Articulated anchor and prestress tensioning method of high strength fibre composite sheet

A hinged, tensioning technology, applied in the field of prestressed tensioning of high-strength fiber composite materials, can solve the problems of reducing the reinforcement effect of concrete beams, affecting the strength of fiber cloth, and the loss of fiber cloth pre-tensioning force, so as to facilitate standardized operations, Effect of increasing tensile stress and reducing project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

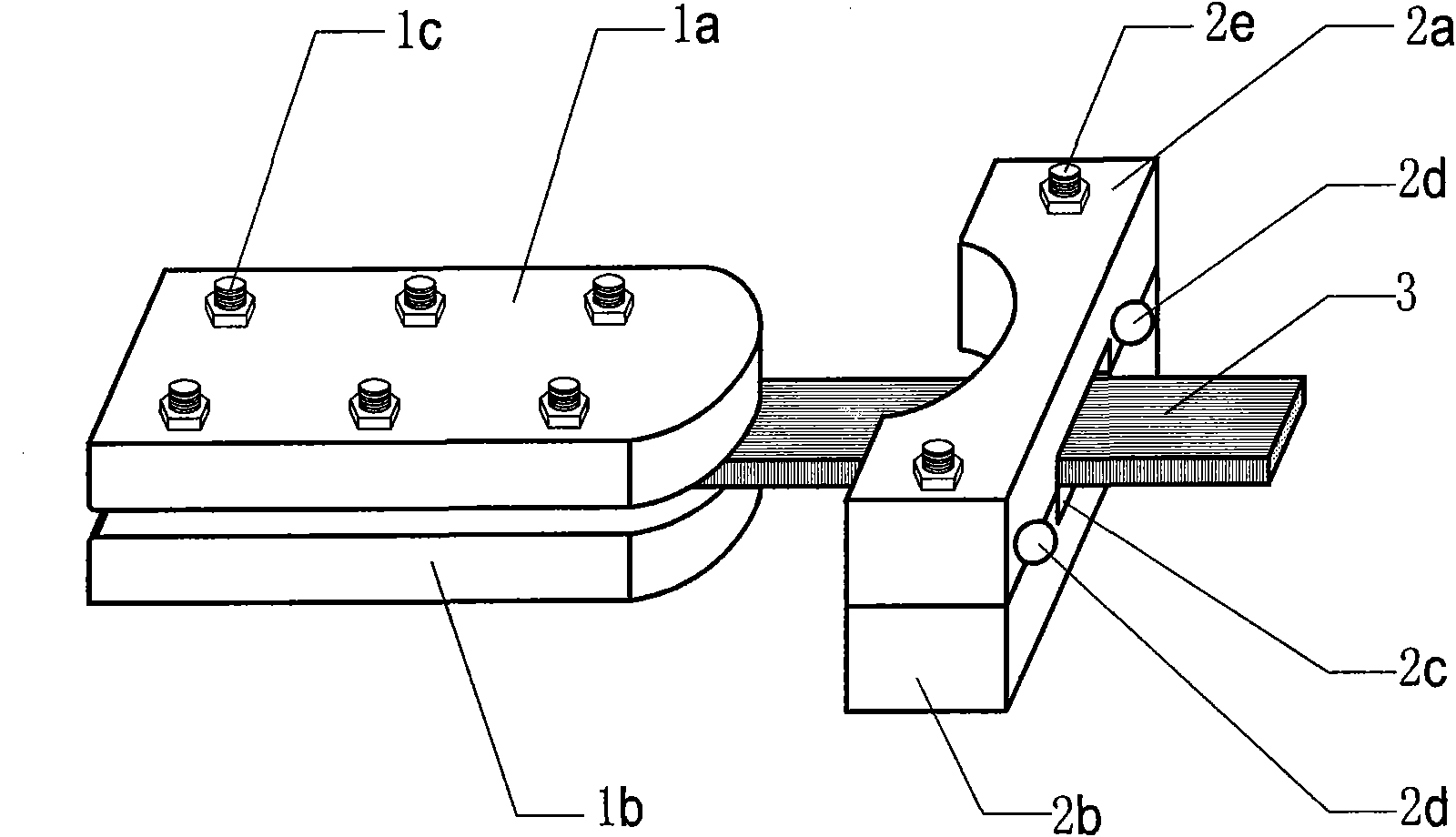

[0042] Such as figure 1 As shown, a hinged anchor mainly includes an anchor head and a pressing and locking device 1c, and the feature is that the anchor head is composed of a convex anchor 1 and a concave block 2. The protruding anchor 1 is composed of upper and lower splints 1a, 1b, and the front ends of the upper and lower splints 1a, 1b of the protruding anchor 1 are arcuate surfaces convex outward. The concave block 2 of the hinged anchor is composed of upper and lower halves 2a, 2b. The middle part of one side of the concave block 2 is an inward concave arc surface, and the convex arc surface of the convex anchor 1 is in contact with the concave arc surface. The concave arc surfaces of the block 2 are matched to form a surface contact and a hinged connection that is freely rotatable with each other. In the middle part of the inner concave arc surface of the upper and lower half blocks 2a, 2b of the concave block 2, an opening groove is respectively set, and when the upp...

Embodiment 2

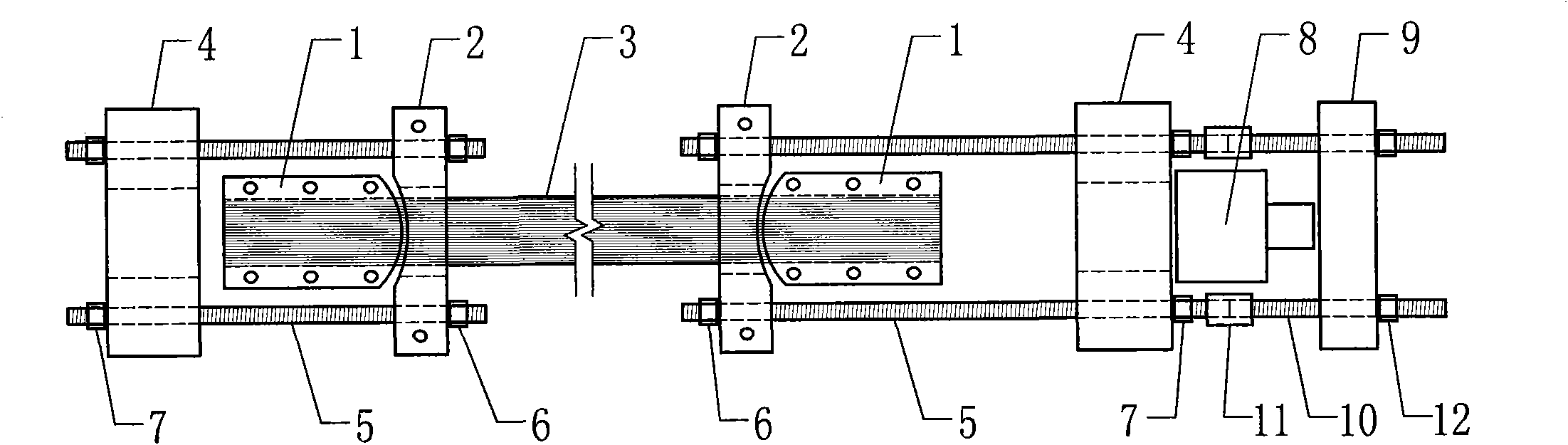

[0044] Such as figure 2 , 3 As shown, the specific method steps of a prestressed stretching method of a high-strength fiber composite material sheet are as follows:

[0045] (1) Clamping and anchoring of FRP sheets

[0046] First, the two anchor blocks 4 are fixedly connected to the surface of the reinforced steel beam 13 by means of welding respectively.

[0047] Install the hinged anchor and clamp and anchor the FRP sheet 3 again. For the fixed end, the hinge anchor is installed on the inner side of the anchor block 4 (that is, the anchor block 4 and the concave block 2 of the hinge anchor are separated by the convex anchor 1 of the hinge anchor), and the two connecting screws 5 are respectively After passing through the connecting screw holes reserved at both ends of the anchor block 4 and the concave block 2 of the hinged anchor, the anchor block 4 and the concave block 2 of the hinged anchor are fixedly connected with the front and rear anchor nuts 6 and 7 respectivel...

Embodiment 3

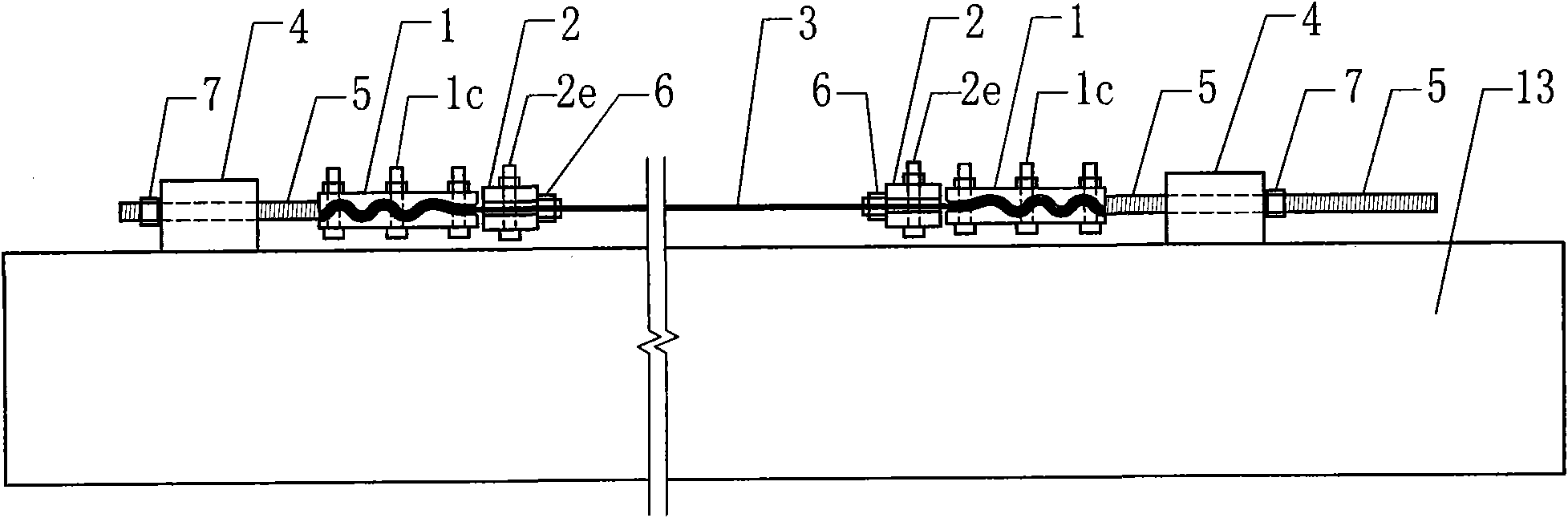

[0053] Such as Figure 4 , 5 Shown, a kind of prestressed stretching method of high-strength fiber composite material sheet, with embodiment 2, wherein:

[0054] In step (1), the two anchoring blocks 4 are fixedly connected to the surface of the reinforced or reinforced concrete beam 14 respectively by means of bolt connection, and the bolt 15 is anchored into the concrete beam 14 in advance. Install the hinged anchor and clamp and anchor the FRP sheet 3 again. For the fixed end, the hinge anchor is installed on the outside of the anchor block 4 (that is, the anchor block and the concave block of the hinge anchor are close together), and the two connecting screws 5 pass through the anchor block 4 and the concave of the hinge anchor respectively. After the connecting screw holes reserved at both ends of the shape block 2, use the front and rear anchor nuts 6 and 7 to fix and connect the anchor block 4 and the concave block 2 of the hinged anchor respectively (that is, back-to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com