Patents

Literature

1444results about "Differential sedimentation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

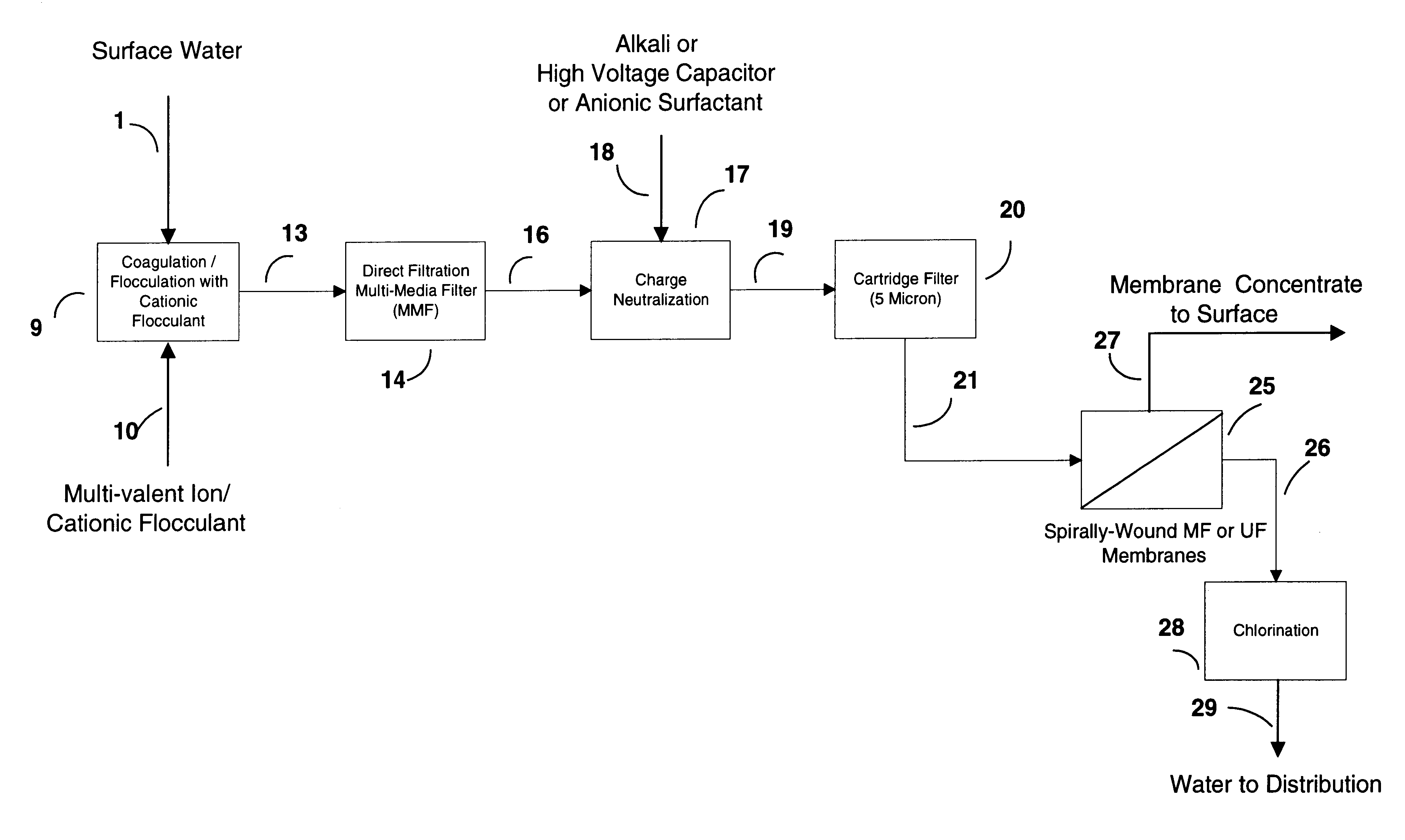

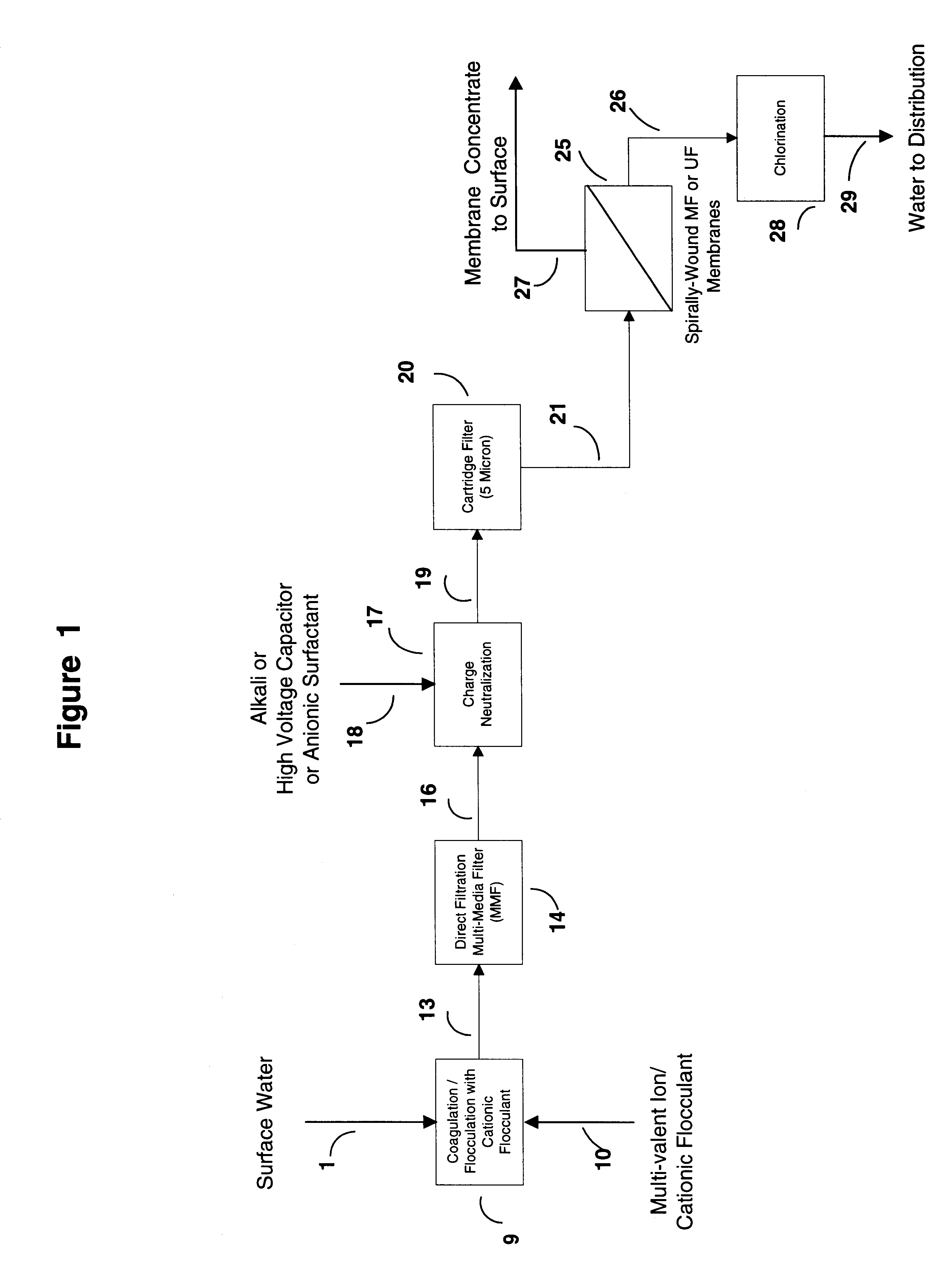

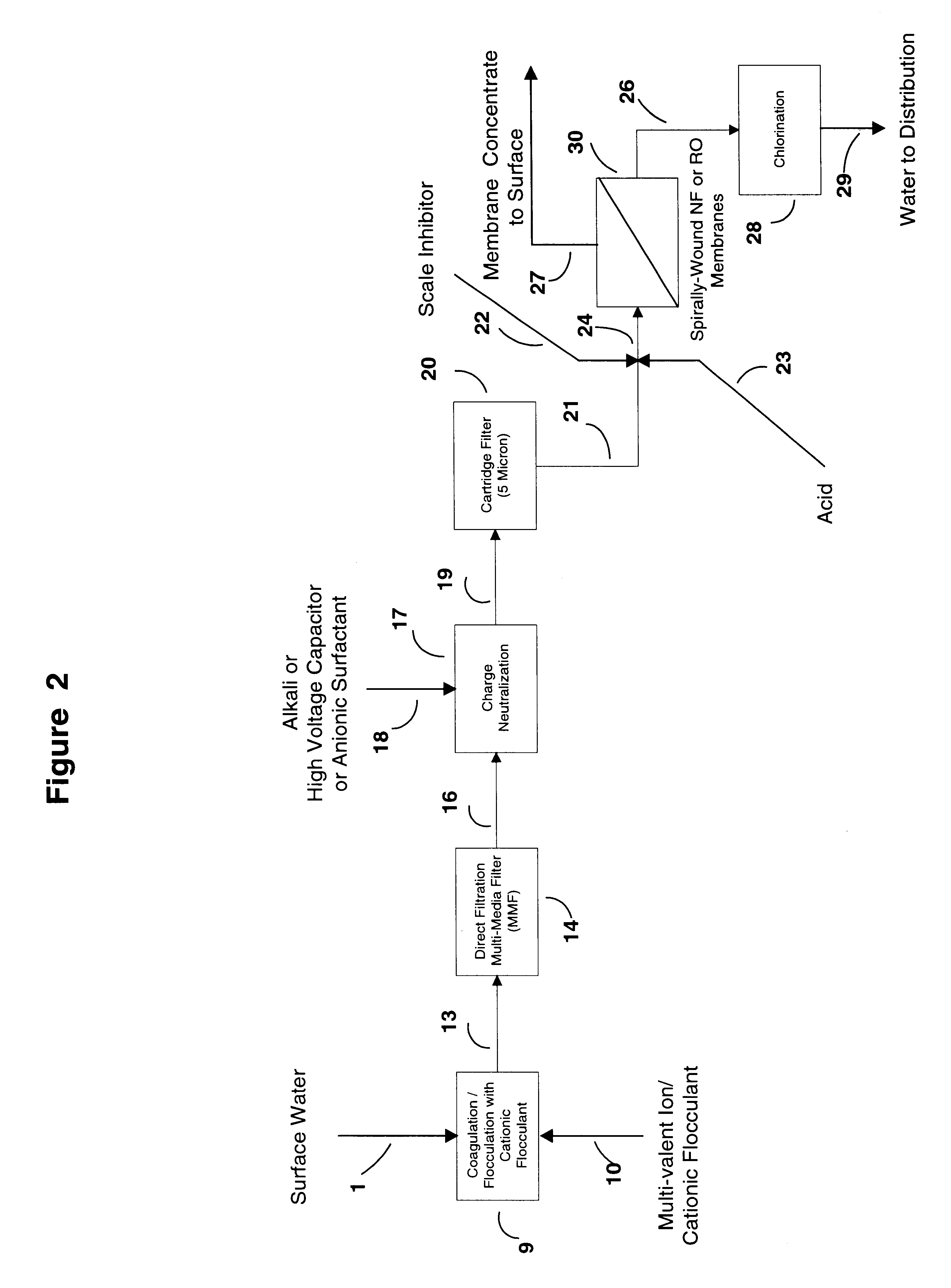

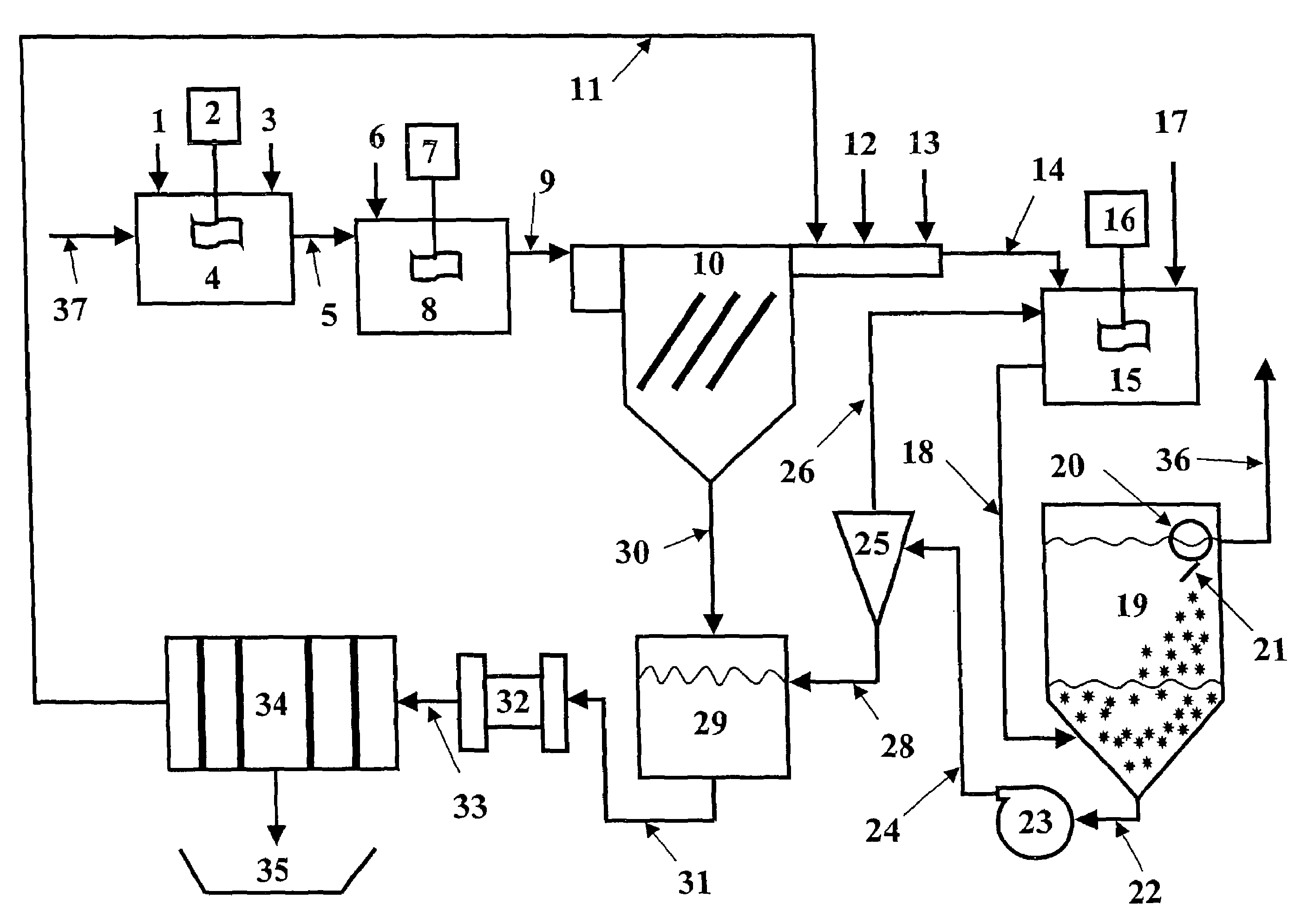

Water treatment process for membranes

InactiveUS6416668B1Effective and safe and reliable to produceCapital and operating costMembranesUltrafiltrationZeta potentialFiltration

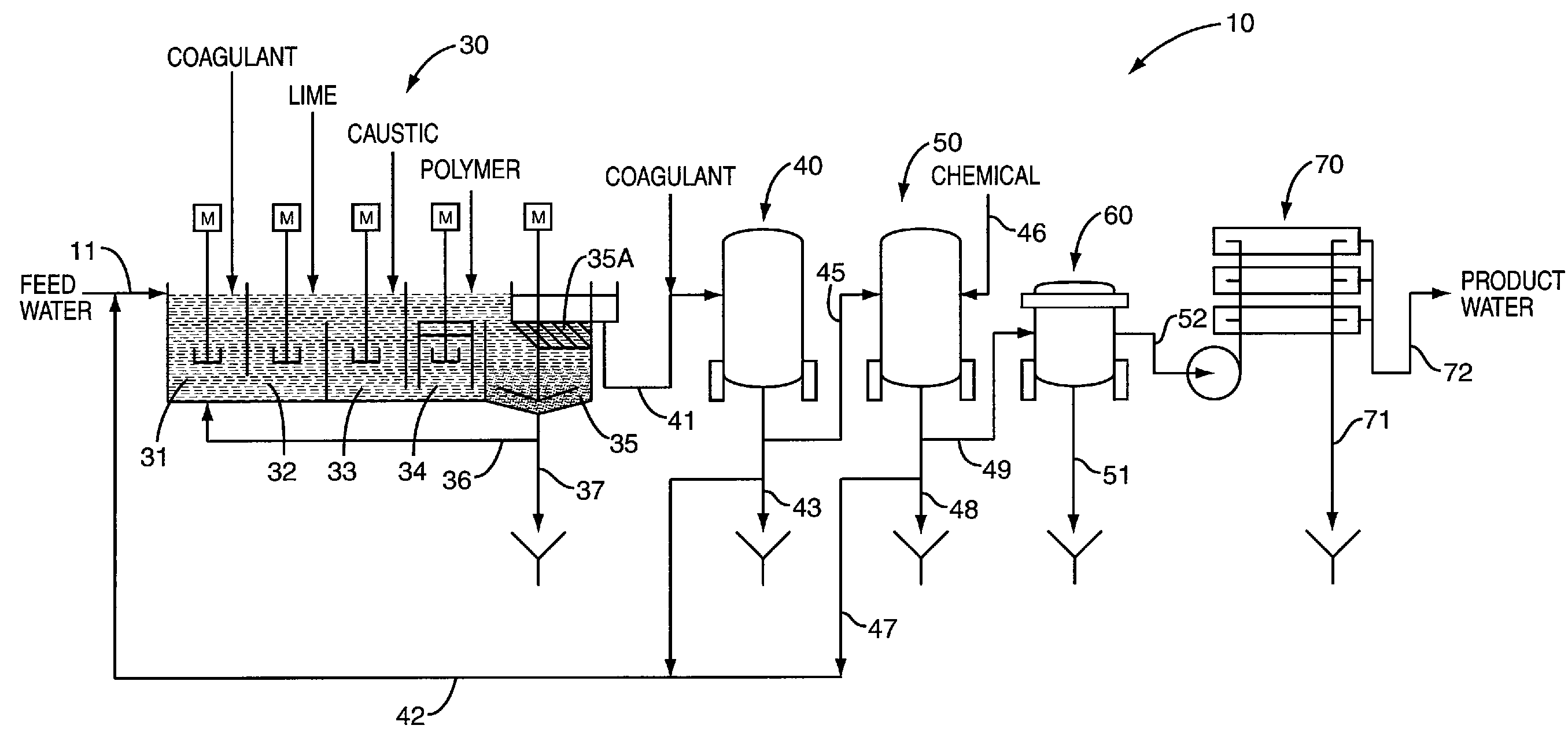

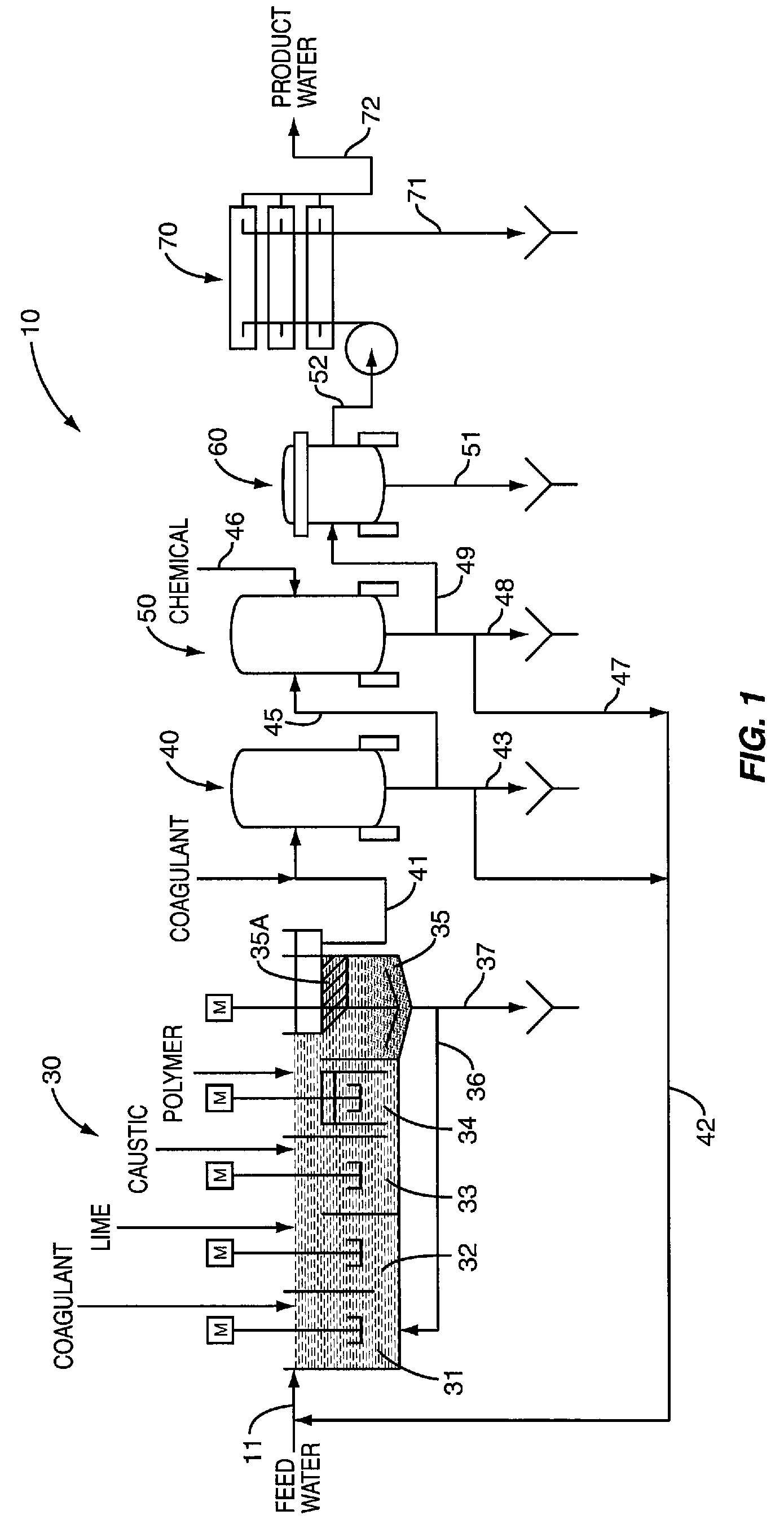

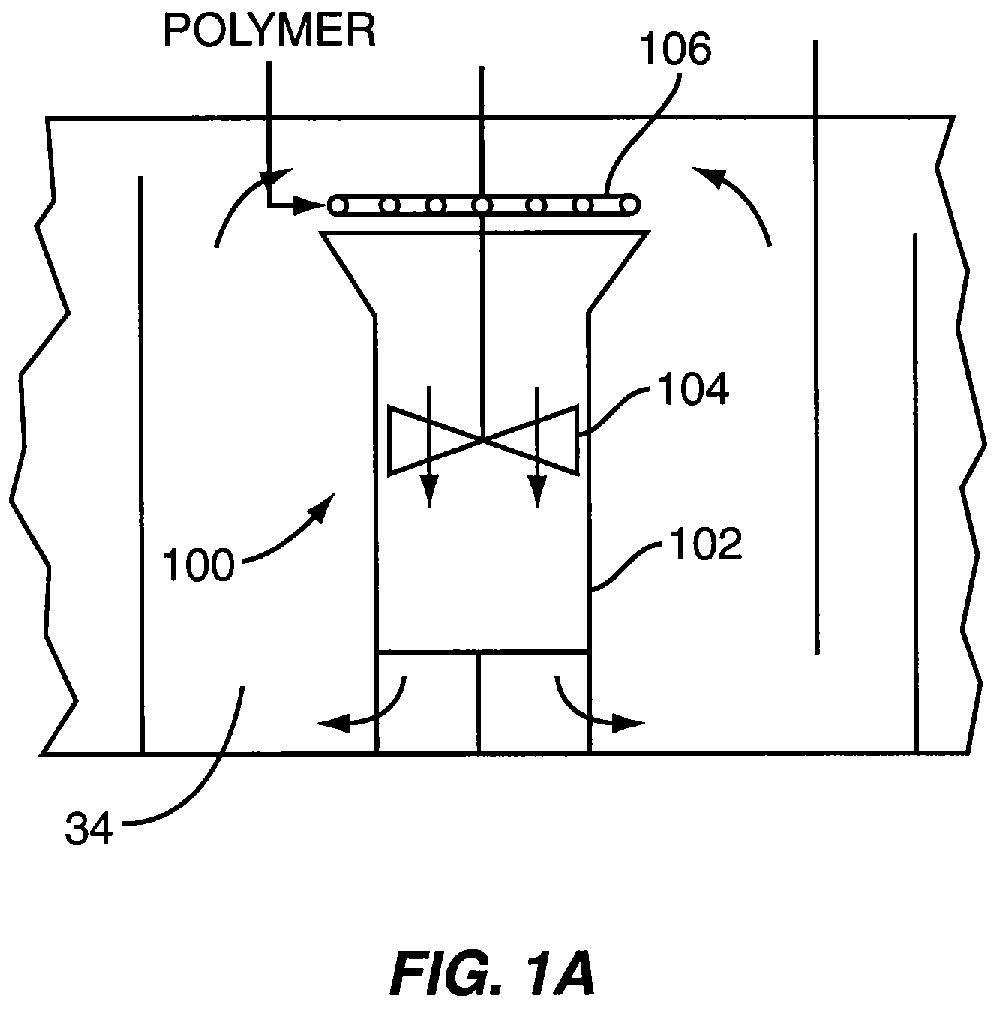

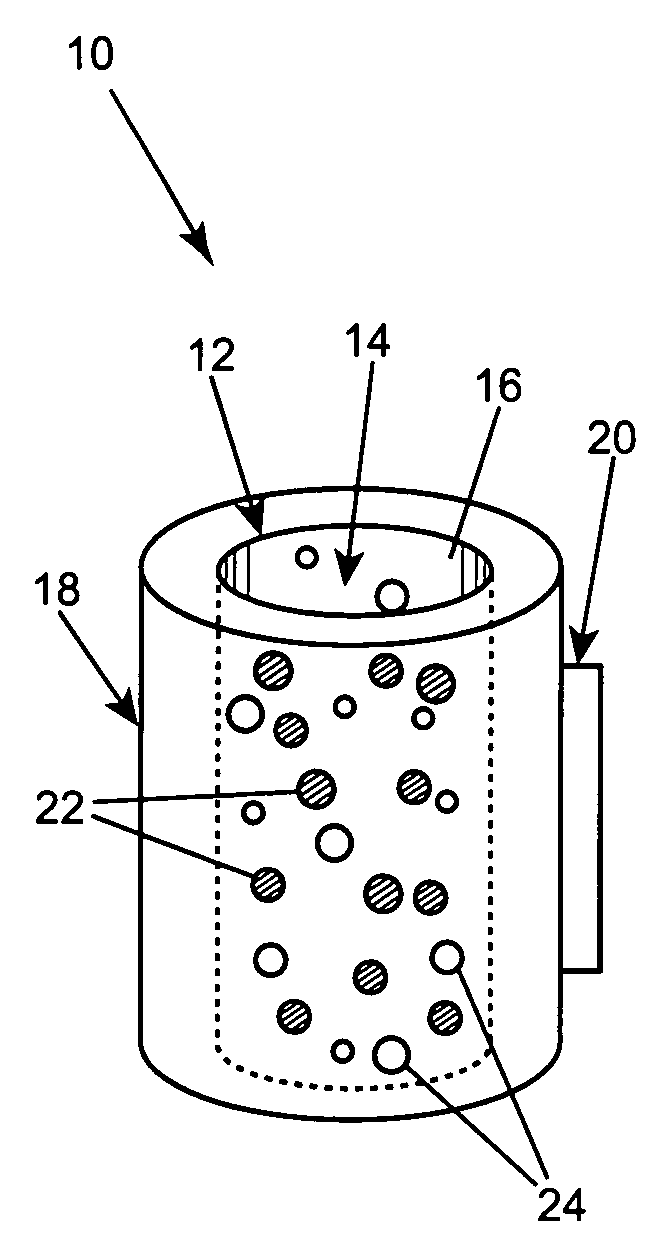

This invention discloses a cost-effective process for separating contaminants and a wide-range of fouling material from surface water, ground water and from industrial effluents. Having undergone effective pre-treatment, the water can be purified further by using high-surface area spirally wound micro-filtration (MF), ultra-filtration (UF), nano-filtration (NF) or reverse osmosis (RO) membranes. High-quality potable water free from pathogen and other contaminants is thus produced at low-cost from the pre-treated surface water and ground-water. Conversely, pre-treated industrial effluents are further purified at a relatively low-cost using NF or RO membranes, thus producing water suitable for recycle or surface discharge. The process of this invention uses cationic inorganic and / or polymeric flocculants to coagulate and flocculate the water-borne colloidal matter (e.g. clays, iron hydroxides, naturally occurring matter (NOM's), etc.), followed by filtration using a multi-media filter, charge neutralization and reversal and final filtration using a 5-micron cartridge filter. These pre-treatment steps provides a good quality water having a low Silt Density Index and a significant negative zeta potential, thereby ensuring against irreversible chemical fouling of the spirally-wound membranes.

Owner:AL SAMADI RIAD A

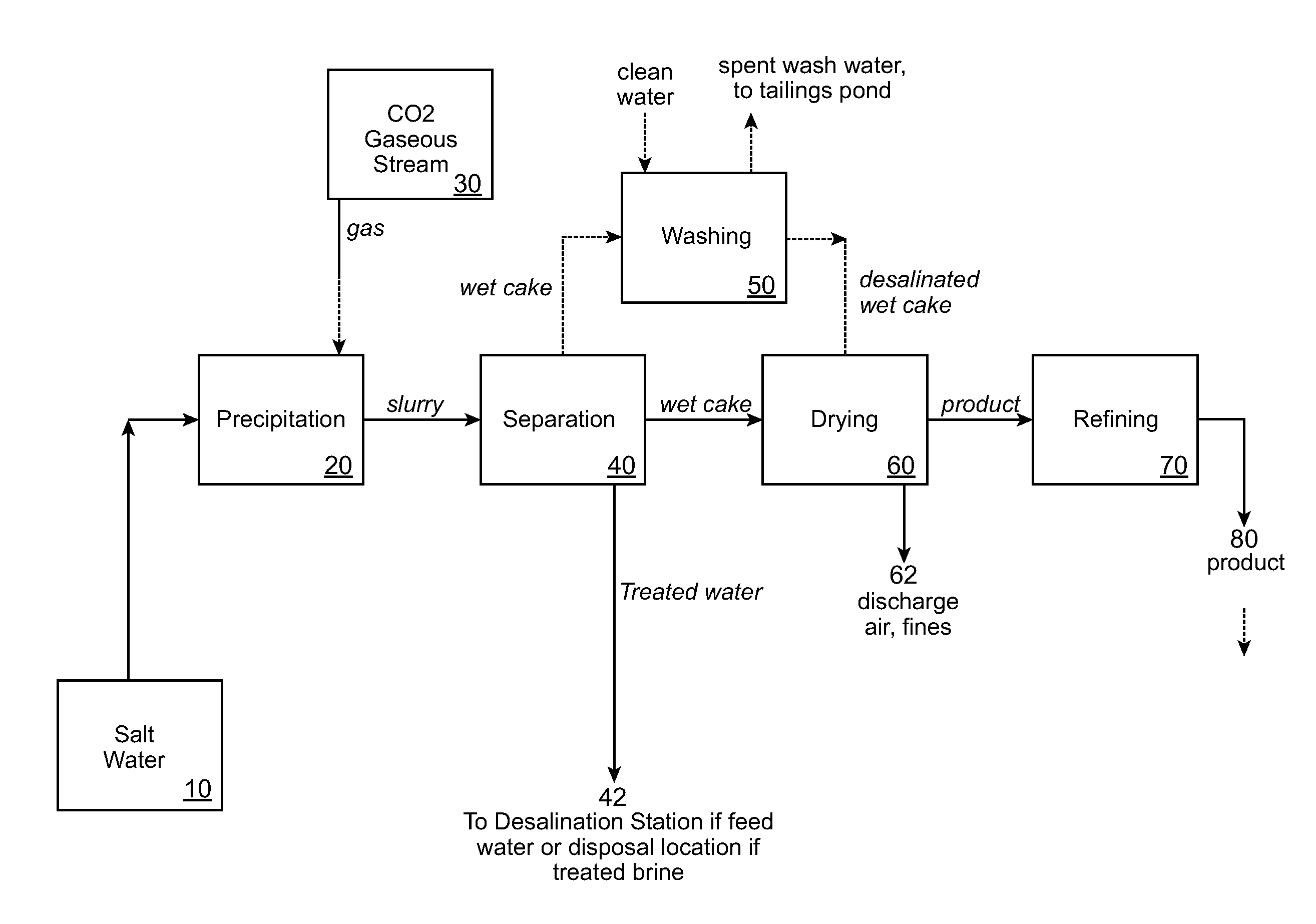

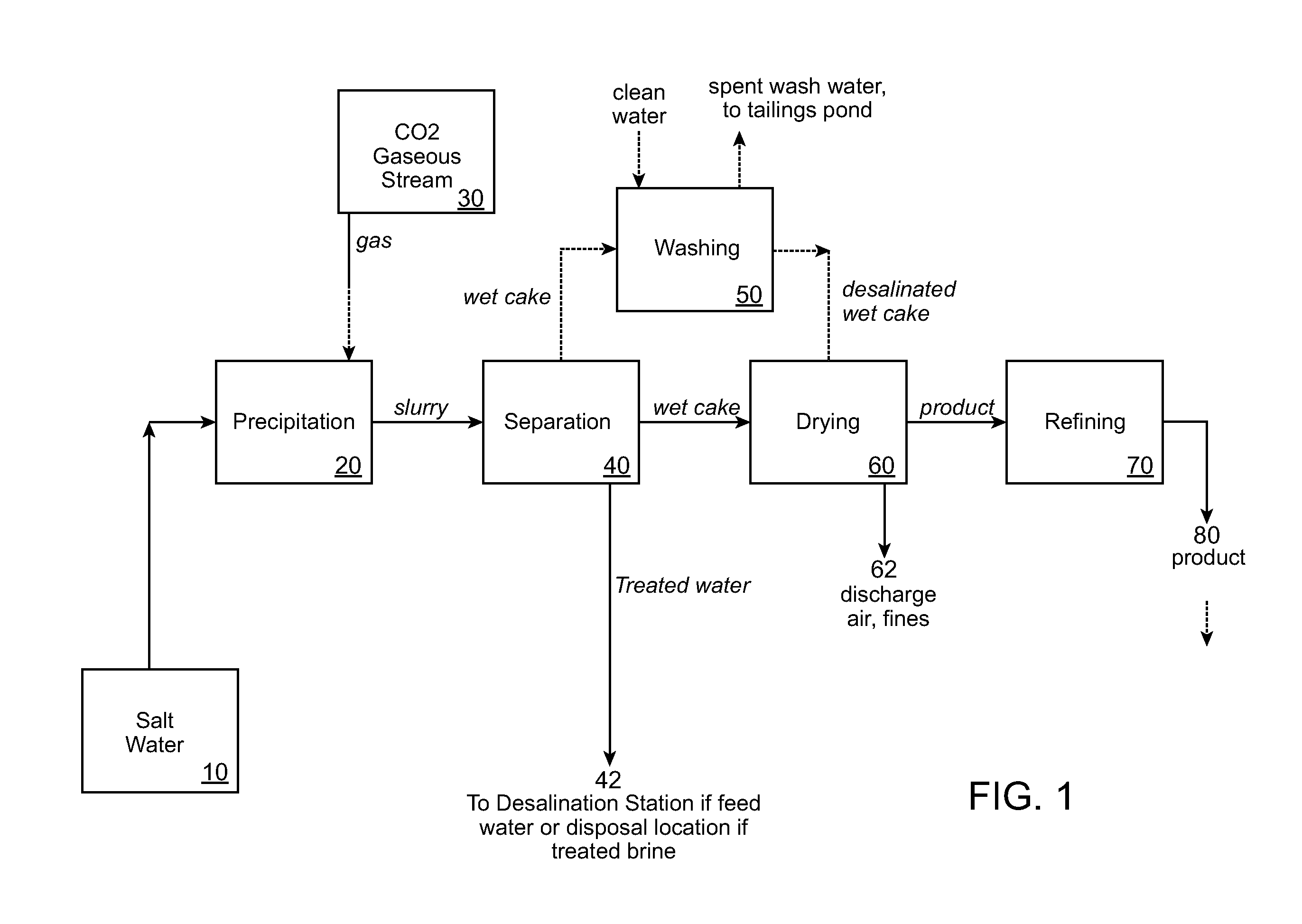

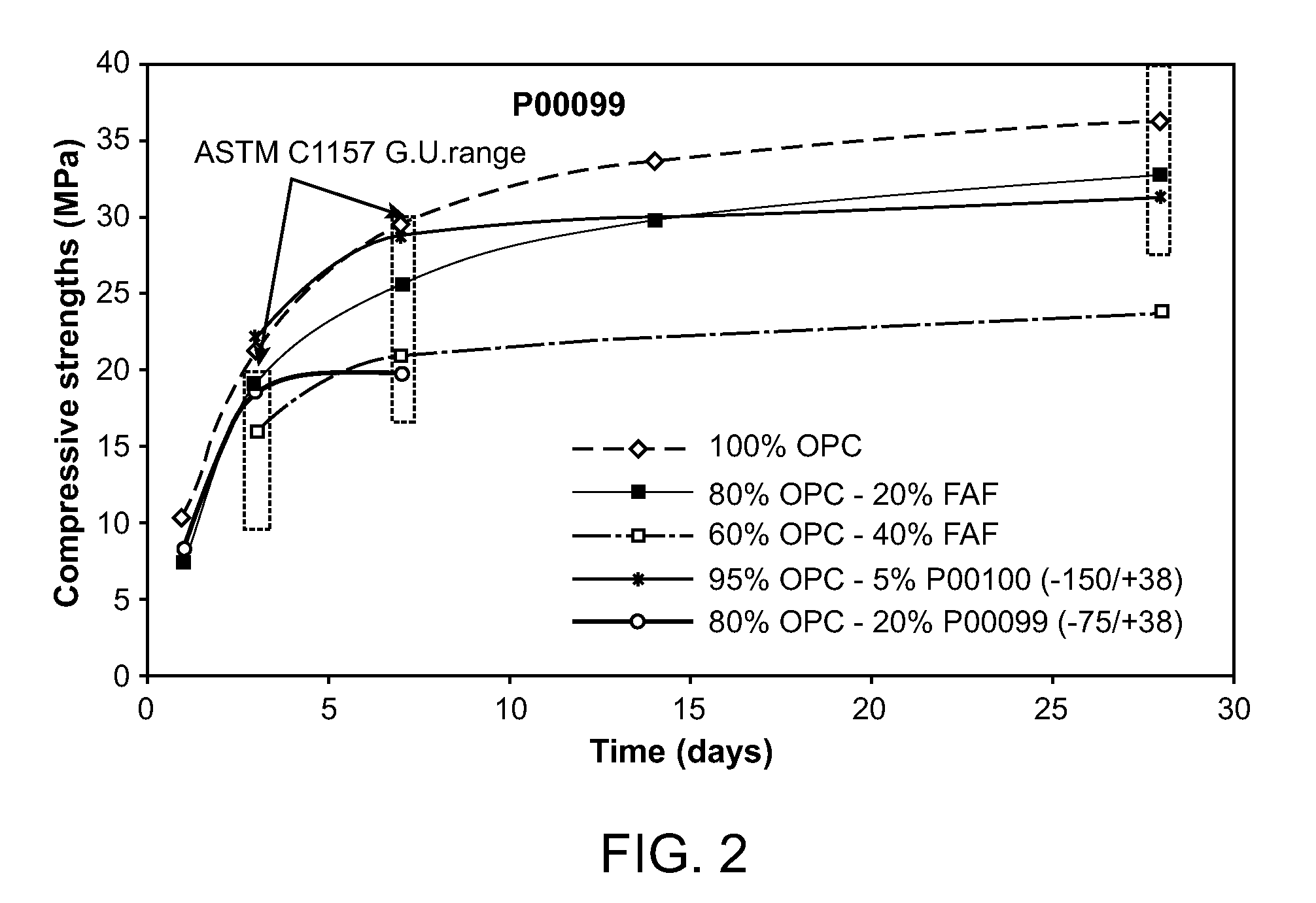

Desalination methods and systems that include carbonate compound precipitation

ActiveUS20090001020A1Easy complianceImprove desalination efficiencyGeneral water supply conservationSeawater treatmentSaline waterDesalination

Desalination methods that include carbonate compound precipitation are provided. In certain embodiments, feed water is subjected to carbonate compound precipitation conditions prior to desalination. In certain embodiments, desalination waste brine is subjected to carbonate compound precipitation conditions. In yet other embodiments, both feed water and waste brine are subjected to carbonate compound precipitation conditions. Aspects of embodiments of the invention include carbone dioxide sequestration. Embodiments of the invention further employ a precipitate product of the carbonate compound precipitation conditions as a building material, e.g., a cement. Also provided are systems configured for use in methods of the invention.

Owner:ARELAC INC

Materials and process for enhancing selective separations

Use of a Maillard reaction product as an adjuvant in a variety of applications including solid-liquid separations, corrosion inhibition, emulsification, dust suppression, slow release fertilization, viscosity modification and others and especially as a depressant or collector in separation processes, including the selective separation of solids and / or ionic species from aqueous media, such as in the process of froth flotation.

Owner:GEORGIA PACIFIC CHEM LLC

Rheology modification of settled solids in mineral processing

InactiveUS6365116B1Low viscosityIncrease speedRotary stirring mixersTransportation and packagingEngineeringSlurry

The present invention comprises a method for reducing the viscosity of the settled mud or underflow of a raked thickener thereby reducing the torque necessary to move the rake blade through the settled mud. The method includes the step of delivering a viscosity modifier to the settled mud and in front of the rake blade by pumping the viscosity modifier down the rake arm to an area in front of the rake blade. The method also includes an improved rake mechanism that includes a means for delivering viscosity modifier to the settled mud and in front of the rake blade. The present invention also includes a method for increasing the rate of consolidation of flocculated solids in a slurry.

Owner:ECOLAB USA INC

Method for treating wastewater or produced water

ActiveUS7815804B2Reduce hardnessReduce dissolved solidWaste water treatment from quariesGeneral water supply conservationWastewaterIon exchange

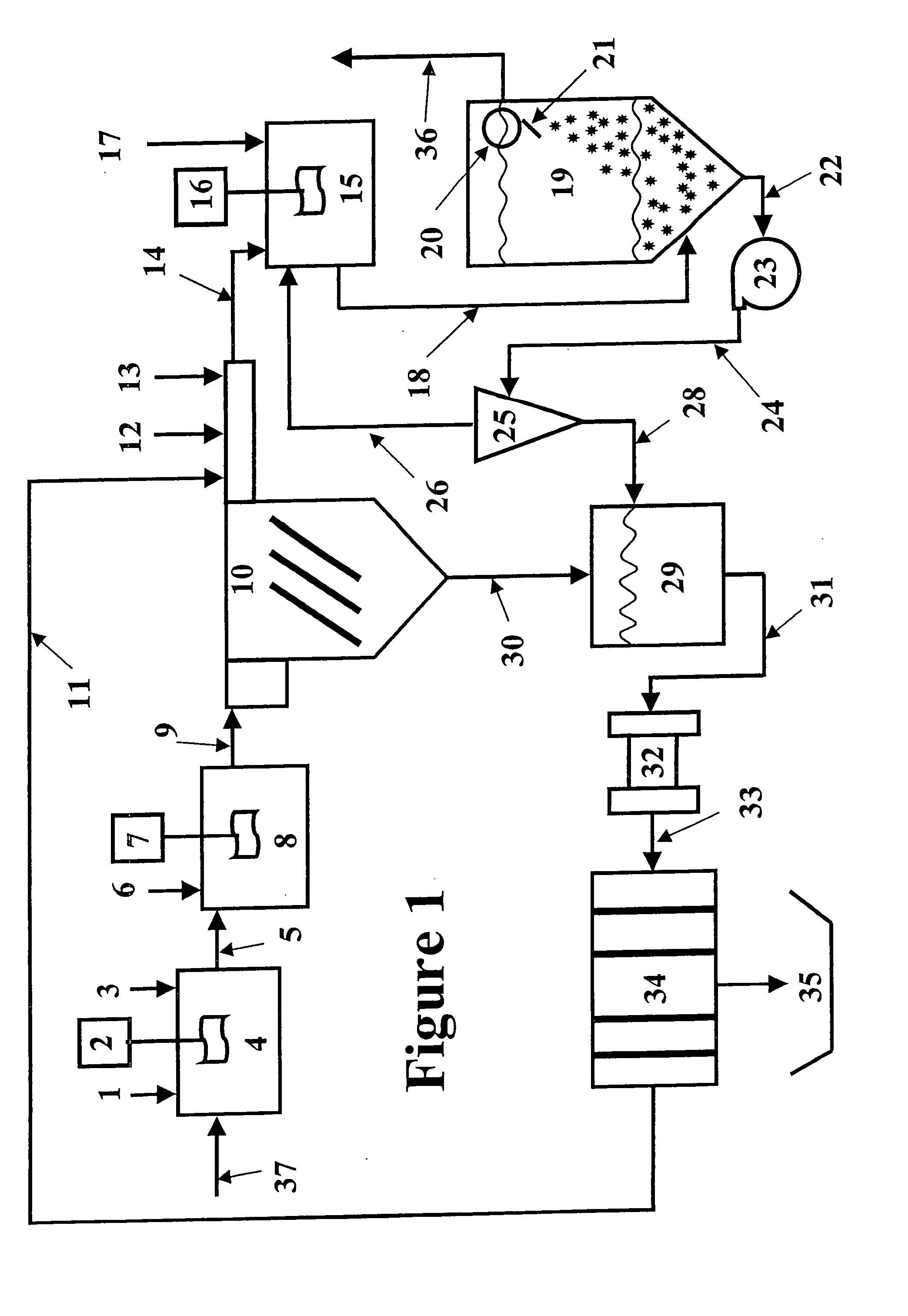

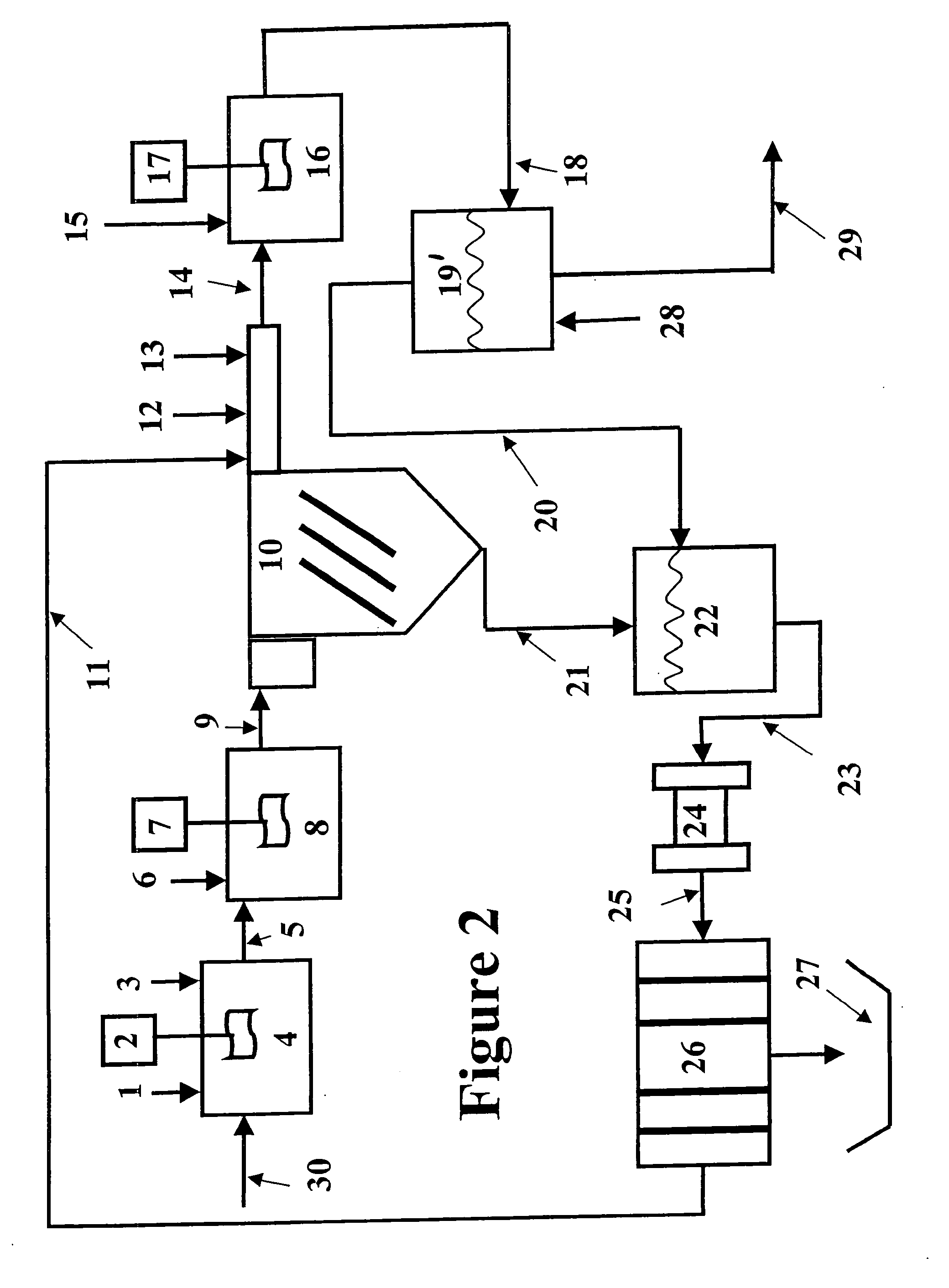

A method or process for treating wastewater containing high organics, silica, boron, hardness, and suspended and dissolved solids. The method includes degasifying the wastewater for the removal of dissolved gases and thereafter chemically softening the wastewater. After the chemical softening step, the wastewater is directed through a media filter or membrane which removes additional solids and precipitants. Thereafter the wastewater is directed through a sodium ion exchange that further softens the wastewater. The effluent from the ion exchange is directed through a cartridge filter and the effluent from the cartridge filter is directed through one or more reverse osmosis units. At a selected phase of the process, prior to the wastewater reaching the reverse osmosis unit or units, the pH of the wastewater is raised and maintained such that the pH of the wastewater reaching a reverse osmosis unit is at a pH greater than 10.5.

Owner:VEOLIA WATER SOLUTIONS & TECH SUPPORT

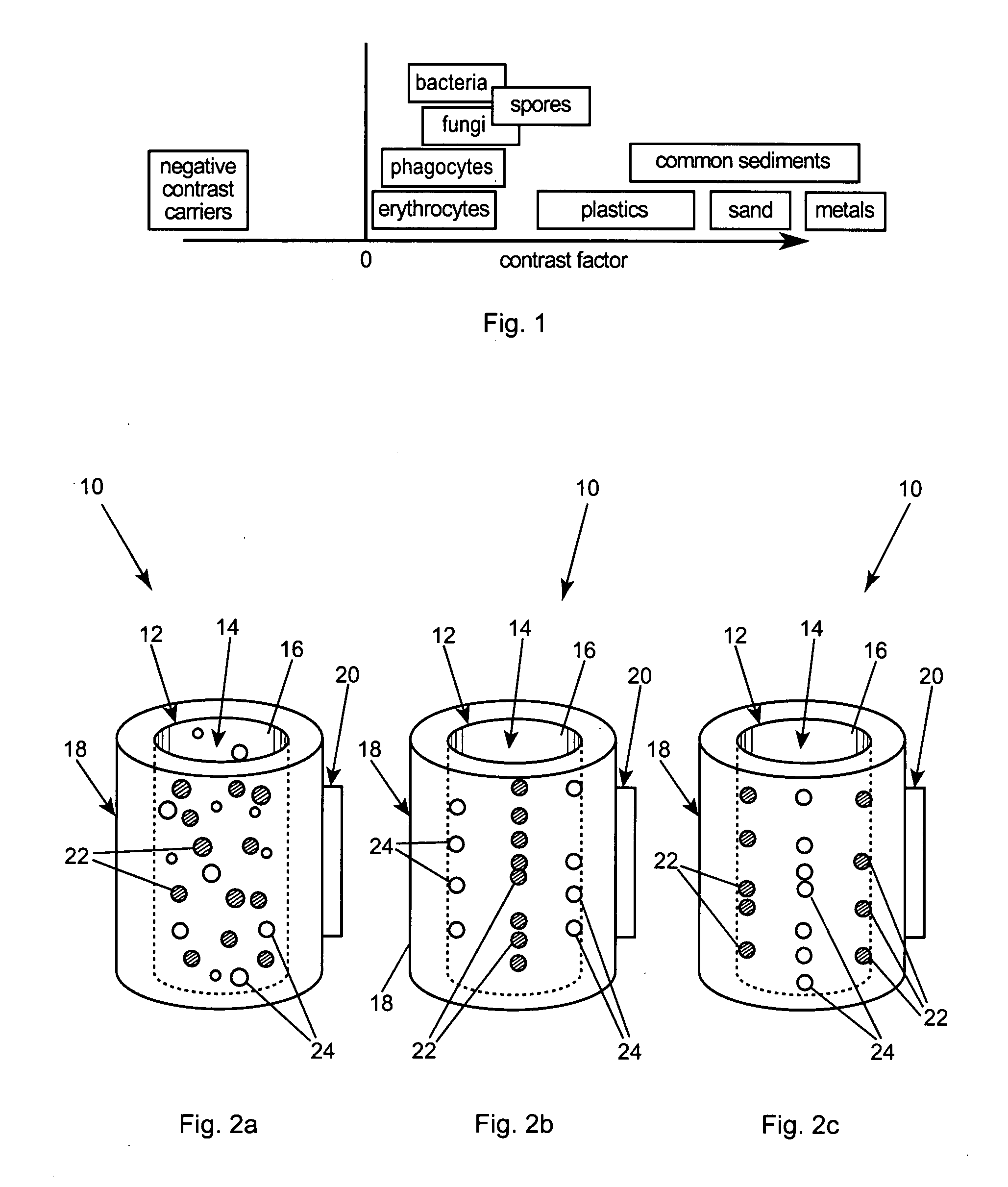

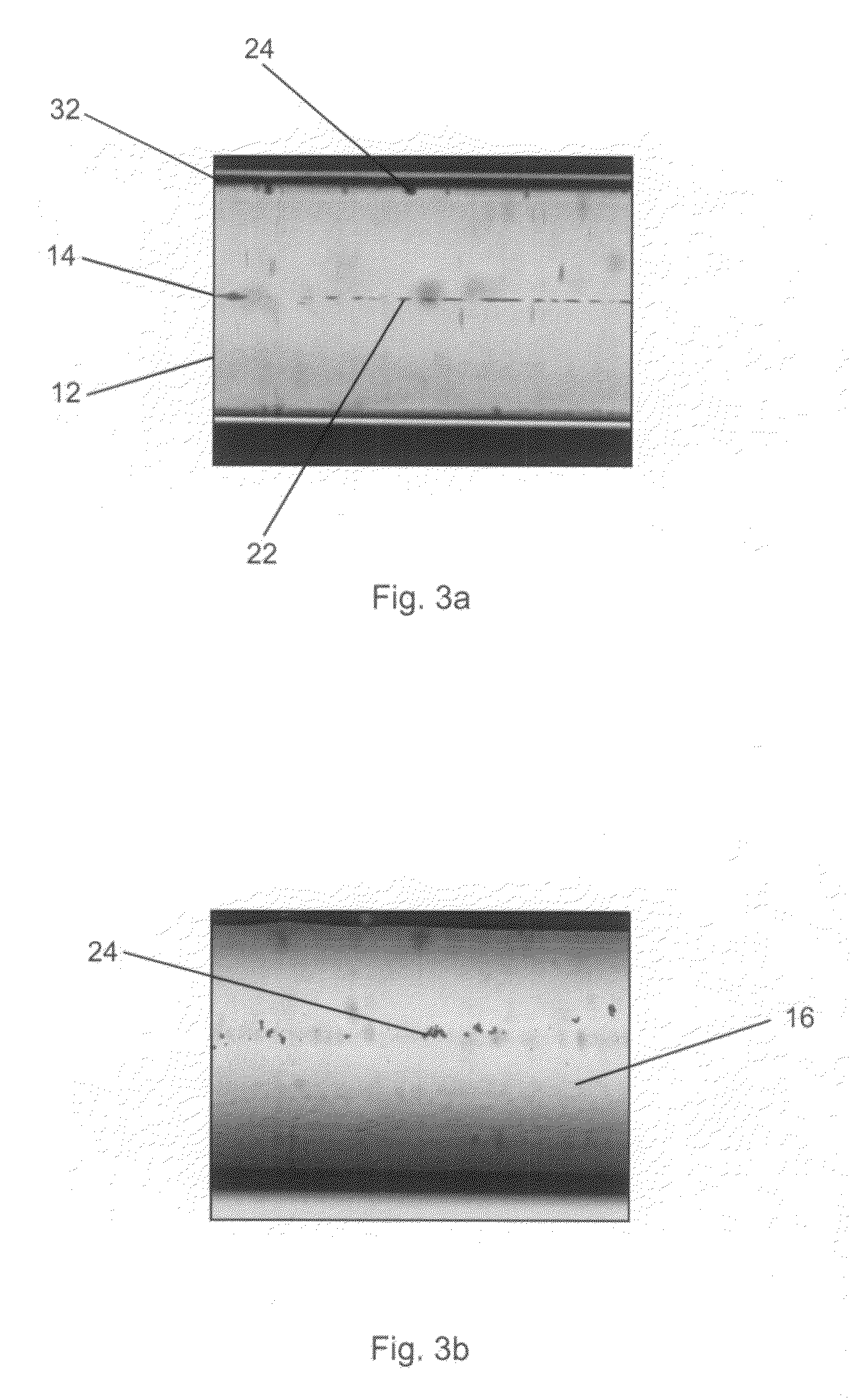

Apparatus for separating particles utilizing engineered acoustic contrast capture particles

Owner:TRIAD NAT SECURITY LLC

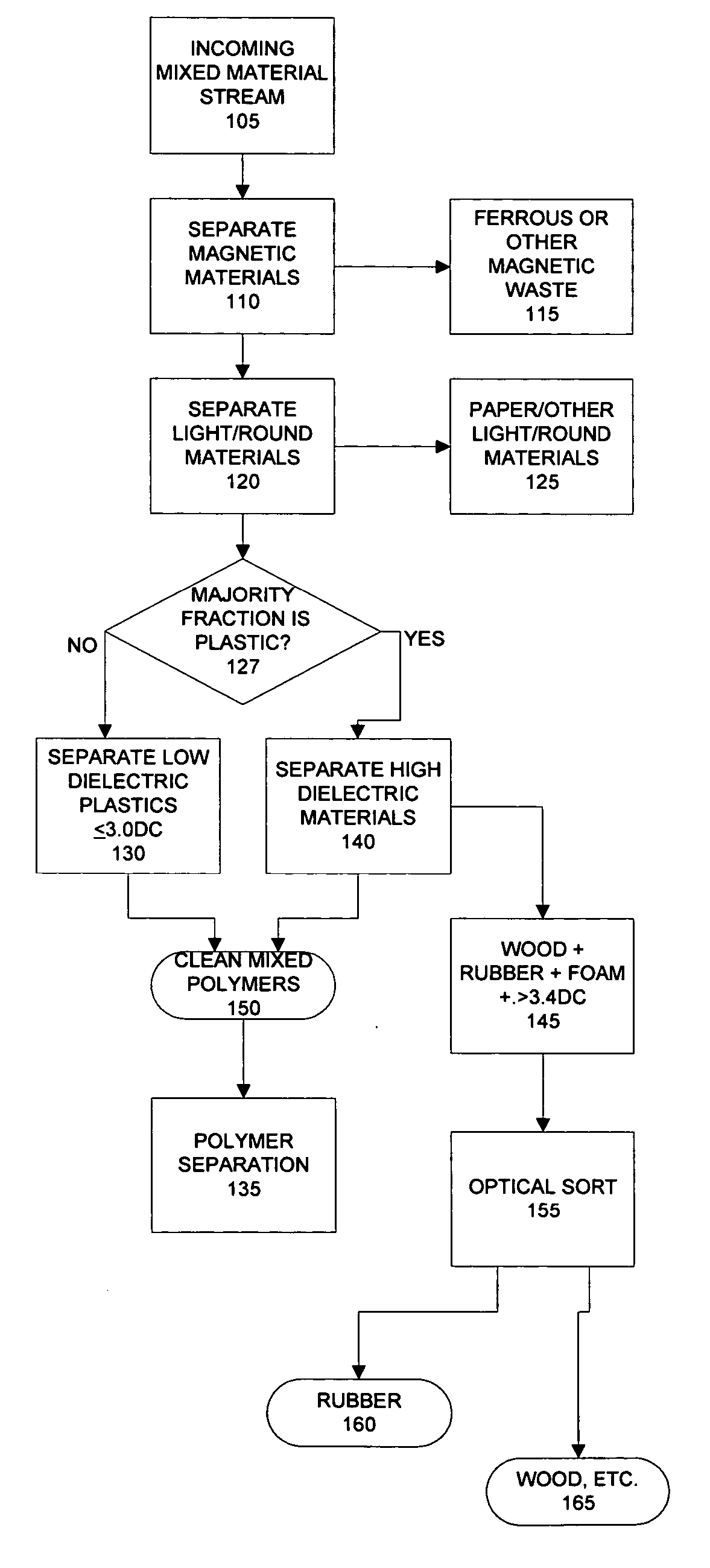

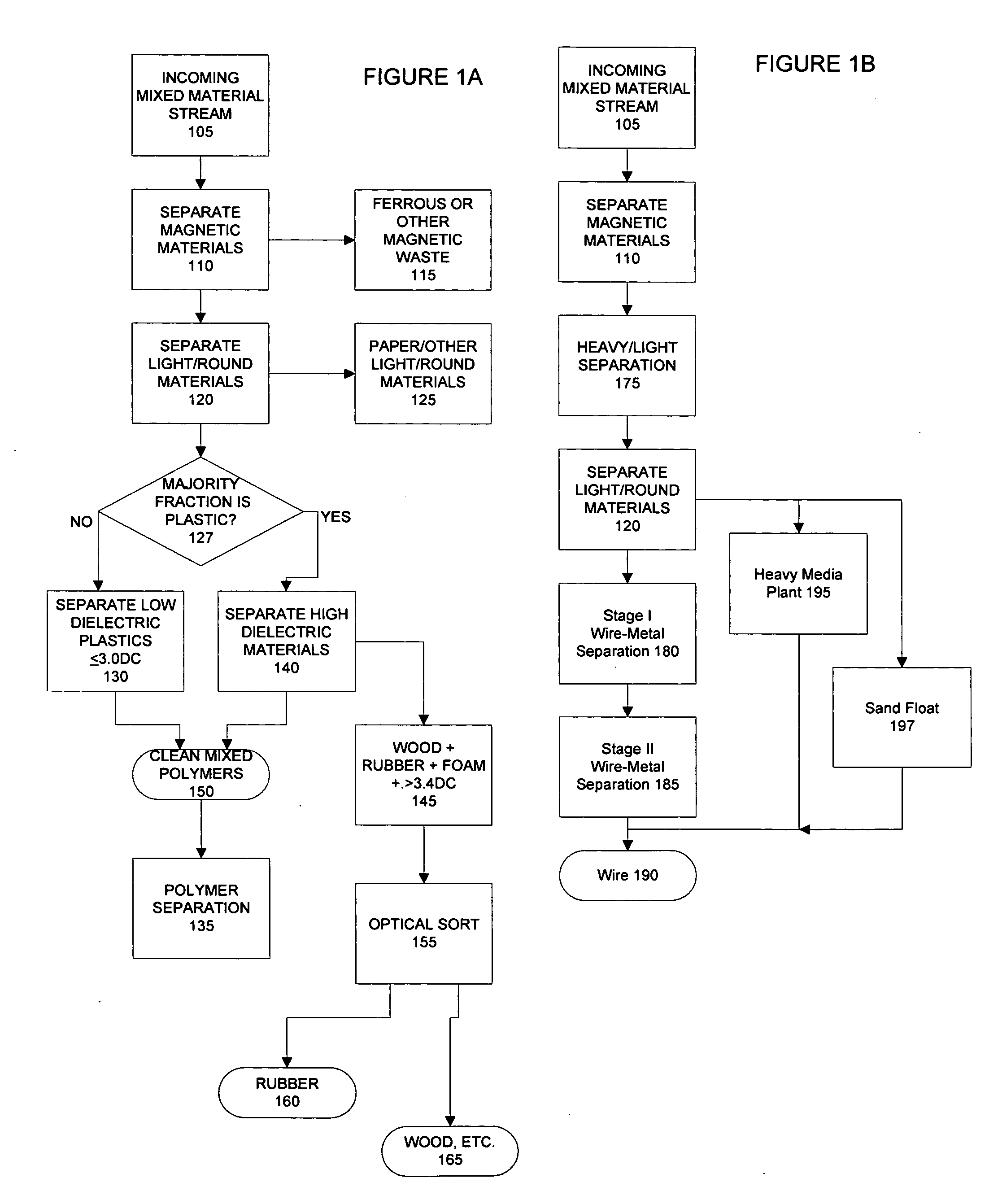

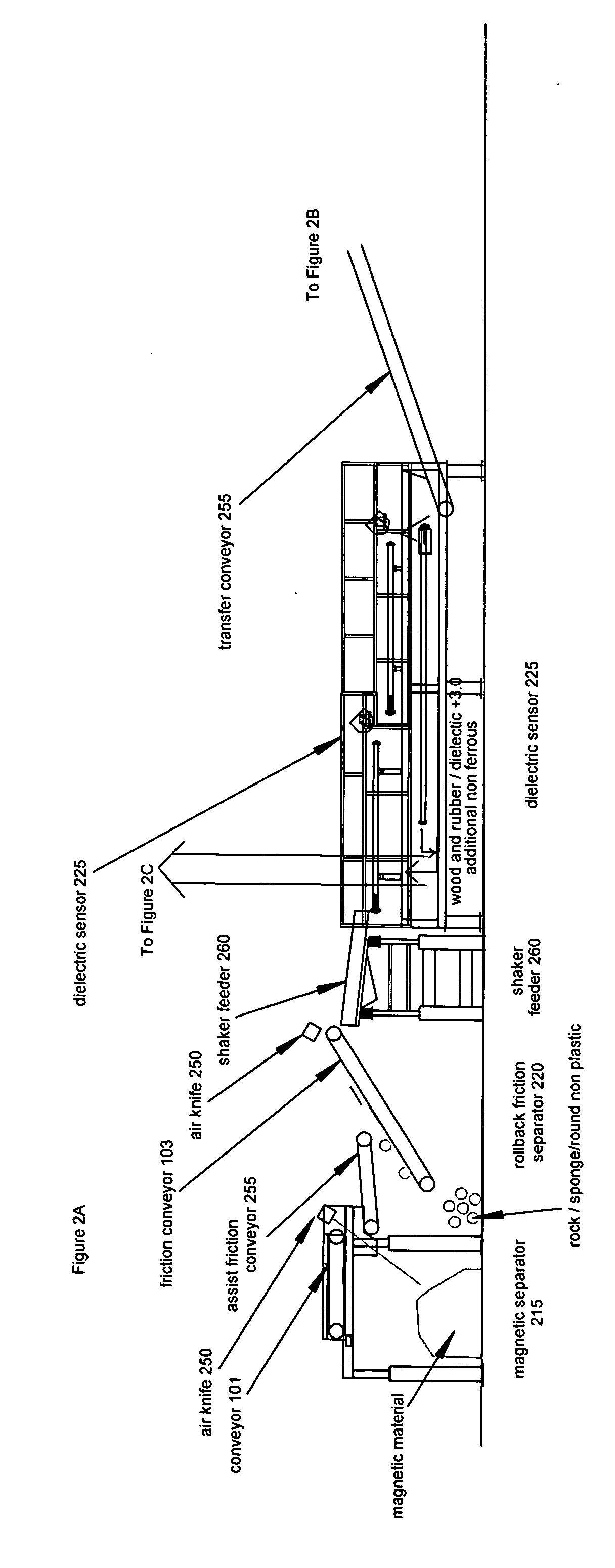

Dissimilar materials sorting process, system and apparata

InactiveUS20070187299A1Improve uniformityUnified operationGas current separationSolid waste disposalElectricityMagnetic separator

An automated system for sorting dissimilar materials, and in particular for sorting plastics from other materials and for sorting different types of plastics from one another comprises, depending upon the embodiment, combinations of a sizing mechanism, a friction separation, an air separator, a magnetic separator, a dielectric sensor sortation bed, shaker screening, a ballistic separator, an inductive sensor sortation system and a float / sink tank. The dielectric sensor sortation system may be either analog or digital, depending upon the particular implementation. One or more float / sink tanks can be used, depending upon the embodiment, each with a media of a different specific gravity. The media may be water, or water plus a compound such as calcium chloride. In addition, multiples of the same general type of module can be used for particular configurations. A heavy media system or a sand float process can be used either alternatively or additionally.

Owner:VALERIO THOMAS A

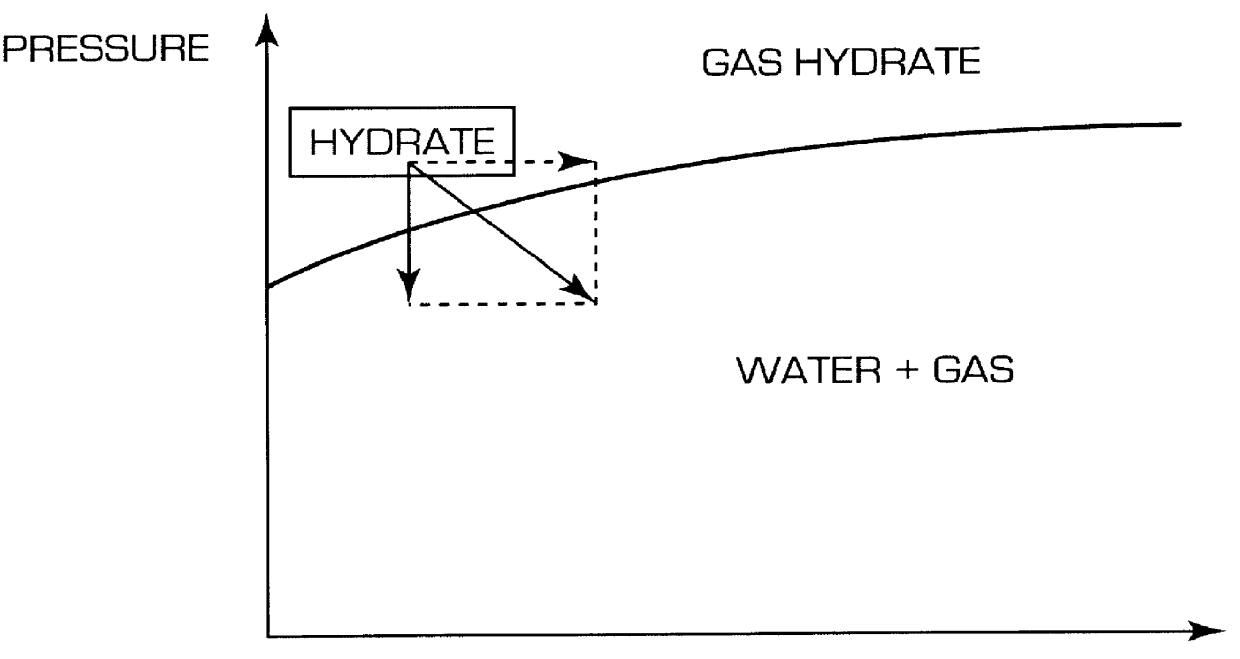

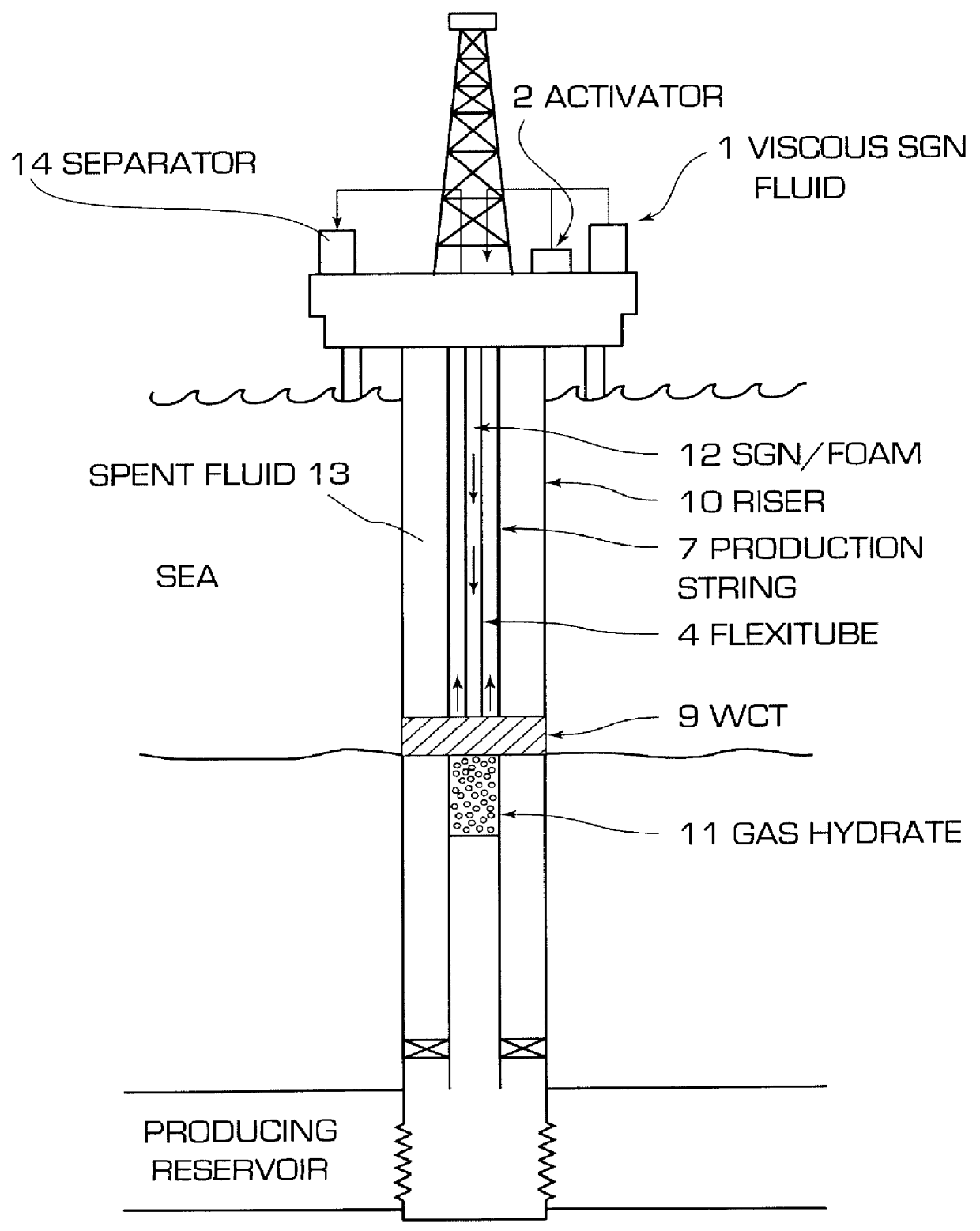

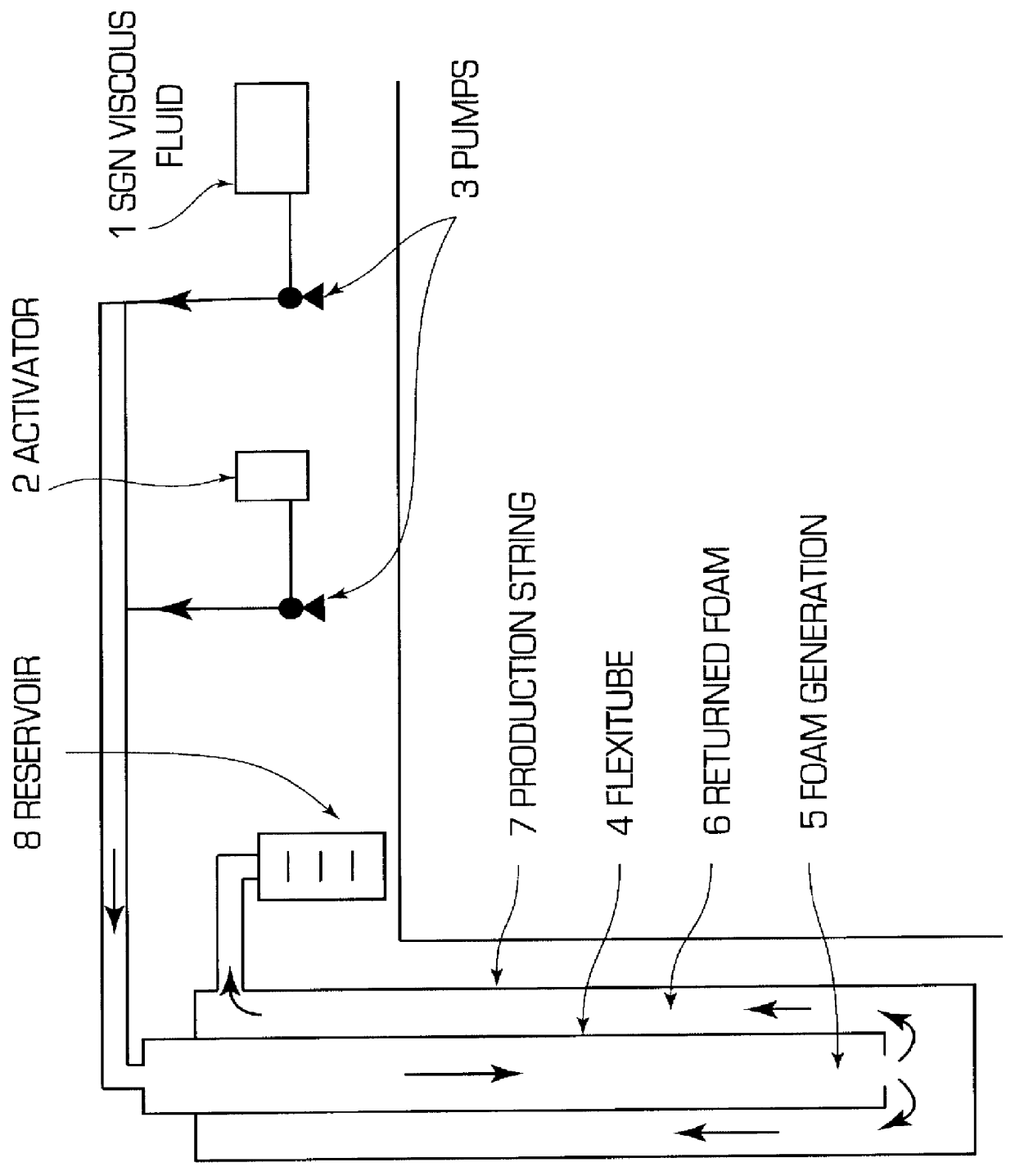

Process for the thermo-hydraulic control of gas hydrates

InactiveUS6035933AInhibition formationPipeline systemsDifferential sedimentationForming gasGas phase

A process for the thermo-hydraulic control of gas hydrates in subsea production and injection wells as well as pipelines which transport liquid or gaseous hydrocarbons is described, the process making use of a Nitrogen Generating System foamed or in solution. The control may signify the prevention of the formation of the gas hydrates or the dissolution of the gas hydrate plug already formed. Under conditions of use designed for the prevention of the formation of gas hydrates the SGN fluid prevents the thermal conditions leading to the gas hydrate plugs. Under conditions of use designed to dissolve the already formed gas hydrate plugs, the SGN fluid alters the thermo-hydraulic conditions which favor the gas hydrate plugs, so that they are dissolved and return to the water+gas phase.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

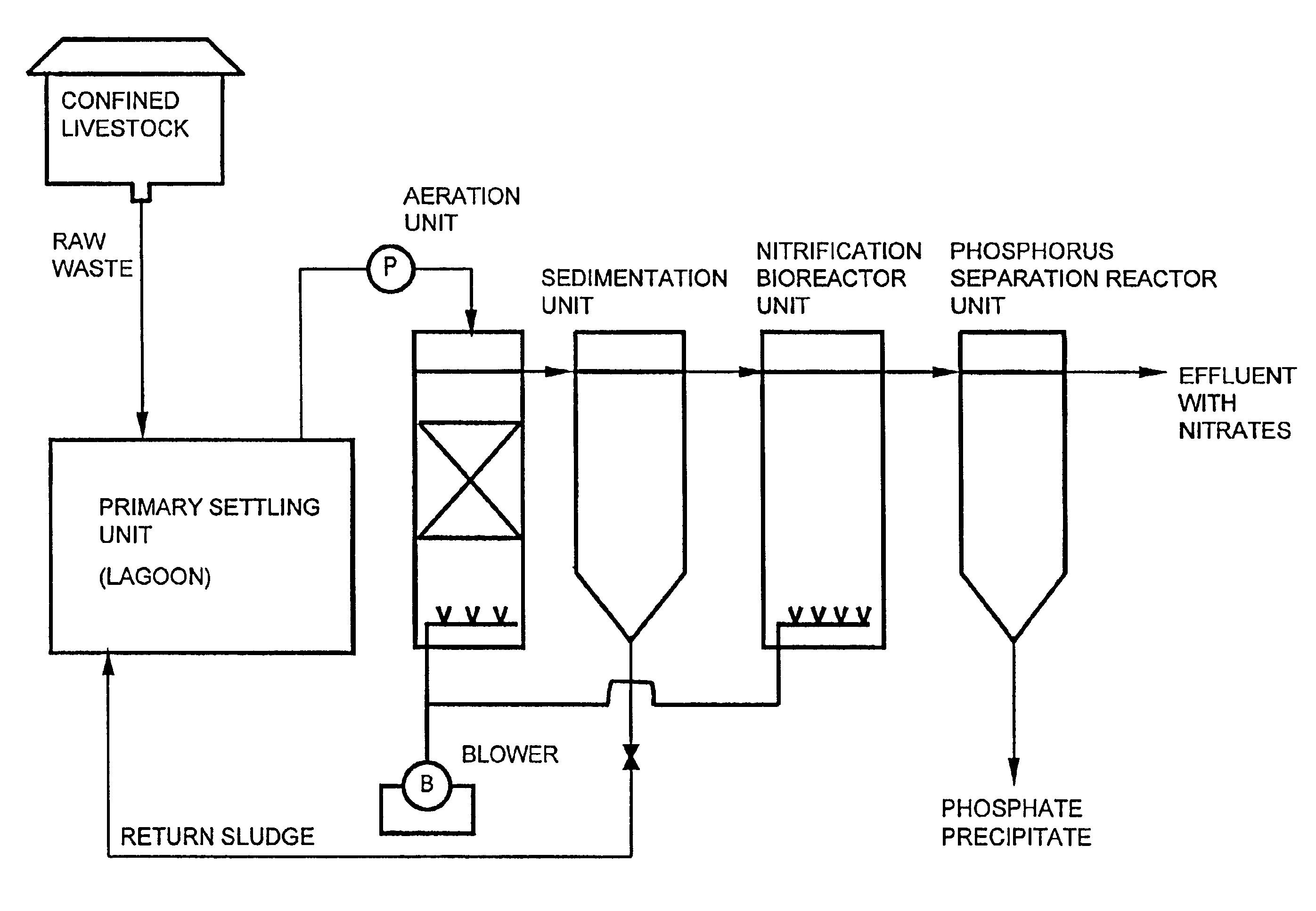

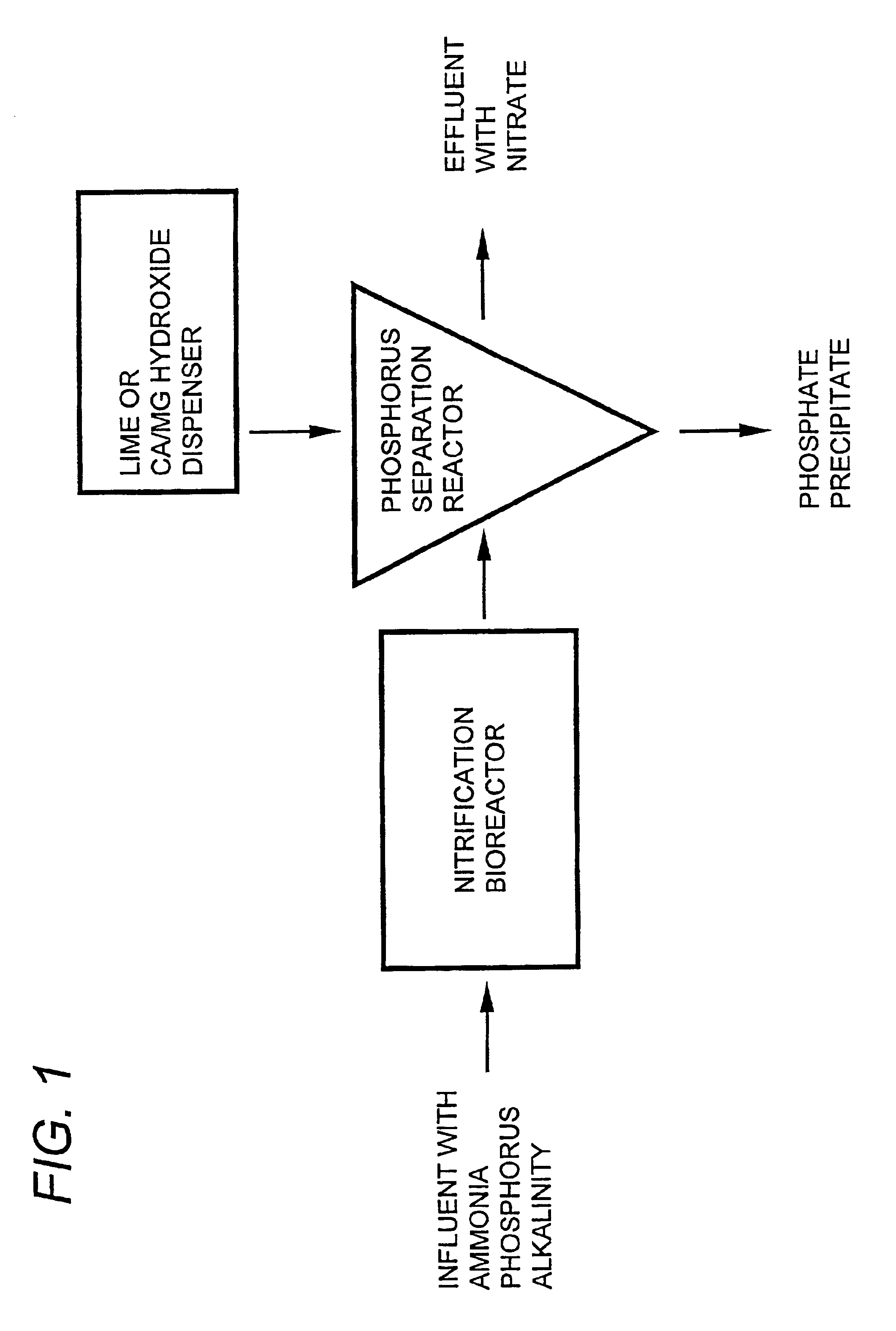

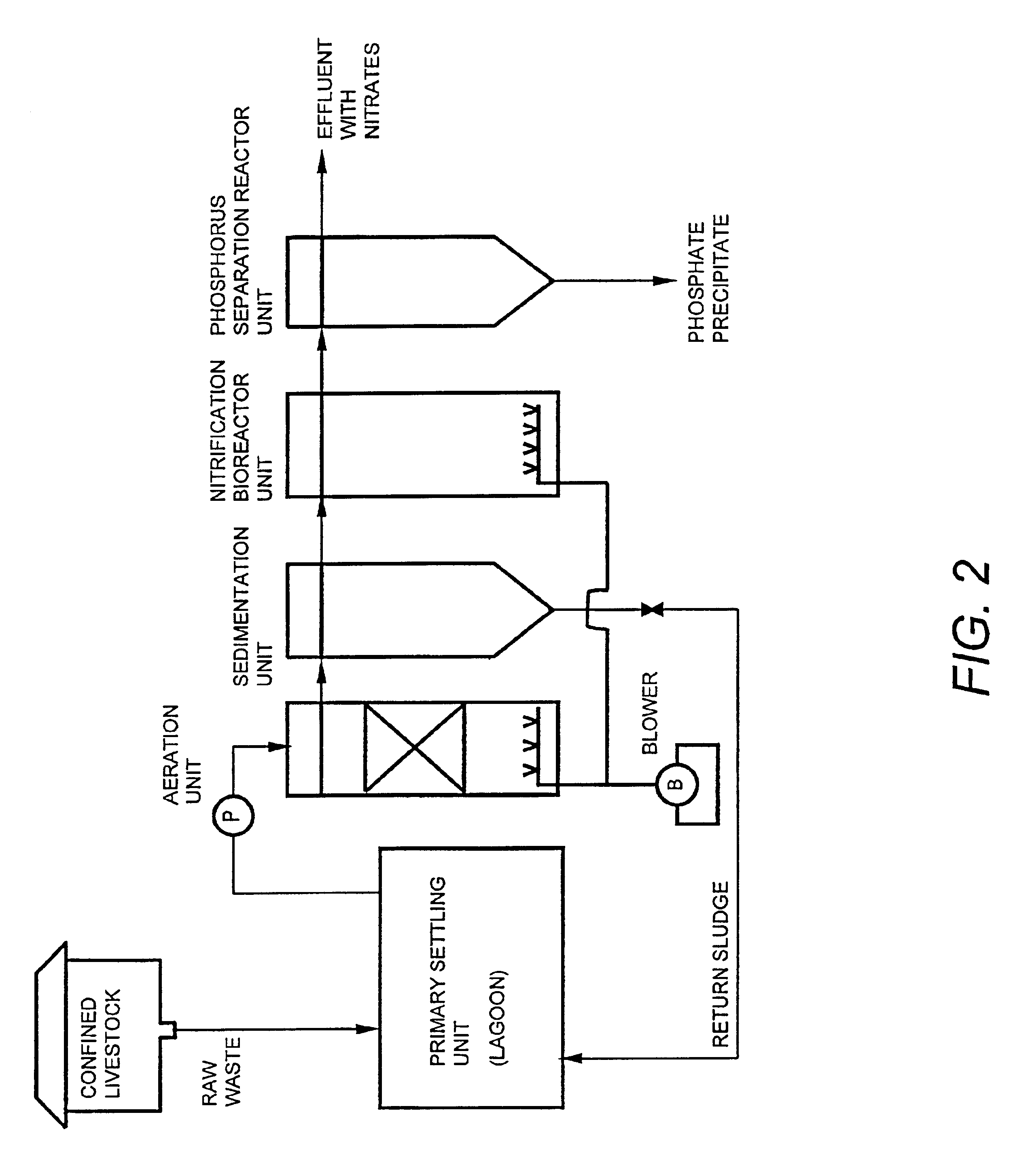

Wastewater treatment system

InactiveUS6893567B1Expand the populationShorten treatment timeTreatment using aerobic processesMixing methodsEnteropathogenic bacteriaTreatment system

Wastewater treatment systems and processes for: removal of solids, pathogens, nitrogen, and phosphorus from municipal and agricultural wastewater include nitrification of wastewater and increasing the pH of the nitrified wastewater by adding a metallic-containing salt and hydroxide to precipitate phosphorus to form a useable effluent having a specified nitrogen:phosphorus ratio that is useful as a fertilizer or spray for remediation of contaminated soils. The presence of infectious microorganism such as enteropathogenic bacteria and picarnoviruses will be reduced in the useable effluent. The precipitated phosphorus is recovered and used to form useable phosphorus products.

Owner:AGRI UNTED STATES OF AMERICA THE AS REPRESENTED BY THE SEC +1

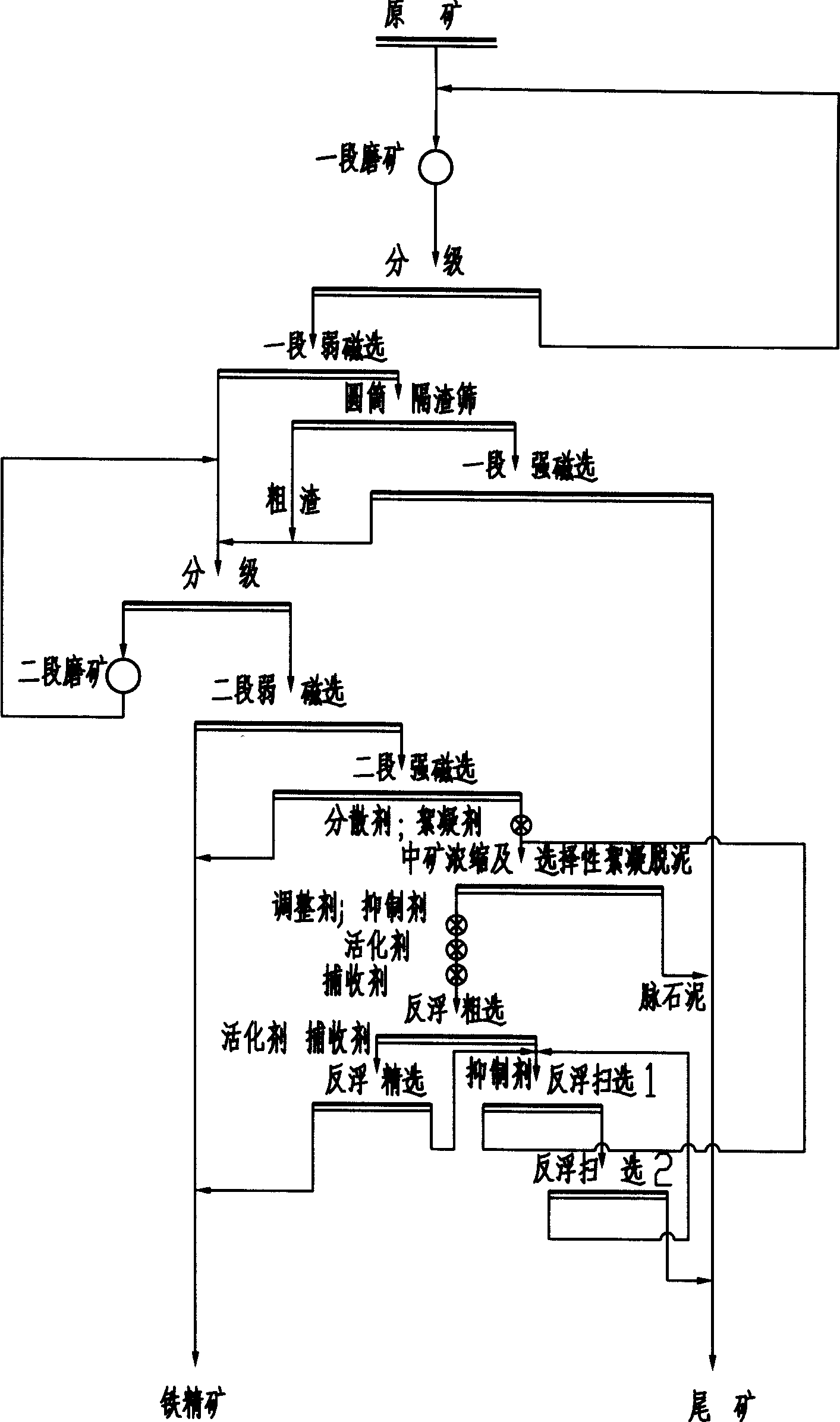

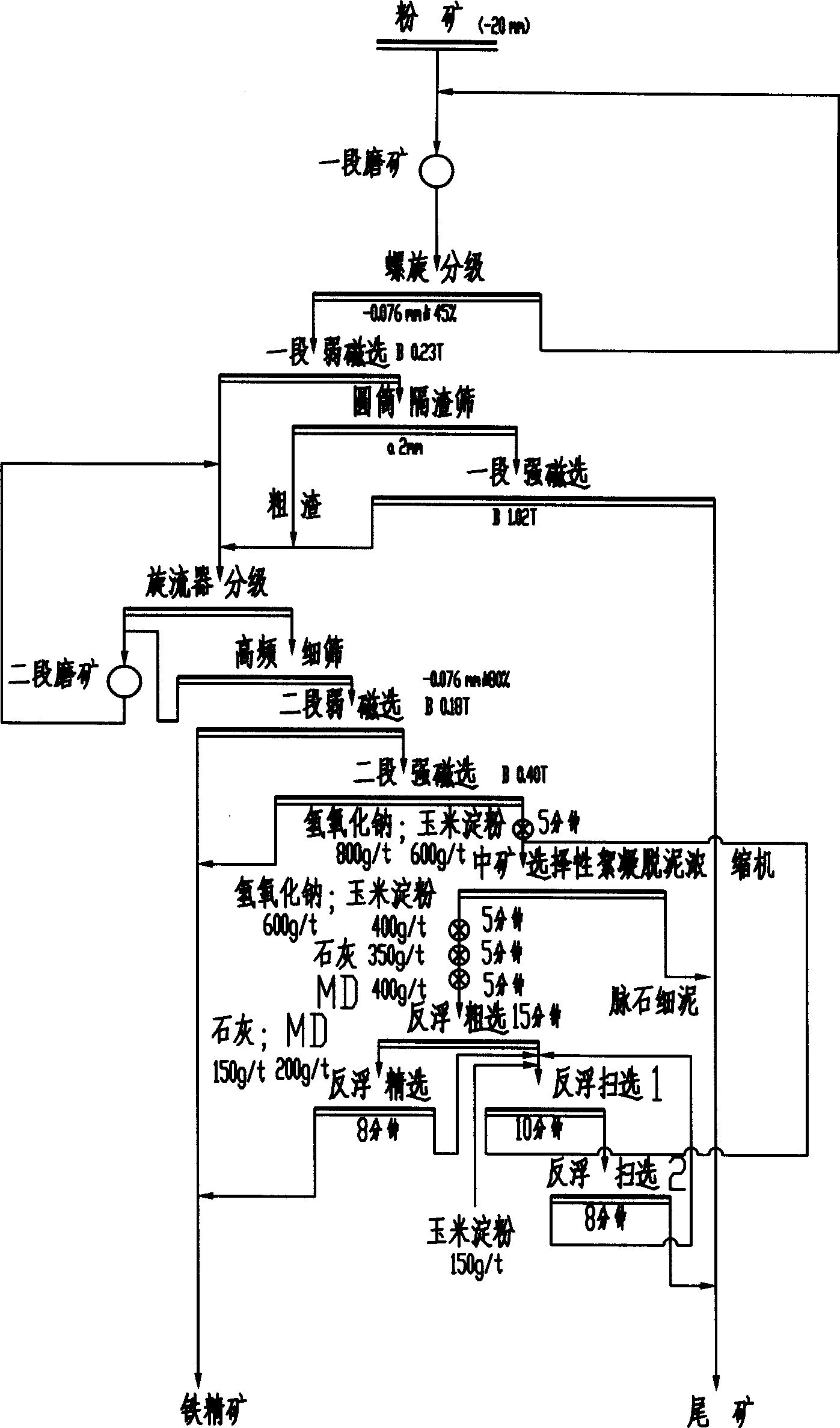

Beneficiation method for recycling specularite

InactiveCN101428248AReduce consumptionReduce the number of equipmentDifferential sedimentationFlotationIronstoneSlag

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

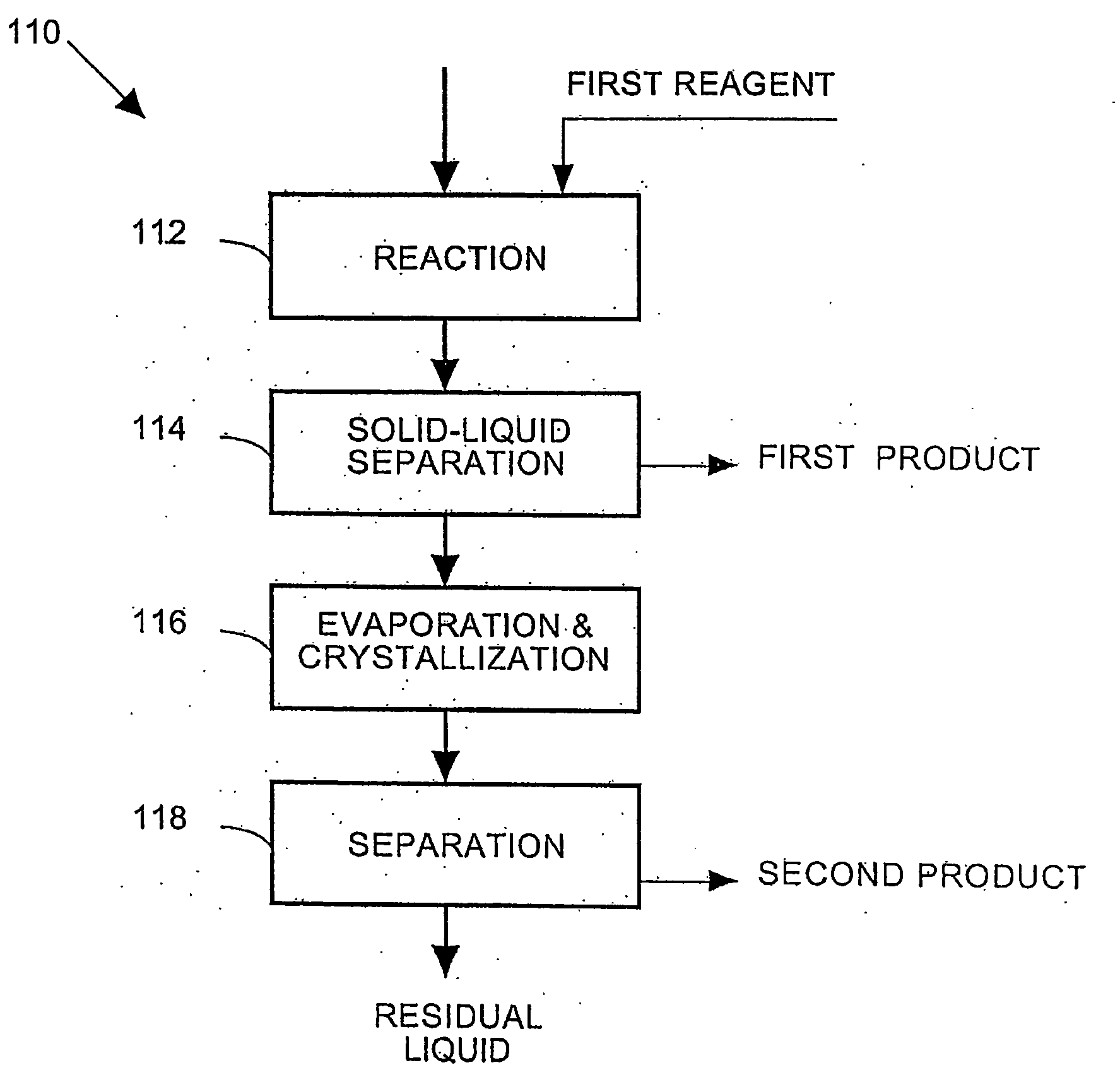

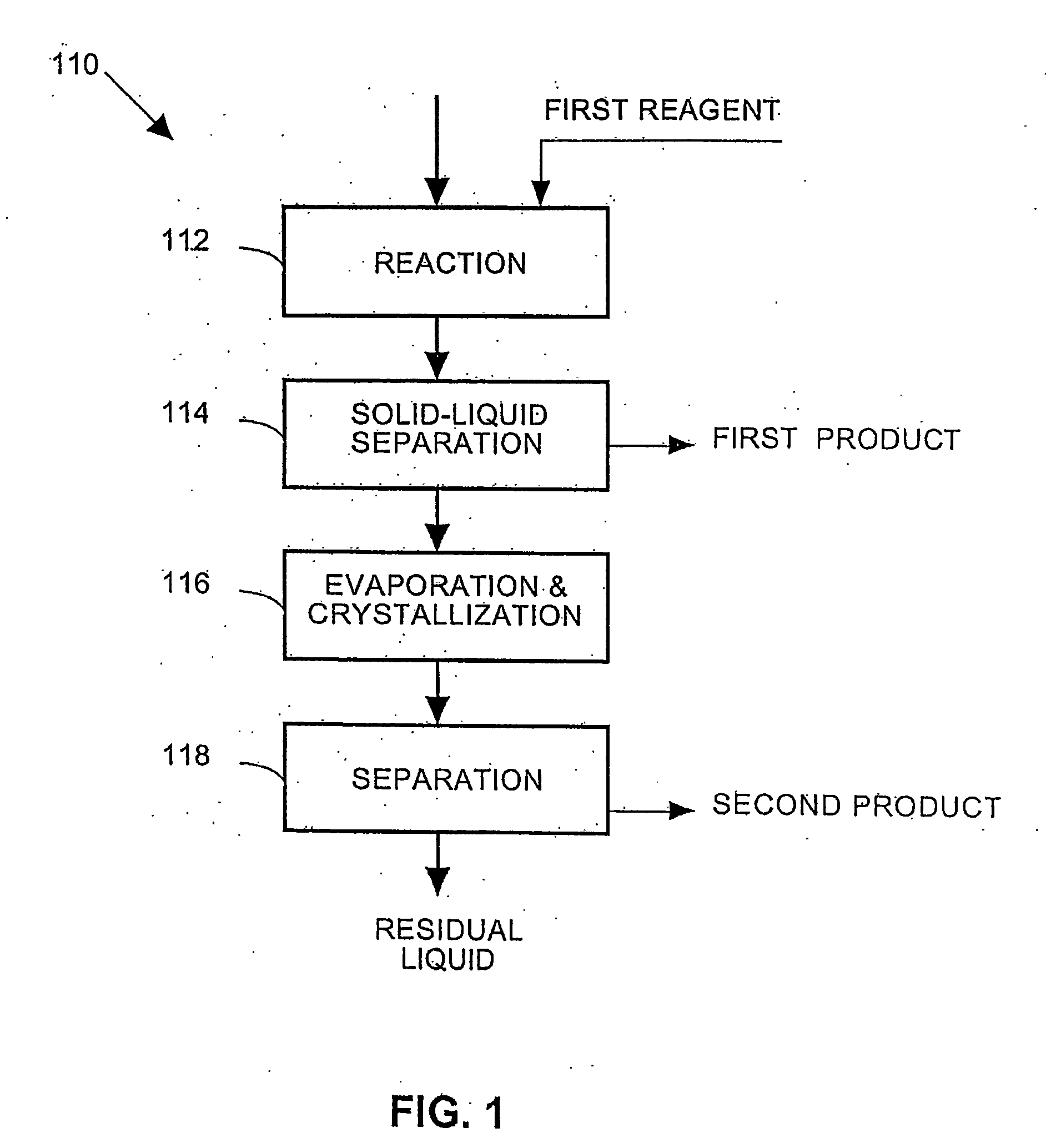

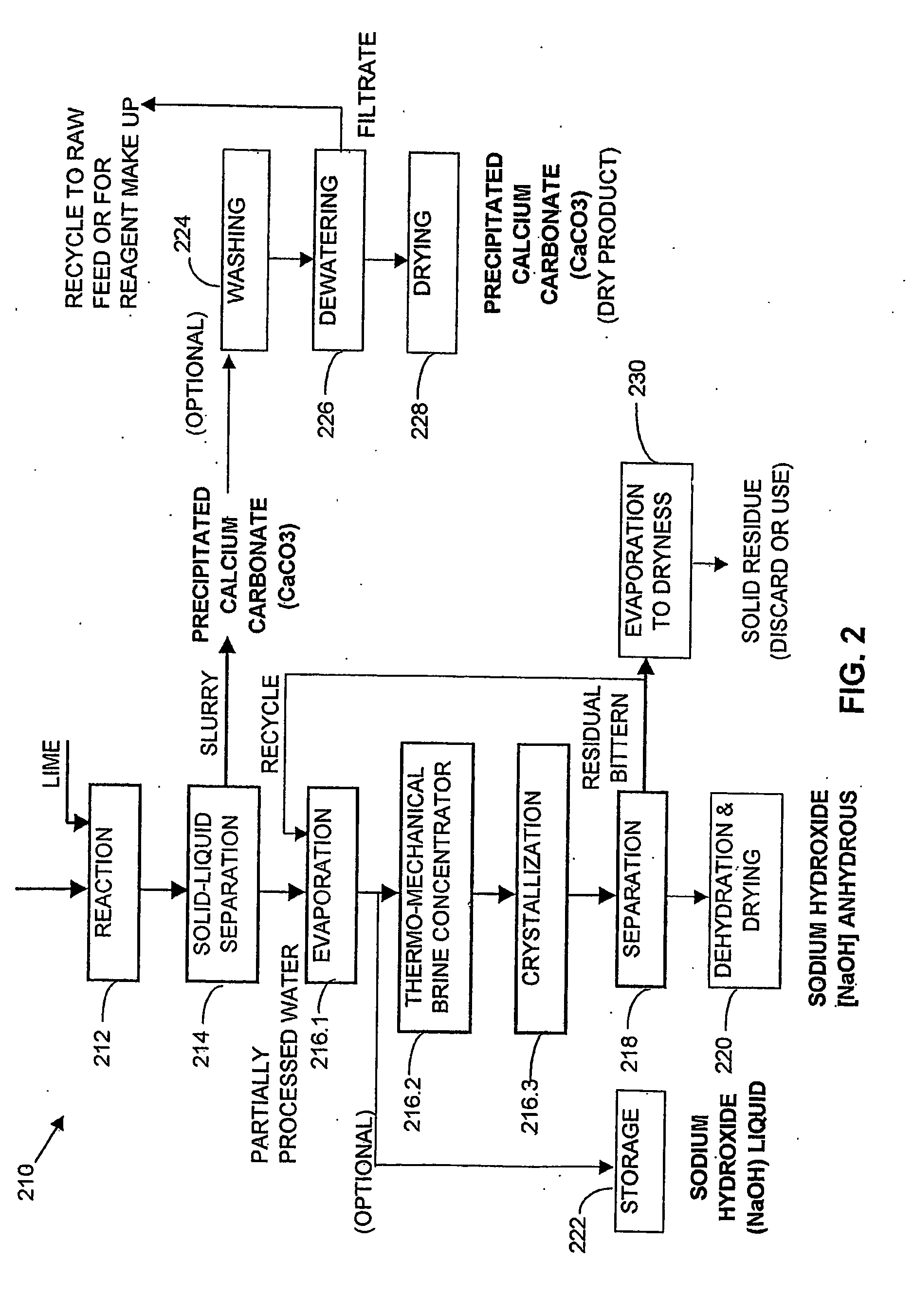

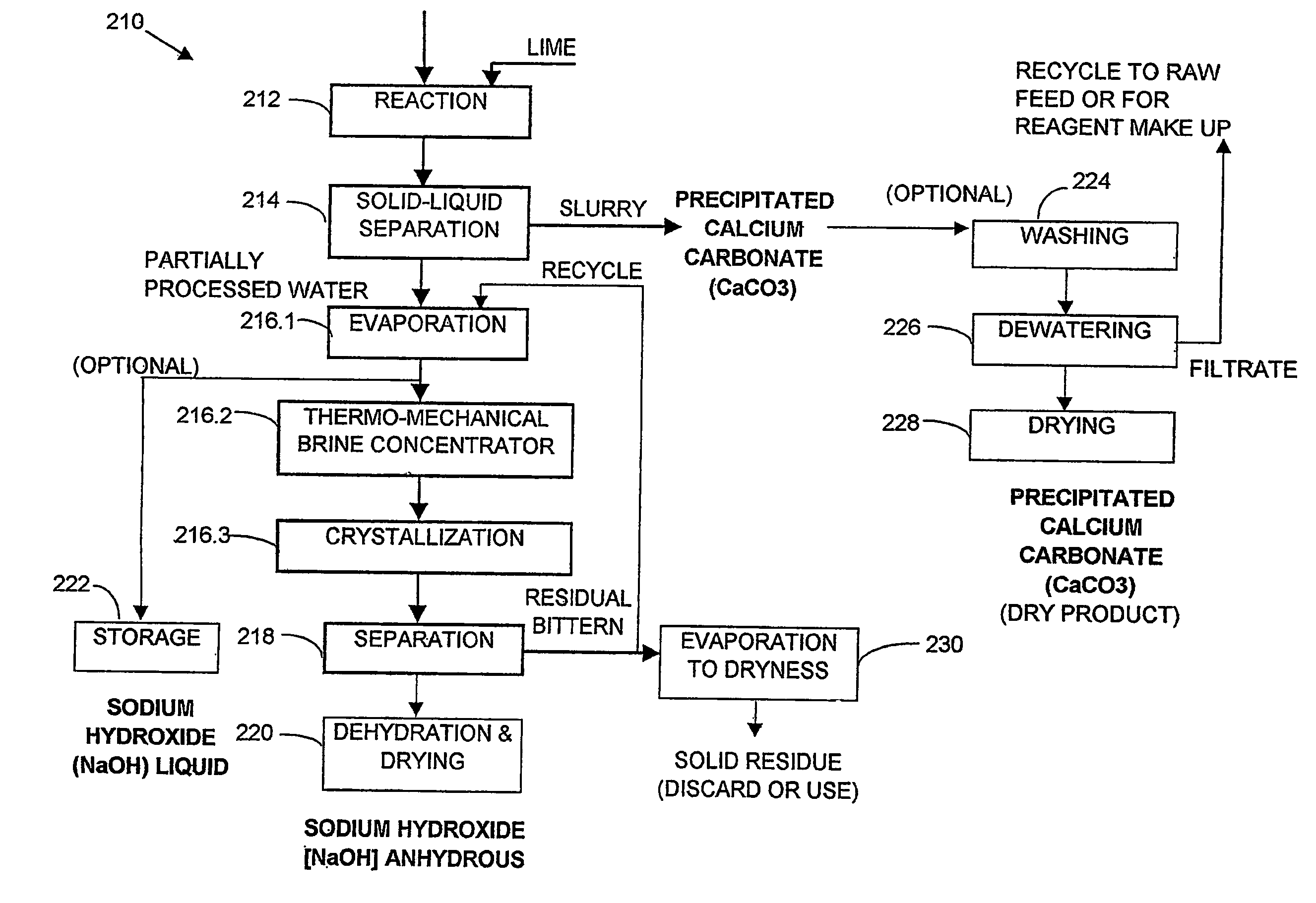

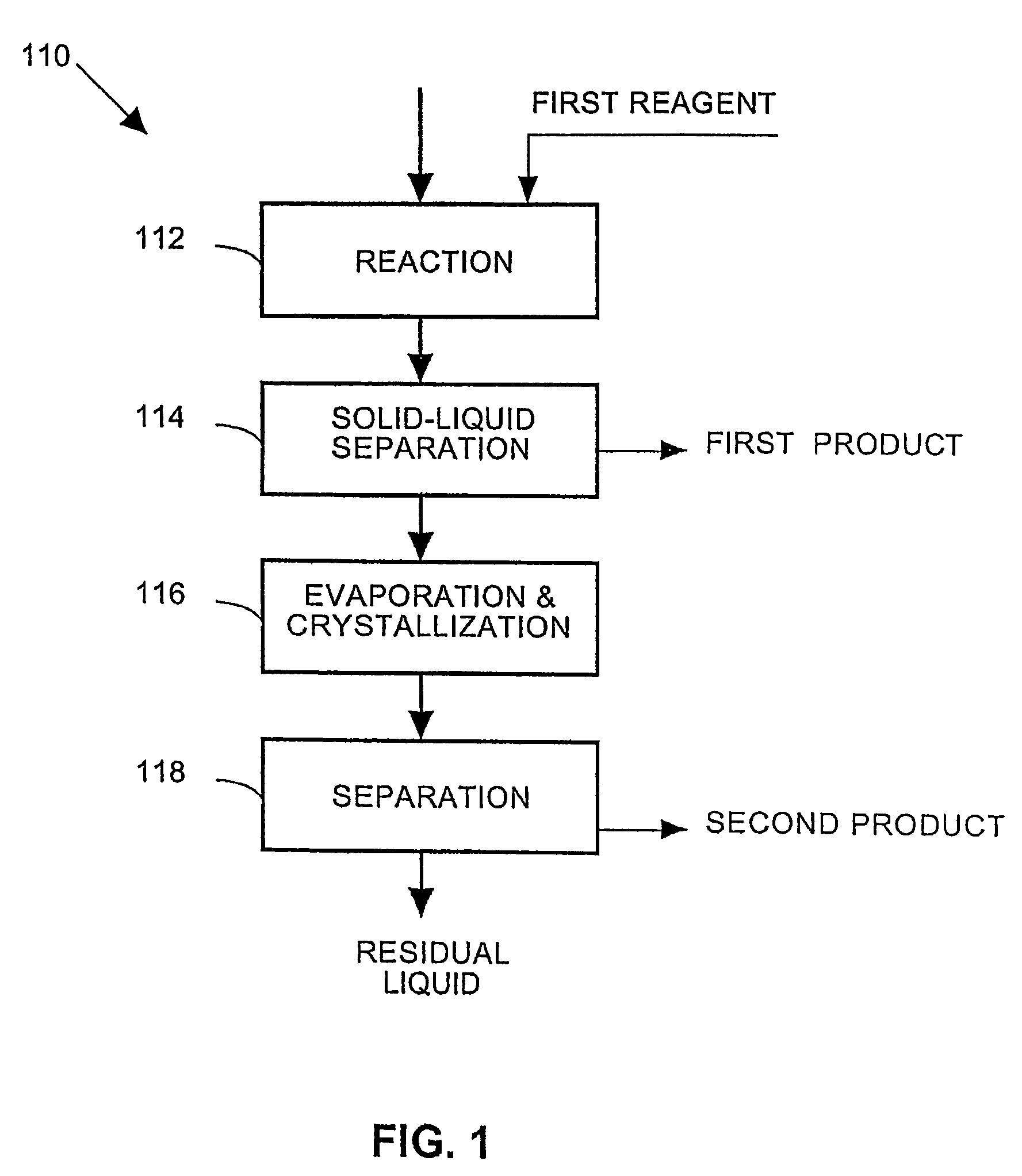

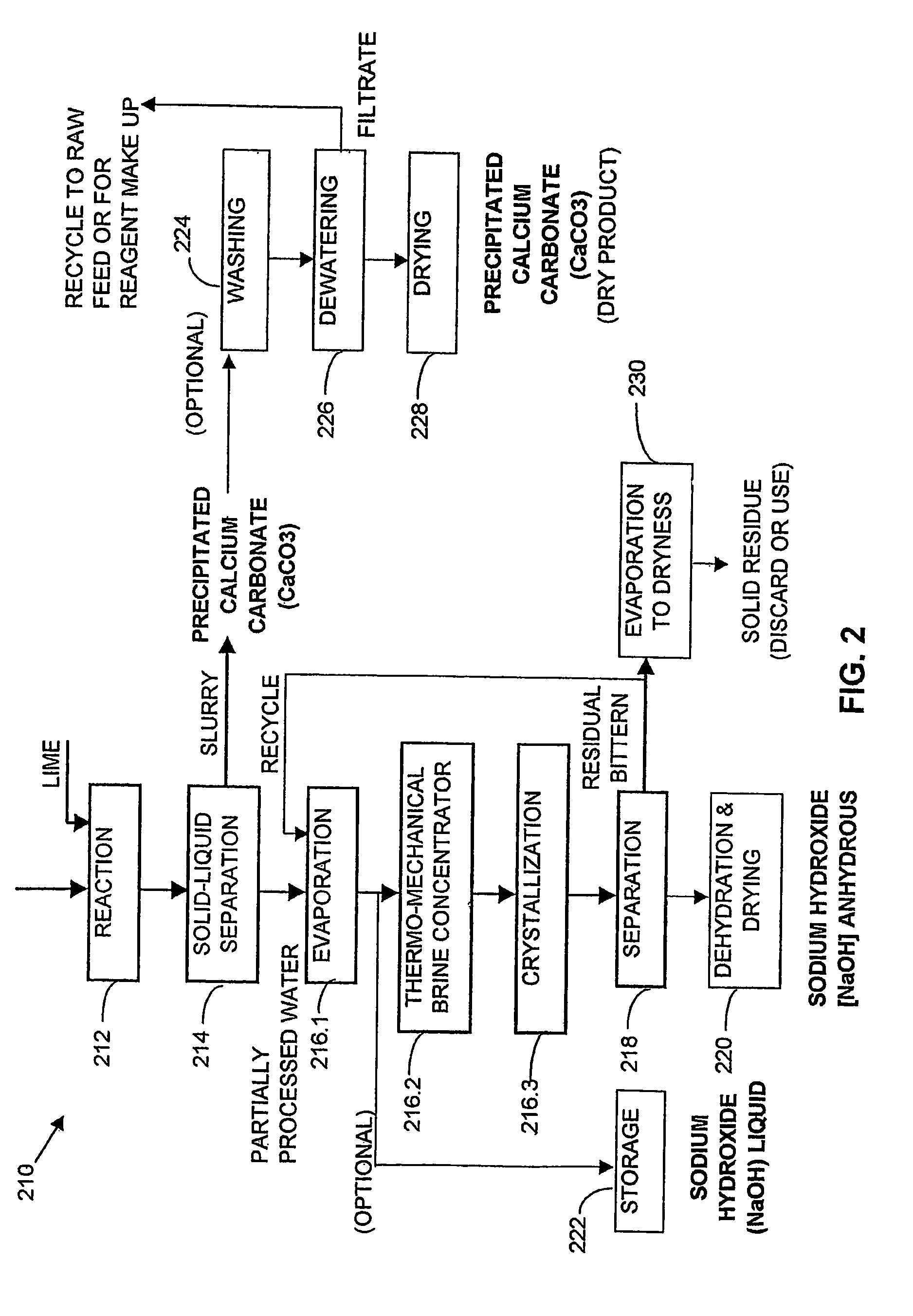

Process and apparatus for the treatment of saline water

InactiveUS20060196836A1Reduce ZLD costReduce loadWaste water treatment from quariesGeneral water supply conservationTotal dissolved solidsEvaporation

A process and an apparatus are described for treating seven types of saline waters each having a concentration of total dissolved solids exceeding 1 g / L, wherein the concentration of total dissolved solids, the ratio of the chloride ion concentration to the bicarbonate ion concentration and the ratio of the chloride ion concentration to the sulphate ion concentration of each of the water types are as indicated in Table 1. The process includes the steps of contacting the water with a first reagent comprising a source of calcium ions selected from calcium oxide and calcium hydroxide to form a first solid product which is recovered. The process includes a further step of subjecting at least a portion of the partially processed water to at least partial evaporation so as to promote the formation of a precipitate and a mother liquor. The precipitate is recovered as a second product.

Owner:GEO PROCESSORS

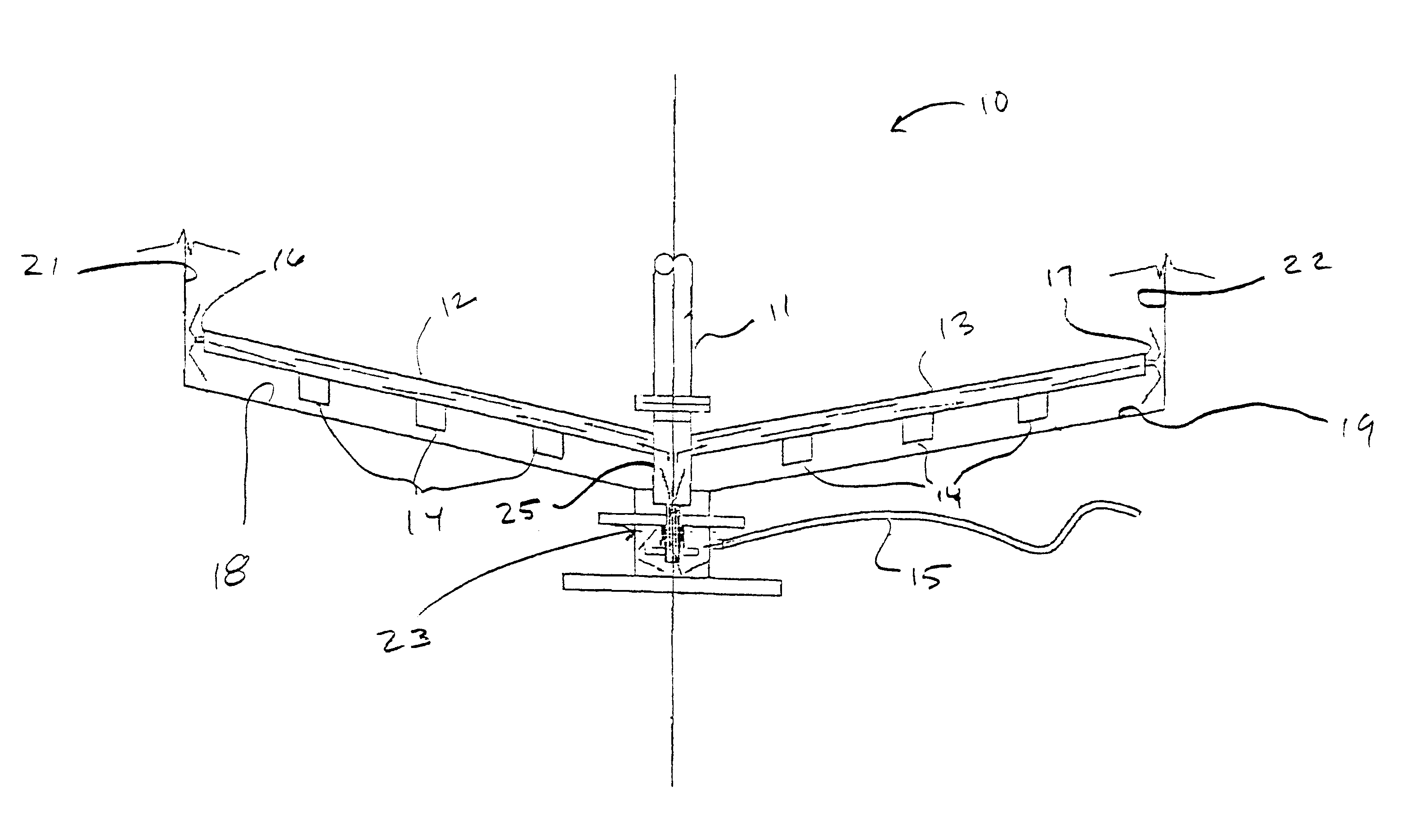

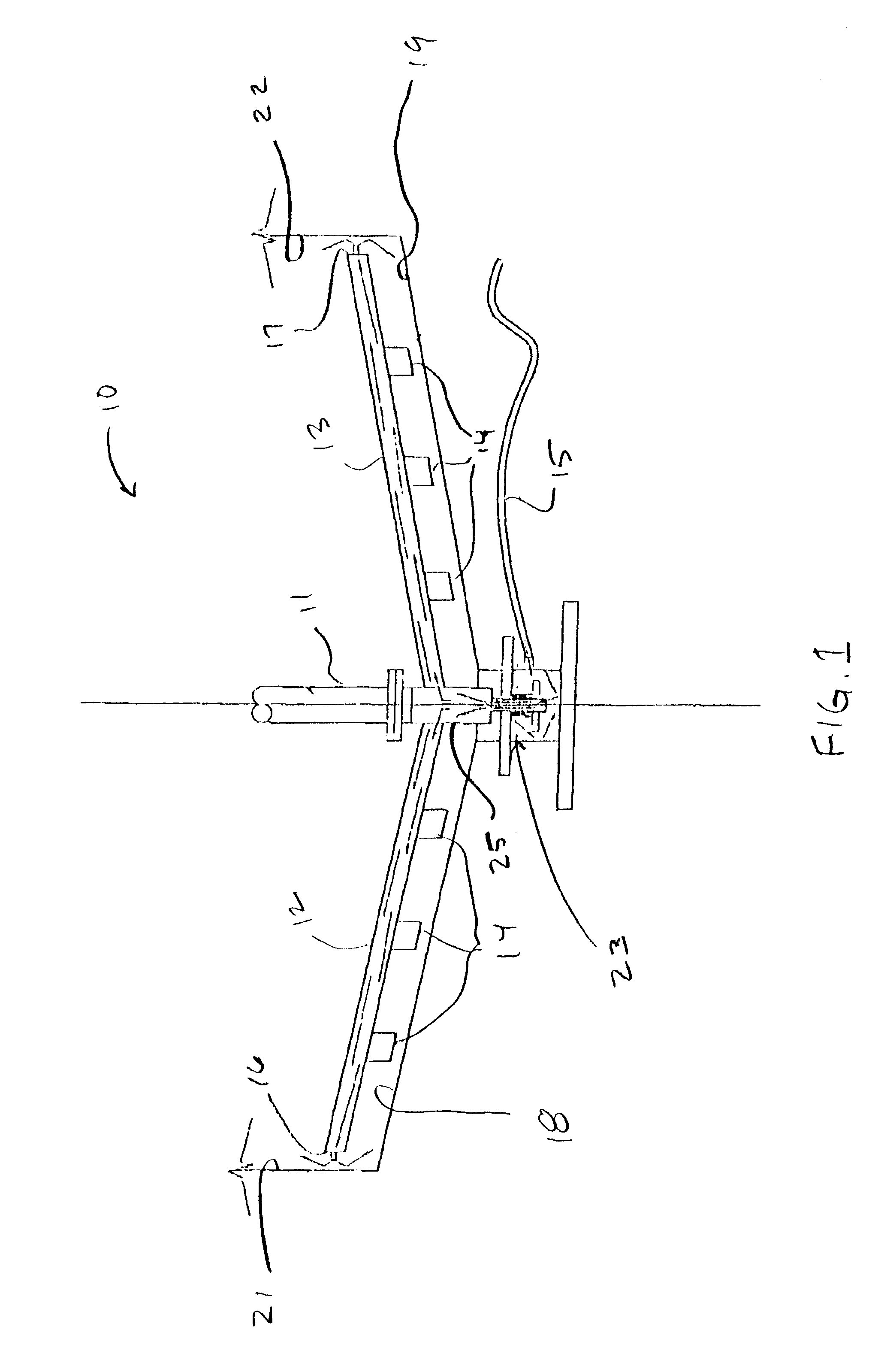

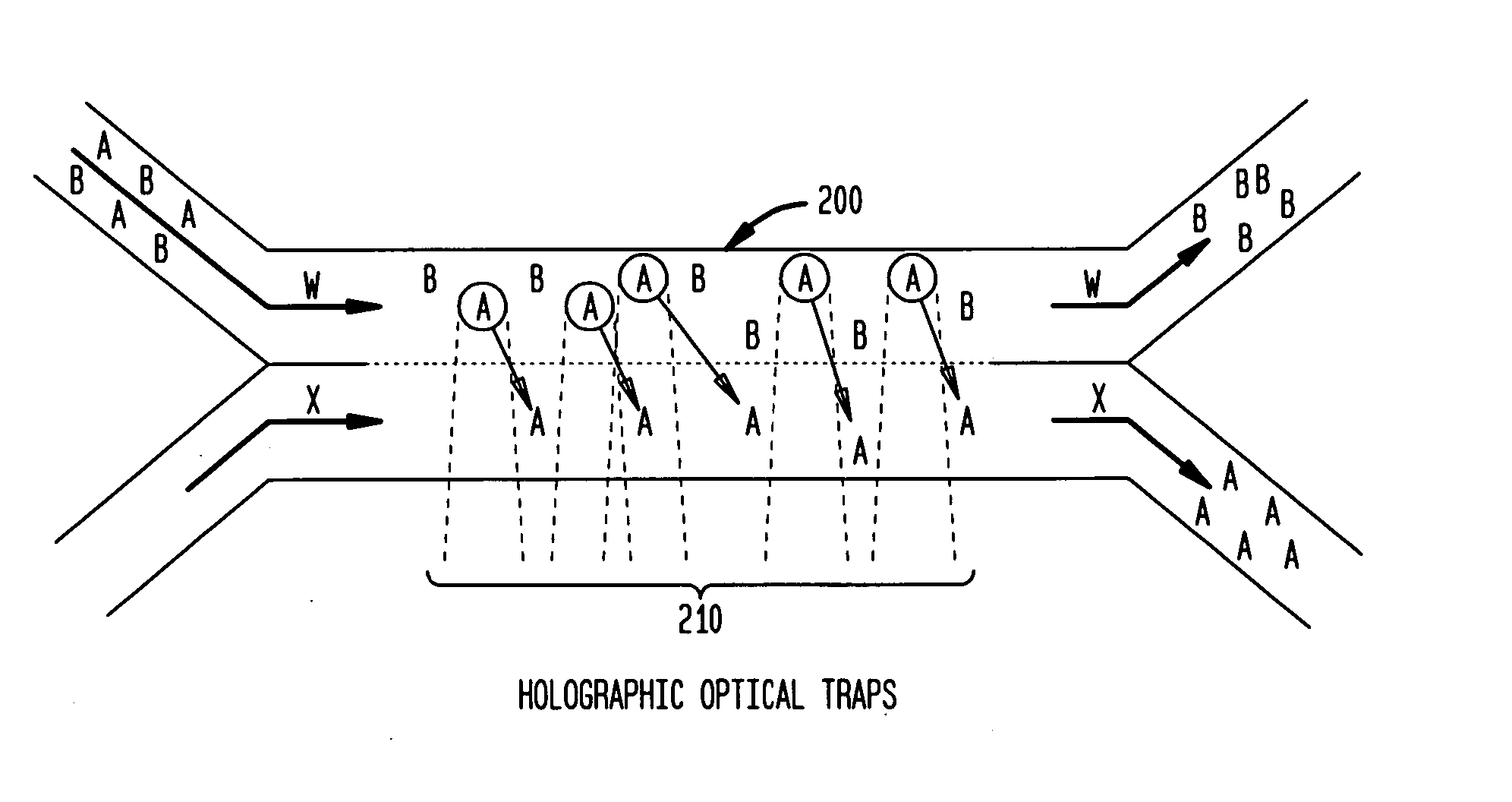

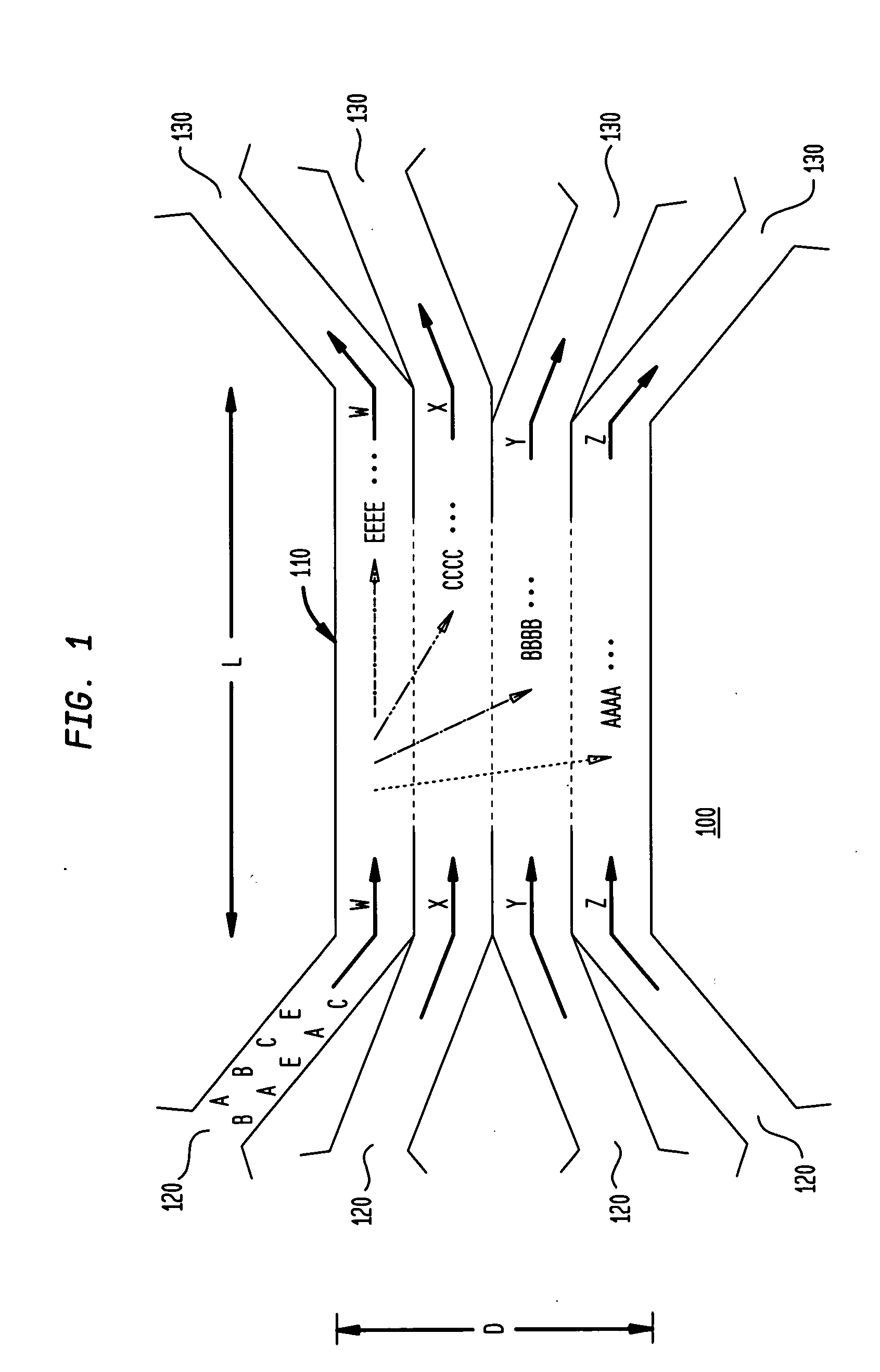

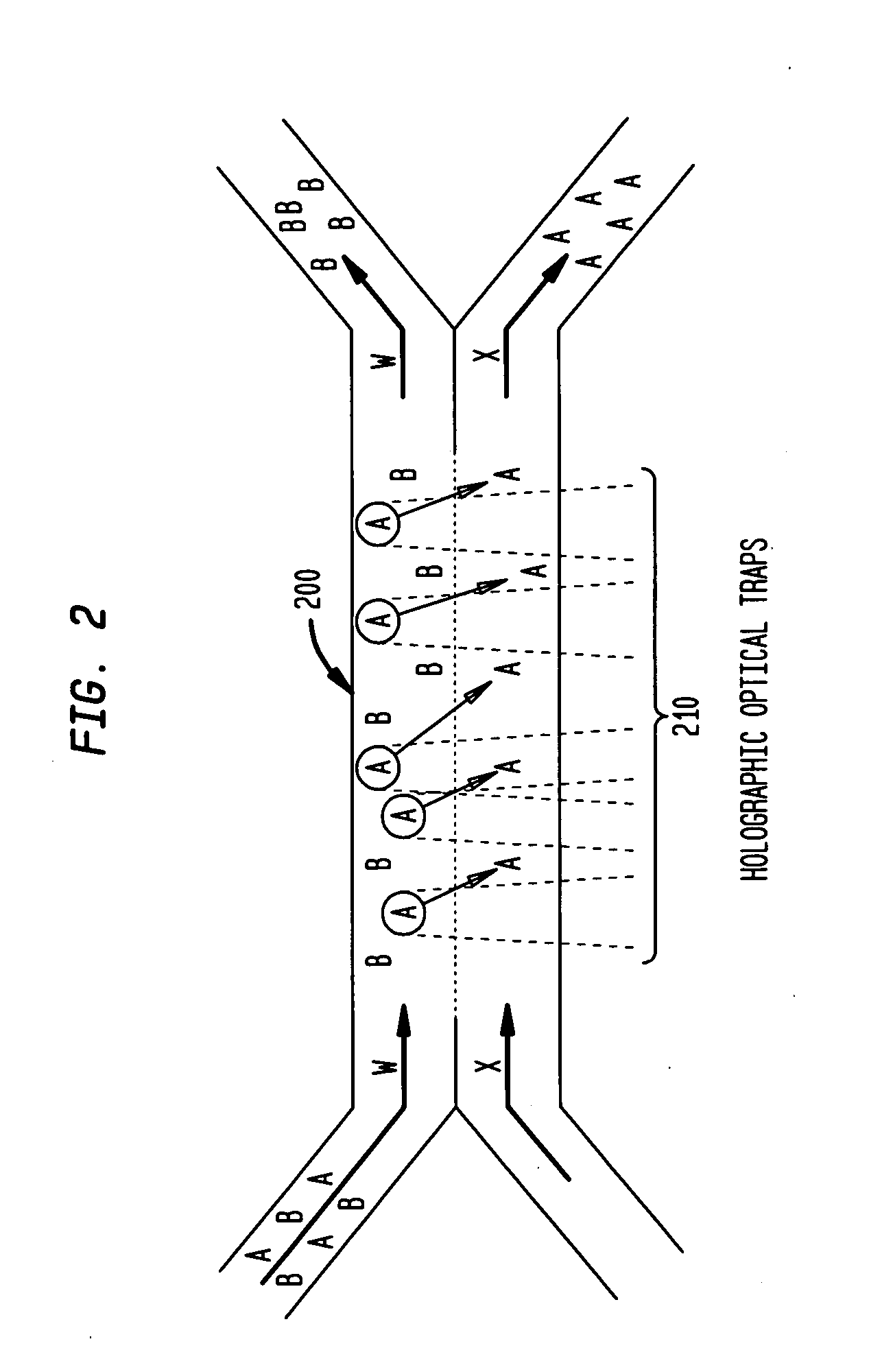

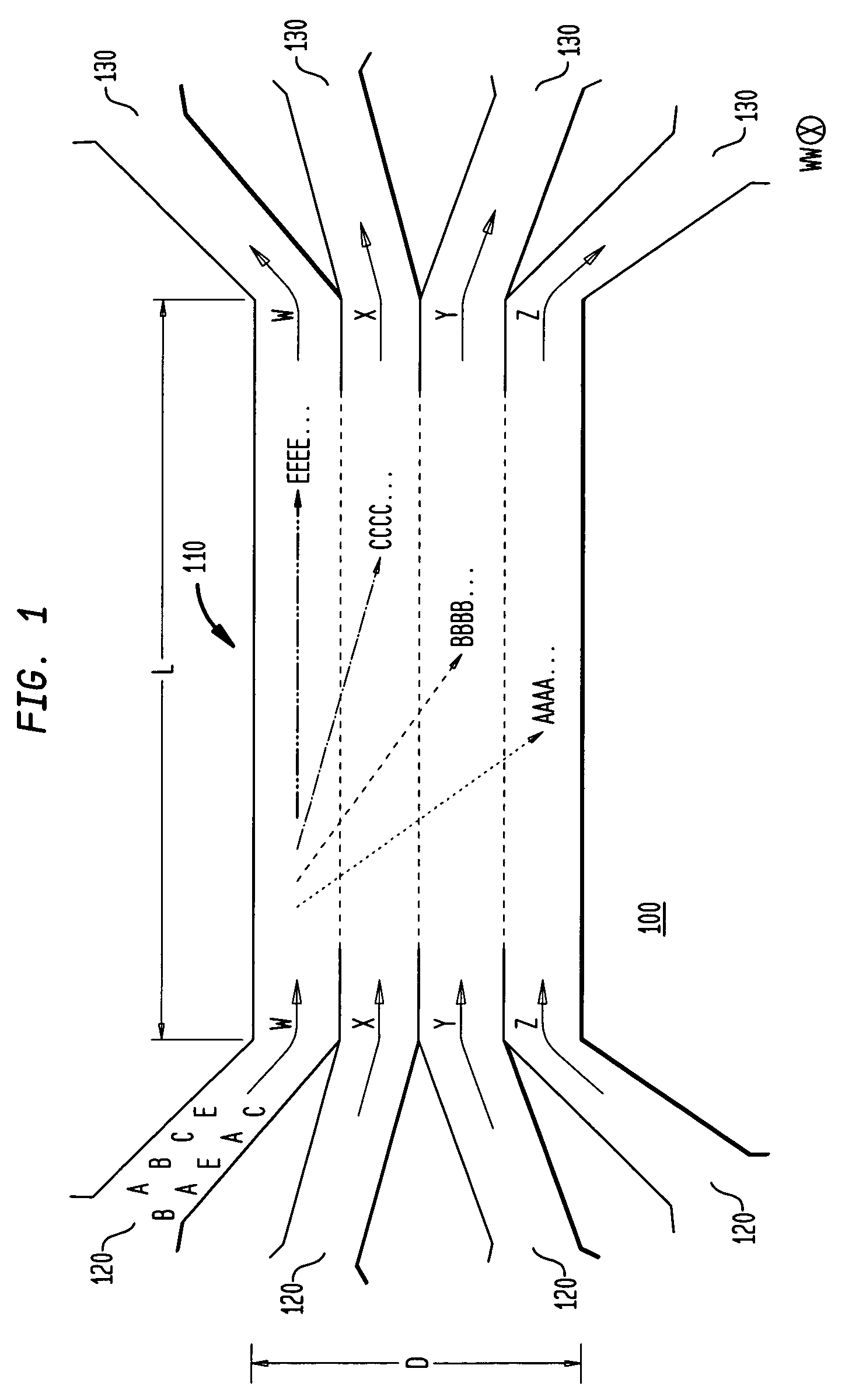

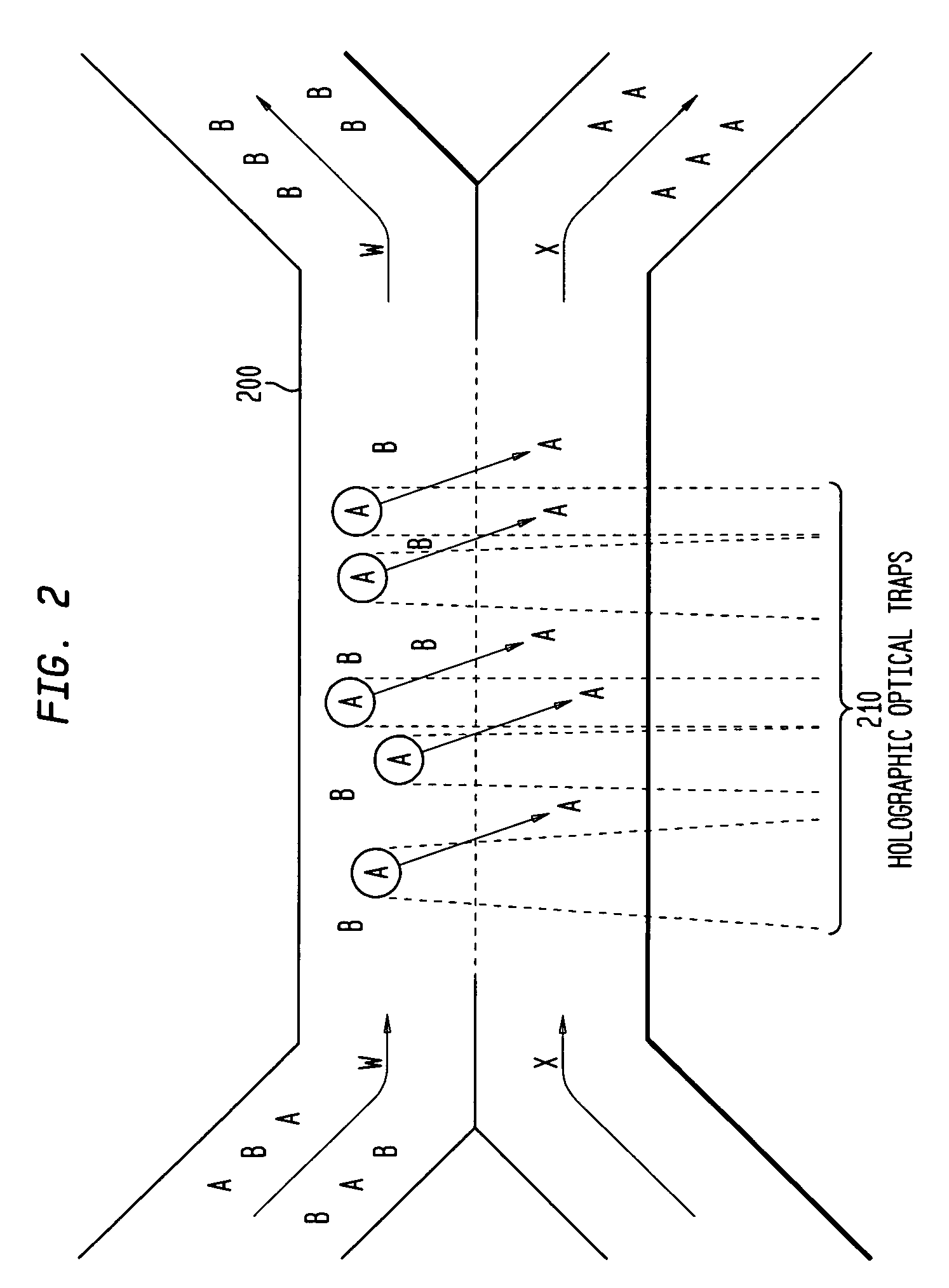

Multiple laminar flow-based rate zonal or isopycnic separation with holographic optical trapping of blood cells and other static components

ActiveUS20050061962A1Improve throughputSave a lot of timeDielectrophoresisOther blood circulation devicesCellular componentBlood component

The invention provides a method and apparatus for separating blood into components, may be expanded to include other types of cellular components, and can be combined with holographic optical manipulation or other forms of optical tweezing. One of the exemplary methods includes providing a first flow having a plurality of blood components; providing a second flow; contacting the first flow with the second flow to provide a first separation region; and differentially sedimenting a first blood cellular component of the plurality of blood components into the second flow while concurrently maintaining a second blood cellular component of the plurality of blood components in the first flow. The second flow having the first blood cellular component is then differentially removed from the first flow having the second blood cellular component. Holographic optical traps may also be utilized in conjunction with the various flows to move selected components from one flow to another, as part of or in addition to a separation stage.

Owner:ABS GLOBAL

Process for removing oil from solid materials recovered from a well bore

InactiveUS6846420B2Low costLower oil levelHollow article cleaningFluid removalSodium hypochlorite solutionResidual oil

The present invention provides a process and an additive package for removing oil from solid material recovered from a well bore, e.g., drill cuttings and produced sand. In this process, the solid material is passed from the well bore to a separation zone. An aqueous acidic solution containing a polymer substituted with an amino group is introduced to the separation zone containing the solid material along with a halogenating agent and optionally one or more surfactants. The polymer, halogenating agent, and optional surfactant constitute the additive package. The polymer substituted with an amino group is preferably chitosan, and the halogenating agent is preferably a sodium hypochlorite solution. The mixture formed in the separation zone is agitated to cause a product of a reaction between the polymer and the halogenating agent to contact the solid material and remove residual oil therefrom.

Owner:HALLIBURTON ENERGY SERVICES INC

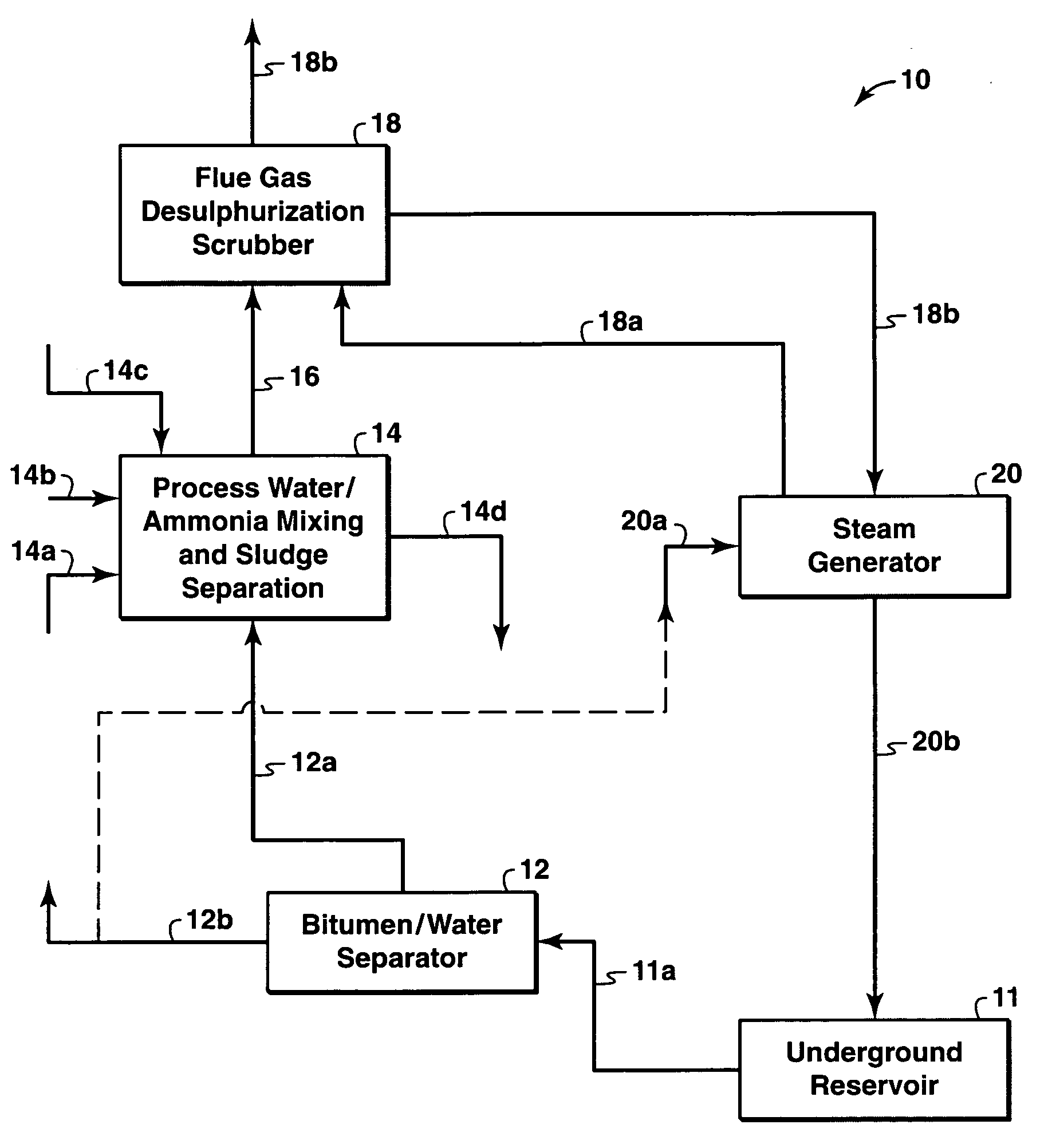

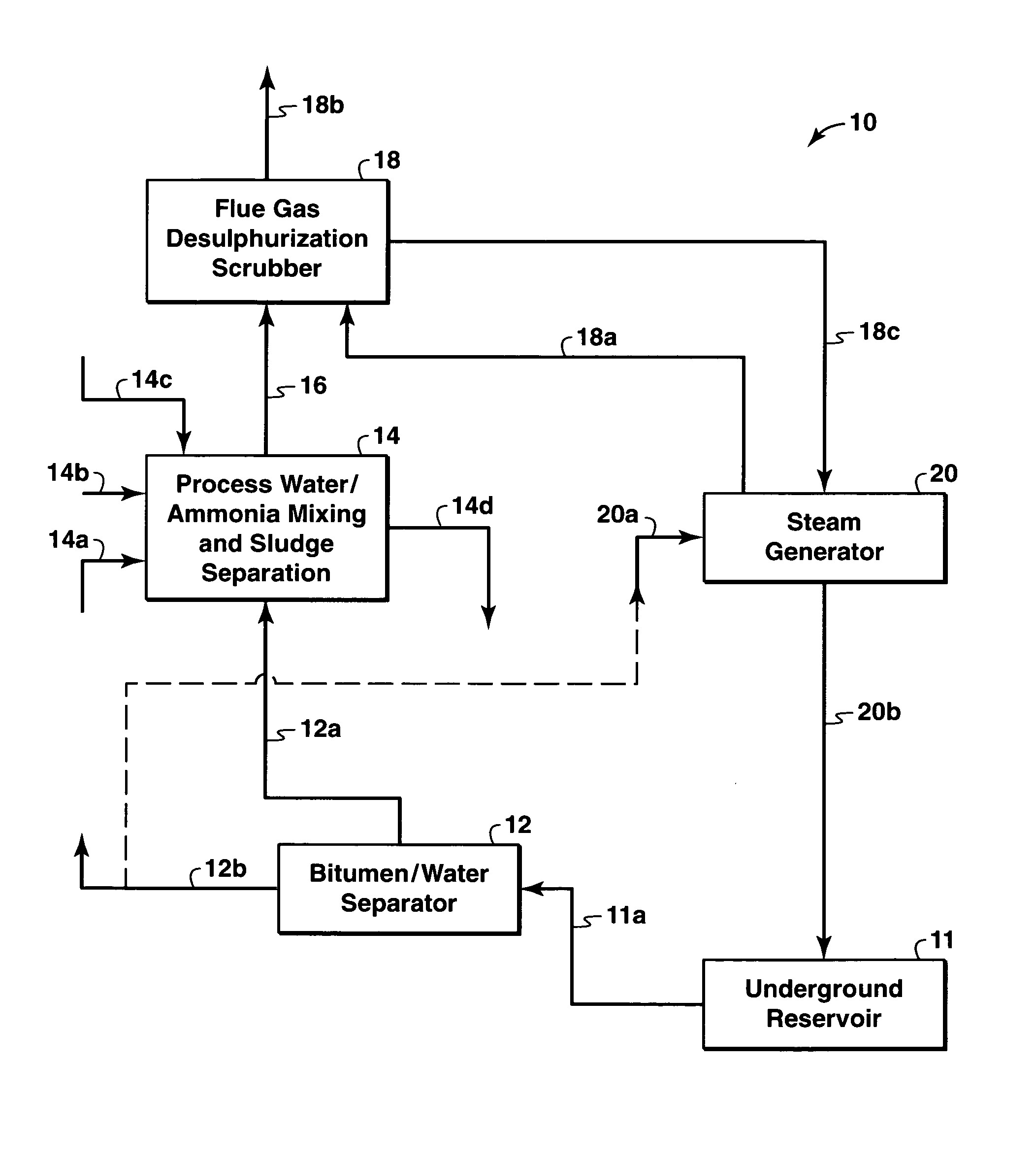

Integrated water treatment and flue gas desulfurization process

A water stream containing hardness minerals is subjected to a water treatment process using an alkali agent to precipitate the hardness minerals and to produce a softened water stream is used to create an integrated water treatment and flue gas desulfurization process. Thereafter, the softened, alkaline water stream is utilized in a scrubber to scrub a flue gas containing sulfur dioxide to produce a sulfur-lean flue gas. The invention may be applied to a steam-based bitumen recovery operation where bitumen, sour produced gas or other sulfur containing fuels are burned for producing steam for bitumen recovery. More specifically, the associated produced water from the bitumen recovery process may be softened for re-use and for utilization as a scrubbing agent for high-sulfur containing flue gas arising from the steam generators. The process provides an economically favorable process while minimizing waste disposal requirements.

Owner:EXXONMOBIL UPSTREAM RES CO

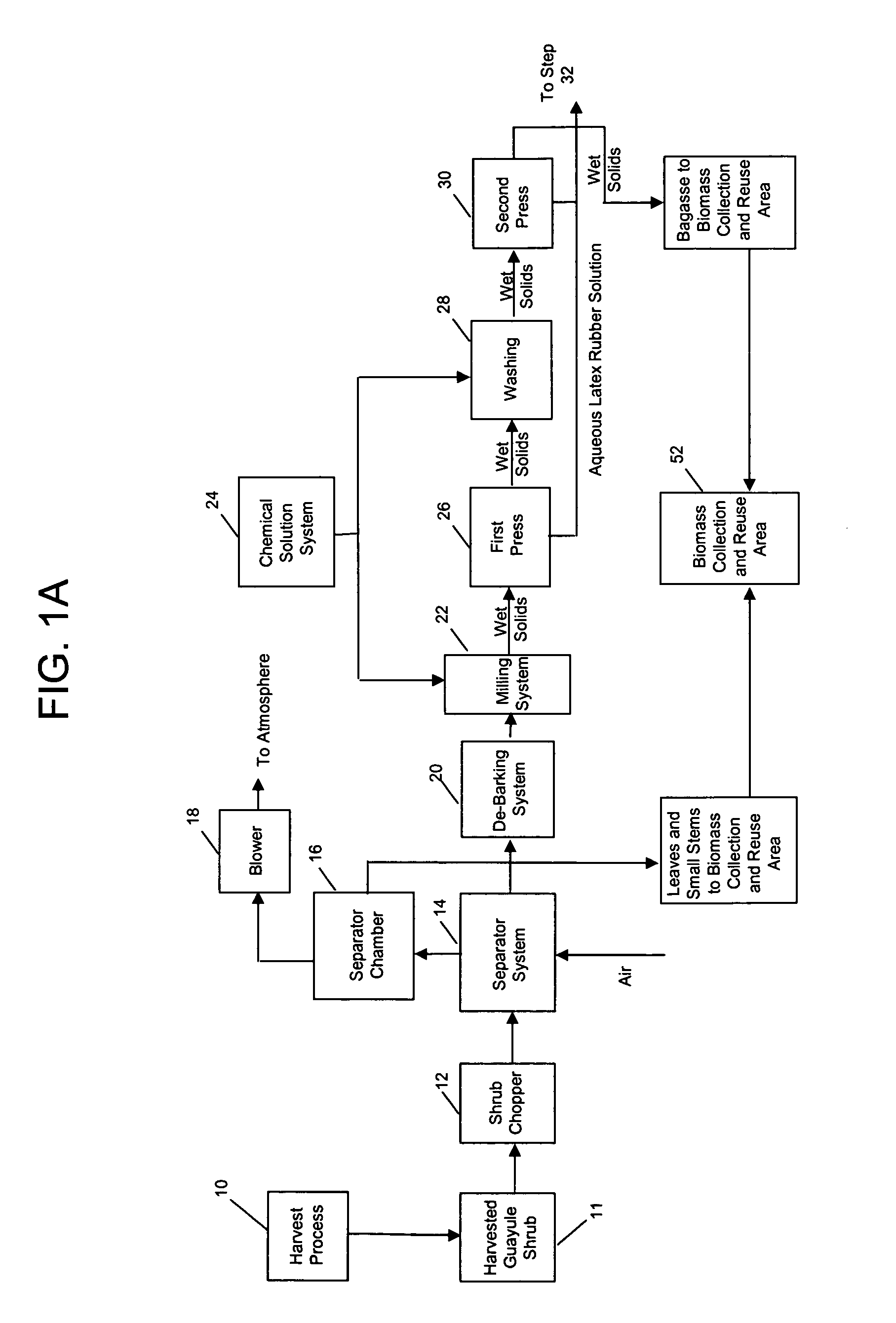

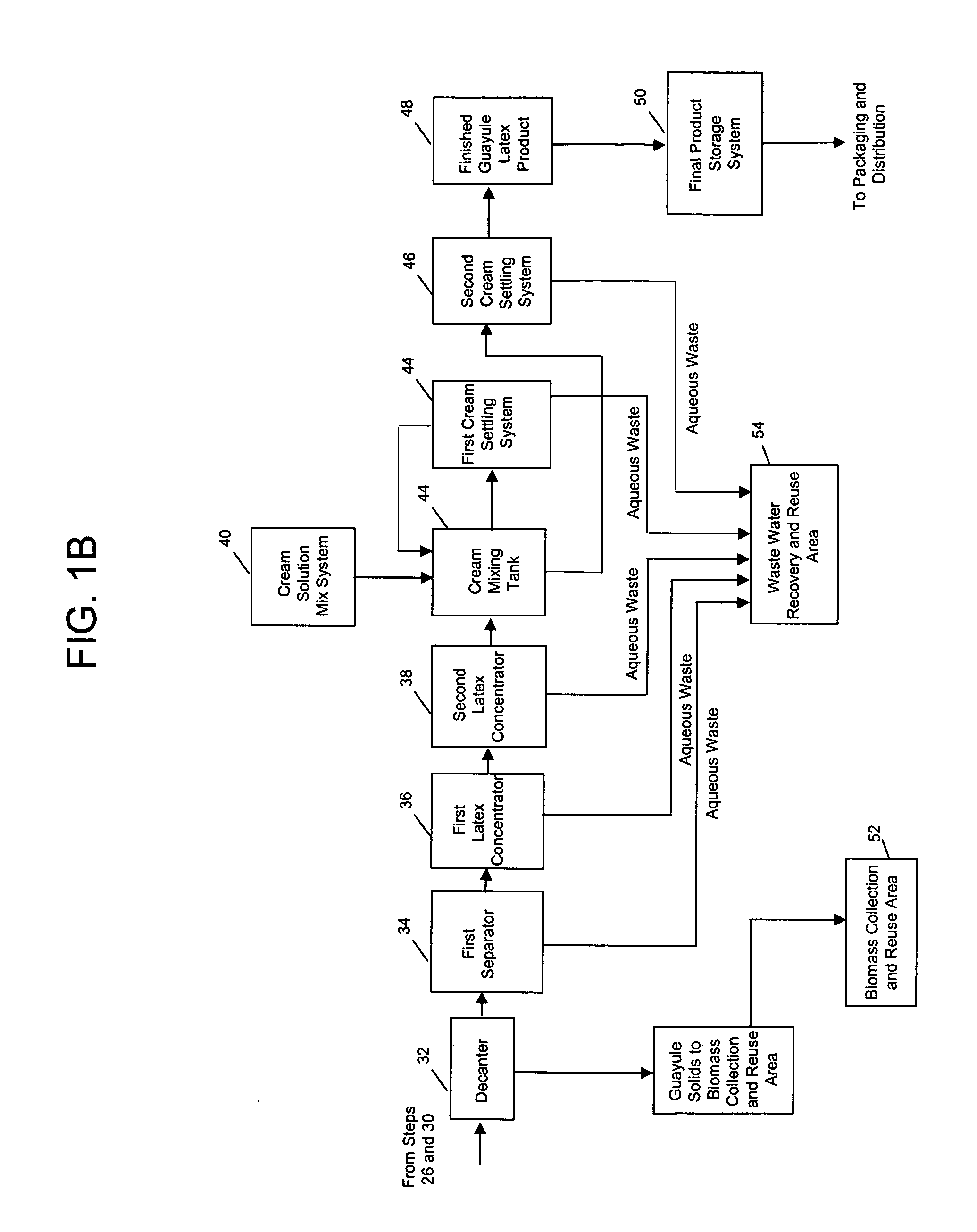

Biopolymer extraction from plant materials

Disclosed is a method and apparatus for the extraction of high molecular weight biopolymers from plants. Specifically, invention described herein relates to the commercial processing of plant material, including that from desert plants native to the southwestern United States and Mexico, such as the guayule plant (Parthenium argentatum), for the extraction of biopolymers, including natural rubbers. More specifically, the invention relates to laboratory to commercial scale extraction of high molecular weight biopolymers from plant materials including the chemical and mechanical processing of the plants and purification of the extracted biopolymer.

Owner:YULEX LLC

Methods for removing heavy metals from water using chemical precipitation and field separation methods

InactiveUS20050258103A1Efficient removalEasy to disassembleSedimentation separationDifferential sedimentationParticulatesSulfide

A two-step chemical precipitation process involving hydroxide precipitation and sulfide precipitation combined with “field separation ” technology such as magnetic separation, dissolved air flotation, vortex separation, or expanded plastics flotation, effectively removes chelated and non-chelated heavy metal precipitates and other fine particles from water. In the first-step, the non-chelated heavy metals are precipitated as hydroxides and removed from the water by a conventional liquid / solids separator such as an inclined plate clarifier to remove a large percentage of the dissolved heavy metals. The cleaned water is then treated in a second precipitation step to remove the residual heavy metals to meet discharge limits. In the second precipitation step, any metal precipitant more effective than hydroxide for metal precipitation can be used. The invention improves metal removal, lowers cost because fewer chemicals are used, produces less sludge, and reduces the discharge of toxic metals and metal precipitants to the environment. Magnetic separation is preferred for the separation of particles precipitated in the second stage. Similar methods can be employed for separation of other particulates from water. Particulates can also be removed by causing them to adhere to particles of expanded plastic, forming a floc lighter than water, so that the floc can be removed by flotation.

Owner:CORT CHERYL J

Aqueous based surfactant compositions

InactiveUS6177396B1Low viscosityUnstable structureInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsFlocculationHydrophilic monomer

The use of a stabiliser comprising a hydrophilic polymeric chain of more than four hydrophilic monomer groups and / or having a mass greater than 300 amu, linked at one end to a hydrocarbon-soluble hydrophobic group to reduce or prevent the flocculation of systems comprising a flocculable surfactant and a liquid medium which is capable of flocculating the surfactant and in which the stabiliser is capable of existing as a micellar solution at a concentration of at least 1% by weight.

Owner:HUNTSMAN INT LLC

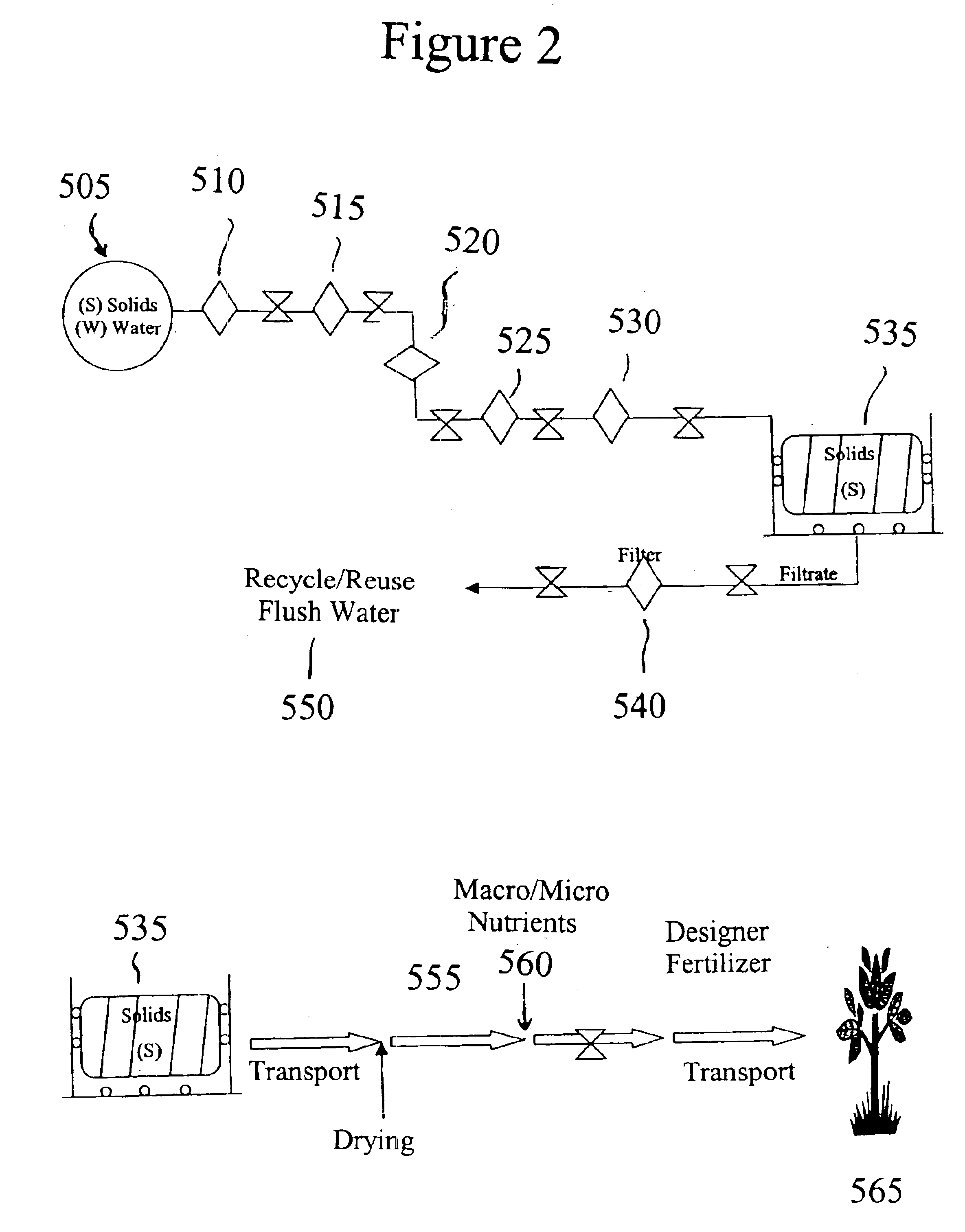

Animal waste effluent treatment

Animal waste such as fecal material from swine, chicken, turkey, and cattle is converted into useful forms such as fertilizer, other types of soil builders, and even nutrient feed additives. Devices, systems, and methods are provided that allow economical conversion and in many instances, alleviate the production and release of undesirable gases such as sulfide and ammonia. In one embodiment, undesirable anaerobic and facultative anaerobic bacteria are killed at a greater rate than desirable soil compatible aerobic bacteria. The use of low temperature killing diminishes off gassing commonly associated with other techniques, and the use of gas trapping additives such as zeolites provides enhanced soil building qualities such as slow release of nitrogen and slow release of moisture to soil. The methods allow convenient adjustment of composition, allowing conversion of waste into tailored designer fertilizer suited for particular soils. Other embodiments provide other soil building qualities as well as nutrient qualities for feedstock used in animal husbandry such as aquaculture.

Owner:SHEETAB SR RICHARD G

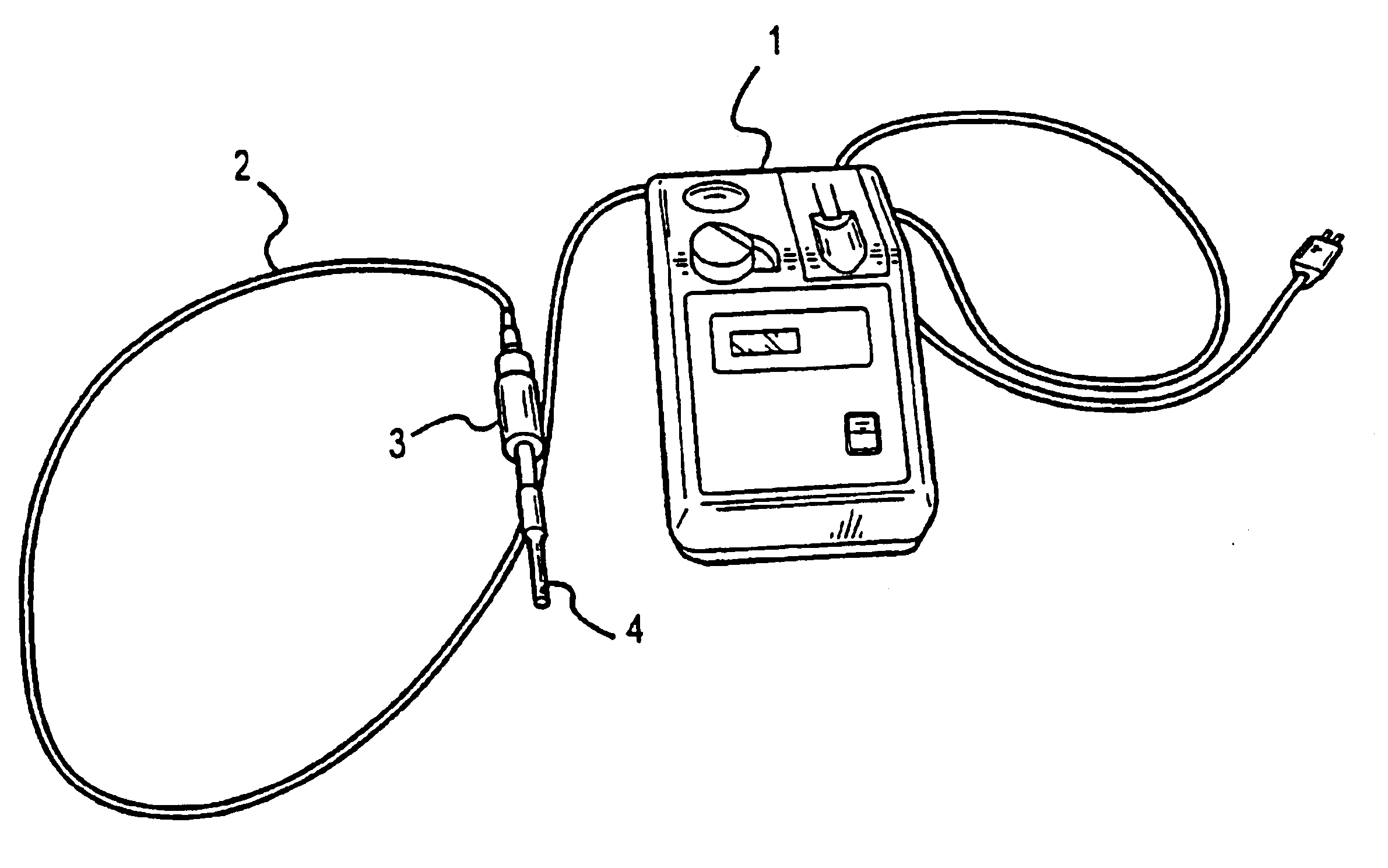

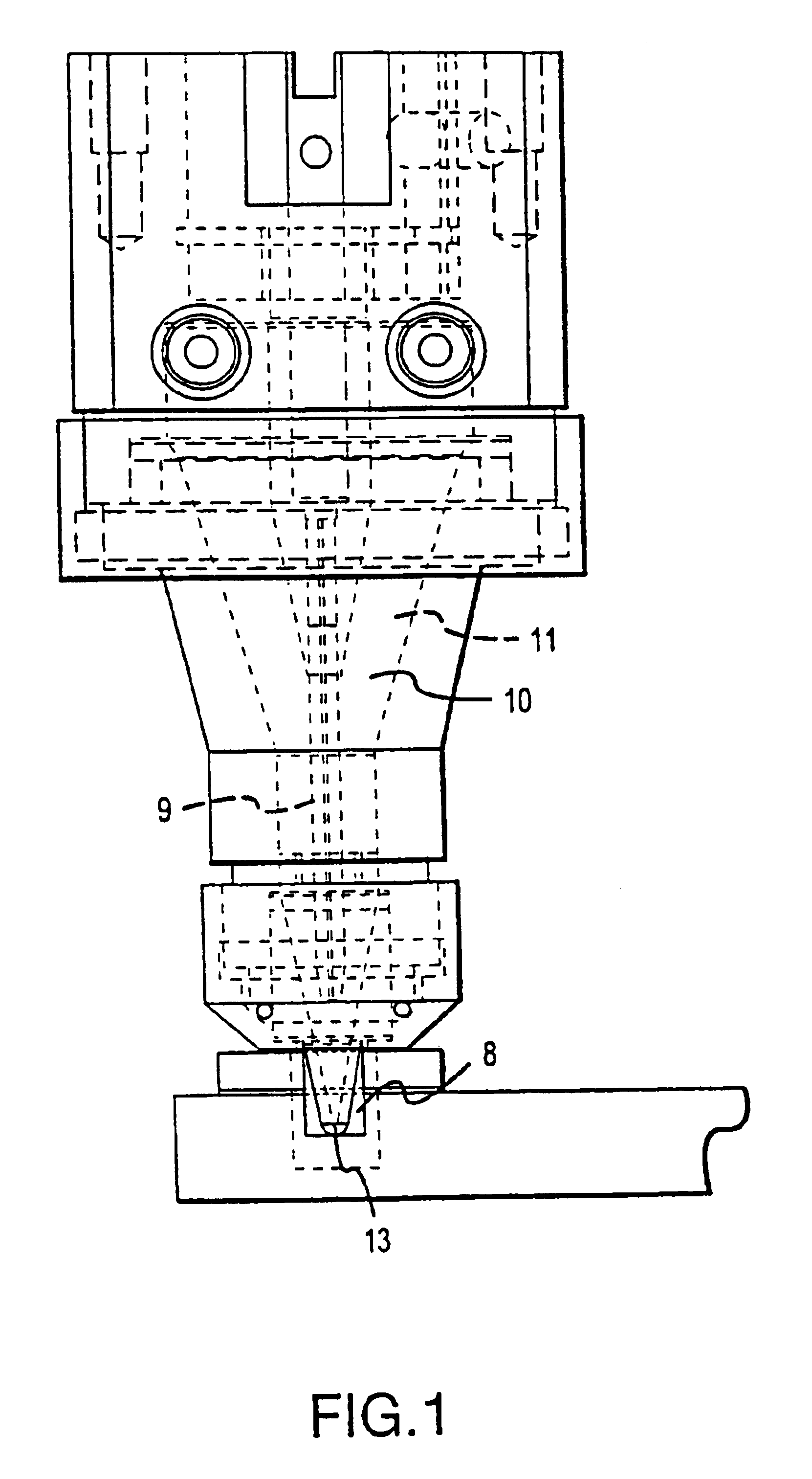

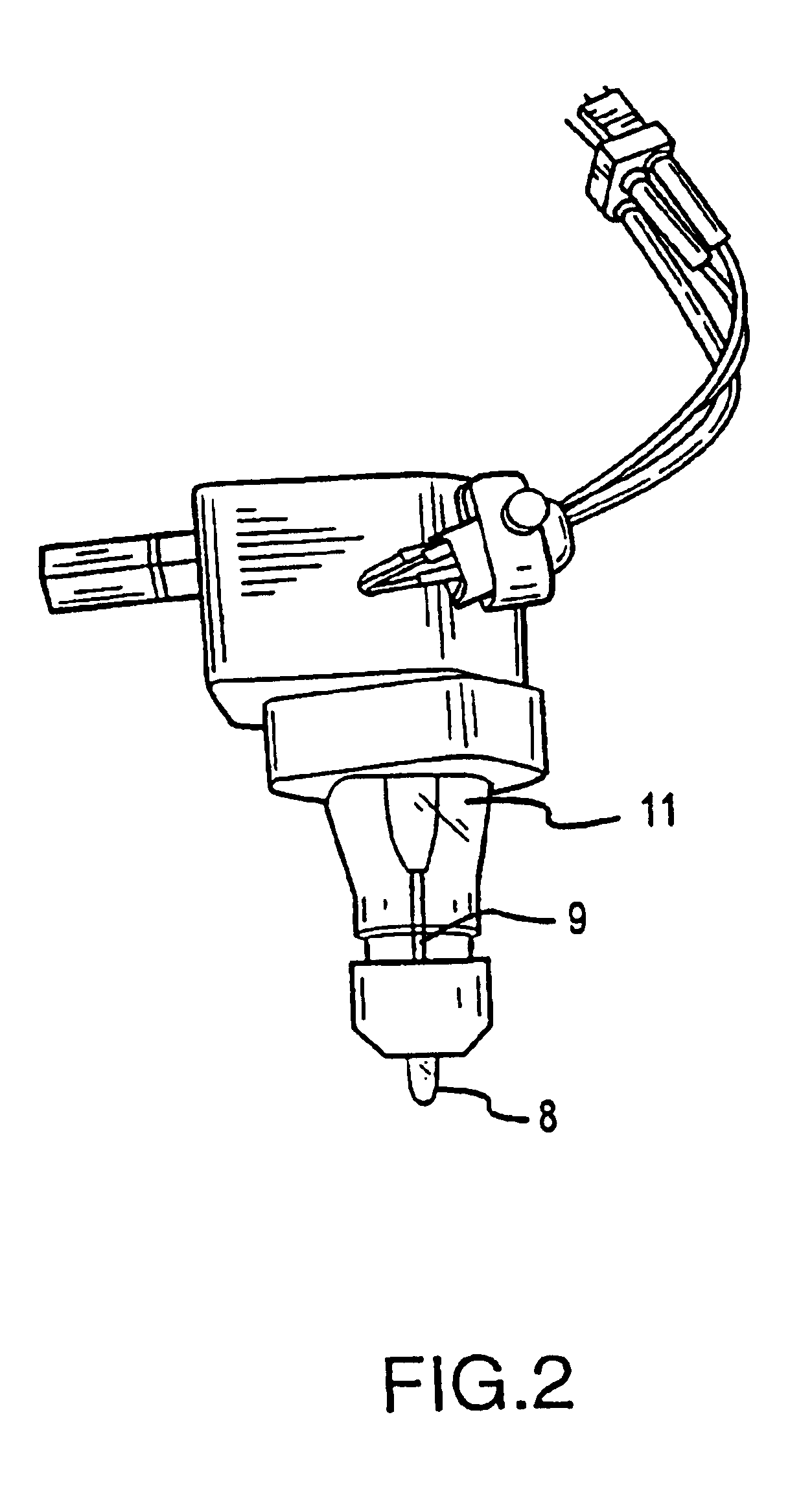

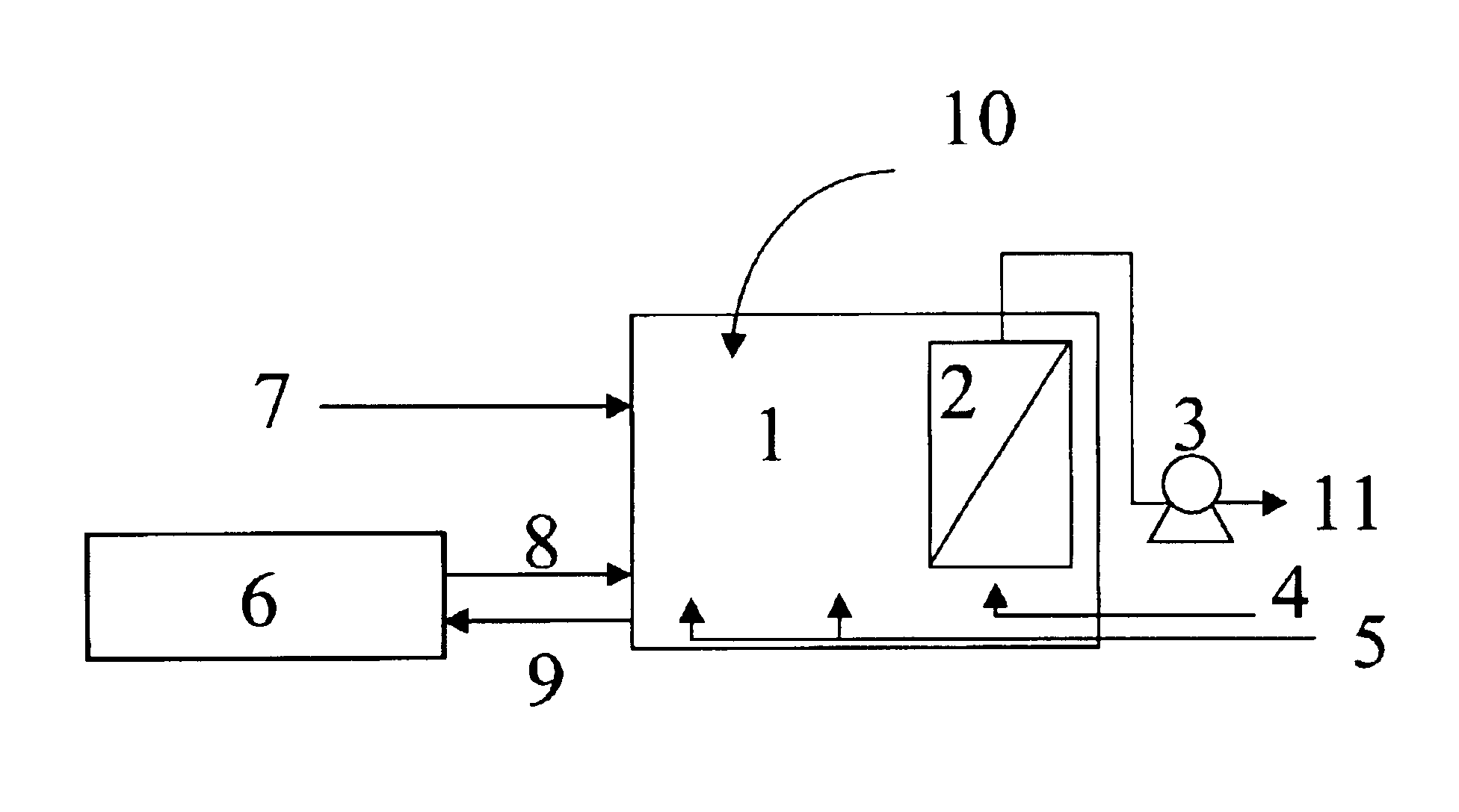

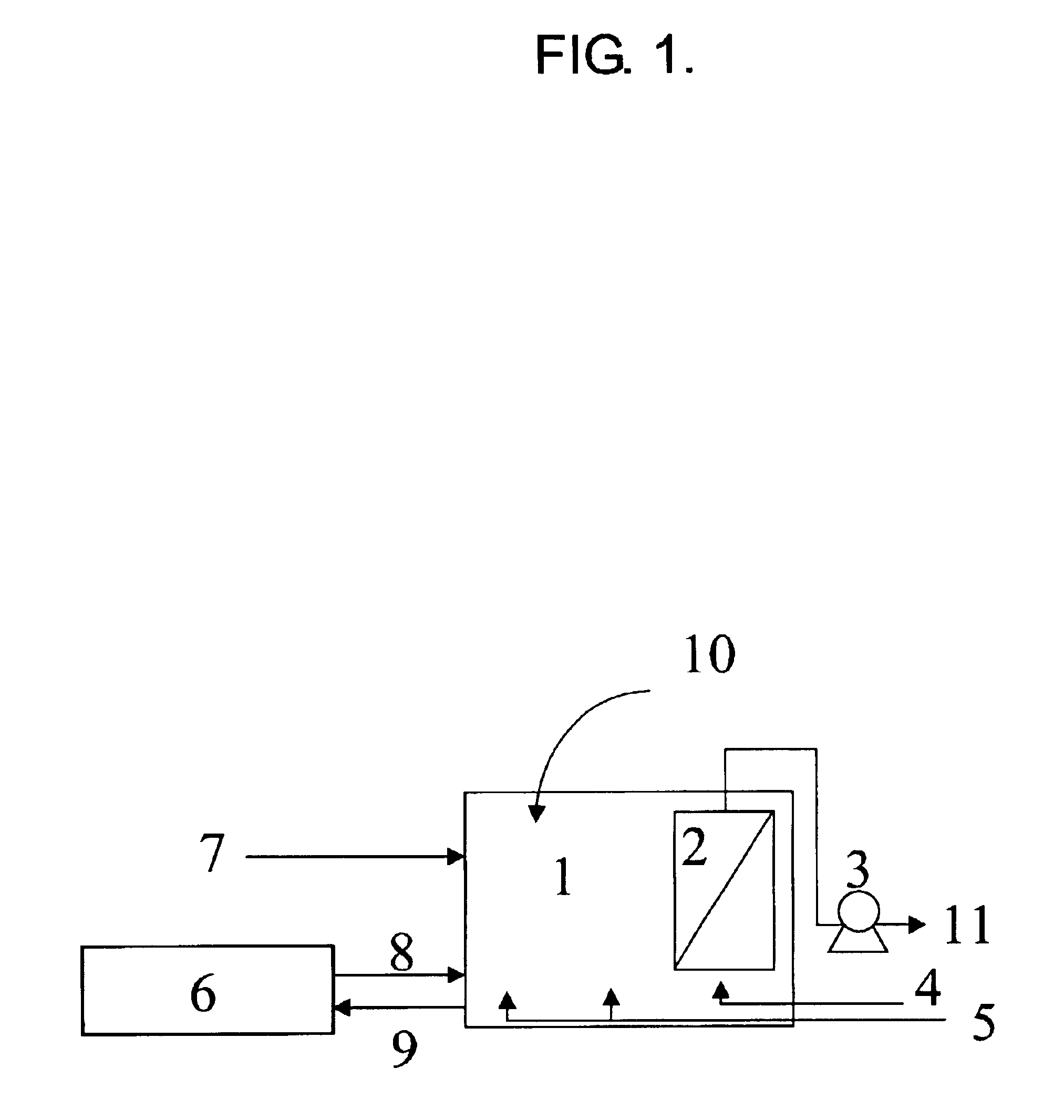

Vibratory system for a sorting flow cytometer

InactiveUS6746873B1Raise the possibilityReduce resultElectrostatic separationMaterial analysis by electric/magnetic meansEngineeringElectric signal

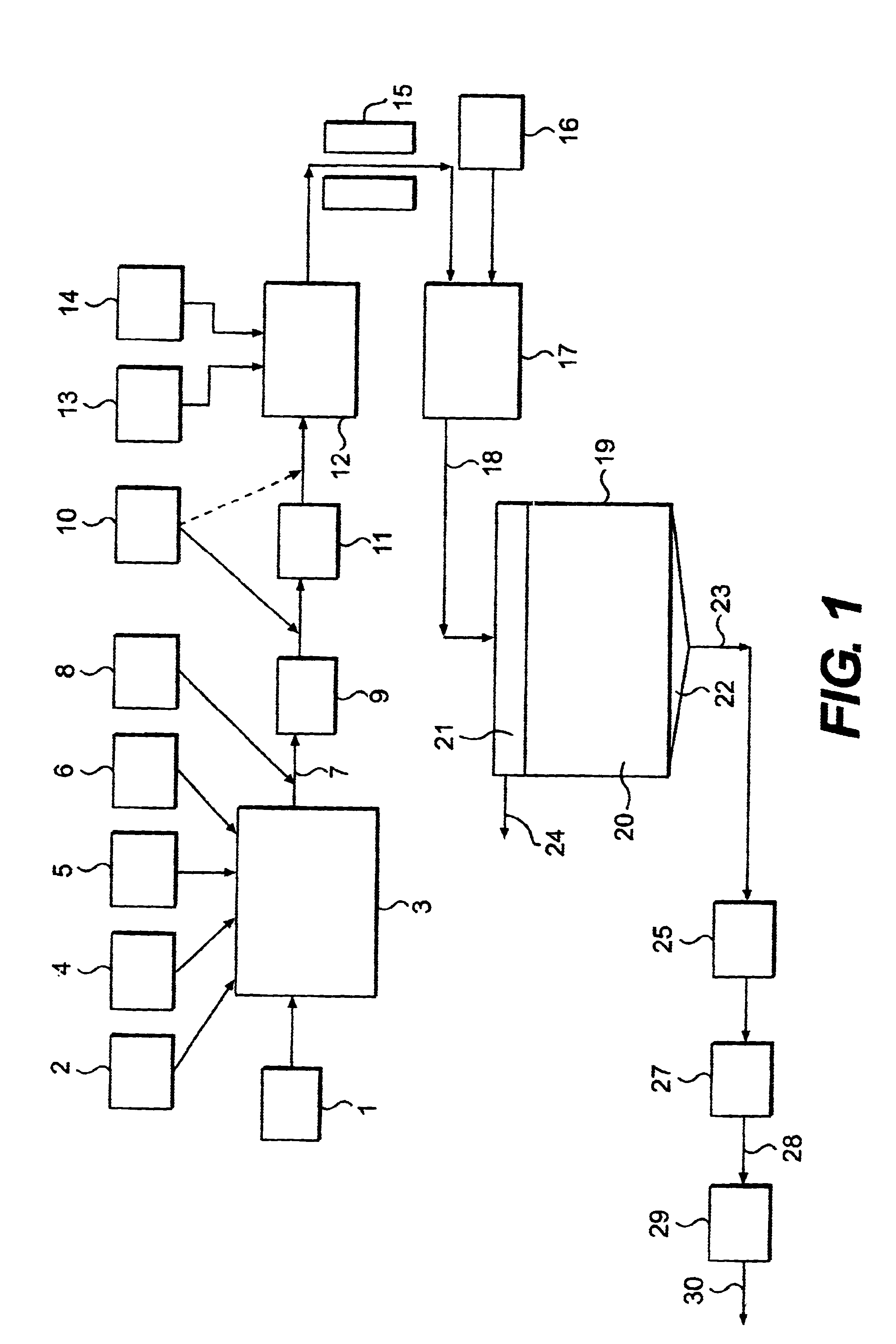

A flow cytometry system is disclosed for oscillating the exterior of a flow cytometer nozzle. Oscillating the exterior of a flow cytometer nozzle at selected oscillations or a sweeping range of oscillations disintegrates particles and gas entrapped within the flow cytometer nozzle. Adherents absorbed to the exterior of the flow cytometer nozzle may also be removed. An energy source (1) serves to generate a selected oscillation or range of oscillations. The energy source (1) is connected to a flexible transfer element (2) which conducts the electrical signals to an oscillation system (3). The oscillation system (3) turns the electrical energy from the energy source (1) into mechanical oscillations and is connected to a portable device (4) which disintegrates particles, dislocates gas within the flow cytometer nozzle and cleans the exterior of the flow cytometer aperture.

Owner:DAKO COLORADO +1

Two-step method for dehydrating plastic dispersions

InactiveUS6287470B1Avoid excessive wearQuality improvementLiquid degasificationRotary stirring mixersPolymer scienceOrganic chemistry

The invention relates to a method for dehydrating a two-phase liquid mixture consisting of a thermoplastic synthetic melt phase and an aqueous phase, comprising the following steps: a) coagulation of the two-phase liquid mixture in a first extruder; b) dehydration of the coagulate in a twin screw extruder with a de-watering zone and screws working in an opposite direction; c) separation of constituents by degasifying. The inventive method is characterized in that a single screw extruder or a twin screw extruder with screws working in the same direction is used as a first extruder in step a).

Owner:EVONIK ROEHM GMBH

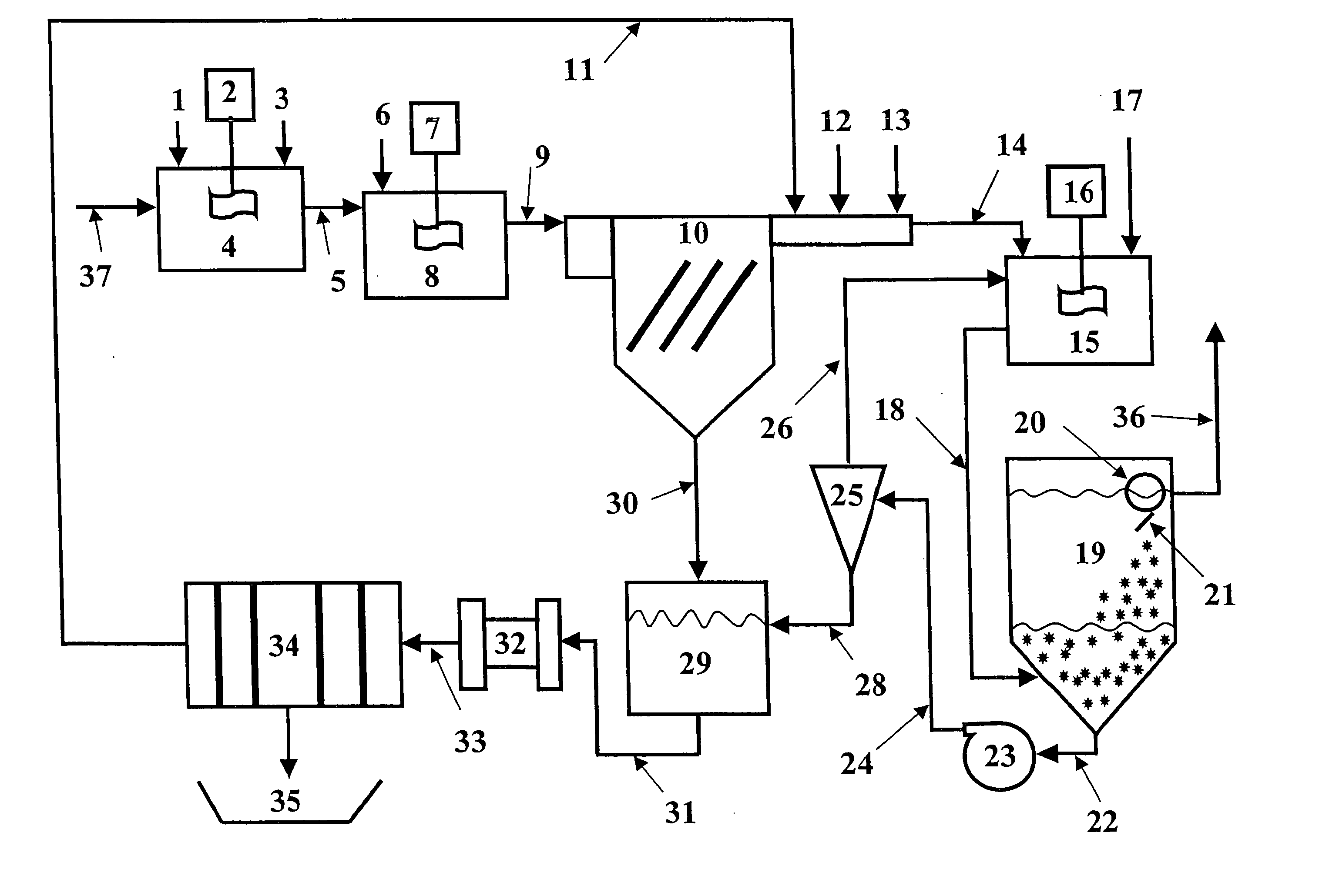

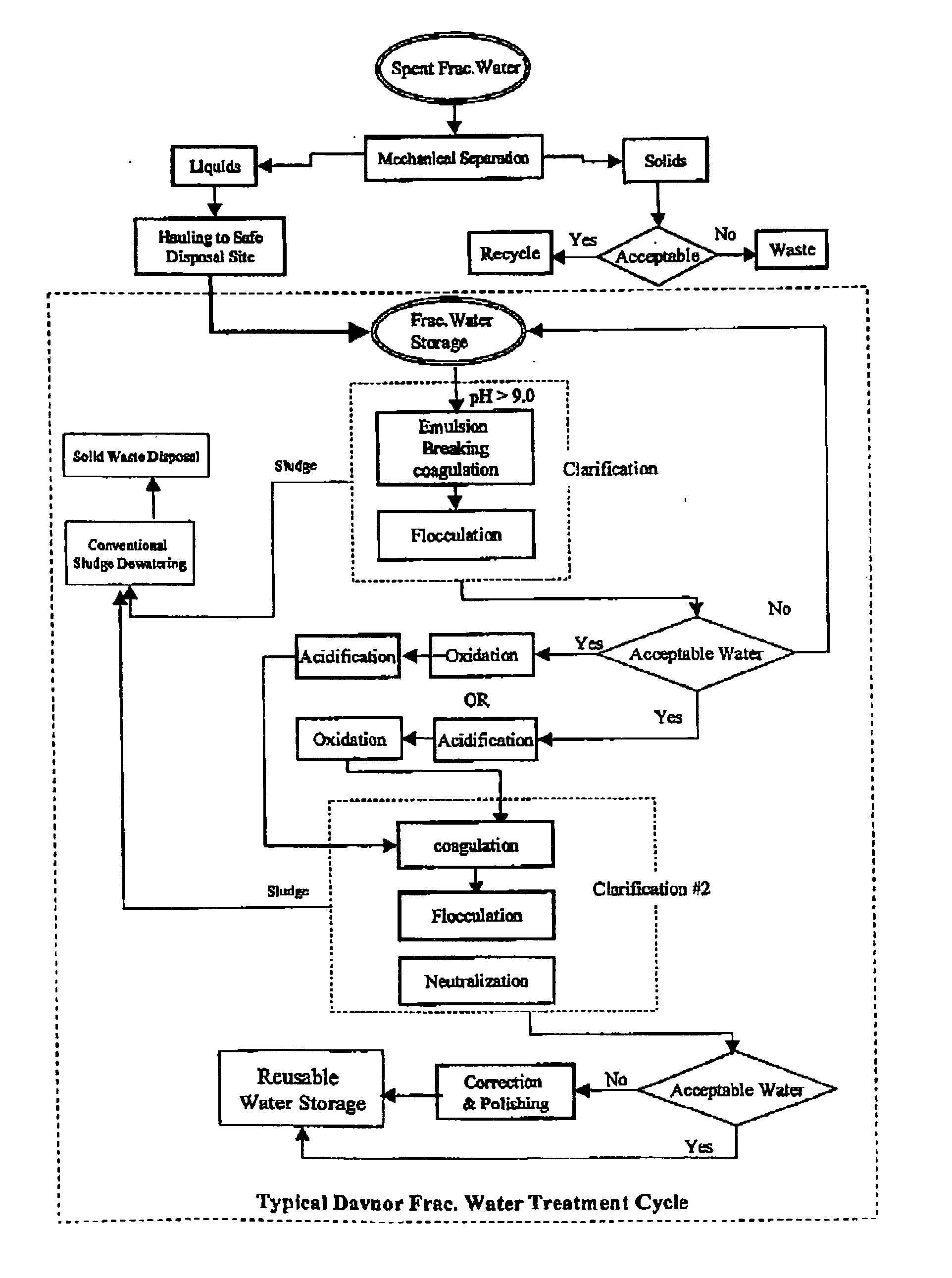

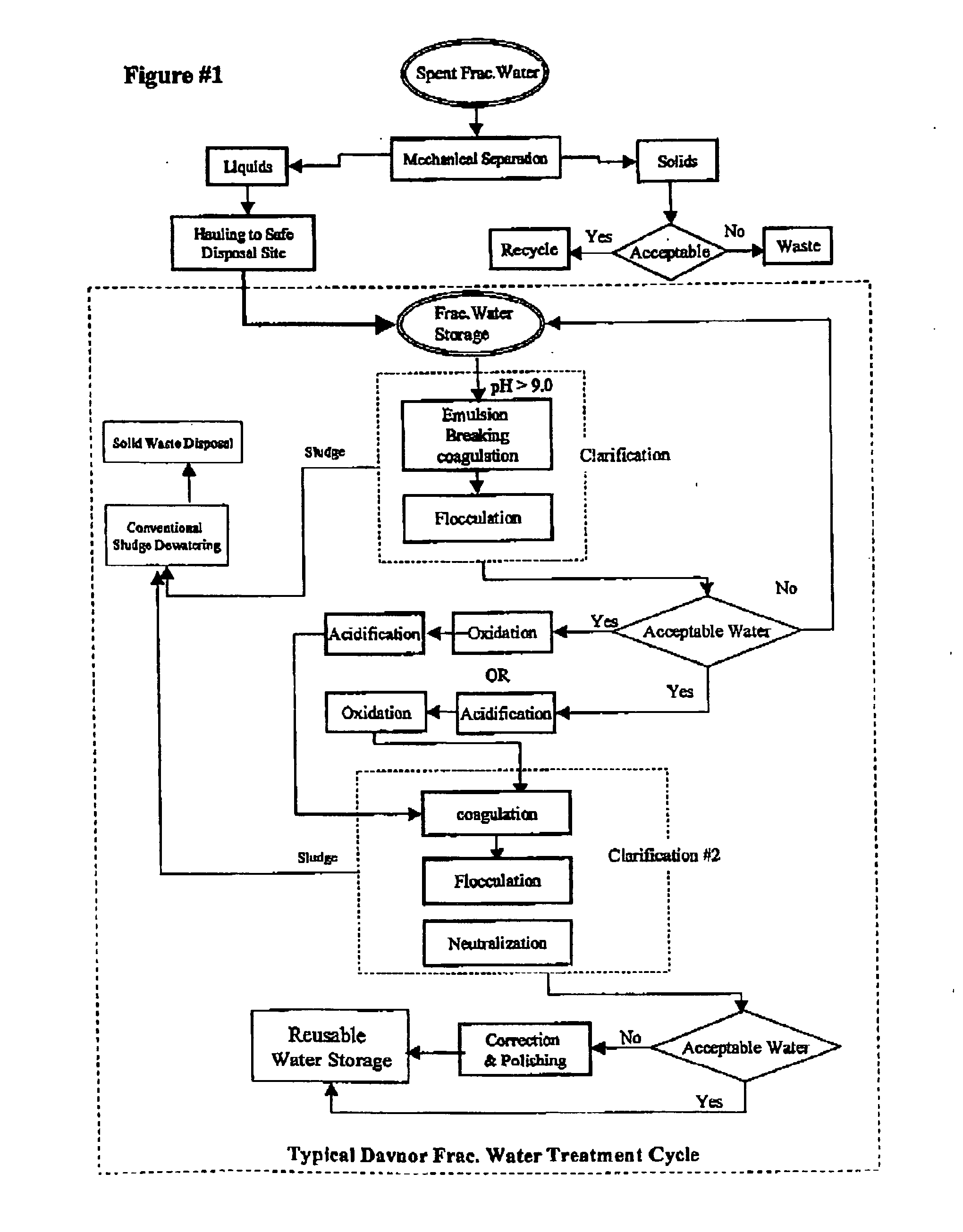

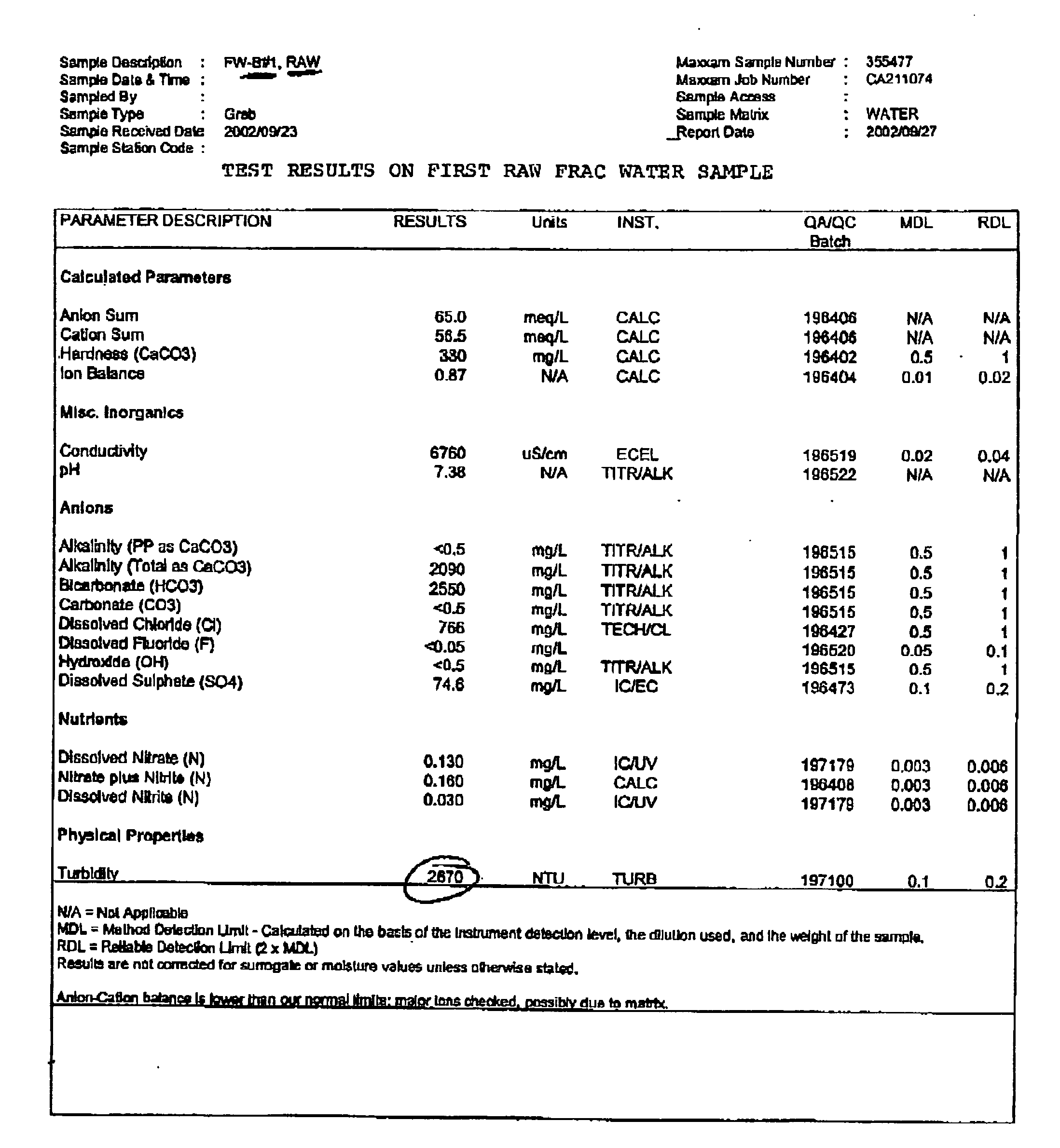

Oil and gas well fracturing (frac) water treatment process

InactiveUS20050098504A1Reduced pHRaise the pHWaste water treatment from quariesDewatering/demulsification with chemical meansFracturing fluidOxidizing agent

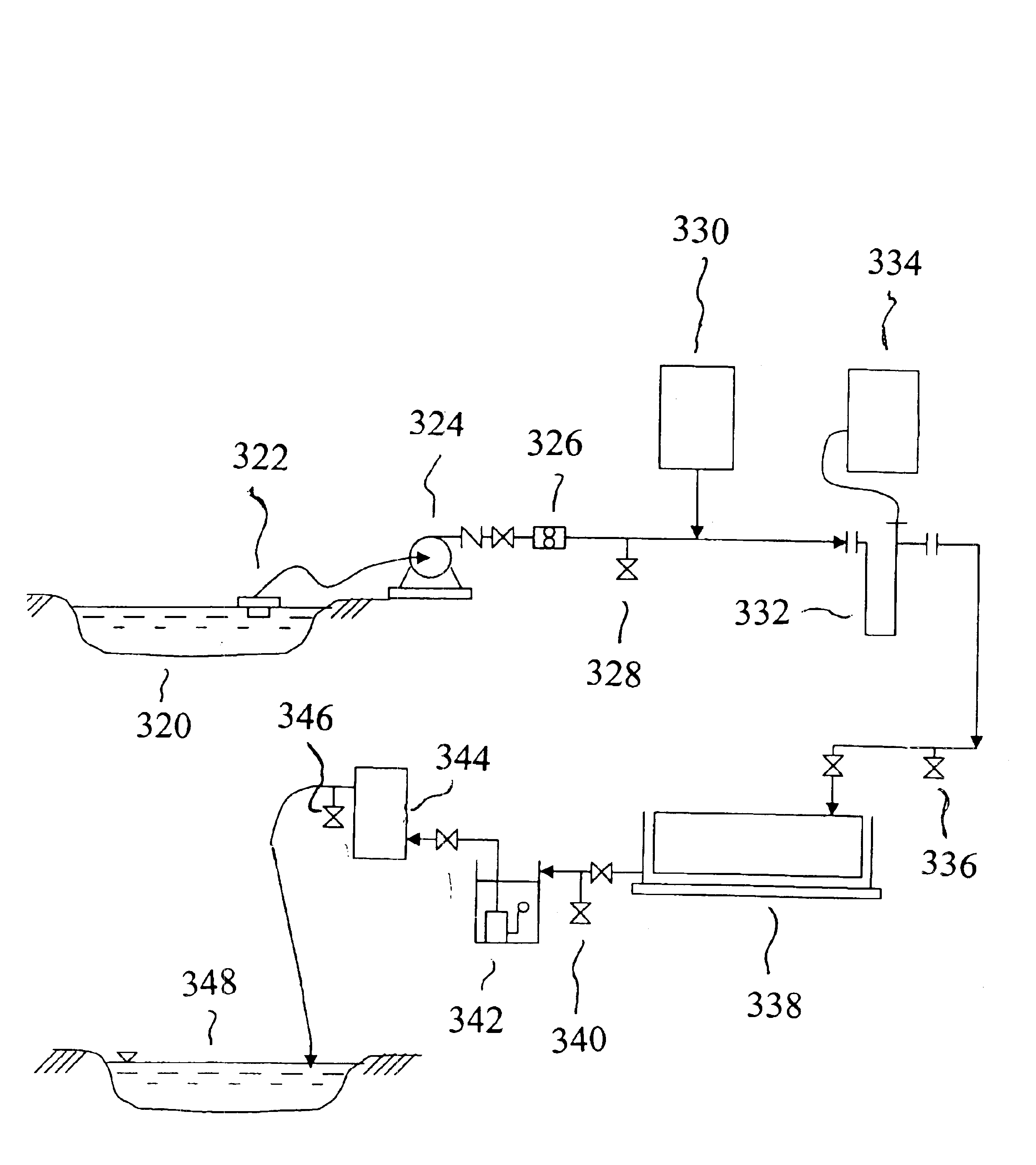

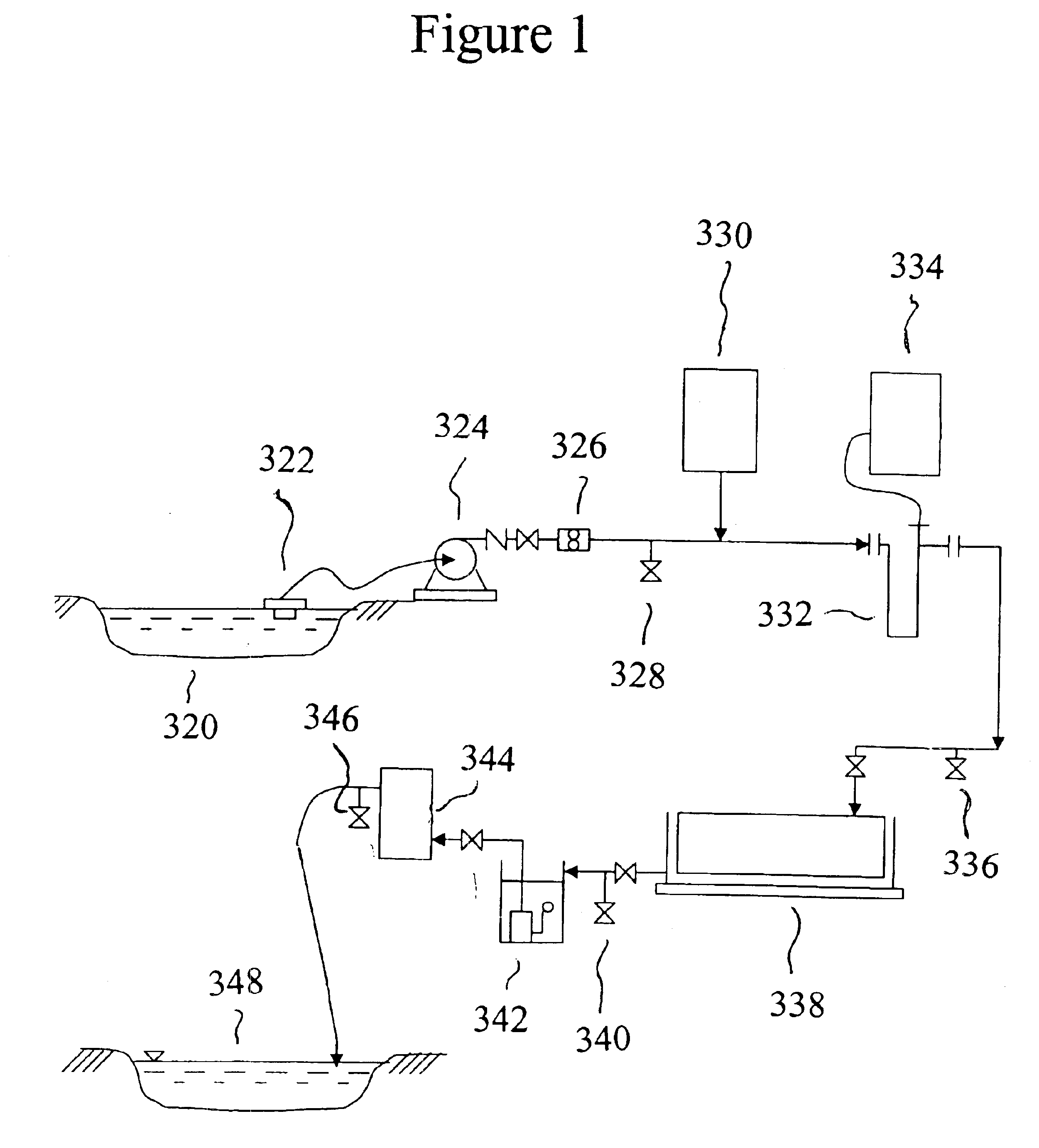

This invention relates to a novel process for treating and removing undesirable impurities from oil and gas well fracturing fluid. A method for treating fracturing water comprising: (a) passing contaminated fracturing water containing solids and liquid through a mechanical separator to remove solids from the liquid; (b) treating the fracturing water liquid with an alkaline agent to increase the pH of the liquid to a level of above 9; (c)) adding a coagulant to the fracturing water to form an agglomerate and separating the agglomerate from the fracturing water; (d) reducing the pH of the fracturing water of step (c)) to a level of less than about 5.5; and (e) adding an oxidizing agent to the fracturing water of step (d) to oxidize oxidizable impurities in the fracturing water.

Owner:DAVNOR WATER TREATMENT TECH

Multiple laminar flow-based particle and cellular separation with laser steering

InactiveUS7118676B2Save a lot of timeImprove throughputDielectrophoresisOther blood circulation devicesCellular componentBlood component

Owner:PREMIUM GENETICS UK

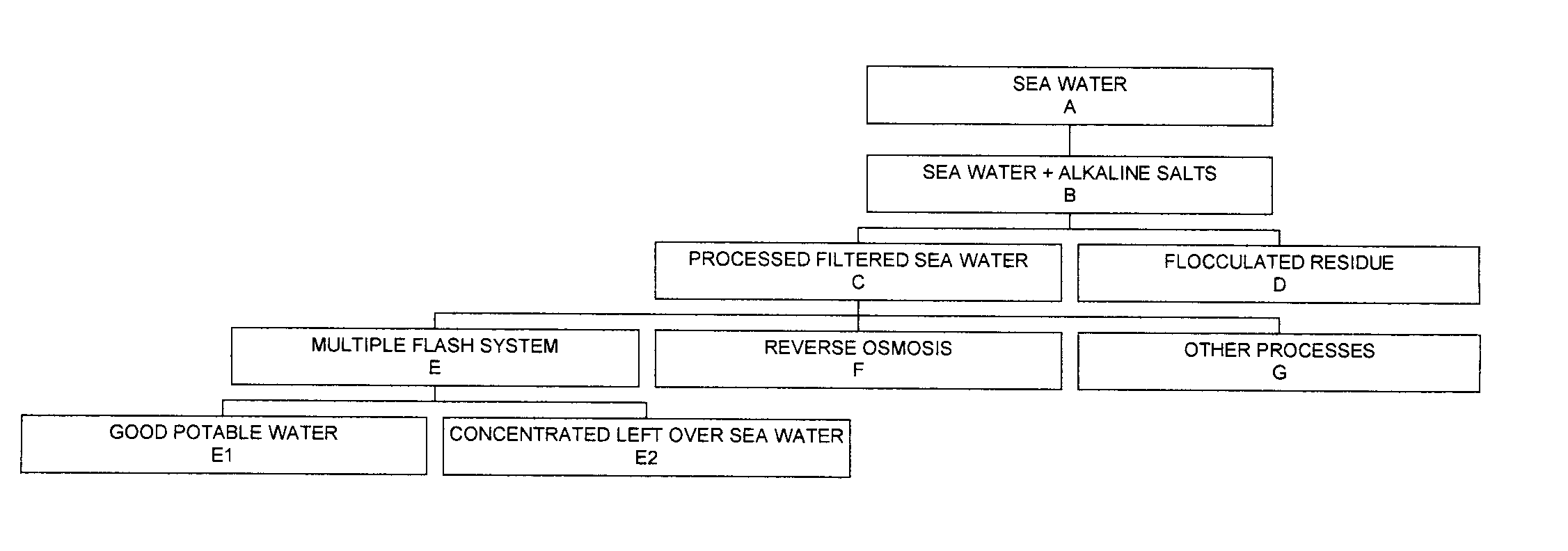

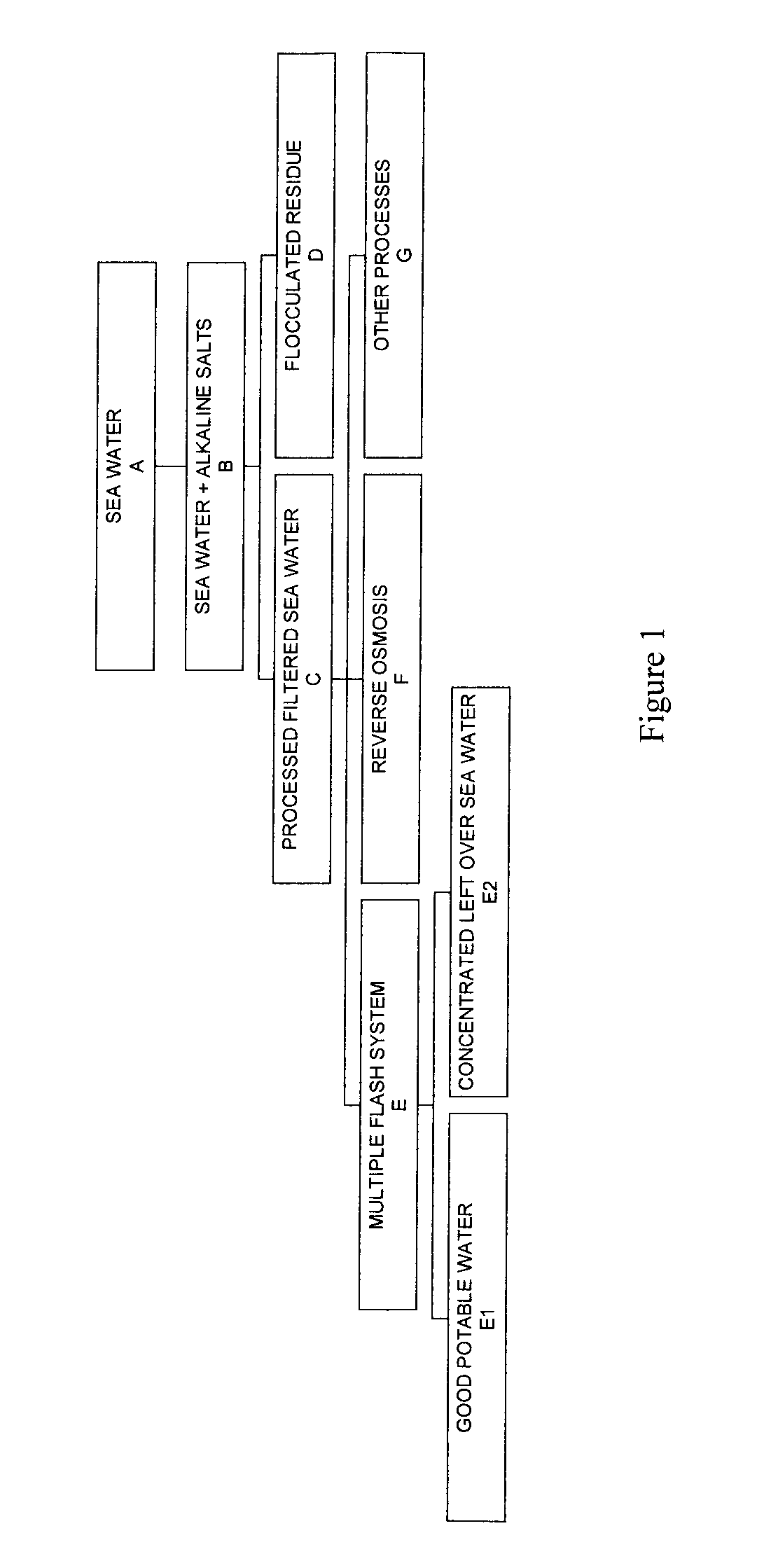

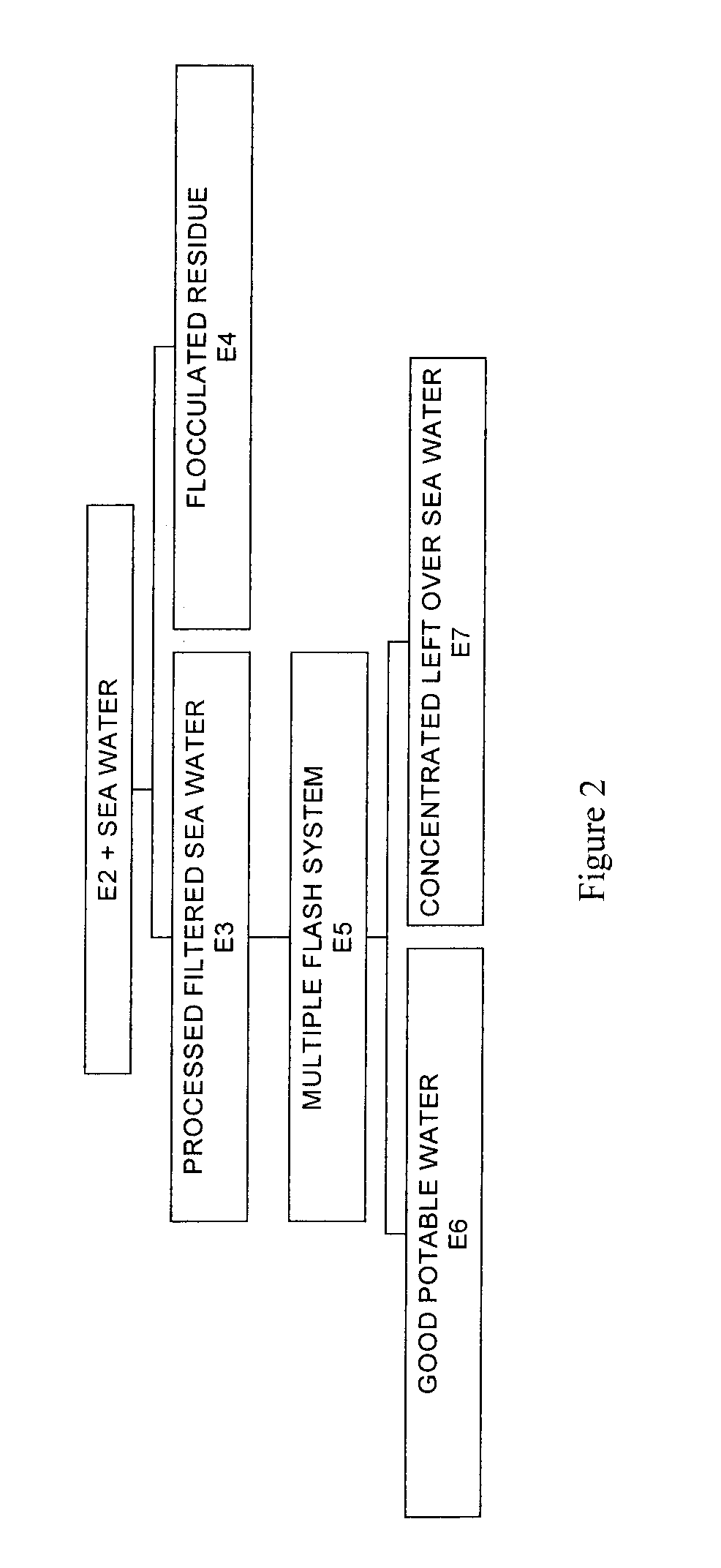

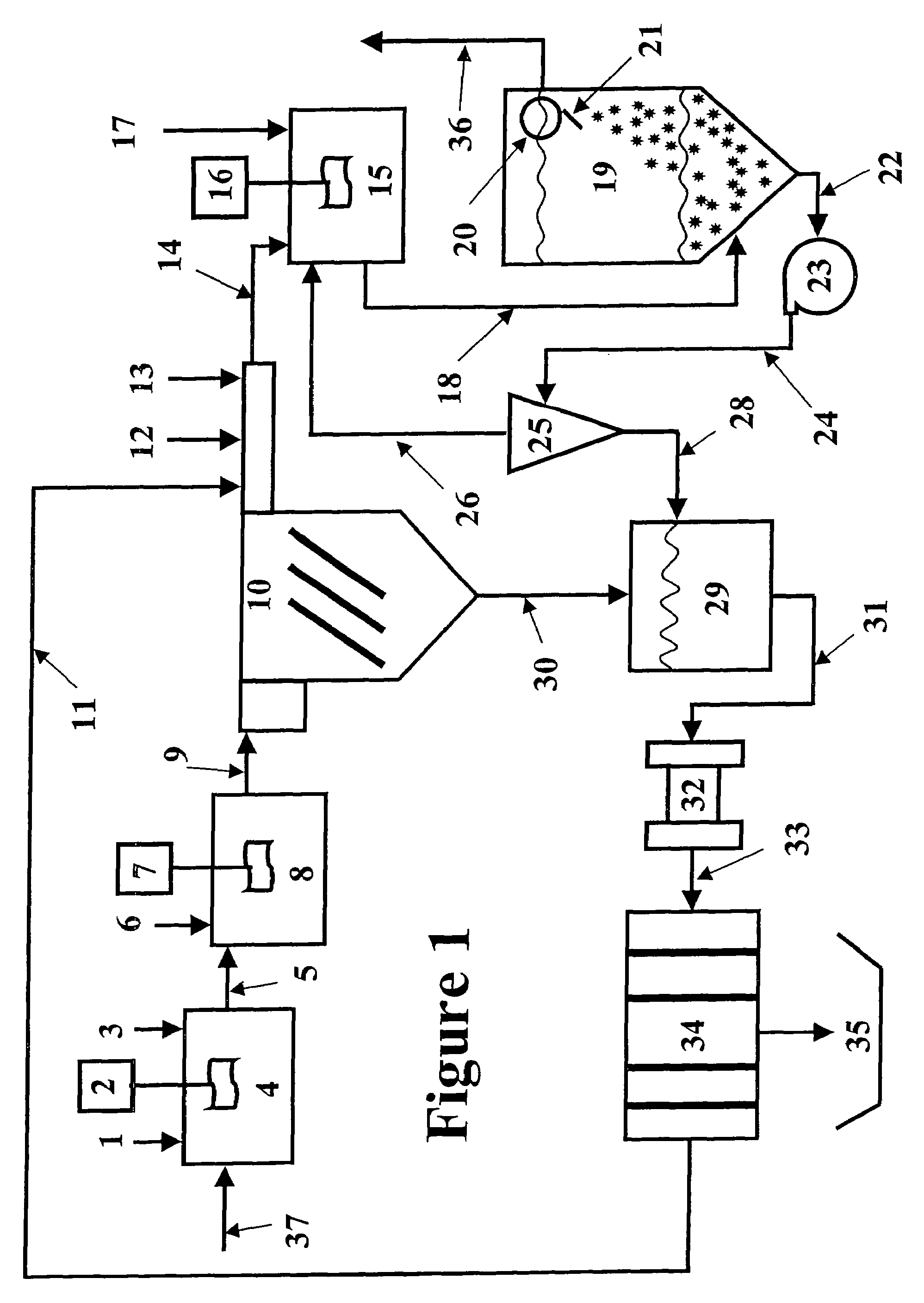

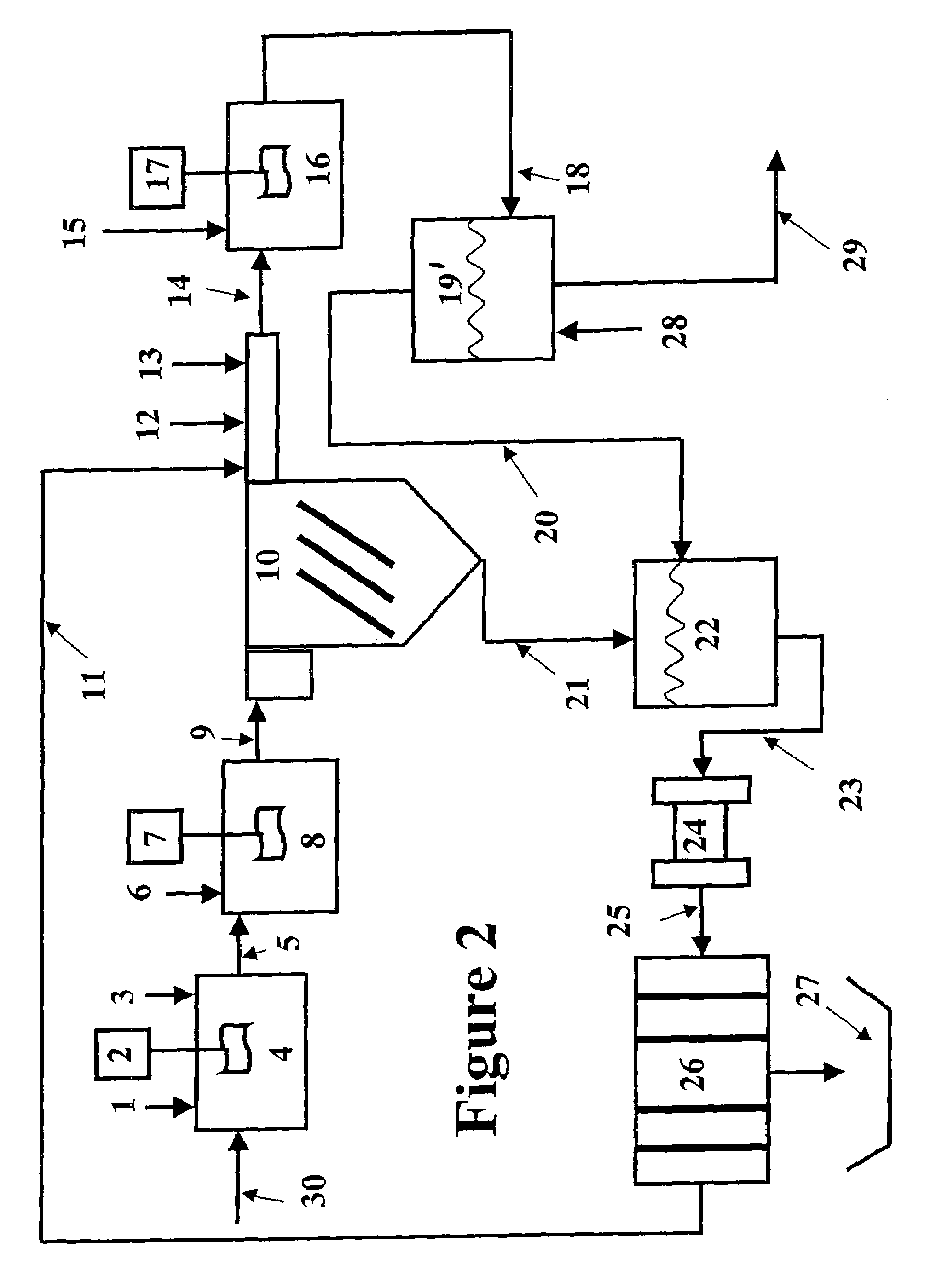

Process for pre-treating and desalinating sea water

ActiveUS20050098499A1Reduce maintenanceExtend equipment lifeGeneral water supply conservationSeawater treatmentCalcium bicarbonatePotassium hydroxide

Water containing dissolved salts, such as calcium sulfate, calcium chloride, magnesium sulfate, magnesium chloride, sodium carbonate, sodium chloride, sodium sulfate, calcium bicarbonate, and mixtures thereof, is treated to reduce the concentration of those salts. About 0.1 to about 60 g / L of sodium hydroxide, sodium carbonate, potassium hydroxide, potassium carbonate, calcium hydroxide, calcium carbonate, aluminum hydroxide, aluminum sulfate, aluminum potassium sulfate, and mixtures thereof is added to the water, whereby a precipitate forms in the water. The precipitate is separated from said water and the water is desalinated using reverse osmosis, flash evaporation, or another method. The process is preferably performed by first adding calcium oxide or calcium hydroxide, separating the precipitate that forms, then adding sodium hydroxide and sodium carbonate to form a second precipitate.

Owner:HUSSAIN MOHAMMED AZAM

Methods for removing heavy metals from water using chemical precipitation and field separation methods

InactiveUS7255793B2Cost- and chemically-effectiveSedimentation separationWater/sewage treatment by neutralisationParticulatesSulfide

A two-step chemical precipitation process involving hydroxide precipitation and sulfide precipitation combined with “field separation ” technology such as magnetic separation, dissolved air flotation, vortex separation, or expanded plastics flotation, effectively removes chelated and non-chelated heavy metal precipitates and other fine particles from water. In the first-step, the non-chelated heavy metals are precipitated as hydroxides and removed from the water by a conventional liquid / solids separator such as an inclined plate clarifier to remove a large percentage of the dissolved heavy metals. The cleaned water is then treated in a second precipitation step to remove the residual heavy metals to meet discharge limits. In the second precipitation step, any metal precipitant more effective than hydroxide for metal precipitation can be used. The invention improves metal removal, lowers cost because fewer chemicals are used, produces less sludge, and reduces the discharge of toxic metals and metal precipitants to the environment. Magnetic separation is preferred for the separation of particles precipitated in the second stage. Similar methods can be employed for separation of other particulates from water. Particulates can also be removed by causing them to adhere to particles of expanded plastic, forming a floc lighter than water, so that the floc can be removed by flotation.

Owner:CORT CHERYL J

Process for the treatment of saline water

InactiveUS7595001B2Waste water treatment from quariesGeneral water supply conservationTotal dissolved solidsEvaporation

A process and an apparatus are described for treating seven types of saline waters each having a concentration of total dissolved solids exceeding 1 g / L, wherein the concentration of total dissolved solids, the ratio of the chloride ion concentration to the bicarbonate ion concentration and the ratio of the chloride ion concentration to the sulphate ion concentration of each of the water types are as indicated in Table 1. The process includes the steps of contacting the water with a first reagent comprising a source of calcium ions selected from calcium oxide and calcium hydroxide to form a first solid product which is recovered. The process includes a further step of subjecting at least a portion of the partially processed water to at least partial evaporation so as to promote the formation of a precipitate and a mother liquor. The precipitate is recovered as a second product.

Owner:GEO PROCESSORS

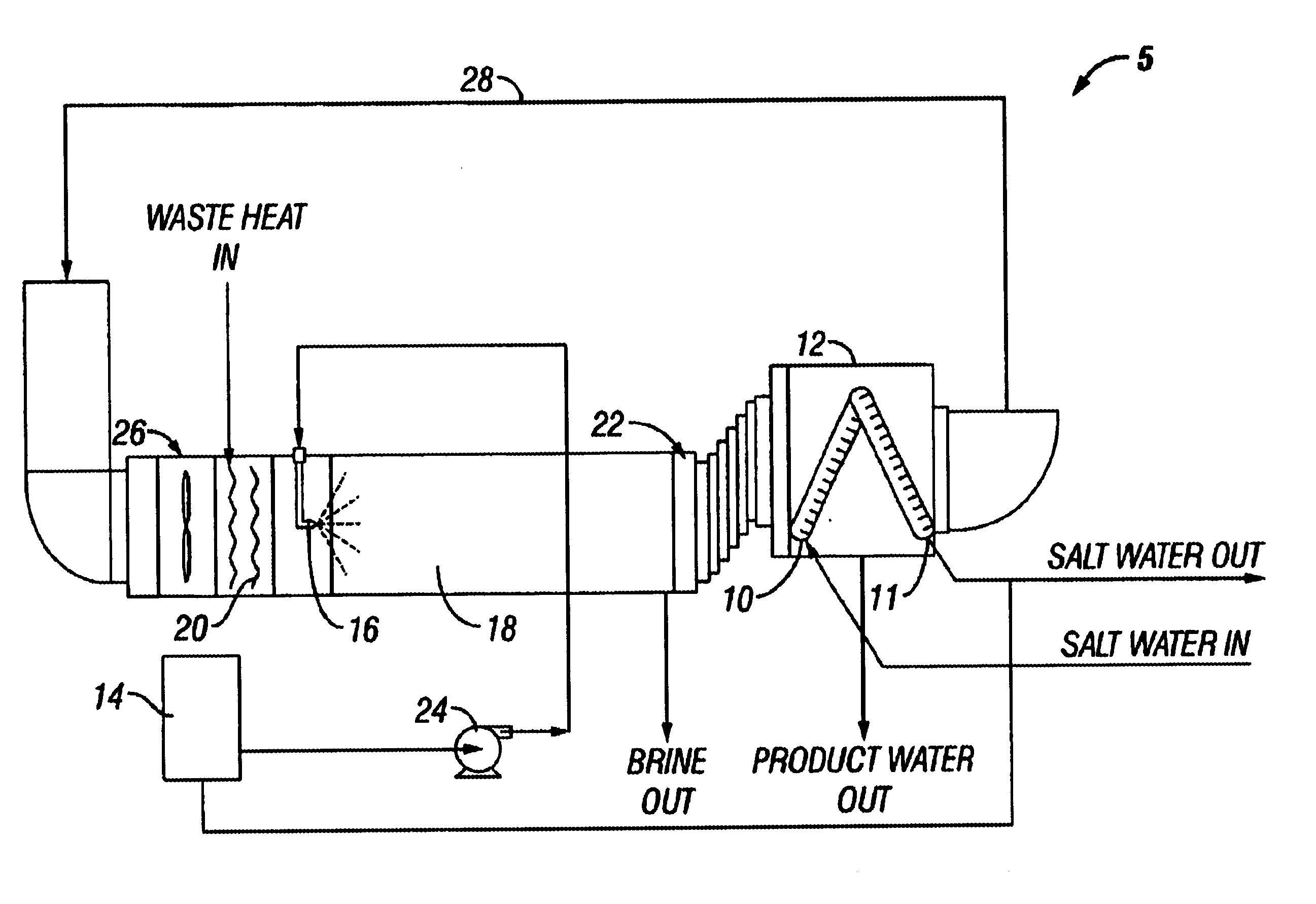

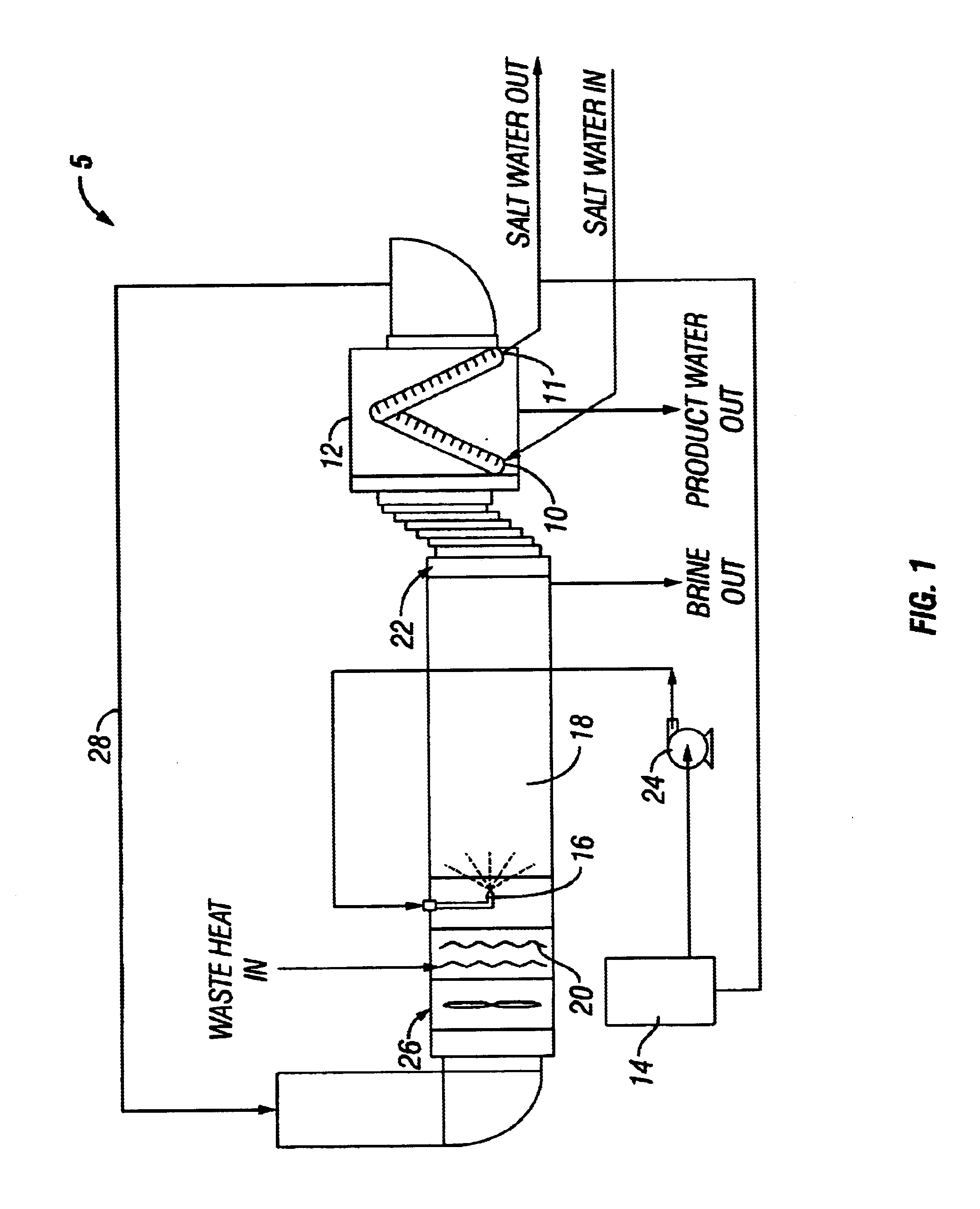

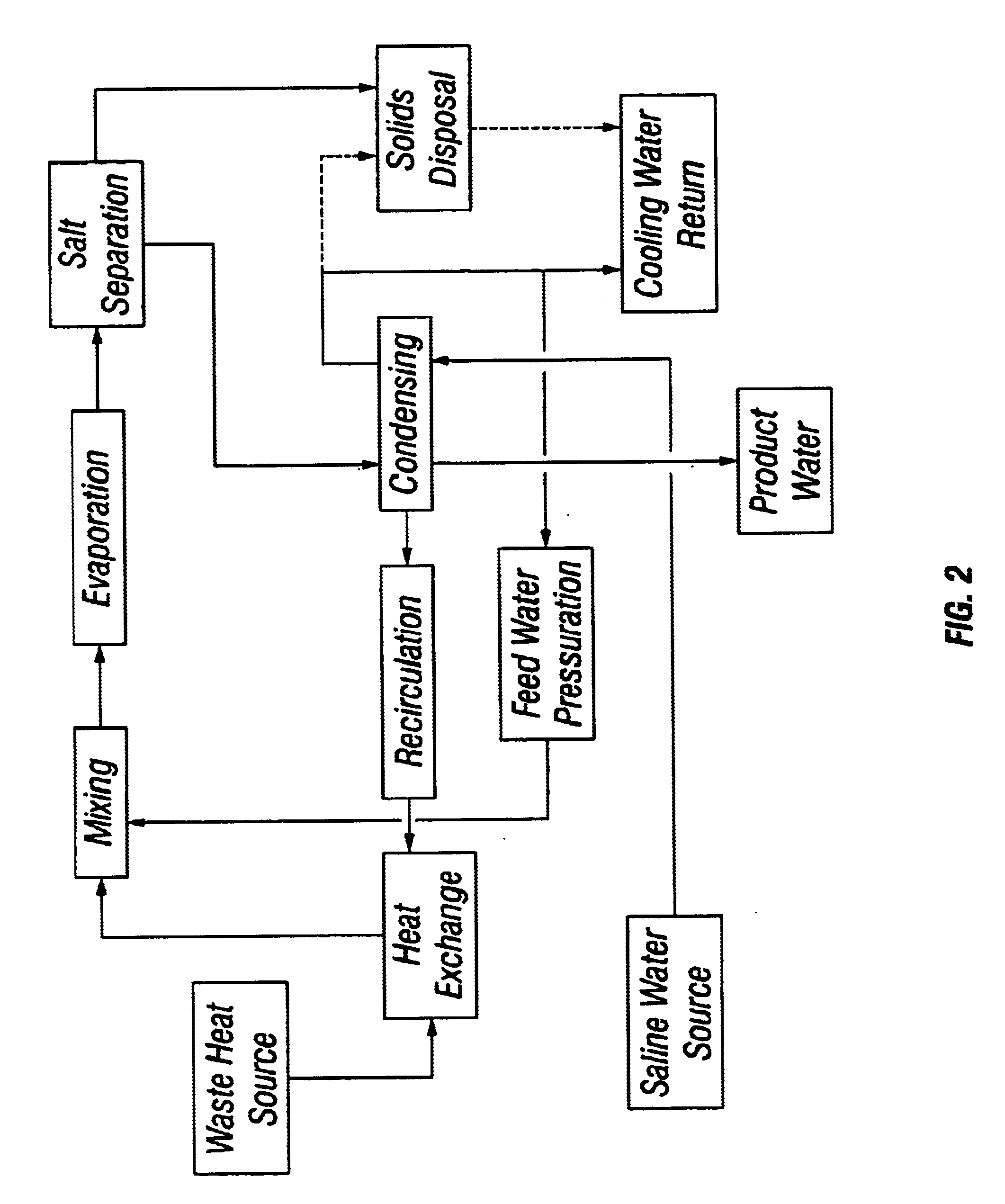

Apparatus and method for thermal desalination based on pressurized formation and evaporation of droplets

A method for removing dissolved solids, particularly salts, from water. An apparatus for performing the inventive method is disclosed. The aqueous solution to be treated, for example sea water, is atomized using special non-pneumatic nozzles, and sprayed into an evaporation chamber through which air, heated by waste heat, is blown. The micro-droplets undergo rapid evaporation in the chamber, resulting in the separation of the salt solids from the vapor phase of the water. The mixture of suspended solids and water vapor is filtered to remove and collect the salts, and the water vapor is condensed to collect the salt-free water.

Owner:AQUASONICS RSE INC

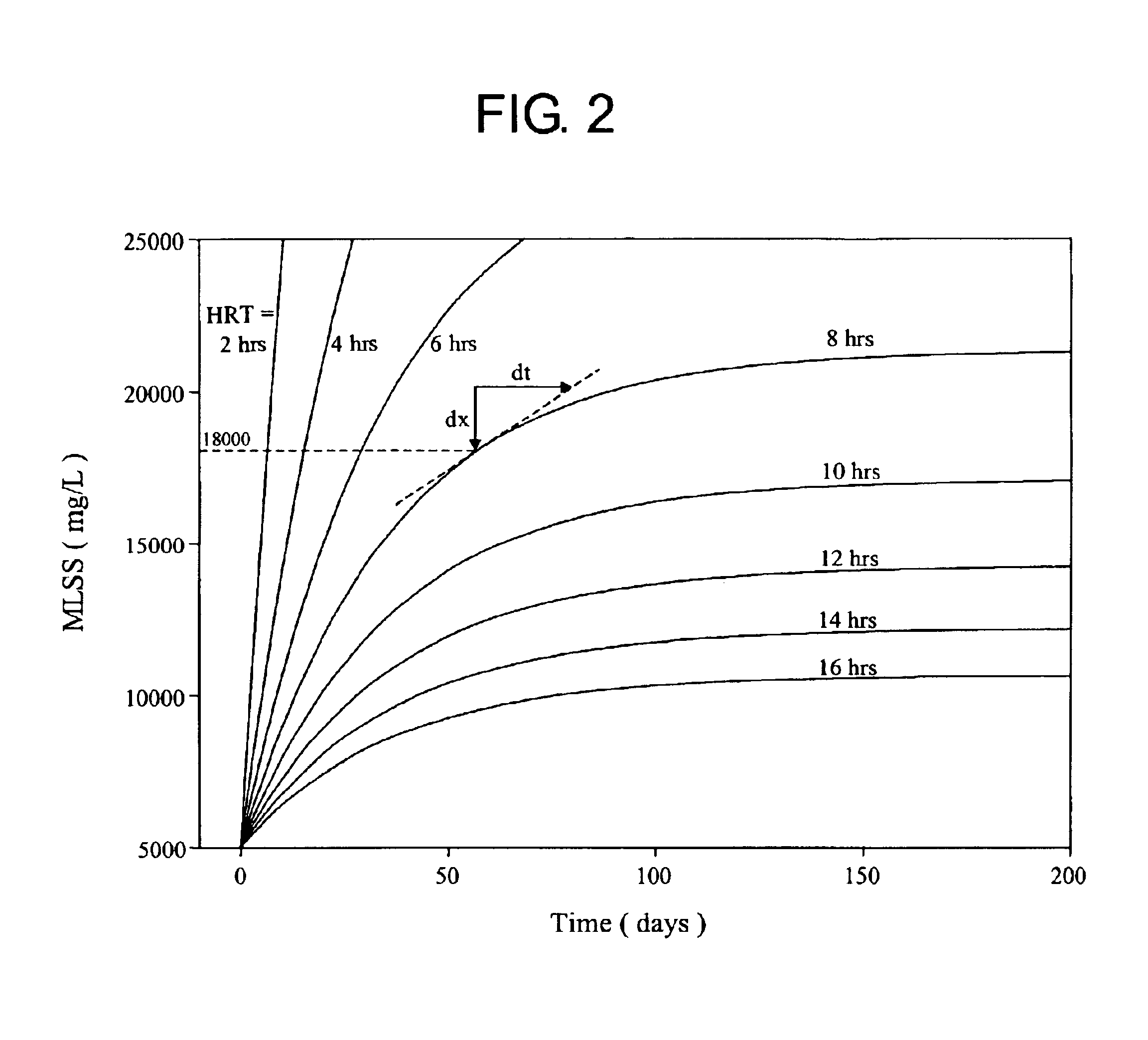

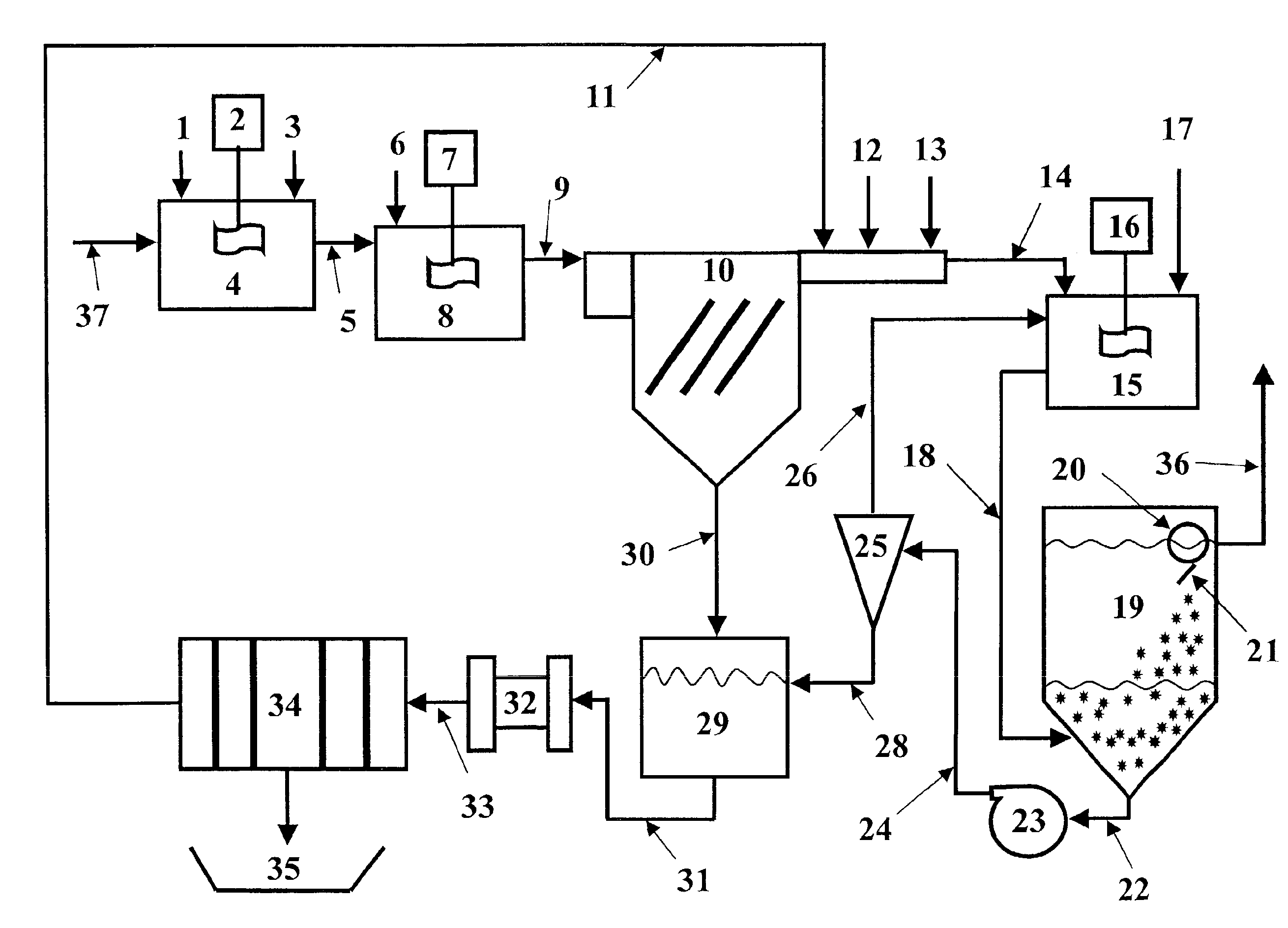

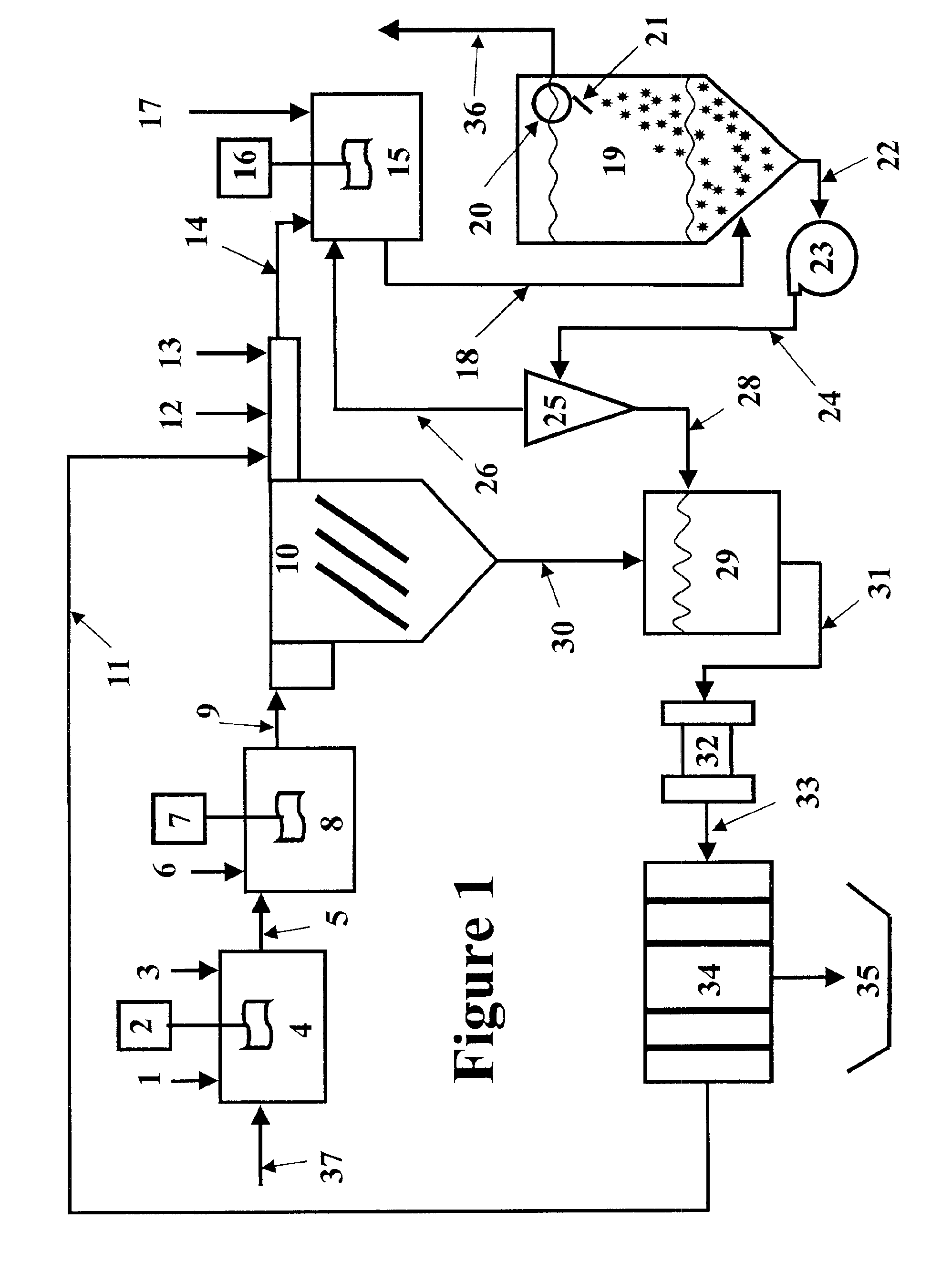

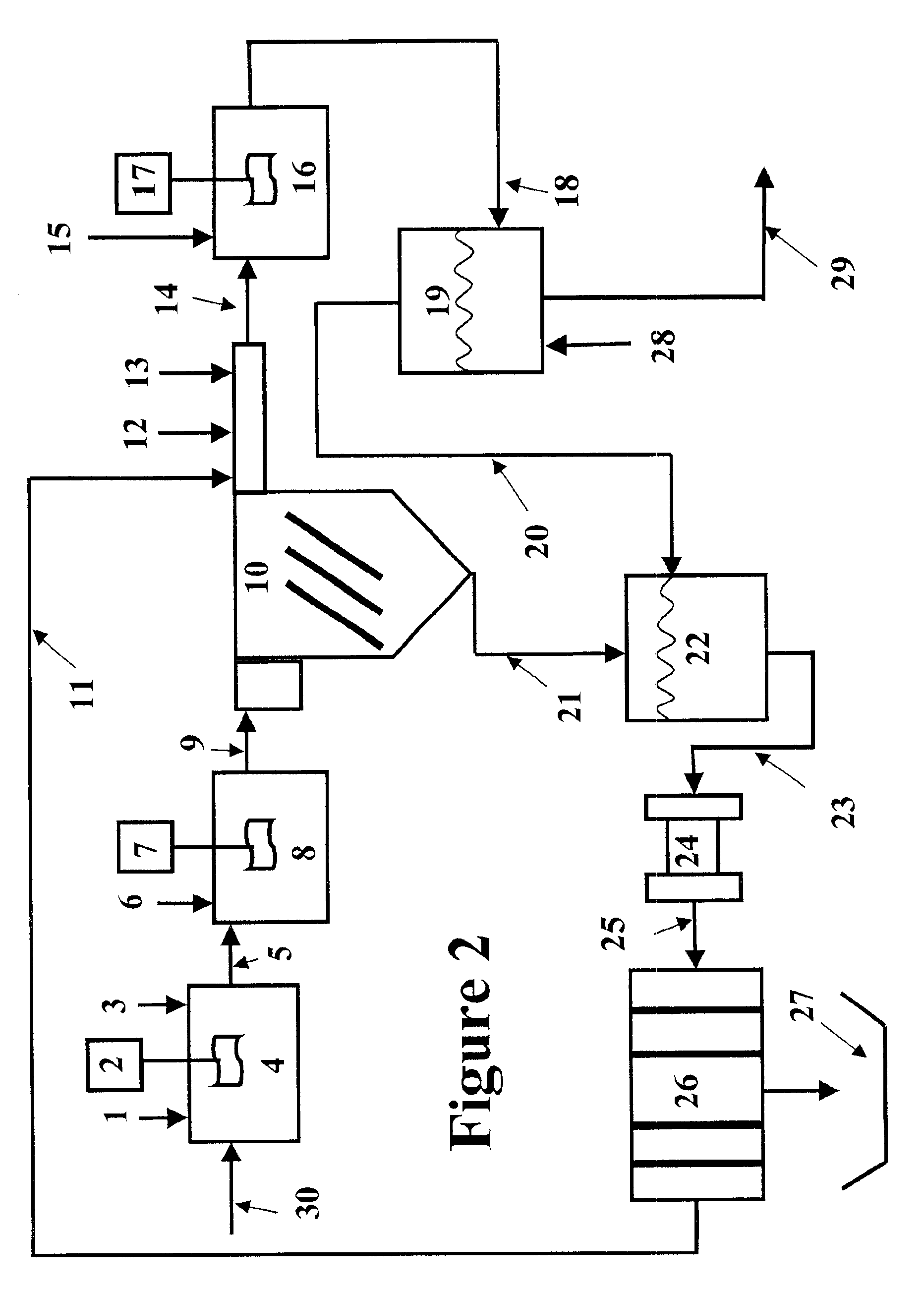

Method of using water soluble polymers in a membrane biological reactor

InactiveUS6926832B2Amount of timeLower cost of capitalMembranesTreatment using aerobic processesMembrane foulingWater soluble

A method of conditioning mixed liquor in a membrane biological reactor comprising adding to the mixed liquor an effective coagulating and flocculating amount of one or more water soluble cationic, amphoteric or zwitterionic polymers, or combination thereof and methods of reducing membrane fouling, enhancing membrane flux and reducing sludge production.

Owner:ECOLAB USA INC

Methods for removing heavy metals from water using chemical precipitation and field separation methods

InactiveUS6896815B2Small sizeChemical cost reductionSolid sorbent liquid separationGold compoundsWater useSludge

A two-step chemical precipitation process involving hydroxide precipitation and sulfide precipitation combined with “field separation” technology such as magnetic separation, dissolved air flotation, vortex separation or expanded plastics flotation, effectively removes chelated and non-chelated heavy metal precipitates and other fine particles from water. In the first-step, the non-chelated heavy metals are precipitated as hydroxides and removed from the water by a conventional liquid / solids separator such as an inclined plate clarifier to remove a large percentage of the dissolved heavy metals. The cleaned water is then treated in a second precipitation step to remove the residual heavy metals to meet discharge limits. In the second precipitation step, any metal precipitant more effective than hydroxide for metal precipitation can be used. The invention improves metal removal, lowers cost because fewer chemicals are used, produces less sludge, and reduces the discharge of toxic metals and metal precipitants to the environment.

Owner:CORT STEVEN L

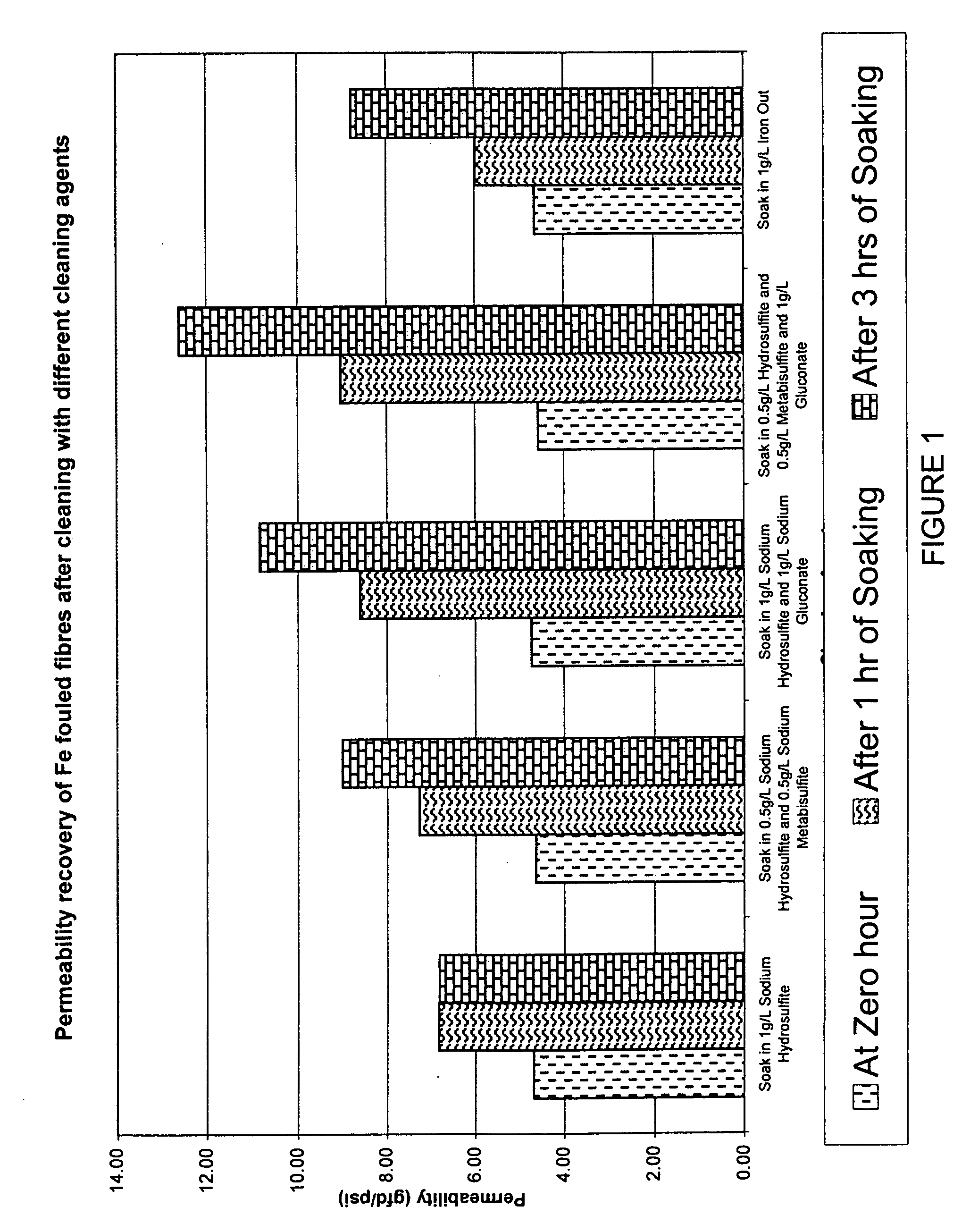

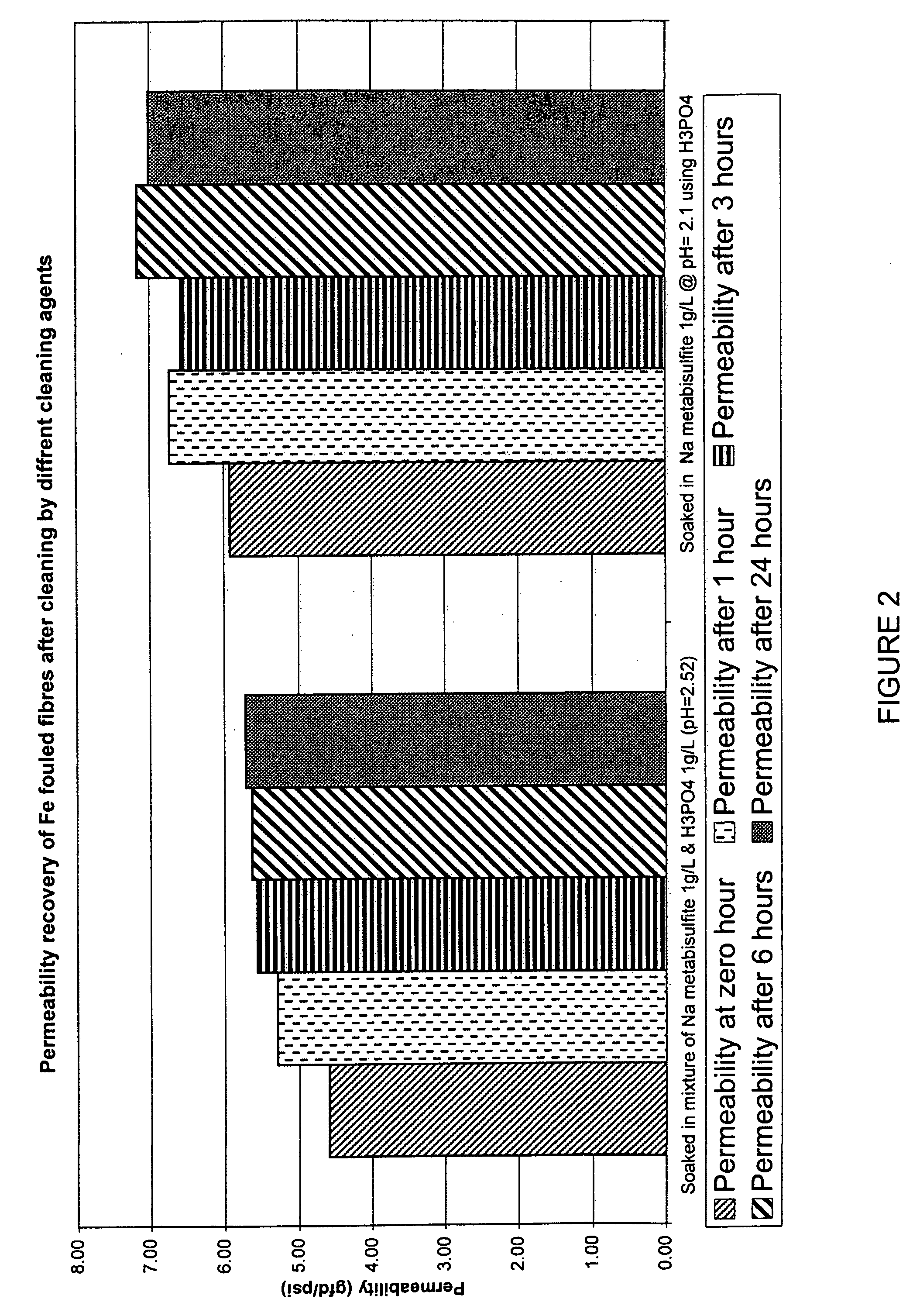

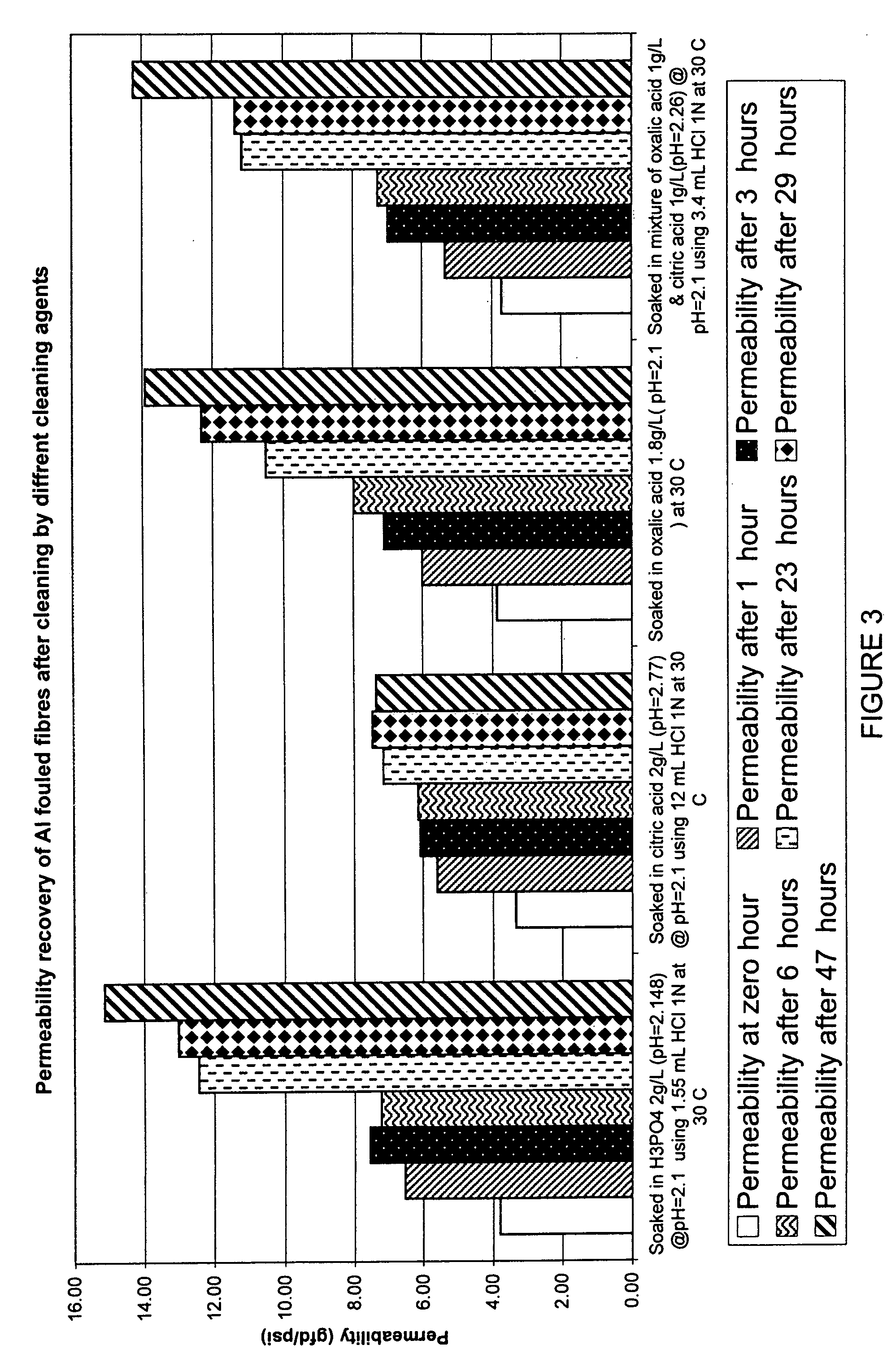

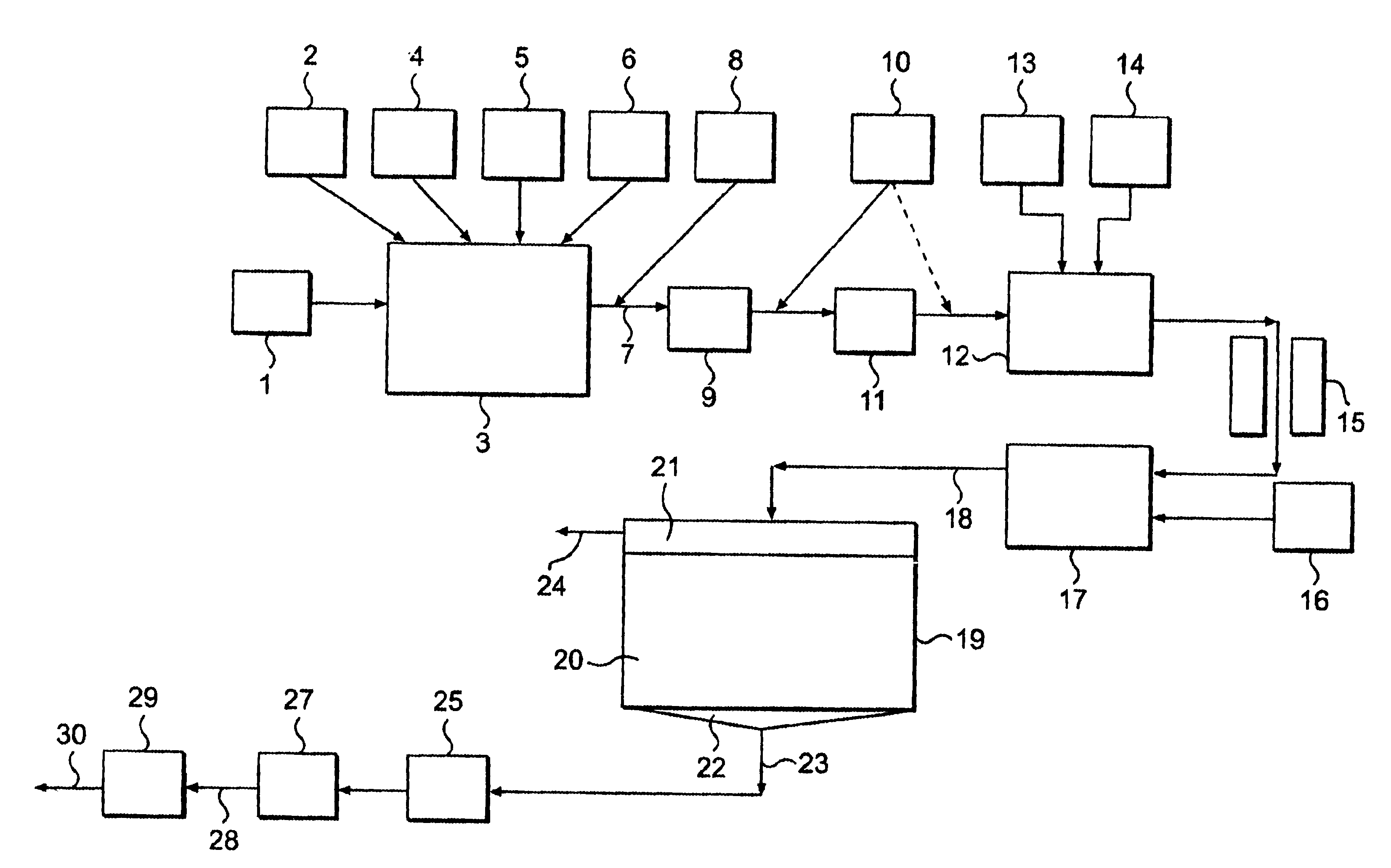

Chemical cleaning for membranes

Membranes, for example immersed polymeric ultrafiltration or microfiltration membranes, are cleaned by contacting them with a chemical cleaner comprising one or more of a gluconate, a hydrosulfite, a metabisulfite or an acid, for example phosphoric acid. The membranes may have been exposed to organic or inorganic foulants, some of which may have resulted from pretreatment involving adding coagulants, for example coagulants containing iron or aluminum, to water to be treated. Methods for treating a waste cleaning solution were described.

Owner:SYED MURTUZA ALI +3

Method of treating an aqueous suspension of kaolin

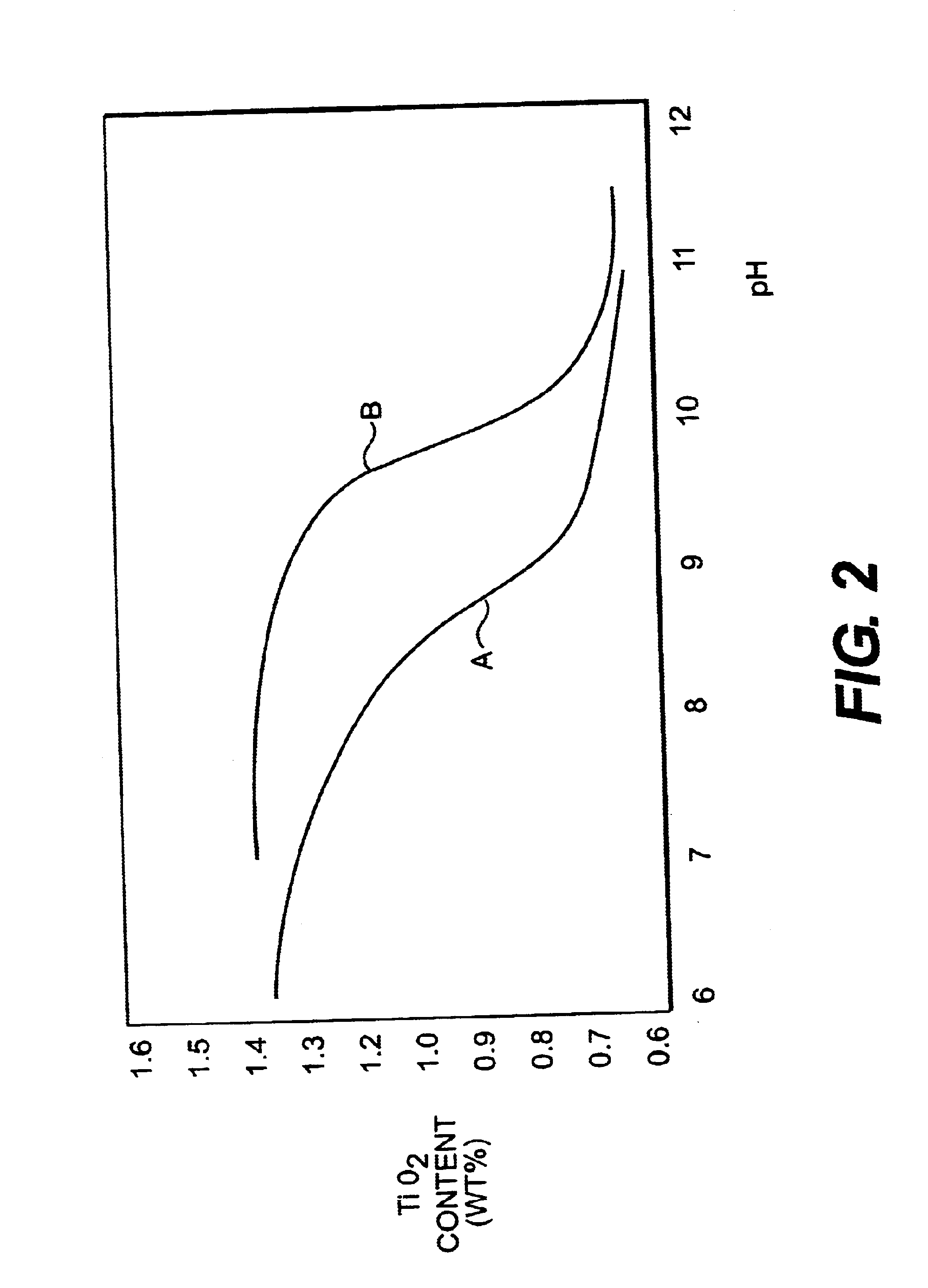

InactiveUS6615987B1Improve effectivenessImproves floc formationPigmenting treatmentSedimentation separationFlocculationSolid particle

A method of treating a kaolin particulate material to improve its properties by removal of impurities which includes the steps of:(a) producing a dispersed aqueous suspension of a kaolin particulate material containing at least 0.1% by weight, based on the dry weight of the kaolin particulate material, of separable impurity by adding a dispersing agent to the kaolin particulate material to deflocculate solid particles of the material in the suspension;(b) conditioning the suspension prior to adding selective flocculation polymer thereto by allowing the suspension to age for a period of at least 30 minutes and optionally by adding one or more conditioning chemicals thereto;(c) adjusting the pH of the suspension to be at least about 9.5;(d) adding to the suspension at a pH of at least about 9.5 a selective flocculation polymer which facilitates separation of the separable impurity from the kaolin by flocculating the kaolin and allowing the separable impurity to be or remain deflocculated;(e) allowing the suspension at a pH of at least about 9.5 in a selective flocculation separator to separate into layers comprising a flocculated product layer and a deflocculated impurity layer containing the separable impurity; and(f) extracting the separated layers from the separator.

Owner:IMERYS USA INC

Popular searches

Water/sewage treatment bu osmosis/dialysis Reverse osmosis Filtration separation Water/sewage treatment by flocculation/precipitation Water/sewage treatment by oxidation Energy based wastewater treatment Water cleaning Water/sewage treatment by heating Ammonium nitrate fertilisers Colloidal chemistry details

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com