Dissimilar materials sorting process, system and apparata

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

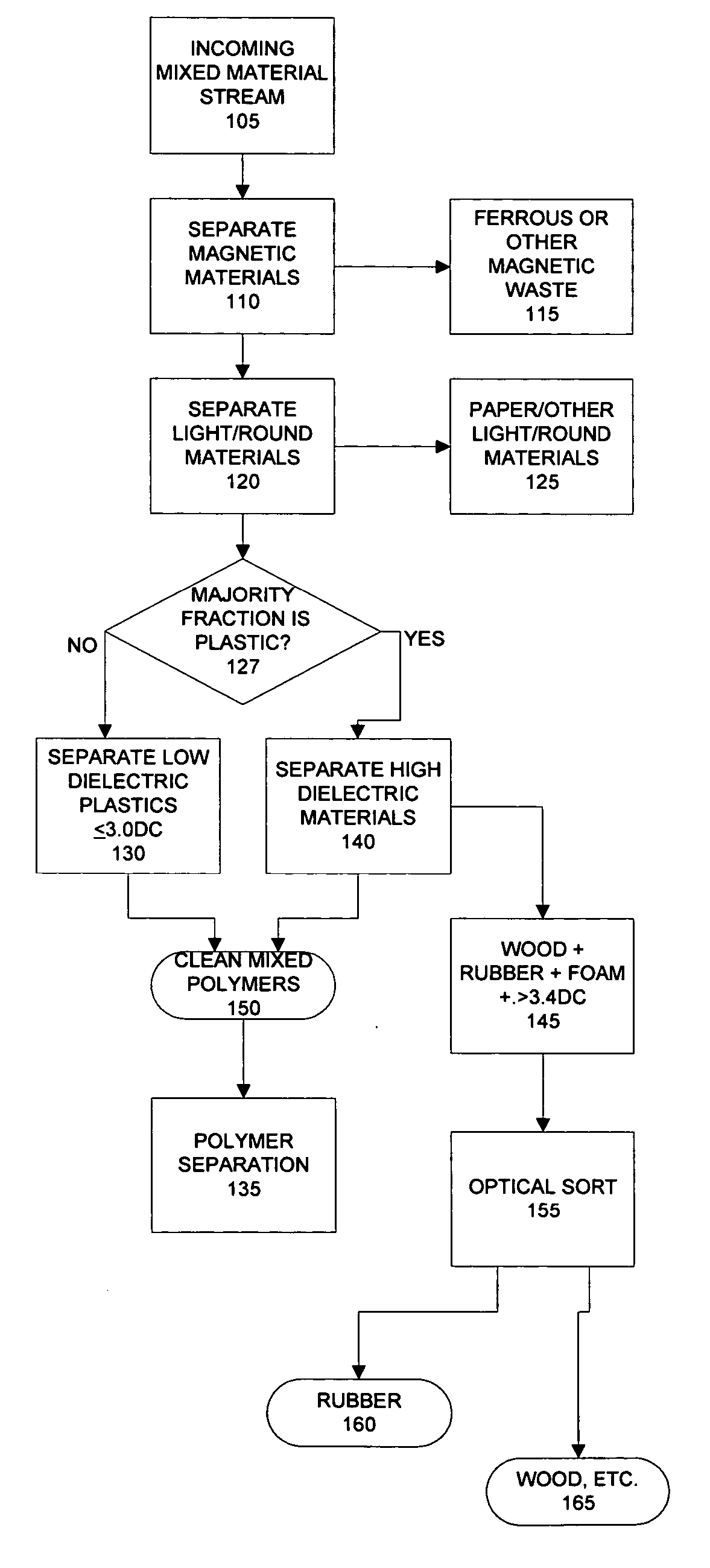

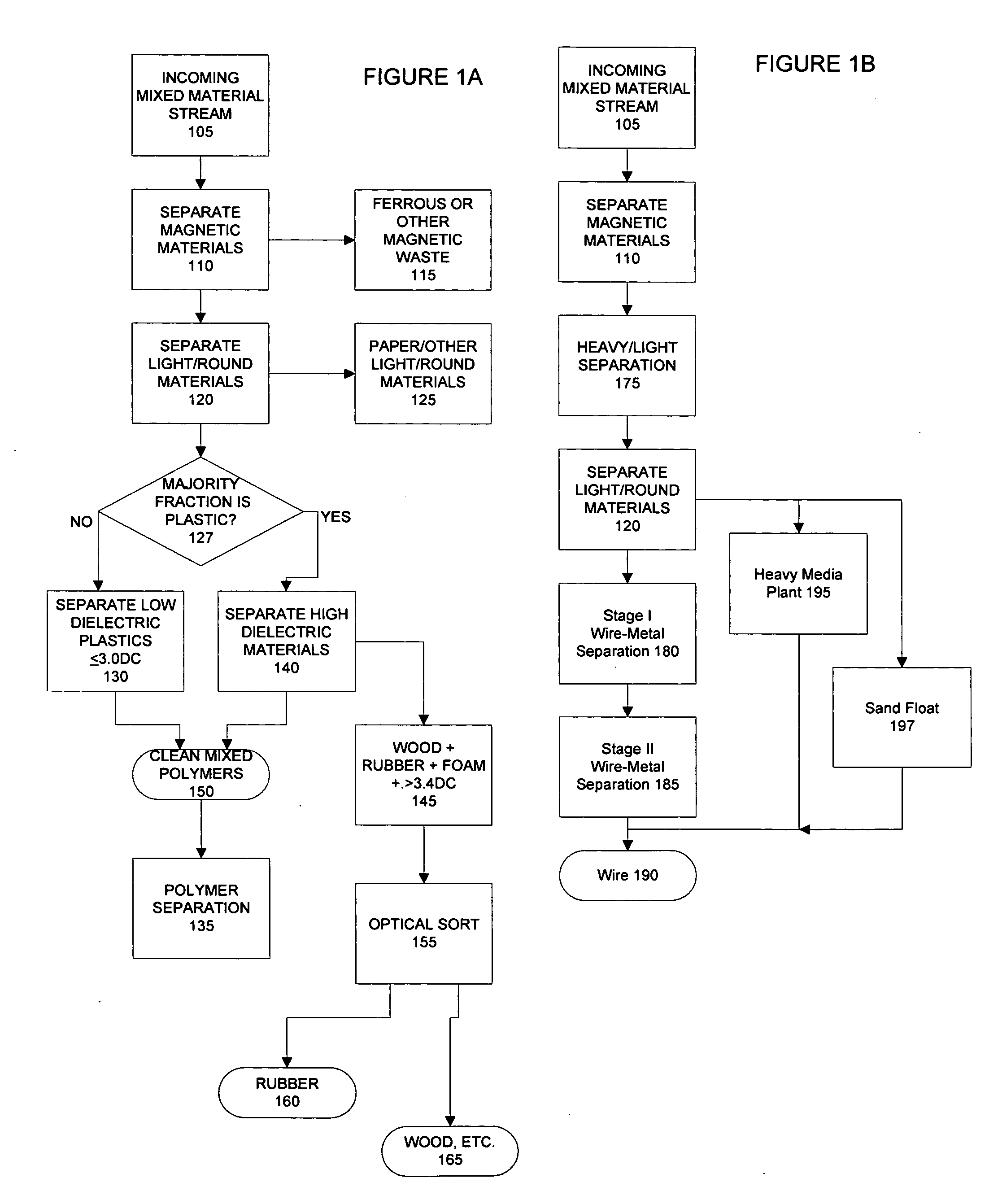

[0025] Referring first to FIG. 1A, an aspect of the process of the present invention, indicated generally at 100, may be better appreciated. As indicated at step 105, an incoming stream of mixed material typically includes wood, rubber, ferrous and non-ferrous metals, wire including insulated wire coated with a plastic cover, and a variety of types of plastic pieces, including foam, polyethylene, polystyrene, ABS, and so on.

[0026] In the illustrated embodiment, the process proceeds at step 110 by separating out the magnetic materials, which typically includes the ferrous metals such as iron and steel, as well as certain ceramics. In most instances, the valuable magnetic materials have already been removed from the stream, and so the magnetic materials remaining at this stage is mostly waste. These materials are diverted for further processing as required by the particular implementation, as shown at 115. For many streams, the further processing may be nothing more than disposal, al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com