Patents

Literature

152results about How to "Good lubricity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cold rolled silicon steel rolled oil composition

The invention discloses a cold rolled silicon steel rolled oil composition. The composition comprises the following components in percentage by weight: 60 to 90 percent of alcohol ester oiliness agent, 5.0 to 12 percent of animal and vegetable oiliness agent, 2.0 to 12.0 percent of nonionic surfactant, 0.6 to 8 percent of phosphate antiwear additive and 0.5 to 8 percent of antirust additive. The rolling lubricating property of the cold rolled silicon steel rolled oil composition is high; the cleanness of the rolling environment and a memorial archway is good; and the degreasing property, the rust-proof performance and the anti-oil burn property are high.

Owner:CHINA PETROCHEMICAL CORP +1

High temperature resistant and wear resistant lubricating paint

A refractory antiwear lubricating paint is prepared from thermosetting epoxy resin, boron modified phenolic resin, MoS2, Sb2O3 and cerium fluoride. Its advantages are high antiwear, load-bearing and lubricating performance, and excellent refractory performance.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Ceramic composite body of silicon carbide/boron nitride/carbon

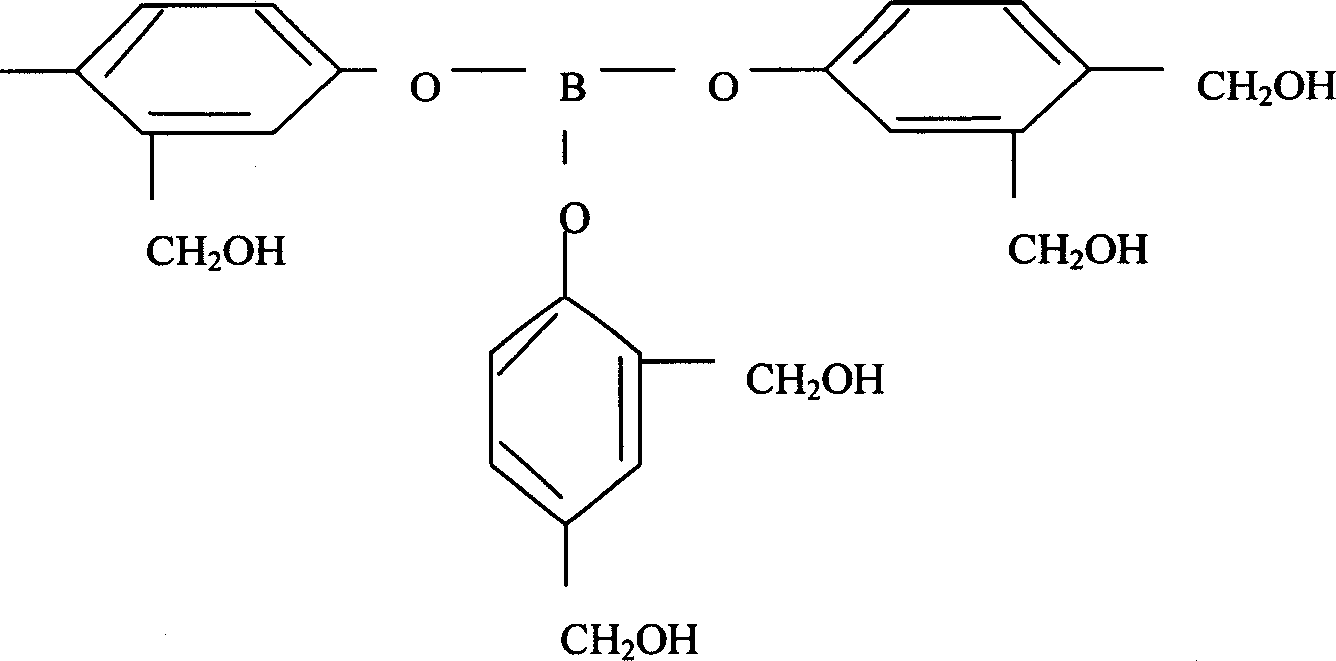

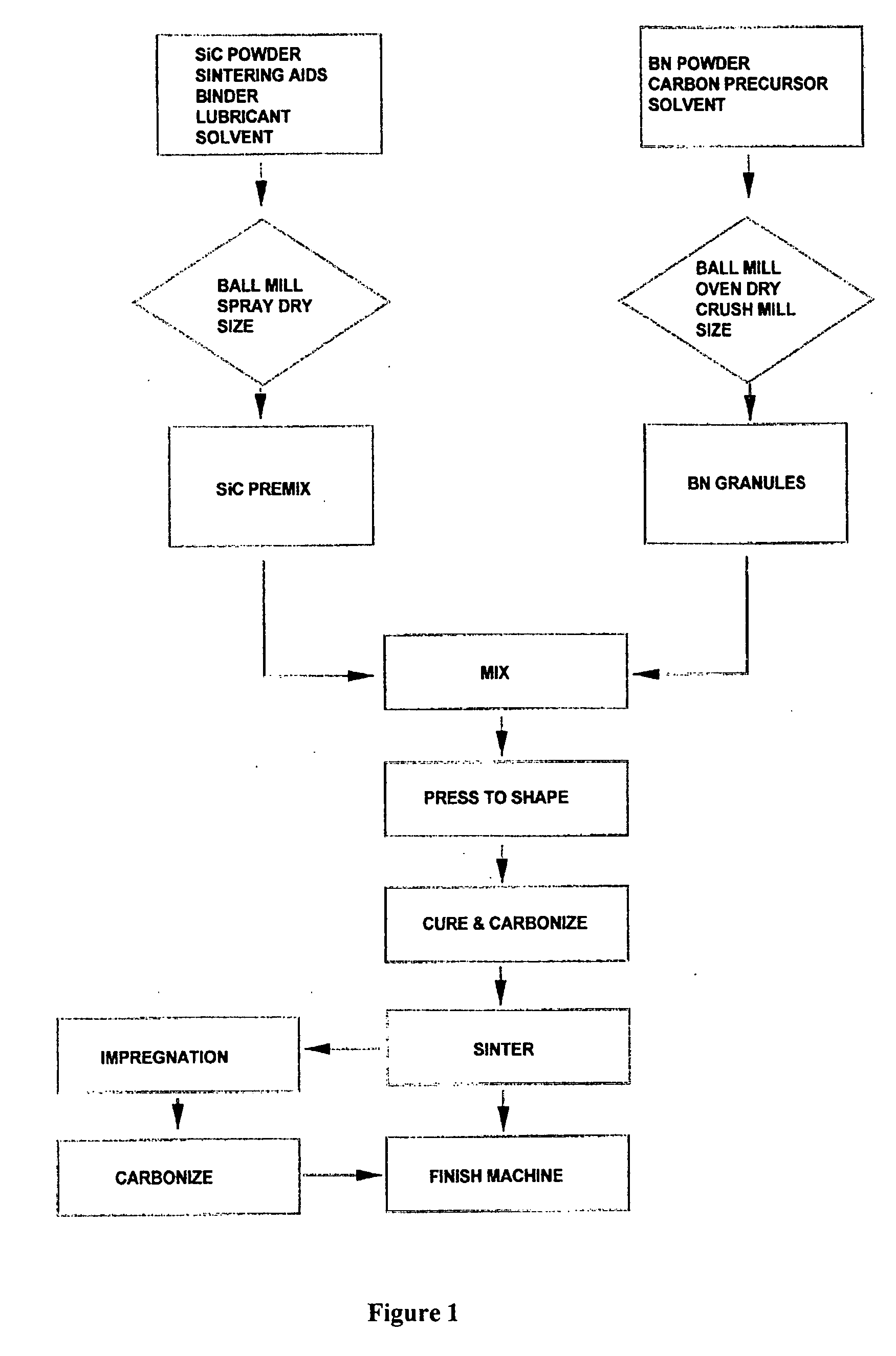

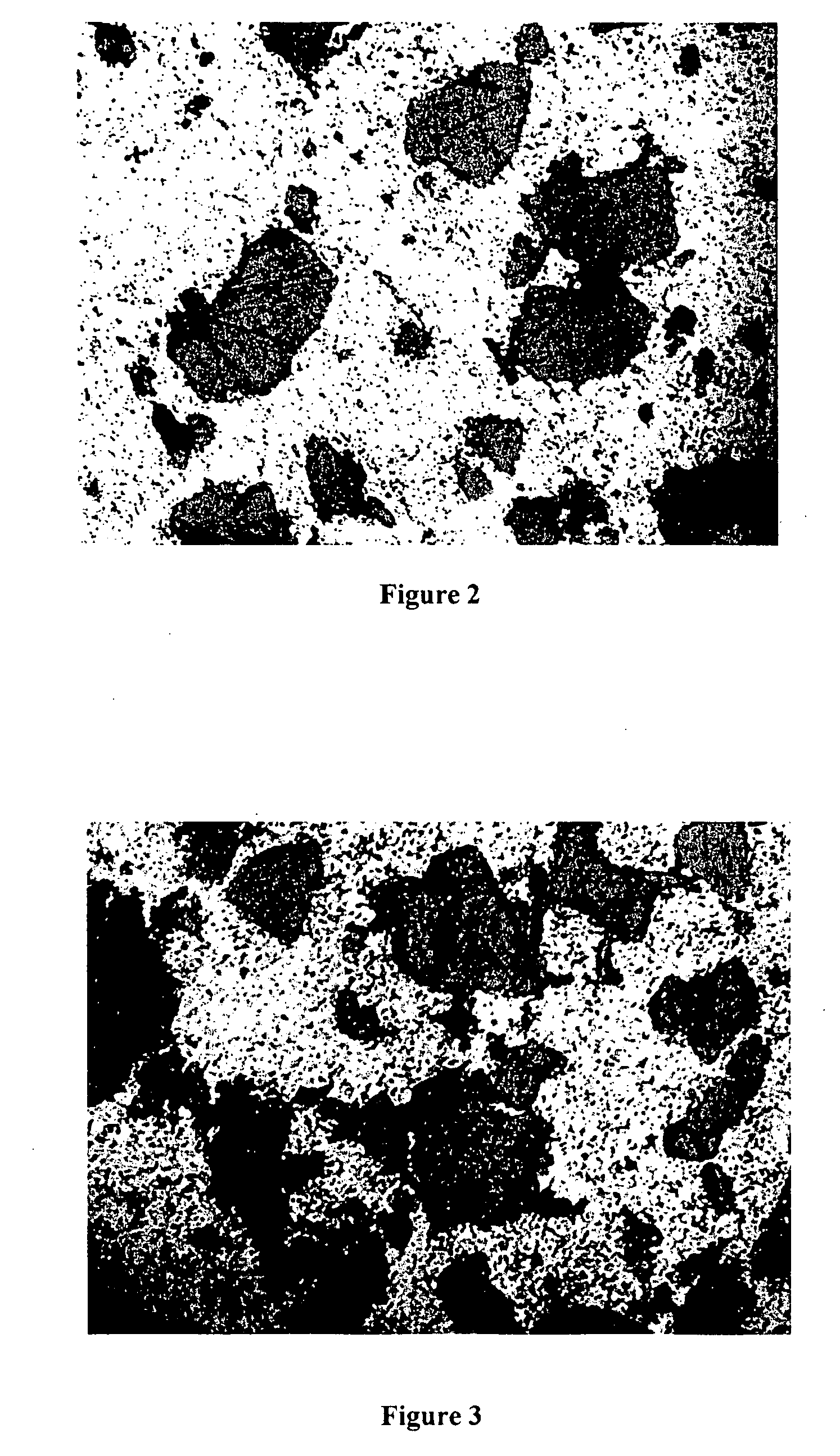

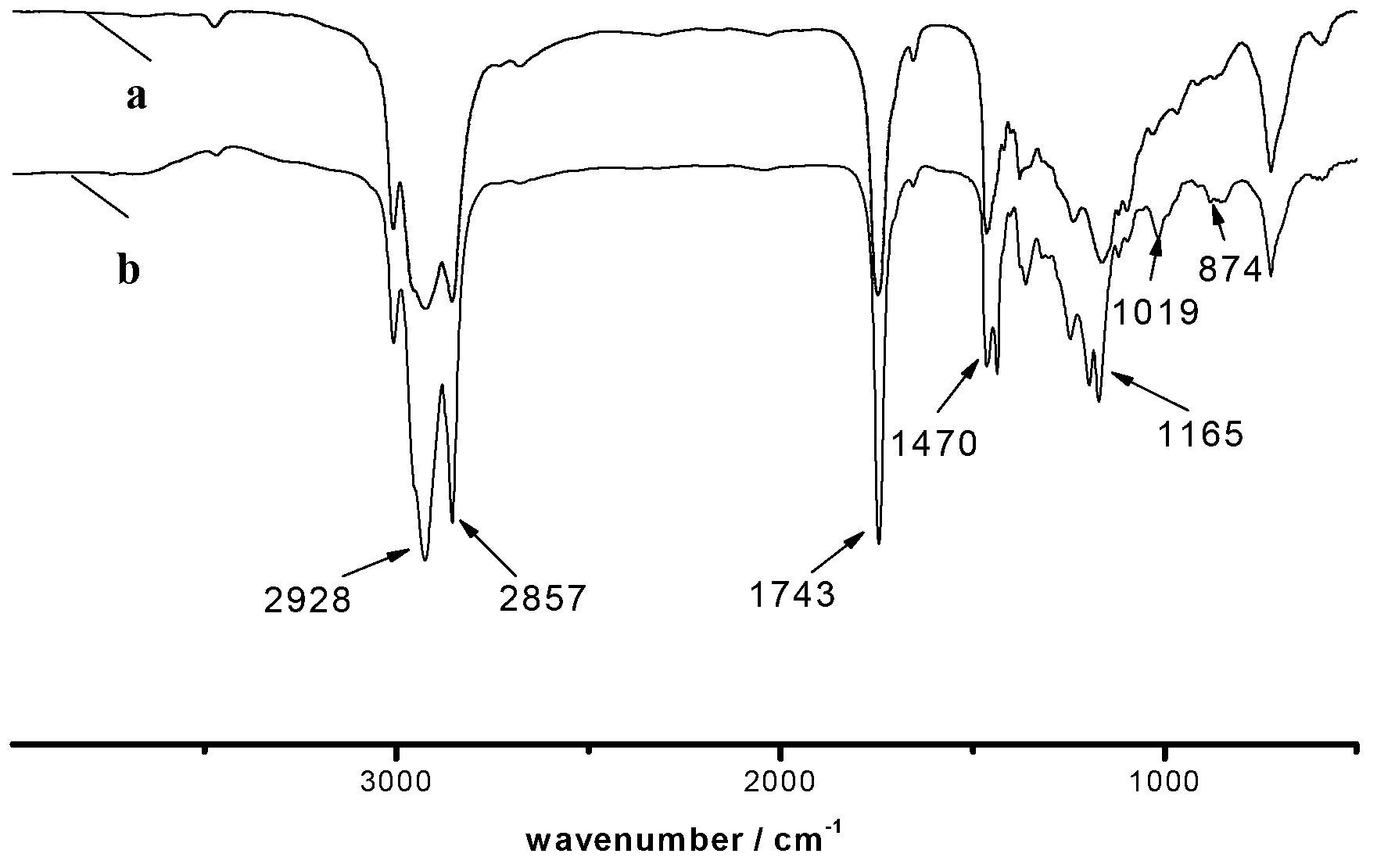

A ceramic composite body comprising sintered silicon carbide as major phase, dispersed boron nitride / carbon granules as minor phase, and the boron nitride / carbon granules comprise hexagonal phase boron nitride powders bonded together by glassy carbon. The composite body contains at least 3 weight percent of boron nitride, the average size of the boron nitride granules is greater than 10 micrometers, and the shape of majority of the granules is irregular. The composite body of high boron nitride loading can be further processed to improve mechanical and thermal properties by filling the porosity with glassy carbon, obtained from carbonizing glassy carbon precursor. The composite material exhibits superior thermal and tribological characteristics than monolithic silicon carbide.

Owner:CHEN XIN

Biodegradable quasi dry cutting oil and preparation method thereof

InactiveCN102002419AGood lubricityGood extreme pressure and anti-wear propertiesLubricant compositionChemistryPolyester

The invention relates to the technical field of chemistry, in particular to biodegradable quasi dry cutting oil and a preparation method thereof. The biodegradable quasi dry cutting oil is characterized in that the cutting oil is prepared from the following raw materials in percentage by weight: 30 to 40 percent of diester, 30 to 40 percent of polyol ester, 20 to 30 percent of poly alpha-olefin PAO20, 5 to 6 percent of zinc dialkyl dithiophosphate (ZDDP), 2 to 3 percent of polyester and 1 to 2 percent of N-laurel acyl alanine. Compared with the prior art, the cutting oil has good lubricating property and extreme pressure abrasion resistance, is biodegradable, and reduces the environmental pollution to minimum.

Owner:上海通快实业有限公司

Method for preparing organic silicon modified plant oil

InactiveCN103266016AGood lubricityGood stabilityFatty acid chemical modificationBase-materialsOrganosiliconOxidation stability

The invention discloses a method for preparing organic silicon modified plant oil. The method comprises the following steps of: by taking colza oil as a raw material, preparing a colza oil alcohol orderly through methanol ester exchange, peracetic acid epoxidation and acetic acid ring opening; and then reacting organic silicon with the hydroxyl in the colza oil alcohol, thereby obtaining the organic silicon modified plant oil. The organic silicon modified plant oil produced by the method has good lubrication effect; and in addition, the oxidation stability of the organic silicon modified plant oil is also greatly improved.

Owner:HEFEI UNIV OF TECH

Methylglucoside polyamine drilling fluid and preparation process thereof

InactiveCN103382385AStrong inhibitoryGood lubricityDrilling compositionO methylglucoseDrilling fluid

The invention relates to the technical field of drilling fluids in petroleum drilling engineering and particularly relates to a methylglucoside polyamine drilling fluid and a preparation process thereof. The preparation process for the methylglucoside polyamine drilling fluid comprises the steps of placing a required amount of bentonite into water to be mixed uniformly, standing the mixture, adding required amounts of a coating agent, a fluid loss additive, a blocking agent, a polyamine class shale inhibitor, a flow pattern conditioning agent, methylglucoside and a lubricating agent into the mixture, and mixing uniformly to obtain the methylglucoside polyamine drilling fluid. In addition to the excellent performance of existing water-based drilling fluids, the methylglucoside polyamine drilling fluid has strong inhibition performance and good lubricating performance, and meanwhile, the methylglucoside polyamine drilling fluid has the advantages of being environmentally friendly and low in cost.

Owner:CNPC XIBU DRILLING ENG

Biodiesel lubricant for water-based drilling fluid and preparation method and application thereof

The invention discloses a biodiesel lubricant for a water-based drilling fluid and a preparation method and application thereof. The biodiesel lubricant for the water-based drilling fluid comprises the following raw components in part by weight: 70-90 parts of biodiesel and 10-30 parts of water, with a total weight of 100%; and the biodiesel lubricant for the water-based drilling fluid further comprises 1-6% of lipophilic emulsifier, 1-8% of hydrophilic emulsifier, 1-10% of extreme pressure lubricant, 1-5% of solid lubricant and 0.05-0.3% of dispersing agent. The biodiesel lubricant for the water-based drilling fluid has the advantages of no fluorescence, low biotoxicity, easy biodegration, good compatibility with the drilling fluid, high salt resistance, especially good lubricating property at high temperature, relatively low cost, wide source of raw materials and wide applicability.

Owner:DAQING BEIHUA CHEM PLANT

Preparation of lubricant oil containing high dispersion fullerene C60

The invention belongs to the technical field of materials, and in particular relates to a method for preparing lubricant oil containing high-dispersity fullerene (C60). The method comprises: firstly, acylating and halogenating long-chain fatty acid, utilizing the activity of acyl halide groups to react with metal azides, and obtaining long-chain fatty acid derivatives of which end groups are subjected to azide; secondly, utilizing azide groups to react with C60, connecting the long-chain fatty acid derivatives of which the end groups are subjected to azide to the surface of the C60 in a mode of covalent bonds, and preparing C60 which is modified by the long-chain fatty acid; and thirdly, respectively adding the C60 which is modified by the long-chain fatty acid into lubricant oil according to certain proportion for ultrasonic dispersion. The method utilizes the similarity and intermiscibility of the long-chain fatty acid and lubricant oil molecules to well disperse the C60, gives full play to the self-lubrication function of the C60, and finally obtains the lubricant oil with superior lubrication.

Owner:TONGJI UNIV

Lubricant composite, preparation method thereof and trace lubricant made of same

ActiveCN103361151AGood lubricityGood extreme pressure and anti-wear propertiesLubricant compositionChemistryPolyethylene glycol

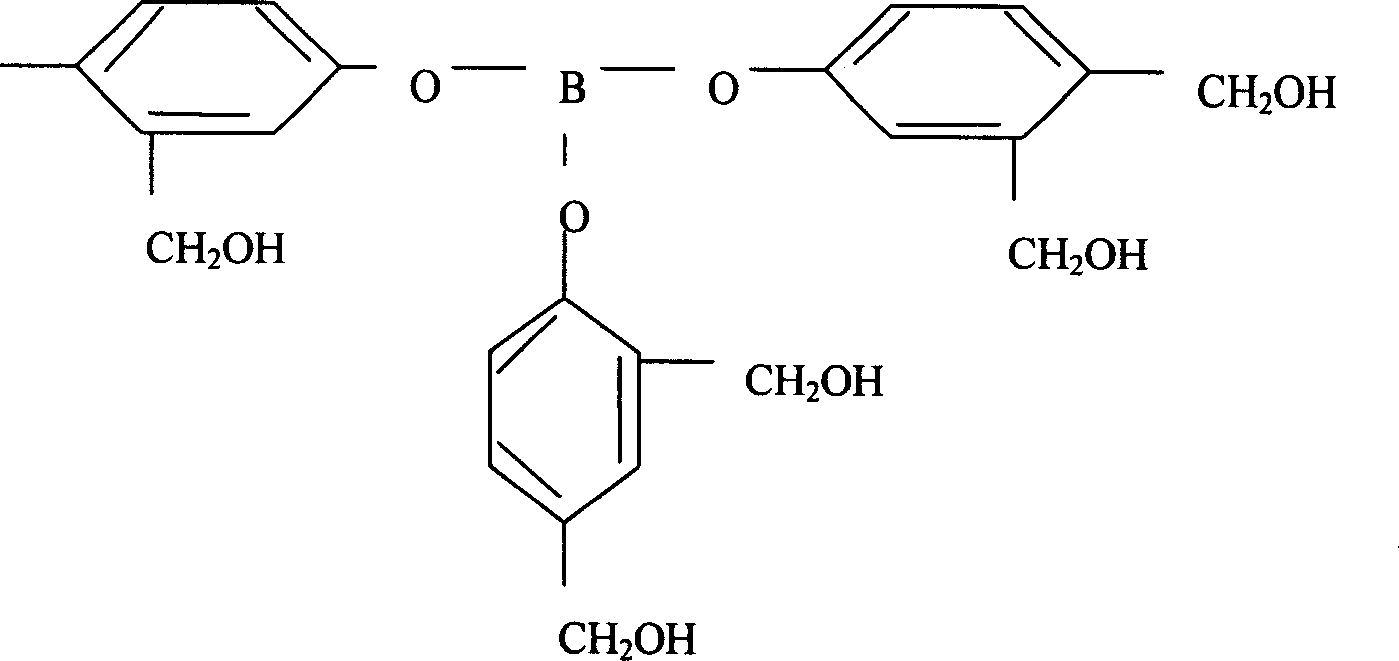

The invention provides a lubricant composite, a preparation method thereof and a method of preparing a lubricant made of the lubricant composite. The lubricant composite is characterized by being made of boric acid, hydramine, carboxylic acid and polyethylene glycol, wherein the mol ratio of boric acid to hydramine to carboxylic acid is 1:1 to 4: 1 to 1.5, and the weight of polyethylene glycol is 25 to 30% of the total weight of the reaction product of boric acid, hydramine and lauric acid. The trace lubricant prepared with the lubricant composite has the advantages of excellent lubricity, cooling ability, extreme pressure anti-wear property and good rust-proof ability. Just a little trace lubricant can satisfy the needs of lubricating, cooling, extreme pressure anti-wearing and rust preventing for the metal processing. The trace lubricant can be corporately used with a trace lubricant device, the usage amount of cutting fluid can be reduced by 90%, the oil spray system of the trace lubricant device will not be obstructed after being used for a long time, and has prominent effects on energy saving, discharge reducing and environmental protecting.

Owner:深圳市龙威科技发展有限公司

A kind of cold rolling extremely thin plate rolling oil composition

The invention discloses a novel cold rolling extreme thin plate rolling oil composition. Synthesized ester and an alkylphenol epoxypropane compound are compounded to be used as an oily agent and can form a layer of quite dense protective film on the surface of metal to form favorable annealing detergency and heat stability. A nonionic compounded emulsifying agent can increase the diameter of the elaioplast of emulsion and shows better lubricity by matching with the interaction of a metal passivator, a sulfur-containing extreme pressure antiwear agent, and the like.

Owner:石家庄新泰特种油有限公司

High-hardness automotive connection rod forged through ferrum-based powder in metallurgical manner and manufacturing method thereof

The invention provides a high-hardness automotive connection rod forged through ferrum-based powder in a metallurgical manner. The high-hardness automotive connection rod is manufactured from, by weight, 93-94 parts of iron powder, 2.5-2.8 parts of cuprous iodide, 2-2.3 parts of Ni powder, 0.8-1.1 parts of Mn powder, 0.3-0.4 part of nickel-plated carbon powder, 0.5-0.6 part of boric acid lead, 0.3-0.4 part of zinc stearate, a proper amount of silane coupling agent kh 550, a proper amount of nano tungsten disulfide, a proper amount of polyethylene glycol and a proper amount of deionized water. According to the high-hardness automotive connection rod forged through ferrum-based powder metallurgy and a manufacturing method thereof, the nano-sized tungsten disulfide is used when water-atomized powder is made, the dispersity and lubricating property of the powder are good, the consumption of a lubricant is reduced, the density of a green body is increased, pores in finished products are few, the strength of alloy is improved greatly, the forging pressure and temperature are lowered, and energy is saved; and through the cuprous iodide, the Ni powder, the Mn powder, the nickel-plated carbon powder and the boric acid lead, the abrasive resistance and lubricating property of the connection rod are improved, the surface quality is good, hardness is improved, and the service life is prolonged.

Owner:李学峰

Phosphatide based metal processing emulsion

The invention relates to a phosphatide based metal processing emulsion, which comprises the following components in percentage by volume: 10 to 50 percent of modified soybean phosphatide, 3 to 16 percent of tween-80, 0.3 to 5 percent of absolute ethyl alcohol, 0.5 to 6 percent of phosphating solution antirust agent, 0.5 to 8 percent of sym-triazine preservative bactericide, 0.5 to 7 percent of organic silicon antifoaming agent, 1.5 to 8 percent of 20- 45% (w / v) NaOH aqueous solution, and the balance of water. During preparation, the components are uniformly mixed, and then the mixture is homogenized to prepare the emulsion. The phosphatide based metal processing emulsion has a reasonable formula, and the product has excellent lubricating property, rust-preventing characteristic, cooling characteristic, cleaning characteristic, bactericidal characteristic and high stability, can meet the uses and various processing requirements of machine tools, grinding machines, turning machines and the like, also has the advantages of low volatility, non-toxicity, high biodegradability, reutilization and the like, and can be used as a universal metal processing cutting solution to replace mineral oil based metal processing fluid; besides, the performance of the phosphatide based metal processing emulsion is superior to that of common mineral oil based processing fluid.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Glass cutting fluid

ActiveCN105296106ASafety and environmental protection costGood lubricityLubricant compositionChemistrySide effect

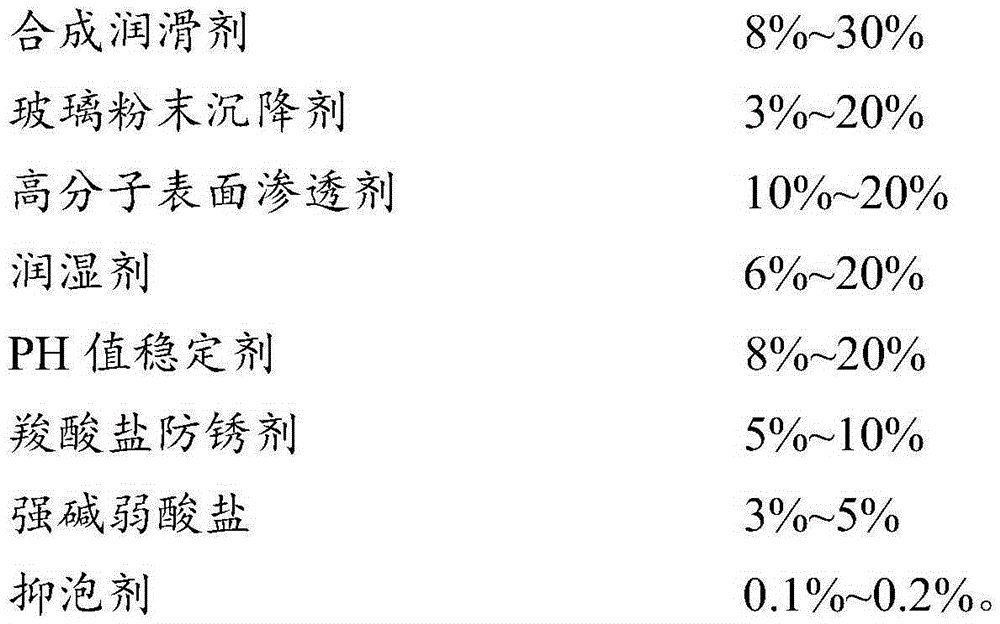

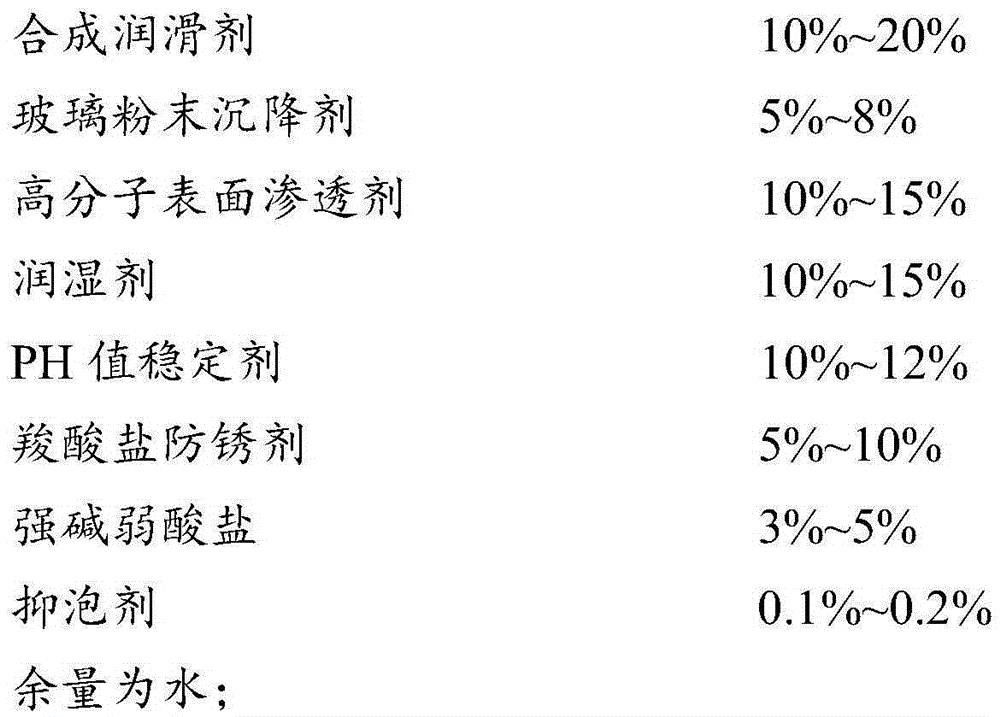

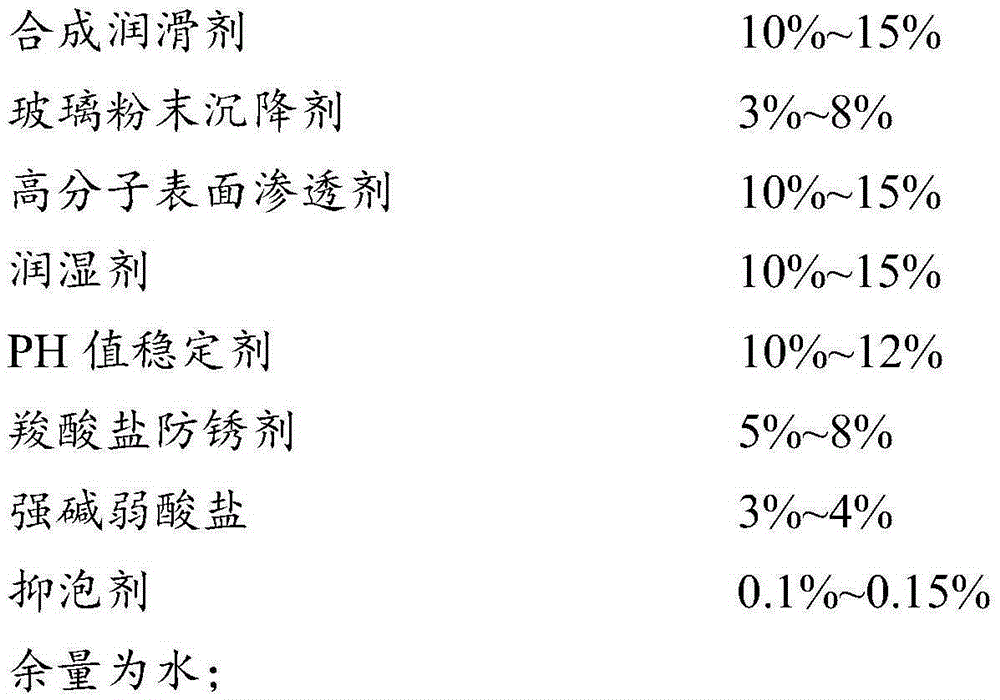

The invention discloses glass cutting fluid. The glass cutting fluid is prepared from, by mass, 8-30% of synthetic lubricant, 3-20% of glass powder sinking agent, 10-20% of macromolecule surface penetrating agent, 6-20% of wetting agent, 8-20% of PH value stabilizer, 5-10% of carboxylate antirust agent, 3-5% of strong alkali and weak acid salt and 0.1-0.2% of foam inhibitor. By means of the glass cutting fluid, the lubricating and cooling effect and the glass powder sinking effect are improved, the machining efficiency and surface smoothness of optical lenses and cell phone touch screen glass are improved, the glass cutting fluid is free of toxic and side effects on human bodies, and the product is safe, environmentally friendly and low in cost.

Owner:SHENZHEN XINJUNXIANG TECHCAL

Micro emulsion type cutting liquid with high lubrication, low foam and long service life

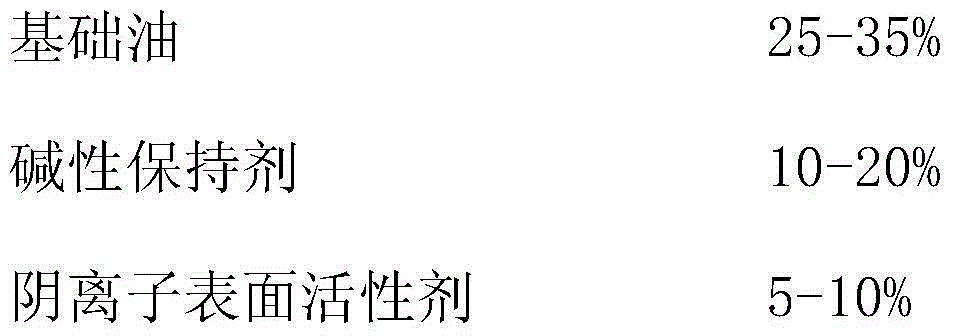

The invention relates to a cutting liquid for metal processing and a preparation method of the cutting liquid, and in particular relates to a micro emulsion type cutting liquid with high lubrication, low foam and long service life. The cutting liquid comprises the following components in percentage by weight: 25-35% of base oil. 10-20% of alkali holding agent, 5-10% of anionic surfactant, 5-8% of anti-rusting agent, 3-4% of coupling agent, 0.5-1% of emulsifier, 5-7% of extreme pressure agent, 0.1-0.2% of defoaming agent, 0.2-0.5% of bactericide and the balance of water. The preparation method of the micro emulsion type cutting liquid with high lubrication, low foam and long service life comprises the following steps: in a system of base oil, adding the alkali holding agent, the anionic surfactant, the anti-rusting agent, the coupling agent, the emulsifier, the extreme pressure agent, the defoaming agent, the bactericide and the water, and uniformly mixing and stirring. Compared with the prior art, the cutting liquid is not only good in lubrication property, improves the processing precision and surface smoothness and reduces the source for generating foam, but also is long in service life and convenient to manage.

Owner:马思特(上海)化学有限公司

Method for preparing novel medical lubricating antibacterial catheter

The invention discloses a method for preparing a novel medical lubricating antibacterial catheter, which comprises the following steps of: blending and extruding high-concentration polypropylene-based nanometer silver antibacterial powder or antibacterial master batches and polylactic acid slices by using a screw extruder to prepare polylactic acid antibacterial master slices; and preparing the medical lubricating antibacterial catheter by using a precision melting extruder. The method is obvious in bacteriostatic effect, bacteria on the surface of the catheter can be inhibited from being propagated effectively, and the efficiency is more than 98 percent; and the catheter prepared by the method is high in biocompatibility, has surface self-lubricating property, and can be widely used for the water delivery and transfusion of patients and relevant instruments.

Owner:SHANGHAI LANGYI FUNCTIONAL MATERIALS

Gear machining minimum-quantity lubricating oil and preparation method and application thereof

InactiveCN102585983AGood lubricityGood extreme pressure and anti-wear propertiesLubricant compositionChemistryPetroleum

The invention belongs to the technical filed of lubricating oil and particularly relates to gear machining minimum-quantity lubricating oil and a preparation method and application thereof. The gear machining minimum-quantity lubricating oil is characterized by being prepared by the following raw materials by weight: 30-40% of compound synthetic ester, 20-30% of bright stock, 10-12% of compound phosphate, 10-12% of chlorinated paraffin, 8-10% of vulcanized animal oil, 2-3% of petroleum calcium sulfonate with a high alkali value, 2-3% of ricinoleic acid and 1-2% of dispersing agents. The compound synthetic ester adopts mixture formed by any two or more than two of dioctadecyl adipate, pentaerythritol ester, trimethylolpropane trioleate, dimethyl phthalate and diethyl phthalate. The compound phosphate adopts mixture formed by any two or more than two of dibutyl phosphate, o-tolyl phosphate and triphenyl thiophosphate. Compared with the prior art, the gear machining minimum-quantity lubricating oil has good lubricity and extreme pressure and anti-wear property.

Owner:阜宁县特种油品有限公司

Water-soluble and oil-soluble diamond grinding liquid and preparation method thereof

The invention discloses water-soluble and oil-soluble diamond grinding liquid, and belongs to the field of precise finishing and polishing processing. The liquid is prepared by the following raw materials in percentages by weight: 54-87% of base oil, 5-15% of an emulsifier, 5-10% of a co-emulsifier, 0.1-1% of an anti-aging agent of oil products, 0.05-5% of a diamond abrasive, and the balance being water. The invention also discloses a preparation method of the water-soluble and oil-soluble diamond grinding liquid, and the method comprises the following steps: (1) the base oil, the emulsifier, the co-emulsifier and the anti-aging agent of oil products are mixed and poured into a reaction vessel, and heating is carried out with stirring at 70 DEG C for 10-20 minutes; (2) the diamond abrasive is added into water and placed in supersonic wave with stirring for 10 minutes, and mixed liquor is obtained; (3) the mixed liquor with dispersed diamond abrasive is slowly added into a reaction vessel, temperature is raised to 70 DEG C with stirring for 30 minutes, temperature is reduced to room temperature with stirring, and the water-soluble and oil-soluble diamond grinding liquid is obtained.

Owner:HENAN UNION ABRASIVES

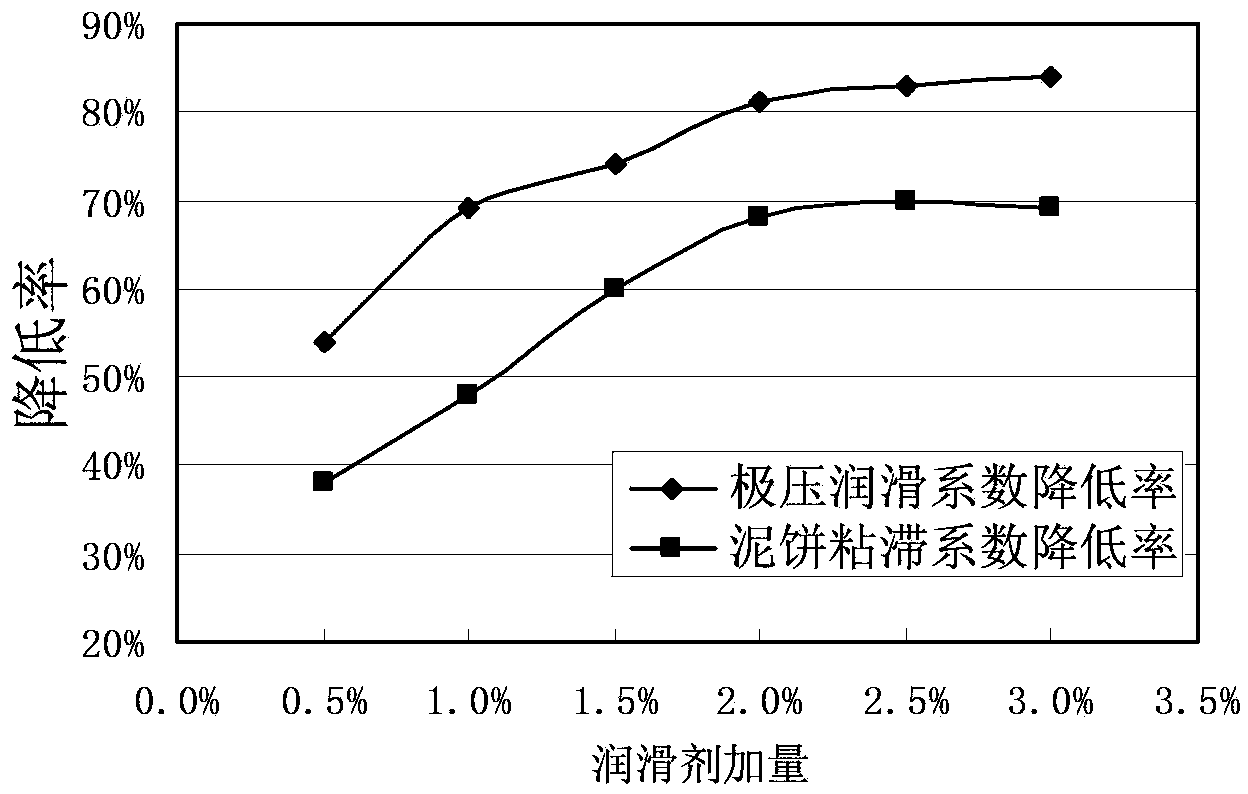

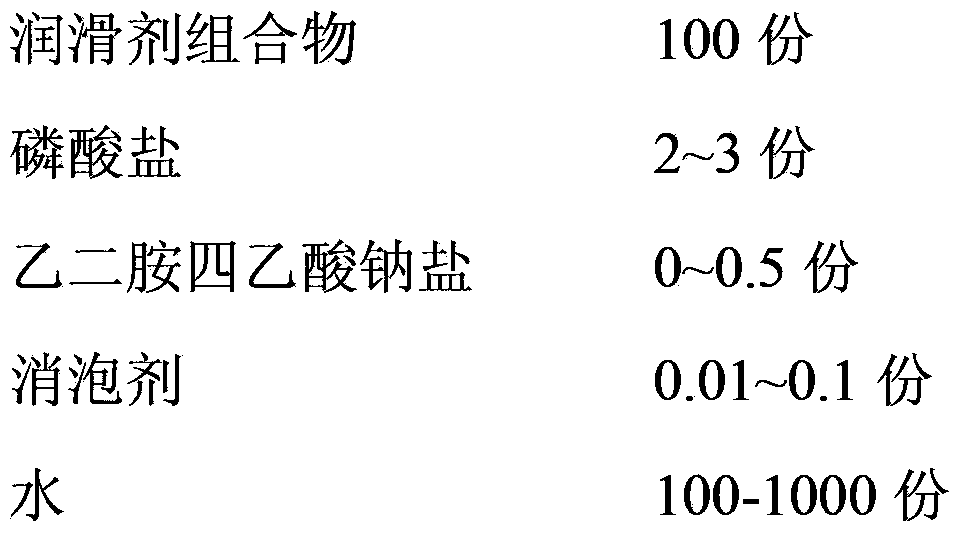

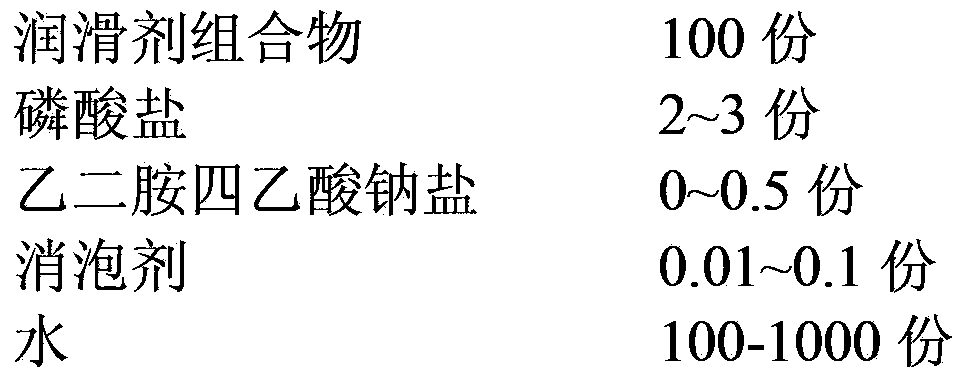

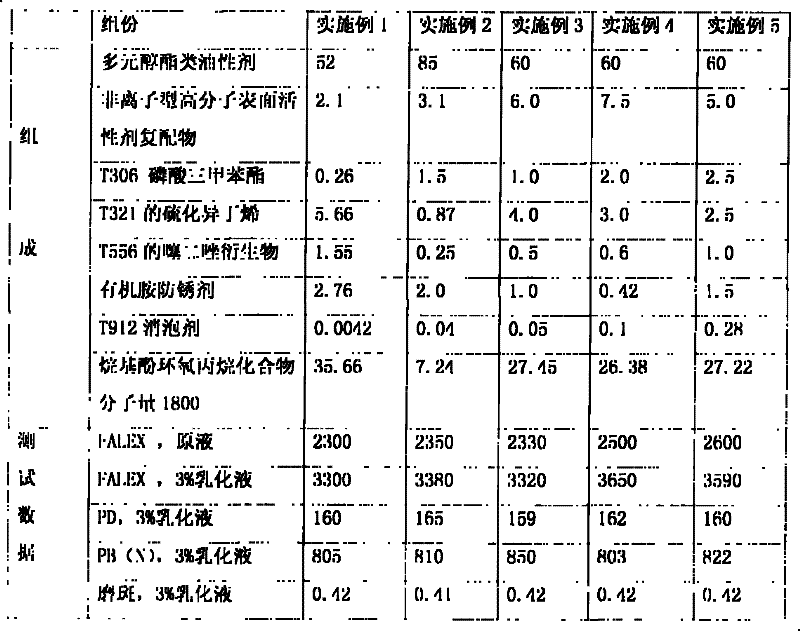

Lubricant for well drilling liquid and preparation process thereof

The invention relates to the technical field of oil well drilling, in particular to a lubricant for well drilling liquid and a preparation process thereof. The lubricant for the well drilling liquid comprises synthetic fatty acid and polyhydric alcohol amine mixture, wherein the polyhydric alcohol amine mixture comprises anhydride alcohol and alcohol amine, the weight ratio of the anhydride alcohol to the alcohol amine is 1: 1, the weight percent of the synthetic fatty acid is 80-90%, and the weight percent of the polyhydric alcohol amine mixture is 20-10%. The process for preparing the lubricant for the well drilling liquid comprises the following steps: taking the synthetic fatty acid and the polyhydric alcohol amine mixture by weight percent, mixing the synthetic fatty acid and the polyhydric alcohol amine mixture together, continuously stirring the mixture at the temperature of 100 DEG C-120 DEG C for 0.5-2.5 hours, sub-packaging and preparing the lubricant for the well drilling liquid. The prepared lubricant has no toxicity, no pollution, no corrosion, no fluorescence, good lubrication performance, high-temperature resistance, good compatibility with various polymer processing agents and good water solubility.

Owner:CNPC GREATWALL DRILLING ENG

Whitening and water compensating skin caring cosmetic without essence, coloring matter, mineral oil or antiseptic

Disclosed is a skin care cosmetics containing no essence, coloring matter, mineral oil and preservative agent, whose (w / w) composition includes 2-ethylhexyl palmitate 3-5%, Squalane 1-2%, methyl glycol 2-5%, polyacrylic resin 0.1-0.5%, jojoba oil 2-4%, vitamin E 0.5-1.5%, dimethyl silicon oil 0.5-1.5%, pentanediol 3-5%, fresh flower extract 0.1-0.5%, yeast extract 0.5-2%, bisabolol 0.5-1.5%, vitamin B3 1-3%, polyoxyethylene 20 methyl glucose stearate 2-5%, methyl glucose stearate 2-5%, deionized water 100%.

Owner:广州市采诗化妆品有限公司

High temperature-resistant bearing grease and preparation method thereof

InactiveCN109337737AGood high and low temperature resistanceGood lubricityLubricant compositionChemistryParaffin oils

The invention relates to the field of lubricating grease, in particular to high temperature-resistant bearing grease and a preparation method thereof. The high temperature-resistant bearing grease comprises the following components in percentage by weight: 70-80% of base oil, 12-18% of a thickening agent and 8-15% of additives, wherein the base oil comprises paraffin oil, polyol ester, di-n-octyladipate and poly-alpha olefin; the thickening agent comprises bentonite and calcium sulfonate complex ester; and the additives comprises an antioxidant, a rust inhibitor, an extreme pressure wear-resistant agent and other additives. The invention furthermore discloses the preparation method of the high temperature-resistant bearing grease. The produced bearing grease produced has excellent high and low temperature properties, lubricating performance, water resistance and extreme pressure wear resistance, low noise and long service life. At the same time, the preparation method is simple and strong in operability.

Owner:安徽中天石化股份有限公司

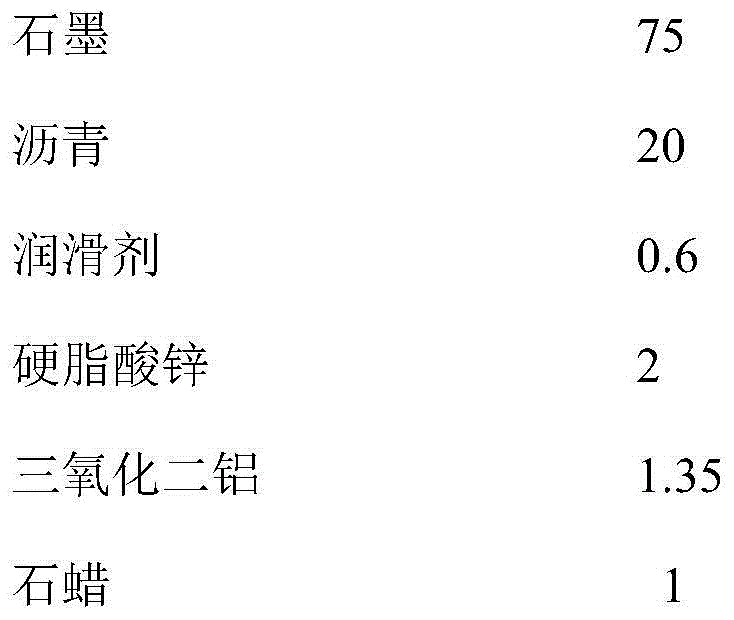

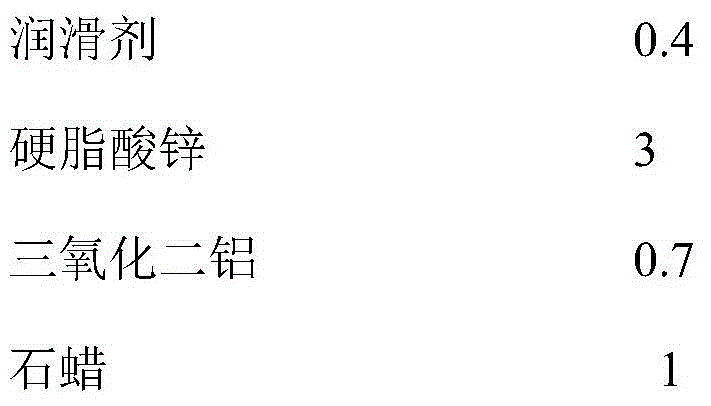

Electric brush for motor of electric tool and preparation method for electric brush

ActiveCN104659626ALight in massGood lubricityRotary current collectorBrushes manufactureElectric machineryAluminium

The invention discloses an electric brush for a motor of an electric tool and a preparation method for the electric brush. Constituent materials of the electric brush for the motor belong to the field of material science and the electric brush is prepared from the following raw materials in parts by weight: 30-90 parts of graphite, 10-35 parts of asphalt, 0.2-1.0 part of a lubricating agent, 0.5-5 parts of zinc stearate, 0.5-3 parts of aluminum oxide and 0.5-5 parts of paraffin. The electric brush disclosed by the invention is low in resistivity, excellent in abrasion resistance, high in commutation performance, high in interference resistance and long in service life and is importantly high in abrasion resistance and high-voltage resistance and low in spark grade.

Owner:SUZHOU DONEKA NEW MATERIALS CORP LTD

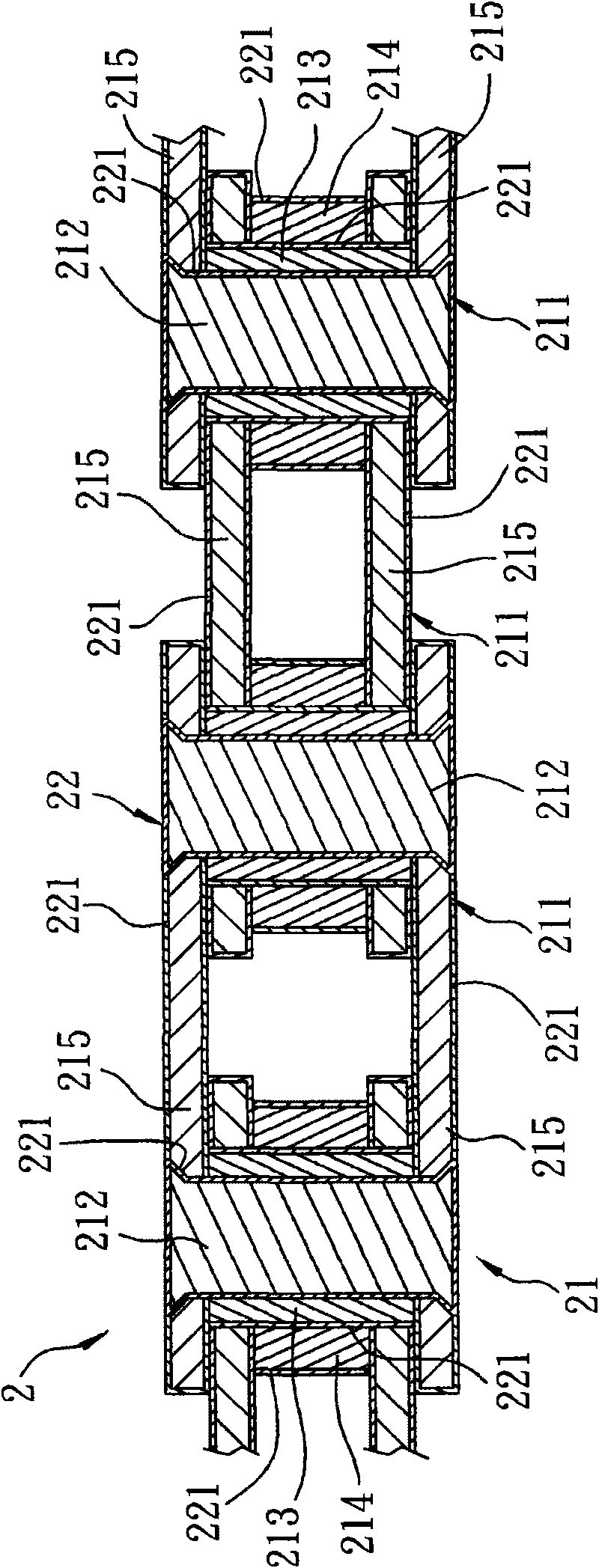

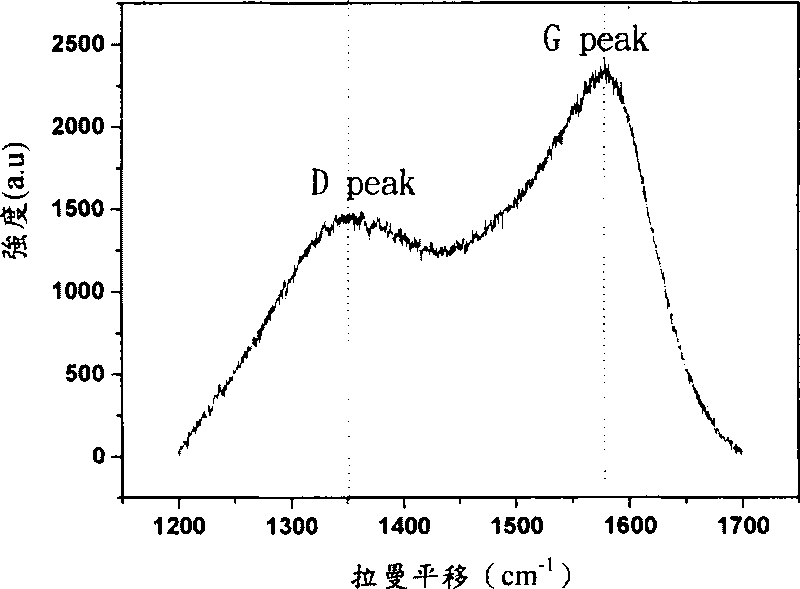

Wear-resisting chain

InactiveCN101737454AImprove the lubrication effectAccelerated corrosionDriving chainsGraphiteSpectral analysis

The invention relates to a wear-resisting chain which comprises a chain body and a wear-resisting layer unit which covers a local part or the total part of the chain body. The wear-resisting layer unit can generate a graphite characteristic peak and a disordered characteristic peak by Raman spectral analysis. By utilizing the structural characteristics of the wear-resisting layer unit, the wear-resisting chain can generate the efficacy of abrasion and corrosion resistance, high lubrication degree and long service life, and the like.

Owner:超汇桂盟传动(苏州)有限公司

Water-based complete synthesis quartz glass cutting liquid and preparation method thereof

InactiveCN109097175AGood lubricityWaste liquid treatment is simpleLubricant compositionIonOrganic acid

The invention provides water-based complete synthesis quartz glass cutting liquid. The water-based complete synthesis quartz glass cutting liquid comprises the components in percentage by weight of 20-30% of polyether, 1-5% of an ion-type quaternary ammonium settlement agent, 5-10% of a water-base extreme-pressure lubricant, 2-8% of organic acid, 2-10% of organic amine, 1-5% of an antirusting agent, 1-5% of an ether coupling agent, 0.1-1% of an anti-hardening aqueous solution, 0.01-0.1% of a defoaming agent, and 40-60% of pure water. The water-based complete synthesis quartz glass cutting liquid solves the problems of potential risks in the cutting process and fire-breaking-out accidents in the cutting process, the environment state of workers in workshops is greatly improved, the oil mistin the workshops is reduced, and besides, the water-based complete synthesis quartz glass cutting liquid has excellent lubricating properties, anti-rusting properties, permeability and glass abrasivedust settlement properties. The water-based complete synthesis quartz glass cutting liquid is free from substances of chlorine, phosphorus, sulphur, nitrite, phenol and the like, bacterium generationand smelling are not liable to cause, chafing and skin irritation cannot be caused, waste liquid is easy to treat, and pollution and discharge are reduced.

Owner:YANTAI HENGBANG CHEM

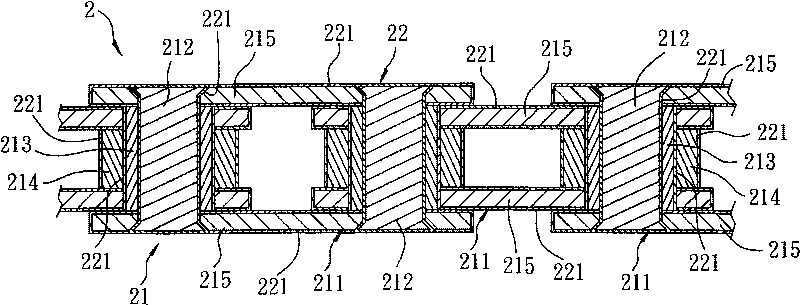

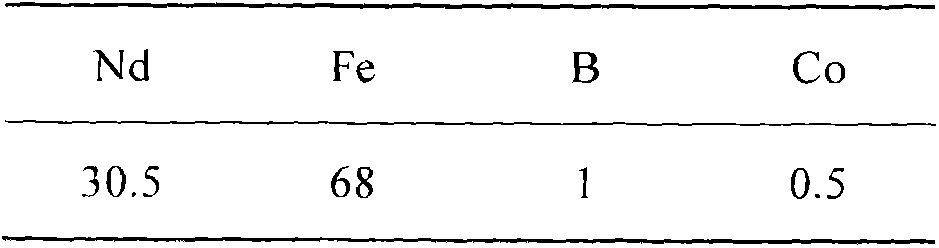

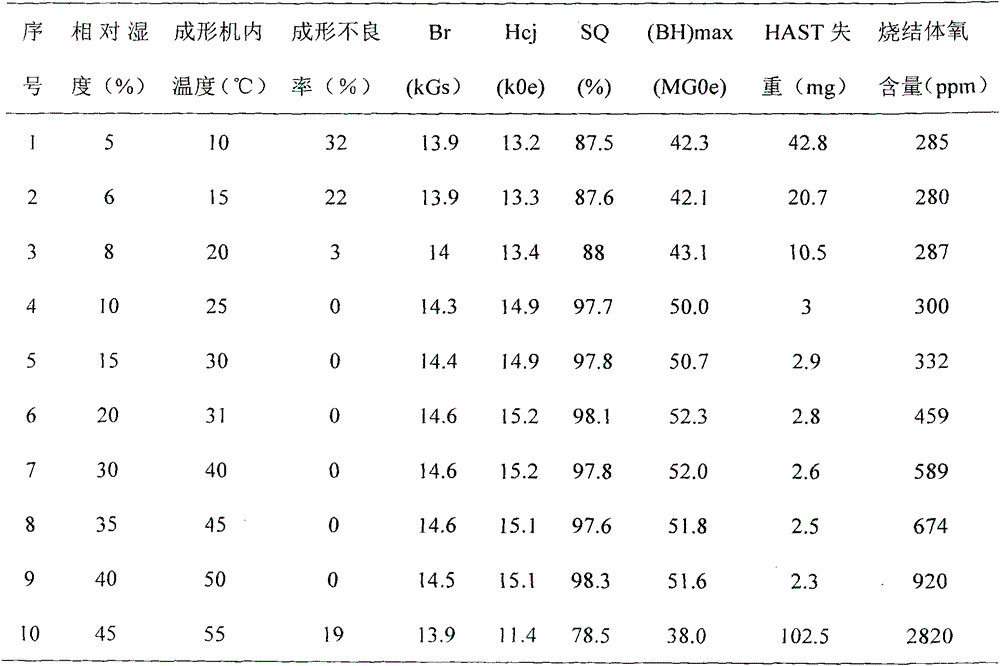

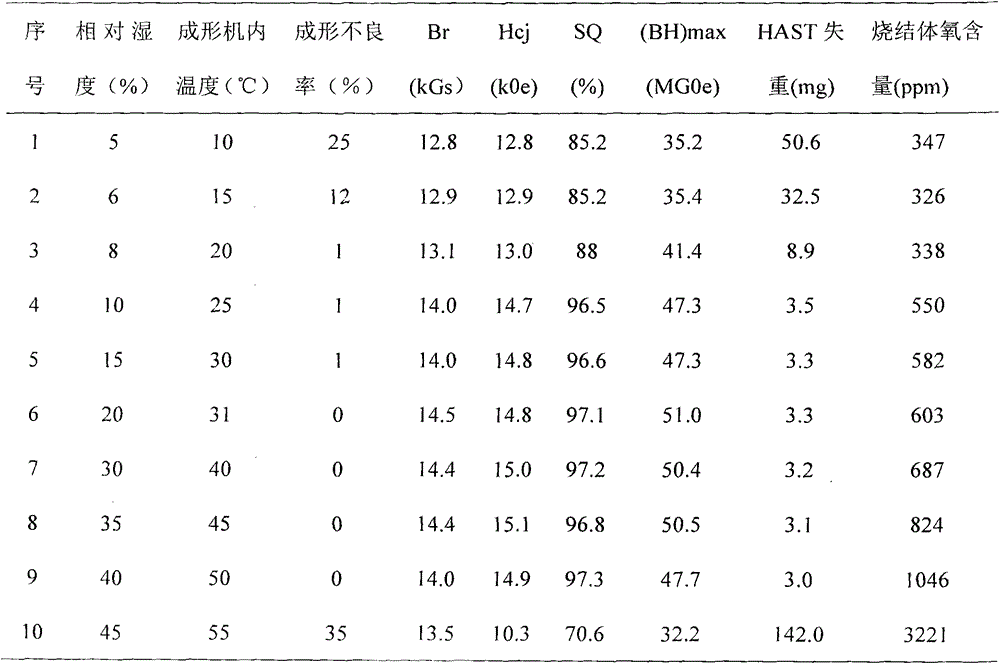

Production method for rare earth alloy magnetic powder forming body and rare-earth magnet

ActiveCN103600070AImprove liquidityGood lubricityInductances/transformers/magnets manufactureMagnetic materialsMagnetic powderRelative humidity

The invention discloses a production method for a rear earth alloy magnetic powder forming body and a rare-earth magnet. The production method for the rear earth alloy magnetic powder forming body comprises pressing organic additive added rear earth alloy magnetic powder through a one section forming method under the atmosphere with the temperature of 25 to 50 DEG C and the relative humidity of 10 to 40 % in inert gas atmosphere enclosed space. The production method for the rear earth alloy magnetic powder forming body has the advantages of restraining poor forming (fracture, unfilled corner and crack) of a low oxygen content magnet after sintering and rising the degree of orientation, Br and (BH) max due to specific setting of the temperature and the humidity of the inert gas atmosphere in a completely enclosed environment.

Owner:FUJIAN CHANGJIANG GOLDEN DRAGON RARE EARTH CO LTD

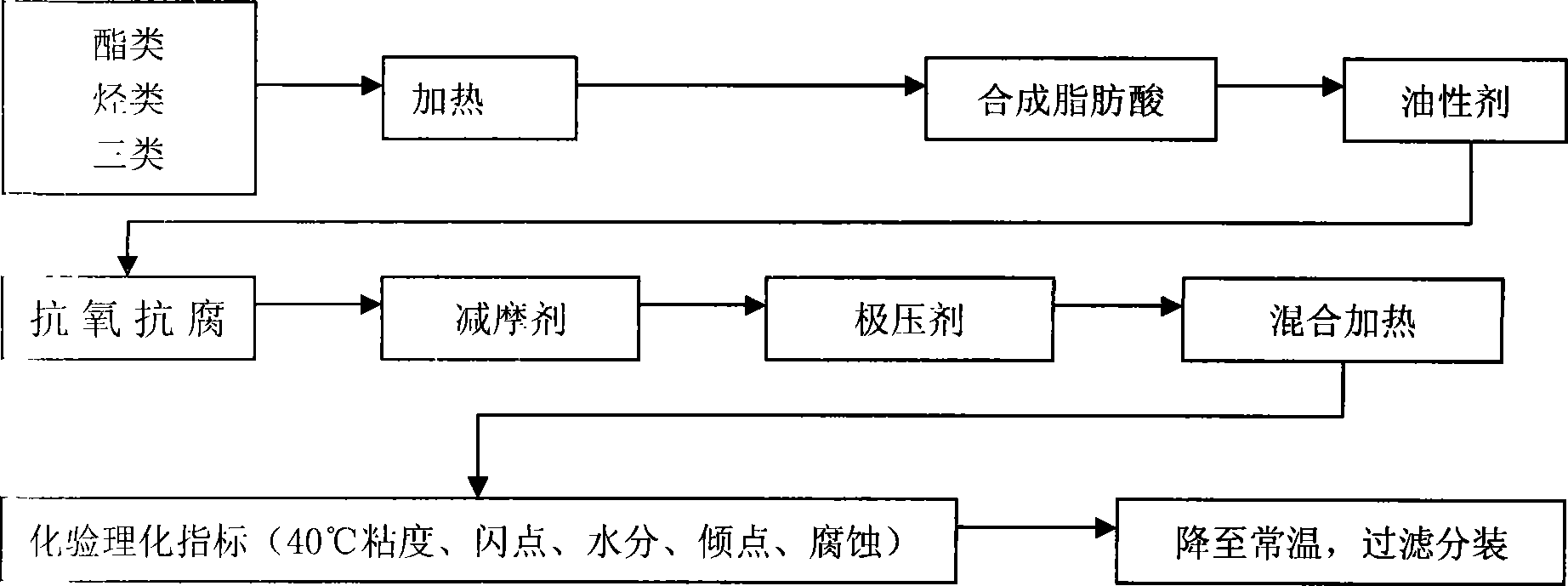

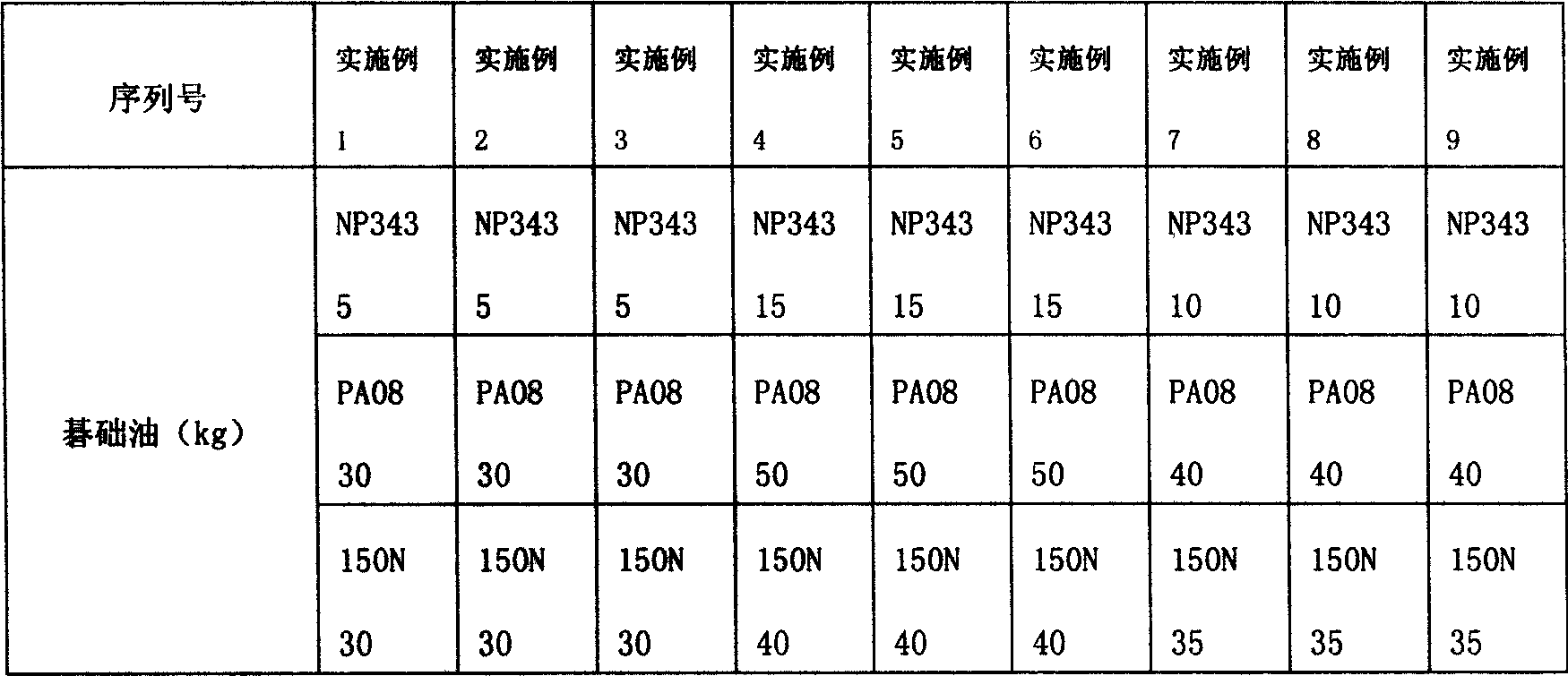

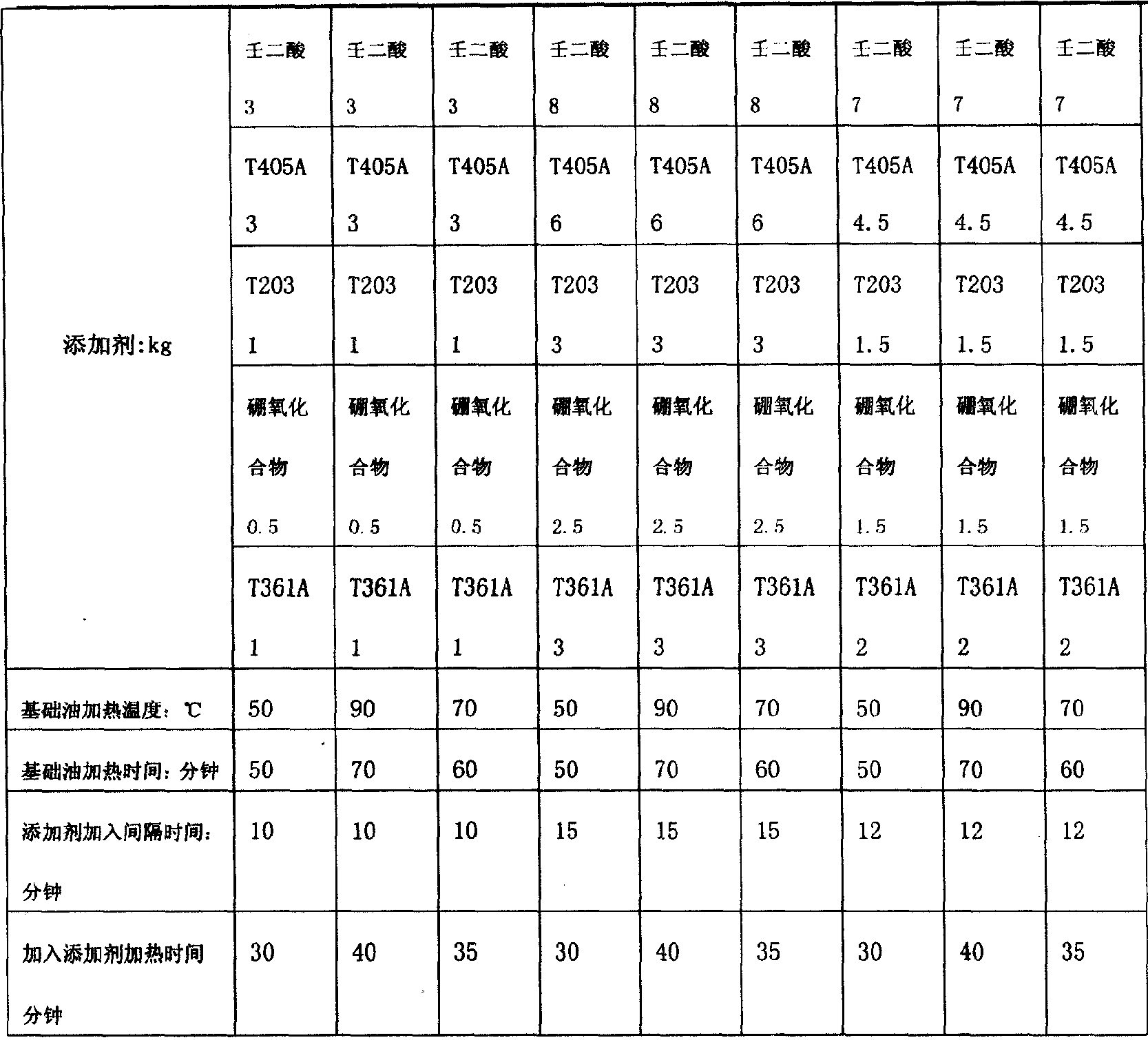

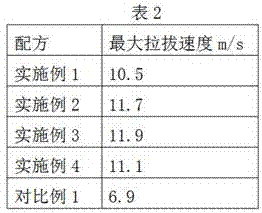

Novel condensing lubricant oil and preparation method thereof

ActiveCN101451088AGood high temperature stabilityGood lubricityAdditivesBase-materialsOxidation resistantChemistry

The invention discloses novel condensed lubricant and a preparation method thereof. The novel condensed lubricant is prepared from the following raw materials by weight portion: 5 to 15 portions of esters, 30 to 50 portions of hydrocarbons, 30 to 40 portions of tertiary basic oil, 3 to 8 portions of synthetic fatty acid, 3 to 6 portions of oiliness agent, 1 to 3 portions of oxidation and corrosion inhibitor, 0.5 to 2.5 portions of antifriction and 1 to 3 portions of extreme pressure agent, wherein the ethers are one or more than one selected from NP343, NP372 and P81; the hydrocarbons are oneor more than one selected from PA08, PA06 and PA012; the tertiary basic oil is one or more than one selected from 150N, 75N and HL-68; the synthetic fatty acid is one or more than one selected from azelaic acid, sebacic acid and cinnamic acid; the oiliness agent is one or more than one selected from T405A, T403 and T405; the oxidation and corrosion inhibitor is one or two selected from T203 and T204; the antifriction is one or more than one selected from boron-nitrogen compounds, T304, T301 and 309; and the extreme pressure agent is one or two selected from T361A and 3745P. The novel condensed lubricant has superior high-temperature stability, antioxidation stability, abrasion resistance, corrosion resistance and anti-rust performance, strong adhesivity and permeability and small volatility, can form a solid lubricant membrane on the surface of metal, effectively reduce energy consumption and splash, and prolong the service life of equipment, and does not pollute the working environment.

Owner:LUOHE BEIJIA BILL SCI & TECH CHEM

Modified metal wire drawing powder and preparation method thereof

The invention relates to the technical field of wire drawing, and particularly discloses modified metal wire drawing powder. The modified metal wire drawing powder is prepared from the following components in parts by mass: 10 to 60 parts of lubricant, 10 to 60 parts of friction-reduction additive, 1 to 15 parts of extreme pressure agent, 0.3 to 10 parts of anti-rust agent and 5 to 25 parts of alkaline metal / alkaline earth metal hydroxide, wherein the extreme pressure agent comprises methylphenyl silicone oil. A preparation method of the modified metal wire drawing powder comprises the following steps of mixing and stirring the lubricant, the friction-reduction additive and the anti-rust agent, heating, adding a saturated water solution of the alkaline metal / alkaline earth metal hydroxide, preserving heat and reacting for a period of time, adding the extreme pressure agent, uniformly stirring, drying, and crushing, so as to obtain the modified metal wire drawing powder. The modified metal wire drawing powder has the advantages that the lubricating property and anti-corrosive property are good, the high temperature and high pressure-resistant property is realized, the cost is low, the abrasion consumption is low, and the storage is easy.

Owner:河北纳泰化工有限公司 +1

Anti-static ceramic

The invention is an antistatic ceramic, which is made of the following raw materials in parts by weight: silicon nitride 60-75, kaolin 10-16, aluminum oxide 2-8, silicon dioxide 2-5, tin oxide 3‑9, zirconia 1‑5, molybdenum disilicide 1‑3, antimony powder 10‑15, titanium dioxide 1‑3, conductive graphite 5‑6, silicon carbide 1‑5, boron carbide 1‑2, aluminum nitride 1 ‑2, thorium oxide 2‑4, appropriate amount of deionized water. The ceramic prepared by the present invention has certain electrical and thermal conductivity, prevents the generation of static electricity, prevents frictional overheating, prolongs the service time of pipelines and channels, and the ceramic of the present invention also has certain corrosion resistance and oxidation resistance, and has Good toughness.

Owner:苏州志英明建信息科技有限公司

Oil for high-efficiency copper hot rolling

InactiveCN102010776APromote degradationImprove machining accuracyLubricant compositionNonferrous metalBenzotriazole

The invention provides oil for high-efficiency copper hot rolling, which relates to oil for processing nonferrous metals. The oil for high-efficiency copper hot rolling comprises the following components in percentage by weight: 50-70% of transformer oil 10#, 5-20% of polyalcohol saturated ester, 5-15% of tall oil fatty acid, 1-10% of diamidodimethyl, 2-10% of triethanolamine, 1-10% of bactericide, 5-40% of non-ionic surfactant, 5-20% of anionic surfactant, 2-30% of sorbitan monooleate, 0.1-10% of benzotriazole and 0.1-10% of benzotriazole derivatives. The oil for high-efficiency copper hot rolling has the advantages of high stability, long life cycle, excellent cooling property and lubricating property, environment friendliness, favorable degradability, high antirust performance and high corrosion resistance, and has favorable protective function on the rolling machine and rolled pieces.

Owner:广东垠星科技发展有限公司

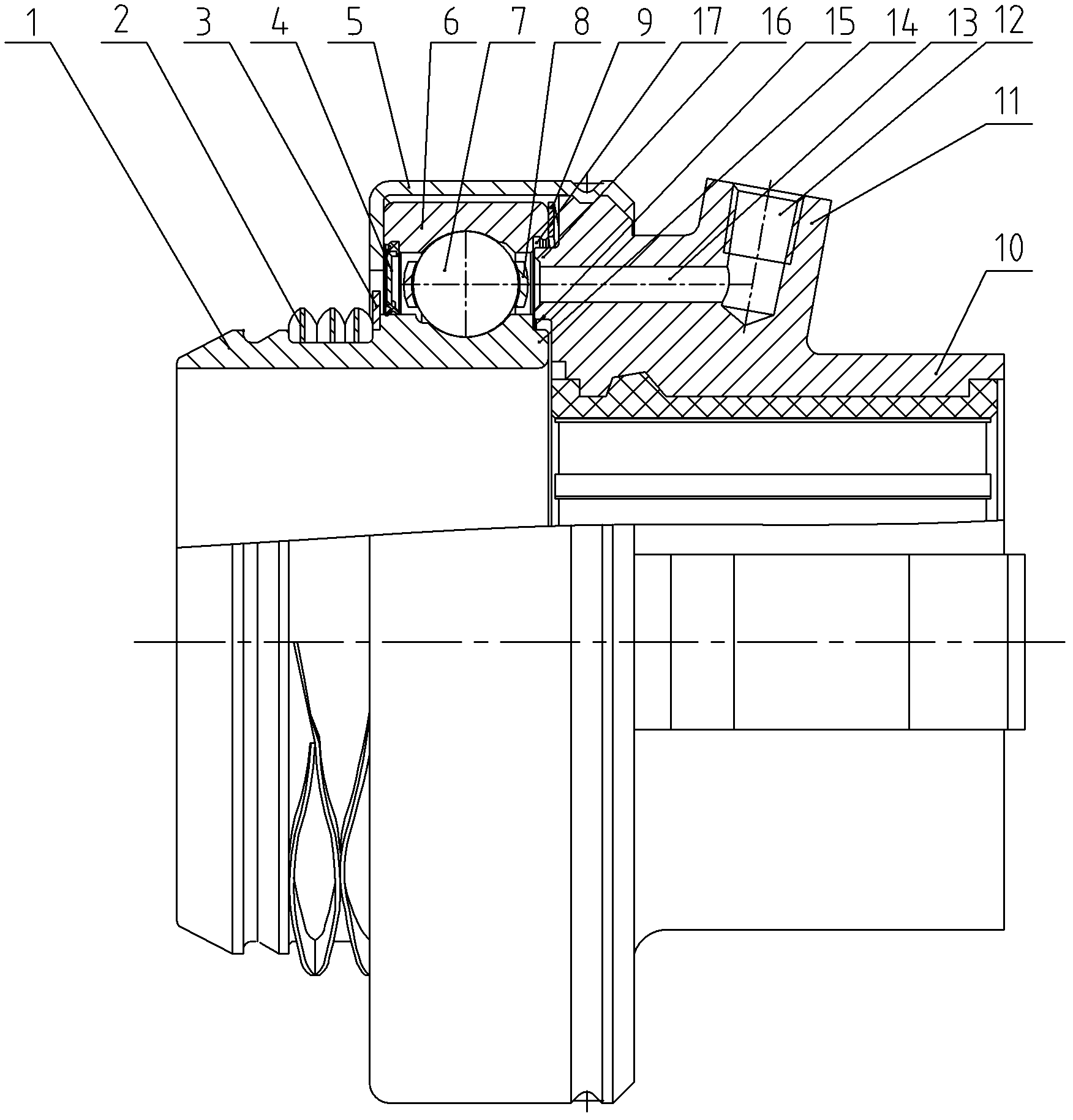

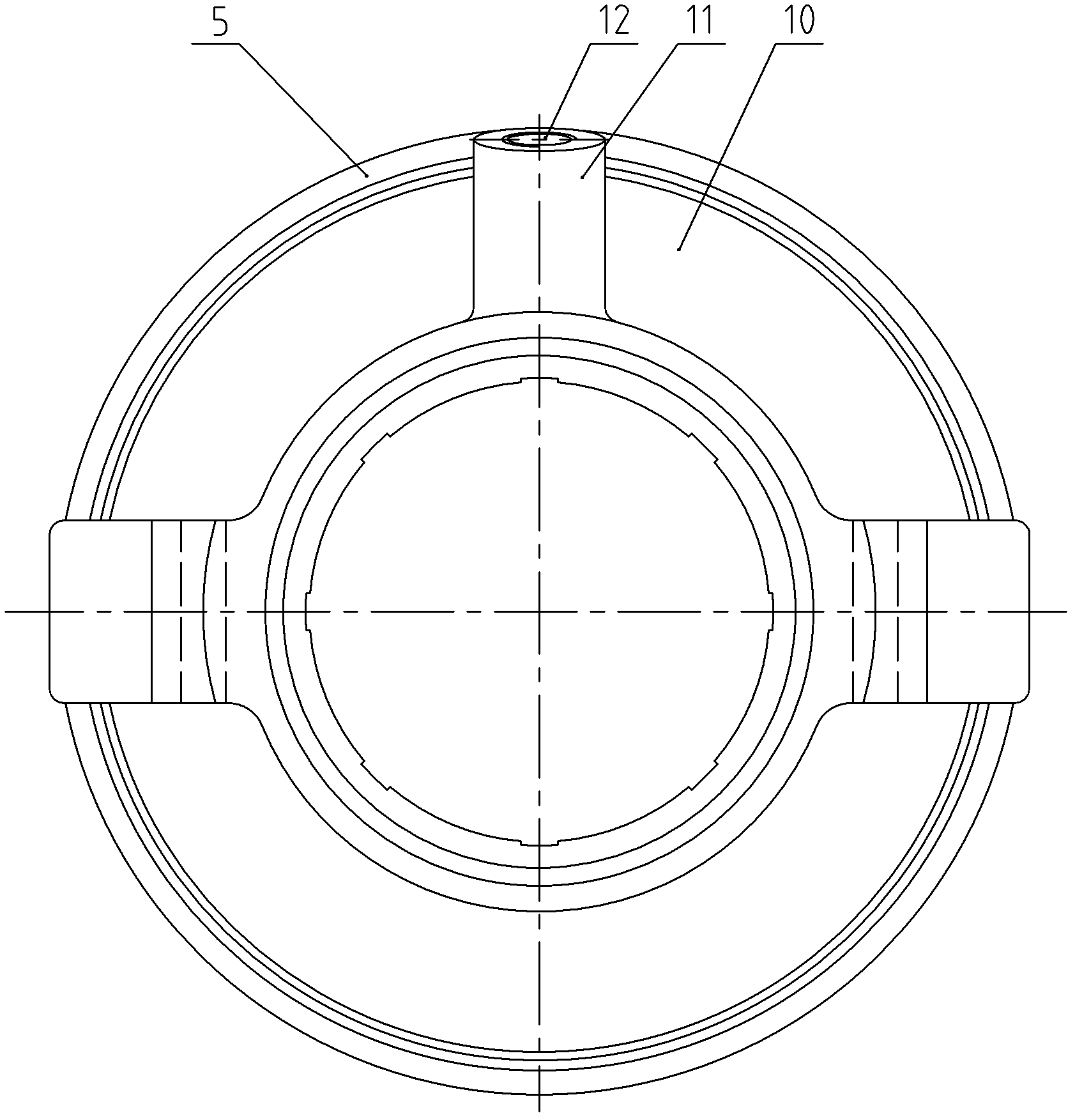

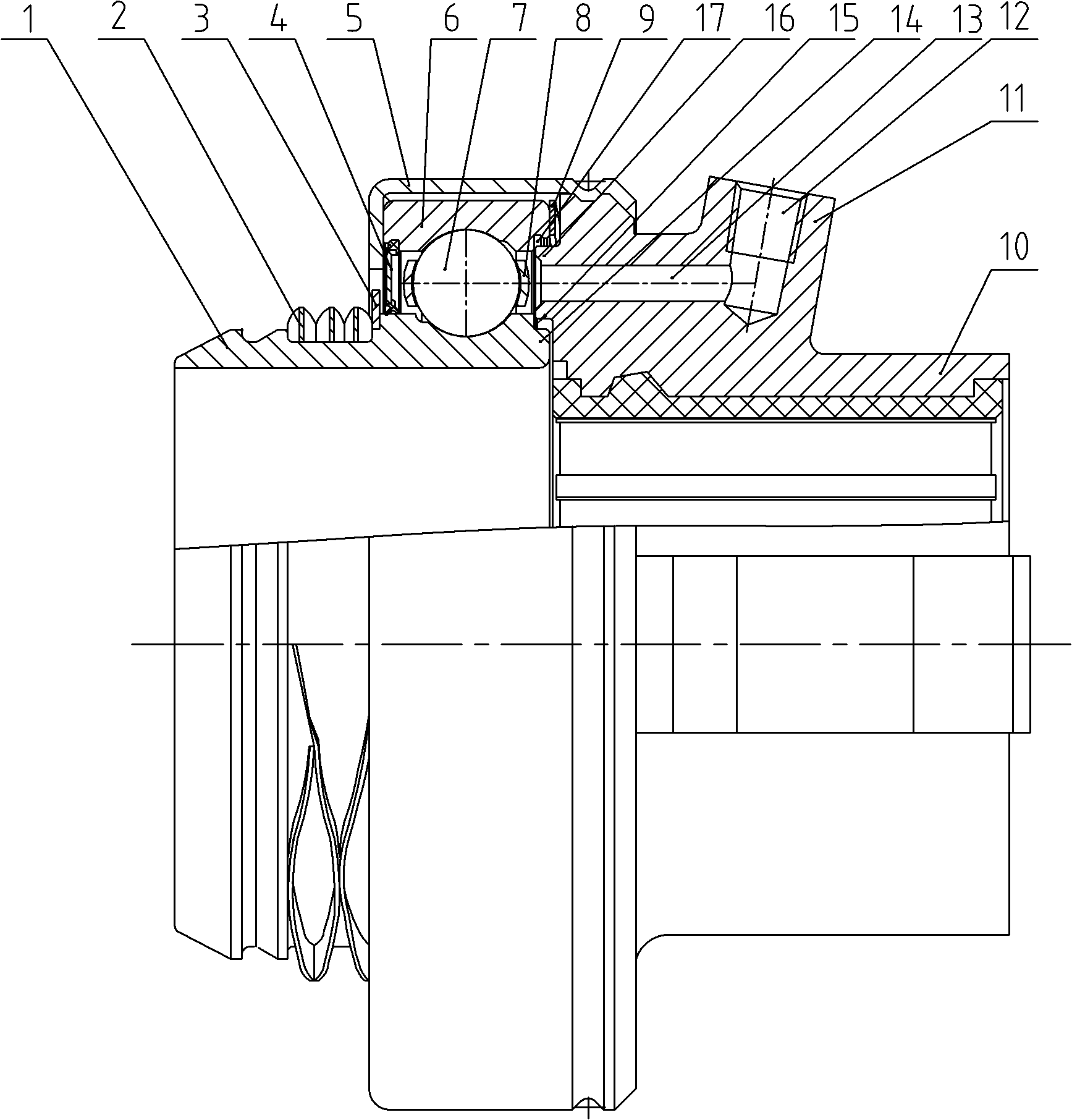

Pull type clutch release bearing capable of injecting grease for lubricating

ActiveCN102537115AGood lubricityExtended service lifeMechanical actuated clutchesBearing componentsClutchEngineering

The invention relates to a pull type clutch release bearing capable of injecting grease for lubricating, which includes a release sleeve and a bearing outer ring, a ball and a bearing inner ring that are positioned on one side of the release sleeve, wherein a seal ring is arranged between the bearing outer ring and the bearing inner ring on the outer side of the ball; a support spring is arrangedbetween the bearing outer ring and the end surface of the release sleeve; a housing is fixed between the outer end surface of the bearing outer ring and the outer wall surface of the release sleeve; an annular groove is arranged on the inner side end surfaces of the bearing outer ring and the bearing inner ring; a convex ring in clearance fit with the annular groove is arranged on inner side end surface of the release sleeve; and a grease injecting hole communicated with the inside of the annular groove is formed in the release sleeve. By forming the grease injecting hole communicated with the interior of the release bearing in the release bearing, when the lubricating grease in the release bearing fails and flows away due to high temperature during the use of the release bearing, the lubricating grease can be timely replenished to the interior of the release bearing through the grease injecting hole, so as to retain the excellent lubricating performance of the bearing, and prolong the service life of the release bearing.

Owner:WUXI MINLIAN AUTOMOBILE PARTS CO LTD

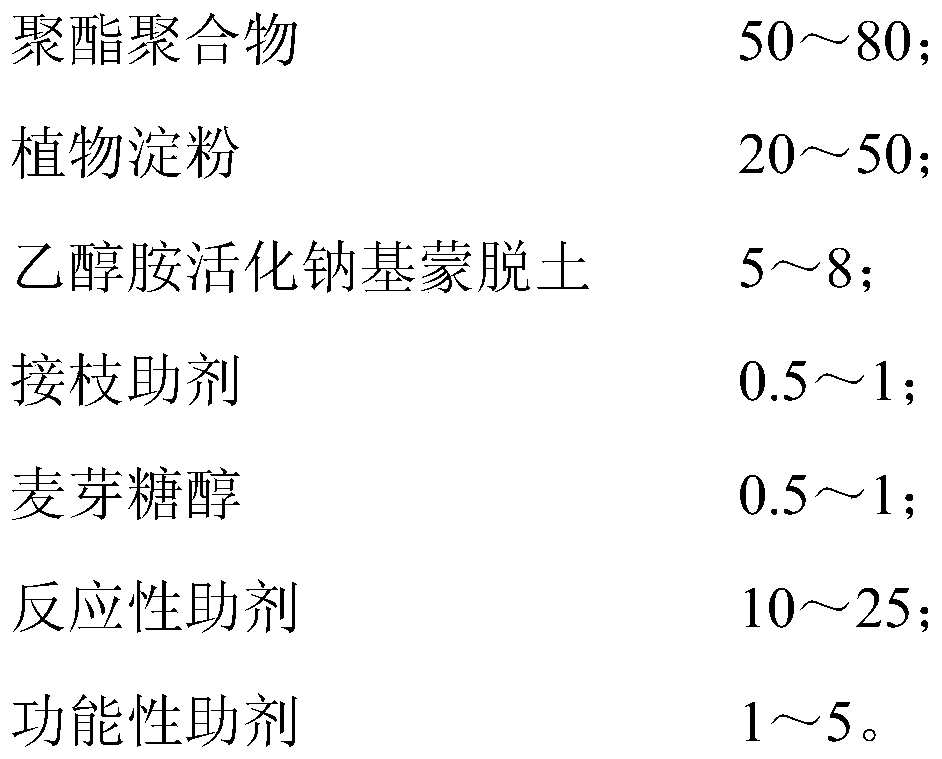

Ethanolamine activated Na-montmorillonite and polymer composite biodegradable film blowing resin and preparation method

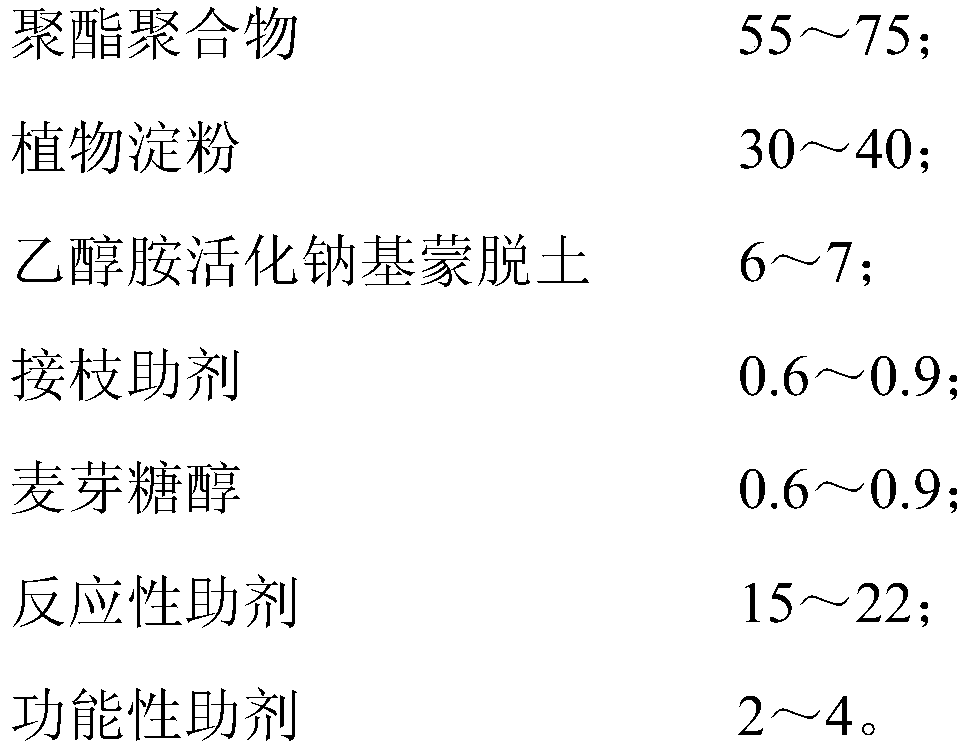

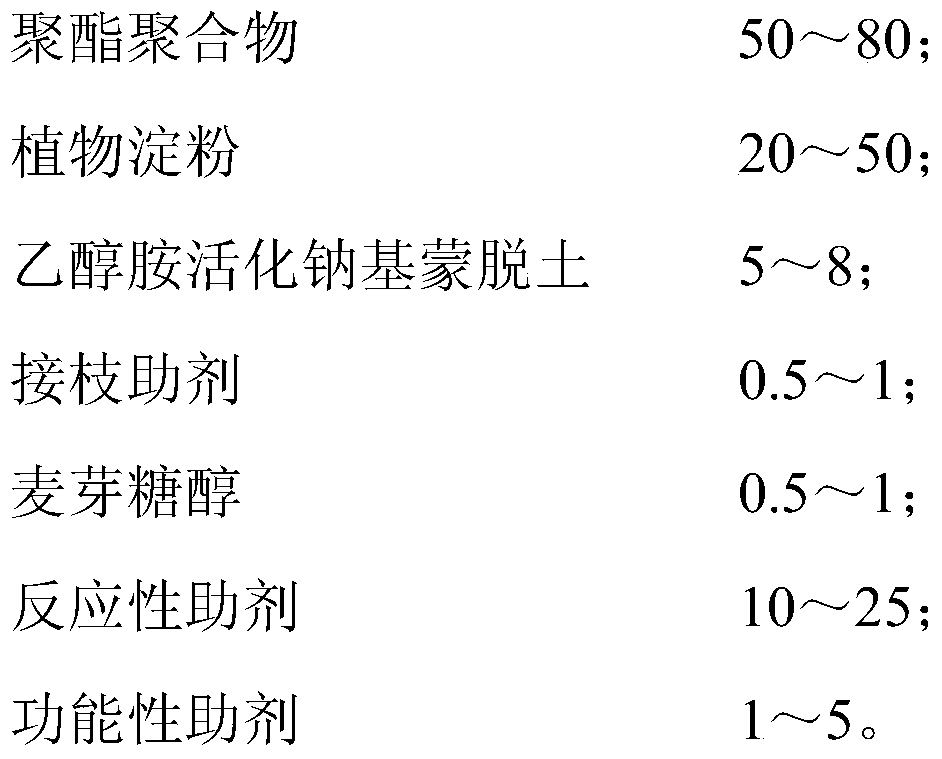

The invention belongs to the technical field of film blowing resin and particularly relates to ethanolamine activated Na-montmorillonite and polymer composite biodegradable film blowing resin. The resin is prepared from, by weight, 50-80 parts of polyester polymer, 20-50 parts of plant starch, 5-8 parts of ethanolamine activated Na-montmorillonite, 0.5-1 part of a grafting auxiliary, 0.5-1 part of maltitol, 10-25 parts of a reactive assistant and 1-5 parts of a functional assistant. According to the resin, plant starch serves as a raw material and is subjected to gelatinization and starch compound plastification modification, the composite materials are mixed through ethanolamine activated Na-montmorillonite, the lamellar structure of modified montmorillonite is evenly dispersed in the mixture so that the molecular structure of the mixture can be more stable, then the grafting auxiliary is added for grafting of starch and copolymerization of starch and polymer, the molecular structure of starch and polyester in the composite materials is changed, and accordingly the aims of improving tensile strength and tear strength of the composite material, increasing the breaking elongation of the composite material, reducing cost and the like are achieved.

Owner:东莞市酬勤包装制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com