Pneumatic activator

A technology of pneumatic controller and air source, applied in the direction of engine control, machine/engine, mechanical equipment, etc., can solve the problems of unstable action and unreliable effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

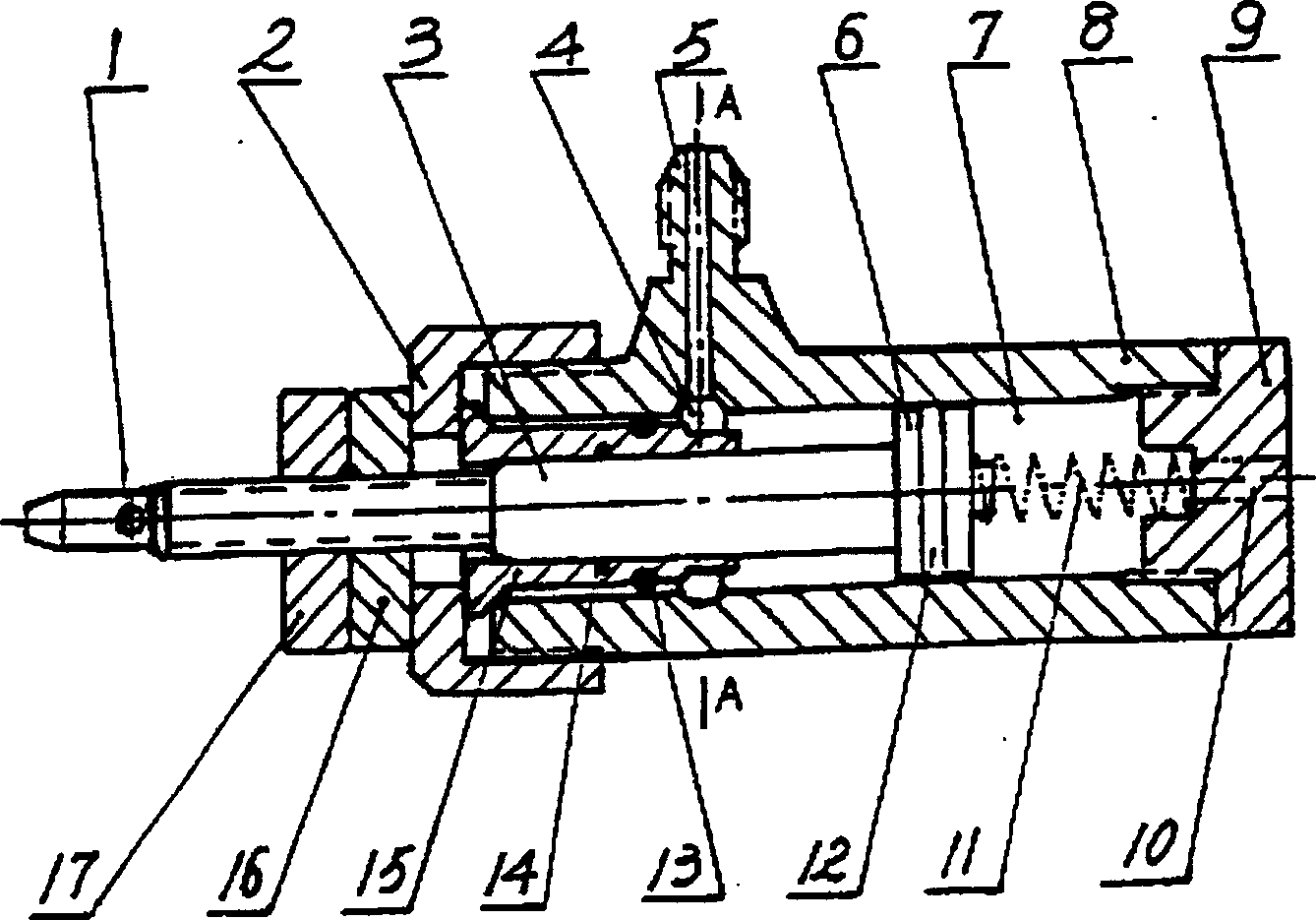

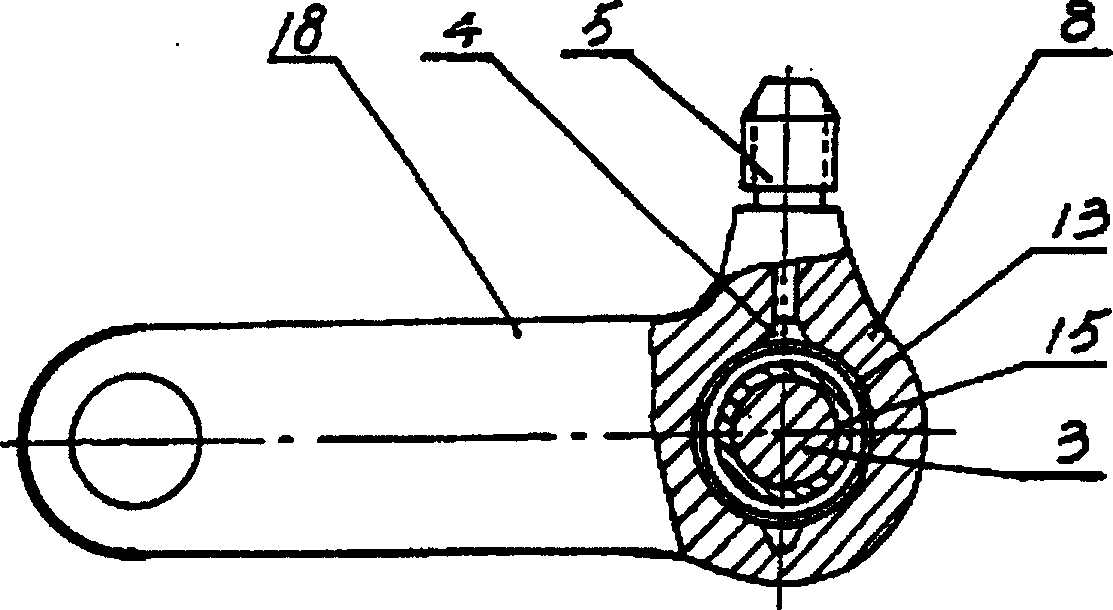

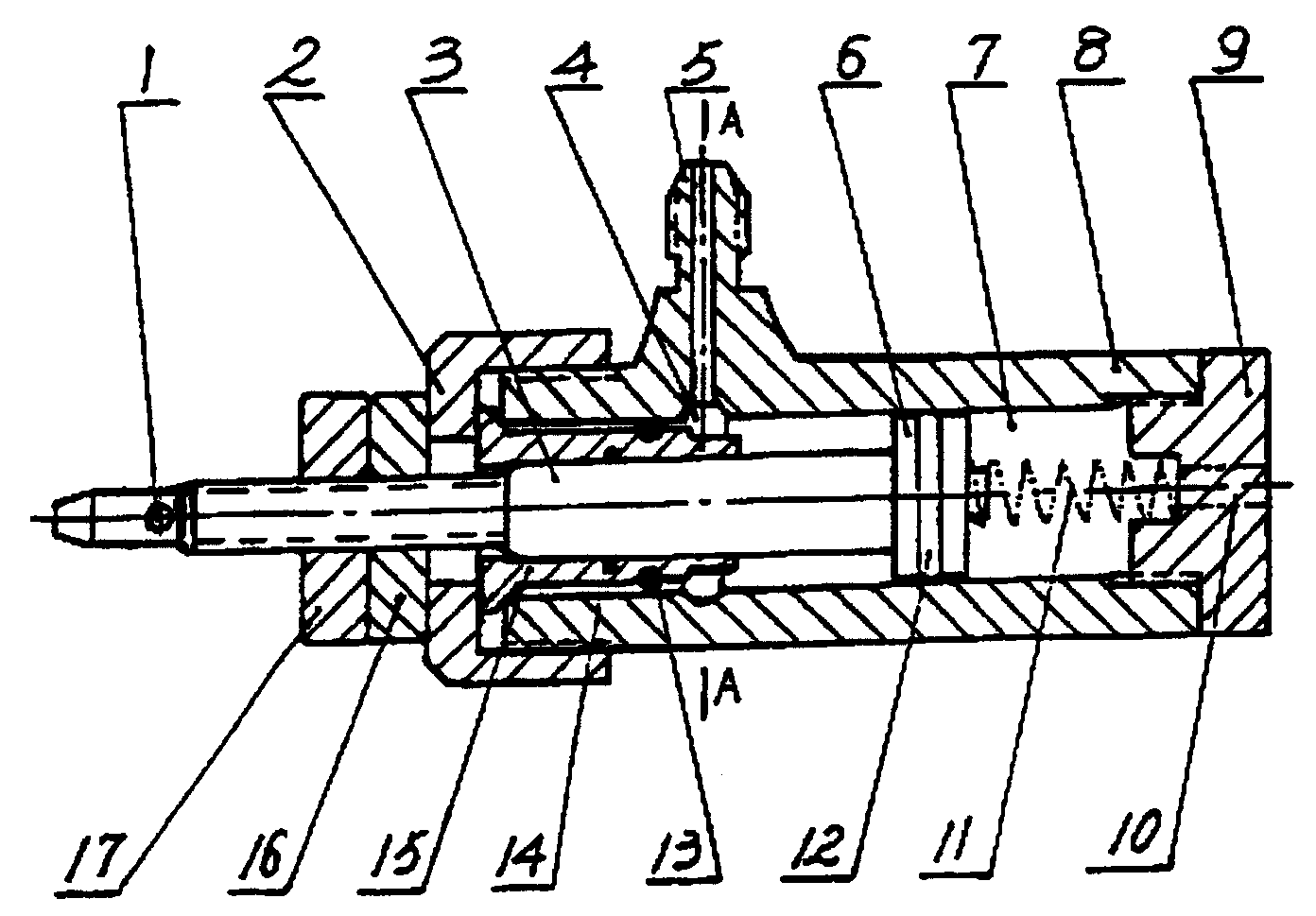

[0008] The present invention relates to a pneumatic controller used in internal combustion engine-driven air compressor equipment. There is a cylinder body 8 which can be made into a cylindrical shape, and a piston 6 and a piston rod 3 are installed in the cylinder body, and a sealing ring 12 is arranged in the piston 6. The outer end of the piston rod 3 is formed with an internal-combustion engine throttle cable connecting hole 1, and the outer wall of the cylinder body 8 is respectively formed with an air source joint 5 and a fixing piece 18 connected to the gas storage tank. The source joints are the two external connections of the pneumatic controller. The inner hole of the air source connector 5 is connected to the cylinder cavity, and the inner wall of the cylinder at the air intake place can be shaped with a groove 4 . There is a pressure chamber 7 at the other end of the cylinder body 8, and there is a promotion in the pressure chamber to cooperate with the piston 6 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com