Intermediate blank connecting device and system

A technology of connecting device and clamping device, applied in welding equipment, other manufacturing equipment/tools, non-electric welding equipment, etc., can solve problems such as high equipment investment and maintenance costs, low connection strength of intermediate blanks, and influence of the strength of the connection area. , to achieve the effect of improving the mechanical properties of the joint, shortening the welding time, simplifying the process and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

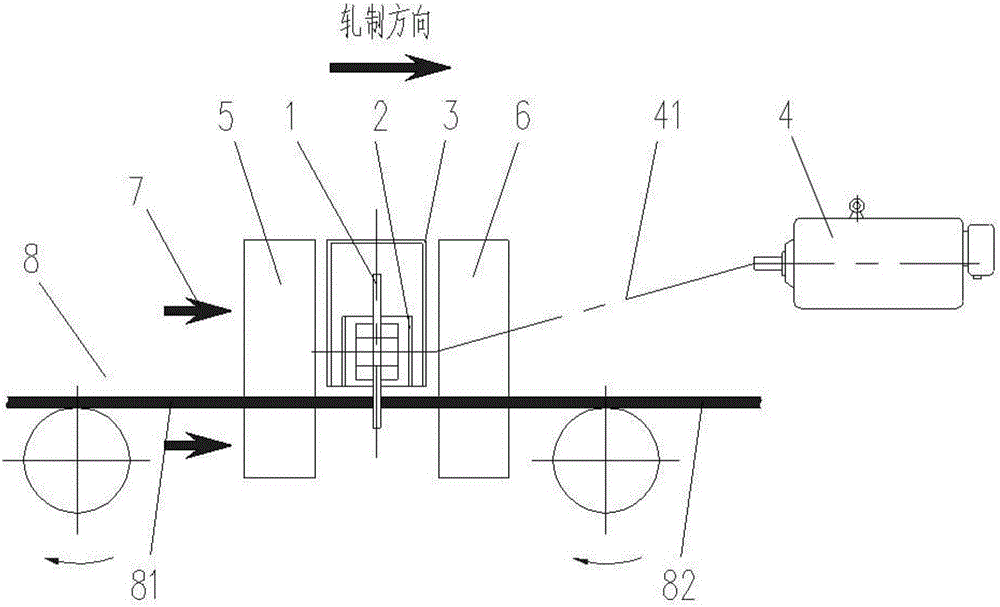

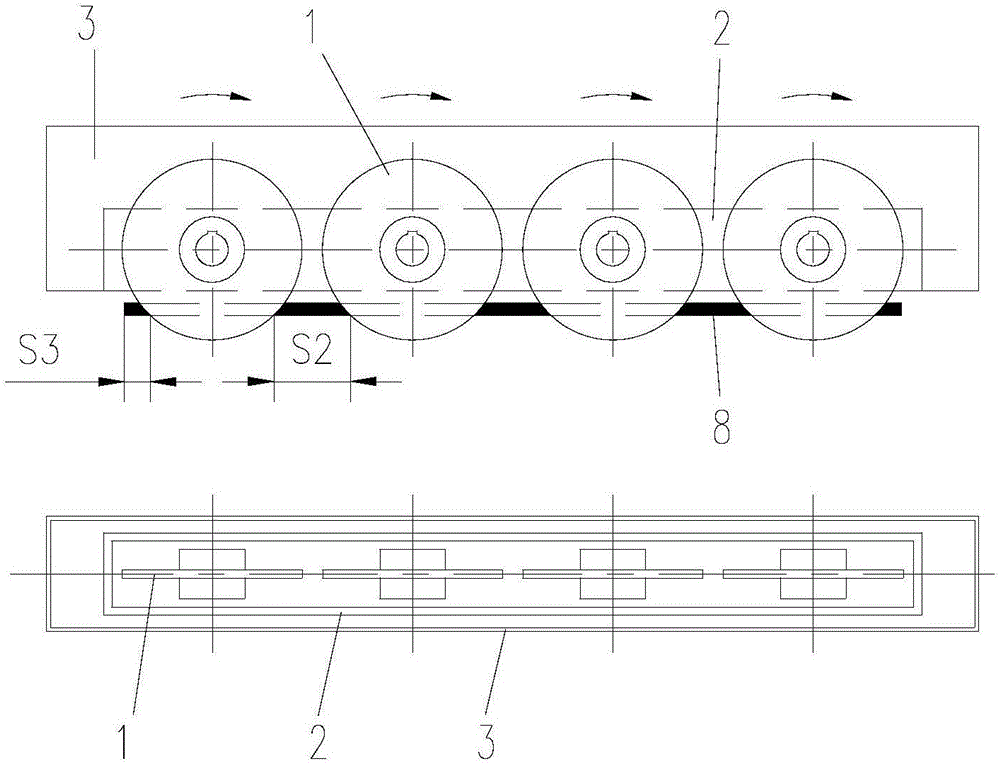

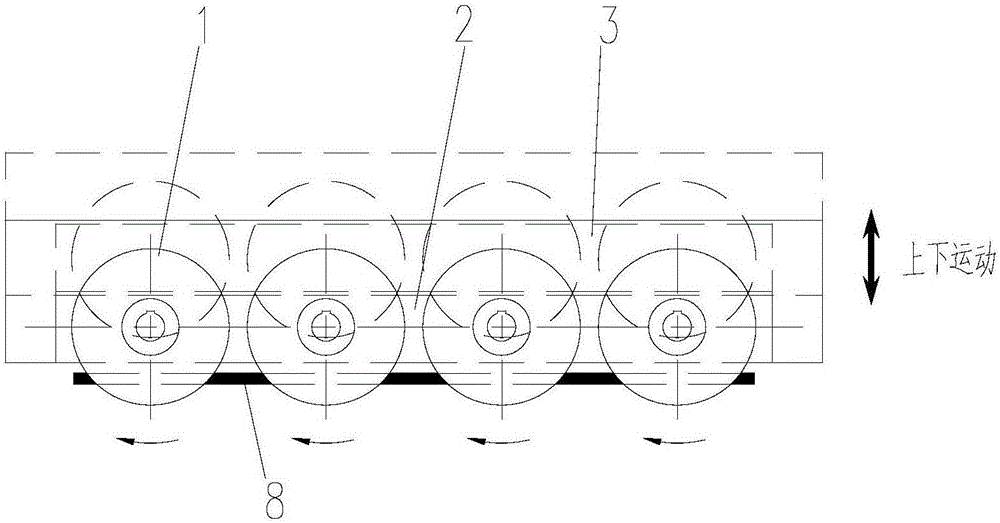

[0058] like figure 1 As shown, the present invention provides an intermediate billet connection device for connecting the front intermediate billet 82 and the rear intermediate billet 81, including an inlet clamping device 5, an outlet clamping device 6, a friction disc 1 and an upsetting device 7 , wherein, the inlet clamping device 5 is used to clamp the rear block intermediate blank 81, the outlet clamping device 6 is used to clamp the front block intermediate blank 82, and the friction disc 1 is located between the inlet clamping device 5 and the outlet clamping device 6 between the front block middle blank 82 and the back block middle blank 81 for friction, the upsetting device 7 is located in front of the entrance clamping device 5, and the upsetting device 7 passes through the entrance clamping device 5 to the rear block middle blank 81 Apply upsetting force. It also includes a driving mechanism, which directly or indirectly drives the friction disc 1 to rotate and mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com