Patents

Literature

1671 results about "Rust converter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rust converters are chemical solutions or primers that can be applied directly to an iron or iron alloy surface to convert iron oxides (rust) into a protective chemical barrier. These compounds interact with iron oxides, especially iron(III) oxide, converting them into an adherent black layer that is more resistant to moisture and protects the surface from further corrosion. They are sometimes referred to as "rust remover" or "rust killer".

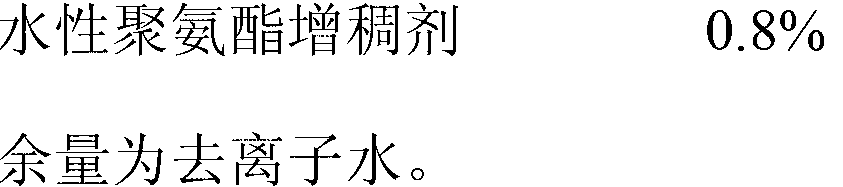

Water soluble full-alloy metal grinding fluid

ActiveCN104017636ALubricity achievedImprove stabilityLubricant compositionOrganic EsterNonferrous metal

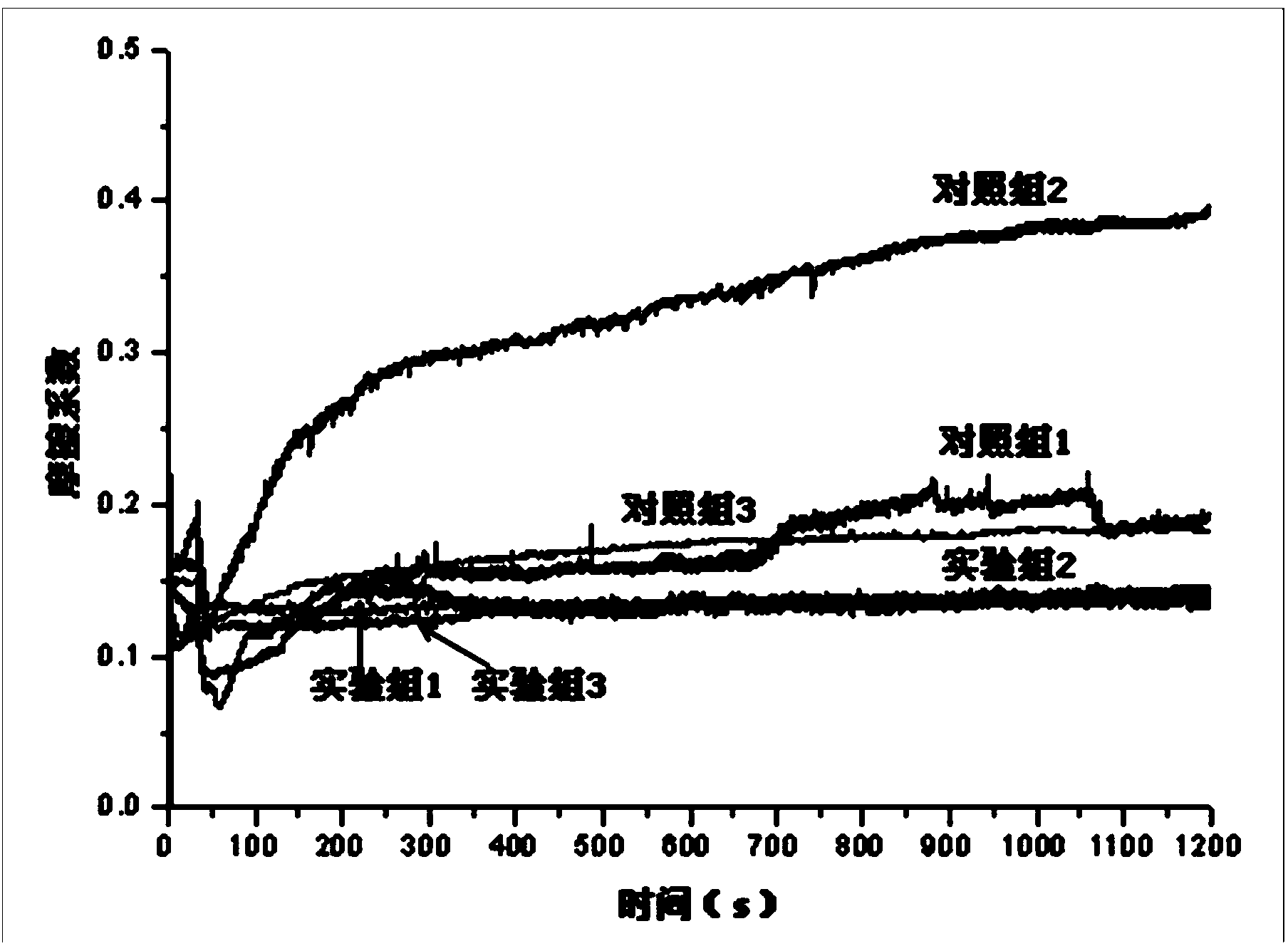

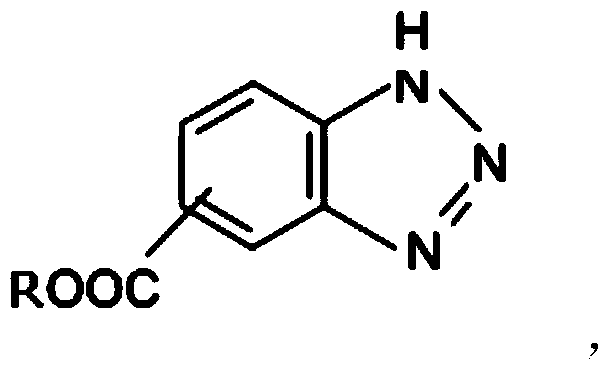

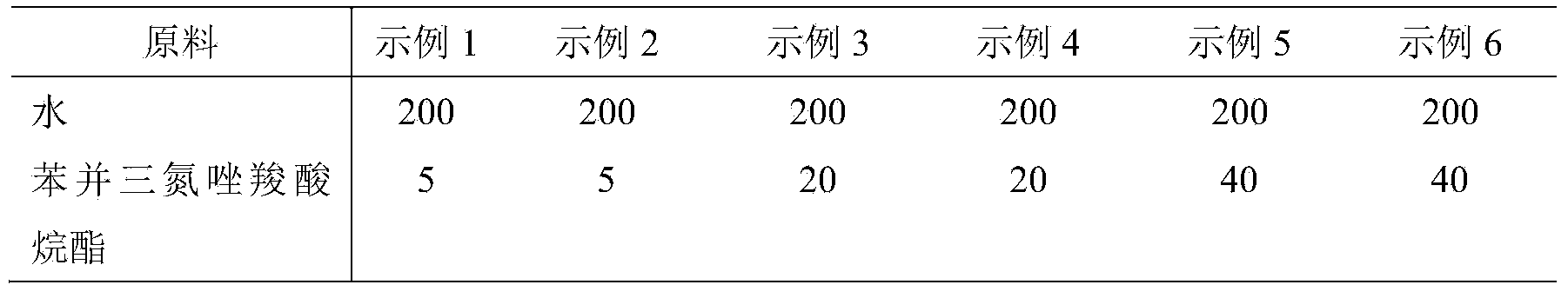

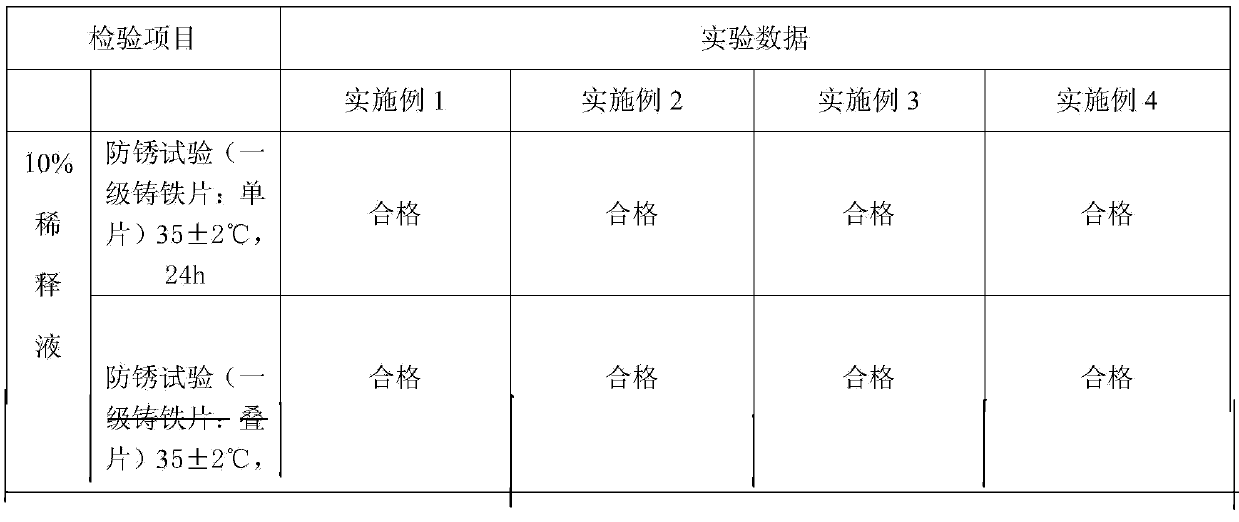

The invention discloses a water soluble full-alloy metal grinding fluid which belongs to the technical field of metal grinding fluids. The metal grinding fluid is prepared from the following components in percentage by weight: 5-40wt% of an antirust agent, 1-20wt% of a cleaning agent, 0.1-10wt% of a lubricating corrosion inhibitor, 1-20wt% of a penetrant, 1-20wt% of a solubilizer, 10-40wt% of a PH adjustor, 0.5-5wt% of a defoamer and the balance of water. Based on the total weight of the water soluble full-alloy metal grinding fluid, the pH value of the water soluble full-alloy metal grinding fluid is 7-11. The lubricating corrosion inhibitor is long chain nitrogen heterocyclic ring organic ester. The water soluble full-alloy metal grinding fluid has excellent lubricating, rust-preventing, cleaning and cooling performances and can be widely applied to grinding of ferrous metals and nonferrous metals.

Owner:TSINGHUA UNIV

Boron-free chlorine-free formaldehyde-free microemulsified cutting fluid and application thereof

The invention discloses a boron-free chlorine-free formaldehyde-free microemulsified cutting fluid and application thereof. The microemulsified cutting fluid is prepared from the following raw materials in percentage by mass: 30-60% of base oil, 1-5% of rust inhibitor, 0-5% of extreme pressure agent, 1.5-8% of bactericide, 3-15% of mixed base, 0-5% of coupling agent, 1-8% of anti-hard water agent, 1.2-5% of corrosion inhibitor, 5-20% of lubricant, 3-15% of anionic surfactant, 3-20% of emulsifier and the balance of water. The microemulsified cutting fluid disclosed by the invention has excellent lubricating properties, and can simultaneously satisfy multiple processing modes, including fraising, boring, tapping, threading, high-speed milling, hole drilling and the like. The microemulsified cutting fluid is especially suitable for processing electronic aluminum alloys. In addition, the microemulsified cutting fluid has the advantages of excellent defoaming property, excellent wettability, high raw liquor stability, high emulsifying stability, high biological stability, longer service life, lower consumption and lower cost.

Owner:GUANGZHOU MECHANICAL ENG RES INST

General water-based quick-drying anti-rust paint and preparation method thereof

InactiveCN102993810AAdvanced Technology FormulaAdvanced DesignRosin coatingsAnti-corrosive paintsWater basedLacquer

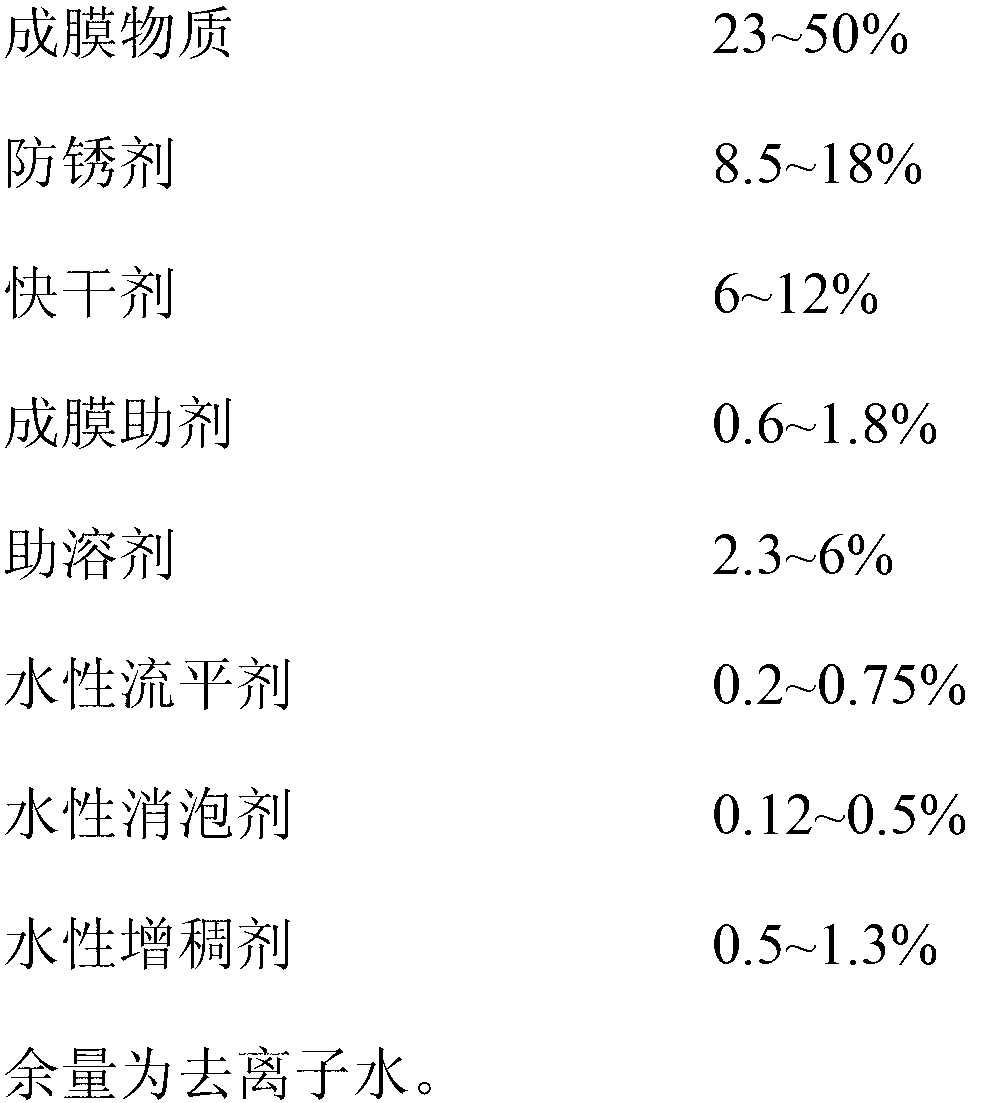

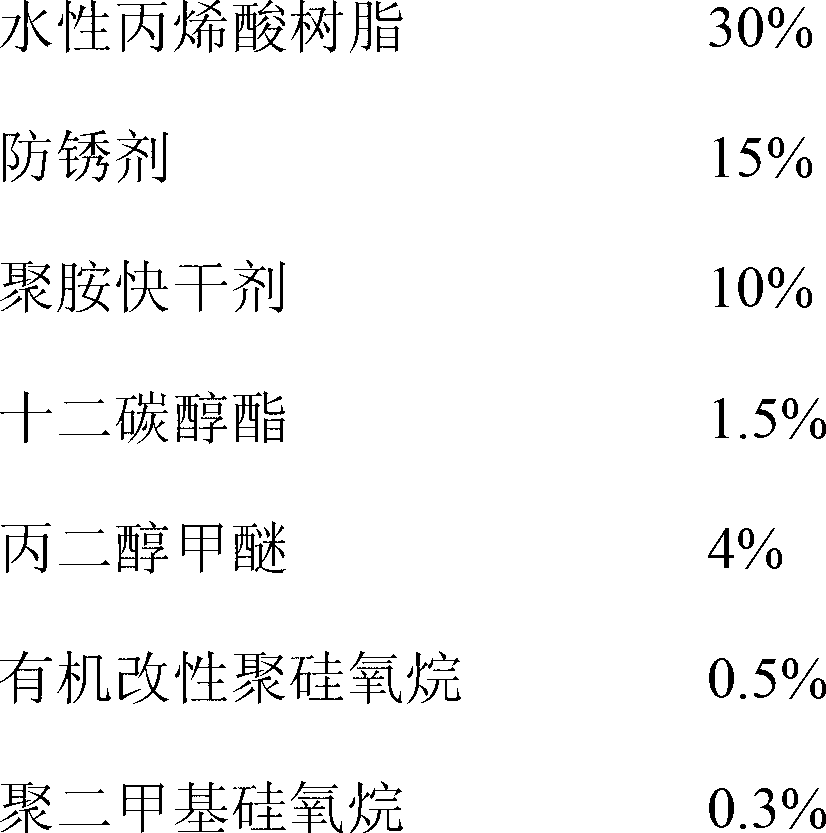

The invention relates to a general water-based quick-drying anti-rust paint and a preparation method thereof. The general water-based quick-drying anti-rust paint comprises the following components in percentage by weight: 18%-55% of film-forming substance, 6%-22% of anti-rust agent and the balance of water. The preparation method comprises the following steps of: firstly pre-dispersing the components except the anti-rust agent according to the formula ratio; then adding the anti-rust agent according to the formula ratio; and re-dispersing to obtain the general water-based quick-drying anti-rust paint. The general water-based quick-drying anti-rust paint disclosed by the invention is safe and nontoxic, contains no lead, chromium or other hazard pigments and derivatives, can not burn or explode, is suitable for safe production, has the advantages of plump paint film, excellent decoration and protection, excellent adhesive force and adjustable glossiness, and is simpler in production process compared with an oil paint.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

Aqueous grinding fluid applied to super precision grinding of hard and brittle materials and application method thereof

ActiveCN102311718AGood suspensionImprove dispersion stabilityOther chemical processesLapping machinesDispersion stabilitySuspending Agents

The invention discloses an aqueous grinding fluid applied to super precision grinding of hard and brittle materials and an application method thereof. The grinding liquid contains chelant 0.1-5, a pH value regulator 5-15, a suspending agent 0.2-5, a dispersion stabilizer 0.5-10, a lubricant 5-20, an antirusting agent 0.5-5, fungicide 0-2, a defoamer 0-2 and deionized water compensating the balance of total amount of 100 parts. Under an alkali condition, the aqueous grinding fluid applied to super precision grinding of hard and brittle materials is beneficial for grinding materials with various sizes, has good suspension property and dispersion stability; when the aqueous grinding fluid is used for super precision grinding of various different hard and brittle materials, especially high-hardness materials, scratches, etching pits and other defects are not produced easily; and the grinding speed is high, the subsequent cleaning is convenient; and the aqueous grinding fluid has excellent lubricating property and antirusting property when in matched use with the grinding materials, and the mixing liquid is uniform in color and has no sediment in 48 h. When the aqueous grinding fluid is used for grinding a wafer on a grinding machine, the ground wafer is subjected to water-added ultrasonic washing, and the wafer has good surface smooth finish, no scales, etching pits and other defects, and the surface roughness can be within 2 microns.

Owner:AMER TECH CO LTD

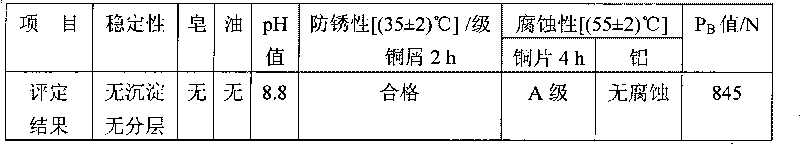

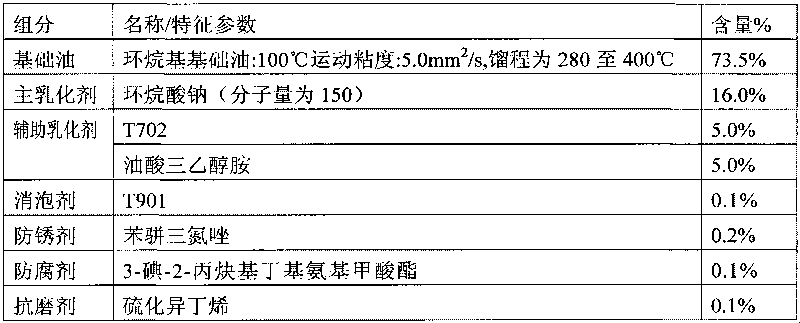

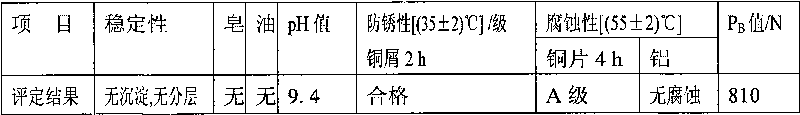

Copper and aluminum wire drawing oil and preparation method and use method thereof

The invention relates to the technical field of petroleum base lubricant composition and a preparation method thereof, which is copper and aluminum wire drawing oil and a preparation method thereof. The copper and aluminum wire drawing oil comprises base oil, an emulsifying agent, an auxiliary emulsifying agent, a defoaming agent, an antirusting agent, a preservative and an antiwear agent. The preparation method can be carried out by the following steps that: the copper and aluminum wire drawing oil is mixed into 3 percent to 45 percent of water-based emulsion according to the weight percentage. The water-based emulsion is showered into a wire drawing die cavity in the copper and aluminum wire drawing process. The product of the invention has good lubricating property, excellent light stability and storage stability, low cost, good cooling effect, fast heat-transfer speed, little temperature-rise amplitude, nonflammability and easy cleaning, thus guaranteeing safety of use environment. Copper wires and aluminum wires which are drawn by adopting the product have even line shapes, bright surfaces, and rustless property, and also have good ultraviolet and storage stability and good stability.

Owner:PETROCHINA KARAMAY PETROCHEMICAL CO LTD

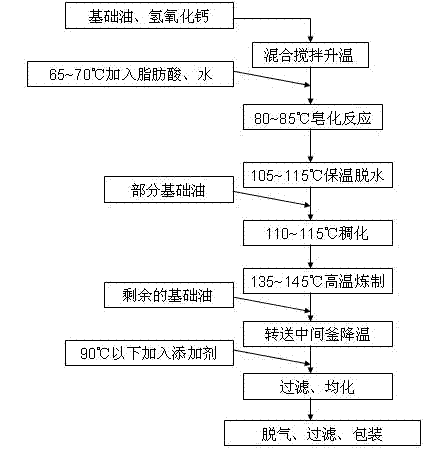

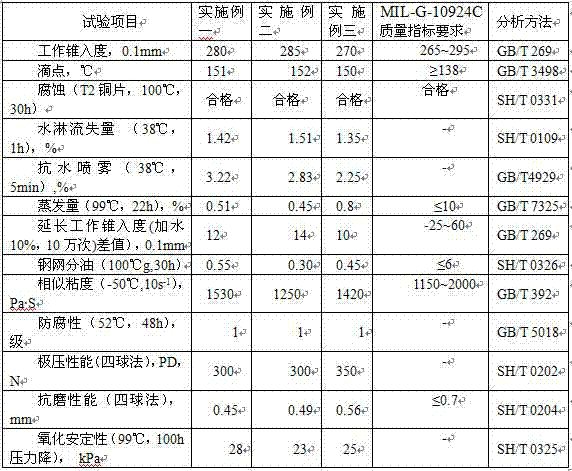

Anhydrous albany grease and preparation method thereof

ActiveCN102757847AMeet the requirements of wide temperature rangeExcellent water shear stabilityLubricant compositionChemical industryCalcium hydroxide

The invention belongs to the technical field of the chemical industry, and relates to grease and a preparation method thereof, in particular to anhydrous albany grease and the preparation method thereof. The anhydrous albany grease and the preparation method comprises the following components by weight: 82-90% of base oil, 1-4% of calcium hydroxide, 6-15% of fatty acid, 0.3-1% of antioxygen, 0.5-1.5% of rust inhibitor, and 0.5-3% of extreme pressure antiwear additive. The anhydrous albany grease and the preparation method have the benefits as follows: the grease is simple in preparation process and easy to control; and the prepared product has better water erosion resistance, favorable metal adhesivity and extreme pressure abrasion resistance, and can provide outstanding lubrication and abrasion resistance protection for wheel bearings and chassis.

Owner:JIANGSU LOPALTECH

Water-based cutting fluid used for processing neodymium-iron-boron material slices and application method thereof

ActiveCN102311860AGuaranteed lubrication effectGuaranteed anti-rust performanceLubricant compositionSolubilityWater based

The invention discloses a water-based cutting fluid used for processing neodymium-iron-boron material slices and an application method thereof. The cutting fluid comprises the following components in parts by weight: organic amine, organic acid, water-soluble phosphate, polyether, antirust corrosion inhibitor, dispersing agent and surfactant, antiseptic bactericide, anti-hard-water agent, defoaming agent, auxiliary agent and water, wherein environmentally-friendly lubricating agent, extreme-pressure agent and antirust agent are reasonably matched in the cutting fluid disclosed by the invention, thus the lubricating property, extreme pressure property and antirust property of the cutting fluid are guaranteed; organic base, organic acid and special auxiliary agent are reasonably matched, thus the corrosion dissolution phenomenon of the cutting fluid to adhesive is greatly weakened; the dispersing agent and the surfactant are used for reducing surface tension of solution, thus permeability and settlement performance of the cutting fluid are enhanced; pH value of a final product is 7.5-8.5; and solubility of the cutting fluid to adhesive used for binding neodymium-iron-boron material in a processing cycle is extremely low, and the condition that product processing accuracy error is large or a tool is damaged as the adhesive is dissolved by the cutting fluid can not be caused.

Owner:AMER TECH CO LTD

Lubricating material for cold rolling and its preparation method and use

ActiveCN103589491ASolving Stress Corrosion ProblemsHarm reductionLubricant compositionEmulsionChlorinated paraffins

The invention belongs to the technical field of lubricating materials and discloses a lubricating material for cold rolling and its preparation method and use. The lubricating material for cold rolling comprises, by mass, 20-60% of base oil, 0.3-1% of an anti-oxidant, 20-60% of a lubricant, 3-10% of an extreme pressure agent, 0-5% of an antirust agent, 1-3% of a purification dispersant, 3-9% of an emulsifier, and 2-6% of an anionic surfactant. The lubricating material is especially suitable for a four-roller four continuous rolling unit having the size of 650mm and high lubricity requirements, does not contain chlorinated paraffin, prevents stress corrosion on a cold-rolled finished product, and has excellent lubricity. Compared with the common emulsion on the current market, the lubricating material reduces a rolling force by 7-10%, prolongs a roller service life by 10-15%, reduces comprehensive energy consumption by 10-15% and effectively prolongs a rolling mill bearing service life.

Owner:GUANGZHOU MECHANICAL ENG RES INST

Aluminum-magnesium alloy cutting fluid

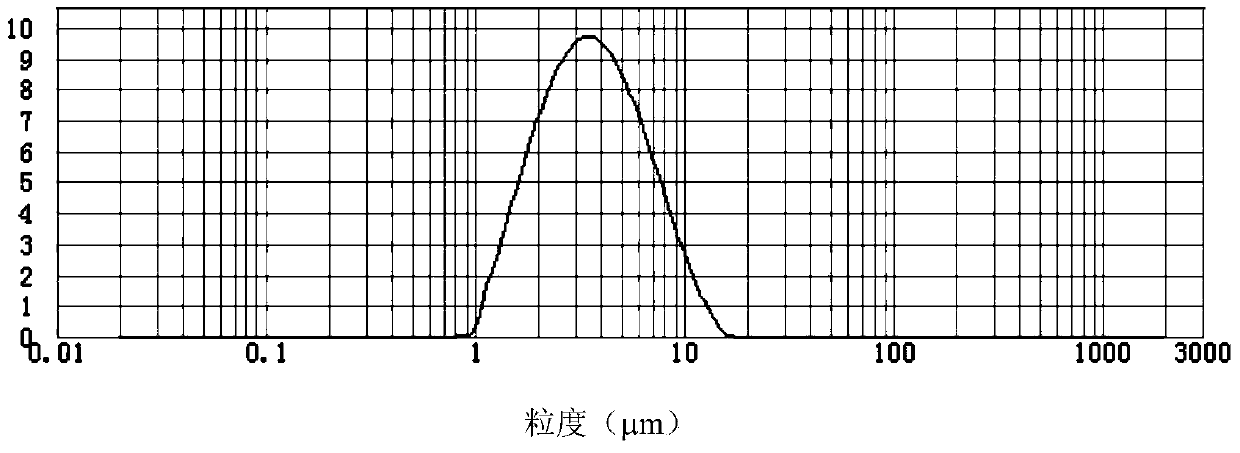

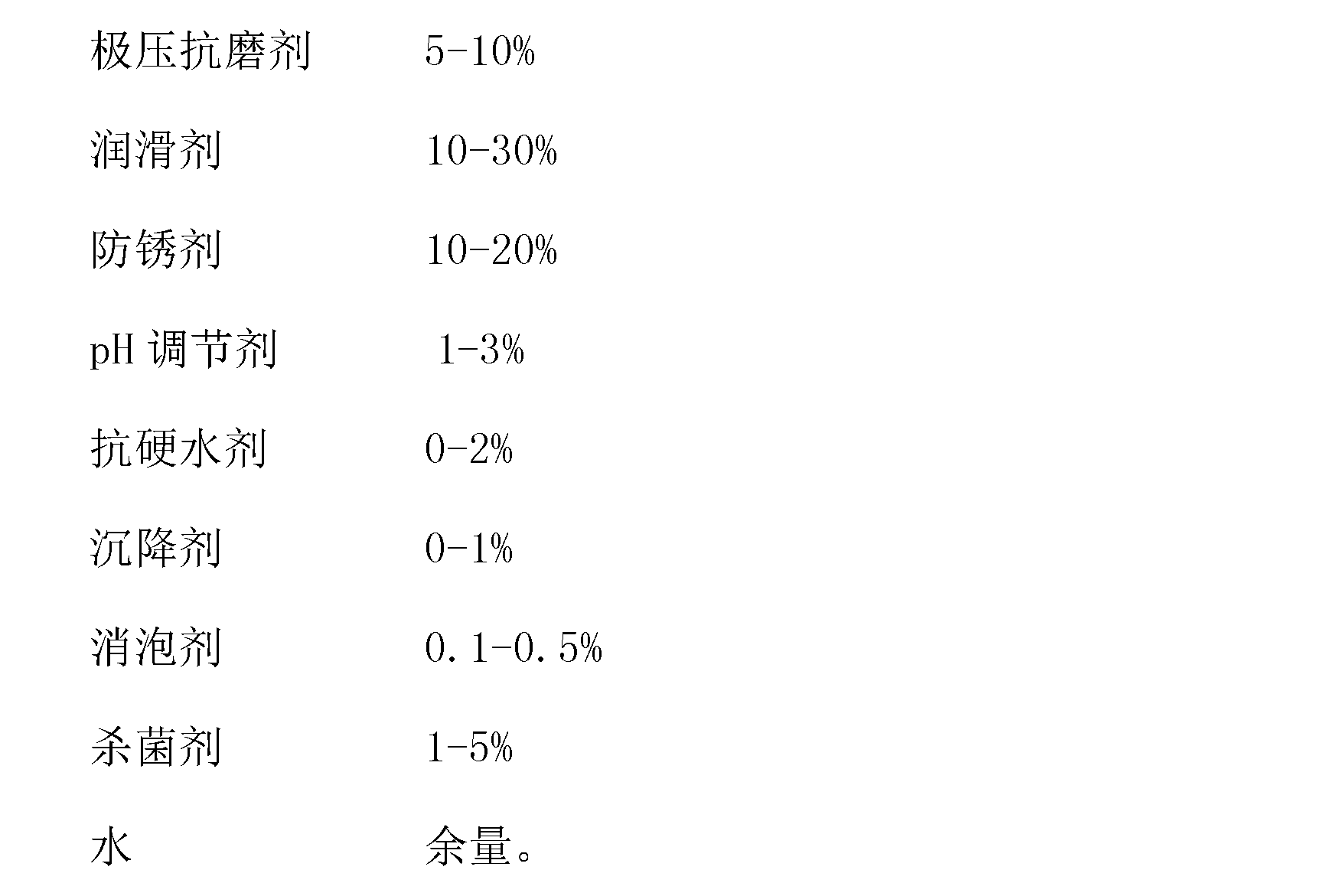

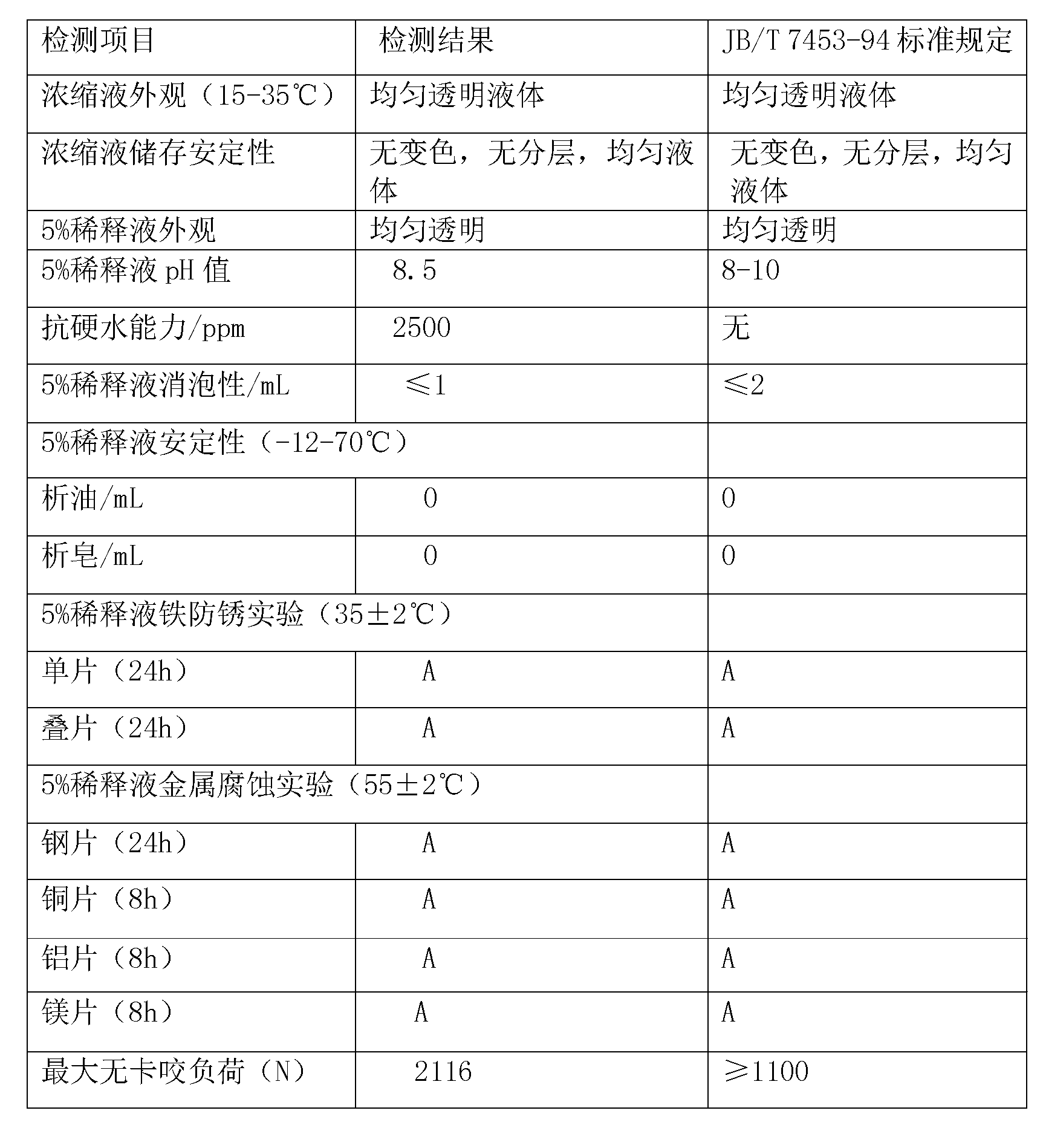

ActiveCN102703194AExcellent lubricating and anti-wear propertiesImprove cooling effectLubricant compositionRust converterDefoaming Agents

The invention discloses an aluminum-magnesium alloy cutting fluid which consists of the following components in percentage by weight: 5-10 percent of extreme pressure anti-wear additive, 10-30 percent of lubricating agent, 10-20 percent of anti-rusting agent, 1-3 percent of pH regulator, 0-2 percent of hard water resisting agent, 0-1 percent of settling agent, 0.1-0.5 percent of defoaming agent, 1-5 percent of sterilizing agent and the balance of water. According to the aluminum-magnesium alloy cutting fluid, excellent lubricating and wear resisting performances, cleaning and cooling performance and rust and corrosion resisting performances are obtained, thus cutting bumps can be avoided, a cutter is effectively protected and the processing quality is improved; more heat generated in the processing process is taken away, so that the temperature of the processing surface is reduced and the defects of the curling and the deformation of workpieces caused by high temperature, flammabilityof scrap magnesium at high temperature and the like are effectively overcome; and a processing technique is simplified, and thus the processing period is shortened and the production efficiency is increased.

Owner:上海福岛新材料科技有限公司

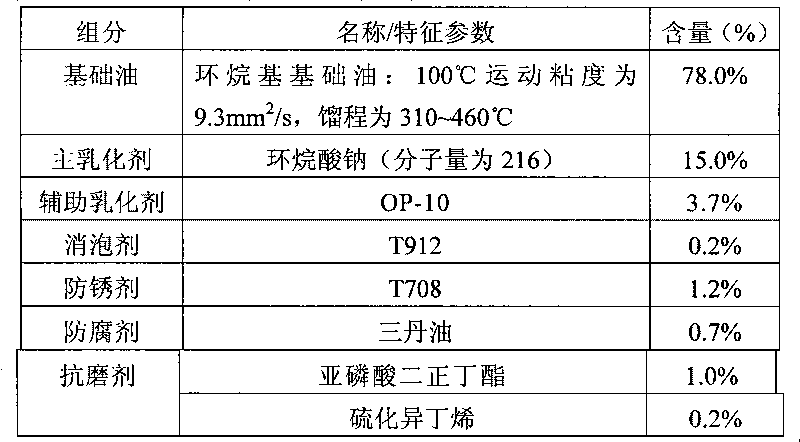

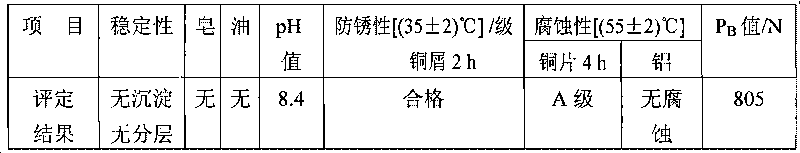

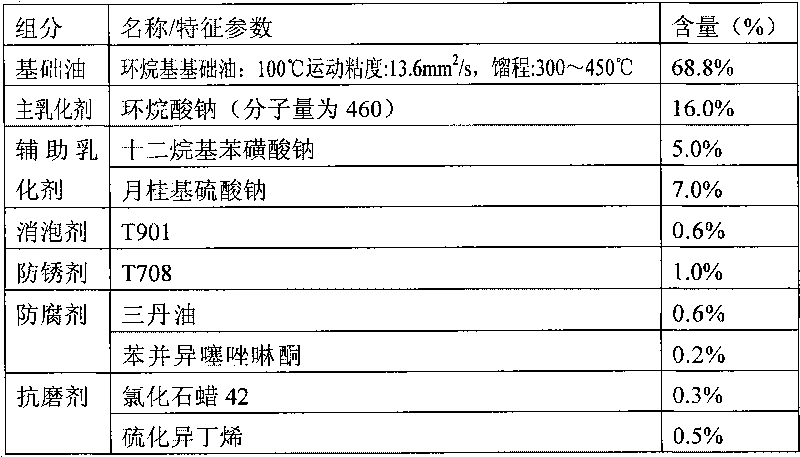

Water-based copper and aluminum wiredrawing oil composite and preparation method thereof

The invention relates to an oil-based lubricating composite and a preparation method thereof, in particular to a water-based copper and aluminum wiredrawing oil composite and a preparation method thereof. The water-based copper and aluminum wiredrawing oil composite comprises base oil, an emulsifier, an auxiliary emulsifier, a defoaming agent, a rust-proof agent, an antiseptic and an antiwear agent. The preparation method comprises the following steps of: configuring the water-based copper and aluminum wiredrawing oil composite into 3 percent to 45 percent water-based emulsion according to weight percentage; and spraying the water-based emulsion into a wiredrawing die cavity in the copper and aluminum wiredrawing process. The water-based copper and aluminum wiredrawing oil composite has the advantages of excellent lubricating property, great optimal light stability and storage stability, low cost, good cooling effect, fast heat transfer, little temperature increase in the using process, difficult combustion and easy cleaning and ensures the safety of the service environment; and in addition, a copper wire and an aluminum wire drawn by the method have the advantages of uniform wireshape, bright surfaces, difficult corrosion, good ultraviolet and storage stability and good stability.

Owner:PETROCHINA KARAMAY PETROCHEMICAL CO LTD

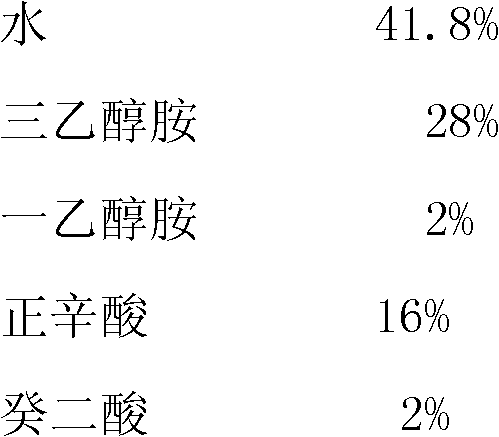

Anti-magnesium hard water anti-magnesium corrosion environmentally-friendly water soluble cutting solution

ActiveCN101560433APrevent corrosion and discolorationExcellent anti-magnesium hard water performanceLubricant compositionDisinfectantDefoaming Agents

The invention discloses an anti-magnesium hard water anti-magnesium corrosion environmentally-friendly water soluble cutting solution, which is composed of organic acid, organic amine, corrosion inhibitor, base oil, synthetic ester, surfactant, water and other additives. The invention employs particular surfactant to improve the anti-magnesium hard water performance of the product, employs special compound corrosion inhibitor to enhance the anticorrosion performance of the product, and compounds a plurality of rust inhibitors, lubricants, disinfectants and defoaming agents, the product has excellent anti-magnesium hard water performance, anti-magnesium corrosion performance and operating safety performance, and can heighten the service performance and processing performance of the product greatly. Meanwhile, the product, which is good for environmental protection, is an environmentally-friendly magnesium alloy cutting solution with excellent performances.

Owner:QIDONG YUSHIRO CHEMICAL INDUSTRY CO LTD +1

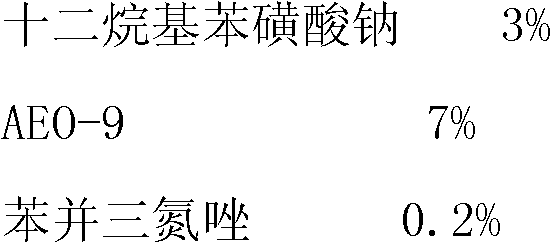

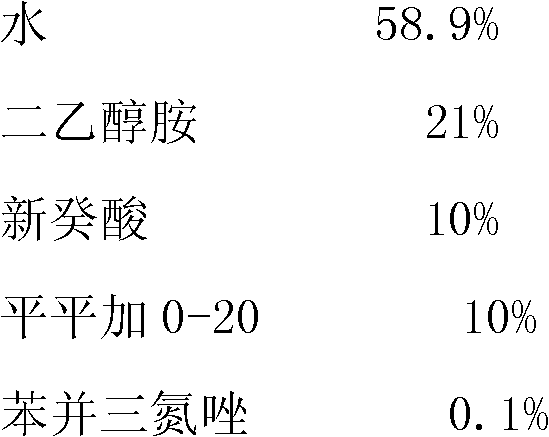

Environment-friendly water-based cleaning agent

The invention discloses an environment-friendly water-based cleaning agent which is characterized by comprising the following components in percentage by weight: 15-60% of antirust agent, 5-20% of surfactant, 0.1-0.5% of nonferrous metal corrosion inhibitor, 0-0.5% of bactericide and the balance of water. The environment-friendly water-based cleaning agent disclosed by the invention has the beneficial effects of no toxicity or phosphorus, excellent antirust performance, favorable inter-process antirust effect, wide application range, suitability for cleaning various metals including black metal, aluminum alloy and copper alloy, no corrosion to nonferrous metal, excellent cleaning capability for oil stain with higher viscosity, long service cycle and effective range, simplicity and practicability in use and maintenance, multiple functions for efficiently removing oil, preventing rusting and the like, no harm to body health and no adverse effect on the environment.

Owner:LOCKS LUBE SHANGHAI

Anticorrosive, anti-fading and environmentally-friendly water-based magnesium alloy cutting fluid

InactiveCN104498164AImprove the lubrication effectImprove rust resistanceLubricant compositionWater basedCombustion

The invention discloses anticorrosive, anti-fading and environmentally-friendly water-based magnesium alloy cutting fluid. The anticorrosive, anti-fading and environmentally-friendly water-based magnesium alloy cutting fluid is prepared from the following components in percentage by mass: 5 to 10 parts of base oil, 5 to 15 parts of an oiliness agent, 10 to 25 parts of organic amine, 5 to 15 parts of a synthetic rust inhibitor, 15 to 25 parts of a functional polyether surfactant, 0.2 to 3 parts of an extreme pressure additive, 3 to 8 parts of a solubilizer, 0.1 to 2 parts of a metal corrosion inhibitor, 0.1 to 2 parts of a magnesium alloy anti-fading agent, 0.1 to 2 parts of a bactericide, 0.1 to 1 part of an antifoaming agent, 0.1 to 10 parts of a pH regulator and 15 to 30 parts of water. The nticorrosive, anti-fading and environmentally-friendly water-based magnesium alloy cutting fluid is outstanding in ticorrosive and lubricating and has water resisting performances, and is high in cleaning and cooling effects, and effectively reduces the major technical problems such as corrosion, oxidative combustion, fading of magnesium alloy, demulsification and layering of the cutting fluid in the magnesium alloy processing process; the pH ranges from 9 to 11, and therefore, the demand of magnesium alloy cutting process can be met well.

Owner:苏州禾川化学技术服务有限公司

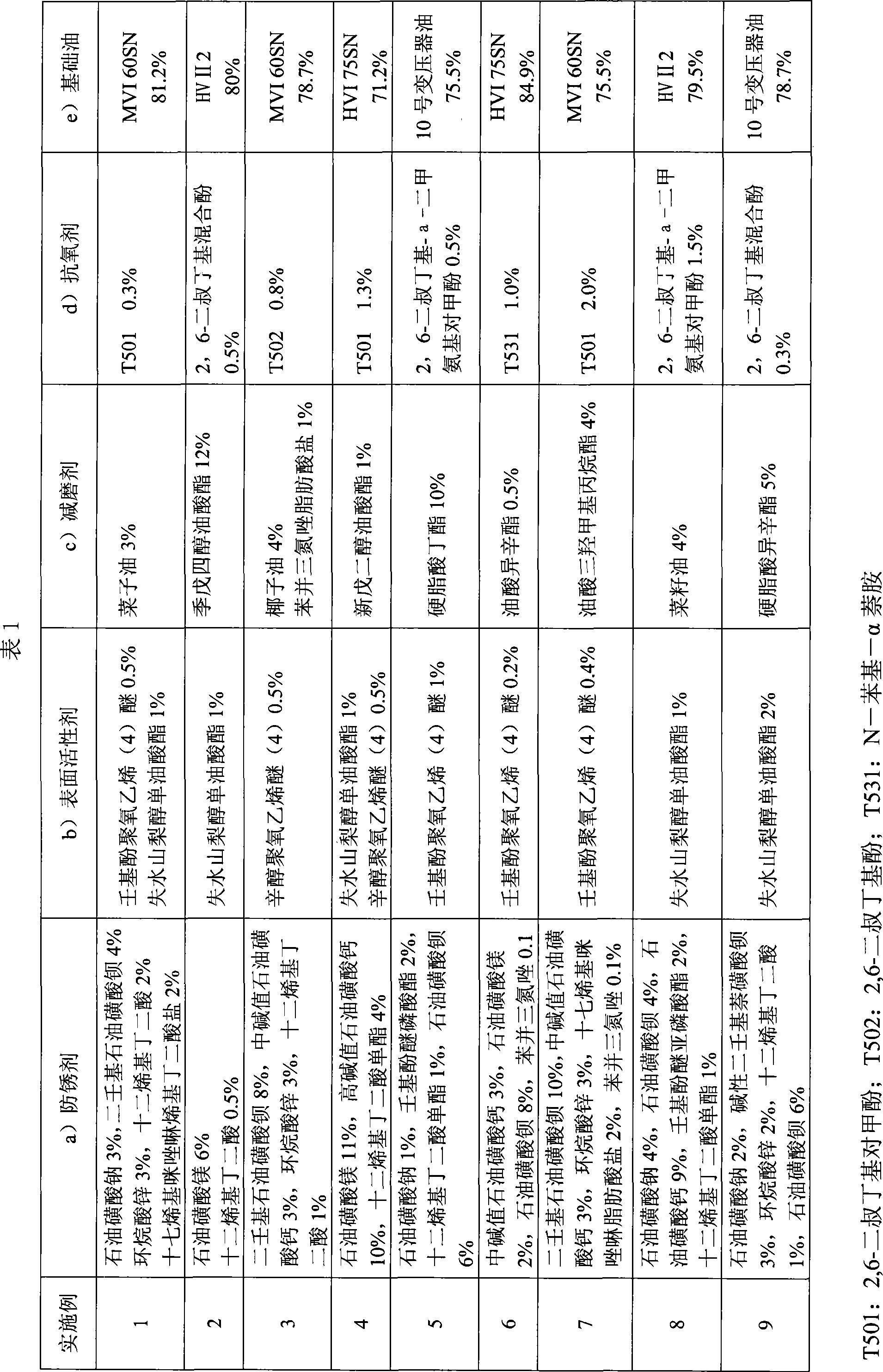

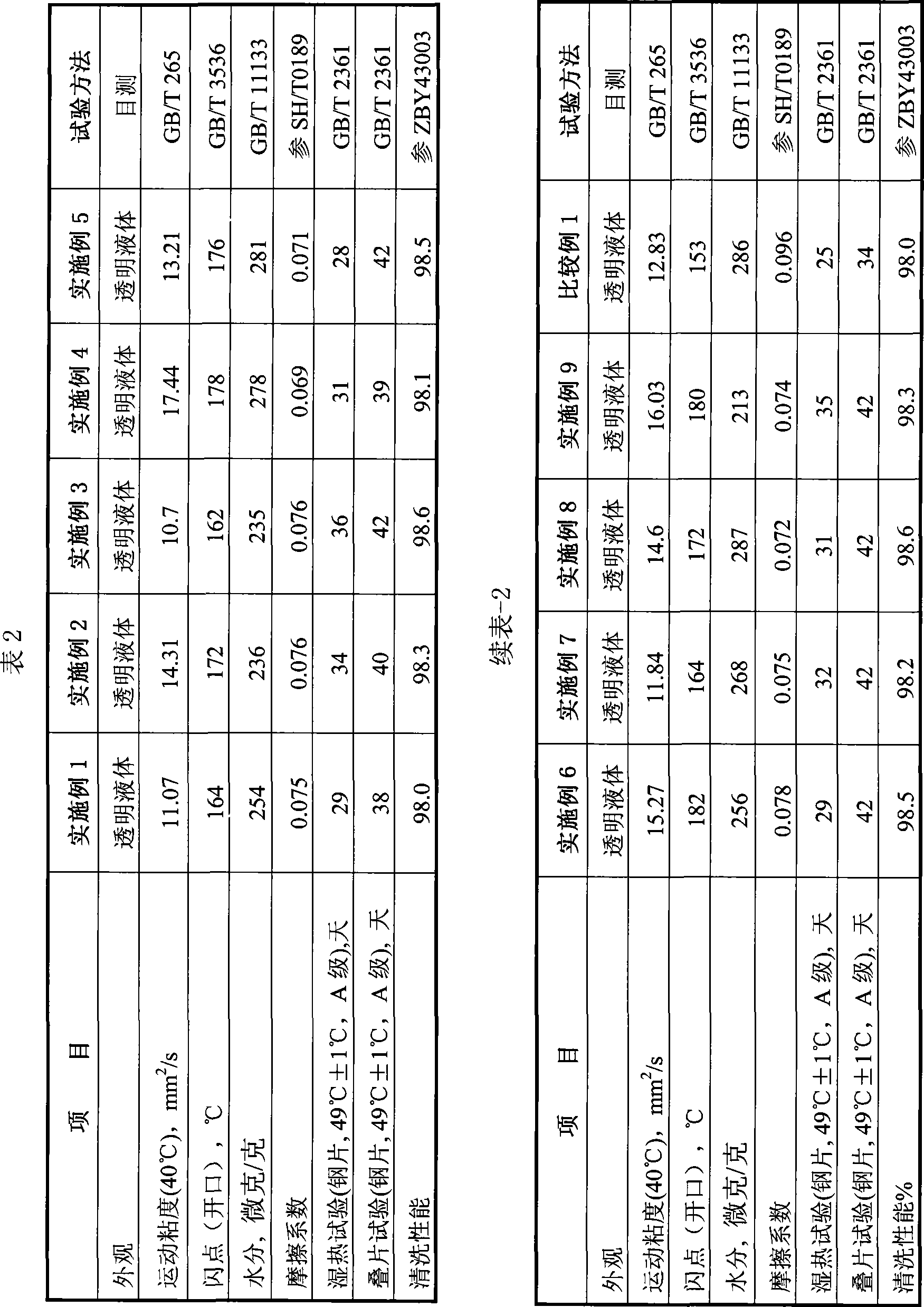

Electrostatic painting anticorrosive oil and production method thereof

ActiveCN101486945ADoes not affect post-processing effectsPost-processing effect is reducedAdditivesAntioxidantBase oil

The invention relates to electrostatic spraying anti-rust oil and a production method thereof, which essentially solves the problems of the prior art that the lubricating property of the anti-rust oil is poor; and interlayer sliding is caused due to larger tension during the reeling process of the steel plate, resulting in steel plate scratch and having impact on the surface quality of the steel plate. The electrostatic spraying anti-rust oil commendably solves the problems by using the technical proposal comprising components of weight percentages as follows: a) 5 to 30 percent of anti-rust agent, b) 0.1 to 5 percent of surface activator, c) 0.1 to 15 percent of anti-friction composition, d) 0.1 to 5.0 percent of antioxidant and e) 50 to 90 percent of base oil, and can be used for the electrostatic spraying rust resistance of the cold-rolled carbon steel plate, galvanized plate and aluminized zinc silicon plate of the steel enterprises.

Owner:CHINA PETROLEUM & CHEM CORP

Bearing lubricating grease and preparation method thereof

ActiveCN102977978AHigh dropping point temperatureNot collapseLubricant compositionLithium hydroxideAntioxidant

The invention relates to bearing lubricating grease comprising the following components of: (a) a compound thickening agent formed by lithium 12-hydroxystearate soap, lithium binary acid soap and lithium borate, (b) an additive, and (c) base oil, wherein the compound thickening agent is formed by soapnifying 12-hydroxystearic acid, binary acid and boric acid with lithium hydroxide; and the additive amount of the boric acid is 1-5 parts by weight while the weight of the base oil is 100 parts by weight, wherein the additive is one or combination of at least two of an antioxidant, an antirusting agent, an anti-wear reagent at extreme pressure and a metal passivator. The dropping point temperature of the bearing lubricating grease provided by the invention is more than or equal to 300 DEG C, and the bearing lubricating grease provided by the invention does not collapse or fade and has the characteristics of long service life, silence and high temperature resistance.

Owner:安徽意博润滑科技有限公司

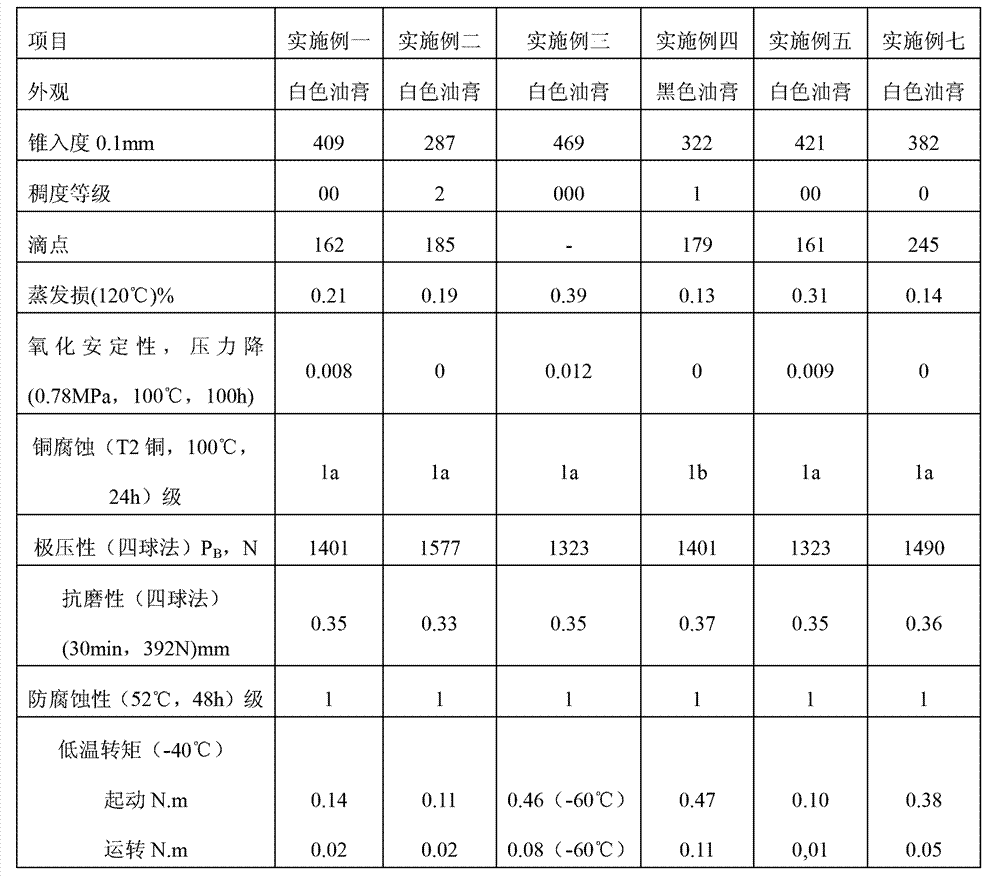

Low-temperature worm and gear lubricating grease composition and preparation method thereof

The invention provides a low-temperature worm and gear lubricating grease composition. The low-temperature worm and gear lubricating grease composition consists of the following components in percentage by weight: 40.5-94.55% of synthesis base oil, 2-20% of thickening agents, 2-20% of solid lubricants, 0.5-8% of extreme-pressure anti-wear reagents, 0.5-5% of friction improvers, 0.2-2% of antirust agents, 0.05-0.5% of metal passivator and 0.2-4% of antioxidants. The invention further provides a preparation method of the low-temperature worm and gear lubricating grease composition. The low-temperature worm and gear lubricating grease provided by the invention is prepared by refining low-middle-viscosity synthesis base oil, thickening agents and a plurality of additives and has the advantages that the starting torque and the low operation torque under a low-temperature environment equal to or lower than -40 DEG C are low, meanwhile, the extreme-pressure wear resistance, the antirust and anticorrosion properties and the leak resistance are excellent, the friction coefficient is low, the output efficiency is high, and the service life is extreme long.

Owner:武汉博达特种润滑技术有限公司

Corrosion-resistant bearing and method for making same

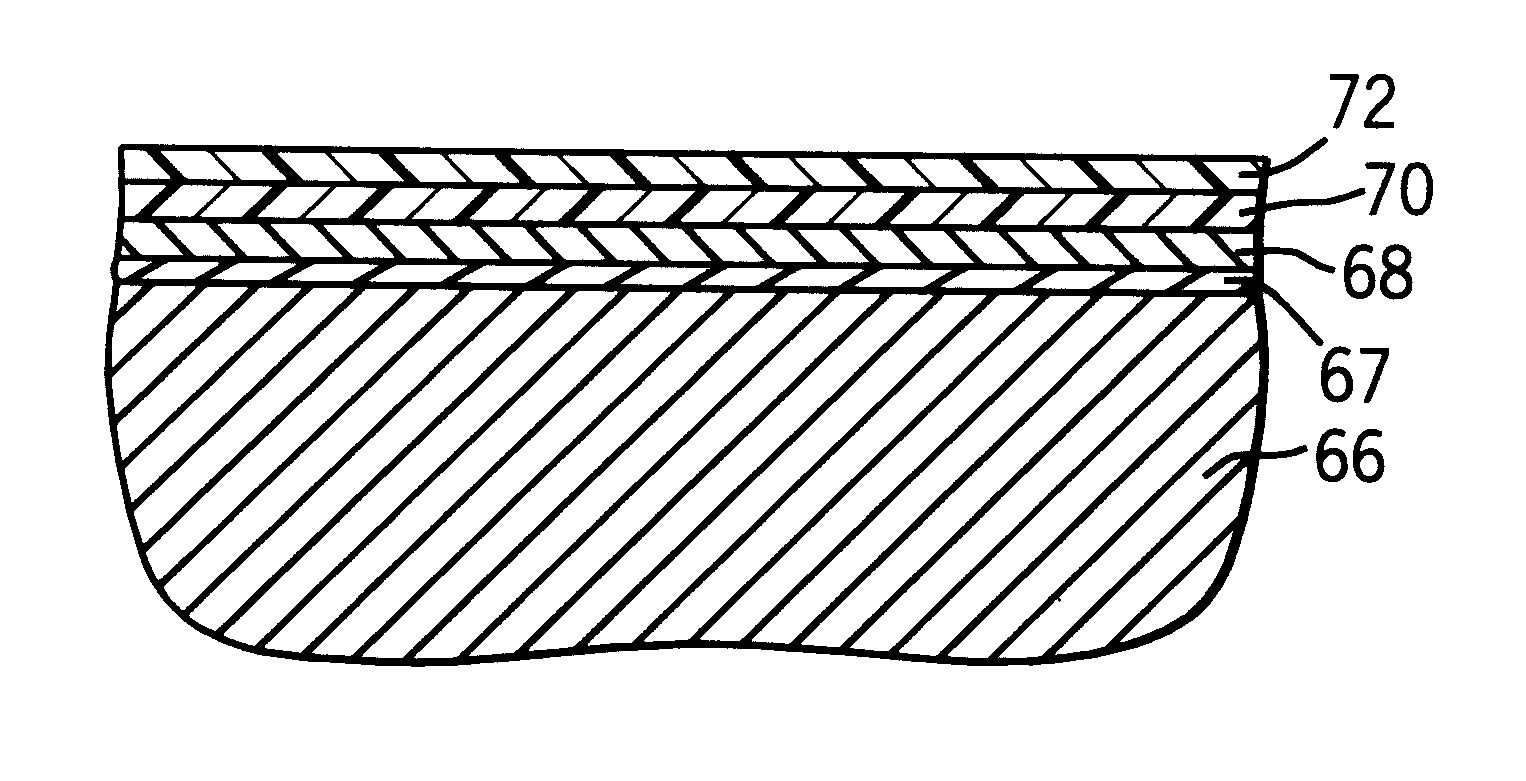

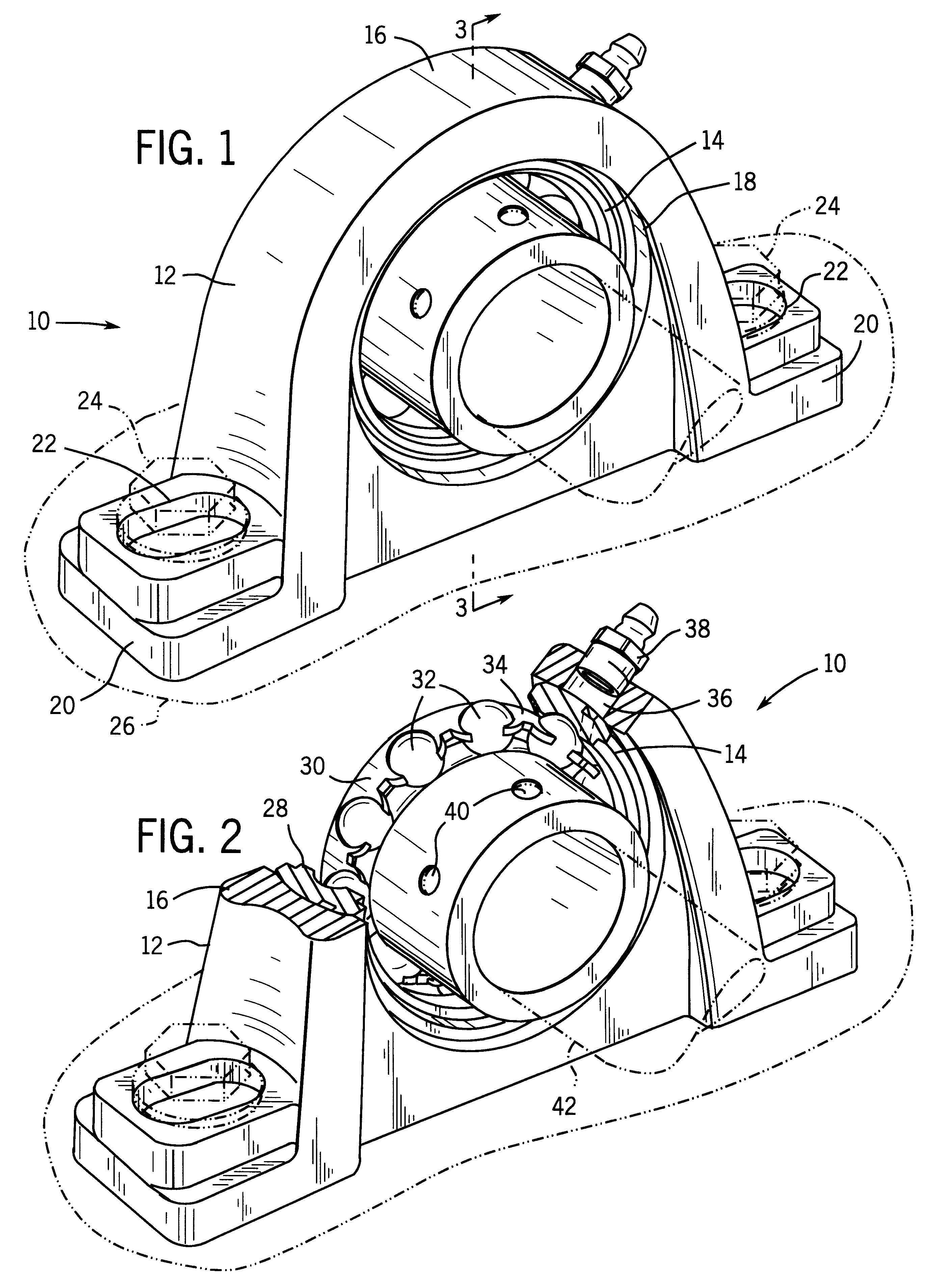

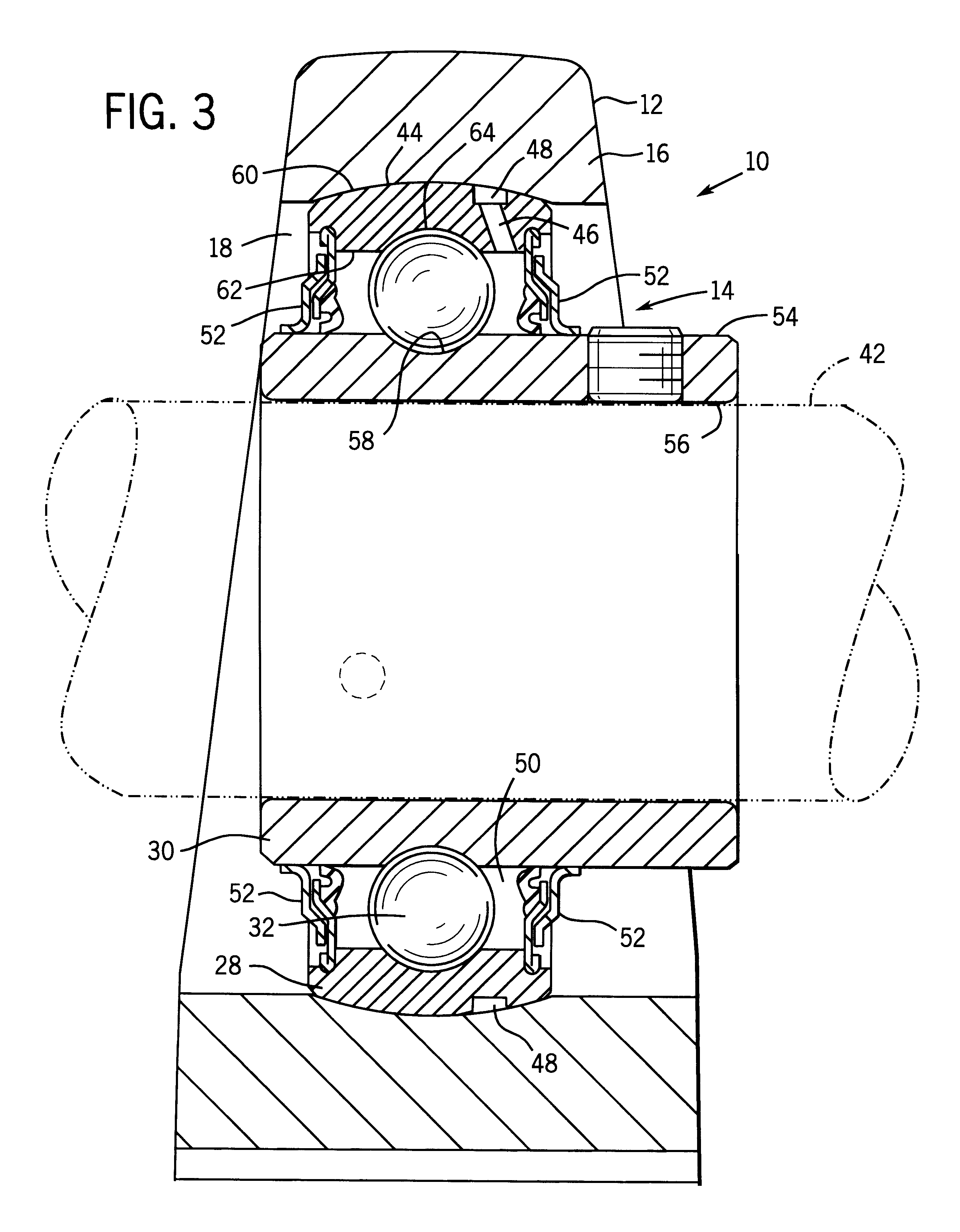

InactiveUS6318898B1Improve corrosion resistanceMore cost-effectiveBall bearingsBearing componentsAlloyProtection system

A corrosion-resistant antifriction bearing is disclosed that includes a multi-layer corrosion protection system over a metallic substrate. The corrosion-resistant system may be applied to a single or multiple components of the bearing, including inner and outer rings, bearing elements, collars, and so forth. The system includes a nickel-phosphorous alloy plating layer applied by an autocatalytic process after surface preparation of the protected component. The surface preparation aids in adherence of the nickel-phosphorous alloy plating layer to the substrate. The preparation may include the application of rust inhibitors, liquid vapor honing, acid neutralizing, and so forth. Additional topcoat layers may be applied to the nickel-phosphorous alloy plating layer. These may include a chromate conversion coating and a polymeric topcoat layer. The polymeric topcoat layer, such as polytetrafluoroethylene, may include a UV marker to enable identification of the bearing when placed in service and throughout its useful life.

Owner:BALDOR ELECTRIC COMPANY

Water-based fully-synthetic ferrous metal processing liquid with high-hard-water-rust resistance

PendingCN108277077ANo pollution in the processOvercome the disadvantage of poor antirust performance in high hard waterLubricant compositionWater basedHard water

The invention provides a water-based fully-synthetic ferrous metal processing liquid with high-hard-water-rust resistance, wherein the water-based fully-synthetic ferrous metal processing liquid comprises, by weight, 5-25 parts of a composite rust inhibitor, 5-30 parts of a lubricant, 5-30 parts of a pH value stabilizer, 1-9 parts of a coupling agent, 0.1-2 parts of an antifoaming agent, 1-4 partsof a sterilization agent, and 20-50 parts of water. According to the preset invention, the ferrous metal processing liquid has advantages of no environment pollution, excellent rust resistance, excellent cooling performance, excellent hard-water resistance and high biological stability, and can overcome the disadvantage of poor high-hard-water-rust resistance of the traditional water-based fully-synthetic ferrous metal processing liquid.

Owner:超滑科技(佛山)有限责任公司

Fast-drying hard film rust preventive oil and preparation method thereof

ActiveCN103087808AReduce adhesionImprove applicabilityLubricant compositionAntioxidantNonferrous metal

Owner:布兰诺工业包装材料(上海)有限公司

Antirust oil for high-speed railway track switch and production method thereof

InactiveCN101812359AReduce adhesionImprove rust resistanceLubricant compositionAntioxidantEngineering

The invention relates to the field of metal rust prevention, in particular to antirust oil for a high-speed railway track switch, which is environmental friendly and has the function of removing rust and a production method thereof. The antirust oil comprises the following components in parts by weight: 40-60 parts of base oil, 5-25 parts of antirust agent, 1-20 parts of film former, 1-5 parts of span-80, 1-10 parts of tackifier and 0.1-2 parts of antioxidant. The method comprises the following steps of: firstly, adding base oil into a reaction kettle to heat and stir until the temperature reaches 100-140 DEG C and adding an antirust agent; adding a film former, a tackifier and an antioxidant, continuously stirring and cooling to 30-50 DEG C and then adding span-80 and the balance of base oil, continuously stirring for 1-3 h and filtering to obtain a finished product. The viscosity of an oil product is controlled to be 20-50 mm<2> / s at 40 DEG C through screening out the composite ratio of the base oil and various additives for many times, thereby ensuring the favorable permeability and drying within 1-2 h, the metal is maintained to be stored out-of-doors, weathers wind and rain, and has favorable antirust property in the severe sun-baked environment. Furthermore, the oil product belongs to hard coat antirust oil and is stored out-of-doors after dried, reduces the adhesion of dust, and ensures the attractive appearance of the product.

Owner:北京天一精人石化科技有限公司 +1

Water-based antirust agent

InactiveCN101240141AImprove bindingStay the sameLiquid surface applicatorsAnti-corrosive paintsWater basedWater vapor

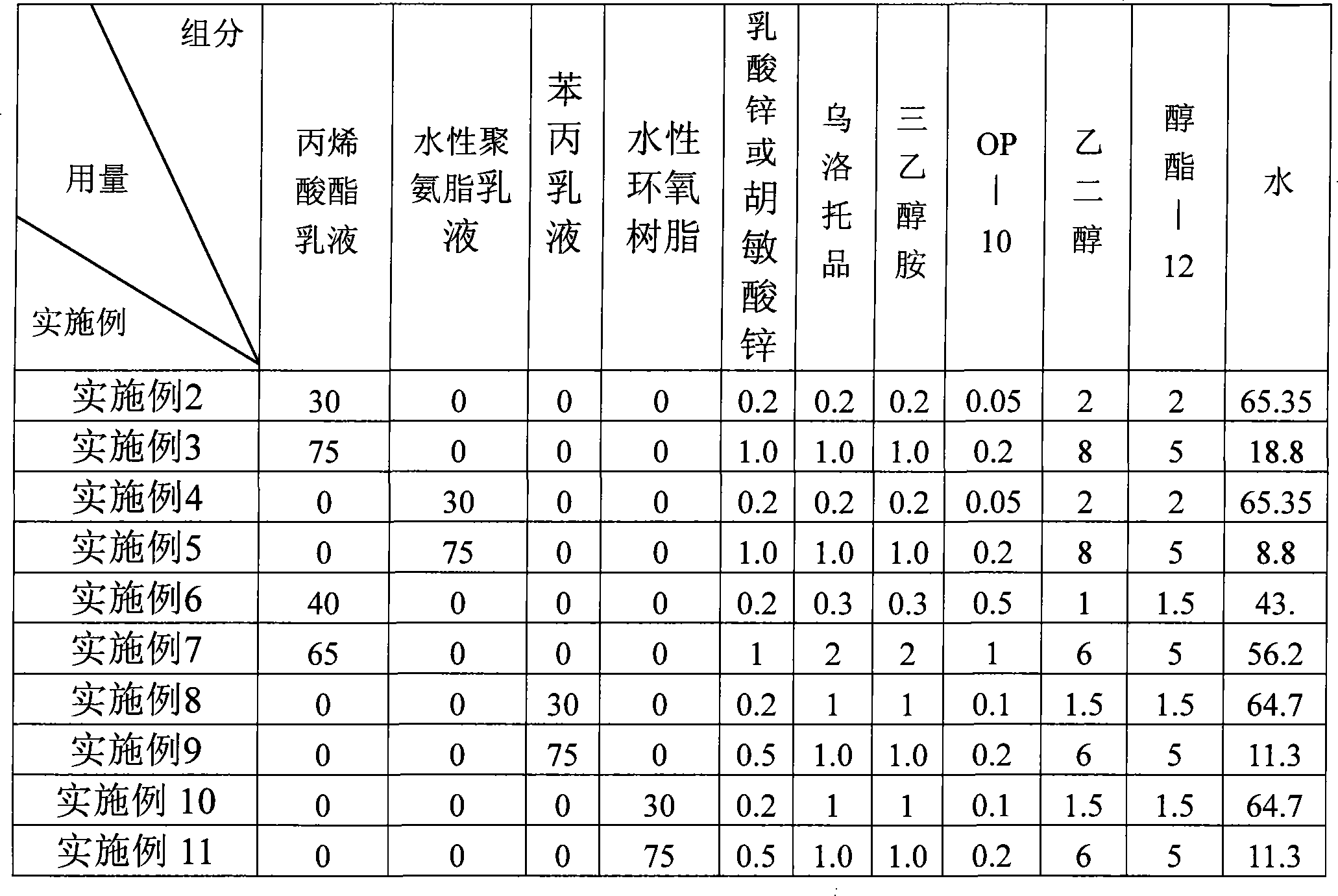

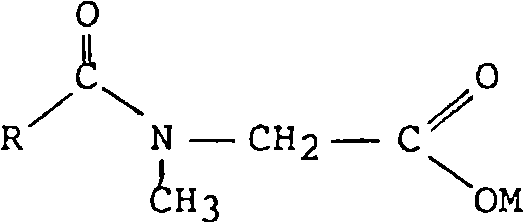

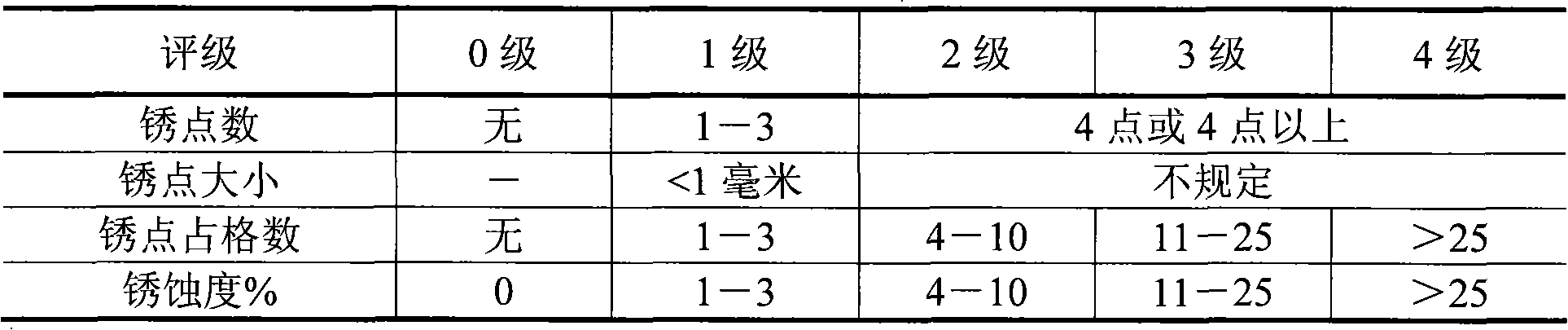

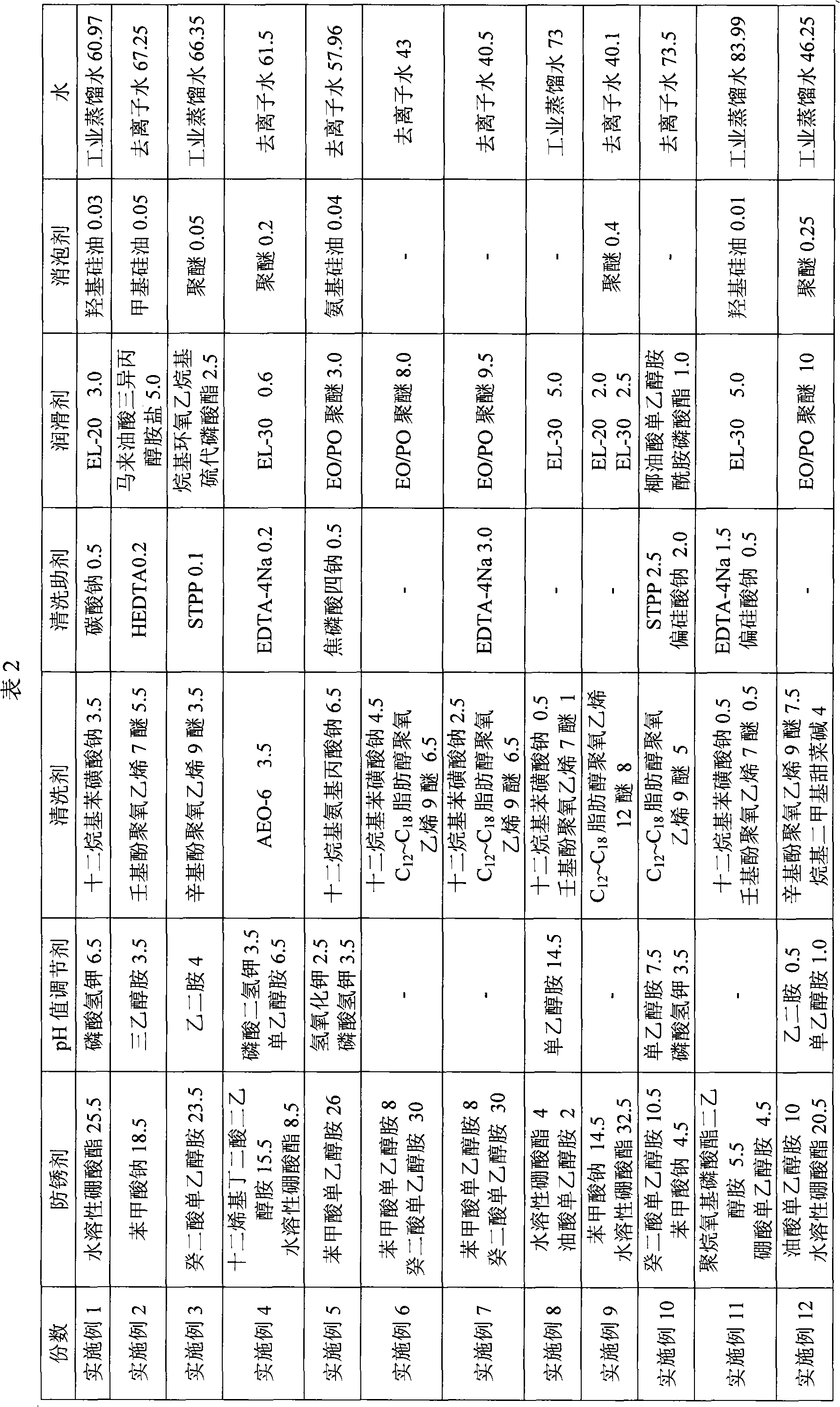

The invention discloses a water-base anti-rust agent composed of 30% to 75% film-forming agent, 0.5% to 6.0% inhibitor, 2% to 16% accessory ingredient and water. Bonding force of film layer to basal body is improved by adopting acrylic ester emulsion or water-base polyurethane emulsion as film-forming substance associated with components of inhibitor, accessory ingredient, etc. The water-base anti-rust agent is brushed on steel surface to form continuous compact protection layer, isolating steel surface from oxygen and water vapor effectively, for long lasting rust prevention. The anti-rust period of steel piece might be more than one year. The protecting film is quite compact, which maintains fundamental color of steel piece invariable. User can process next step of treatment directly without removing the protecting film, which reduces tiresome process of removing anti-rust coat. Operation modes include soaking, spraying, brush coating, etc. The invention is incombustible, nontoxic and environment-friendly. Contents of free formaldehyde, heavy metal and volatile organic meet qualified criteria. Bond strength of twice-brushed deformed steel bar to concrete is more than non-brushed test piece.

Owner:焦占付

Wet leveling liquid composition and use thereof

The invention relates to a wet leveling liquid composition and use thereof, and mainly solves the problem that wet leveling liquid cannot meet the requirement that a down rate is greater than 3.0 percent in the leveling process in the prior art. By adopting a technical scheme that: the wet leveling liquid composition comprises the following components in part by weight: a) 5 to 50 parts of antirust additive; b) 1 to 12 parts of cleaning agent; c) 0.5 to 10 parts of lubricating agent; and d) 28 to 93.5 parts of water, the invention better solves the problem and can be used in the leveling process of cold-rolled steel sheets.

Owner:CHINA PETROLEUM & CHEM CORP

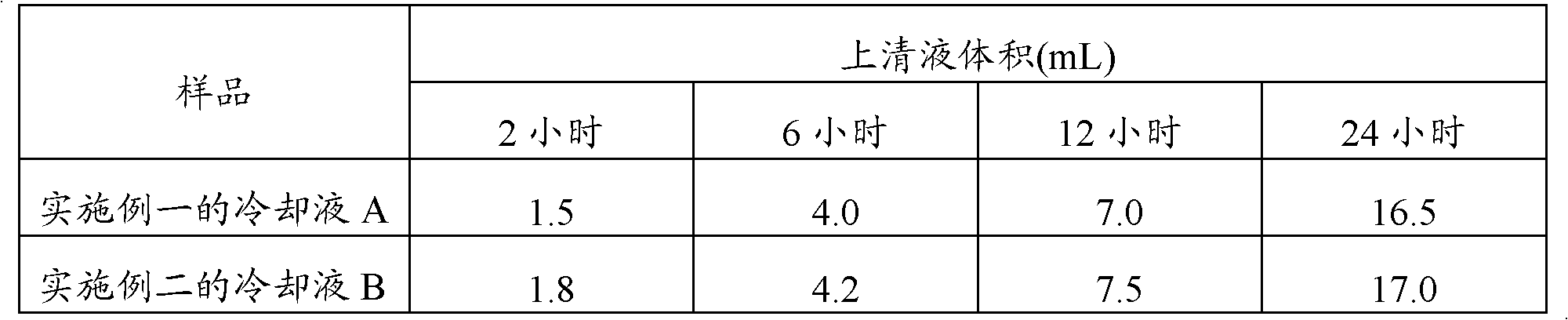

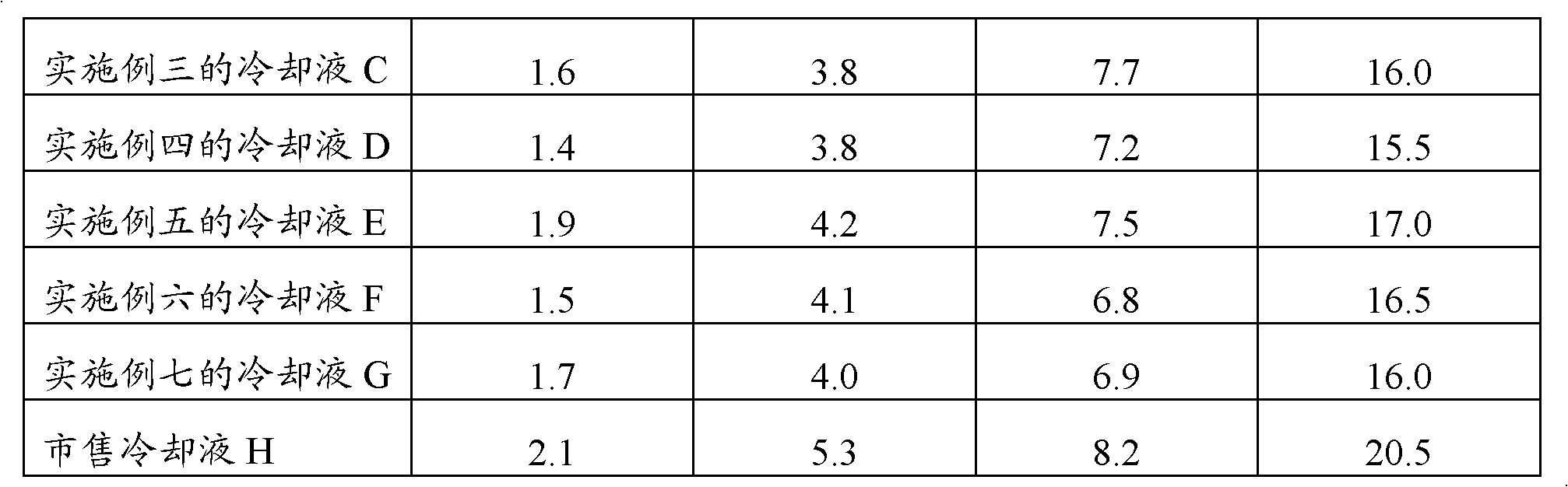

Cooling liquid for diamond wire cutting technology

ActiveCN103184094AImprove the lubrication effectImprove cooling effectWorking accessoriesLubricant compositionSurface finishPreservative

The invention relates to cooling liquid for diamond wire cutting technology, which mainly comprises a lubricant, an emulsifier, an antirust agent, a dispersant, a preservative, and deionized water, wherein the mass percents of the components are 5-50% of the lubricant, 0.05-10% of the emulsifier, 0.1-5% of the antirust agent, 0-10% of the dispersant, 0-5% of the preservative, and the balance being deionized water. The cooling liquid has excellent lubricity and dispersibility, is easy to clean, suitable for cutting of hard and brittle materials such as crystal silicon, sapphire, and the like, can not only meet requirements for diamond wire high-speed cutting, but also realize good surface finish of cut pieces, and can significantly increase product qualified rates.

Owner:LIAONING OXIRANCHEM INC

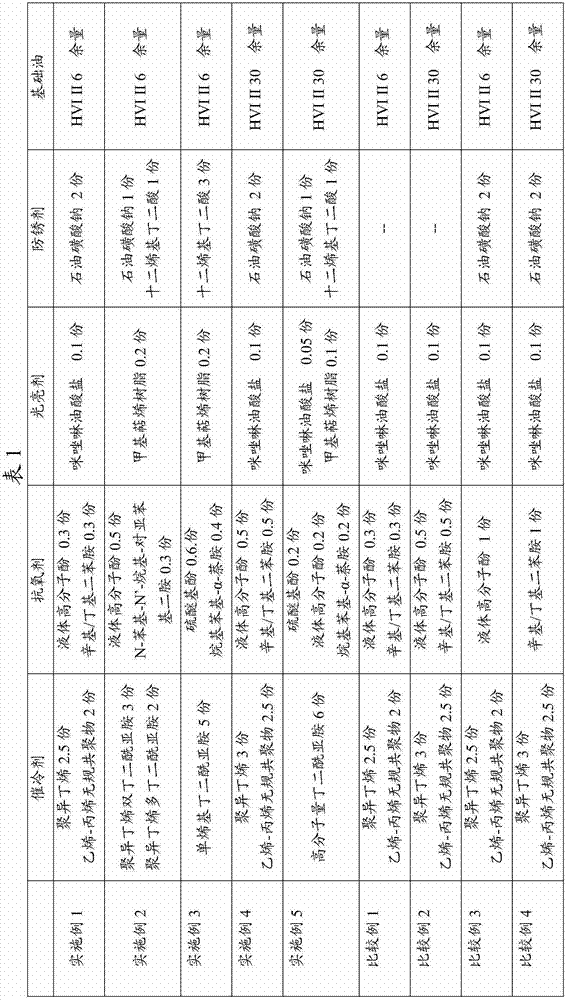

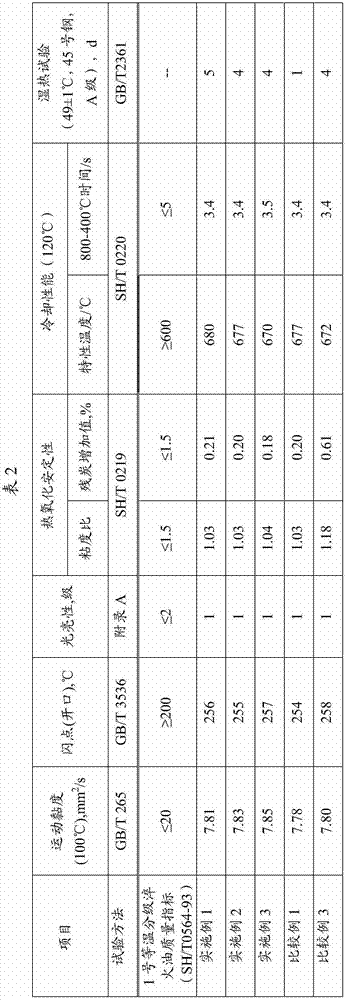

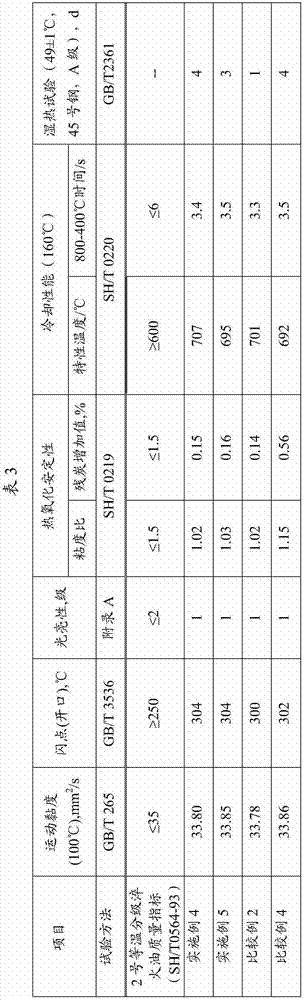

Isothermal graded quenching oil composition and uses thereof

ActiveCN103710083ABright surfaceMeet the requirements of high temperature quenchingQuenching agentsLubricant compositionPhenolic antioxidantSteel ball

The invention relates to an isothermal graded quenching oil composition and uses thereof, mainly aims at further improvement of cooling performances, thermal oxidation stability and brightness of isothermal graded quenching oil in the prior art, and solves the problem that the isothermal graded quenching oil has no corrosion resistant performance on workpieces after quenching. The isothermal graded quenching oil composition comprises the following components: by weight, a) 0.3 to 8 parts of a cooling accelerant; b) 0.1 to 3 parts of an antioxidant; c) 0.001 to 1 part of a brightener; d) 0.03 to 5 parts of an anti rust agent; and e ) 78 to 98 parts of base oil; in the technical scheme, the antioxidant is selected from a phenolic antioxidant or a mixture of amine antioxidants, the technical scheme can well solve the problem, and the isothermal graded quenching oil composition can be used for quenching of wearable steel balls, saw blade, auto gearbox gears, gear rings, gear sleeves, shafts and other precision parts.

Owner:CHINA PETROLEUM & CHEM CORP +1

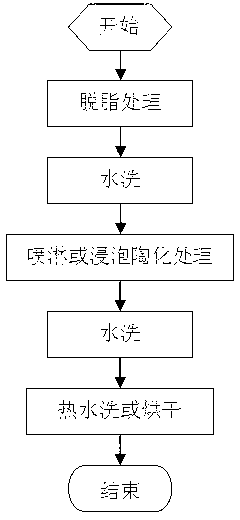

Metal surface vitrification agent and application method thereof

ActiveCN102747355AImprove corrosion resistanceStrong impact resistanceMetallic material coating processesSilanesConversion coating

The invention provides a metal surface vitrification agent and an application method thereof, aiming for solving the problem of possibility of environmental pollution caused by waste water discharge in a treatment process or after treatment in the existing metal surface phosphating treatment technology. According to the invention, the metal surface vitrification agent comprises 2.0-38.0% of zirconium titanium salt, 0.1-8.0% of silane, 0.5-18.0% of a buffer agent, 0.01-5.00% of film forming assistant, 0.1-6.1% of an anti-rust agent and 0.2-7.0% of a complexing agent, wherein the surface appearance is clear transparent liquid and no suspended matter exists; pH value is 1-2, and the specific gravity is 1.05+ / -0.02 g / cm<3>. The metal surface vitrification agent has the advantages that an embedded hybrid indissolvable nanometer ceramic conversion coating is formed on the metal surface at normal temperature and is excellent in impact resistance, the adhesion force of the coating is improved, and the corrosion resistance of the metal surface is enhanced. In addition, the metal surface vitrification agent, provided by the invention, contains no component capable of causing environmental pollution, and can be directly discharged without environmental pollution.

Owner:CHOGNQING CHANGYU METAL SURFACE TREATMENT TECH

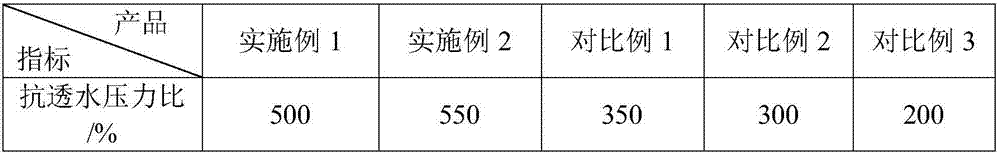

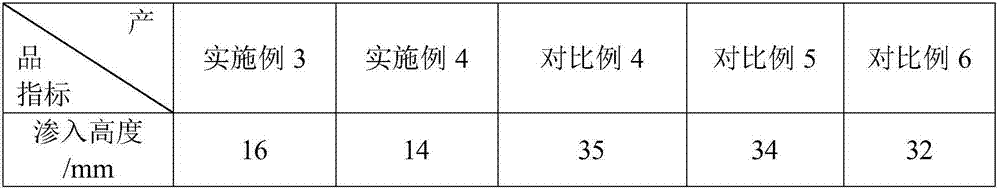

Water-based capillary crystalline type waterproof material with controllable reaction speed as well as preparation method and application of waterproof material

The invention discloses a water-based capillary crystalline type waterproof material with the controllable reaction speed as well as a preparation method and an application of the waterproof material. The waterproof material is mainly prepared from raw materials in parts by weight as follows: 30-40 parts of sodium silicate, 0.05-0.15 parts of a surfactant, 0-1 part of a reaction retarder, 0.1-0.2 parts of a reducing agent, 0-5 parts of a reaction accelerant, 0.06-0.1 parts of an anti-freezing agent, 0.1-0.3 parts of a metal ion blocking agent, 0.4-0.8 parts of a surface enhancer, 0.2-0.4 parts of an antirust agent and 53-69 parts of deionized water. The waterproof material has properties of lasting water resistance, durability, aging resistance, good permeability resistance, cracking resistance, high seepage capacity and the like and can reach the optimal waterproof effect for concrete under different porosity conditions; besides, the preparation method is simple, low in cost, pollution-free and convenient to conduct in concrete waterproof application.

Owner:SUZHOU GUARDEX NEW MATERIAL TECH CO LTD

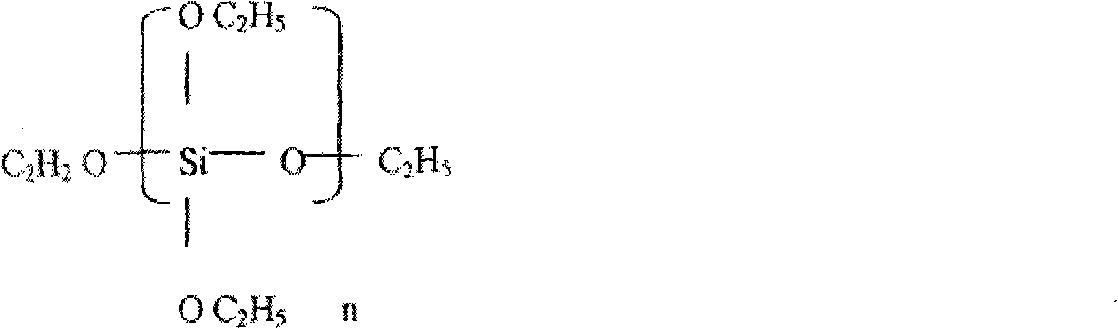

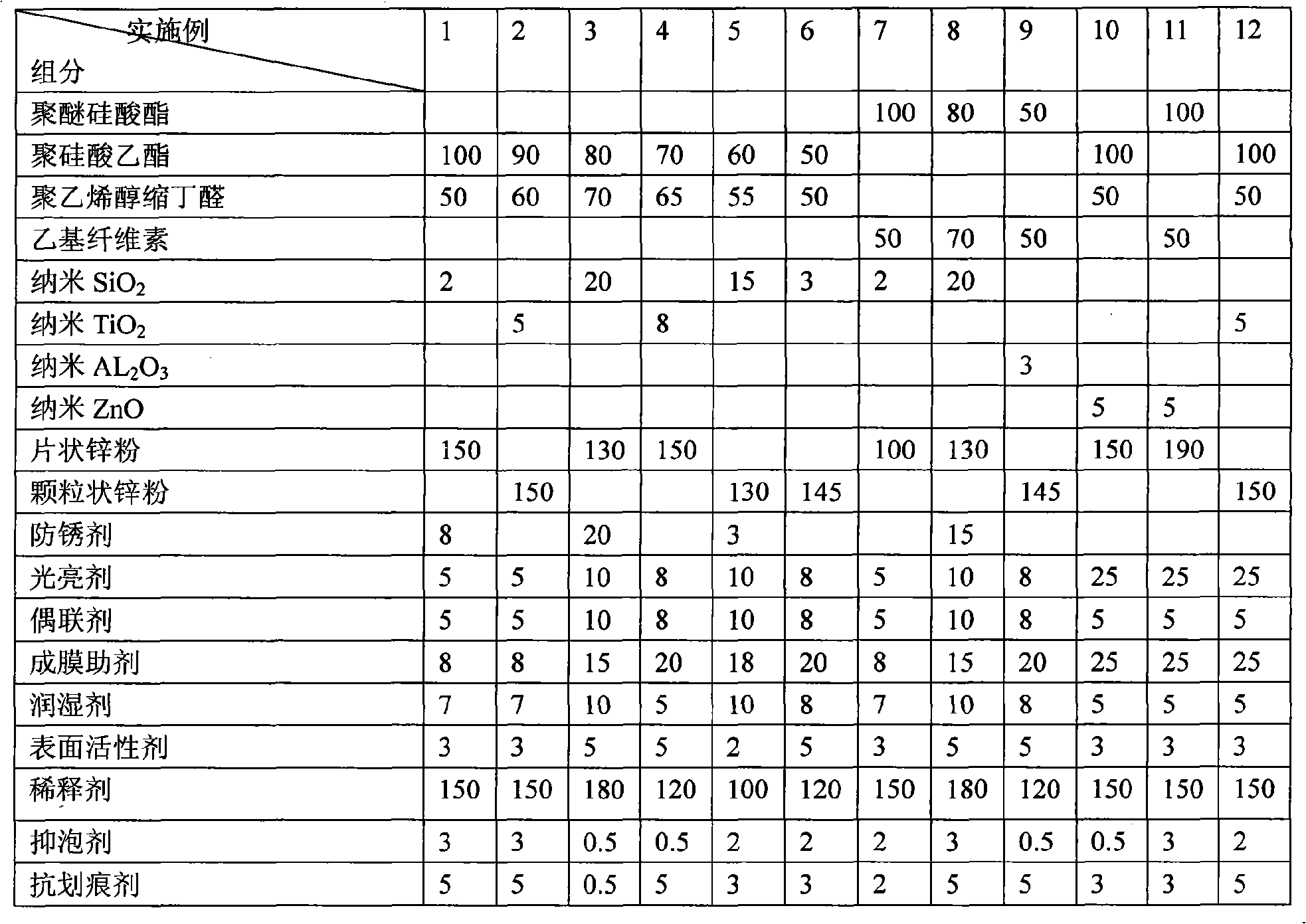

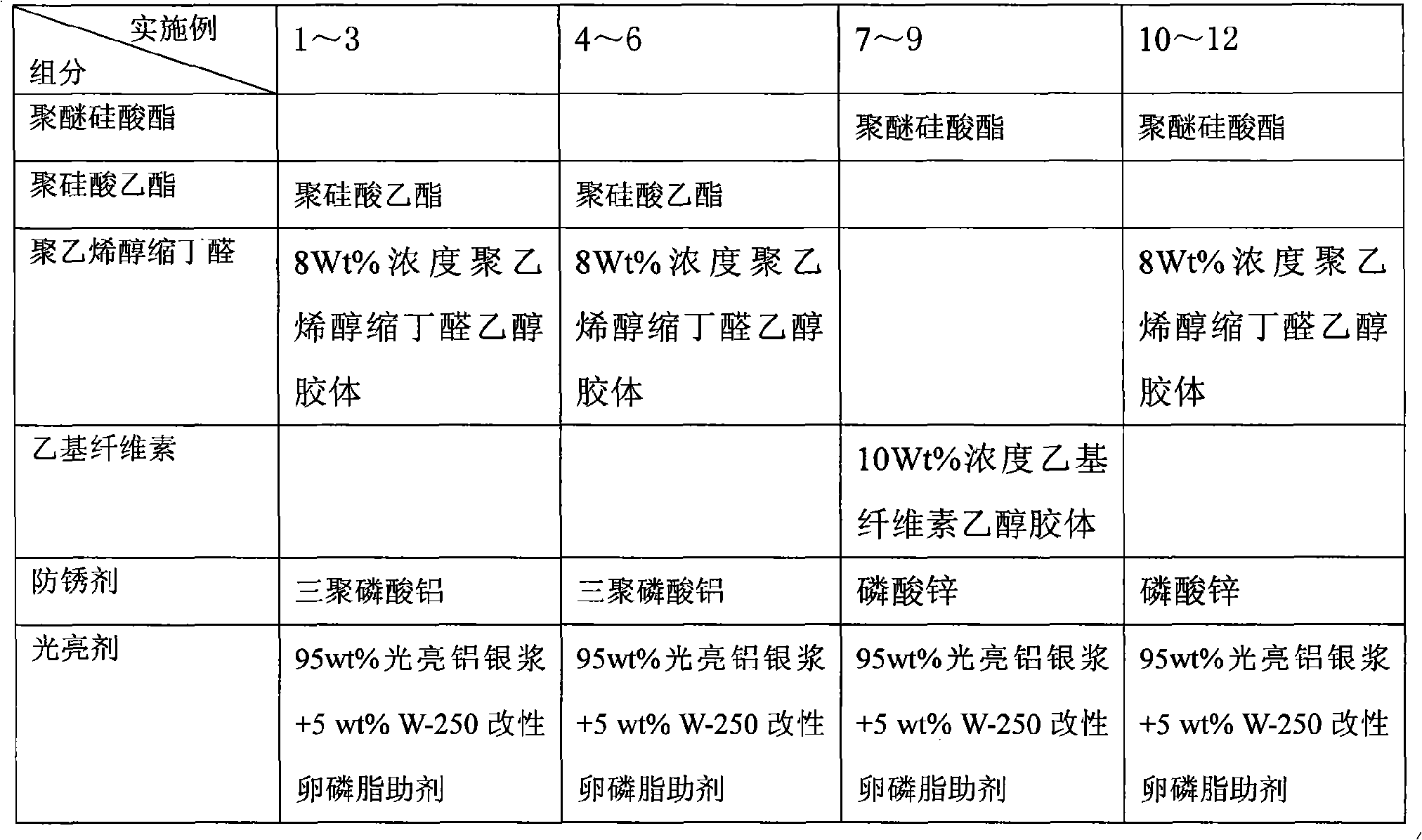

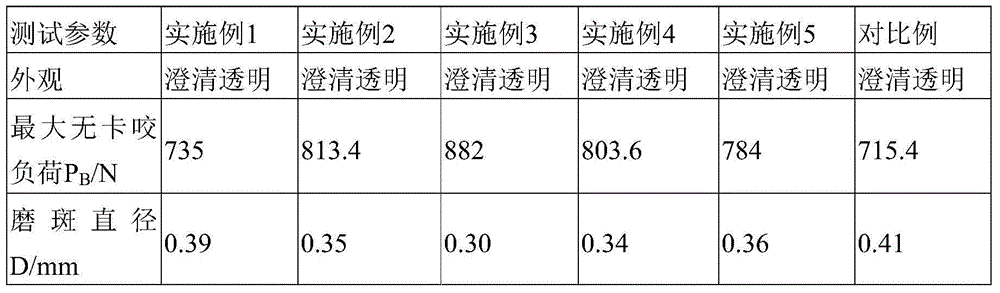

Zinc metallic coating

The invention discloses a zinc metal coating layer, the zinc metal coating is characterized in that when being calculated according to the parts by weight, the components of the the zinc metal coating are as follows: 50 parts to 100 parts of polyether silicate ester or polymerized silica acid ester, 50 parts to 100 parts of polyvinyl butyral or ethyl cellulose, 1 part to 20parts of one or a plurality of component (s) among nanometer silicon dioxide, nanometer titanium dioxide, nanometer molybdenum dioxide, or nanometer zinc oxide, 80 parts to 200 parts of zinc powder, 0 to 20 parts of rust preventing agent,, 5 parts to 100 parts of coupling agent, 5 parts to 25 parts of brightening agent, 8 parts to 250 parts of film forming auxiliary agent, 5 parts to 10 parts of wettinh agent, 1 part to 5 parts of surface activating agent, 100 parts to 200 parts of thinning agent, 0.5 part to 3 parts of anti-foaming agent and 0.5 part to 5 parts of anti-scratching agent. The bright metal zinc coating layer related by the invention can be taken as the anti-corrosive oxidation resistant zinc metal coating layer of metal product, particularly the black metal product, which can replace the commonly adopted galvanizing technology. The bright zinc metal coating layer of the invention can very conveniently and effectively paint a zinc metal coating layer the binding of which is firm on the metal product, particularly the black metal product.

Owner:胡仲寅

Metal cutting fluid containing graphene dispersion solution and preparation method thereof

The invention relates to a metal cutting fluid containing a graphene dispersion solution and a preparation method thereof. The metal cutting fluid is composed of the following raw materials: 0.2-2.0% of lubricating additive, 5-7% of rust inhibitor, 0.2-0.5% of corrosion inhibitor, 0.05-0.15% of hard water resisting agent, 15-20% of lubricant and the balance of water. The lubricating additive is the graphene dispersion solution. The metal cutting fluid has favorable lubricating property and antirust property; by using the water base as the carrier, the metal cutting fluid is free of base oil; and the production process has the advantages of low energy consumption and low production cost, and is simple to operate.

Owner:SHANGHAI HITECRUN SPECIAL LUBRICATE SCI & TECH

Anticorrosive paint for weather-resistant corrosion-resistant steel pipe outer wall

ActiveCN102120909AFast dryingDry fastGeneral water supply conservationAnti-corrosive paintsEpoxyWeather resistance

The invention relates to an anticorrosive paint for a weather-resistant corrosion-resistant steel pipe outer wall, which is prepared from 30-50 parts of alkyd resin, 2-5 parts of epoxy resin, 10-15 parts of terpene resin, 30-50 parts of hydrocarbon solvent, 3-8 parts of anticorrosive agent and 1-3 parts of drying agent. The paint provided by the invention can be applied by brushing, spraying, dipcoating, curtain coating or the like, and is naturally dried at normal temperature. The terpene resin adopted in the invention has high stability for oxygen, heat and light, and has excellent ageing resistance, so that the paint has excellent weather resistance. The rust inhibitor adopted in the invention can form a compact protective layer with high adhesive force on the surface of a steel pipe,and thus, prevents or slows the permeation of oxygen and water in the environment under the isolation action, thereby inhibiting the generation of corrosion microcells and performing a favorable anticorrosive protection function.

Owner:TIANJIN COLOROAD COATING & CHEM

Lubricating composition for use in cold extrusion forming process

InactiveCN102041144AImprove anti-wear performanceReduce coefficient of frictionFoundry mouldsFoundry coresHigh wear resistancePre treatment

The invention discloses a lubricating composition for use in a cold extrusion forming process, which comprises the following components in part by weight: 100 parts of base oil, 0.5 to 20 parts of antiwear agent, 10 to 40 parts of friction modifier, 0.1 to 2 parts of antirusting agent, 0.1 to 2 parts of ashless dispersant, 0.001 to 2 parts of antioxygen and 0.2 to 5 parts of chlorine catcher. Thelubricating composition has very high wear resistance and very low friction coefficient. On the premise of avoiding processed material pretreatment such as phosphorization and saponification in the cold extrusion forming process, the lubricating composition can allow processed parts to be removed from molds smoothly and make product bright and precise, thereby greatly improving the production efficiency of cold extrusion forming and prolonging the service life of the molds.

Owner:屠伟刚

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com