Patents

Literature

11839 results about "Refractory" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A refractory material or refractory is a heat-resistant material: that is, a mineral that is resistant to decomposition by heat, pressure, or chemical attack, most commonly applied to a mineral that retains strength and form at high temperatures..

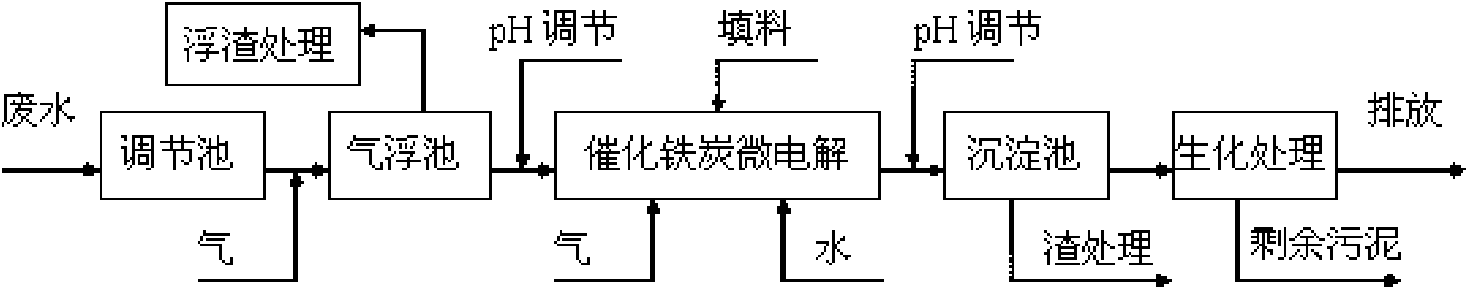

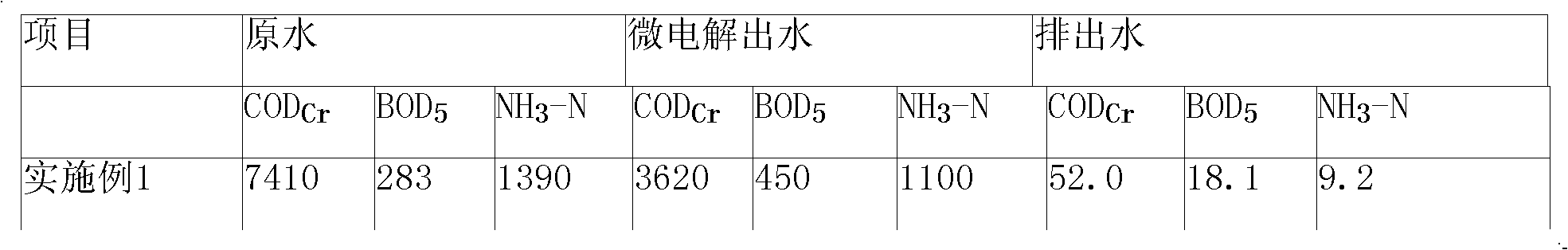

Catalysis and micro-electrolysis combined technology for high-concentration refractory organic wastewater

InactiveCN101665311AReduce processing loadEasy to handleTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentHigh concentrationElectrolysis

The invention relates to a catalysis and micro-electrolysis combined technology for high-concentration refractory organic wastewater; the organic wastewater is collected to an adjusting tank and enters an air floatation tank for air floatation treatment to remove part of the organic matters after the adjustment of water volume and water quality; the scruff is collected or recovered; the wastewatergoes through Ph adjustment and then enters a catalytic iron-carbon and micro-electrolysis unit to improve the biochemical quality; the effluent goes through Ph adjustment and then enters a sedimentation tank; the effluent of the sedimentation tank adopts anoxic-aerobic biochemistry treatment to remove the organic matters and ammonia nitrogen and then is emitted after reaching the standard; and the filler of the catalytic iron-carbon and micro-electrolysis unit comprises iron, carbon and a catalyst, wherein the mass ratio of the iron, carbon and catalyst is 1: (0.3-1.5): (0.01-0.5). The invention can effectively improve the micro-electrolysis electrochemical reaction efficiency and the degrading capability to the organic matters, and reduce the wastewater treatment cost with convenient technological operation.

Owner:CENT SOUTH UNIV

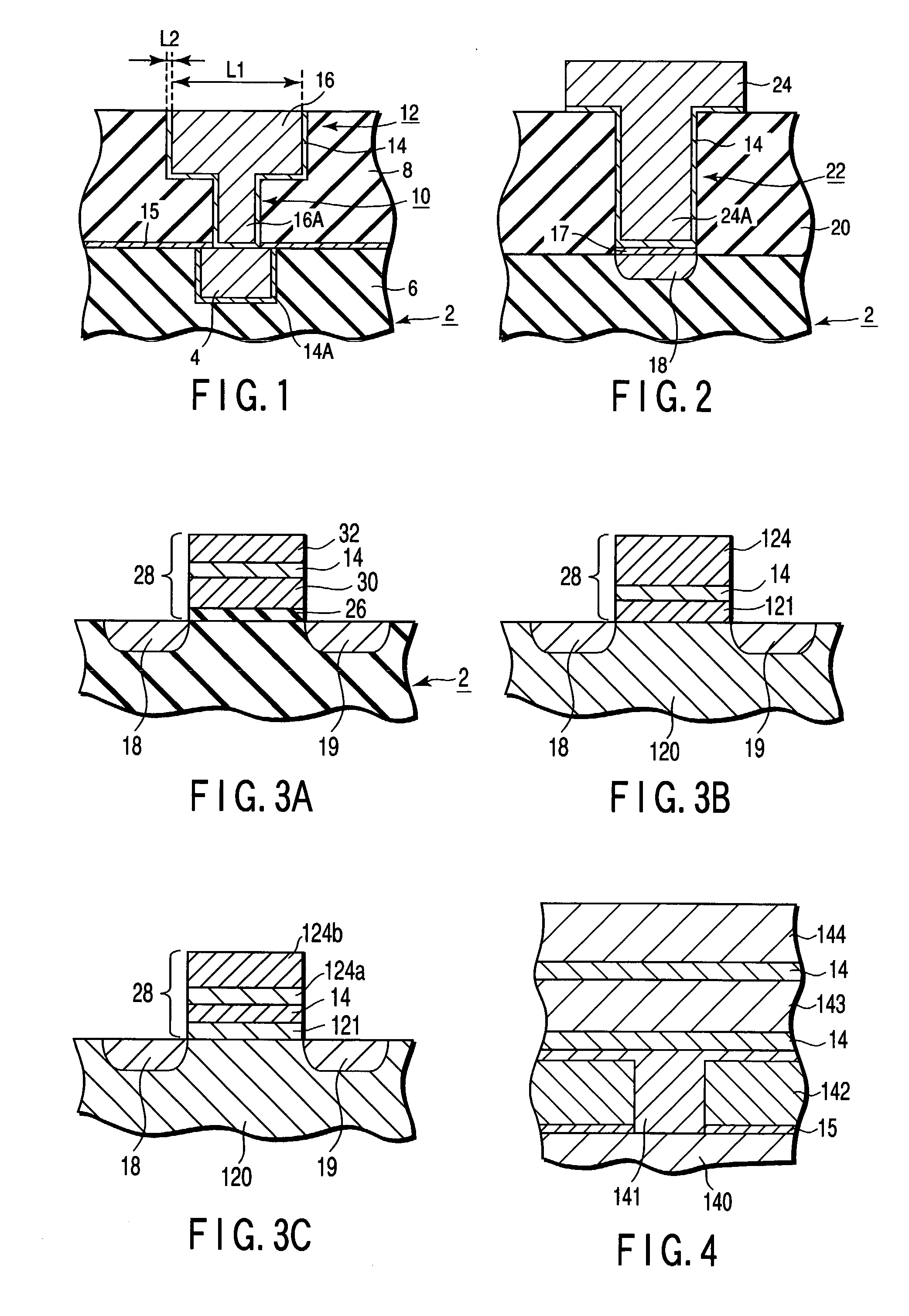

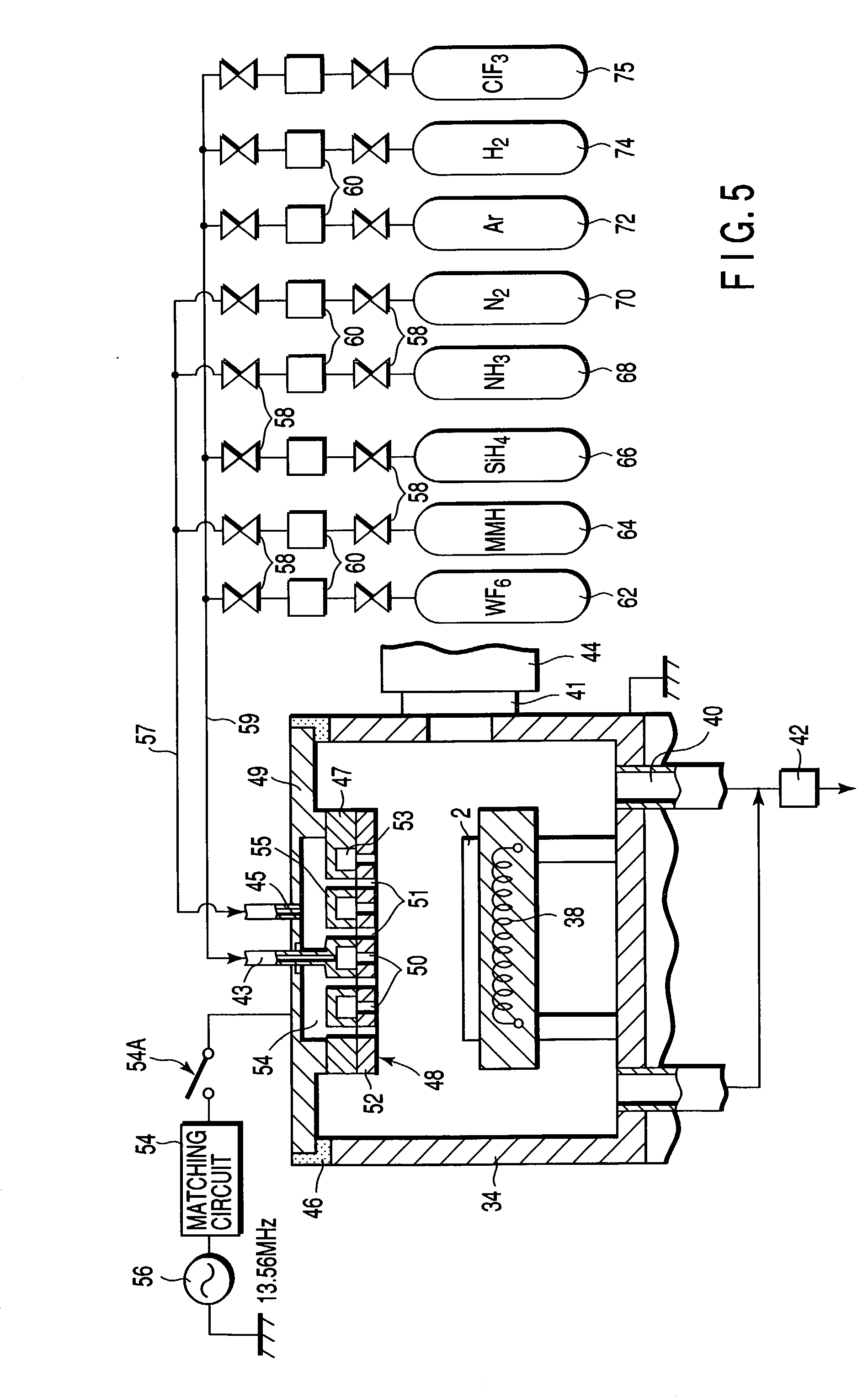

Method of forming a barrier film and method of forming wiring structure and electrodes of semiconductor device having a barrier film

There is provided a method of forming a barrier metal which is designed to be interposed between a metal layer and an insulating layer, both constituting a multi-layered structure of semiconductor device, the method comprising the steps of positioning a substrate having the insulating layer formed thereon at a predetermined position inside a processing vessel forming a processing space, and alternately introducing a gas containing a refractory metallic atom, a gas containing Si atom and a gas containing N atom into the processing vessel under a predetermined processing pressure, thereby allowing a refractory metal nitride or a refractory metal silicon nitride to be deposited on the insulating layer by way of atomic layer deposition.

Owner:TOKYO ELECTRON LTD

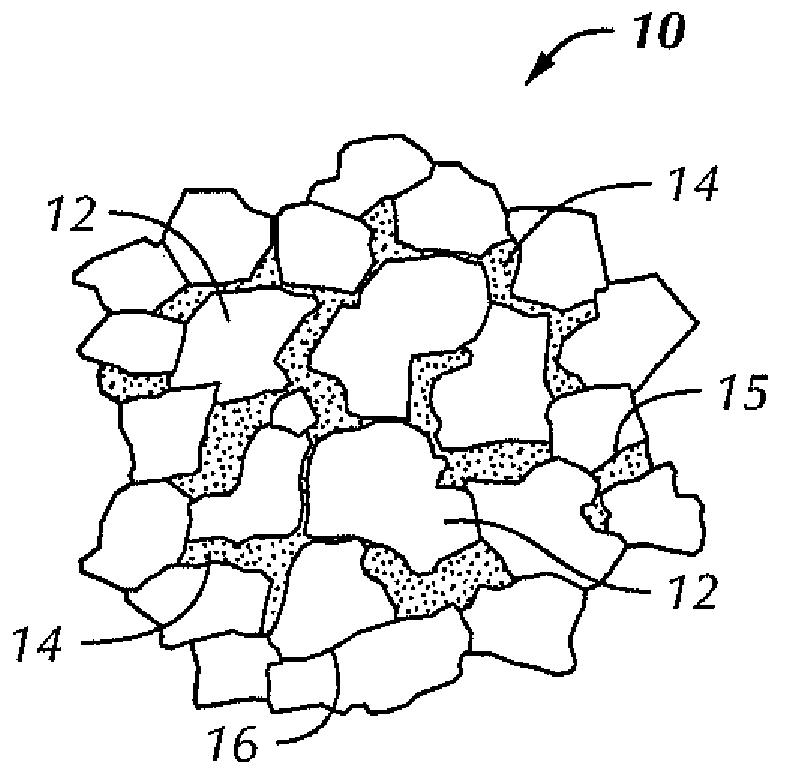

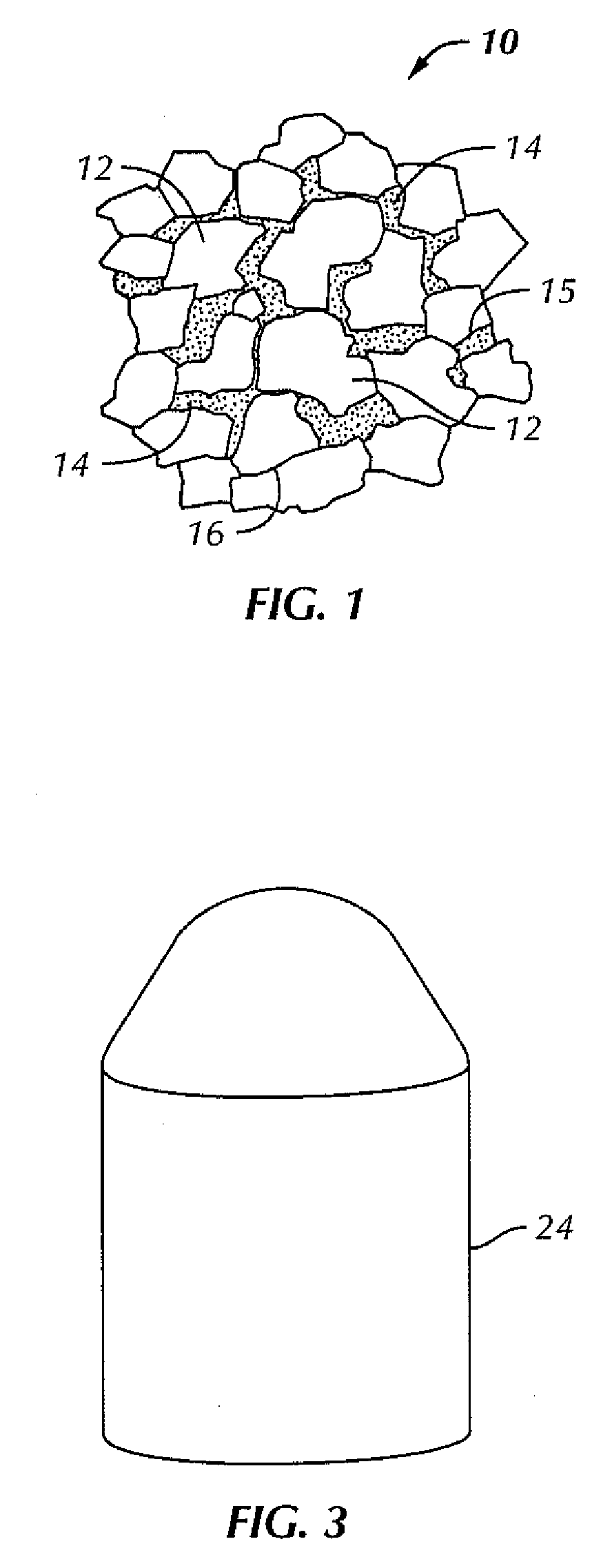

Polycrystalline composites reinforced with elongated nanostructures

A sintered polycrystalline composite for cutting tools that includes a plurality of diamond or cubic boron nitride particles; a plurality of nanotube materials; and a refractory or binder material is disclosed. Methods of forming such polycrystalline composites that include integrating or mixing a plurality of nanotube materials with diamond or cubic boron nitride particle and / or refractory or binder particles are also disclosed.

Owner:SMITH INT INC

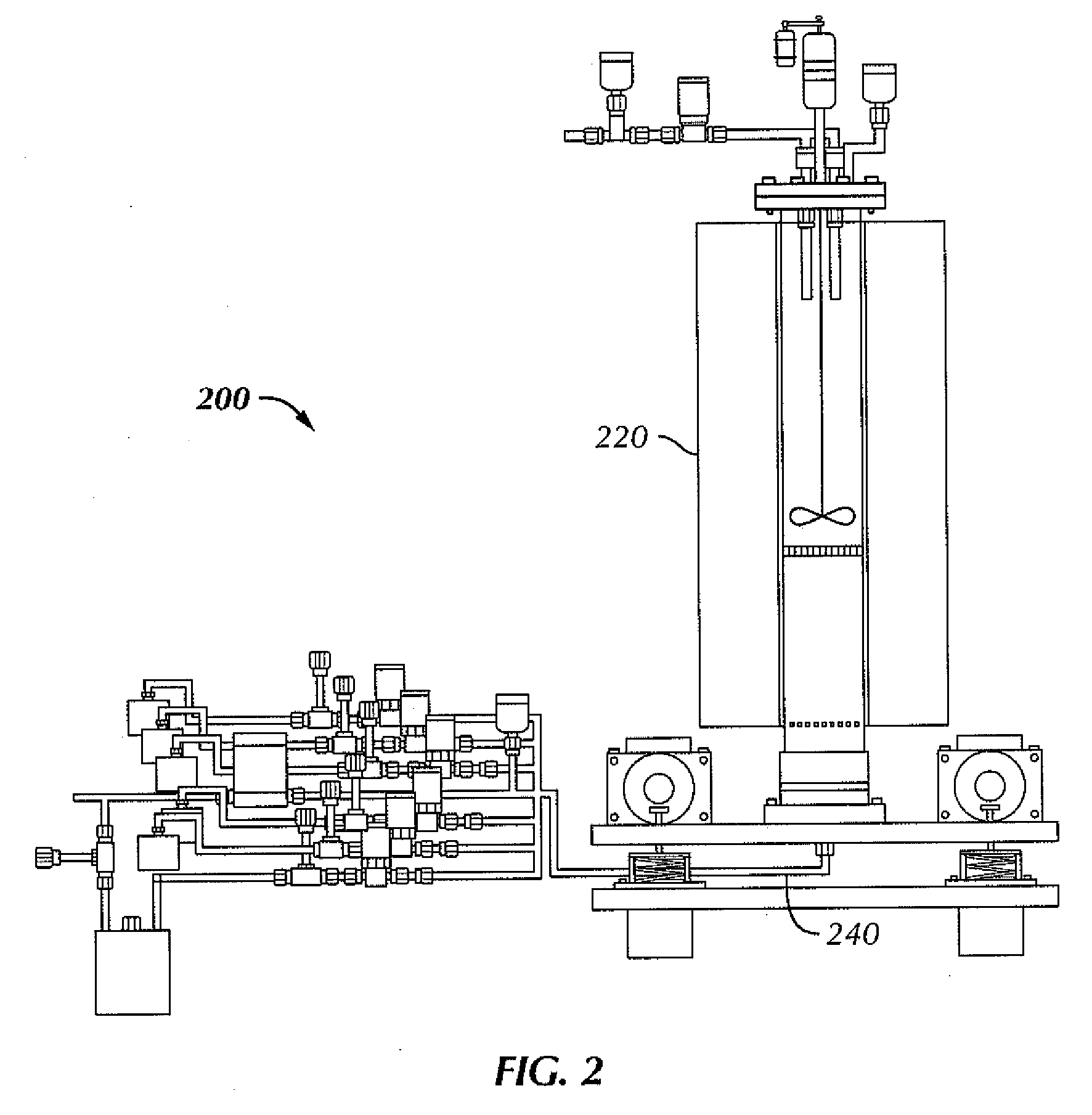

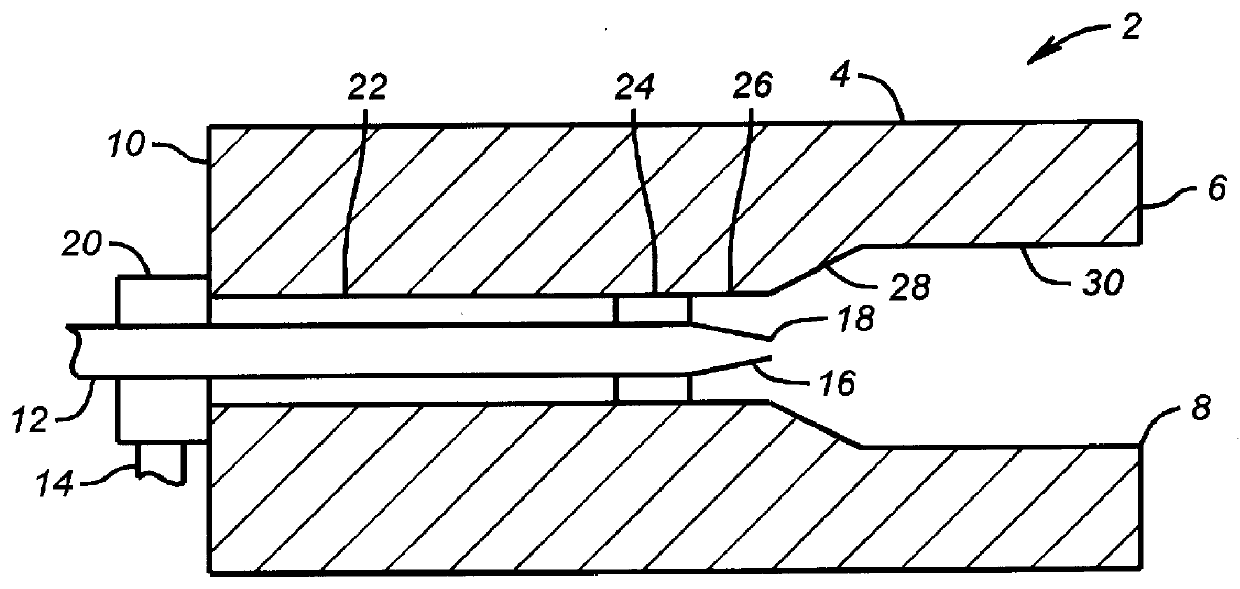

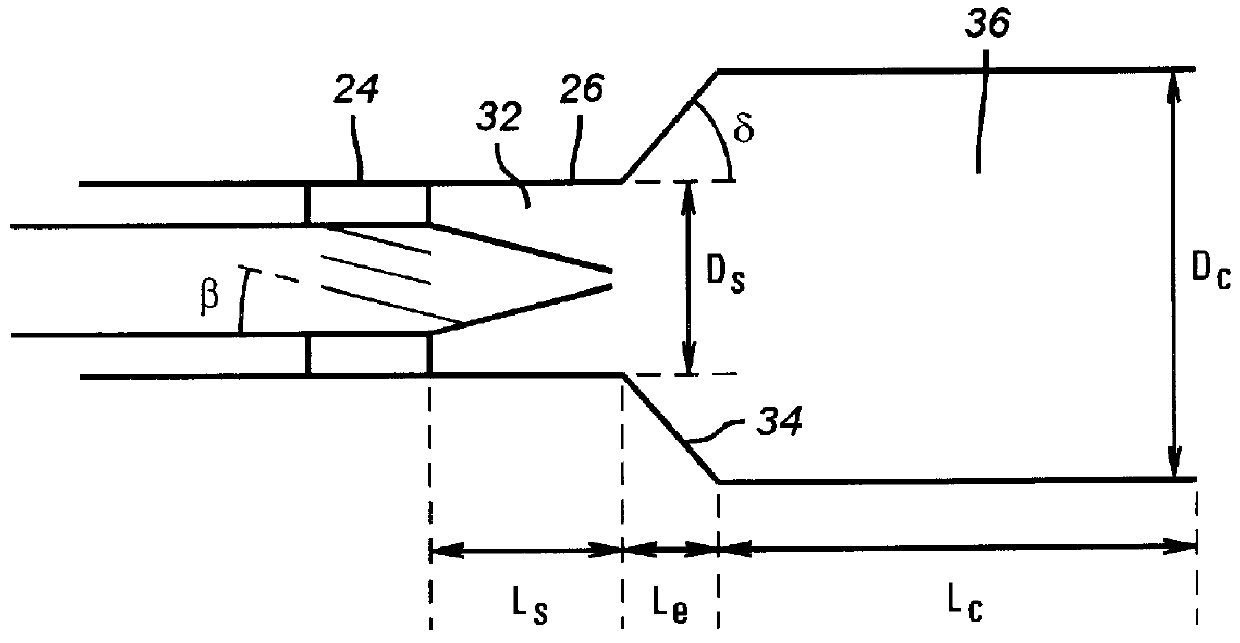

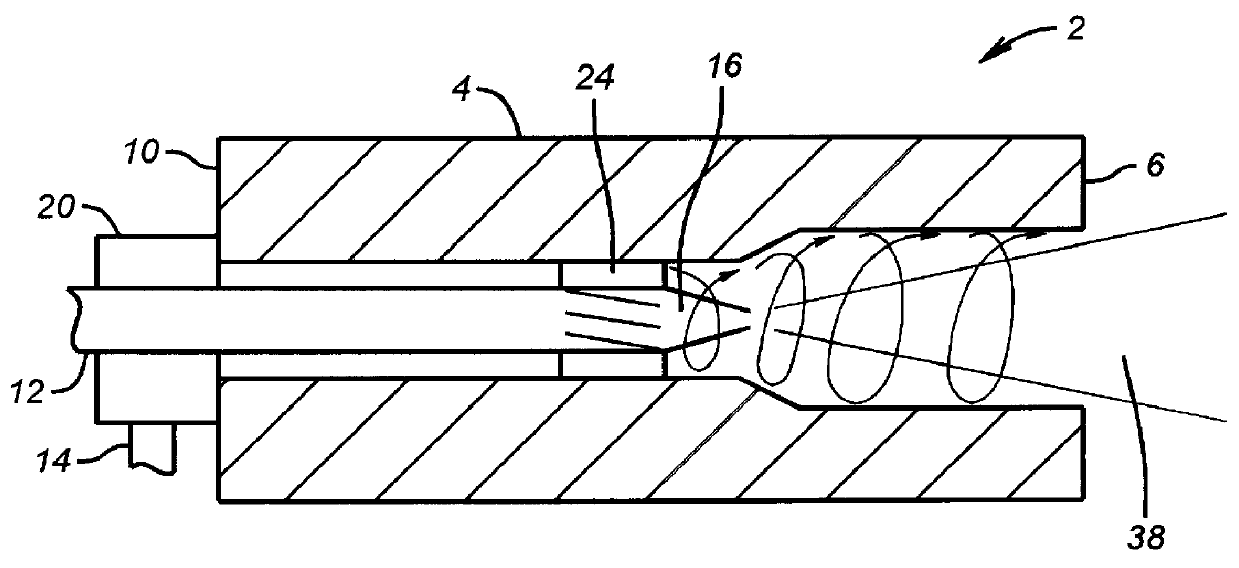

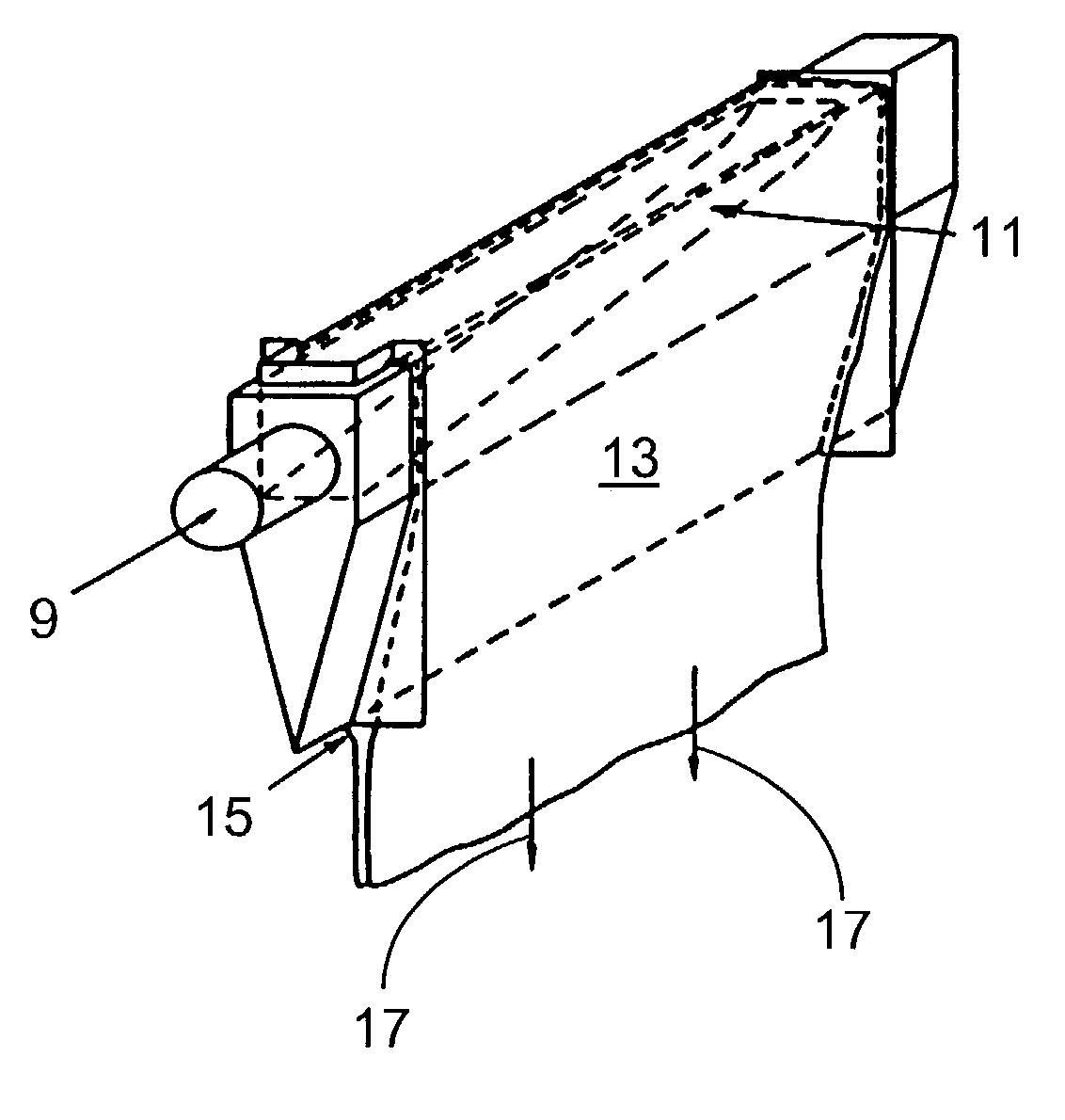

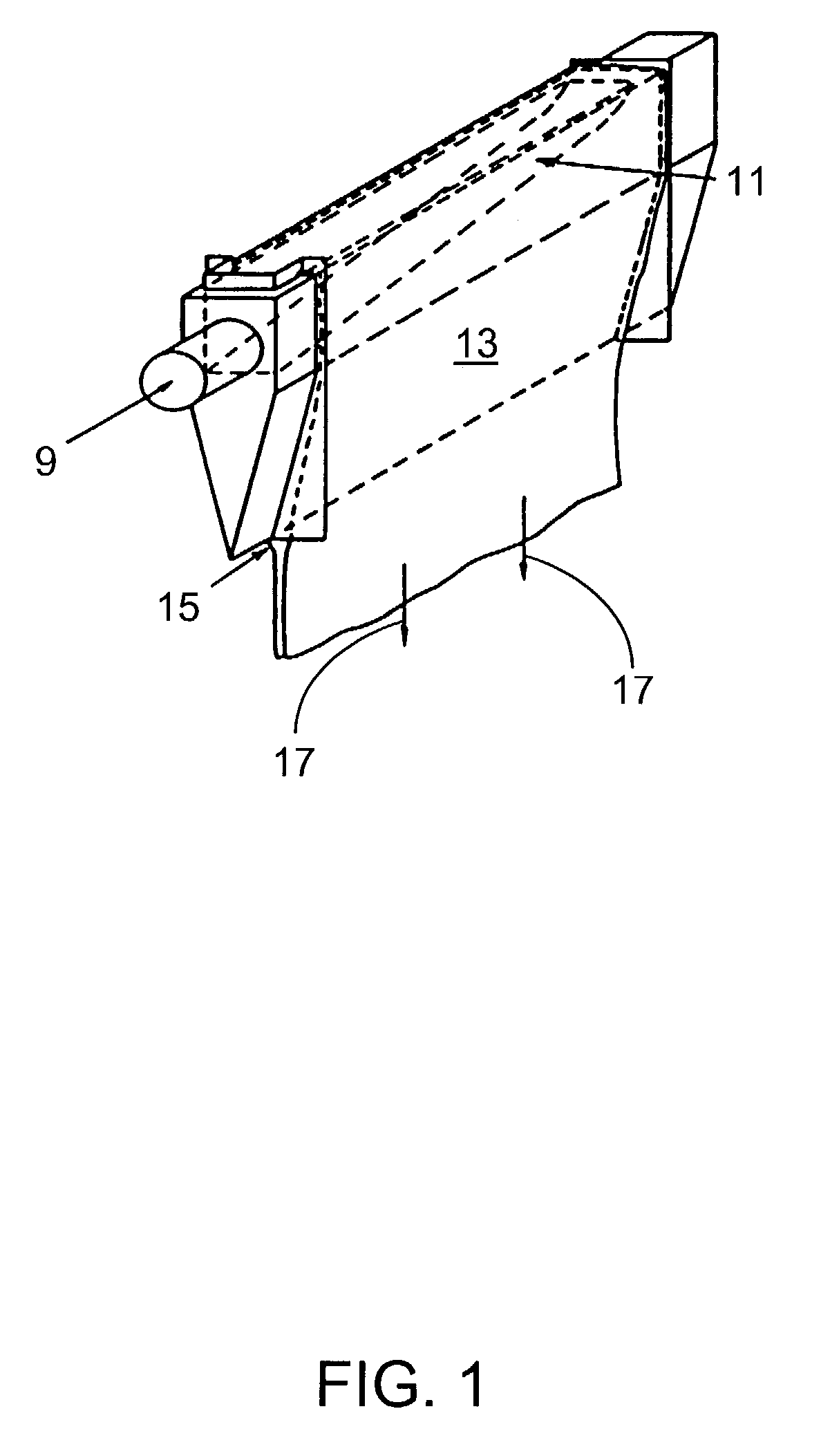

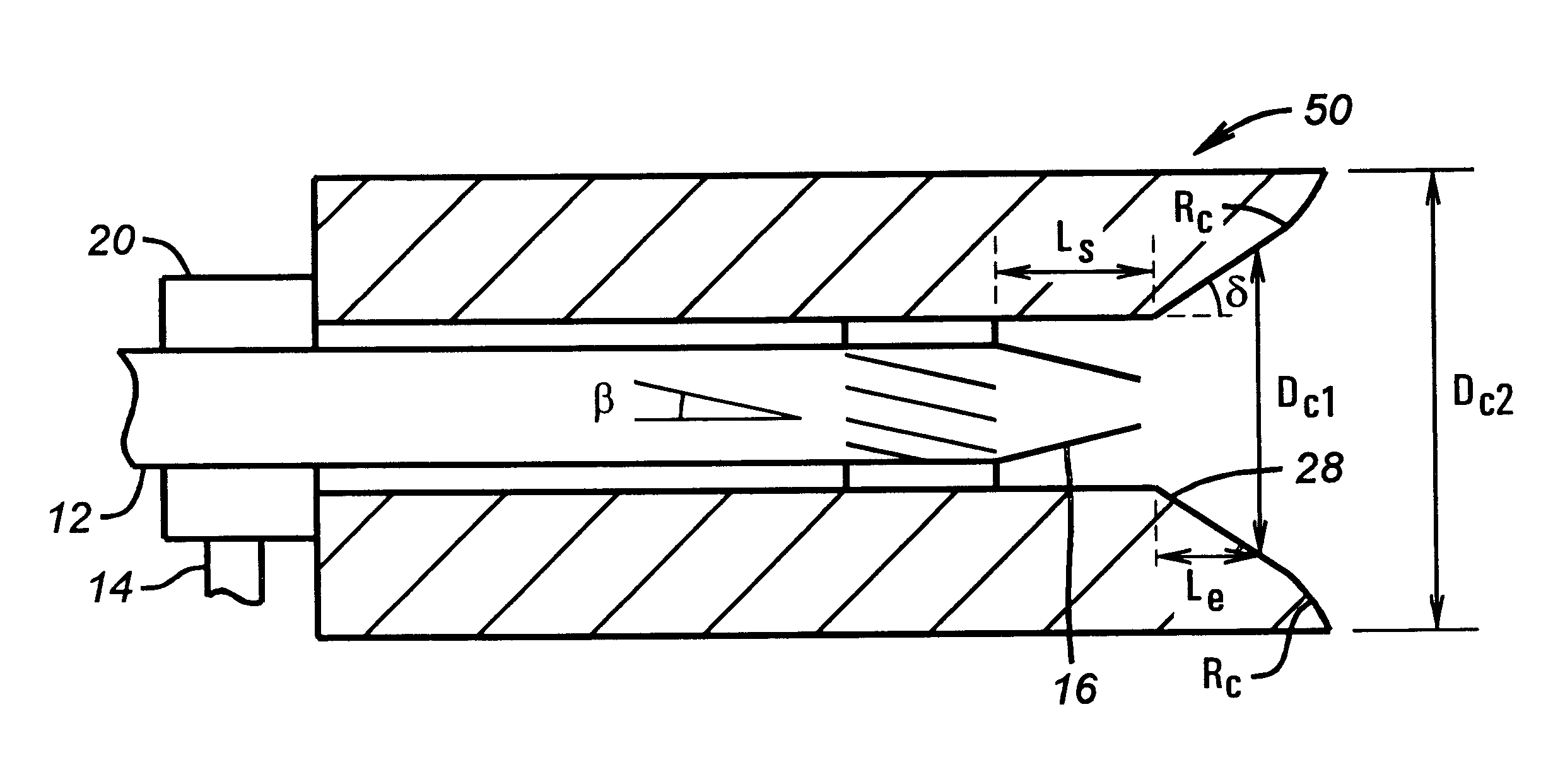

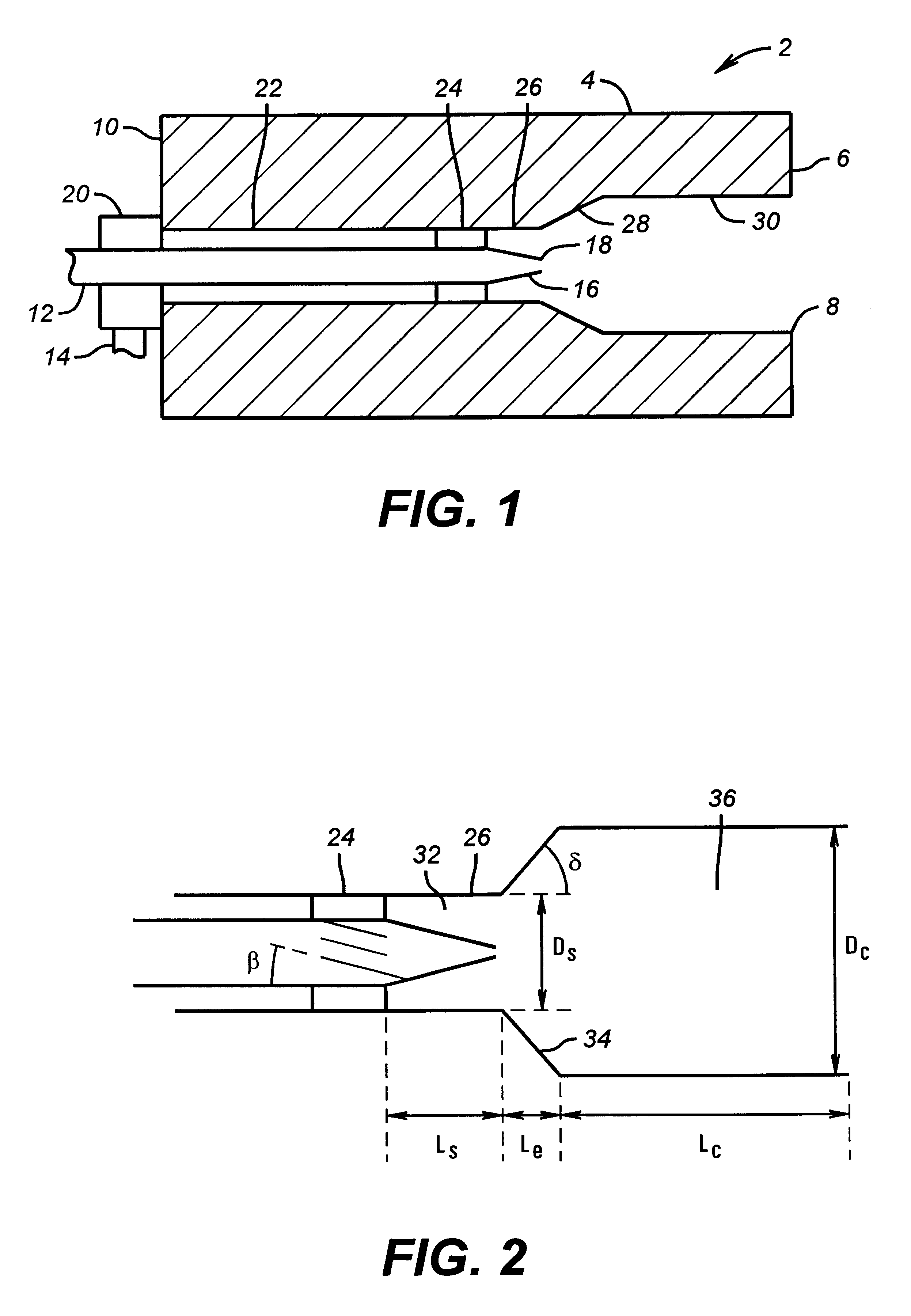

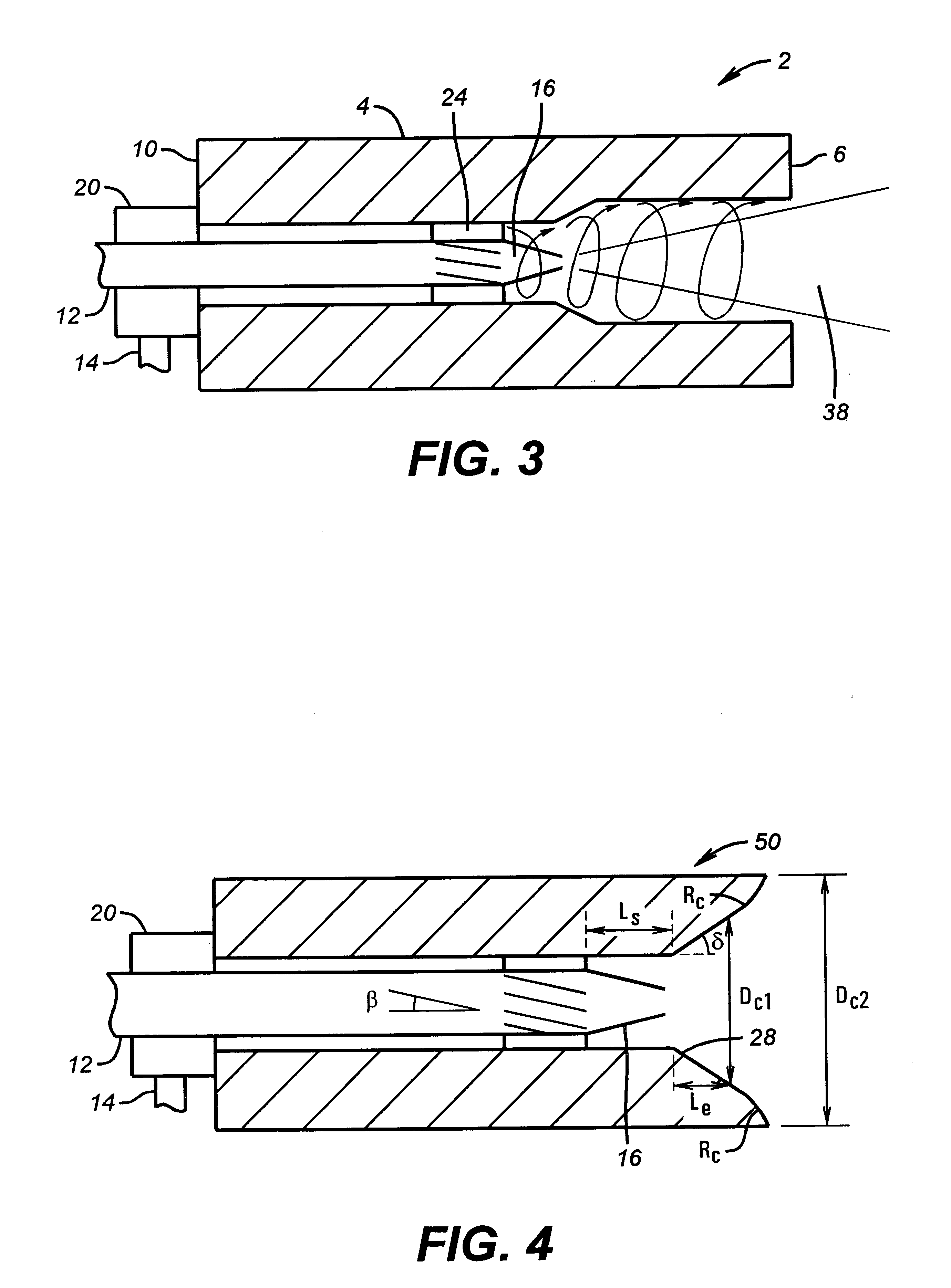

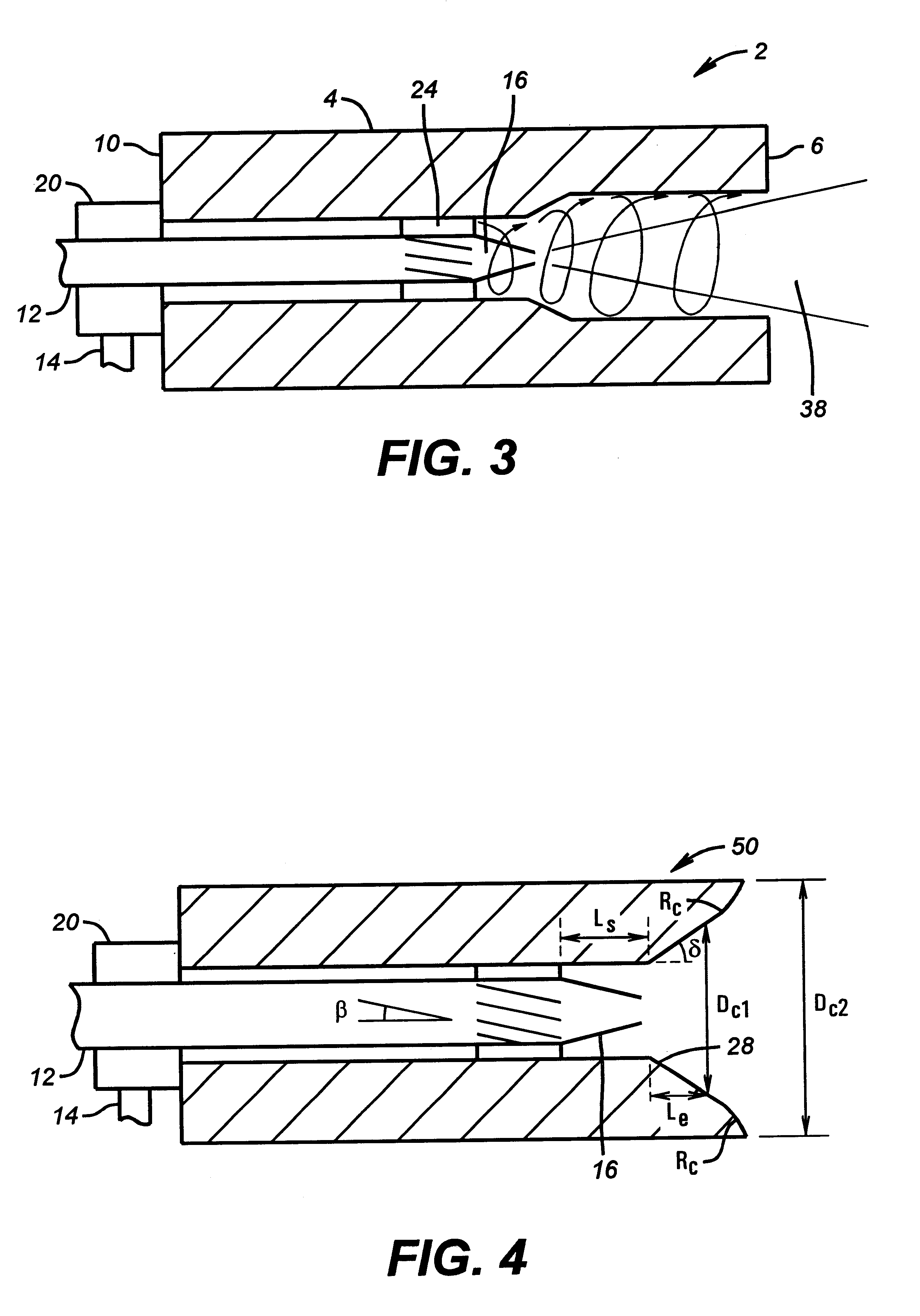

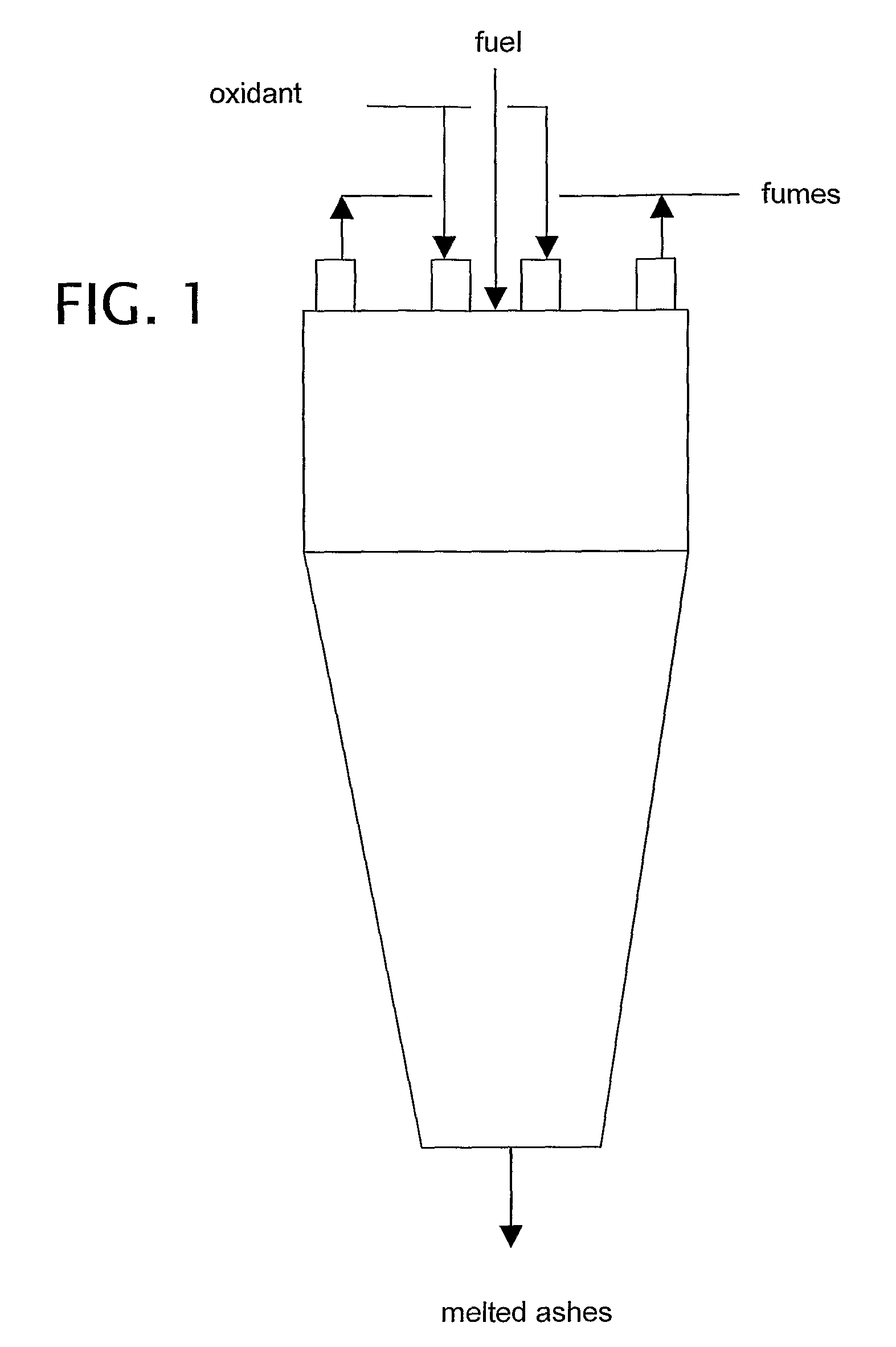

Self-cooled oxygen-fuel burner for use in high-temperature and high-particulate furnaces

InactiveUS6123542AAvoiding particulate inspiration.TheControl expansionGlass furnace apparatusGlass melting apparatusParticulatesCombustor

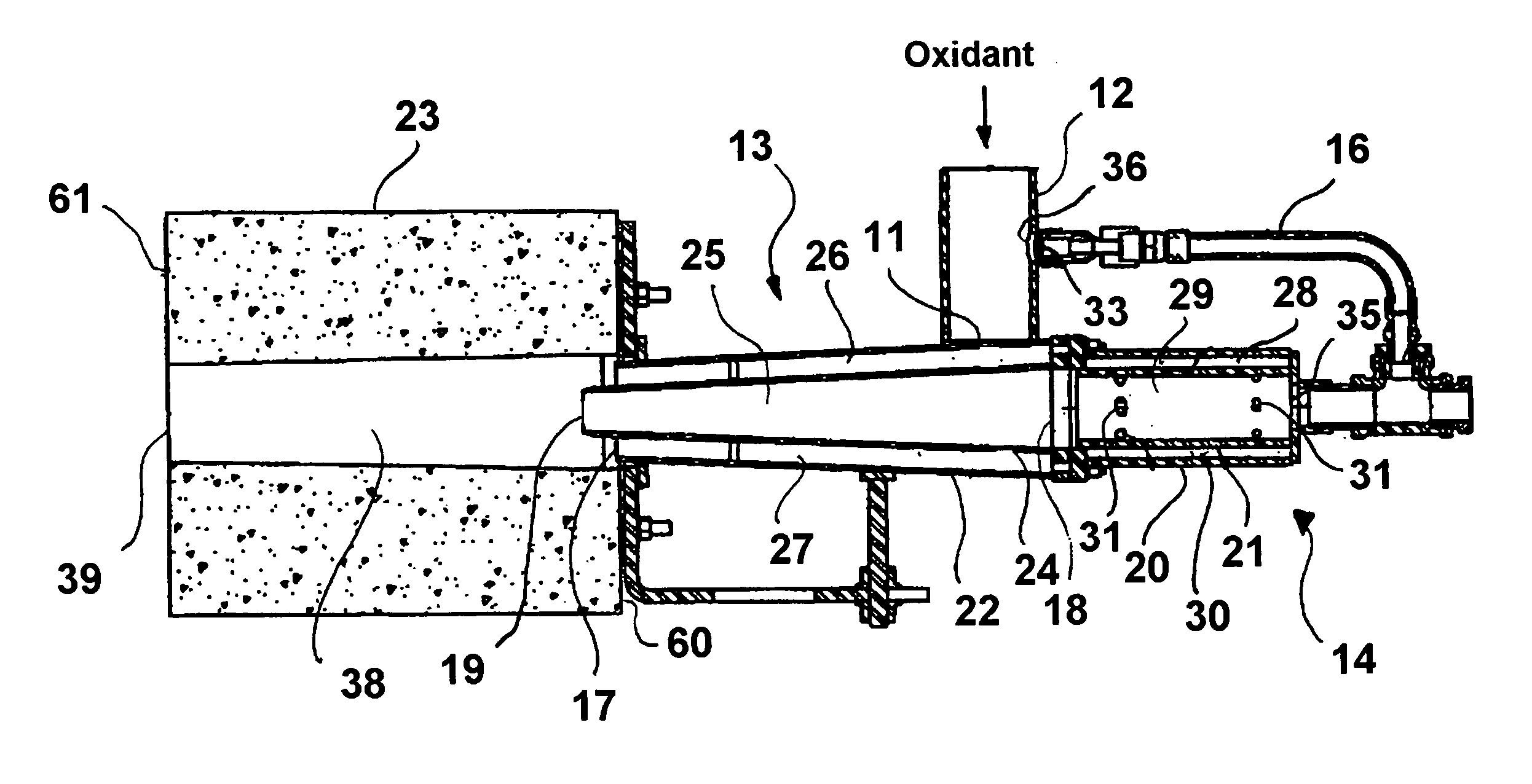

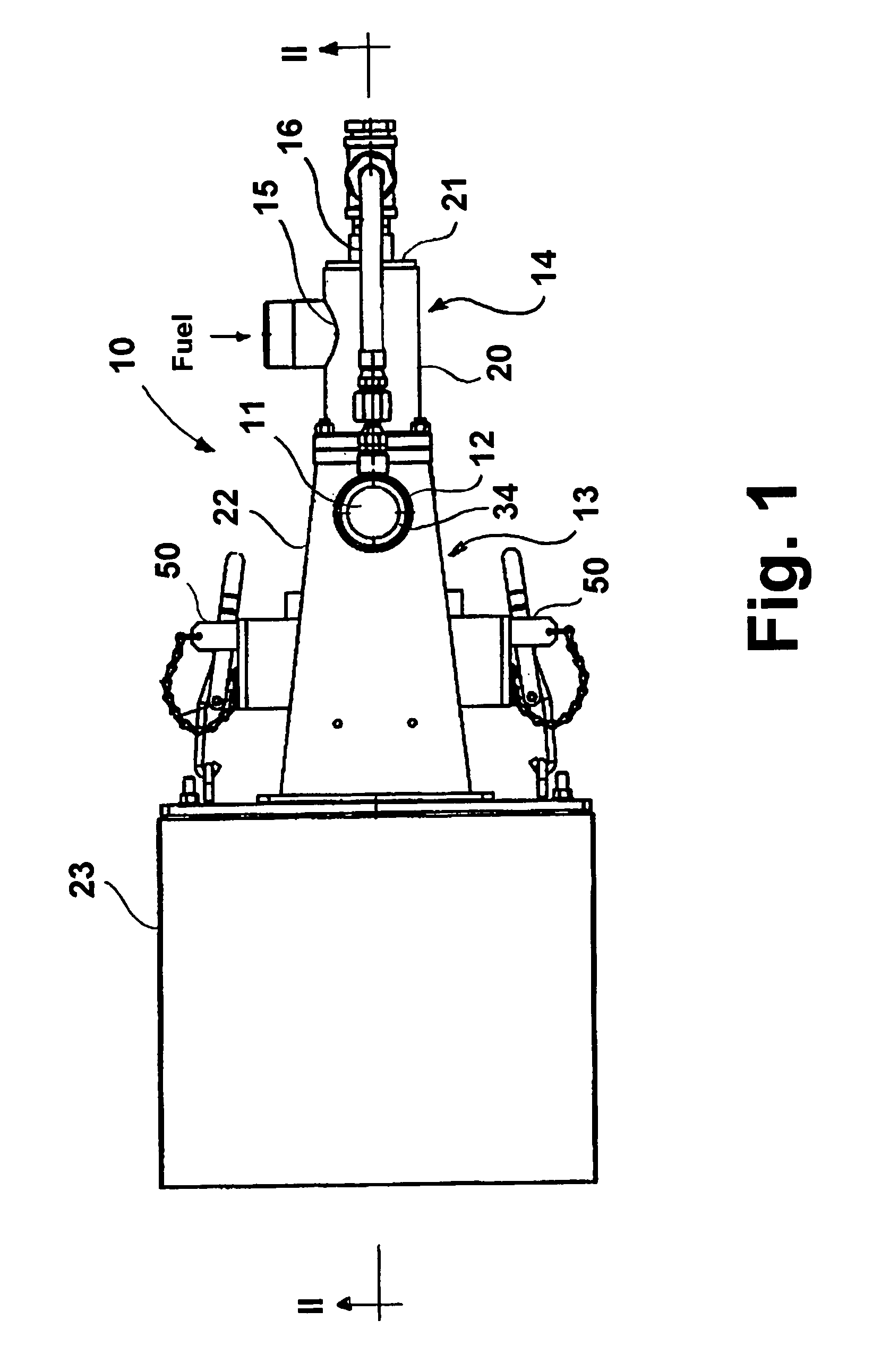

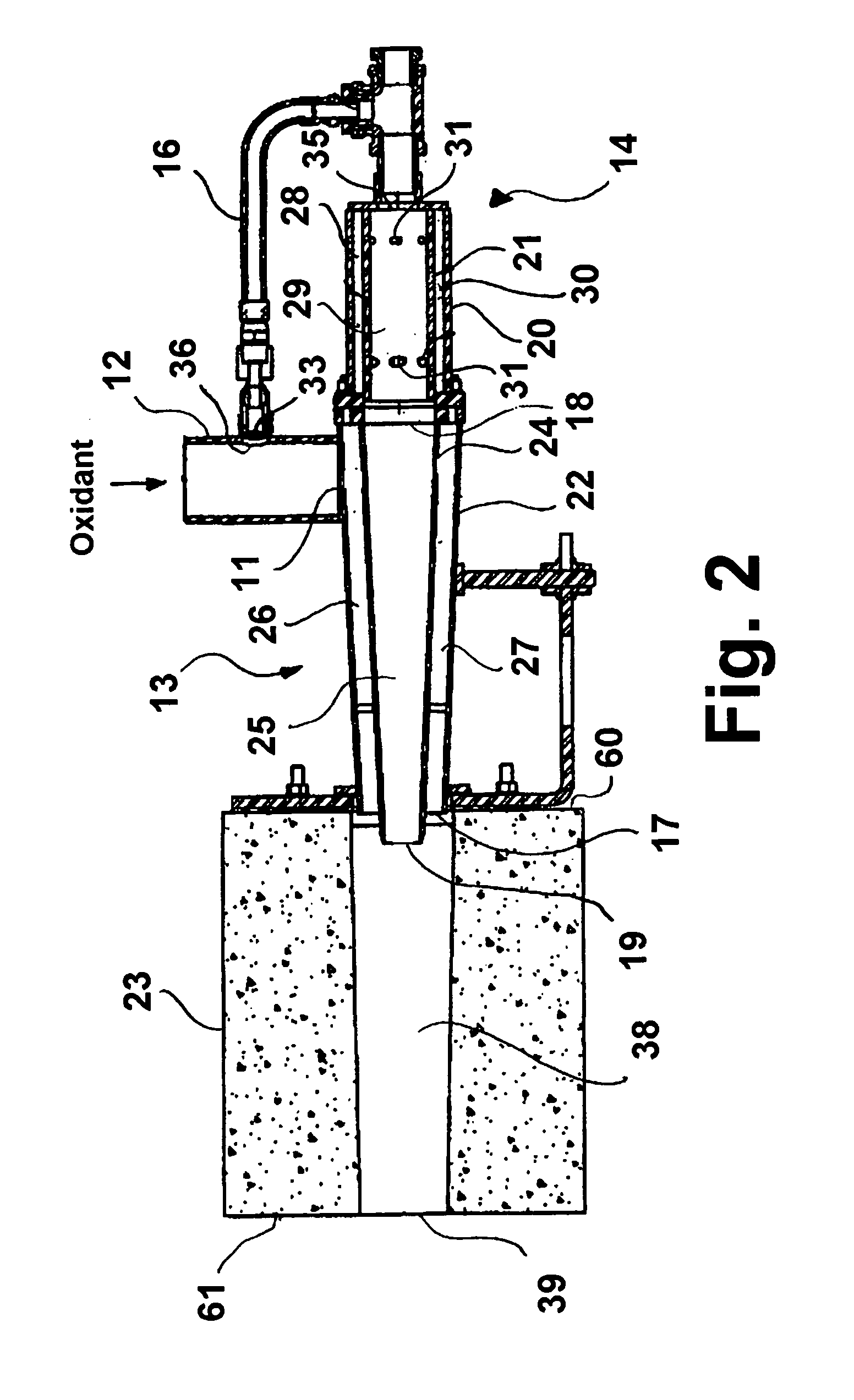

A self-cooled oxidant-fuel burner consisting novel fuel and oxidant nozzles and three compartment refractory burner block design is proposed. The new oxidant-fuel burner can fire in high-temperature (2200 DEG F. to 3000 DEG F.) and high-particulate (or high process volatiles / condensates) furnaces without over-heating or causing chemical corrosion damage to it's metallic burner nozzle and refractory burner block interior. Using various embodiments of nozzle and block shape, the burner can offer a traditional cylindrical flame or flat flame depending on the heating load requirements. The new features of this burner include unique fuel nozzle design for the streamline mixing of fuel and oxidant streams, a controlled swirl input to the oxidant flow for desired flame characteristics, a controlled expansion of flame envelope in the radial and axial dimensions, and efficient sweeping of burner block interior surface using oxidant to provide convective cooling and prevent any build up of process particulates. In addition, a relatively thick wall metallic nozzle construction with heat conduction fins enable efficient heat dissipation from the nozzle tip and providing a maintenance free burner operation.

Owner:LAIR LIQUIDE SA POUR L ETUD ET LEXPLOITATION DES PROCEDES GEORGES CLAUDE +1

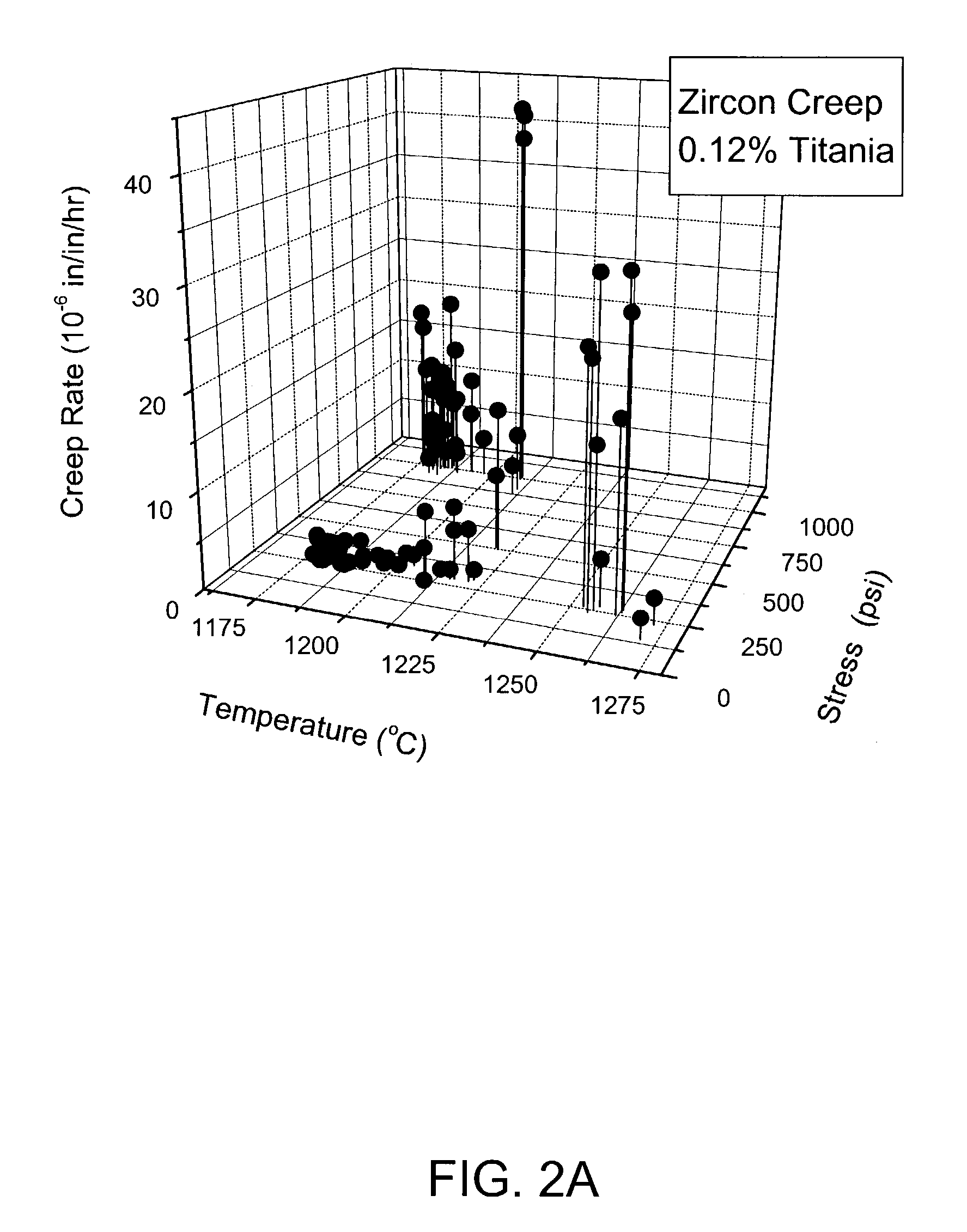

Sag control of isopipes used in making sheet glass by the fusion process

Isopipes for use in making sheet glass by a fusion process are provided which exhibit reduced sag. The isopipes are composed of a zircon refractory which has a mean creep rate (MCR) at 1180° C. and 250 psi and a 95 percent confidence band (CB) for said mean creep rate such that the CB to MCR ratio is less than 0.5, the MCR and the CB both being determined using a power law model. The zircon refractory can contain titania (TiO2) at a concentration greater than 0.2 wt. % and less than 0.4 wt. %. A concentration of titania in this range causes the zircon refractory to exhibit a lower mean creep rate than zircon refractories previously used to make isopipes. In addition, the variation in mean creep rate is also reduced which reduces the chances that the zircon refractory of a particular isopipe will have an abnormally high creep rate and thus exhibit unacceptable sag prematurely.

Owner:CORNING INC

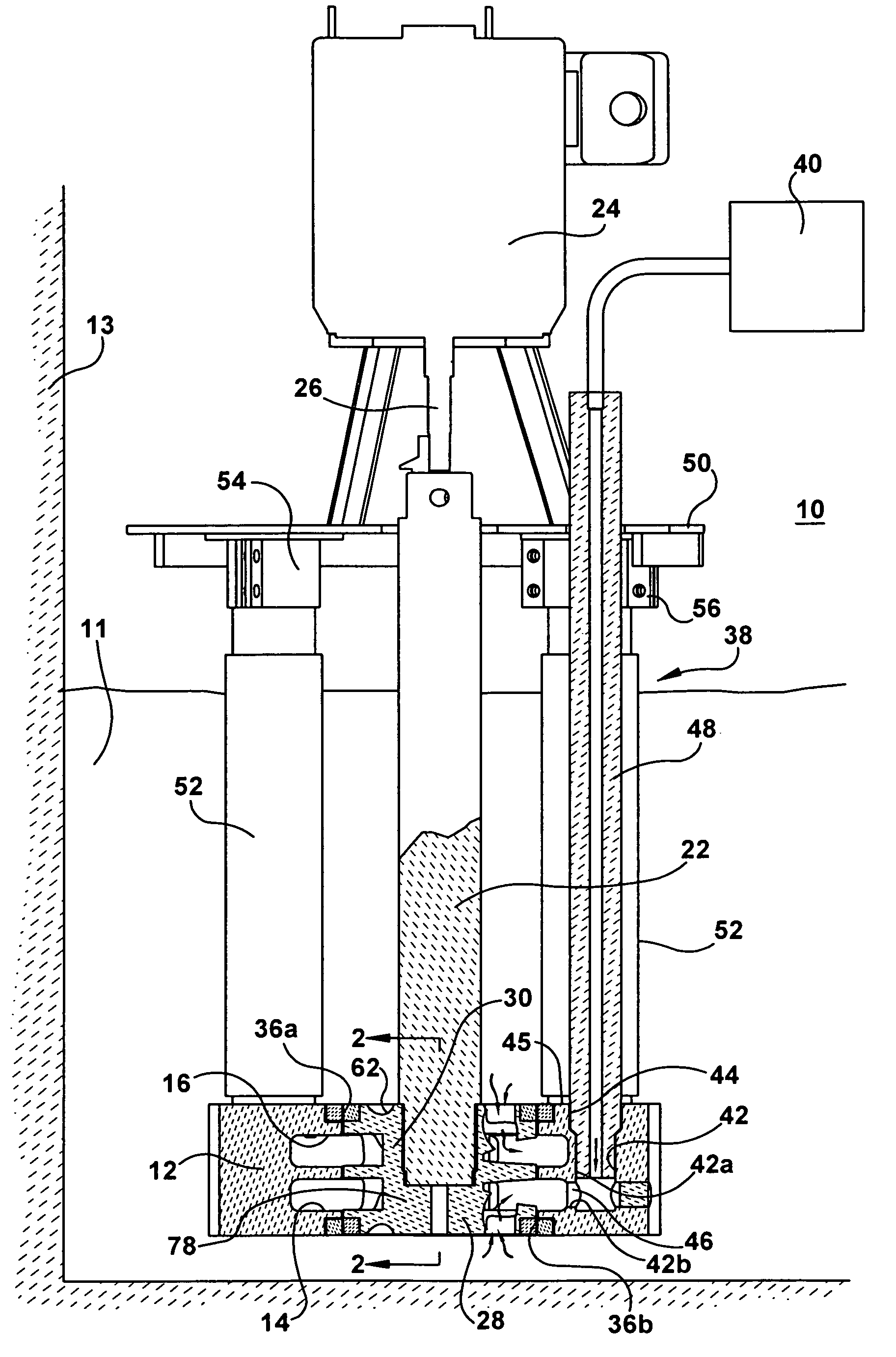

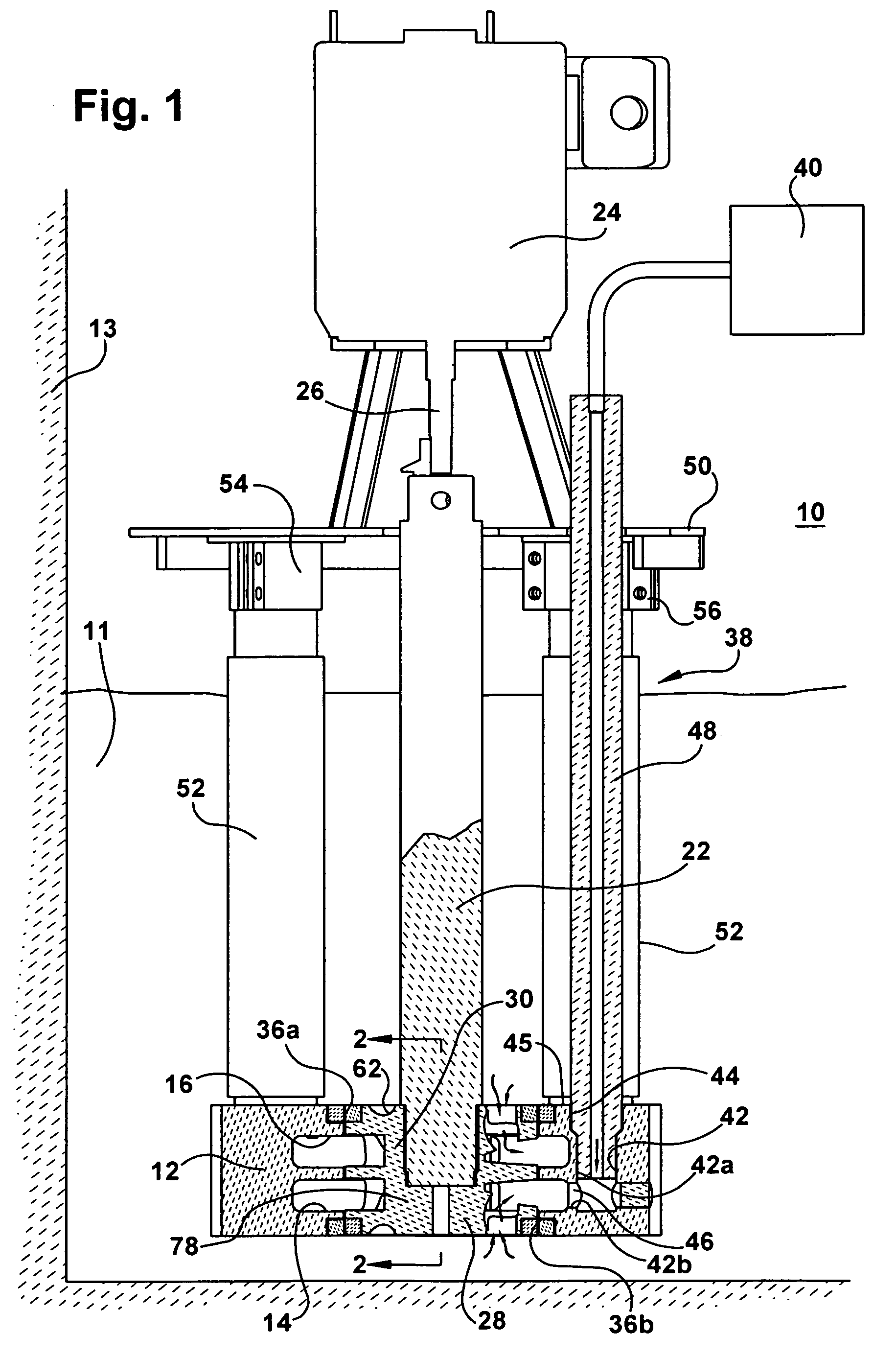

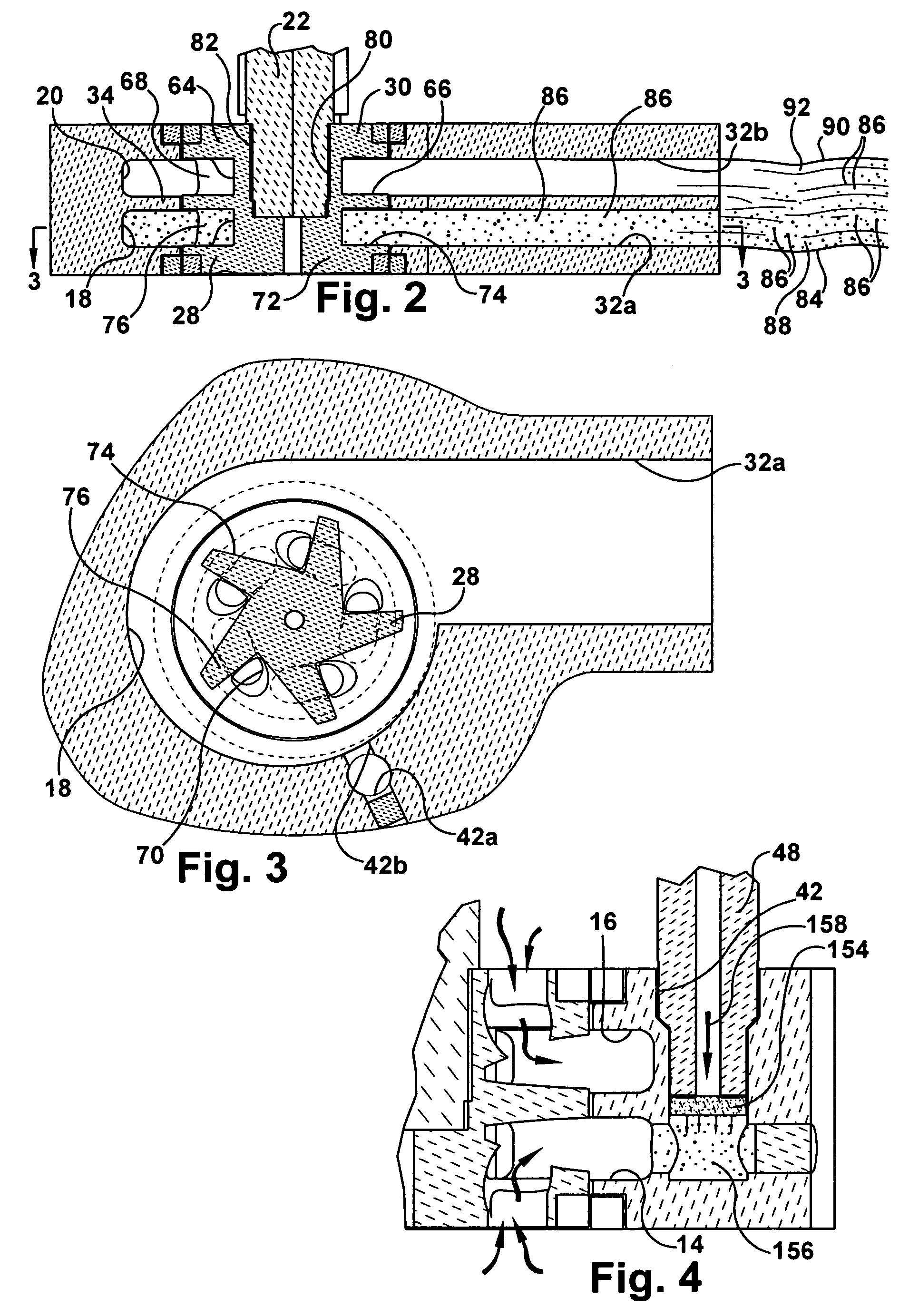

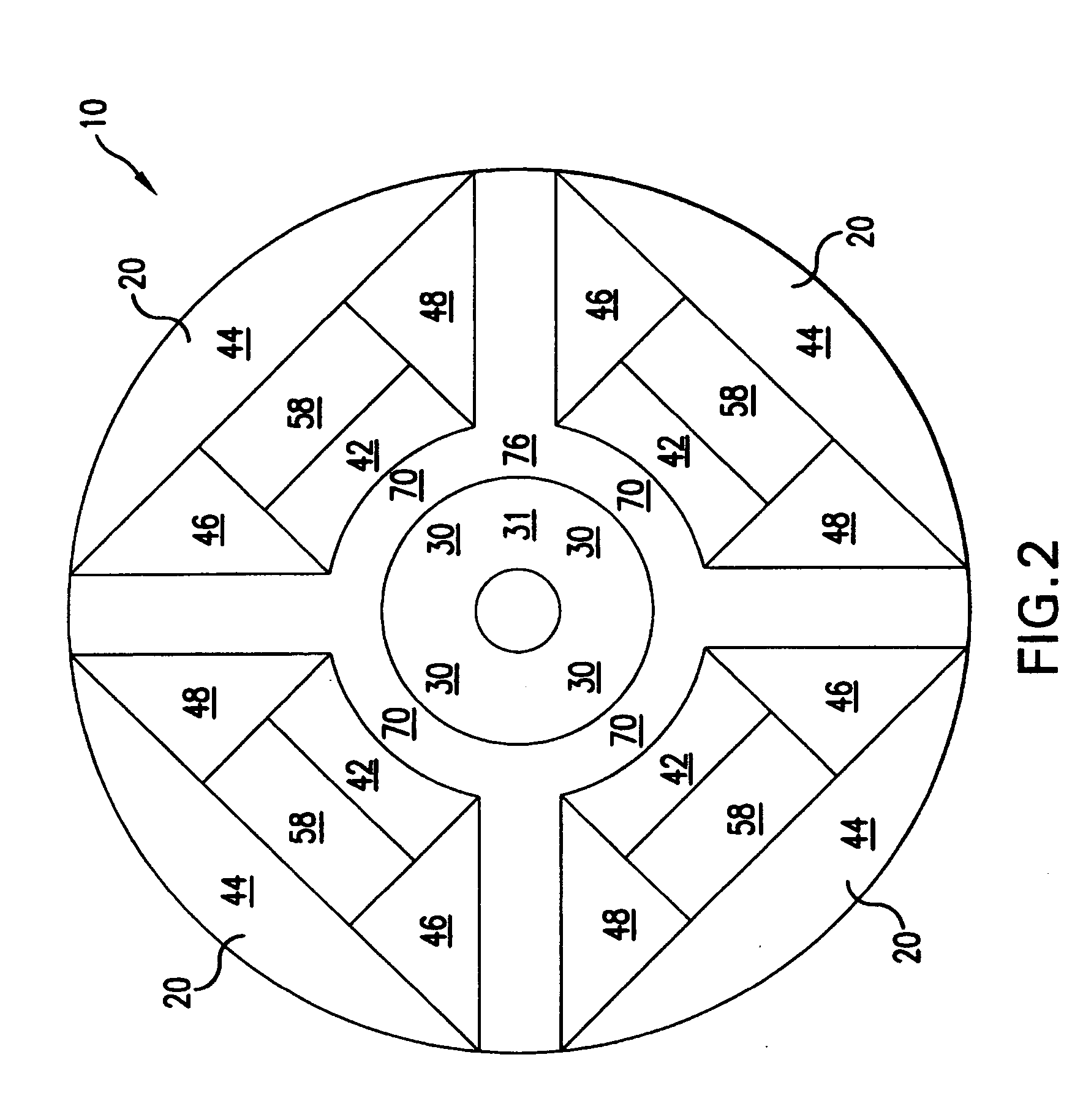

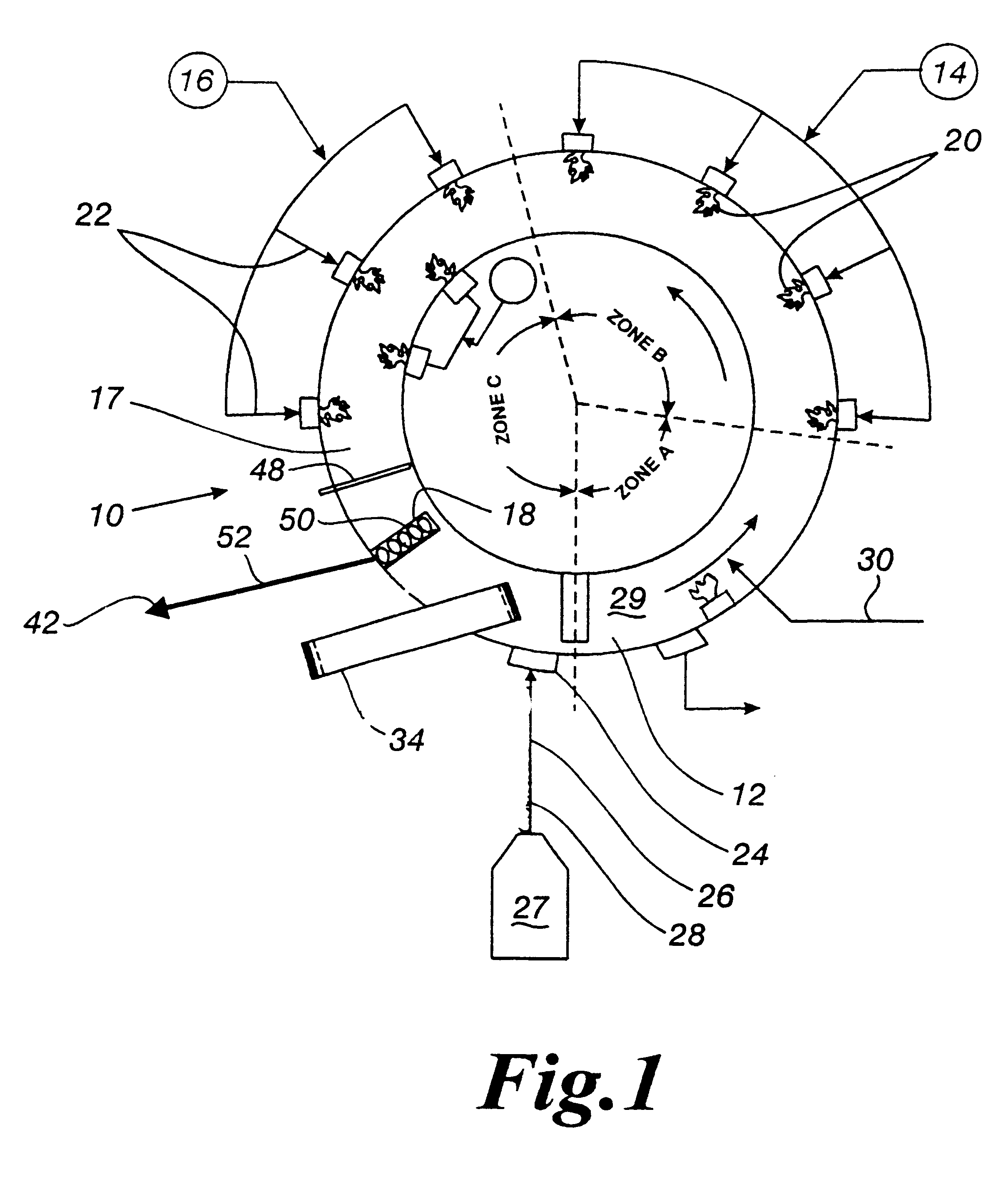

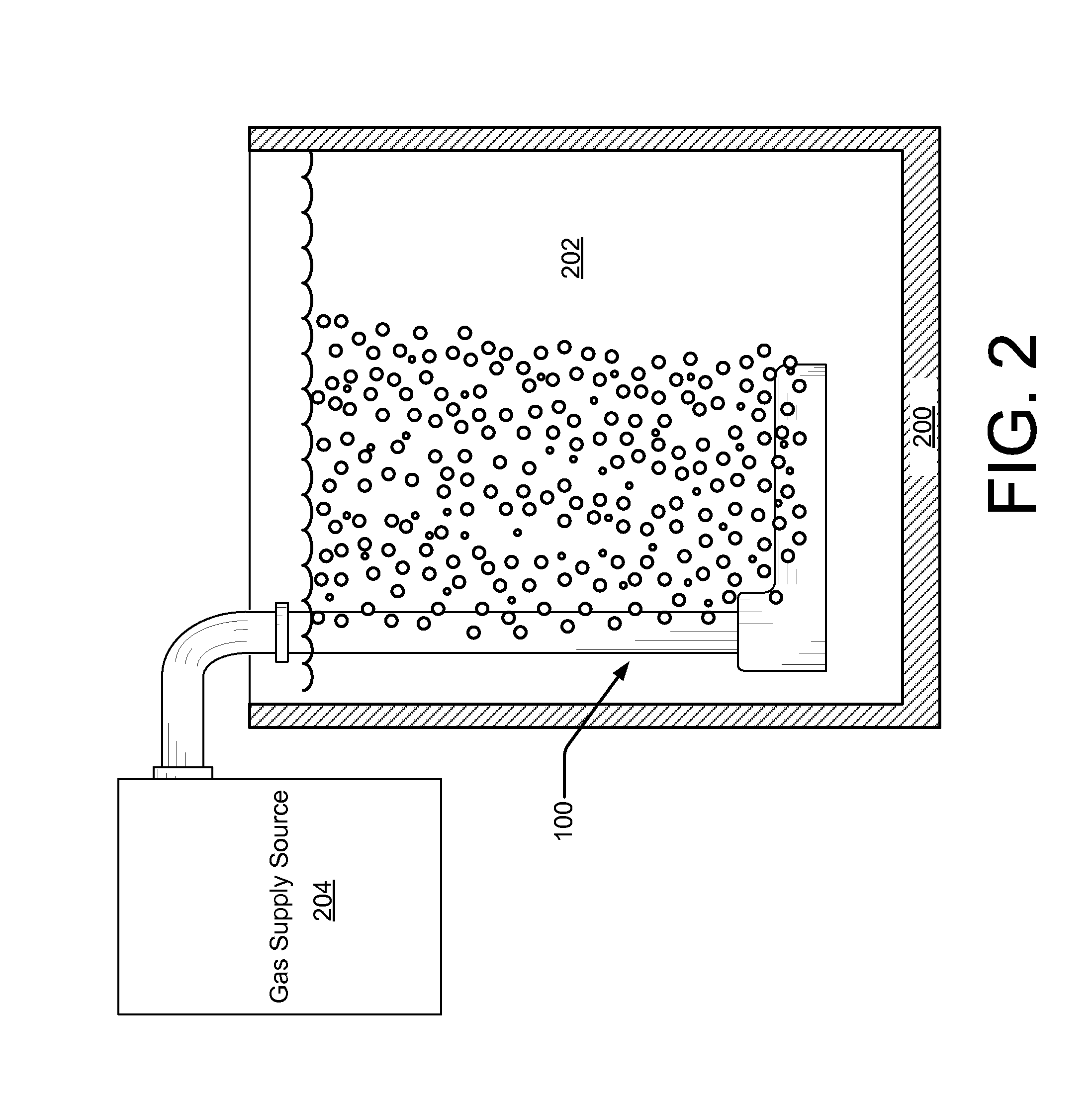

Gas mixing and dispersement in pumps for pumping molten metal

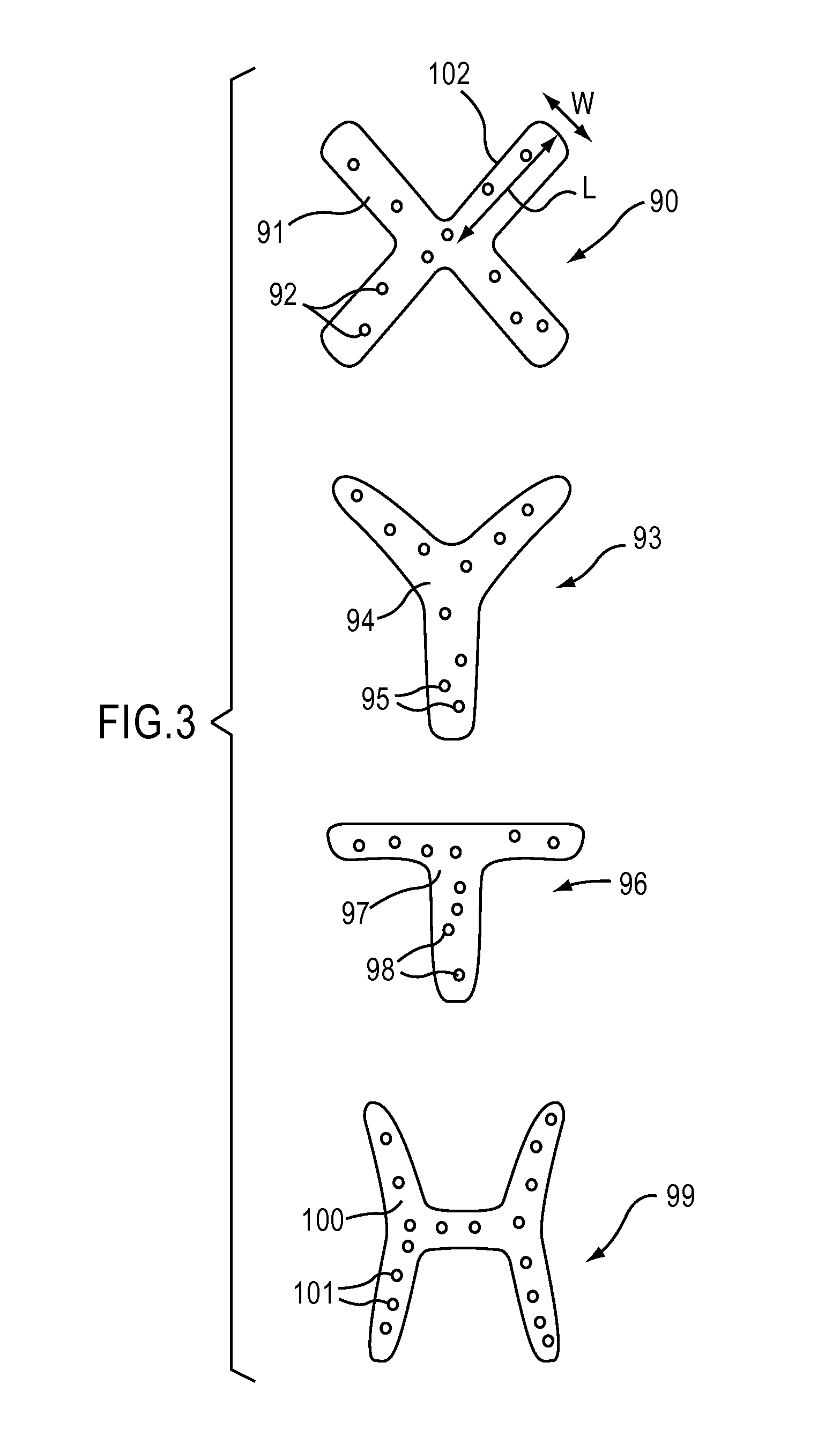

InactiveUS7476357B2Well mixedEfficient pumpingMelt-holding vesselsCharge manipulationImpellerPump chamber

A molten metal pump including a pump base with an inlet and outlet, a mixing impeller chamber for mixing gas and molten metal, a pumping impeller chamber for pumping molten metal. First and second impeller members supported by a shaft are adapted to rotate in mixing and pumping chambers respectively. The impeller members may be integrally formed of a single impeller or separate impellers on one or more shafts. A gas passageway extends from a gas source to the mixing chamber in the base. A gas dispersement pump includes a base with an impeller chamber and inlet and an outlet. An impeller is mounted to a shaft and adapted to be rotated in the impeller chamber. A gas passageway extends from a gas source to a gas outlet proximate to the impeller chamber. A gas dispersement member of porous refractory material is adapted to disperse gas from the gas passageway. In a gas dispersement and gas / molten metal mixing pump, the dispersement member disperses the gas stream entering the mixing chamber where the gas is mixed with molten metal. Molten metal is pumped in the pumping chamber. A gas / molten metal mixture is discharged from the mixing chamber and molten metal is discharged from the pumping chamber.

Owner:THUT BRUNO H

Self-cooled oxygen-fuel burner for use in high-temperature and high-particulate furnaces

InactiveUS6210151B1Avoiding particulate inspiration.TheControl expansionIndirect carbon-dioxide mitigationGaseous fuel burnerParticulatesVolatiles

A self-cooled oxidant-fuel burner consisting novel fuel and oxidant nozzles and three compartment refractory burner block design is proposed. The new oxidant-fuel burner can fire in high-temperature (2200° F. to 3000° F.) and high-particulate (or high process volatiles / condensates) furnaces without over-heating or causing chemical corrosion damage to it's metallic burner nozzle and refractory burner block interior. Using various embodiments of nozzle and block shape, the burner can offer a traditional cylindrical flame or flat flame depending on the heating load requirements. The new features of this burner include unique fuel nozzle design for the streamline mixing of fuel and oxidant streams, a controlled swirl input to the oxidant flow for desired flame characteristics, a controlled expansion of flame envelope in the radial and axial dimensions, and efficient sweeping of burner block interior surface using oxidant to provide convective cooling and prevent any build up of process particulates. In addition, a relatively thick wall metallic nozzle construction with heat conduction fins enable efficient heat dissipation from the nozzle tip and providing a maintenance free burner operation.

Owner:AIR LIQUIDE AMERICA INC +1

Therapy of rituximab-refractory rheumatoid arthritis patients

A method is disclosed of treating a rituximab-refractory rheumatoid arthritis (RA) patient comprising administering an anti-CD20 antibody other than rituximab to the patient in an amount effective to treat the RA.

Owner:GENENTECH INC

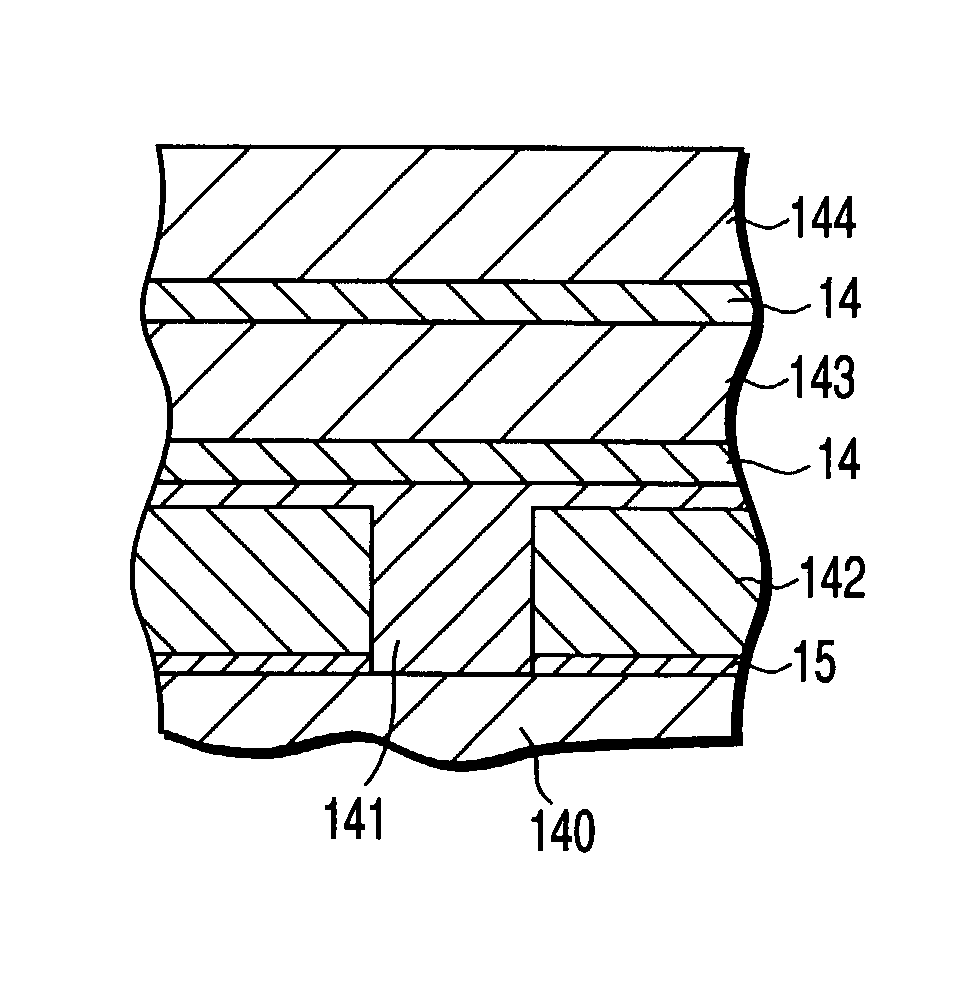

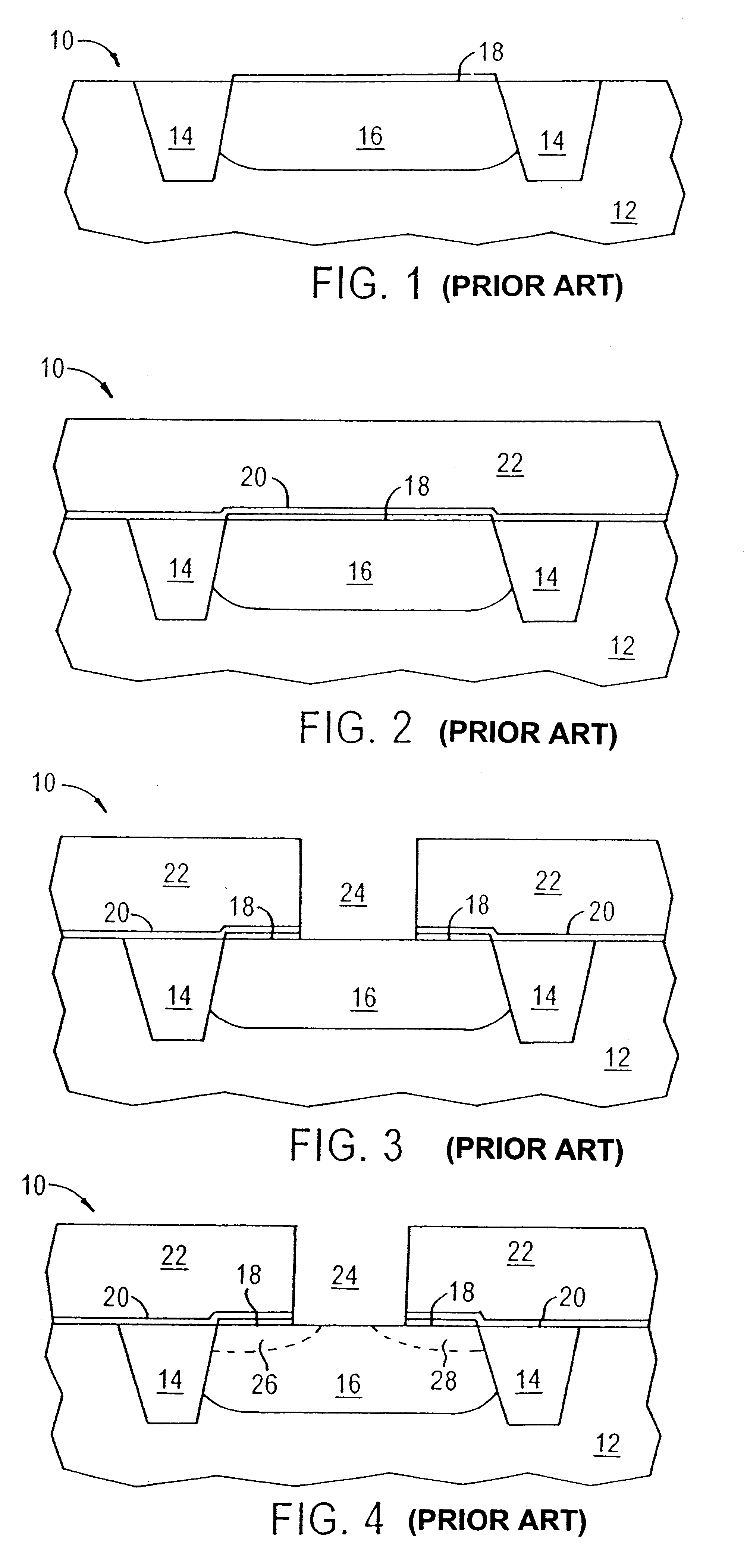

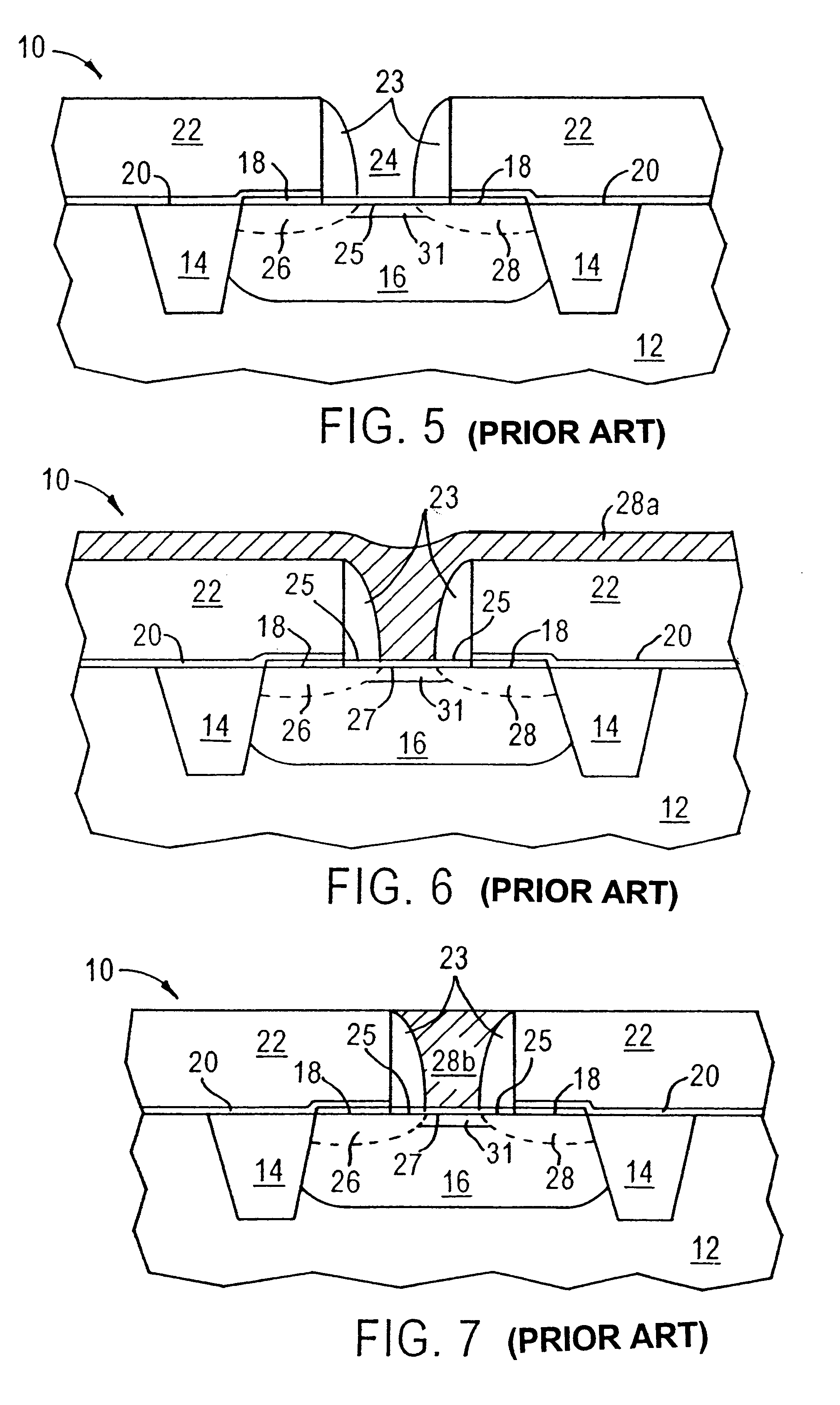

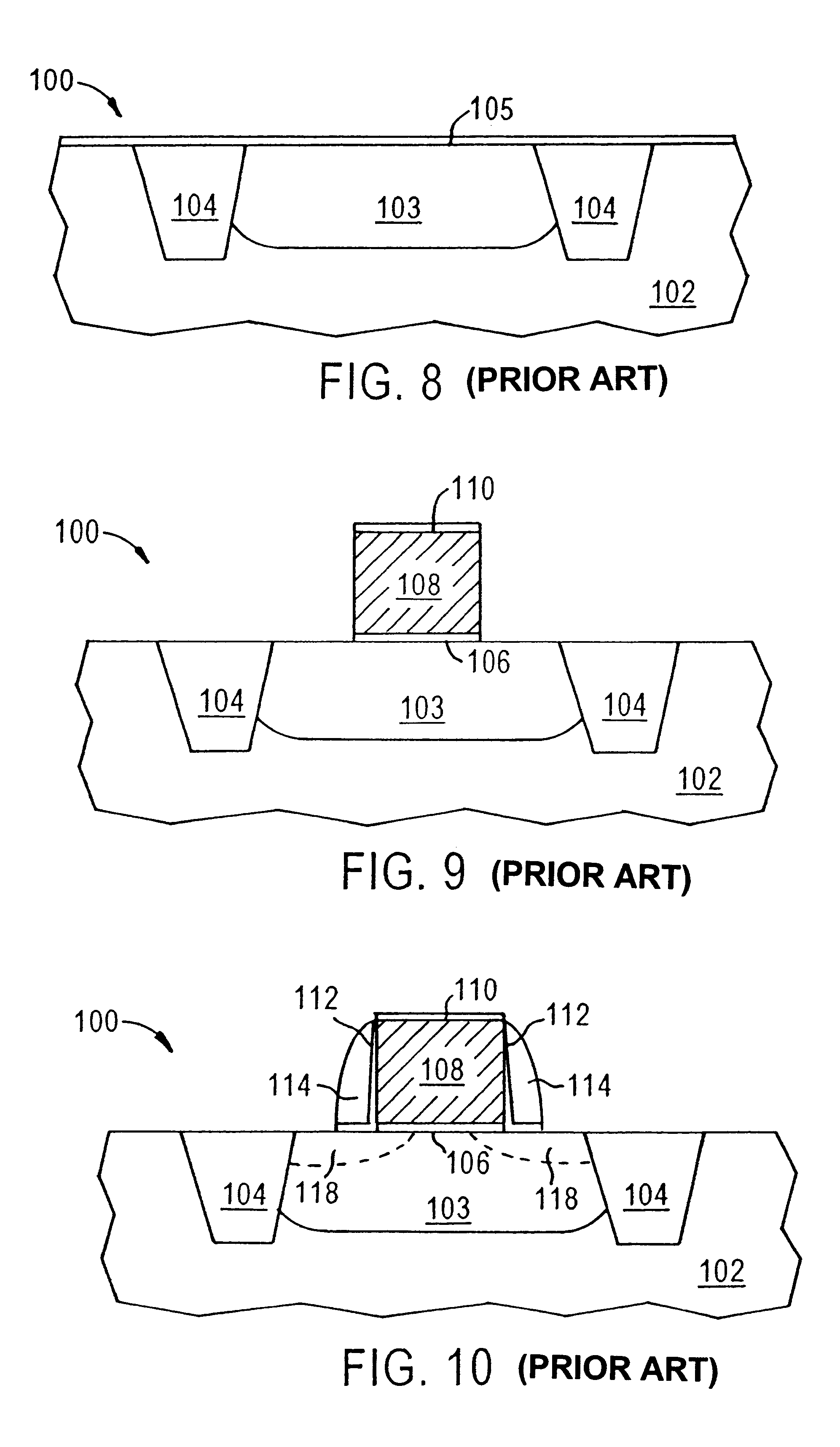

Electrolytic deposition of dielectric precursor materials for use in in-laid gate MOS transistors

InactiveUS6300203B1Semiconductor/solid-state device manufacturingSemiconductor devicesElectrolysisOxygen

High quality dielectric layers, e.g., high-k dielectric layers comprised of at least one refractory or lanthanum series transition metal oxide or silicate, for use as gate insulator layers in in-laid metal gate MOS transistors and CMOS devices, are formed by electrolytically plating a metal or metal-based dielectric precursor layer comprising at least one refractory or lanthanum series transition metal, on a semiconductor substrate, typically a silicon-based substrate, and then reacting the precursor layer with oxygen or with oxygen and the semiconductor substrate to form the at least one refractory or lanthanum series transition metal oxide or silicate. The inventive methodology prevents, or at least substantially reduces, oxygen access to the substrate surface during at least the initial stage(s) of formation of the gate insulator layer, thereby minimizing deleterious formation of oxygen-induced surface states at the semiconductor substrate / gate insulator interface.

Owner:GLOBALFOUNDRIES US INC

Phosgard, a new way to improve poison resistance in three-way catalyst applications

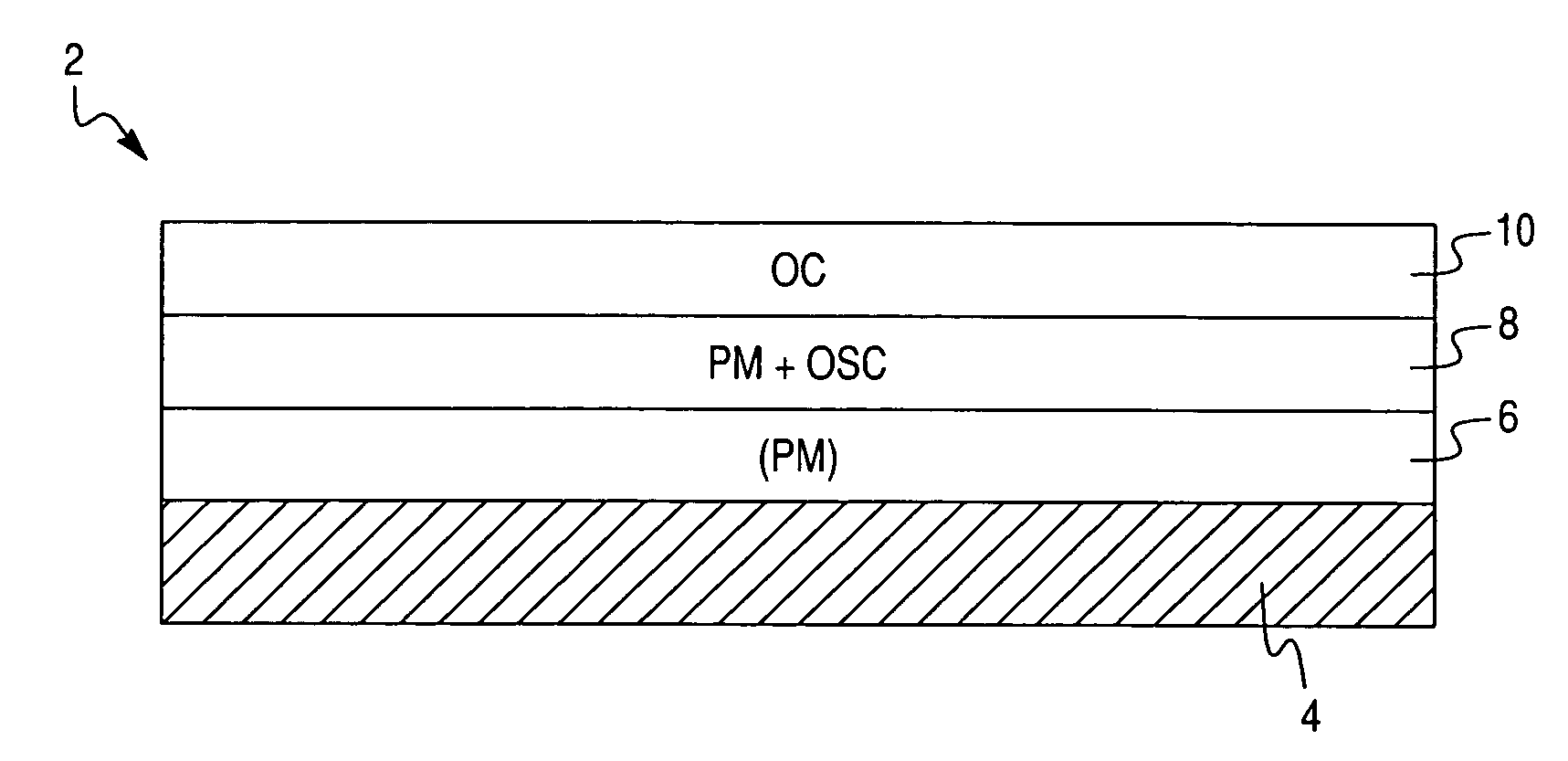

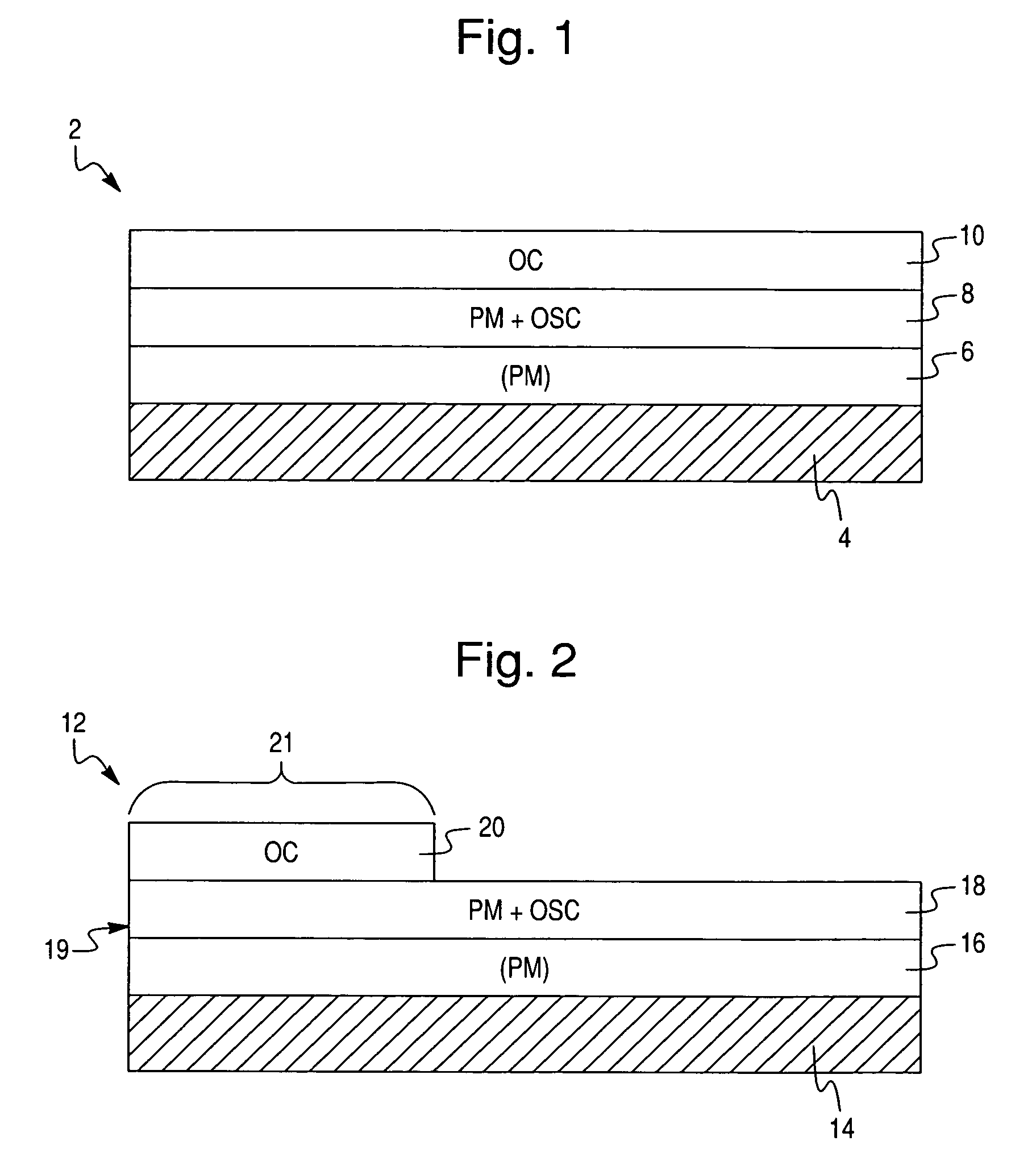

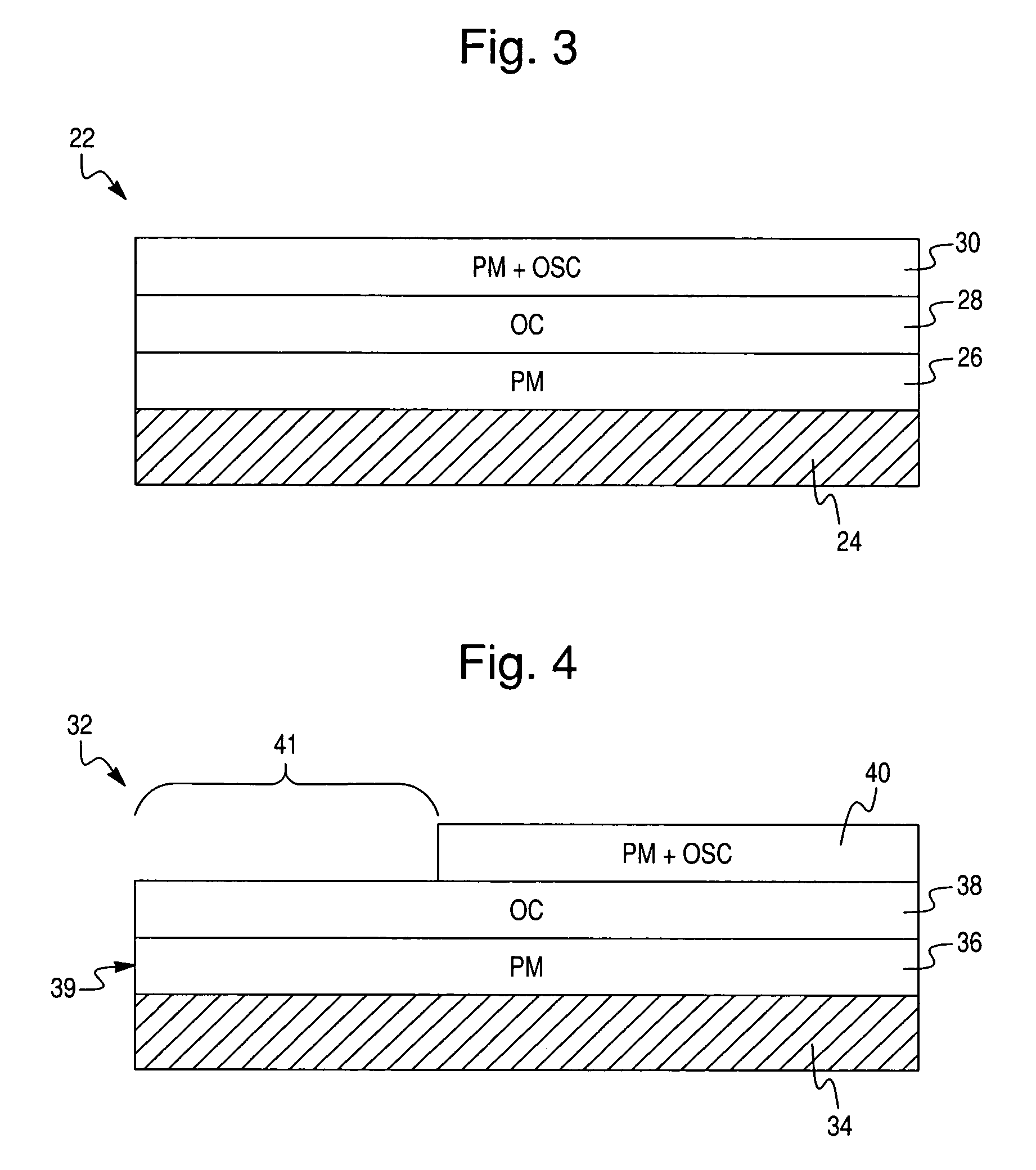

ActiveUS7749472B2Mitigates deleterious poisoning of a catalytic memberPreventing and reducing fouling and poisoningNitrogen compoundsInternal combustion piston enginesToxicantRefractory

The present invention provides for novel poisoning-resistant catalysts used for automobile exhaust gas treatment systems. To alleviate the detrimental affects of engine oil and / or fuel additive poisoning the present invention provides for an overcoat layer comprising a porous refractory oxide and one or more base metal oxides, which is coated over one or more precious metal containing washcoat layers. The overcoat of the present invention prevents phosphorous as well as other poisoning deposits, from fouling and / or negatively interacting with the underlying precious metal containing washcoats. In an alternative embodiment, the present invention provides for the coating of the upstream end of a catalytic member by the overcoat layer, thereby creating an upstream poison capture zone.

Owner:BASF CORP

Oxygen-fired front end for glass forming operation

A front end for a glass forming operation comprises an open channel and at least one burner. The channel has at least one surface. The surface has at least one hole therein. The burner is oriented in the hole at an acute angle relative to the surface. In another embodiment of the invention, the channel has a top and a pair of sidewalls each having a surface. At least one hole is in at least one of the surfaces. The hole is at an acute angle relative to at least one surface. The burner is an oxygen-fired burner. In yet another embodiment of the invention, the top and sidewalls each have a super structure surface constructed of refractory material. The channel has an upstream end and a downstream end. At least one of the surfaces has a plurality of holes therein. The burners extend at an acute angle relative to at least one surface and in a plane extending between the upstream end and the downstream end and perpendicular to at least one surface. Oxygen-fired burners extend axially through corresponding holes.

Owner:OCV INTELLECTUAL CAPITAL LLC

Monolithic honeycomb structure made of porous ceramic and use as a particle filter

InactiveUS6582796B1Prevent the evaporation of the waterEasy curingInternal combustion piston enginesSilencing apparatusSodium BentoniteOxygen

A monolithic honeycomb-type structure useful in particular as a particle filter for exhaust gases from diesel engines has a number of passages that empty into the end faces of said monolith, but are alternately open and sealed. The monolith consists of a porous refractory material that comprises: 70 to 97% by mass of alpha and / or beta crystallographic-type silicon carbide that has at least one particle size and preferably at least two particle sizes, and 3 to 30% by mass of at least one bonding ceramic phase in the form of a micronic powder or particles that are obtained by atomization, comprising at least one simple oxide, for example, B2O3, Al2O3, SiO2, MgO, K2O, Li2O, Na2O, CaO, BaO, TiO, ZrO2 and Fe2O3 and / or at least one mixed oxide, for example, the alkaline aluminosilicates (of Li, Na, or K) or alkaline-earth aluminosilicates (of Mg, Ca, Sr or Ba), clays, bentonite, feldspars or other natural silico-aluminous materials. The production of the monolith comprises a calcination stage under an oxygen-containing atmosphere at a temperature up to 1650° C., but less than 1550° C.

Owner:INST FR DU PETROLE

Self-cooled oxygen-fuel for use in high-temperature and high-particulate furnaces

InactiveUS6276924B1Avoiding particulate inspiration.TheControl expansionGlass furnace apparatusGlass melting apparatusParticulatesCombustor

A self-cooled oxidant-fuel burner consisting novel fuel and oxidant nozzles and three compartment refractory burner block design is proposed. The new oxidant-fuel burner can fire in high-temperature (2200° F. to 3000° F.) and high-particulate (or high process volatiles / condensates) furnaces without over-heating or causing chemical corrosion damage to it's metallic burner nozzle and refractory burner block interior. Using various embodiments of nozzle and block shape, the burner can offer a traditional cylindrical flame or flat flame depending on the heating load requirements. The new features of this burner include unique fuel nozzle design for the streamline mixing of fuel and oxidant streams, a controlled swirl input to the oxidant flow for desired flame characteristics, a controlled expansion of flame envelope in the radial and axial dimensions, and efficient sweeping of burner block interior surface using oxidant to provide convective cooling and prevent any build up of process particulates. In addition, a relatively thick wall metallic nozzle construction with heat conduction fins enable efficient heat dissipation from the nozzle tip and providing a maintenance free burner operation.

Owner:AIR LIQUIDE AMERICA INC +1

Method of making iron and steel

InactiveUS6149709AEasy to getLess impurity contentProcess efficiency improvementElectric furnaceHigh energyRefractory

Molten iron is prepared by (1) providing iron oxide and a carbonaceous reducing agent, (2) preparing a shaped product from the carbonaceous reducing agent and the iron oxide, (3) preparing solid reduced iron from the shaped product, wherein the solid reduced iron has a metallization of at least 60%, a specific gravity of at least 1.7, and a carbon content of at least 50% of the theoretical amount required for reducing the iron oxide remaining in the solid reduced iron, and, (4) before substantial cooling occurs, heating the solid reduced iron in an arc heating-type melting furnace at a high temperature. The molten iron can be prepared efficiently from iron ores of relatively low iron content without causing erosion of refractories, at high energy and high reduction efficiencies, and by a simple operation in a simple facility.

Owner:KOBE STEEL LTD

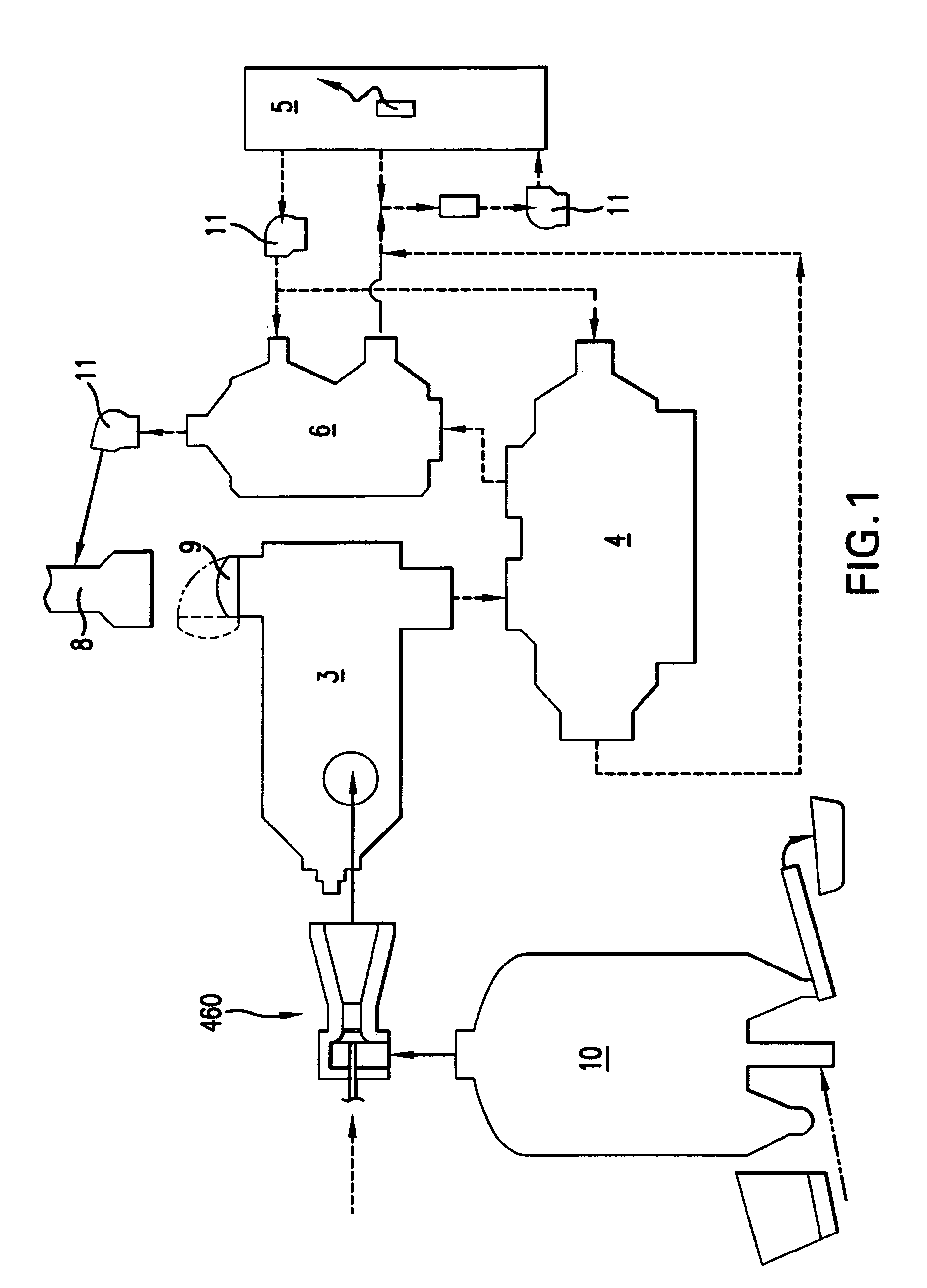

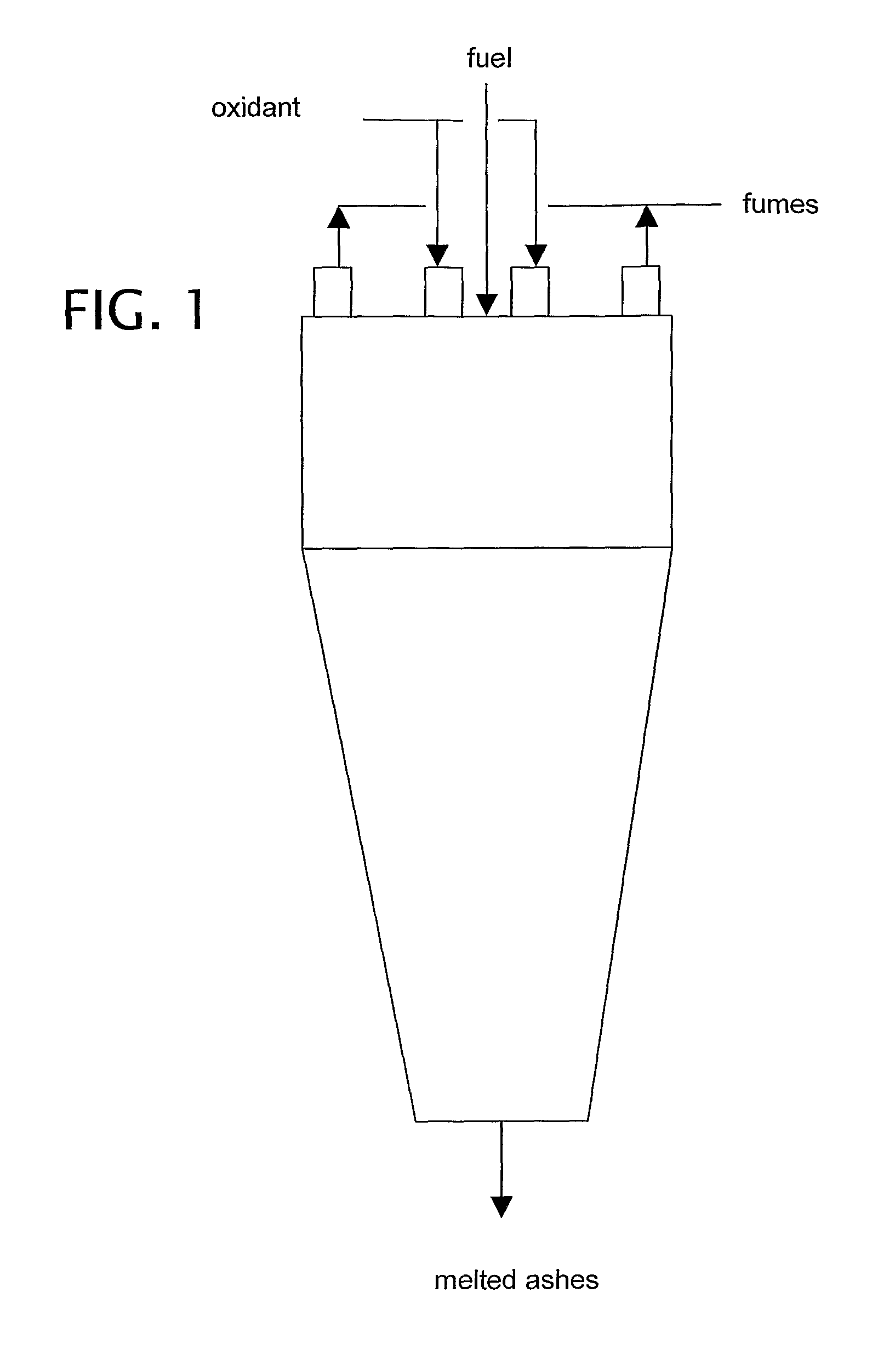

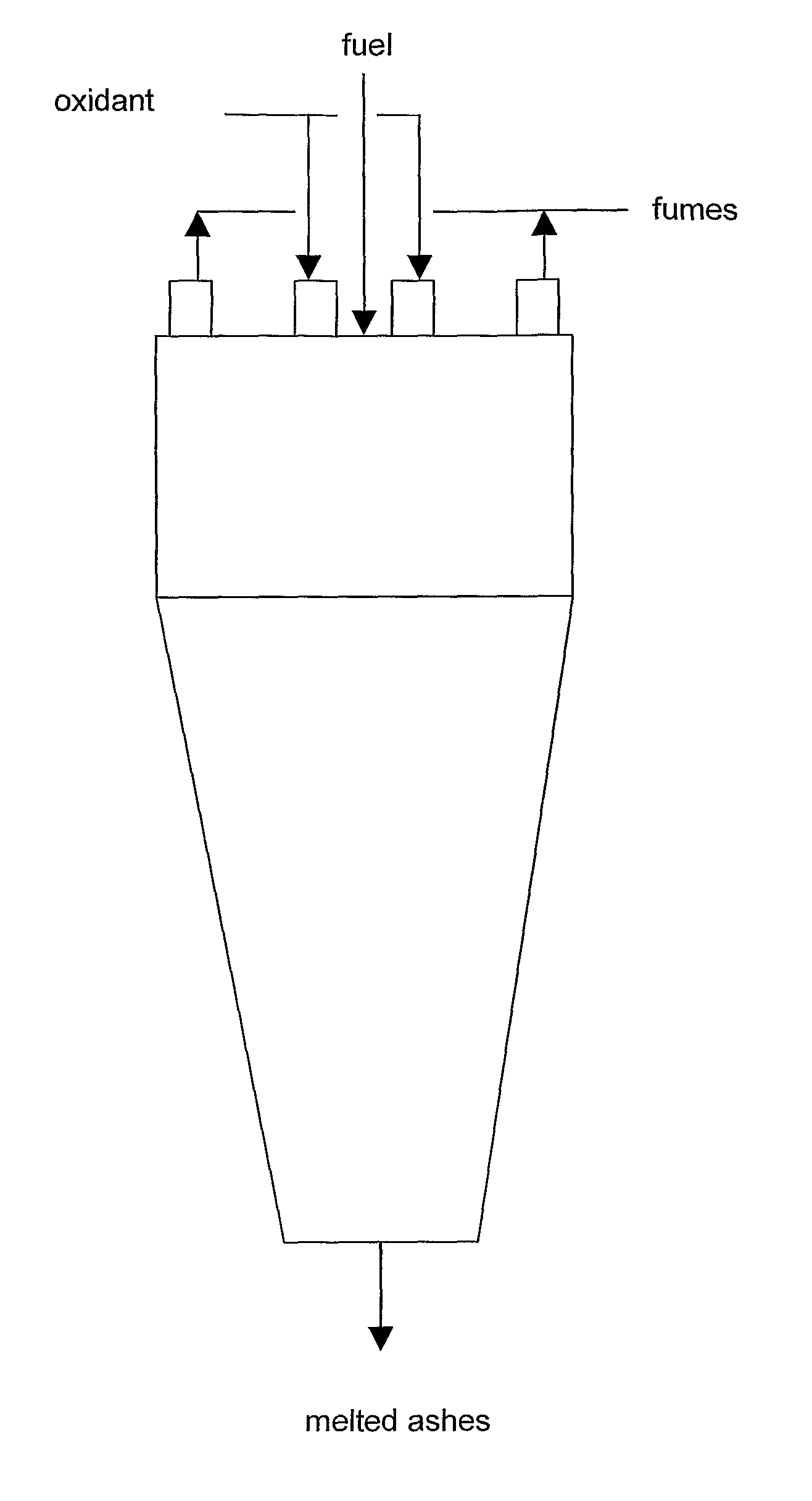

Pyrolyzing gasification system and method of use

InactiveUS20050109603A1High gasifier discharge temperatureEfficient processGasifier mechanical detailsBiofuelsHydrocotyle bowlesioidesExternal combustion engine

Pyrolyzing gasification system and method of use including primary combustion of non-uniform solid fuels such as biomass and solid wastes within a refractory lined gasifier, secondary combustion of primary combustion gas within a staged, cyclonic, refractory lined oxidizer, and heat energy recovery from the oxidized flue gas within an indirect air-to-air all-ceramic heat exchanger or external combustion engine. Primary combustion occurs at low substoichoimetric air percentages of 10-30 percent and at temperatures below 1000 degrees F. Secondary combustion is staged and controlled for low NOx formation and prevention of formation of CO, hydrocarbons, and VOCs. The gasifier includes a furnace bed segmented into individual cells, each cell is independently monitored using a ramp temperature probe, and provided with controlled air injection. Gasifier air injection includes tuyere arrays, lances, or both. The oxidizer includes three serially aligned stages separated by air injecting baffles, and ability to adjust the exit air temperature.

Owner:HEAT TRANSFER INT

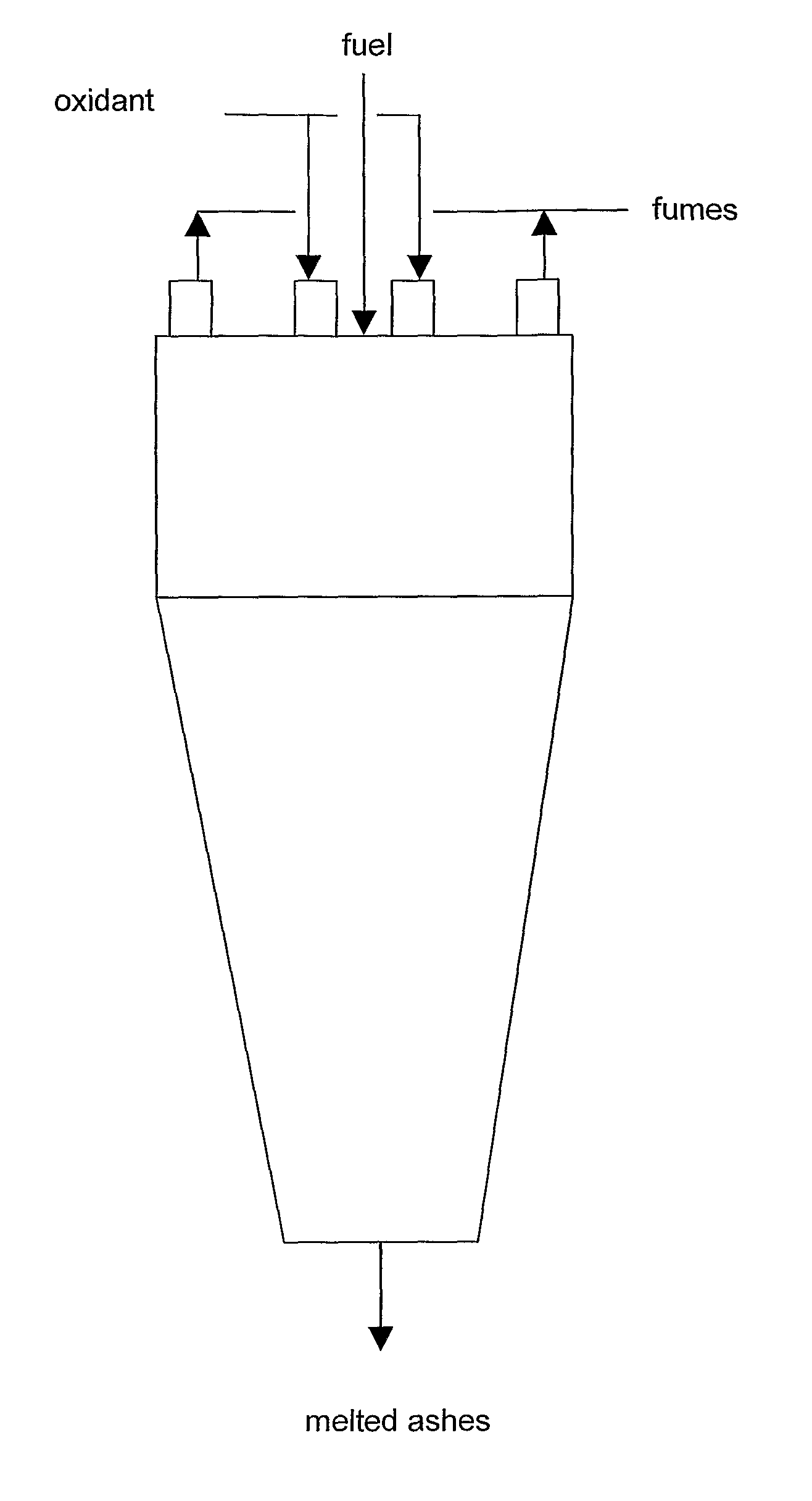

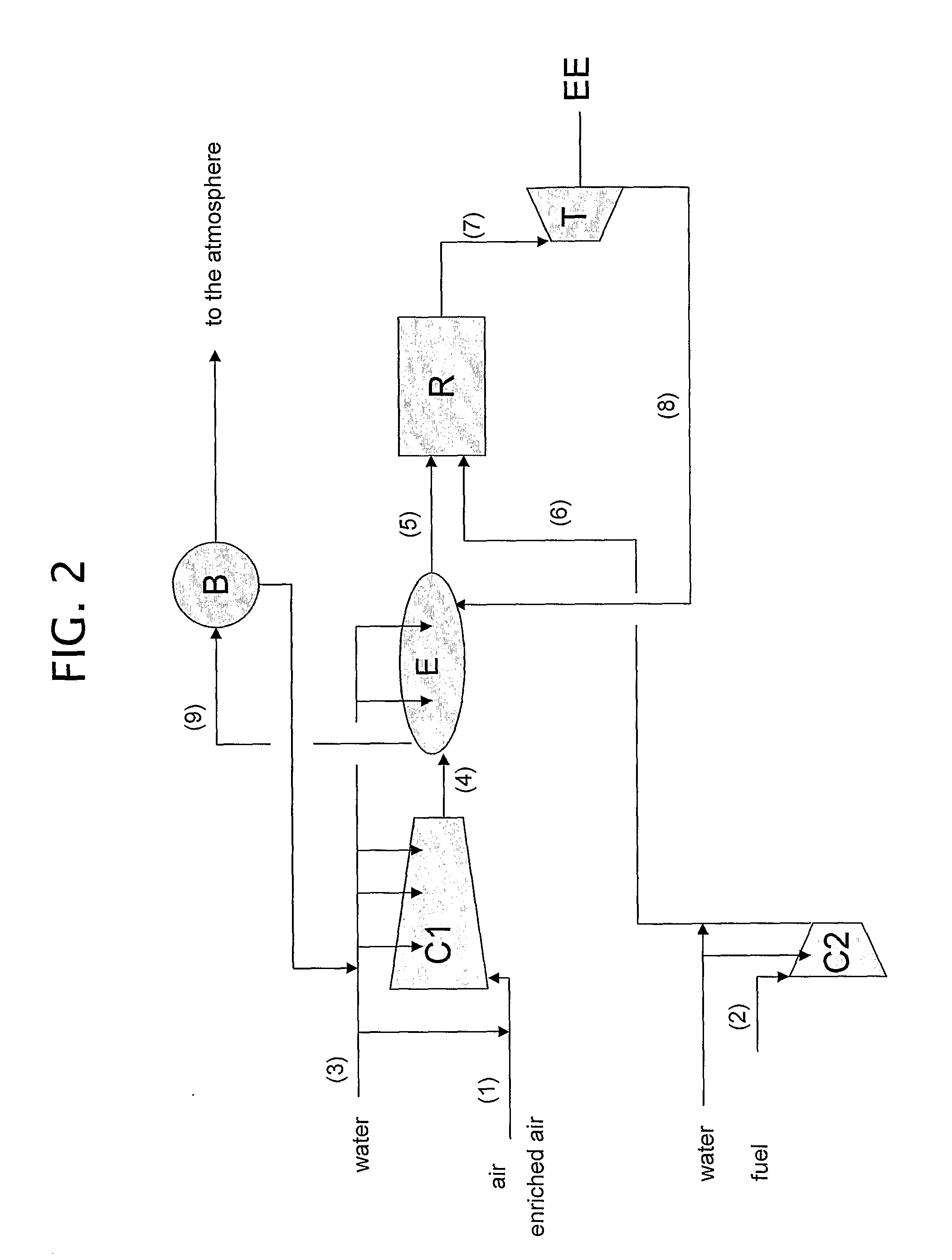

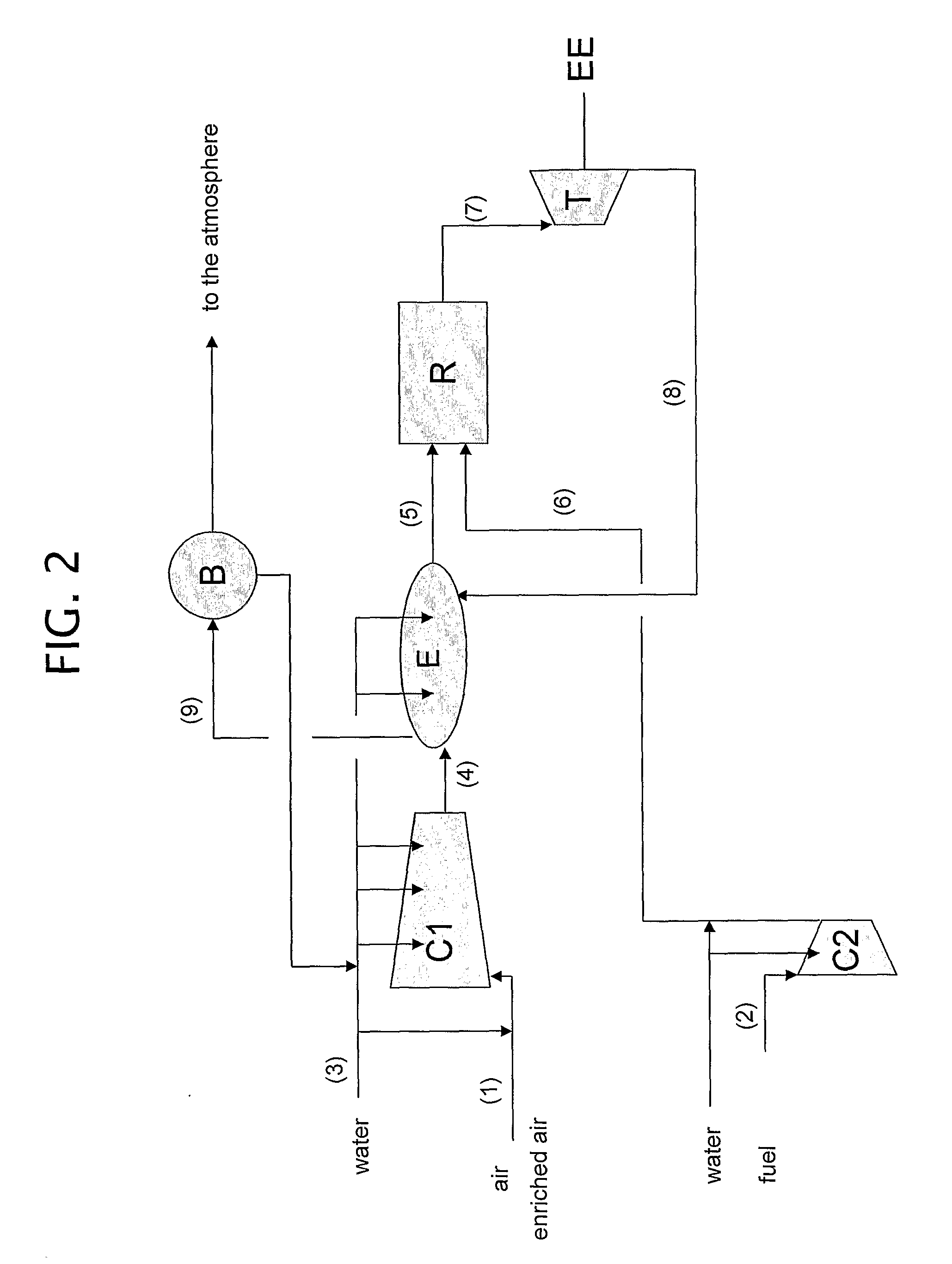

High-Efficiency Combustors with Reduced Environmental Impact and Processes for Power Generation Derivable Therefrom

A process for combusting solid liquid or gaseous fuels in a high temperature refractory-lined reactor with the aim of generating electric power comprises mixing at least one fuel with steam. The refactory material of the reactor and the opaque gases of the reaction environment bring about high power infrared radiation which substantially instantaneously preheats the reactants on input including said reactants being intrinsically transparent to infrared radiation (N2 / O2) but rendered opaque and thus absorbers of energy from infrared radiation thanks to dilution with steam. A high efficiency combustor is provided for carrying out the above-stated process.

Owner:ITEA SPA

Apparatus and method for friction stir welding of high strength materials, and articles made therefrom

InactiveUS20040238599A1Reduce the cross-sectional areaWelding/cutting auxillary devicesAuxillary welding devicesHigh intensityTungsten

An apparatus for friction stir welding, a weld tool for friction stir welding, and a method for making a weld tool for friction stir welding are presented. The weld tool comprises a tungsten-based refractory material. A method for manufacturing an article, where the method comprises providing the apparatus for friction stir welding, and the article produced by this method are also presented.

Owner:GENERAL ELECTRIC CO

High-efficiency combustors with reduced environmental impact and processes for power generation derivable therefrom

A process for combusting solid liquid or gaseous fuels in a high temperature refractory-lined reactor with the aim of generating electric power comprises mixing at least one fuel with steam. The refactory material of the reactor and the opaque gases of the reaction environment bring about high power infrared radiation which substantially instantaneously preheats the reactants on input including said reactants being intrinsically transparent to infrared radiation (N2 / O2) but rendered opaque and thus absorbers of energy from infrared radiation thanks to dilution with steam. A high efficiency combustor is provided for carrying out the above-stated process.

Owner:ITEA SPA

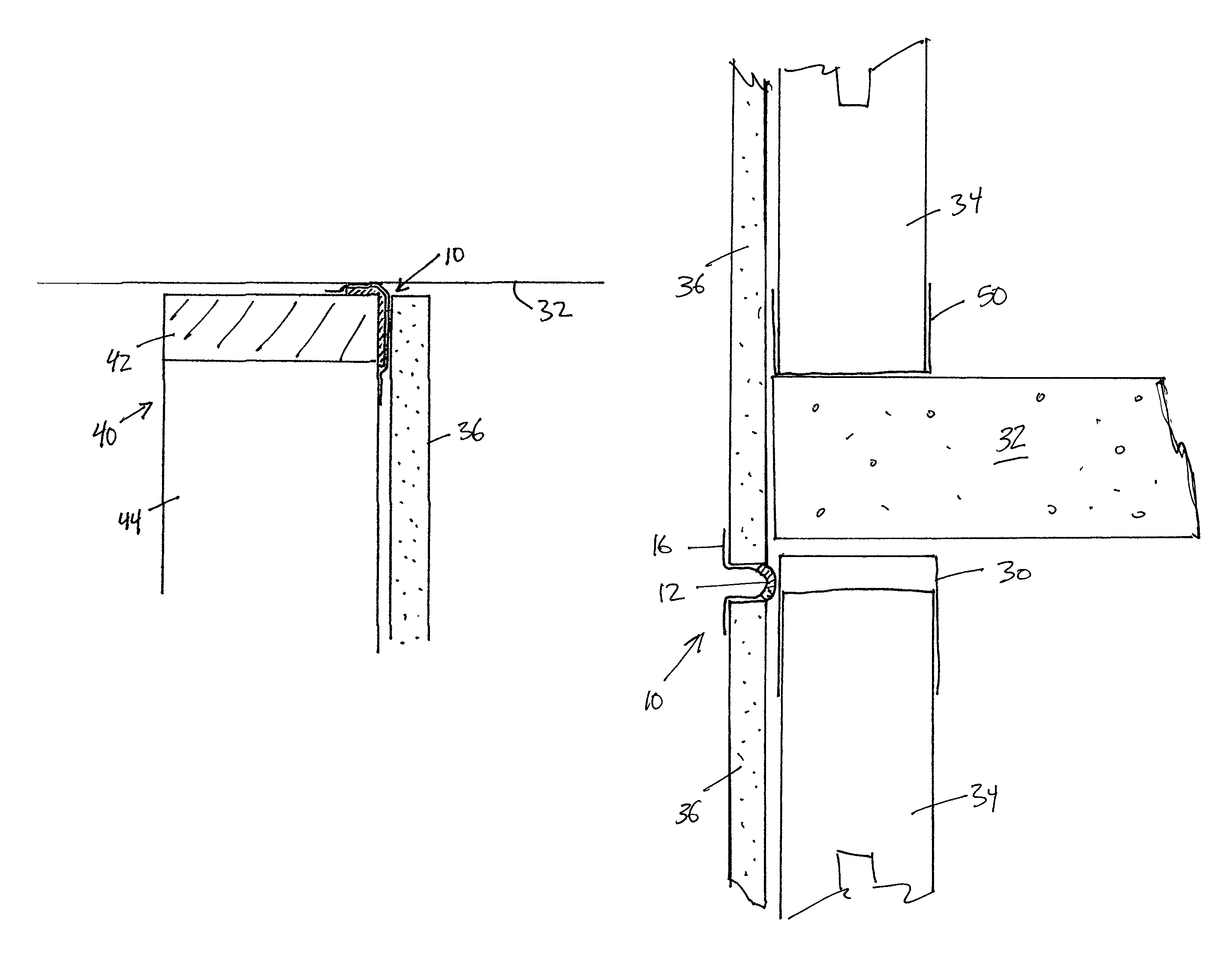

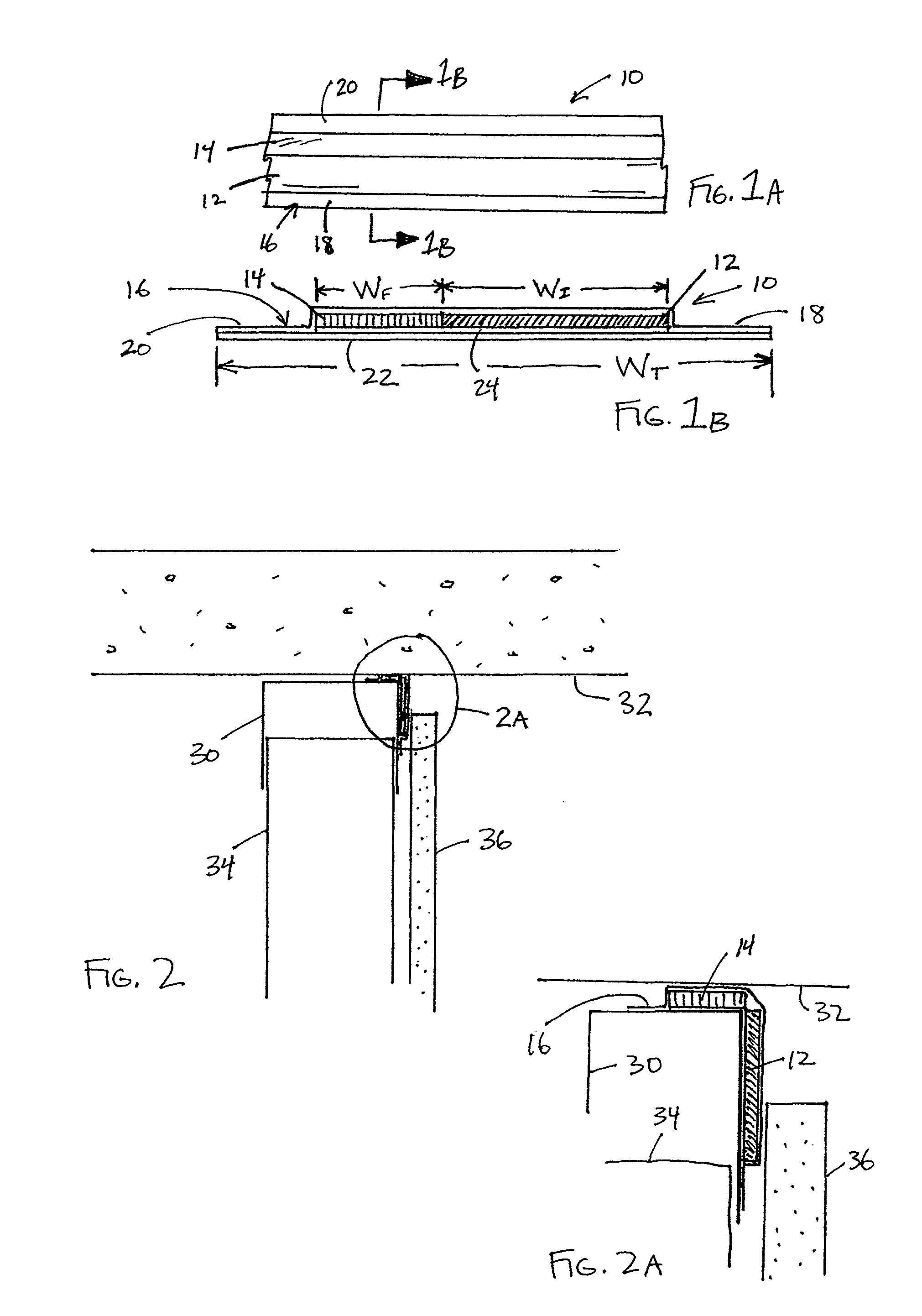

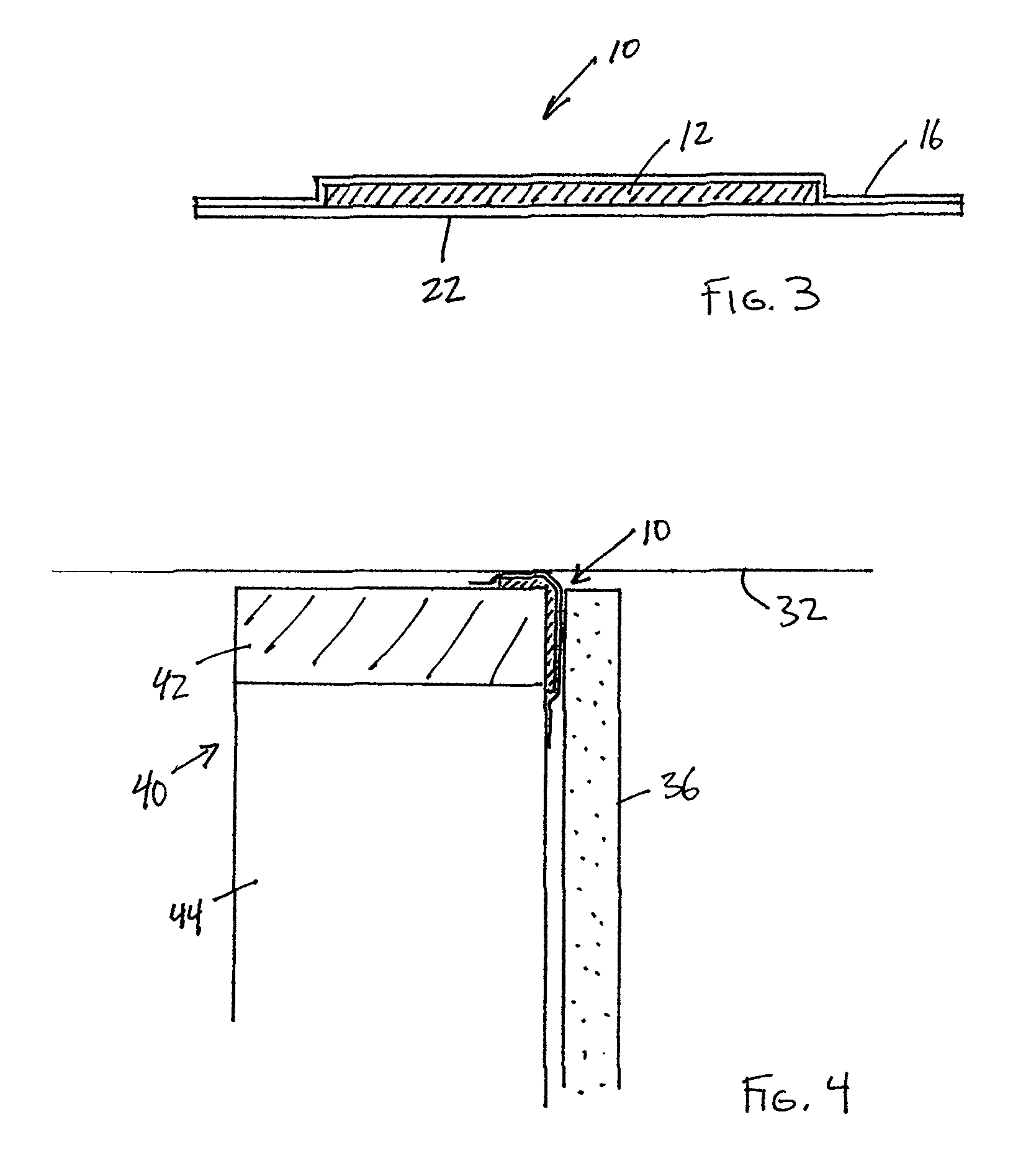

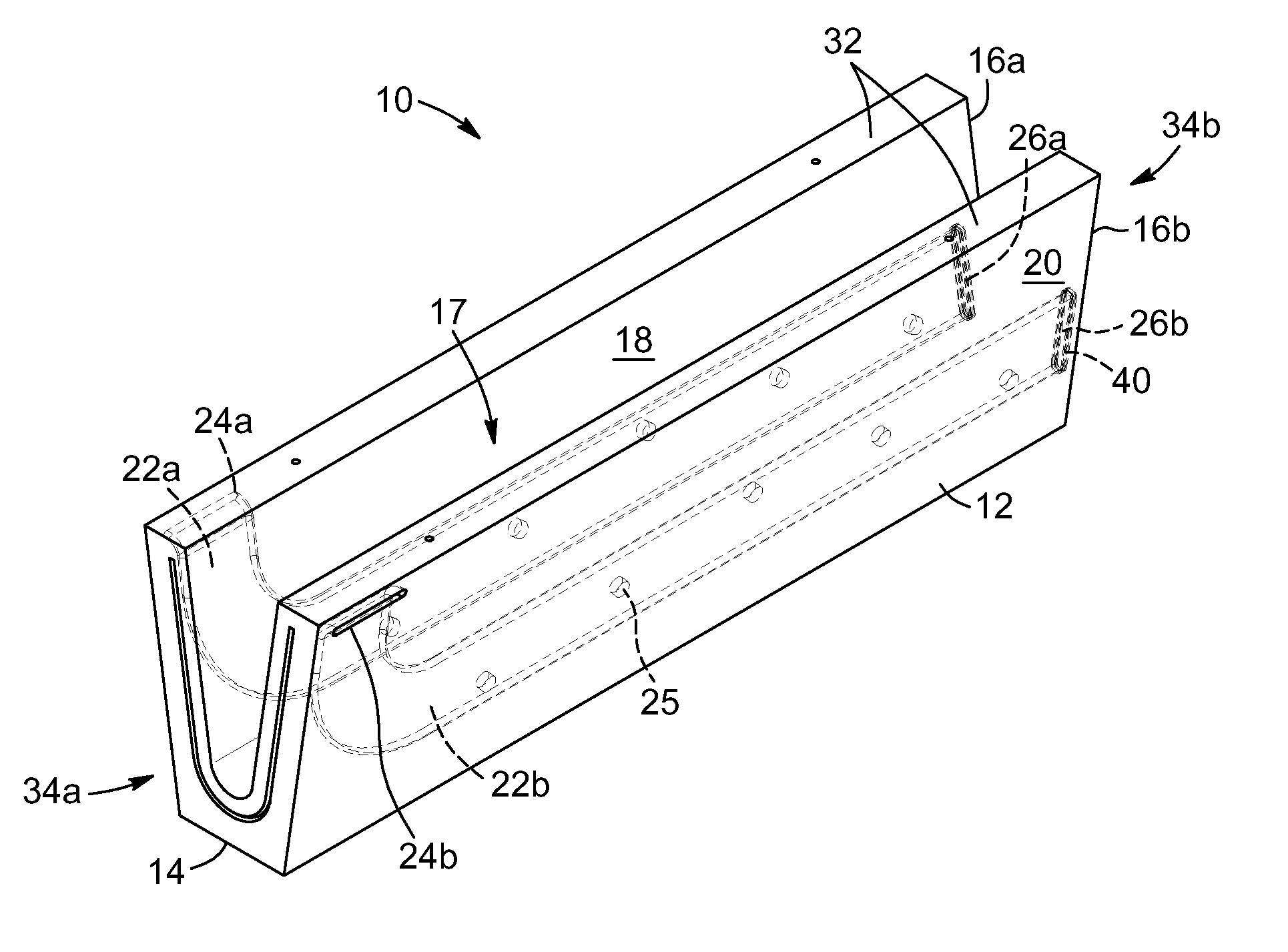

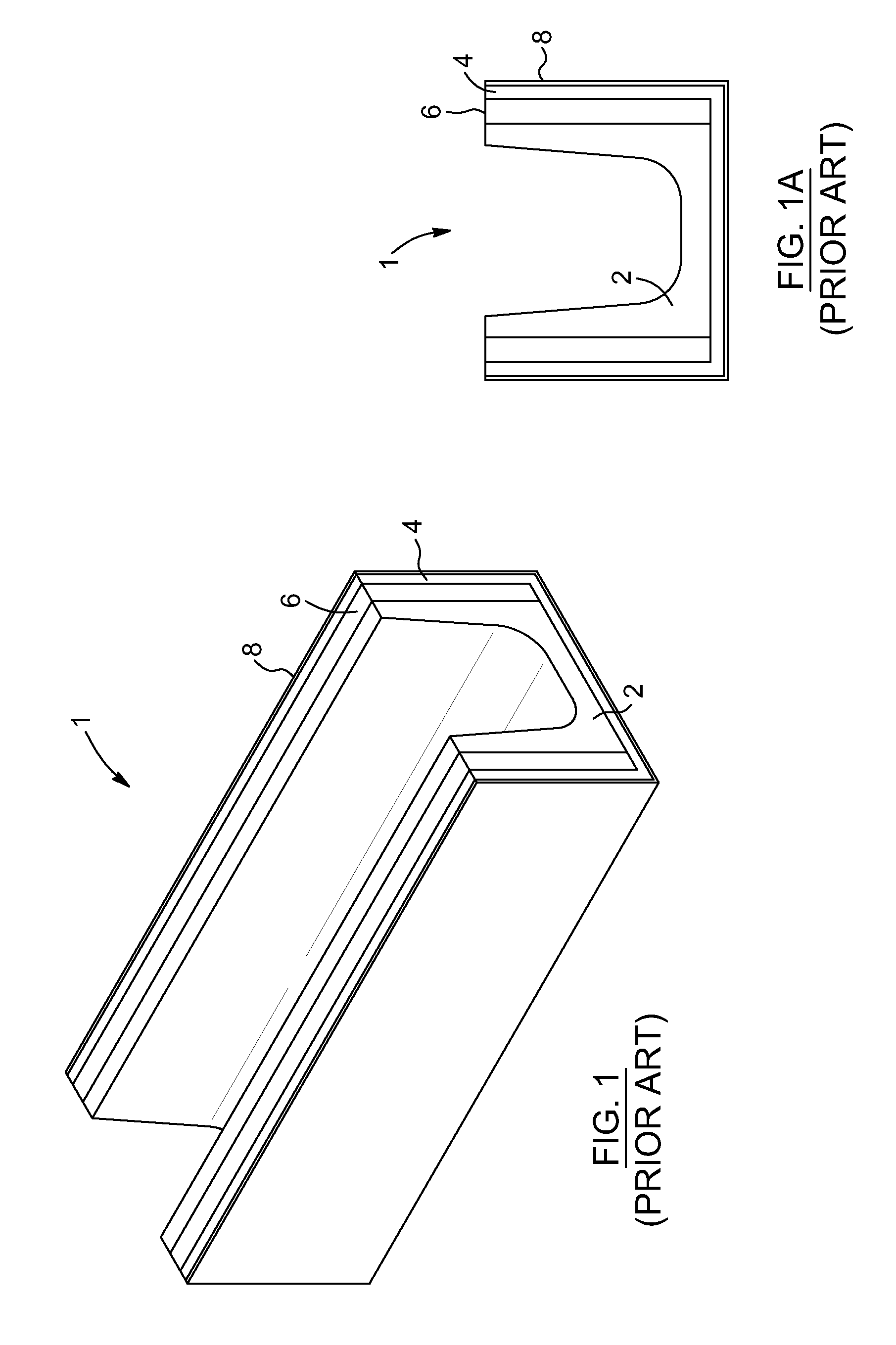

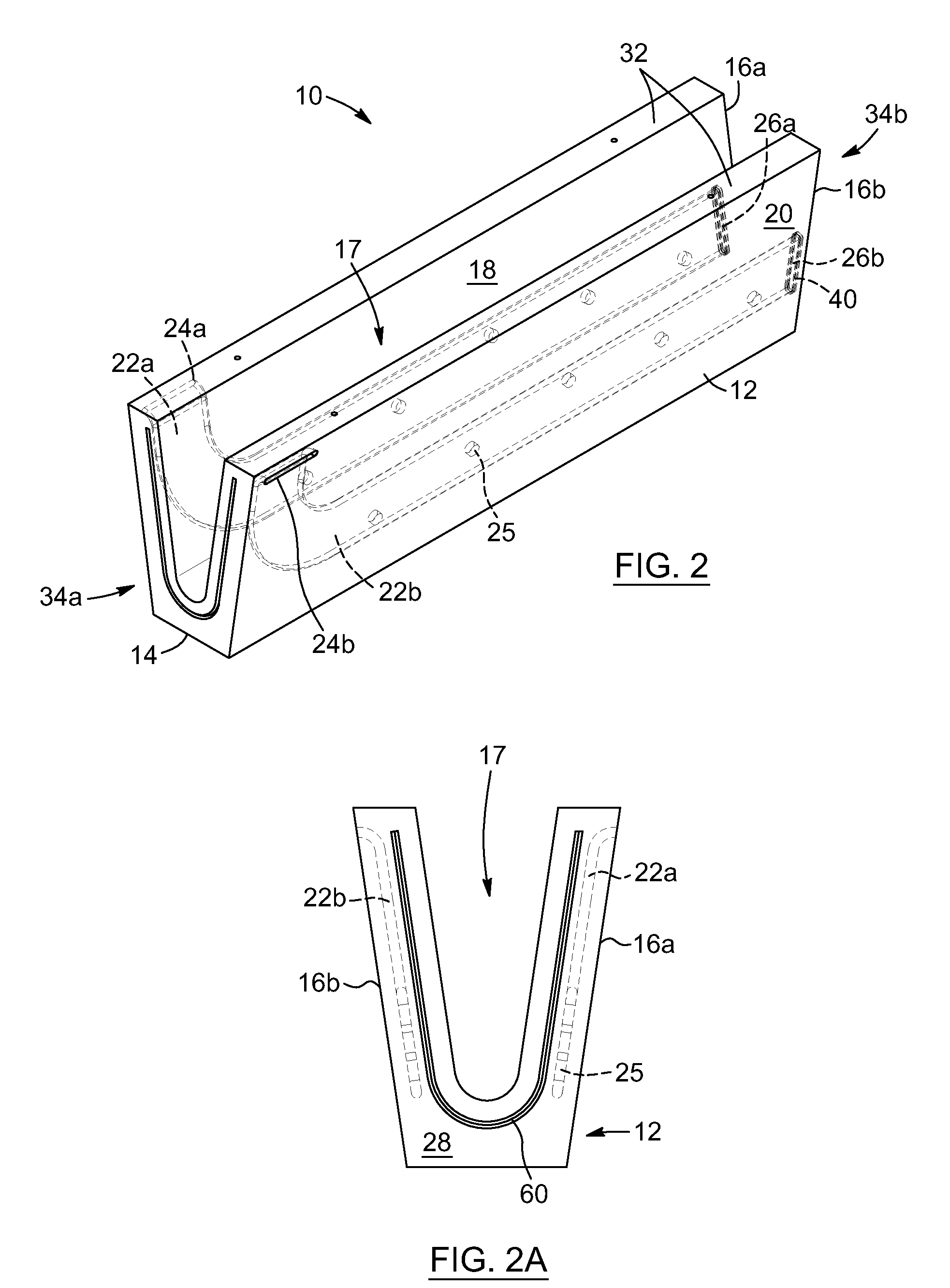

Wall gap fire block device, system and method

Fire block devices for application to a wall component. The fire block device can be a strip that includes a fire-resistant material strip comprised of a material that expands in response to sufficient heat to create a fire-resistant barrier. An optional foam strip comprised of a foam material can be placed side-by-side with the fire-resistant material strip. A cover layer covers the fire-resistant material strip and the optional foam strip, if present. The cover layer includes opposing side portions positioned on opposing sides of the fire-resistant material strip and foam strip, if present. The cover layer is comprised of a tape having an adhesive on an underneath surface thereof such that adhesive on the side portions are capable of securing the fire block strip to a wall component. The fire block strip can be applied to a header track, footer track or wall stud, among other possible components.

Owner:CEMCO LLC

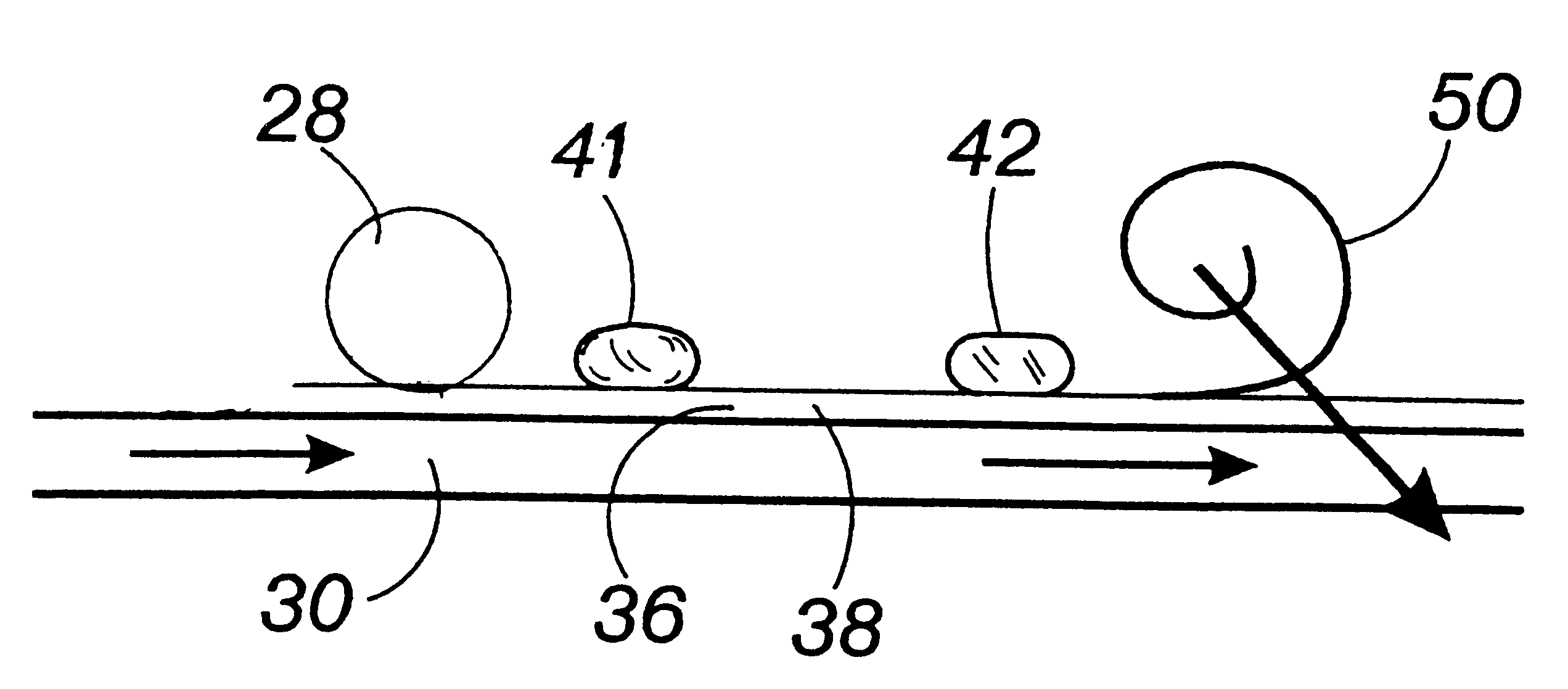

Iron production method of operation in a rotary hearth furnace and improved furnace apparatus

The present invention is an apparatus and method for the direct reduction of iron oxide utilizing a rotary hearth furnace to form a high purity carbon-containing iron metal button. The hearth layer may be a refractory or a vitreous hearth layer of iron oxide, carbon, and silica compounds. Additionally, coating materials may be introduced onto the refractory or vitreous hearth layer before iron oxide ore and carbon materials are added, with the coating materials preventing attack of the molten iron on the hearth layer. The coating materials may include compounds of carbon, iron oxide, silicon oxide, magnesium oxide, and / or aluminum oxide. The coating materials may be placed as a solid or a slurry on the hearth layer and heated, which provides a protective layer onto which the iron oxide ores and carbon materials are placed. The iron oxide is reduced and forms molten globules of high purity iron and residual carbon, which remain separate from the hearth layer. An improved apparatus includes a cooling plate that is placed in close proximity with the refractory or vitreous hearth layer, cooling the molten globules to form iron metal buttons that are removed from the hearth layer. The improvements due to the present apparatus and method of operation provide high purity iron and carbon solid buttons, which are separate from slag particulates, and discharged without significant loss of iron product to the interior surfaces of the furnace.

Owner:MIDREX INT B V ROTTERDAM

Formula and preparation process of alcohol group nanometer composite and surface modified dry powder mold paint

The invention relates to an auxiliary material for casting and moulding, in particular to a formula of alcohol group dry powder mold paint for sand mold casting. The dry powder mold paint comprises surface modifier, suspending agent, binder and refractory powder, wherein the surface modifier is 0.6-4.2wt% of refractory powder, the suspending agent is 4.0-8.0wt% of refractory powder and the binderis 4.0-6.2wt% of refractory powder. The alcohol group nanometer composite and surface modified dry powder mold paint of the invention adopts nanometer layered clay and nano-SiO2 to form composite suspending agent so that the controllability of operation technological parameters of the alcohol group dry powder mold paint is good and the process performance and operating performance of the obtainedpulp-type paint can both meet the demand of the casting factory.

Owner:深圳市景鼎现代科技有限公司

Fluxless heat-and wear-resistant cast iron alloy surfacing welding electrodes and manufacture thereof

InactiveCN1530201AReduce labor intensityImprove welding productivityArc welding apparatusWelding/cutting media/materialsWear resistantRefractory

An uncoated refractory antiwear welding cast iron alloy electrode for build-up welding contains C (2.5-6.5 wt.%), Si (0.8-2.5), Mn (0.4-1.5), Cr (16-35), Nb (0-1.5), Mo (0-3.5), Ni (0-2.0), W (0-2.5), V (0.1-2.0), Ti (0-0.8), Cu (0-1.0), S (0-0.08), P (0-0.1), O (0-0.08), N (0-0.08), Al (0-0.1) and Fe (rest), and is made up by casing method. Its advantages are high hardness of welded layer (more than 42 HRC), and low cost.

Owner:攀钢集团钢城企业总公司溶解乙炔厂

Receptacle for handling molten metal, casting assembly and manufacturing method

InactiveUS20130334744A1Simpler and less cumbersomeEasy to manufactureMelt-holding vesselsDischarging arrangementRefractoryEngineering

A receptacle for handling molten metal is provided. The receptacle has bottom and side walls and includes a refractory defining a cavity within which the molten metal is conveyed or contained. The receptacle has at least one channel extending within at least one of its walls. The channel has an inlet and an outlet. The inlet is connectable to a source for circulating a fluid within the channel. The outlet allows the fluid to be expelled from said channel. The channel allows, when the fluid is circulated in it, to regulate the temperature of the refractory and thereby of the metal conveyed or contained. A casting assembly and a method for casting the refractory are also provided.

Owner:PYROTECK INC

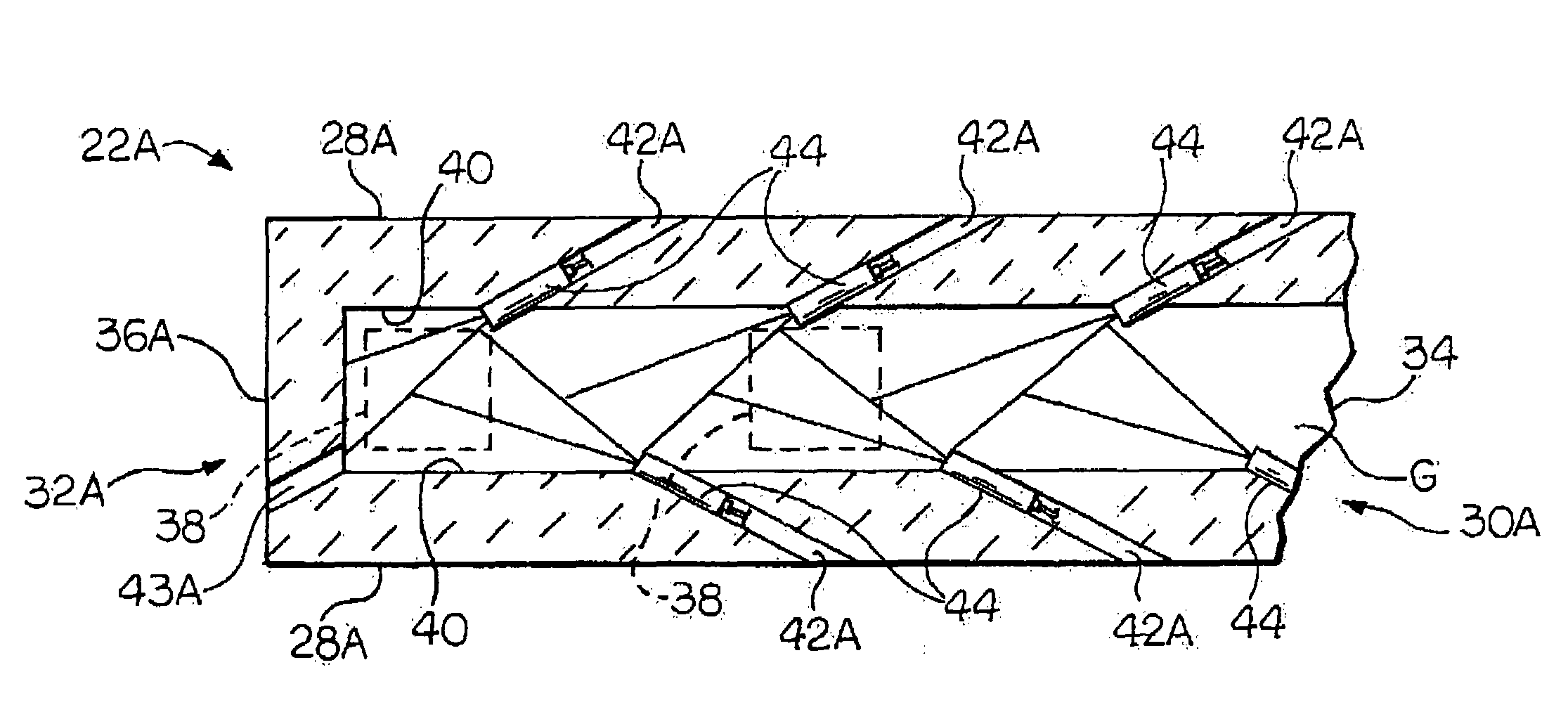

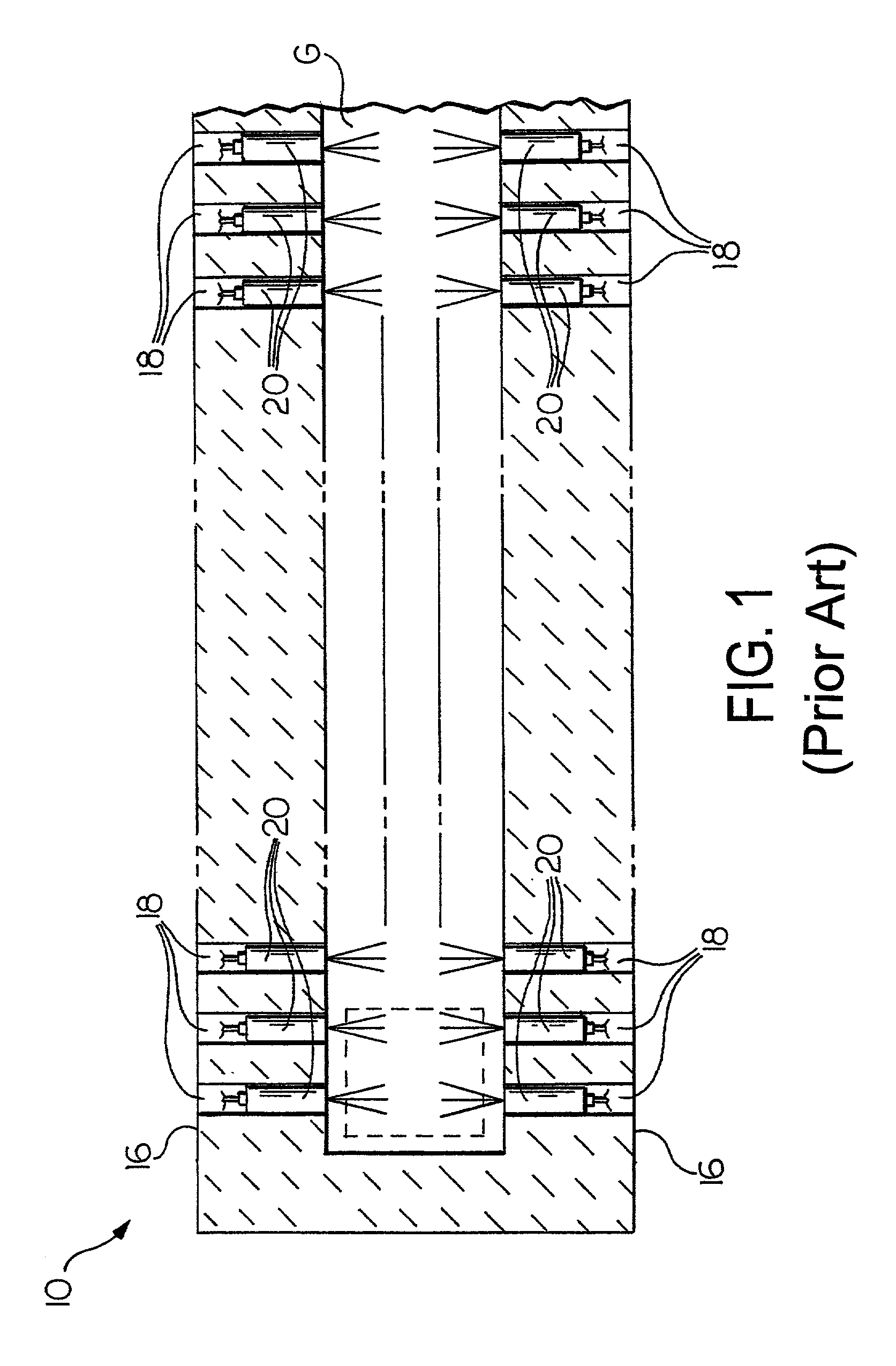

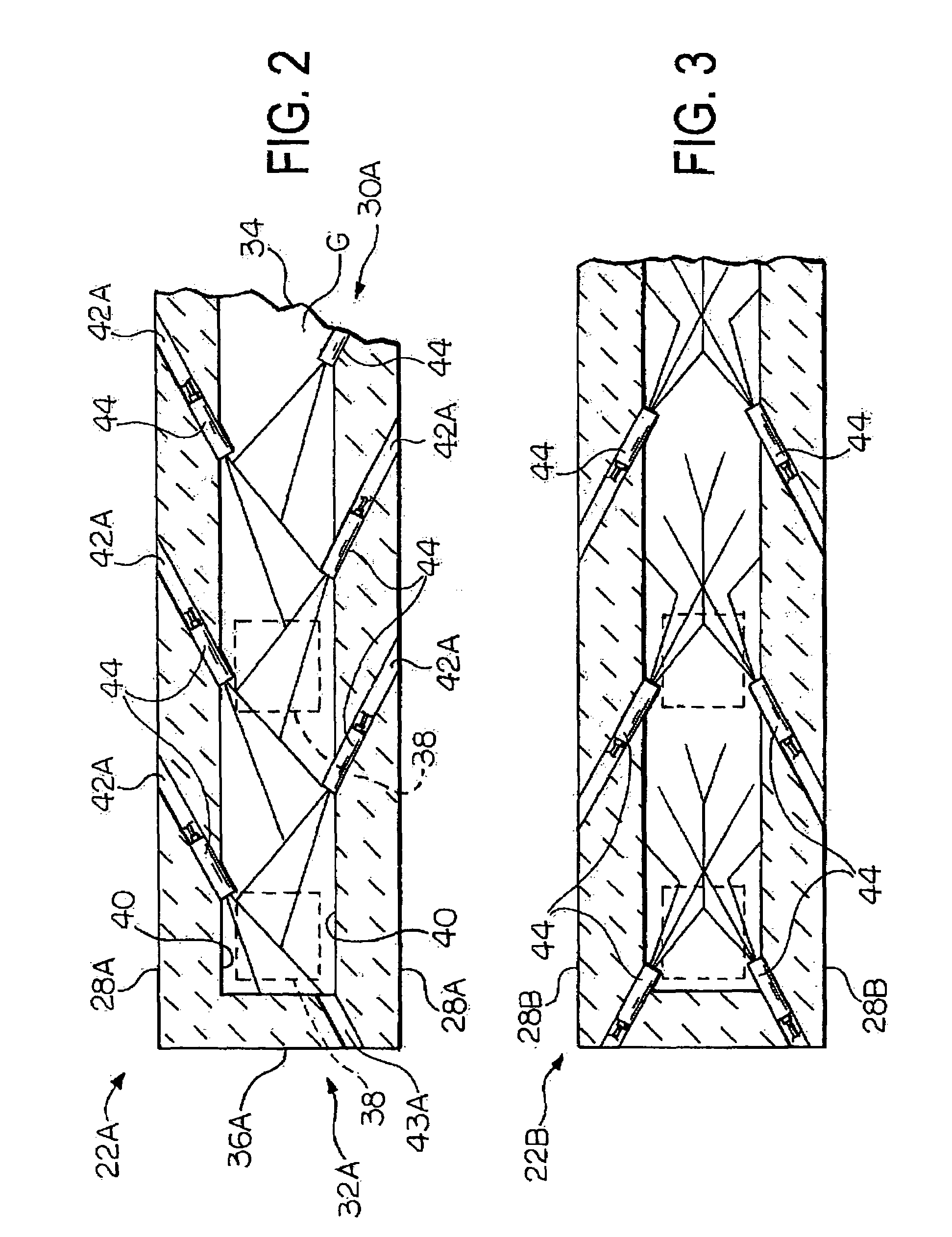

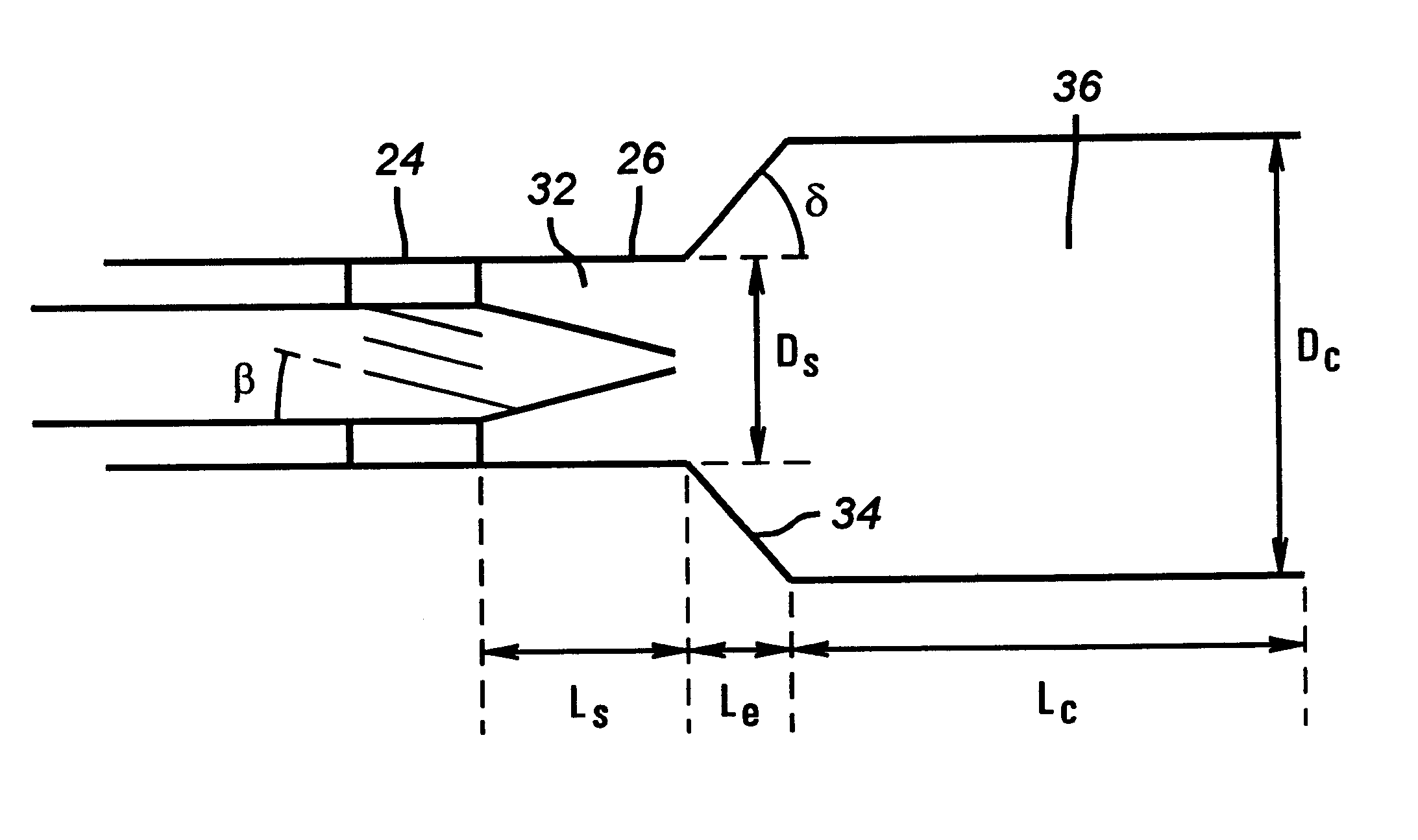

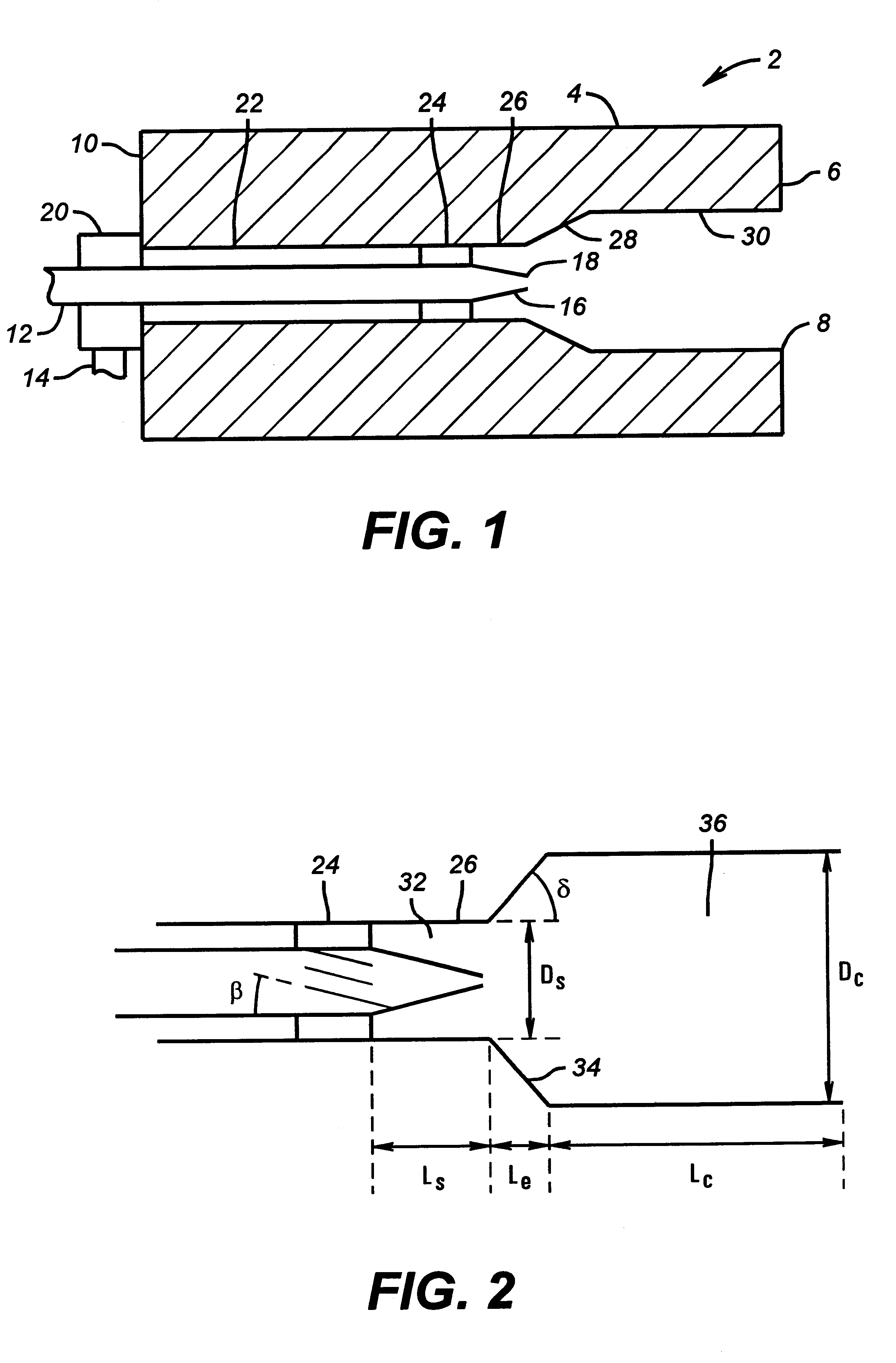

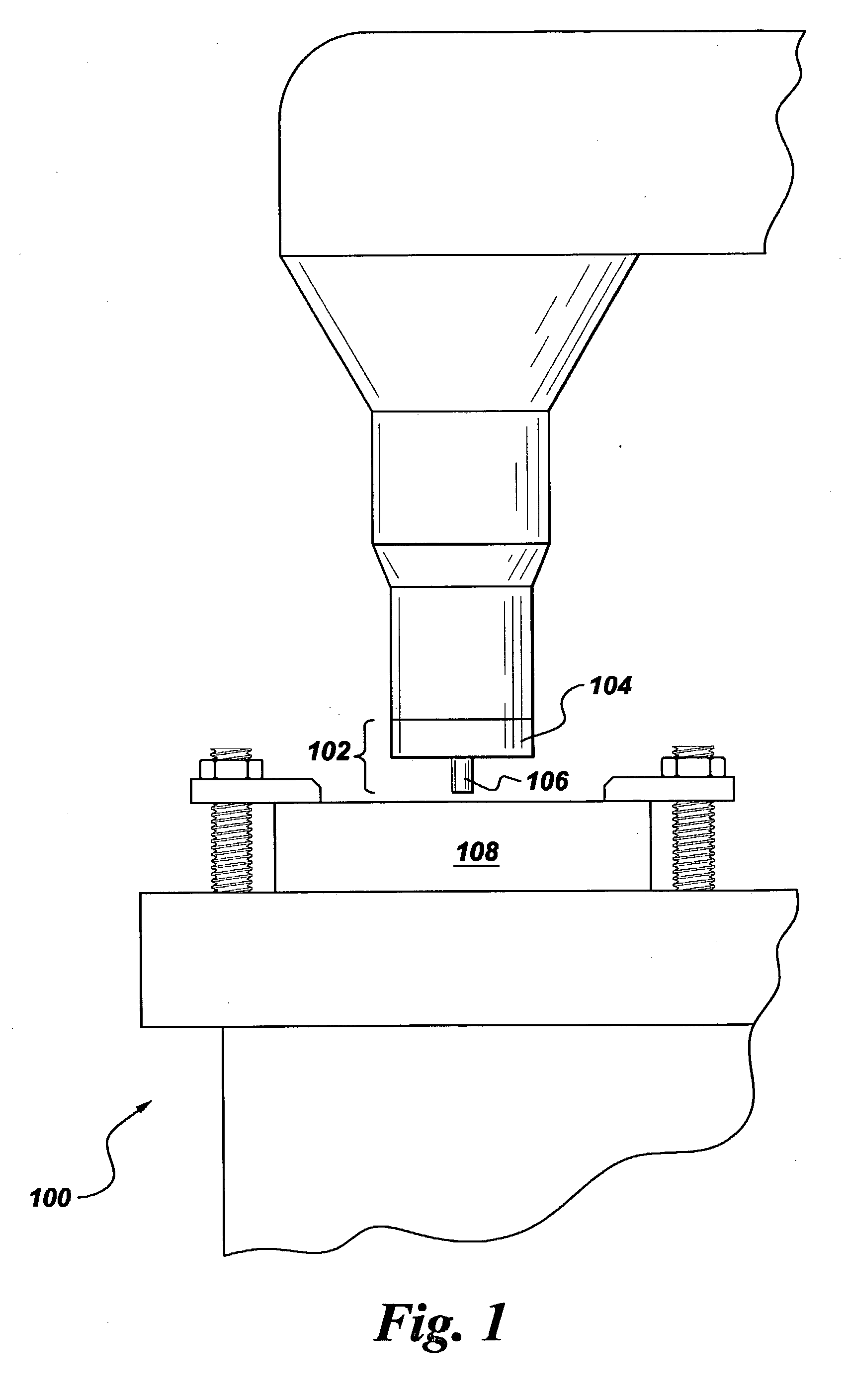

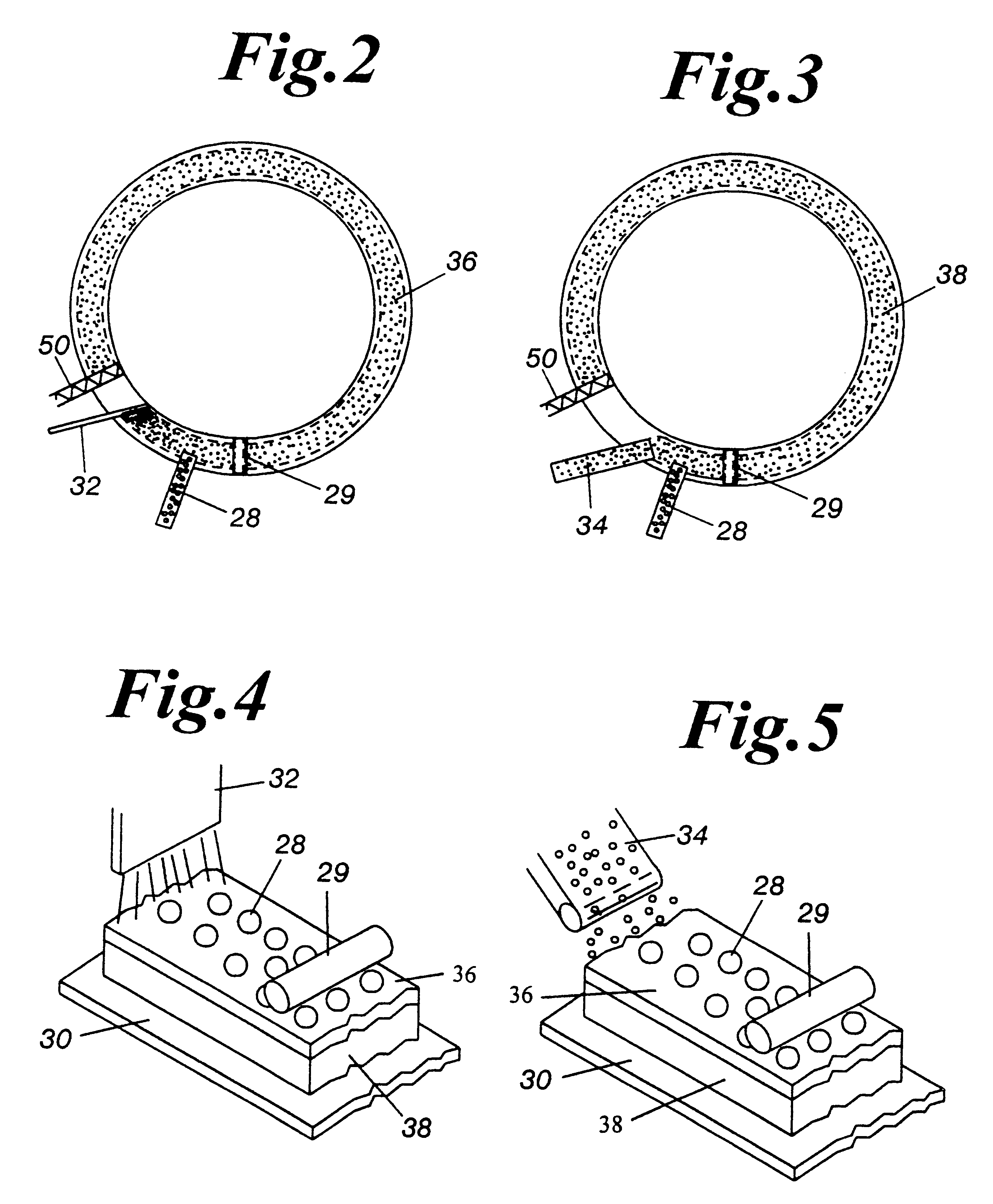

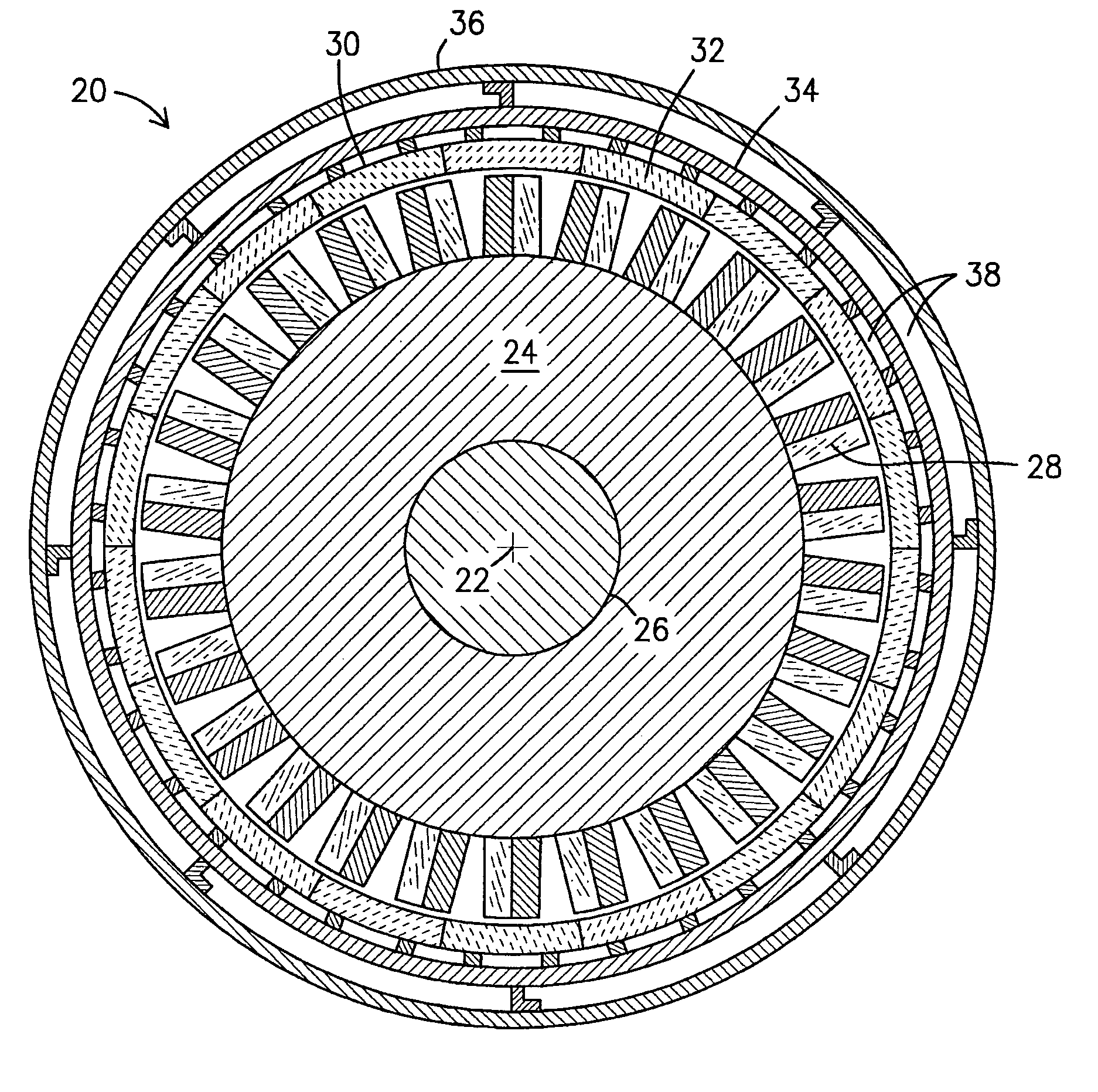

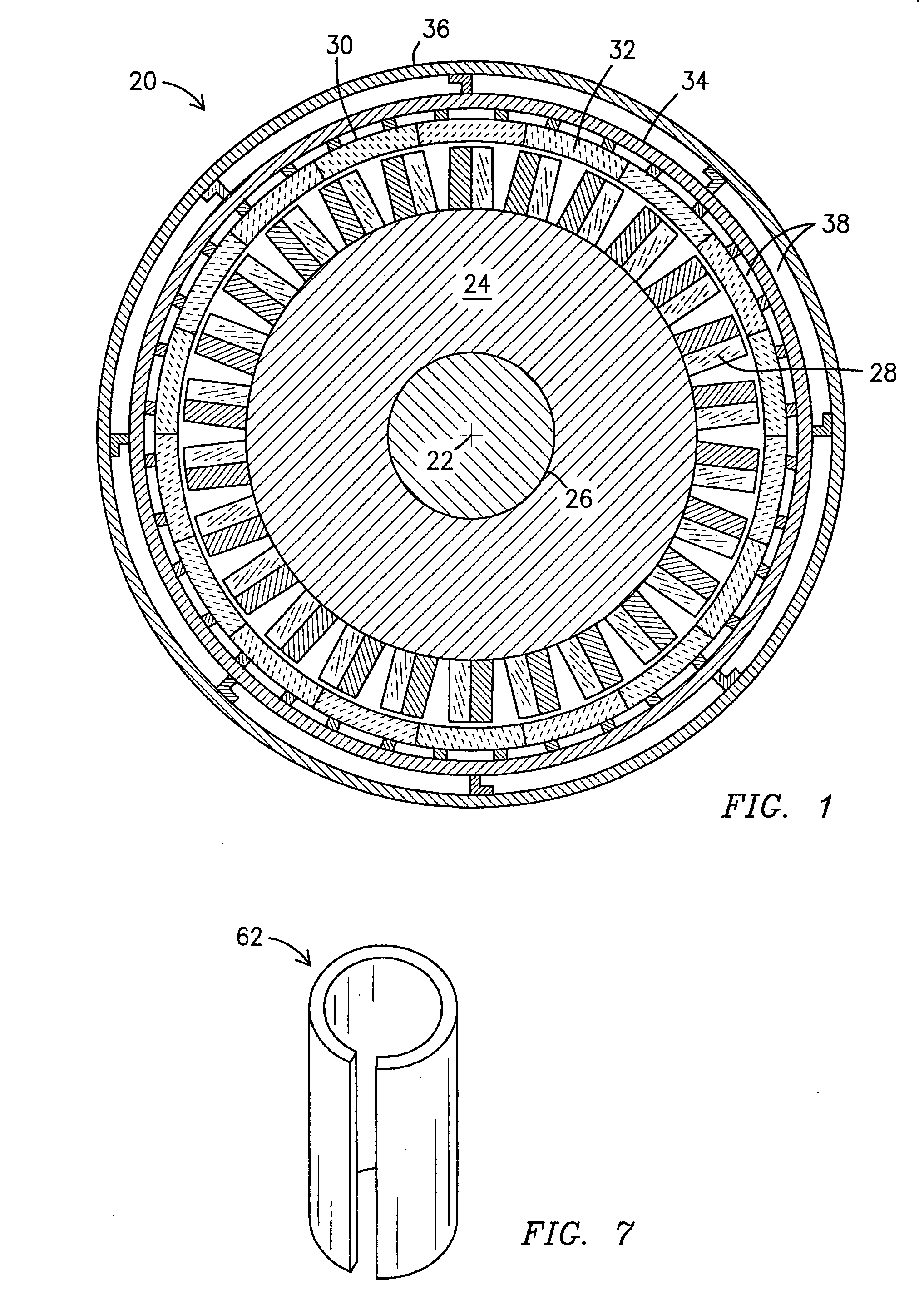

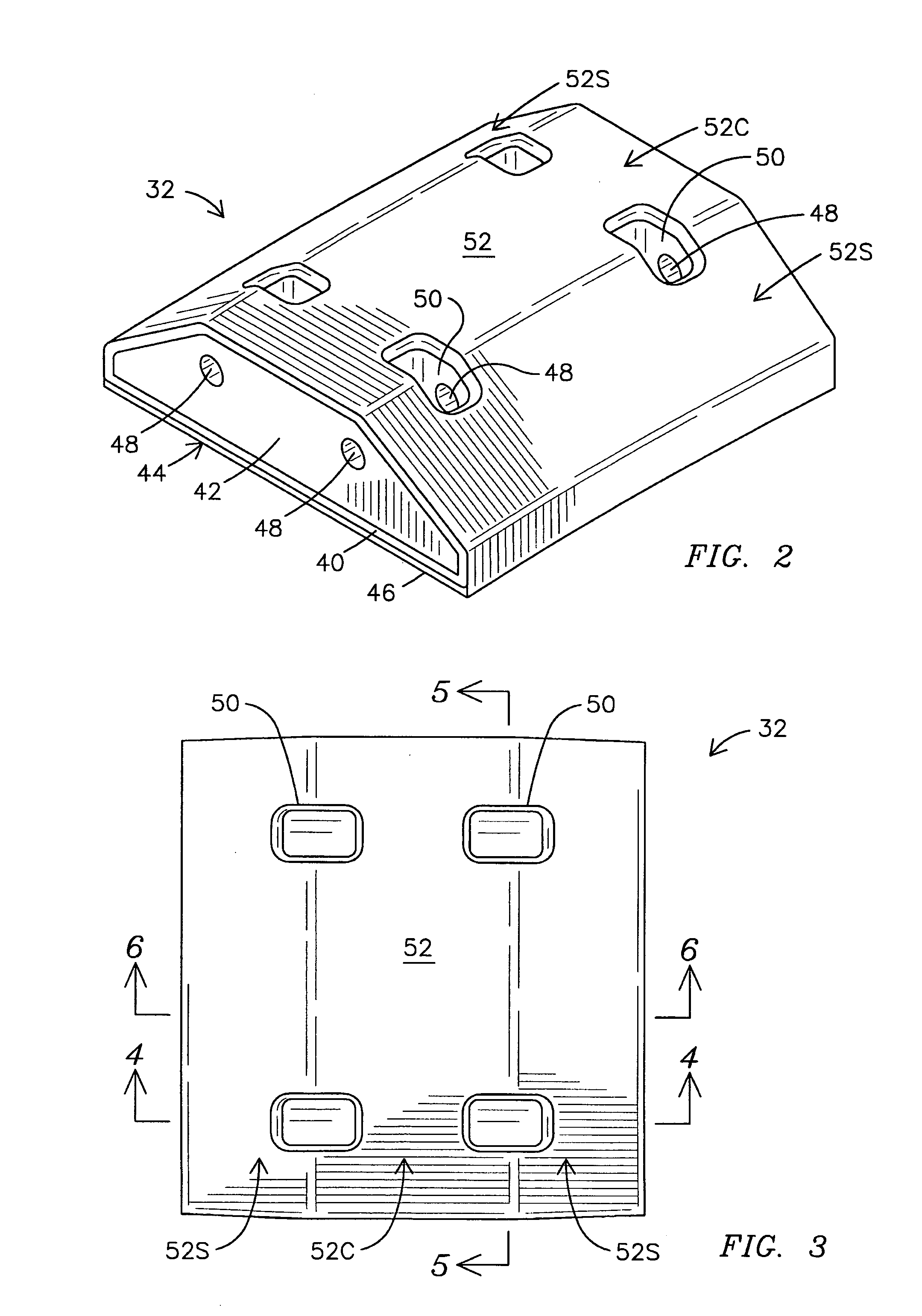

Pin-loaded mounting apparatus for a refractory component in a combustion turbine engine

An apparatus for mounting a refractory component such as a turbine shroud ring segment (32) with a ceramic core (42) onto a combustion turbine engine structure (34). The ring segment has a ceramic matrix composite skin (40), and optionally, a thermal insulation layer (46). A pin (60) is inserted through a bore (48) in the core and through an attachment bar (54) with ends received in wells (50) in the core. The attachment bar may be attached to a backing member, or tophat (64), by a biasing device (76) that urges the refractory component snugly against the backing member to eliminate vibration. The backing member and refractory component have mating surfaces that may include angled sides (52S, 70). The backing member is attached to the engine structure. Turbine shroud ring segments can be attached by this apparatus to a surrounding structure to form a shroud ring.

Owner:SIEMENS ENERGY INC

Fibers and articles having combined fire resistance and enhanced reversible thermal properties

A fabric, fiber or article comprising a plurality of fiber bodies, the plurality of fiber bodies including a first fiber material and a second fiber material, wherein the first fiber material comprises a cellulosic material and a phase change material dispersed in the cellulosic material, the phase change material forming a plurality of domains dispersed in the cellulosic material, the phase change material having a latent heat of at least 5 Joules per gram and a transition temperature in the range of 0° C. to 100° C., the phase change material providing thermal regulation based on at least one of absorption and release of the latent heat at the transition temperature. Wherein the second fiber material comprises a fire resistant material.

Owner:OUTLAST TECH LLC

High-heat transfer low-NOx combustion system

ActiveUS6939130B2Lower NO<sub>xIncrease brightnessCombustion using gaseous and pulverulent fuelBurner safety arrangementsCombustion systemVertical plane

Owner:GAS TECH INST

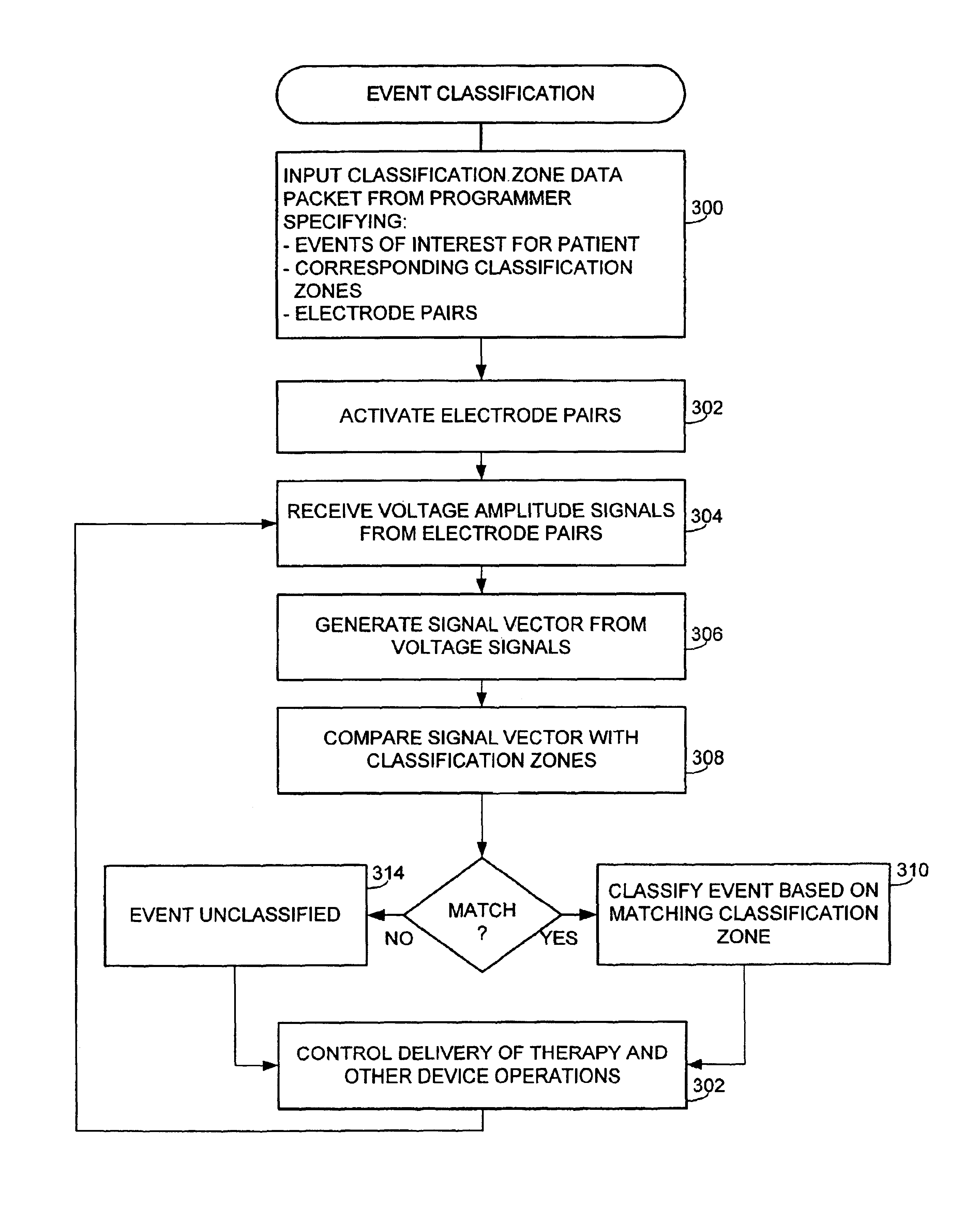

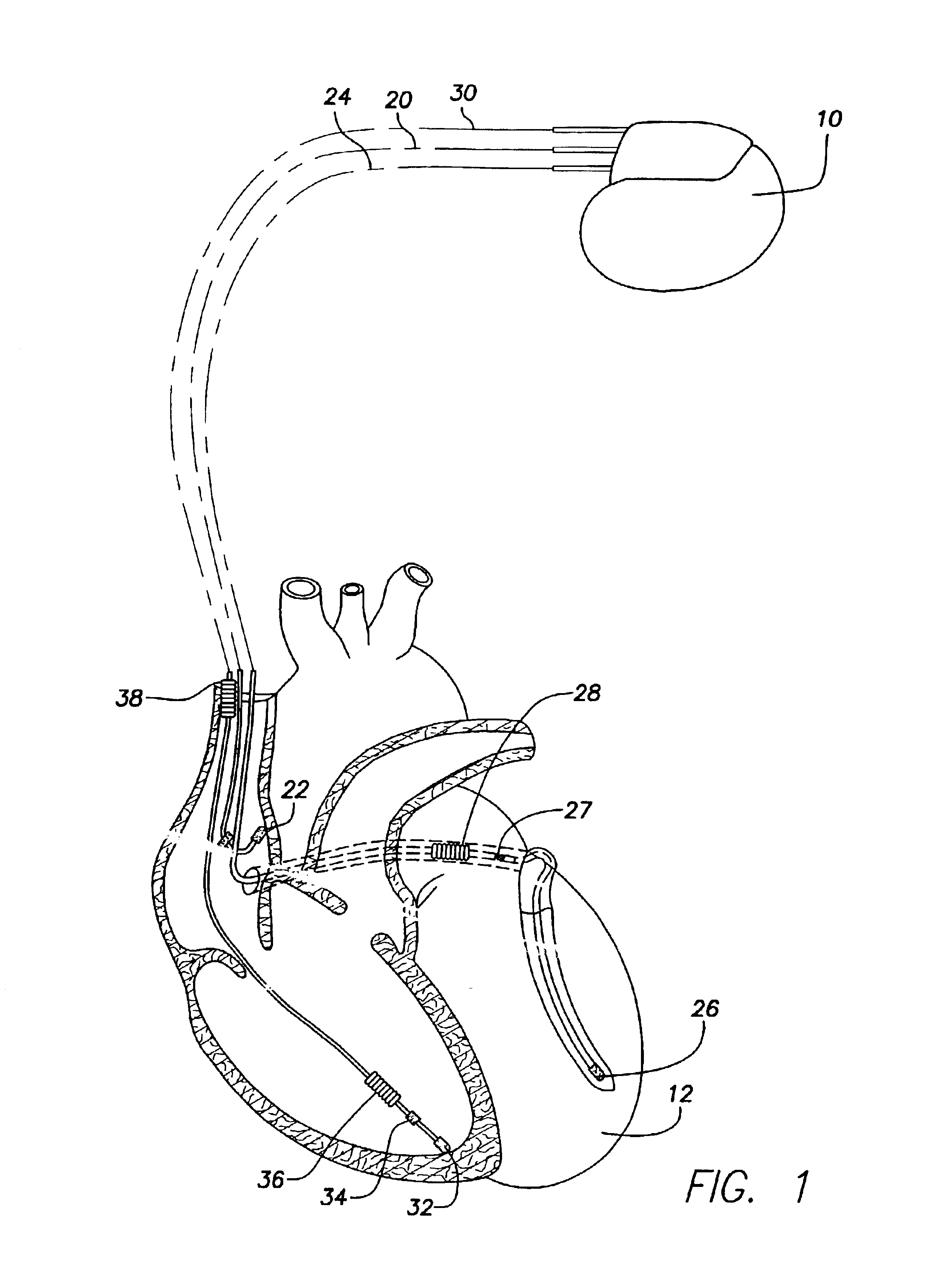

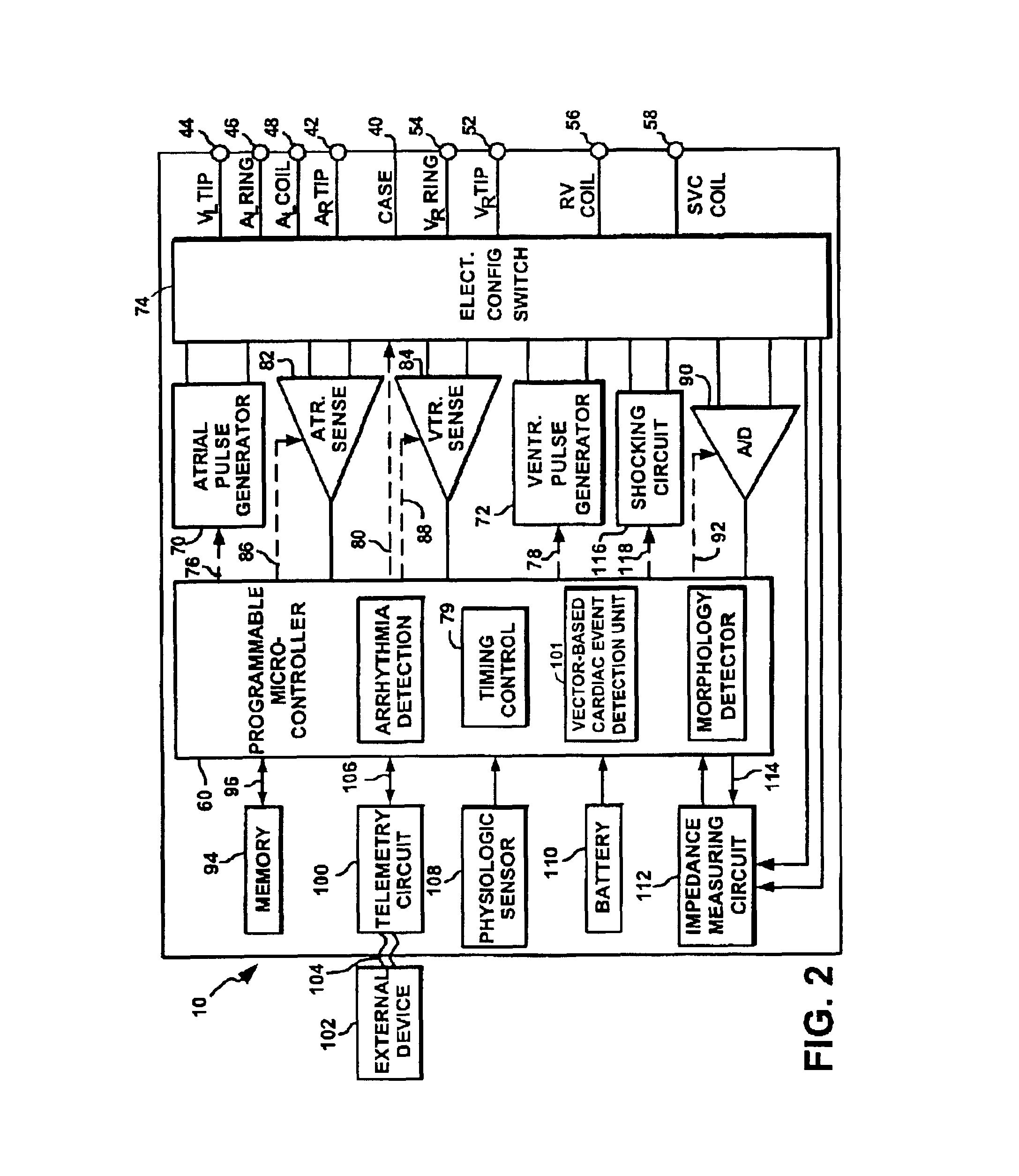

Implantable medical device and method for detecting cardiac events without using of refractory or blanking periods

Cardiac electrical events are detected by comparing signal vectors with pre-determined classification zones representative of different cardiac events. The signal vector is generated by sensing the voltages between various combinations of electrodes, such as A-tip to V-tip, A-tip to A-ring, and A-ring to V-ring. The signal vector is compared with a set of classification zones corresponding to different events, such as P-waves, R-waves, T-waves, A-pulses, and V-pulses, to determine whether the vector lies within any of the classification zones. In this manner, cardiac events are detected using only the voltages received from the electrodes and no refractory periods or blanking periods are required to distinguish one event from another. The classification zones vary from patient to patient and a technique is provided herein for generating a set of vector classification zones for a particular patient. Signal vectors corresponding to various unknown cardiac events are generated by the implanted device and are transmitted to an external device programmer. ECG signals, generated by a surface ECG detector, are simultaneously received by the external programmer. The external programmer identifies the cardiac electrical event corresponding to each signal vector based on the ECG signals and then generates classification zones for each event type using only the signal vectors corresponding to the event.

Owner:PACESETTER INC

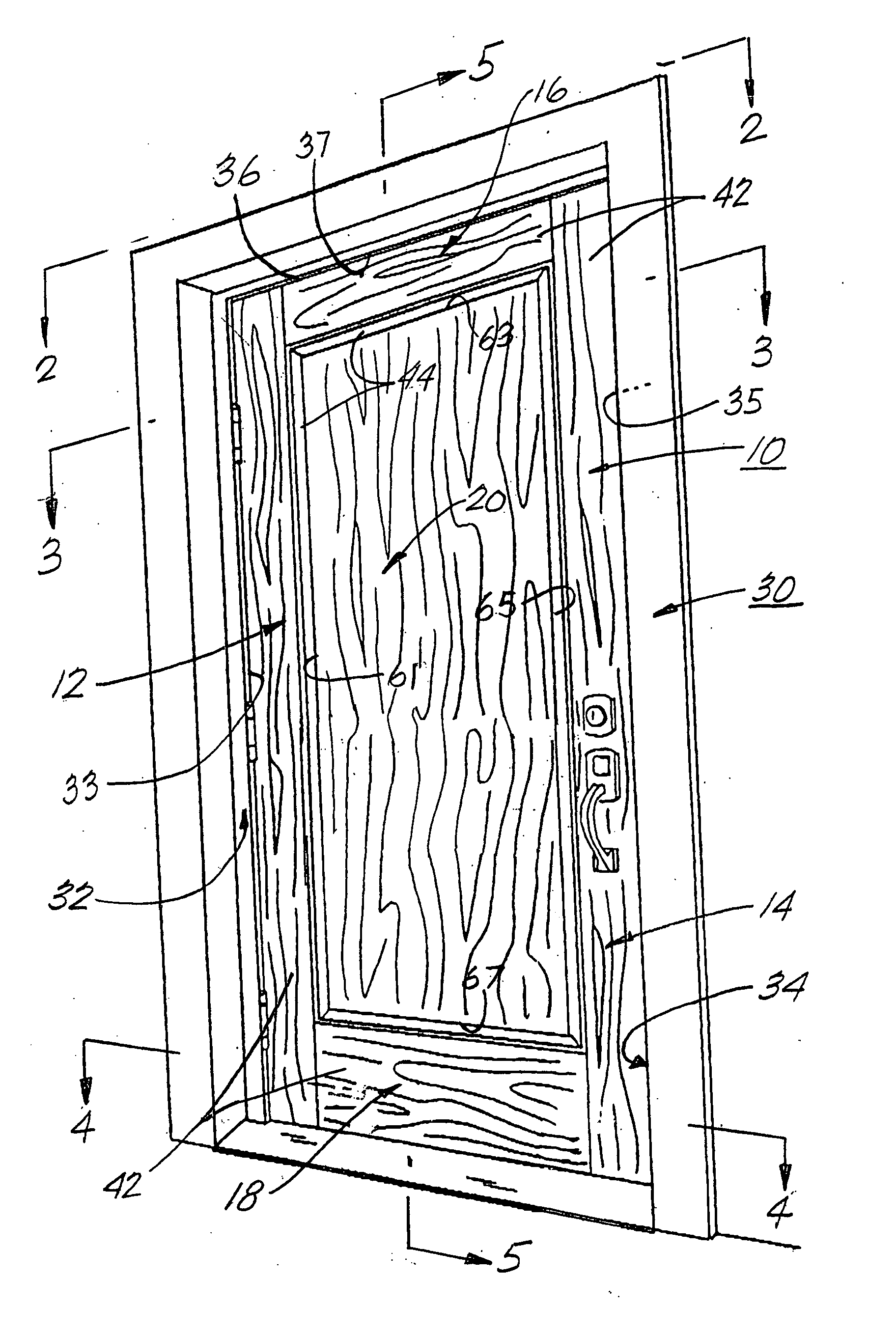

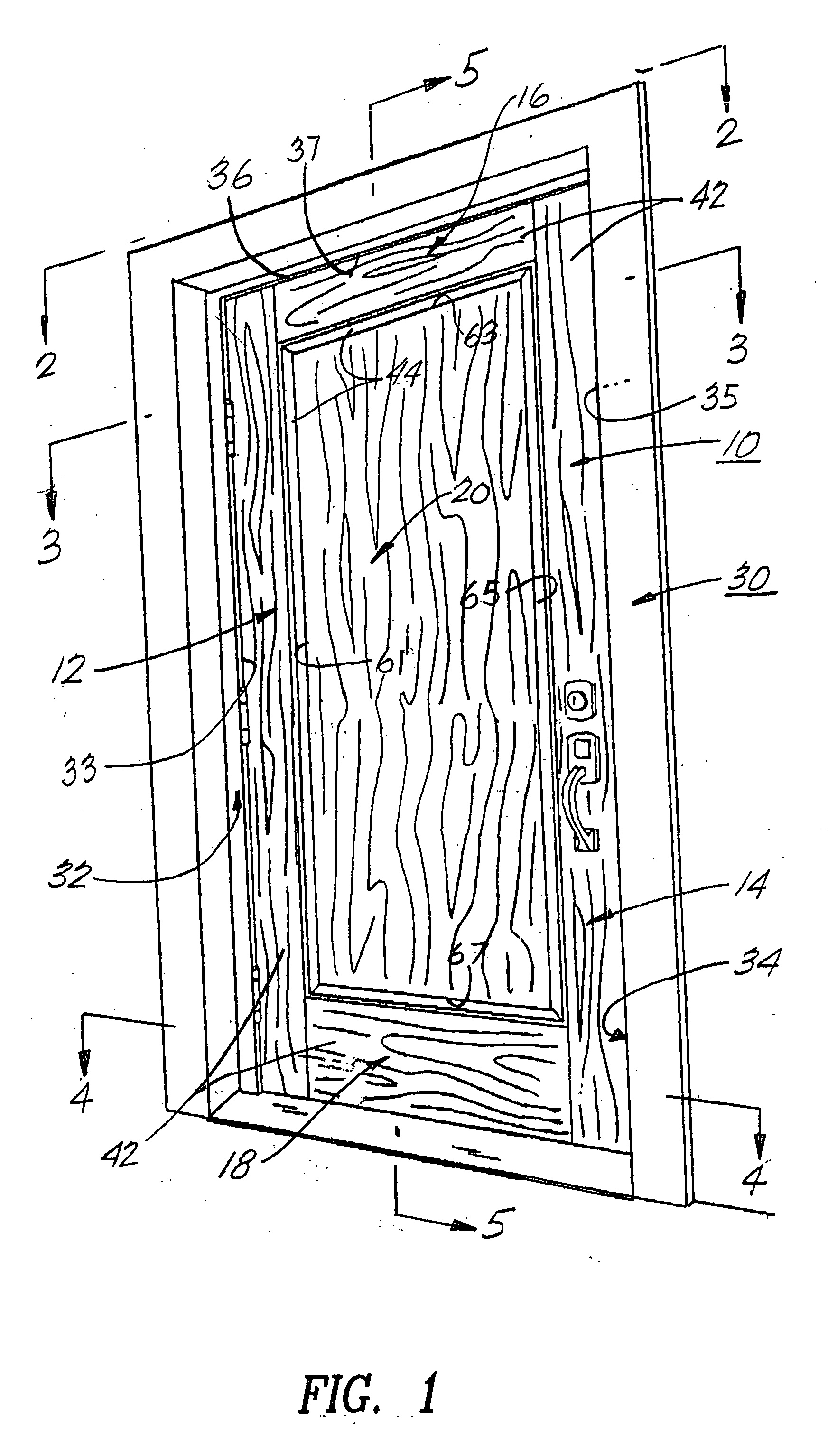

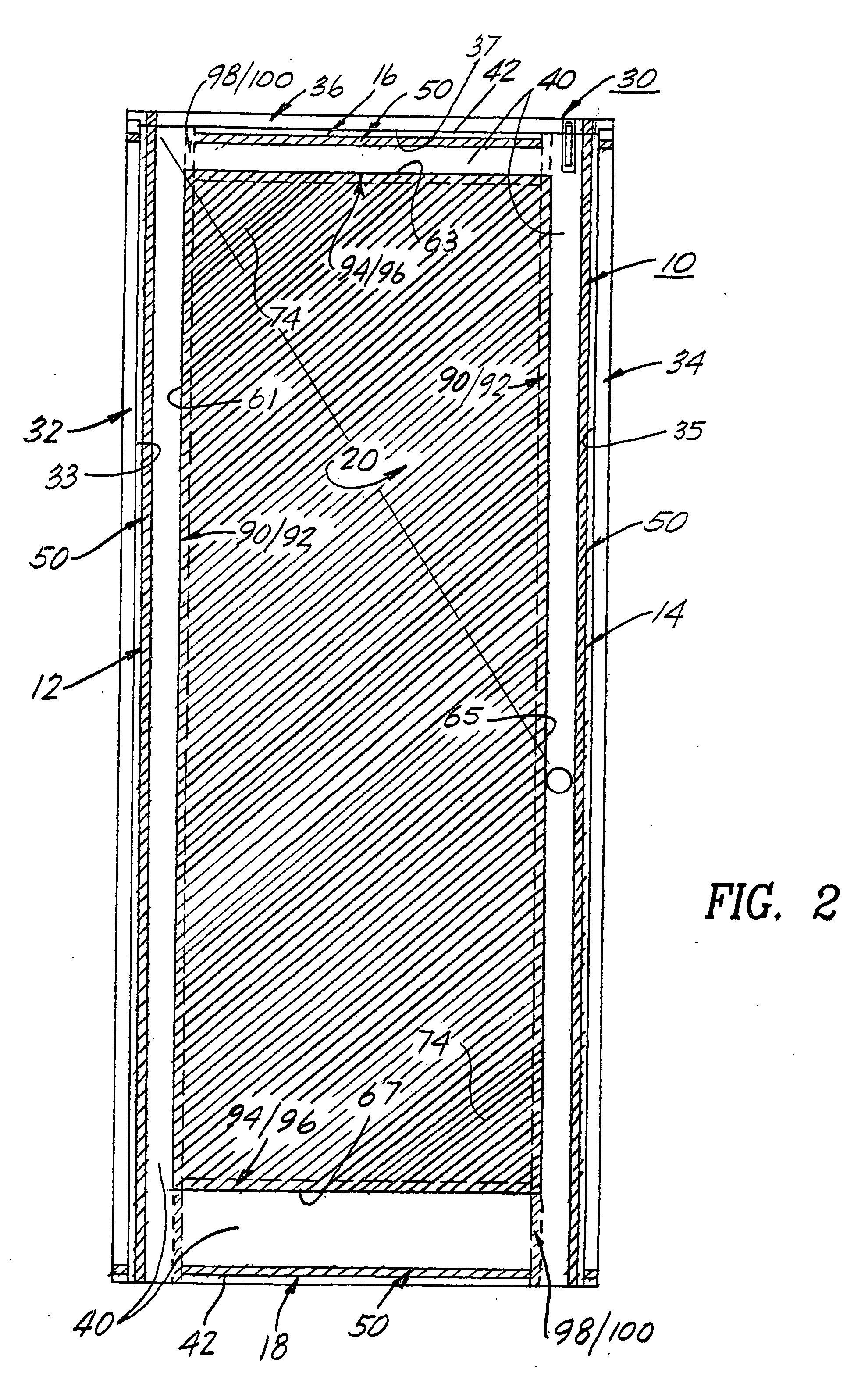

Fire retardant panel door and door frame having intumescent materials therein

InactiveUS20050284030A1Prevent the spread of fireFireproof doorsBuilding locksComposite laminatesRefractory

A fire retardant panel door and door frame that prevents the spread of fire through the door during a fire. The fire retardant panel door has at least one door panel and stiles and rails. The door panel includes an interior center composite section formed by a first plurality of layers of intumescent materials and a first plurality of layers of fire resistant materials disposed between and laminated to a pair of outer sections formed of wood for enclosing the interior center composite section to form a composite laminated door panel. Each of the stiles includes a first center core formed of wood enclosed by a second plurality of layers of intumescent materials and a second plurality of layers of fire resistant materials; and the second layers of intumescent and fire resistant materials are enclosed by a first applique layer formed of wood to form a composite laminated stile. Each of the rails includes a second center core formed of wood enclosed by a third plurality of layers of intumescent materials and a third plurality of layers of fire resistant materials; and the third layers of intumescent and fire resistant materials are enclosed by a second applique layer formed of wood to form a composite laminated rail. The first, second, and third plurality of layers of intumescent materials are activated to expand upon exposure to heat and / or fire to prevent the heat and / or fire from passing through at least one door panel, the stiles and the rails of the panel door during a fire for at least 90 minutes. At least one door panel is connected to the panel door by tongue and groove joints; and the tongue and groove joints have a fourth plurality of layers of intumescent materials and a fourth plurality of layers of fire resistant materials in the tongue and groove joints; and wherein the fourth plurality of layers of fire resistant materials in the tongue and groove joints are activated to expand upon exposure to heat and / or fire to seal the joints in order to prevent the heat and / or fire from passing through the panel door during a fire for at least 90 minutes.

Owner:ATRISTIC DOORS & WINDOWS

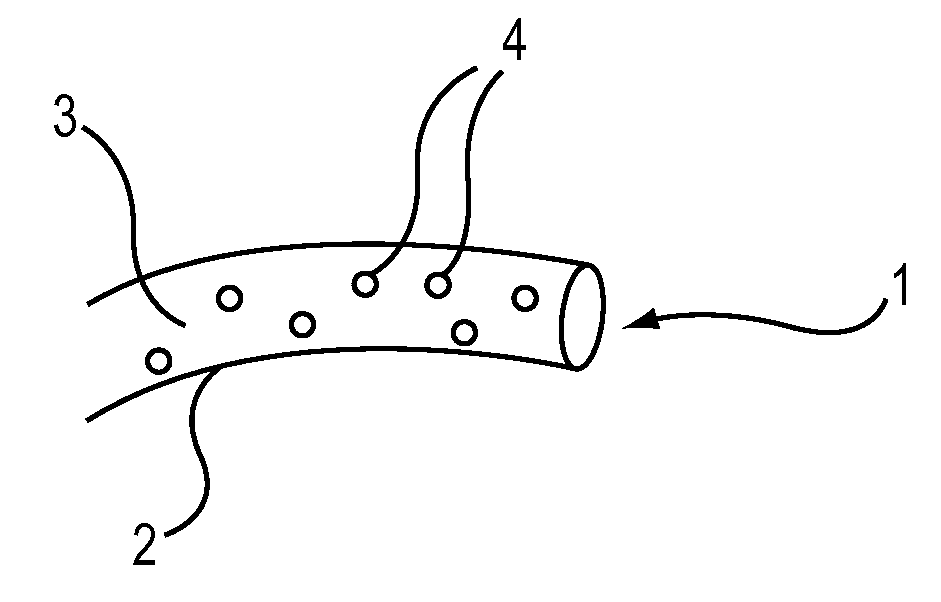

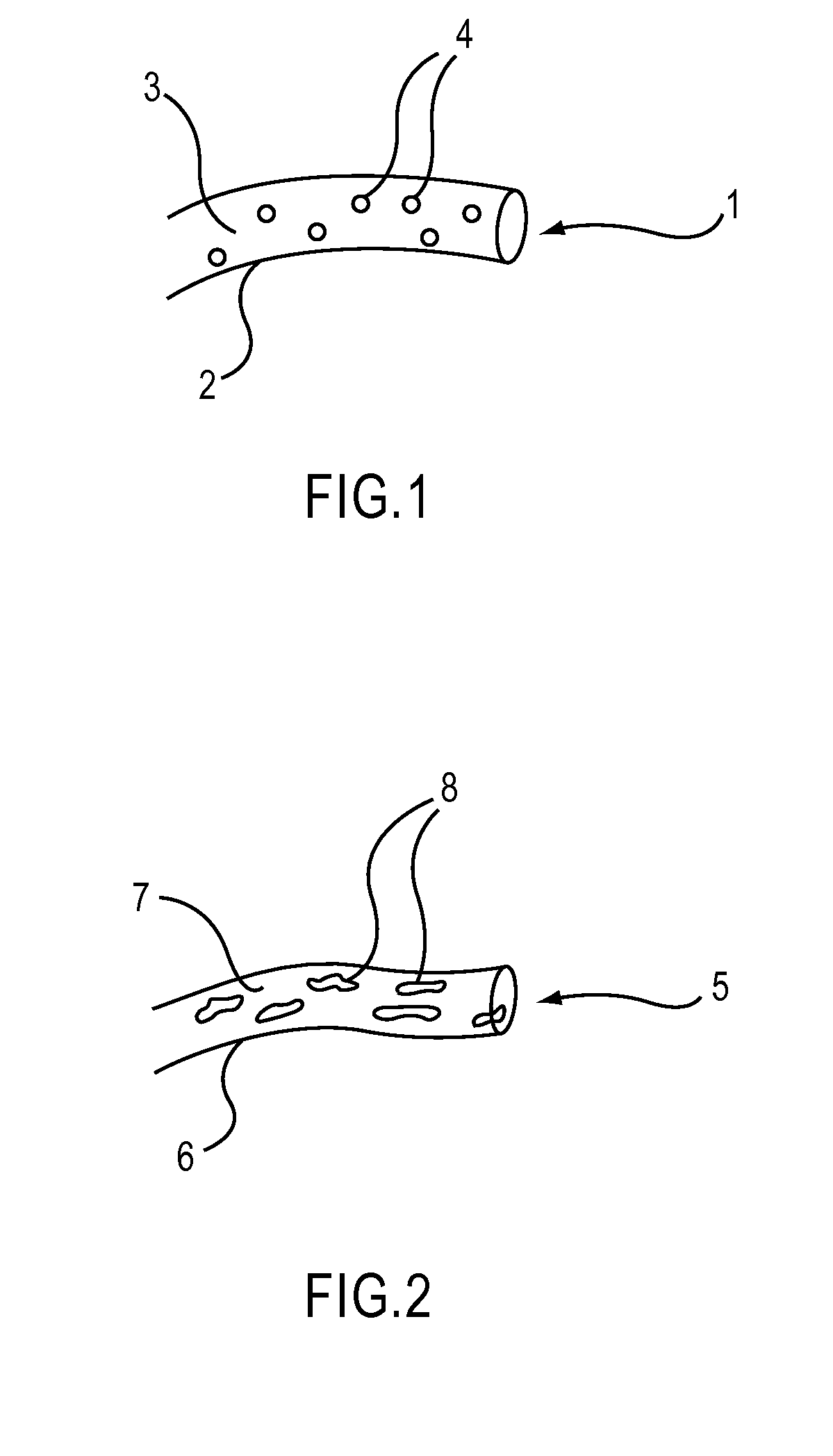

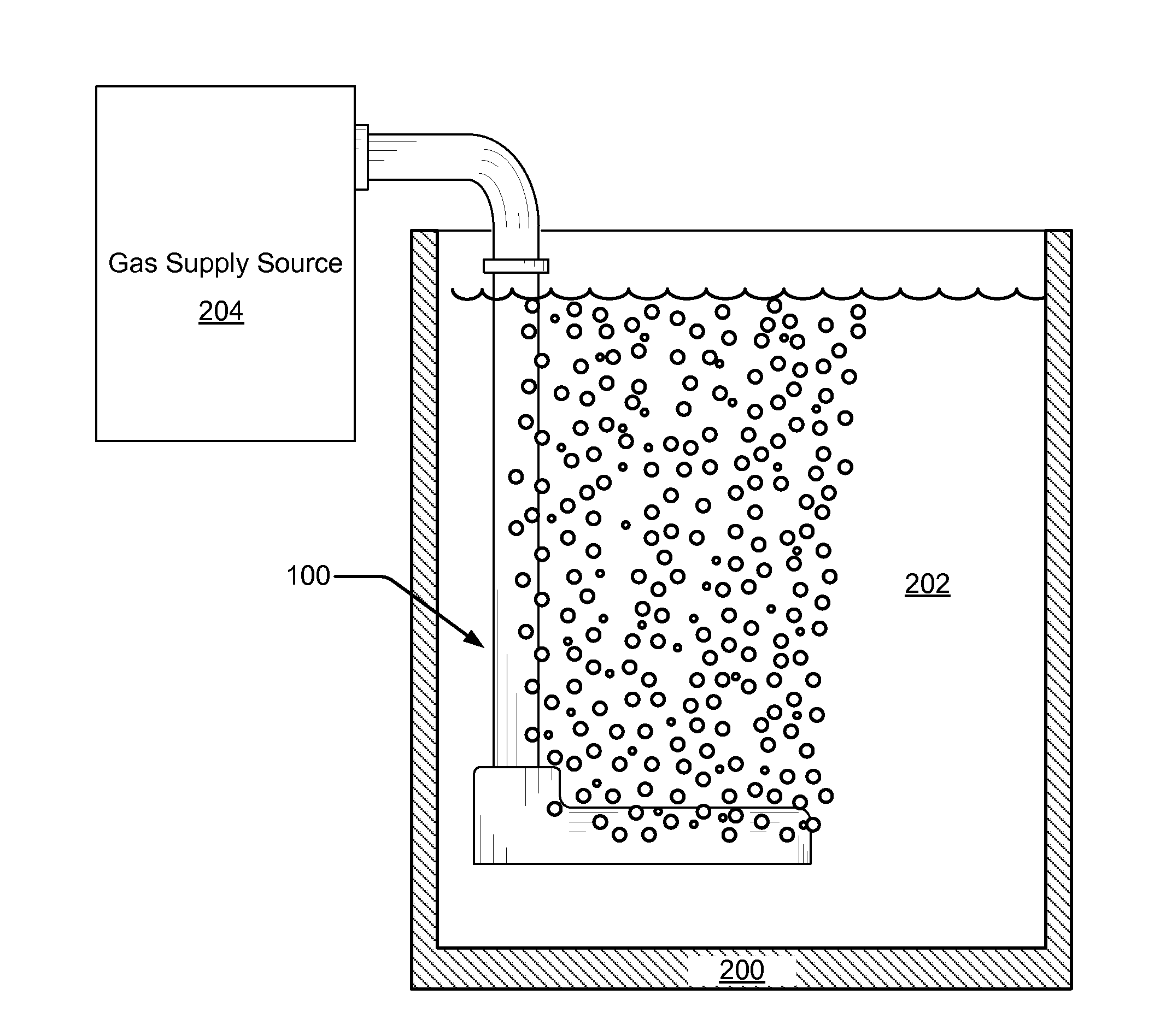

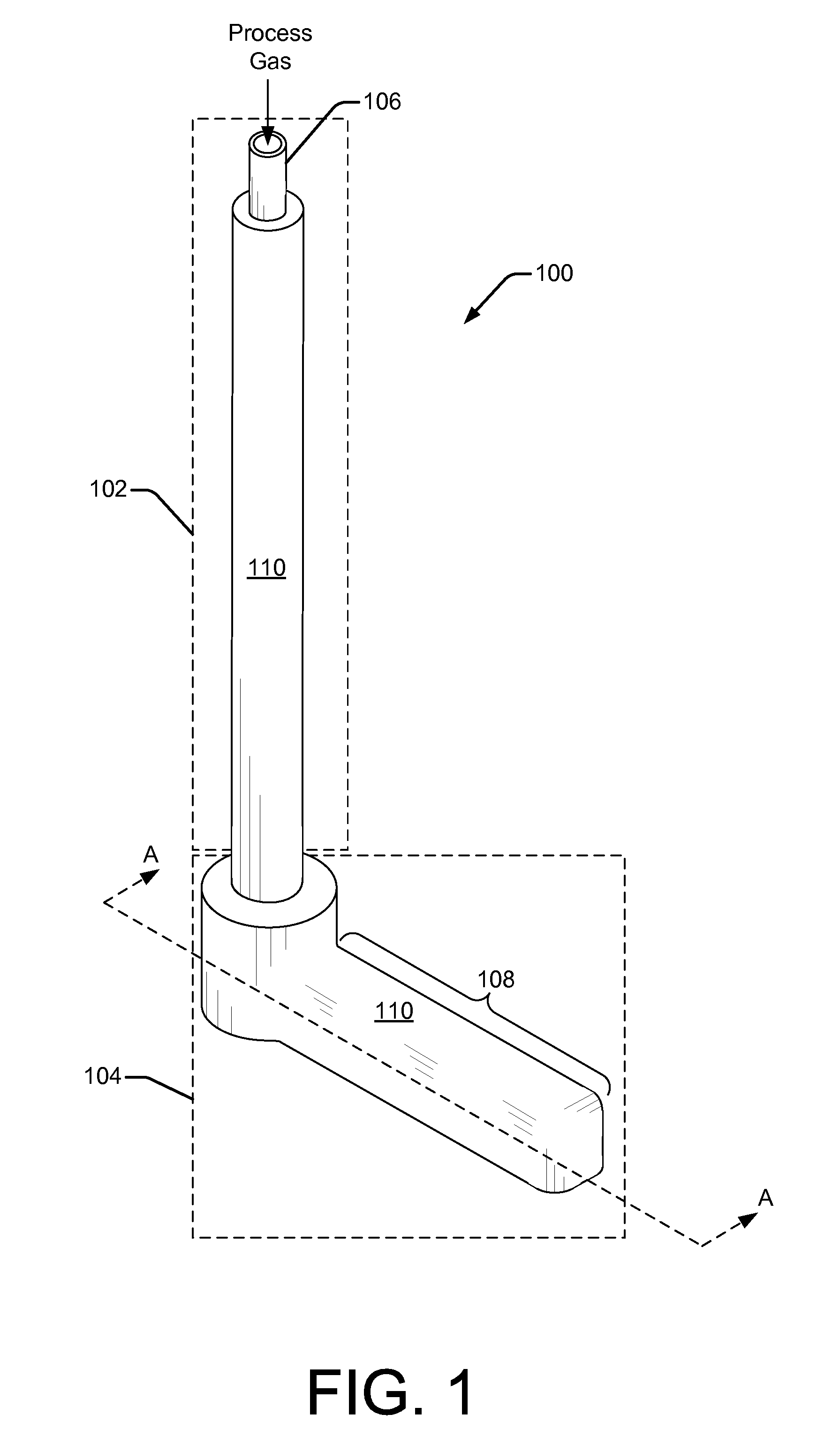

Composite degassing tube

InactiveUS20140210144A1Light weightMinimizing dross buildupCharge manipulationRefractoryMolten metal

Disclosed is a degassing tube formed, at least partially, of a composite material and configured to degas molten metal. The degassing tube may include a supply tube configured to deliver gas received from a supply source to an outlet of the degassing tube, and a diffuser body coupled to the supply tube and formed, at least partially, of a composite material. In some embodiments, a combination of the composite material and a phosphate bonded refractory material may be used to form respective sections of the diffuser body. The composite material may include layers of a woven fiber reinforcing fabric embedded within a ceramic matrix. In some embodiments, the phosphate bonded refractory material is a castable monolithic refractory which chemically bonds to the composite material.

Owner:PYROTECK INC

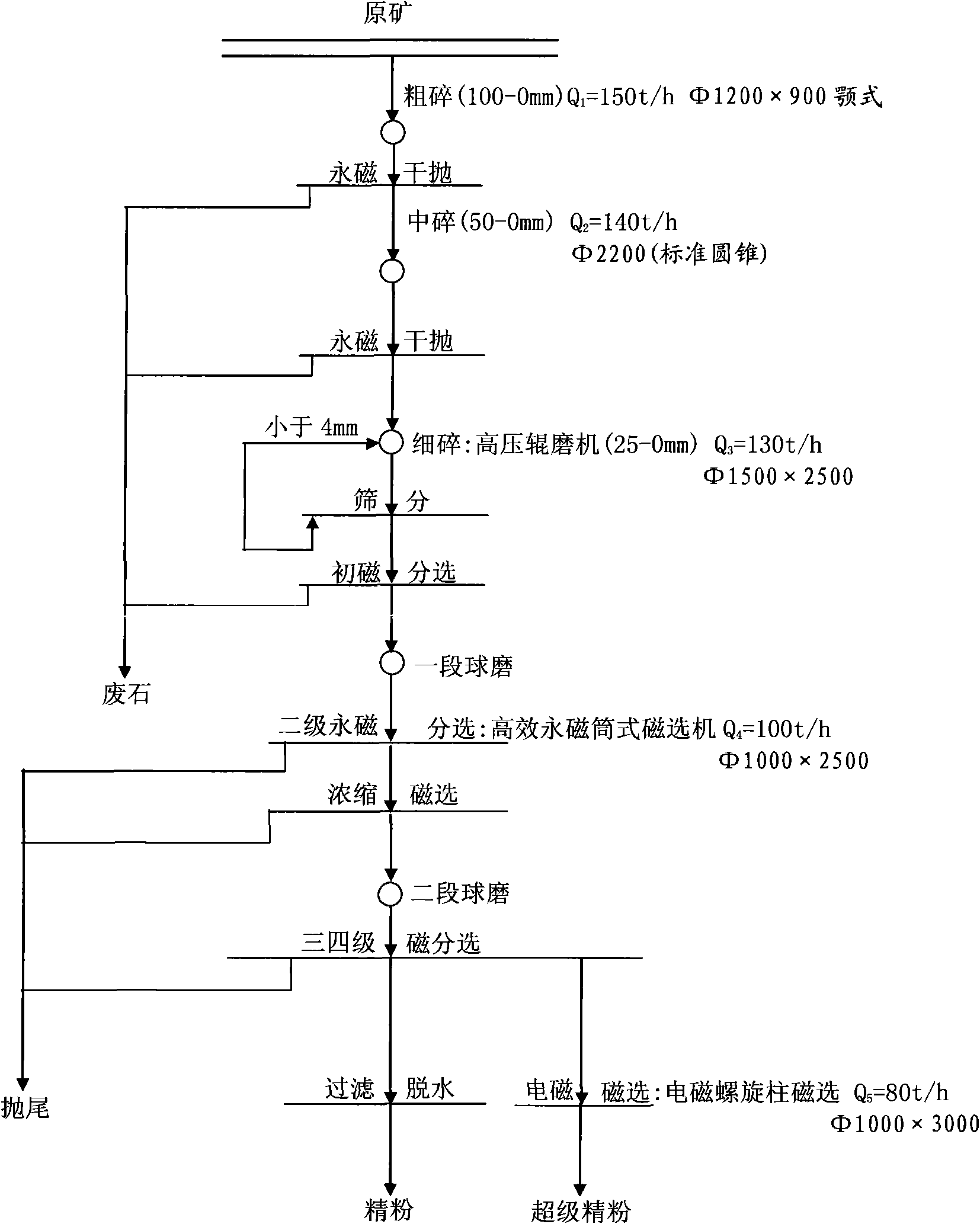

Method for concentrating extremely low-grade refractory magnetite

ActiveCN101559403AIncrease productionImprove product indicatorsMagnetic separationGrain treatmentsLower gradeRefractory

The invention discloses a method for concentrating extremely low-grade refractory magnetite to achieve higher-grade iron ore concentrate. The process proposal comprises the following steps of: dry type magnetic separation and tailing rejecting, stage grinding, wet type magnetic separation, magnetic concentrate fine screening classification, minus sieve magnetic separation, plus sieve regrinding and recleaning and concentrate extraction directly through magnetic separation of an electromagnetic wreathed column. Namely, on the basis of conducting stage grinding separation on crude ore, electromagnetic concentration, fine screening and plus sieve regrinding and recleaning are implemented to improve the final iron ore concentrate grade. With the method adopted, the production cost is reduced,the concentrate grade is raised up to 71.96 percent, the tailings grade is decreased to 4.50 percent and the secondary pollution to the environment is also avoided.

Owner:安徽大昌矿业集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com