Noise elimination system and noise elimination method for air inlet and exhaust system and vehicle

A technology of intake and exhaust and muffler, which is applied in the field of vehicles and can solve problems such as changing noise environments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

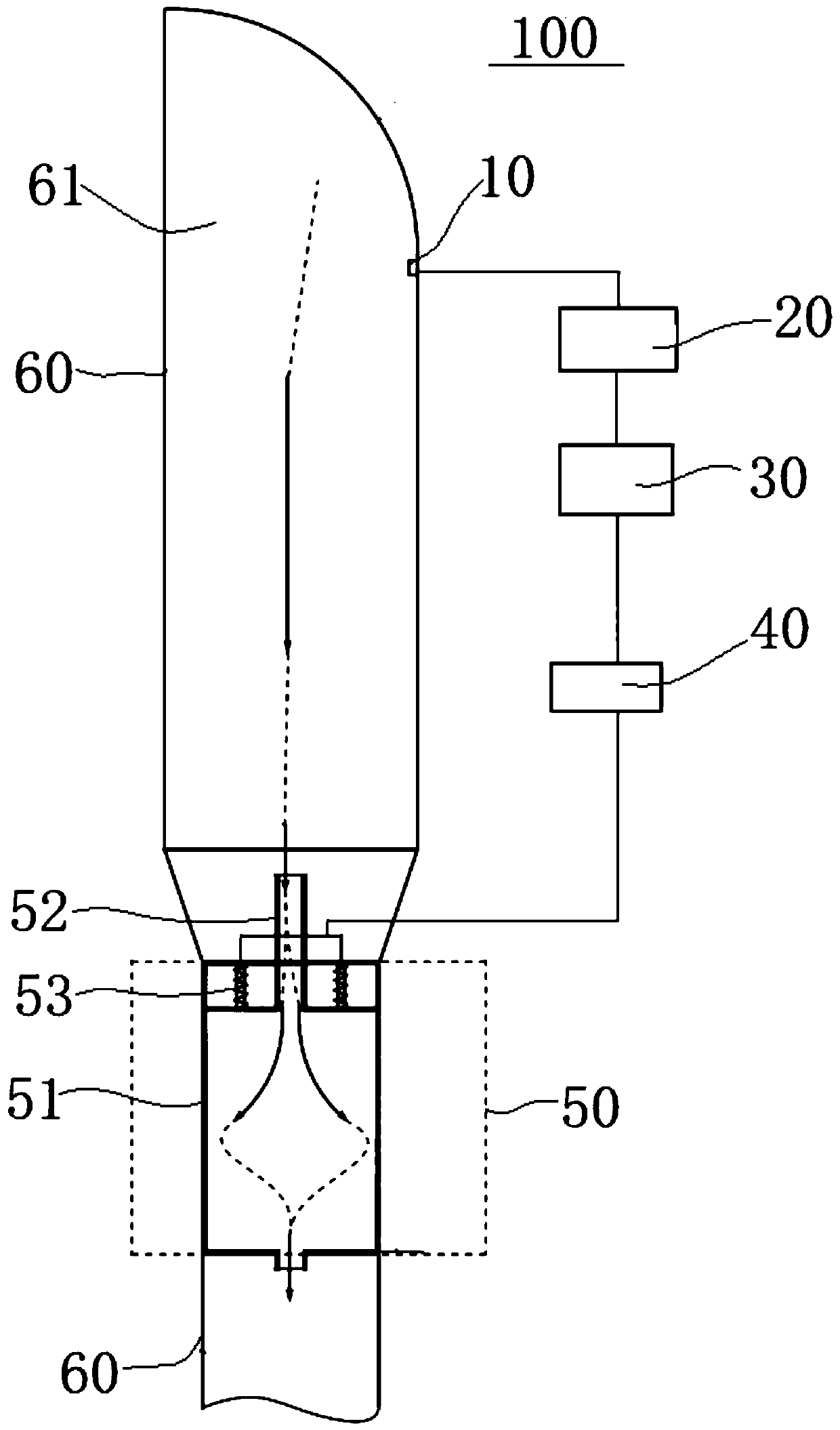

[0044] see figure 1 , in the intake and exhaust pipeline of the engine, when the engine is working, the air flow passes through the intake pipeline 60, and the flow route of the air in the intake pipeline 60 is as follows figure 1 As indicated by the arrow in the middle, the wall of the intake pipeline 60 collides, changing the flow field distribution of the air in the intake chamber 61 of the intake pipeline 60 , and generating vibration and noise.

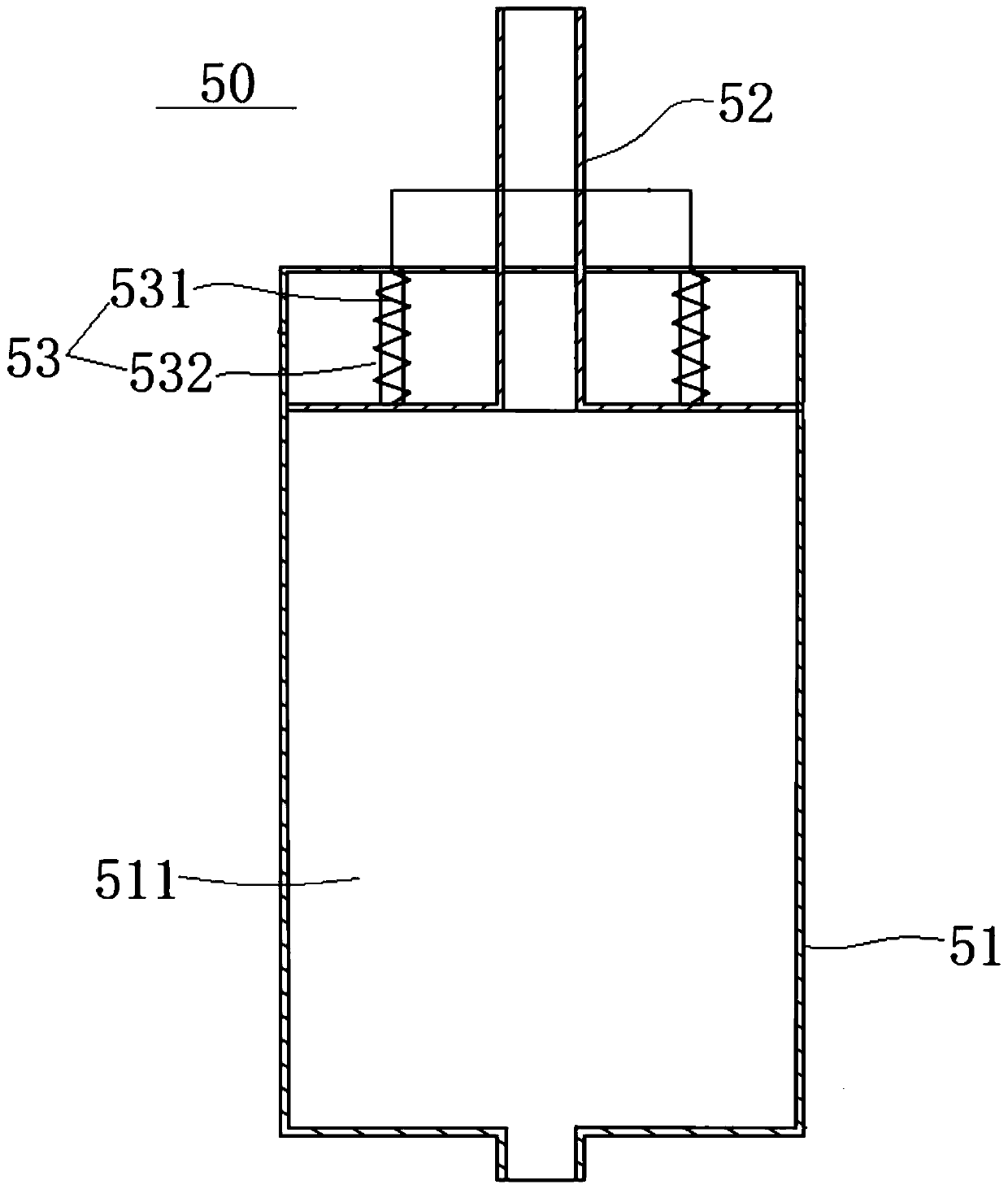

[0045] see figure 1 and figure 2 , the muffler system 100 for the intake and exhaust system of the present invention is mainly composed of a signal acquisition unit, a control unit 30 and an execution unit 40 . Wherein, the signal collection unit is used for collecting the sound pressure signal in the air intake cavity 61 of the air intake pipeline. The control unit 30 is used to analyze the frequency spectrum of the collected sound pressure signal to obtain the actual peak frequency in the intake cavity 61, compare the actua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com