Wet leveling liquid composition and use thereof

A technology for wet leveling liquid and composition, applied in the field of wet leveling liquid composition, can solve problems such as the inability of wet leveling liquid to meet the requirements, achieve good anti-rust performance and cleaning performance, reduce wear, and solve the effects of reducing cleaning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

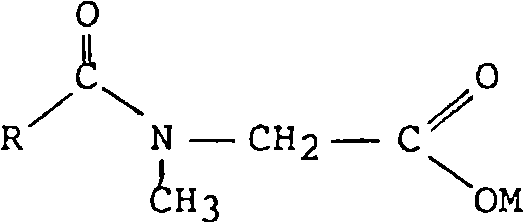

Method used

Image

Examples

Embodiment 1~12

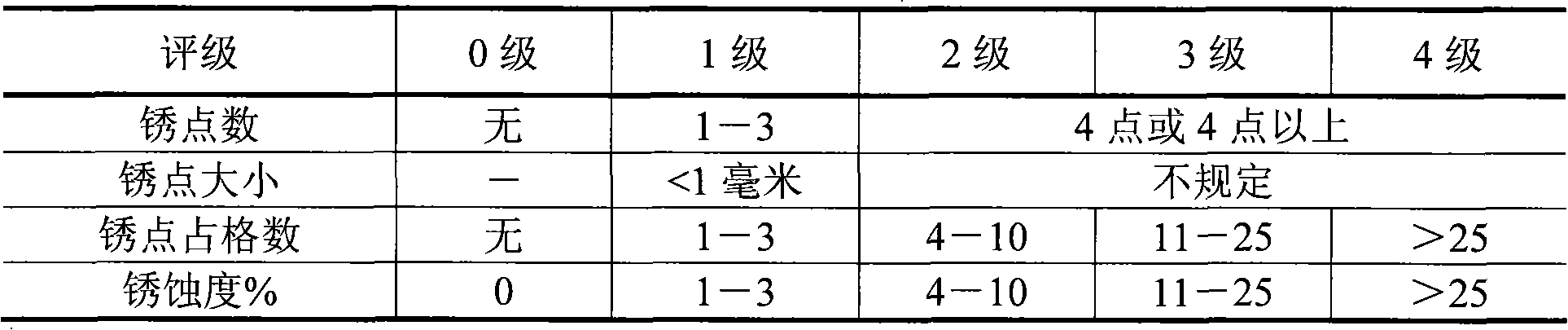

[0028] Heat the water to 40°C, add the required amount of anti-rust agent, pH regulator, cleaning agent, cleaning aid, lubricant and defoamer in sequence during stirring, stop stirring and heating after 2 hours of sufficient stirring, and let it stand After 1.5 hours, filter and fill. Each component and its content are shown in Table 2, and the properties are shown in Table 3. Table 2,

[0029] EL-20: castor oil polyoxyethylene ether HEDTA: sodium diamine triacetic acid

[0030] STPP: sodium tripolyphosphate EDTA-4Na: tetrasodium ethylenediaminetetraacetic acid

[0031] EL-30: castor oil polyoxyethylene ether AEO-6: fatty alcohol polyoxyethylene 6 ether

[0032] EO / PO polyether: ethylene oxide / propylene oxide polyether

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com