Patents

Literature

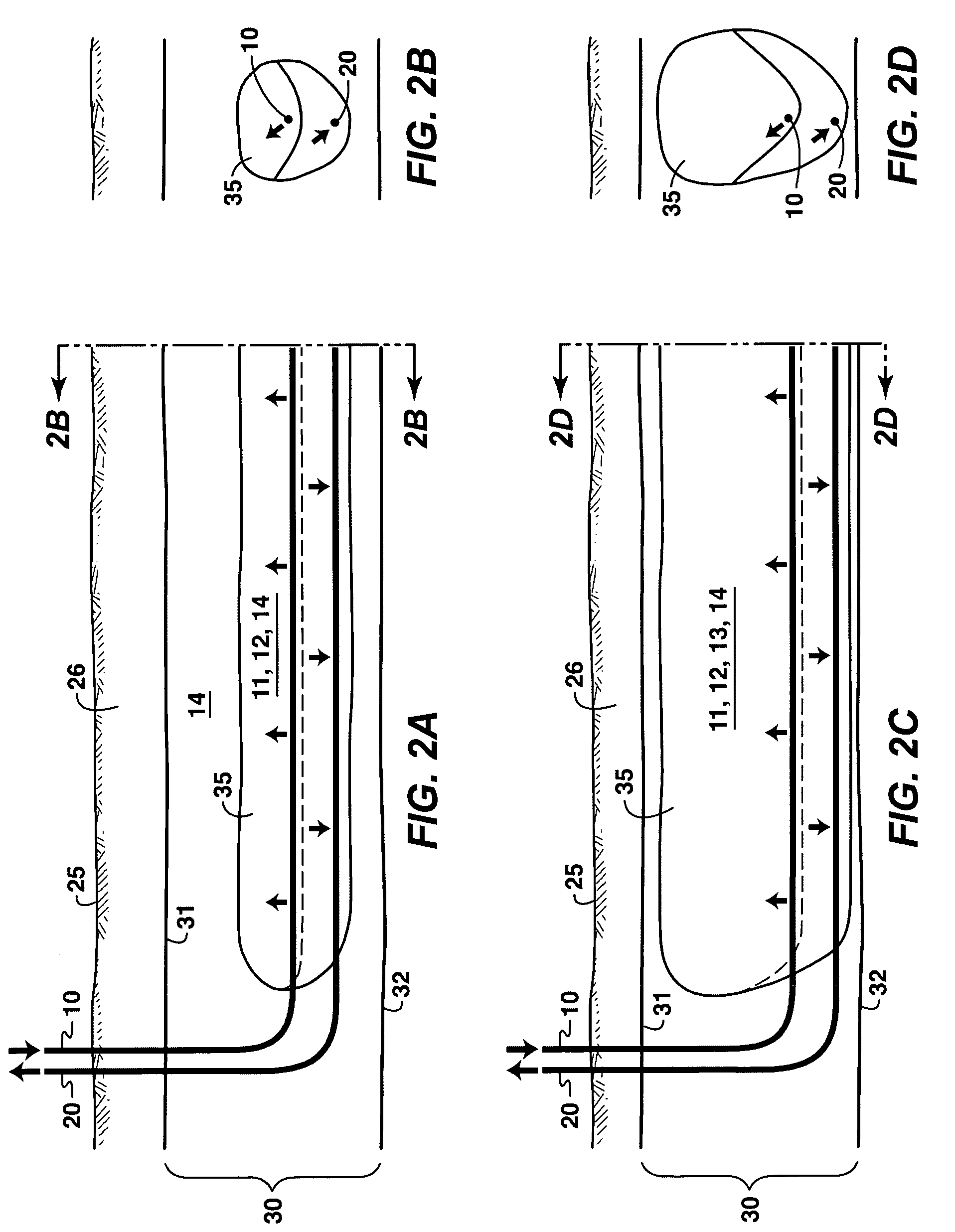

2006 results about "Injection well" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An injection well is a device that places fluid deep underground into porous rock formations, such as sandstone or limestone, or into or below the shallow soil layer. The fluid may be water, wastewater, brine (salt water), or water mixed with chemicals.

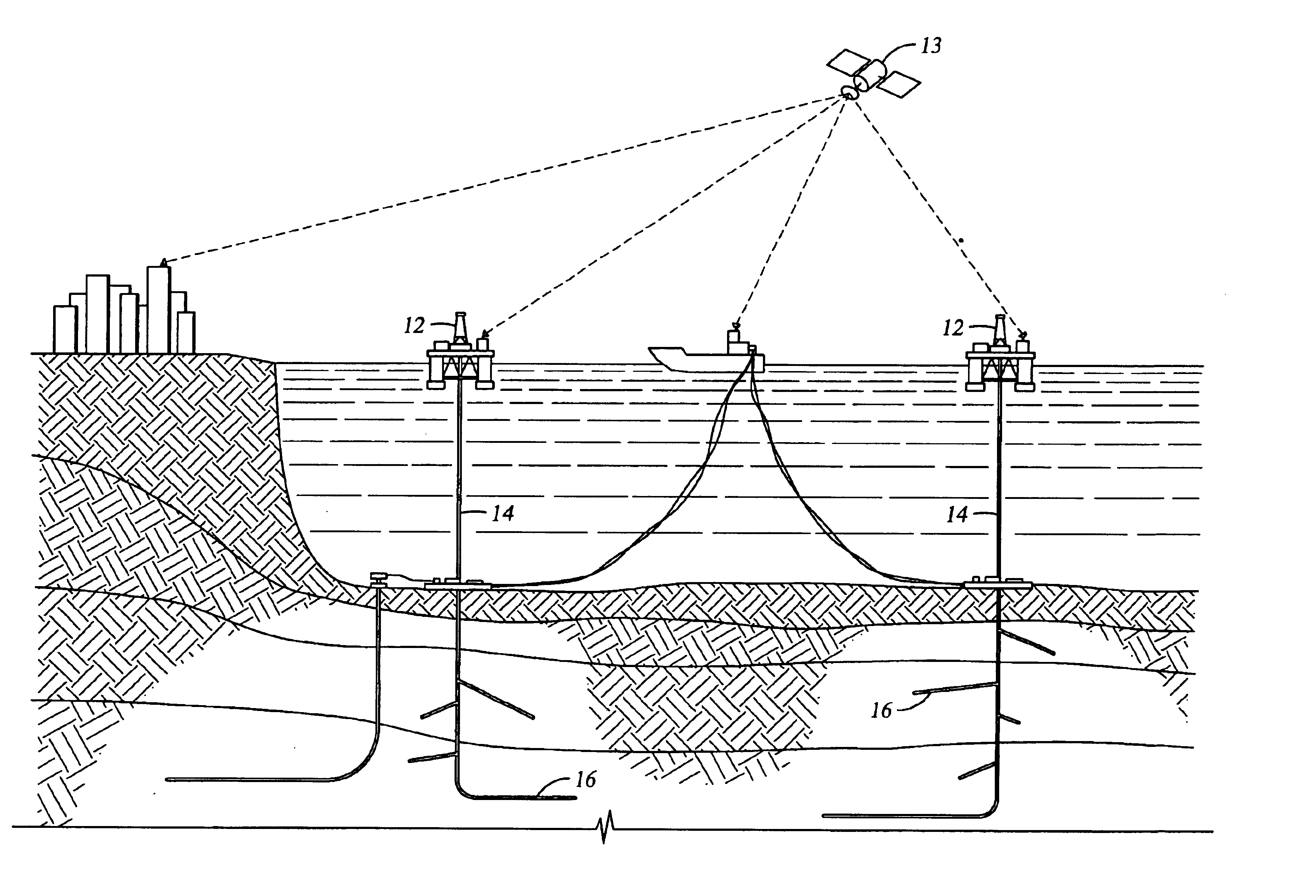

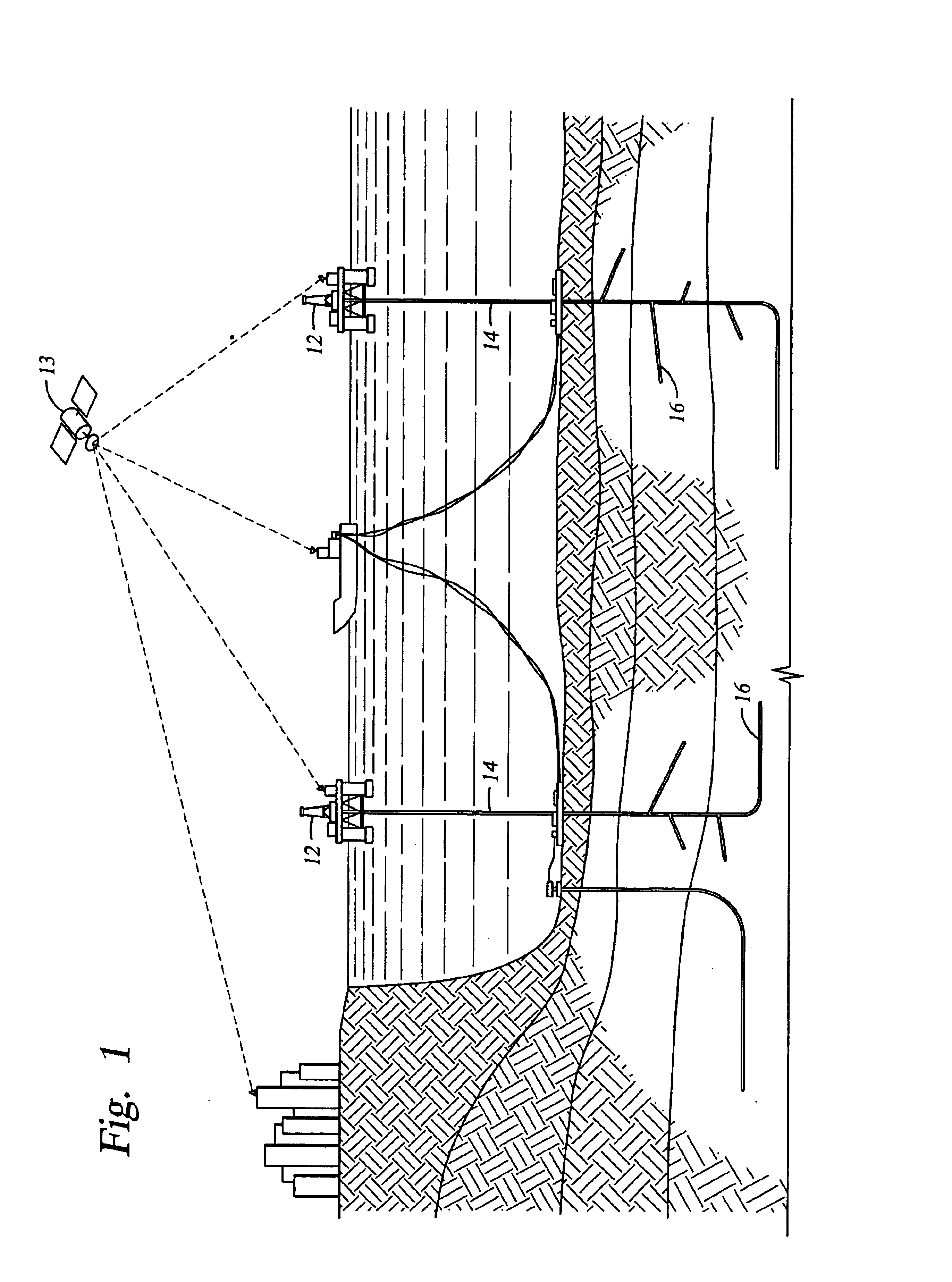

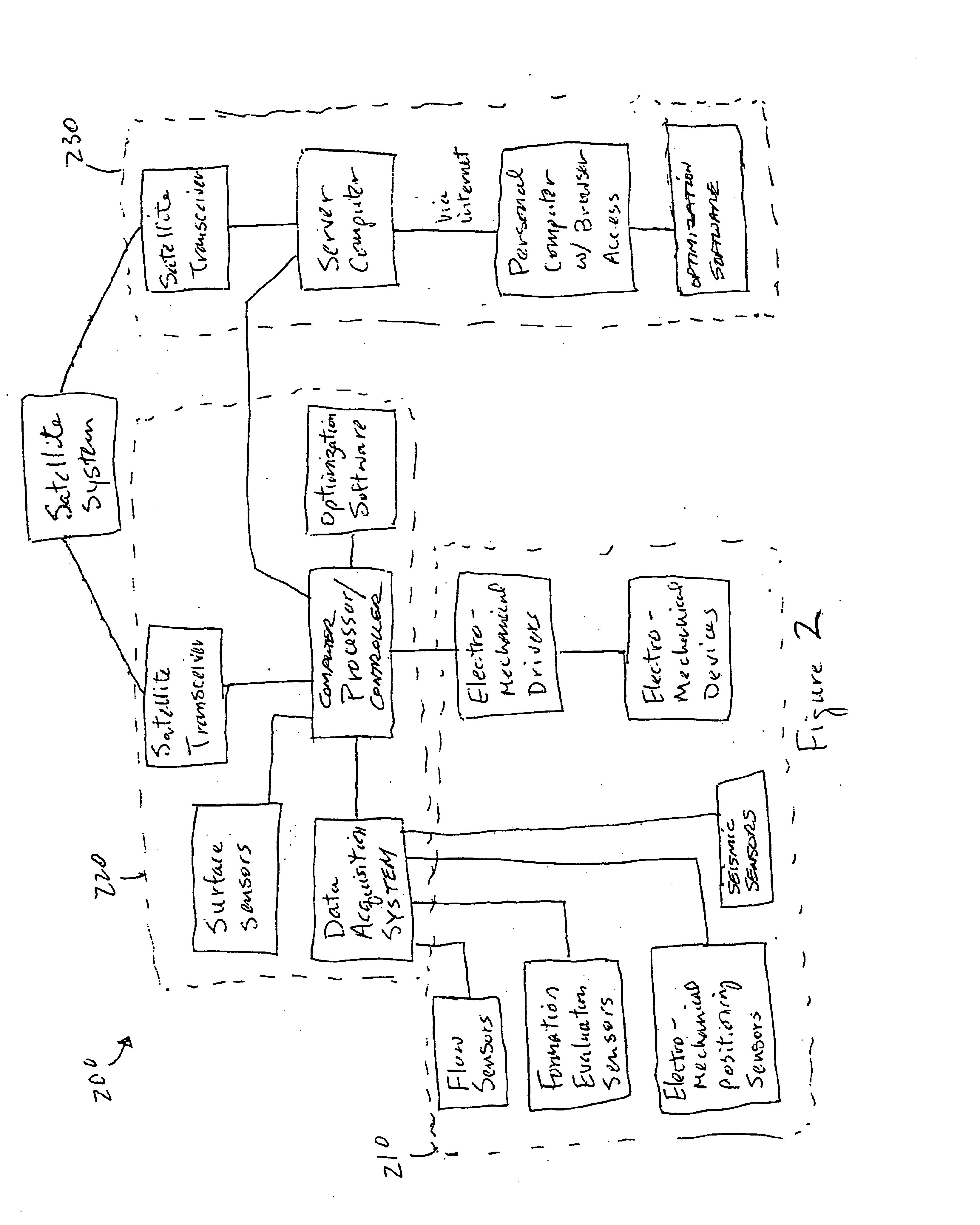

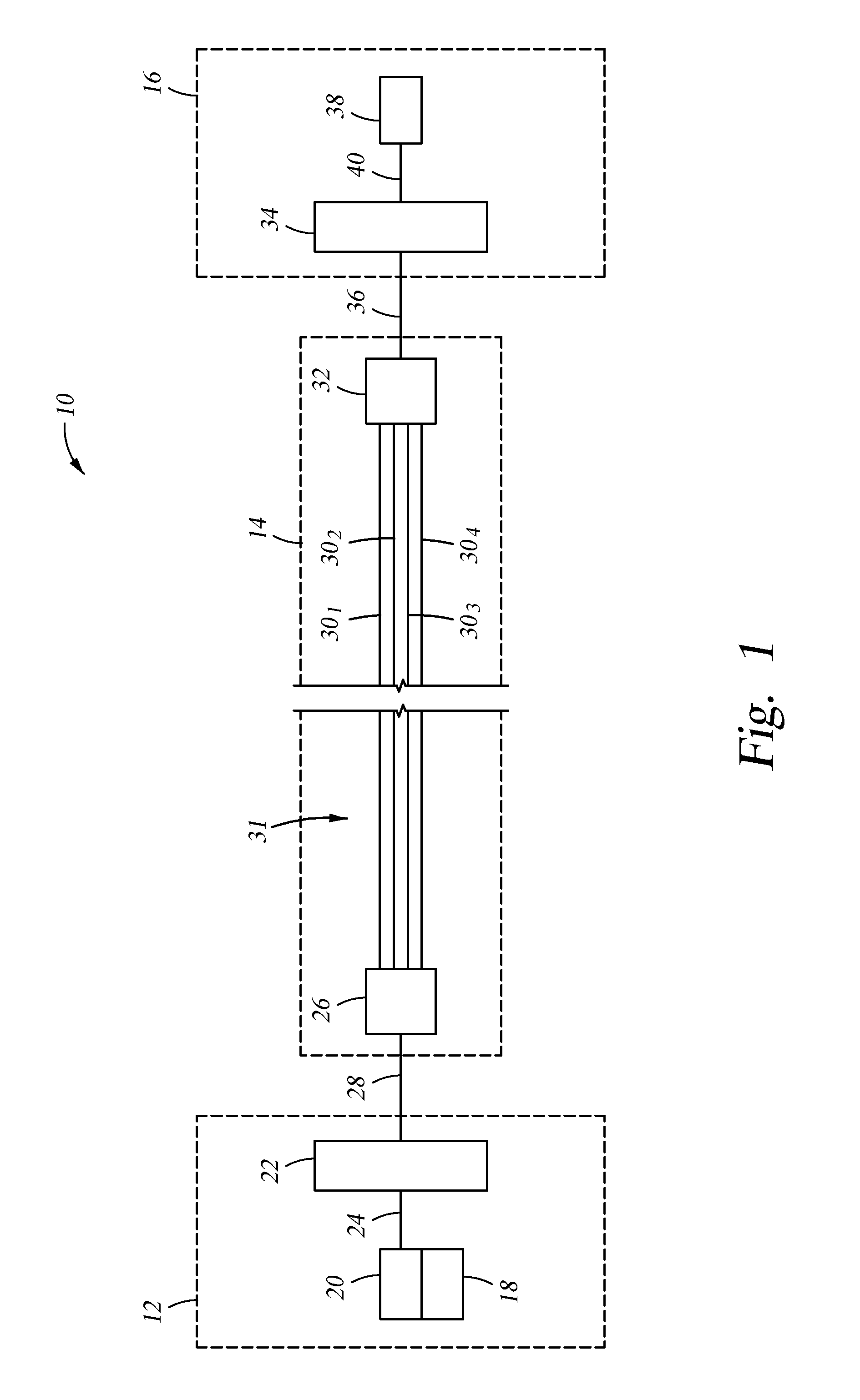

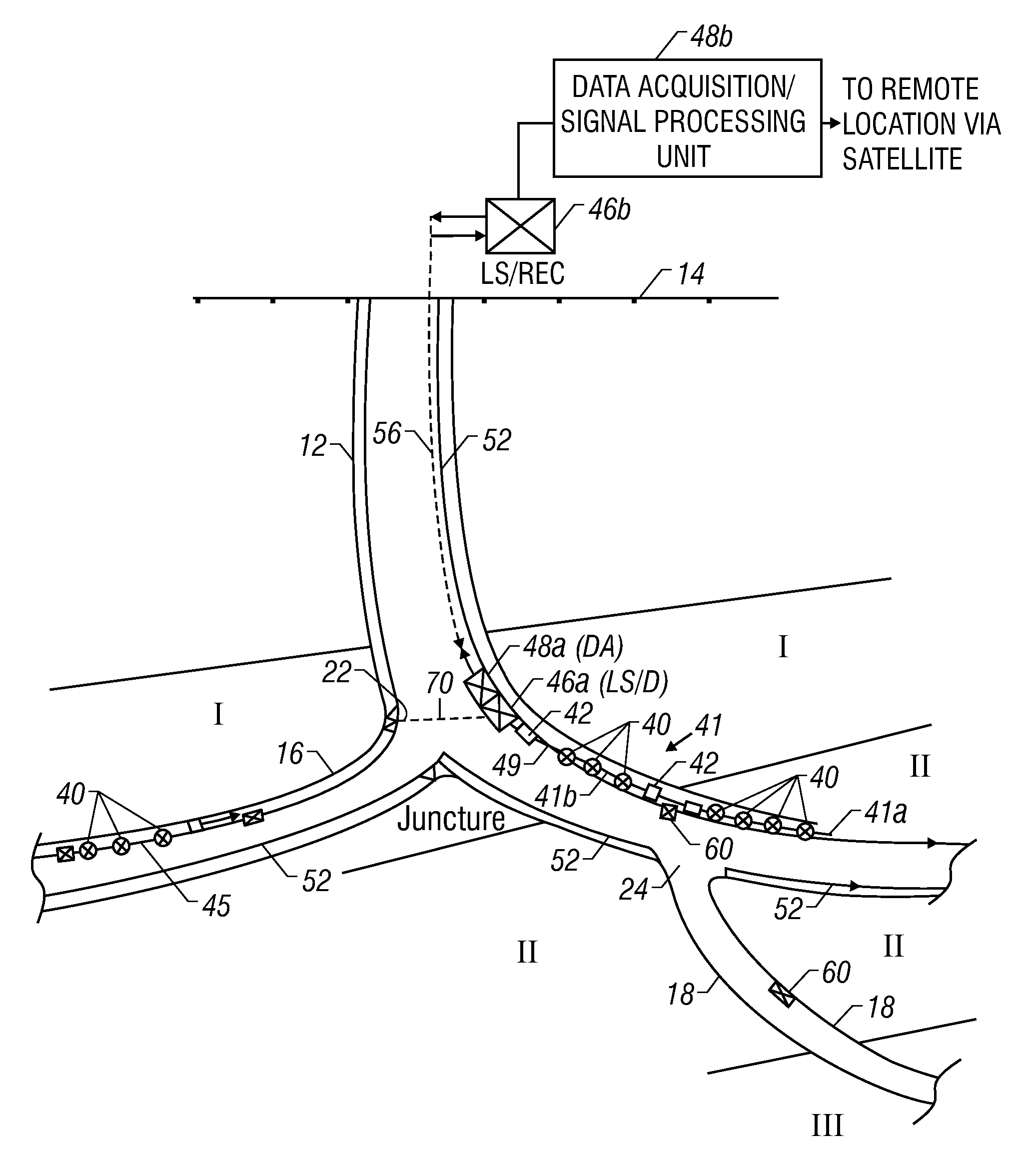

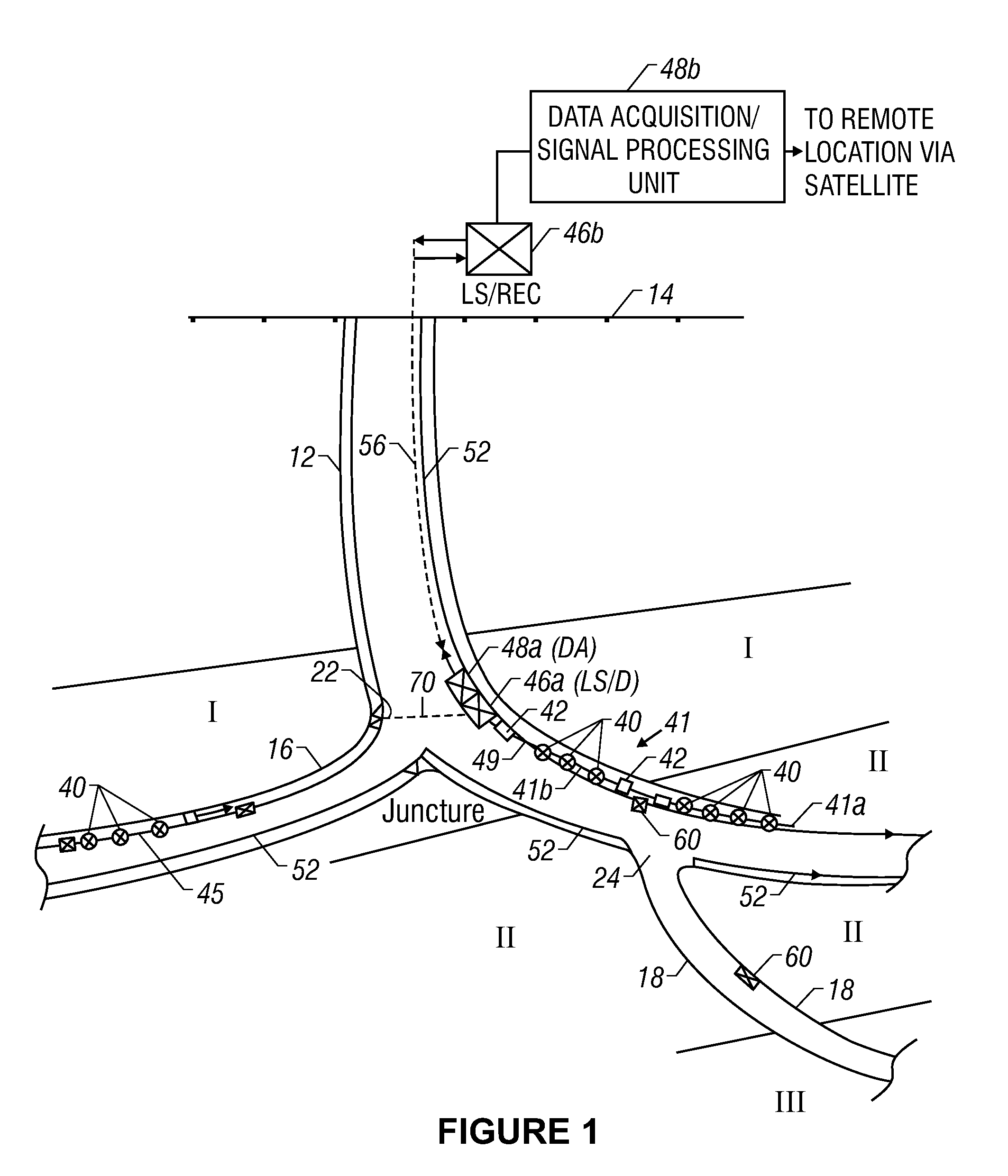

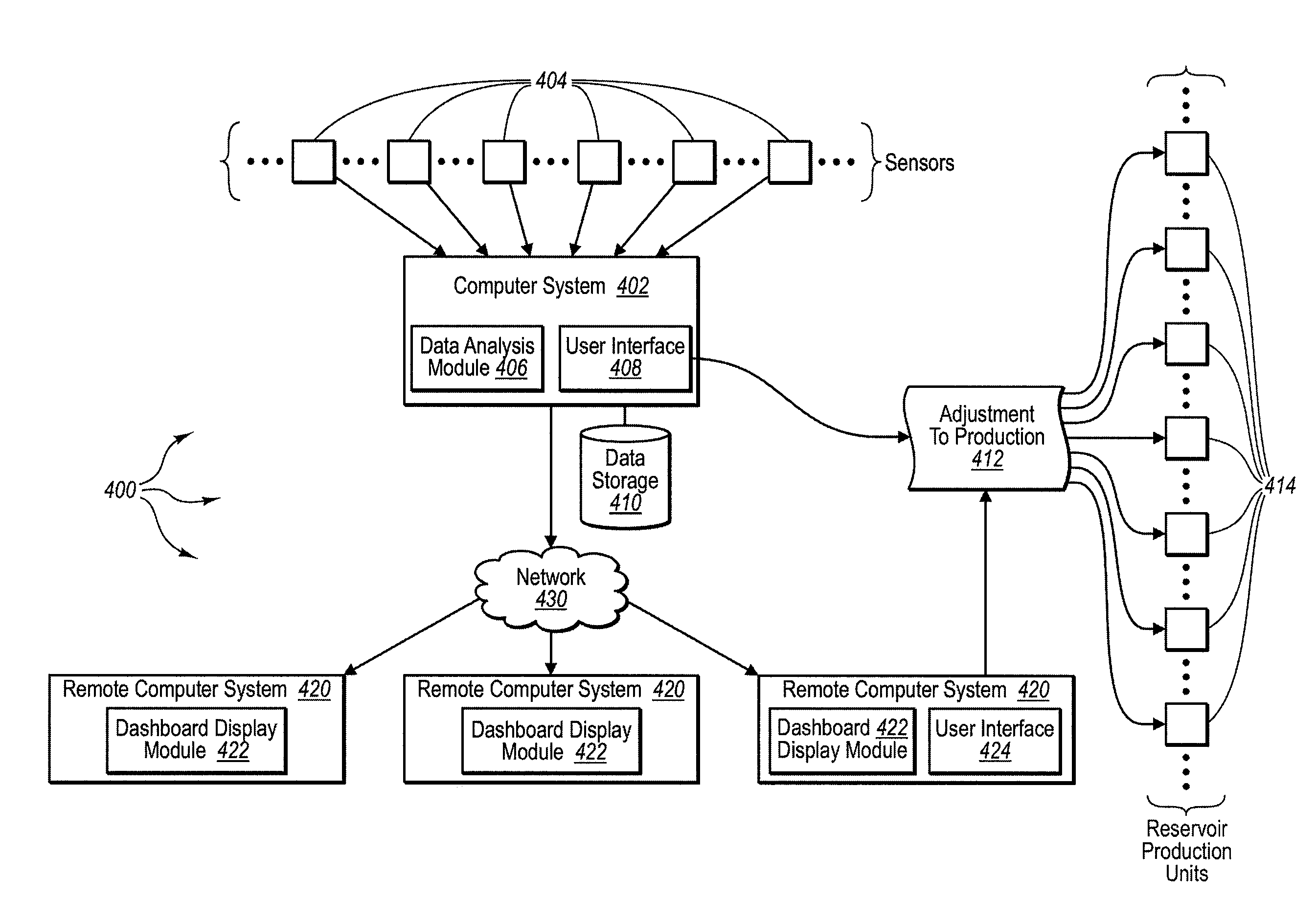

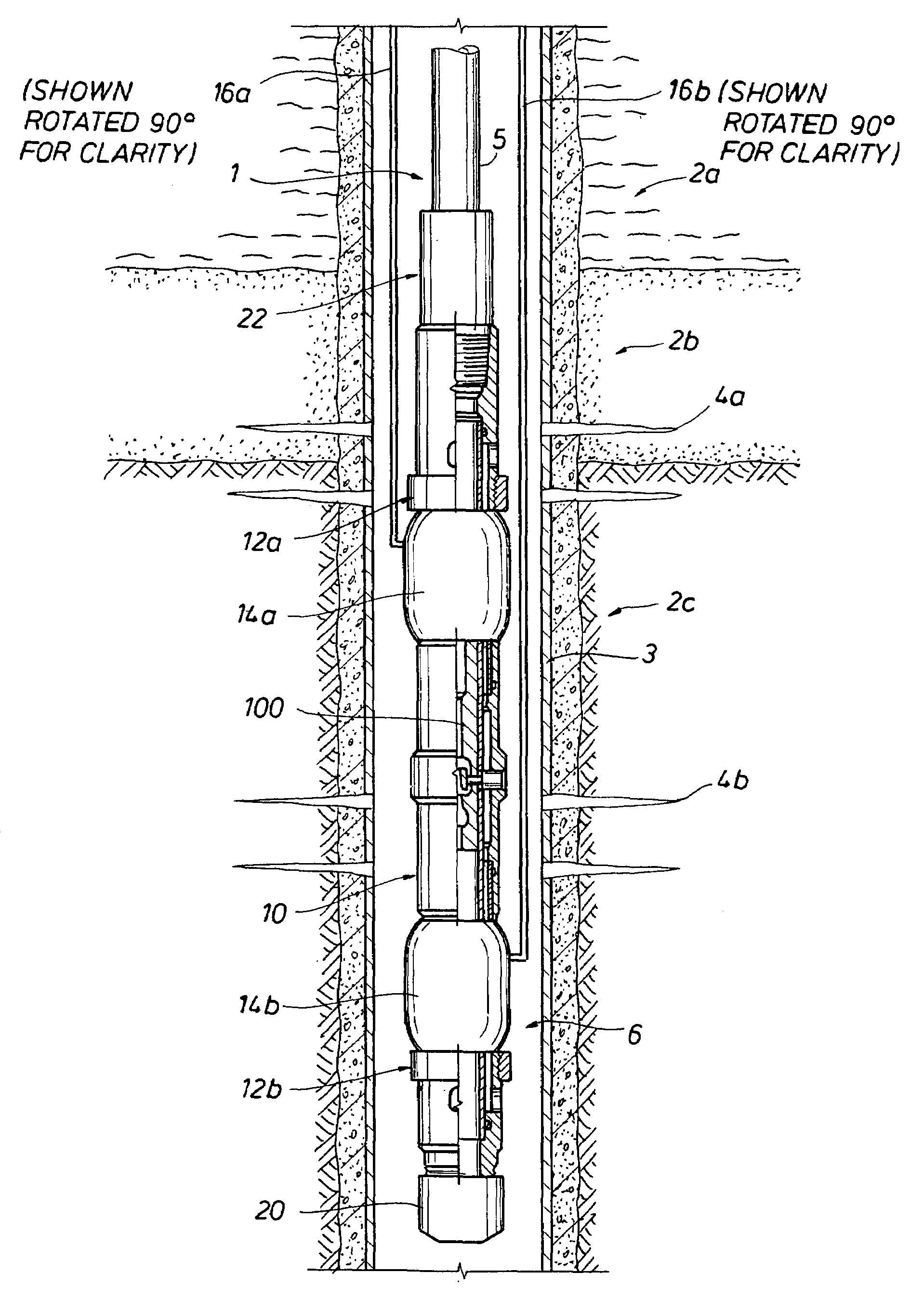

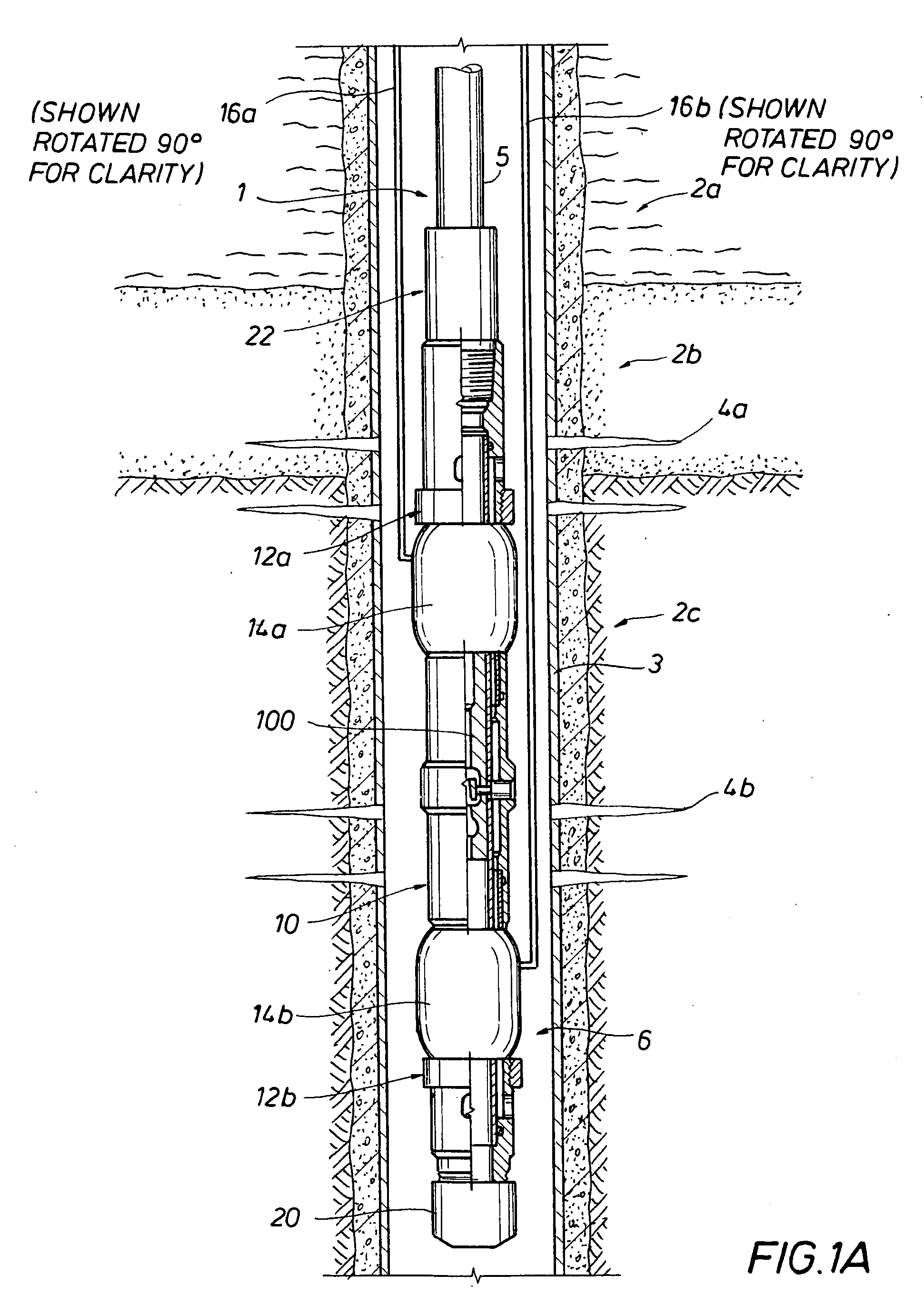

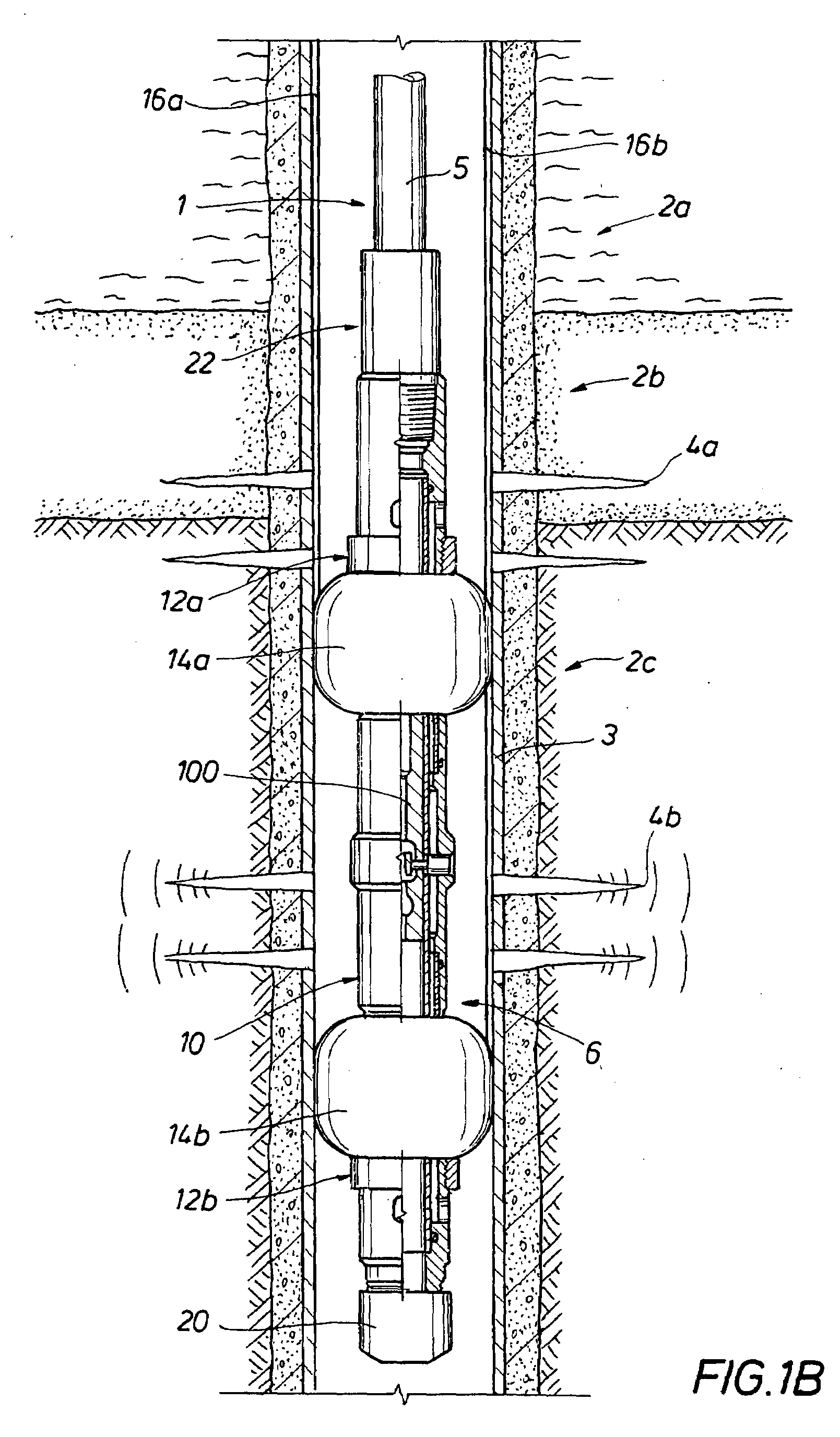

Methods and apparatus for monitoring and controlling oil and gas production wells from a remote location

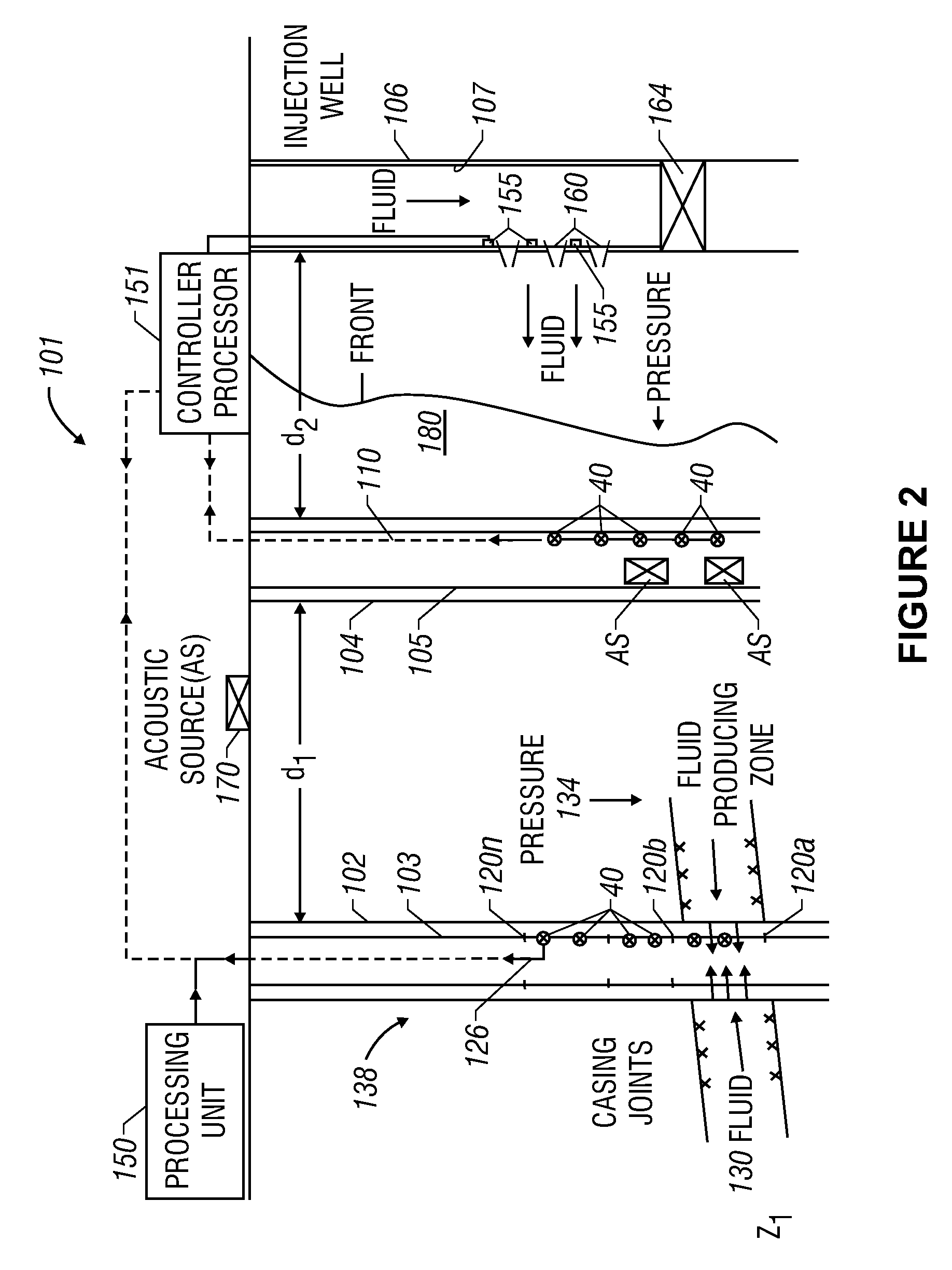

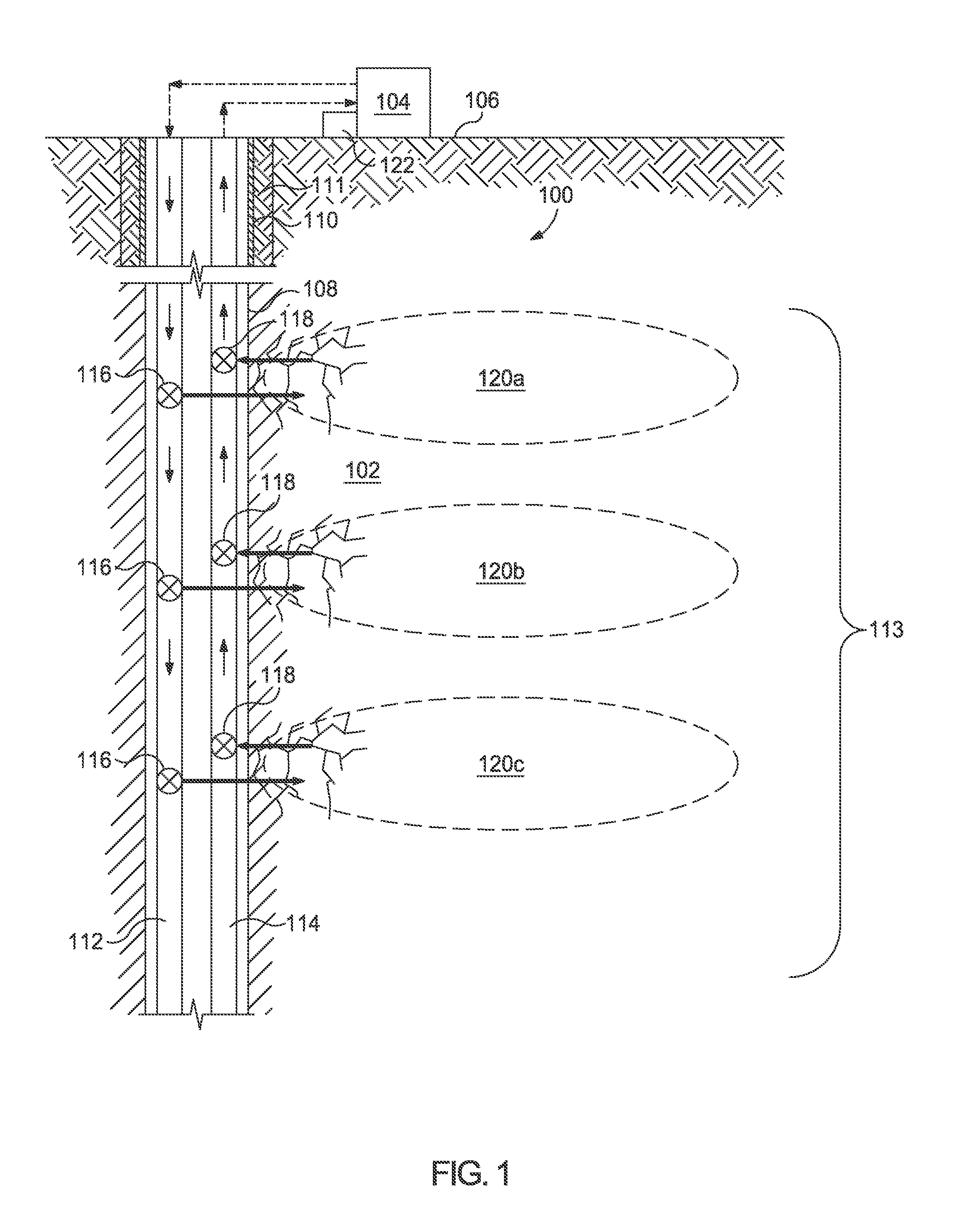

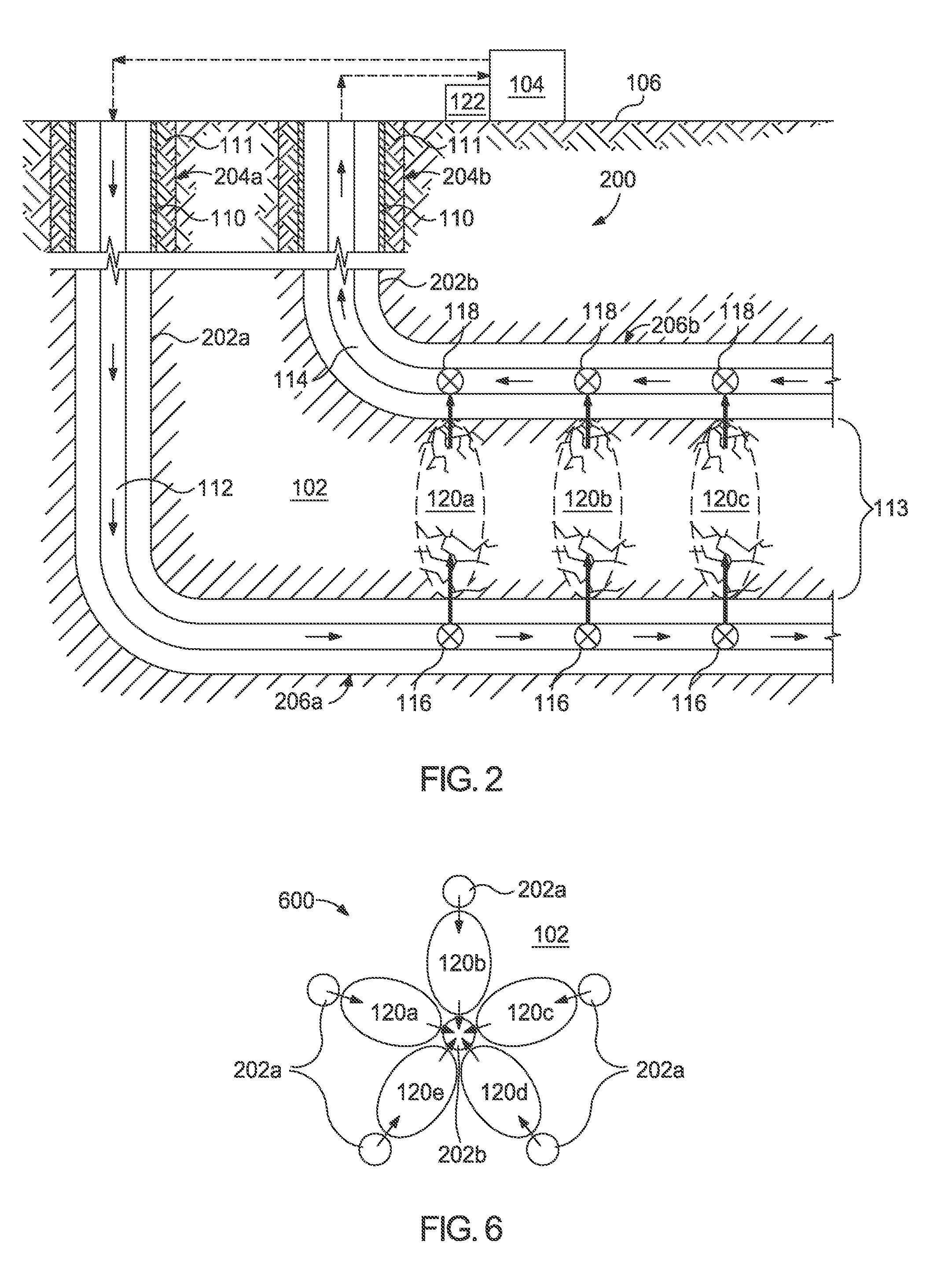

The invention provides apparatus and methods for monitoring and controlling hydrocarbon production wells and / or injection wells from a remote location. The apparatus for monitoring and controlling one or more hydrocarbon production wells or injection wells from a remote location comprises one or more surface control and data acquisition systems; one or more sensors disposed in communication with the one or more control and data acquisition systems; one or more downhole flow control devices disposed in communication with the one or more control and data acquisition systems; and one or more remote controllers disposed in communication with the one or more control and data acquisition systems. Preferably, the remote controller comprises a computer having an internet access disposed in communication with the one or more control and data acquisition systems through a communication device comprising an internet web site server. The method for monitoring and controlling a downhole hydrocarbon production well or an injection well comprises: transmitting data collected by a downhole sensor module to a control and data acquisition system; evaluating downhole operating conditions and optimizing downhole operating parameters utilizing an optimization software program disposed in communication with the control and data acquisition system; and transmitting signals between the control and data acquisition system system and a remote controller utilizing a satellite communication system, the remote controller comprising a computer and an internet browser control access adapted to display operating conditions and parameters and to accept instructions to change operating parameters.

Owner:WEATHERFORD TECH HLDG LLC

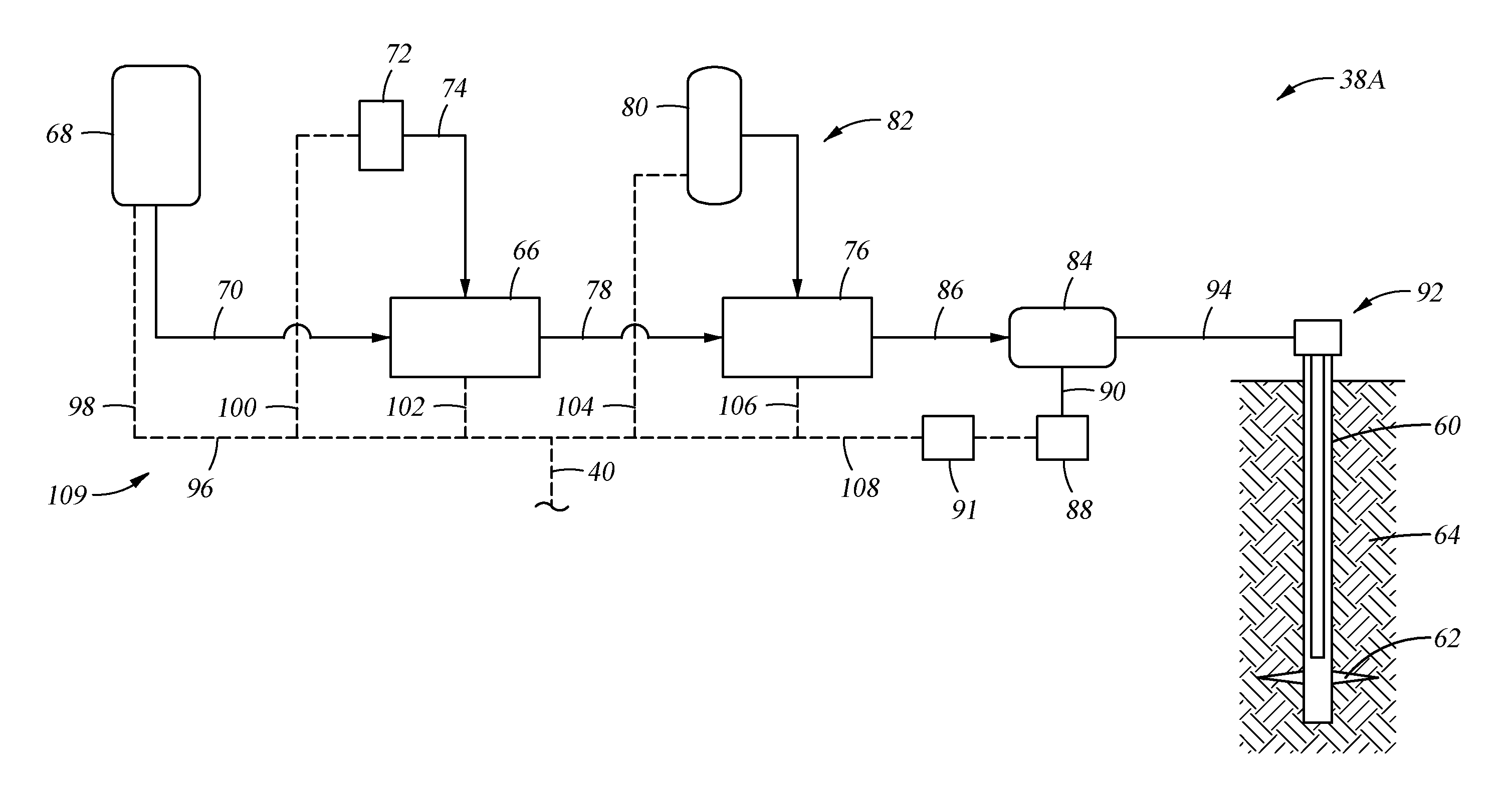

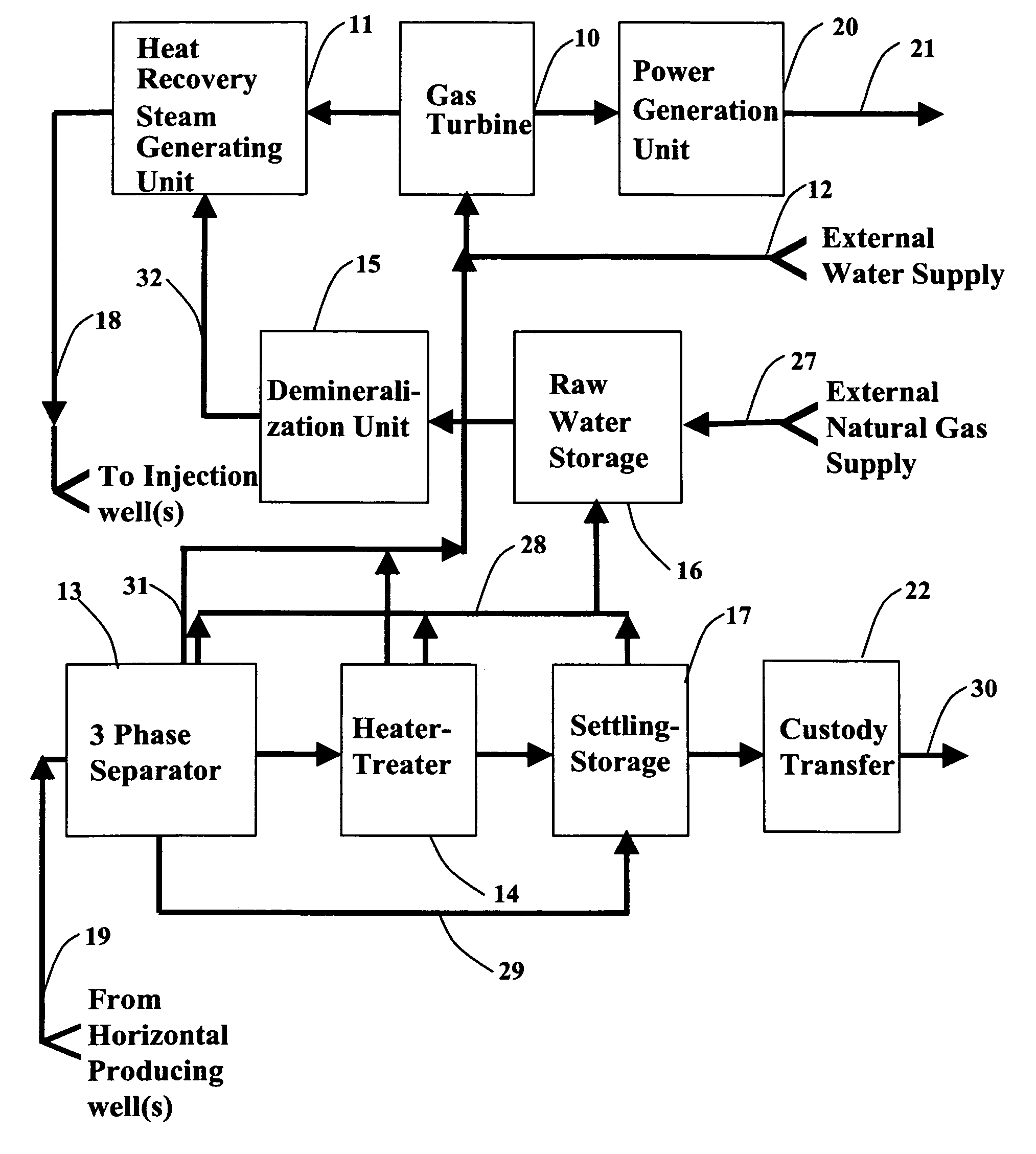

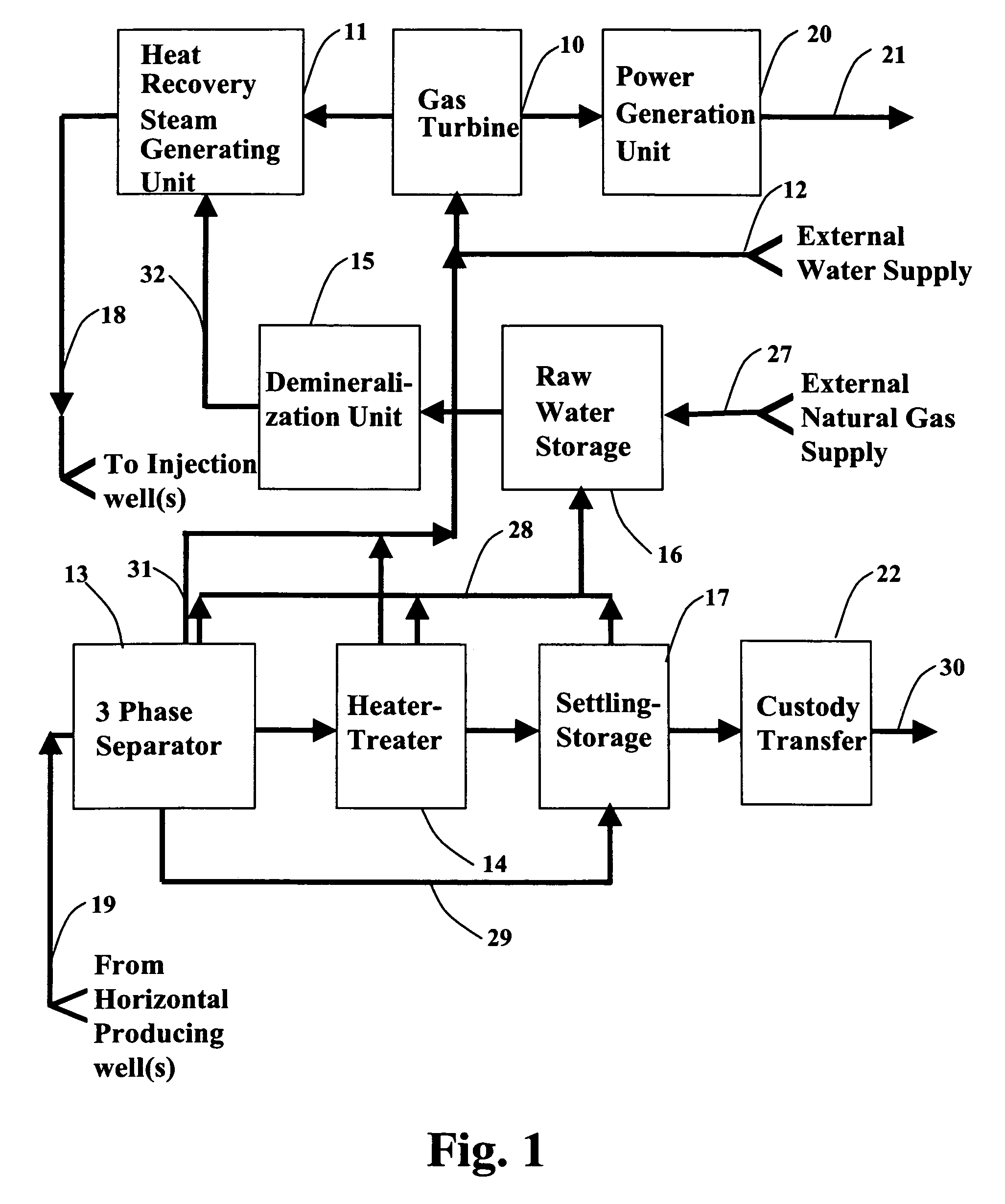

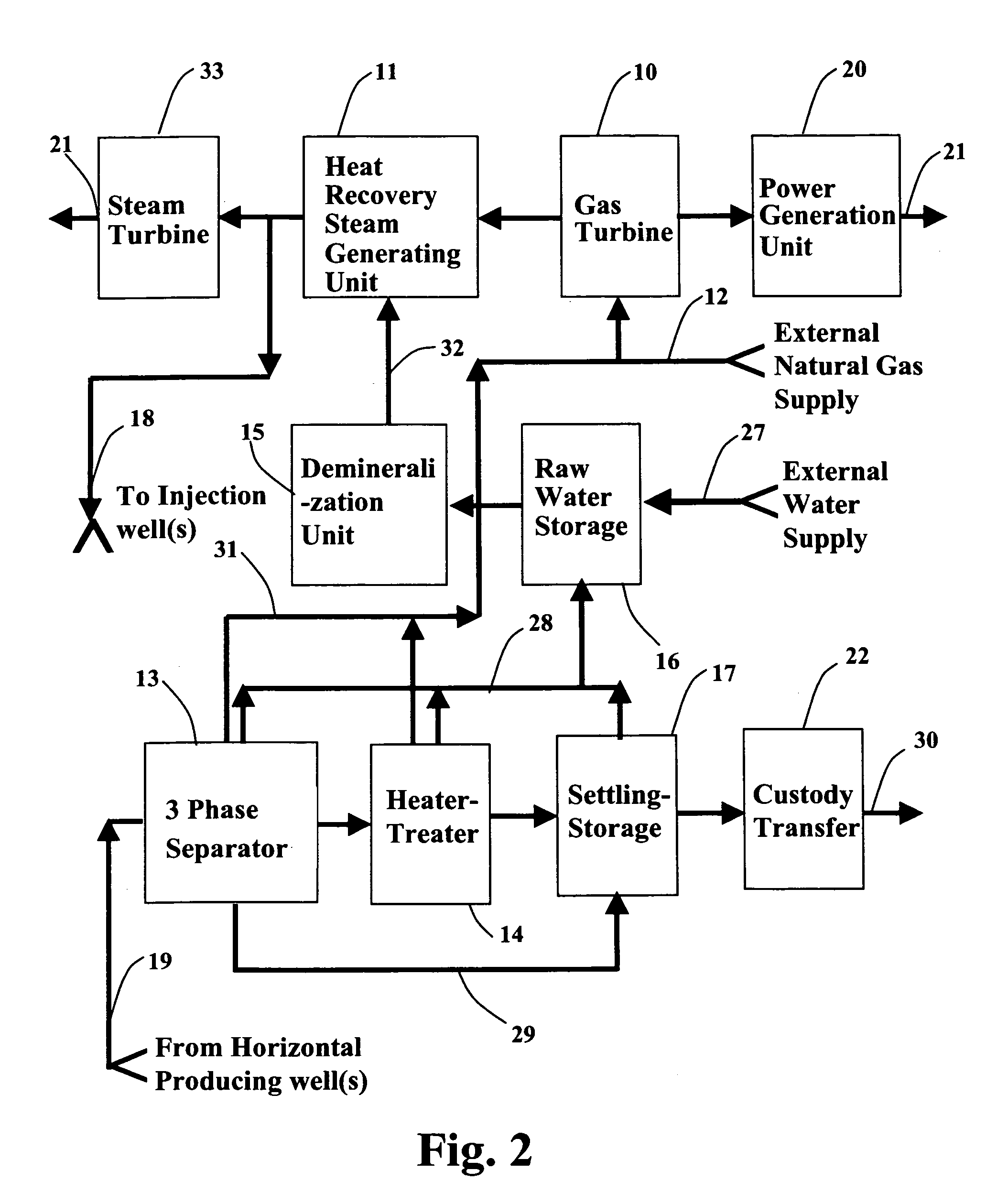

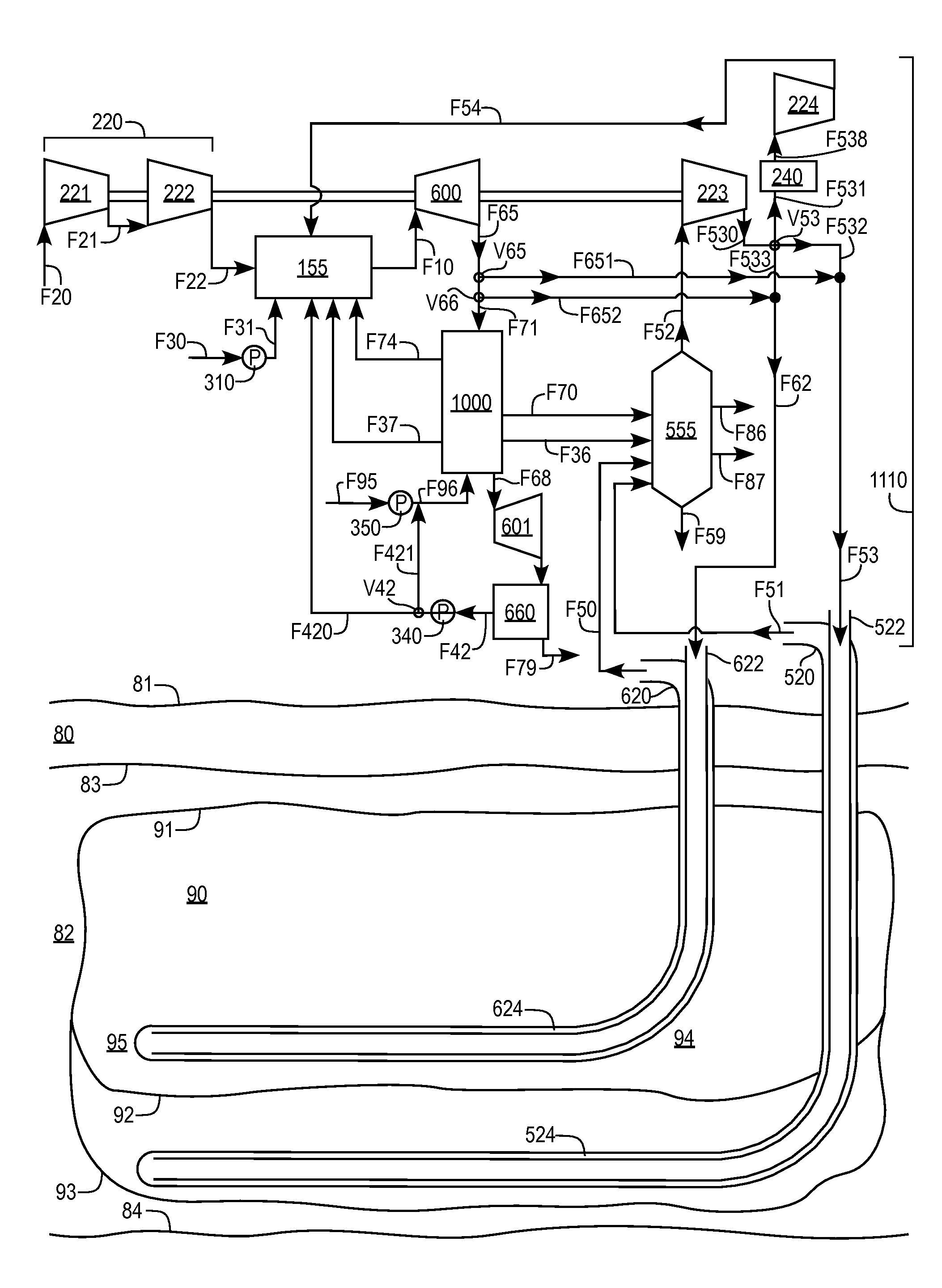

Cogeneration systems and processes for treating hydrocarbon containing formations

InactiveUS20070095536A1Thermal non-catalytic crackingCatalytic crackingElectricityNuclear engineering

A system for treating a hydrocarbon containing formation includes a steam and electricity cogeneration facility. At least one injection well is located in a first portion of the formation. The injection well provides steam from the steam and electricity cogeneration facility to the first portion of the formation. At least one production well is located in the first portion of the formation. The production well in the first portion produces first hydrocarbons. At least one electrical heater is located in a second portion of the formation. At least one of the electrical heaters is powered by electricity from the steam and electricity cogeneration facility. At least one production well is located in the second portion of the formation. The production well in the second portion produces second hydrocarbons. The steam and electricity cogeneration facility uses the first hydrocarbons and / or the second hydrocarbons to generate electricity.

Owner:SHELL OIL CO

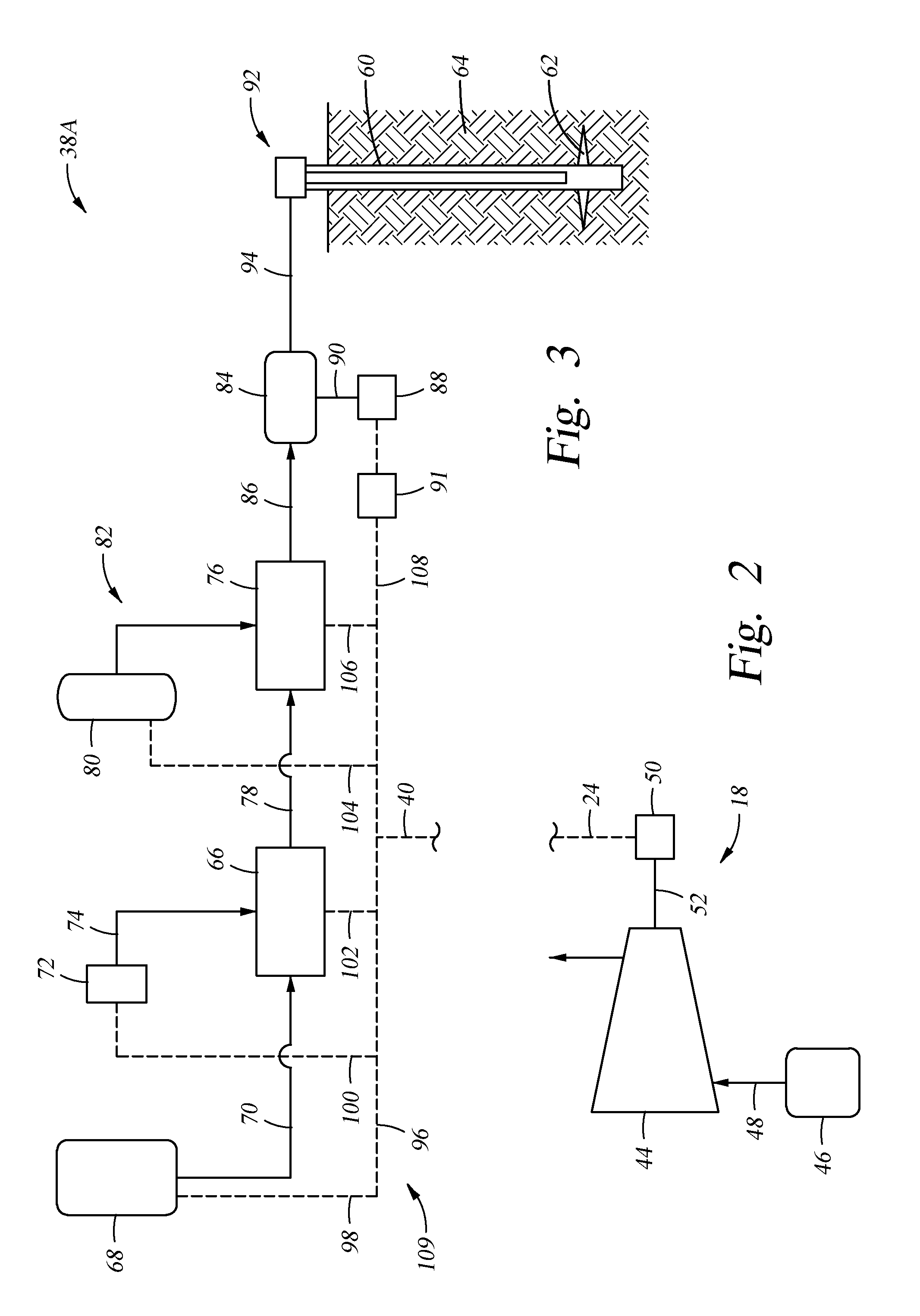

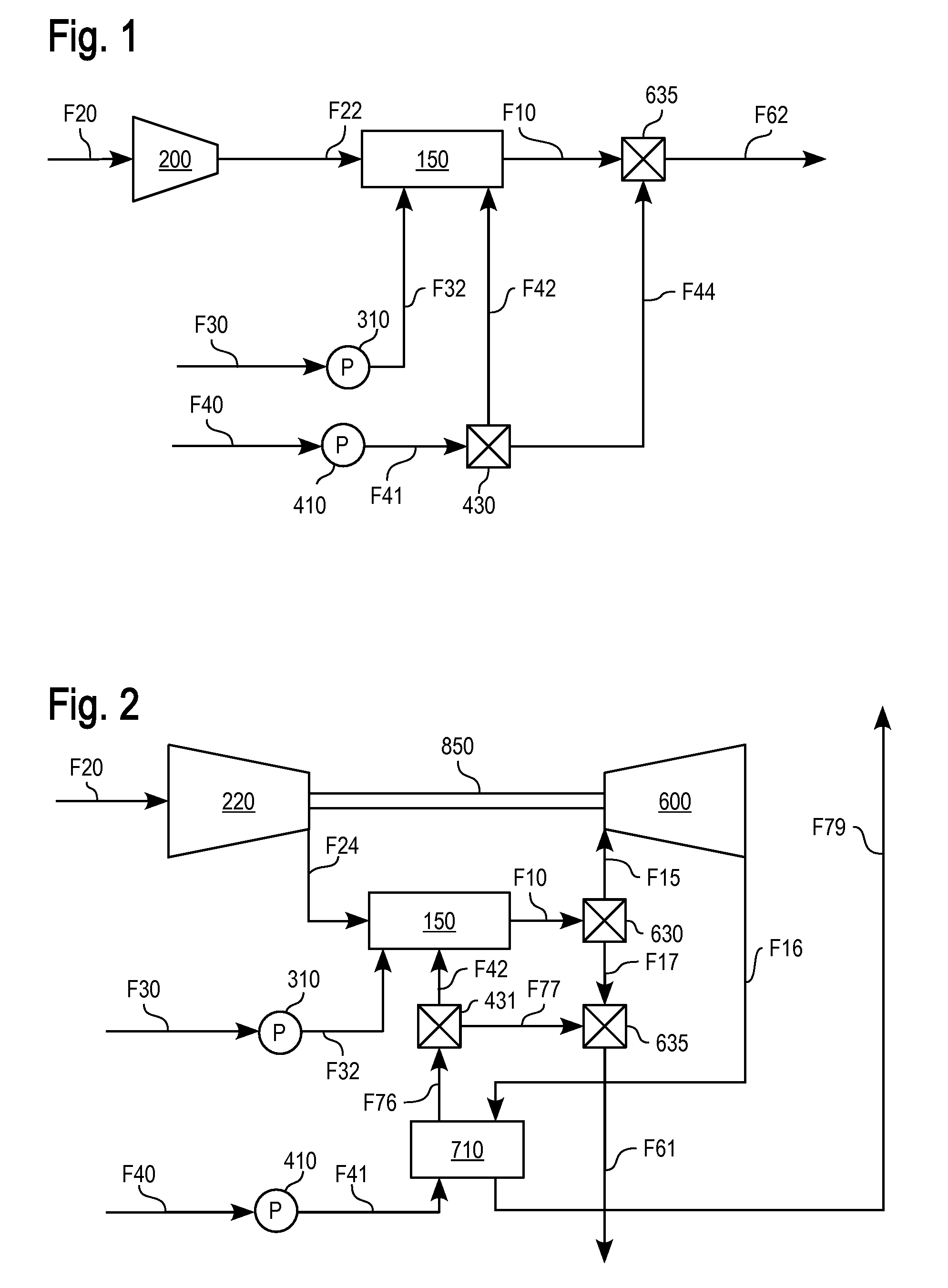

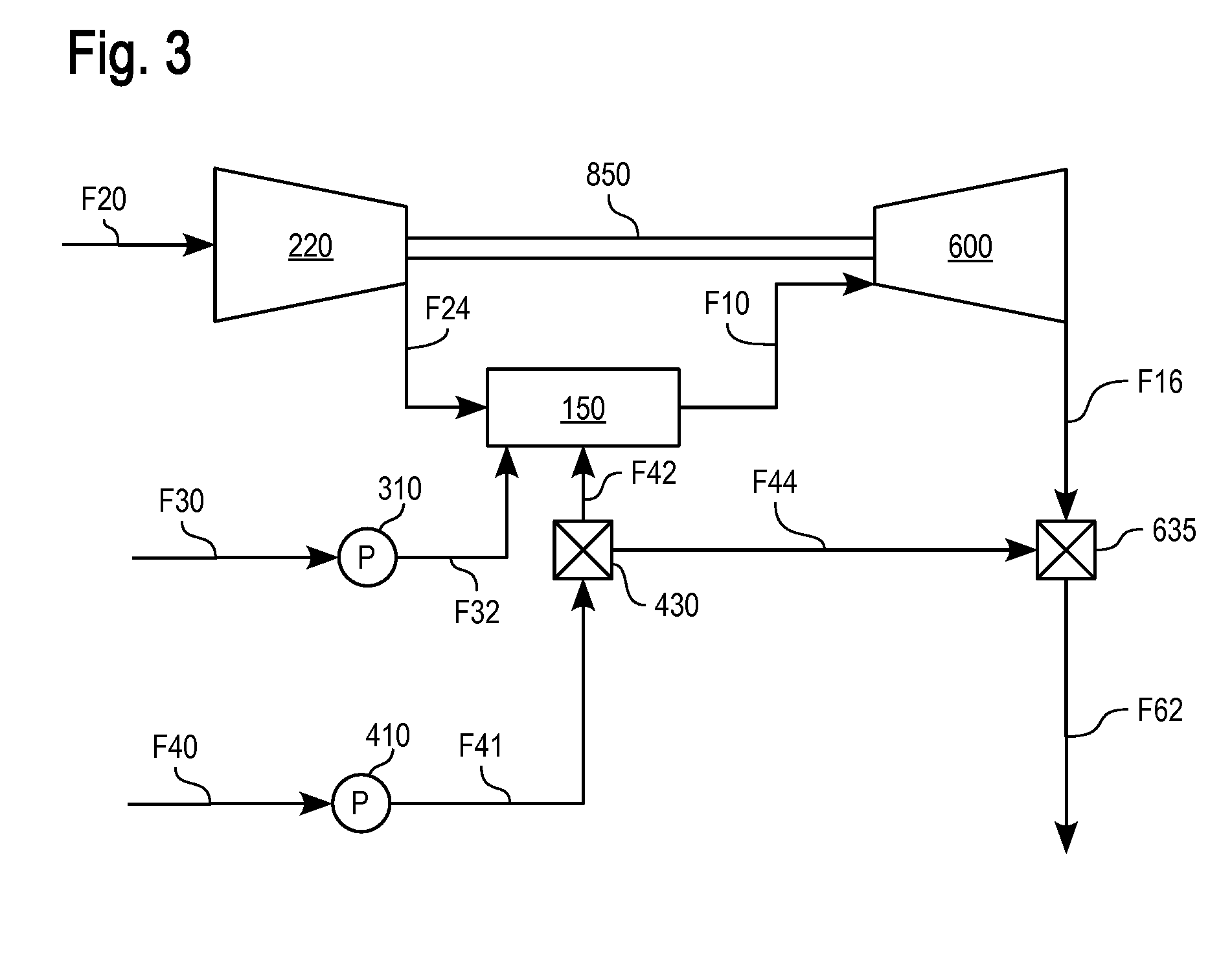

Modular remote power generation and transmission for hydraulic fracturing system

ActiveUS20160290114A1Prevent be damageAvoid damageElectric motor controlFluid removalModularityElectric generator

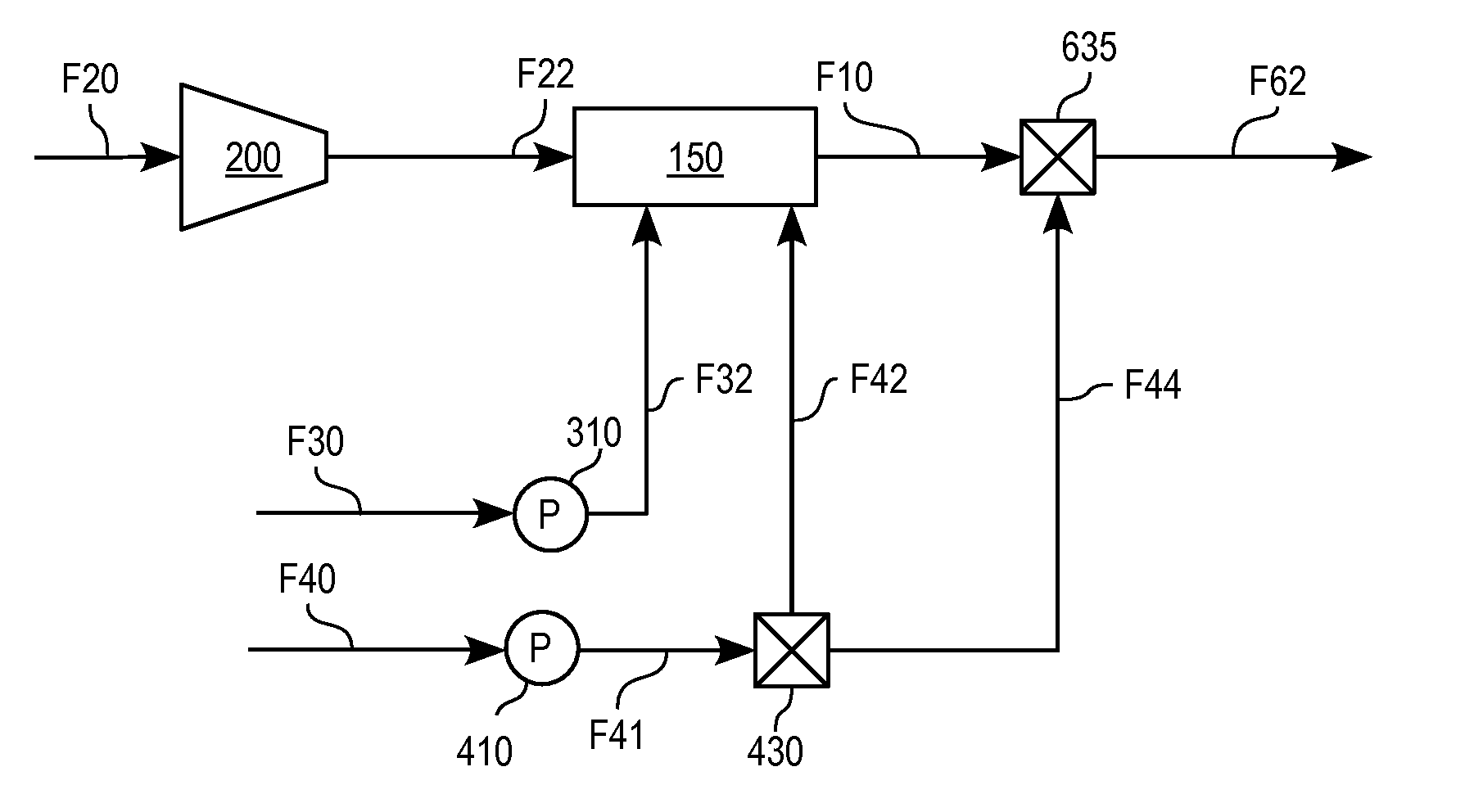

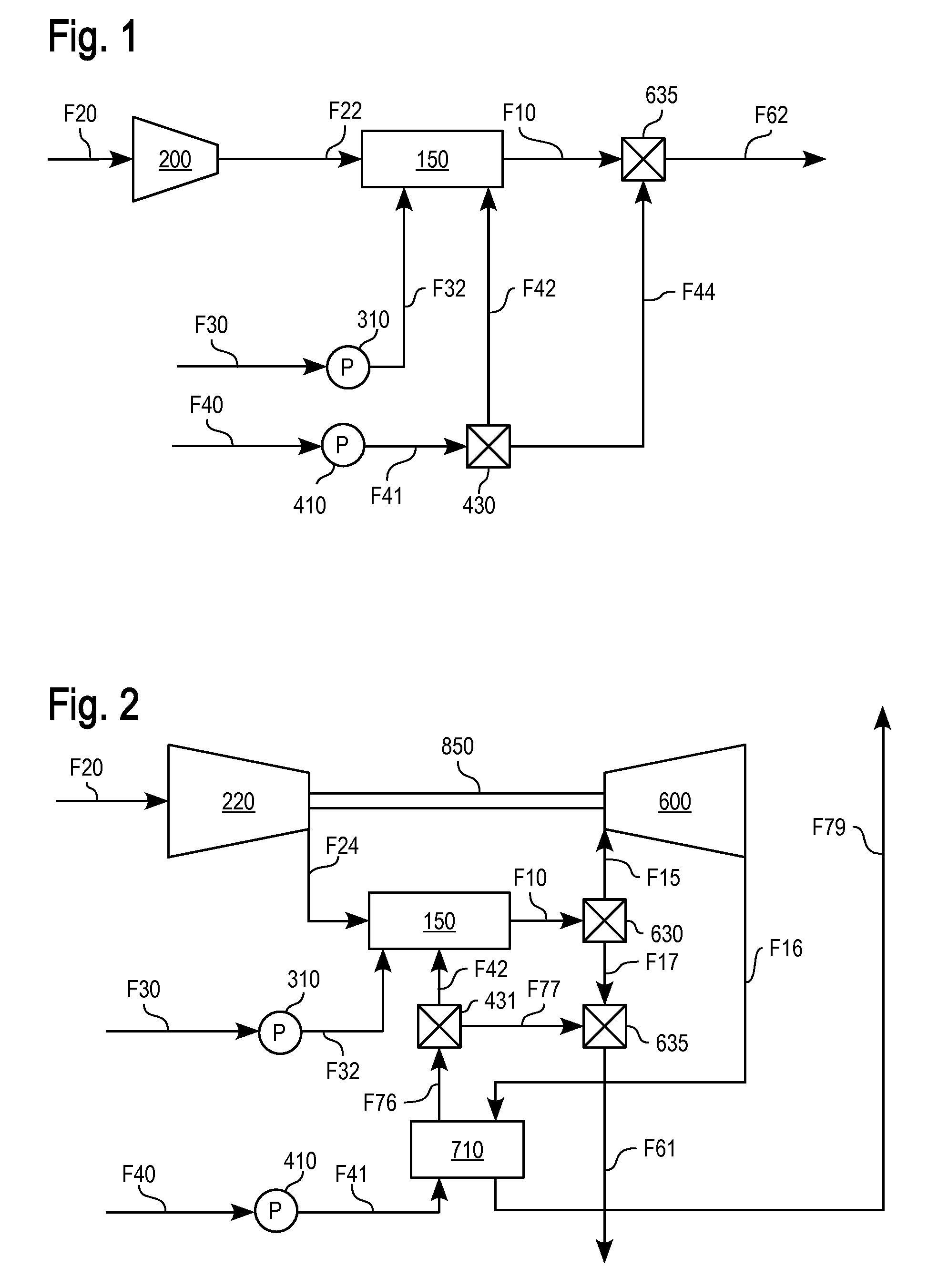

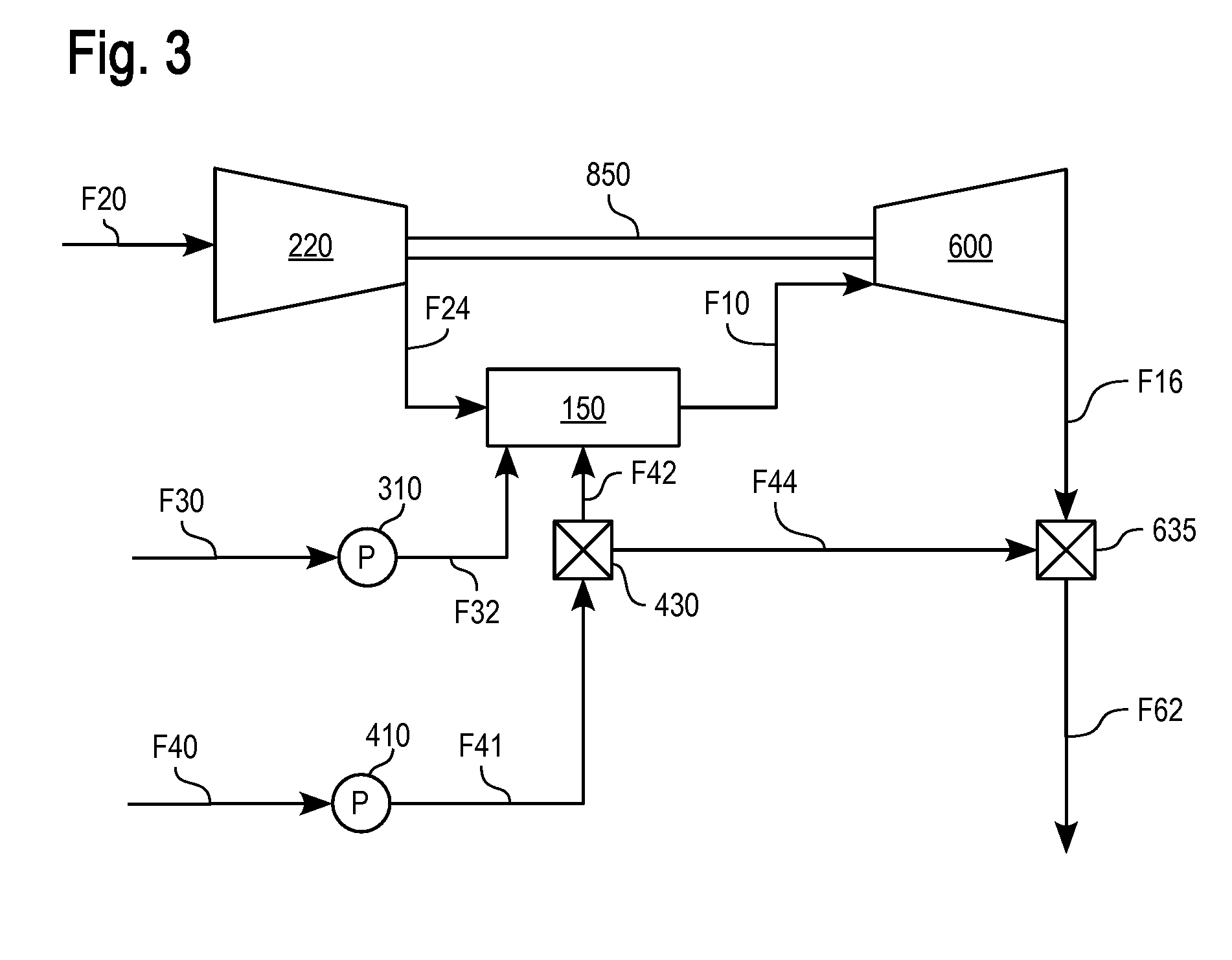

A hydraulic fracturing system for fracturing a subterranean formation includes a power generation system, a transmission section, and an equipment load section. The power generation system includes a turbine generator that generates electricity that is used to power equipment in the equipment load section. The equipment in the equipment load section conditions and pressurizes fluid that is injected into a wellbore for fracturing the formation. The power generation and equipment load sections are distal from one another are separated by a long distance. The transmission section connects the power generation and equipment load sections, and thus spans the long distance between these sections.

Owner:US WELL SERVICS LLC

SAGD-plus

A combination of SAGD with cogeneration technology for exploiting shallow heavy oil and bitumen reservoirs under primary, secondary and tertiary thermal recovery. Superheated steam is generated by the heat recovery from the exhaust of an above-ground hydrocarbon powered turbine driven electric generator cogeneration plant and is injected through well bores into the hydrocarbon bearing reservoir that is traversed by at least one horizontal producing well bore and one injection well bore to heat the reservoir formation and to induce gravity drainage of the hydrocarbons and allowing their recovery from the horizontal producing well bore. Electrical power that is generated is sold to the electric grid and can be used to offset the fuel costs for the above ground hydrocarbon turbine-driven elector generators.

Owner:BABCOCK JOHN A

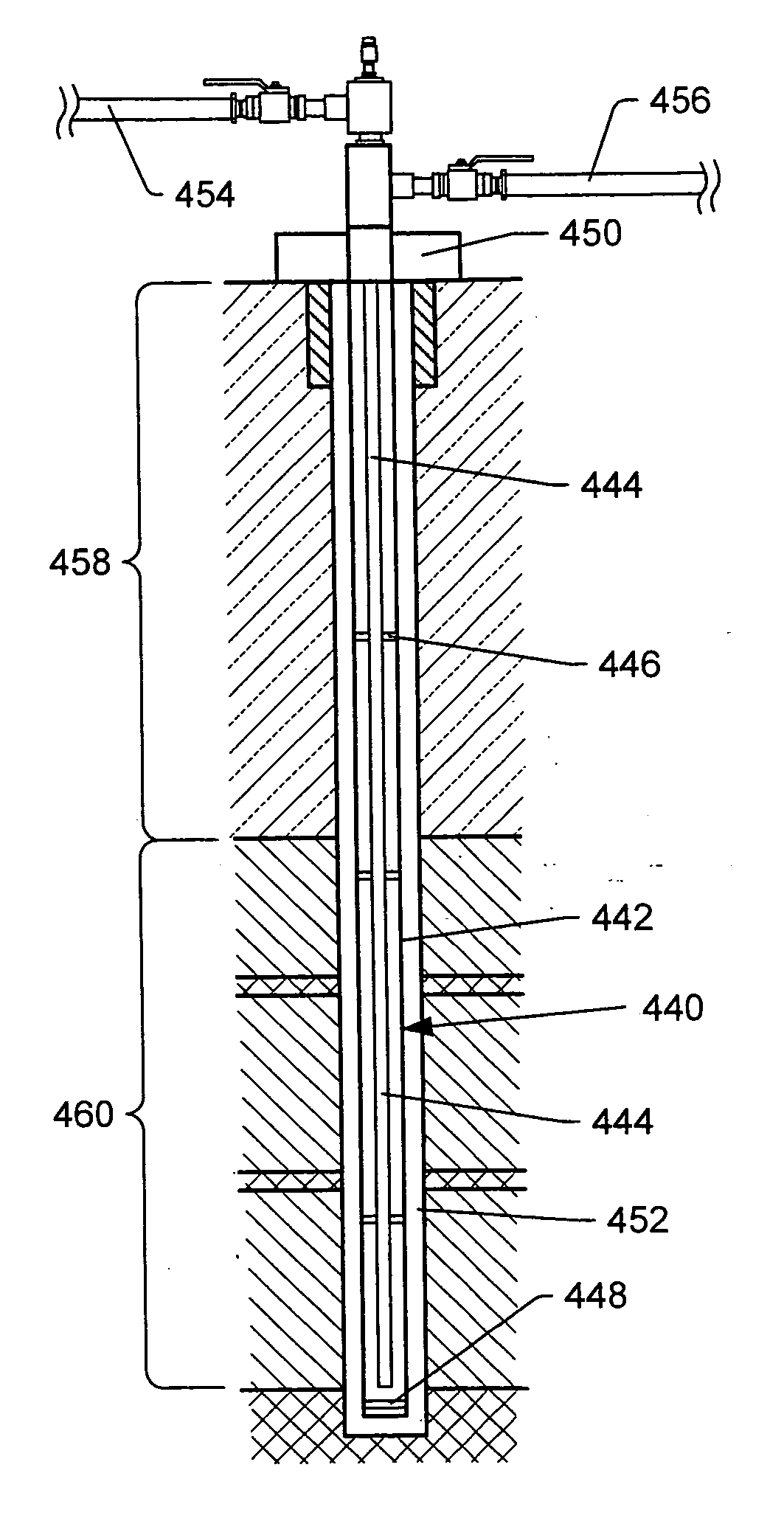

Method For Completing Injection Wells

InactiveUS20040014606A1Reducing surface storage capacity requirementEliminate needCleaning apparatusFluid removalEngineeringWater well

This invention proposes a method for completing an interval of an open-hole injection wellbore penetrating a subterranean formation, said wellbore being communicating with the formation by way of an interface that comprises at least a filter cake invaded zone comprising bridging materials and other embedded solid materials, said method comprising the steps of injecting a clean-up fluid and contacting it with the filtercake for a period of time sufficient to loose some of the other solids embedded in the filter cake; removing the loosened solids by a high-rate displacement fluid comprising suspending additives; and then injecting a dissolving fluid comprising a diverter and an effective amount of a salt or acid capable of dissolving the bridging material.

Owner:SCHLUMBERGER TECH CORP

Monitoring of Downhole Parameters and Tools Utilizing Fiber Optics

The present disclosure provides systems utilizing fiber optics for monitoring downhole parameters and the operation and conditions of downhole tools and controlling injection operations based on measurements in an injection well and / or a production well.

Owner:BAKER HUGHES INC

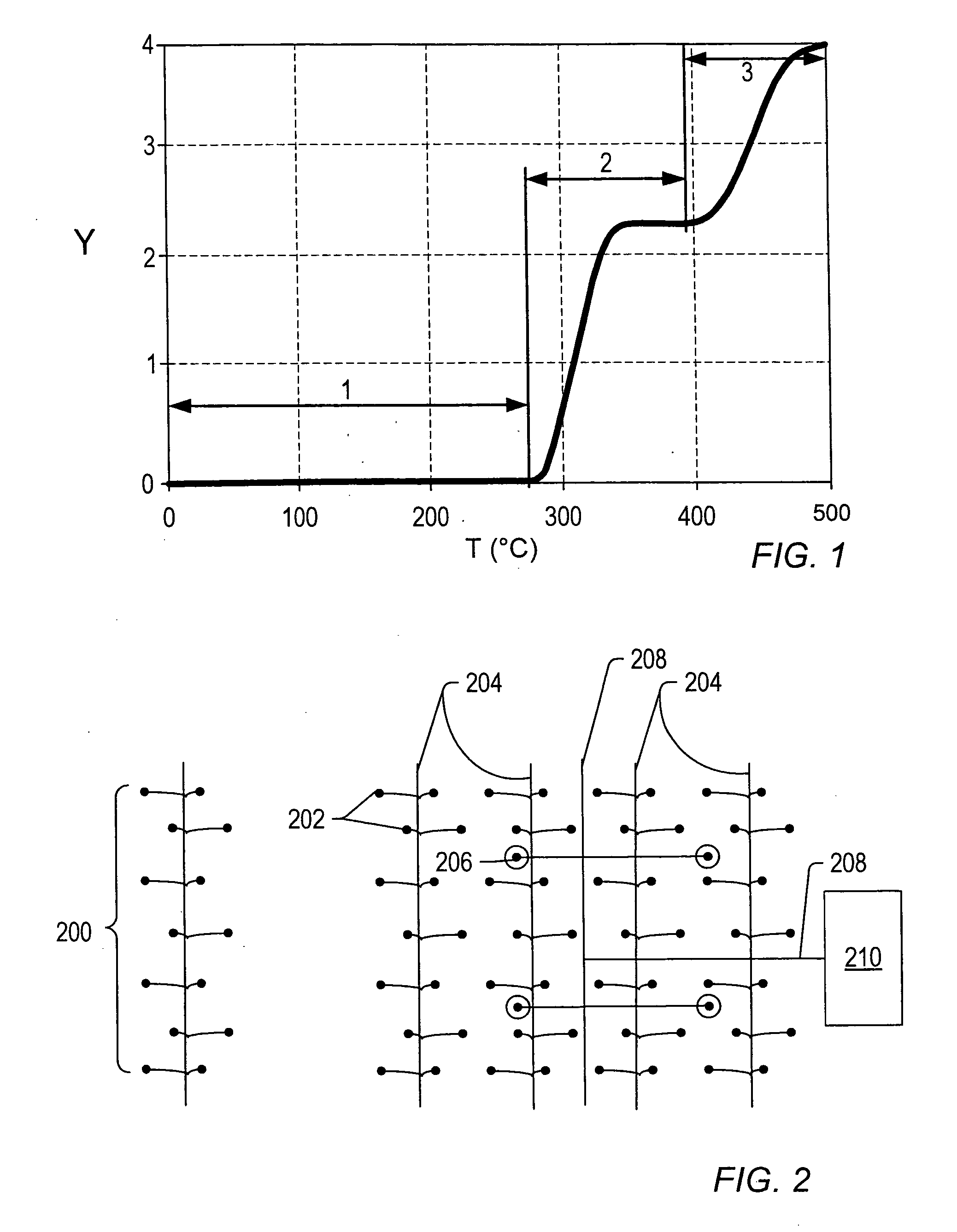

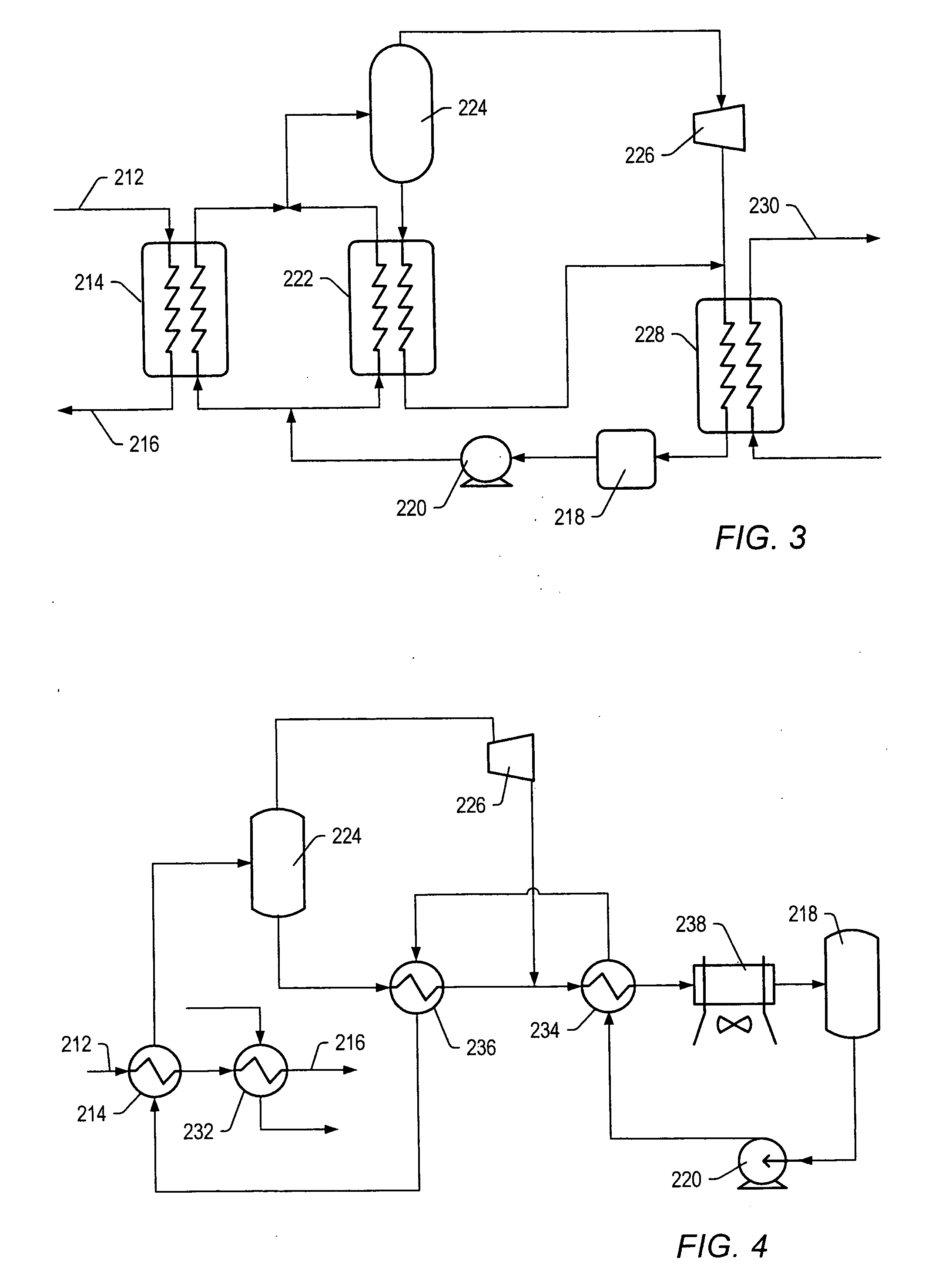

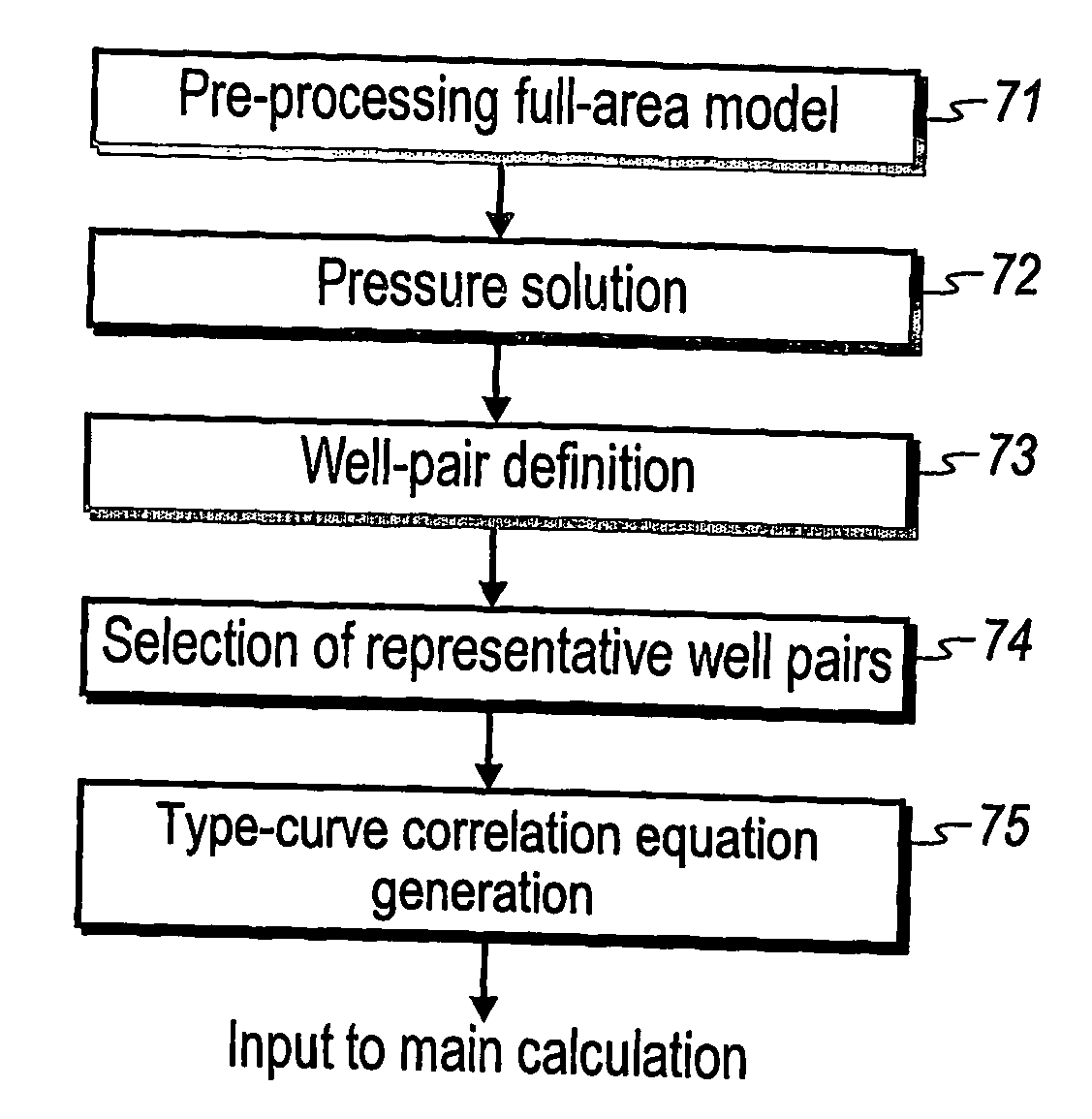

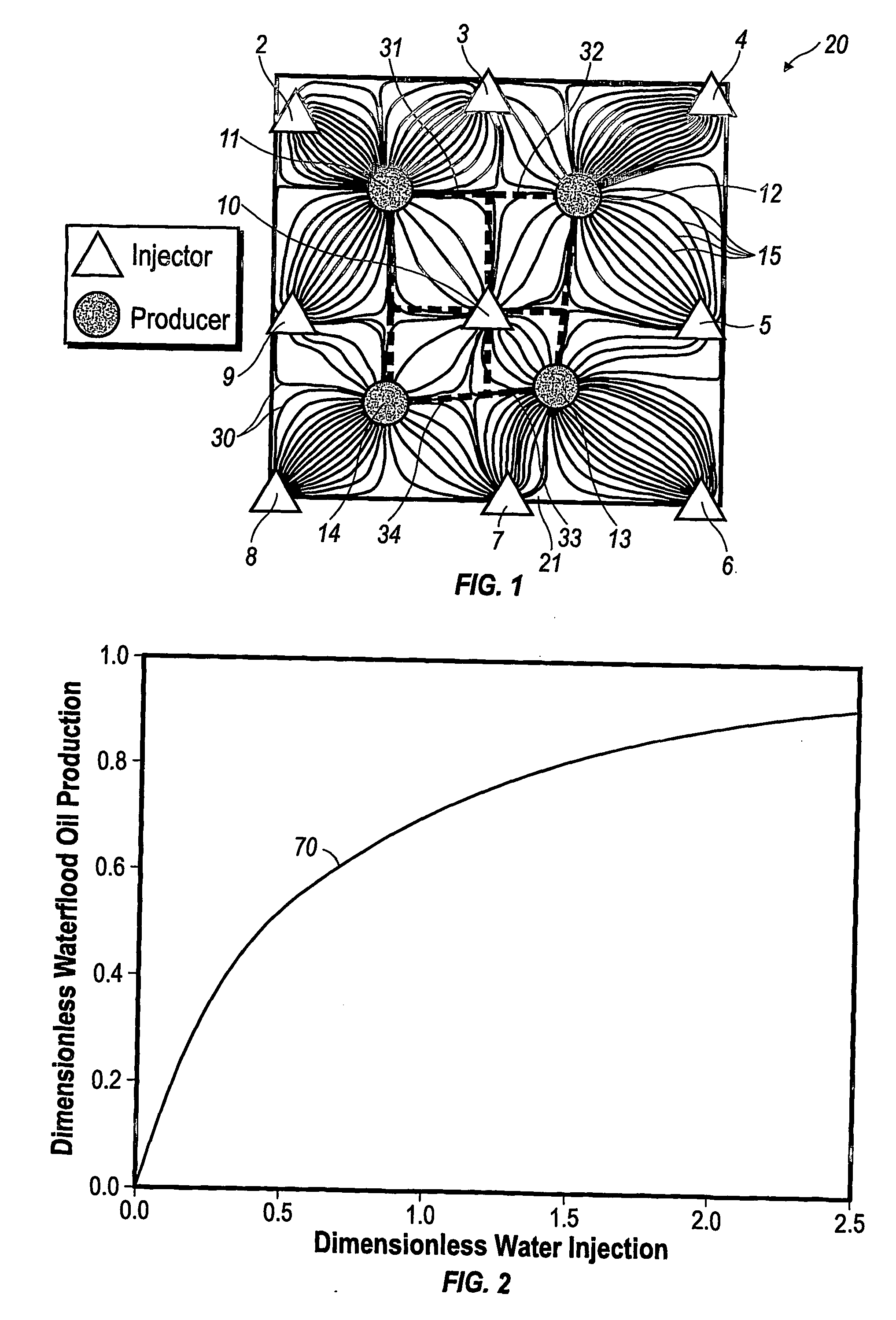

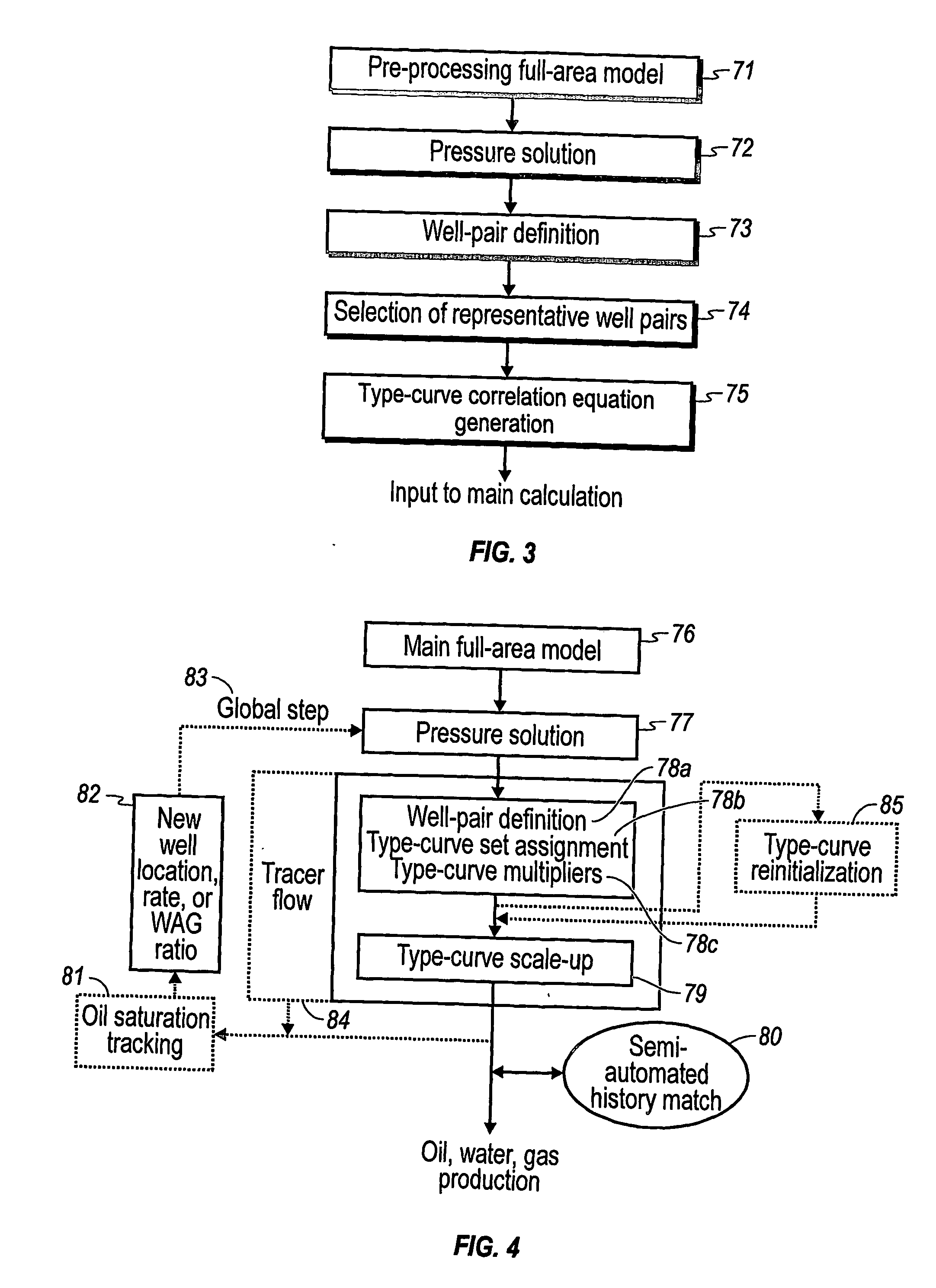

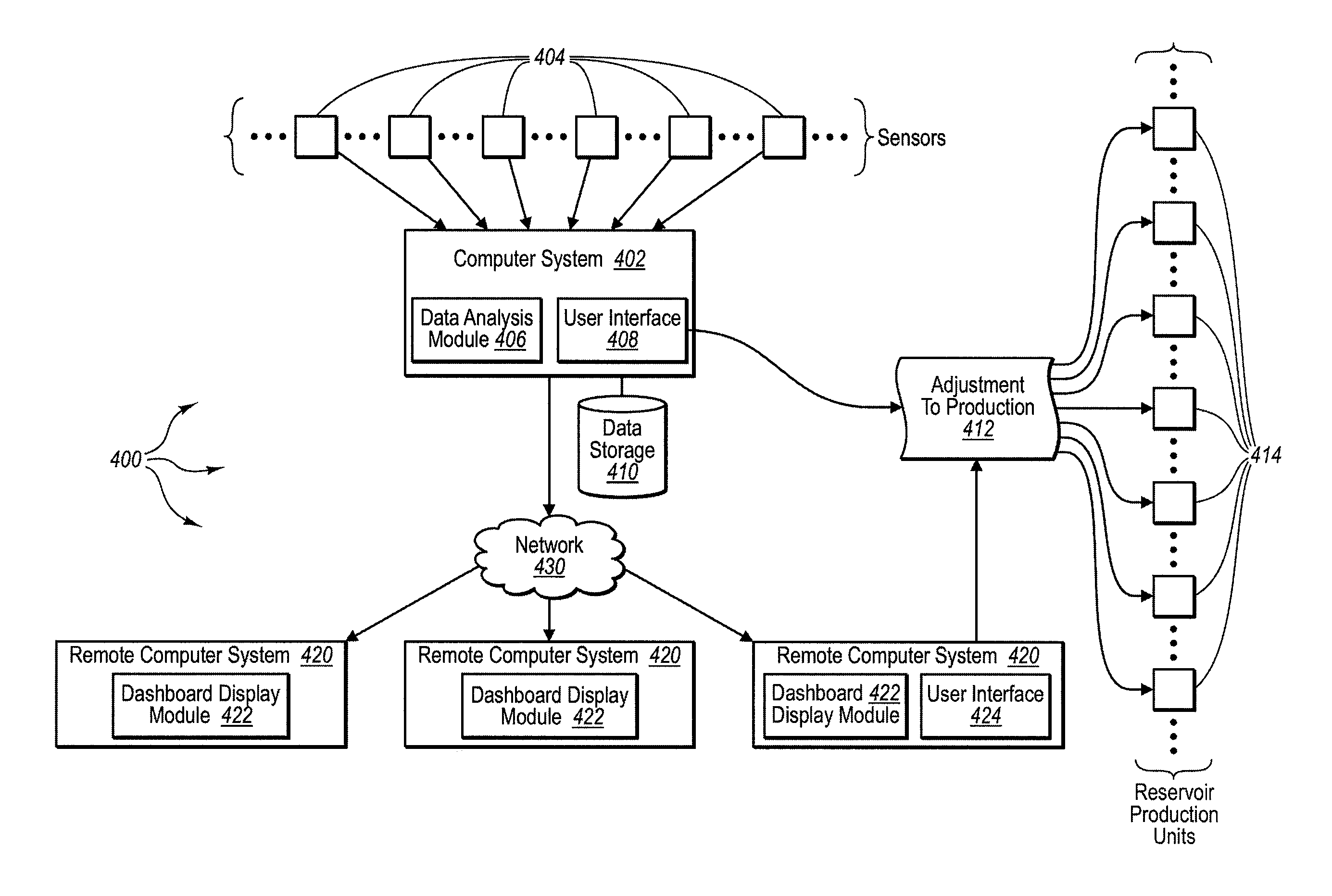

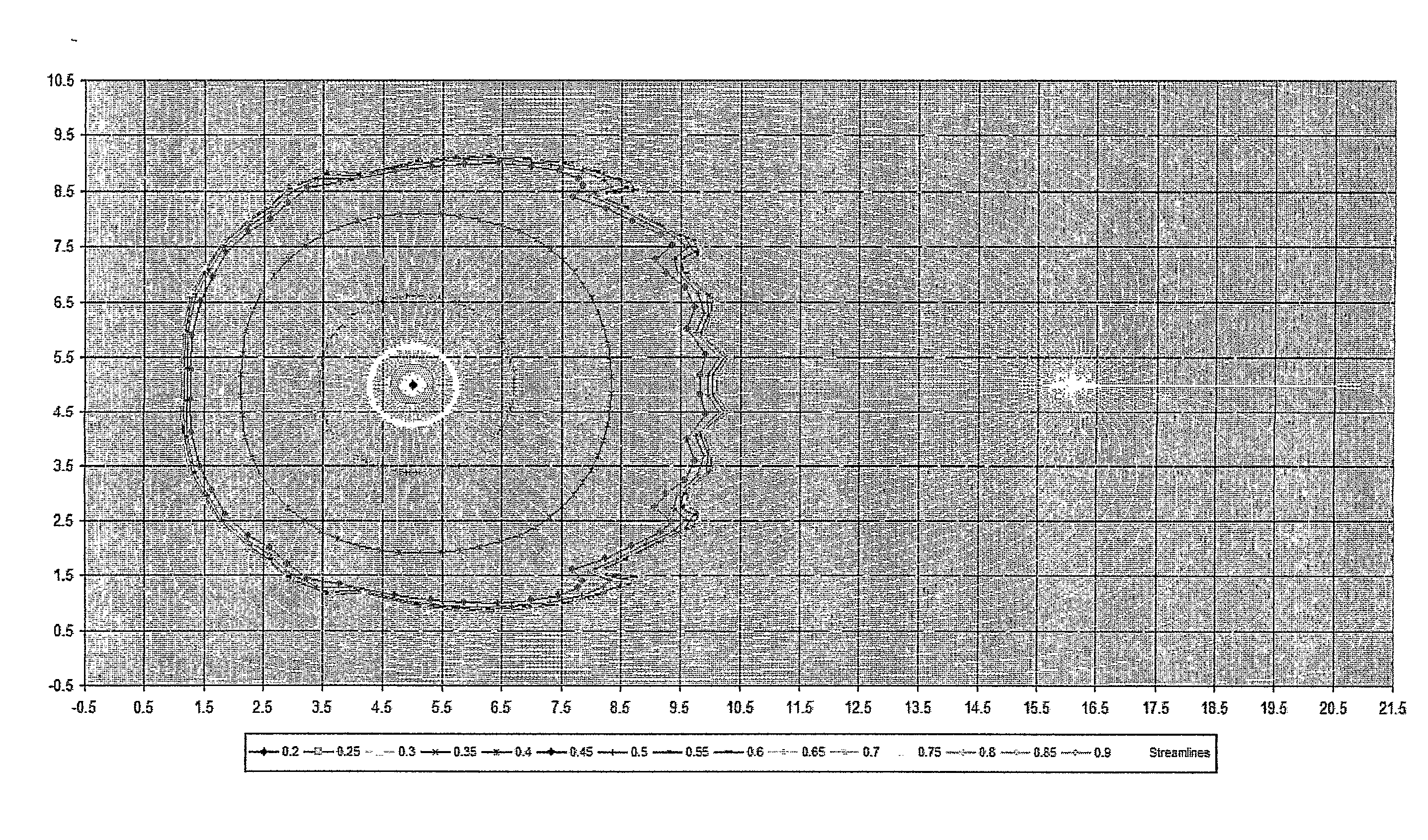

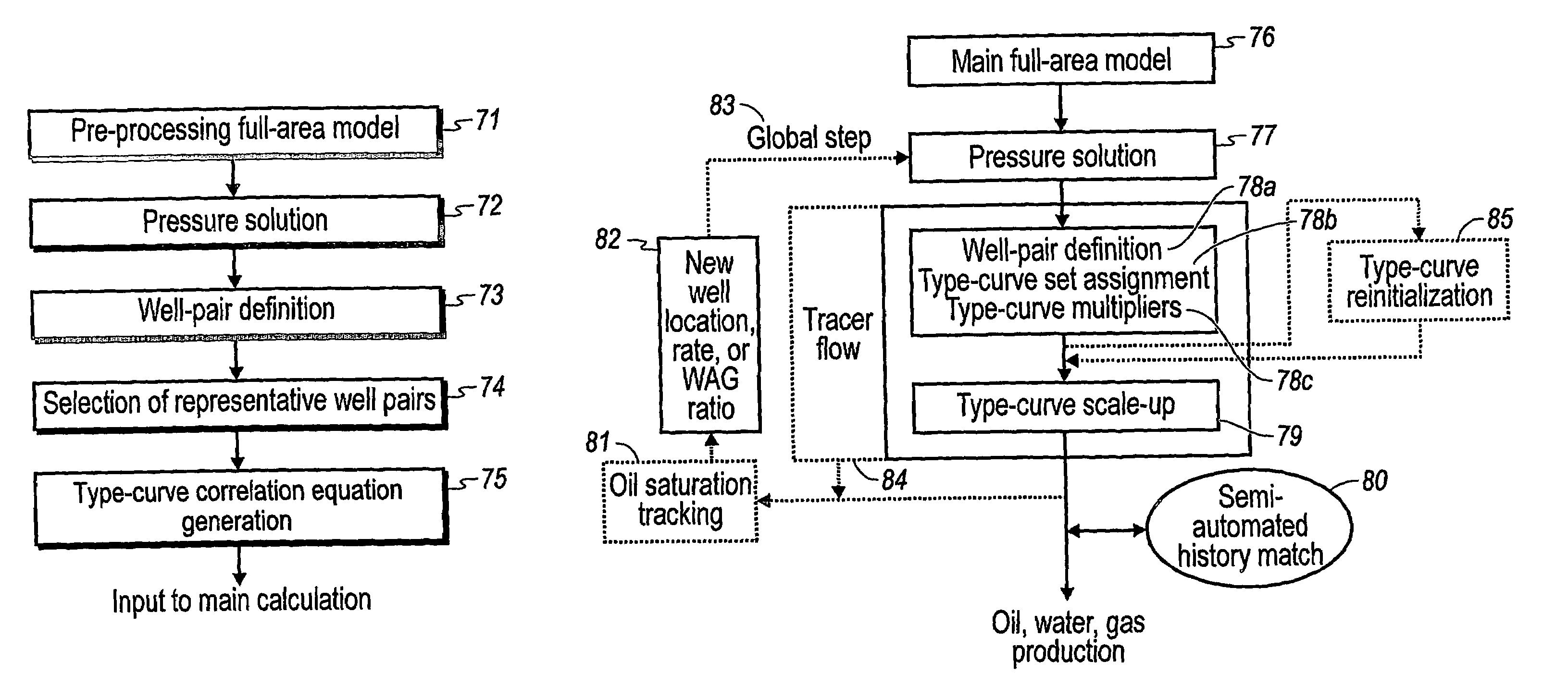

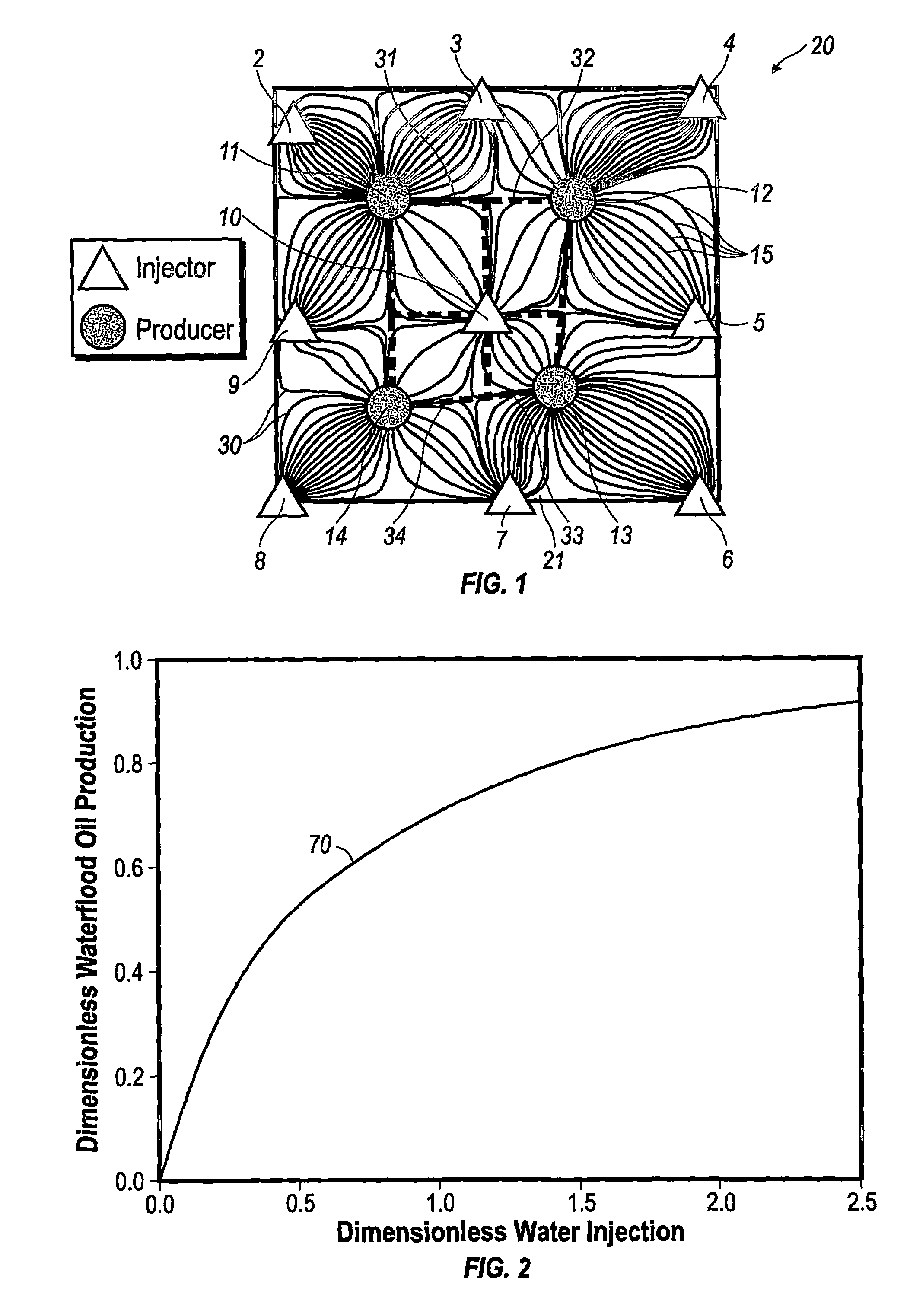

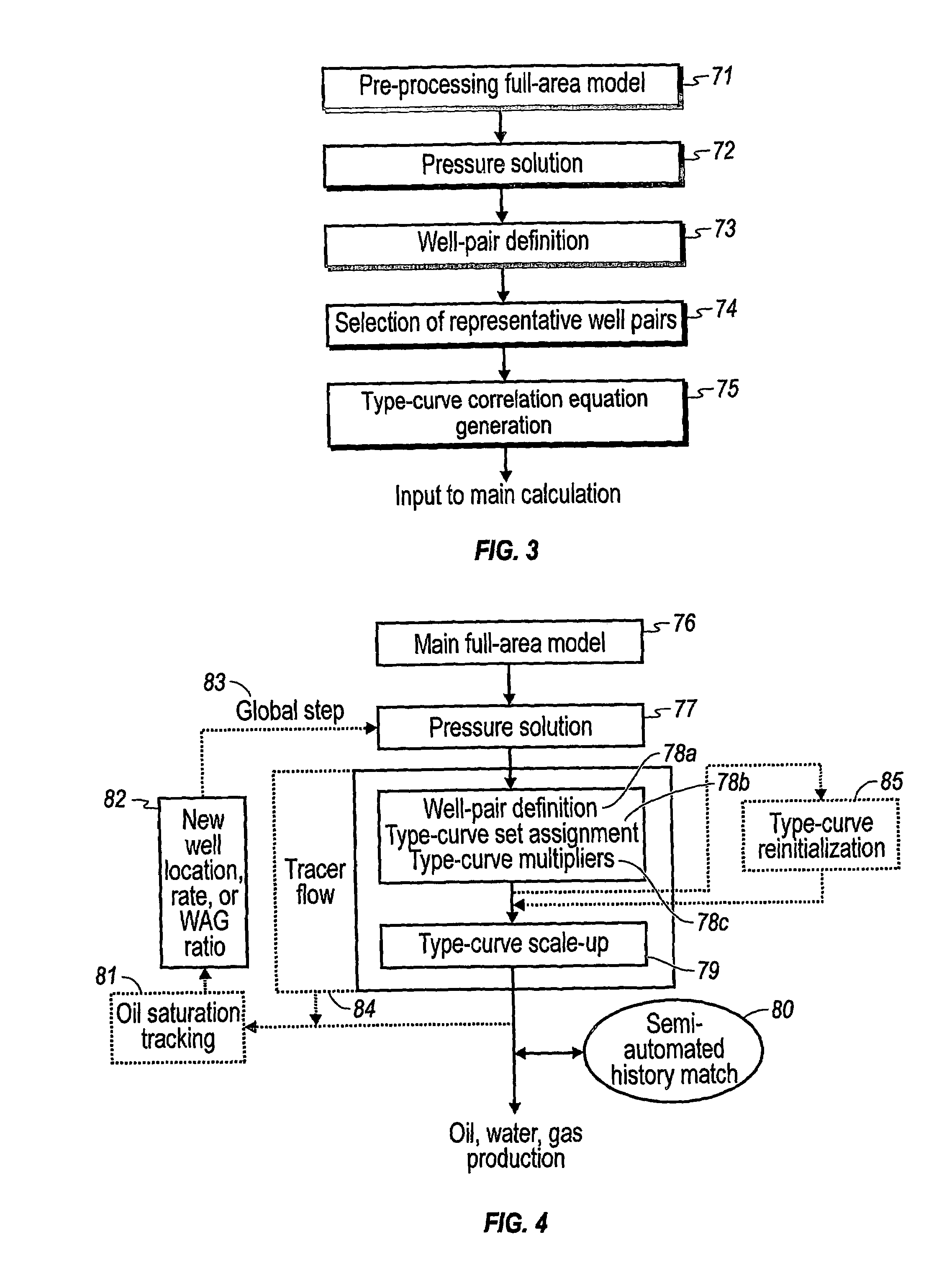

Performance prediction method for hydrocarbon recovery processes

The invention relates to a method for predicting the performance of large-scale hydrocarbon-bearing reservoir floods. One embodiment of the invention includes a method for predicting performance of a patterned flooding process in a subterranean hydrocarbon-bearing formation, said formation being penetrated by a plurality of injector wells and producer wells, comprising the steps of: determining flow-based pairs of injector to producer wells [FIG. 4, item 78a] (first well pairs) using a geological model [item 76]; developing a connective pore volume distribution curve for each first well pair item [78b]; selecting at least two first well pairs (selected well pairs) that reflect narrow and wide connective pore volume distributions that correspond to high and lower oil recovery levels; developing a 3-D simulation model for each selected well pair, performing a reservoir simulation for each selected well pair for the corresponding flooding process; and generating prototype performance curves for each selected well pair. An alternate embodiment of the invention includes a method for predicting the performance of large-scale hydrocarbon-bearing reservoir floods where injection well location, production well location, a process parameter, or a well processing rate is modified.

Owner:EXXONMOBIL UPSTREAM RES CO

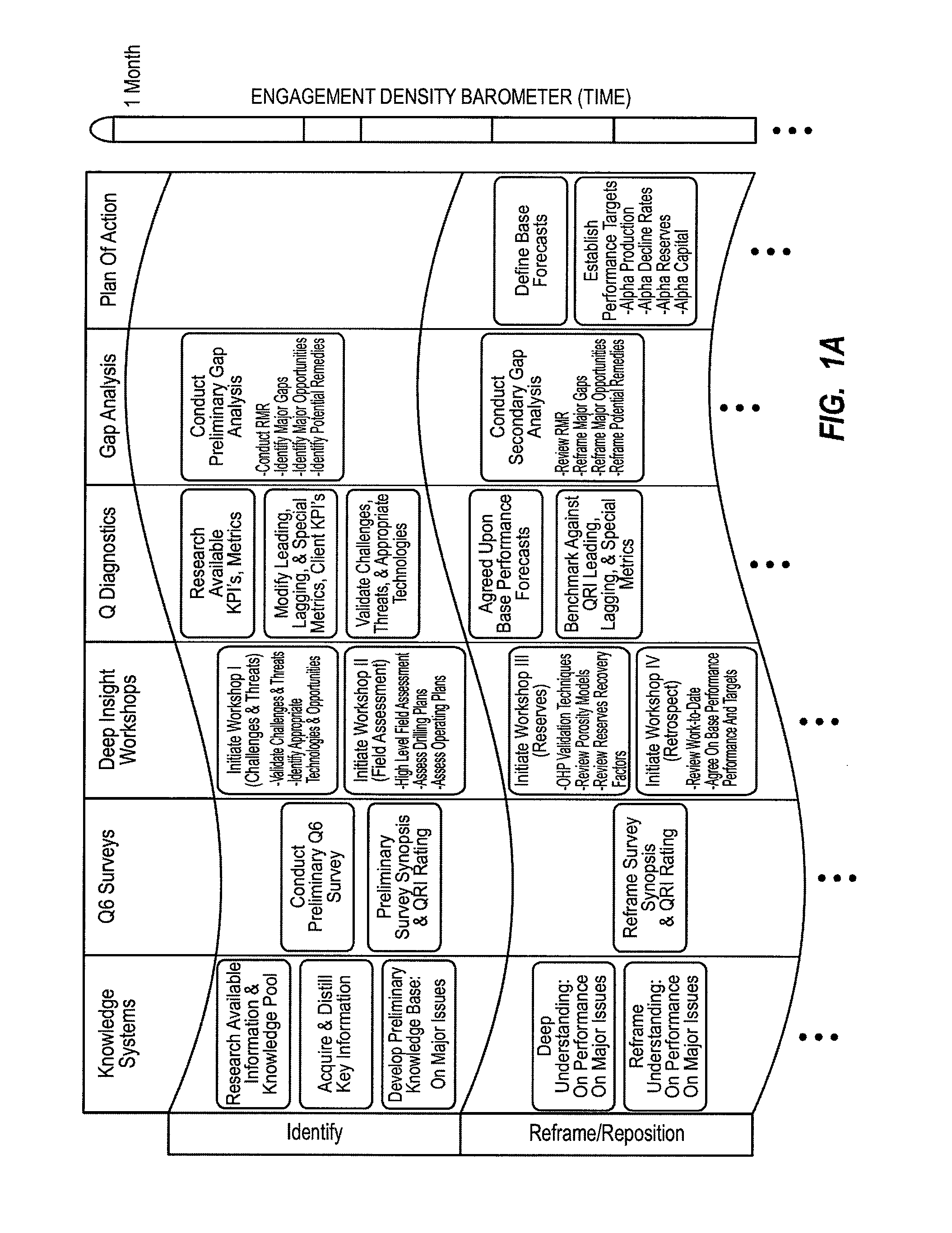

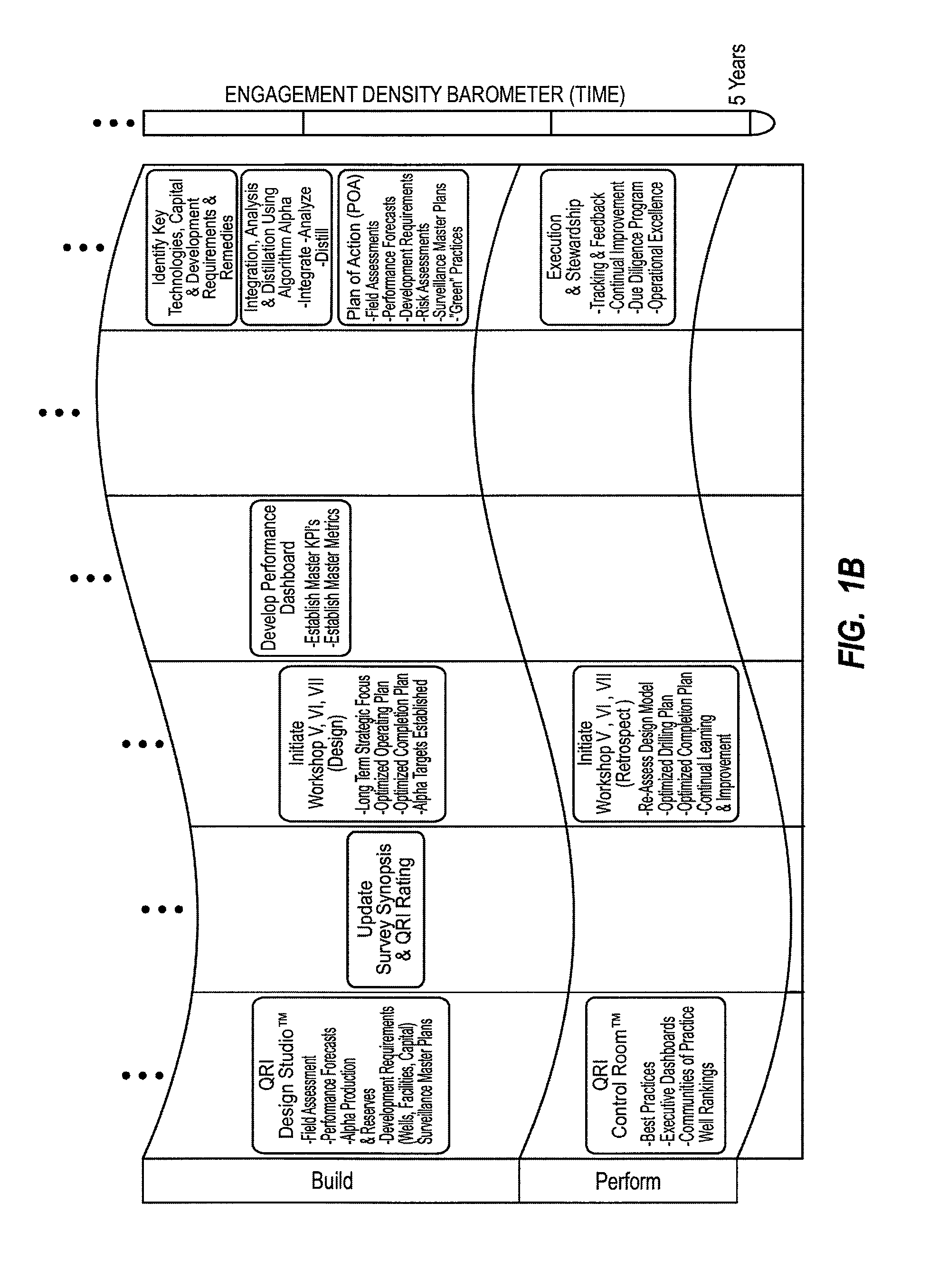

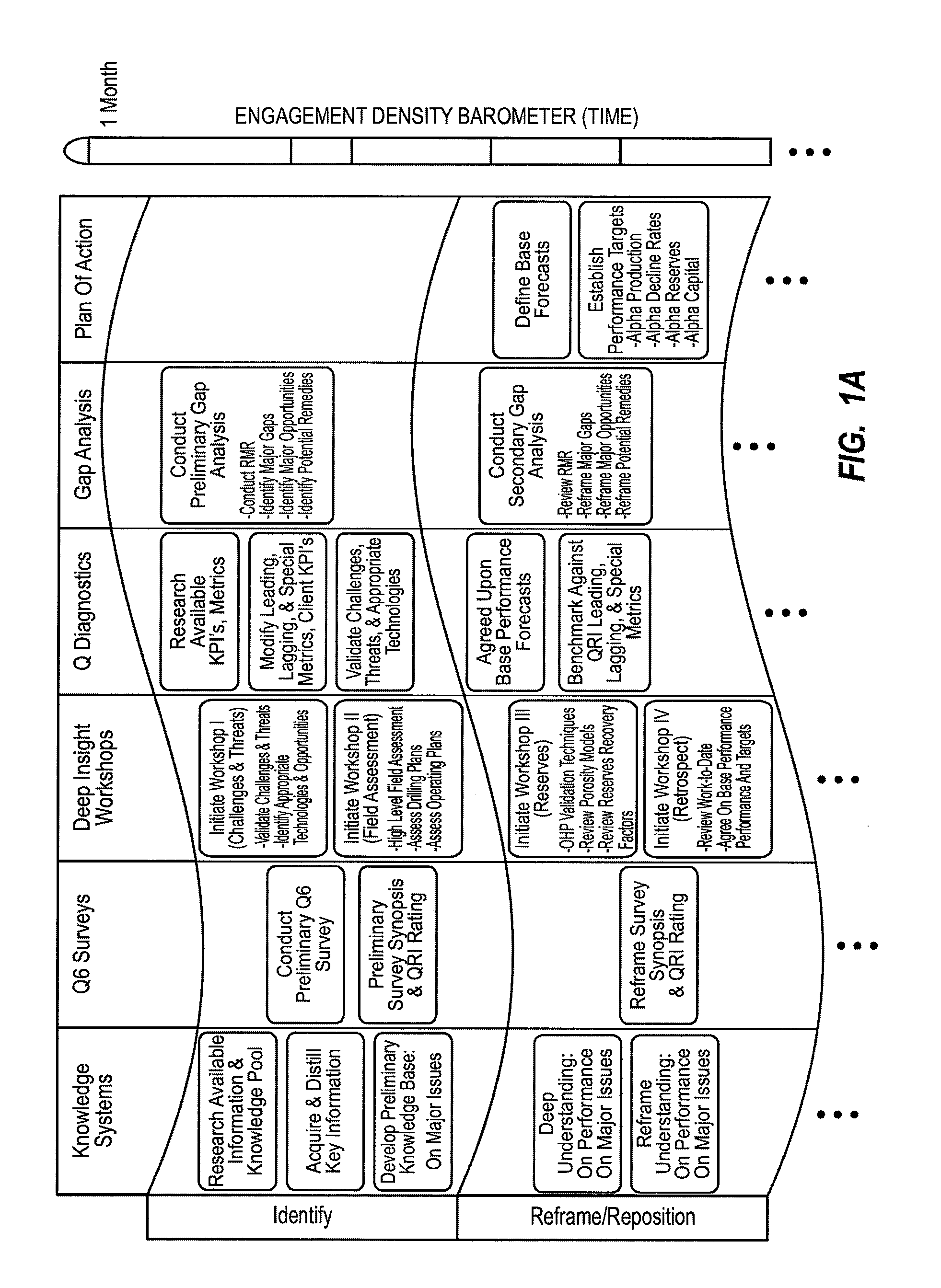

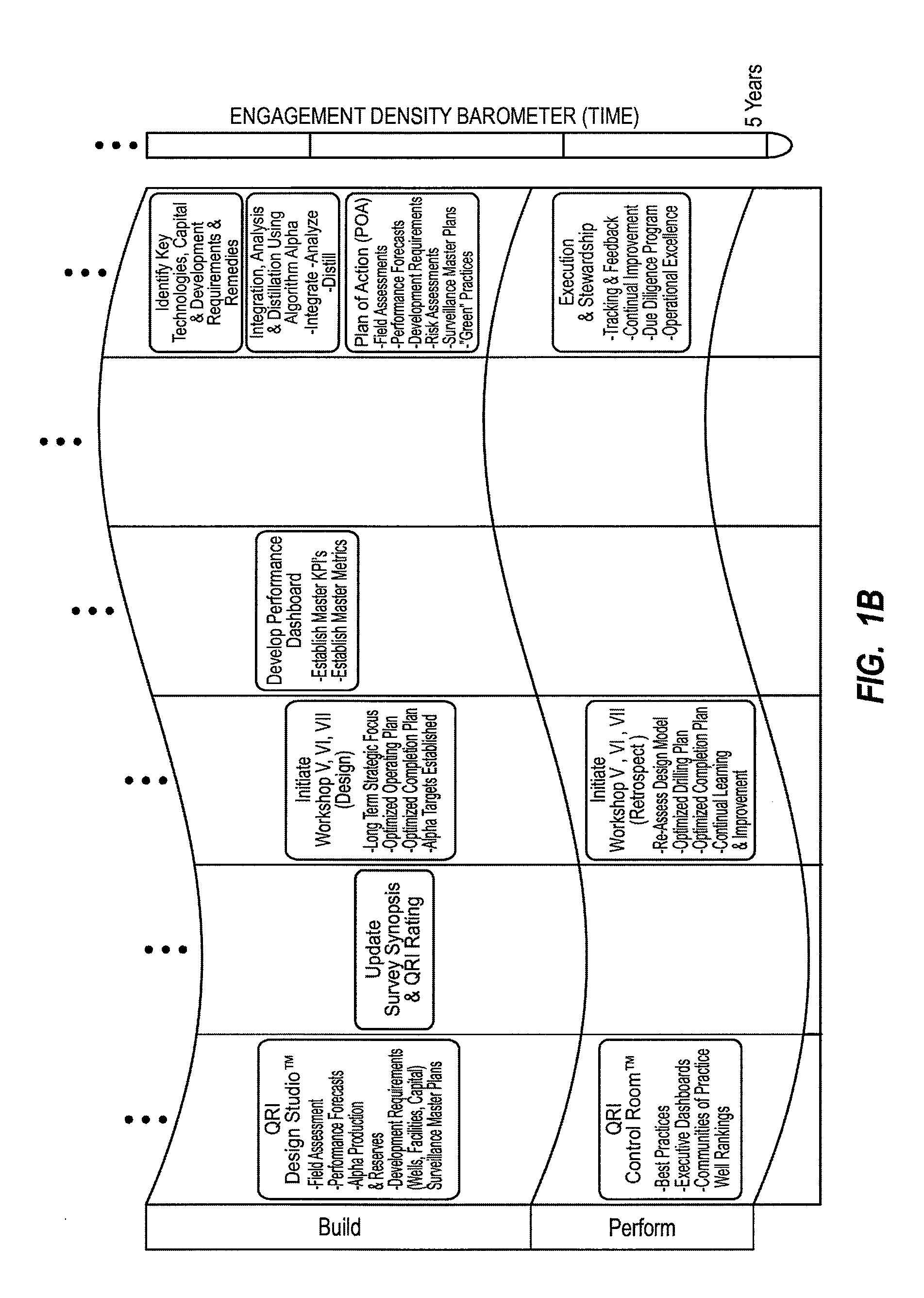

Method for dynamically assessing petroleum reservoir competency and increasing production and recovery through asymmetric analysis of performance metrics

InactiveUS7963327B1Increase short-term production rate and long-term recoveryAccurate assessmentElectric/magnetic detection for well-loggingSurveyProcess engineeringPetroleum reservoir

Methods for accurately assessing the condition of a petroleum reservoir and designing and implementing a plan of action to increase production and recovery of petroleum from the reservoir. Information is gathered using a unique set of metrics and information gathering techniques and analyzed in a targeted fashion by properly weighting the data in the context of the particular reservoir and goals of the producer. A reservoir rating is generated using asymmetric analysis of metrics and then used to formulate a plan of action. Production architecture (e.g., number, location and manner of constructing oil and injector wells) is then constructed according to the plan of action. Reservoir performance can be continuously monitored and used to verify production and recovery goals and / or provide triggers or alarms to alter production equipment.

Owner:QRI GROUP

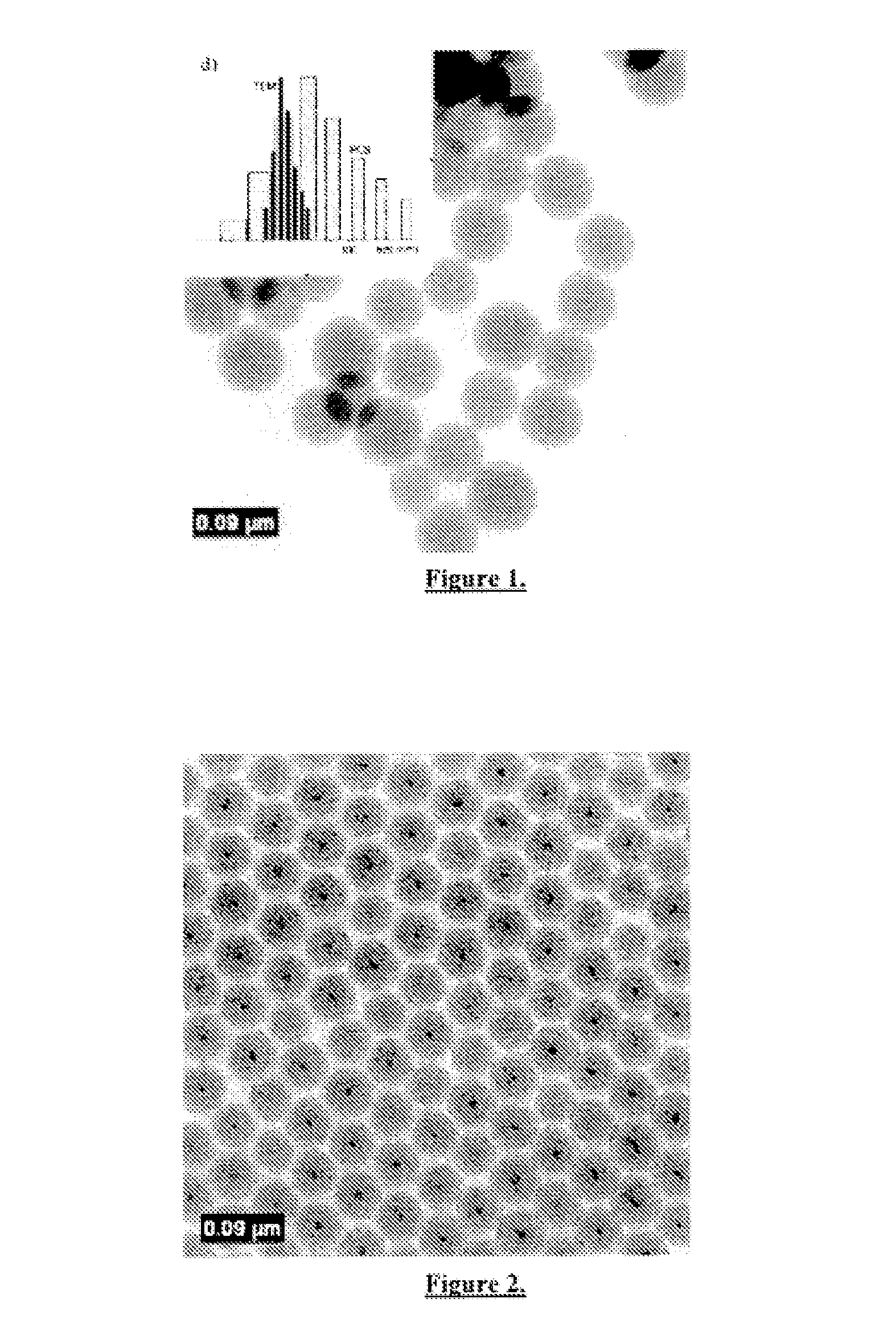

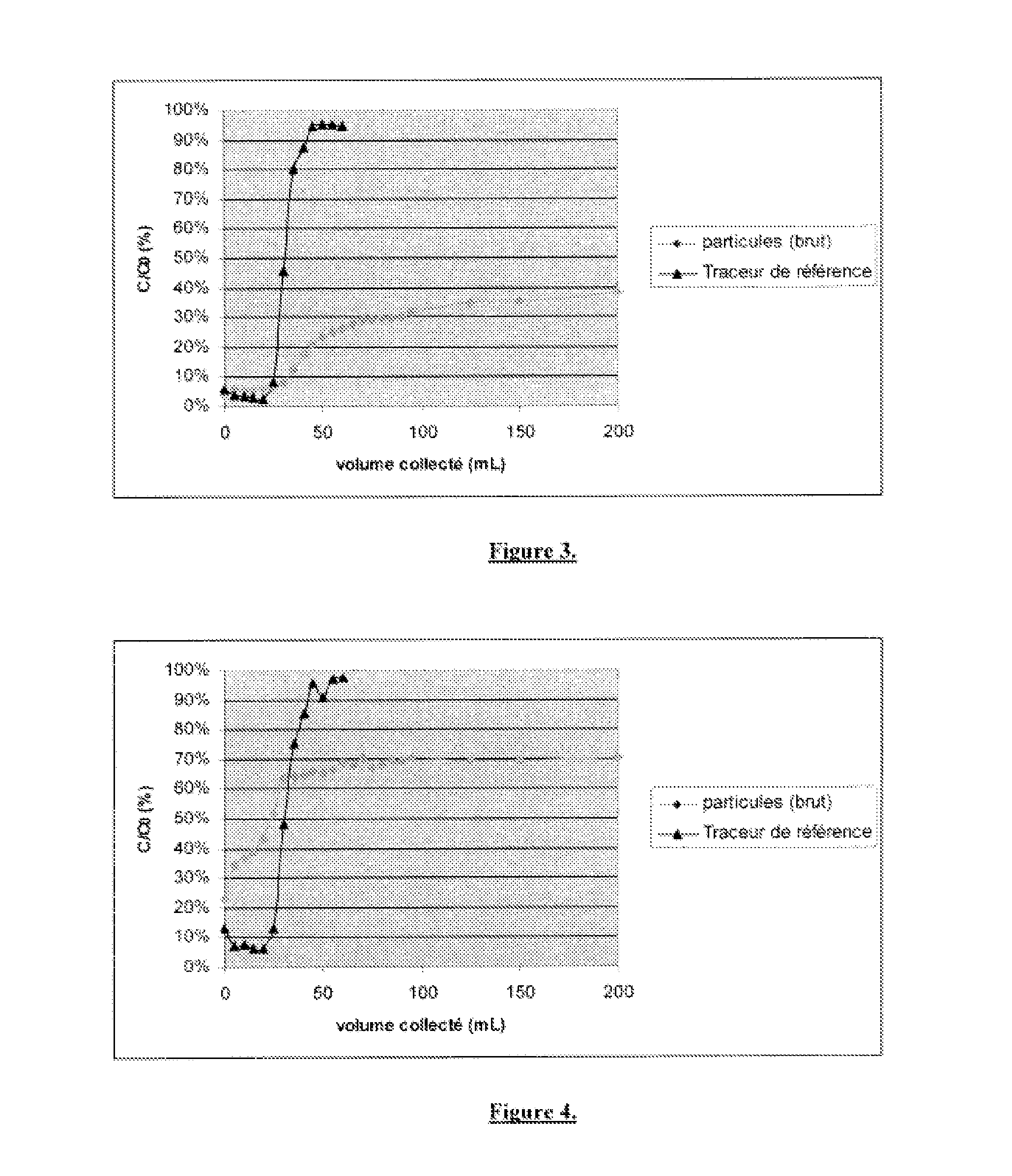

Use of nanoparticles for labelling oil field injection waters

InactiveUS20130084643A1Effective sizeEasy to implementOptical radiation measurementSurveyInjection wellOrganosilicon

The present invention relates to the development of tracer fluids, more generally, that of aqueous liquids, intended to be injected under pressure in an oil reservoir, for example from an injection well up to a production well.The object of the invention is to propose a new method of study of a solid medium, i.e. an oil reservoir, by diffusion of a liquid (i.e. injection waters) containing tracers, through said solid medium, which is simple to implement and economical and which remedies the drawbacks of the known tracers for injection waters of oil reservoirs.This method essentially consisting of injecting, in this solid medium, an injection liquid comprising a nanoparticle-based tracer having average dimensions comprised between 20 and 200 nm, detectable by means of one or several S signals at dilutions of less than or equal to 10−7, adapted to form a stable colloidal suspension in a saline medium, at least a portion of which is constituted of a core and a coating provided with an adjustable hydrophilic-lipophilic balance (HLB) and comprising at least one organic and / or organosilicon component; recovering the liquid having diffused; and analyzing this liquid having diffused to measure the quantity of tracer by detection of the signal or signals S.

Owner:TOTAL PUTEAUX FR

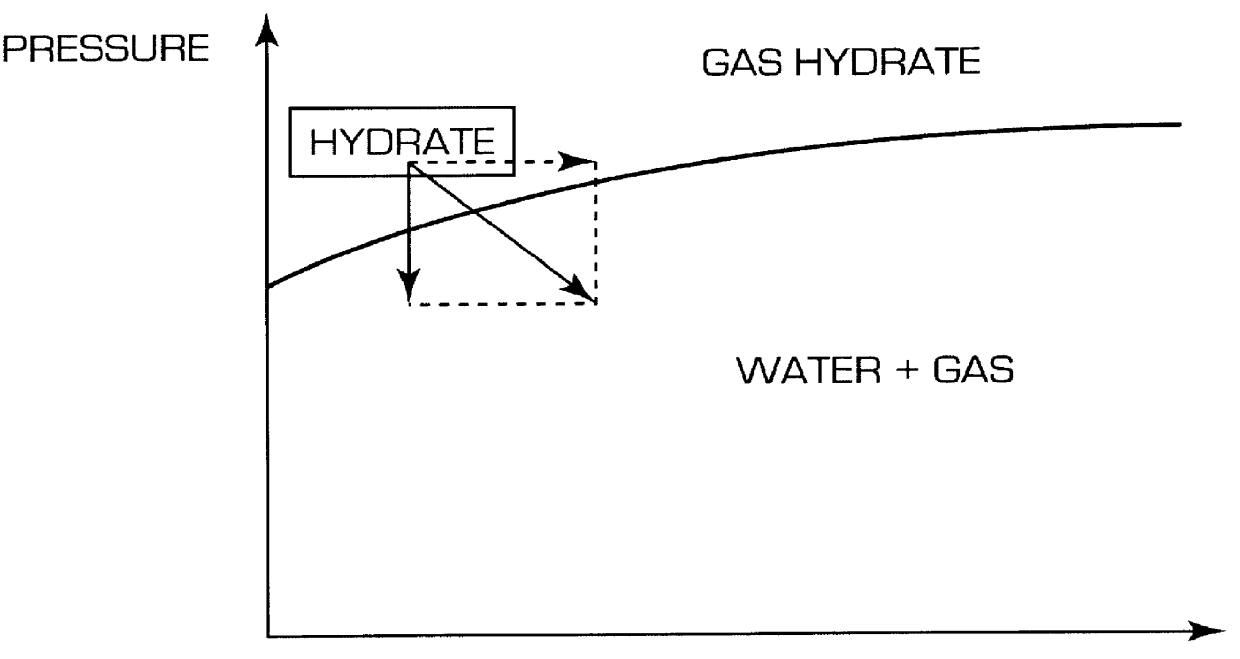

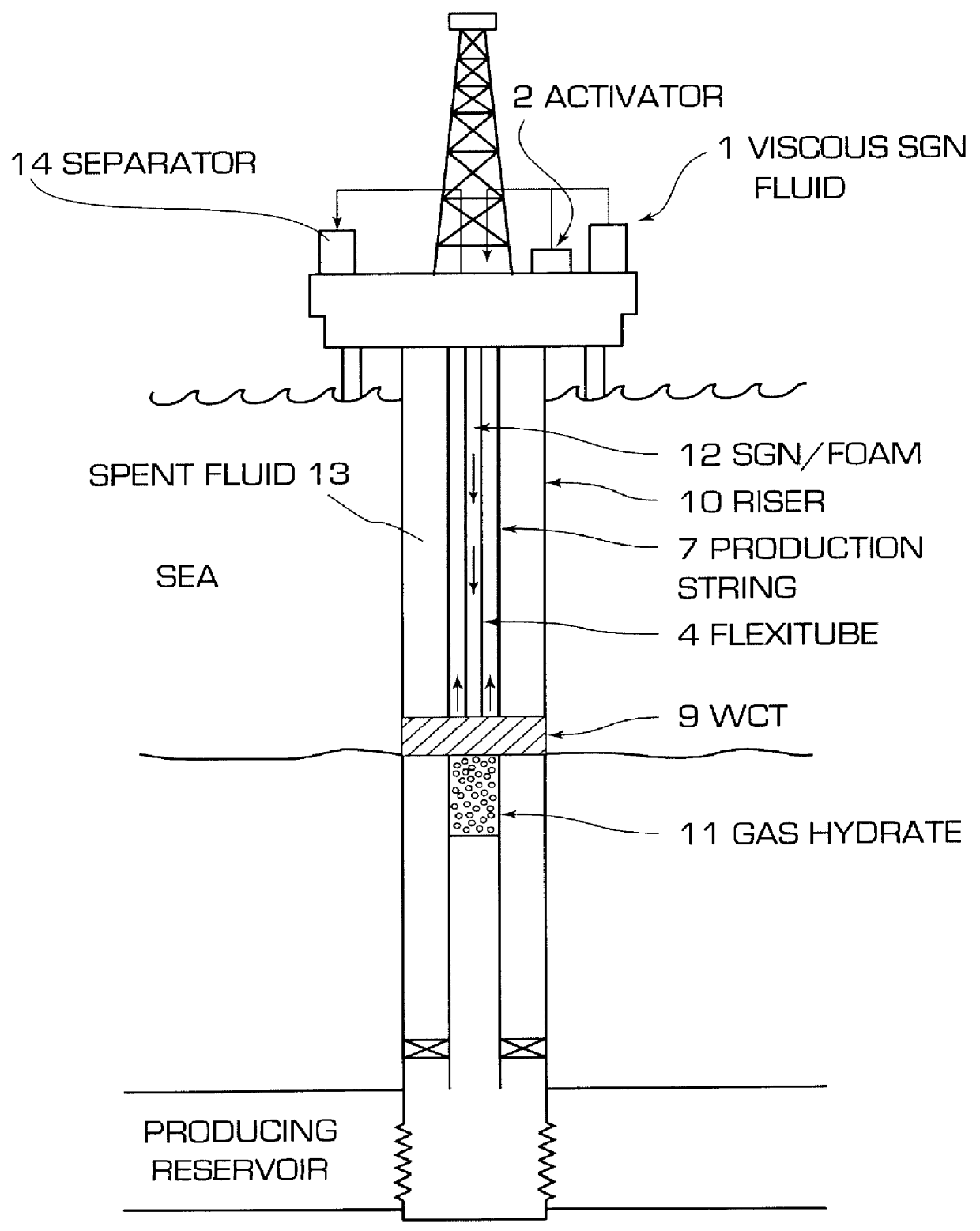

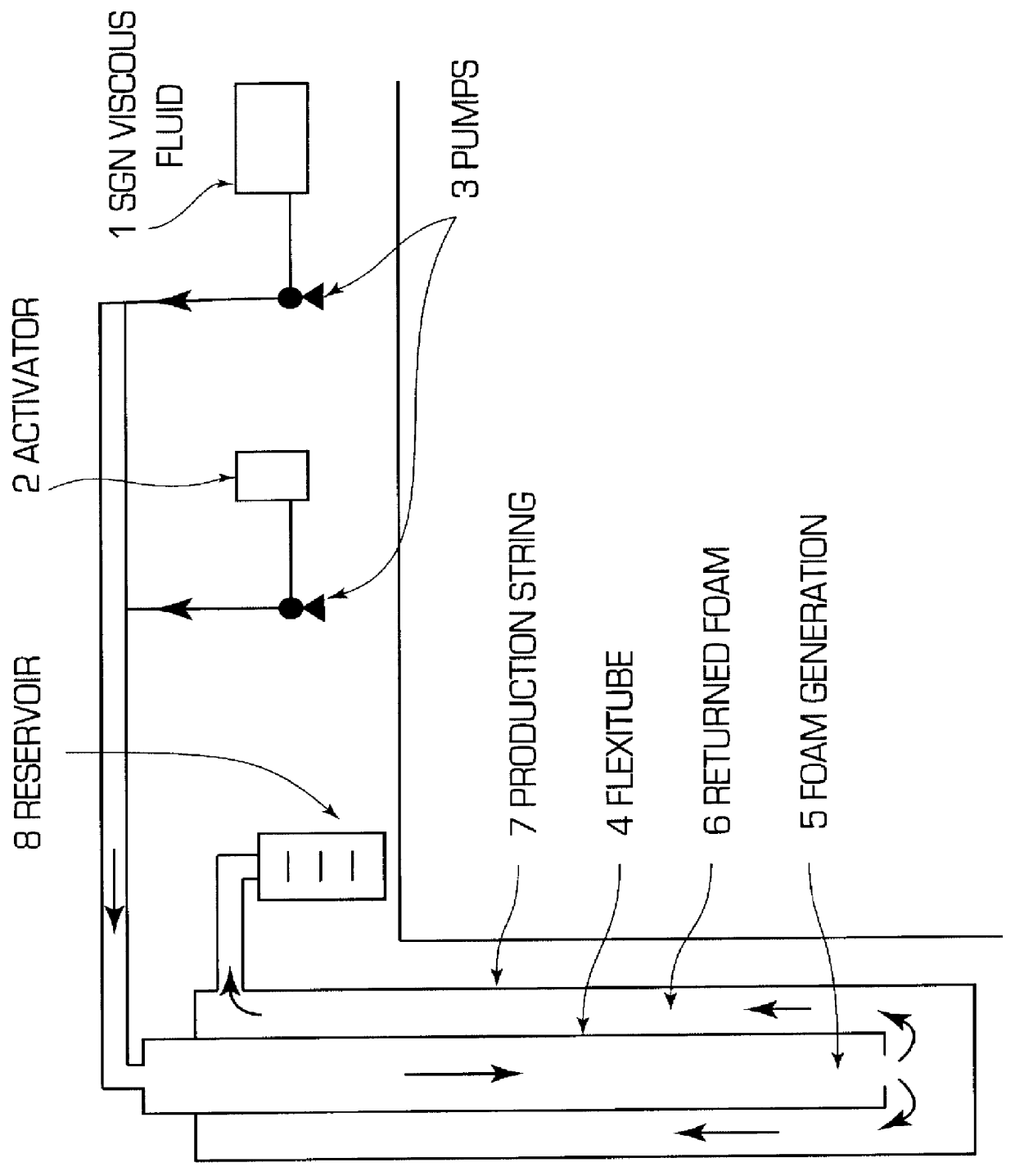

Process for the thermo-hydraulic control of gas hydrates

InactiveUS6035933AInhibition formationPipeline systemsDifferential sedimentationForming gasGas phase

A process for the thermo-hydraulic control of gas hydrates in subsea production and injection wells as well as pipelines which transport liquid or gaseous hydrocarbons is described, the process making use of a Nitrogen Generating System foamed or in solution. The control may signify the prevention of the formation of the gas hydrates or the dissolution of the gas hydrate plug already formed. Under conditions of use designed for the prevention of the formation of gas hydrates the SGN fluid prevents the thermal conditions leading to the gas hydrate plugs. Under conditions of use designed to dissolve the already formed gas hydrate plugs, the SGN fluid alters the thermo-hydraulic conditions which favor the gas hydrate plugs, so that they are dissolved and return to the water+gas phase.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

Method for removing filter cake from injection wells

InactiveUS6978838B2Eliminate needReduce capacity requirementsCleaning apparatusFluid removalBridge materialHigh rate

A method is given for completing an interval of an open-hole injection well penetrating a subterranean formation when the interface between the wellbore and the formation includes a zone invaded by a filter cake that includes bridging materials and other embedded solid materials. The method includes the steps of injecting a clean-up fluid and contacting it with the filtercake for a period of time sufficient to loosen some of the other solids embedded in the filter cake; removing the loosened solids by a high-rate displacement fluid containing suspending additives; and then injecting a dissolving fluid containing a diverter and an effective amount of a salt or acid capable of dissolving the bridging material.

Owner:SCHLUMBERGER TECH CORP

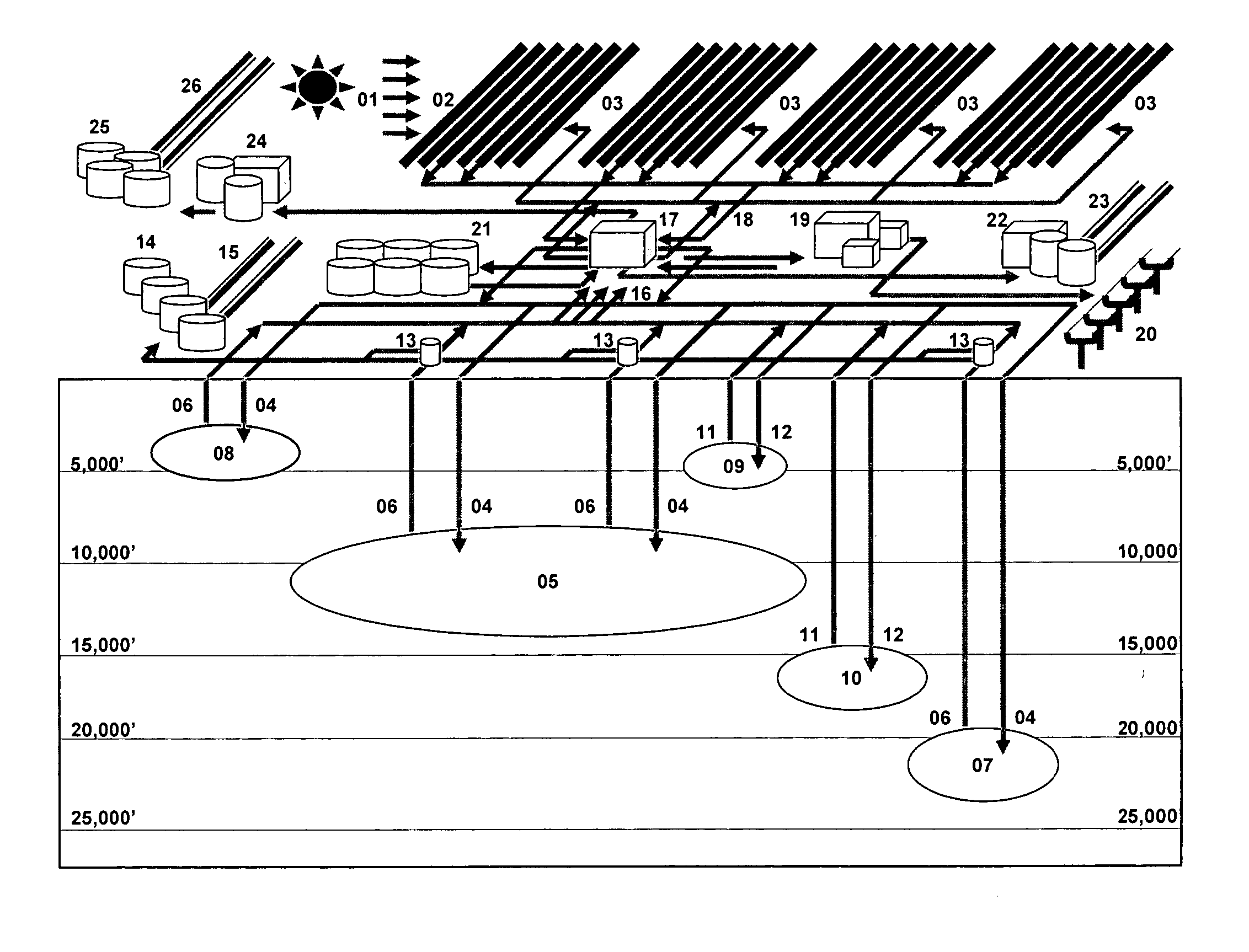

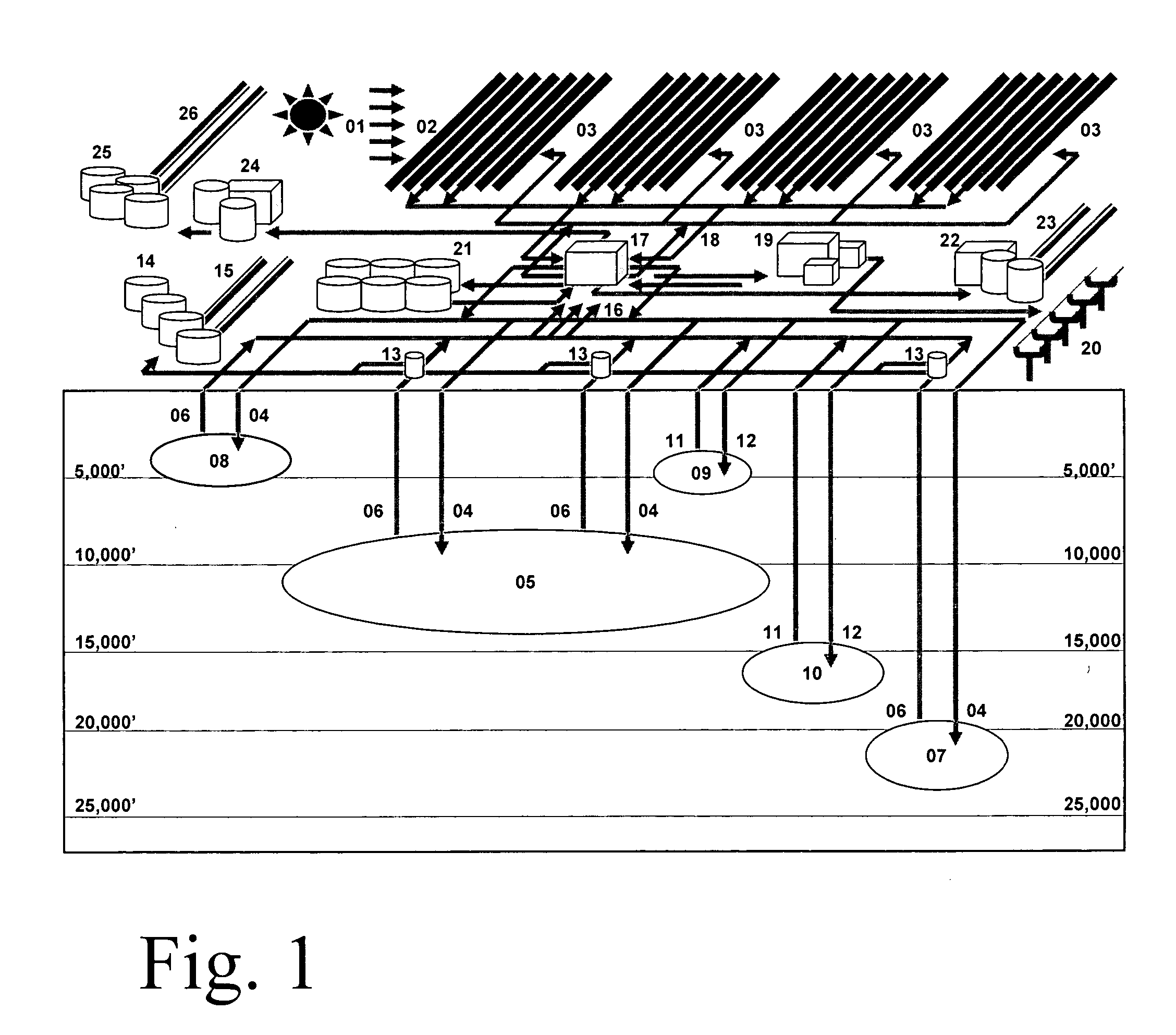

Solar augmented geothermal energy

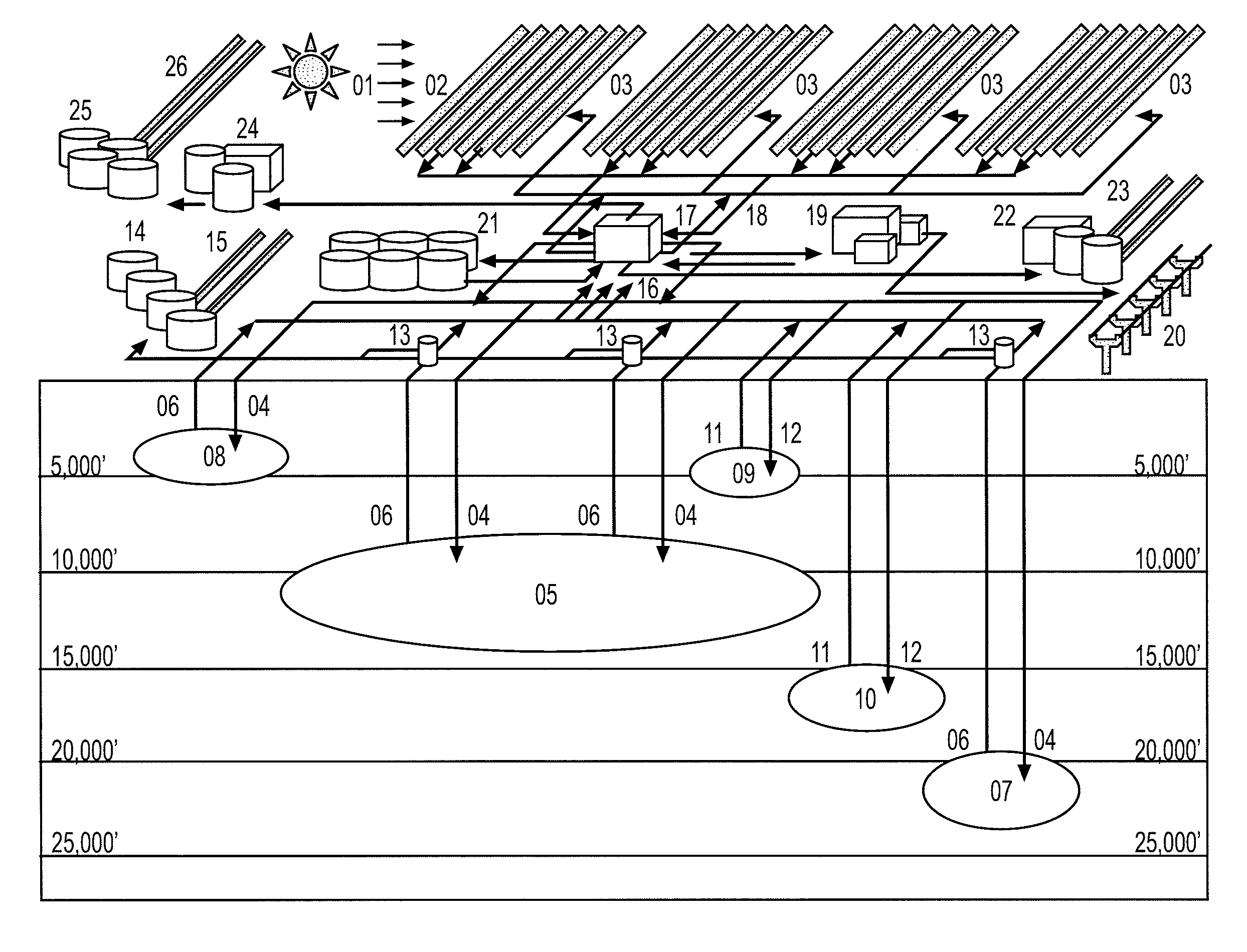

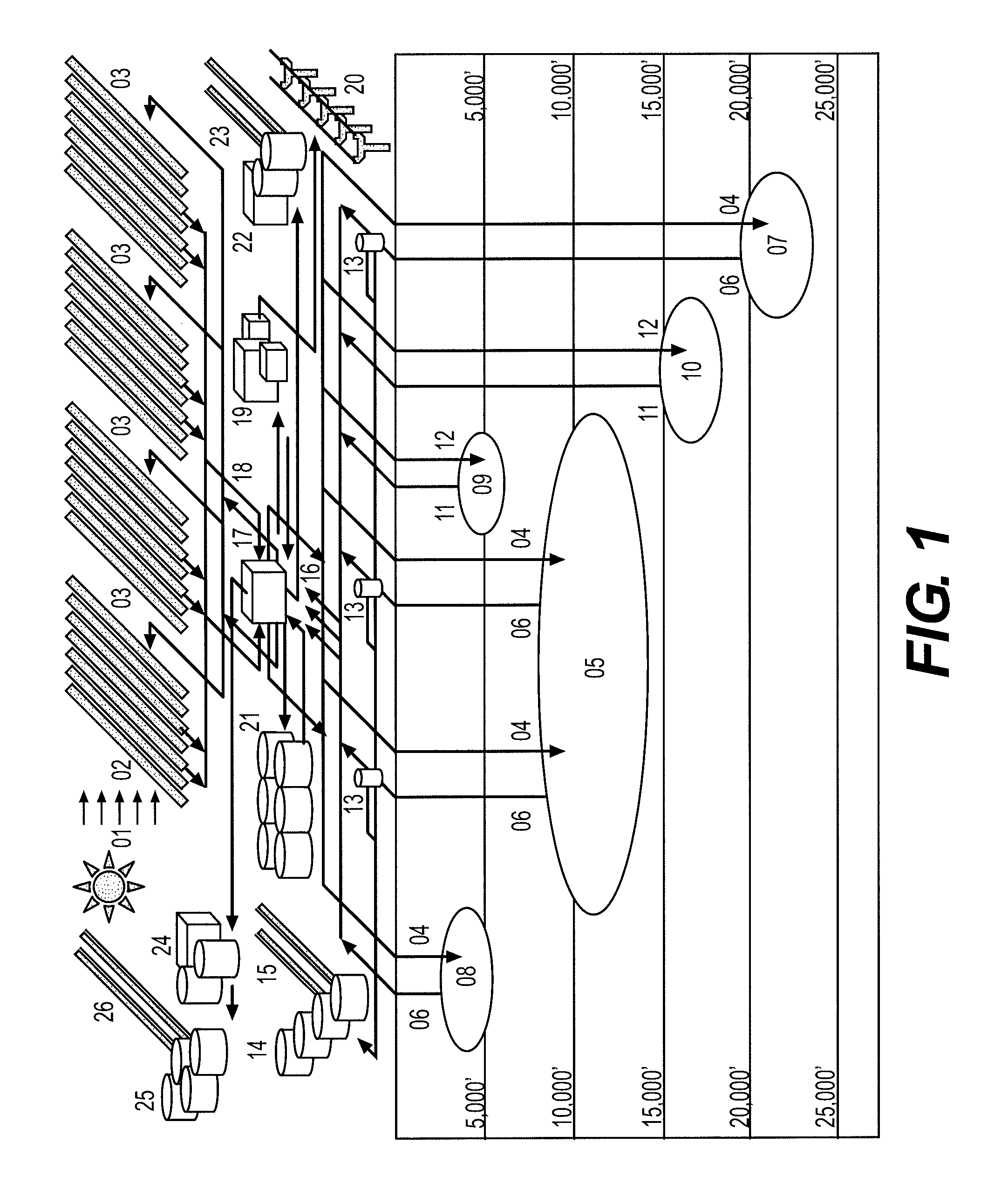

ActiveUS20060048770A1Maximize oil productionIncrease flow rateSolar heating energyAuxillary drivesHydrocotyle bowlesioidesOil field

An apparatus and a method is disclosed for storage of solar energy in a subsurface geologic reservoir. The method includes transferring concentrated solar thermal energy to a fluid, thereby generating a supercritical fluid. The supercritical fluid is then injected into the subsurface geologic reservoir through at least one injection well. The subsurface geologic reservoir may be a highly permeable and porous sedimentary strata, a depleted hydrocarbon field, a depleting hydrocarbon field, a depleted oil field, a depleting oil field, a depleted gas field, or a depleting gas field. Once charged with the supercritical fluid, the subsurface geologic formation forms a synthetic geothermal reservoir.

Owner:MEKSVANH NINO

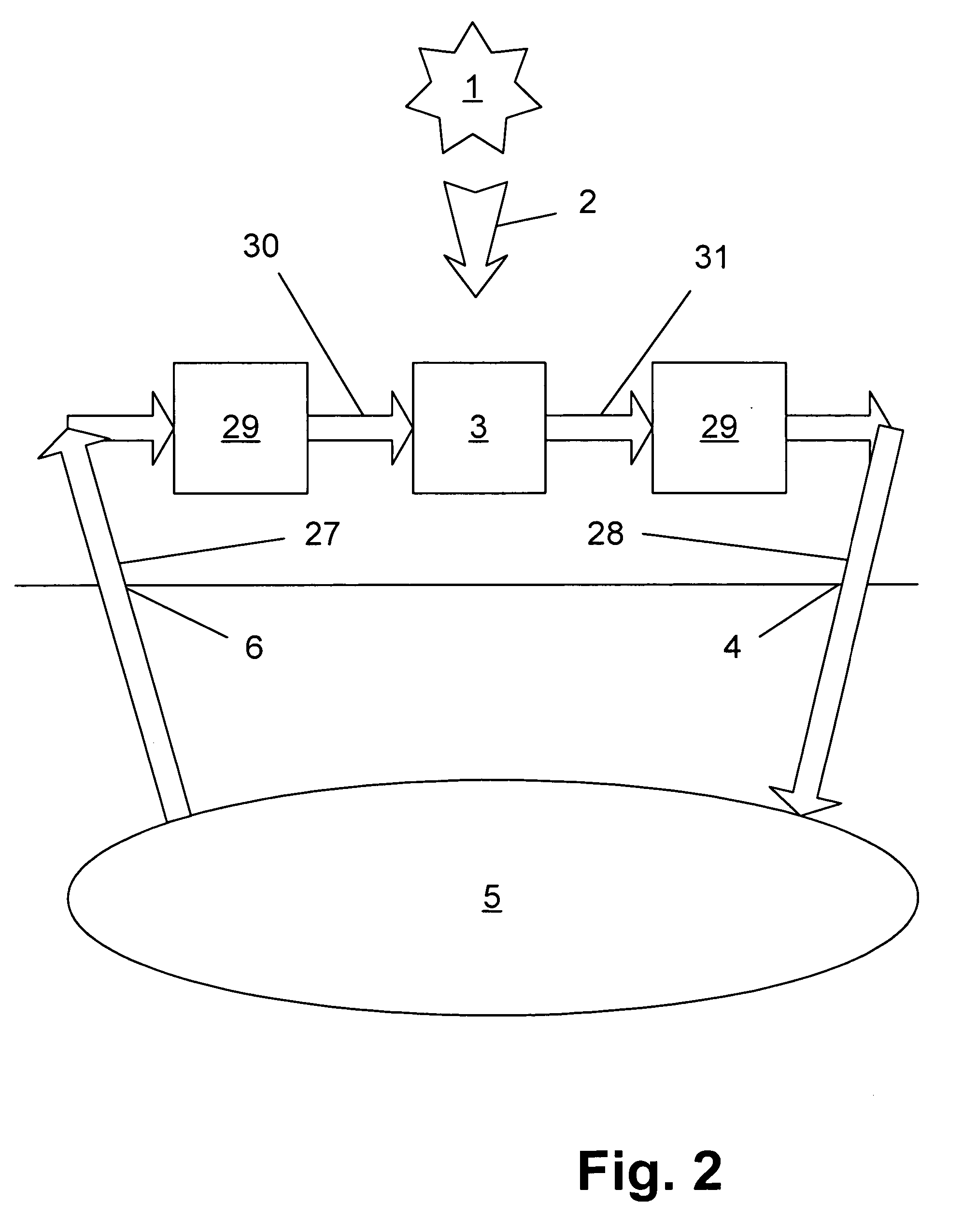

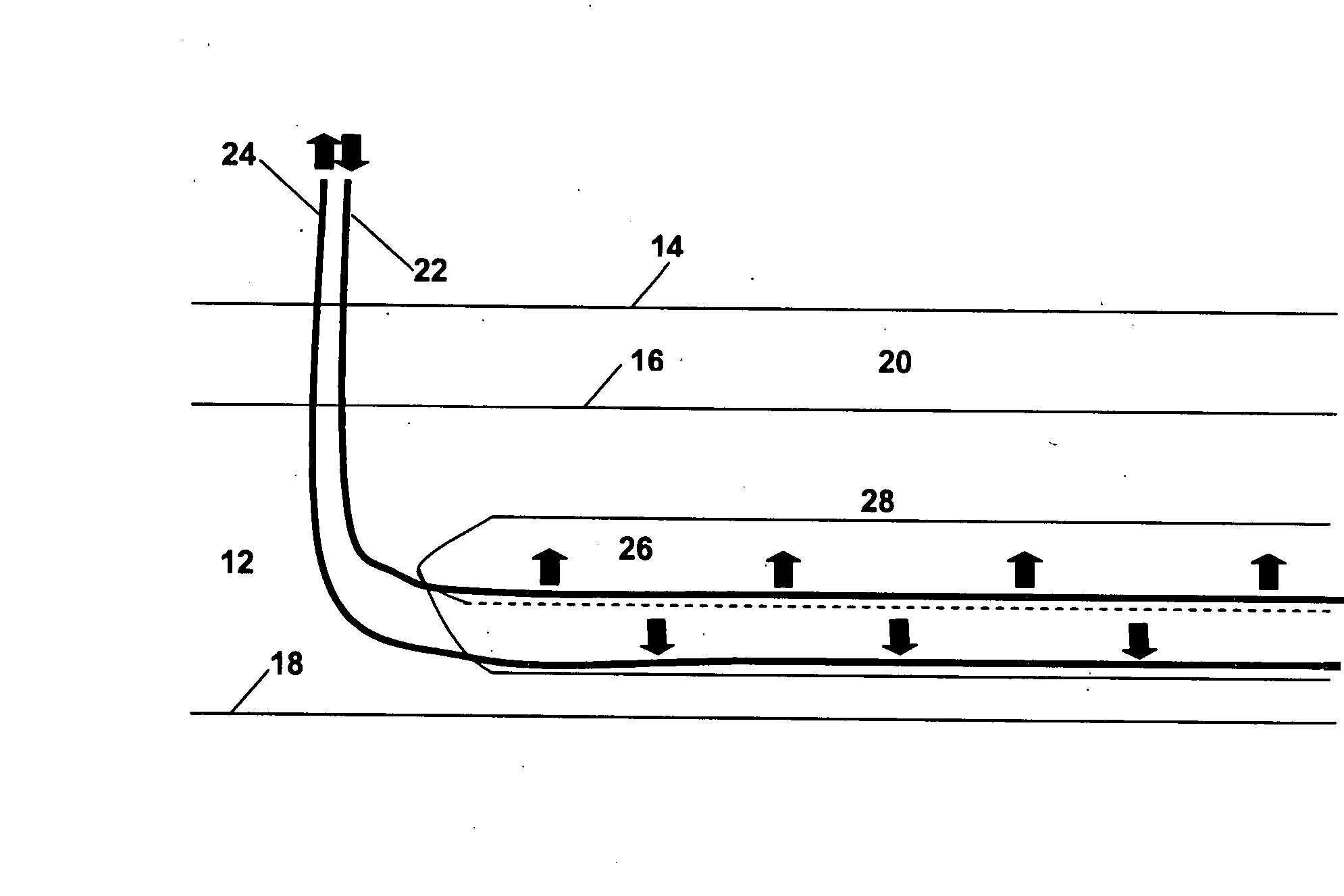

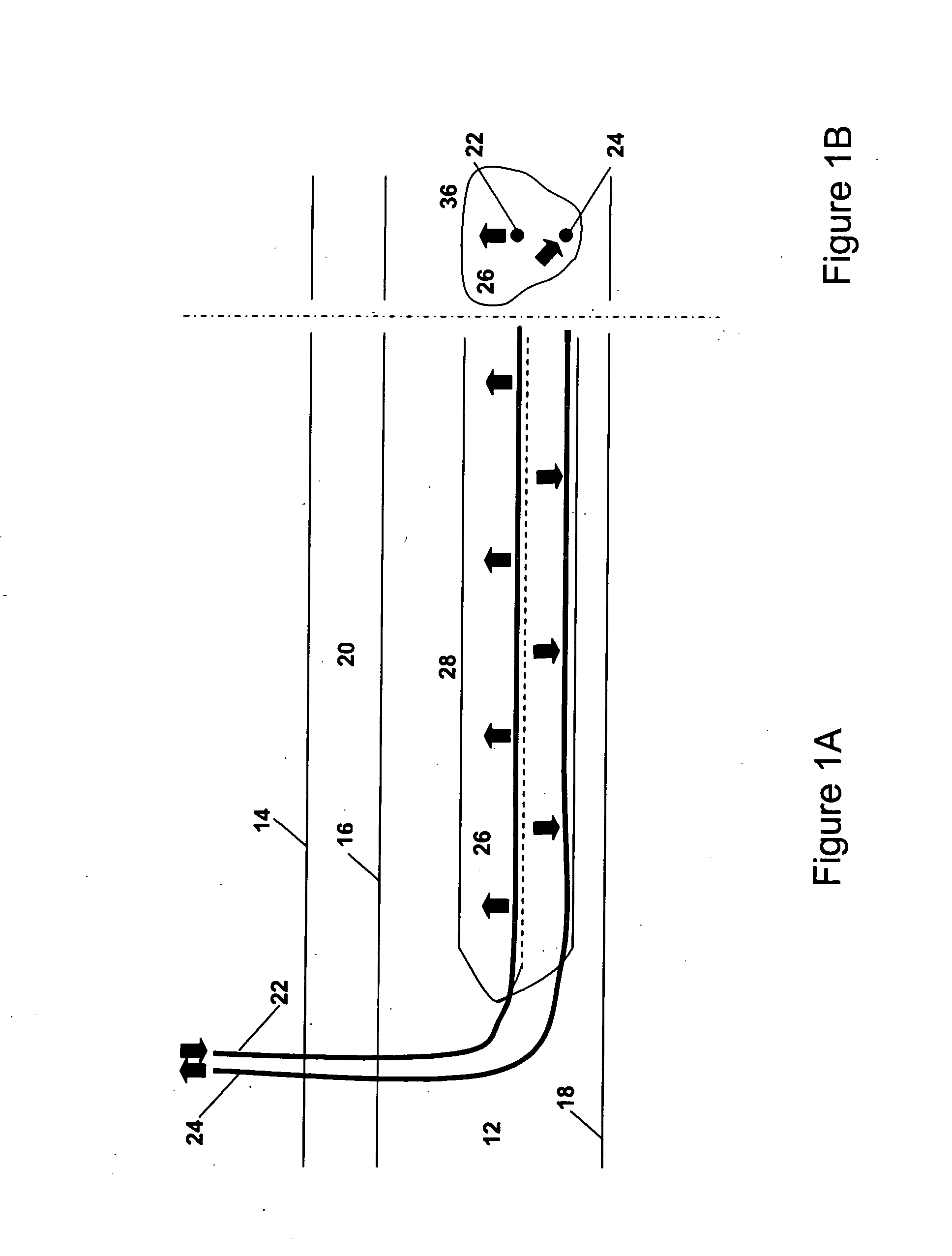

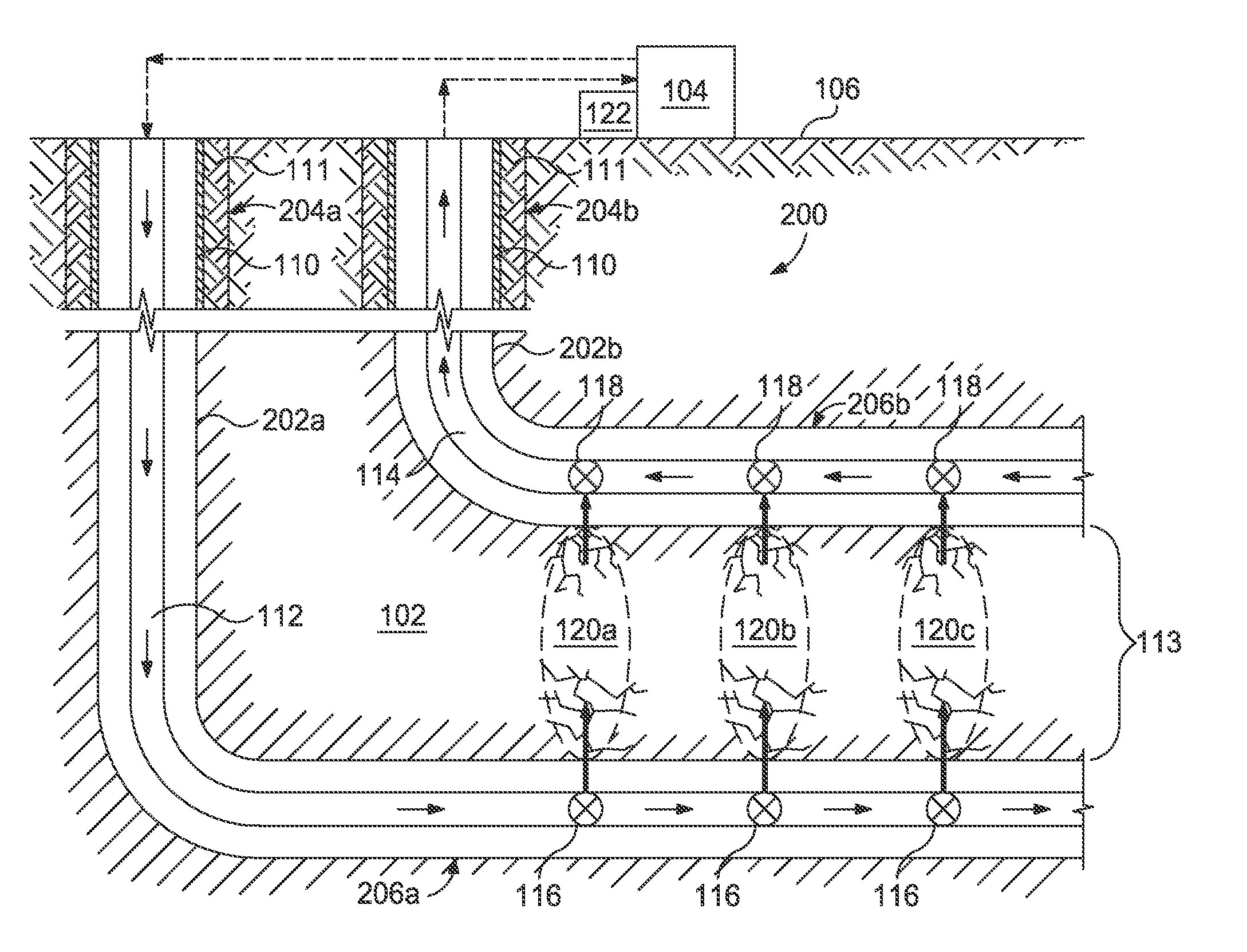

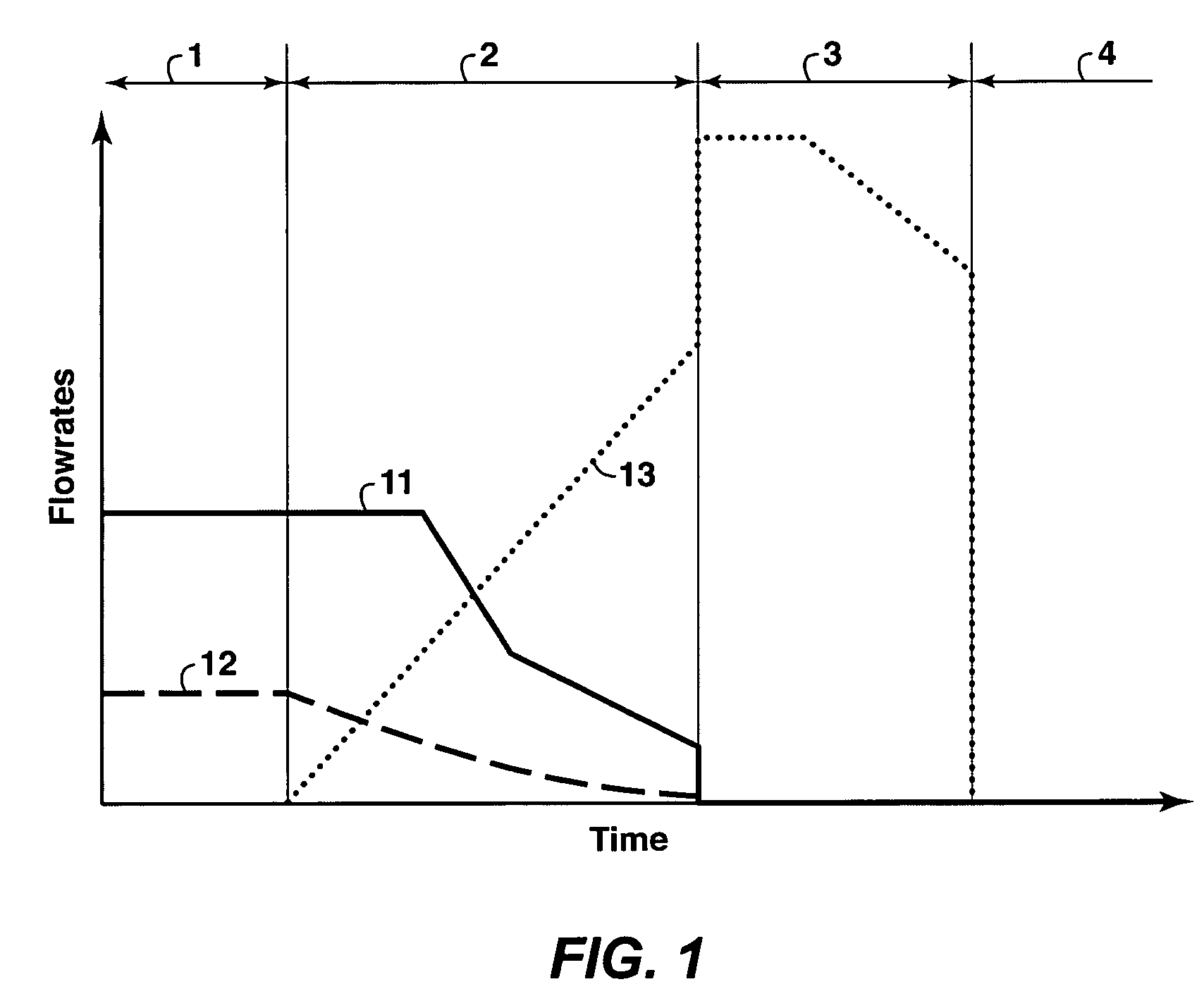

Method and apparatus for using geothermal energy for the production of power

ActiveUS20060026961A1Delay water lossLow densityEngine fuctionsGas turbine plantsPower stationTemperature difference

The method of the invention comprises enhancing the flow of geothermal fluid (water and / or steam and / or mixtures thereof) from at least one injection well to at least one production well, by the following steps: providing a first, horizontal, geothermal well, which is used as said injection well; injecting water into said injection well; providing a second, horizontal, geothermal well, which issued as said production well such that said second, horizontal, production, geothermal well is substantially horizontally and vertically spaced from said first, horizontal, injection, geothermal well and located at a shallower depth than said first, horizontal, injection, geothermal well; recovering geothermal fluid from said production well; and generating a water density difference and a pressure difference between said first horizontal, injection well and said second horizontal, production well. Furthermore, the invention comprises an apparatus for enhancing the flow of geothermal fluid from at least one injection well to at least one production well, which comprises a first horizontal geothermal well, which is used as said injection well and into which water is injected; a second horizontal, geothermal well, which is used as said production well and from which geothermal fluid issues, wherein said second, horizontal, production, geothermal well is substantially horizontally and vertically spaced from said first, horizontal, injection, geothermal well and located at a shallower depth than said first, horizontal, injection, geothermal well; and means for producing a pressure difference between said first horizontal, injection well and said second horizontal, production well and utilizing the water density difference induced by the temperature difference. Preferably, binary geothermal power plants or combined cycle geothermal power plants can be used to produce power from geothermal fluid recovered from the production well.

Owner:ORMAT TECH INC

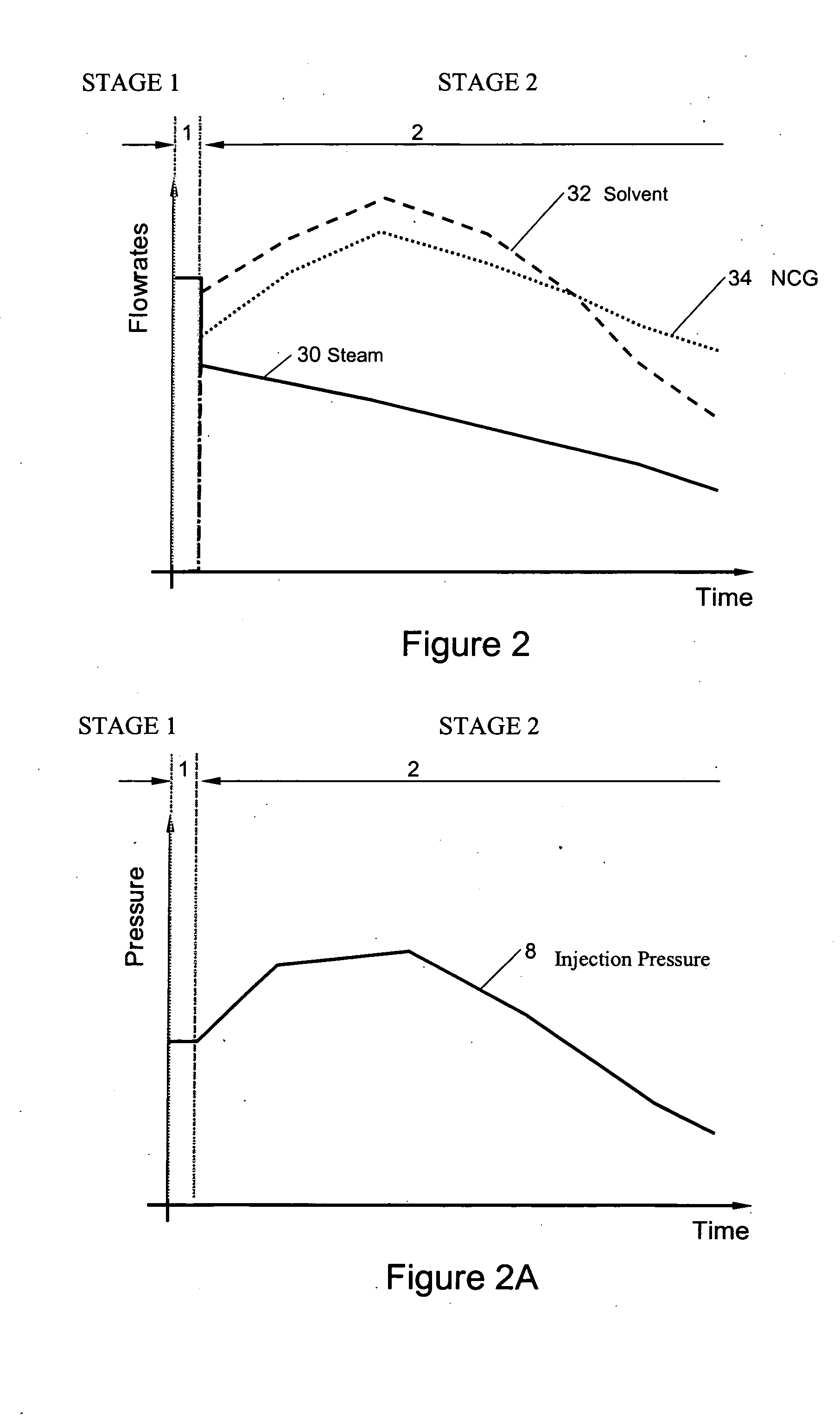

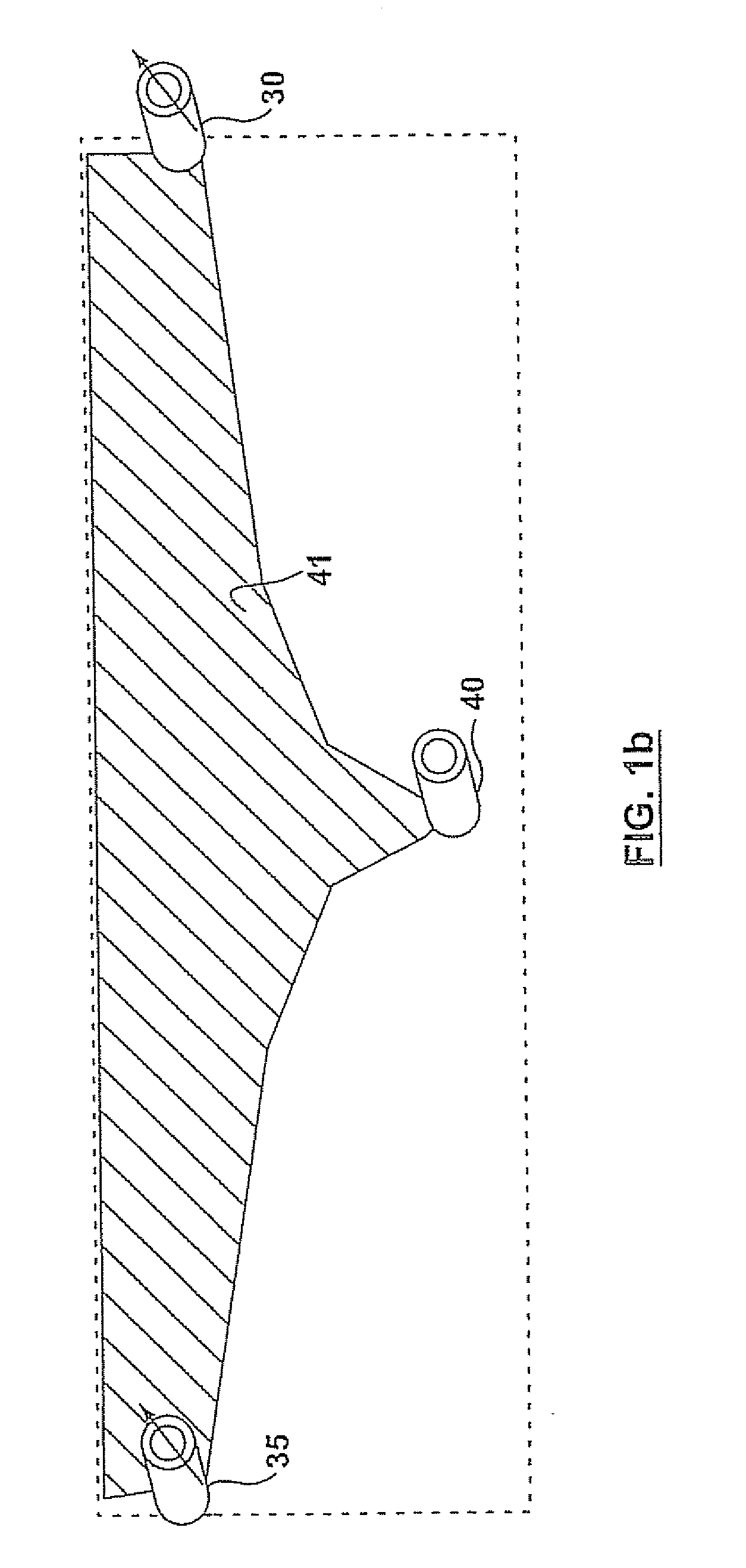

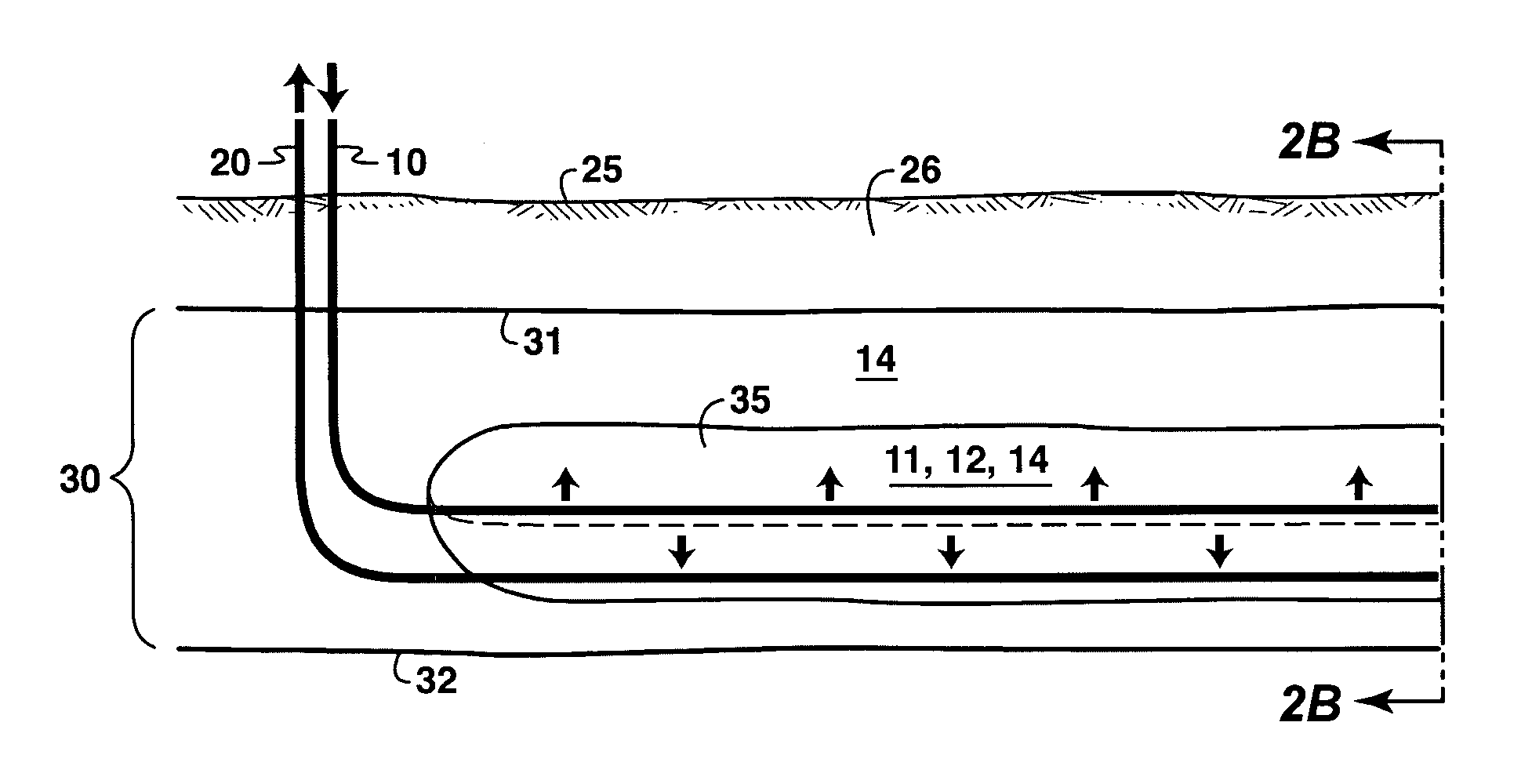

In situ process to recover heavy oil and bitumen

InactiveUS20080017372A1Maximize actionLow viscositySurveyFluid removalHydrocarbon solventsFluid viscosity

An in situ reservoir recovery process consisting of a horizontal injection well and a horizontal production well to extract bitumen or heavy oil from a reservoir. The process consists of a first phase operated at high-pressure in which steam, hydrocarbon solvent and non-condensable gases are injected into the reservoir and a second phase in which the injected fluids are transitioned to a high content of solvent and non-condensable gas and a reduced amount of steam to maintain a warm zone in the neighbourhood of the injection and production wells. The steam injection is sufficient to promote vapor transport of the solvent into the vapor depletion chamber and maintain the process at elevated temperatures in order to maintain low fluid viscosities in the production wellbore and to achieve preferred phase behaviour of the solvent hydrocarbon and the heavy oil or bitumen. The operating pressure of the process is controlled to prevent losses of the solvent hydrocarbon to the formation and to aid in solvent production to the production well in order for future re-cycling.

Owner:PARAMOUNT RESOURCES LTD

Heavy oil recovery with fluid water and carbon dioxide

ActiveUS20090071648A1Improves hydrocarbon extraction efficiencySpeed up the extraction processFluid removalFuel oilInjection well

Diluted wet combustion forms a hot process fluid or VASTgas comprising carbon dioxide (CO2) and fluid water which is delivered geologic formations and / or from surface mined materials to reduce the viscosity and / or increase hydrocarbon extraction. This may improve thermal efficiency and / or increases heat delivery for a given combustor or per capital investment. High water and / or CO2 content is achieved by reducing non-aqueous diluent and / or adding or recycling CO2. Power recovered from expanding the VASTgas may be pressurize the VASTgas for delivery by partial expansion through a Direct VAST cycle, and / or by diverting compressed oxidant through a parallel thermogenerator in a Diverted VAST cycle. Pressurized VASTgas may be injected into well within the hydrocarbon formation or with mined material into a heavy hydrocarbon separator vessel to heat, mobilize, solubilize and / or extract heavy hydrocarbons. Light hydrocarbons may be mixed in with the hot process fluid to enhance hydrocarbon mobilization and recovery. Microwaves may further heat the VASTgas and / or hydrocarbon. Sulfur oxidation, calcining limestone and / or recycling may increase CO2. Oxygen enrichment may increase the specific power. VASTgas may be delivered through and back injection wells and / or production wells, and / or between sequential injection wells in alternating and / or paired zigzag formations with multiple wells per VAST combined heat and power recovery system.

Owner:VAST HLDG LLC

Method for pumping coalbed gas by heating coal bed

ActiveCN101418679AAchieve separationEfficient extractionFluid removalGas removalWater vaporDistilled water

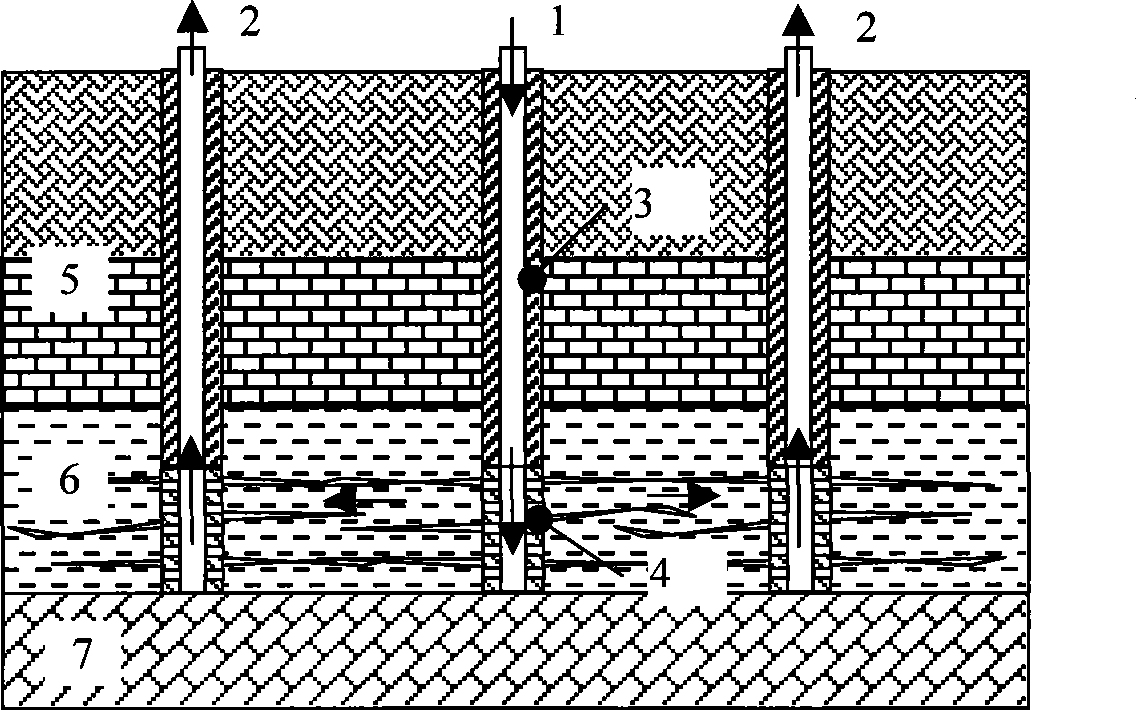

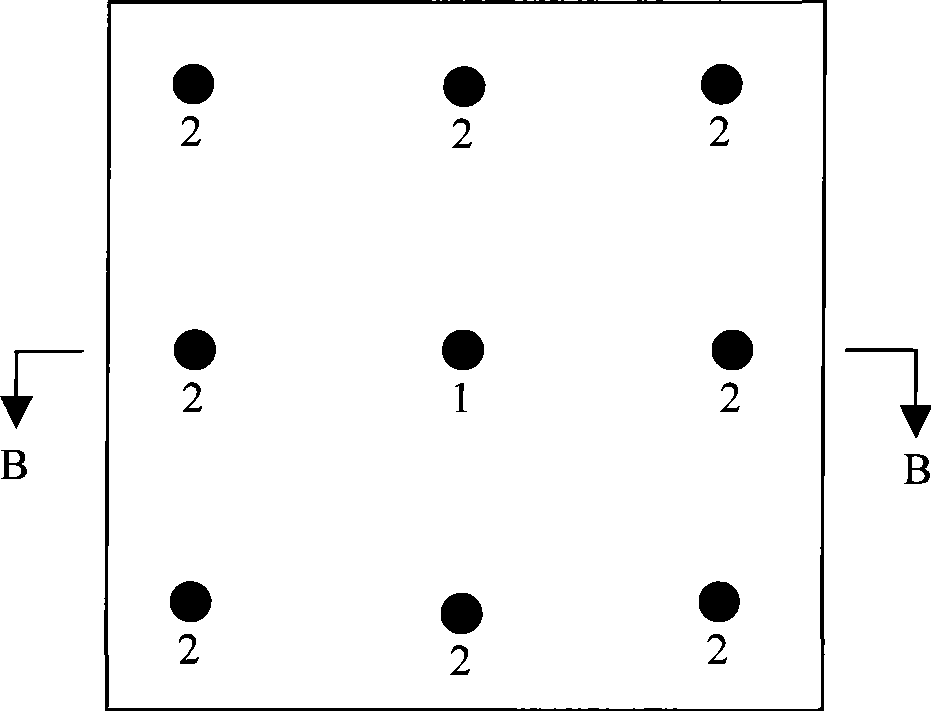

Provided is a method for heating coal seam and extracting coal seam gas. Firstly, a plurality of vertical wells are drilled from the ground to the coal seam, after the drilled well reached to the coal seam, the coal seam is inserted with a screen tube casing (4), the section above the coal seam is inserted with a heat insulation casing (31) and the well is correspondingly fixed. At least one well of the wells is selected to be a heat source injection well (1) and other wells are gas production wells (2), steam with high temperature and high pressure is injected into the heat source injection well (1) to perform fracturing to communicate all the wells in the network. Drainage and pressure reduction are performed to the gas production wells (2) to extract the mixed gas of the coal seam gas and steam. The mixed gas of the coal seam gas and steam is cooled by known cooling method so as to obtain gaseous coal seam gas and liquid distilled water to realize the separation of the mixed gas. According to the change of the coal seam temperature, the heat source injection well (1) and the gas production wells (2) are allocated to control the heated coal seam and extract coal seam gas. The method of he invention can effectively perform the extraction of the coal seam gas, accelerate the coal seam extraction speed, and improve the extraction rate.

Owner:TAIYUAN UNIV OF TECH

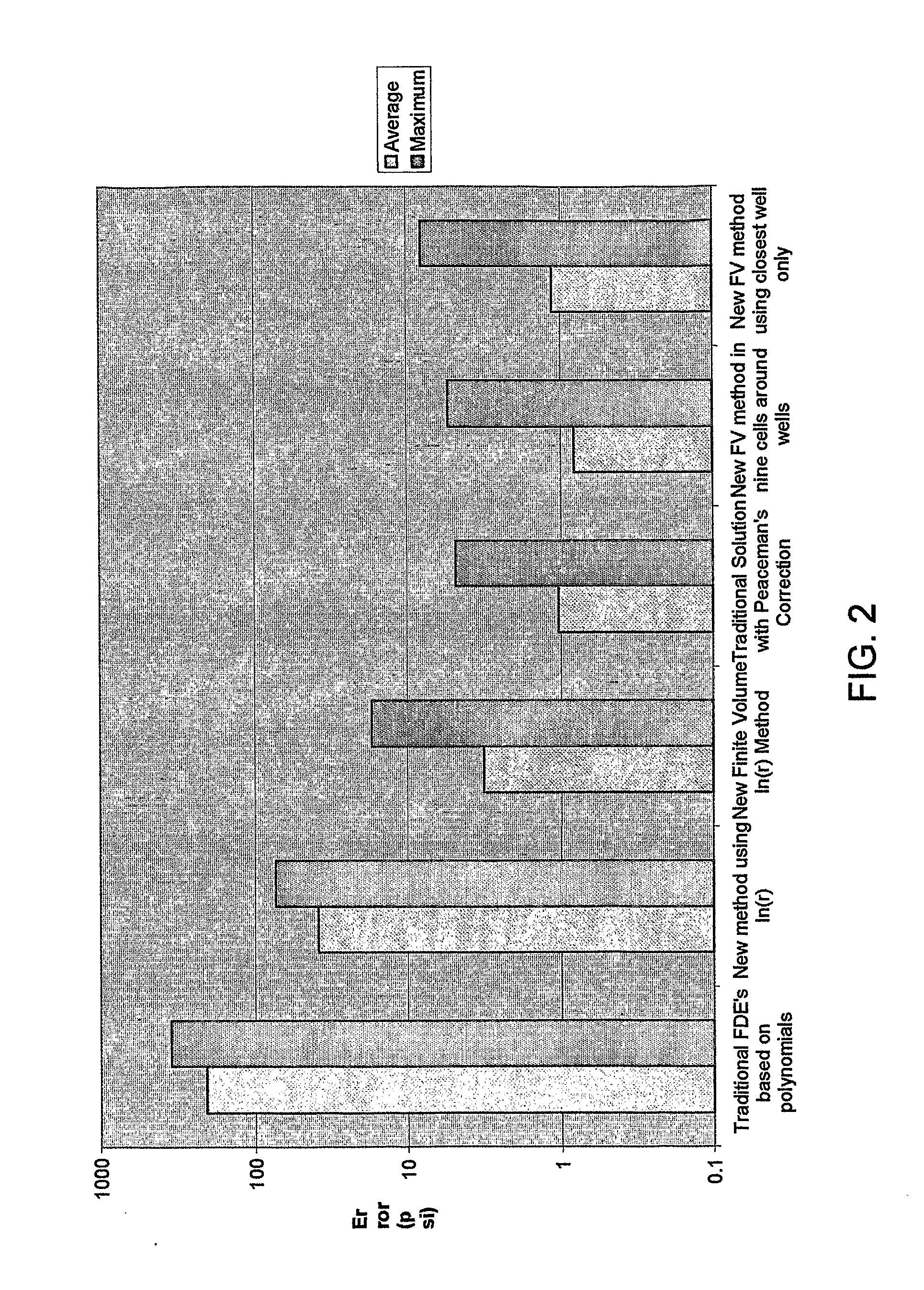

Reservoir Simulation

InactiveUS20080167849A1Easy to predictIncrease speedFluid removalMaterial testing goodsFinite difference methodInjection well

Owner:HALES HUGH

Method for dynamically assessing petroleum reservoir competency and increasing production and recovery through asymmetric analysis of performance metrics

InactiveUS20110168391A1Increase short-term production rate and long-term recoveryAccurate assessmentElectric/magnetic detection for well-loggingSurveyProcess engineeringPetroleum reservoir

Owner:QRI GROUP

Heavy oil recovery with fluid water and carbon dioxide

Diluted wet combustion forms a hot process fluid or VASTgas including carbon dioxide (CO2) and fluid water which is delivered to geologic formations and / or to surface mined materials to reduce the viscosity and / or increase hydrocarbon extraction. High water and / or CO2 content is achieved by reducing non-aqueous diluent and / or adding or recycling CO2. Power recovered from expanding the VASTgas may be used to pressurize the VASTgas for delivery by partial expansion through a Direct VAST cycle, and / or by diverting compressed oxidant through a parallel thermogenerator in a Diverted VAST cycle. Pressurized VASTgas may be injected into a well within the hydrocarbon formation or with mined material into a heavy hydrocarbon separator vessel to heat, mobilize, solubilize and / or extract heavy hydrocarbons. Light hydrocarbons may be mixed in with the hot process fluid to enhance hydrocarbon mobilization and recovery. Microwaves may further heat the VASTgas and / or hydrocarbon. Sulfur oxidation, calcining limestone and / or recycling may increase CO2. Oxygen enrichment may increase the specific power. VASTgas may be delivered through and back injection wells and / or production wells, and / or between sequential injection wells in alternating and / or paired zigzag formations with multiple wells per VAST combined heat and power recovery system.

Owner:VAST HLDG LLC

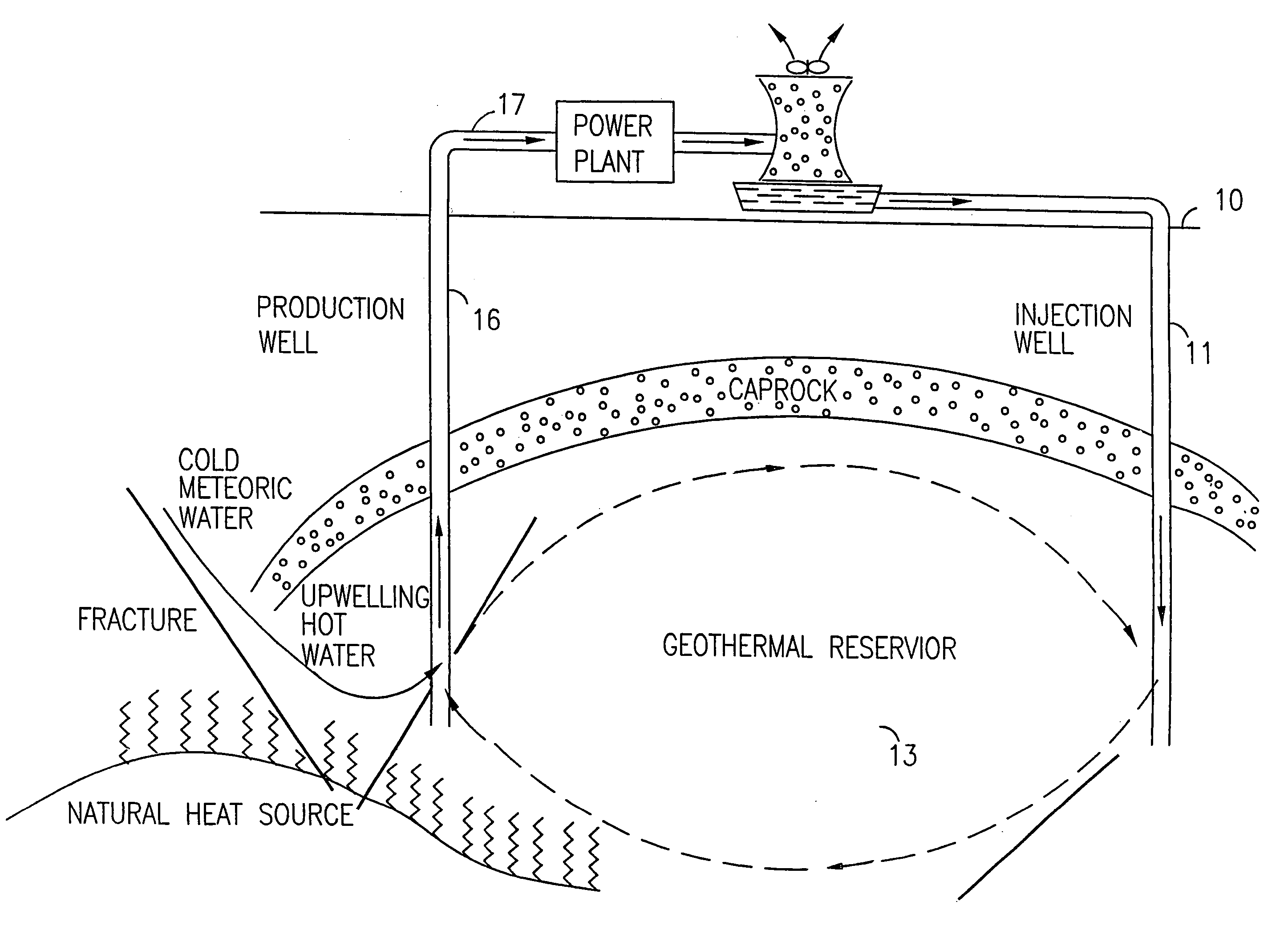

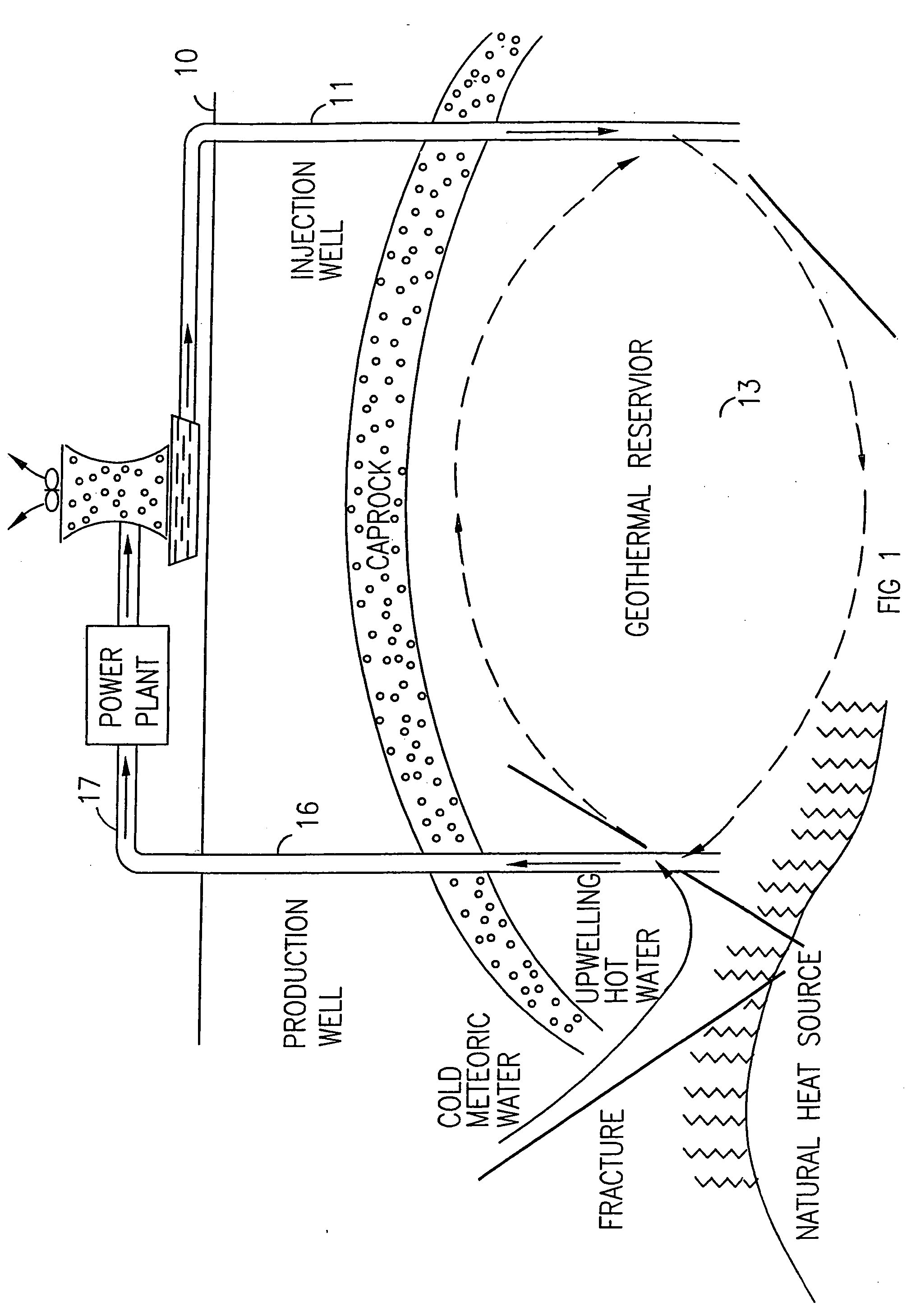

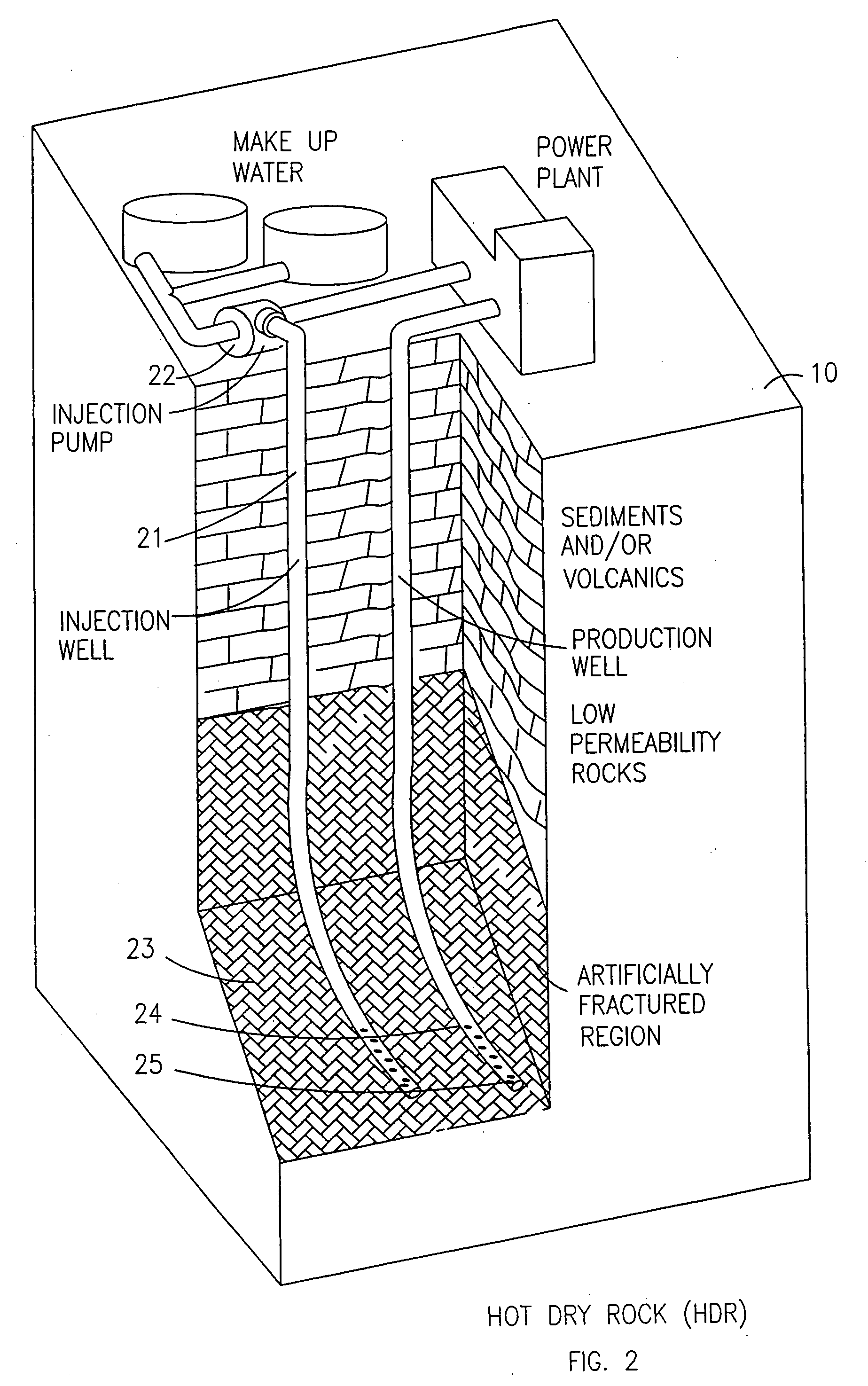

Enhanced Geothermal Systems and Methods

ActiveUS20150300327A1Collector components/accessoriesGeothermal energy generationWorking fluidInjection well

The present invention relates to systems and methods of intelligently extracting heat from geothermal reservoirs. One geothermal well system includes at least one injection well extending to a subterranean formation and configured to inject a working fluid into the subterranean formation to generate a heated working fluid. At least one production well extends to the subterranean formation and produces the heated working fluid from the subterranean formation. A production zone defines a plurality of production sub-zones within the subterranean formation and provides fluid communication between the at least one injection well and the at least one production well. Each production sub-zone is selectively accessed in order to extract heated working fluid therefrom and thereby provide a steady supply of heated working fluid to the surface.

Owner:HALLIBURTON ENERGY SERVICES INC

Compound chemical blocking removing agent of oil field polymer injection well

ActiveCN102925128AAdaptableImprove visual water absorption indexDrilling compositionWater qualityElectronegativity

The invention relates to a compound chemical blocking removing agent of an oil field polymer injection well. The compound chemical blocking removing agent is characterized in that a high molecular extending agent with strong electronegativity is used for hydrating and extending condensed and agglomerated polymer macromolecule chains again; peroxide is used as a primary oxidation agent; polybasic carboxylic acid which can slowly and uniformly ionize hydrogen ions is used as controlled-release acid; auxiliary agents such as a corrosion inhibitor, a penetrant, a metal ion chelating agent, a dual-metal coupling agent, an iron ion stabilizer, a bacteriacide, a stratum protective agent, and the like are added at the same time; and macromolecular polymers in blocking substances, which are near the oil field polymer injection well, and are fully extended by the extending agent, are oxidized and degraded by active hydroxyl which is produced from the reaction of the primary oxidation agent and the controlled-release acid, so that blocking of the polymer injection well is removed, and the apparent water injectivity index is improved. The chemical blocking removing agent is non-toxic and environment-friendly, has a wide applicable range of temperature and water quality, and has the advantages of simplicity in construction technique, safety and convenience in use and storage, and the like; and the viscosity-reducing rate of the compound chemical blocking removing agent to polyacrylamide gel can reach above 99%.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

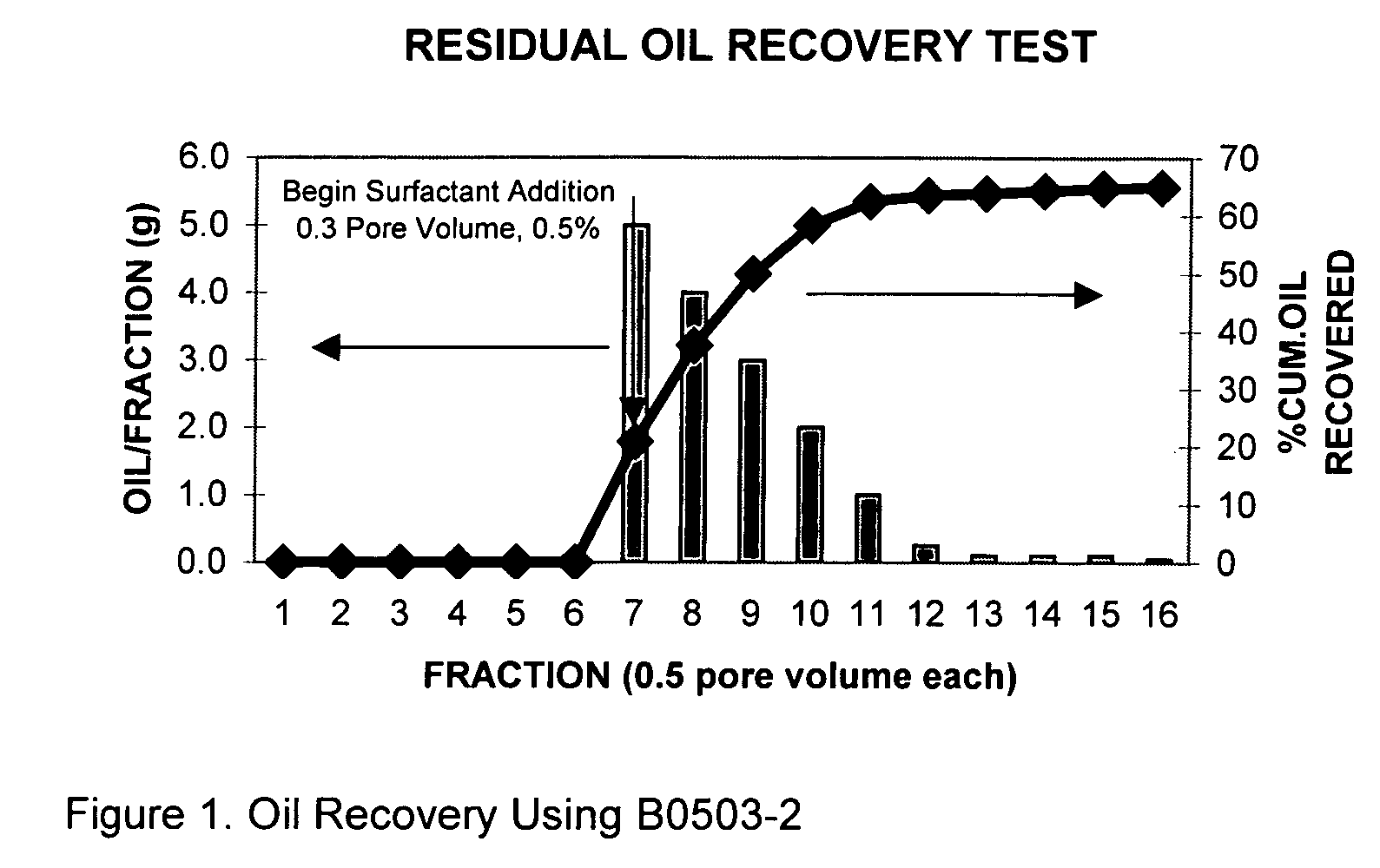

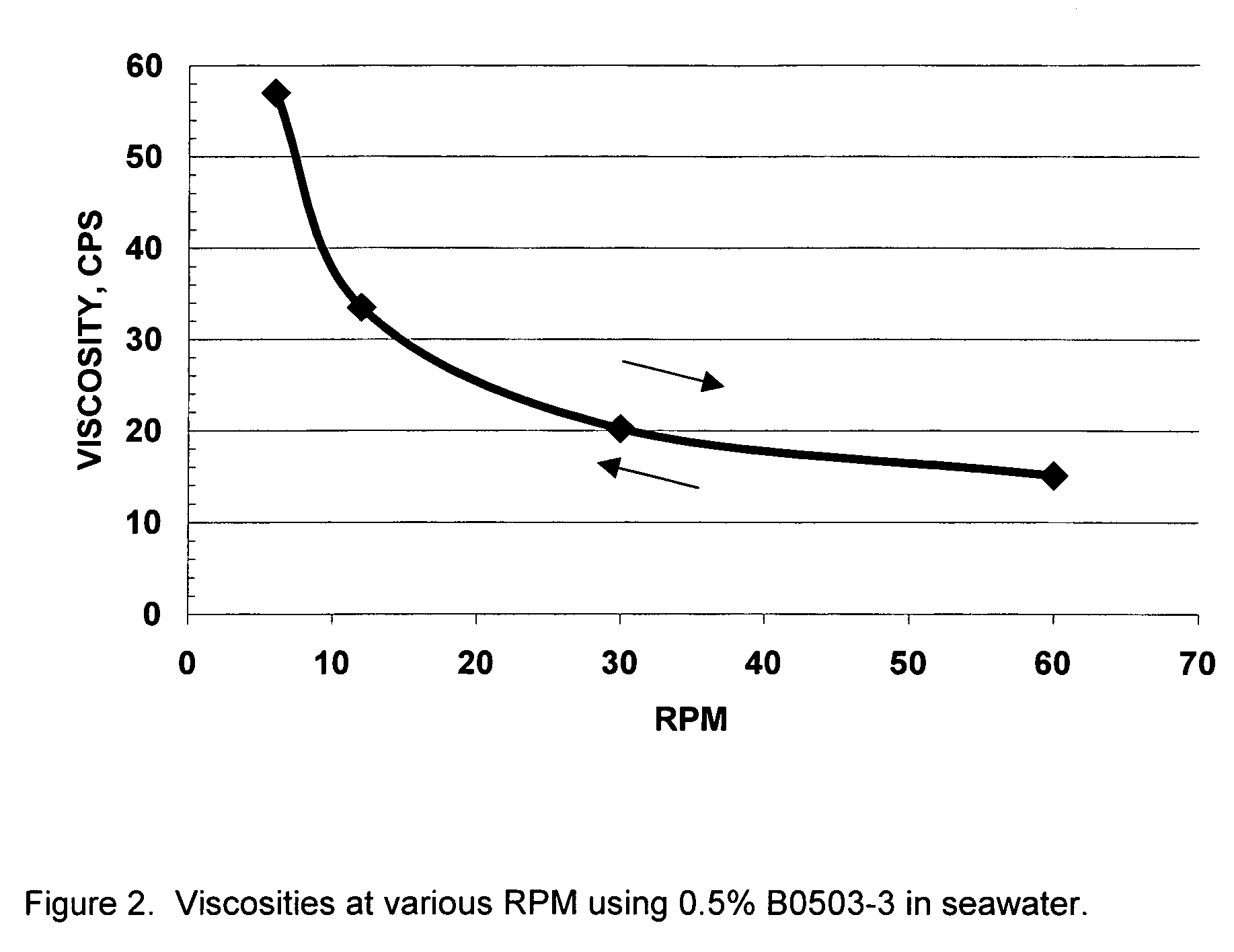

Process for oil recovery employing surfactant gels

Owner:OIL CHEM TECH

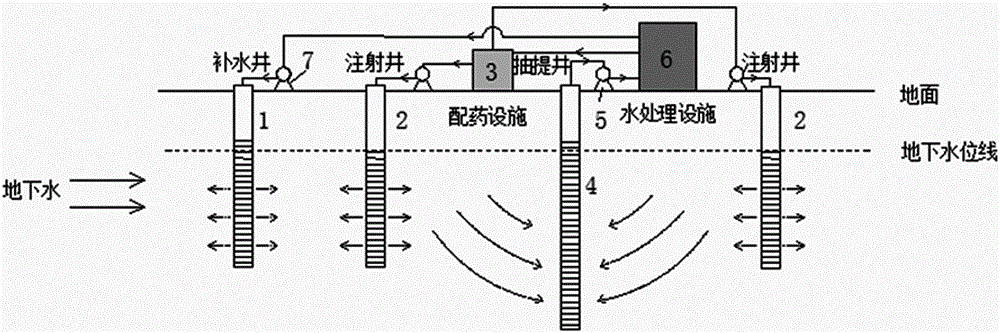

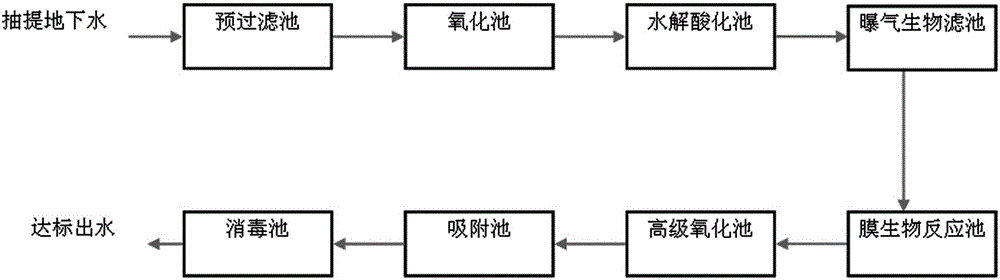

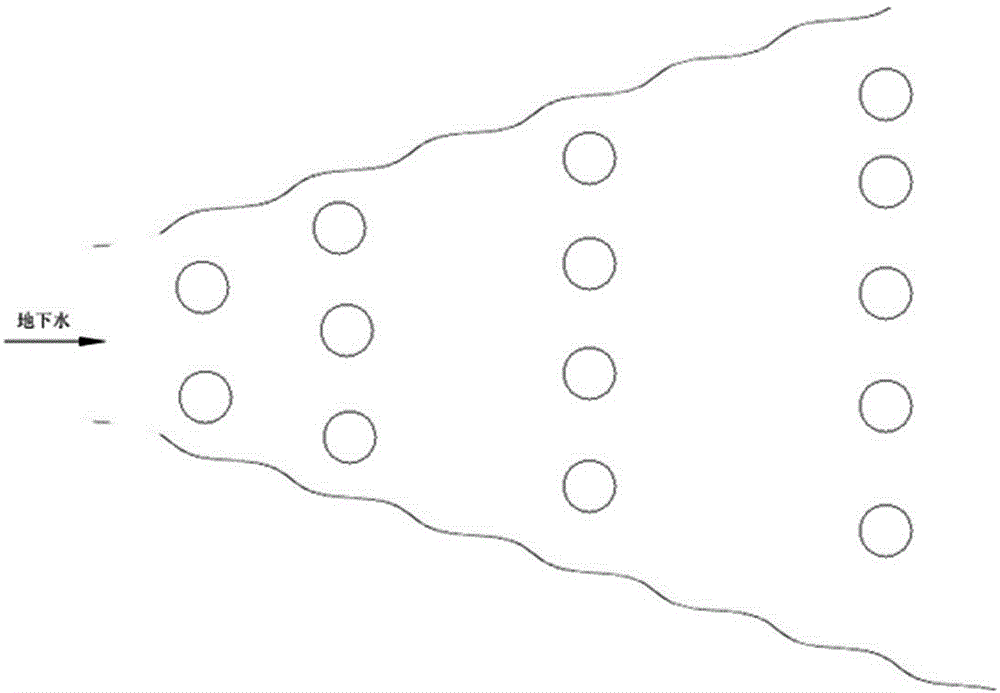

In-situ injection-extraction-water replenishing circulatory disposal system for organic contaminated soil and groundwater and combined remediation method

ActiveCN105032916ASpeed up the flowIncrease the speed of diffusionContaminated soil reclamationMultistage water/sewage treatmentInjection wellWater treatment

The invention discloses an in-situ injection-extraction-water replenishing circulatory disposal system for organic contaminated soil and groundwater and a combined remediation method. The system is consist of an injection well, an extraction well, a water replenishing well, a water treatment facility, a dispensing facility. The method comprises the following steps: extracting a pollution source or groundwater in a seriously polluted area to the ground for processing, then using the processed groundwater as a preparation drug or as replenished water to be directly injected to the underground, and injecting the drug into the underground pollution plume area through the injection well. The system and the method are used for processing the organic contaminated soil and groundwater in situ and have the advantages of being small in disturbance, environmental-friendly, short in remediation cycle and wide in range of application and has no secondary pollution.

Owner:中节能大地(杭州)环境修复有限公司

Performance prediction method for hydrocarbon recovery processes

The invention relates to a method for predicting the performance of large-scale hydrocarbon-bearing reservoir floods. One embodiment of the invention includes a method for predicting performance of a patterned flooding process in a subterranean hydrocarbon-bearing formation, said formation being penetrated by a plurality of injector wells and producer wells, comprising the steps of: determining flow-based pairs of injector to producer wells [FIG. 4, item 78a] (first well pairs) using a geological model [item 76]; developing a connective pore volume distribution curve for each first well pair item [78b]; selecting at least two first well pairs (selected well pairs) that reflect narrow and wide connective pore volume distributions that correspond to high and lower oil recovery levels; developing a 3-D simulation model for each selected well pair, performing a reservoir simulation for each selected well pair for the corresponding flooding process; and generating prototype performance curves for each selected well pair. An alternate embodiment of the invention includes a method for predicting the performance of large-scale hydrocarbon-bearing reservoir floods where injection well location, production well location, a process parameter, or a well processing rate is modified.

Owner:EXXONMOBIL UPSTREAM RES CO

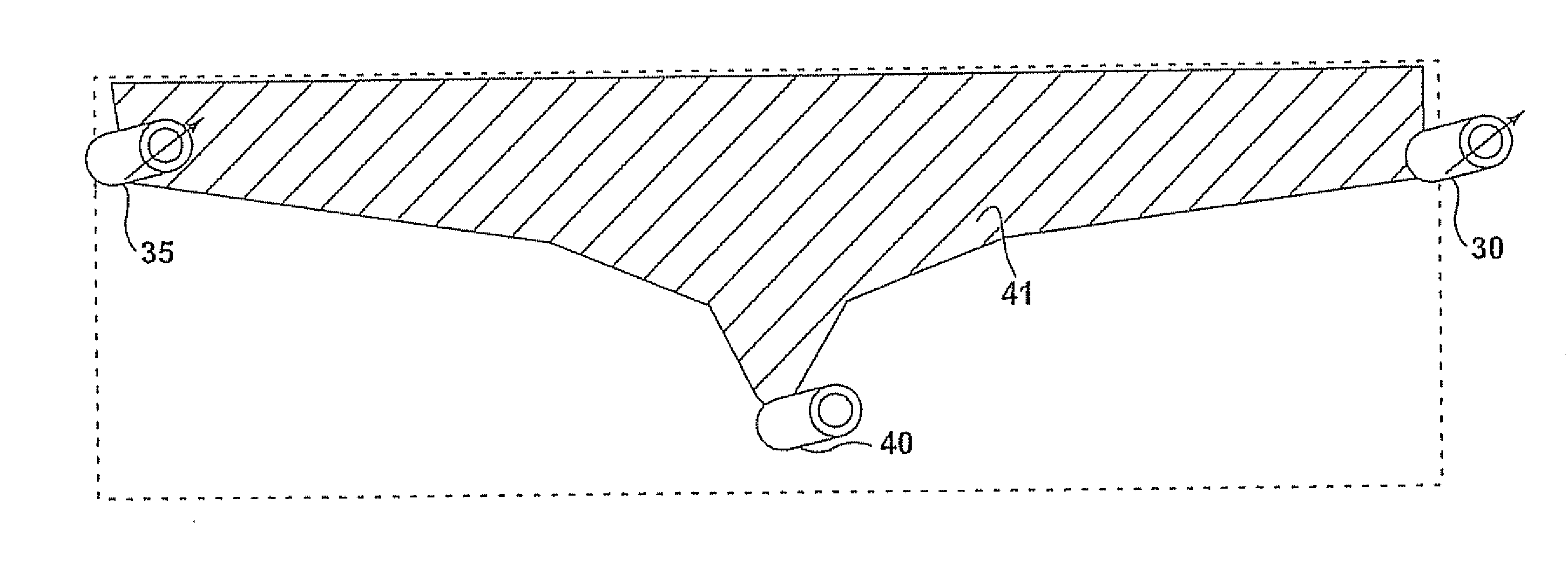

Methods for injecting a consolidation fluid into a wellbore at a subterranian location

Disclosed are apparatuses and methods for stabilizing portions of a subterranean formation and controlling the production of water from those subterranean formations. In one aspect, a method of treating a plurality of discrete portions of a subterranean formation penetrated by a wellbore, the method comprising the steps of: (a) moving a treatment tool through the wellbore on work tubing to a desired subterranean location, wherein the treatment tool comprises: (i) a fluidic oscillator; and (ii) a lower packer positioned below the fluidic oscillator; (b) expanding the cross-section of the lower packer to engage the wellbore, thereby isolating a portion of the wellbore from another portion below the lower packer; (c) injecting a consolidation fluid through the tubing and through the fluidic oscillator into the isolated portion of the wellbore; (d) reducing the cross-section of the lower packer, thereby disengaging the tool from the wellbore.

Owner:HALLIBURTON ENERGY SERVICES INC

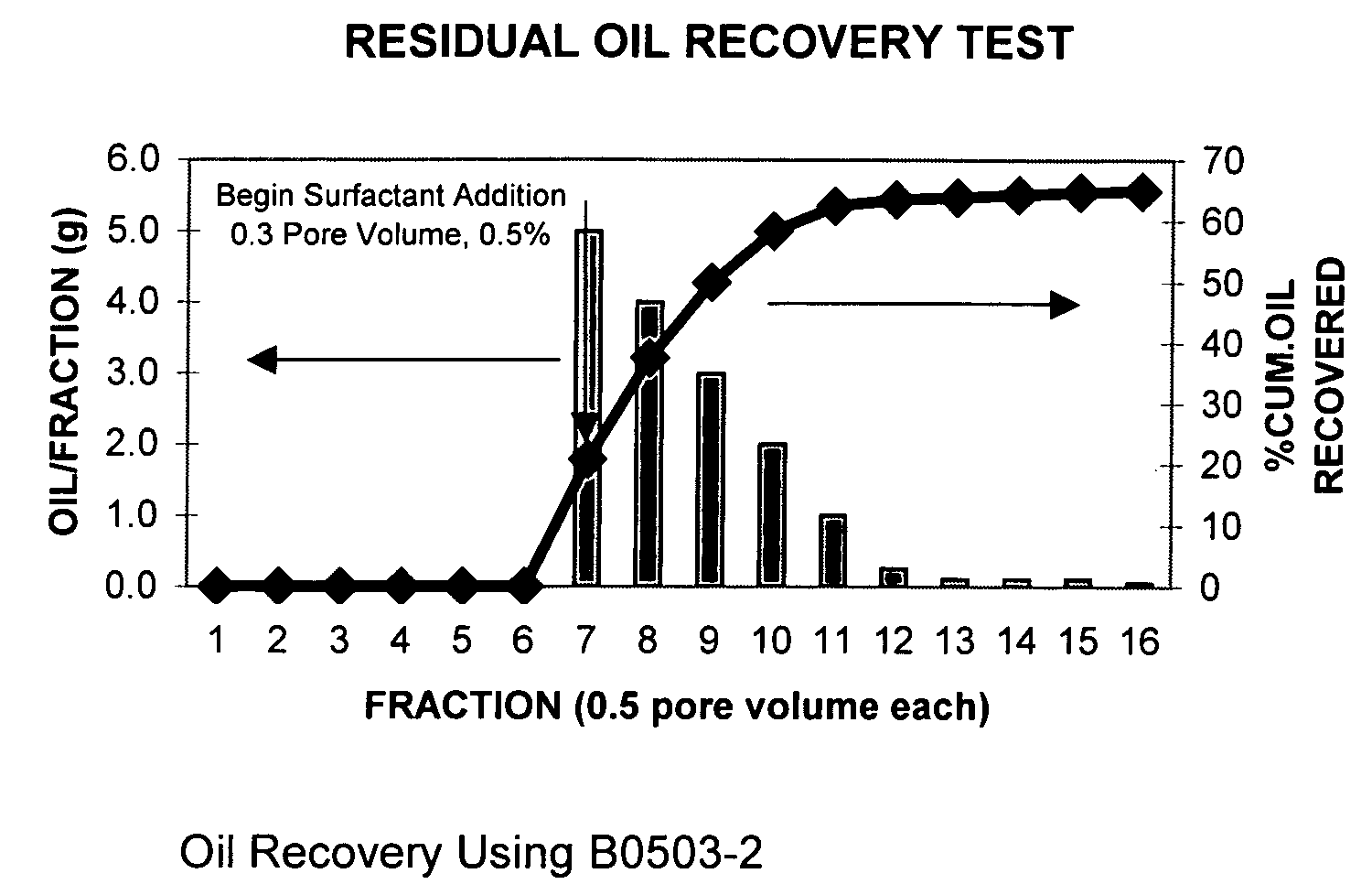

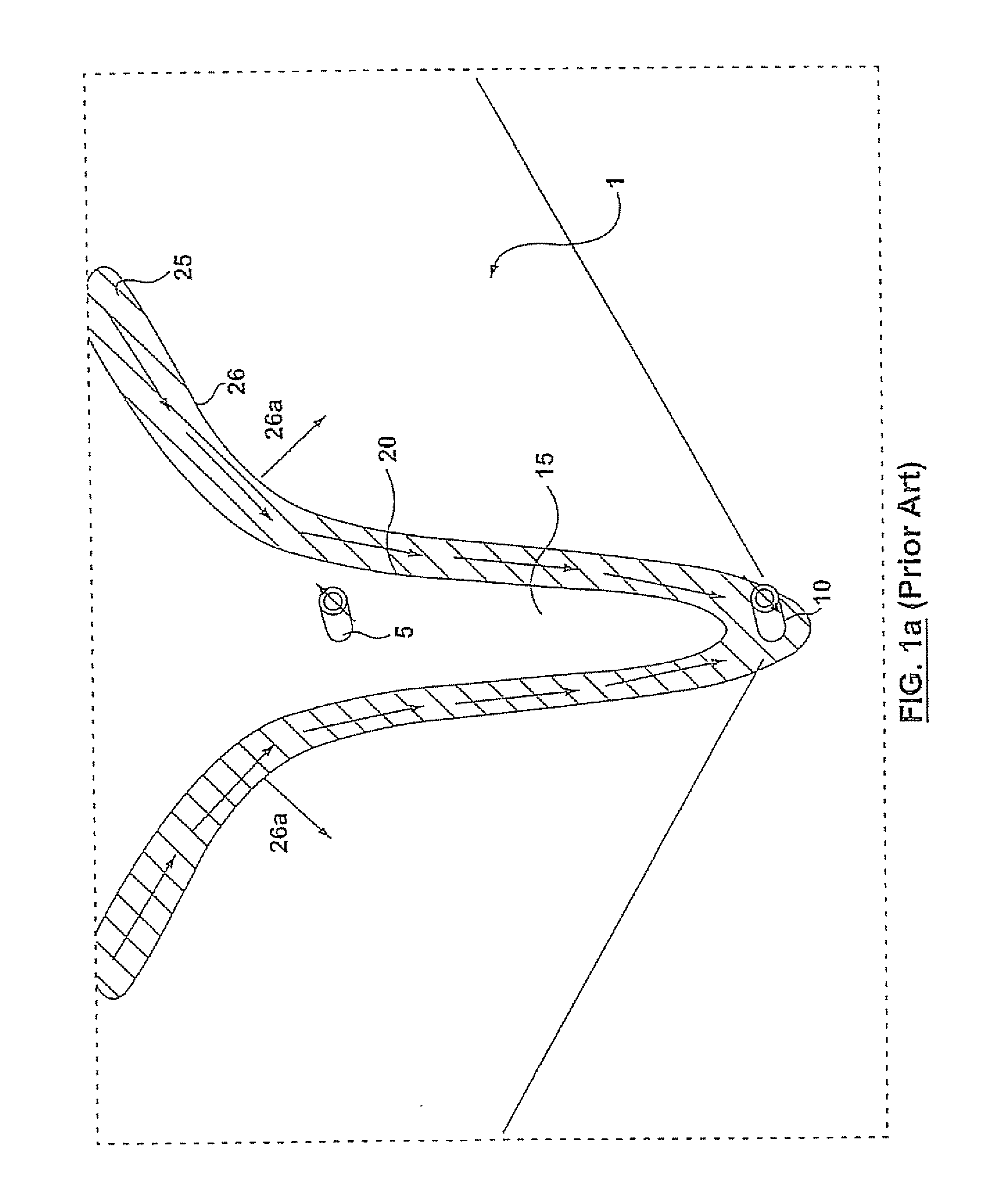

Methods of Improving Heavy Oil Production

The invention provides an improved method for extracting heavy oil or bitumen contained in a reservoir. The invention involves directing the formation of a solvent fluid chamber through the combination of directed solvent fluid injection and production at combinations of horizontal and / or vertical injection wells so as to increase the recovery of heavy oil or bitumen contained in a reservoir. The wells are preferably provided with flow control devices to achieve uniform production.

Owner:CNOOC PETROLEUM NORTH AMERICA ULC

Process for in situ recovery of bitumen and heavy oil

A process is described for in situ recovery of bitumen or heavy oil from a reservoir having a horizontal injection well and a horizontal production well. The process includes a first phase in which steam and a heavy hydrocarbon solvent are injected into the reservoir, a second phase in which the steam and heavy hydrocarbon injections are transitioned to a light hydrocarbon solvent injection, and a third phase in which a light hydrocarbon solvent is injected without further steam or heavy hydrocarbon injection. A displacement gas may be added during any of the phases, and production of hydrocarbons continues throughout all phases. The process employs a high-production start-up phase, followed by lower cost phases which progress a depletion chamber within the reservoir.

Owner:EXXONMOBIL UPSTREAM RES CO

Solar augmented geothermal energy

ActiveUS7472548B2Increase valueReliable water sourceSolar heating energyAuxillary drivesOil fieldInjection well

An apparatus and a method is disclosed for storage of solar energy in a subsurface geologic reservoir. The method includes transferring concentrated solar thermal energy to a fluid, thereby generating a supercritical fluid. The supercritical fluid is then injected into the subsurface geologic reservoir through at least one injection well. The subsurface geologic reservoir may be a highly permeable and porous sedimentary strata, a depleted hydrocarbon field, a depleting hydrocarbon field, a depleted oil field, a depleting oil field, a depleted gas field, or a depleting gas field. Once charged with the supercritical fluid, the subsurface geologic formation forms a synthetic geothermal reservoir.

Owner:MEKSVANH NINO

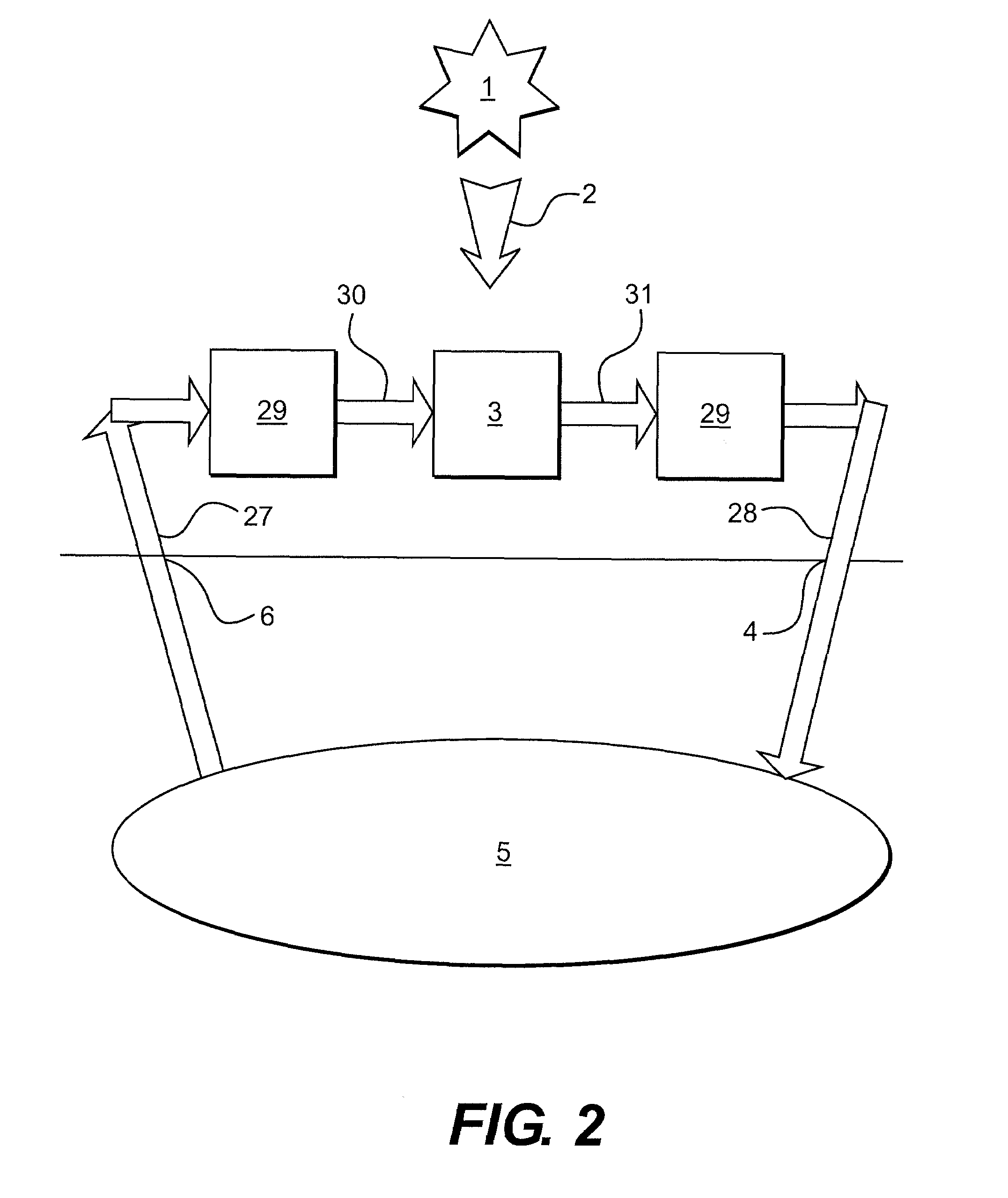

Methods and apparatus for disposing of deleterious materials from a well

InactiveUS6745856B2Save spaceSave equipmentCargo handling apparatusAuxillariesDrill siteHazardous substance

An improved method and apparatus for processing deleterious material on a floating vessel during transportation from a well to a disposal site. The vessel contains equipment for the slurrification and agitation of the deleterious material. Such equipment includes storage tanks, slurrification units, and agitation units, as well as transfer equipment such as flow lines and vacuum or pump means. The deleterious material is transferred from the drill site to the storage tanks on the vessel. The vessel then transports the material to a disposal site, such as an injection well. During transportation, the deleterious material is processed. Such processing can include slurrification and / or agitation of the deleterious material to maintain the slurry, adding fluid if necessary. Once at the disposal site, the deleterious material slurry is then transferred from the vessel to the disposal site.

Owner:MI

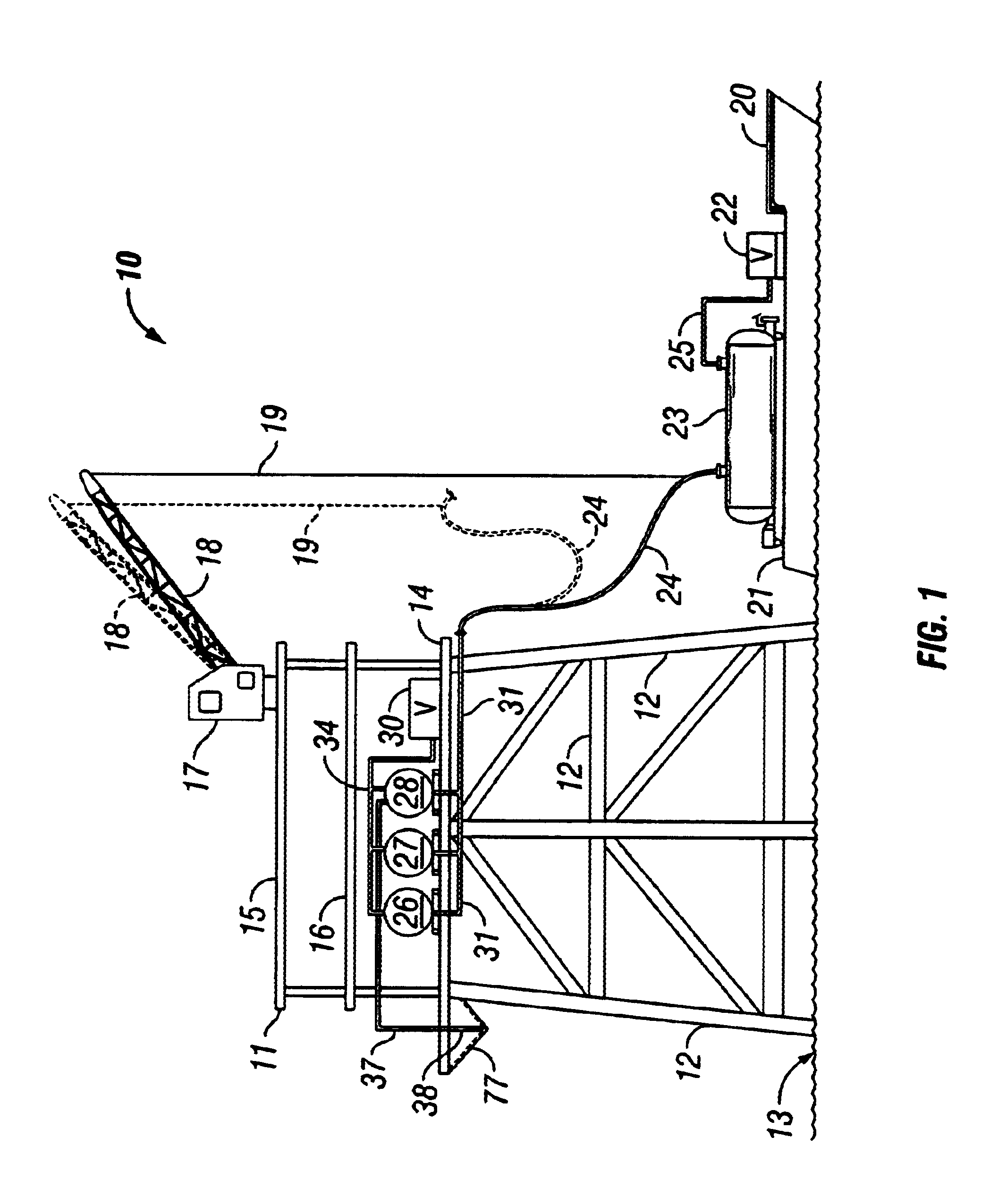

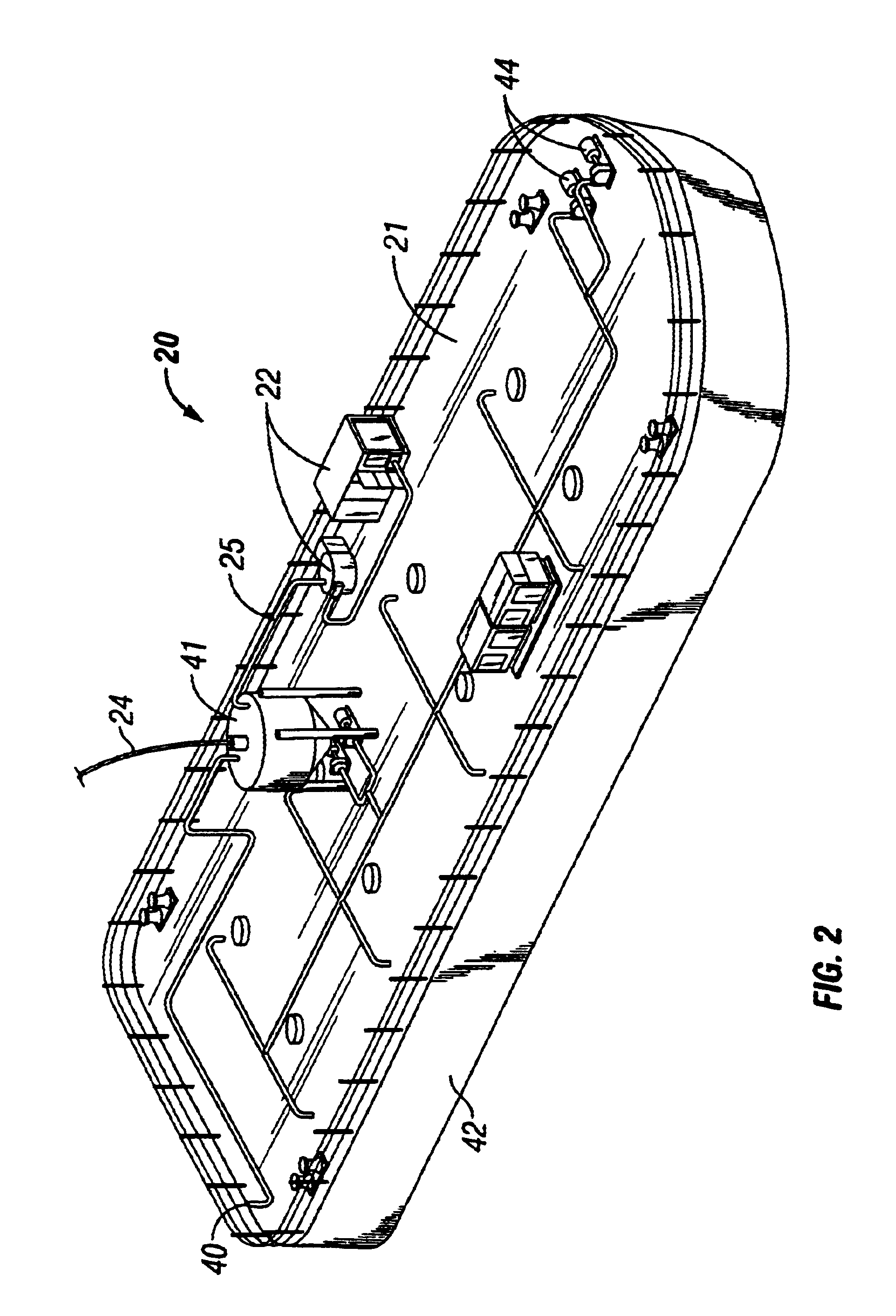

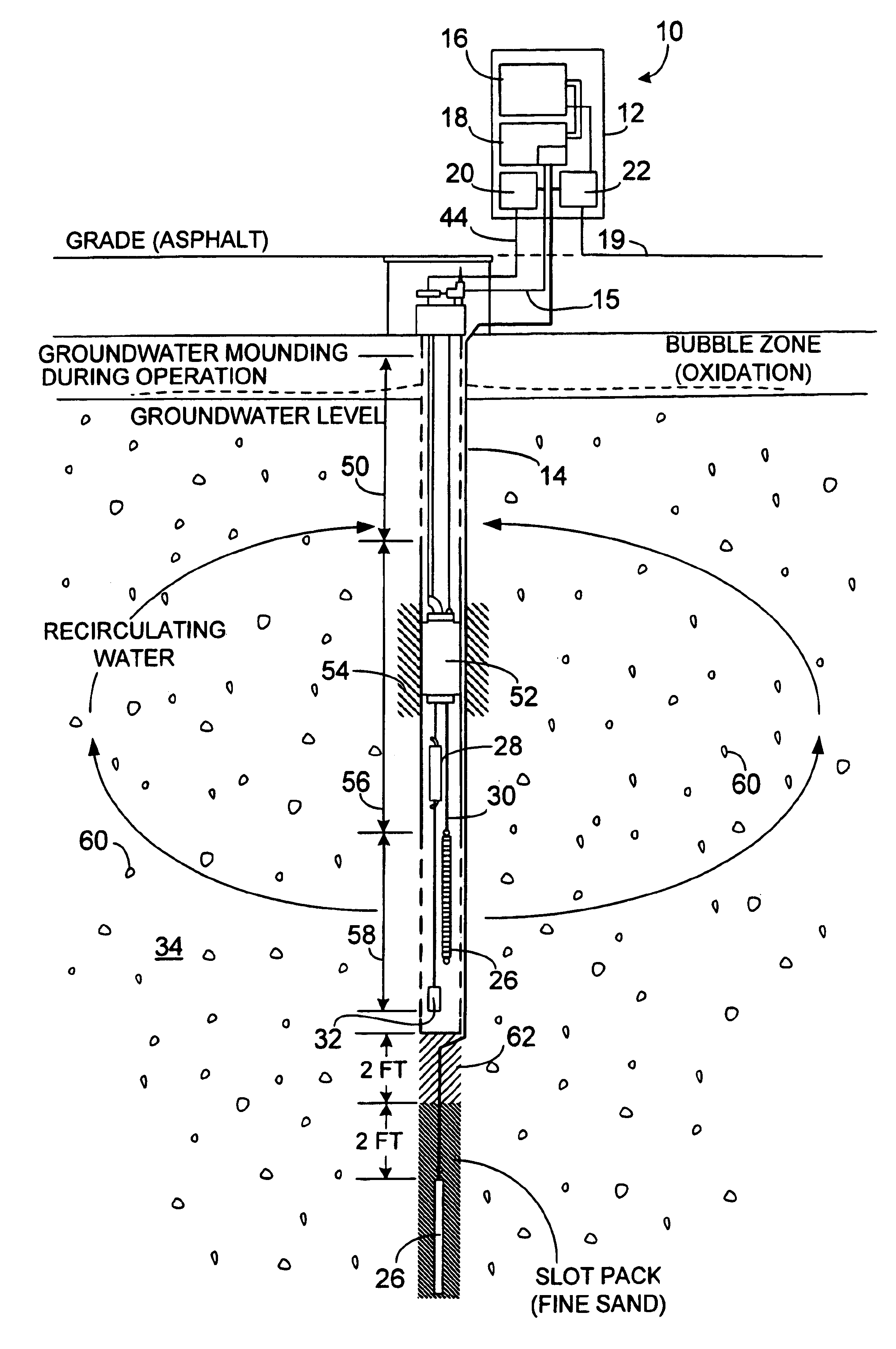

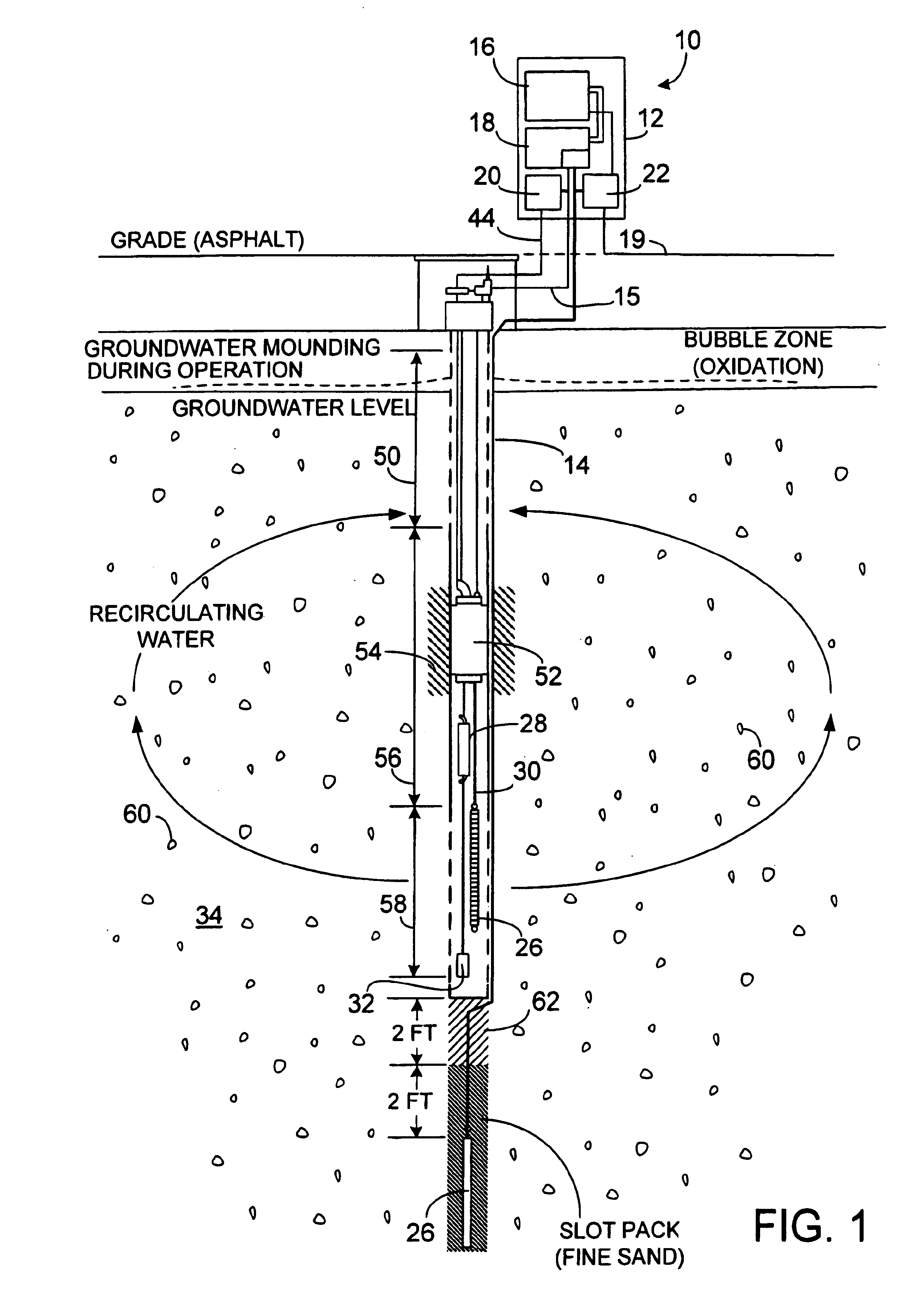

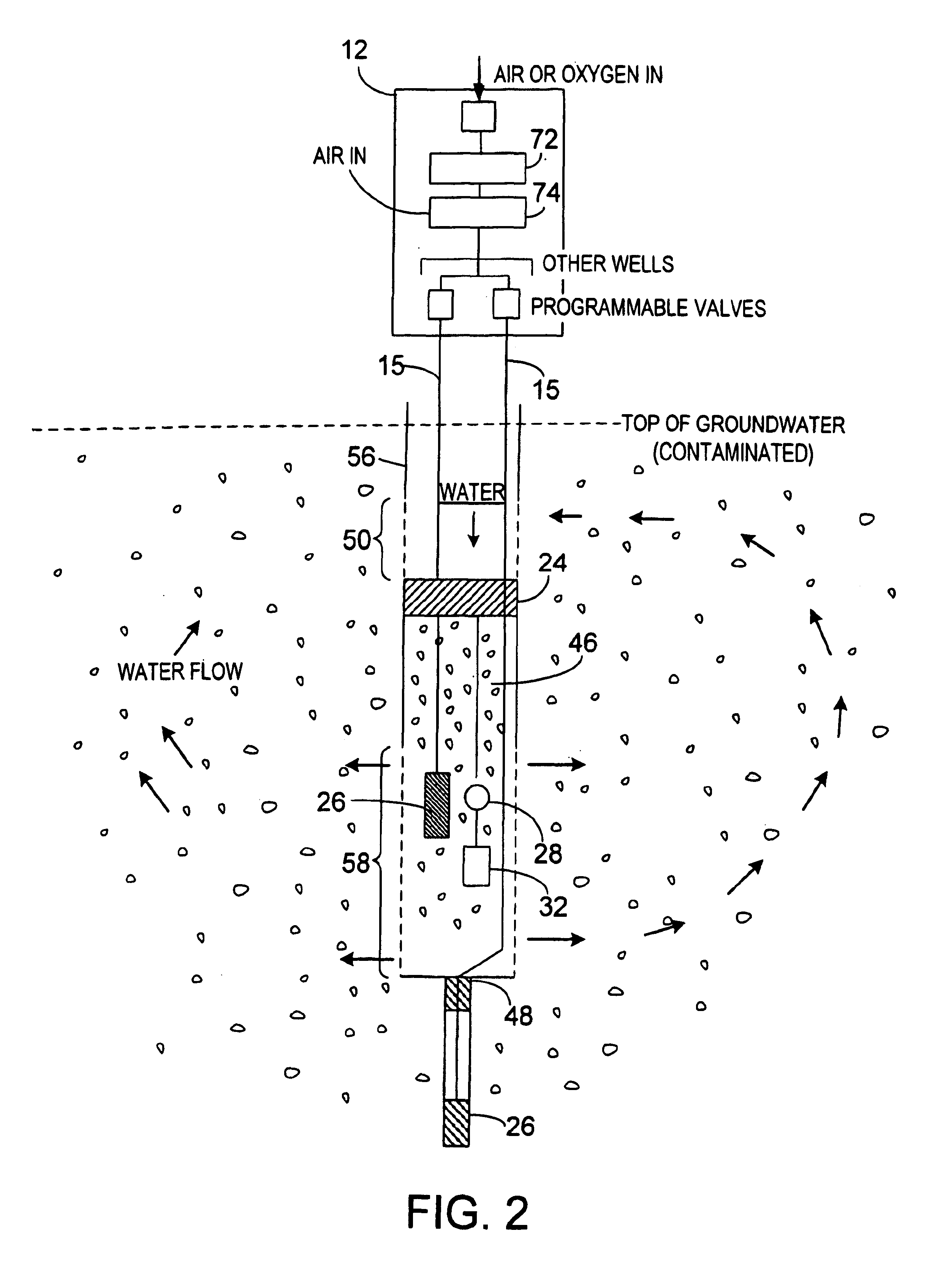

Microporous diffusion apparatus

InactiveUS6872318B2Efficient removalTreatment using aerobic processesTransportation and packagingDecompositionBioremediation

Apparatus for active in situ multi-element gas sparging for bioremediation or physico-chemical degration for removal of contaminants in a soil formation containing a subsurface groundwater aquifer or a substantially wet unsaturated zone, the multi-gas contained in bubbles, wherein the apparatus includes a plurality of injection wells extending to a depth of a selected aquifer; introducing an oxidizing agent comprising ozone mixed with ambient air to provide a multi-element gas by means of microporous diffusers, without applying a vacuum for extraction of stripped products or biodegration by-products, wherein said diffusers form micro-fine bubbles containing said multi-element gas that oxidizes, by stripping and decomposition, chlorinated hydrocarbons from the aquifer and surrounding saturated soil formation into harmless by-products; also including a pump for agitating water in the well selecting microbubbles, injecting them into the aquifer and effective to alter the path of micro-fine bubbles through a porous solid formation whereby enhanced contact between the oxidizing agent contained in each said bubble by stripping pollutant from solution in ambient water into the mini-atmosphere of each bubble effective to increase the efficiency and speed of remediation of a site.

Owner:KERFOOT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com