Patents

Literature

50results about How to "Stir evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for removing heavy metal in soil

InactiveCN102319725AEasy to handleGood effectContaminated soil reclamationPollution soilCombined use

The invention discloses a method for removing heavy metal in soil, and belongs to the field of polluted soil treatment. The method comprises the following steps: adjusting the water content of the soil to be treated to 8%-12%; uniformly adding a magnetic adsorption material into the soil with adjusted water content, wherein the adding amount of the magnetic adsorption material is 10-50 g per 1 kg of soil; regularly adjusting the water content of the soil after magnetic adsorption material addition, maintaining the water content of the soil to 8%-12%, regularly and uniformly stirring the soil; collecting the magnetic adsorption material in the soil treated by above procedures for a certain period in a manner of magnetic separation so as to complete the removal of heavy metal in the soil. The method has simple operations, can realize high-efficient low-cost treatment of heavy metal-polluted soil, and has the advantages of low energy consumption and environment protection; the method can be combined with common technology of phytoremediation of heavy metal-polluted soil, and has good popularization and application value.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

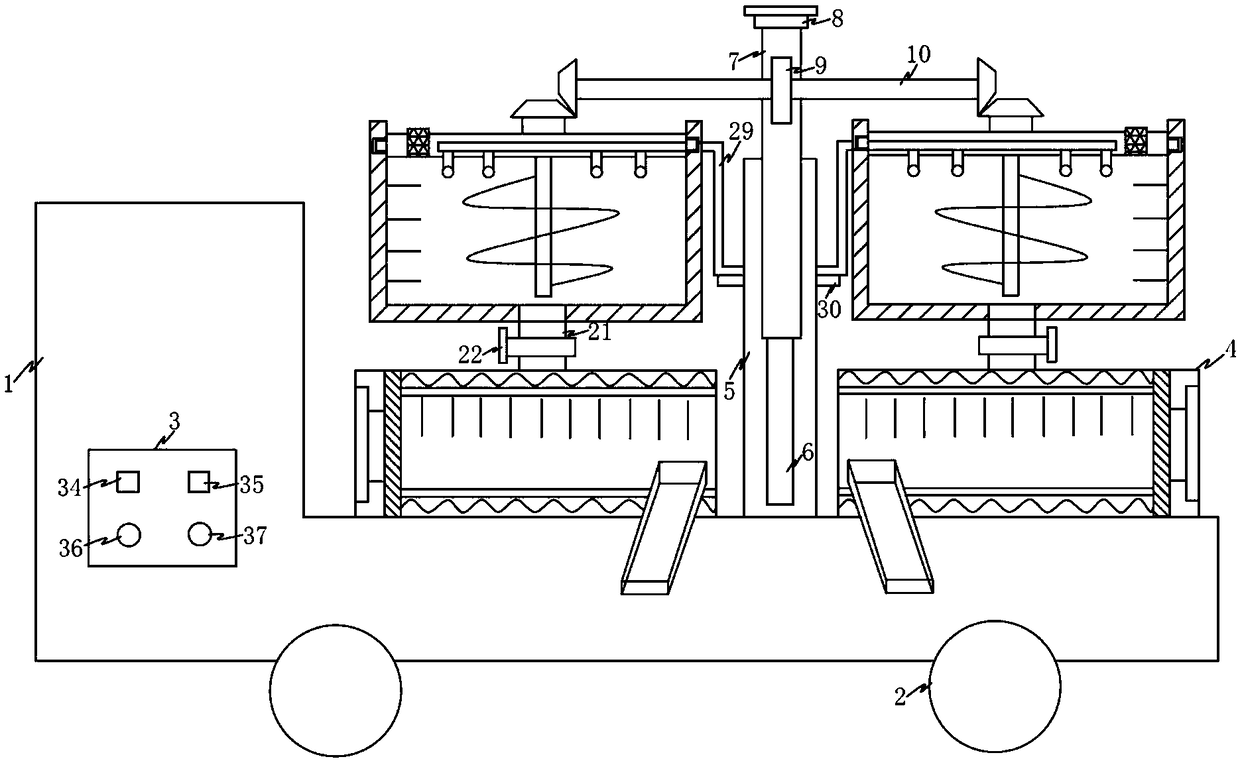

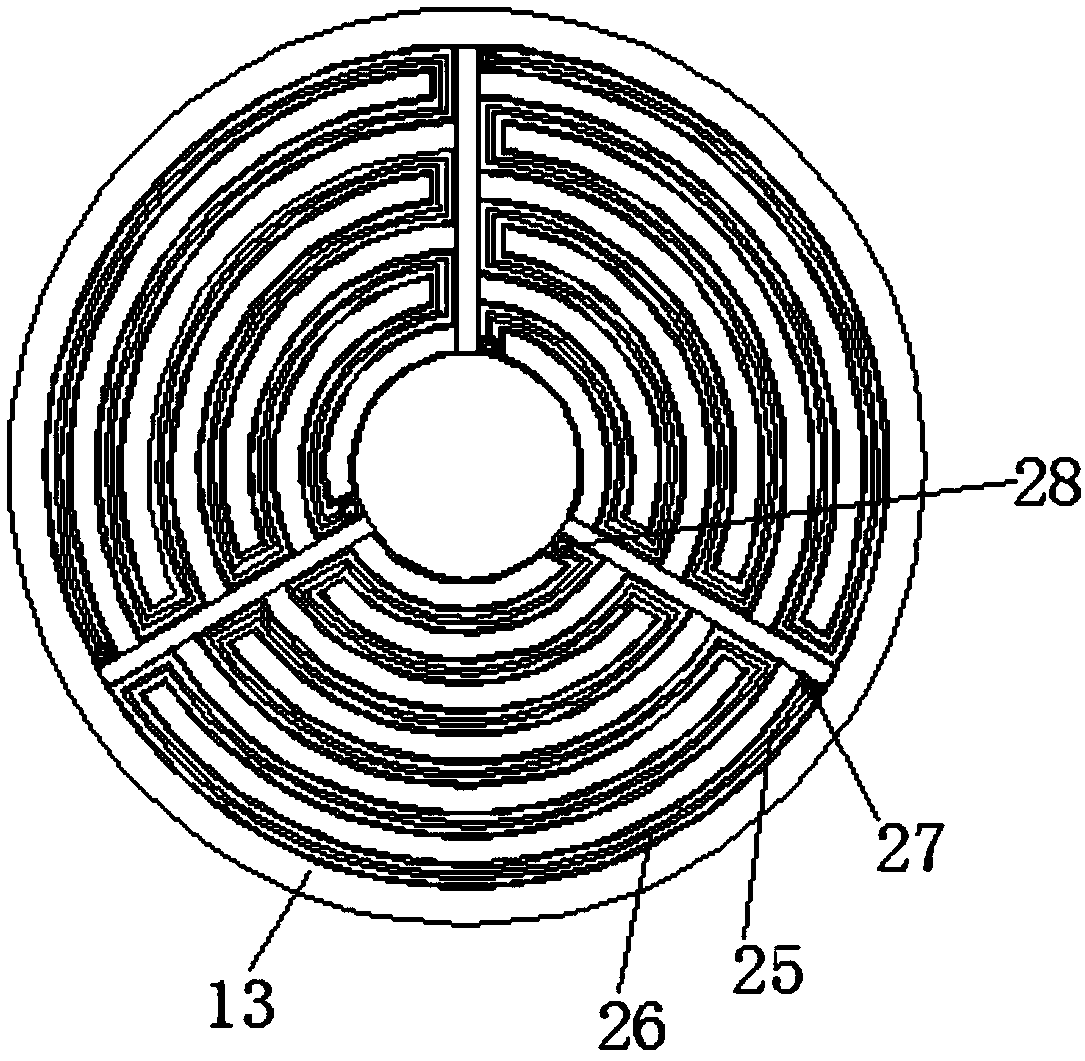

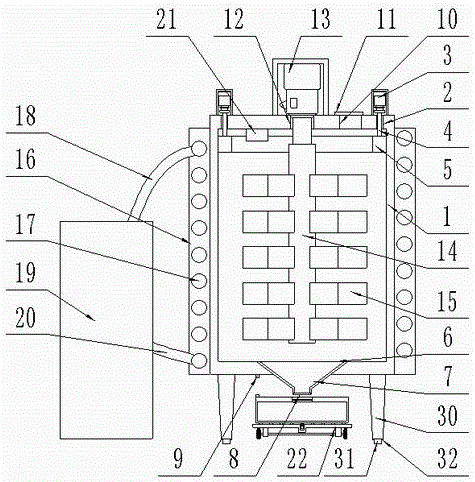

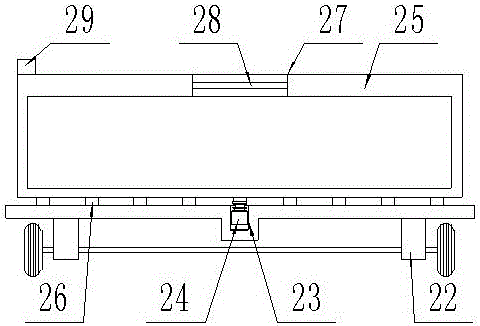

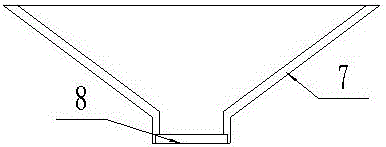

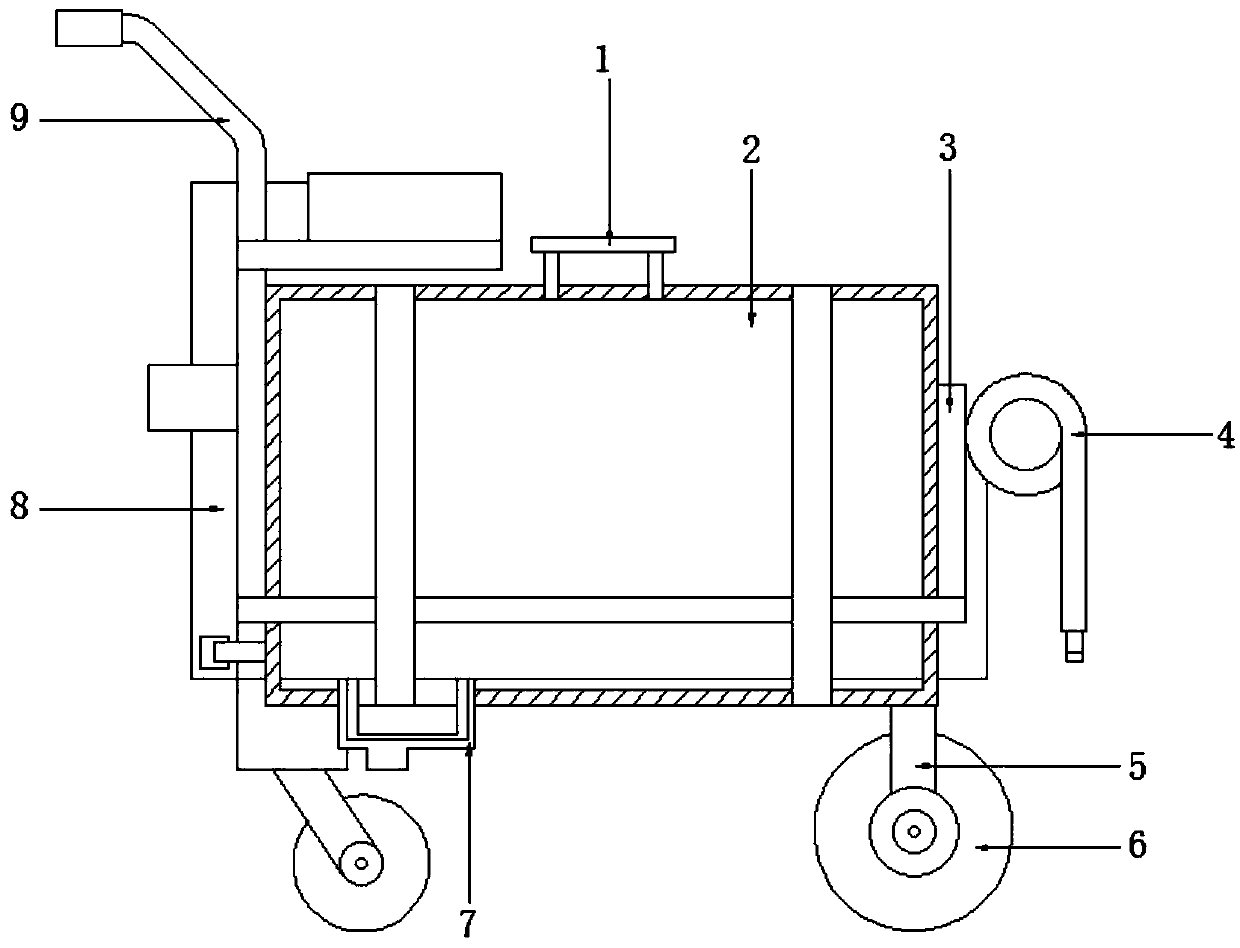

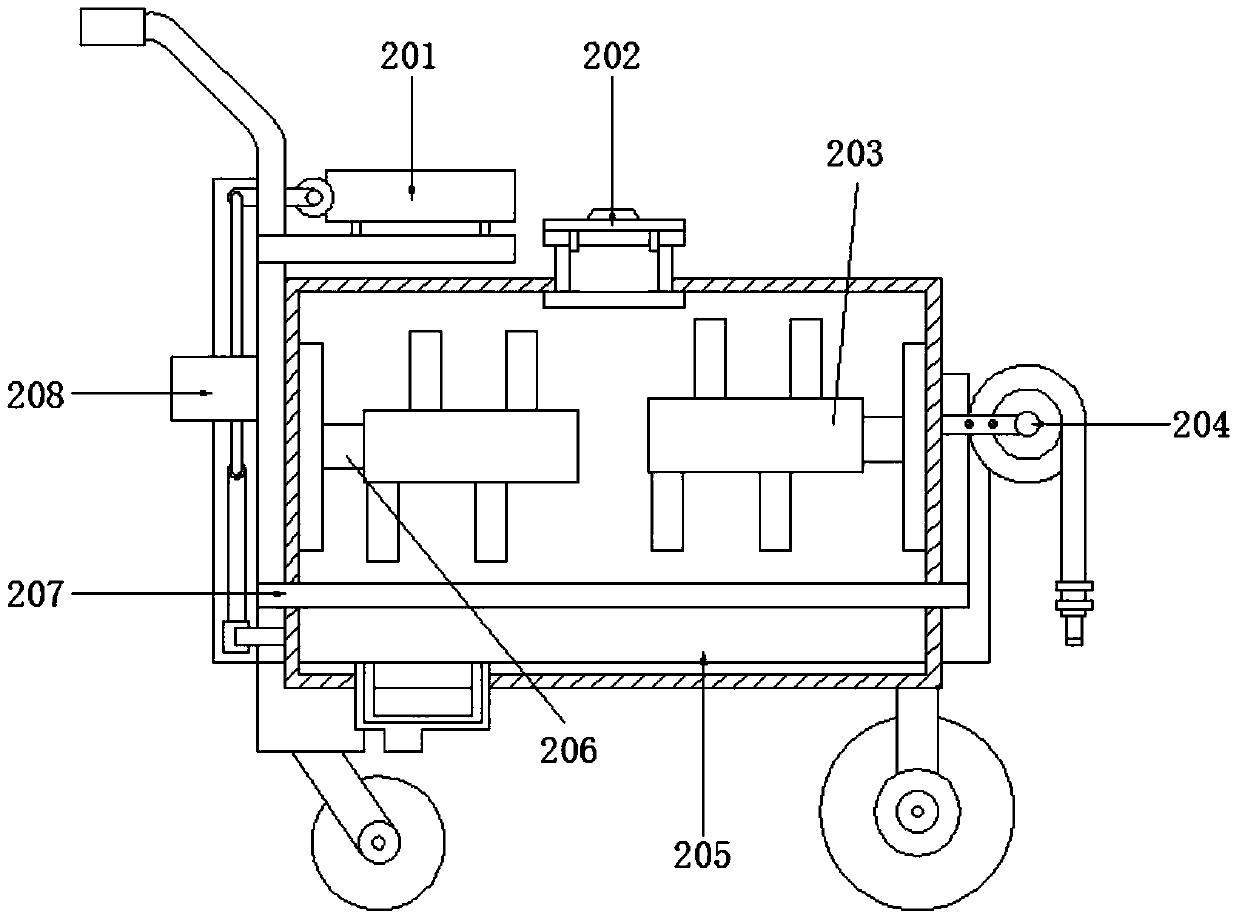

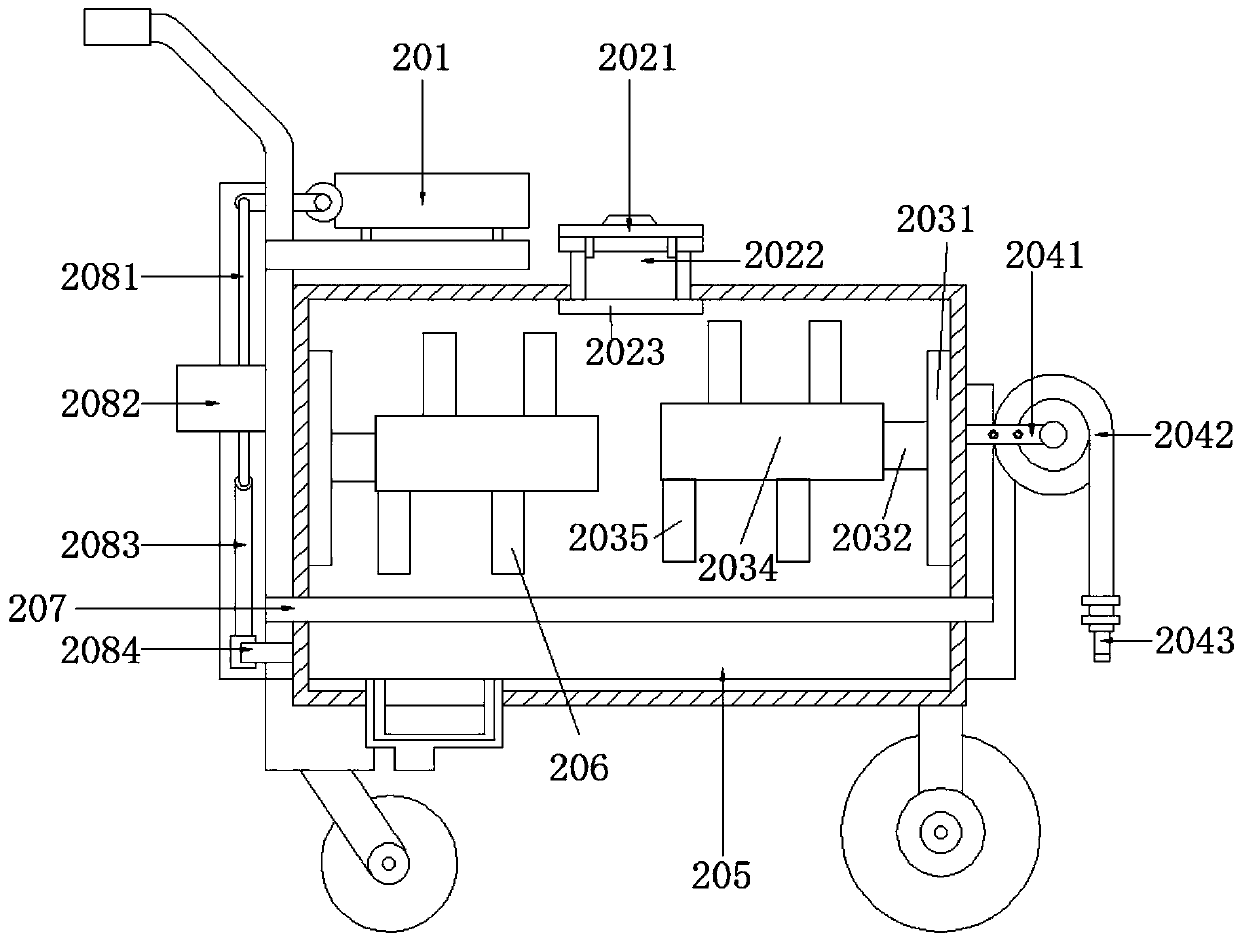

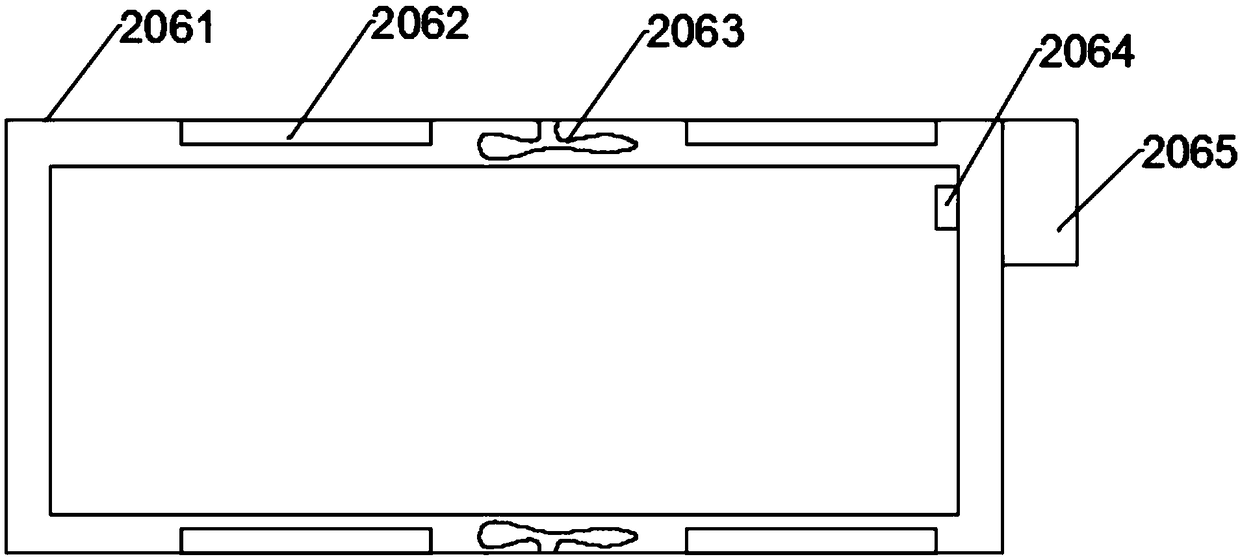

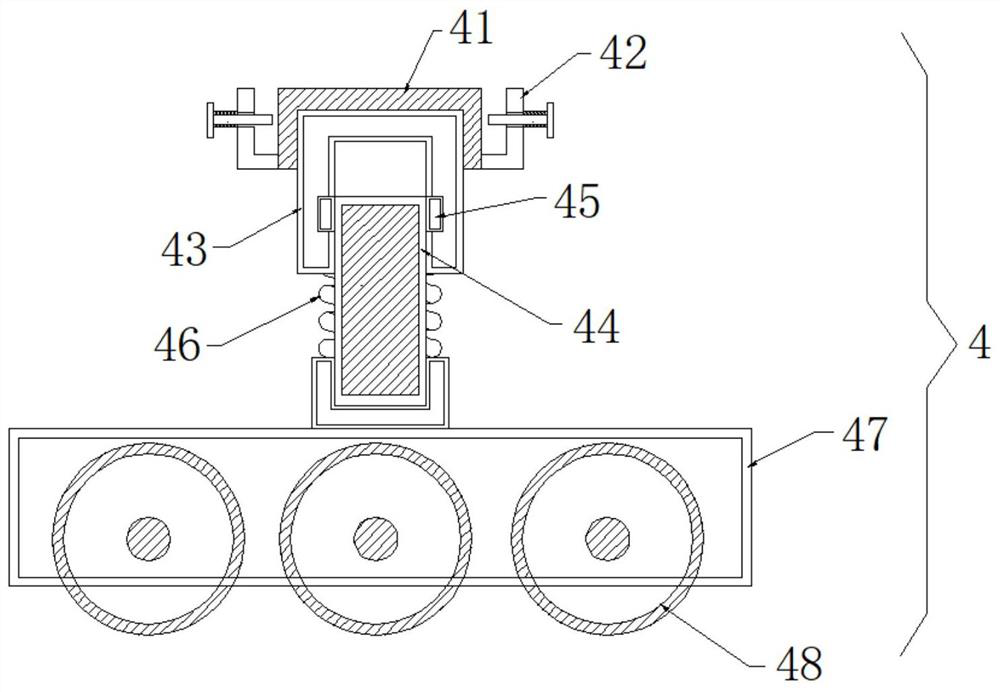

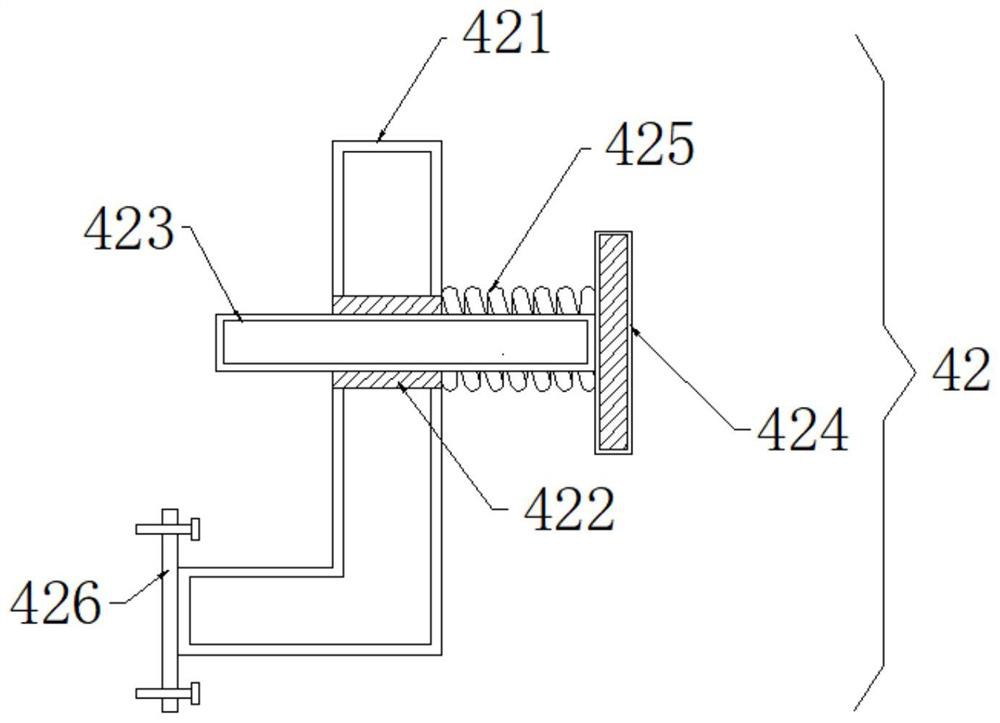

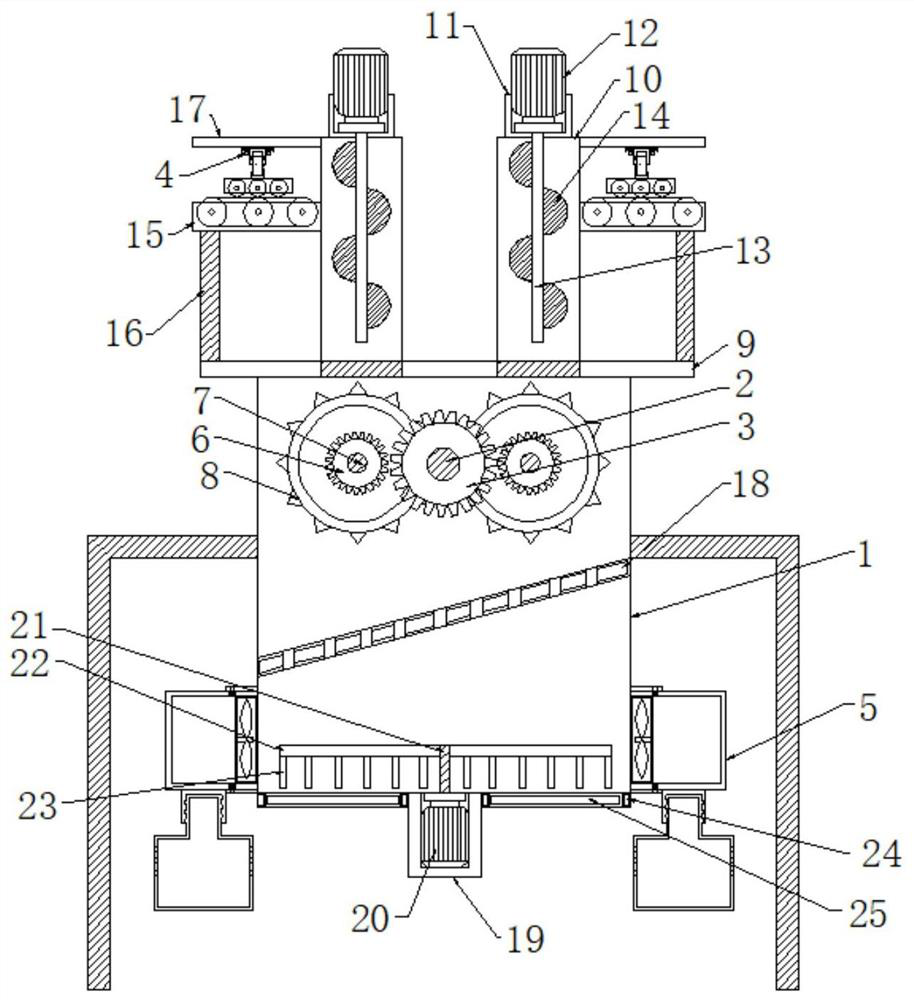

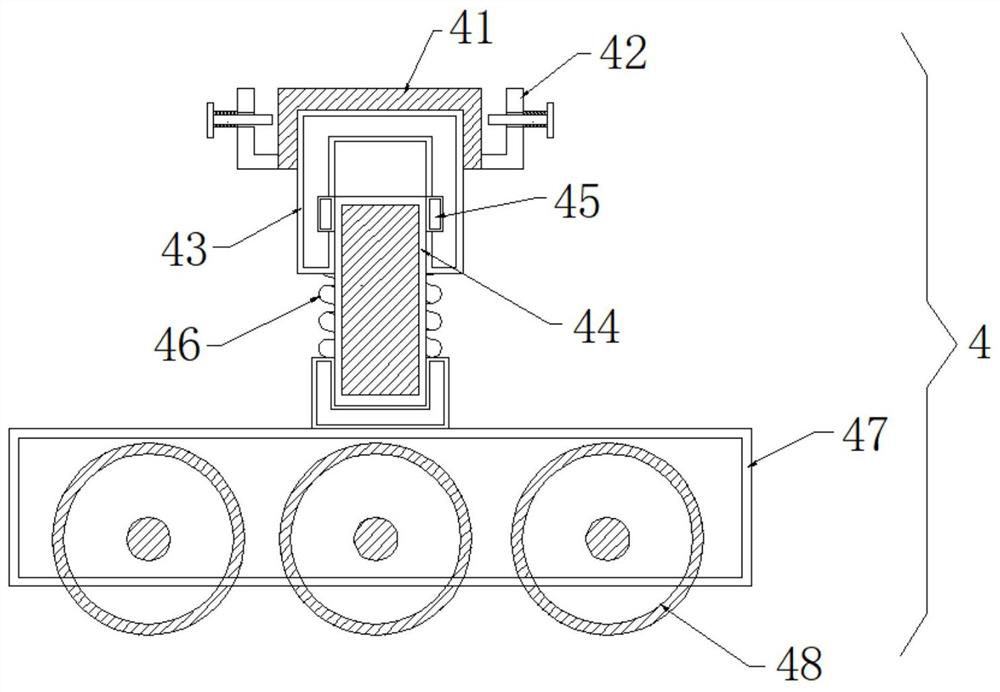

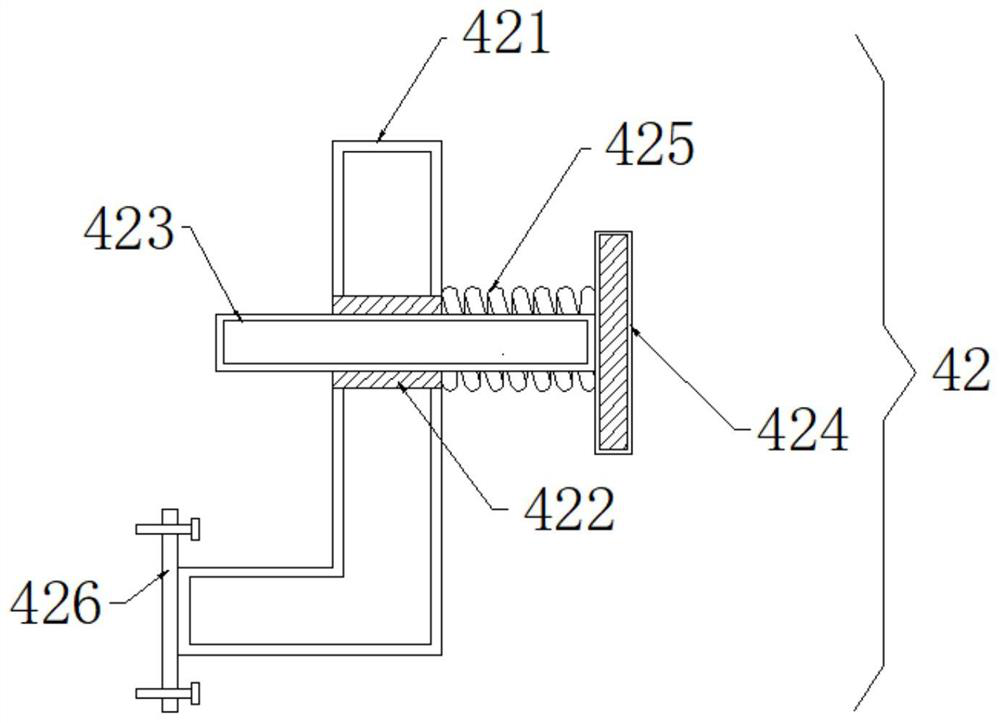

Intelligent mechanical feeding trolley

PendingCN108967237AReduce manual labor intensityStir evenlyAnimal feeding devicesAnimal ForagingEngineering

The invention discloses an intelligent mechanical feeding trolley. The trolley comprises a trolley body, on which a control box, forage stirring devices and quantitative feeding boxes are arranged. Arack is movably equipped with a gear. The center of the gear is fixedly equipped with a connecting rod in a penetrating manner. Two ends of the connecting rod are symmetrically equipped with driving bevel gears which are movably connected with driven bevel gears. The driven bevel gears are connected with cover boards through connecting blocks. The centers on one sides, away from the connecting blocks, of the cover boards are fixedly equipped with support columns. Spiral rods are fixedly arranged on the support columns. The side walls of the quantitative feeding boxes are fixedly equipped withsecond electric push rods fixedly connected with push boards. The intelligent mechanical feeding trolley is internally equipped with devices used for uniformly stirring forages. Therefore, human resources are saved. According to conditions of livestock, types of forages are flexibly selected and forage weight is adjusted. The trolley is simple in operation. Meanwhile, a built-in water tank is usedfor cleaning the trolley. The trolley has concentrated functions and is widely used.

Owner:ANHUI YOMO MACHINERY TECH

Method for processing mushroom powder

InactiveCN101297693ARetain nutrientsKeep the delicious aromaNervous disorderMetabolism disorderAdditive ingredientShiitake mushrooms

The invention discloses a processing method for fungus powder, which comprises the steps: 1. fresh mushroom and mushroom root are dried; 2. the products of the step 1 are soaked and cleaned; 3. the products of the step 2 are dehydrated; 4. the products of the step 3 are dried or sun-dried; 5. the products of the step 4 are smashed; 6. final products are packaged; wherein, the temperature of the drying or sun-drying in the step 4 is 50 to 150 DEG C, and the water content of the product is 4 percent to 15 percent. The method has simple technique, can be produced in great batches, maintains the original nutrient element and the delicious incense of the mushroom, and increases aroma; the product fungus powder is easy to be absorbed, can be eaten, and can be used as medical ingredient, being convenient to be evenly stirred.

Owner:毛仁贺

Crushing, melting and extruding integrated equipment for plastic production

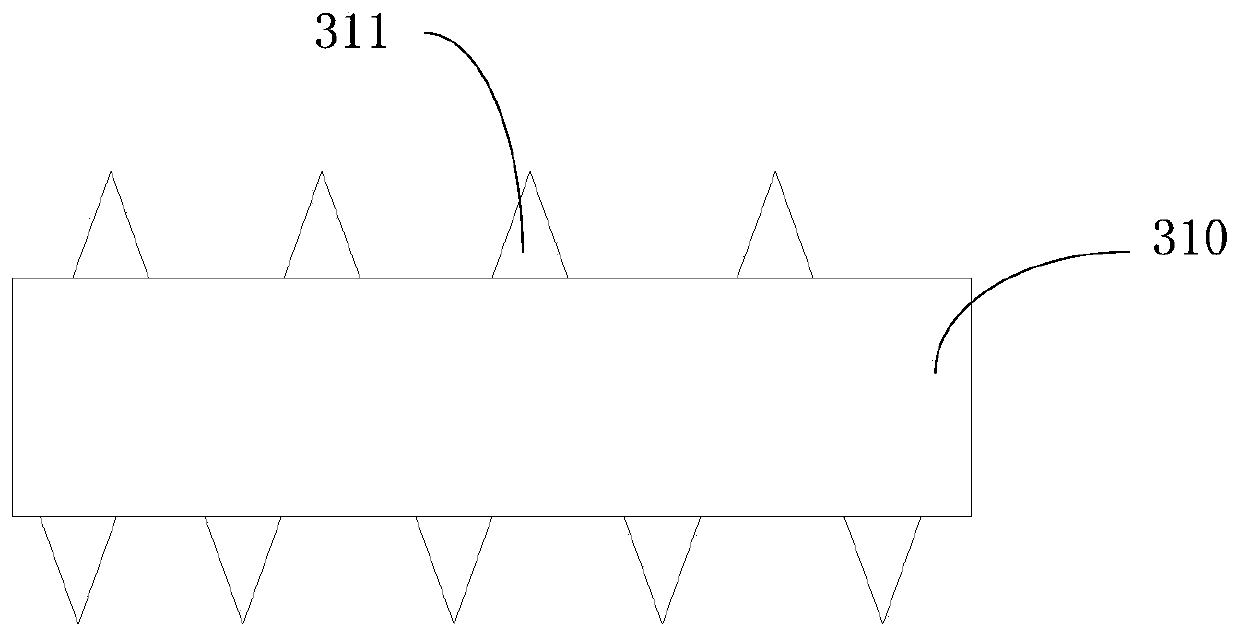

The invention relates to crushing, melting and extruding integrated equipment for plastic production. The crushing, melting and extruding integrated equipment for the plastic production comprises a main barrel, a vertical knife, a connecting block, an inlet and a blocking ball. A motor is arranged on the middle portion above the main barrel, and a first rotary shaft is arranged under the motor. Afeed inlet penetrates through the left side of the upper portion of the main barrel. A hydraulic cylinder is arranged on the lower portion of the left side of the main barrel, and a push plate is fixed to the right side of the hydraulic cylinder. A hinge is installed on the left side of the main barrel, and a barrel door is arranged on the left side of the hinge. A main crushing knife with an arc-shape pointed structure is arranged, plastic can be crushed, and thus the melting speed of the plastic is accelerated, the working efficiency is improved. Through the arrangement of a secondary crushing knife and the vertical knife, the degree of plastic crushing can be improved. A filter plate with hollowed-out structure can block the unbroken plastic to ensure that the plastic volume passing through the filter plate conforms to the melting standard, and secondly, a stirring rod is arranged in a saw tooth structure.

Owner:ANHUI WANSHUN PIPE IND

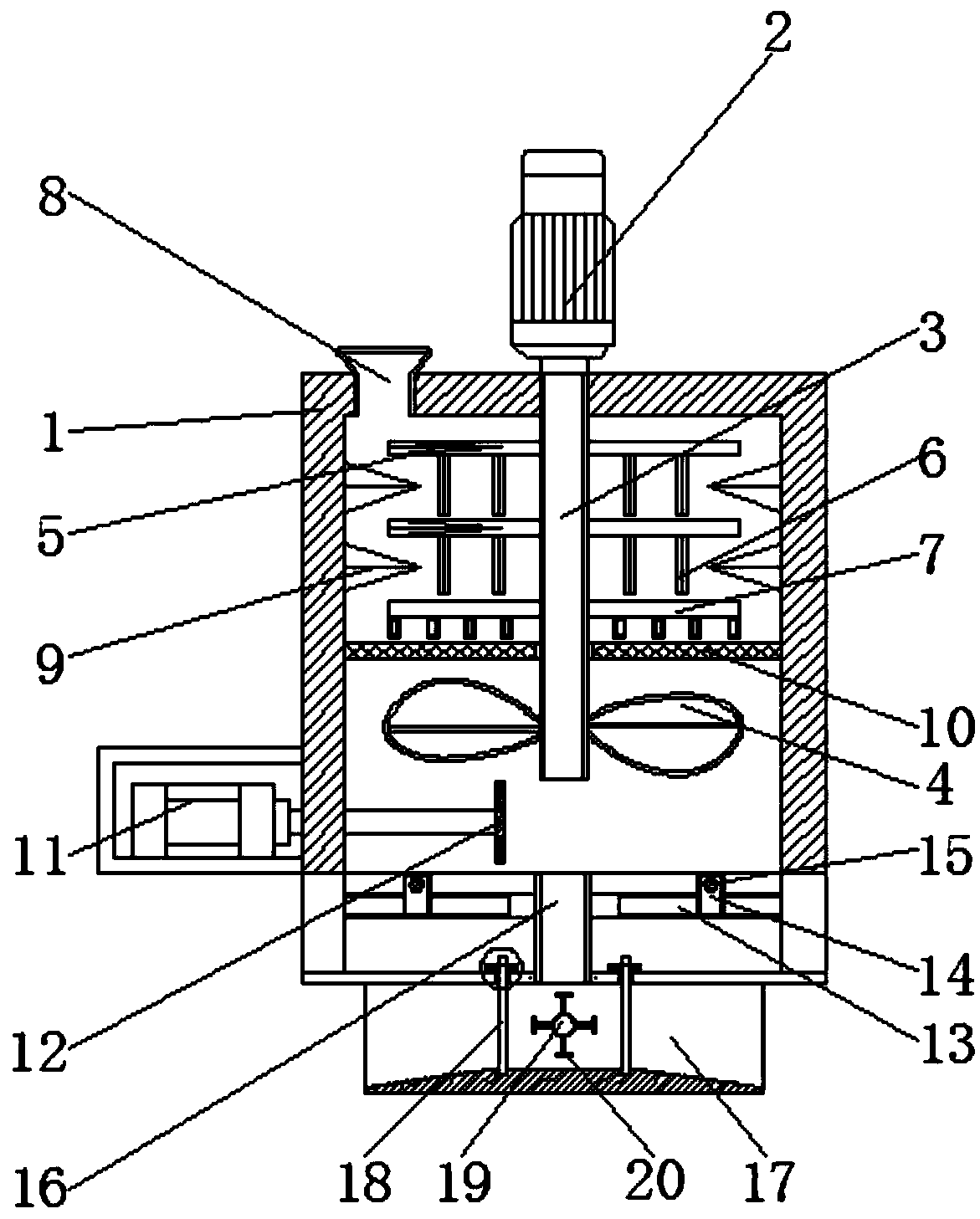

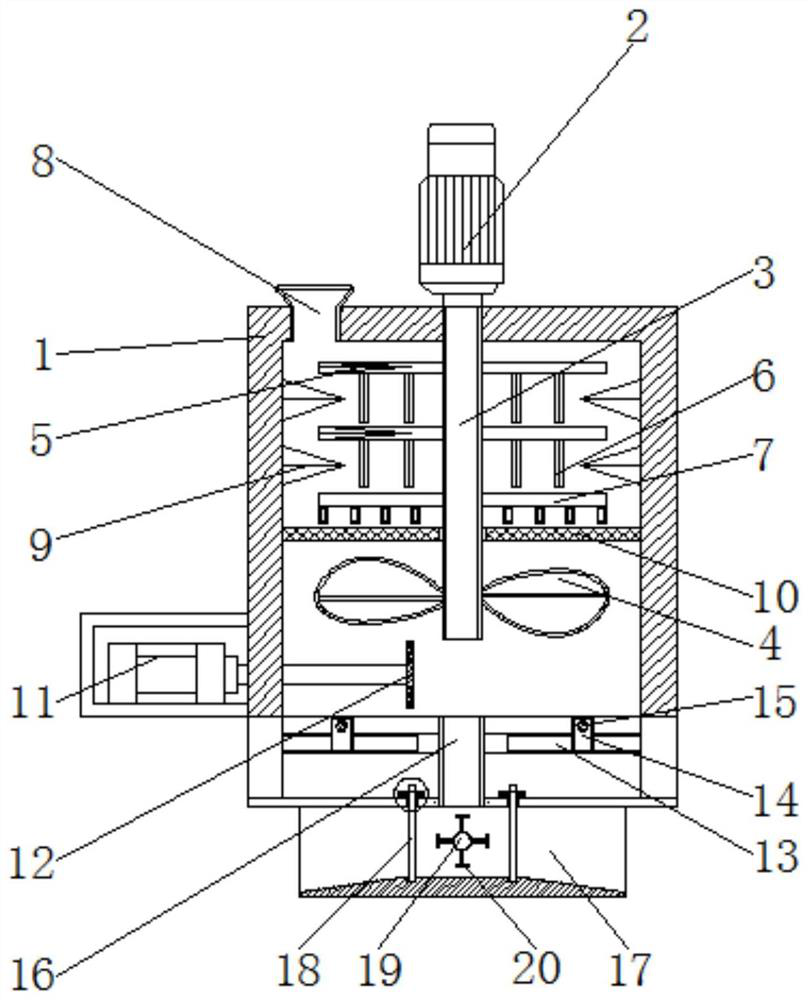

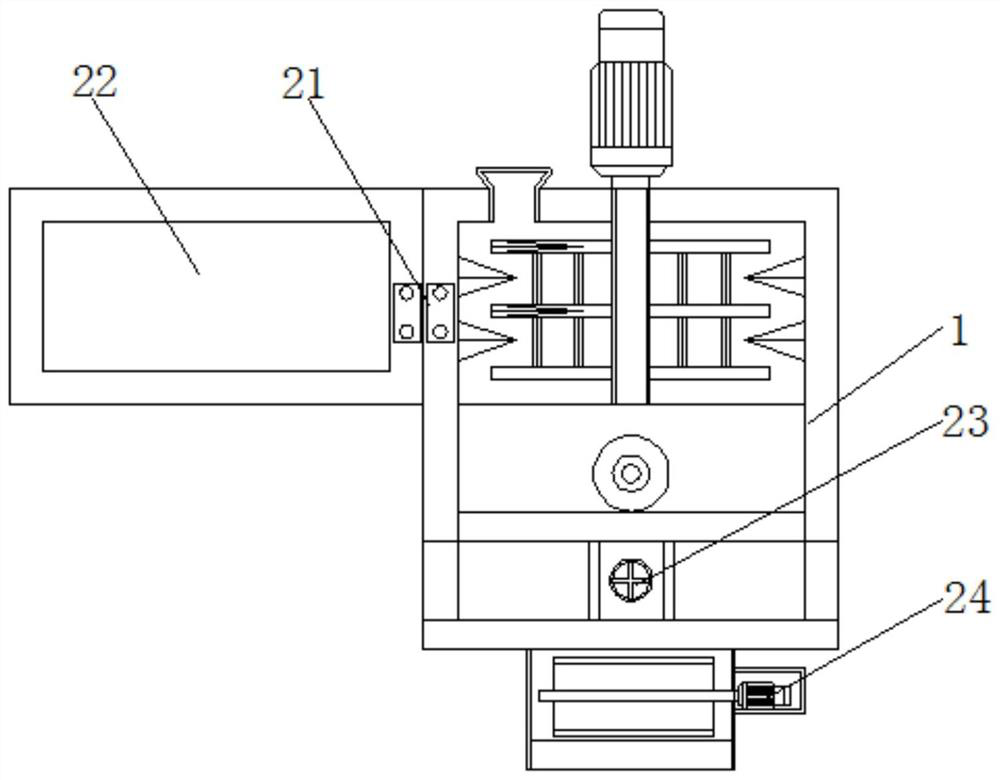

Stirring device for production of cosmetics

InactiveCN107175005AFully dispersedEvenly dispersedRotary stirring mixersTransportation and packagingBiochemical engineeringManagement system

The invention discloses a stirring device for production of cosmetics. The stirring device comprises a stirring box, wherein a stirring device and a wall scraping device are arranged on the stirring box; a heat-insulation device is arranged on the surface of the outer side of the stirring box; an automatic feeding device is arranged below the outside of the stirring box; a discharging opening is formed in the lower surface of the stirring box; a wide-opening guiding cover is arranged at the position of the discharging opening; an outlet valve is arranged at the lower end of the inside of the wide-opening guiding cover; an infrared transmitter is arranged on the lower surface of the outside of the stirring box; an opening is formed in the upper surface of the stirring box; a buckle cover is connected to the upper surface of the stirring box through a hinge and is positioned at the opening; and a cosmetics production and management system is arranged at a cosmetics production and management position and is electrically connected with the stirring device, the wall scraping device, the heat-insulation device, the automatic feeding device, the outlet valve and the infrared transmitter respectively. The stirring device has the beneficial effects that full stirring can be implemented, and homogeneous dispersion can also be implemented.

Owner:烟台慧湶企业管理咨询有限公司

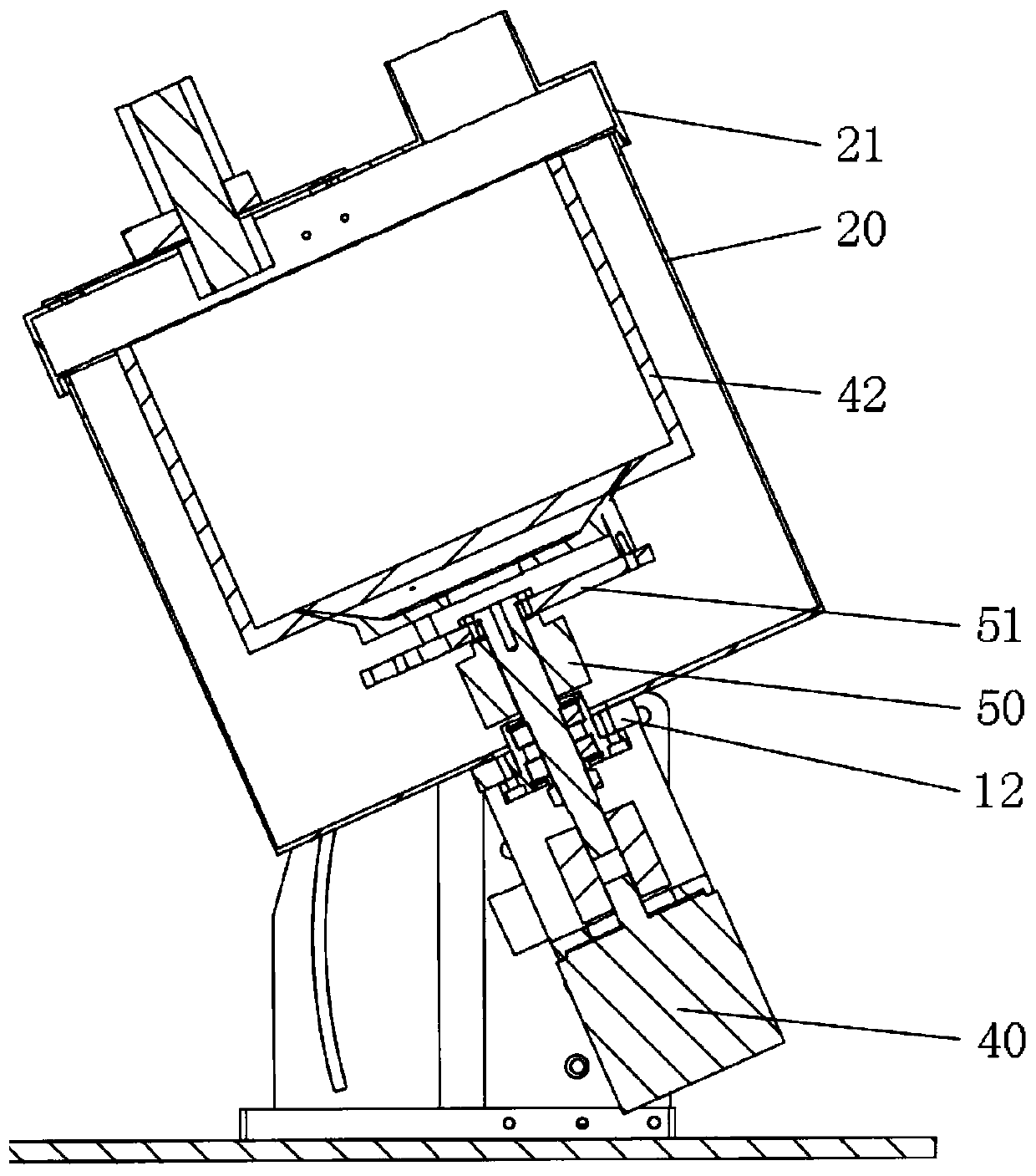

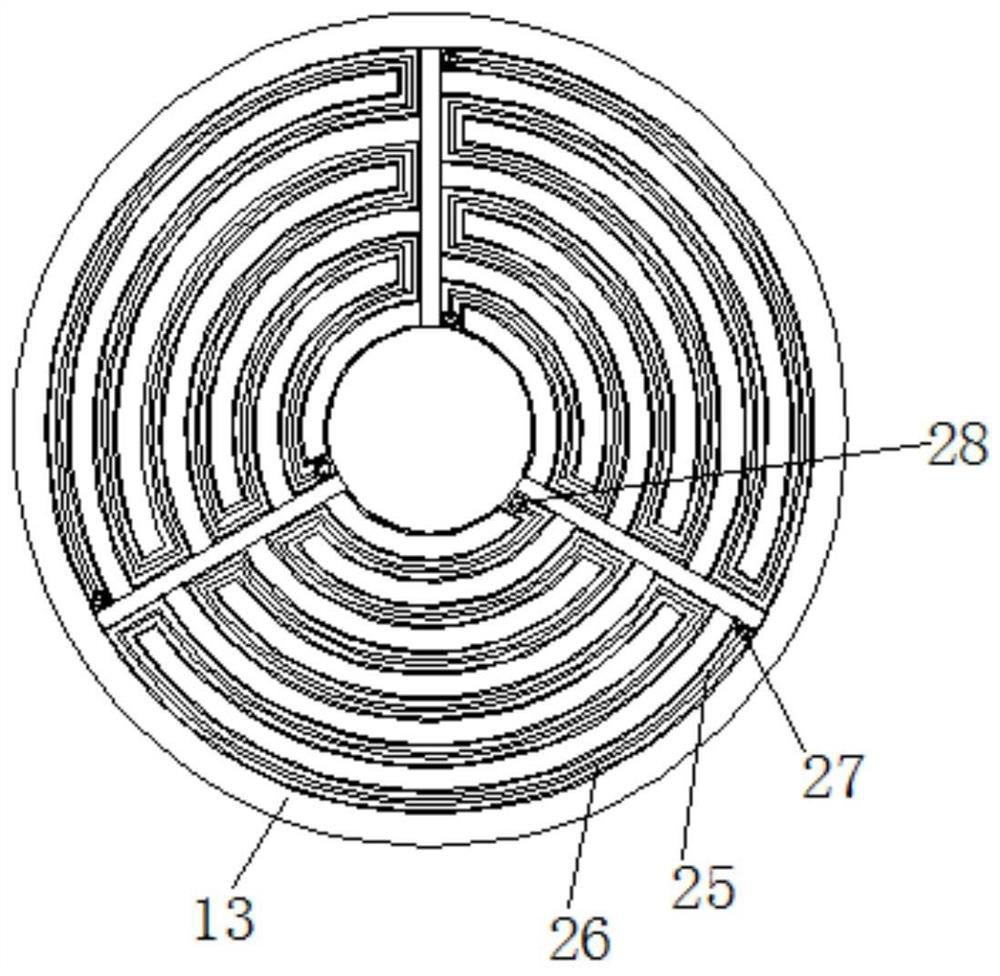

Different-direction stirring and mixing method for chemical raw materials

ActiveCN110652906AReduce labor intensityGood mixing effectRotary stirring mixersTransportation and packagingProcess engineeringBLENDER/MIXER

The invention discloses a different-direction stirring and mixing method for chemical raw materials. The method comprises the following steps: sequentially putting to-be-stirred materials into a stirring tank by an operator; fully and uniformly stirring the obtained inner ring mixture by using an inner ring stirring part; fully and uniformly stirring the obtained outer ring mixture by an outer stirring part during the stirring of the inner ring mixture with the inner stirring part; stopping running of a different-direction stirring mechanism after the mixture is fully and uniformly stirred, turning on an automatic pouring mechanism to make the stirring tank obliquely arranged in order to pour out the uniformly stirred mixture in the stirring tank, reversely running the automatic pouring mechanism to recover the stirring tank to the original position, and performing the next round of mixture stirring. The whole mixture discharging process is fully automatic without manual operation of workers, so the labor intensity of the workers is greatly reduced; and the inner ring and outer ring different-direction stirring mode is adopted, so the mixture can be fully and evenly stirred, and the stirring effect is good.

Owner:重庆安盛钾业有限公司

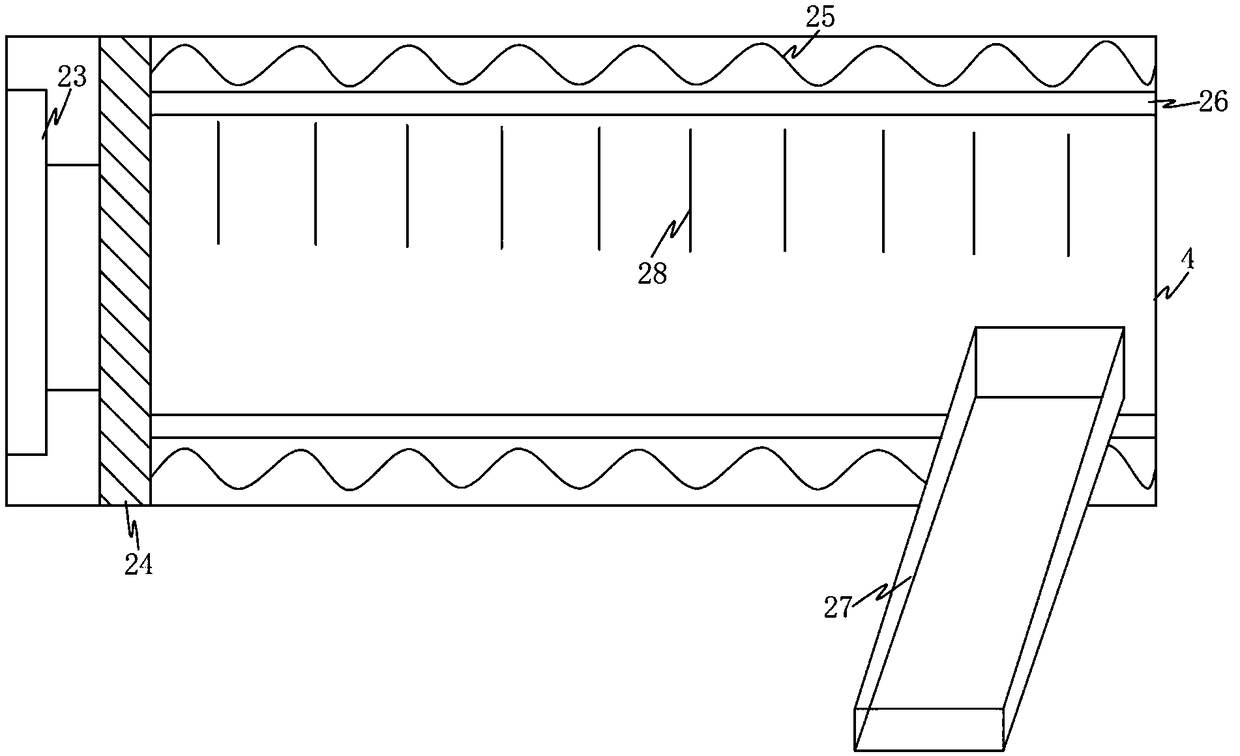

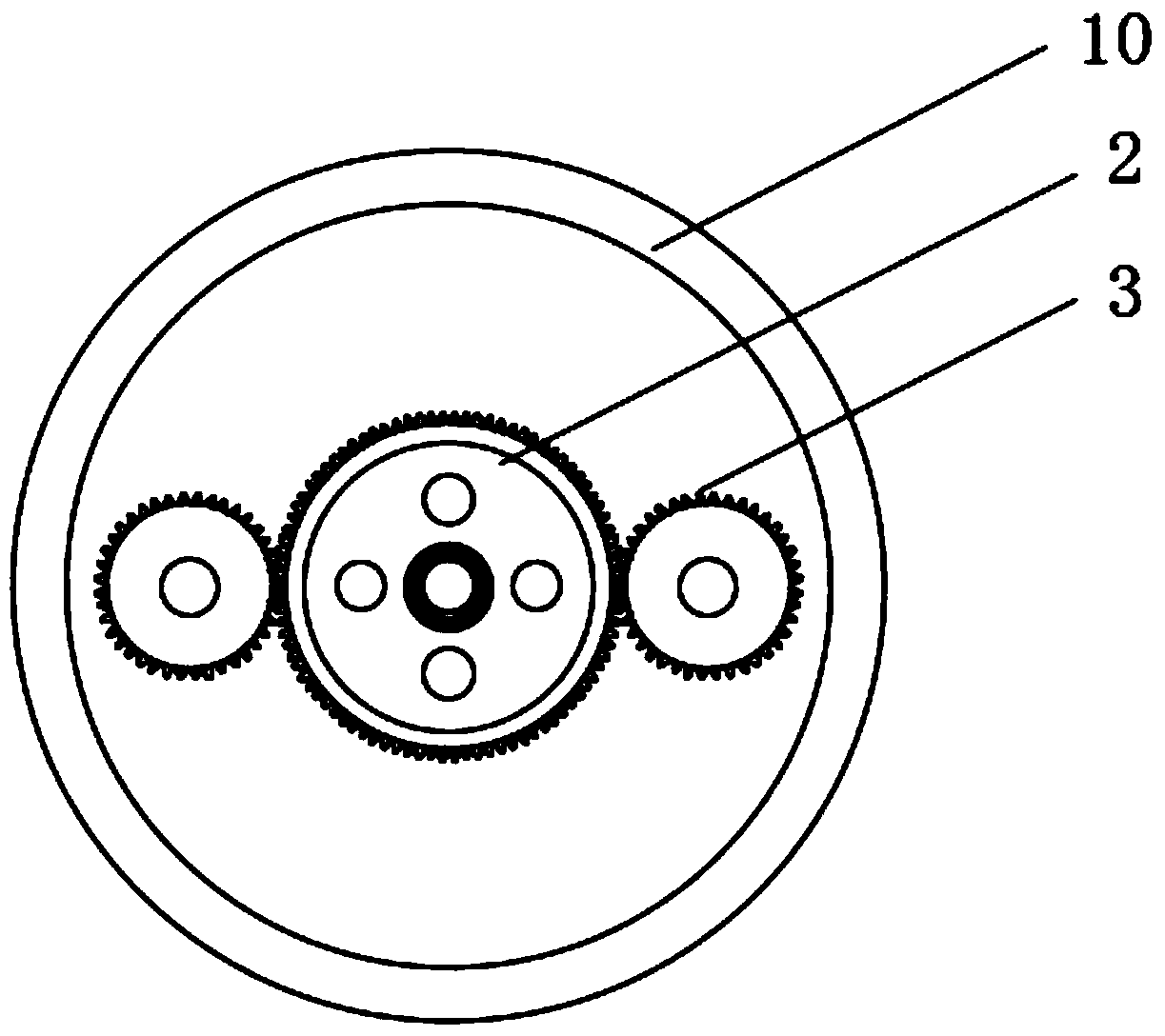

Raw material stirring and mixing device for bond paper production

InactiveCN108786574AStir evenlyHigh precisionRotary stirring mixersTransportation and packagingGear drivePaper production

The invention discloses a raw material stirring and mixing device for bond paper production. The stirring and mixing device comprises a servo motor and a device body. A sun gear is arranged at one endof the servo motor in a transmission mode, and a stirring paddle is arranged at the bottom of the sun gear in the device body. One side of the sun gear is connected to a planetary gear in the rotating meshing mode, and the bottom end of the planetary gear located inside the device body is provided with an auxiliary paddle in the rotating mode. The servo motor provided by the device is utilized todrive the stirring paddle through the sun gear to stir raw materials inside the device body, and the planetary gear drives the auxiliary paddle to rotate in the opposite direction during stirring, sothat the raw materials are more evenly stressed during stirring, and the working efficiency of stirring and mixing and the uniform quality of stirring are greatly improved. Further, a heating plate arranged on the surface of the stirring paddle is utilized to heat the mixed raw materials to improve the molecular activity, and the raw materials can be uniformly mixed even in a cold climate.

Owner:芜湖韩大防伪科技有限公司

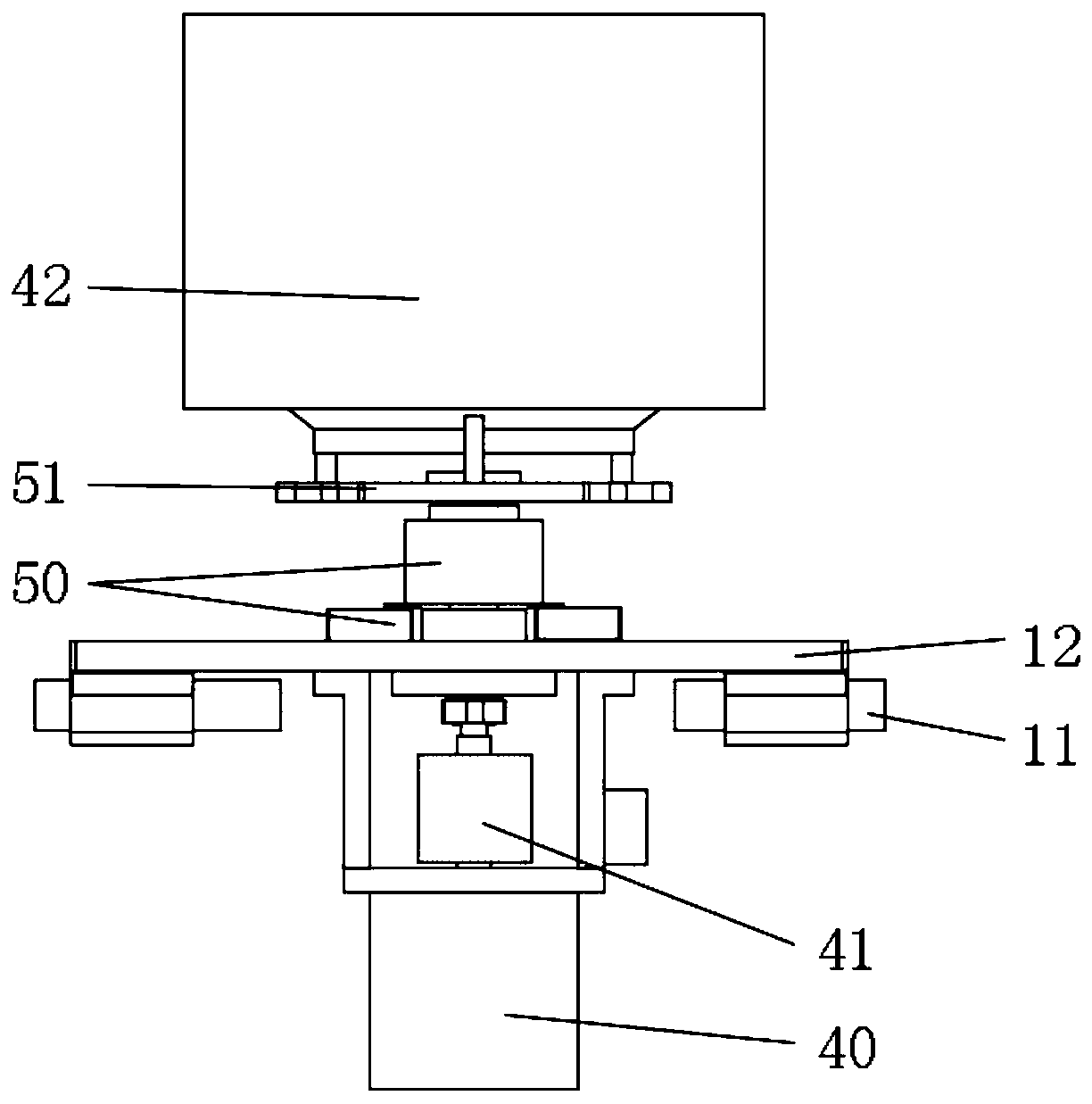

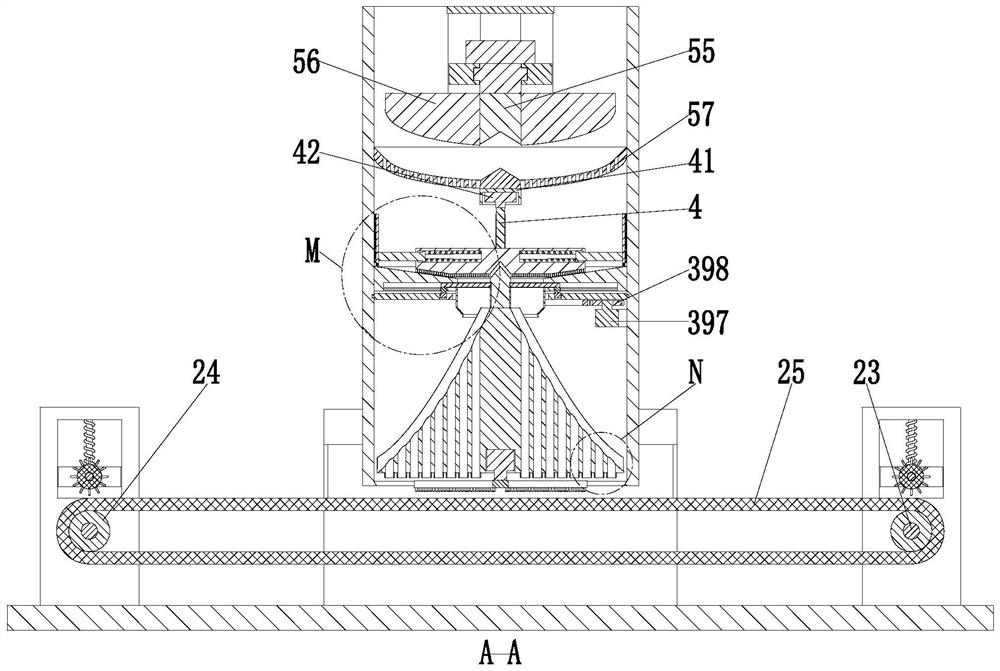

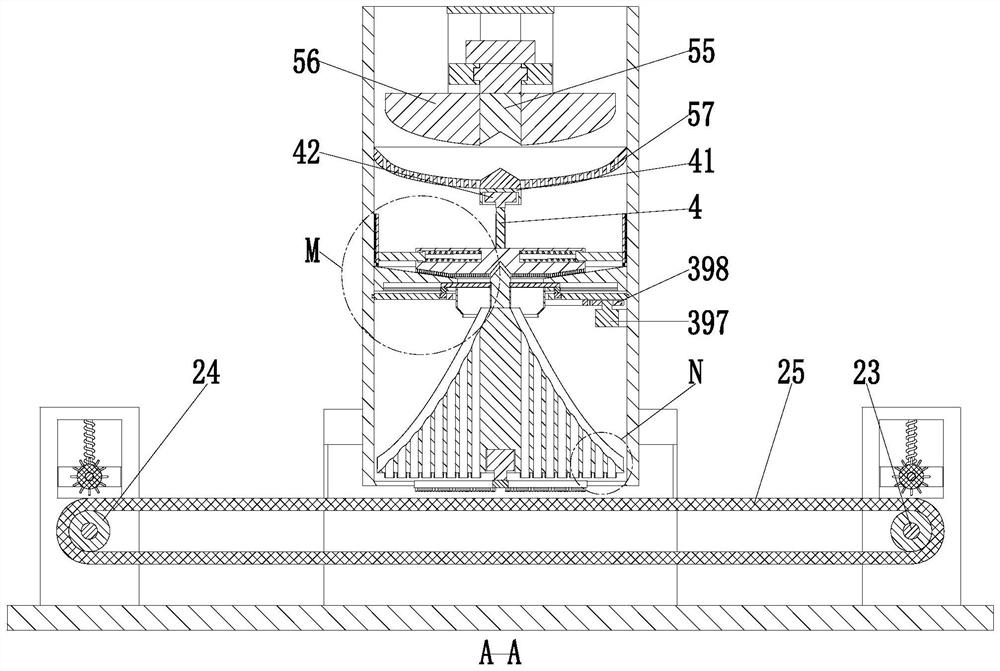

Coaxial opposite-direction self-unloading stirring equipment for promoting uniform mixing of chemical raw materials

ActiveCN110585967AStir wellStir well stir wellShaking/oscillating/vibrating mixersTransportation and packagingEngineeringUltimate tensile strength

Owner:山西瑞峰百合化工有限公司

Portable fire extinguishing device

InactiveCN110604889ABetter rescue measuresRescue measures are goodFire rescueVehicle frameWater discharge

The invention belongs to the technical field of fire-fighting and particularly relates to a portable fire extinguishing device. The problems that in the prior art, a fire extinguishing device is heavyand is not portable during running, fire which breaks out in a higher place cannot be extinguished in time, and the device materials are limited and cannot be supplemented in time are solved. In order to solve the technical problems, the portable fire extinguishing device provided by the invention comprises a body, a water spraying apparatus and an external-connection movable apparatus, and the external-connection movable apparatus comprises a filter, a fixing frame, a pipe winder, land wheel ascending plates, land wheels, a water discharging outlet, a multi-way valve and a vehicle frame pushhandle. The portable fire extinguishing device has the effects that pushing is convenient, the fire extinguishing materials can be supplemented in time, the spraying distance is long, and the devicecan adapt to various occasions.

Owner:安徽新兴翼凌机电发展有限公司

Coaxial and counter-rotating self-unloading mixing equipment to promote uniform mixing of chemical raw materials

ActiveCN110585967BStir wellStir well stir wellShaking/oscillating/vibrating mixersTransportation and packagingBLENDER/MIXERProcess engineering

Owner:山西瑞峰百合化工有限公司

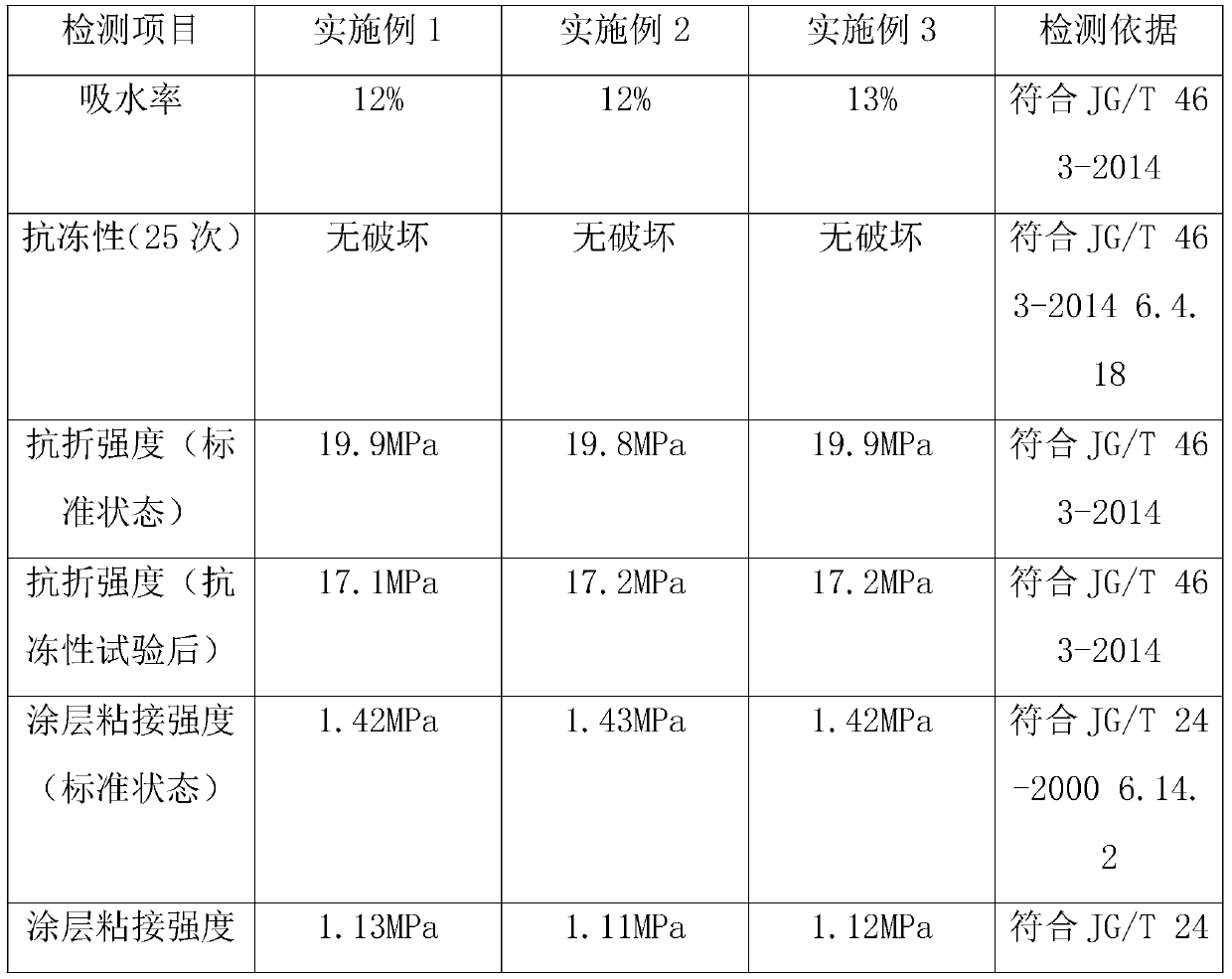

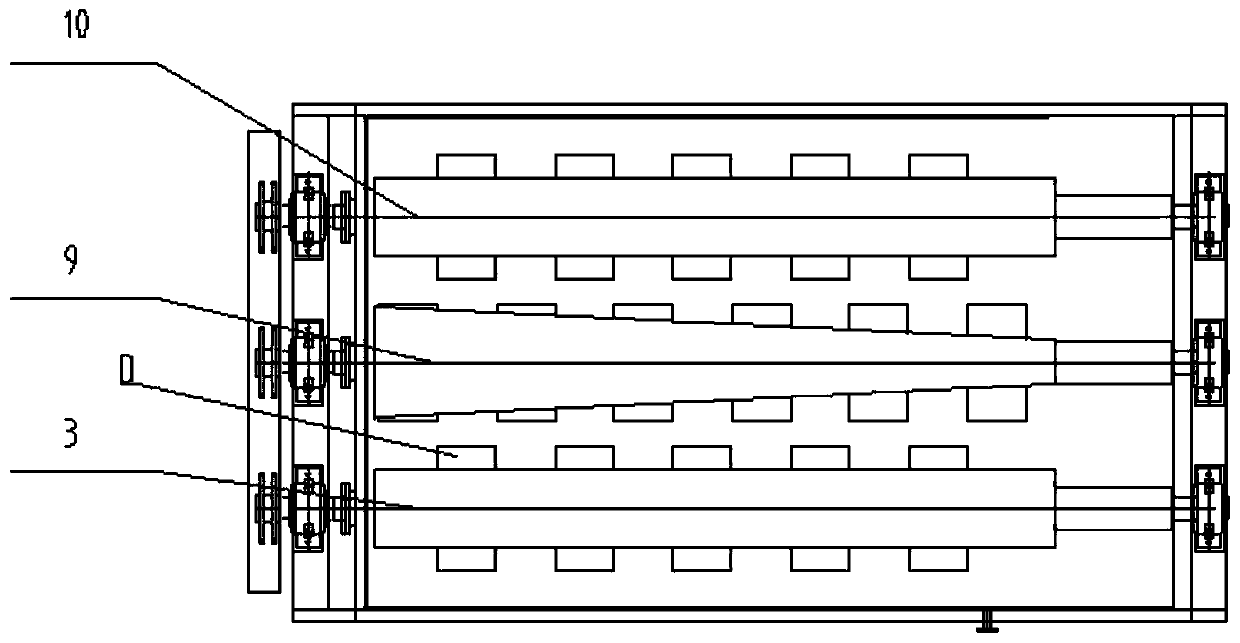

Stone slab processing system and processing method thereof

PendingCN110281402ARealize processing automationReduce in quantityPolishing machinesGrinding machinesEngineeringMachining system

The invention discloses a stone slab processing system. The stone slab processing system comprises a slab feeding device, a spraying device, a steam curing device, a surface treatment device, a cutting device and a slab discharging device. A pretreated stone slab sequentially passes through the slab feeding device and a conveying line to be conveyed to the spraying device, and a decoration layer is sprayed; the stone slab obtained after spraying is carried out is conveyed to the steam curing device to be subjected to steam curing; the stone slab obtained after steam curing is carried out stands for 72-96 hours at normal temperature, and then the stone slab is conveyed to the surface treatment device through the conveying line to be subjected to surface treatment; dust on the surface of the stone slab obtained after surface treatment is carried out is cleared up, and the stone slab is evenly coated with a protection film; and the stone slab coated with the protection film is conveyed to the cutting device through the conveying line to be cut according to needs, an edge groove is formed in the transverse edge of the stone slab, a finished stone slab is obtained, and finally the slab is discharged through the slab discharging device. According to the stone processing system, processing automation of the stone slab can be achieved, the number of field operators is reduced, and the production efficiency is improved.

Owner:河北大自然石材有限公司

Raw material stirring device for manufacture of plastic shells for electronic products

The invention relates to the field of manufacture of electronic product shells, in particular to a raw material stirring device for manufacture of plastic shells for electronic products, aiming at overcoming the defect of uneven stirring in the prior art. The raw material stirring device comprises a shell and a stirring device, wherein the shell has a biliary structure, and a mounting plate is rotatably connected with the upper part of the shell; the stirring device is installed at the lower side of the mounting plate, a push rod motor is installed at the upper side of the mounting plate, andan output end of the push rod motor is connected with a connecting rod; the lower end of the connecting rod is fixedly connected with a connecting plug, and a sealed bearing sleeves the upper part ofthe connecting plug; the lower end of the shell is fixedly connected with a discharge pipe, and the inner wall of the discharge pipe is provided with a connecting groove. The device is simple in structure, and can be used for stirring around the wall of a container; the sealed bearing can extend into the inside of the discharge pipe, block the discharge pipe at the bottom and rotate along with thestirring device, thereby avoiding the accumulation of materials in the discharge pipe; the device is good in stirring effect and smooth in material drop, and reduces the waste of raw materials.

Owner:浙江亚鼎科技有限公司

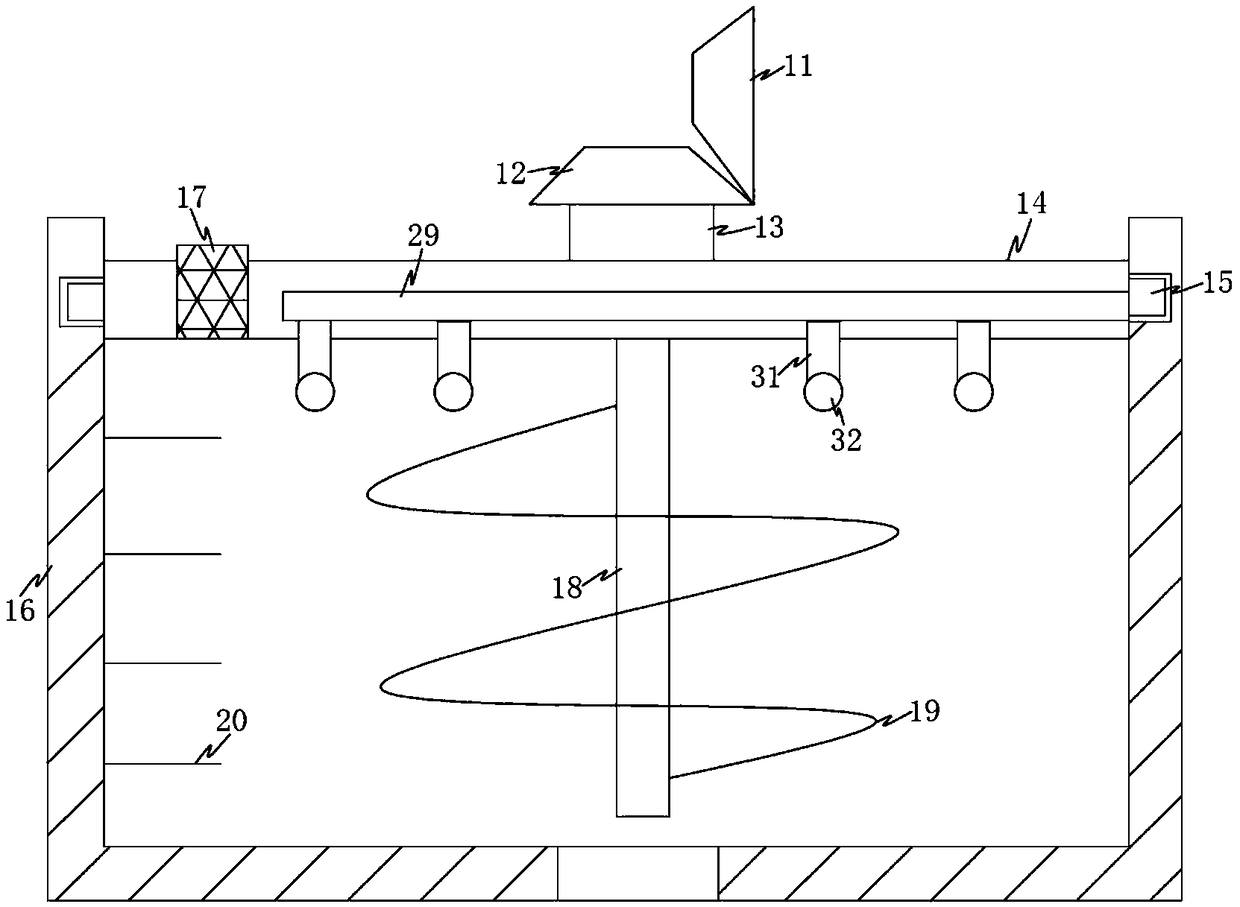

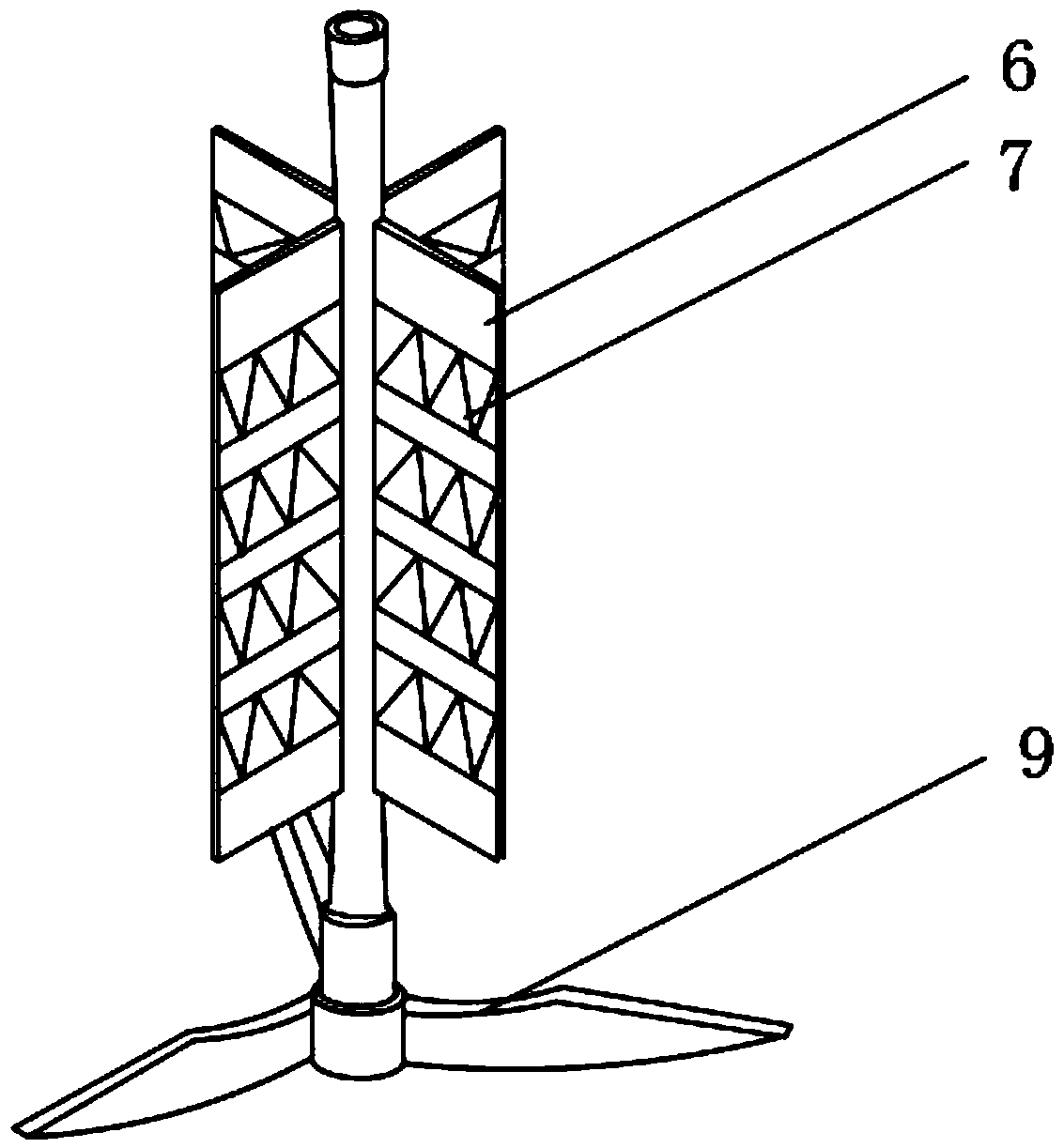

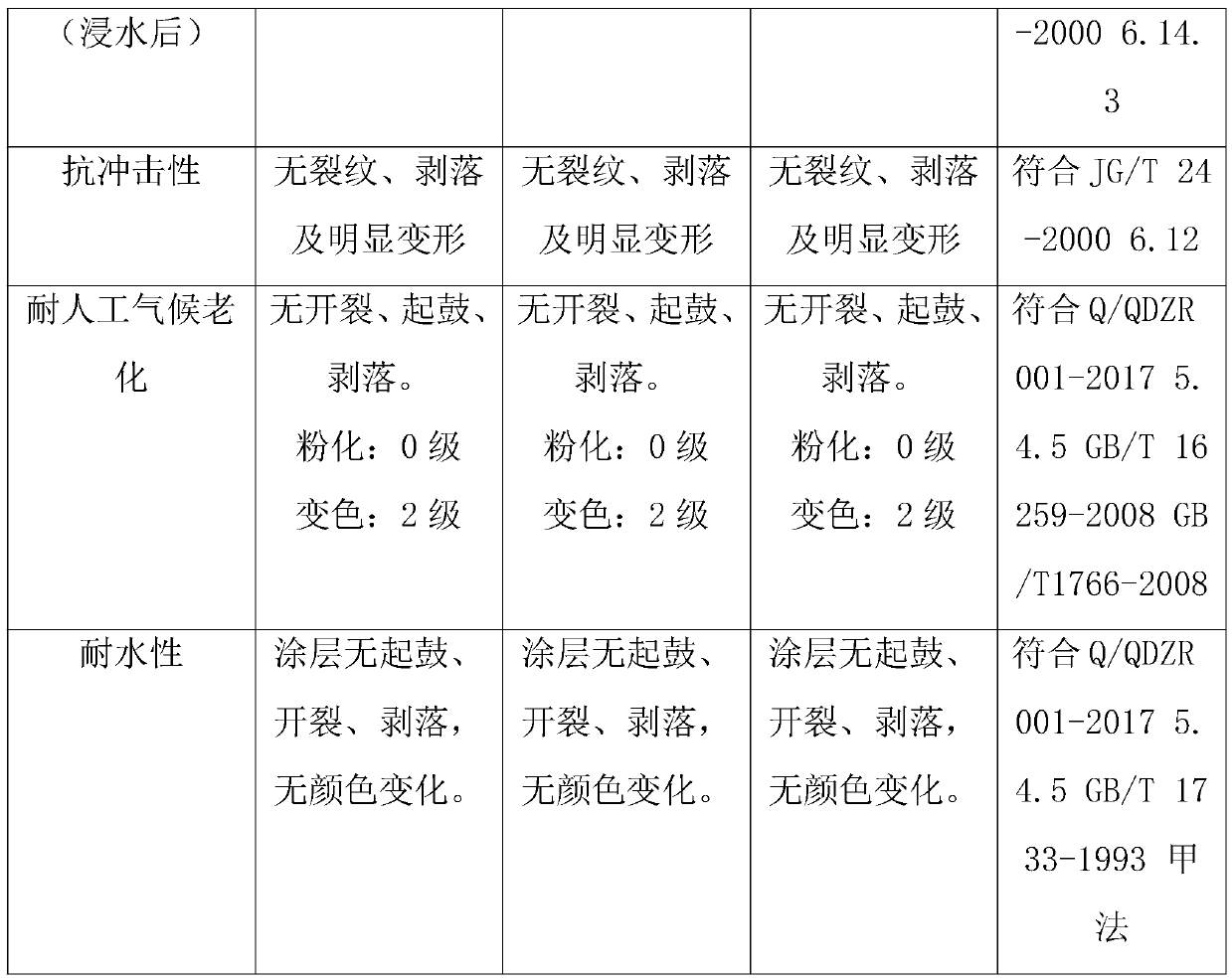

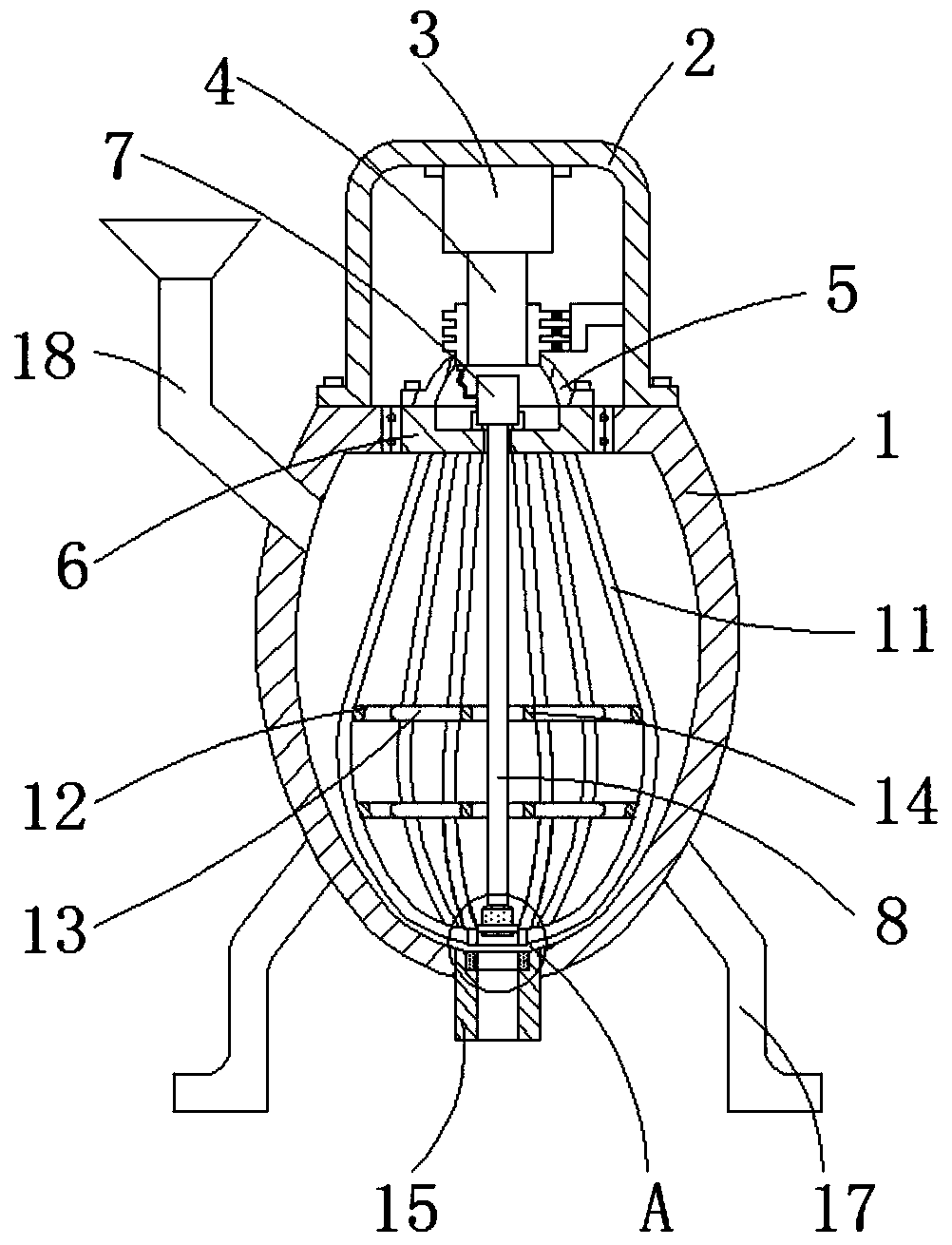

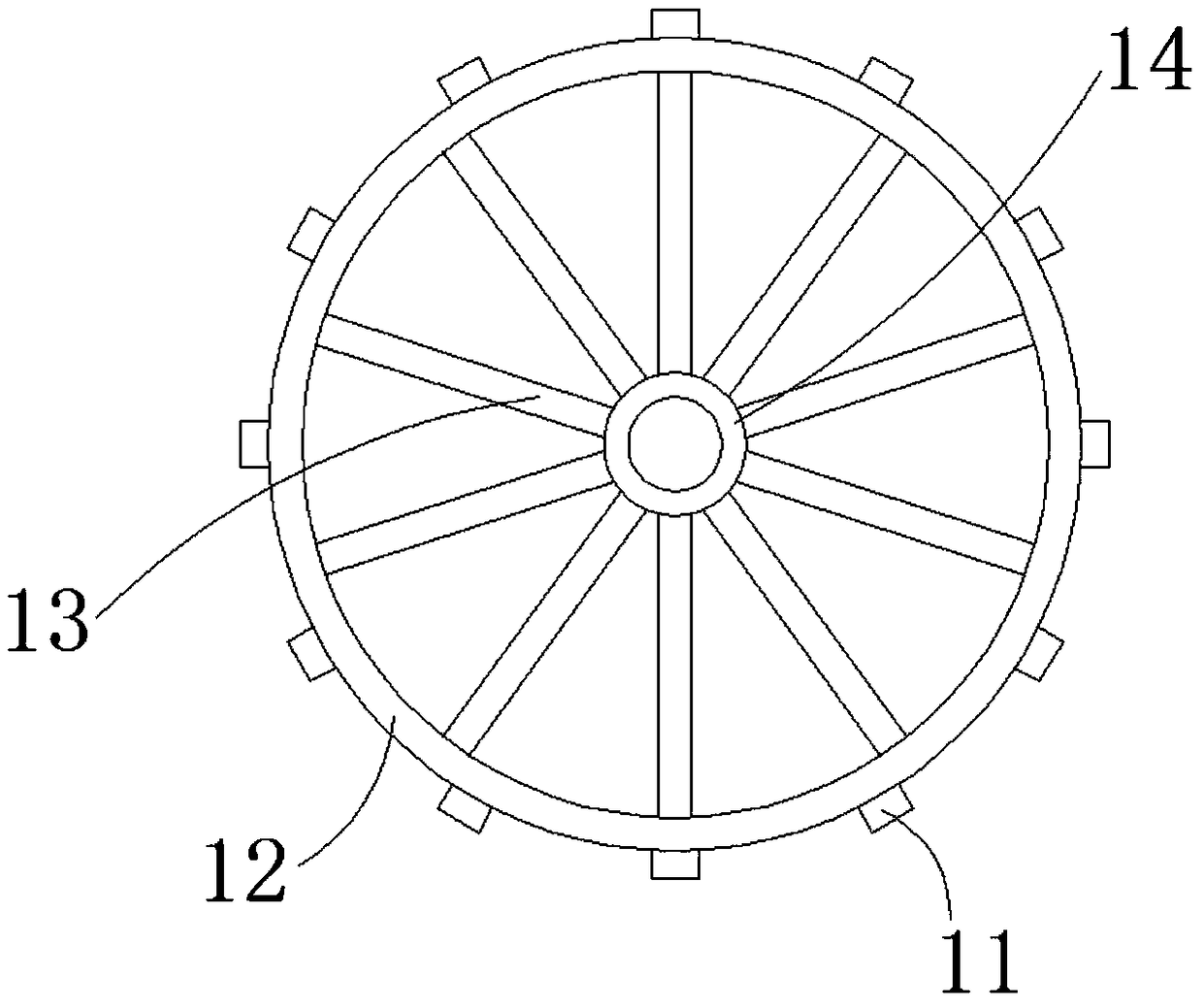

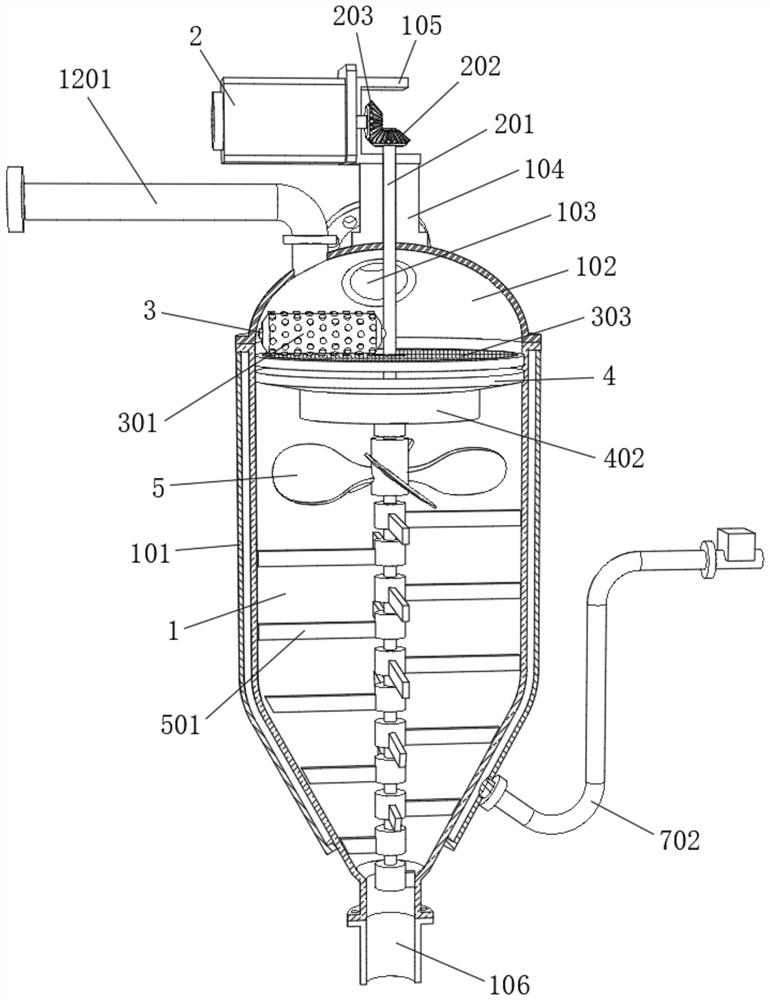

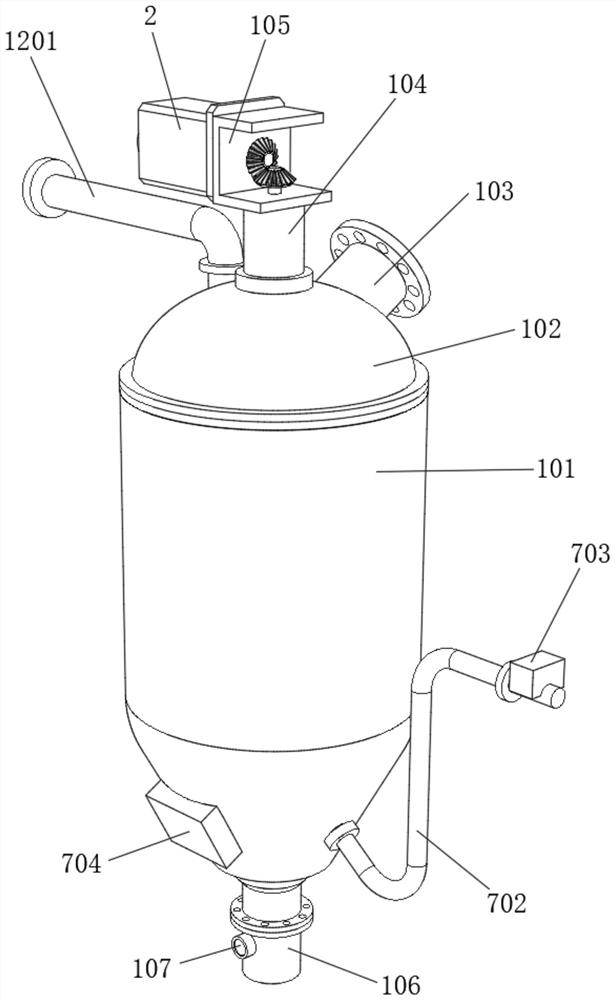

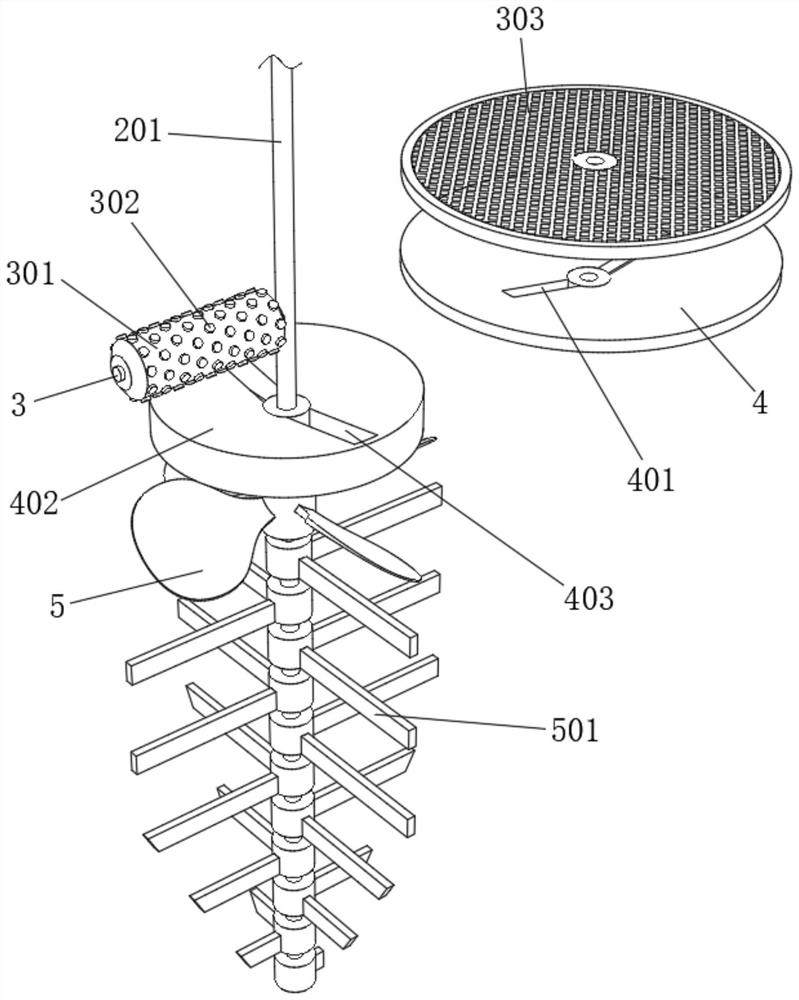

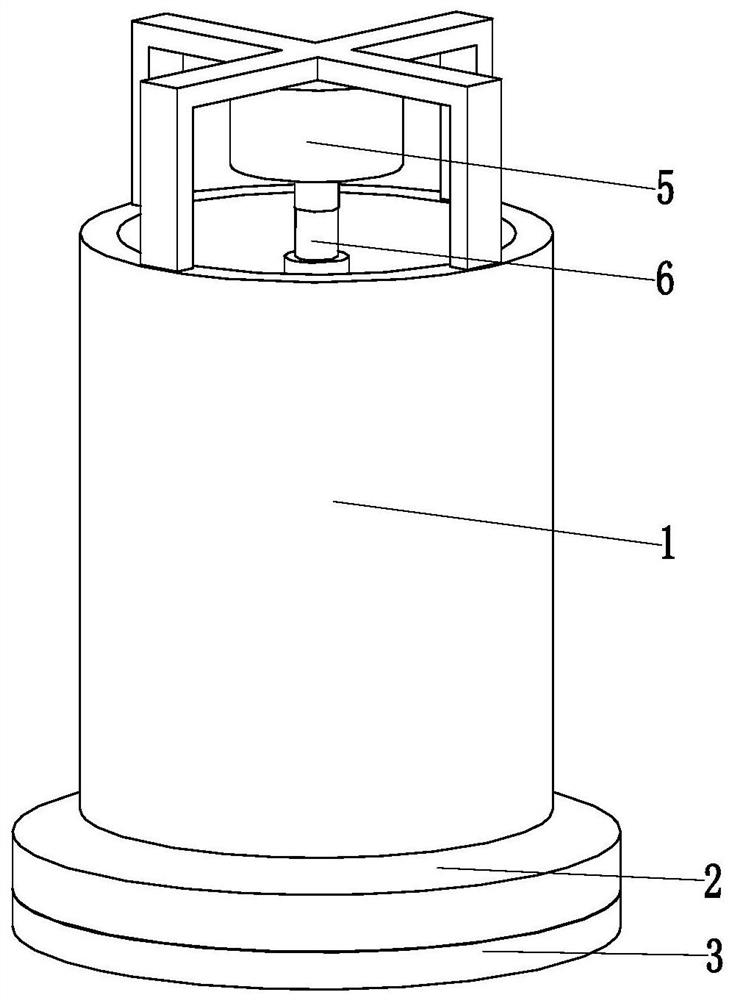

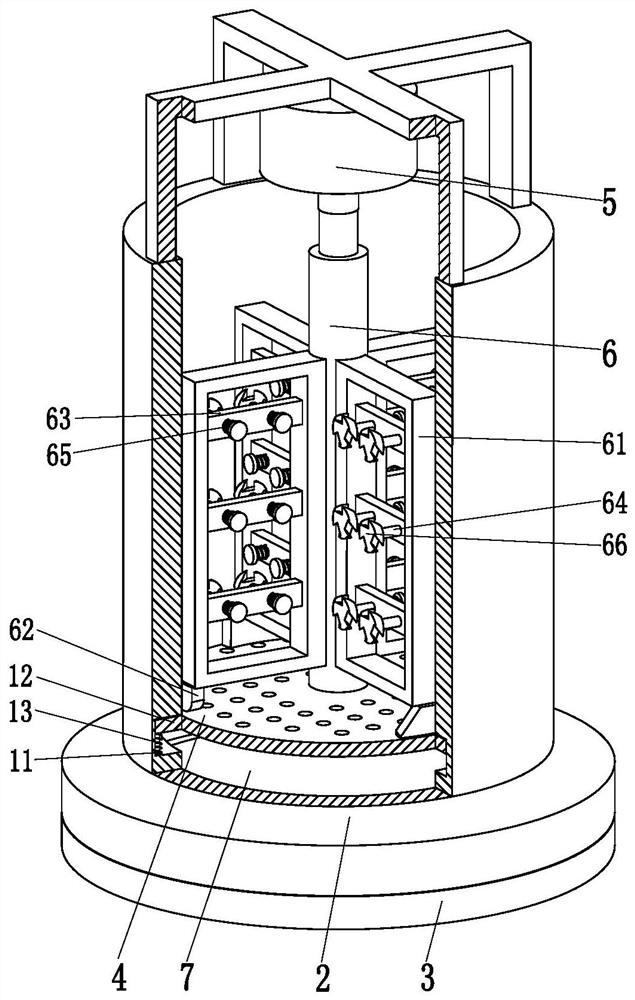

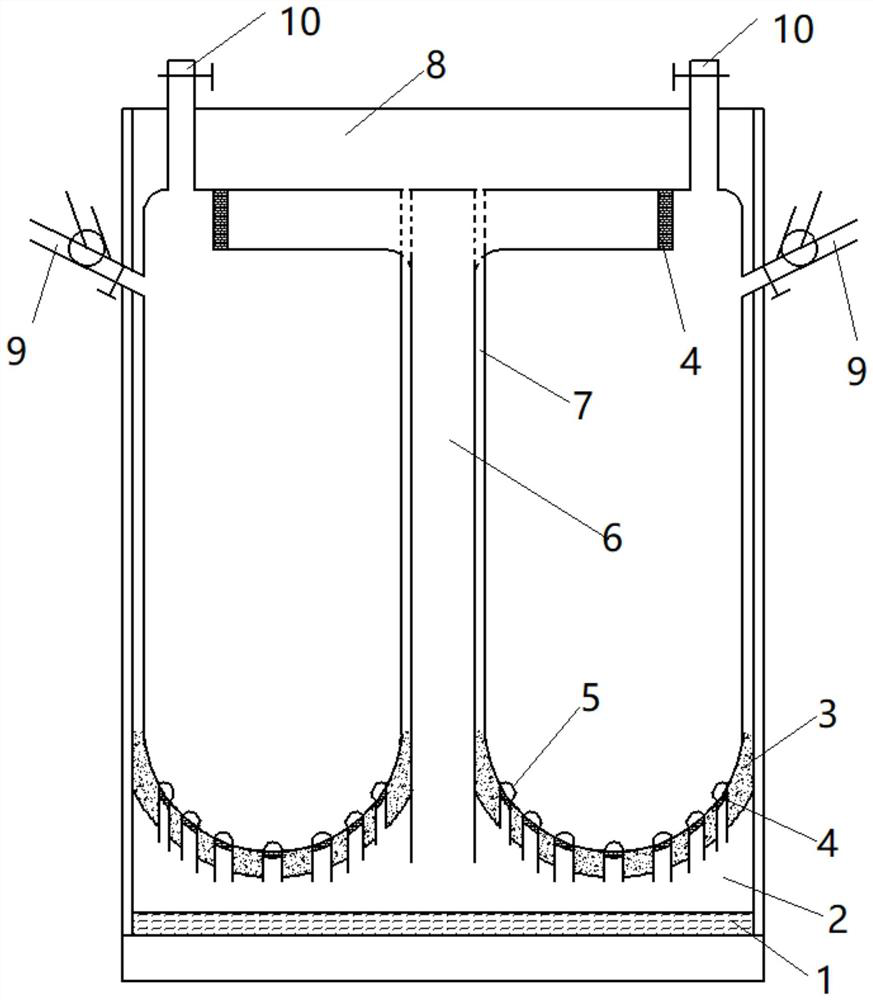

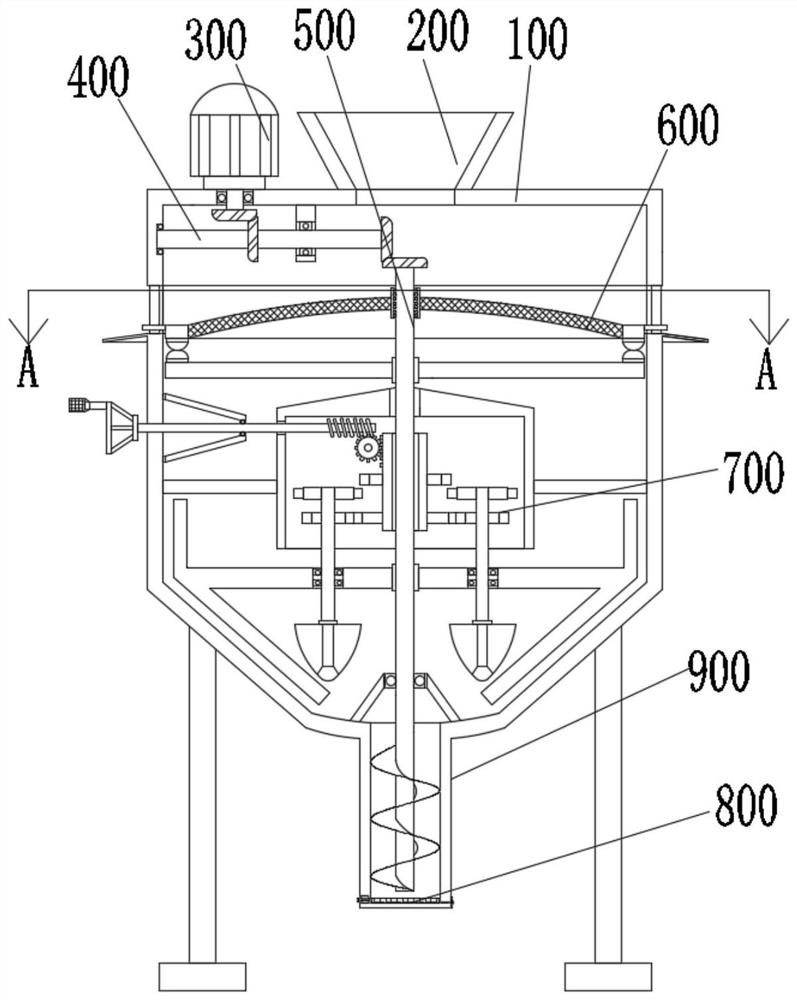

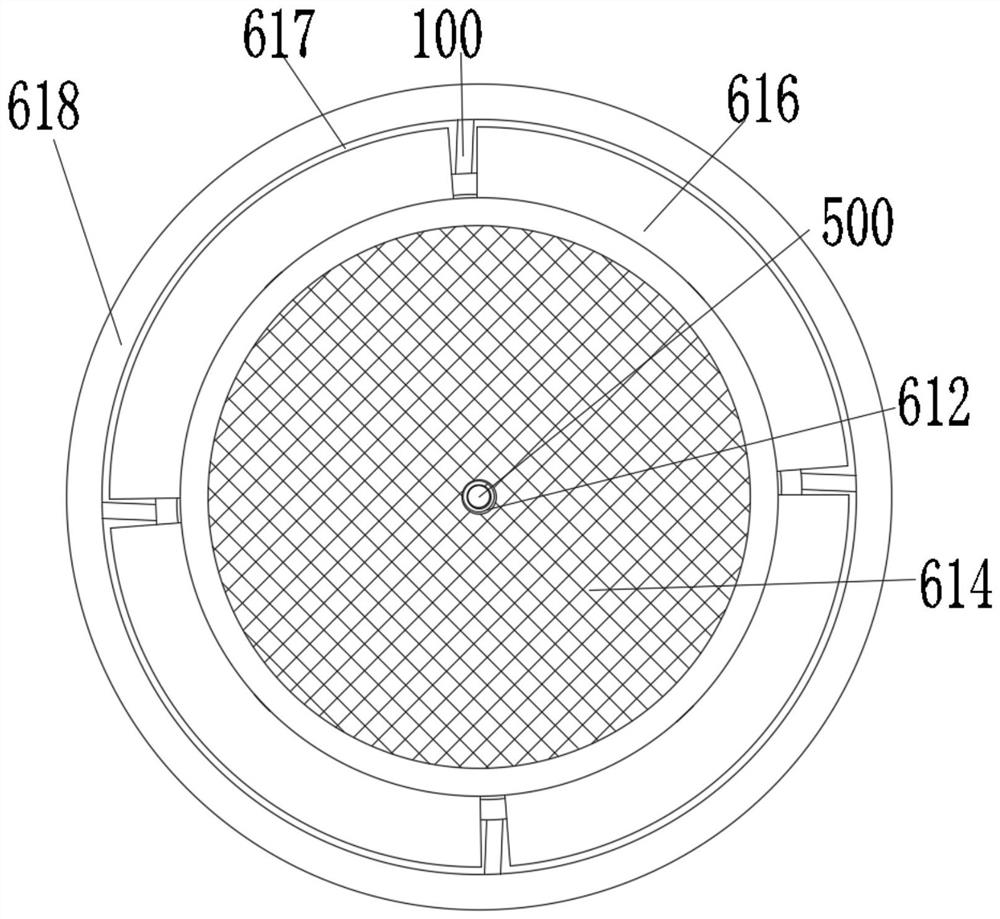

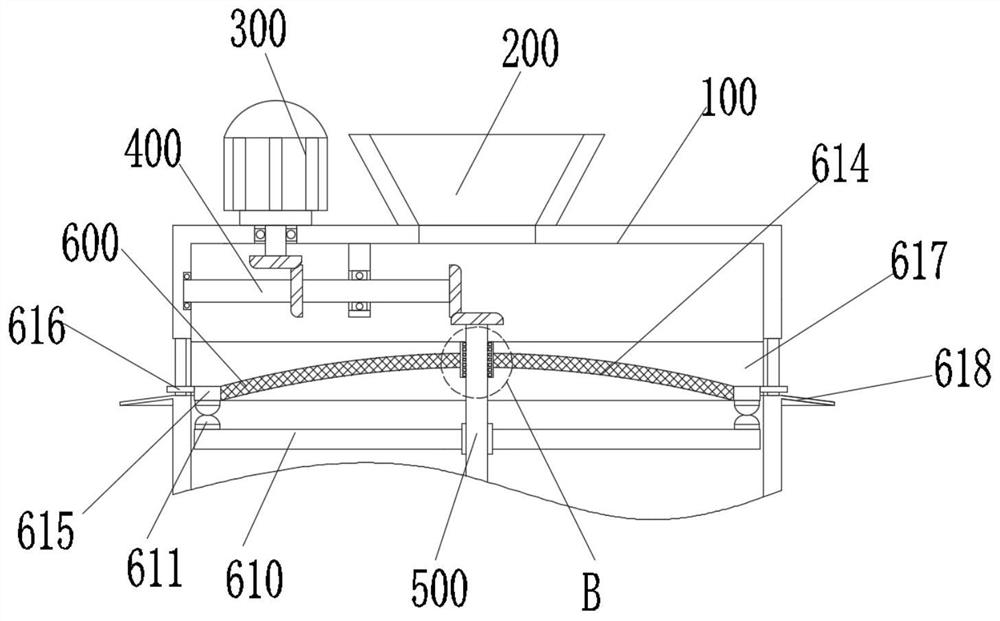

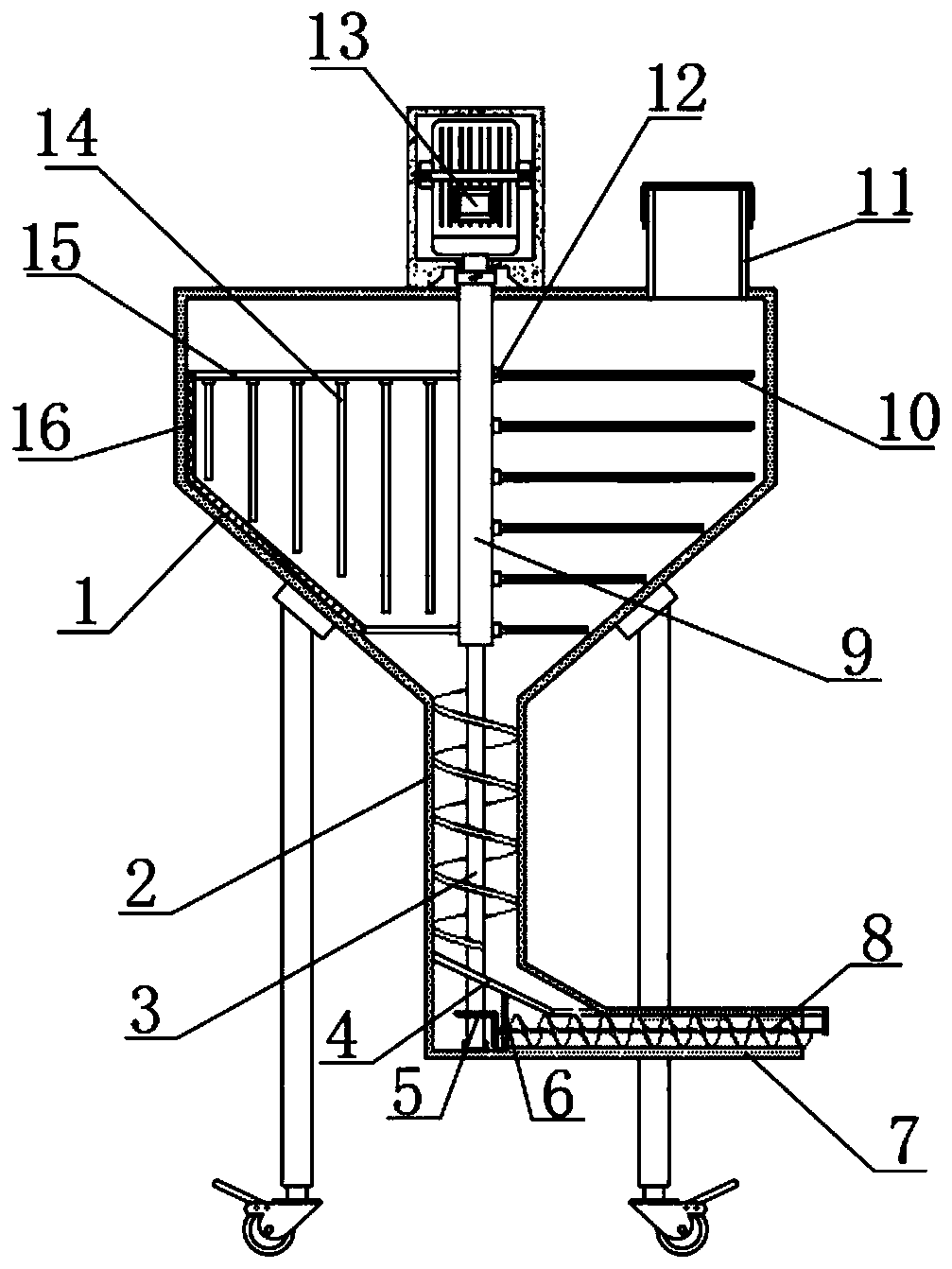

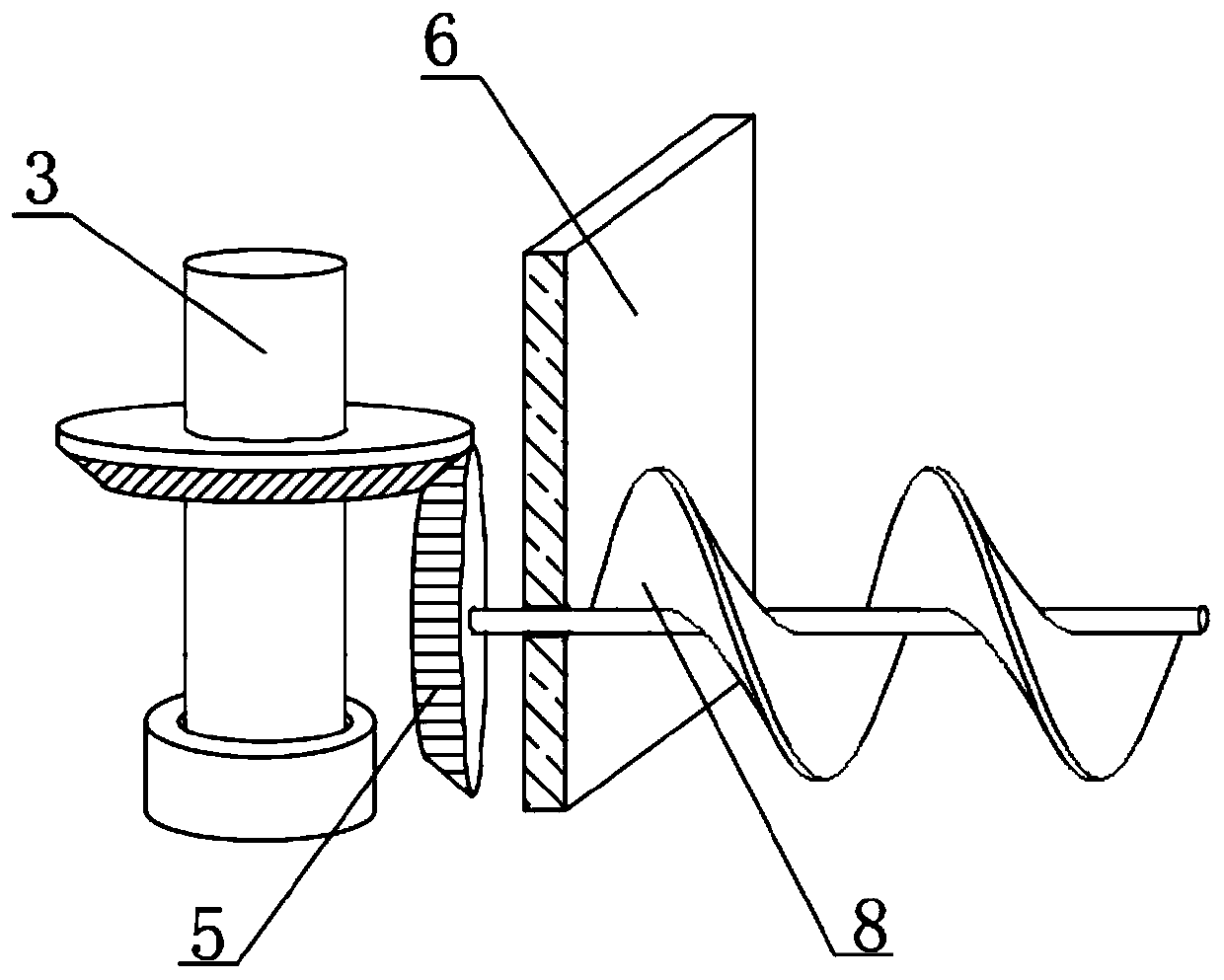

Vertical sludge drying machine

PendingCN113511795AUniform conveyingKeep drySludge treatment by de-watering/drying/thickeningSludgeElectric machinery

The invention relates to the technical field of sludge drying machines, and discloses a vertical sludge drying machine which comprises a bottom plate and a reaction kettle; the outer surface of the reaction kettle is sleeved with a shell, an oil guide layer is arranged between the shell and the reaction kettle, the top of the reaction kettle is fixedly connected with a cover body, and a feeding pipe is inserted into the top of the cover body; a filter plate and a first conical plate are fixedly connected to the top of the circumferential inner wall of the reaction kettle, the filter plate and the first conical plate are arranged up and down, and a discharging opening is formed in the upper surface of the first conical plate; a supporting column is fixedly connected to the upper surface of the cover body, a C-shaped base is fixedly connected to the top of the supporting column, and a motor is fixedly connected to one side of the C-shaped base; and one end of an output shaft of the motor is fixedly connected with a longitudinal bevel gear. According to the vertical sludge drying machine, the discharging opening can be indirectly opposite to a material passing opening, so that sludge can be conveyed at a constant speed, sludge drying in the later period is facilitated, and the dryness of the sludge is guaranteed.

Owner:QINGDAO ZHONGWANFANG ENERGY TECH CO LTD

Master batch special for flexible containers

ActiveCN107141606AImprove and enhance the processImprove and enhance physical propertiesCouplingAdditive ingredient

Belonging to the technical field of woven bag added auxiliary materials, the invention relates to a master batch special for flexible containers. The master batch is characterized by comprising the following raw materials by weight: 7-9 parts of polypropylene powder, 1.3-1.7 parts of POE, 0.8-1.3 parts of EVA, 100 parts of calcium carbonate, 0.017-0.023 part of an antioxidant 1010, 0.026-0.034 part of an anti-ultraviolet agent, 1.3-1.7 parts of an aluminic acid ester coupling agent, 1.3-1.7 parts of stearic acid, 1.3-1.7 parts of zinc stearate, and 6-9 parts of polyethylene wax. The sub-nanometer scale master batch special for flexible containers and woven bags provided by the invention can improve and enhance the technological performance and physical properties of woven bags, and also can be added by a maximum dosage under the premise, thus lowering the ingredient cost.

Owner:淄博聚鑫丰塑胶科技有限公司

Surface insulation spraying device and spraying process of electronic component

The invention discloses a spraying device. The spraying device comprises a spraying unit, a dip angle unit, a rotating unit and a heating unit; a spraying process is characterized by comprising the following steps of placing components into a sealed roller, wherein the ratio of the volume of the component stack to the volume of the roller is 1:8 to 10; heating the bottom of the roller to be 95-105DEG C and then enabling the roller to perform rotation; providing an epoxy resin mixed solution, atomizing the epoxy resin mixed solution to spray into the roller by a spraying gun, wherein the distance between the spraying gun and the component is 80-120mm, and the spraying amount of the epoxy resin mixed solution is 1.5-5 ml / min; meanwhile, injecting hot air into the roller, wherein the temperature of the hot air is 75-85 DEG C, the pressure is not greater than 0.2MPa, and the gluing rate of the product is 5-10[mu]m / min; and after the spraying time is reached, completing spraying. By adoption of the method, thermal spraying can be realized, the spraying reliability, the controllability and the uniformity are strong, the oxidation resistance and salt mist corrosion resistance after beingsprayed are high, the spraying time is short, and the efficiency is high.

Owner:SHENZHEN HUALUO ELECTRONICS CO LTD

Constant-temperature low-voltage spinning forming device for polymer fibers

ActiveCN108977898AStir evenlyImprove uniformityFilament/thread formingFilament-forming treatmentFiberLow voltage

The invention discloses a constant-temperature low-voltage spinning forming device for polymer fibers, and includes a supporting rack and a feeding mechanism arranged on the supporting rack, the output port of the feeding mechanism is connected with a strand silk cooling mechanism, a winding mechanism is arranged on the supporting rack, the feeding mechanism includes a material storage tank arranged on the supporting rack, a squeezing plug is arranged in the material storage tank, two plunger pumps are arranged on a side face of the material storage tank, the upper end of the material storagetank is provided with a feed pipe, a fixed supporting plate is arranged between the plunger pumps and the supporting frame, the outer side of the material storage tank is provided with a constant temperature-maintaining mechanism, the constant temperature-maintaining mechanism comprises a heat insulating plate that wraps the outer side of the material storage tank and a plurality of heating quartztubes uniformly arranged on the outer surface of the material storage tank, and a plurality of uniformly distributed soaking fans are arranged on the heat insulating plate. The uniformity of temperature and fluidity of materials is improved, so that the pressure of the polymer fibers arriving at a discharge capillary tube is unified, a spinning forming effect is good, an adverse effect of air disturbance on the fiber forming process is avoided and the production efficiency is improved.

Owner:ANHUI HEBANG TEXTILE TECH CO LTD

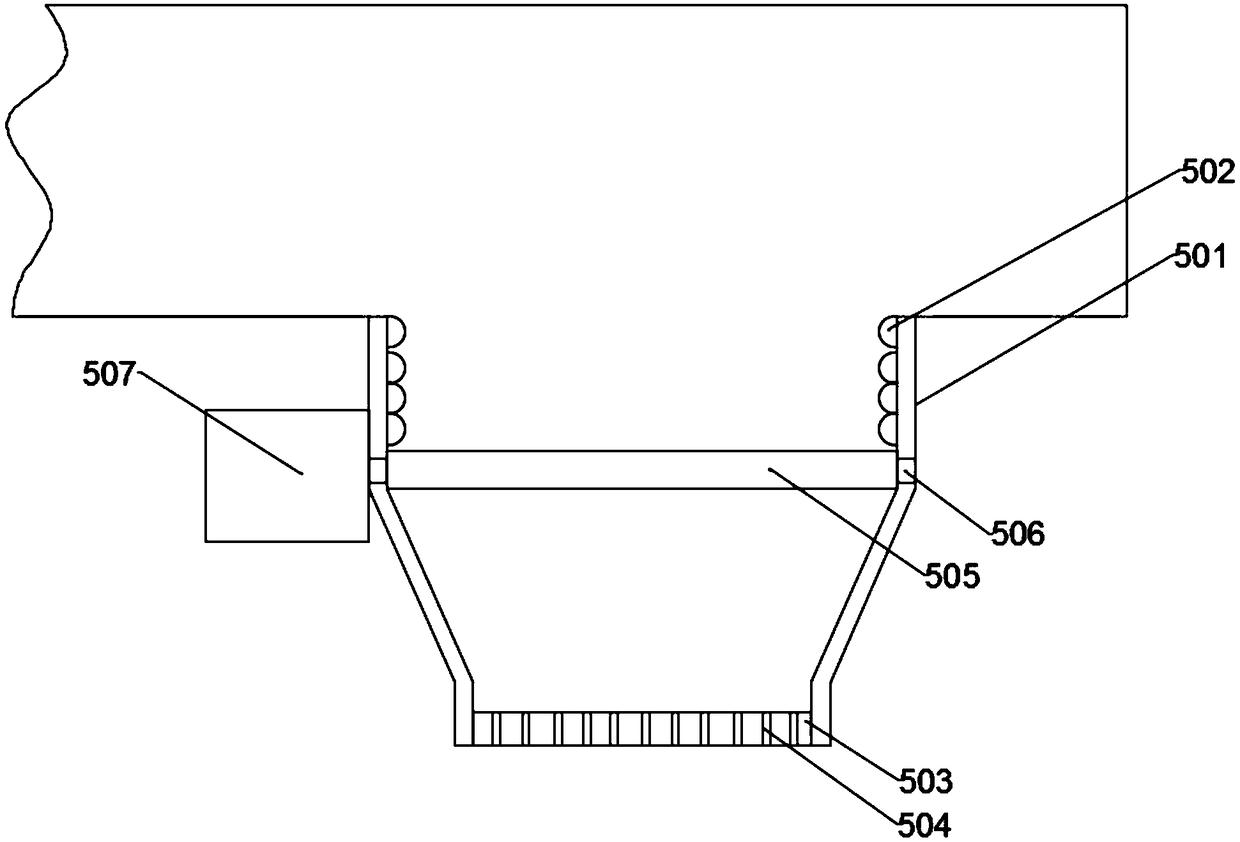

Processing equipment for solid-liquid separation

ActiveCN109883167AGuaranteed volatilityMeet the requirements of complete evaporationCoke ovensRetortsWaste processingPulp and paper industry

The invention provides processing equipment for solid-liquid separation, and relates to the technical field of solid-liquid waste processing. The processing equipment comprises a cylinder body, wherein a mixing cavity and a stirring assembly are formed in the cylinder body; the stirring assembly is rotatably arranged in the mixing cavity; protrusion parts are arranged in the cylinder body and arein a spiral shape, the protrusion parts enable the solid-liquid waste in the mixing cavity to perform high-speed and stable circular motion along the inner wall of the cylinder body; through mutual action of the protrusion parts and the stirring assembly, the heat generated by friction of the solid-liquid waste and the inner wall of the cylinder body is enabled to be stable, and the technical problems that in the prior art, the outer surface area of a grinding rod is small, friction of drilling cuttings is insufficient, the wear-resisting processing cost is high, the effect is poor, the temperature rising per unit time is not stable, the work-heat transformation rate is low, and only single waste can be processed are solved.

Owner:TIANJIN WENDA PETROLEUM DRILLING ENG EQUIP

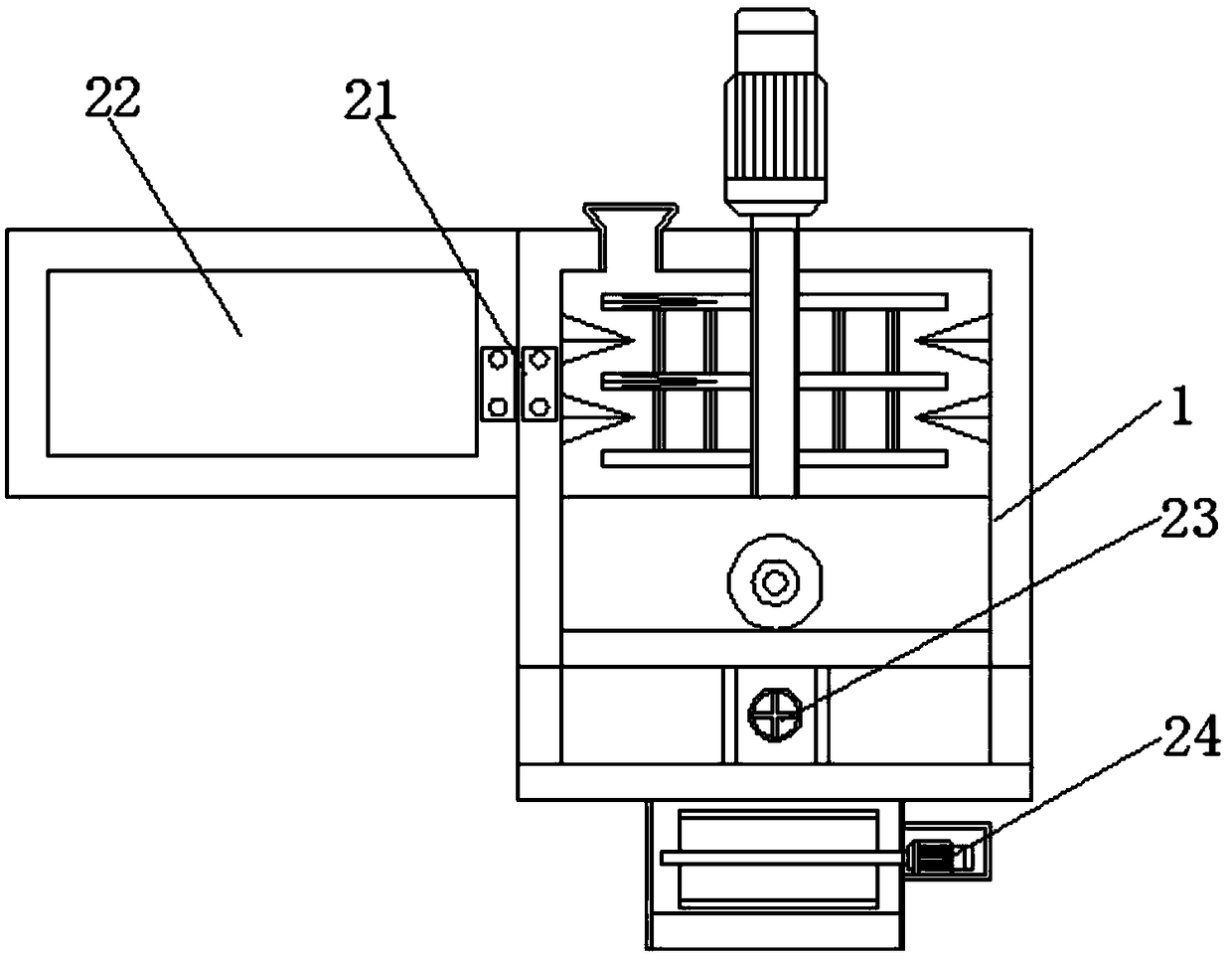

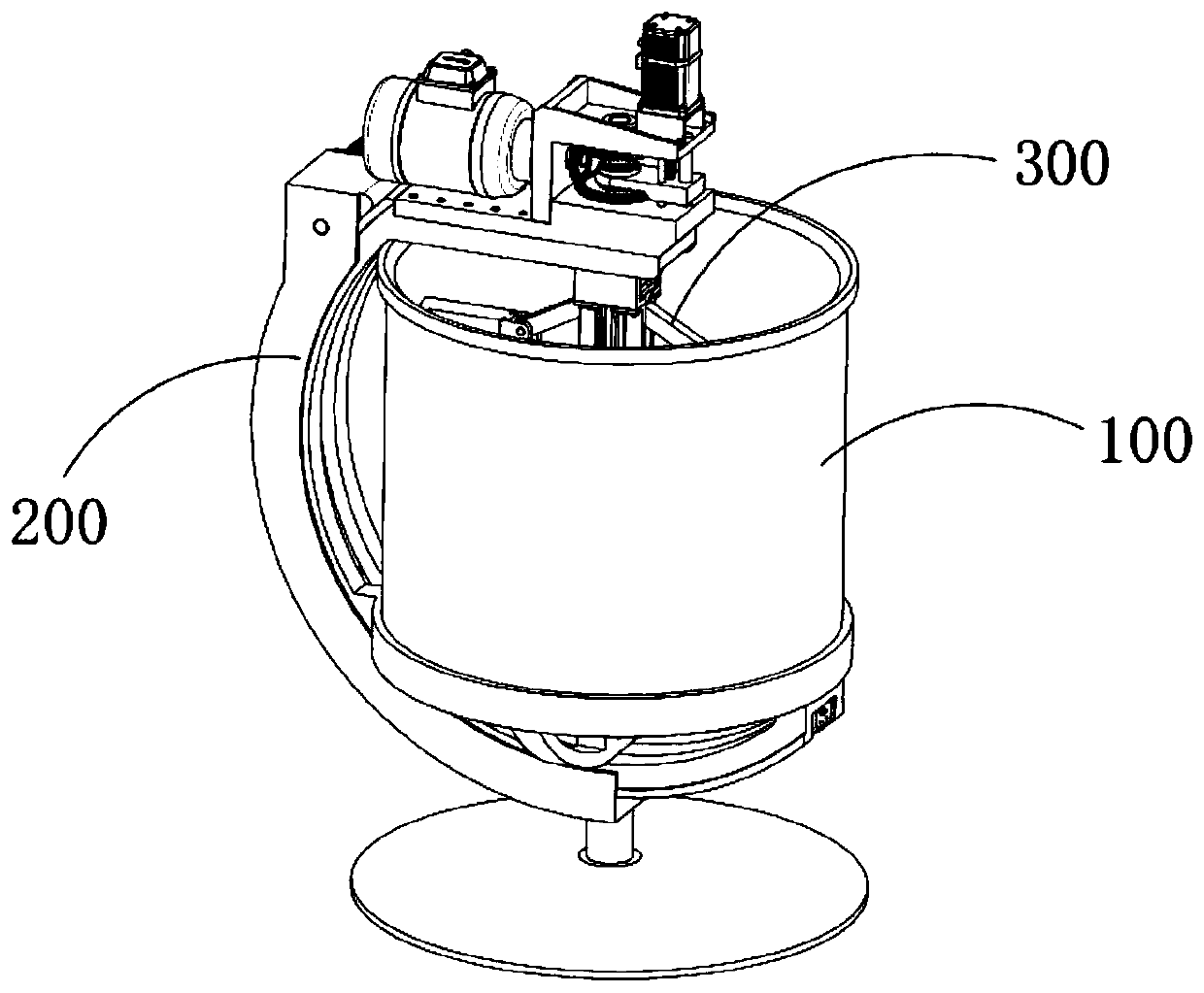

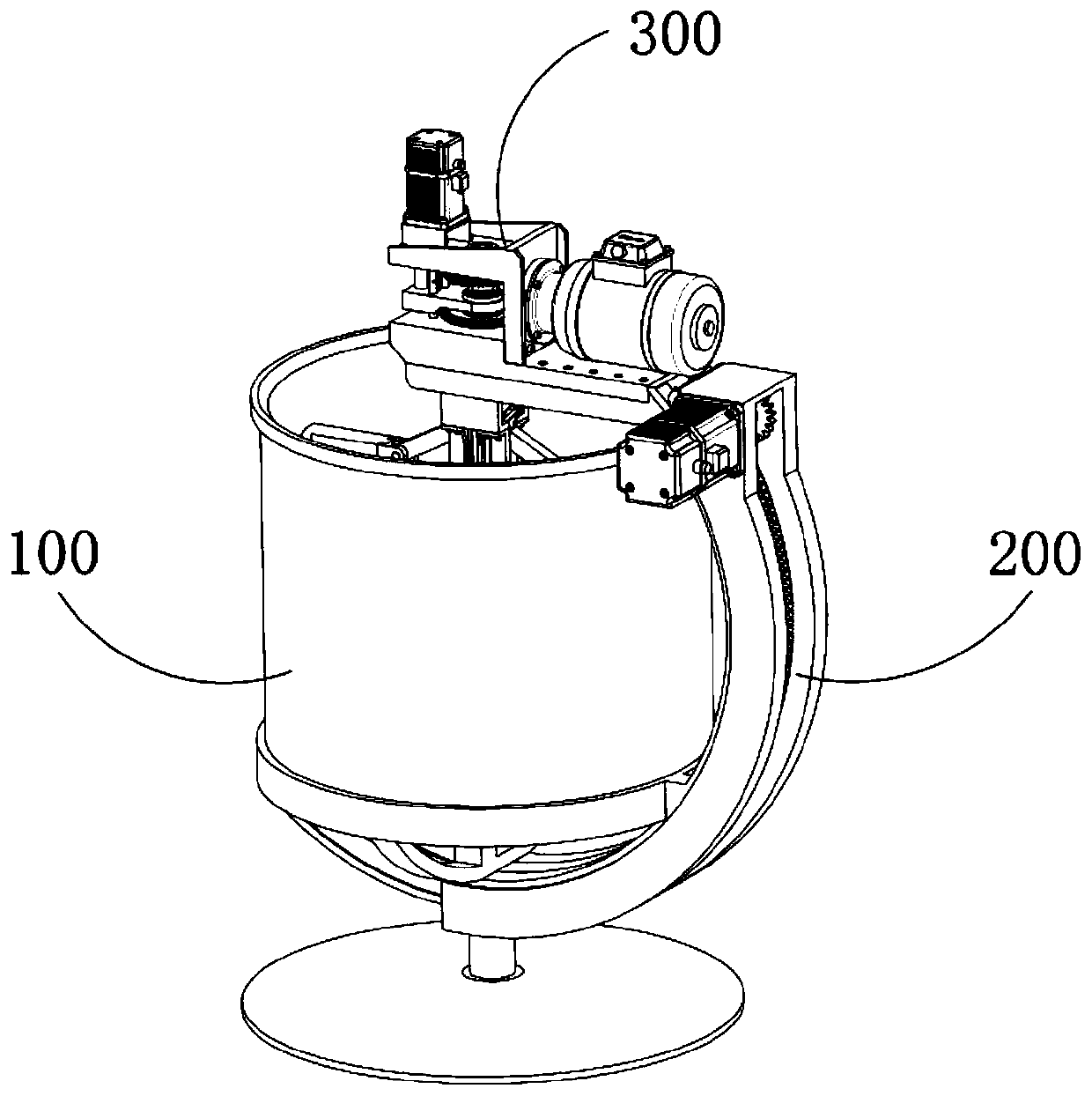

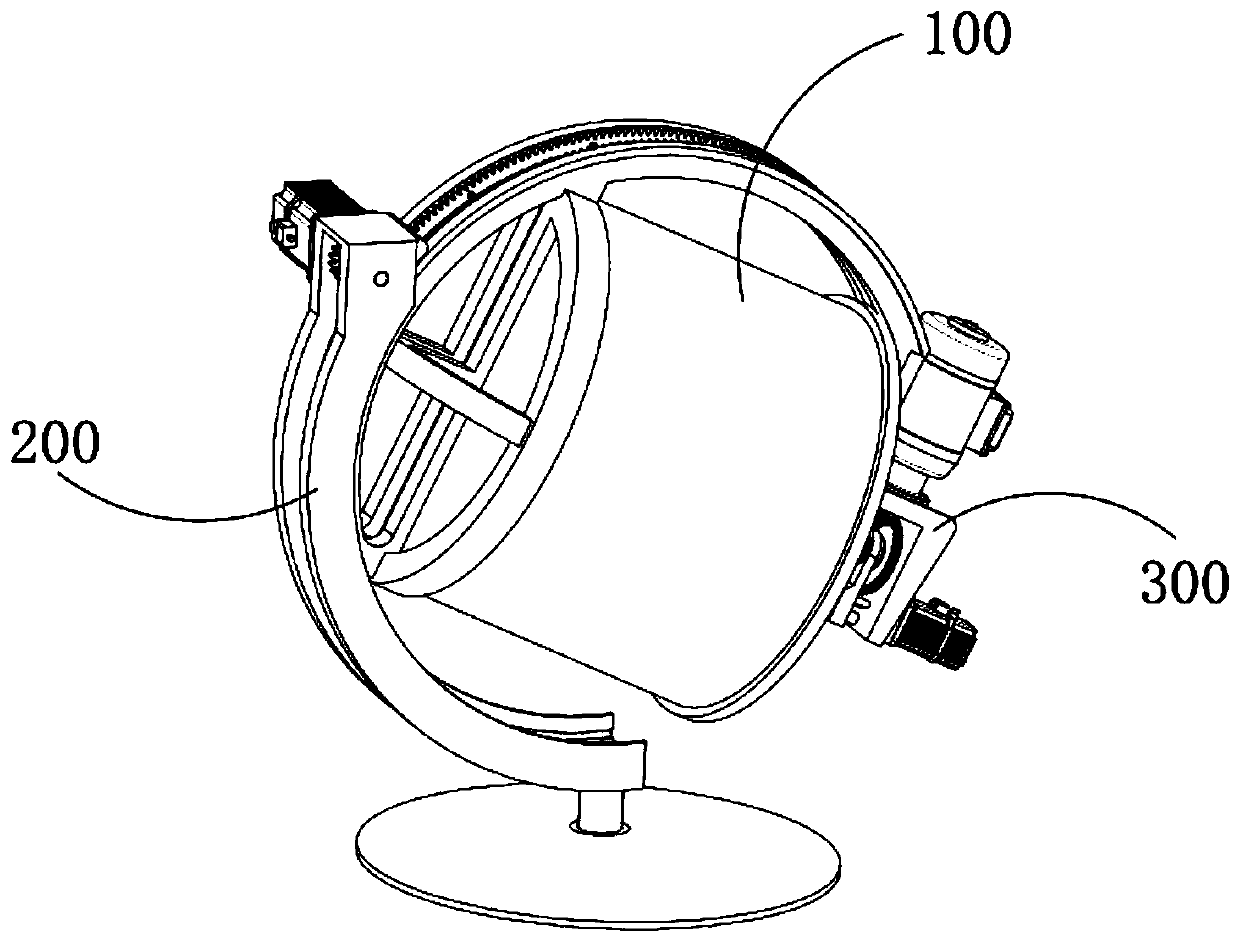

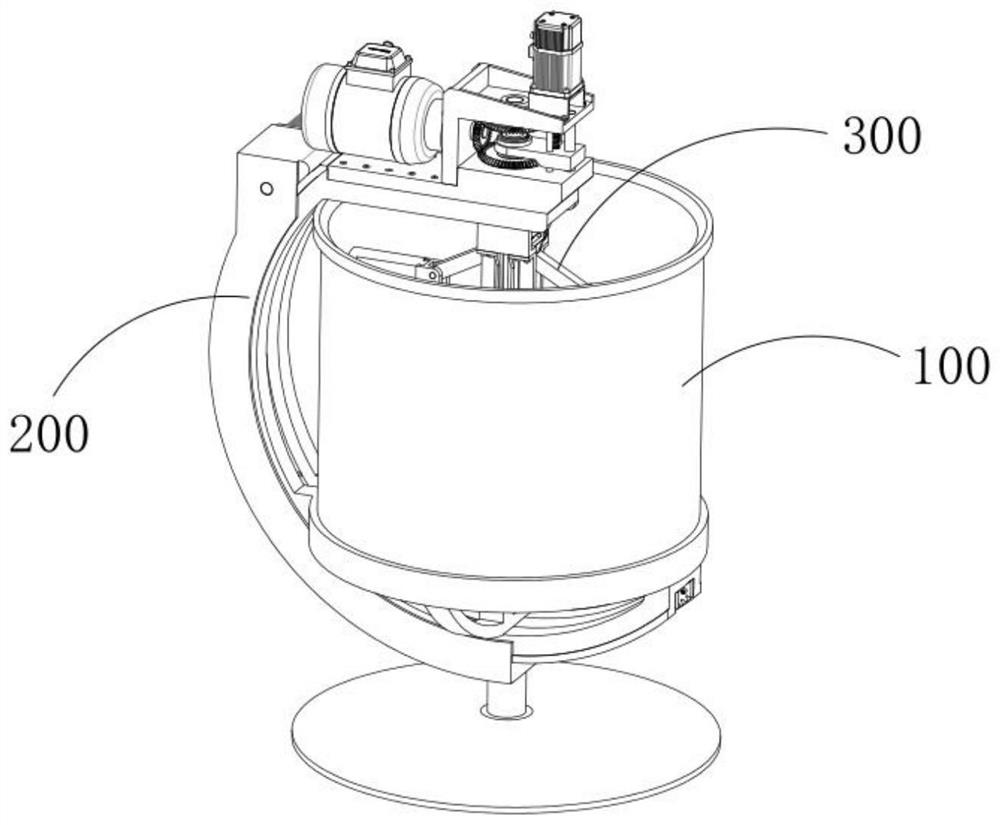

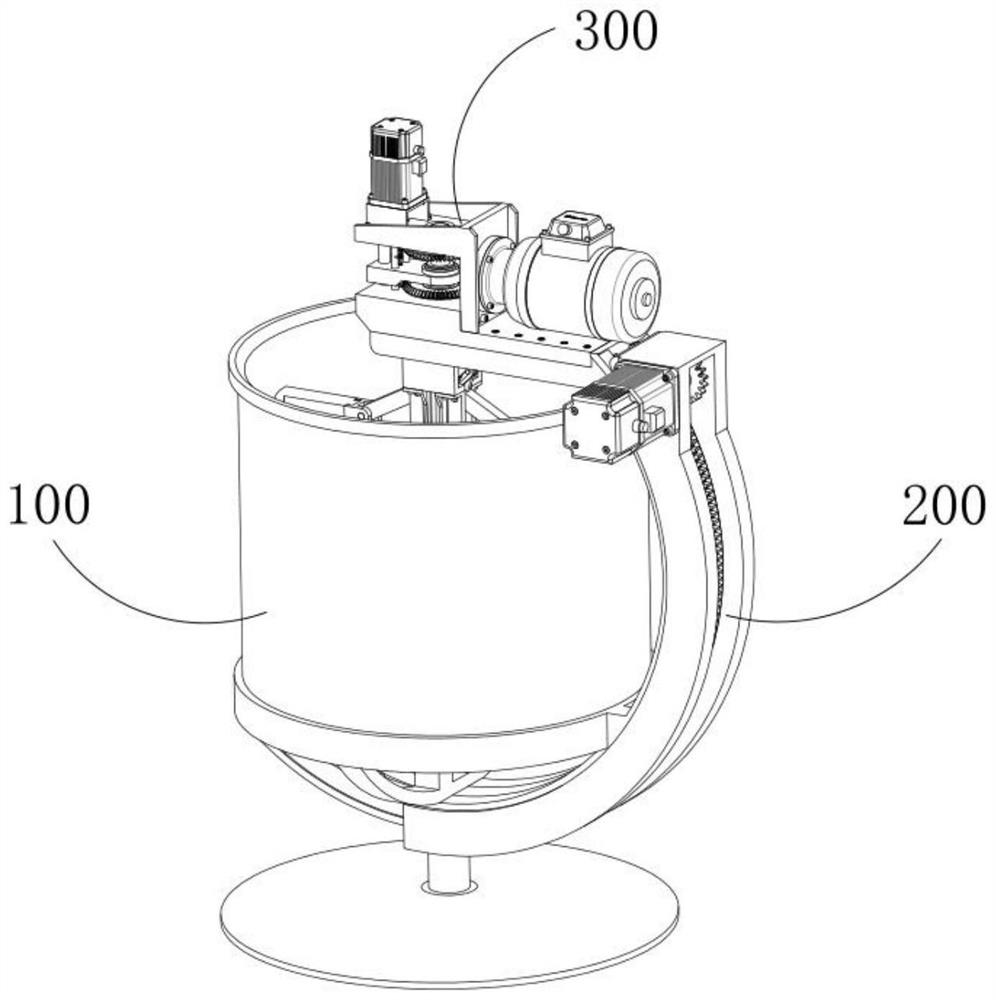

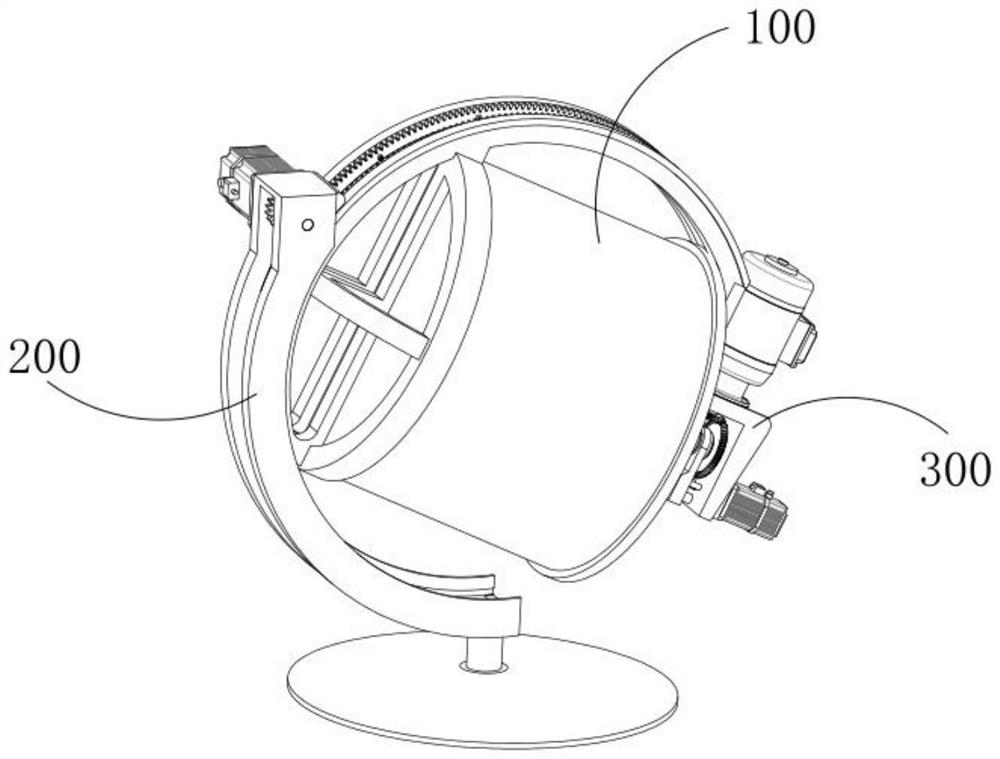

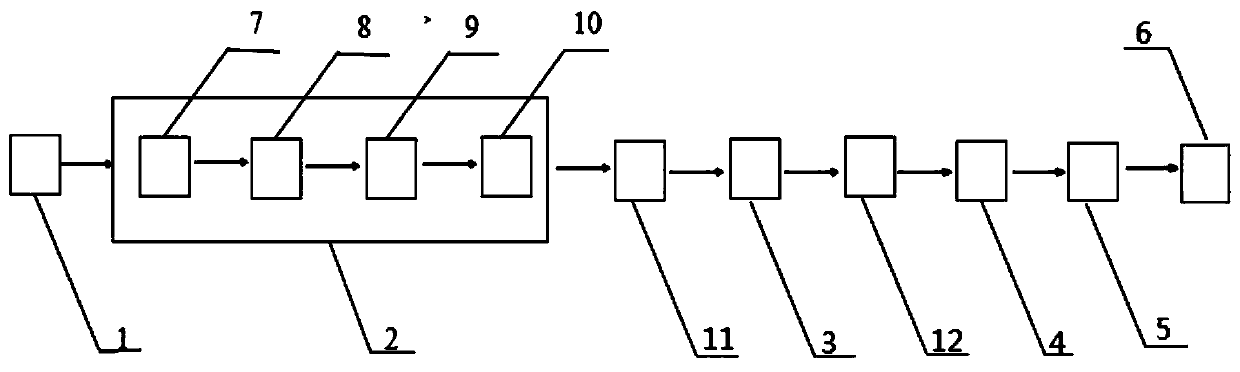

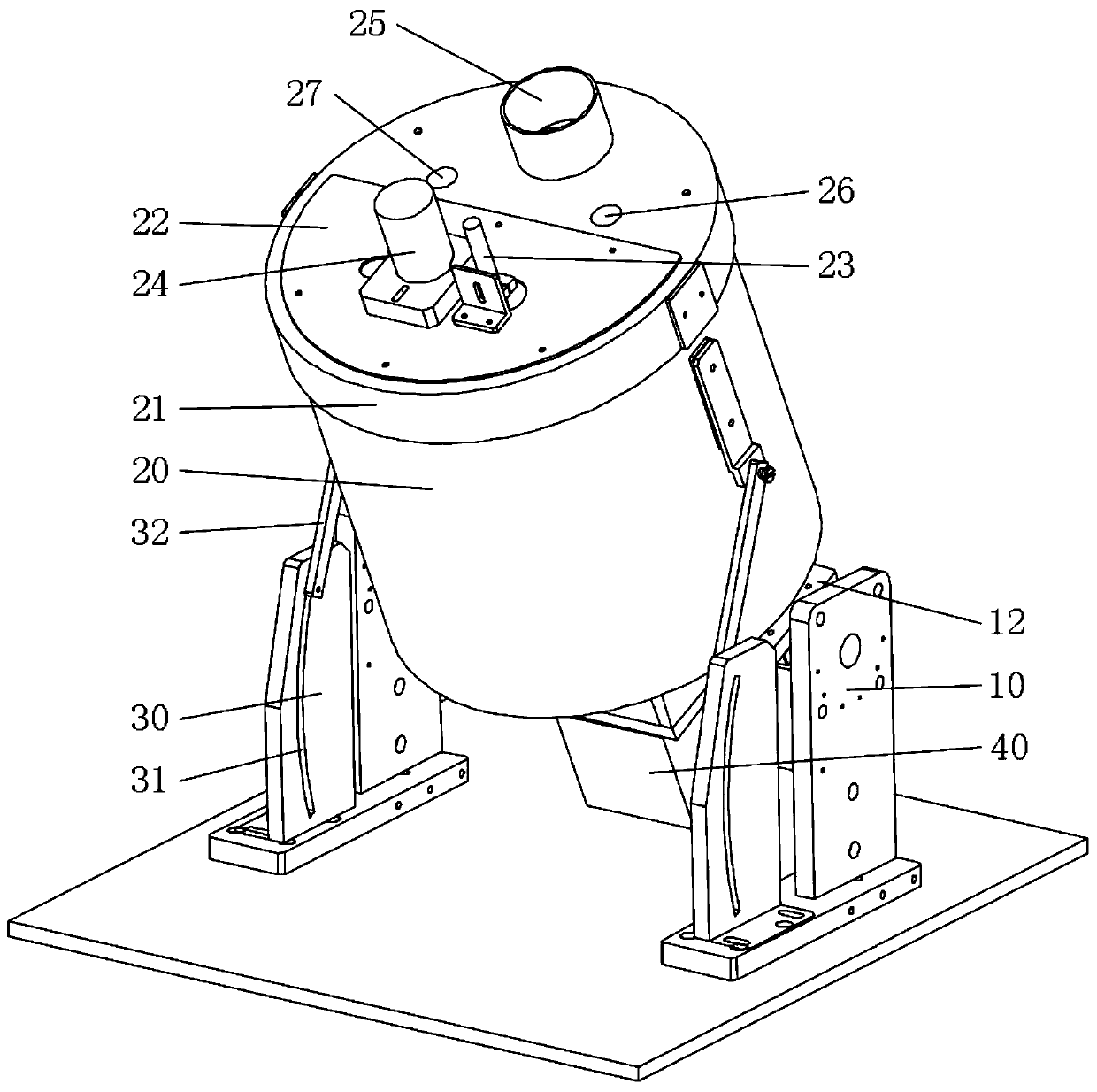

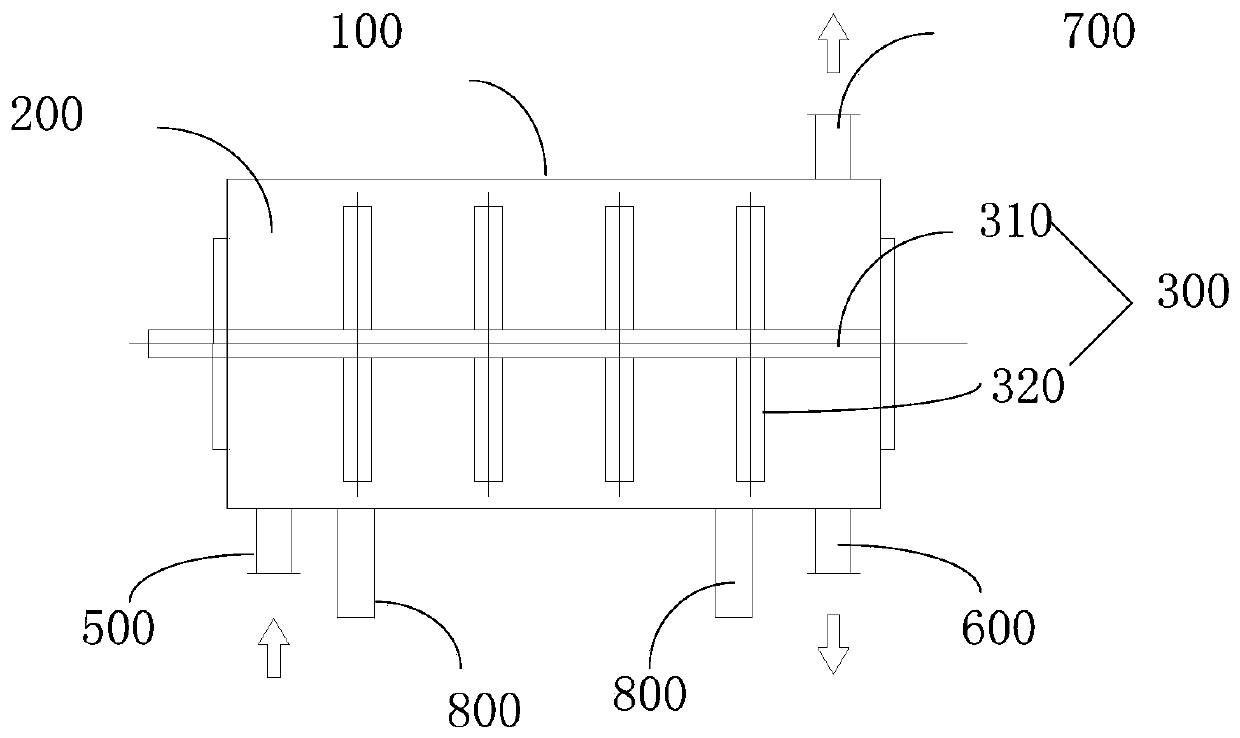

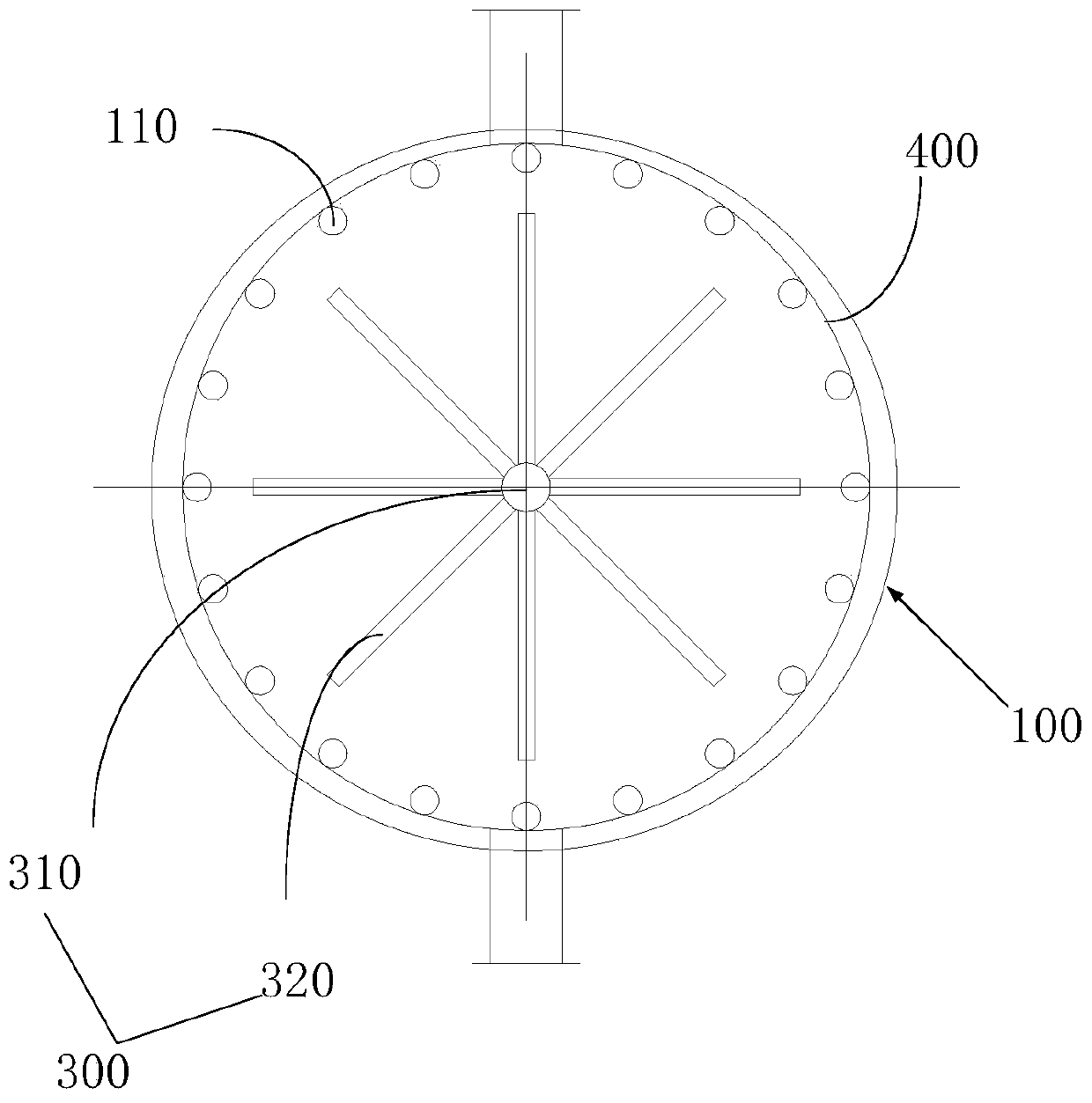

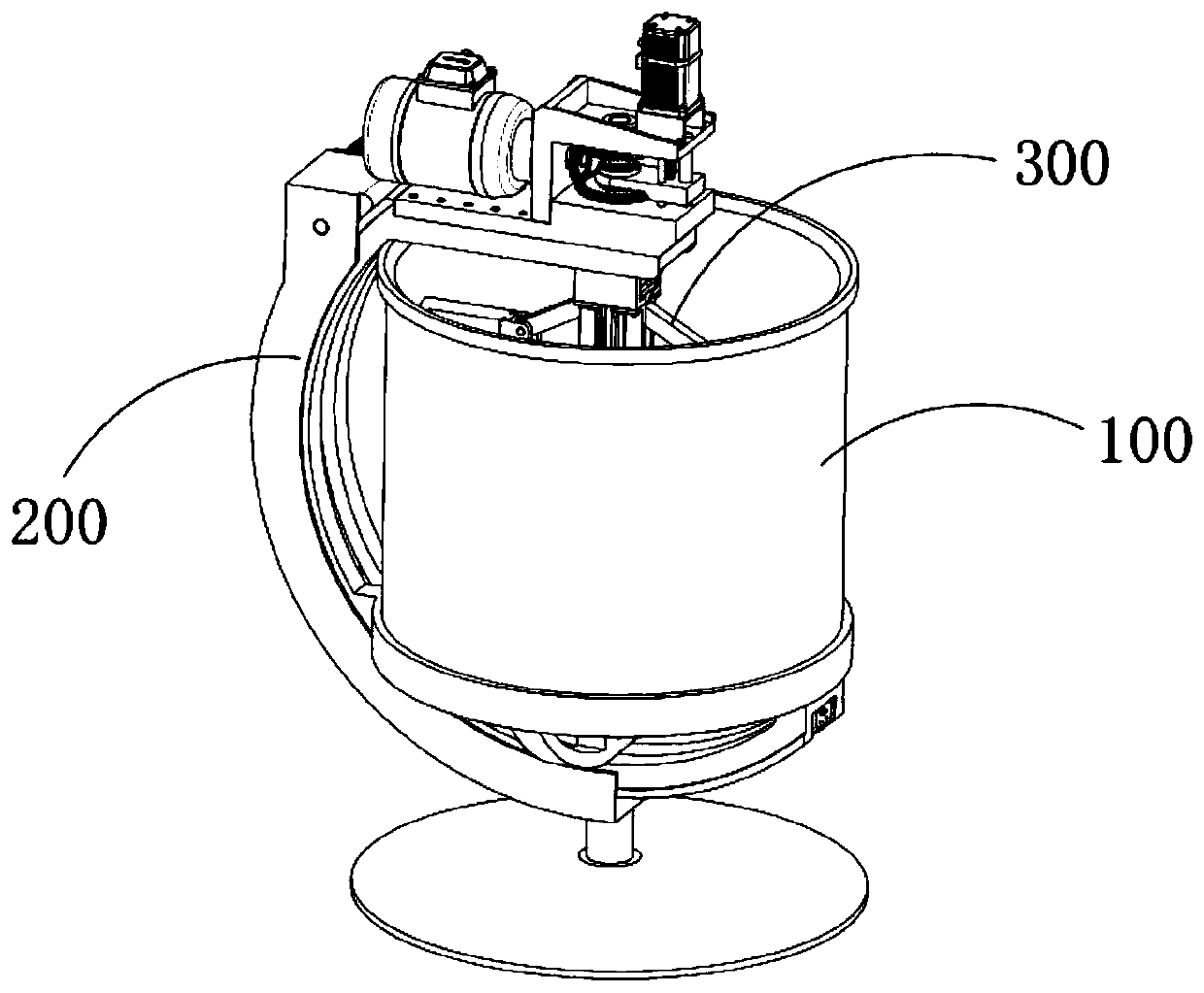

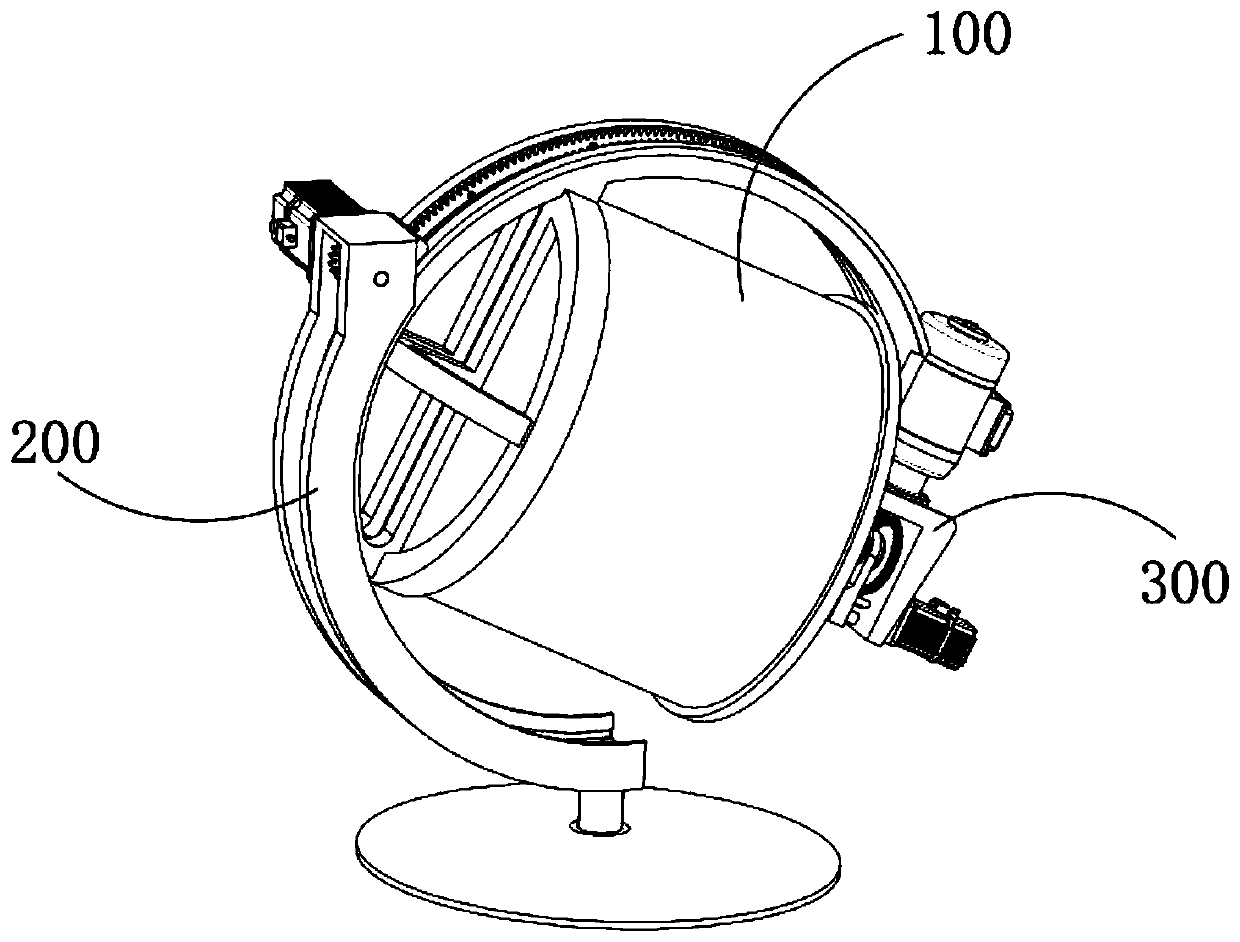

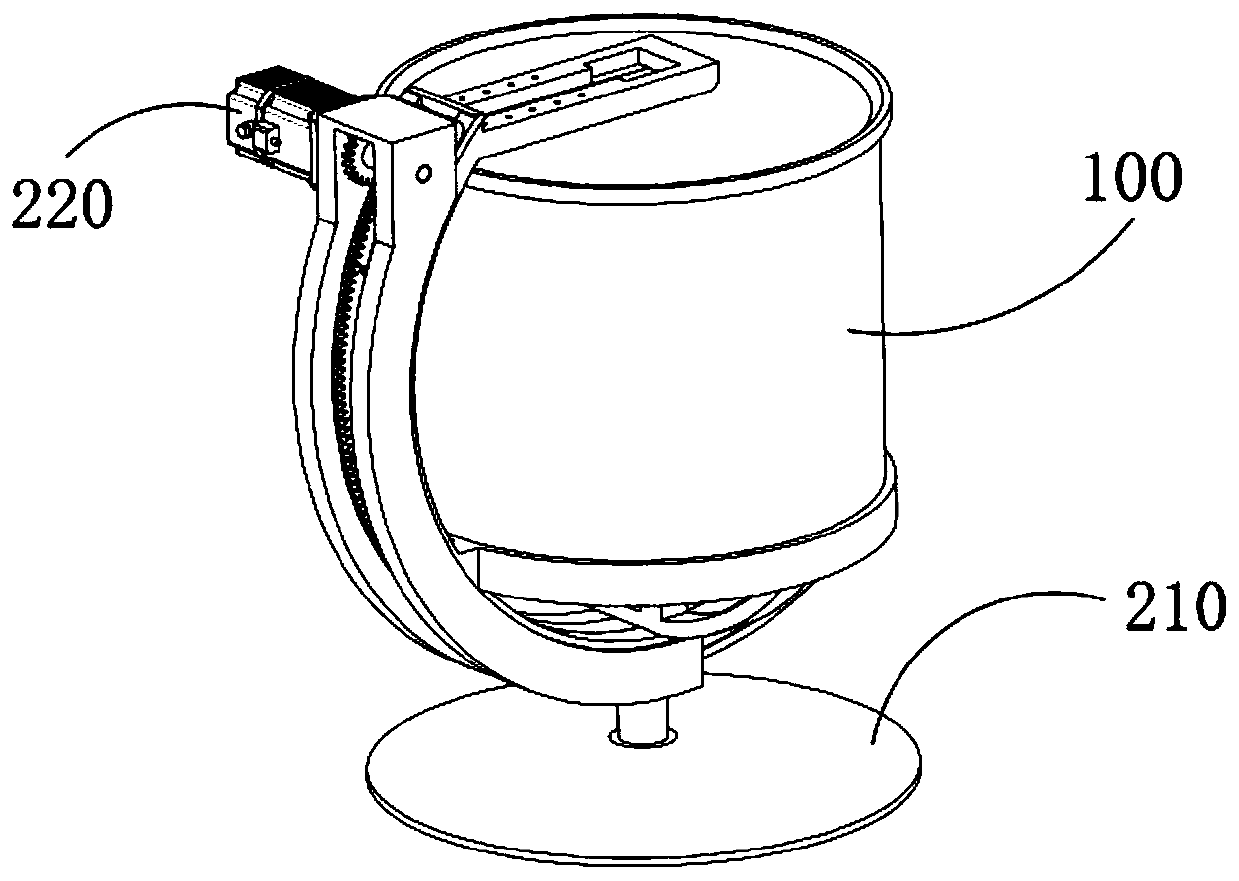

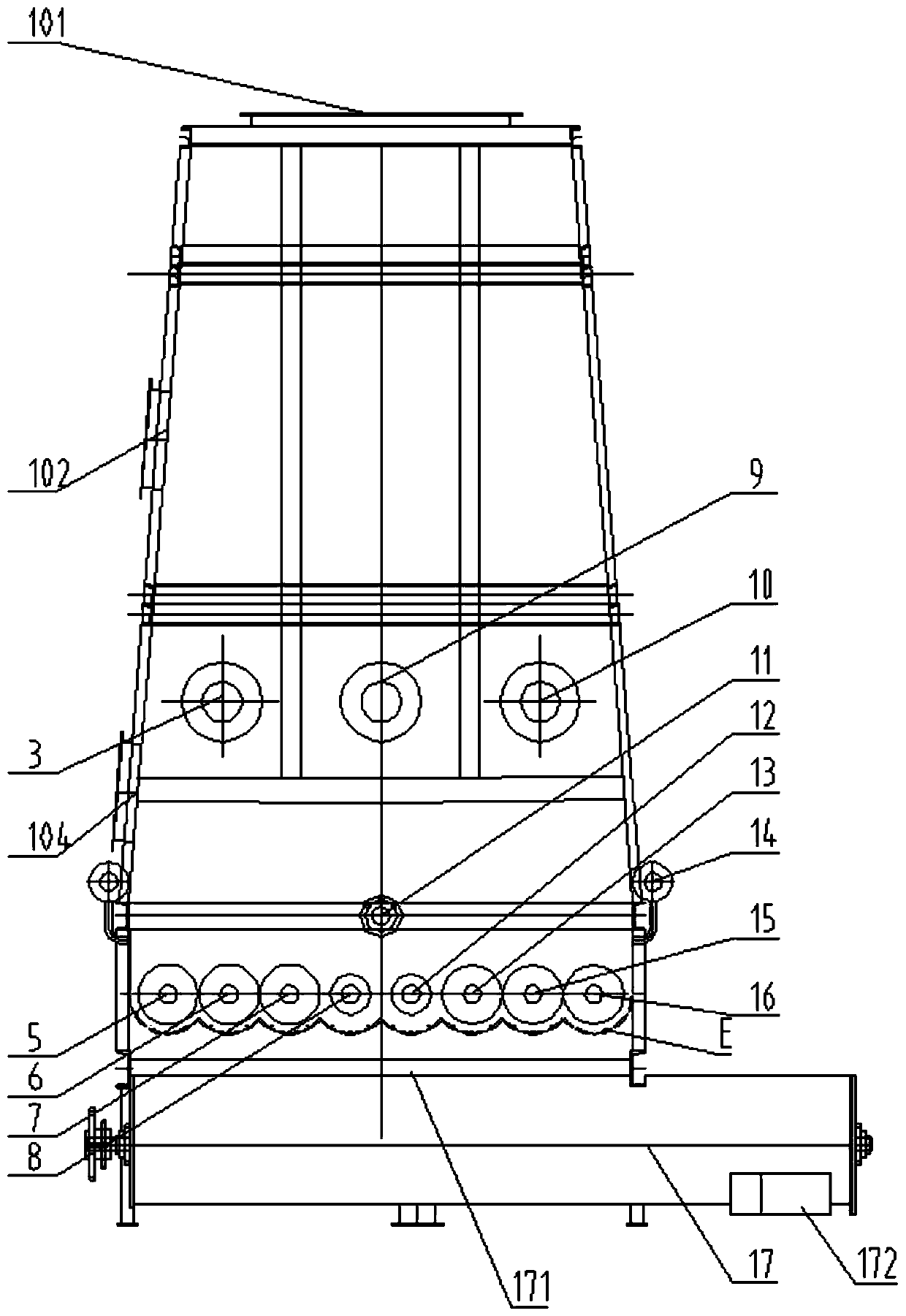

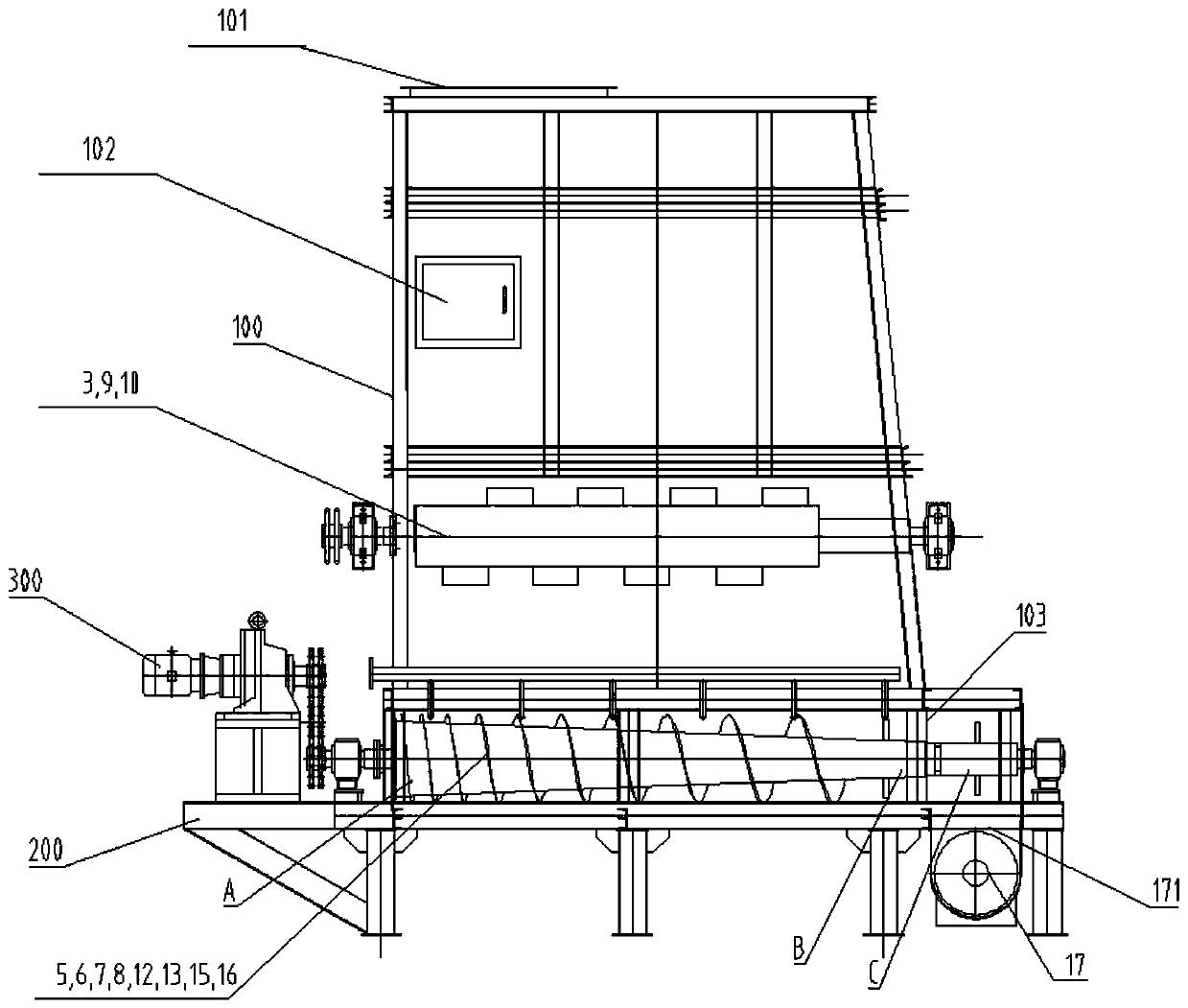

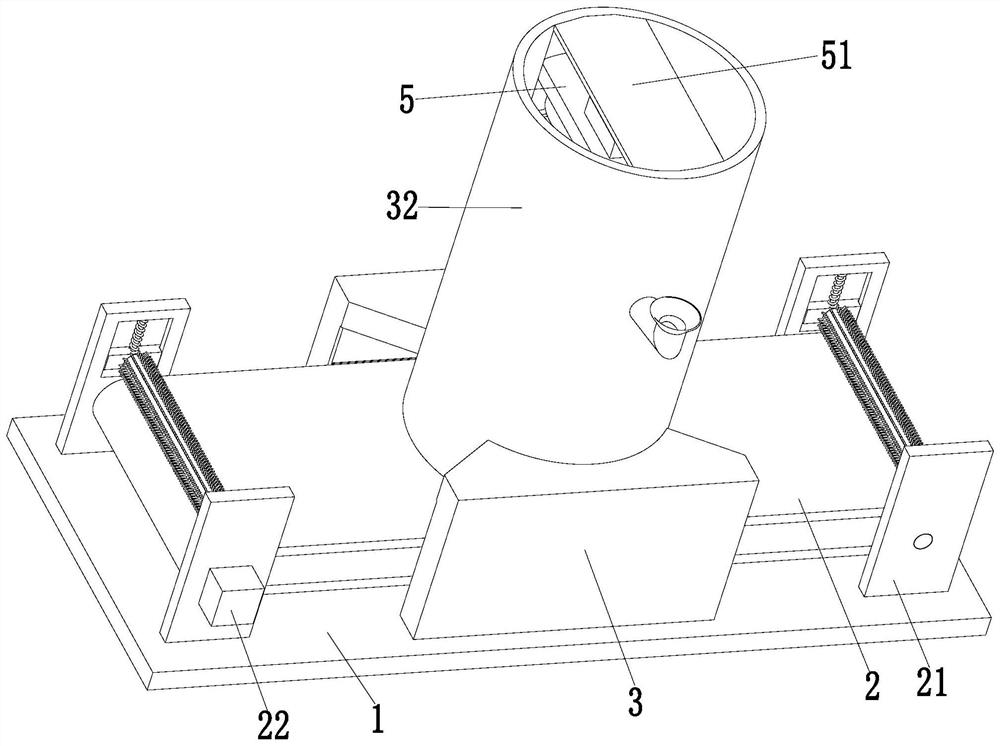

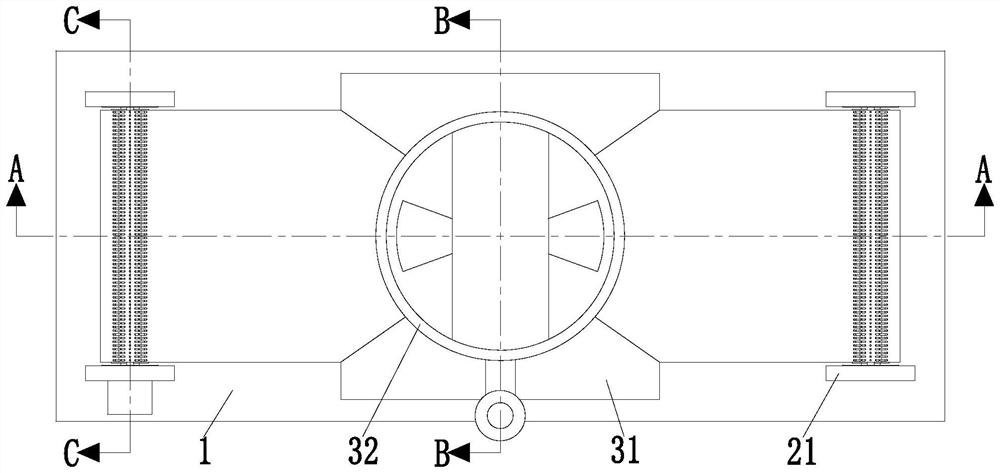

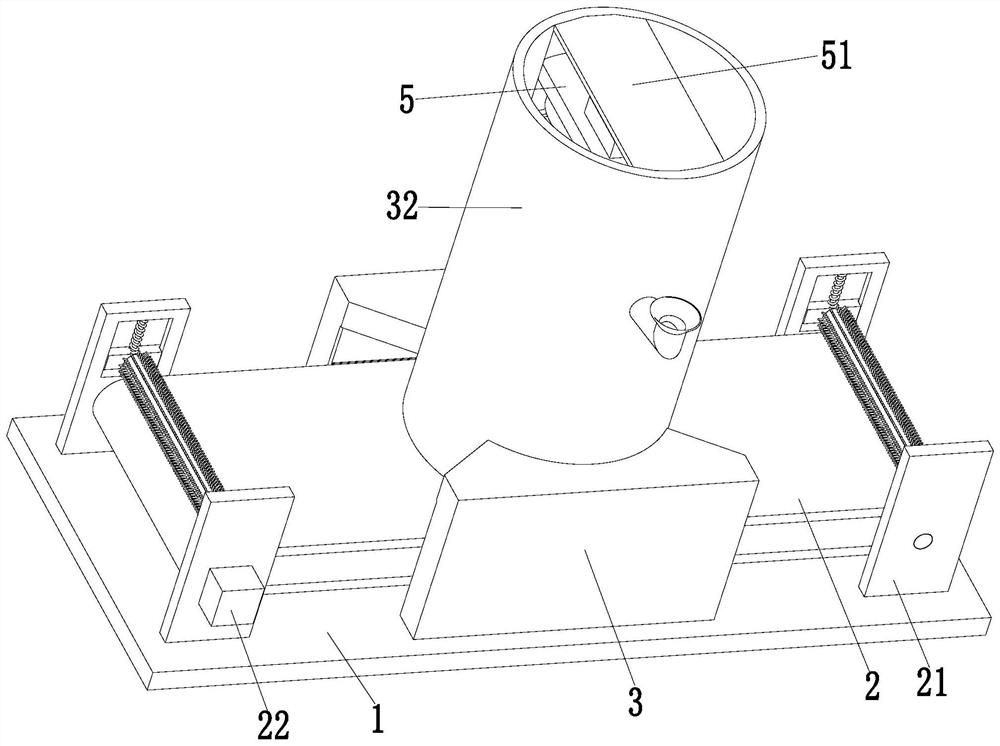

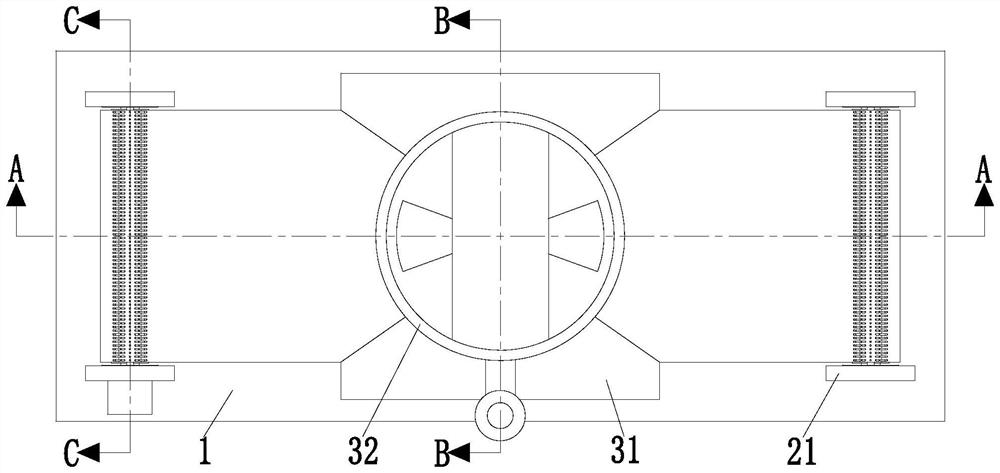

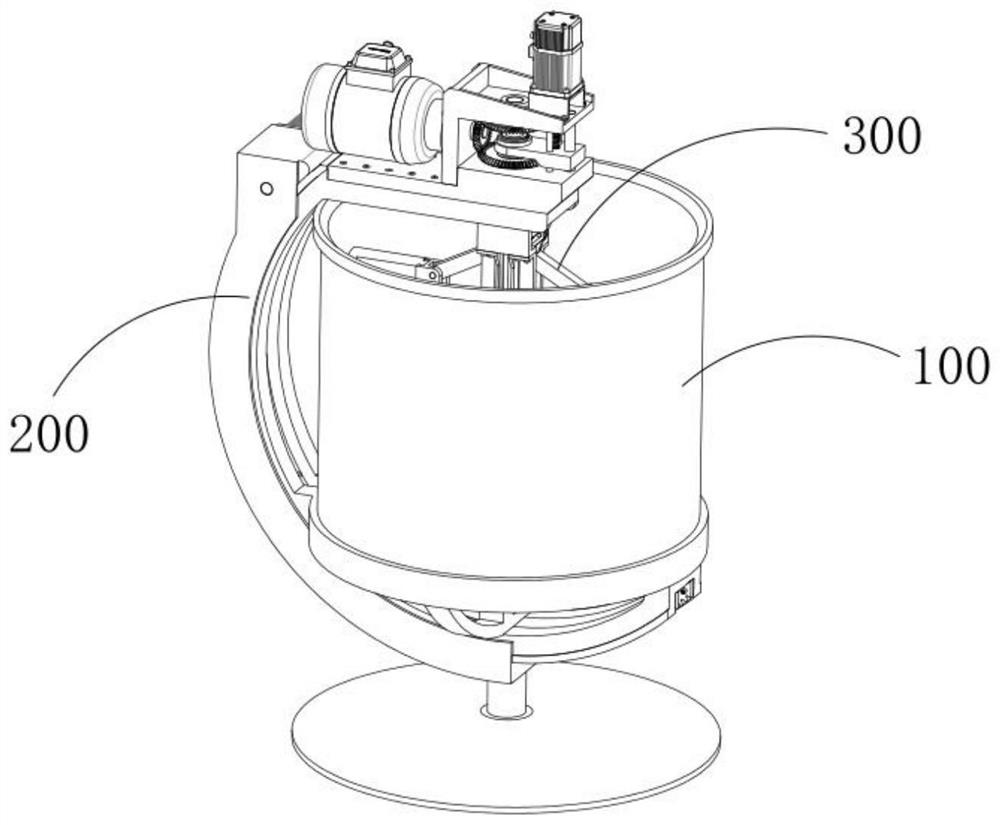

Stirring assembly for promoting mixing of chemical raw materials in different-direction stirring mode

ActiveCN110652907AStir wellStir well stir wellRotary stirring mixersTransportation and packagingBLENDER/MIXERMechanical engineering

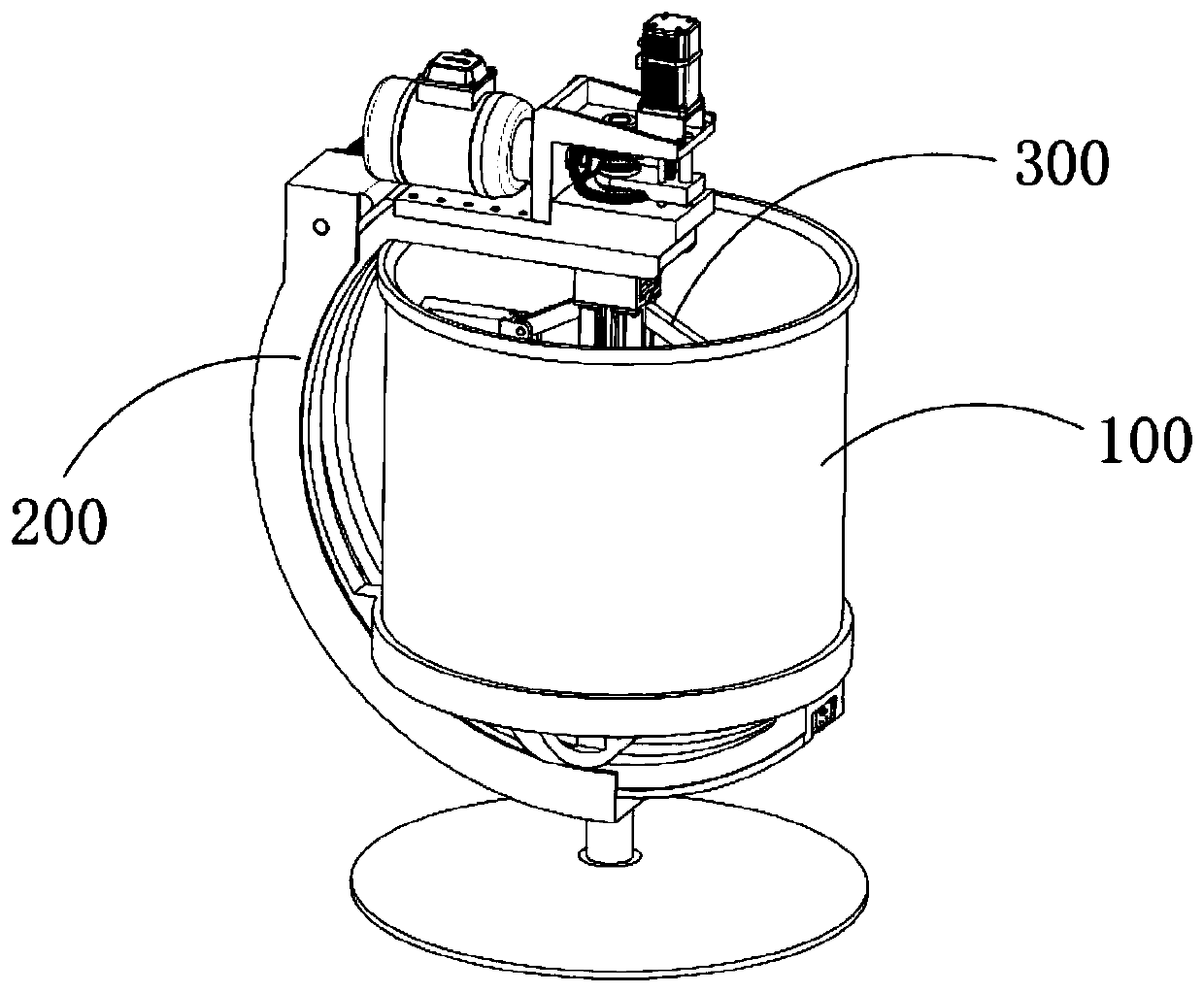

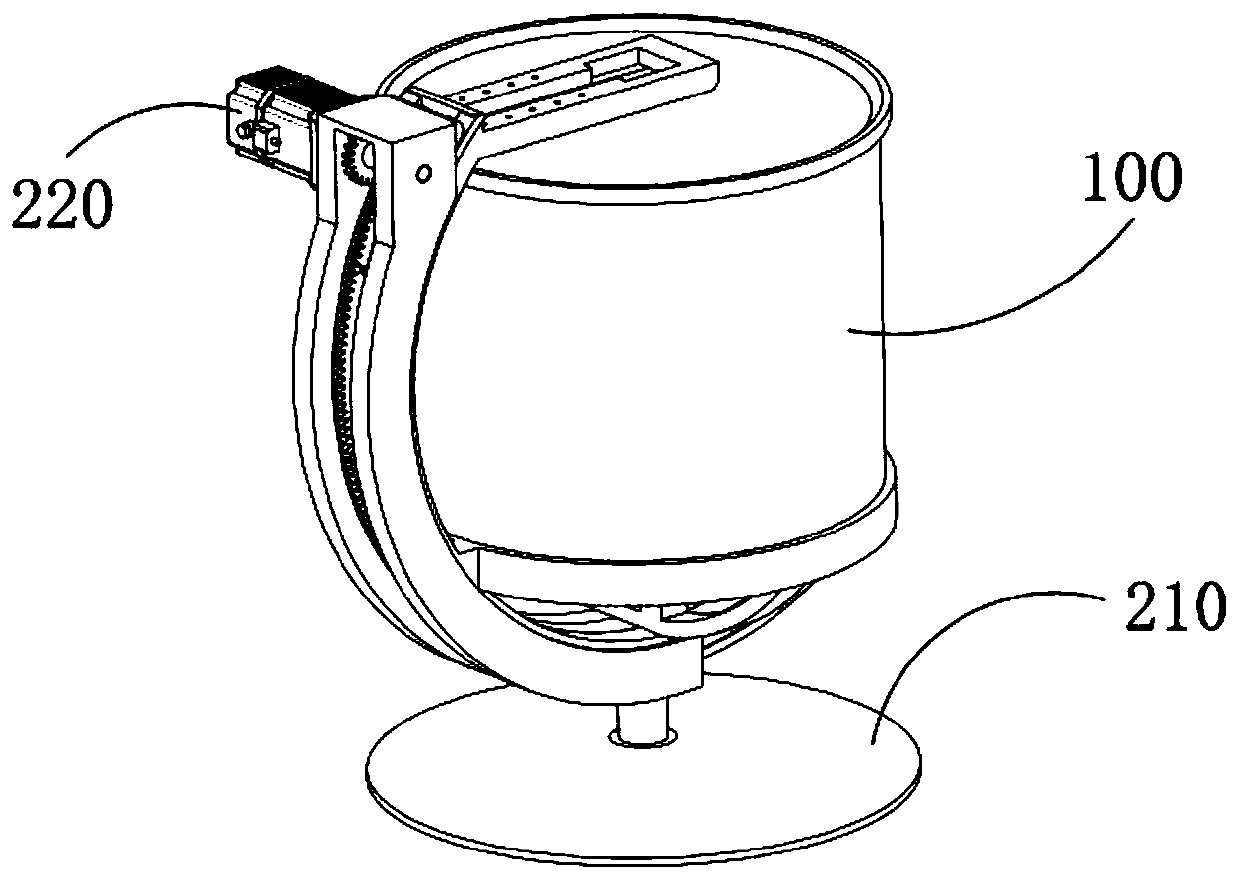

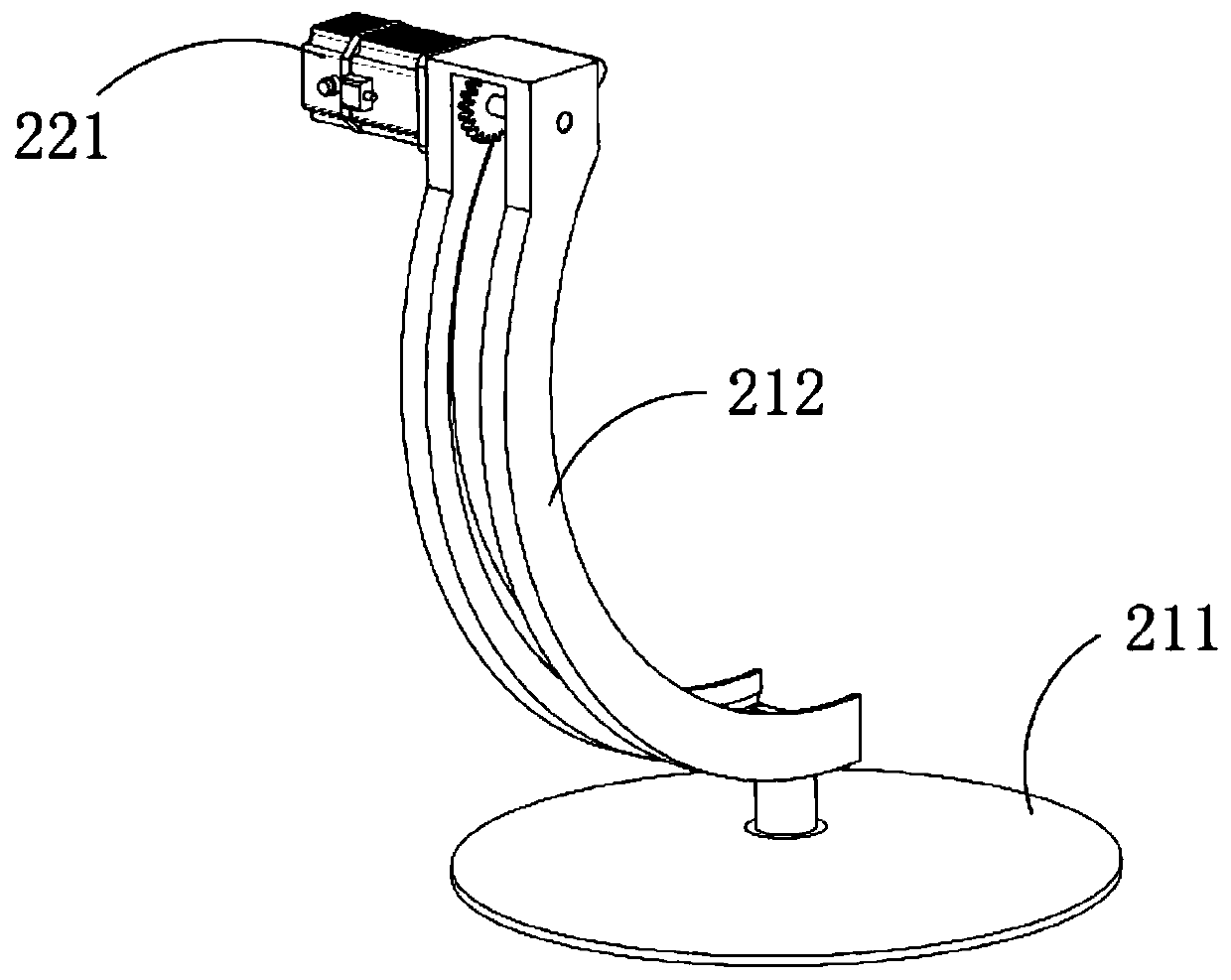

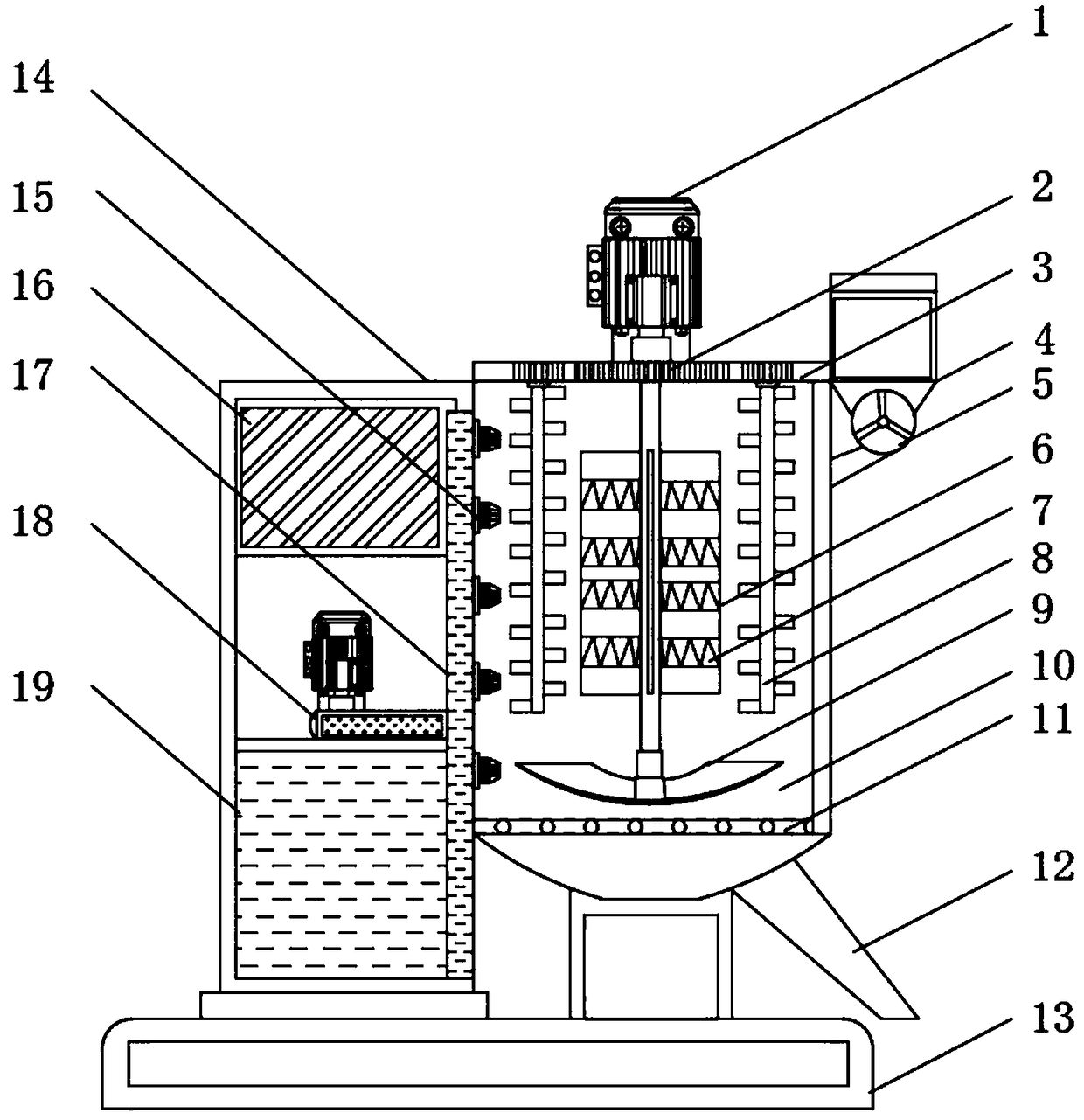

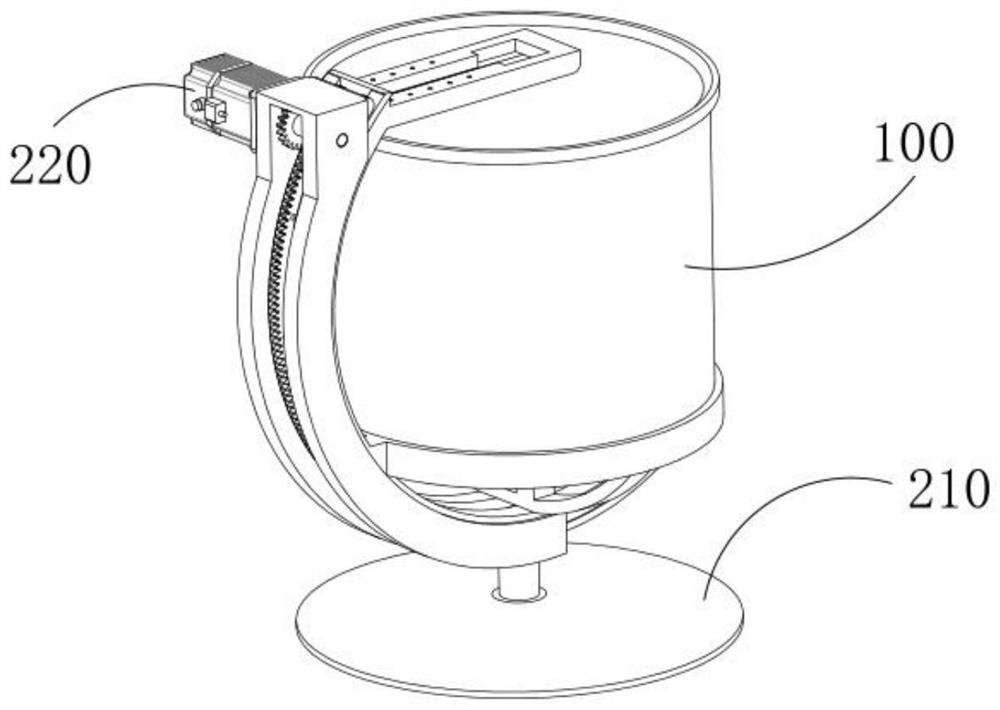

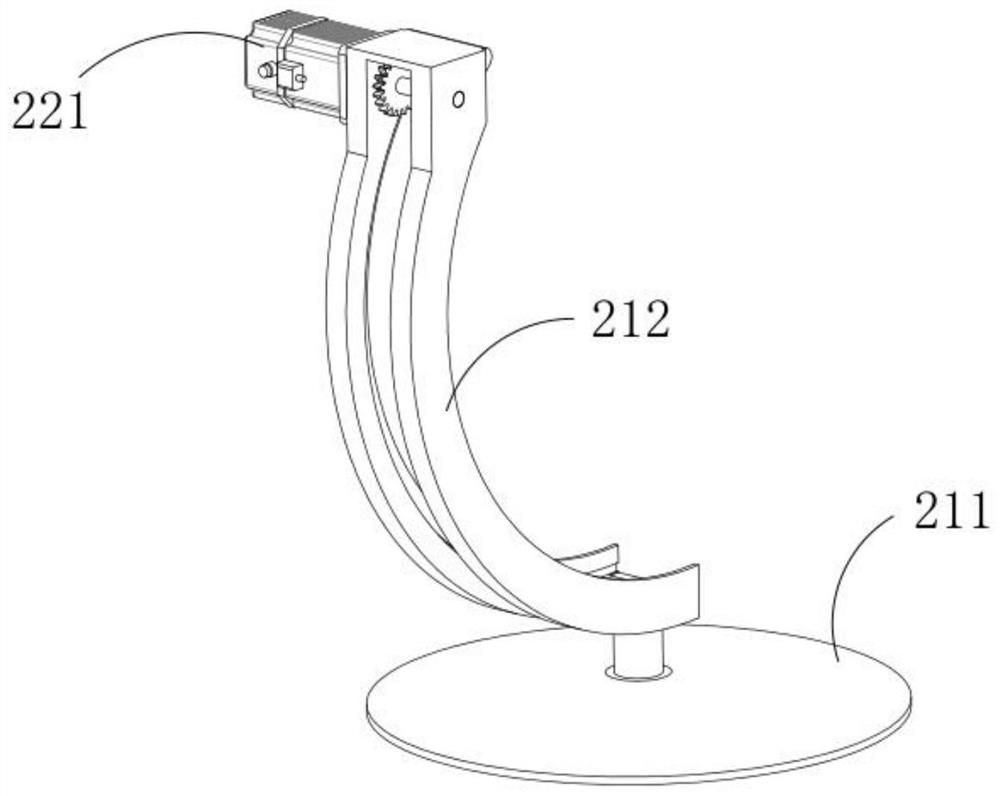

The invention provides a stirring assembly for promoting mixing of chemical raw materials in a different-direction stirring mode. The stirring assembly comprises a stirring tank (100), a main frame body (210) and a different-direction stirring mechanism (300), the stirring tank (100) and the different-direction stirring mechanism (300) are both mounted on the main frame body (210), the different-direction stirring mechanism (300) comprises a connecting bracket (310), a stirring member (320) and a driving member (330), the connecting bracket (310) is fixedly mounted on a mounting bracket (215),the stirring member (320) and the driving member (330) are both mounted on the connecting bracket (310), the stirring member (320) is used for uniformly stirring a mixture in the stirring tank (100),and the driving member (330) is used for driving the stirring member (320) to run. The whole mixture discharging process is fully automatic, and does not need manual operation of workers, so the labor intensity of the workers is greatly relieved; and the inner ring and outer ring different-direction stirring mode is adopted, so the mixture can be fully and evenly stirred, and the stirring effectis good.

Owner:宁夏宏民生物科技有限公司

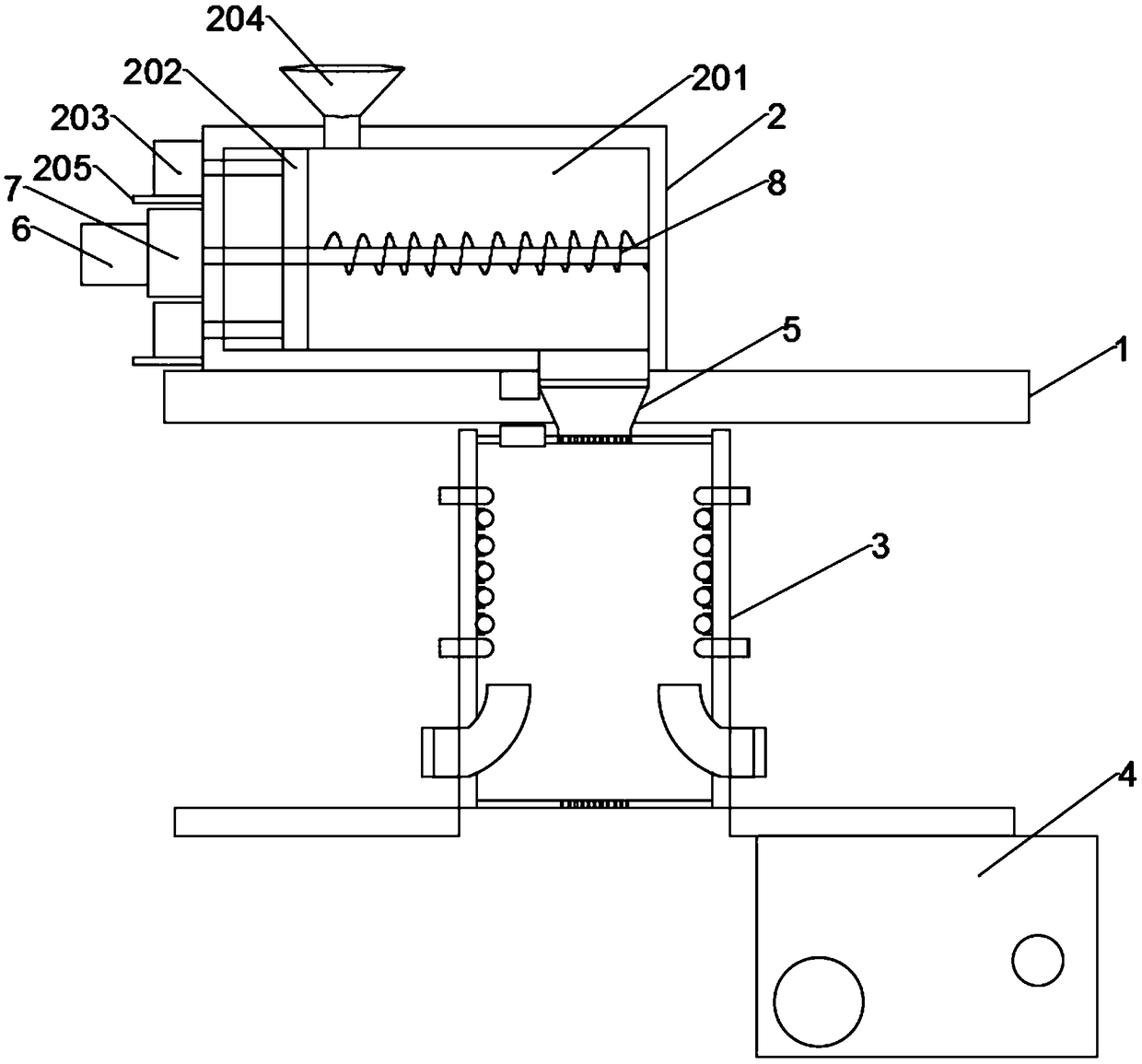

Food material stirring equipment

PendingCN109529708AStir evenlyIncrease productivityRotating receptacle mixersTransportation and packagingEngineeringIngested food

The invention discloses food material stirring equipment, which comprises a feeding device, a first conveying device, a material conveying device, a material stirring device, a material discharging device and a second conveying device in sequential connection, wherein a feeding box outlet of the feeding device is connected with a feeding opening of the first conveying device; a discharging openingof the first conveying device is connected with the material conveying device; a material conveying opening of the material conveying device corresponds to a first material stirring barrel of the material stirring device; a second material stirring barrel of the material stirring device corresponds to the material discharging device; the positions of the first material stirring barrel and the second material stirring device can be mutually converted through rotation; a material discharging groove of the material discharging device is connected with a feeding opening of the second conveying device. The structure of the food material stirring equipment is simple; the design is ingenious; the work procedure of food material stirring is merged into a production line; the labor is saved; the production efficiency is improved; the sealed conveyance is used; the pollution of the food in the conveyance process is reduced; the product quality is improved.

Owner:BEIJING KAIDA HENGYE AGRI TECH DEV

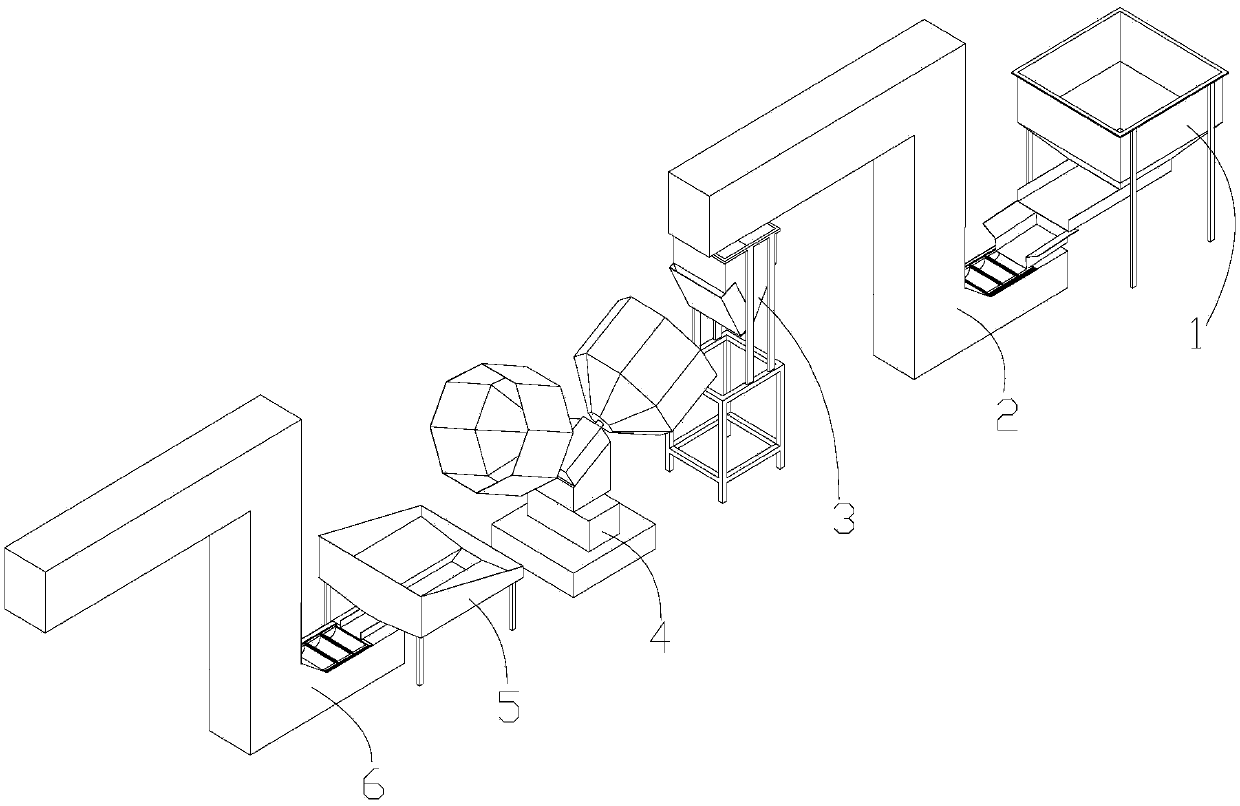

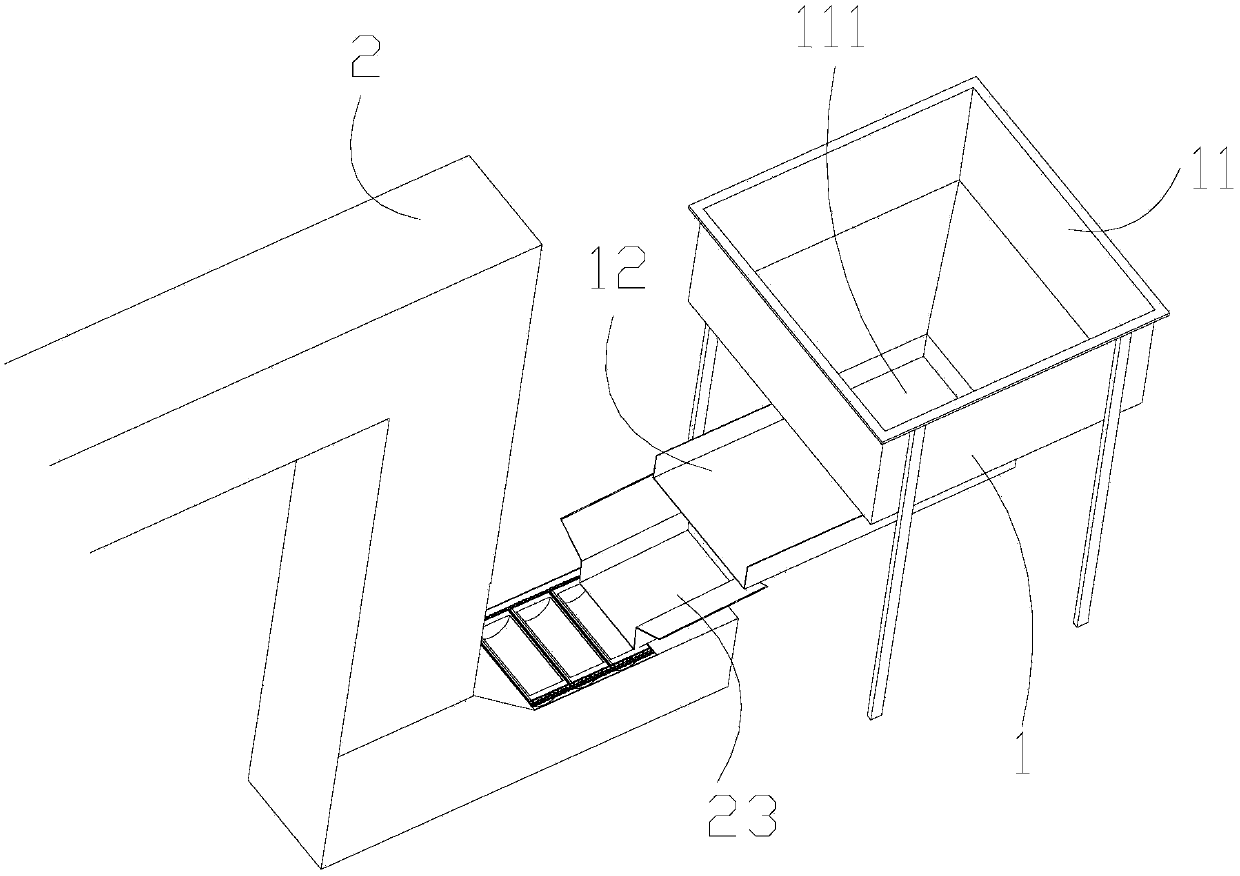

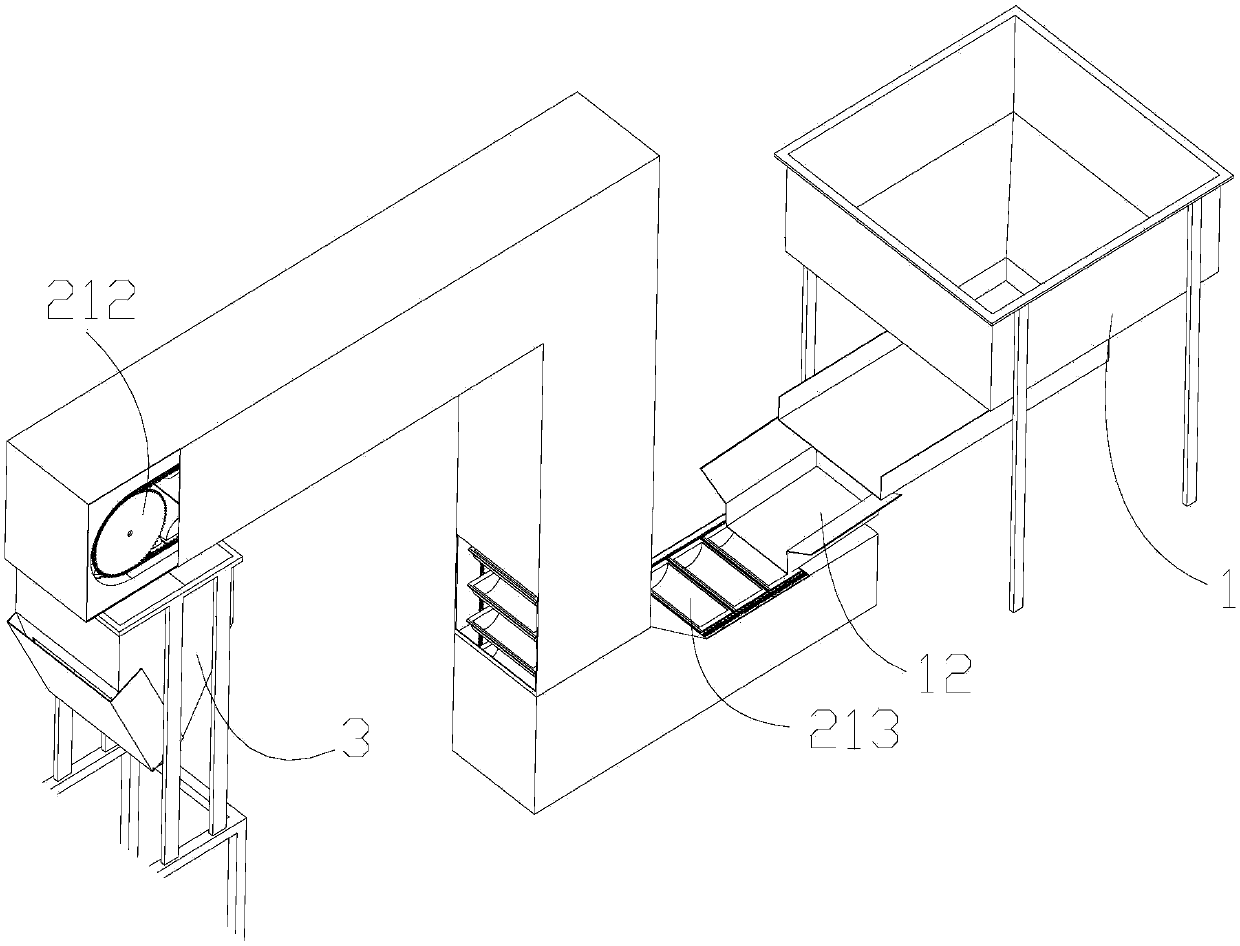

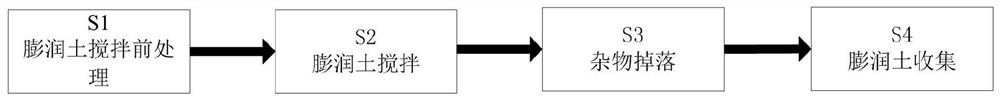

Modified bentonite preparation method

InactiveCN112279258AStir evenlyImprove the preparation effectMixing methodsTransportation and packagingBentonite suspensionPhysical chemistry

The invention relates to a modified bentonite preparation method, the modified bentonite preparation method adopts the following modified bentonite preparation device, the modified bentonite preparation device comprises a stirring cylinder, a storage ring, a base, a sieve plate, a stirring motor, a stirring rod and a sliding mechanism; the preparation method adopting the modified bentonite preparation device comprises the following steps: S1, bentonite is subjected to stirring pretreatment; s2, bentonite is stirred; s3, sundries fall off; s4, bentonite collection is performed. The following problems can be solved: when the bentonite is stirred in the prior art, the stirring time of the bentonite is long, a large number of impurities in the bentonite are left in bentonite suspension liquiddue to incomplete stirring of the bentonite, the preparation effect of the bentonite is poor, and the preparation purity is low; and when the bentonite is stirred, impurities can be accumulated at thebottom of the stirring cylinder, and part of the impurities can be turned up again to reach bentonite suspension liquid along with stirring.

Owner:张百顺

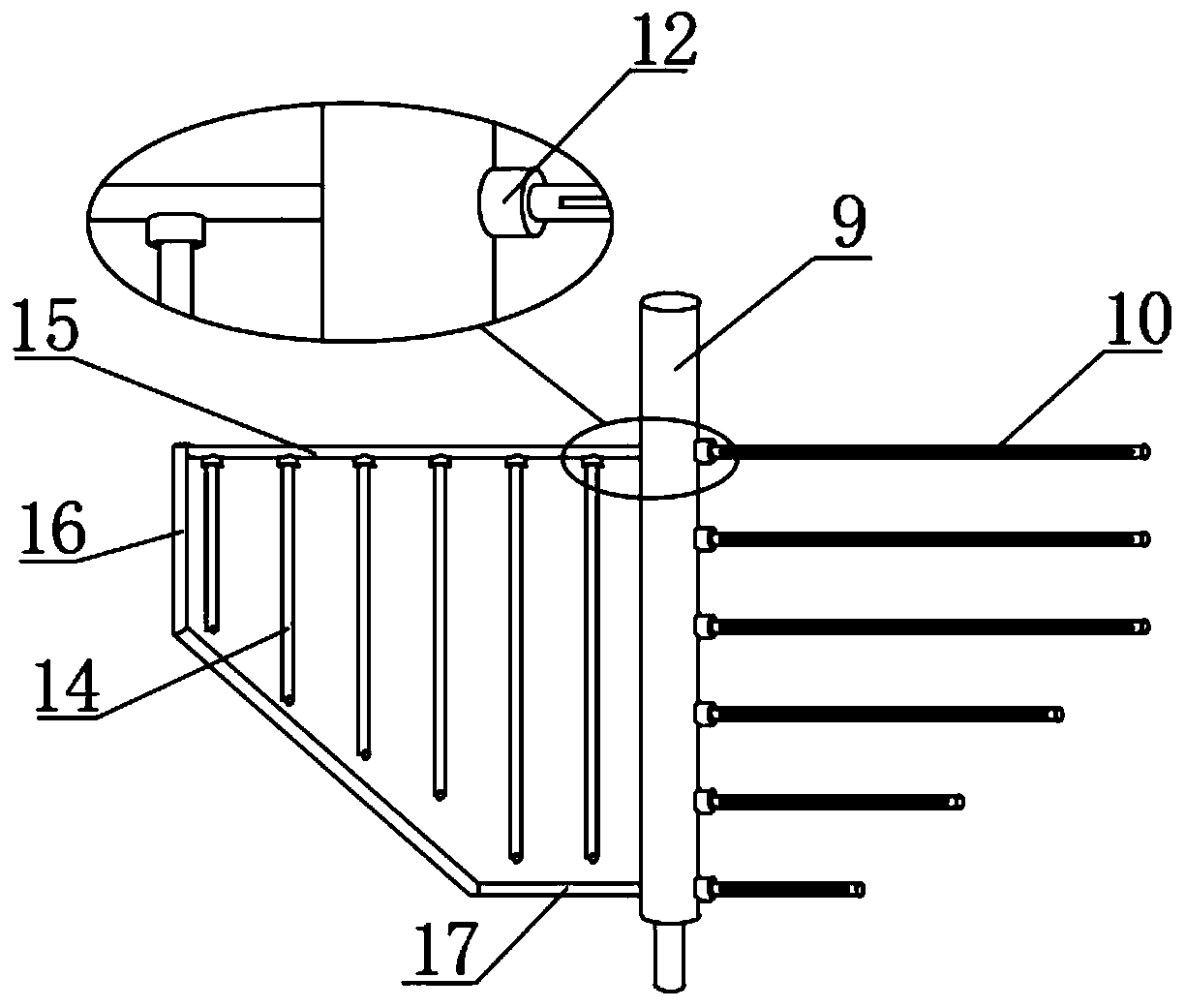

Pre-treatment reaction bin used for rice and wheat straw fiber extracting

PendingCN111501109AEvenly heatedStir evenly in the warehouseVegetable materialFiberAgricultural engineering

The invention provides a pre-treatment reaction bin used for rice and wheat straw fiber extracting. The bin comprises a bin body, a first feeding opening is formed in the position, close to the side of the bin body, of the upper end face of the bin body, a first discharging opening is formed in the front side face of the lower portion of the bin body, three bearing rollers which are located on thesame horizontal plane are rotatably mounted below the first feeding opening, the axis lines of the bearing rollers are parallel to the direction from the rear side to the front side, a gap is reserved between the two adjacent bearing rollers, the periphery of each bearing roller is provided with multiple shifting teeth which protrude outwards in the radial direction, eight forward conveying screws which convey the straw from back to front and discharge the straw out of the bin body from the first discharging opening are rotatably connected to the position, below the bearing rollers, of the bottom in the bin body, the axis lines of the eight forward conveying screws are located on the same horizontal plane, and a material groove corresponding to each forward conveying screw is formed in the bottom face of the bin body correspondingly. According to the reaction bin, uniform heating, in-bin turning and smashing, stable discharging and free-lamping can be achieved.

Owner:TIANJIN RONGYEDA TECH DEV

Preparation device and method of 2,3-difluoro-5-chloropyridine

PendingCN114042427AStir evenlyUniform heating effectOrganic chemistryDispersed particle filtrationPyridyneNitrogen gas

The invention relates to a preparation device and method of 2,3-difluoro-5-chloropyridine. A temperature difference along an air column is formed through evaporation-condensation of a heat conducting liquid, so that a dynamic air pressure difference for air flow flowing is provided for nitrogen in a kettle cavity; and materials are heated in an externally-wrapped mode through the heat conducting liquid, the interiors of the materials are heated in an aeration mode in combination with flowing nitrogen, and the materials are pushed to rotate in the circumferential direction through aeration aerodynamic force, so that the uniform stirring and heating effects are achieved. The evaporated-condensed heat conducting liquid effectively leads out part of heat in a kettle cavity, so that the risk of overhigh internal pressure caused by overhigh temperature in a closed space is effectively prevented according to the PV / T principle, and the safety is improved. The device is simple in structure, convenient to use, good in heating effect, uniform and stable, effectively utilizes pressure difference caused by temperature difference to provide power for airflow, then utilizes the power to heat and stir materials from the interior of the materials, effectively improves the reaction efficiency, and has high practicability and wide applicability.

Owner:JIANGSU HENGAN CHEM

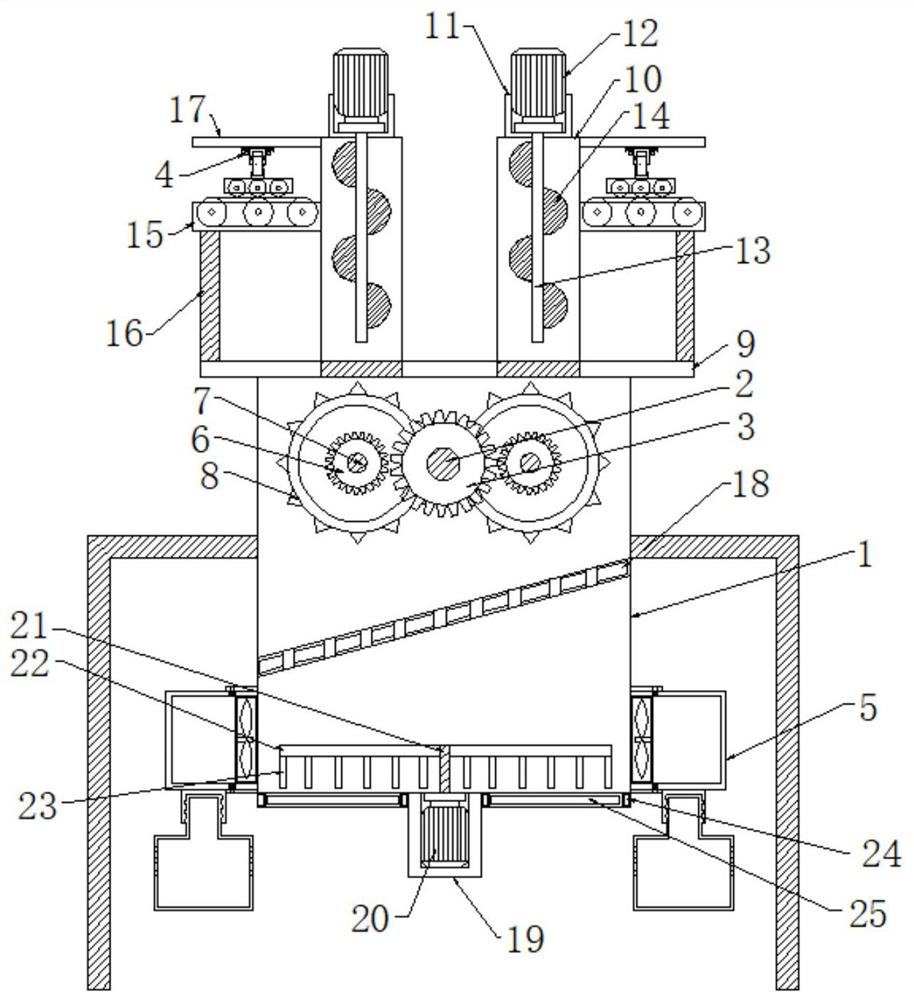

An automatic coating treatment equipment for conductive carbon-coated copper foil

The invention relates to an automatic coating treatment equipment for conductive carbon-coated copper foil. A splitting mechanism, a grinding mechanism is installed at the top of the splitting mechanism, and a stirring mechanism is installed at the lower end of the grinding mechanism. The present invention can solve the following problems in the process of coating the carbon-coated slurry on the surface of copper foil. 1. Generally, the raw materials need to be manually ground Then carry out stirring treatment, manual grinding and stirring are not uniform, which reduces the coating quality of carbon-coated copper foil; 2. It is necessary to manually use a brush to coat the uniformly stirred carbon-coated slurry on the surface of copper foil, and the efficiency of manual coating Low, and the artificial coating of carbon-coated slurry is uneven, which affects the subsequent use of carbon-coated copper foil.

Owner:GUANGDONG FINE YUAN SCI TECH CO LTD

Automatic coating treatment equipment for conductive carbon-coated copper foil

ActiveCN113814112AImprove mixing qualityImprove production qualityLiquid surface applicatorsCoatingsCopper foilElectrically conductive

The invention relates to automatic coating treatment equipment for conductive carbon-coated copper foil. The automatic coating treatment equipment comprises an operation table, a feeding mechanism, a flow dividing mechanism, a stirring mechanism and a grinding mechanism; and the feeding mechanism is installed on the operation table, the flow dividing mechanism is installed in the middle of the operation table, the grinding mechanism is installed at the top end of the flow dividing mechanism, and the stirring mechanism is installed at the lower end of the grinding mechanism. The automatic coating treatment equipment can solve the following problems existing in the process of coating the surface of the copper foil with the carbon-coated slurry, specifically, 1, the coating quality of the carbon-coated copper foil is reduced due to non-uniformity of manual grinding and stirring since raw materials generally need to be manually ground and then stirred at present; and 2, the surface of the copper foil needs to be manually coated with the carbon-coated slurry which is uniformly stirred by using a brush, the manual coating efficiency is low, the manual coating of the carbon-coated slurry is not uniform, and the subsequent use of the carbon-coated copper foil is influenced.

Owner:GUANGDONG FINE YUAN SCI TECH CO LTD

Mortar mixing device with efficient mixing structure

PendingCN112936597AEfficient screeningEasy to scatterDischarging apparatusMixing operation control apparatusElectric machineryEngineering

The invention relates to the technical field of mortar mixing, in particular to a mortar mixing device with an efficient mixing structure. The mortar mixing device comprises a mortar mixer main body and a motor, one end of the mortar mixer main body is provided with a feed opening, the motor is mounted on one side of one end of the mortar mixer main body, a linkage shaft is arranged at one end inside the mortar mixer main body, and one end of the surface of a first stirring rod is fixedly connected with a discharging mechanism assembly. According to the mortar mixing device with the efficient mixing structure, the stirring range of the device for materials put inside the device can be well enlarged through a linkage stirring mechanism assembly, multi-directional stirring is achieved, the stirring degree of the materials put inside the device becomes more uniform, the materials put inside the mortar mixer main body can be well screened through a screening mechanism assembly, part of large-particle substances in the fed materials are quickly removed, the screened materials can be uniformly scattered at the bottom of the mortar mixer main body, and the mixing efficiency of the device on the materials is enhanced.

Owner:乐伟波

A threshing machine for agricultural machinery with a protective device

The invention discloses a threshing machine for agricultural machinery with a protection device in the technical field of agricultural machinery. On the end face, the left and right sides of the threshing cylinder are provided with matching slave gears, the two sets of slave gears are plugged and fixed with rotating shafts, and the outer peripheries of the two sets of rotating shafts are sleeved with threshing cylinders, and the threshing cylinders The top is provided with a fixed platform, the top of the fixed platform is provided with push cylinders corresponding to the two groups of threshing cylinders, and the corresponding positions of the fixed platform and the bottom of the two groups of push cylinders are provided with a through hole one, and the two groups of The top of the push cylinder is provided with a motor seat 1, and the inner cavity of the two groups of motor seats 1 is provided with a reducer 1, and the bottom of the two groups of said reducer 1 is connected with a rotating rod. This device realizes the efficient threshing operation of rice. , During the threshing operation, the grains can be screened efficiently, and the grains with full grains can be kept.

Owner:台州市路桥凯通管业有限公司

Powder conveying device for curing agent coating production

The invention discloses a powder conveying device for curing agent coating production, which comprises a material storage tank with legs welded at the four corners of the bottom, wherein a deceleration motor is fixedly arranged on the outer wall of the top of the material storage tank; an output shaft of the deceleration motor is connected with a driving rod rotationally connected with the material storage tank through a coupling; the outer wall of one side of the driving rod is provided with first stirring rods which are horizontally distributed at equal distances; and the outer wall of one side of the driving rod which is far away from the first stirring rod is welded with a fixing rod. The outer wall of the bottom of the fixed rod is provided with second stirring rods which are vertically distributed at equal distances, and arc-shaped connecting blocks are welded on the opposite sides of the first stirring rod and the driving rod and the opposite sides of the second stirring rod andthe fixed rod. According to the invention, through the horizontally arranged first stirring rods and the vertically arranged second stirring rods, powder in the storage tank can be uniformly stirredalong with the rotation of the deceleration motor, and the powder conveying device has the advantage of preventing agglomeration.

Owner:湖北汉耐尔新材料科技有限公司

Agricultural machinery thresher with protection device

The invention discloses an agricultural machinery thresher with a protection device, and relates to the technical field of agricultural machinery. The agricultural machinery thresher with the protection device comprises a threshing cylinder, wherein a motor is arranged in an inner cavity of the threshing cylinder, a motor shaft of the motor penetrates through a rear end surface of the threshing cylinder, matching driven gears are arranged on both the left and right sides of the threshing cylinder, rotating shafts are fixed onto the two sets of driven gears in an embedded mode, the peripheriesof both sets of rotating shafts are sleeved with threshing rollers, a fixing platform is arranged on the top of the threshing cylinder, pushing cylinders are arranged in positions, corresponding to both sets of threshing rollers, on the top of the fixing platform, first through holes are formed in positions, corresponding to the bottoms of both sets of pushing cylinders, of the fixing platform ina through mode, first motor bases are arranged on the tops of both sets of pushing cylinders, first reducers are arranged in inner cavities of both sets of first motor bases, and rotating rods are connected with the bottoms of both sets of first reducers. By means of the device, efficient rice threshing work is achieved, and efficient grain screening work can be conducted during threshing work, sothat plump grains are kept.

Owner:台州市路桥凯通管业有限公司

A crushing, melting and extruding integrated equipment for plastic production

The invention relates to crushing, melting and extruding integrated equipment for plastic production. The crushing, melting and extruding integrated equipment for the plastic production comprises a main barrel, a vertical knife, a connecting block, an inlet and a blocking ball. A motor is arranged on the middle portion above the main barrel, and a first rotary shaft is arranged under the motor. Afeed inlet penetrates through the left side of the upper portion of the main barrel. A hydraulic cylinder is arranged on the lower portion of the left side of the main barrel, and a push plate is fixed to the right side of the hydraulic cylinder. A hinge is installed on the left side of the main barrel, and a barrel door is arranged on the left side of the hinge. A main crushing knife with an arc-shape pointed structure is arranged, plastic can be crushed, and thus the melting speed of the plastic is accelerated, the working efficiency is improved. Through the arrangement of a secondary crushing knife and the vertical knife, the degree of plastic crushing can be improved. A filter plate with hollowed-out structure can block the unbroken plastic to ensure that the plastic volume passing through the filter plate conforms to the melting standard, and secondly, a stirring rod is arranged in a saw tooth structure.

Owner:ANHUI WANSHUN PIPE IND

Different direction stirring and mixing method of chemical raw materials

ActiveCN110652906BStir wellStir well stir wellRotary stirring mixersTransportation and packagingBLENDER/MIXERProcess engineering

The invention discloses a method for mixing chemical raw materials in opposite directions. The steps are as follows: the operator puts the materials to be stirred into the mixing tank in sequence; While the mixture in the inner ring is being stirred, the stirring member in the outer ring is fully and uniformly stirring the mixture in the outer ring; after the mixture is fully stirred evenly, the counter-rotating mechanism stops running, and at the same time the automatic dumping mechanism operates to make the mixing tank tilted, so that the The evenly stirred mixture in the mixing tank is poured out, and then the automatic dumping mechanism can be reversed to restore the mixing tank to its original state, and the next round of mixture stirring can be carried out; the entire mixture discharging process is fully automated without manual operation by the staff , which greatly reduces the labor intensity of the staff. At the same time, the inner and outer rings are used to stir in different directions, so that the mixture can be fully stirred evenly, and the stirring effect is better.

Owner:重庆安盛钾业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com