Lubricant composite, preparation method thereof and trace lubricant made of same

A lubricant composition and micro lubricant technology, applied in the field of lubrication, can solve the problems of affecting the health of operators, using a large amount of lubricant, wasting resources, etc., achieving remarkable environmental protection effects, good extreme pressure and anti-wear properties, The effect of saving usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1# micro lubricant

[0034] Step 1: Weigh 61.83kg (1000mol) of boric acid and 213.79kg (3500mol) of monoethanolamine into the reaction kettle, stir and heat to 125°C, react for 3.5 hours, and discharge the water generated by the reaction under reduced pressure;

[0035] Step 2: Weigh 250.4kg (1250mol) of lauric acid and add it to the reaction kettle of step 1, stir and heat up to 175°C, react for 1.5 hours, and discharge the moisture generated by the reaction under reduced pressure;

[0036] Step 3: When step 2 decompresses and cools down to 105°C, add 147.29kg (28% of the total weight of raw materials in the above step) of polyethylene glycol (PEG400), keep stirring at constant temperature for 1.5 hours, and remove water under reduced pressure. A lubricant composition is prepared.

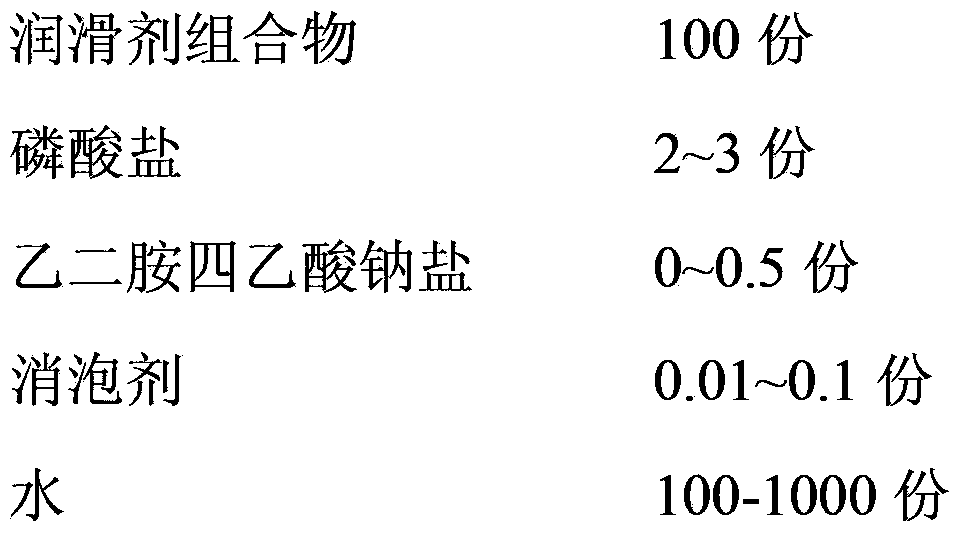

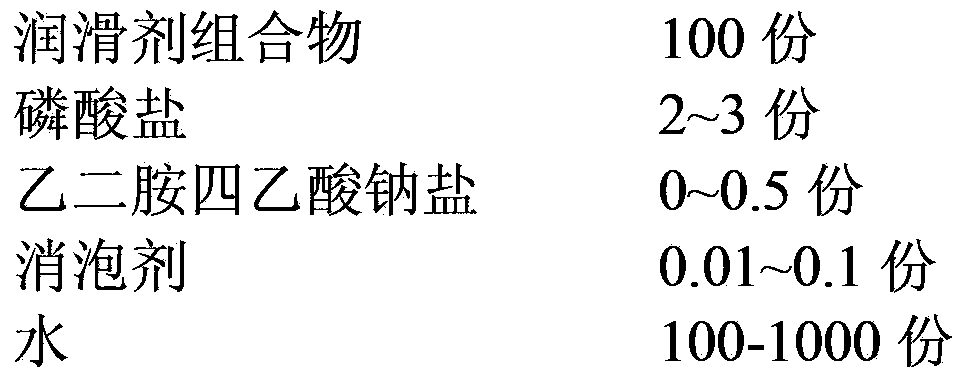

[0037] Step 4: Take 100kg of the lubricant composition prepared in Step 3, add 2.5kg of dipotassium hydrogen phosphate, 0.3kg of EDTA-2Na, 0.05kg of antifoaming agent simethicone, and 500k...

Embodiment 2

[0046] 2# micro lubricant

[0047] Step 1: Weigh 61.83kg (1000mol) of boric acid and 157.71kg (1500mol) of diethanolamine into the reaction kettle, stir and heat to 120°C, react for 3 hours and discharge the water generated by the reaction under reduced pressure;

[0048] Step 2: Weigh 426.72 kg (1500 mol) of stearic acid and add it to the reaction kettle of step 1, stir and heat up to 170° C., react for 2 hours, and discharge the moisture generated by the reaction under reduced pressure;

[0049] Step 3: When step 2 decompresses and cools down to 100°C, add 161.57kg (25% of the total weight of raw materials in the above step) polyethylene glycol (PEG200), keep stirring at constant temperature for 1.5 hours, and remove water under reduced pressure. A lubricant composition is prepared.

[0050] Step 4: Take 100kg of the lubricant composition prepared in step 3 and add a mixture of 1kg sodium hexametaphosphate and 1kg disodium hydrogen phosphate, 0.5kg EDTA-4Na, 0.01kg of antifoa...

Embodiment 3

[0052] 3# micro lubricant

[0053] Step 1: Weigh 61.83kg (1000mol) of boric acid and 179.03kg (1200mol) of triethanolamine into the reactor, stir and heat to 120°C, react for 4 hours and discharge the water generated by the reaction under reduced pressure;

[0054] Step 2: Weigh 282.47kg (1000mol) of oleic acid and add it to the reaction kettle of step 1, stir and heat up to 180°C, react for 1 hour, and discharge the water generated by the reaction under reduced pressure;

[0055] Step 3: When step 2 depressurizes and cools down to 110°C, add 157kg (30% of the total weight of raw materials in the above step) of polyethylene glycol (PEG600), keep stirring at constant temperature for 1 hour, and remove water under reduced pressure. A lubricant composition is prepared.

[0056] Step 4: Take 100kg of the lubricant composition prepared in Step 3, add 3kg of potassium hexametaphosphate, 0.1kg of antifoaming agent polyether-modified polysiloxane, and 1000kg of water, and stir and mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com