Patents

Literature

420results about How to "Improve detergency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

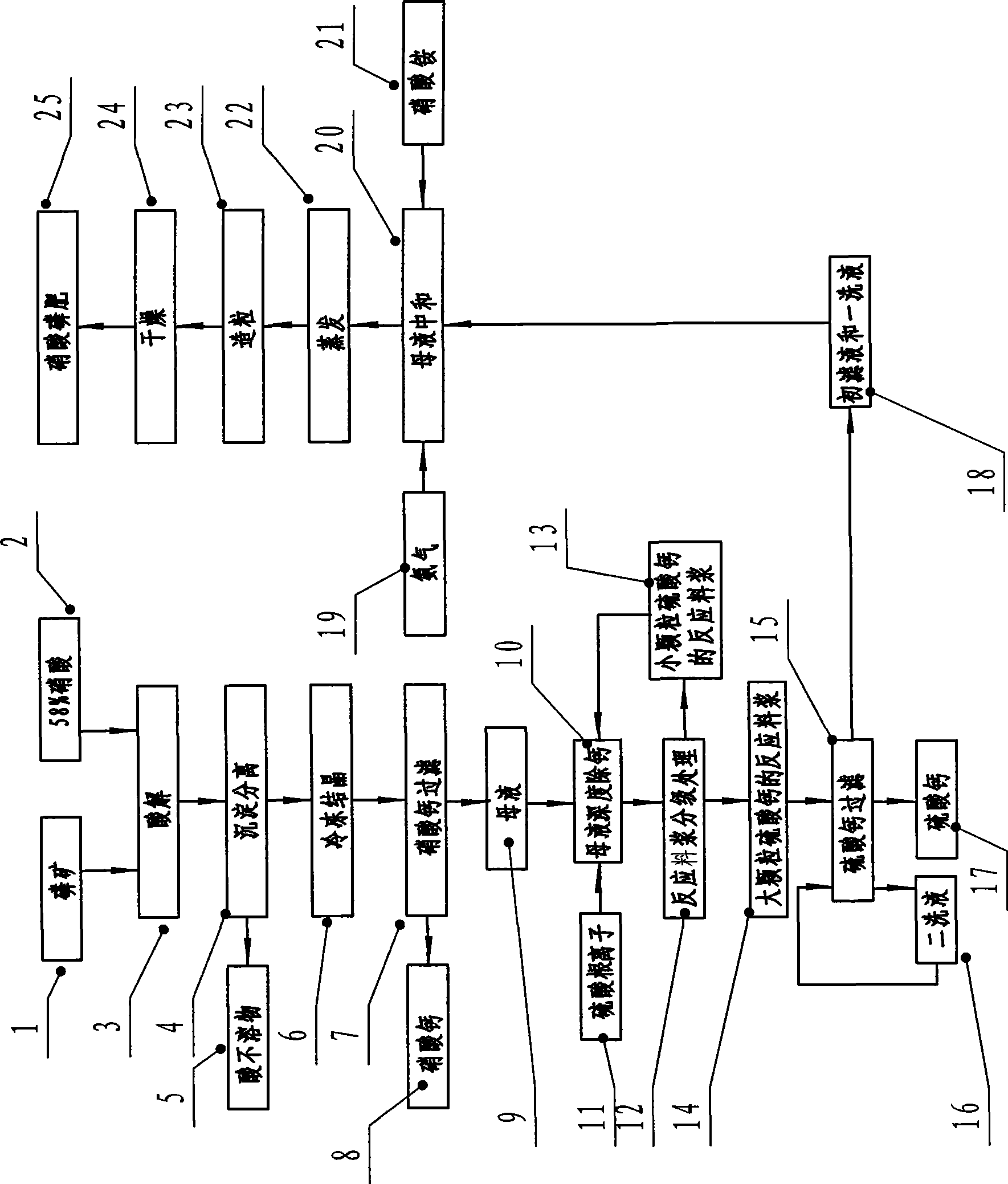

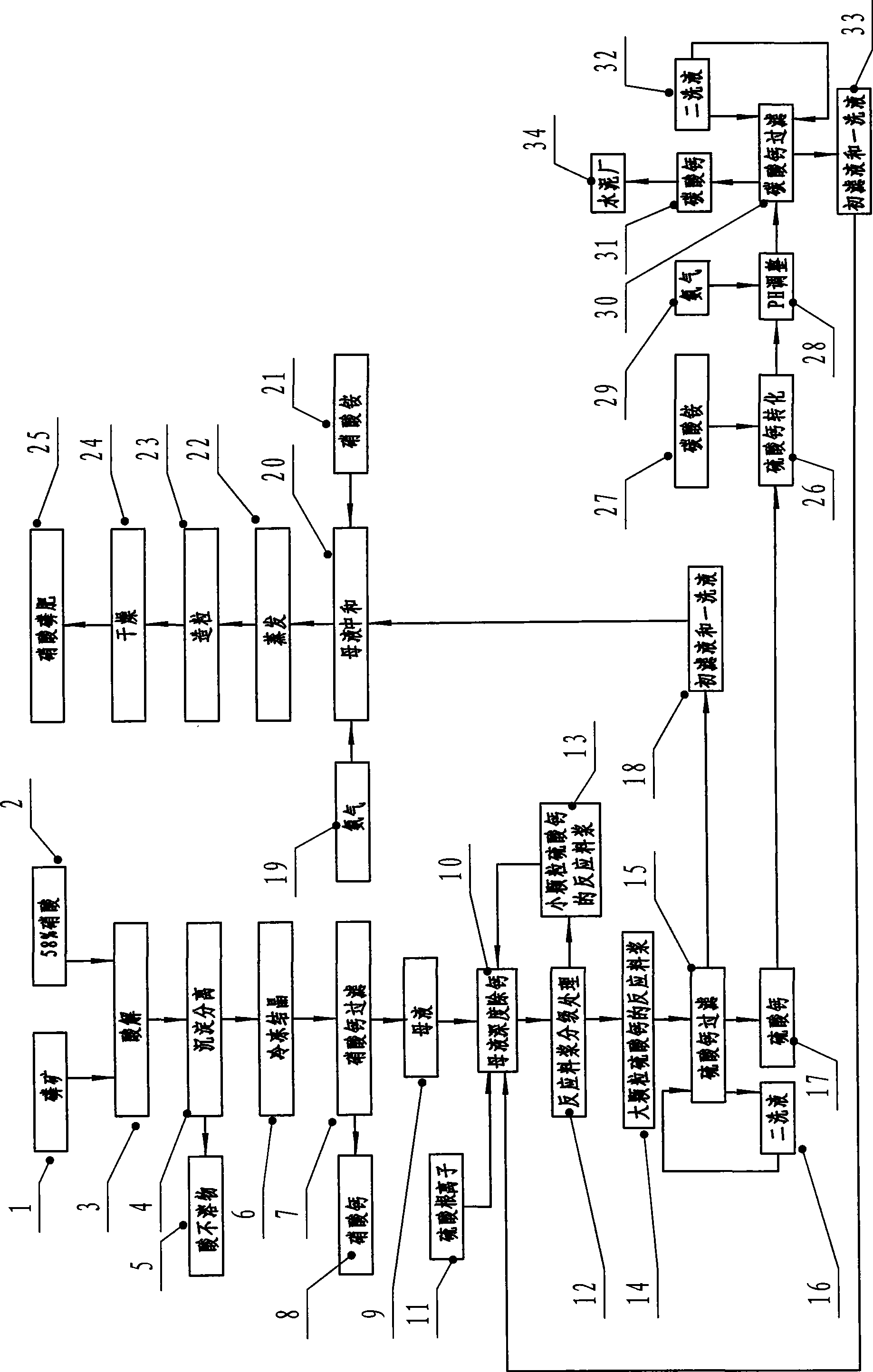

Technological process for producing high concentration nitric-phosphate fertilizer

The invention discloses a technique method for producing high-concentration nitric phosphate, which comprises the following steps of: adding nitric acid into phosphorus ore for acidolysis, depositing and separating acid non-soluble substance, freezing and crystallizing calcium nitrate, filtering the calcium nitrate, neutralizing the mother liquid, vaporization, pelleting and drying. The invention is characterized in that: a step of thoroughly removing the calcium of the mother liquid is arranged between the steps of filtering the calcium nitrate, and neutralizing the mother liquid. The steps comprise the following steps of: I) thoroughly removing the calcium of the mother liquid and adding sulfuric acid or ammonium sulfate; the calcium ions and the sulfate ions in the mother liquid generate dihydrate calcium sulfate crystal; II) the grading processing of reaction slurry: employing a grading device to carry out grading processing to the reaction slurry; returning the reaction slurry provided with small grain calcium sulfate to the mother liquid for thoroughly removing the calcium, and feeding the reaction slurry provided with large grain calcium sulfate to the calcium sulfate for filtering; and III) filtering and washing the filtering reaction slurry of calcium sulfate by a filter, feeding the primary filtrate and the primary lavage fluid into the working procedure of neutralizing, and returning the secondary lavage fluid to the filter. The invention has the advantage of using middle-low quality phosphorite to prepare the high-concentration nitric phosphate.

Owner:TIANJI COAL CHEM IND GROUP +1

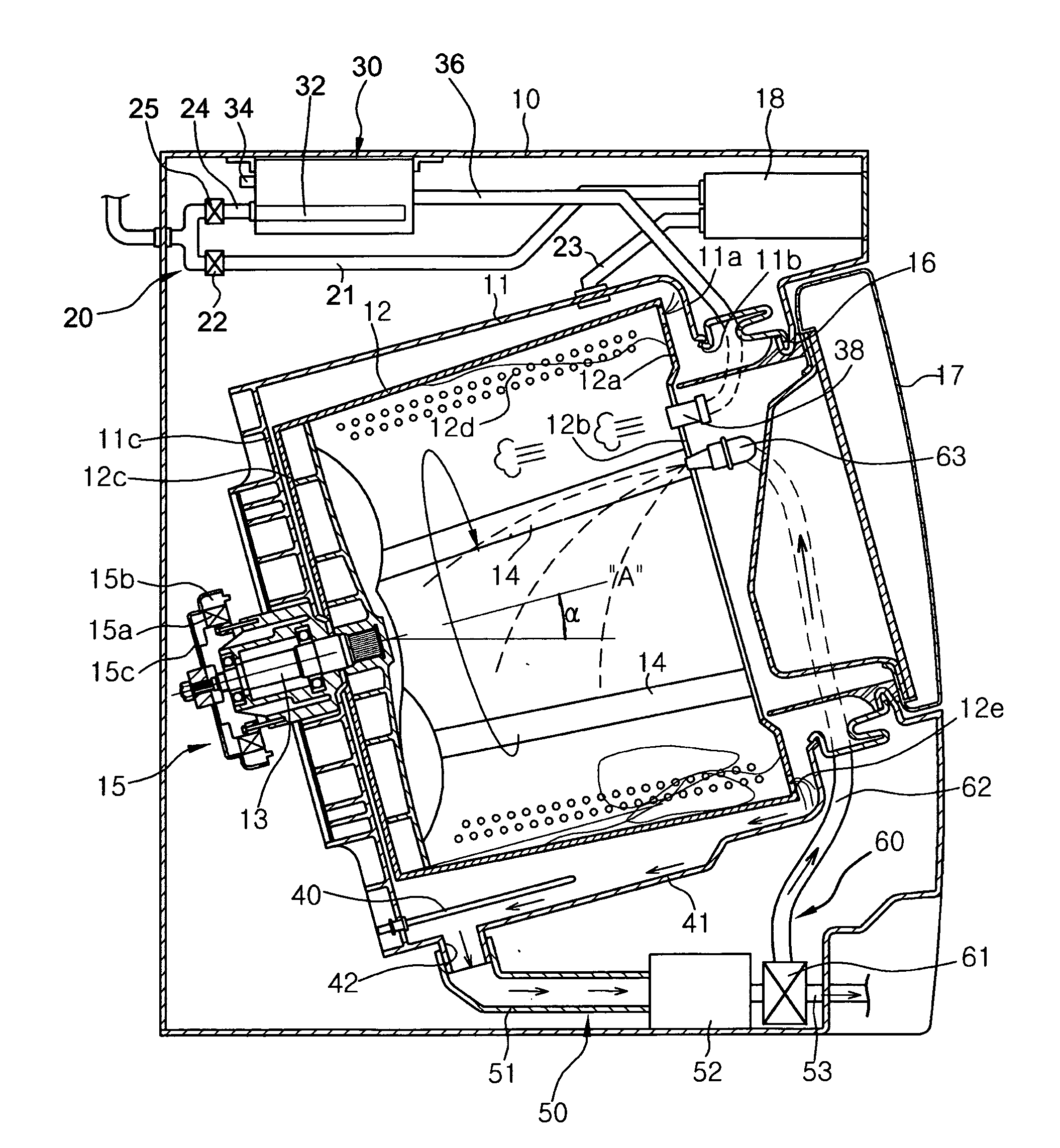

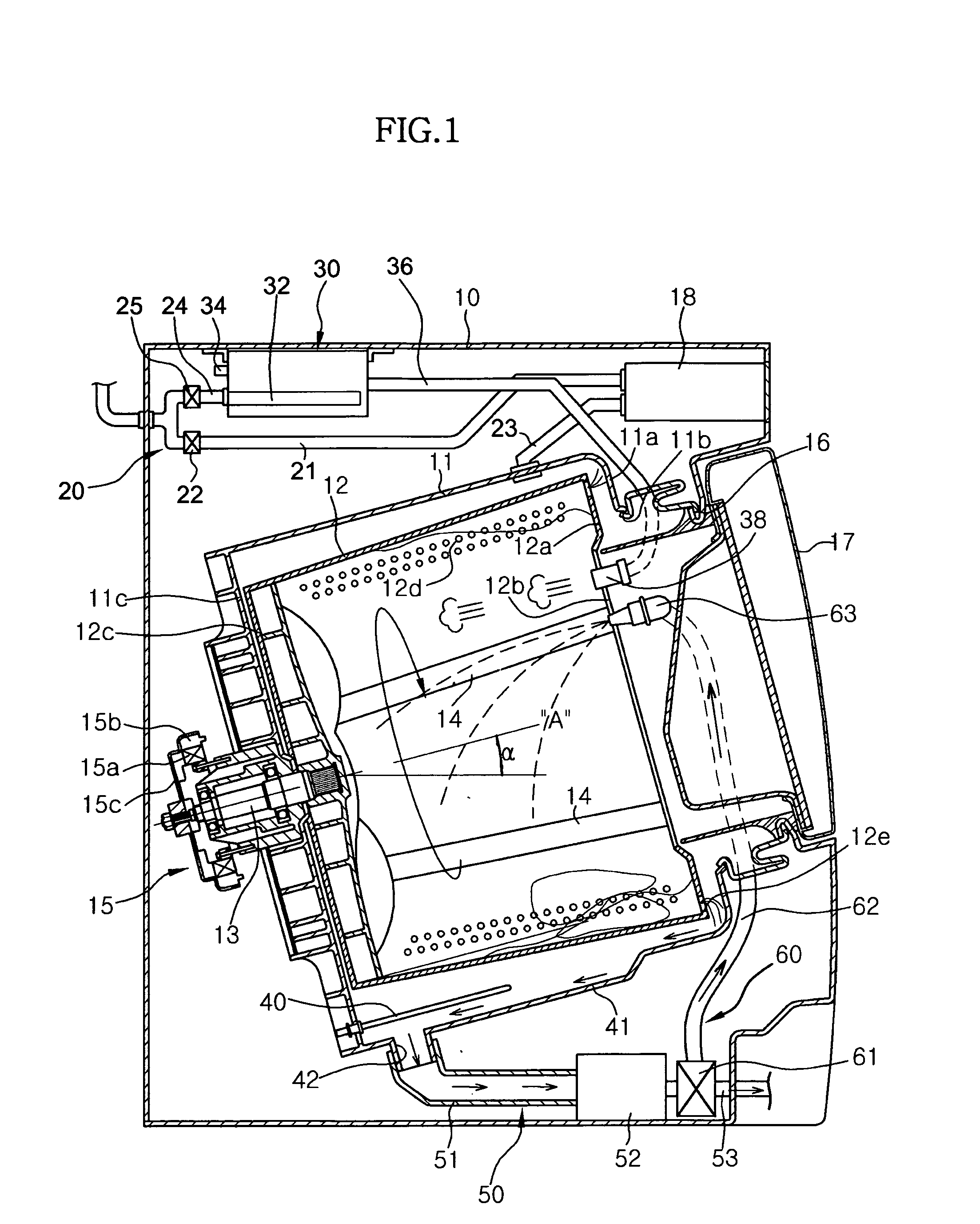

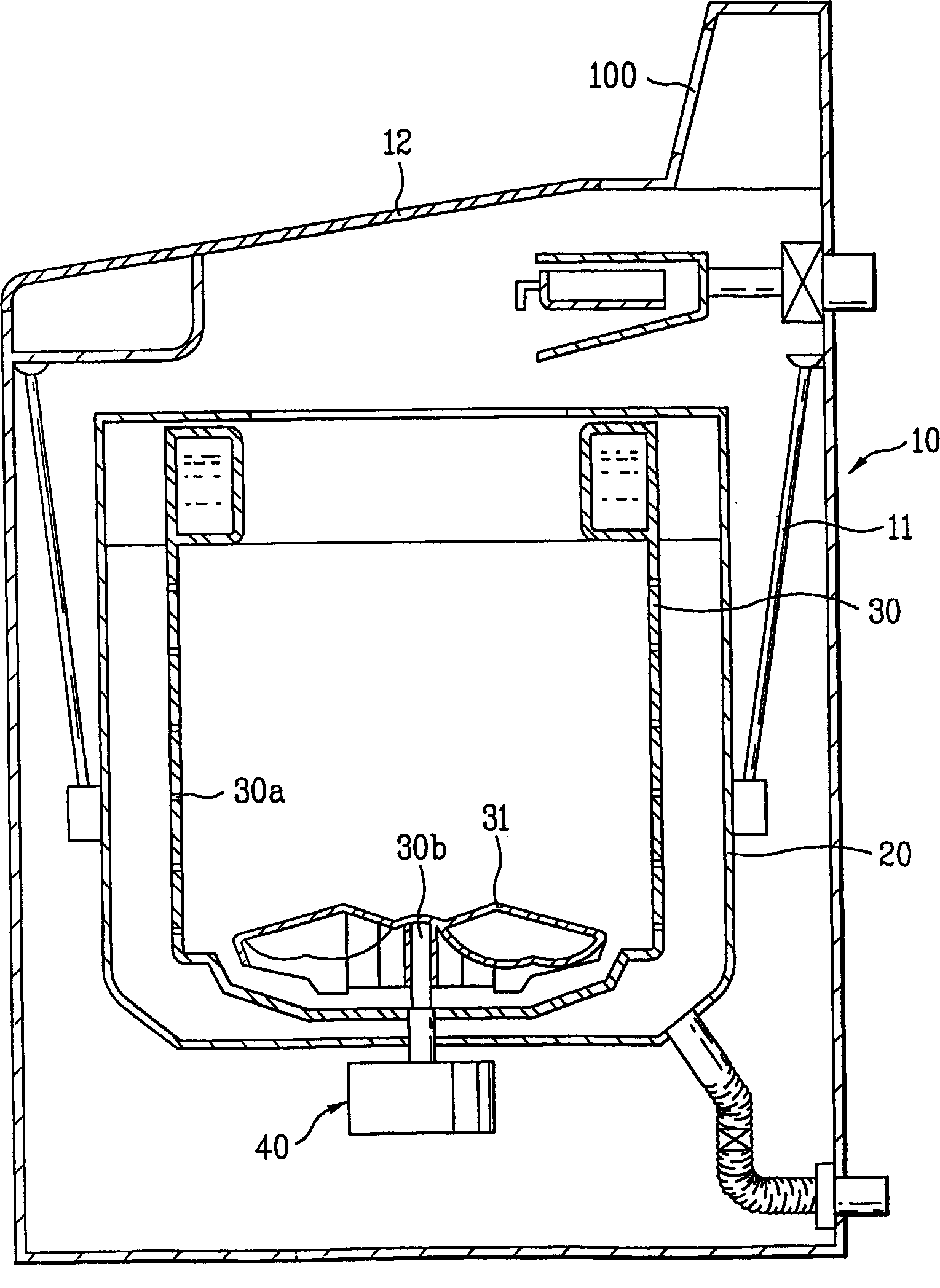

Washing machine and method for controlling the same

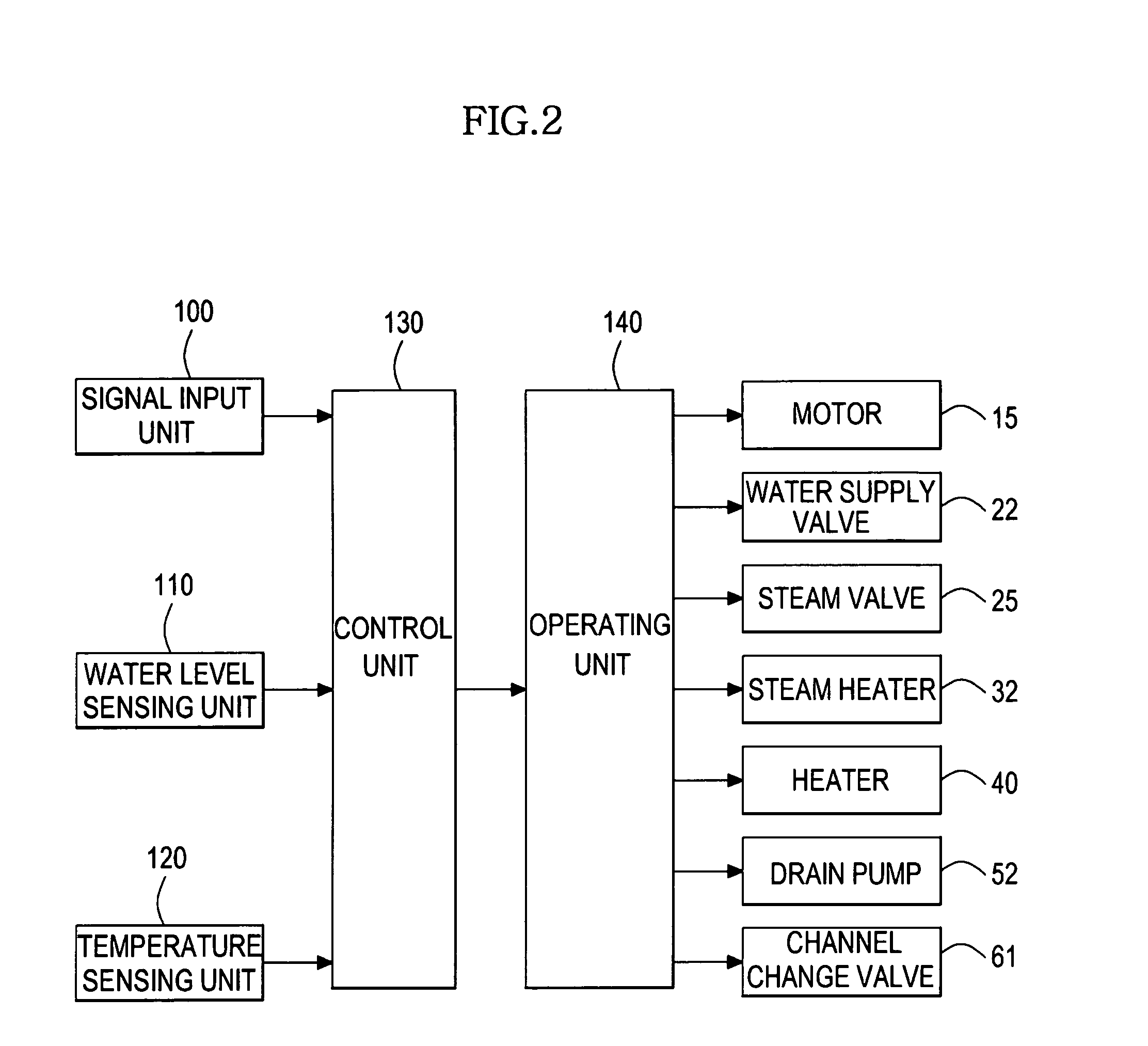

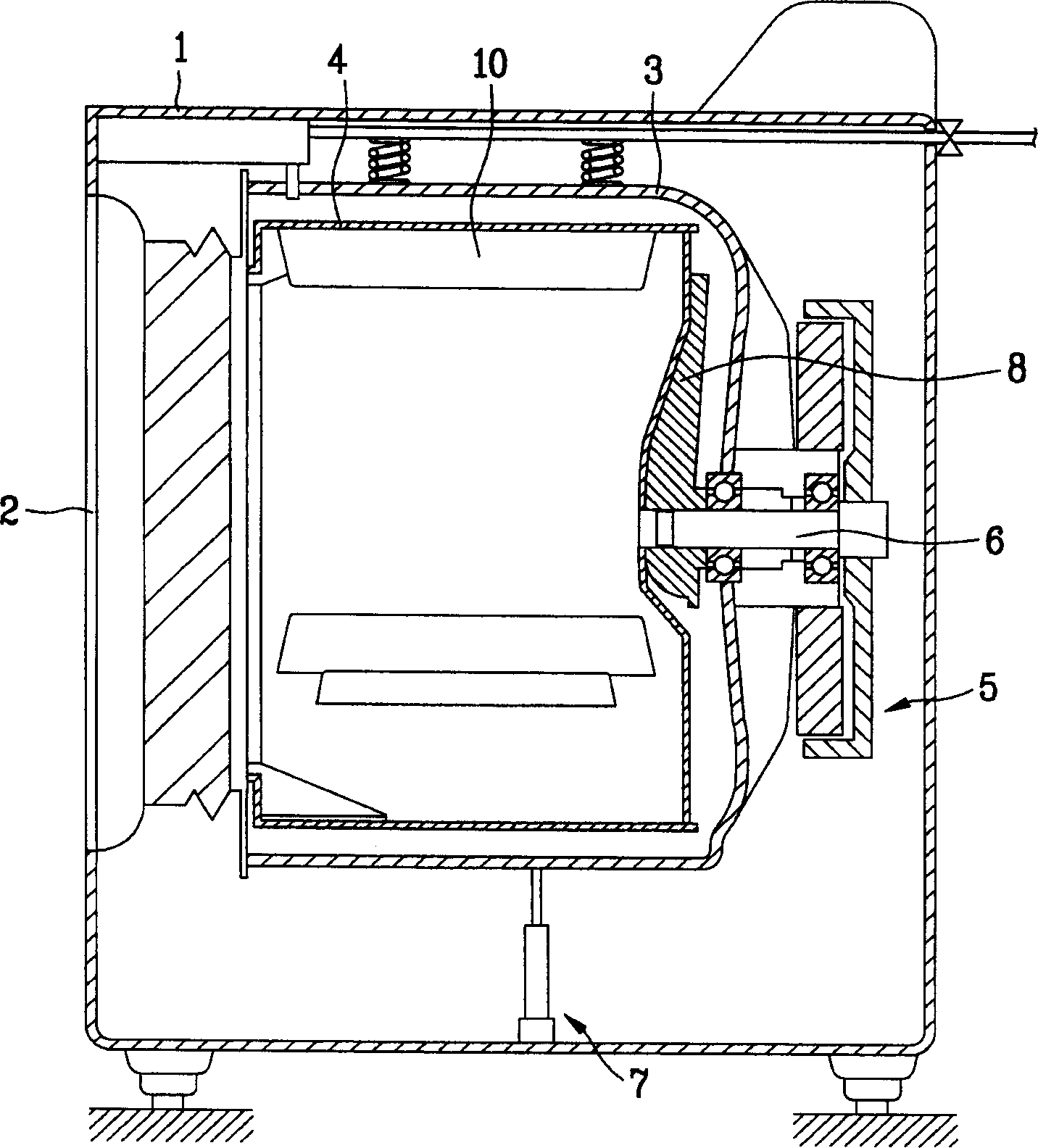

InactiveUS20060101586A1Shorten washing timeImprove washing effectOther washing machinesControl devices for washing apparatusProcess engineeringEnergy consumption

A washing machine having a steam generating device for directly heating wash water to generate optimum steam, and a method for controlling the same are provided. The method includes sensing a temperature of the steam generating device; controlling water supply means according to the temperature of the steam generating device such that wash water is supplied to the steam generating device; and controlling a quantity of wash water supplied from the water supply means. Further, the steam is supplied so as to rapidly soak laundry, thereby shortening overall washing time, and reducing energy consumption. Also, the steam is sprayed onto the laundry to provide sterilizing effects. Soaking effects of the laundry are improved, as well, so as to increase washing efficiency and eliminate wrinkling.

Owner:SAMSUNG ELECTRONICS CO LTD

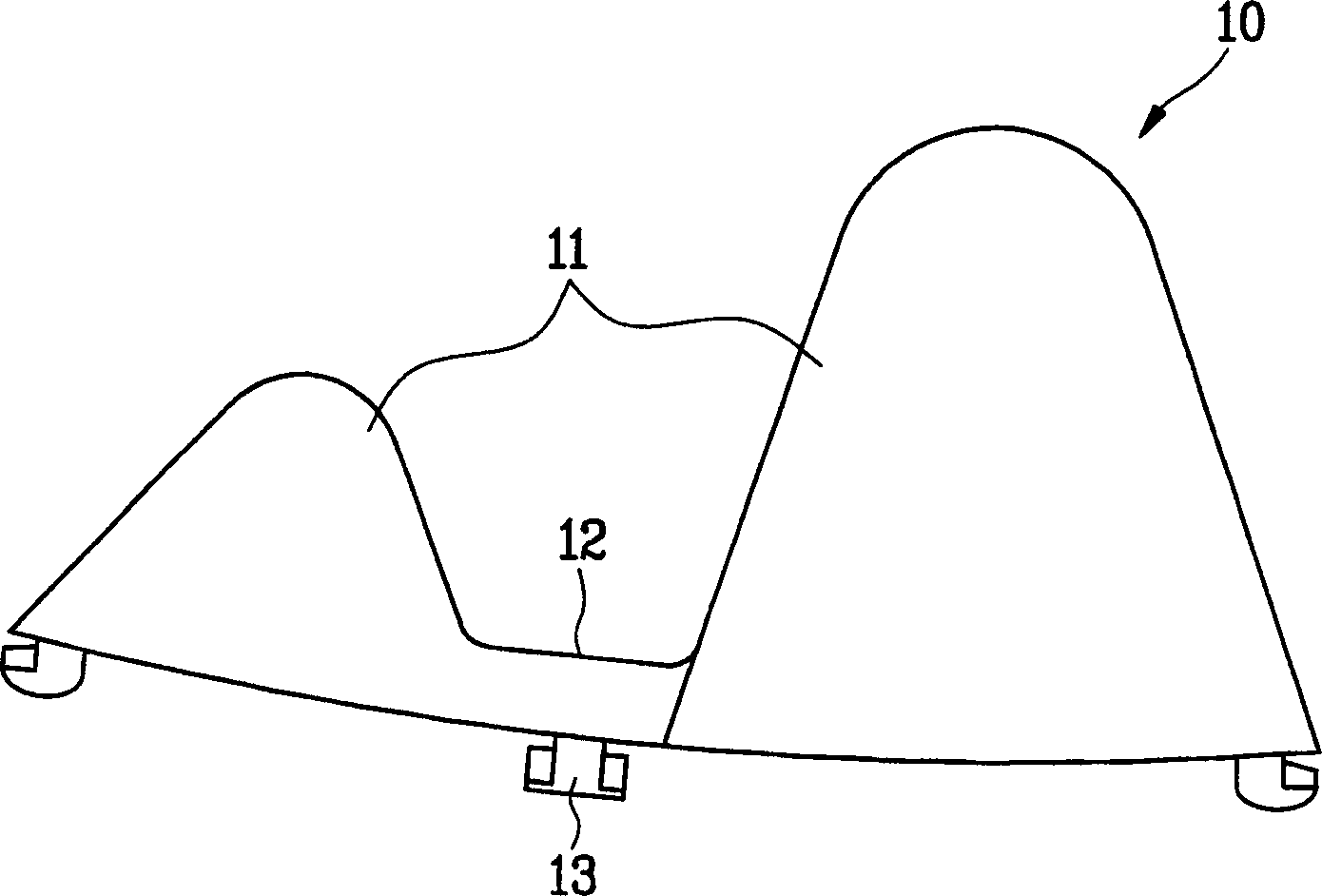

Washing machine

InactiveCN1414163AImprove detergencyEasy to take outOther washing machinesWashing machine with receptaclesFree rotationWash water

Washing machines having improved frictional forces with laundry. Those machines include a cabinet with a door, a tub inside for retaining wash water, and an internal vessel, inside the tub that is coupled with a motor that rotates the internal vessel. A friction member inside the internal vessel rubs against laundry. The frictional member includes a friction enhancer, such as a spherical structure or a freely rotating ball, that enhances laundry friction during washing and reduces adhesion of laundry after a dehydration cycle.

Owner:LG ELECTRONICS INC

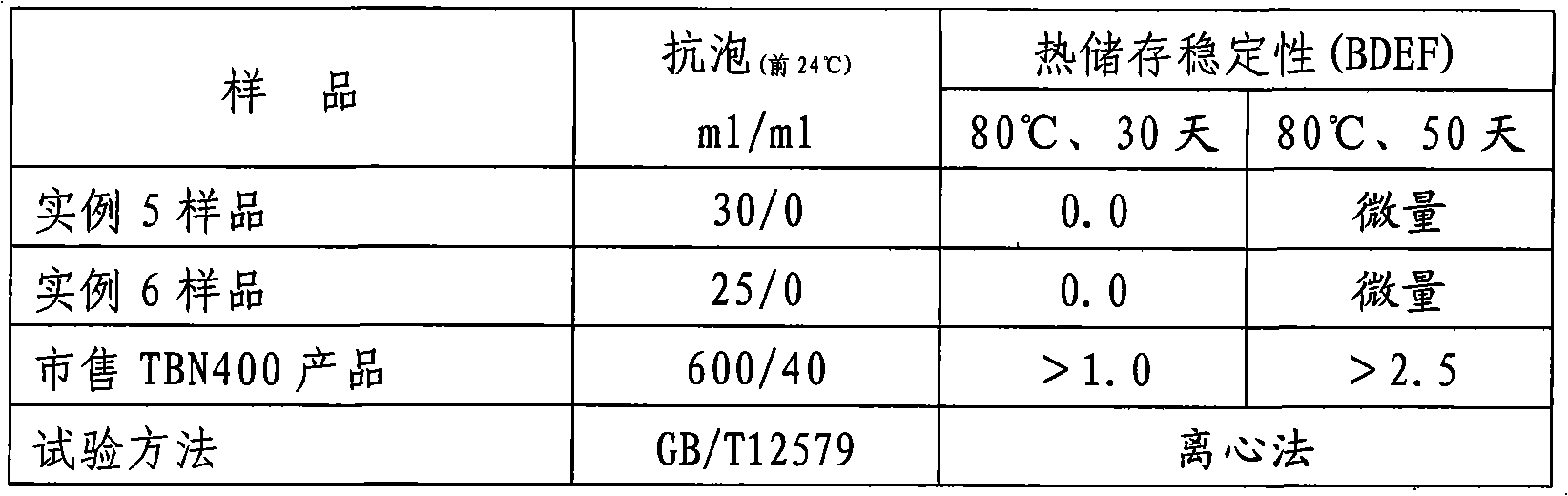

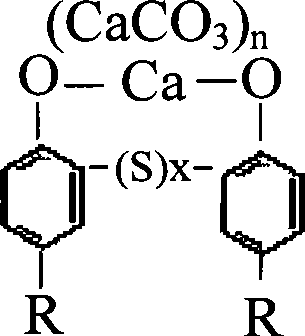

Method for preparing high-alkali value (TBN400) synthesized calcium alkyl benzene sulfonate

ActiveCN101318915AImprove cleanlinessGood dispersionAdditivesSulfonic acid preparationTotal Base NumberAlkaline earth metal

The invention provides a method for preparing high base number (TBN400) synthetic calcium alkyl-benzene sulfonate. The method comprises the following steps of: adopting a mixed acid of long-chain linear alkyl-benzene sulfonic acid and high-boiling heavy alkyl-benzene sulfonic acid, calcium oxide and / or calcium hydroxide, low-carbon alcohol, alkaline-earth metal halide or nitrate, and a mixture of alkaline-earth metal alkylphenol or alkaline-earth metal alkylphenate and polyisobutylene succinic anhydride for a neutralization reaction in the presence of a solvent and cutback oil at a temperature of between 40 and 80 DEG C; then, passing through carbon dioxide to a product of the neutralization reaction at a temperature of between 40 and 60 DEG C for a carbonation reaction; and producing high base synthetic alkyl-benzene sulfonate with a total base number (TBN) of 400mgKOH / g by adopting a process of a one-step method. The product is divided into high-base number (TBN400) synthetic alkyl-benzene sulfonate containing chlorine and high-base number (TBN400) synthetic alkyl-benzene sulfonate without the chlorine. The product produced by adopting the method with low viscosity, small turbidity, easy filtration, light color and no skin formation has the advantages of excellent high-temperature detergency, excellent anti-foaming property and excellent heat storage stability.

Owner:JINZHOU DPF TH CHEM CO LTD

Cold-rolled sheet rolling emulsified oil containing modified nano copper and preparation method thereof

The invention relates to a cold-rolled sheet rolling emulsified oil containing a modified nano copper and preparation method thereof, which belong to the field of organic chemistry. The emulsified oil comprises the following components, in percentage by weight: 54-80% of a base oil, 15-32% of an oiliness agent, 0.1-1% of a modified nano copper particle, 2-4% of an extreme pressure agent, 0.5-2% of an anti-rusting agent, 2-6% of an emulsifier, 0.4-1% of an anti-oxidant, 0.03-0.1% of an anti-foaming agent, and 0.2-0.6% of an anti-mildew agent. The cold-rolled sheet rolling emulsified oil containing the modified nano copper is diluted with water into a 2-6 wt% emulsion, and the emulsion is directly used in the cold rolling process of the strip steel and has very good lubrication, cleaning property of the rolling mill and annealing cleaning property, after annealing, the steel plate not subjected to degreasing has a clean surface without pollutants, so as to satisfy rolling production requirement under high pressure at high speed.

Owner:NORTHEASTERN UNIV

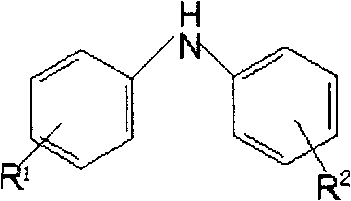

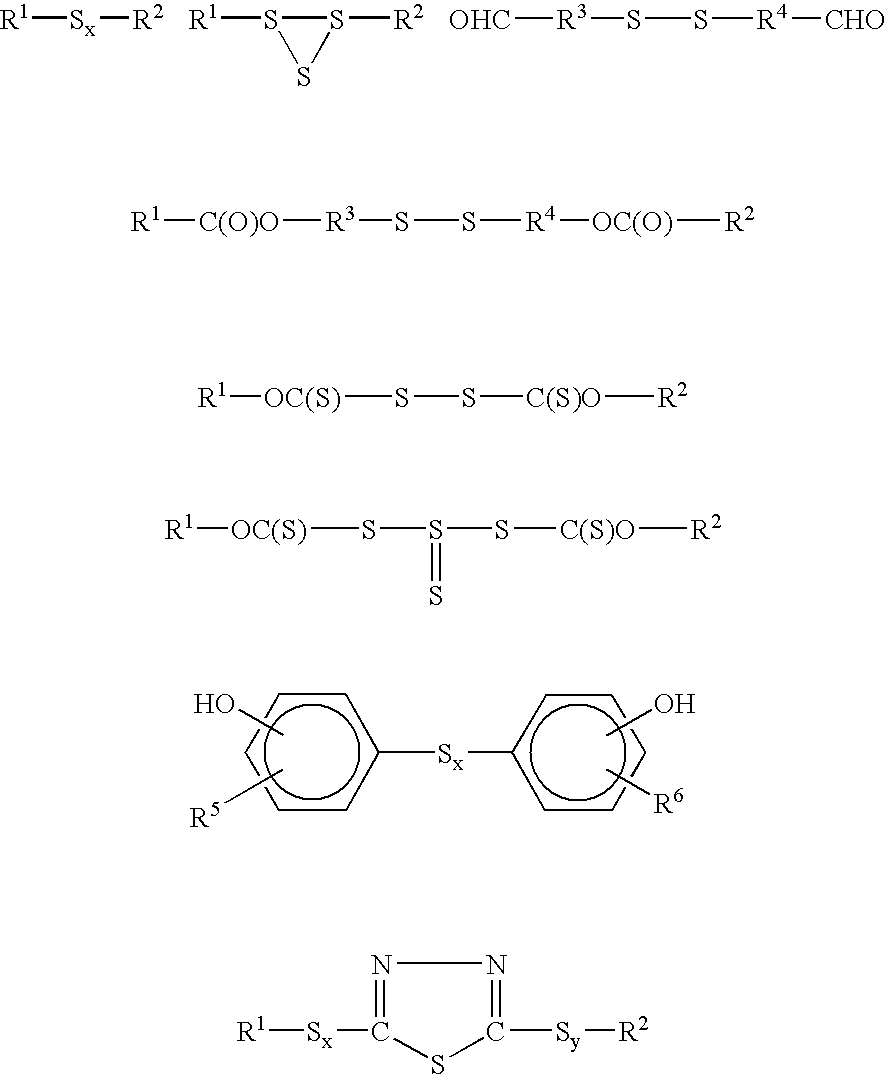

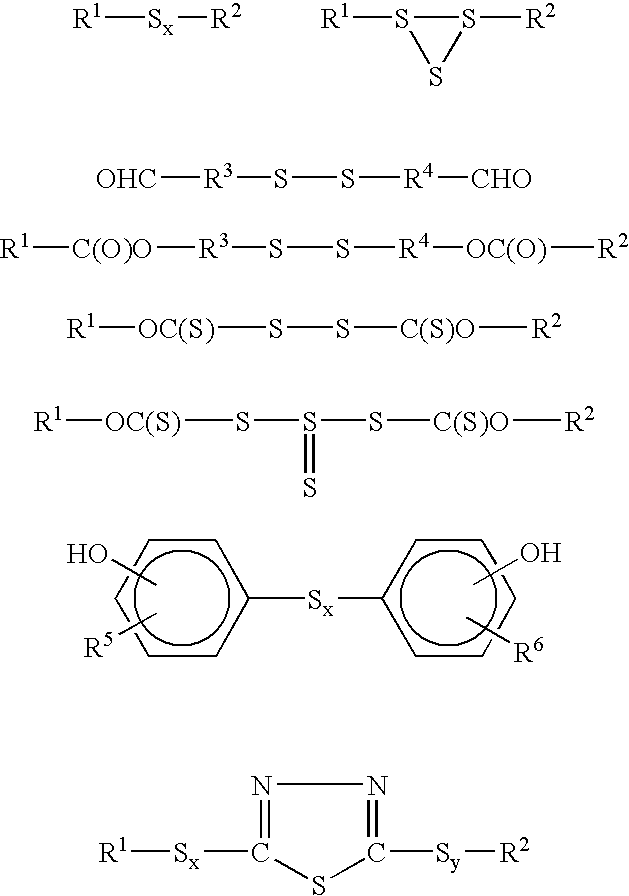

Lubricant composition for gasoline engine

ActiveCN102690711AMeet performance requirementsImprove antioxidant capacityAdditivesAlkaline earth metalAntioxidant

The invention relates to a lubricant composition for a gasoline engine. The lubricant composition contains: by mass, less than or equal to 0.08% of phosphorus and less than or equal to 0.9% of sulfate ash. The lubricant composition comprises A) a composite antioxidant comprising at least ingredients of 1, an alkylated diphenylamine antioxidant, 2, a thiophenolic ester antioxidant and 3, an unessential phenolic thioether antioxidant, B) a polyisobutylene succinimide ashless dispersant and / or a boronized polyisobutylene succinimide dispersant, C) one or more alkaline earth metal salicylate cleaning agents, D) at least one zinc dialkyl dithiophosphate, E) one or more oil-soluble organic molybdenum friction modifiers, F) one or more ashless friction modifiers, and G) a main amount of lubricating base oil. The lubricant composition for a gasoline engine has synergistic effect of the additives, can satisfy antioxidation requirements of a high-grade gasoline engine lubricant, and has excellent piston cleanliness, wear resistance and a viscosity increasing control capacity.

Owner:CHINA PETROLEUM & CHEM CORP +1

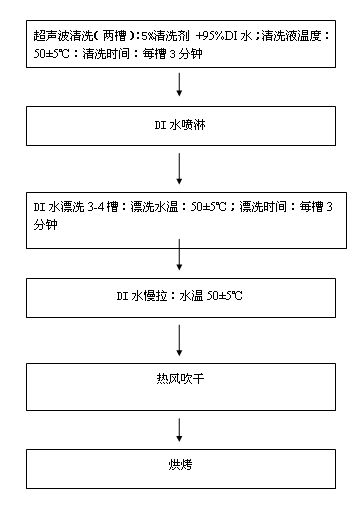

Cleaning agent for optical glass

ActiveCN102604751AEasy to cleanPromote wettingOrganic detergent compounding agentsNon-ionic surface-active compoundsOrganic baseCarbon chain

The invention discloses a cleaning agent for optical glass, which comprises the following components in weight percentage: 2-4% of long carbon chain dibasic acid; 6-10% of an anionic surfactant; 2-4% of an inorganic base; 2-6% of a nonionic surfactant; 2-4% of a special surfactant; 6-12% of a chelator; 10-20% of an organic base; and 40-70% of deionized water, wherein the long carbon chain dibasic acid is dicarboxylic acid with 21 carbon atoms, the anionic surfactant is dodecylbenzene sulfonic acid, the inorganic base is industrial NaOH, the nonionic surfactant is primary alcobol ethoxylate AEO9, the special surfactant is sodium POE nonylphenol ether sodiosulfosuccinate, the chelator is a mixture of Tetrasodium Ethylenediamine Tetraacetate and sodium gluconate, and the organic base is diethanol amine. The cleaning agent for optical glass provided by the invention has low corrosivity and good cleaning effect.

Owner:SHENZHEN FISHER NEW MATERIALS CO LTD

Bearing cleaning composition and method of use

ActiveUS7241723B2Easy to distinguishHigh in calciumRotary combination bearingsBearing componentsSulfonateEngineering

A composition for cleaning bearings in rotating equipment and industrial machinery that contains powdered limestone having a high calcium content dispersed in a calcium sulfonate grease, together with a colorant that readily enables a user to differentiate between contaminated grease, cleaning composition and fresh grease. A method is also disclosed that enables a user to clean and re-lubricate bearings without the need for removing the bearings from service or for shutting down the associated equipment or machinery.

Owner:NCH CORP

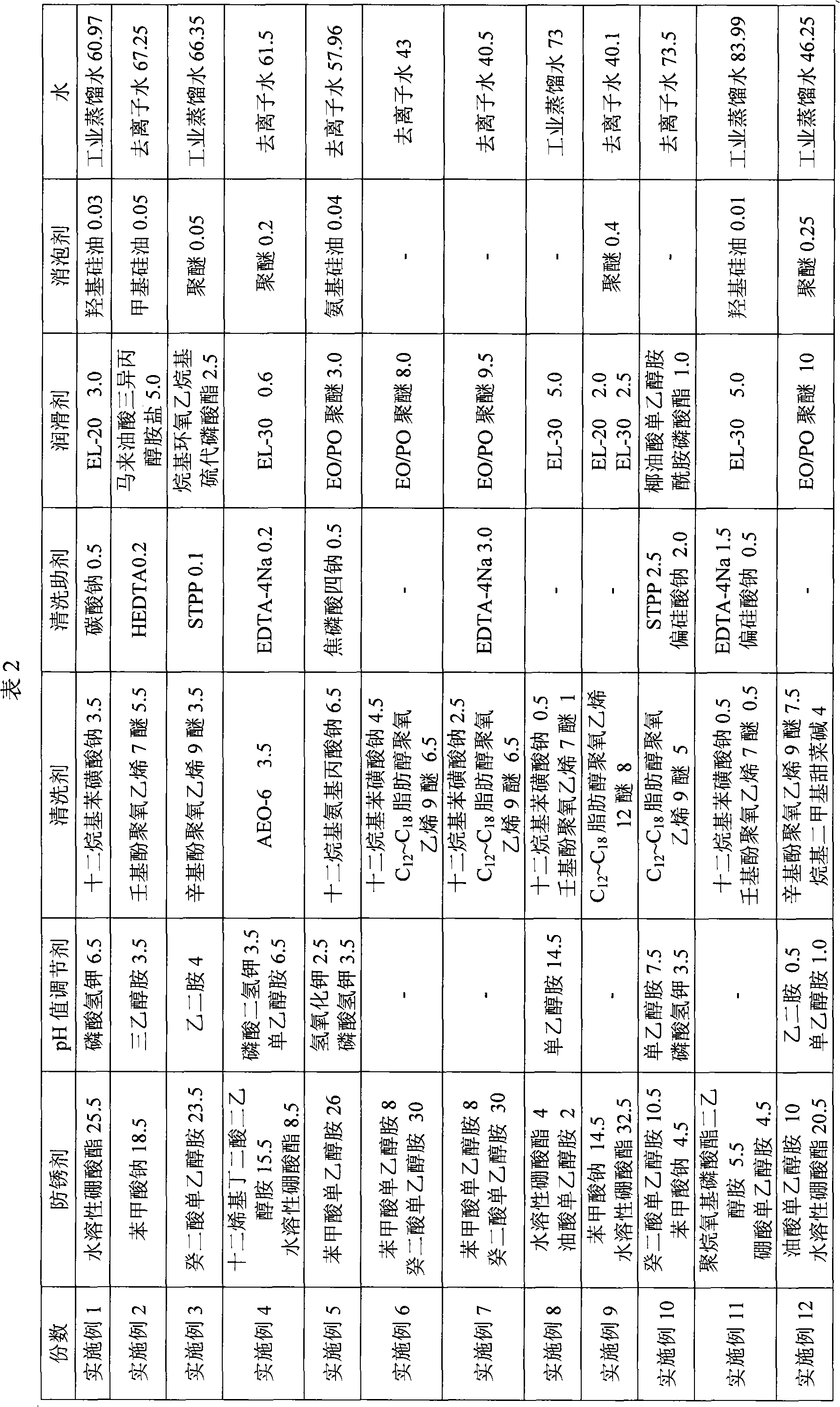

Wet leveling liquid composition and use thereof

The invention relates to a wet leveling liquid composition and use thereof, and mainly solves the problem that wet leveling liquid cannot meet the requirement that a down rate is greater than 3.0 percent in the leveling process in the prior art. By adopting a technical scheme that: the wet leveling liquid composition comprises the following components in part by weight: a) 5 to 50 parts of antirust additive; b) 1 to 12 parts of cleaning agent; c) 0.5 to 10 parts of lubricating agent; and d) 28 to 93.5 parts of water, the invention better solves the problem and can be used in the leveling process of cold-rolled steel sheets.

Owner:CHINA PETROLEUM & CHEM CORP

Lubricating oil and fuel compositions

ActiveUS20070155631A1Reduce formationImprove Oxidation StabilityLiquid carbonaceous fuelsGroup 3/13 element organic compoundsSimple Organic CompoundsCompound (substance)

Disclosed herein are reaction products of an acidic organic compound, a boron compound, and an alkoxylated amine and / or alkoxylated amide. Also disclosed are lubricating oil compositions and fuel compositions containing the reaction products.

Owner:LANXESS SOLUTIONS US INC

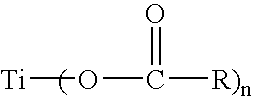

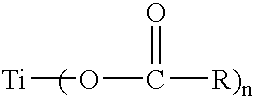

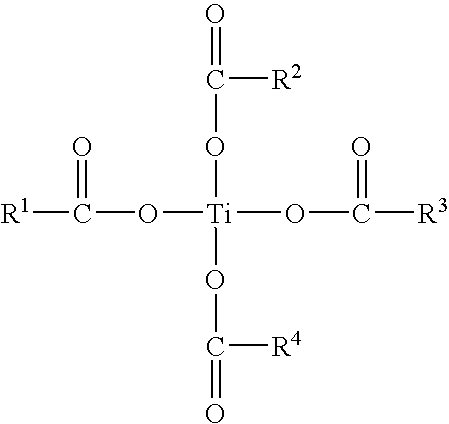

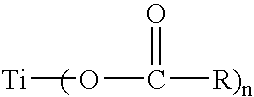

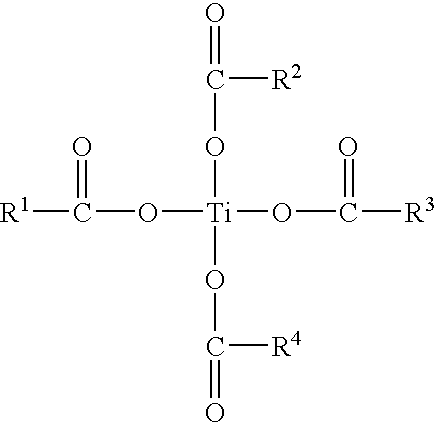

Titanium-containing lubricating oil composition

ActiveUS20070132274A1Improve fuel economyImprove wear characteristicsVehicle seatsWindowsTitanium metalPhysical chemistry

A lubricating oil composition comprising a) an oil of lubricating viscosity having a viscosity index of at least about 95; b) at least one calcium detergent; c) at least one oil soluble titanium compound; d) at least one friction modifier; and e) at least one metal dihydrocarbyldithiophosphate compound. The composition has a Noack volatility of about 15 wt. % or less, and contains from about 0.05 to about 0.6 wt. % calcium from the calcium detergent, titanium metal in an amount of at least about 10 ppm up to about 1500 ppm titanium from the titanium compound, and phosphorus from the metal dihydrocarbyldithiophosphate compound in an amount up to about 0.1 wt. %.

Owner:AFTON CHEMICAL

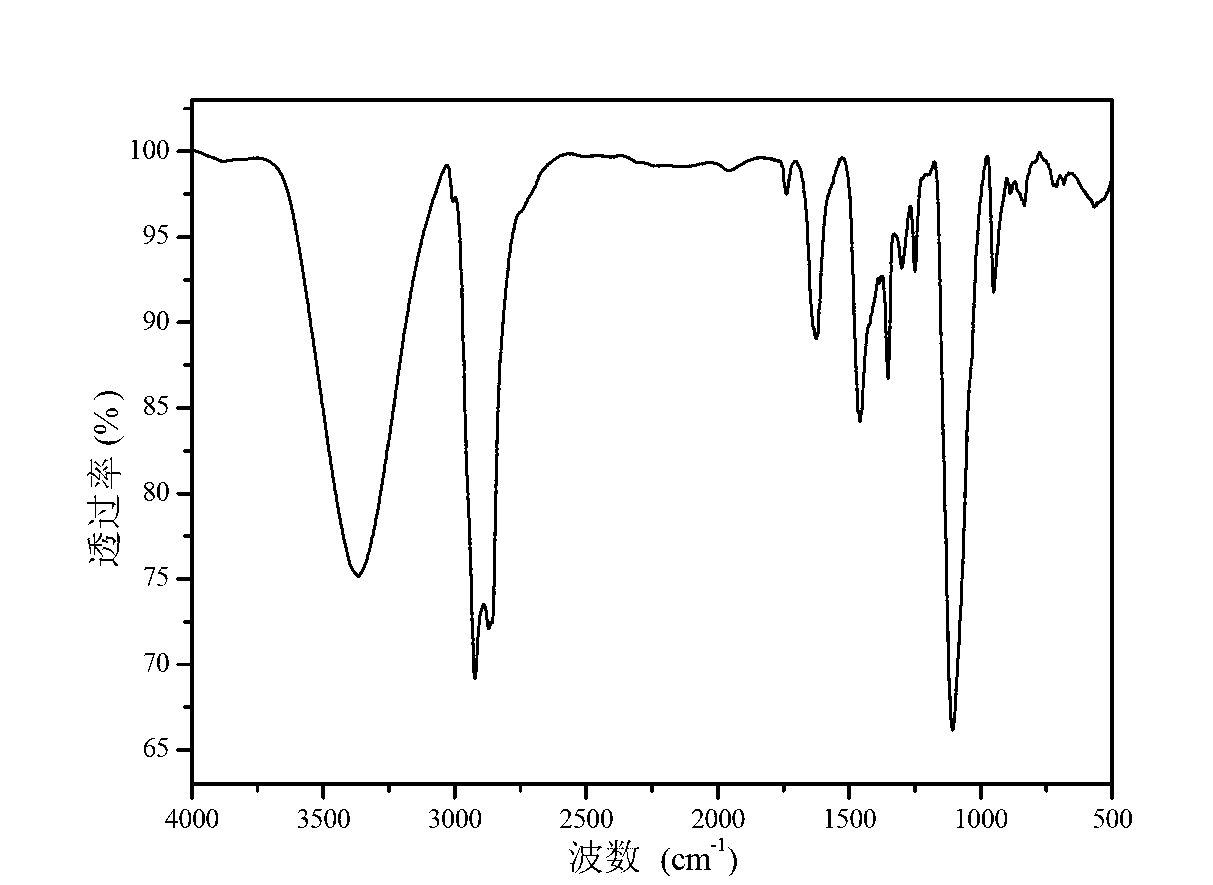

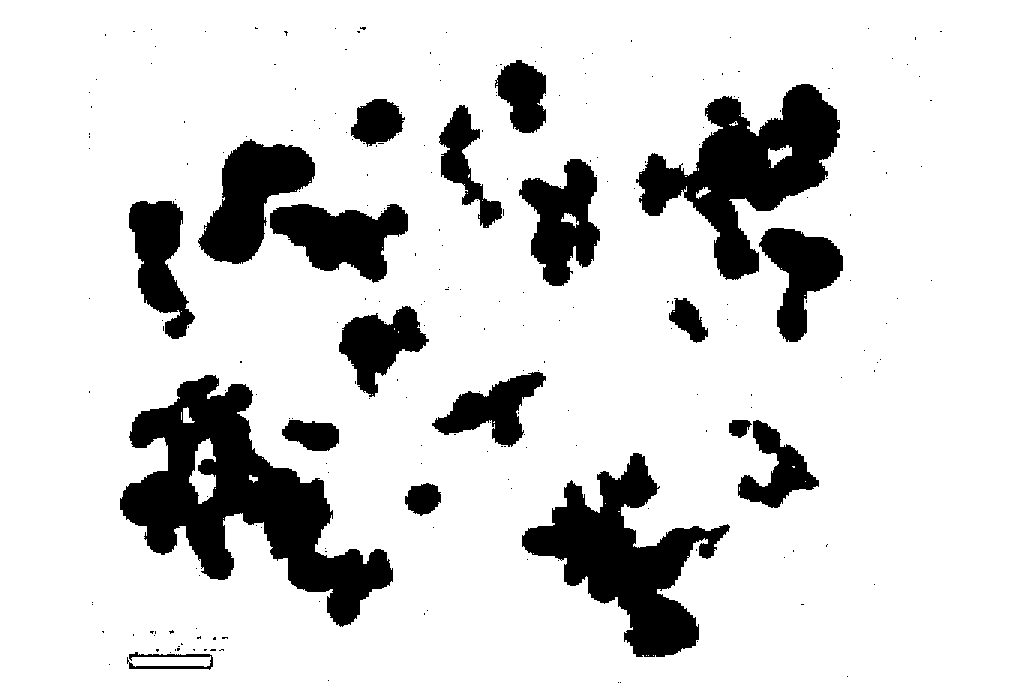

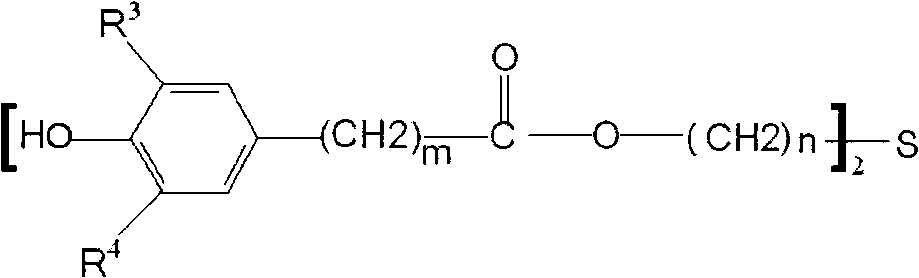

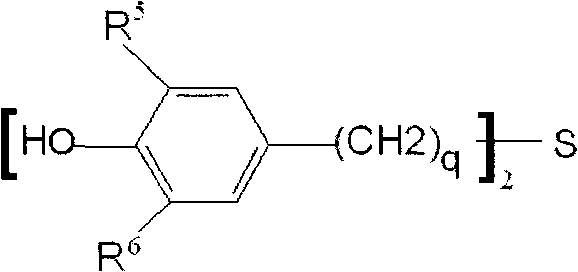

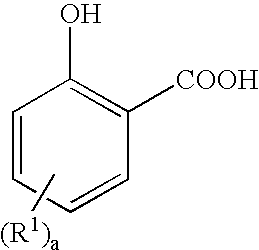

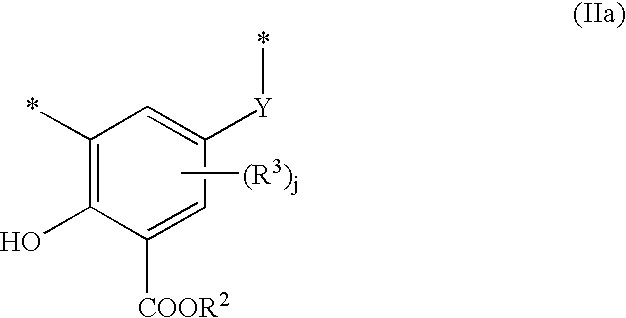

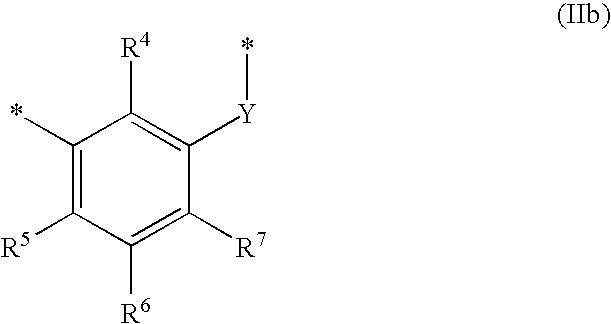

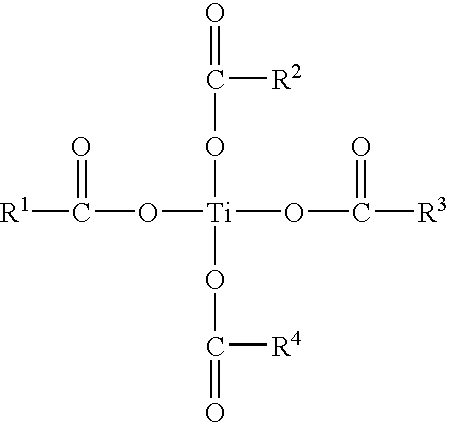

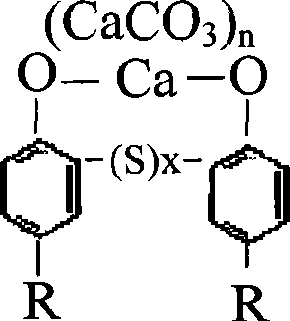

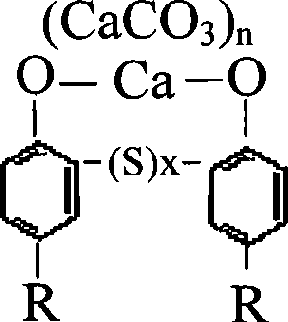

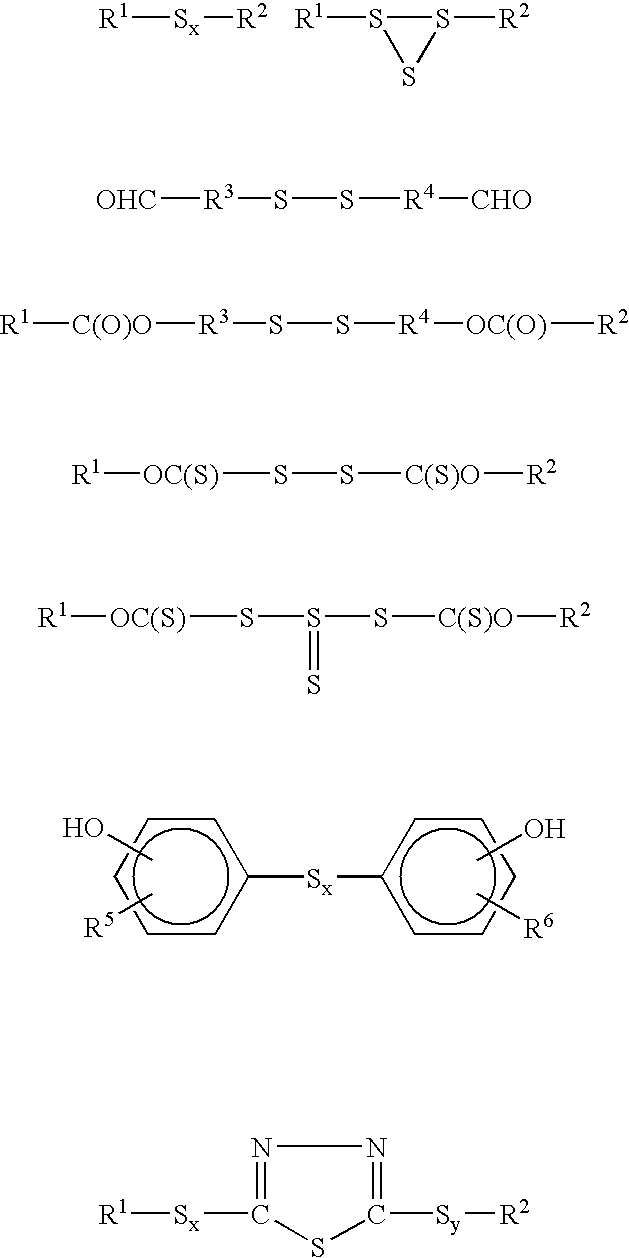

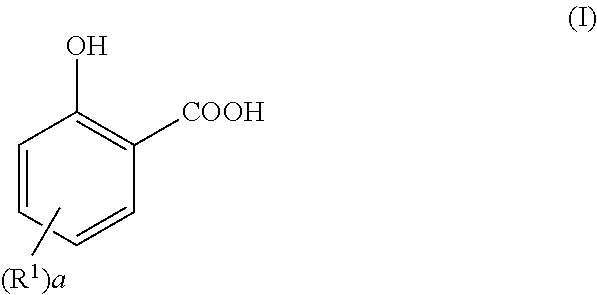

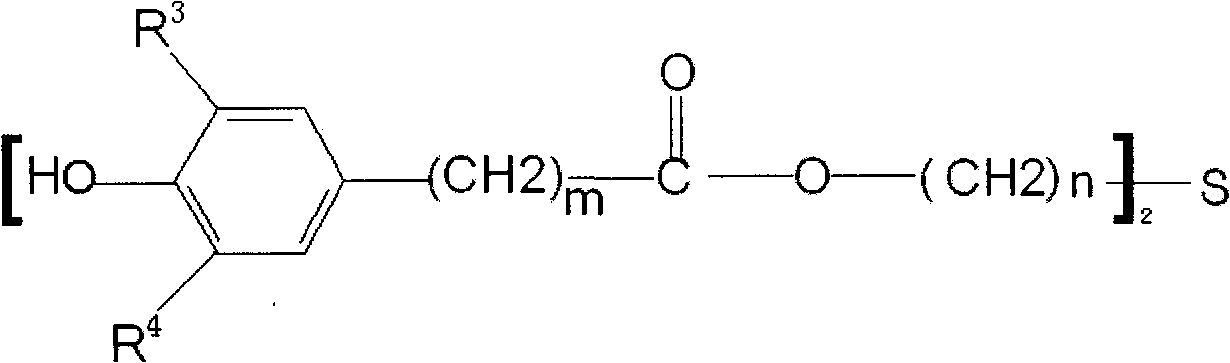

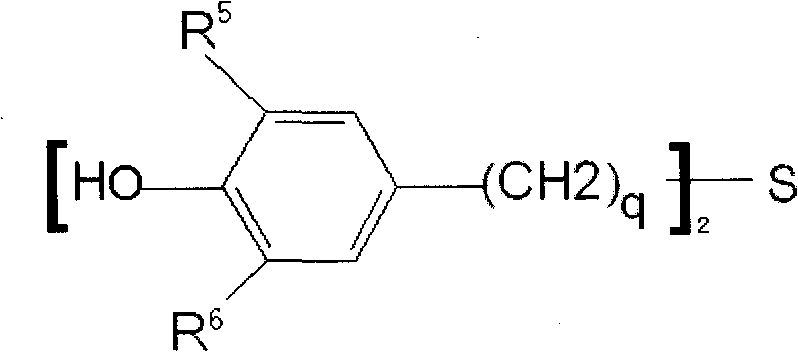

High basic value (TBN400) sulfurized calcium alkyl and preparation method thereof

ActiveCN101423483AWide range of usesImprove performanceAdditivesHydropoly/poly sulfide preparationChemical structureCarboxylic acid

The invention relates to high base number (TBN400) vulcanized alkyl phenol calcium and a preparation method thereof. The vulcanized alkyl phenol calcium has a chemical structure as right. The preparation method is as follows: in a system containing solvent and diluent oil, alkyl phenol compound, shielded phenol compound, calcium oxide and / or calcium hydroxide and sulfur are subjected to sulfonation / neutralization reaction at a temperature of between 60 and 180 DEG C to generate phenolate intermediate; balanced calcium oxide and / or calcium hydroxide are added into the mixture, carbon dioxide is introduced, and the mixture is subjected to carbonation reaction; and alkyl polylol is added into the mixture at the sulfonation / neutralization reaction or respectively at the sulfonation / neutralization reaction and the carbonation reaction to participate in the reaction, long-chain carboxylic acid is added into the mixture at the sulfonation / neutralization reaction or respectively at the sulfonation / neutralization reaction and the carbonation reaction to participate in the reaction, and products are obtained through refining. The vulcanized alkyl phenol calcium has the characteristics of high base number, low viscosity, low precipitation number, good heat storage stability, and the like, and has excellent combination property, does not cause environmental protection problem during use, and belongs to an environment-friendly product, and adopts a one-stage process, has mild reaction conditions, and is easy to filter.

Owner:JINZHOU DPF TH CHEM CO LTD

Rolling oil composition for 12-roller reversing mill

The invention relates to a rolling oil composition used for a twelve-high reversing cluster mill; the rolling oil composition belongs to the field of metallurgical steel rolling oil products, and comprises the components according to weight percent as follows: 60-70 percent of compound neopentyl polyol ester, 14-28 percent of mineral oil, 1-5 percent of phosphorus-containing extreme-pressure and anti-wear agent, 1-5 percent of sulfur-containing extreme-pressure and anti-wear agent, 2-12 percent of compound emulsifier, 1-3 percent of anti-rust agent, 1-3 percent of antioxidant and 0.01-0.5 percent of defoamer; the rolling oil composition takes the compound neopentyl polyol ester synthetic ester with excellent lubricating performance as the lubricating basic component; an oiliness agent main body with high lubricating performance and high extreme-pressure and anti-wear performance is composed by adding the scientific components of the phosphorus-containing and the sulfur-containing extreme-pressure and anti-wear agents; and the anti-rust performance and the emulsion stability are ensured by adopting the mineral oil, the anti-rust oil, the emulsifier and the antioxidant with the appropriate proportion for coordination, thereby creatively solving the contradiction between the lubricating performance and the detergence, ensuring the requirements on the lubricating performance of the quality when rolling steel plates with thin specifications, protecting the lubricating requirements of back-up bearings and ensuring the volatility and the annealing detergence under the cleaning-free condition.

Owner:WUHAN TONGSHENG FINE CHEM TECH DEV

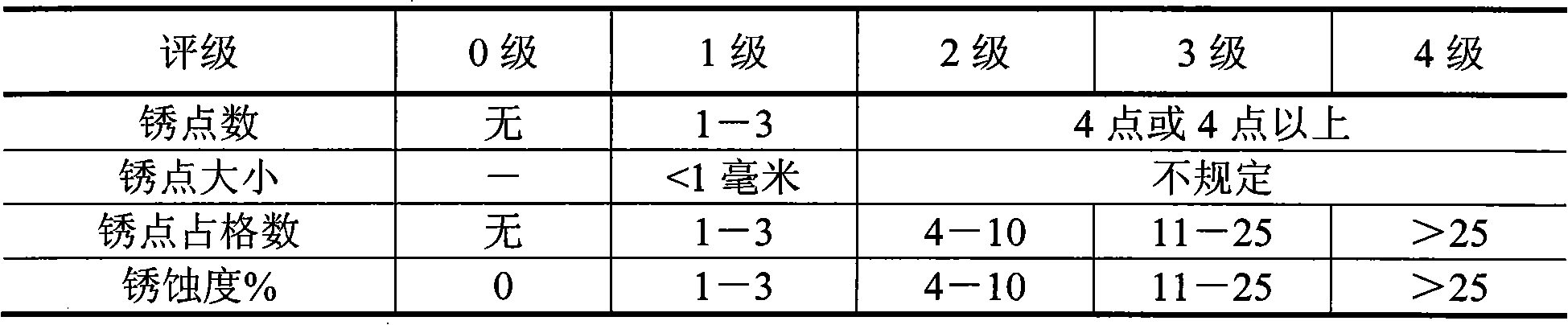

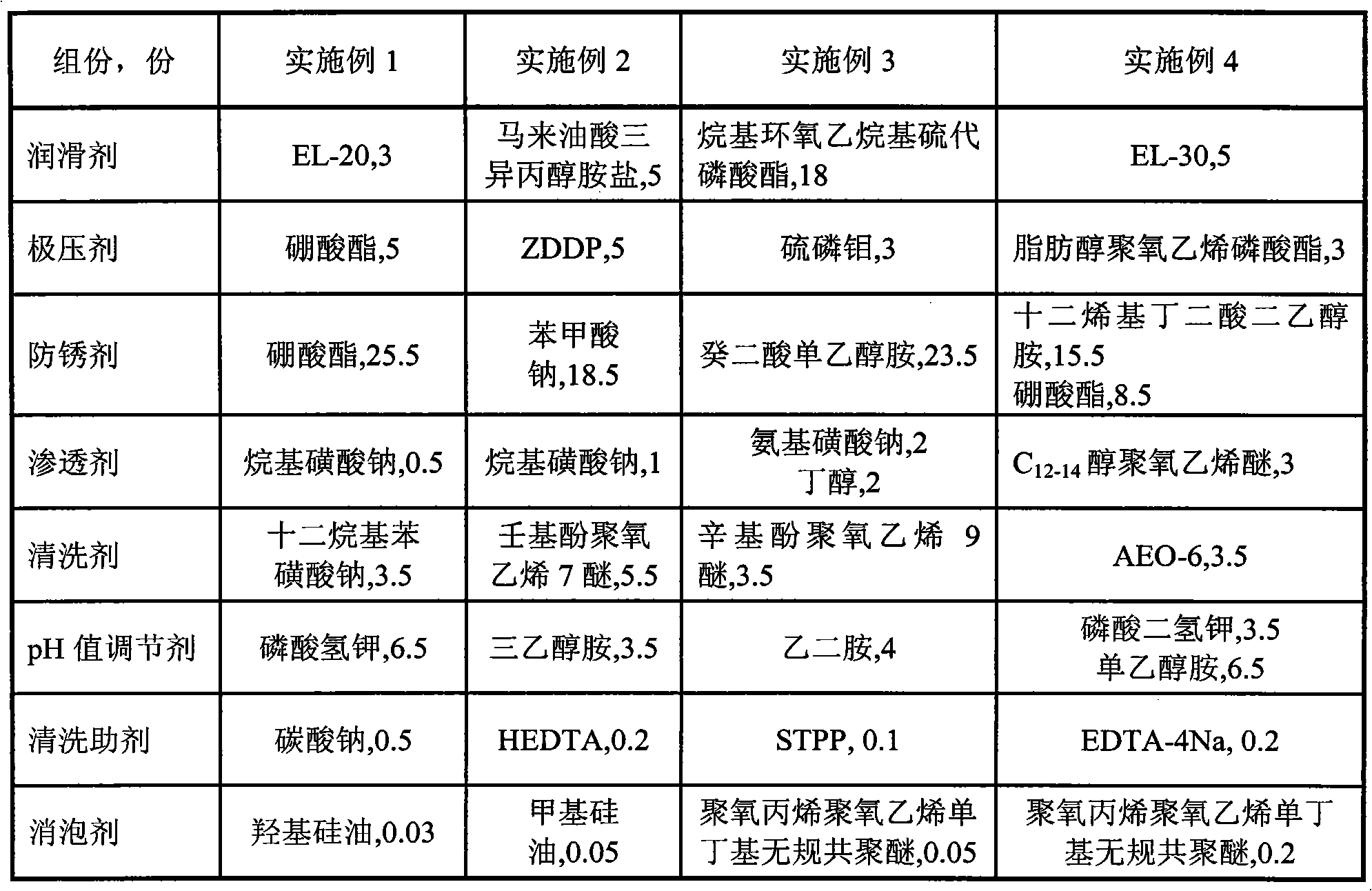

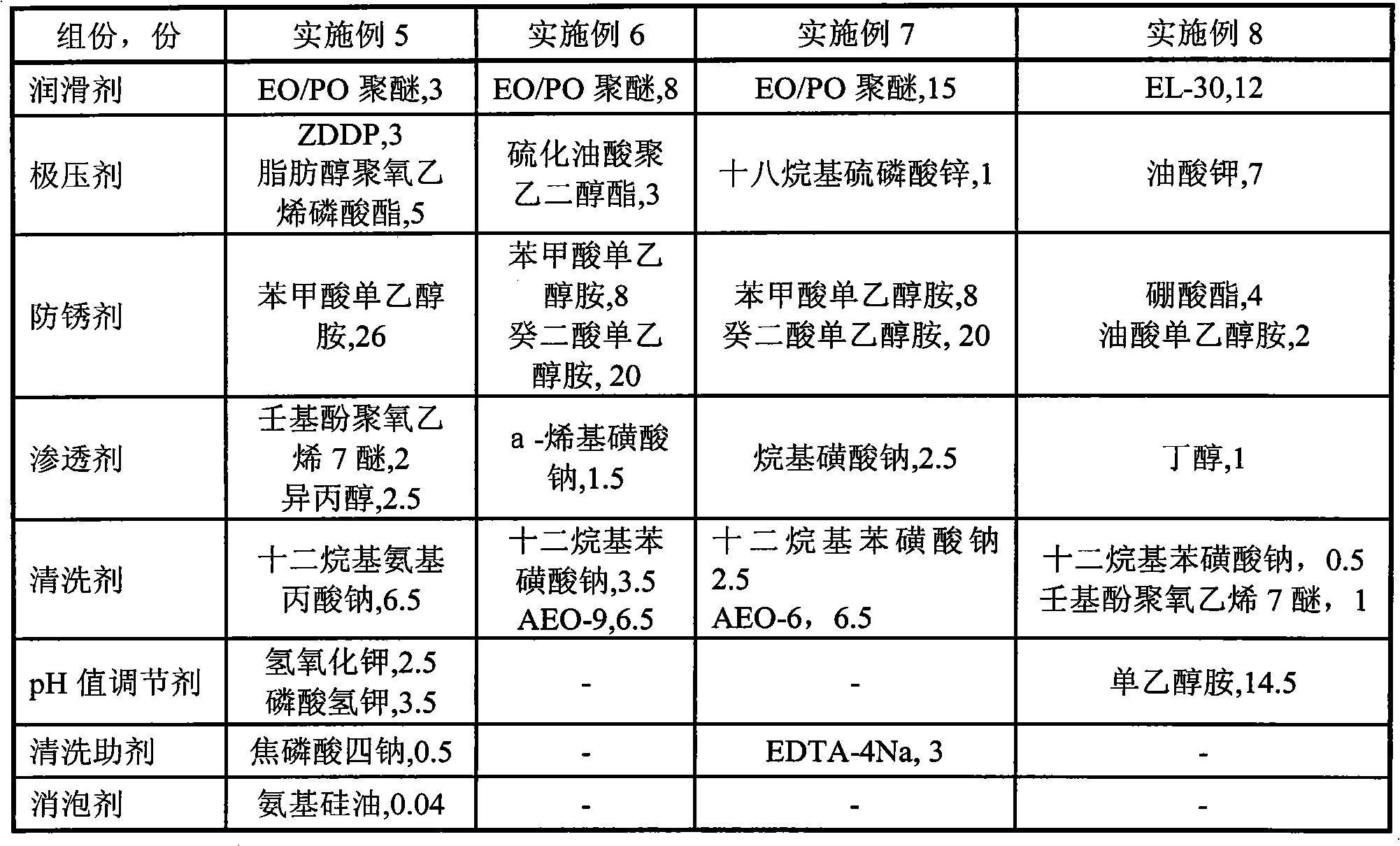

Water-soluble rolling liquid composition and application thereof

ActiveCN102757848AImprove the lubrication effectImprove rust resistanceLubricant compositionEmulsionMetallurgy

The invention relates to a water-soluble rolling liquid composition and application thereof. The water-soluble rolling liquid composition mainly solves the problems of low cooling performance of pure oil type rolling liquid and low emulsion stability and low detergency of emulsion type rolling liquid in the prior art. The water-soluble rolling liquid composition comprises the following components by weight: a) 3 to 30 parts of lubricating agent; b) 0.5 to 10 parts of extreme pressure additive; c) 5 to 30 parts of antirusting agent; d) 0.1 to 5 parts of penetrating agent; e) 0.1 to 10 parts of cleaning agent; and f) 15 to 92.3 parts of water. Through the adoption of the technical scheme, the problem is solved well and the water-soluble rolling liquid composition can be applied to the rolling and lubricating procedure of a cold-rolled steel plate.

Owner:CHINA PETROLEUM & CHEM CORP

Titanium-containing lubricating oil composition

ActiveUS20070111908A1Improved performance characteristicsImprove featuresMixingAdditivesImideMolybdenum compounds

A fully formulated lubricating oil, lubricated surface, and lubricant additive concentrates for lubricants providing reduced sludge formation. The fully formulated lubricating oil composition has therein at least one succinimide dispersant derived from a polyalkylene compound having from about 50 to about 85% vinylidene double bonds in the compound, a metal containing detergent, at least one wear reducing agent, at least one antioxidant, and a hydrocarbon soluble titanium compound as a friction modifier. The lubricating oil composition is also substantially free of molybdenum compounds.

Owner:AFTON CHEMICAL

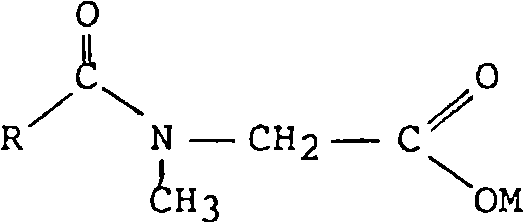

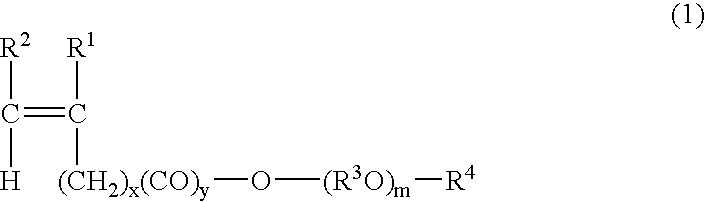

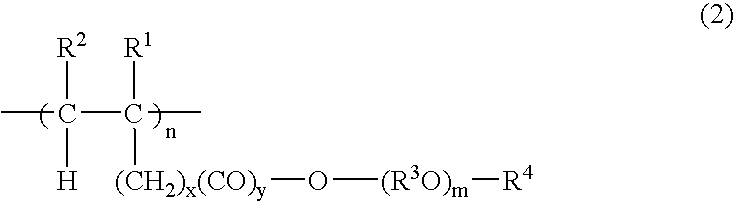

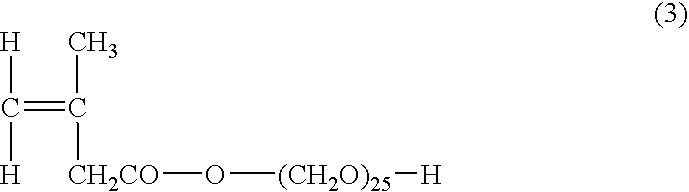

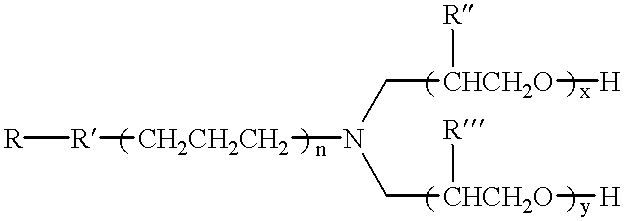

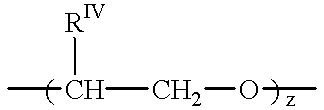

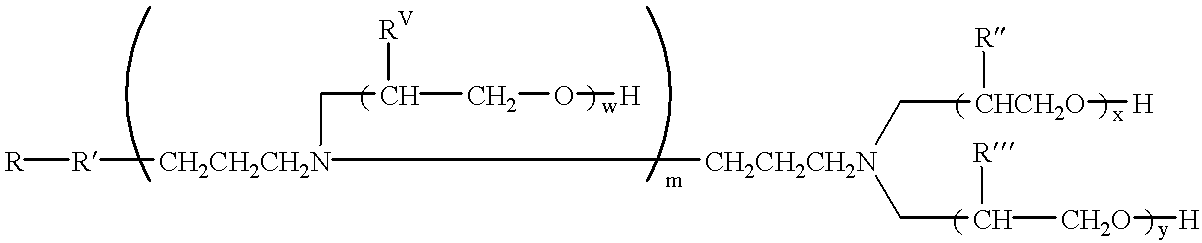

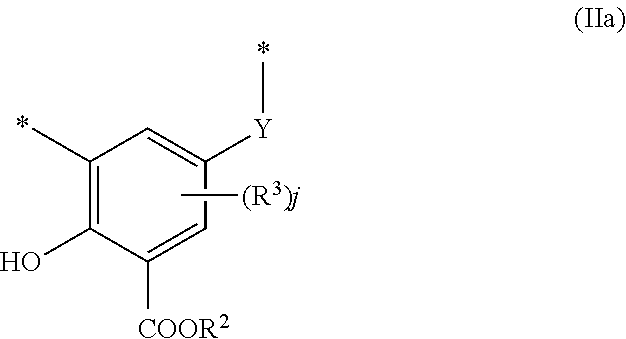

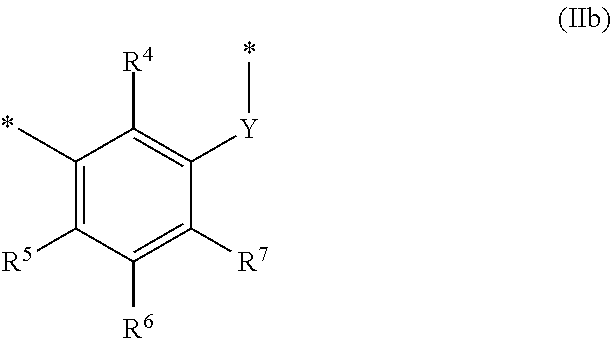

Polymer, process for preparing the same, and use of the same

InactiveUS20050113541A1Improve detergencyNo adverse effectsOrganic detergent compounding agentsAdverse effectSaturated carboxylic acid

An object of the present invention is to provide a polymer which is suitable as a detergent builder in that it exerts an excellent detergency and it has no adverse effect on the environment, and is suitable as a cement admixture in that it is excellent in cement dispersibility, and workability is better. As a means of achieving this object, a polymer of the present invention is: a polymer obtained by a polymerization reaction using a polyaminepolyether compound, an unsaturated carboxylic monomer and polyalkylene glycols as a raw material, characterized in that an amount of a polyaminepolyether compound is 50% by weight or larger relative to a total amount of a polyaminepolyether compound and polyalkylene glycols; or a polymer obtained by a polymerization reaction using a polyaminepolyether compound and an unsaturated carboxylic monomer as a raw material, characterized in that an amount of an unsaturated carboxylic monomer is less than 15% by weight relative to a total amount of a polyaminepolyether compound and an unsaturated carboxylic monomer, or an unsaturated carboxylic monomer contains acrylic acid as an essential component, and an amount of remaining acrylic acid after the reaction is less than 3% by weight.

Owner:NIPPON SHOKUBAI CO LTD

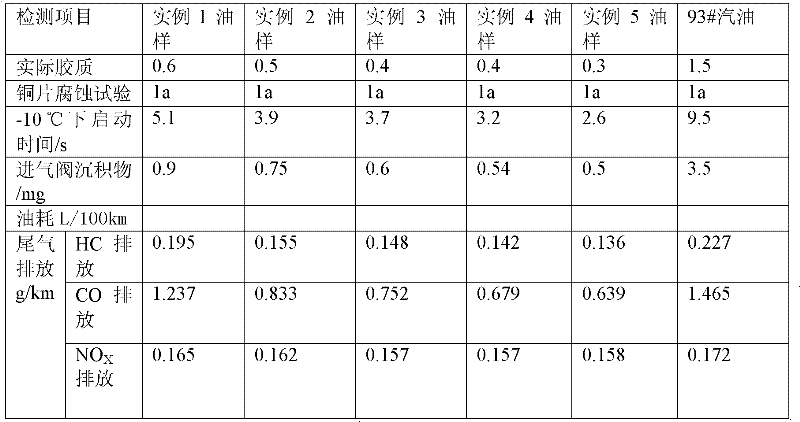

Gasoline compound additive

ActiveCN102643691AImprove detergencyImprove antioxidant capacityLiquid carbonaceous fuelsFuel additivesEngineeringFuel oil

The invention provides a multifunctional gasoline compound additive which is capable of reducing fuel consumption and decreasing the pollution caused by tail gas emission. The additive comprises a gasoline cleaning agent, a combustion improver, a low temperature start improving agent, an antiknock agent, an anti-oxidizing and anti-gum agent and a metal corrosion inhibitor. By adopting the gasoline compound additive, the cleanness, oxidation resistance and anti-corrosion performance of gasoline can be improved; and meanwhile, the combustion performance of fuel oil can be improved, the fuel consumption is reduced, and the automobile tail gas pollutants can be reduced.

Owner:山东京博众诚清洁能源有限公司

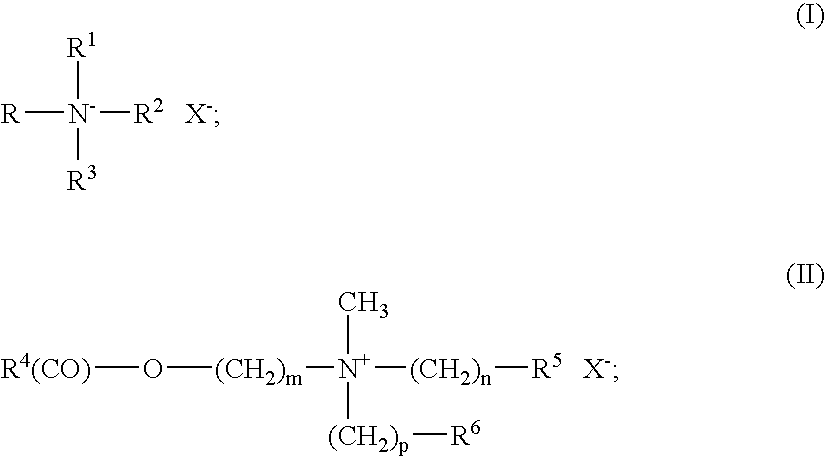

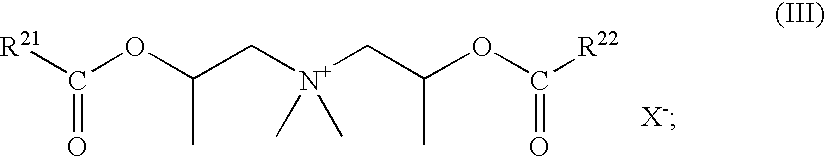

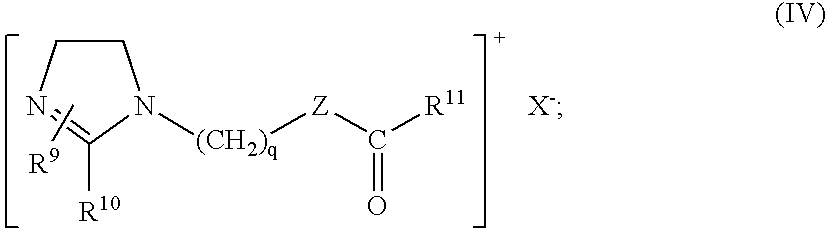

Detergent compositions having polyalkoxylated amine foam stabilizers

InactiveUS6221822B1Increase productionSimple compositionCationic surface-active compoundsOrganic detergent compounding agentsOrganic chemistryStabilizing Agents

The disclosure is directed to novel detergent compositions having polyalkoxylated amine foam stabilizers. The new foam stabilizers of the inventive detergent compositions build or enhance foaming and are particularly useful because of their surprisingly mild, non-skin-irritating characteristics. Mildness is a requirement of components to be included in or used in applications such as liquid dish detergents, hand cleaners and car washes.

Owner:AIR PROD & CHEM INC

Low Ash Lubricant and Fuel Additive Comprising Polyamine

ActiveUS20150299606A1High TBNReduce formationLiquid carbonaceous fuelsAdditivesMetal freeOrganic compound

A metal-free detergent and antioxidant additive comprising the reaction product of an acidic organic compound, a boron compound, a polyamine such as polyethylene imine, and optionally an alkoxylated amine and / or an alkoxylated amide, is provided. The additives of the present invention have higher TBN than similar compounds known in the art.

Owner:LANXESS SOLUTIONS US INC

Composition and Method of Manufacturing Calcium Sulfonate Greases Using Alkali Metal Hydroxide and Delayed Addition of Non-Aqueous Converting Agents

ActiveUS20160230112A1High detergency/dispersancyImprove welfareThickenersAdditivesSulfonateNuclear chemistry

An overbased calcium sulfonate grease composition and method of manufacture comprising added alkali metal hydroxide alone or in combination with (a) calcium hydroxyapatite and / or added calcium carbonate used as calcium containing bases for reacting with complexing acids) and / or (b) at least one delay period between the addition of water as a converting agent and addition of a portion of a non-aqueous converting agent. A delay period may involve the period of time it takes to adjust the temperature of the mixture, a period of time during which the mixture is held at a temperature or within a range of temperatures, and multiples and any combination thereof. These calcium sulfonate greases have improved thickener yield and high dropping points compared to greases made without added alkali metal hydroxide and delay between the additions of water and a non-aqueous converting agent, particularly when a poor quality overbased calcium sulfonate is used.

Owner:NCH CORP

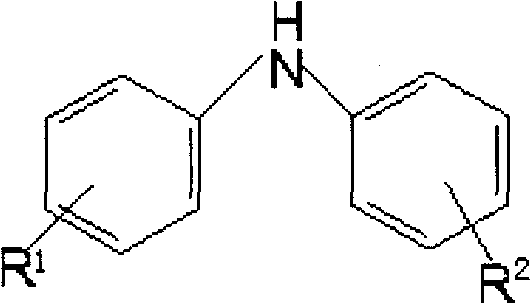

Lubricant composition for diesel engine

ActiveCN102690707AImprove antioxidant capacityImprove high temperature wear resistanceAdditivesAntioxidantDiesel engine

The invention relates to a lubricant composition for a diesel engine. The lubricant composition for a diesel engine contains less than or equal to 0.09% by mass of phosphorus, less than or equal to 0.4% by mass of sulfur and less than or equal to 1.0% by mass of sulfate ash. The lubricant composition for a diesel engine comprises A) a composite antioxidant comprising at least components of 1, an alkylated diphenylamine antioxidant, 2, a thiophenolic ester antioxidant and 3, an unessential phenolic thioether antioxidant, B) a polyisobutylene succinimide ashless dispersant and / or a boronized polyisobutylene succinimide dispersant, C) a mixture of magnesium sulfate and sulfurized calcium alkyl phenate, D) at least one zinc dialkyldithiophosphate, E) one or more ashless friction modifiers, and F) a main amount of lubricating base oil. The lubricant composition for a diesel engine has a synergistic effect of the additives, can satisfy high-temperature antioxidation requirements of lubricating oil for a diesel engine, and has excellent piston cleanliness, wear resistance and a viscosity increasing control capacity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Titanium-containing lubricating oil composition

ActiveUS20080139429A1Improve performance characteristicImprove detergencyMixingLiquid carbonaceous fuelsTitaniumChemical composition

A fully formulated lubricating oil, lubricated surface, and lubricant additive concentrates for lubricants providing reduced sludge formation. The fully formulated lubricating oil composition has therein at least one succinimide dispersant, a metal containing detergent, at least one antioxidant, and a hydrocarbon soluble titanium compound. The lubricating oil has improved sludge reducing properties compared to the same lubricating oil composition devoid of the titanium compound.

Owner:AFTON CHEMICAL

Nonyl alcohols with a low degree of branching and their derivatives

ActiveUS20120310004A1Low degree of branchingImprove featuresPreparation by oxo-reaction and reductionOrganic compound preparationAlkylLower degree

The invention relates to nonyl alcohols with a low degree of branching and derivatives produced using them. In particular the present invention relates to mixture of primary nonyl alcohols in which at least 80% of the alkyl chains are linear and at least 15% of the alkyl chains are branched at the 2-carbon position and its derivatives. The low degree of branching produces derivatives that are more elongated and less bulky that similar derivatives produced with more highly branched alcohols.

Owner:SHELL USA INC

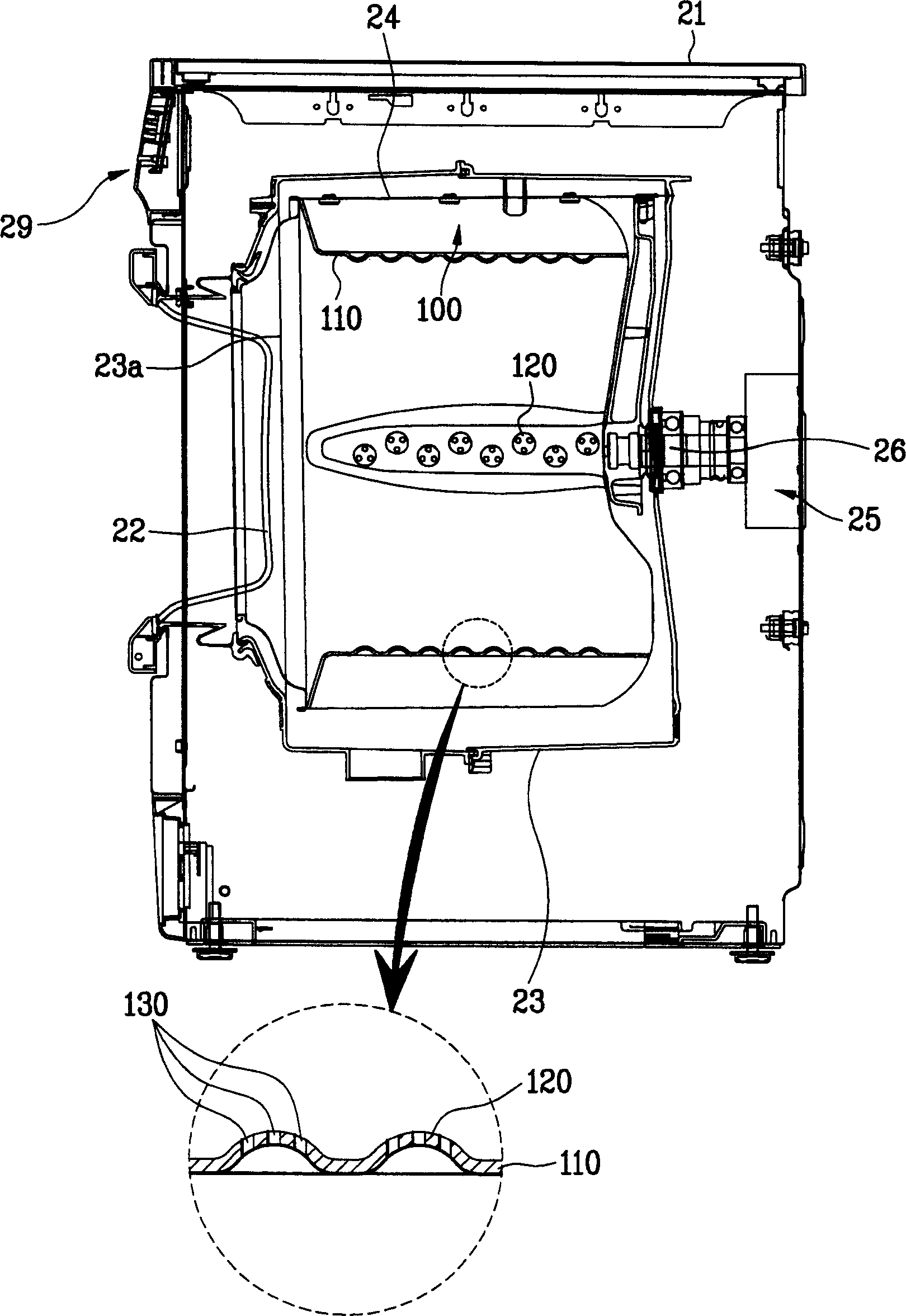

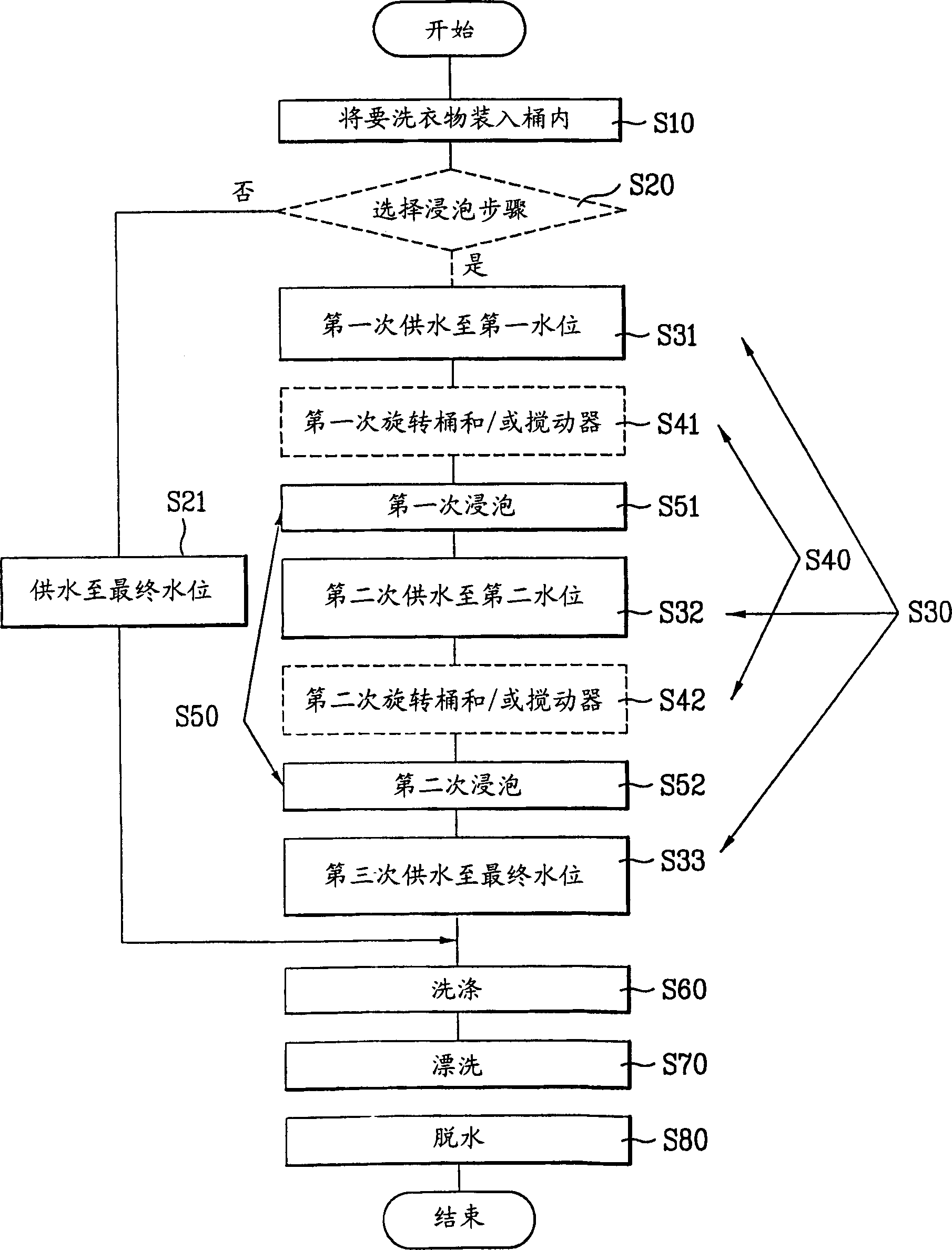

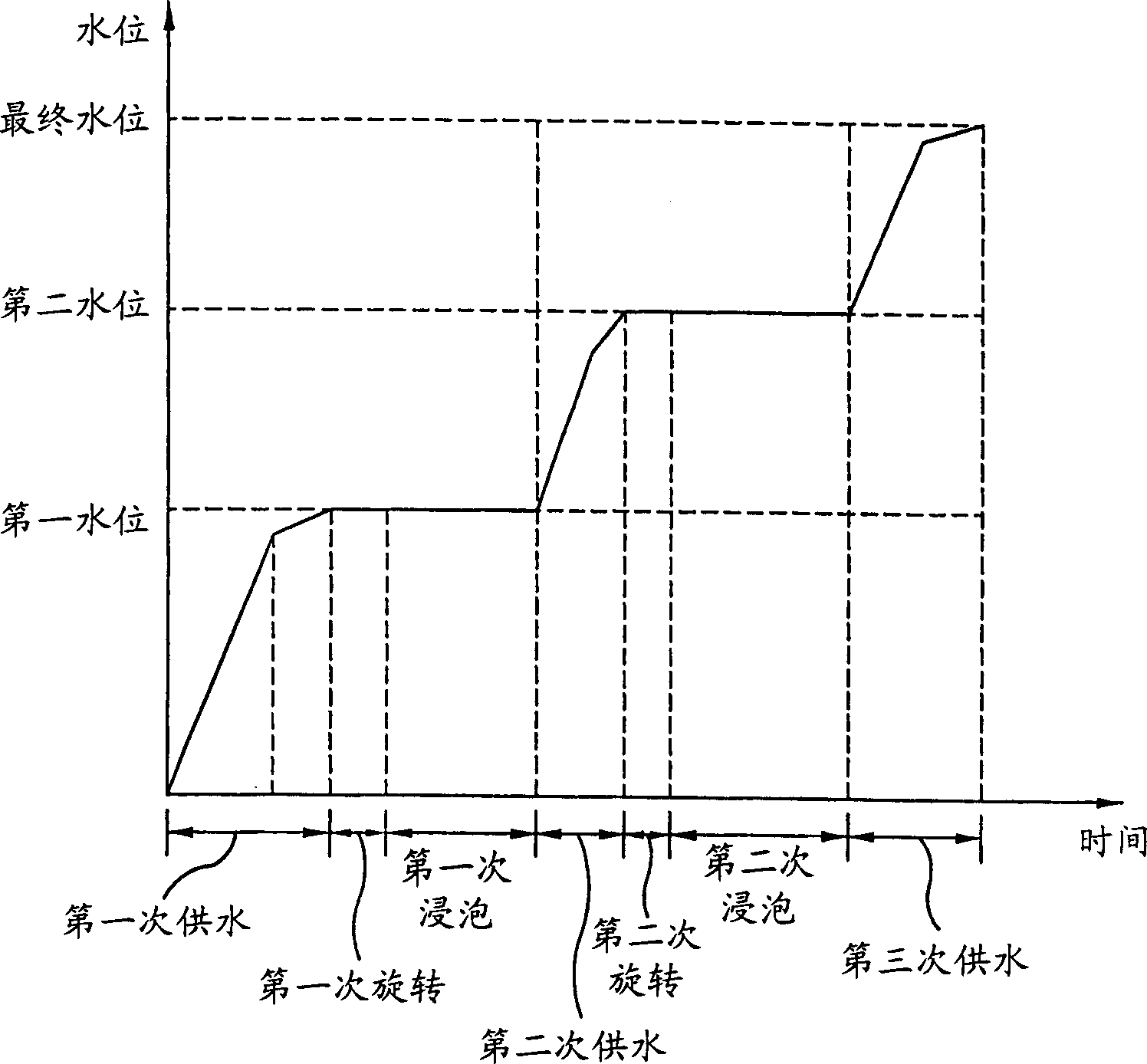

Washing method of washer

InactiveCN1509357AAvoid getting dirty againImprove detergencyOther washing machinesControl devices for washing apparatusWater levelLaundry

Disclosed is a washing method a washing machine in which laundry is soaked effectively and conveniently. The washing method includes the steps of: loading laundry into a tub of the washing machine; supplying the tub with washing water such that water level increases step by step to a final level for a predetermined time period; repeatedly soaking the laundry for a predetermined time period within the washing water at the respective increased levels; and rotating the tub and a drum to wash the soaked laundry.

Owner:LG ELECTRONICS INC

Multifunctional cleaning solution for automobile windshield

InactiveCN102766551AImprove performanceLow costSurface-active non-soap compounds and soap mixture detergentsSoftened waterActive agent

The invention relates to a daily maintenance appliance of automobile glass, in particular to a cleaning solution for an automobile windshield. The invention aims to provide a multifunctional cleaning solution for an automobile windshield. The multifunctional cleaning solution has the effects of cleaning, preventing freezing and fog, lubricating, resisting static electricity, preventing corrosion, delaying the aging of rubber and plastics, refreshing, restoring consciousness and the like. According to the technical scheme, each liter of the cleaning solution for the automobile windshield contains 10 to 50 grams of anti-freezing agent, 0.01 to 0.2 gram of surfactant, 0.05 to 0.5 gram of chelant, 0.1 to 1 gram of corrosion inhibitor, 0.1 to 1 gram of antioxidant, 0.02 to 0.1 gram of essence, 0.01 to 0.5 gram of colorant and the balance of softened water. The cleaning solution has the advantages that the washing performance at low temperature and intermediate temperature is enhanced greatly, and the cost is low; and the ingredients in the cleaning solution are high in biodegradability, harmless to human bodies and environment-friendly.

Owner:SHANDONG INST OF COMMERCE & TECH

Bearing cleaning composition and method of use

ActiveUS20050054541A1Improve waterproof performanceImprove detergencyRotary combination bearingsWork treatment devicesSulfonateEngineering

A composition for cleaning bearings in rotating equipment and industrial machinery that contains powdered limestone having a high calcium content dispersed in a calcium sulfonate grease, together with a colorant that readily enables a user to differentiate between contaminated grease, cleaning composition and fresh grease. A method is also disclosed that enables a user to clean and re-lubricate bearings without the need for removing the bearings from service or for shutting down the associated equipment or machinery.

Owner:NCH CORP

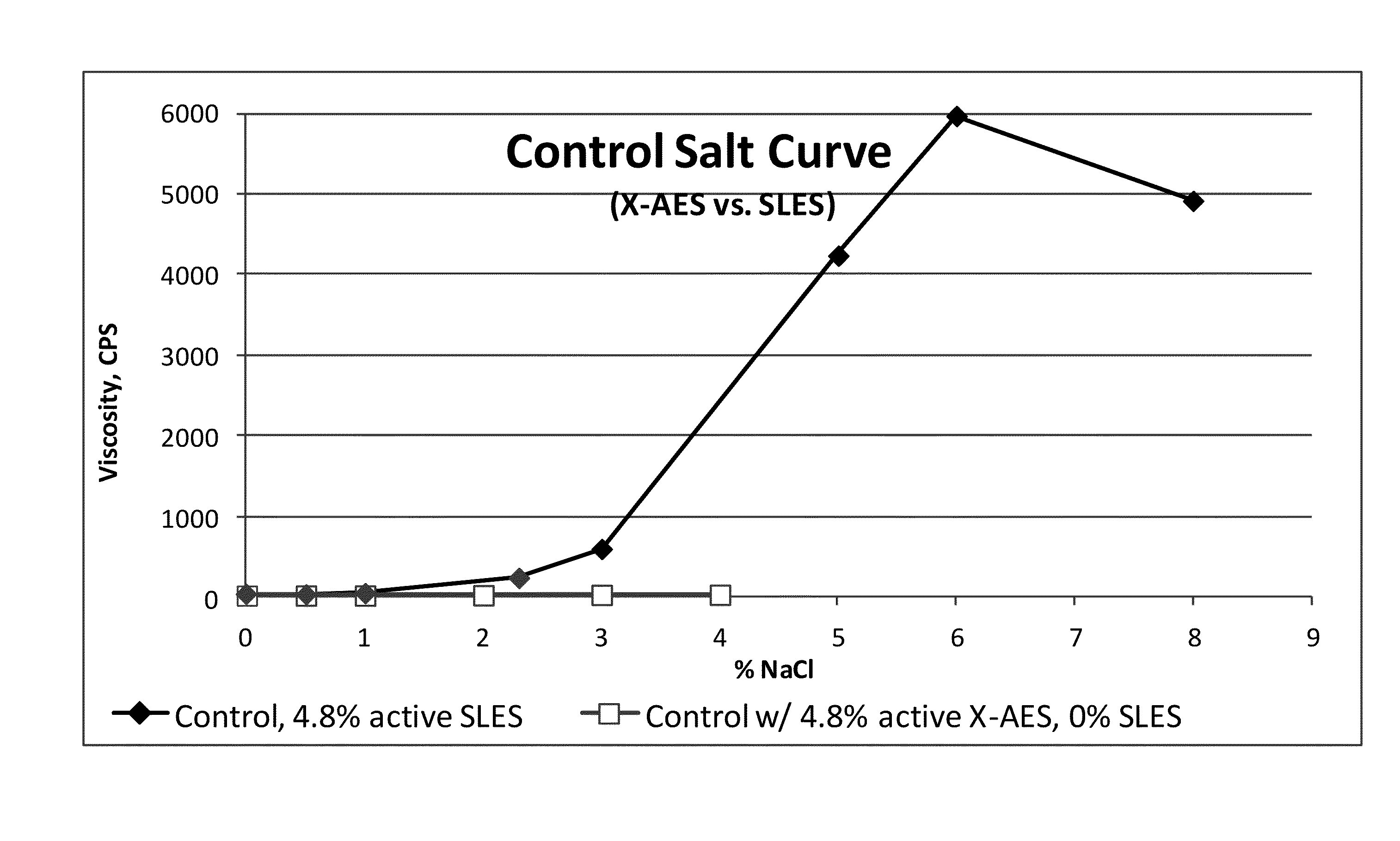

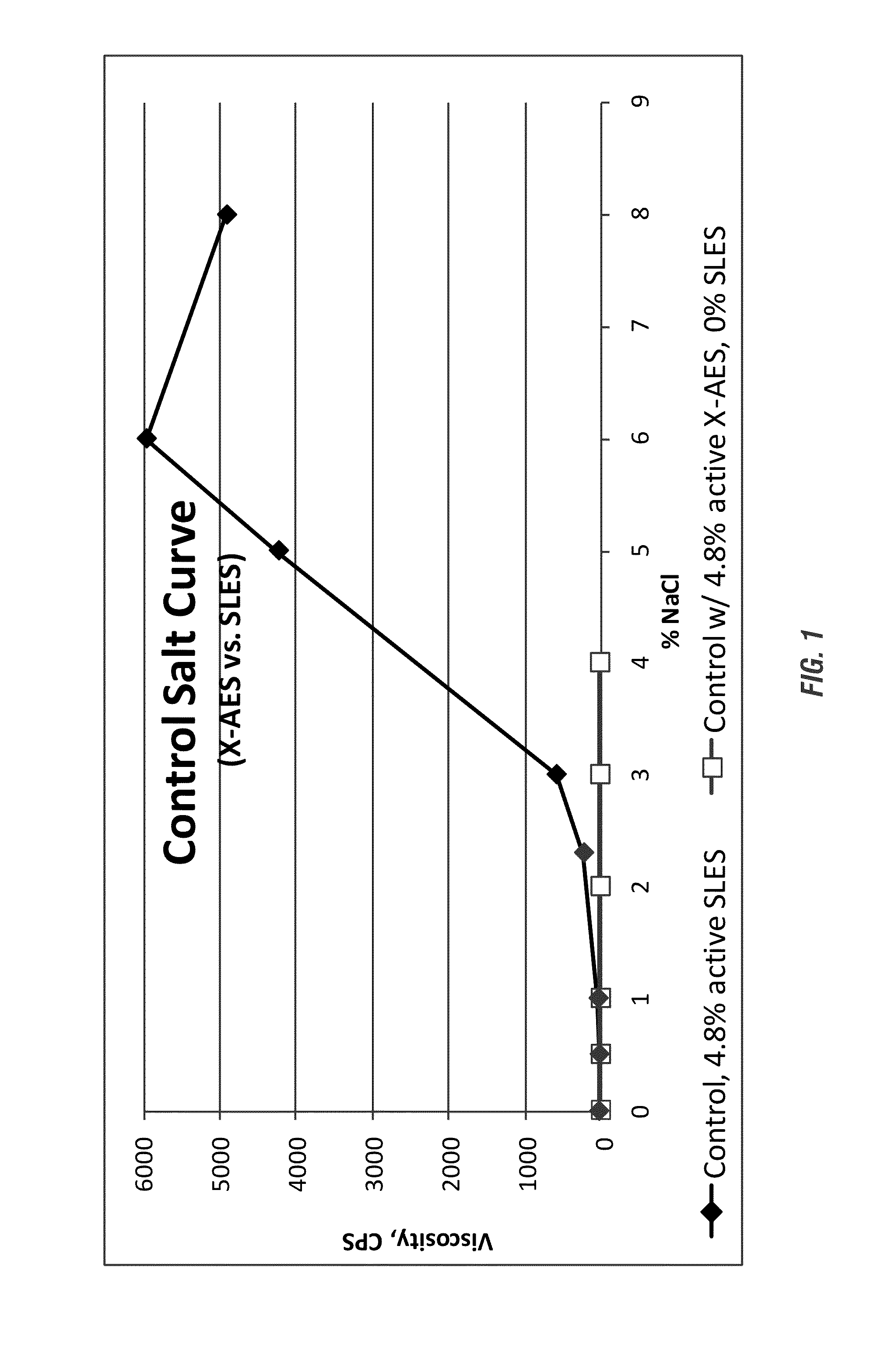

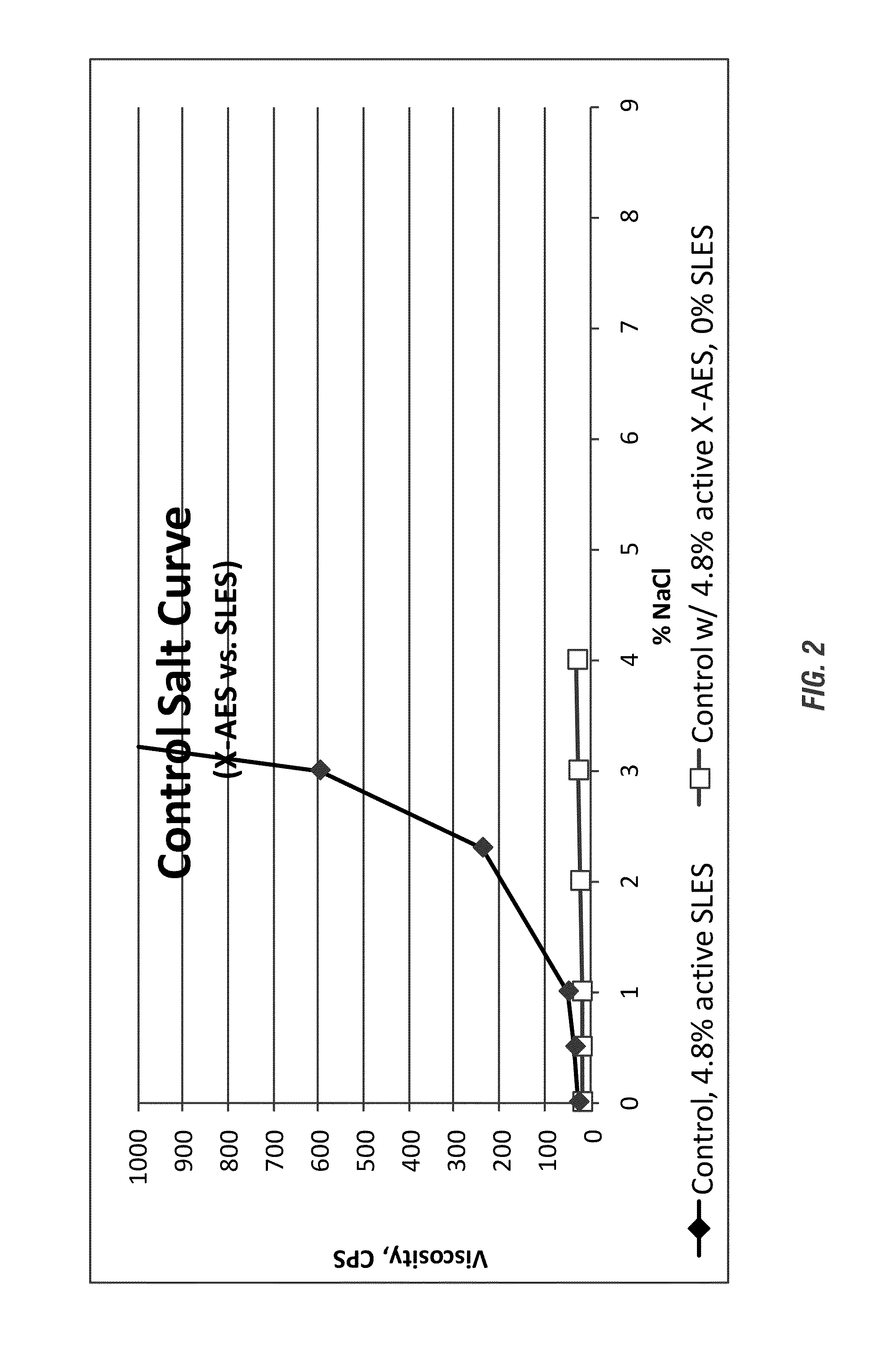

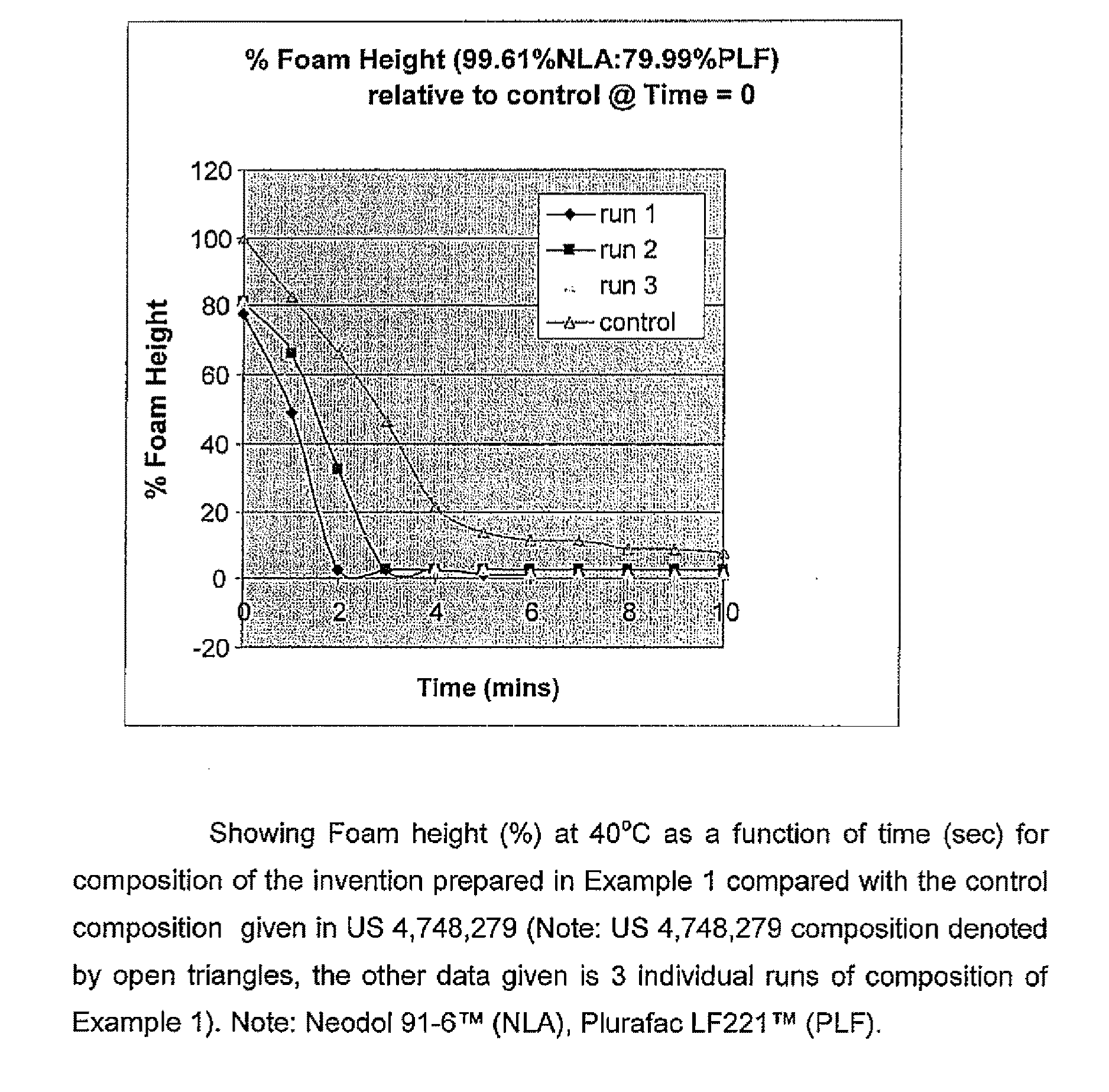

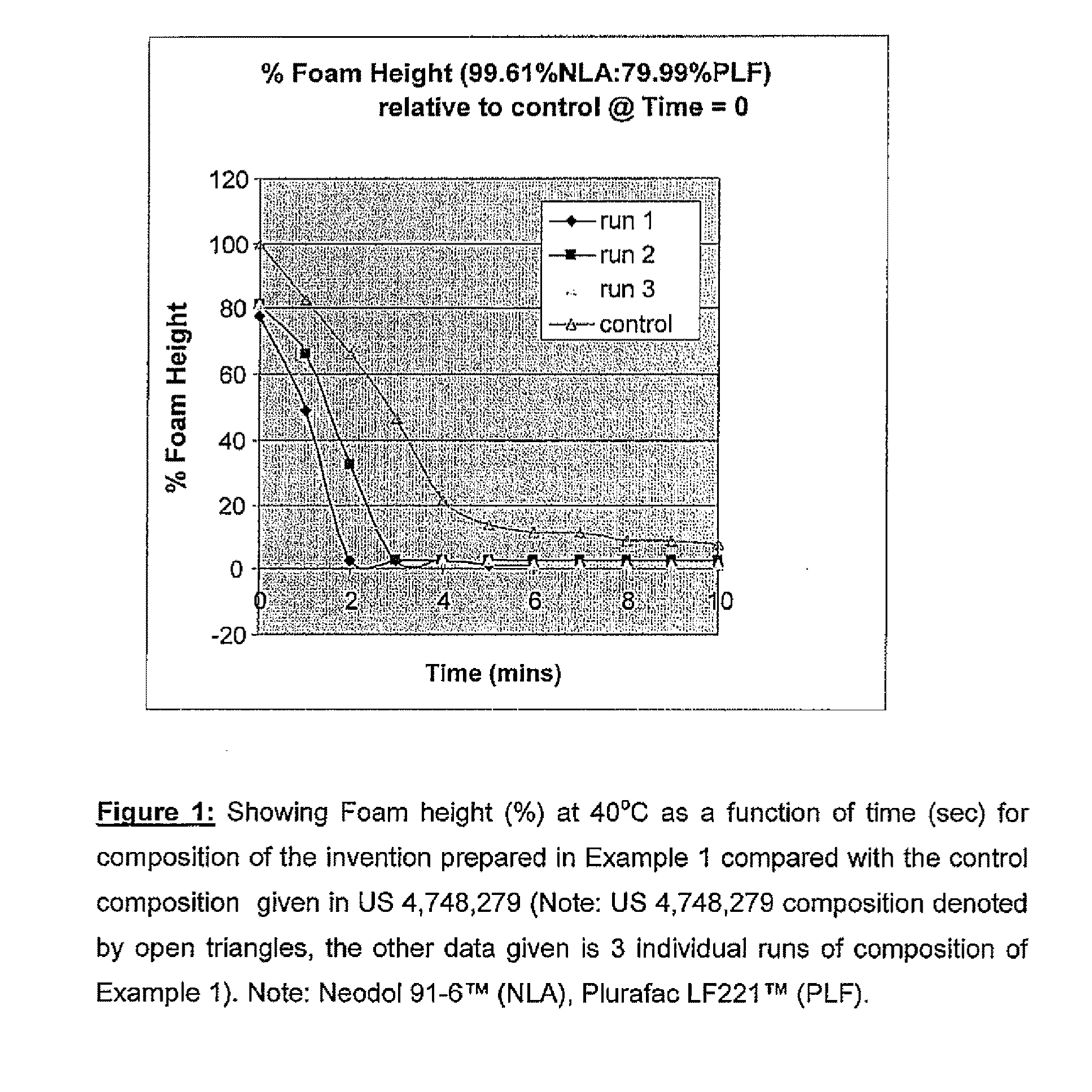

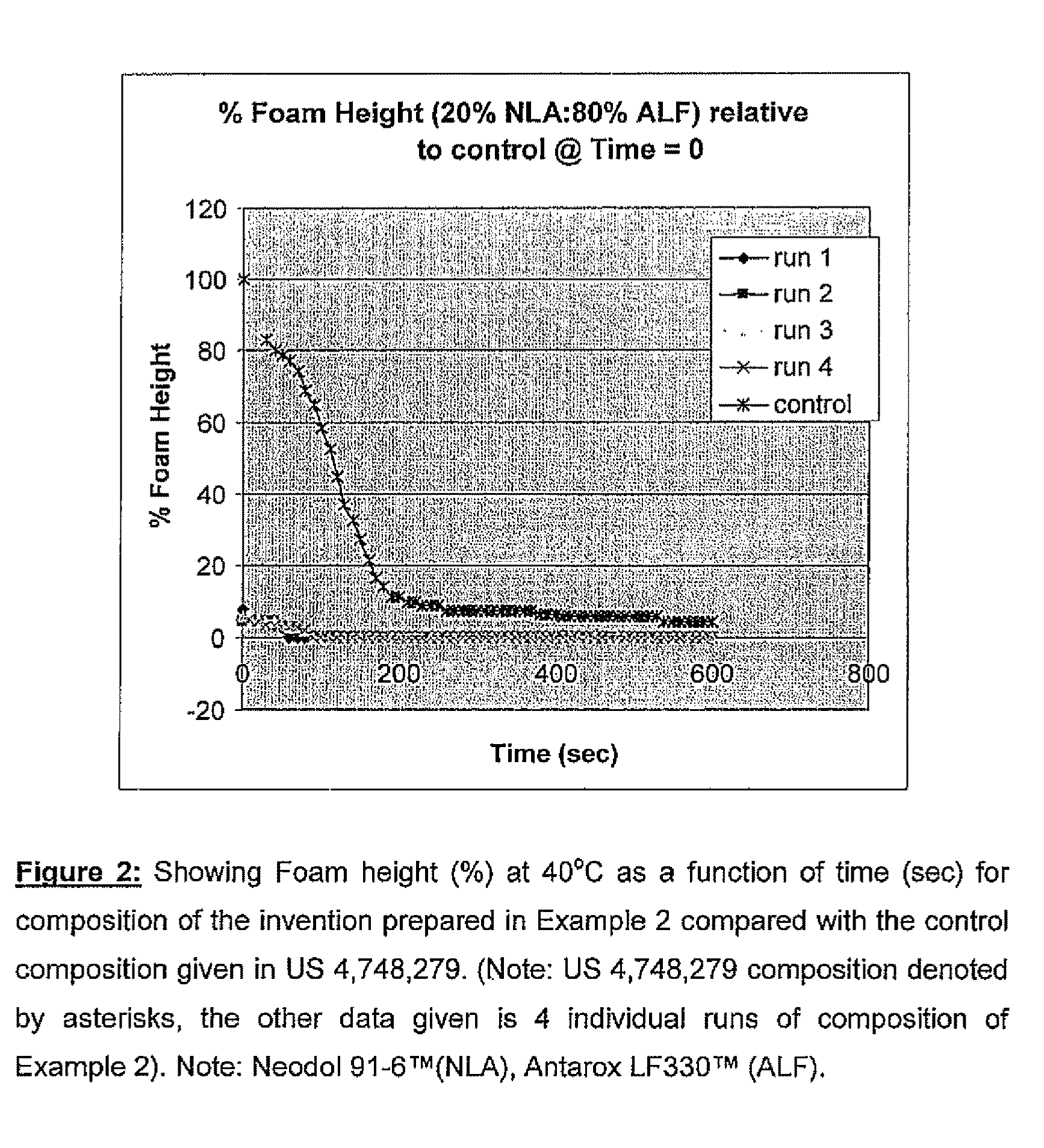

High performance low viscoelasticity foaming detergent compositions employing extended chain anionic surfactants

ActiveUS9034813B2Improve stabilityHigh viscosityCationic surface-active compoundsNon-ionic surface-active compoundsEmulsionViscoelasticity

The invention meets the needs above by providing a surfactant system, mixture or blend that can be used as a part of a soaking composition. The surfactant system is capable of forming emulsions with, and thus removing, oily and greasy stains. In a preferred embodiment the surfactant compositions of the invention can remove non-trans fat and fatty acid stains. The invention involves foaming soaking compositions that have some or part of the anionic surfactant present in the same replaced with an extended chain anionic surfactant.

Owner:ECOLAB USA INC

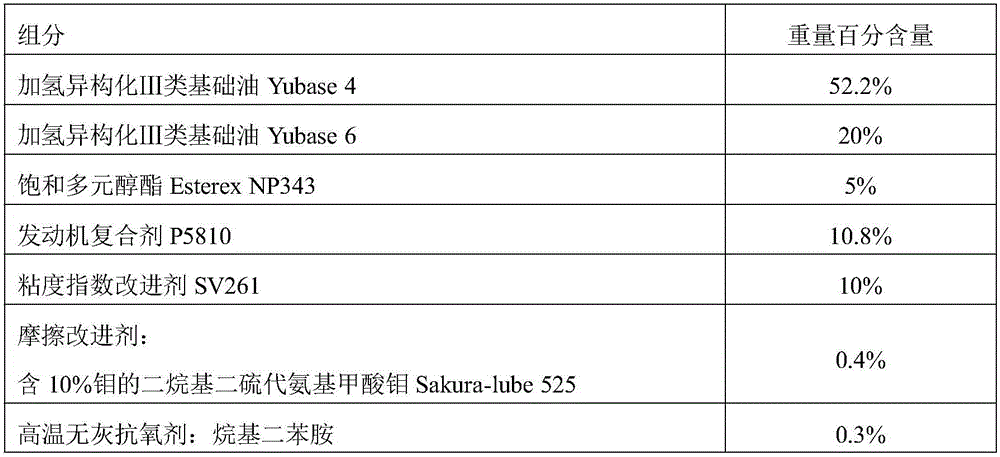

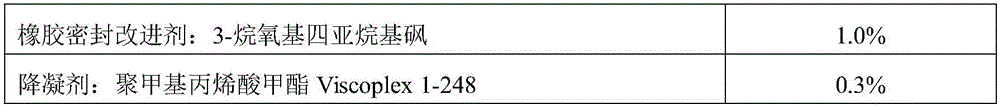

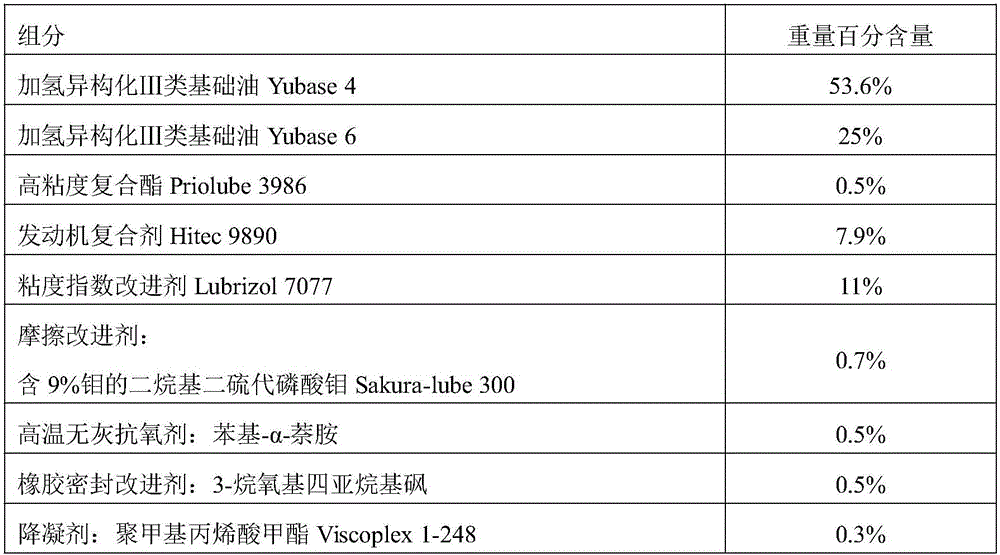

Lubricating oil composition for turbocharging direct injection engine

ActiveCN106190505AImprove high temperature detergency and dispersibilityGood for wear protectionLubricant compositionEngineeringViscosity index

The invention discloses a lubricating oil composition for a turbocharging direct injection engine. The composition is prepared from, by weight, 75-85% of base oil, 7-12% of engine oil complexing agent, 4-12% of viscosity index improver, 0.3-1.0% of friction improver, 0.3-1.0% of high-temperature ashless antioxidant, 0.3-2% of rubber seal improver and 0.1-0.5% of pour point reducer. According to the lubricating oil composition, the content of calcium, phosphorus and molybdenum in finished lubricating oil is reasonably controlled, so that the obtained product has excellent high-temperature oxidation resistance and piston cleanliness, high grease controllability and remarkable anti-wear protective property; the occurrence rate of low-speed preignition of the turbocharging direct injection engine can be effectively reduced, the fuel economy of vehicles can be improved, and the service life of the engine can be prolonged.

Owner:JIANGSU LOPALTECH

Laundry detergent with odor control

InactiveUS20070049511A1Neutralize odorEffective in controlling malodorNon-ionic surface-active compoundsDeodrant compositionsZinc ricinoleateNon ionic

A laundry detergent for neutralizing malodors comprising a liquid detergent a non-ionic surfactant from about 1% to about 10% by weight of the composition, an an-ionic surfactant from about 1% to about 15% by weight of the composition, a metallic salt comprising zinc ricinoleate from about 0.01% to about 3% by weight of the composition, and the composition having a pH level from about 6.5 to about 9.

Owner:DIAL CORPORATION

Sterilizing composition

ActiveUS20100249245A1Significant comprehensive benefitsReduce the amount requiredBiocideDead animal preservationPolyolAmmonium compounds

Disclosed is a sterilizing composition including (i) at least one mono or dialdehyde; (ii) at least one glycol or polyol or derivative thereof; (iii) a non-ionic first surfactant; and (iv) a second surfactant having a cloud point in the range of about 30° C. to 50° C. Also disclosed is a sterilizing composition including (i) at least one mono or dialdehyde; (ii) at least one glycol or polyol or derivative thereof; (iii) a non-ionic first surfactant; and (iv) a second surfactant, wherein the second surfactant is a quaternary ammonium compound. A process for preparing the compositions of the invention is also disclosed. The compositions of the invention are low or substantially non-foaming under high pressure, high temperature conditions, thus allowing maximum benefit from the new, more reliable, generation of automated endoscope reprocessing machines.

Owner:WHITELEY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com