Patents

Literature

31results about How to "Realize processing automation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

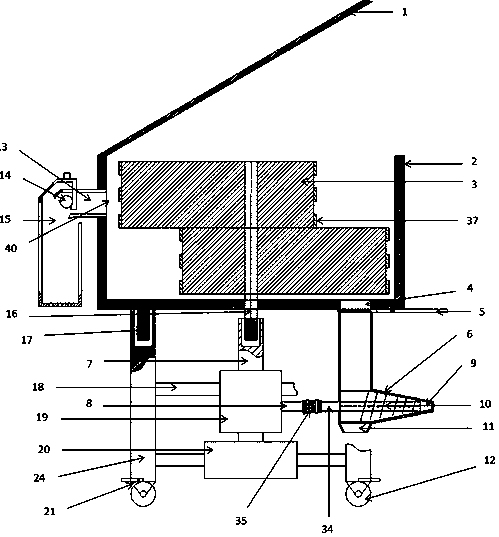

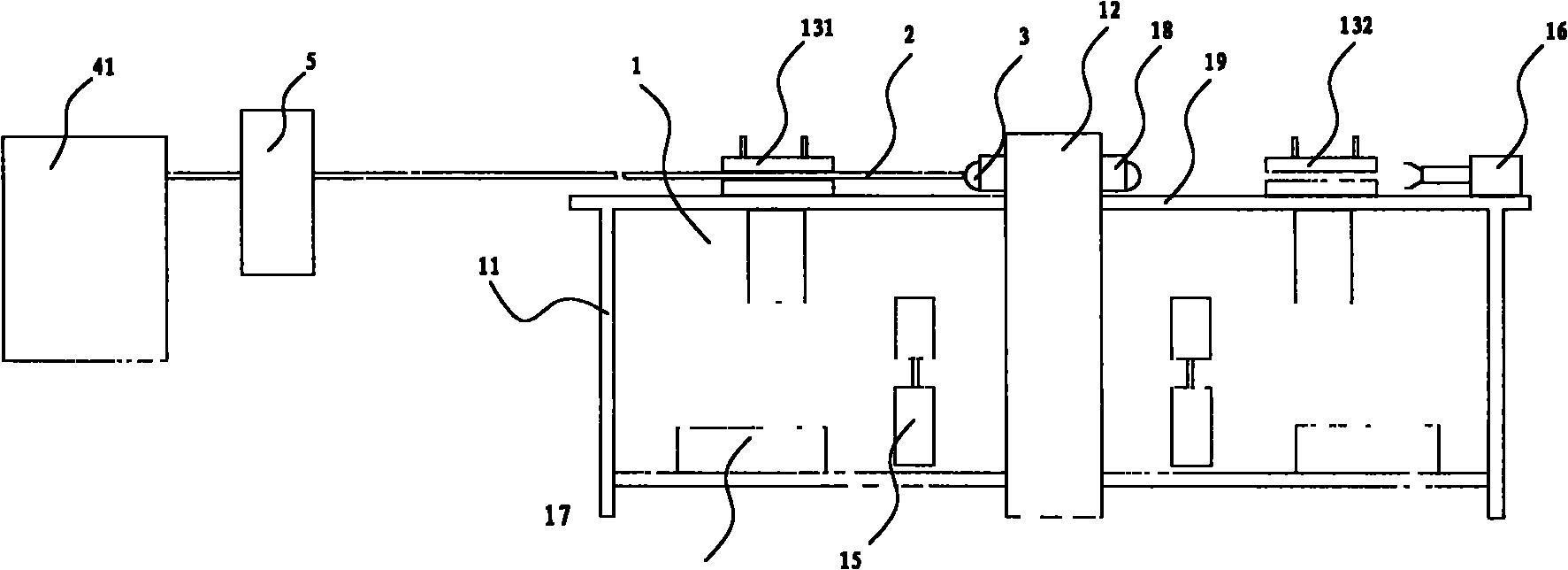

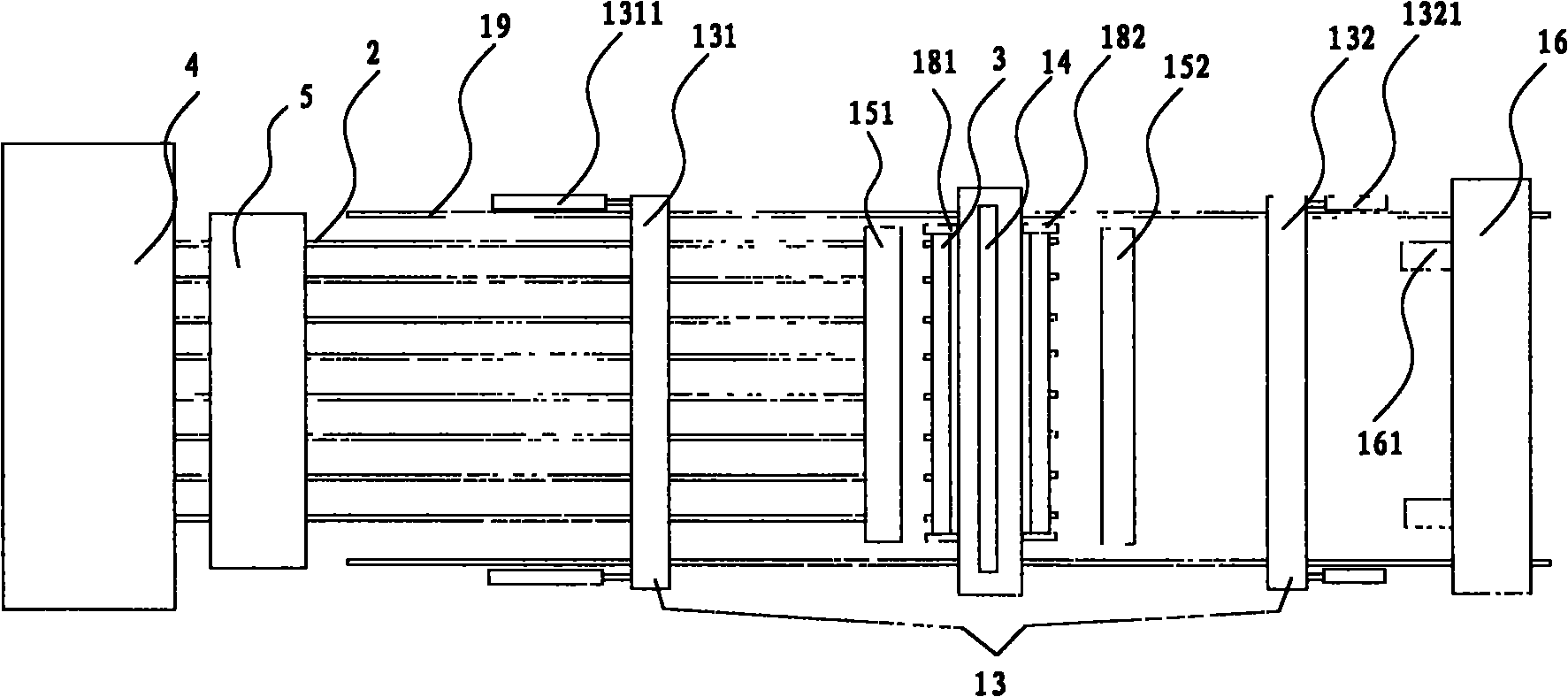

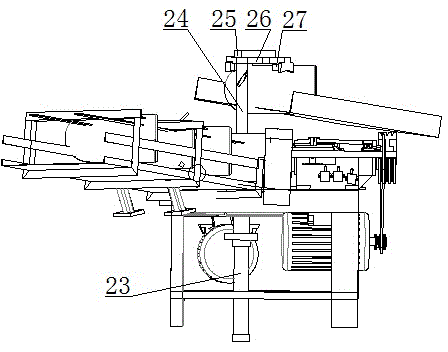

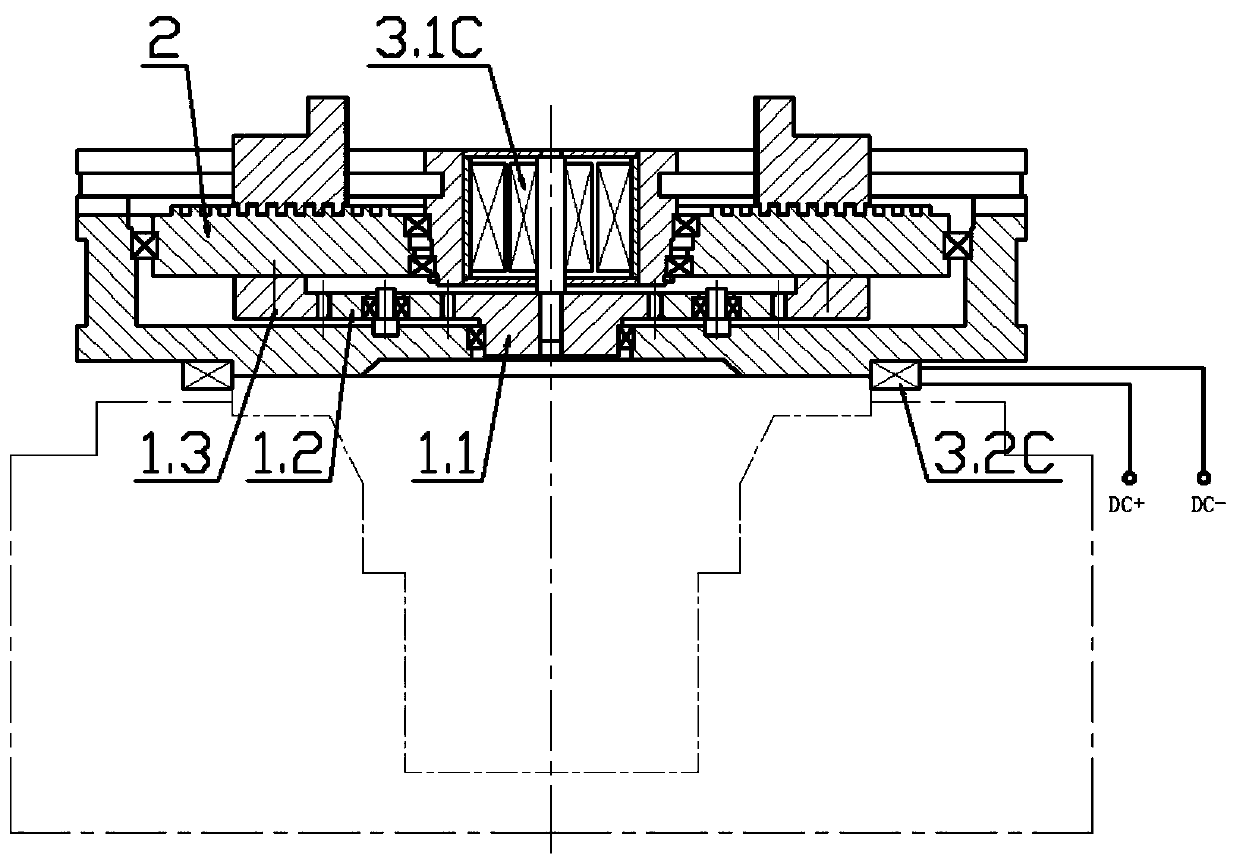

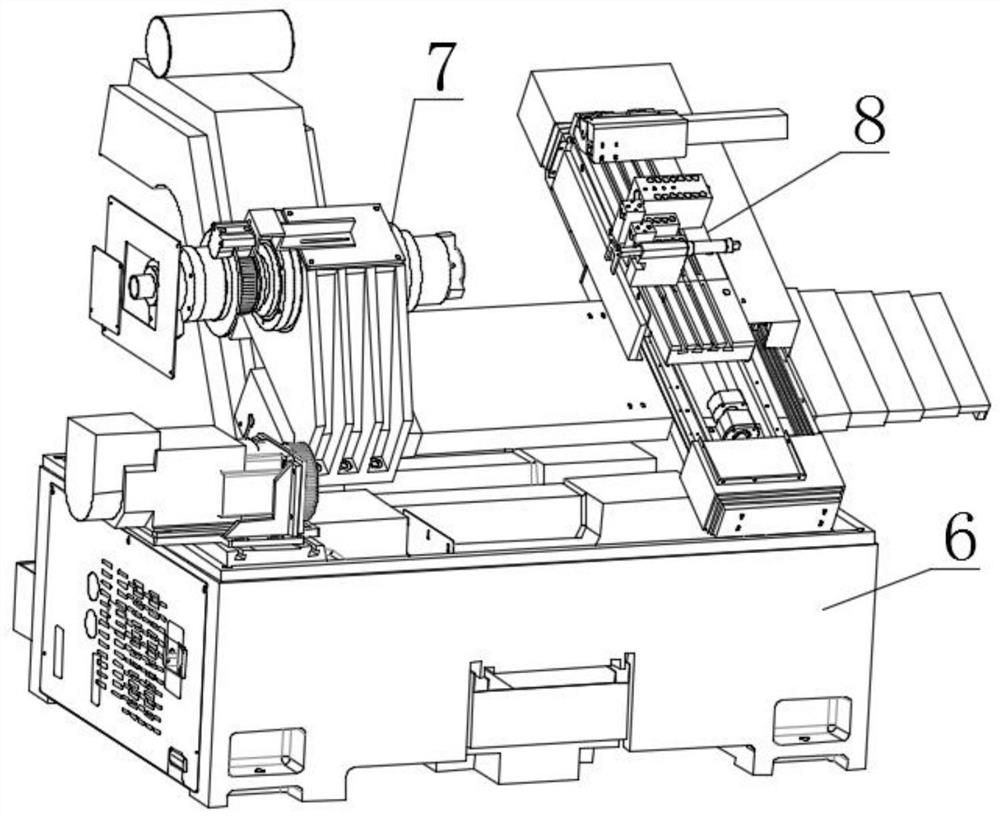

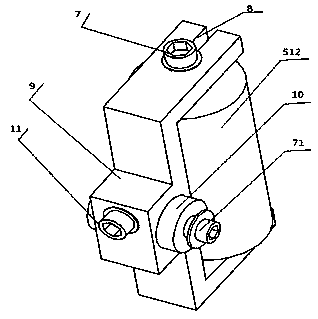

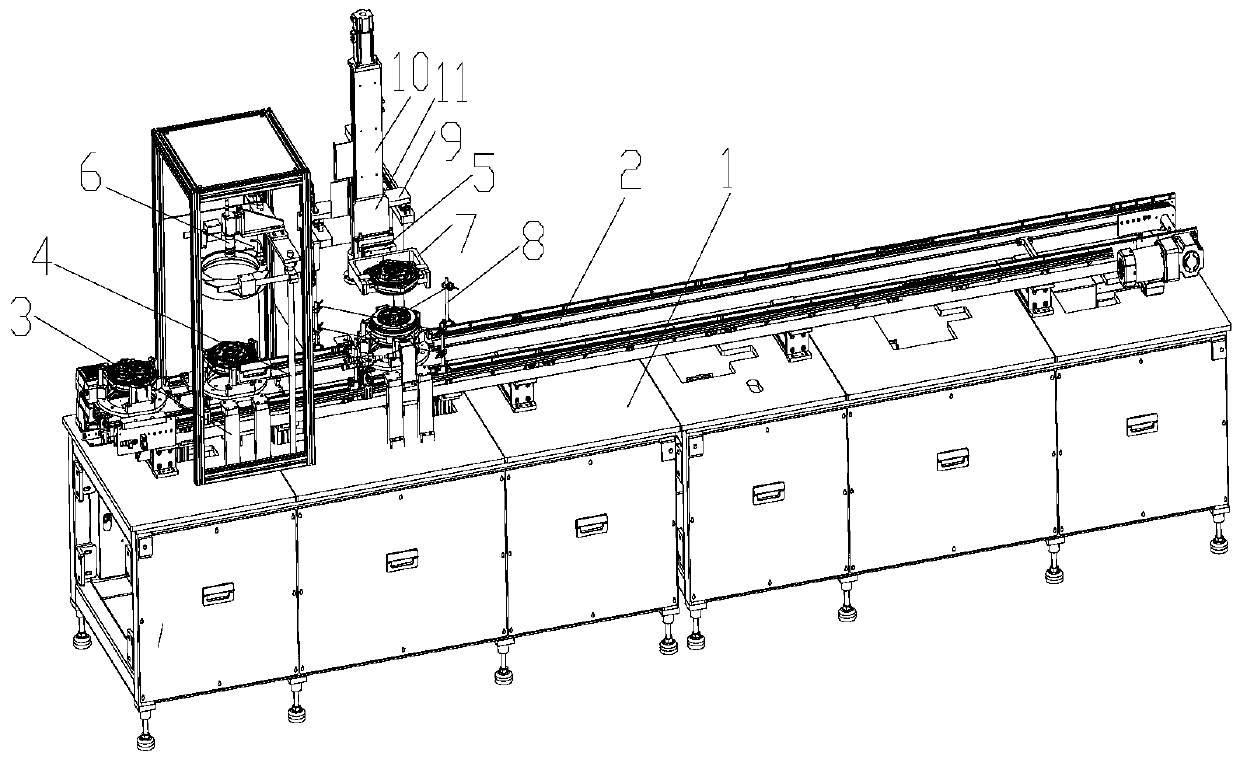

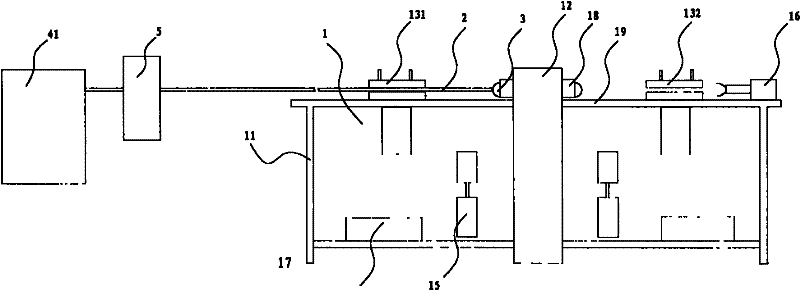

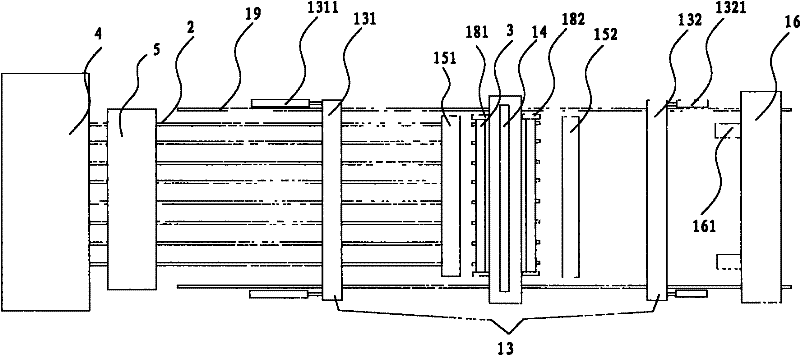

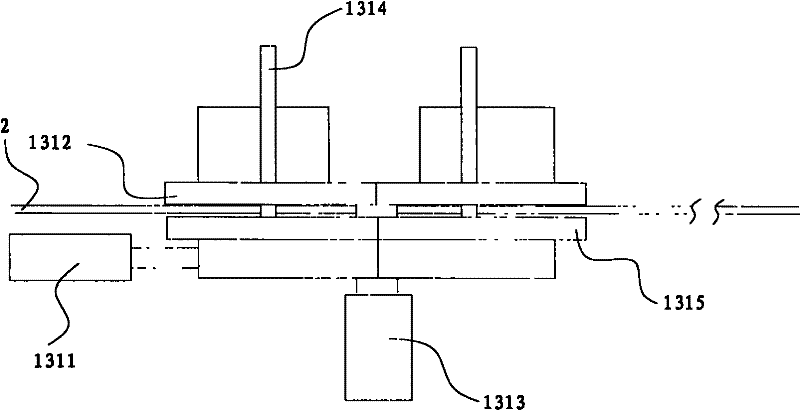

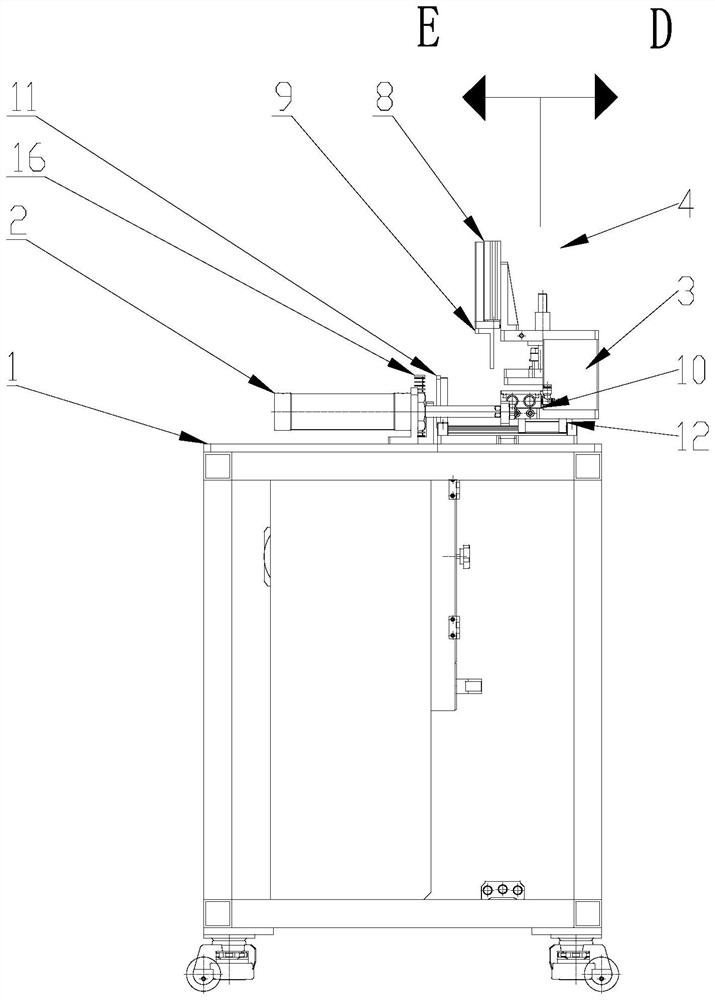

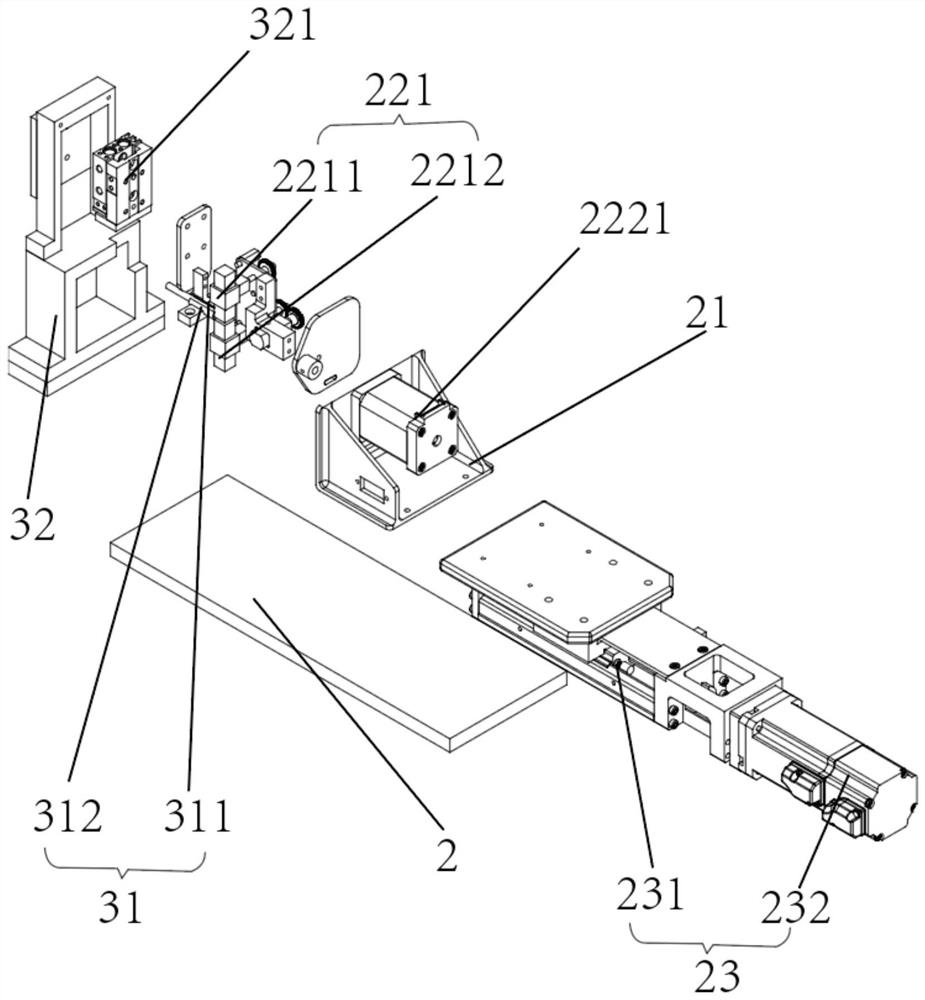

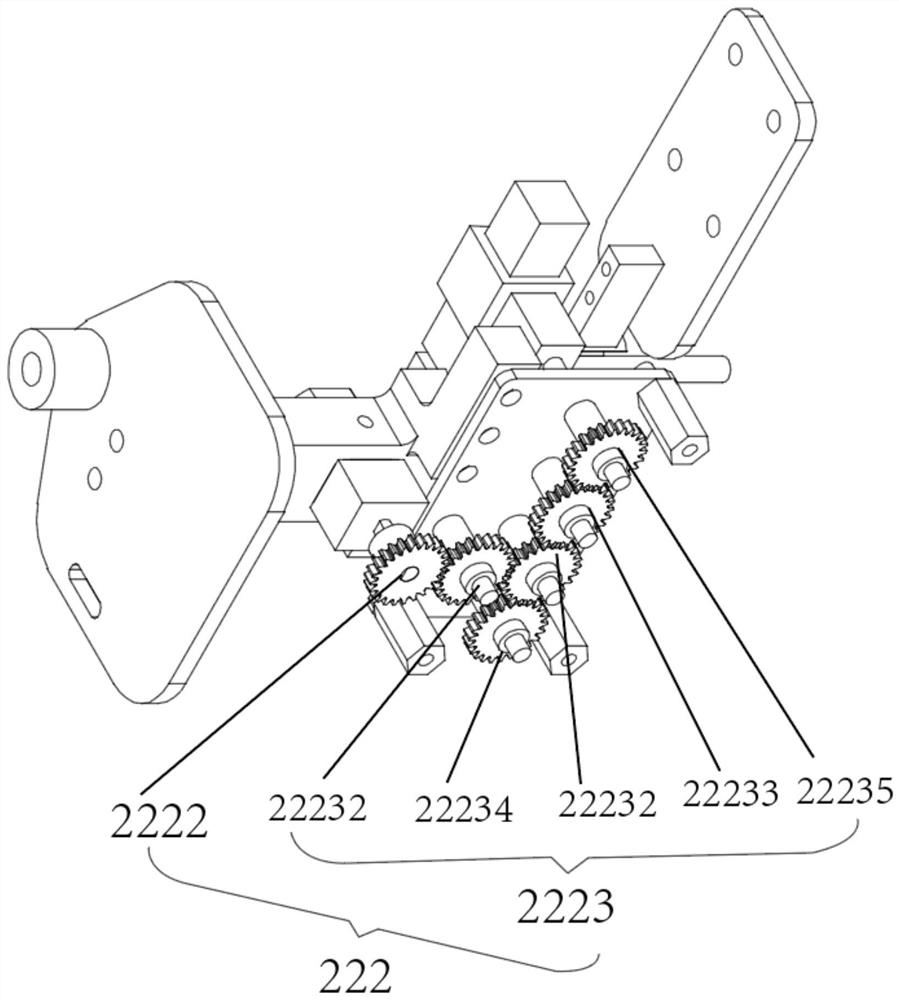

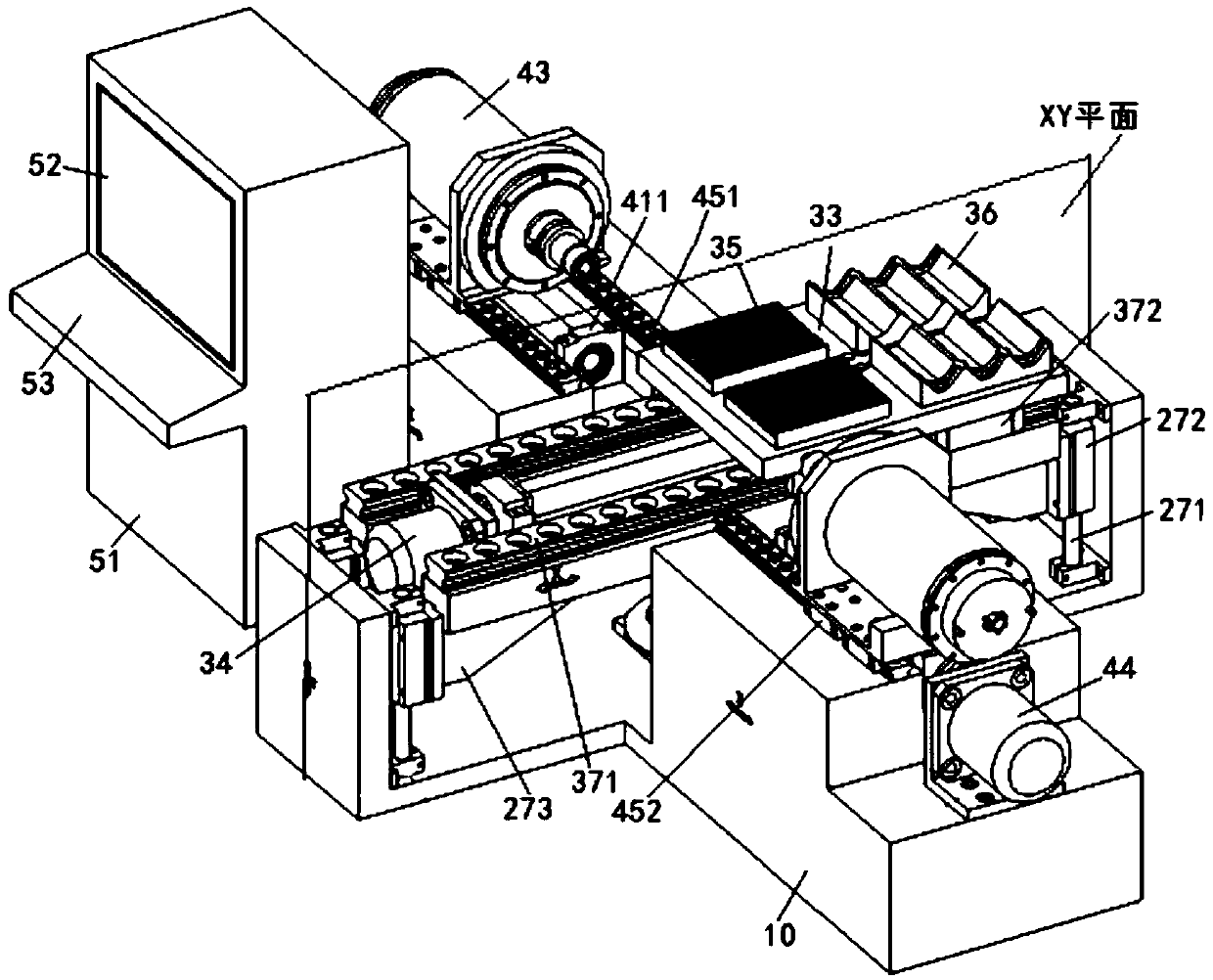

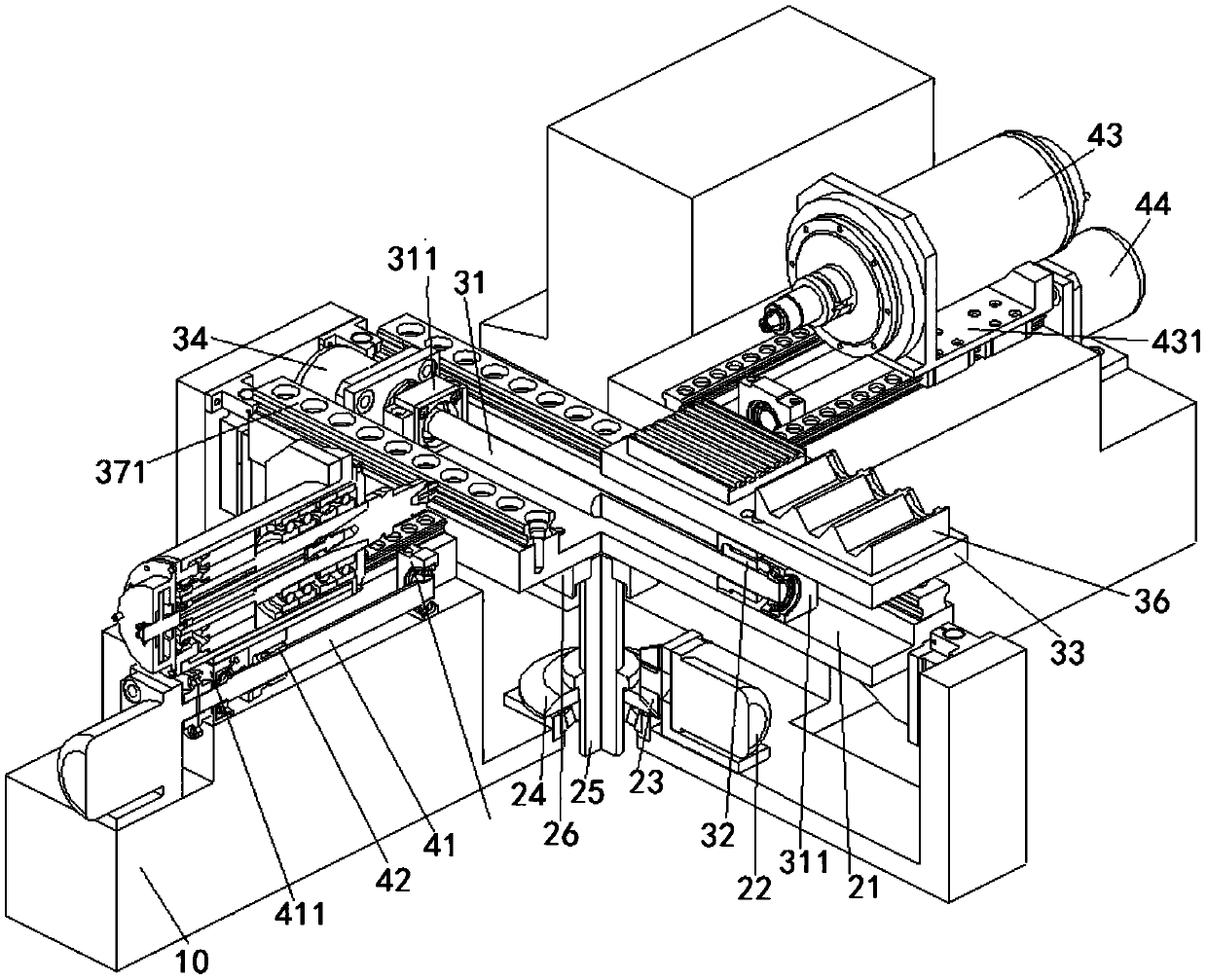

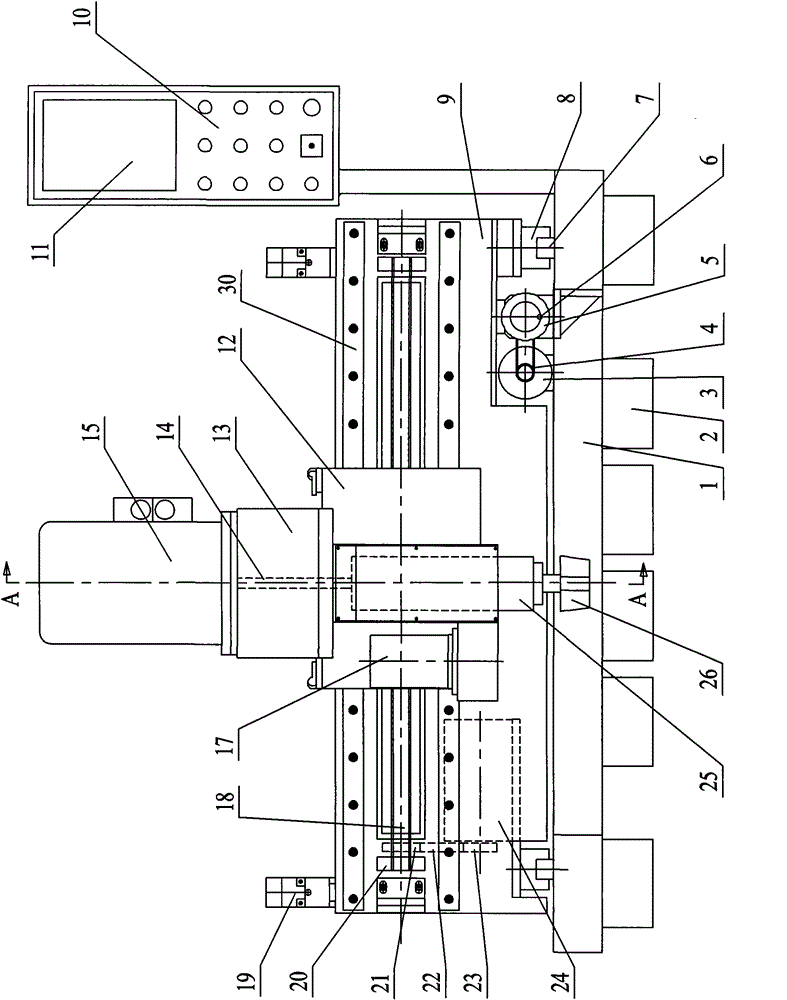

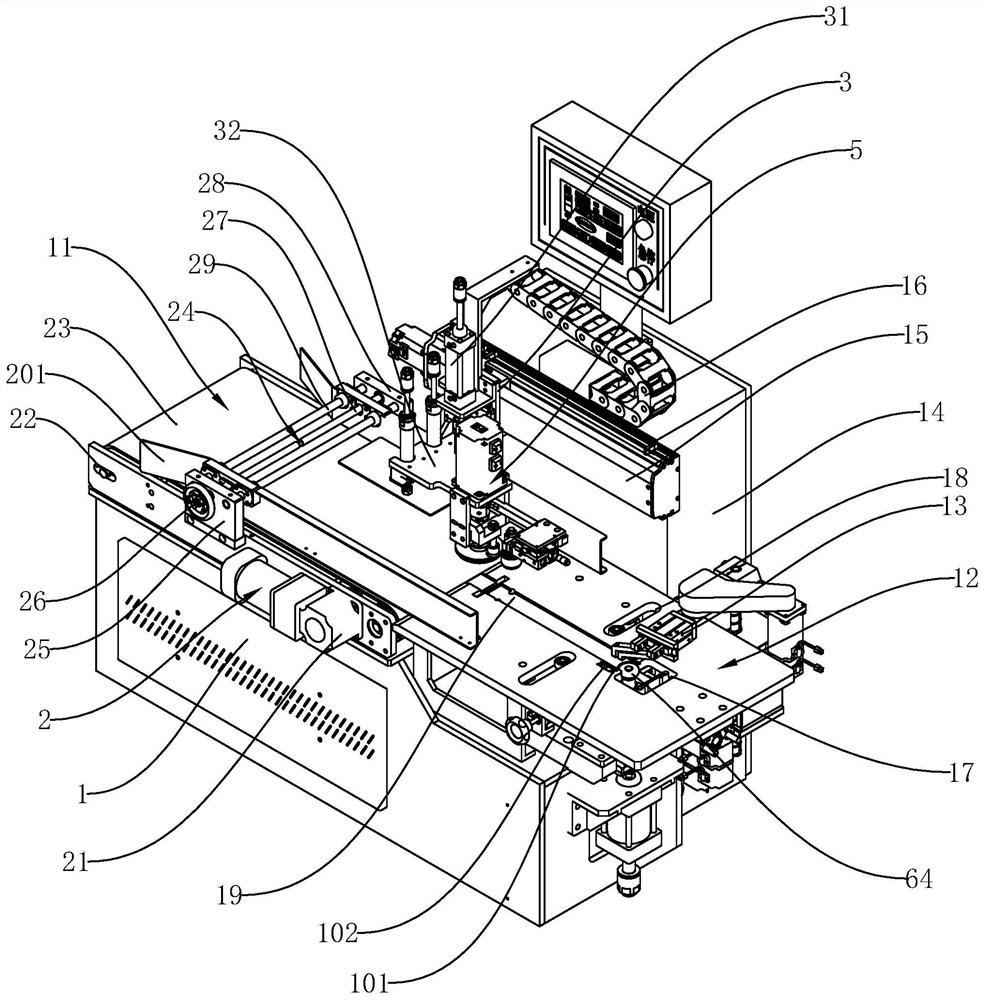

Special numerical control machine tool for machining small part

InactiveCN107971750ASolve processing problemsRealize processing automationFeeding apparatusOther manufacturing equipments/toolsNumerical controlEngineering

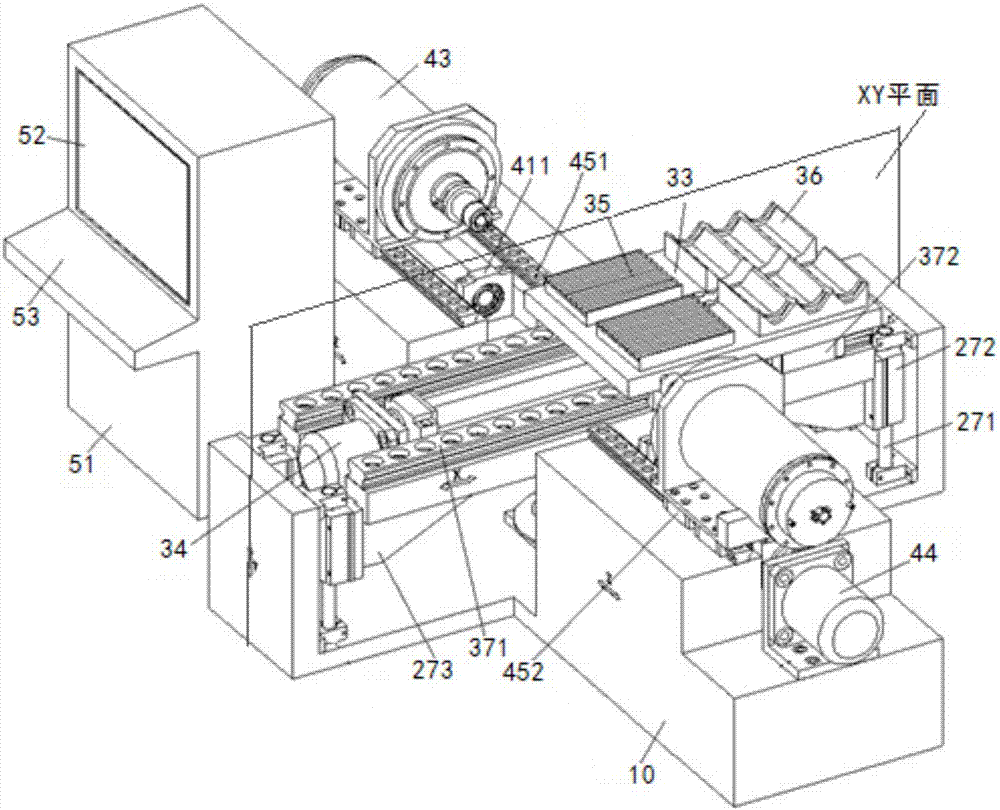

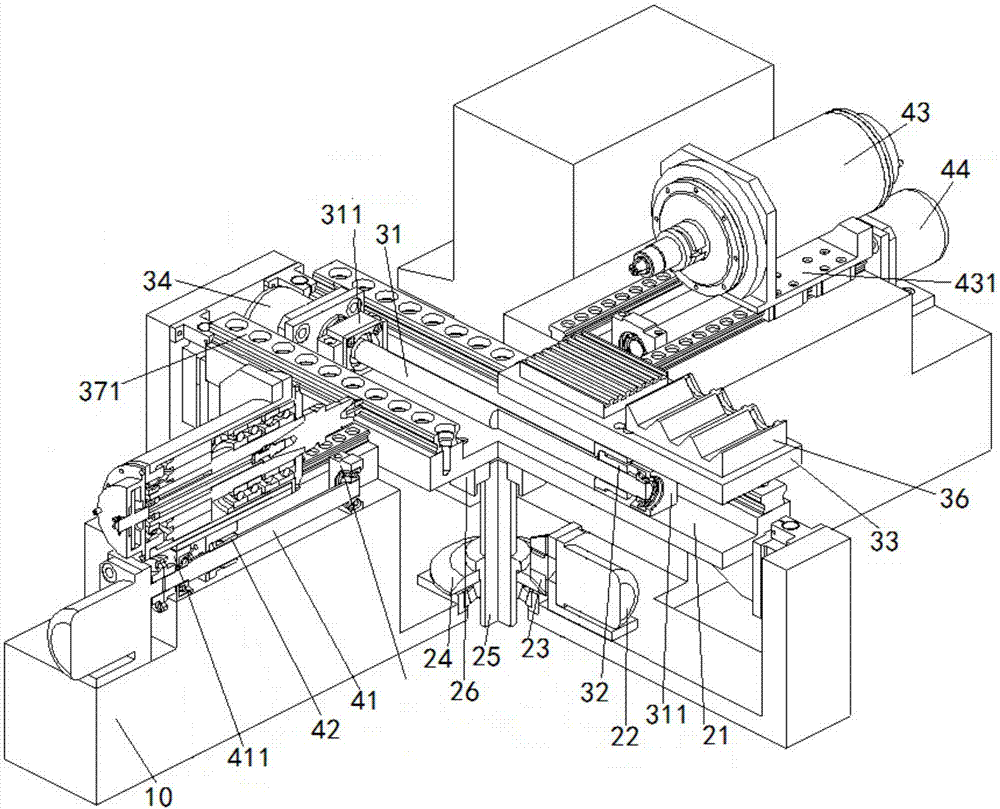

The invention discloses a special numerical control machine tool for machining a small part. The special numerical control machine tool comprises a machine tool body, a control mechanism and a three-axis machining mechanism; the Y-axis machining mechanism comprises a liftable large slide carriage; an X-axis machining mechanism comprises an X-axis ball screw; an X-axis stepping motor is used for driving the X-axis ball screw so that a small slide carriage can be driven to move horizontally by an X-axis nut; two groups of worktables and a row tool type tool magazine are detachably installed on the small slide carriage; two Z-axis machining mechanisms are arranged; each Z-axis machining mechanism comprises a Z-axis ball screw; and each Z-axis stepping motor is used for driving the corresponding Z-axis ball screw so that an electric spindle can be driven to move horizontally by a Z-axis nut. The special numerical control machine tool disclosed by the invention improves the part machining efficiency, increases the percent of pass of products, guarantees the machining quality and the stability of the machining quality, can be provided with different cutting tools according to the machining content of different types of work pieces so as to implement various machining of milling, drilling, chamfering, deburring and the like, realizes procedure centralization and machining automation of the small part, and alleviates the labor intensity of a worker.

Owner:SHANGHAI DIANJI UNIV

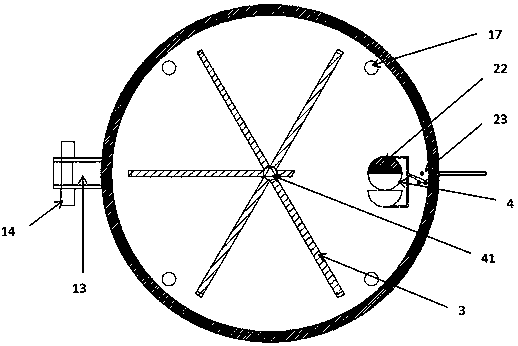

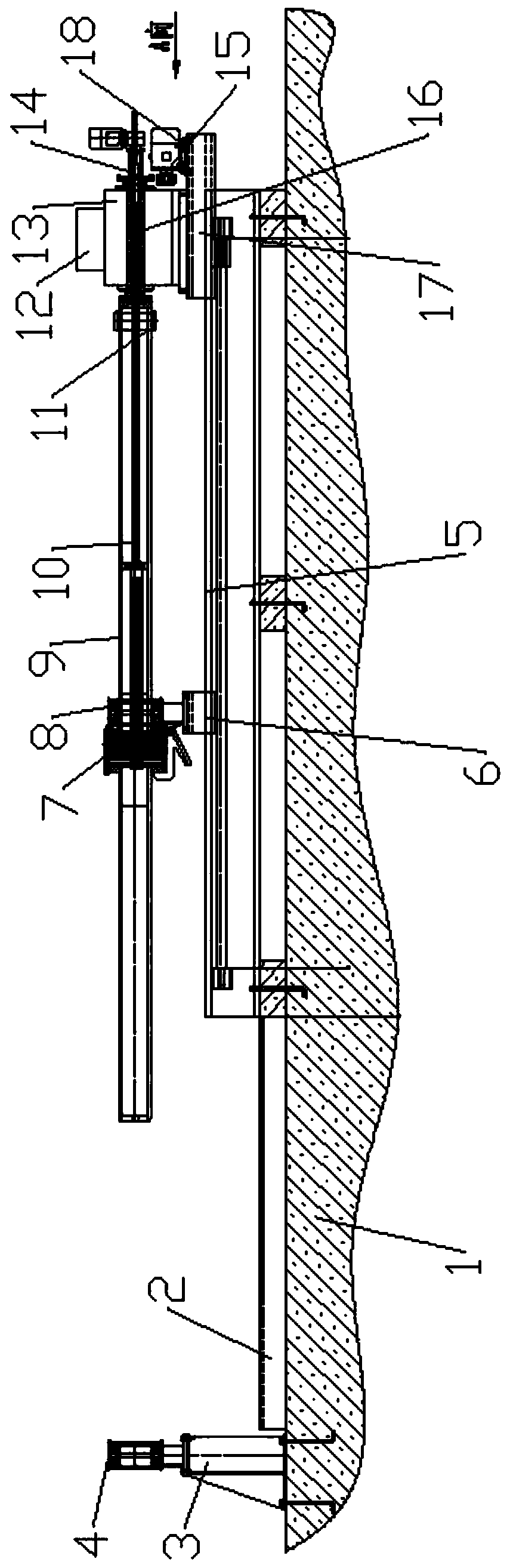

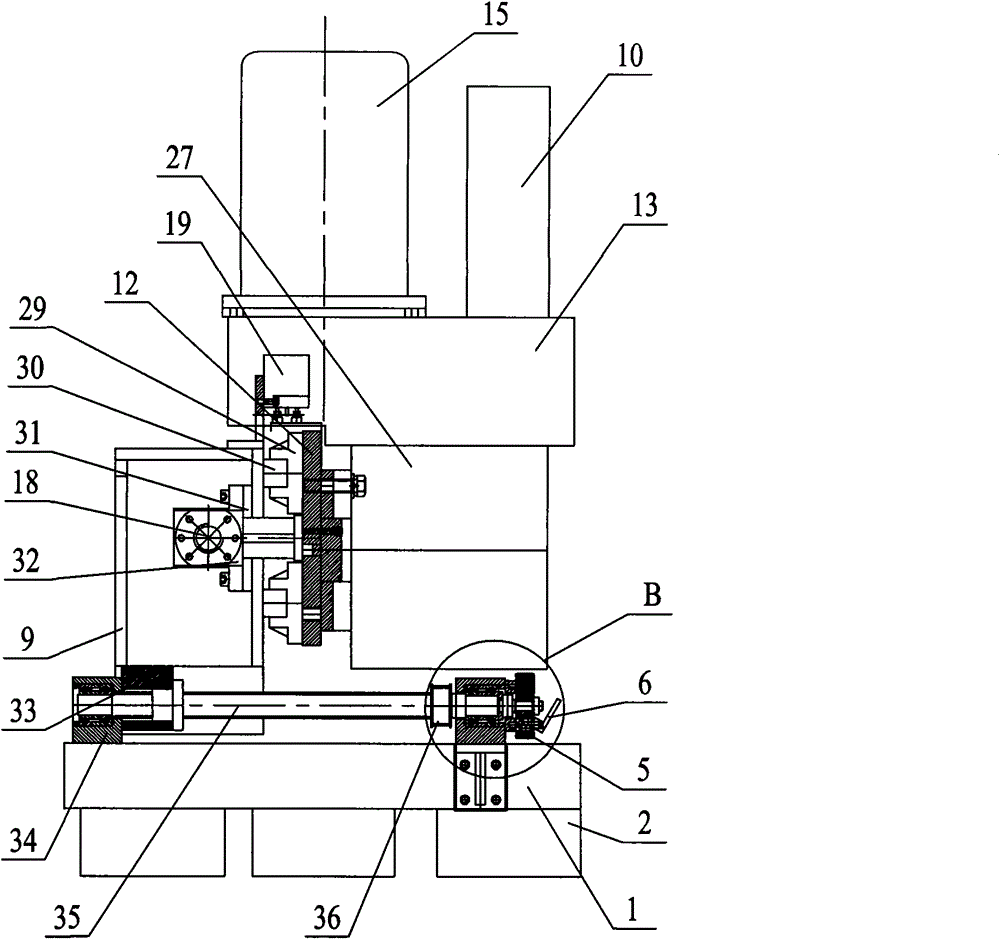

Automatic magnetic seat milling device

InactiveCN101704194AIngenious structureMove preciselyLarge fixed membersMilling equipment detailsNumerical controlMilling cutter

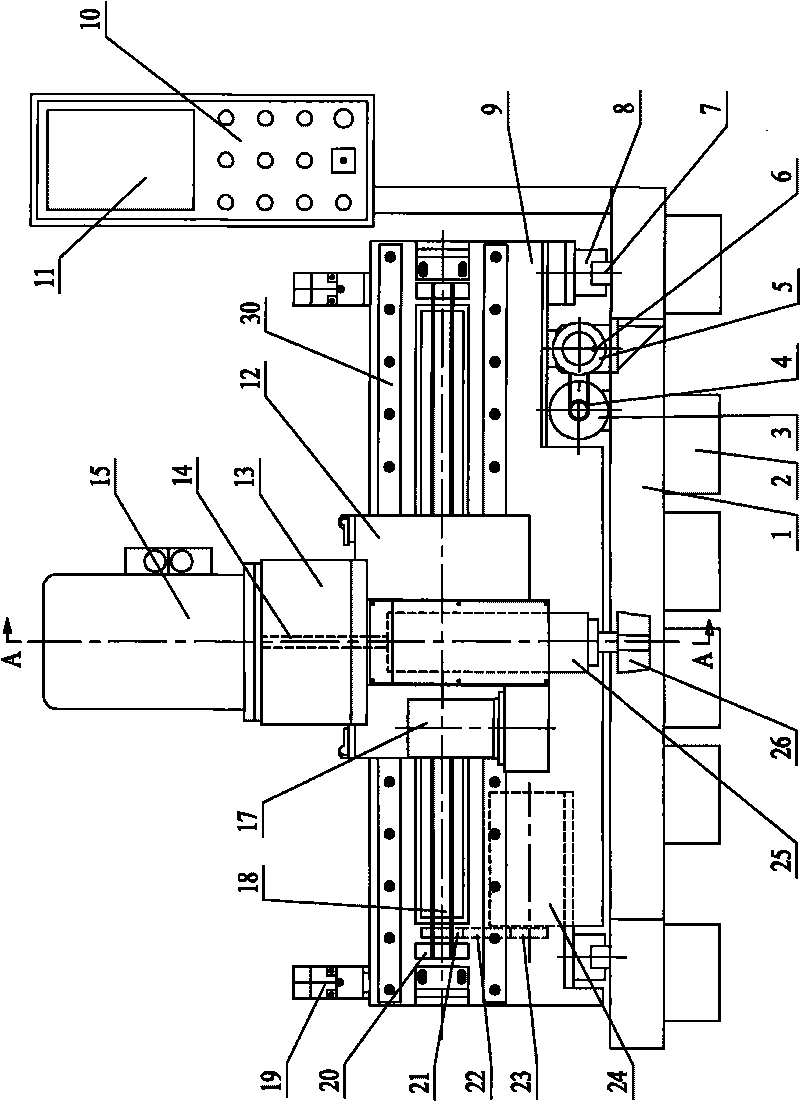

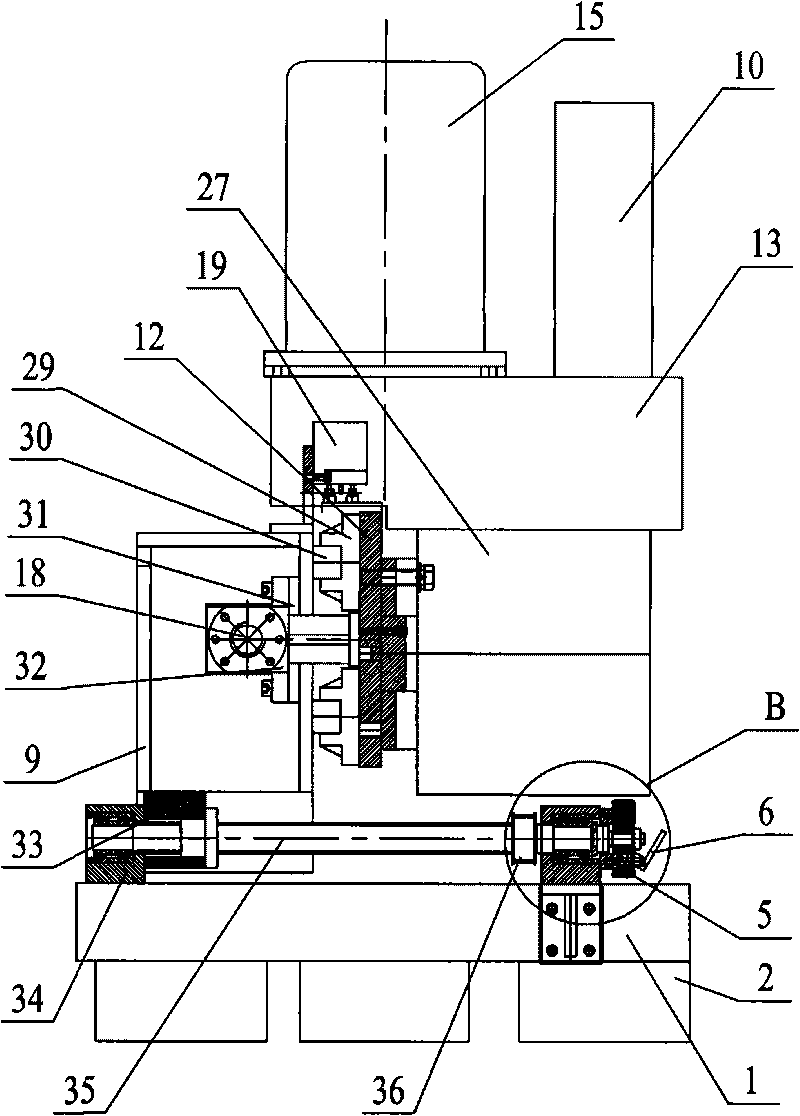

The invention belongs to the technical field of machining equipment, which relates to an automatic magnetic seat milling device capable of precisely moving in longitudinal, transverse and vertical directions. The automatic magnetic seat milling device comprises a lathebed and is characterized in that the lower part of the lathebed is provided with a magnetic seat; the upper part of the lathebed is provided with a longitudinal moving mechanism; a transverse moving mechanism is arranged on the longitudinal moving mechanism; a vertical moving and milling mechanism is arranged on the transverse moving mechanism; and a numerical control mechanism is arranged at one side of the lathebed. The magnetic seat automatic milling device has skillful, compact and reasonable structure and precise movement and can machine surfaces which cannot be machined by the traditional equipment and ensure that the machined surfaces are even and smooth, thereby realizing machining automation, greatly improving the working efficiency and obviously reducing the cost. A longitudinal moving rack and a base are formed by welding steel plates and have good rigidity. Because a milling cutter disk can be vertically lifted, the surface of a machining piece can be higher than a plane sucked by a milling machine and also be lower than the plane, and the application range of the automatic magnetic seat milling device is wide.

Owner:WUXI YAZHONG PNEUMATIC HYDRAULIC

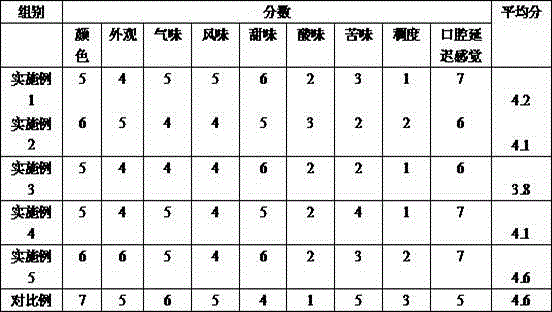

Processing method of cold-brewed tea

InactiveCN106359667ARapid extractionEfficient extractionPre-extraction tea treatmentAdditive ingredientRefrigeration

The invention provides a processing method of cold-brewed tea, which includes the steps of: S1) weighing dry tea and adding a proper amount of cold water, wherein material-to-water ratio of the dry tea to the water is 4 kg : 3 L to 5 kg : 8 L, and the temperature of the cold water is 0-10 DEG C; S2) allowing the dry tea and the water to stand at 0 DEG C for rehydrating the tea for 15-25 min until water content of the tea leaves is 38-48%, and freezing the rehydrated tea leaves in a refrigeration room at -22 - -15 DEG C for 2.5-6 h; S3) after refrigeration, moving the tea leaves out from the refrigeration room, naturally de-freezing the tea at constant temperature of 18-22 DEG C and rehydrating the tea for 30-50 min; and S4) puffing the defrozen and rehydrated tea leaves. The cold-brewed tea is greatly increased in mass percentage of extracts under a cold water environment without out damage on bio-chemical components in the cold-brewed tea, and especially, the anthocyanin in the tea is not damaged and can be released as most as possible, thus further improving physiologically health-caring effects of the cold-brewed tea.

Owner:张天才

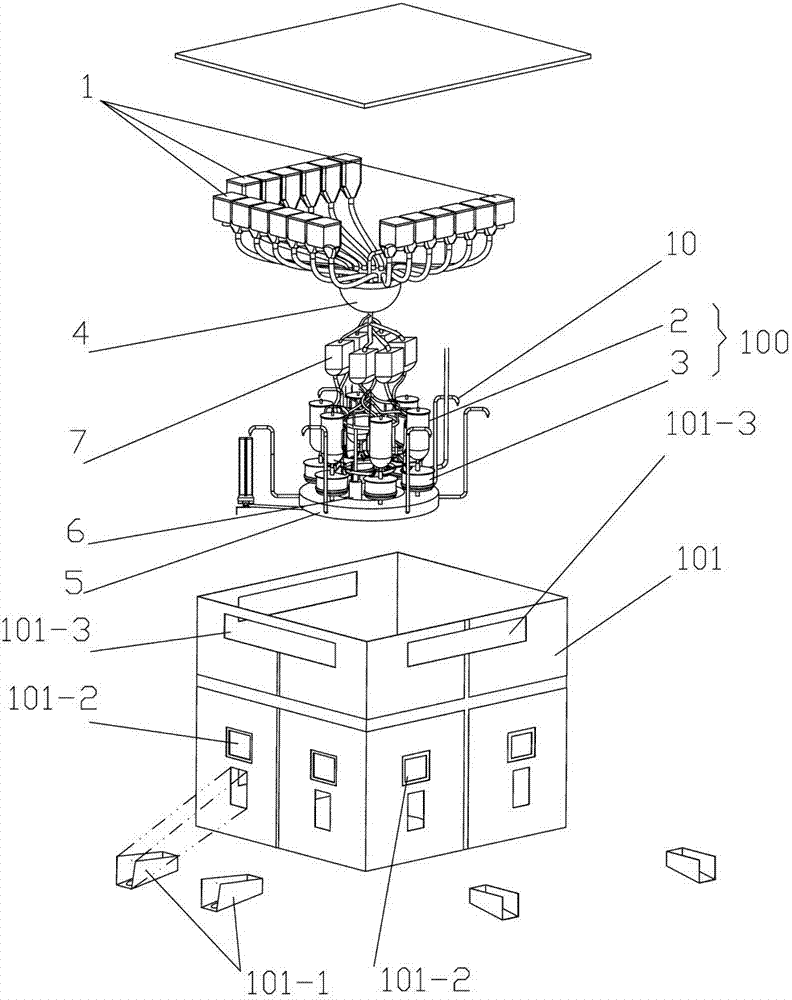

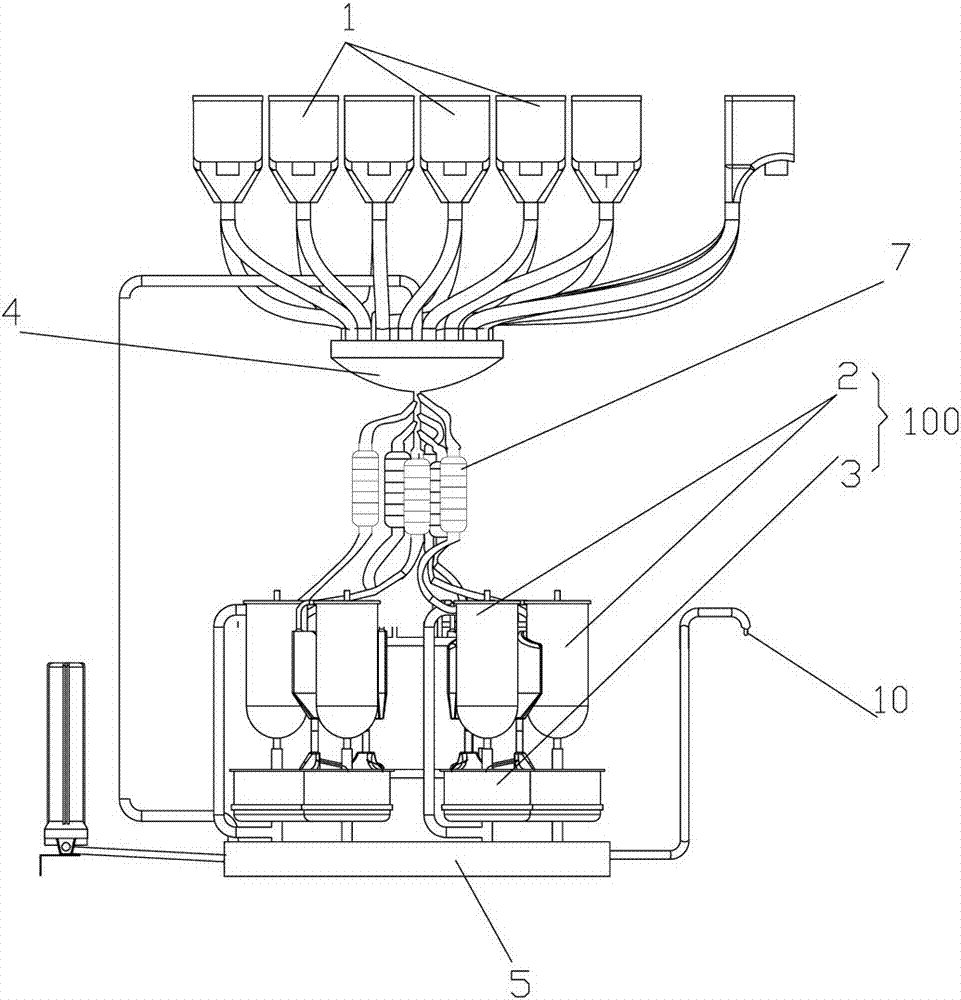

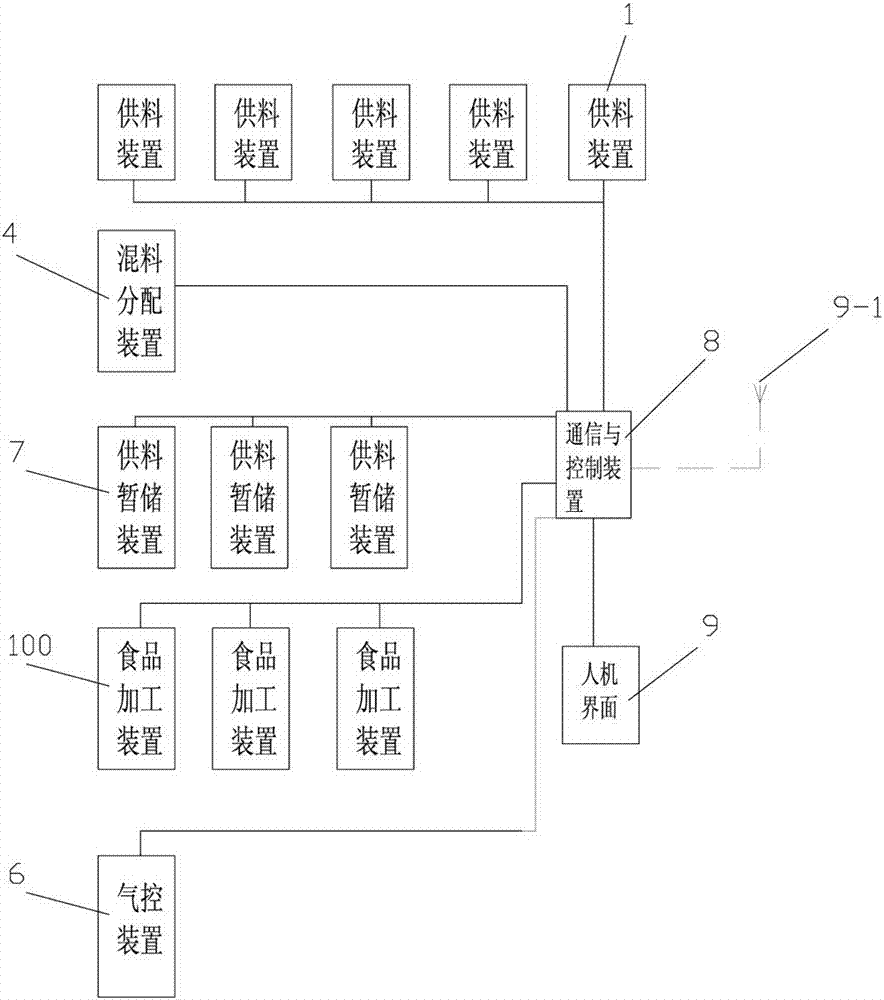

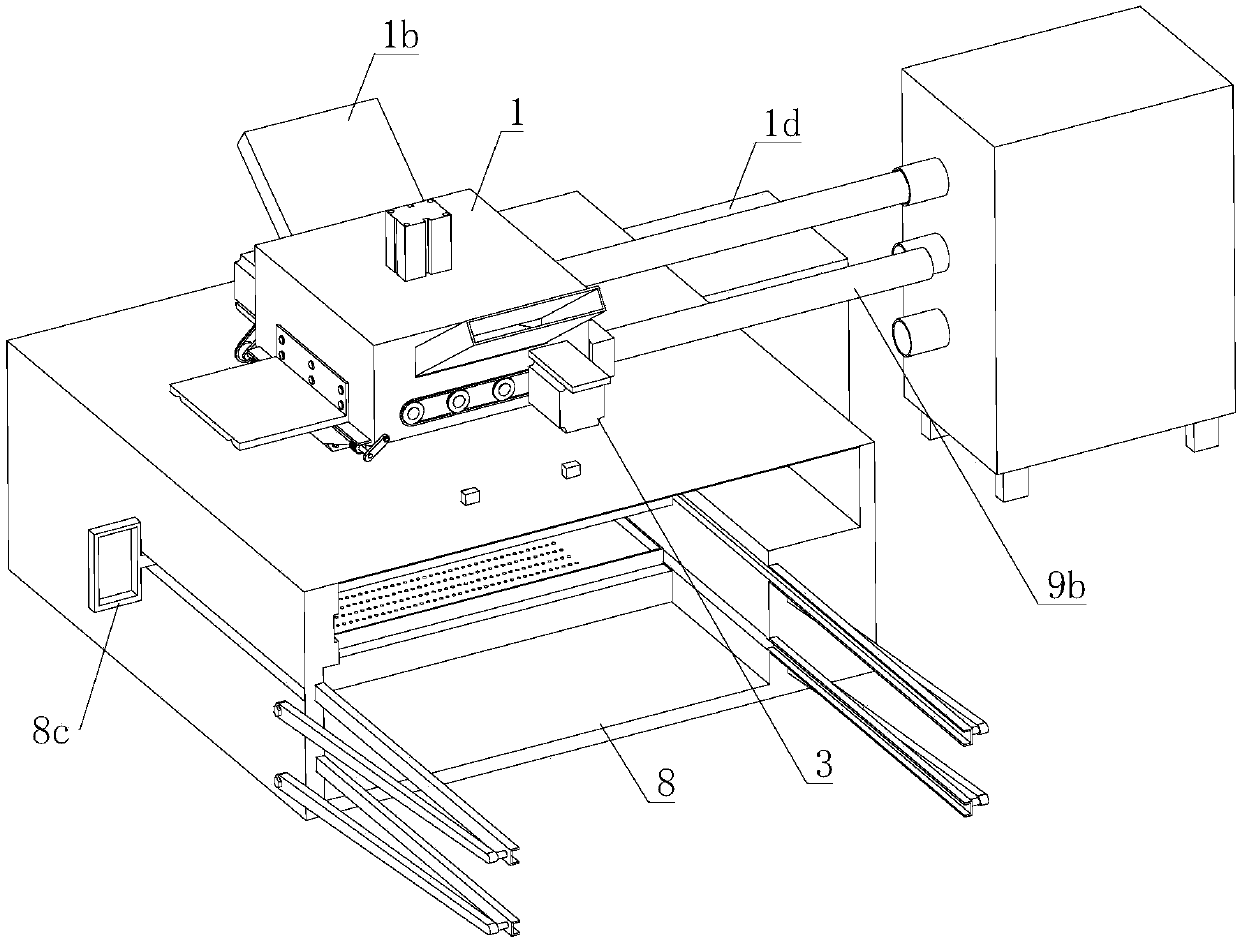

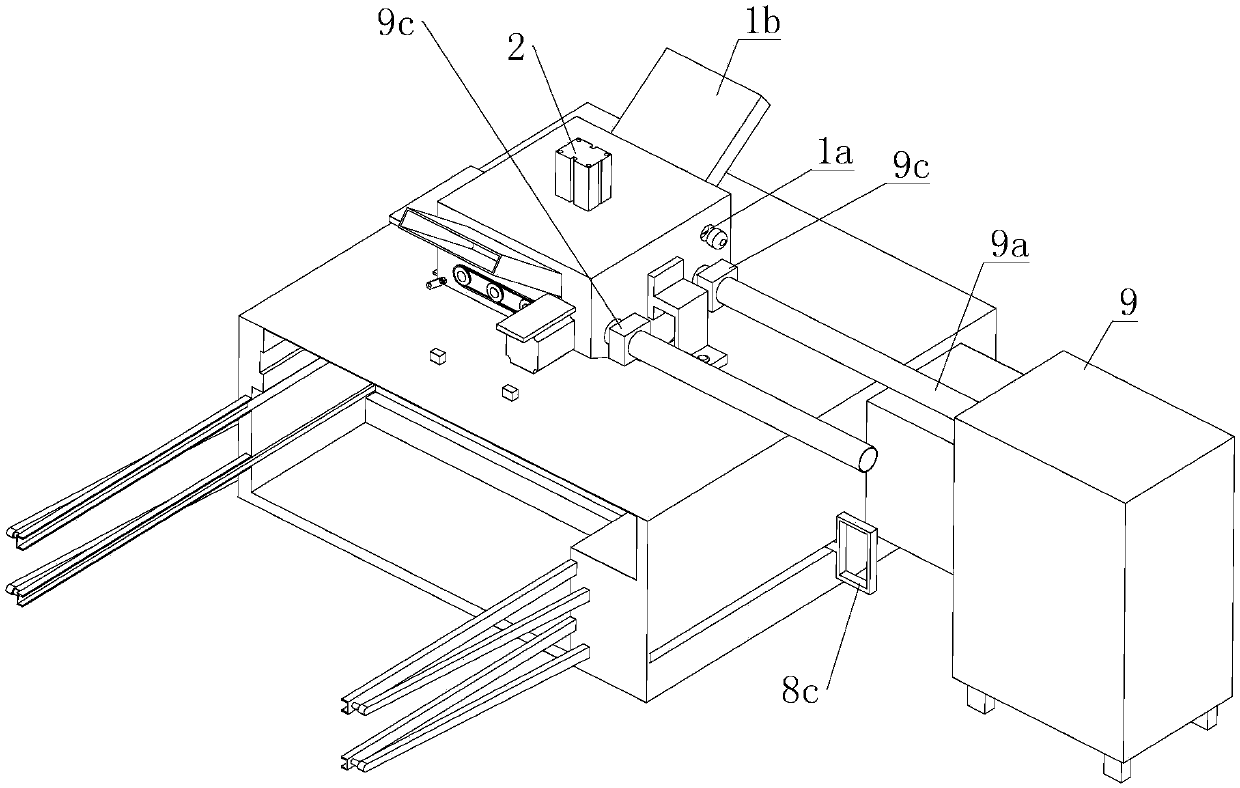

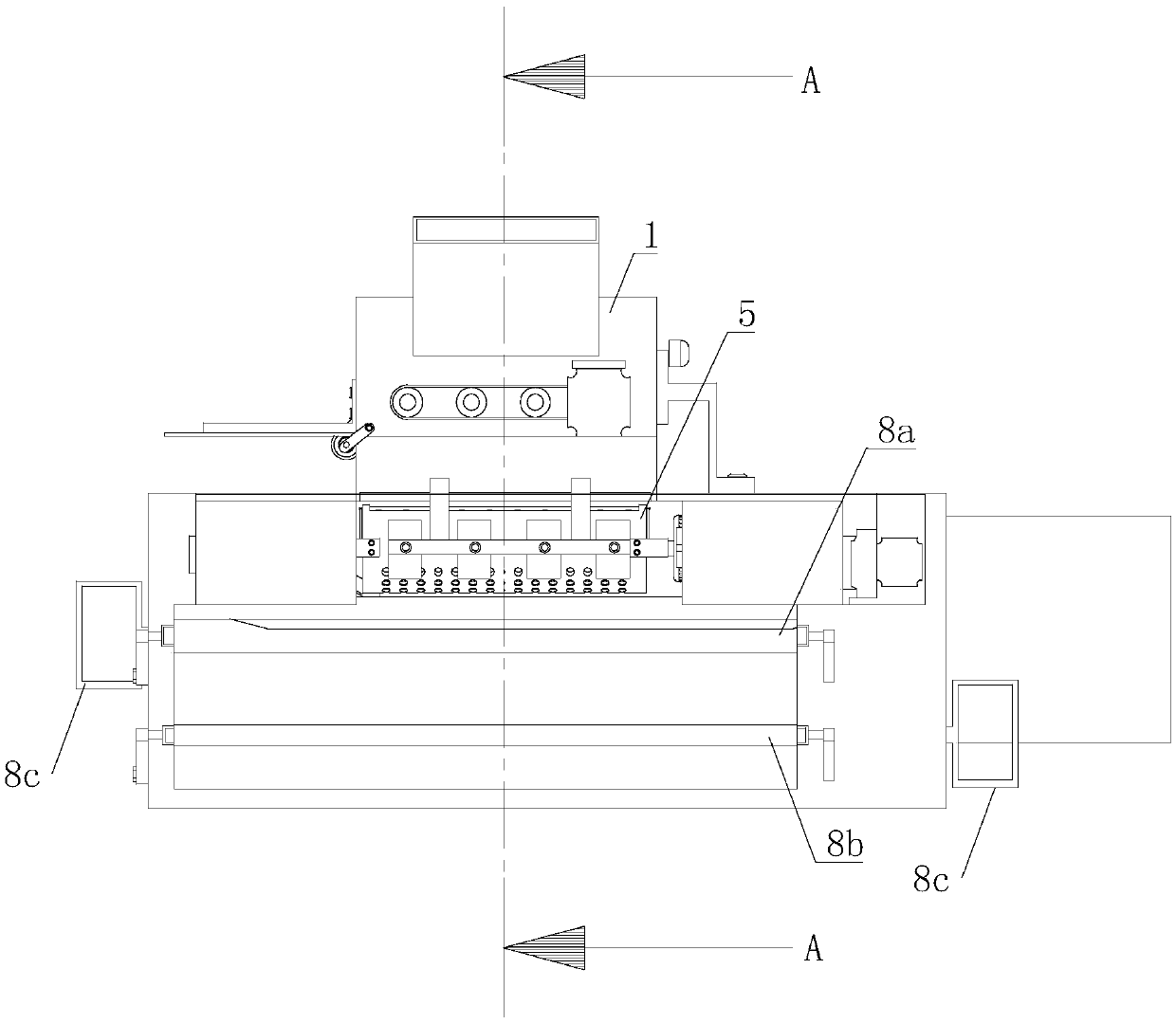

Pulped drink food processing machine and pulped drink food processing method

PendingCN106901604AWill not be introducedRealize processing automationBeverage vesselsHuman–machine interfaceEngineering

The invention discloses a pulped drink food processing machine and a pulped drink food processing method. The pulped drink food processing machine comprises a material supply device, a food processing device, a pulped drink outlet, a rack, a pneumatic device, a supplied material temporary storage device, a communication and control device and a human-machine interface, wherein the material supply device, the food processing device, the supplied material temporary storage device and the human-machine interface are all electrically connected with the communication and control device; the pneumatic device, the supplied material temporary storage device, the human-machine interface and the communication and control device are all mounted on the rack; the material supply device is connected with the supplied material temporary storage device; the supplied material temporary storage device is connected with the food processing device; the supplied material temporary storage device comprises a material storage container and a plurality of valve mechanisms; the valve mechanisms are electrically connected with the communication and control device; the valve mechanisms are fixedly connected to the material storage container and divide the material storage container into a plurality of small cavities. According to the pulped drink food processing machine and the processing method, the container for temporarily storing food materials is provided, so that automatic processing can be realized, and no secondary pollution is caused; pulped drink food can be discharged in delay or in advance, and the automation degree is high.

Owner:上海洛瓷动力科技有限公司

Automatic clam cleaning and meat-shell separation equipment and application method thereof

PendingCN109566709ASpeed up sand spitAdd block sand spit efficiencyBivalves processingClimate change adaptationSteam cookingElectric machine

The invention relates to the field of preparation of clams, in particular to automatic clam cleaning and meat-shell separation equipment. The equipment comprises a cleaning bin, a transition bin, a steam cooking device and a separation device, wherein the cleaning bin is arranged on the top of the transition bin and is communicated with the transition bin; the separation device comprises a separation barrel, a servo motor, a shedding mechanism and a translation mechanism which are arranged in the transition bin; the separation barrel is horizontally hinged with the upper part of the interior of the transition bin; the shedding mechanism and the servo motor are respectively arranged at the two ends of the separation barrel; the translation mechanism is arranged by the side of the servo motor; the cleaning bin is internally provided with a cover device; the steam cooking device comprises a steam generator, a steam inlet pipeline and a sewage discharge pipeline; the sewage discharge pipeline is communicated with the interior of the cleaning bin; and a steam outlet end of the steam generator is communicated with the interior of the cleaning bin through the steam inlet pipeline. According to the invention, the clams are effectively cleaned and then rapidly cooked for shell opening, and then the clams with shells opened in batches are subjected to meat-shell separation, so that product processing automation is realized, and product processing efficiency is further increased.

Owner:HALAODA FUJIAN FOOD

Multifunctional garlic processing device

InactiveCN111194933AInnovative designReduce energy consumptionFood treatmentBiotechnologyEngineering

The invention discloses a multifunctional garlic processing device. The device mainly comprises a splitting and garlic skin removing device, a garlic skin collecting device, a handle device, a motor-driven gearbox device, a garlic clove deep processing device, a rolling wheel and a wheel locking device which are arranged in an upper barrel. The device integrates the functions of splitting, peelingand garlic skin collecting of the whole garlic, can complete deep processing of chopping and extruding the garlic cloves into paste, has the characteristics of high processing efficiency, high garlicskin removing rate and high garlic clove integrity rate, has the characteristics of simplicity in garlic skin collection and environmental protection, and is more energy-saving than similar productson the market without a high-power air compressor. The equipment is simple in structure and convenient to operate, disassemble and clean, so that the garlic processing cost and the equipment use and maintenance cost are greatly reduced, and the device is suitable for being popularized and used in catering enterprises with large garlic seasoning demands, such as chafing dish and Chinese food.

Owner:SOUTHWEST UNIVERSITY

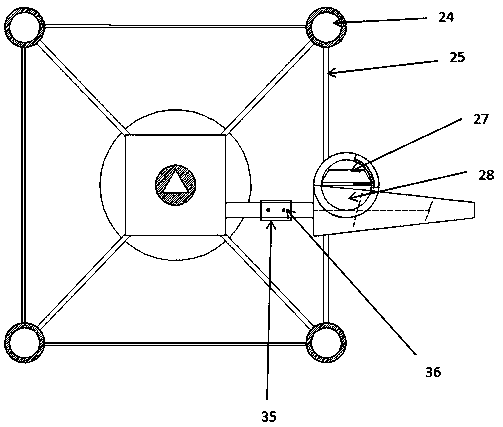

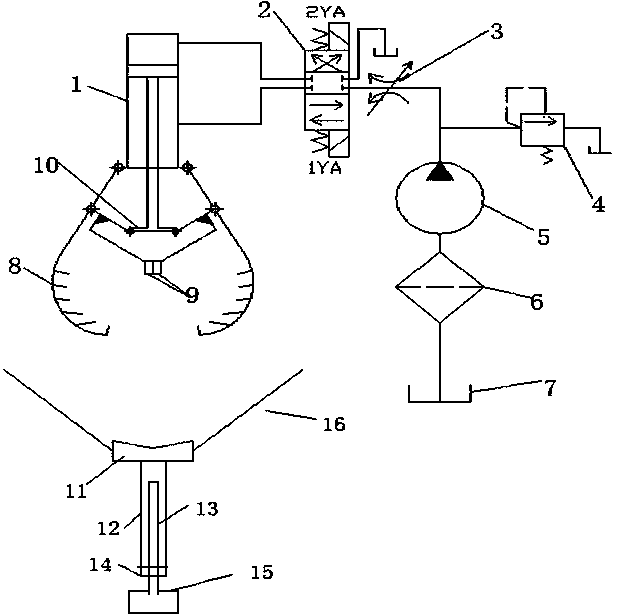

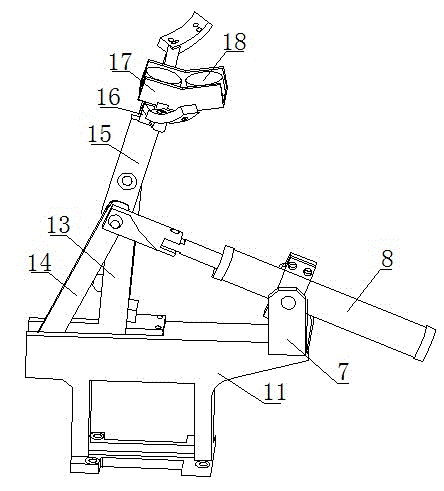

Automatic mesocarp stripping machine for coconuts

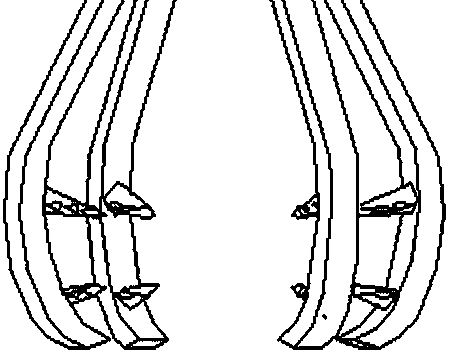

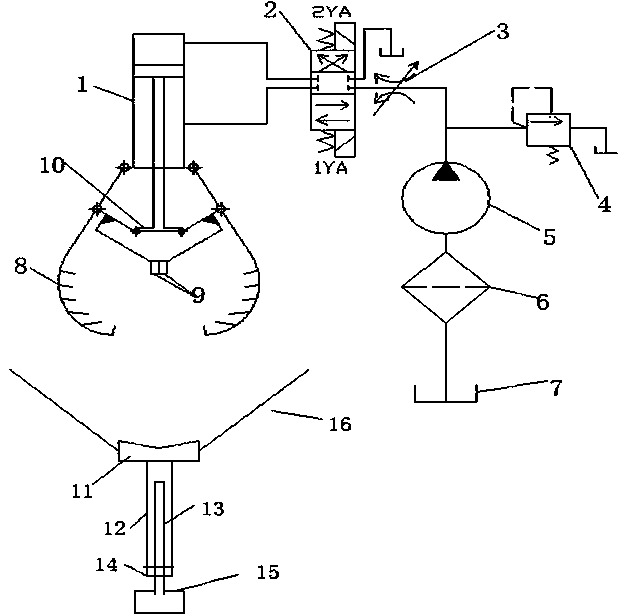

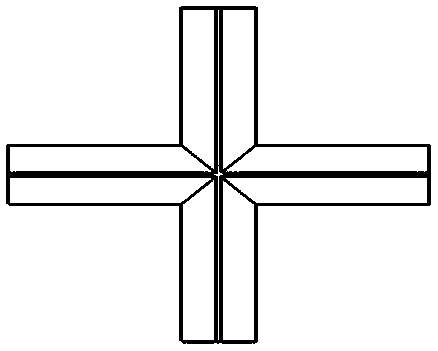

ActiveCN108514128AEfficient and easy stripping processRealize processing automationHuskingHullingMagnetic exchangeHydraulic cylinder

The invention relates to an automatic mesocarp stripping machine for coconuts. The machine mainly comprises a hydraulic cylinder, an magnetic exchange valve, a throttle valve, an overflow valve, a hydraulic pump, an oil filter, an oil tank, side cutters, an upper cutter, a sliding pressing plate, a tray, a tray support, a lifting lead screw, a lifting nut, a lifting servo motor and a feeding disc;the right side of the hydraulic cylinder is connected to the magnetic exchange valve; the throttle valve is connected to the magnetic exchange valve; the overflow valve is connected to the throttle valve; the hydraulic pump is connected to the throttle valve and the overflow valve; the hydraulic pump is connected to the oil filter; the oil filter is positioned above the oil tank; the side cuttersare arranged below the hydraulic cylinder in connection relation; the sliding pressing plate is arranged rightly below the hydraulic cylinder; and the sliding pressing plate is connected to the uppercutter. The automatic mesocarp stripping machine for coconuts adopts hydraulic transmission as power output, takes the feeding disc combining a lead screw mechanism with a nut mechanism as a feedingdevice. The upper cutter cooperates with the side cutters, so that coconut mesocarp can be pulled apart from the top, the side surface and the bottom end of a coconut at the same time, and the mesocarp stripping is rapid and simple, and the processing automation can be realized.

Owner:HAINAN UNIVERSITY

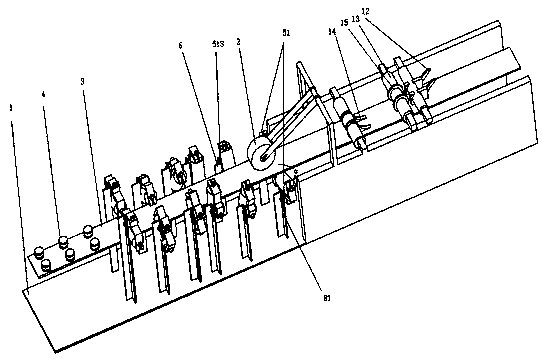

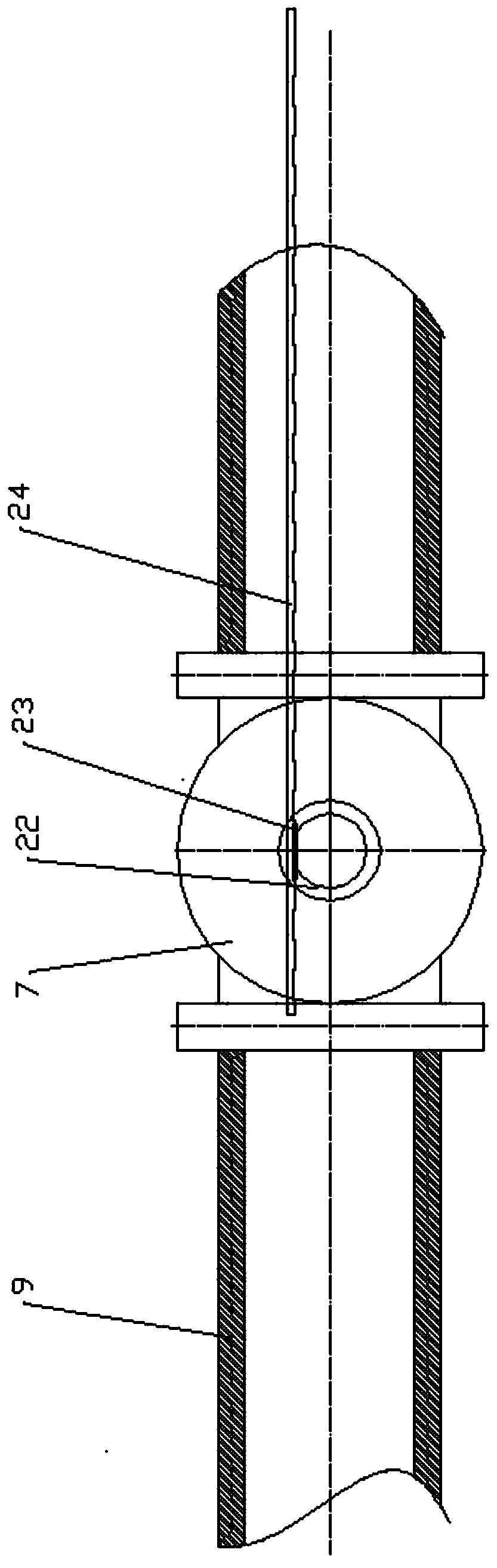

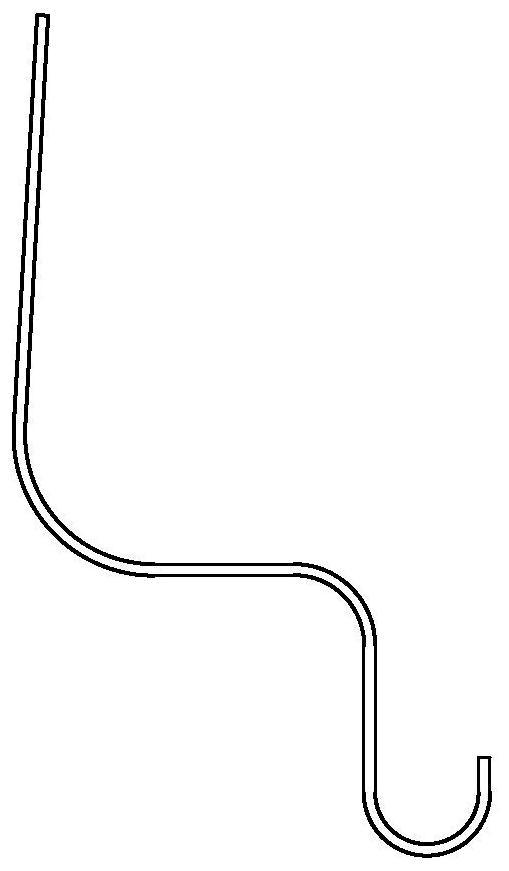

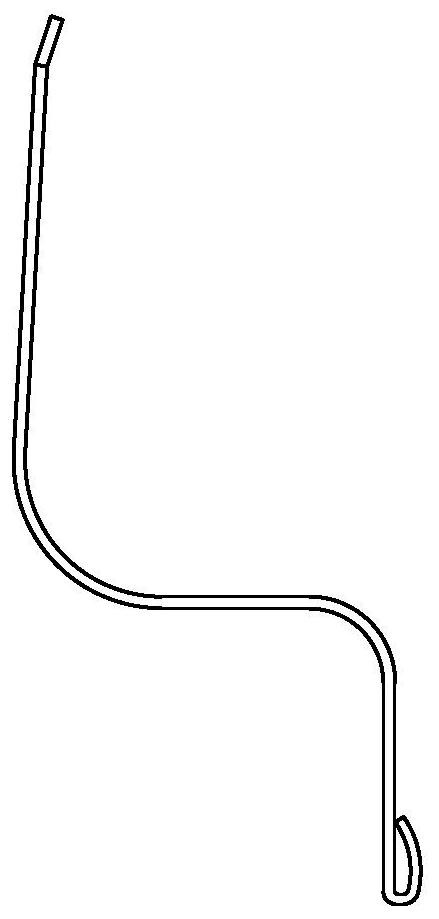

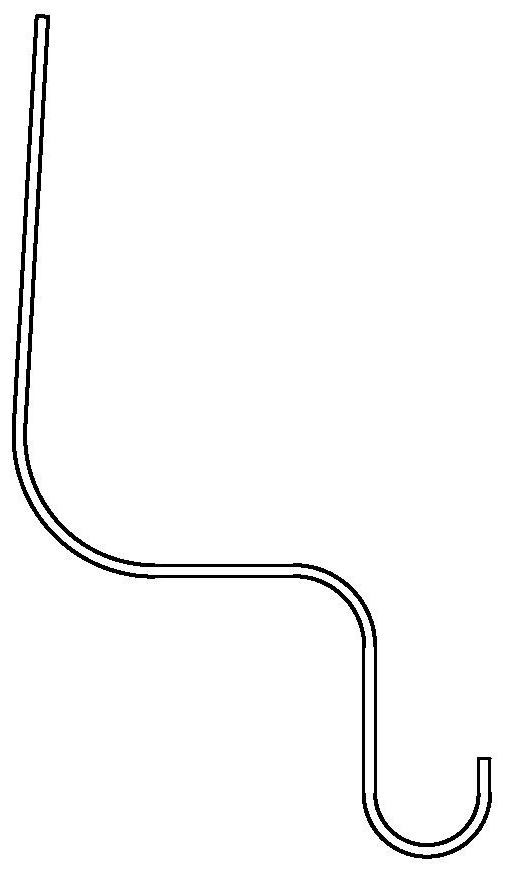

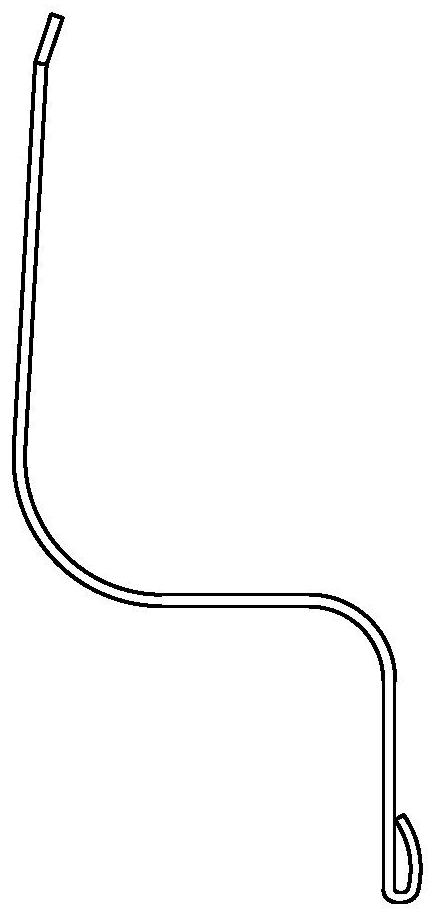

Hot melting plastic capillary grid welding processing apparatus and method

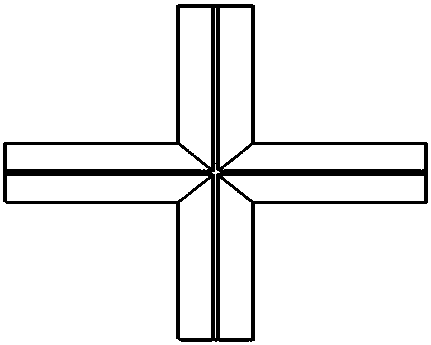

The invention relates to a hot melting plastic capillary grid welding processing apparatus and a method for processing hot melting plastic capillary grids by the apparatus; the apparatus comprises a console, a tubule accommodating shelf, a tubule clamping device, a main tube clamping device, a cutting device, a heating device, a manipulator and a control device. Based on the processing apparatus of the technical scheme of the invention, the processing to hot melting plastic capillary grids has high an automatic production degree; the processing method of hot melting plastic capillary grids by using the apparatus is simple, increases the labor productivity by several times, saves production time, and thus reduces production cost; and the produced products have good consistency, low product reject rate, and excellent product performance.

Owner:李世鹏

Ultrasonic welding machine and use method

InactiveCN107160697ARealize product processing automationImprove work efficiencyEngineeringWeld strength

The invention discloses an ultrasonic welding machine. The ultrasonic welding machine comprises a microcomputer-controlled automatic circuit system, wherein the microcomputer-controlled automatic circuit system comprises an automatic frequency tracer; the microcomputer-controlled automatic circuit system presets a rated sound wave frequency; and in the case of too high or too low sound wave frequency of the ultrasonic welding machine during a use process, the automatic frequency tracer feeds back a signal into the microcomputer-controlled automatic circuit system, and the microcomputer-controlled automatic circuit system re-adjusts the sound wave frequency. According to the ultrasonic welding machine and a use method, the sound wave frequency is adjusted to adapt to the actual welding need of a workpiece through the automatic tracer of the microcomputer-controlled automatic circuit system, the automation of product machining is realized, and the working efficiency is increased; and a high welding speed and firm welding are achieved, and the welding strength is capable of approaching to the strength of a raw material.

Owner:镇江金杯新能源发展有限公司

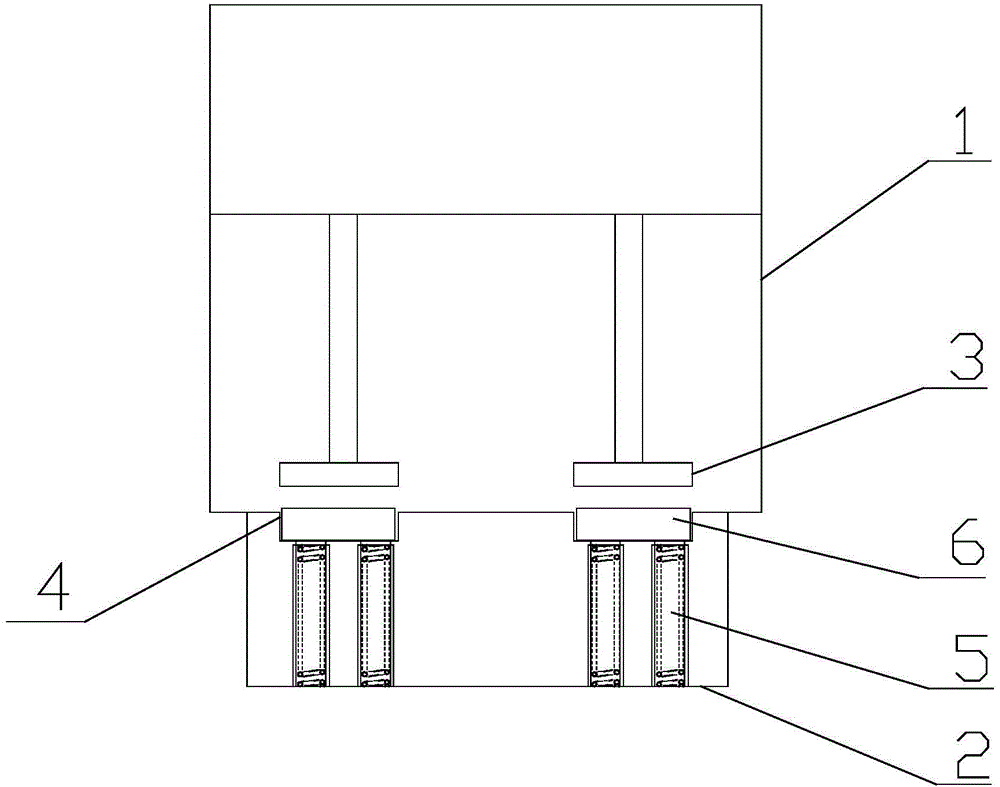

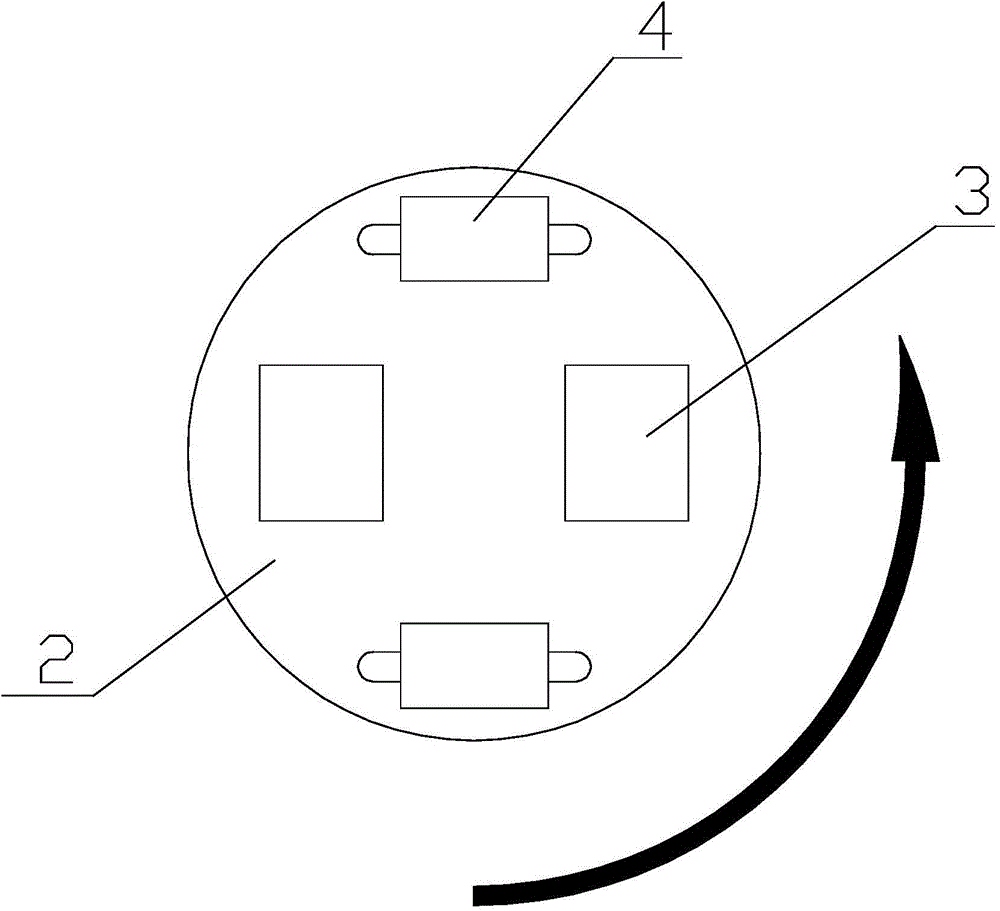

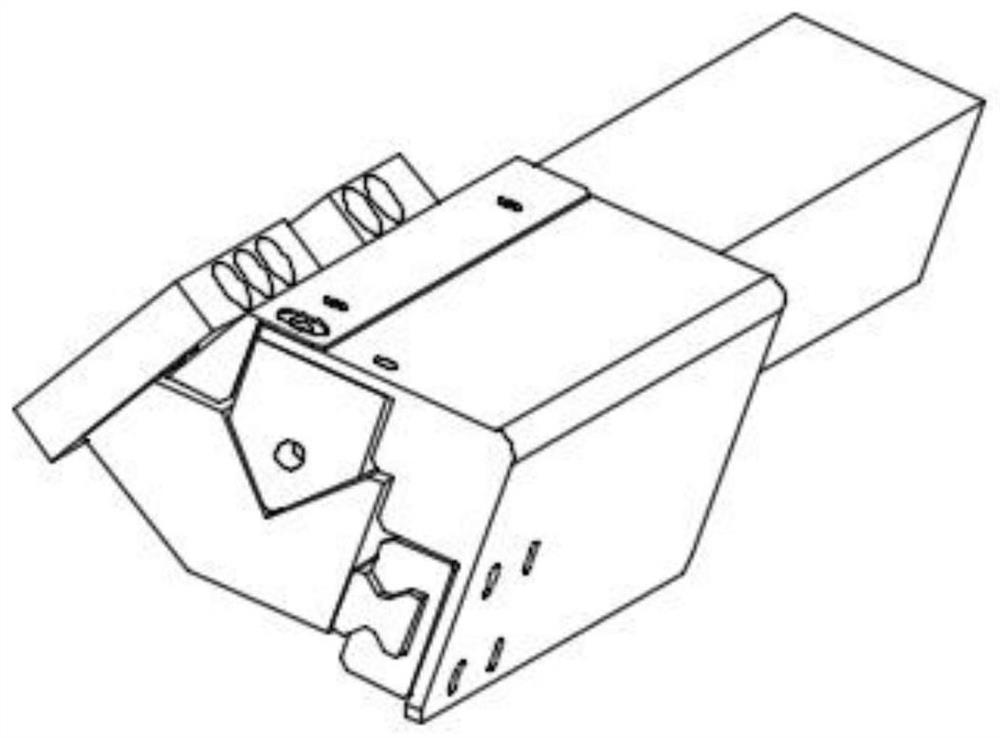

False sticking equipment

InactiveCN104470217ARealize processing automationIncrease productivityLaminating printed circuit boardsFlexible circuitsHot press

The invention discloses false sticking equipment, and relates to the technical field of flexible circuit board processing. The false sticking equipment comprises a rotary table and a base, hot-pressing blocks are arranged on the rotary table, hot-pressing grooves are formed in the base, and spring ejector pins are arranged at the bottoms of the hot-pressing grooves. The rotary table can rotate, ascend and descend, and the hot-pressing blocks are made to be aligned with the hot-pressing grooves.

Owner:SUZHOU MIDAS PRECISION ELECTRONICS

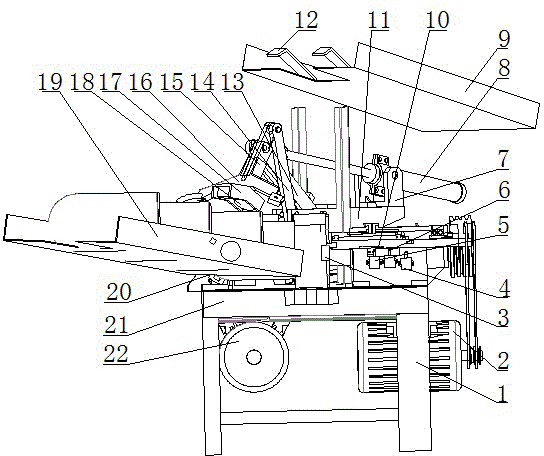

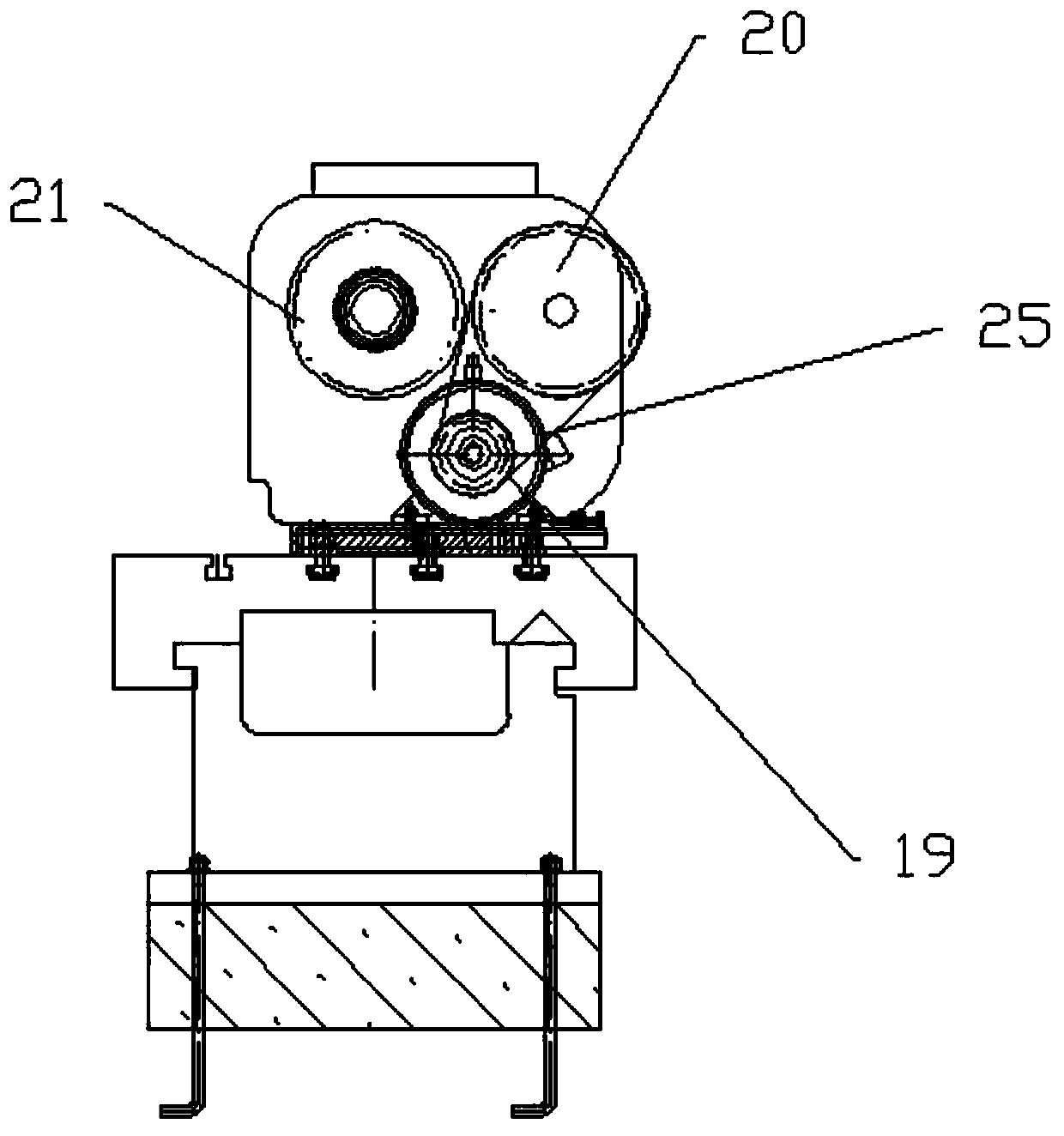

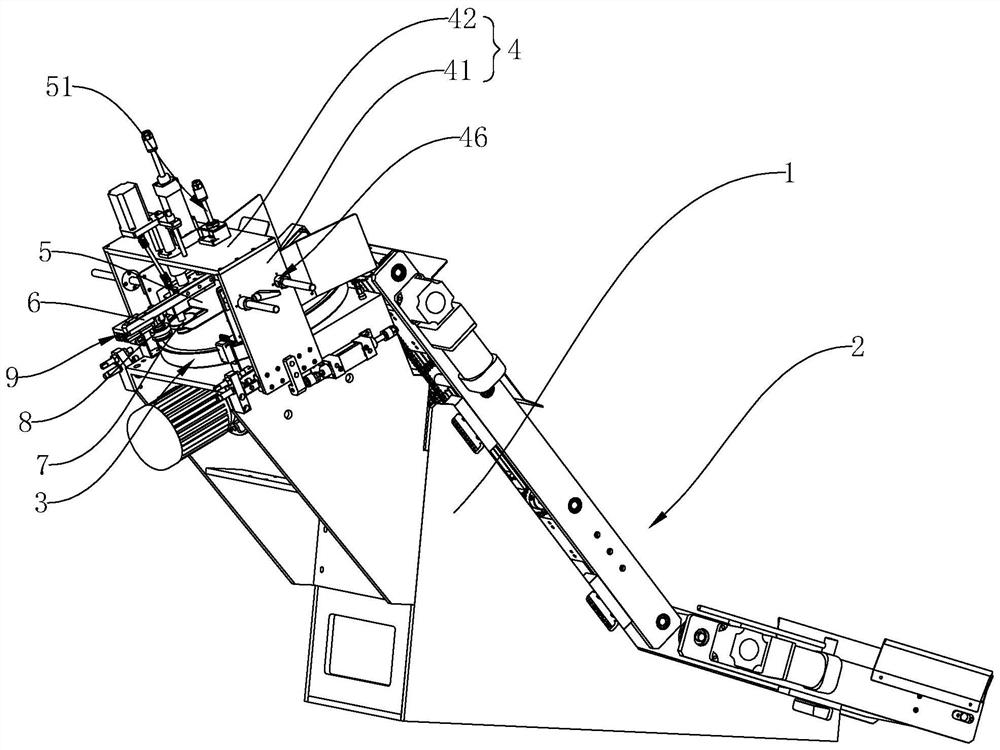

Automatic processing machine tool for bended tubes

InactiveCN104625179AImprove processing efficiencyRealize processing automationMilling equipment detailsDriving apparatusMilling cutterAgricultural engineering

The invention discloses an automatic processing machine tool for bended tubes and belongs to the technical field of machining equipment. A rectangular platform is arranged at the upper end of a frame body, a motor I and a motor II, corresponding to belt pulleys of milling heads, are respectively mounted at the lower end of the platform, and are connected with the belt pulleys of the milling heads through belt pulleys; milling heads are arranged at two adjacent right-angle sides at the upper end of the platform, respectively; the milling heads are connected with a sleeve, a lead screw device is mounted at the side end of the sleeve, the axis angles of the two milling heads can be respectively set as 1200, 900 and 450 degrees according to demand, a slide block is arranged at the upper end of the side of each milling head, a feeding channel is arranged on the platform at the right-angled end of each of the milling heads, and a hydraulic clamp is arranged between the two milling heads; an overturning device and a material receiving groove are structured in that the middle of the platform is hinged with the lower ends of a main supporting rod and an auxiliary supporting rod, the upper end of the main supporting plate is hinged to the middle of an upper rotating rod and the front end of a transverse oil cylinder at the same time, the upper end of the auxiliary supporting rod is hinged with the rear end of the upper rotating rod, the front end of the upper rotating rod is connected with the rear end of a fork-shaped connecting rod, the front end of the fork-shaped connecting rod is connected with a magnet seat, and two electromagnets I are respectively mounted on the magnet seat.

Owner:刘永伟

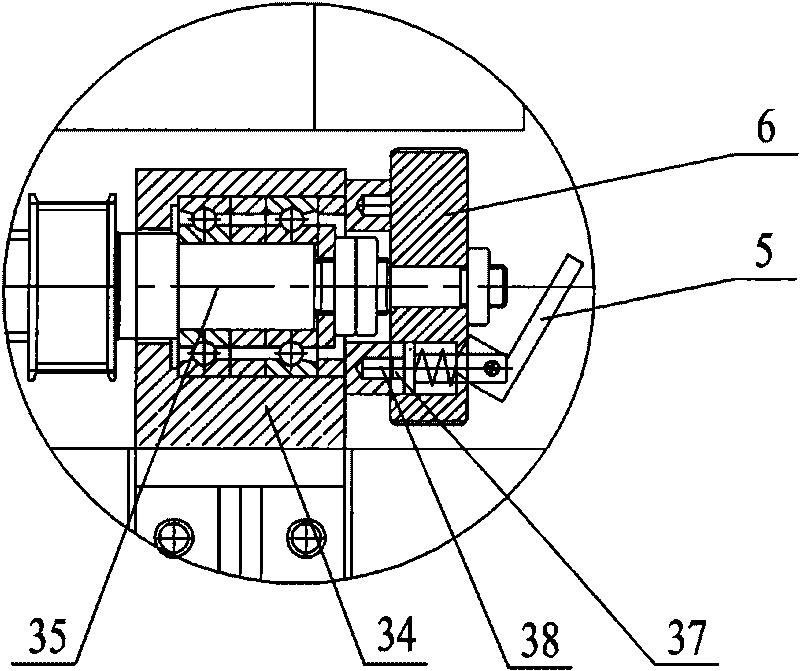

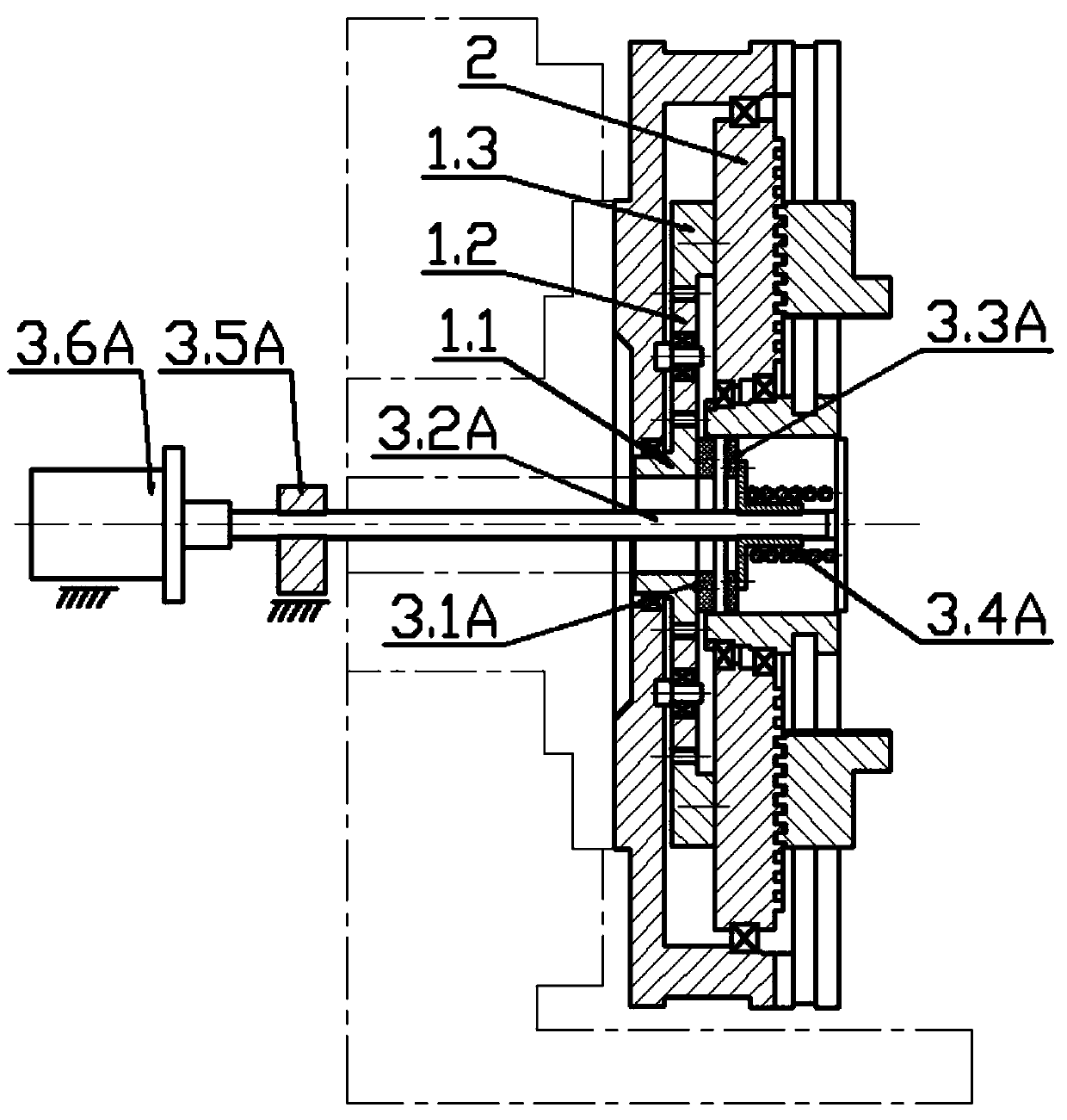

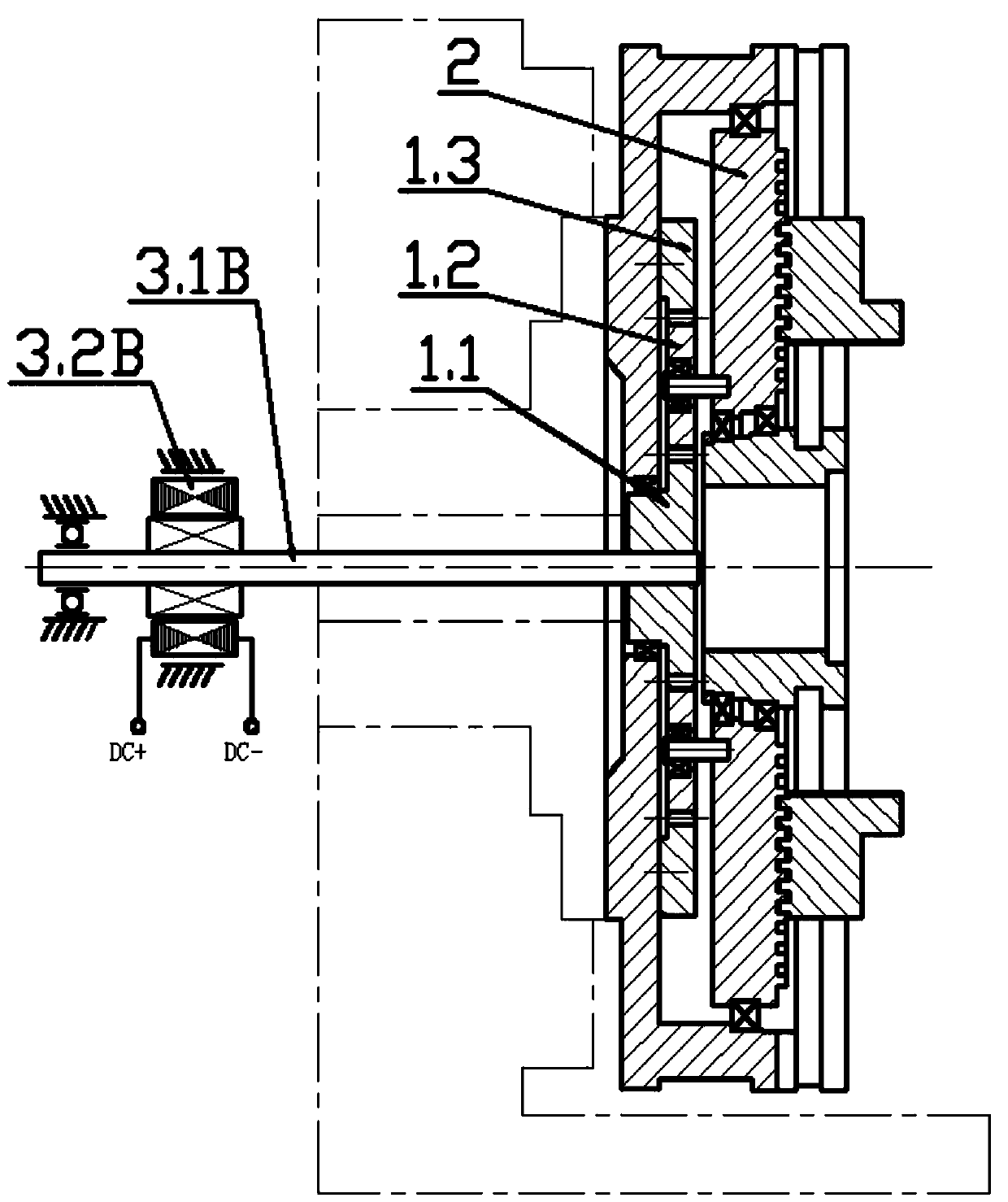

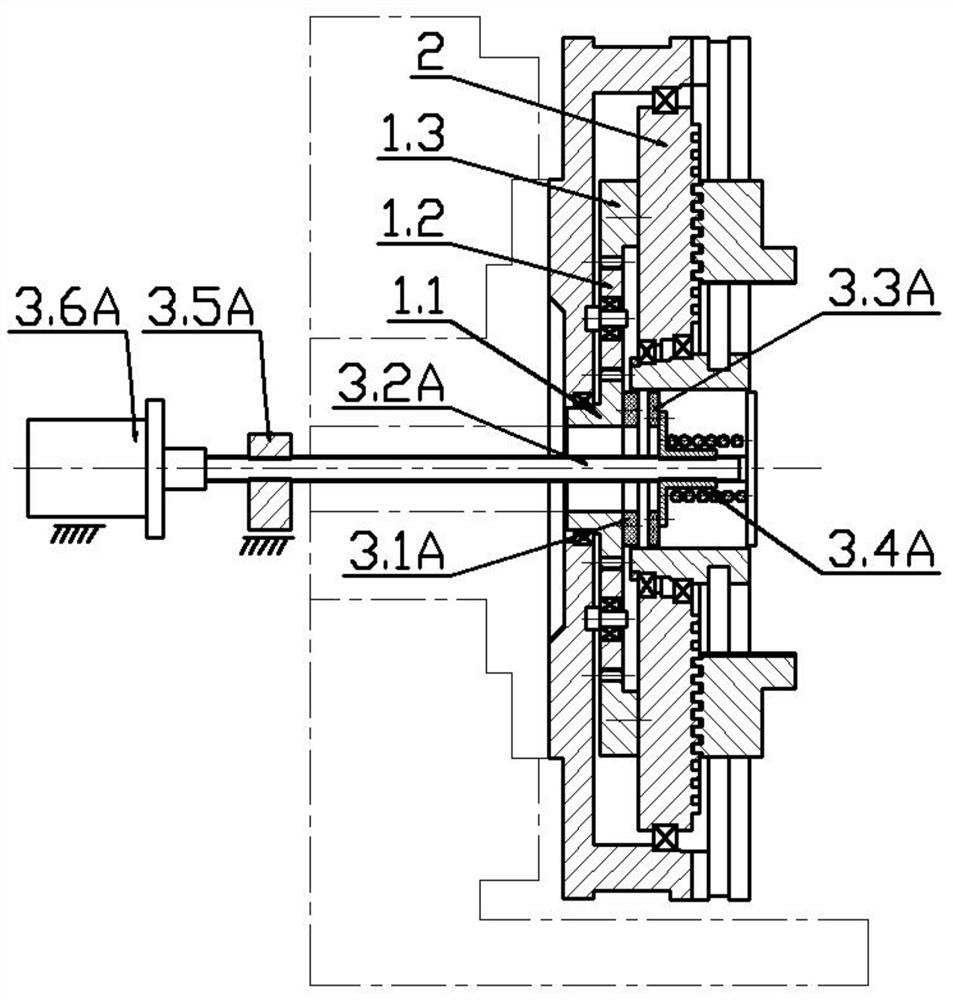

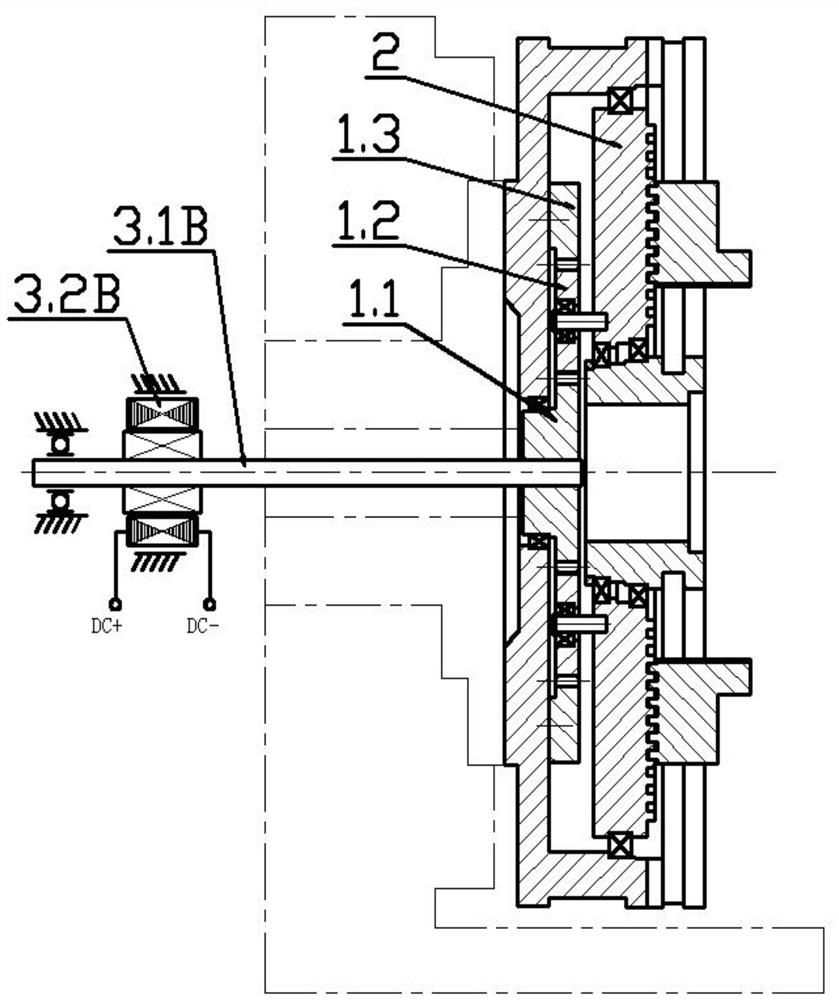

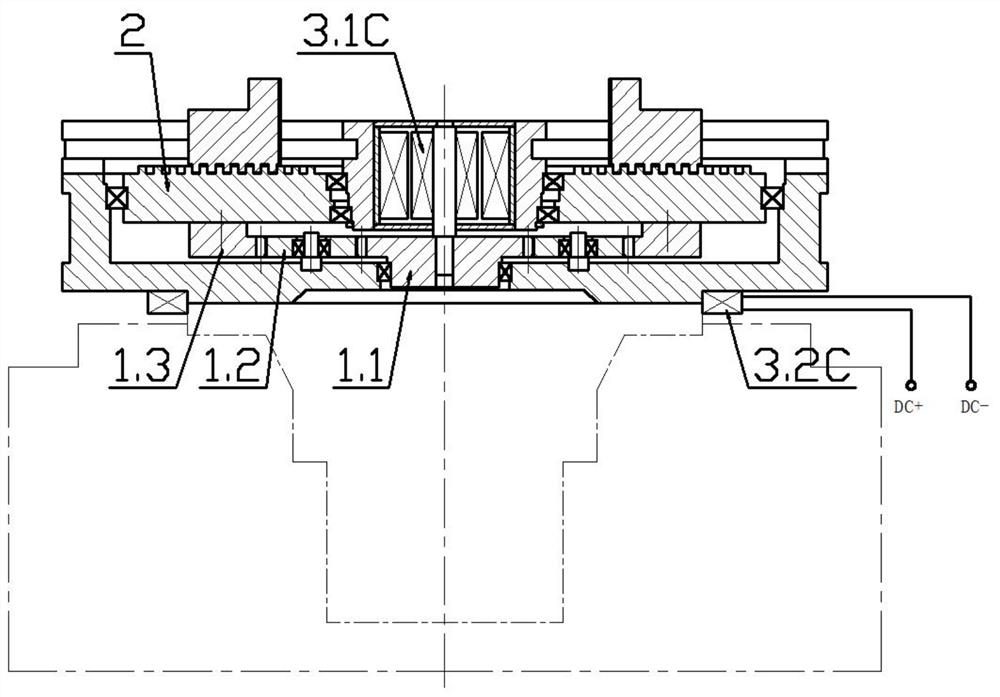

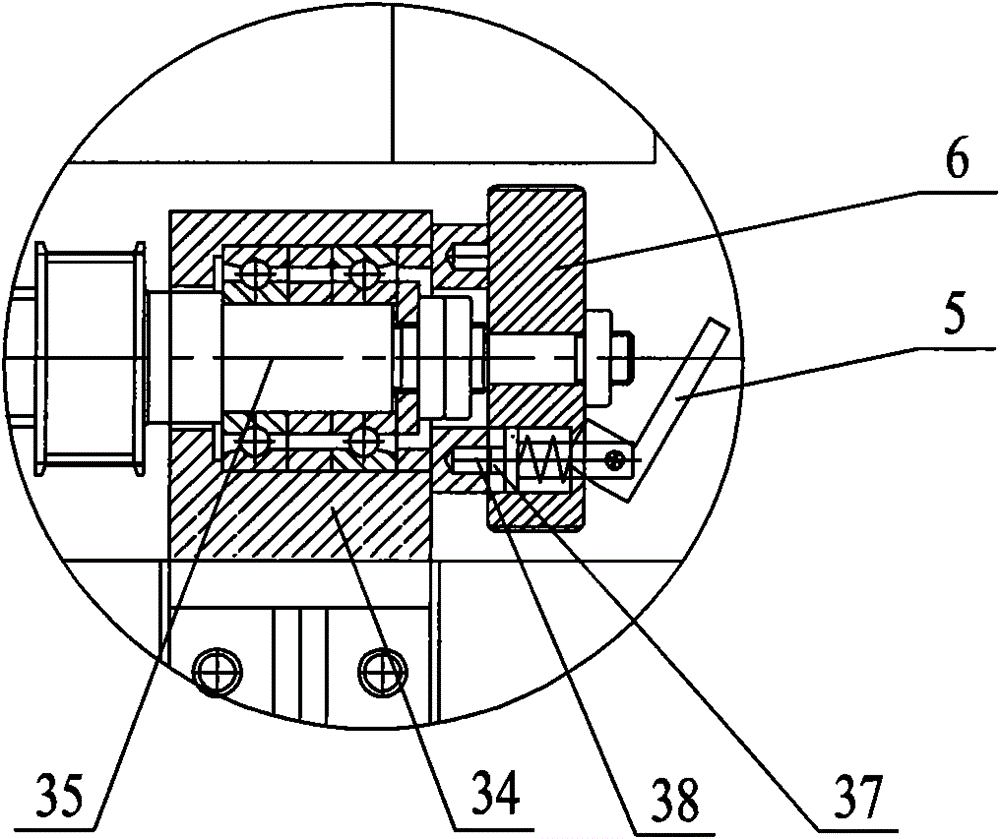

Lathe chuck

The invention discloses a lathe chuck. The lathe chuck comprises a chuck body, wherein a planetary speed reduction mechanism is coaxially arranged in the chuck body, the output end of the planetary speed reduction mechanism is connected with a spiral slot disc in the chuck body, and a resistance moment input mechanism is movably connected to the input end of the planetary speed reduction mechanism. The spiral slot disc follows the chuck body to achieve synchronous rotation, when the input end of the planetary speed reduction mechanism is connected with the resistance moment input mechanism, the spiral slot disc rotates relative to the chuck body, and in this way, a plurality of claws connected with the spiral slot disc move simultaneously in the radial direction of the chuck body. According to the lathe chuck, by controlling the resistance moment input from the outside, workpiece clamping force is freely adjusted. Besides, through the further utilization of a numerical control system,the opening and closing positions of the jaws can be controlled. The lathe chuck has large clamping stroke and multiple control functions, the labor intensity is lowered, the protection efficiency isimproved, and meanwhile, machining automation of a lathe is convenient to implement.

Owner:洛阳先驱自动化设备有限公司

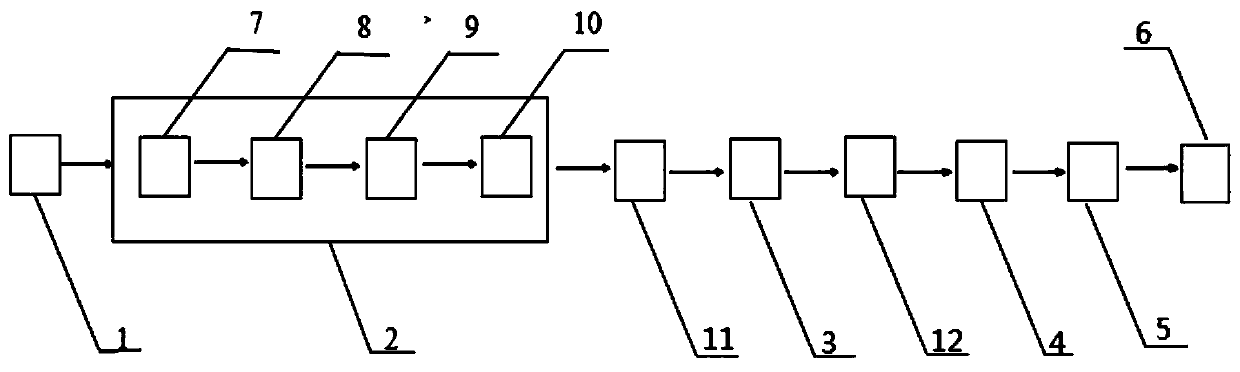

Stone slab processing system and processing method thereof

PendingCN110281402ARealize processing automationReduce in quantityPolishing machinesGrinding machinesEngineeringMachining system

The invention discloses a stone slab processing system. The stone slab processing system comprises a slab feeding device, a spraying device, a steam curing device, a surface treatment device, a cutting device and a slab discharging device. A pretreated stone slab sequentially passes through the slab feeding device and a conveying line to be conveyed to the spraying device, and a decoration layer is sprayed; the stone slab obtained after spraying is carried out is conveyed to the steam curing device to be subjected to steam curing; the stone slab obtained after steam curing is carried out stands for 72-96 hours at normal temperature, and then the stone slab is conveyed to the surface treatment device through the conveying line to be subjected to surface treatment; dust on the surface of the stone slab obtained after surface treatment is carried out is cleared up, and the stone slab is evenly coated with a protection film; and the stone slab coated with the protection film is conveyed to the cutting device through the conveying line to be cut according to needs, an edge groove is formed in the transverse edge of the stone slab, a finished stone slab is obtained, and finally the slab is discharged through the slab discharging device. According to the stone processing system, processing automation of the stone slab can be achieved, the number of field operators is reduced, and the production efficiency is improved.

Owner:河北大自然石材有限公司

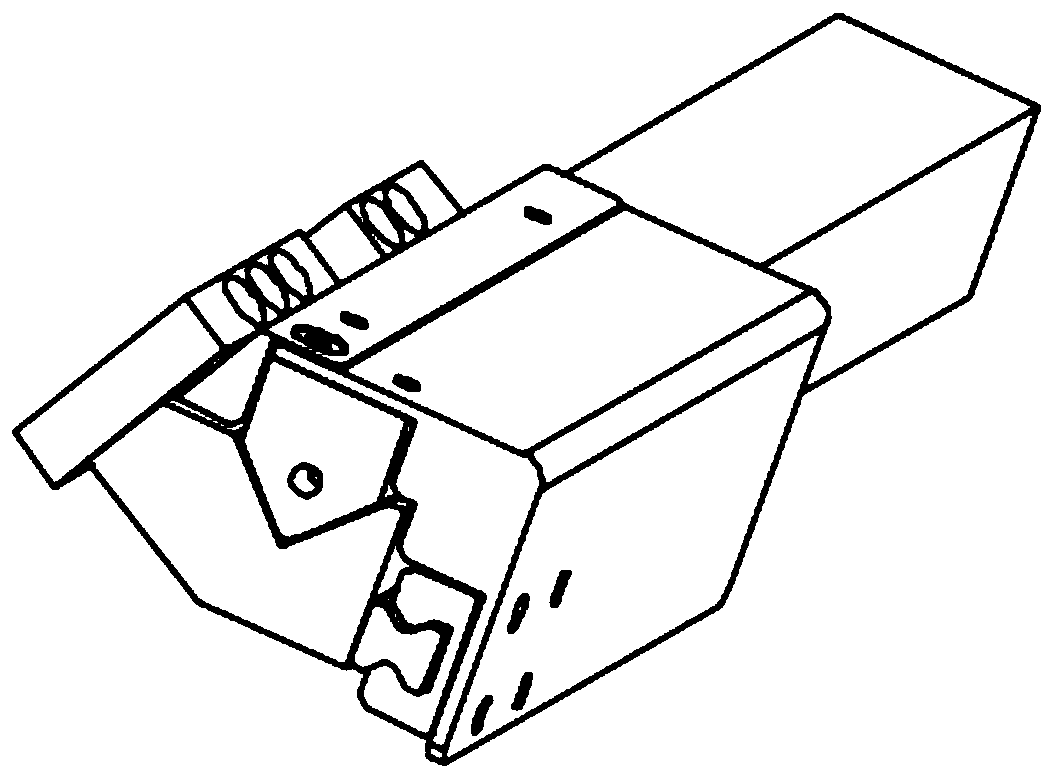

Hydraulic upsetter loose tooling locking device

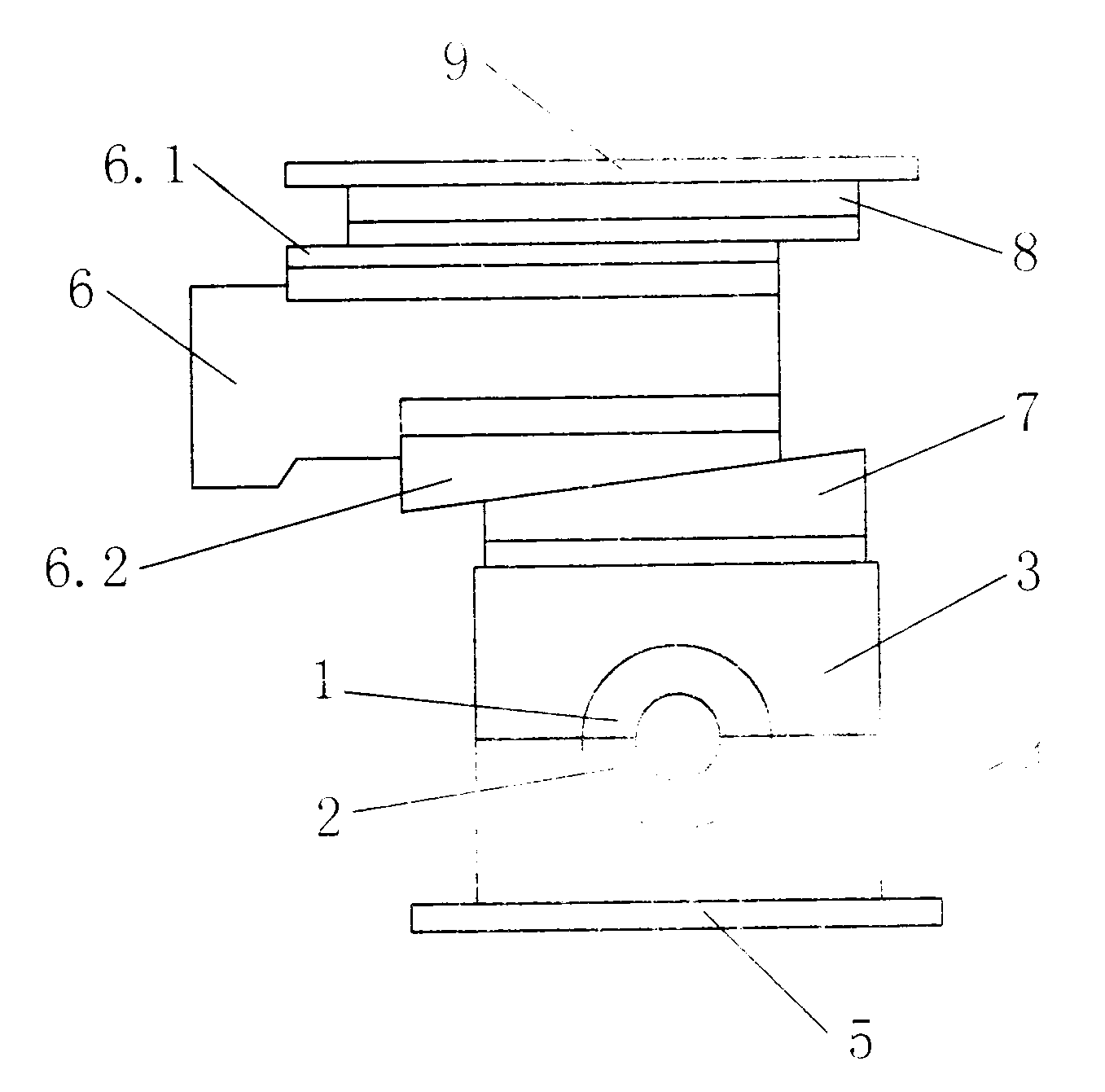

InactiveCN103252435AQuick lockRealize processing automationUpsetting pressesSwagging pressesSlide plateEngineering

The invention provides a hydraulic upsetter loose tooling locking device. A lower bed mould and an upper bed mould. A lower die is embedded in the lower bed mould. An upper die is embedded in the upper bed mould. A fixed wedge is mounted on the upper bed mould. A movable wedge and a movable block are mounted on the fixed wedge. A movable slide plate, a fixed slide plate and a top cover are mounted on the upper portion of the movable block. During use, the dies can be locked fast, machining efficiency and product quality can be increased, and automatic upsetting of an upsetter can be achieved. The hydraulic upsetter loose tooling locking device is applicable to loose tooling locking during upsetting.

Owner:杜洋

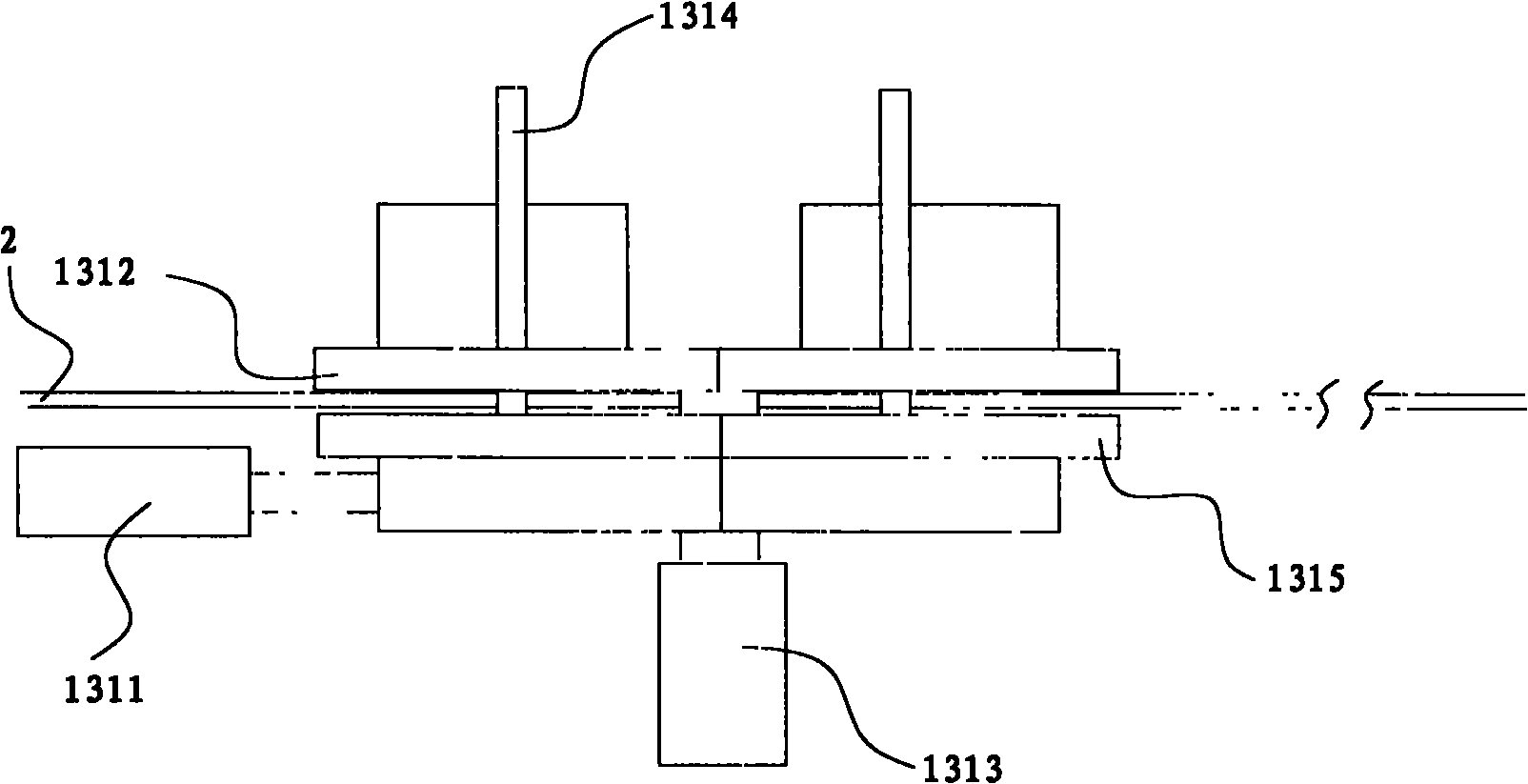

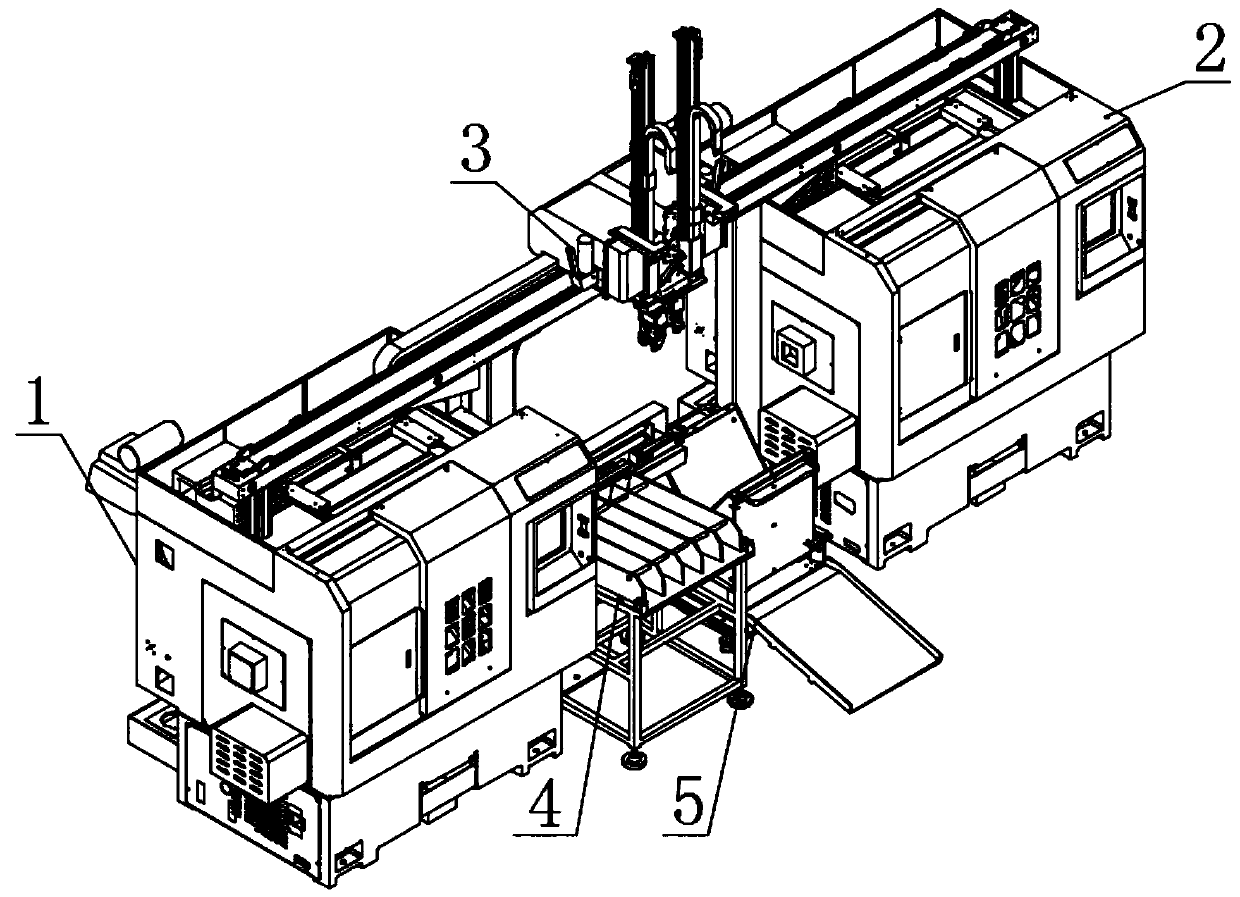

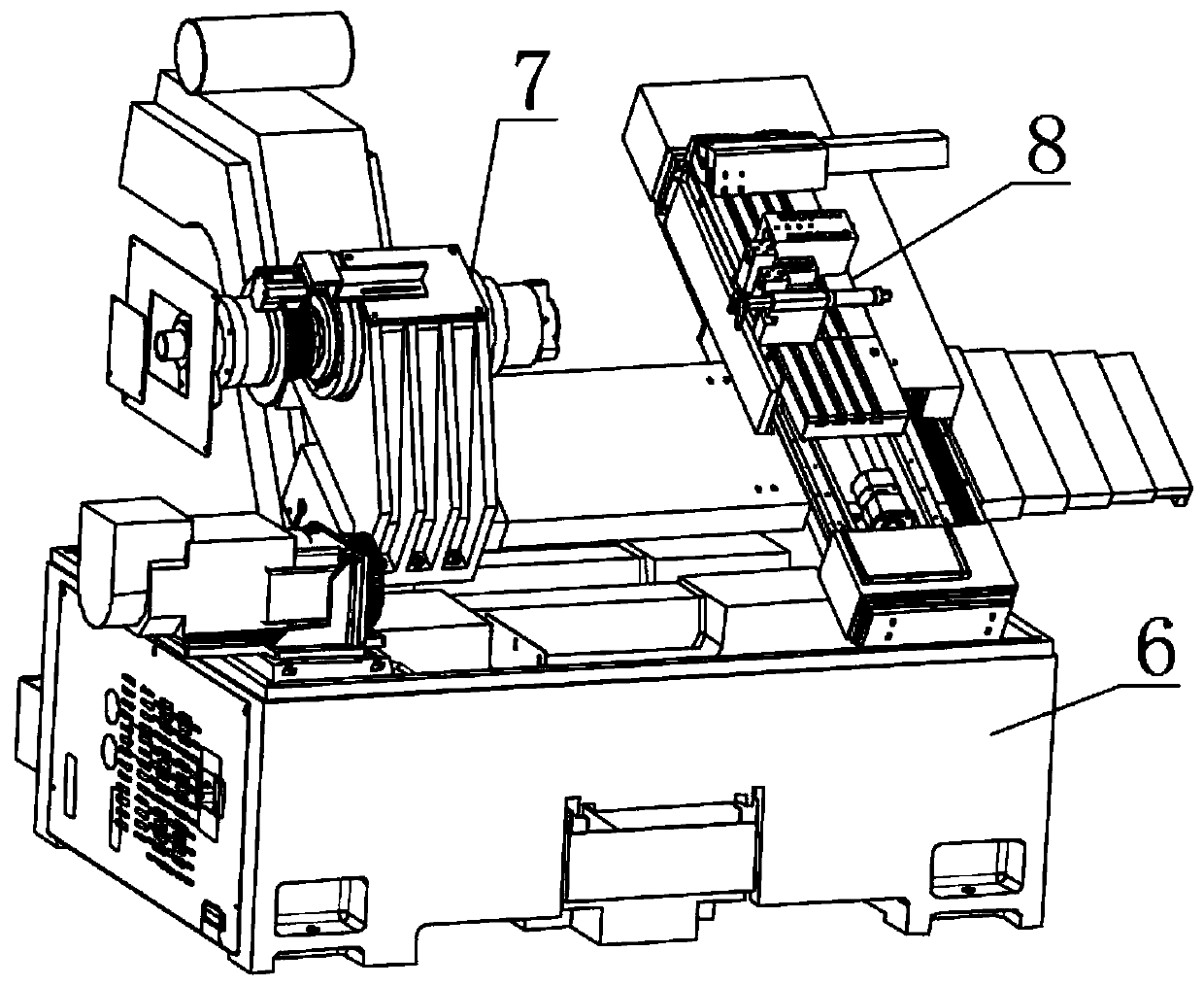

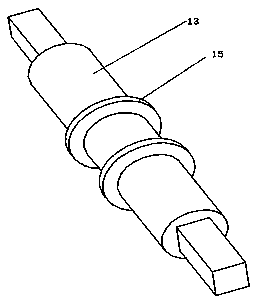

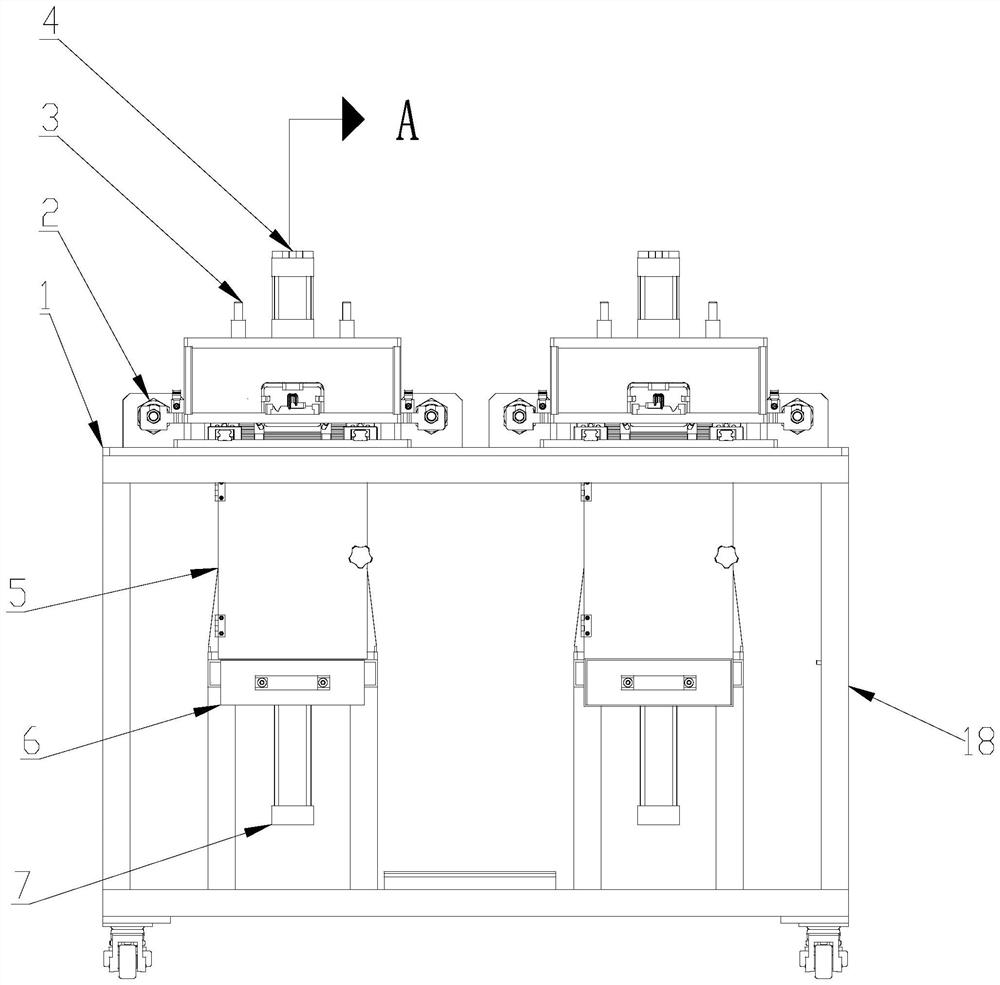

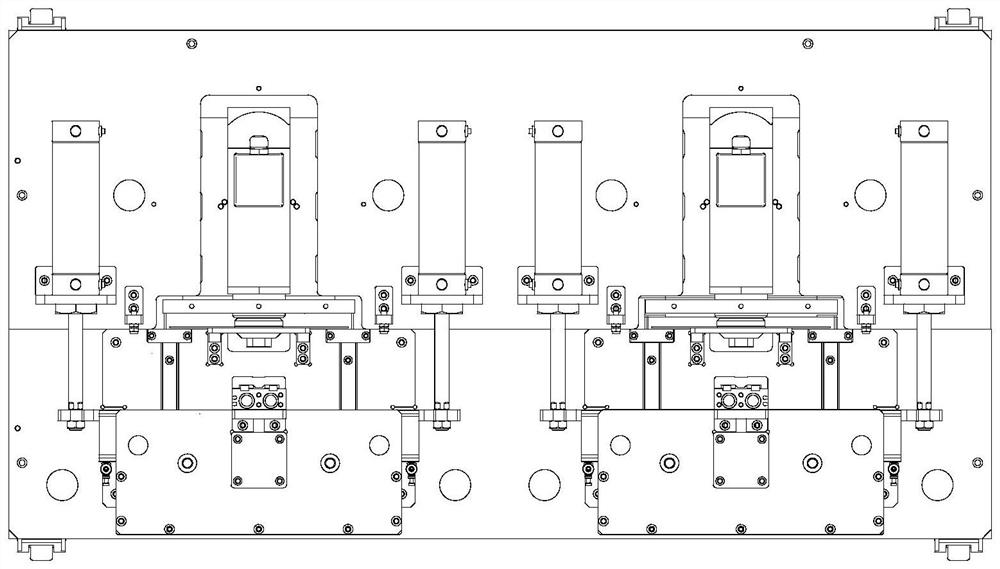

A multi-axis truss robot for large piston pins with one dragging two CNC machining machines

ActiveCN110394681BRealize processing automationIncrease productivityMetal working apparatusControl engineeringProcess engineering

The invention discloses a multi-axis truss robot one-to-two numerical control processing machine for large piston pins, which comprises a first piston pin numerical control machine, a second piston pin numerical control machine, a beam robot, a storage hoist, a receiving storage machine, a first piston pin The pin numerical control machine, material storage hoist, receiving storage machine and the second piston pin numerical control machine are arranged in sequence, and both the first piston pin numerical control machine and the second piston pin numerical control machine are provided with material trough seats and are matched by the material trough seats. The beam robot carries out the feeding and unloading work of the machine tool processing. The beam robot is respectively installed on the top of the first piston pin CNC machine and the second piston pin CNC machine, and is installed on the first piston pin CNC machine, the storage hoist, the receiving storage The material is conveyed between the machine and the second piston pin numerical control machine; the multi-axis truss robot one-to-two numerical control machining machine for the large piston pin can realize the automation of piston pin processing and improve the production efficiency of piston pins.

Owner:佛山市名将自动化设备有限公司

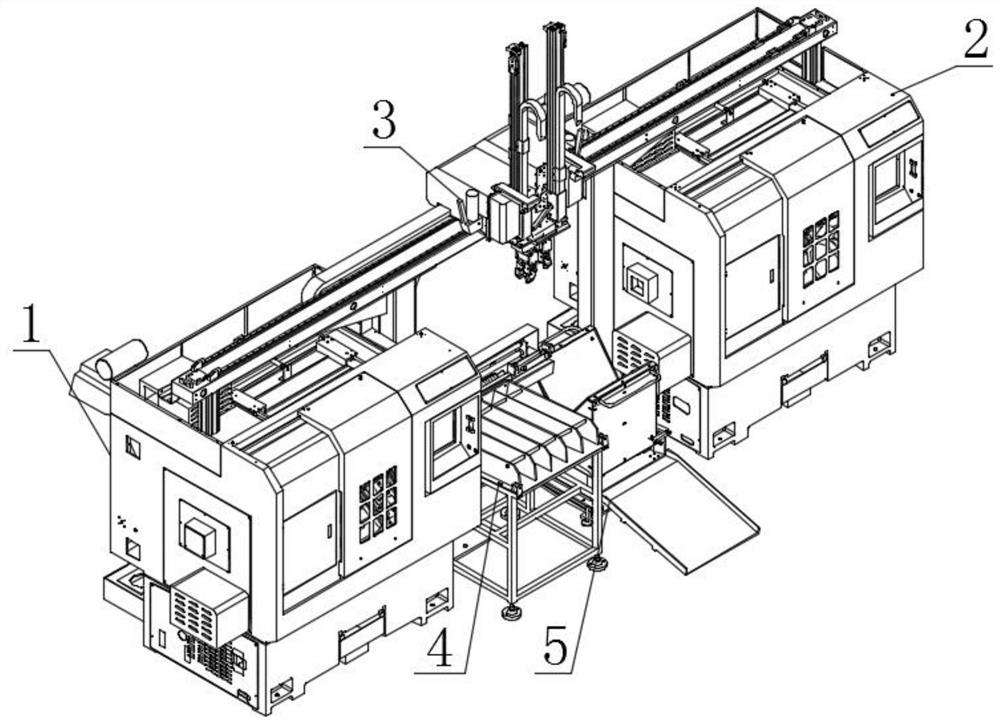

One-drive-two numerically controlled machining tool of multi-axis truss robot for large piston pin

ActiveCN110394681ARealize processing automationIncrease productivityMetal working apparatusEngineeringMulti axis

The invention discloses a one-drive-two numerically controlled machining tool of a multi-axis truss robot for a large piston pin. The one drive two numerically controlled machining tool comprises a first piston pin numerically controlled machine, a second piston pin numerically controlled machine, cross beam robots, a storage lifter and a receiving storage machine. The first piston pin numericallycontrolled machine, the storage lifter, the receiving storage machine and the second piston pin numerically controlled machine are successively arranged, trough seats are arranged in both the first piston pin numerically controlled machine and the second piston pin numerically controlled machine which are matched with the cross beam robots through the trough seats for feeding and unloading work of machining tool machining, and the cross beam robots are separately mounted on the tops of the first piston pin numerically controlled machine and the second piston pin numerically controlled machineand clamp and convey materials among the first piston pin numerically controlled machine, the storage lifter, the receiving storage machine and the second piston pin numerically controlled machine. The one-drive-two numerically controlled machining tool of the multi-axis truss robot for the large piston pin can achieve automatic machining of the piston pin and improves the production efficiency of the piston pin.

Owner:佛山市名将自动化设备有限公司

Sanitary coffin reinforcing plate processing device

PendingCN109291519ARealize processing automationQuality improvementMechanical working/deformationMetal working apparatusEngineeringAngle alpha

The invention provides a sanitary coffin reinforcing plate processing device. The sanitary coffin reinforcing plate processing device comprises a rack, a material carrying plate, a slotting device anda bending device, wherein the material carrying plate is arranged on the rack and is used for conveying reinforcing plates; the slotting device and the bending device are arranged in sequence in a reinforcing plate conveying direction; the bending device comprises a plurality of pairs of guide roller groups which are arranged in the reinforcing plate conveying direction; each pair of guide rollergroups comprise two guide roller groups which are symmetrically arranged at the two sides of the rack; each guide roller group comprises a guide roller; an included angle alpha is formed between thecentral axis of the guide roller and the horizontal plane of the material carrying plate; the included angles alpha decrease successively in the reinforcing plate conveying direction; and the guide roller groups are adjustably fixed to the rack. The sanitary coffin reinforcing plate processing device has the advantages that the sanitary coffin reinforcing plate processing device is simple in structure, realizes the automation of reinforcing plate processing and is suitable for various plates; the produced reinforcing plates have table and reliable quality; the molding efficiency is high; and the labor intensity is low for workers.

Owner:HUNAN HUAWANG TECH

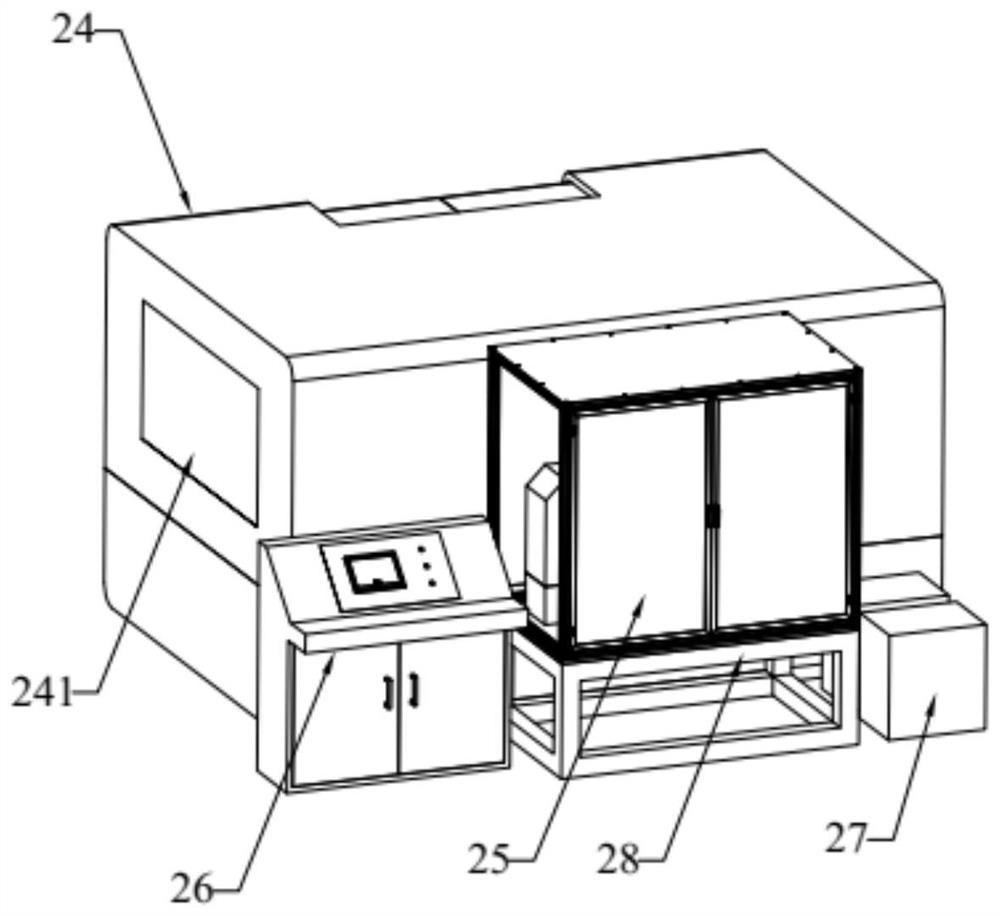

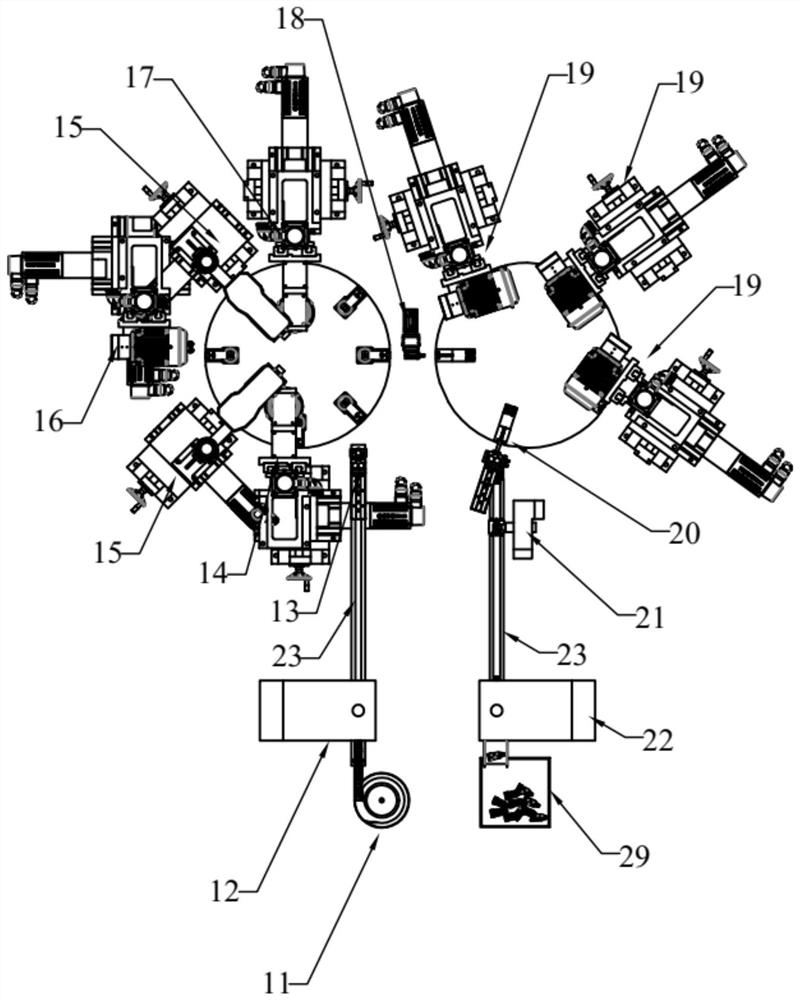

Gun head machining equipment

PendingCN113635066ARealize processing automationReduce labor costsOther manufacturing equipments/toolsMetal working apparatusPunch pressMilling cutter

The invention discloses gun head machining equipment. The gun head machining equipment comprises a punch press base, wherein a vibration feeding plate, a reverse burr punching assembly, a turntable feeding assembly, a first milling cutter disc assembly, a thread expanding and tapping assembly, a second milling cutter disc assembly, a third milling cutter disc assembly, a conversion disc assembly, a middle groove rough milling device, a fourth milling cutter disc assembly, a turntable discharging assembly, a middle groove deburring assembly and a positive notching assembly are sequentially arranged on the punch press base in the circumferential direction of the punch press base ; and the vibration feeding plate, the reverse burr punching assembly, the turntable feeding assembly, the first milling cutter disc assembly, the thread expanding and tapping assembly, the second milling cutter disc assembly, the third milling cutter disc assembly, a conversion disc assembly, the fourth milling cutter disc assembly, the turntable discharging assembly, the middle groove deburring assembly and the positive notching assembly are connected at a time through a conveyor belt, so that gun heads can be conveyed and operated at a time. The equipment has the advantages that the labor cost is reduced, the equipment is high in precision, small in error, high in speed and high in stability, and the production efficiency is greatly improved.

Owner:LINHAI CITY RAUL MACHINE

Motor hot melt detection method

The invention discloses a motor hot melt detection method. The motor hot melt detection method comprises the following steps that 1), a workpiece subjected to hot melting treatment is moved to two clamping frames through an assembly line groove; 2), a camera shooting unit is used for shooting the workpiece clamped on the two clamping frames; 3), the qualified workpiece after shooting treatment ismoved to a position close to the motor turnover mechanism through the assembly line groove; 4), a vertical support frame moves in the vertical direction so that a turnover clamp can move in the vertical direction to clamp the workpiece; 5), a transition block is turned over by taking the vertical center line of a fixed block as a central axis to turn over the workpiece clamped on the turnover clamp; and 6), the overturned workpiece is placed on a machining station and is conveyed to the next work station through the assembly line groove. According to the motor hot melt detection method, semi-finished product processing automation can be realized, after the hot melt detection is qualified, the workpiece can be quickly conveyed to the next work station, so that the labor consumption is reduced.

Owner:安徽安元智能科技有限公司

A lathe chuck

ActiveCN111112665BRealize processing automationFacilitate processing automationChucksControl systemDrag torque

A lathe chuck, comprising a chuck body coaxially provided with a planetary reduction mechanism in the chuck body, the output end of the planetary reduction mechanism is connected to a spiral groove disc in the chuck body, and the input end is movably connected with a resistance torque input mechanism; The spiral grooved disk rotates synchronously with the chuck body. When the input end of the planetary reduction mechanism is connected to the resistance torque input mechanism, the spiral grooved disk rotates relative to the chuck body, so that the multiple jaws connected to the spiral grooved disk move along the chuck simultaneously. Radial movement of the disc body. The invention realizes the free adjustment of the workpiece clamping force through the control of the resistance torque input from the outside, and also realizes the controllability of the opening and closing positions of the jaws by combining with the numerical control system. The invention has large clamping stroke and multiple control functions, reduces labor intensity, improves production efficiency, and facilitates the realization of machine tool processing automation.

Owner:洛阳先驱自动化设备有限公司

Hot melting plastic capillary grid welding processing apparatus and method

ActiveCN102320128BRealize processing automationShorten the timeDomestic articlesProduction rateRobot hand

The invention relates to a hot melting plastic capillary grid welding processing apparatus and a method for processing hot melting plastic capillary grids by the apparatus; the apparatus comprises a console, a tubule accommodating shelf, a tubule clamping device, a main tube clamping device, a cutting device, a heating device, a manipulator and a control device. Based on the processing apparatus of the technical scheme of the invention, the processing to hot melting plastic capillary grids has high an automatic production degree; the processing method of hot melting plastic capillary grids byusing the apparatus is simple, increases the labor productivity by several times, saves production time, and thus reduces production cost; and the produced products have good consistency, low productreject rate, and excellent product performance.

Owner:李世鹏

Numeral control boring machine for super-long hole machining

InactiveCN111215664ARealize processing automationOvercoming the Phenomenon of StabilityDrilling/boring measurement devicesBoring/drilling machinesTool bitEngineering

The invention discloses a numeral control boring machine for super-long hole machining. The numeral control boring machine comprises a boring machine main body, and the upper portion of the boring machine main body is provided with a workbench where a workpiece can be placed; a fixing seat bracket is installed on one side of the workbench, and the upper portion of the fixing seat bracket is provided with a fixing seat; the other side of the workbench is provided with a slide rail, and the slide rail slidably cooperates with a slide block; a moving seat is installed on the slide block, and a boring cutter head is arranged on the moving seat and connected with a cutter feeding rod and a boring rod; the boring cutter head is further provided with a boring slide sleeve in a matched mode; and avertical toothed plate is installed on the boring slide sleeve and cooperates with a transverse toothed plate. The numeral control boring machine has the beneficial effects that the cutter penetration depth can be determined precisely, quantitative cutter feeding is achieved, automation of super-long hole machining is achieved, and the machining stability, the machining precision and the machining speed can be ensured; and the vertical toothed plate and the transverse toothed plate are wound together all the time, the phenomenon that the oil pressure is unstable is avoided, and cutter feedingand discharging are flexible and reliable.

Owner:湘潭市汇丰设备制造有限公司

A steel ring presser foot chamfering all-in-one machine

ActiveCN111570584BReduce labor intensityRealize processing operationsMetal-working feeding devicesPositioning devicesDrive wheelEngineering

The invention discloses a steel ring presser foot chamfering integrated machine, which comprises a frame; a transmission mechanism, which is arranged on the frame, and is used for transferring steel rings to be processed; a turntable mechanism, which is arranged on the frame The mobile frame, the mobile frame can move back and forth and is set on the frame, and is located above the turntable mechanism; the lower pressure rod, the lower pressure rod can move up and down through the lower pressure mechanism and is set on the mobile frame; the driving wheel, the driving wheel can be rotated and set At the lower end of the lower pressure rod, the lower part of the driving wheel is provided with an arc-shaped groove for pressing the steel ring, and the upper part of the driving wheel is provided with a first inclined plane; the auxiliary wheel, which can move forward and backward through the displacement mechanism, is set on the lower pressure rod The lower end of the lower end of the auxiliary wheel is close to or away from the driving wheel. The lower part of the auxiliary wheel is provided with a second slope, and a chamfering gap is formed between the first slope and the second slope; the advantages are that it can realize automatic processing, reduce labor intensity, and can Improve safety and work efficiency.

Owner:NINGBO JINSHIHONG MACHINERY EQUIP CO LTD

Automatic steel core removing machine

PendingCN114453666AIngenious structureMove preciselyMetal sawing devicesMetal sawing accessoriesStructural engineeringManufacturing engineering

The invention belongs to the technical field of rubber strip processing equipment, and relates to an automatic steel core removing machine, which comprises a rack, and a rack top plate is arranged at the upper end of the rack, and is characterized in that at least one group of rubber strip positioning mechanisms is arranged on the rack top plate so as to realize vertical direction pressing and horizontal direction clamping of a steel core; a rubber strip front blocking mechanism is arranged on the rubber strip positioning mechanism so as to limit the steel core; a longitudinal moving mechanism is further arranged on the top plate of the rack and can drive the adhesive tape positioning mechanism to reciprocate; an adhesive tape peeling mechanism is mounted in front of the longitudinal moving mechanism; a saw cutting mechanism is arranged on the rack and corresponds to each adhesive tape positioning mechanism, and the saw cutting mechanisms can ascend and descend. The automatic steel core removing device is ingenious and reasonable in structure, accurate in movement, good in removing effect and high in automation degree.

Owner:无锡鑫盛德智能设备科技有限公司

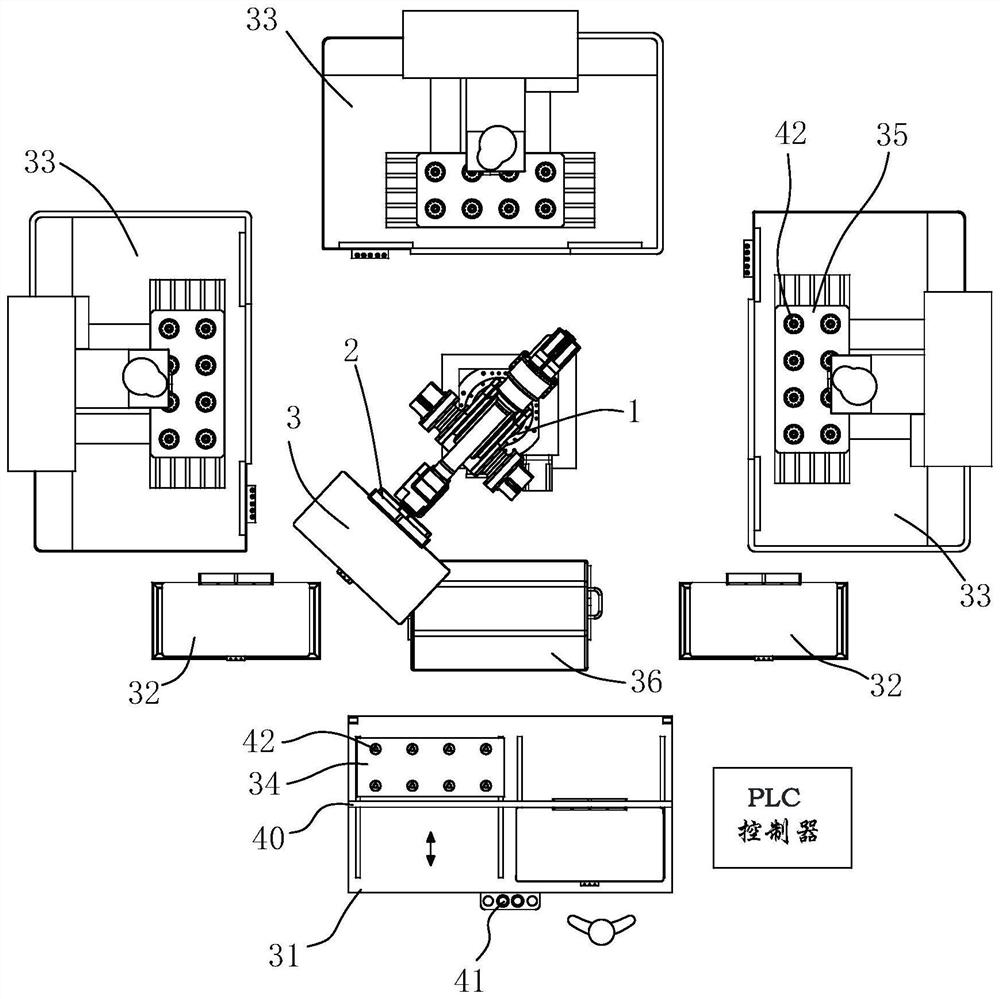

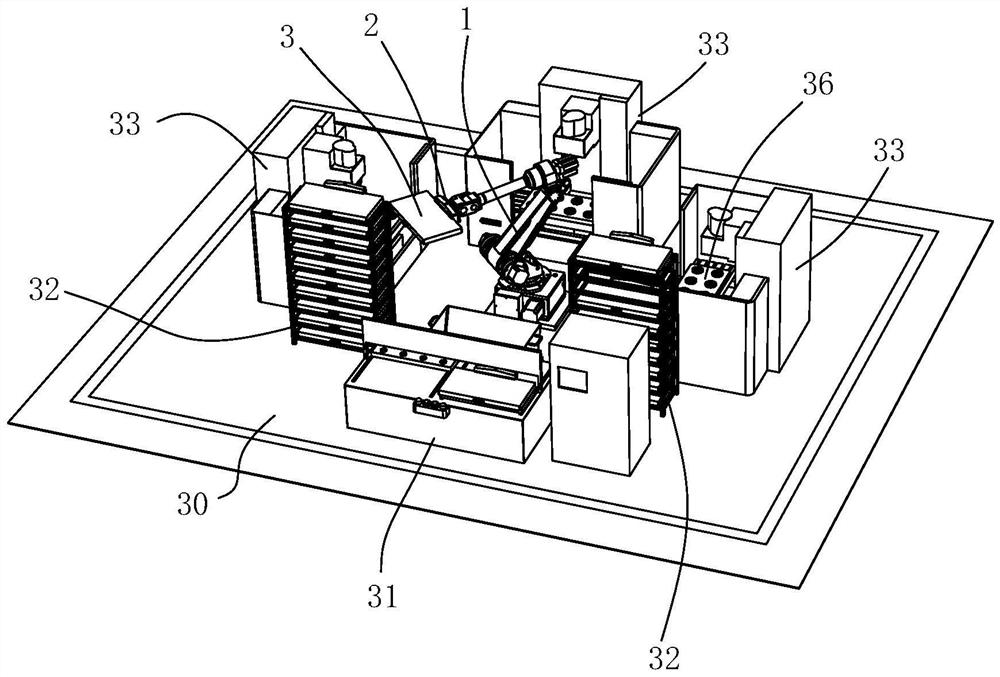

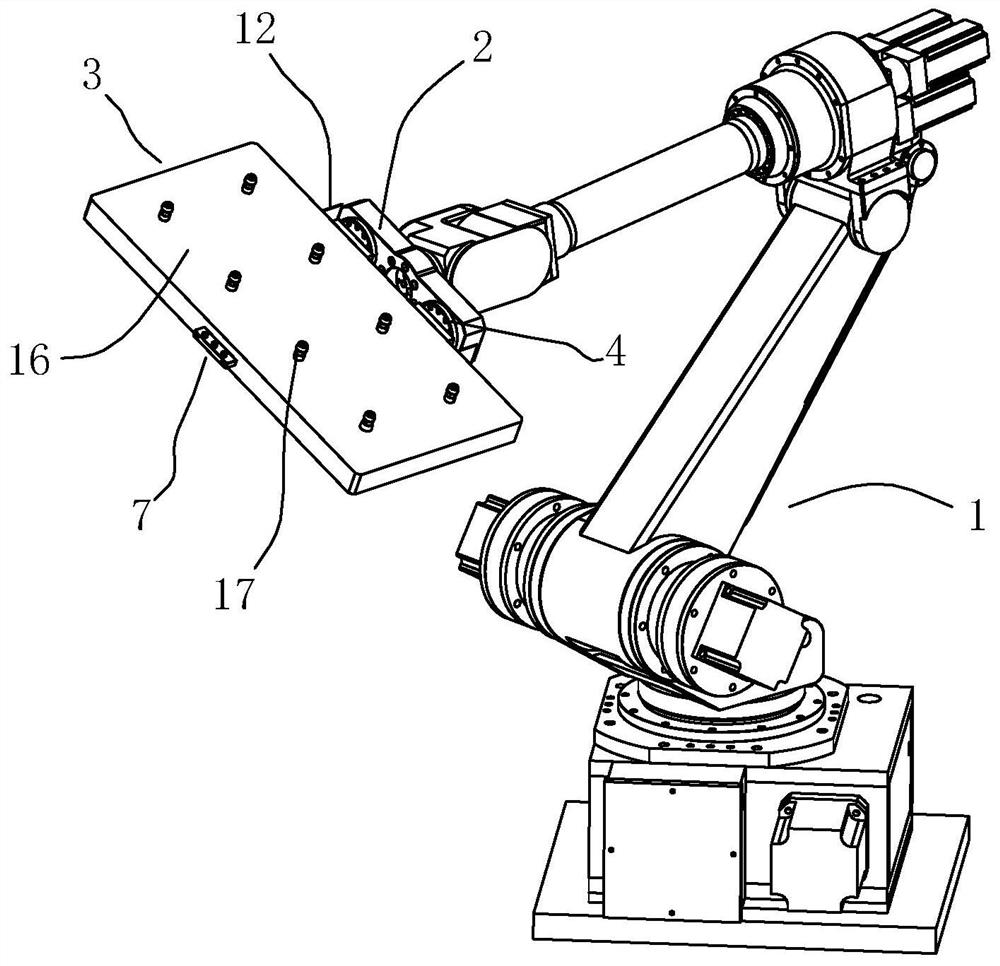

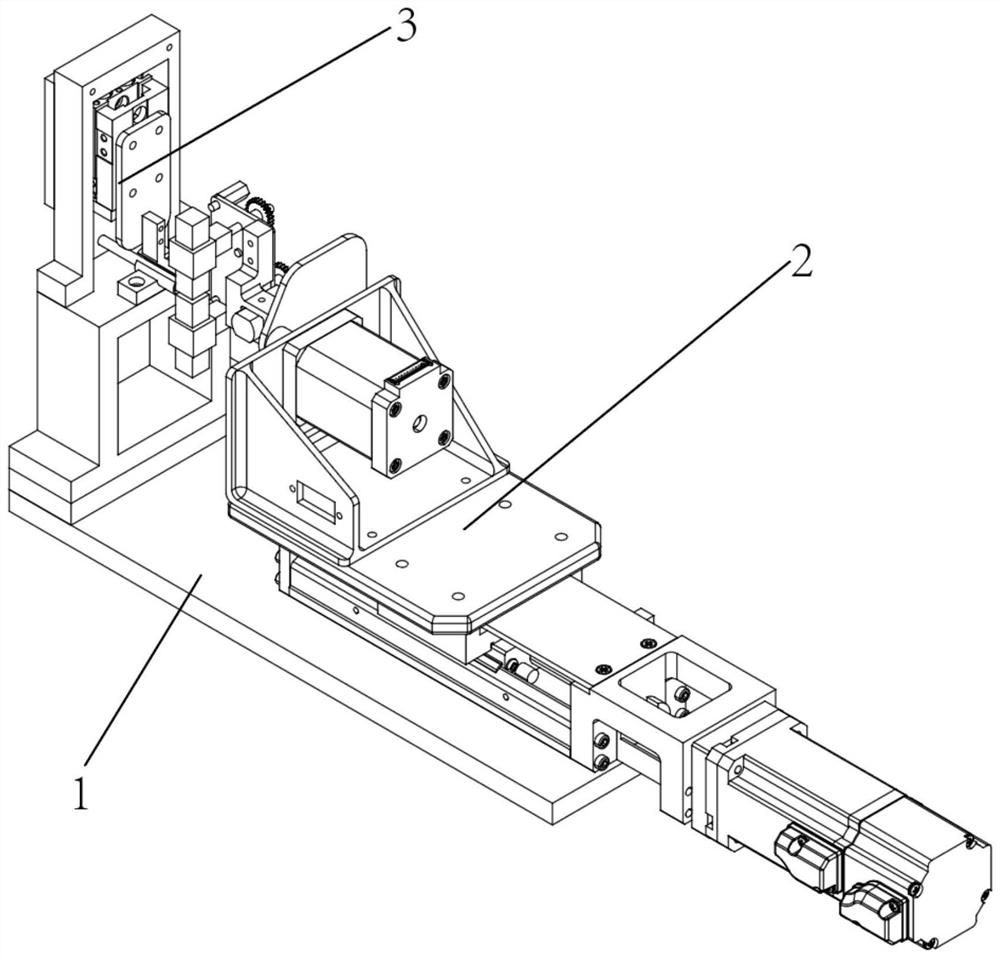

A robot automatic loading and unloading production unit

ActiveCN110524299BNovel structureIngenious designMetal working apparatusMaintainance and safety accessoriesProduction unitMachining

Owner:无锡南兴装备有限公司 +1

Wire brushing device

PendingCN112216444AEasy to chooseEvenly distributedManufacturing wire harnessesEngineeringStructural engineering

A wire brushing device comprises a substrate, and a wire brushing module and a wire harness fixing module which are arranged on the substrate. The wire brushing module comprises a wire brushing base and a wire brushing assembly arranged on the wire brushing base, the wire brushing assembly comprises a wire brush and a driving piece installed on the wire brushing base and connected with the wire brush, and the wire harness fixing module comprises a columnar wire harness fixing cylinder. The driving piece can drive the wire brush to uniformly brush a shielding wire exposed out of a wire outlet of a wire harness fixing cylinder onto the outer cylinder wall of the wire harness fixing cylinder. The device has the beneficial effects that the wire brush brushes the wires up and down to scatter the wires, and brushes the wires on the outer cylinder wall of the wire harness fixing cylinder to be uniformly distributed, so that part of wire harnesses are convenient to select in subsequent processing just by selecting the wire harnesses on the corresponding cylinder wall; for example, if one third of the wire harnesses need to be selected, only the wire harnesses corresponding to one third ofthe cylinder wall need to be selected, not only machining automation is achieved, but also the means for obtaining part of the wire harnesses is simpler.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

A special CNC machine tool for small parts processing

InactiveCN107971750BSolve processing problemsRealize processing automationFeeding apparatusOther manufacturing equipments/toolsNumerical controlBall screw

Owner:SHANGHAI DIANJI UNIV

A Coconut Automatic Stripping Machine

ActiveCN108514128BEfficient and easy stripping processRealize processing automationHuskingHullingHydraulic cylinderHydraulic pump

The invention relates to an automatic mesocarp stripping machine for coconuts. The machine mainly comprises a hydraulic cylinder, an magnetic exchange valve, a throttle valve, an overflow valve, a hydraulic pump, an oil filter, an oil tank, side cutters, an upper cutter, a sliding pressing plate, a tray, a tray support, a lifting lead screw, a lifting nut, a lifting servo motor and a feeding disc;the right side of the hydraulic cylinder is connected to the magnetic exchange valve; the throttle valve is connected to the magnetic exchange valve; the overflow valve is connected to the throttle valve; the hydraulic pump is connected to the throttle valve and the overflow valve; the hydraulic pump is connected to the oil filter; the oil filter is positioned above the oil tank; the side cuttersare arranged below the hydraulic cylinder in connection relation; the sliding pressing plate is arranged rightly below the hydraulic cylinder; and the sliding pressing plate is connected to the uppercutter. The automatic mesocarp stripping machine for coconuts adopts hydraulic transmission as power output, takes the feeding disc combining a lead screw mechanism with a nut mechanism as a feedingdevice. The upper cutter cooperates with the side cutters, so that coconut mesocarp can be pulled apart from the top, the side surface and the bottom end of a coconut at the same time, and the mesocarp stripping is rapid and simple, and the processing automation can be realized.

Owner:HAINAN UNIVERSITY

Automatic magnetic seat milling device

InactiveCN101704194BIngenious structureMove preciselyLarge fixed membersMilling equipment detailsNumerical controlMilling cutter

The invention belongs to the technical field of machining equipment, which relates to an automatic magnetic seat milling device capable of precisely moving in longitudinal, transverse and vertical directions. The automatic magnetic seat milling device comprises a lathebed and is characterized in that the lower part of the lathebed is provided with a magnetic seat; the upper part of the lathebed is provided with a longitudinal moving mechanism; a transverse moving mechanism is arranged on the longitudinal moving mechanism; a vertical moving and milling mechanism is arranged on the transverse moving mechanism; and a numerical control mechanism is arranged at one side of the lathebed. The magnetic seat automatic milling device has skillful, compact and reasonable structure and precise movement and can machine surfaces which cannot be machined by the traditional equipment and ensure that the machined surfaces are even and smooth, thereby realizing machining automation, greatly improving the working efficiency and obviously reducing the cost. A longitudinal moving rack and a base are formed by welding steel plates and have good rigidity. Because a milling cutter disk can be vertically lifted, the surface of a machining piece can be higher than a plane sucked by a milling machine and also be lower than the plane, and the application range of the automatic magnetic seat milling device is wide.

Owner:WUXI YAZHONG PNEUMATIC HYDRAULIC

Steel ring machining equipment integrating foot pressing and chamfering

ActiveCN112935822ASmooth rotationRealize the chamfering actionOther manufacturing equipments/toolsMachiningCaster

The invention discloses steel ring machining equipment integrating foot pressing and chamfering. The steel ring machining equipment comprises a rack, a feeding mechanism, a moving frame, a lifting plate, a pressing plate, an inner chamfering wheel, an outer chamfering wheel, and an inner foot pressing wheel, wherein a feeding area and a machining area are arranged on the rack; the feeding mechanism is arranged at the feeding area; the moving frame can be arranged on the rack in a front-back moving manner; The lifting plate can be arranged on the moving frame in an up-down moving manner; the pressing plate is arranged on the lifting plate through a lifting mechanism and used for making contact with a steel ring to be machined; the inner chamfering wheel is rotatably arranged on the lifting plate; the outer chamfering wheel is arranged on the lifting plate in a front-back moving mode through a displacement mechanism so as to be close to or away from the inner chamfering wheel, and the outer chamfering wheel is matched with the inner chamfering wheel to carry out chamfering action on the upper portion of the steel ring; and the inner foot pressing wheel is rotatably arranged on the lifting plate through a rotating mechanism and is located below the inner chamfering wheel. The equipment has the advantages that automatic machining can be realized, the labor intensity of workers can be reduced, and the safety and the working efficiency can be improved.

Owner:NINGBO JINSHIHONG MACHINERY EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com