Patents

Literature

144results about How to "Improve high temperature wear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lubricant composition for gasoline engine

ActiveCN102690711AMeet performance requirementsImprove antioxidant capacityAdditivesAlkaline earth metalAntioxidant

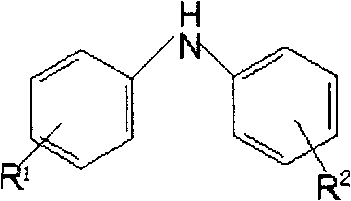

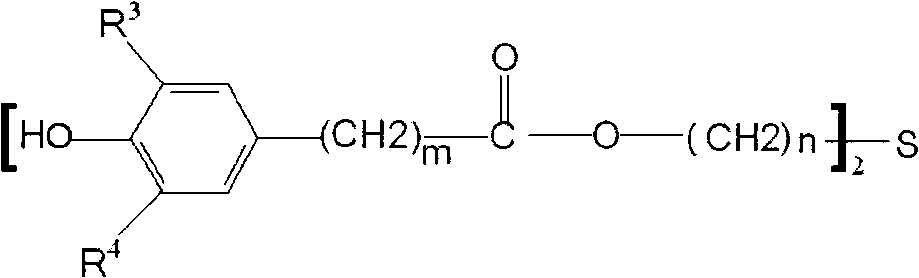

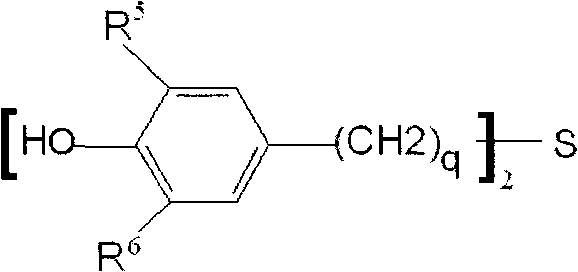

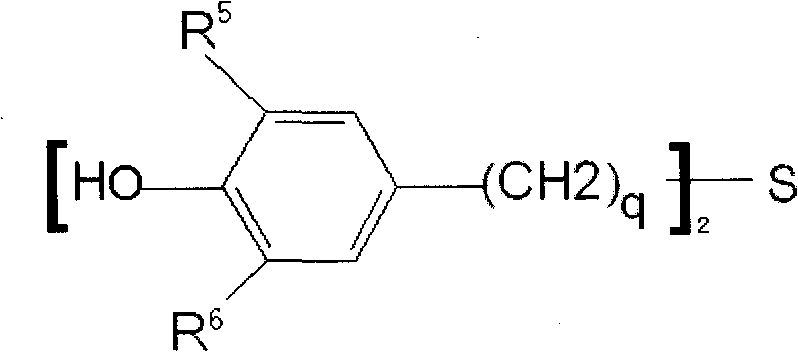

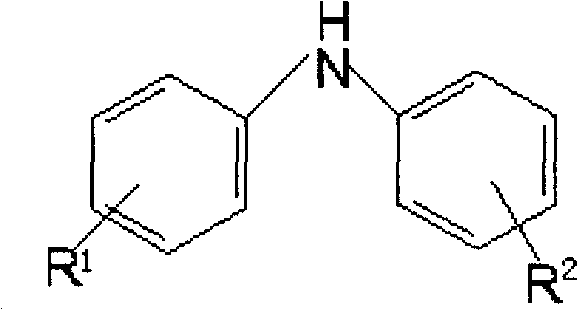

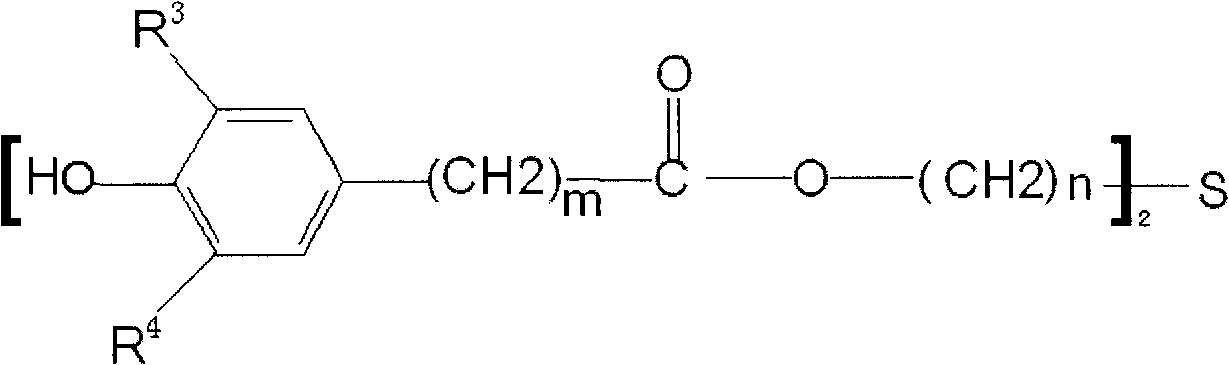

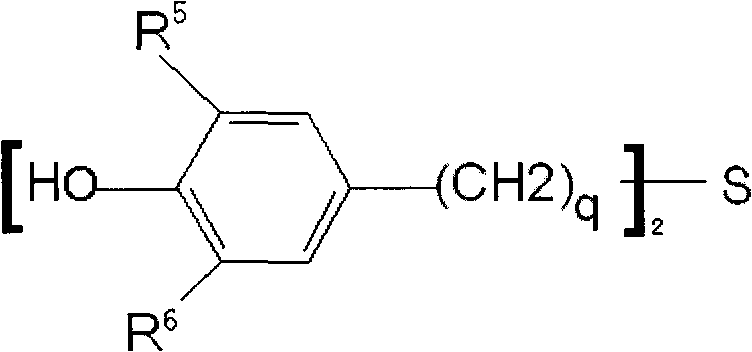

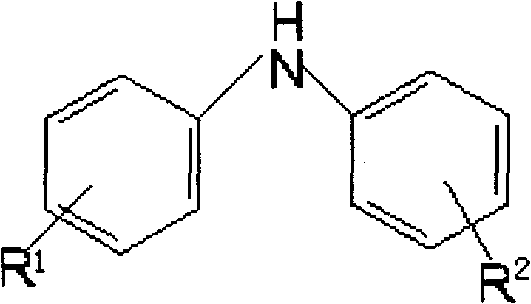

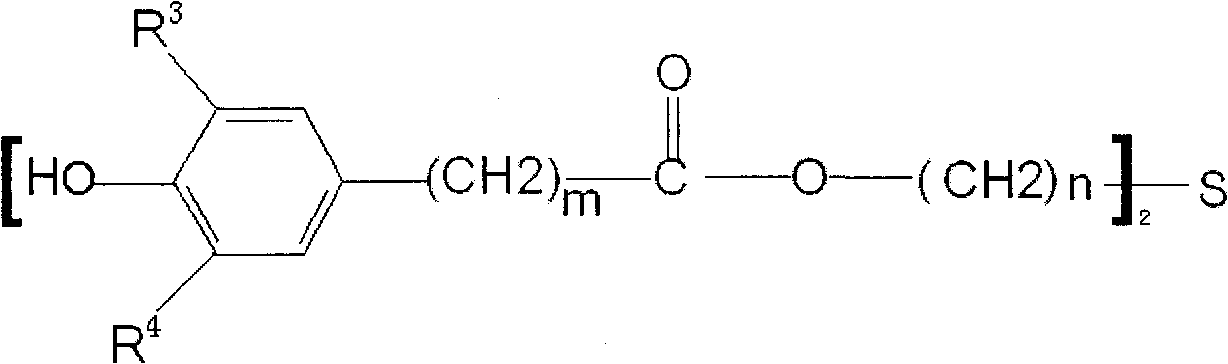

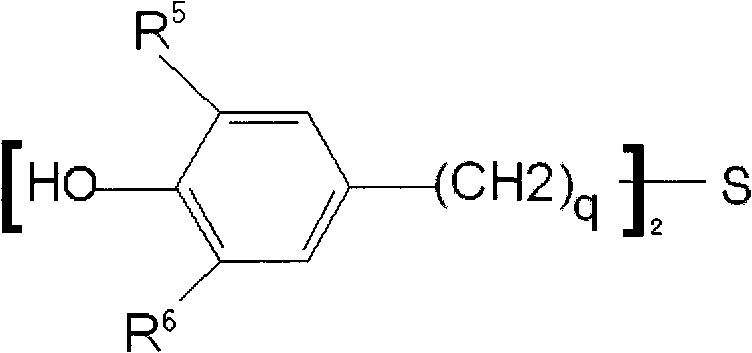

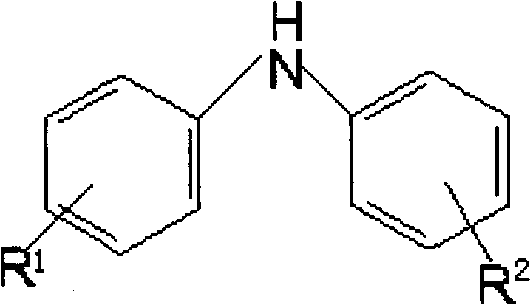

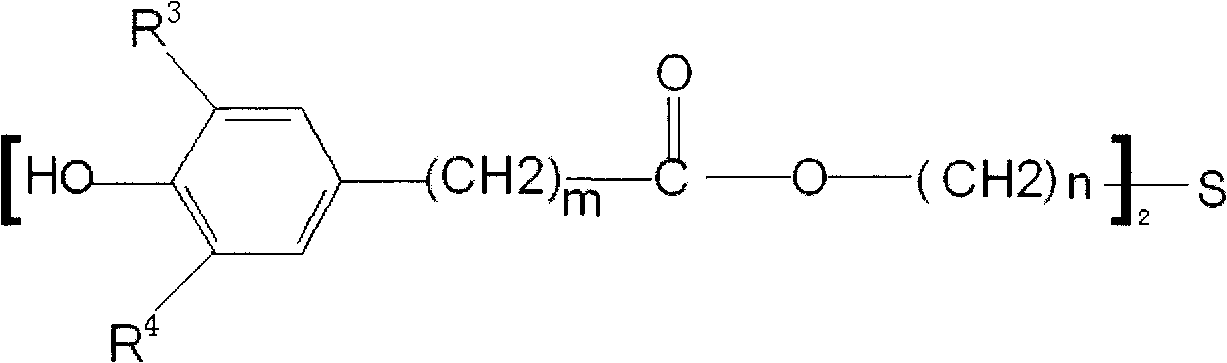

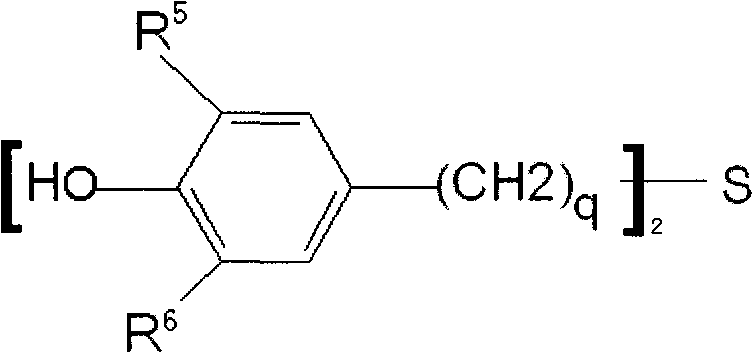

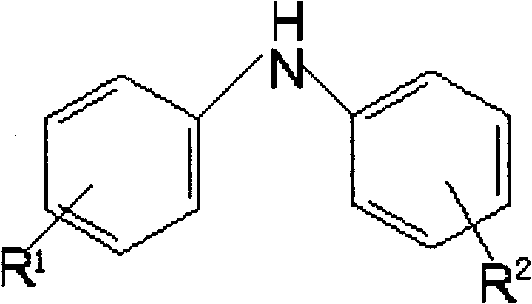

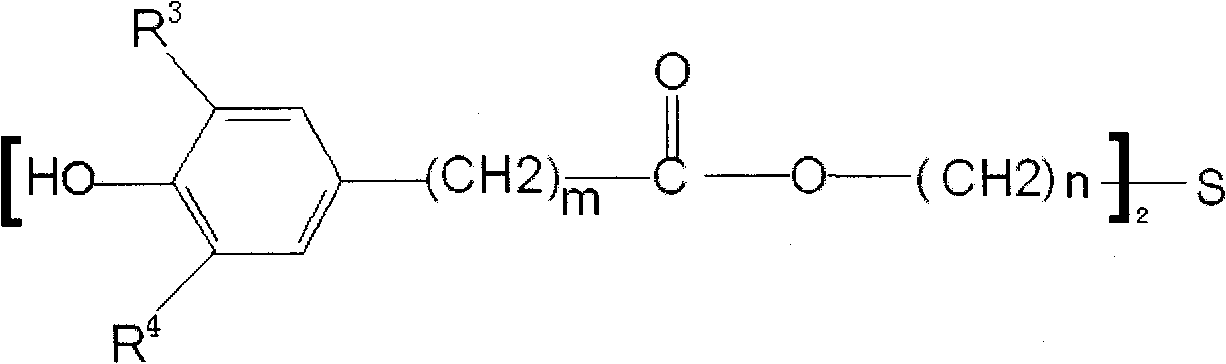

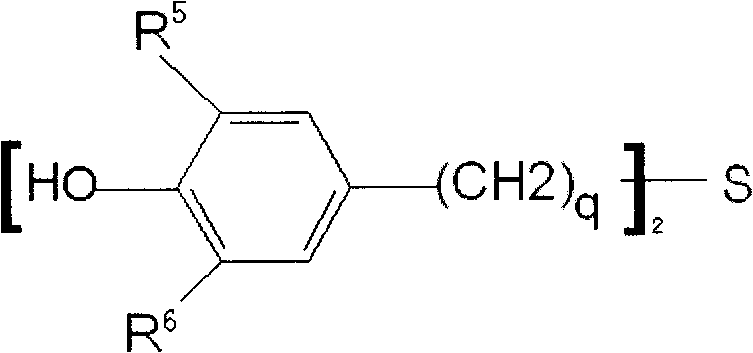

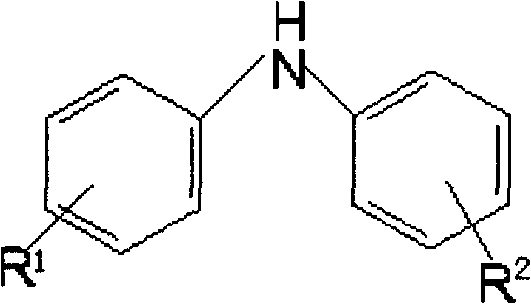

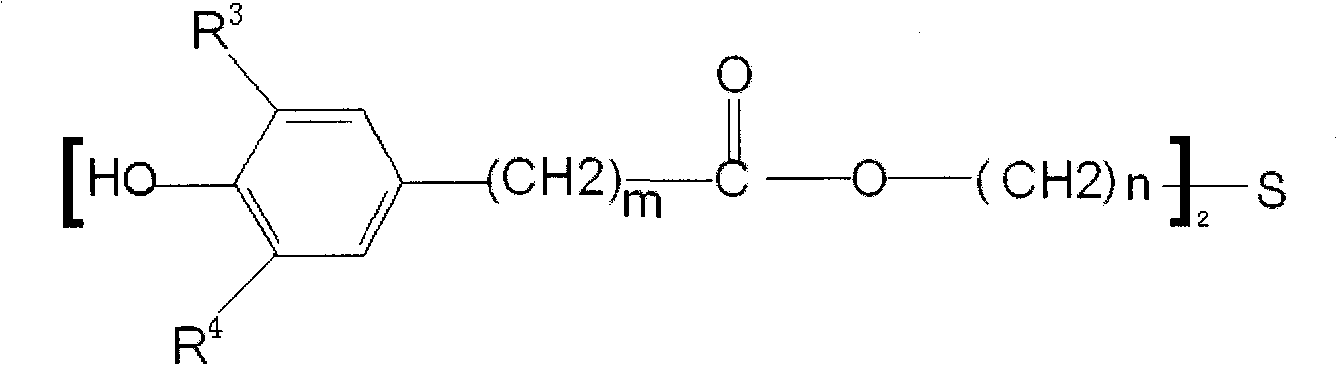

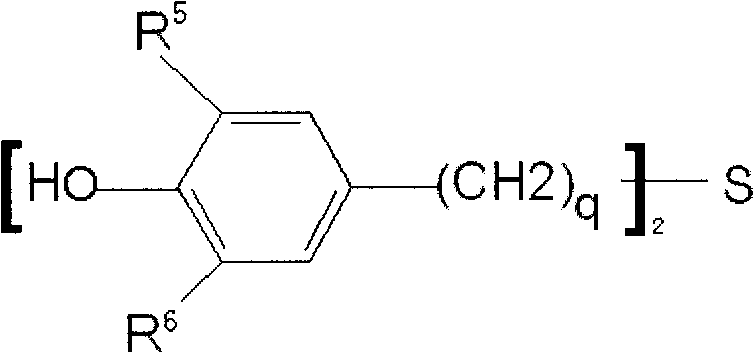

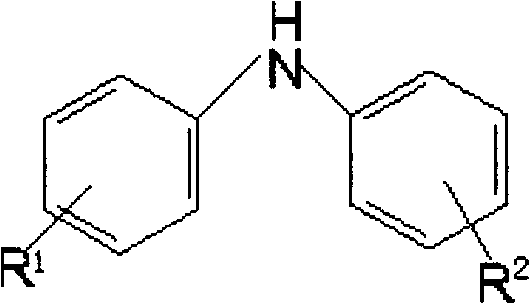

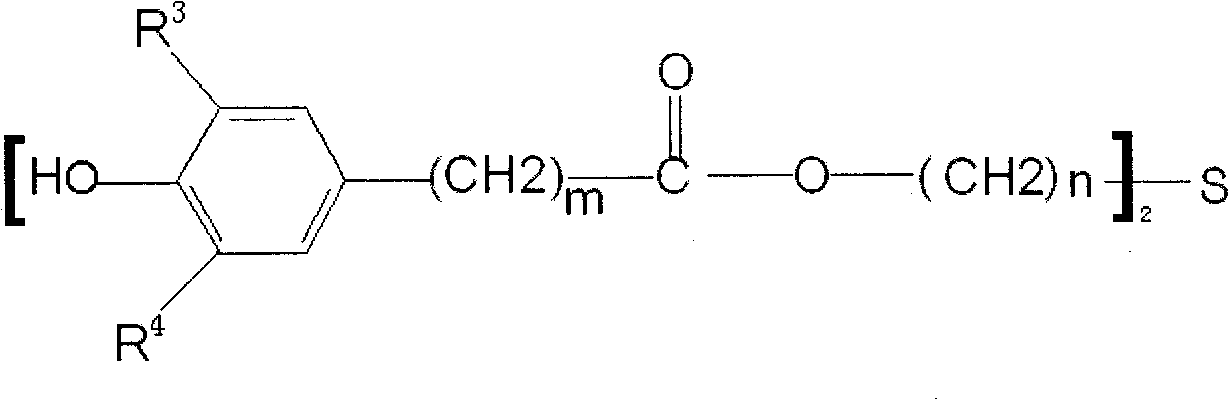

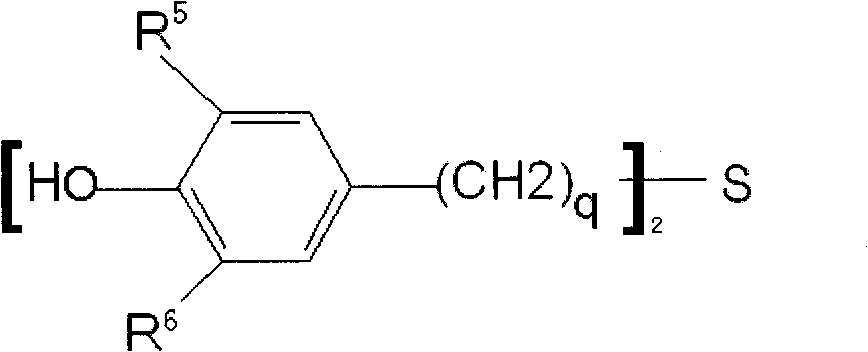

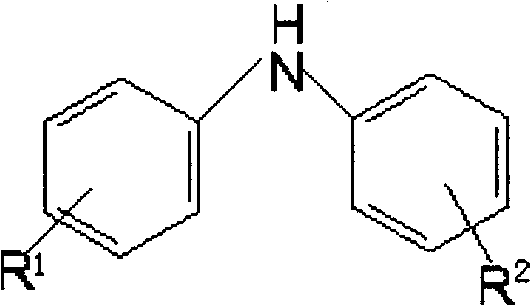

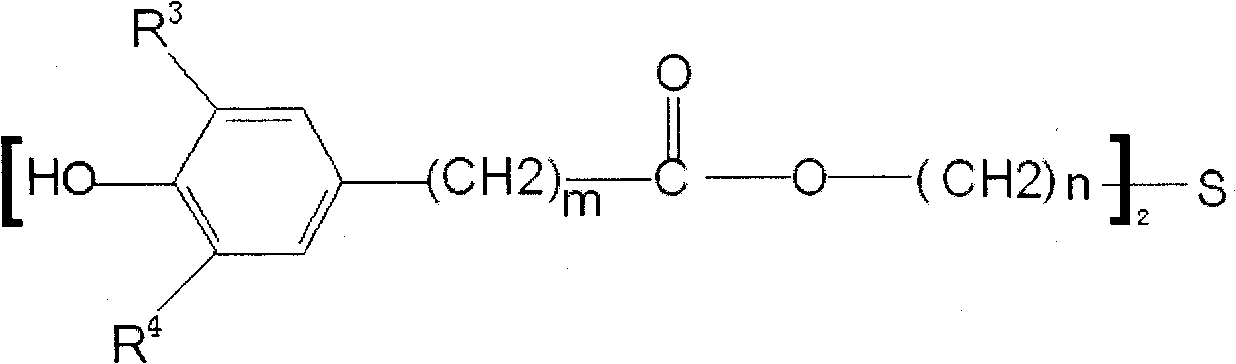

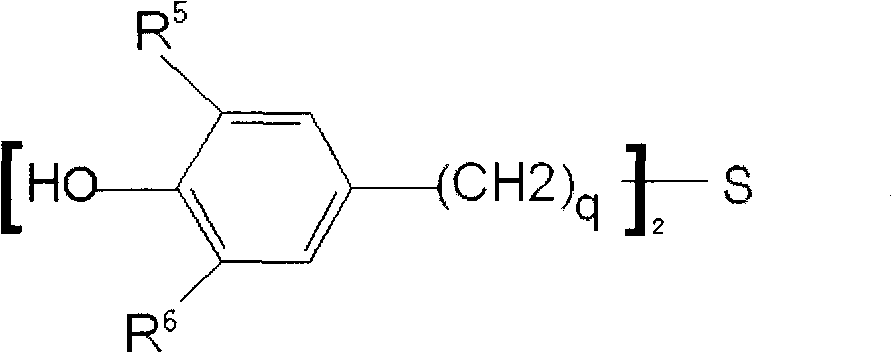

The invention relates to a lubricant composition for a gasoline engine. The lubricant composition contains: by mass, less than or equal to 0.08% of phosphorus and less than or equal to 0.9% of sulfate ash. The lubricant composition comprises A) a composite antioxidant comprising at least ingredients of 1, an alkylated diphenylamine antioxidant, 2, a thiophenolic ester antioxidant and 3, an unessential phenolic thioether antioxidant, B) a polyisobutylene succinimide ashless dispersant and / or a boronized polyisobutylene succinimide dispersant, C) one or more alkaline earth metal salicylate cleaning agents, D) at least one zinc dialkyl dithiophosphate, E) one or more oil-soluble organic molybdenum friction modifiers, F) one or more ashless friction modifiers, and G) a main amount of lubricating base oil. The lubricant composition for a gasoline engine has synergistic effect of the additives, can satisfy antioxidation requirements of a high-grade gasoline engine lubricant, and has excellent piston cleanliness, wear resistance and a viscosity increasing control capacity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Copper-base crystallizer surface laser cladding method

ActiveCN101532133AHigh hardnessImprove wear resistanceMolten spray coatingSuperimposed coating processHardnessCo2 laser

A copper-base crystallizer surface laser cladding method is characterized in that the method comprises the following steps in sequence: (1) preparing a nickel-base transition layer with thickness of 0.3-0.5mm; (2) melting the transition layer by using a mixing mode CO2 laser beam; (3) preparing a nickel-base or cobalt-base alloy work layer with thickness of 0.6-1.0mm by ultrasonic spraying; (4) melting transition layer by using the mixing mode CO2 laser beam; and (5) processing a laser cladding layer into a smooth surface. By the method of the invention, excellent metallurgically bonded cladding layers are formed on copper-base materials. The hardness and wearing resistance experiments show that the hardness of the work layer is above Hv350, which is improved by more than 3 times compared with the hardness of copper alloy; the wear loss of the laser cladding nickel-base or cobalt-base work layer is about 10mg and the high temperature wearing resistance is over 5 times as high as that of the copper alloy, thus having the effect of strengthening the copper alloy. The method of the invention is suitable for not only strengthening the copper-base crystallizer but also strengthening various copper-base alloy surfaces.

Owner:GUANGDONG INST OF NEW MATERIALS

Lubricant composition for diesel engine

ActiveCN102690707AImprove antioxidant capacityImprove high temperature wear resistanceAdditivesAntioxidantDiesel engine

The invention relates to a lubricant composition for a diesel engine. The lubricant composition for a diesel engine contains less than or equal to 0.09% by mass of phosphorus, less than or equal to 0.4% by mass of sulfur and less than or equal to 1.0% by mass of sulfate ash. The lubricant composition for a diesel engine comprises A) a composite antioxidant comprising at least components of 1, an alkylated diphenylamine antioxidant, 2, a thiophenolic ester antioxidant and 3, an unessential phenolic thioether antioxidant, B) a polyisobutylene succinimide ashless dispersant and / or a boronized polyisobutylene succinimide dispersant, C) a mixture of magnesium sulfate and sulfurized calcium alkyl phenate, D) at least one zinc dialkyldithiophosphate, E) one or more ashless friction modifiers, and F) a main amount of lubricating base oil. The lubricant composition for a diesel engine has a synergistic effect of the additives, can satisfy high-temperature antioxidation requirements of lubricating oil for a diesel engine, and has excellent piston cleanliness, wear resistance and a viscosity increasing control capacity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hard surfacing sintered flux and manufacturing method thereof

InactiveCN101564804AMeet different requirements of hardnessImprove performanceWelding/cutting media/materialsSoldering mediaMaterials preparationThermal fatigue

The invention relates to a hard surfacing sintered flux and a manufacturing method thereof. The sintered flux comprises MgO of 30 percent to 50 precent, CaO of 2 percent to 10 percent, Al2O3 of 10 percent to 20 percent, CaF2 of 18 percent to 28 percent, SiO2 of 10 percent to 20 percent, SiC of 0 percent to 1.5 percent and other components of 0 percent to 5 percent such as ferroalloy mainly playing a role of desoxidation and the like. Material preparation, dry mixing and wet mixing by adding soluble glass into a blender are conducted until granules which have the required sizes are formed, then the granules are dried in a rotary drying way at the low temperature of 200 DEG C to 250 DEG C, and then finished products are obtained by high-temperature sintering in a rotary drying oven at the high temperature of 700 DEG C to 750 DEG C, sieving and packaging. The invention has low flux cost so as to meet the requirements of different hardness, excellent technique and good high-temperature slag detachability; the deposited metal has no gas hole, no crackle but adjustable hardness; and the high-temperature wear-resistance, oxide etch resistance and cold and thermal fatigue resistance of a hot roll are greatly improved.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

Lubricant composition for gas engine

ActiveCN102690709AImprove antioxidant capacityImprove wear resistanceAdditivesAlkaline earth metalAntioxidant

The invention relates to a lubricant composition for a gas engine. The lubricant composition contains: by mass, less than or equal to 0.08% of phosphorus and less than or equal to 0.8% of sulfate ash. The lubricant composition comprises A) a composite antioxidant comprising at least ingredients of 1, an alkylated diphenylamine antioxidant, 2, a thiophenolic ester antioxidant and 3, an unessential phenolic thioether antioxidant, B) a dispersant, C) one or more sulfurized alkaline earth metal alkyl phenolate cleaning agents, D) at least one zinc dialkyl dithiophosphate, E) one or more ashless friction modifiers, F) one or more metal deactivators and G) a main amount of lubricating base oil. The lubricant composition for a gas engine adopts optimized combination of the multiple ashless antioxidants, is blended with the appropriate clearing agent and the dispersant, has a synergistic effect of the additives, can satisfy high-temperature antioxidation requirements of lubricating oil for a gas engine, and has excellent piston cleanliness, high / low-temperature wear resistance and a good viscosity increasing control capacity.

Owner:CHINA PETROLEUM & CHEM CORP +1

SiC particle-enhanced aluminum based composite with high-temperature wear resistance and preparation method of SiC particle-enhanced aluminum based composite

The invention provides a SiC particle-enhanced aluminum based composite with high-temperature wear resistance and a preparation method of the SiC particle-enhanced aluminum based composite and belongsto the field of aluminum alloy materials. The preparation method comprises the following steps of smelting industrial pure aluminum, aluminum-silicon alloy, aluminum-copper alloy, pure magnesium, thealuminum-copper alloy, aluminum-nickel alloy, aluminum-zinc alloy, aluminum-titanium alloy and aluminum-magnesium alloy at 700-800 DEG C according to a mass ratio; performing degassing refining; performing casting at 700-750 DEG C; using vacuum smelting, stirring and casting equipment to smelt a substrate at 700-800 DEG C; adding micron-size SiC particles; performing semi-solid state stirring at550-570 DEG C; performing casting at 700-750 DEG C; and performing T6 heat treatment. For the SiC particle-enhanced aluminum based composite with the high-temperature wear resistance and the preparation method, the substrate alloy components are designed self according to an alloy phase diagram, and a proper element content is selected, so that a high temperature resistant hard phase occurs aftersubstrate alloy heat treatment, and the substrate hardness at high temperature is ensured; and meanwhile, by adding an SiC-enhanced phase, the high temperature resistance of the composite is further improved.

Owner:TONGJI UNIV

Lubricant composition for intermediate-speed trunk piston-type engine of ship

ActiveCN102690710AGood antioxidant propertiesGood high temperature cleanAdditivesOxidation resistantAntioxidant

The invention relates to a lubricant composition for an intermediate-speed trunk piston-type engine of a ship. The lubricant composition comprises A) a composite antioxidant composing at least components of 1, an alkylated diphenylamine antioxidant, 2, a thiophenolic ester antioxidant and 3, an unessential phenolic thioether antioxidant, B) a polyisobutylene succinimide ashless dispersant, C) a mixture of magnesium sulfate and sulfurized calcium alkyl phenate, D) at least one zinc dialkyldithiophosphate, E) dialkyldithiocarbamate, F) one or more metal deactivators, G) one or more ashless friction modifiers, and H) a main amount of lubricating base oil. The lubricant composition utilizes optimized combination of the multiple ashless antioxidants, is compounded with the appropriate clearing agent and the dispersant, has a synergistic effect of the additives, can satisfy high-temperature antioxidation requirements of lubricating oil for an intermediate-speed trunk piston-type engine of a ship, and has excellent piston cleanliness, high / low-temperature wear resistance and a good viscosity increasing control capacity.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-temperature oxidation resistant wearproof Co-based alloy wire and preparation method thereof

ActiveCN106756257AGood high temperature and wear resistanceHigh temperature and wear resistanceWire rodOxidation resistant

The invention discloses a high-temperature oxidation resistant wearproof Co-based alloy wire and a preparation method thereof. The high-temperature oxidation resistant wearproof Co-based alloy wire comprises the following ingredients: 13-17% of Cr, 11-15% of Ni, 10-14% of W, 2.4-4.3% of Mo, 1.2-1.6% of Al, 2.8-3.6% of Ti, 0.1-0.5% of Nb, 1.2-1.8% of Ta, 0.03-0.06% of Re, 0.01-0.05% of Ce, 0.02-0.1% of C, 0.005-0.015% of B, 0.02-0.07% of Zr and the balance of Co. The alloy preparation process route is vacuum melting-remelting-forging-hot rolling-drawing-solid solution treatment-aging treatment. Raw materials are compounded according to percentage by mass and then melted and re-melted; after that, forging and rolling are performed to obtain an alloy wire rod; multi-drawing is conducted to prepare an alloy wire of phi 0.06-0.4 mm; and finally, solid solution treatment and aging treatment are performed. Through reasonable ingredient control and adding of alloy elements, the alloy wire has high yield and excellent high-temperature wear resistance, high-temperature corrosion resistance, oxidation resistance and high strength. As a sealing brush wire material, the high-temperature oxidation resistant wearproof Co-based alloy wire has the advantages that the sealing effect can be effectively improved, and the service life is prolonged.

Owner:SOUTHEAST UNIV

Wear resistant high iron-aluminum based welding wire for build-up welding

InactiveCN1424173AUniform weld compositionGood welding performanceArc welding apparatusWelding/cutting media/materialsWear resistantWeld seam

Owner:WUHAN UNIV OF TECH

Lubricant composition for methanol engine

ActiveCN102690706AImprove antioxidant capacityImprove wear resistanceAdditivesAntioxidantPolyisobutylene succinimide

The invention relates to a lubricant composition for a methanol engine. The lubricant composition comprises A) a composite antioxidant comprising at least ingredients of 1, an alkylated diphenylamine antioxidant, 2, a thiophenolic ester antioxidant and 3, an unessential phenolic thioether antioxidant, B) a polyisobutylene succinimide ashless dispersant and / or a polyisobutylene succinate dispersant, C) a mixture of magnesium sulfonate and sodium sulfonate, D) at least one zinc dialkyl dithiophosphate, E) one or more oil-soluble organic molybdenum friction modifiers, and F) a main amount of lubricating base oil. The lubricant composition for a methanol engine utilizes optimized combination of the multiple ashless antioxidants, is compounded with the appropriate clearing agent and the dispersant, has a synergistic effect of the additives, can satisfy high-temperature antioxidation requirements of lubricating oil for a methanol engine, and has excellent piston cleanliness, high / low-temperature wear resistance and a good viscosity increasing control capacity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of wear-resistant molybdenum alloy

The invention discloses a preparation method of a wear-resistant molybdenum alloy. The preparation method comprises the following steps: firstly, preparing a solutions by taking aluminium nitrate, citric acid and ammonium molybdate as raw materials, mixing the solutions to solate and gelate, and drying and roasting the gel to obtain Al2O3 / MoO3 mixed powder; secondly, carrying out hydrogen reduction on the Al2O3 / MoO3 mixed powder; thirdly, ball-milling the Al2O3 / MoO3 mixed powder by use of a planetary ball mill; and finally carrying out hot pressed sintering to obtain the molybdenum alloy. The preparation method has the following beneficial effects: in the prepared molybdenum alloy, the alumina and molybdenum grains are very fine, the molybdenum grain size is 0.8-1.8 microns and the alumina grain size is 100-300 nanometers; the recrystallization temperatures of the prepared molybdenum alloy can be about 1550 DEG C; the high-temperature wear resistance and tensile strength of the molybdenum alloy are improved by 5-9% and 3-10% respectively compared with those of molybdenum base composites in CN101698919A; and the density and microhardness of the prepared molybdenum alloy are obviously improved, thereby achieving the aim of improving the high-temperature wear resistance of the wear-resistant molybdenum alloy.

Owner:HENAN UNIV OF SCI & TECH

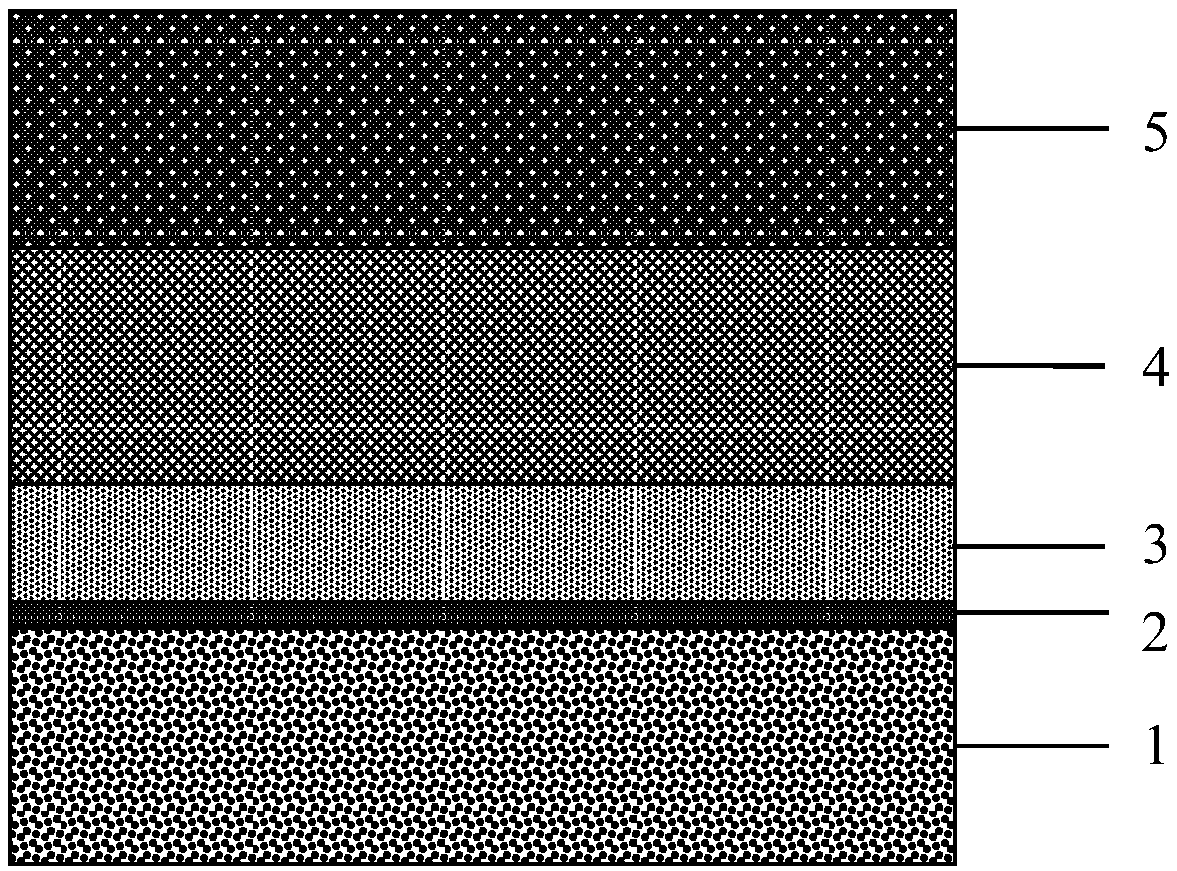

Metal-based material for preparation of crystallizer or tuyere as well as preparation method of metal-based material

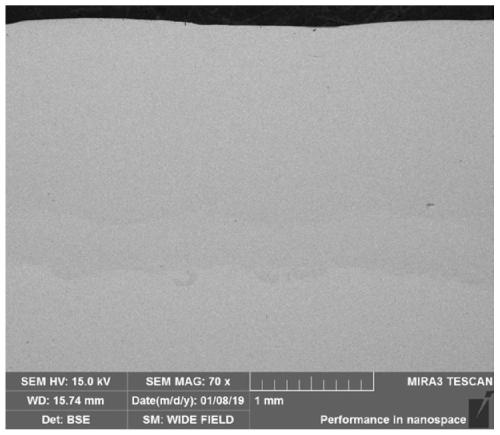

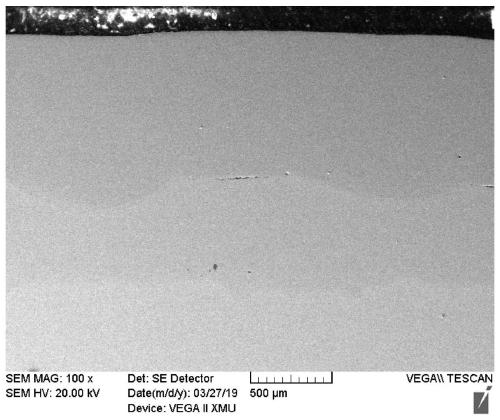

ActiveCN110144582AImprove high temperature wear resistanceLower perfect fitMetallic material coating processesSurface engineeringAlloy

The invention discloses a metal-based material for the preparation of a crystallizer or a tuyere and belongs to the technical field of surface engineering. According to the metal-based material, a transition layer is innovatively arranged between a Cu or Cu alloy matrix and a high-abrasion-resistance working layer by the adoption of a metallurgical bonding method, and made of at least one of pureCo metal, pure Ni metal, pure Cr metal, pure Cu metal, pure Mo metal, pure Ag metal and a NiCr or MCrAlY alloy; through the transition layer, the functions of improving the laser absorption rate, lowering the matrix heat conductivity, and lowering the dilution rate can be achieved; due to the existence of the transition layer, the thickness of the working layer can be adjusted within a range of 0.01-3 mm and the formation of surface cracks can be avoided; furthermore, the ratio of the thickness of the transition layer to that of the high-abrasion-resistance working layer is 1:(1-3), so that the perfect bonding of the transition layer and the high-abrasion-resistance working layer can be guaranteed within the ratio range; the formation of a high-abrasion-resistance coating or coating product which is free of surface cracks and subjected to metallurgical bonding on the Cu or Cu alloy matrix can be improved; the reliability of the crystallizer or the tuyere can be improved; and the service life of the crystallizer or the tuyere can be prolonged.

Owner:XI AN JIAOTONG UNIV

Plasma arc fusion covering repair method for continuous casting rollers

The invention discloses a plasma arc fusion covering repair method for continuous casting rollers. The plasma arc fusion covering repair method includes steps of preliminarily examining a continuous casting roller; removing a fatigue layer of the surface of the continuous casting roller; performing magnetic particle inspection and ultrasonic inspection; preparing mixed alloy powder of Ni45 and WC (wolfram carbide) according to a proportion by a mechanical powder mixer; mixing and stirring the mixed alloy powder and white emulsion according to a proportion; coating the mixed alloy powder on the surface of a base material of the continuous casting roller, scanning the pre-coated alloy powder by a single plasma arc channel via plasma arc fusion covering equipment to form an alloy layer; and finely finishing the continuous casting roller by a lathe or a grinder to obtain a continuous casting roller meeting technical requirements. Compared with the prior art, the plasma arc fusion covering repair method has the advantages of capabilities of obviously prolonging the service life of the continuous casting roller and reducing alloy consumption, high heat resistance and controllability, simplicity in process, low cost and energy consumption, and the like.

Owner:QINHUANGDAO GERUIDE ENERGY SAVING TECH SERVICE

Preparation method of high-temperature anti-wear Fe-Cr-B-Al alloy

InactiveCN104164668AHigh hardnessHigh strengthMetallic material coating processesAl powderIron powder

The invention discloses a preparation method of a high-temperature anti-wear Fe-Cr-B-Al alloy and belongs to the technical field of wear-resistant materials. The alloy is prepared by adopting a laser cladding process. The preparation method comprises the following steps: firstly, uniformly mixing 12.0wt%-15.0wt% of low-carbon Cr-Fe powder, 12.0wt%-15.0wt% of high-carbon Cr-Fe powder, 6.0wt%-8.0wt% of B-Fe powder, 5.0wt%-6.0wt% of metal Al powder, 1.5wt%-2.0wt% of re-Si-Fe powder, 4.0wt%-5.0wt% of Fe2O3 powder and 52wt%-57wt% of pure Fe powder, wherein the particle size of the powder is within a range of 100-160 meshes; and secondly, inputting heat by adopting an optical fiber laser device, and feeding the powder materials by adopting a laser cladding synchronous powder feeder to obtain the Fe-Cr-B-Al alloy which is high in hardness and good in high-temperature wear resistance, wherein in the cladding process, the powder feeding rate is 15-20g / min, the laser power is 1500-2500W, and the scanning speed is 3-8mm / s.

Owner:BEIJING UNIV OF TECH

Wear resistant surfacing alloy containing ceramic phase with molybdenum and chromium elements and production technology thereof

InactiveCN103769765AIncrease production costLow costPlasma welding apparatusWelding/cutting media/materialsWear resistantAlloy

The invention discloses a wear resistant surfacing alloy containing ceramic phase with molybdenum and chromium elements and a production technology thereof. The wear resistant surfacing alloy containing the ceramic phase with the molybdenum and chromium elements is characterized in that alloy composition comprises 15 to 30 % of chromium, 3 to 12 % of molybdenum, 0.5 to 1 % of nickel, 6 to 10 % of carbon and the remaining is ferrum and unavoidable impurities. The production technology of the wear resistant surfacing alloy containing the ceramic phase with the molybdenum and chromium elements comprises mechanically mixing ferrochrome powder, molybdenum powder, nickel powder, graphite and reduced iron powder; uniformly mixing through a dry type ball mill of a ball grinder; coating the powder on a carbon steel plate after the powder is cooled; uniformly mixing into a coating layer with the thickness of 4 mm through water glass; standing under room temperature; drying in a drying oven; enabling the temperature to be cooled to the room temperature in the drying oven; performing ion surfacing. The production technology of the wear resistant surfacing alloy containing the ceramic phase with the molybdenum and chromium elements has the advantages of being simple in technological process, less in added alloy variety and low in cost and enabling hard phase of obtained alloy surfacing layer to be good in bonding performance with base materials, not easy to fall off, high in rigidity and wear resistance, obvious in adhesive wear resistant effect compared with other iron-based surfacing wear resistant alloy.

Owner:SHENYANG POLYTECHNIC UNIV

Lubricant composition for four-stroke motorcycle engine

ActiveCN102690715AImprove cleanlinessMeet lubrication requirementsAdditivesAntioxidantPolyisobutylene succinimide

The invention relates to a lubricant composition for a four-stroke motorcycle engine. The lubricant composition comprises A) a composite antioxidant comprising at least components of 1, an alkylated diphenylamine antioxidant, 2, a thiophenolic ester antioxidant and 3, an unessential phenolic thioether antioxidant, B) a polyisobutylene succinimide dispersant and / or a polyisobutylene succinate dispersant, C) a mixture of calcium sulfonate and sulfurized calcium alkyl phenate, D) at least one zinc dialkyl dithiophosphate, E) one or more ashless friction modifiers, and F) a main amount of lubricating base oil. The lubricant composition adopts optimized combination of the multiple ashless antioxidants, is blended with the appropriate clearing agent and the dispersant, has a synergistic effect of the additives, can satisfy high-temperature antioxidation requirements of lubricating oil for a four-stroke motorcycle engine, and has excellent piston cleanliness, high / low-temperature wear resistance and a good viscosity increasing control capacity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composite structure coating and spraying method thereof

ActiveCN101613852AAccelerated corrosionImprove high temperature wear resistanceMolten spray coatingStellite alloyFunctional composite

The invention discloses a composite structure coating which is characterized by comprising a stellite alloy layer coated on the surface of a roller body, a MoB / CoCr metal ceramic layer coated on the surface of the stellite alloy layer and a barrier layer arranged on the surface of the MoB / CoCr metal ceramic layer. In the invention, the functional composite structure coating manufactured by the thermal spraying technology and special coating after being subjected to hole sealing can ensure single use time and accumulative service life of a sinking roller and stable roller to be increased by 1-3 times of roller bodies without coatings, so that steel plants improve use efficiency of high value roller bodies, thus improving production efficiency and product quality.

Owner:SHANGHAI JUSN SURFACE TECH ENG +1

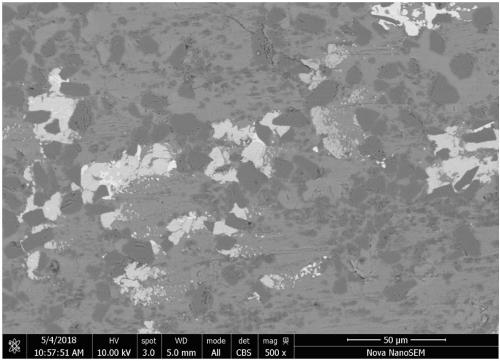

A laser clad Co-based WC coating

InactiveCN108165976AImprove high temperature wear resistanceMetallic material coating processesAdhesive wearHardness

A laser clad Co-based WC coating is disclosed. Co-based WC composite powder is subjected to laser cladding on a surface by adopting a semiconductor laser. The microhardness and high-temperature wear resistance of the coating after laser cladding are improved to a large extent. The major constitution phases of the coating are a supersaturated solid solution Co, and hard phases including CoCx, Fe<3>W3C, (Cr,Fe)<23>C6, and the like. In a wear process of the coating at a high temperature of 600 DEG C, on the one hand, a Co-rich area which is relatively low in hardness is worn firstly so that carbide hard phases having high hardness are shown on the surface and wearing action of a material is prevented; and on the other hand, Co and Cr elements promote formation of CoO and CoO.Cr2O3 oxide filmshaving lubricating functions in a high-temperature friction process so that the friction coefficient is reduced, and therefore high-temperature wear resistance of the clad layer is increased by about2 times. High-temperature wear mechanisms of the clad layer mainly include abrasive particle wear and adhesive wear.

Owner:高扬

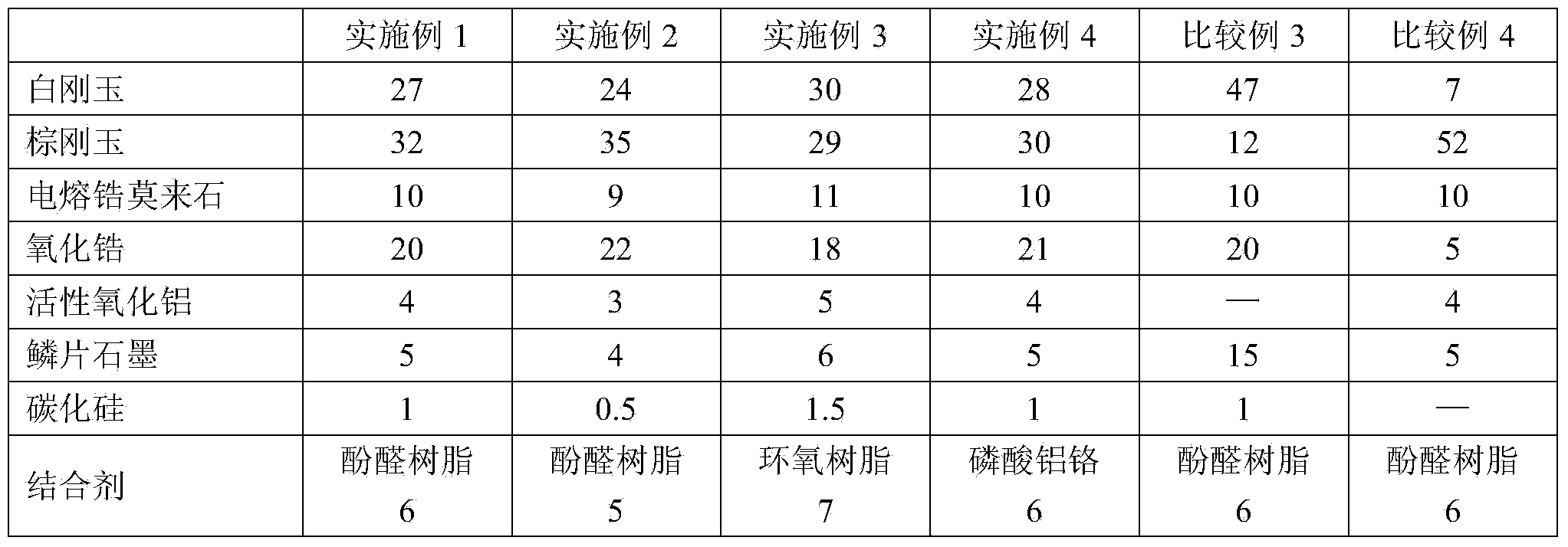

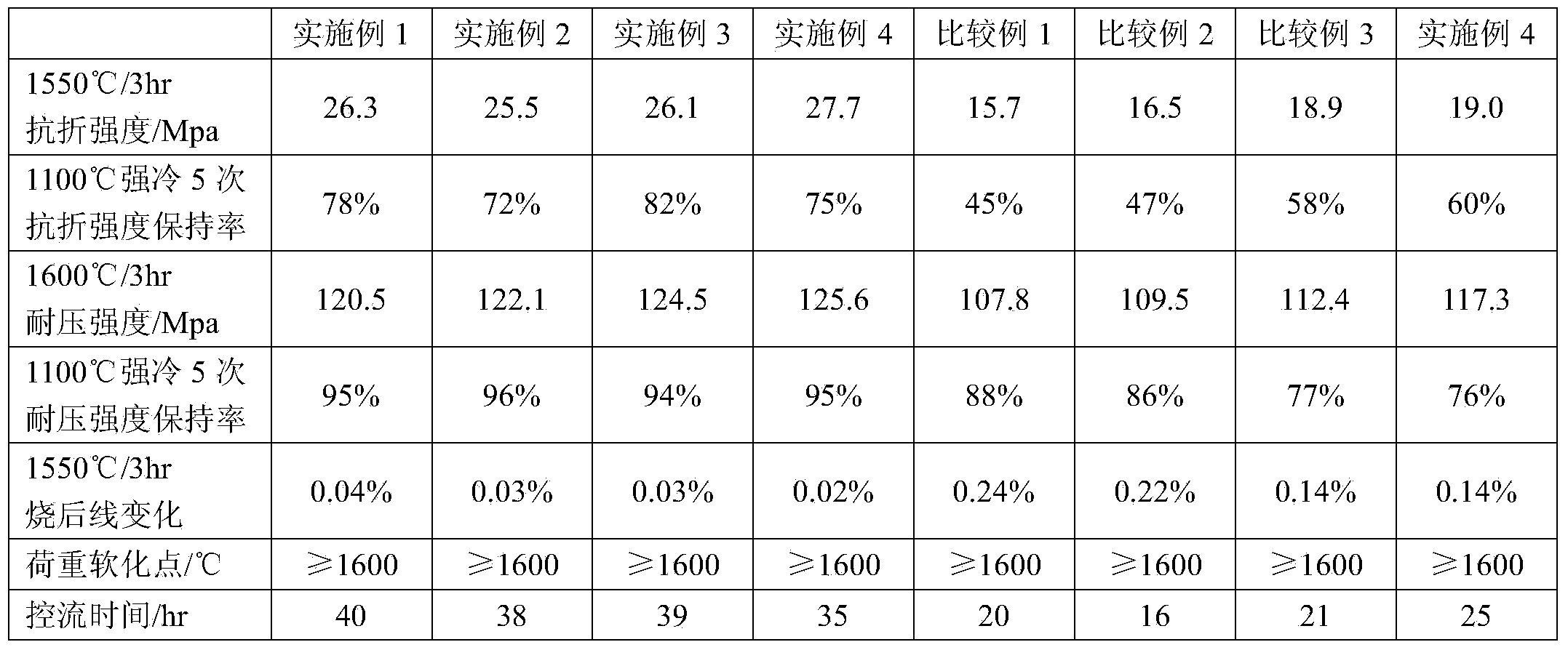

Continuous-casting flow-control refractory material and application thereof

The invention discloses a continuous-casting flow-control refractory material and application thereof. The continuous-casting flow-control refractory material comprises the following components in parts by weight: 24-30 parts of white alundum, 29-35 parts of brown fused alumina, 9-11 parts of electrofused zirconium mullite, 18-22 parts of zirconium dioxide, 3-5 parts of active aluminum oxide, 4-6 parts of flake graphite, 0.5-1.5 parts of silicon carbide and 5-7 parts of binder. The high strength, high-temperature erosion resistance, high-temperature wear resistance, peel resistance and other requirements of the continuous-casting flow-control refractory material are ensured, and the flow control time can be further prolonged. The continuous-casting flow-control refractory material is especially suitable to be used as continuous-casting flow-control functional components of long nozzles and bowl parts thereof, brick cups and bowl parts thereof, and the like.

Owner:HUZHOU YONGLIAN REFRACTORY MATERIALS

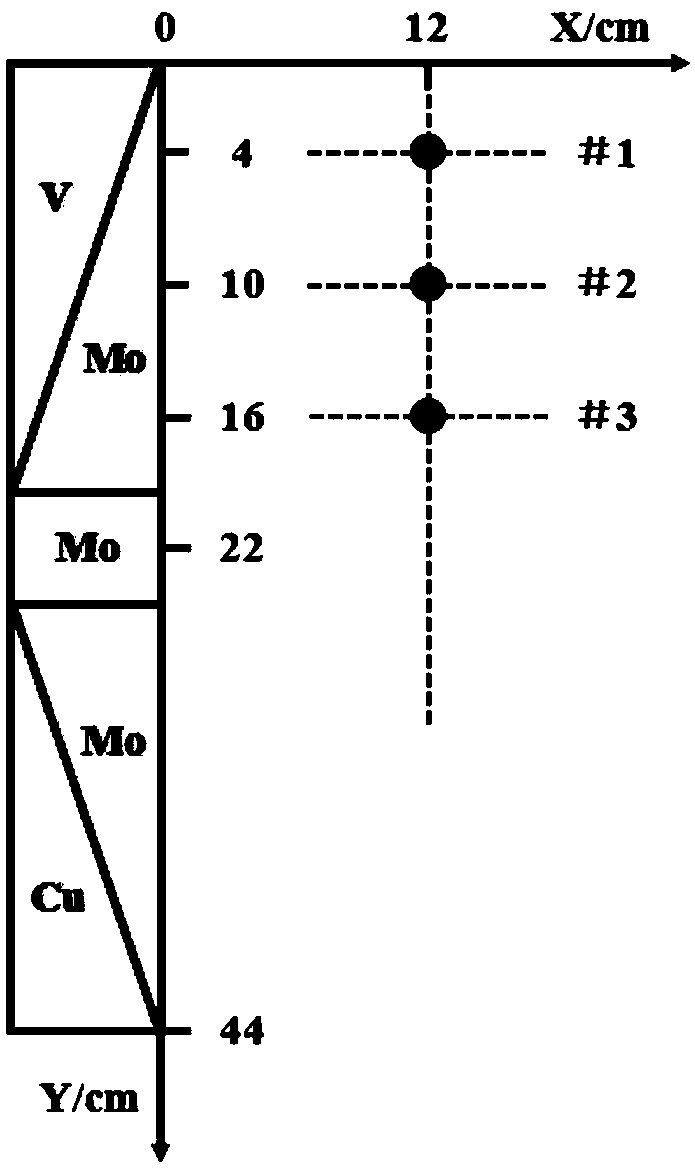

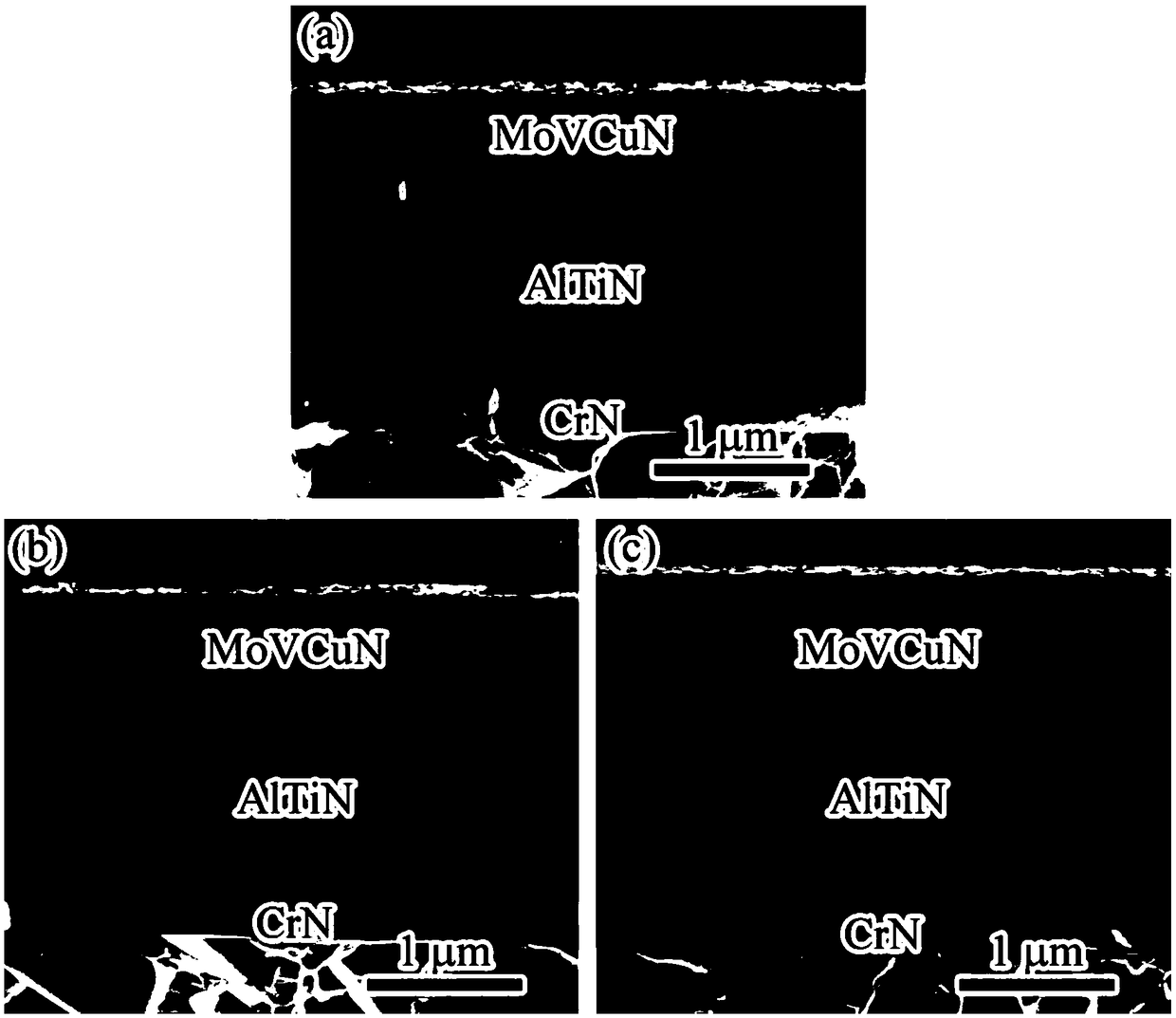

Multilayer multi-element nano composite self-lubricating hard coating and preparation method and application thereof

ActiveCN108866480AImprove performanceHigh hardnessVacuum evaporation coatingSputtering coatingAlloyHardness

The invention belongs to the technical field of preparation of cutter coatings and surface protection coatings, and discloses a multilayer multi-element nano composite self-lubricating hard coating and a preparation method and application thereof. The multilayer multi-element nano composite self-lubricating hard coating comprises a Cr bombardment implant layer, a CrN transition layer, an AlTiN hard core layer and a MoVCuN surface lubricating layer which are deposited on a hard alloy or high-speed steel cutter matrix from bottom to top, wherein the MoVCuN surface lubricating layer is prepared through anode layer ion source-assisted magnetron sputtering deposition; and the MoVCuN surface lubricating layer comprises the following elements by atomic percent: 34 to 44 at.% of Mo, 6 to 10 at.% of V, 0.3 to 0.5 at.% of Cu and 50 to 55 at.% of N. According to the multilayer multi-element nano composite self-lubricating hard coating and the preparation method and application thereof, advantagesof the arc ion plating composite anode layer ion source-assisted magnetron sputtering deposition technology are organically combined, the prepared coating is high in hardness and low in friction coefficient, and a self-lubricating effect of a certain wide-temperature range can be achieved.

Owner:GUANGDONG UNIV OF TECH

Lubricant composition for crosshead ship engine crankcase system

ActiveCN102690712AImprove cleanlinessMeet lubrication requirementsAdditivesAntioxidantOxidation resistant

The invention relates to a lubricant composition for a crosshead ship engine crankcase system. The lubricant composition comprises A) a composite antioxidant comprising at least components of 1, an alkylated diphenylamine antioxidant, 2, a thiophenolic ester antioxidant and 3, an unessential phenolic thioether antioxidant, B) polyisobutylene succinimide, C) a mixture of magnesium sulfonate and calcium sulfonate, D) at least one zinc dialkyl dithiophosphate, E) one or more dialkyl dithiocarbamates, F) one or more metal deactivators, and G) a main amount of lubricating base oil. The lubricant composition adopts optimized combination of the multiple ashless antioxidants, is blended with the appropriate clearing agent and the dispersant, has a synergistic effect of the additives, can satisfy high-temperature antioxidation requirements of lubricating oil for a crosshead ship engine crankcase system, and has excellent piston cleanliness, high / low-temperature wear resistance and a good viscosity increasing control capacity.

Owner:CHINA PETROLEUM & CHEM CORP +1

TiB2-Ni-based metal-ceramic composite feed for thermal spraying and preparation method of TiB2-Ni-based metal-ceramic composite feed

InactiveCN108356274AHigh sphericityImprove liquidityMolten spray coatingTransportation and packagingComposite constructionCeramic composite

The invention discloses TiB2-Ni-based metal-ceramic composite feed for thermal spraying and a preparation method of the TiB2-Ni-based metal-ceramic composite feed. The preparation method comprises thefollowing steps: (1) in a protective atmosphere, adding TiB2 powder and Ni-based alloy powder into a stirring grinder, adding a process control agent, a binding agent and a grinding medium, and thencarrying out grinding, so as to obtain slurry of composite powder A; (2) carrying out spray granulation on the slurry of the composite powder A in a spray drying system, so as to obtain composite powder B; (3) carrying out heat preservation on the composite powder B in drying equipment, so as to obtain composite powder C; and (4) passing the composite powder C through a spheroidizing system, so asto obtain high-sphericity composite powder. The powder prepared through the preparation method disclosed by the invention is high in flowability and excellent in performance; the demand of thermal spraying equipment for the powder flowability can be met; the problem that nanometer metal-ceramic composite powder is hard to spray can be solved; and the improvement of the coating surface performancecan be facilitated.

Owner:SOUTH CHINA UNIV OF TECH

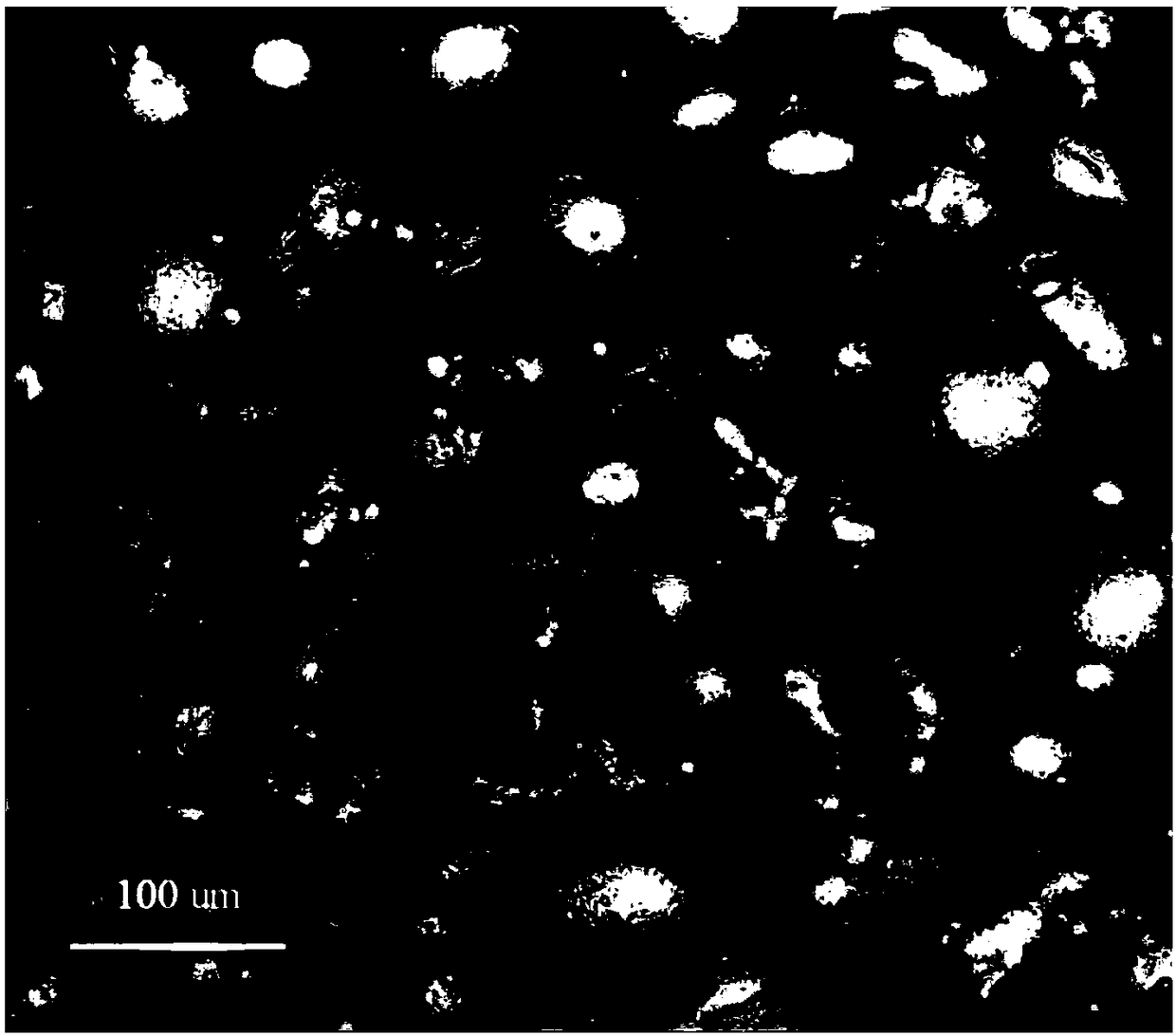

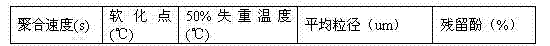

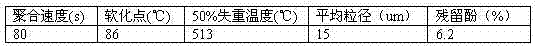

Novolak phenolic resin microspheres and preparation method thereof

The invention relates to novolak phenolic resin microspheres and a preparation method thereof, and belongs to the field of chemical synthesis. The microspheres consist of the following components in part by weight: 80 to 100 parts of absolute ethanol, 95 to 105 parts of phenol, 100 to 115 parts of formaldehyde, 6 to 12 parts of triethylenetetramine, 2 to 6 parts of boric acid and 1 to 1.75 parts of polyvinylpyrrolidone. The method comprises the following steps of: sequentially feeding the reactants with heating, reacting for a certain period of time, cooling, discharging, precipitating, performing centrifugal separation, and drying. The novolak phenolic resin microspheres prepared by the method have high dispersibility, have the particle size of 5 to 50mu m, are easily mixed with other aids uniformly, have the thermal decomposition temperature of more than 450 DEG C after being cured, and have high toughness, moisture absorption property and strength; and the preparation process is short, easy to operate and low in cost, and products can be used for an organic friction material, a molding compound, a grinding wheel bonding material, a thermal insulation material, a fireproof material and the like, so the microspheres can replace the traditional phenolic resin.

Owner:重庆阁林环保科技有限公司

Functional layer alloy powder and method for repairing finish-rolling descaling box pinch roller through laser cladding

ActiveCN109576603AGuaranteed wear resistanceGuaranteed stabilityMetallic material coating processesThermal fatigueAlloy

The invention provides functional layer alloy powder for repairing a finish-rolling descaling box pinch roller through laser cladding. The functional alloy powder is composed of the components, by mass percentage, of 2-15 % of TiC powder, 0.1-1.1 % of C, 2.0-5.0 % of Si, 3-6 % of B, 5-10 % of Cr, 1-5 % of Ni, and the balance Fe. Meanwhile, the invention provides a method for repairing the finish-rolling descaling box pinch roller through laser cladding, the size of an original roller can be restored by repairing the finish-rolling descaling box pinch roller through the method, properties of the high-temperature wear resistance and the thermal fatigue resistance are improved, the repair cost is reduced, and the service life of the finish-rolling descaling box pinch roller is prolonged, so that the roller consumption is reduced and the production cost of enterprises is reduced.

Owner:沈阳大陆激光工程技术有限公司

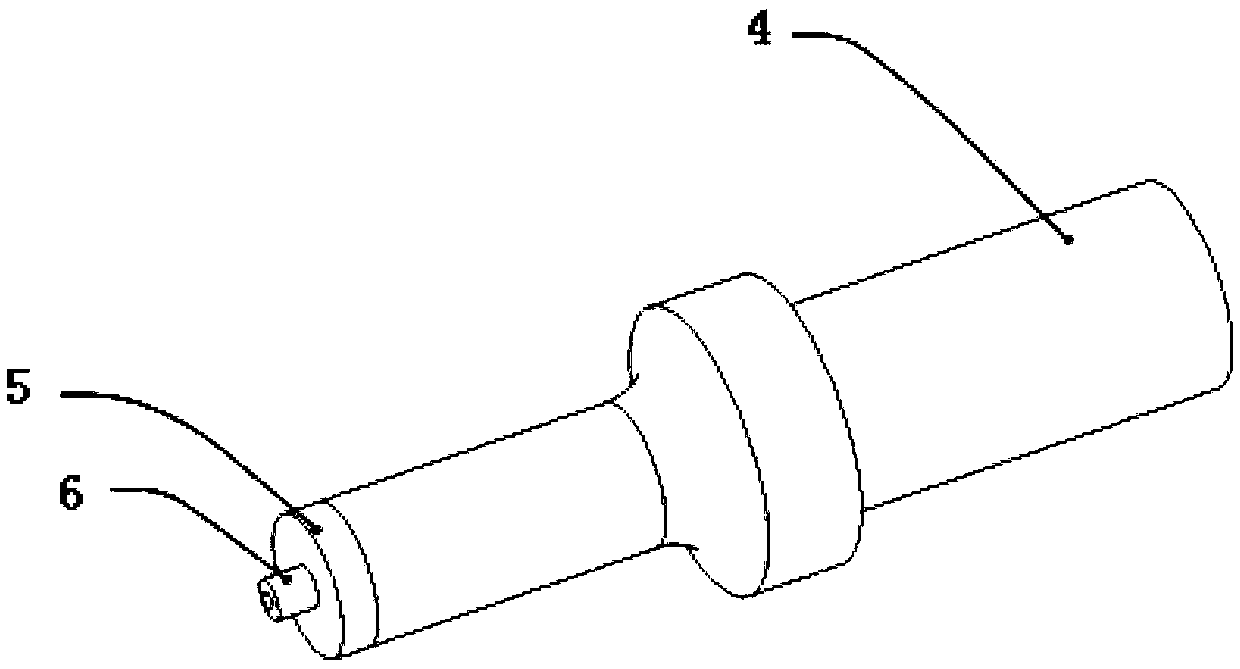

Laser-cladding repairing process for centering roller

InactiveCN105297009AConsistent thicknessImprove cladding efficiencyMetallic material coating processesThermal fatigueSlag

The invention relates to a laser-cladding repairing process for a centering roller. The abraded surface of the centering roller is repaired through modified laser cladding, meanwhile, the corrosion and abrasion resistance performance of the centering roller is improved, and the service life and the replacement cycle of the centering roller are effectively prolonged. The process comprises the following steps of (1) surface treatment on the centering roller needing repairing, (2) clamping and aligning, (3) laser-cladding repairing and (4) detection, flaw detection and machining. Compared with the prior art, the laser-cladding repairing process has the beneficial effects that (1) compared with a traditional cladding mode, a cladding layer formed by modified cladding is basically uniform in thickness, the cladding efficiency is improved by 10-20 times, and the production cost is low; (2) the bonding strength of a base body and the laser cladding layer is not lower than 90% of that of an original base material, and the cladding layer and an interface of the cladding layer are compact in structure, fine in grain and free of the defects of holes, slag inclusion, cracks and the like; (3) the surface hardness of a repaired layer is HV450-550, and the repaired centering roller has better high-temperature abrasion resistance performance, high creep limit, good endurance strength and better thermal fatigue and breakage resistance performance.

Owner:宋禹辰

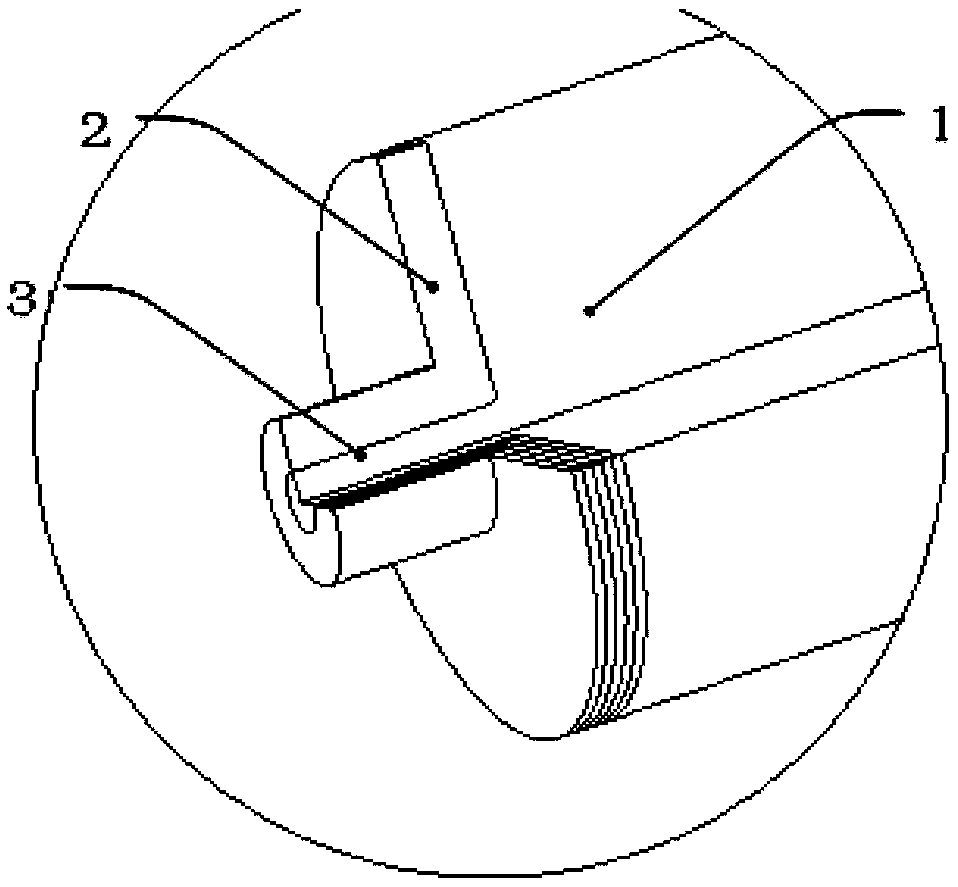

Alloy material of functional layer of laser manufacturing and remanufacturing crystallizer copper plate

ActiveCN106591631AImprove high temperature wear resistanceHigh V and C contentMetallic material coating processesMelting tankAlloy

The invention provides an alloy material of a functional layer of a laser manufacturing and remanufacturing crystallizer copper plate. The alloy material comprises 15%-20% of Cr, 3% or less of Ni, 2%-4% of Mo, 4%-6% of W, 1%-3% of C, 8%-10% of V and the balance Co. A preparation method for the functional layer comprises the following steps that (1) one layer of transitional layer alloy powder with the thickness being 1.0-2.0 mm is pre-arranged on the surface of the crystallizer copper plate through pre-arranging Ni-Al-Cu alloy powder, an optical fiber laser is chosen for scanning and fusion covering, then machining is conducted, and the thickness of the transitional layer is retained to be 0.5-1.5 mm; and (2) a CO2 laser is chosen, the powder is directly fed into a molten pool for scanning and fusion covering by adopting a mode of synchronous powder feeding. According to the alloy material of the functional layer of the laser manufacturing and remanufacturing crystallizer copper plate, a Ni-Al-Cu transitional alloy layer is covered in a fusion mode firstly, then a cobalt-based functional layer is covered on the Ni-Al-Cu transitional alloy layer in a fusion mode, and thus the properties of high temperature, corrosion and abrasion resistance of the surface of a crystallizer are improved.

Owner:沈阳大陆激光工程技术有限公司

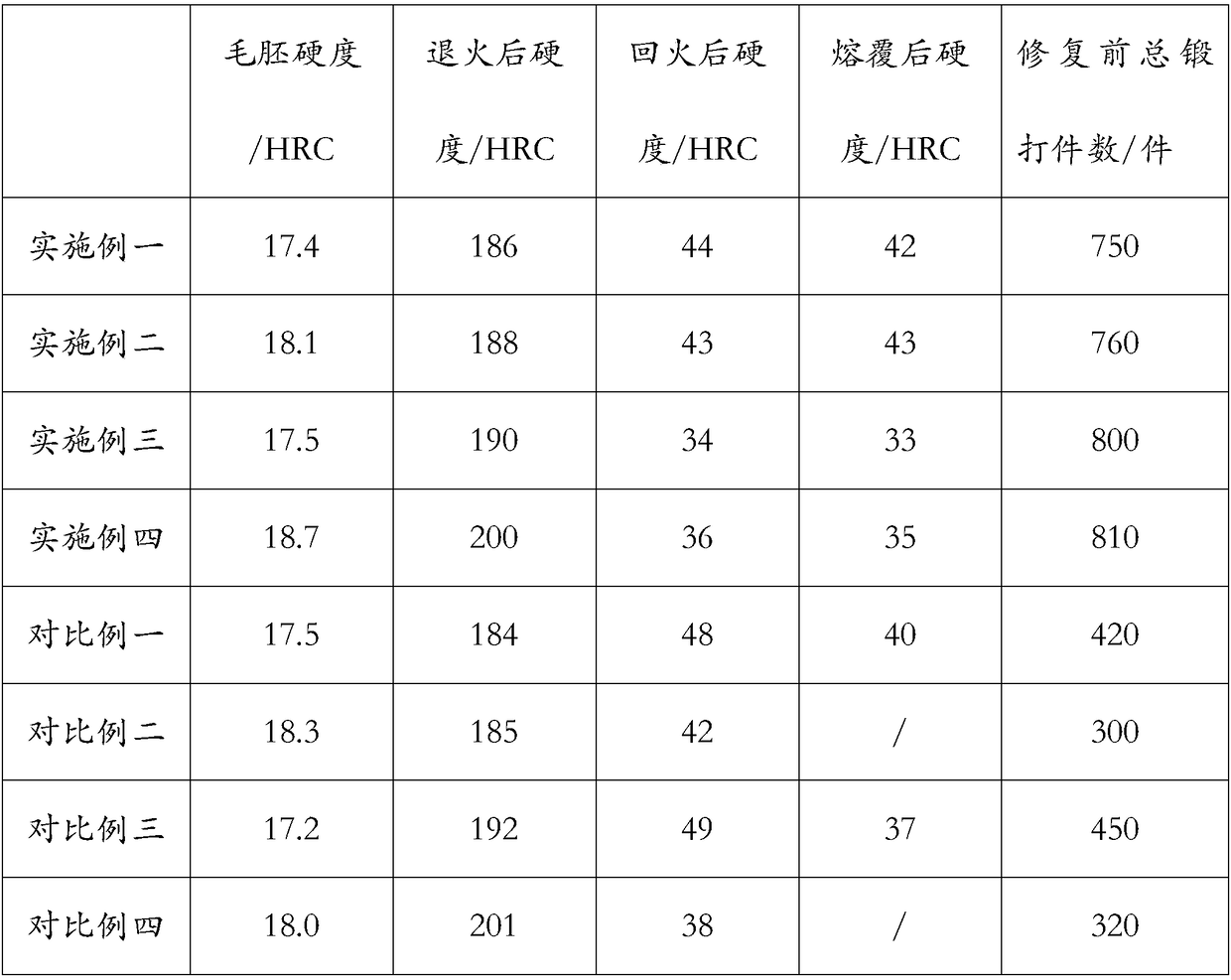

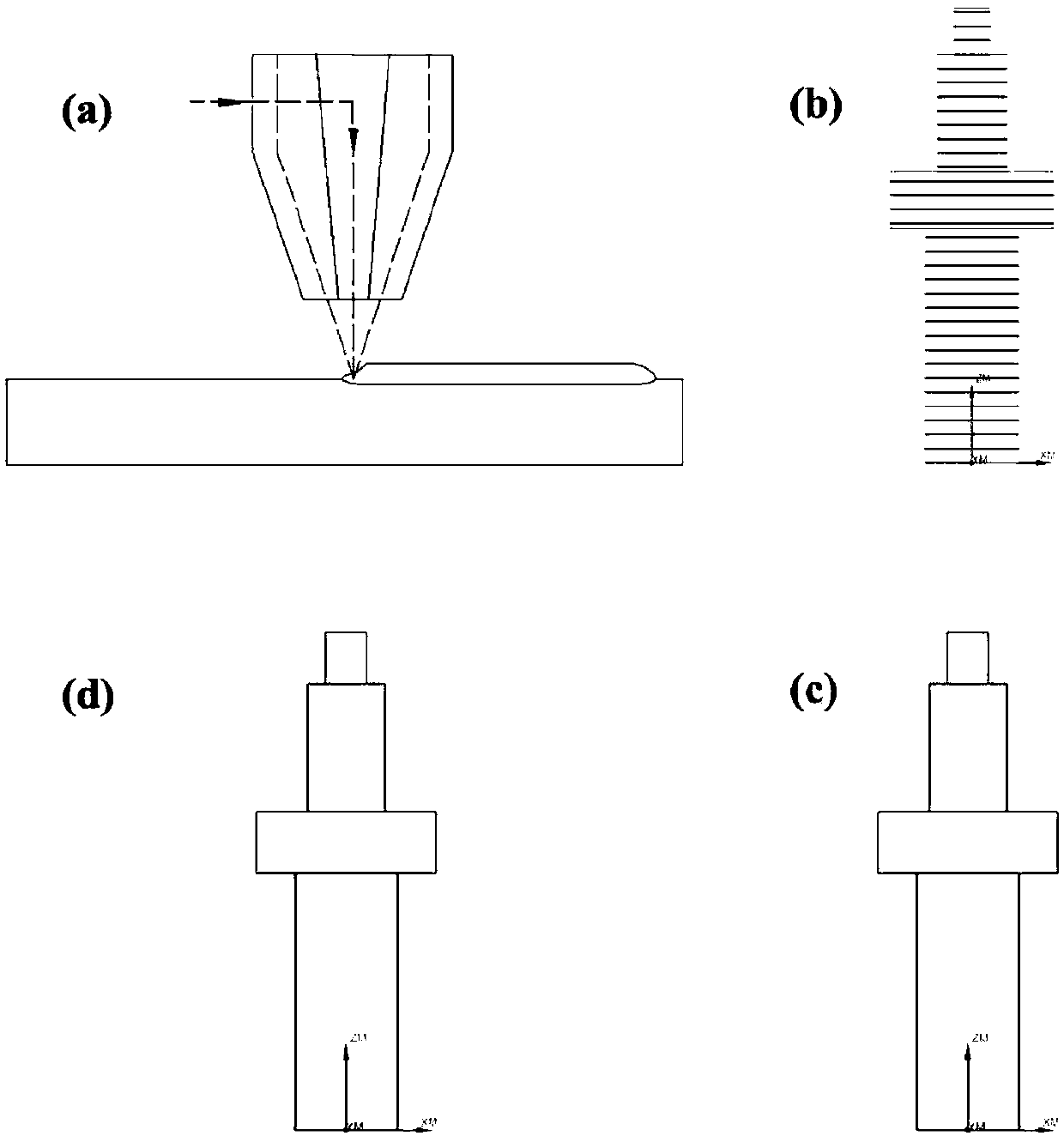

Method for prolonging service life of hot forging die

InactiveCN108118332AReduce heat radiationExtended service lifeForging/hammering/pressing machinesMetallic material coating processesHardnessLife time

The invention discloses a method for prolonging the service life of a hot forging die. The die is sequentially subjected to the technologies of forging and pressing, annealing, quenching, tempering and laser cladding. According to the method, the die heat treatment technology and the laser cladding technology are combined, and a brand new die hot forging method is formed; by utilization of the heat treatment technology, forging inner stress is eliminated, grains are refined, and die hardness uniformity is promoted; and by utilization of the laser cladding technology, a cladding layer excellentin abrasion resisting performance is formed, influences of conventional abrasion on the service life of the die are weakened, the service life of the die is prolonged, and the enterprise operating cost is reduced.

Owner:SHANDONG LUNAN GRP ENERGY EQUIP MFG

Laser near net forming method of functional graded friction stir welding stirring head

ActiveCN109514075AGood binding performanceEnhanced high temperature wear resistanceLaser beam welding apparatusNon-electric welding apparatusTungstenBoron nitride

The invention provides a preparation method of a functional graded friction stir welding stirring head. According to the preparation method, high-temperature wear resistant materials are adopted in friction positions with workpieces, i.e. the surfaces of a stirring pin and a shaft shoulder; materials with good toughness, high strength and good economy are adopted in non-contact positions of the center of the stirring pin and the end surface of the shaft shoulder, and finally, a laser near net forming mode is adopted so as to realize graded transition of the two materials and near net forming of the stirring head. According to the laser near net forming method of the functional graded friction stir welding stirring head, the stirring pin and the shaft shoulder which make direct contact withmetal when the stirring head is operated can have good high-temperature wear resistant performance, and the whole stirring head has the advantages of good toughness, high strength and good economy. Compared with traditional tool steel and die steel, the laser near net forming method has the advantages that the application range of a stirring tool is enlarged, and the service life is prolonged; compared with a tungsten-based stirring head and a polycrystalline cubic boron nitride stirring head, the laser near net forming method has the advantage that the whole fracture toughness and the manufacturing economy of the stirring head are greatly increased.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

Lubricant composition for railway high-speed diesel engine

ActiveCN102690714AImprove antioxidant capacityGood high temperature cleanAdditivesAntioxidantOxidation resistant

The invention relates to a lubricant composition for a railway high-speed diesel engine. The lubricant composition comprises A) a composite antioxidant comprising at least components of 1, an alkylated diphenylamine antioxidant, 2, a thiophenolic ester antioxidant and 3, an unessential phenolic thioether antioxidant, B) a polyisobutylene succinimide ashless dispersant and / or a polyisobutylene succinate dispersant, C) a mixture of calcium sulfonate and calcium naphthenate, D) at least one extreme pressure anti-wear agent, E) one or more ashless friction modifiers, and F) a main amount of lubricating base oil. The lubricant composition has a synergistic effect of the additives, can satisfy high-temperature antioxidation requirements of lubricating oil for a railway high-speed diesel engine, and has excellent piston cleanliness, high / low-temperature wear resistance and a good viscosity increasing control capacity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Lubricant composition for ship outboard engine

ActiveCN102690713AImprove cleanlinessMeet lubrication requirementsAdditivesAntioxidantOxidation resistant

The invention relates to a lubricant composition for a ship outboard engine. The lubricant composition comprises A) a composite antioxidant composing at least components of 1, an alkylated diphenylamine antioxidant, 2, a thiophenolic ester antioxidant and 3, an unessential phenolic thioether antioxidant, B) a polyisobutylene succinimide ashless dispersant, C) a mixture of calcium salicylate and sulfurized calcium alkyl phenate, D) at least one zinc dialkyldithiophosphate, E) at least one extreme pressure anti-wear reagent, F) one or more metal deactivators, and G) a main amount of lubricating base oil. The lubricant composition utilizes optimized combination of the multiple ashless antioxidants, is compounded with the appropriate clearing agent and the dispersant, has a synergistic effect of the additives, can satisfy high-temperature antioxidation requirements of lubricating oil for a ship outboard engine, and has excellent piston cleanliness, high / low-temperature wear resistance and a good viscosity increasing control capacity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com