Preparation method of WC-based hard alloy with high-entropy powder as binder

A high-entropy alloy and cemented carbide technology, which is applied in the field of cermet materials, can solve the problems of failing to give full play to the characteristics of high-entropy alloys, and achieve good high-temperature oxidation resistance and wear resistance, high hardness and good mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

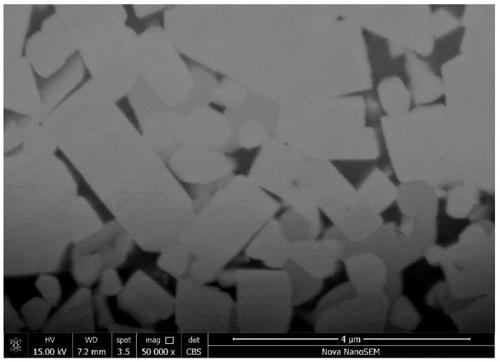

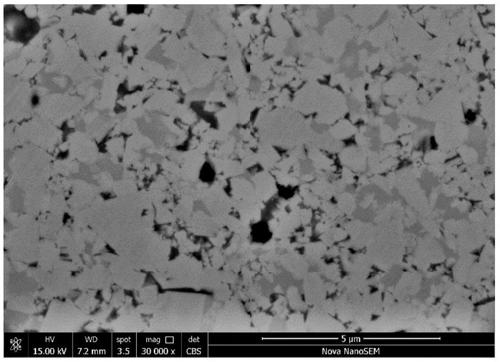

[0030] Take five elements such as Fe, Co, Cr, Ni, Al, etc., according to an equimolar ratio of 1:1:1:1:1, weigh a total of 80g, put it into a ball mill jar, add 2ml of ball mill control agent n-heptane Alkanes reagent, the ball-to-material ratio is 15:1, the ball milling speed is 250rpm, and the high-energy ball milling is carried out for 60h to obtain mechanically alloyed high-entropy alloy powder. Weigh 10% high-entropy alloy powder and 90% WC powder according to the mass ratio and put it into a ball mill jar, add 50ml of alcohol solution, put the ball mill jar into a planetary ball mill for low-energy ball milling, the ball mill speed is 150rpm, and the ball-to-material ratio is 8:1. Then unload and vacuum dry for storage for later use. Vacuum sintering is adopted. Weigh 80g of powder, add 1.2% paraffin wax as a molding agent, and press it into a blank with a 6.3t press, then degrease at 500°C, sinter at 1400°C under vacuum after degreasing, and measure its properties. Th...

Embodiment 2

[0032] Take five elements such as Fe, Co, Cr, Ni, Al, etc., according to an equimolar ratio of 1:1:1:1:1, weigh a total of 80g, put it into a ball mill jar, add 2ml of ball mill control agent n-heptane Alkanes reagent, the ball-to-material ratio is 15:1, the ball milling speed is 250rpm, and the high-energy ball milling is carried out for 60h to obtain mechanically alloyed high-entropy alloy powder. Weigh 10% high-entropy alloy powder and 90% WC powder according to the mass ratio and put it into a ball mill jar, add 50ml of alcohol solution, put the ball mill jar into a planetary ball mill for low-energy ball milling, the ball mill speed is 150rpm, and the ball-to-material ratio is 8:1. Then unload and vacuum dry for storage for later use. Vacuum hot pressing sintering method is adopted. Weigh 80g of powder, put it into a graphite mould, and sinter under vacuum at 15Mpa at 1400°C to obtain a sample, and measure its properties, and its hardness is 1850HV.

Embodiment 3

[0034] Take five elements such as Fe, Co, Cr, Ni, Al, etc., according to an equimolar ratio of 1:1:1:1:1, weigh a total of 80g, put it into a ball mill jar, add 2ml of ball mill control agent n-heptane Alkanes reagent, the ball-to-material ratio is 15:1, the ball milling speed is 250rpm, and the high-energy ball milling is carried out for 60h to obtain mechanically alloyed high-entropy alloy powder. Weigh 10% high-entropy alloy powder and 90% WC powder according to the mass ratio and put it into a ball mill jar, add 50ml of alcohol solution, put the ball mill jar into a planetary ball mill for low-energy ball milling, the ball mill speed is 150rpm, and the ball-to-material ratio is 8:1. Then unload and vacuum dry for storage for later use. Using spark plasma sintering. Weigh 80g of powder, put it into a graphite mold, and sinter at 1400°C under vacuum with a pressure of 40Mpa to obtain a sample, and measure its properties, and its hardness is 1900HV.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com