Lubricant composition for ship outboard engine

A technology for lubricating oil composition and outboard engine, applied in lubricating composition, petroleum industry, additives and other directions, can solve the problems of harsh anti-oxidation requirements, easy oxidative deterioration and corrosion of lubricating oil, and achieve excellent anti-oxidative performance, Good high temperature cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1-4

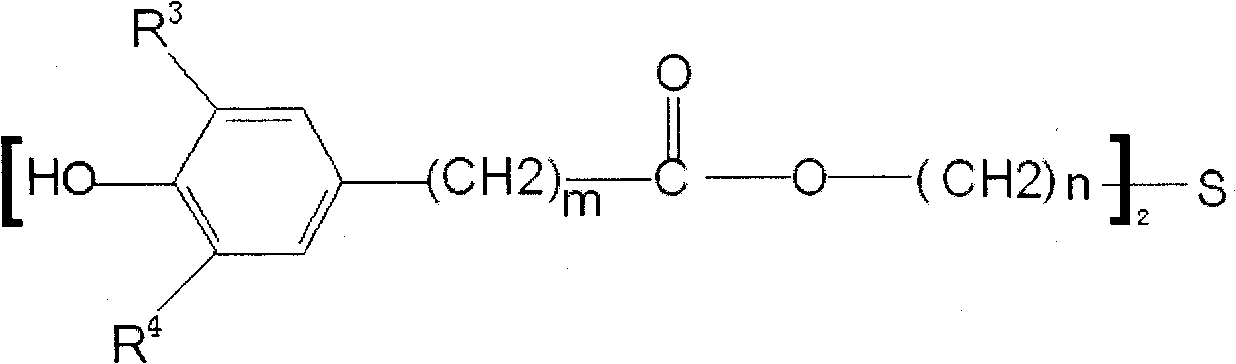

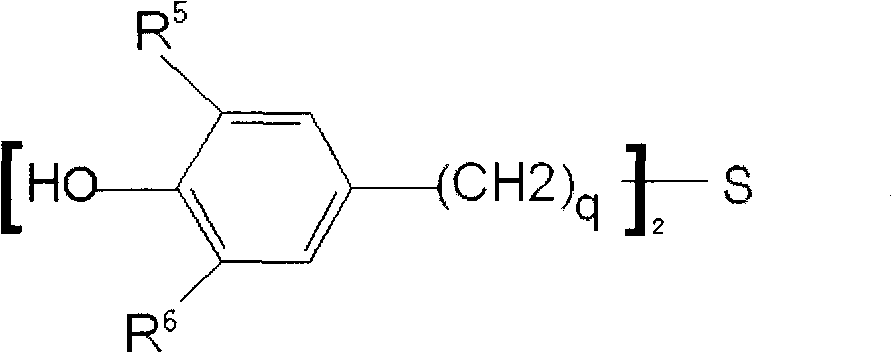

[0058] Add antioxidants T534, 1035, and methylidene 4426-S into the mixing container in proportion, heat at 60°C-90°C under normal pressure, and stir for 1 hour-2 hours to obtain a uniform transparent light yellow viscous liquid. Invented component A composite antioxidant. The composition ratio (mass fraction) of composite antioxidant preparation examples 1-4 is shown in Table 1.

[0059] Table 1

[0060] serial number

Embodiment 1

[0062] Embodiments 1-5 are the composition and main properties of the marine outboard motor lubricating oil of the present invention. Add each component into a blending container in proportion, heat at 45°C-80°C under normal pressure, and stir for 1 hour-2 hours to prepare a marine outboard motor lubricating oil with a viscosity grade of SAE 10W-30. In comparative examples 1, 2, and 3-1, single-component antioxidants were added, namely T534, 1035, and methylene 4426-S, and in comparative example 3-2, a double-component antioxidant prepared by the method of patent CN100460490C was added. Divide compound antioxidant, wherein embodiment 1 and comparative example 1, embodiment 2 and comparative example 2 have all identical formulas except antioxidant respectively, and embodiment 3 and comparative example 3-1, 3-2 also have All the same formula composition except antioxidant. See Table 2 for the composition ratios (mass fractions) of Examples 1-5 and Comparative Examples 1, 2, 3-1...

Embodiment 6、7

[0071] Embodiment 6,7 and comparative example 4-6

[0072] According to the composition of Table 5, the marine outboard engine oil with a viscosity grade of 10W-30 was prepared. Each 300ml of the oil products of Examples 6 and 7 and Comparative Examples 4-6 were subjected to a coke-forming test. The formulation compositions and coke plate test results of the examples and comparative examples are shown in Table 5. Wherein embodiment 6,7 added is the mixture of high alkali value calcium salicylate and high alkali value sulfurized alkylphenate calcium, and what added in comparative example 4,5 is the high alkali value calcium salicylate of single component respectively Or high base value sulfurized calcium alkylphenate. The difference between Example 6 and Comparative Example 6 is that a metal deactivator 2-mercaptobenzothiadiazole is added in Example 6, and no metal deactivator is added in Example 6.

[0073] table 5

[0074]

[0075] The equipment used in the coke plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com