Novel industrialized production efficiently-assembled type building frame column beam and manufacturing method

A prefabricated and factory-like technology, which is applied in the direction of construction, building structure, and building material processing, can solve problems such as unstable quality and time-consuming inability to achieve fast connection speed, high connection strength, and stable quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

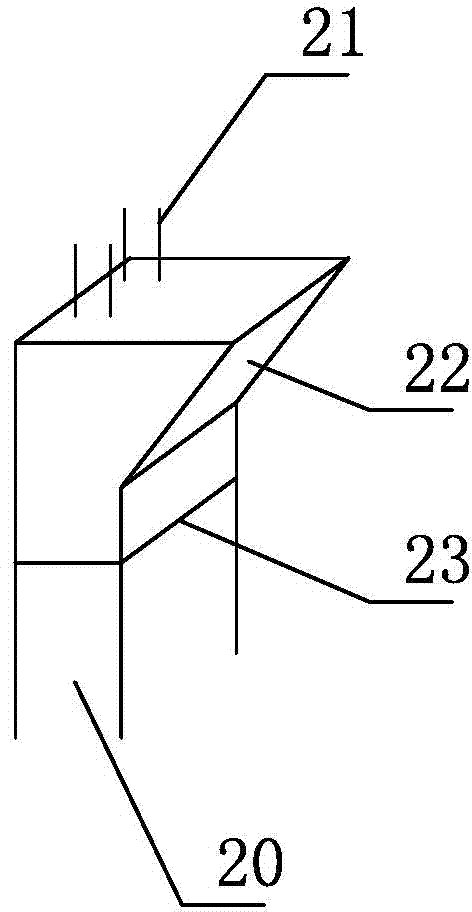

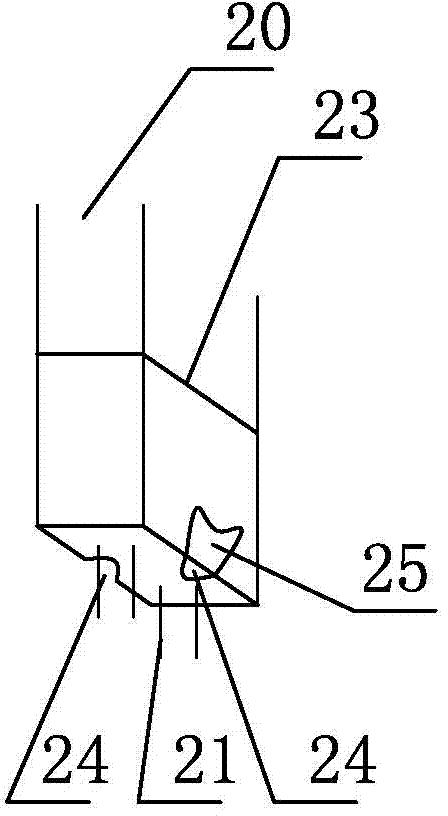

[0034] Embodiment 1: The factory production of the present invention is a novel high-efficiency assembly type building frame column and beam, as attached figure 1 ——attached Figure 19 As shown, a column 20 and a beam 30 comprising concrete, the upper side wall of the column 20 is provided with a structure 22 supporting the end of the beam 30, and the top surface of the structure 22 is flush with the upper surface of the column 20; the two sides of the column 20 and the beam 30 The outer circumference of the end is covered with steel plates, and the two ends of the column 20 and the beam 30 are provided with exposed steel bar heads 21 .

[0035] The side wall of the bottom end face of the column 20 is provided with a concave notch 24, and the steel plate covering the bottom of the column 20 is provided with an introduction groove 25 at a position corresponding to the notch 24; Shape, the bottom communicates with the notch 24. It is convenient for grouting operation, and the ...

Embodiment 2

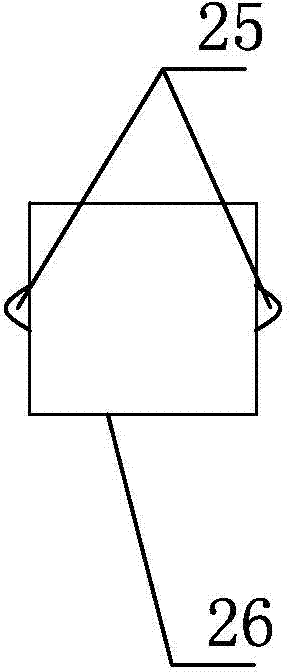

[0039] Embodiment 2: The manufacturing method of the novel high-efficiency prefabricated building frame column beam of the present invention, when the column 20 and the beam 30 are assembled, the two columns 20 are set up and down, the bottom end of the upper column 20 is connected with the upper end of the lower column 20, and the beam The ends of 30 are placed on the structure 22 of the lower column 20, and the steel bars 21 at the ends of the two columns 20 and the beam 30 are welded; The lead-in groove 25 on the steel plate at the bottom of 20 is poured into the concrete slurry; when the two columns 20 and the beam 30 welded connection ends are not wound to form a closed cavity, use the closure 31 to cover the ends of the three to form a closed cavity, and then from The guide groove 25 on the steel plate at the bottom end of the upper column 20 is poured into the concrete slurry.

[0040] After the grouting is completed, the guide groove 25 on the steel plate at the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com