Patents

Literature

85results about How to "Uniform profile" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Intrench profile

ActiveUS20130260533A1Uniform profileSemiconductor/solid-state device manufacturingHydrogenFluorine containing

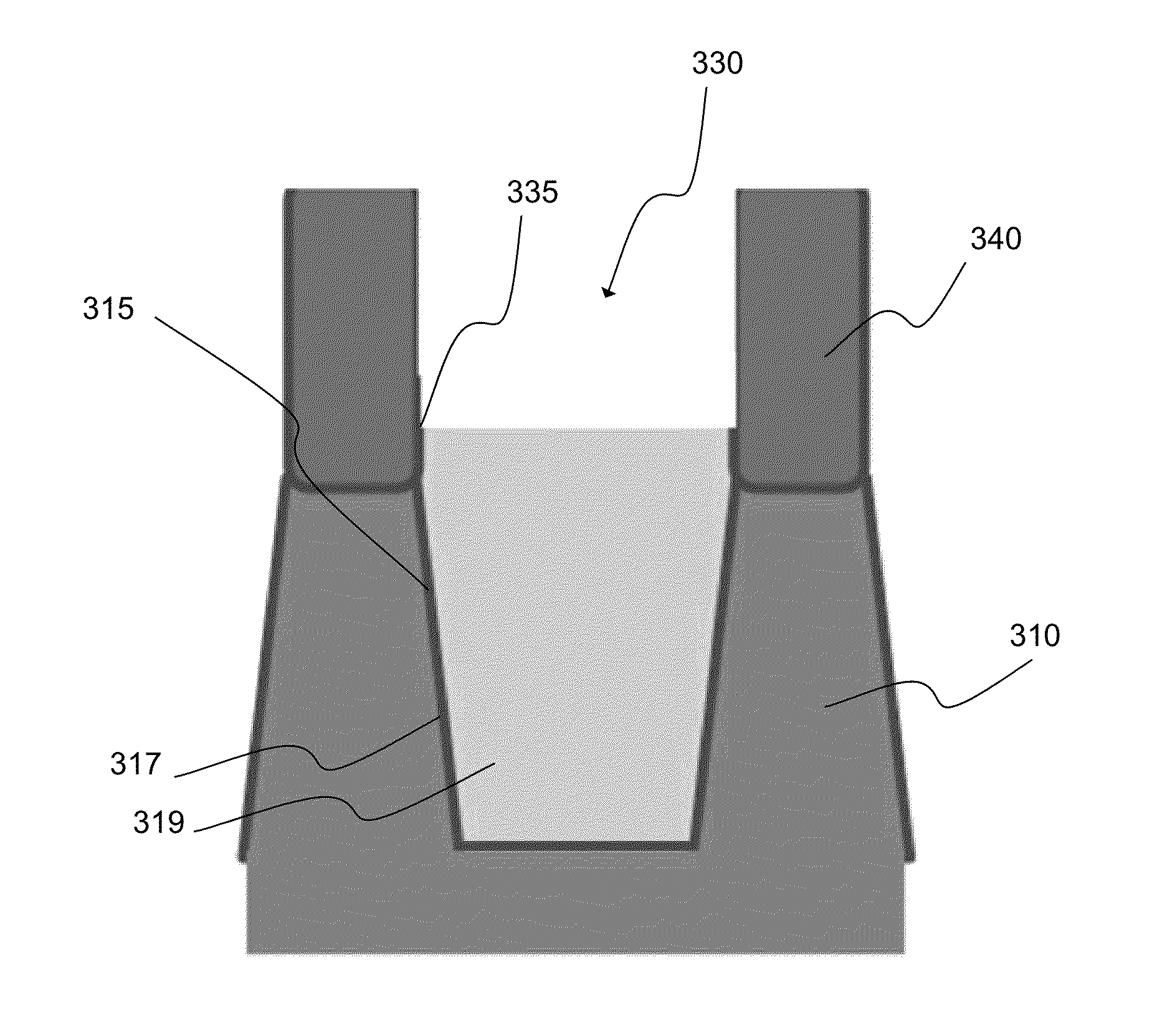

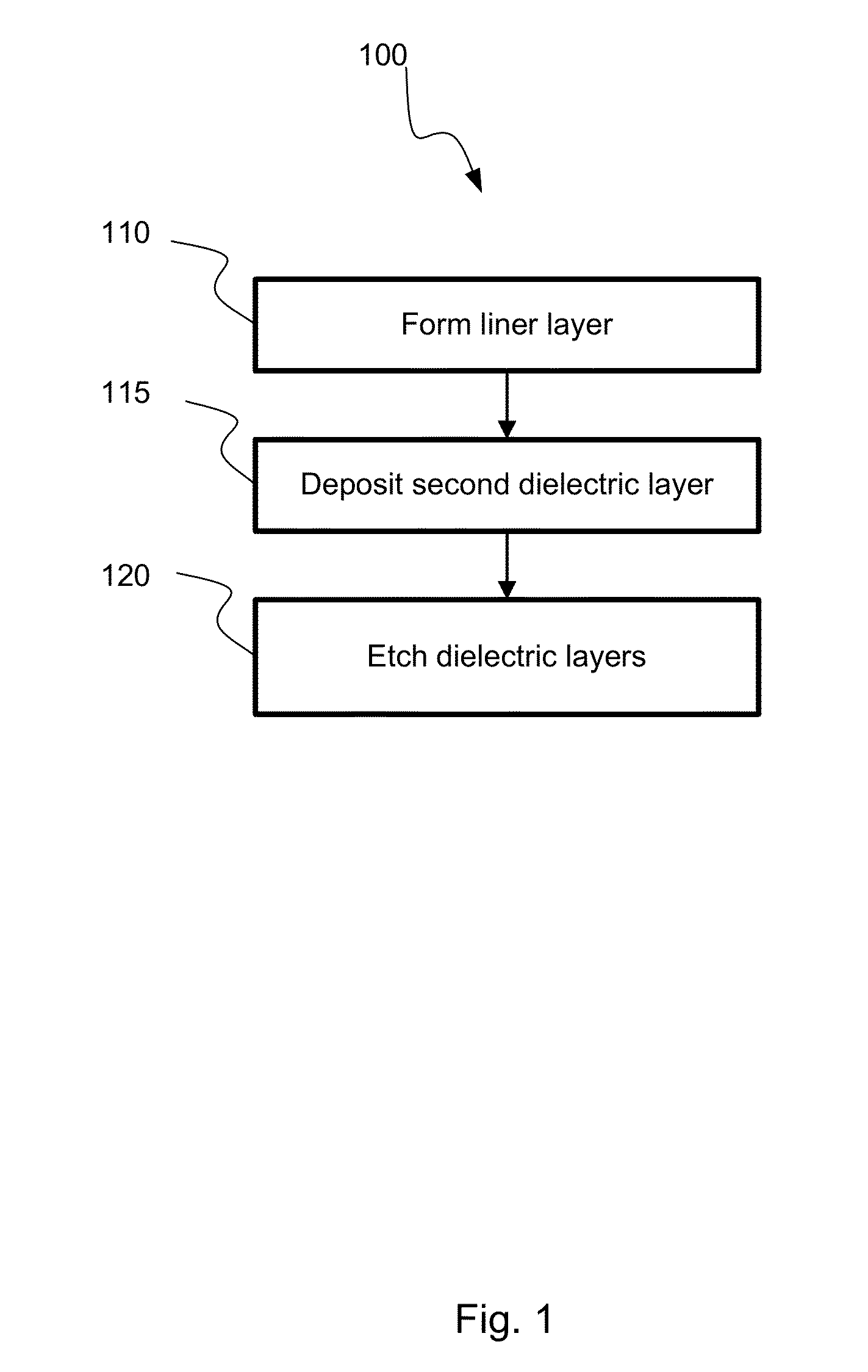

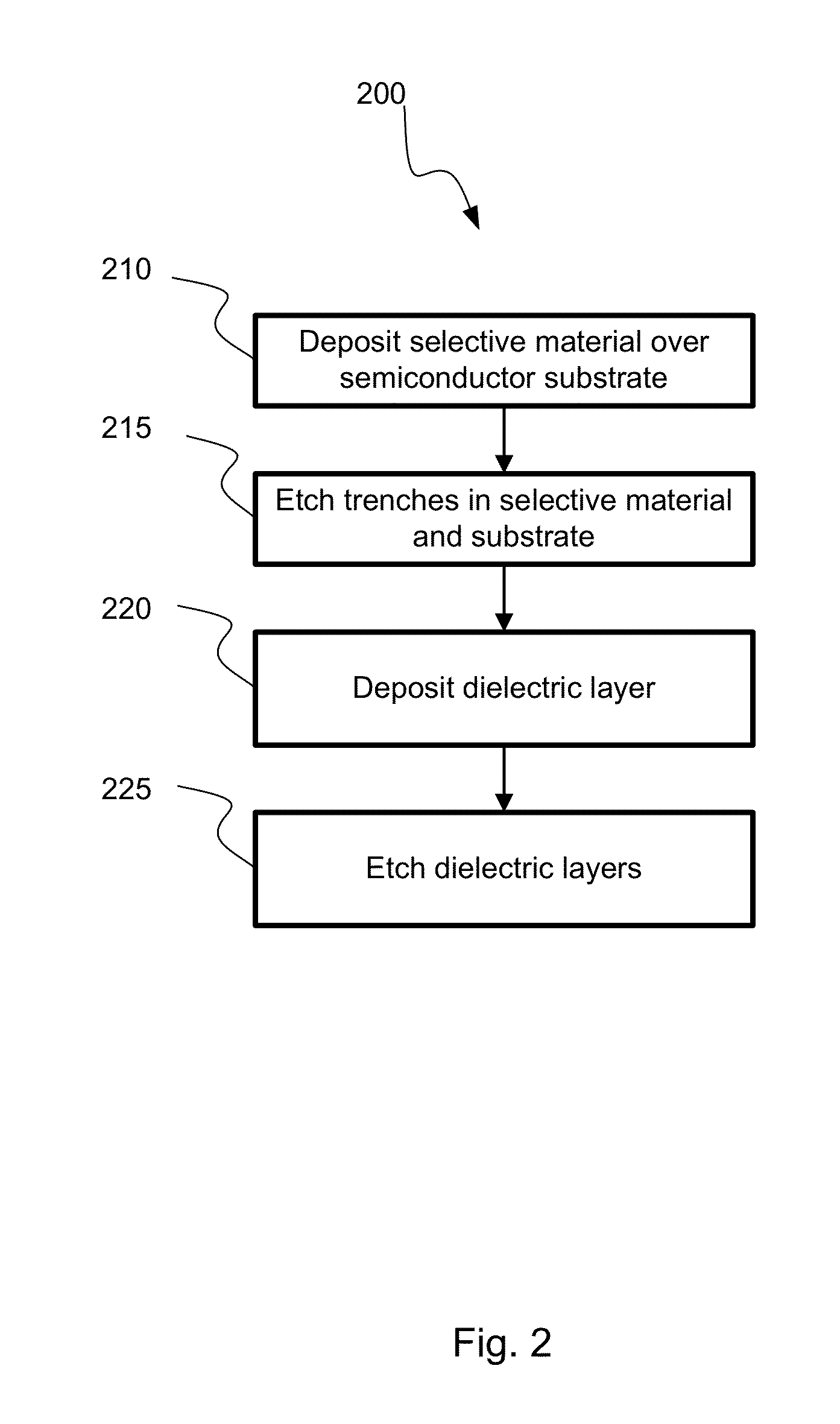

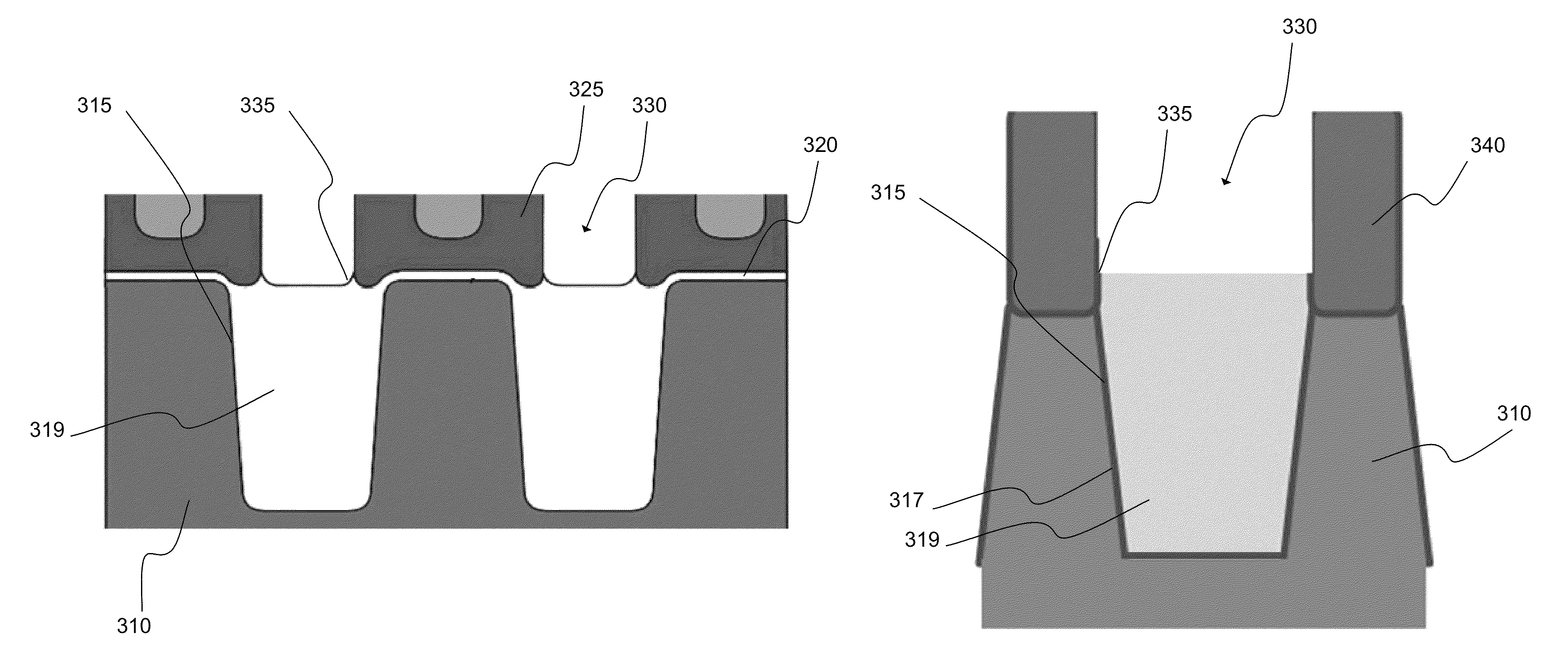

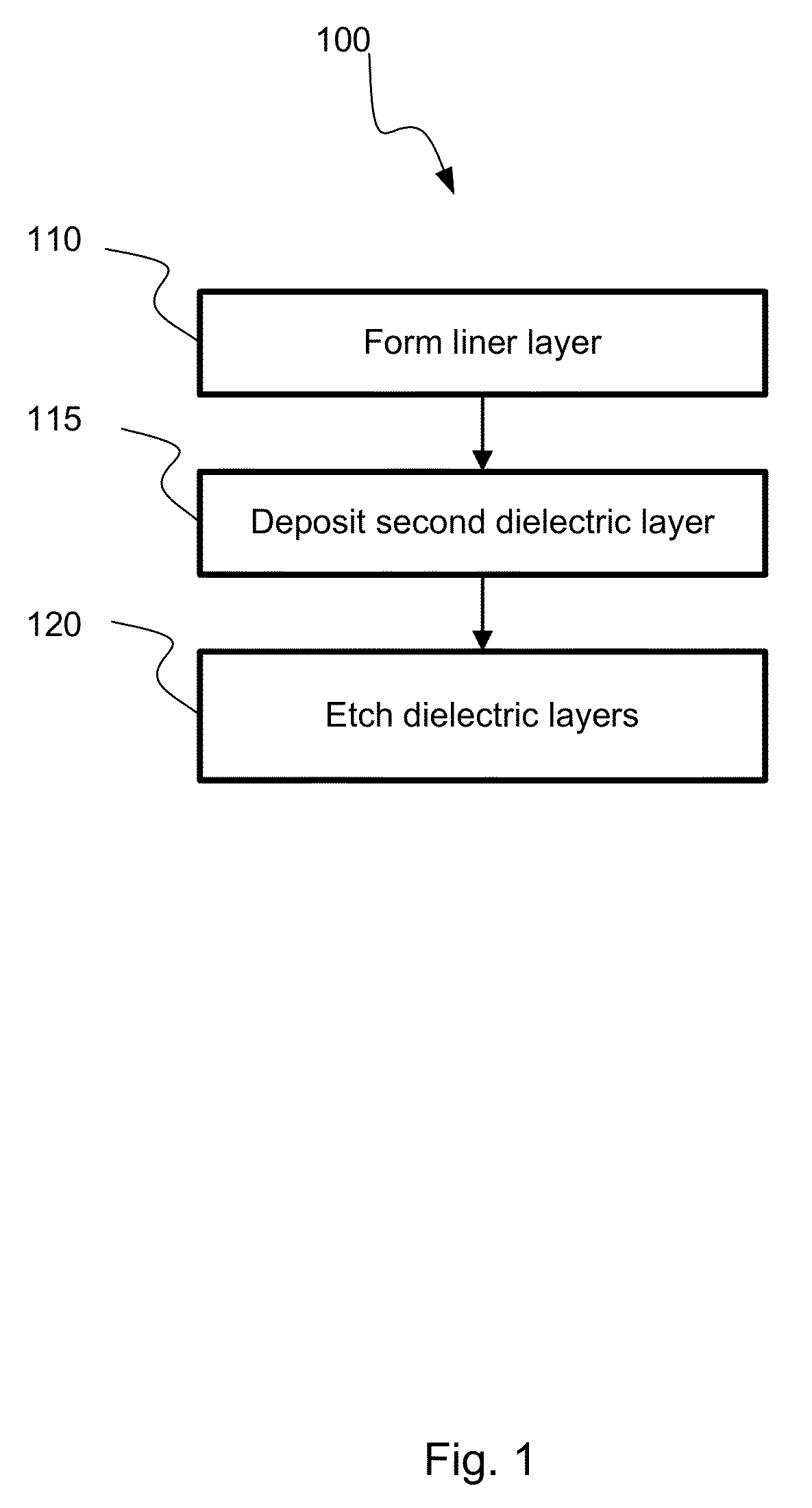

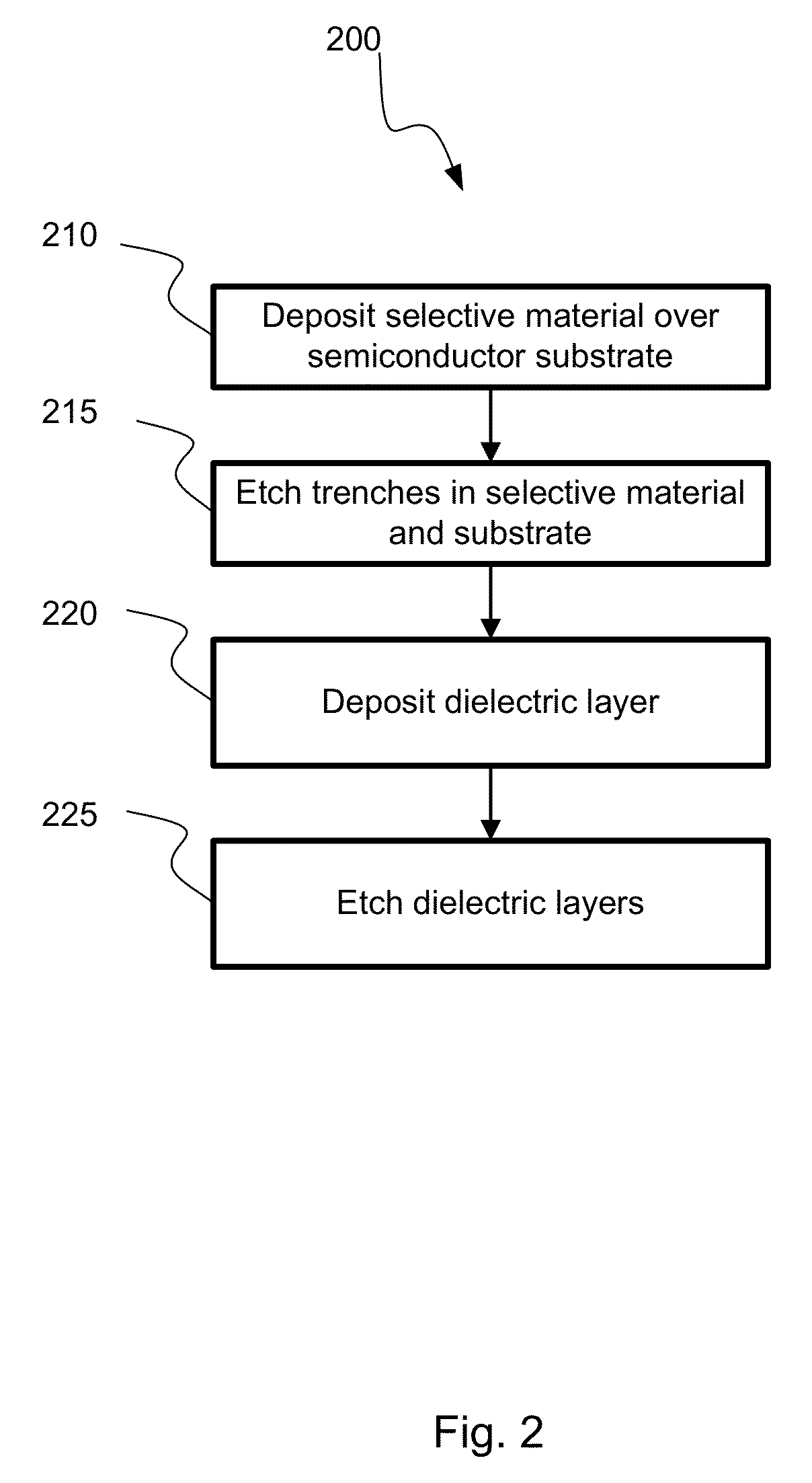

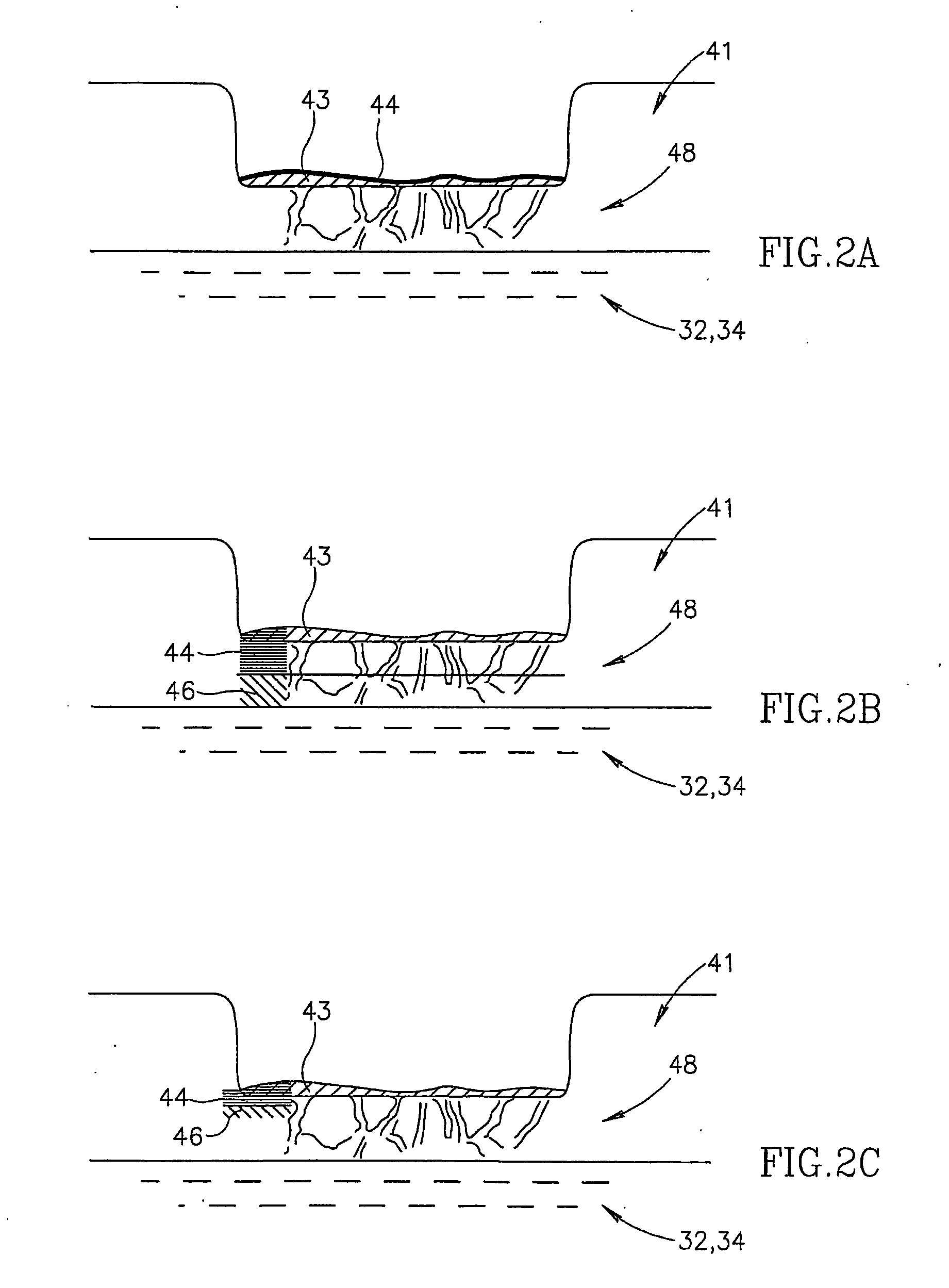

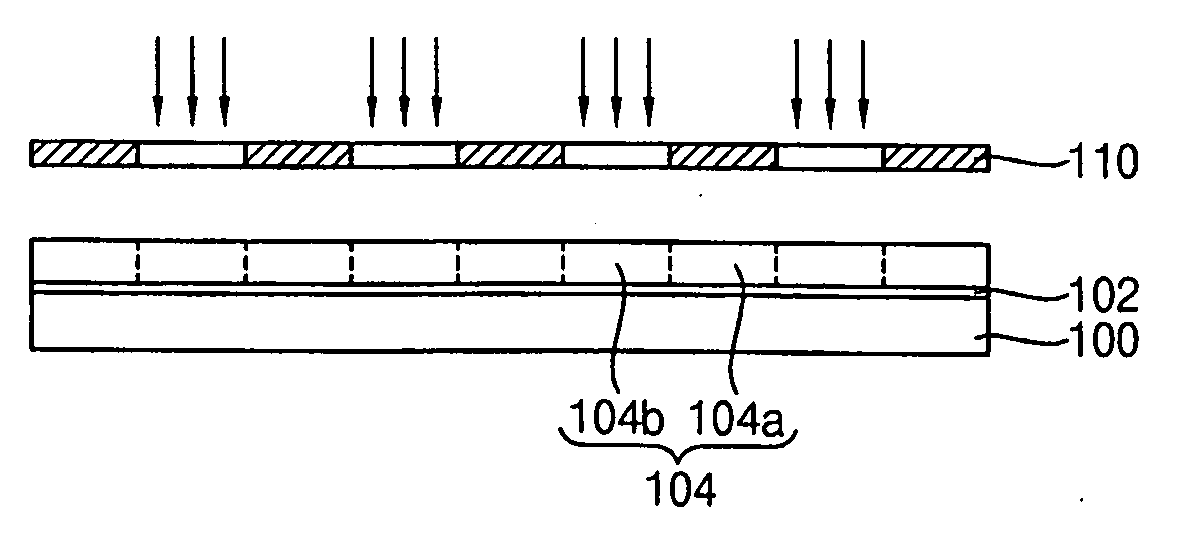

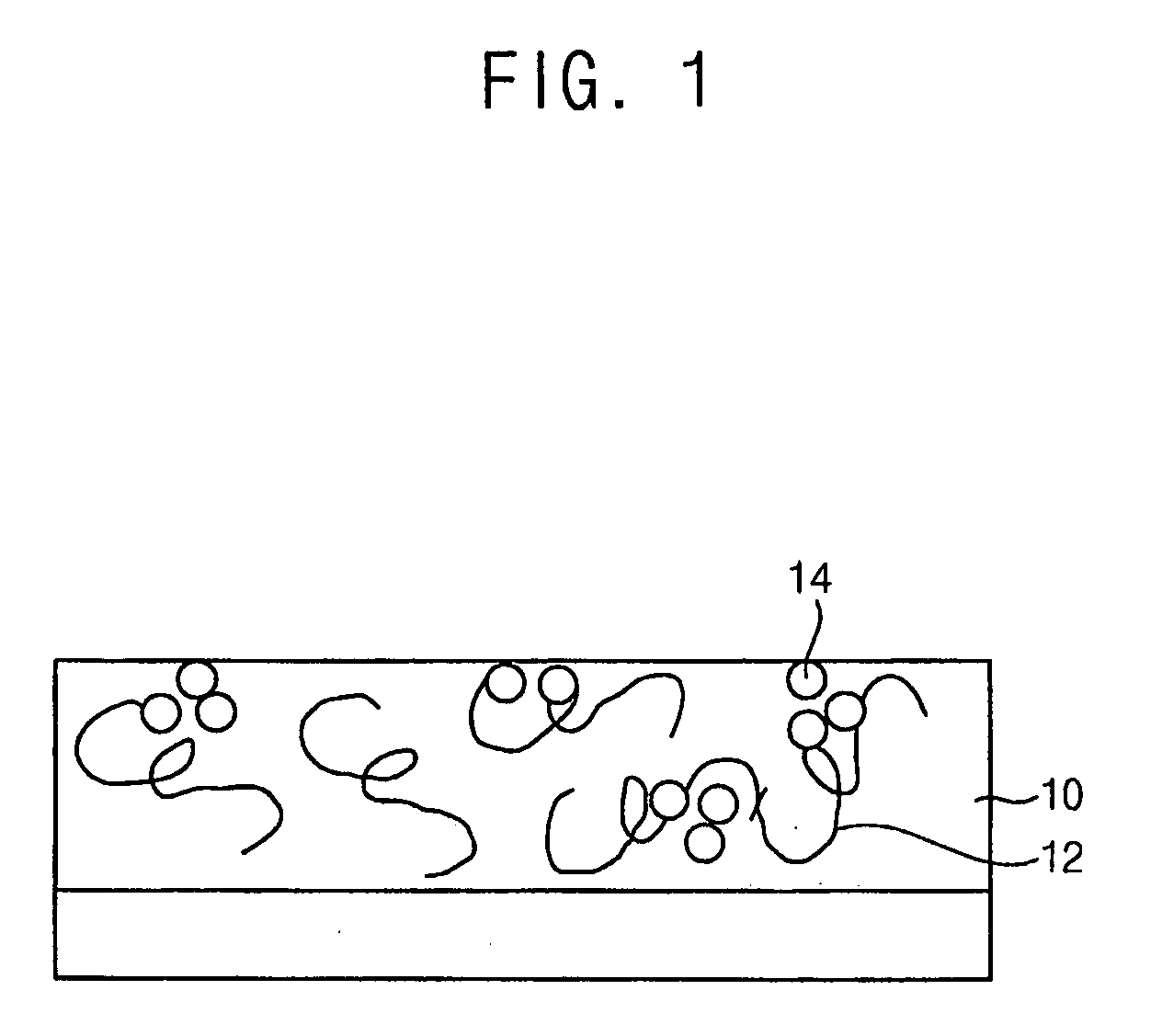

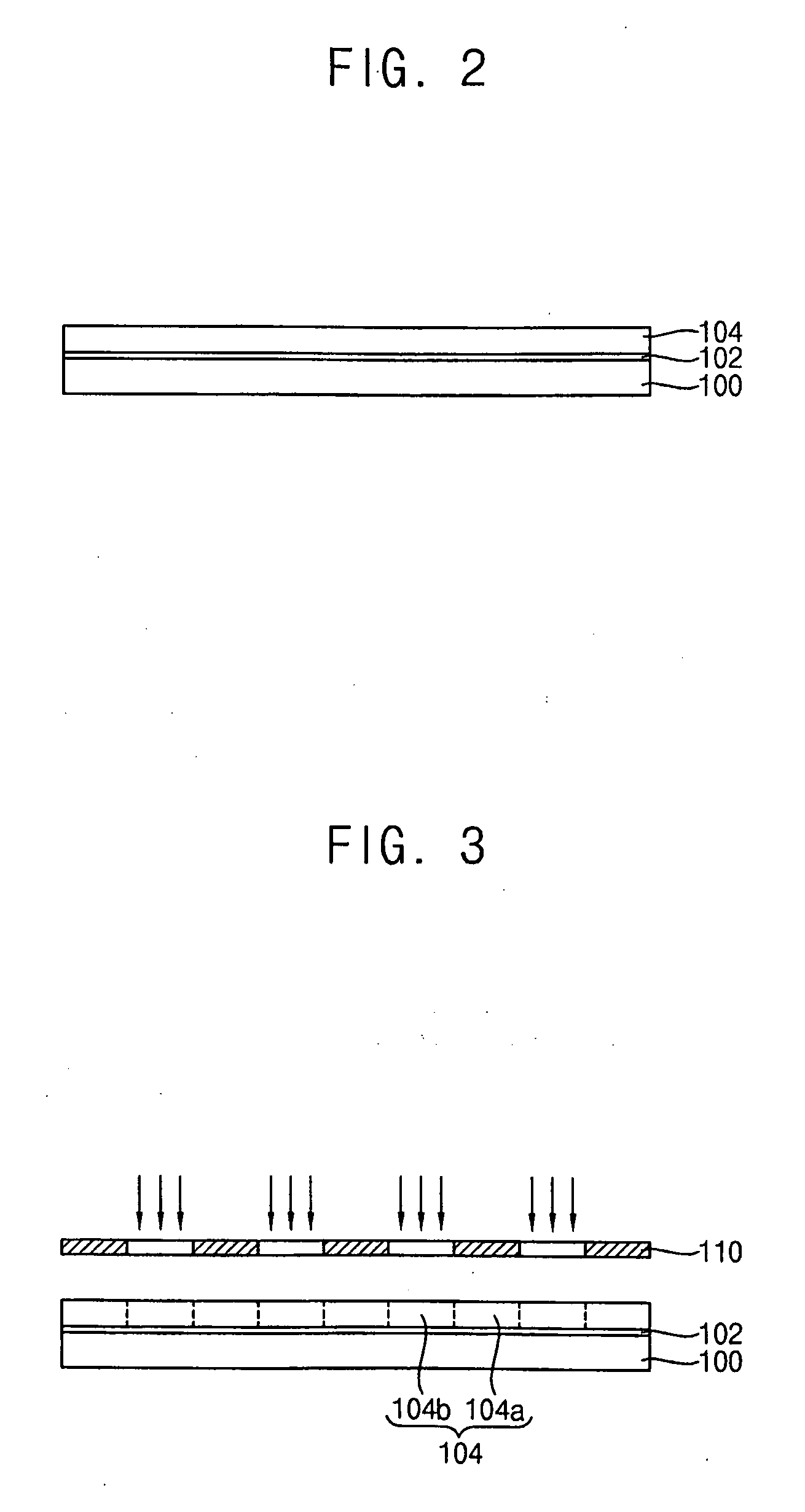

A method of etching a recess in a semiconductor substrate is described. The method may include forming a dielectric liner layer in a trench of the substrate where the liner layer has a first density. The method may also include depositing a second dielectric layer at least partially in the trench on the liner layer. The second dielectric layer may initially be flowable following the deposition, and have a second density that is less than the first density of the liner. The method may further include exposing the substrate to a dry etchant, where the etchant removes a portion of the first liner layer and the second dielectric layer to form a recess, where the dry etchant includes a fluorine-containing compound and molecular hydrogen, and where the etch rate ratio for removing the first dielectric liner layer to removing the second dielectric layer is about 1:1.2 to about 1:1.

Owner:APPLIED MATERIALS INC

Intrench profile

ActiveUS8927390B2Uniform profileSemiconductor/solid-state device manufacturingHydrogenOptoelectronics

A method of etching a recess in a semiconductor substrate is described. The method may include forming a dielectric liner layer in a trench of the substrate where the liner layer has a first density. The method may also include depositing a second dielectric layer at least partially in the trench on the liner layer. The second dielectric layer may initially be flowable following the deposition, and have a second density that is less than the first density of the liner. The method may further include exposing the substrate to a dry etchant, where the etchant removes a portion of the first liner layer and the second dielectric layer to form a recess, where the dry etchant includes a fluorine-containing compound and molecular hydrogen, and where the etch rate ratio for removing the first dielectric liner layer to removing the second dielectric layer is about 1:1.2 to about 1:1.

Owner:APPLIED MATERIALS INC

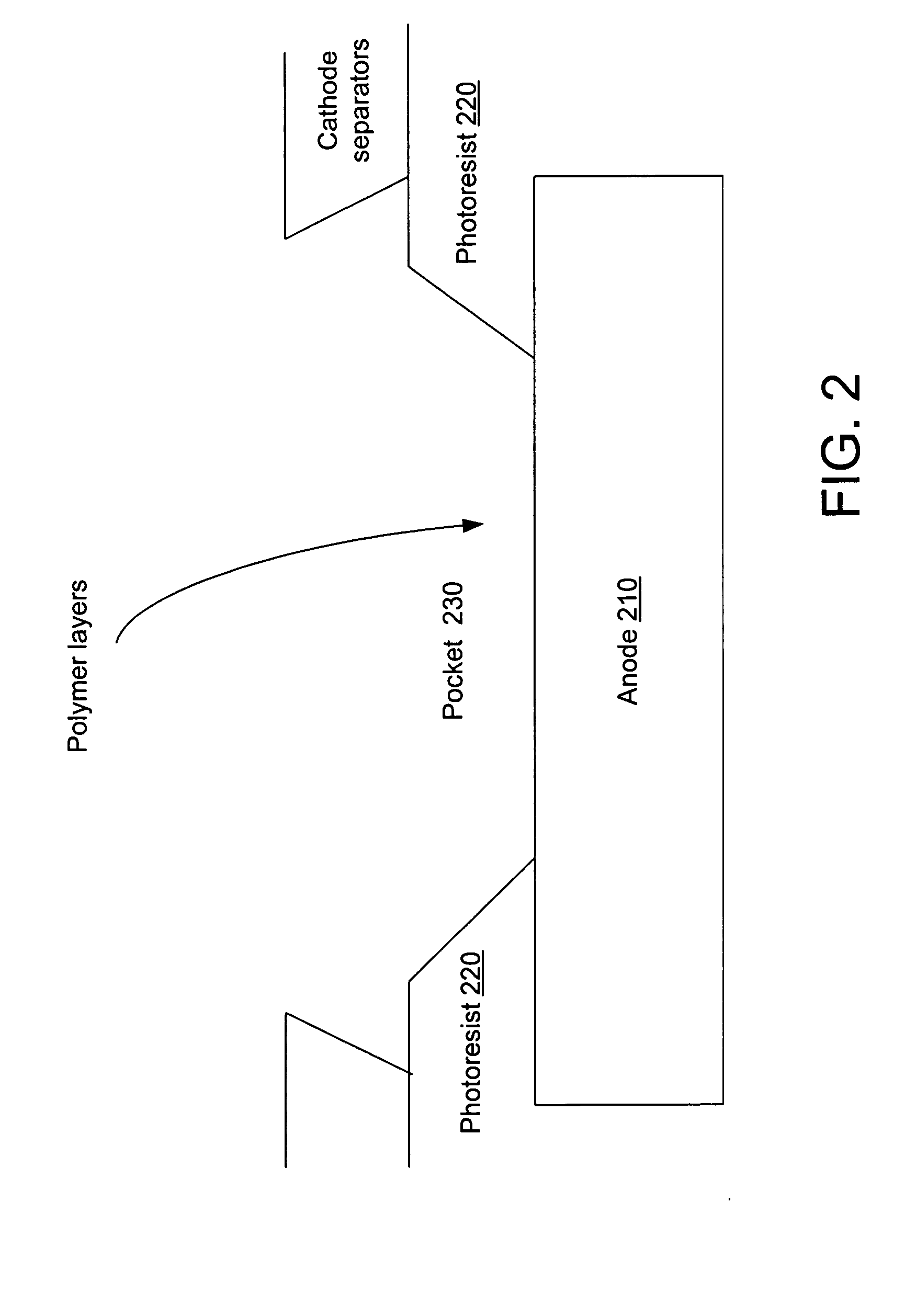

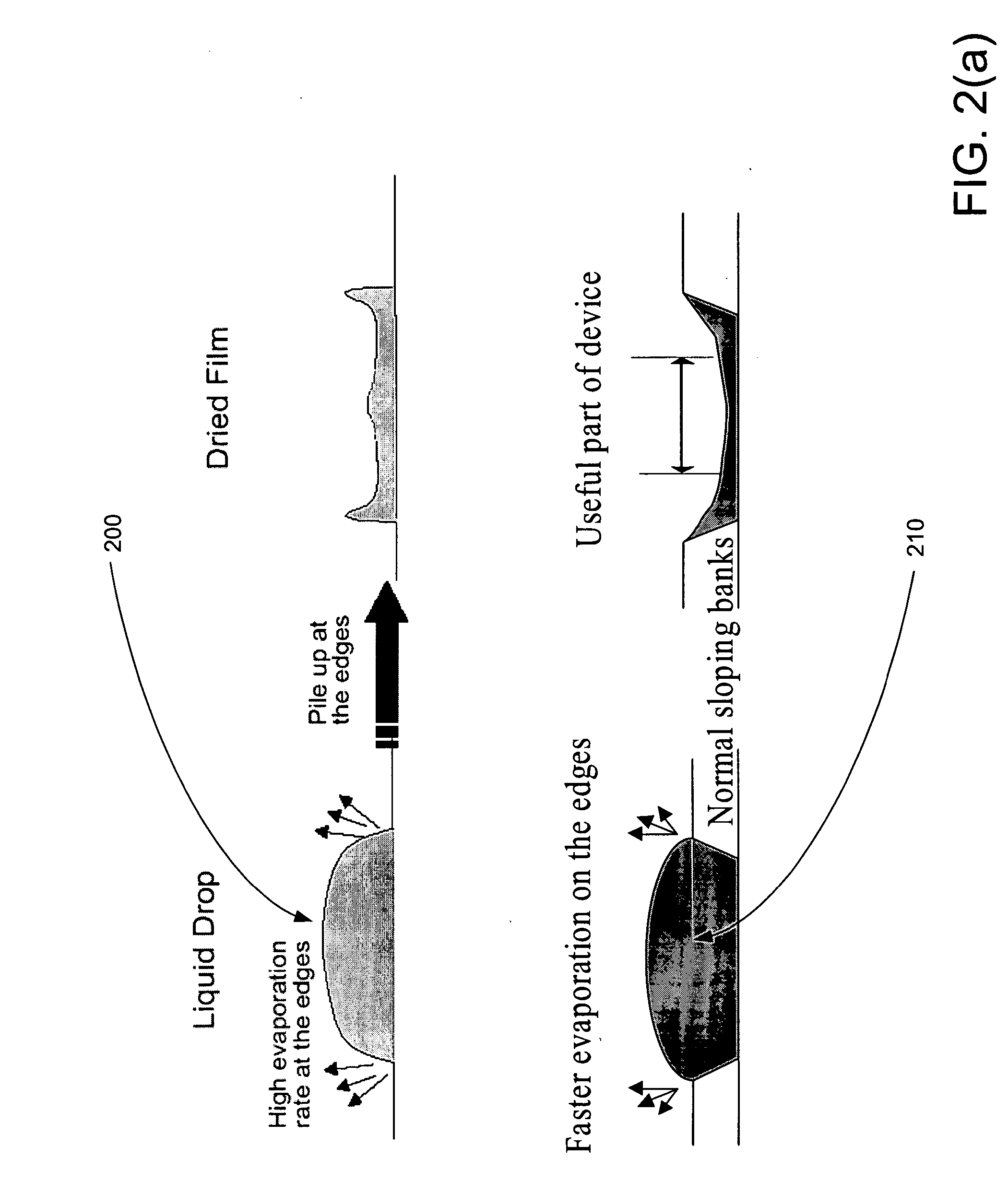

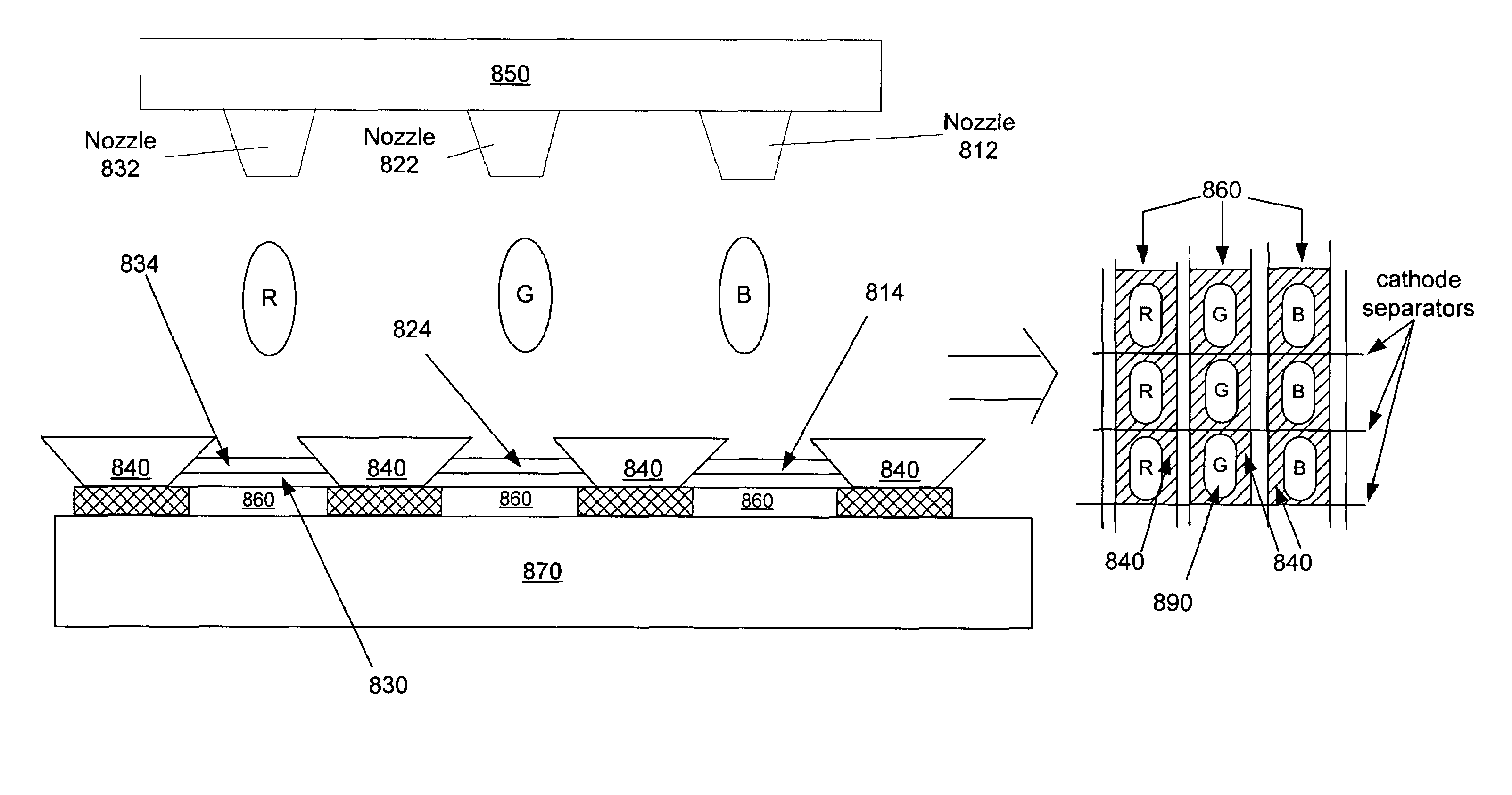

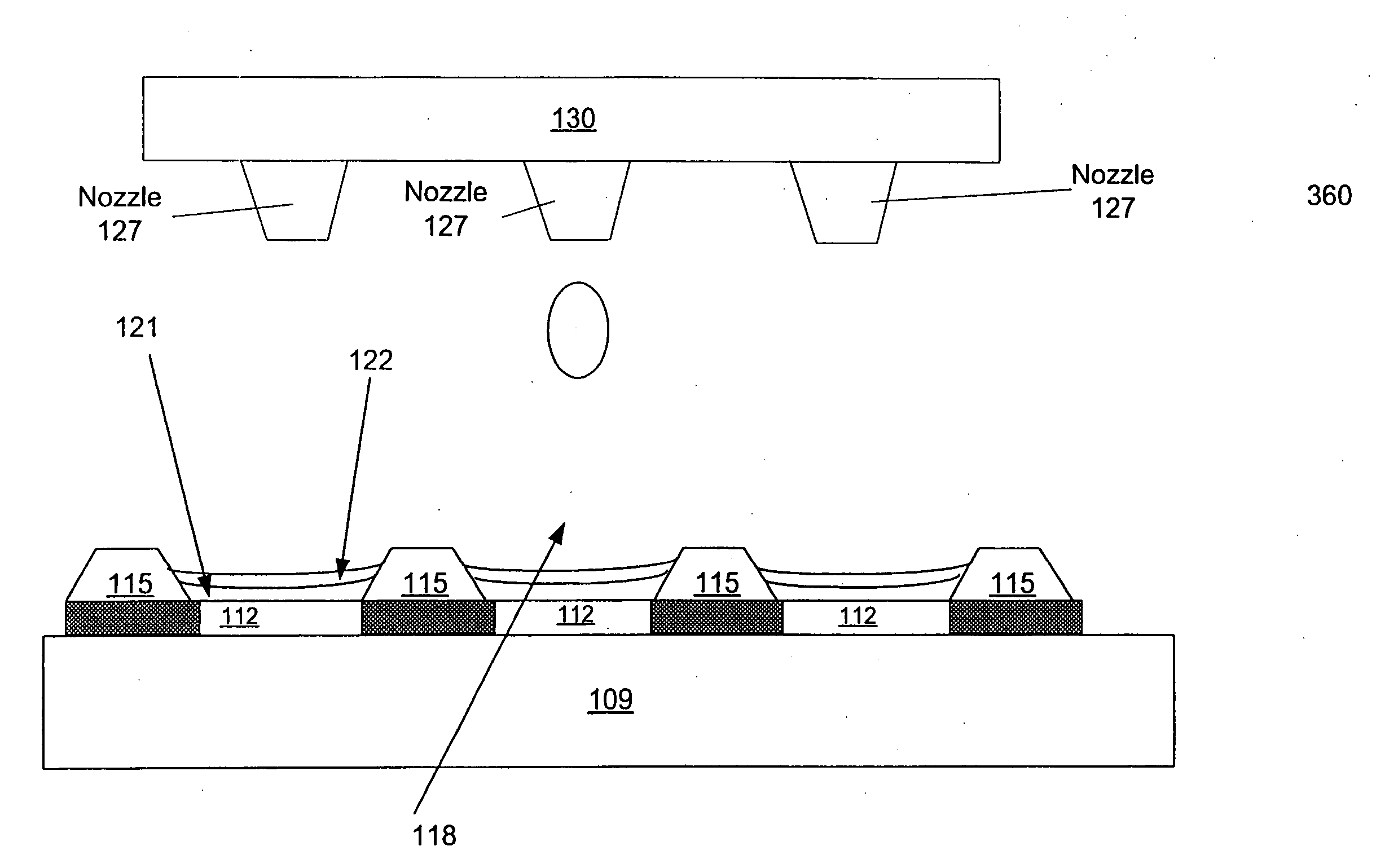

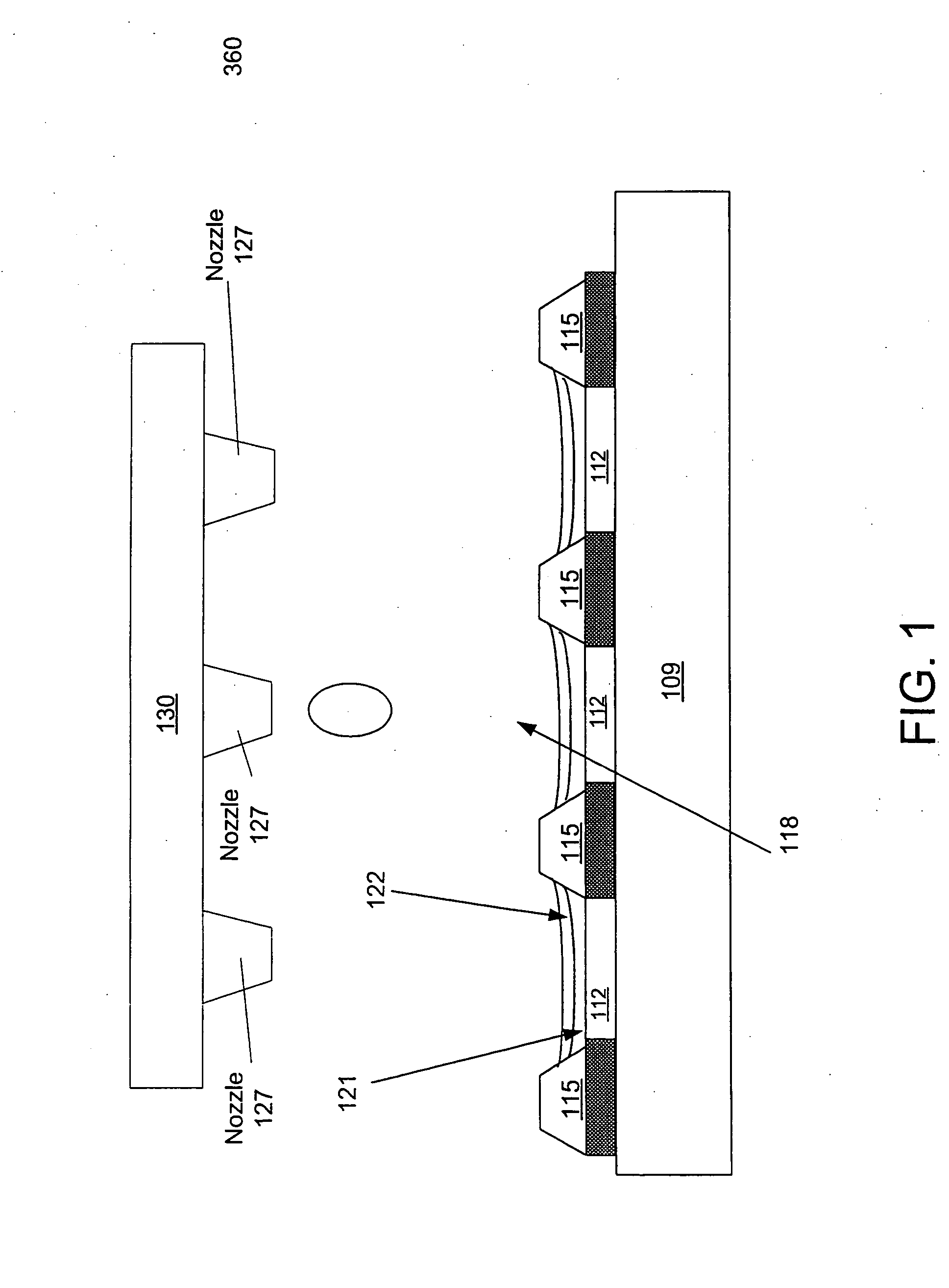

Optimal bank shapes for inkjet printing

ActiveUS20050052120A1Uniform drying profileLower Level RequirementsDischarge tube luminescnet screensElectroluminescent light sourcesResistEngineering

The shapes of the photo-resist layer “banks” which define pockets for inkjet printing or other patterned processes are optimized to provide a more uniform drying profile for substances which are to be deposited in those pockets and dried therein. Preferably, the shapes of the banks are “mushroom” shaped such that a portion of the photo-resist layer overhangs the exposed lower electrode layer.

Owner:DOLYA HOLDCO 5 LTD

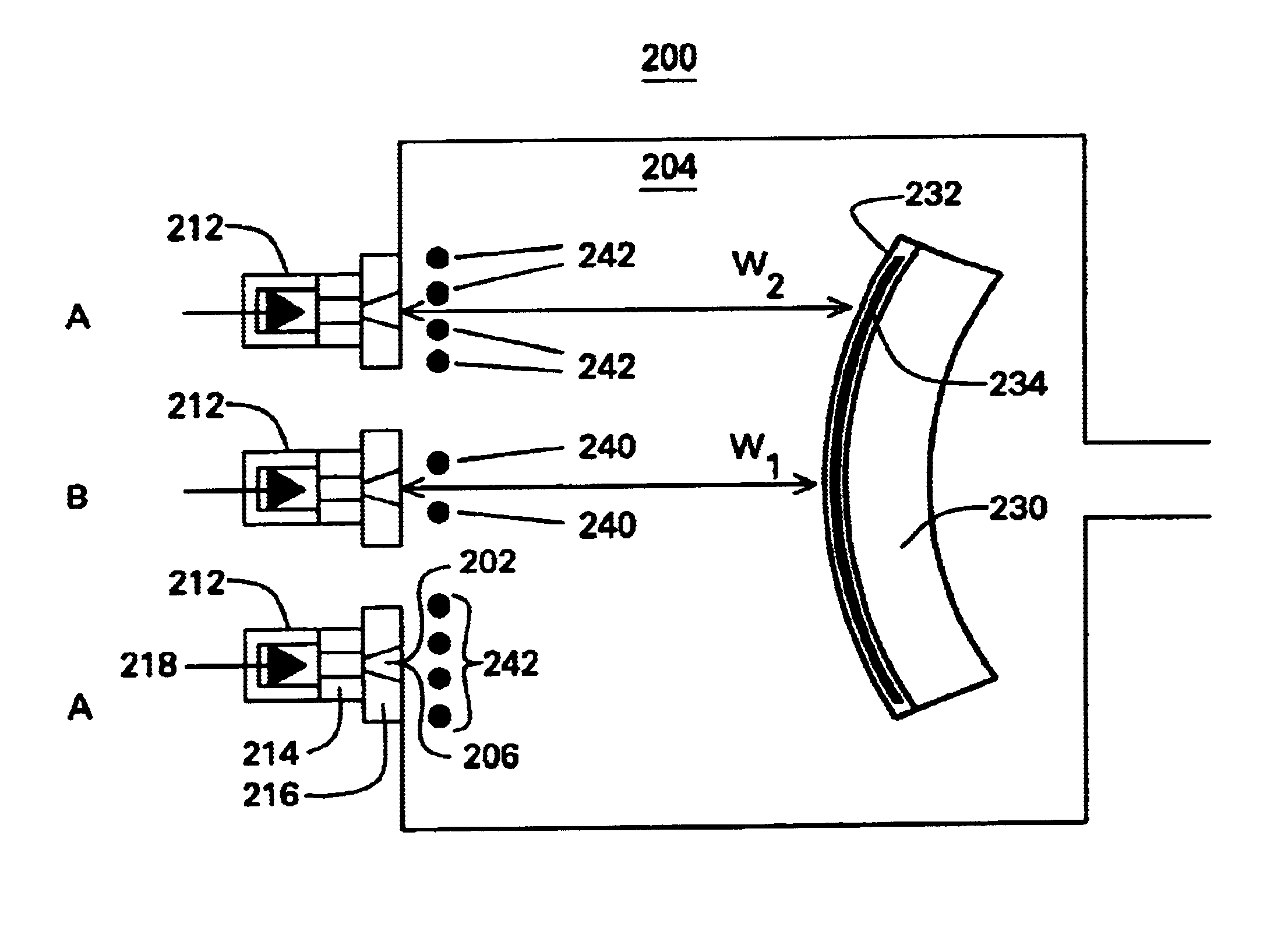

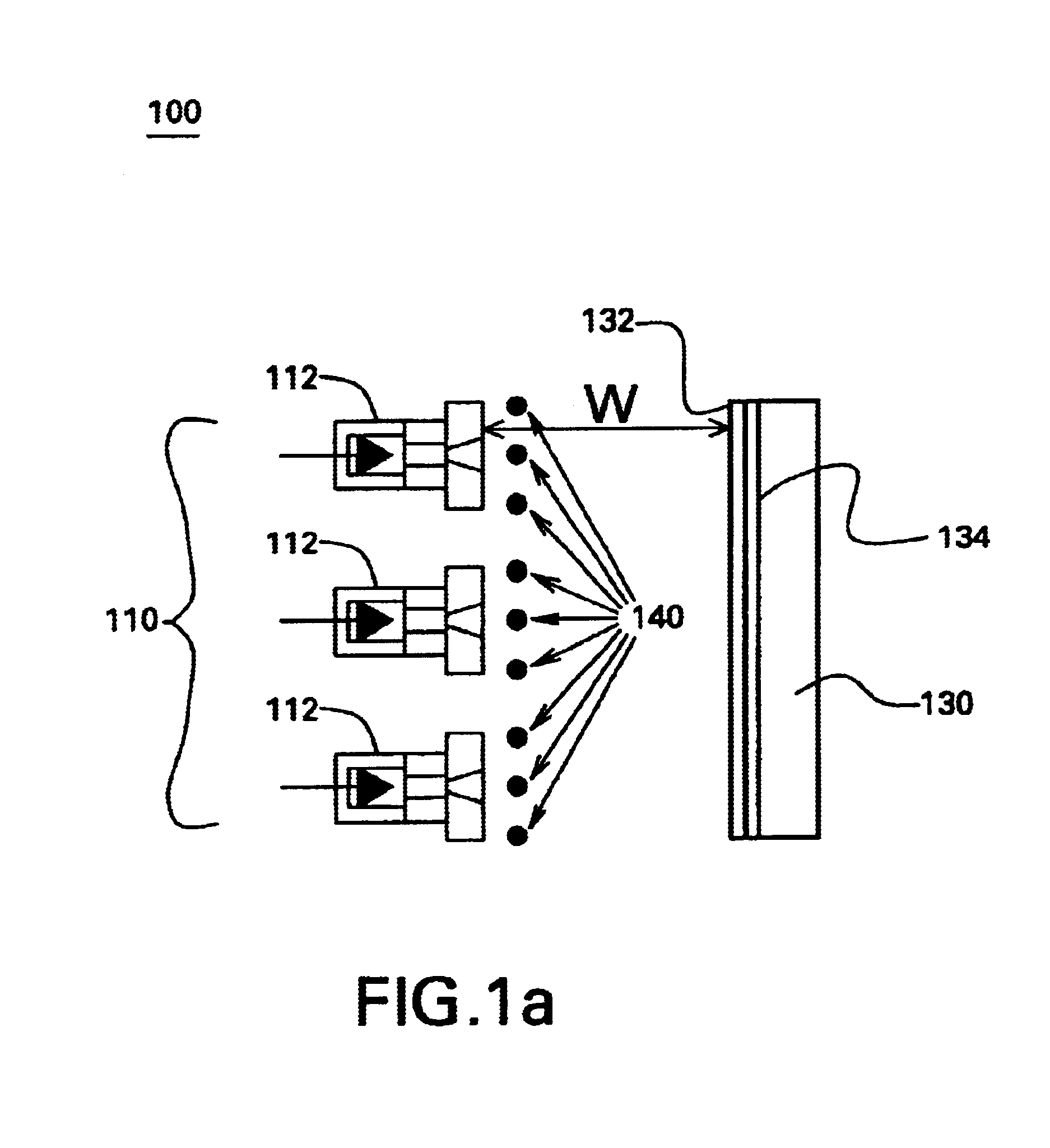

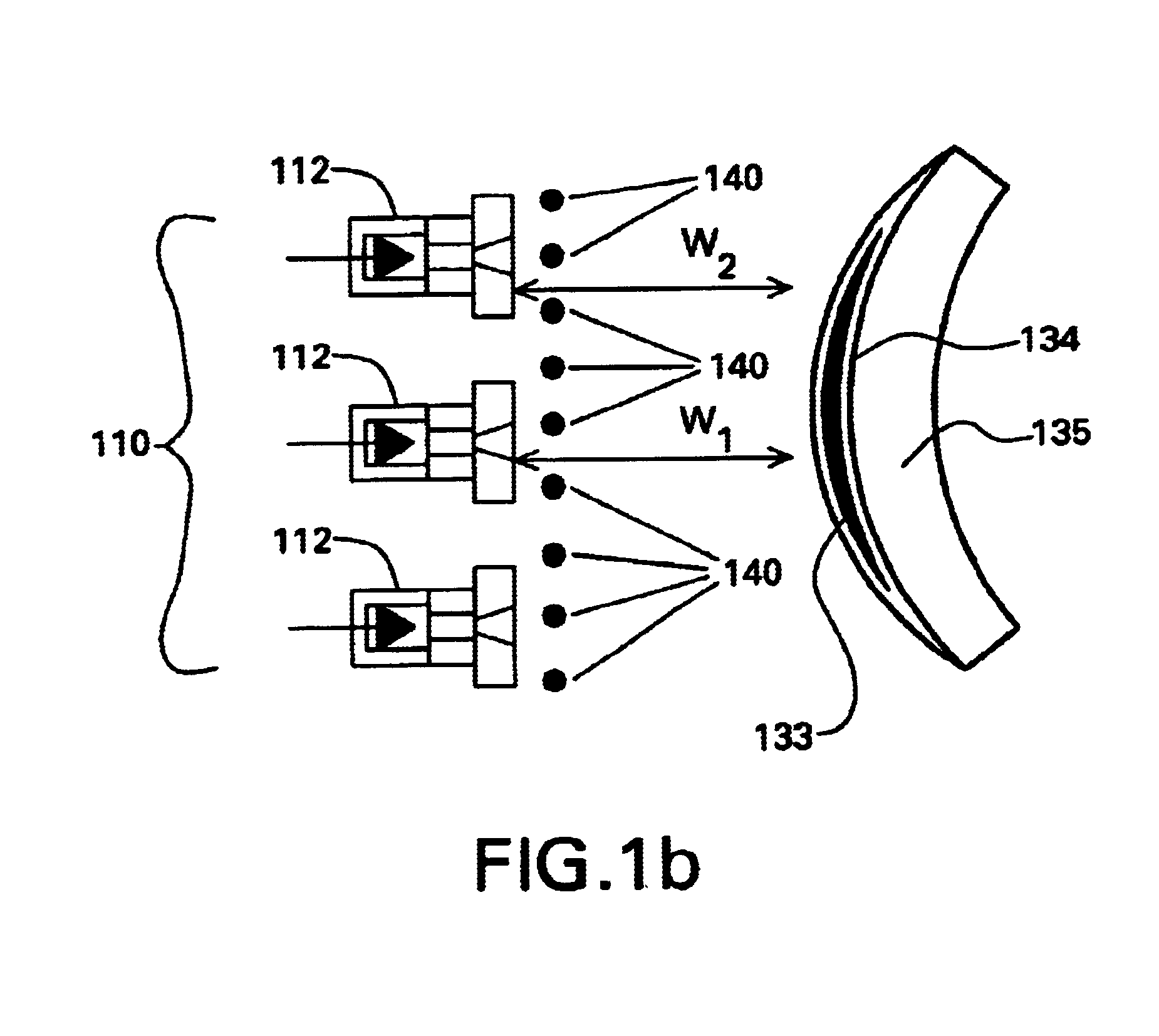

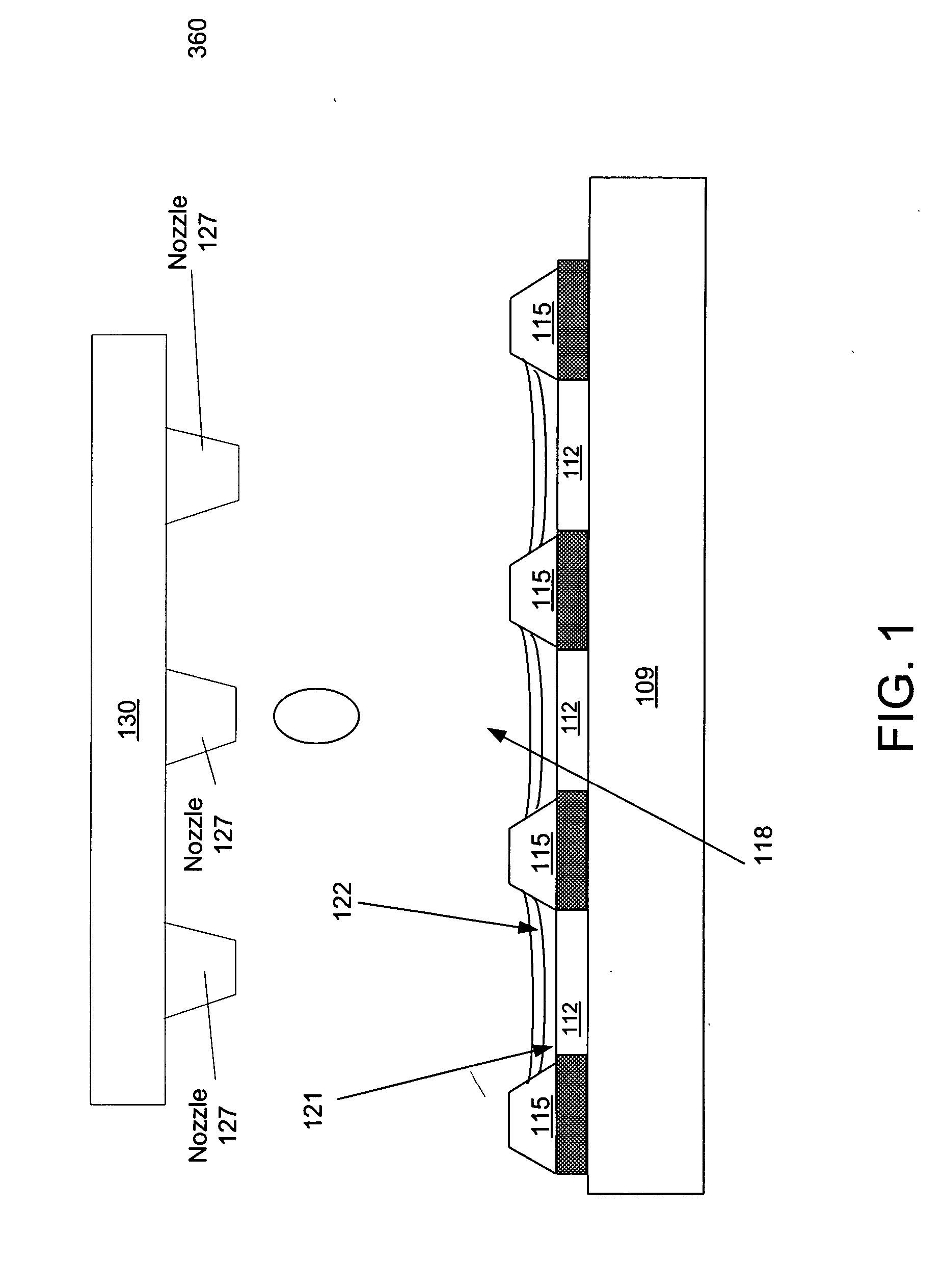

Apparatus and method for depositing large area coatings on non-planar surfaces

InactiveUS6681716B2Low deposited thicknessUniform profileSemiconductor/solid-state device manufacturingChemical vapor deposition coatingChemical physicsReactive plasma

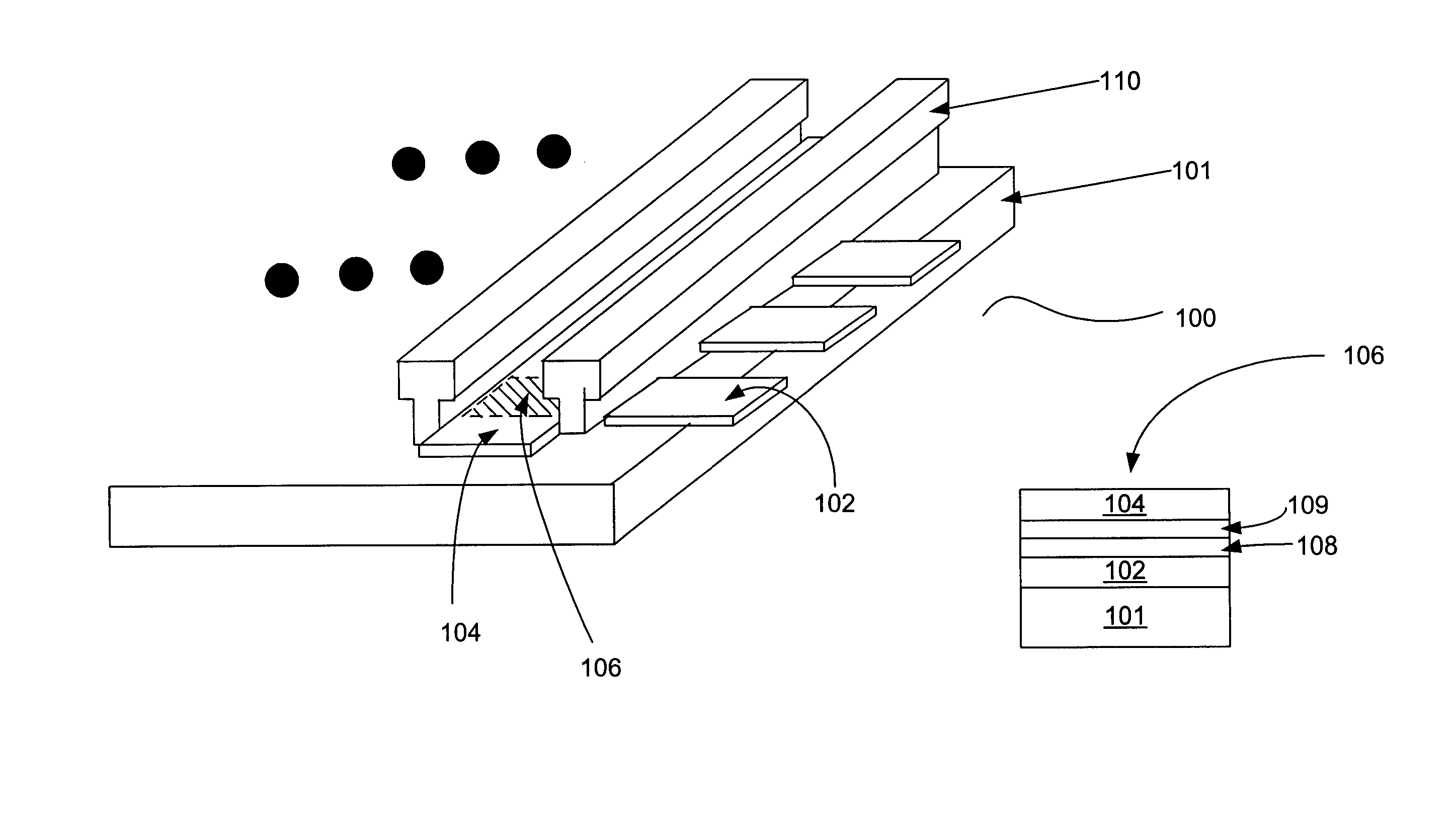

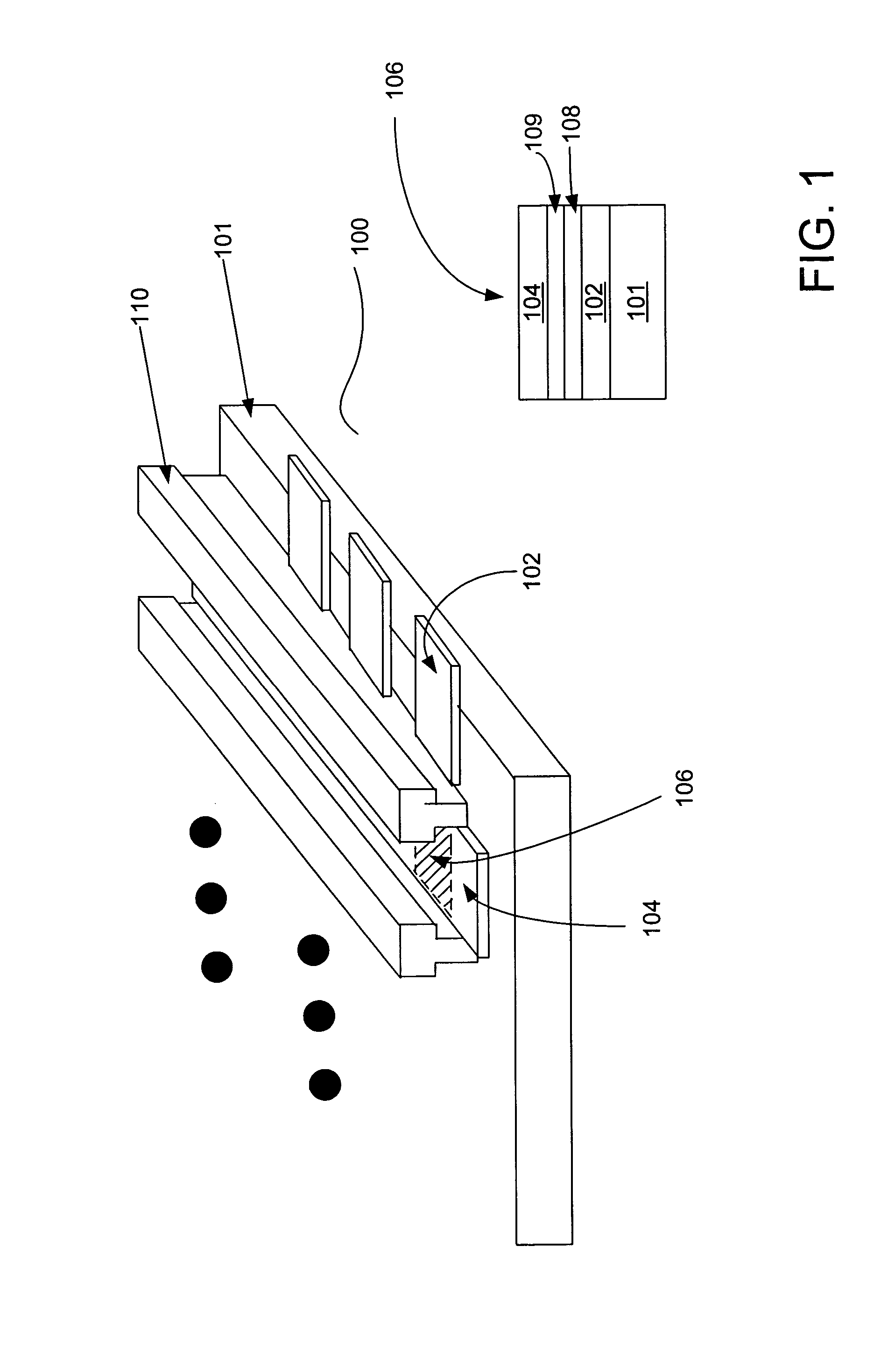

A method and apparatus for depositing a uniform coating on a large area, non-planar surface using an array of multiple plasma sources. The apparatus comprises at least one array of a plurality of plasma sources for generating a plurality of plasmas, wherein each of the plurality of plasma sources has a cathode, anode, and an inlet for a non-reactive plasma source gas disposed in a plasma chamber, and at least one reactant gas injector for differentially injecting at least one reactant gas into the plurality of plasmas. The reactant gas injector and substrate are located in a deposition chamber in fluid communication with each plasma chamber. Individual adjustment of the flow of deposition precursor into each of the plasmas generated by the multiple plasma array compensates for changes in substrate processing conditions due to local variations in the working distance between the plasma source and the surface of the substrate.

Owner:SABIC INNOVATIVE PLASTICS IP BV

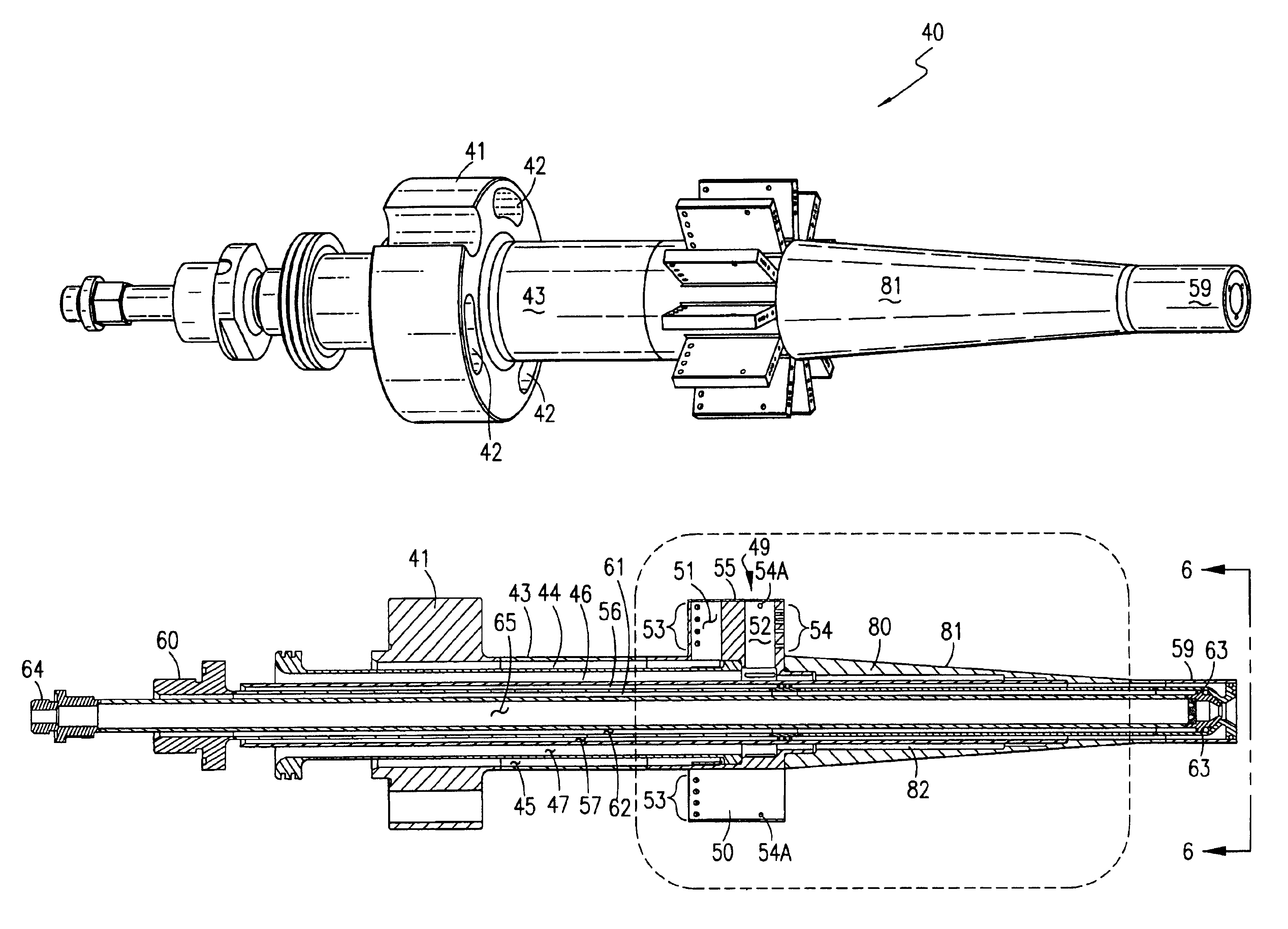

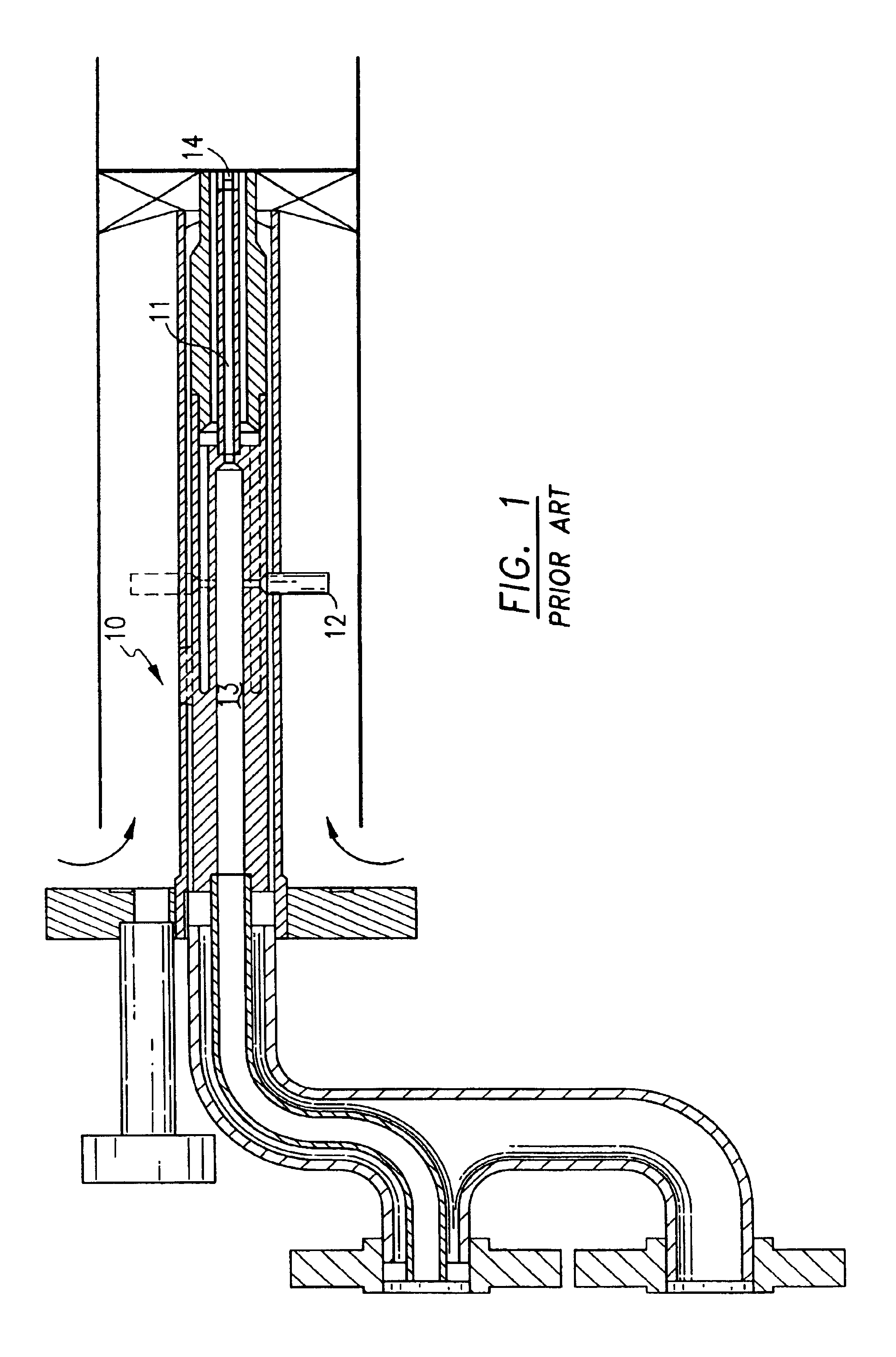

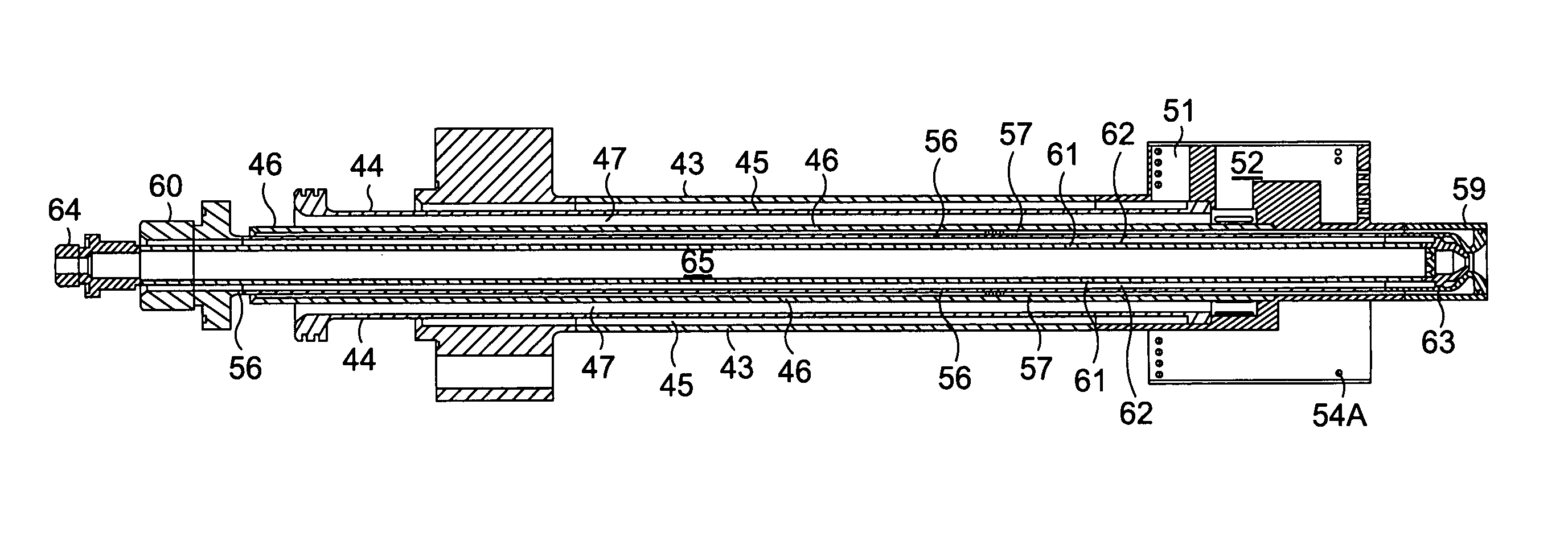

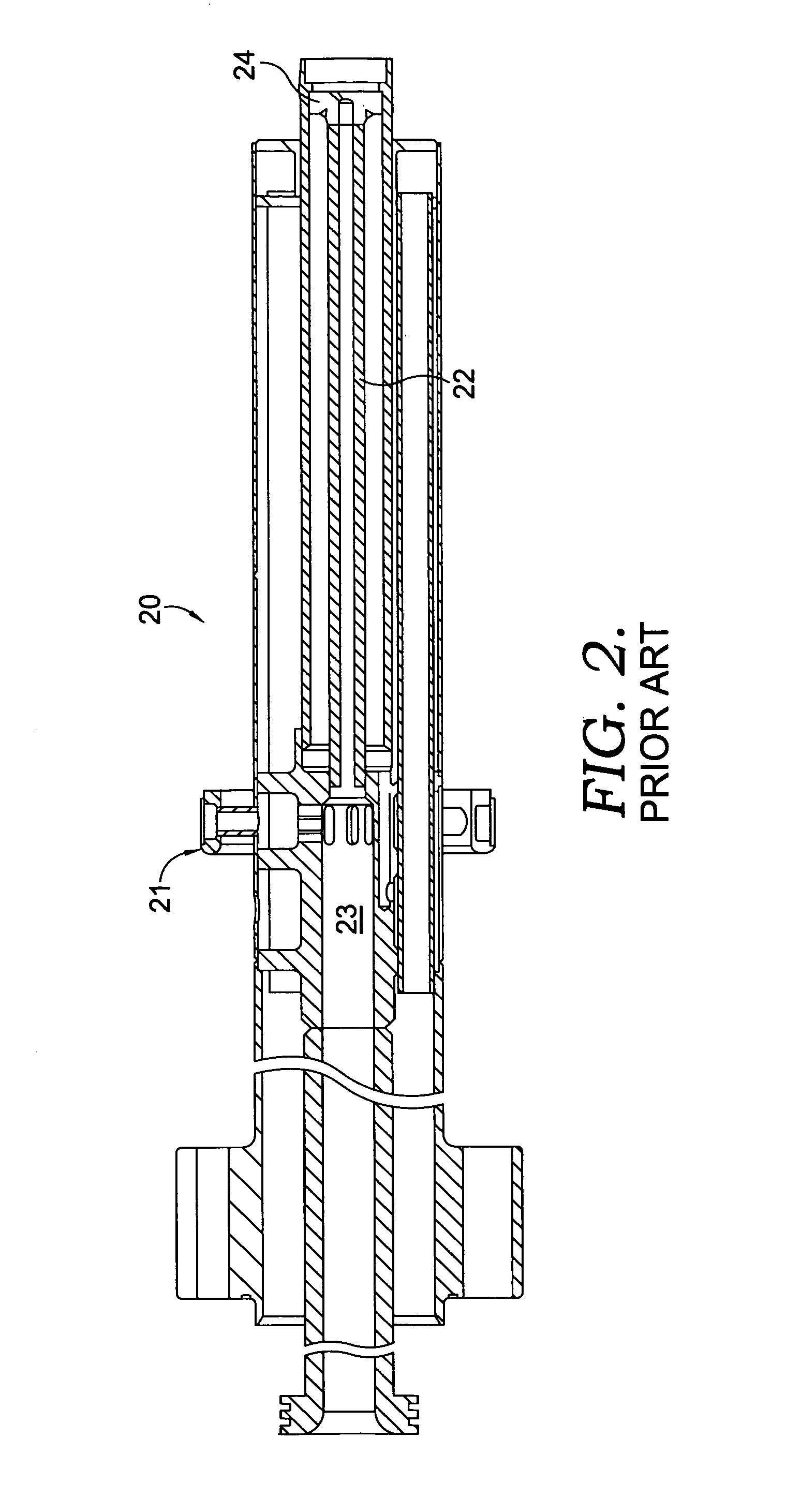

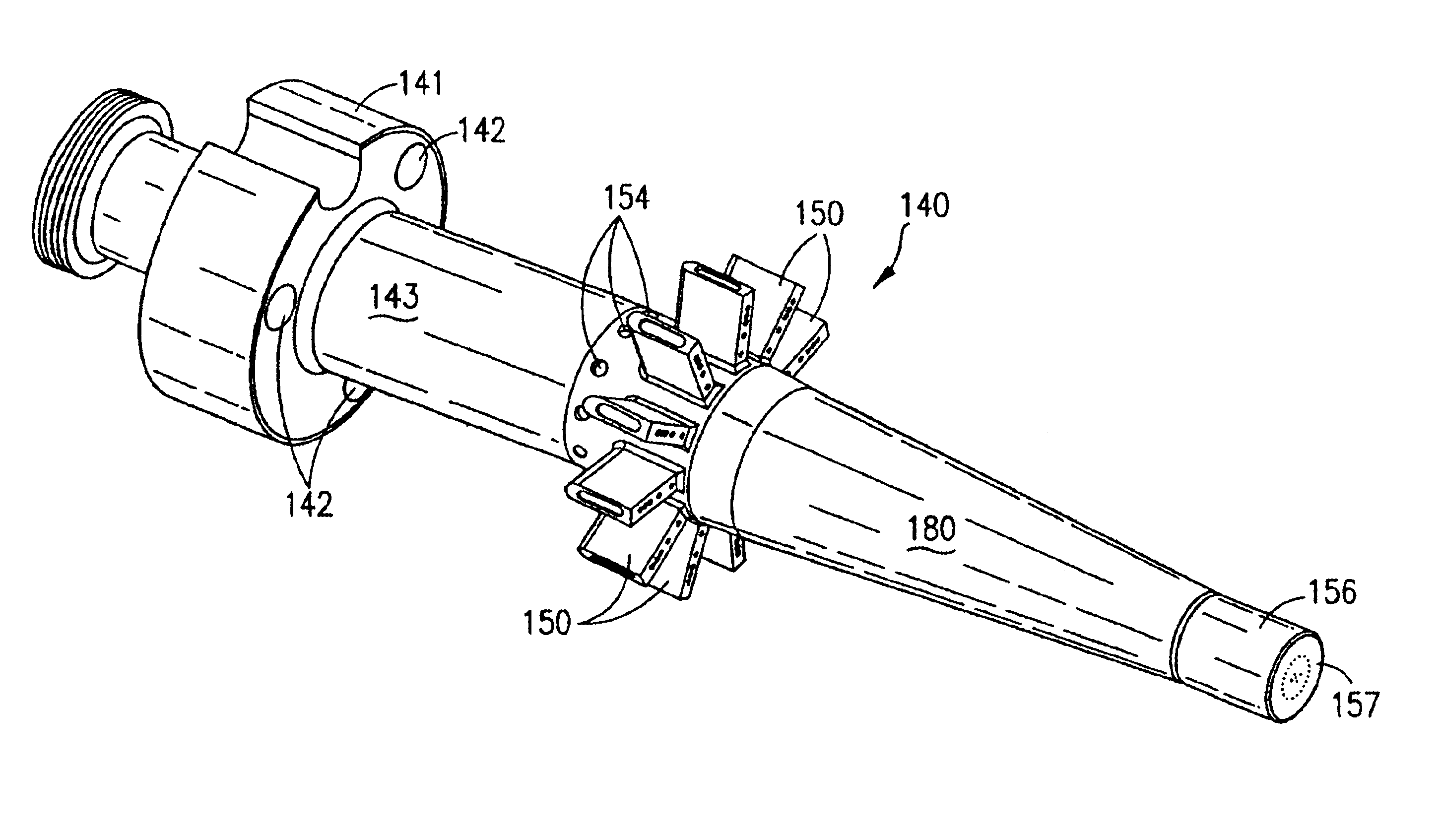

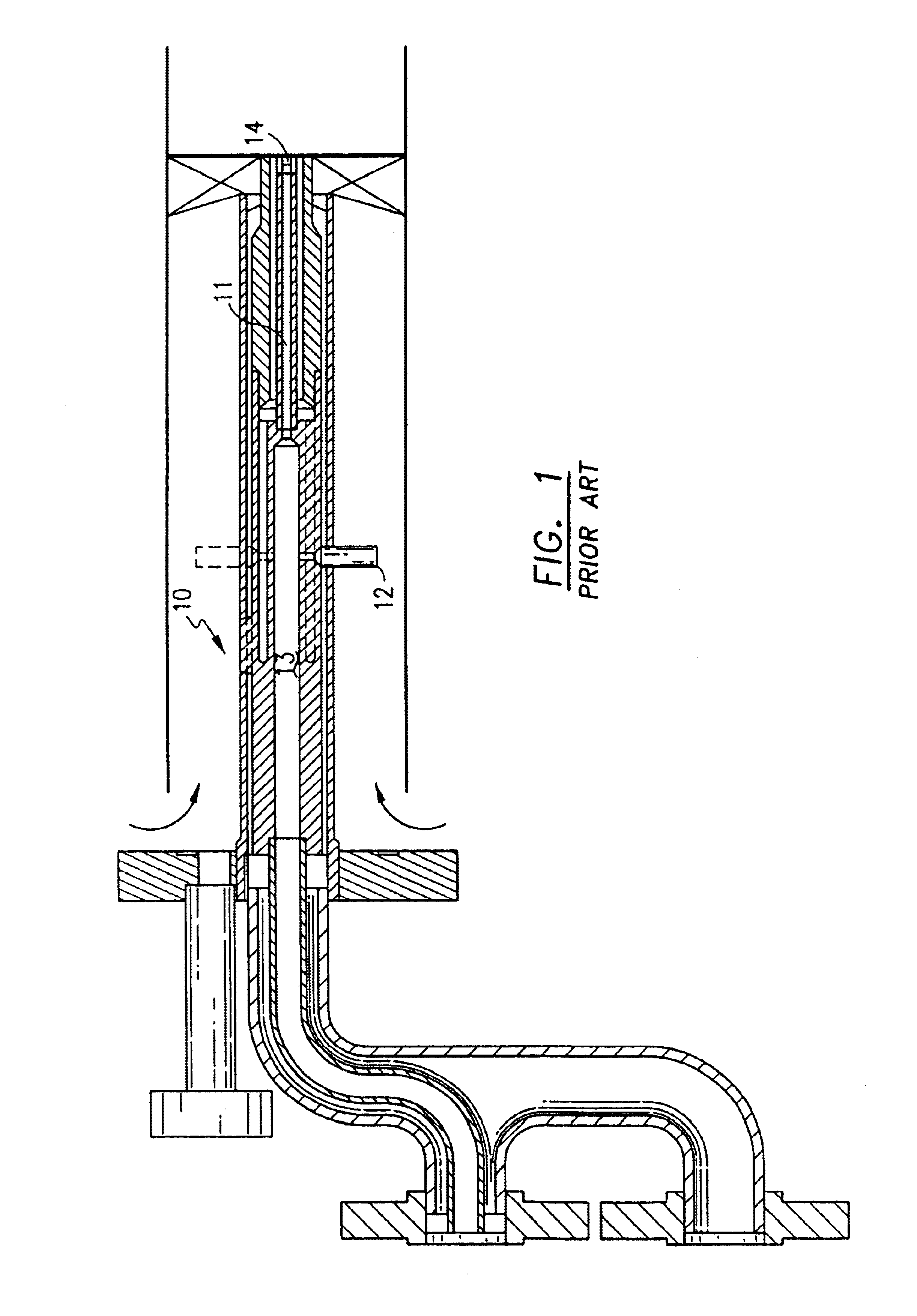

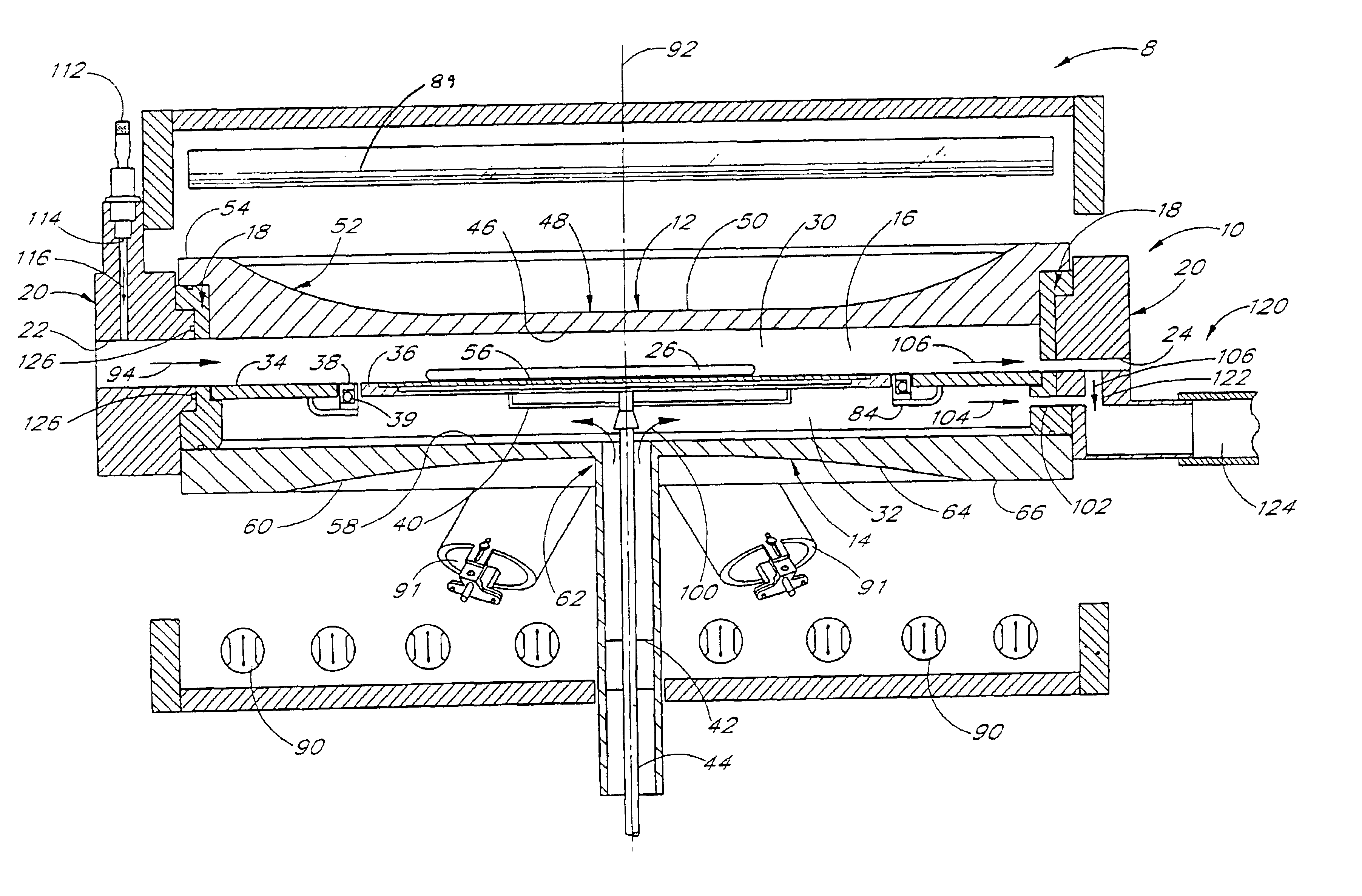

Dual fuel fin mixer secondary fuel nozzle

InactiveUS6915636B2Reduces NOx and other air pollutantUniform profileBurnersBurner safety arrangementsCombustion chamberCombustor

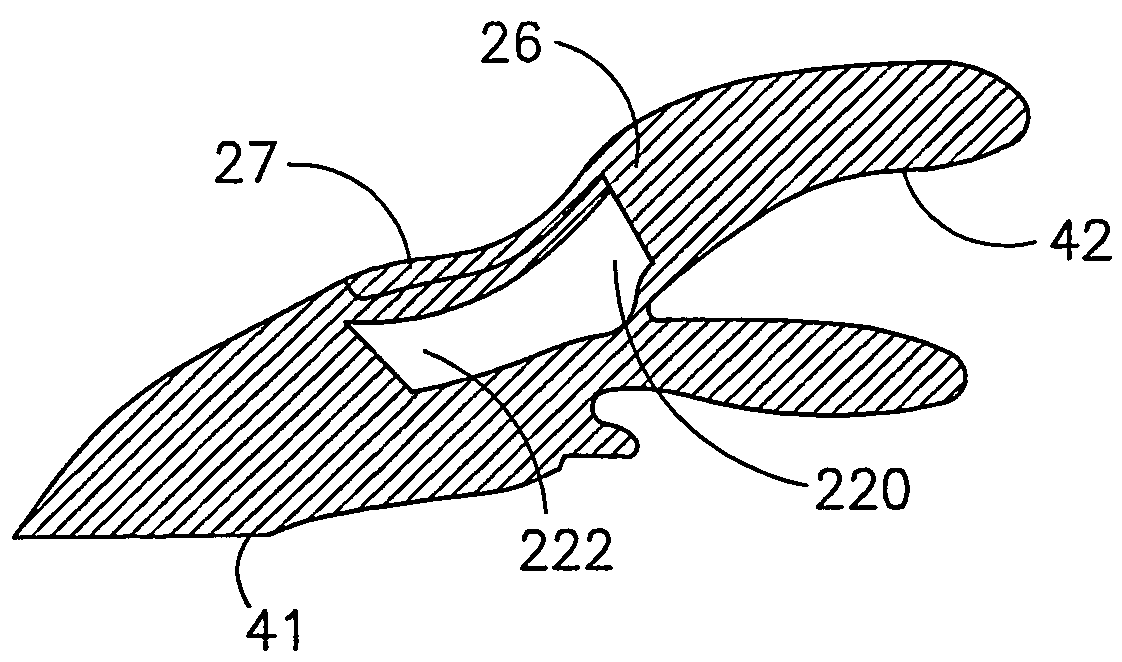

A dual fuel premix nozzle and method of operation for use in a gas turbine combustor is disclosed. The dual fuel premix nozzle utilizes a fin assembly comprising a plurality of radially extending fins for injection of gas fuel and compressed air in order to provide a more uniform injection pattern and homogeneous mixture. The premix fuel nozzle includes a plurality of coaxial passages, which provide gaseous fuel and compressed air to the fin assembly. When in liquid fuel operation, the gas circuits are purged with compressed air and liquid fuel and water pass through coaxial passages to the tip of the dual fuel premix fuel nozzle, where they inject liquid fuel and water into the secondary combustion chamber. An alternate embodiment includes an additional gas fuel injection region located along a conically tapered portion of the premixed fuel nozzle, downstream of the fin assembly. A second alternate embodiment is disclosed which reconfigures the injector assembly and fuel injection locations to minimize flow blockage issues at the injector assembly and simplify fuel nozzle manufacturing.

Owner:ANSALDO ENERGIA SWITZERLAND AG

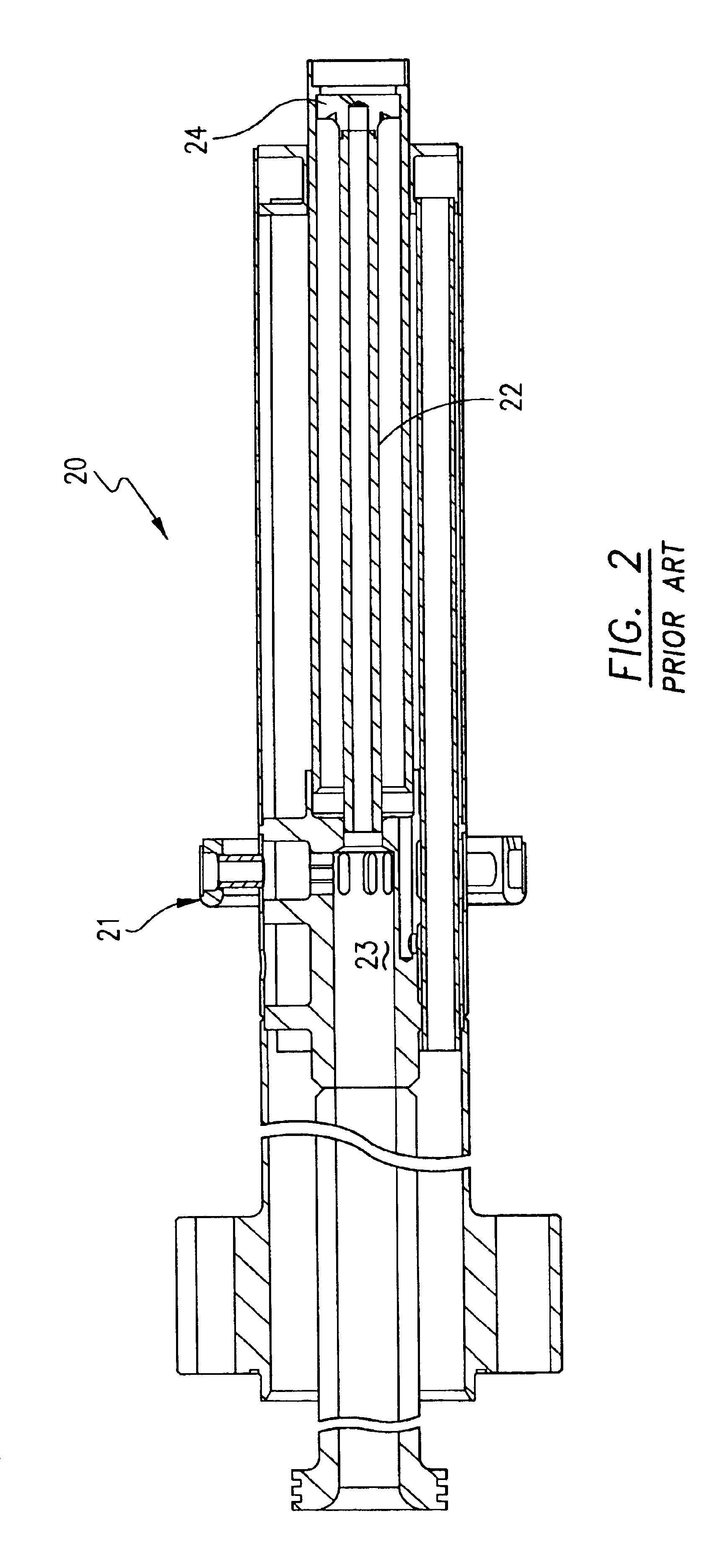

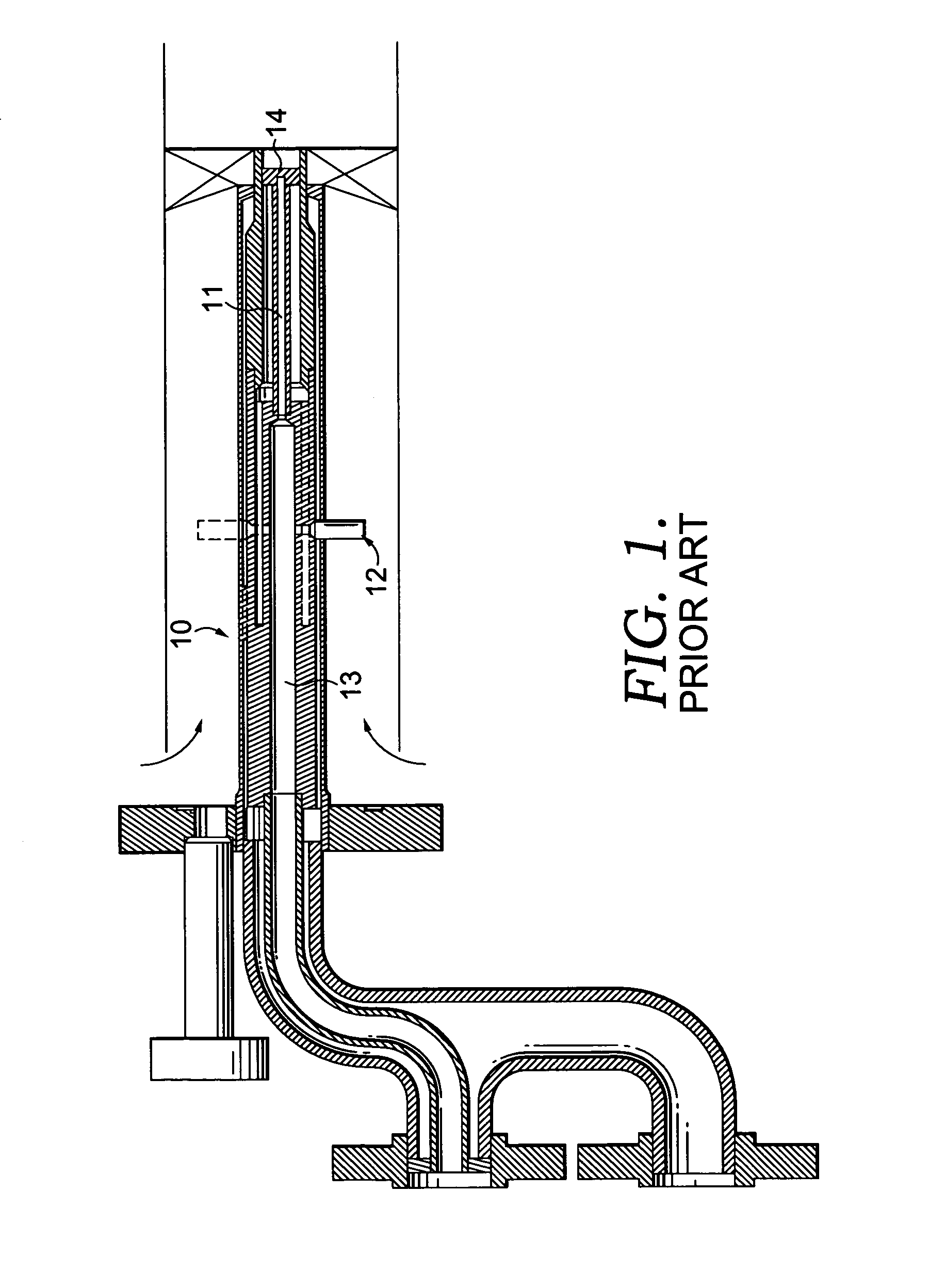

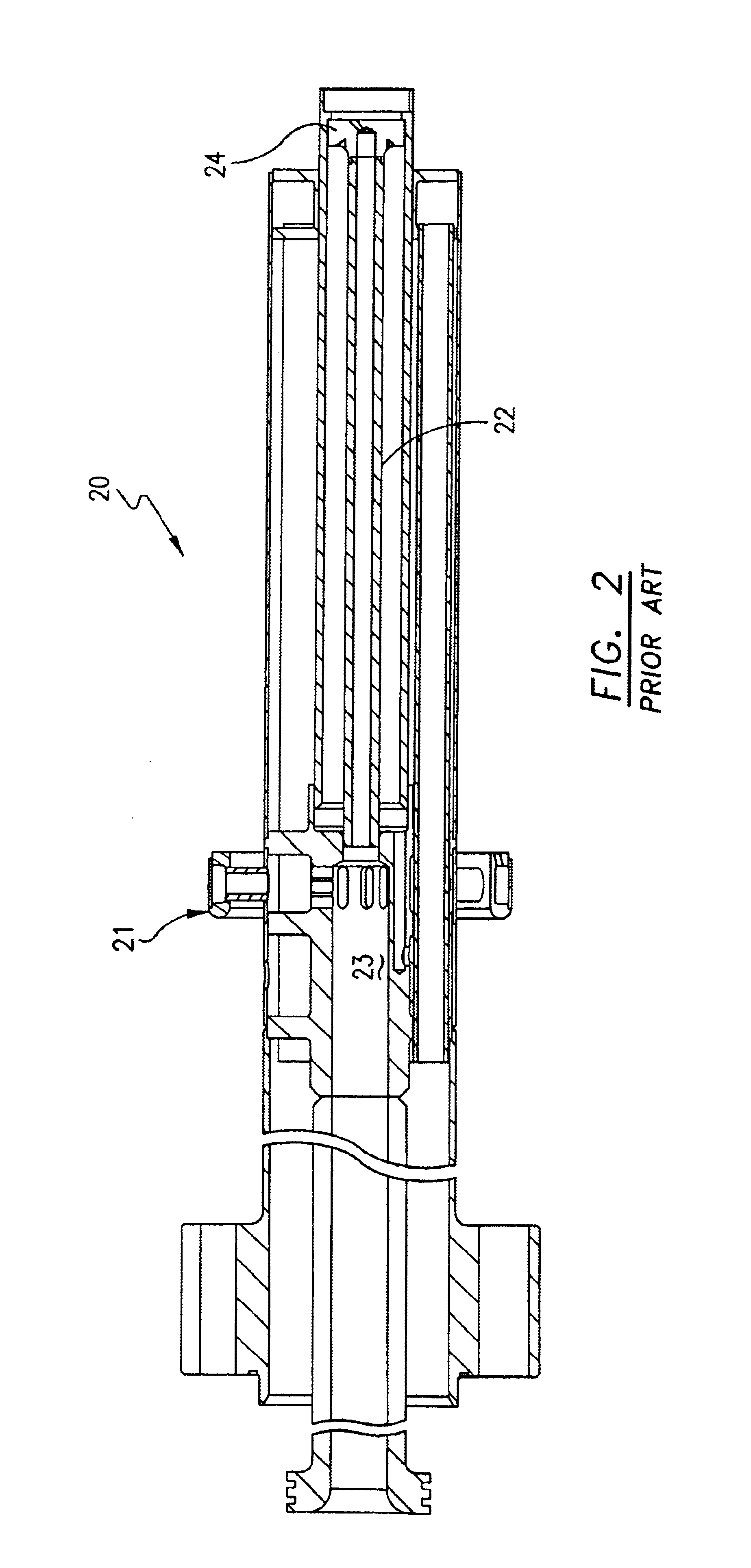

Fully premixed secondary fuel nozzle with dual fuel capability

InactiveUS7165405B2Reduces NOx and other air pollutantUniform profileBurner safety arrangementsBurnersCombustorCombustion chamber

A dual fuel premix nozzle and method of operation for use in a gas turbine combustor is disclosed. The dual fuel premix nozzle utilizes a fin assembly comprising a plurality of radially extending fins for injection of fuel and compressed air in order to provide a more uniform injection pattern. When in gas operation, the fuel and compressed air mixes upstream of the combustion chamber and flows into the combustion chamber as a homogeneous mixture. The premix fuel nozzle includes a plurality of coaxial passages, which provide gaseous fuel and compressed air to the fin assembly. When in liquid fuel operation, the gas circuits are purged with compressed air and liquid fuel and water pass through coaxial passages to the tip of the dual fuel premix fuel nozzle, where they inject liquid fuel and water into the secondary combustion chamber.

Owner:ANSALDO ENERGIA SWITZERLAND AG

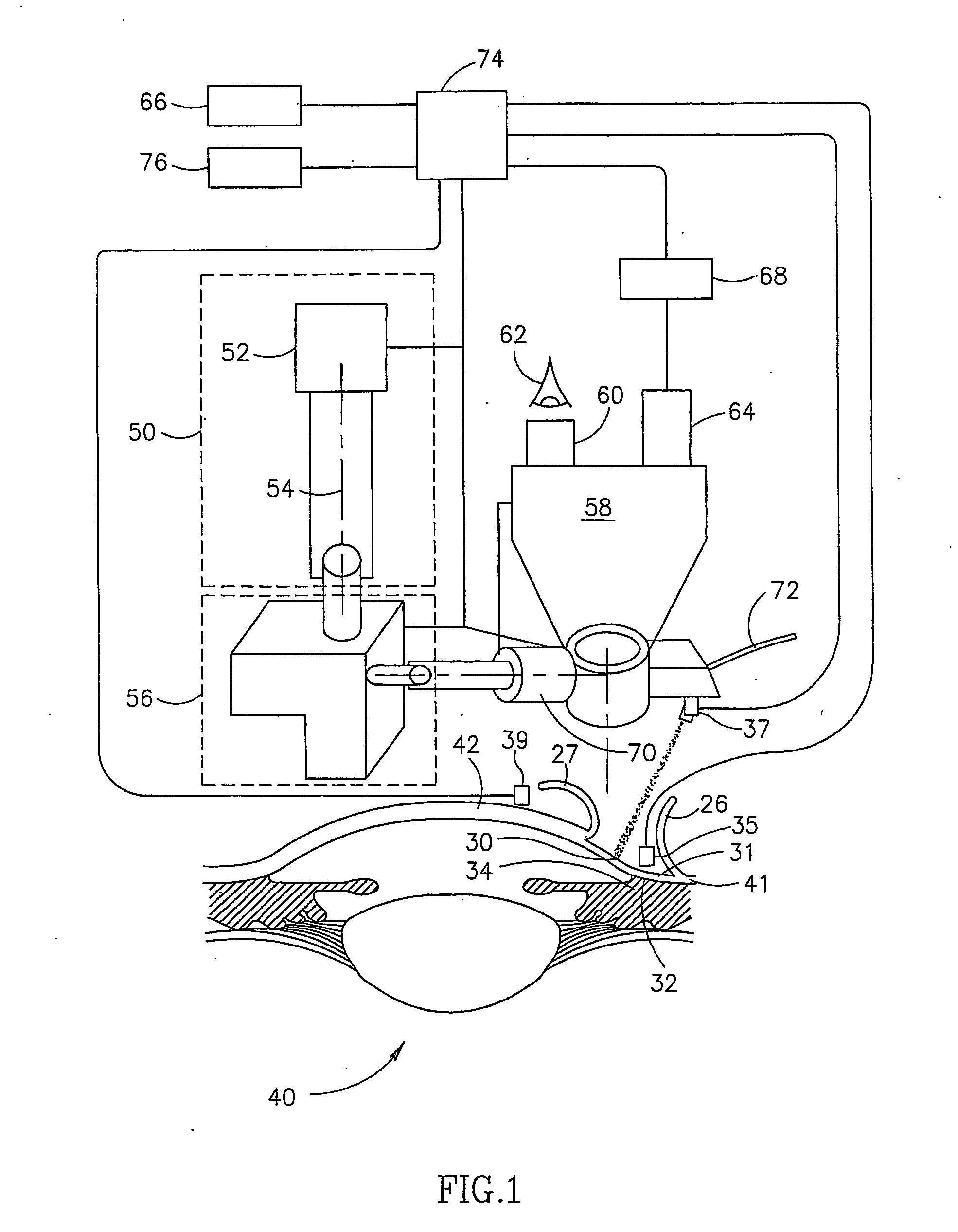

Non-penetrating filtration surgery

ActiveUS20050096639A1Raise security concernsReduce and eliminate scanningLaser surgeryDiagnosticsLight beamFiltration surgery

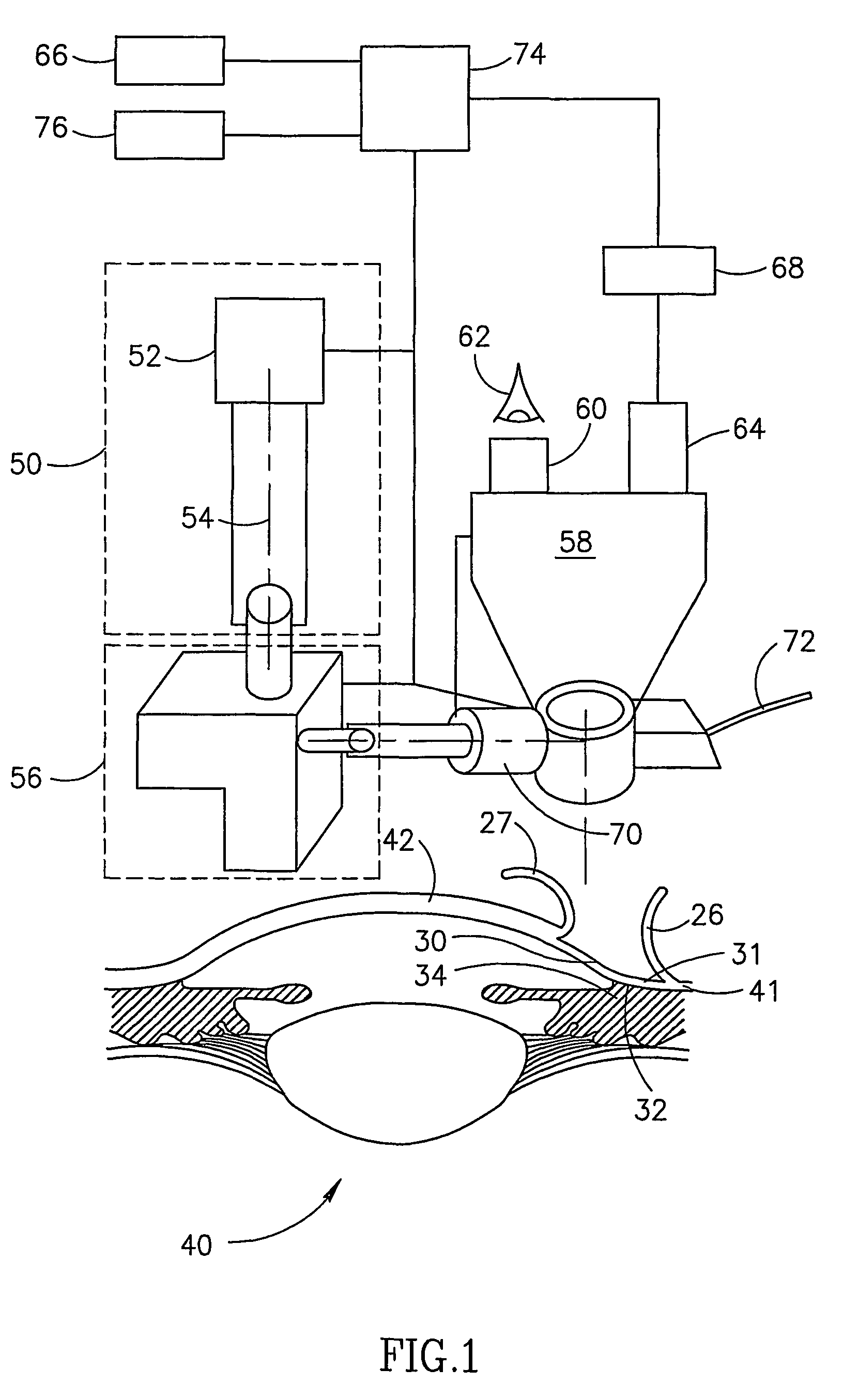

Apparatus for ophthalmic surgery, especially non-penetrating filtration surgery, comprising a laser source that ablates sclera tissue at steps of intermediate thickness. Optionally, the beam is scanned using a scanner and its results viewed using an ophthalmic microscope.

Owner:I OPTIMA LTD

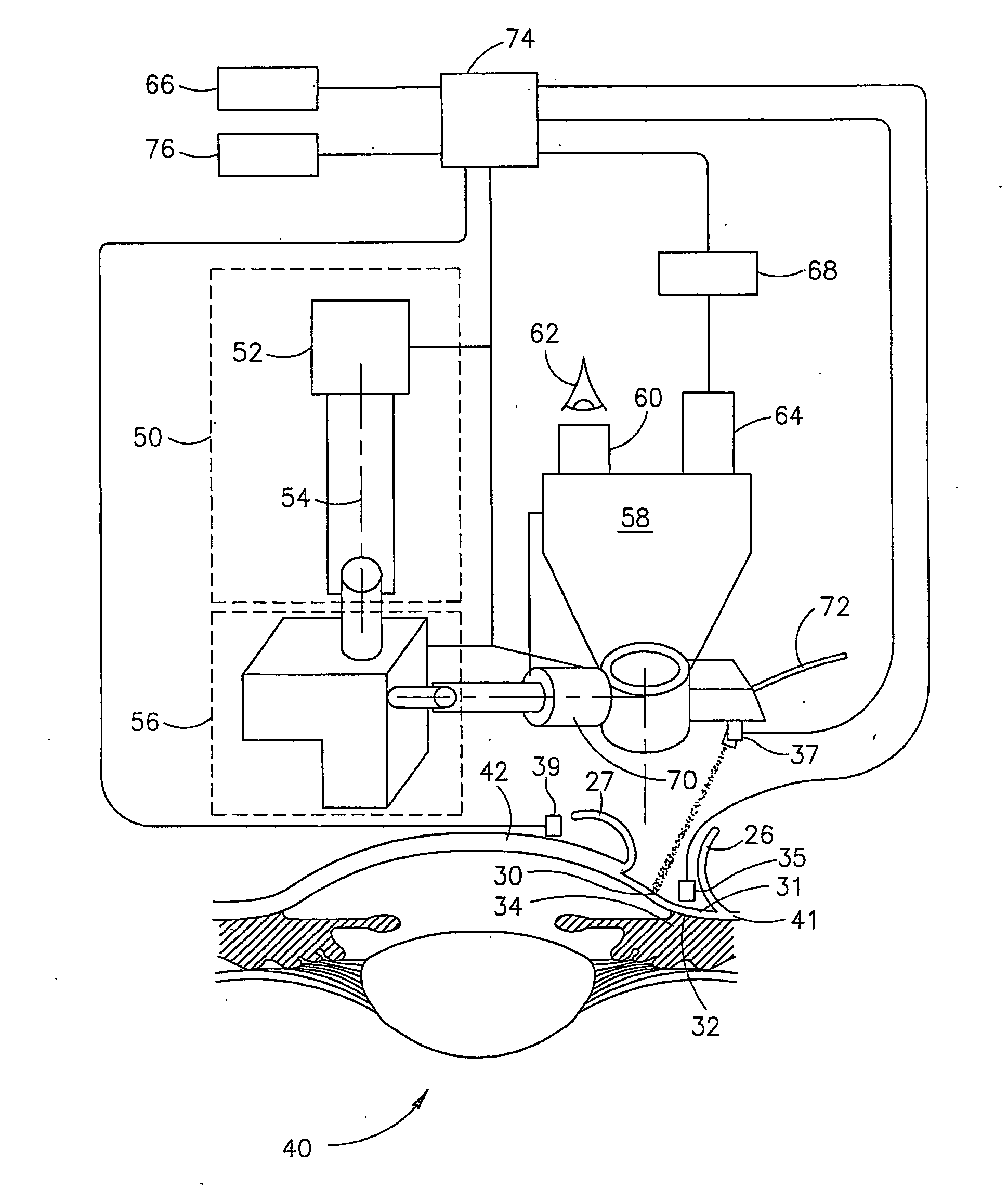

Non-penetrating filtration surgery

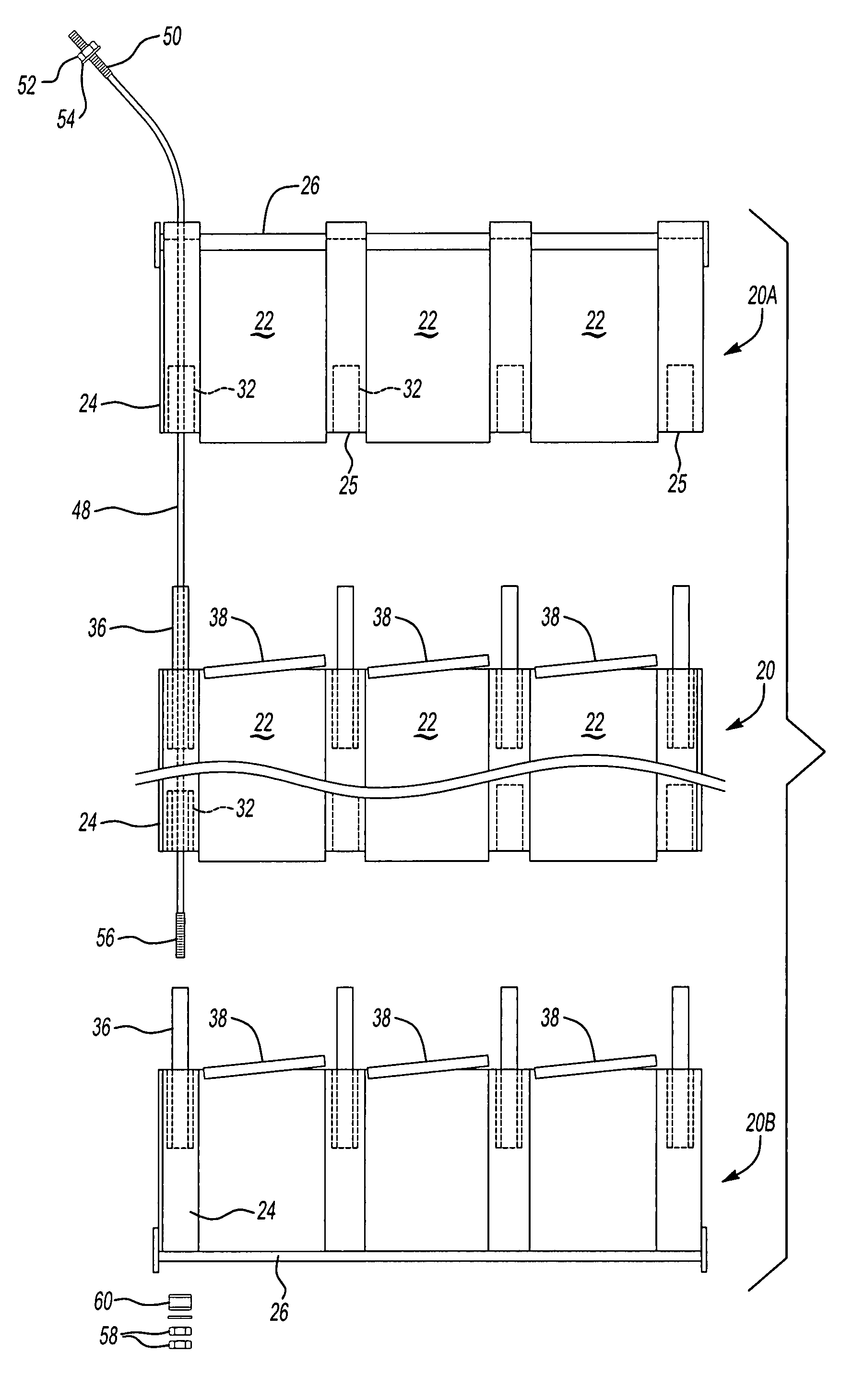

InactiveUS7135016B1Reduce penetrationDispersing heatLaser surgerySurgical instrument detailsPhysicsMicroscope

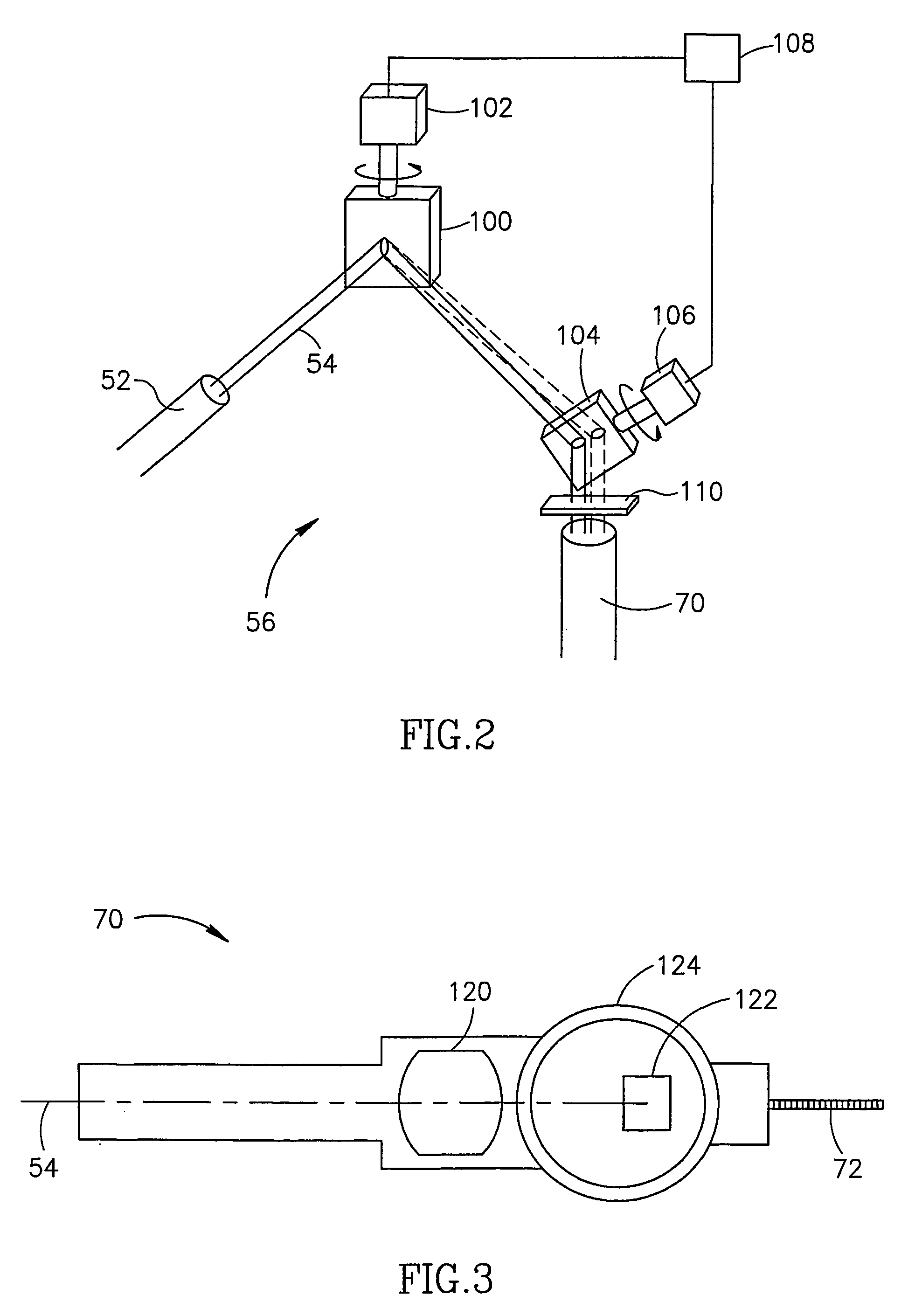

This invention is an apparatus for ophthalmic surgery comprising a laser source (52) that generates a laser beam (54); a scanner (56) comprising an input for said laser beam, and an output of a spatially scanned laser beam (54); controlling circuitry that drives said scanner (56) to remove tissue in a desired pattern on the eye (40); a microscope (58) for viewing said tissue removal; and a beam combiner (70) comprising a first input for a line of sight of said microscope (58) and second input for said spatially scanned beam (54).

Owner:I OPTIMA LTD

Gas only fin mixer secondary fuel nozzle

InactiveUS6898937B2Reduces NOx and other air pollutantUniform profileBurnersContinuous combustion chamberCombustorCombustion chamber

A premix fuel nozzle and method of operation for use in a gas turbine combustor is disclosed. The premix fuel nozzle utilizes a fin assembly comprising a plurality of radially extending fins for injection of fuel and compressed air in order to provide a more uniform injection pattern. The fuel and compressed air mixes upstream of the combustion chamber and flows into the combustion chamber as a homogeneous mixture. The premix fuel nozzle includes a plurality of coaxial passages, which provide fuel and compressed air to the fin assembly, as well as compressed air to cool the nozzle cap assembly. An alternate embodiment includes an additional fuel injection region located along a conically tapered portion of the premixed fuel nozzle, downstream of the fin assembly. A second alternate embodiment is disclosed which reconfigures the injector assembly and fuel injection locations to minimize flow blockage issues at the injector assembly.

Owner:H2 IP UK LTD

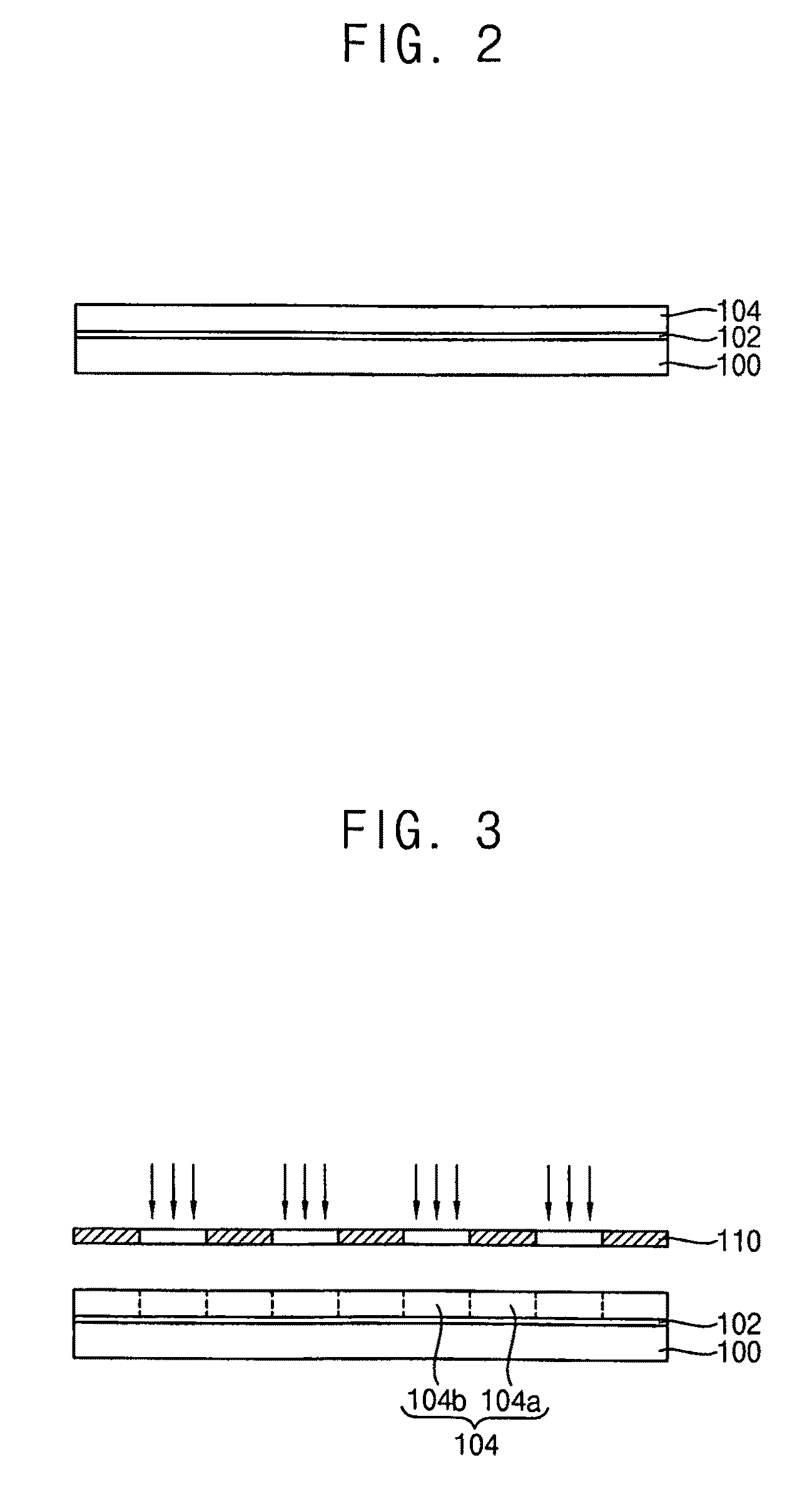

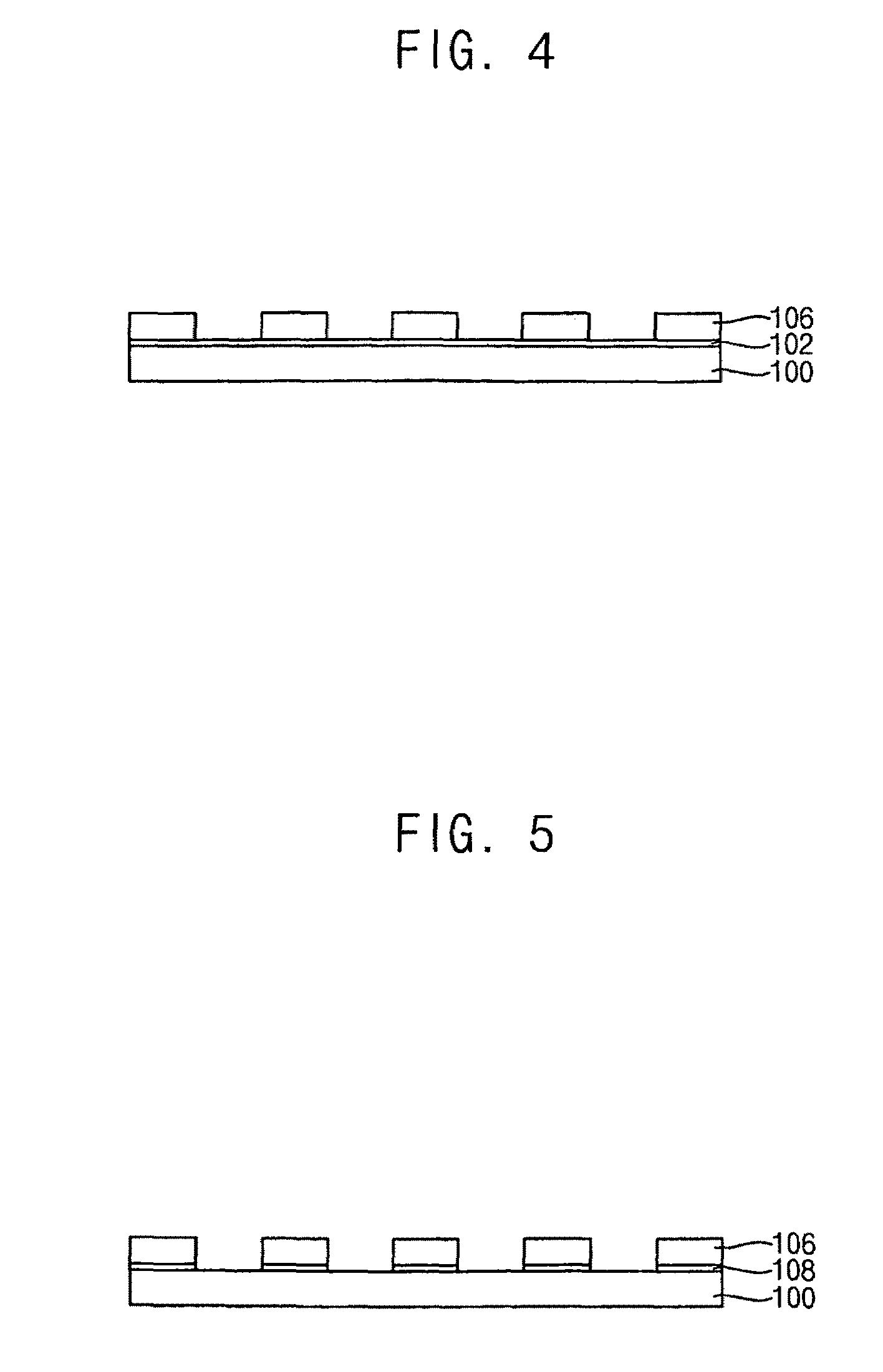

Photoacid generators, photoresist composition including the same and method of forming pattern using the same

InactiveUS20080182203A1Uniform profileIncrease line widthOrganic chemistryOrganic compound preparationPhotoacid generatorSulfonium

A photoresist composition includes about 4% to about 10% by weight of a photoresist resin, about 0.1% to about 0.5% by weight of a photoacid generator having a sulfonium-salt cationic group and a sulfonium-salt anionic group containing a carboxyl group as a hydrophilic site and a remainder of a solvent. The photoresist composition may form a photoresist pattern having a uniform profile.

Owner:SAMSUNG ELECTRONICS CO LTD

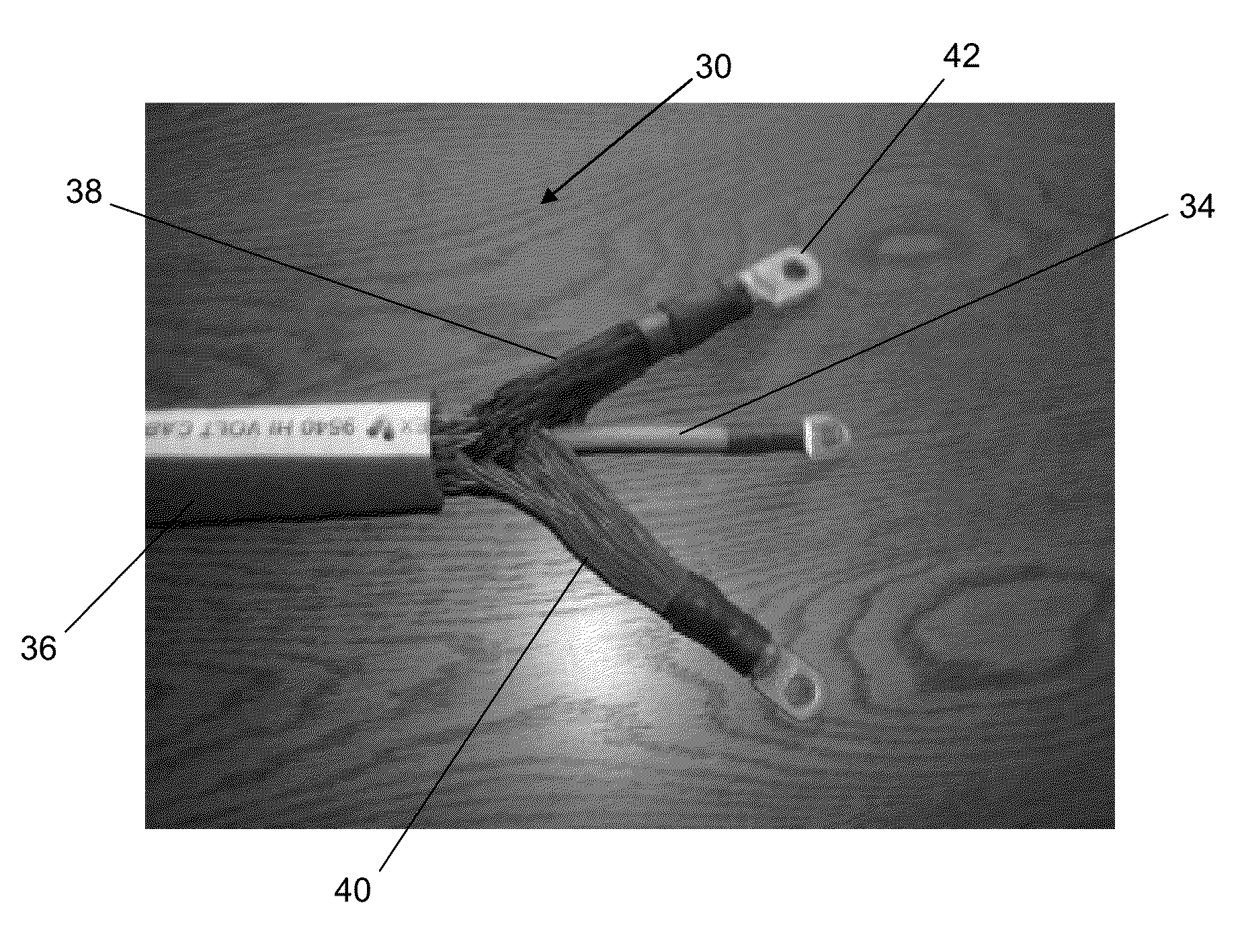

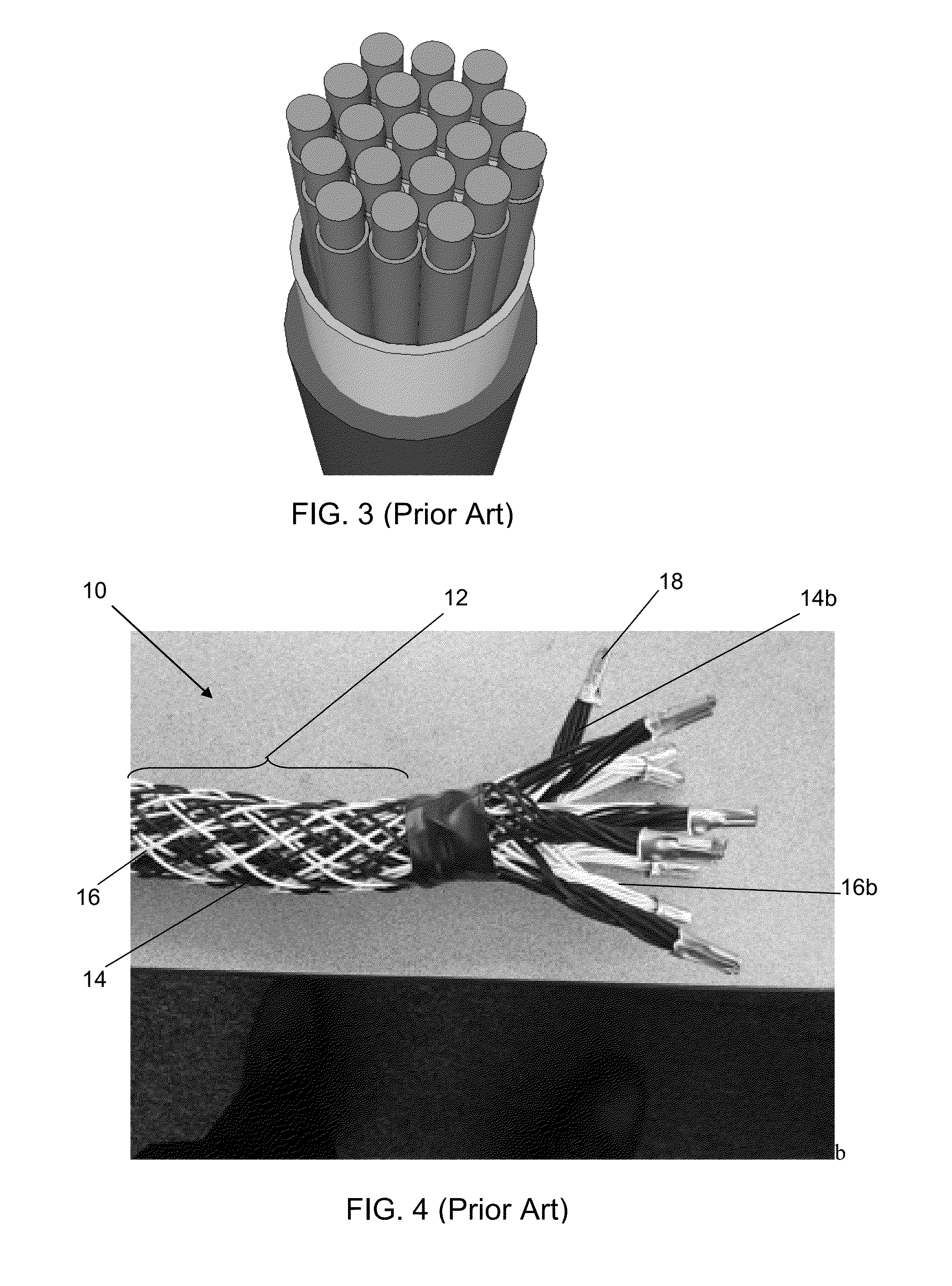

Low inductance electrical transmission cable

ActiveUS9293240B2High current loadUniform profileElectrically conductive connectionsInsulated cablesCurrent loadElectrical conductor

An electrical transmission cable is provided with low inductance properties capable of carrying high current loads with a more uniform heating or loss profile. The low inductance properties of the cable lead to lower current losses resulting in a cooler and more efficient operation of the cable even at higher alternating current (AC) frequencies. Higher current loads are accommodated by a plurality of conductor bundles configured as braided wire strands that are separated and joined into like conductors prior to termination. Equal lengths of the insulated wire strands within the conductor bundles contribute to uniform heating along the length of the inventive cable embodiments. Uniform operating temperature is manifest as more uniform current transmission across the various strands of an inventive cable. In addition, the more equal weave position for all the wire strands making up each braided wire bundle tends to induce cancellation of inductive effects.

Owner:FLEX CABLE

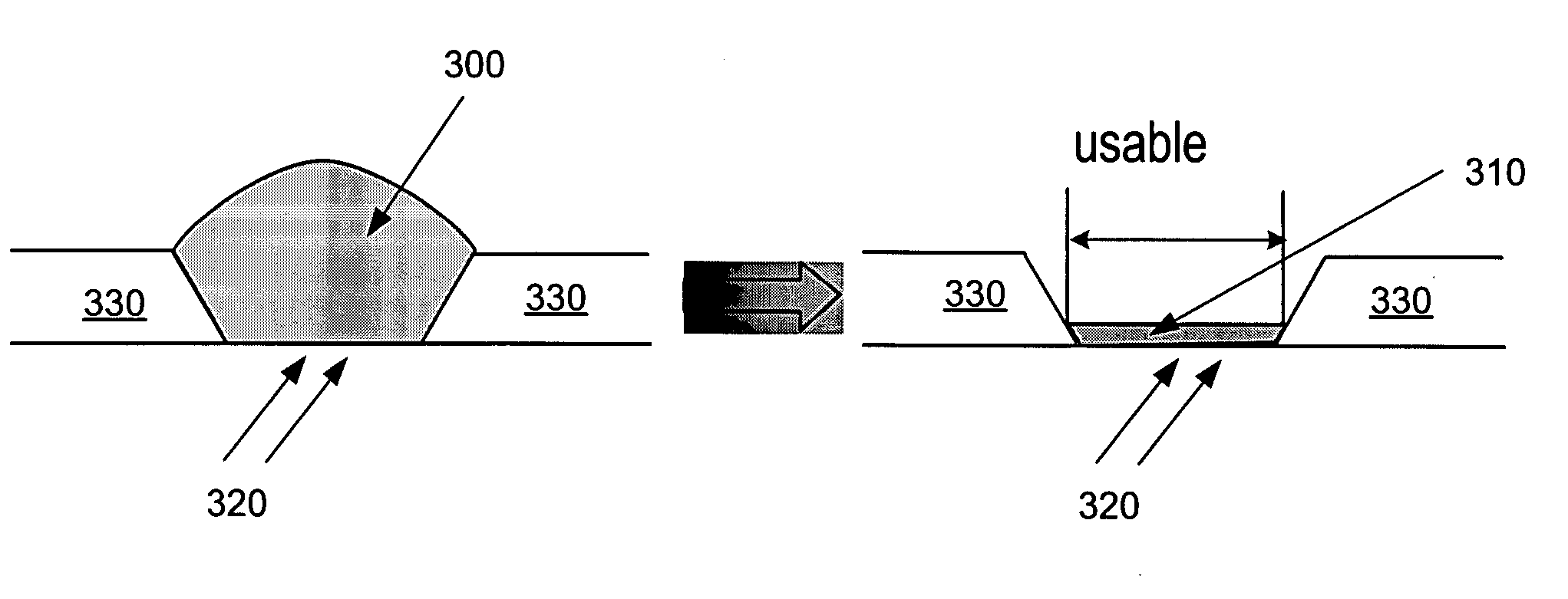

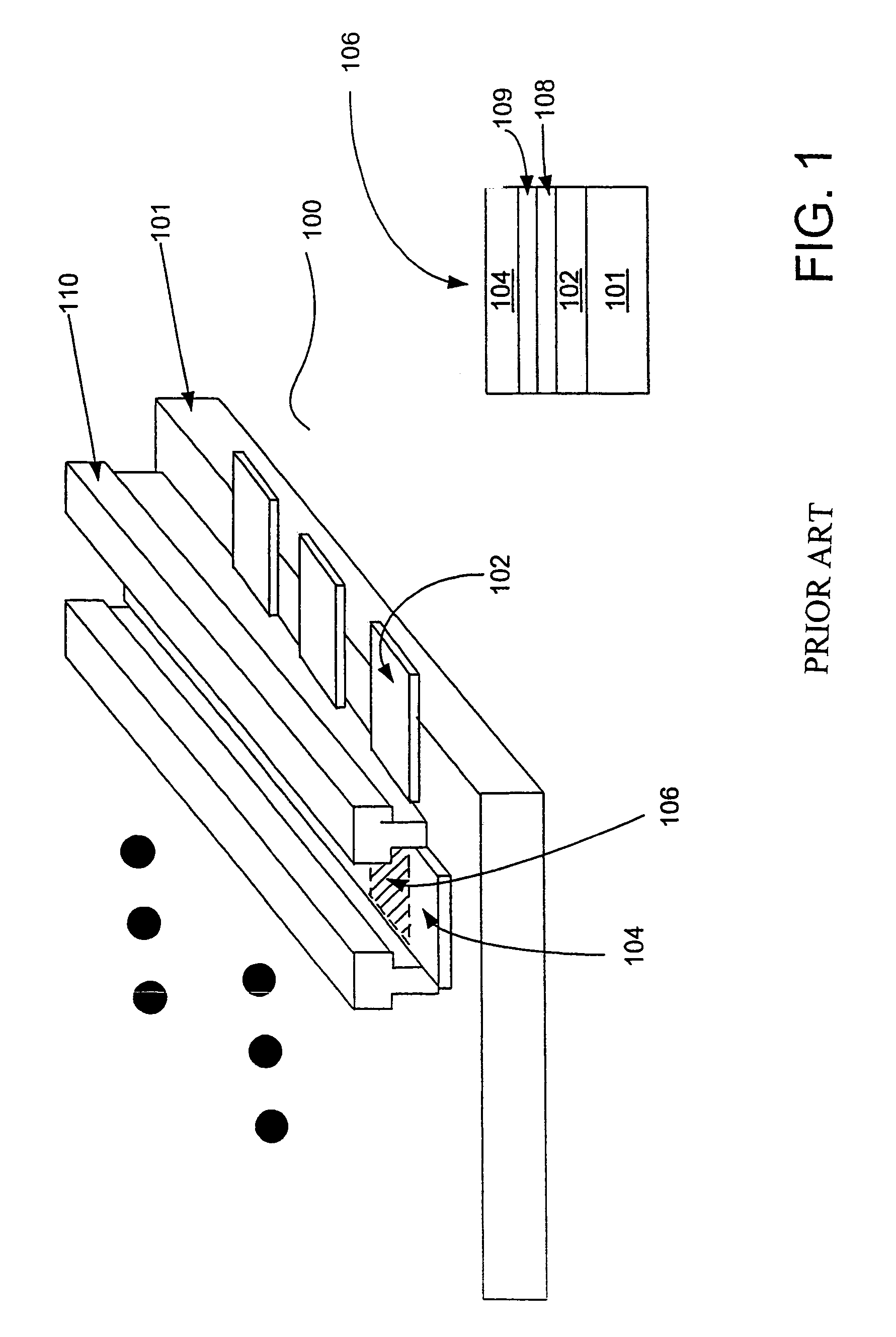

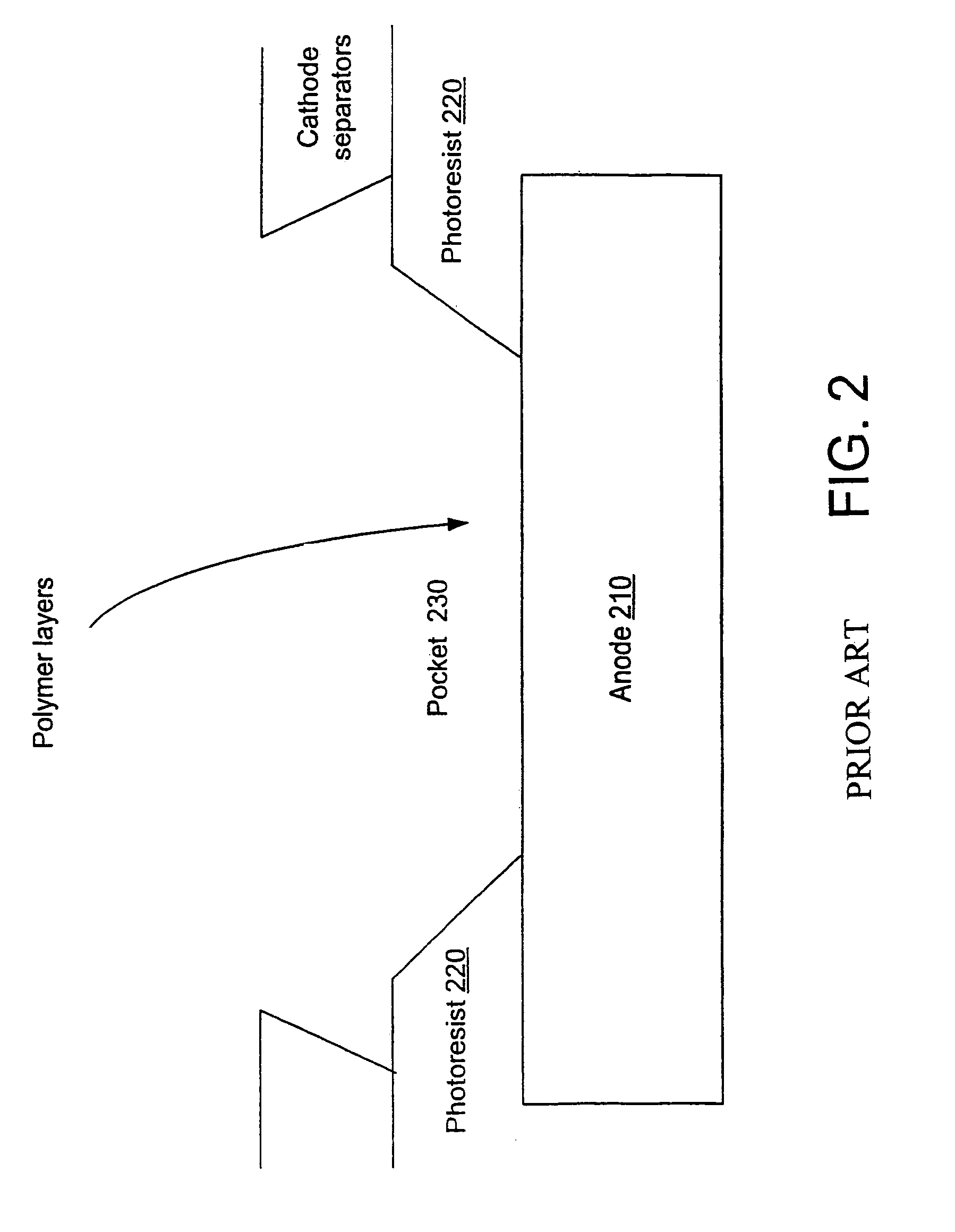

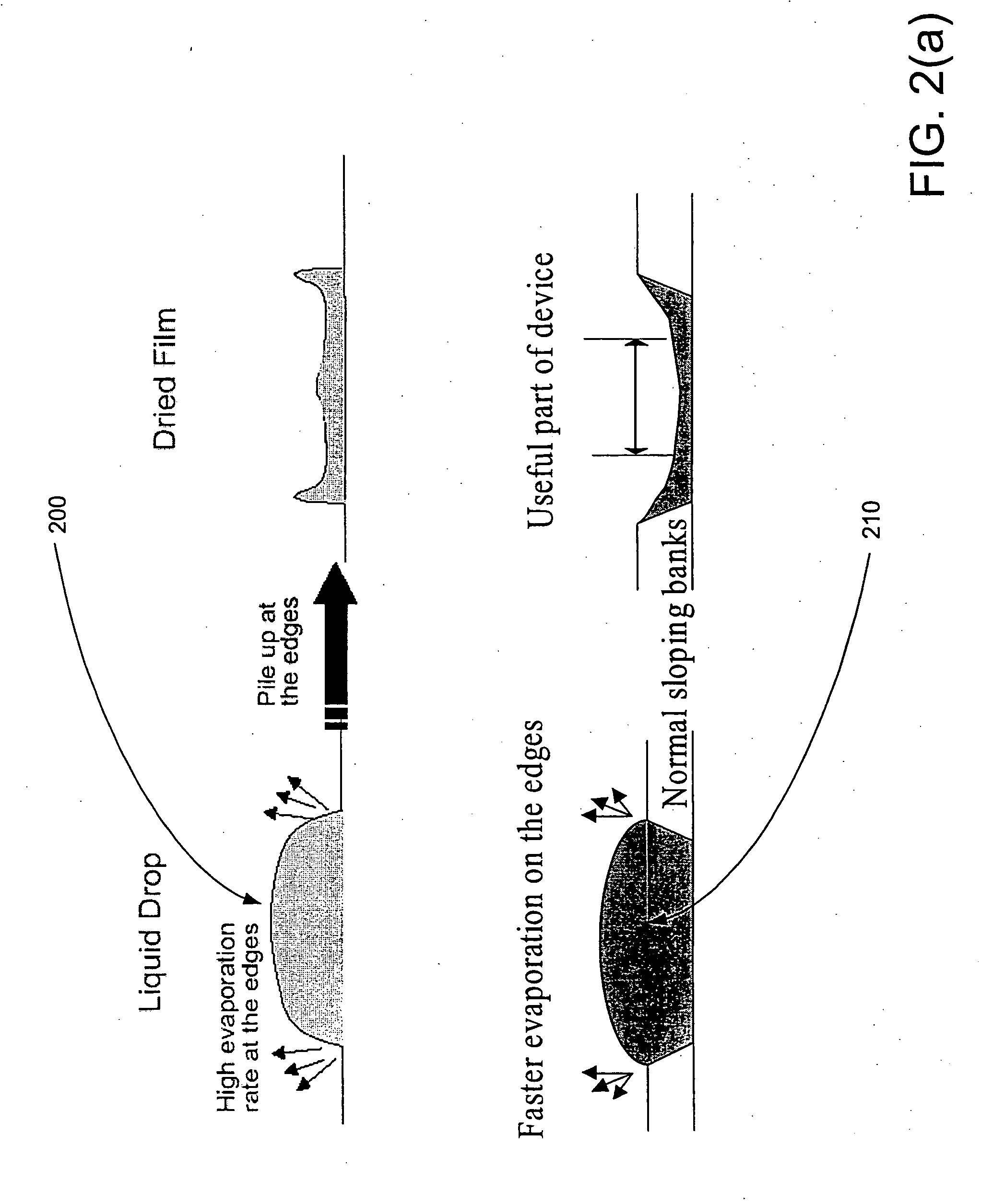

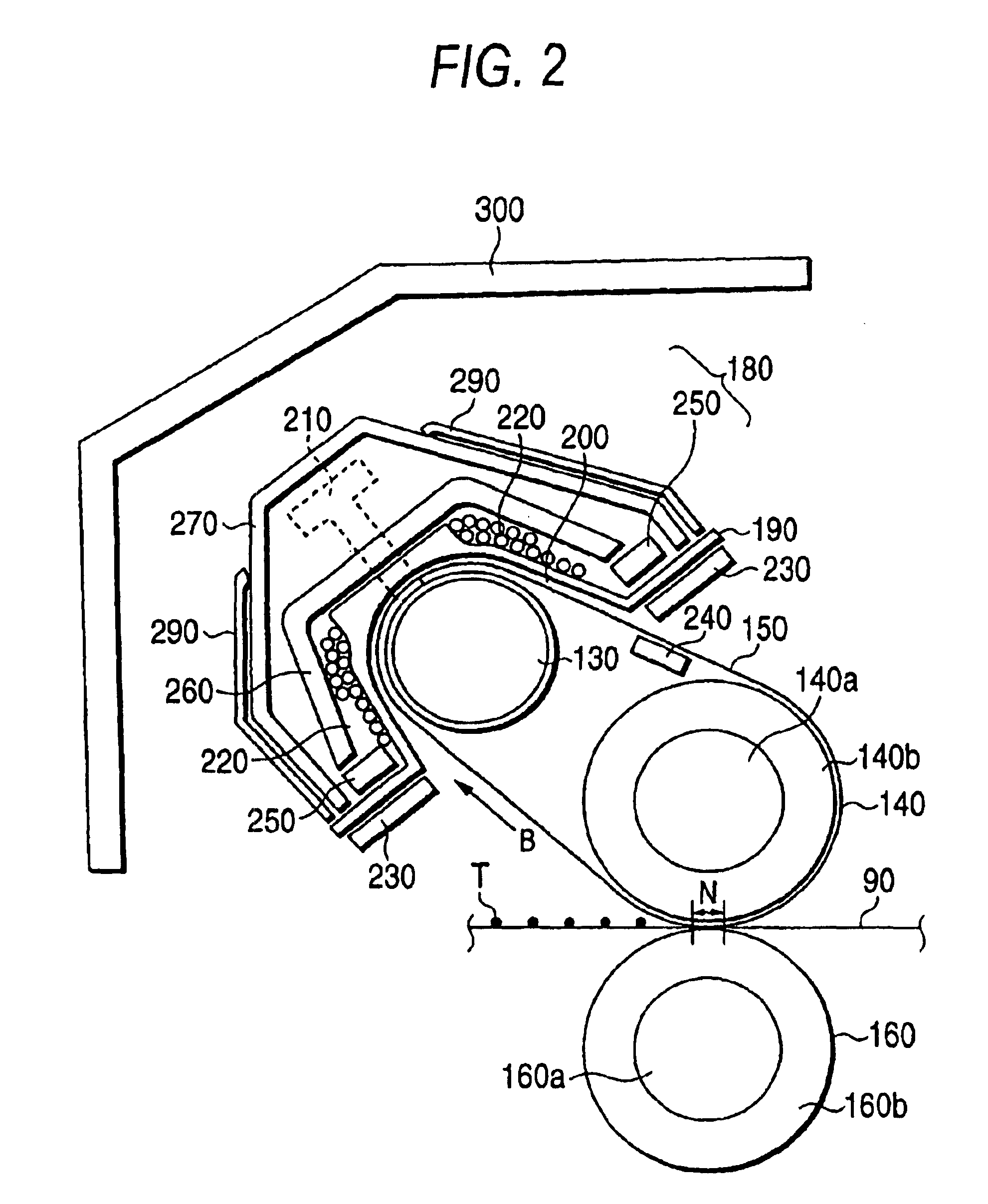

Printing of organic electronic devices

InactiveUS20050153114A1Uniform and flatter profileExtended drying timeDecorative surface effectsSolid-state devicesConductive polymerInorganic chemistry

The composition of a organic (e.g. conducting polymer) solution is reformulated and the device upon which the organic solution is to be deposited is plasma treated to provide a more uniform and flat drying profile for the resulting dried film. This reformulation and treatment induces a more uniform and flatter profile when the reformulated organic solution is allowed to dry into a film on the treated device.

Owner:OSRAM OPTO SEMICONDUCTORS GMBH & CO OHG

Optimal bank shapes for inkjet printing

ActiveUS7132788B2Lower Level RequirementsUniform drying profileDischarge tube luminescnet screensElectroluminescent light sourcesResistEngineering

Owner:DOLYA HOLDCO 5 LTD

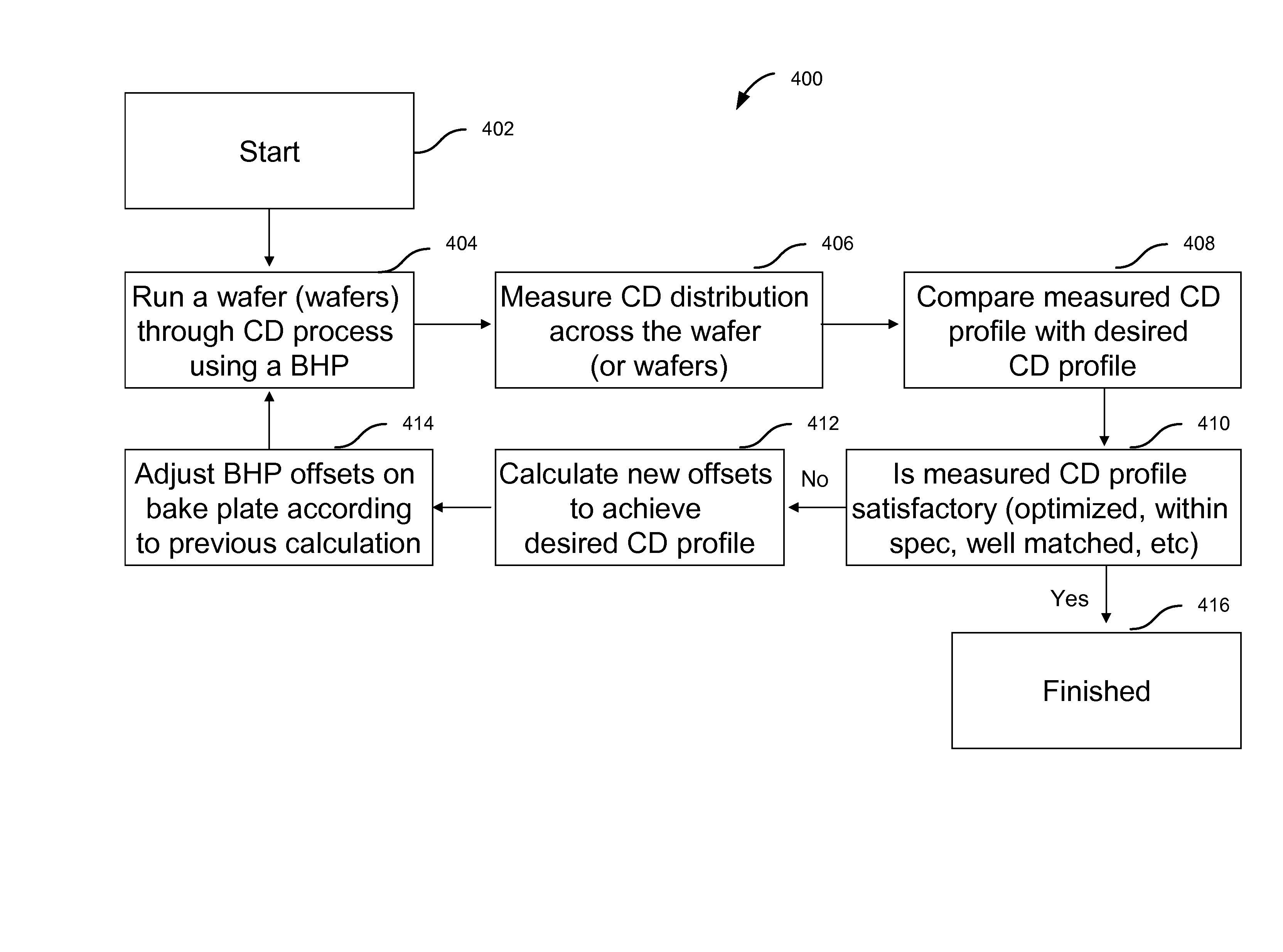

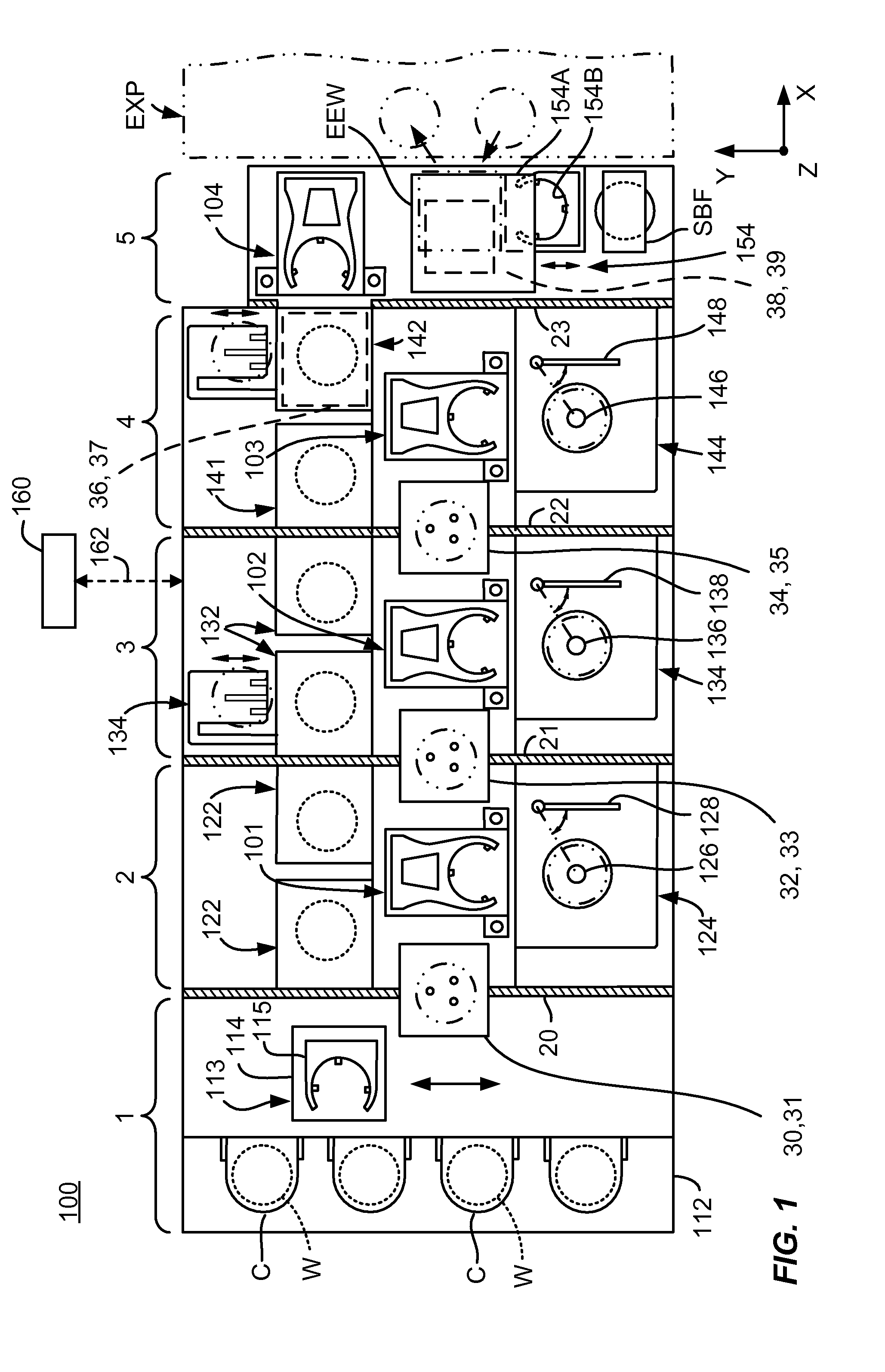

Methods and systems for controlling critical dimensions in track lithography tools

ActiveUS20080032426A1Improved CD uniformityBetter CD uniformityLiquid surface applicatorsSemiconductor/solid-state device testing/measurementLithographic artistEngineering

A method of controlling wafer critical dimension (CD) uniformity on a track lithography tool includes obtaining a CD map for a wafer. The CD map includes a plurality of CD data points correlated with a multi-zone heater geometry map. The multi-zone heater includes a plurality of heater zones. The method also includes determining a CD value for a first heater zone of the plurality of heater zones based on one or more of the CD data points and computing a difference between the determined CD value for the first heater zone and a target CD value for the first heater zone. The method further includes determining a temperature variation for the first heater zone based, in part, on the computed difference and a temperature sensitivity of a photoresist deposited on the wafer and modifying a temperature of the first heater zone based, in part, on the temperature variation.

Owner:SCREEN SEMICON SOLUTIONS CO LTD

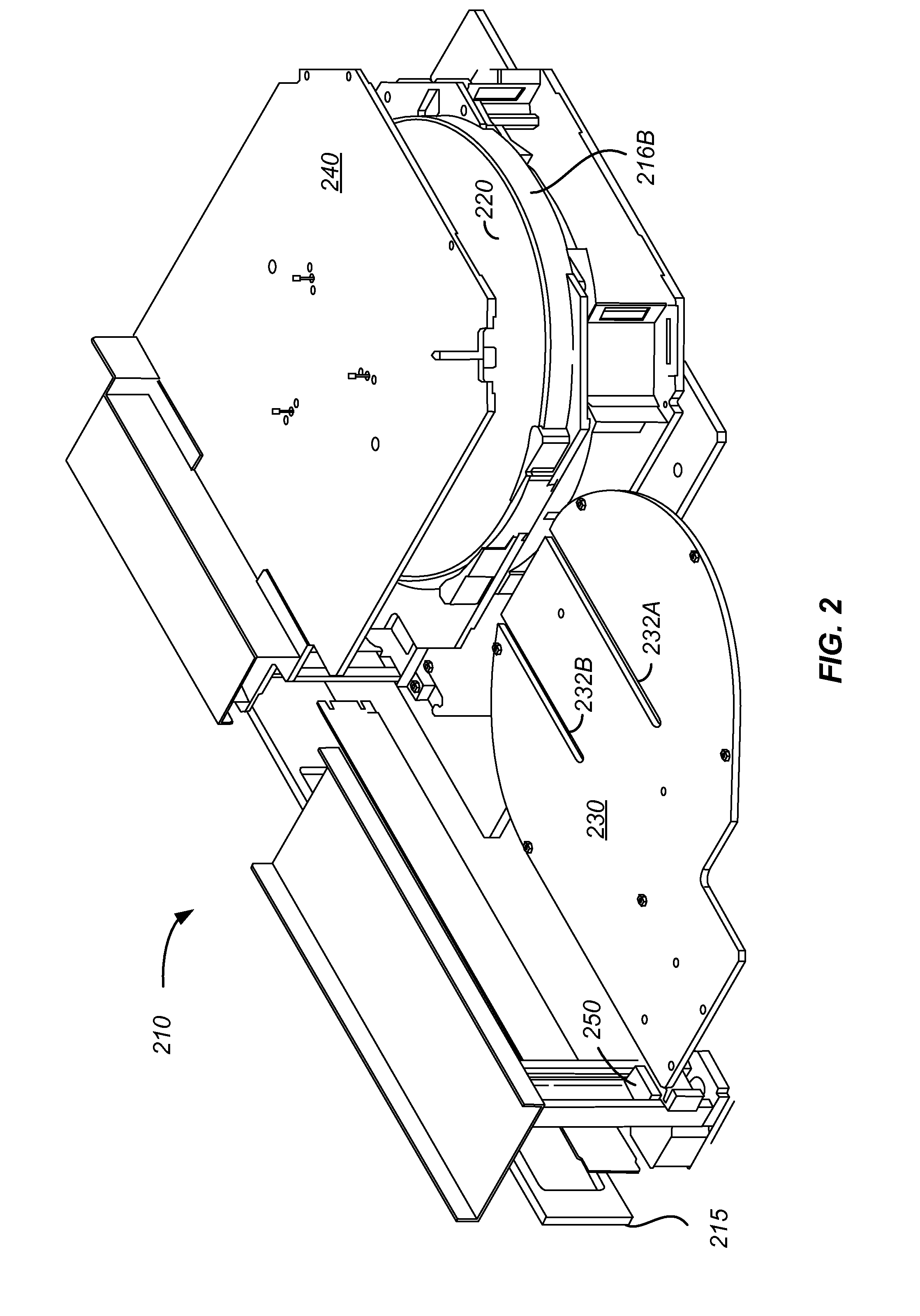

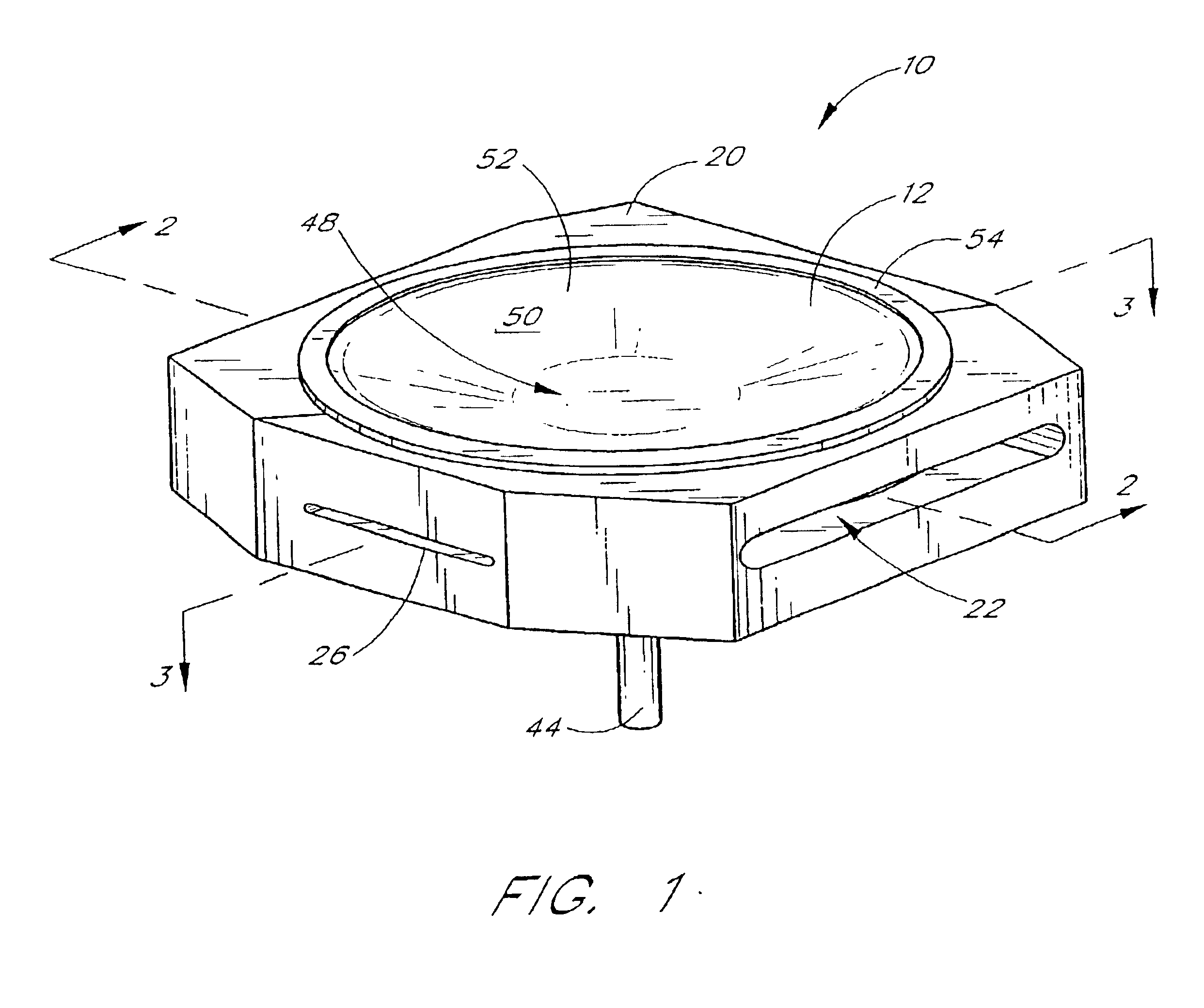

Compact process chamber for improved process uniformity

InactiveUS6869485B2Uniform deposition profileIncreasing the thicknessDrying solid materials with heatVacuum evaporation coatingEngineeringSemiconductor

A semiconductor processing chamber, capable of withstanding low pressures while transmitting radiant energy, is provided in a lightweight, compact design. The inner surface of the window is preferably substantially flat and parallel to the wafer to be processed. The window is thin in a center portion and thicker in a surrounding peripheral portion. The thickness increases in the radially outward direction, defined between the flat inner surface and a concave outer surface. Deposition uniformity is improved by employing multiple outlet ports for distributing gas laterally in a short length, enabling a compact, symmetrical geometry. Preferably, a quadra-flow system of gas distribution is used, whereby the chamber contains one inlet port and three outlet ports distributed approximately at 90 degrees around a cylindrical side wall defining the chamber space.

Owner:ASM AMERICA INC

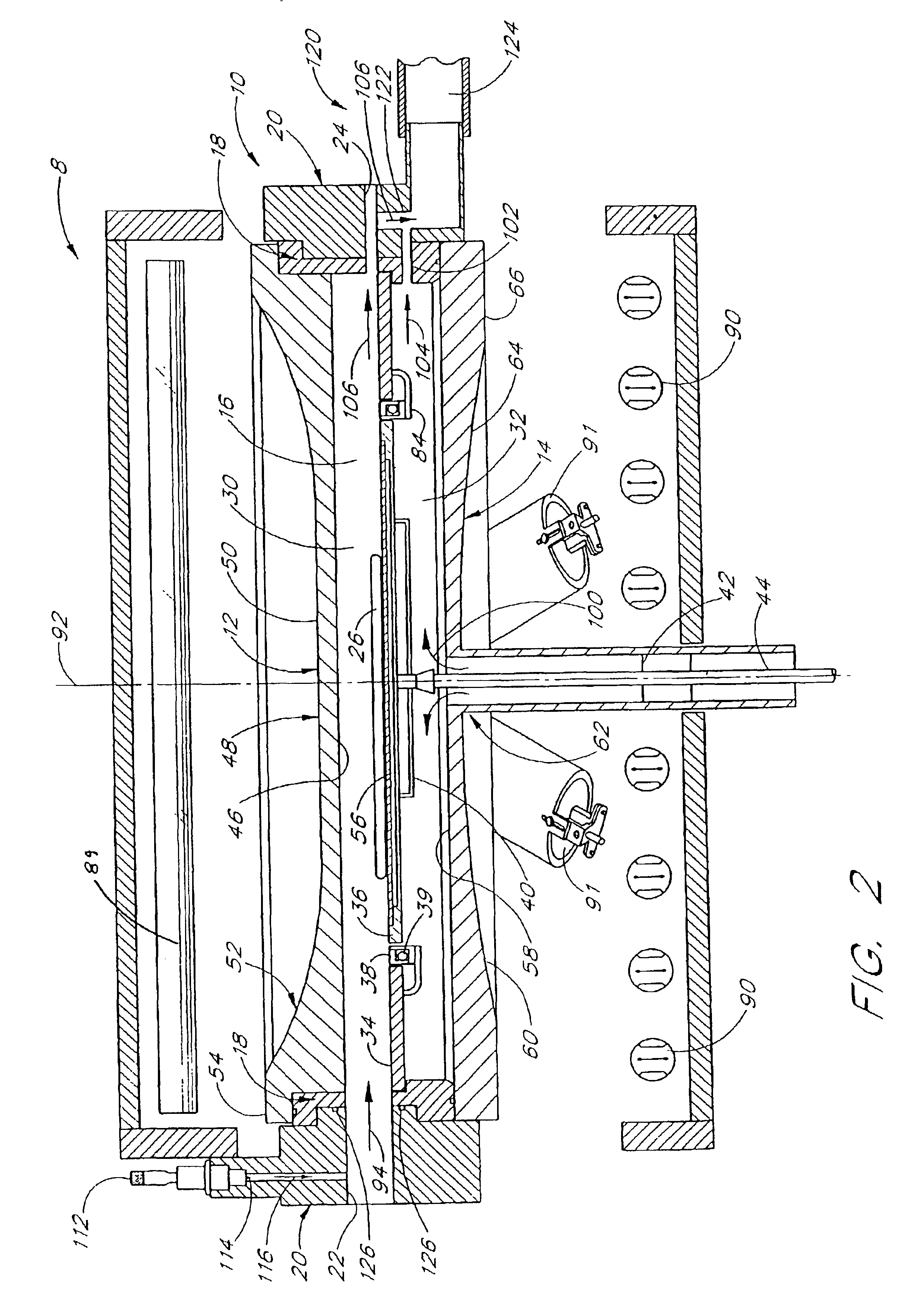

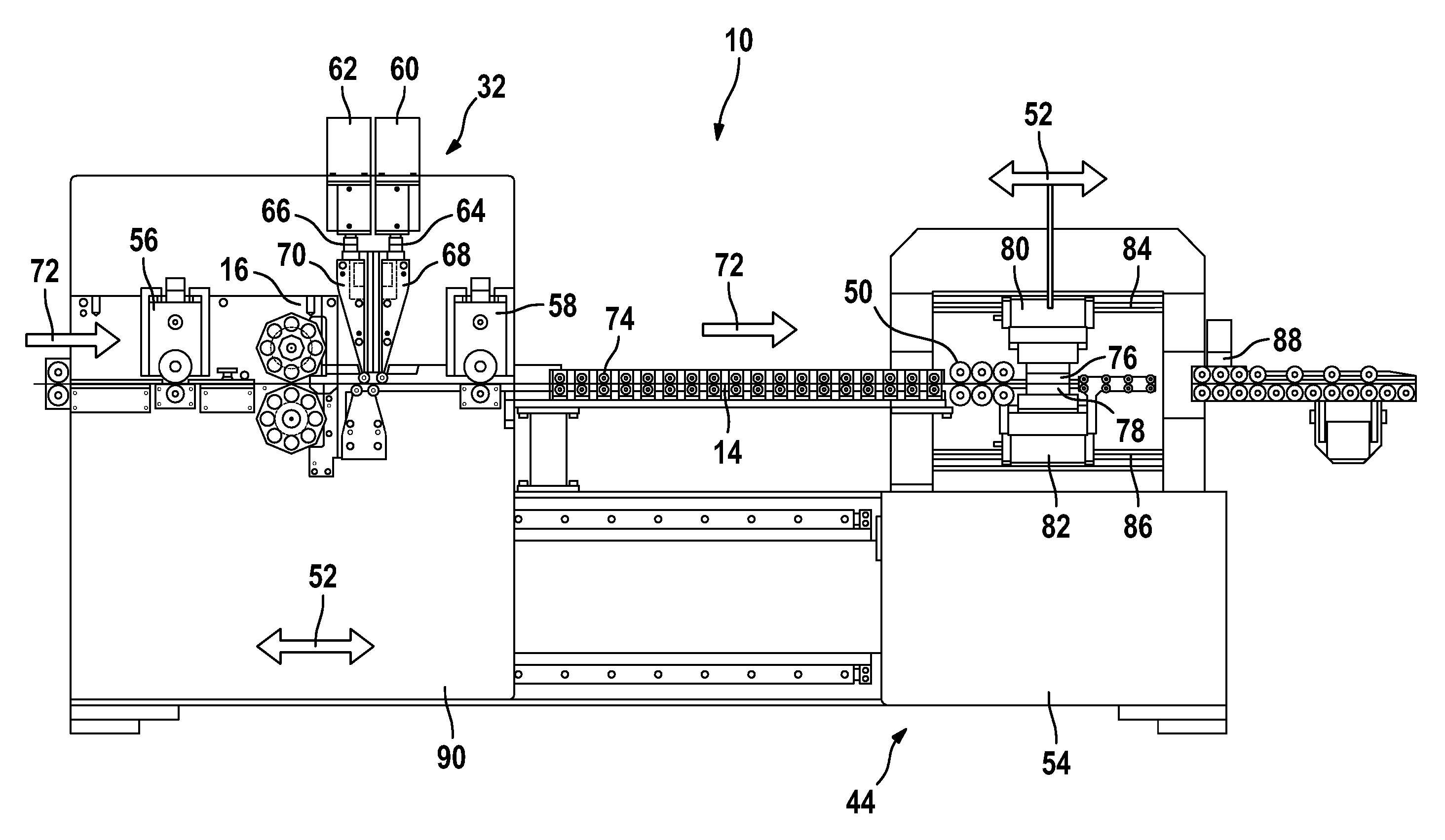

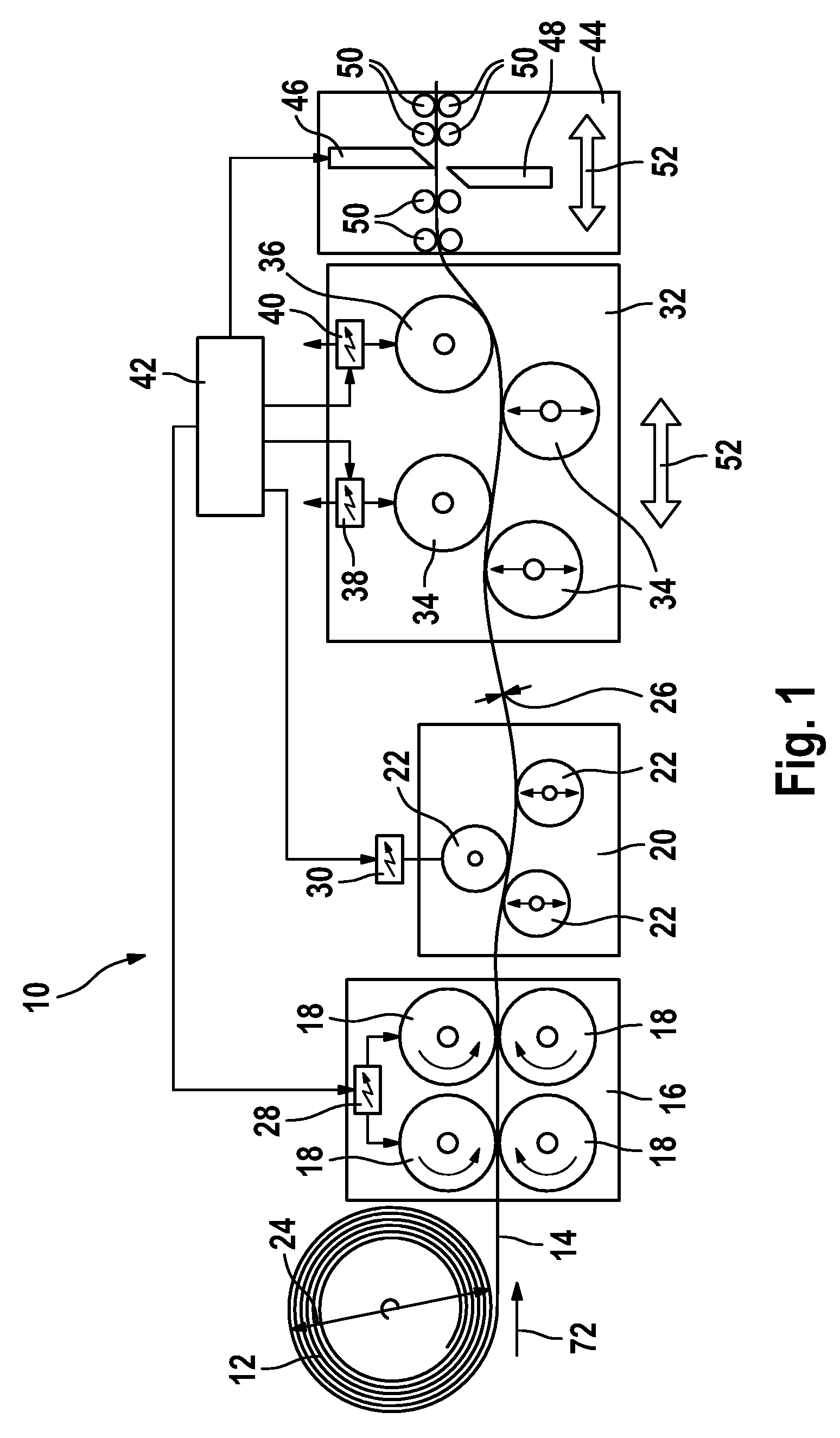

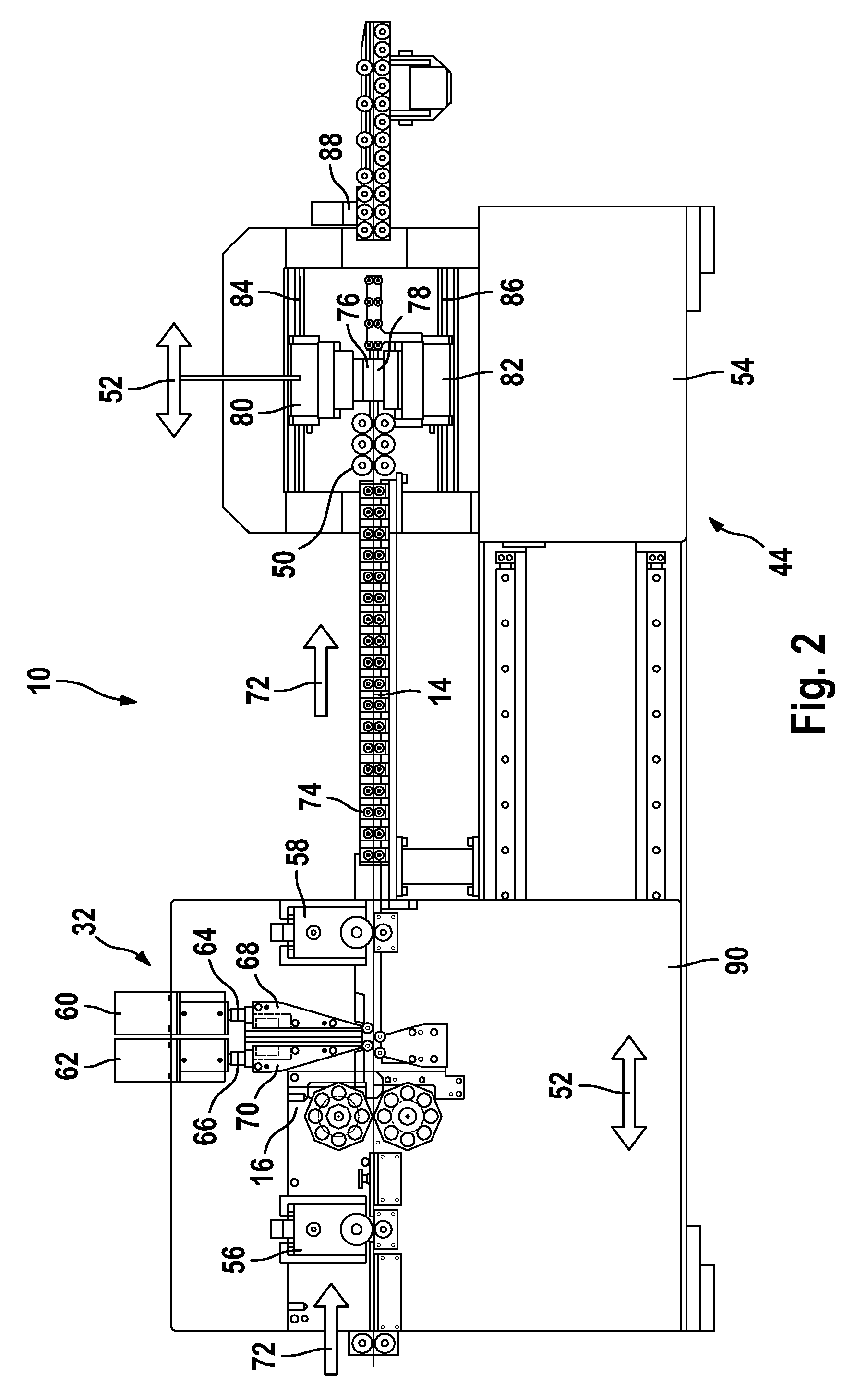

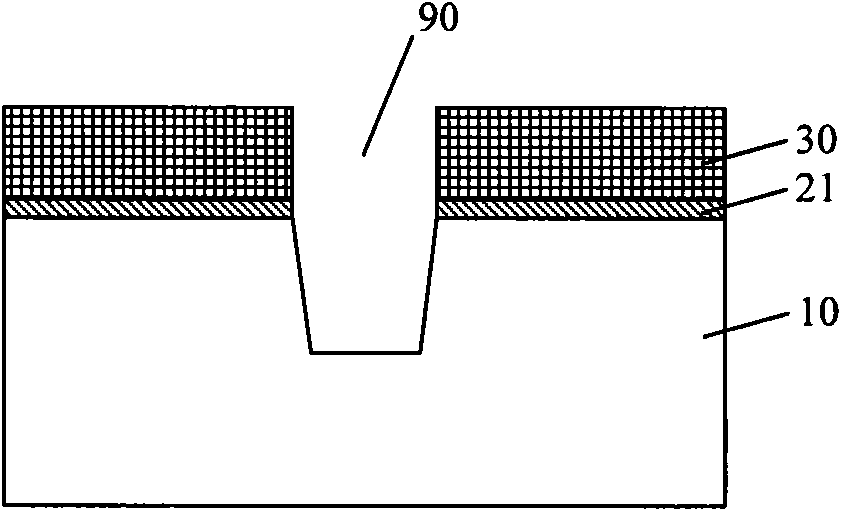

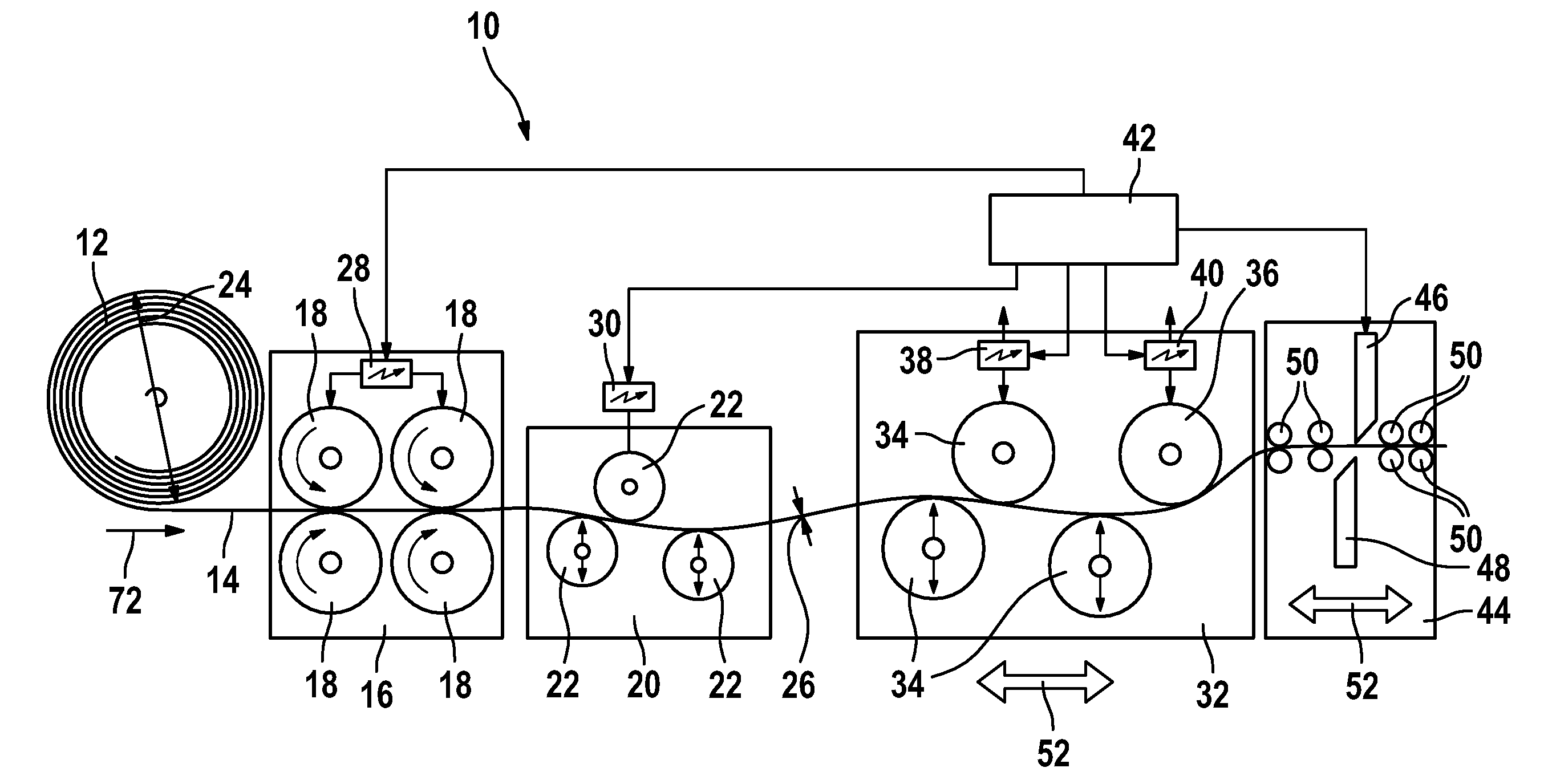

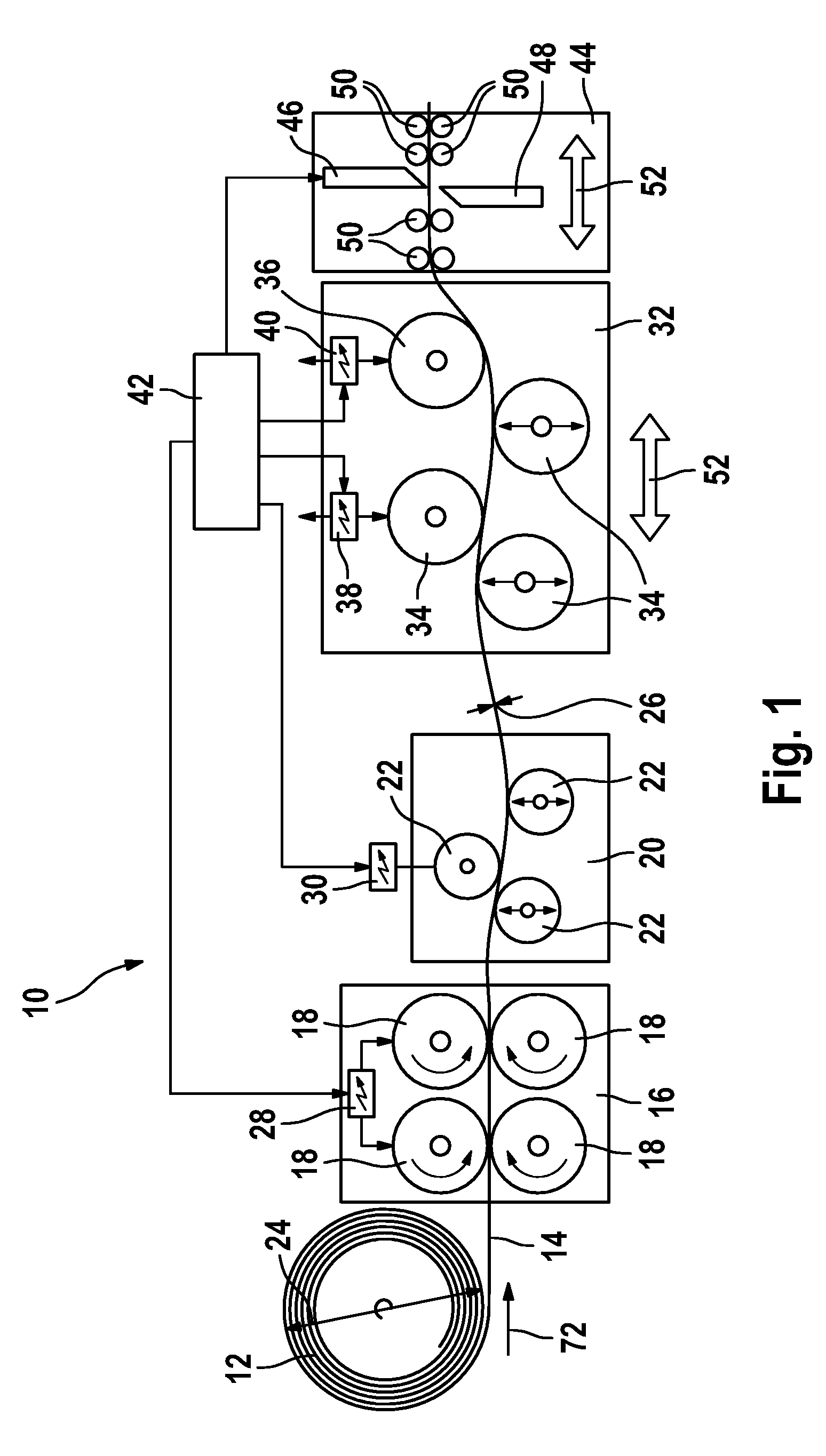

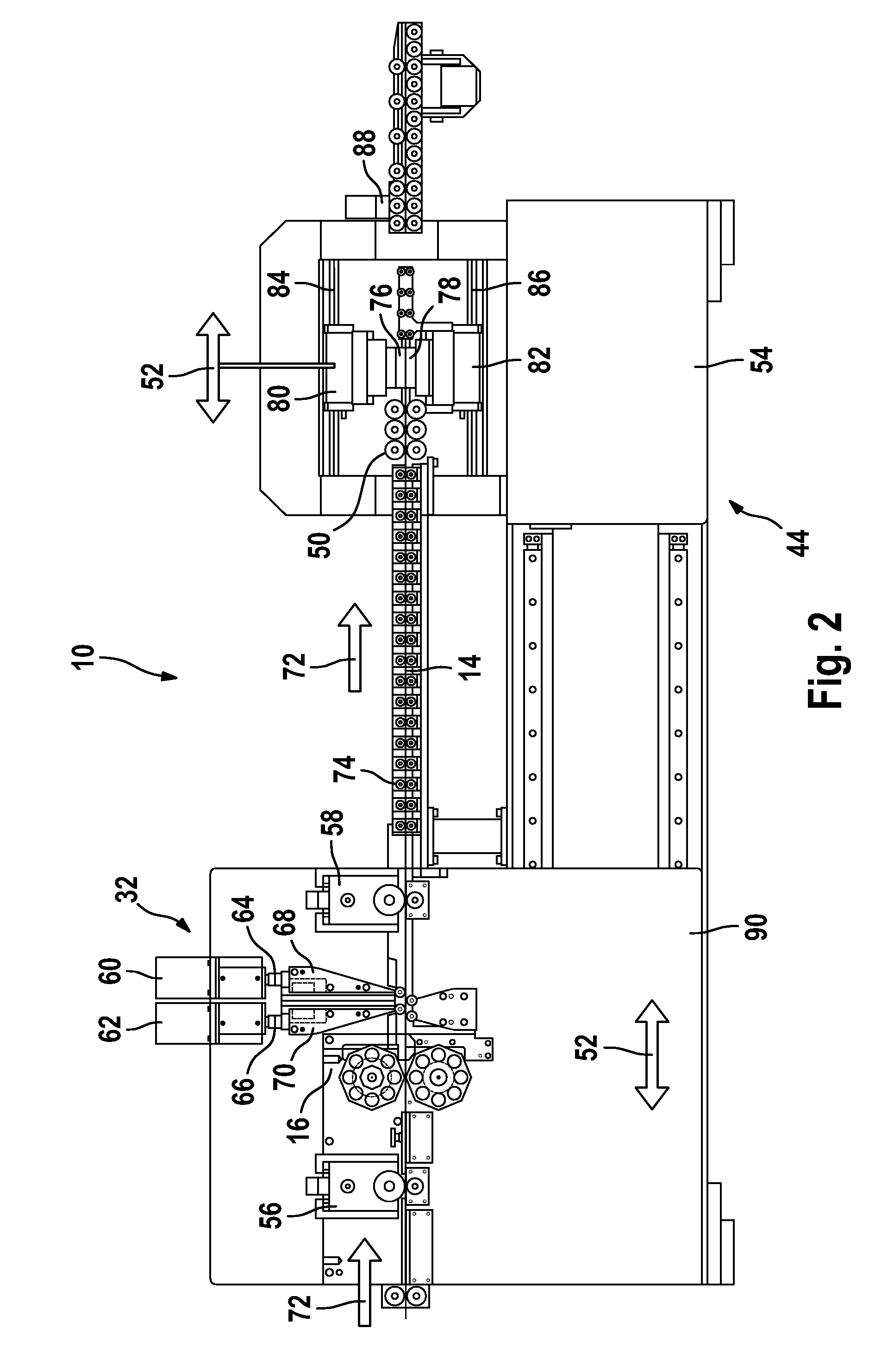

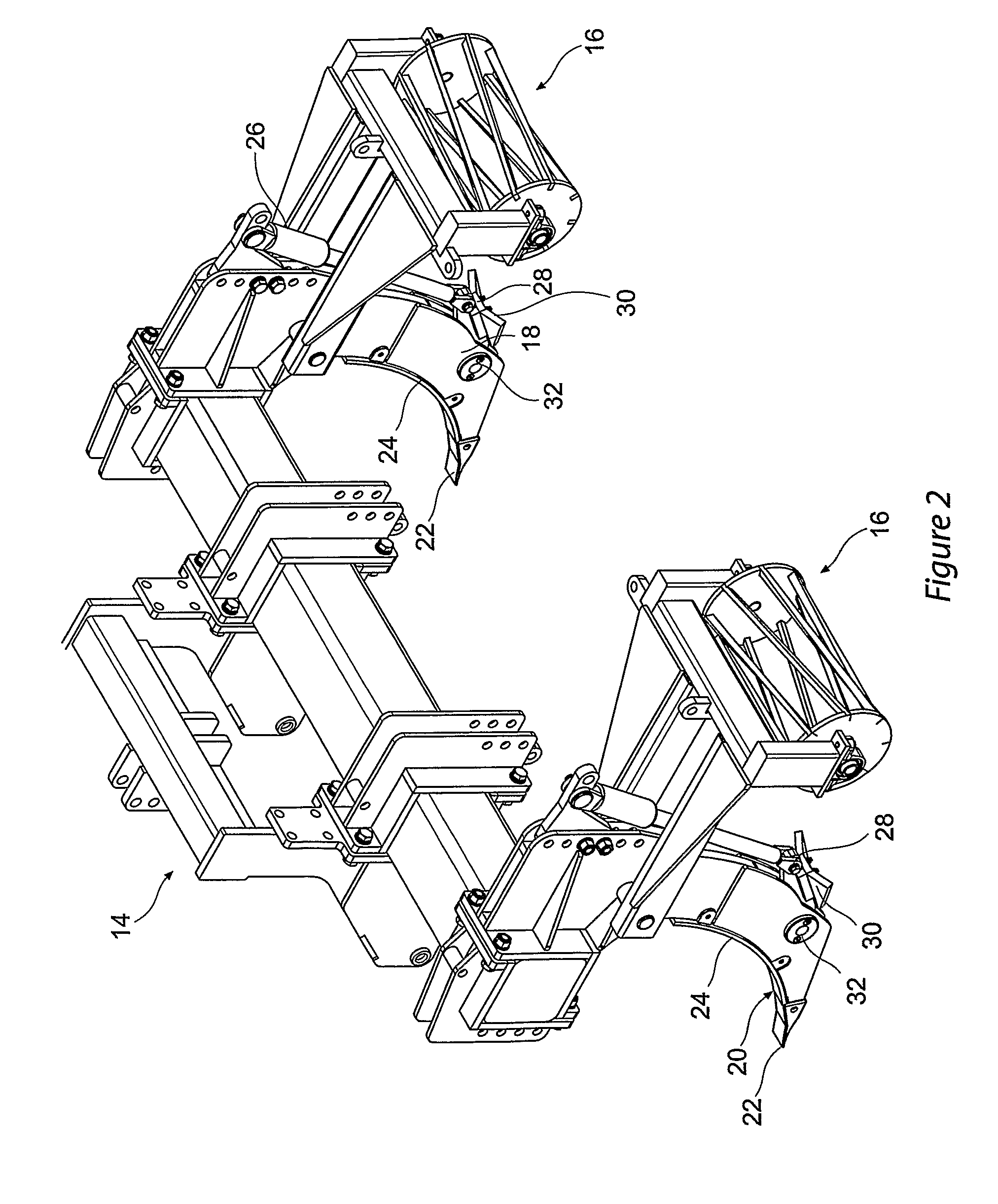

Method and device for producing bent spring elements

InactiveUS8333093B2Different speedImprove the level ofStock shearing machinesVehicle cleaningControl mannerSpring steel

The invention is based on a method of producing bent spring elements from a spring steel strip (14), wherein a feed unit (16) delivers the spring steel strip (14) from a supply roll (12) to a bending unit (32) having at least three bending rollers (34) and a reverse bending roller (36), of which at least one bending roller (34) and the reverse bending roller (36) can be adjusted transversely to the spring steel strip (14) by bending motors (60, 62), and wherein a cutting-off unit (44) adjoins the bending unit (32), said cutting-off unit (44) cutting off the spring steel strip (14) into individual spring elements by means of cutting-off tools (46, 48; 76, 78). It is proposed that the cutting-off tools (46, 48; 76, 78) be movable in the longitudinal direction of the spring steel strip (14) in a numerically controlled manner and that they be synchronized with the feed movement of the spring steel strip (14) during the cutting-off operation.

Owner:ROBERT BOSCH GMBH

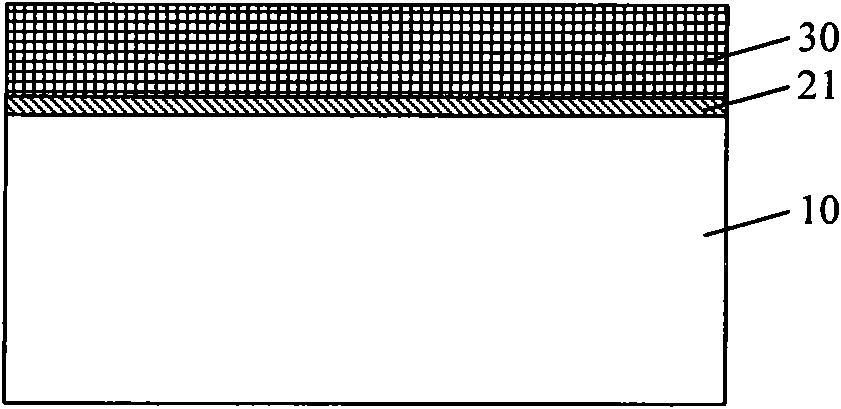

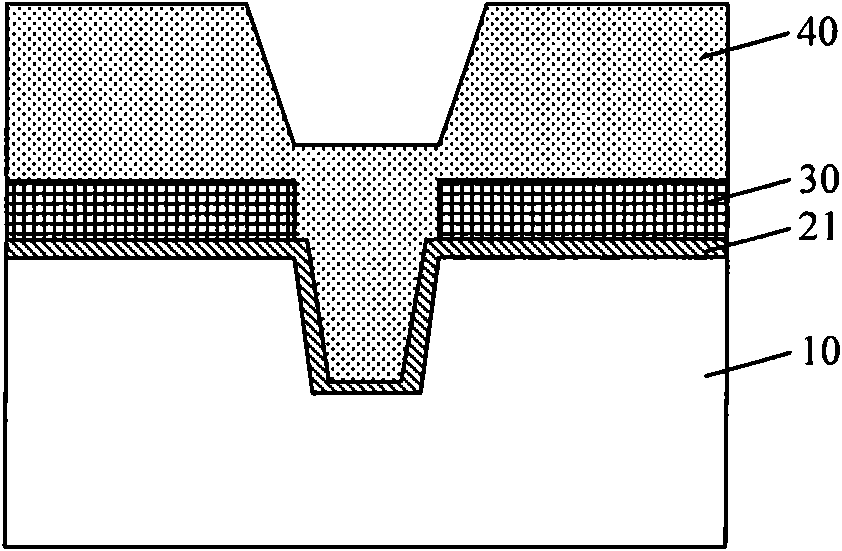

Method for forming shallow trench isolation structure and shallow trench isolation structure

InactiveCN101673701AUniform profileGuaranteed performanceSolid-state devicesSemiconductor/solid-state device manufacturingSilicon oxideHeight difference

The invention discloses a method for forming a shallow trench isolation structure and the shallow trench isolation structure. In the process of forming the shallow trench isolation structure, double-layer hard masking films are adopted, namely that an oxide, such as a silicon oxide film is additionally arranged on an original nitride, such as a silicon nitride film. Because the selection ratio ofetching to the silicon oxide is higher than that of the silicon nitride, the surface of the silicon nitride film can not be damaged in the etching process, and the surface of the silicon nitride filmis still smooth and uniform after being etched. The invention ensures that after CMP, the height difference generated between each active region and each adjacent field oxide region on same Wafer plane is consistent, thereby ensuring a uniform outline of grown multi-crystal silicon and ensuring the performance of an integrated circuit.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP

Method and Device For Producing Bent Spring Elements

InactiveUS20080302157A1Avoid excessive wearIncrease productionWire springsStock shearing machinesControl mannerEngineering

The invention is based on a method of producing bent spring elements from a spring steel strip (14), wherein a feed unit (16) delivers the spring steel strip (14) from a supply roll (12) to a bending unit (32) having at least three bending rollers (34) and a reverse bending roller (36), of which at least one bending roller (34) and the reverse bending roller (36) can be adjusted transversely to the spring steel strip (14) by bending motors (60, 62), and wherein a cutting-off unit (44) adjoins the bending unit (32), said cutting-off unit (44) cutting off the spring steel strip (14) into individual spring elements by means of cutting-off tools (46, 48; 76, 78). It is proposed that the cutting-off tools (46, 48; 76, 78) be movable in the longitudinal direction of the spring steel strip (14) in a numerically controlled manner and that they be synchronized with the feed movement of the spring steel strip (14) during the cutting-off operation.

Owner:ROBERT BOSCH GMBH

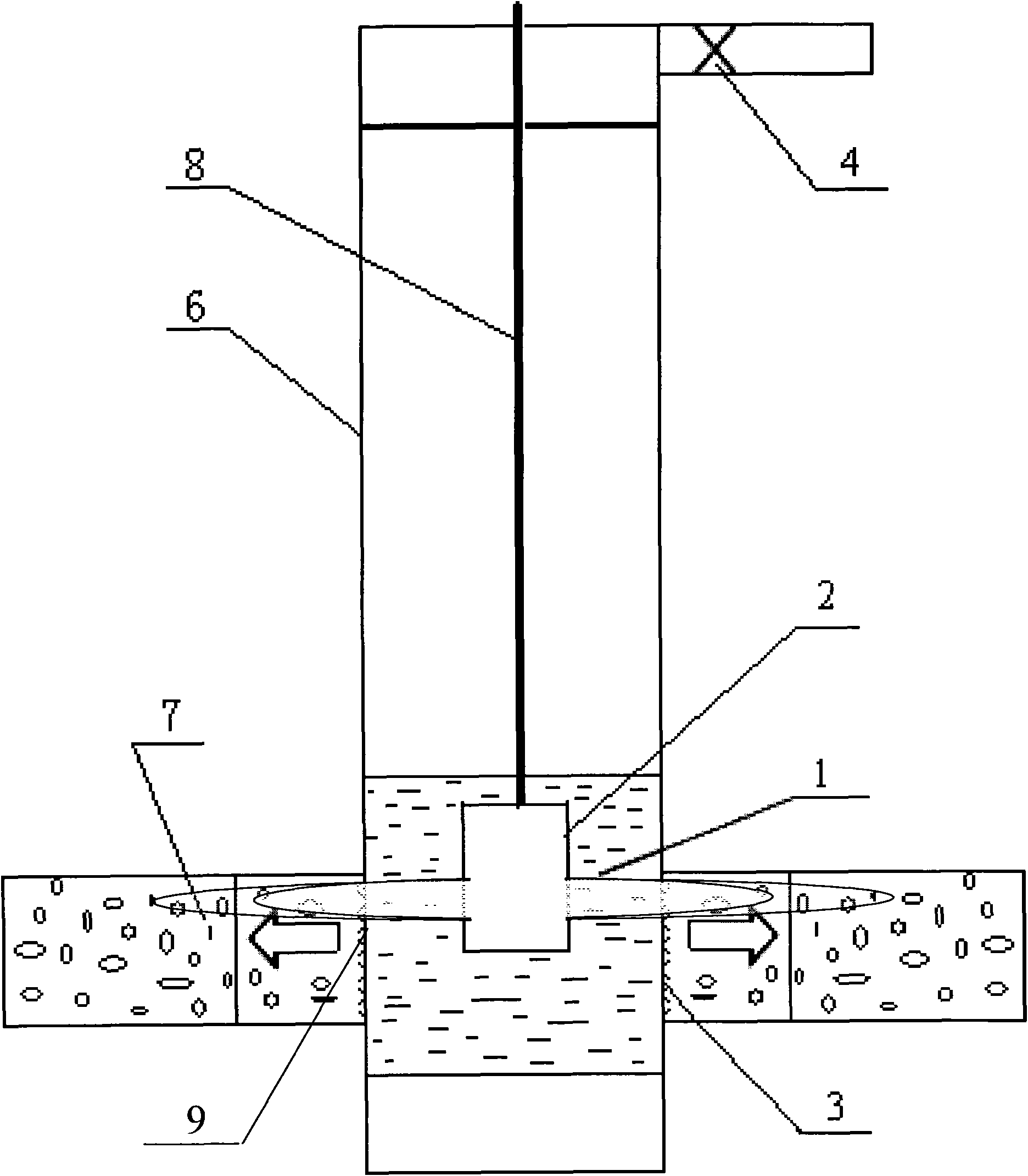

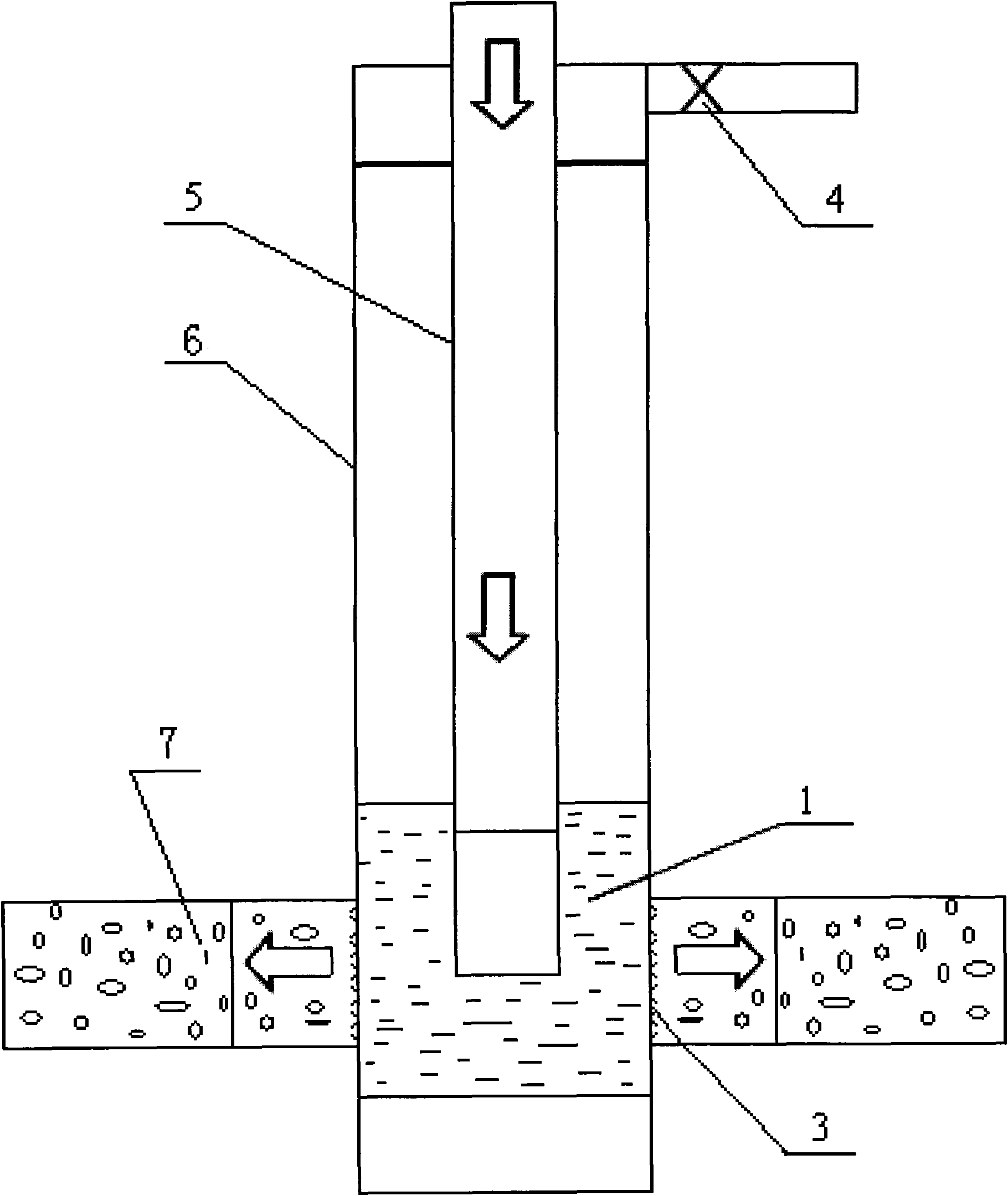

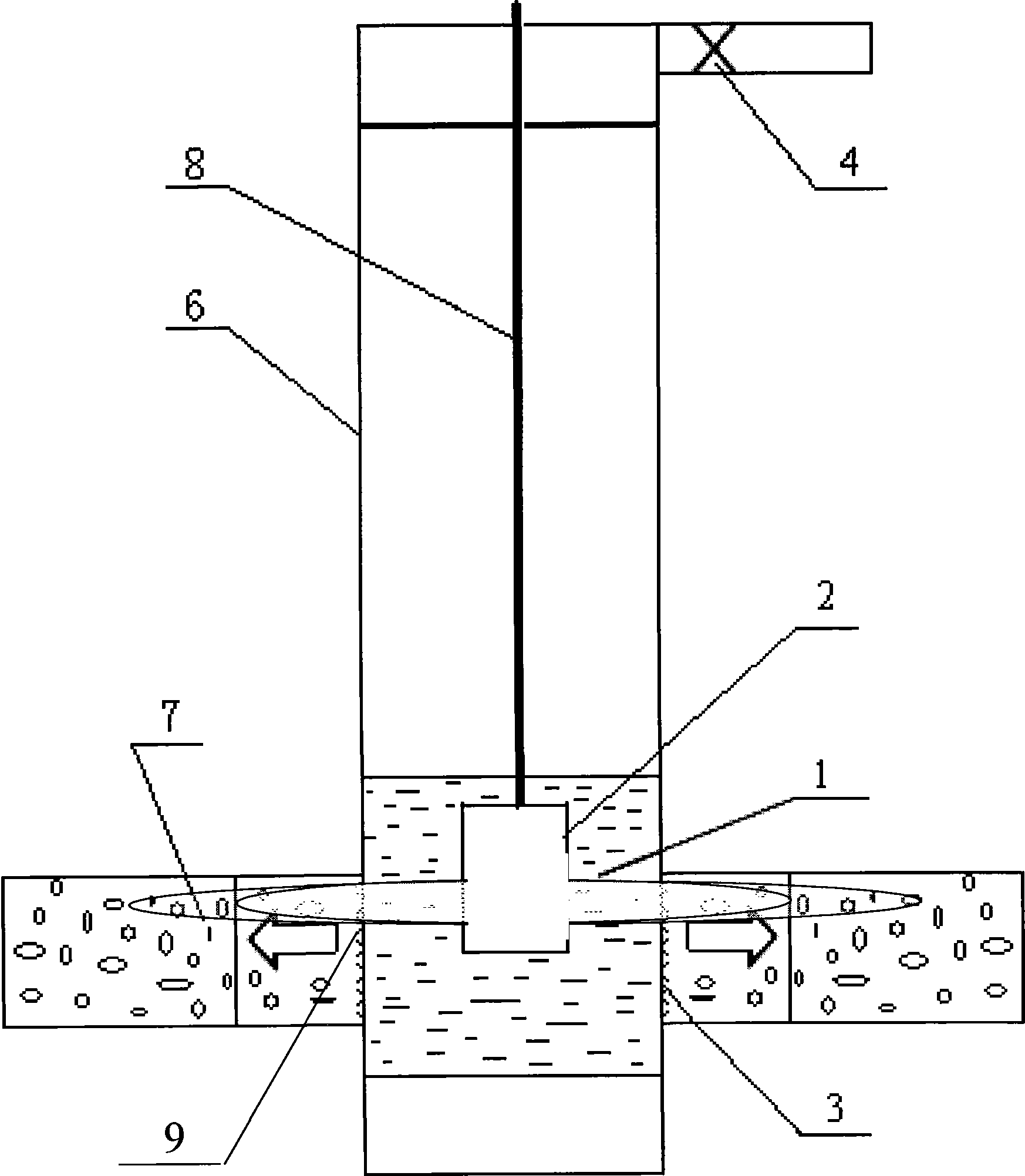

Method for removing blockage of oil-water well through magnetic positioning pulse acidification

The invention discloses a method for removing the blockage of an oil-water well through magnetic positioning pulse acidification, which is used for acidifying an oil well in an oil field. The method comprises the following steps of: clearing and reshaping a mine shaft with a drift size gauge, washing the mine shaft with active water, and substituting acidizing fluid for the active water in an oil pipe until the active water reaches the middle part of an oil layer; and lifting an oil outlet pipe, loading in a high-power pulse processing device, magnetically positioning a perforation interval of required measurement, checking data, starting the device to process, lifting the device to an interval needing to be processed to process again after meeting a design requirement, taking out the high-power pulse processing device after processing, loading a pump and completing the well after discharging liquid from a production well, and completing the well after loading a production oil pipe into a water injection well to backwash the water injection well. The method has the advantages that: the high-power pulse processing device can precisely position the perforation interval of the oil-water well; and after processing with the acidizing fluid during pulse processing, the processing radius and the processing efficiency of the acidizing fluid can be effectively guaranteed and blocking substances in ducts can be more effectively corroded.

Owner:PETROCHINA CO LTD

Printing of organic electronic devices

InactiveUS20060159842A1Uniform profileExtended drying timeSolid-state devicesSemiconductor/solid-state device manufacturingConductive polymerInorganic chemistry

The composition of a organic (e.g. conducting polymer) solution is reformulated and the device upon which the organic solution is to be deposited is plasma treated to provide a more uniform and flat drying profile for the resulting dried film. This reformulation and treatment induces a more uniform and flatter profile when the reformulated organic solution is allowed to dry into a film on the treated device.

Owner:OSRAM OLED

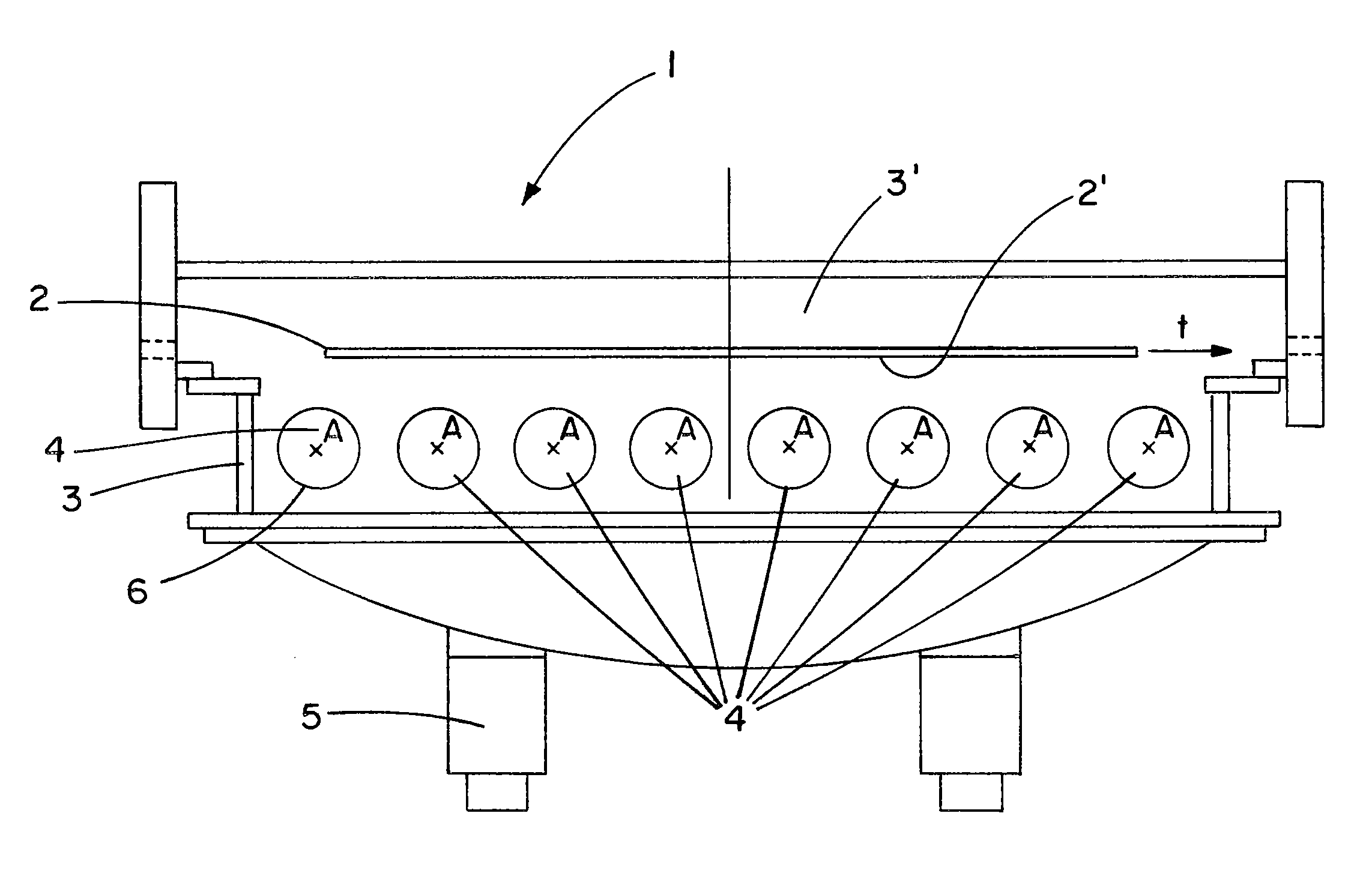

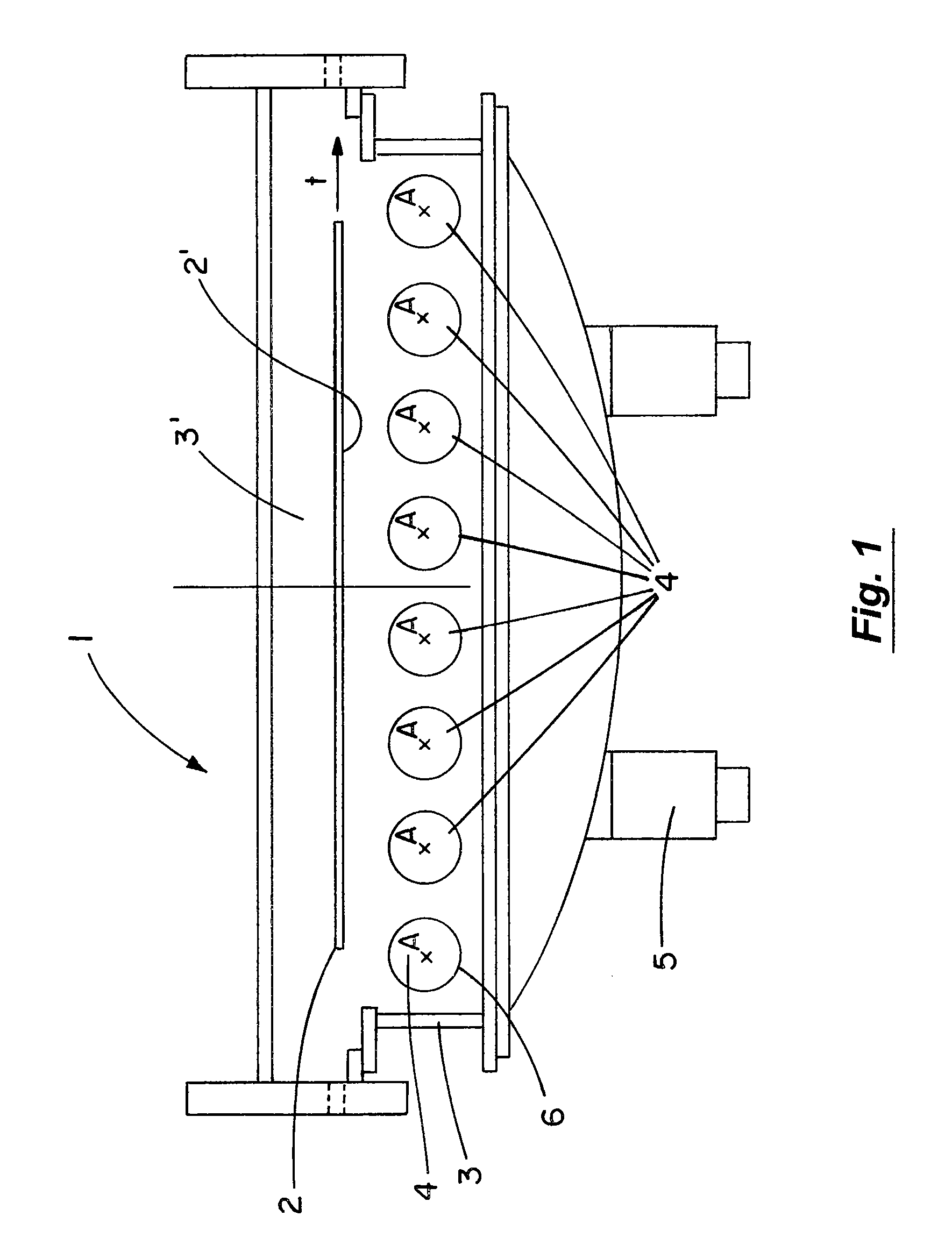

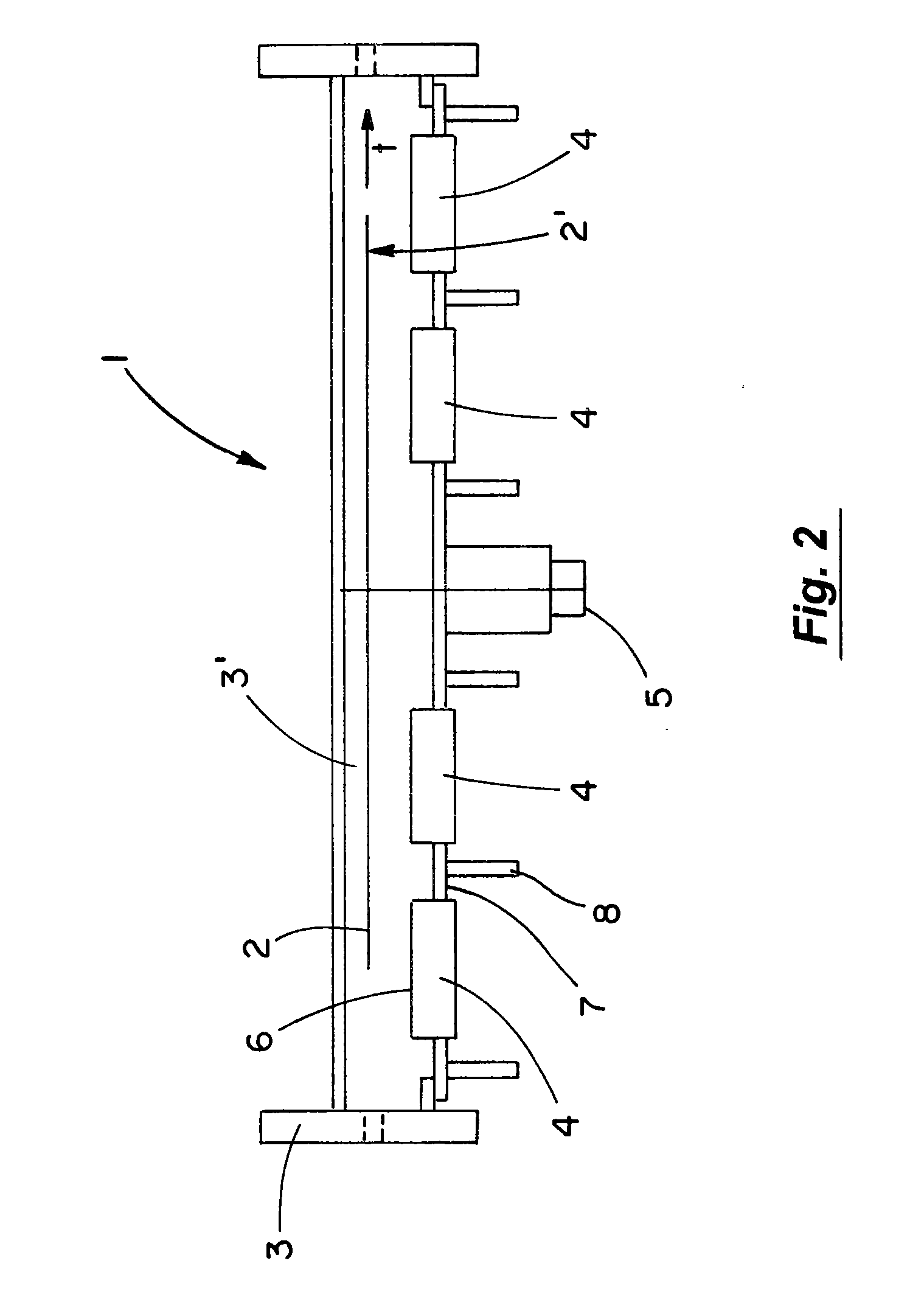

Sputter coating device

InactiveUS20090178919A1Save acquisition costPromote exchangeCellsElectric discharge tubesEngineeringHigh pressure

A sputter coating installation 1 comprises a vacuum chamber having an interior space 3′. The interior space 3′ of the vacuum chamber is defined by chamber walls 3. According to the present invention, an array of target units 9 is arranged in line inside the vacuum coating chamber. Particularly, the target units 9 are arranged tiltable relative to the vacuum chamber and relative to a transport path t of a substrate 2. The target units 9 are cathode units or magnetron units and comprise a target and a housing. The housing is attached to the target and defines an interior space of the target unit. Within the interior space of the target units a number of components are arranged, e.g. a combination of a magnet yoke and a magnet system, a magnet yoke drive, a cooling system (arranged near the target), an electric current supply for supplying energy for the sputter process, etc. The combination of the magnet yoke and the magnet system is movable on a linear path to perform a reciprocating movement relative to the target during the operation of the target unit. Outside the housing a vacuum pressure pv is generated vacuum pumps 5 arranged in a chamber wall 3c of the vacuum chamber behind the target units 9 for enabling the sputter coating process. In the interior space of the housing another pressure p may prevail, particularly a considerably higher pressure p. For example, the pressure p in the interior space of the housing may be an atmospheric pressure. Therefore, the housing provides a vacuum sealing of the interior space of the housing relative to the outside of the housing.

Owner:APPLIED MATERIALS INC

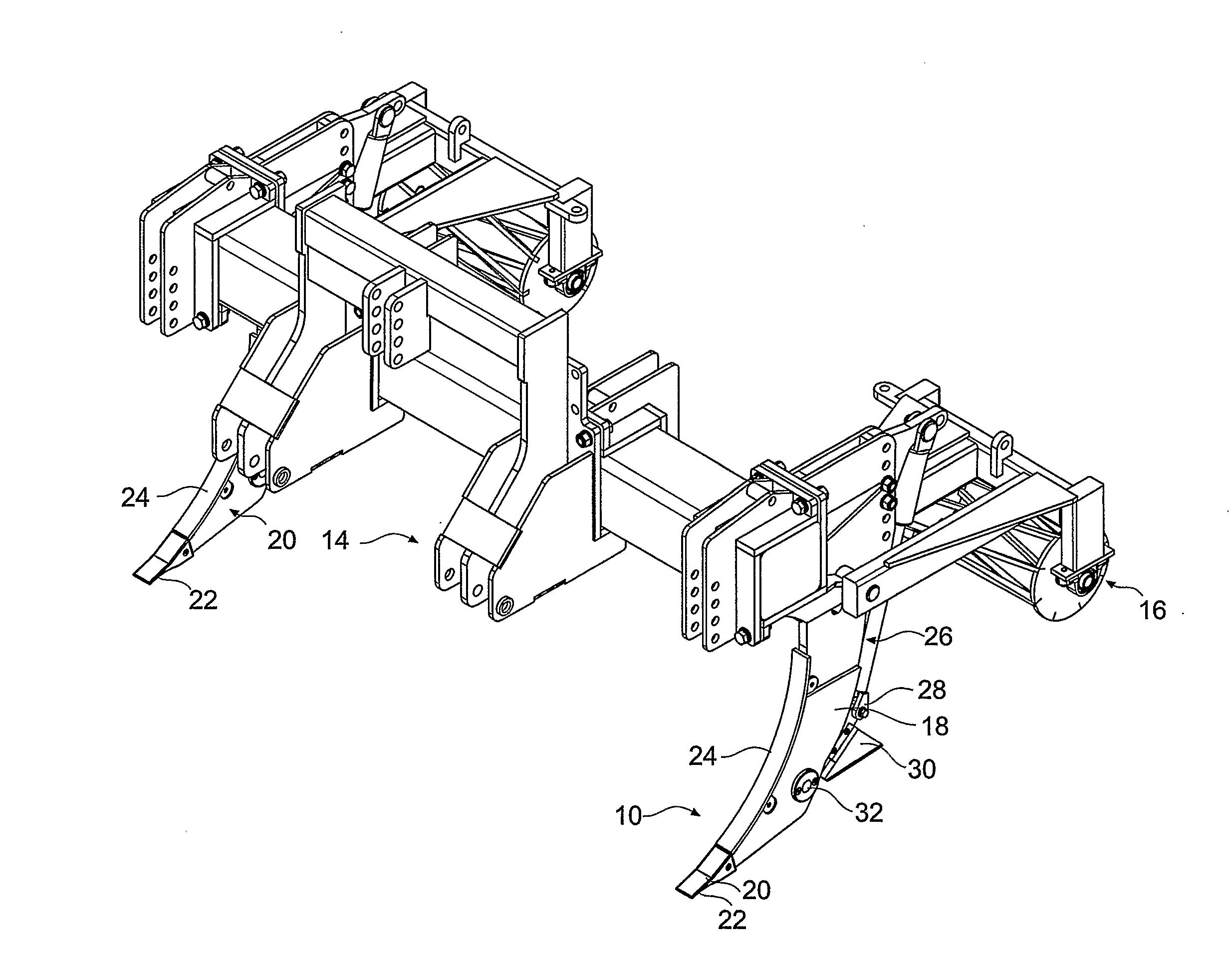

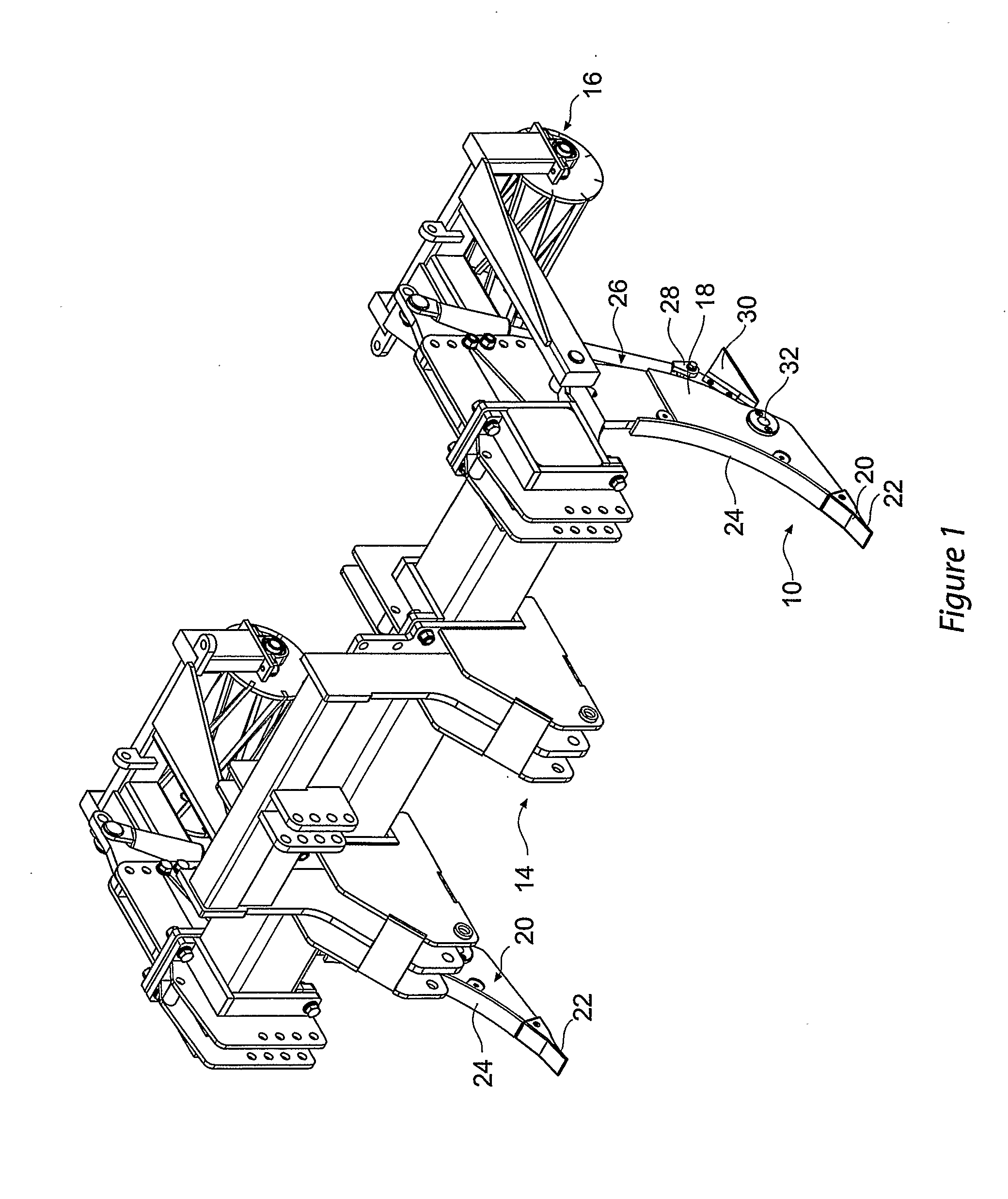

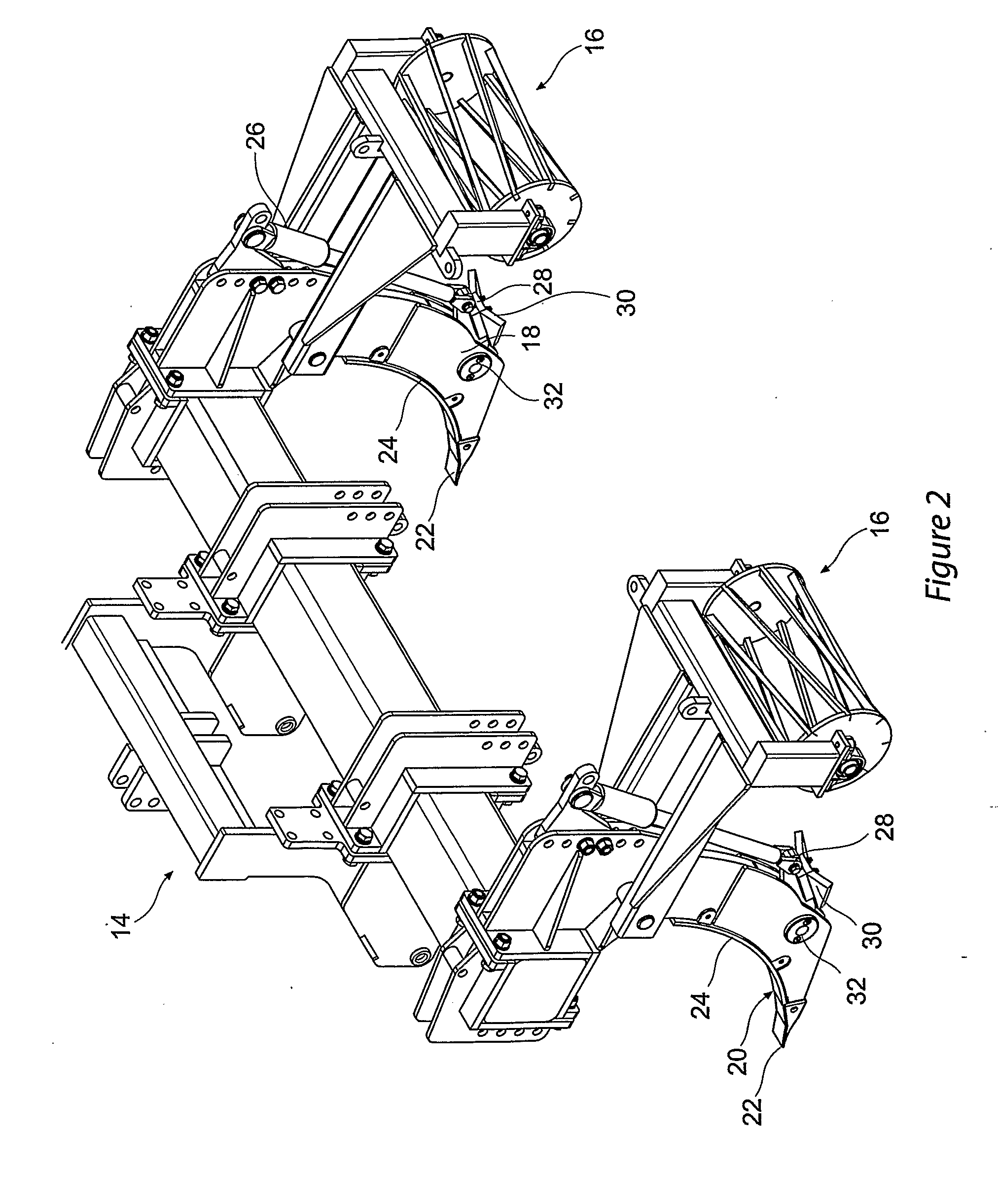

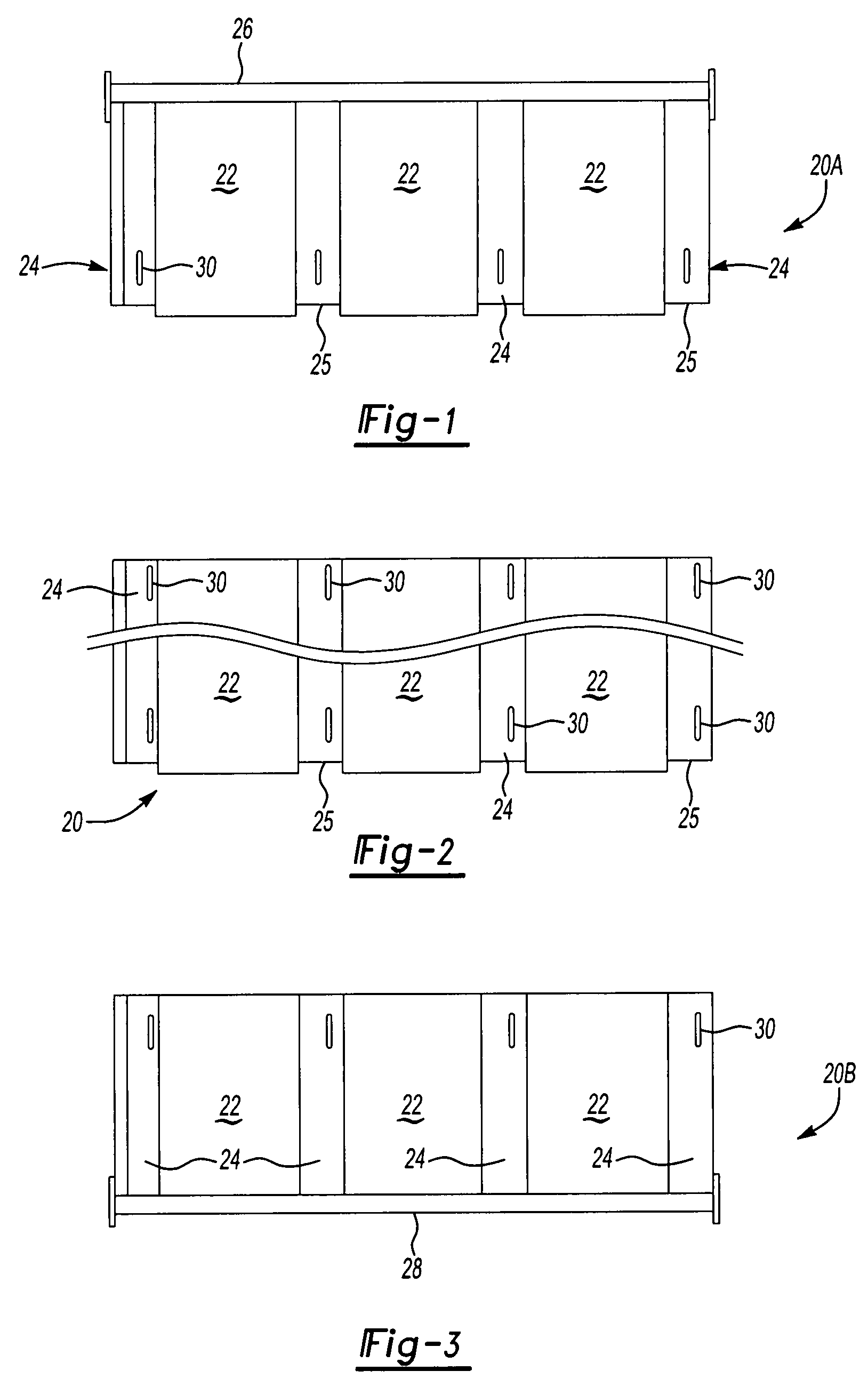

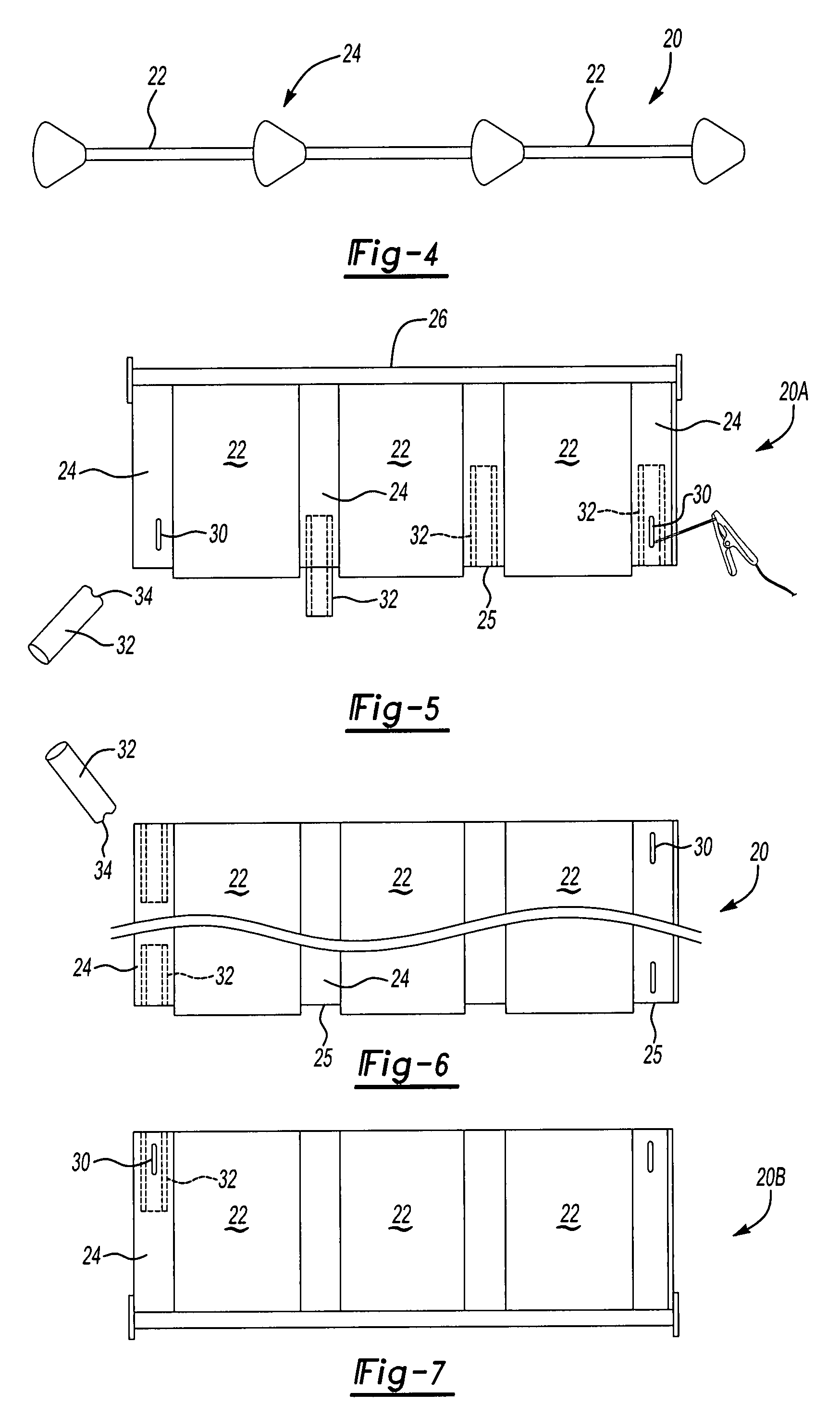

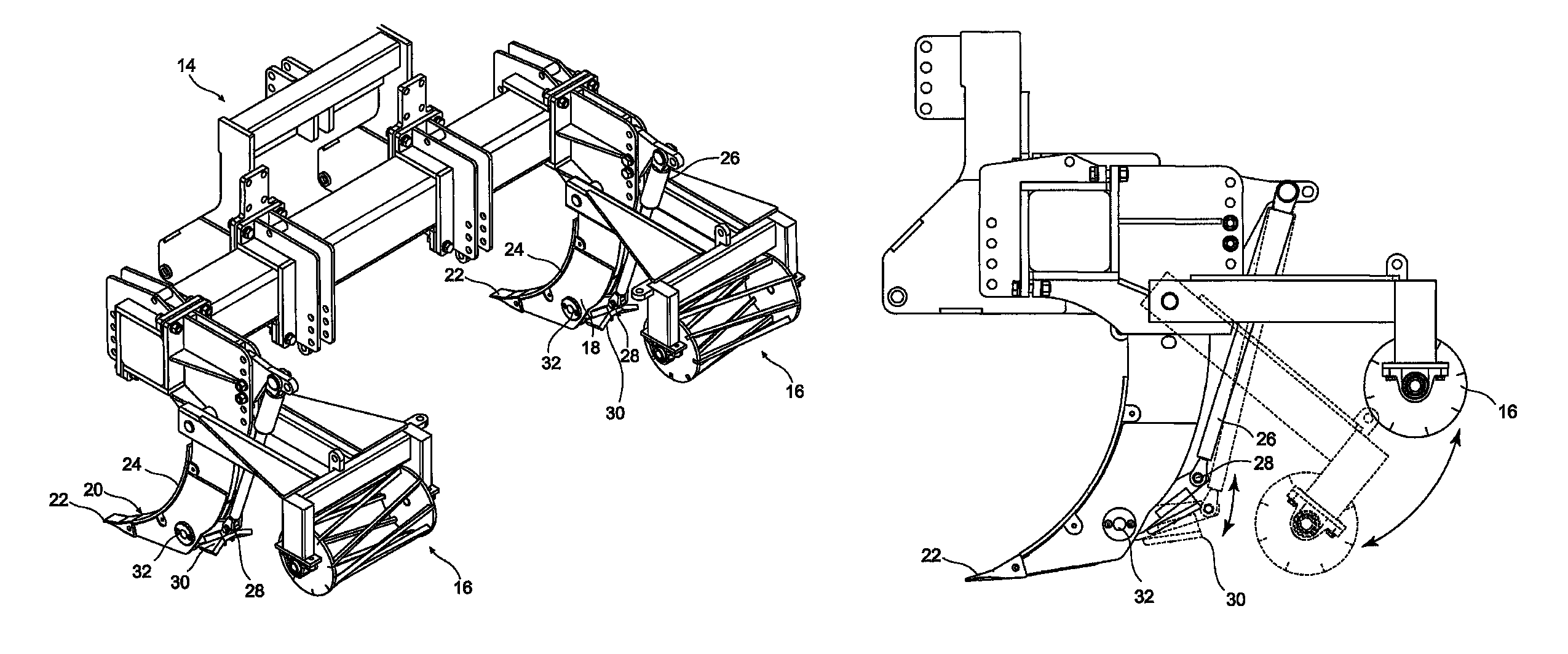

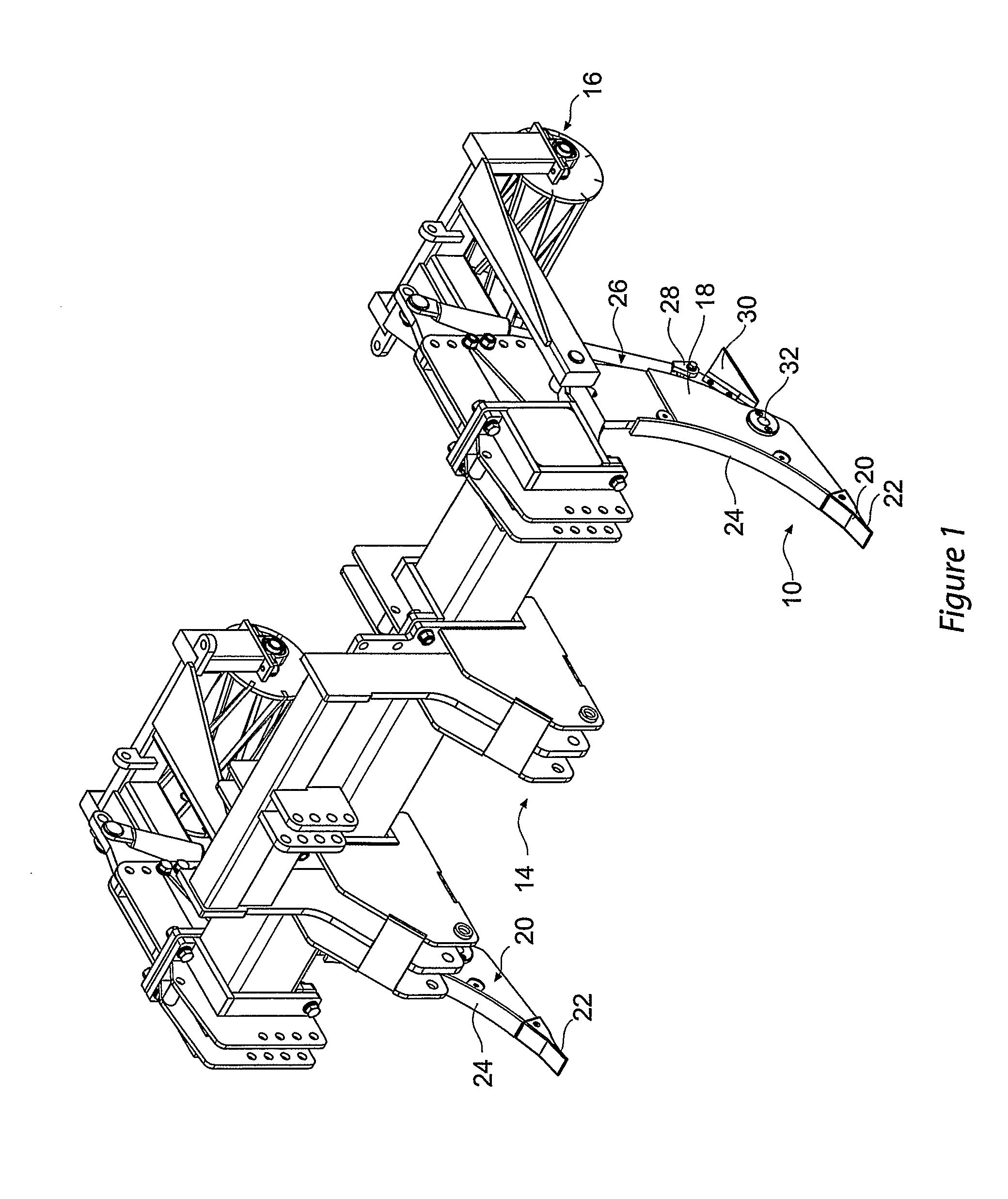

Cultivation system and a subsoil tool

ActiveUS20110010314A1Limit any undesirable incorporationFast infiltrationSpadesData processing applicationsSoil scienceHydraulic ram

A method and system of tillage and tillage management that includes the steps of establishing a plurality of soil profiles over an area of soil to be cultivated, creating soil map database by combining these soil profiles to establish a treatment and cultivation regime, cultivating the ground in accordance regime and recording the cultivation in the soil map database. A subsoil tool for carrying out the method and system, with a shank (18) connected to a vehicle and to a ripper foot (20) terminating in a ripper tooth (22); a hydraulic ram (26) attached at a lower end to a first pivot connection (28) and at an upper end to an actuator means; the first pivot connection is attached to a rear end of a laterally extending wing member (30), a front end of the wing member being pivotally attached to the shank through a second pivot point (32) and the wing member is selected in accordance with soil profile at any position on a soil map database and is oscillated in response to actuation of the ram.

Owner:AGSOILWORKS TECH CO LLC

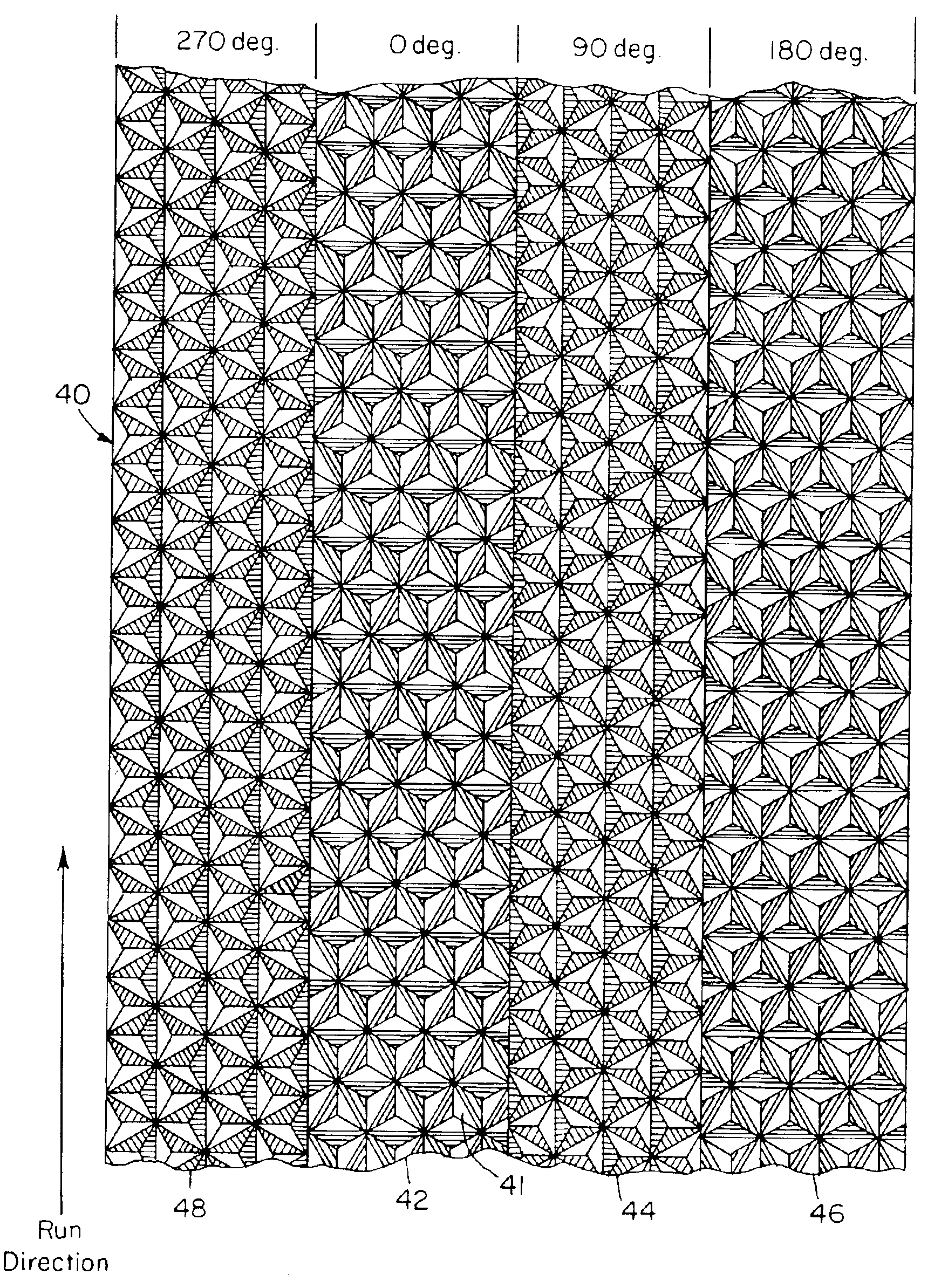

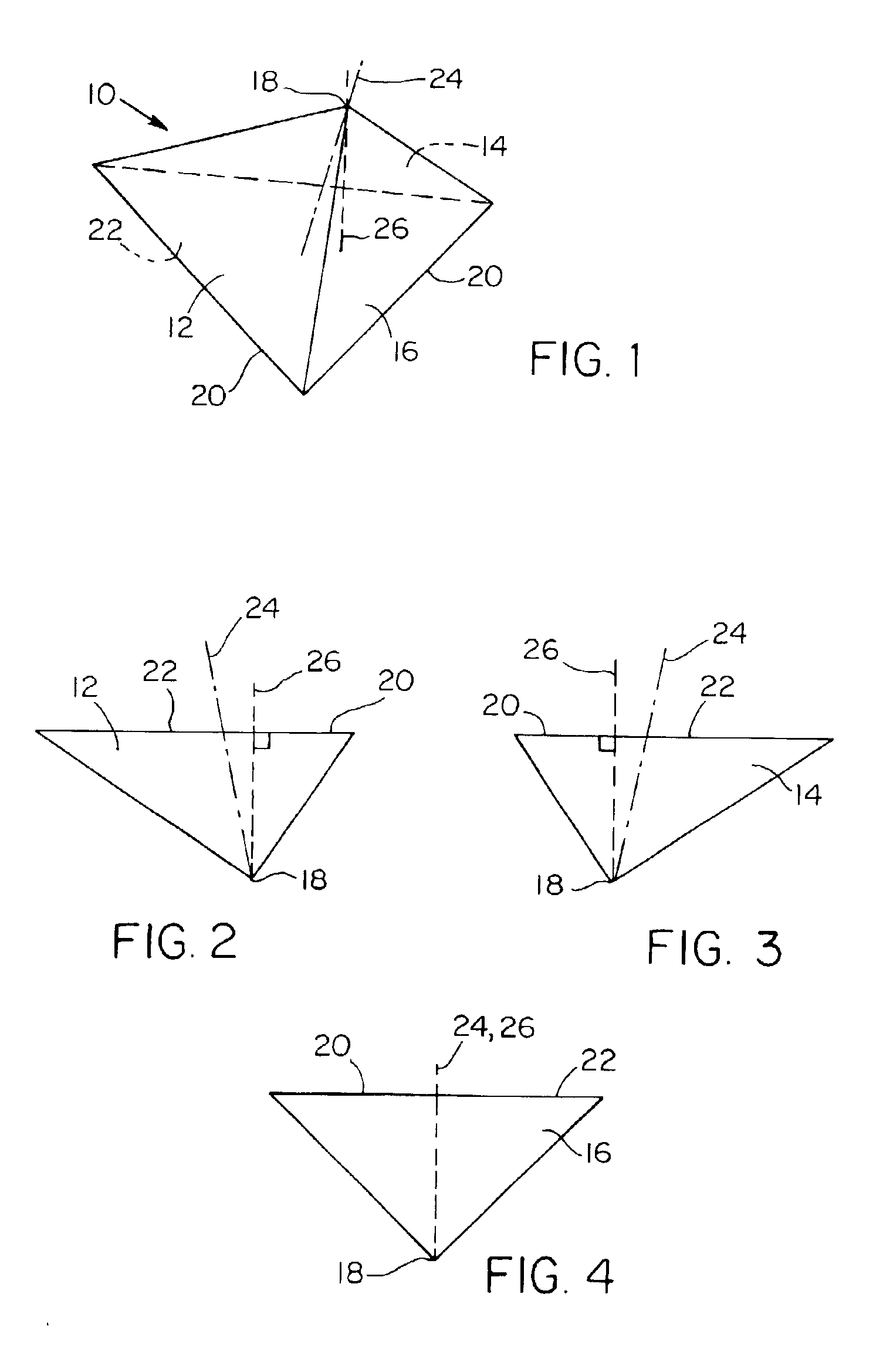

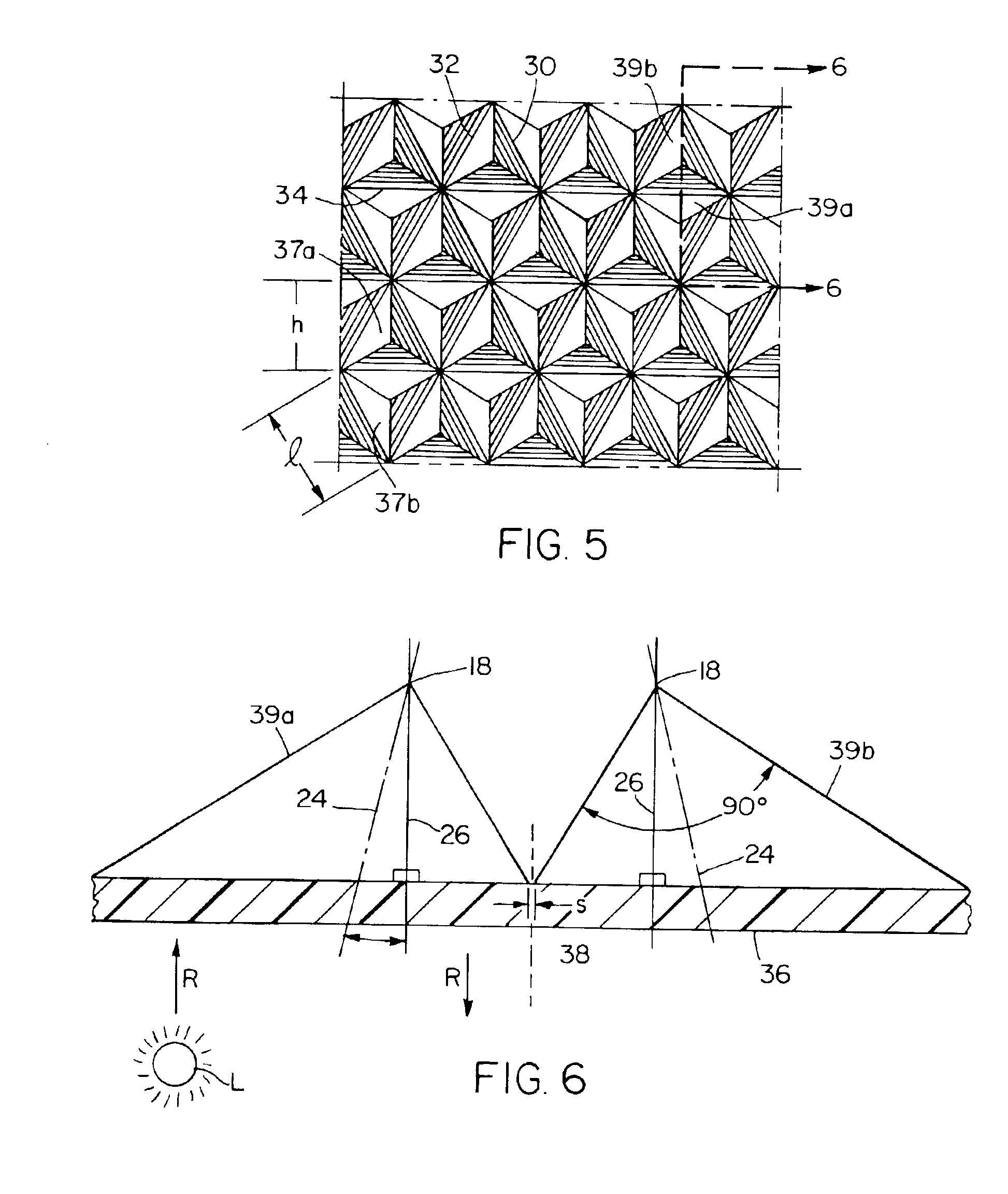

Multi-orientation retroreflective structure

InactiveUS6877866B2Uniform retroreflection profileImprove visibilityReflex reflectorsEngineeringSpecular reflection

A retroreflective structure is disclosed that has cube corner retroreflective elements. The structure includes a first array of retroreflective elements oriented in a first direction within a plane and a second array of retroreflective elements oriented in a second direction within the plane, wherein said second direction being about 90° to said first direction. The structure further includes a third array of retroreflective elements oriented in a third direction within the plane, wherein said third direction being about 180° to said first direction and a fourth array of retroreflective elements oriented in a fourth direction being about 270° to said first direction. In one embodiment, the retroreflective structure includes the retroreflective elements having cube corner elements having a pitch between elements in the range of between about 0.0035 and 0.0045 inches (0.088 and 0.114 millimeters). In a preferred embodiment, the retroreflective structure includes a metalized layer on the facet side of the retroreflective elements for specular reflection, and the retroreflective elements are tilted by about −3 degrees.

Owner:ORAFOL AMERICAS

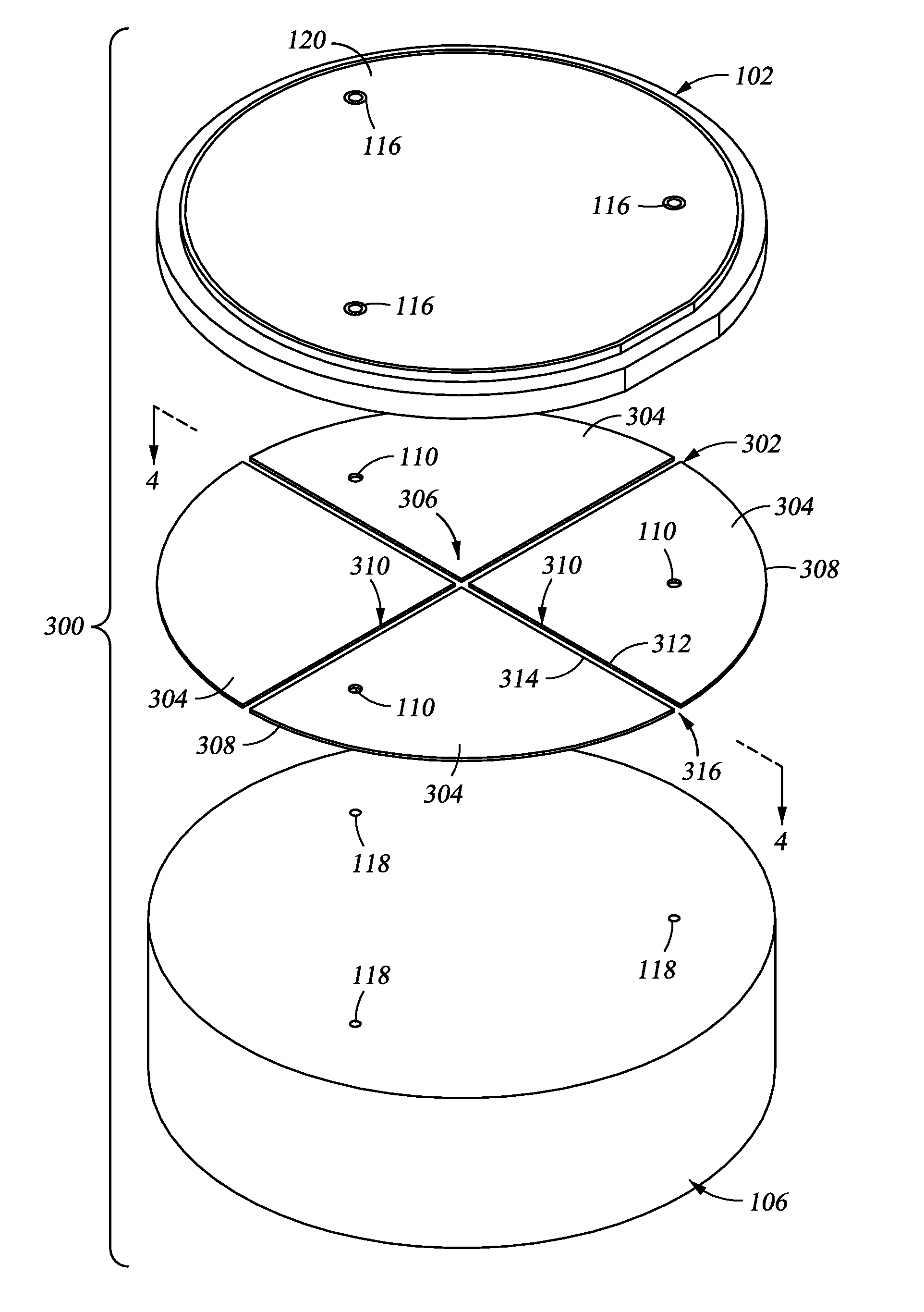

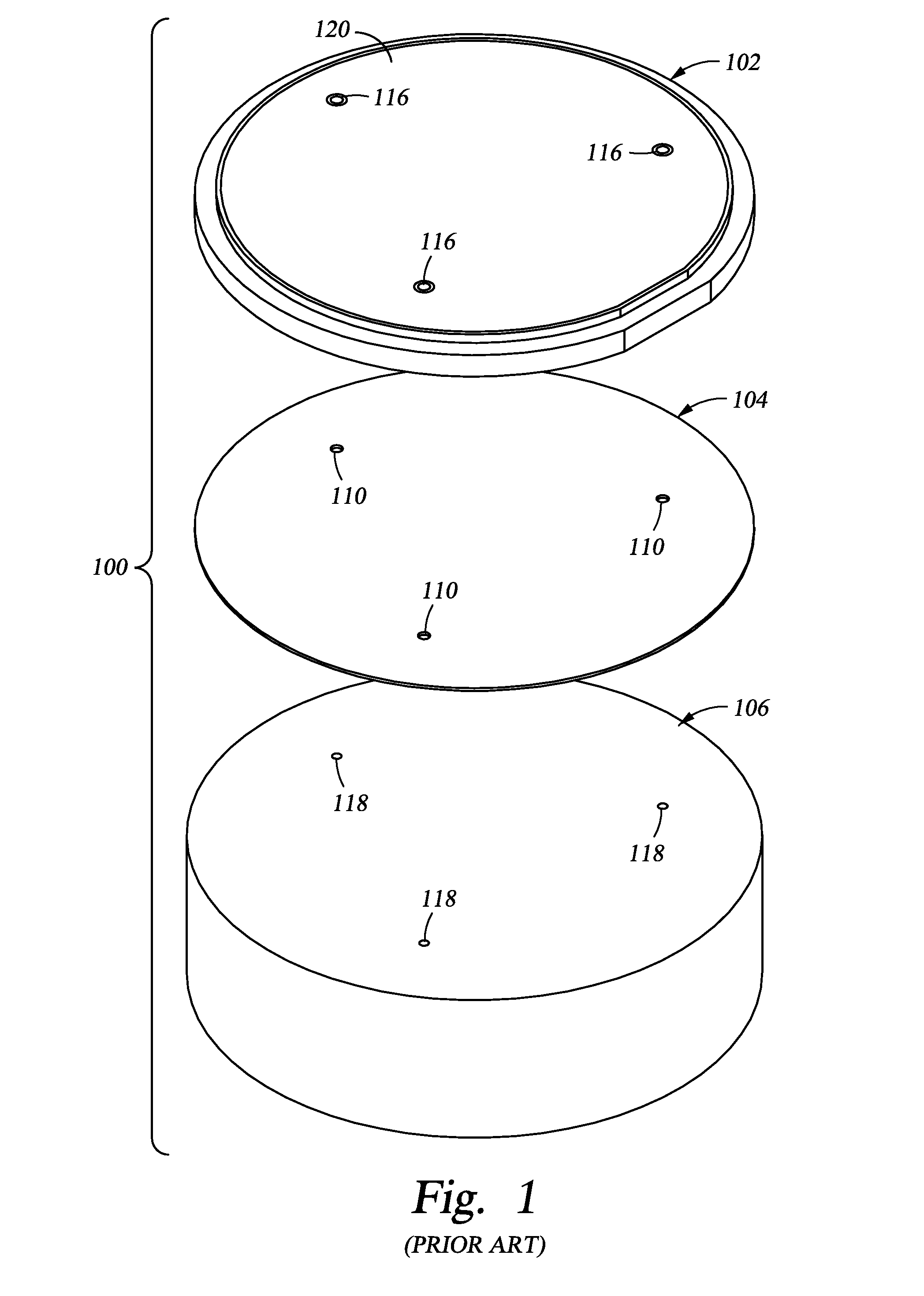

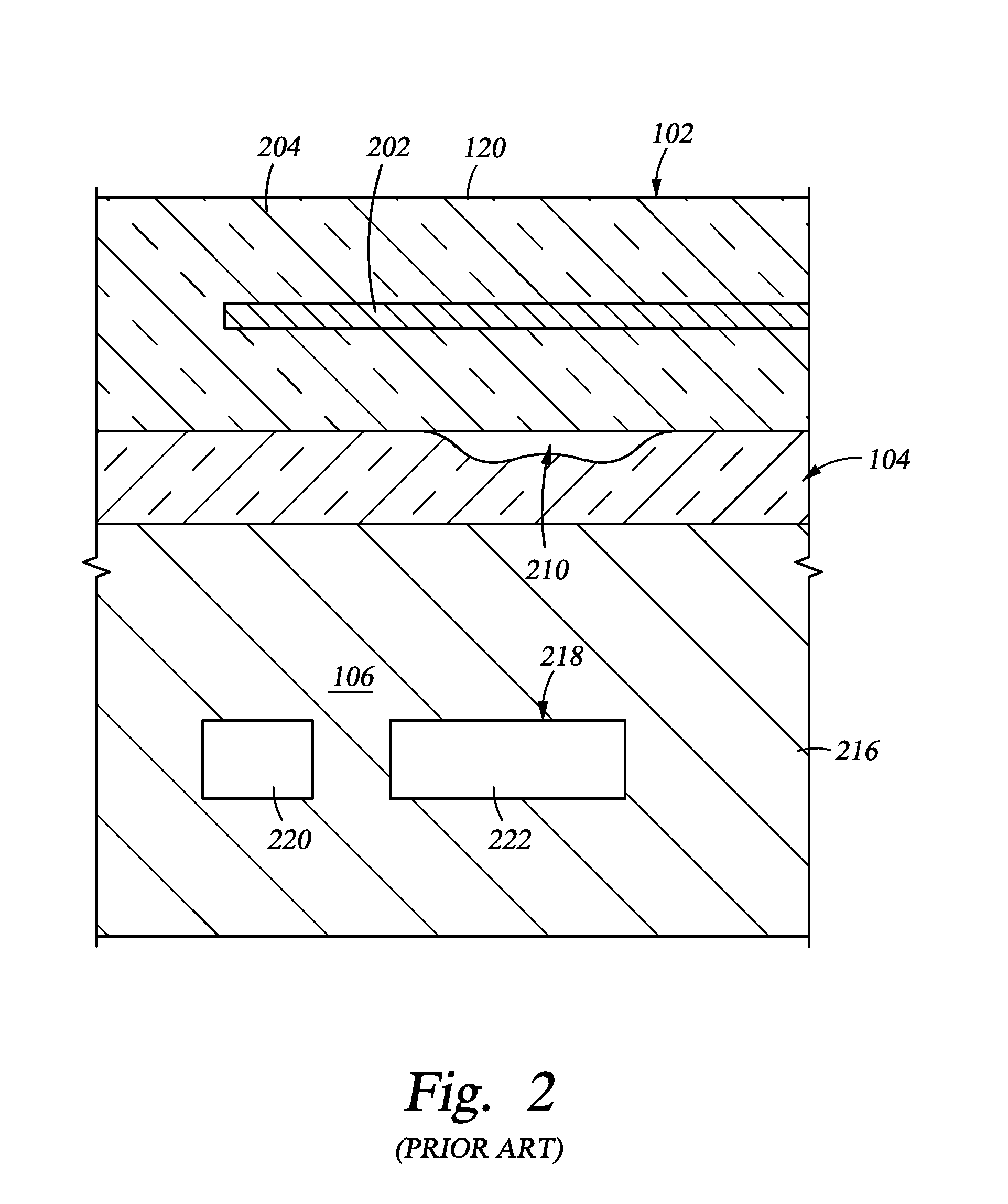

Methods for bonding substrates

ActiveUS20140099485A1Easily debondedUniform temperature profile and heat transfer performanceSleeve/socket jointsSolid-state devicesAdhesiveMechanical engineering

Methods for bonding substrates, forming assemblies using the same, along with improved methods for refurbishing said assemblies are disclosed that take advantage of at least one channel formed in an adhesive utilized to join two substrates to improve fabrication, performance and refurbishment of the assemblies. In one embodiment an assembly includes a first substrate secured to a second substrate by an adhesive layer. The assembly includes a channel having at least one side bounded by the adhesive layer and having an outlet exposed to an exterior of the assembly.

Owner:APPLIED MATERIALS INC

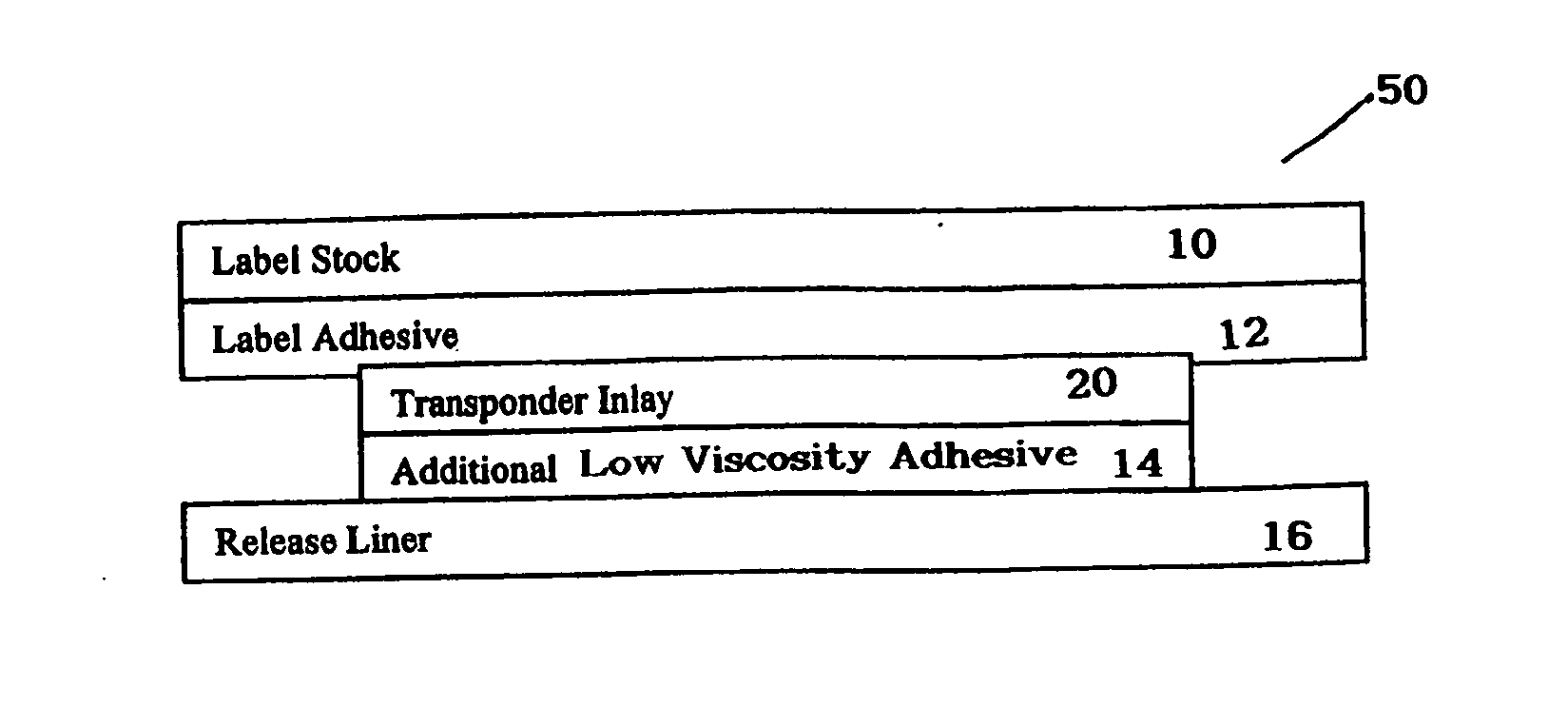

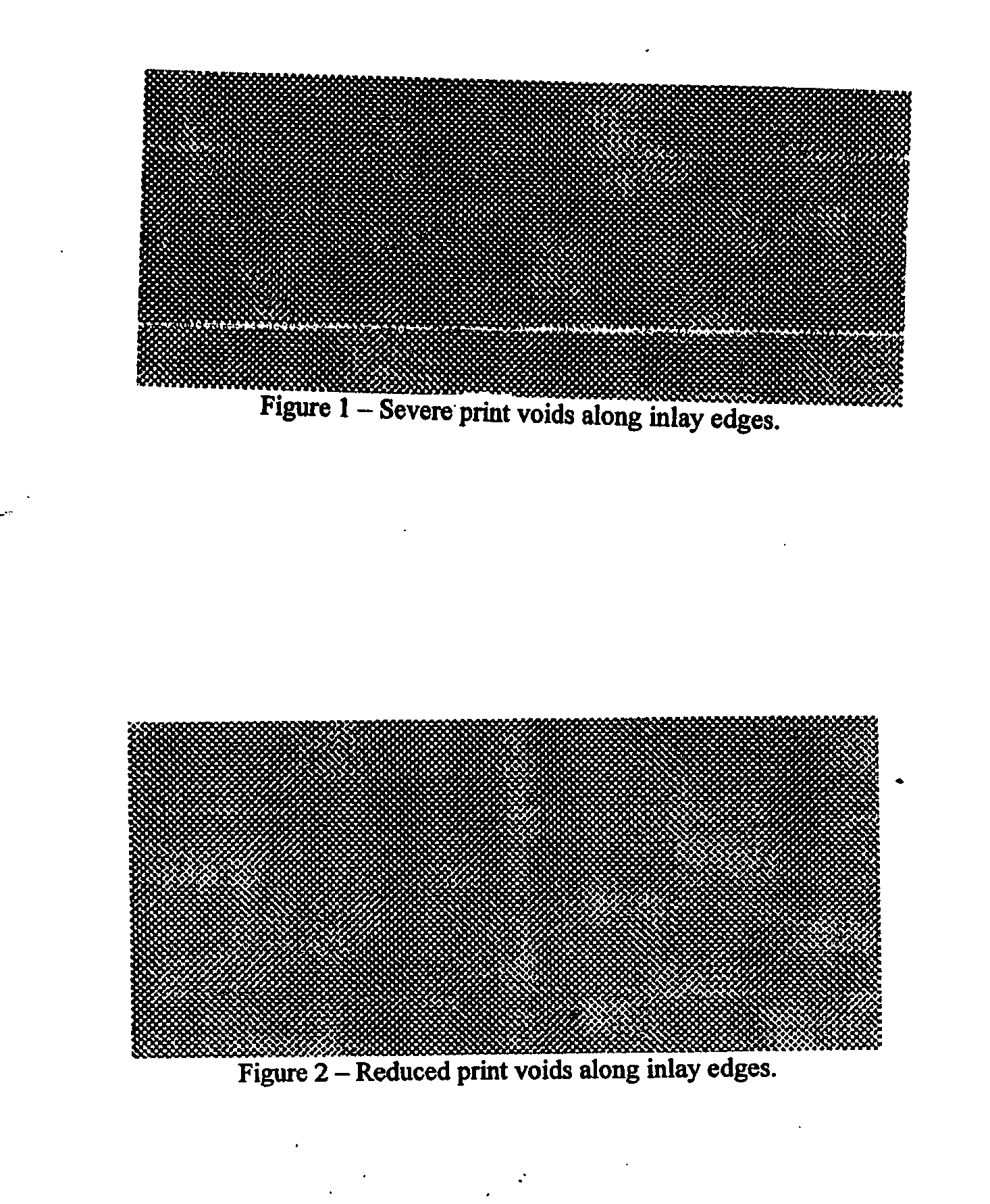

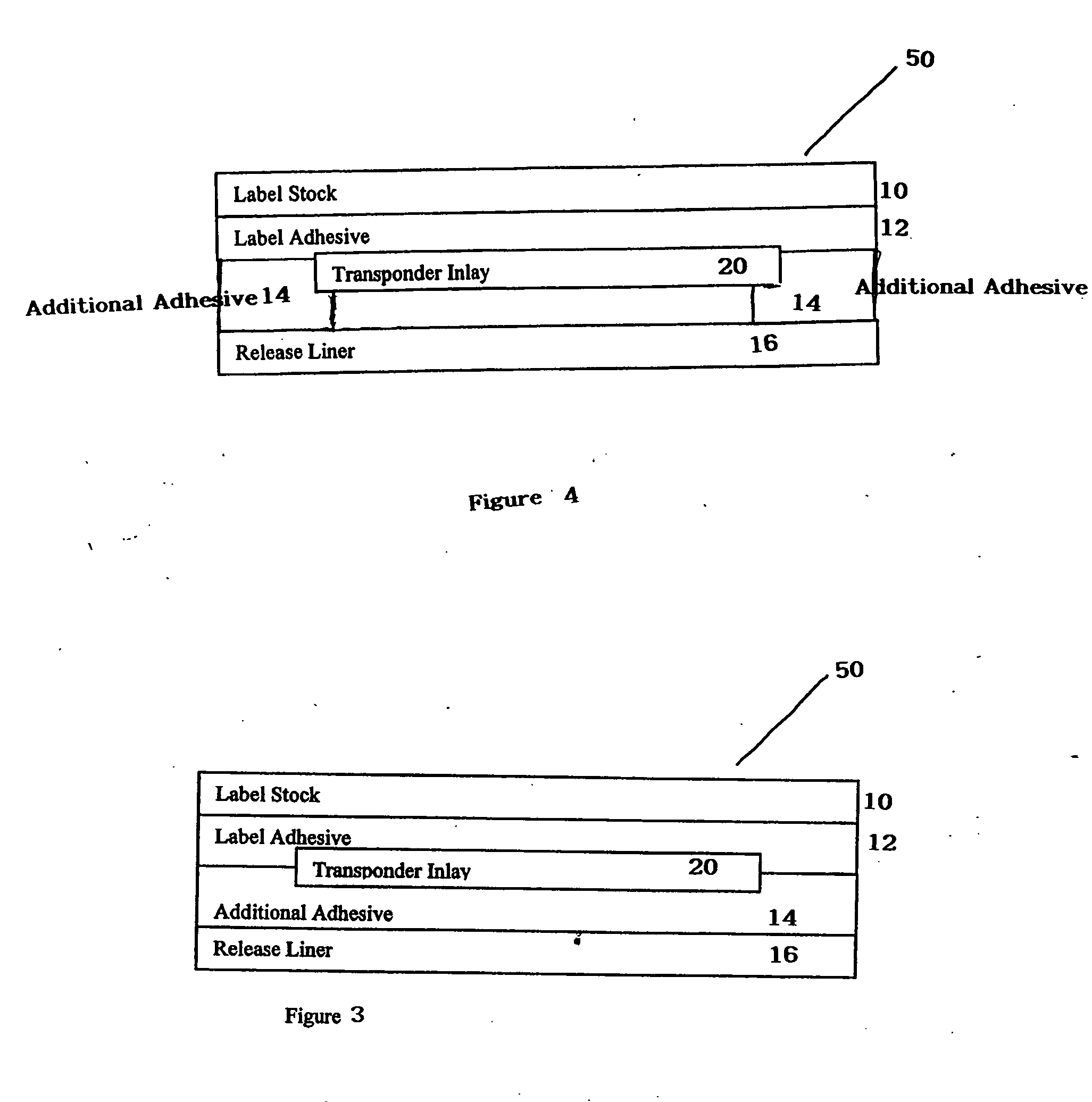

Profile correction for RFID label with transponder

InactiveUS20060292316A1Low viscosityReduce printer off outStampsDuplicating/marking methodsPressure sensitiveTrailing edge

A smart label construction that provides a more uniform profile for improved print performance in a thermal label printer. The preferred label design has a layer of pressure sensitive piece of applied over the inlay and beyond the edges of the inlay to provide a smoother step transition and eliminates printing voids along the inlay edges. An oversized adhesive patch is applied at the insert. The adhesive patch extends beyond the perimeter edges of the inlay masking the thickness transition of the inlay base film. Alternatively, a coat of additional adhesive is applied only on the leading and trailing edges of the transponder. Alternatively, a low viscosity adhesive is applied to the backside of the inlay prior to singulating the inlay and inserting it into the label stock. The low viscosity adhesive flows beyond the perimeter of the transponder and fills voids. Alternativley, transponder may compress into a low viscosity of adhesive on the label substrate.

Owner:INTERMEC IP

Method of making replacement collecting electrodes for an electrostatic precipitator

InactiveUS7438743B2Improve performanceImprove rigidityElectrode carrying meansGas separationElectrodeRapping

A method of forming a modular collecting electrode for an electrostatic precipitator, including forming a plurality of horizontal collecting electrode sections, each section having vertical planar portions separated by vertical tubular portions, and wherein the method includes inserting interconnecting support elements into the tubular portions of adjacent collector electrode sections and compressing the interconnected electrode sections to form a rigid modular assembly. In one preferred embodiment, the method includes applying stiffening members across the ends of the planar portions of adjacent electrode sections for transmitting rapping forces through the assembled sections.

Owner:HAMON RES COTTRELL

Cultivation system and a subsoil tool

ActiveUS8626401B2Limit any undesirable incorporationFast infiltrationSpadesData processing applicationsSoil scienceHydraulic ram

A method and system of tillage and tillage management that includes the steps of establishing a plurality of soil profiles over an area of soil to be cultivated, creating soil map database by combining these soil profiles to establish a treatment and cultivation regime, cultivating the ground in accordance regime and recording the cultivation in the soil map database. A subsoil tool for carrying out the method and system, with a shank (18) connected to a vehicle and to a ripper foot (20) terminating in a ripper tooth (22); a hydraulic ram (26) attached at a lower end to a first pivot connection (28) and at an upper end to an actuator the first pivot connection is attached to a rear end of a laterally extending wing member (30), a front end of the wing member being pivotally attached to the shank through a second pivot point (32) and the wing member is selected in accordance with soil profile at any position on a soil map database and is oscillated in response to actuation of the ram.

Owner:AGSOILWORKS TECH CO LLC

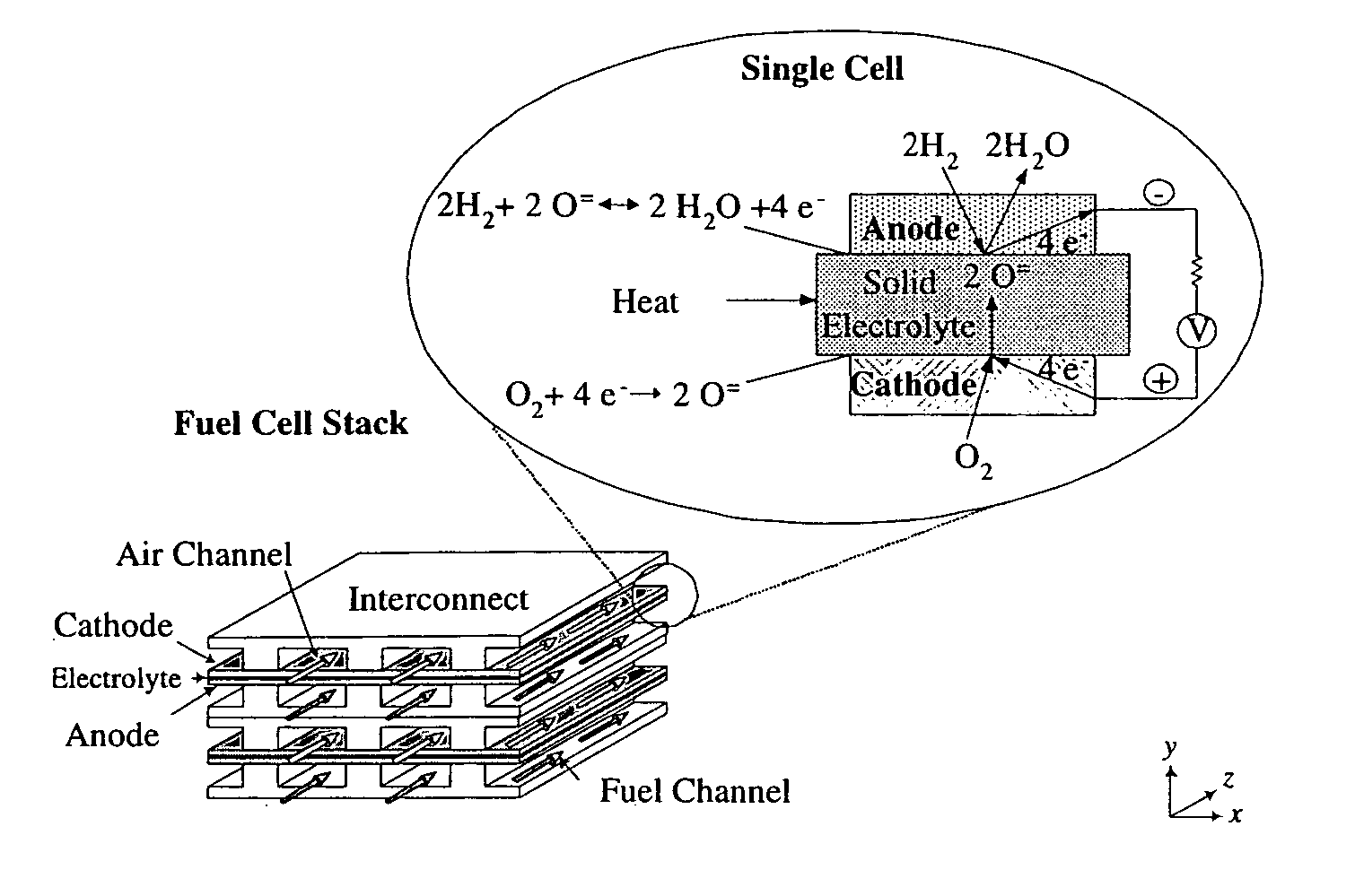

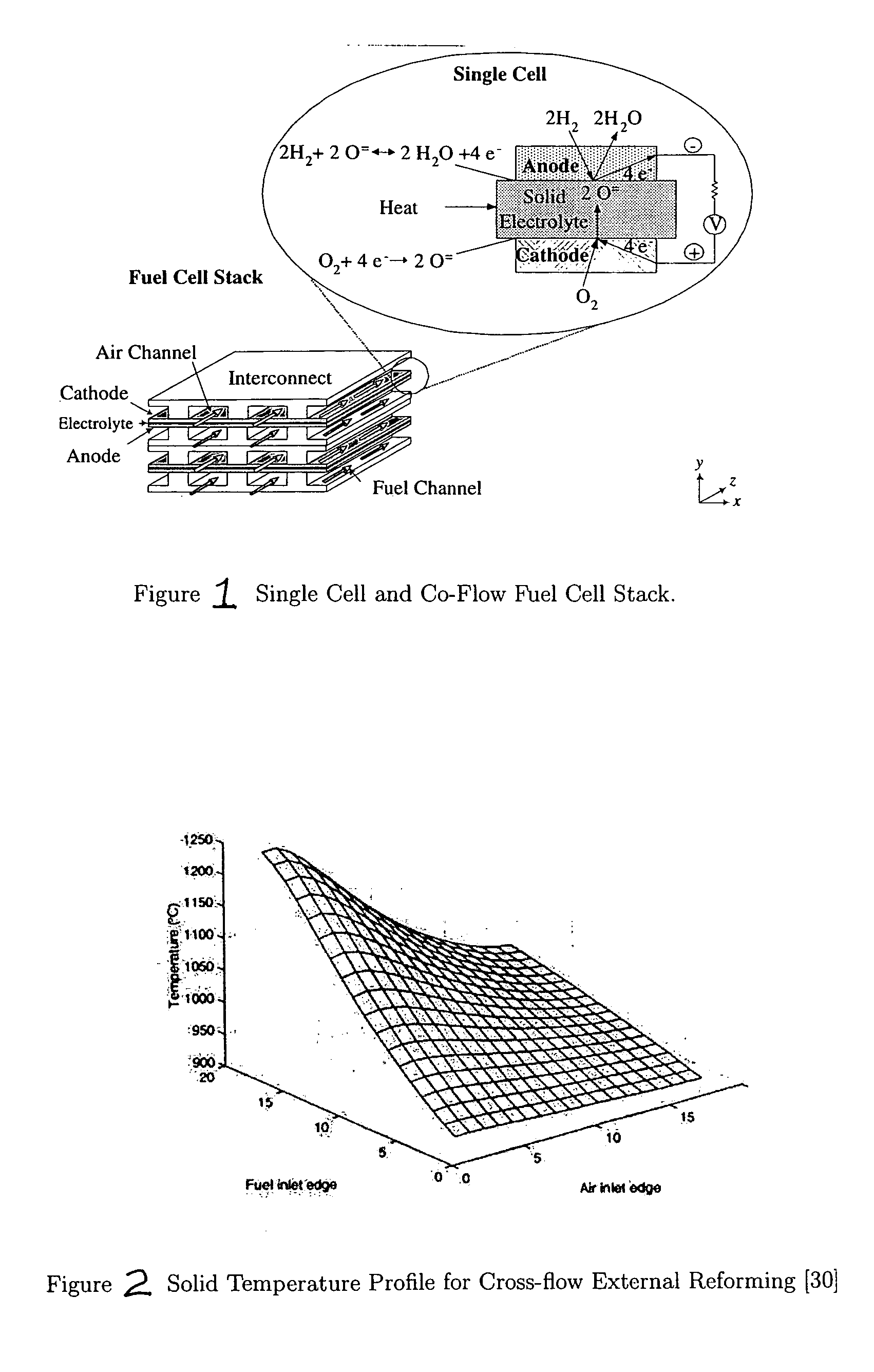

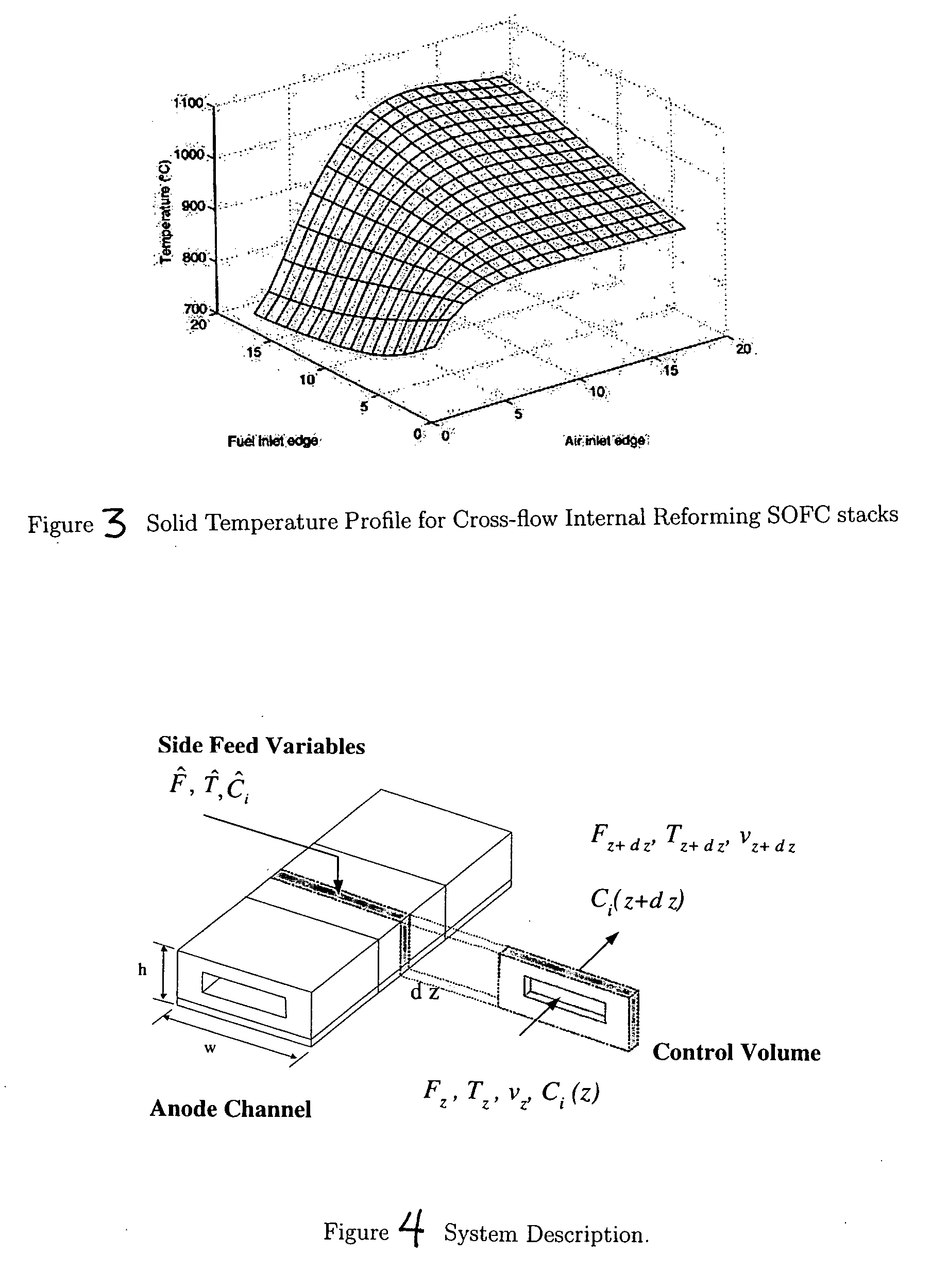

Distributed feed fuel cell stack

InactiveUS20050123821A1Improved thermal managementImprove power densityFuel cells groupingFuel cell auxillariesFuel cellsHeat generation

A fuel cell having a distributed fuel feed in which the heat generation profile can be better controlled. Fuel channel stack and system efficiency improvements are achieved.

Owner:ILLINOIS INSTITUTE OF TECHNOLOGY

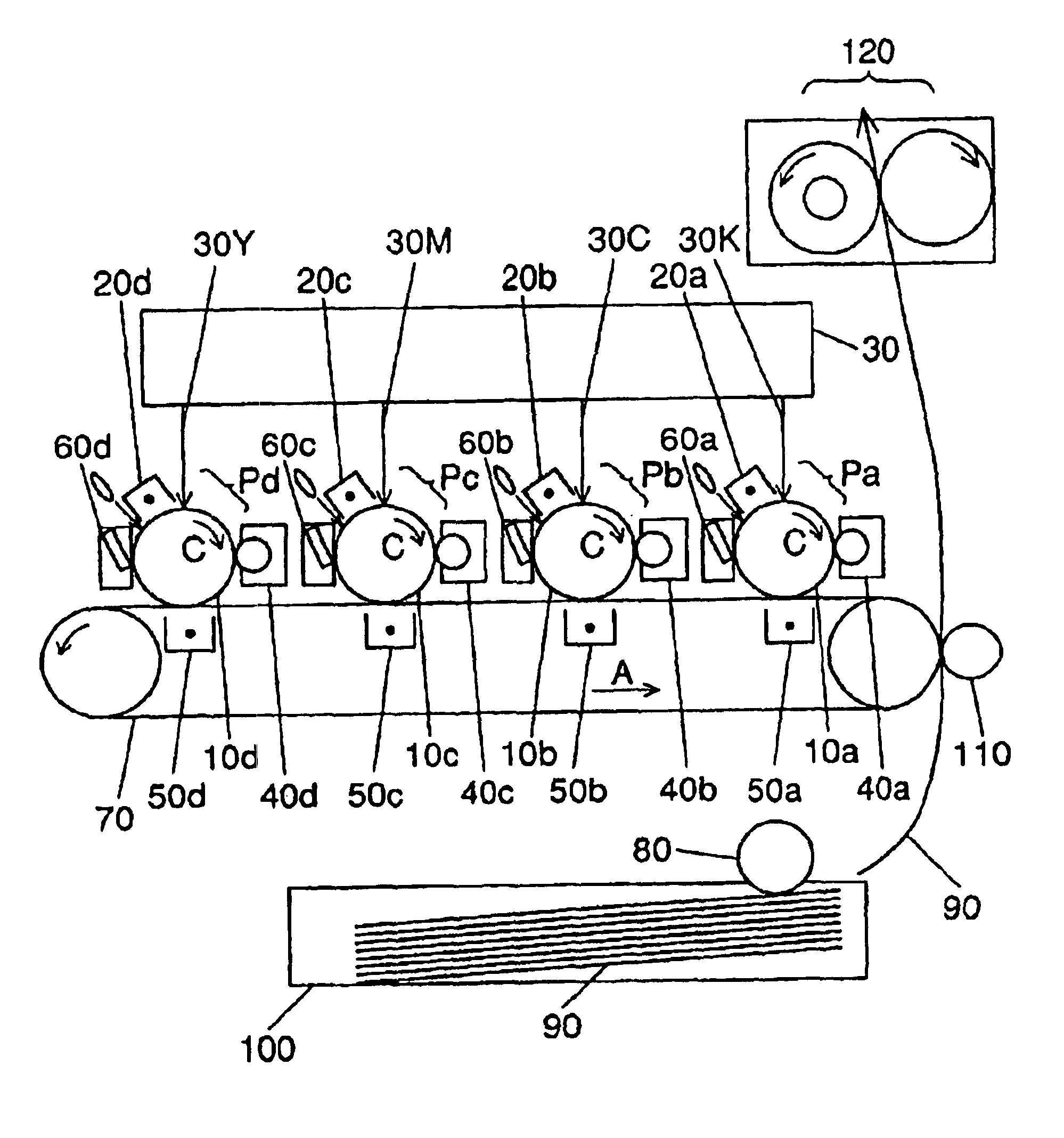

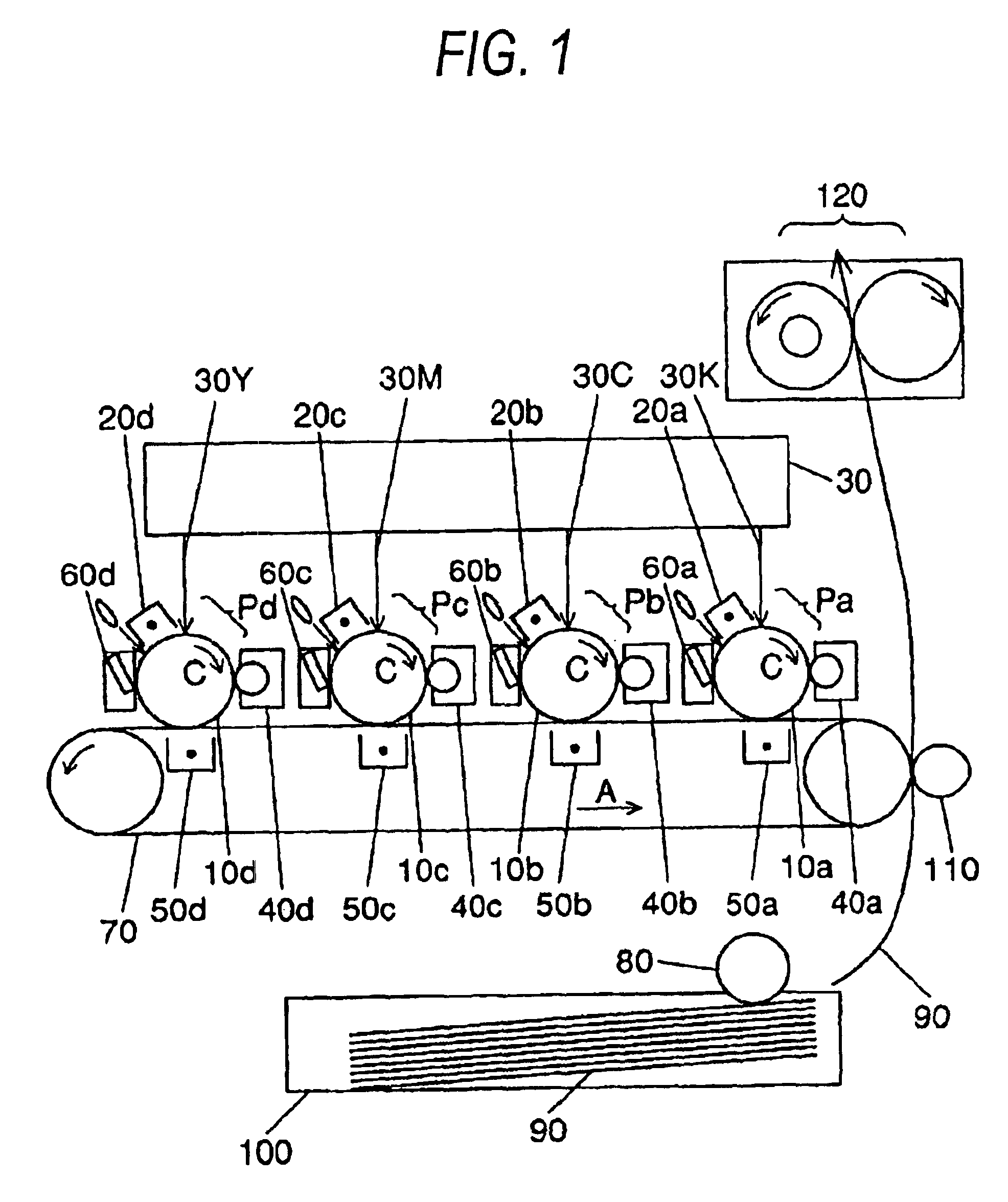

Heating device and fuser utilizing electromagnetic induction

InactiveUS6888113B2Improve workabilityGood effectCoil arrangementsElectrographic process apparatusElectromagnetic shieldingConductor Coil

A heating device utilizing electromagnetic induction is provided with an induction heating unit that is opposed to a heating member and causes the heating member to heat through electromagnetic induction. The induction heating unit has an exciting coil for generating a magnetic field and a coil guide member on which the exciting coil is wound. The exciting coil is formed in at least two layers in such a manner that a first layer is formed on a circumferential surface of the coil guide member by winding a plurality of turns and a second layer is formed around and outside the first layer on the side opposite to the coil guide member, and winding of each of the second layer and following layers is started from a position close to a winding start position of the first layer.

Owner:PANASONIC CORP

Photoacid generators, photoresist composition including the same and method of forming pattern using the same

InactiveUS7527913B2Uniform profileIncrease line widthOrganic chemistryOrganic compound preparationPhotoacid generatorSulfonium

A photoresist composition includes about 4% to about 10% by weight of a photoresist resin, about 0.1% to about 0.5% by weight of a photoacid generator having a sulfonium-salt cationic group and a sulfonium-salt anionic group containing a carboxyl group as a hydrophilic site and a remainder of a solvent. The photoresist composition may form a photoresist pattern having a uniform profile.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com