Patents

Literature

1587results about How to "Improve oxidation resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nanostructured chemicals as alloying agents in fluorinated polymers

InactiveUS7193015B1Reduce melt viscosityLow dielectric constantMaterial nanotechnologyMolecular levelCompression set

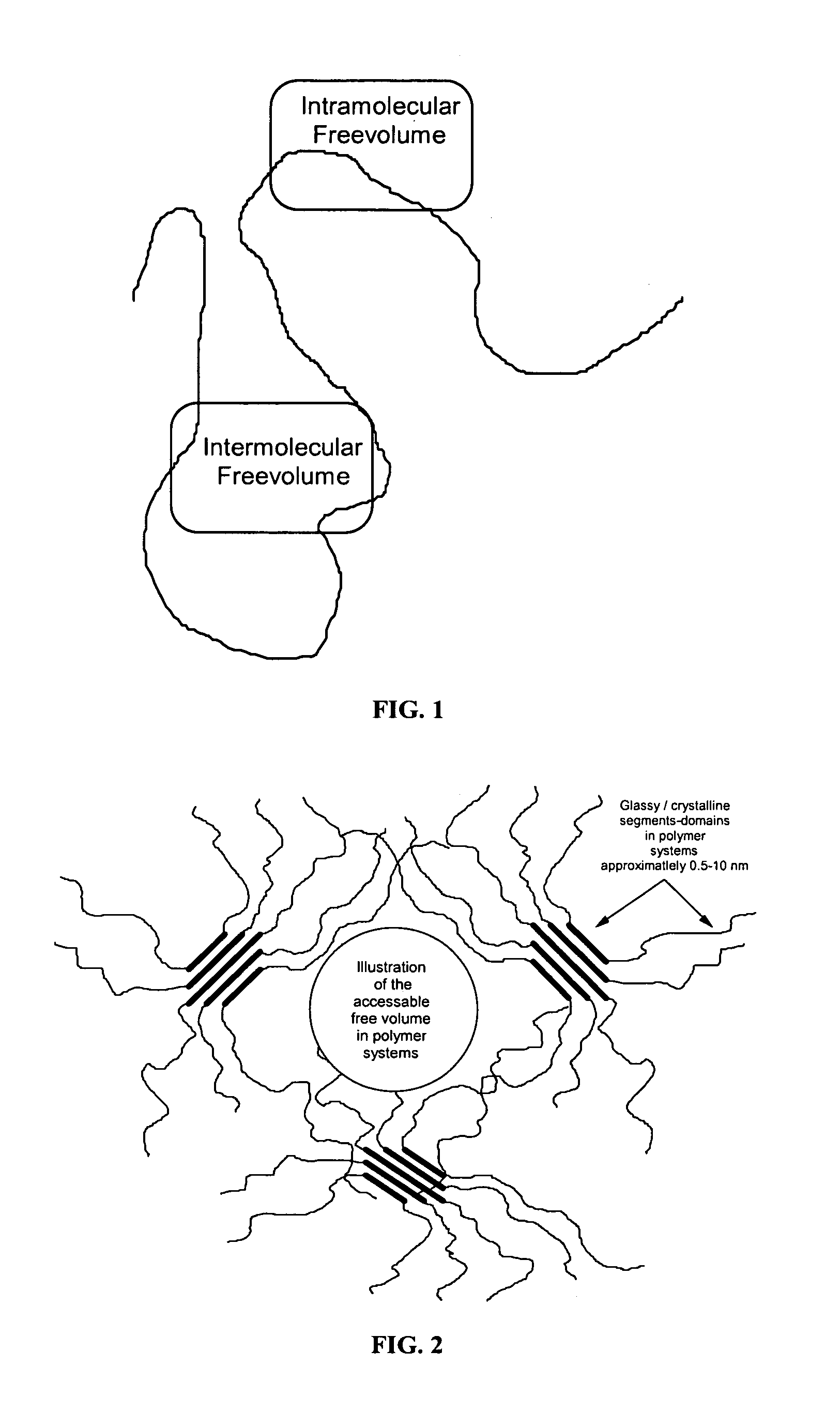

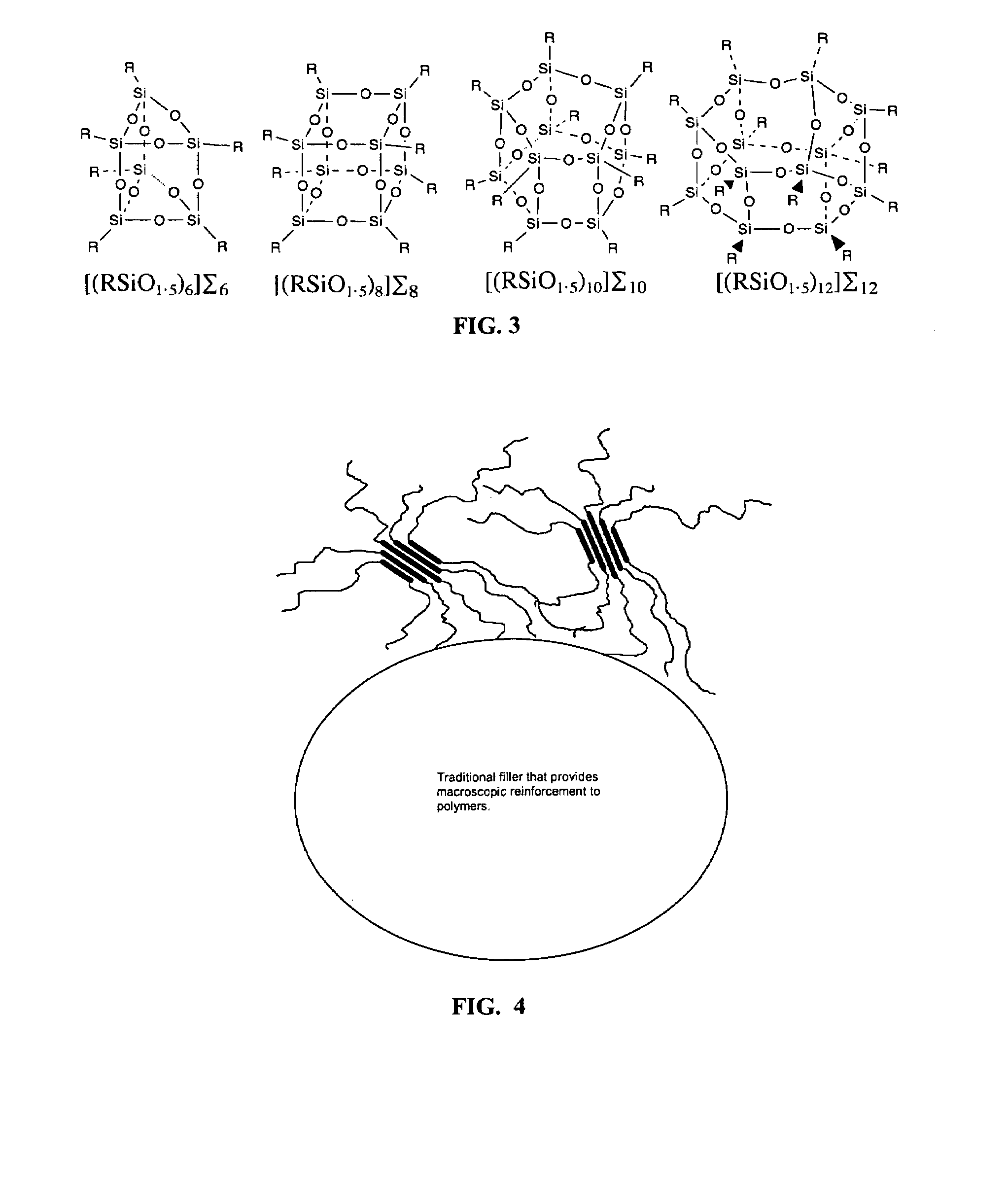

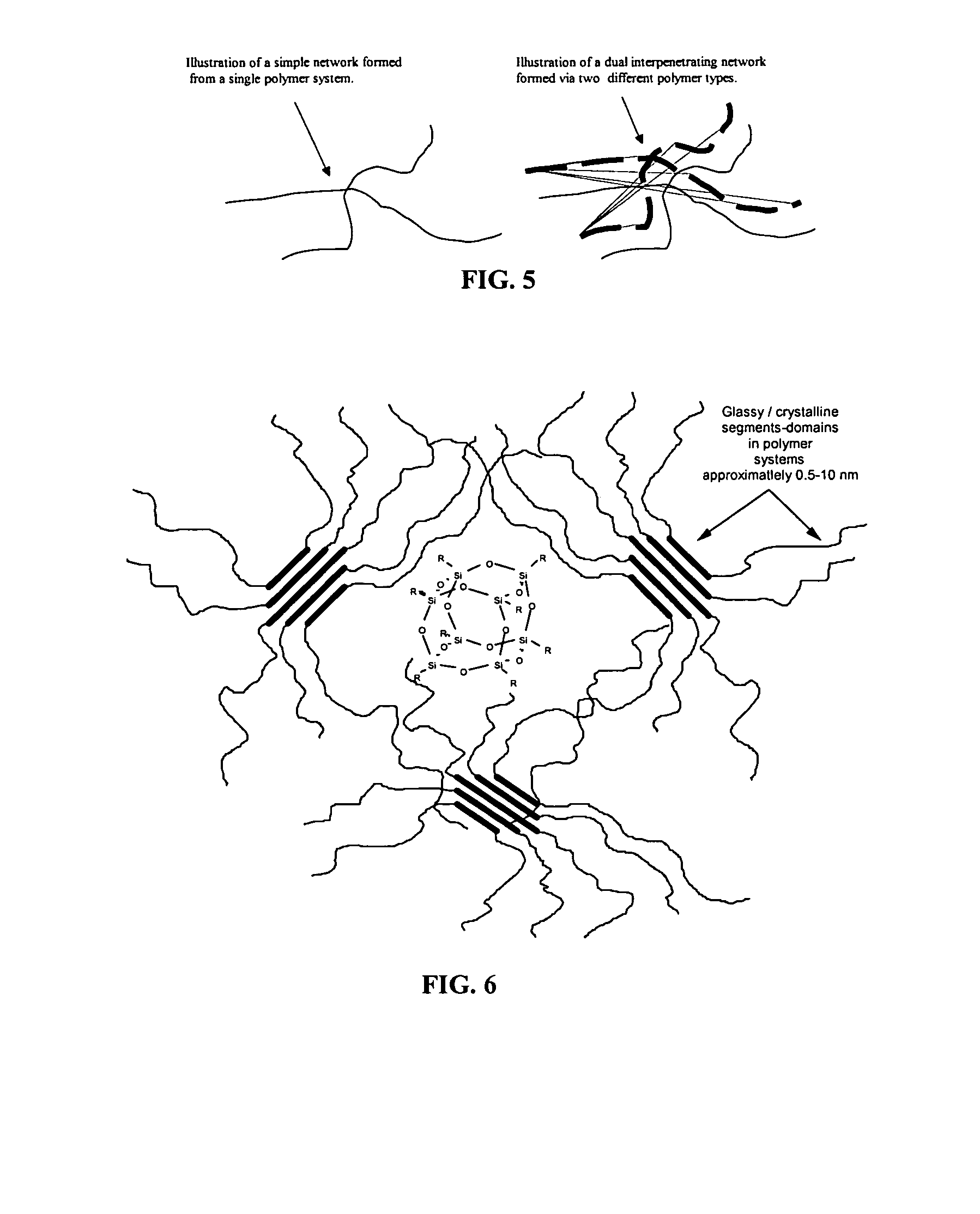

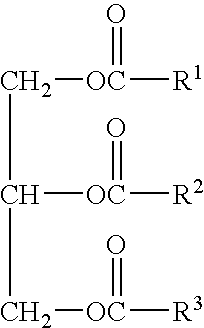

A method of using nanostructured chemicals as alloying agents for the reinforcement of flouropolymer microstructures, including polymer coils, domains, chains, and segments, at the molecular level. Because of their tailorable compatibility with fluorinated polymers, nanostructured chemicals can be readily and selectively incorporated into polymers by direct blending processes. Properties most favorably improved are time dependent mechanical and thermal properties such as heat distortion, creep, compression set, shrinkage, modulus, hardness and abrasion resistance. In addition to mechanical properties, other physical properties are favorably improved, including lower thermal conductivity, fire resistance, and improved oxygen permeability. These improved properties may be useful in a number of applications, including space-survivable materials and creep resistant seals and gaskets. Improved surface properties may be useful for applications such as anti-icing or non-wetting surfaces or as low friction surfaces.

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

Electromagnetic shielding conductive coating and preparation method thereof

InactiveCN102618145AReduce dosageImprove shielding effectEpoxy resin coatingsElectrically-conductive paintsConductive coatingElectromagnetic shielding

The invention provides an electromagnetic shielding conductive coating and a preparation method thereof. The electromagnetic shielding conductive coating comprises film-forming substances, conductive powder, thickening agents, coupling agents and curing agents. The mass ratio of the film-forming substances to the conductive powder to the thickening agents to the coupling agents to the curing agents is 5-20:50-75:5-30:0.7-4:6.5-15. Auxiliaries are added into the film-forming substances and stirred to be completely dissolved, the thickening agents are added into mixture, the coupling agents are then added into the mixture, the conductive powder is added into the mixture after stirring, and the curing agents are added into the mixture, so that the electromagnetic shielding conductive coating is obtained. By means of composition and proportioning for the conductive coating, the prepared coating is excellent in electric conductivity and resistant to acid, alkaline and oxidization. Besides, the resistivity of the conductive coating prepared by the preparation method is continuously reduced, and conductive high molecular polymer for the conductive powder in the conductive coating is well compatible with organic resin, so that air bubbles and needle holes in the coating can be decreased.

Owner:KUNMING UNIV OF SCI & TECH

High temperature biobased lubricant compositions from boron nitride

InactiveUS20100105583A1Improve the lubrication effectEnhanced anti-wearBase-materialsBoron nitrideAlpha-olefin

This present invention discloses a method for the preparation of an improved high temperature engine lubricant composition comprising the steps of: 1) providing at least one biobased natural oil or biobased synthetic oil selected from the group consisting of natural or synthetic vegetable oil, natural or synthetic animal oil, genetically modified vegetable oil, genetically modified synthetic vegetable oil, natural or synthetic tree oil, and mixtures thereof; 2) providing at least one boron nitride; and 3) optionally, providing at least one base oil selected from the group consisting of a synthetic ester, solvent refined petroleum oil, a hydrocracked petroleum white oil, an all hydroprocessed synthetic oil, Fischer Tropsch oil, petroleum oil group I, group II, group III, a polyalphaolefin (PAO), and mixtures thereof; 4) optionally, providing at least one additive or combination of additives selected from the group consisting of anti-oxidant(s), corrosion inhibitor(s), metal deactivator(s), viscosity modifier(s), anti-wear inhibitor(s), friction modifier(s), and extreme pressure agent(s); 5) blending 1), 2), 3), and 4) in any sequence to form said composition.

Owner:RENEWABLE LUBRICANTS INC

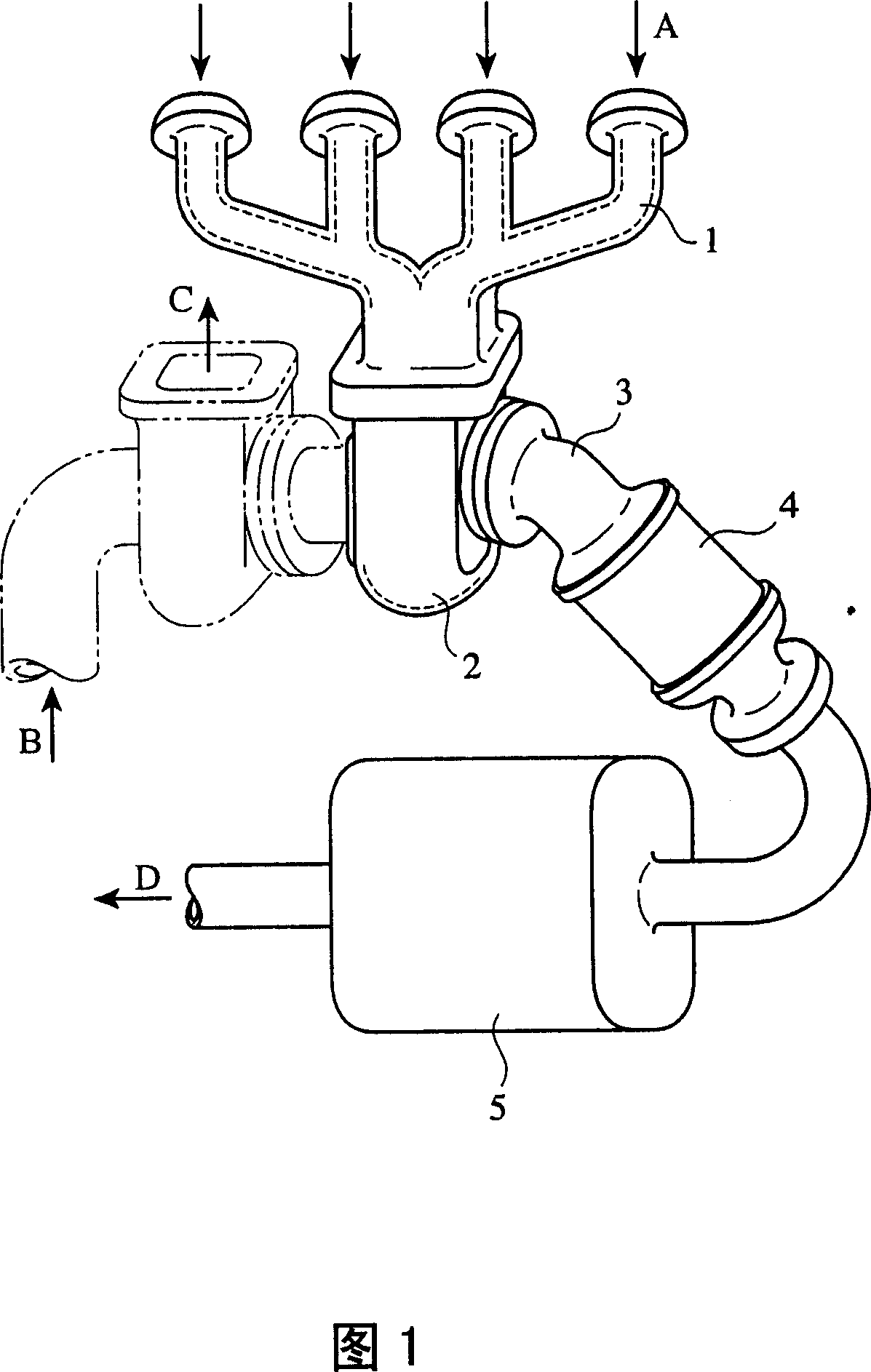

High-cr high-ni austenitic heat-resistant cast steel and exhaust system component produced from same

ActiveCN1942598AHigh temperature yield pointImprove oxidation resistanceSilencing apparatusMachines/enginesThermal fatigueImpurity

Disclosed is a high-Cr high-Ni austenitic heat-resistant cast steel having a composition mainly containing C, Si, Mn, Cr, Ni, W and / or Mo, and Nb, and further containing, in weight%, 0.01-0.5% of N, not more than 0.23% of Al, not more than 0.07% of O and the balance of Fe and unavoidable impurities. Since this high-Cr high-Ni austenitic heat-resistant cast steel is excellent in high-temperature resistance, oxidation resistance and thermal fatigue life, it is preferably used for exhaust system components.

Owner:PROTERIAL LTD

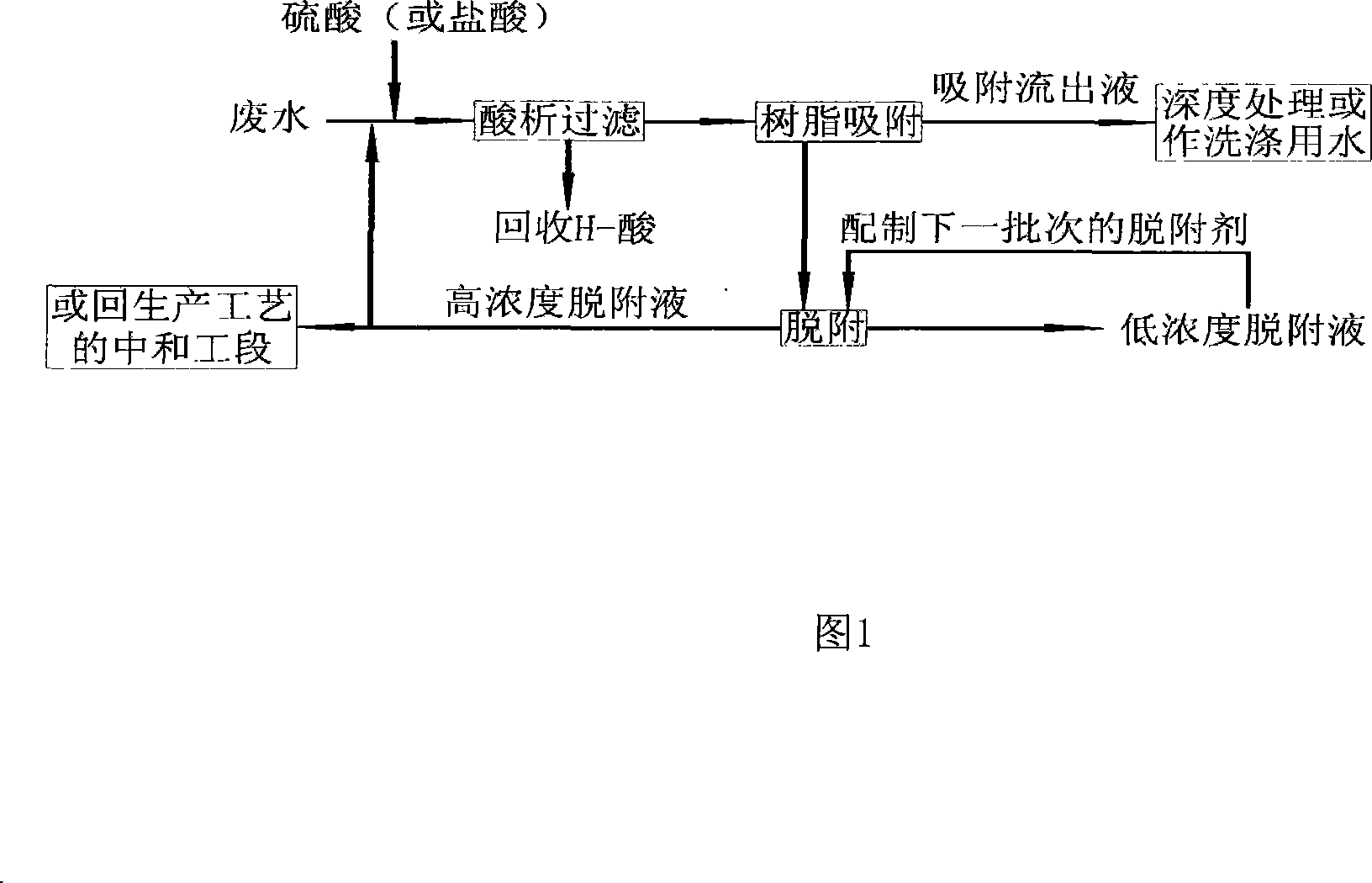

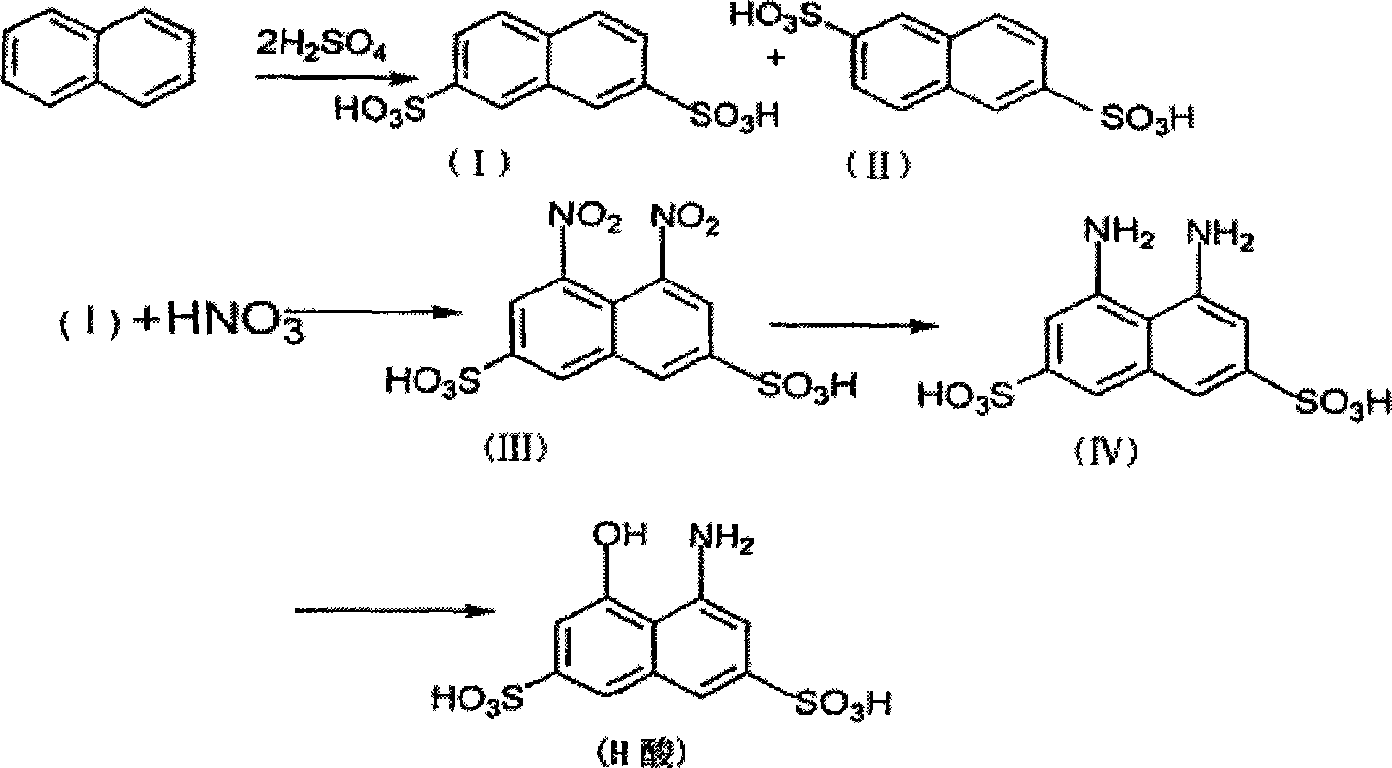

Method for treating waste water of H-acid production

InactiveCN101104533ANot affected by the adsorption effectImprove practicalityOrganic chemistryIon-exchange column/bed processesResource utilizationDesorption

The present invention is a treatment method for naphthalene dye intermediate H-acid production wastewater. After H-acid pretreatment wastewater is preprocessed, organic compounds such as, 1-amido-8- naphthol-3, 6-disulfonic acid (H-acid) and intermediate products, are adsorbed on the resin through alkalescence macroporous adsorption resin; the adsorbed water is added with lye for desorption regeneration and the regenerated liquid will be back into the previous production process for application. The CODcr of the treated wastewater can be effectively reduced to reach the national emission standards; the reclaimed H-acid sodium salt can be used. The resin can be desorbed and regenerated through lye for repeated use. The desorbed liquid is distilled and reclaimed, and the distilled effluent can be used repeatedly. The H-acid sodium salt and the intermediate products reclaimed through the invention can be used as raw materials for the original production process; therefore, the invention not only helps treating wastewater but also realizes waste resource utilization.

Owner:NANKAI UNIV

Nano mirror spray coating

InactiveCN1944710AExtended use timeImprove adsorption capacityLiquid/solution decomposition chemical coatingPotassium borohydrideSpray coating

The nanometer mirror spraying process includes the following steps: 1. eliminating surface dust; 2. spraying primer; 3. sensitizing and activating treatment; 4. spraying solution A comprising silver nitrate solution, ammonia water solution and sodium hydroxide solution and solution B comprising sodium borohydride, potassium borohydride or p-methylaminophenol sulfate solution in the volume ratio of 1 to 1-1.7 to produce reduction; 5. shaping and developing; 6. blowing to dry; and 7. drying. The present invention has the advantages of diversified products, high corrosion resistance, suitability to mass production, high hardness, low cost, etc.

Owner:方宏亮

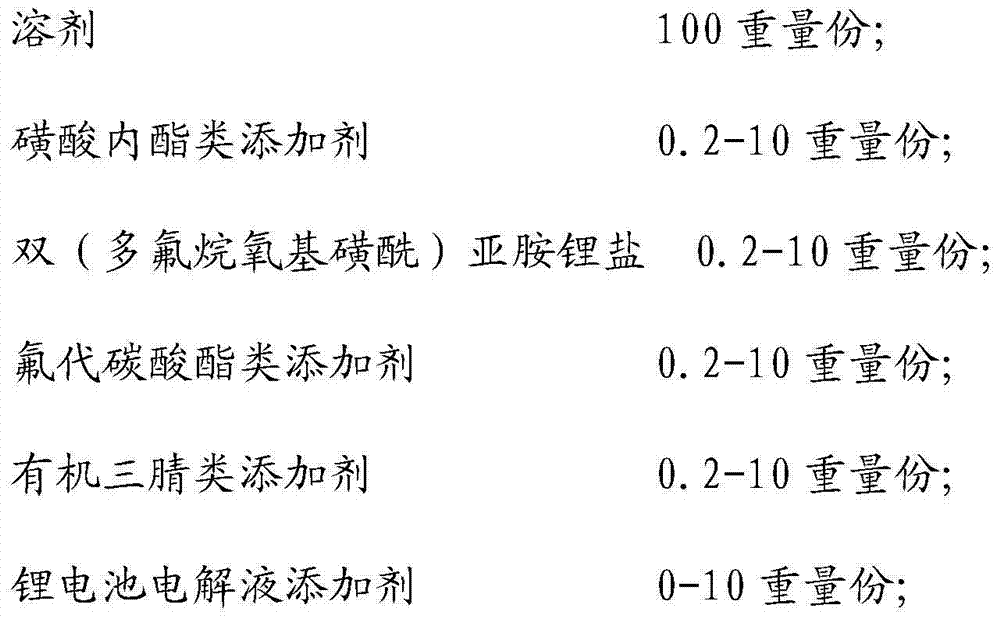

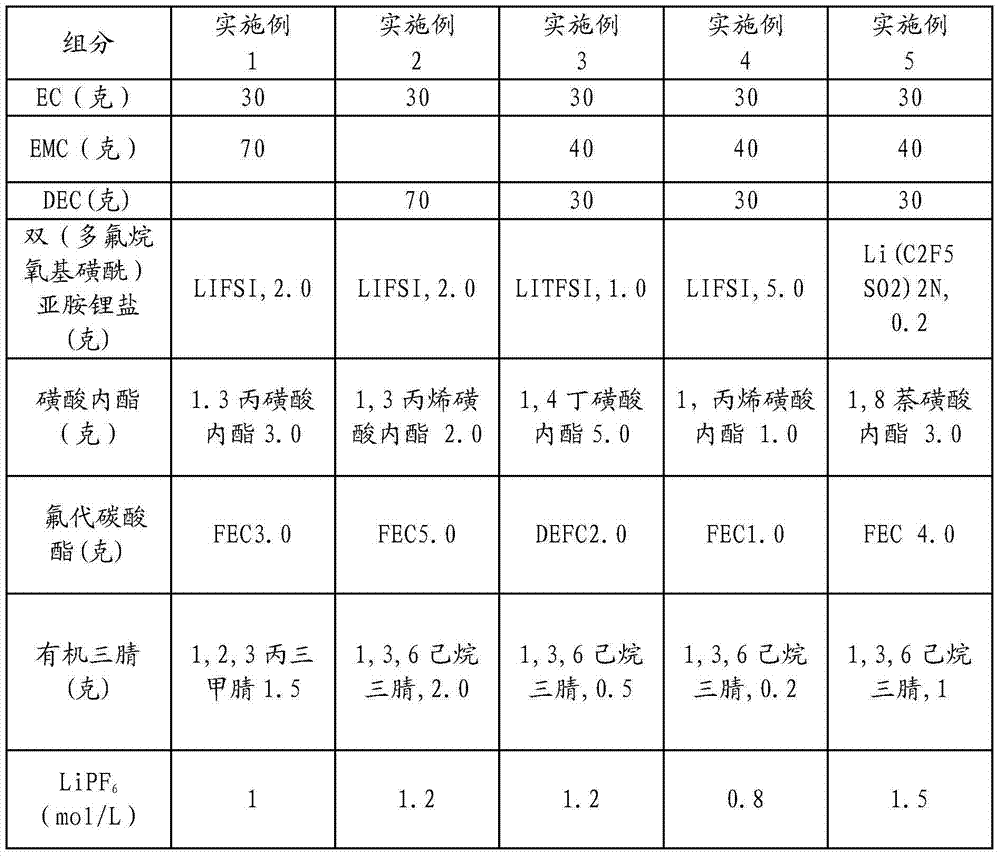

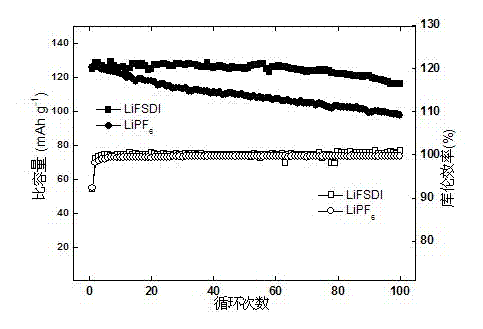

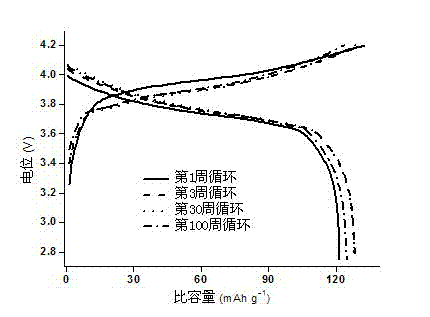

Nonaqueous electrolyte for high-voltage lithium ion battery

ActiveCN104505535AImprove wettabilityImprove oxidation resistanceSecondary cellsCarbonate esterCombined use

The invention discloses nonaqueous electrolyte for a high-voltage lithium ion battery. The nonaqueous electrolyte consists of a solvent, an inorganic lithium salt, a fluoro-ester additive, a sultone additive, an organic tri-nitrile additive, a bi(polyfluoroalkoxy sulfonyl) imine lithium salt and a lithium battery electrolyte additive, wherein the addition amount of the solvent is 100 weight parts; the addition amount of the fluoro-carbonate additive is 0.2-10 weight parts; the addition amount of the nitrile additive is 0.2-10 weight parts; the addition amount of the bi(polyfluoroalkoxy sulfonyl) imine lithium salt is 0.2-10 weight parts; the addition amount of the common lithium battery electrolyte additive is 0-10 weight parts; the solvent refers to cyclic carbonate and / or chain carbonate; and the molar concentration of the inorganic lithium salt in the solvent is 0.8-1.5mol / L. According to combined use of the sultone additive, the fluoro-ester carbonate additive, the bi(polyfluoroalkoxy sulfonyl) imine lithium salt and the organic tri-nitrile additive, the oxidation resistance of the SEI film during primary formation of the electrolyte can be improved, and the normal-temperature and high-temperature cycle performance of the high-voltage electrolyte is obviously improved.

Owner:ZHUHAI SMOOTHWAY ELECTRONICS MATERIALS

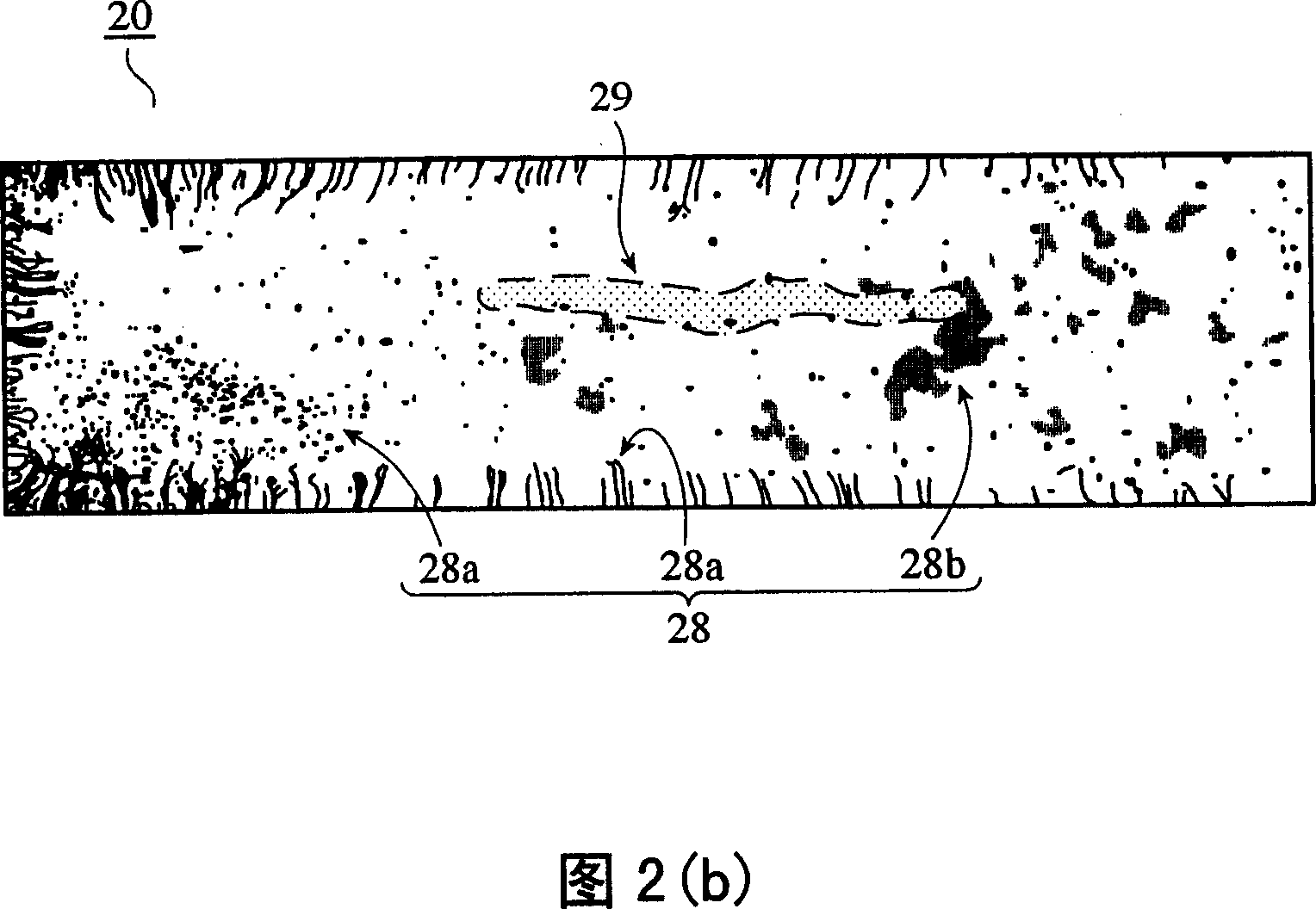

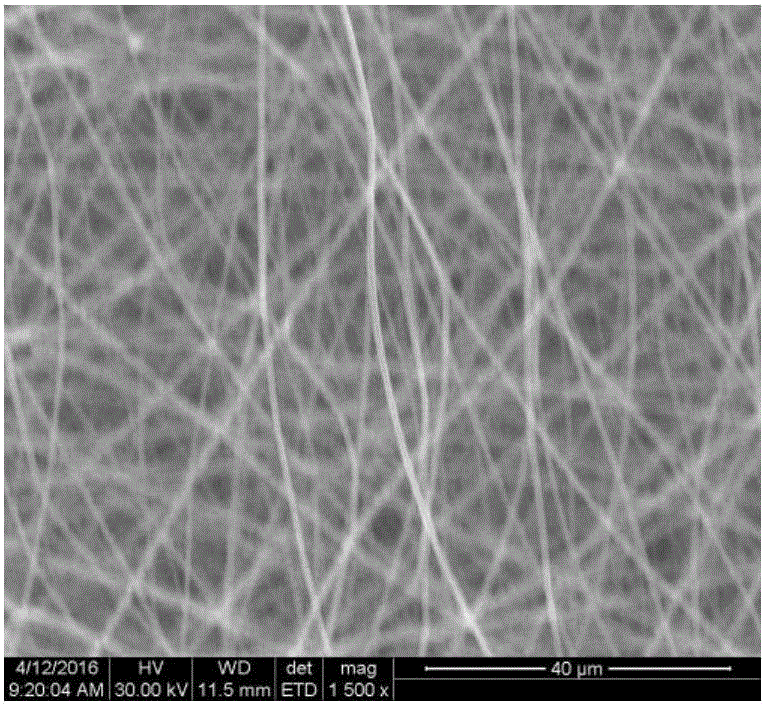

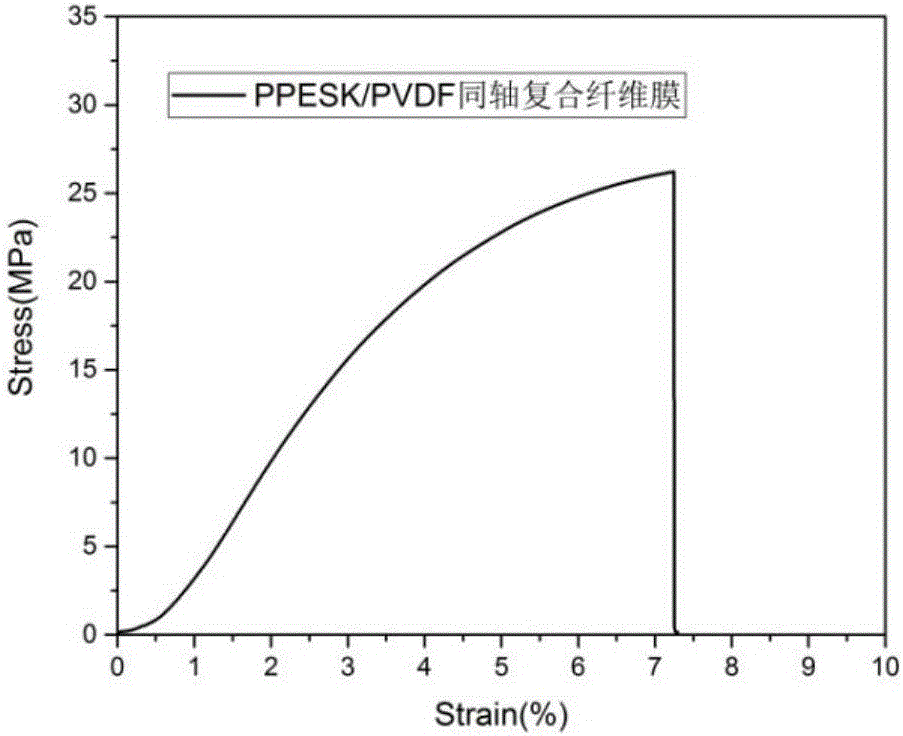

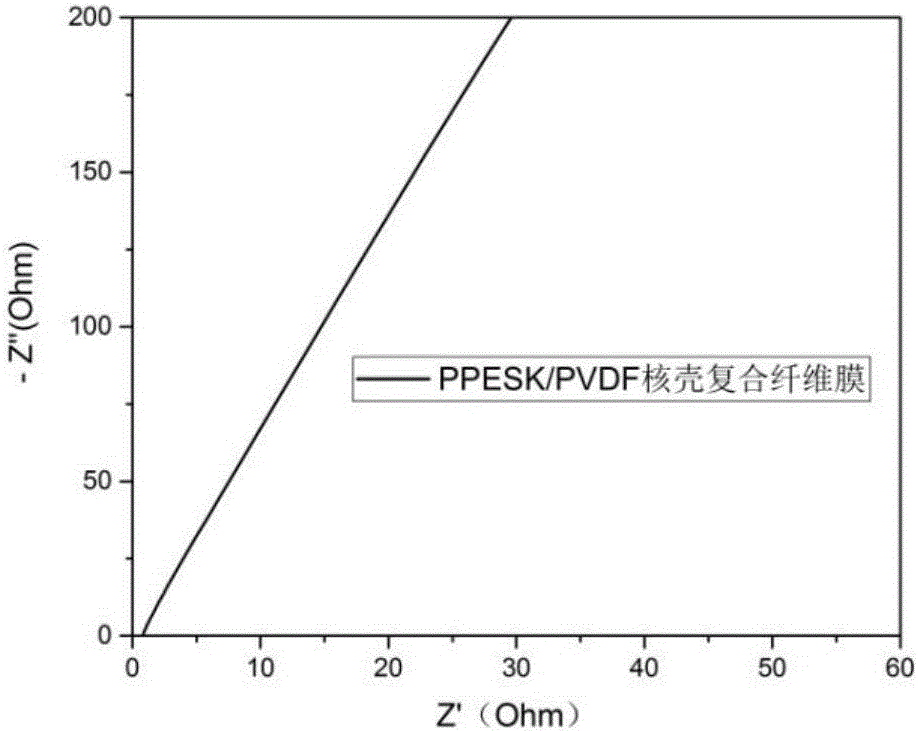

Method for preparing novel lithium battery diaphragm by coaxial electrostatic spinning

ActiveCN106450101AGood high temperature resistanceImproved high temperature thermal stabilityElectro-spinningCell component detailsPolyvinylidene fluorideElectrospinning

The invention provides a method for preparing a novel lithium battery diaphragm by coaxial electrostatic spinning, and belongs to the technical field of the lithium battery diaphragm. The novel lithium battery diaphragm is a composite fiber membrane prepared by a coaxial electrostatic spinning technology and having a core / shell structure; the core and shell layers of the composite fiber membrane are concentric-coaxial-shaped; the core layer consists of high-melting-point polyarylether sulfone ketone nanofibers; the shell layer consists of low-melting-point polyvinylidene fluoride nanofibers; particularly, the coaxial composite diaphragm is subjected to hot-press treatment at certain temperature and pressure; and the shell layer fibers generate micro melting or melting to enhance the binding power between fibers, so that the tensile strength of the composite diaphragm in each direction is greatly improved. The porosity of the novel lithium battery diaphragm reaches greater than 75%; and the electrolyte absorption rate reaches greater than 550%; the diaphragm can withstand a temperature of 180 DEG C, so that the diaphragm prepared by the method has good electrochemical property, thermal performance and mechanical performance, which has high application value in the fields of aviation, spaceflight, electric vehicle and the like.

Owner:DALIAN UNIV OF TECH

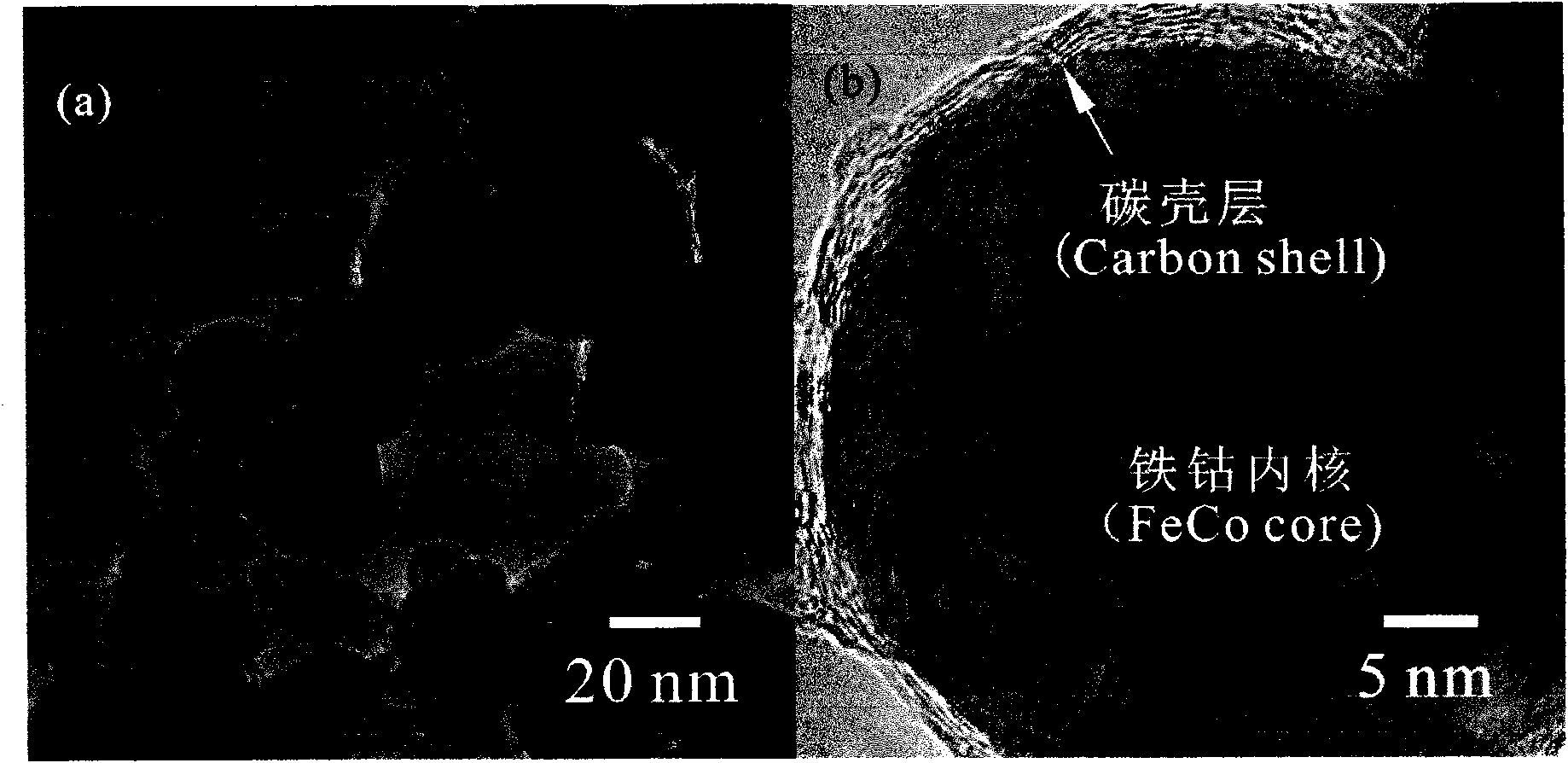

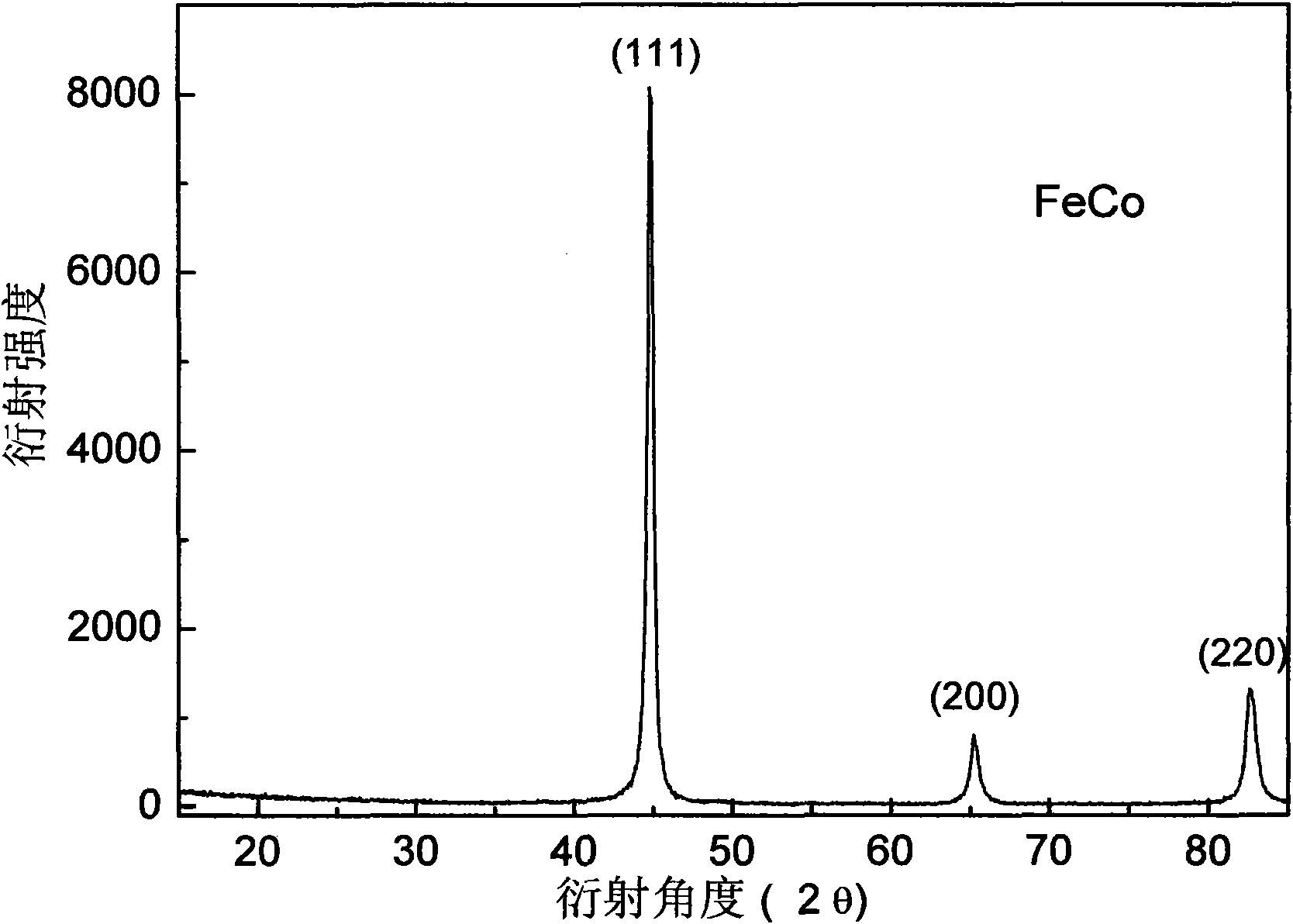

Method for preparing carbon-wrapped iron-cobalt nano wave-absorbing material

InactiveCN101567224AGood microwave absorptionImprove oxidation resistanceScreening apparatusPlasma techniqueOxidation resistantNanometre

The invention provides a method for preparing a carbon-wrapped iron-cobalt nano composite material with broad band and strong absorption. The composite material is prepared by adopting the technology that plasmas is generated by arc discharge of a negative electrode and a positive electrode under working gas, wherein the working gas is argon gas, simultaneously organic substances which can provide carbon elements and do not introduce impurities except C, H and O are added, the negative electrode is made of metals with high melting point and volatile difficulty such as tungsten and the like, and a target material for the positive electrode is iron-cobalt alloy, wherein the iron element accounts for 10 to 90 percent of alloy atomic. The carbon-wrapped iron-cobalt nano wave-absorbing material prepared by the method is a nano capsule formed by wrapping carbon outside the nano-scale iron-cobalt alloy; on one hand, a carbon shell layer is used as an oxidation resistant layer to increase the stability of a nano compound; and on the other hand, the carbon shell layer is used as a dielectric material and compounded with a magnetic iron-cobalt inner core so that the wave-absorbing property of the wave-absorbing material is superior to most classical ferrite and other most nano compound wave-absorbing materials.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

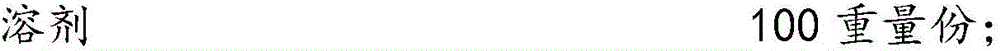

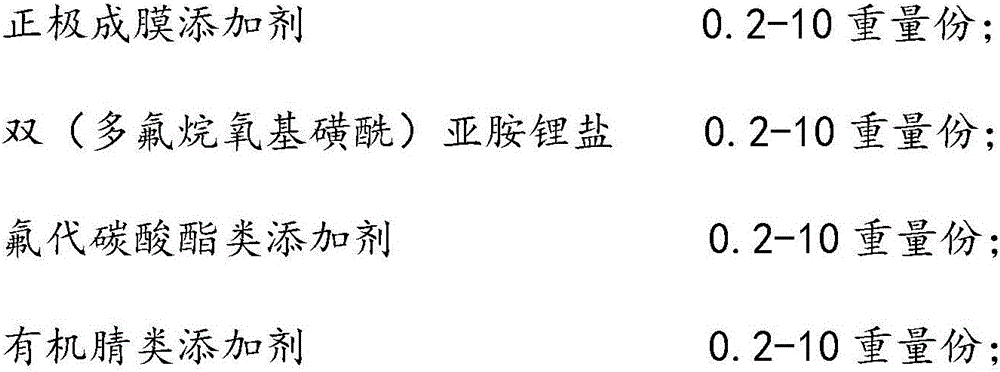

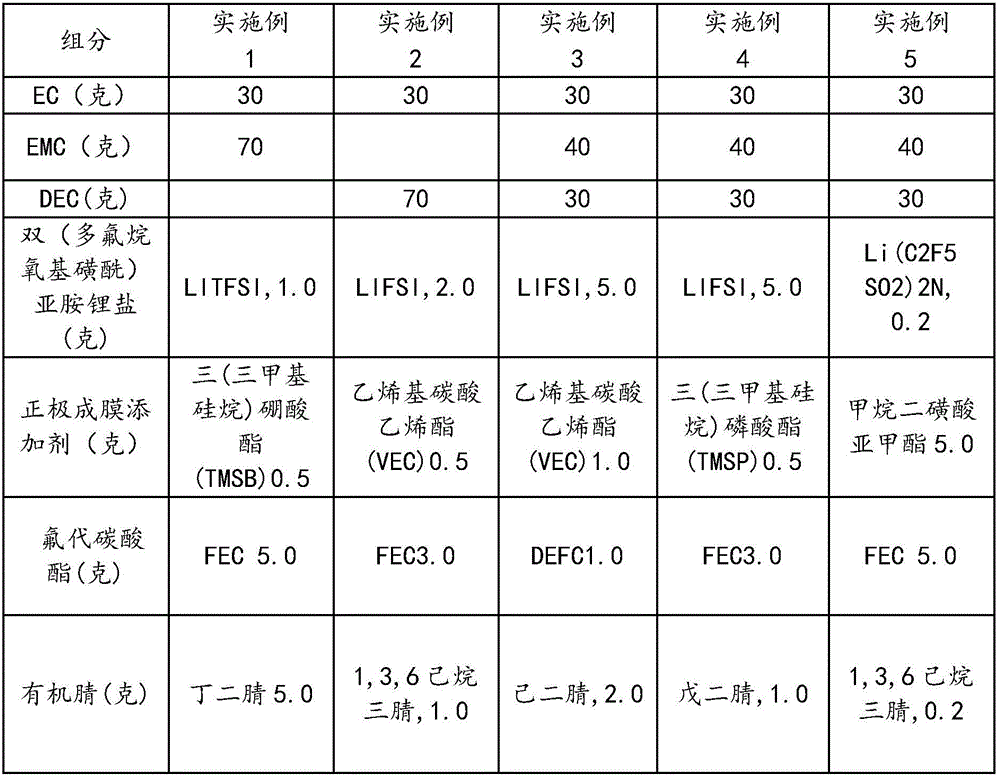

Non-aqueous electrolyte for high-voltage rapid-charging type lithium ion battery

InactiveCN105703007AImprove oxidation resistanceImprove wettabilitySecondary cellsOrganic electrolytesHigh temperature storageSolvent

The invention discloses a non-aqueous electrolyte for a high-voltage rapid-charging type lithium ion battery. The non-aqueous electrolyte comprises a solvent, a commonly-used lithium salt, a positive electrode film-forming additive, lithium bis(polyfluoroalkyloxysulfonyl) imide, a fluoro-ester additive, an organic nitrile additive and a lithium battery electrolyte additive, wherein the ingredients are as follows in parts by weight: 100 parts of solvent, 0.2-10 parts of positive electrode film-forming additive, 0.2-10 parts of lithium bis(polyfluoroalkyloxysulfonyl) imide, 0.2-10 parts of fluoro-ester additive and 0.2-10 parts of organic nitrile additive; the solvent is cyclic carbonate and / or chain carbonate; and the molar concentration of the commonly-used lithium salt in the solvent is 0.8-1.5mol / L. According to the non-aqueous electrolyte provided by the invention, the oxidation resistance and wettability of the electrolyte, the oxidation resistance of the positive electrode SEI film in initial formation and the stability of the negative electrode SEI film can be improved; and the normal temperature rapid-charging circulation, the high-temperature 45-DEG C rapid-charging circulation and the high-temperature storage of the high-voltage electrolyte can be greatly improved.

Owner:ZHUHAI SMOOTHWAY ELECTRONICS MATERIALS

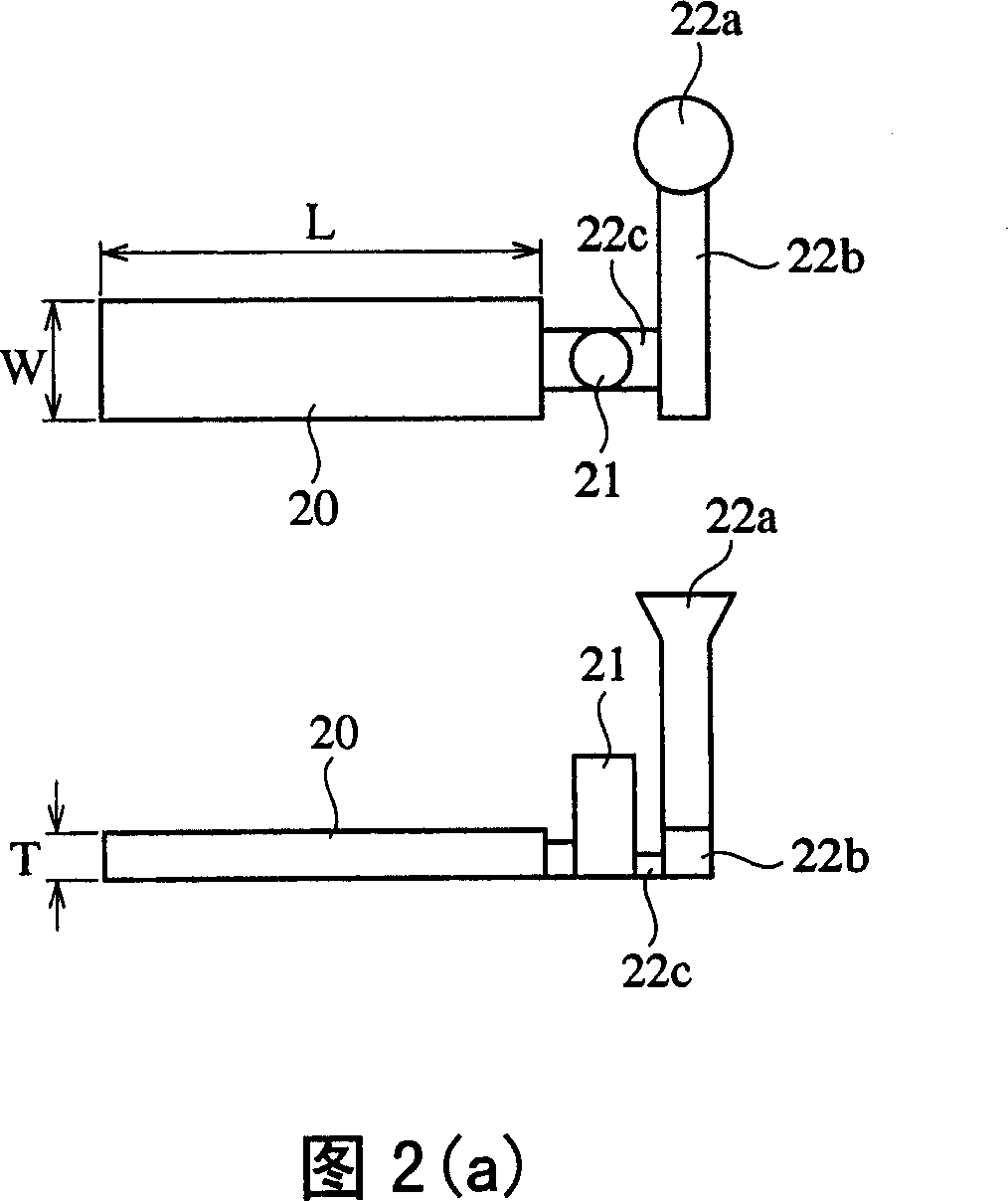

Material for probe pins

ActiveUS20060197542A1Solve the lack of hardnessImprove oxidation resistanceSemiconductor/solid-state device testing/measurementElectrical measurement instrument detailsTungstenIridium

Probe pins related to the present invention are formed from a material which consists essentially of one or more elements selected from the group consisting of platinum, iridium, ruthenium, osmium, palladium and rhodium. A material obtained by adding one or more elements selected from the group consisting of tungsten, nickel and cobalt to this metal may also be used.

Owner:TANAKA PRECIOUS METAL IND

Aluminum enamel composite material and preparation method

The invention relates to an aluminum enamel composite material and a production method, and the composite material comprises the following components by weight: 25-60% of aluminum enamel, 25-60% of aluminum or / and aluminum alloy and 10-30% of aggregate. The production method comprises the following steps: directly adding an aluminum enamel material in a fusion state in the aluminum or / and aluminum alloy, uniformly pugging at 400-600 DEG C, and then cooling and directly extruding to obtain a finished product or a parison. The aluminum enamel composite material has excellent comprehensive properties, the heat conduction coefficient is 70-200w / m.k through testing, the insulating property is good, and the aluminum enamel composite material can bear the high temperature at 400-500 DEG C, the anti-oxidation property is excellent; and the production cost is low with 15-20yuan / kg. The aluminum enamel composite material has the advantages of excellent comprehensive property and low production cost, is an ideal substitution material for aluminum and aluminum alloy, and can be widely used in many fields.

Owner:江苏朔耘石化装备有限公司

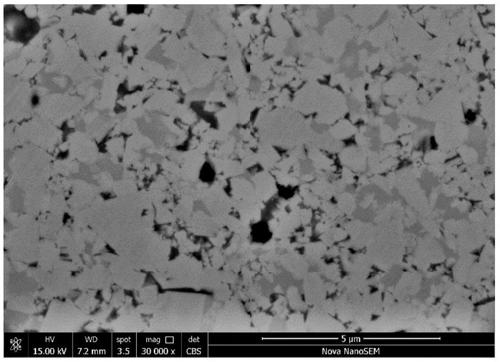

Preparation method of WC-based hard alloy with high-entropy powder as binder

The invention provides a preparation method of WC-based hard alloy with high-entropy powder as a binder. The binder is the high-entropy powder, and comprises iron, cobalt, chromium, nickel, aluminum,vanadium, titanium, copper, zirconium, manganese and the like, and is not added with other elements such as carbon, boron and silicon and metallic compounds. The hard alloy is prepared from the following raw material components in percentage by weight: 6%-30% of high-entropy powder as the binder and 70%-94% of WC powder. The preparation method of the hard alloy comprises the steps: (1) preparing the high-entropy powder as the binder; (2) mixing; and (3) performing sinter molding. The WC-based hard alloy is prepared by adopting three different sintering methods, and the hard alloy shows a highmechanical property.

Owner:FUJIAN UNIV OF TECH

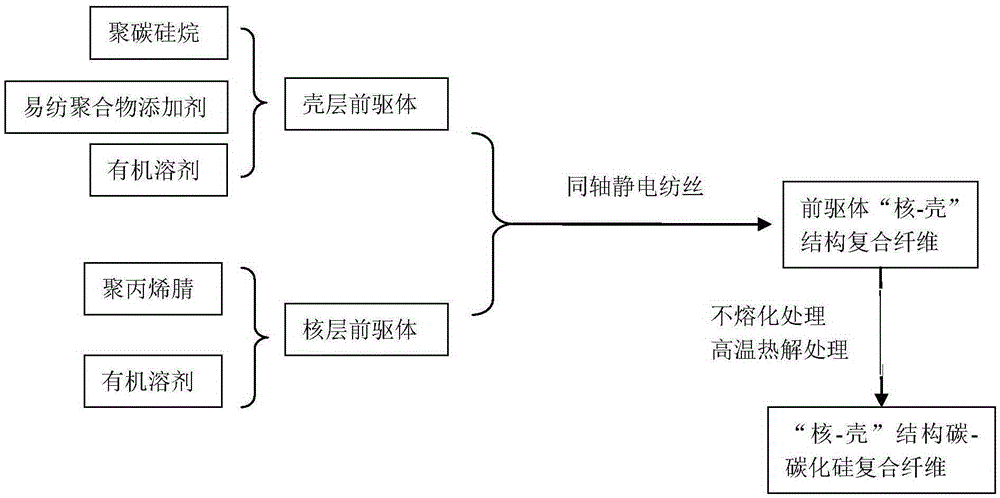

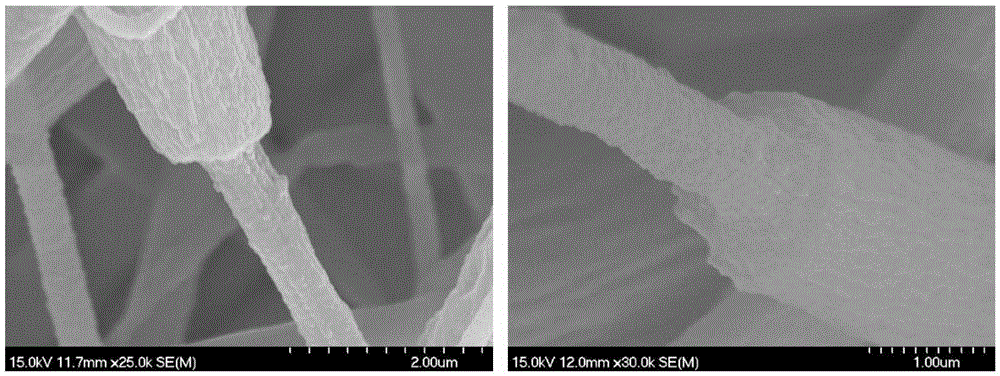

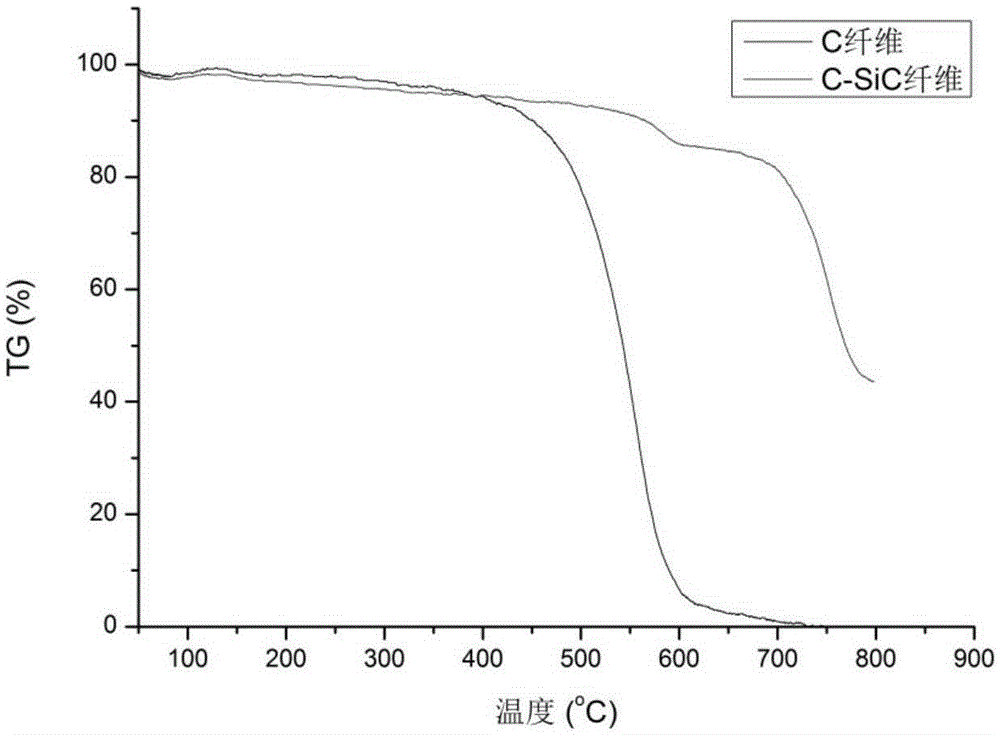

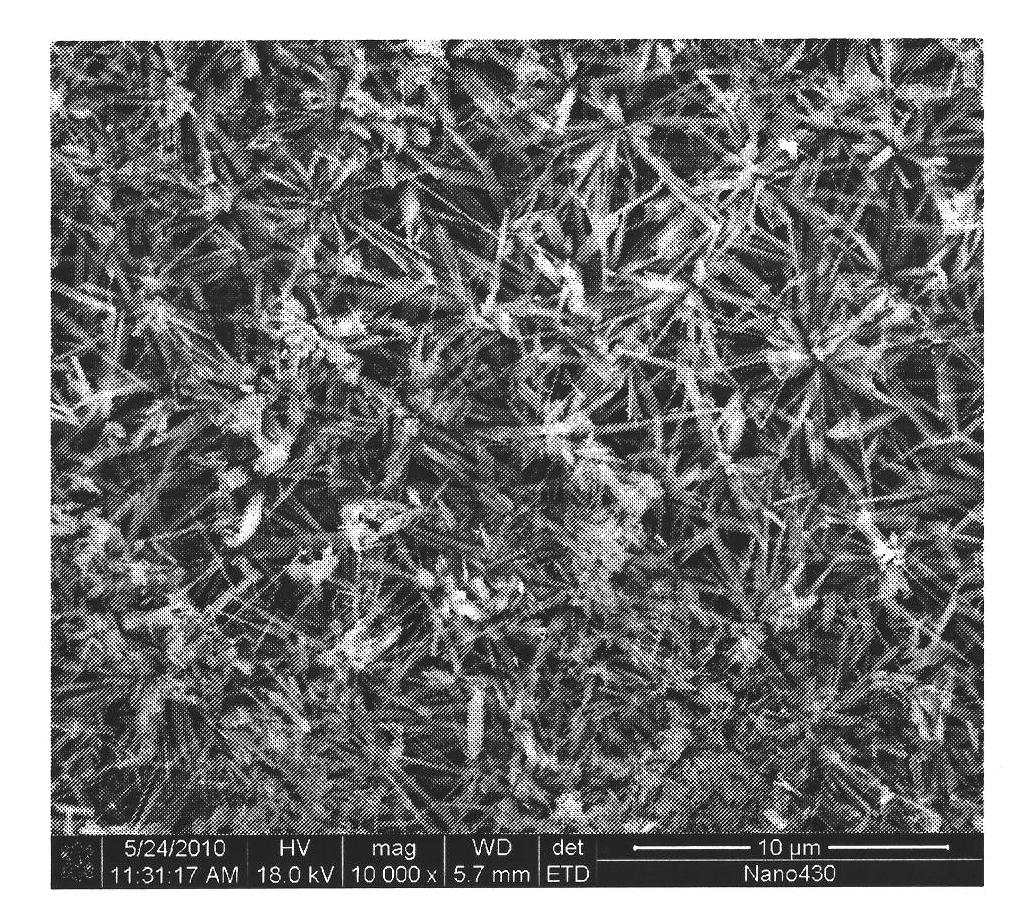

Core-shell structured carbon-silicon carbide composite nano-fibers based on coaxial electrostatic spinning process and preparation method thereof

ActiveCN105256407ATo achieve an organic combinationImprove production efficiencyFilament/thread formingConjugated artificial filamentsMicro structureCarbon fibers

The invention relates to core-shell structured carbon-silicon carbide composite nano-fibers based on a coaxial electrostatic spinning process and a preparation method thereof. The preparation method comprises the following steps: (1) taking a polycarbosilane (PCS) solution and a polyacrylonitrile (PAN) solution as a shell-layer precursor and a core-layer precursor respectively; (2) carrying out electrostatic spinning on the shell / core precursor by using electrostatic spinning equipment with a coaxial needle so as to obtain precursor fibers with a core-shell structure; and (3) carrying out non-smelting treatment and high-temperature pyrolysis treatment on the precursor fibers to finally obtain C-SiC composite fibers with a core-shell structure. The invention provides the novel process method for preparing the core-shell structured composite fibers with carbon fiber cores covering ceramic-phase SiC shells, which have a controllable micro-structure, high efficiency and low cost; and the prepared composite fibers overcome the disadvantage that ceramic fibers are relatively fragile, and functional properties of high intensity and flexibility of the fiber and internal conduction and external insulation are realized.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

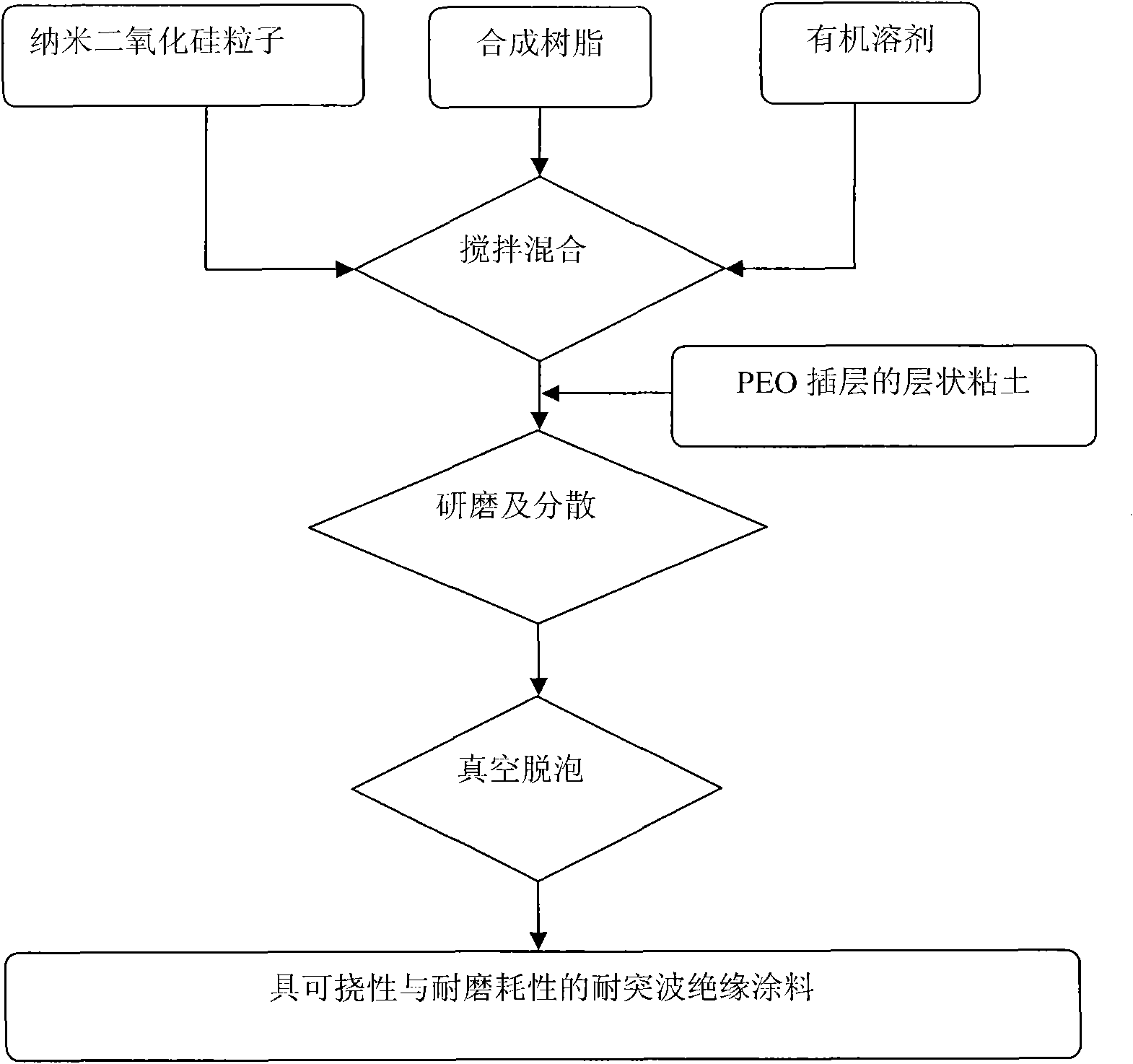

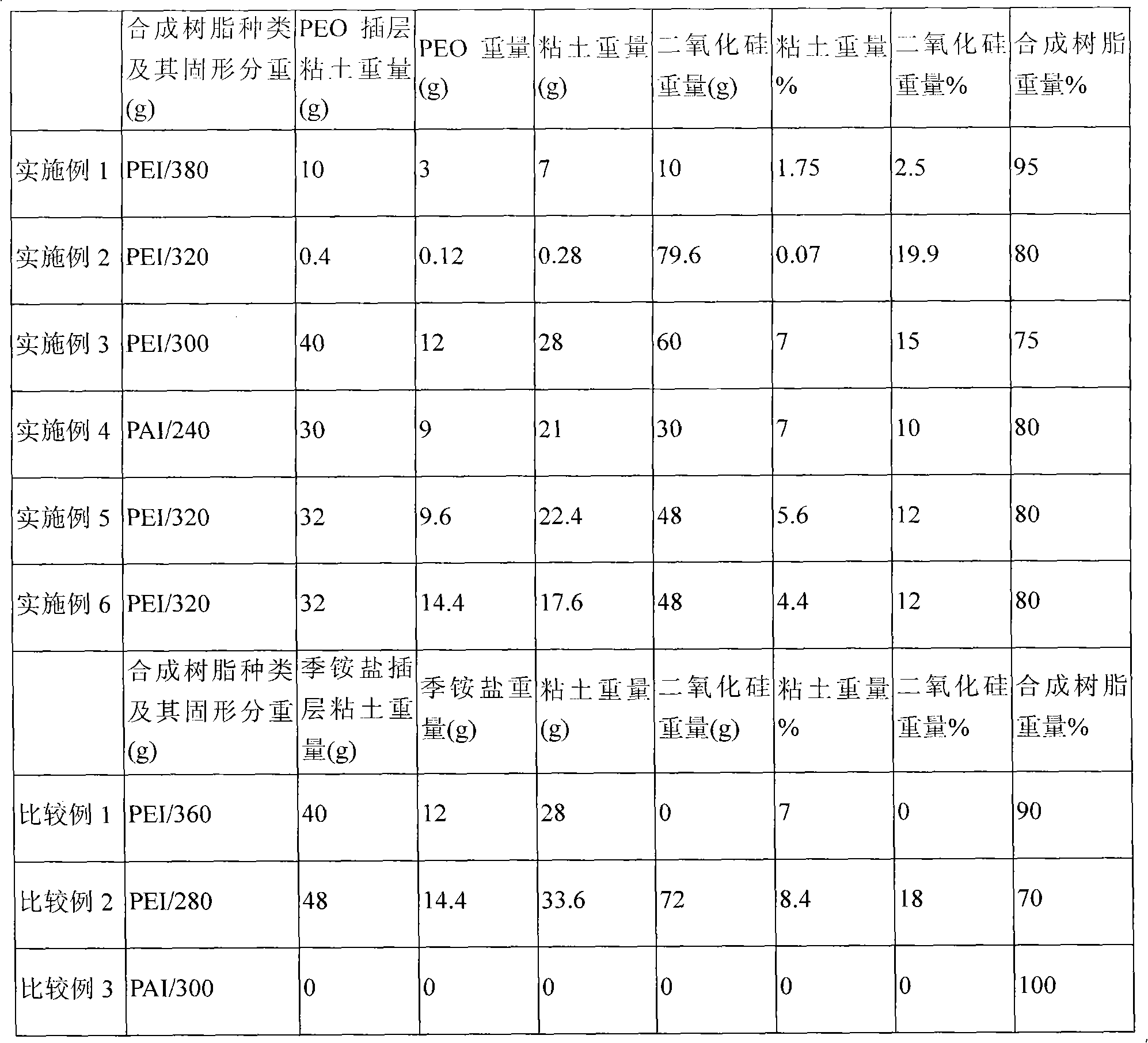

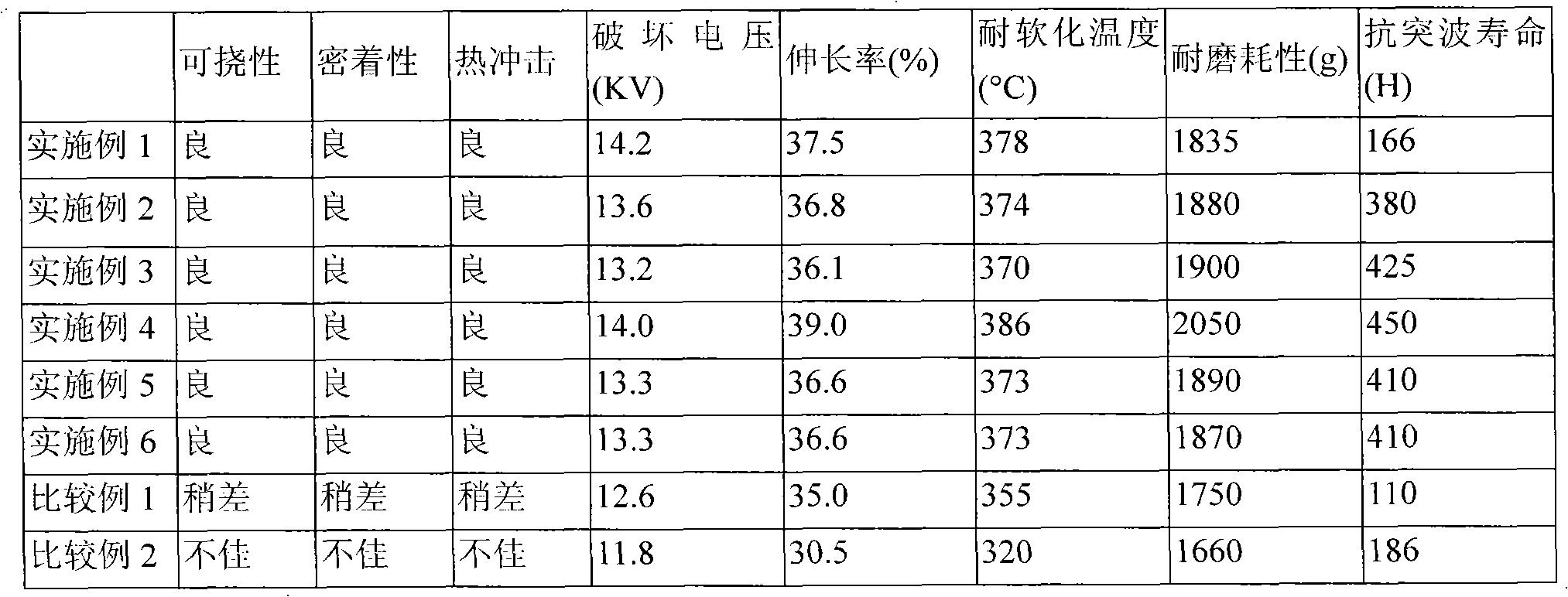

Surge-withstanding insulating paint with flexibility and attrition resistance

ActiveCN102079945AHigh dielectric constantHigh strengthPolyurea/polyurethane coatingsPolyether coatingsNano siliconCapacitance

The invention relates to a surge-withstanding insulating paint with flexibility and attrition resistance, which comprises the following components: 12-76wt% of synthetic resin, 20-80wt% of organic solvent, 0.005-16wt% of polyethylene oxide (PEO) intercalation modified laminated clay material and 0.995-16wt% of organic dispersible nano silicon oxide particle. Since the paint contains the clay with high dielectric constant and superior attrition resistance and the nano silicon oxide particles, the insulating film formed by the paint can generate a capacitor-like effect, thereby absorbing and uniformly dispersing surges, and preventing damages caused by the surges; the insulating film also has fine attrition resistance; and since the PEO structure is soft and flexible, the insulating film for enamel wires has better softness.

Owner:FU PAO CHEM CO LTD

Ultra high-temperature resistant nickel-chrome alloy and manufacturing method thereof

InactiveCN101684530AImprove high temperature resistanceImprove oxidation resistanceNickelHeat processing

The invention provides an ultra high-temperature resistant nickel-chrome alloy and a manufacturing method thereof, wherein the ultra high-temperature resistant nickel-chrome alloy has a higher meltingpoint, can resist the high temperature higher than 1300 DEG C for a long time and has better tensile strength and yield strength simultaneously. The ultra high-temperature resistant nickel-chrome alloy basically comprises the following components in percentage by weight: 21-25 of Cr, 58-63 of Ni, Al which is not less than 1 and not more than 1.7, Cu which is not less than 0.5 and not more than 1.0, C which is not less than 1 and more than 0.1, Si which is not less than 0.5 and more than 0, Mn which is larger than 0 and not more than 1.0, S which is larger than 0 and less 0.015, and the balance of Fe. The manufacturing method comprises the following steps: mixing the materials according to the alloy components and then smelting; carrying out secondary refining; first heating the mixture to900-1200 DEG C, keeping the temperature for 10-40 minutes, and then forging; cold processing; and water cooling. The invention improves the high-temperature resistant performance, the tensile strength and the yield strength of the alloy, and has better comprehensive benefit. The manufacturing method solves the problems of alloy smelting and heat processing, and improves the product purity.

Owner:杭正奎

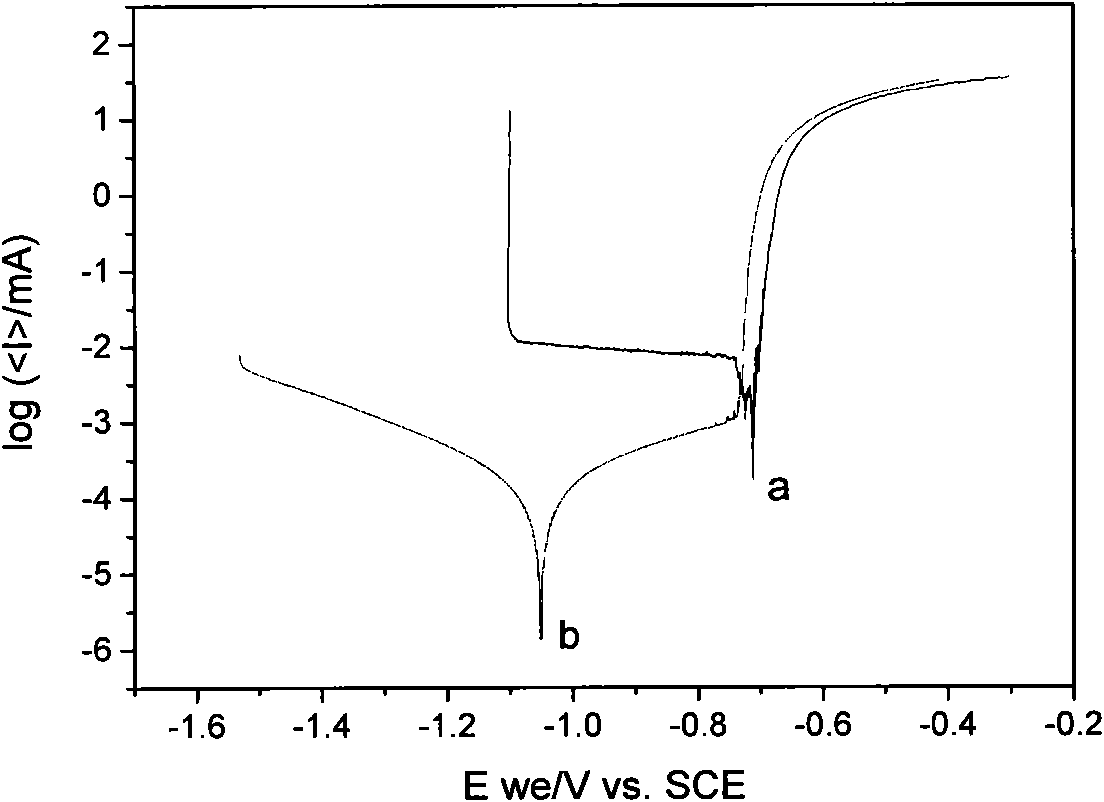

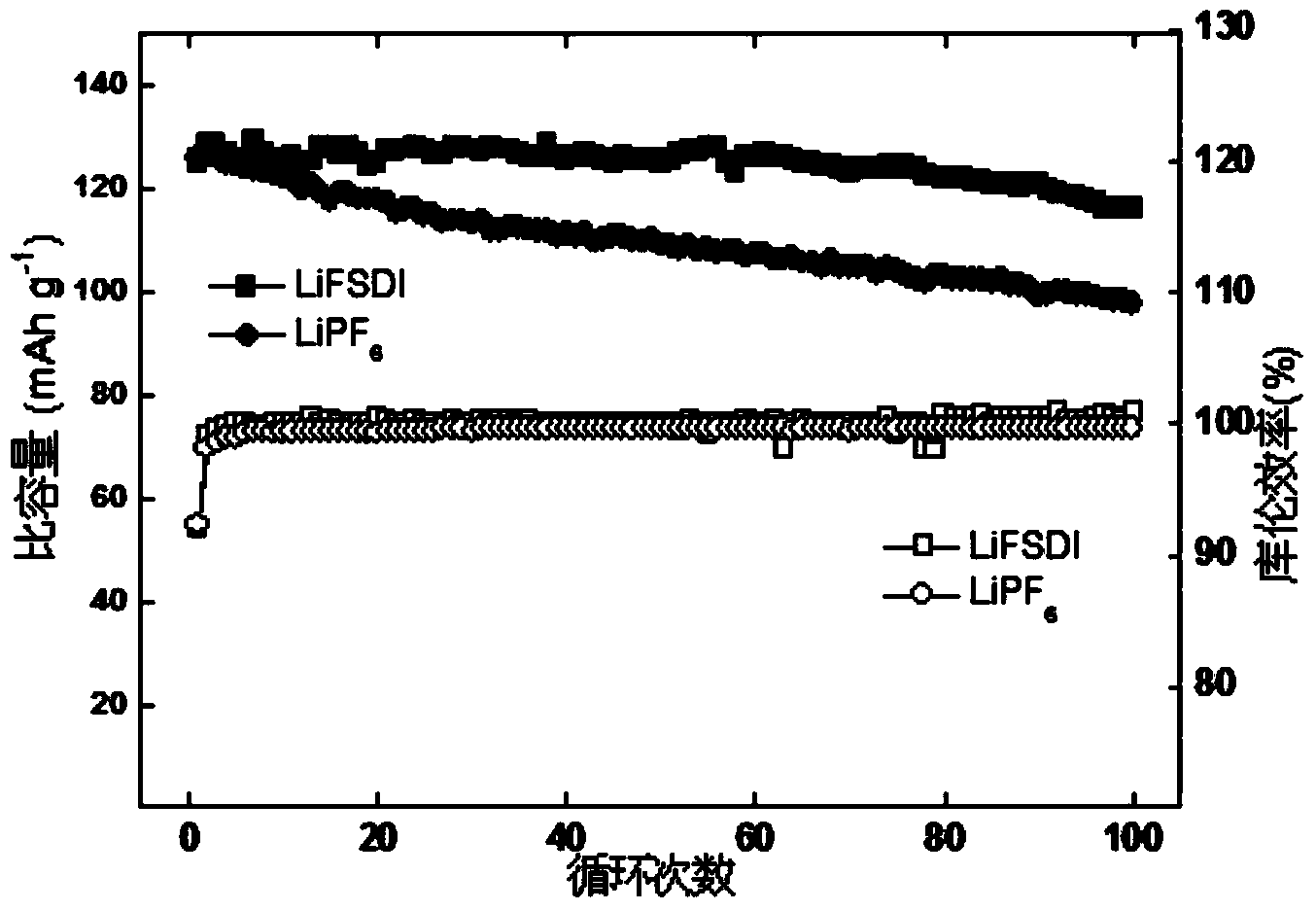

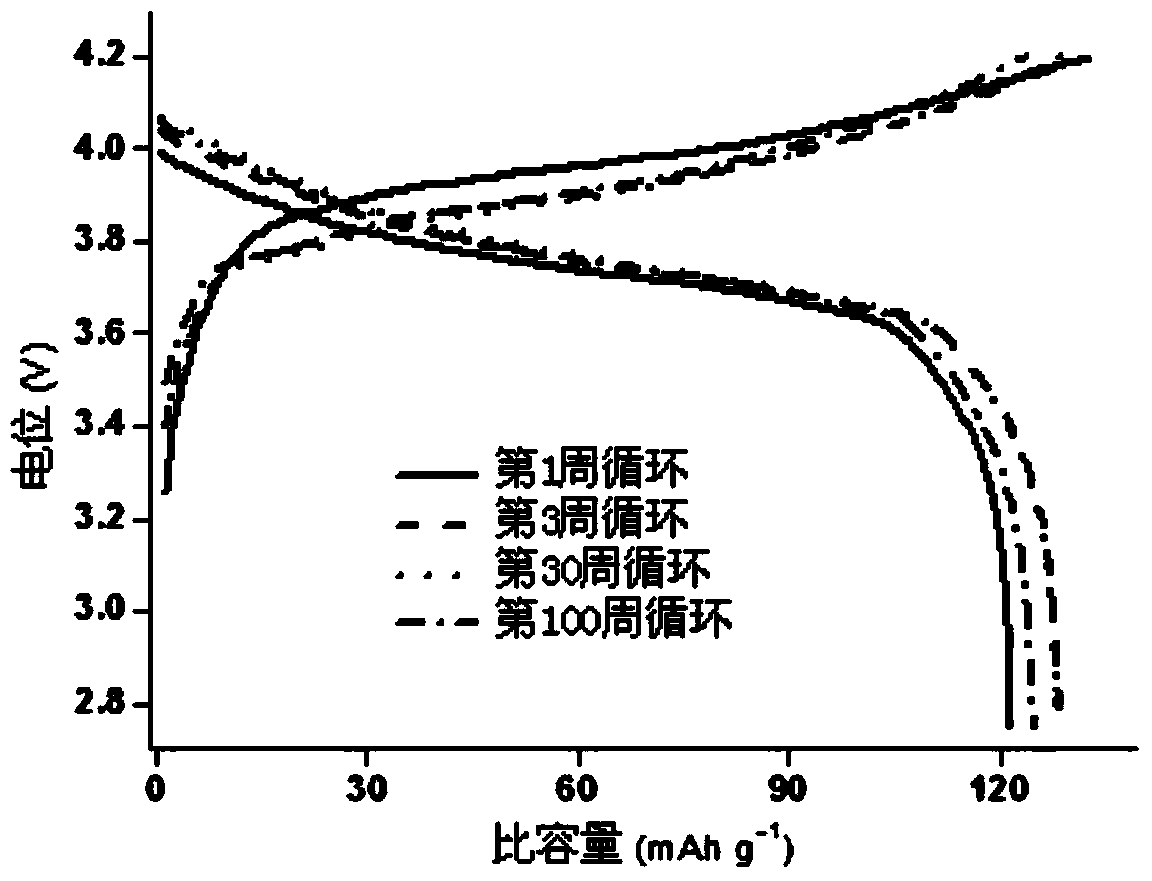

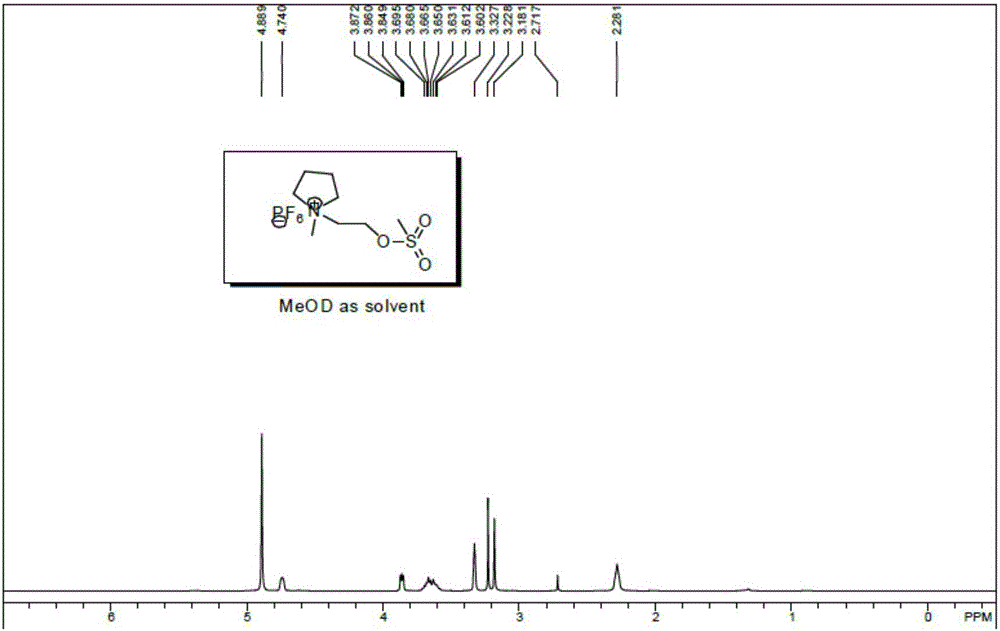

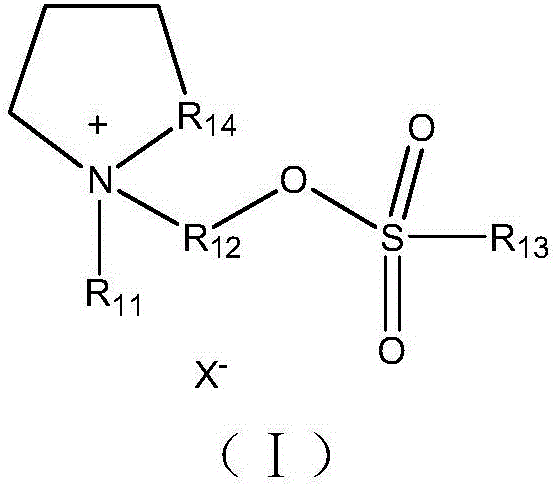

Binary or ternary fluorine-containing sulfimide alkali metal salt and ionic liquid and applications thereof

InactiveCN102786443AEasy to separate and purifyHigh yieldElectrolytic capacitorsSecondary cellsElectrochemical windowHydrolysis

The invention discloses a method for preparing binary or ternary fluorine-containing sulfimide alkali metal salts, a method for preparing ionic liquid by the binary or ternary fluorine-containing sulfimide alkali metal salts, and applications of the alkali metal salts and ionic liquid as electrolytes in carbon-based super capacitors, secondary lithium (ion) batteries, and the like. The method for preparing the binary or ternary fluorine-containing sulfimide alkali metal salts provided by the invention is short in operation steps, easy for product separation and purification, and high in product yield and purity; the binary or ternary fluorine-containing sulfimide lithium provided by the invention has good thermal stability and hydrolysis resistance; a nonaqueous electrolytic solution of the binary or ternary fluorine-containing sulfimide lithium has high conductivity and lithium ion transference number, and also exhibits good oxidation resistance and good compatibility with widely-used electrode materials; meanwhile, the ionic liquid containing the binary or ternary fluorine-containing sulfimide anions exhibits the properties of low viscosity and high conductivity, and has a wide electrochemical window.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Method for preparing magnesia carbon brick non-aluminum antioxidant coating

InactiveCN101928480AHigh strengthAvoid enteringAlkali metal silicate coatingsCarboxymethyl celluloseBrick

The invention more particularly relates to a method for preparing magnesia carbon brick non-aluminum antioxidant coating, which has the technical scheme of comprising the steps of: firstly mixing 40-60wt% of boron glass, 5-20wt% of SiC, 20-35wt% of fused quartz, 1-5wt% of MgO, 5-10wt% of CaO and 0.1-0.3% of carboxymethyl cellulose, and additionally adding ludox accounting for 20-40wt% of the mixed material or liquid water glass accounting for 40-60wt% of the mixed material, then additionally adding water accounting for 50-60wt% of the mixed material, carrying ball-milling for 20-40min, and preparing antioxidant paint; then, evenly painting the prepared antioxidant paint on the surface of a magnesia carbon brick, naturally drying and stoving at 110 DEG C; and finally, putting the stoved magnesia carbon brick in a high temperature furnace, heating up to 1150-1250 DEG C, carrying out heat preservation for 20-40min, and preparing the magnesia carbon brick non-aluminum antioxidant coating. The invention has the characteristics of simple technique and low cost, and can be glazed at the temperature range of 500-1200 DEG C; and the prepared magnesia carbon brick non-aluminum antioxidant coating has good anti-oxidation performance.

Owner:WUHAN UNIV OF SCI & TECH

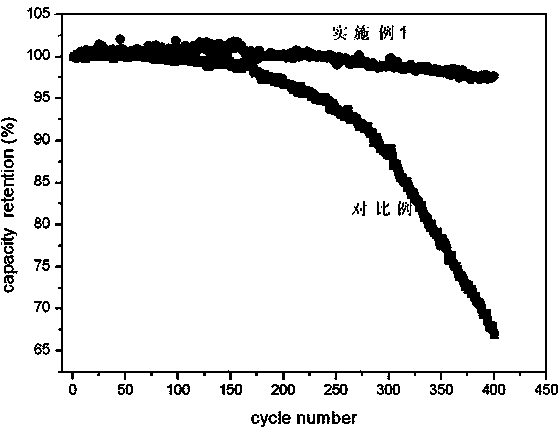

High-pressure electrolyte for high-nickel ternary cathode material system lithium ion battery

ActiveCN104332650AImprove oxidation resistanceImprove high temperature resistanceSecondary cellsOrganic electrolytesLithium electrodeOrganic solvent

The invention discloses a high-pressure electrolyte for a high-nickel ternary cathode material system lithium ion battery. The high-pressure electrolyte is composed of an organic solvent, an electrolyte lithium salt, a cathode film-forming additive, an anode film-forming additive and an anti-oxidation additive; the cathode film-forming additive is 1,5,2,4-dioxadithiane 2,2,4,4-tetraoxide, the anode film-forming additive is 4-fluoro-1,3-dioxolan-2-one, the anti-oxidation additive is tris[2-[2-(2-methoxyethoxy)ethoxy]ethyl]orthoborate, and by taking the total mass of the high-pressure electrolyte as a reference, the addition amount of the athode film-forming additive is 0.5-1%, the addition amount of the anode film-forming additive is 2-5%, and the addition amount of the anti-oxidation additive is 0.5-1%. The high-pressure electrolyte has relatively good oxidation resistance, high temperature resistance and safety characteristics, guarantees the battery to have relatively good cycle life, also has relatively high electrical conductivity, is capable of guaranteeing the high rate and power characteristics of the battery, also has relatively high safety, and is capable of substantially improving the safety performance of the power battery.

Owner:WANXIANG 123 CO LTD

TiAl intermetallic compound-based alloys and methods for preparing same

PCT No. PCT / JP95 / 01349 Sec. 371 Date Mar. 26, 1996 Sec. 102(e) Date Mar. 26, 1996 PCT Filed Jul. 6, 1995 PCT Pub. No. WO96 / 12820 PCT Pub. Date May 2, 1996TiAl intermetallic compound-based alloys comprising Ti, Al, Nb and Cr and, if necessary, further comprising Ni and Co, which have excellent plastic workability, good resistance to oxidation at high temperatures, high strength or good creep resistance.

Owner:MITSUBISHI HEAVY IND LTD

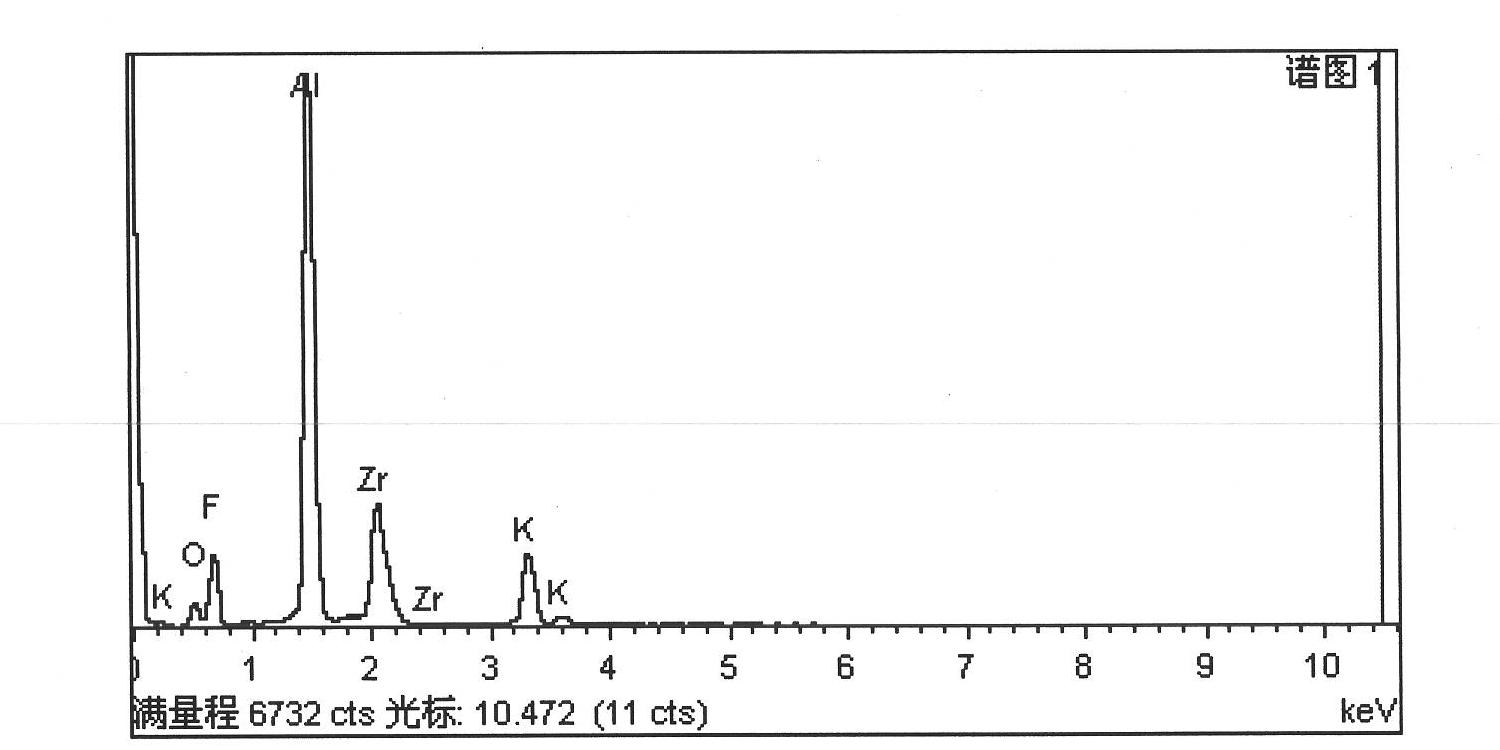

Treating fluid for preparing zirconium-containing coloring passive film on surface of aluminum alloy and treating method thereof

InactiveCN101985750AHigh bonding strengthImprove the protective effectMetallic material coating processesPotassium fluorideCompound (substance)

The invention discloses a treating fluid for preparing a zirconium-containing coloring passive film on the surface of an aluminum alloy and a treating method thereof. The zirconium chemical passive treating fluid comprises the following main components of: potassium fluoride, a pH value regulator, fluorozirconate and / or potassium fluozirconate; and the pH value of the treating fluid is between 2.5 and 4.5, and the film can be formed within 3 to 10 minutes. The color of the passive layer prepared by the method is black gray; the film layer is tightly combined with a substrate; and the film layer has high strength and high corrosion resistance. The method is simple in operating process, and a coating does not contain hexavalent chromium which is harmful to the environment and human bodies.

Owner:SOUTH CHINA UNIV OF TECH

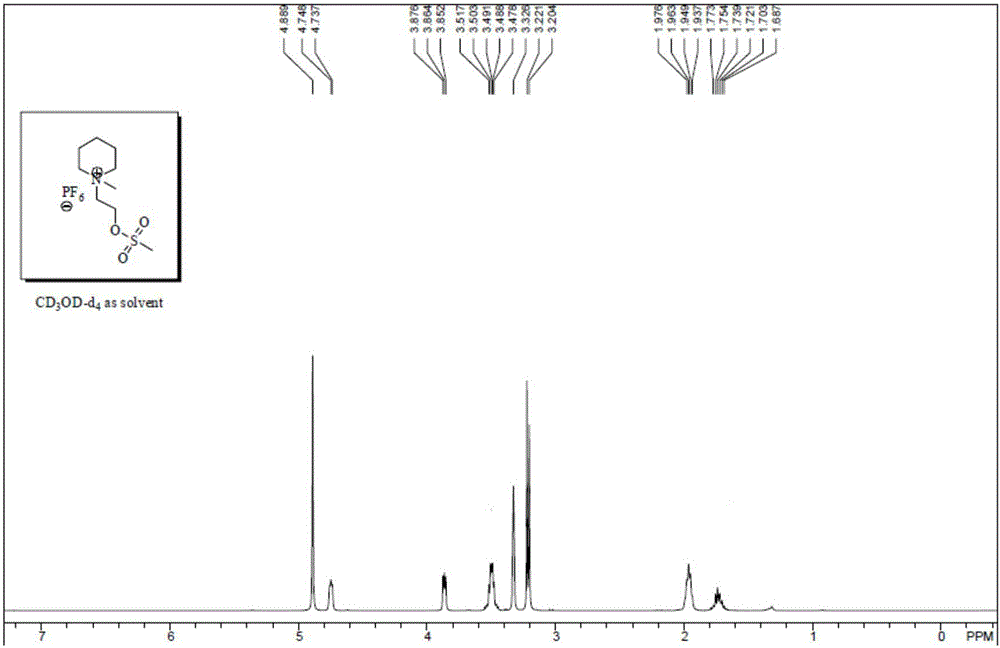

Alkali metal salts of binary or ternary fluorine-containing sulfimide and ionic liquid and applications thereof

InactiveCN103641751AEasy to separate and purifyHigh yieldHybrid capacitor electrolytesCarboxylic acid nitrile preparationElectrochemical windowHydrolysis

The invention discloses alkali metal salts of binary or ternary fluorine-containing sulfimide, a method for preparing ionic liquid from the alkali metal salts of binary or ternary fluorine-containing sulfimide, and applications of the alkali metal salts and the ionic liquid as electrolytes in carbon-based supercapacitors, secondary lithium (ion) batteries, and the like. The method for preparing the alkali metal salts of binary or ternary fluorine-containing sulfimide provided by the invention is short in operation steps, and the product is easy to separate and purify, and very high in yield and purity; the binary or ternary fluorine-containing lithium sulfimide provided by the invention is good in thermal stability and hydrolysis resistance; the non-aqueous electrolyte has high conductivity and lithium ion transport number, exhibits good oxidation resistance, and has good compatibility with widely-used electrode materials; meanwhile, the ionic liquid containing binary or ternary fluorine-containing sulfimide anions is characterized by low viscosity and high conductivity, and has a wide electrochemical window.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Surface treating agent for tin or tin alloy material

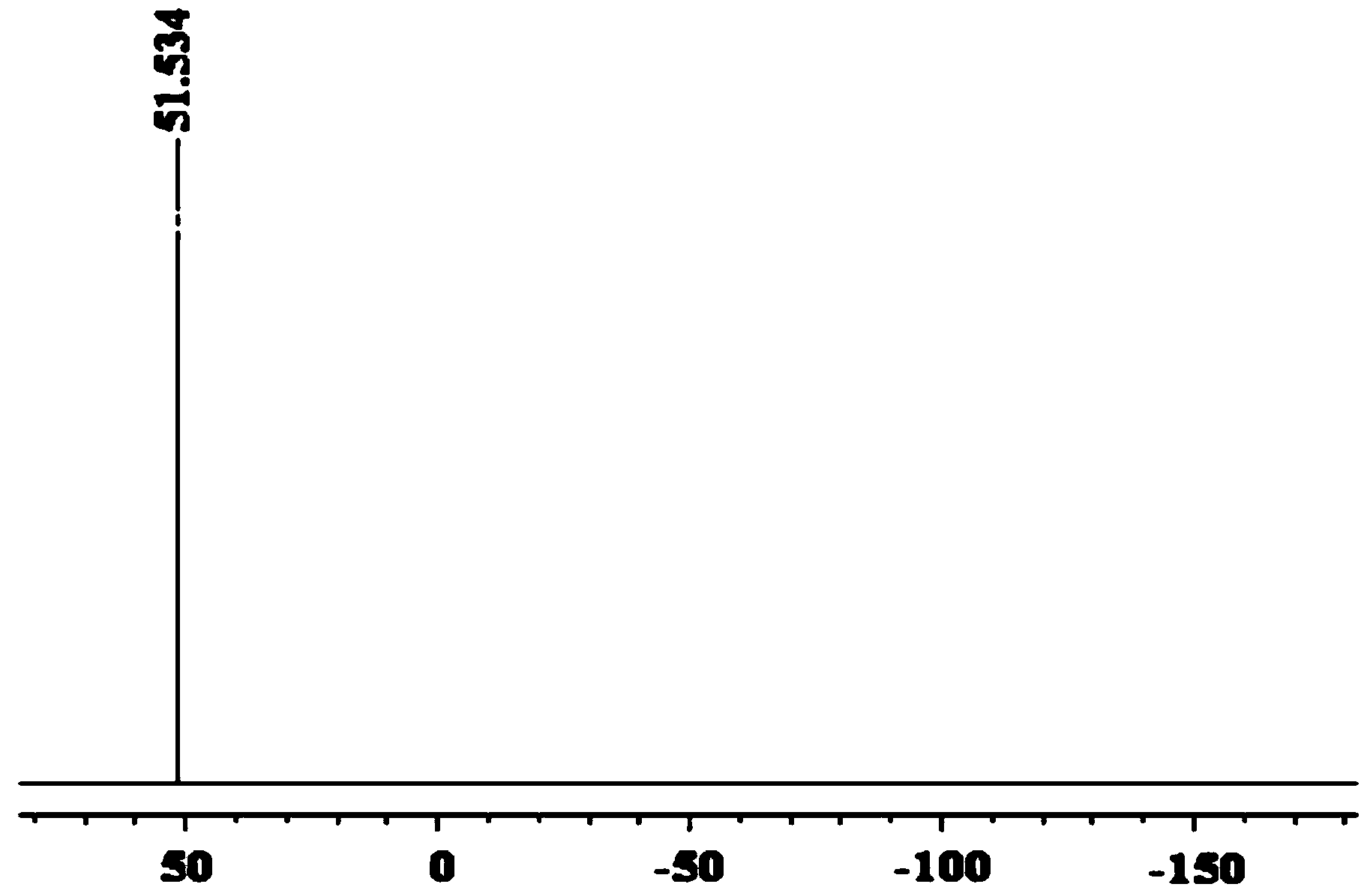

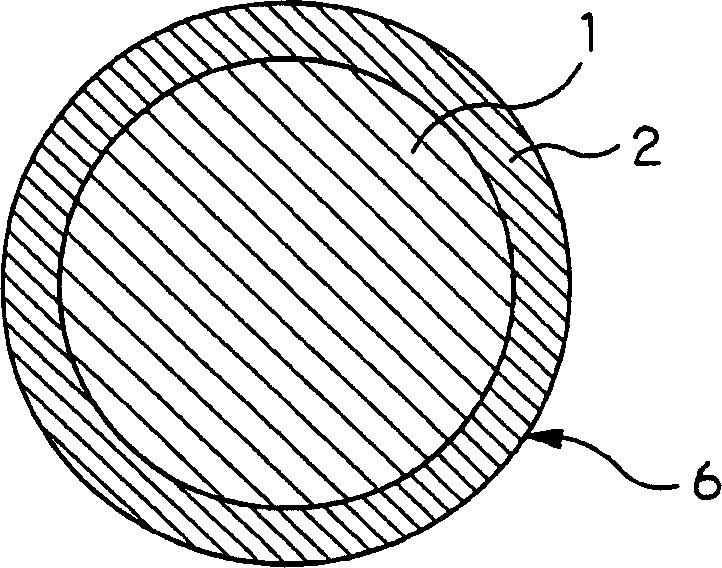

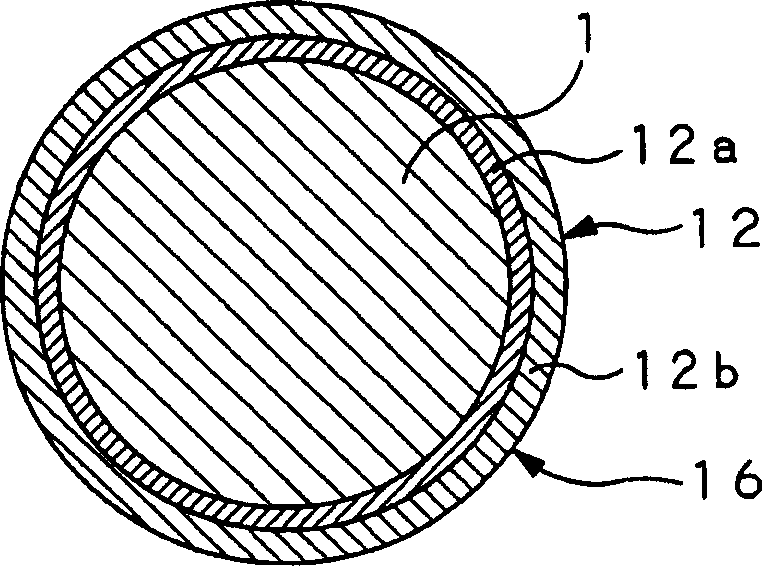

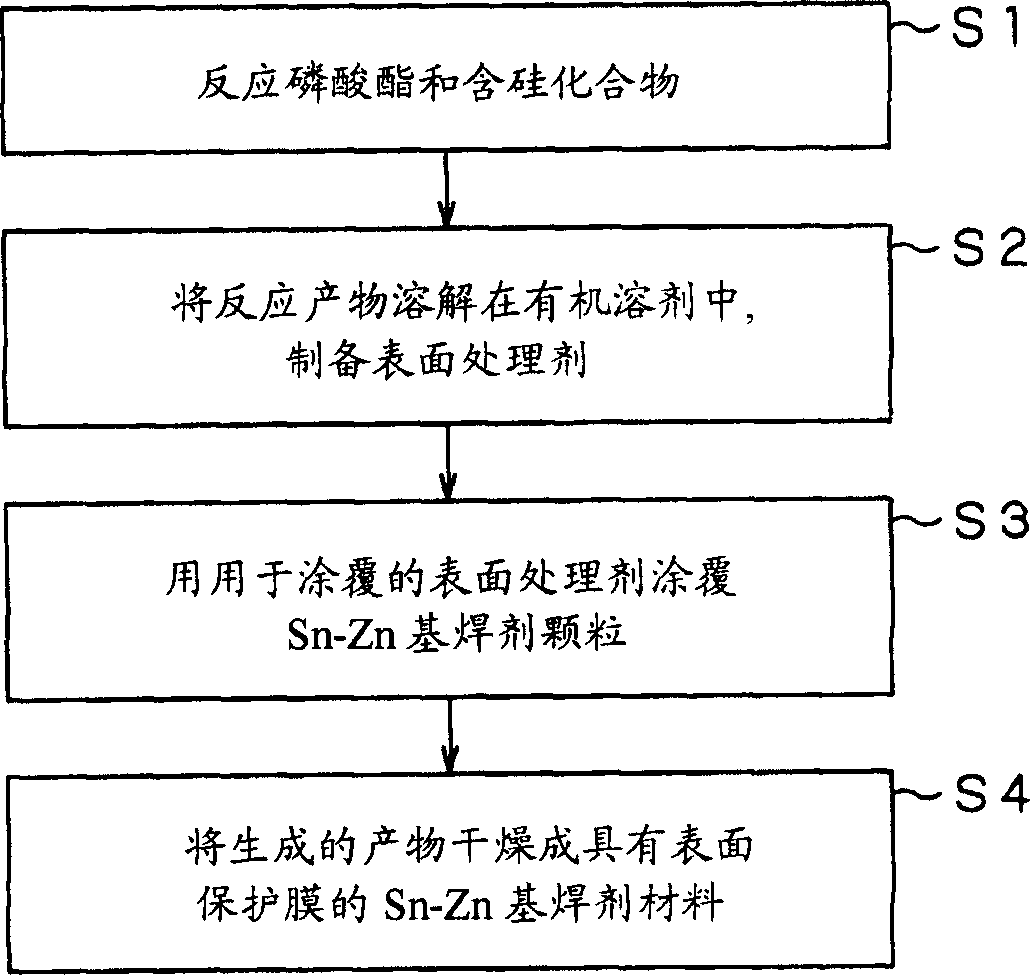

InactiveCN1823181AAvoid conversionPrevent oxidationHot-dipping/immersion processesFinal product manufacturePhosphateMetallic materials

There is disclosed is a method comprising surface-processing a Sn based, Sn alloy based or Sn-Zn alloy based solder particle (1), applied as a coating, such as by electrical plating or melt plating, to the surface of a metal material, such as iron, a steel plate or copper, with a phosphate and a silicium containing compound, to form a protective film (2). There are also disclosed a solder material (6) in which a protective film (2) formed of a phosphate and a silicium containing compound is formed on the surface of the Sn-Zn based solder particle (1), and a solder paste formed of this solder material (6) and the flux.

Owner:SONY CORP +2

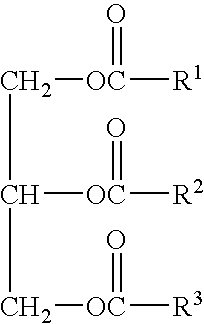

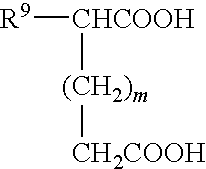

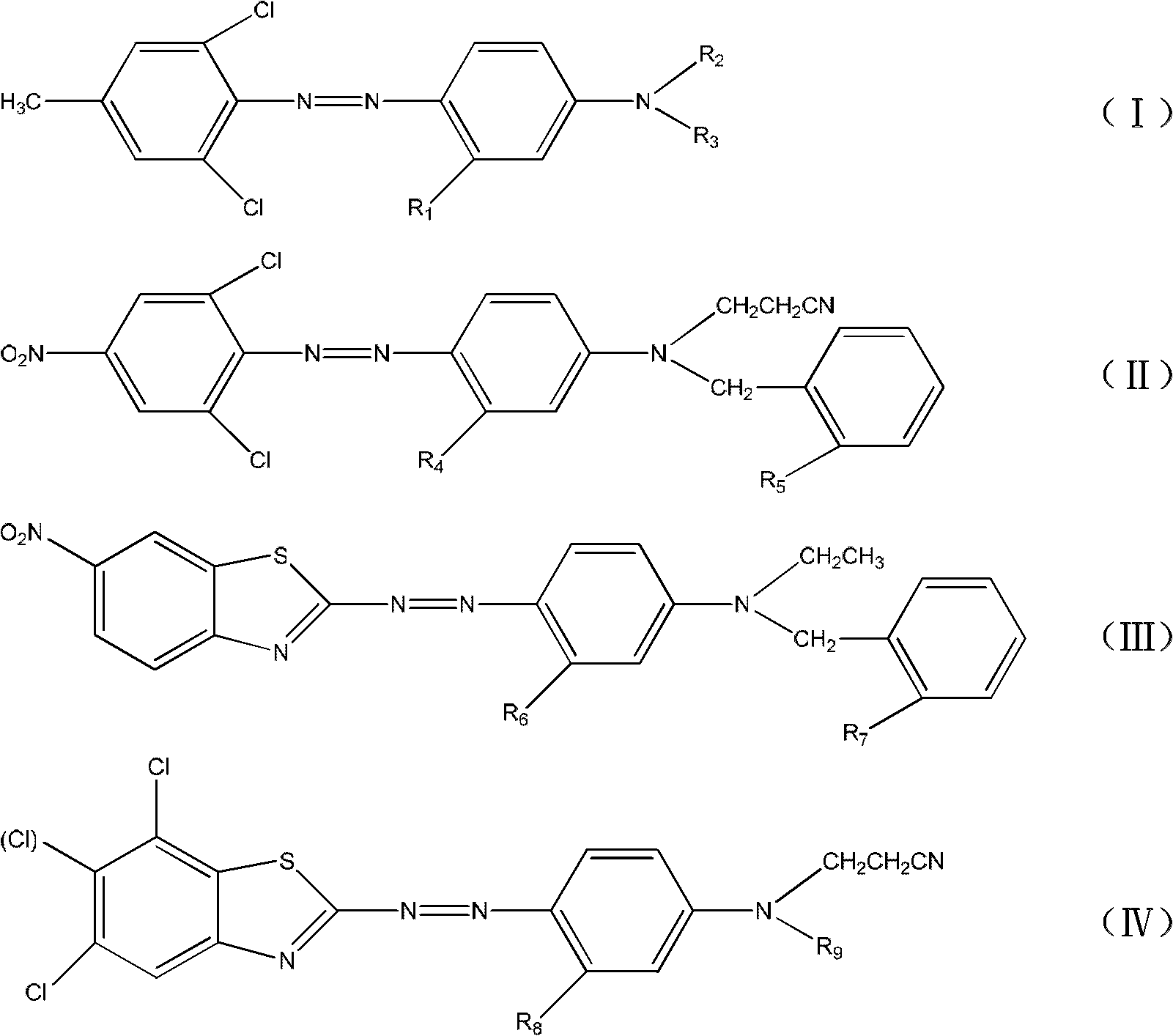

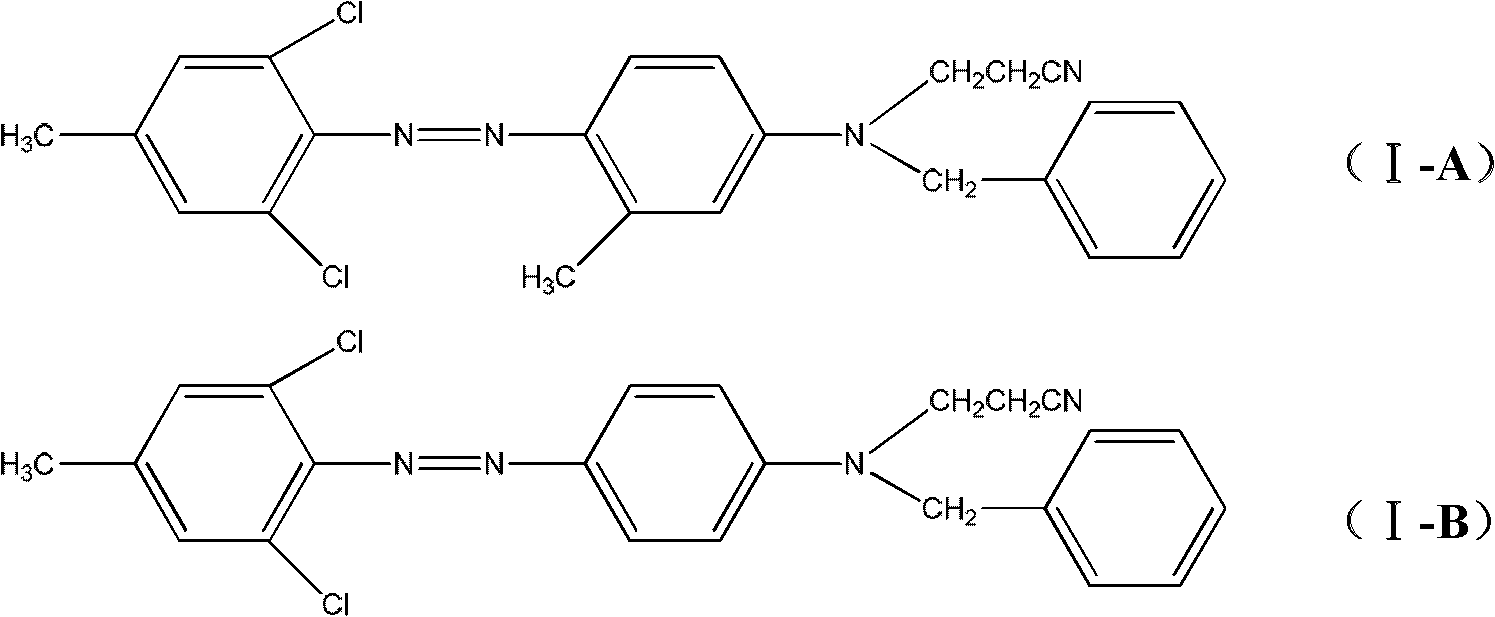

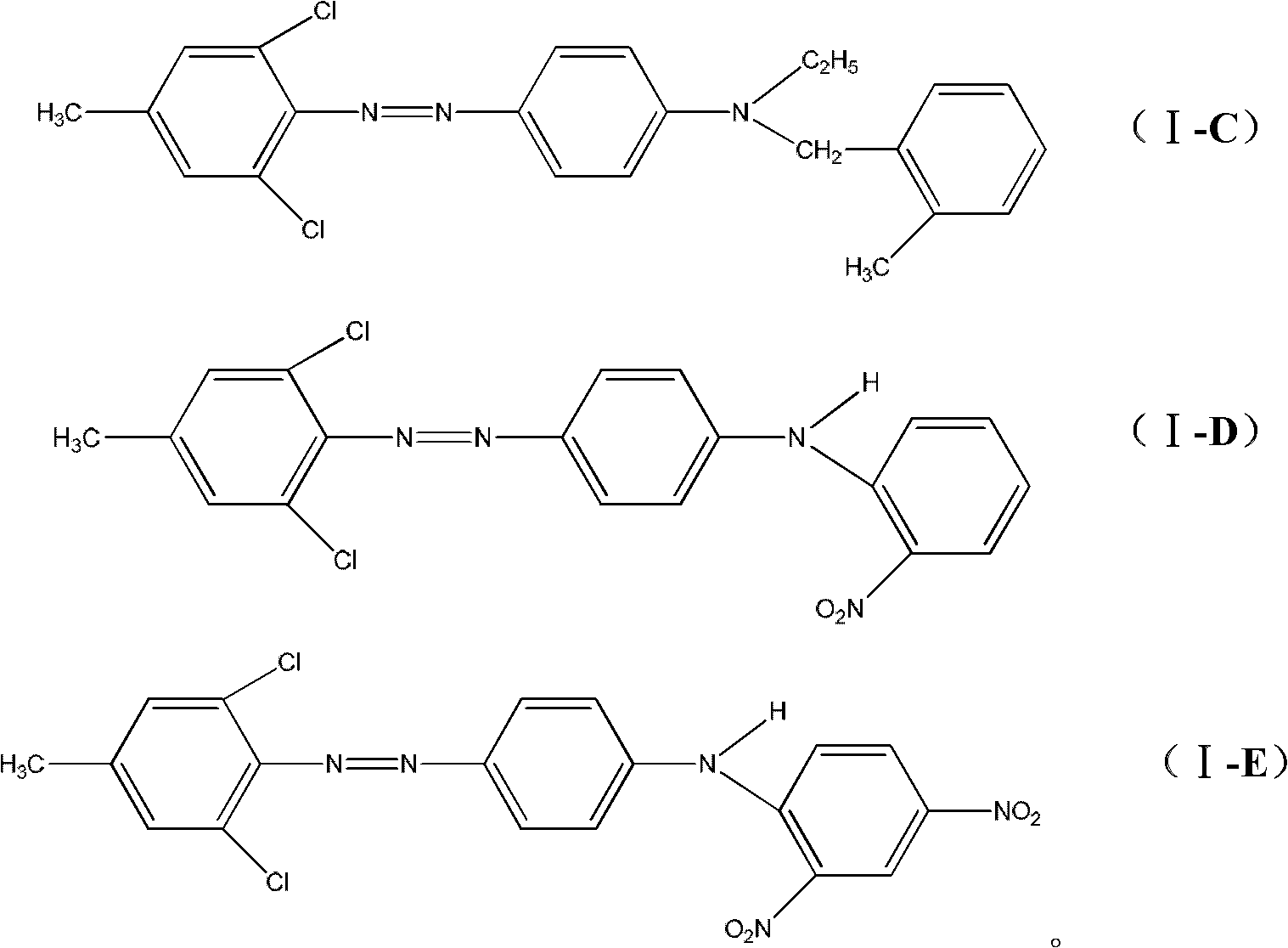

Oxidation-resistant disperse dye composition and preparation and application thereof

ActiveCN102660146AImprove oxidation resistanceWide concentration rangeFibre treatmentOrganic dyesDisperse dyeYELLOW DYE

The invention relates to an oxidation-resistant disperse dye composition and preparation and an application thereof. The oxidation-resistant disperse dye composition comprises the combination of any 2-4 of a yellow dye shown as a general formula (I), an orange dye shown as a general formula (II), a blue dye shown as a general formula (III) and a red dye shown as a general formula (IV), not more than two types of dyes are shown as each general formula; and the oxidation-resistant disperse dye composition is applied to pre-treatment dyeing of dacron or polyester-cotton blended fabrics. The disperse dye composition can be used for dyeing polyesters and blended fabrics thereof under the strong oxidative condition that the mass concentration of H2O2 is 0.1-0.5 percent, and an obtained fabric has the advantages of stable chromatic light, bright color, neat cloth cover and excellent fabric style; and according to the disperse dye composition, pretreatment and one-bath and one-step dyeing of polyester fiber or blended fabrics thereof are realized, efficiency is increased, production cost is reduced, and dyeing waste water is reduced.

Owner:ZHEJIANG WANFENG CHEM +1

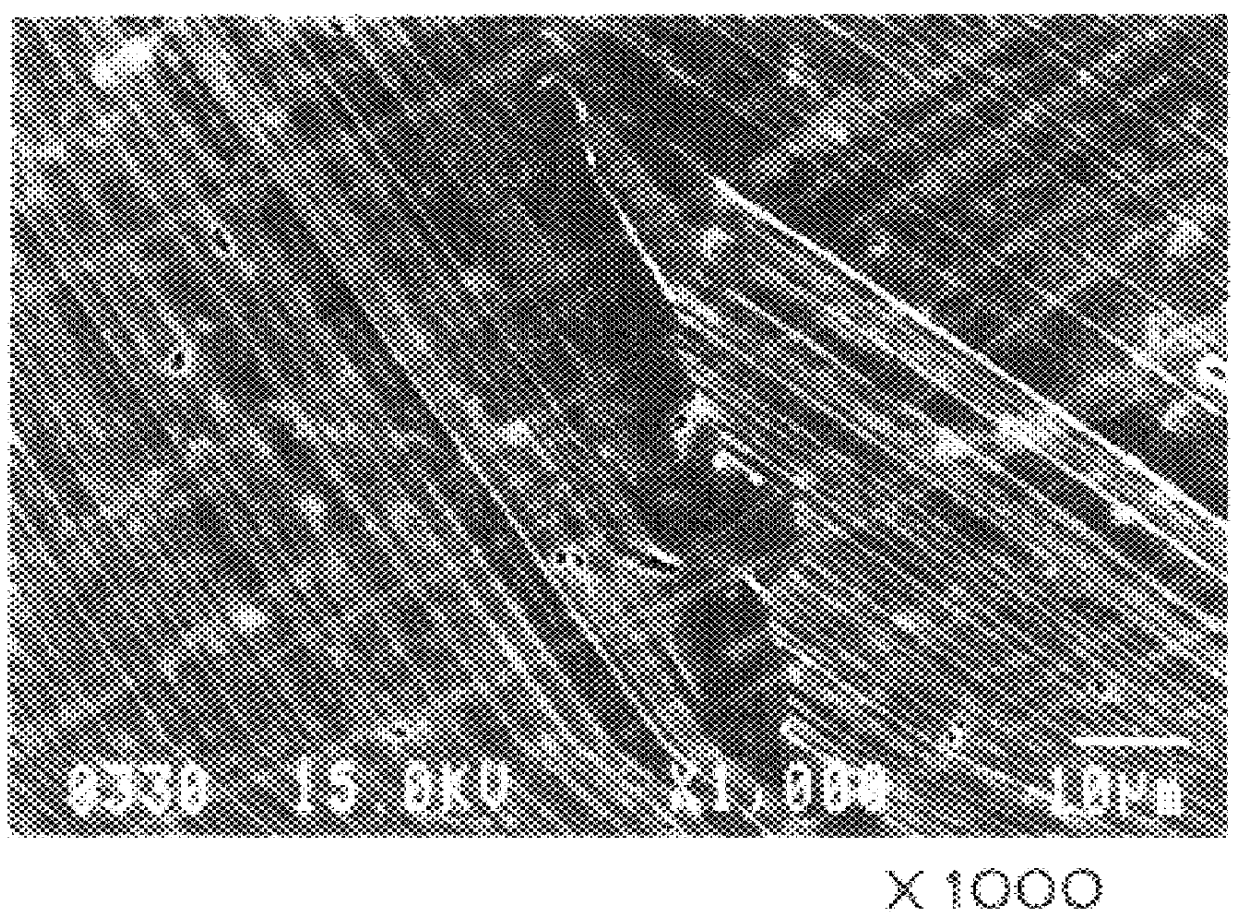

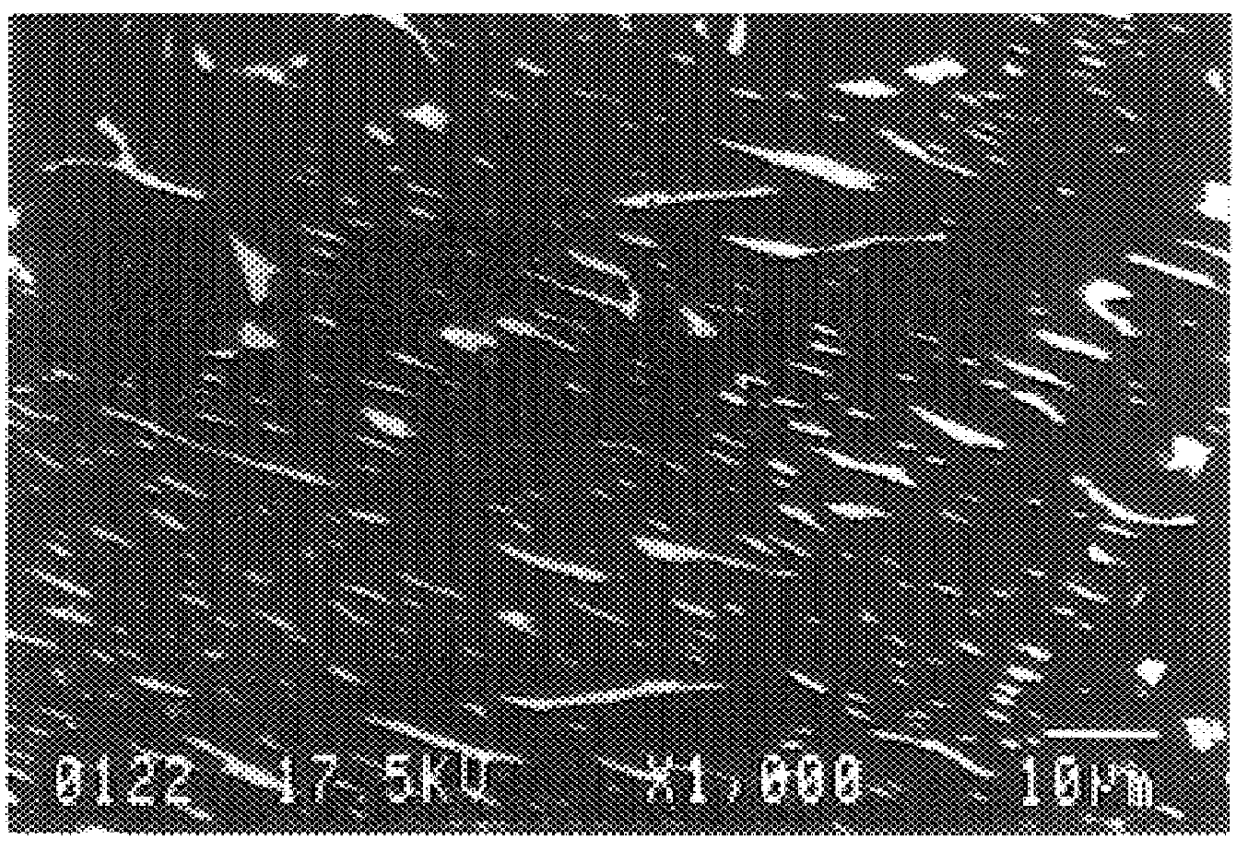

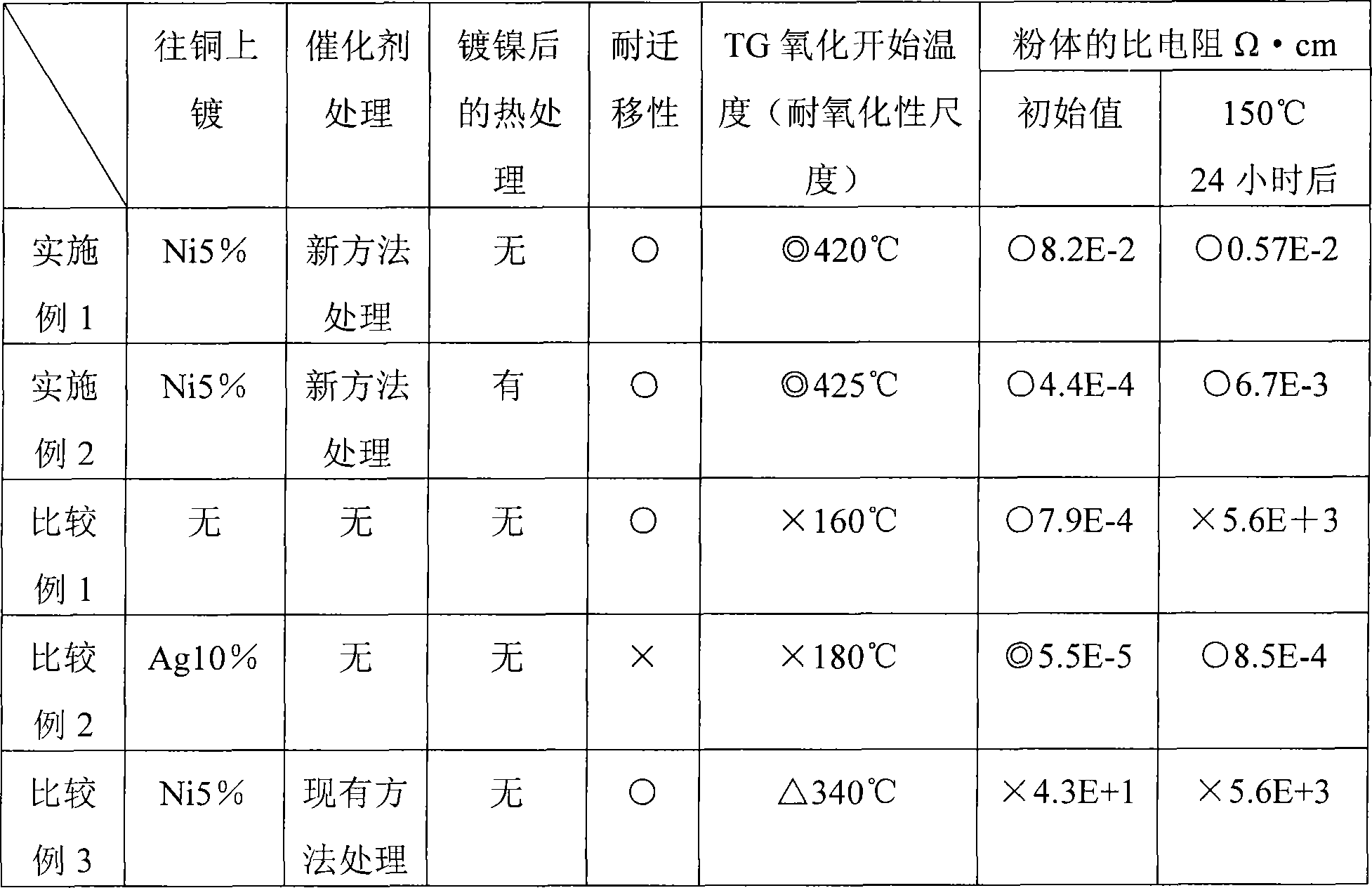

Nickel coated copper powder and process for producing the same

InactiveCN1988973AImprove adhesionImprove uniformityNon-insulated conductorsConductive materialConductive pasteElectroless nickel

An antioxidant nickel coated copper powder for conductive paste capable of forming conductive wiring parts for electronic circuits; and a process for producing the same. In particular, use is made of a nickel coated copper powder characterized by comprising a nickel coated copper powder produced by providing a copper powder as a core material, fixing a plating catalyst on the surface of copper powder through reduction reaction and applying electroless nickel plating to the outermost surface thereof. The reduction reaction is characterized in that hydrazine is used as a reducing agent.

Owner:MITSUI MINING & SMELTING CO LTD

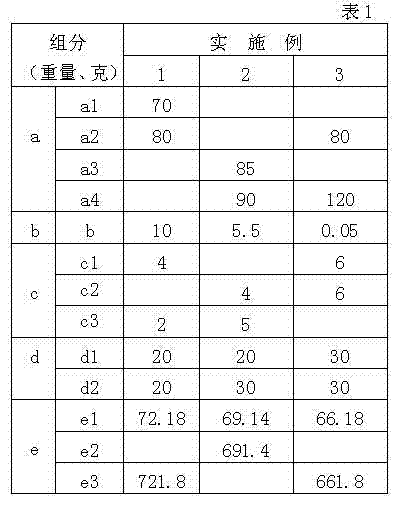

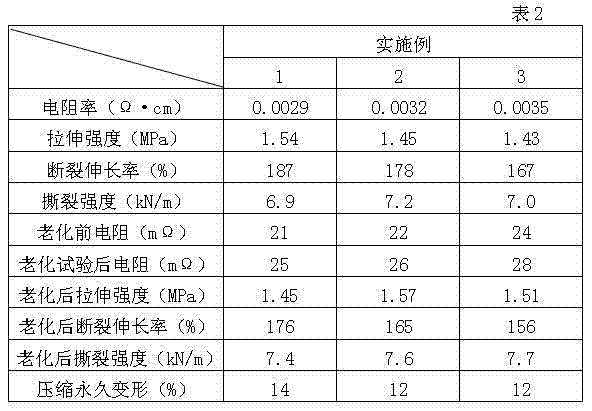

High-performance silicon-based conductive rubber and preparation method thereof

ActiveCN102250472AImprove conductivityImprove shielding effectNon-conductive material with dispersed conductive materialAviationFire retardant

The invention discloses a high-performance silicon-based conductive rubber and a preparation method thereof. The conductive rubber is mainly composed of silicon rubber, silane coupling agent, vulcanizing agent, fire retardant and conductive powder, wherein the conductive powder is mixture of powder with different particle diameters, and the silane coupling agent covers the conductive powder. The high-performance silicon-based conductive rubber has the advantages of excellent electrical characteristic and physical property, excellent conductive property, aging resistance high and low temperature resistance, stable resistance time characteristic, controllable resistance temperature coefficient, higher temperature limitation and the like. The high-performance silicon-based conductive rubber is mainly used for military shelters and military electronic equipment in the fields of aviation, aerospace, ships and the like, as well as electronic products, telecommunication equipment, high-frequency control equipment and other occasions which requiring a very wide watertight, airtight or frequency range and needing excellent shielding performance.

Owner:江苏晶河电子科技有限公司

Electrolyte and secondary battery containing same

ActiveCN105870505AOvercome the disadvantages of incompatibilityImprove oxidation resistanceSecondary cellsOrganic electrolytesLithiumOrganic solvent

The invention relates to the field of batteries, in particular to an electrolyte and a secondary battery containing the same. The electrolyte comprises lithium salt, an organic solvent and an additive. The additive comprises sulphonate quaternary ammonium salt, and the organic solvent contains a sulphone compound. Sulphonate quaternary ammonium salt is added to a graphite cathode, film forming is achieved before the sulphone compound, the defect that a sulphone solvent makes contact with graphite for a reaction, so that incompatibility is generated is overcome, and the circulation performance of the battery is improved.

Owner:NINGDE AMPEREX TECH

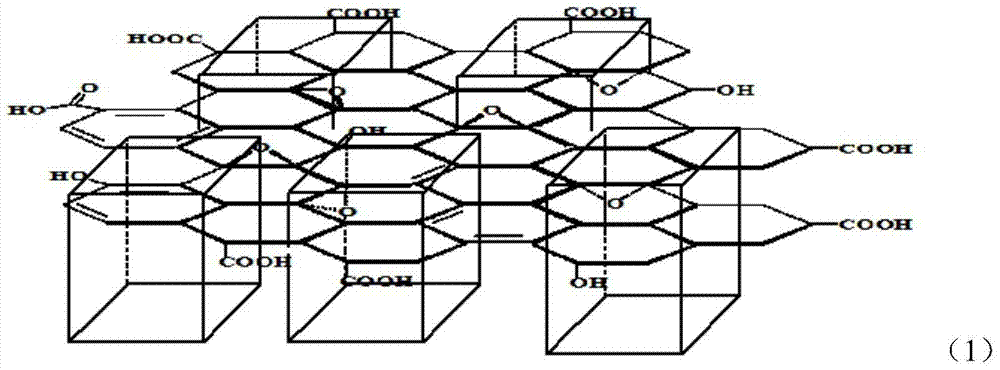

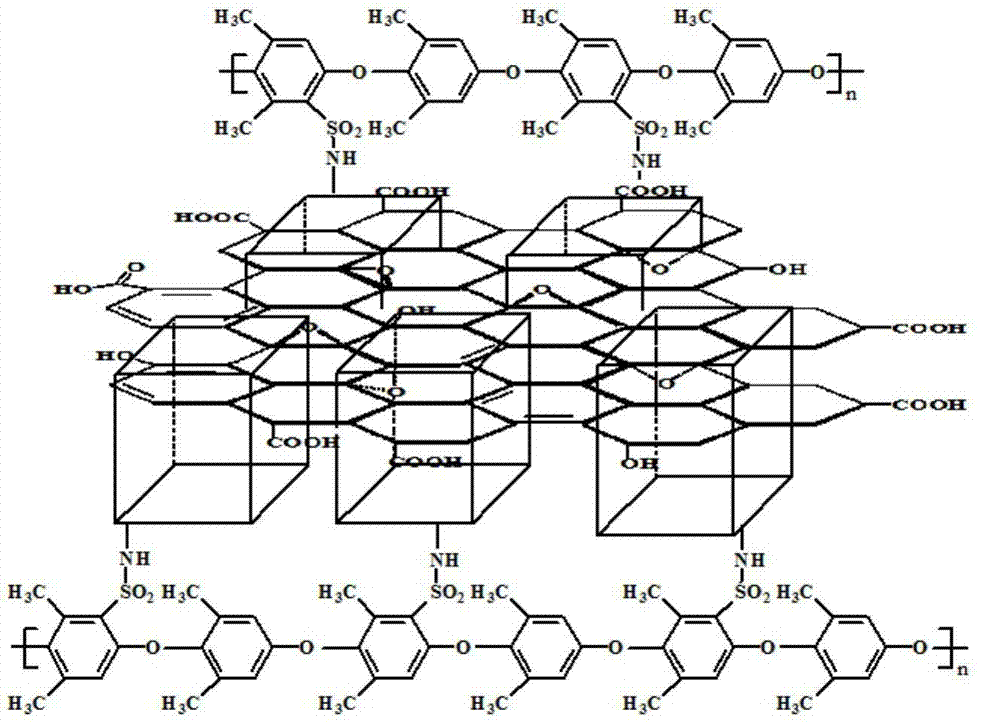

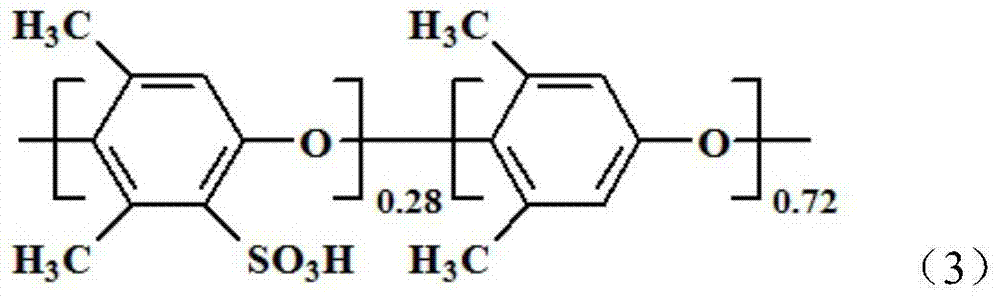

Method for preparing high-temperature proton exchange membrane

ActiveCN103779597AImprove conductivityImprove oxidation resistanceFinal product manufactureSolid electrolyte fuel cellsSodium hydroxidePolyphenylene oxide

The invention discloses a method for preparing a high-temperature proton exchange membrane. The method is characterized by comprising the following steps: introducing a precursor composition with a metal organic frame into oxidized graphene to form a coexisting body of the oxidized graphene and the metal organic frame, subsequently adding the coexisting body together with a sodium hydroxide solution into an N-methyl pyrrolidone solution of sulfonyl chlorination polyphenyl ether to perform Hinsberg reaction to obtain polymer membrane casting liquid with the coexisting body, coating and drying so as to obtain the high-temperature proton exchange membrane. According to the method, the metal organic frame is introduced into the oxidized graphene by using a hydrothermal method to form the coexisting body, and is further prepared into the high-temperature proton exchange membrane together with sulfonated polyphenyl ether in a chemical bond mode, the membrane is good in mechanical strength, thermal stability and excellent high-temperature proton conductivity and oxidative resistance, and can be applied to high-temperature proton exchange membrane fuel batteries.

Owner:UNIV OF SCI & TECH OF CHINA

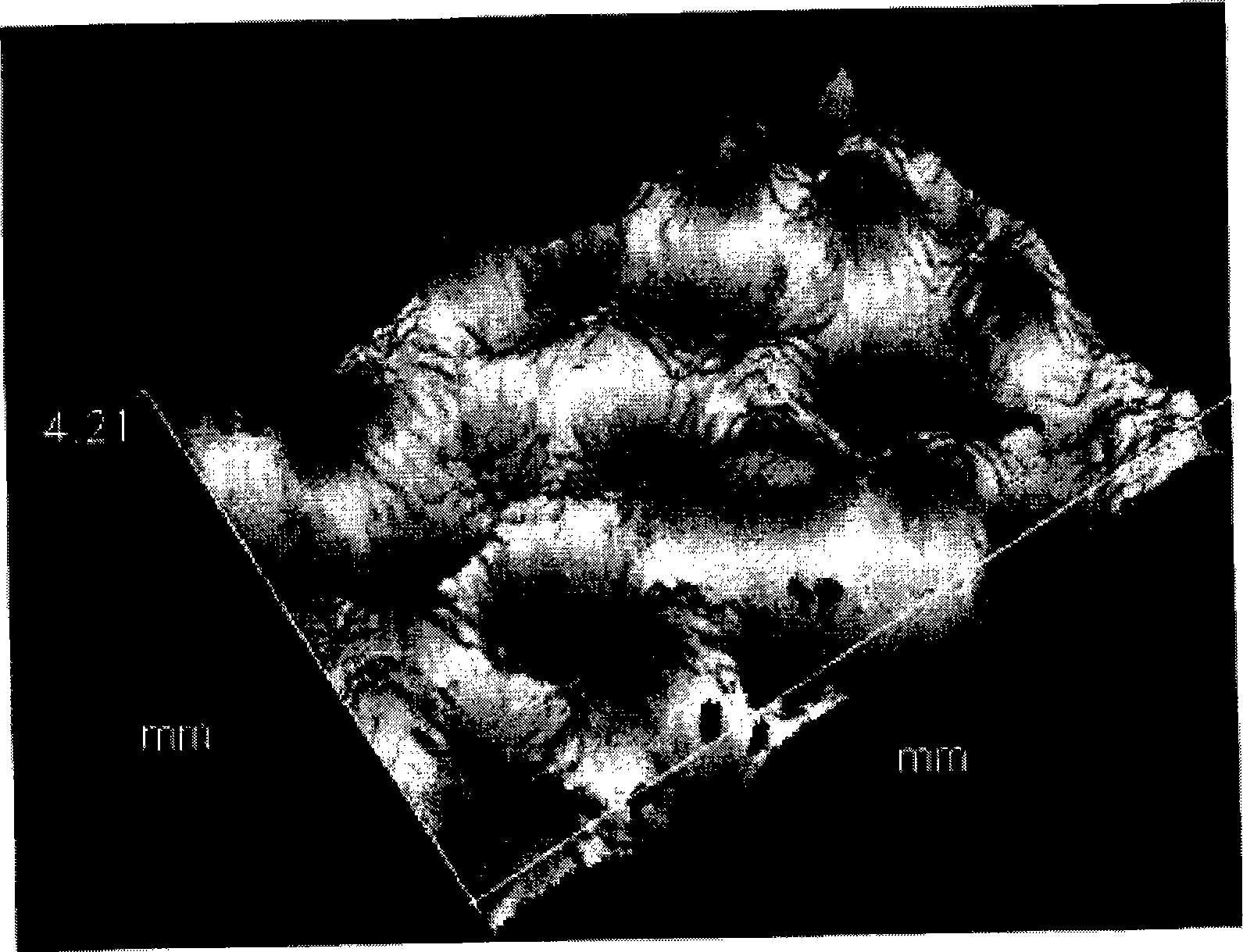

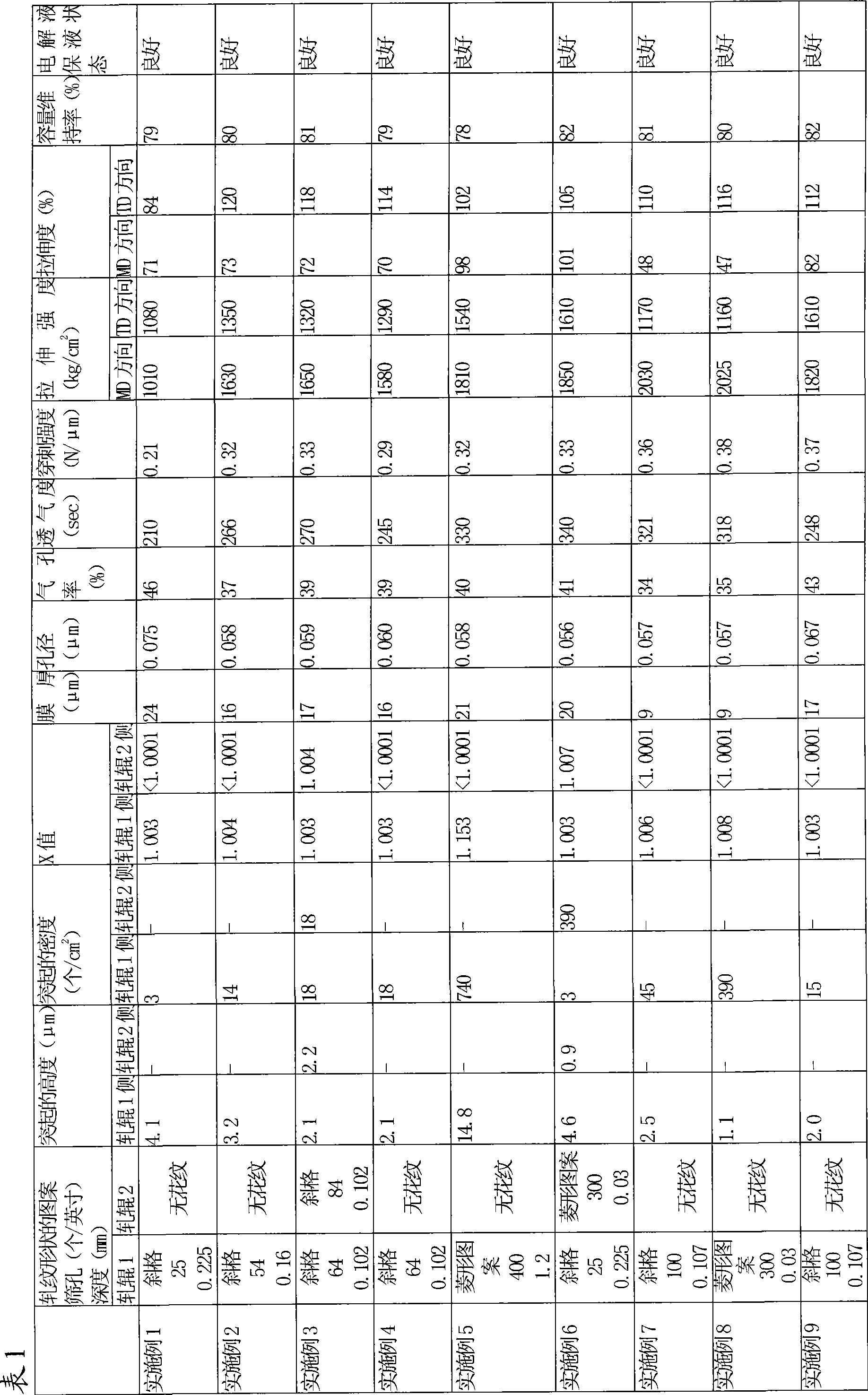

Polyolefin microporous membrane

ActiveCN101535386AAvoid compressionAvoid destructionSolid electrolytesCell seperators/membranes/diaphragms/spacersPolyolefinPolymer science

A polyolefin microporous membrane, which has a thickness of 1-100[mu]m, a pore diameter of 0.01-1[mu]m and a protrusion having a height of 0.5-30[mu]m arranged by embossing at least on one surface, is provided. A method for manufacturing the membrane and a battery separator made of the membrane are also provided.

Owner:ASAHI KASEI KK

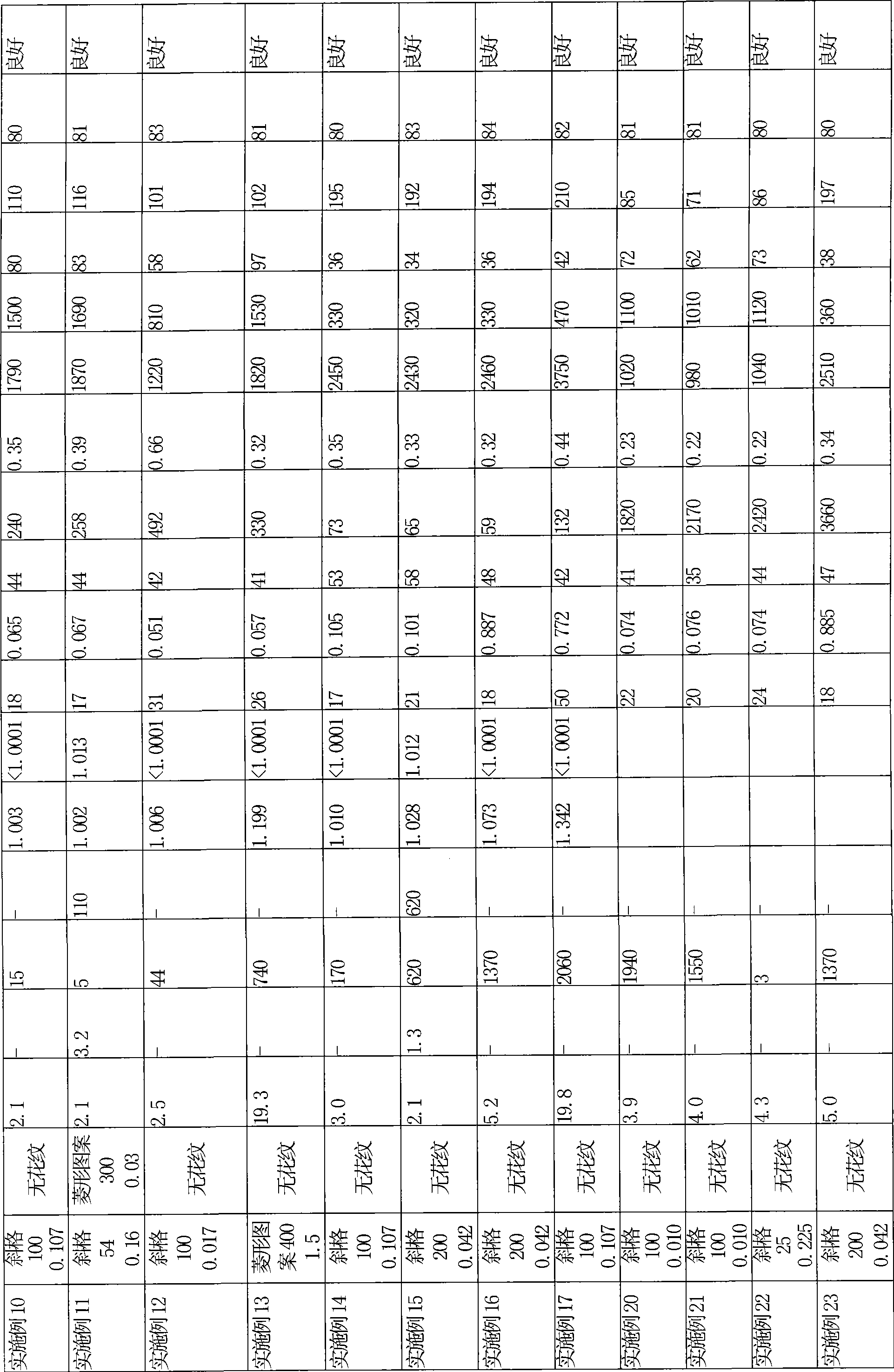

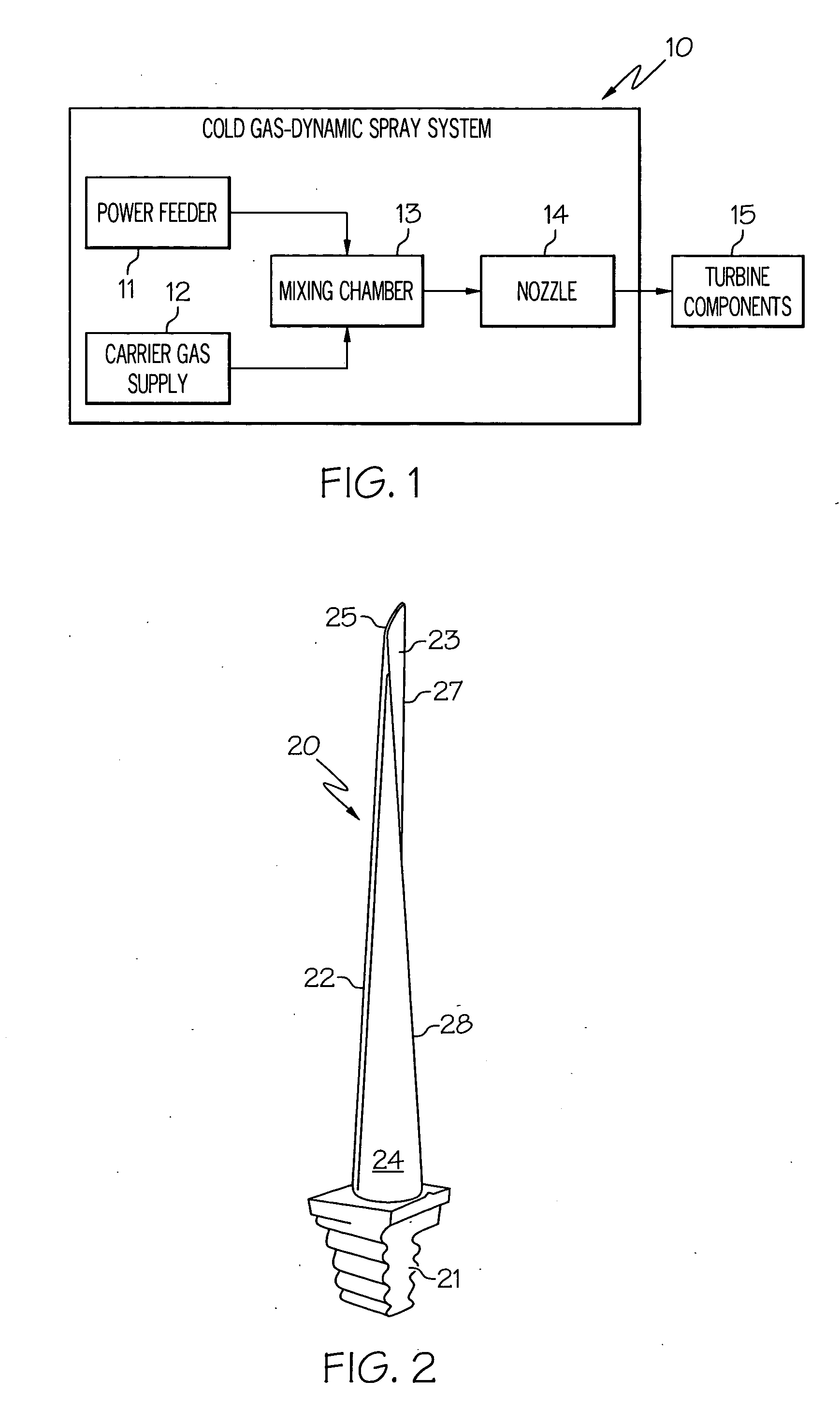

Method for applying environmental-resistant mcraly coatings on gas turbine components

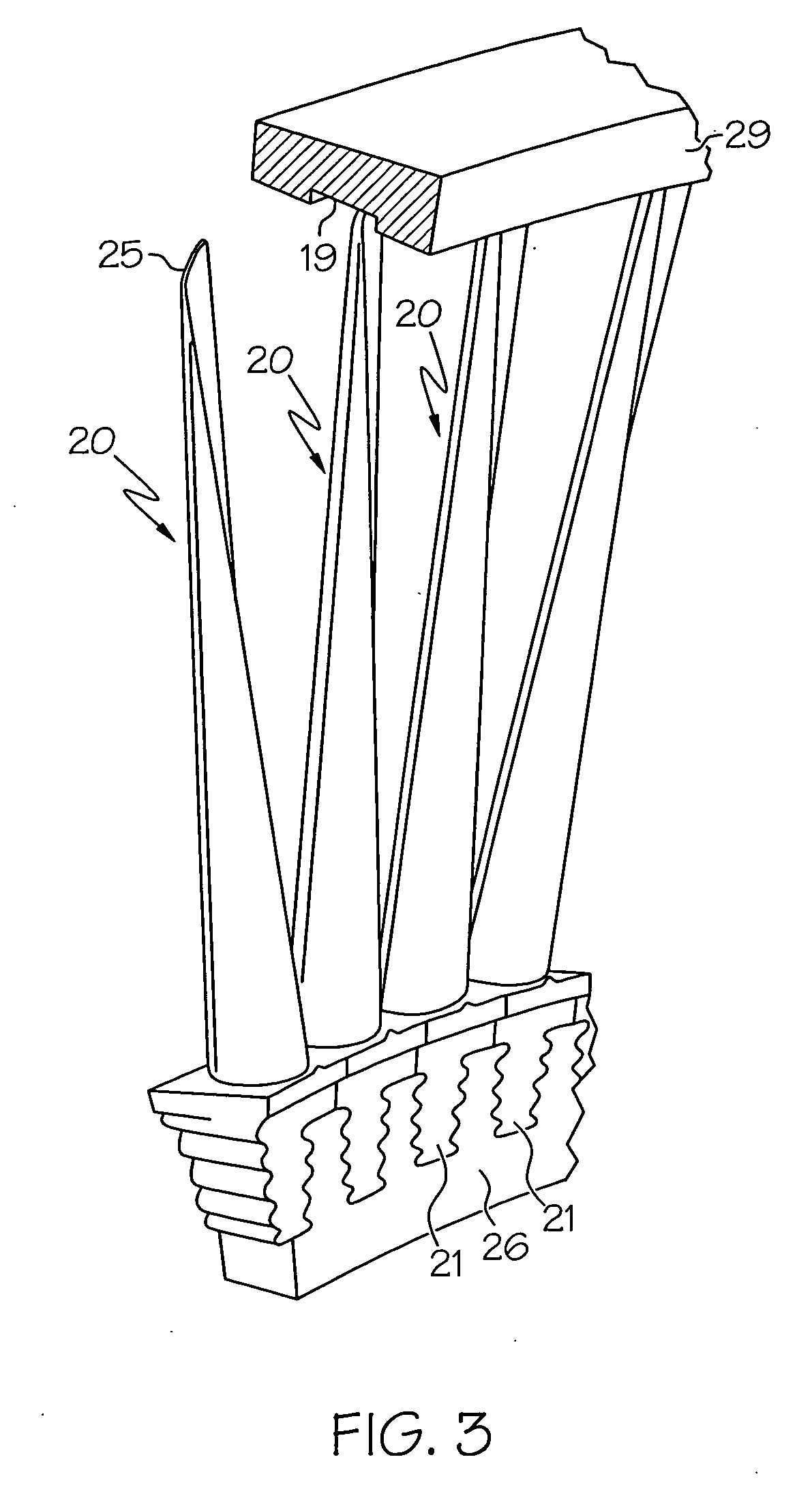

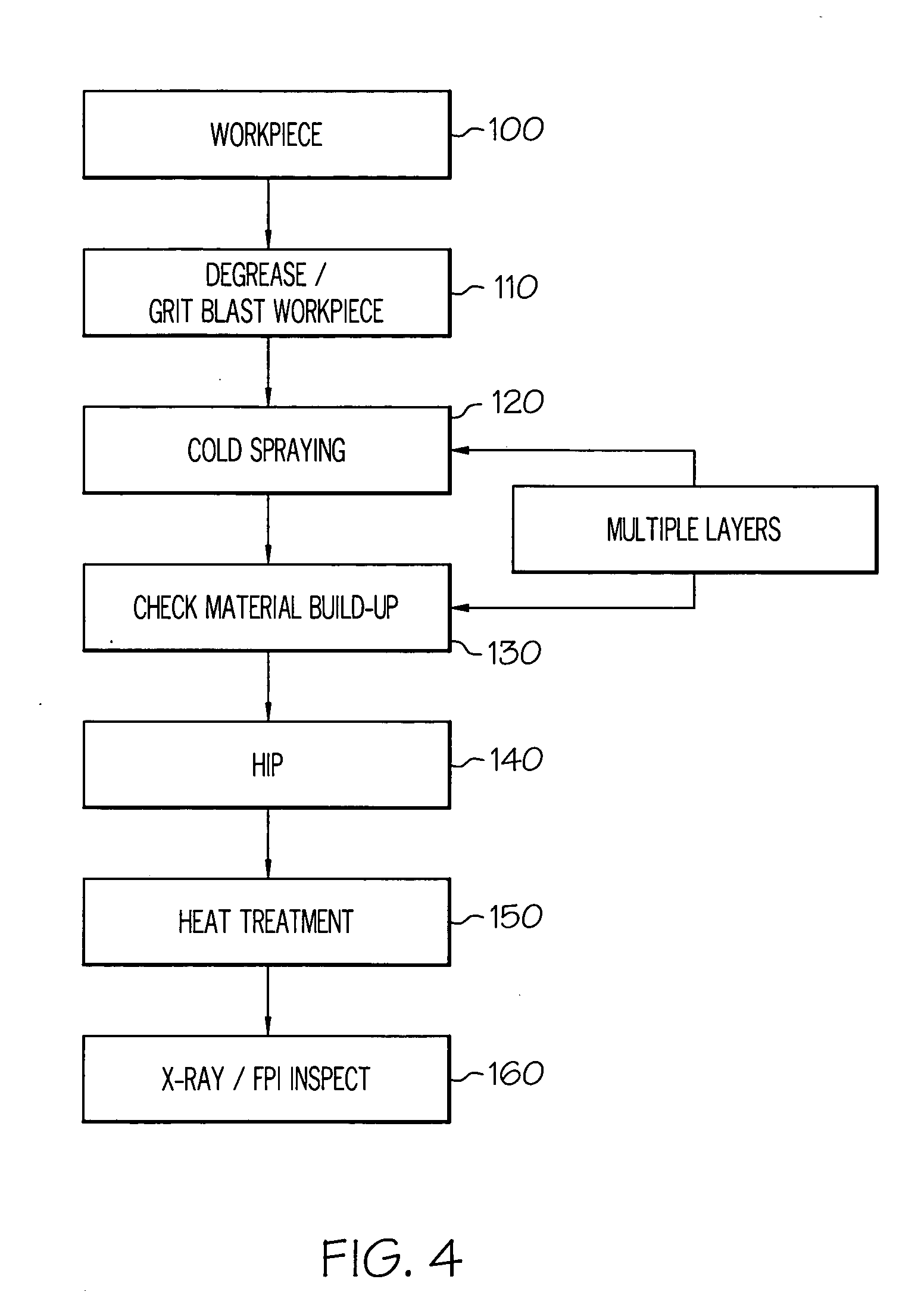

ActiveUS20080038575A1Improve relationshipImprove performanceEngine manufacturePretreated surfacesEnvironmental resistanceSuperalloy

There is provided a method for depositing a modified MCrAlY coating on a surface of a gas turbine engine component. The method includes cold gas dynamic spraying techniques to provide a metallurgical bond between a substrate, such as a superalloy substrate, and the modified MCrAlY composition. The method further includes post deposition heat treatments including hot isostatic pressing. The modified MCrAlY composition includes one or more elements of Pt, Hf, Si, Zr, Ta, Re, Ru, Nb, B, and C, which improves the corrosion and environmental resistance of the coated component

Owner:HONEYWELL INT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com