Hydraulic upsetter loose tooling locking device

A technology of locking device and upsetting machine, which is applied in the driving device of forging press, upsetting press, forging/pressing/hammer device, etc., which can solve problems affecting processing efficiency and achieve the goal of improving processing efficiency and product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

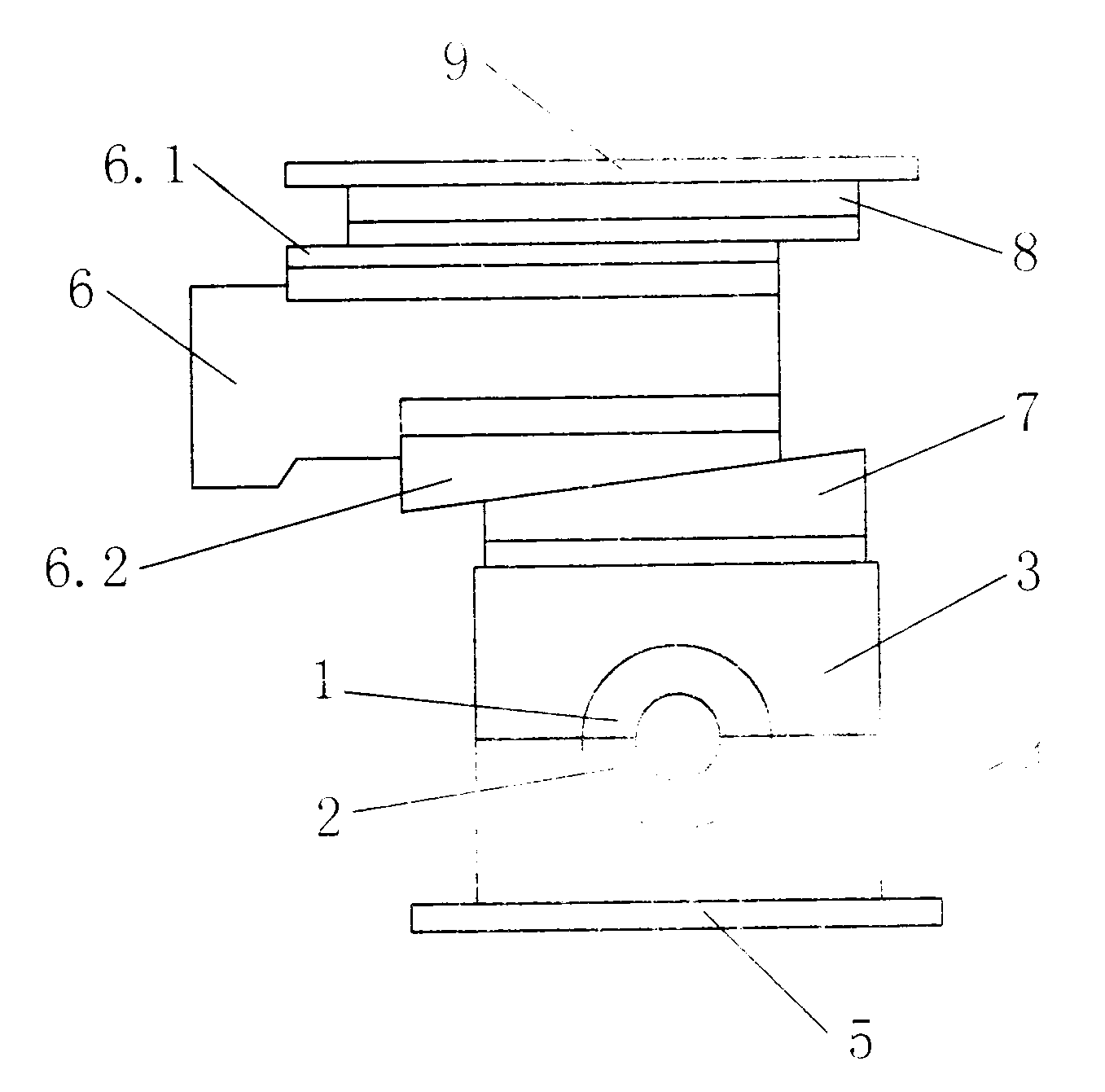

[0009] As shown in the figure, the lower tire plate 4 and the upper tire plate 3 are installed on the machine base 5, the lower mold 2 is embedded in the lower tire plate, and the upper mold 1 is embedded in the upper tire plate; Fixed wedge 7 is arranged; Movable wedge 6.2 and movable block 6 are housed on the fixed wedge; Movable slide plate 6.1, fixed slide plate 8 and top cover 9 are equipped with on the movable block top.

[0010] Working process of the present invention:

[0011] After the upper and lower tire plates and the upper and lower molds formed between the machine base and the top cover are fastened, the movable wedge is driven to run in the direction of the fixed wedge by pushing the movable slide plate and the movable block, and the movable wedge is opposite to the fixed wedge. Generate pressure, press the upper tire plate, and lock the upper mold and the lower mold.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com