Method for removing blockage of oil-water well through magnetic positioning pulse acidification

A magnetic positioning, oil-water well technology, applied in the direction of earthwork drilling, wellbore/well components, production fluids, etc., can solve the problems of difficult acid liquid, large impact on reservoirs, water channeling, etc., to improve processing efficiency, Improvement of the profile and the effect of increasing the processing radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

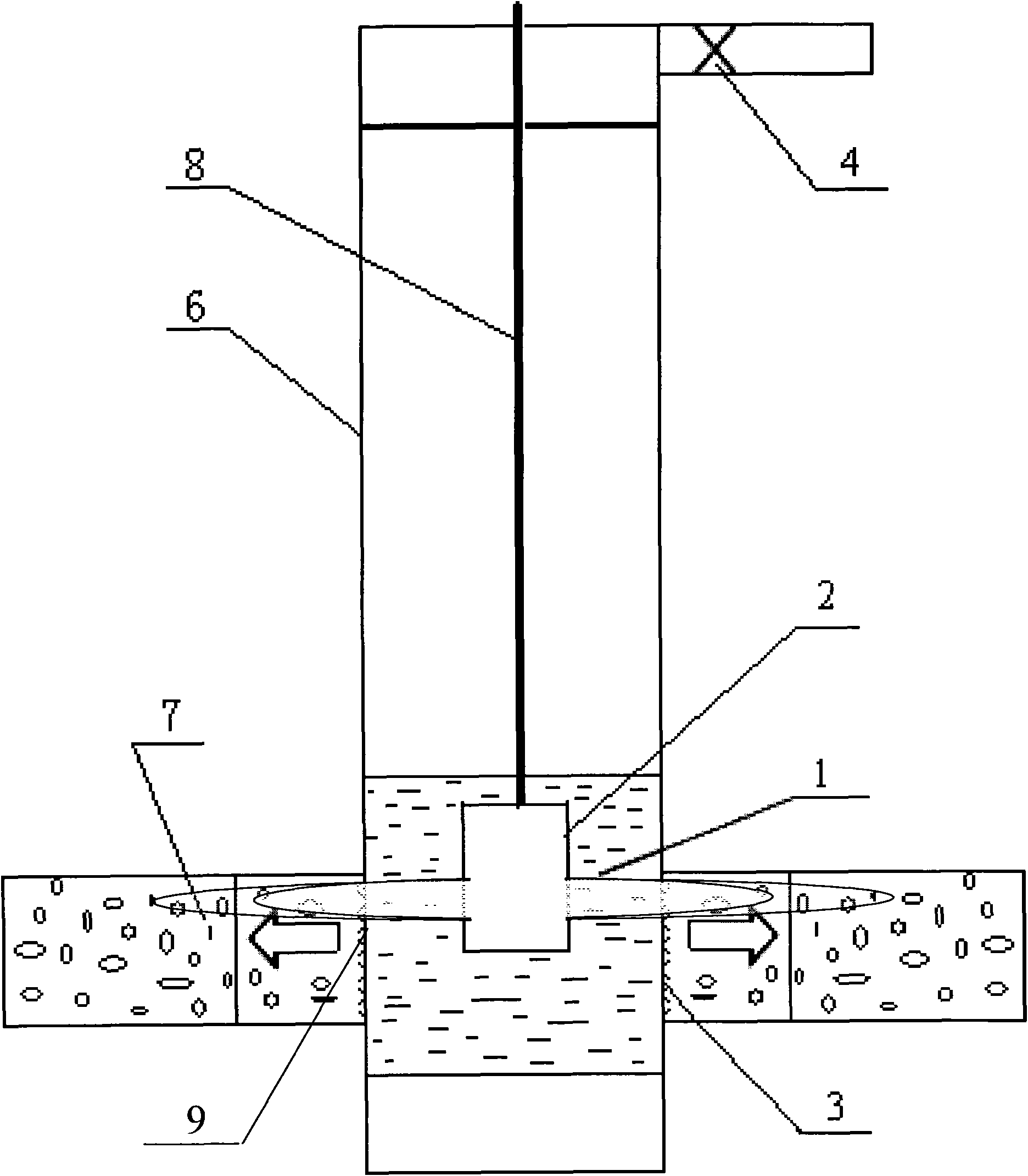

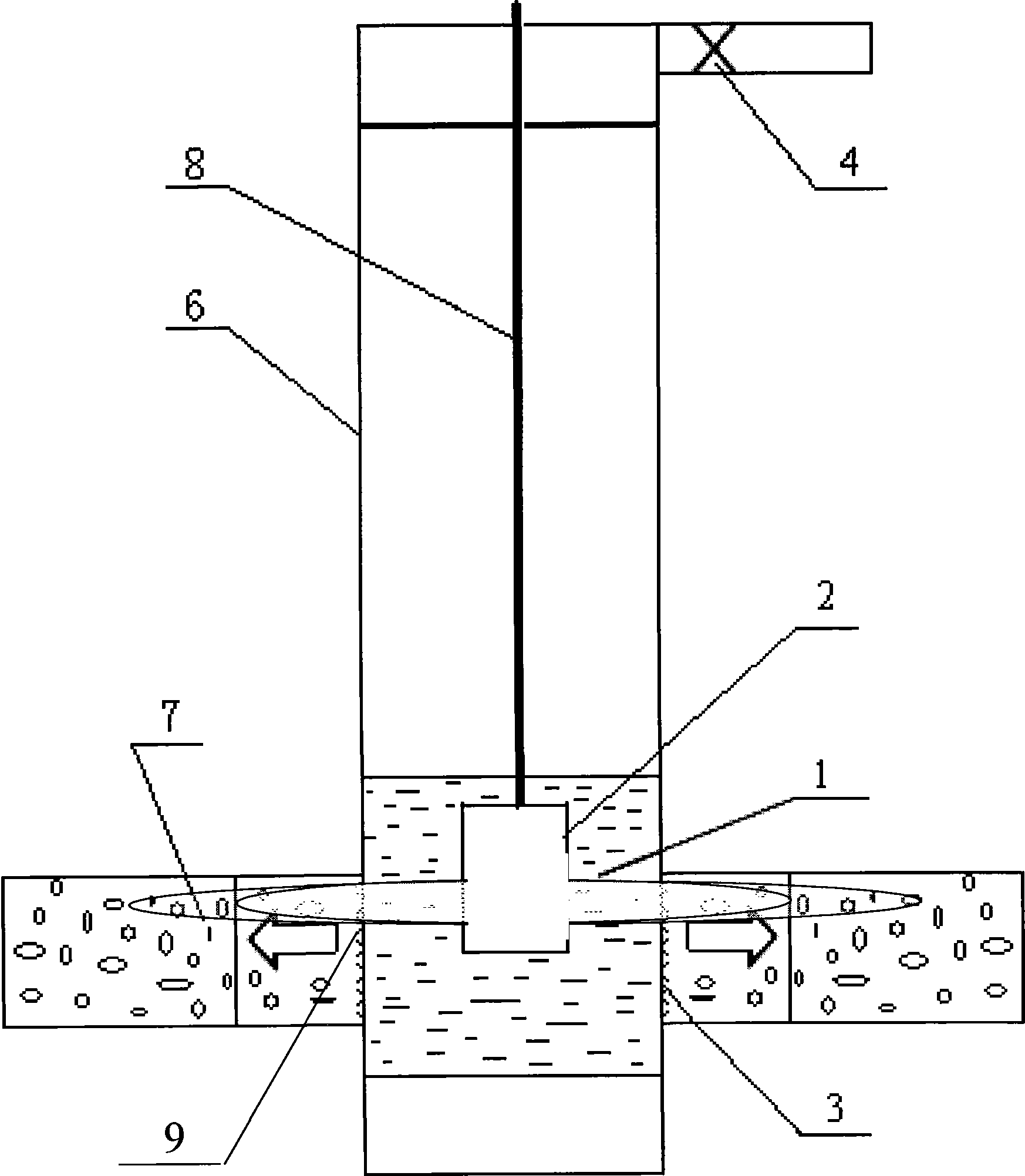

[0026] Example 1: An oil well with an inner diameter of casing 6 of 120 mm, a well depth of 2400 meters, a thickness of reservoir 7 of 5 meters, and a position of reservoir 7 of 2000-2005 meters, using the magnetic positioning pulse acidizing method for oil-water wells As an example, the present invention will be further described in detail.

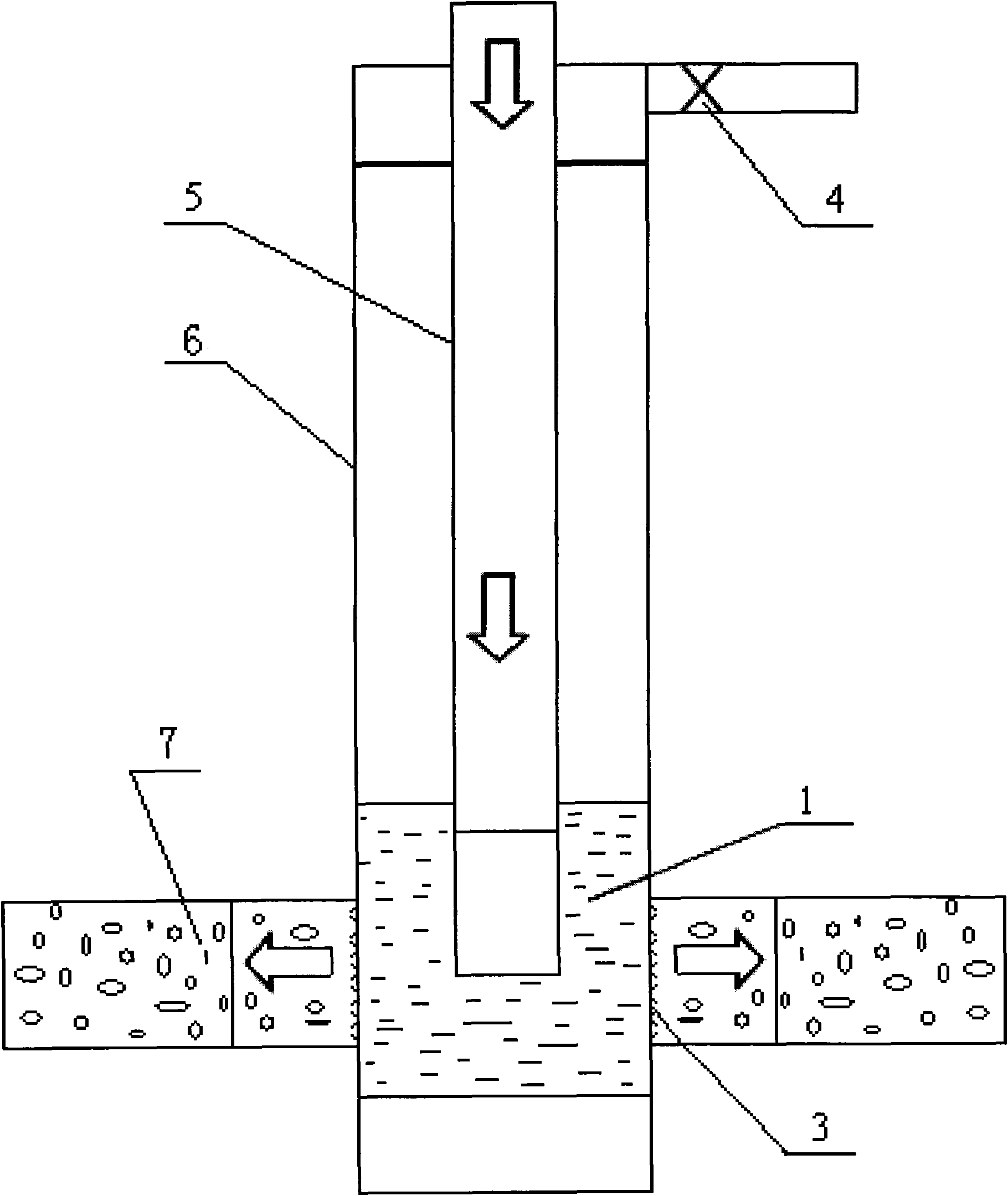

[0027] A. First carry out well drilling, refer to figure 2 . Connect the well gauge with an outer diameter of 118 mm to the lower end of the tubing 5 and run it into the casing 6, and use the well gauge to clean and shape the inner wall of the casing 6 in the whole well, so that the well gauge can pass through the casing 6 without hindrance .

[0028] B. Inject active water with surfactant and anti-swelling agent through oil pipe 5 to perform positive flushing operation on the inner wall of casing 6 to remove dirt in the wellbore;

[0029] C. Insert 6m into oil pipe 5 3 Acid solution 1, use acid solution 1 to replace active water in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com