Patents

Literature

135results about How to "Unified operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

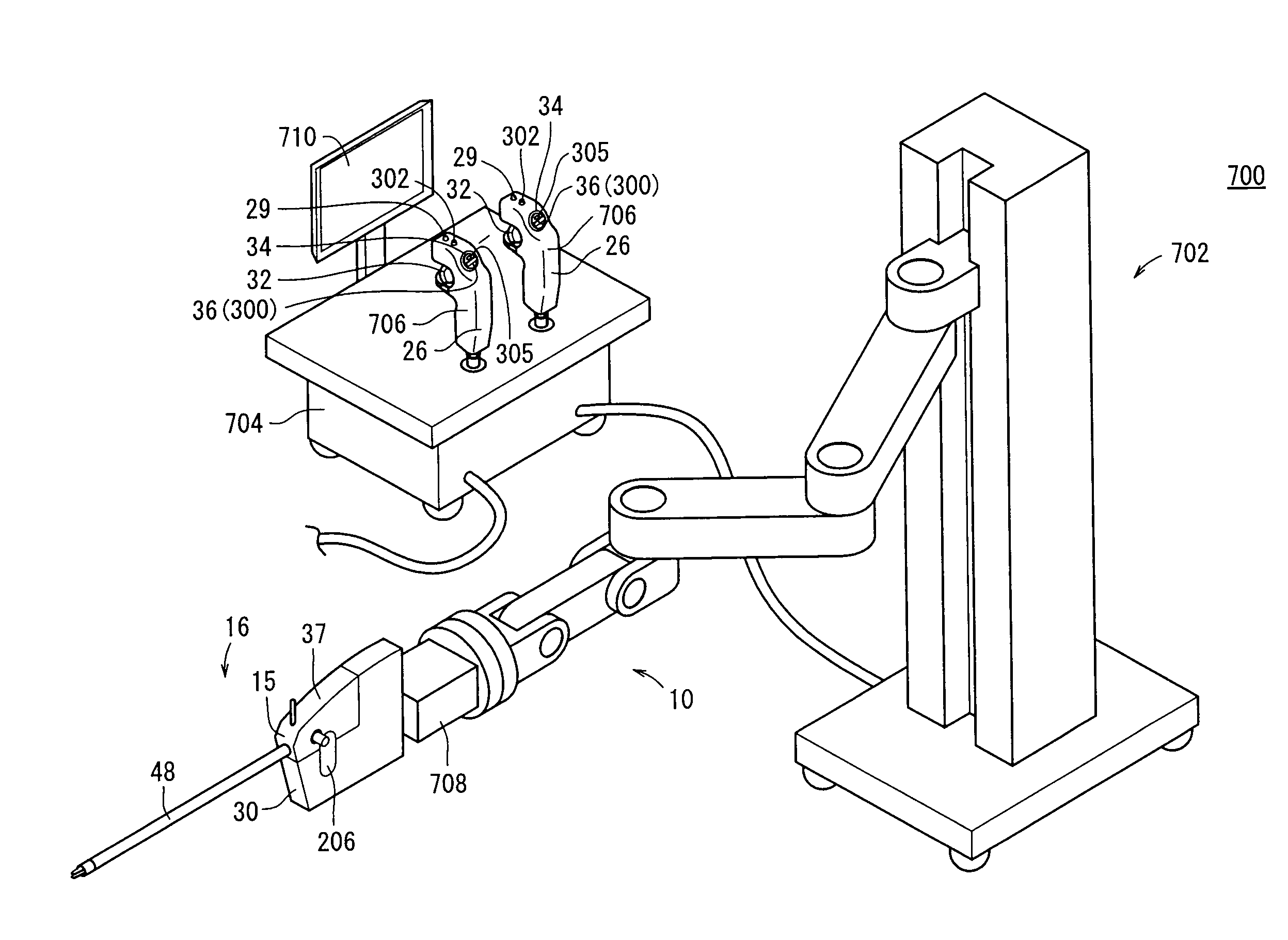

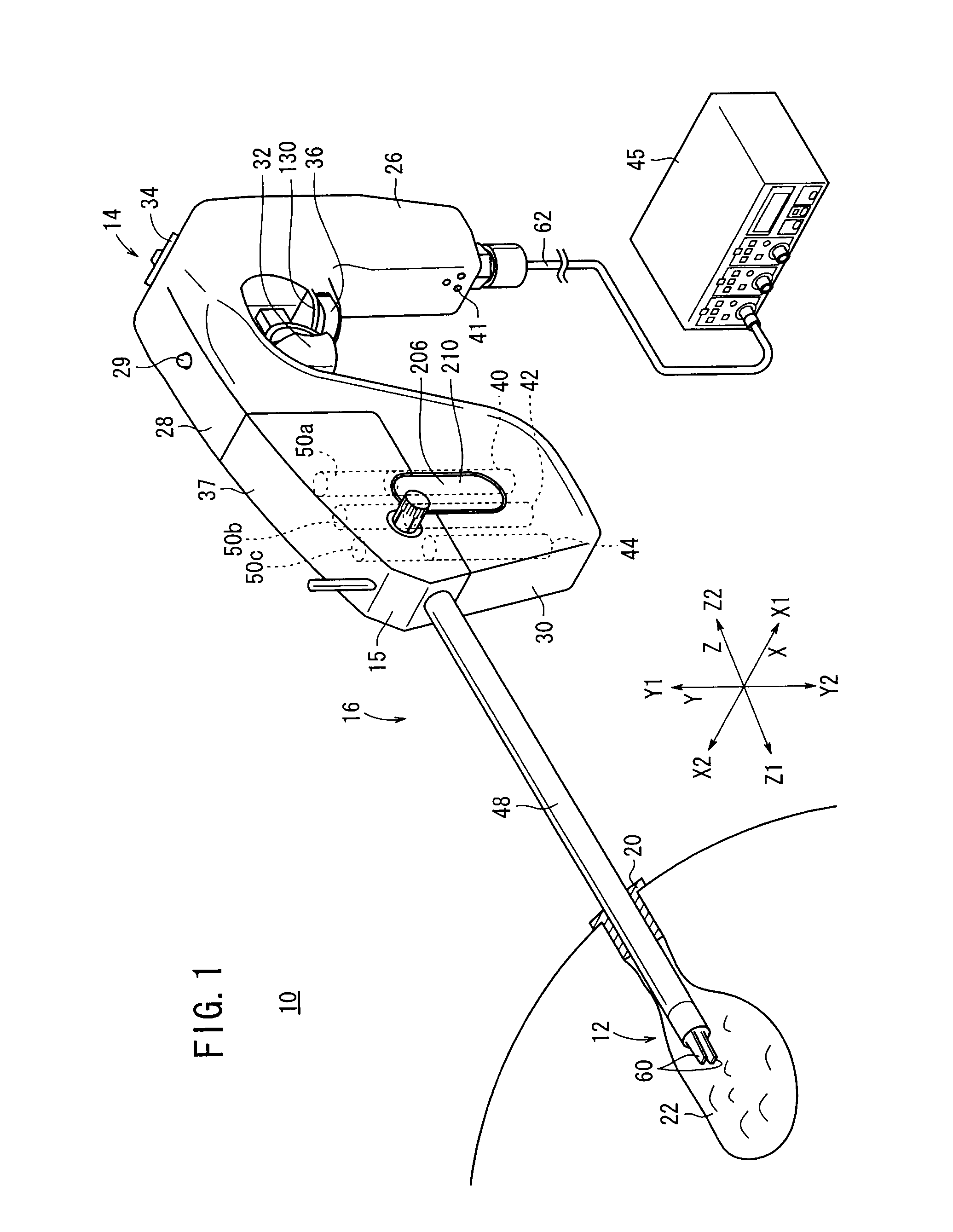

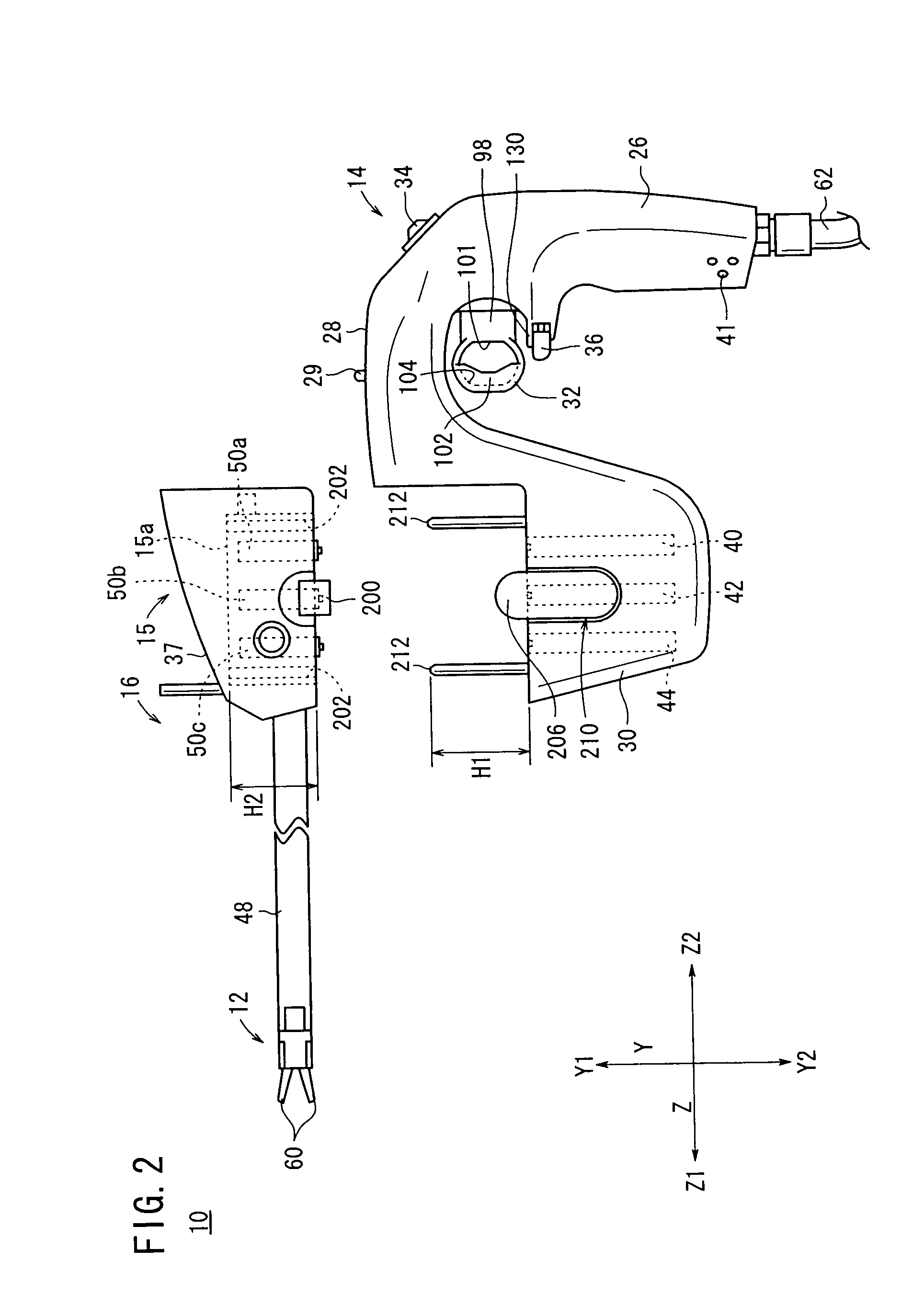

Operating mechanism, medical manipulator, and surgical robot system

InactiveUS20090030428A1Easy to operateAccurately closingDiagnosticsSurgical manipulatorsManipulatorEngineering

A medical manipulator includes an operation command unit having motors and a working unit detachably mounted on the operation command unit. The operation command unit includes a grip handle for being gripped by a human hand, and a trigger lever movable toward and away from the grip handle. The trigger lever comprises a pulling member which can be pulled toward the grip handle by a finger held against the pulling member, and a pushing member which can be pushed away from the grip handle by the finger held against the pushing member, the pushing member being disposed in facing relation to the pulling member. The pushing member has a hemispherical cavity defined in a surface thereof which faces the pulling member.

Owner:TERUMO KK

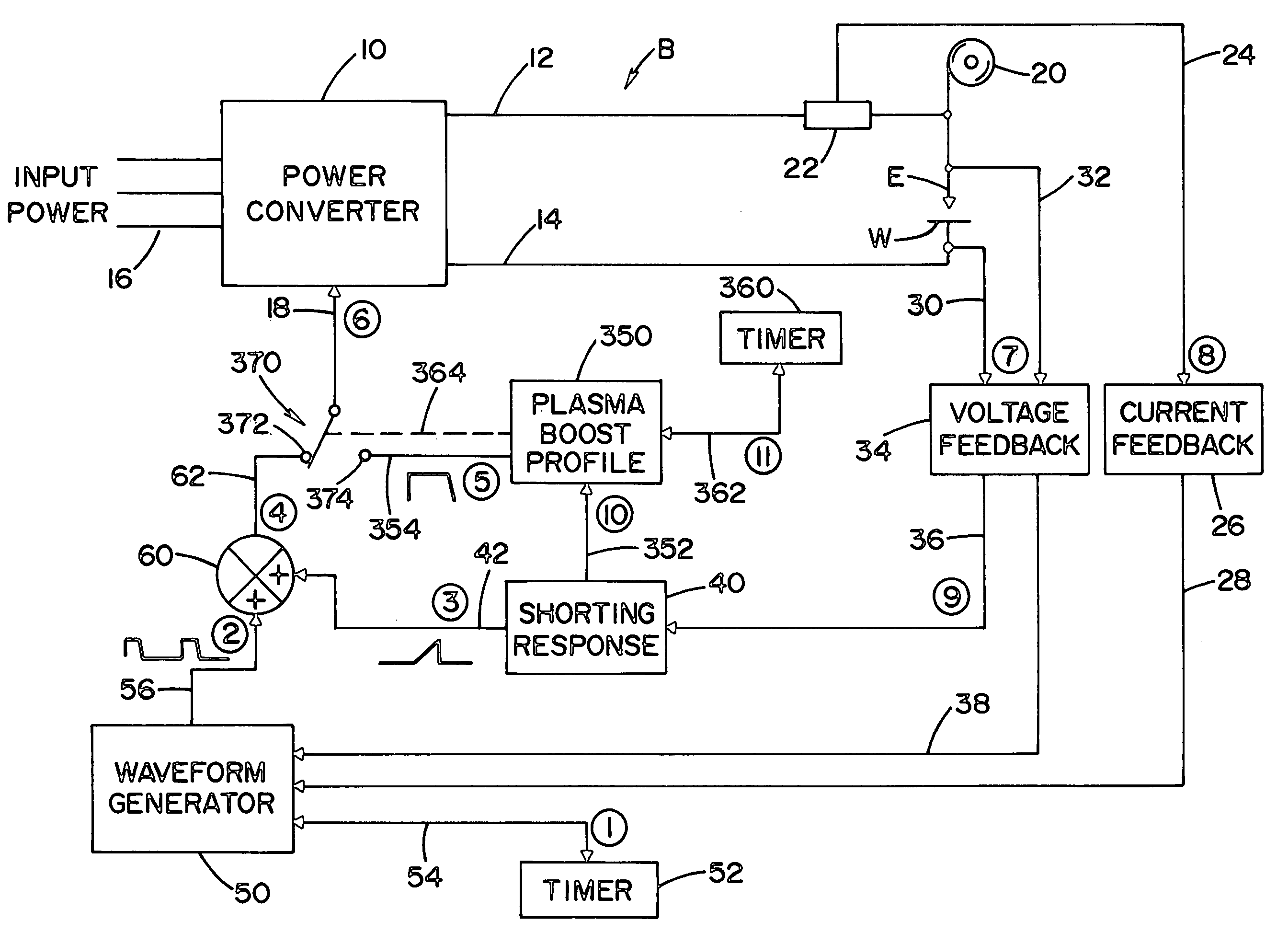

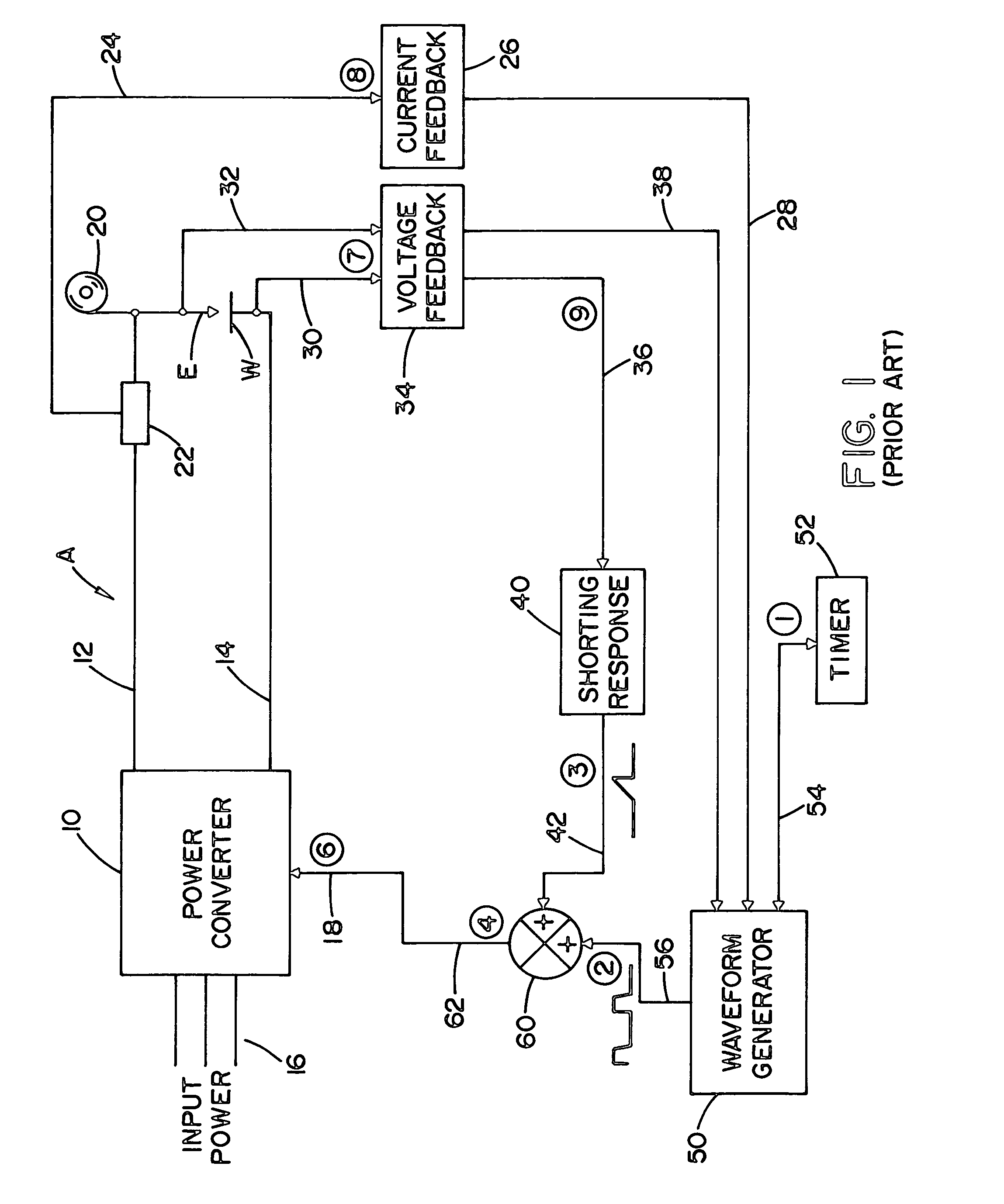

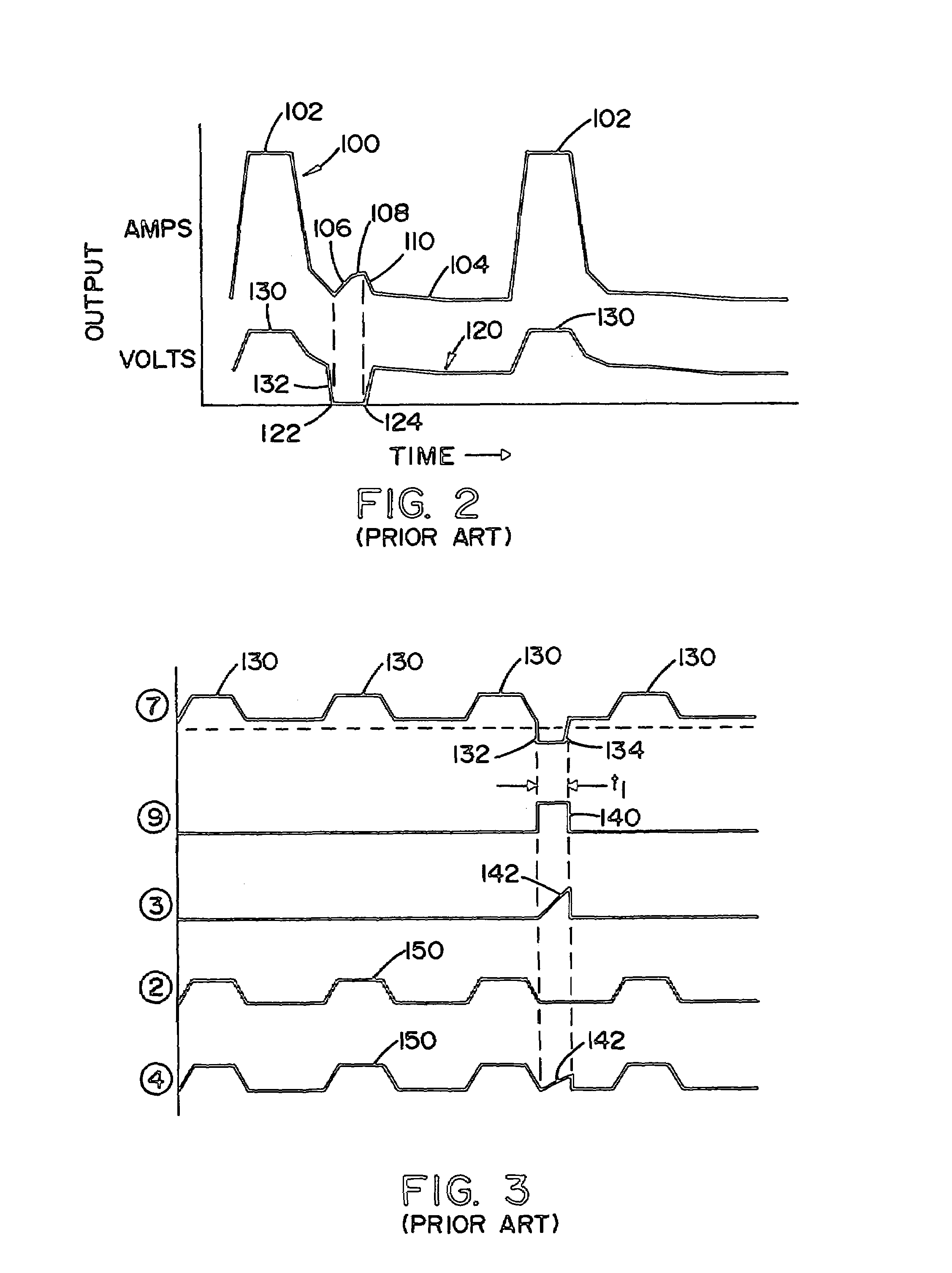

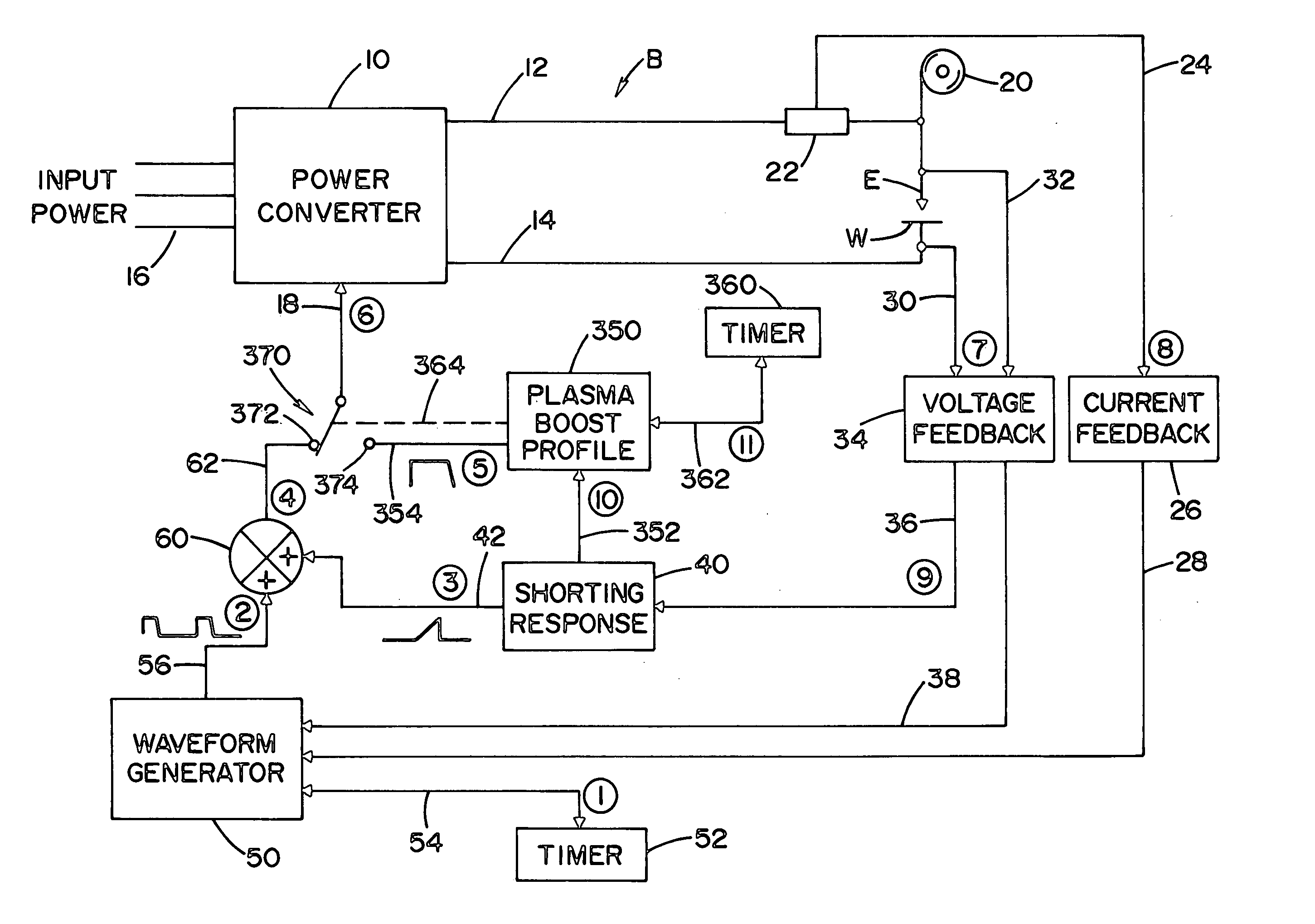

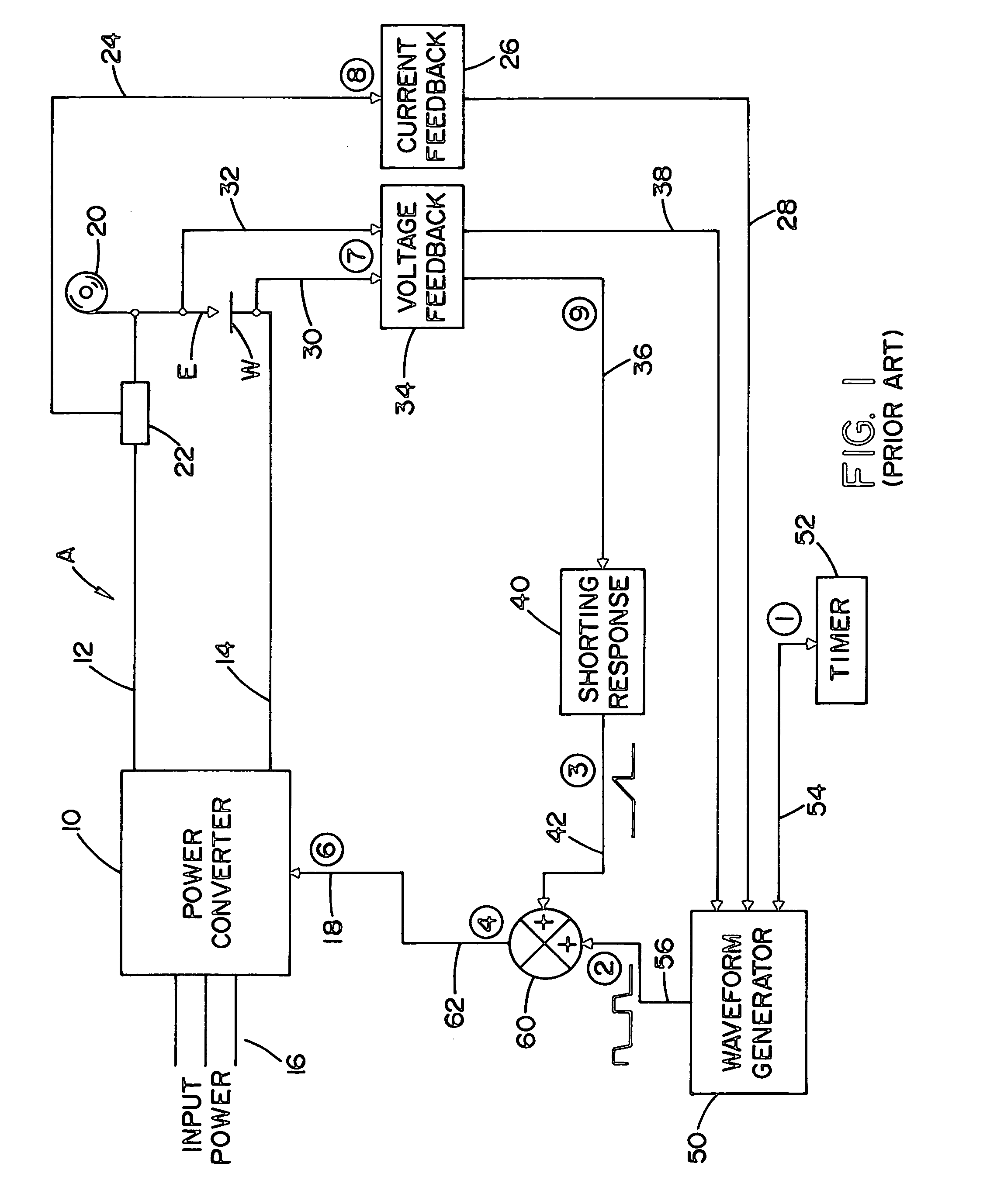

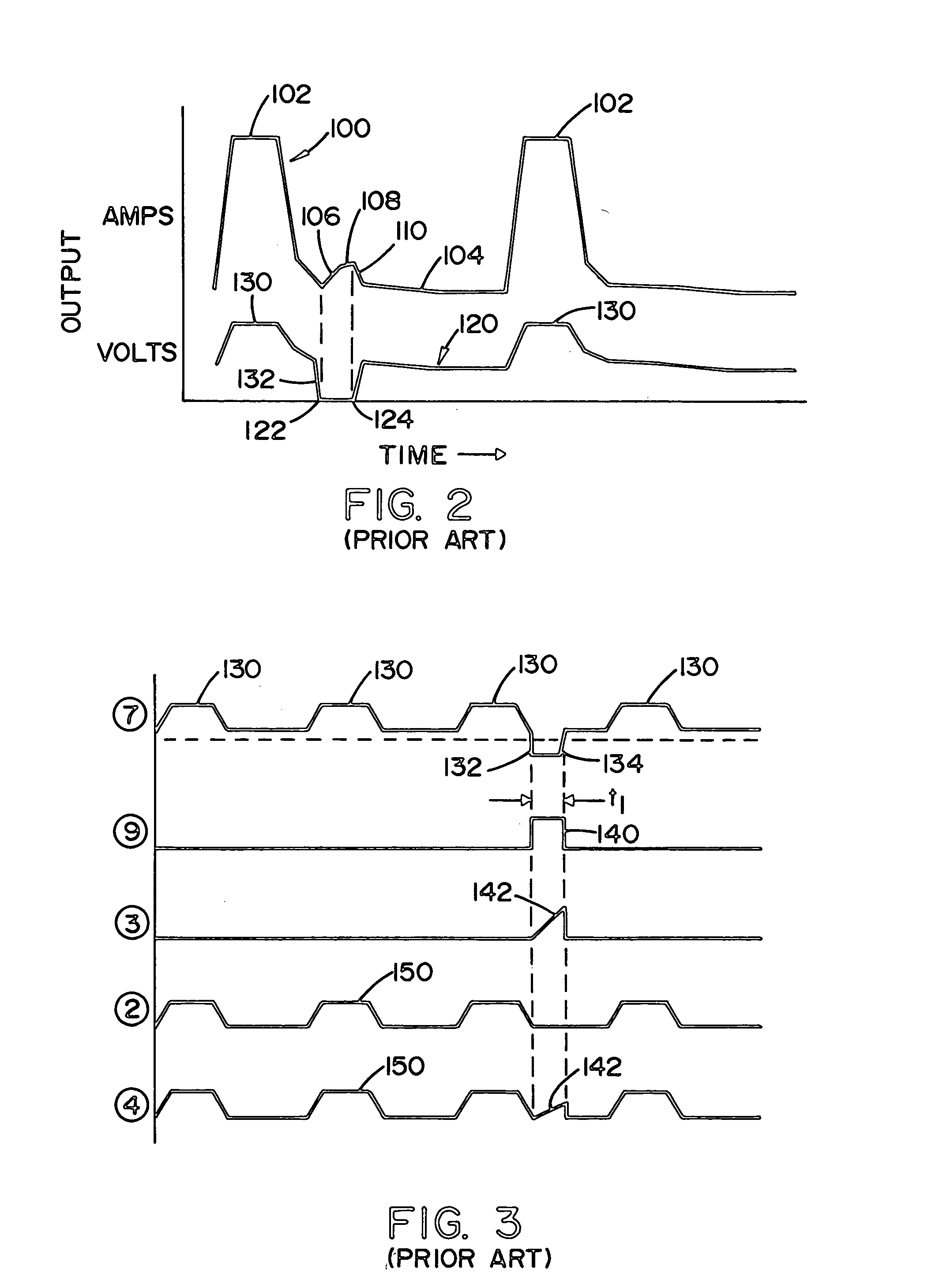

Pulse welder and method of using same

ActiveUS7304269B2Reduce arc forcePromote shorting eventsCoin-freed apparatus detailsArc welding apparatusPower flowEngineering

An electric arc welder for performing a pulse welding process by a current between an advancing electrode and workpiece where the welder comprises a short detecting circuit for creating a short signal upon occurrence of a short circuit between the advancing electrode and the workpiece and a boost circuit to create a plasma boost pulse after the short circuit is cleared during the time period when the welder is not outputting the peak pulse current.

Owner:LINCOLN GLOBAL INC

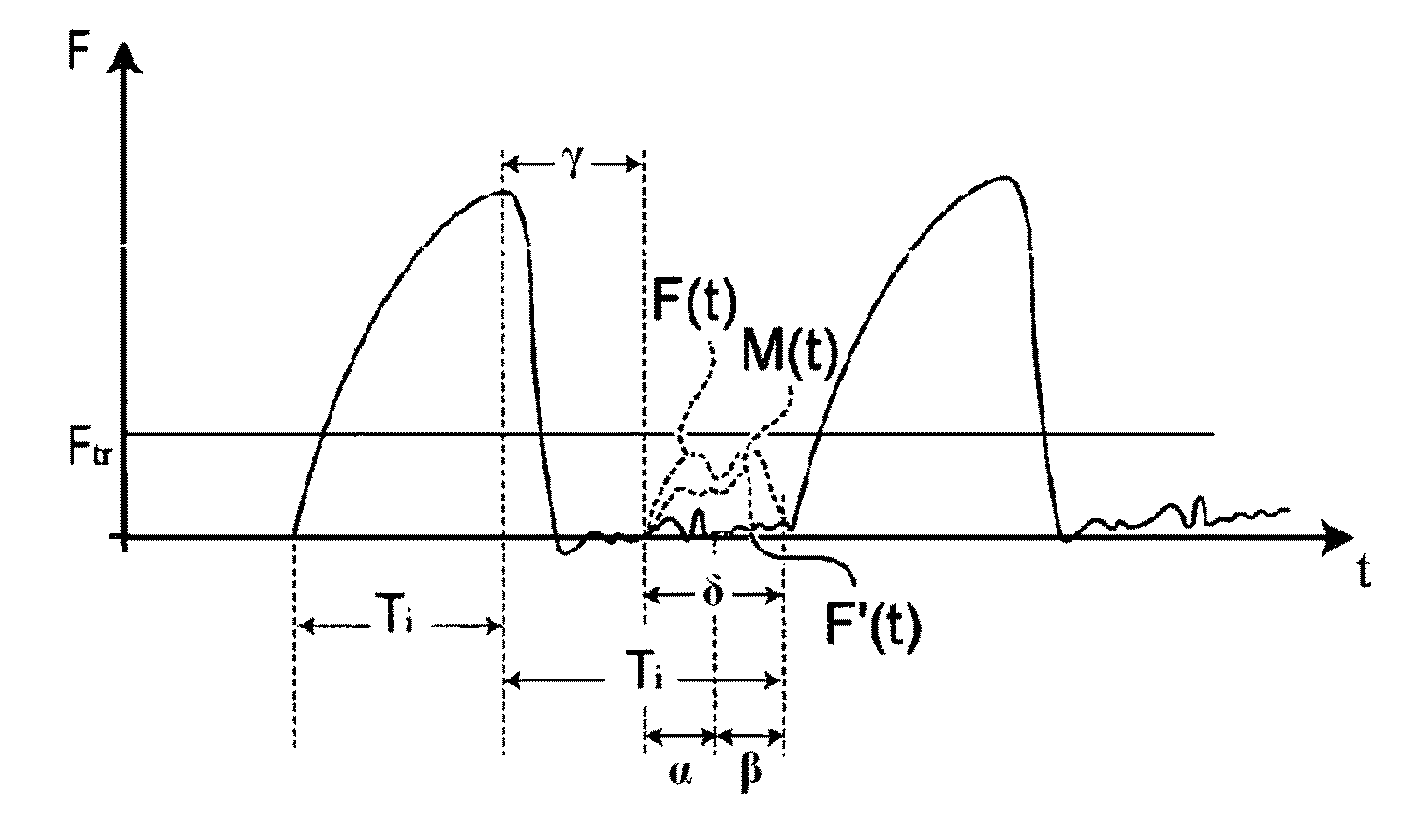

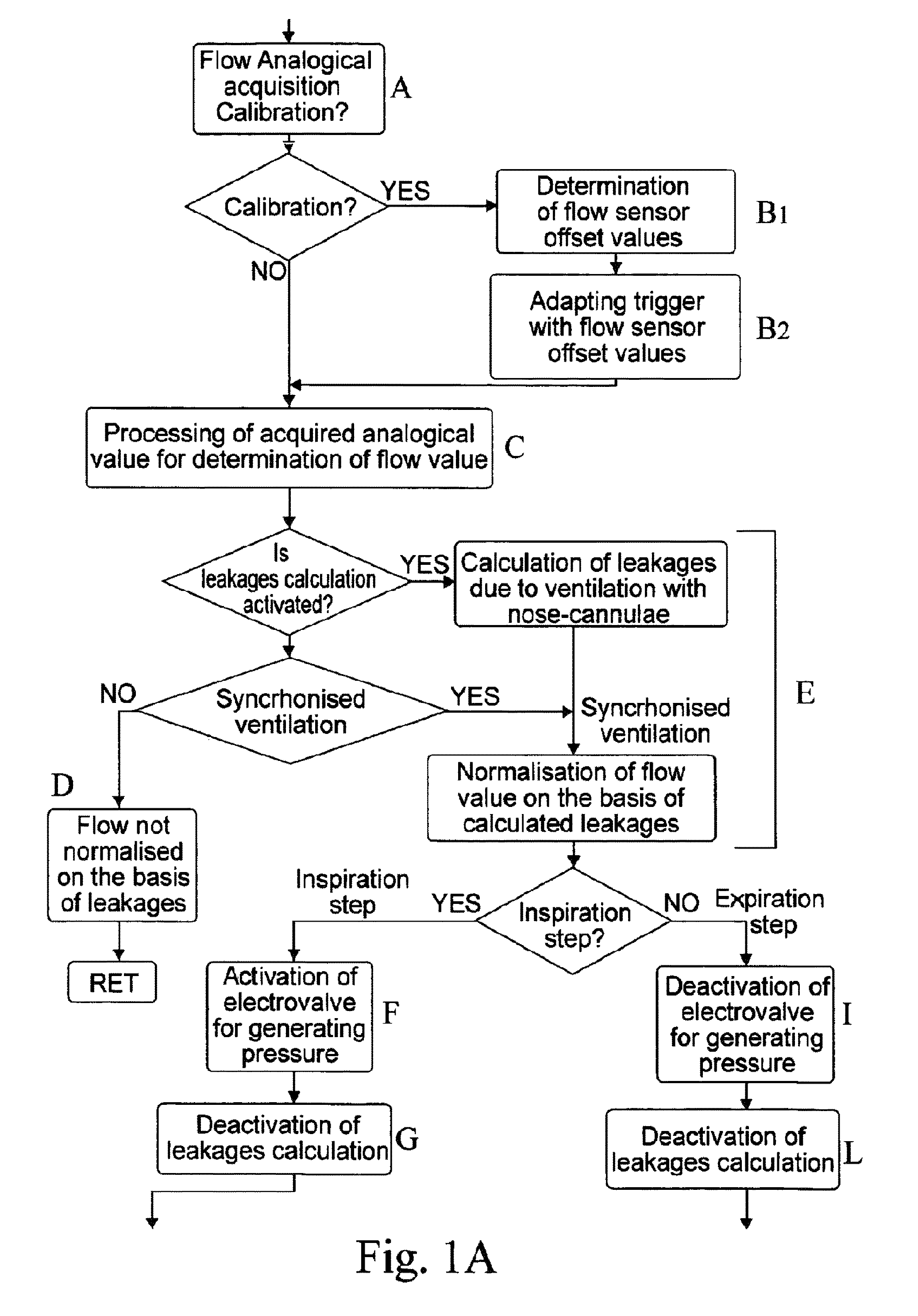

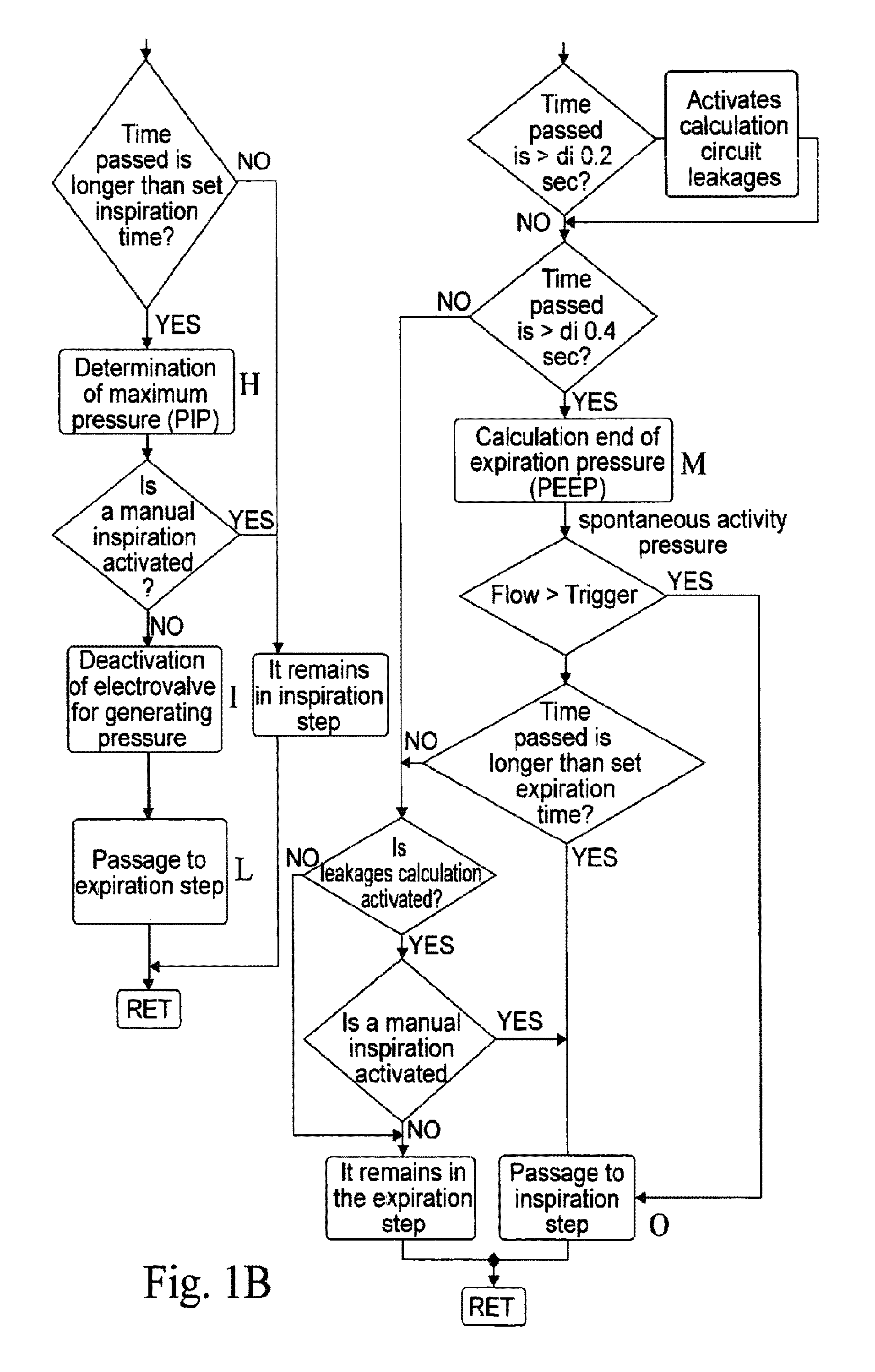

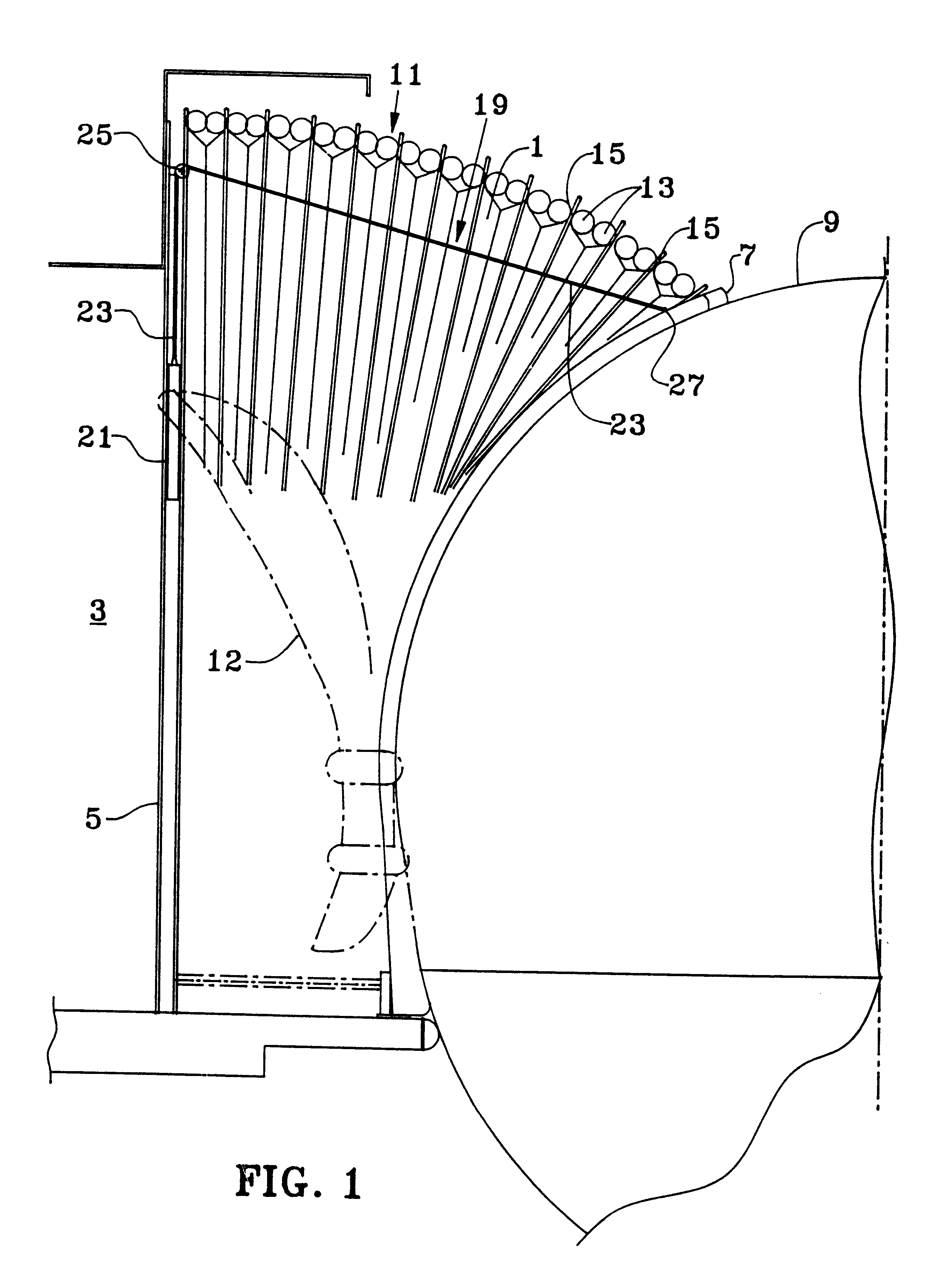

Method and relevant apparatus for nasal ventilation, particularly for flow-synchronised neonatal assisted ventilation

ActiveUS7814906B2Stable and uniform signalUnified operationRespiratorsOperating means/releasing devices for valvesAssisted ventilationNasal cavity

In a method for nasal ventilation and relevant apparatus, particularly for flow-synchronized neonatal assisted ventilation, wherein F(t) is a signal proportional to the ventilation flow, the following steps are performed:(a) inspiration, having a time length Ti, during which air is introduced at an inspiration pressure;(b) expiration, having a time length Te, during which the introduction of air is interrupted;(c) return to step (a);with a flow threshold Ftr, during the expiration step (b) the following steps are provided:(b1) a waiting step having a time length γ before activation of computation of the leakages; and(b2) a step of leakage computation, having a time length δ, so that γ+δ=Te, wherein if a normalized signal F′ (t), obtained by a processing by way of an algorithm of the surveyed signal F(t), exceeds the threshold Ftr, a spontaneous respiration activity is detected and the inspiration step (a) is reactivated.

Owner:GINEVRI SRL

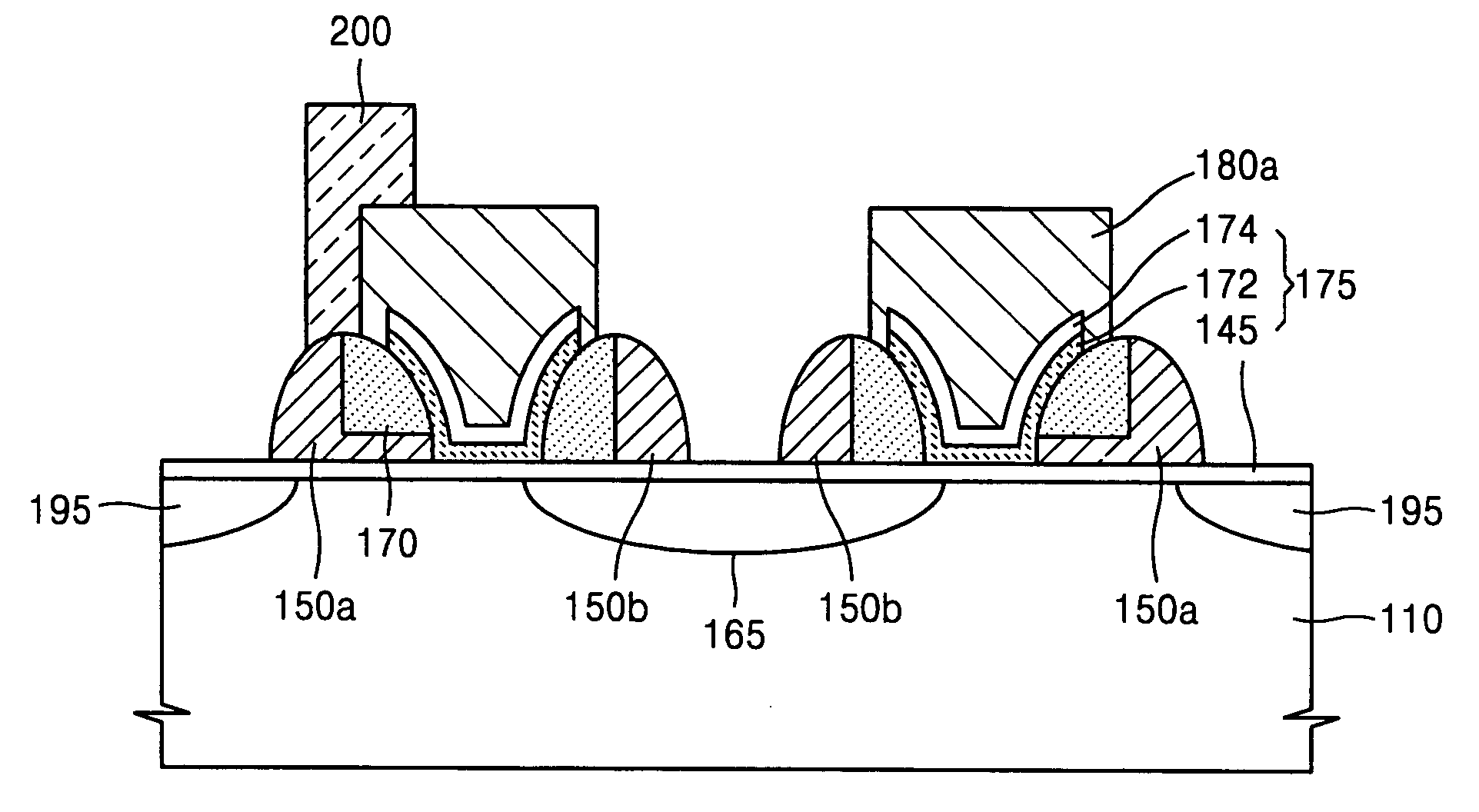

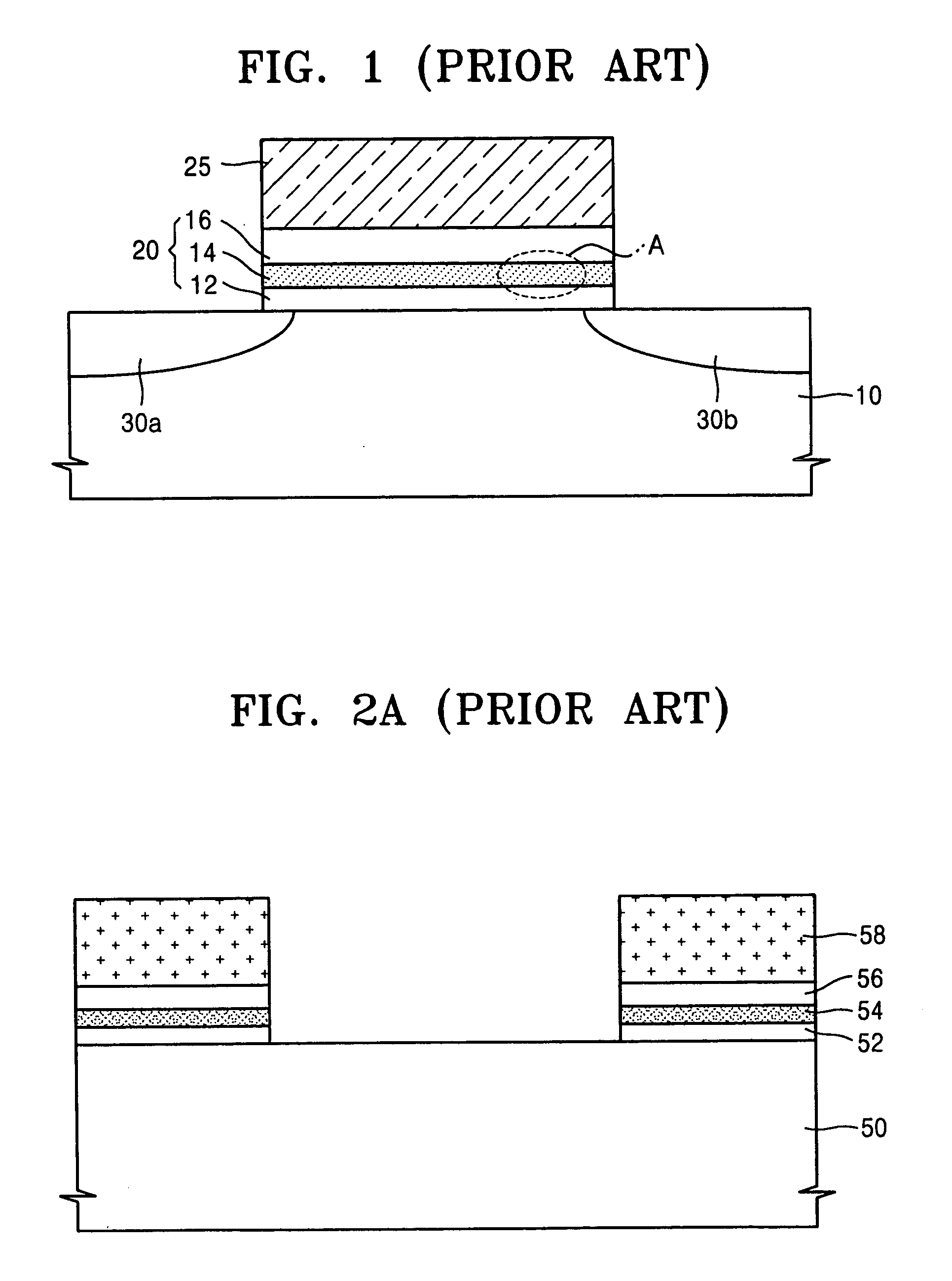

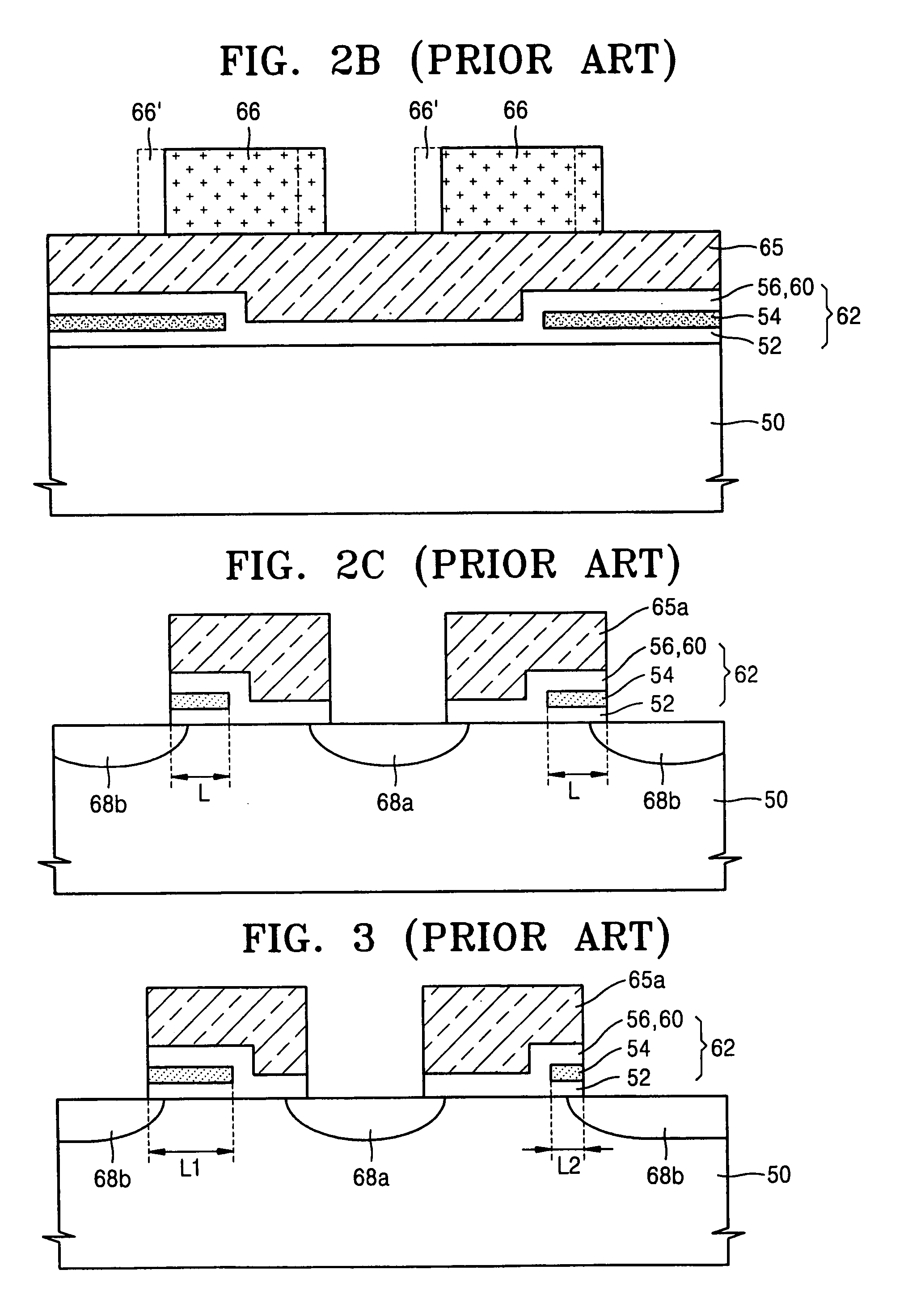

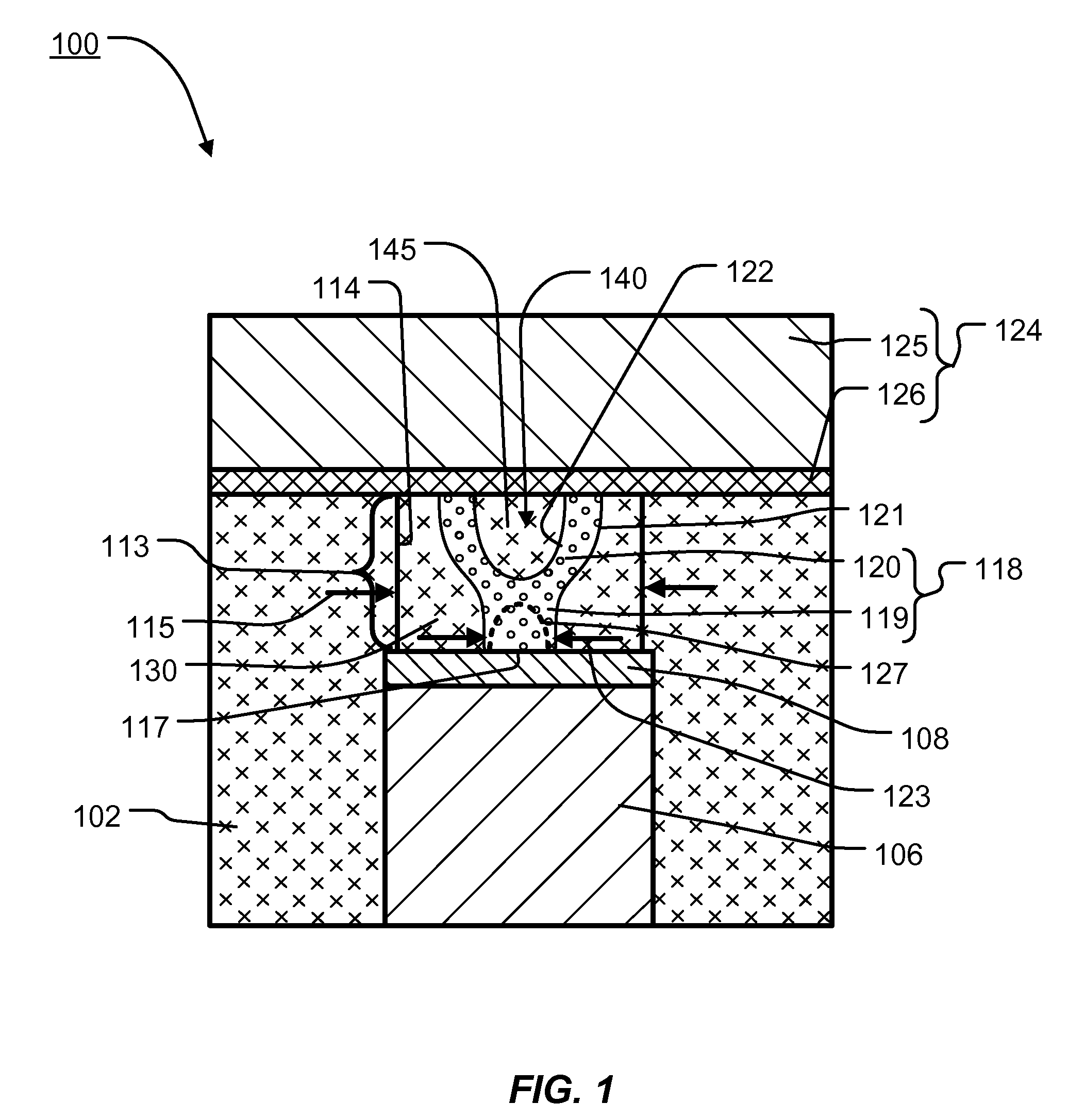

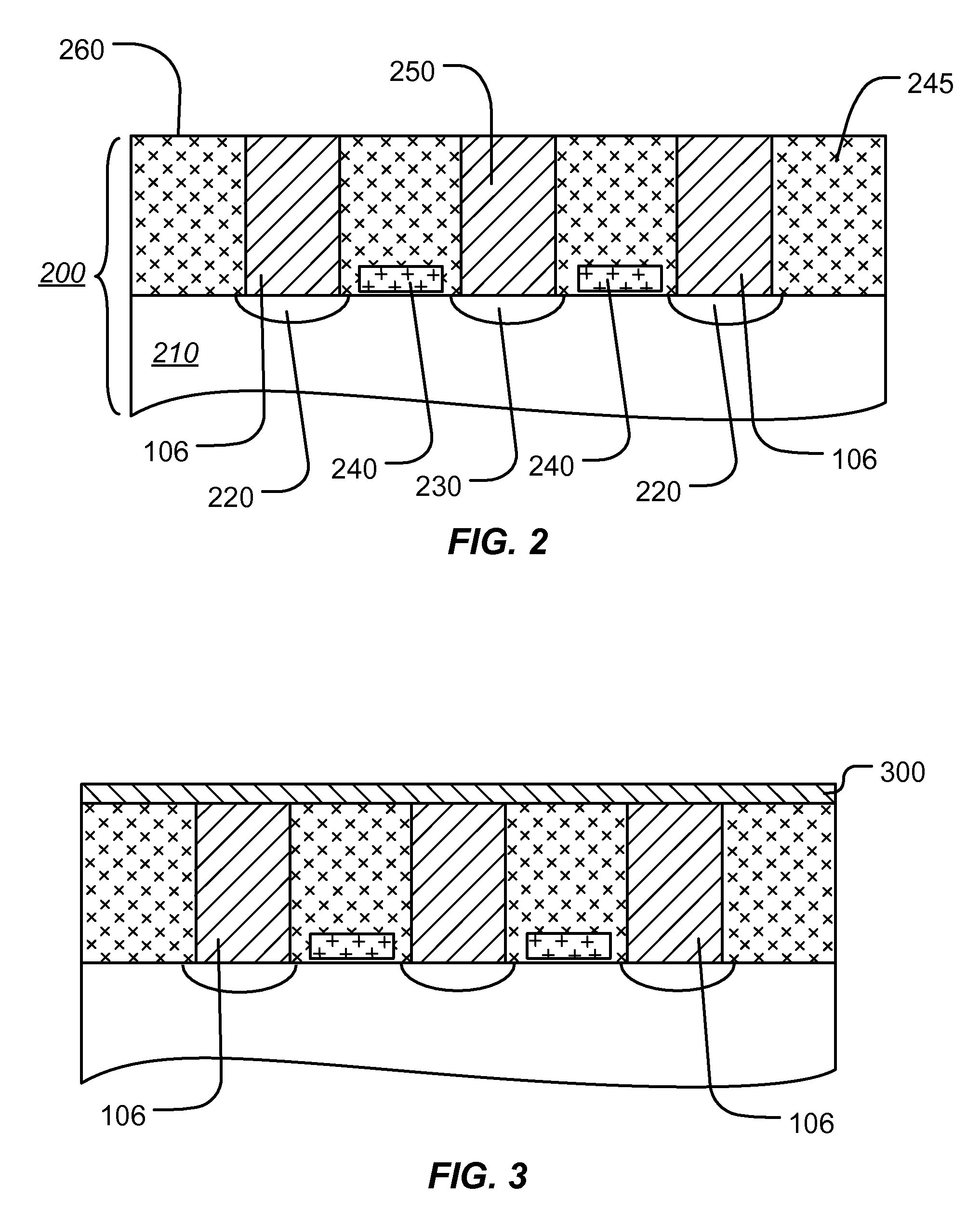

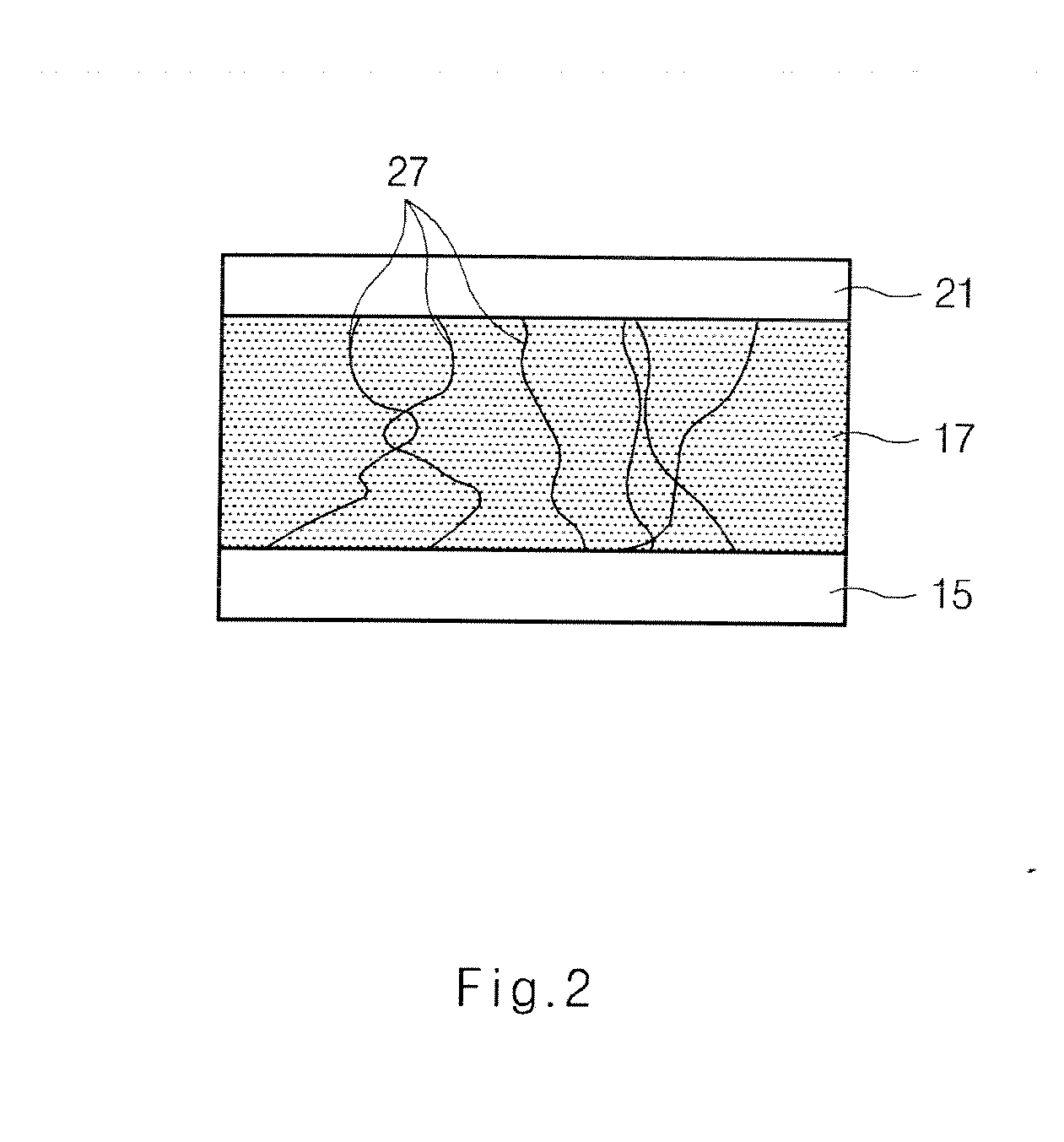

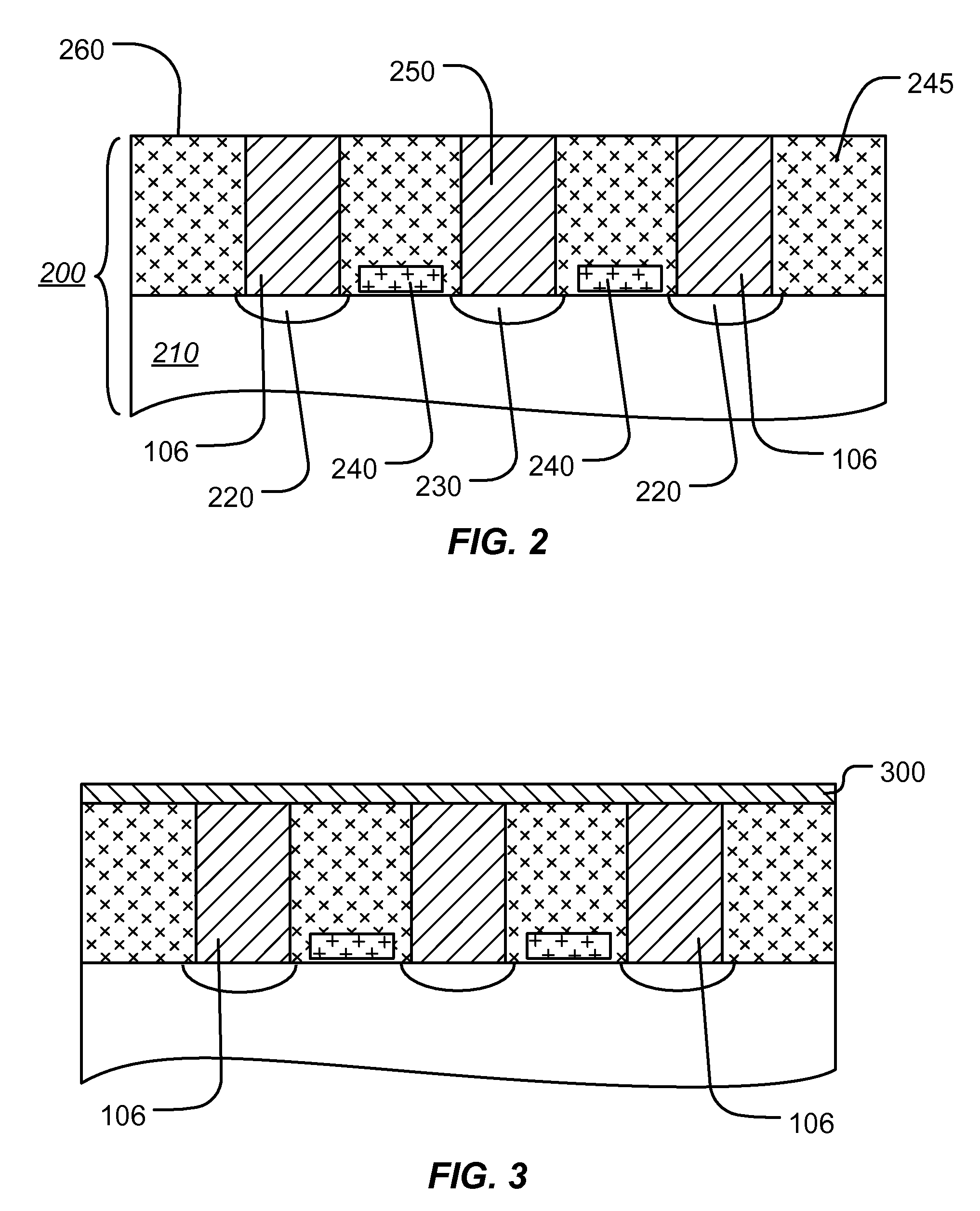

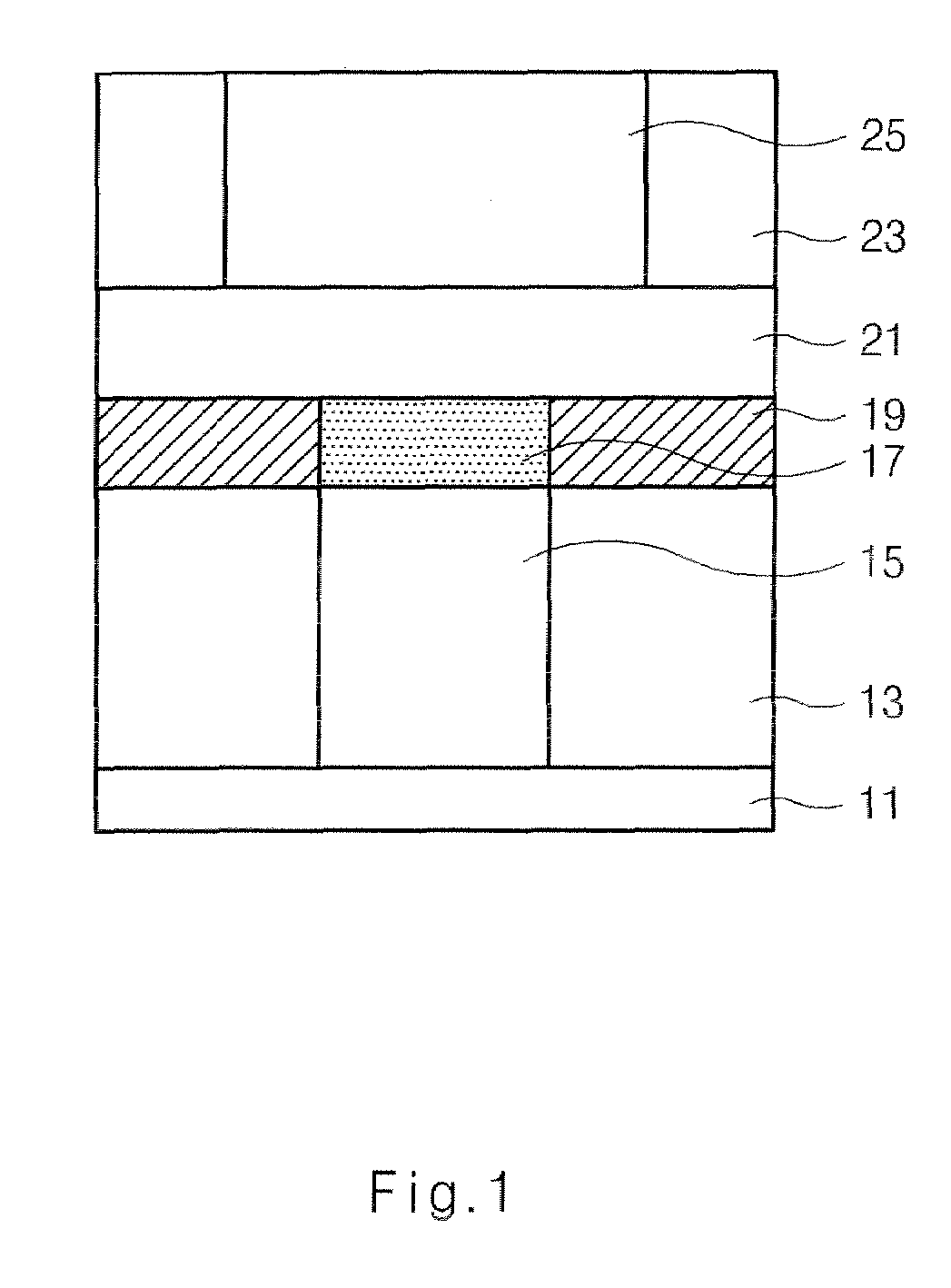

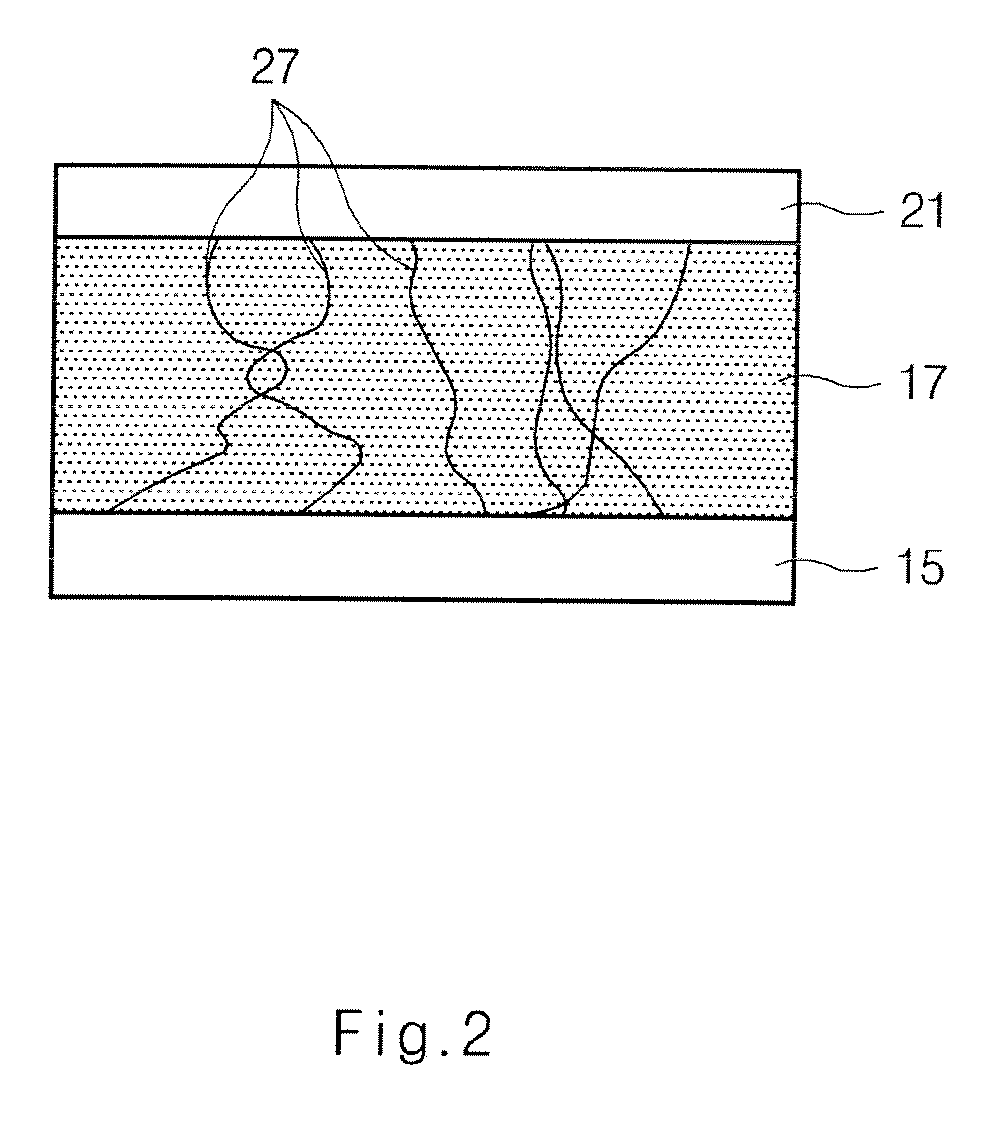

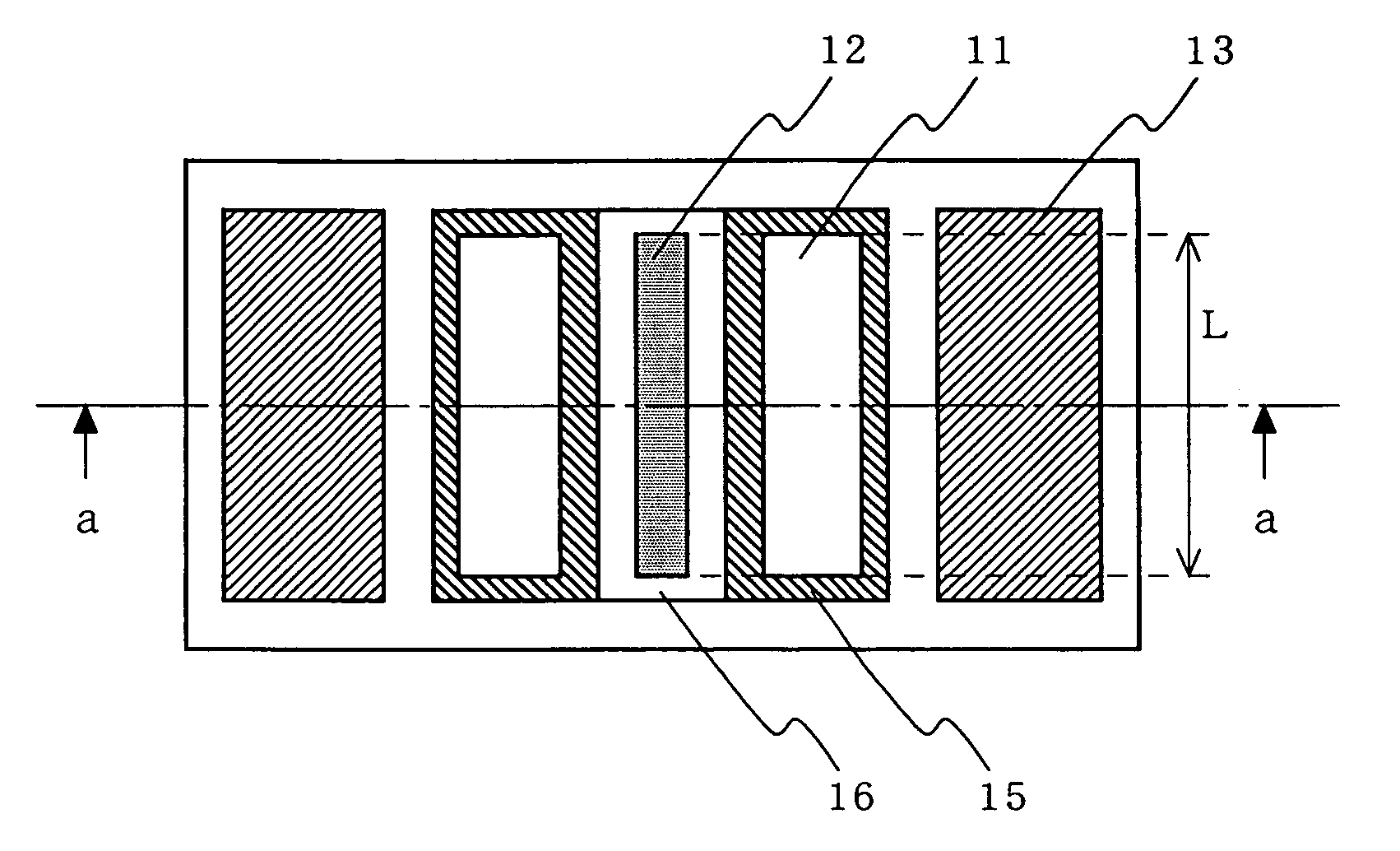

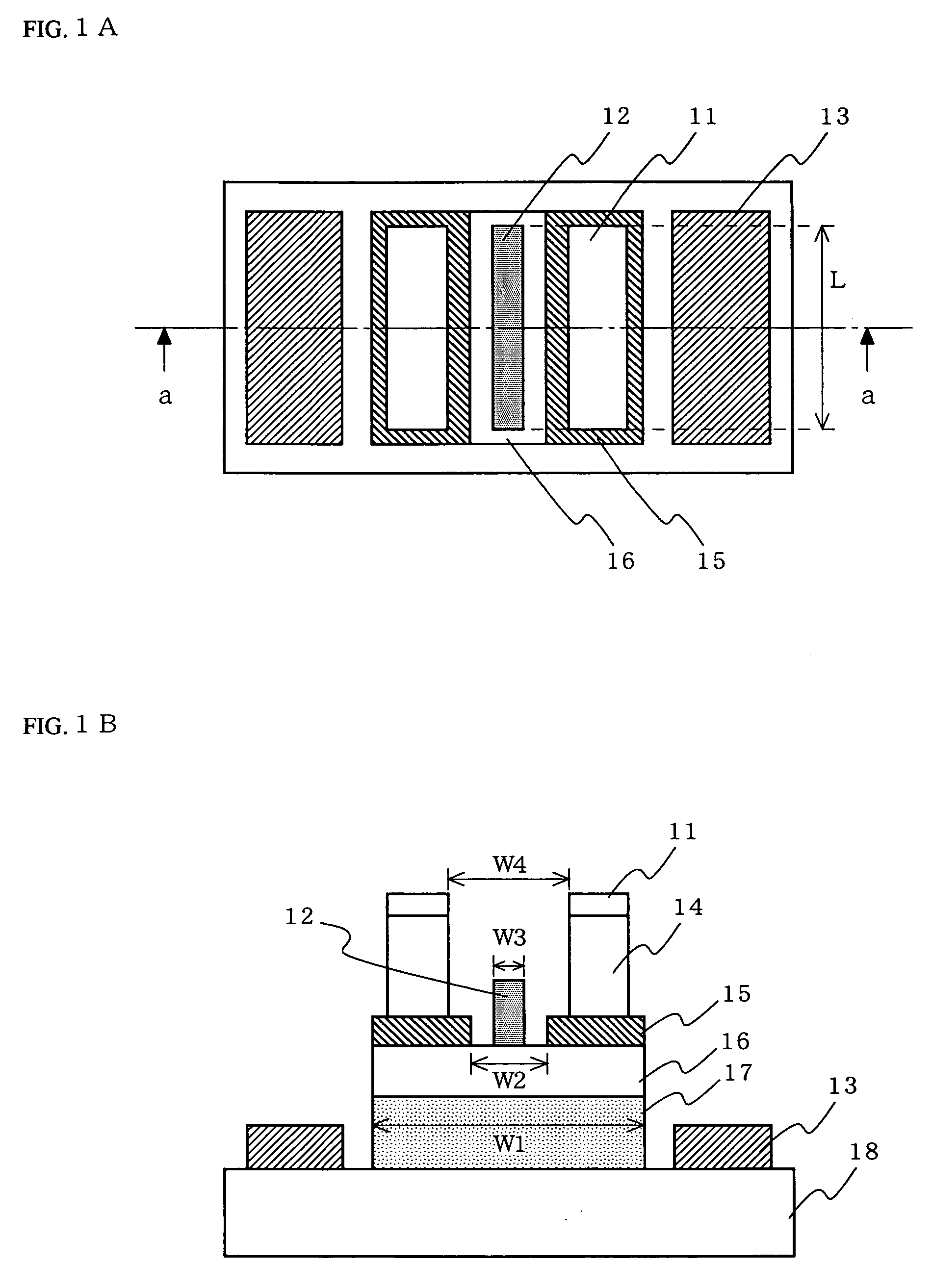

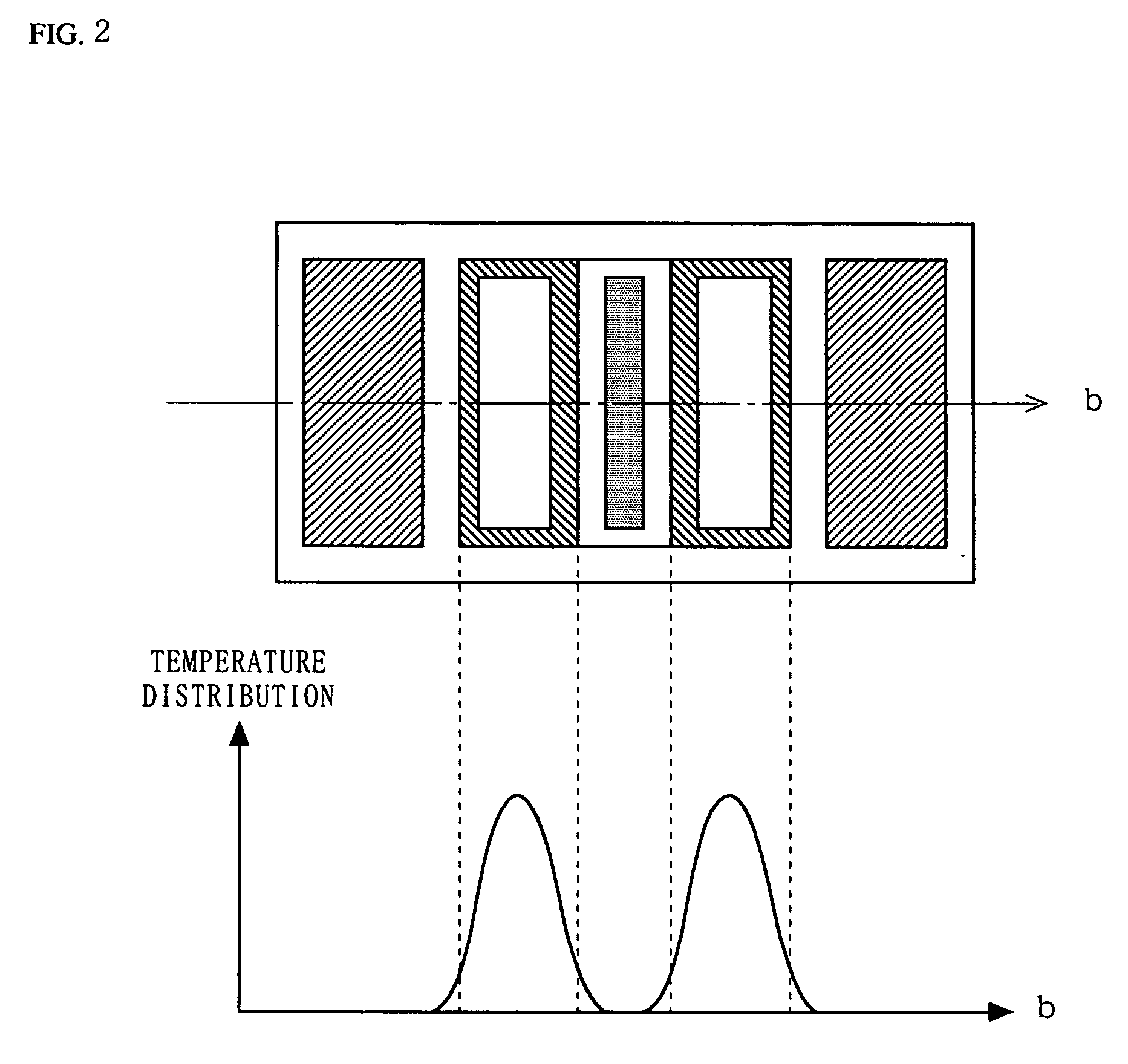

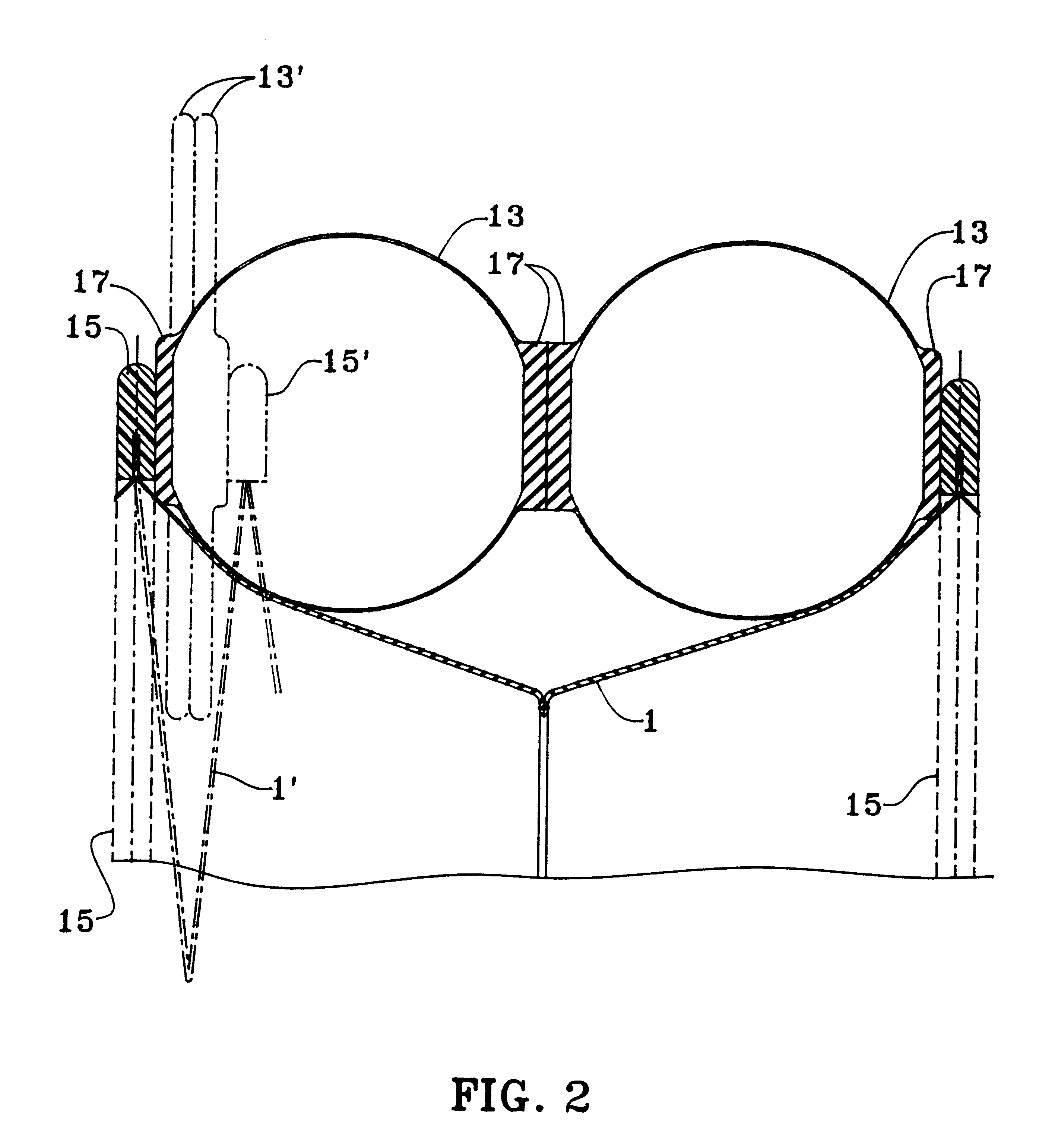

Local SONOS-type nonvolatile memory device and method of manufacturing the same

InactiveUS20050054167A1Uniform operating characteristicEasy to scaleTransistorSolid-state devicesEngineeringGate oxide

Provided are a local SONOS-type memory device and a method of manufacturing the same. The device includes a gate oxide layer formed on a silicon substrate; a conductive spacer and a dummy spacer, which are formed on the gate oxide layer and separated apart from each other, the conductive spacer and the dummy spacer having round surfaces that face outward; a pair of insulating spacers formed on a sidewall of the conductive spacer and a sidewall of the dummy spacer which face each other; an ONO layer formed in a self-aligned manner between the pair of insulating spacers; a conductive layer formed on the ONO layer in a self-aligned manner between the pair of insulating spacers; and source and drain regions formed in the silicon substrate outside the conductive spacer and the dummy spacer.

Owner:SAMSUNG ELECTRONICS CO LTD

Pulse welder and method of using same

ActiveUS20050269306A1Reduce forceSmall droplet sizeCoin-freed apparatus detailsArc welding apparatusElectric arcEngineering

An electric arc welder for performing a pulse welding process by a current between an advancing electrode and workpiece where the welder comprises a short detecting circuit for creating a short signal upon occurrence of a short circuit between the advancing electrode and the workpiece and a boost circuit to create a plasma boost pulse after the short circuit is cleared during the time period when the welder is not outputting the peak pulse current.

Owner:LINCOLN GLOBAL INC

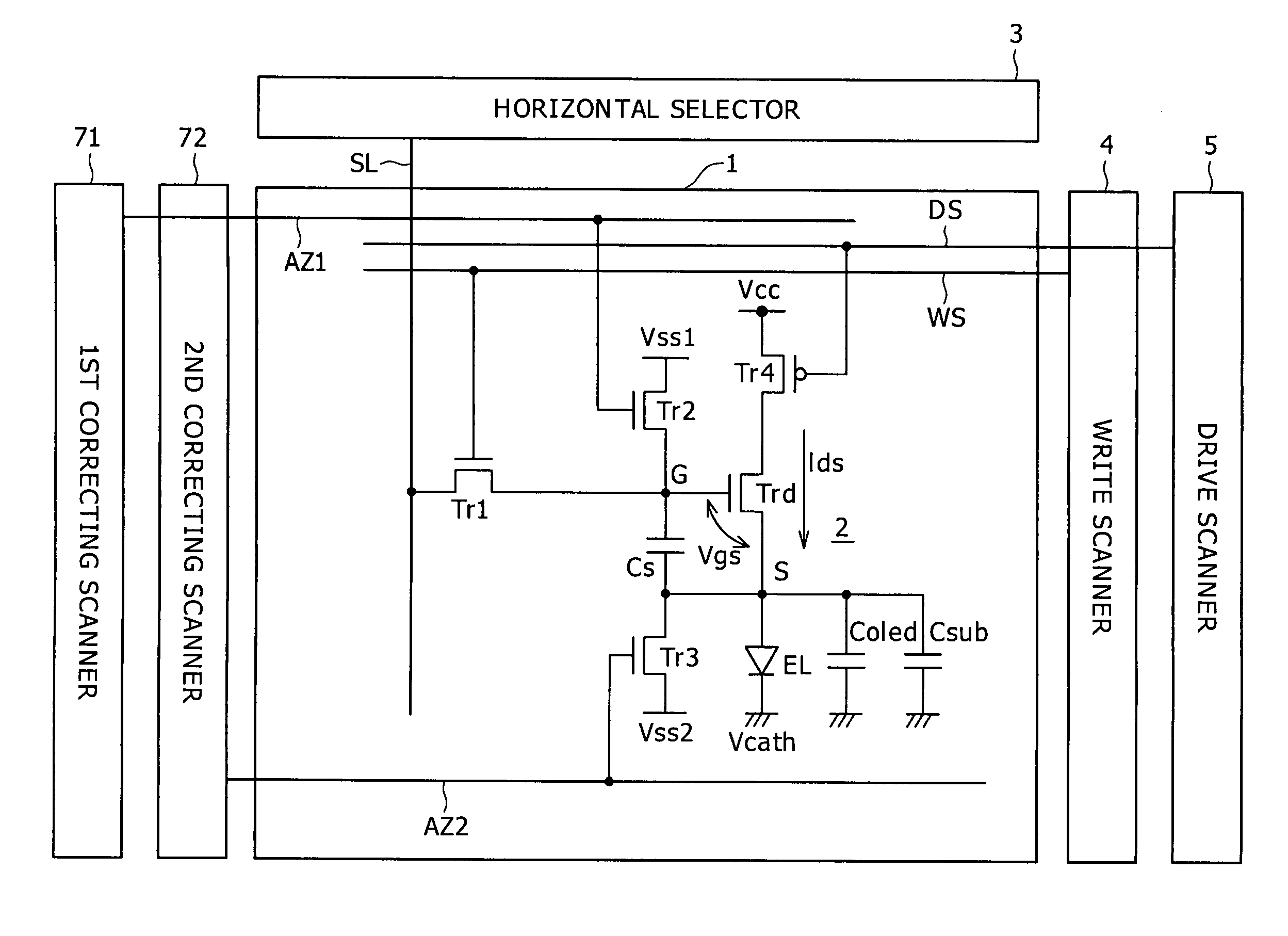

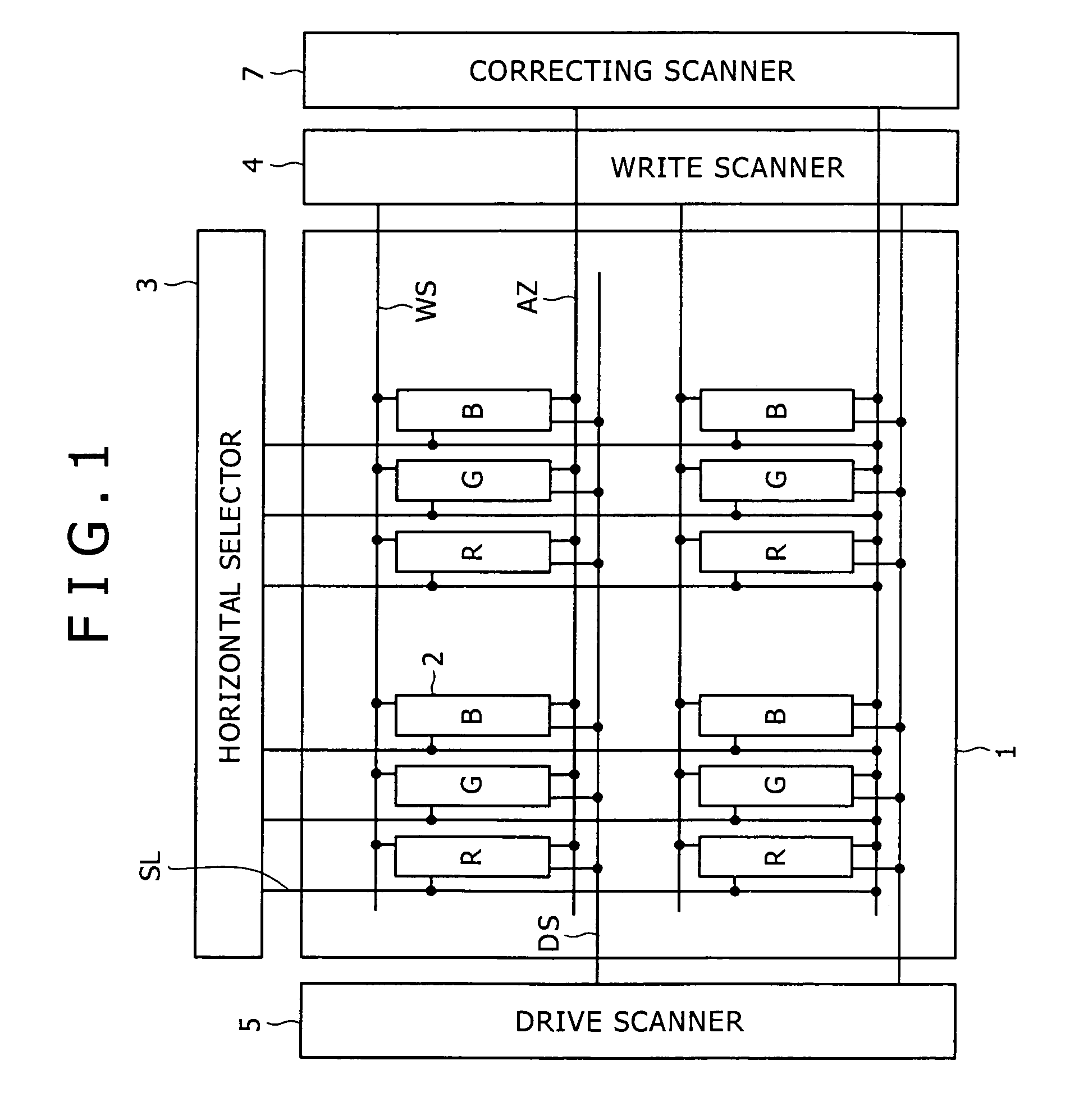

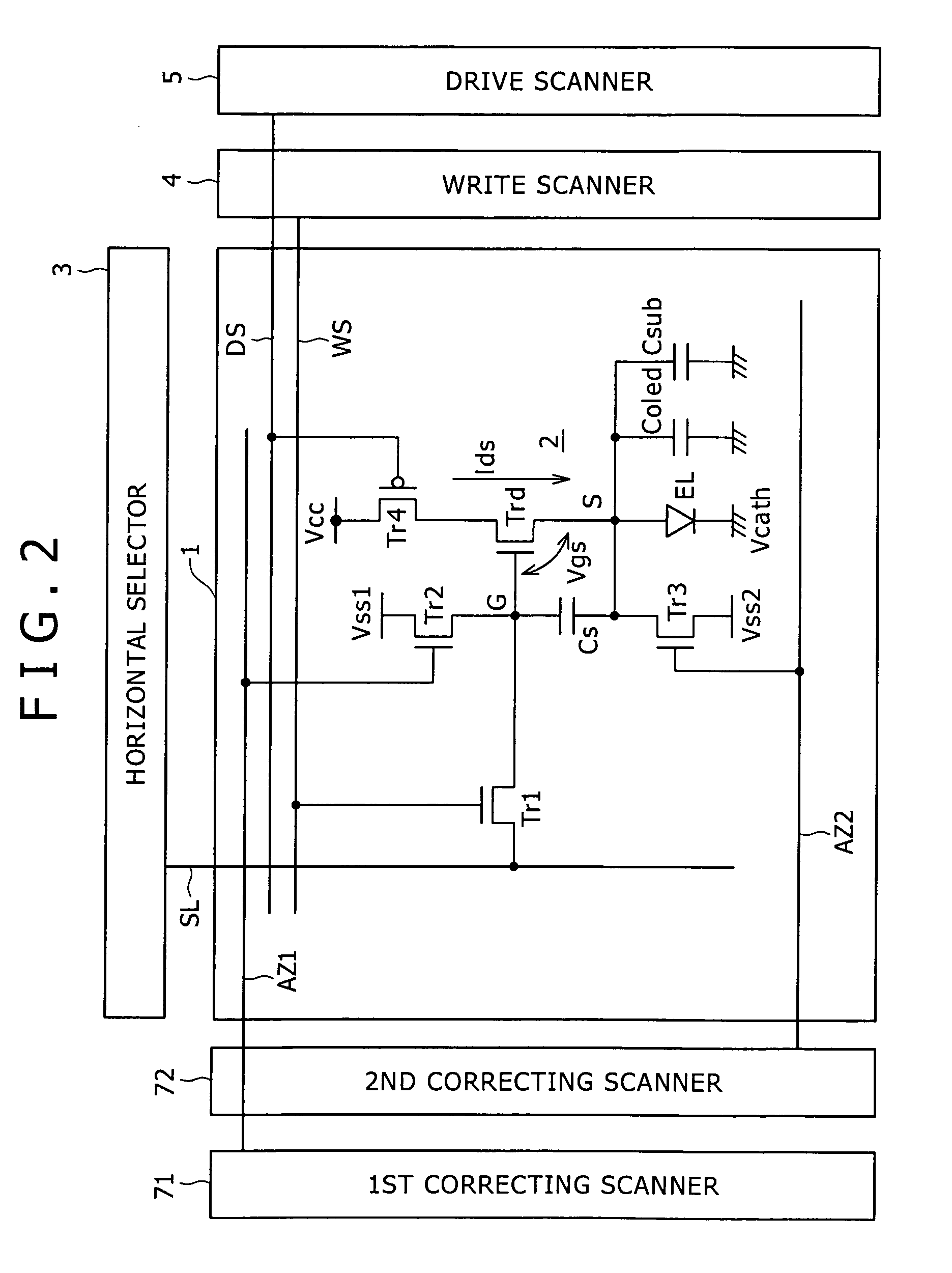

Pixel circuit and display apparatus

ActiveUS7659872B2Guaranteed uptimeUnified operationElectrical apparatusElectroluminescent light sourcesCapacitanceTiming margin

Disclosed herein is a pixel circuit that includes a correcting section configured to correct the input voltage sampled in the pixel capacitance in order to cancel out the dependency of the output current on the carrier mobility. In the pixel circuit, the correcting section operates depending on the control signal supplied from the scanning line to extract the output current from the drive transistor and introduce the extracted output current into a capacitance of the light-emitting device and the pixel capacitance, thereby correcting the input voltage. The pixel circuit further includes an additional capacitance added to the capacitance of the light-emitting device. In the pixel circuit, a portion of the output current extracted from the drive transistor flows into the additional capacitance to give a time margin to operation of the correcting section.

Owner:SONY CORP

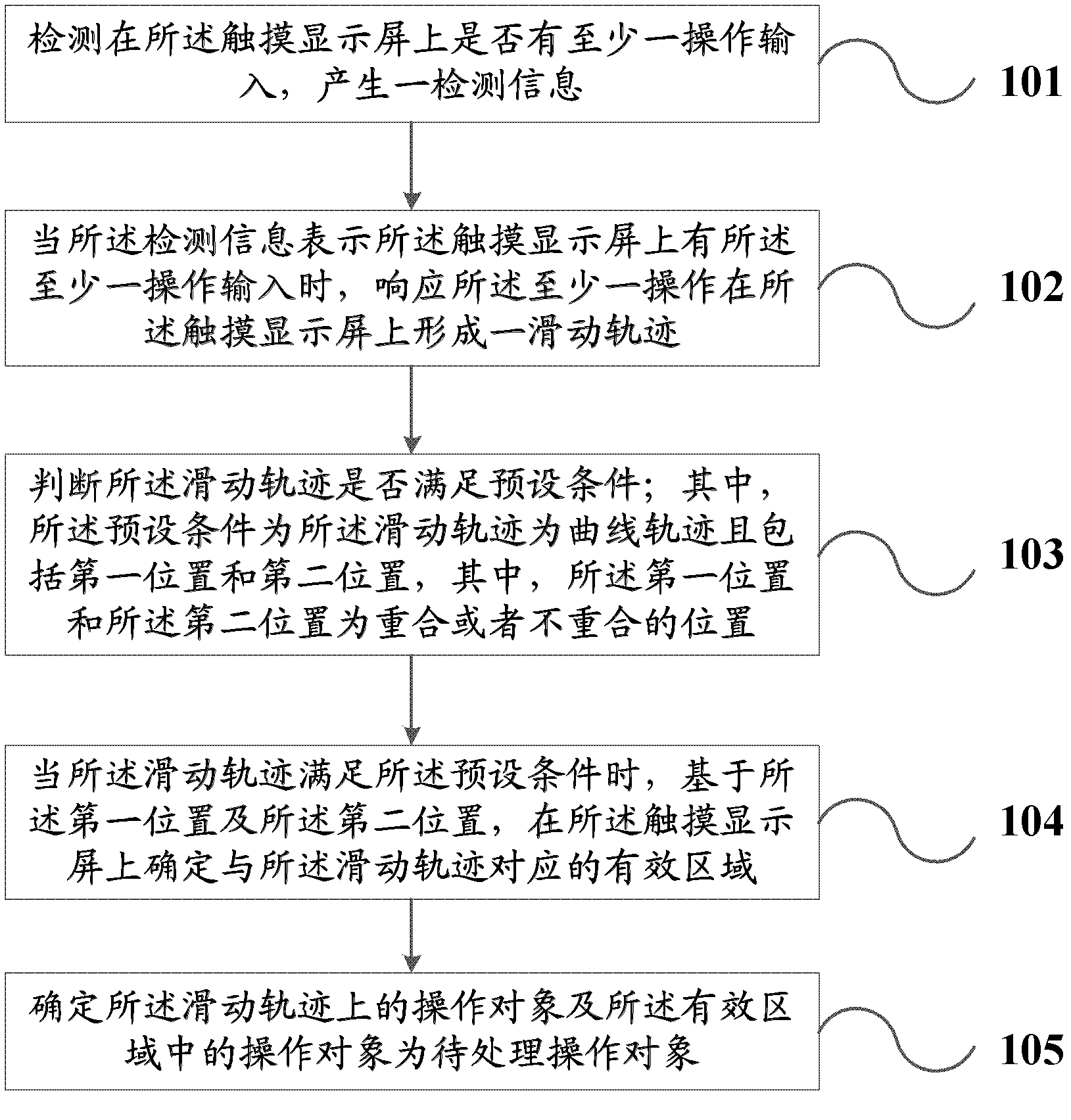

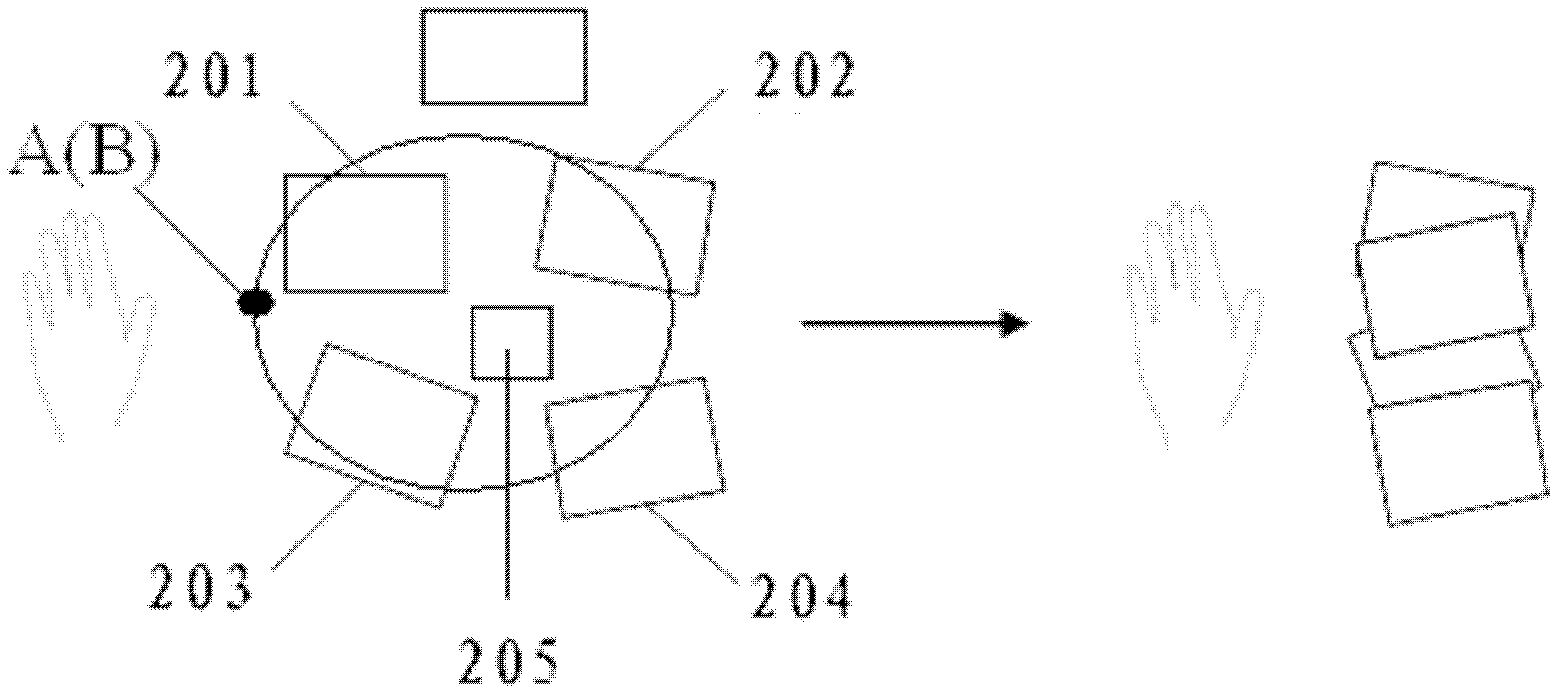

Method and device for determining operands

ActiveCN102760006AIn line with operating habitsReduce learning costsInput/output processes for data processingOperandHuman–computer interaction

The invention discloses a method and a device for determining operands, and is characterized in that the method is applied to electronic equipment, wherein the electronic equipment comprises a touch display screen capable of displaying at least one operand, the method comprises the following steps: detecting whether the touch display screen has at least one operation input and generating a piece of detection information; when the detection information shows that the touch display screen has at least one operation input, responding at least one operation to form a sliding track on the touch display screen; judging whether the sliding track meets predetermined conditions, wherein the predetermined conditions are as follows: the sliding track is a curved track and comprises a first position and a second position, and the first position and the second position are coincident positions or non-coincident positions; when the judging information shows that the sliding track meets the predetermined conditions, determining an effective area corresponding to the sliding track on the touch display screen based on the first position and the second position; and determining an operand on the sliding track and an operand in the effective area as operands to be processed.

Owner:LENOVO (BEIJING) LTD

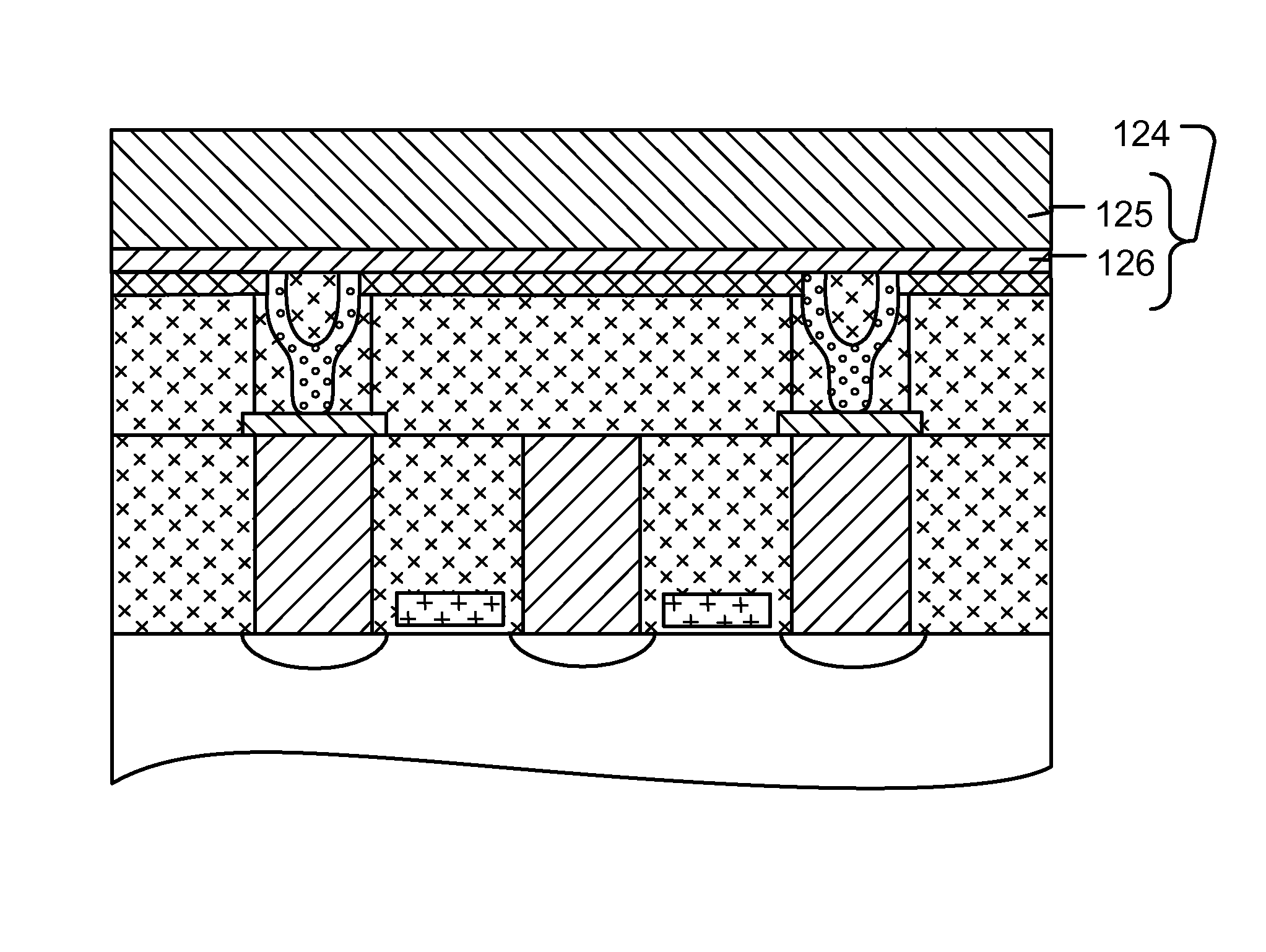

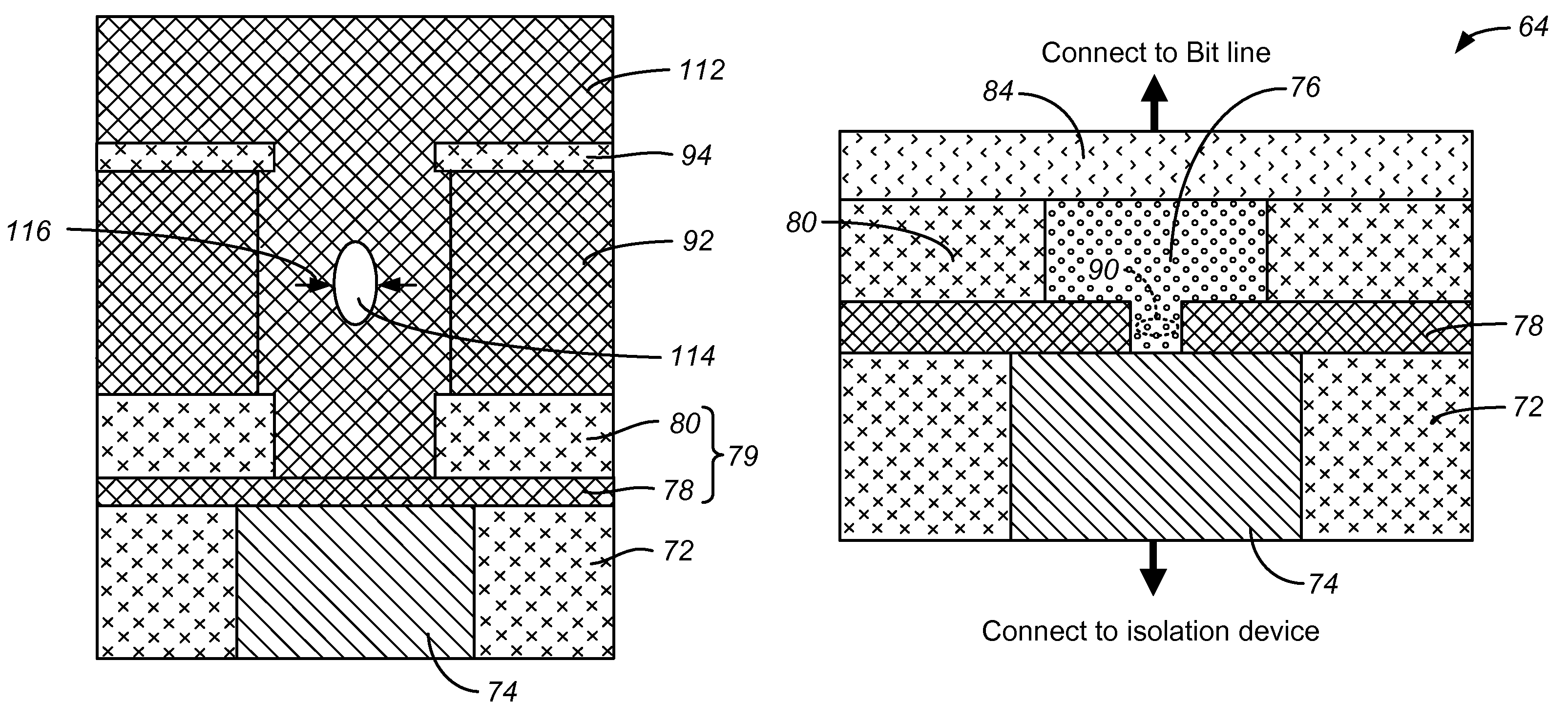

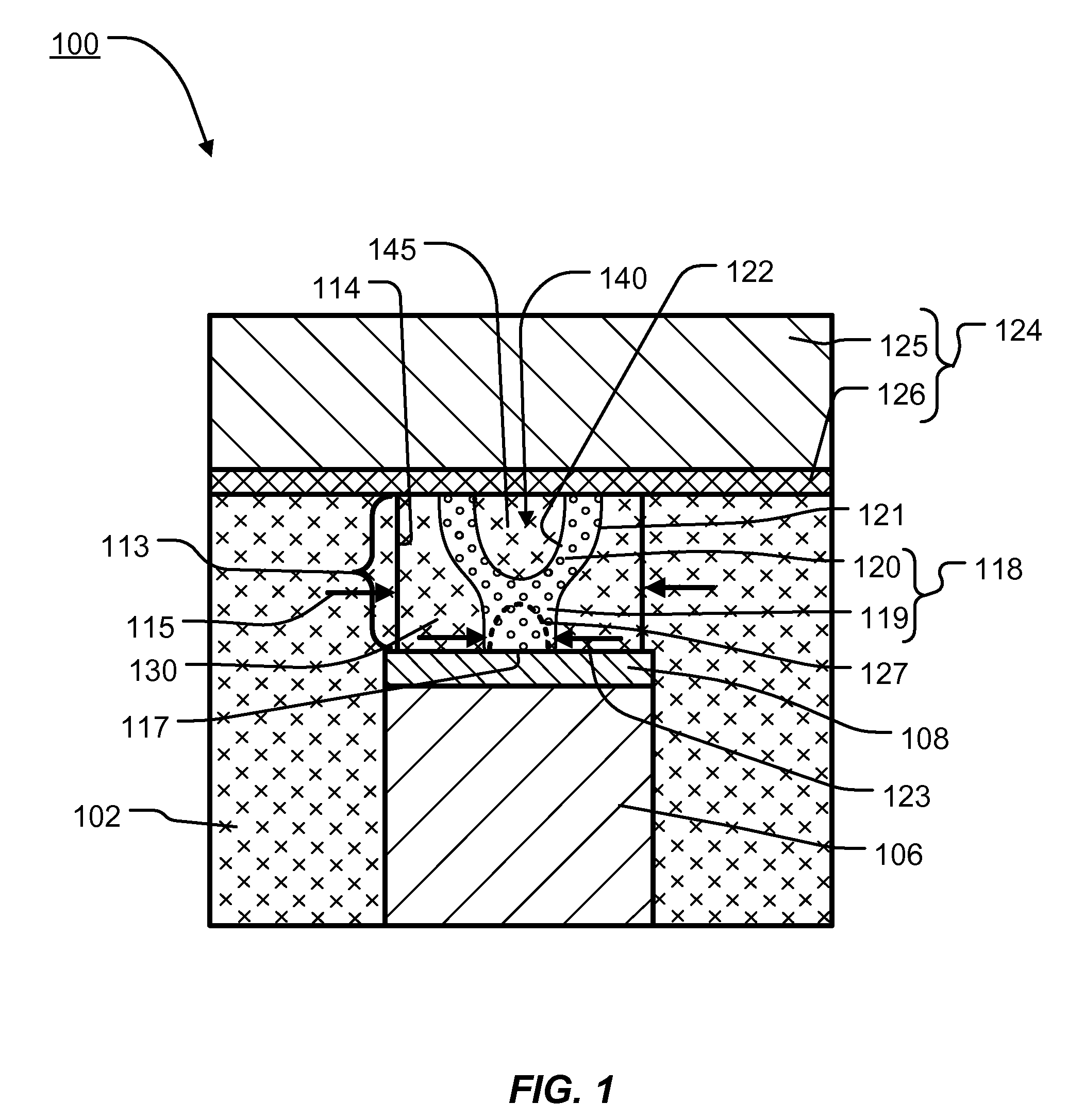

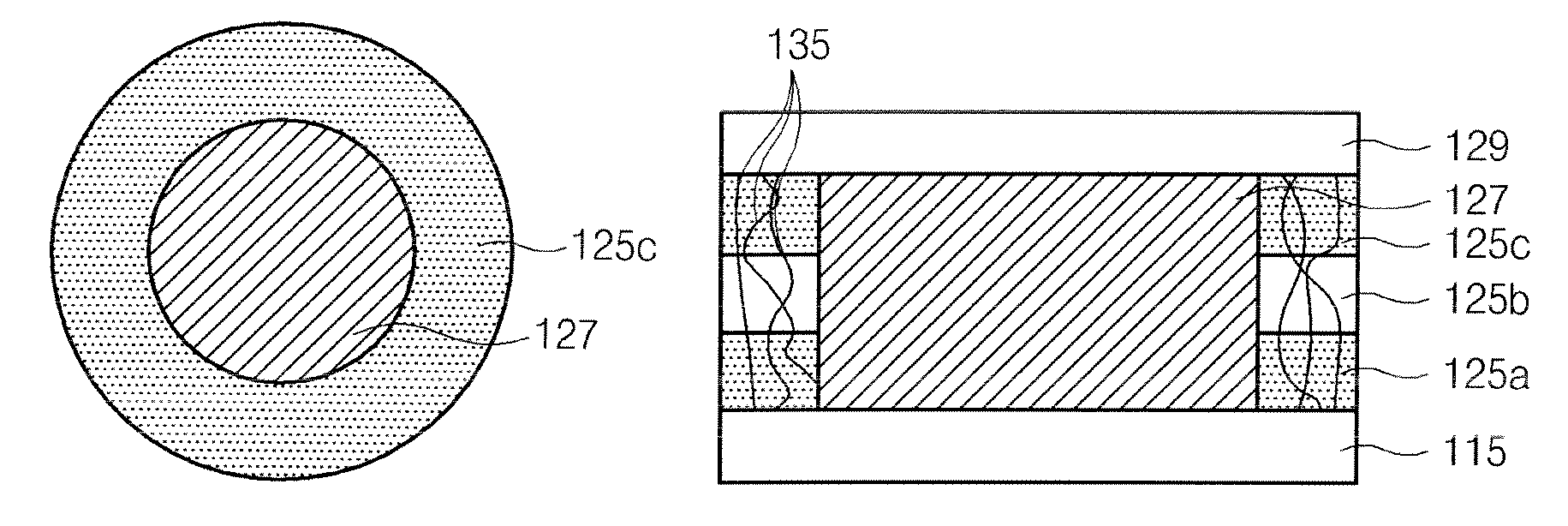

Phase change memory cell with filled sidewall memory element and method for fabricating the same

ActiveUS20080191186A1Reduce the amount requiredWeakening rangeSolid-state devicesSemiconductor/solid-state device manufacturingPhase-change memoryFilling materials

Memory cells are described along with methods for manufacturing. A memory cell described herein includes a bottom electrode, a top electrode overlying the bottom electrode, a via having a sidewall extending from a bottom electrode to a top electrode, and a memory element electrically coupling the bottom electrode to the top electrode. The memory element has an outer surface contacting a dielectric sidewall spacer that is on the sidewall of the via, and comprises a stem portion on the bottom electrode and a cup portion on the stem portion. A fill material is within an interior defined by an inner surface of the cup portion of the memory element.

Owner:MACRONIX INT CO LTD

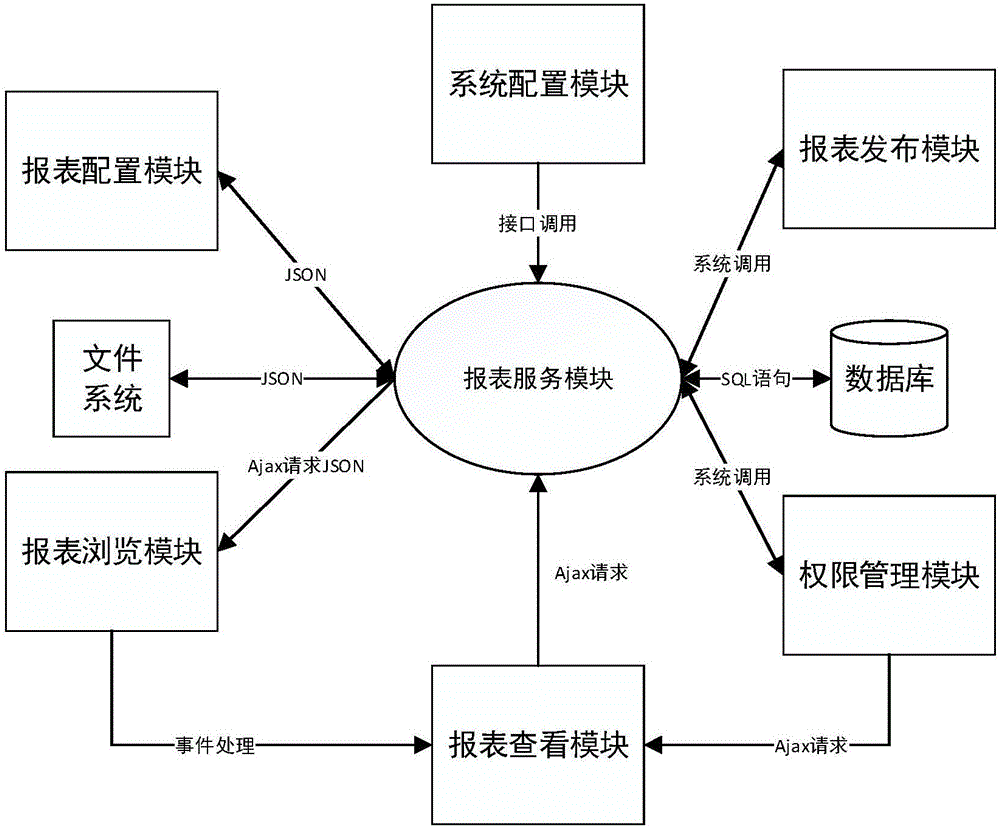

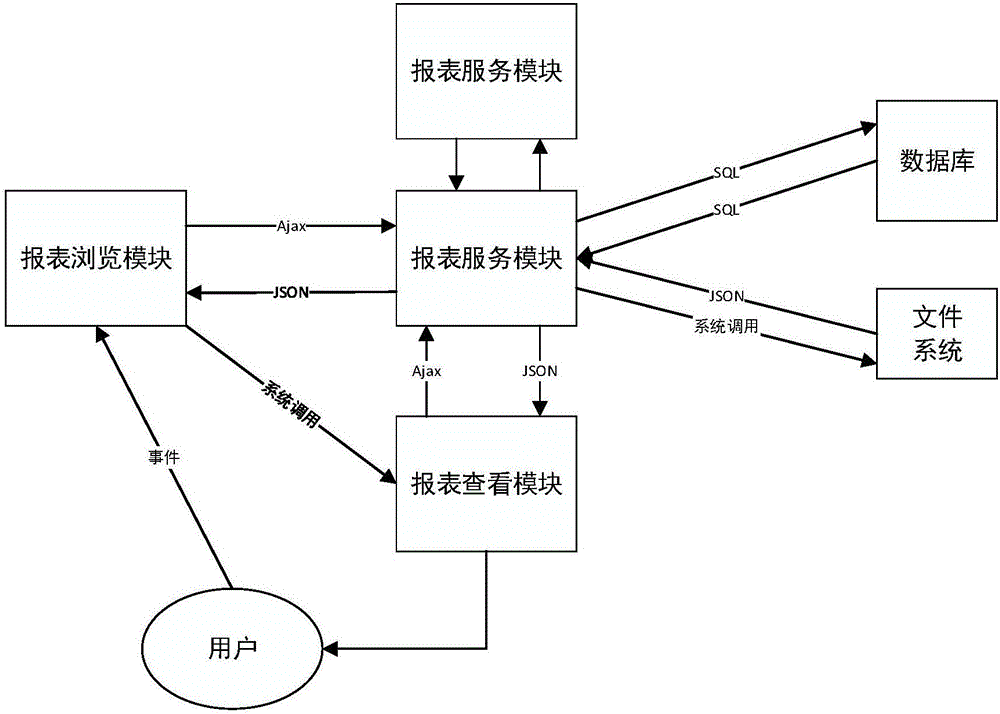

JSON self-definition-based report generation system and method

InactiveCN106649225ASimplify the configuration processImprove efficiencyText processingSpecial data processing applicationsBusiness PersonnelWeb service

The invention discloses a JSON self-definition-based report generation system and method, and belongs to the field of industrial enterprise data statistics. An industrial enterprise report system comprises a system configuration module, a report template configuration module, a report service module, a report release module, a report browsing module, a permission management module and a report viewing module. All the modules are deployed in a Web server of an enterprise local area network, and a client accesses the server through the local area network. The client is mainly a browser installed in a computer, an IP address of the Web server of the local area network is input through an address bar of the browser, and a system is accessed through an Http protocol. The system and the method have the advantages that an interactive process of report template configuration is simplified, so that the template configuration efficiency is improved; the problems that enterprise complex reports only can be manually filled through Excel and do not have historical data query are solved, so that the working efficiency of enterprise statistical personnel is improved; and report browsing provides query of data point trends in the reports, so that the data observation correctness of business personnel is facilitated.

Owner:AUTOMATION RES & DESIGN INST OF METALLURGICAL IND

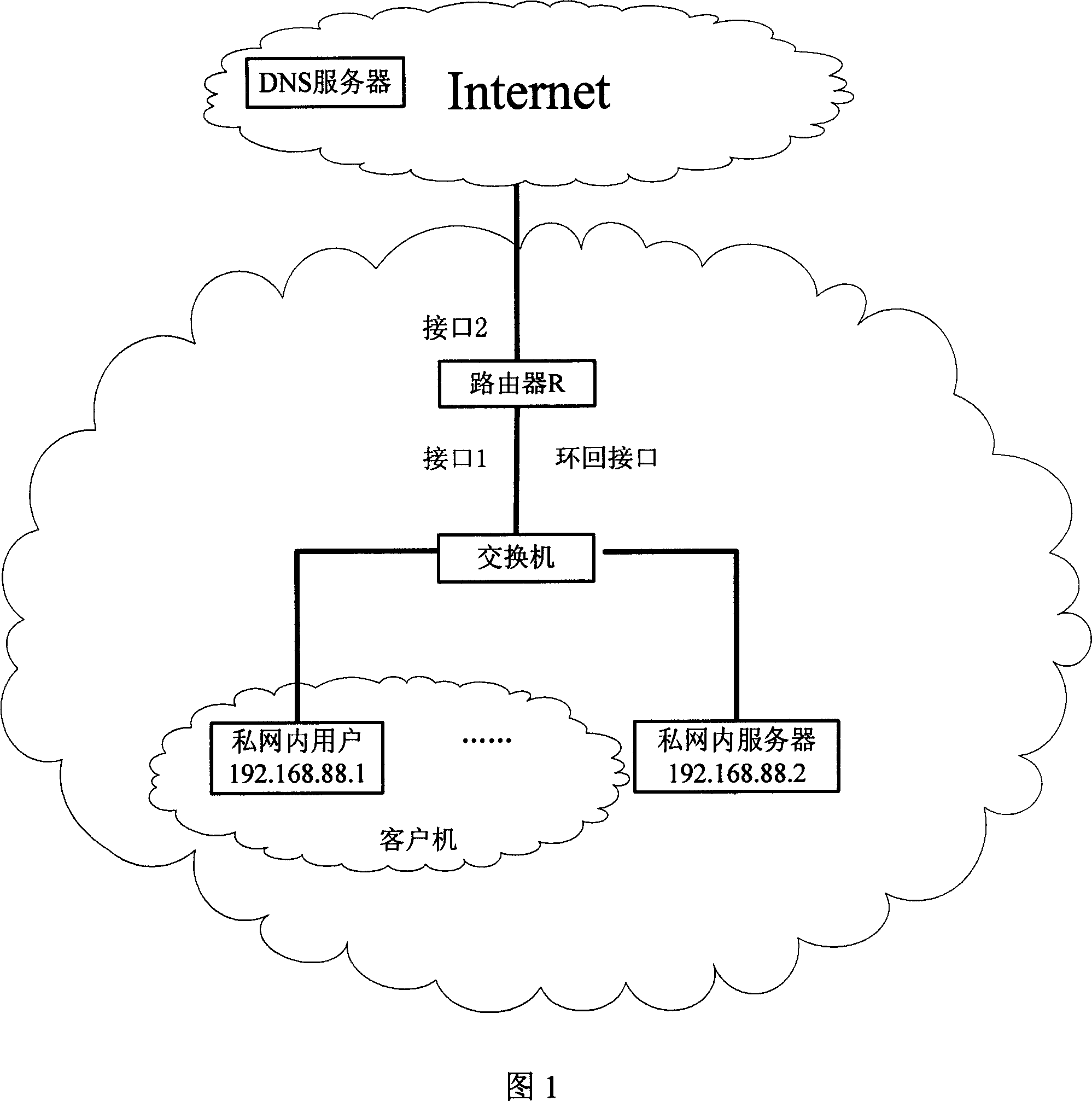

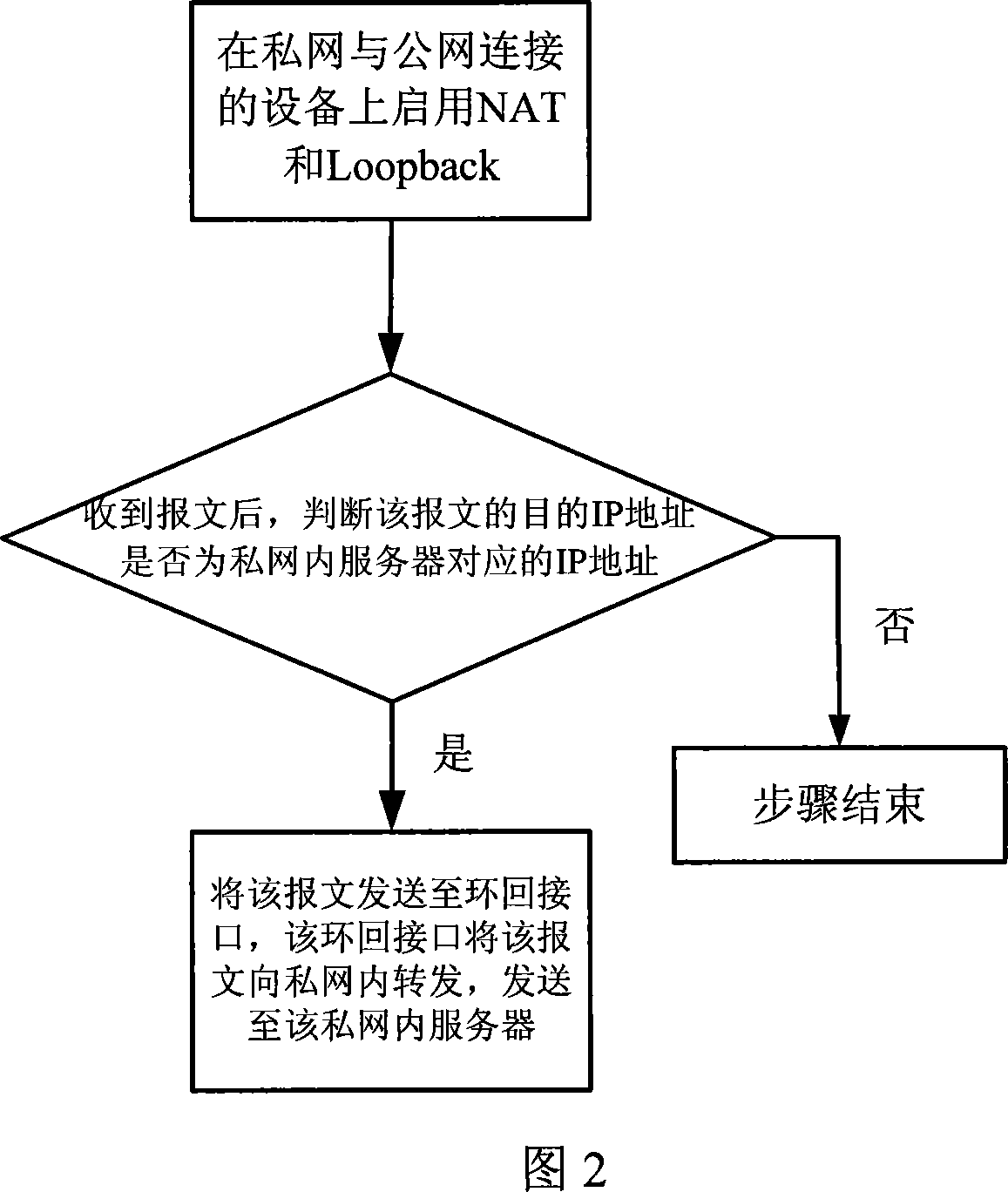

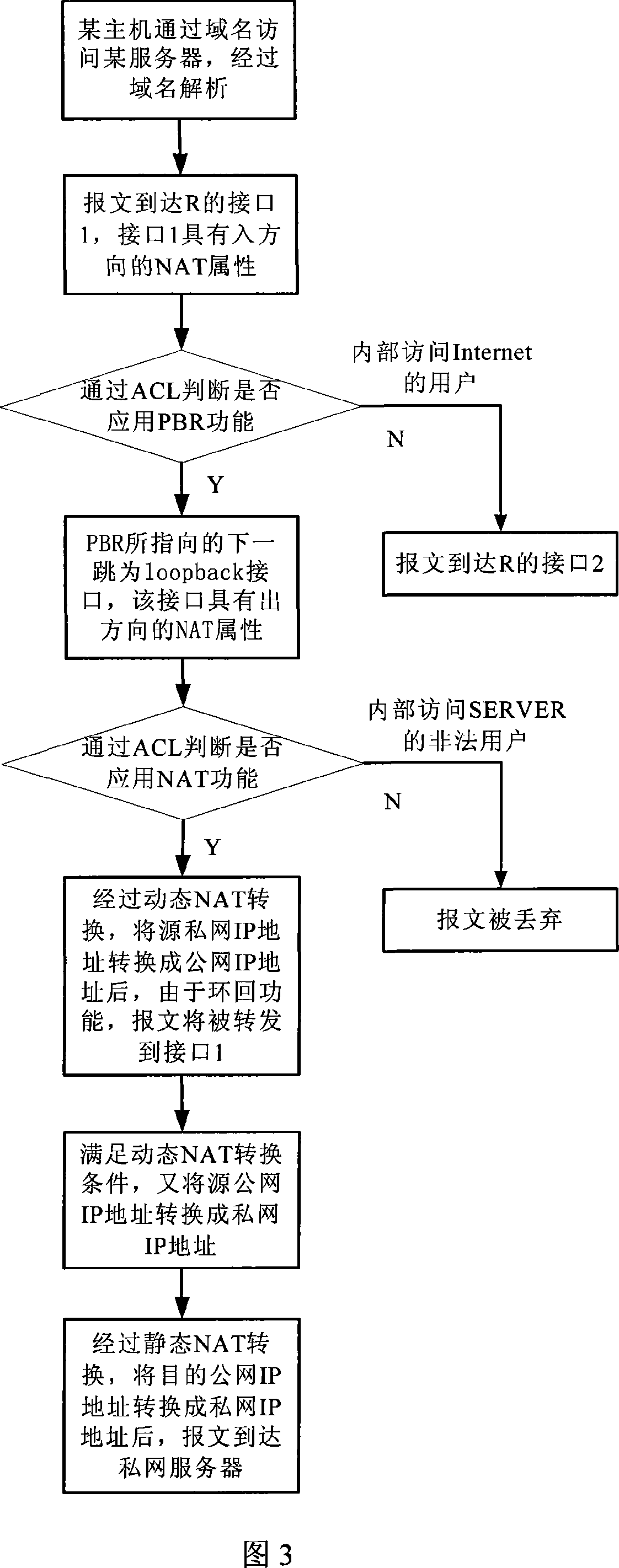

A method of private network user access the server in a private network through domain name

The disclosed method of visiting private server for user in private network comprises: 1. starting at least the loop interface and address conversion on the device connecting private and public networks, and setting static address conversion for the private server; 2. when recieivng user message from private network, deciding whether the objective IP address is the public IP address relative in private network, yes to step 3, or lese end; and 3. sending message to the loop interface to transmit the message toward private network till the server. This invention makes user in private network eliminate setting DNS server to visit private server.

Owner:ZTE CORP

Fill-in etching free pore device

ActiveUS7879645B2Reduce amountWeakening rangeMagnetic-field-controlled resistorsSolid-state devicesDielectric layerElectrical contacts

A memory cell includes a memory cell layer with a first dielectric layer over a bottom electrode layer, a second dielectric layer over the first dielectric layer, and a top electrode over the second dielectric layer. The dielectric layers define a via having a first part bounded by the first electrode layer and the bottom electrode and a second part bounded by the second dielectric layer and the top electrode. A memory element is within the via and is in electrical contact with the top and bottom electrodes. The first and second parts of the via may comprise a constricted, energy-concentrating region and an enlarged region respectively. The constricted region may have a width smaller than the minimum feature size of the process used to form the enlarged region of the via. A method for manufacturing a memory cell is also disclosed.

Owner:INT BUSINESS MASCH CORP +1

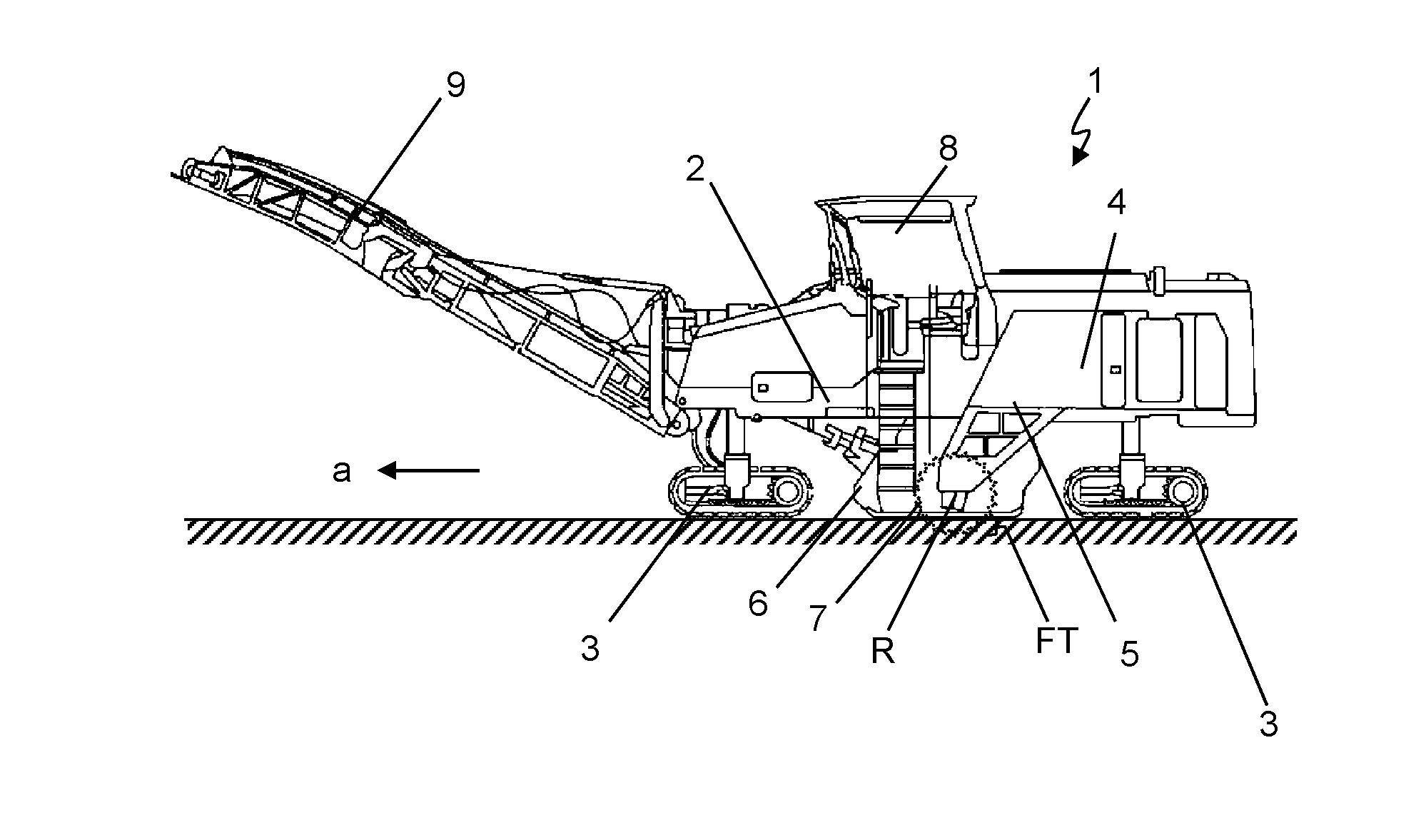

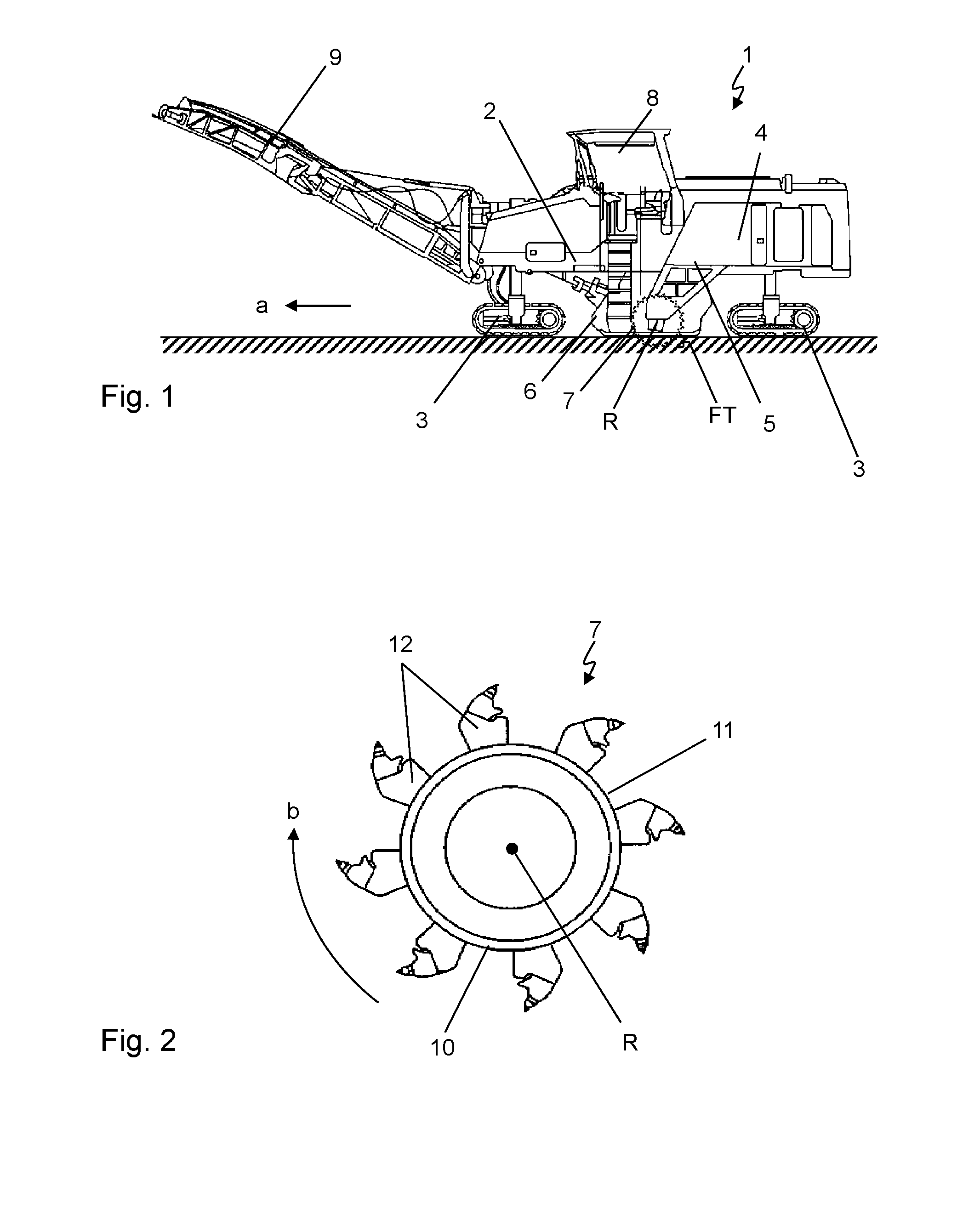

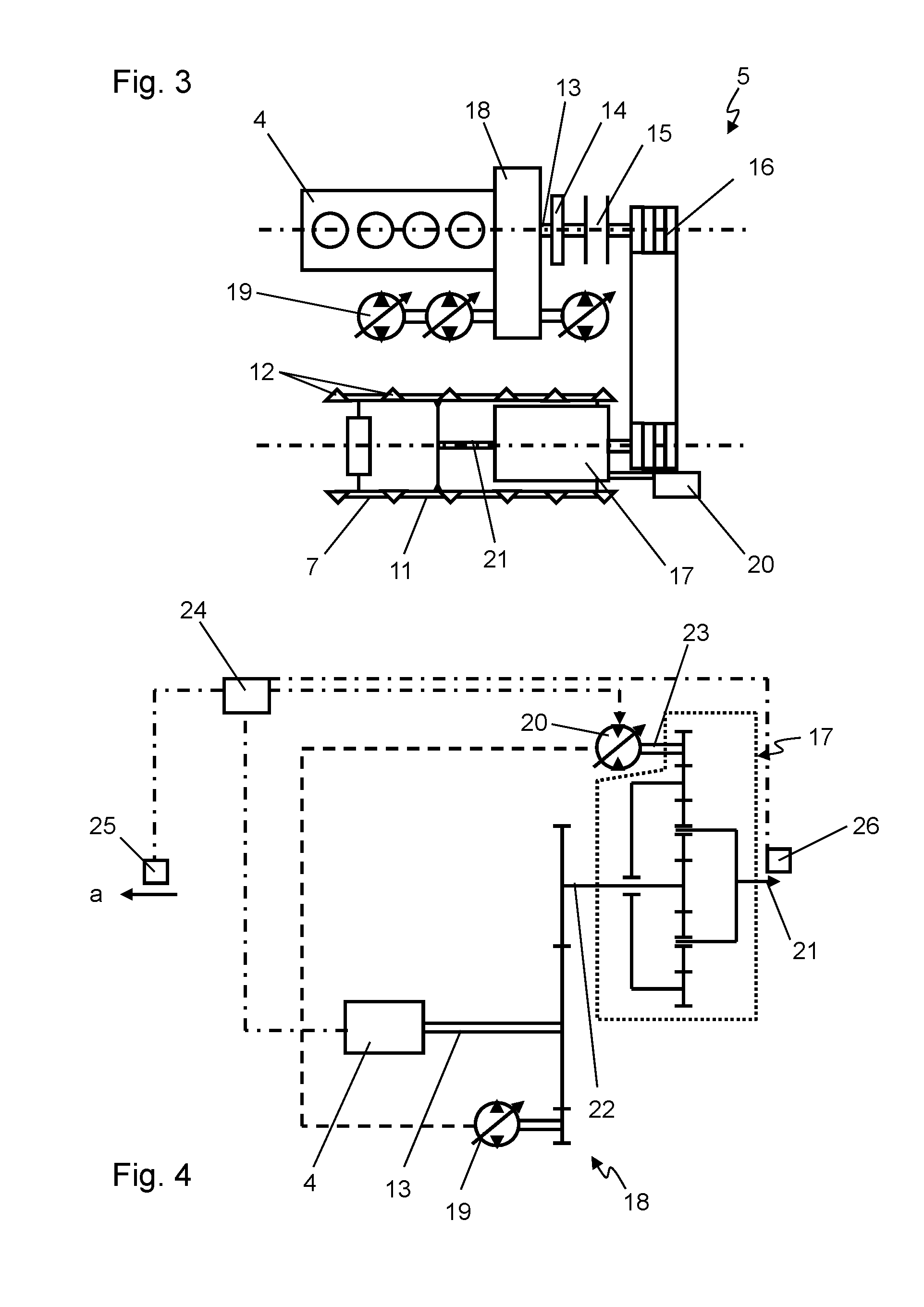

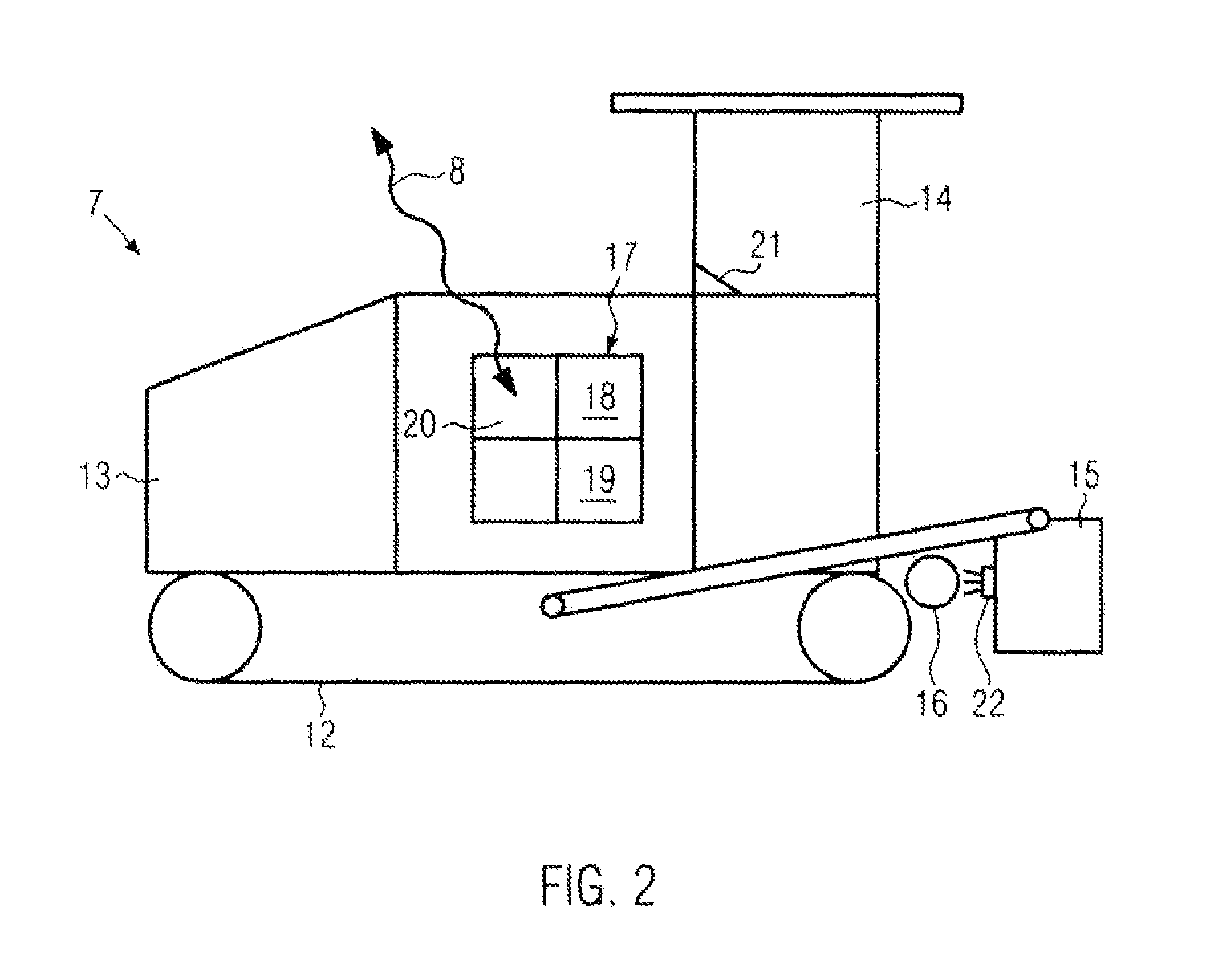

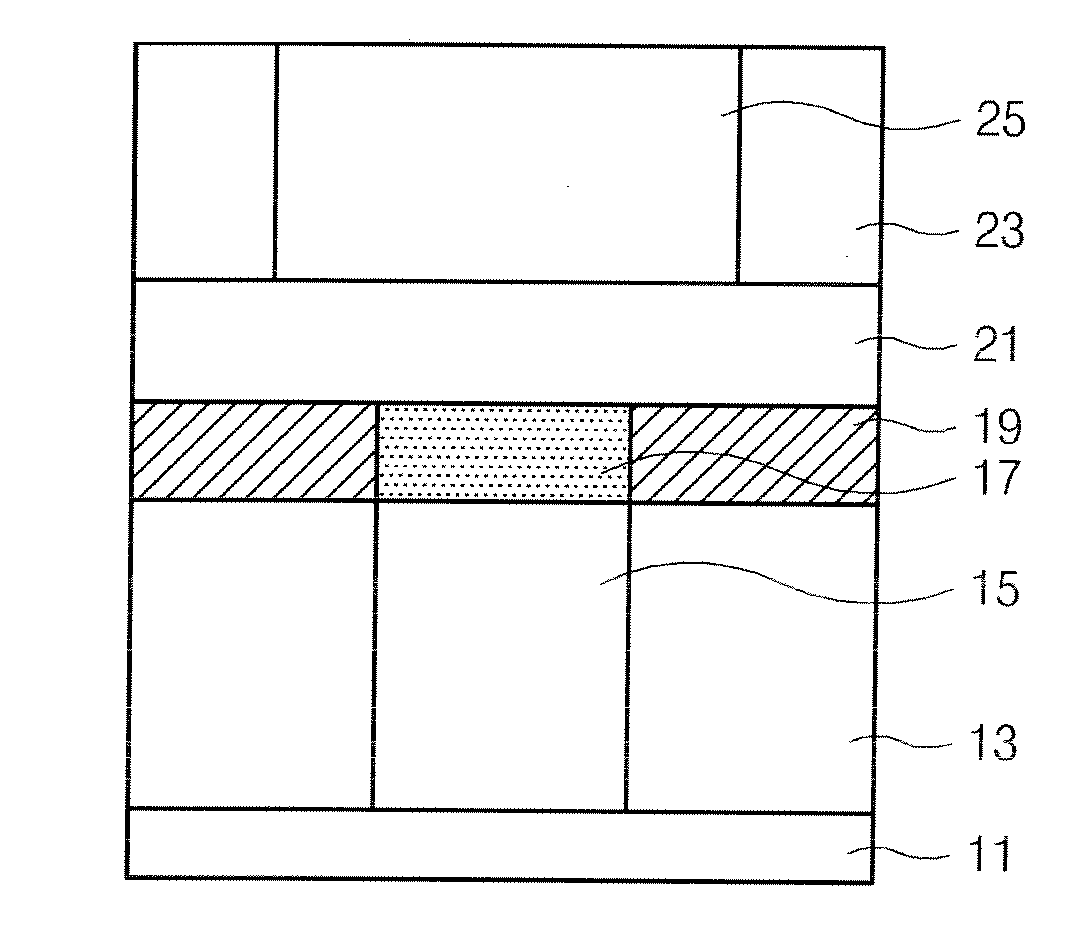

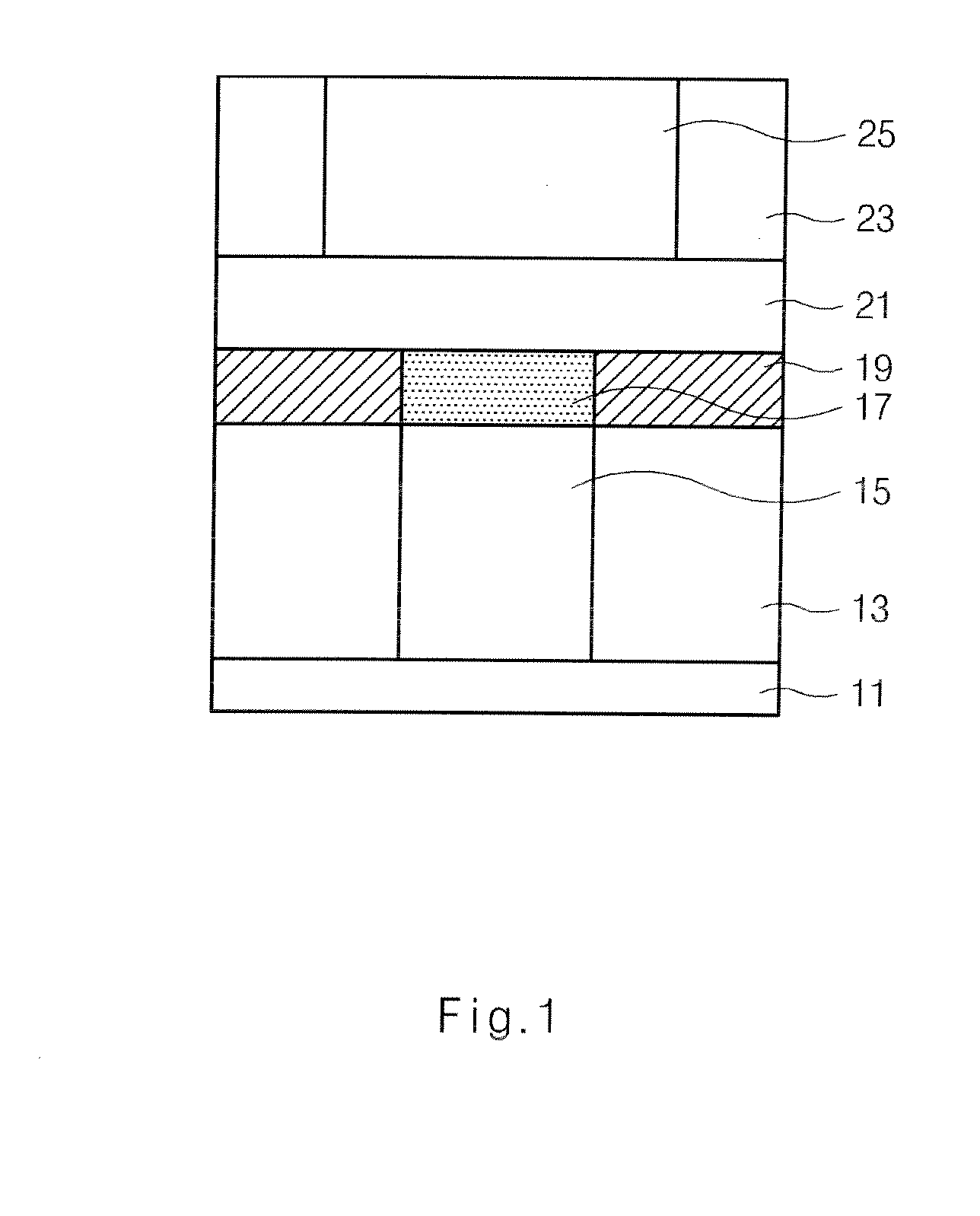

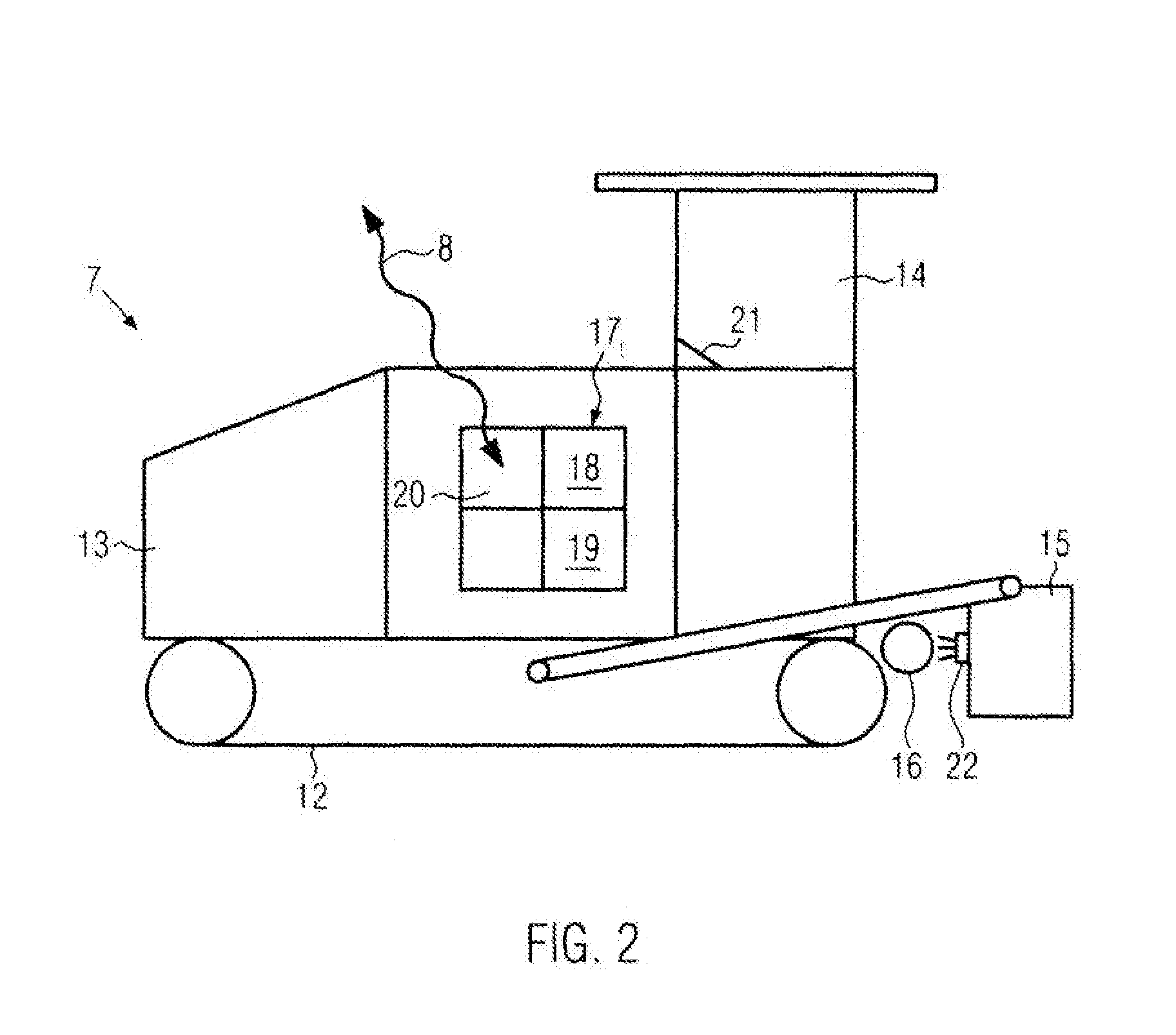

Method For Optimizing An Operating Function Of A Ground Milling Machine And Ground Milling Machine

ActiveUS20150227120A1Optimal maximum advance velocityReduce stepsSlitting machinesRoads maintainenceAutomotive engineeringProcess engineering

The present invention relates to a method for optimizing an operating function of a ground milling machine by way of the adaptation of operating parameters and to a ground milling machine which is implemented, in particular, for carrying out this method. In an essential aspect an operating parameter of a milling machine is provided starting from a starting value of the operating parameter to optimize an operating function of the ground milling machine in milling operation.

Owner:BOMAG

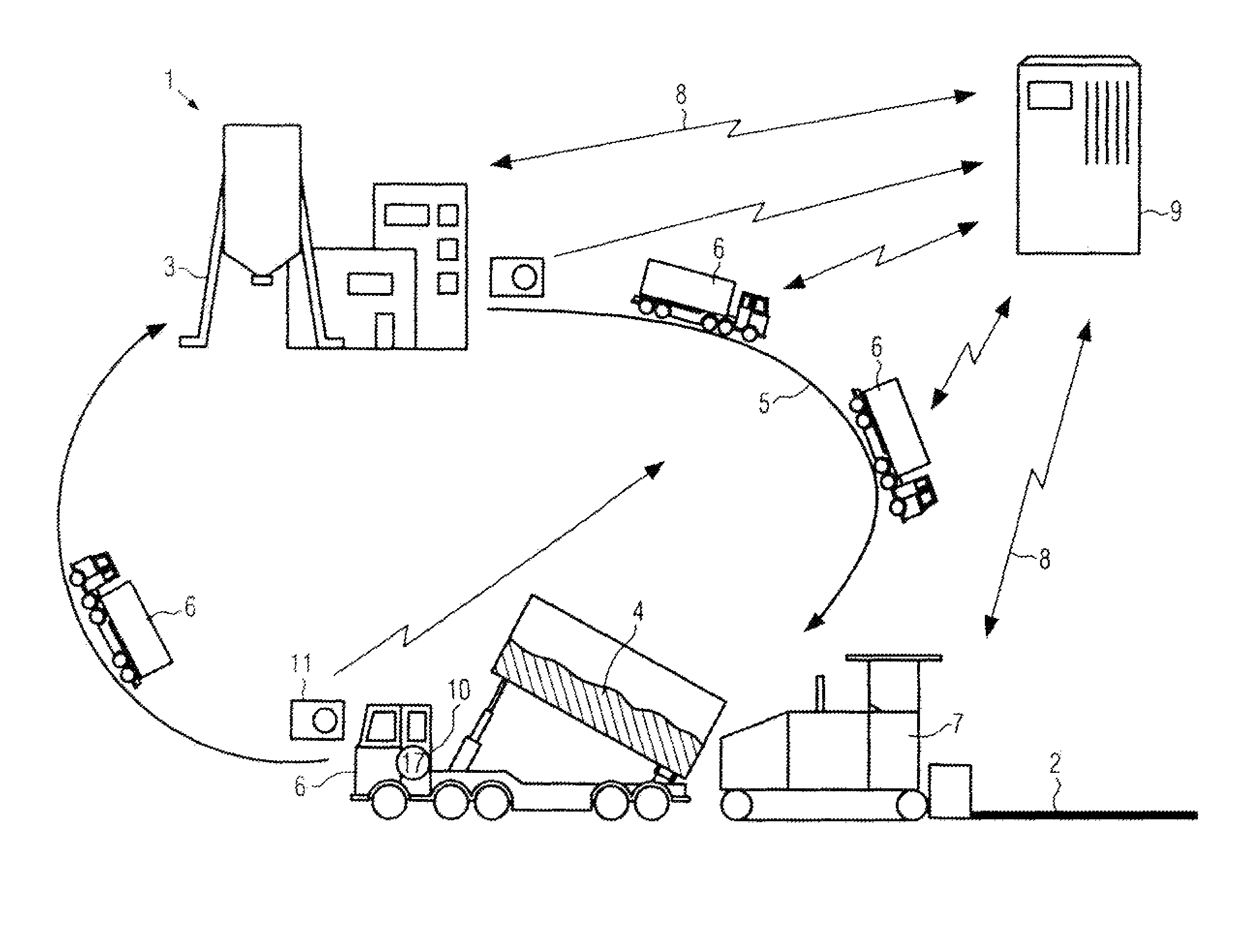

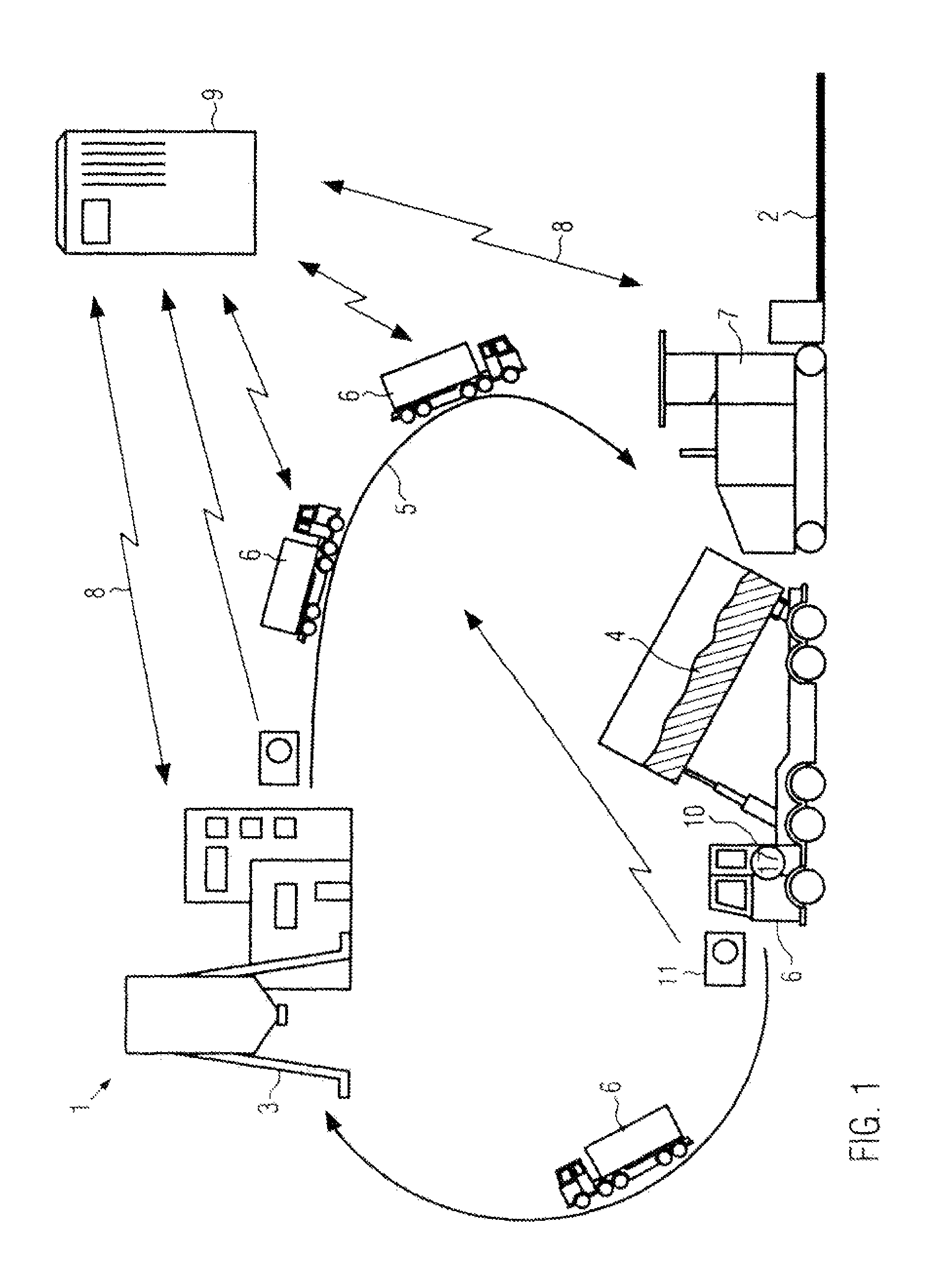

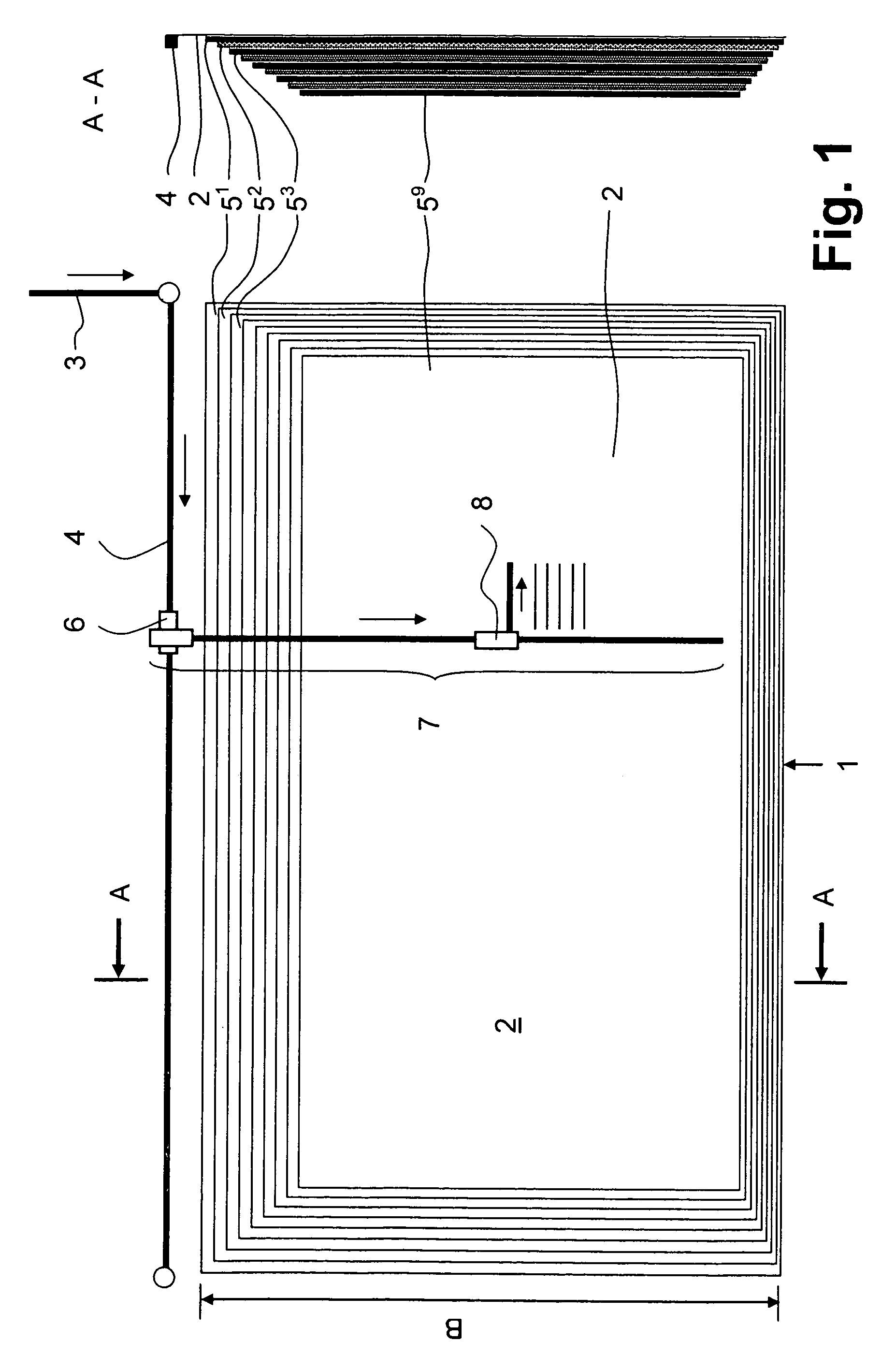

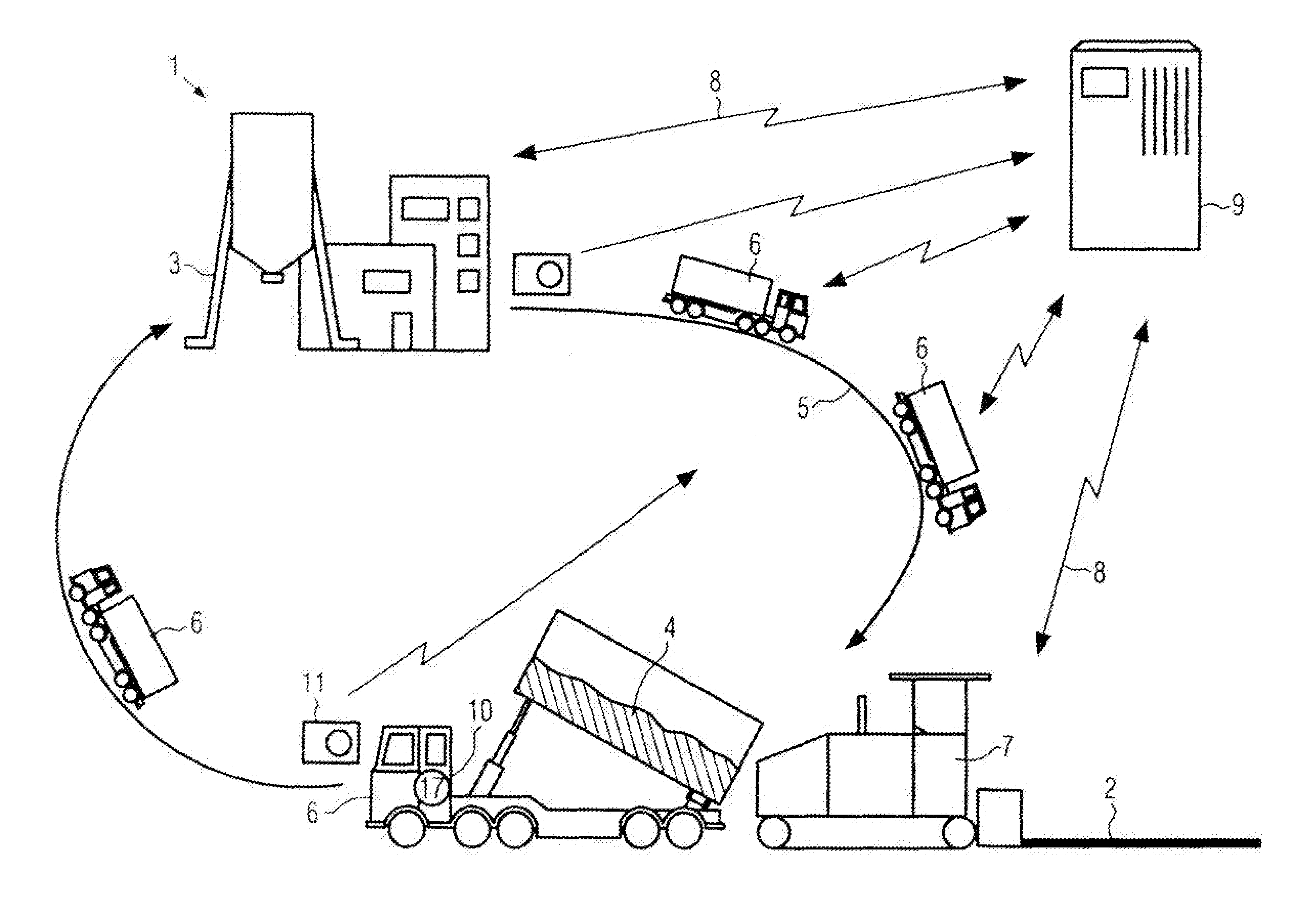

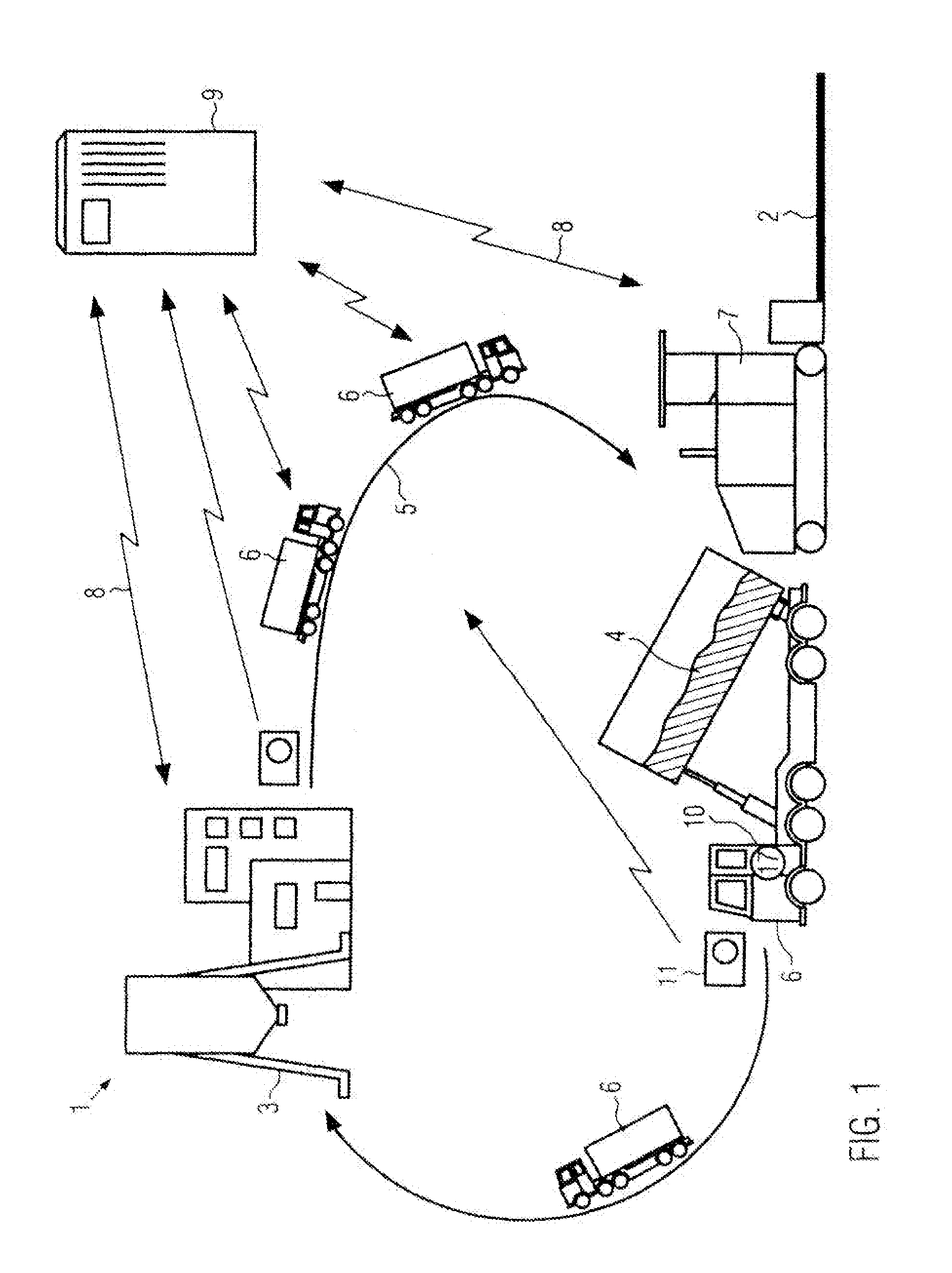

Method and system for applying a road surface

ActiveUS9011038B2Quality improvementSimple methodPaving detailsRoads maintainenceProduction rateRoad surface

A method and a system for applying a road surface using a mixing plant for producing laying material, a road finishing machine processing the laying material to a road surface, and a supply chain transporting the laying material from the mixing plant to the road finishing machine. Request commands are transmitted from the road finishing machine to the mixing plant and / or to the supply chain, and, depending on these request commands, the production rate of the laying material in the mixing plant, the temperature of the laying material produced in the mixing plant, and / or the mass flow of laying material supplied to the road finishing machine per time unit by means of the supply chain are adjusted.

Owner:JOSEPH VOEGELE AG

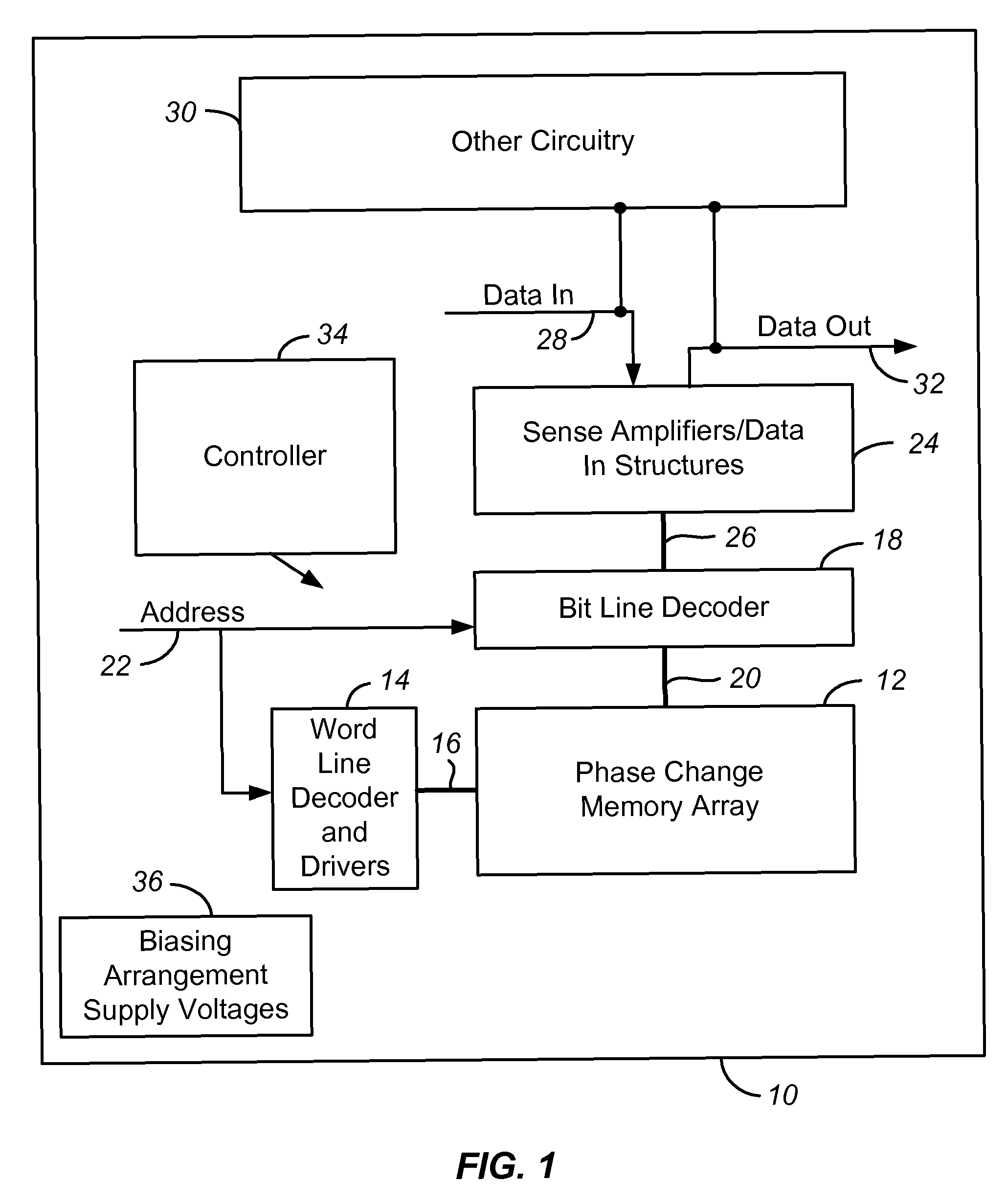

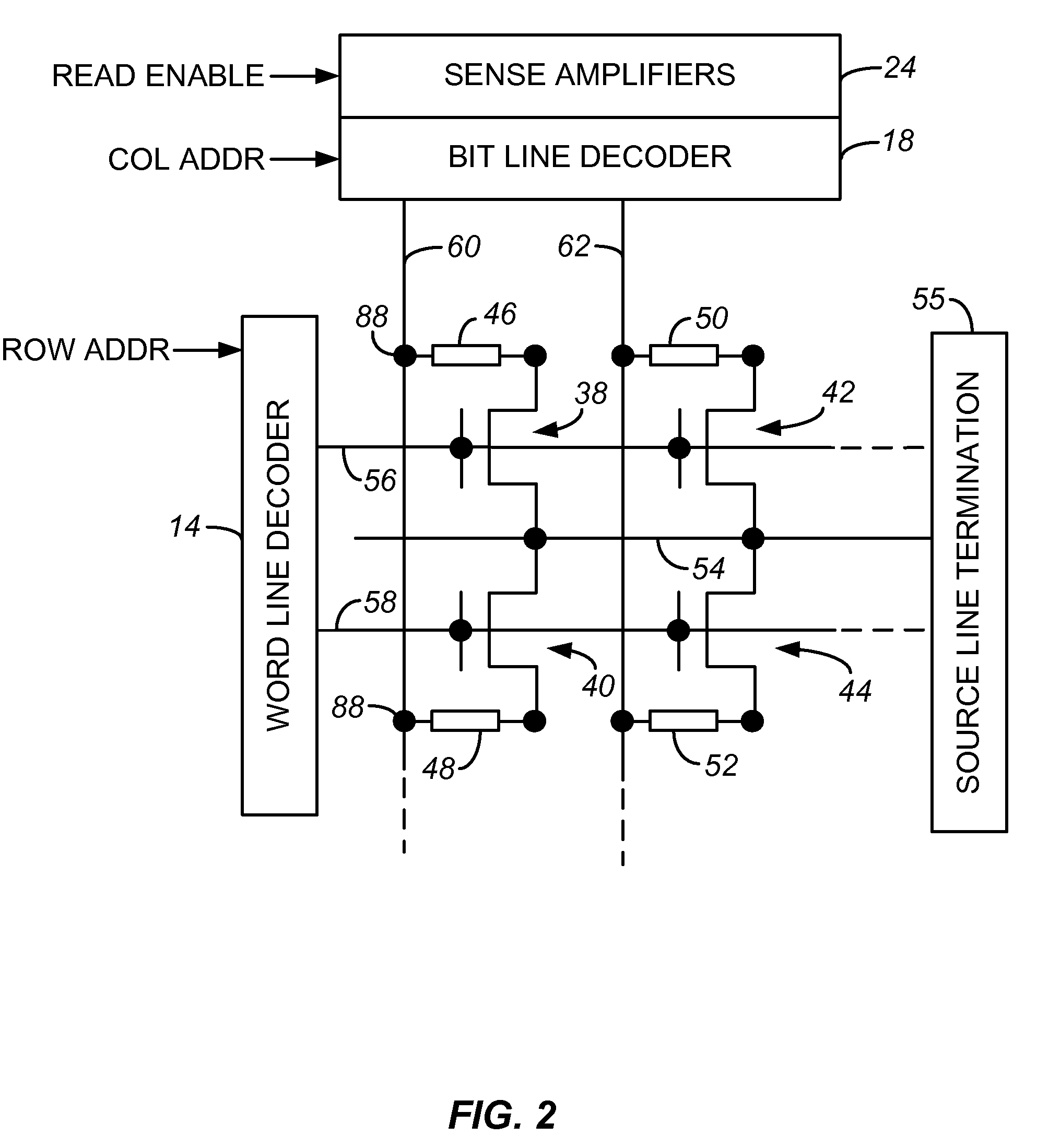

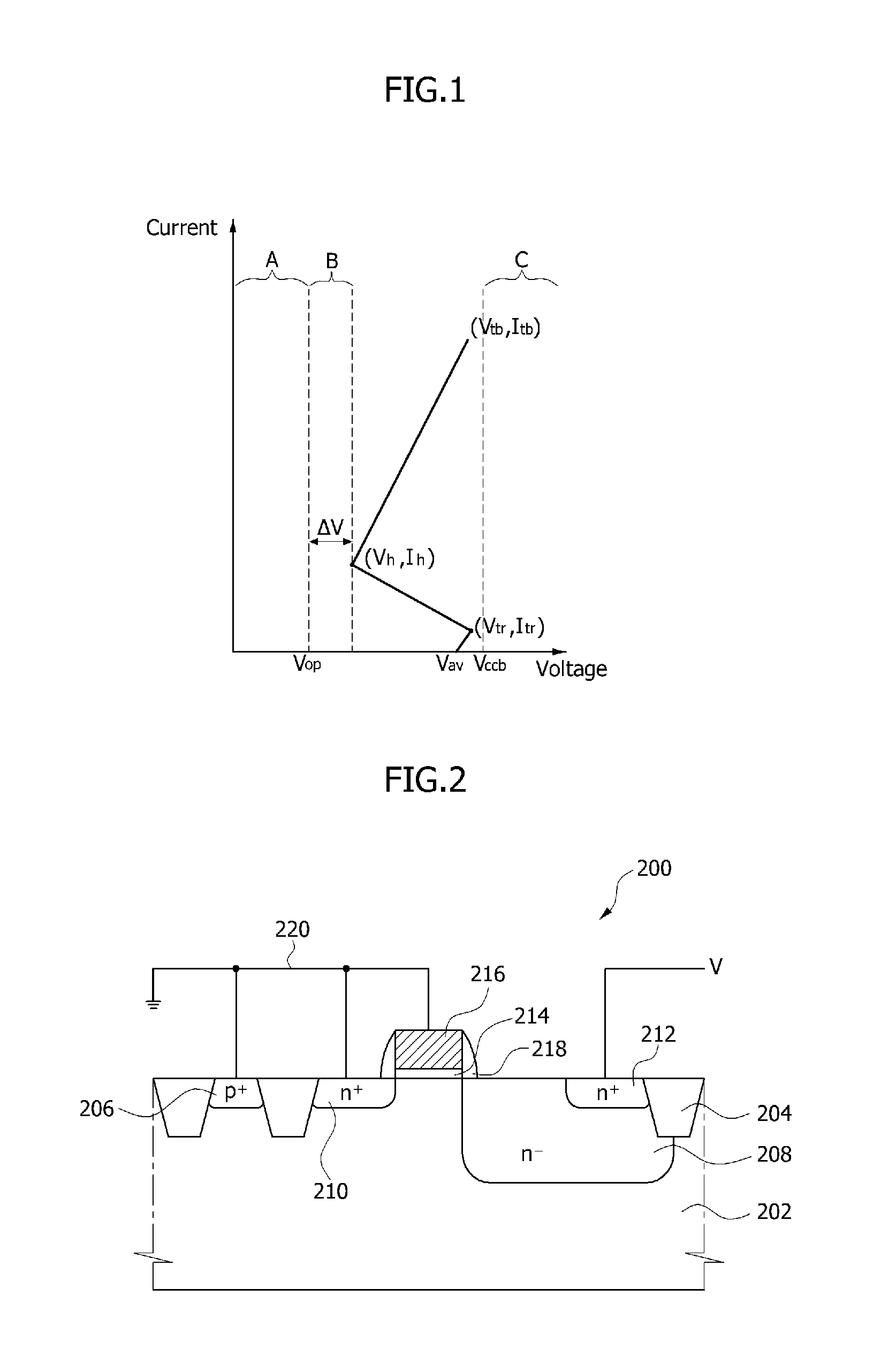

Nonvolatile Memory Device and Fabrication Method Thereof

ActiveUS20080083916A1Unified operationStable levelSemiconductor/solid-state device manufacturingDigital storageEngineeringNon-volatile memory

Owner:SK HYNIX INC

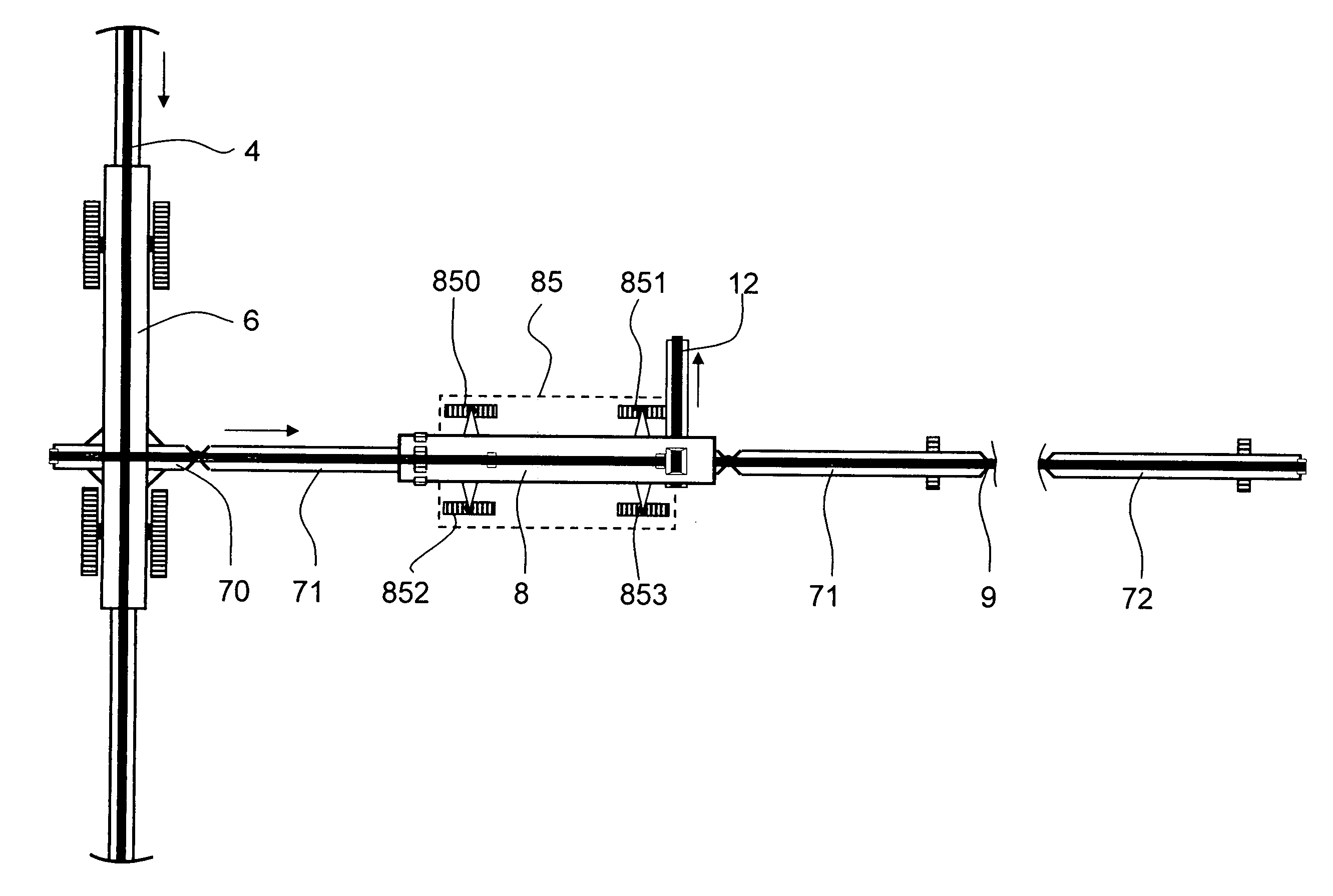

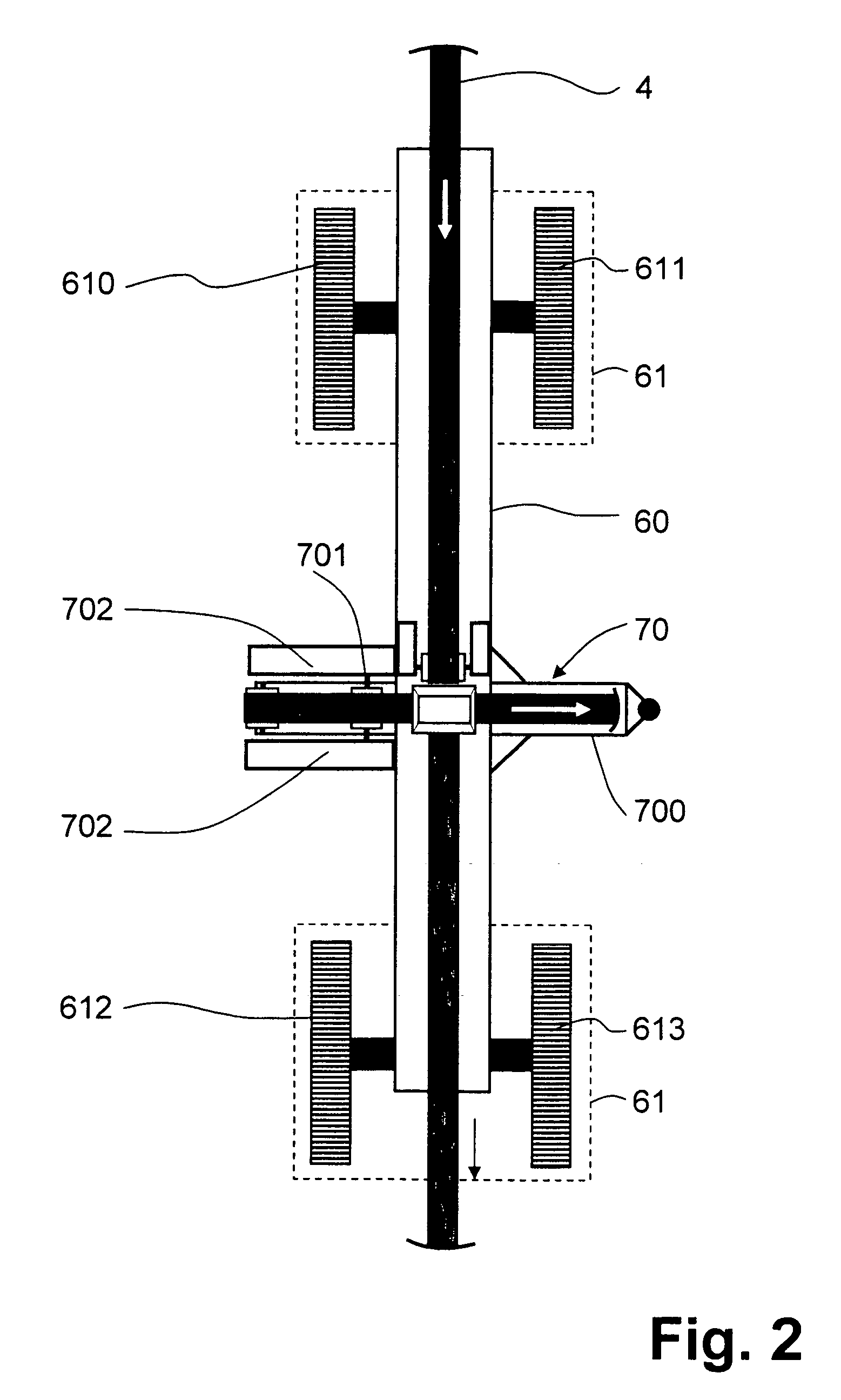

Movable belt conveyor system

ActiveUS7191888B2Reduce weightUsed economicallyUnderground miningSoil-shifting machines/dredgersSurface pressureCopper

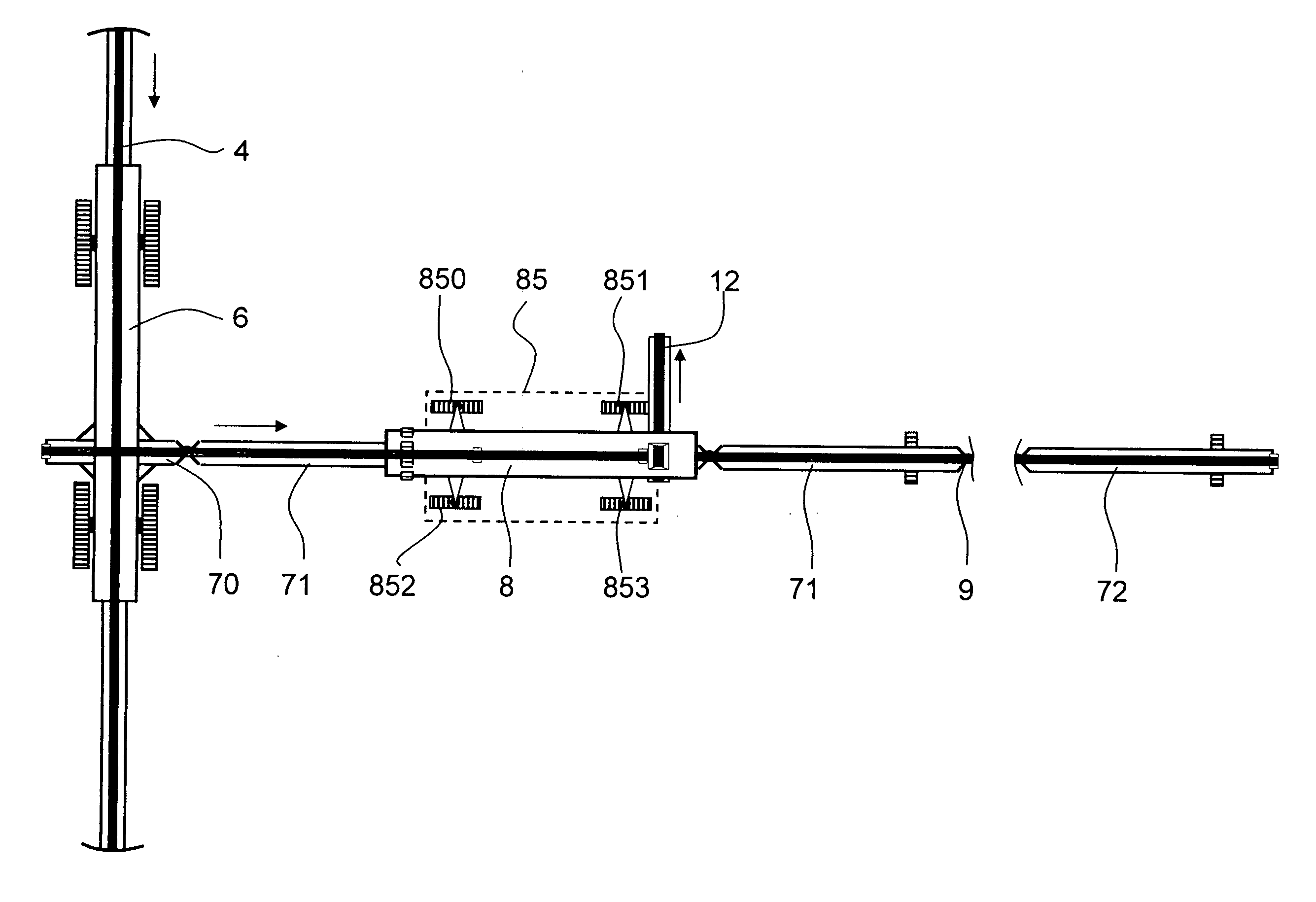

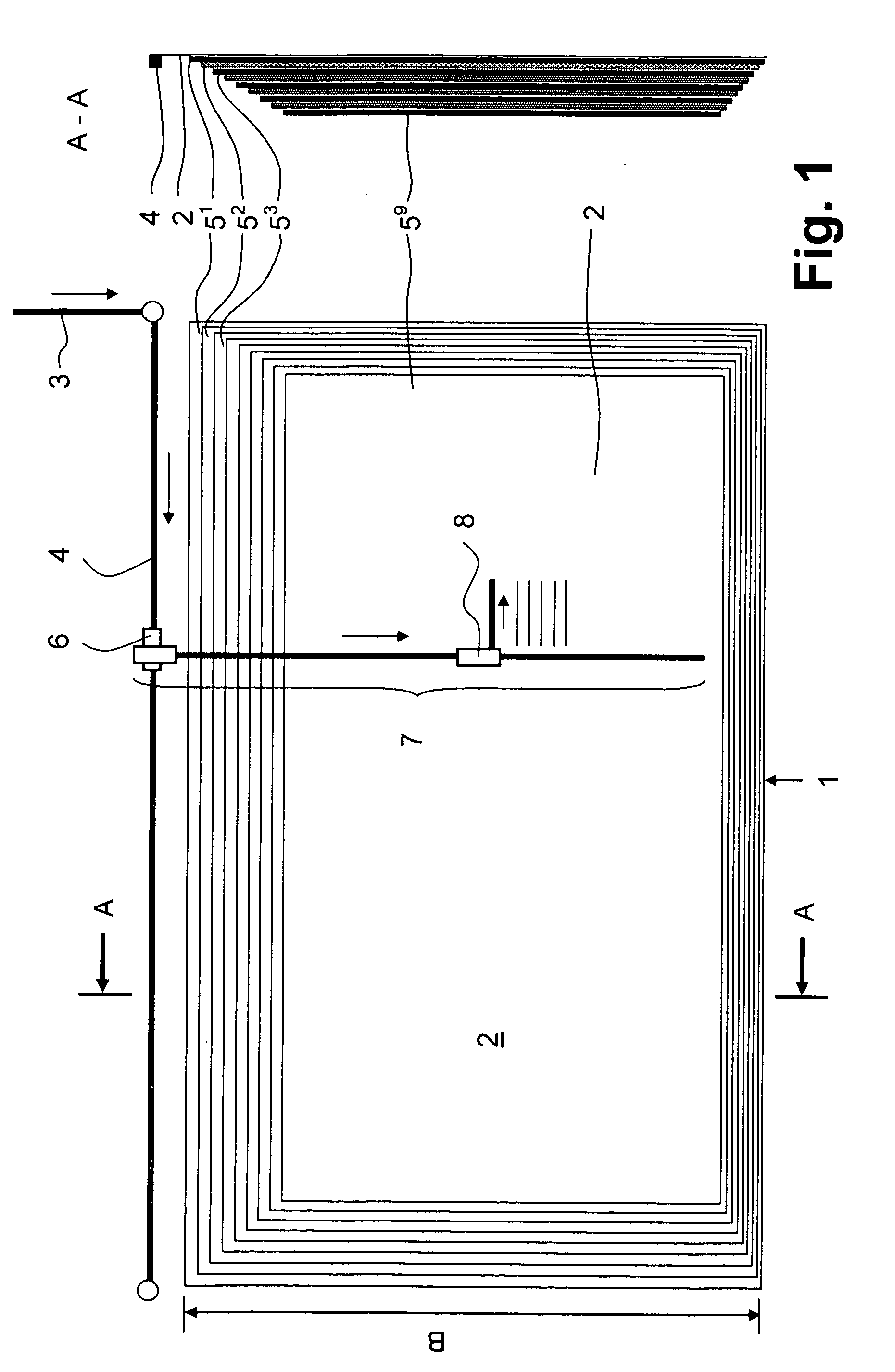

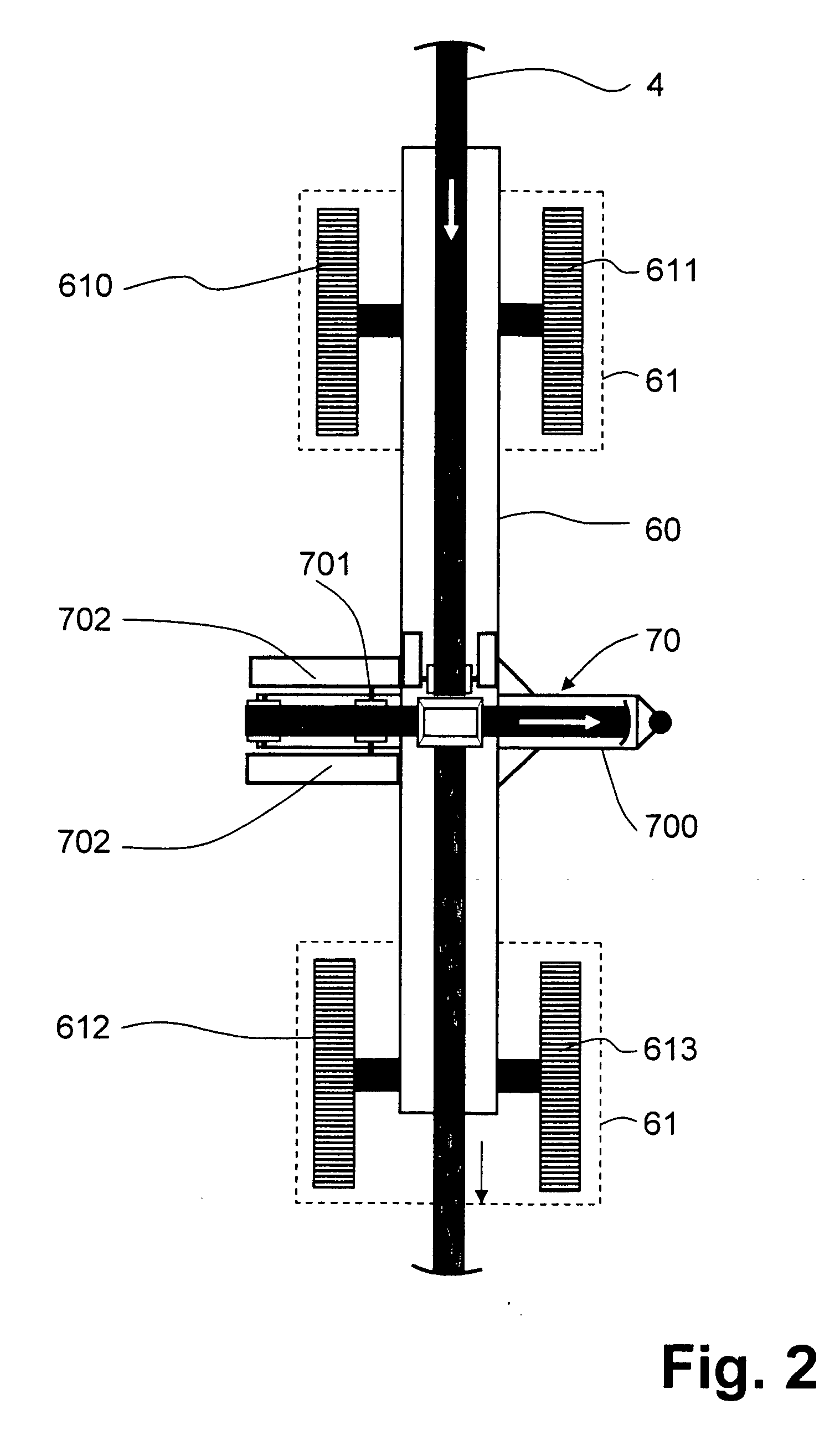

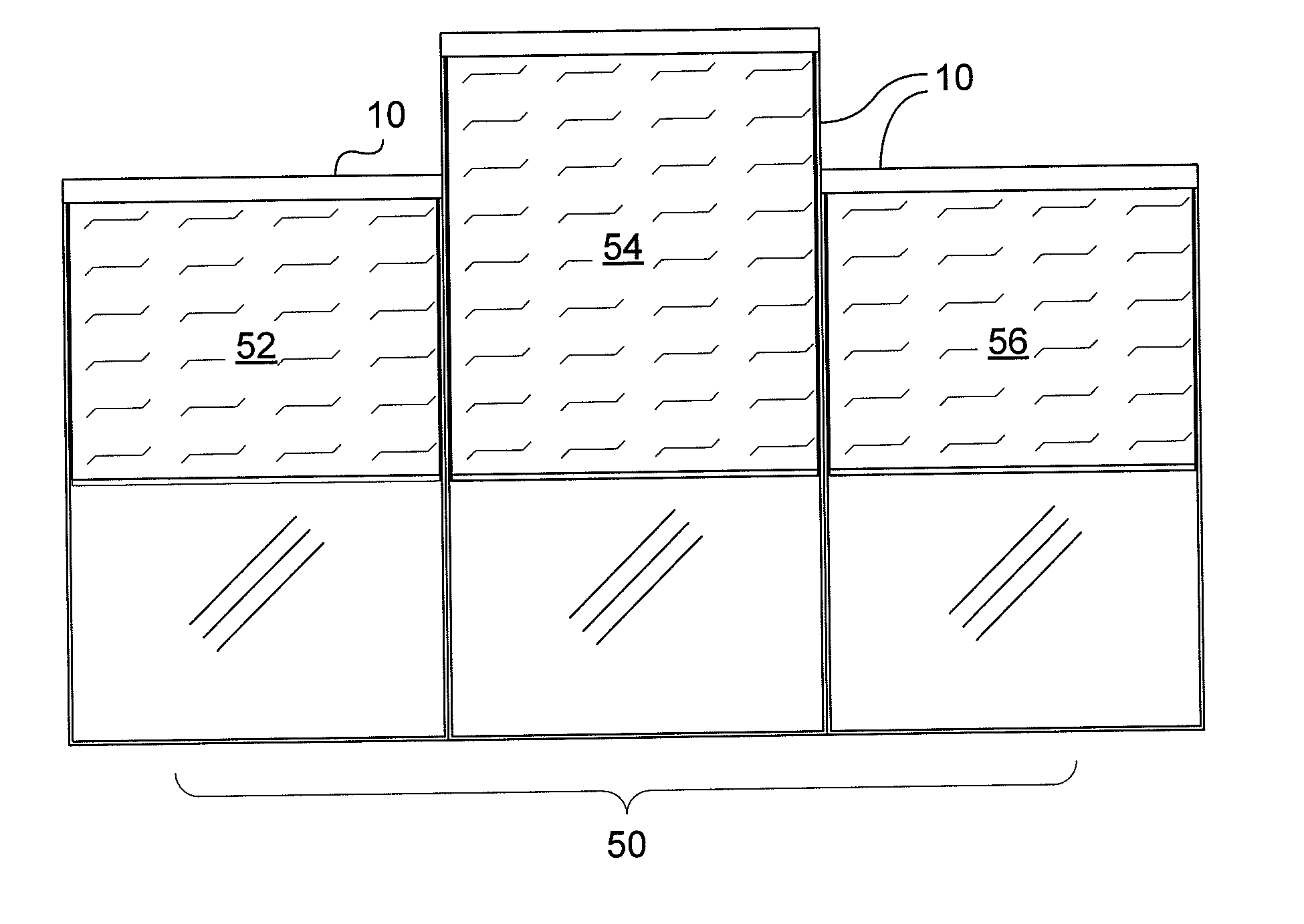

A movable belt conveyor system for a leach pad for use for sulfidic copper ore, where favorable conditions are to be generated for leaching out the copper by a slight compaction of the ore piled up into a dump for the microbiological leaching technology. The movable belt conveyor system of a length of up to several km is composed of a plurality of smaller belt segments, comprising a tail segment (70), standard segments (711-n) and a head segment (72), as well as a traveling tripper (8). To prevent the loading by these individual components from being excessively compacted by the weight of the device during multiple travel over the dump during the moving process, the belt drives with the driving drum are accommodated in the tail element (70), which is supported on the soil next to the leach pad. In addition, the traveling tripper (8) is designed as an independent unit with the belt drums, additional belt drives and the belt-tensioning means, which unit is autarchically displaceable on a caterpillar-type moving gear (85) of its own. Due to the moving of the belt on the caterpillar-type moving gears of the standard segments (711-n), on the head segment (72) and on the traveling tripper (8) as well as due to the absorption of the weight of the tail segment (70) by the transfer carriage (6), the surface pressure acting locally on the dump is reduced and the compaction of the ore on the dump due to being traveled over by the belt conveyor system remains low. Traveling over with a moving device, which frequently happens with the use of a moving caterpillar, is eliminated.

Owner:MAN TAKRAF FORDERTECHN

Movable belt conveyor system

ActiveUS20070039802A1Reduce weightUsed economicallyUnderground miningSoil-shifting machines/dredgersEngineeringSurface pressure

A movable belt conveyor system for a leach pad for use for sulfidic copper ore, where favorable conditions are to be generated for leaching out the copper by a slight compaction of the ore piled up into a dump for the microbiological leaching technology. The movable belt conveyor system of a length of up to several km is composed of a plurality of smaller belt segments, comprising a tail segment (70), standard segments (711-n) and a head segment (72), as well as a traveling tripper (8). To prevent the loading by these individual components from being excessively compacted by the weight of the device during multiple travel over the dump during the moving process, the belt drives with the driving drum are accommodated in the tail element (70), which is supported on the soil next to the leach pad. In addition, the traveling tripper (8) is designed as an independent unit with the belt drums, additional belt drives and the belt-tensioning means, which unit is autarchically displaceable on a caterpillar-type moving gear (85) of its own. Due to the moving of the belt on the caterpillar-type moving gears of the standard segments (711-n), on the head segment (72) and on the traveling tripper (8) as well as due to the absorption of the weight of the tail segment (70) by the transfer carriage (6), the surface pressure acting locally on the dump is reduced and the compaction of the ore on the dump due to being traveled over by the belt conveyor system remains low. Traveling over with a moving device, which frequently happens with the use of a moving caterpillar, is eliminated.

Owner:MAN TAKRAF FORDERTECHN

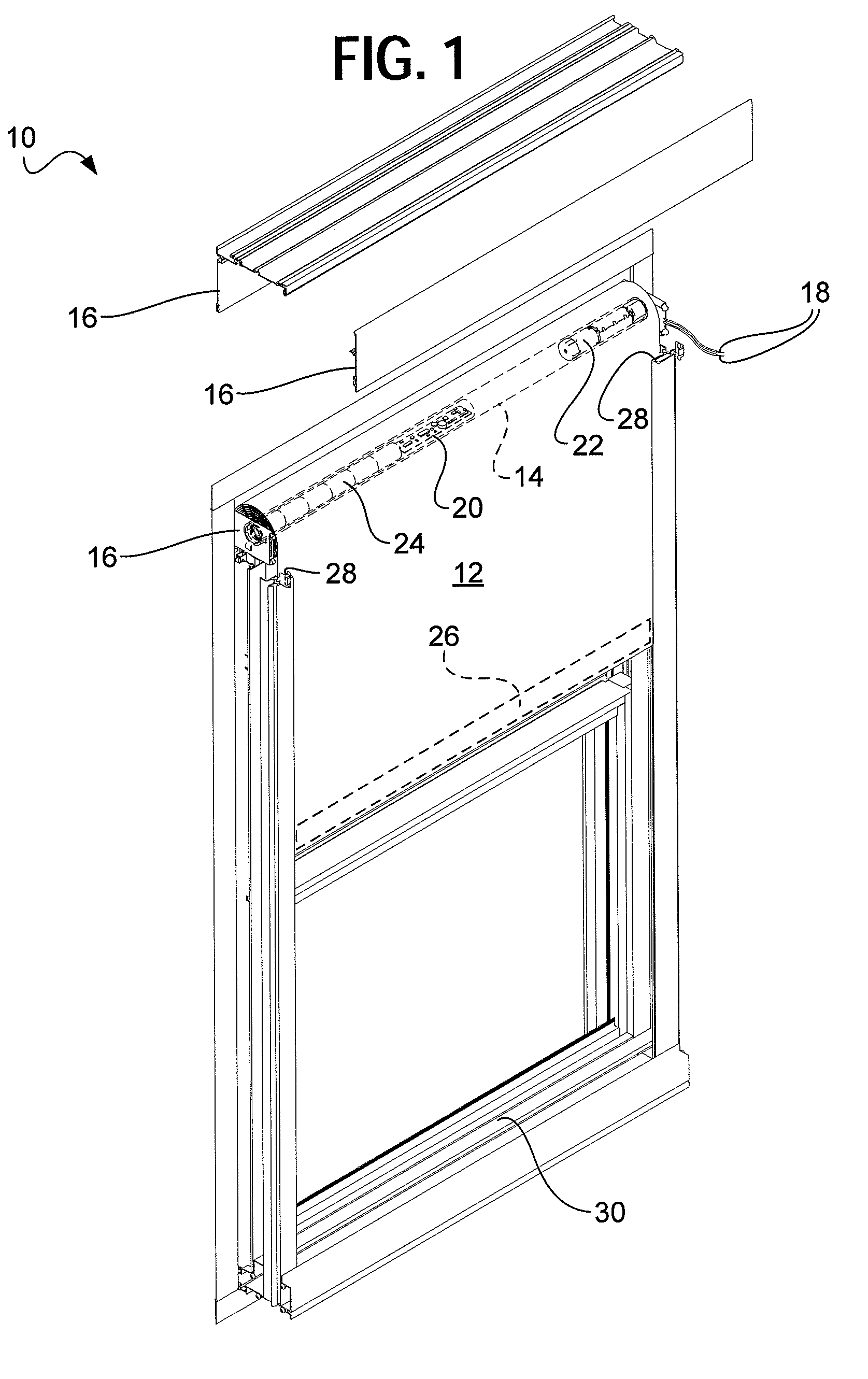

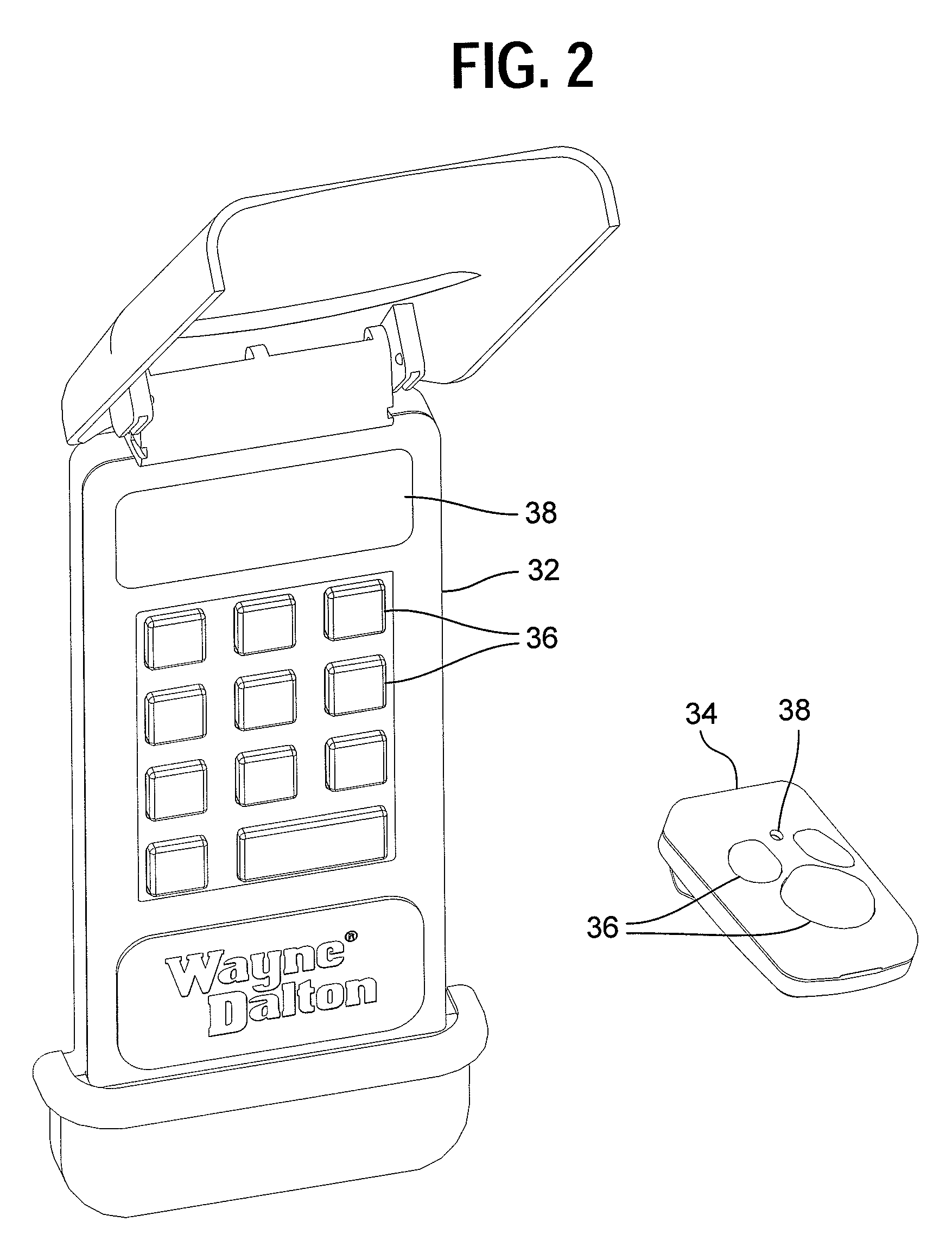

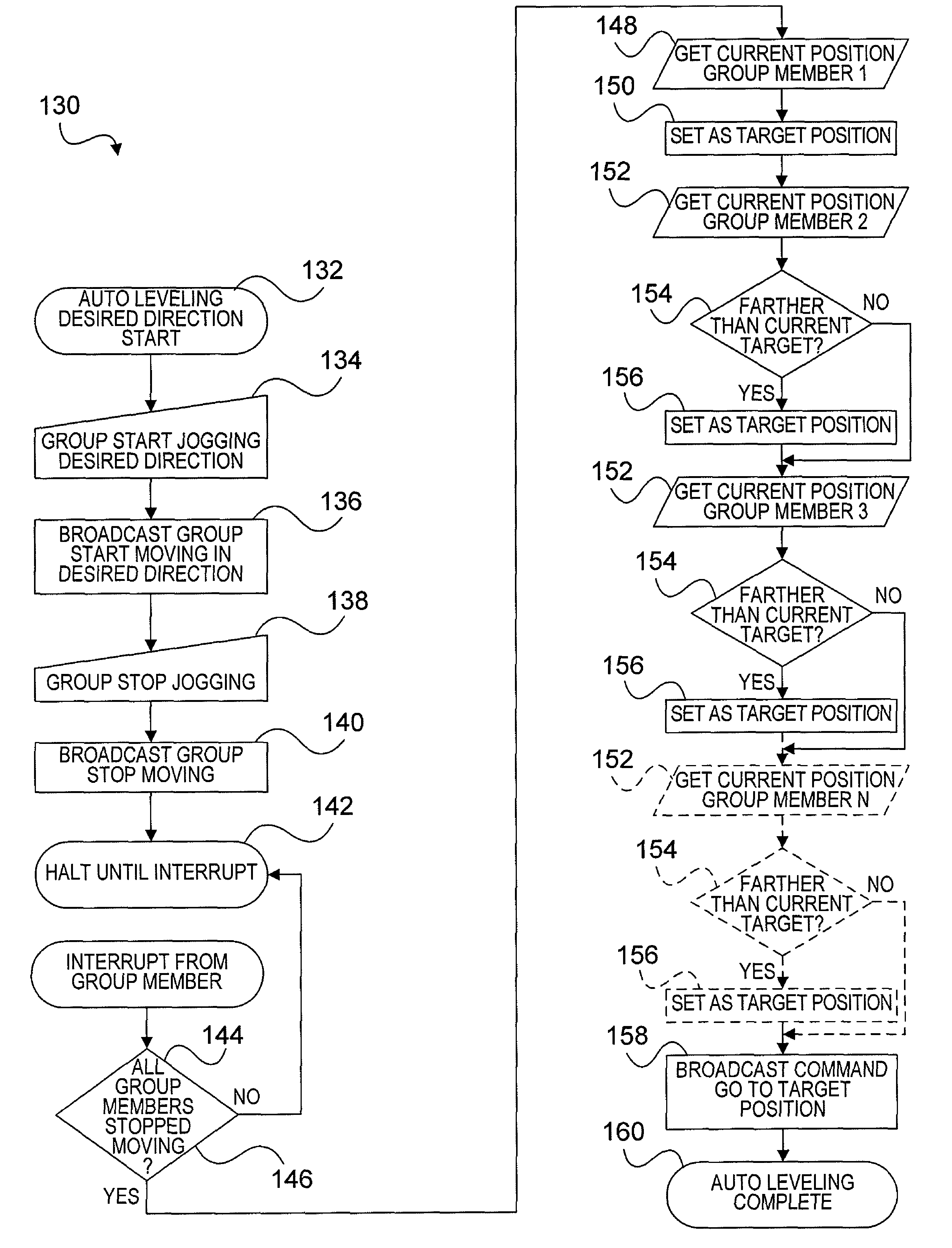

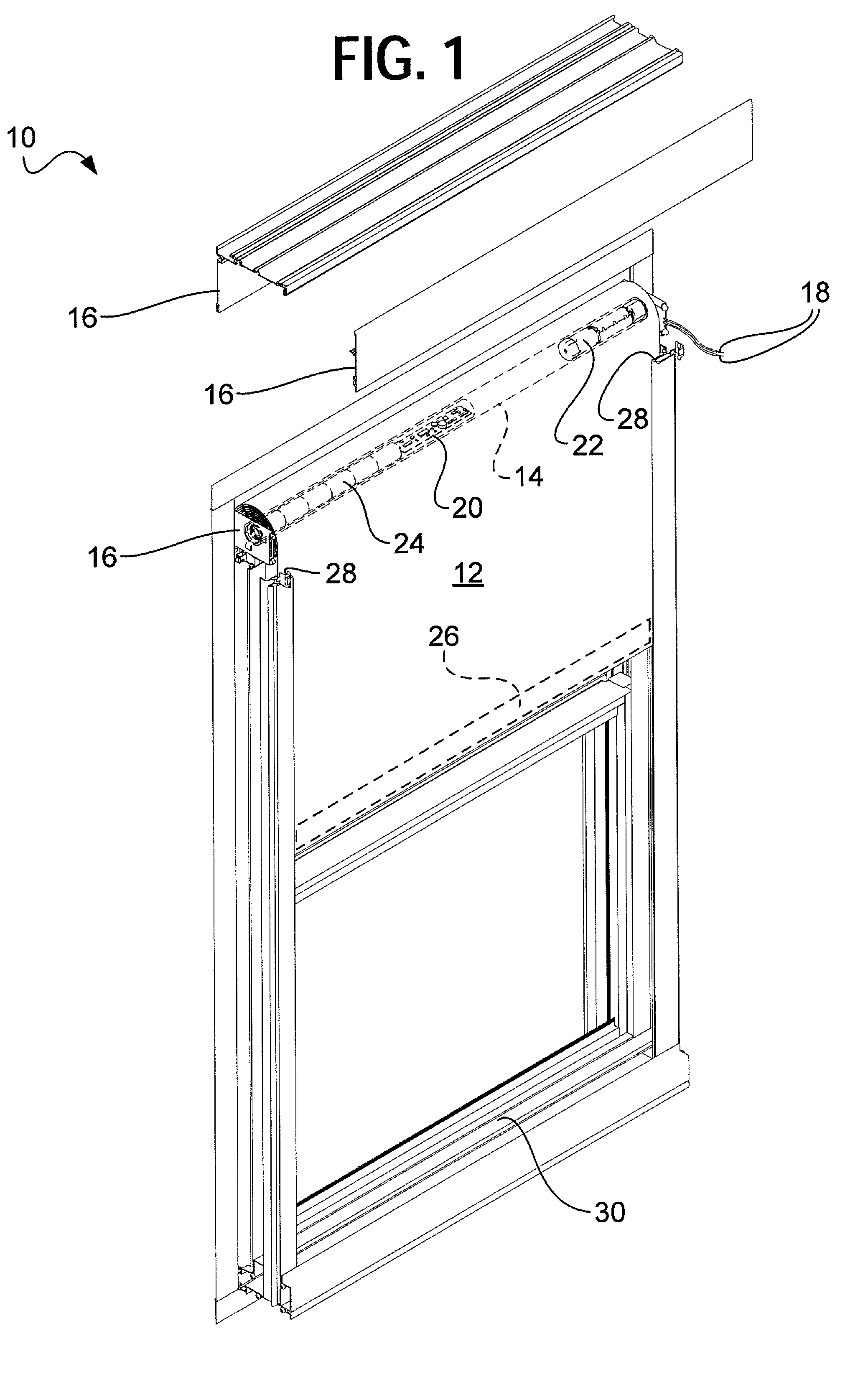

Control for positioning multiple barriers apparatus and method

InactiveUS20100087958A1Uniform net operationEasy to operate and controlDC motor speed/torque controlDoor/window protective devicesTransceiverEngineering

A control routine for groups of remotely controlled, variable-position, position-aware, transceiver-equipped actuators manages data discrepancies by issuing a first set of generic actuation commands to start and stop the actuators, then polling the actuators to report their achieved positions. The routine then applies a rule to determine a preferred position value from among the reports and issues a second set of position-specific actuation commands to all of the actuators. The routine can further poll the actuators to confirm the extent to which the commands have been realized, and can retain and apply compensation factors for performance deviations in the individual actuators. The routine can further manage multiple groups of actuators, dissimilar activators within groups, assignment of an actuator to more than one group, and application of variable control factors as inputs modifying the rule applied by the routine for determining the commands to be issued.

Owner:THE WATT STOPPER

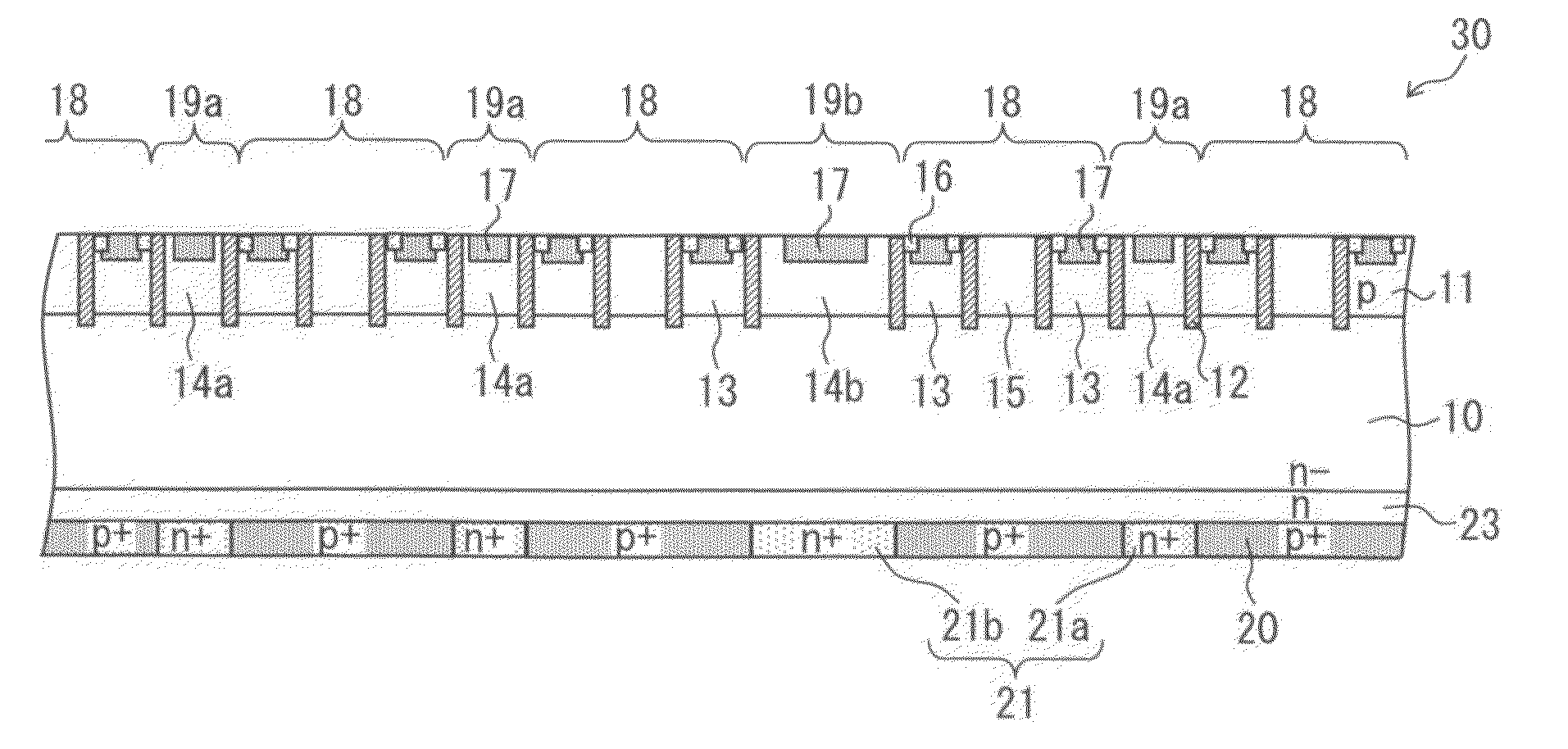

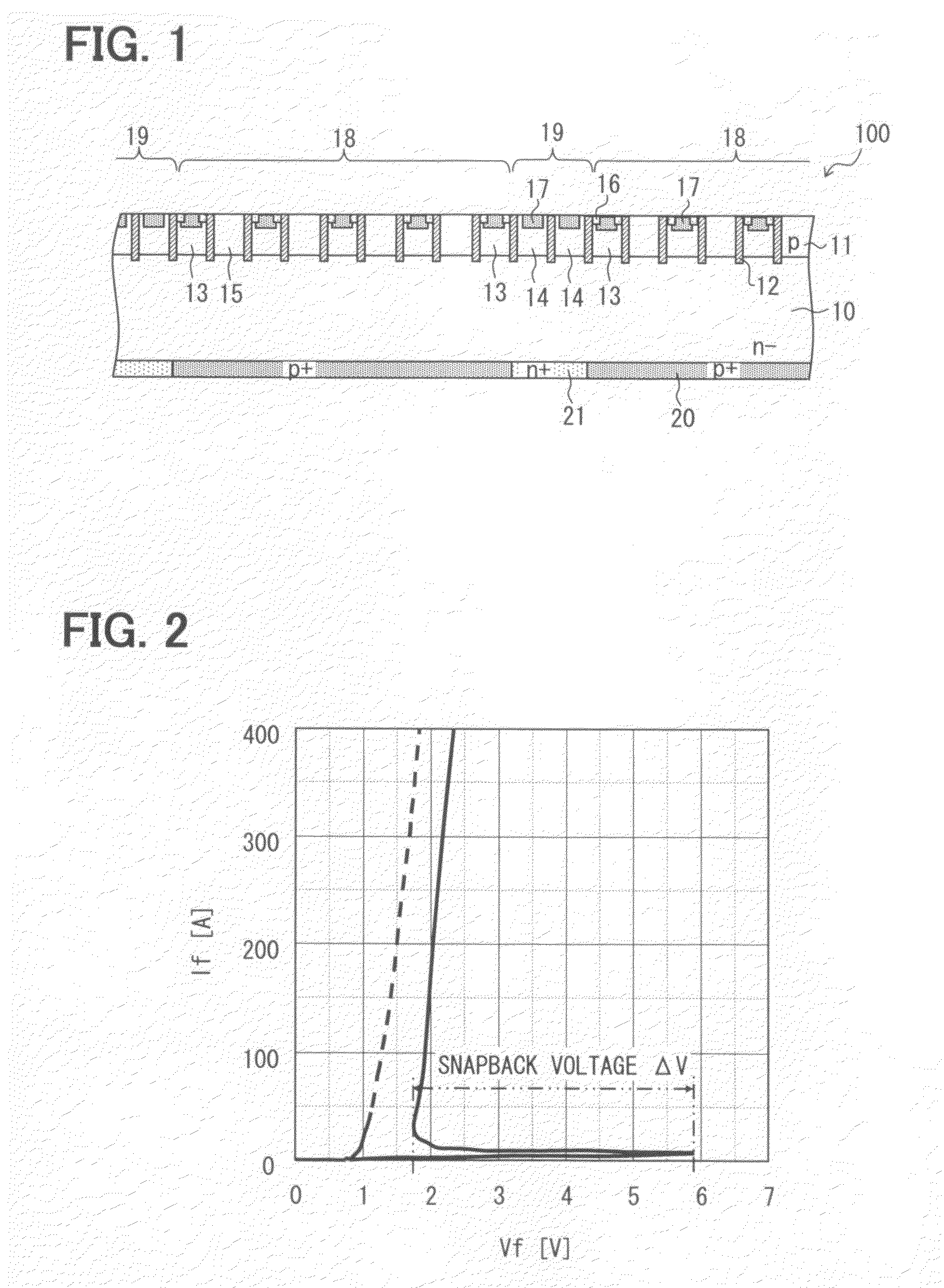

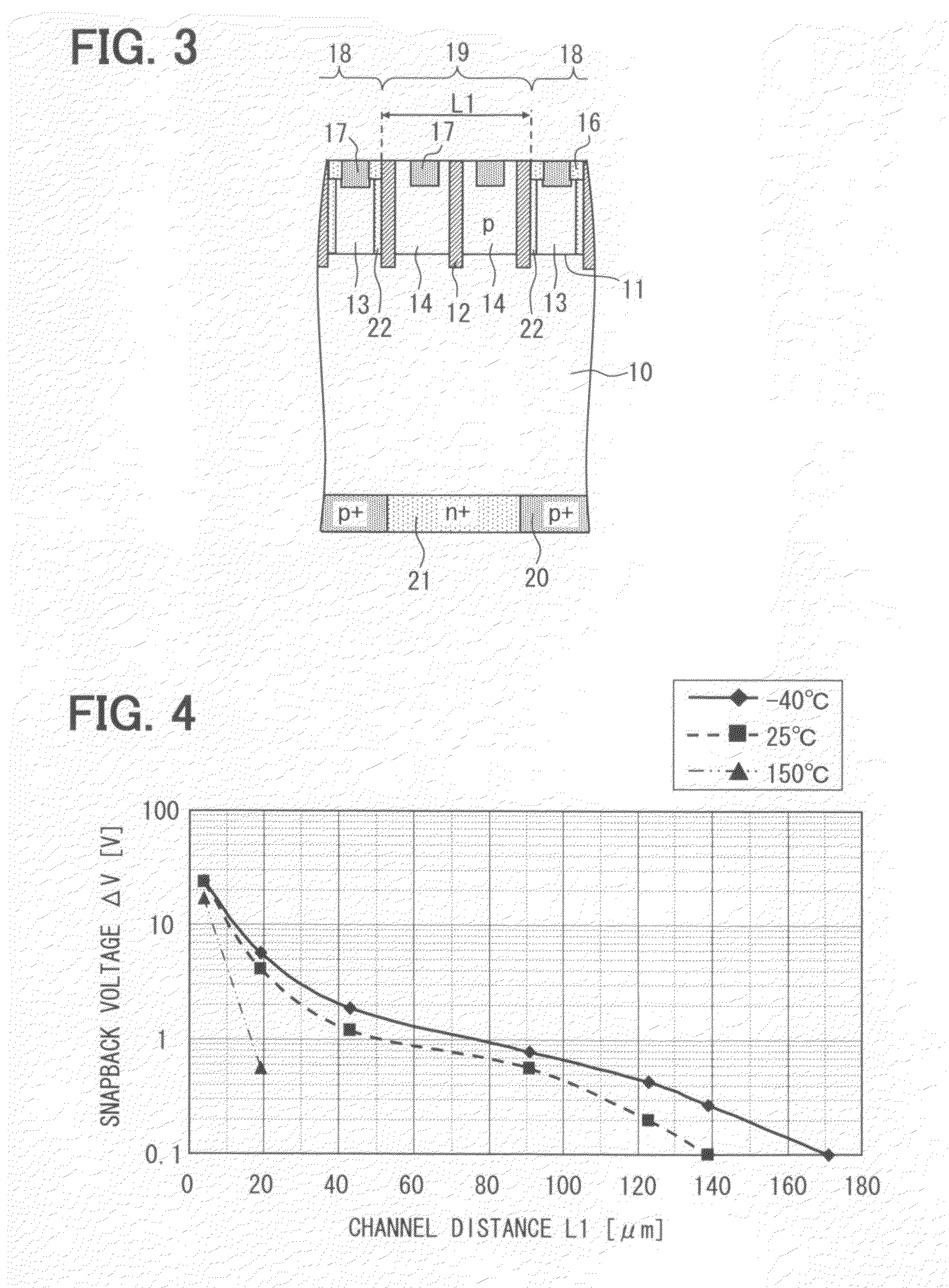

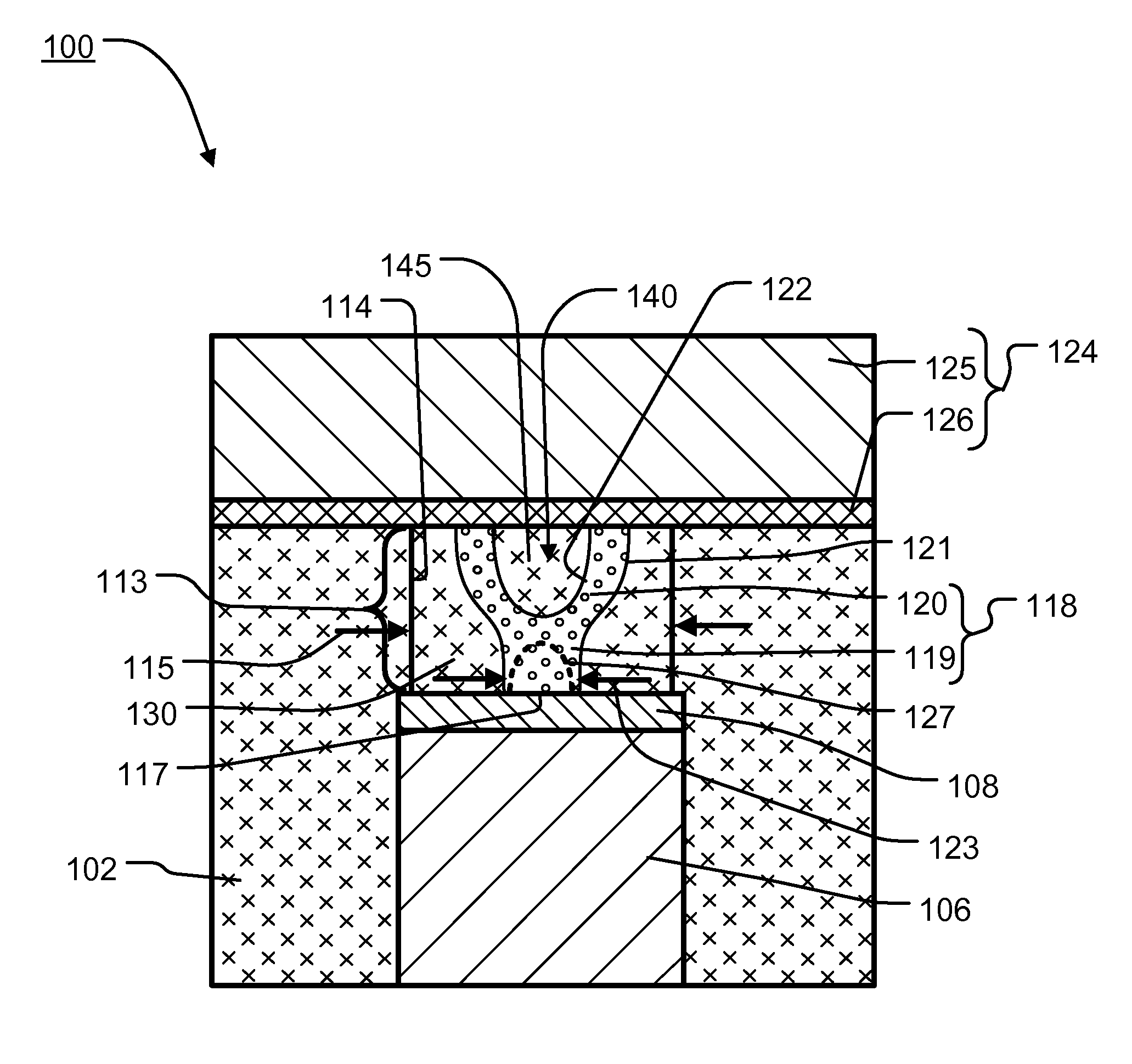

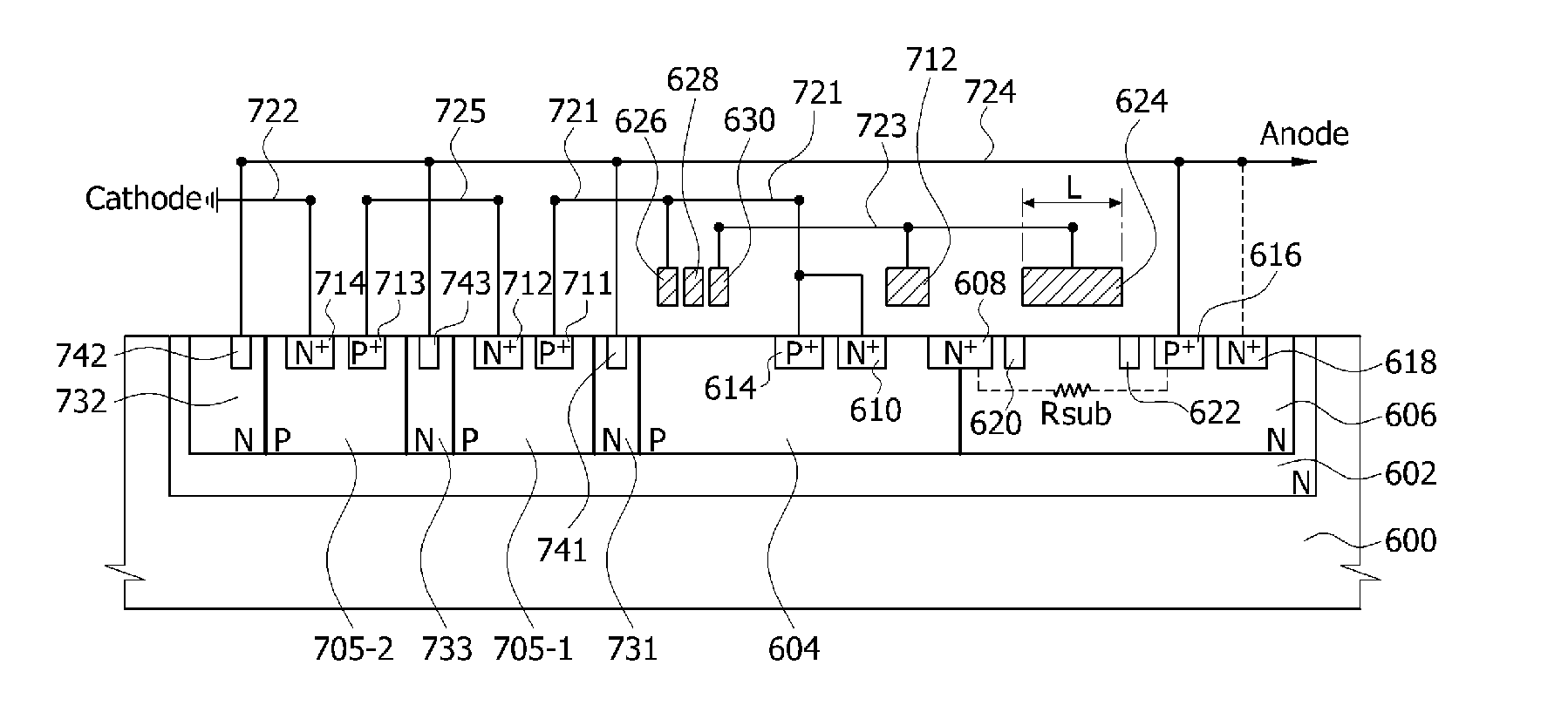

Semiconductor device including insulated gate bipolar transistor and diode

ActiveUS8080853B2Snapback of the FWD can be reducedUnified operationTransistorSolid-state devicesParasitic bipolar transistorEngineering

A semiconductor device includes a vertical IGBT and a vertical free-wheeling diode in a semiconductor substrate. A plurality of base regions is disposed at a first-surface side portion of the semiconductor substrate, and a plurality of collector regions and a plurality of cathode regions are alternately disposed in a second-surface side portion of the semiconductor substrate. The base regions include a plurality of regions where channels are provided when the vertical IGBT is in an operating state. The first-side portion of the semiconductor substrate include a plurality of IGBT regions each located between adjacent two of the channels, including one of the base regions electrically coupled with an emitter electrode, and being opposed to one of the cathode regions. The IGBT regions include a plurality of narrow regions and a plurality of wide regions.

Owner:DENSO CORP

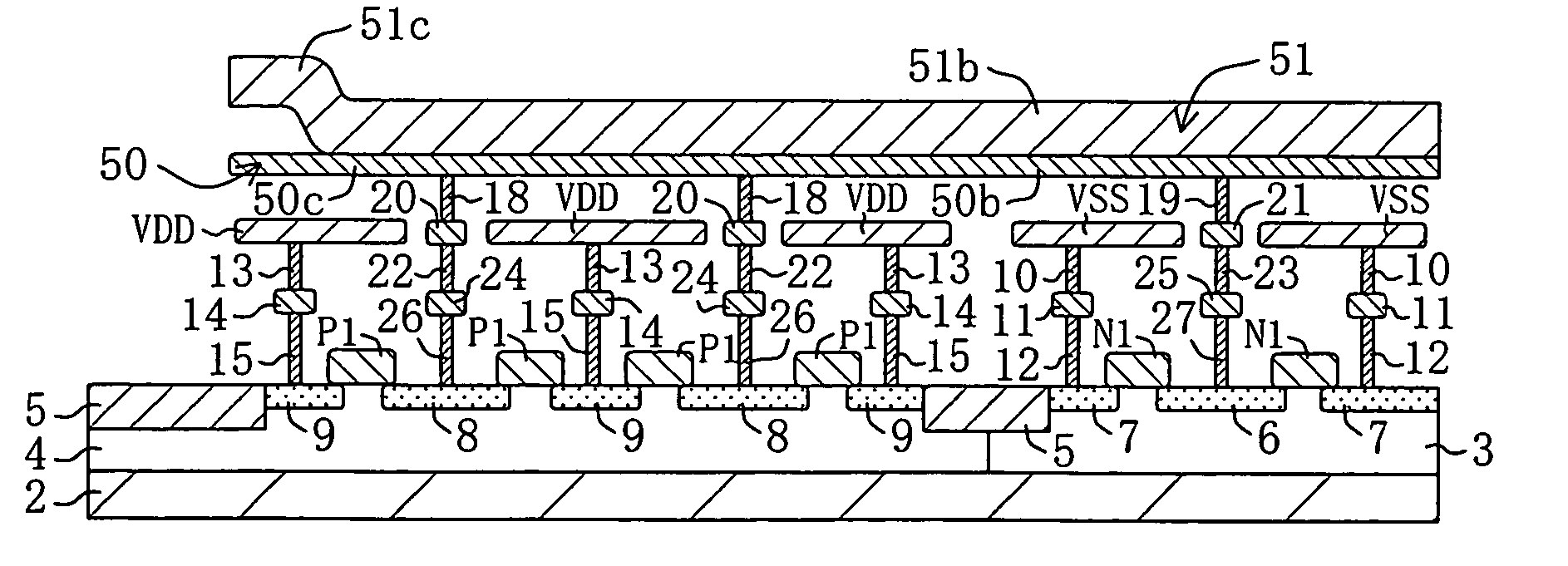

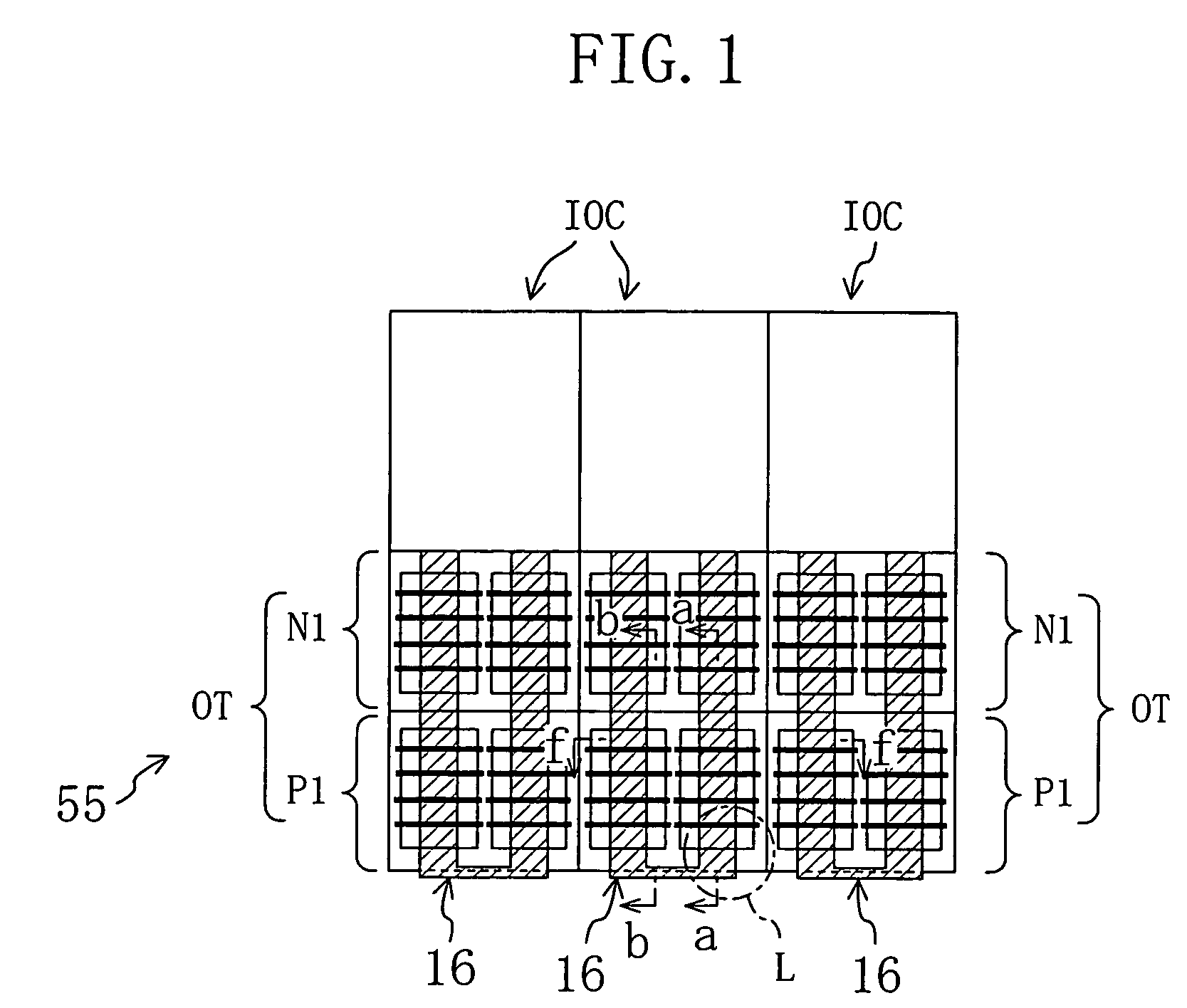

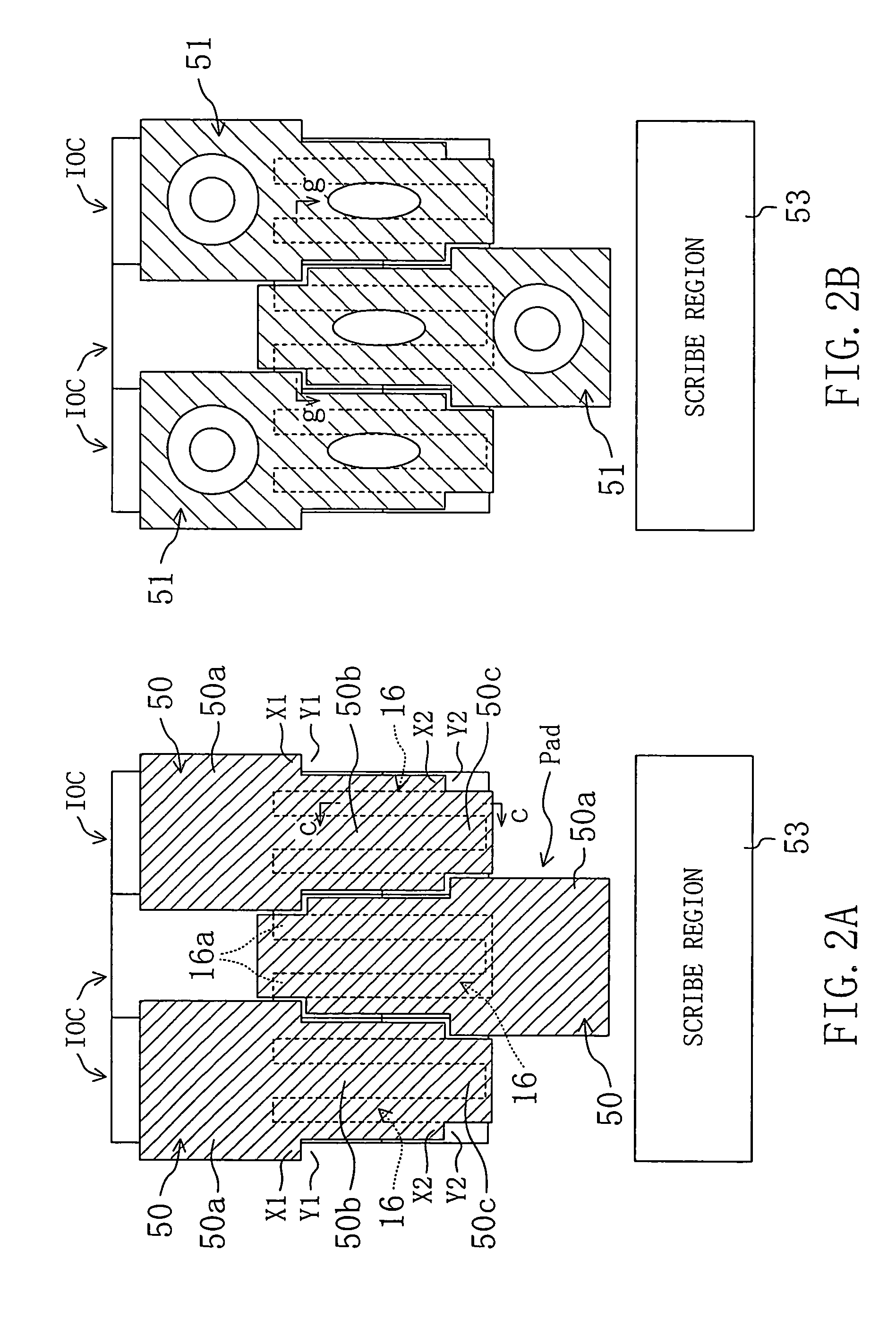

Semiconductor device

ActiveUS6992356B2Good for power supplySmall widthSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsElectrostatic dischargeSemiconductor chip

In an I / O circuit unit located in the periphery of a semiconductor chip, a plurality of ESD protection transistors are provided in each I / O cell. An electrode pad cell has a two-layer structure including a lower electrode pad and an upper electrode pad. The electrode pad cell is arranged so as to be present over a connection line of ESD protection transistors of an associated I / O cell. With part of the first pad portion of an adjacent electrode pad located in an end portion of the second pad portion of the electrode pad, the second pad portion can not extend further onward but the third pad portion having a smaller width than that of the second pad portion is arranged onward. Thus, destruction of the ESD protection transistors is not caused, so that an internal circuit is protected from an electrostatic discharge which comes into electrode pads.

Owner:SOCIONEXT INC

Phase change memory cell with filled sidewall memory element and method for fabricating the same

ActiveUS7884343B2Reduce the amount requiredWeakening rangeSolid-state devicesSemiconductor/solid-state device manufacturingPhase-change memoryFilling materials

Owner:MACRONIX INT CO LTD

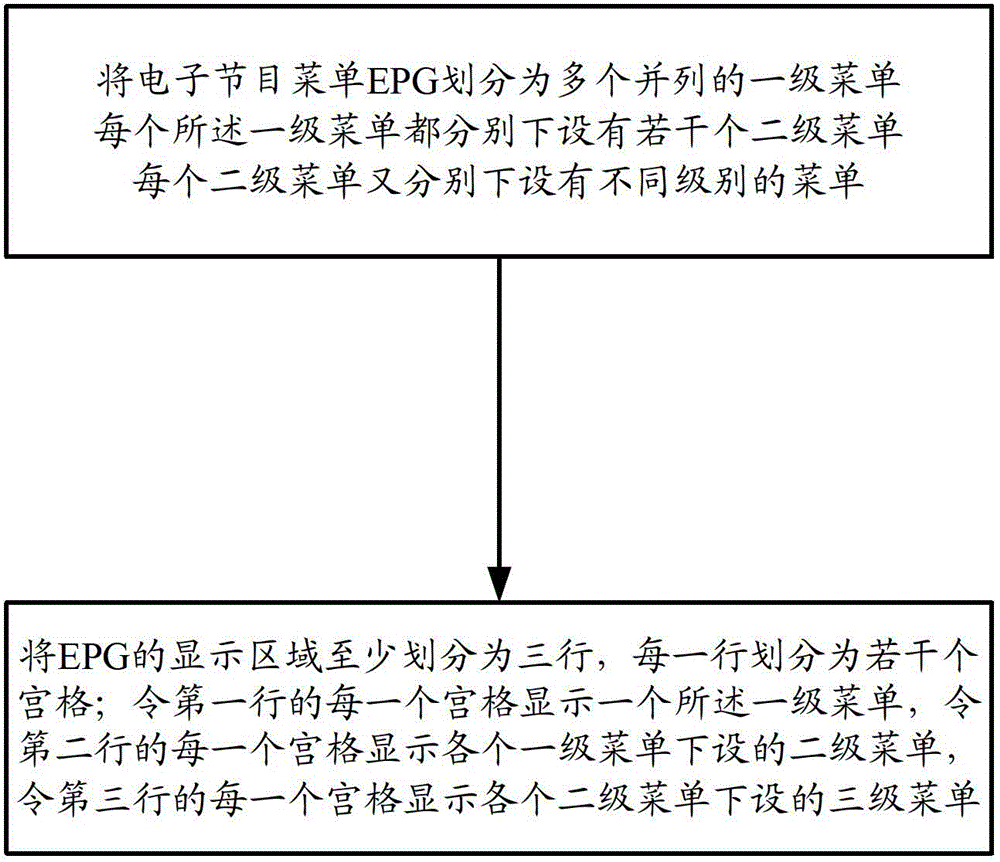

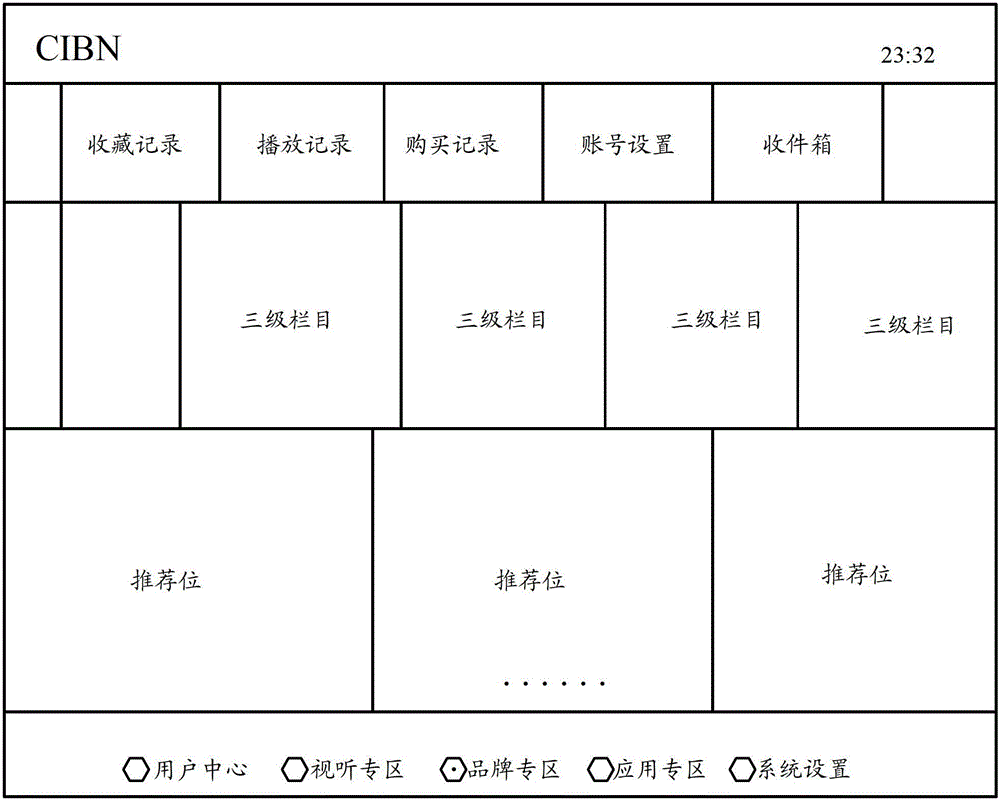

Display method of electronic program guide

InactiveCN102752655AInteraction does not changeUnified InteroperabilitySelective content distributionThree levelComputer science

The invention discloses a display method of an electronic program guide. The display method includes dividing the electronic program guide (EPG) into a plurality of first-level guides in parallel, enabling each first-level guide to be provided with a plurality of second-level guides and each second-level guide to be provided with guides in different levels, dividing a display area of the EPG into at least three rows, dividing each row into a plurality of cases, enabling each case in the first row to display one first-level guide, enabling each case in the second row to display the second-level guides of each first-level guide and enabling each case in the third row to display three-level guides of each second-level guide. By means of the technical scheme, users can change arrangement of the EPG at will and insert or delete case content at will to combine new content without damaging the whole content framework. Focus movement cannot change with change of pages, so that form correcting efficiency is greatly improved.

Owner:国广东方网络(北京)有限公司

Nonvolatile memory device and fabrication method thereof

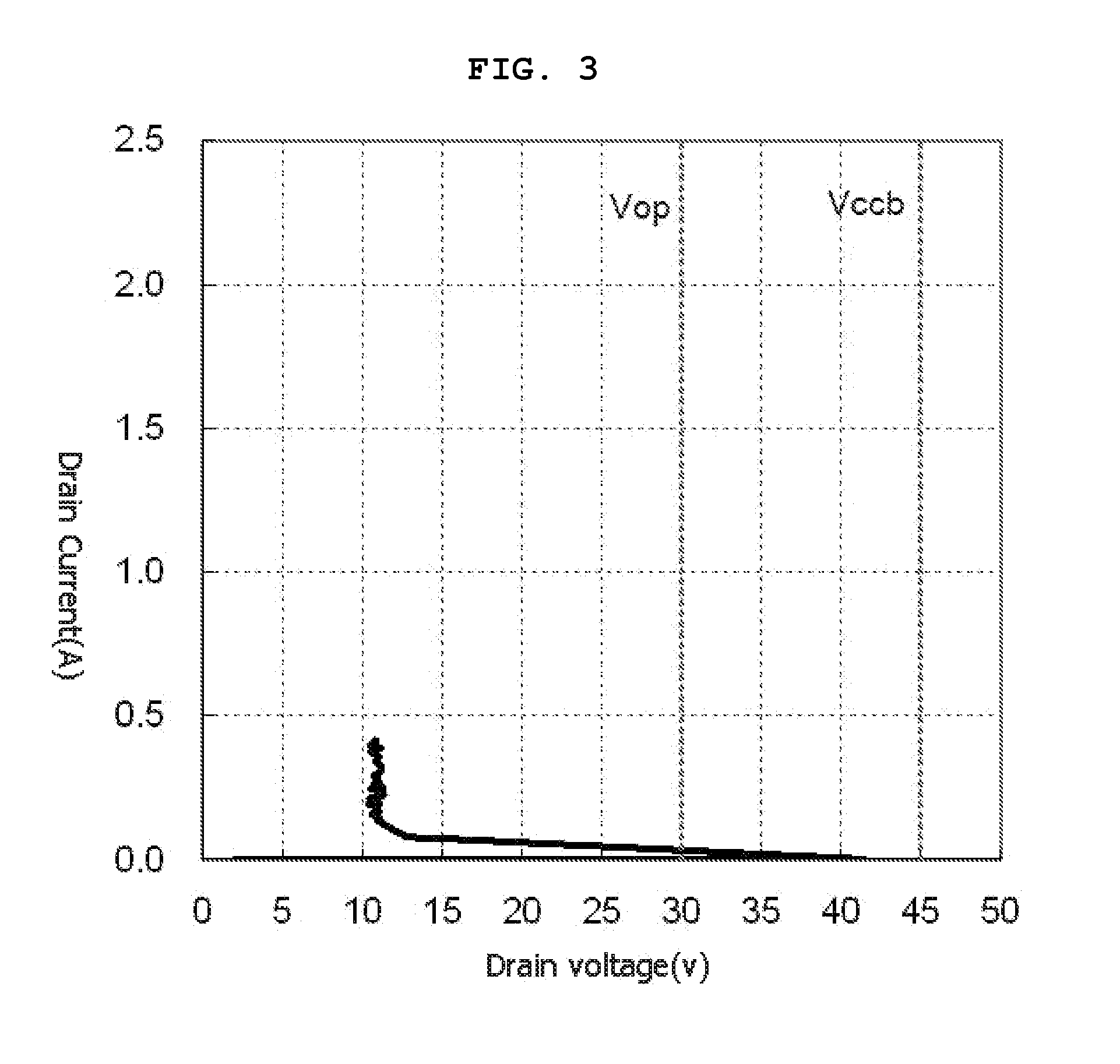

ActiveUS7615769B2Unified operationStable levelDigital storageBulk negative resistance effect devicesNon-volatile memoryVoltage

Owner:SK HYNIX INC

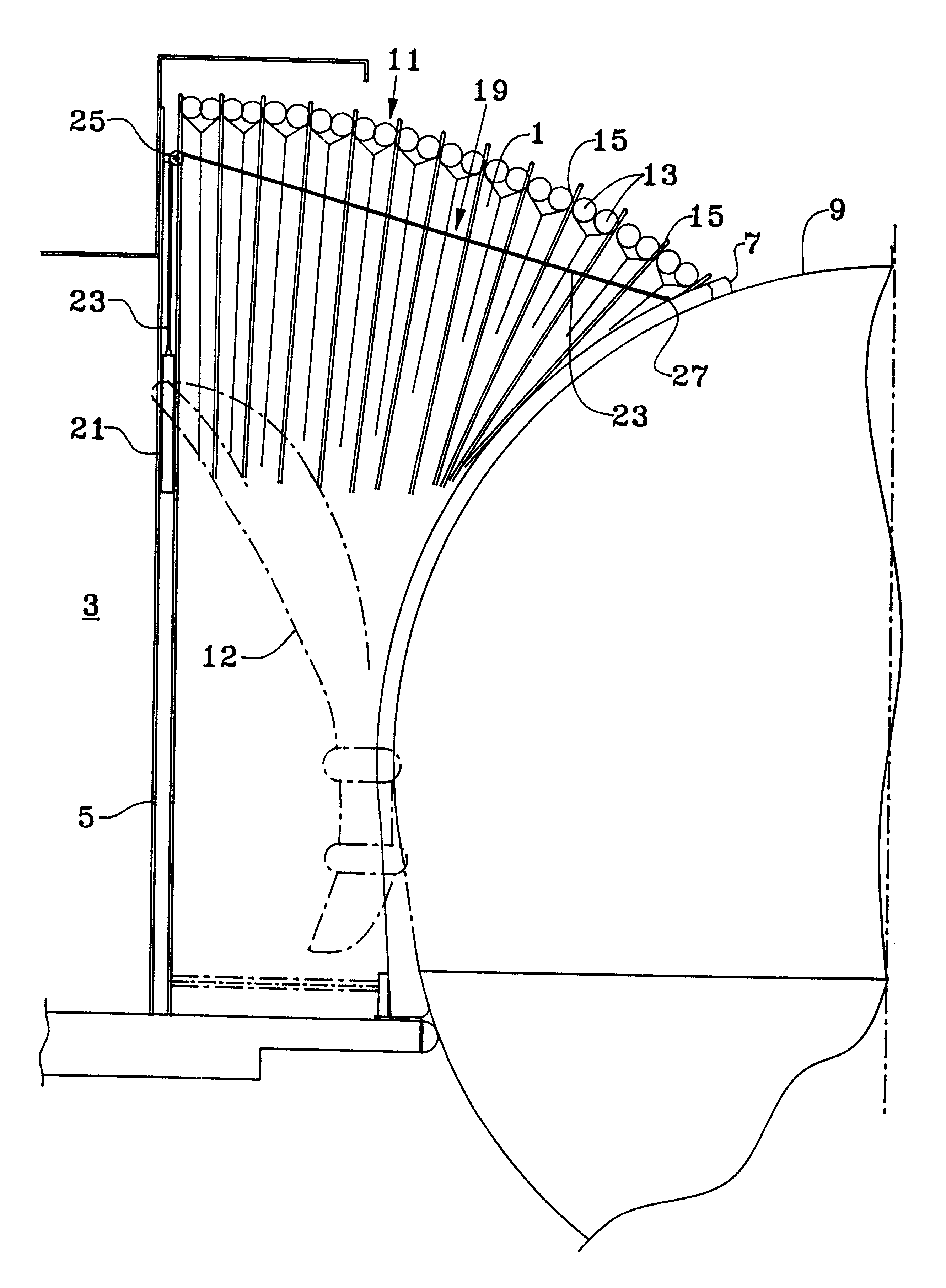

Bipolar transistor and power amplifier

ActiveUS20070012949A1Evenly heatedImprove featuresSemiconductor/solid-state device manufacturingSemiconductor devicesAudio power amplifierEngineering

A base mesa finger (an emitter ledge layer 15, a base layer 16, and a collector layer 17) is interposed between two collector fingers (collector electrodes 13), and on the base mesa finger, a base finger (a base electrode 12) and two emitter fingers (an emitter layer 14 and an emitter electrode 11) on both sides of the base finger, are formed. The two emitter fingers are formed symmetric with respect to the base finger as a reference.

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

Bellows and corridor for access to airplanes

InactiveUS6418582B1Improve sealingEasy maintenancePassenger handling installationsBridgesLongitudinal planeEngineering

A bellows for an airplane boarding corridor for passengers, and a corridor including such bellows. A bellows actuator device of the invention has chambers that can be inflated and deflated on command to enable the bellows to be extended and to allow the bellows to be retracted, and it also returns the bellows to the retracted condition. Advantageously, the inflatable chambers of the actuator device of the invention form at least two rows of tubes disposed symmetrically or substantially symmetrically about a longitudinal plane of symmetry of the bellows, each row being individually inflatable. The present invention is mainly applicable to making equipment, in particular weatherproofing bellows, for airport boarding corridors for passengers.

Owner:LE JOINTS FRANCAIS SA

Control for positioning multiple barriers apparatus and method

InactiveUS8065039B2Unified operationEasy to operate and controlDC motor speed/torque controlDoor/window protective devicesEngineeringActuator

Owner:THE WATT STOPPER

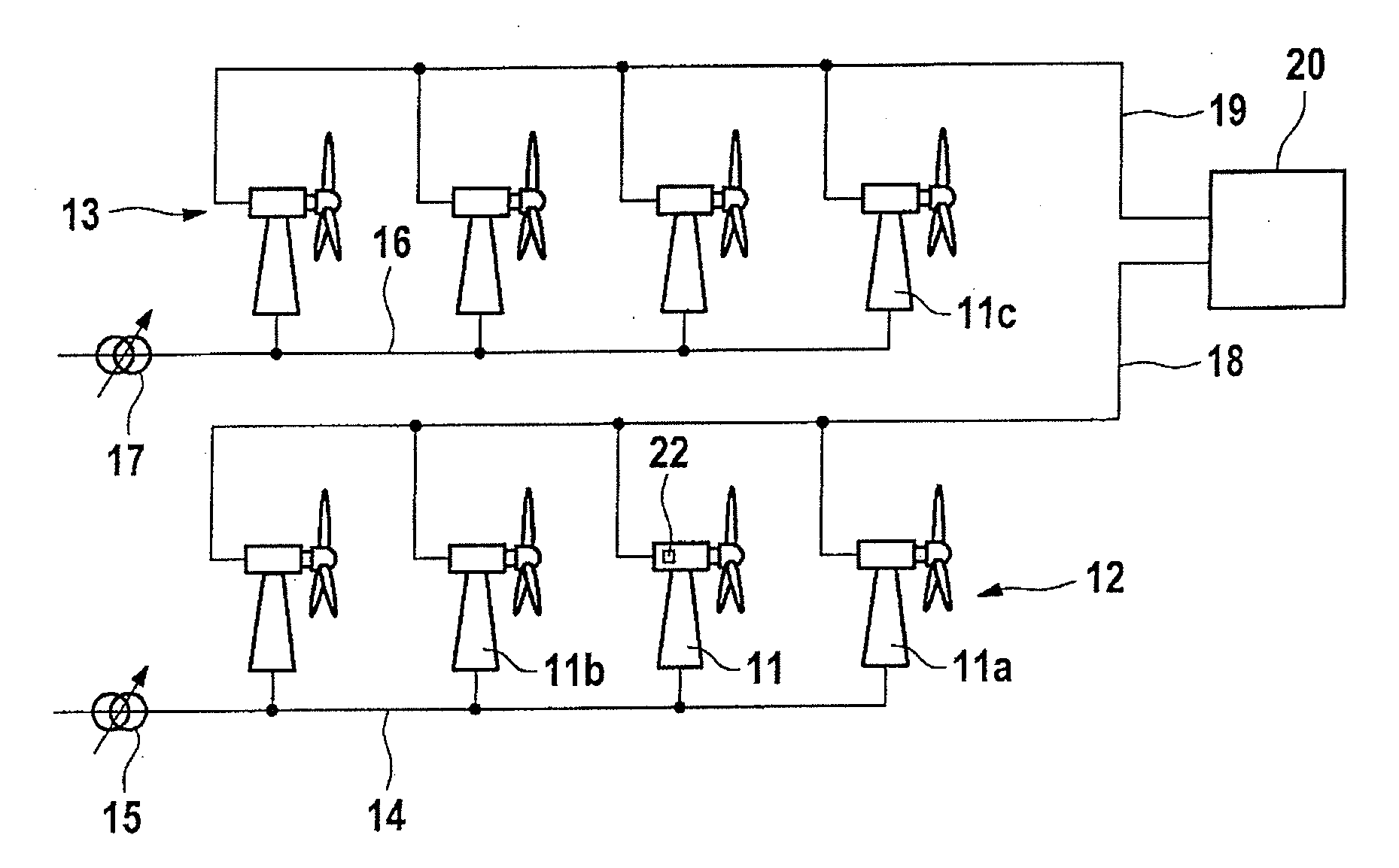

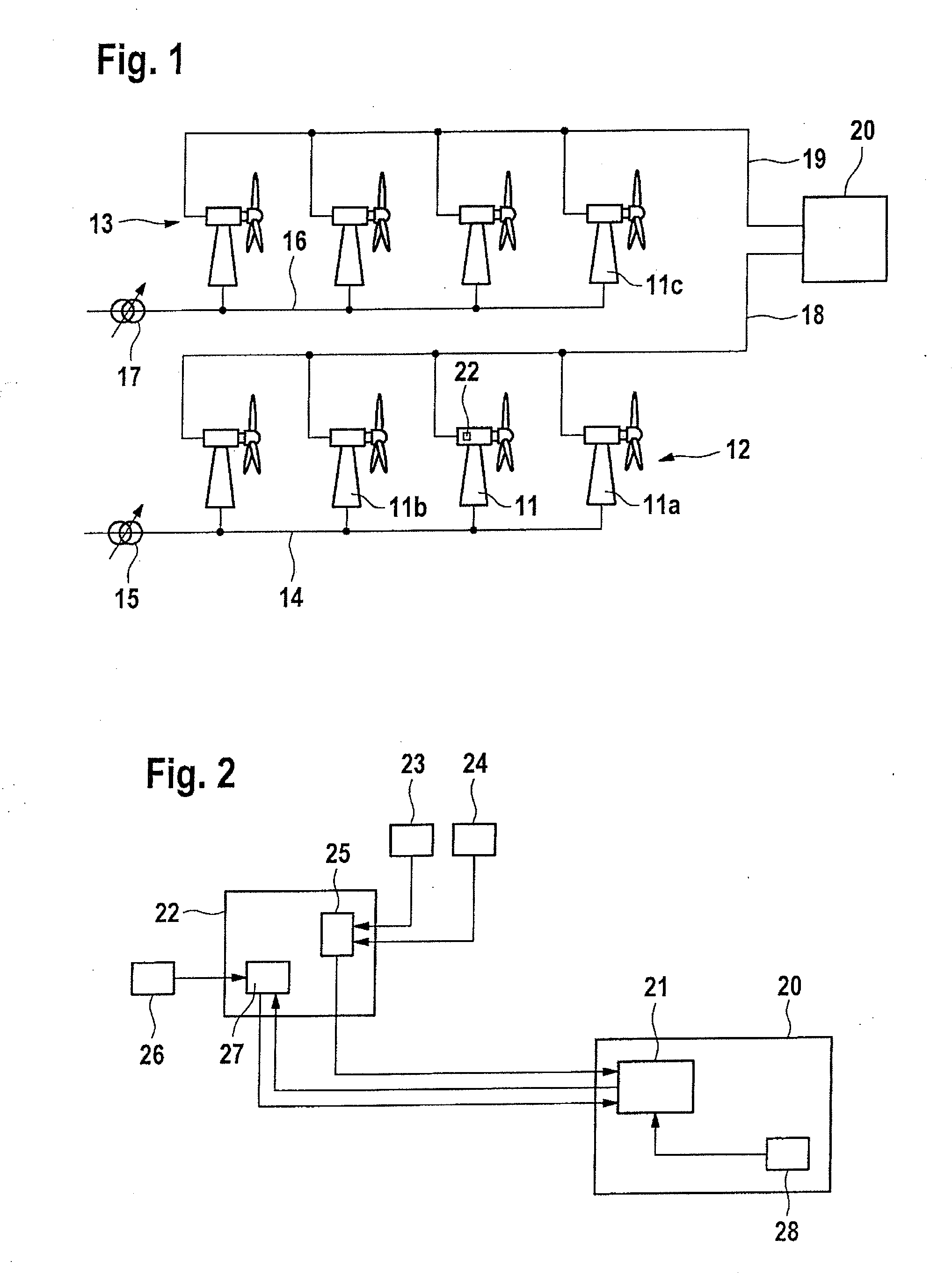

Method and system for monitoring a wind energy installation

ActiveUS20100179773A1Large capacityUniform operationPlug gaugesMachines/enginesEngineeringFailure probability

A method and system for monitoring the operation of a wind energy installation. State data relating to the wind energy installation is recorded and discrepancies are found between the state data and an associated comparison value. A failure probability of the wind energy installation is determined based on any found discrepancy. An availability value for the wind energy installation is determined from the ratio of the actually produced amount of electrical energy to the total amount of energy which can potentially be produced. The availability value and the failure probability are then combined to form a repair priority, which is associated with the wind energy installation. Accordingly, more uniform operation of wind energy installations can be achieved.

Owner:SIEMENS GAMESA RENEWABLE ENERGY SERVICE GMBH

Method and system for applying a road surface

ActiveUS20120263530A1Down rateReduced mass flowPaving detailsRoads maintainenceProduction rateMaterial supply

A method and a system for applying a road surface using a mixing plant for producing laying material, a road finishing machine processing the laying material to a road surface, and a supply chain transporting the laying material from the mixing plant to the road finishing machine. Request commands are transmitted from the road finishing machine to the mixing plant and / or to the supply chain, and, depending on these request commands, the production rate of the laying material in the mixing plant, the temperature of the laying material produced in the mixing plant, and / or the mass flow of laying material supplied to the road finishing machine per time unit by means of the supply chain are adjusted.

Owner:JOSEPH VOEGELE AG

Electrostatic discharge protection device

InactiveUS20120098046A1Increased avalanche breakdown voltageUnified operationTransistorSemiconductor/solid-state device detailsGgNMOSEngineering

An ESD protection device is provided. The ESD protection device includes a first group of electrostatic discharge protection devices connected to a first terminal and including at least one of an LORGGR and an HORGGR, and a second group of electrostatic discharge protection devices connected in series to the first group of electrostatic discharge protection devices and a second terminal and including at least one of a GGNMOS, a GGPMOS and a diode.

Owner:BAUABTECH

Slurry mixer for a battery electrode

ActiveUS20210213403A1Stir evenlyShorten mixing timeElectrode manufacturing processesMixing methodsProcess engineeringMixed materials

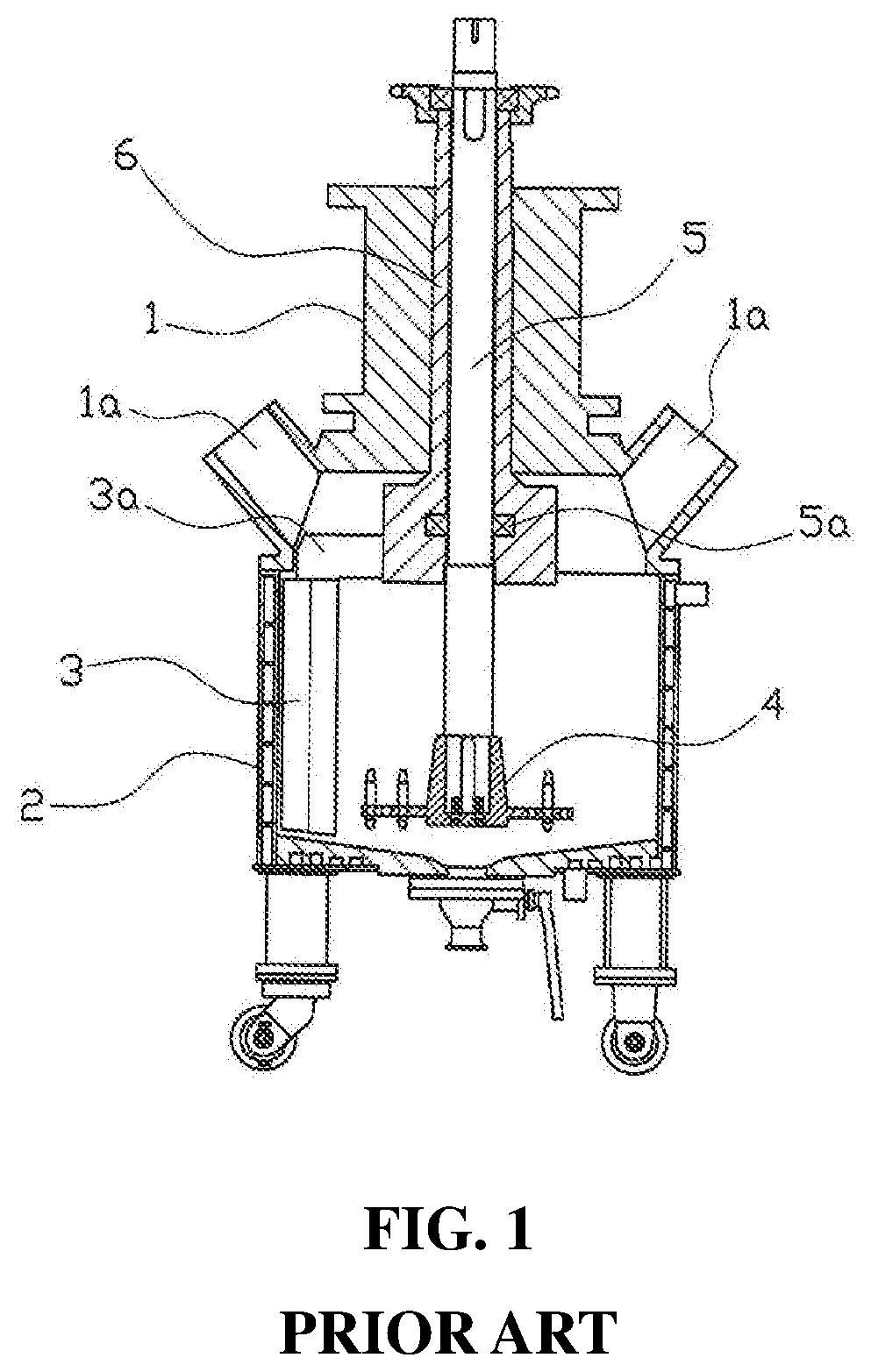

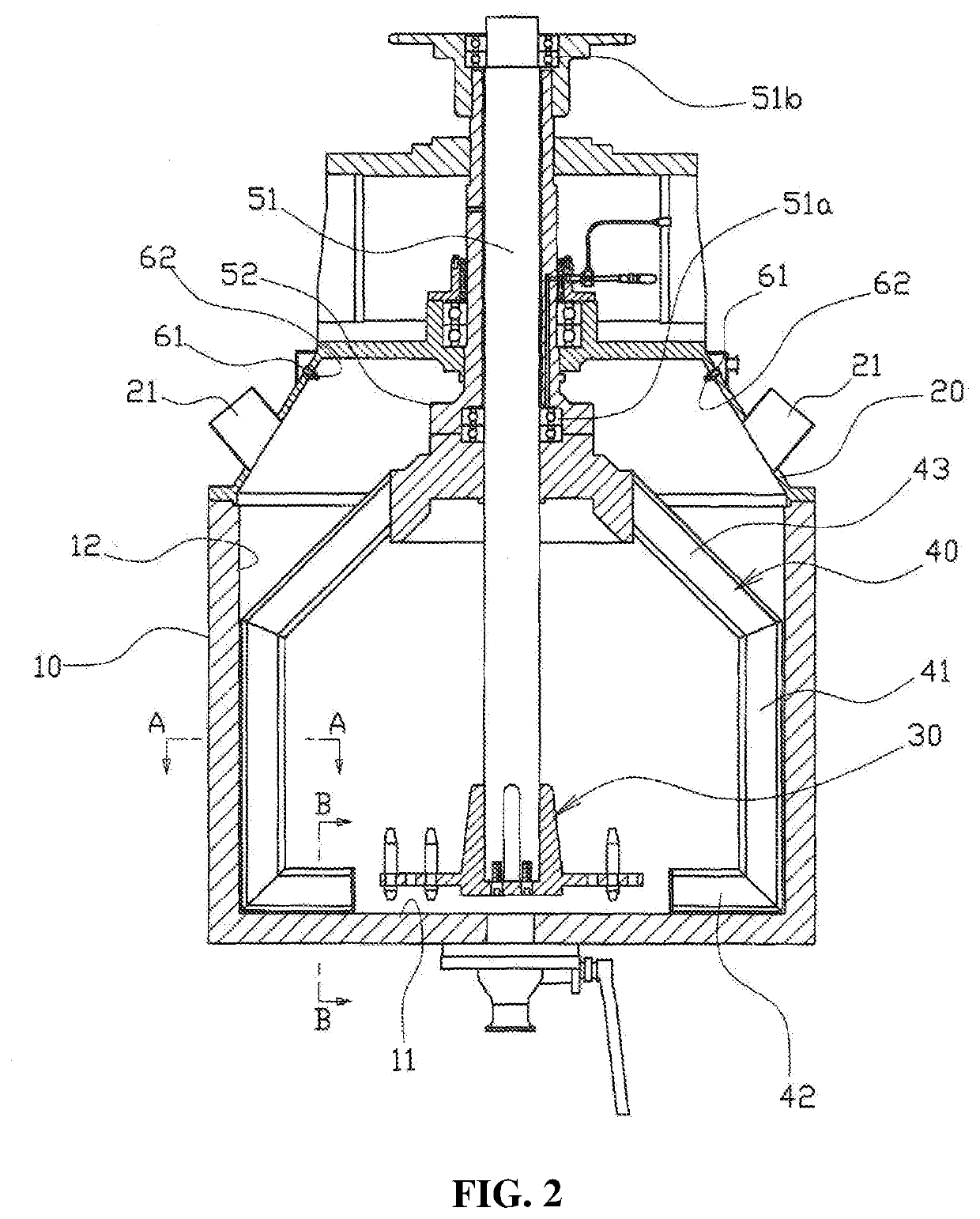

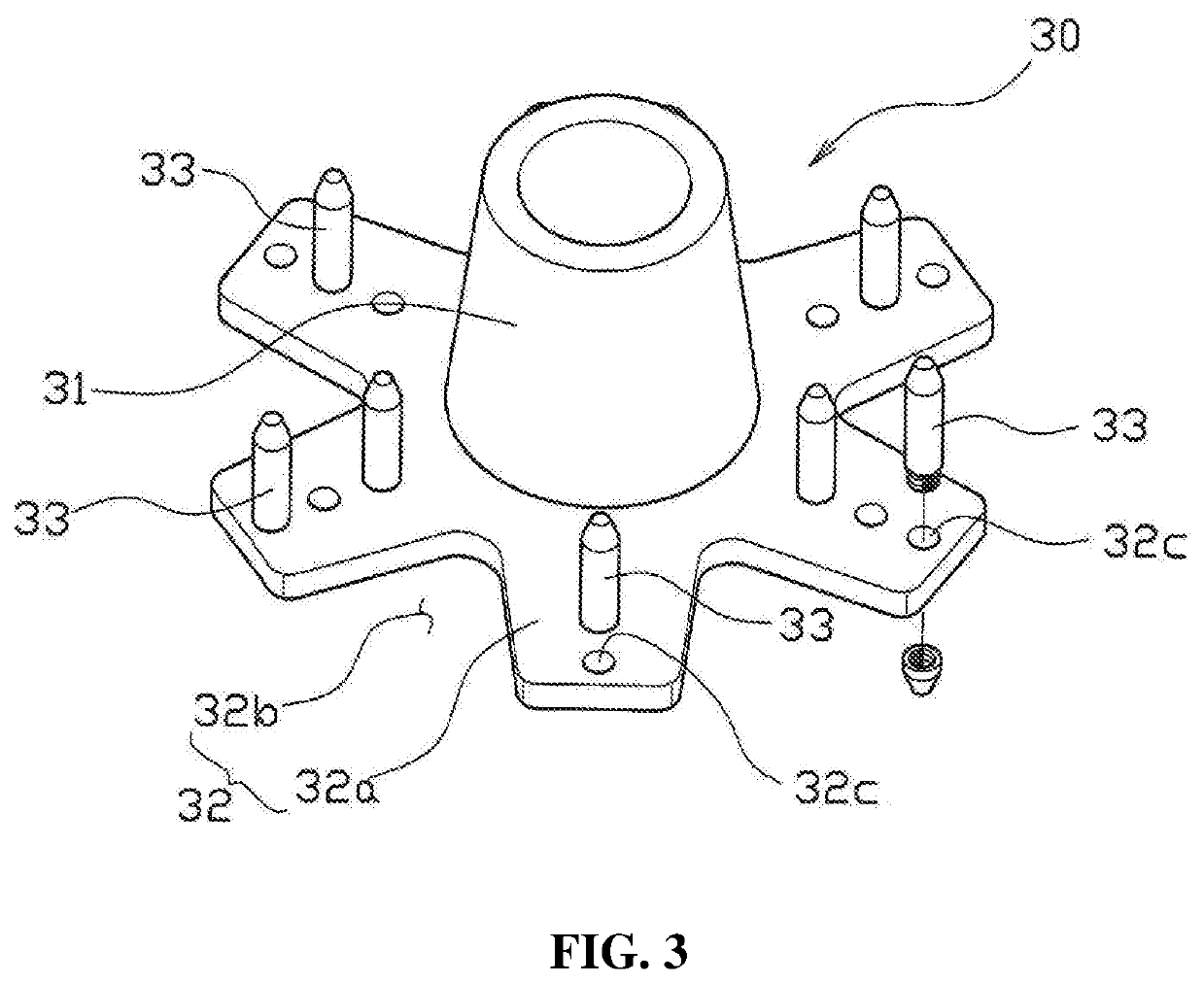

A slurry mixer for a battery electrodecapable of maximally simplifying a configuration of a high-speed stirring body to minimize a rotational load, such that a stirring time of the slurry may be greatly reduced and productivity may be increased, preventing a powdery material from being accumulated on an upper side face and an upper surface of a low-speed stirring body, preventing a deterioration in a performance, failure and a reduction in a life span of a high-speed stirring shaft and bearing, and uniformly stirring mixed materials located at inner corners and a bottom of a container, thereby further increasing stirring efficiency.

Owner:TSI CO LTD

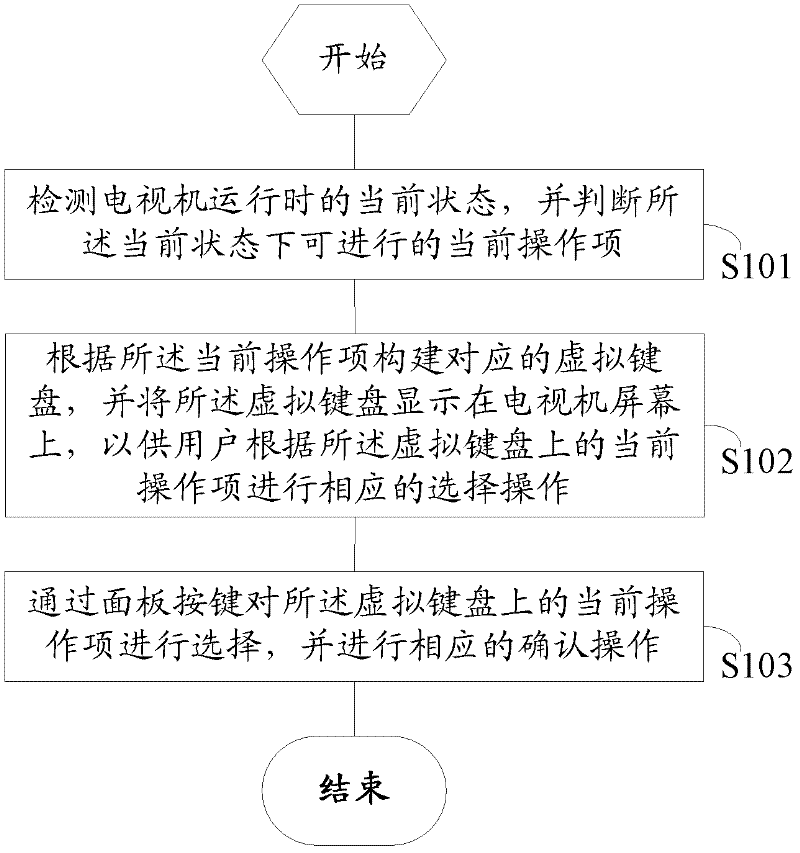

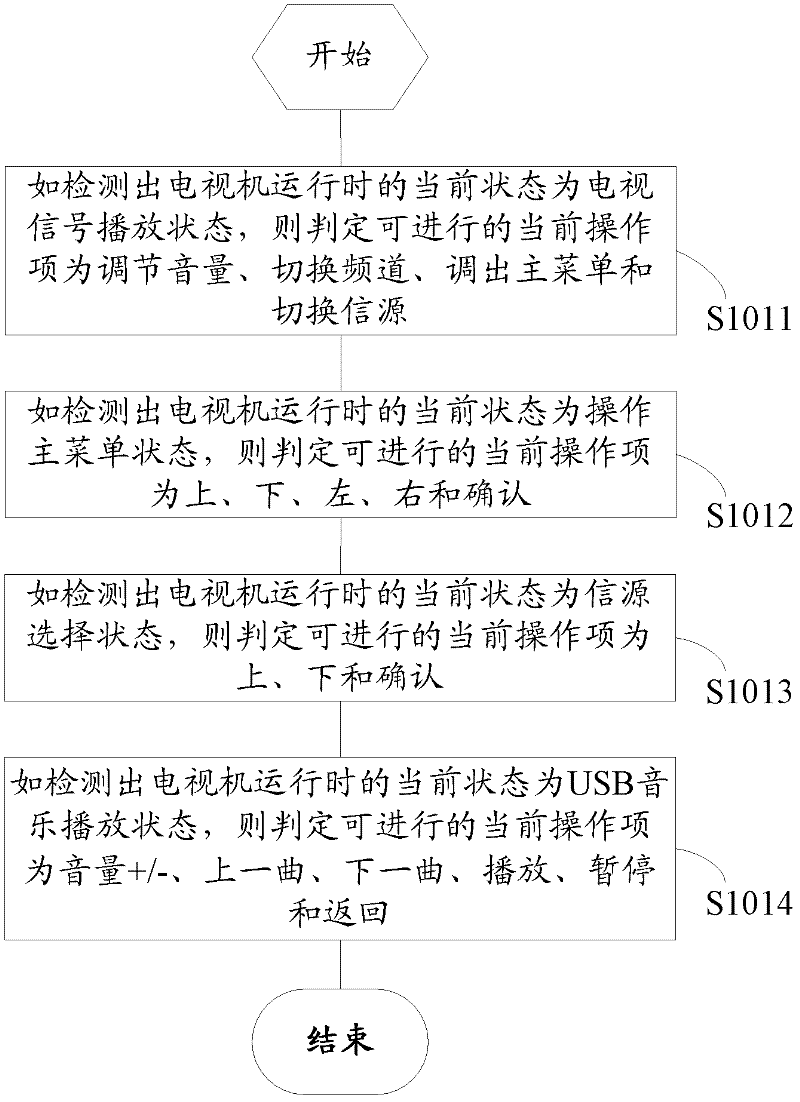

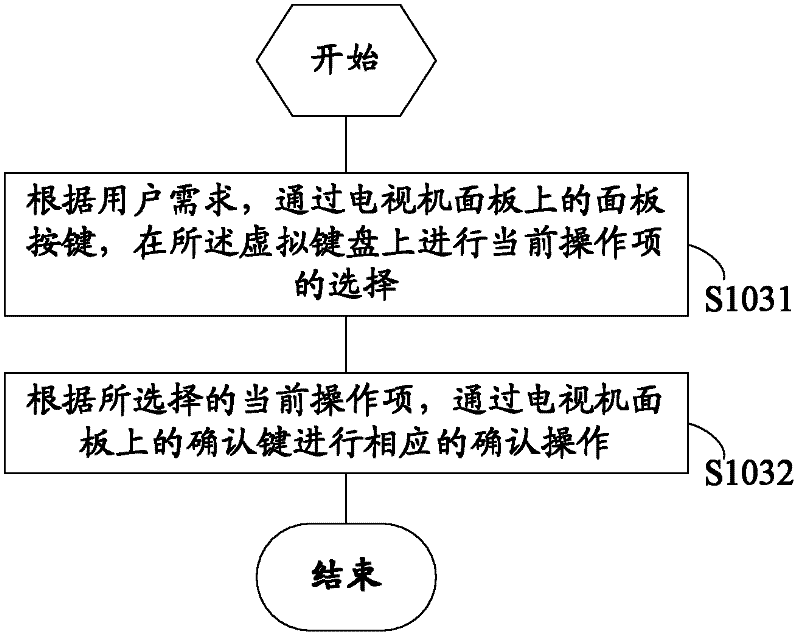

Method and device for controlling television functions by panel keys

InactiveCN102523396AEasy to operateEasy to useTelevision system detailsColor television detailsVirtual keyboardTelevision screen

The invention discloses a method for controlling television functions by panel keys, which comprises the steps of: detecting the current operation state of a television, and judging the current operable operation items at the current state; creating a corresponding virtual keyboard according to the current operation items, and displaying the virtual keyboard on a television screen to enable users to perform corresponding selection operations according to the current operation items on the virtual keyboard; and selecting the current operation items on the virtual keyboard by panel keys, and performing corresponding confirmation operations. The invention also provides a corresponding device for controlling television functions by panel keys. The method and device for controlling television functions by panel keys provided by the invention have the advantages of realizing all television functions capable of being realized by a remote controller via few panel keys, having simple and uniform operation and convenience for use, and reinforcing the experience effects of the users.

Owner:SHENZHEN TCL NEW-TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com