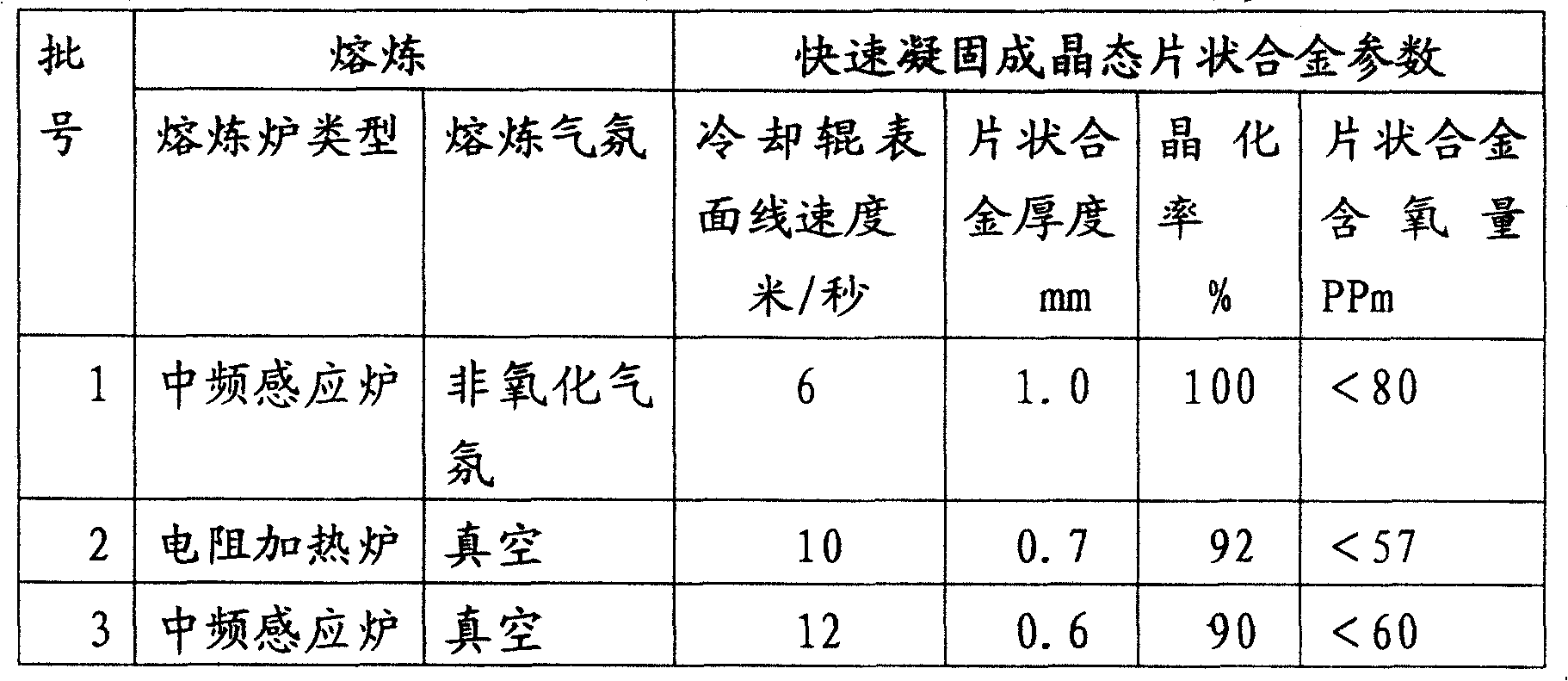

Method for manufacturing soft-magnetic alloy powder

The production method of soft magnetic alloy powder includes the following steps: smelting soft magnetic mother alloy, making molten metal be quickly coagulated into crystalline sheet alloy, breaking the sheet alloy to obtain alloy powder, and making the alloy powder undergo the processes of activation, annealing treatment and passivation treatment. Said soft magnetic alloy powder is low in oxygen content, stable in property and good in magnetic powder core performance.

Owner:CENT IRON & STEEL RES INST

Novel exposure blueprinting method for screen printing plate

ActiveCN104228314ARemove connectionEliminate disconnectionForme preparationLower limitScreen printing

The invention relates to a novel exposure blueprinting method for a screen printing plate. The method comprises steps as follows: firstly, a PET film is produced; then a base of a clean stainless steel mesh is dried after being pre-coated with an a-component photosensitive adhesive, the total thickness of 1 mu m is reserved during scraping coating of a printing surface, then the printing surface is coated with two lines of a b-component photosensitive adhesive, meanwhile, the PET film is applied slowly from bottom to top, drying is performed, the PET film is torn down when the printing surface is almost dried and drying is performed continuously until the printing surface is not sticky; finally, exposure can be performed when the organic PET film is torn down when the printing surface is almost dried and drying is performed continuously until the printing surface is not sticky, the set value of the exposure is the lower limit value of the exposure peek, and the stainless steel screen printing plate with a required printing graph is produced. A full-automatic precise coating machine and a parallel light printer are used in the method, the flatness of a photosensitive adhesive film surface coated with the technology is excellent, and the surface of an exposure mask is subjected to ionization treatment, so that the surface of the produced screen printing plate is smoother than that of a traditional screen printing plate, and the graph duplication is more accurate.

Owner:FUZHOU UNIV

Beneficiating process for increasing recovery rate of aurum in tailings of aurum

InactiveCN101474596AWide process adaptabilitySimple processFlotationProcess efficiency improvementGold oreSodium silicate

Owner:ZIJIN MINING GROUP

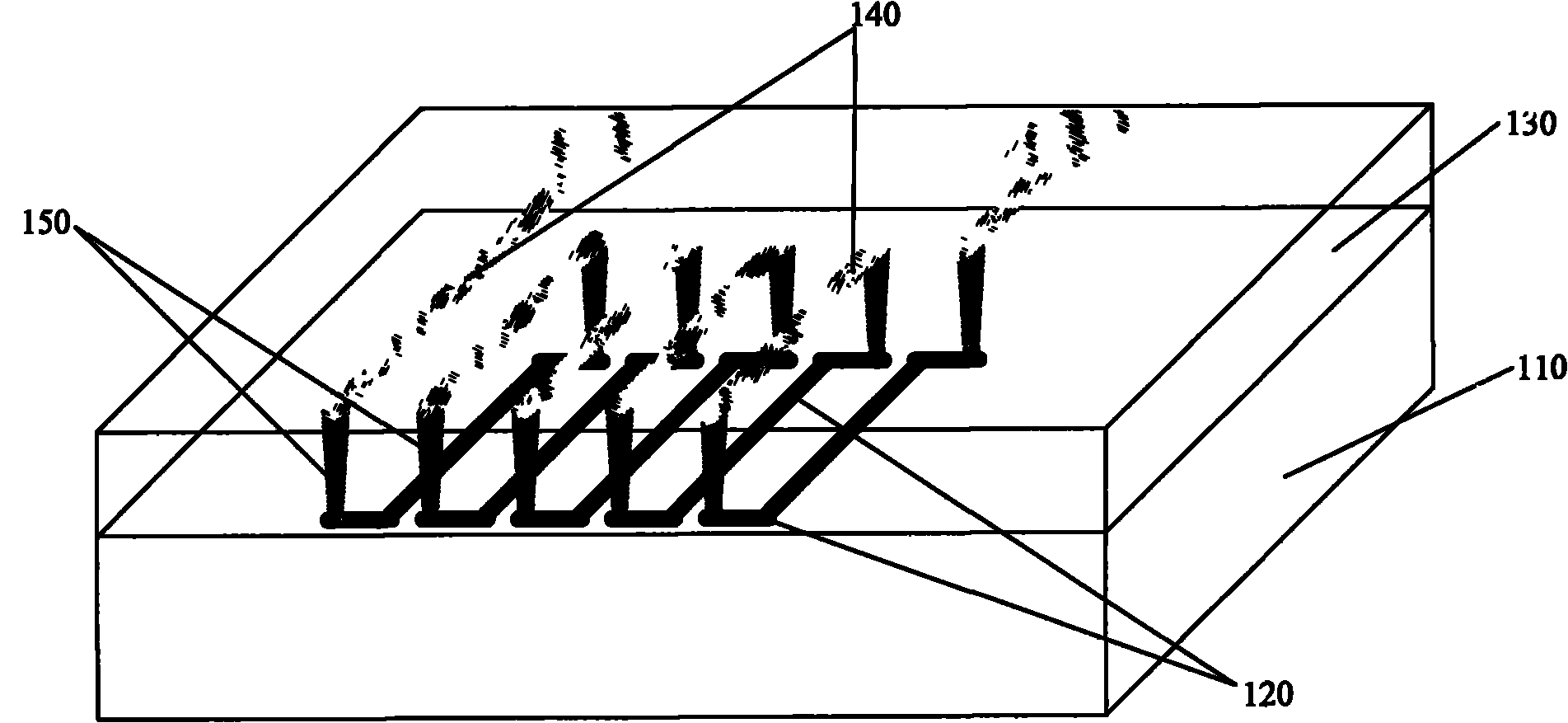

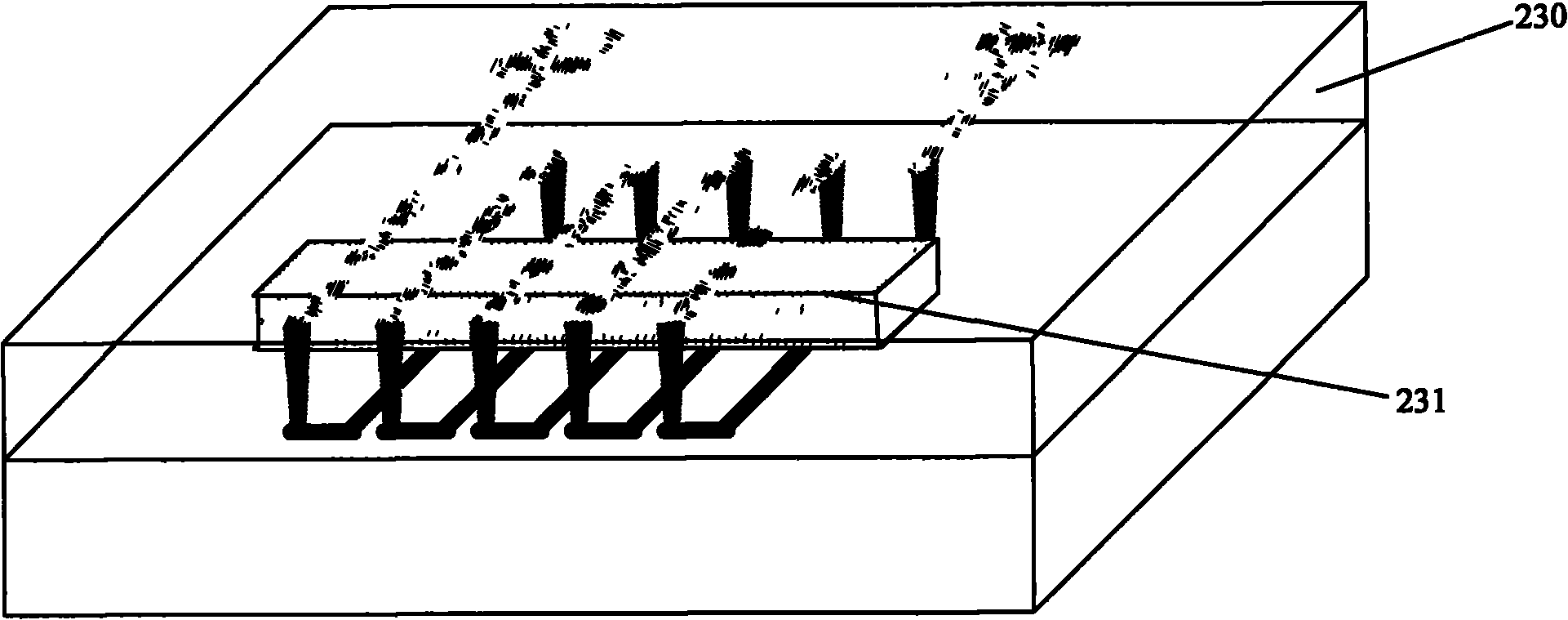

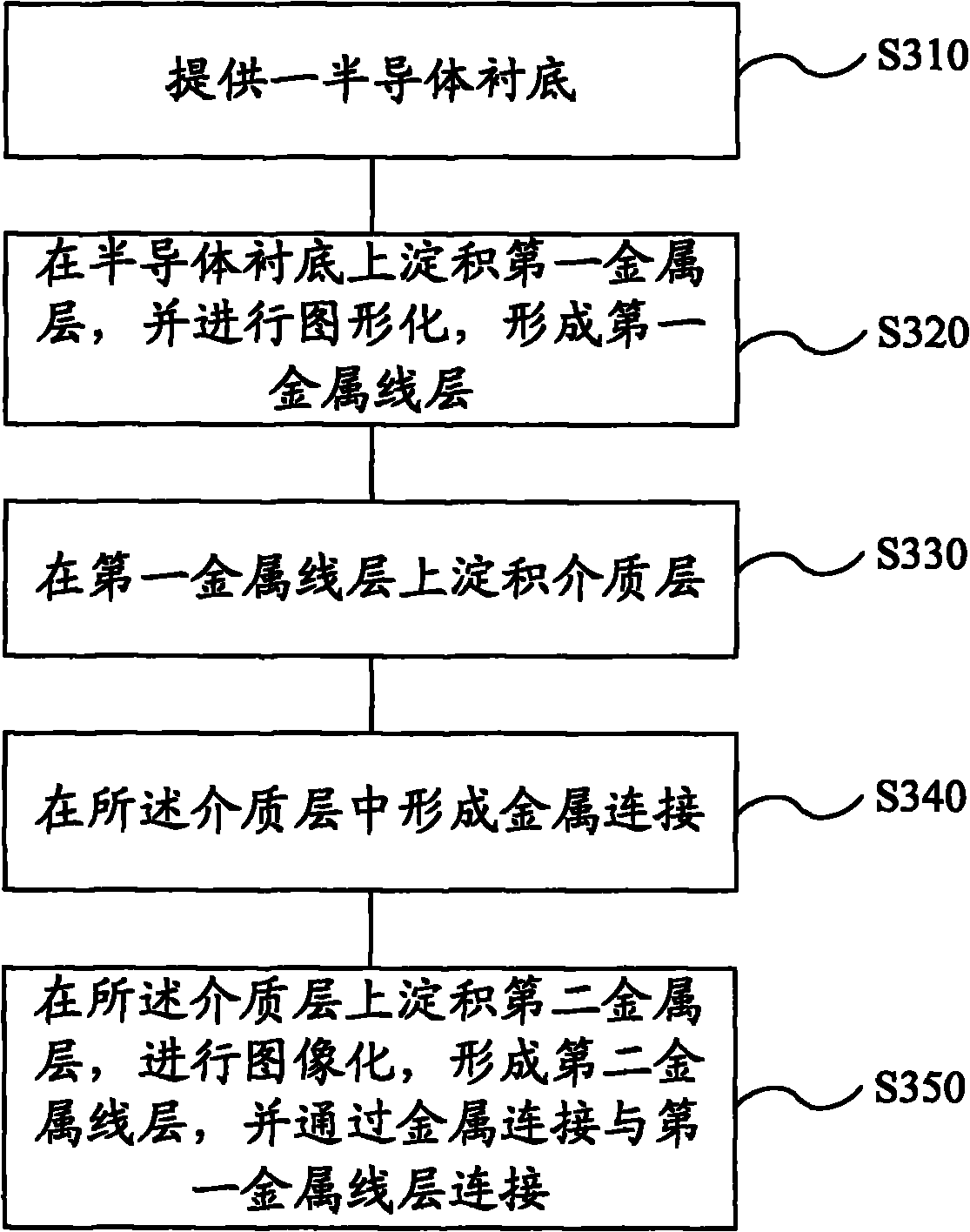

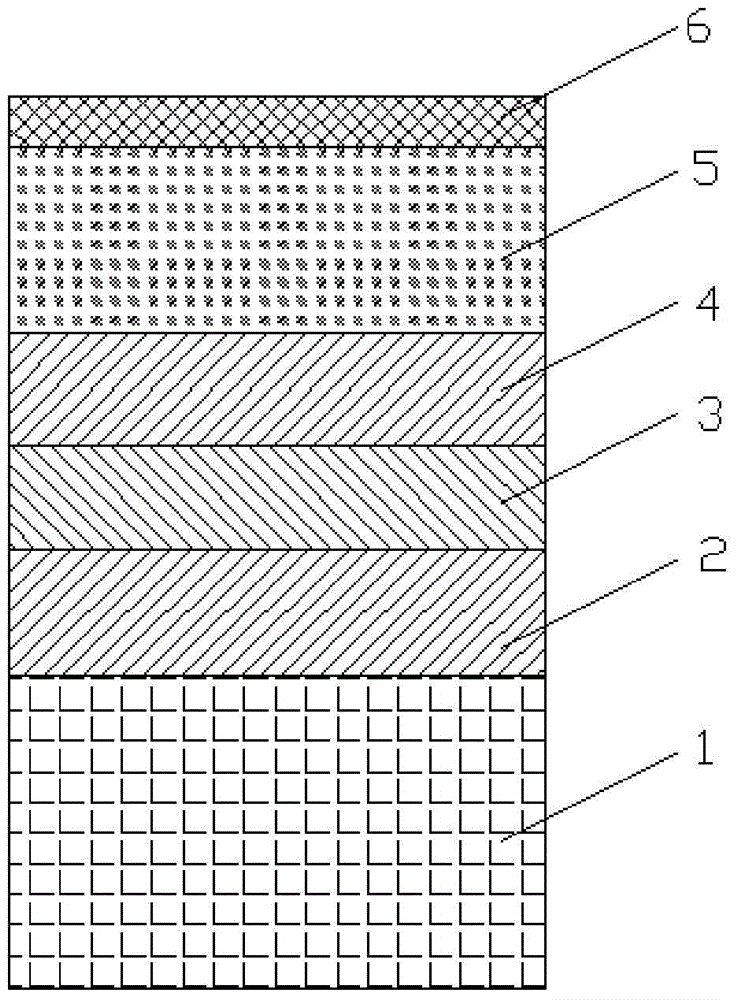

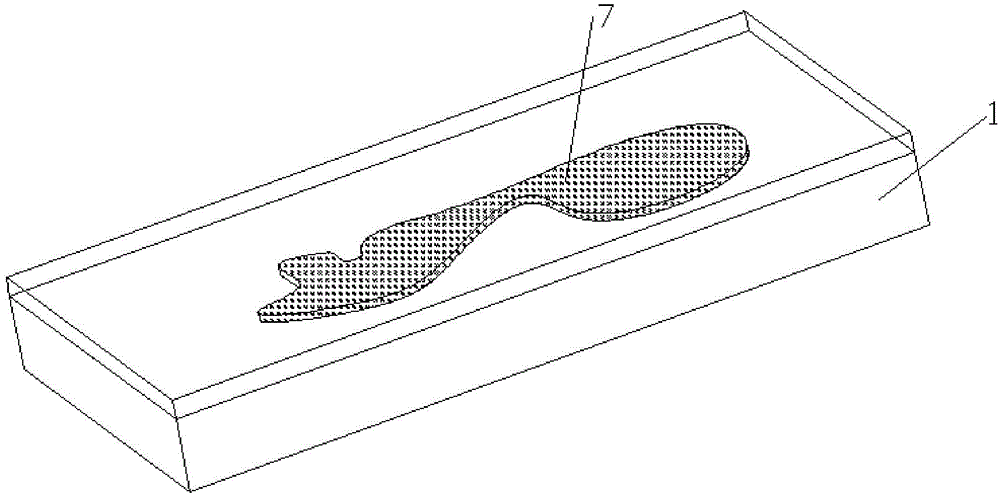

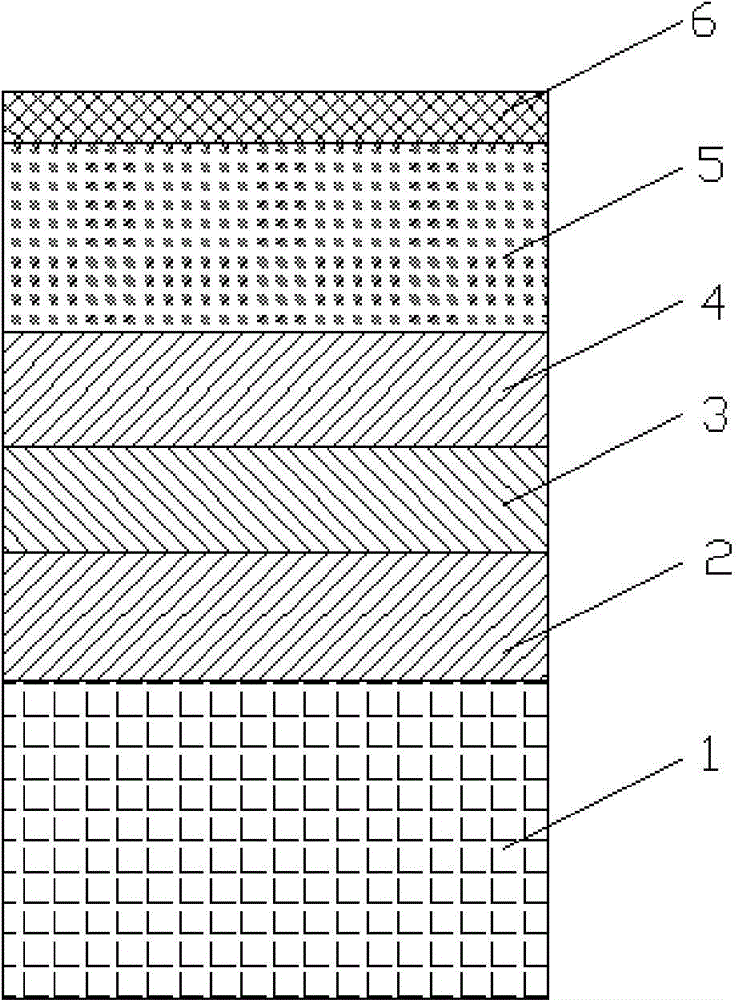

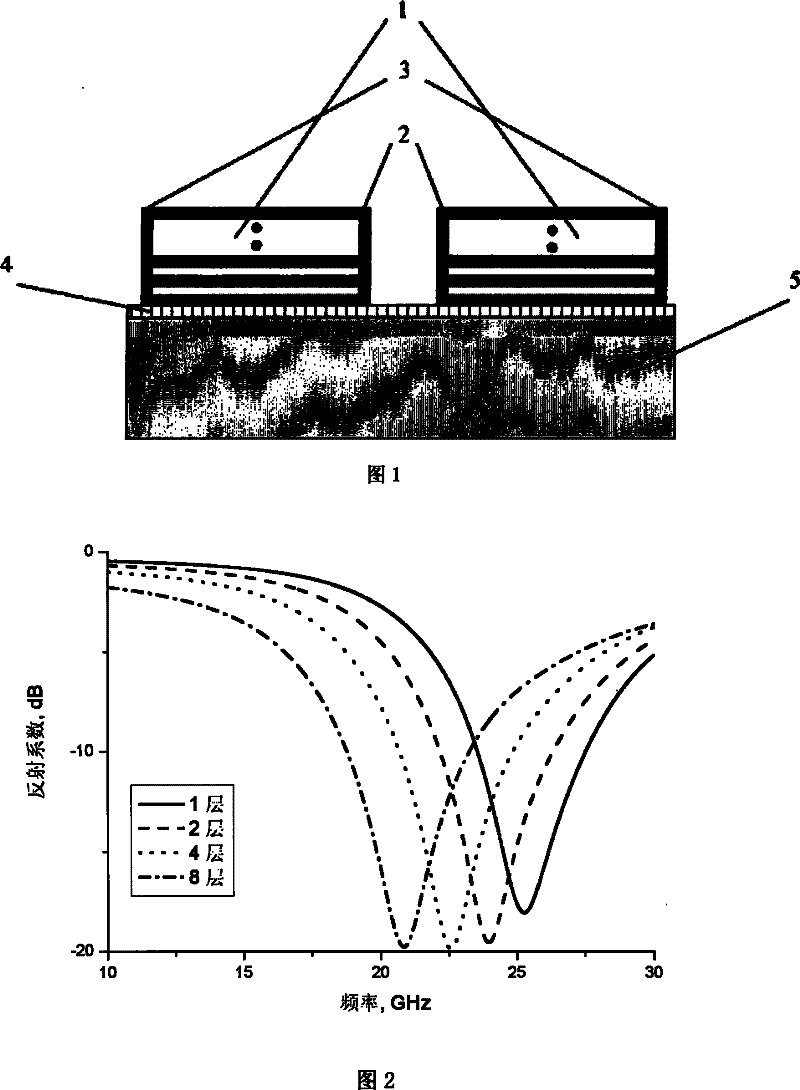

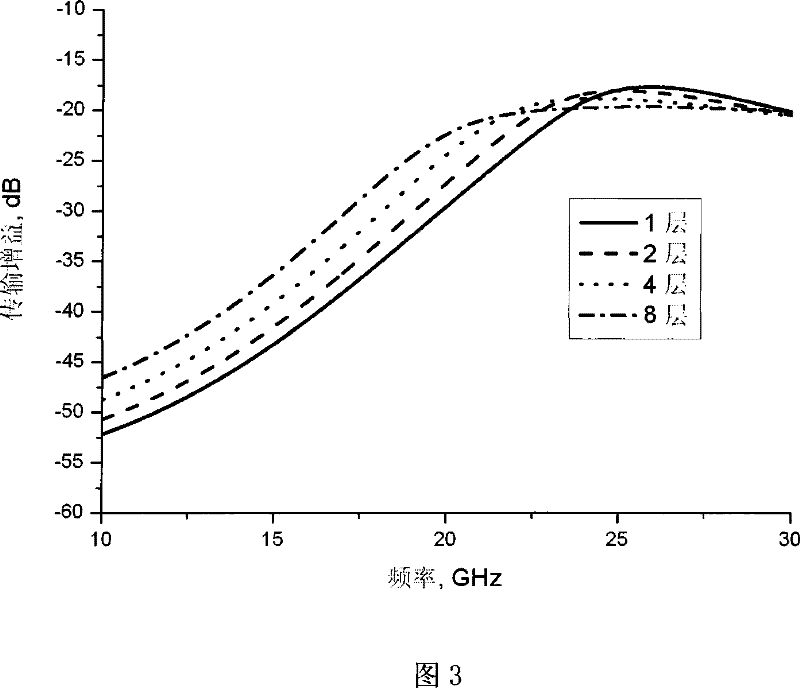

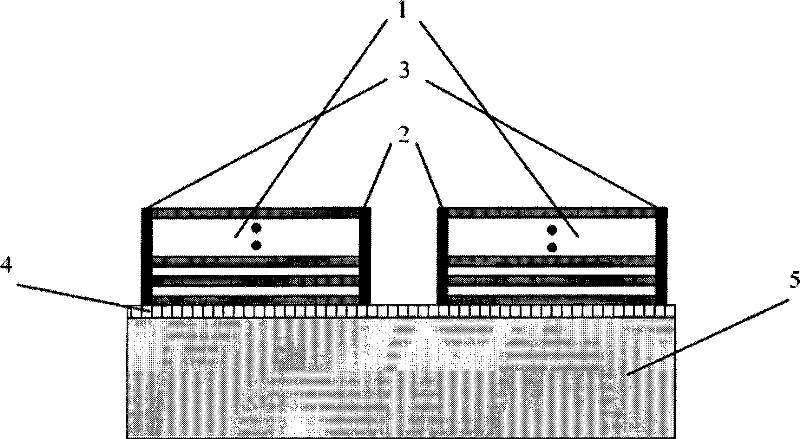

On-chip antenna structure in integrated circuit and manufacturing method thereof

InactiveCN101777698AIncrease Radiation VolumeSmall sizeLoop antennas with ferromagnetic coreAntenna supports/mountingsInter layerEngineering

The invention discloses an on-chip antenna structure in an integrated circuit and a manufacturing method thereof. The on-chip antenna structure comprises a semiconductor substrate, a first metal wire layer arranged on the semiconductor substrate, a medium layer arranged on the first metal wire layer, a second metal wire layer arranged on the medium layer, an inter-layer connector arranged in the medium layer for connecting the first metal wire layer and the second metal wire layer. In the structure, a multilayer metal connected layer combined structure is adopted, so the radiation power of an on-chip antenna is increased, the size of the on-chip antenna is reduced, the impedance bandwidth of the on-chip antenna is increased, the transmission gain of the on-chip antenna in wireless internet application is improved obviously, and no extra chip area is occupied.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT

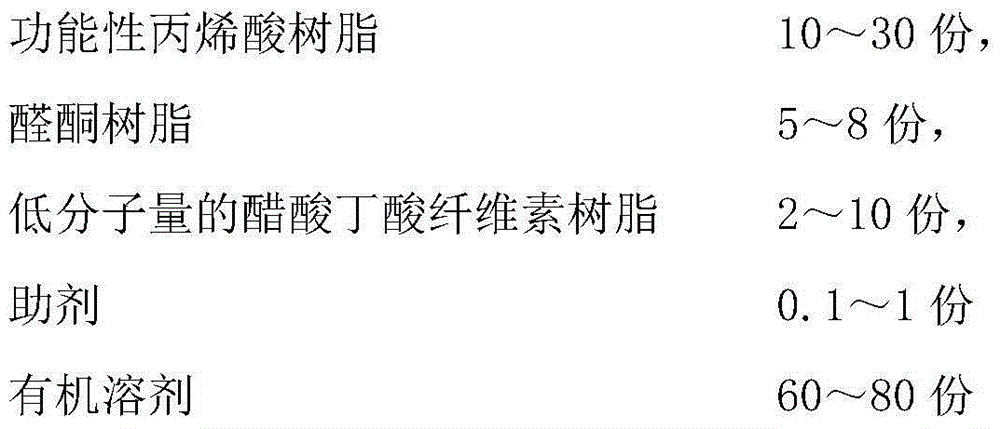

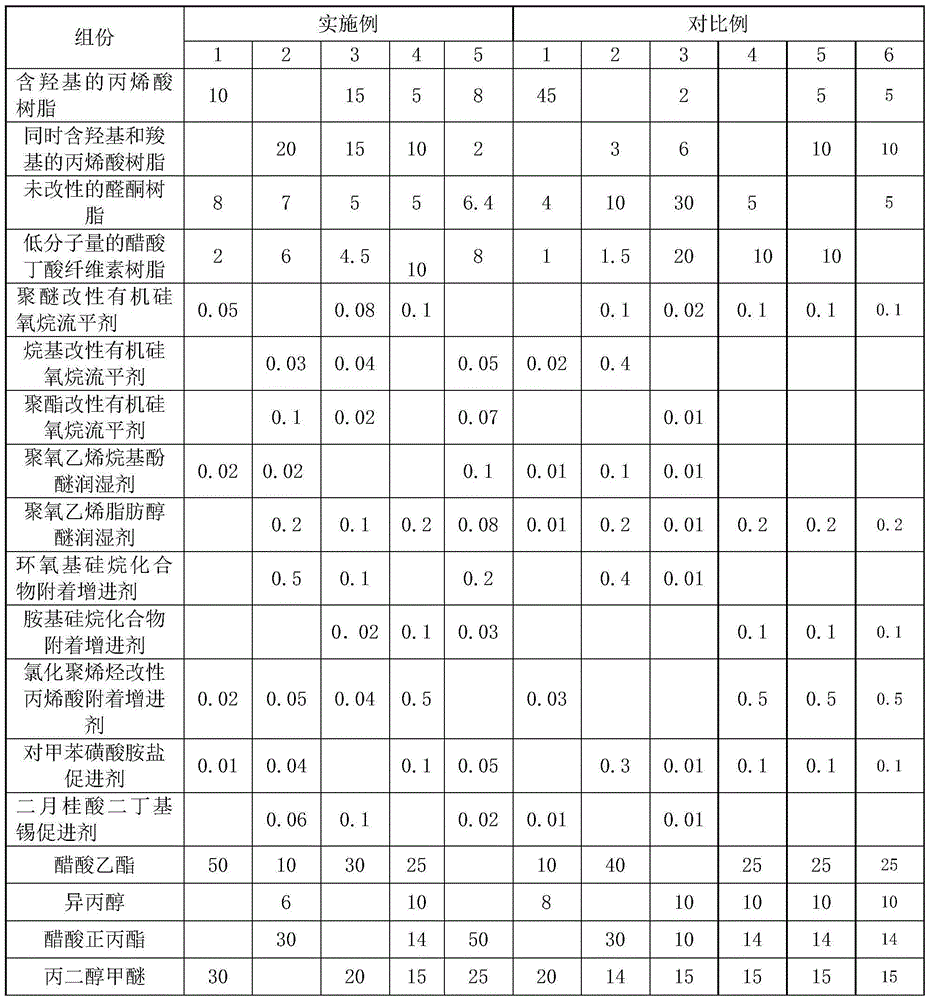

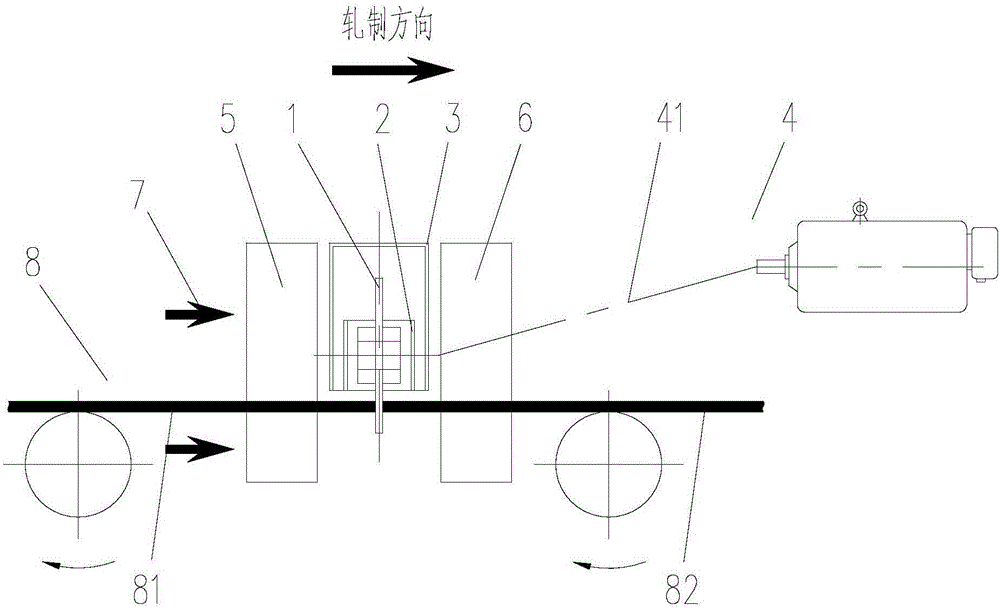

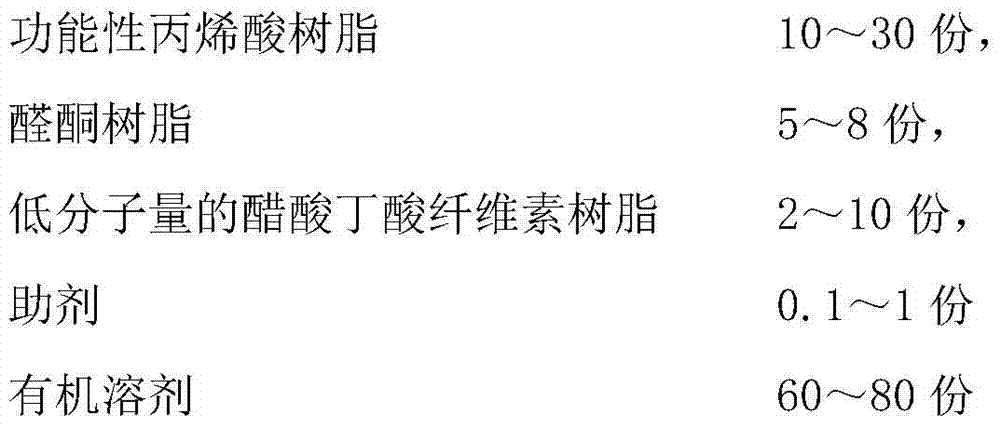

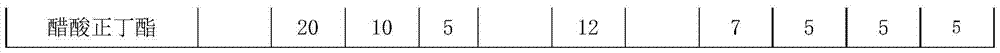

Multifunctional paint used for outer package of wine box and preparation method thereof

ActiveCN104404819AGood adhesionImprove matchCoatingsPaper forming aids additionOrganic solventAcrylic resin

The invention provides a multifunctional paint used for outer package of wine box and a preparation method thereof. The multifunctional paint comprises the following components by weight: 10-30 parts of functional acrylic resin, 5-8 parts of keto-aldehyde resin, 2-10 parts of cellulose acetate butyrate resin with low molecular weight, 0.1-1 part of auxiliary agent and 60-80 parts of organic solvent. According to the invention, the acrylic resin containing a functional group is matched with keto-aldehyde resin, cellulose acetate butyrate resin with low molecular weight is combined, so that the paint has the advantages of good adhesion fastness, bright moulding rainbow effect and good printing adaptability.

Owner:SHANGHAI WEIKAI CHEM +1

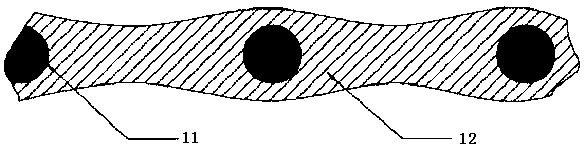

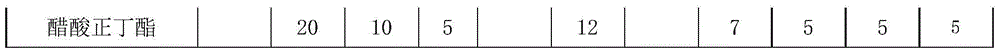

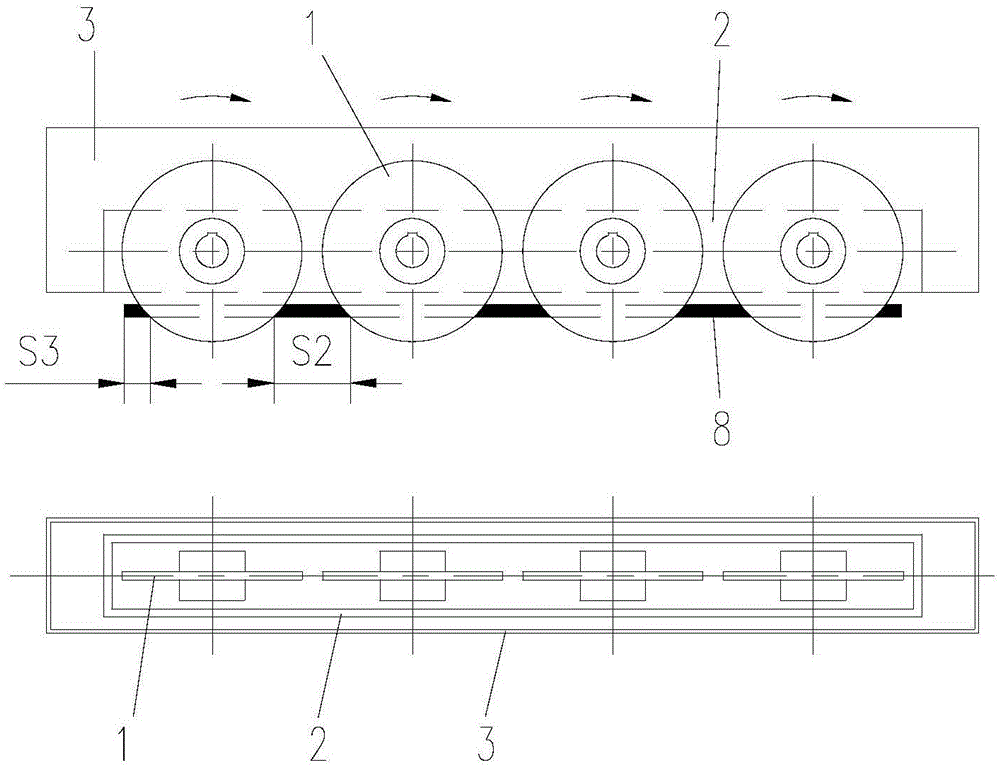

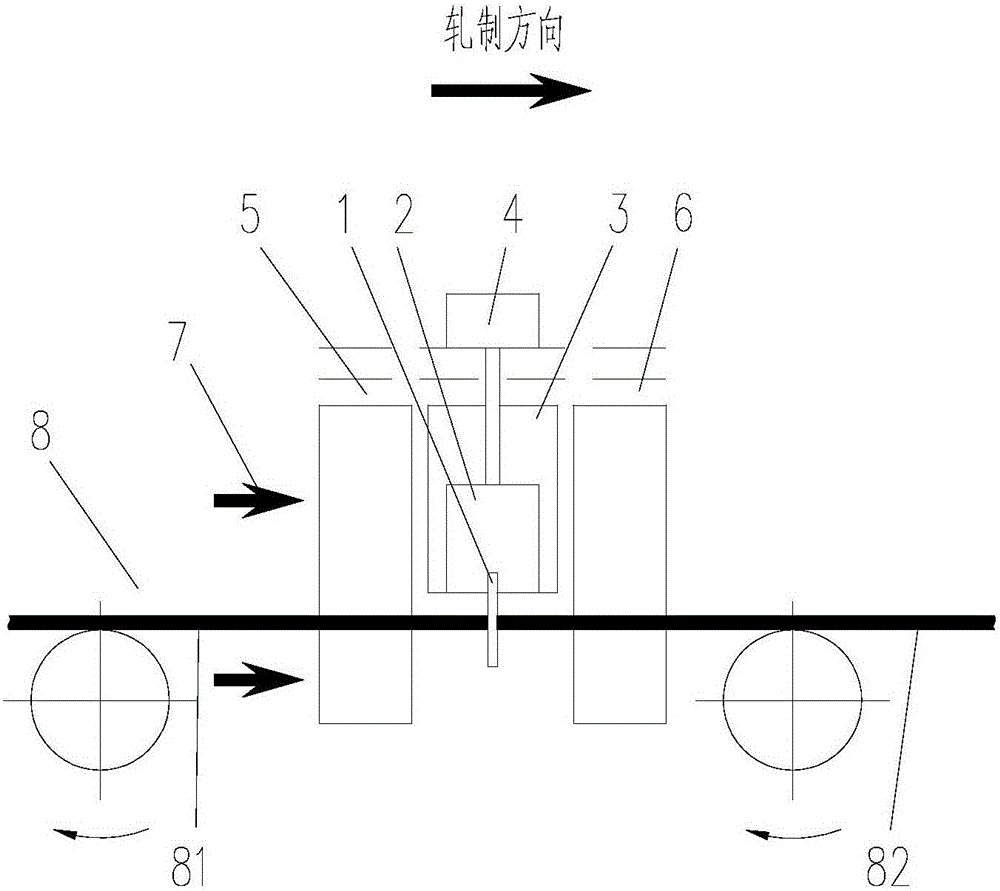

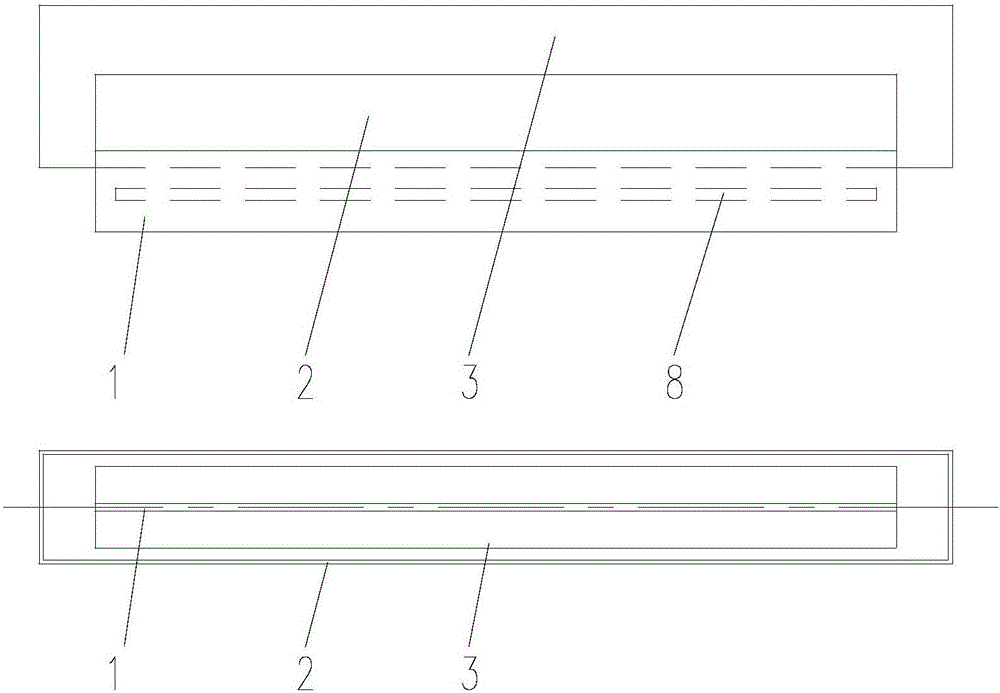

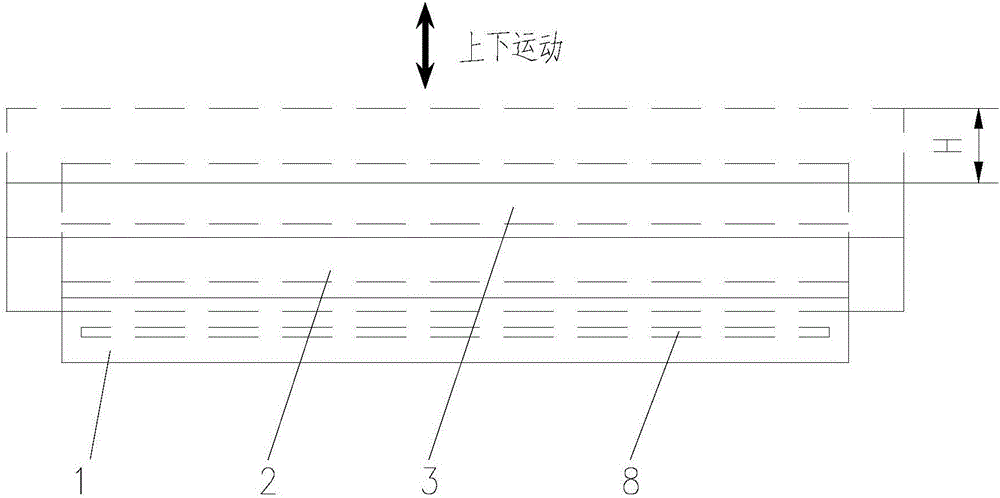

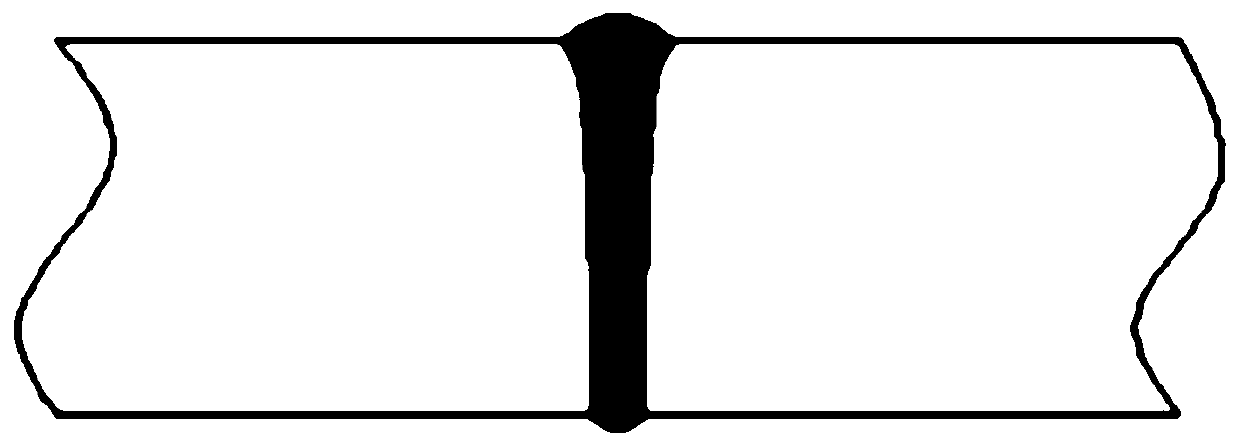

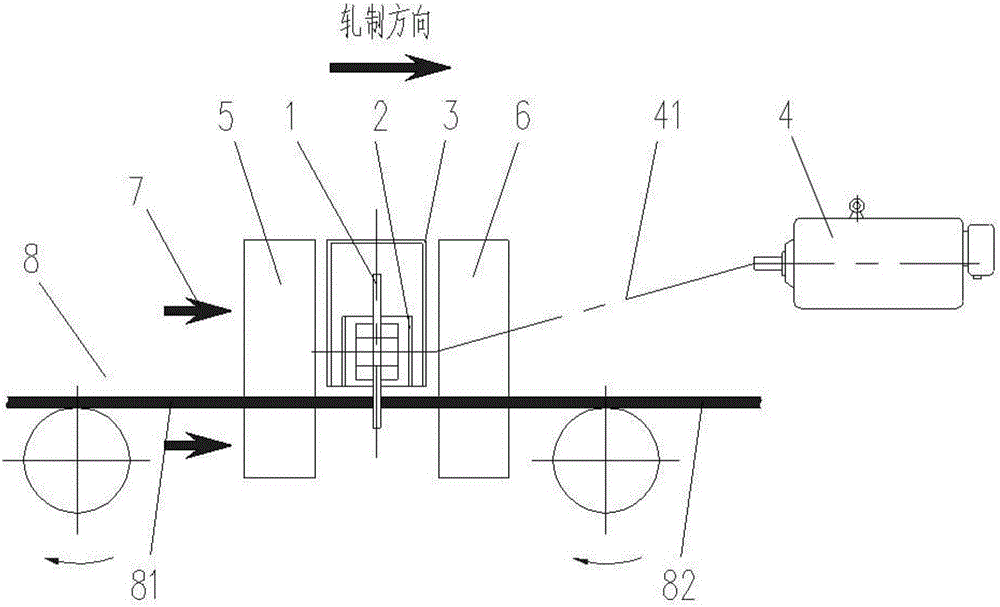

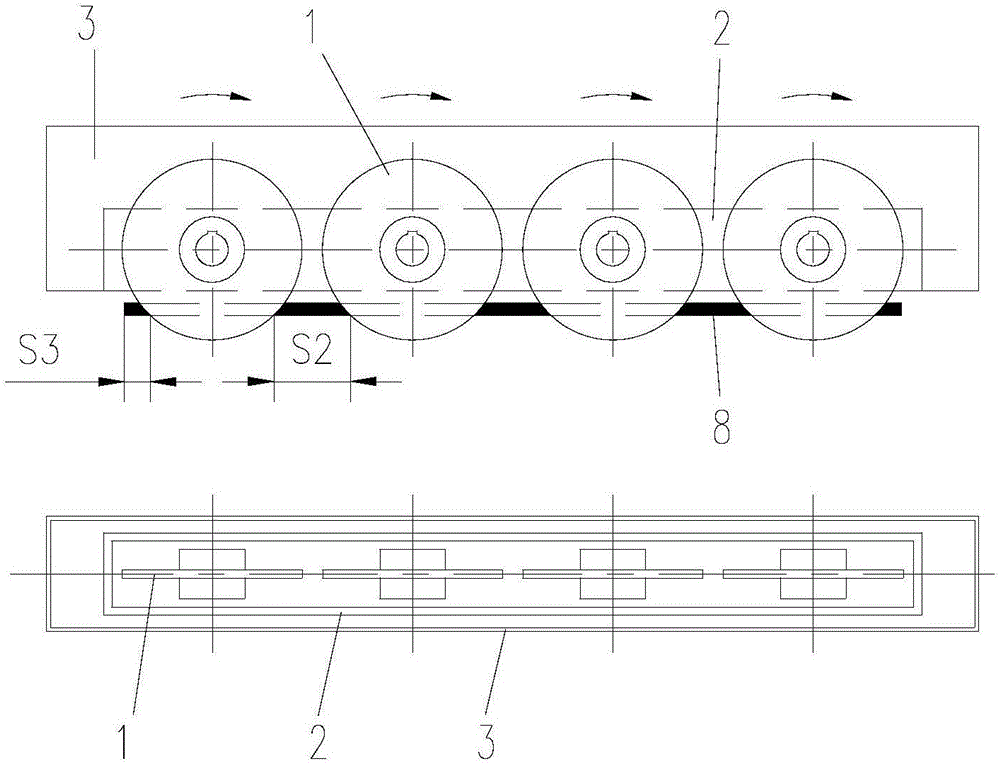

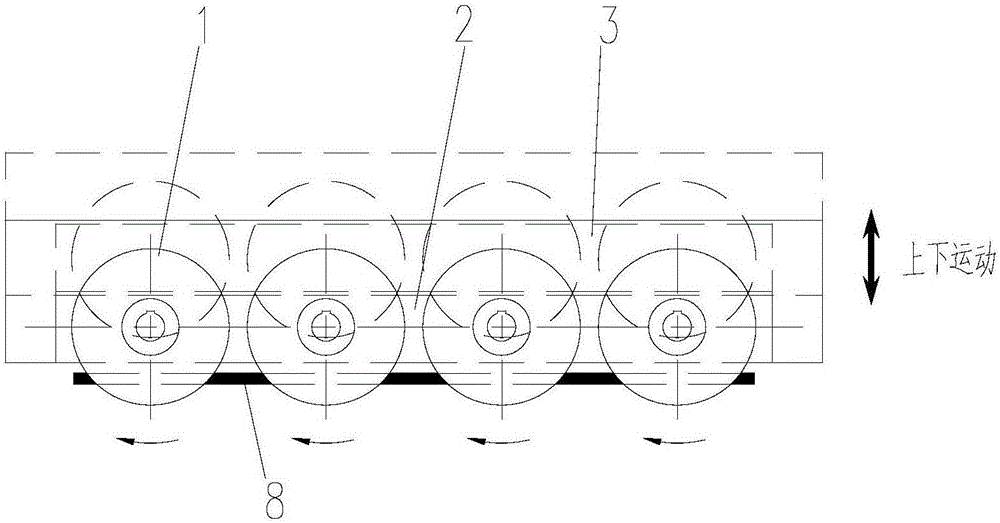

Connecting method and system for endless rolled intermediate slabs

ActiveCN106808082AFast connectionImprove connection strengthMetal rolling arrangementsNon-electric welding apparatusUltimate tensile strengthMechanical engineering

The invention provides a connecting method for endless rolled intermediate slabs. The method comprises the following steps: aligning the head and tail end portions of front and back intermediate slabs; rubbing the tail portion end surface of the front intermediate slab and the head portion end surface of the back intermediate slab; applying a forward force to the back intermediate slab in the rubbing period; and when the temperature of the connecting end surface of the front and back intermediate slabs is raised to a viscoplastic state, connecting the head of the back intermediate slab forward together with the tail portion of the front intermediate slab under the action of an upsetting force. The method provided by the invention is high in connecting strength, fast in connecting speed and low in energy consumption and is suitable for connecting slabs made from different materials.

Owner:CISDI ENG CO LTD

Furniture screen printing internal engraving 3D (three-dimensional) paint process

ActiveCN103551294AWide adaptabilityThick inkPolyurea/polyurethane coatingsSpecial surfacesDecomposition3d image

The invention discloses a furniture screen printing internal engraving 3D (three-dimensional) paint process, which is characterized in that a technical flow process comprises the following steps that (1) puttying is carried out, and a substrate layer is obtained; (2) a nanometer sealing primer is sprayed, the grinding is carried out, and a sealing primer layer is obtained; (3) PE (polyethylene) primer is sprayed, and an upper primer layer is obtained; (4) 3D image preparation and decomposition is carried out, which means that 3D images to be subjected to screen printing are prepared and are decomposed into a plurality of transverse plane pattern layers and a plurality of longitudinal cloud point 3D pattern layers; (5) the multilayer screen printing and the finish paint spraying are carried out, and a plurality of compound finish paint layers with pattern layers are obtained; (6) the laser internal engraving is carried out, and longitudinally and transversely nested 3D images are formed. The process has the advantages that through the multilayer screen printing and the internal engraving, the 3D images with 3D effect are formed on products, and vivid and visual effects are realized. The invention also discloses epoxy modified waterborne polyurethane, which has the characteristics of high bonding capability, high modulus and intensity, high temperature resistance and good heat stability, and is suitable for the laser internal engraving.

Owner:DONGGUAN FUBAO SOFA MFG

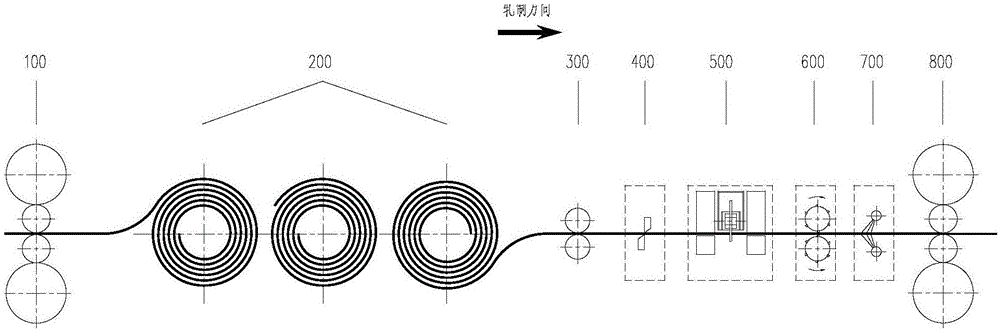

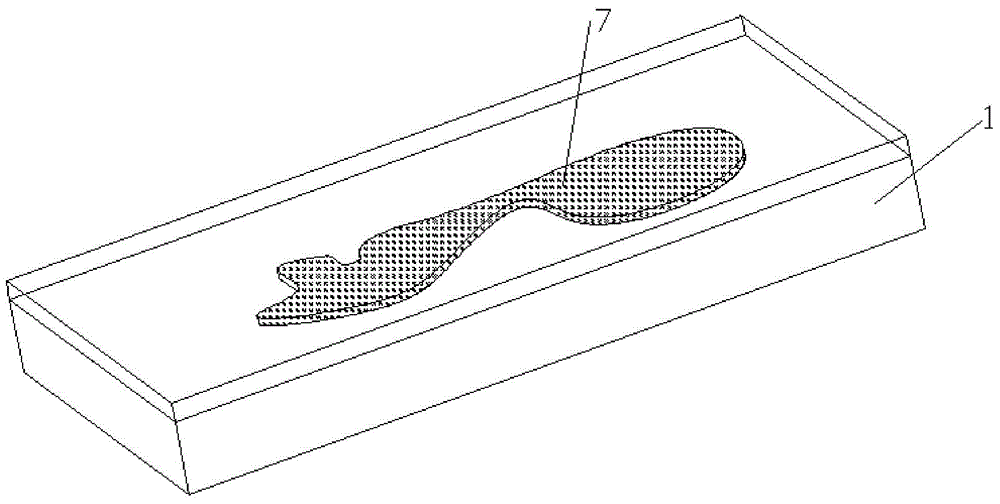

Intermediate slab connecting equipment and system

ActiveCN106694553AFast connectionImprove connection strengthMetal rolling arrangementsNon-electric welding apparatusUltimate tensile strengthMechanical engineering

The invention provides intermediate slab connecting equipment. The intermediate slab connecting equipment comprises an outlet clamping device for clamping a front intermediate slab, an inlet clamping device for clamping a back intermediate slab, a friction blade for rubbing the connecting end surfaces of the front intermediate slab and the back intermediate slab, and an upsetting device for applying upsetting force; the friction blade is positioned between the inlet clamping device and the outlet clamping device; and the friction blade is connected with a friction blade vibration device. The friction blade extends between the front intermediate slab and the back intermediate slab for rubbing the end surfaces of the two, so that the end surfaces of the intermediate slabs and near areas are quickly heated to reach a viscoplasticity state; the upsetting device applies the upsetting force to the back intermediate slab; after the friction blade is shifted away, the front intermediate slab is connected with the back intermediate slab. The intermediate slab connecting equipment is simple in structure, high in connecting strength, fast in connecting speed, low in energy consumption and suitable for connecting slabs with different materials.

Owner:CISDI ENG CO LTD

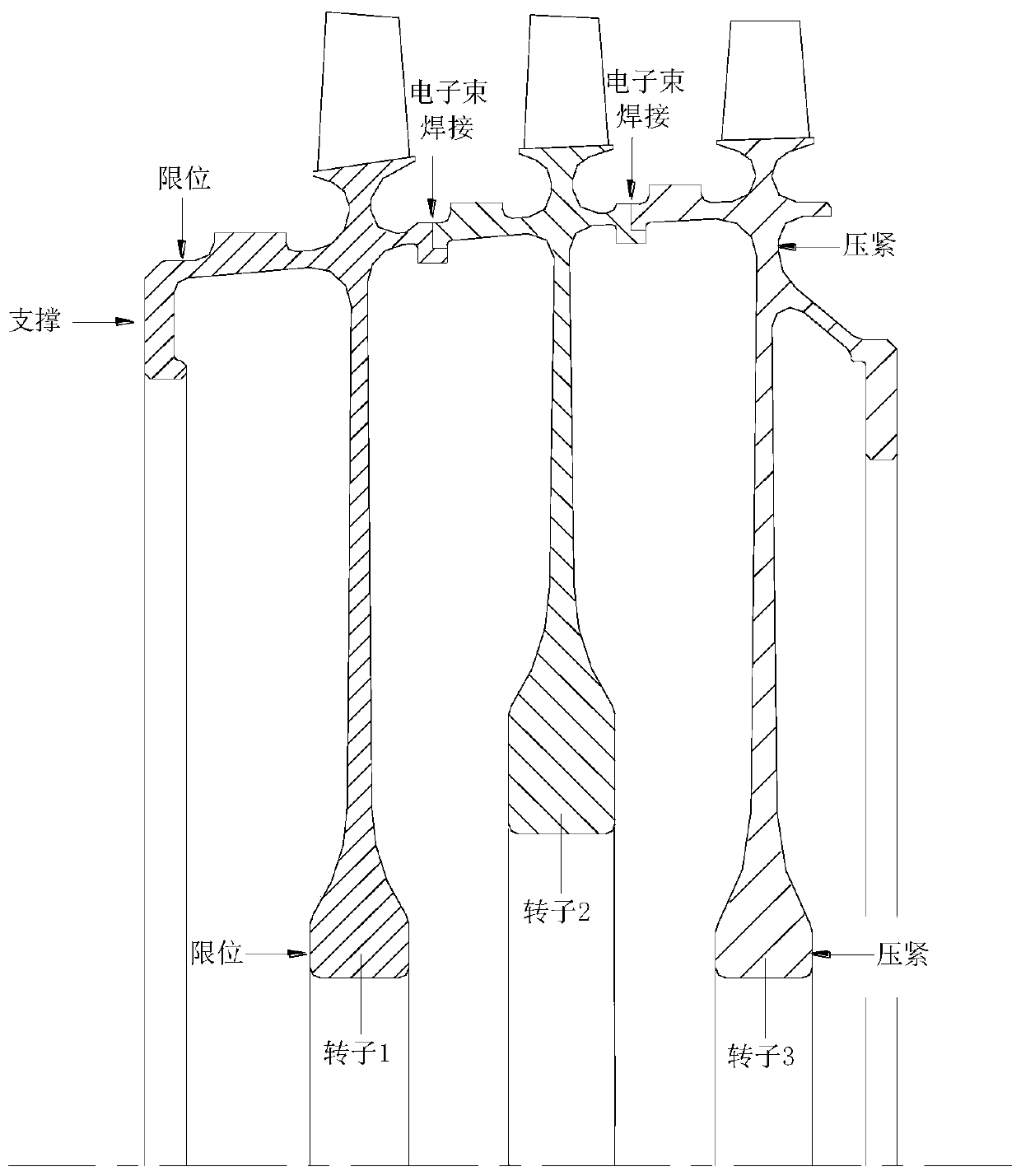

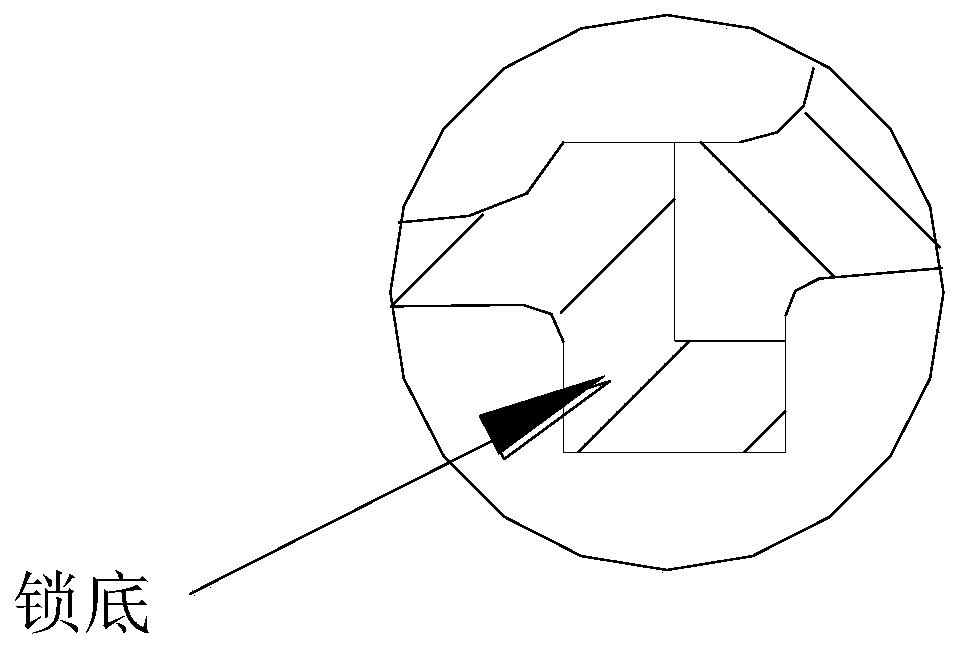

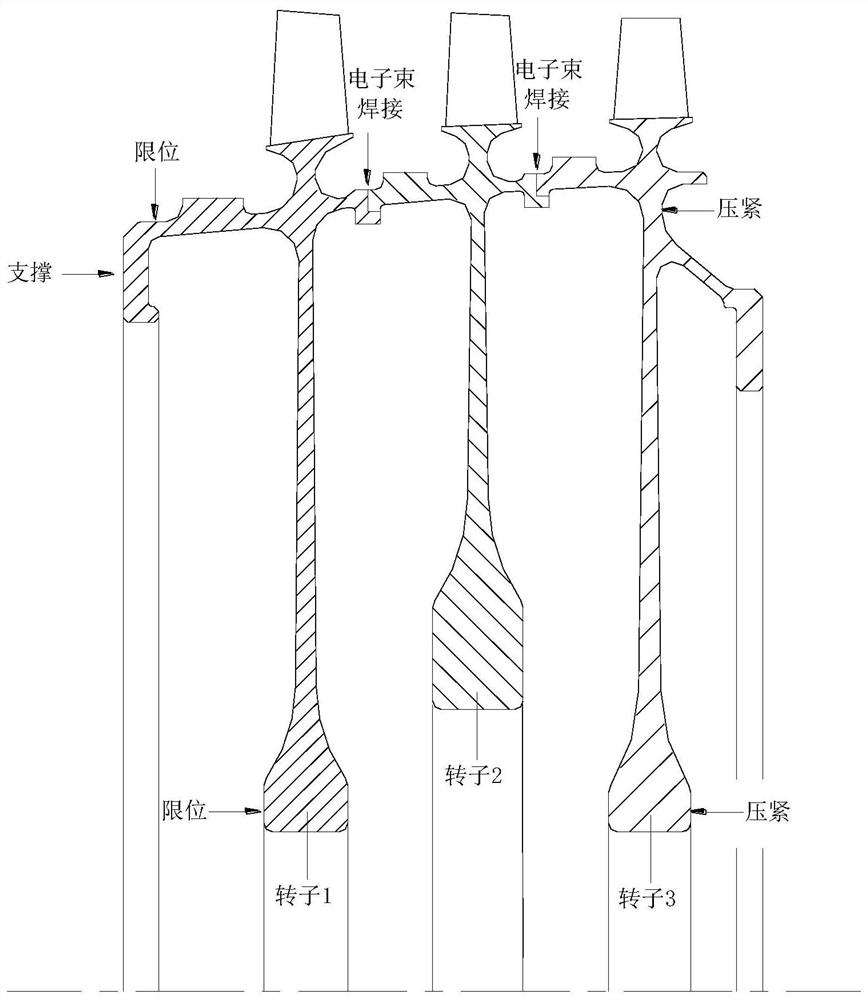

Precise control method for electron beam welding deformation of rotor type parts

ActiveCN110977131AImprove rigidityIncrease rigidityElectron beam welding apparatusDeformation controlWelding deformation

The invention discloses a precise control method for electron beam welding deformation of rotor type parts, and belongs to the technical field of rotor type part electron beam welding. The method comprises the following steps of 1, designing an electron beam welding structure; 2, determining electron beam welding parameters; 3, designing an electron beam welding tool; 4, adjusting the material state of parts before welding; 5, determining part welding shrinkage; and 6, performing electron beam welding of the rotor type parts. For structural characteristics of rotor type parts, the technology starts from the aspects of improving parts rigidity, realizing rigid fixation, reducing residual stress, improving the distribution uniformity of residual stress and the like, corresponding technological measures are adopted, electron beam welding deformation precise control is realized, and compared with the prior art, by adopting the technology, the parts are high in connecting quality, low in cost, wide in technological adaptability and good in deformation control effect.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

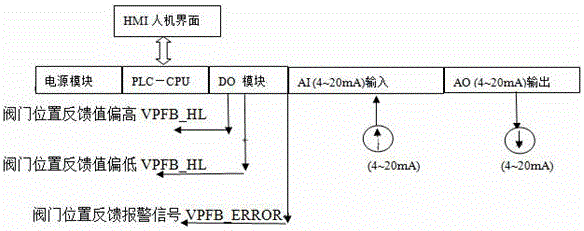

Realization method for detection controller for valve position adjustment abnormity of industrial pulverized coal boiler

The invention relates to a realization method for a detection controller for valve position adjustment abnormity of an industrial pulverized coal boiler. The detection controller comprises a multi-channel proportional controller, an electric adjustment valve, an upper threshold comparator, a lower threshold comparator, a delayer I, a delayer II, an or-logic gate, a PLC / DCS controller, a DO module, an AI input module and an AO output module. During the combustion process of pulverized coal, when error values between the control values and the feedback values of the adjustment valve exceed maximum allowance upper limit values and lower limit values, the feedback values pass through the threshold comparators; timing alarming control is started; and experienced time is error overrun time. If the error overrun time exceeds preset normal input response time, logic signals output by the delayers drive the intermediate relay of PLC or DCS, and a program alarming and combustion interrupting signal is output. Compared with a conventional special valve positioning controller which consists of PCB columnwise elements, the detection controller has the obvious characteristics of low cost, flexible configuration, wide technological applicability and high antijamming capability.

Owner:JIANGSU SHUANGLIANG BOILER

High-strength hull steel with excellent low-temperature toughness and one-steel multi-level heat treatment technology of hull steel

The invention provides high-strength hull steel with excellent low-temperature toughness and a one-steel multi-level heat treatment technology of the hull steel. The hull steel comprises the chemicalcomponents of, by mass, 0.12-0.15% of C, 0.20-0.30% of Si, 1.40-1.70% of Mn, 0.12-0.15% of Ni, 0.16-0.25% of Cr, 0.08-0.12% of Mo, 0.020-0.030% of Nb, 0.012-0.018% of Ti, less than or equal to 0.02% of V, less than or equal to 0.015% of P, less than or equal to 0.002% of S, 0.0020-0.0030% of B and the balance Fe and unavoidable impurities. According to the technology, a high-strength hull steel plate with excellent low-temperature toughness can be produced by combining different quenching technologies with the tempering technology, wherein the maximum thickness of the hull steel plate is 50 mmand the hull steel plate can meet the requirement of E460-E550 strength levels. The alloy cost is low, and the technology adaptability is wide. The high-strength hull steel with the excellent low-temperature toughness and the one-steel multi-level heat treatment technology of the hull steel solve the problems that different components are needed by the steel plates with different steel levels anddifferent thicknesses, and production organization is difficult. Flexible manufacturing of one-steel and multi-level is achieved.

Owner:NANJING IRON & STEEL CO LTD

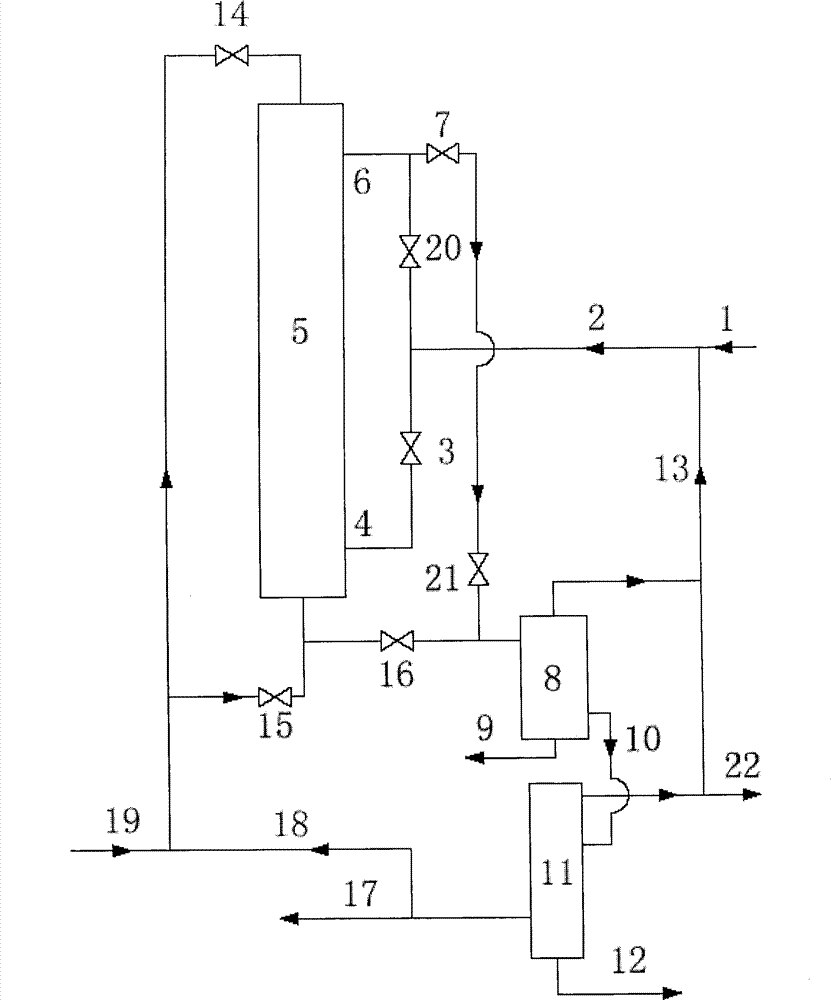

Fischer-Tropsch synthesis process based on fixed bed reactor

ActiveCN101275080BImprove heat transfer phenomenonUniform temperature distributionHydrocarbon from carbon oxidesLiquid hydrocarbon mixture productionSyngasLiquid medium

The present invention provides a ft synthesis reaction process based on the fixed bed reactor is that the cycling medium enters from the top of the fixed bed reactor after preheated, the feed gas formed by mixing the syngas with the tail gas enters from the lower of the fixed bed reactor to contact with the catalyst to process ft synthesis, the product is fully collected to process the separation of water, a long chain hydrocarbon and a gas phase component; the long chain hydrocarbon processes C5-C18 middle distillate, the separation of C18+hydrocarbon and gaseous low carbon hydrocarbon, one part C5-C18 middle distillate is mixed with the cycling liquid medium, the other part is processed oil product process, C18+hydrocarbon fully enters in the oil product process, the gaseous low carbonhydrocarbon mixing with the gas phase component forms the tail gas, the water component is used as a gas agent to return in the gasification system. The invention has high heat exchange efficiency, high syngas throughput, lower cycling gas quantity, lower energy consumption, stable operation.

Owner:中科潞安能源技术有限公司

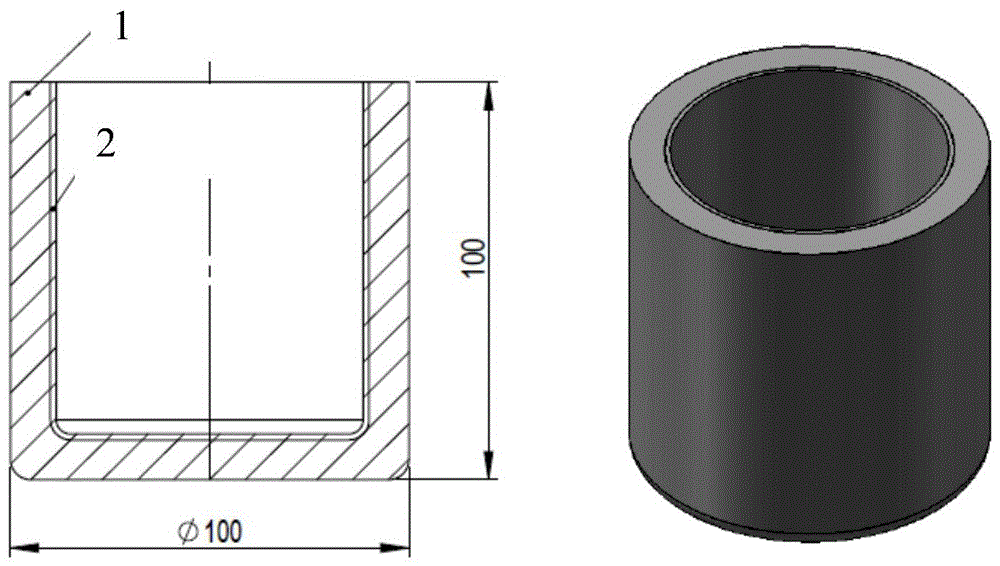

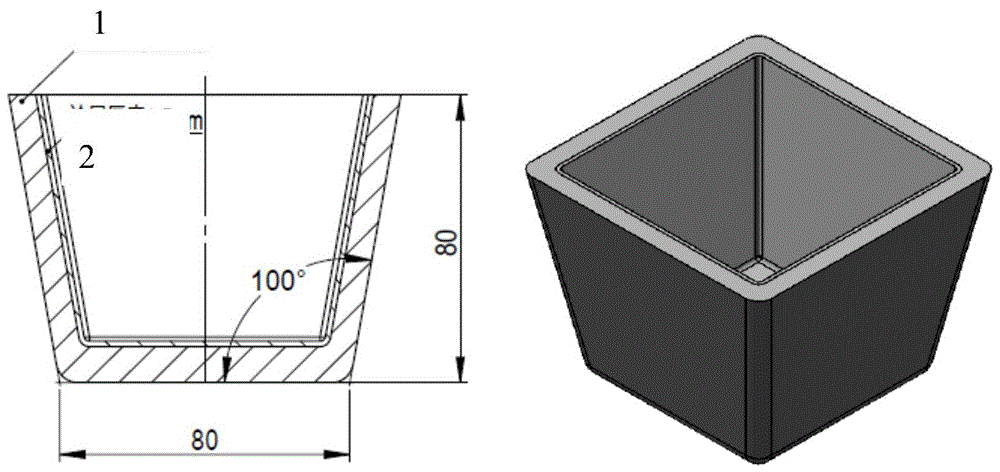

A kind of preparation method of crucible containing tungsten coating

ActiveCN104213096BExtended service lifePrevent infiltrationChemical vapor deposition coatingCrucibleAlloy

The invention discloses a preparation method of a crucible with a tungsten coating. The preparation method comprises the following steps: (1) a needed pure tungsten, pure molybdenum or molybdenum alloy crucible base material is obtained through a specific processing technology according to a needed size; (2) a certain degree of surface roughening treatment is performed for the obtained crucible base material; and then, the surface is cleaned to remove an oxide layer; and (3) tungsten hexafluoride serves as a raw material, hydrogen serves as reducing gas, and the chemical vapor deposition (CVD) is performed for the surface of the crucible base material under the condition of the base material temperature of 350-600 DEG C to form a tungsten coating layer with the thickness of 0.01-3 mm so as to obtain a crucible product coated with the tungsten coating layer. The CVD tungsten coating layer with high purity and high compactness has excellent metal or nonmetallic solution corrosion resistance, so that the protecting effect on the crucible basal body is achieved, and the service life and the performance of the crucible under such high-temperature environments as metal or nonmetal smelting and crystal growth are prolonged and improved.

Owner:XIAMEN HONGLU TUNGSTEN MOLYBDENUM IND CO LTD

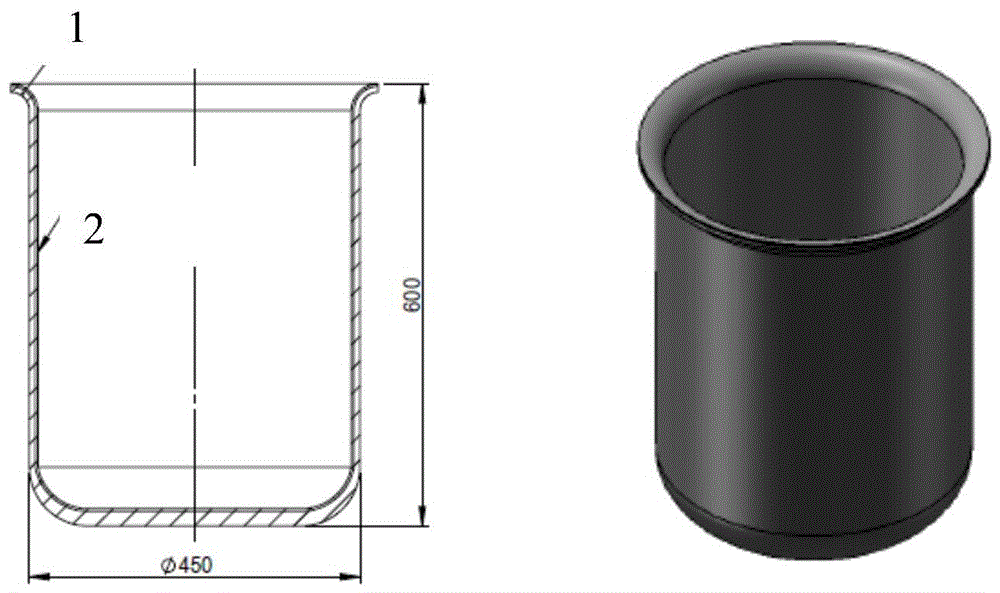

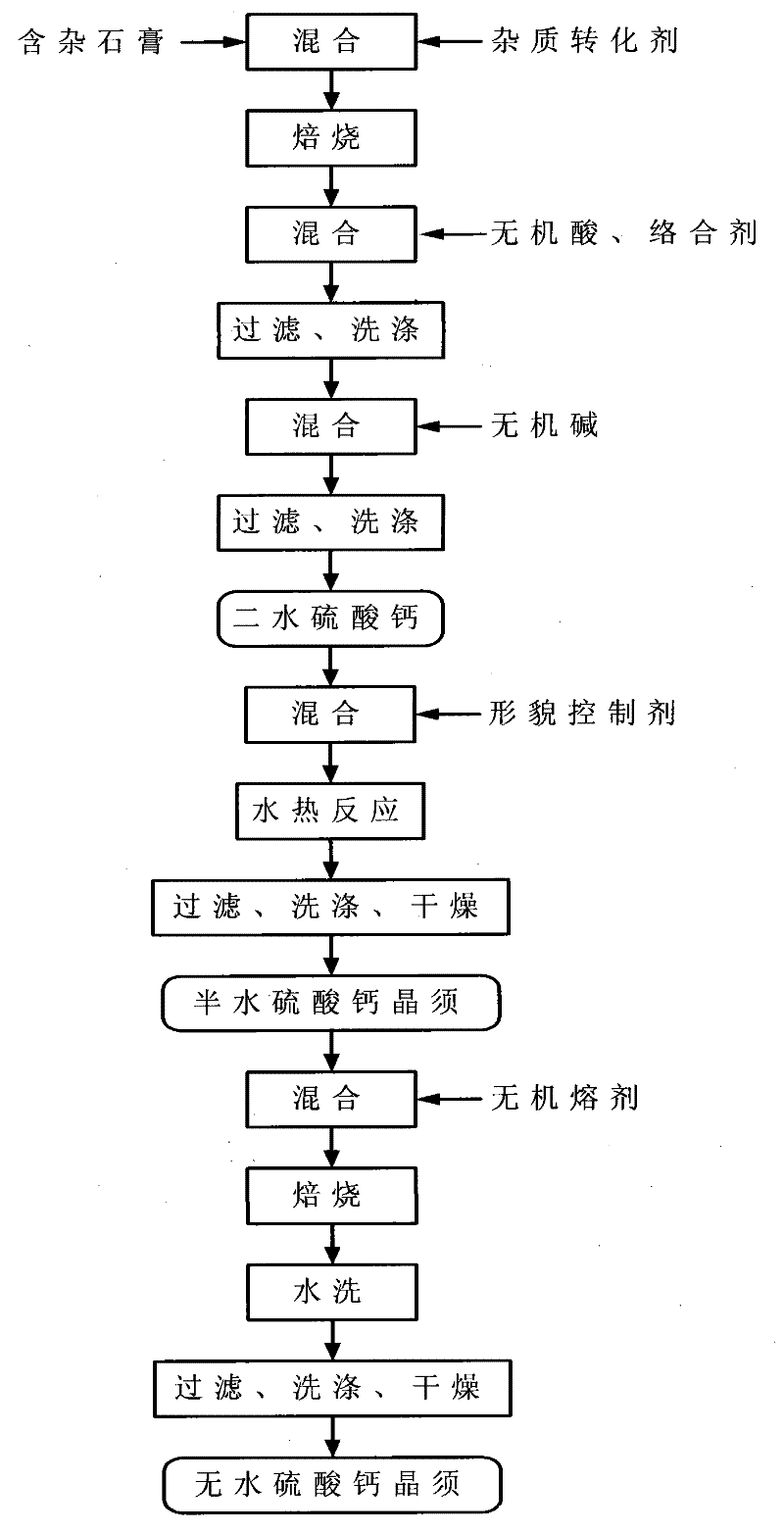

Method for preparing calcium sulfate crystal whiskers by using impurity-containing gypsum as raw material

InactiveCN101736403BHigh purityGood dispersionPolycrystalline material growthCalcium/strontium/barium sulfatesAnhydrous Calcium SulfateDihydrate Calcium Sulfate

The invention relates to a method for preparing calcium sulfate crystal whiskers (CaSO4) by using impurity-containing gypsum as a raw material. The method comprises the following steps of: removing main impurities in the raw material which is the low-priced impurity-containing gypsum resource in a mode of roasting, acid-complex leaching and alkaline leaching and simultaneously thinning crystal grains to obtain a superfine dihydrate calcium sulfate precursor which is high in purity and dispersibility; and preparing the anhydrous calcium sulfate crystal whiskers with a length of 20 to 2,000mu m, a diameter of 0.5 to 20 mu m, a length-diameter ratio of 40 to 1,000 and a weight percent content of over 95 percent in a mode of hydrothermal conversion-roasting of a fluxing agent. The method has the advantages of low-priced and easily bought raw materials, simple process, wide application range, and high added value. The calcium sulfate crystal whiskers prepared by the method have a big length-diameter ratio and regular shape, and can be used as reinforcing, heat insulating or flame retardant materials in industries of plastics, rubbers, coatings, papermaking, building materials and the like.

Owner:KUNMING UNIV OF SCI & TECH

Beneficiating process for increasing recovery rate of aurum in tailings of aurum

InactiveCN101333602AWide process adaptabilitySimple processProcess efficiency improvementSodium silicateXanthate

The invention relates to a beneficiation method for increasing the gold recovery rate in gold tailings, which takes raw ore as a carrier for connecting gold concentrator tailings and being applied with a reagent for beneficiation, and the method sequentially comprises the following processing steps of: a. ore crushing, namely crushing the raw ore; b. ore grinding, gold concentrator tailings are added into the crushed raw ore for being ground together to the fineness of -0.074mm and 60 to 76 percent, by a ratio of 1:1-3 between the raw ore and gold concentrator tailings; c. roughing, the ground mixed ore is added with 20 to 100g / t of butyl xanthate, 1 to 30g / t of ammonium butyl aerofloat and 5 to 20g / t of No.2 oil for roughing; and d. concentrating, the rough concentrate is added with 20 to 100g / t of sodium silicate for concentrating and selecting gold concentrates. The beneficiation method has advantages of broad process adaptability, simple flow, easy operation, non pollution, environmental protection, low production cost and high recovery rate.

Owner:ZIJIN MINING GROUP

Method for manufacturing soft-magnetic alloy powder

ActiveCN100431745CEasy to process, crush and make powderImprove performanceInorganic material magnetismOxygen contentBiological activation

The production method of soft magnetic alloy powder includes the following steps: smelting soft magnetic mother alloy, making molten metal be quickly coagulated into crystalline sheet alloy, breaking the sheet alloy to obtain alloy powder, and making the alloy powder undergo the processes of activation, annealing treatment and passivation treatment. Said soft magnetic alloy powder is low in oxygen content, stable in property and good in magnetic powder core performance.

Owner:CENT IRON & STEEL RES INST

Production method of fodder calcium phosphate salt

InactiveCN101632415BEasy to joinFull responseAnimal feeding stuffAccessory food factorsCalcium biphosphatePhosphoric acid

The invention discloses a production method of fodder calcium phosphate salt. The method comprises the following steps: selecting H3PO4 and CaCO3 in a mol ratio of (1-2):(1-1.01) by a wet method; firstly, carrying out a reaction of 60 percent of H3PO4 and the CaCO3 for 20-60 minutes; then, adding the remained 40 percent of H3PO4; continuing the reaction for 20-40 minutes while controlling the reaction temperature at 90-105 DEG C; after the reaction, enabling slurry to enter a drying tower, spout in drops from a nozzle at the upper part of the drying tower and enter in hot air at 120-160 DEG C; enabling the slurry in a falling process to form an acinous semi-finished product; and drying and cooling the semi-finished product by a cylinder dryer to obtain a finished product. The production method produces a plurality of species of products and has low production cost and product moisture, easily controlled and industrialized production process, stable product quality and uniform acinous appearance.

Owner:王邵东 +2

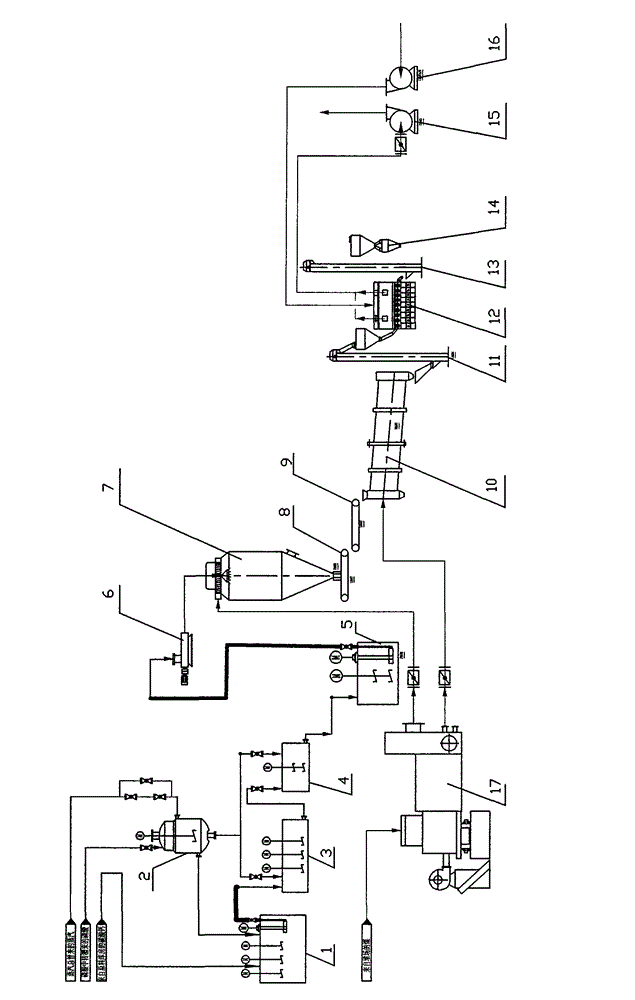

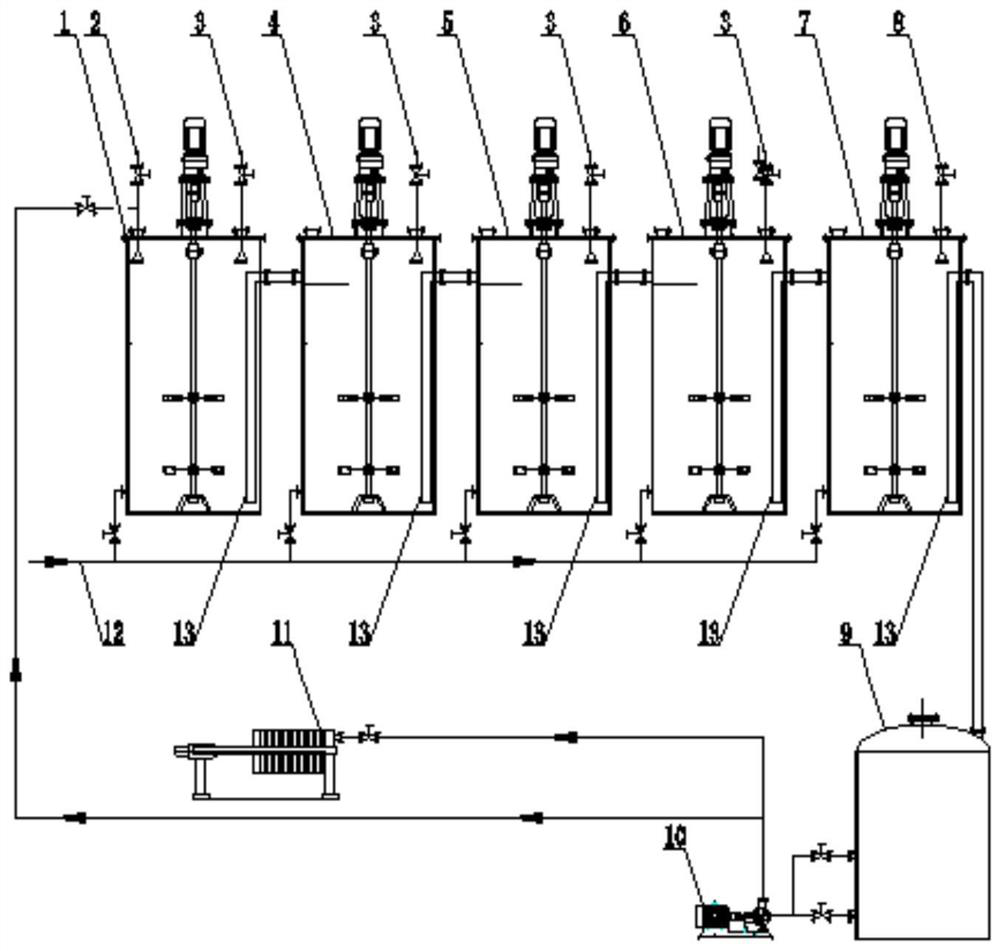

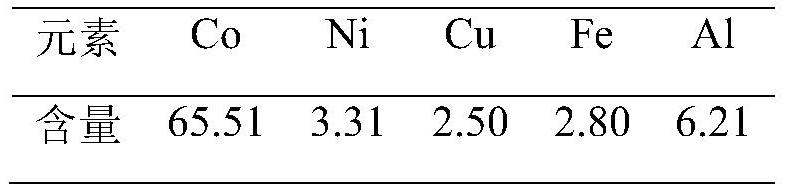

Method for removing aluminum from nickel-cobalt solution

ActiveCN112708780ASpeed up filteringRefine grain sizeProcess efficiency improvementReaction temperatureProcess engineering

The invention discloses a method for removing aluminum from a nickel-cobalt solution. The invention relates to Ni and Co metal salt solution purification, in particular to the method for purifying a leaching solution to remove aluminum in the process of producing nickel and cobalt through a wet method. The method is characterized in that the aluminum removal process sequentially comprises the following steps of (1) controlling the pH value of the solution before aluminum removal to be 2-2.5, and carrying out a stirring reaction; (2) controlling the pH value of the solution after reaction to be 2.5-3.0, and carrying out the stirring reaction; (3) controlling the pH value of the solution after reaction to be 3.5-3.5, and carrying out the stirring reaction; (4) controlling the pH value of the solution after reaction to be 4.5-4.5, and carrying out the stirring reaction; (5) controlling the pH value of the solution after reaction to be 3.3-3.5, and carrying out the stirring reaction; and (6) carrying out solid-liquid separation on the solution after reaction. According to the method, the problem that the solution is extremely difficult to filter is effectively solved, the reaction temperature is low, the energy consumption is low, deep aluminum removal can be achieved, the process adaptability is wide, and when the aluminum content in the solution reaches 6 g / L or above, deep aluminum removal can still be achieved.

Owner:JINCHUAN GROUP LIMITED +1

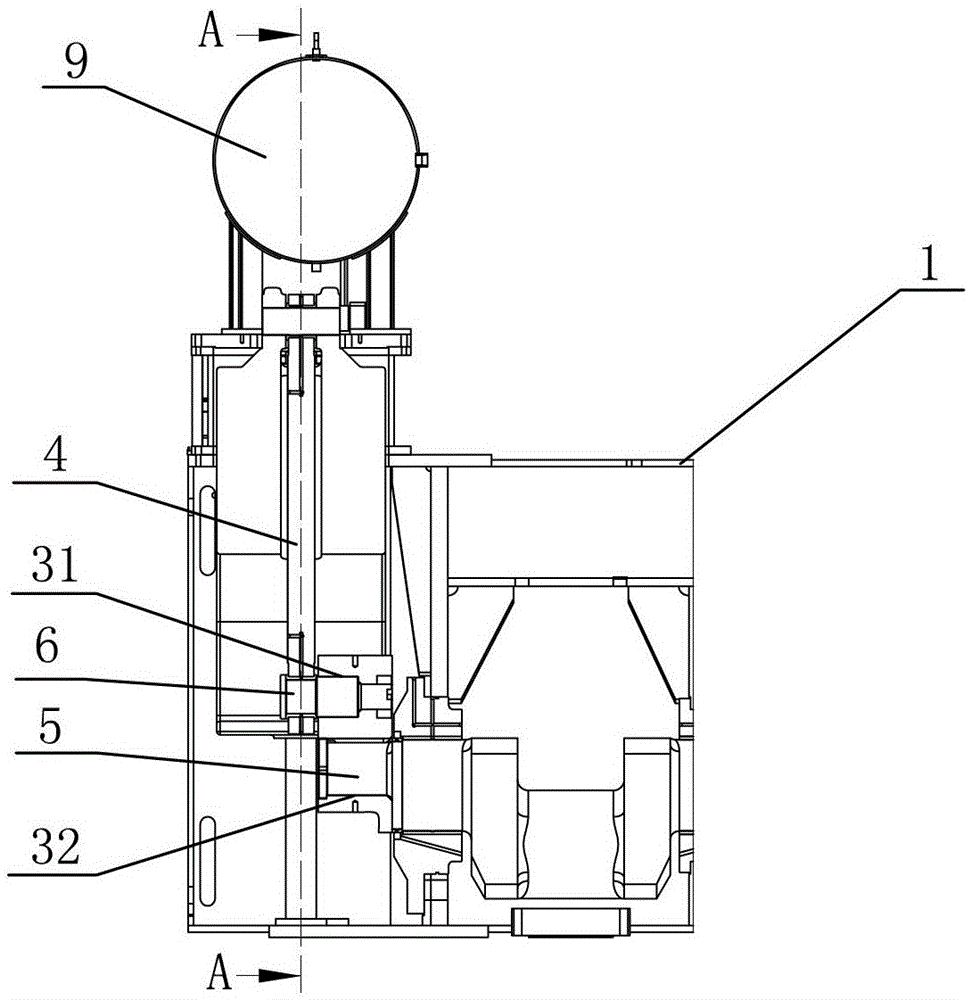

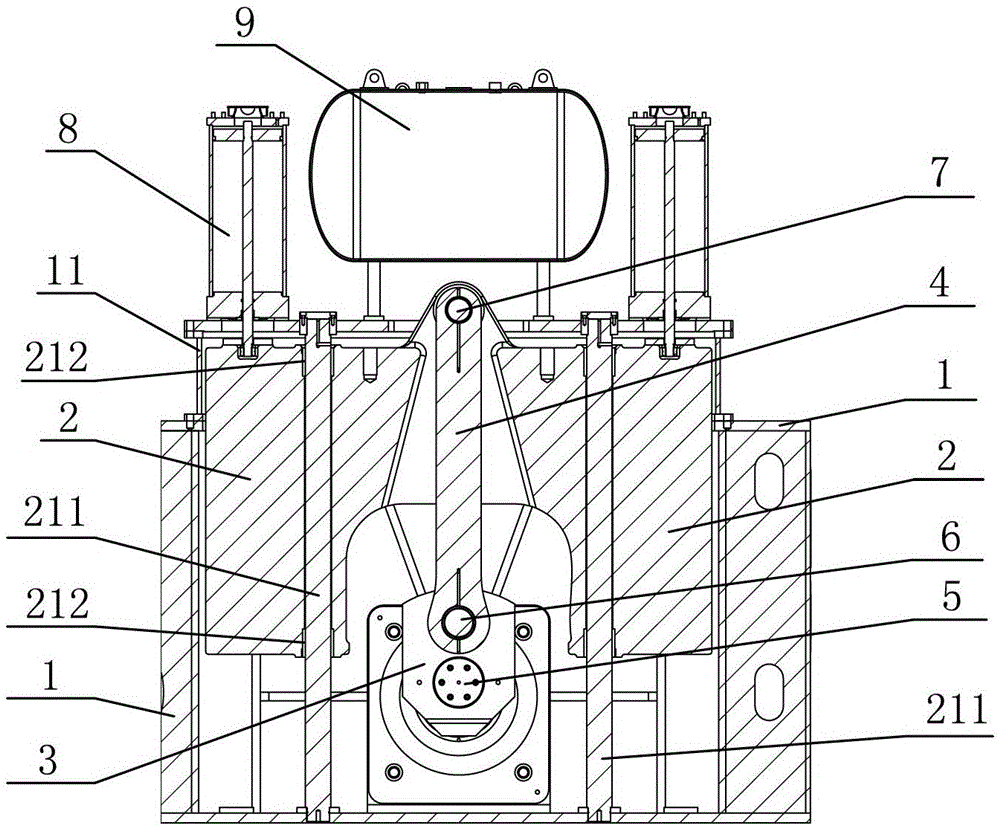

A dynamic balance mechanism for medium and high speed medium and large presses

ActiveCN103335060BReduce vibrationImprove stabilityInertia force compensationCounterweightsDynamic balanceReciprocating motion

The invention discloses a dynamic balancing mechanism for a middle-high speed and middle-large sized pressing machine. The dynamic balancing mechanism is characterized by comprising a rack, a balancing weight, a decentered fixing seat, a connecting bar and a bent axle arranged below the connecting bar, wherein one end of the bent axle is in shaft connection with the decentered fixing seat; the other end of the bent axle is in shaft connection with the rack; the top of the connecting bar is in shaft connection with the balancing weight; the bottom of the connecting bar is in shaft connection with the decentered fixing seat. The dynamic balancing mechanism has the advantages that during operation, the bent axle performs rotational motion; the connecting bar performs pendulum motion; the balancing weight performs straight reciprocating motion in the direction opposite to the moving direction of a sliding block; during the process that the sliding block and the balancing mechanism moves in opposite directions, the vibration of the sliding block is counteracted, so that the vibration of the whole pressing machine is reduced, the stability and the production efficiency of the pressing machine are improved. Therefore, the requirements for long journey and middle-high speed of the middle-large sized pressing machine can be met, and the technological adaptability is wide.

Owner:NINGBO CFG MACHINERY IND

A three-dimensional paint process for furniture screen printing and internal carving

InactiveCN103551294BHigh saturationGood spot color printing effectPolyurea/polyurethane coatingsSpecial surfaces3d patterningEpoxy

Owner:DONGGUAN FUBAO SOFA MFG

Intermediate blank connecting device and system

InactiveCN106826244AFast connectionSuitable for viscoplastic stateOther manufacturing equipments/toolsNon-electric welding apparatusEngineeringUltimate tensile strength

The invention provides an intermediate blank connecting device, which includes an outlet clamping device for clamping the front intermediate blank, an inlet clamping device for clamping the rear intermediate blank, and a connecting device for aligning the front intermediate blank and the rear blank. The friction disc connecting the end surface of the intermediate billet for friction and the upsetting device for applying upsetting force, the friction disc is located between the inlet clamping device and the outlet clamping device, and the friction disc is connected to drive the friction disc to rotate and Mobile drive mechanism. The friction disc extends between the front middle billet and the rear middle billet, and rubs the end faces of the two, so that the end face of the middle billet and the surrounding area rapidly heat up to a viscoplastic state, and the rear middle billet is subjected to a topping by an upsetting device. Forging force, after the friction disc is removed, the front block middle blank and the rear block middle blank are connected together. The invention has the advantages of simple structure, high connection strength, fast connection speed and low energy consumption, and is suitable for connection between slabs of different materials.

Owner:CISDI ENG CO LTD

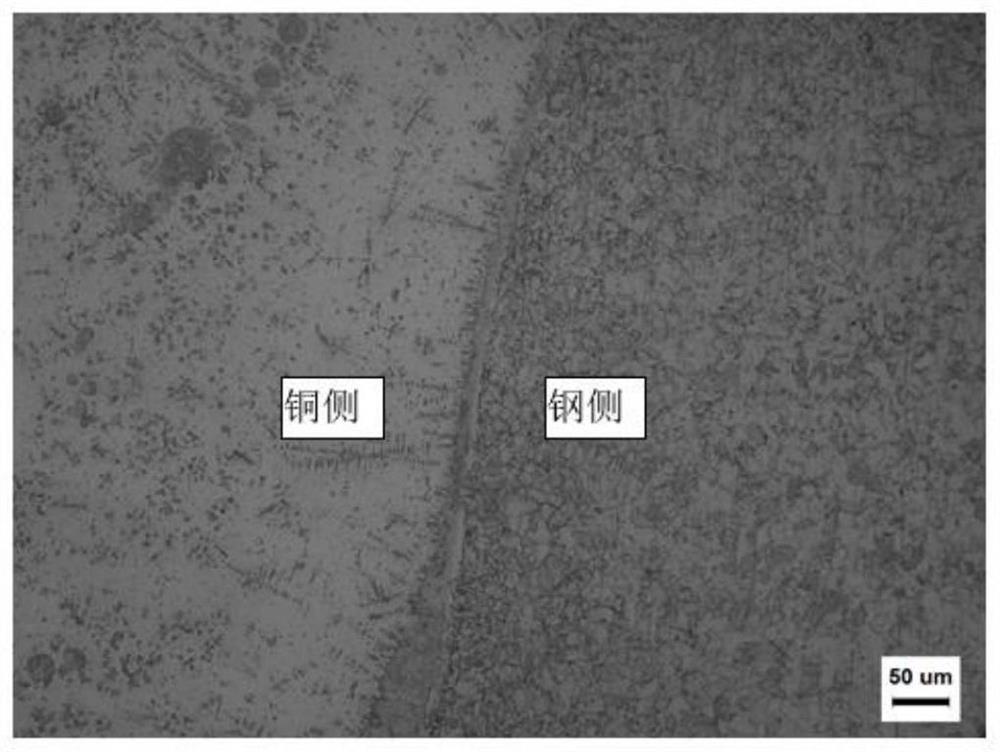

Flux-cored wire and method capable of enhancing copper/steel interface bonding strength

ActiveCN114346514AImprove bindingEvenly distributedArc welding apparatusWelding/cutting media/materialsCopperUltimate tensile strength

The flux-cored wire capable of enhancing the copper / steel interface bonding strength comprises a flux core and a welding skin, and the flux core is composed of, by mass, 10-15% of Mg powder, 10-15% of Cu powder, 10-15% of Ni powder, 10-15% of Ni powder and the balance Fe powder. 10%-15% of Ti powder; 5 to 7 percent of Co powder; 20% of Ni powder; 1% of Si powder; 1-2% of Mn powder; the sum of the mass percentages of the components is 100%. The welding wire is used for improving the copper / steel interface bonding strength and improving the impact resistance of a copper / steel composite structural part. The invention further discloses a method capable of enhancing the copper / steel interface bonding strength.

Owner:XIAN UNIV OF TECH

Self-elevating sliding construction system and construction method

ActiveCN104695337BFast constructionConstruction safetyBridge erection/assemblyArchitectural engineeringSemi automatic

The invention discloses a self-lifting sliding and turnover construction system and a construction method. The system comprises a framework type combination crown block hanging bracket device and a semi-automatic turnover device. The construction method comprises steps as follows: construction of reinforcing steel bars of a pier body, large-area formwork bracket splicing, sliding formwork bracket splicing, self-lifting hanging bracket splicing, concrete pouring, sliding formwork bracket sliding rising, large-area formwork turnover and next stage of reinforcing steel bar construction. A self-lifting technique can be adopted, auxiliary construction by mechanical equipment such as a tower crane, a truck crane and the like can be omitted, high-pier construction is realized with the self-lifting technique, and the method guarantees the construction speed of a sliding formwork and the appearance quality of a turnover formwork without relying on external machines.

Owner:CCCC FIRST HIGHWAY XIAMEN ENG +1

A kind of multifunctional coating for wine box outer packaging and preparation method thereof

ActiveCN104404819BGood adhesionImprove matchCoatingsPaper forming aids additionOrganic solventRainbow

The invention provides a multifunctional coating for wine box outer packaging and a preparation method thereof. The multifunctional coating comprises the following components and parts by weight: 10-30 parts of functional acrylic resin, 5-8 parts of aldehyde and ketone resin , 2-10 parts of low molecular weight cellulose acetate butyrate resin, 0.1-1 part of additives, 60-80 parts of organic solvent. In the invention, the acrylic resin containing functional groups is matched with the aldehyde and ketone resin, and then low-molecular-weight cellulose acetate butyrate resin is combined to obtain a coating with good adhesion fastness, bright rainbow effect of molding, and good printing adaptability.

Owner:SHANGHAI WEIKAI CHEM +1

A precision control method for electron beam welding deformation of rotor parts

ActiveCN110977131BImprove rigidityIncrease rigidityElectron beam welding apparatusEngineeringDeformation control

A precise control method for electron beam welding deformation of rotor parts, belonging to the technical field of electron beam welding of rotor parts, comprising the following steps: step 1: electron beam welding structure design; step 2: determination of electron beam welding parameters; step 3: Design of electron beam welding tooling; Step 4: Adjustment of material state of parts before welding; Step 5: Determination of welding shrinkage of parts; Step 6: Electron beam welding of rotor parts. According to the structural characteristics of rotor parts, this technology starts from the aspects of improving the rigidity of parts, rigidity fixation, reducing residual stress, and improving the uniformity of residual stress distribution, etc., and adopts corresponding technological measures to realize precise control of welding deformation by electron beam welding. There is a process, and the parts using this technology have high connection quality, low cost, wide process adaptability, and good deformation control effect.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Polymetal interconnecting layer combined aerial on chip

InactiveCN101227026BTotal adjustable performanceIncrease Radiation VolumeRadiating elements structural formsSeparate antenna unit combinationsImpedance matchingSilicon dioxide

The invention relates to an assembly antenna with on-chip polymetallic interlocking layer belonging to the technology field of integrated circuits, which comprises a polymetallic interlocking layer radiating element, a feed perforation, a short-circuiting perforation, a silica dioxide layer and a silicon chip, wherein the center of the polymetallic interlocking layer radiating element is connected with the feed perforation, and the two ends of the polymetallic interlocking layer radiating element are connected with the short-circuiting perforation, thereby forming the polymetallic interlocking layer assembly antenna. Due to adopting the polymetallic interlocking layer composite structure, the invention is capable of effectively increasing radiation volume of the on-chip antenna, reducing the measurement of the on-chip antenna, increasing impedance bandwidth of the on-chip antenna, notability improving transmission gain of the on-chip antenna for applying wireless interconnection, and not occupying any additional chip area, otherwise, the invention is totally compatible for main flow CMOS technology, is fit for the silicon chip with miscellaneous specific resistance without additional impedance match components, at the same time is fit for multilayer low-temperature co-melting ceramic technology, and which has extensive technology adaptability.

Owner:SHANGHAI JIAOTONG UNIV

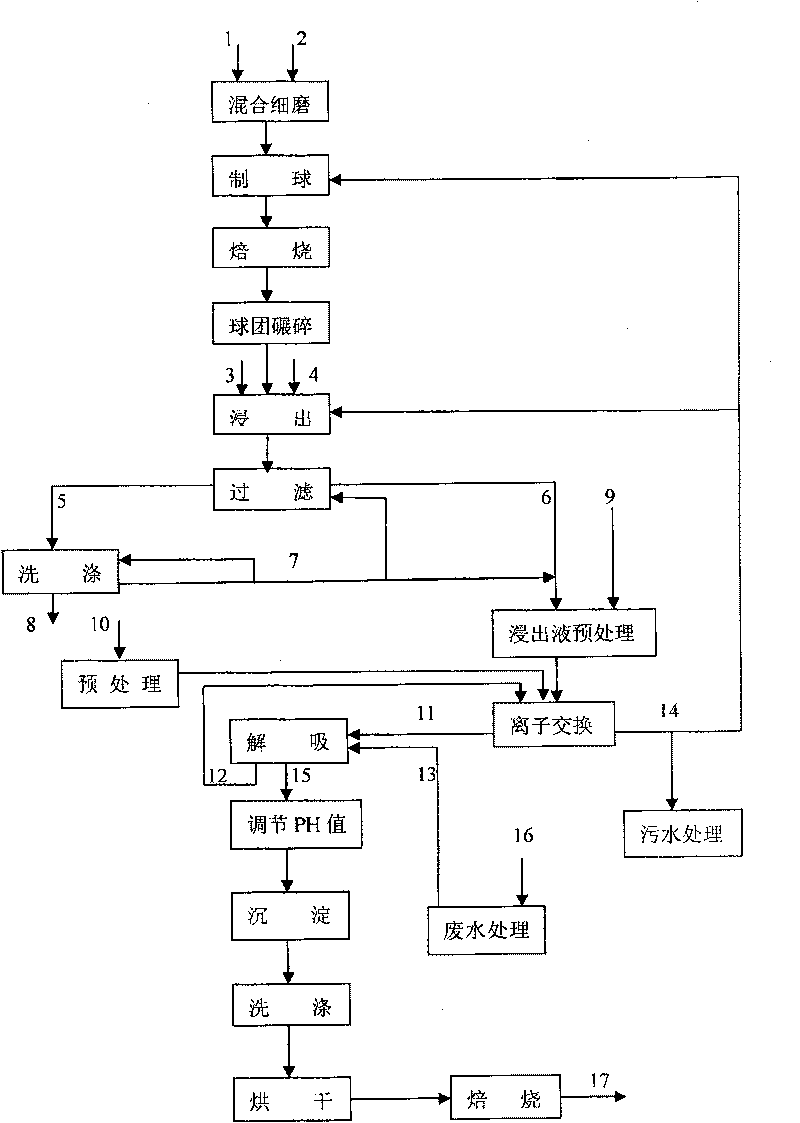

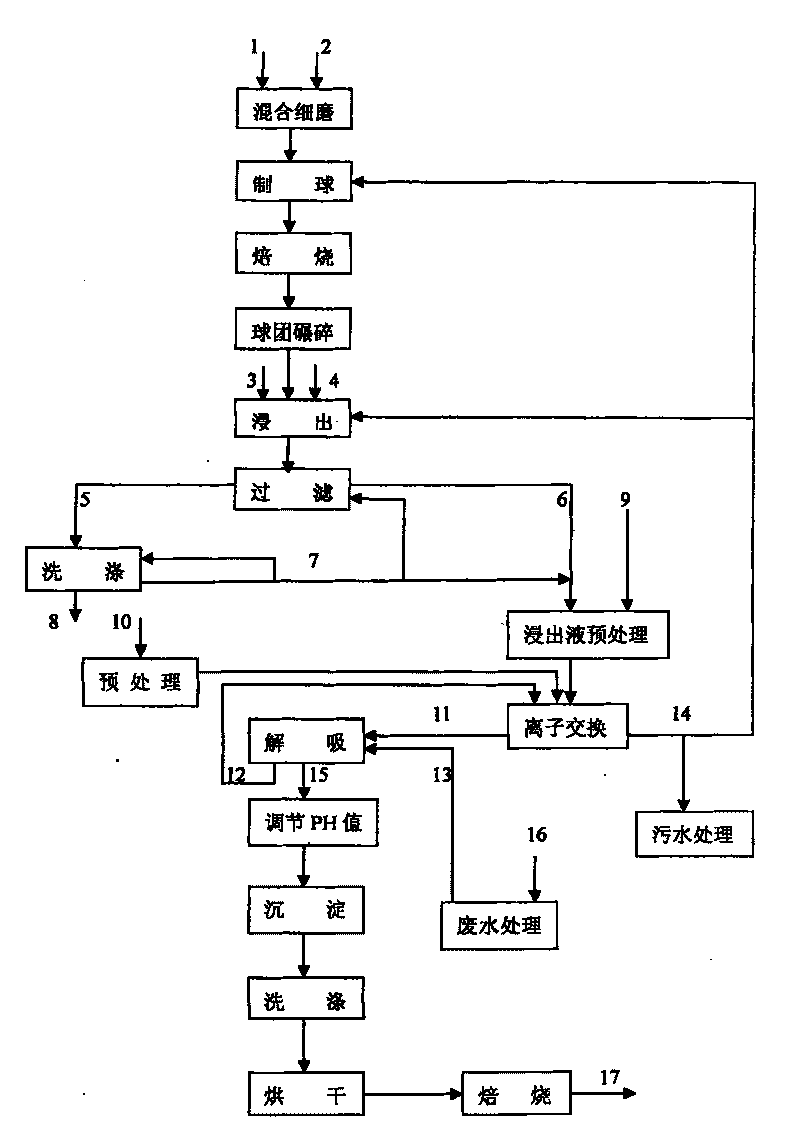

Method for extracting vanadic anhydride from stone coal

The invention relates to a method for extracting vanadic oxide from stone coal, which comprises the process flow in sequence as follows: mixing and fine grinding, limestone mine is added into stone coal vanadium ore for carrying out mixing and fine grinding; pellet making; roasting; grinding of pellets; lixiviation, water and vitriol are added for carrying out lixiviation at normal temperature; filtration, leached slag and leached liquid are filtered; washing-pretreatment of the leached liquid; ion exchange; desorption; regulation of PH value; sedimentation, sedimentation is carried out to obtained ammonium meta-vanadate; washing for removing the ion of incidental elements absorbed on the surface of ammonium meta-vanadate precipitation; drying; roasting and obtaining the vanadic oxide products with the metallurgical purity of 98 to 99. The method is characterized by wide technical applicability, high comprehensive recovery ratio, low exhaust emission, low energy consumption, low production cost and high purity of products, and that waste water can be recycled, and so on.

Owner:ZIJIN MINING GROUP

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com