Patents

Literature

383results about "Burner safety arrangements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

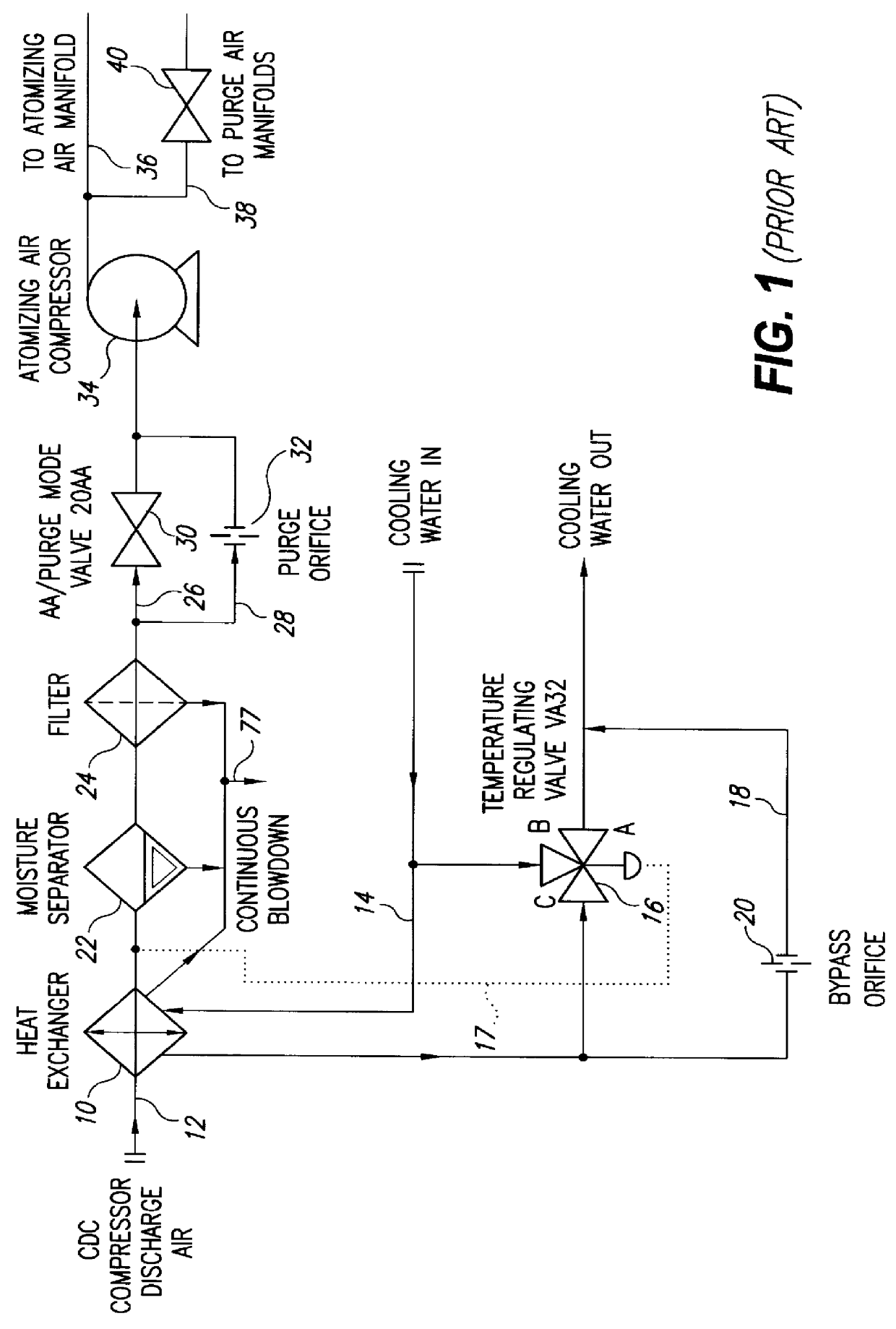

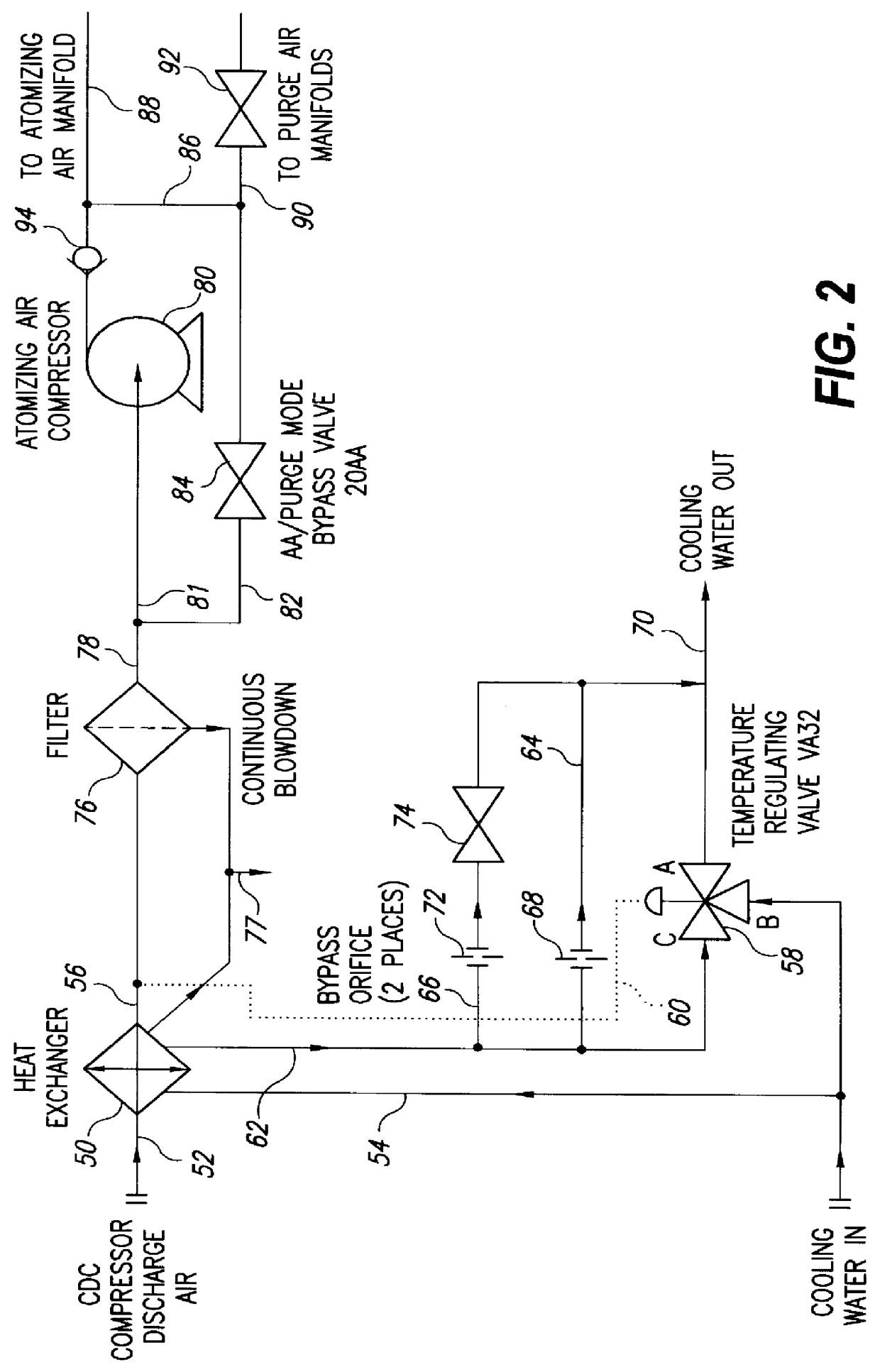

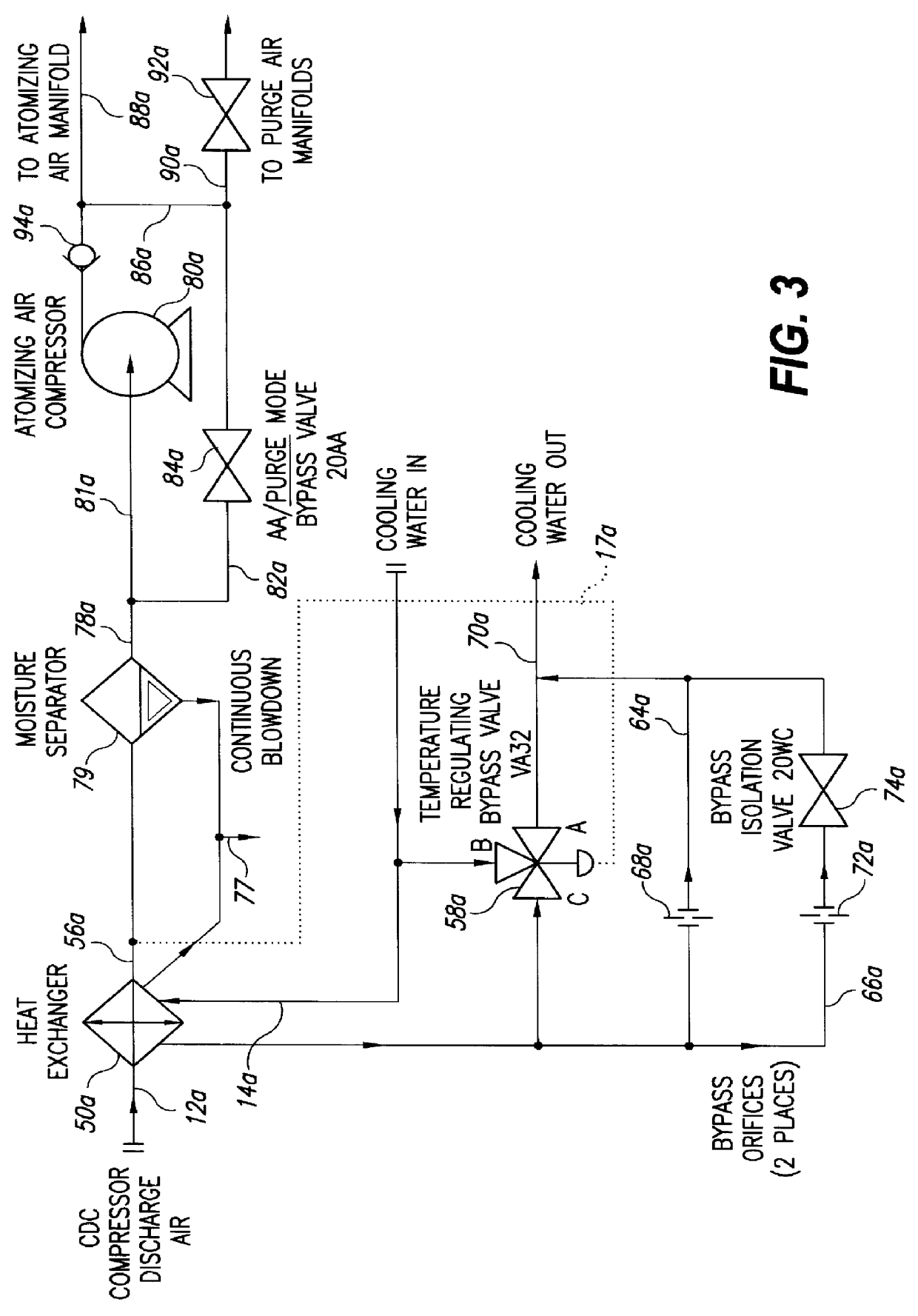

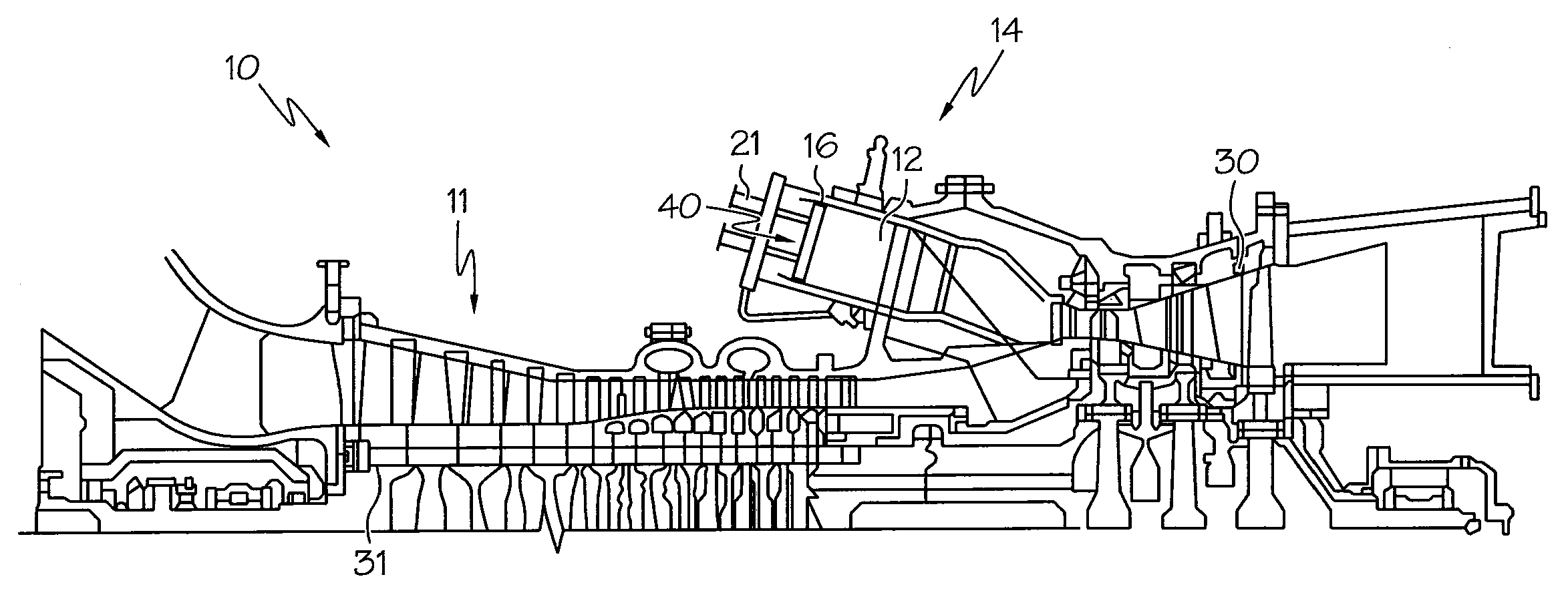

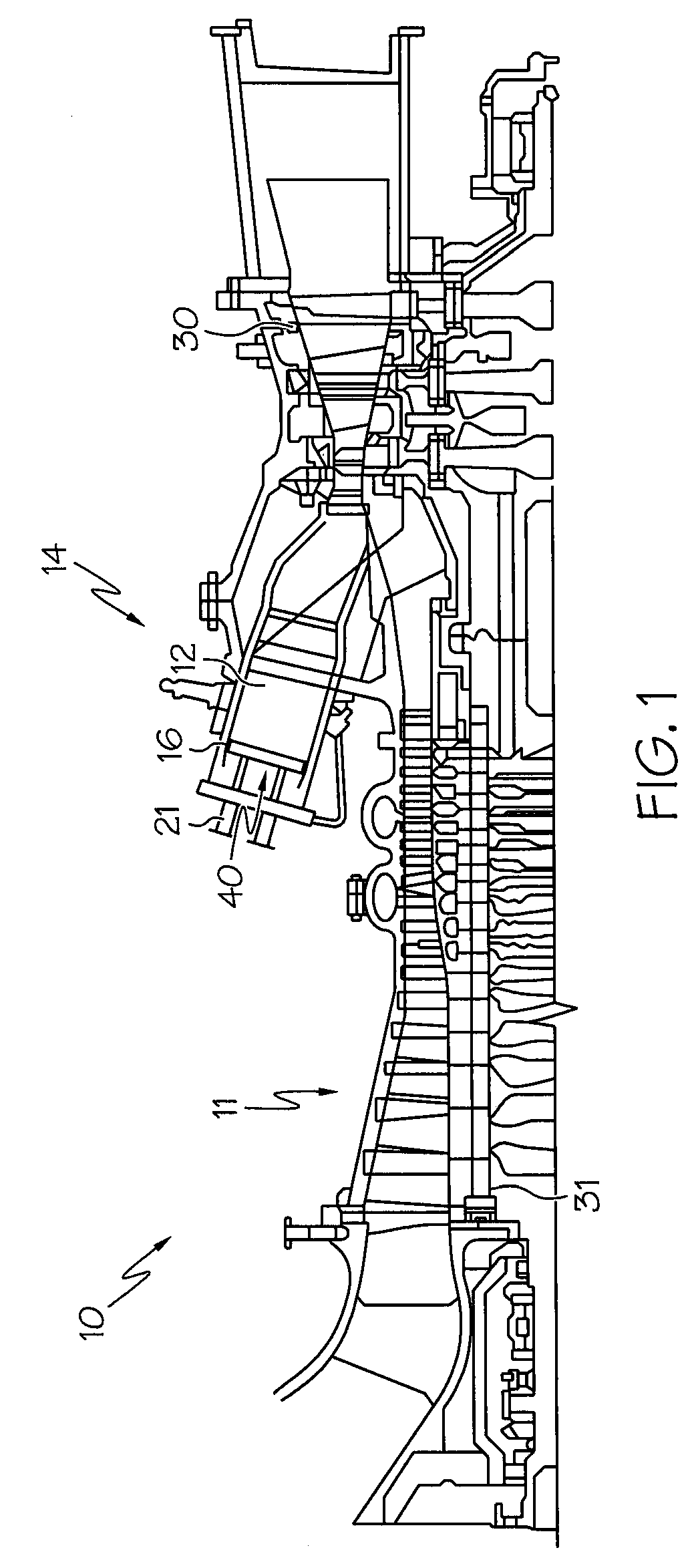

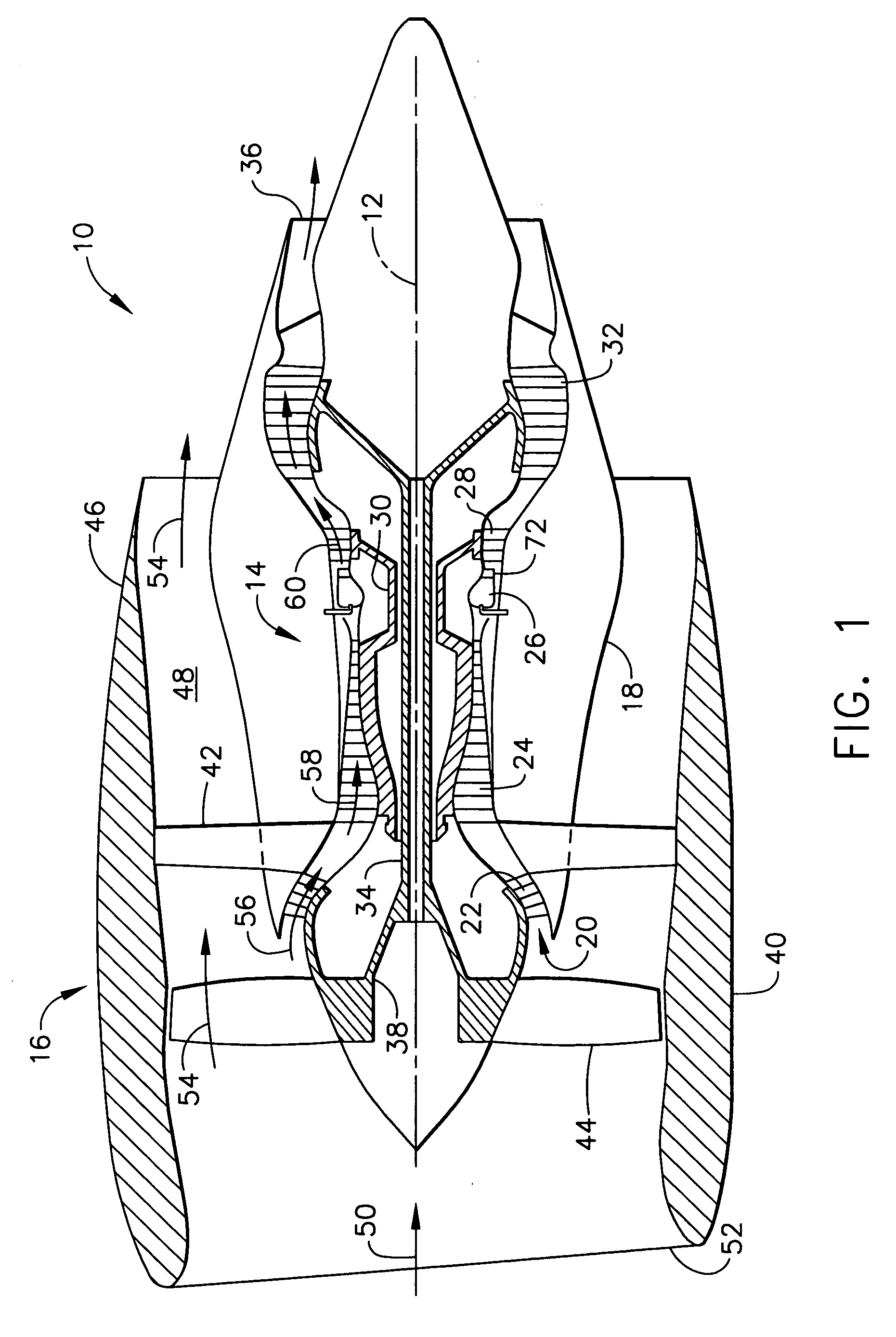

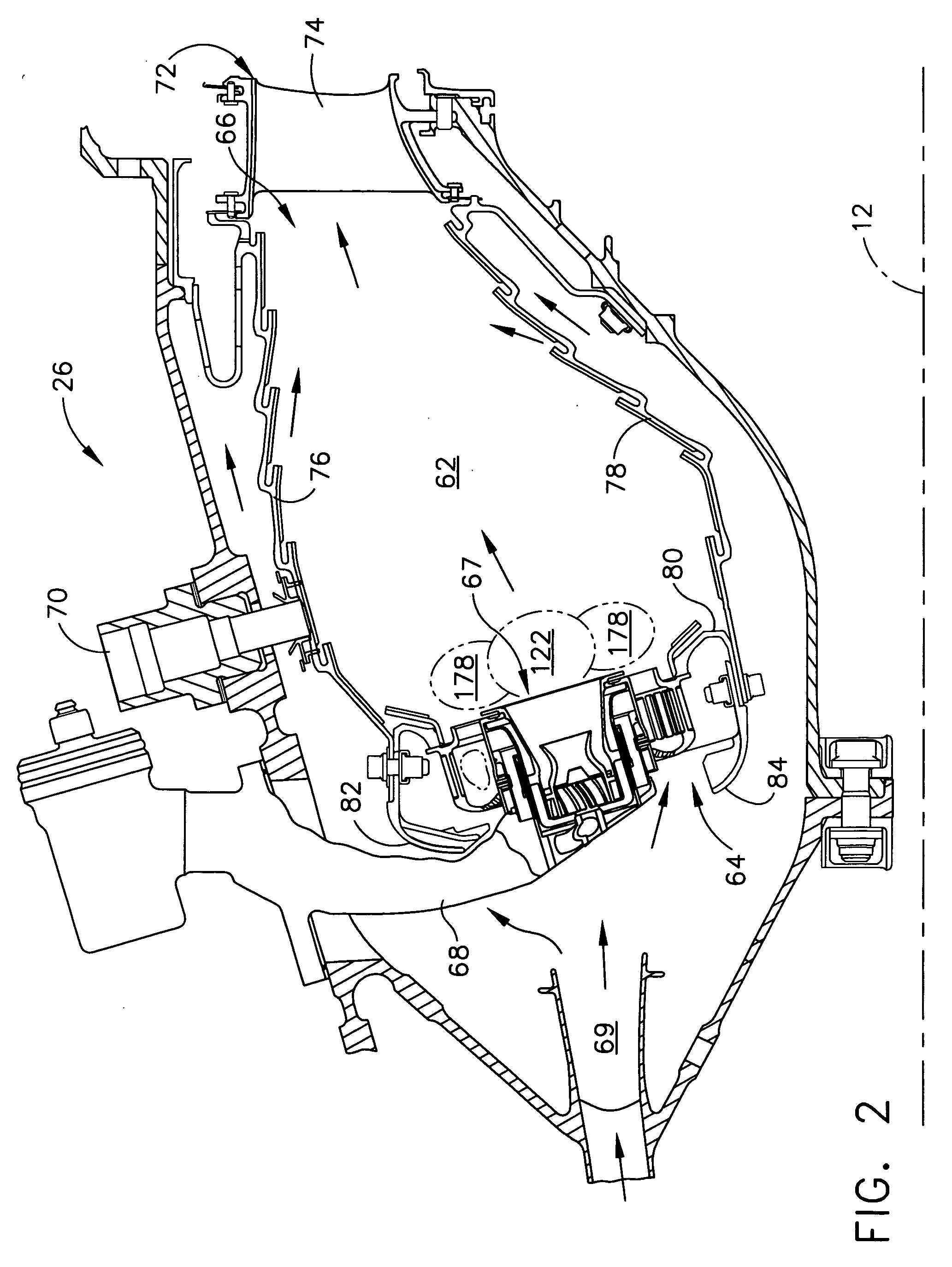

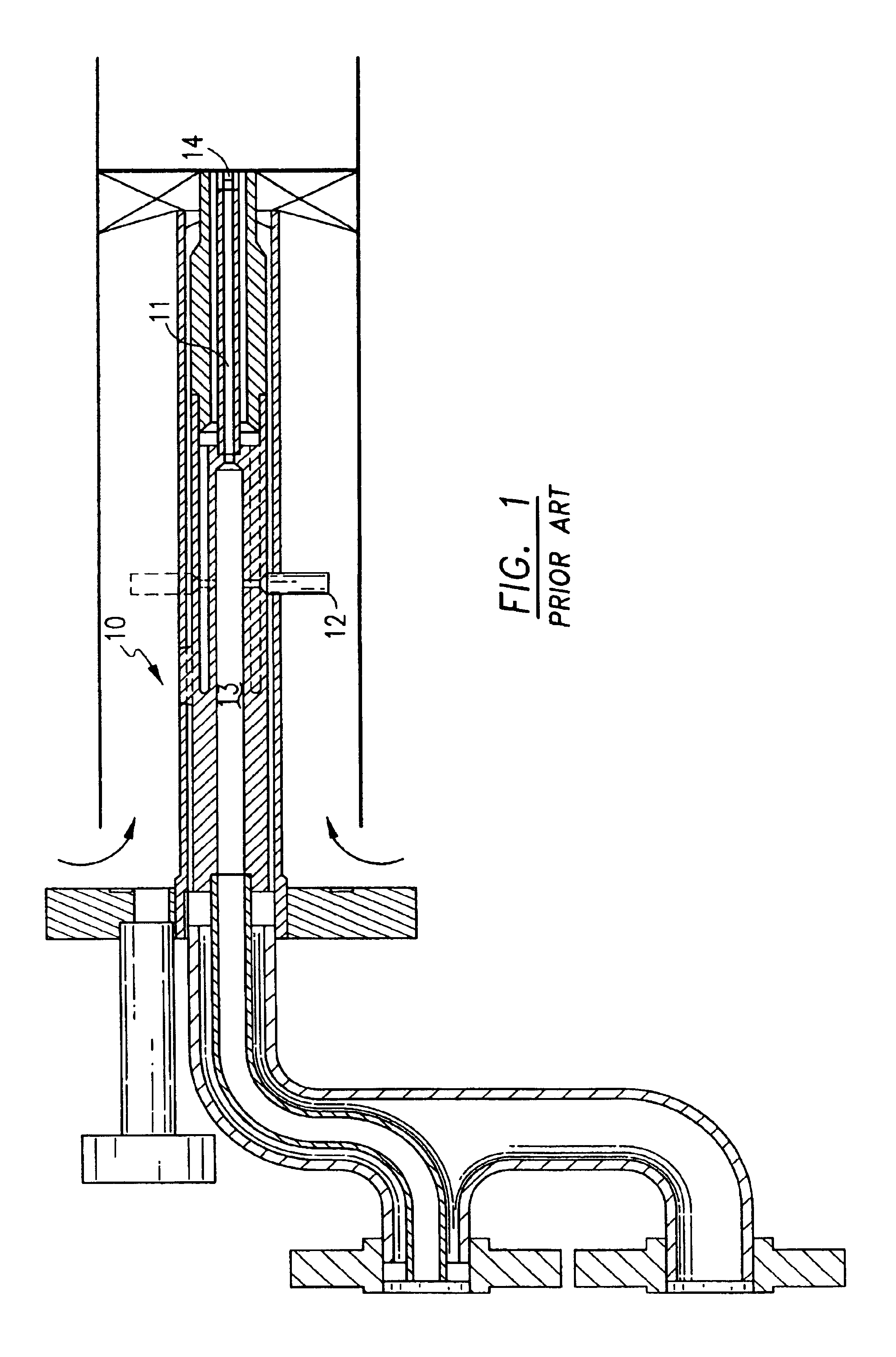

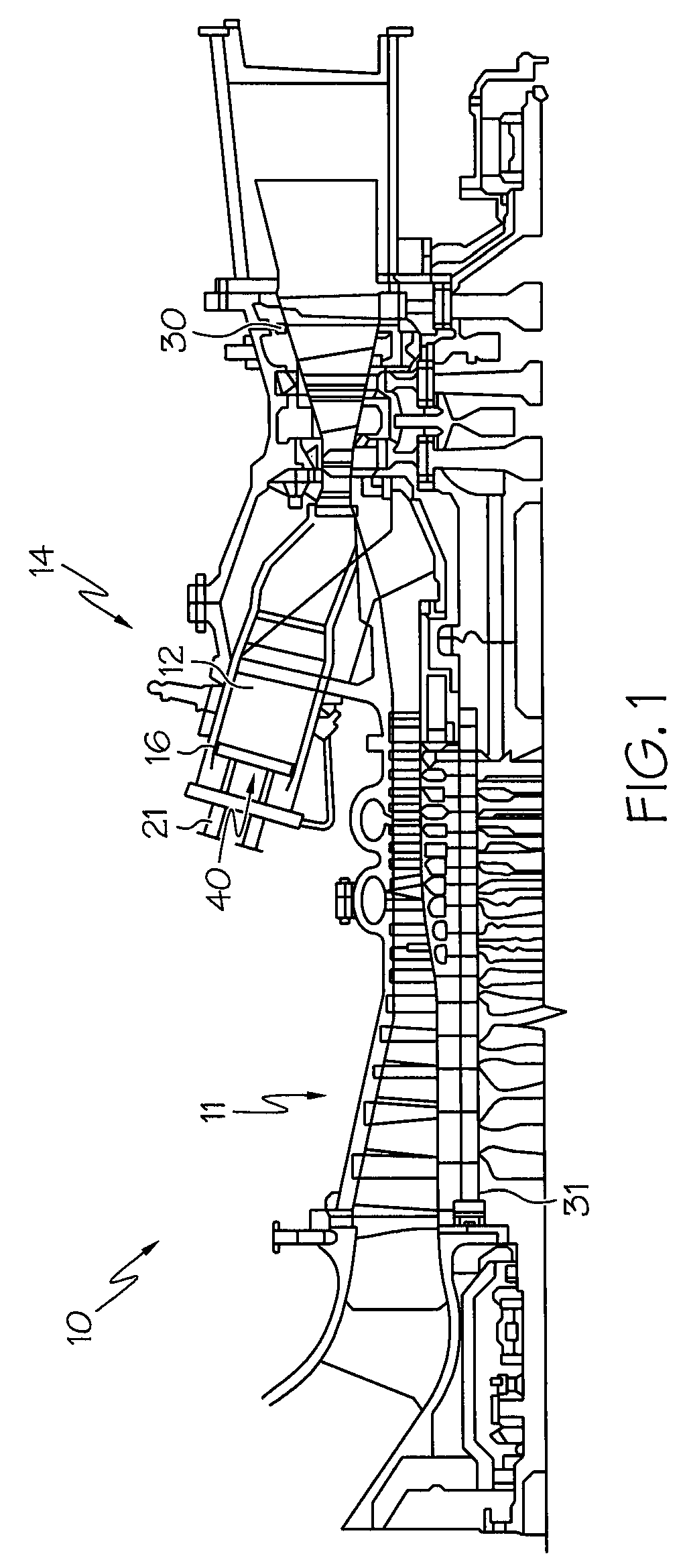

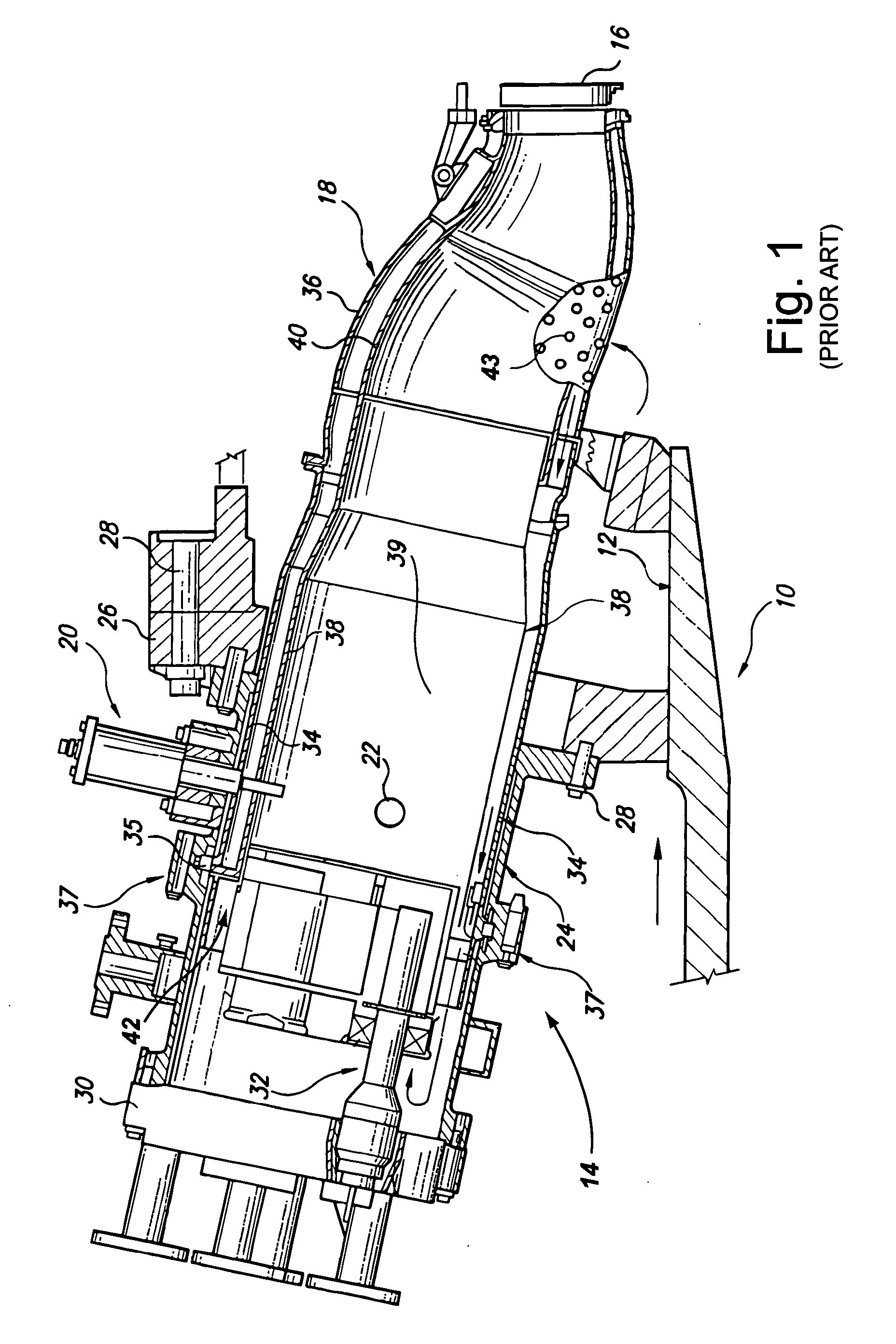

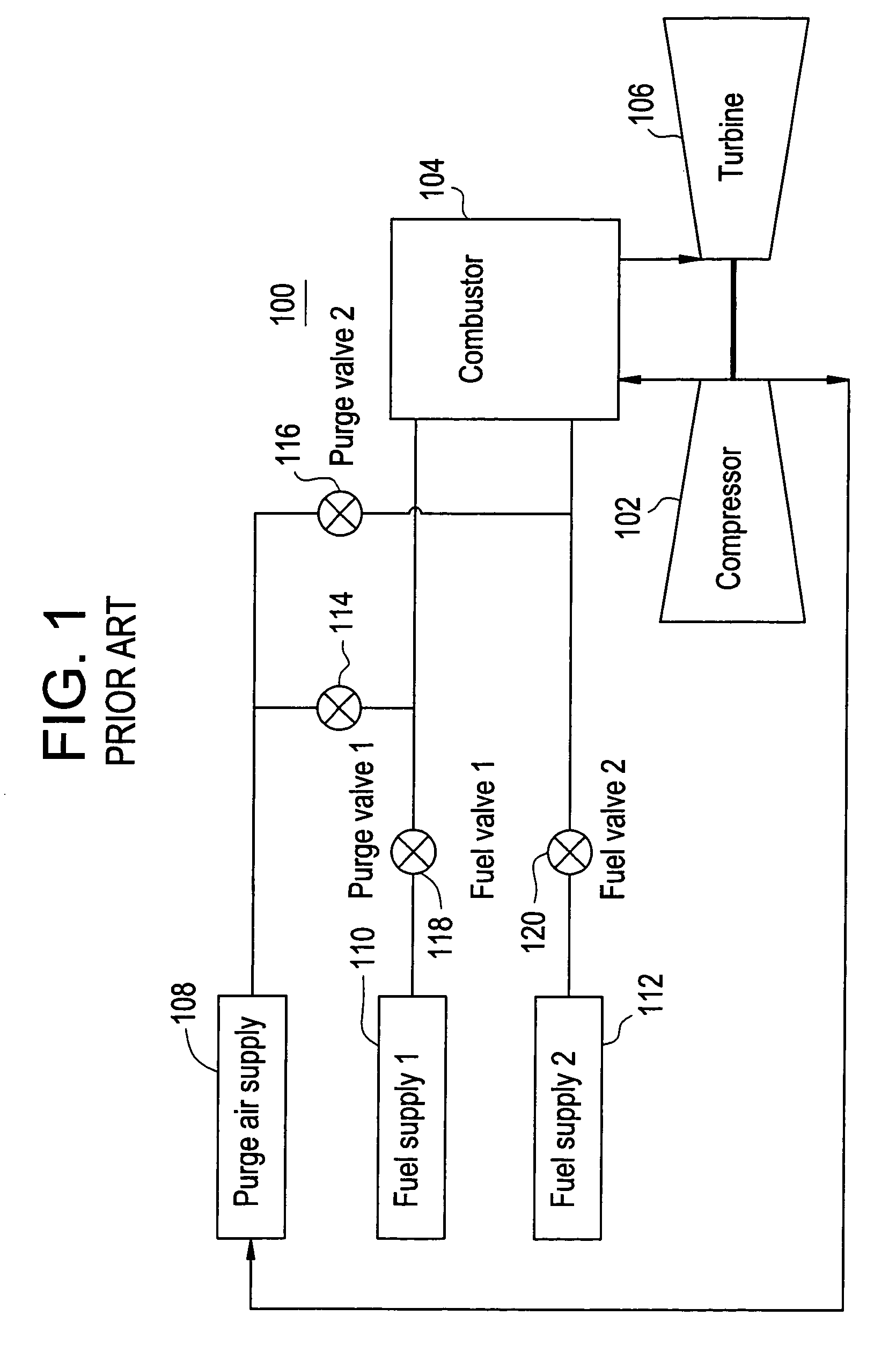

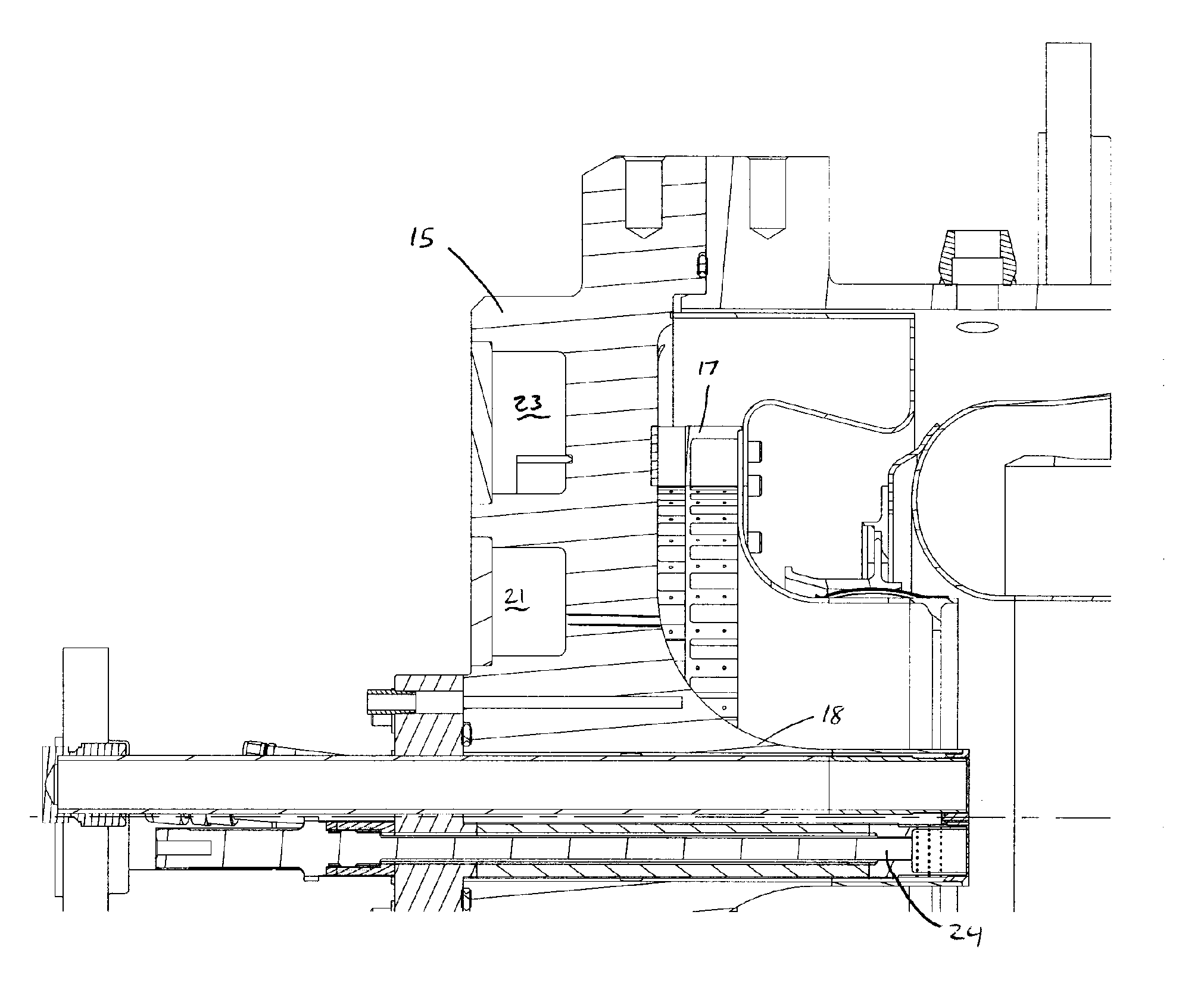

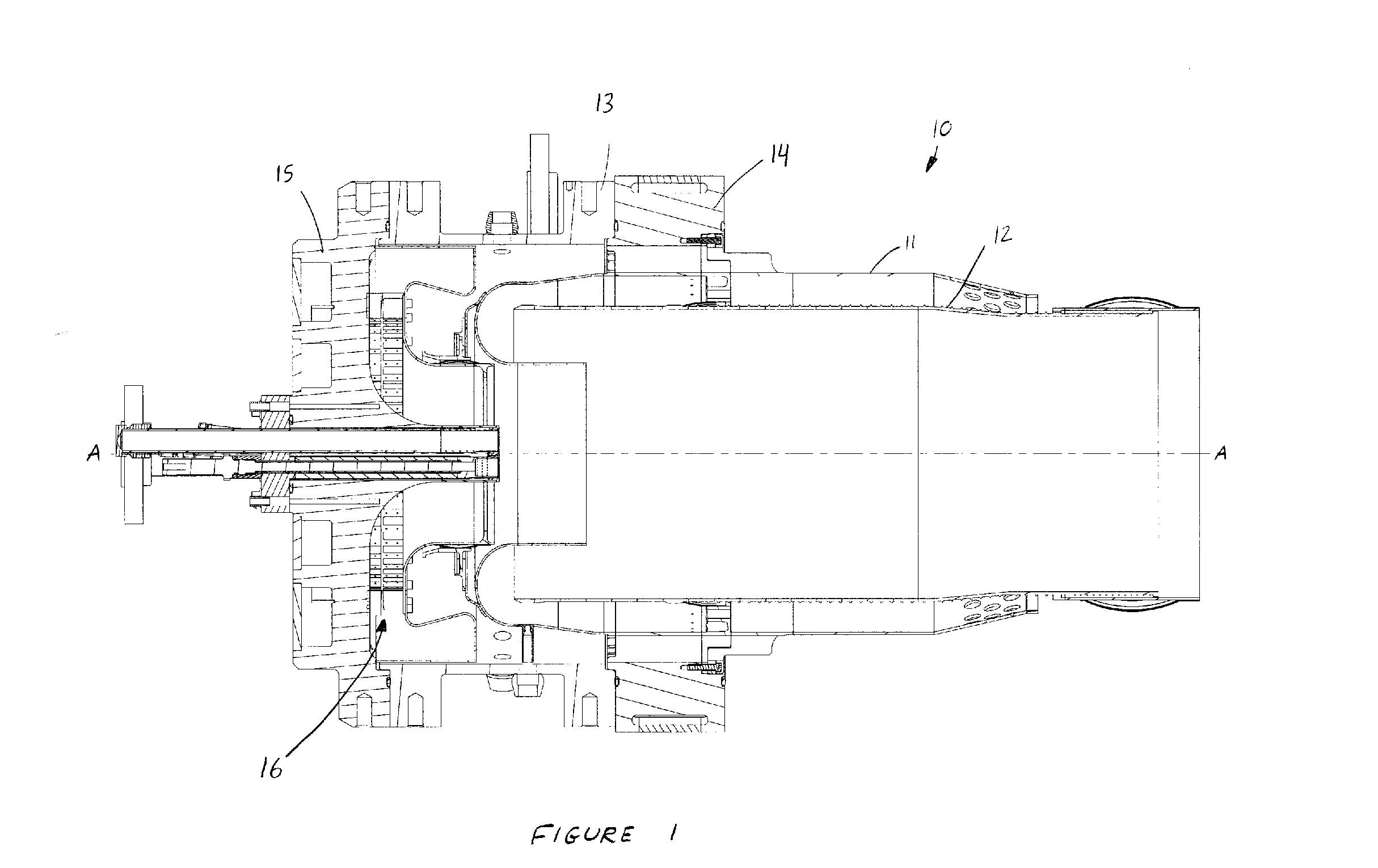

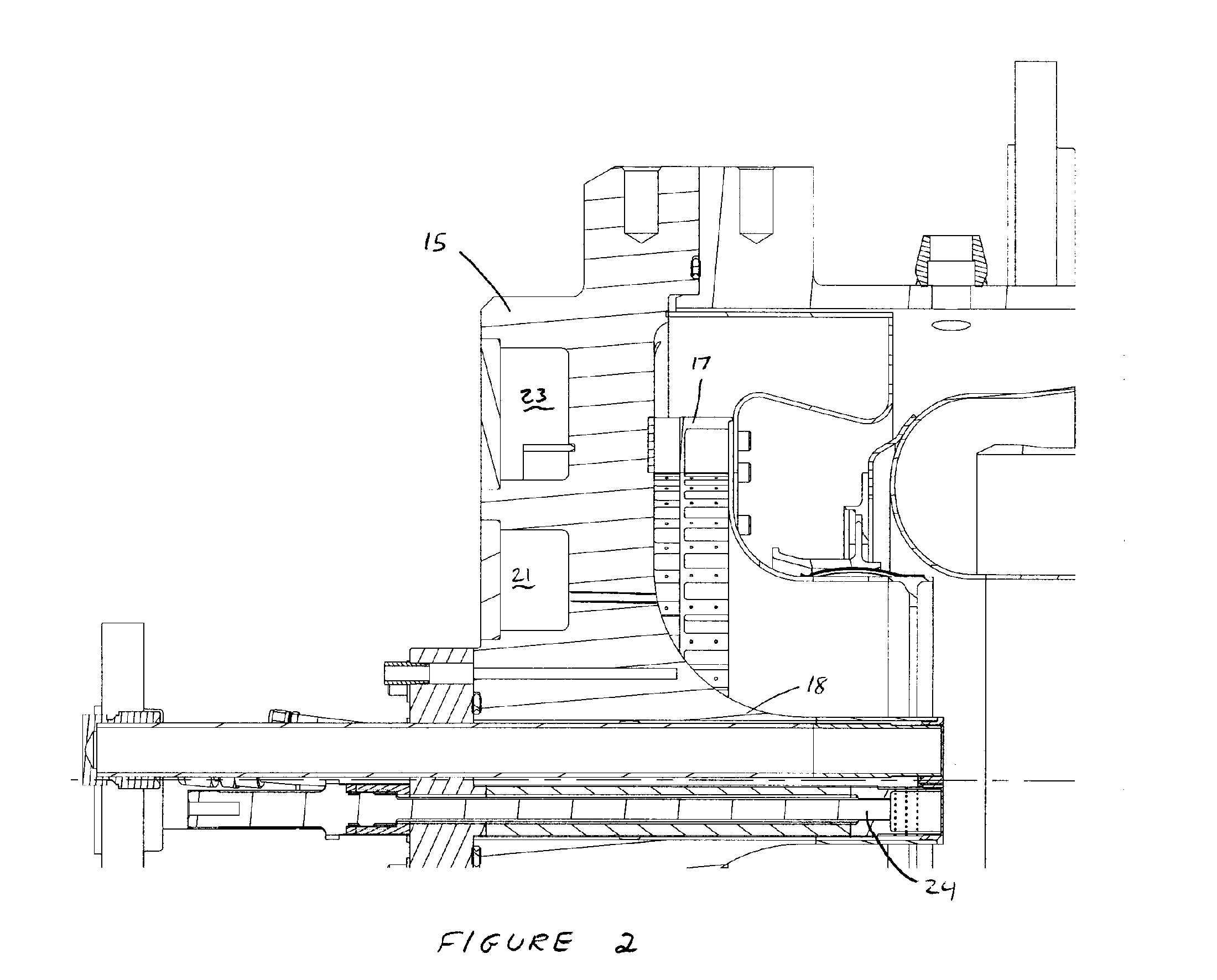

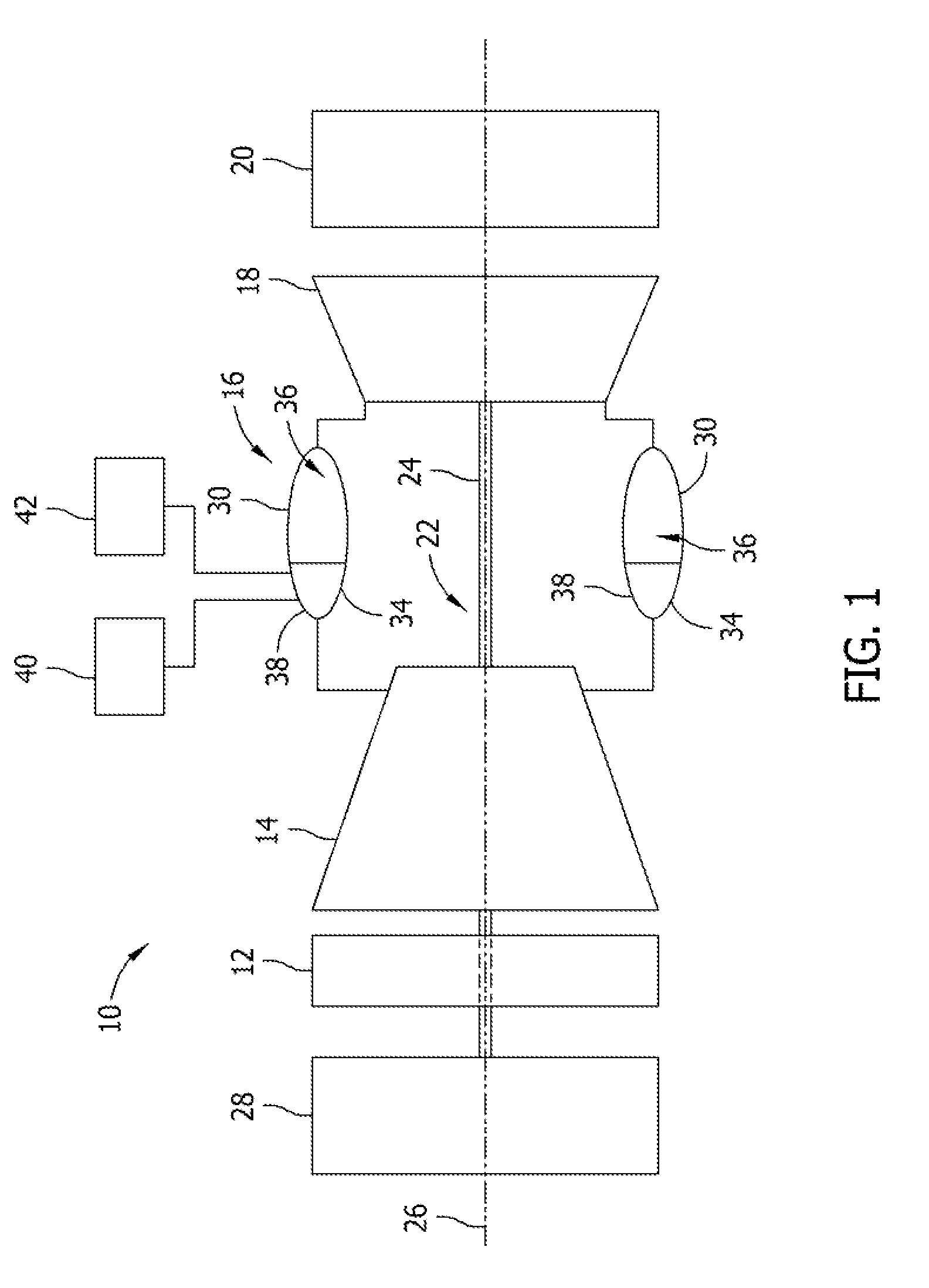

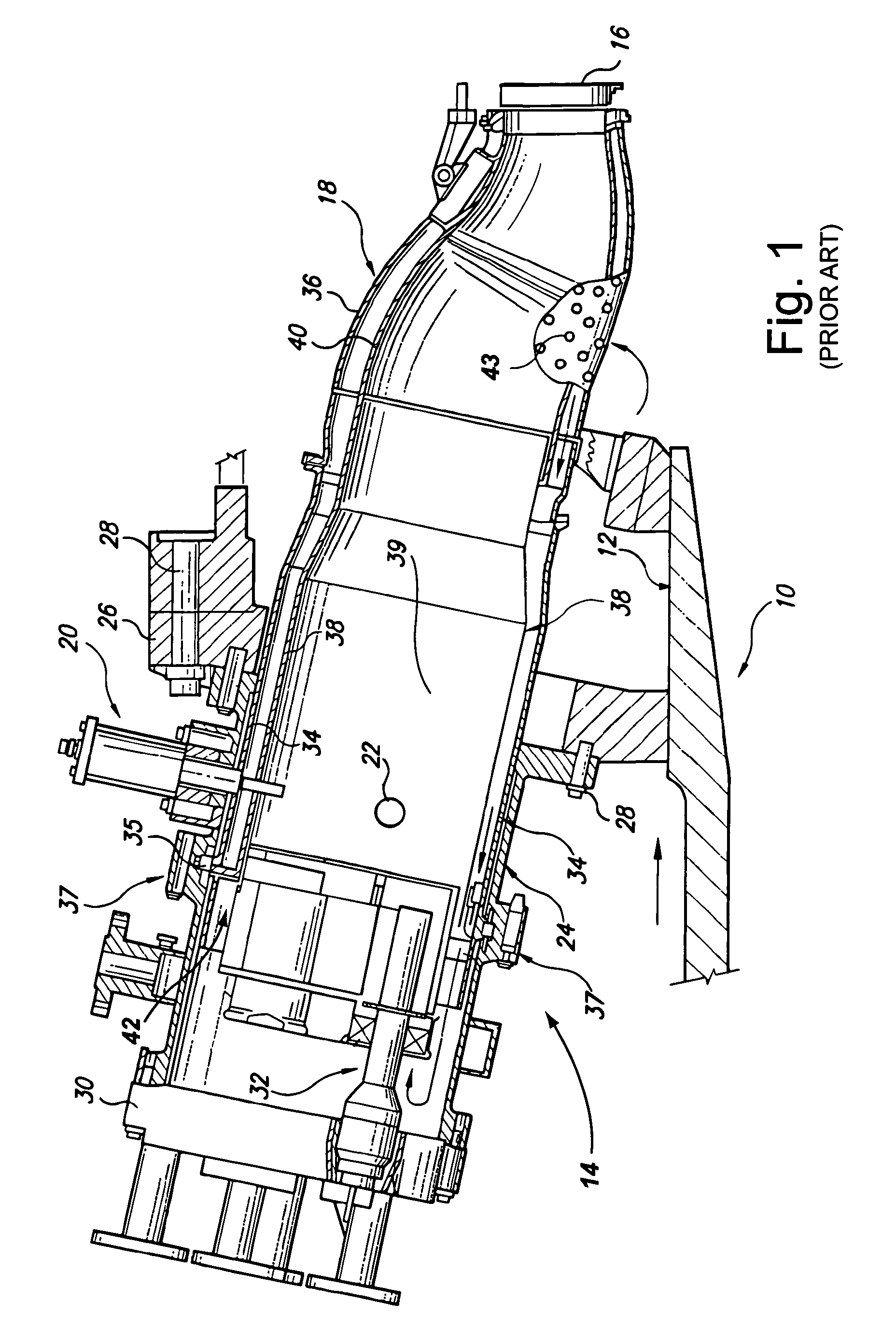

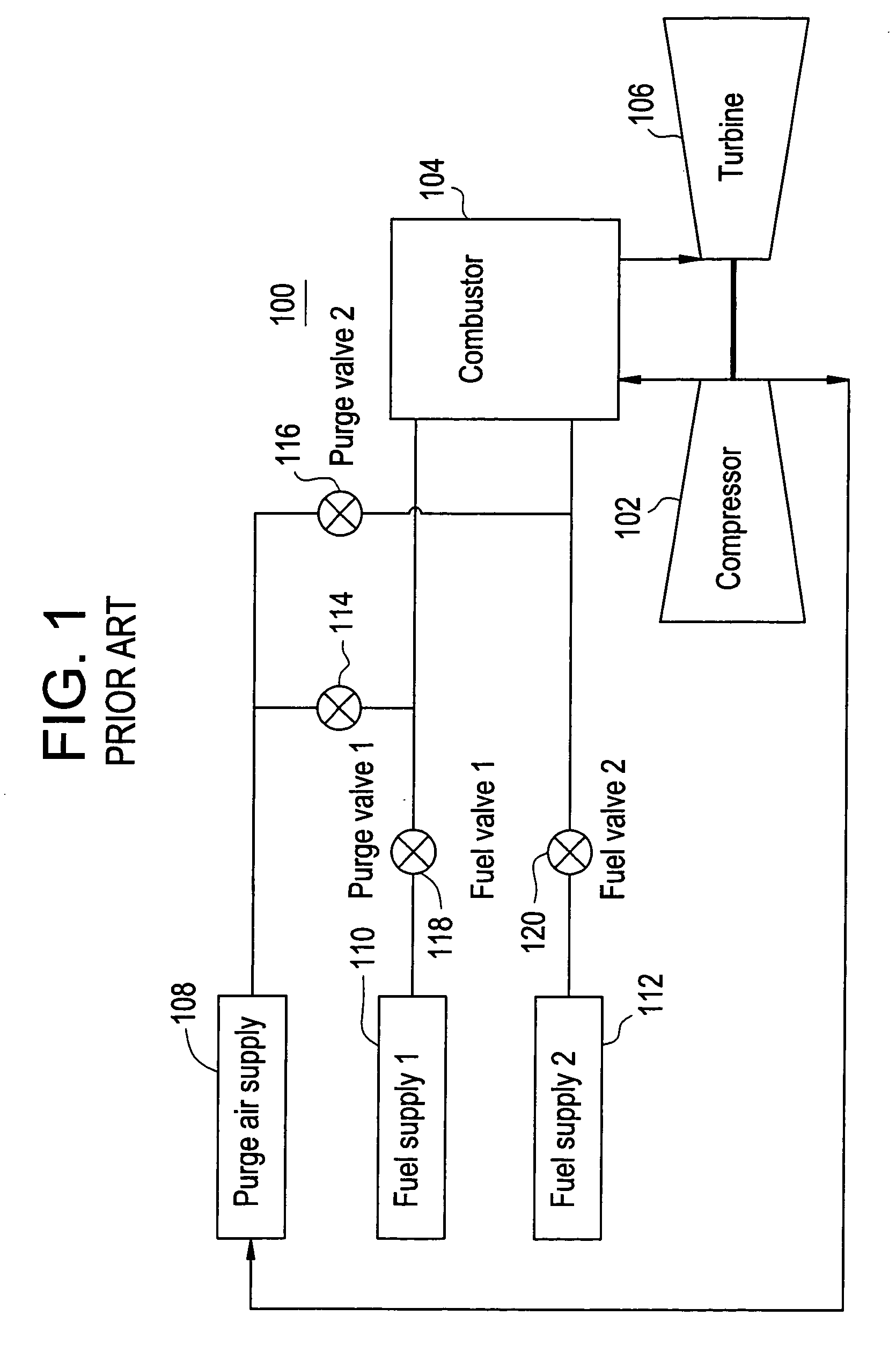

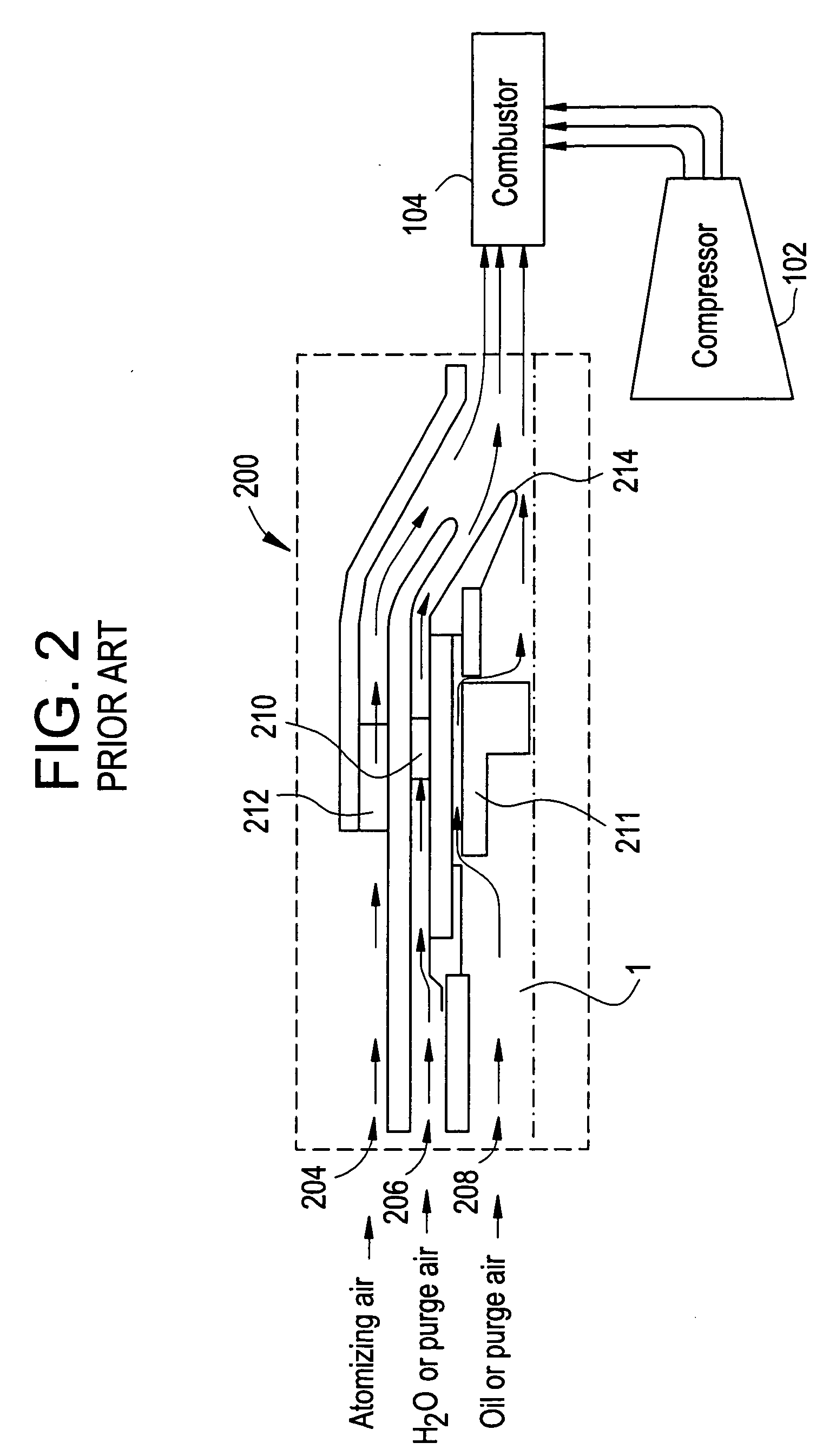

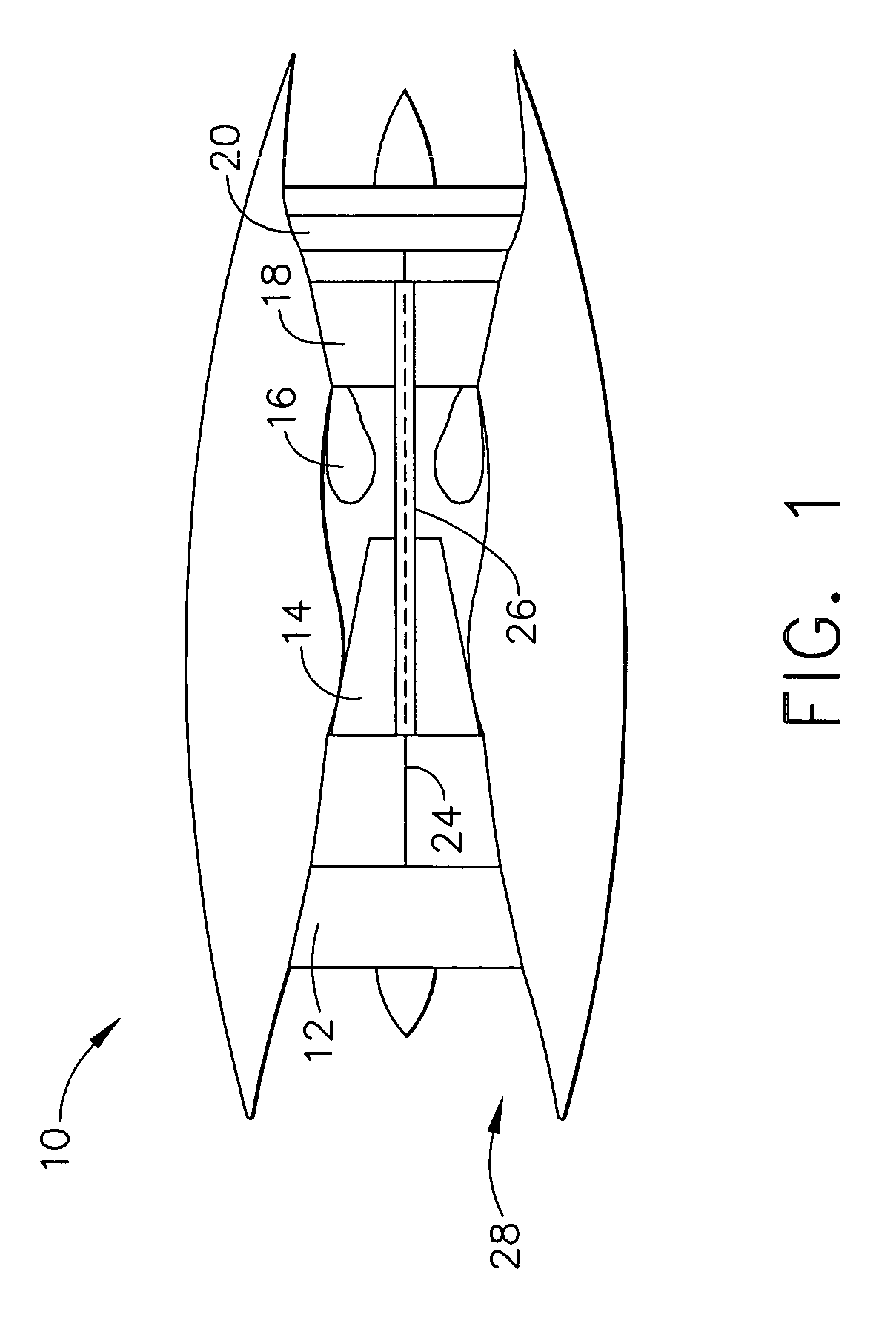

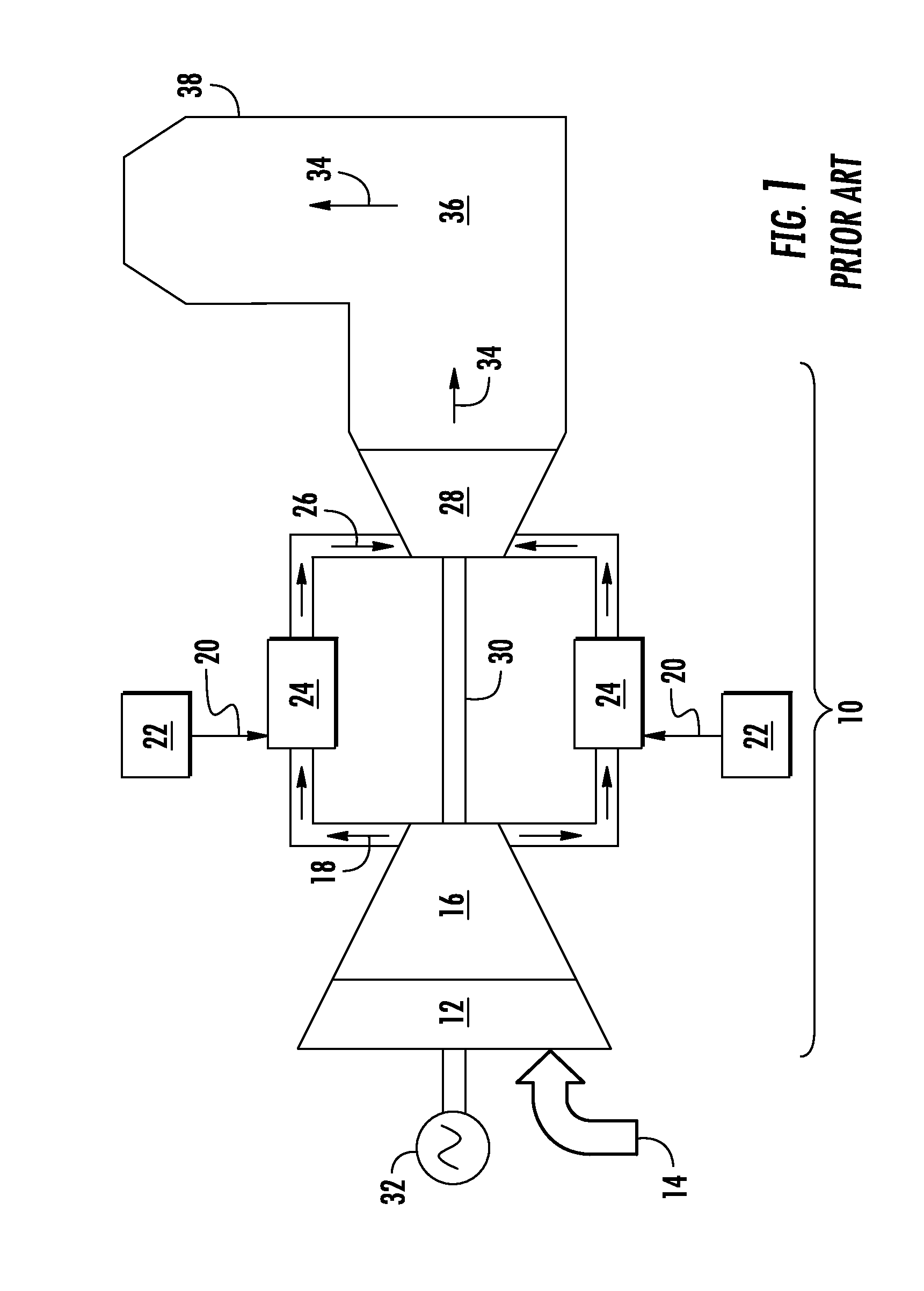

Dual orifice bypass system for dual-fuel gas turbine

InactiveUS6145318AReduce trafficAvoid heat buildupBurner safety arrangementsBurnersCombustorHeat rejection

Compressor discharge air flows through a heat exchanger in heat exchange relation with cooling water and is supplied at reduced temperature in atomizing air and purge modes to combustors in a dual-fuel gas turbine. The heat exchanger has a pair of bypass passages in parallel with a temperature regulating valve controlling flow of water through the heat exchanger in response to the temperature of the compressor discharge air exiting the heat exchanger. Should the flow control valve close in response to low temperature of the compressor discharge air, in the air atomizing mode, the bypass passages with orifices therein provide a minimum protective flow of cooling water to the heat exchanger. In the purge mode where only half the air flow and heat rejection is required in the heat exchanger and the flow control valve closes, a bypass valve in one of the bypass passages closes to enable reduced flow of cooling water through the heat exchanger.

Owner:GENERAL ELECTRIC CO

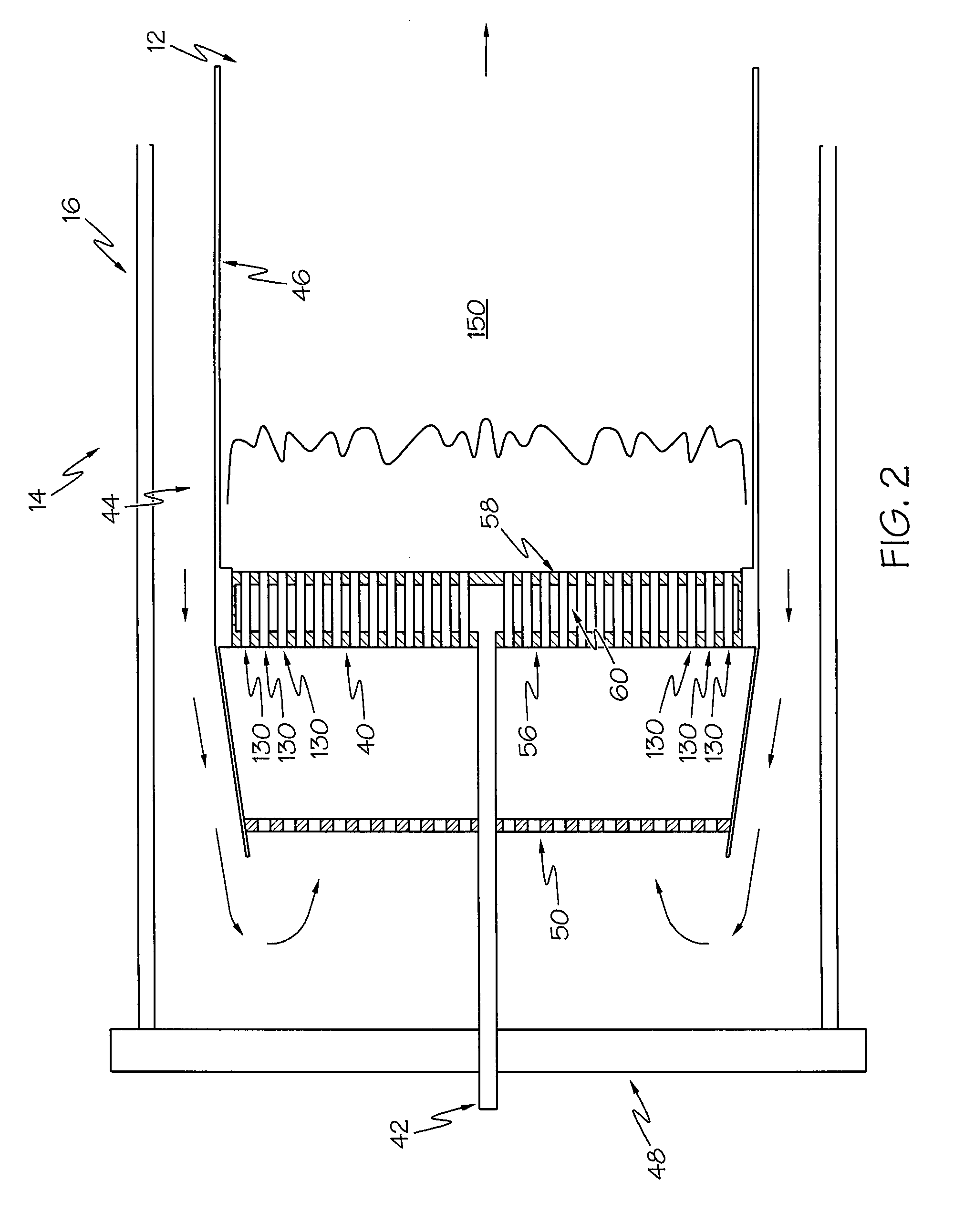

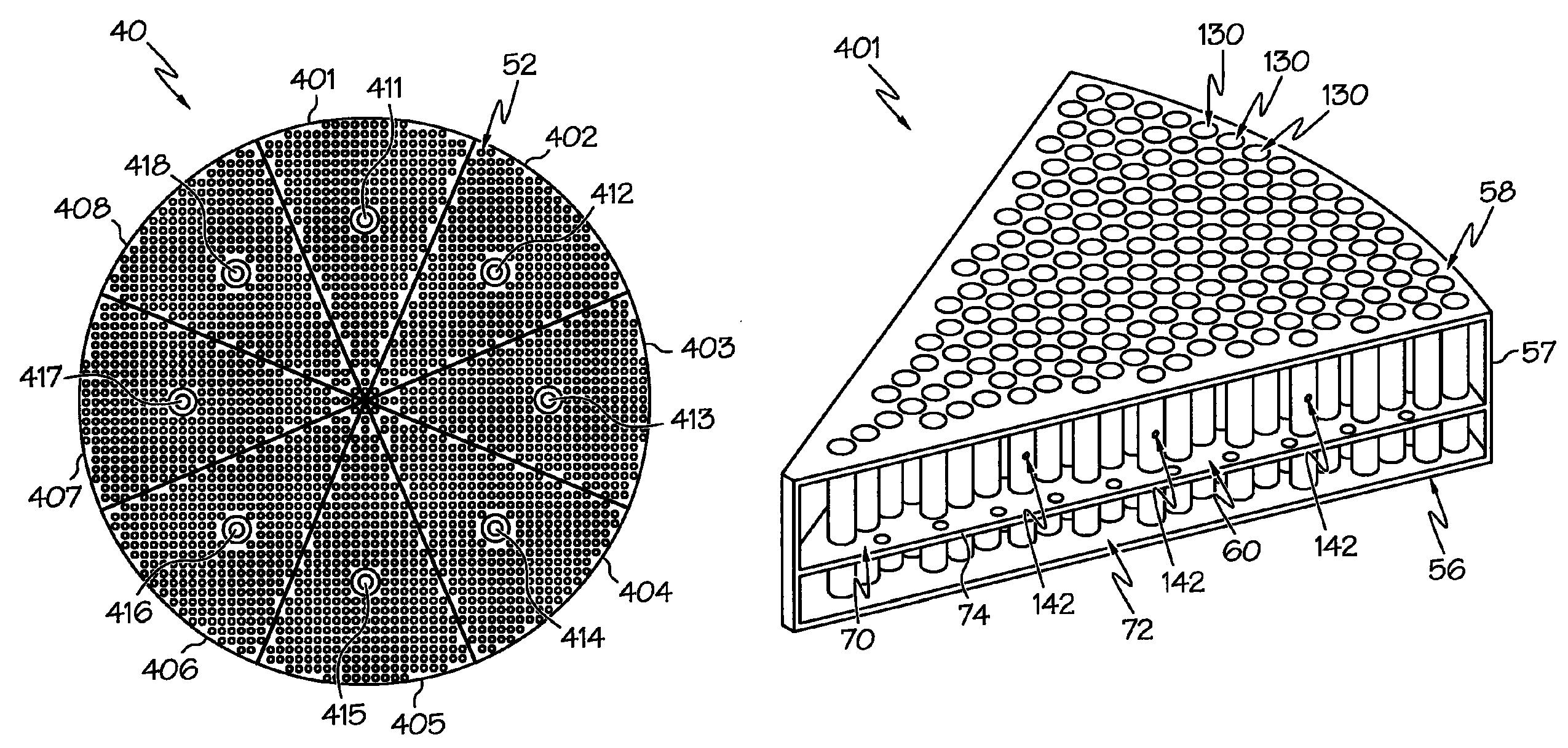

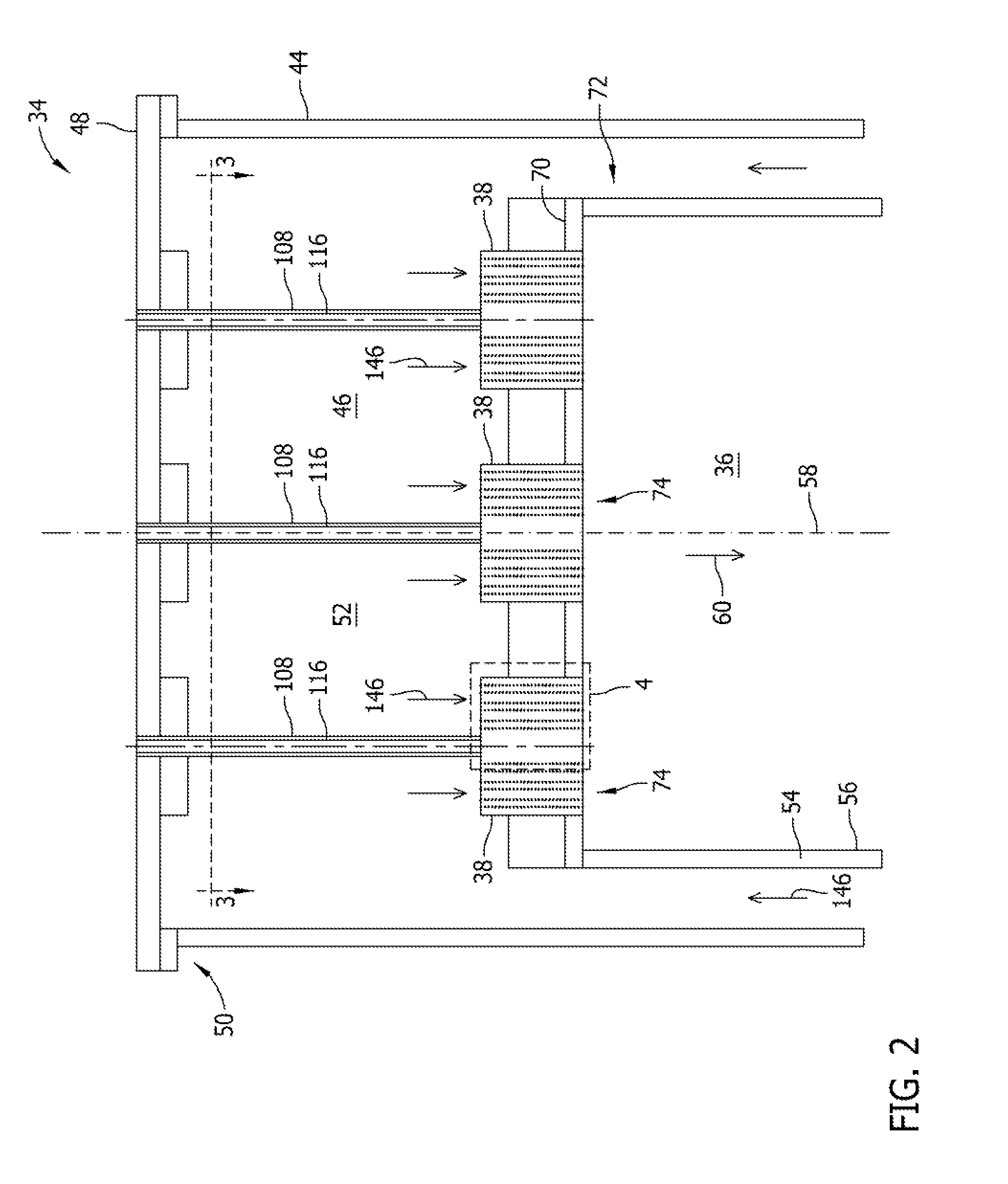

Premixed direct injection disk

ActiveUS20100218501A1Reduce riskAir mix wellBurner safety arrangementsContinuous combustion chamberCombustorEngineering

A fuel / air mixing disk for use in a fuel / air mixing combustor assembly is provided. The disk includes a first face, a second face, and at least one fuel plenum disposed therebetween. A plurality of fuel / air mixing tubes extend through the pre-mixing disk, each mixing tube including an outer tube wall extending axially along a tube axis and in fluid communication with the at least one fuel plenum. At least a portion of the plurality of fuel / air mixing tubes further includes at least one fuel injection hole have a fuel injection hole diameter extending through said outer tube wall, the fuel injection hole having an injection angle relative to the tube axis. The invention provides good fuel air mixing with low combustion generated NOx and low flow pressure loss translating to a high gas turbine efficiency, that is durable, and resistant to flame holding and flash back.

Owner:GENERAL ELECTRIC CO

Swirling flashback arrestor

InactiveUS6179608B1Performance maximizationPipeline systemsGaseous fuel burnerEngineeringGas turbines

A structure is disclosed that will quench a flame front during a flashback event in a gas turbine while simultaneously providing a mixing function during normal operations. The device disclosed consists of two monoliths one upstream of the other. In the basic embodiment of the invention the downstream monolith acts as a mixer while the combination of the upstream monolith and the downstream monolith act as the flashback arrestor. Other embodiments of the device also allow the downstream monolith to be a flameholder.

Owner:PRECISION COMBUSTION

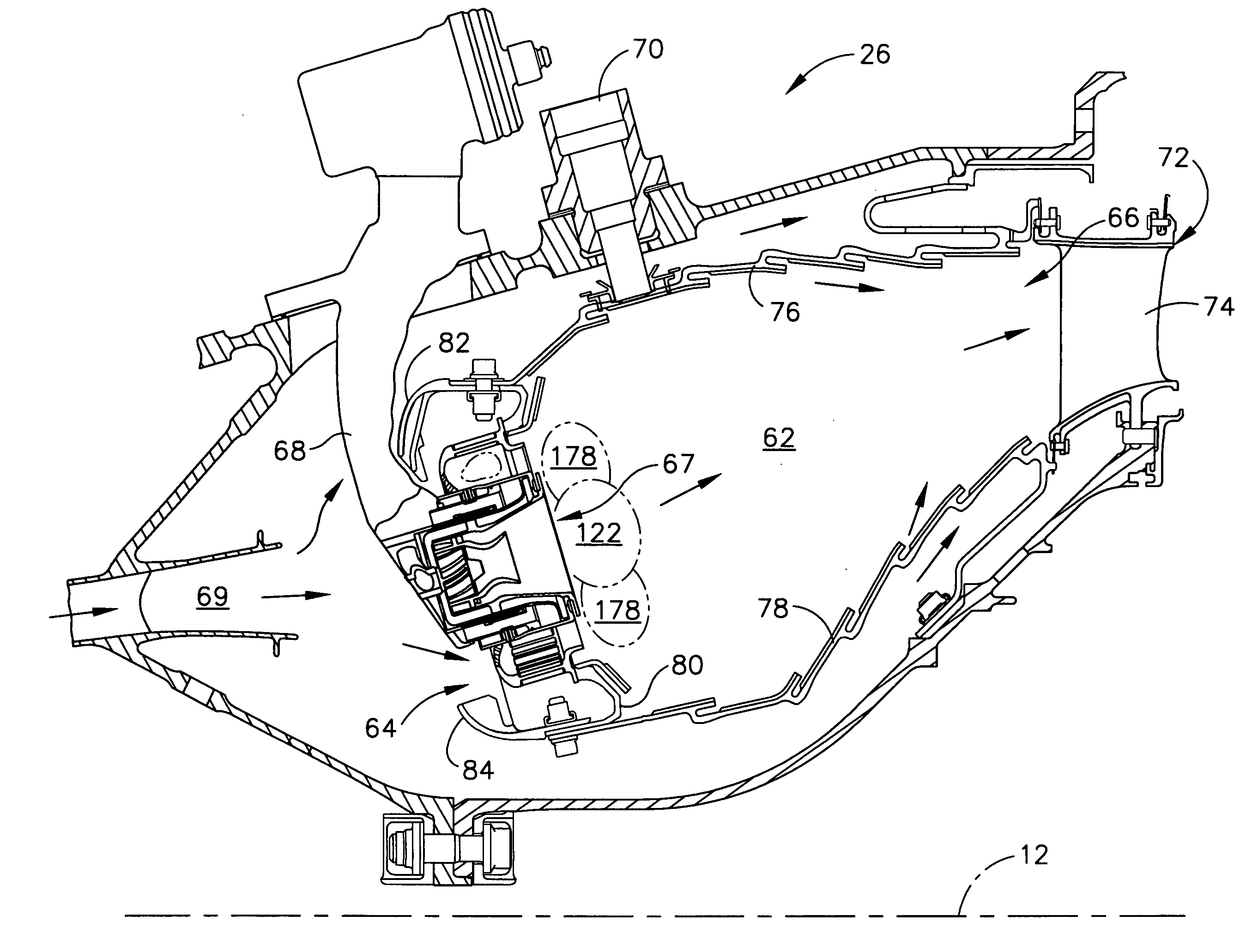

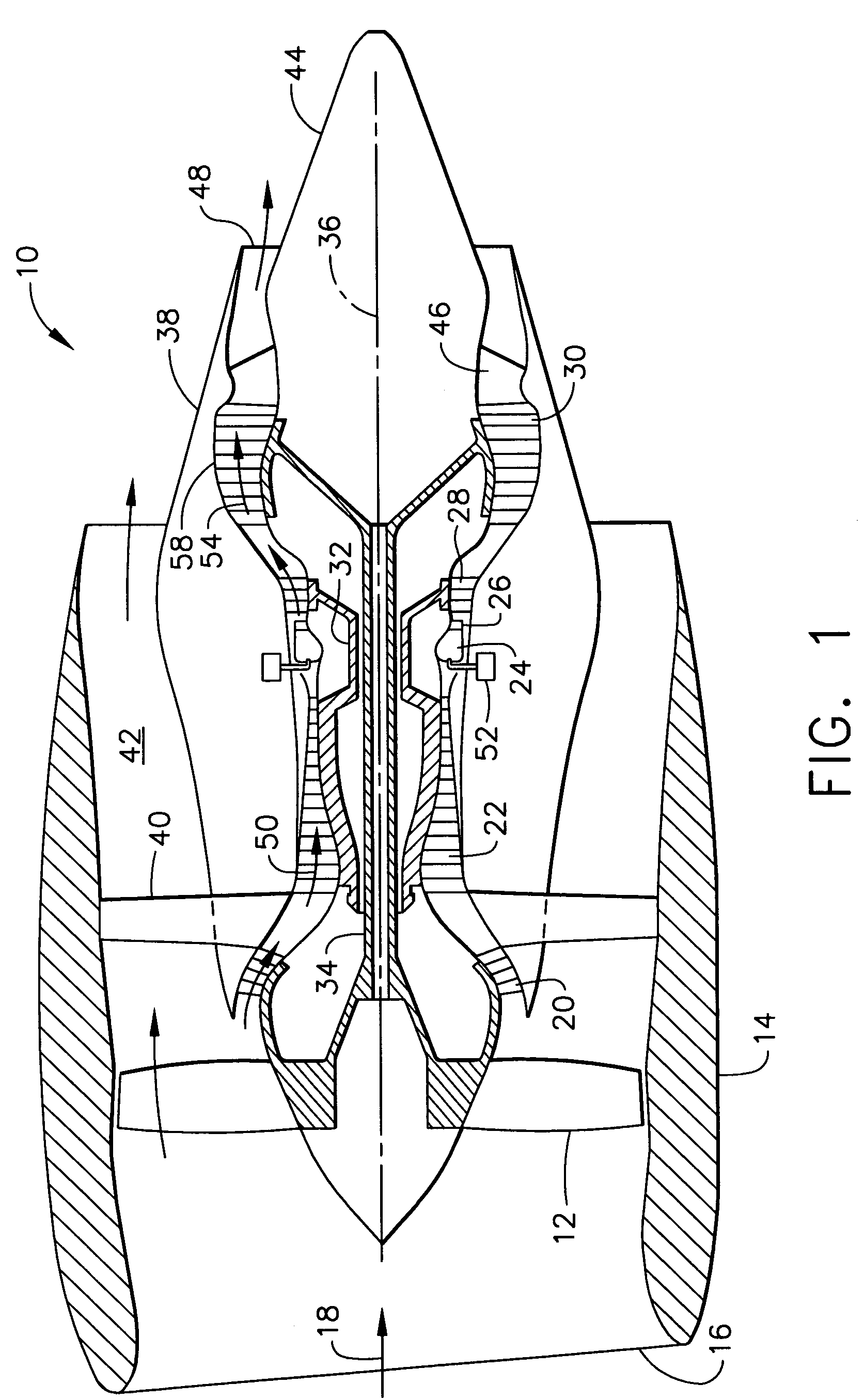

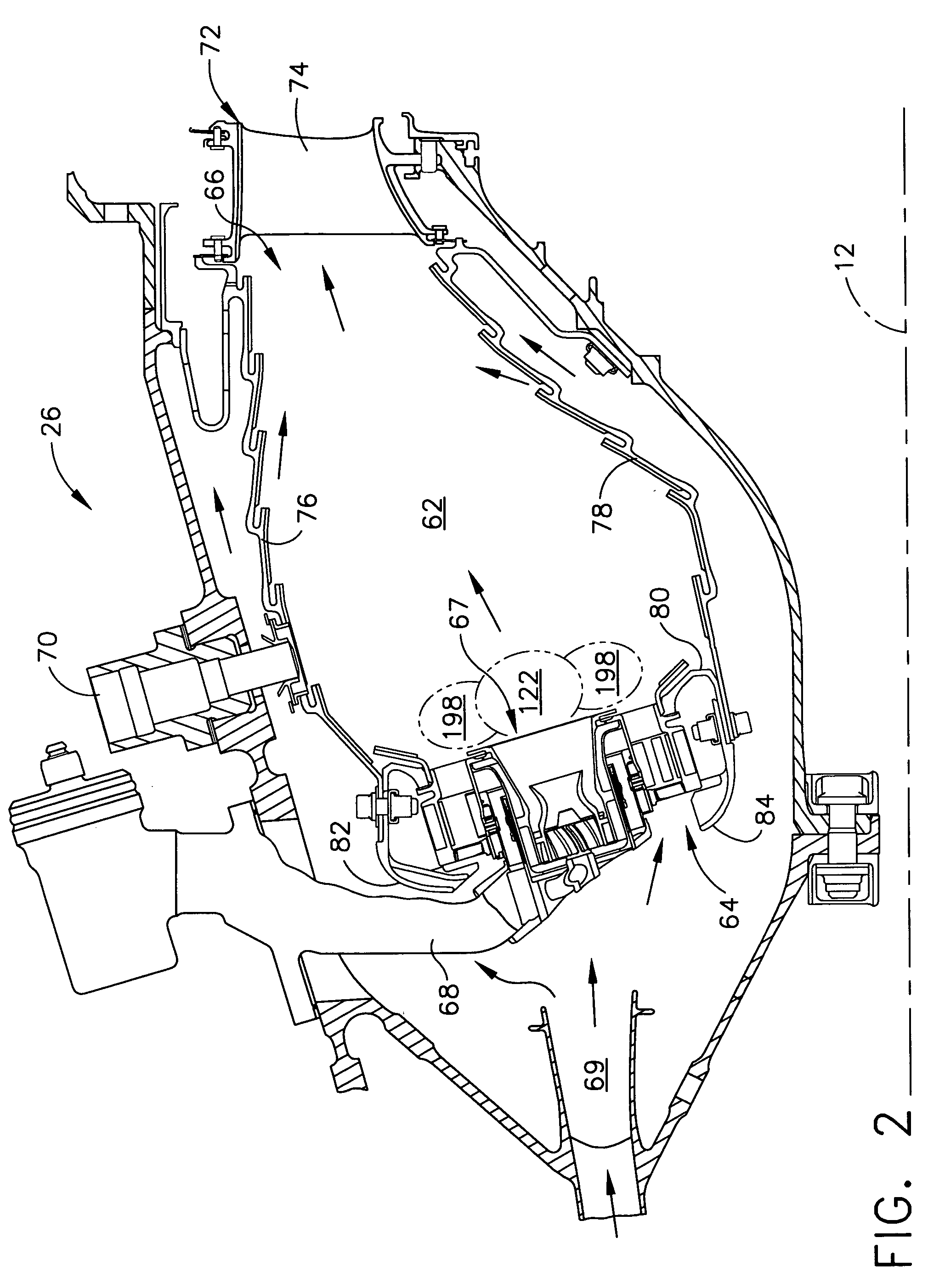

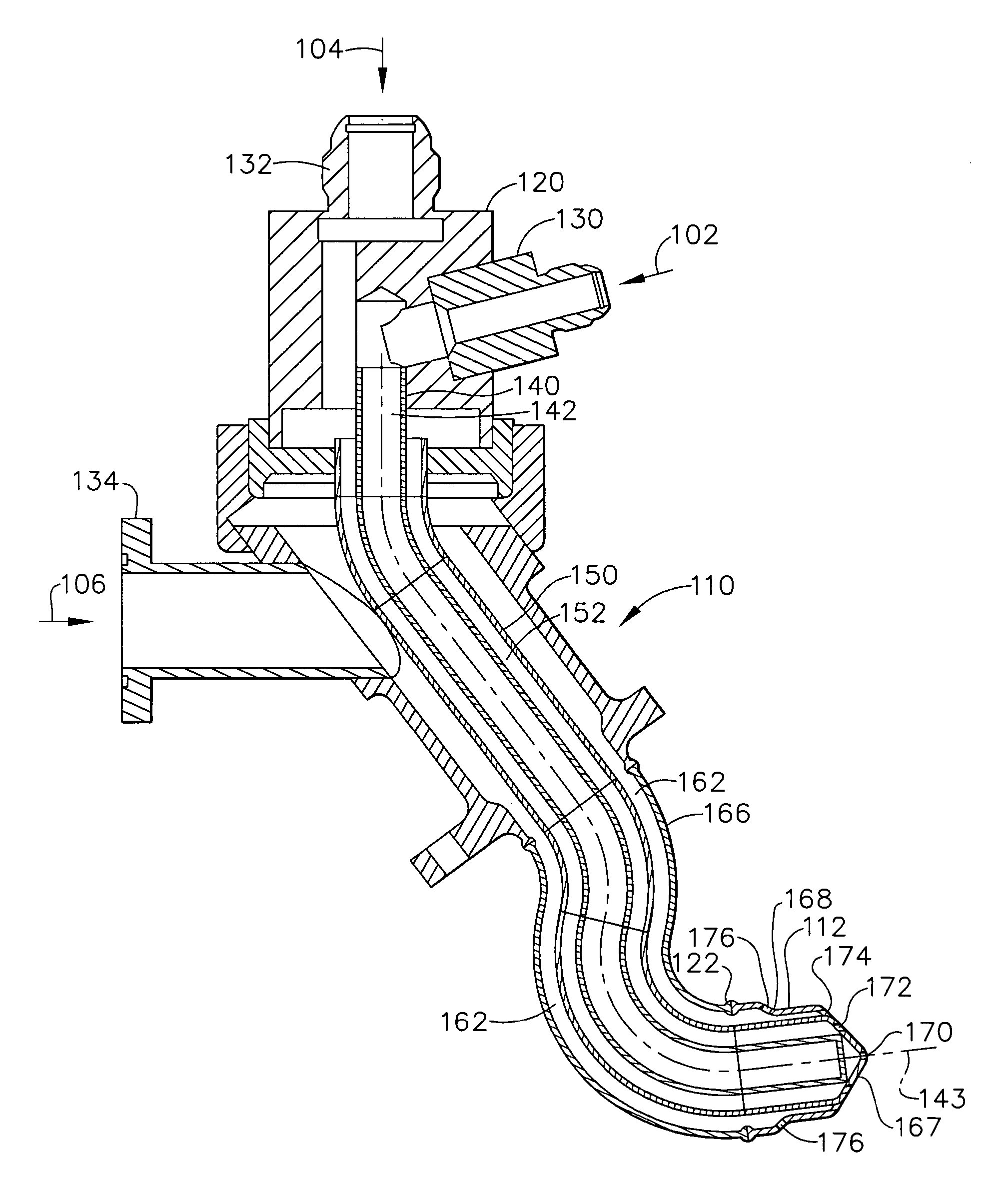

Mixer assembly for combustor of a gas turbine engine having a main mixer with improved fuel penetration

A mixer assembly for use in a combustion chamber of a gas turbine engine includes a pilot mixer, a main mixer, and a fuel manifold positioned between the pilot mixer and main mixer. The pilot mixer includes an annular pilot housing having a hollow interior and a pilot fuel nozzle mounted in the housing and adapted for dispensing droplets of fuel to the hollow interior of the pilot housing. The main mixer includes: a main housing surrounding the pilot housing and defining an annular cavity having an upstream end and a downstream end including an upstream wall, an outer wall and an inner wall; a plurality of fuel injection ports for introducing fuel into the cavity, with the fuel injection ports being circumferentially spaced at a designated axial location of the inner wall of the annular cavity; and a swirler arrangement including at least one swirler in flow communication with the annular cavity, the swirler being incorporated into the outer wall of the annular cavity and extending from an upstream end to a downstream end, wherein each swirler of the arrangement has a plurality of vanes for swirling air traveling through such swirler to mix air and the droplets of fuel dispensed by the fuel injection ports. The main housing further includes a first plurality of passages oriented to provide air jets in a substantially axial direction into the annular cavity and a second plurality of passages oriented to provide air jets in a substantially radial direction into the annular cavity

Owner:GENERAL ELECTRIC CO

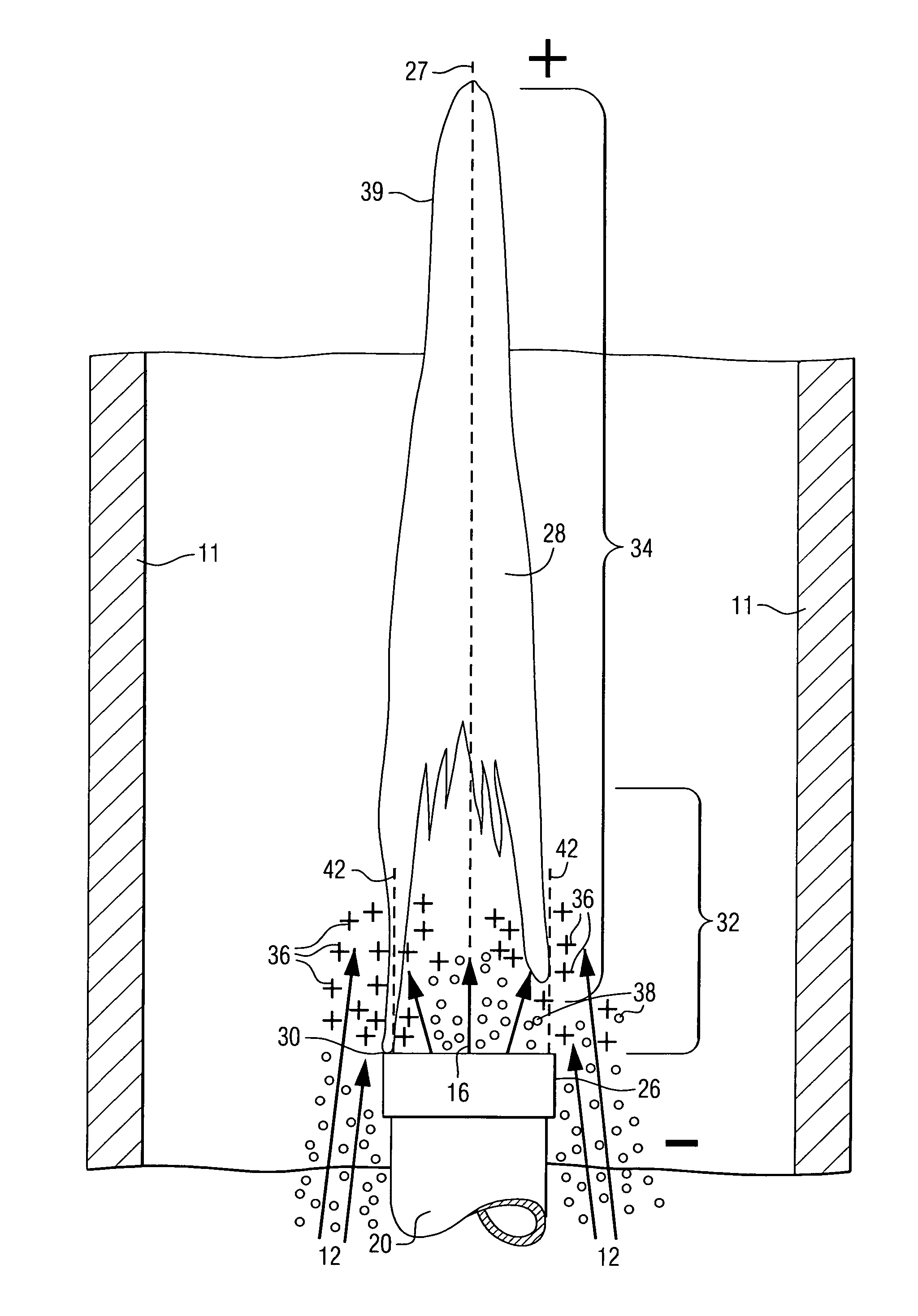

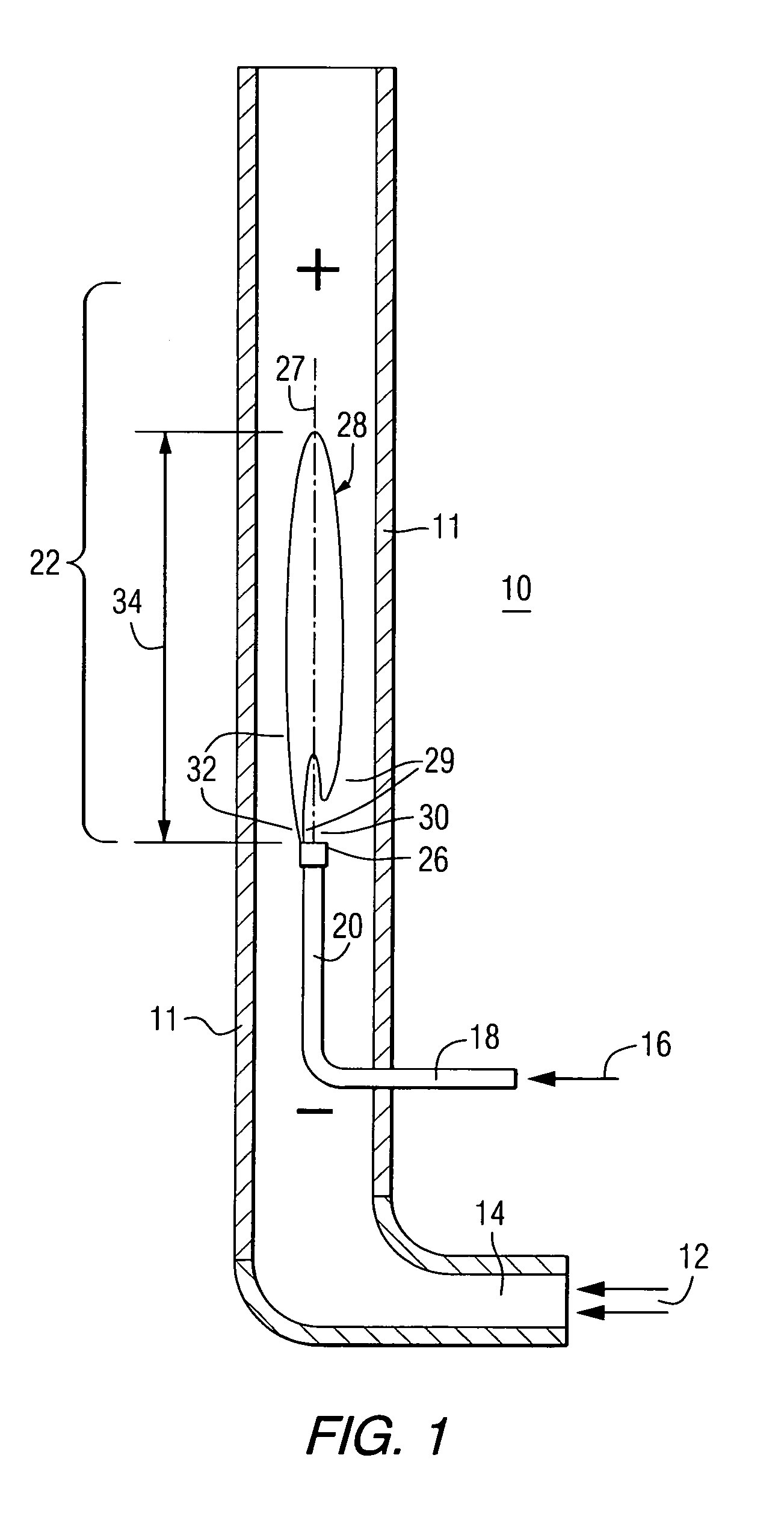

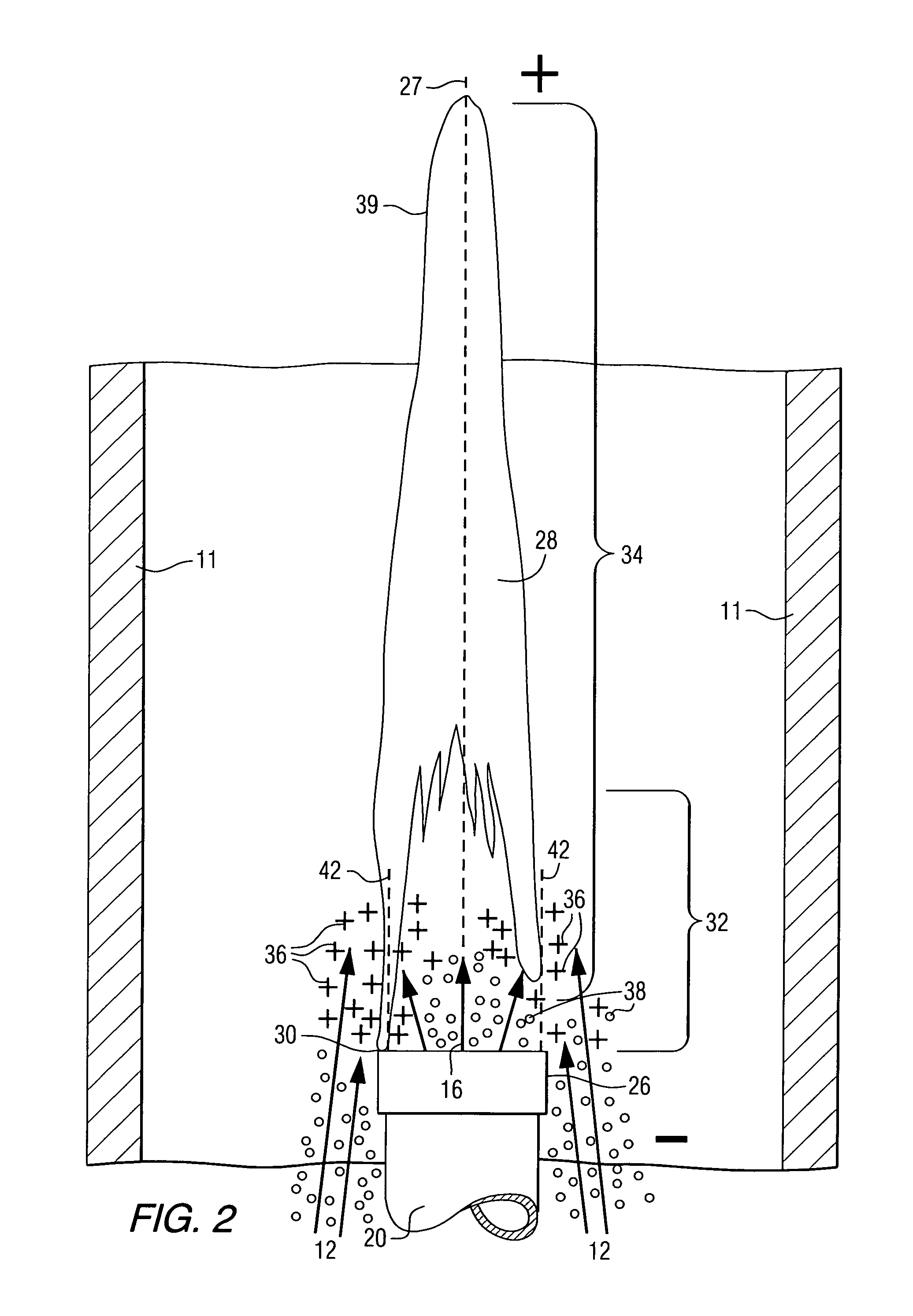

Electric flame control using corona discharge enhancement

InactiveUS7243496B2Increased ionizationPromote combustionTurbine/propulsion fuel supply systemsTurbine/propulsion engine ignitionElectricityCombustor

A method of operating a combustor (10), to provide intimately mixed hot combusted gas (44) for a gas turbine (46), includes feeding gaseous oxidant (12) and gaseous fuel (16) into the combustor (10) near a combustion flame (28) which has a tip end (39) and a root end (29), where corona discharge occurs through adjustment of an electric field (34), and where the corona discharge causes ionized particles (36) to form and also causes intimate turbulent mixing of the gases.

Owner:SIEMENS ENERGY INC

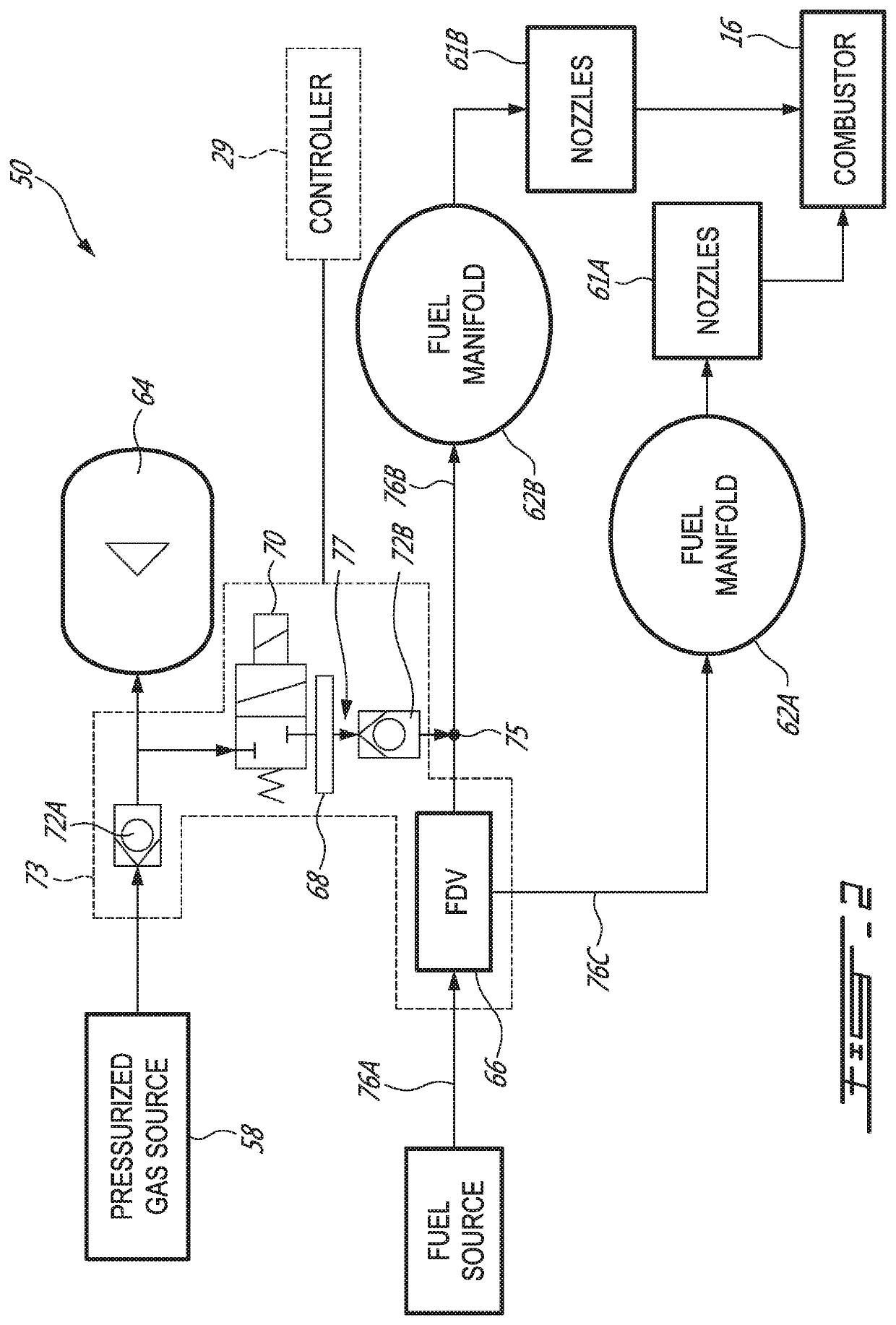

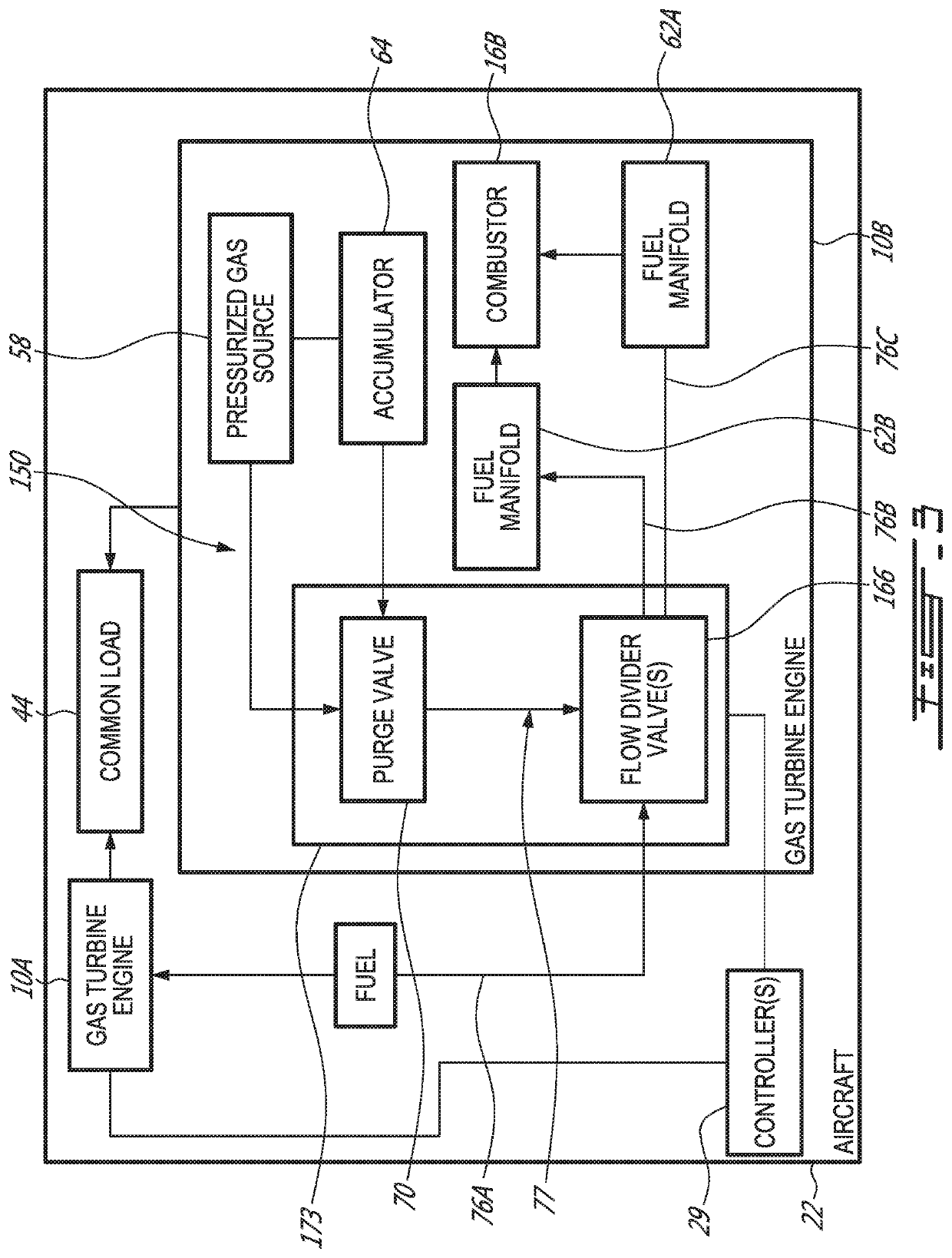

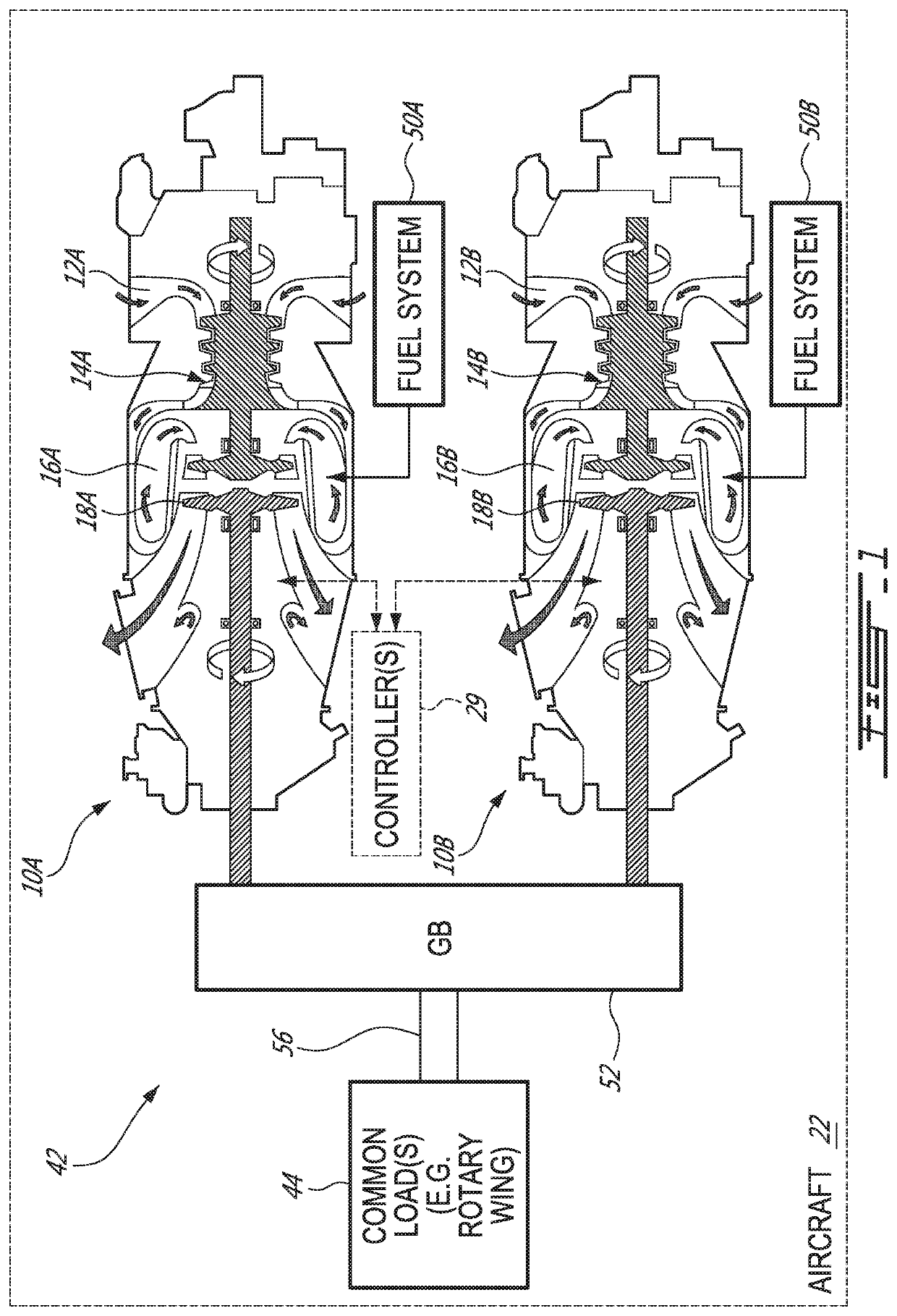

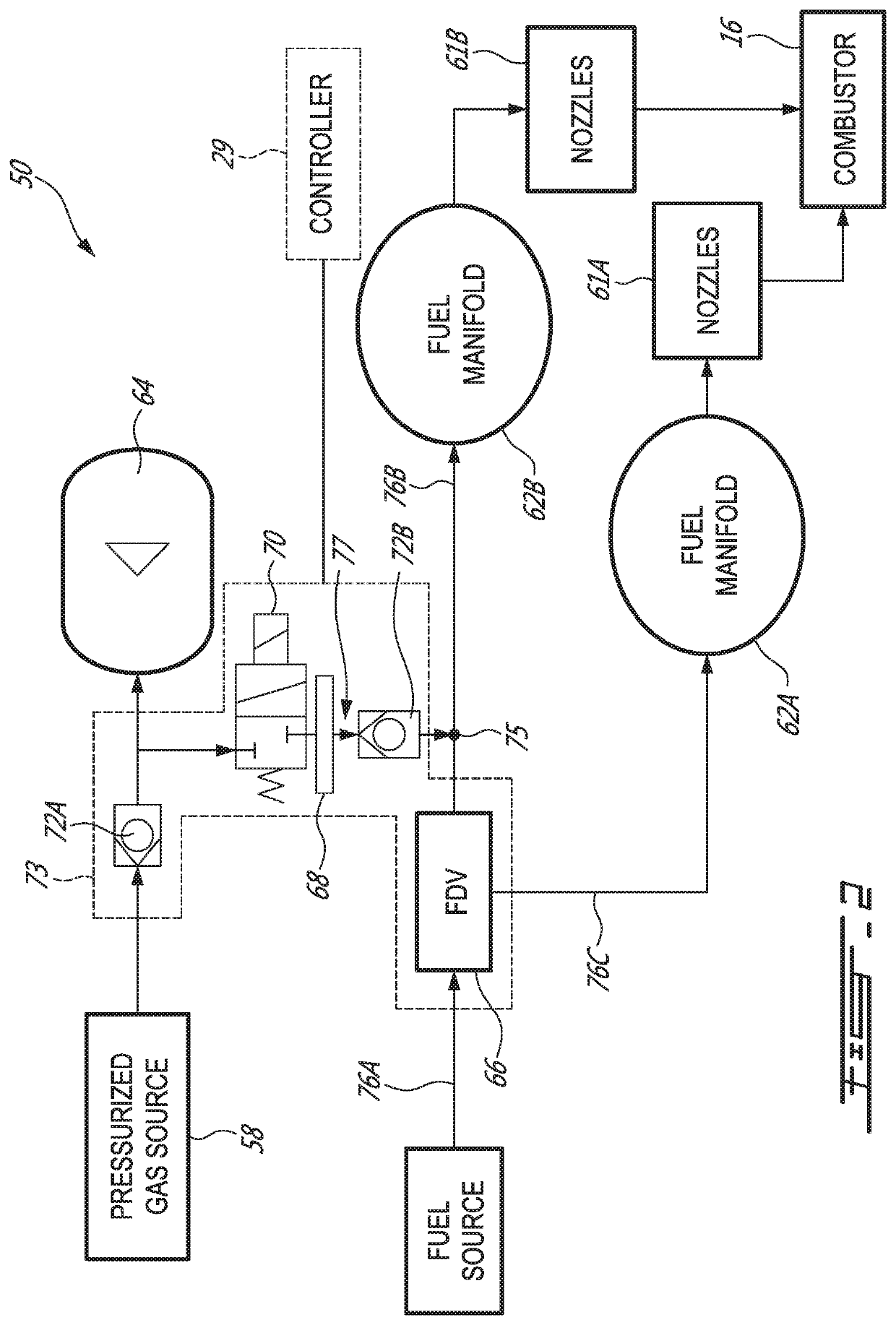

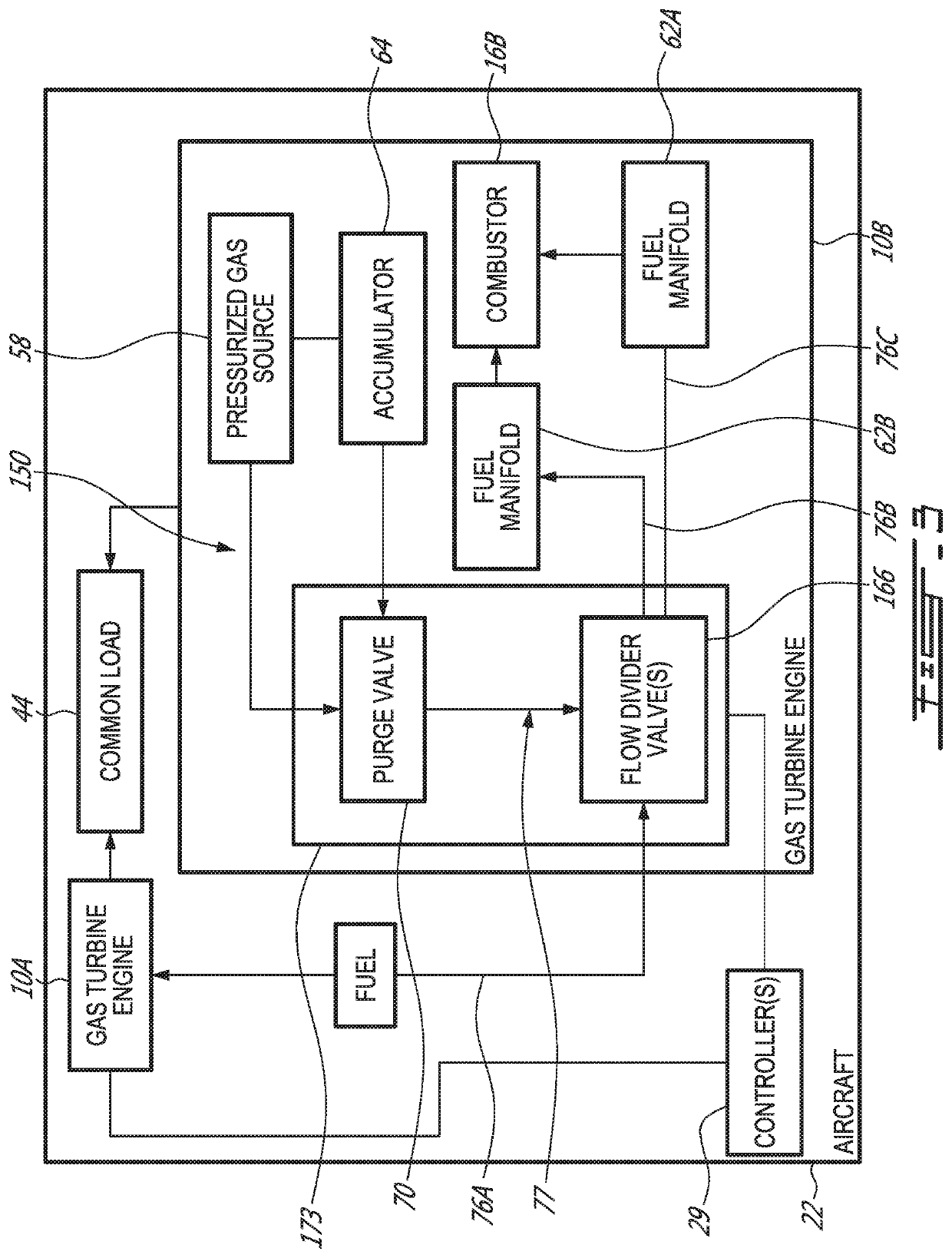

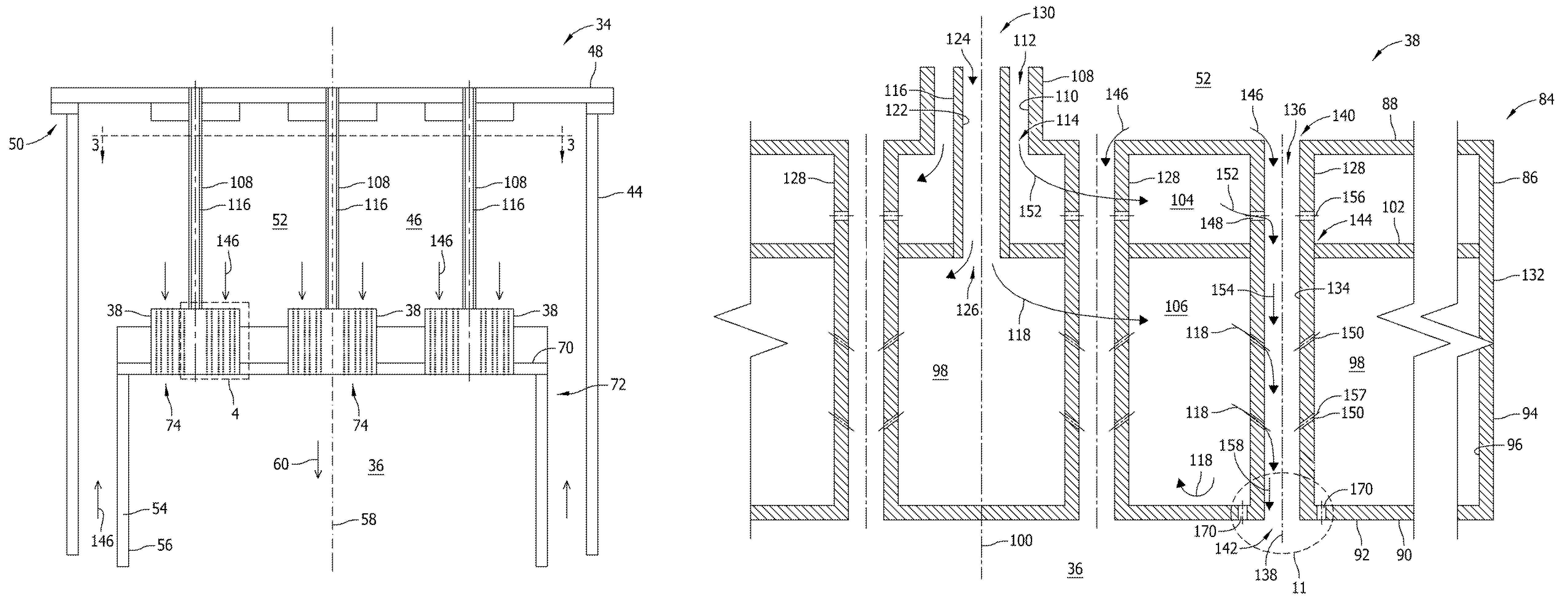

System and method for purging a fuel manifold of a gas turbine engine using a flow divider assembly

Methods and systems of operating a gas turbine engine in a low-power condition are provided. In one embodiment, the method includes supplying fuel to the combustor by supplying fuel to the first fuel manifold via a first flow divider valve and supplying fuel to the second fuel manifold via a second flow divider valve. While supplying fuel to the combustor by supplying fuel to the first fuel manifold, the method includes stopping supplying fuel to the second fuel manifold and supplying pressurized gas to the second fuel manifold via the second flow divider valve to flush fuel in the second fuel manifold into the combustor and hinder coking in the second fuel manifold and associated nozzles.

Owner:PRATT & WHITNEY CANADA CORP

System and method for purging a fuel manifold of a gas turbine engine using an accumulator

Methods and systems of operating a gas turbine engine in a low-power condition are provided. In one embodiment, the method includes supplying fuel to a combustor by supplying fuel to a first fuel manifold and a second fuel manifold of the gas turbine engine. The method also includes, while supplying fuel to the combustor by supplying fuel to the first fuel manifold: stopping supplying fuel to the second fuel manifold; and discharging pressurized air from an accumulator into the second fuel manifold to flush fuel in the second fuel manifold into the combustor and hinder coking in the second fuel manifold and associated fuel nozzles.

Owner:PRATT & WHITNEY CANADA CORP

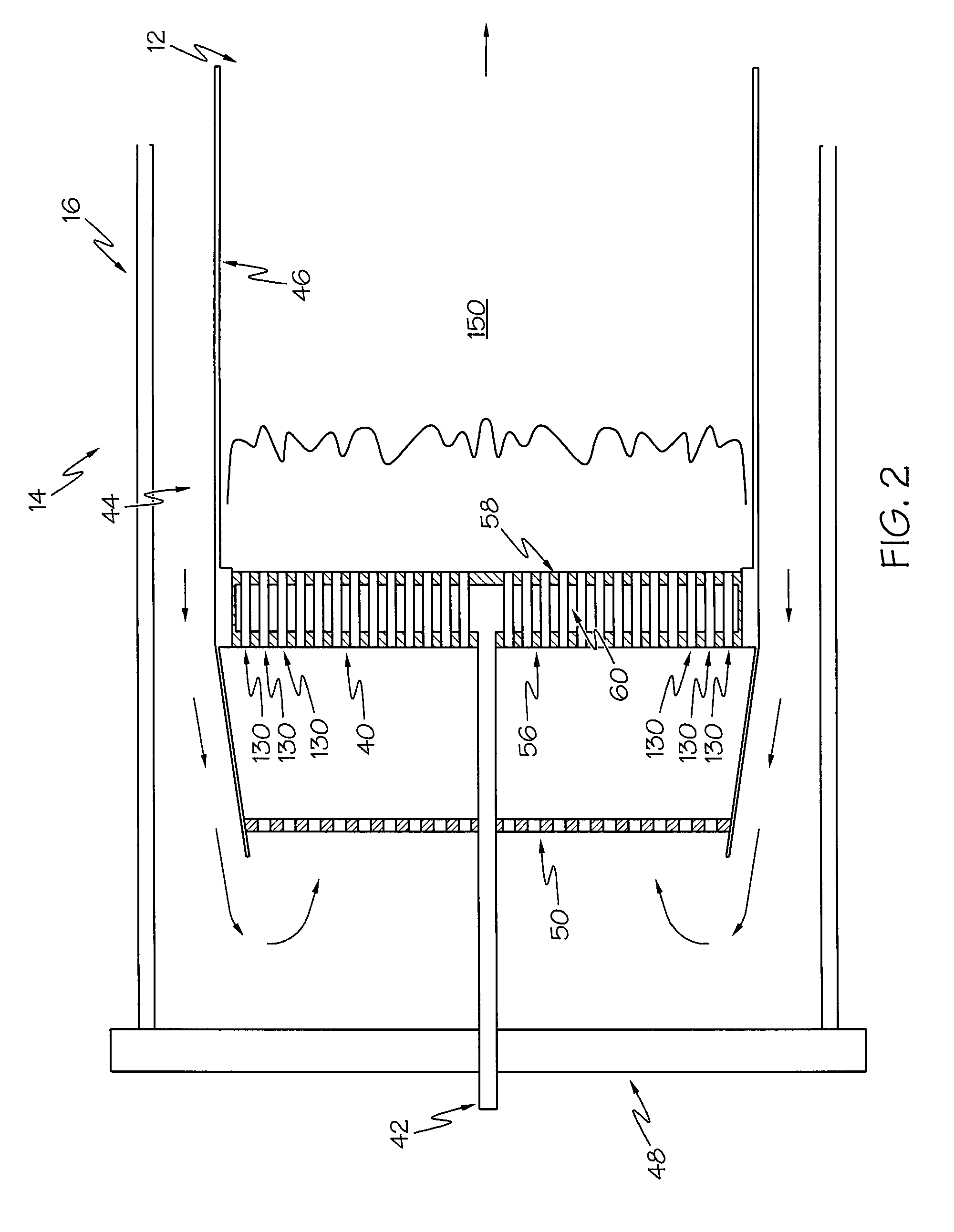

High-heat transfer low-NOx combustion system

ActiveUS6939130B2Lower NO<sub>xIncrease brightnessCombustion using gaseous and pulverulent fuelBurner safety arrangementsCombustion systemVertical plane

Owner:GAS TECH INST

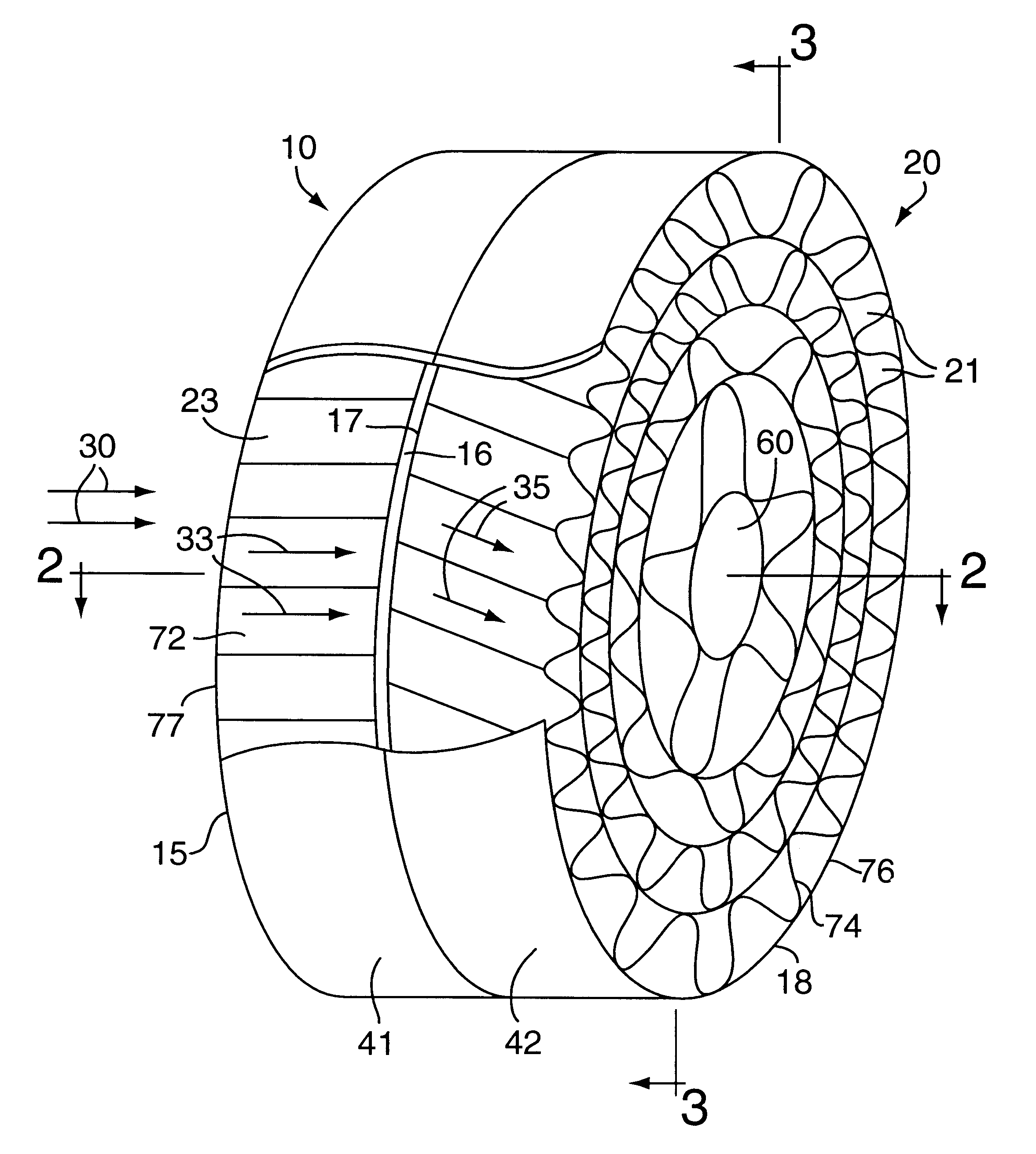

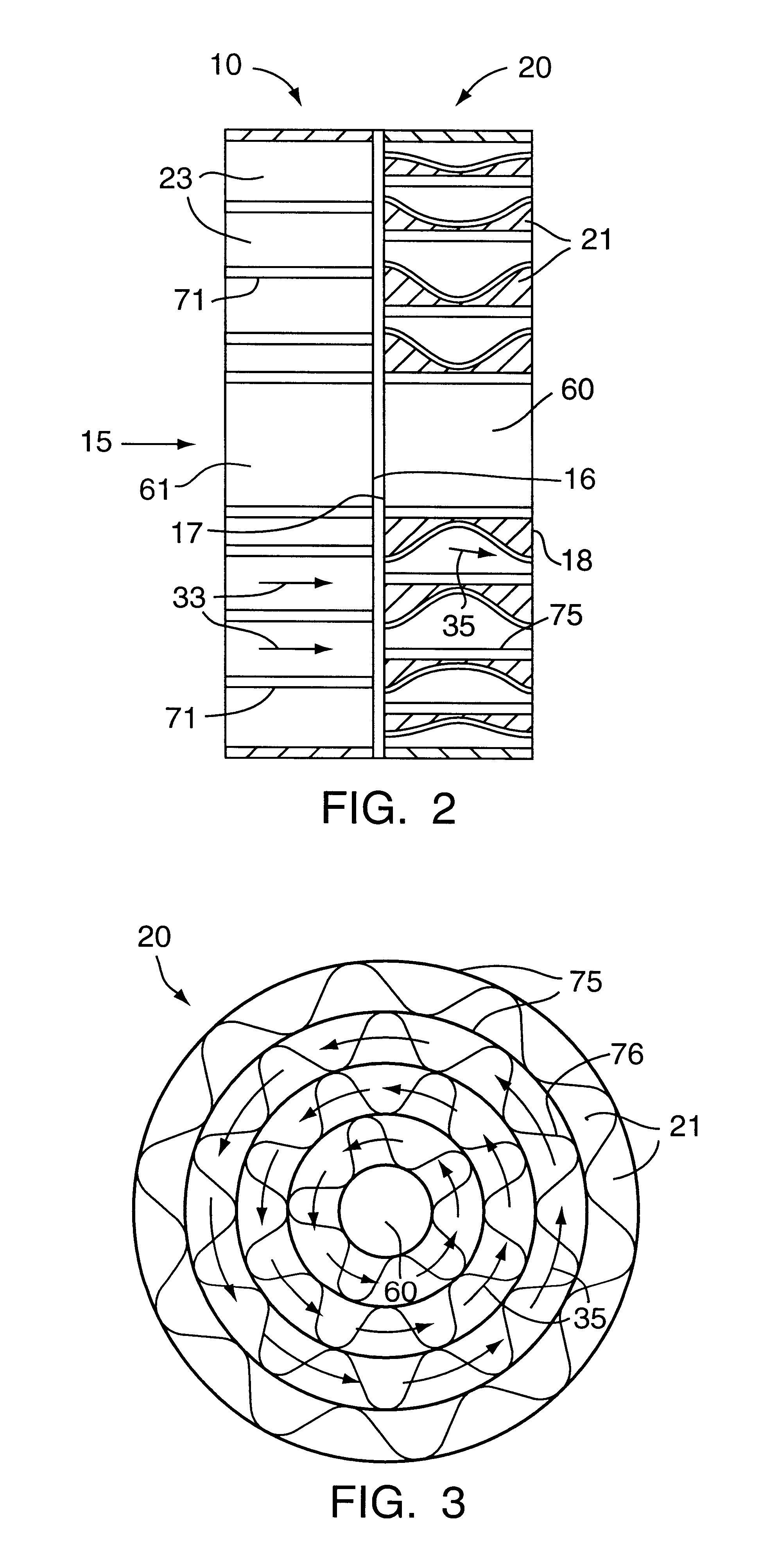

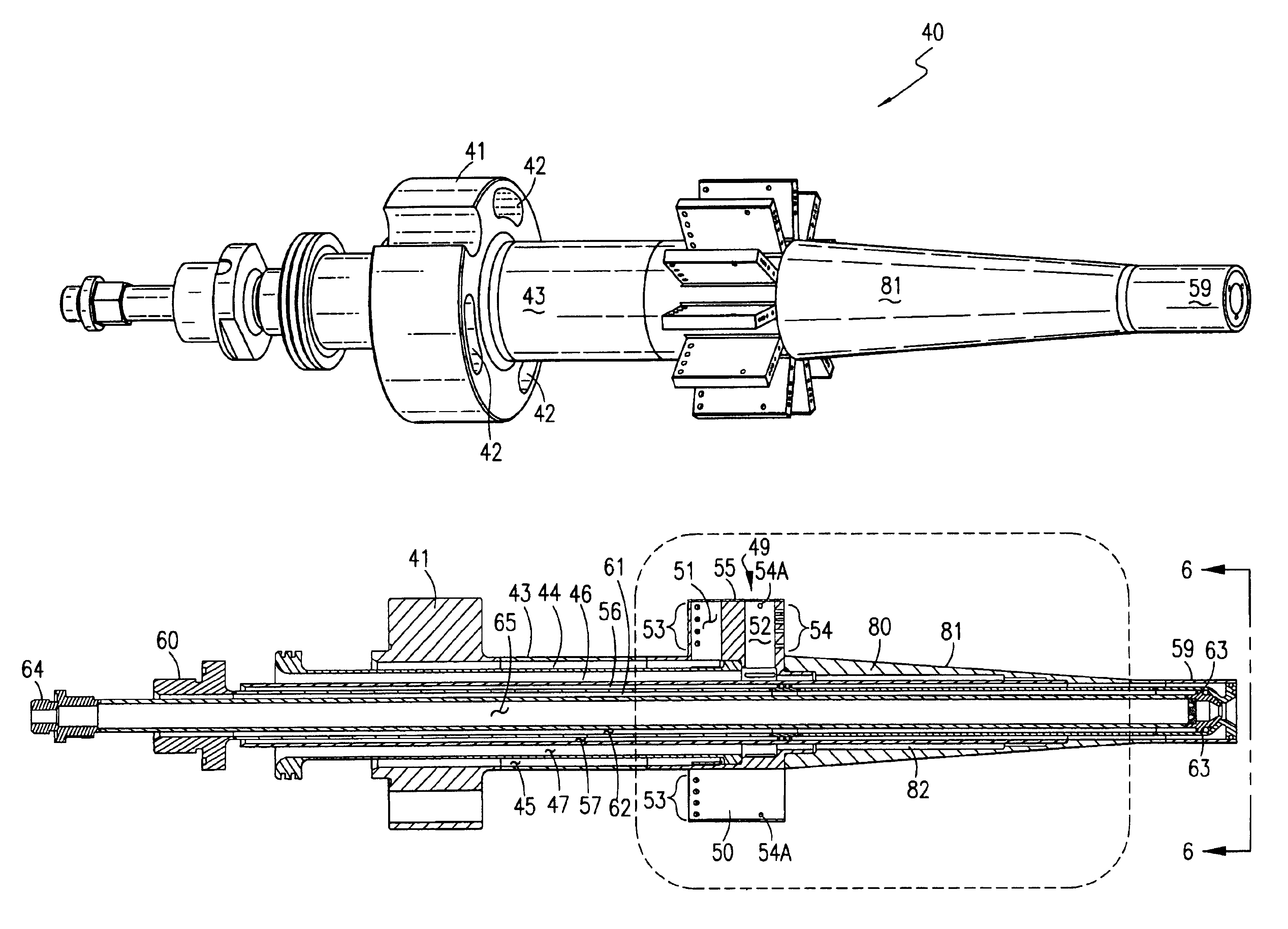

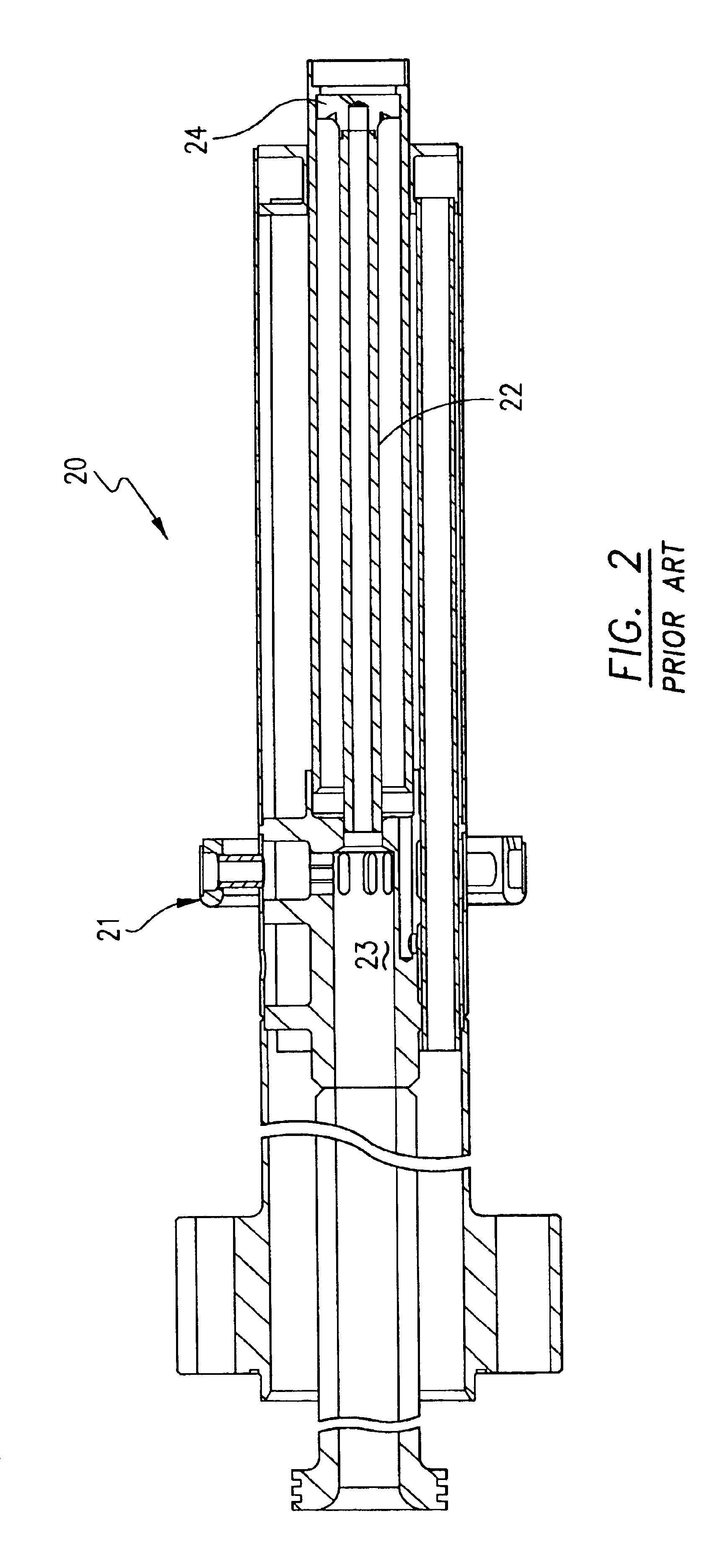

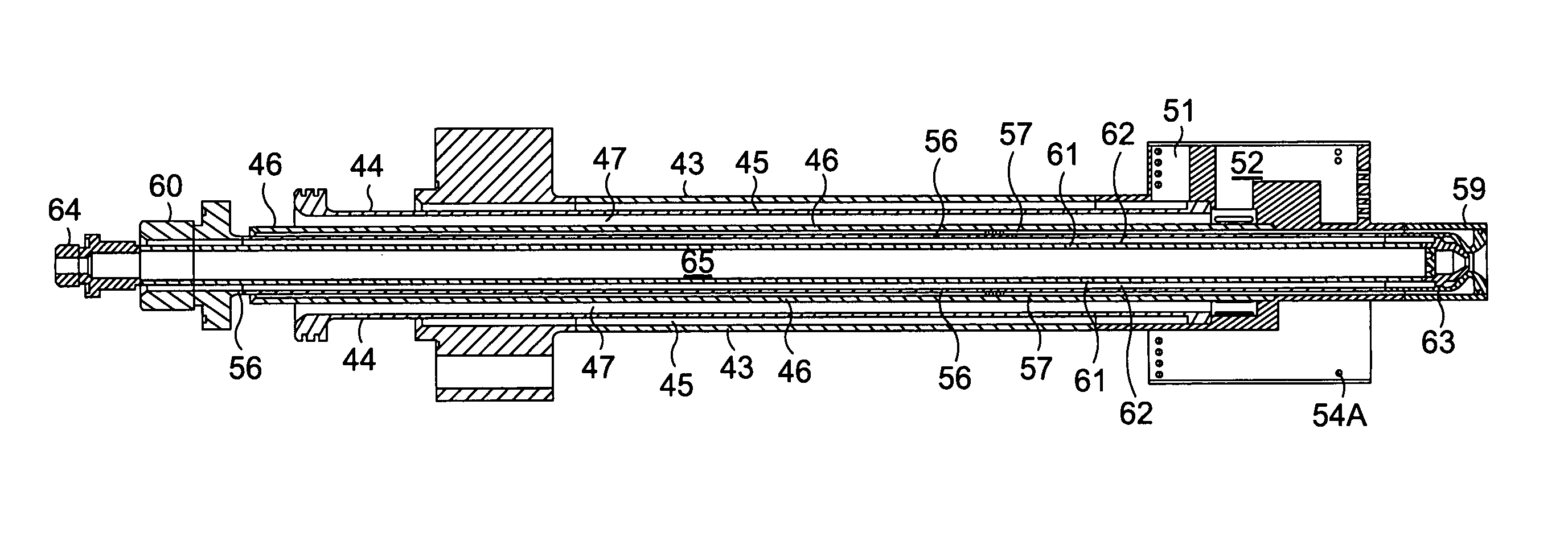

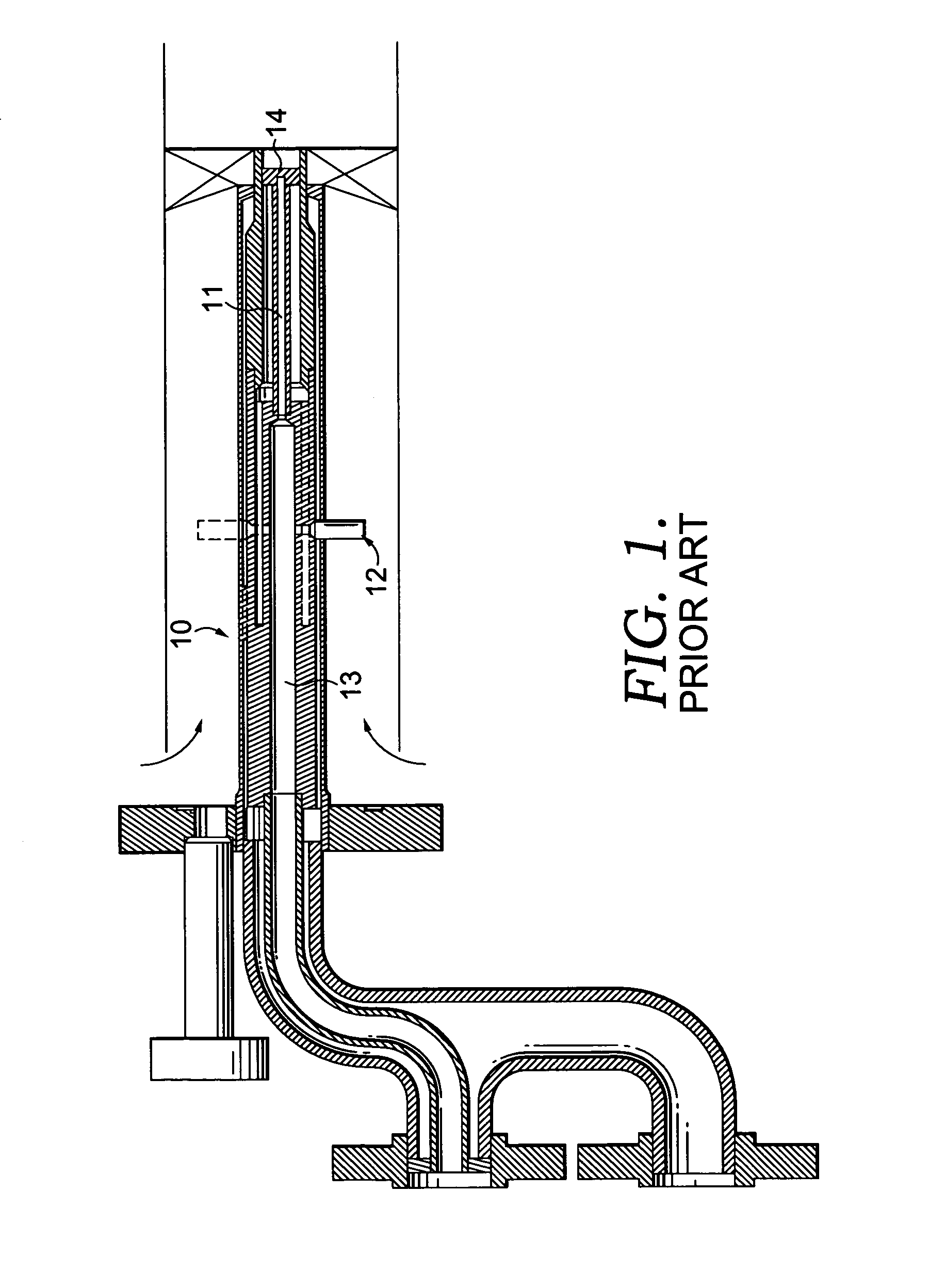

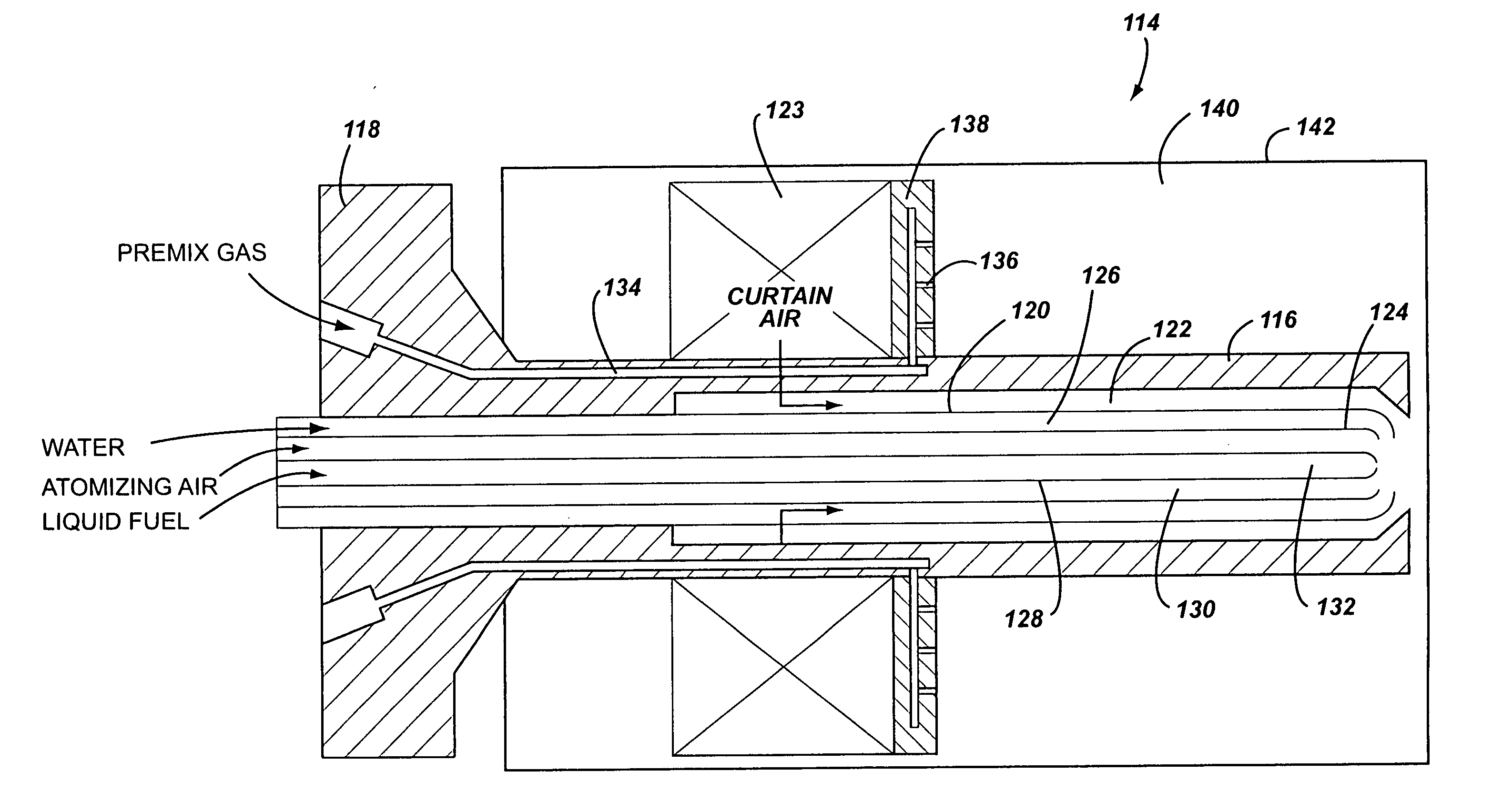

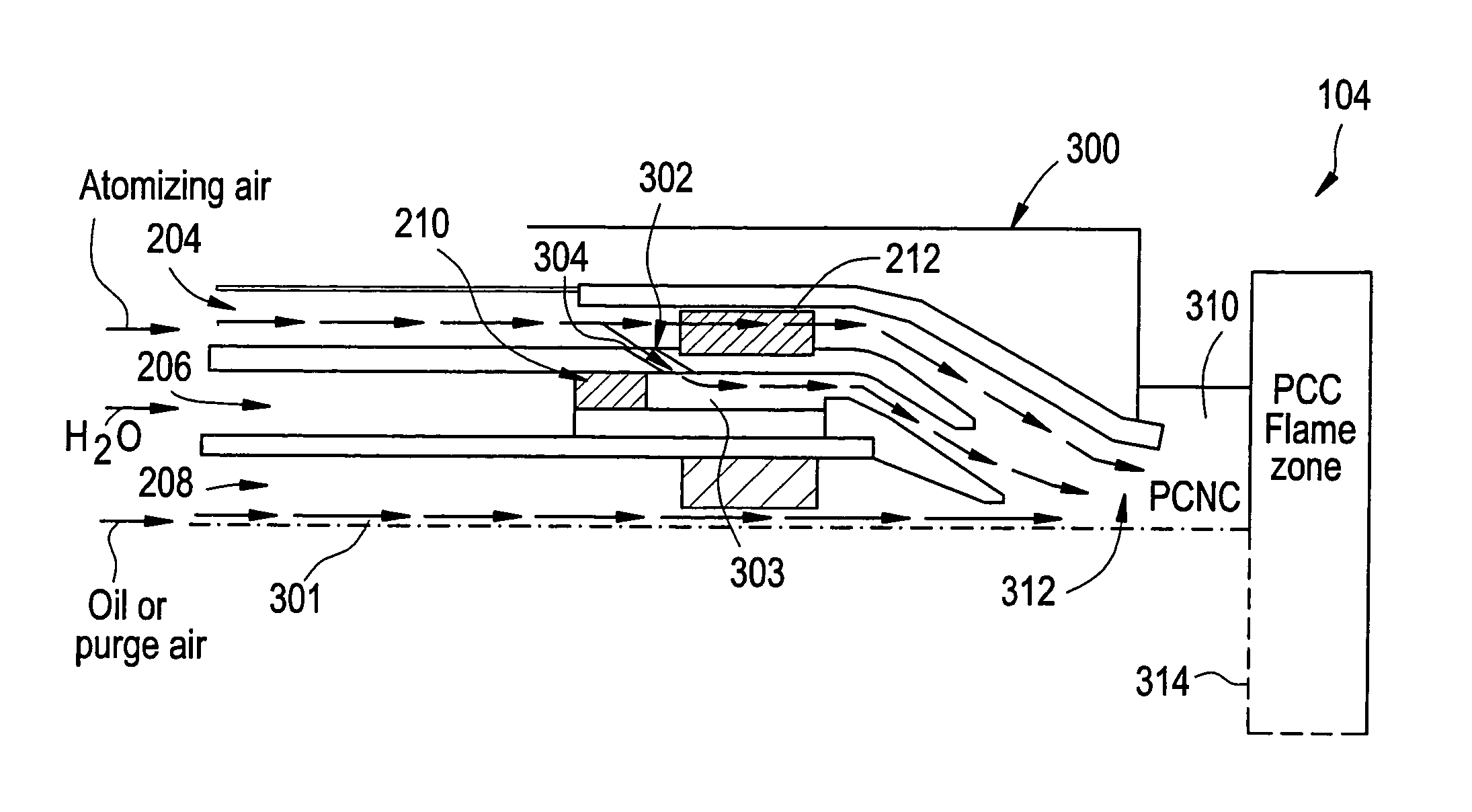

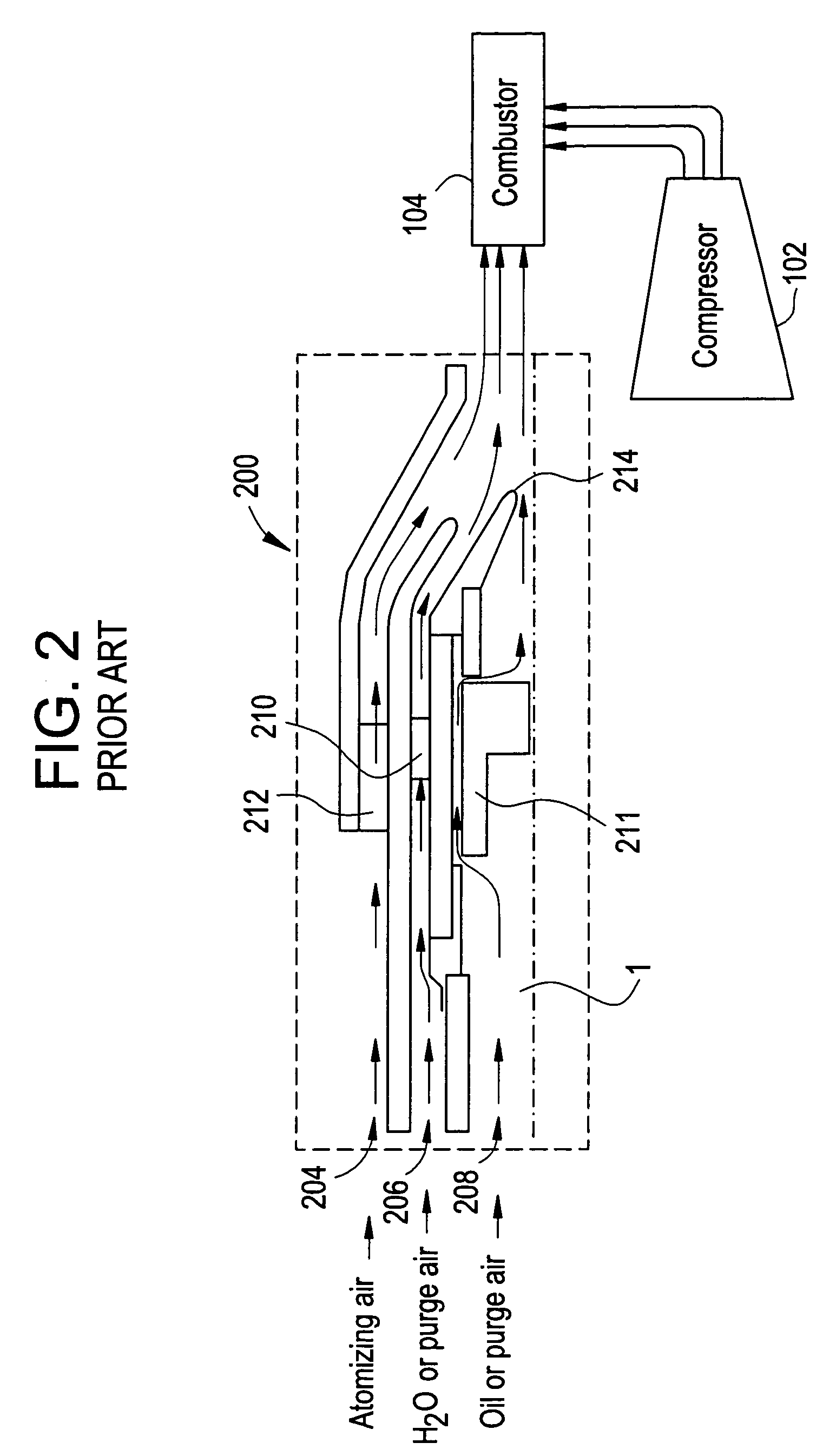

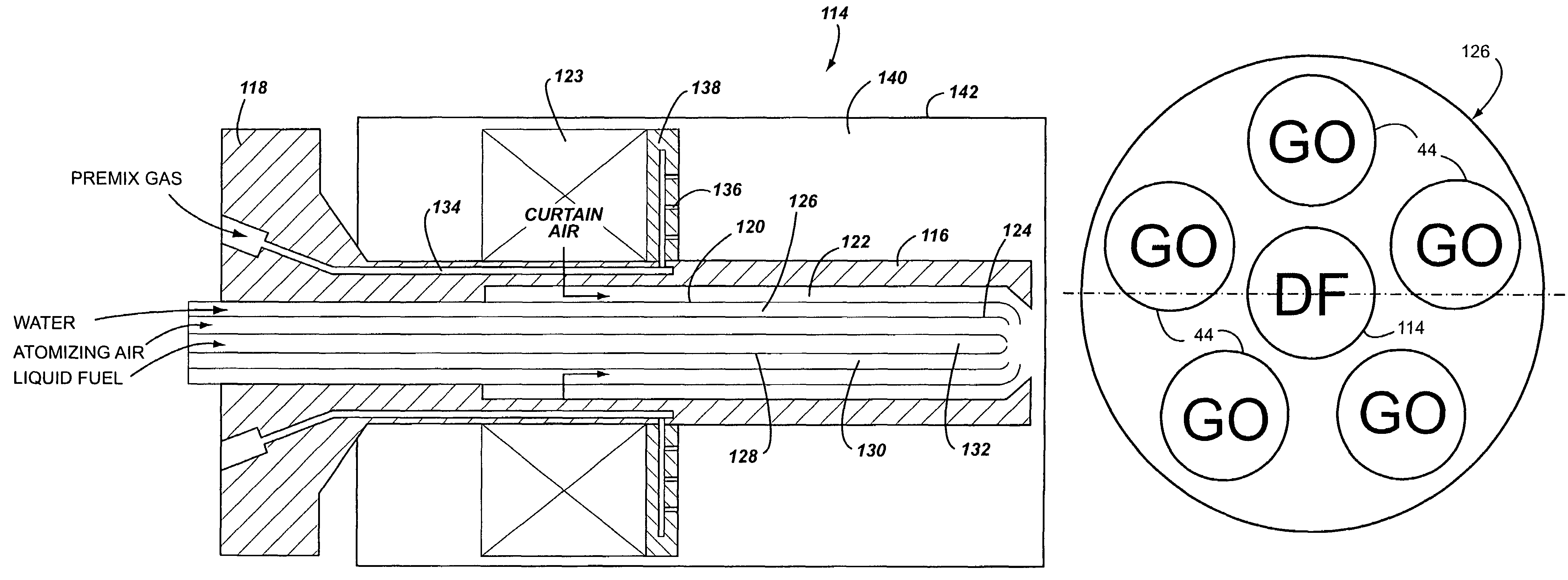

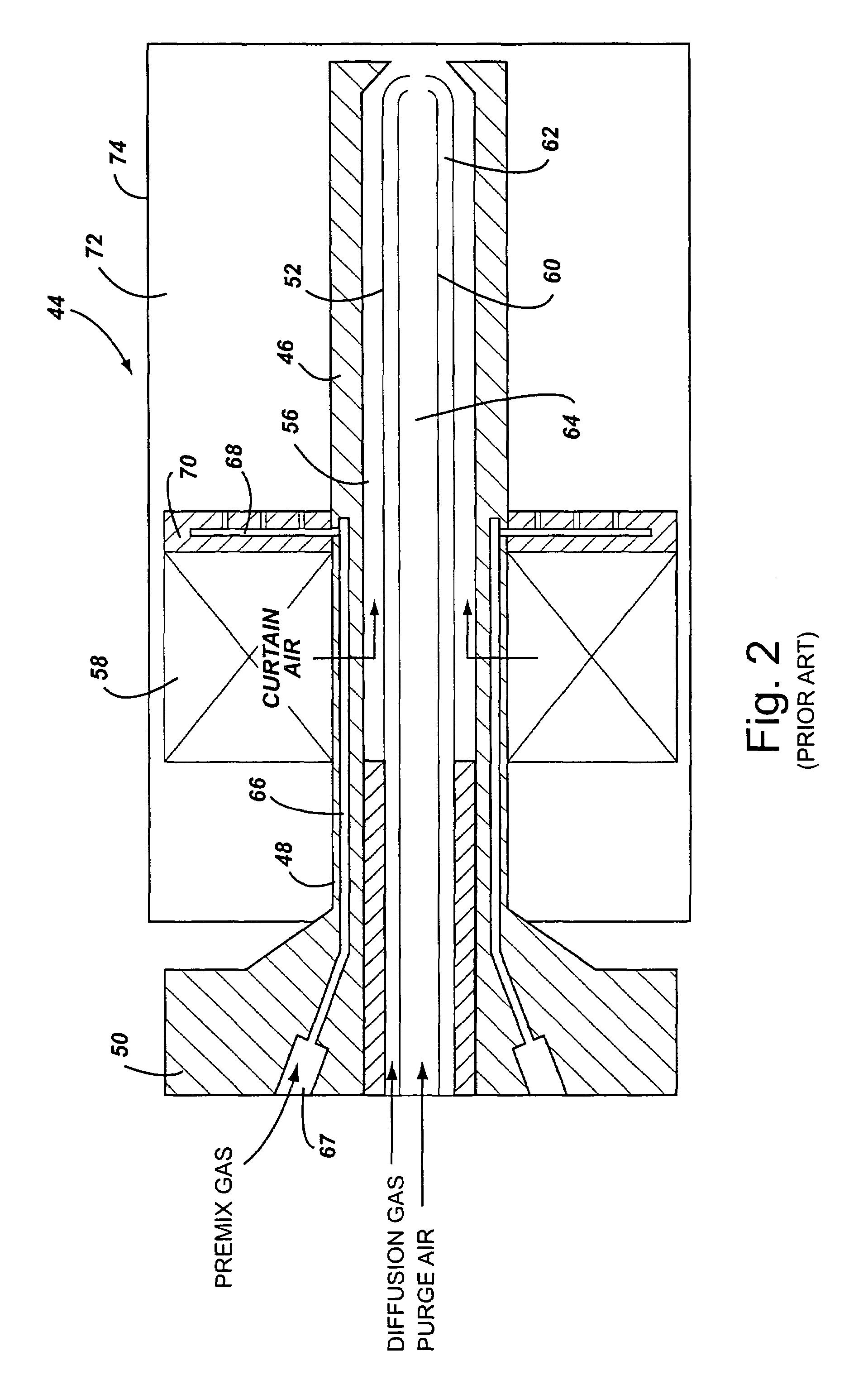

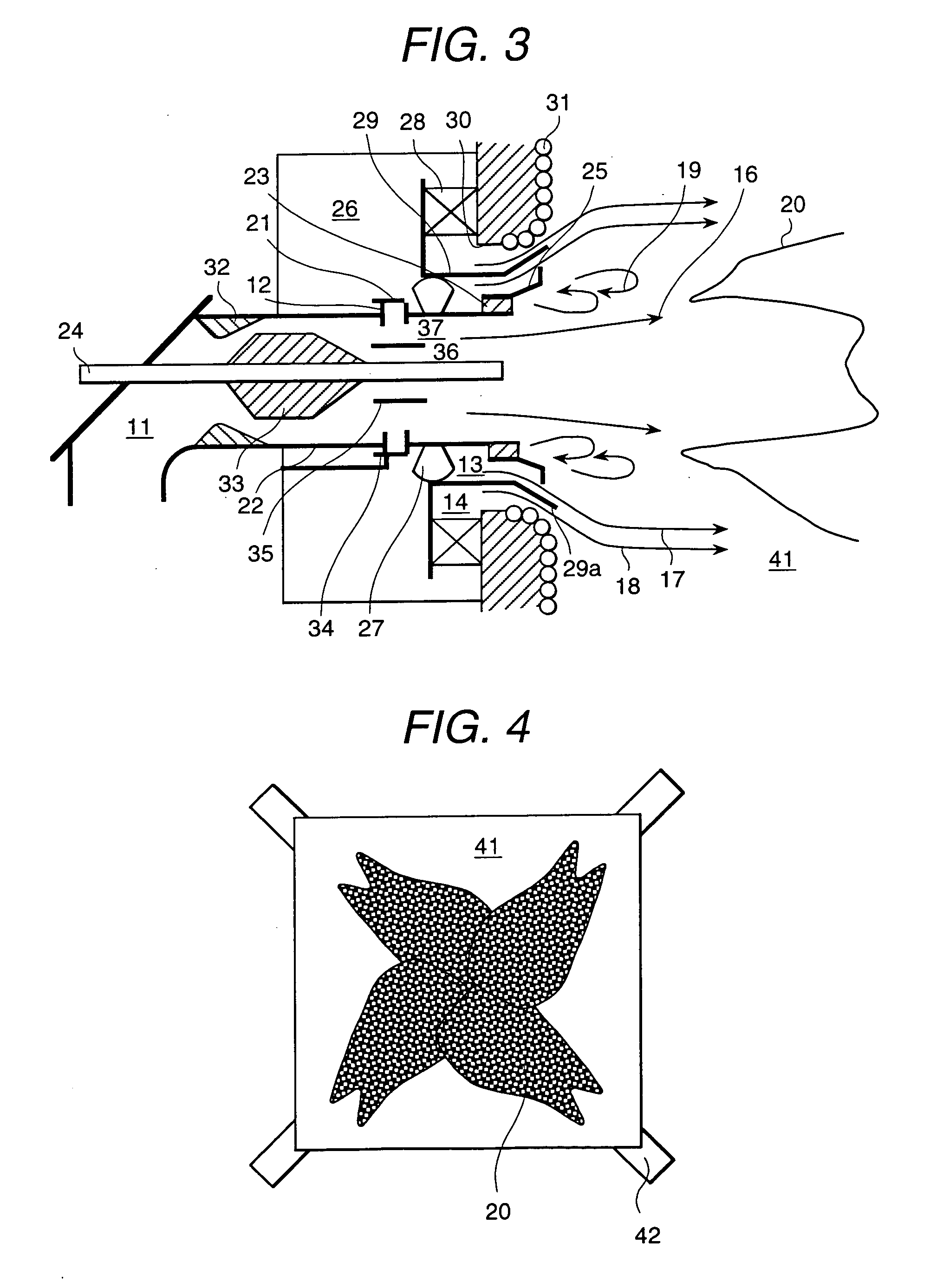

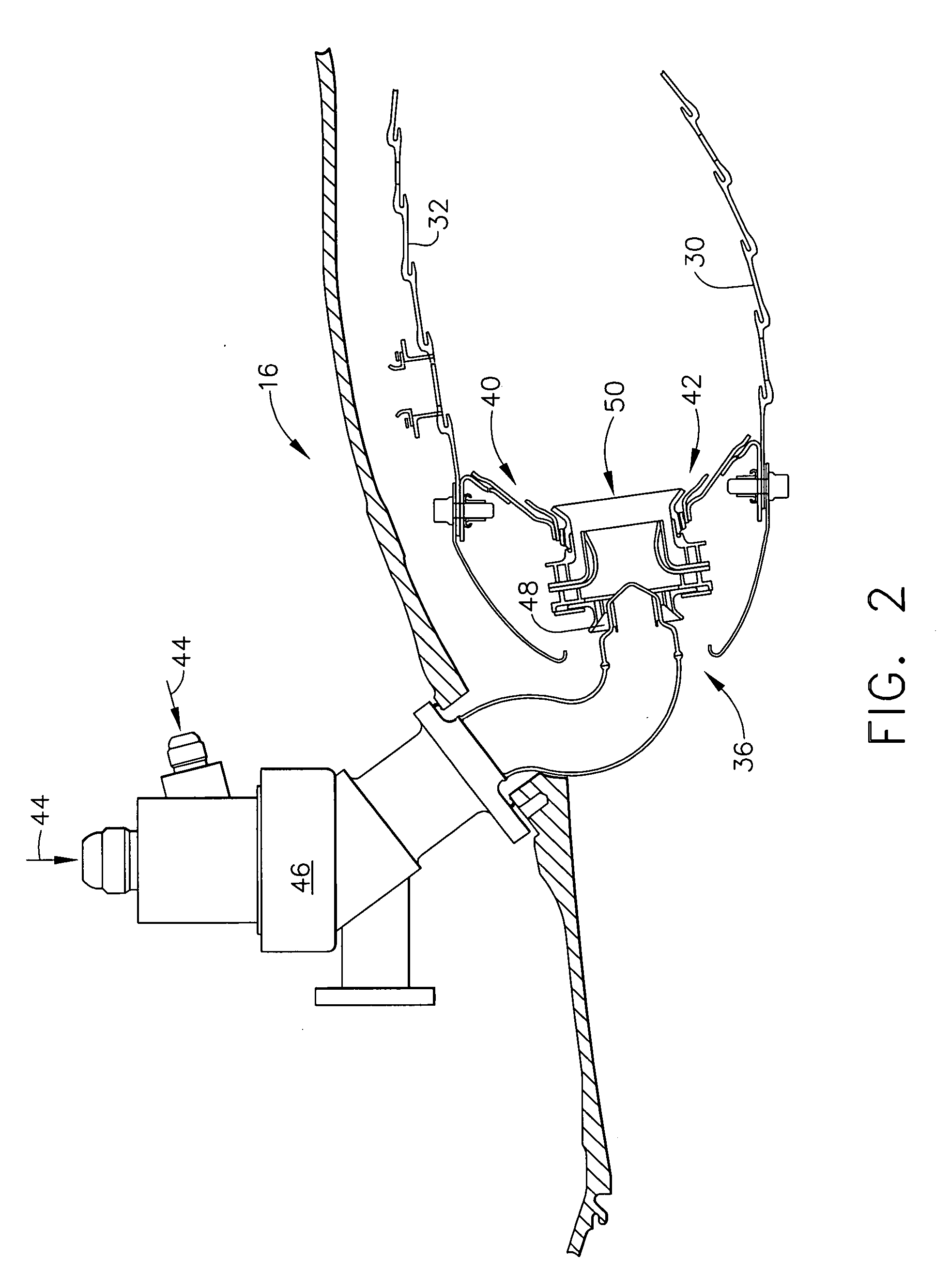

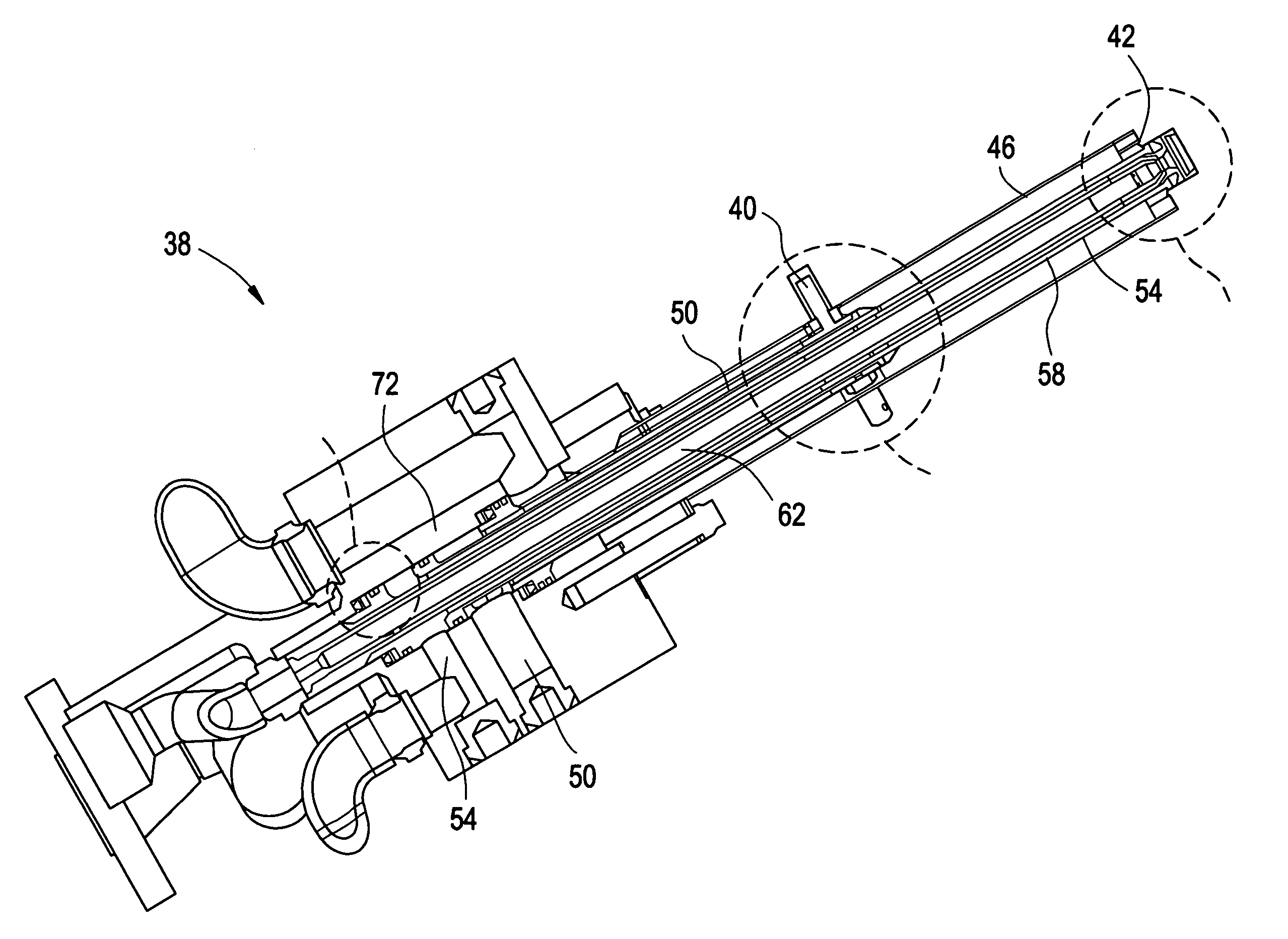

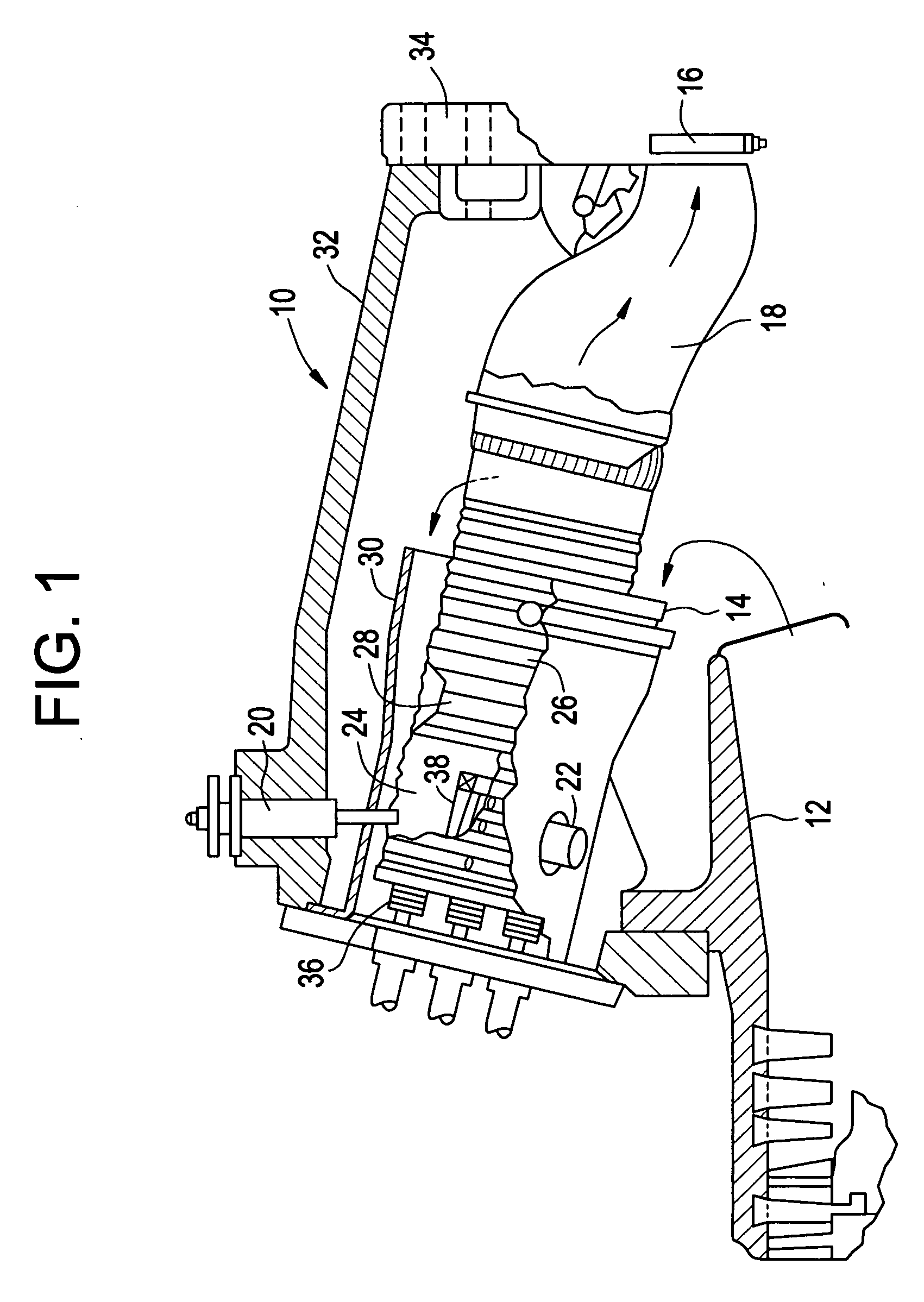

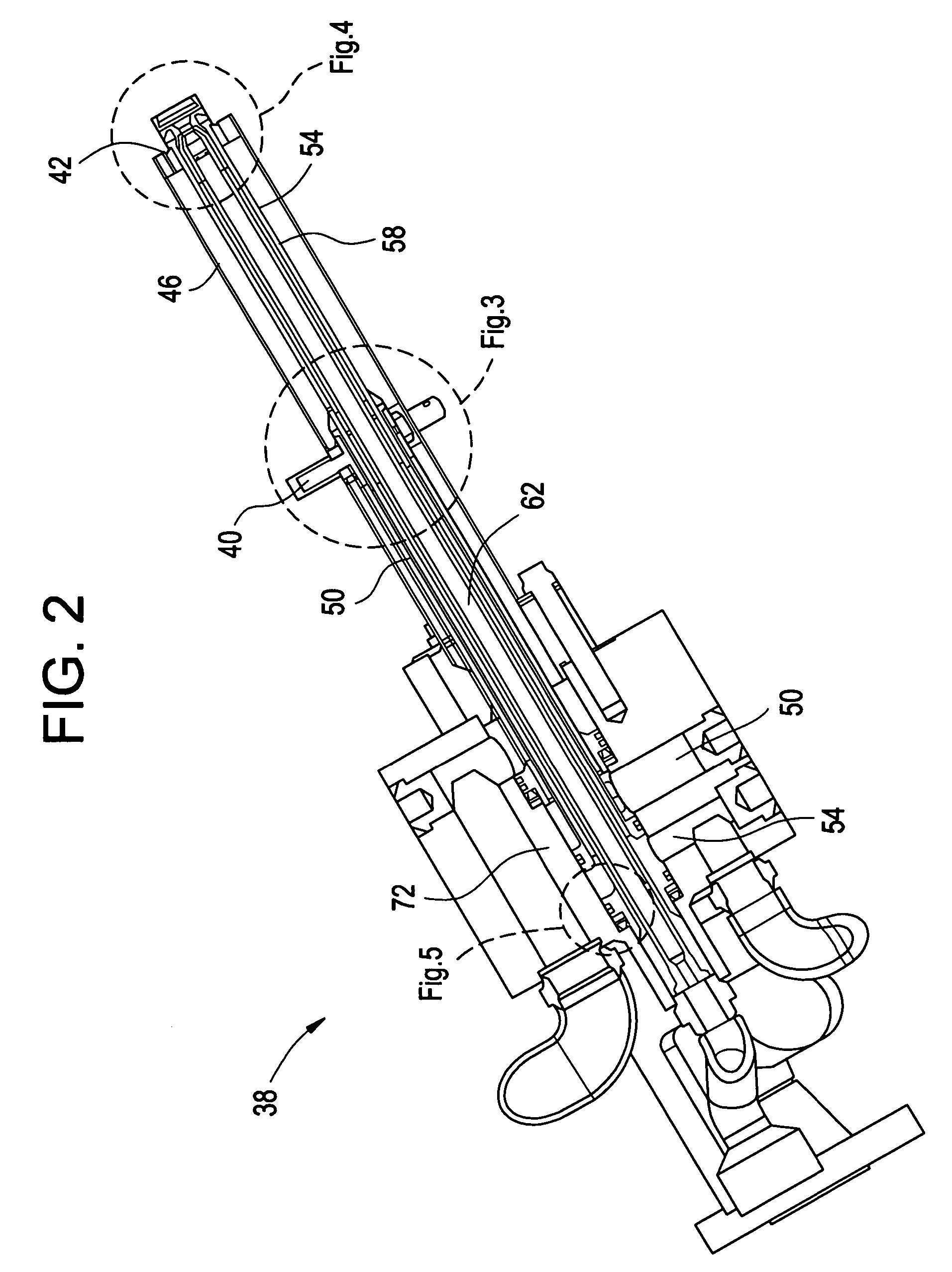

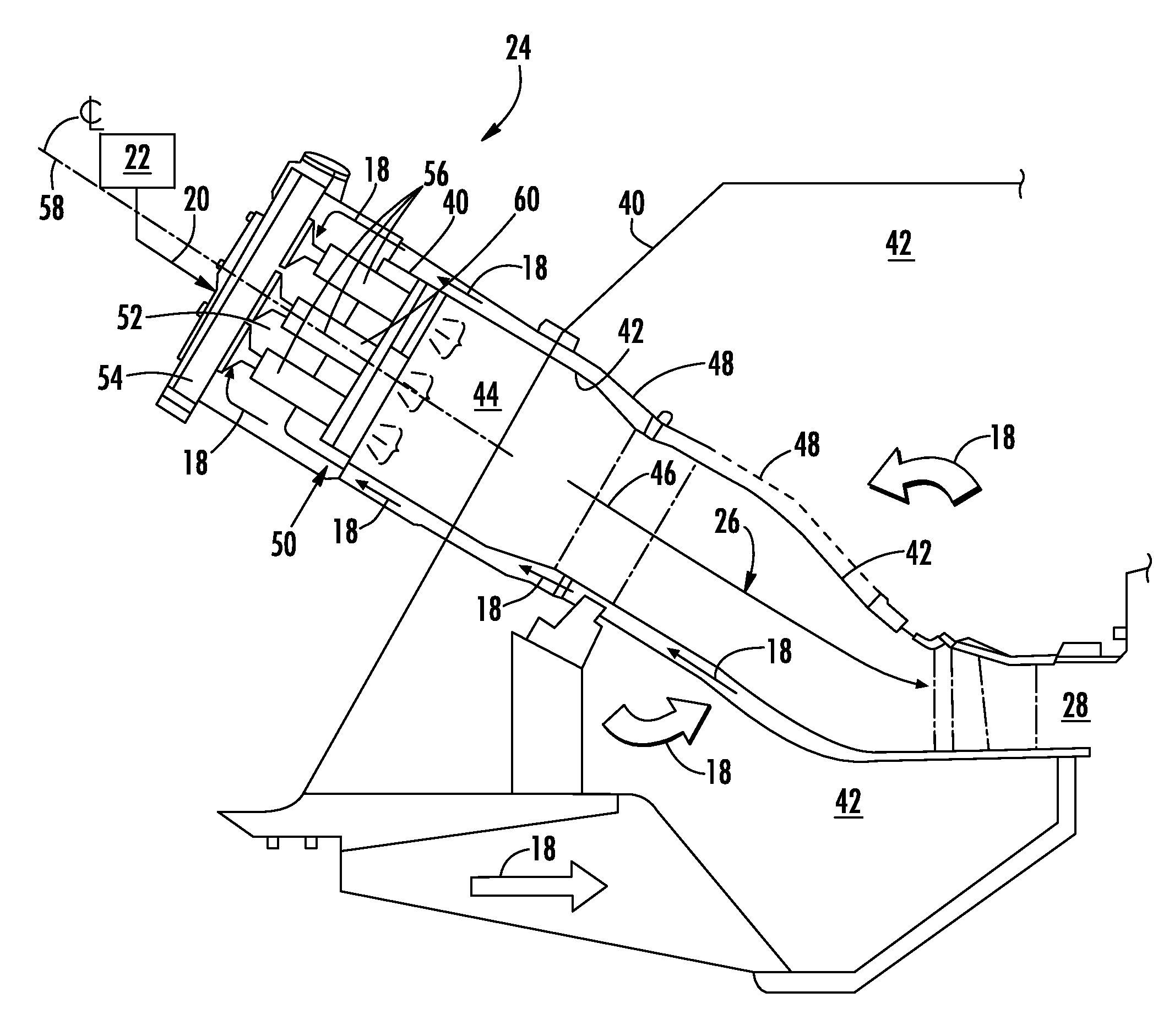

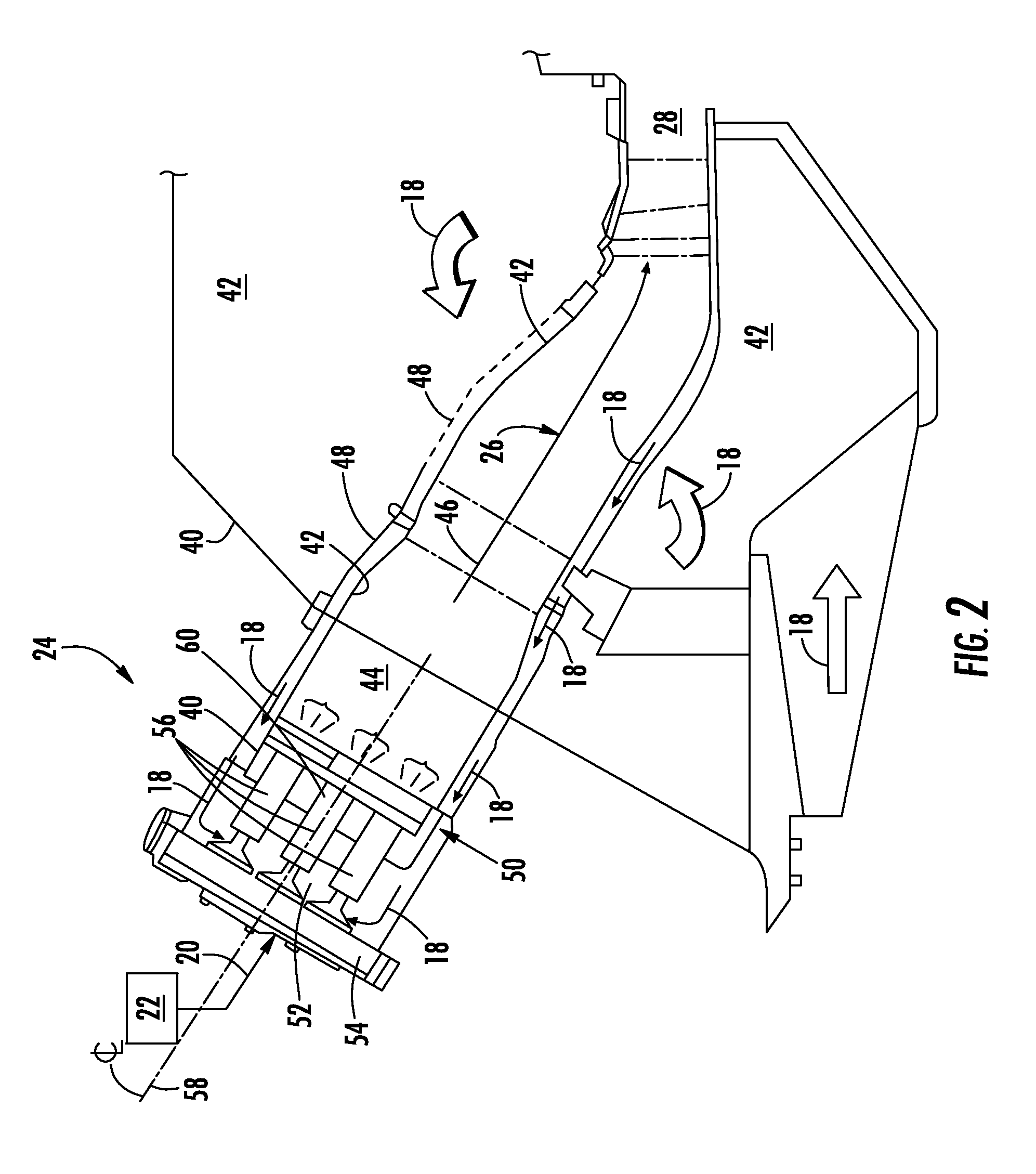

Dual fuel fin mixer secondary fuel nozzle

InactiveUS6915636B2Reduces NOx and other air pollutantUniform profileBurnersBurner safety arrangementsCombustion chamberCombustor

A dual fuel premix nozzle and method of operation for use in a gas turbine combustor is disclosed. The dual fuel premix nozzle utilizes a fin assembly comprising a plurality of radially extending fins for injection of gas fuel and compressed air in order to provide a more uniform injection pattern and homogeneous mixture. The premix fuel nozzle includes a plurality of coaxial passages, which provide gaseous fuel and compressed air to the fin assembly. When in liquid fuel operation, the gas circuits are purged with compressed air and liquid fuel and water pass through coaxial passages to the tip of the dual fuel premix fuel nozzle, where they inject liquid fuel and water into the secondary combustion chamber. An alternate embodiment includes an additional gas fuel injection region located along a conically tapered portion of the premixed fuel nozzle, downstream of the fin assembly. A second alternate embodiment is disclosed which reconfigures the injector assembly and fuel injection locations to minimize flow blockage issues at the injector assembly and simplify fuel nozzle manufacturing.

Owner:ANSALDO ENERGIA SWITZERLAND AG

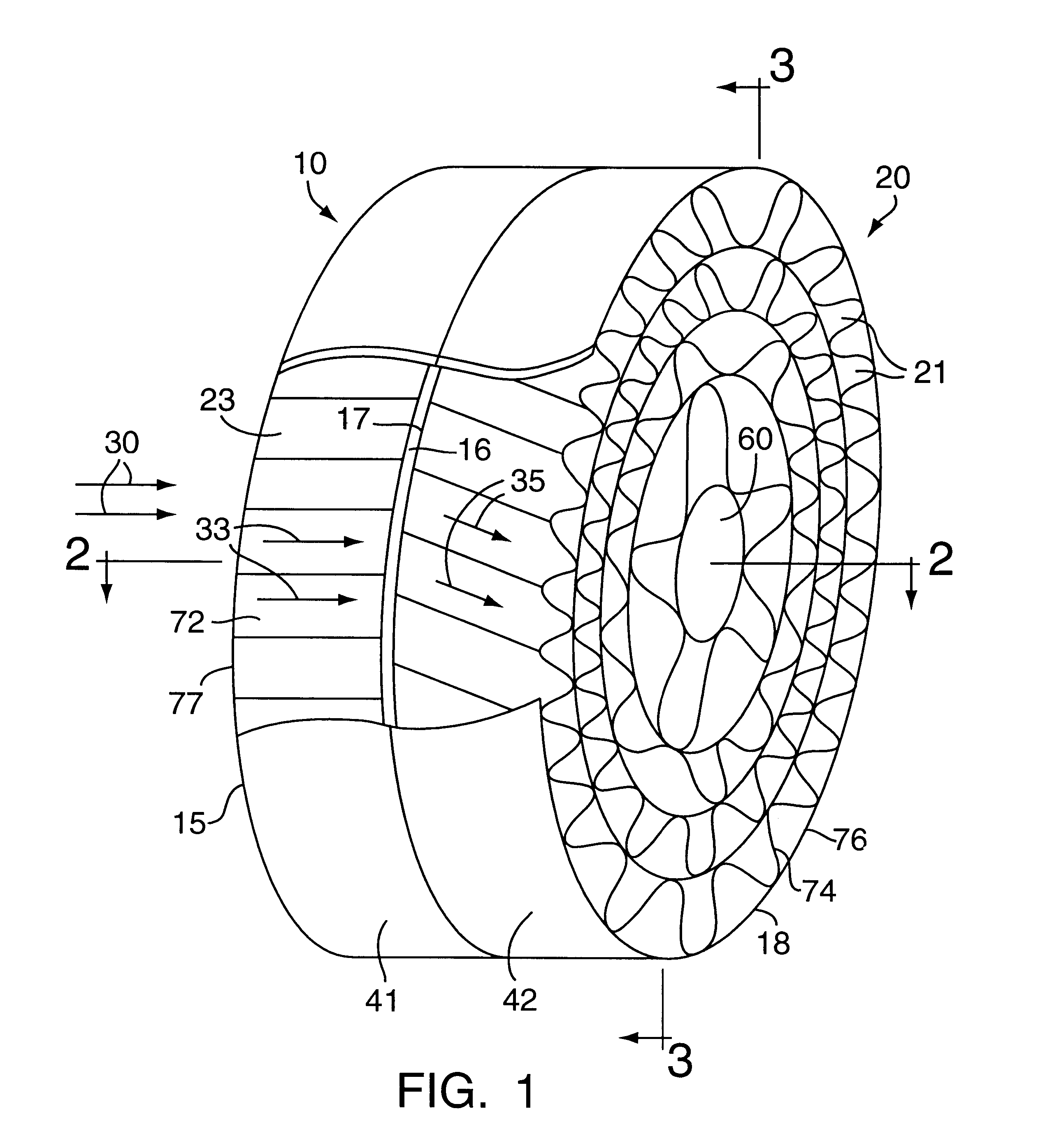

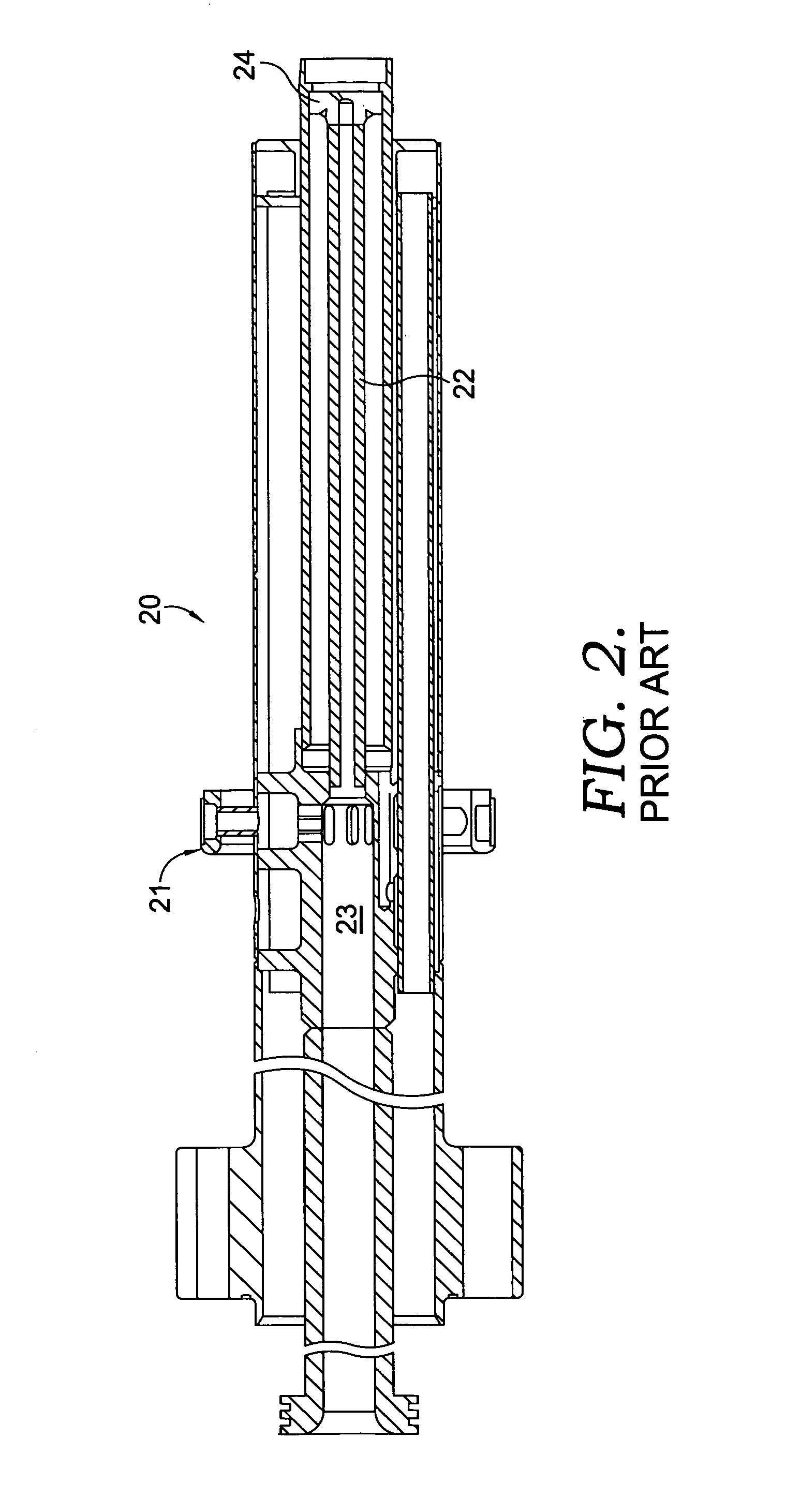

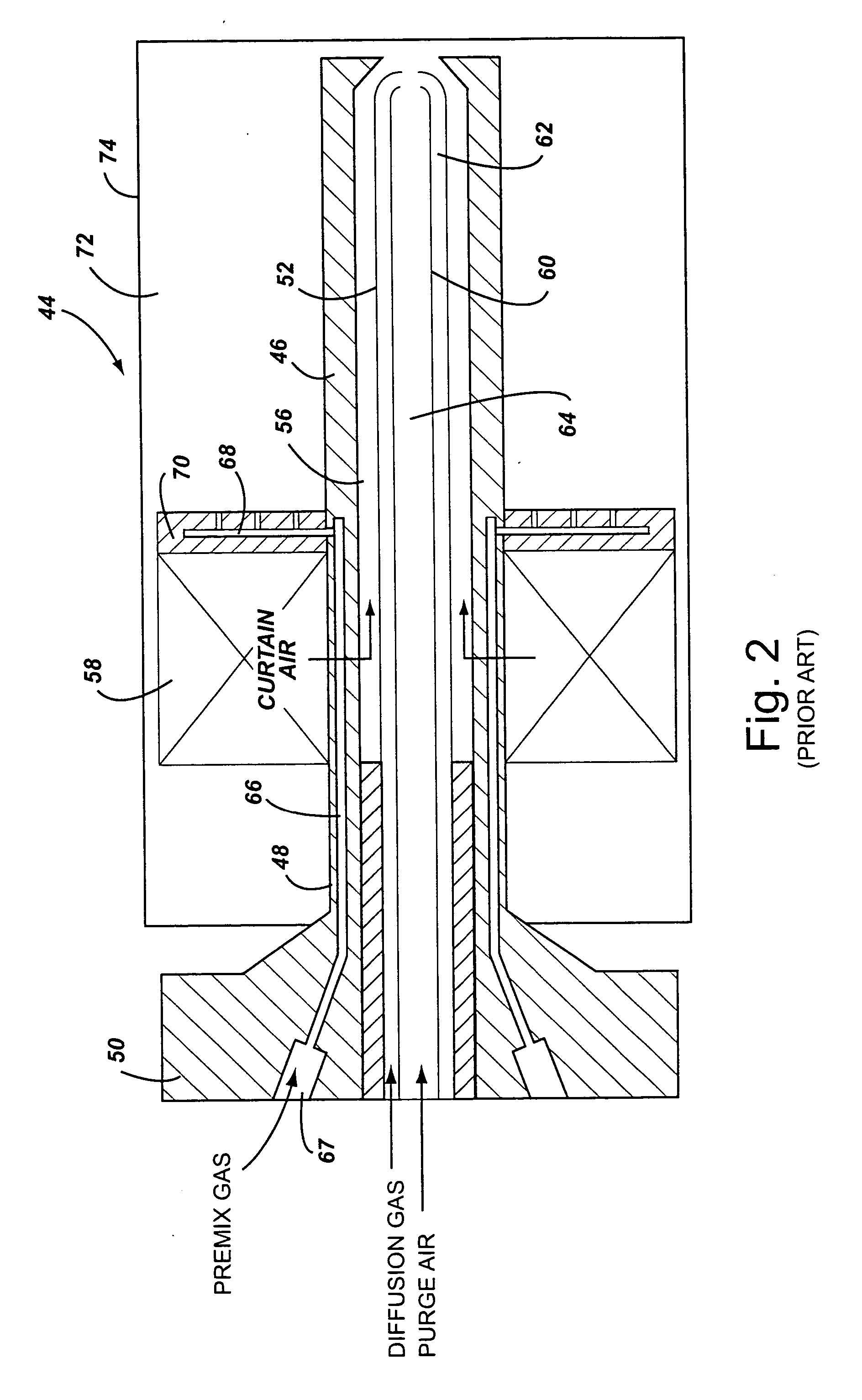

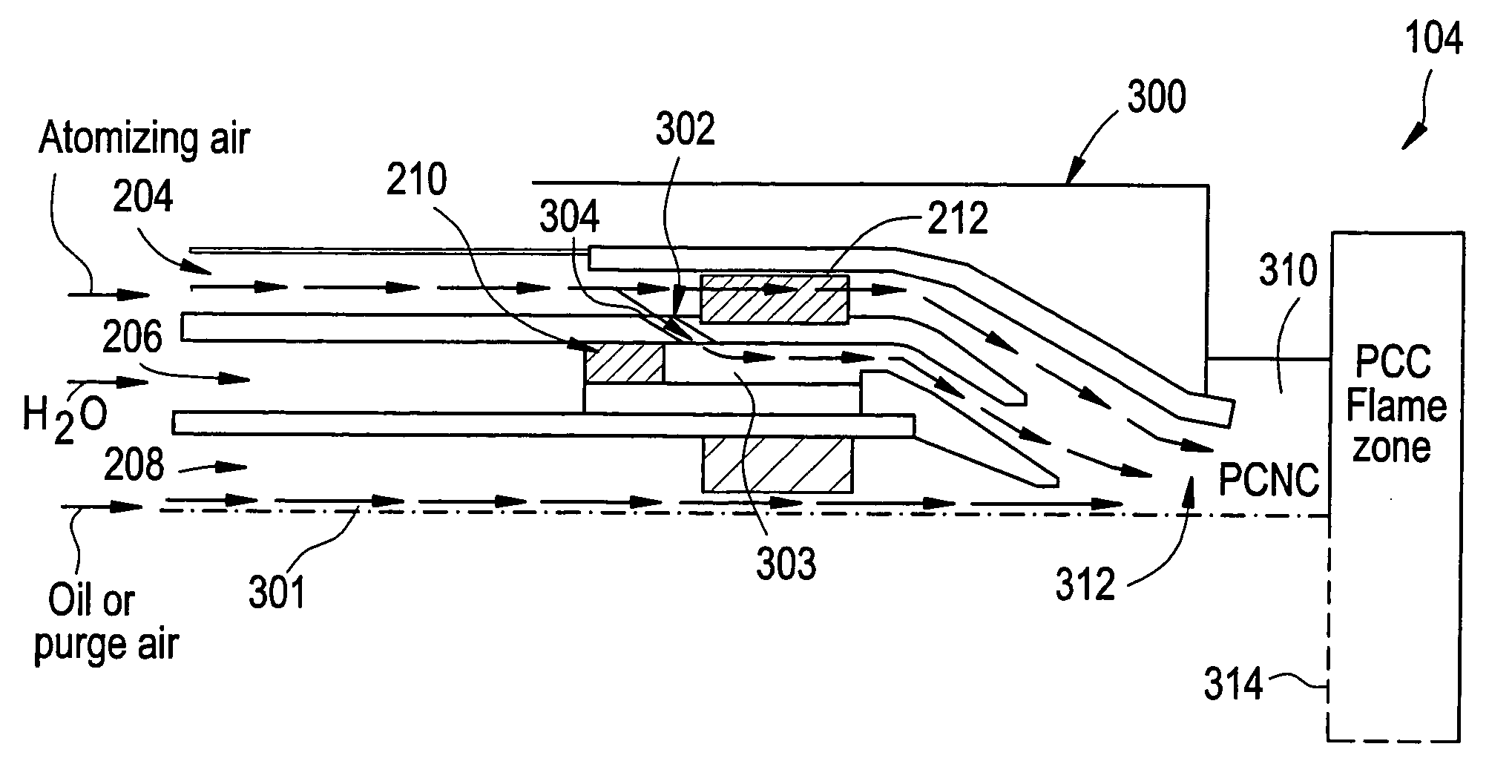

Fully premixed secondary fuel nozzle with dual fuel capability

InactiveUS7165405B2Reduces NOx and other air pollutantUniform profileBurner safety arrangementsBurnersCombustorCombustion chamber

A dual fuel premix nozzle and method of operation for use in a gas turbine combustor is disclosed. The dual fuel premix nozzle utilizes a fin assembly comprising a plurality of radially extending fins for injection of fuel and compressed air in order to provide a more uniform injection pattern. When in gas operation, the fuel and compressed air mixes upstream of the combustion chamber and flows into the combustion chamber as a homogeneous mixture. The premix fuel nozzle includes a plurality of coaxial passages, which provide gaseous fuel and compressed air to the fin assembly. When in liquid fuel operation, the gas circuits are purged with compressed air and liquid fuel and water pass through coaxial passages to the tip of the dual fuel premix fuel nozzle, where they inject liquid fuel and water into the secondary combustion chamber.

Owner:ANSALDO ENERGIA SWITZERLAND AG

Air-assisted fuel injector for mixer assembly of a gas turbine engine combustor

Owner:GENERAL ELECTRIC CO

Premixed direct injection disk

ActiveUS8424311B2Reduce riskAir mix wellBurner safety arrangementsContinuous combustion chamberCombustorGas turbines

Owner:GE INFRASTRUCTURE TECH INT LLC

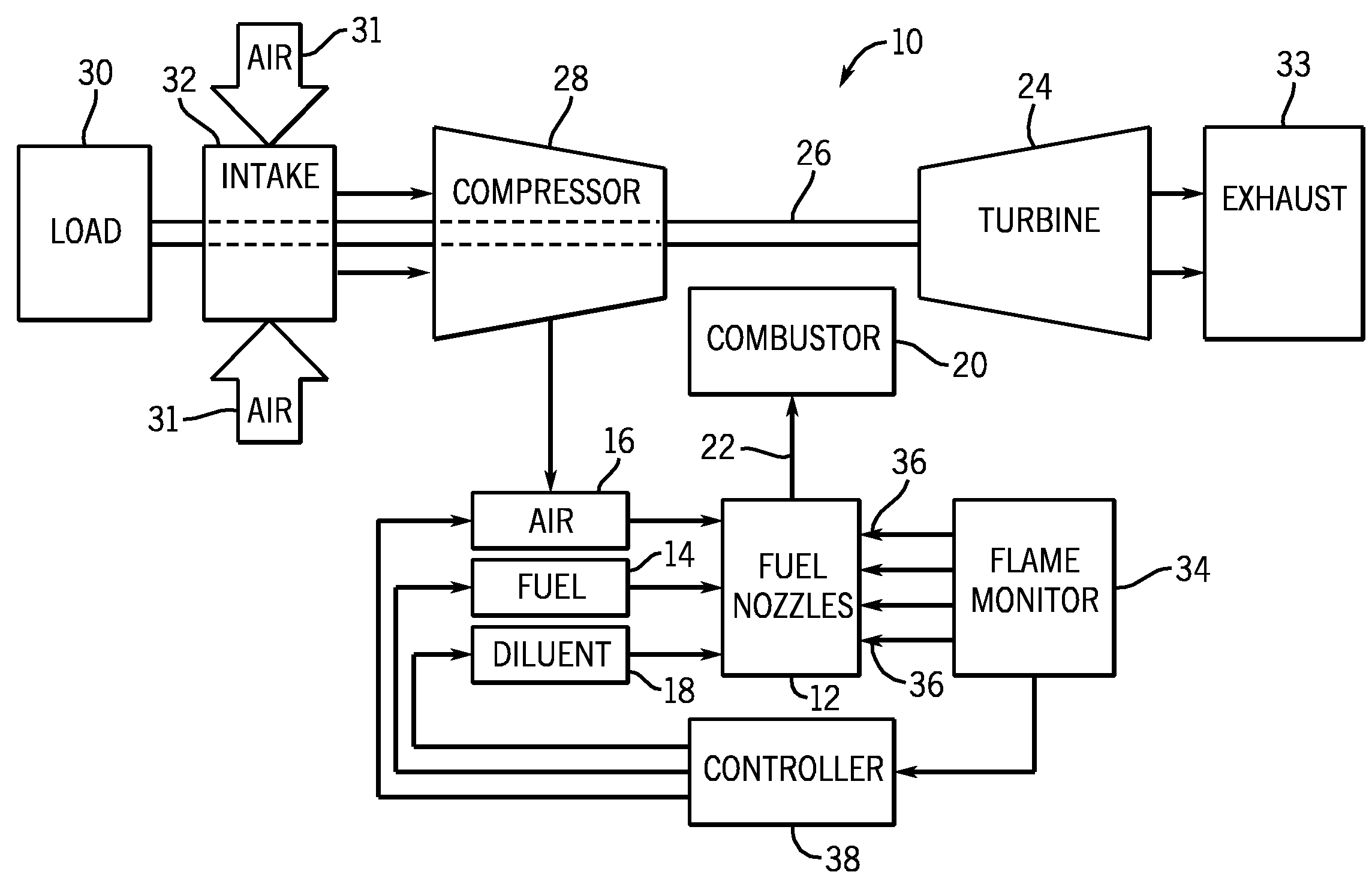

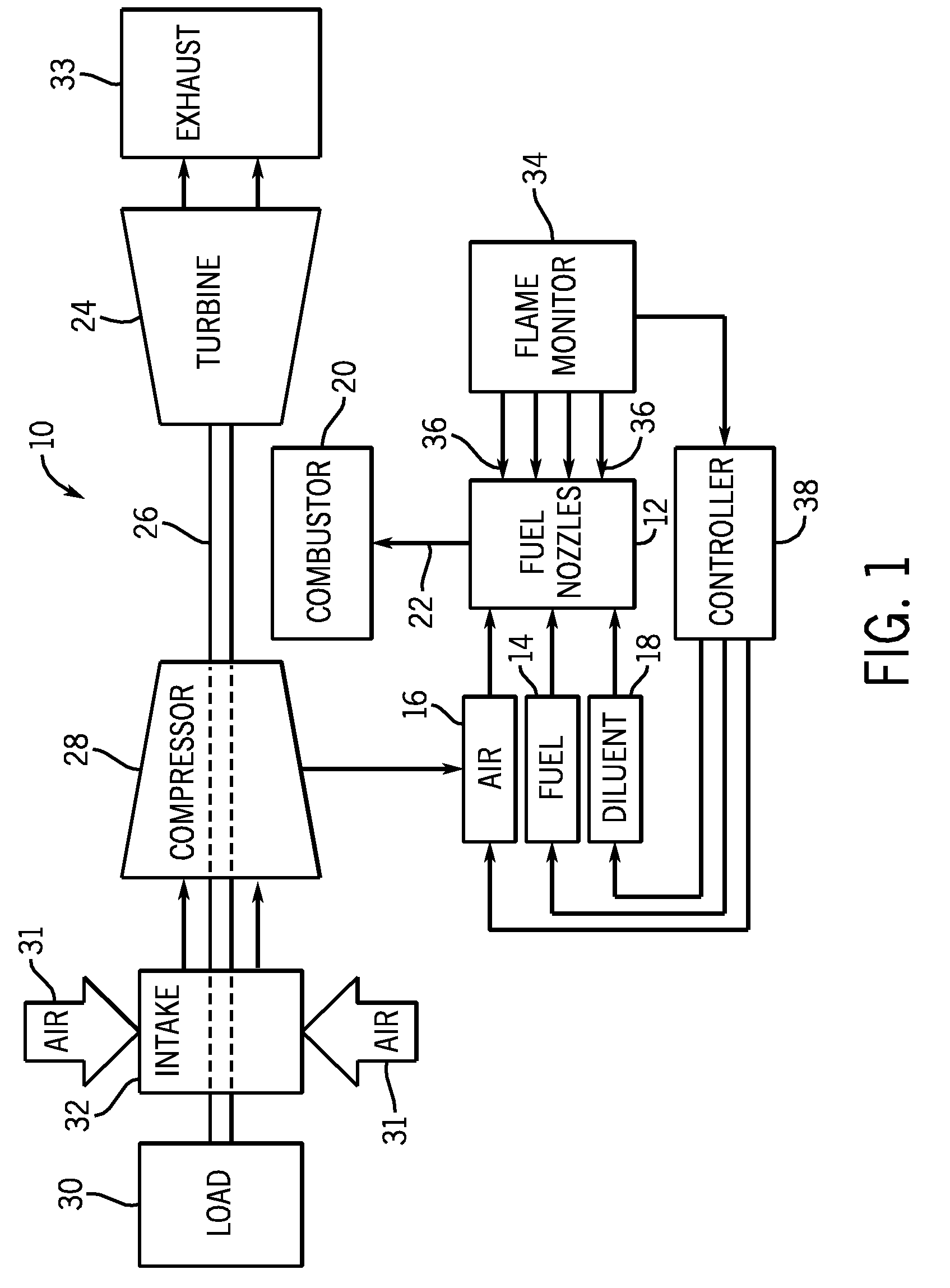

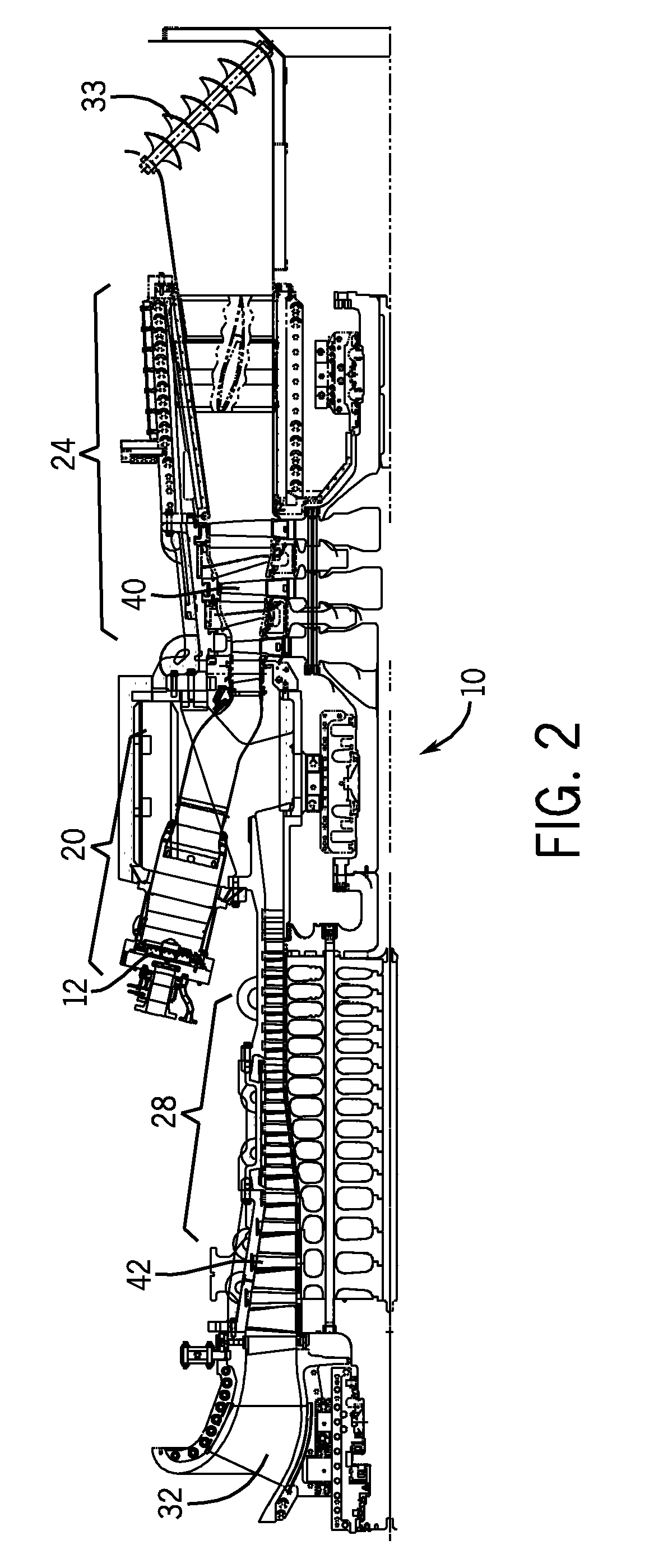

Low-cost dual-fuel combustor and related method

InactiveUS20060080966A1Easy to igniteThe implementation process is simpleBurner safety arrangementsBurnersCombustion chamberCombustor

A combustor for a gas turbine includes a combustion chamber and a plurality of radially outer nozzles surrounding a single, center nozzle, the radially outer nozzles configured to supply only gas fuel to the combustion chamber and the center nozzle configured to supply both gas and liquid fuel to the combustion chamber.

Owner:GENERAL ELECTRIC CO

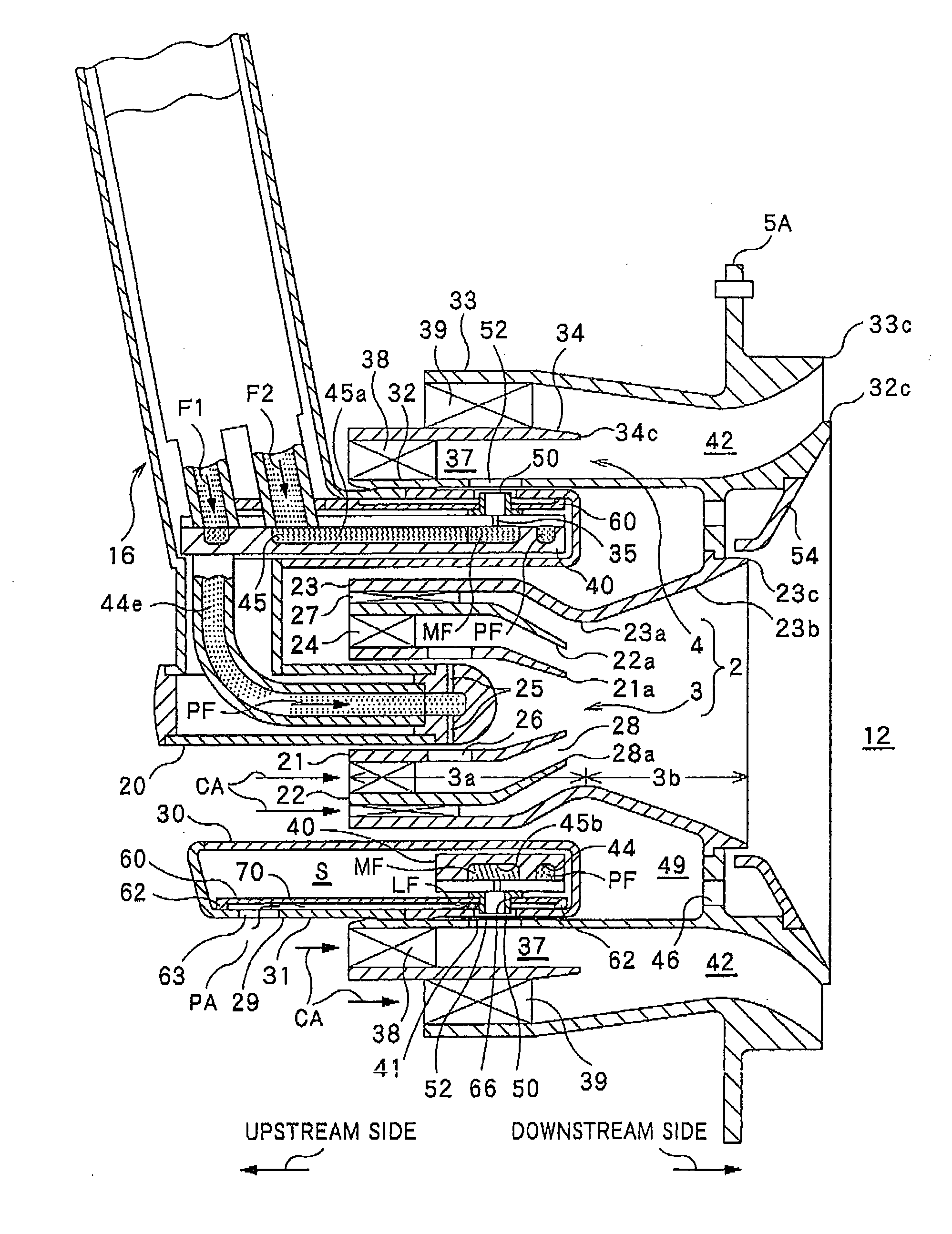

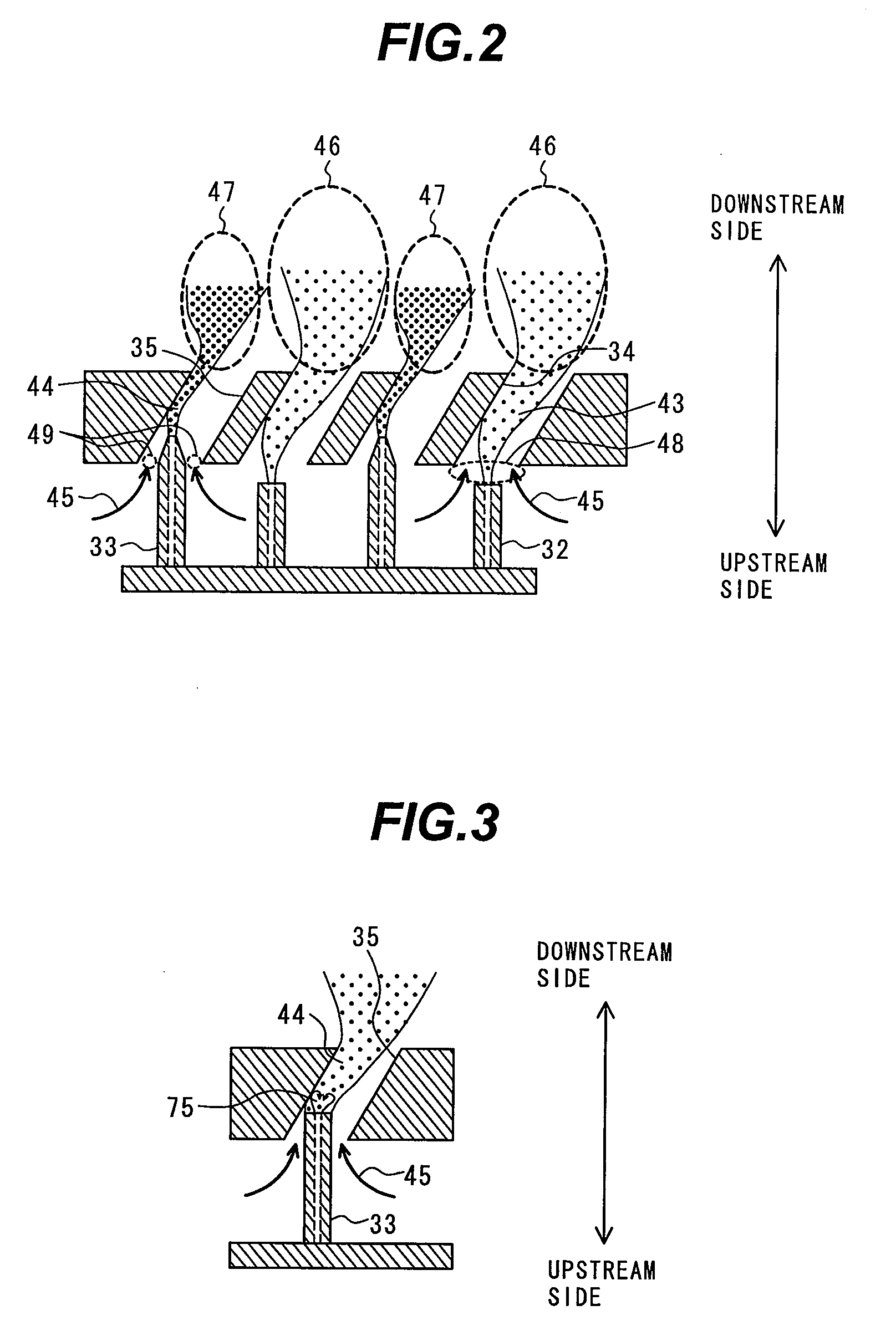

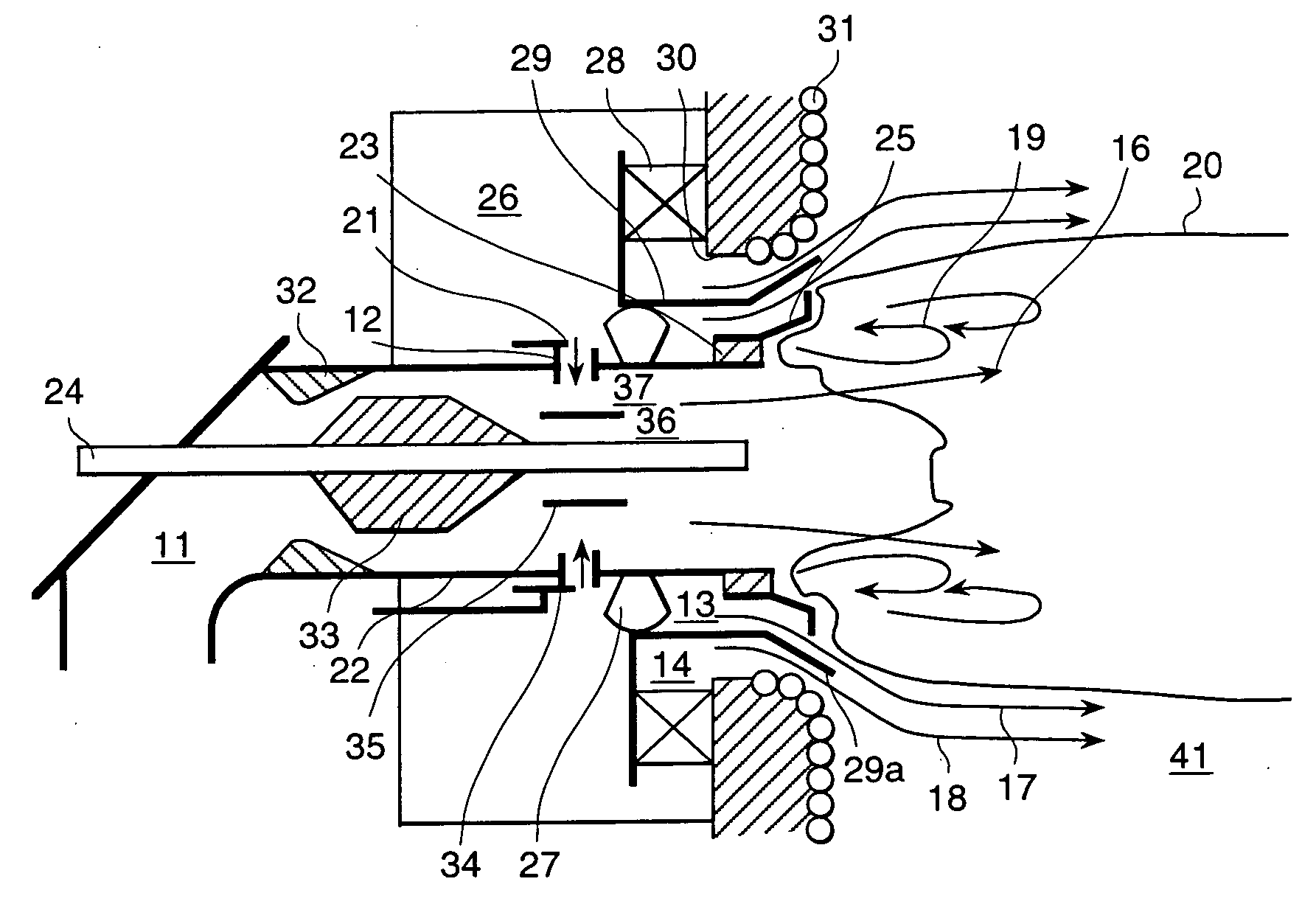

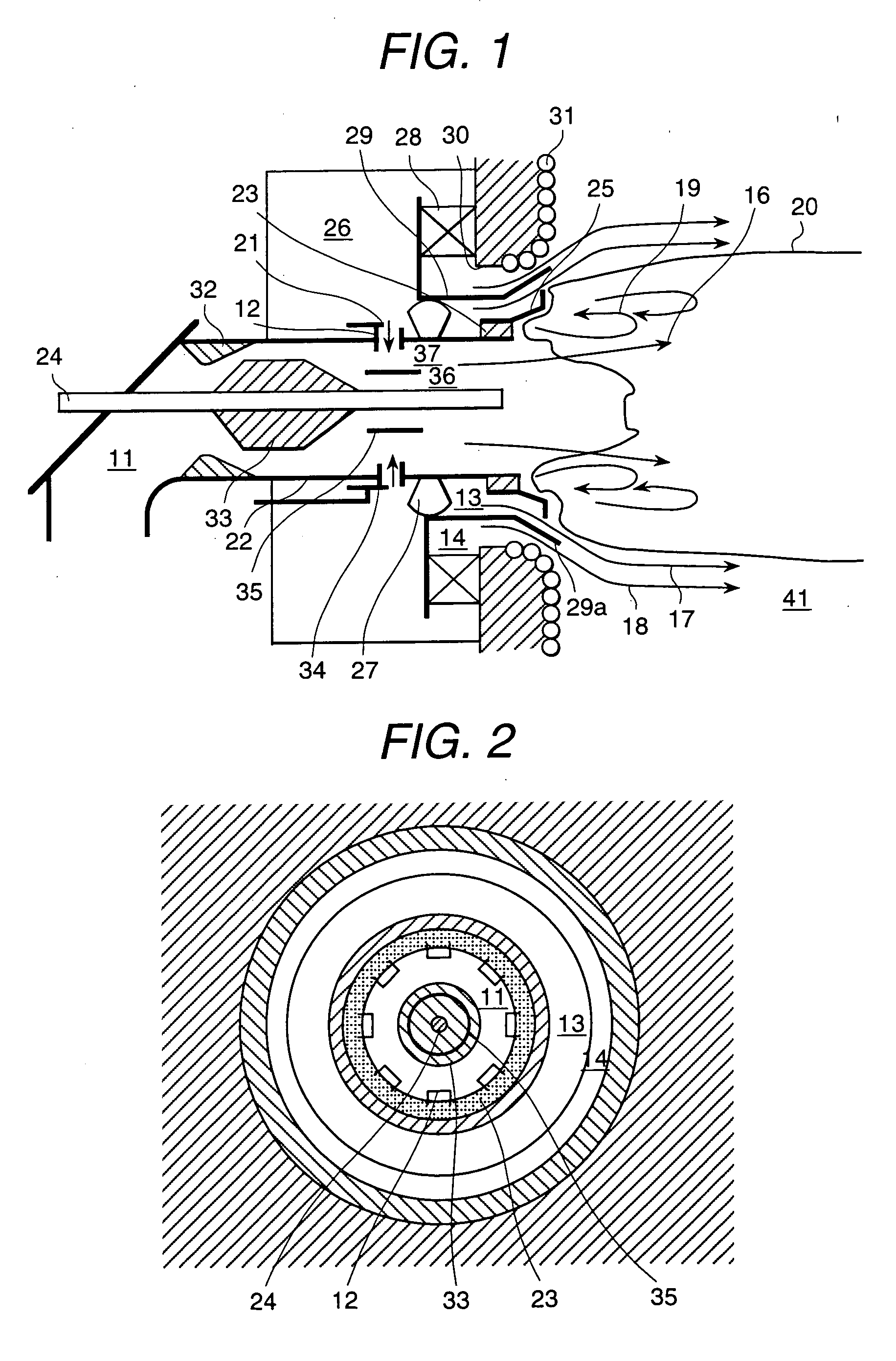

Fuel spray apparatus for gas turbine engine

ActiveUS20100269506A1Easy to provideEffectively blowing offBurner safety arrangementsBurnersProduct gasEngineering

The present invention provides a fuel spray apparatus for a gas turbine engine, including: a pilot part configured to spray a fuel to be used for a diffusion combustion; a main part provided so as to surround the pilot part and configured to inject a pre-mixed gas only upon a high power operation; and a shield body constituting a purge air passage which is configured to take therein an air flowed on an upstream side relative to a fuel injection port of the main part as a purge air, and to blow off a fuel dripping from the fuel injection port toward a main air passage of the main part. The purge air passage is provided in a position opposite to a main fuel passage communicated with the fuel injection port across the shield body.

Owner:KAWASAKI HEAVY IND LTD

Liquid fuel nozzle apparatus with passive water injection purge

In a gas turbine having a compressor, a combustor and a turbine, a gaseous fuel supply coupled to provide gaseous fuel to the combustor, a liquid fuel supply coupled to provide liquid fuel to the combustor via nozzle assembly. The nozzle assembly includes a plurality of passageways for flowing a fluid into the combustor, one of the passageways being an atomizing air passageway conduit interconnecting the atomizing air passageway to one of the plurality of passageways to enable fluid flow therebetween, while not allowing the flow of fluid back into the atomizing air passageway. High pressure air from the atomizing air passageway is diverted into one of the plurality of passageways via the conduit to protect the nozzle from ingestion of hot combustor gases, thus eliminating a need for a dedicated air purge system for that one of the plurality of passageways.

Owner:GENERAL ELECTRIC CO

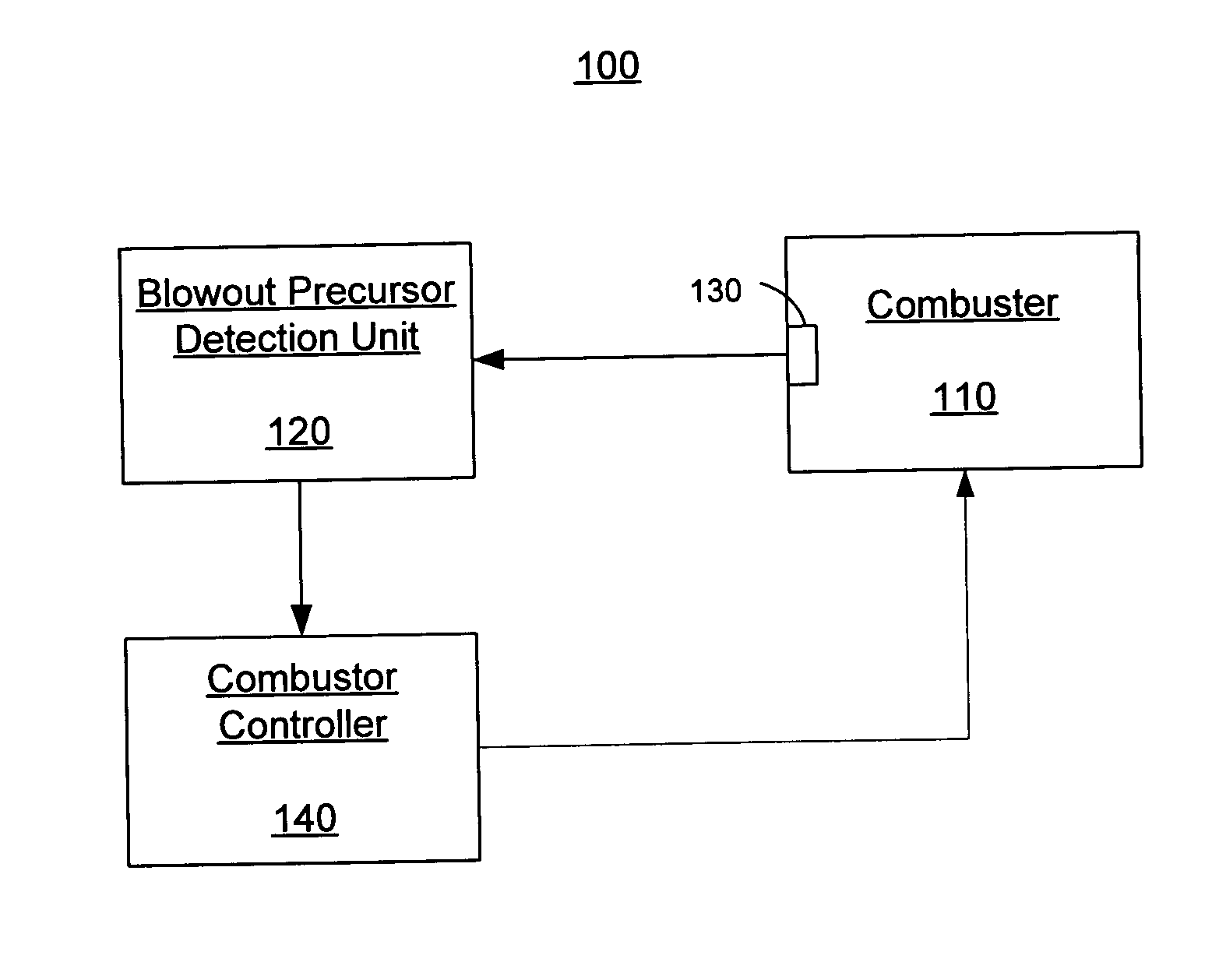

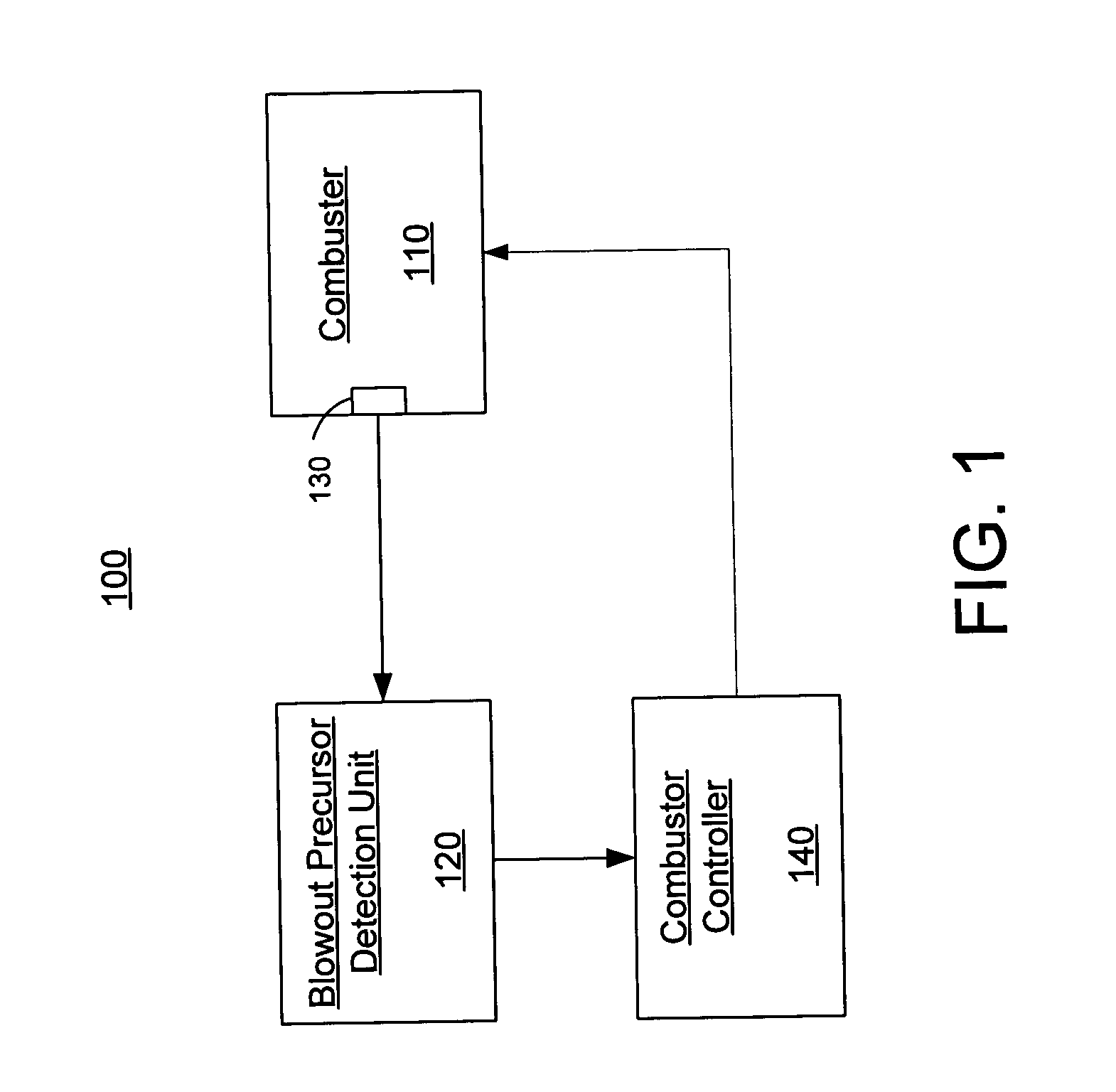

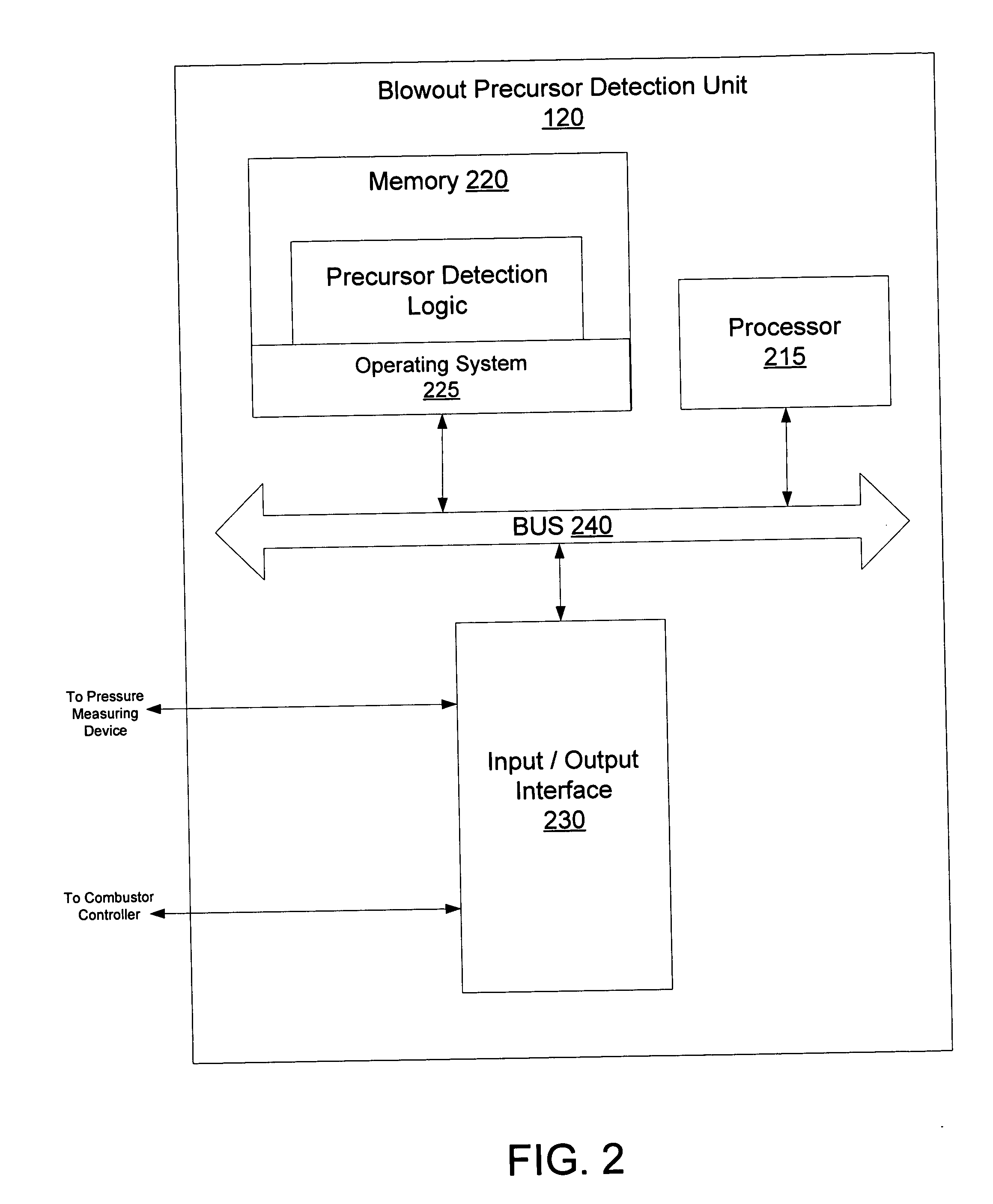

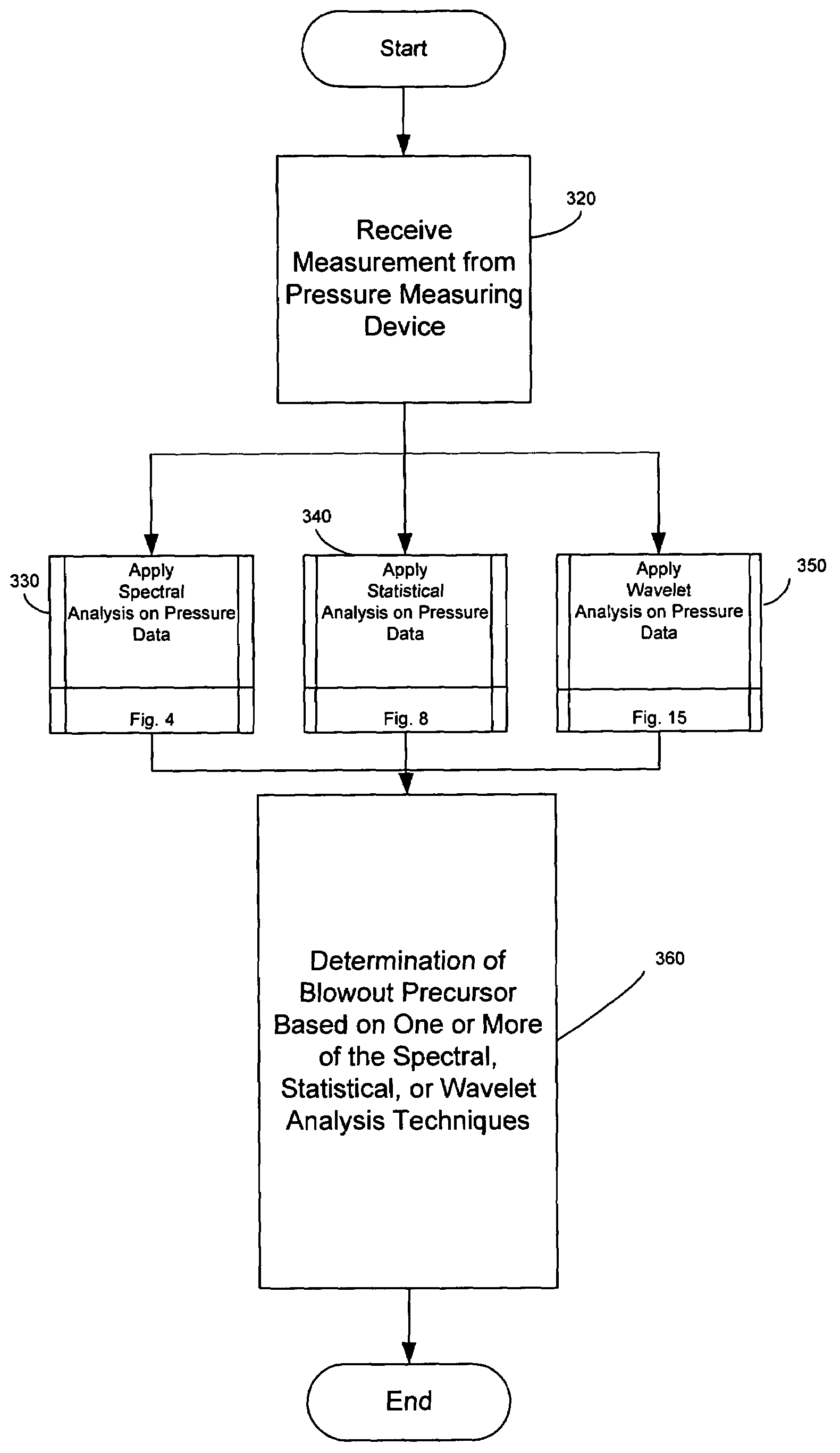

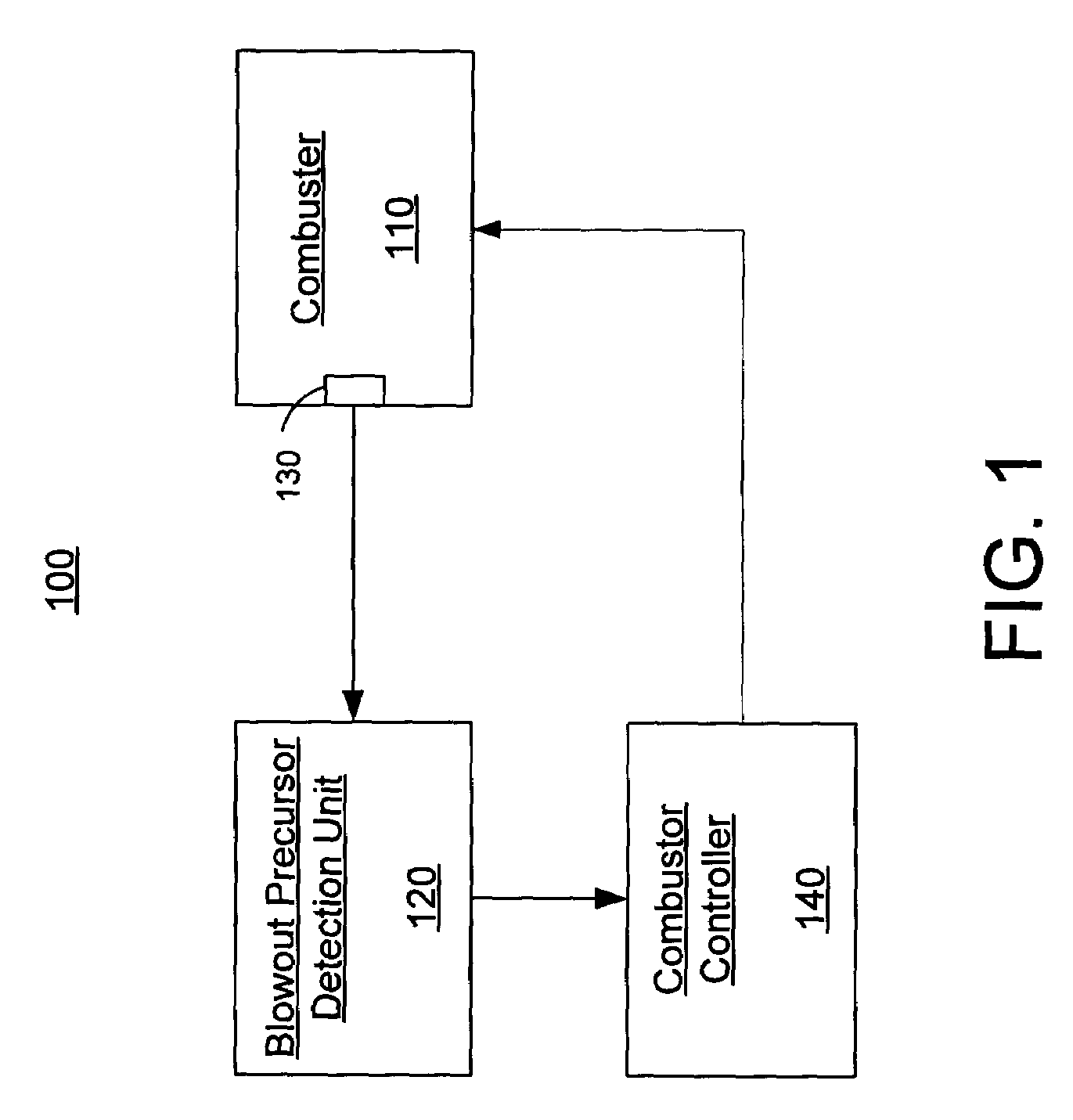

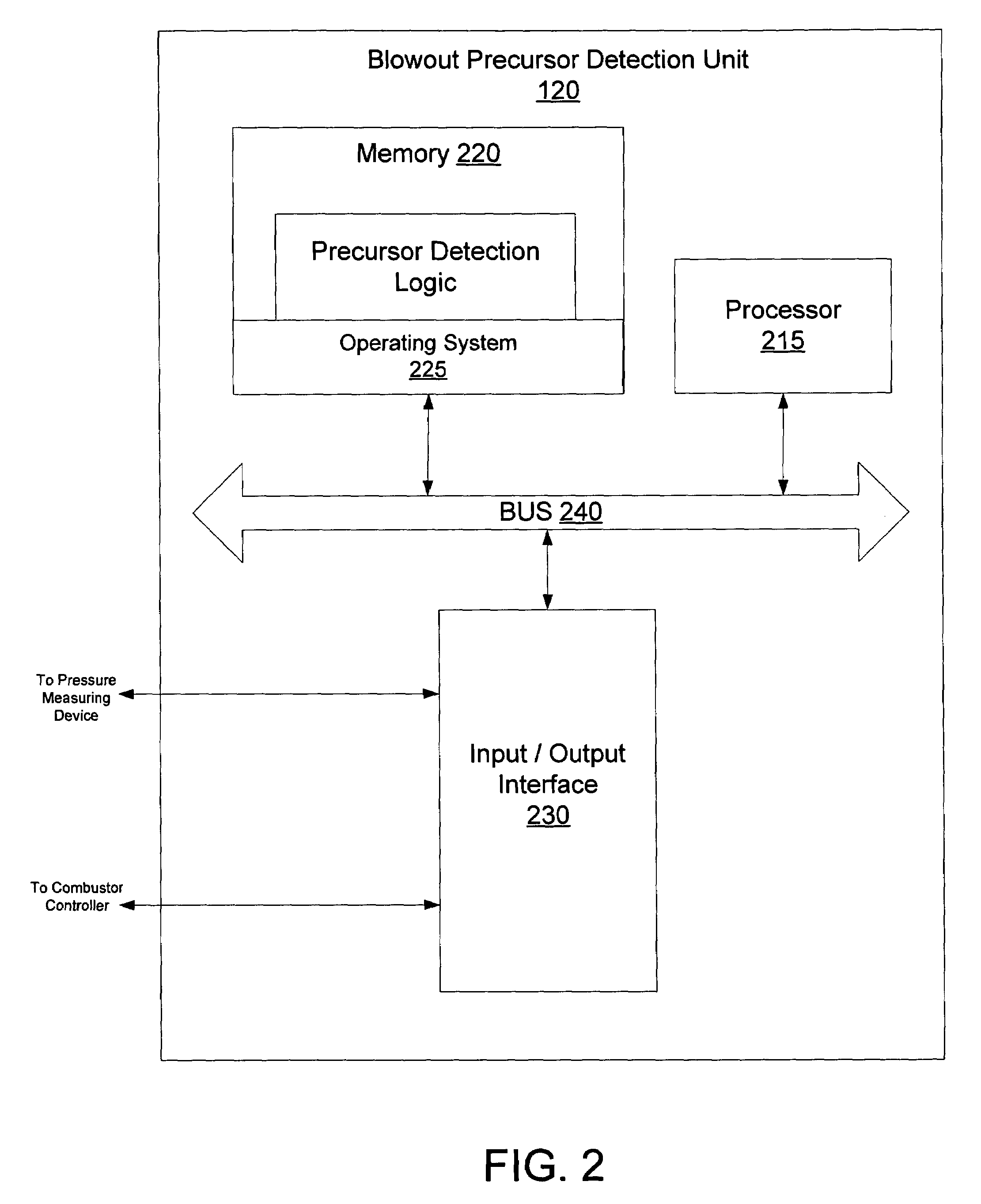

Systems and methods for detection of blowout precursors in combustors

The present invention comprises systems and methods for detecting flame blowout precursors in combustors. The blowout precursor detection system comprises a combustor, a pressure measuring device, and blowout precursor detection unit. A combustion controller may also be used to control combustor parameters. The methods of the present invention comprise receiving pressure data measured by an acoustic pressure measuring device, performing one or a combination of spectral analysis, statistical analysis, and wavelet analysis on received pressure data, and determining the existence of a blowout precursor based on such analyses. The spectral analysis, statistical analysis, and wavelet analysis further comprise their respective sub-methods to determine the existence of blowout precursors.

Owner:GEORGIA TECH RES CORP

Self-Purging Pilot Fuel Injection System

InactiveUS20060168966A1Inhibition of attachmentBurner safety arrangementsBurnersGas turbinesFuel injection

A gas turbine combustor having a self-purging pilot fuel injection system and method of operation thereof is disclosed. The pilot fuel injection system comprises a radial inflow swirler, a generally axially extending centerbody, and at least one fuel injection source. In operation a fluid containing at least air passes along the centerbody outer surface clearing any remaining fuel from proximate the fuel injection source so as to prevent flame attachment proximate the fuel injection source.

Owner:ANSALDO ENERGIA IP UK LTD

Combustor assembly for use in a turbine engine and methods of assembling same

A fuel nozzle assembly for use with a turbine engine is described herein. The fuel nozzle assembly includes a plurality of fuel nozzles positioned within an air plenum defined by a casing. Each of the plurality of fuel nozzles is coupled to a combustion liner defining a combustion chamber. Each of the plurality of fuel nozzles includes a housing that includes an inner surface that defines a cooling fluid plenum and a fuel plenum therein, and a plurality of mixing tubes extending through the housing. Each of the mixing tubes includes an inner surface defining a flow channel extending between the air plenum and the combustion chamber. At least one mixing tube of the plurality of mixing tubes including at least one cooling fluid aperture for channeling a flow of cooling fluid from the cooling fluid plenum to the flow channel.

Owner:GENERAL ELECTRIC CO

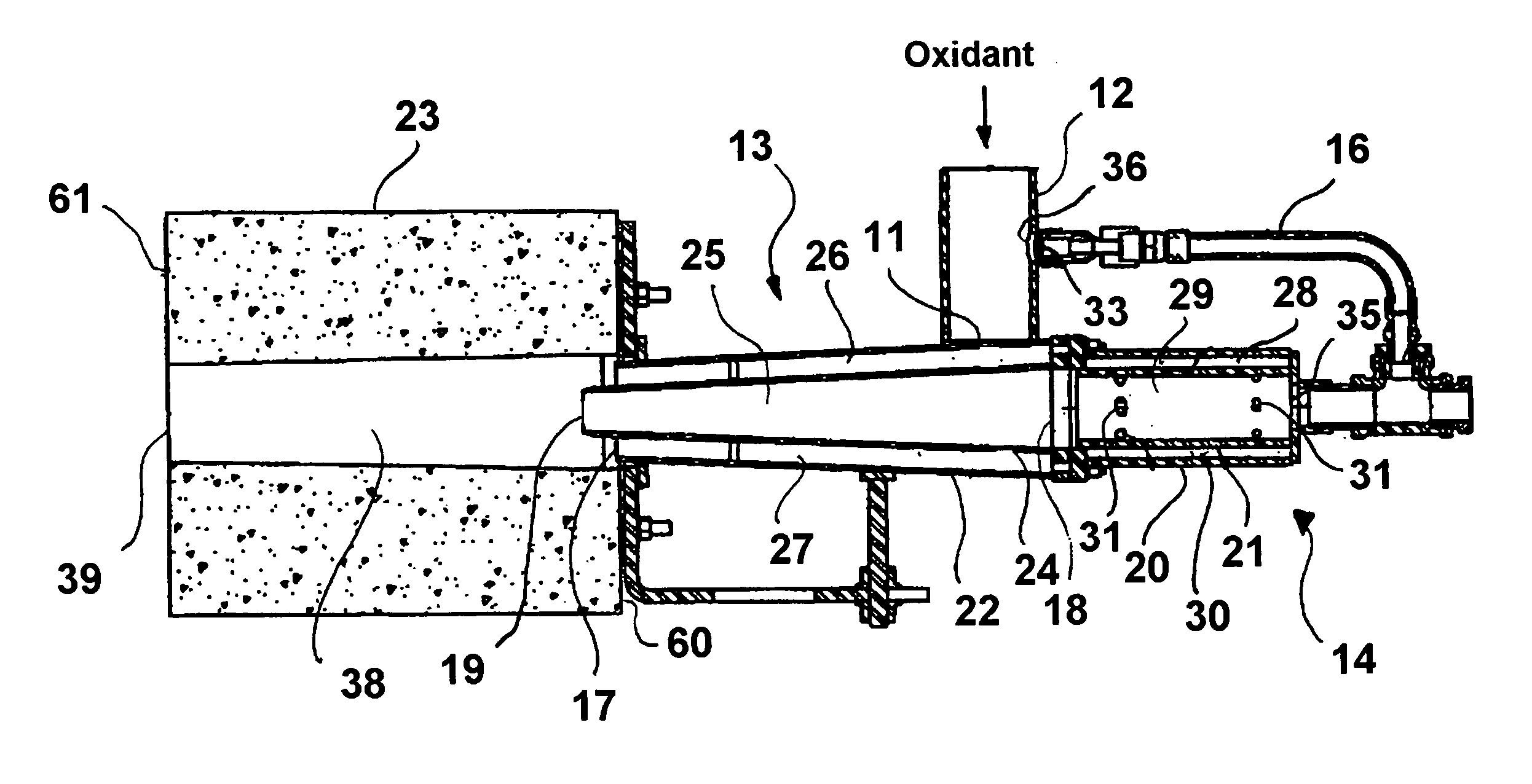

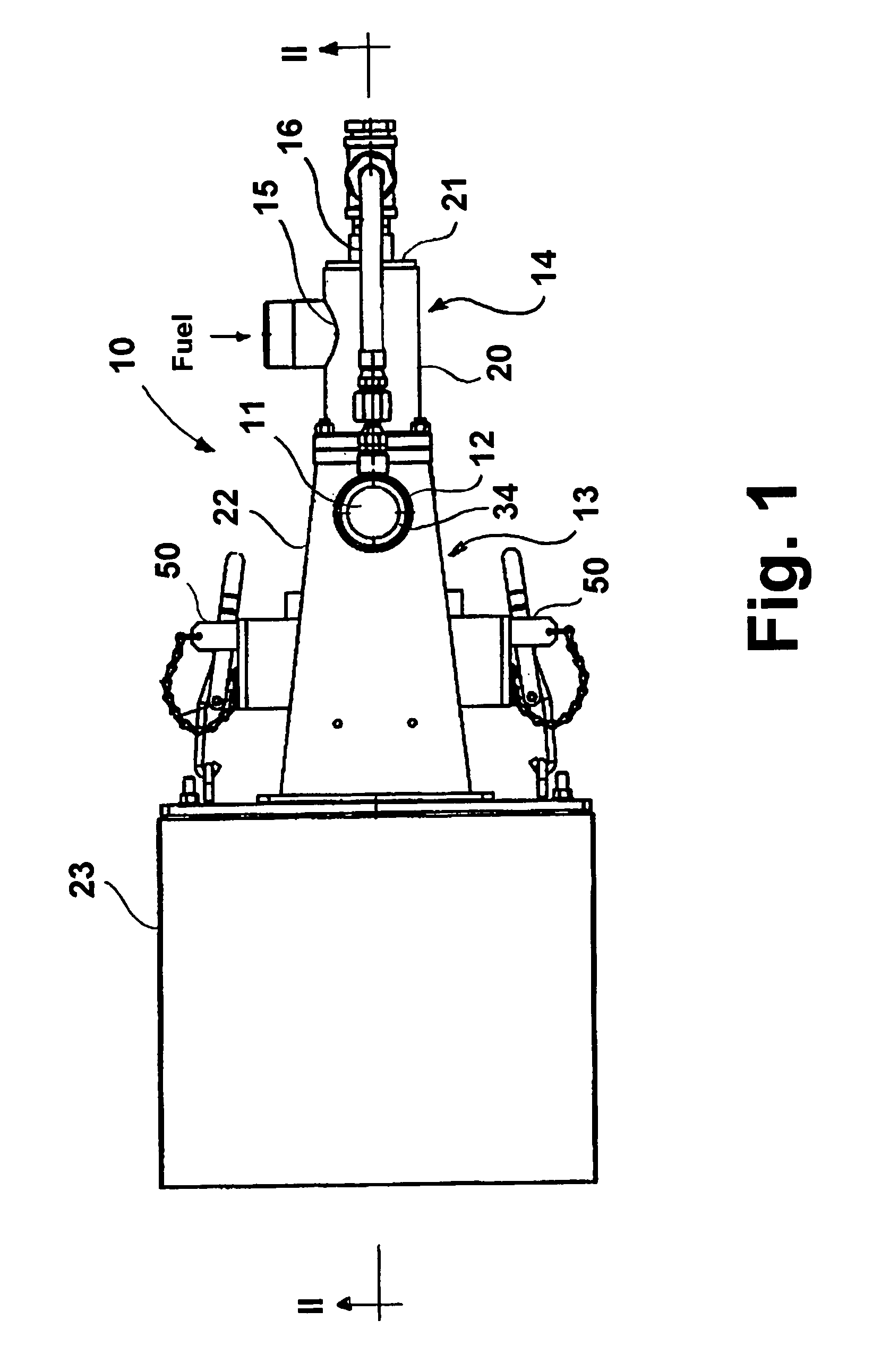

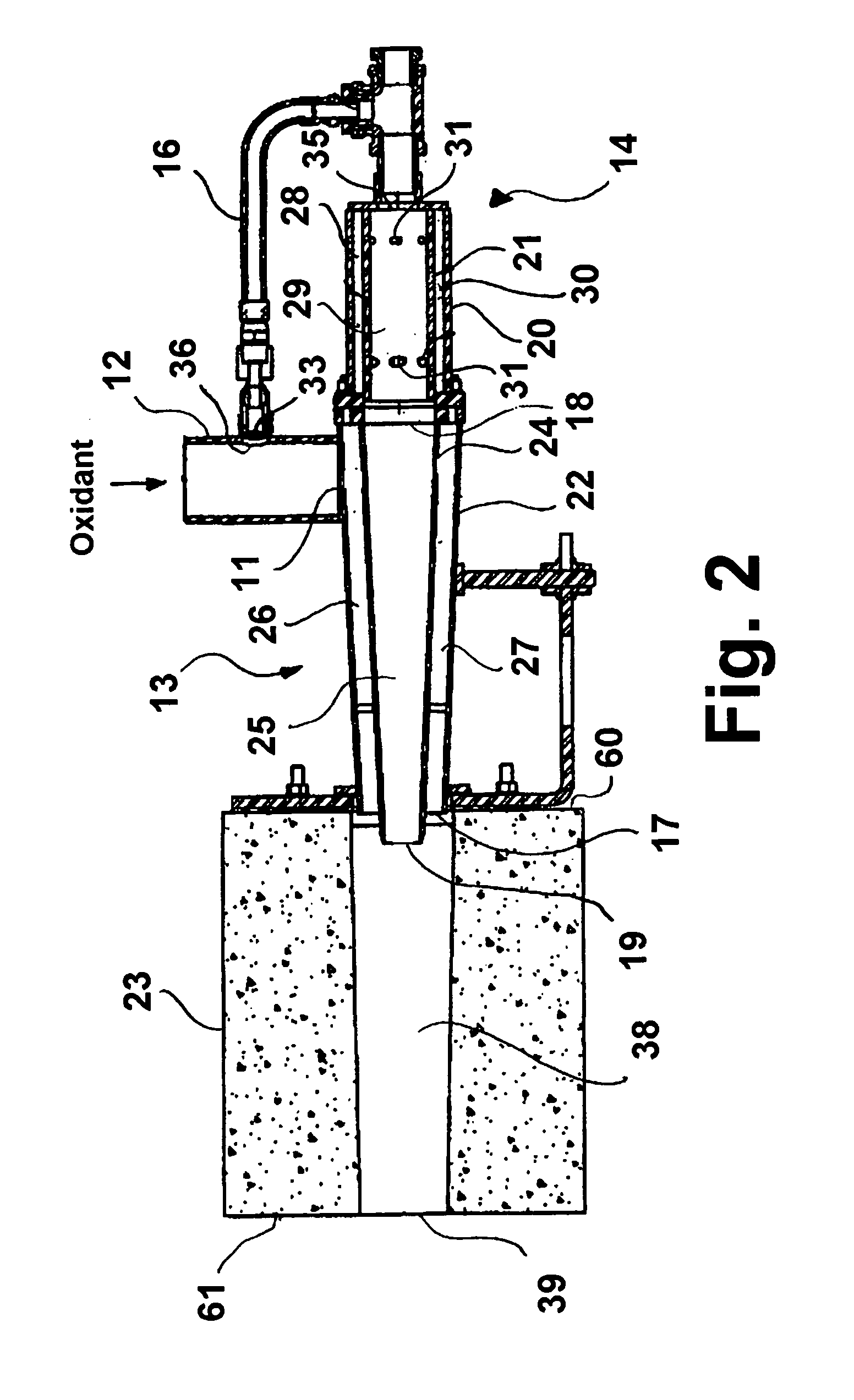

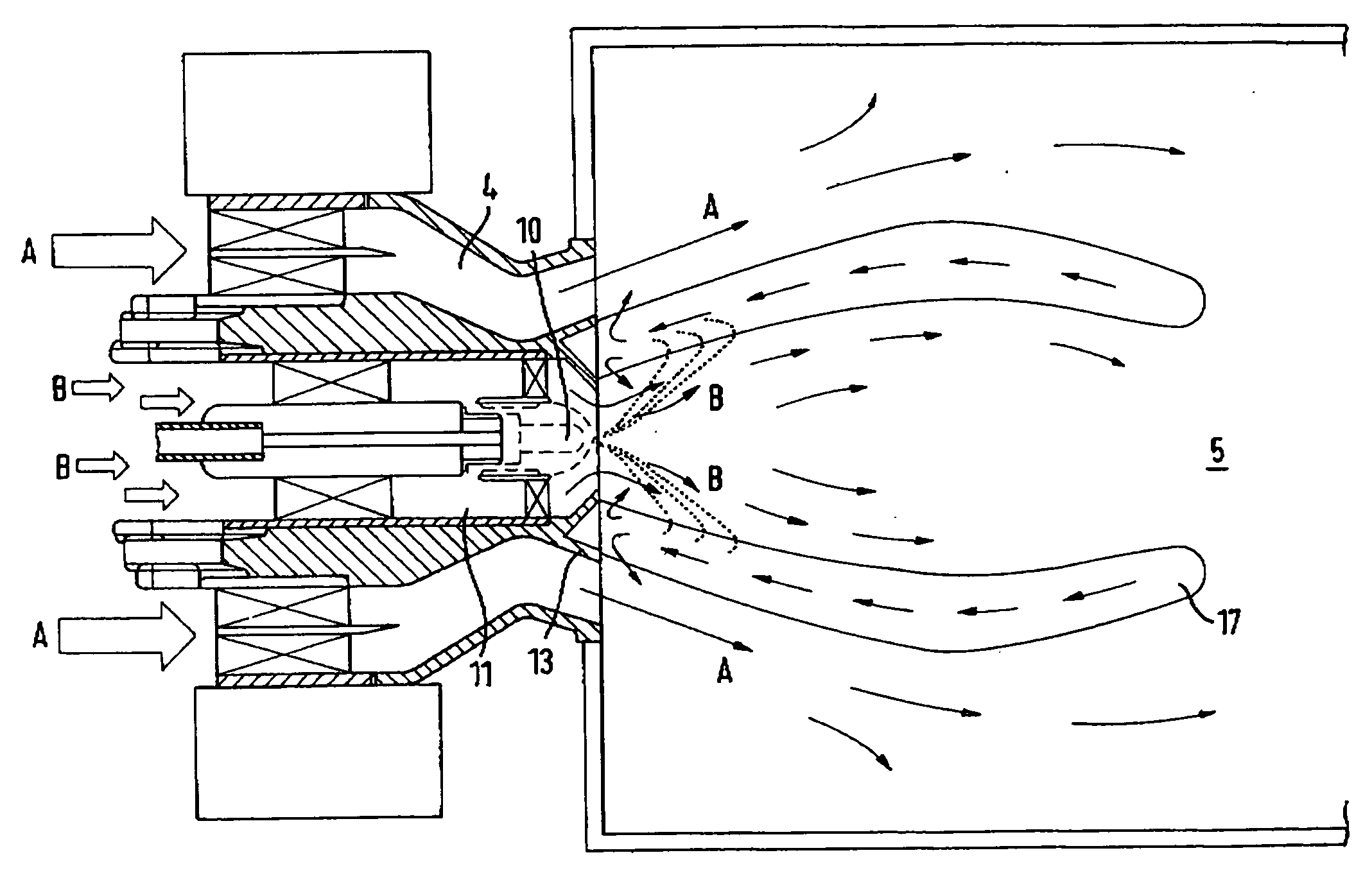

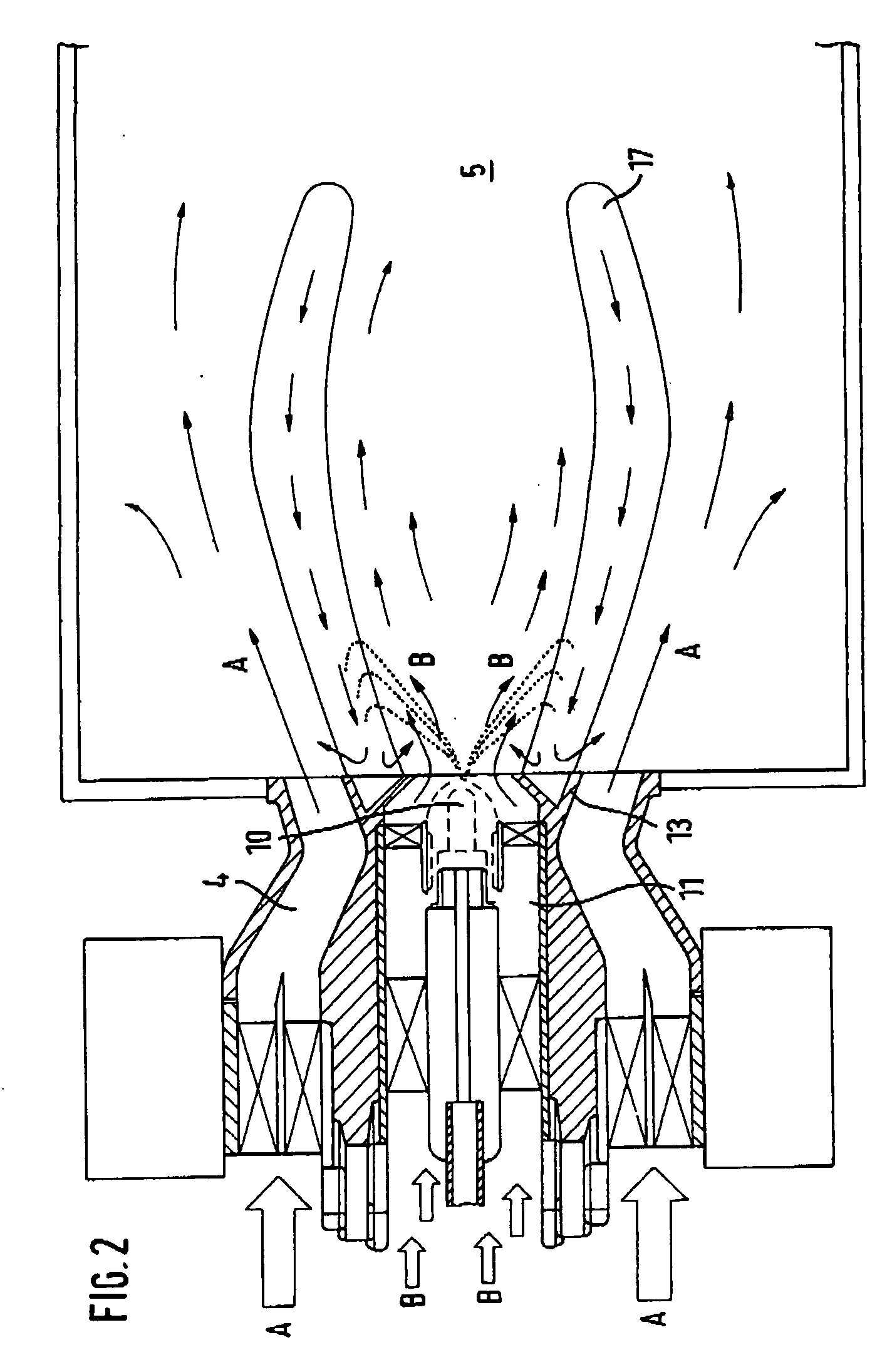

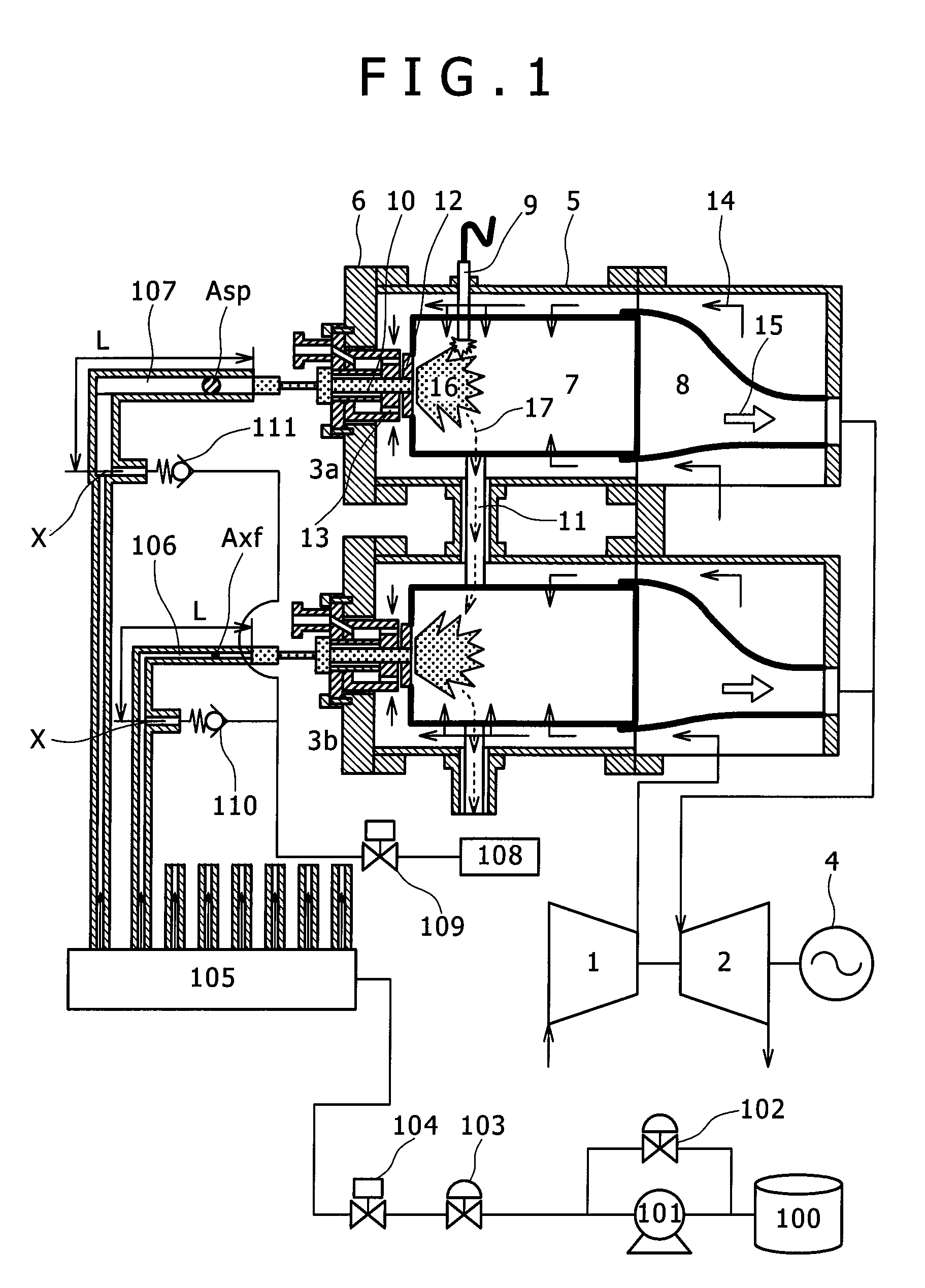

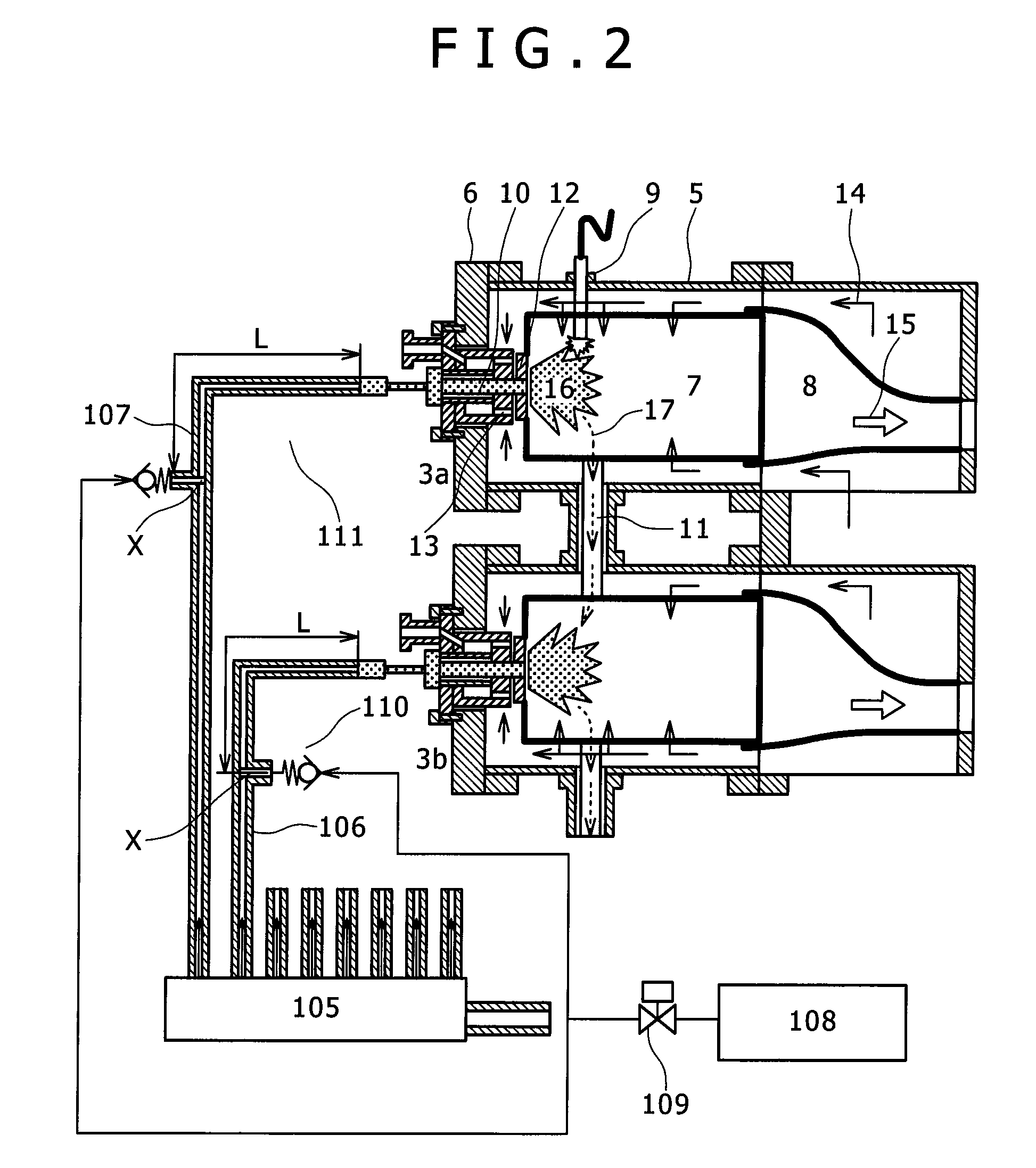

Burner for a gas-turbine combustion chamber

InactiveUS20050028526A1Guarantee stabilityOperational securityBurner safety arrangementsBurnersCombustorCombustion chamber

On a burner for a gas-turbine combustion chamber which comprises a lean premix burner with centrally integrated stabilizing burner, a core air annulus (11) accommodating the atomizer nozzle (10) of the stabilizing burner is concentrically surrounded by a main air annulus (4) supplying the weak air-fuel mixture. In the adjacent issuing areas of the main air annulus and the core air annulus, a flame stabilization ring (13), which is heated by the combustion gases and whose cross-sectional surface increases in area toward the combustion chamber (5), is provided to produce an approximately hollow-cylindrical hot-gas recirculation zone (17) originating at the flame stabilization ring which ensures a stable flame formation throughout the range of operating conditions of the gas turbine.

Owner:ROLLS ROYCE DEUT LTD & CO KG

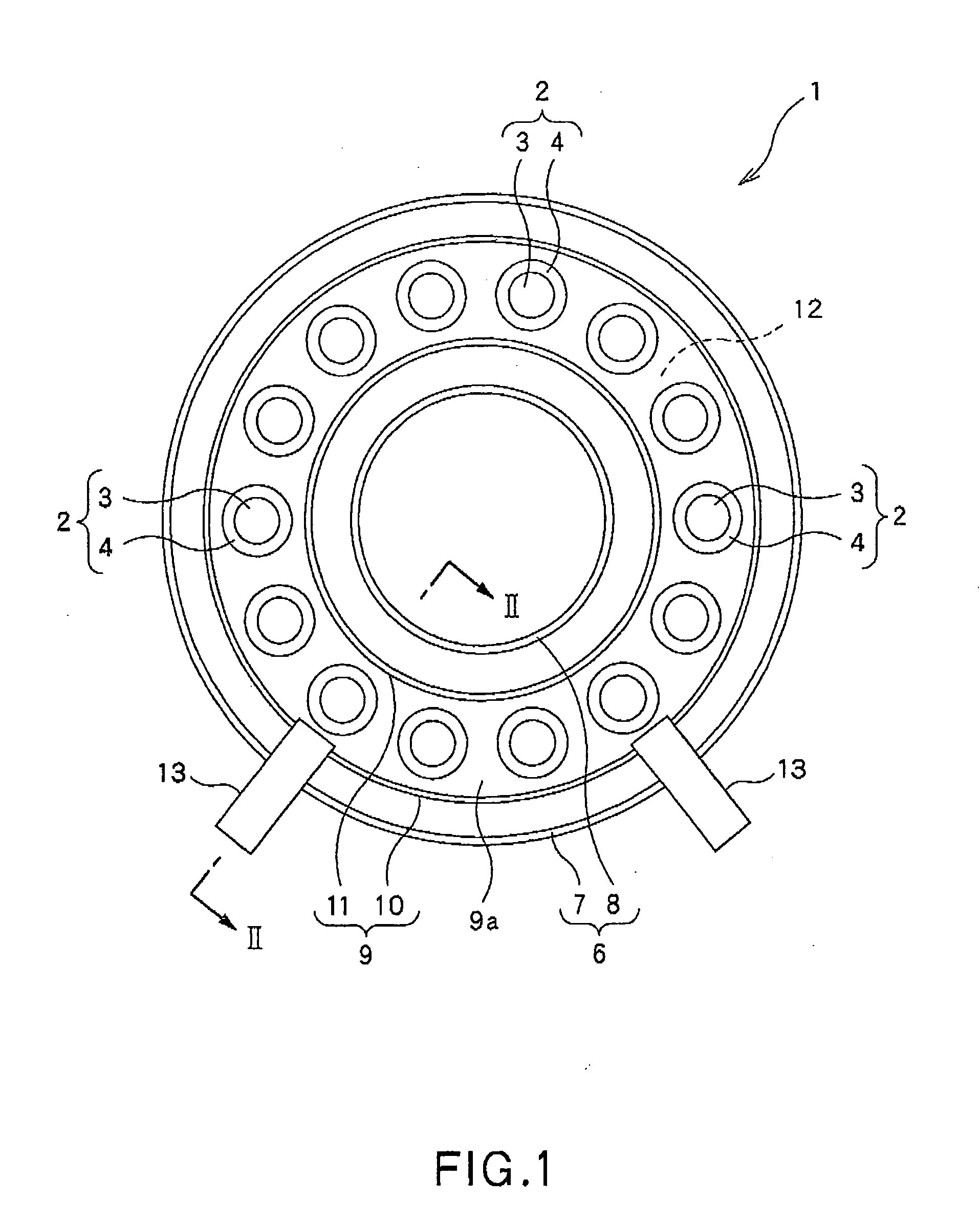

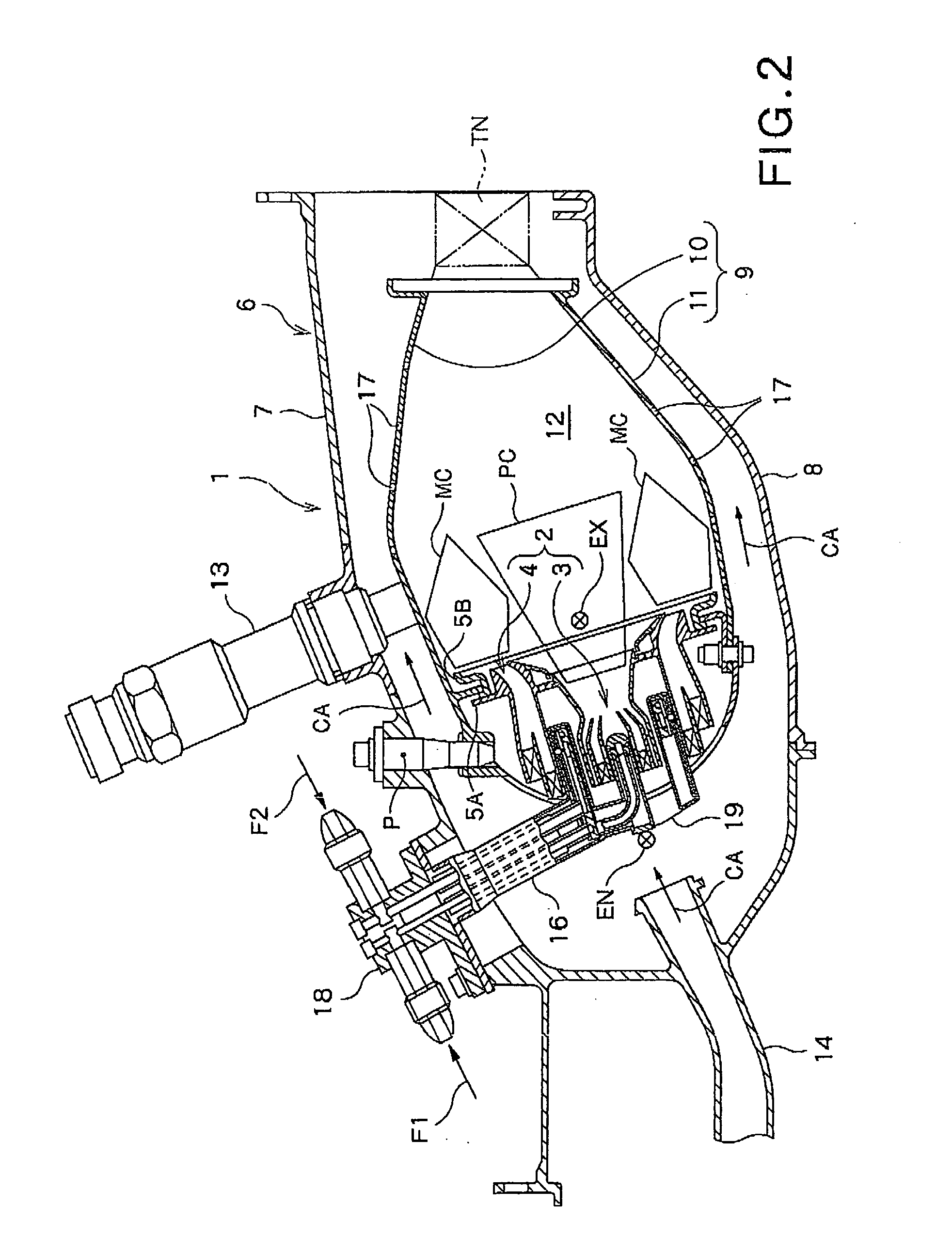

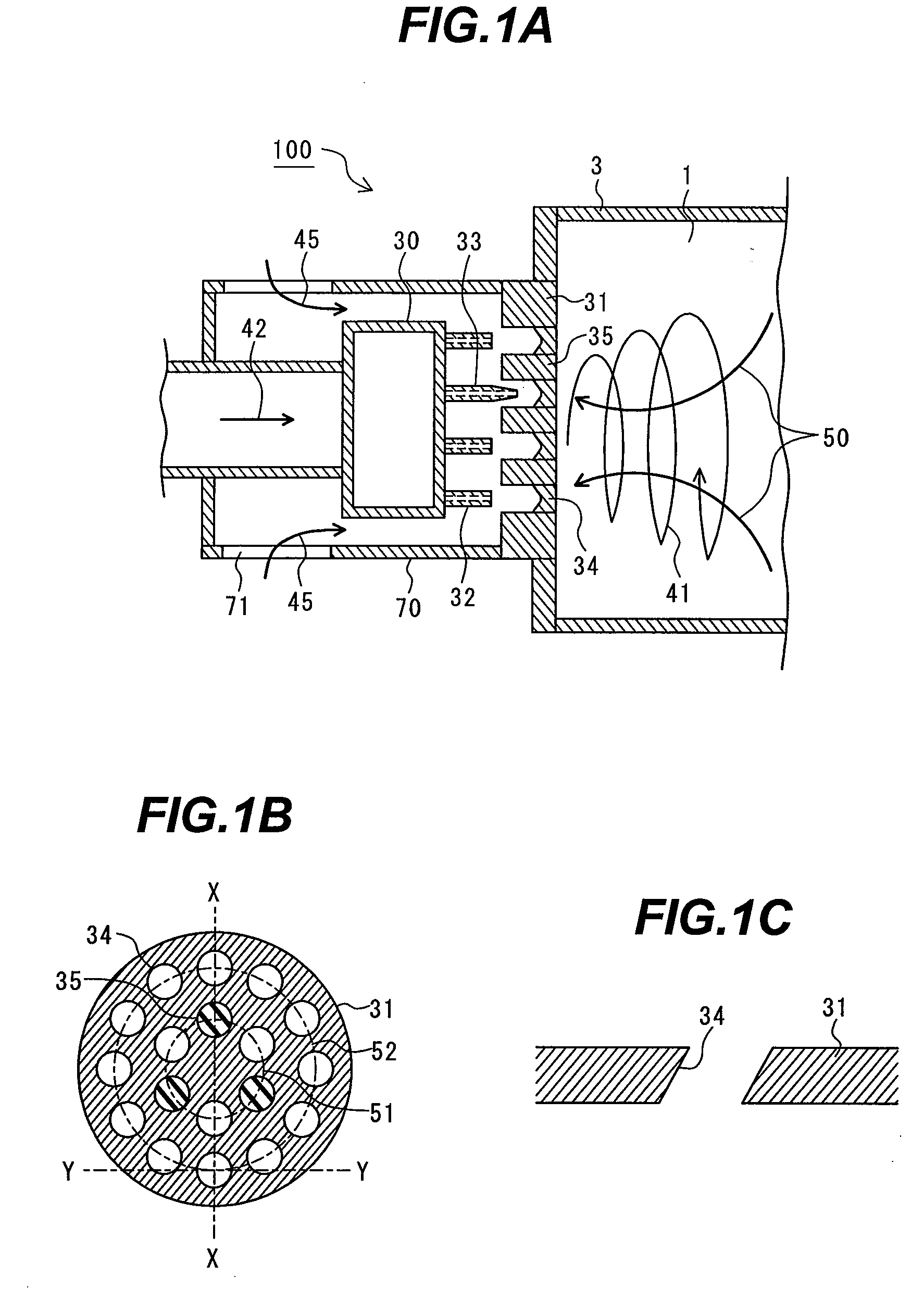

Burner and gas turbine combustor

ActiveUS20090173075A1Improve flame stabilityReduce nitrogen oxide emissionsBurner safety arrangementsContinuous combustion chamberCombustorGas turbines

A burner is provided that has high flame stability and reduces NOx emissions. In the burner, air holes of an air hole member have a central axis inclined relative to a burner central axis. The leading end portion of a first fuel nozzle is configured to be able to suppress turbulence of air-flow flowing on the outer circumference side of the first fuel nozzle. The tip of the first fuel nozzle is located on a fuel jetting-out directional downstream side of the inlet of the fuel hole. The tip of the second fuel nozzle is located on a fuel jetting-out directional downstream side of the air hole inlet.

Owner:MITSUBISHI POWER LTD

Active Control of Flame Holding and Flashback in Turbine Combustor Fuel Nozzle

A system includes a turbine combustor fuel nozzle. The turbine combustor fuel nozzle includes a swirl vane. The turbine combustor fuel nozzle also includes an injection hole configured to inject fluid in a downstream region of the swirl vane. The injection of fluid in a downstream region of the swirl vane may be in response to detection of a condition indicative of a flame inside the turbine combustor fuel nozzle.

Owner:GENERAL ELECTRIC CO

Low-cost dual-fuel combustor and related method

InactiveUS7546735B2The implementation process is simpleBurner safety arrangementsBurnersLiquid fuelGas turbines

A combustor for a gas turbine includes a combustion chamber and a plurality of radially outer nozzles surrounding a single, center nozzle, the radially outer nozzles configured to supply only gas fuel to the combustion chamber and the center nozzle configured to supply both gas and liquid fuel to the combustion chamber.

Owner:GENERAL ELECTRIC CO

Solid fuel burner, burning method using the same, combustion apparatus and method of operating the combustion apparatus

InactiveUS20040211345A1Swirling intensityInhibitionCombustion using gaseous and pulverulent fuelBurner safety arrangementsBrown coalJet flow

A solid fuel burner using a low oxygen concentration gas as a transporting gas of a low grade solid fuel such as brown coal or the like and a combustion method using the solid fuel burner are provided. The solid fuel burner comprises a means for accelerating ignition of the fuel and a means for preventing slugging caused by combustion ash from occurring. Mixing of fuel and air inside a fuel nozzle 11 is accelerated by that an additional air nozzle 12 and a separator 35 for separating a flow passage are arranged in the fuel nozzle 11, and the exit of the additional air nozzle 12 is set at a position so as to overlap with the separator 35 when seeing from a direction perpendicular to a burner axis, and additional air is ejected in a direction nearly perpendicular to a flow direction of a fuel jet flowing through the fuel nozzle 11. An amount of air from the additional air nozzle 12 is varied corresponding to a combustion load. By increasing the amount of air from the additional air nozzle 12 at a low load operation, an oxygen concentration of a circulation flow 19 formed in a downstream portion outside the exit of the fuel nozzle 11 is increased to stably burn the fuel. By decreasing the amount of air from the additional air nozzle 12 at a high load operation, a flame is formed at a position distant from the fuel nozzle 11 to suppress radiant heat received by structures of the solid fuel burner and walls of the furnace.

Owner:HITACHI LTD +1

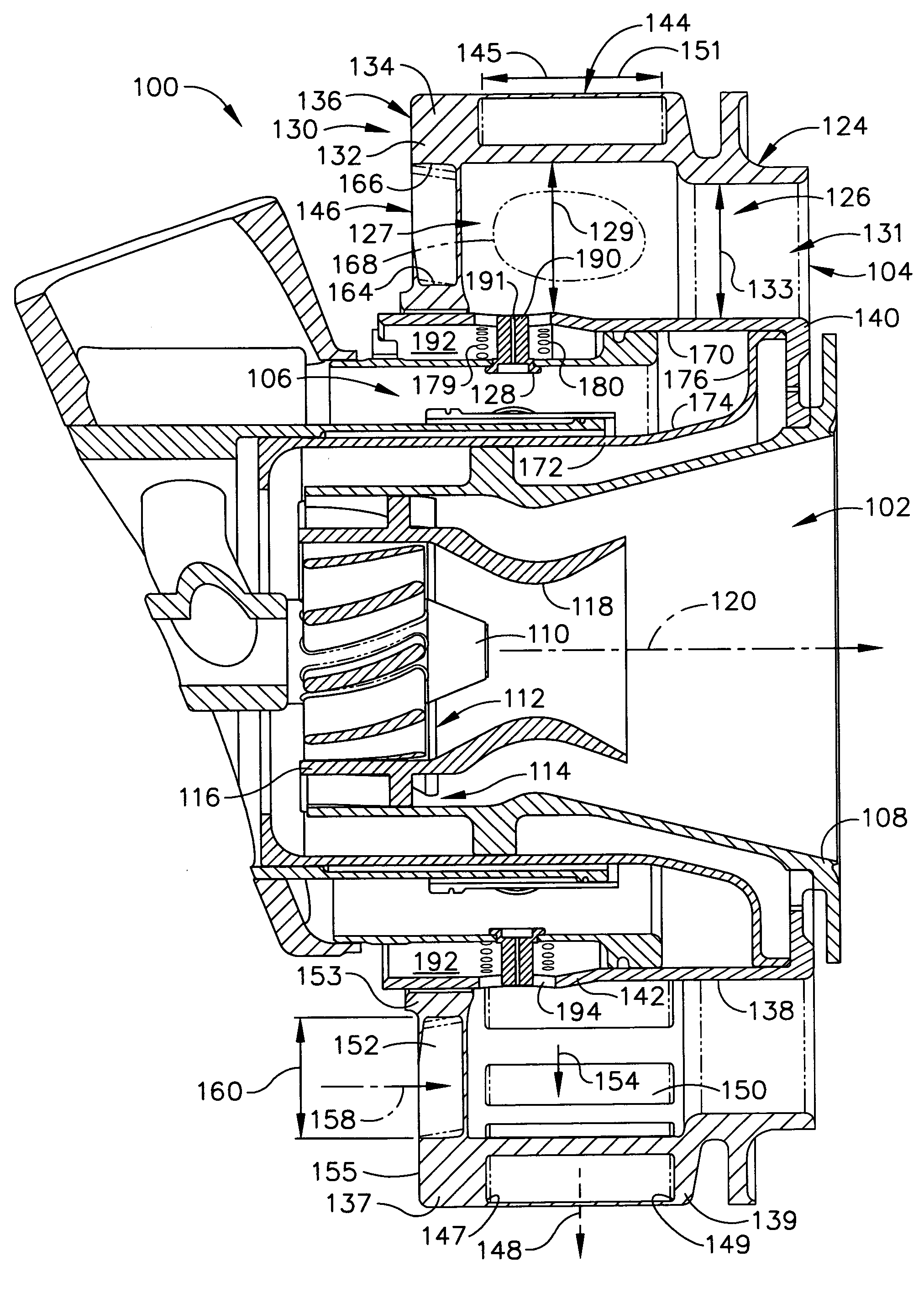

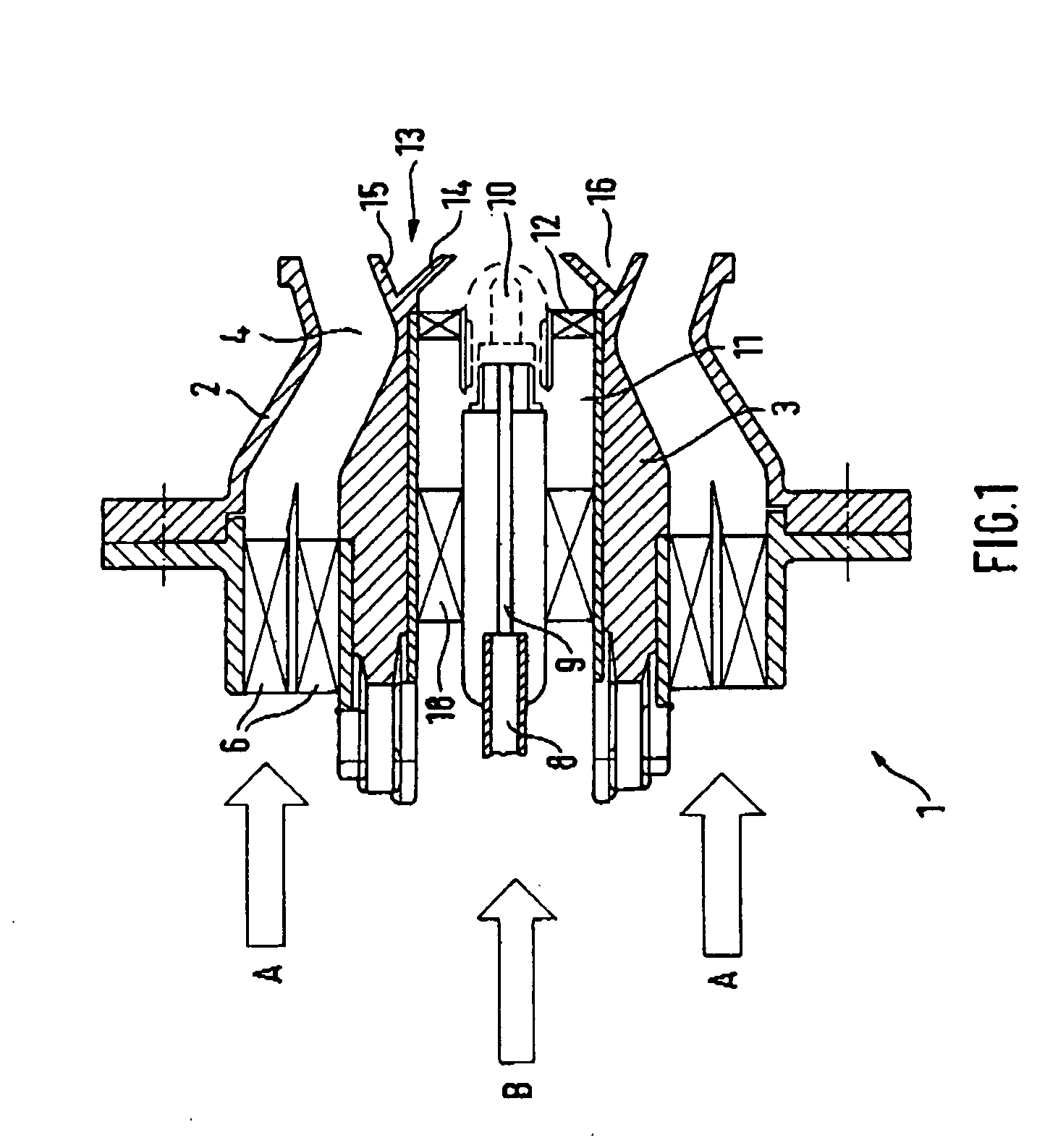

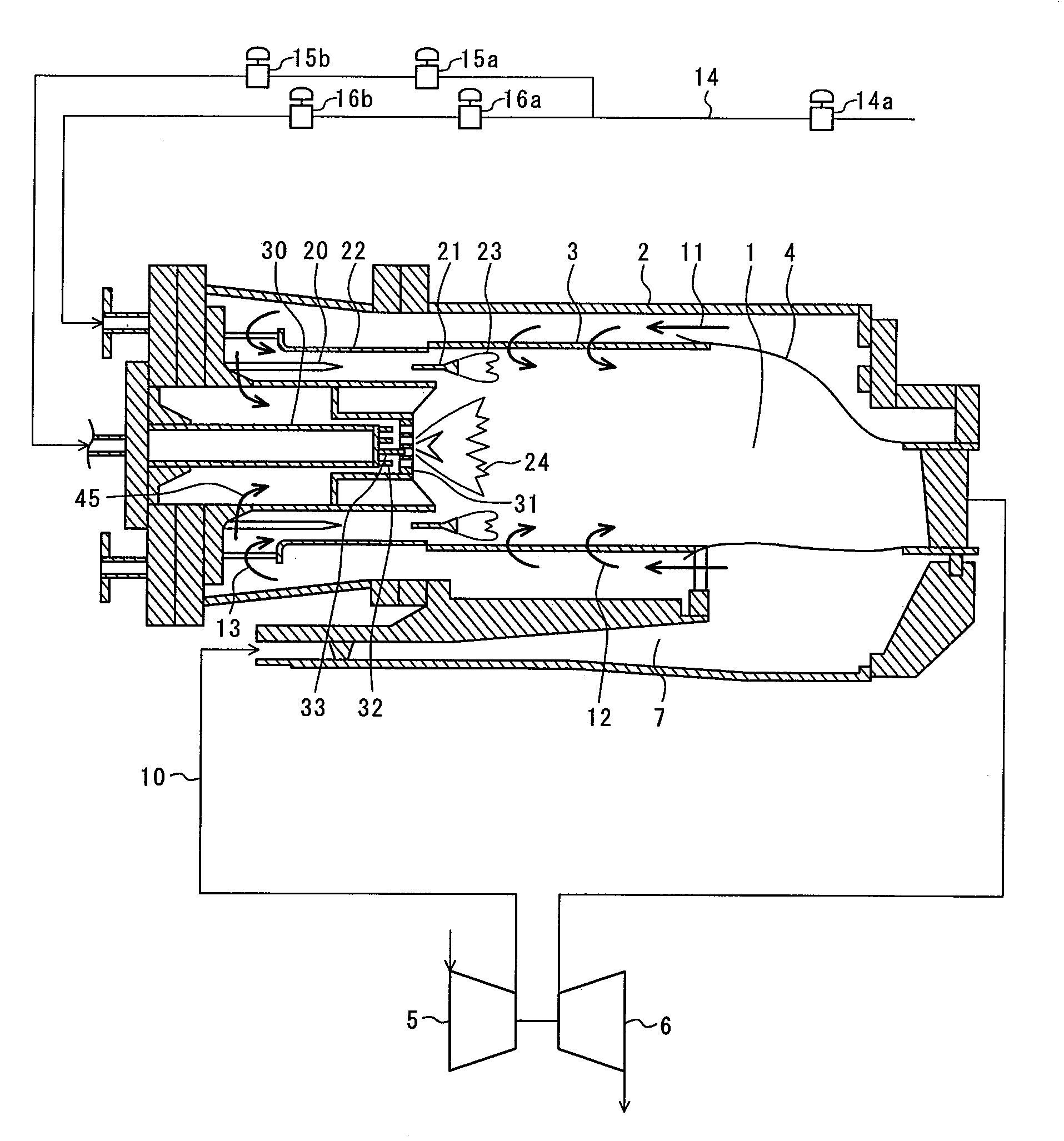

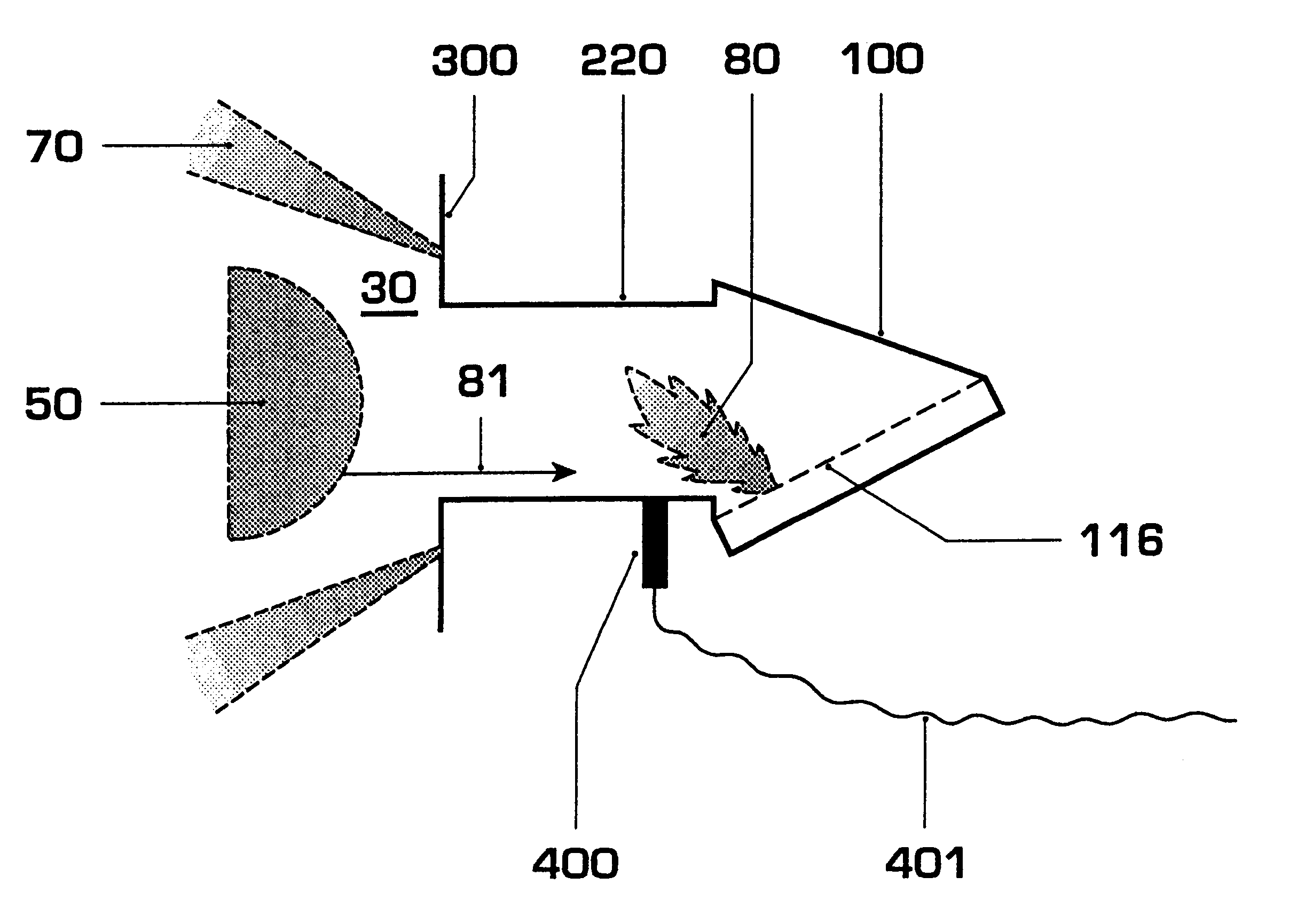

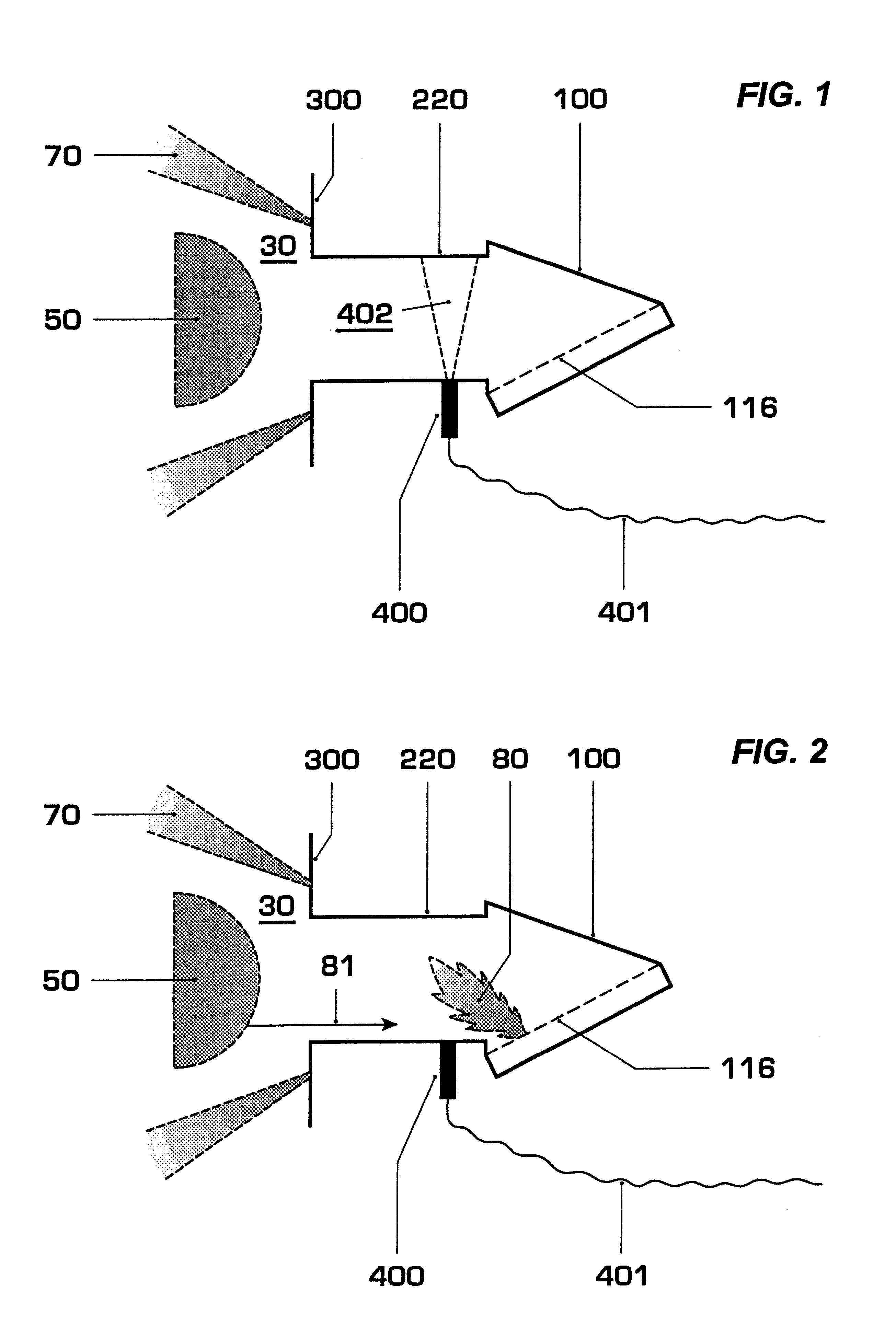

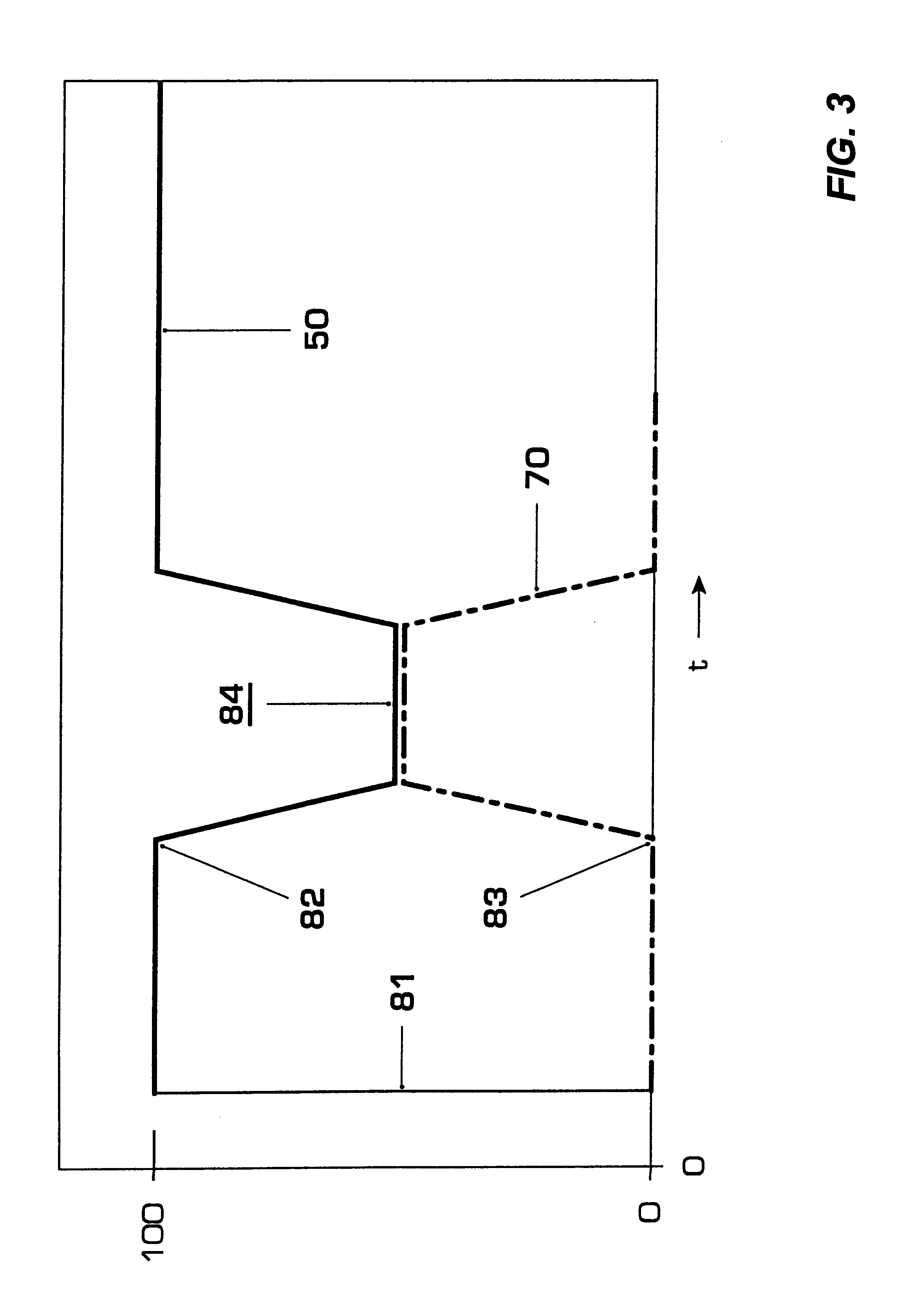

Burner for a heat generator and method for operating the same

InactiveUS6210152B1Avoid destructionBurner safety arrangementsFuel supply regulationCombustorCombustion chamber

In a burner for operating a combustor, the former consists essentially of a rotation generator (100), a transition piece following the rotation generator, and a mixing pipe following this transition piece. Transition piece and mixing pipe form the mixing section (220) of the burner and are located upstream from a combustion chamber (30). In the lower part of the mixing pipe is located a pilot burner system (300) which creates, among other things, a stabilization of the flame front, in particular in the transient load ranges, while minimizing pollutant emissions. A sensor (400) installed in the burner detects a flashback of the flame (80), whereupon the fuel quantity of this flame is at least temporarily reduced and at the same time the fuel quantity for the pilot burner is increased in such a way that the total fuel quantity and thus the turbine output remains constant. This measure prevents a destruction of the burner.

Owner:ANSALDO ENERGIA SWITZERLAND AG

Liquid fuel nozzle apparatus with passive water injection purge

In a gas turbine having a compressor, a combustor and a turbine, a gaseous fuel supply coupled to provide gaseous fuel to the combustor, a liquid fuel supply coupled to provide liquid fuel to the combustor via nozzle assembly. The nozzle assembly includes a plurality of passageways for flowing a fluid into the combustor, one of the passageways being an atomizing air passageway conduit interconnecting the atomizing air passageway to one of the plurality of passageways to enable fluid flow therebetween, while not allowing the flow of fluid back into the atomizing air passageway. High pressure air from the atomizing air passageway is diverted into one of the plurality of passageways via the conduit to protect the nozzle from ingestion of hot combustor gases, thus eliminating a need for a dedicated air purge system for that one of the plurality of passageways.

Owner:GENERAL ELECTRIC CO

Fuel nozzle for gas turbine engines

A gas turbine engine fuel nozzle includes an axis of symmetry extending therethrough, the nozzle body including a first passage extending coaxially therethrough, a second passage, and a third passage, the second passage circumscribing the first passage, the third passage formed radially outward of the second passage, and a nozzle tip coupled to the nozzle body, the nozzle tip including at least one primary discharge opening in flow communication with the first passage, at least one secondary discharge opening in flow communication with the second passage, and at least one tertiary discharge opening in flow communication with the third passage.

Owner:GENERAL ELECTRIC CO

Systems and methods for detection of blowout precursors in combustors

The present invention comprises systems and methods for detecting flame blowout precursors in combustors. The blowout precursor detection system comprises a combustor, a pressure measuring device, and blowout precursor detection unit. A combustion controller may also be used to control combustor parameters. The methods of the present invention comprise receiving pressure data measured by an acoustic pressure measuring device, performing one or a combination of spectral analysis, statistical analysis, and wavelet analysis on received pressure data, and determining the existence of a blowout precursor based on such analyses. The spectral analysis, statistical analysis, and wavelet analysis further comprise their respective sub-methods to determine the existence of blowout precursors.

Owner:GEORGIA TECH RES CORP

Independent pilot fuel control in secondary fuel nozzle

Disclosed herein is a fuel nozzle. The fuel nozzle includes a first fuel introduction location, a second fuel introduction location, and fuel passages. The first fuel introduction location is located radially about the fuel nozzle and is connected with a fuel passage. The second fuel introduction location is located at an end of the fuel nozzle and is connected with another fuel passage such that the fuel passage connected to the first fuel introduction location is separate from the fuel passage connected to the second fuel introduction location.

Owner:GENERAL ELECTRIC CO

Premix fuel nozzle assembly

ActiveUS20160146460A1Burner safety arrangementsLiquid fuel feeder/distributionEngineeringFeeding tube

A premix fuel nozzle assembly includes a center body, a pilot premix fuel nozzle assembly that extends axially through the center body and that includes a premix tip having a plurality of premix tubes that each defines a premix passage and a fuel port. The premix passage of each premix tube is in fluid communication with the pilot air passage. The premix fuel nozzle assembly further includes a purge air cartridge assembly that extends axially within the pilot air passage. The purge air cartridge assembly includes a feed tube portion and a tip portion that define a purge air passage within the pilot air passage. The tip portion comprises an aft wall that extends at least partially through an opening defined by the premix tip. The aft wall includes a single axially extending orifice that is in fluid communication with the purge air passage.

Owner:GENERAL ELECTRIC CO

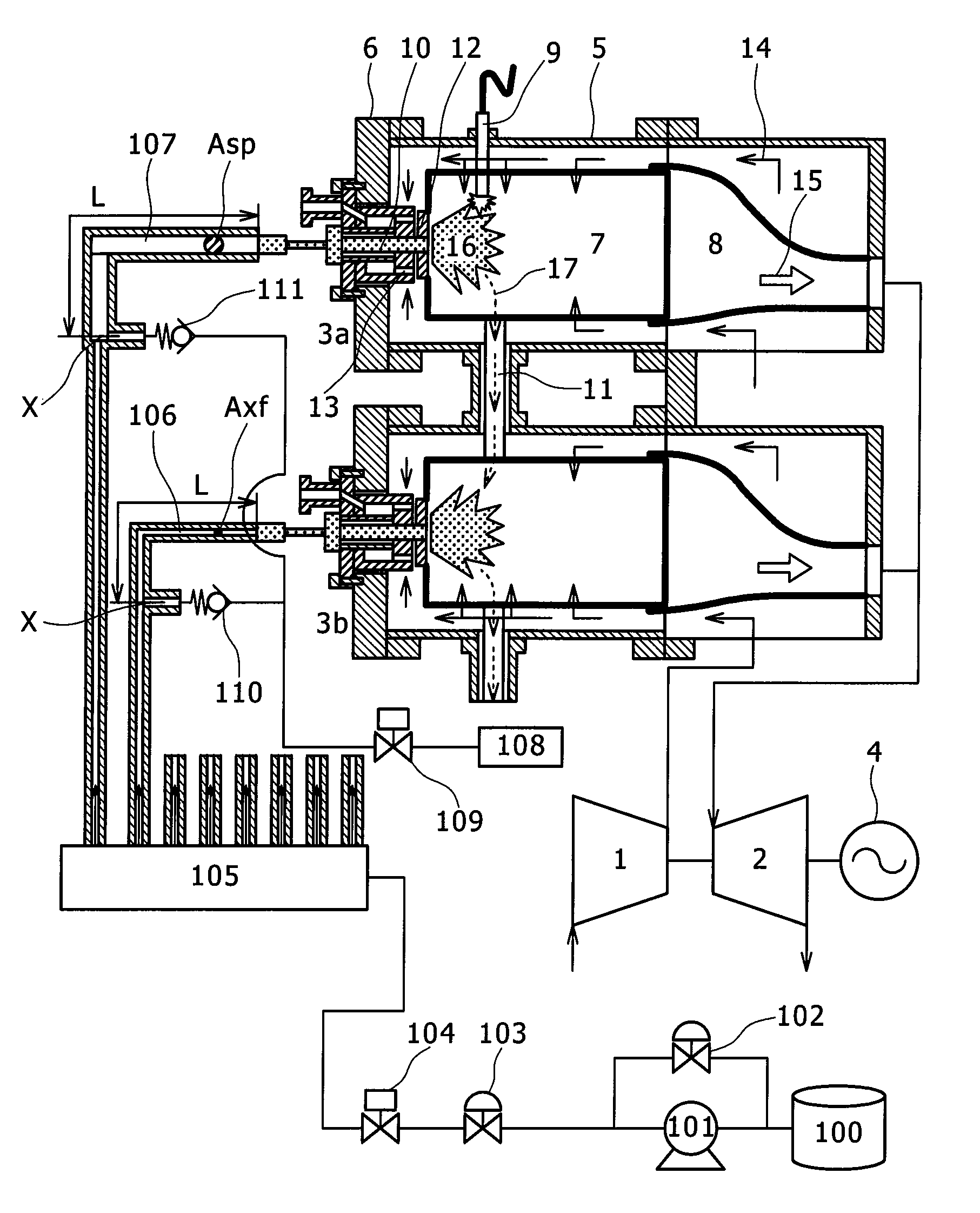

Combusting system, remodeling method for combusting system, and fuel injection method for combusting system

ActiveUS8082724B2Improve performanceImprove reliabilityBurner safety arrangementsBurnersCombustion systemStart time

The present invention improves the reliability of a combusting system including multiple combustors and improves an environmental performance thereof. The invention includes a device that delays the start time of fuel injection from a fuel nozzle of a combustor including a ignitor from the start time of fuel injection from a fuel nozzle of the combustor not including the ignitor.

Owner:MITSUBISHI POWER LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com