Patents

Literature

2227 results about "Concrete beams" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

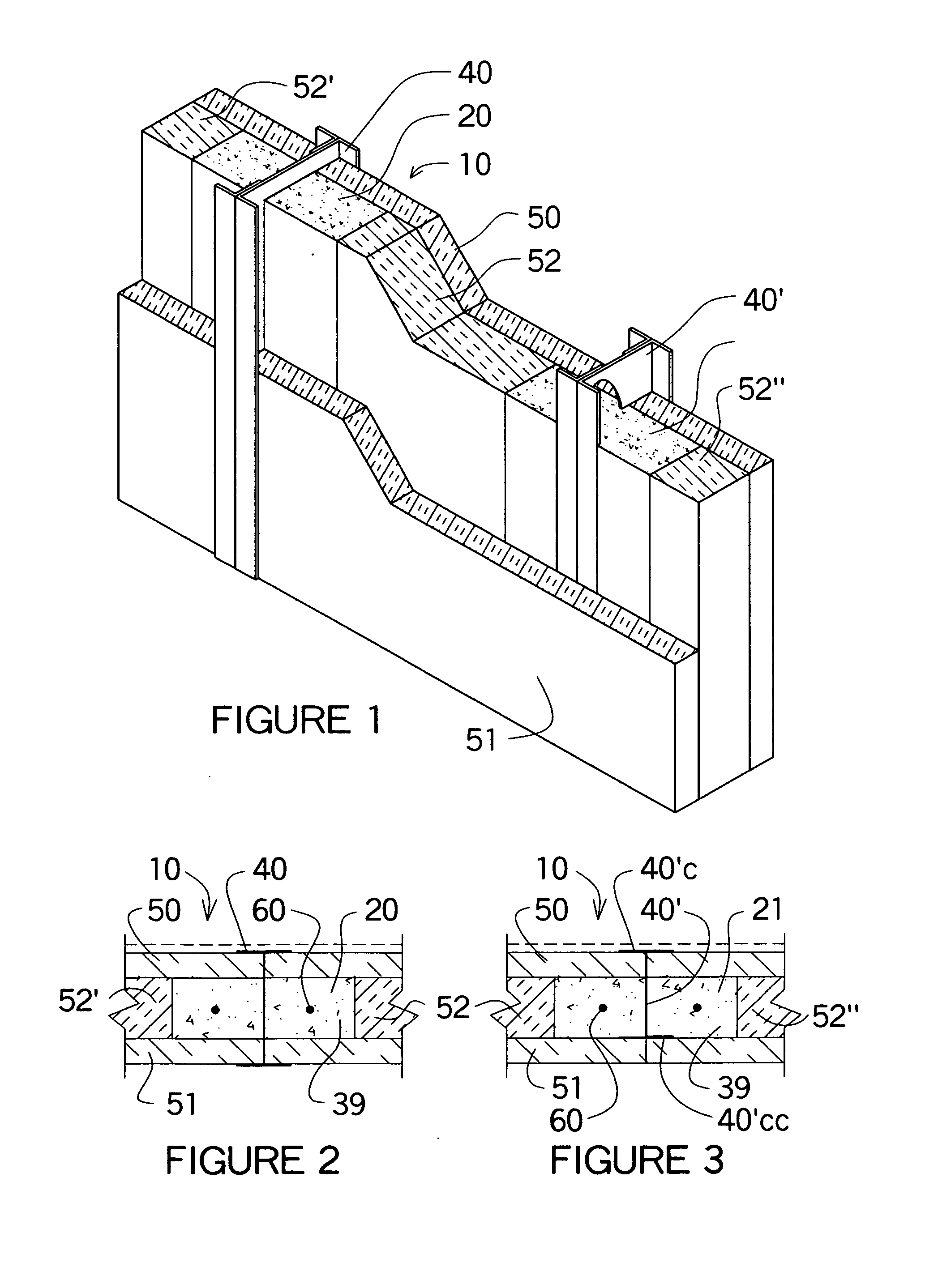

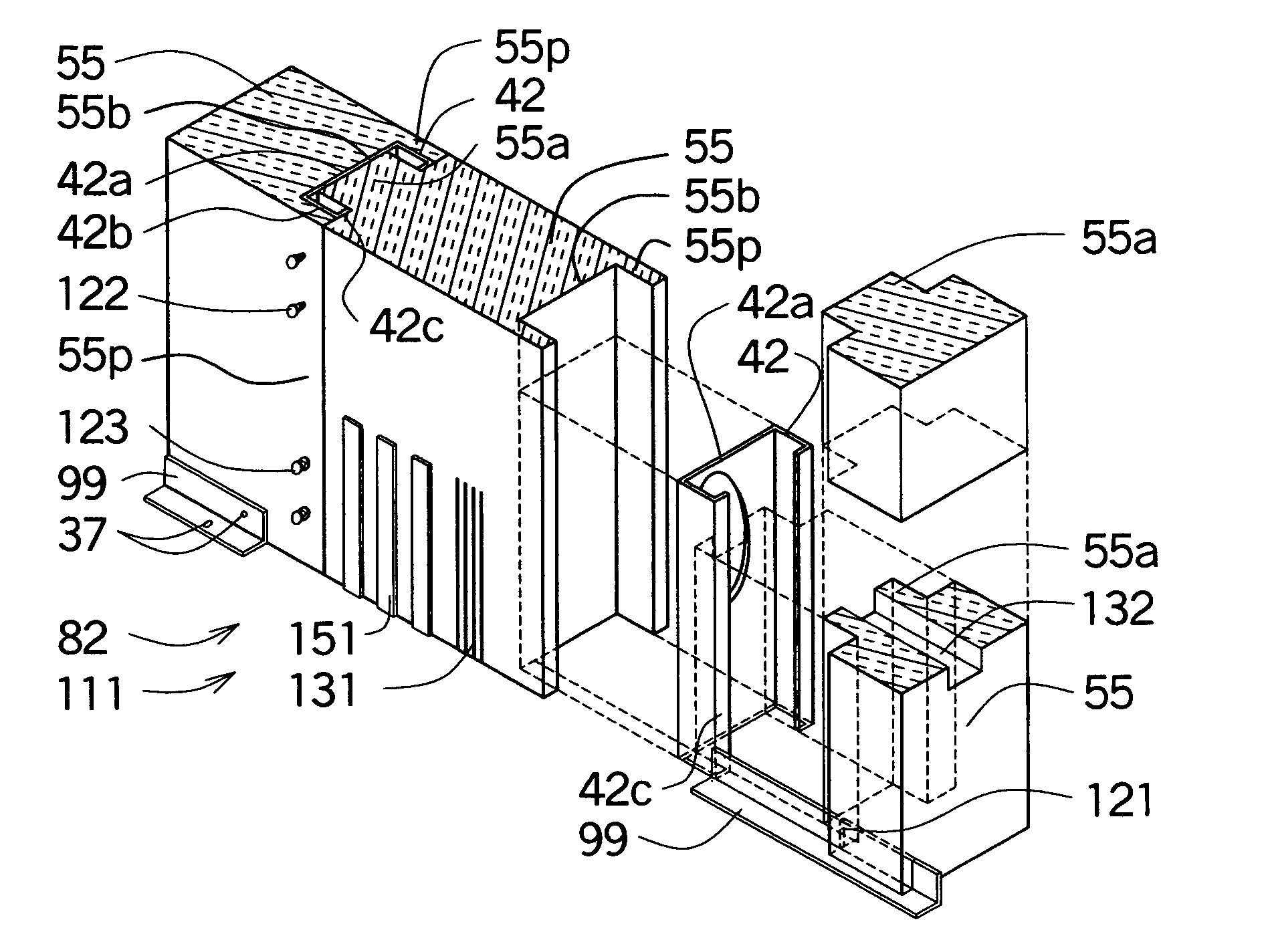

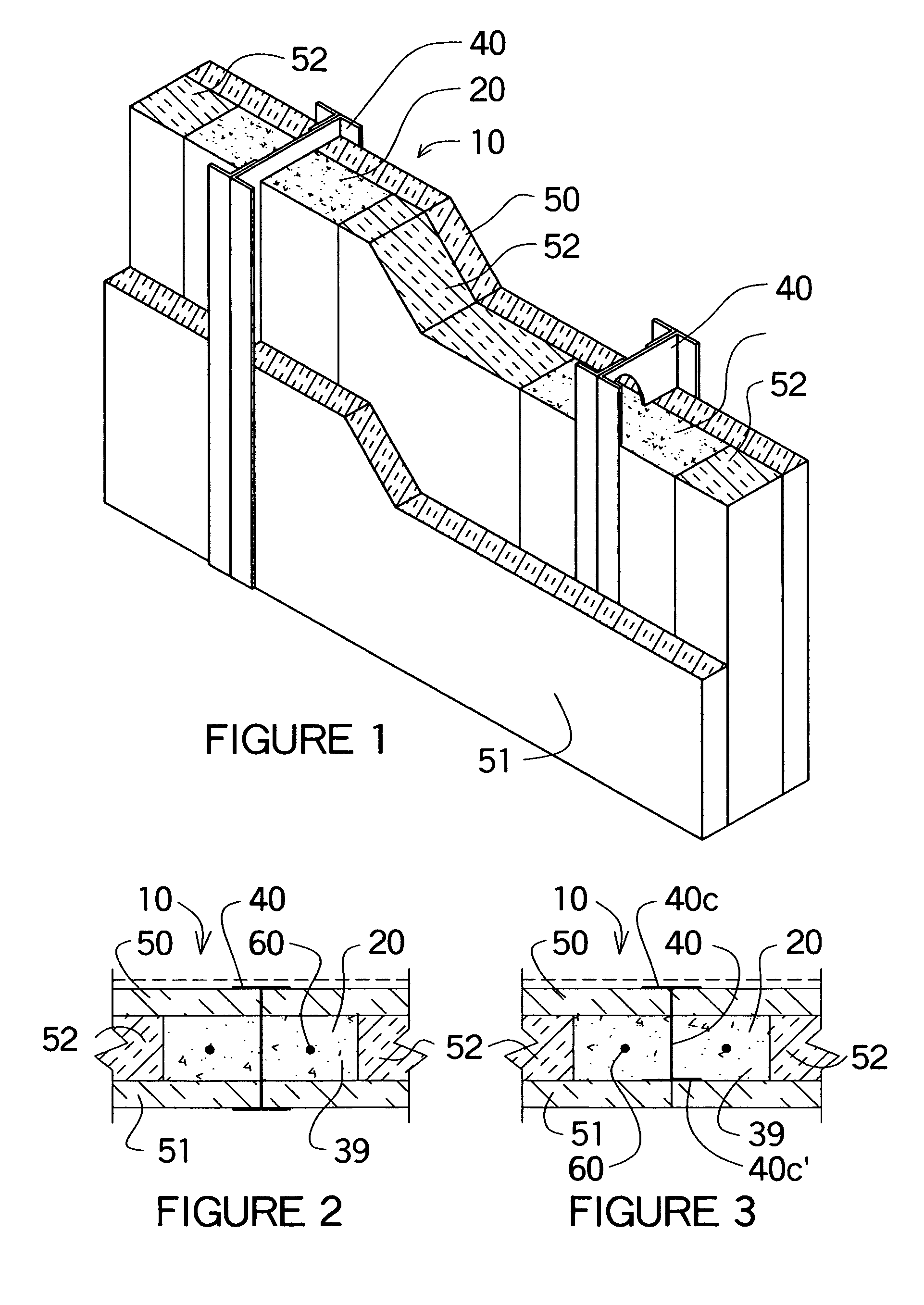

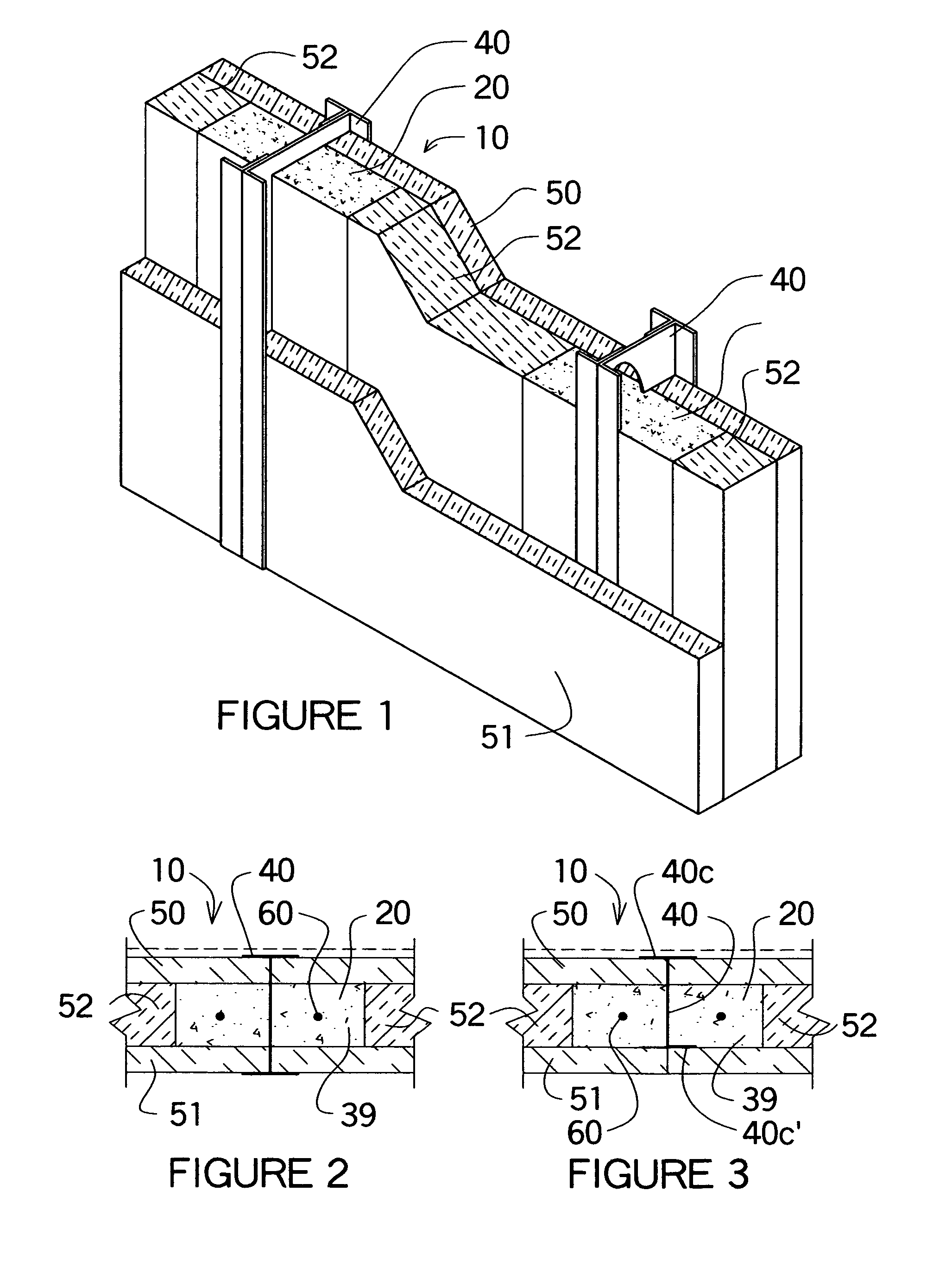

Building construction for forming columns and beams within a wall mold

InactiveUS20090107065A1Simple structureGood adhesionWallsHeat proofingConcrete beamsStructural insulated panel

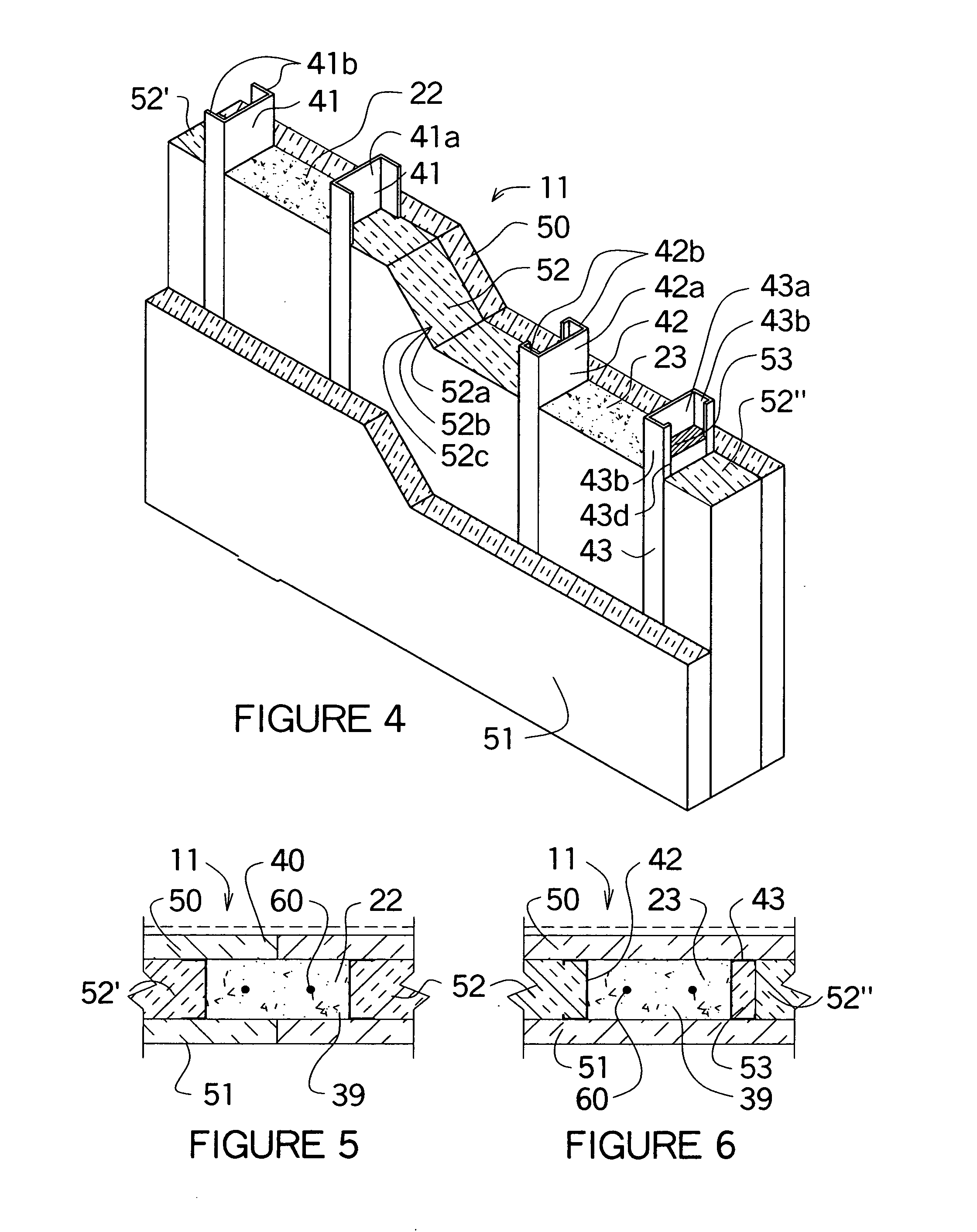

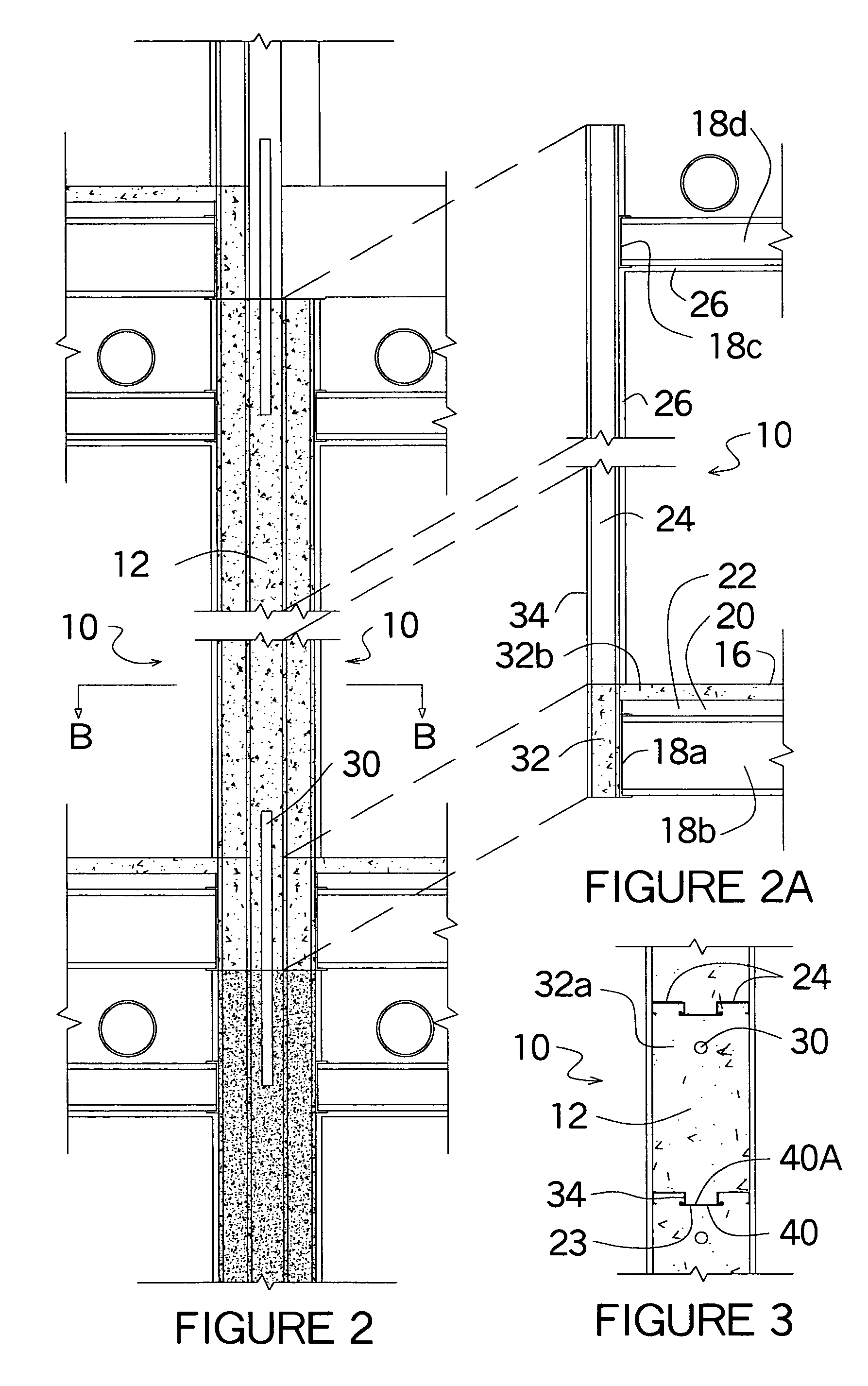

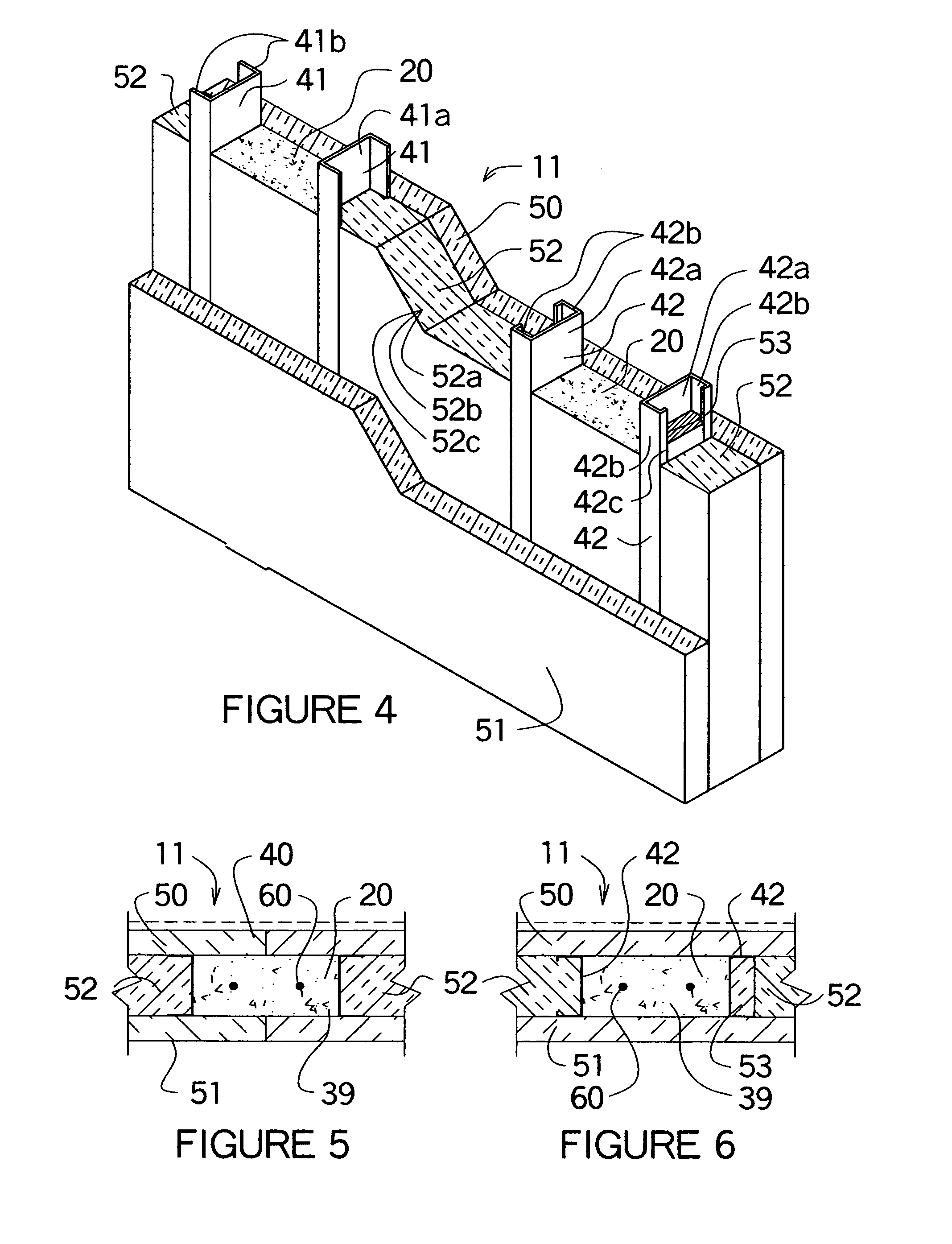

The present invention relates to an improved wall system where a wall form mold has a structural insulated core assembled to form a structural insulated panel (SIP) to form a concrete beam and concrete column to be poured anywhere within the wall as well as between building modules when placed together and erected vertically. The interlocking wall molds interlock within the wall as well as between panels and modules. The wall panels allow concrete columns and beams to be formed in any size and shape. The structural insulated core consists of interlocking foam spacers and support channels which can be glued or screwed together to form an independent wall or as part of a precast wall with columns and beams integrated within the wall panels. Insulated flanges within the wall forming mold separates the wall forming structure from the wall surfaces.

Owner:LEBLANG DENNIS WILLIAM

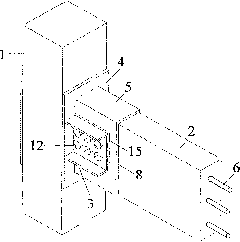

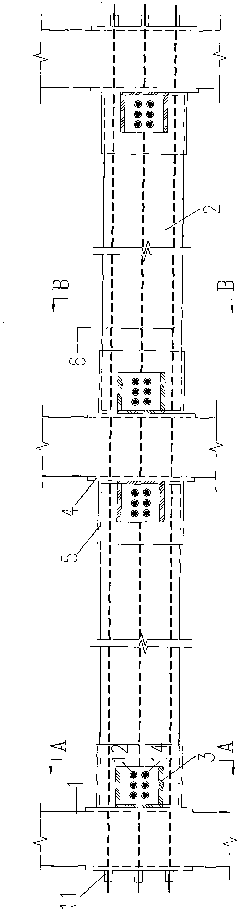

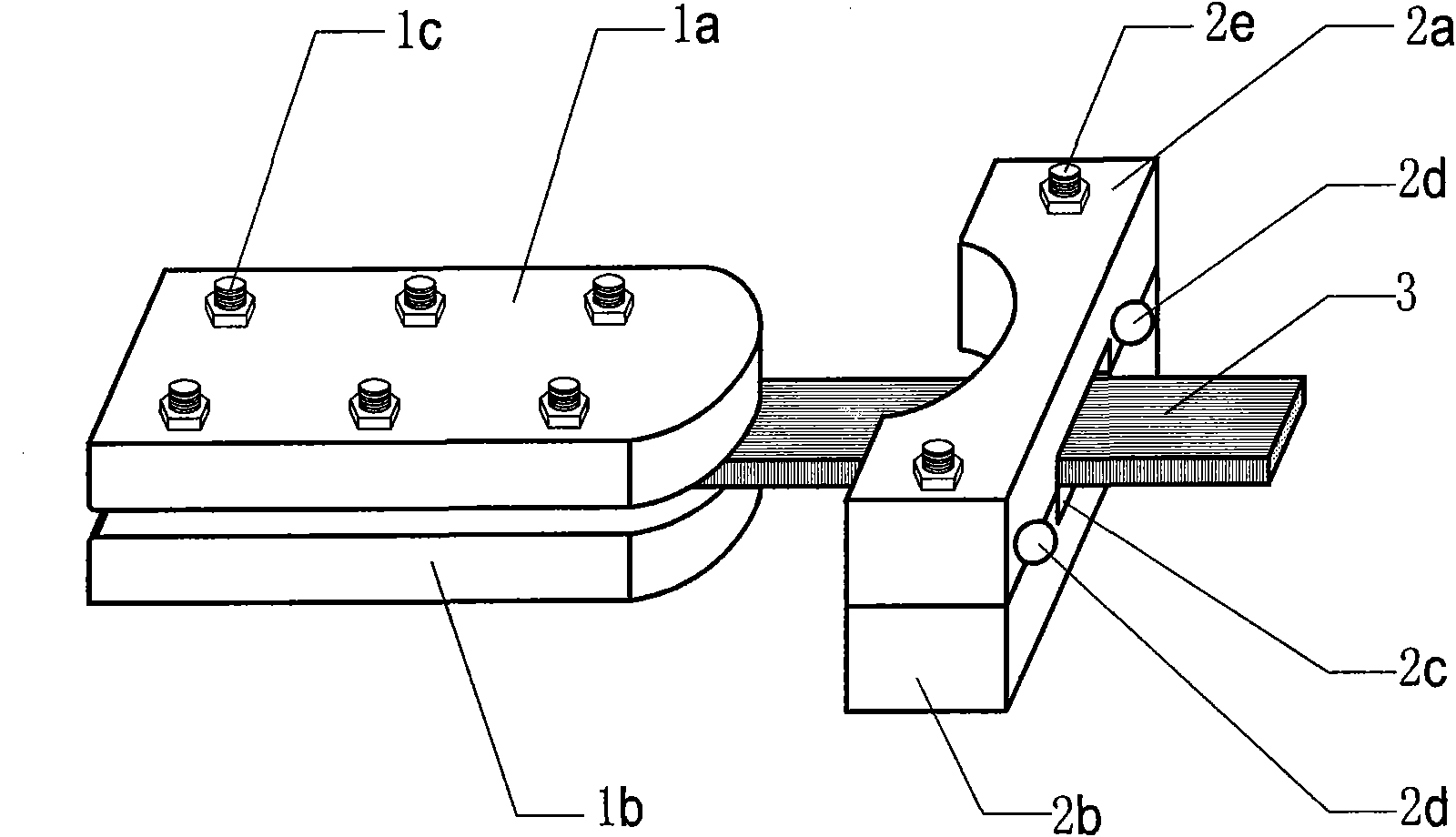

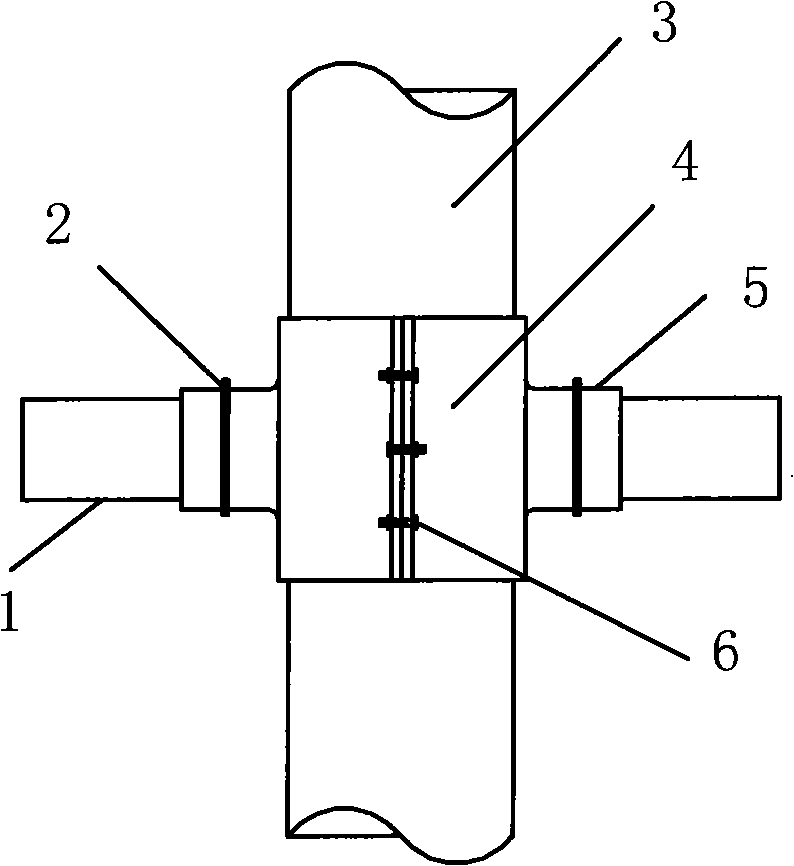

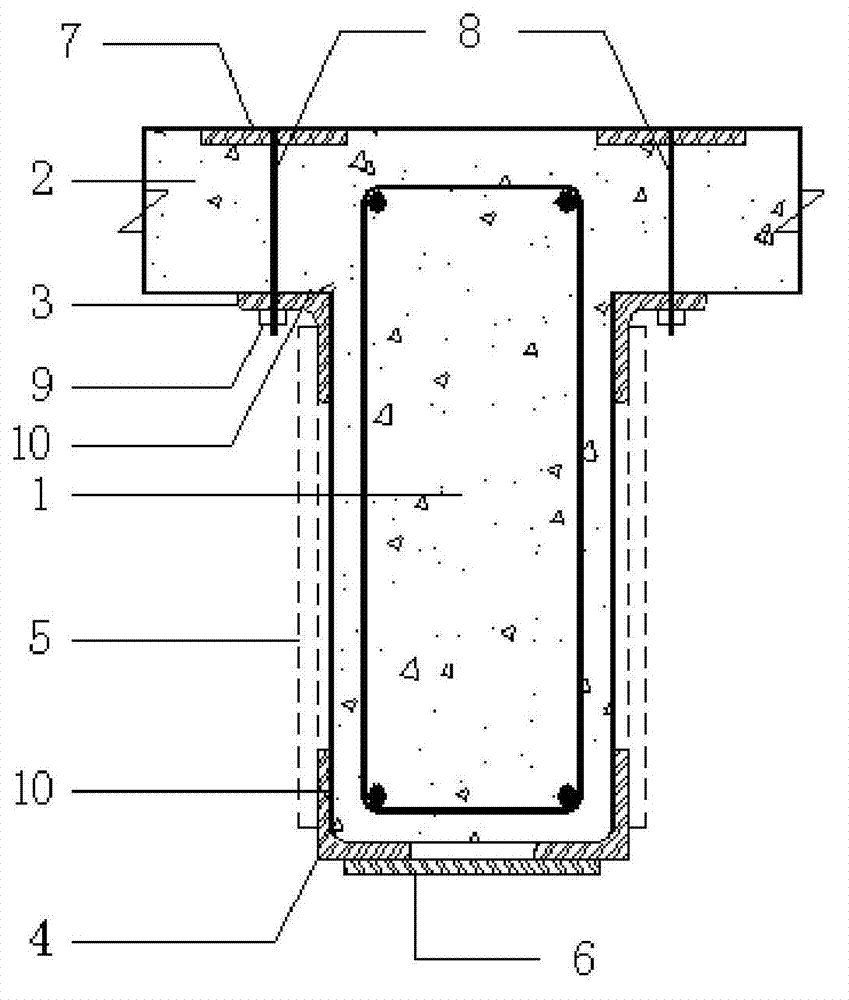

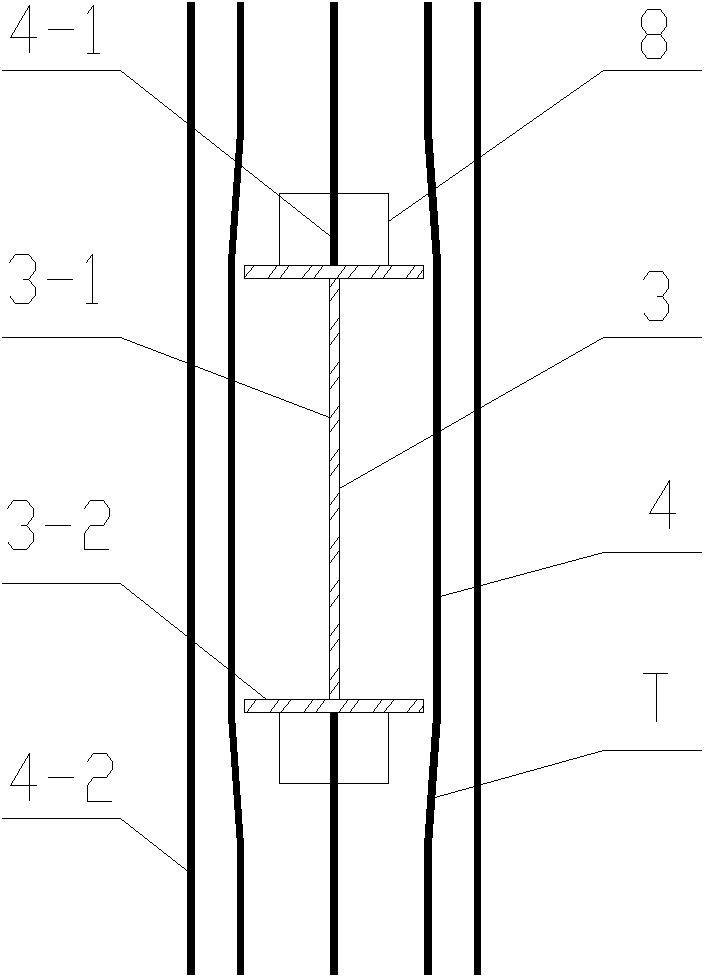

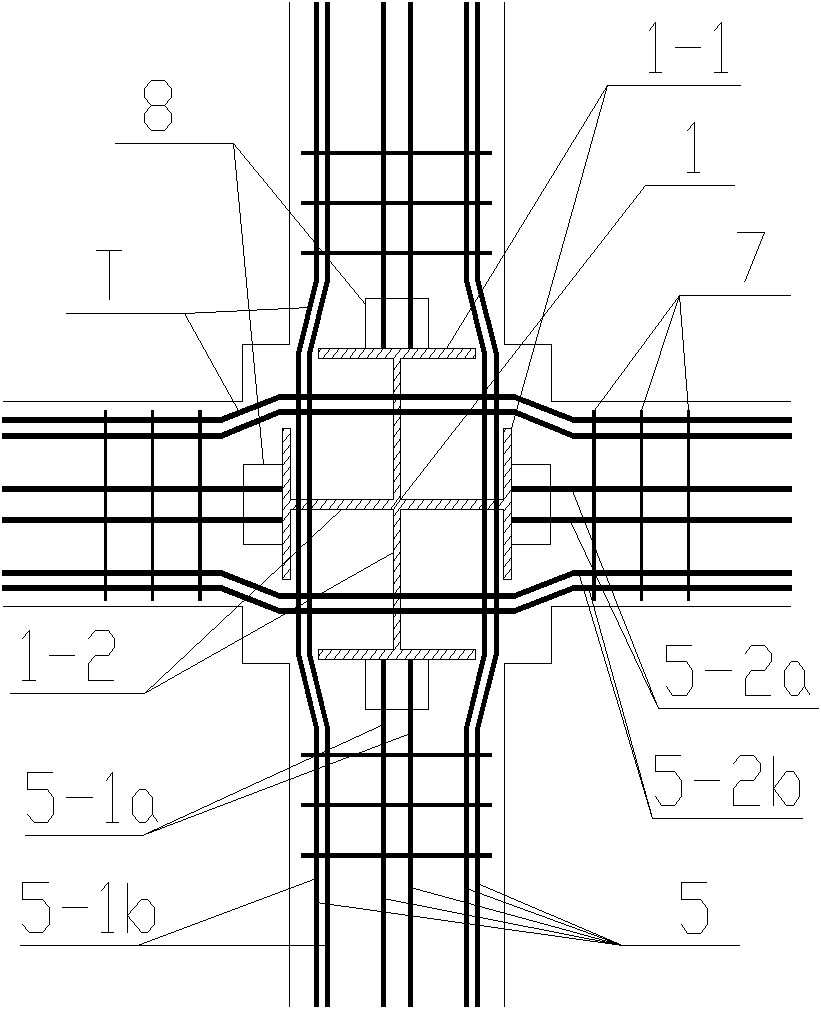

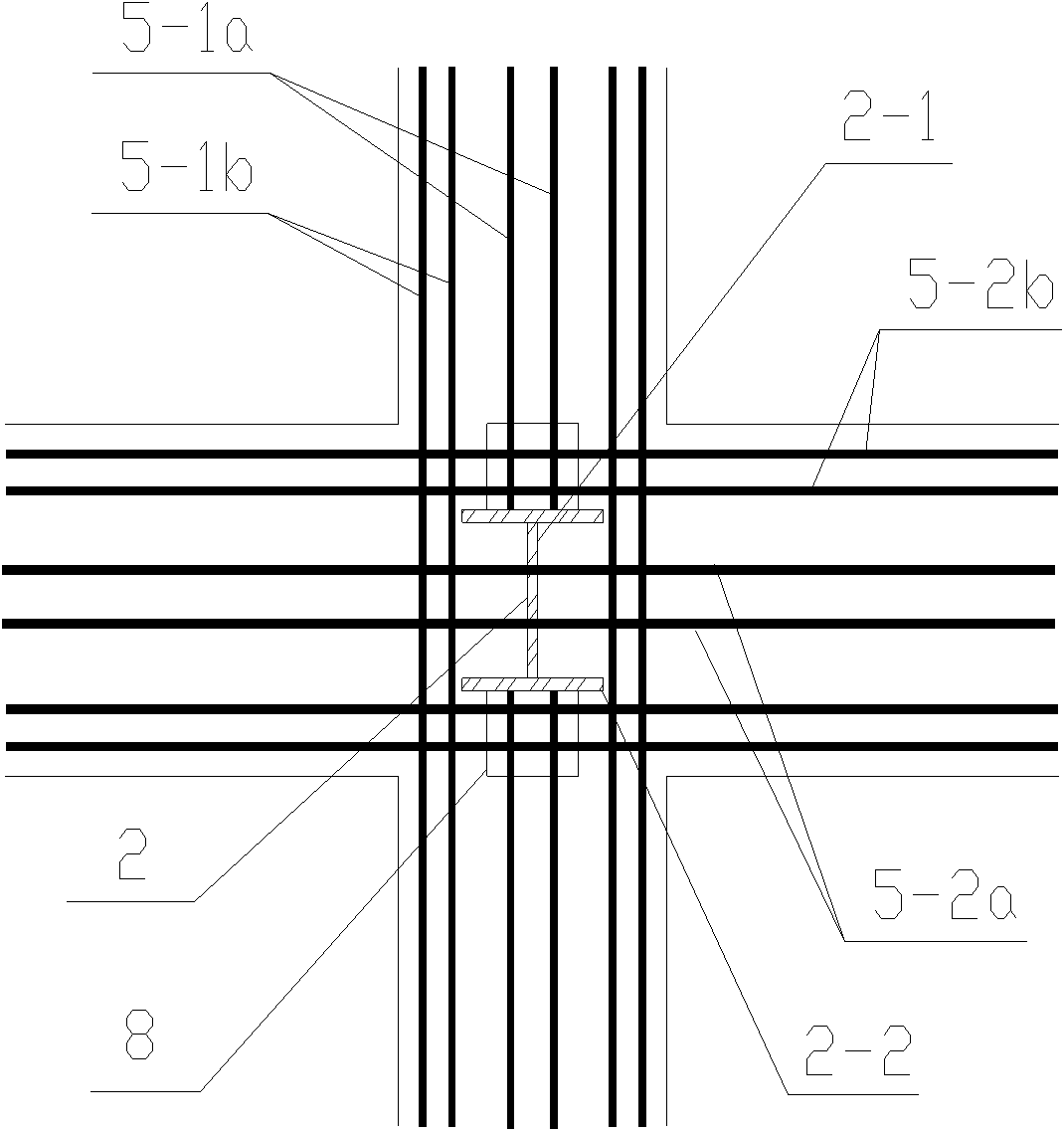

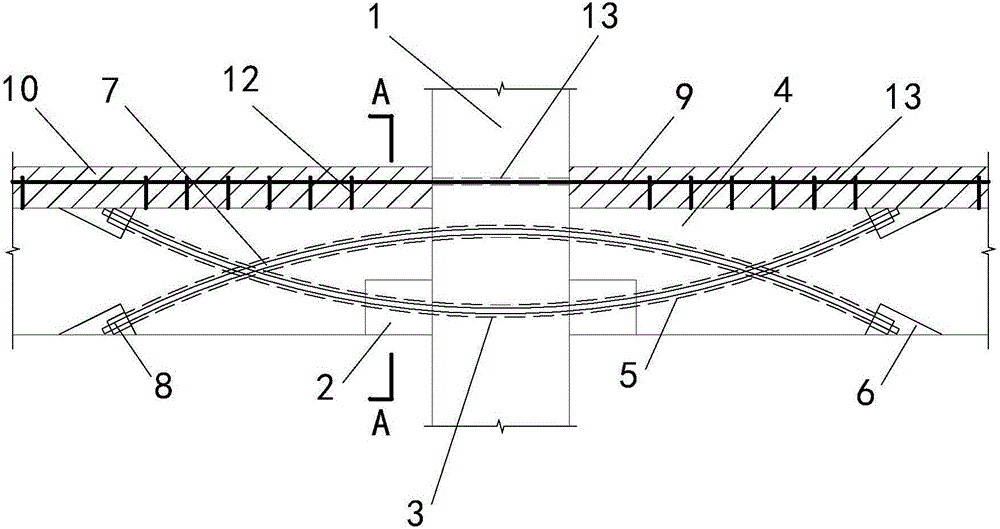

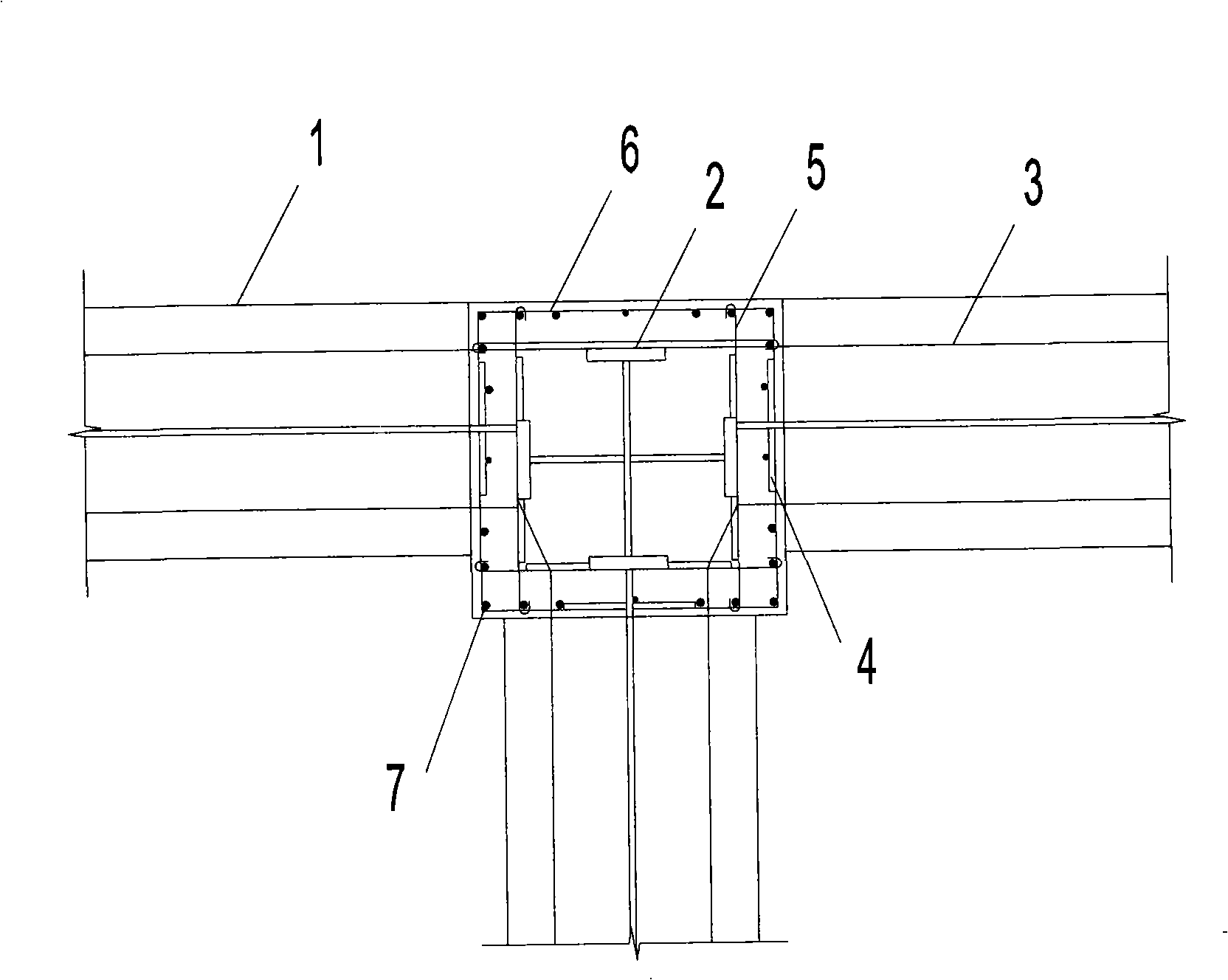

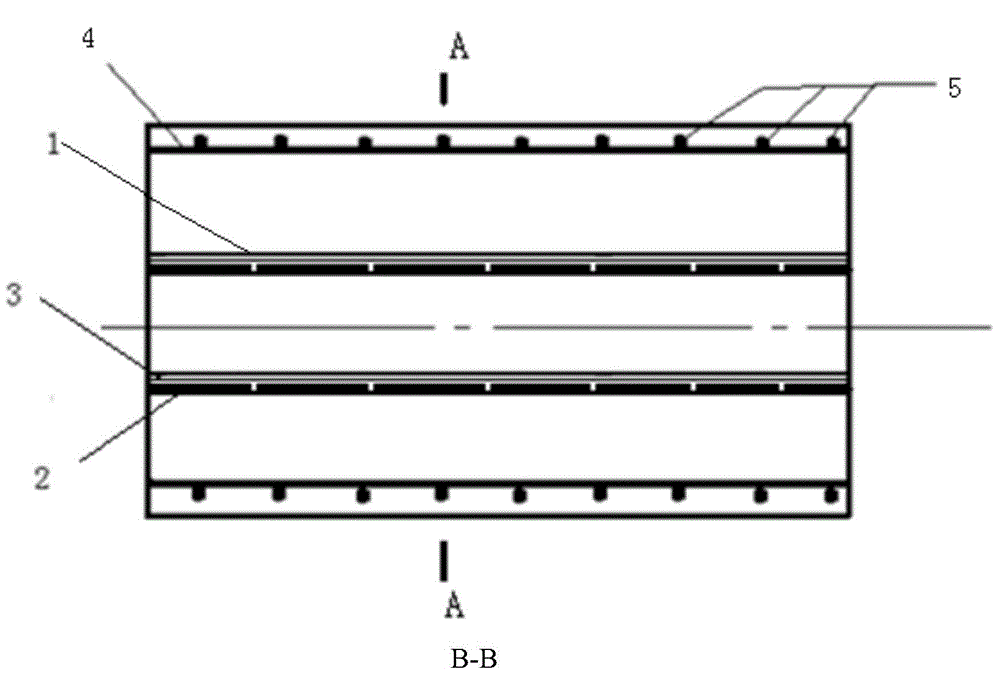

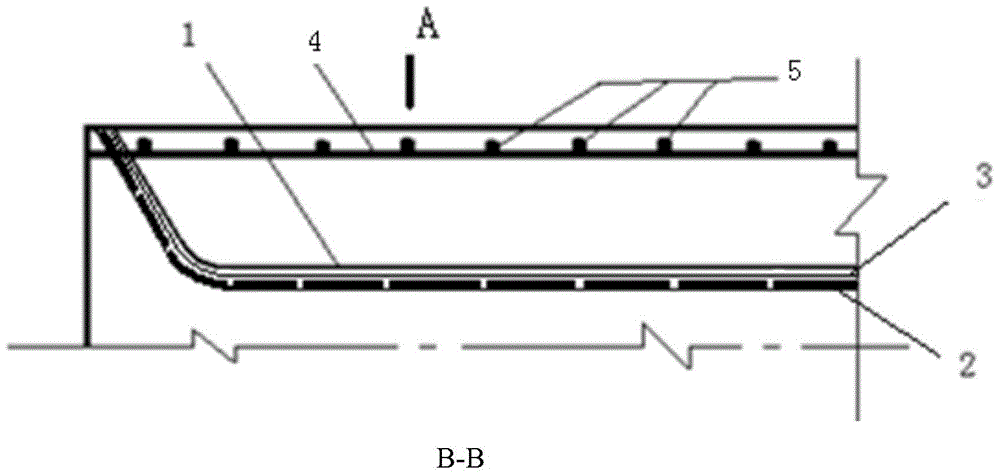

Node connection device for self-centering prestressed concrete frame

InactiveCN101798849ASolve local pressure problemsEliminate or reduce residual deformationShock proofingResidual deformationWhole body

The invention relates to a node connection device for a self-centering prestressed concrete frame. The node connection device is a device used for the connection between the beam and the column of a prefabricated reinforced concrete frame, and aims at improving energy consumption of a frame structure under seismic action and eliminating or reducing the residual deformation and damage of the frame structure. The connection device is characterized in that combined steel parts form an energy consuming device, two external friction steel plates (3) are arranged in the energy consuming device, are respectively and symmetrically arranged on the two sides of a column end reinforcing steel plate (4) and are connected with the column end reinforcing steel plate (4) into a whole body, two internal friction steel plates (8) are arranged between the two external friction steel plates (3), the upper end and the lower end of each internal friction steel plate (8) are respectively provided with a bean end reinforcing steel plate (5), friction discs (15) are respectively arranged between the two internal friction steel plates (8) and the two external friction steel plates (3), and friction-type high-strength bolts (12) penetrate through the external friction steel plates (3), the friction discs (15), the internal friction steel plates (8) and a prefabricated concrete beam (2) and connect all parts together.

Owner:SOUTHEAST UNIV

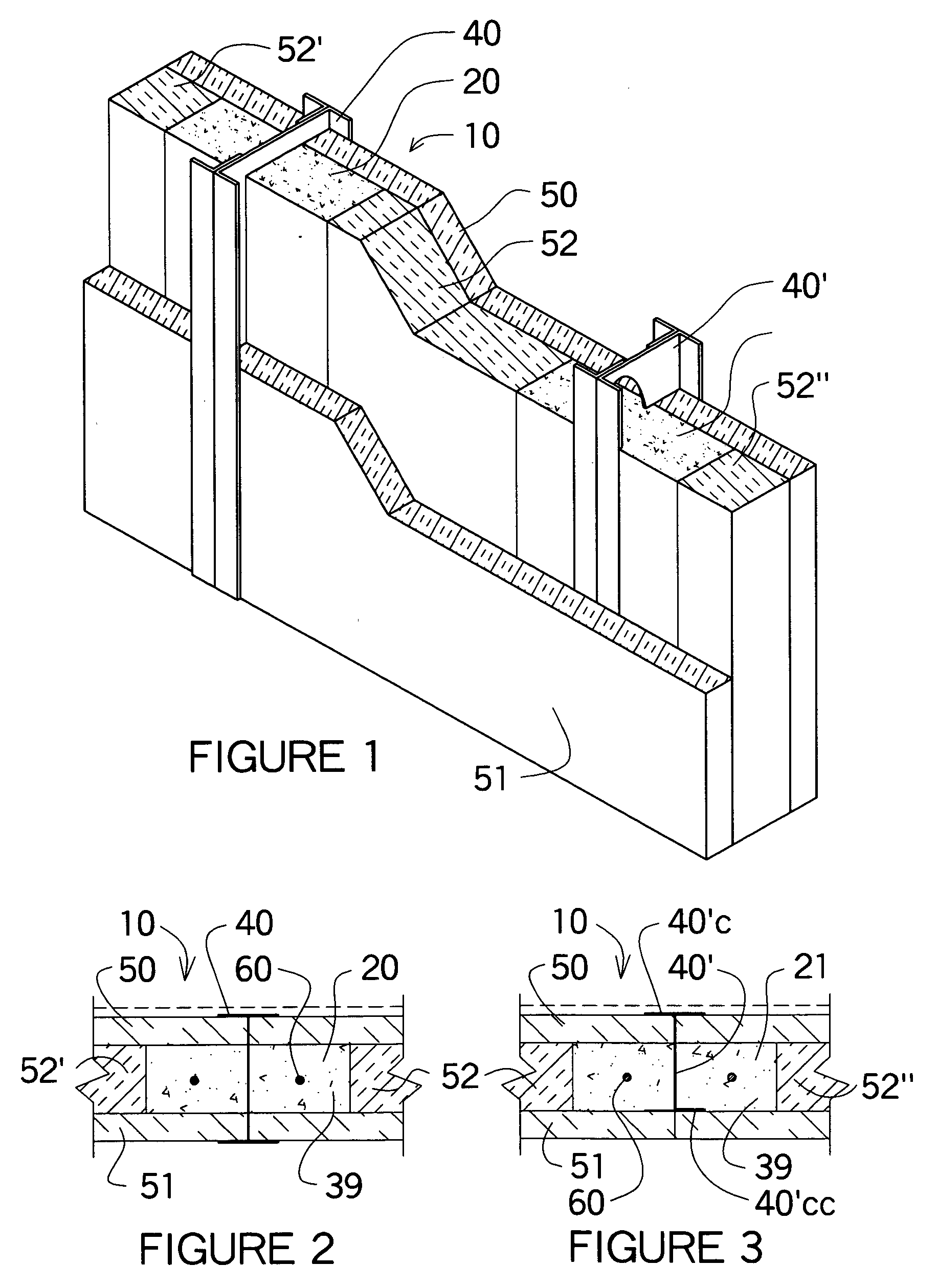

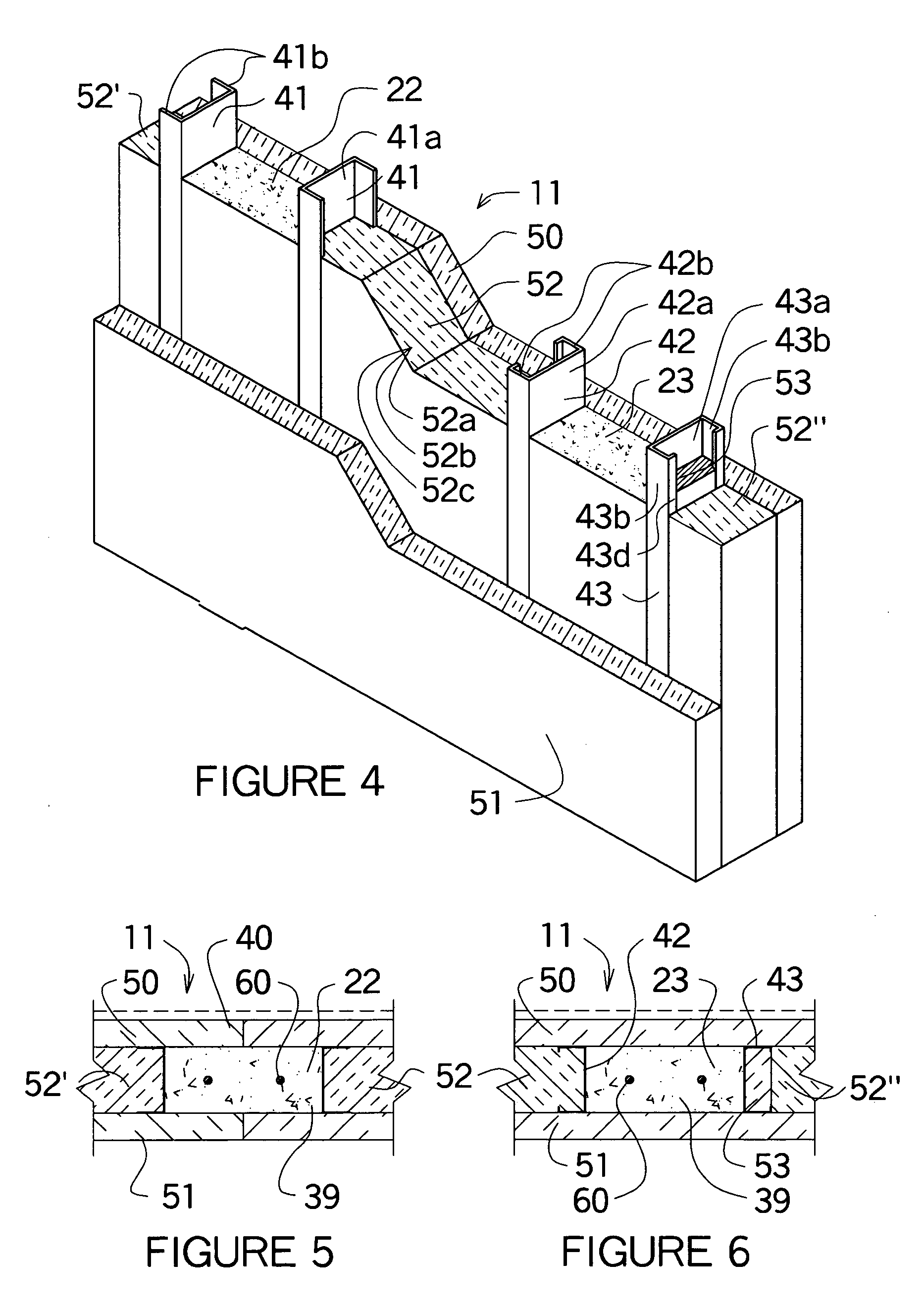

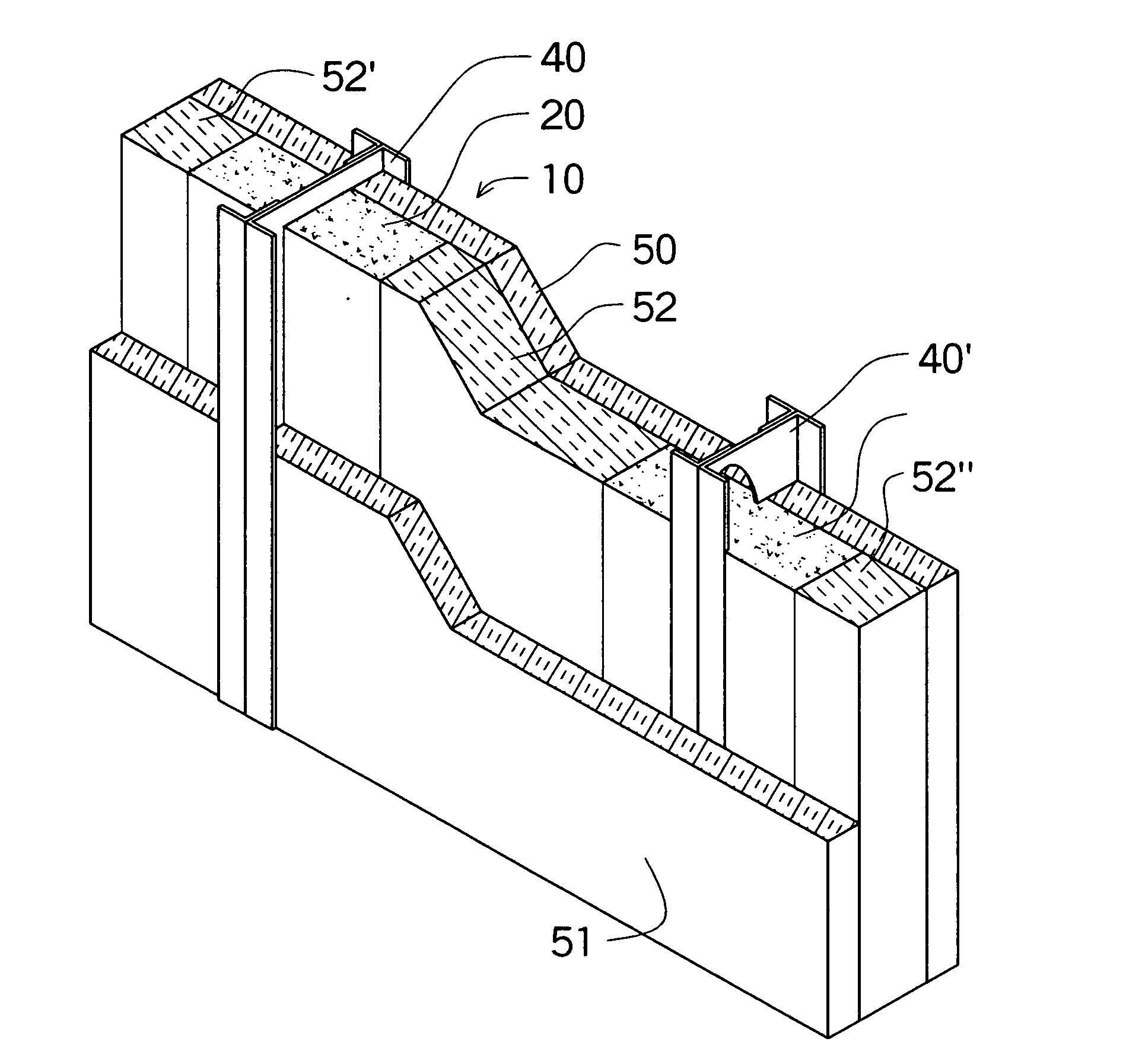

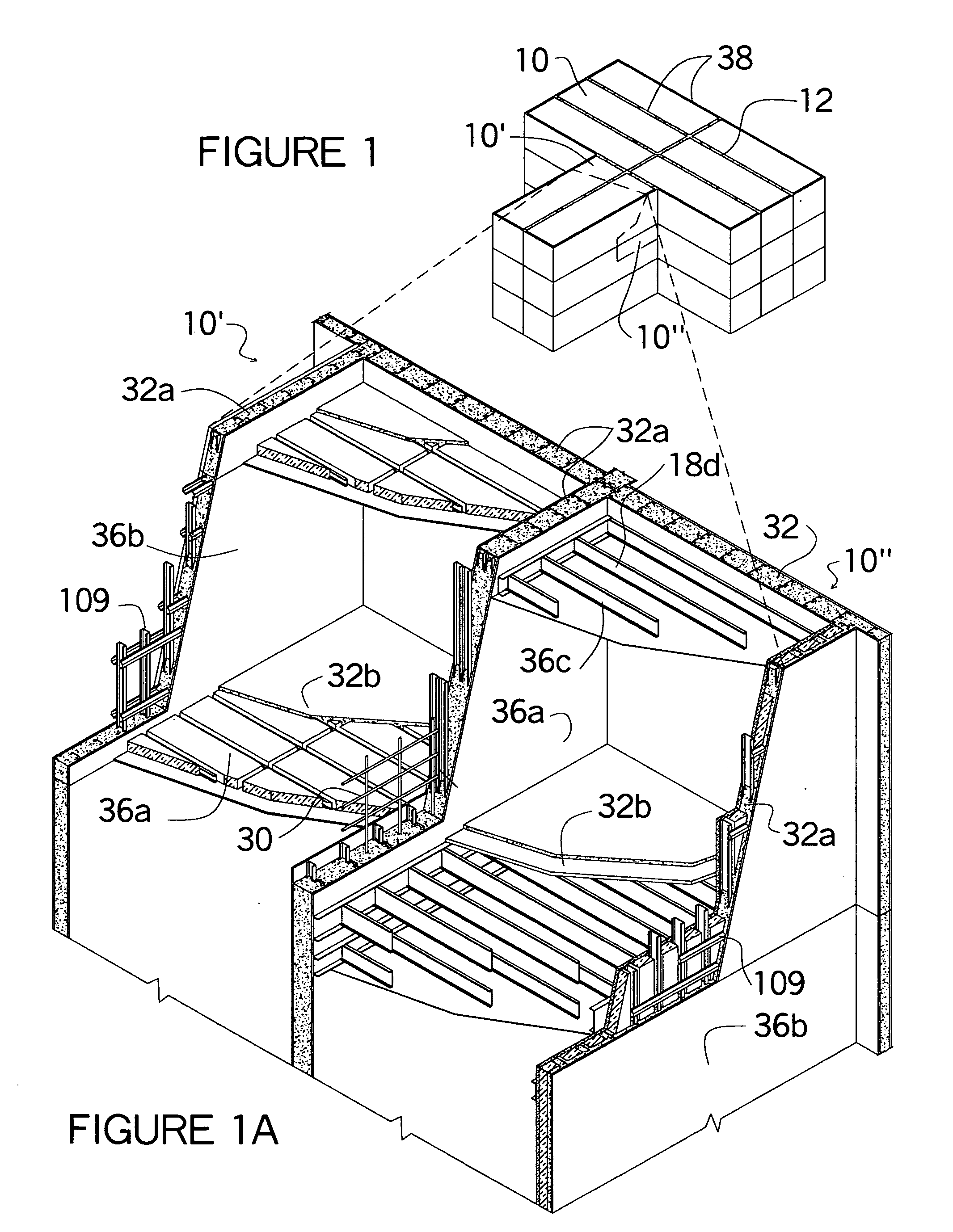

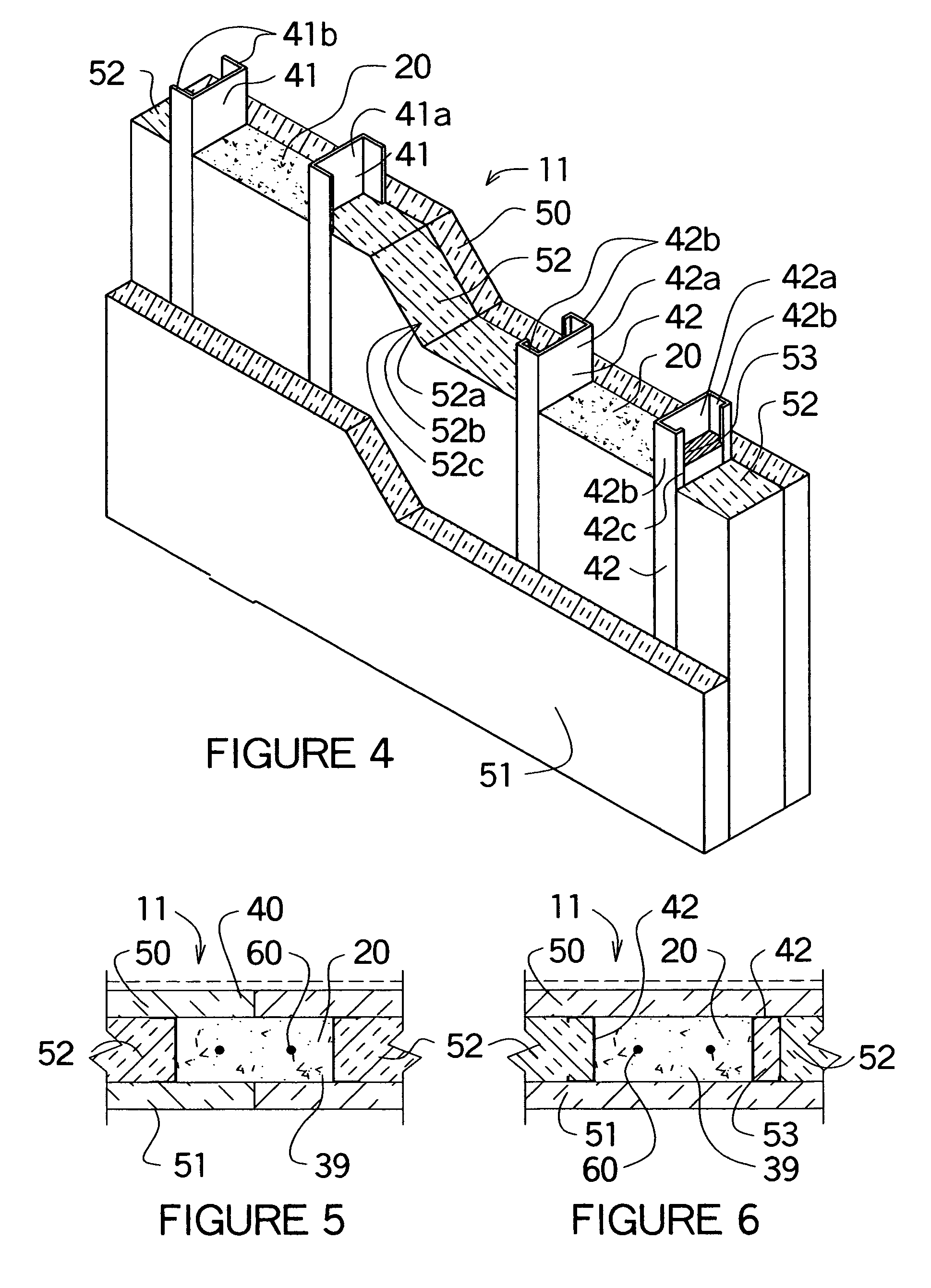

Building construction using structural insulating core

InactiveUS20100058700A1Easy to fixEasy to placeCeilingsWallsConcrete beamsStructural insulated panel

The present invention relates to an improved wall system where a wall form mold has a structural insulated core assembled to form a structural insulated panel (SIP) to form a concrete beam and concrete column to be poured anywhere within the wall as well as between building modules when placed together and erected vertically. The interlocking wall molds interlock within the wall as well as between panels and modules. The wall panels allow concrete columns and beams to be formed with an ICF in any size and shape. The structural insulated core consists of interlocking foam spacers and support channels which can be glued or screwed together to form an independent wall or as part of a precast wall with columns and beams integrated within the wall panels. Expanded and insulating flanges within the wall forming mold separates the wall forming structure from the wall surfaces.

Owner:LEBLANG DENNIS WILLIAM

Reinforcement device for supporting structures

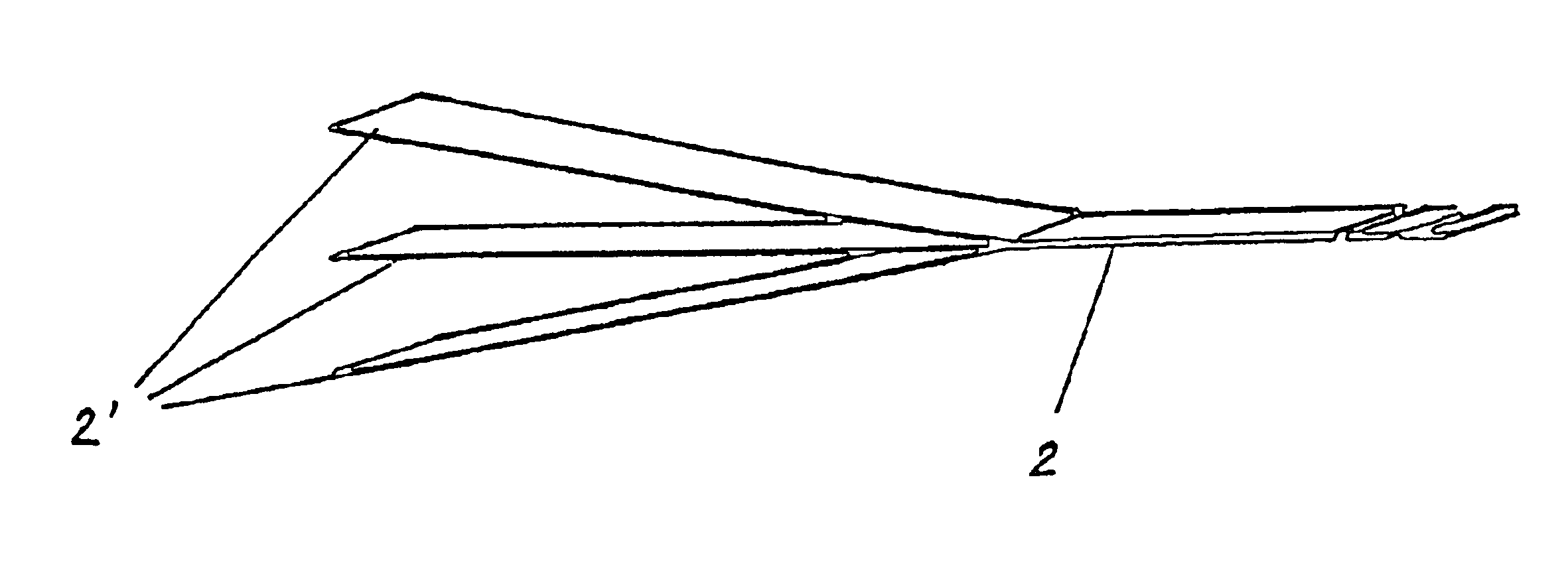

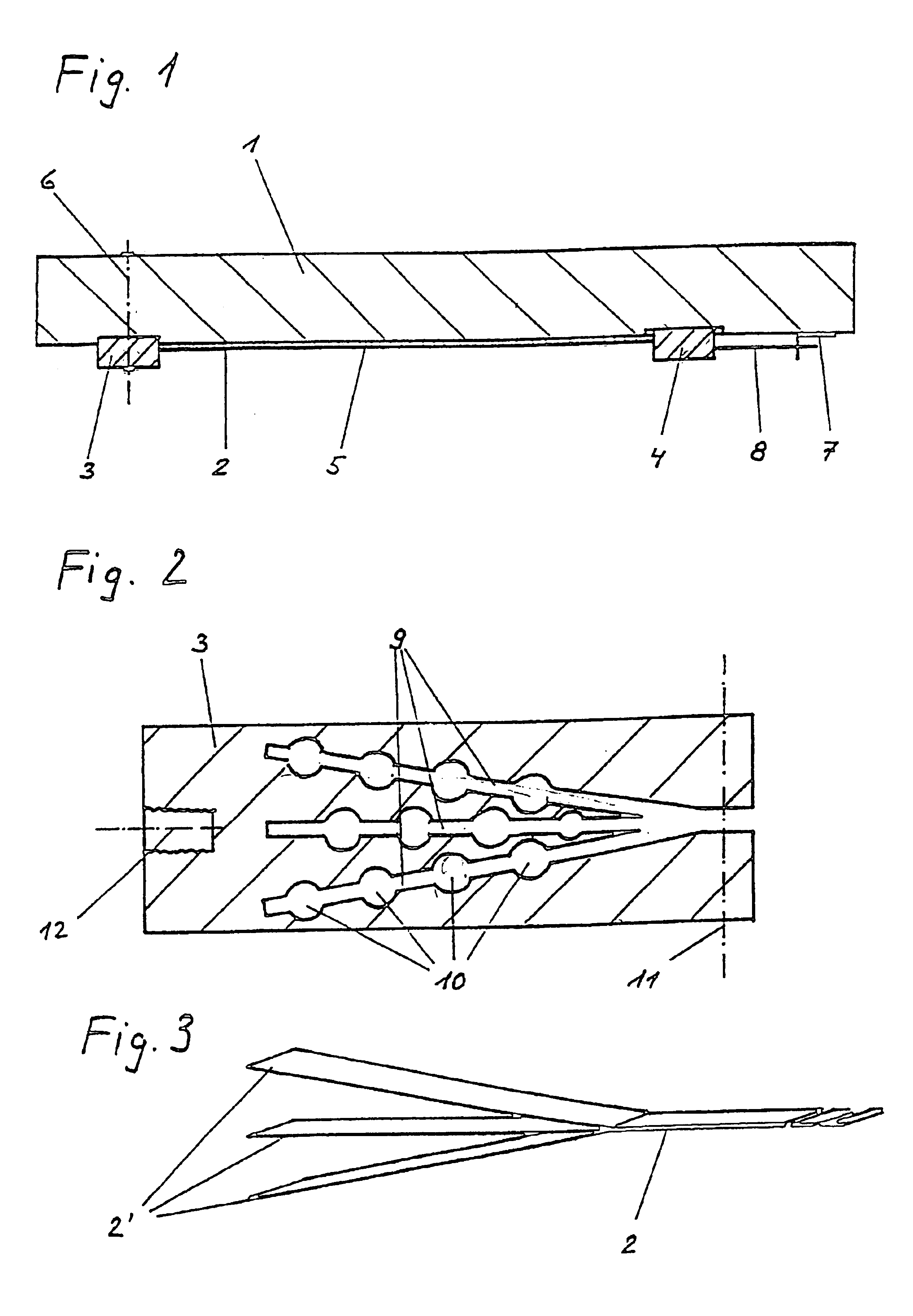

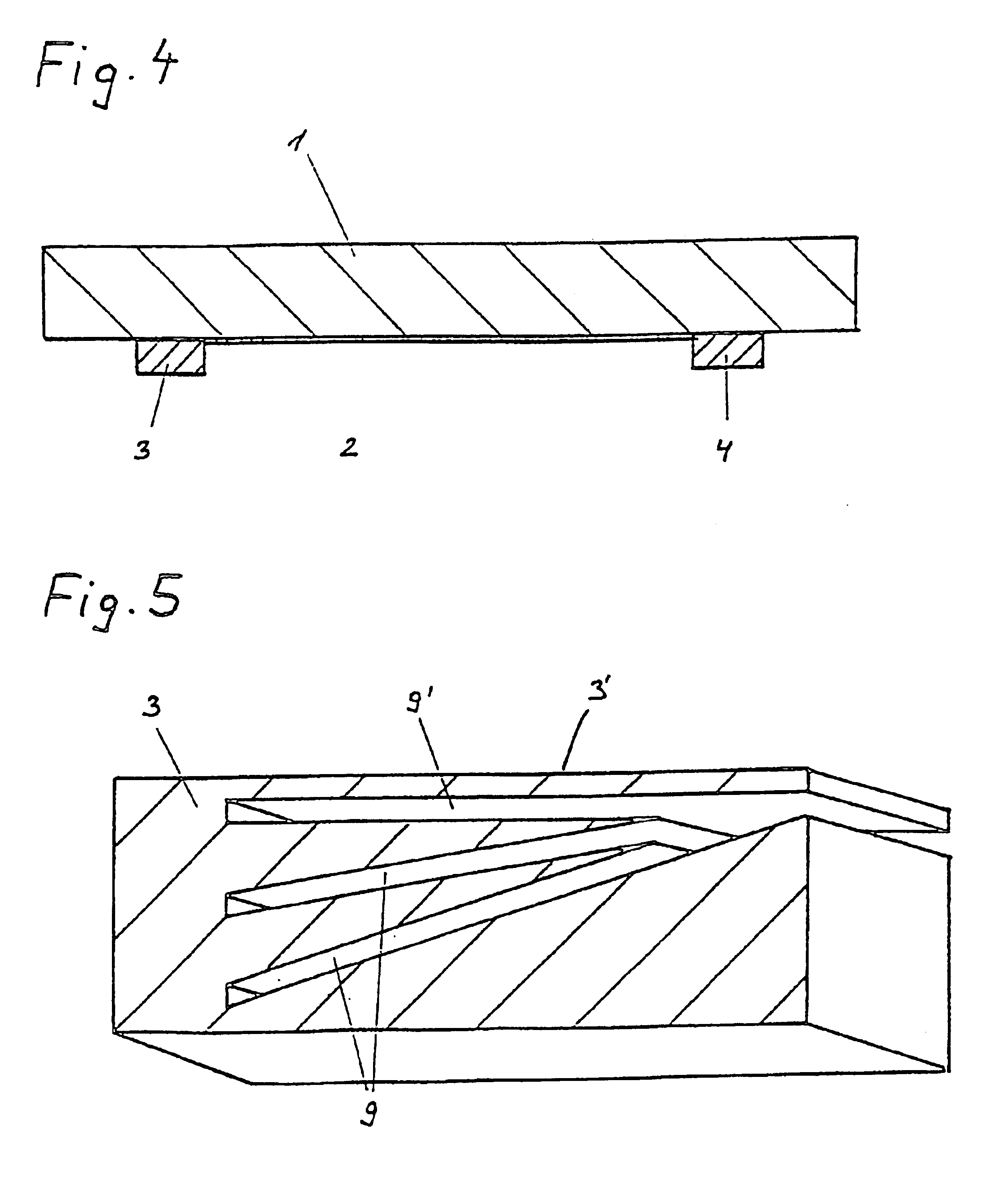

InactiveUS6851232B1Smooth connectionGood initiativeLamination ancillary operationsCovering/liningsConcrete beamsStructural engineering

The ends of carbon plates reinforcing supporting elements, such as concrete beams, are divided into at least two splines having approximately the same thickness and are glued in the appropriate retaining slots of a terminal element. The splines form an angle in relation to each other. This assembly is then glued to the traction side of the supporting element, whereby the carbon plates are directly prestressed by the terminal elements in relation to the supporting element. The terminal element can be inserted into an appropriate groove in the supporting element or glued directly on the surface of the supporting element and / or doweled, optionally by using a transverse tensioning device.

Owner:SIKA SCHWEIZ AG

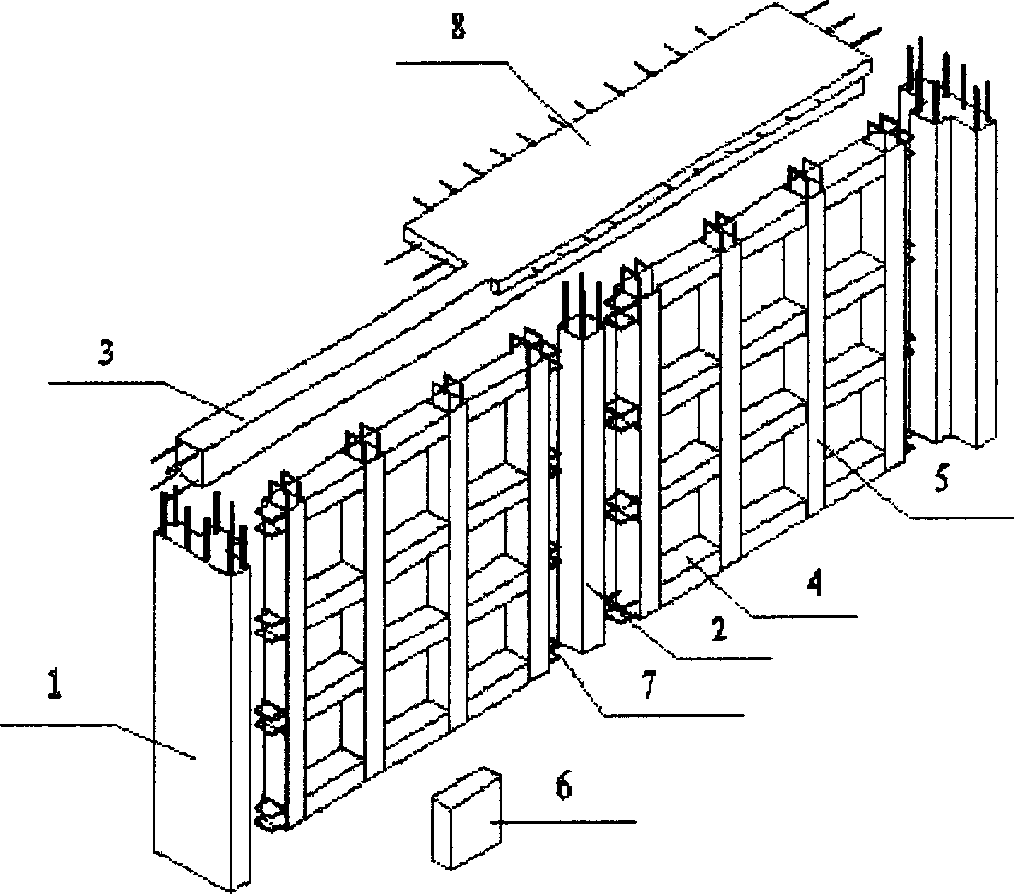

Multi-rib structure system and its connection construction method

InactiveCN1804263AAchieve graded releaseMeet the energy-saving requirements of light buildingsWallsFloor slabPre stressing

The invention relates to a ribbed structure which comprises a ribbed composite wall plate, a hidden frame and a floor. Wherein, the ribbed composite wall plate is a network construction element formed by reinforced steel concrete and light material and divided by the reinforced steel concrete beam as rib beam and rib post in small sections with embedding light material stuffing blocks into the grid; the ribbed composite wall plate also comprises the goatee bar extending from the rib beam and rib post, which is four steel bars with certain anchoring length extending from each rib beam and post and is longitude steel bar whose end is a hook in connection to hook hidden frame; or else the goatee bars are two U-shape closed ring extending from each rob beam an post and is inserted with longitude steel bars in connection; the hidden frame is formed by outer frame post, connection post, and hidden beam which are embedded outside the ribbed composite wall plate while using common concrete, profiled bar concrete or steel structural beam and post; the stuffing material is made from light material with certain strength, volume weight and little elastic modulus; and the floor can select on-situ irrigating concrete, on-sit or prefabricated ribbed composite floor, pre-stress layered floor or special-shaped pre-stress hollow floor.

Owner:姚谦峰

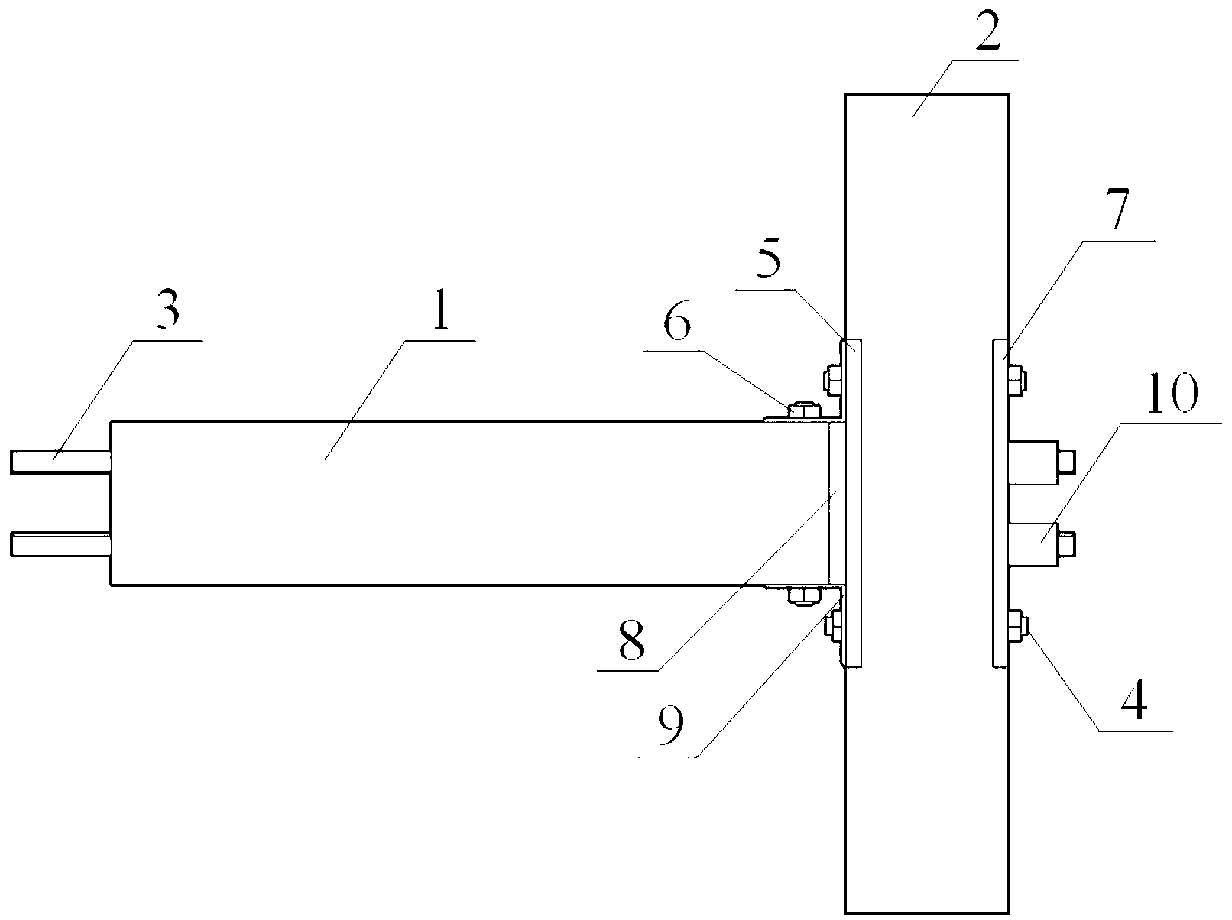

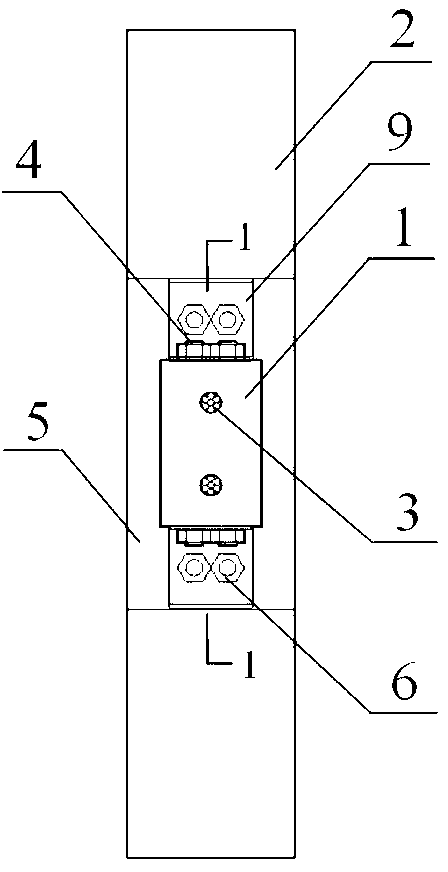

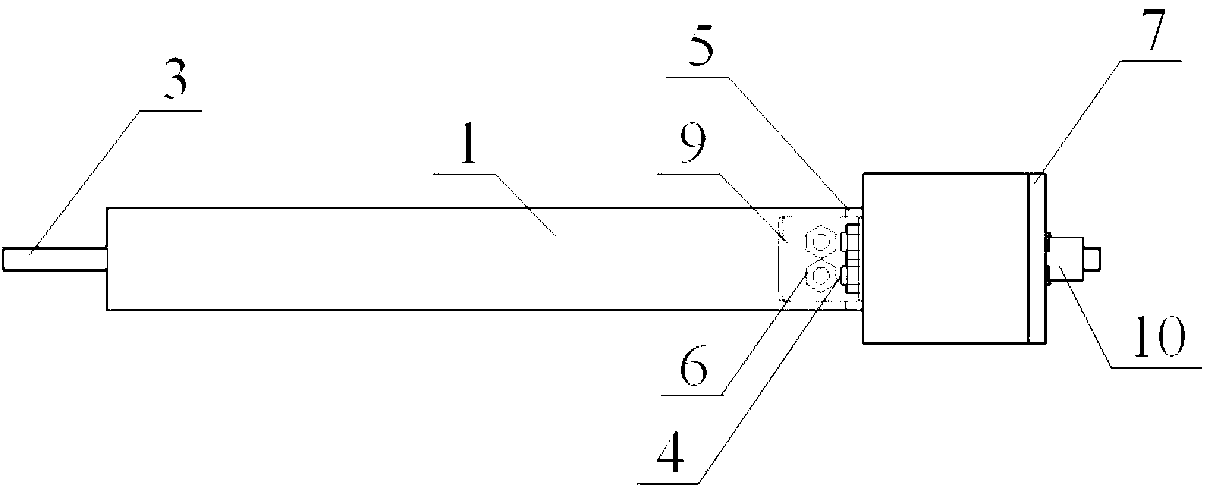

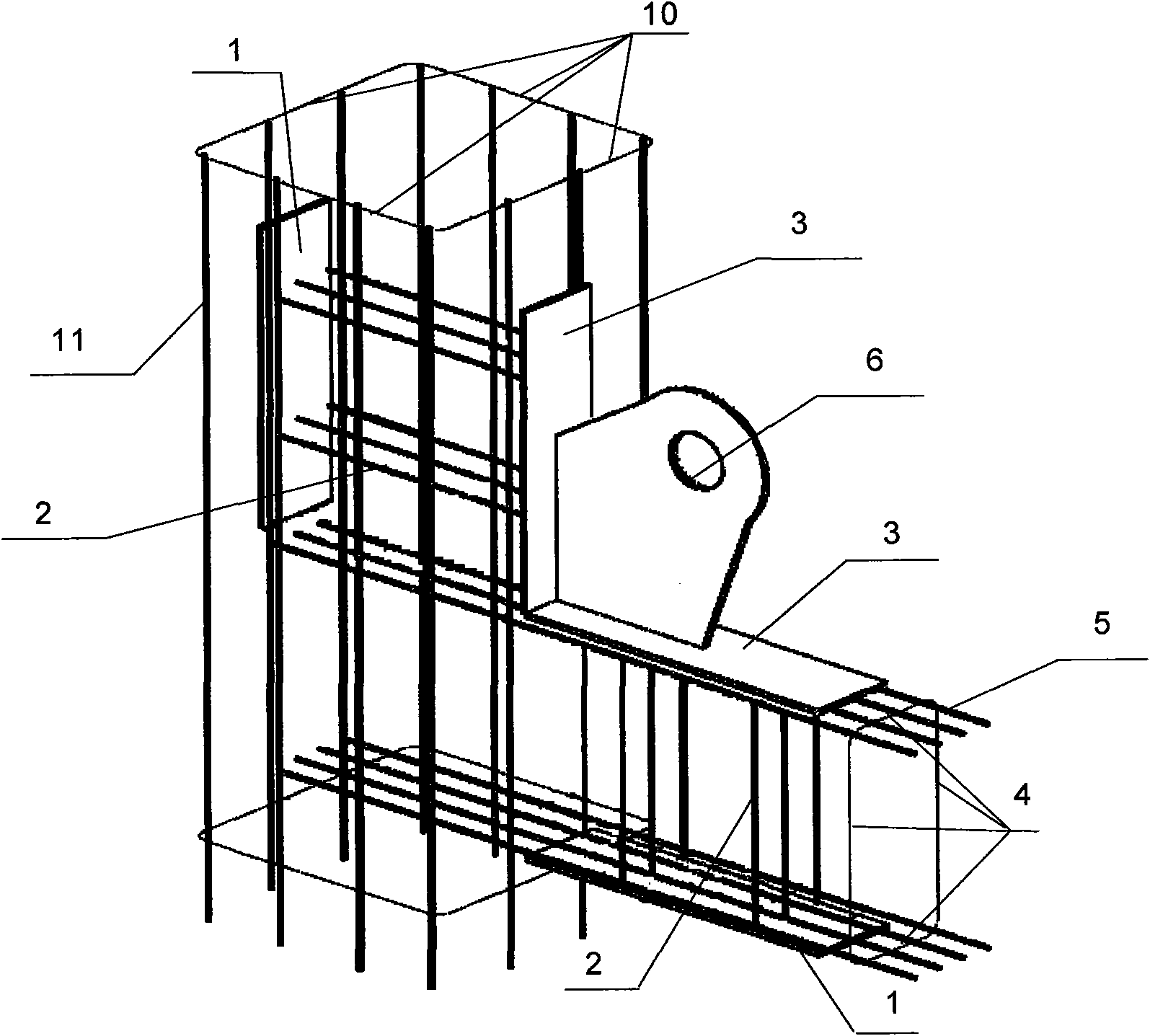

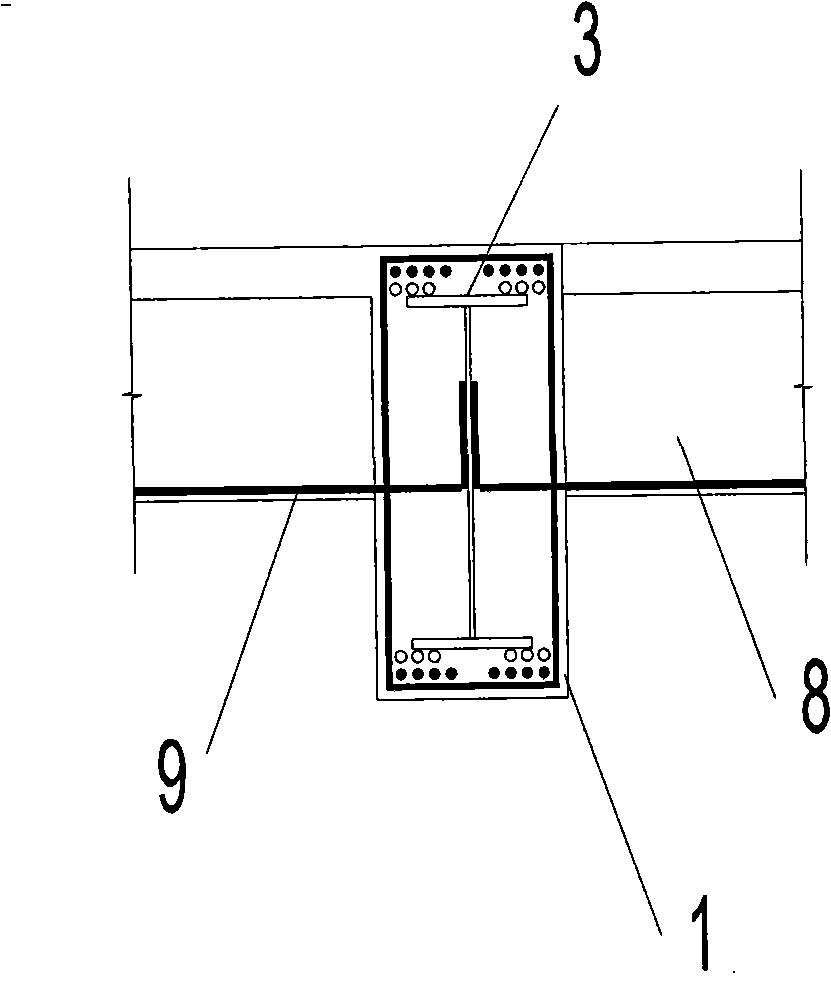

Self-resetting frame joint

The invention belongs to construction field and relates to a self-resetting frame joint. The self-resetting frame joint comprises a concrete beam (1) and a concrete column (2). The concrete beam (1) and the concrete column (2) are connected through an unbonded low-relaxation prestressed steel strand (3) and an angle steel (9), a third steel pate (8) is disposed at the ends of the concrete beam (1), a first steel plate (5) is disposed on the place of the concrete column (2) near the beam side, a second steel plate (7) is disposed on the place of the concrete column (2) facing away from the beam side, and the unbonded low-relaxation prestressed steel strand (3) passing through the third steel pate (8) of beam ends and the first steel plate (5) of the column side is anchored in the outer side of the second steel plate (7) of the column side through an anchorage (10). The concrete beam (1) and the concrete column (2)are respectively connected with the angle steel (9) through a screw (4) and a nut (5), and the first steel plate (5) contacts with the third steel plate (8). The self-resetting frame joint has the advantages of stable structure under small earthquakes, large deformation structure with no damage under strong earthquakes, and self-resetting structure after earthquakes.

Owner:TONGJI UNIV

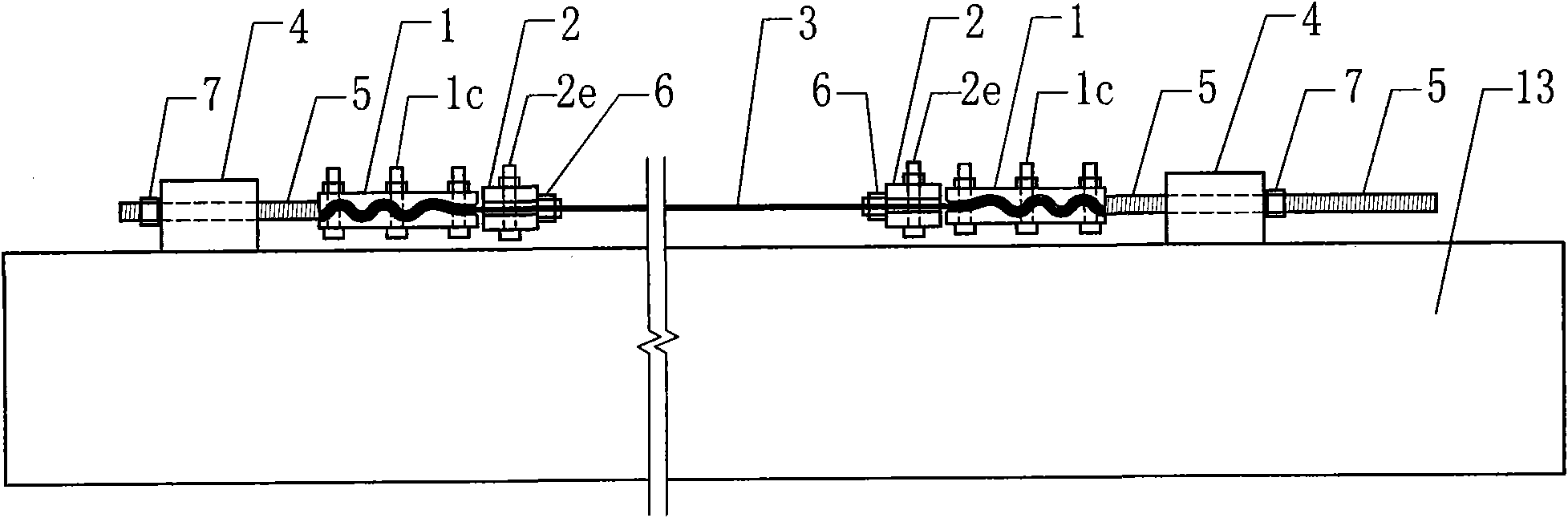

Articulated anchor and prestress tensioning method of high strength fibre composite sheet

ActiveCN101851985AGuaranteed automatic adjustmentGuaranteed uniformityBuilding reinforcementsBuilding material handlingFiberConcrete beams

An articulated anchor and a prestress tensioning method of high strength fibre composite sheet relate to an anchor holder used to perform prestress tensioning to the high strength fibre composite material of the enhancement or reinforcement engineering structure and a method thereof. The articulated anchor of the invention comprises an anchor head and a compression and locking device, and the articulated anchor is characterized in that the anchor head contains a raised head anchor and a concave block. The method of the invention is that the articulated anchor is used to clamp and anchor the two ends of FRP sheet, a jack is used to apply a tension on the concave block and the concave block pushes the raised head anchor to perform prestress tensioning to FRP sheet. The articulated anchor of the invention has simple structure, convenient installation and low cost; and the method of the invention is simple, intuitive and practical, and can ensure the tensioning uniformity of FRP sheet, made full use of the intensity of FRP sheet and effectively increase the bearing capacity of the engineering structure. The articulated anchor of the invention can be widely used to enhance or reinforce the large engineering structures such as bridges or buildings and especially to perform external prestressing reinforcement to longspan concrete beams, longspan concrete slabs and the like.

Owner:卓清

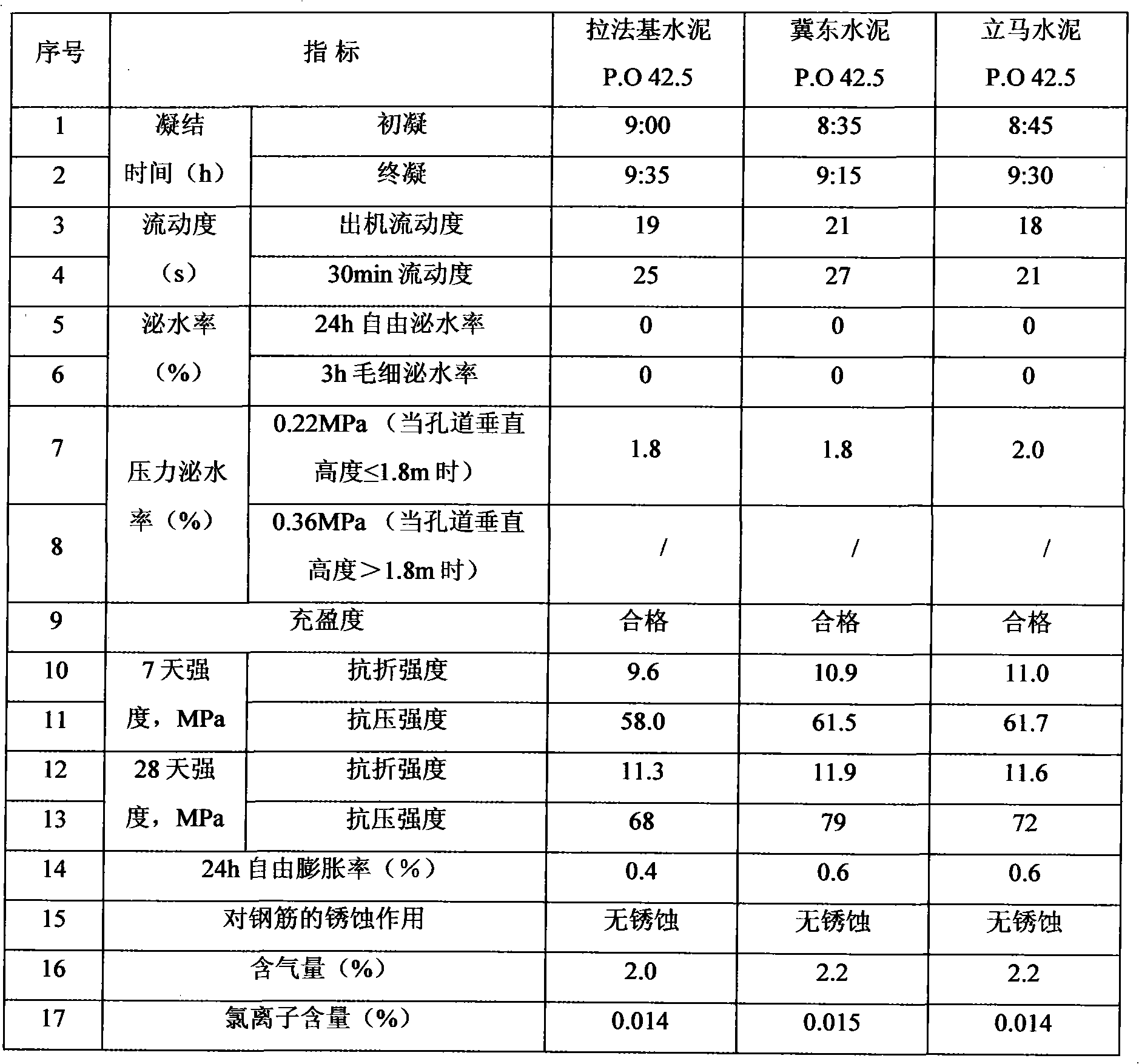

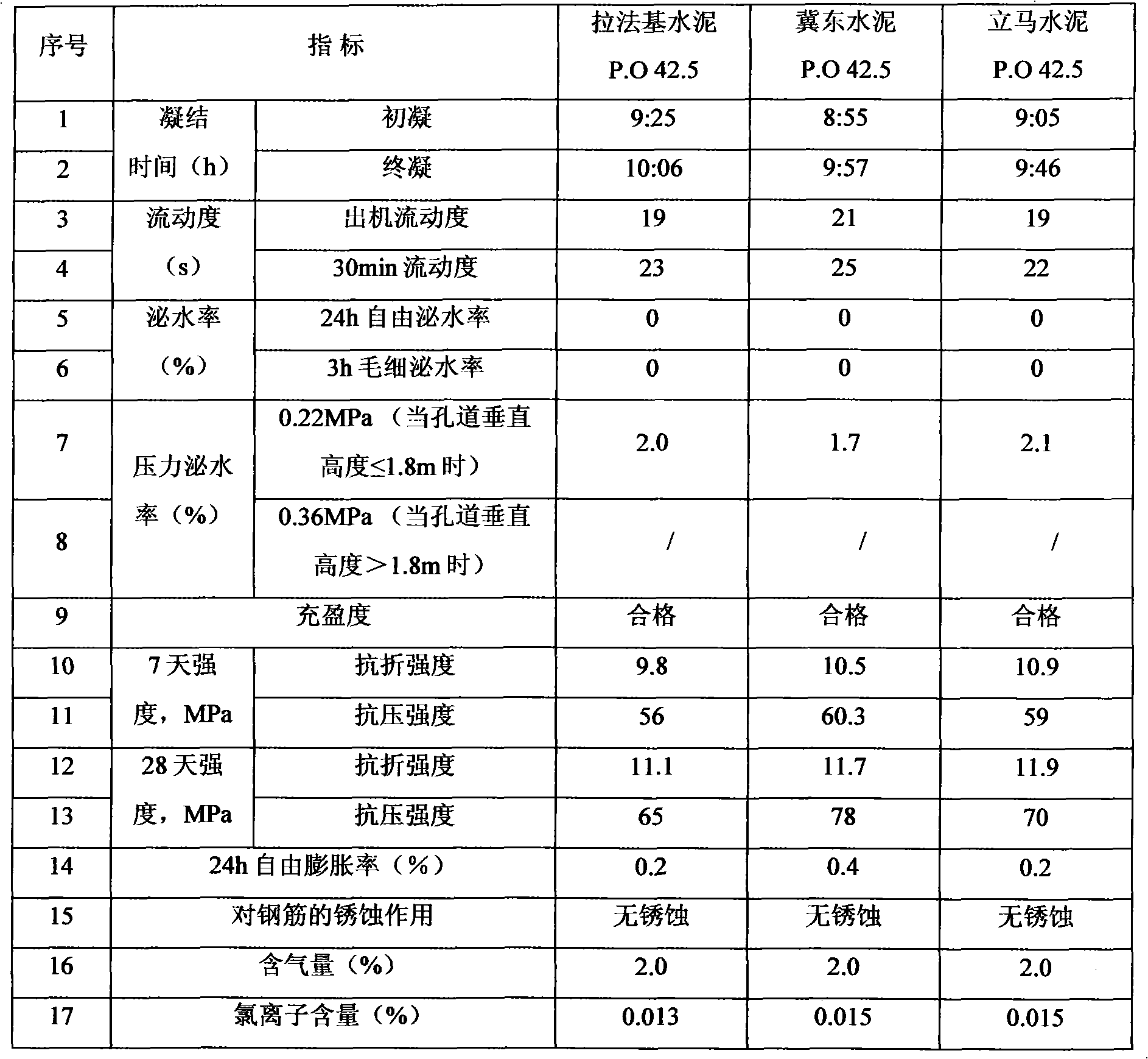

Post stressed concrete beam pipe mudjacking agent

ActiveCN101817656AImprove liquidityHigh micro expansionSolid waste managementPrestressed concrete beamPre stress

The invention provides a post stressed concrete beam pipe mudjacking agent which is characterized by comprising the following components in percent by weight: 1-3 percent of efficient slushing component, 5-10 percent of early-expanded component, 30-50 percent of middle-late expanded component and 40-60 percent of mineral admixture. The invention also provides a preparation method of the post stressed concrete beam pipe mudjacking agent, which comprises the step of uniformly stirring the components in a stirrer according to the weight percent to obtain the post stressed concrete beam pipe mudjacking agent. The post stressed concrete beam pipe mudjacking agent, cement and water are mixed according to a certain proportion to prepare a mudjacking material to be used for construction. The mudjacking agent has optimal flowing property, excellent water holding property, better compactness, full and uniform structure and good early plastic expanded performance, does not contain additives with corrosion on prestressed reinforcing steel, and has very low chloridion content, better adaptability with various cements and lower sensitivity on temperature and humidity.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +1

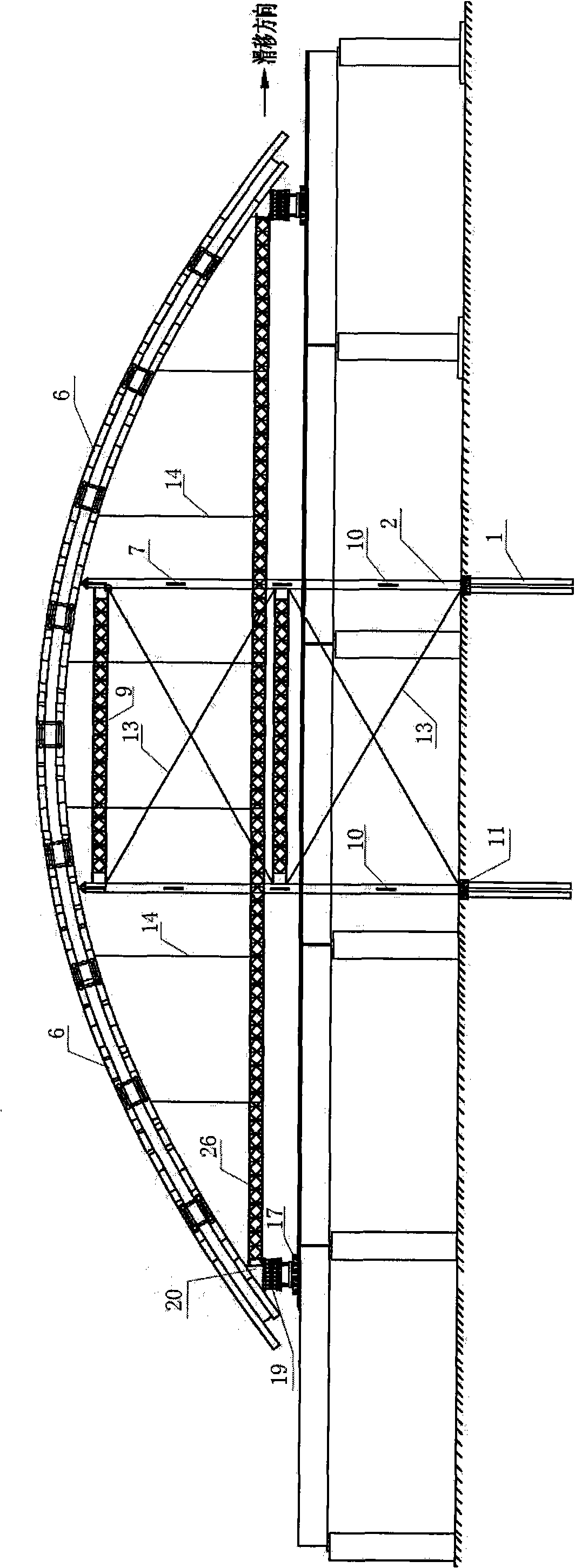

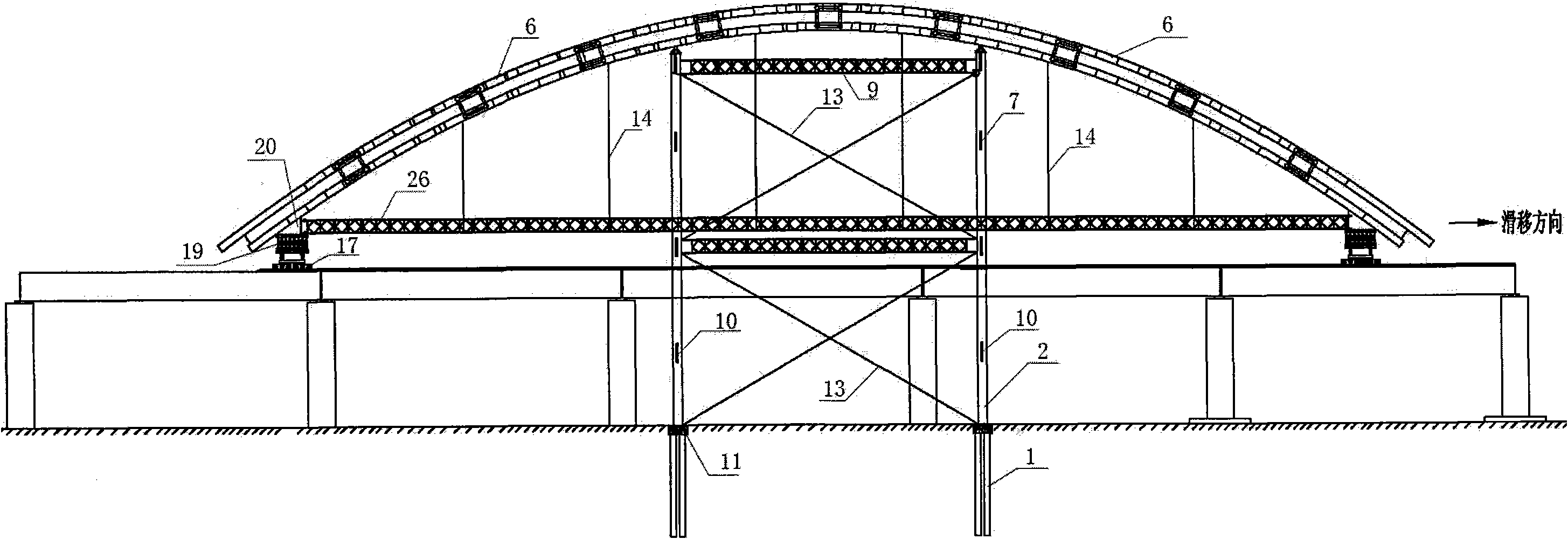

Construction method for integrally sliding large-span steel pipe arch of curved bridge

ActiveCN101935987AReduce occupancyReduce in quantityBridge erection/assemblyBridge engineeringConcrete beams

The invention relates to a construction method for integrally sliding a large-span steel pipe arch of a curved bridge, belonging to the field of bridge engineering construction. The method comprises the following steps: firstly, carrying out on-site splicing and welding on the manufacturing and installing sections of a steel pipe arch to form a large hoisting section; then installing a temporary arch-splicing support on a bridge-site longitudinal splicing site position, arranging arch ribs on the temporary arch-splicing support, and adopting an arch springing restraint device to preload arch springings after finishing splicing the steel pipe arch, thus enabling the steel pipe arch to form a stressed entirety; and finally, dismantling the temporary arch-splicing support, and adopting a pushing power system to realize integrally sliding the whole steel pipe arch into a proper position. The construction method of the invention has the advantages of small site occupation, integral hoisting of large sections, less hoisting subsection and less arch-splicing support amount, thus the construction cost is economical, the high-altitude welding quantity is less, the welding quality is ensured, the arch axis linetype control is easy, the steel pipe arch splicing and a concrete beam can be simultaneously constructed, arch splicing is carried out on an ectopic bridge site, the underbridge navigation is not influenced, the construction is safe and the construction progress can be quickened.

Owner:CHINA FIRST HIGHWAY ENG +1

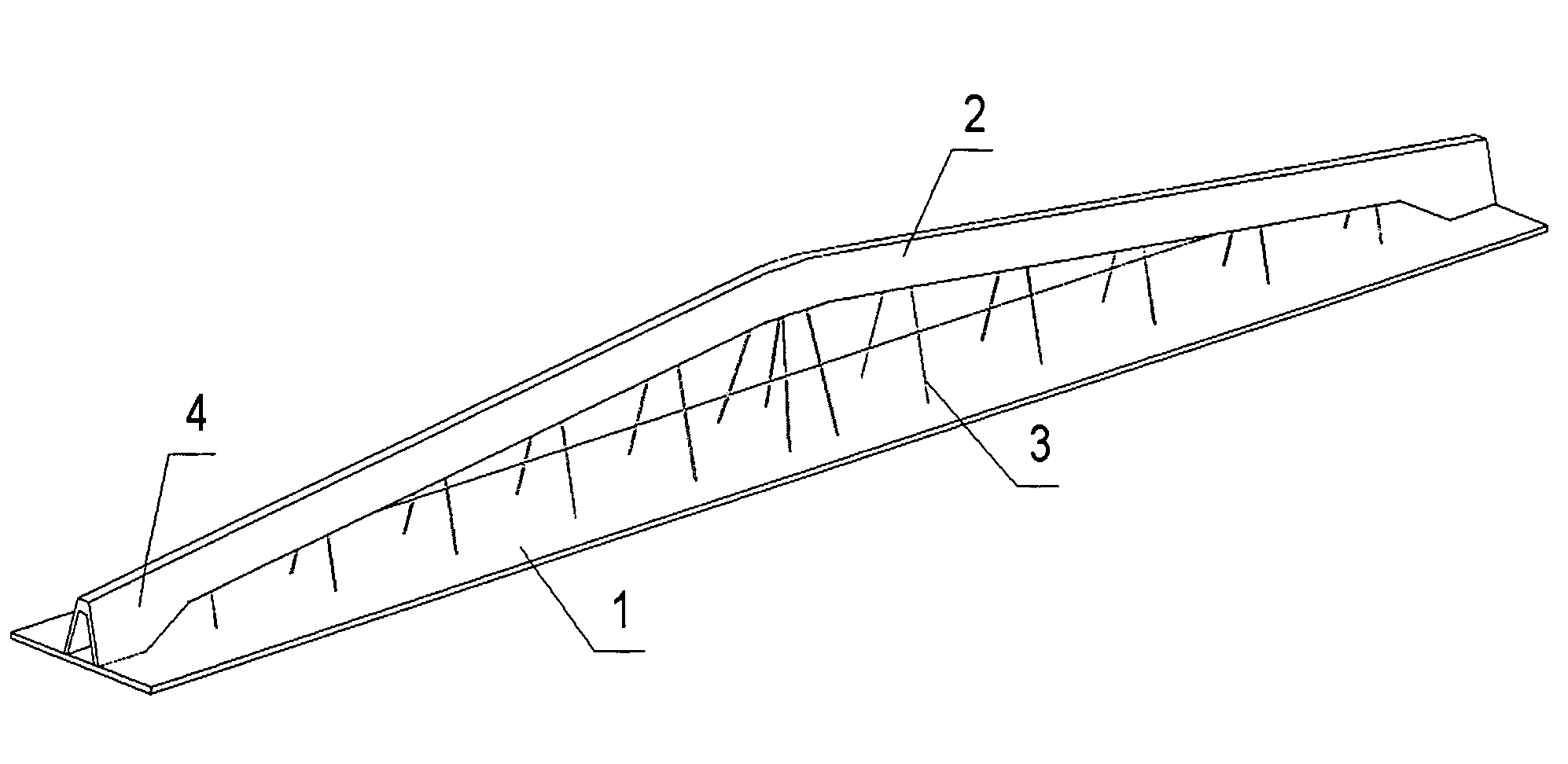

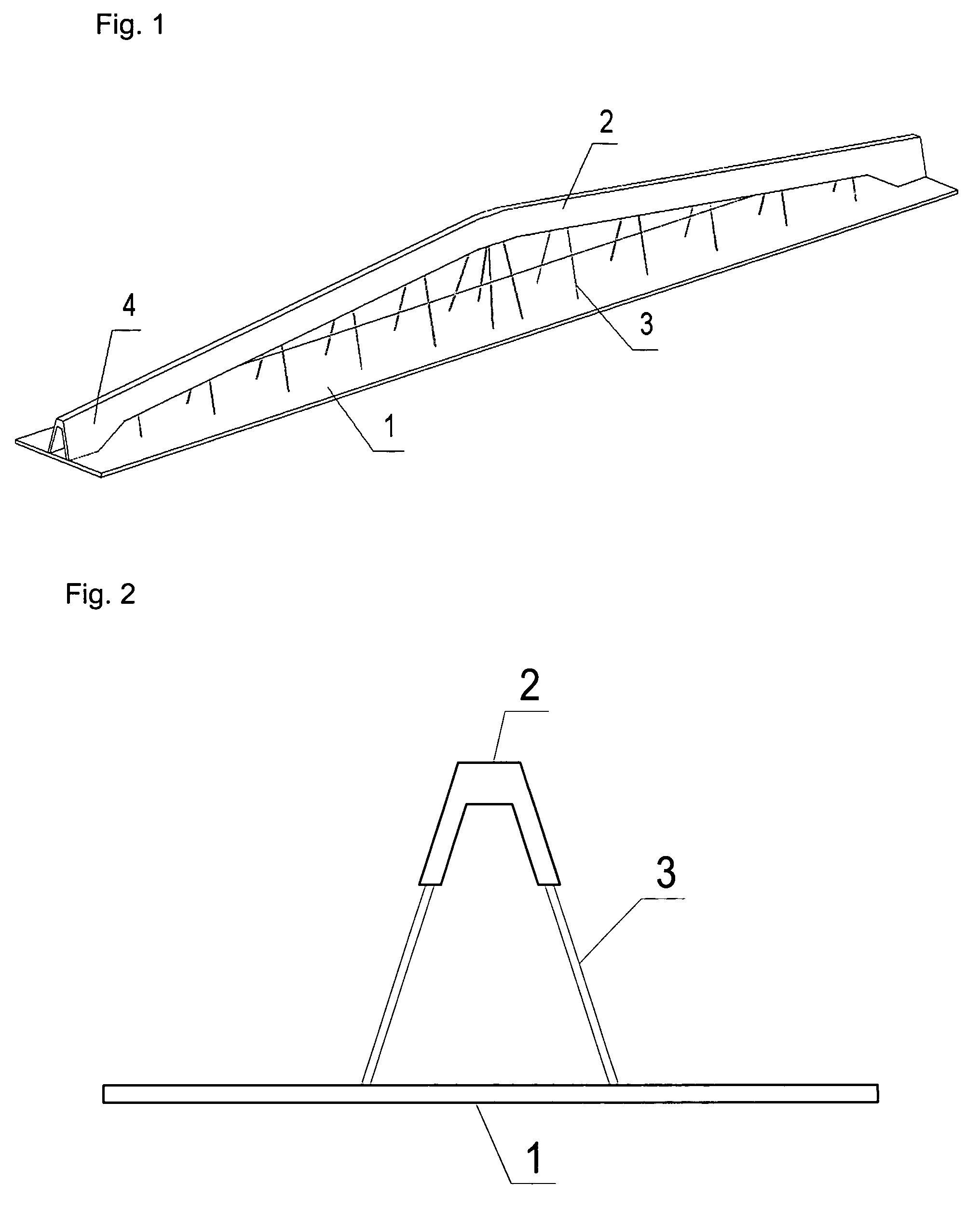

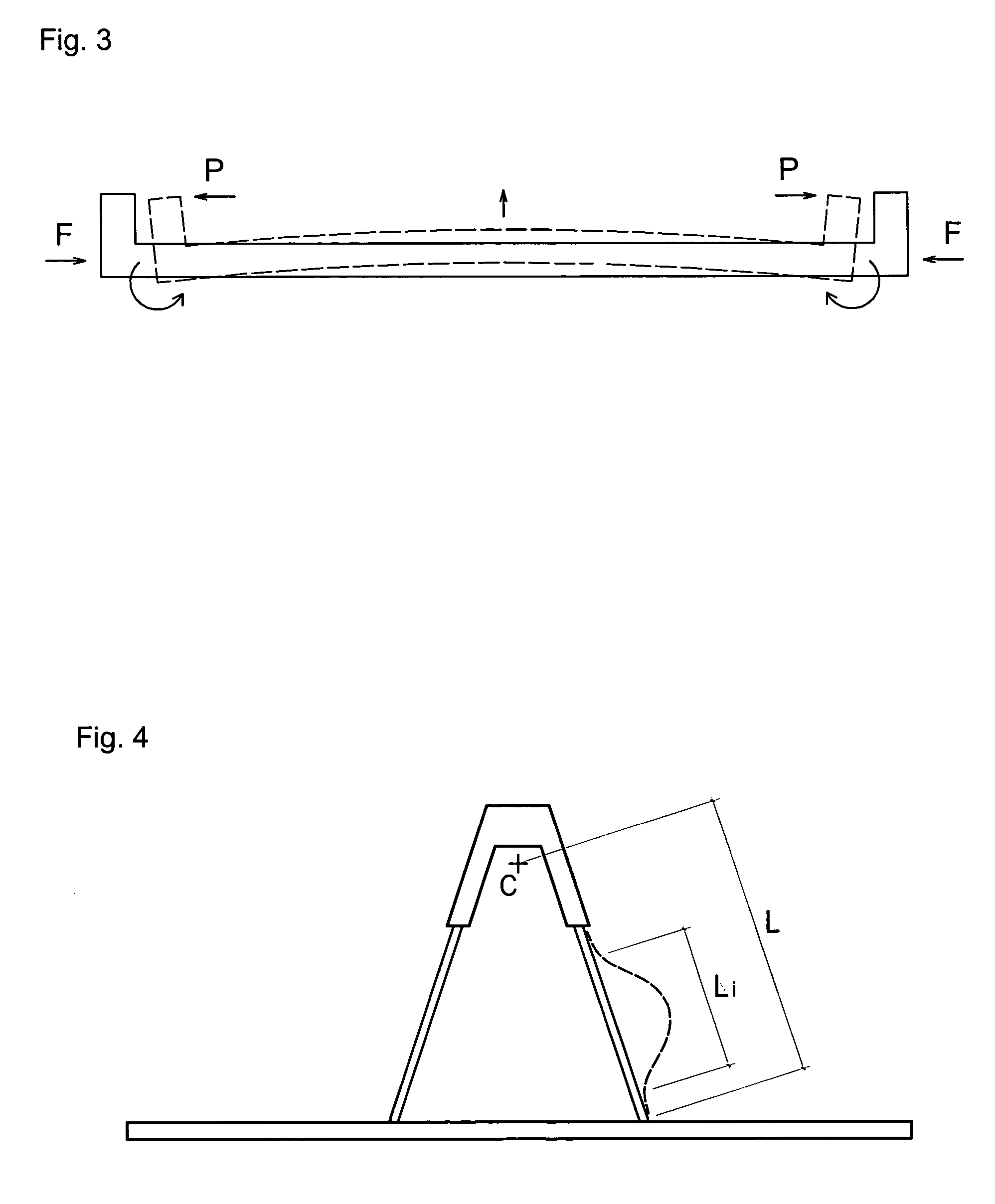

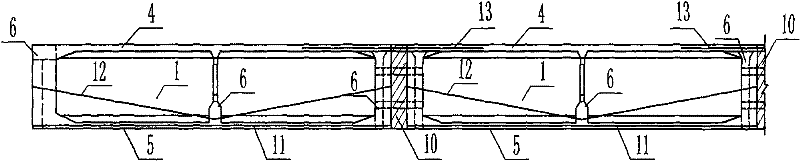

Indirectly prestressed, concrete, roof-ceiling construction with flat soffit

An indirectly prestressed concrete roof-ceiling construction is a prefabricated element for constructing large-span industrial buildings. The construction includes a distinctly wide and thin concrete soffit plate and an upper concrete girder of an inverse “V”-shaped cross section, interconnected by slender steel pipe-rods that are used to stabilize the upper girder against lateral buckling and to prevent the plate and the girder from getting closer or further away from each other. Prestressing of the soffit plate causes compression in the upper girder which passively (indirectly) pushes the ends of the construction, acting on some eccentricity over the center of gravity of the cross section, causing rotation of its ends, bending in that way the soffit plate upwards. There are two efficient methods of prestressing these constructions.

Owner:MARA INST D O O

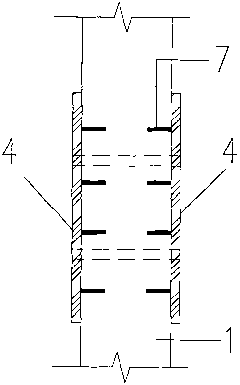

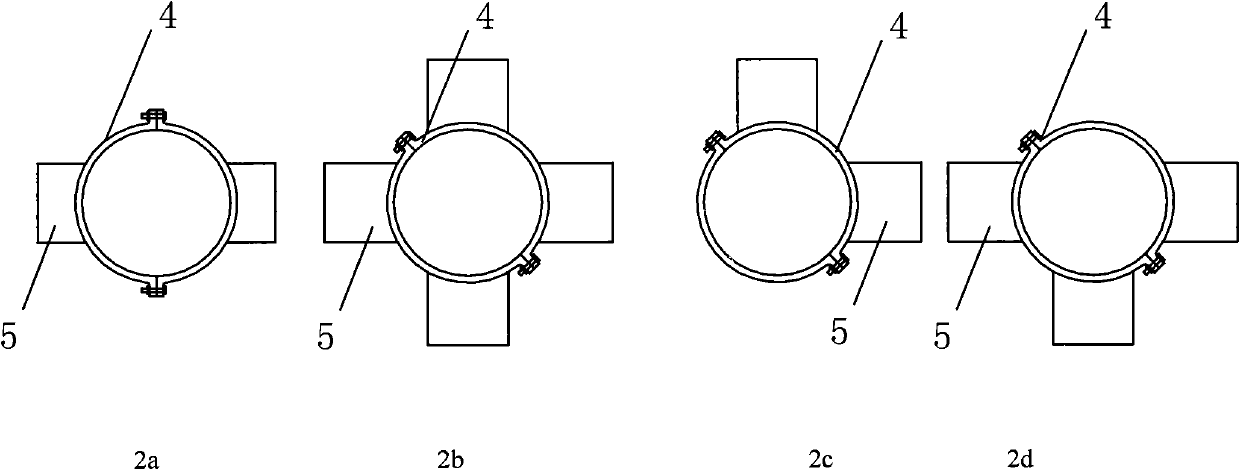

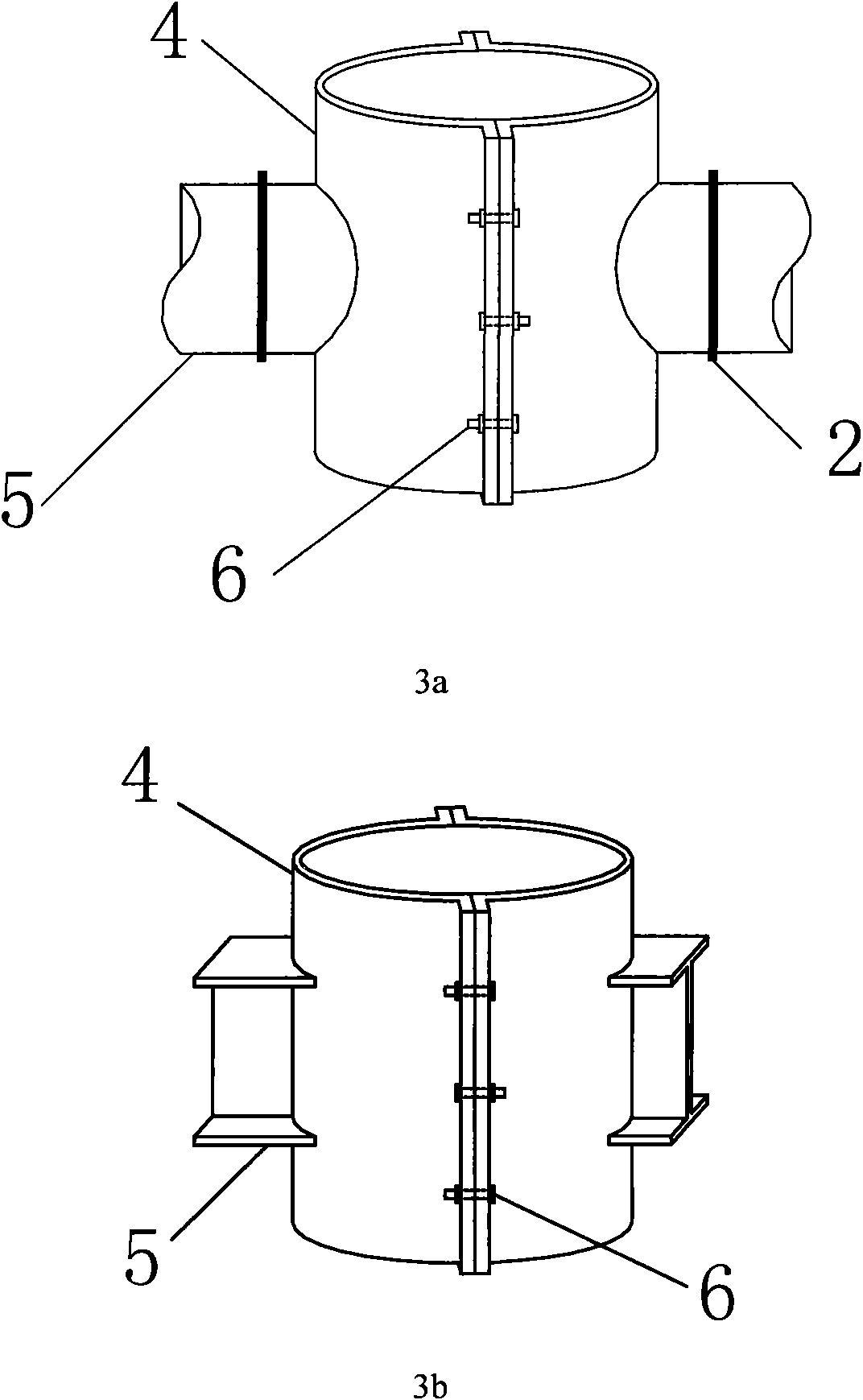

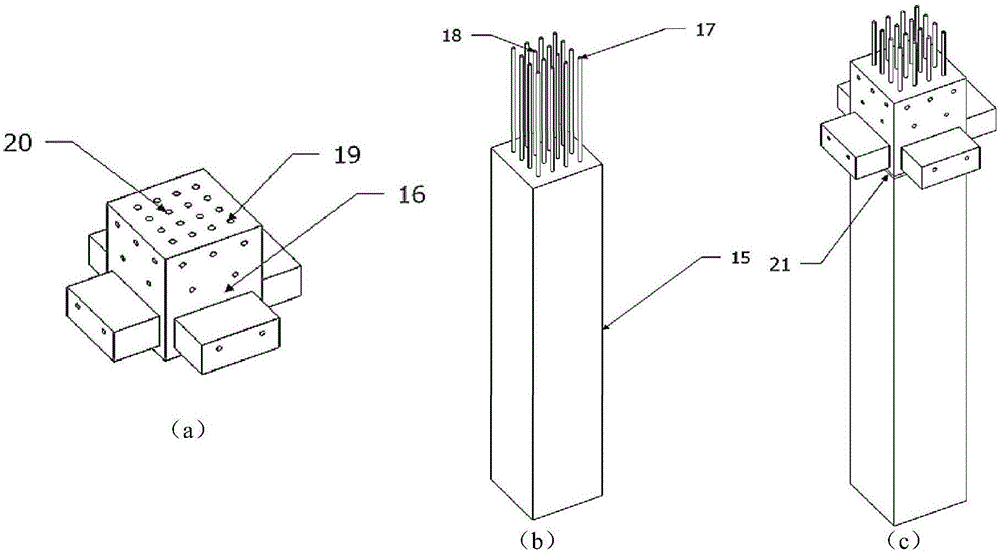

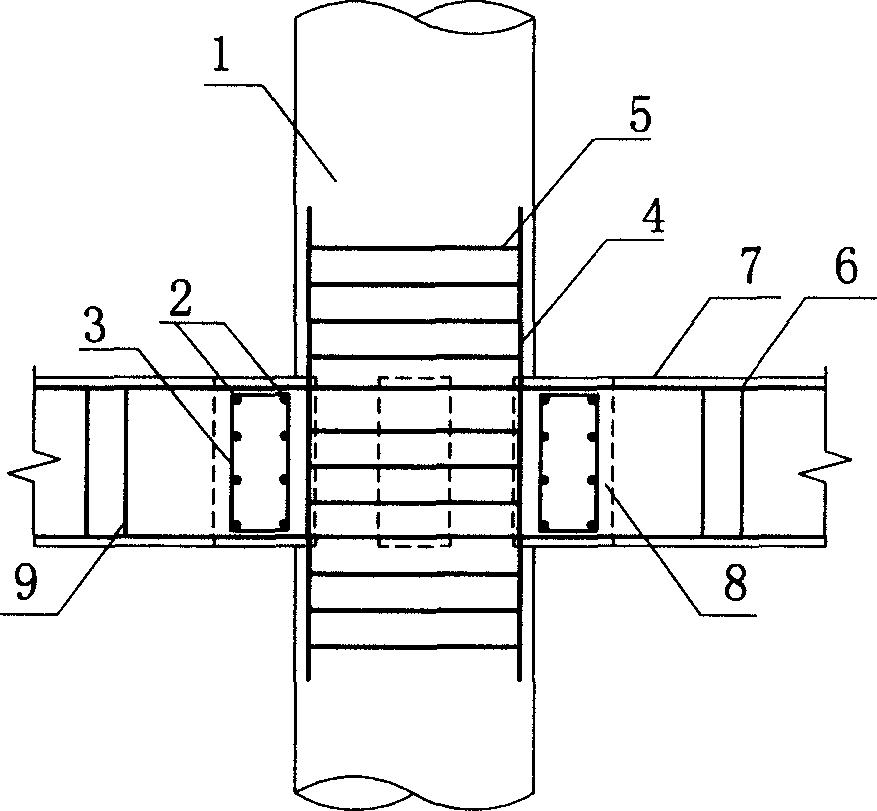

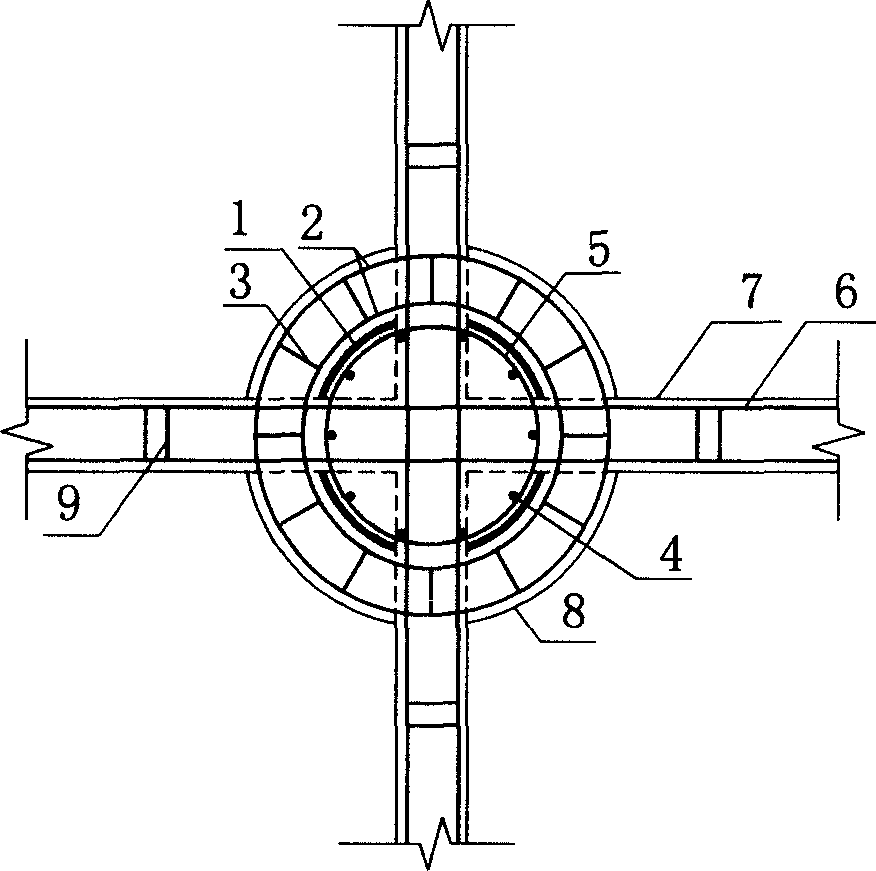

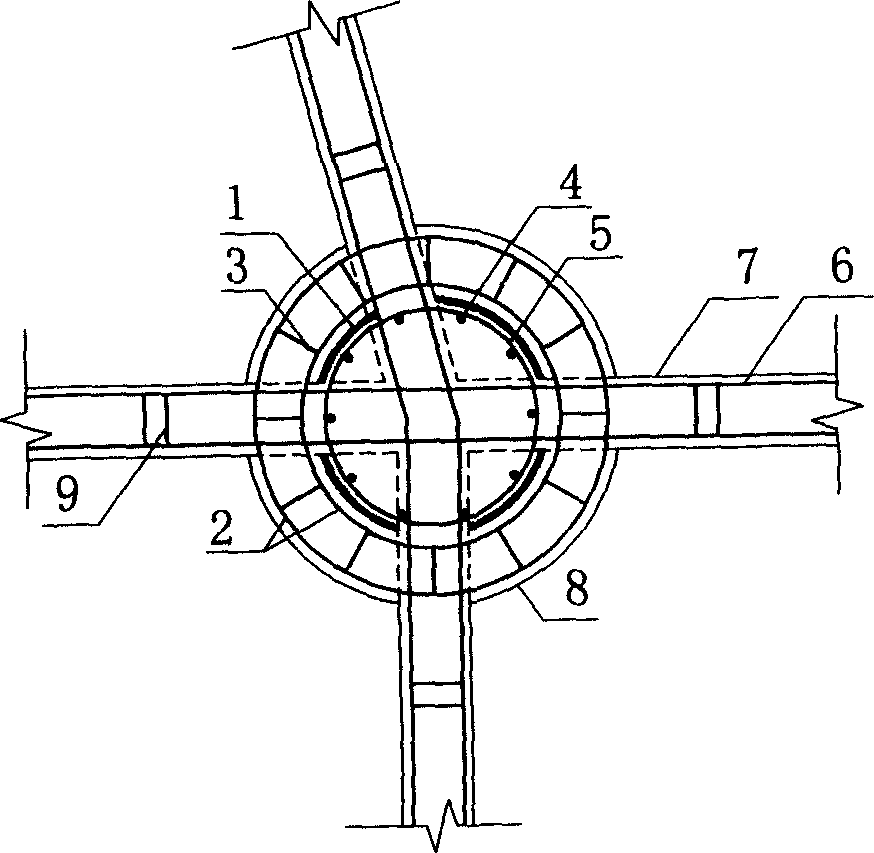

Circular steel tube concrete column and beam node connecting structure

InactiveCN101769011AFirmly connectedNode structure is simpleBuilding constructionsConcrete beamsEngineering

The invention discloses a circular steel tube concrete column and beam node connecting structure, which is characterized in that: the connecting structure comprises a node fastener, a bolt, a circular steel tube concrete column and a beam; the node fastener is composed of two sections of fastening rings and a joint, and the joint is in sleeve type and horizontally H-shaped type, the circular steel tube concrete column penetrates in the fastening rings and is fastened by the bolt, and the beam is connected by the joint on the fastener; the field installation is convenient without welding and the construction is rapid; the fastener is composed of two sections and is connected by the bolt after being fixed, and the circular steel tube concrete column is fixed by tightening force of the fastener; the circular steel tube concrete column is inserted in the sleeve type joint and is fixedly connected with the sleeve type joint by the bolt, and a concrete beam steel bar and a steel girder are welded with the horizontally H-shaped type joint; besides welding of the concrete beam steel bar and the horizontally H-shaped type joint, in the whole process, welding and complex distributed steel do not need, the construction is simple and rapid.

Owner:HOHAI UNIV

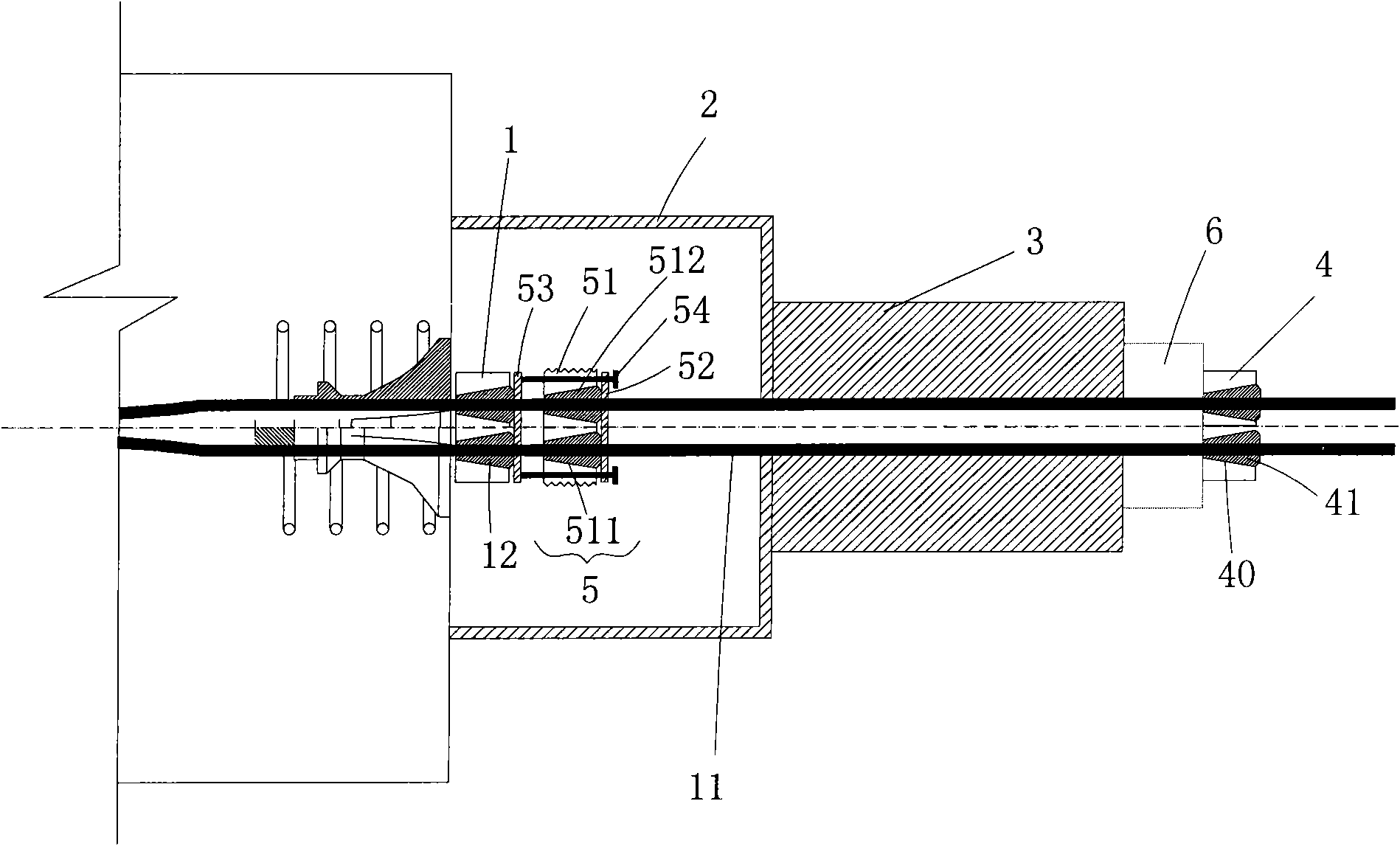

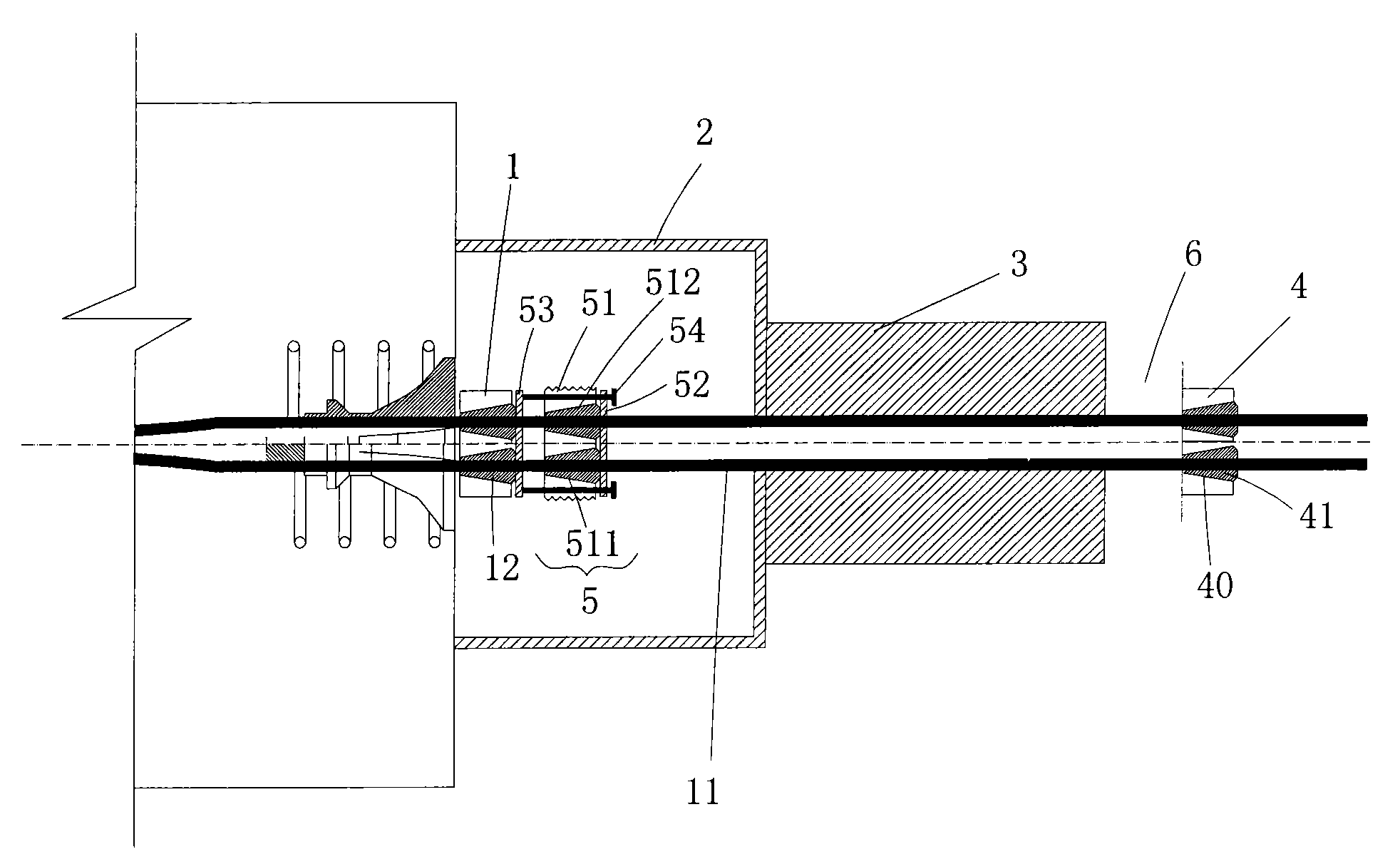

Method for detecting concrete beam anchor lower prestress and device for realizing method

InactiveCN101769075AAvoid wastingImprove quality levelBridge structural detailsExcavationsQuality levelConcrete beams

The invention discloses a method for detecting the concrete beam anchor lower prestress and a device for realizing the method. The device for detecting the concrete beam anchor lower prestress is arranged on an anchor rope of a concrete beam, which is tensioned and is not grouted; and a working anchor is locked at the root part of the anchor rope extending out of the concrete beam. The device comprises a counter-force cylinder, a through jack and a working anchor which are sequentially arranged on the anchor rope in a serial mode; the counter-force cylinder is sleeved outside the working anchor; the bottom of the counter-force cylinder is open; an opening surface is attached to and bears a concrete beam section of the working anchor; the top of the working anchor is provided with a through hole for the anchor rope to pass through; the jack is arranged on the top surface of the counter-force cylinder for tensioning the anchor rope; the working anchor is installed on the jack for locking the anchor rope; and the device also comprises a displacement and load tester which is connected to the anchor rope in series and is positioned between the counter-force cylinder and the working anchor. The method for detecting the concrete beam anchor lower prestress and the device for realizing the method can standardize the quality control behavior of a prestress bridge and improve the integral quality level of the prestress bridge.

Owner:中铁西北科学研究院有限公司深圳南方分院

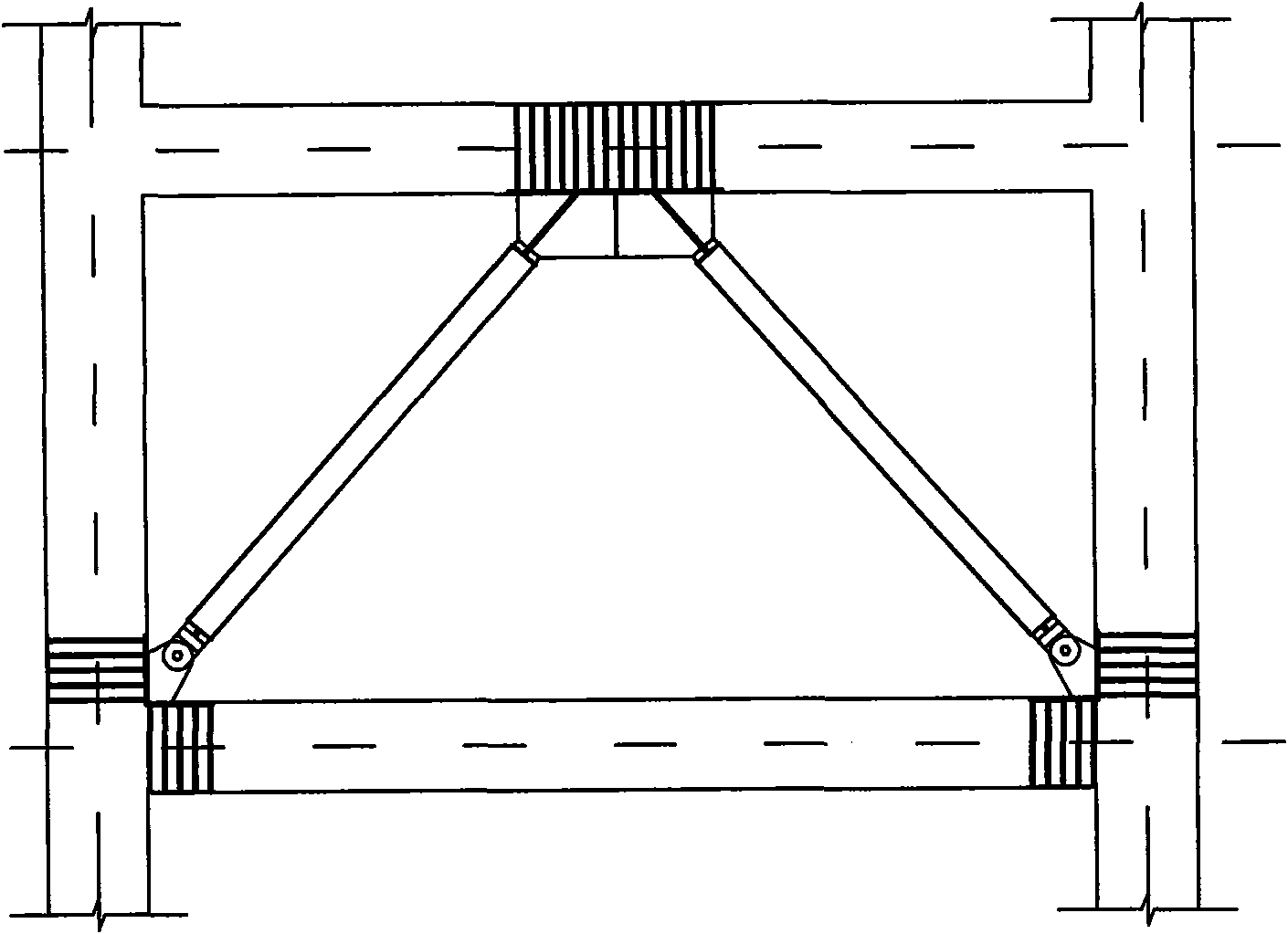

Steel bar concrete beam reinforcing structure with partially restrained steel truss

The invention discloses a steel bar concrete beam reinforcing structure with a partially restrained steel truss, comprising upper angle steel, lower angle steels, a web batten plate, a bottom steel plate, an anchored steel plate, a shear resistant anchor bolt and a bolt, wherein the upper angle steel, the lower angle steels, the web batten plate and the bottom steel plate are spliced to form an opened steel truss for tightly hooping a beam to be reinforced, the lower angle steels are respectively arranged at two lower corners of the beam to be reinforced and are connected with each other by the bottom steel plate, the upper angle steel is mounted between the beam to be reinforced and a slab, and is connected with the lower angle steels by the web batten plate, the anchored steel plate is arranged in the slab and is connected with the shear resistant anchor bolt arranged in the slab, and the shear resistant anchor bolt is connected with the upper angle steel by the bolt in a pre-fastening mode. The steel truss and the steel bar concrete beam form two load bearing protection lines, so the bearing capacity of the steel bar concrete beam meets the reinforcing design requirement, and the safety of a member and a structure can be ensured.

Owner:NANJING UNIV OF TECH

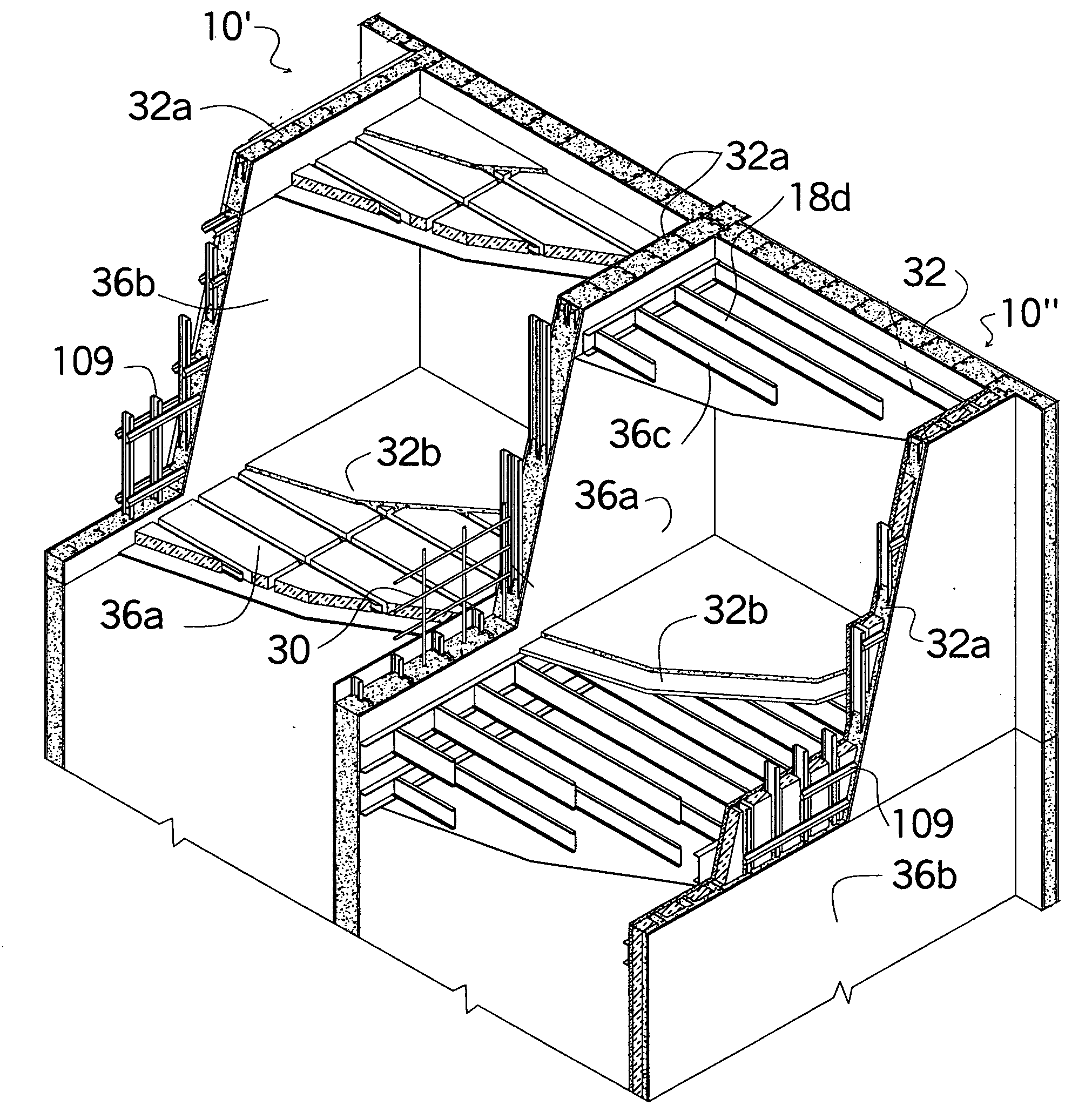

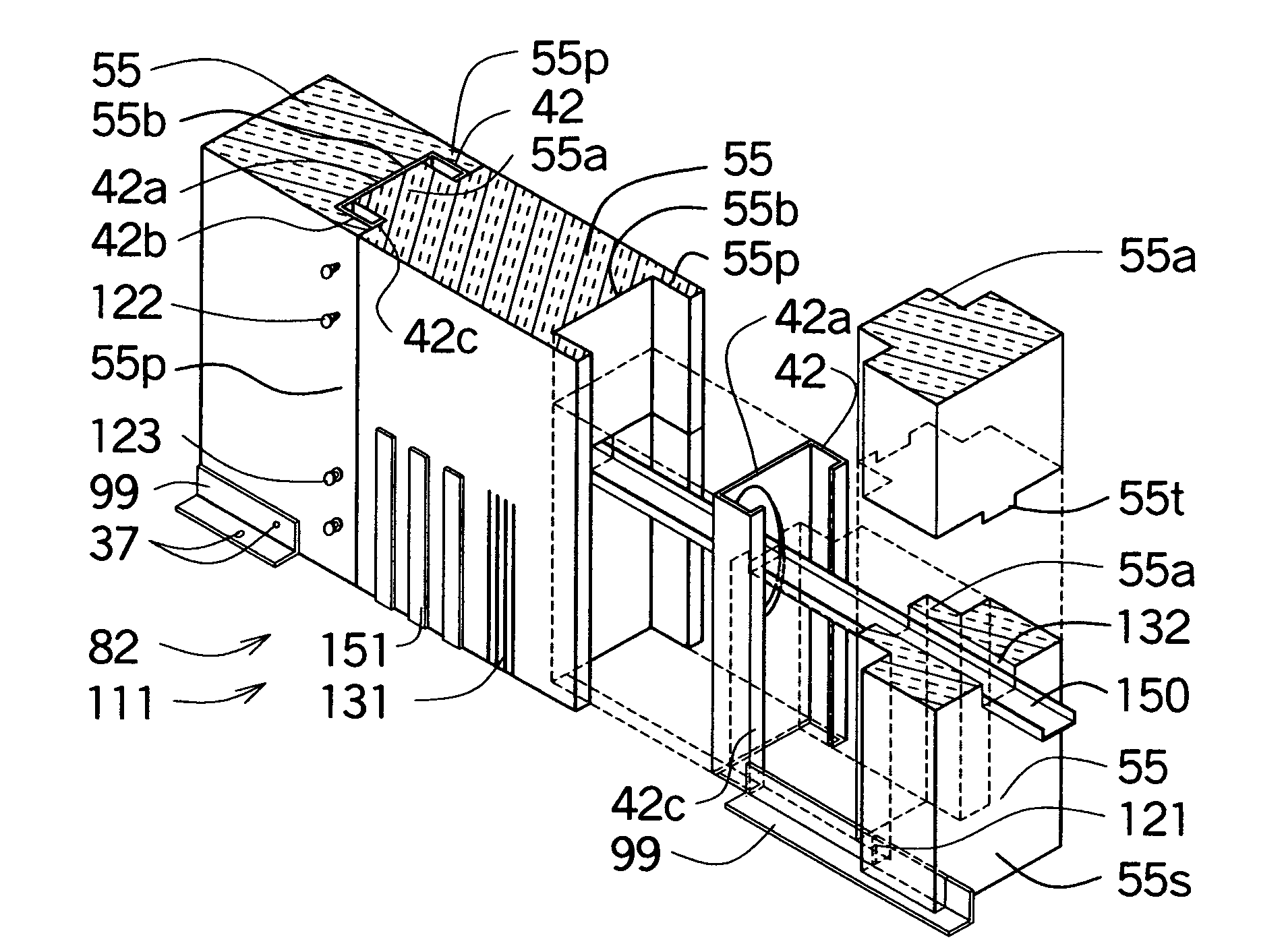

Modular building construction employing concrete mold assembly

A modular building construction where each module consists of self-contained molds to allow concrete to form within the walls of each module as well as between the modules when two or more modules are placed together. The structural load capacities of the modules are transmitted directly into the concrete within the wall without bearing directly on the module below. The forming structure for the modules can be fabricated either using wood or metal construction. The exterior and interior wall finishes are the resulting structure of the molds. Since the molds are self-contained the walls can consist of, either drywall, rigid insulation, thin brick or siding just to name a few. The interior forming structure can extend into the concrete footing or above or to adjacent modules to structurally secure the modules together. The modules can be built with a flooring structure as well as ceiling. The interior walls as well as the floor and ceiling also function as wall supporting braces. The exterior walls have many different forming molds to accommodate many different construction situations. Some forming structures are formed with a thermal break between the exterior and interior forming structure. The thermal break allows the wall to also be used as a heating or cooling distribution system. Different types of connectors are described allowing for the connectors to be hidden. Several methods are shown how the electrical distribution can be provided within a concrete wall by using the forming structure within the mold. A ribbed concrete mold can be formed for a poured-in-place wall as well as for a floor and roof system. Temporary floor bracing can be used when pouring the flooring system, or only just the concrete beams can be poured and the floor can be poured later. The flooring system can be used as concrete wall or as a roof structure.

Owner:LEBLANG DENNIS

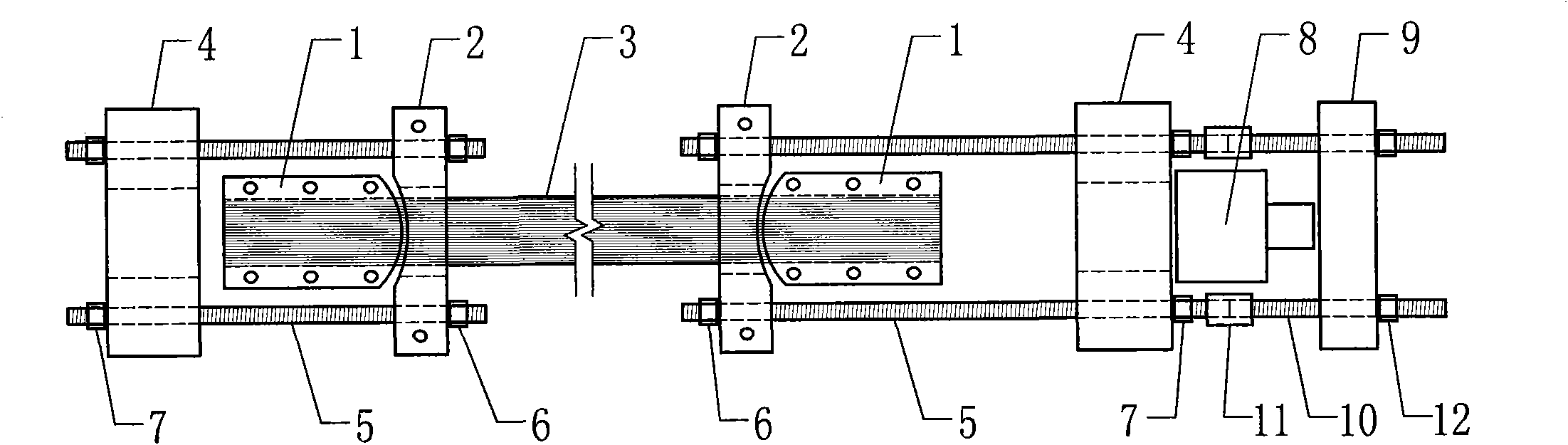

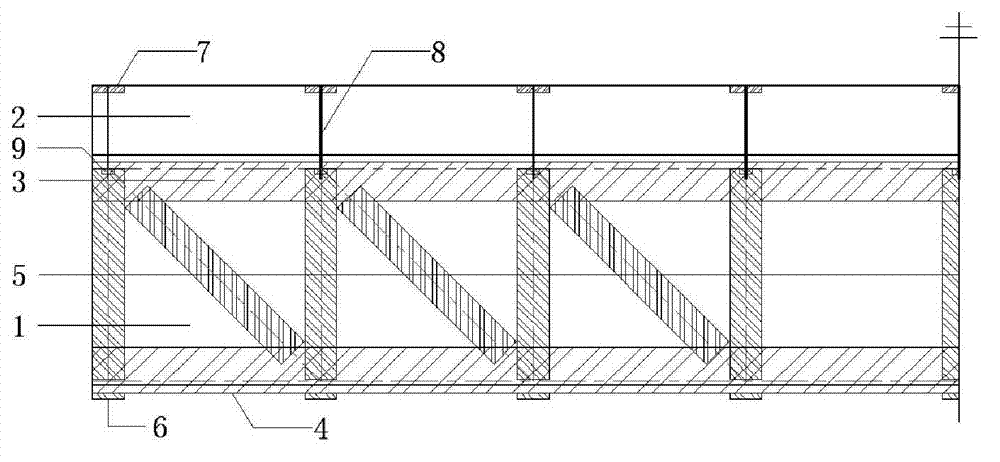

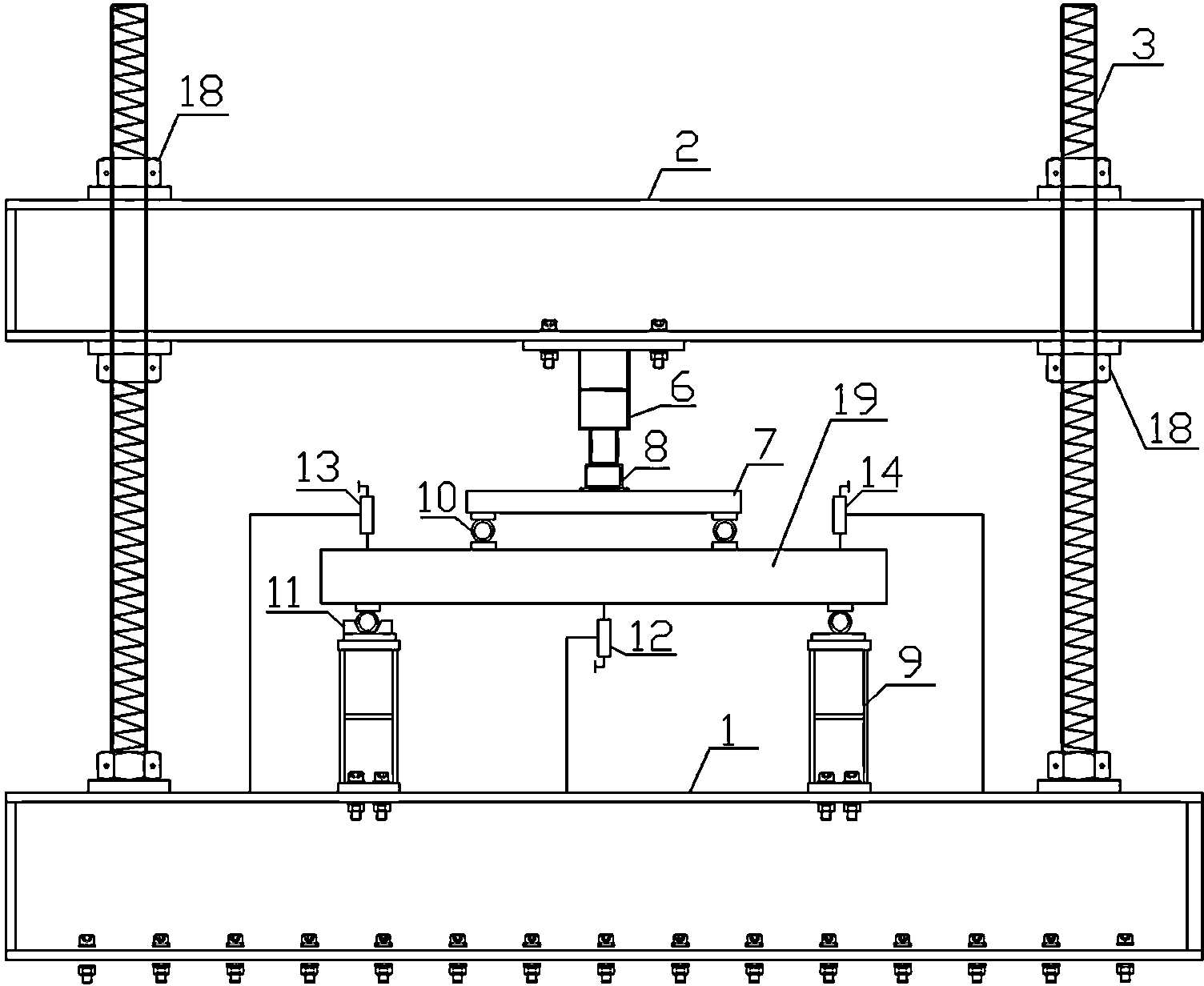

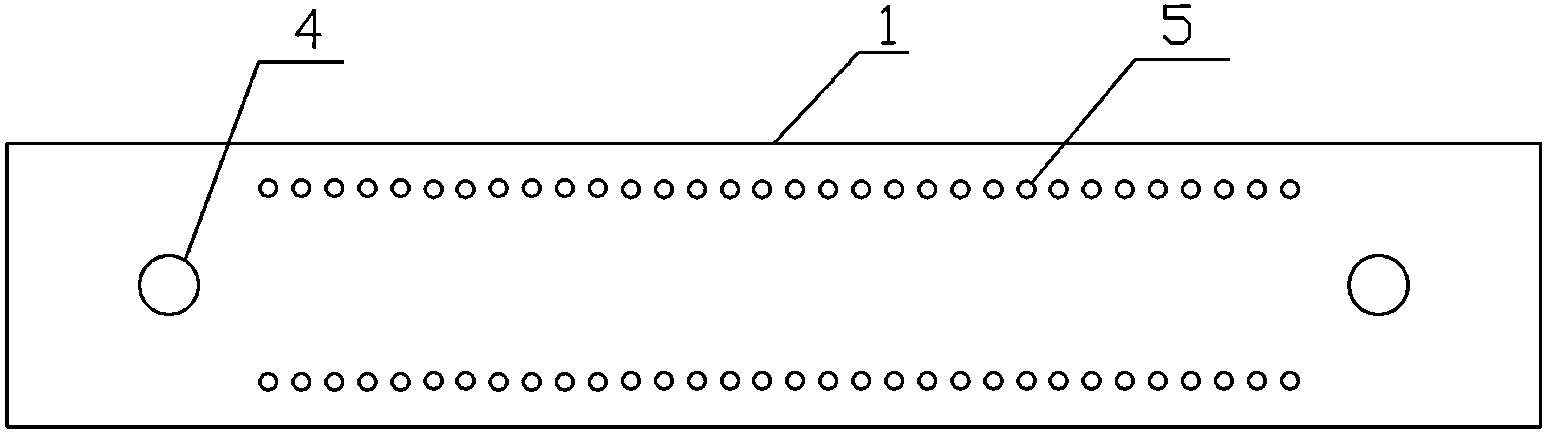

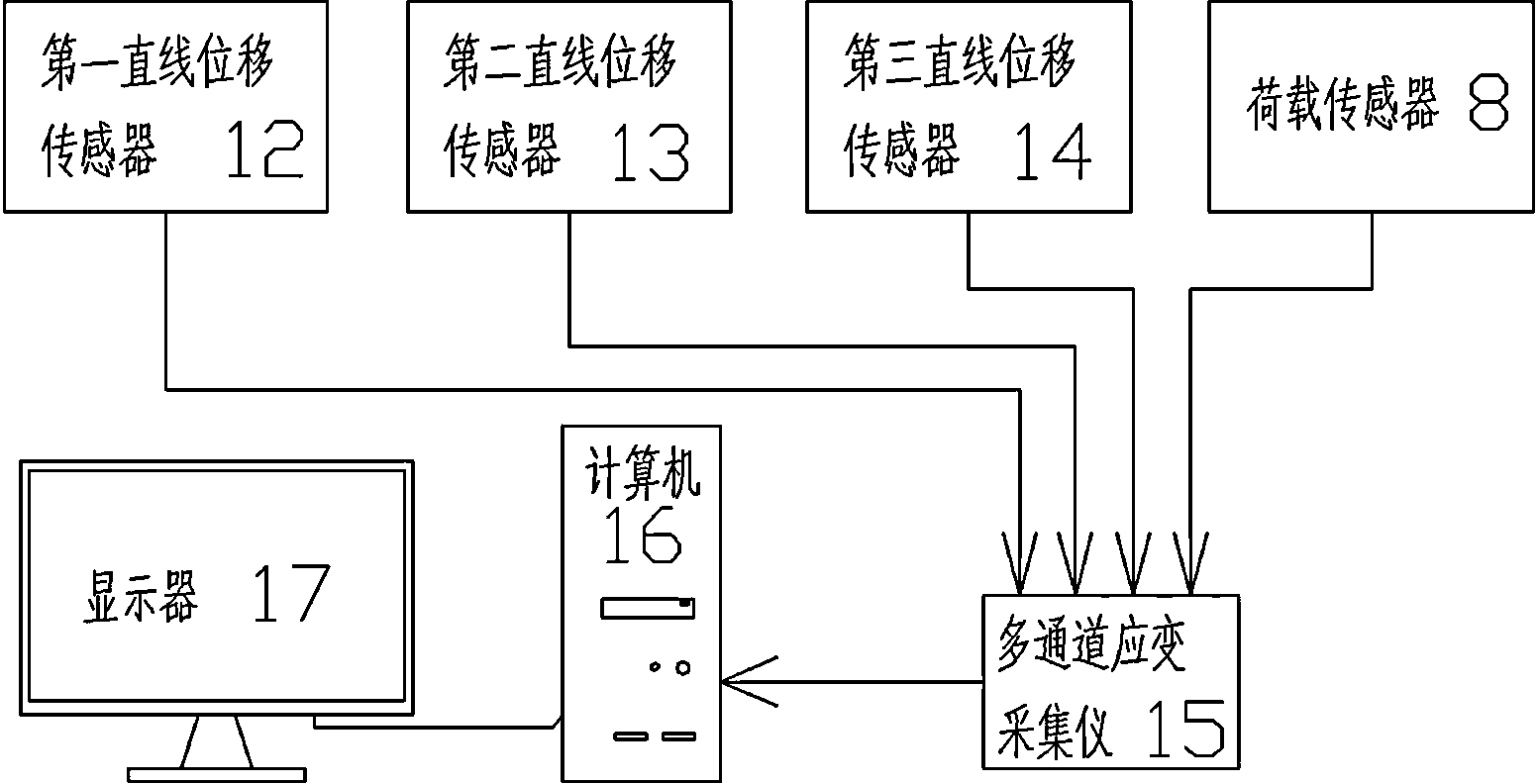

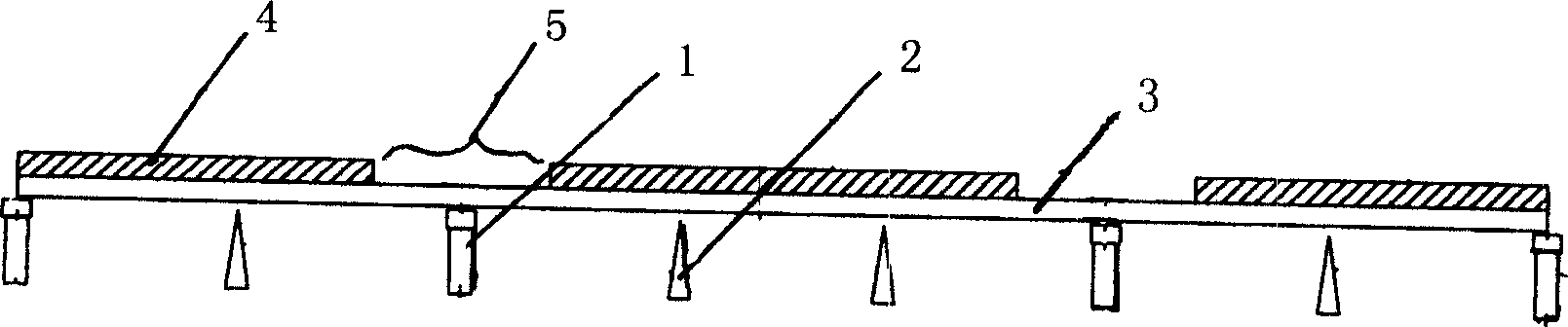

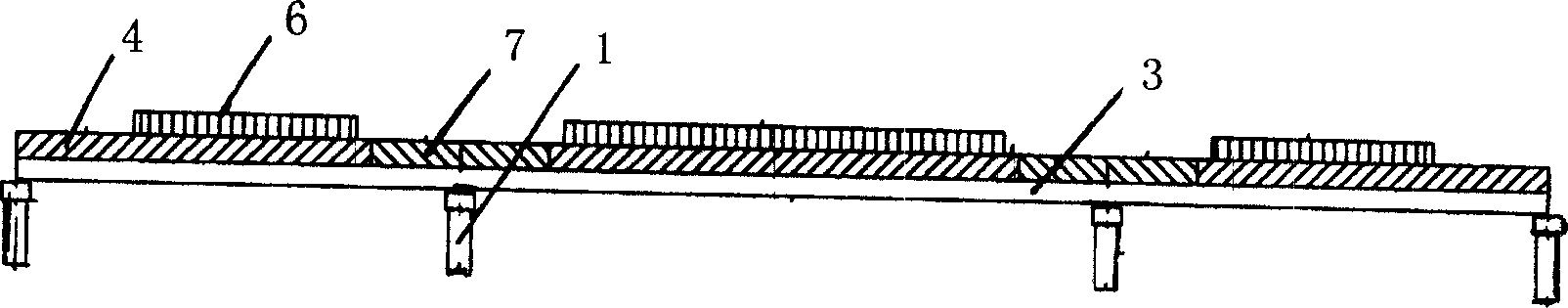

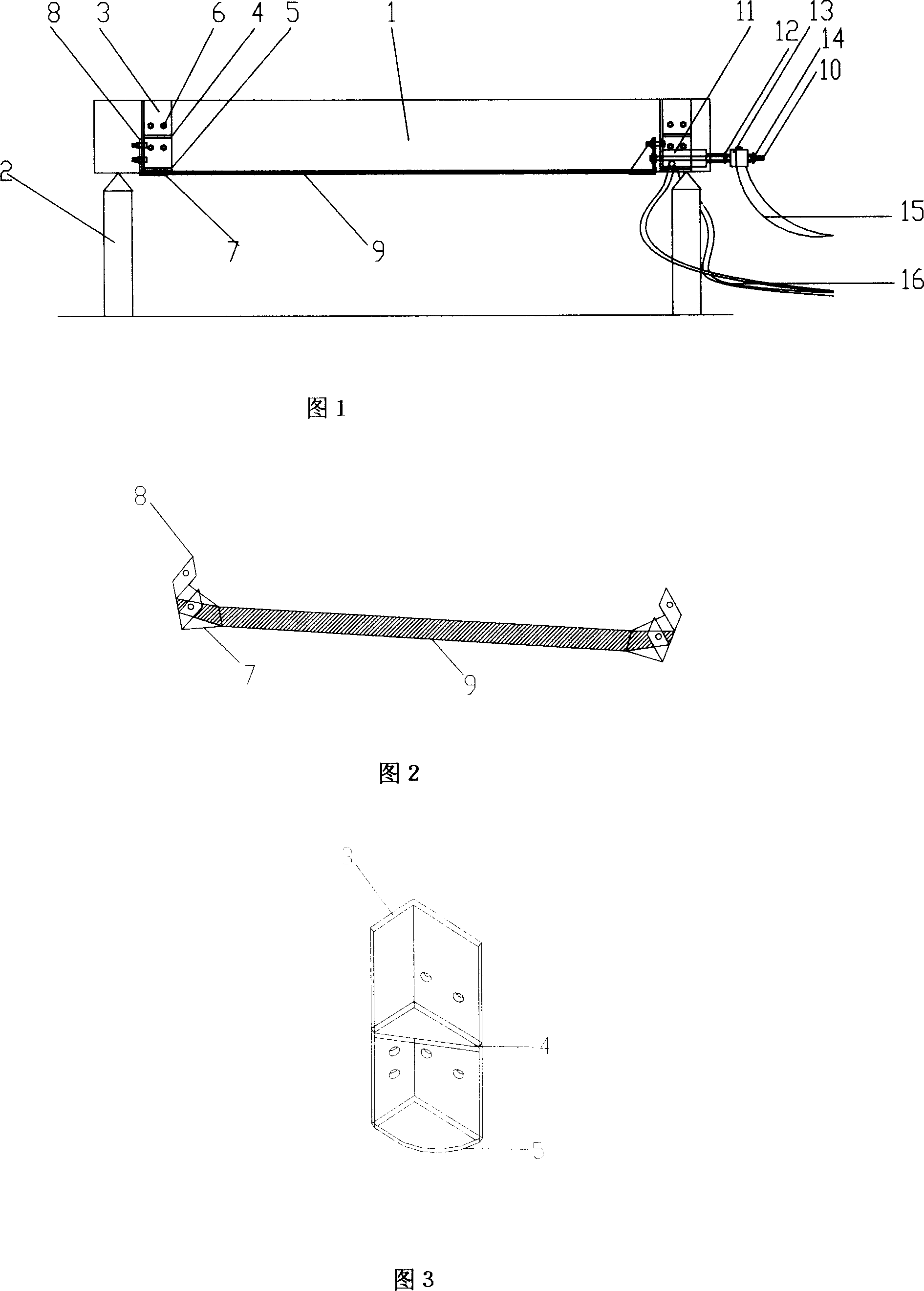

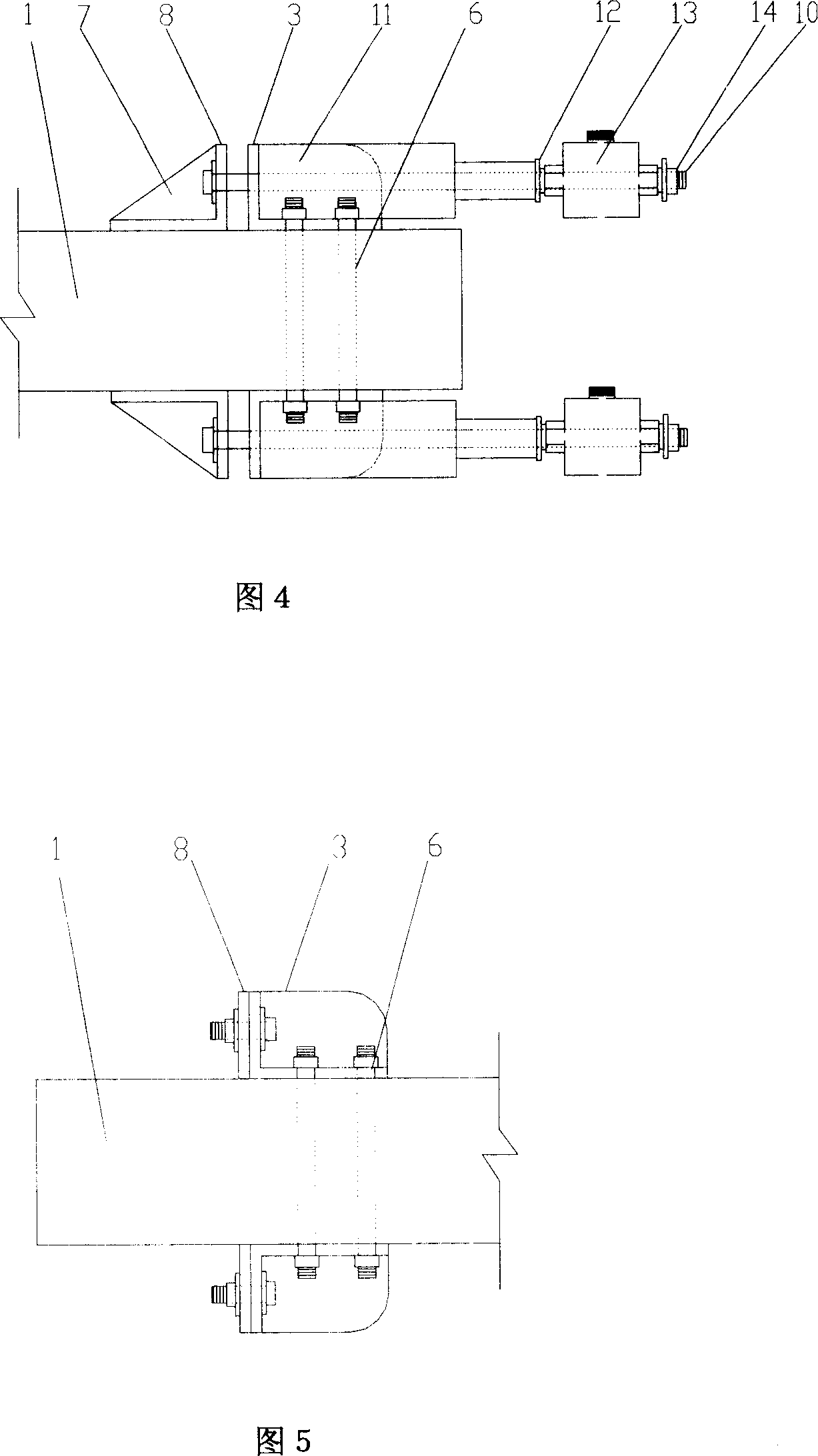

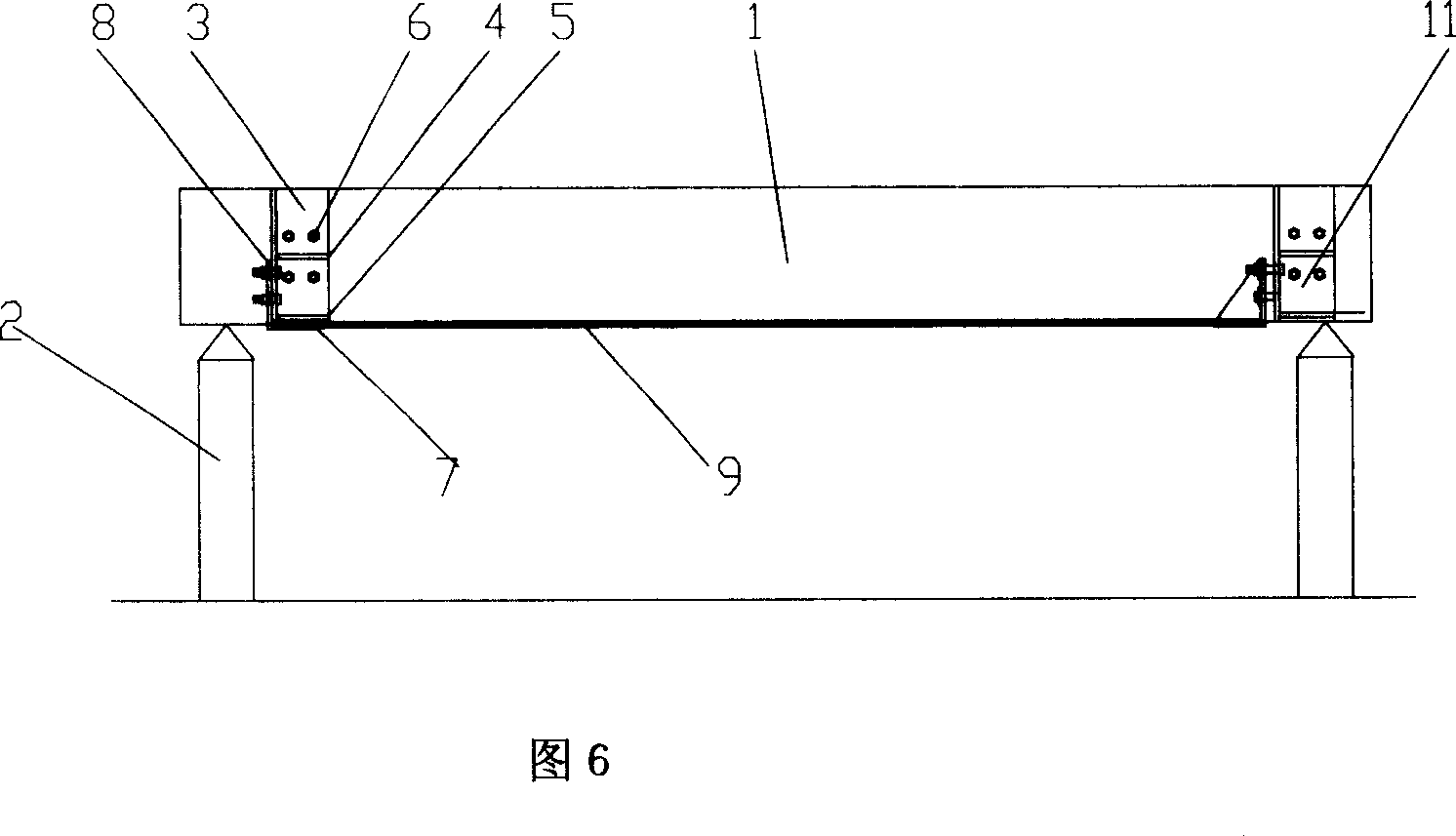

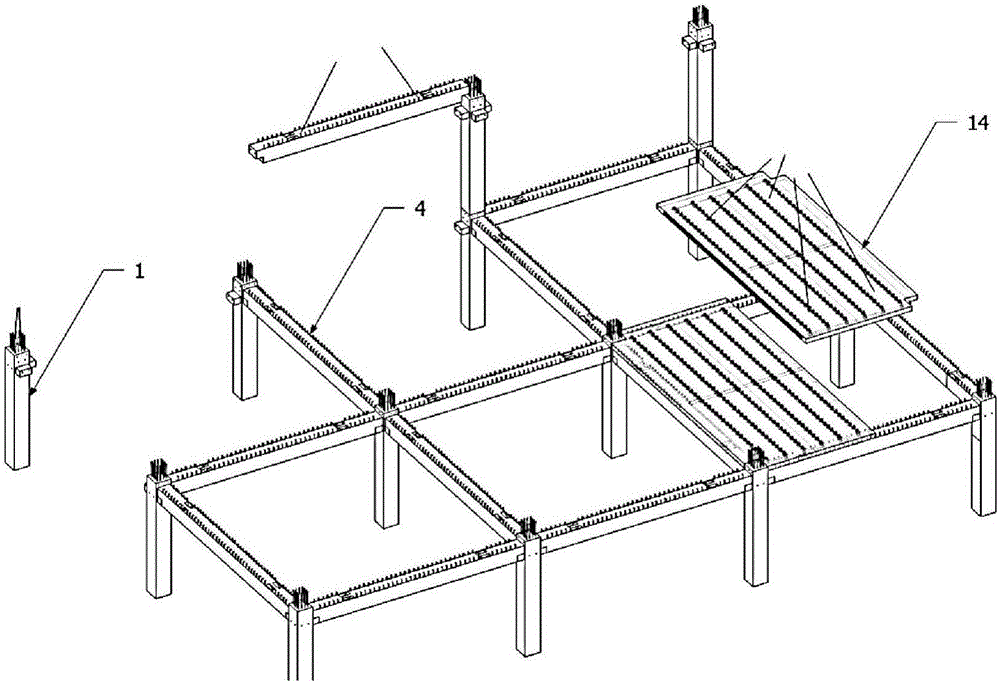

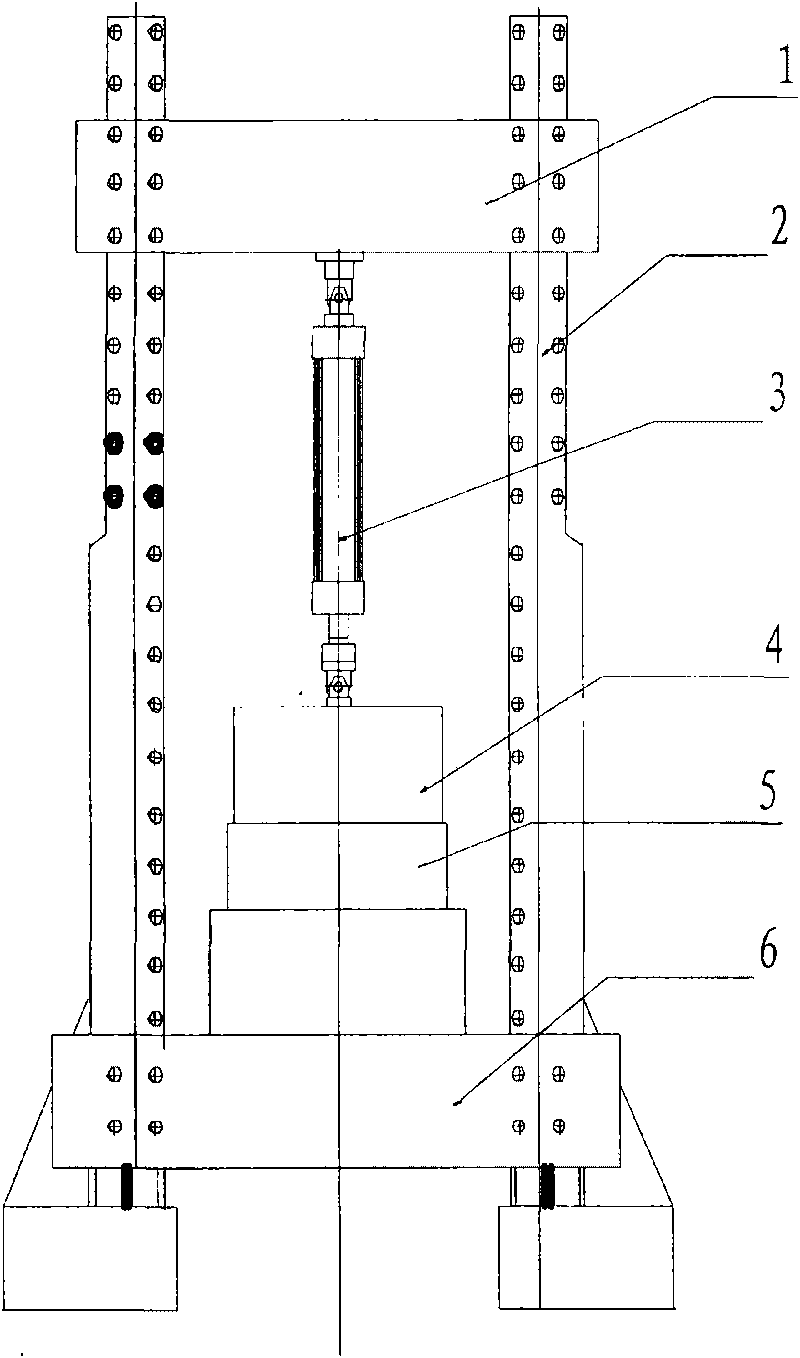

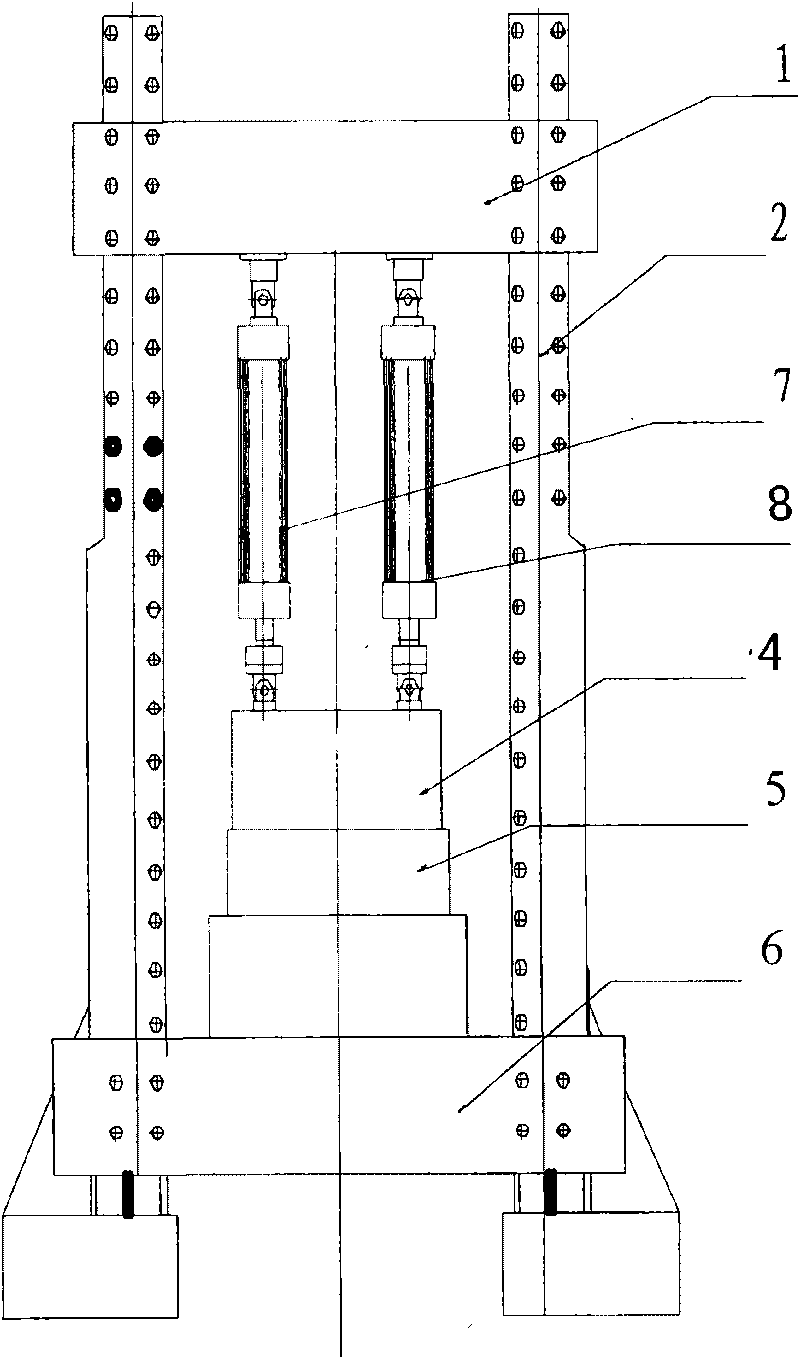

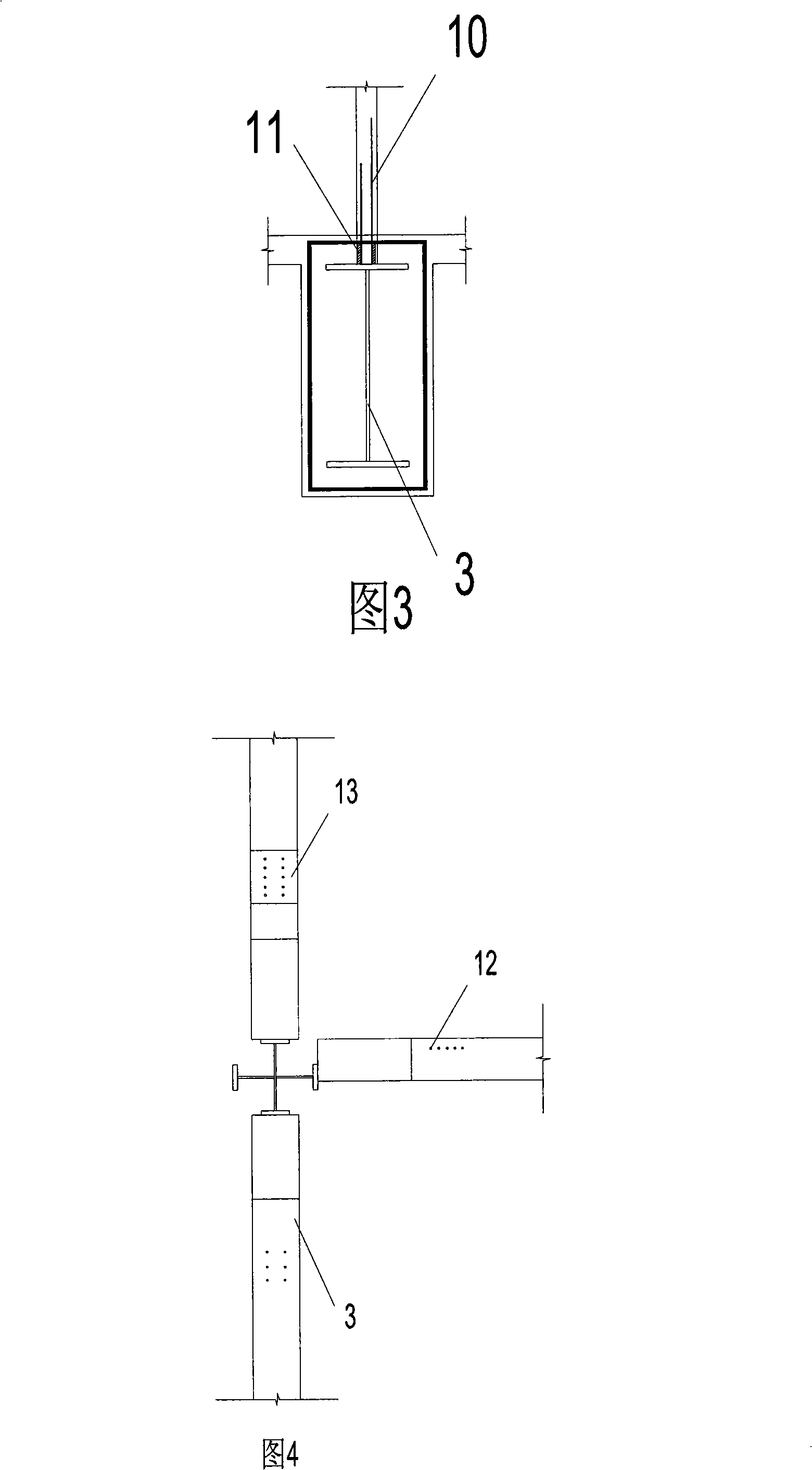

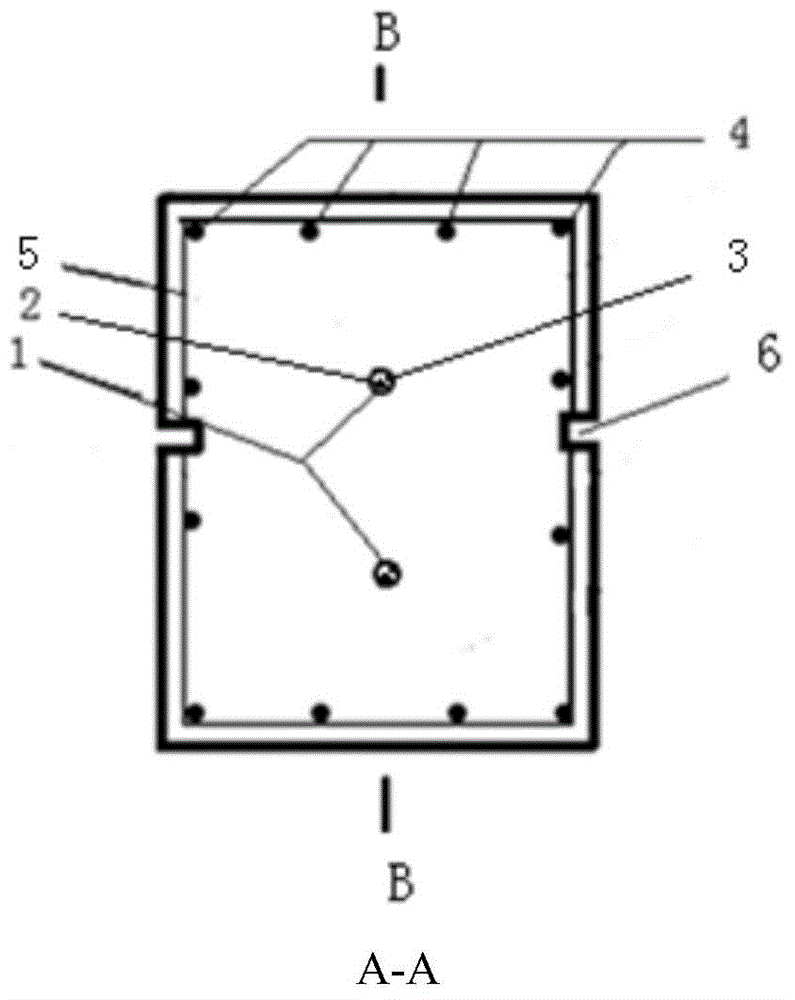

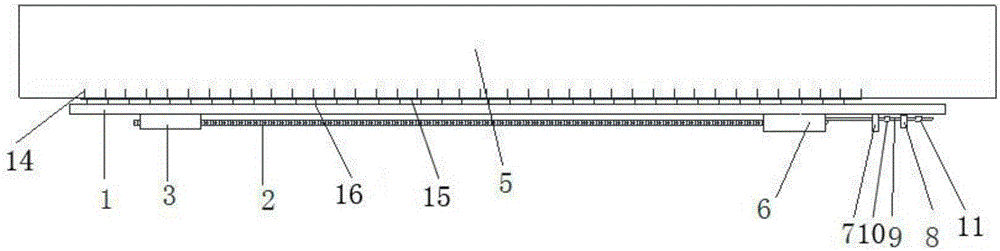

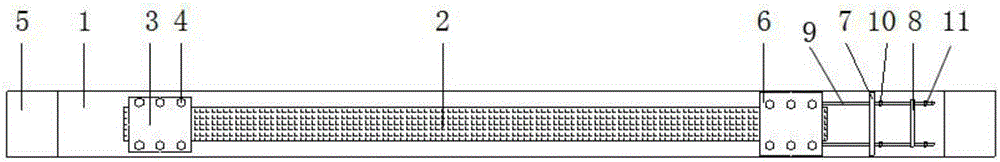

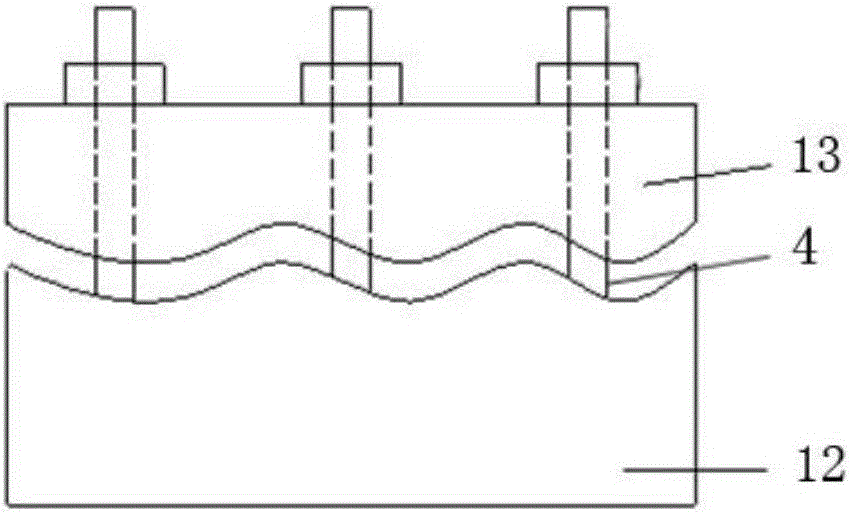

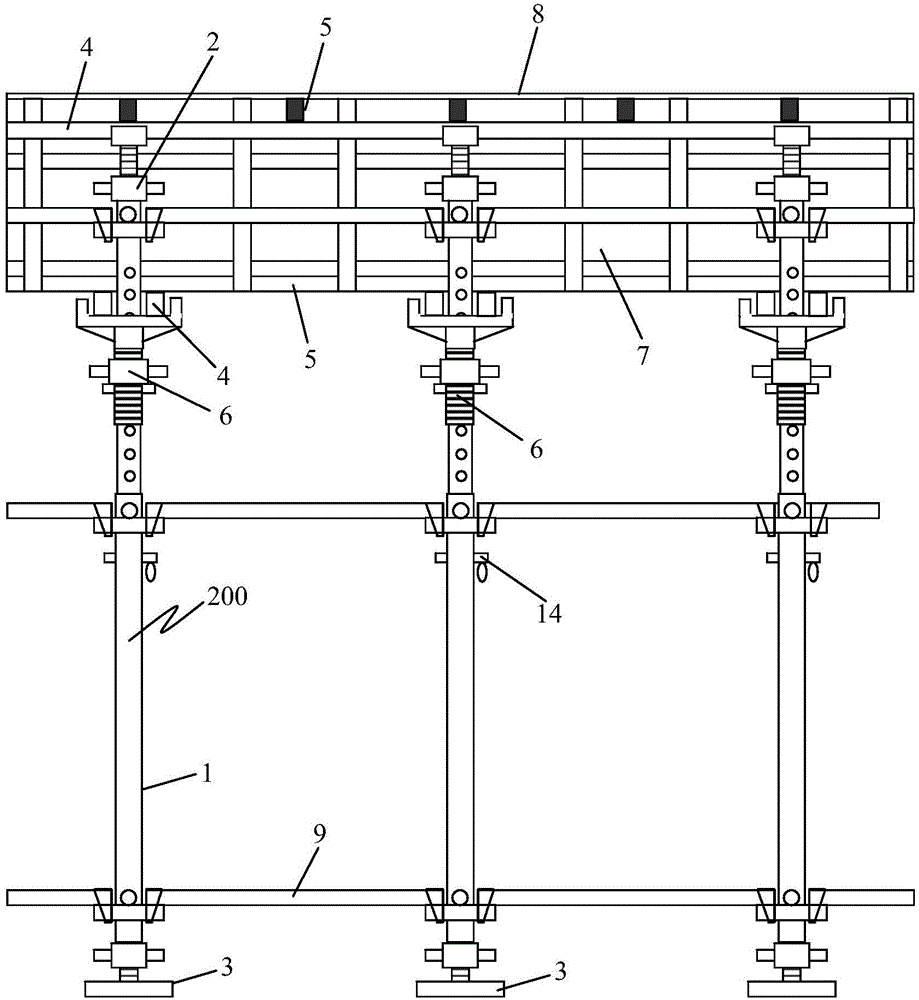

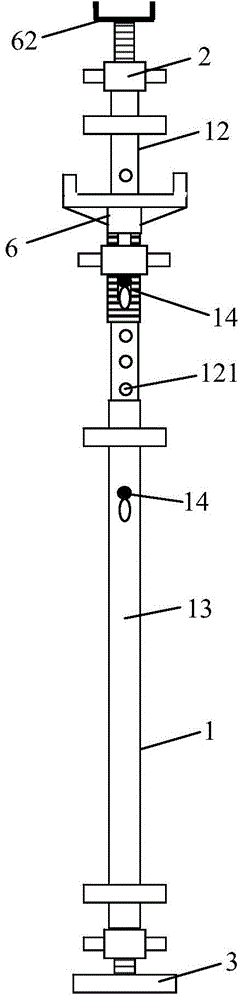

Static force load testing device for concrete beam

InactiveCN103776685AEasy to monitorMeet the test requirementsStrength propertiesConcrete beamsTransducer

The invention discloses a static force load testing device for a concrete beam. The device comprises a base (1), a crossbeam (2), and an upright post (3) provided with an external thread, wherein the upright post (3) is respectively fixedly connected with the base (1) and the crossbeam (2) in a manner of screw-thread fit; a hydraulic jack (6), a load transducer (8) and a load allocation beam (7) are sequentially mounted on the bottom surface of the crossbeam (2); first spherical hinges (10) used for transmitting load to the concrete beam (19) are respectively arranged at the two ends of the bottom surface of the load allocation beam (7); an adjusting hole (5) is formed in the top of the base (1); the base (1) is fixedly connected with a support seat (9) used for supporting the concrete beam (19) through the adjusting hole (5); a second spherical hinge (11) is arranged at the top of the support seat (9); a linear displacement sensor used for detecting the deformation of the concrete beam (19) is mounted on the base (1); the hydraulic jack (6) is used for applying the load to the concrete beam (19), and a computer (16) is used for analyzing and processing acquired signals so as to monitor the test process; the crossbeam (2) and the support seat (9) are regulated to adapt to load tests of concrete beams of different sizes; the overall device can be dismounted and mounted, and is convenient to store and transport.

Owner:ANHUI & HUAI RIVER WATER RESOURCES RES INST +1

Construction method for formed steel reinforced concrete beam-column nodes

InactiveCN102322101AImprove project qualityImprove carrying capacityBuilding constructionsConcrete beamsRebar

The invention relates to a construction method for formed steel reinforced concrete beam-column nodes, belonging to the technical field of industrial and civil building construction. According to the invention, the problem for arranging and binding intricate and complicated steel bars and corresponding formed steel in formed steel beam and formed steel column connection node domains is creatively and sequentially solved; the boring of formed steel wing plates is avoided; the up-and-down adjusting and the bending for horizontal bars of X beams and Y beams can be realized through enabling the horizontal / longitudinal bars of the X beams and the Y beams to intersect with the formed steel columns and opening vertical long-strip holes on web plates of the formed steel columns; the area of the openings on the web plates of the formed steel columns is controlled to exceed 20% of that of the sectional area of the web plates, thus the negative influence on the strength of the web plates of the formed steel columns because of the openings is reduced to the maximum; and hoop bars are orderly arranged on the upper surfaces of column stiffening plates at intervals at the spatial staggered positions of column main bars, the column stiffening plates and column hoop bars, thus the number of steel bar joints is reduced. The construction method provided by the invention not only increases the construction efficiency, but also ensures to enhance the project quality and the node domain bearing capacity for the beam-column connection of formed steel reinforced concrete structures.

Owner:HUBEI HONGYI BUILDING DECORATION ENG

Method for anti-cracking in hogging moment area of steel-concrete combined beam

InactiveCN1587531ALow costEasy constructionLoad-supporting elementsBridge structural detailsConcrete beamsBending moment

The present invention discloses anti-cracking method in negative hogging moment area of combined steel-concrete beam, and belongs to the field of support beam structure in road, bridge and building. The anti-cracking method includes two steps of depositing concrete in the positive hogging moment area and negative hogging moment area of continuous combined steel-concrete beam, laying pre-pressing load in the positive hogging moment area and introducing pre-pressing stress into concrete wing plate in the negative hogging moment area, so as to prevent cracking of the wing plate concrete and raise the durability of the structure. Compared with available technology, the construction method of the present invention is simple, fast and practical.

Owner:TSINGHUA UNIV

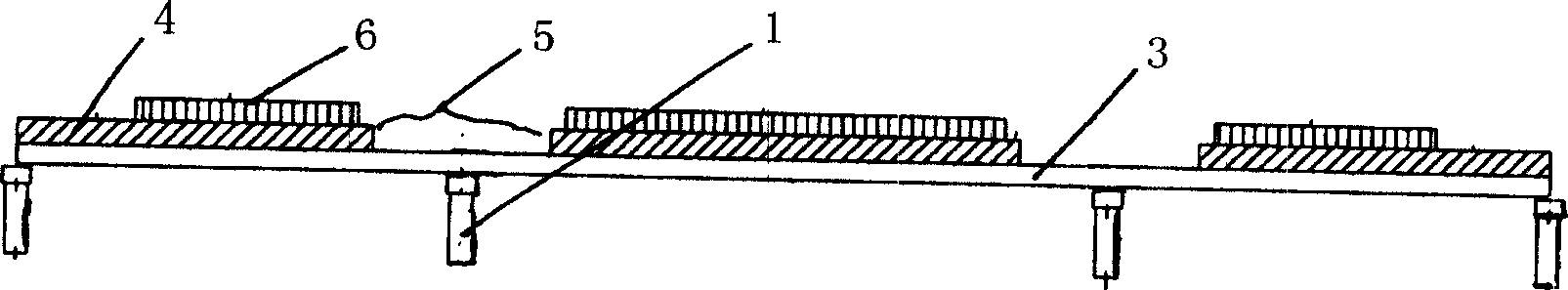

Construction process for pretension carbon fiber cloth reinforced concrete beam

InactiveCN1970974AReduce volumeIncrease stiffnessBuilding repairsBuilding material handlingFiberConcrete beams

The invention relates to a construction technology for strengthening concrete beams with prestretching CFRP, in which fixed angle steel and anchorage device are set on two ends of concrete beams and it is prestretched at one end. There is strengthening ribbed plate in the angle steel and support plate is set at the lower part; one of angle steels is corresponded with another in two angle steels and is fixed with the beam by bolt at two ends of concrete beams. The anchorage device is formed by the bottom plate and two upright plates fixing in vertical direction, between which the interval is set. First of all, base rubber for strengthening is set at the bottom of beam, CFRP fabric is used to wind and paste on base plates of two anchorage devices respectively, concrete beam is set between two upright plates of anchorage devices, each one is fixed with the angle steel. At the end of anchorage device hoisting jack is set on the support plate and the pull-rod, which passes through upright plate of anchorage device, angle steel, hoisting jack, gasket and loading sensor, is fixed with nut. The loading sensor is connected with strain box and the hoisting jack is connected with oil pump and oil pressure sensor. The CFRP fabric is prestretched by oil pressured pump and after that it is fixed. Face glue is used to paint the CFRP fabric again so as to combine the CFRP fabric and concrete beams together.

Owner:TONGJI UNIV

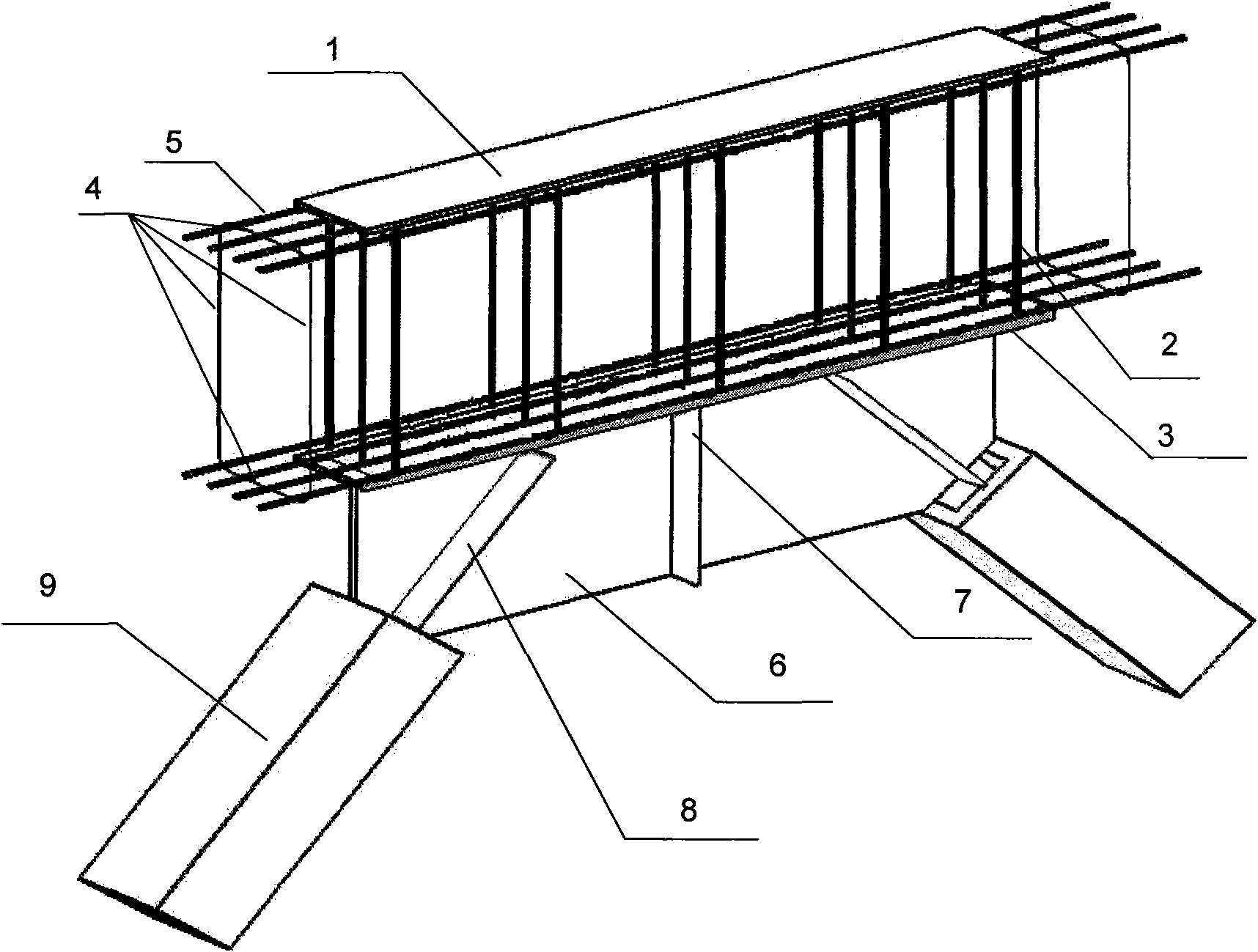

Vertical reinforced concrete component-connection node of buckling-restrained brace

ActiveCN101672071ASimple connection structureSimplify spatial relationshipsBuilding constructionsPunchingBuckling-restrained brace

The invention belongs to the technical field of node connection of architectural structure, in particular to a vertical reinforced concrete component, that is, a connection node of a buckling-restrained brace (BRB), which consists of steel plates, internal-thread steel bars for embedded parts, internal stirrups for concrete beams, internal longitudinal bars for concrete beams, support connection node plates, support node stiffening plates, buckling-restrained supports, internal stirrups for concrete columns and internal longitudinal bars for concrete columns, wherein, two steel plates are connected by the internal-thread steel bars for embedded parts; plug welding holes are formed on the steel plates; steel bars are welded with a first steel plate and a second steel plate at the plug welding holes; a first support connection node plate is located at the upper part of the first steel plate or at the lower part of the second steel plate; a second support connection node plate is connected with the first support connection node plate; one end of the second support connection node plate is fixed at the upper part of the first steel plate or the lower part of the second steel plate, andthe other end thereof is connected with the buckling-restrained brace; and the support node stiffening plates are fixed at one side of the first support connection node plate. The invention solves the problems that steel support connection nodes are difficult to be mounted in a concrete frame, structural steel needs punching when being embedded in a concrete component, and stirrups and longitudinal bars are arranged with difficulties; and the invention has the advantages that the construction is convenient, the stress performance of connection is good, and steel materials can be saved, therefore, the invention has wide application prospect.

Owner:TONGJI UNIV ARCHITECTURAL DESIGN INST GRP CO LTD

Assembly integral type concrete frame structure of dry-wet mixed connection of nodes and construction method

InactiveCN106677339AAchieving Plastic Hinge TransferShorten the construction time of flow waterBuilding material handlingConcrete beamsPre stress

The invention discloses an assembly integral type concrete frame structure of dry-wet mixed connection of nodes and a construction method. The assembly integral type concrete frame structure comprises pre-fabricated concrete pillars, pre-fabricated concrete beams, node local pre-stressed tendons, pre-fabricated concrete plates and rear-poured concrete combined interface layers; in an installation construction stage of a structural system, pre-fabricated components of the beams and the pillars adopt local pre-stress exerting and are connected in a dry mode, step-shaped rabbets at the ends of the pre-fabricated concrete beams are stored on side brackets of the pre-fabricated concrete pillars, and the pre-stressed tendons are inserted into vertical cross arc-shaped porous channels reserved in the beam ends and the node pillar sections of the pre-fabricated concrete pillars and are stretched; after dry-type connection between the pre-fabricated concrete beams and the pre-fabricated concrete pillars is completed, and the structural bearing capacity is achieved; in a using stage, after the pre-fabricated concrete plates or steel bearing plates, the pre-fabricated beams and steel rebars on the upper portions of the pre-fabricated plates are installed, the concrete combined interface layers are poured, and wet-type connection among the pre-fabricated concrete pillars, the pre-fabricated concrete beams and the pre-fabricated concrete plates is completed; and through dry-and-wet-type mixed connection of the nodes, the assembly integral type concrete frame structure is formed.

Owner:SOUTHEAST UNIV

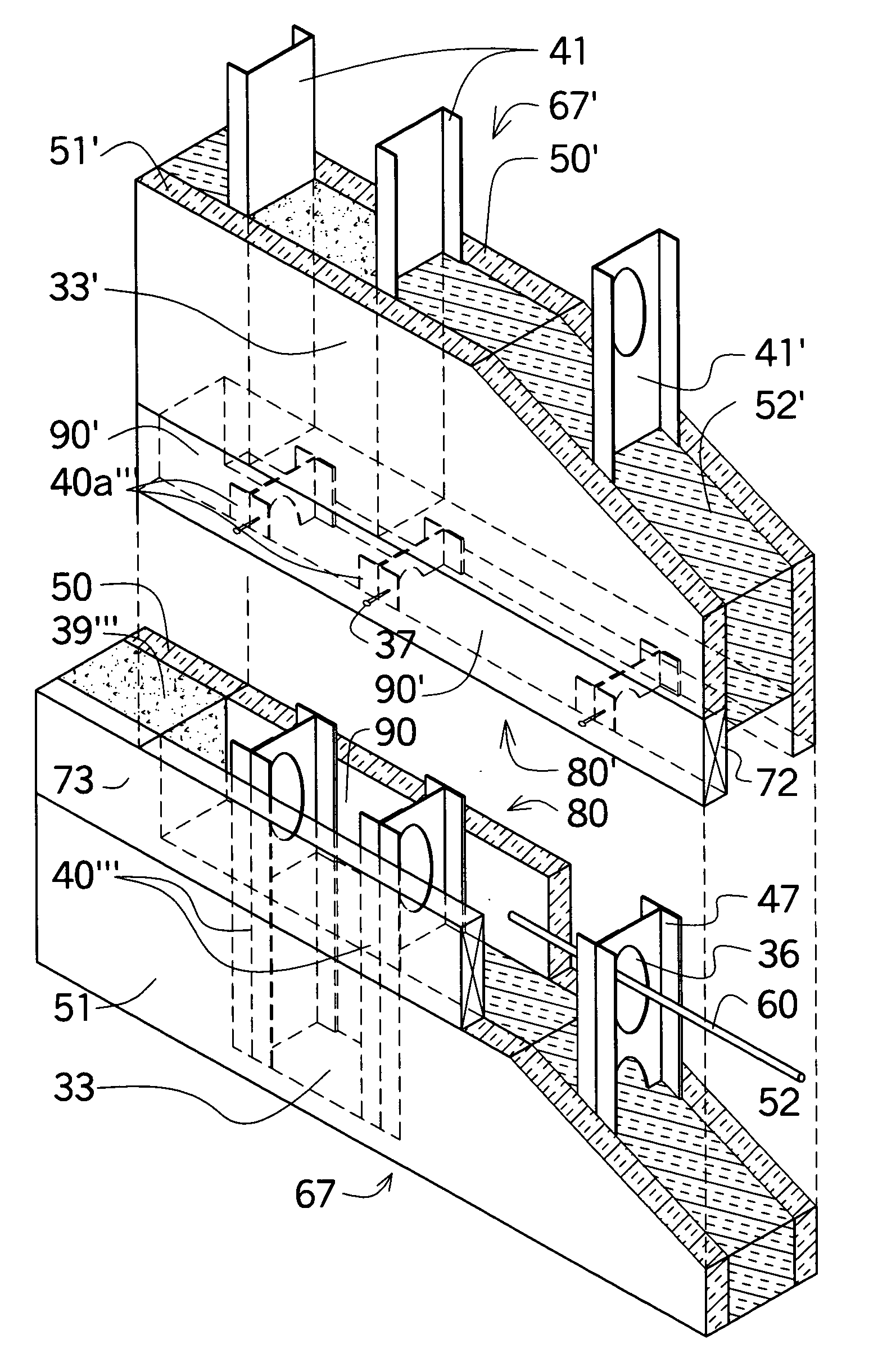

Building construction for forming columns and beams within a wall mold

InactiveUS8176696B2Easy to fixEasy to placeConstruction materialWallsConcrete beamsStructural insulated panel

The present invention relates to an improved wall system where a wall form mold has a structural insulated core assembled to form a structural insulated panel (SIP) to form a concrete beam and concrete column to be poured anywhere within the wall as well as between building modules when placed together and erected vertically. The interlocking wall molds interlock within the wall as well as between panels and modules. The wall panels allow concrete columns and beams to be formed in any size and shape. The structural insulated core consists of interlocking foam spacers and support channels which can be glued or screwed together to form an independent wall or as part of a precast wall with columns and beams integrated within the wall panels. Insulated flanges within the wall forming mold separates the wall forming structure from the wall surfaces.

Owner:LEBLANG DENNIS WILLIAM

Building construction using structural insulating core

The present invention relates to a structural insulating foam core wall that is versatile to be used as an independent framed wall, combination of an independent wall and Insulated Concrete Form (ICF) wall, in conjunction as part of a precast wall or as part of forming system to form a concrete beams and column structure, and modular units with concrete beams and columns. The structural insulating core wall, can also be used as individual foam spacer blocks, with or without brackets and horizontal bracing channels. Various types of flanges extensions are added to form different support channel flanges. The interlocking foam spacers and support channels which can be glued or screwed together to form structural insulating panels (SIPS), independent walls or as part of a precast wall with columns and beams integrated within the wall panels.

Owner:LEBLANG DENNIS WILLIAM

Connection structure of connection of floor beam and steel pipe concrece pole and construction method thereof

InactiveCN1560393ARigid Performance GuaranteeFirmly connectedBuilding reinforcementsHoopingConcrete beams

The invention discloses a joint structure at the connection part of steel pipe concrete pile and floor beam and the constructing method. The joint structure includes steel pipe concrete pile, floor beam and ring type concrete beam. The vertical component steel pile and the parallel component floor beam are connected at the joint, the steel pipe is drilled with a aperture at position correspondent to the joint on the floor, thus the beam lengthwise rib of the beam can pass through the steel pile directly; ring type concrete beams are arranged around the steel pipe in the joint area, the steel bar in the ring concrete beam includes ring type beam lengthwise rib which is concentric with the steel pipe concrete pile and radiate ring beam hooping in radius direction; a steel bar cage concentric with the steel pipe is arranged in the pile, which includes vertical pile connection lengthwise rib and parallel pile connection hooping, the anchor in the steel bar cage extension length is decided by the diameter of the steel bar.

Owner:SOUTH CHINA UNIV OF TECH

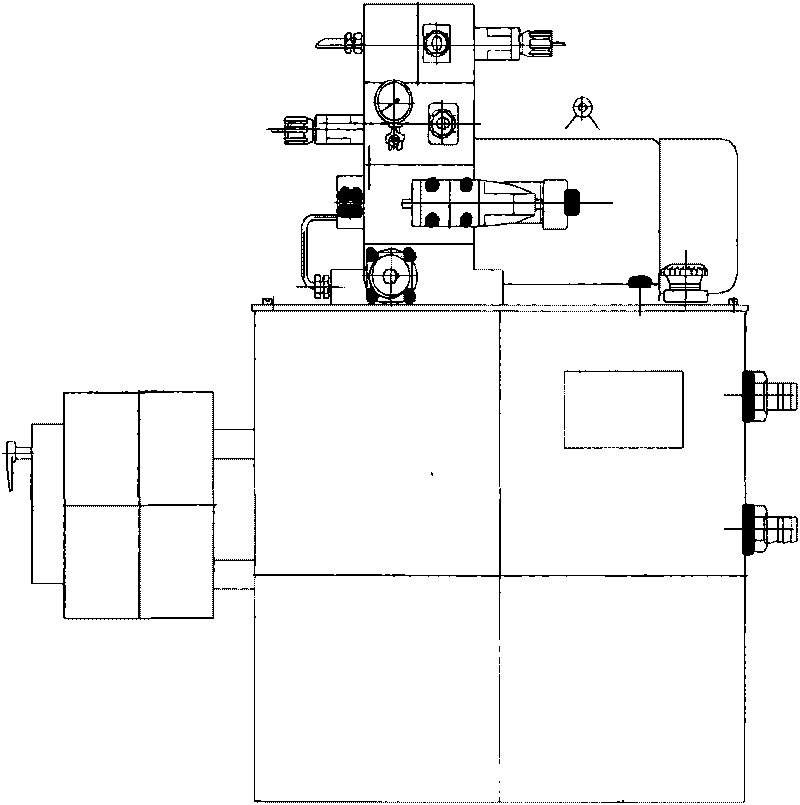

Multipoint loading fatigue tester controlled by microcomputer

InactiveCN101750248AIncrease stiffnessImprove carrying capacityMaterial strength using tensile/compressive forcesStructural/machines measurementMicrocomputer systemConcrete beams

The invention discloses a multipoint loading fatigue tester controlled by a microcomputer, which relates to a material tester and mainly solves the problems of fatigue tests of samples with large volume and high precision requirement in the construction of highways and railway bridges. The tester comprises a host machine, a loading mechanism, a measuring system, a hydraulic system and a control system, wherein the host machine comprises a stand and an attachment on the stand; a moving cross beam is arranged at the upper part of the bearing stand; a bearing cross beam is arranged at the lower part of the bearing stand; the bearing stand is provided with a cushion block; a sample is arranged on the cushion block; a servo loading oil cylinder used as the loading mechanism is arranged between the moving cross beam and the sample; the measuring system is provided with a sensor and a display; the hydraulic system is provided with a hydraulic oil cylinder, an electrohydraulic servo valve, a pipeline and the like; and the control system mainly comprises a microcomputer system. Various test work can be finished by combining the systems and the main machine. The invention can realize a multipoint synchronous pressure-resistant fatigue test and is used for fatigue tests of full-size steel beams, combined beams and concrete beams and pressure-resistant fatigue tests of welding joints, reinforcing steel bars, guy cables and hanger rods.

Owner:TIANSHUI HONGSHAN TESTING MACHINE

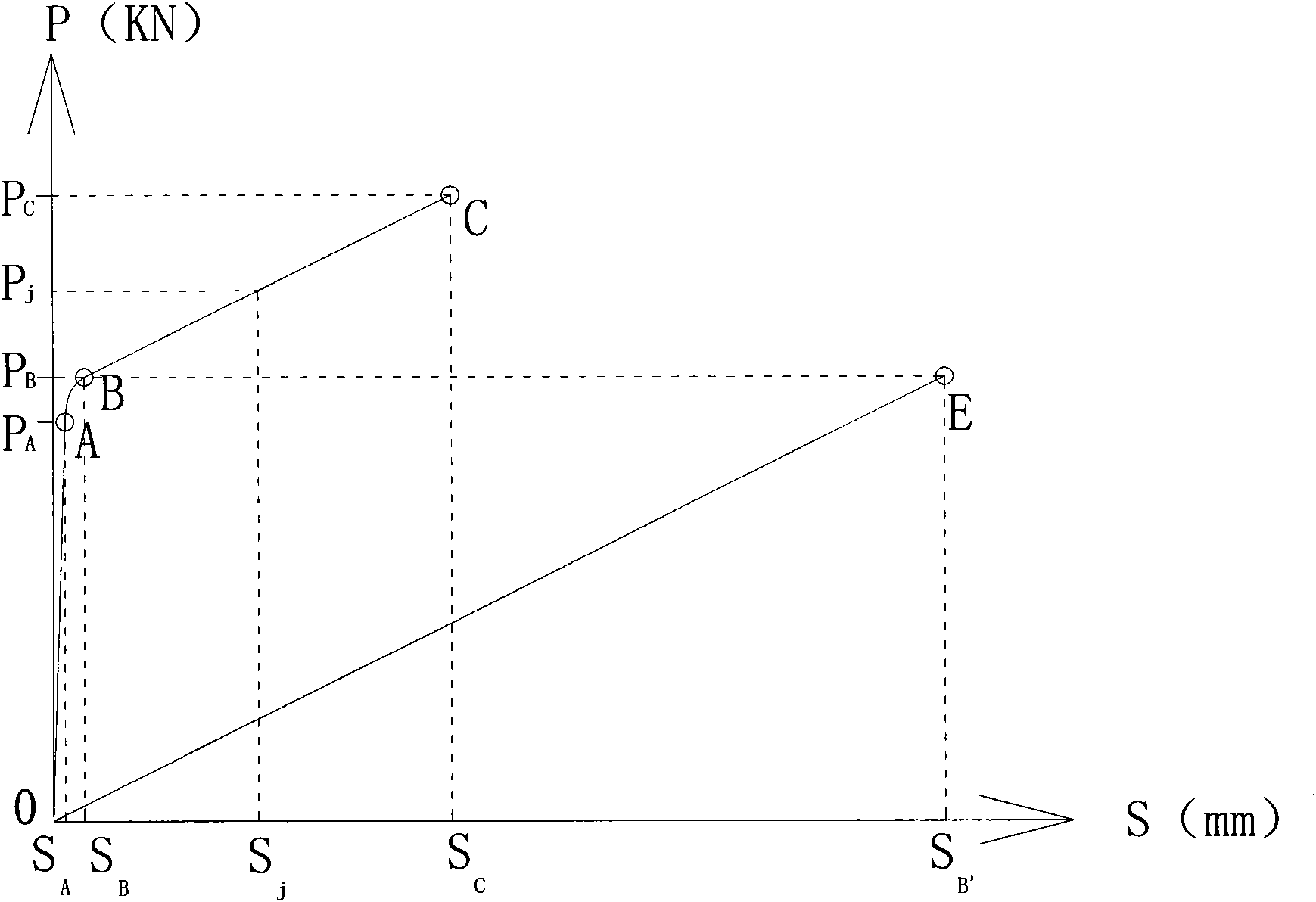

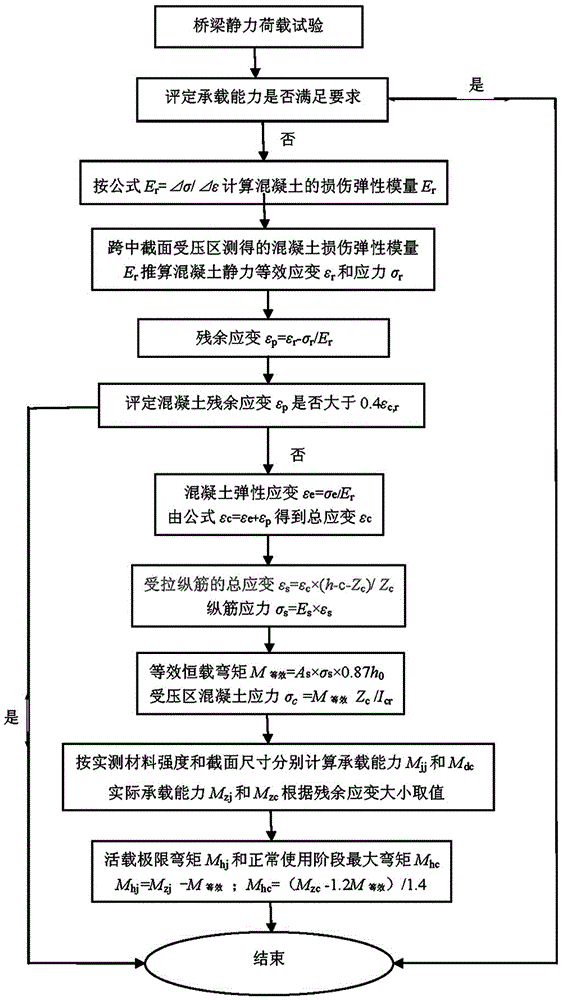

Residual strain based after-damage bearing capacity estimation method of concrete beam bridge

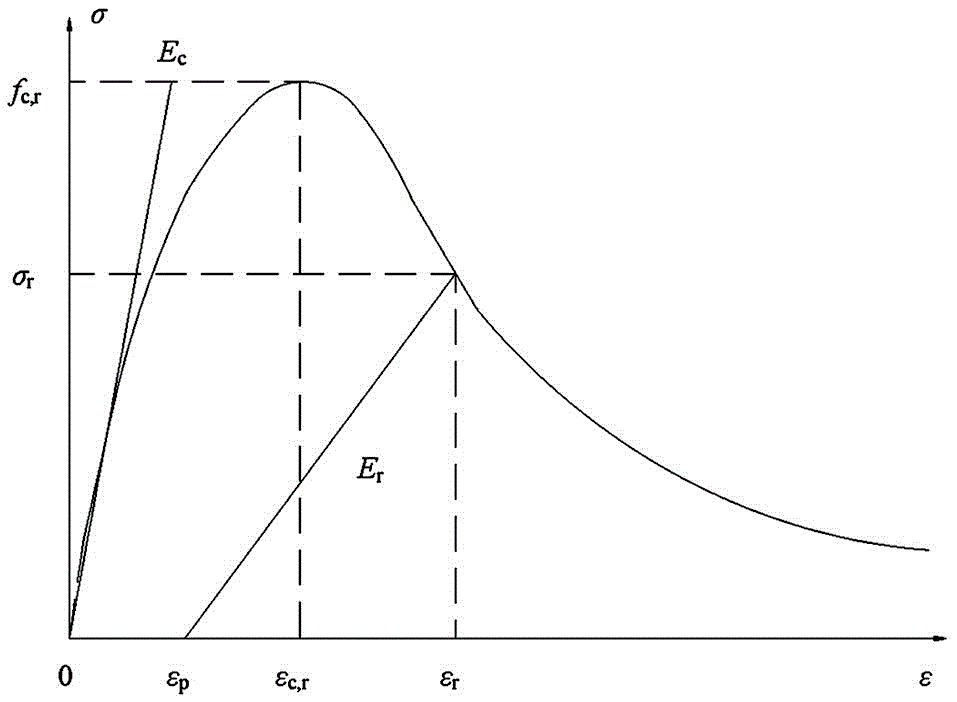

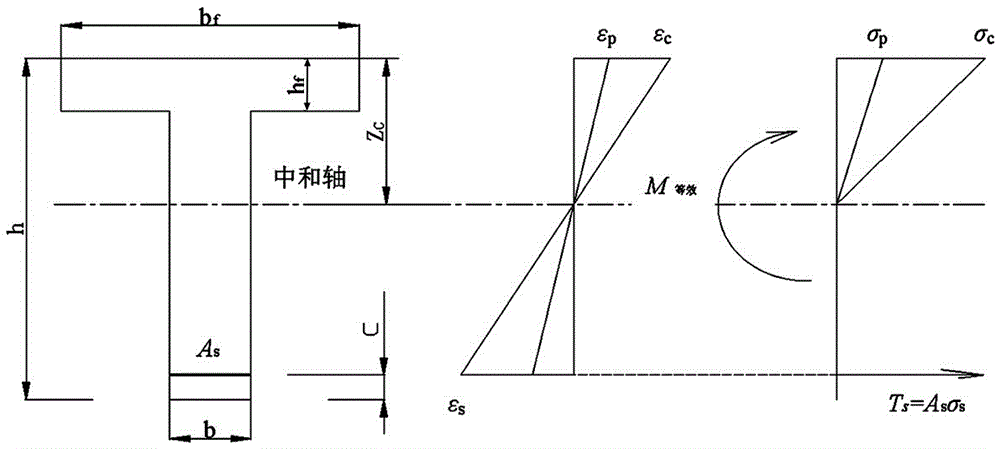

ActiveCN106485029AResidual strain solutionAvoid nonlinear damage process analysisDesign optimisation/simulationSpecial data processing applicationsResidual strainEstimation methods

The invention provides a residual strain based after-damage bearing capacity estimation method of a concrete beam bridge. The method is characterized in that the residual strain ep of concrete in a stressed area of the concrete beam bridge which does not meet the requirement by assessing in a static load test according to the concrete damage elasticity modulus Er in the stressed area; the real strain and stress state of a section can be obtained according to the section load balance and plane surface deformation; the standard extreme bearing bending moment Mjj and design bearing bending moment Mdc are obtained according to the actually-measured concrete strength and section size; the damage degree can be determined according to the concrete residual strain, and thus the actual extreme bearing bending moment Mzj and the bending moment Mzc for normal use can be obtained. With the adoption of the method, the technical problems that the assessment of the bearing capacity of an existing concrete beam bridge is highly influenced by subjective factors, only the bridge performance under test load is assessed in the traditional static load test, and the real working state and bearing capacity of the concrete beam bridge cannot be obtained, can be solved.

Owner:BEIJING MUNICIPAL ENG RES INST

High-rise building frame supported sectional steel concrete girder-like structural transfer floor construction method

InactiveCN101333825ASolve the difficulty of tyingSolve the problem of binding difficultiesBuilding constructionsConcrete beamsRebar

Disclosed is a construction method of the support frame steel concrete girder structure transfer floor for the high-rise buildings, which relates to the high-rise building structural transferring technology. Reinforced plates are welded on a profiled steel girder column flange plate and a profiled steel column flange plate; a profiled steel column stirrup is machined to an open stirrup which is welded on the reinforced plate. A perforation hole used for the stirrup to be inserted into is preset on the web plate of the profiled steel column; an angle table is welded on the profiled steel column flange plate; reinforced steel bars are in lap welding with the angle table. In the intersection of a non-frame girder and the profiled steel girder, the reinforced steel bars disconnect a bent anchor on the profiled steel girder web plate; wall body reinforced plates are generally welded on the upper flange wall body of the profiled steel girder; both sides of the wall body reinforced steel bars are welded on the wall body reinforced plates. Perforation holes used for the stirrup to be inserted into are prearranged on the upper flange of the profiled steel girder for the reinforced steel bar parts of the upper column and the concealed column of the profiled steel concrete girder; tie bars are welded with the tie bar reinforced plates. Spilt bolts are welded on both sides of the profiled steel web plate to reinforce the profiled steel concrete girder mould plate. The construction method of the support frame steel concrete girder structure transfer floor for the high-rise buildings has the advantages that the important technical problem the support frame steel concrete girder structure transfer floor in the construction process of the high-rise buildings is solved; the intensity, rigidity and the vibration resistance of the profiled steel concrete girder are reinforced.

Owner:BEIJING SHOUGANG CONSTR GROUP +1

Axial embedded blast hole of reinforced concrete beam and blasting demolition method

The invention provides an axial embedded blast hole of a reinforced concrete beam and a blasting demolition method. The blast hole is formed in the mode that a pipe is embedded in the beam in the axial direction, continuous or discontinuous charging is adopted in the blast hole, a detonating fuse is arranged in the blast hole in an overall-length mode, a stirrup is cut off, and other technical means are taken. In this way, drilling operation is avoided, the number of blast holes and the number of detonators are reduced, consumption of explosive and the detonators is reduced, the smashing effect on reinforced concrete is improved, and the damage of explosion to the environment is reduced. The axial embedded blast hole of the reinforced concrete beam and the blasting demolition method can bring remarkable economic and social benefits.

Owner:HUBEI UNIV OF TECH +1

Method for reinforcing concrete beam by prestressed carbon fiber plate and steel-concrete

ActiveCN105887702AImprove bearing capacitySolve the problem of difficult anchoringBridge erection/assemblyBridge strengtheningSheet steelCement composites

The invention provides a method for reinforcing concrete beam by a prestressed carbon fiber plate and steel-concrete. The method comprises the following main steps of firstly, chiseling off a concrete protecting layer on the bottom surface of the concrete beam, drilling and embedding steel bars, and arranging a layer of a steel bar mesh; secondly, blanking a steel plate, and respectively welding waved toothed plates at an anchoring end and a tensioning end of the steel plate for constraining the carbon fiber plate; thirdly, fixing the steel plate on the steel bar mesh, and taking the reinforcing steel plate as a bottom die to prepare and cast self-compacting concrete; fourthly, applying prestress by adopting a jack, tensioning the carbon fiber plate and anchoring; finally, varnishing cement composite mortar on the surface of the prestressed carbon fiber plate and the waved toothed plates as protecting layers to finish the bending resistance and reinforcing of concrete. According to the reinforcing method provided by the invention, the convenience in construction is realized, and the required equipment is simple; the bending capacity, rigidity and the durability of the existing concrete beam can be remarkably improved, and the service life is prolonged; the reinforcing method is particularly suitable for conditions of concrete spalling, carbonization and other damages at the bottom of the concrete beam.

Owner:WUHAN UNIV OF TECH

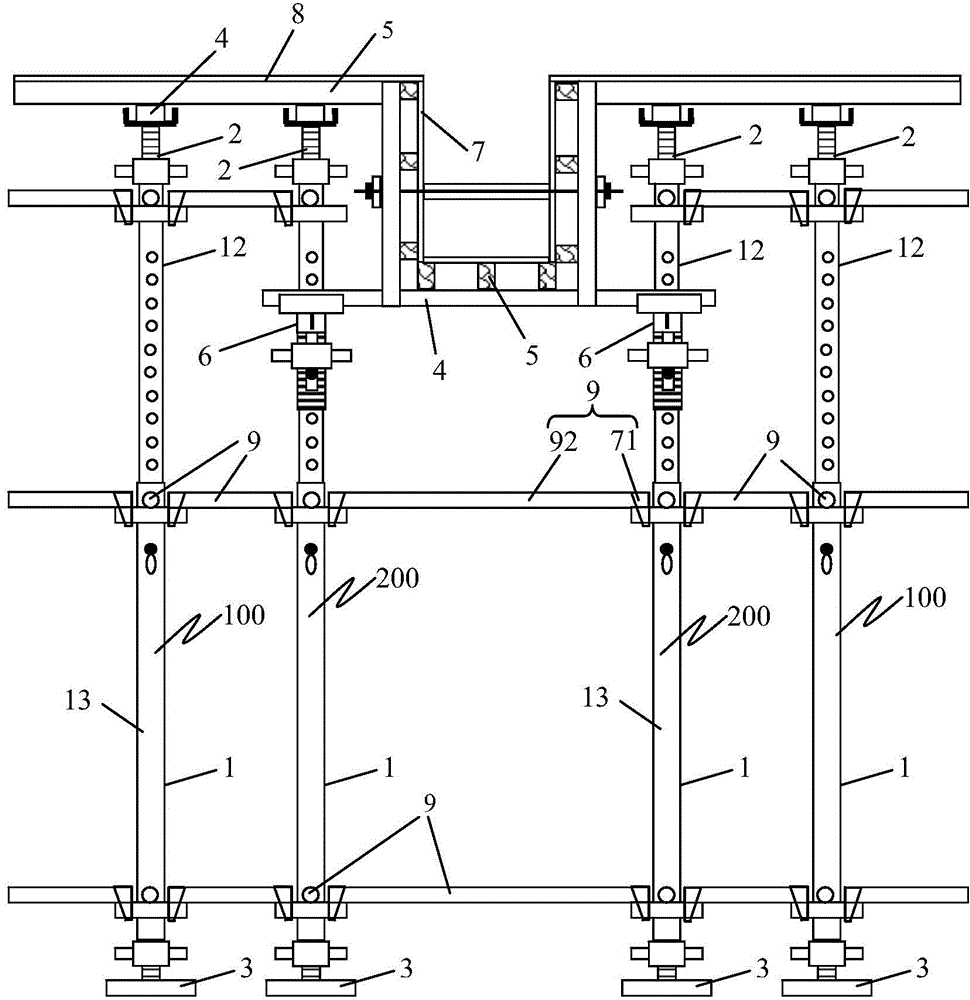

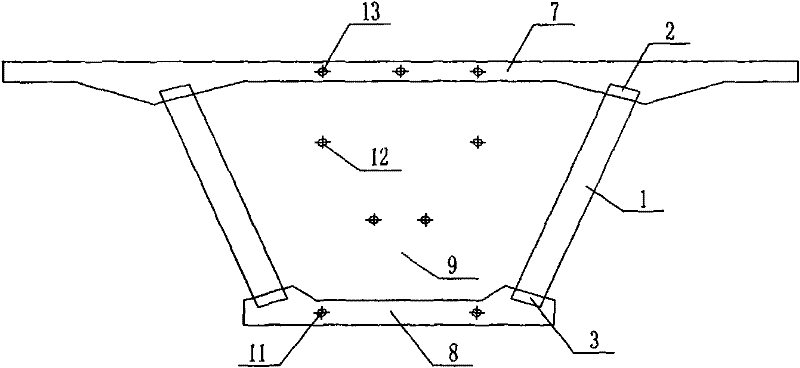

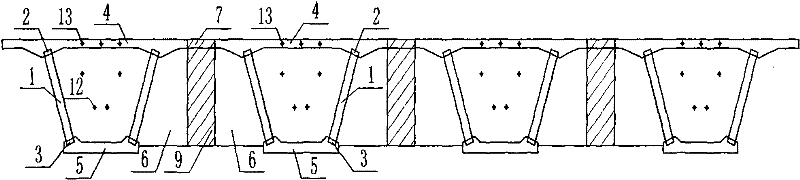

Construction method of support system for templates of concrete beams and slabs

InactiveCN104652809AEasy to set upReduce dosageForms/shuttering/falseworksSupporting systemConcrete beams

The invention provides a construction method of a support system for templates of concrete beams and slabs. The support system comprises a plurality of groups of support rod components, wherein each group of support rod components comprises a first support rod component and a second support rod component; the first support rod component comprises a telescopic support upright rod, an adjustable top support, an adjustable base and a support beam; the telescopic support upright rod is sheathed by a plurality of trays; the second support rod component is formed by arranging a beam support on the telescopic support upright rod of the first support rod component; the telescopic support upright rod comprises an inner casing pipe and an outer casing pipe; a plurality of holes are formed in the inner casing pipe at certain intervals from top to bottom; a tray is arranged near the upper end of the inner casing pipe; two trays respectively sleeve near the upper end and the lower end of the outer casing pipe; a through hole is formed in the lower part of the upper stray of the outer casing pipe; all the parts of the support system are constructed according to the construction structure diagram. The support system is simple in structure and convenient to be operated; the construction quality is improved.

Owner:FUJIAN UNIV OF TECH +1

Corrugated steel web prestressed concrete continuous box girder and construction method thereof

ActiveCN102220739AHigh section stiffnessImprove carrying capacityBridge structural detailsBridge erection/assemblyConcrete beamsPre stress

The invention discloses a corrugated steel web prestressed concrete continuous box girder. In the box girder, after being fixedly connected with a corresponding steel bar in a cast-in-place member, transverse steel bars of a precast concrete top plate, a precast concrete bottom plate and a precast concrete beam or a precast concrete diaphragm plate of two adjacent corrugated steel web prestressed concrete flanged beam units which are erected are connected by a cast-in-place concrete top plate between the adjacent precast concrete top plates, a cast-in-place concrete bottom plate between the adjacent precast concrete bottom plates and a cast-in-place concrete beam or a cast-in-place concrete diaphragm plate between the adjacent precast concrete beams or precast concrete diaphragm plates to form closed box girders; and external prestressed bars in the closed box girders are pulled and anchored, the closed girders corresponding to two adjacent holes are connected by pouring cast-in-place concrete longitudinal beams, hogging moment prestressed bars on pillar tops are pulled and anchored, and temporary supports are removed to form the continuous box girder. The corrugated steel web prestressed concrete continuous box girder has the characteristics of high stressed performance, high utilization rate of materials and obvious economic benefit, and is easy and convenient to construct.

Owner:HENAN PROVINCIAL COMM PLANNING & DESIGN INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com