Patents

Literature

4627 results about "Storage garage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

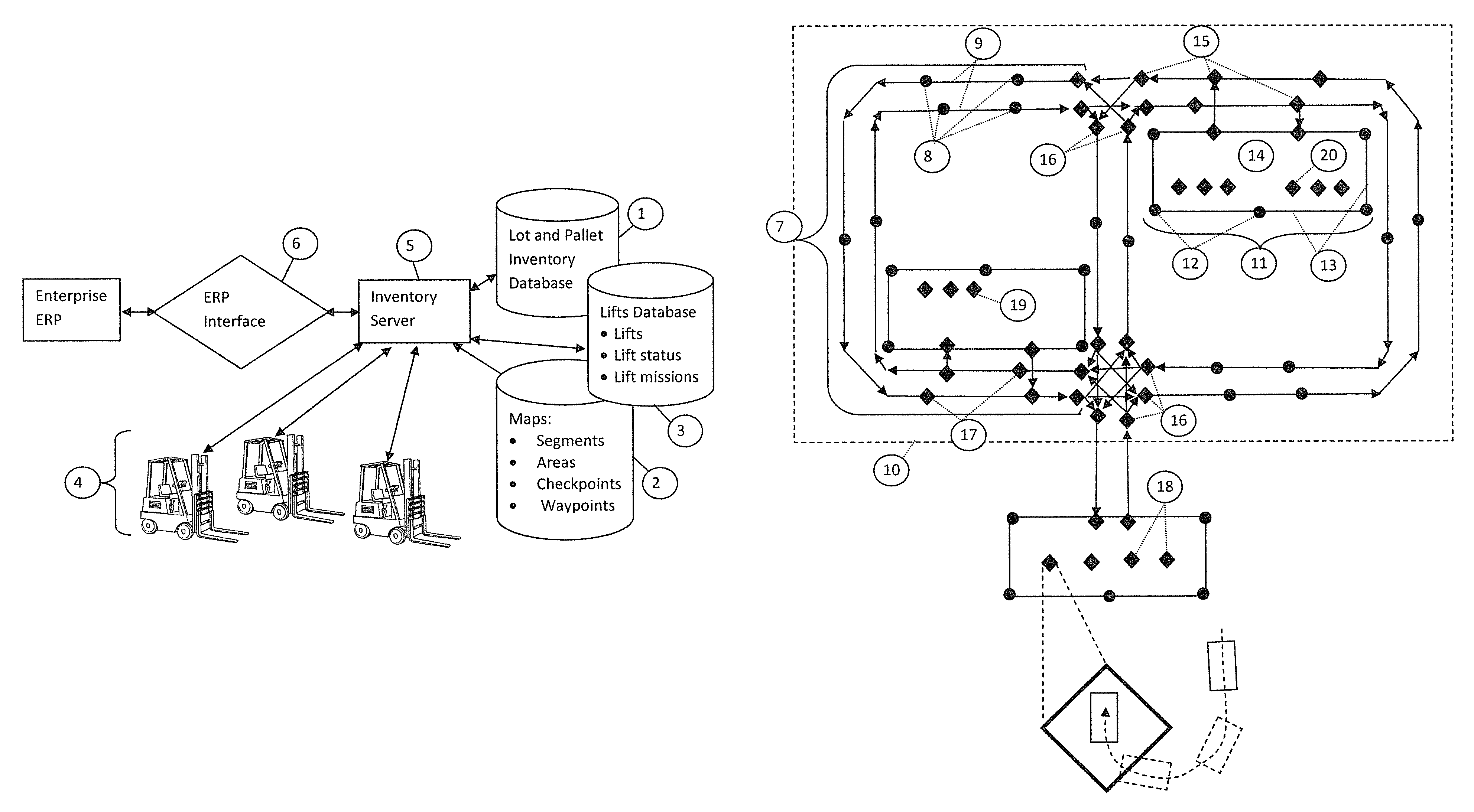

Automated warehousing using robotic forklifts

ActiveUS20140277691A1Low costReduce rateDigital data processing detailsLifting devicesOn boardInventory management

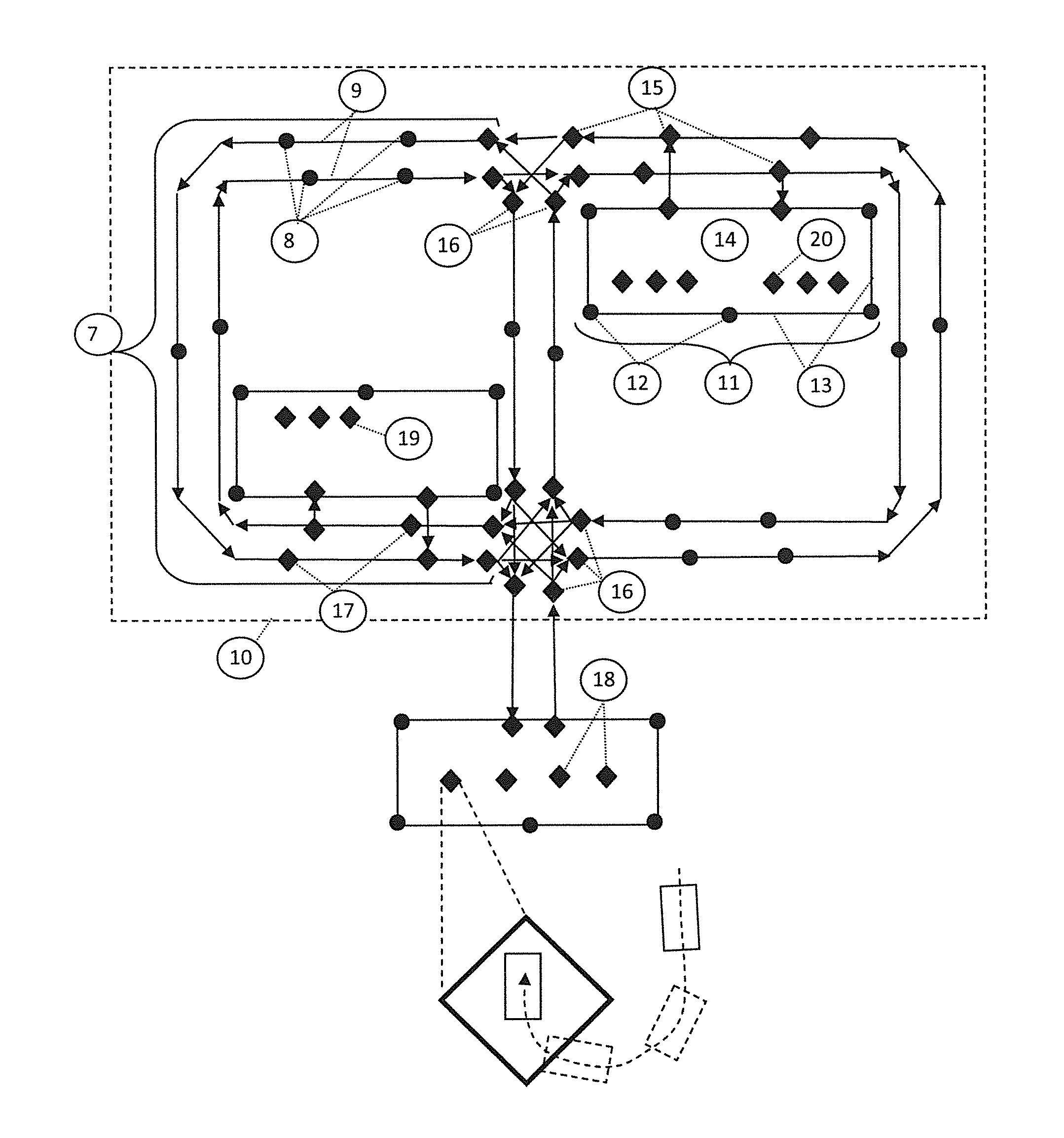

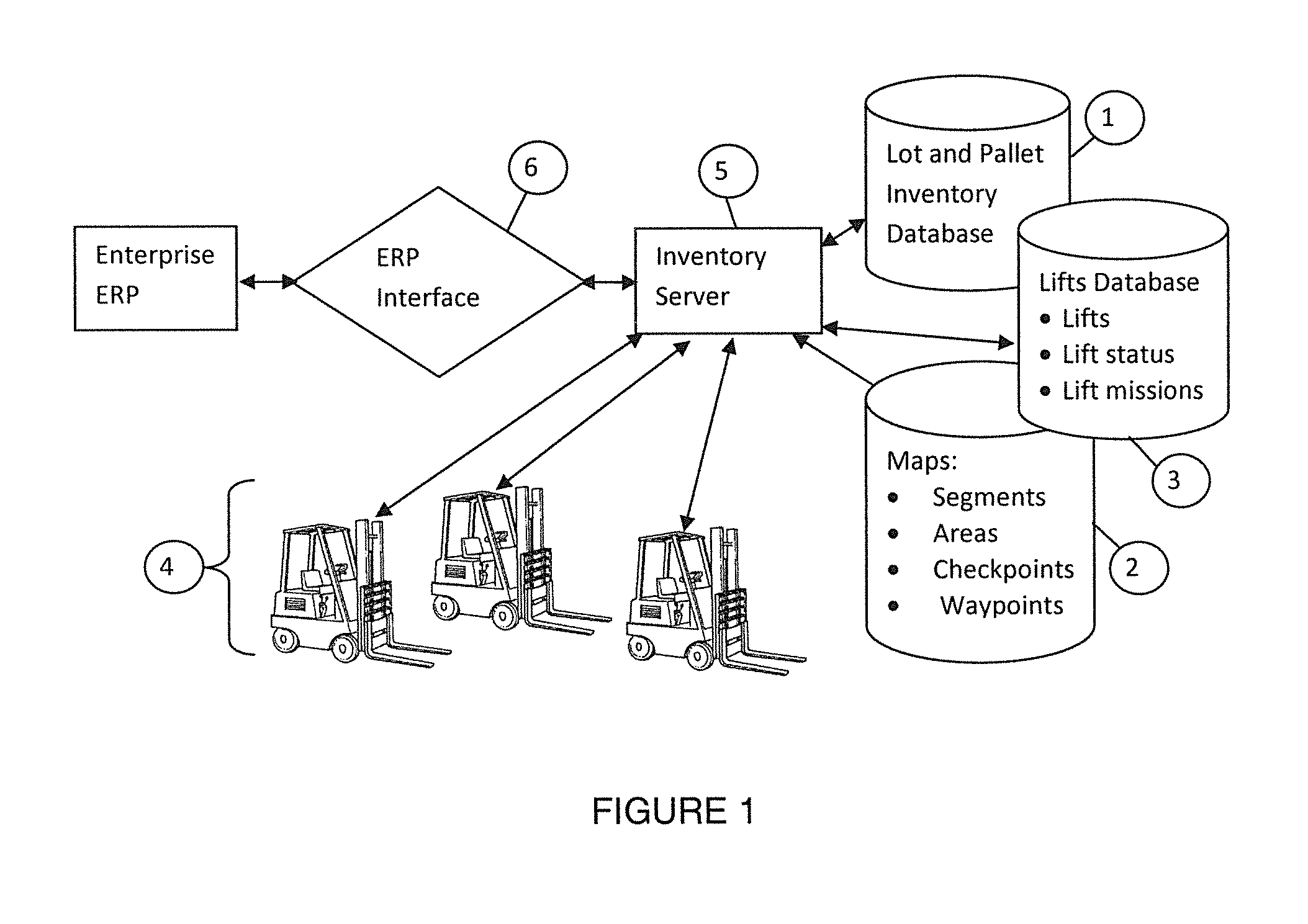

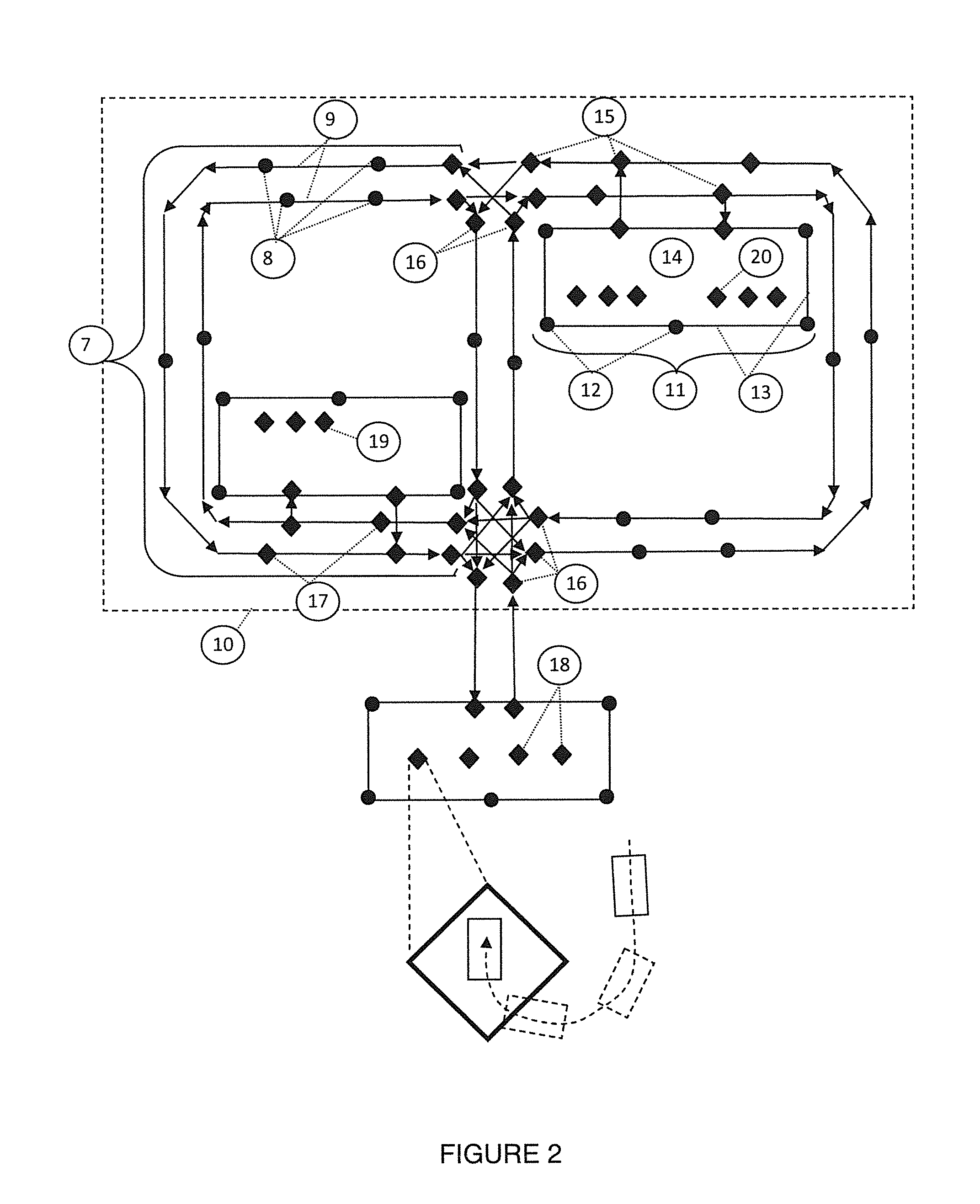

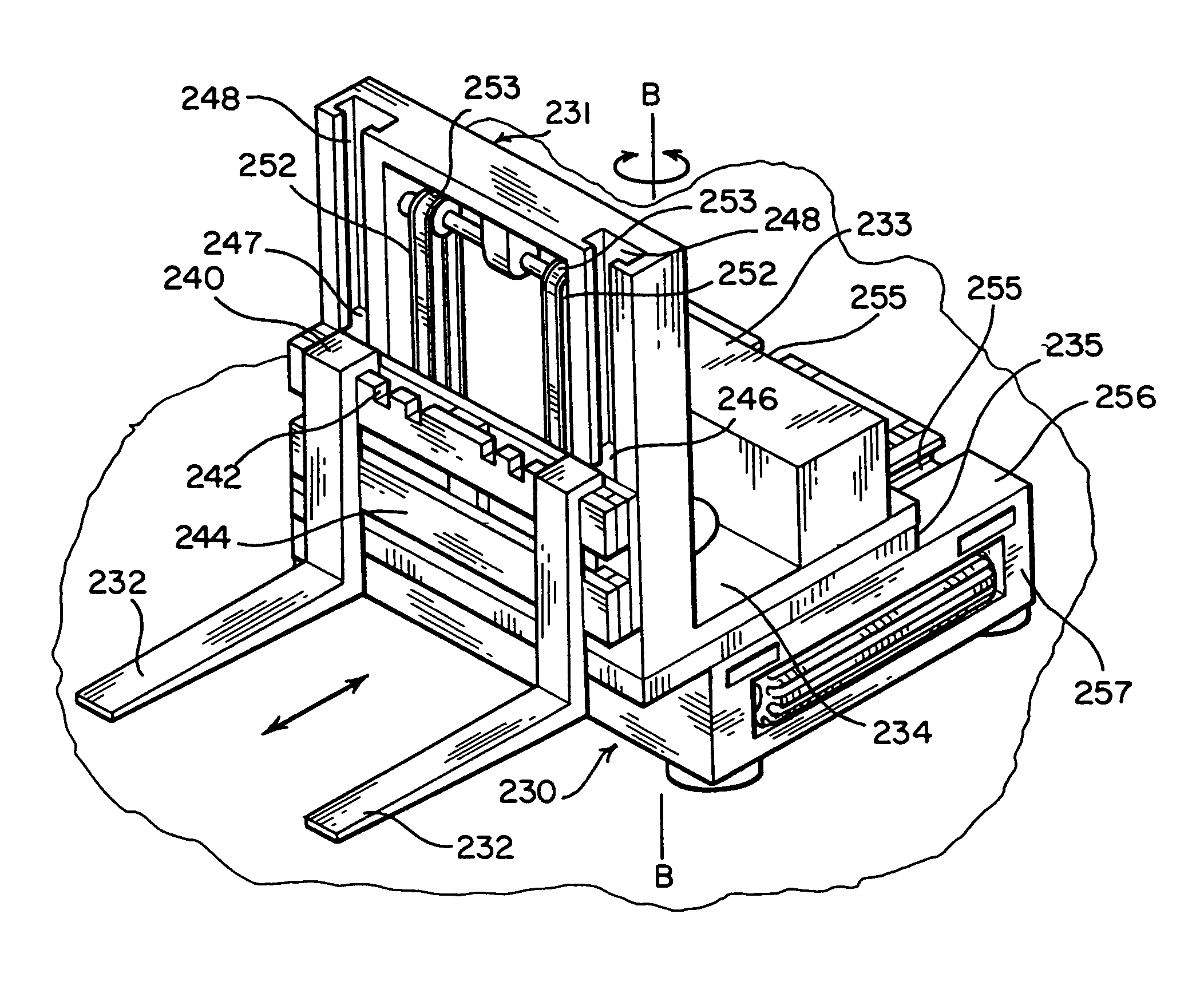

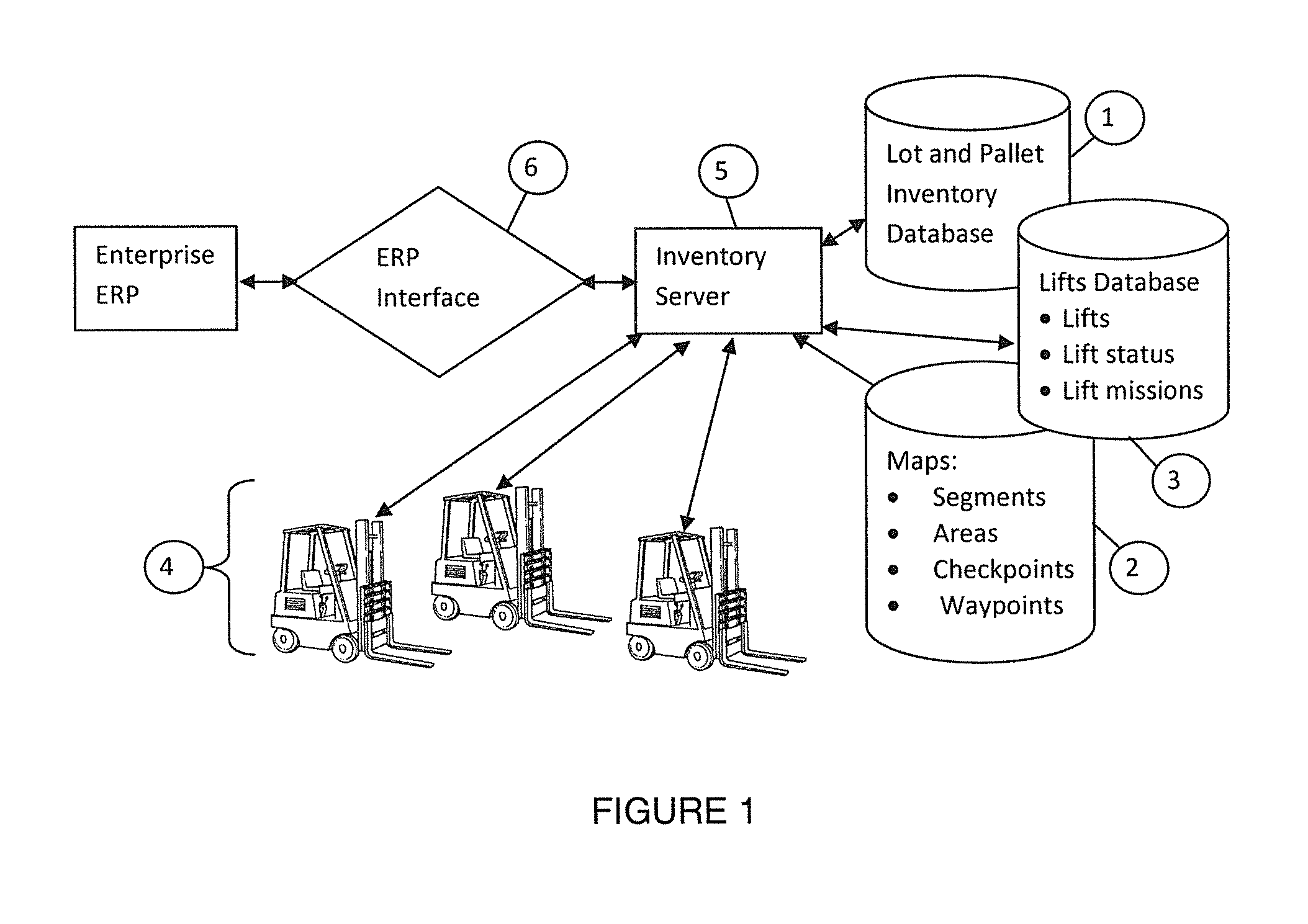

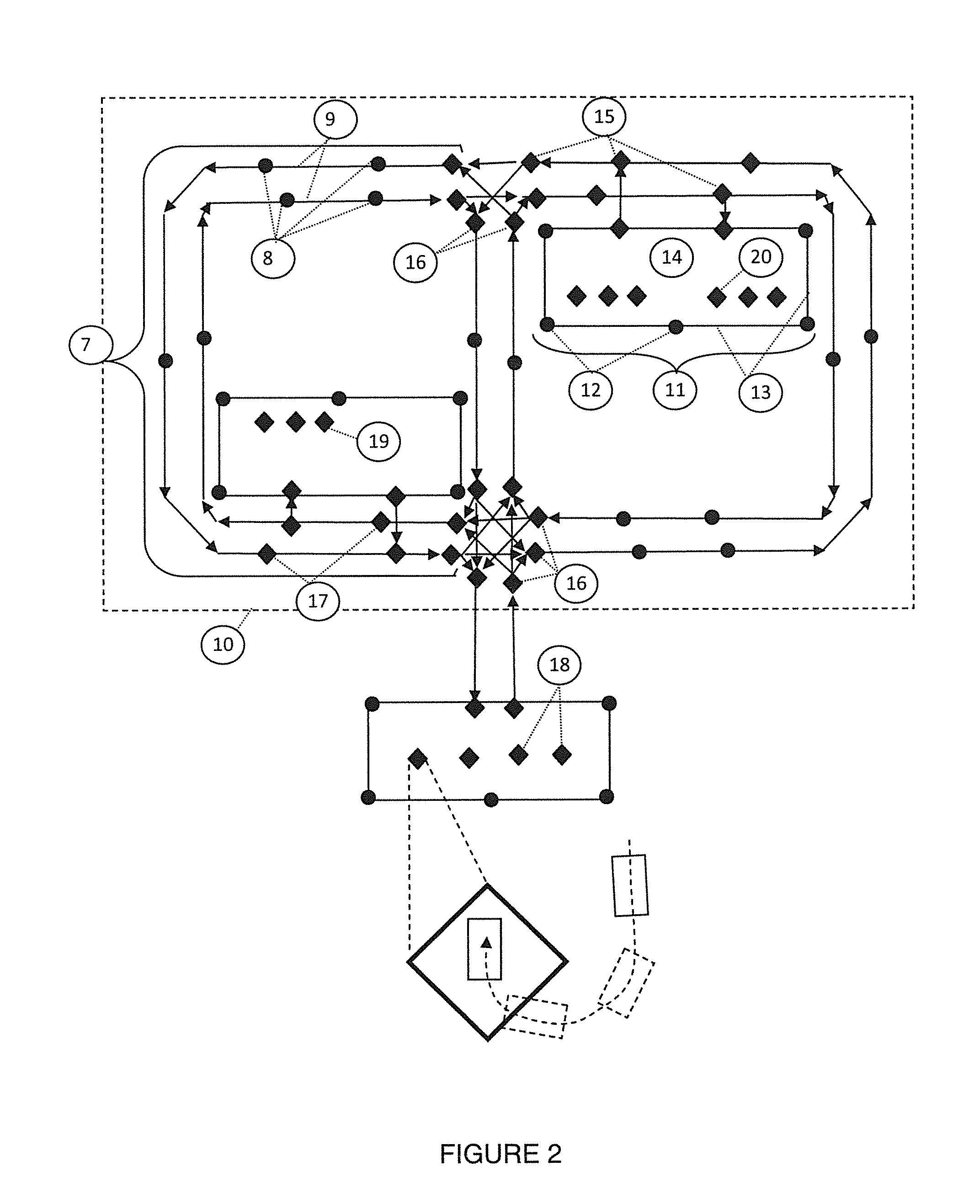

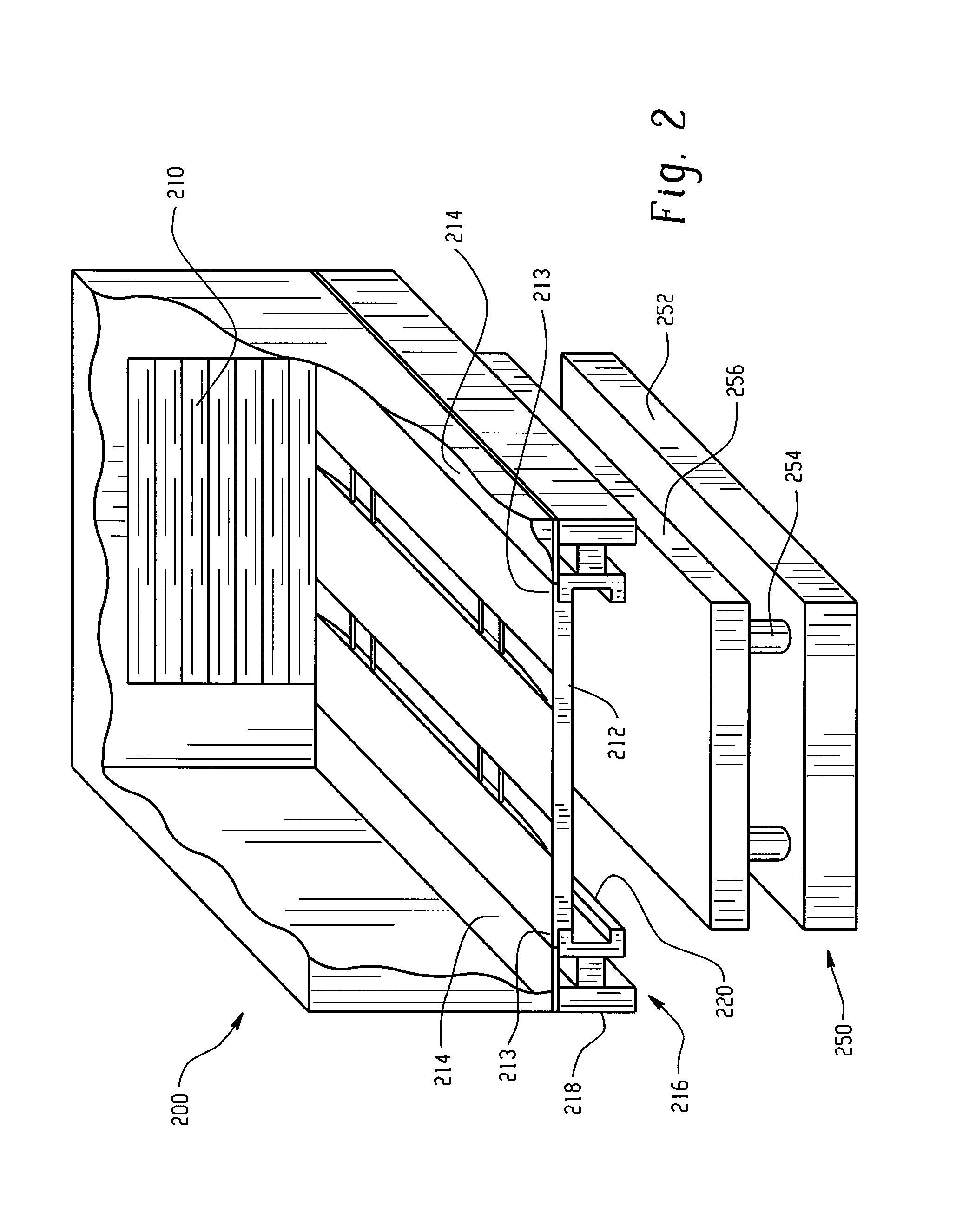

A system for automated inventory management and material handling removes the requirement to operate fully automatically or all-manual using conventional vertical storage and retrieval (S&R) machines. Inventory requests to place palletized material into storage at a specified lot location or retrieve palletized material from a specified lot are resolved into missions for autonomous fork trucks, equivalent mobile platforms, or manual fork truck drivers (and their equipment) that are autonomously or manually executed to effect the request. Automated trucks plan their own movements to execute the mission over the warehouse aisles or roadways sharing this space with manually driven trucks. Automated units drive to planned speed limits, manage their loads (stability control), stop, go, and merge at intersections according human driving rules, use on-board sensors to identify static and dynamic obstacles, and human traffic, and either avoid them or stop until potential collision risk is removed.

Owner:CYBERNET SYST

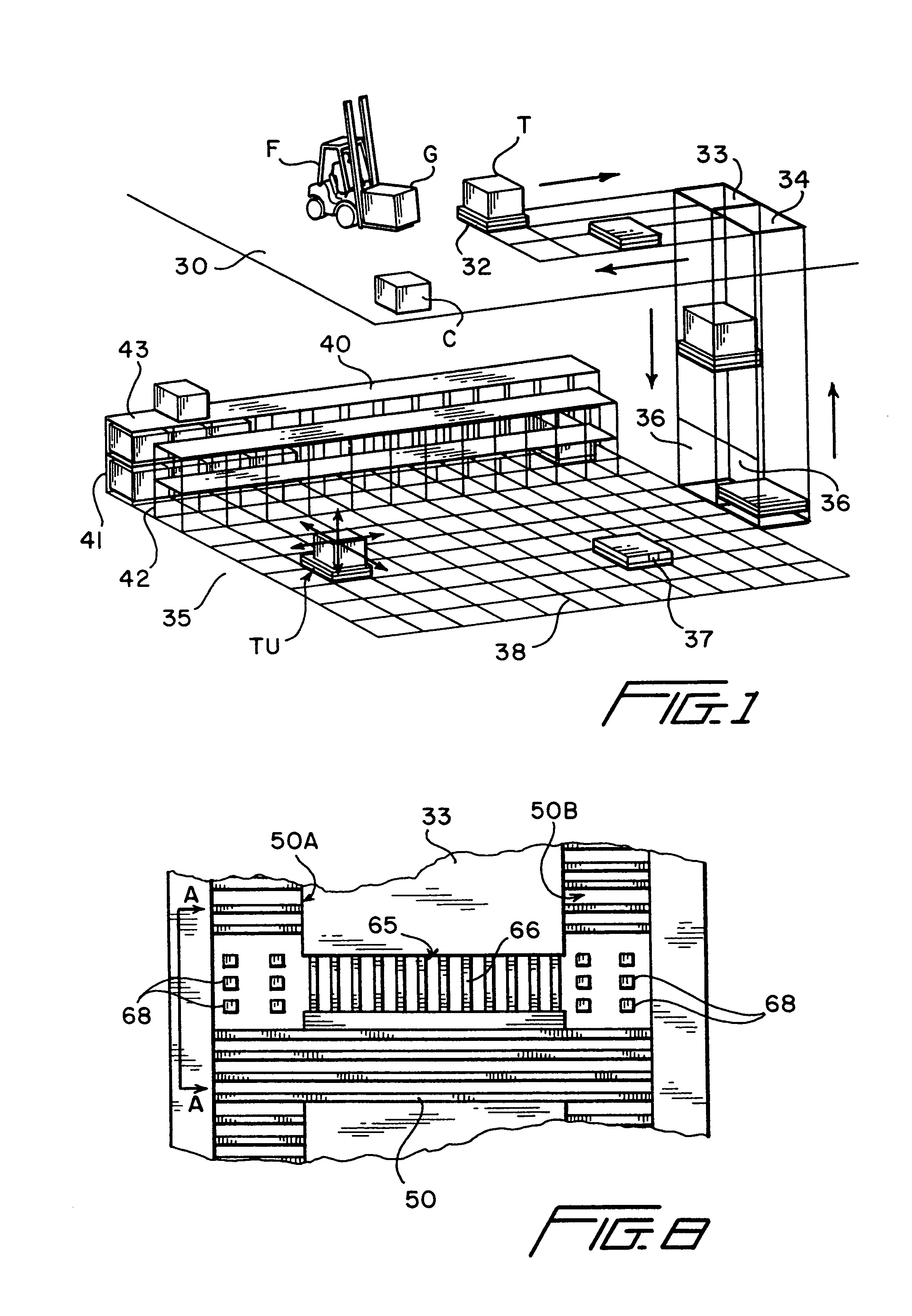

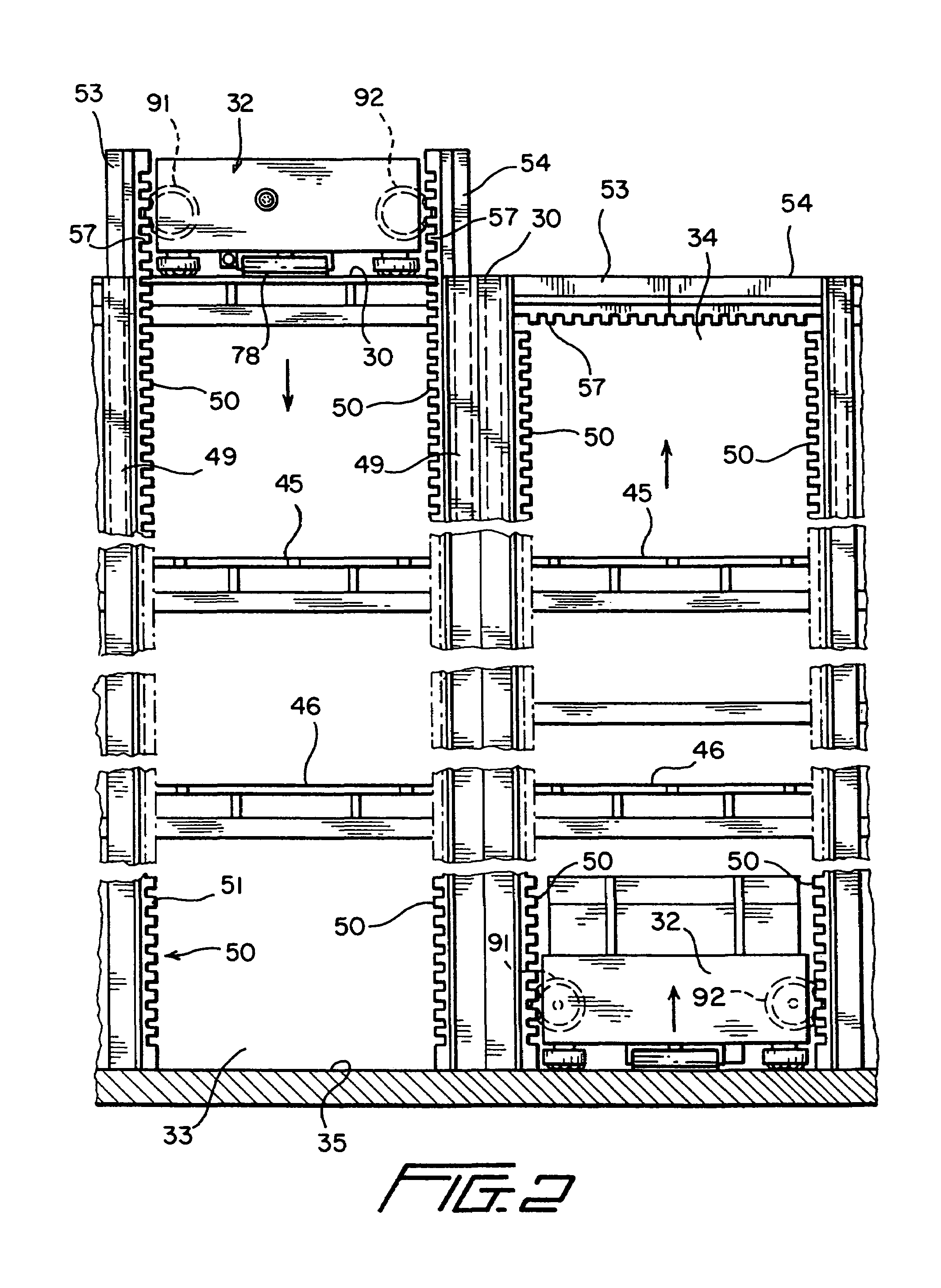

Automated material handling system with motorized transfer vehicles

InactiveUS7101139B1Improve securityProvide energyAutomatic initiationsLoad accommodationMaterial handlingTreatment system

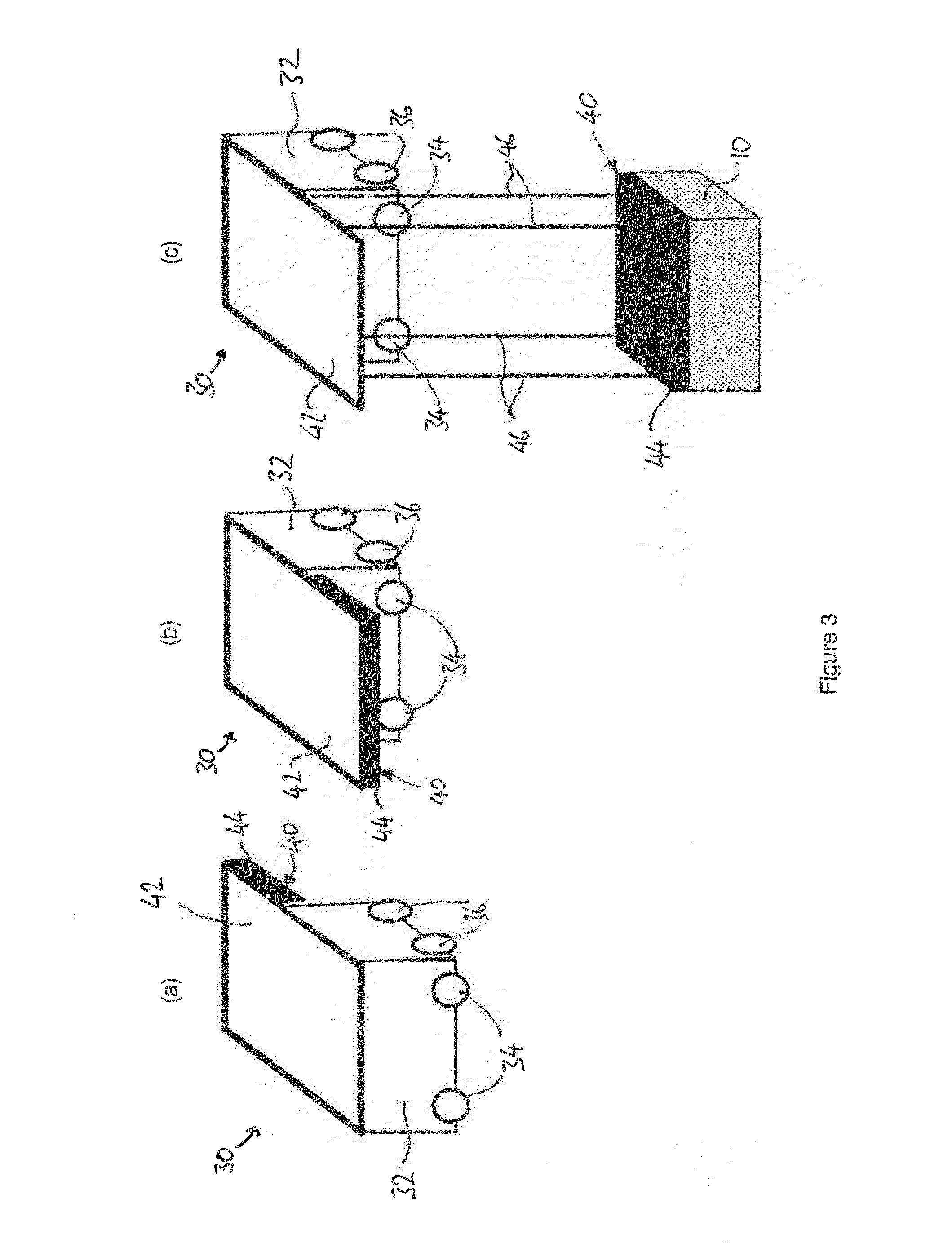

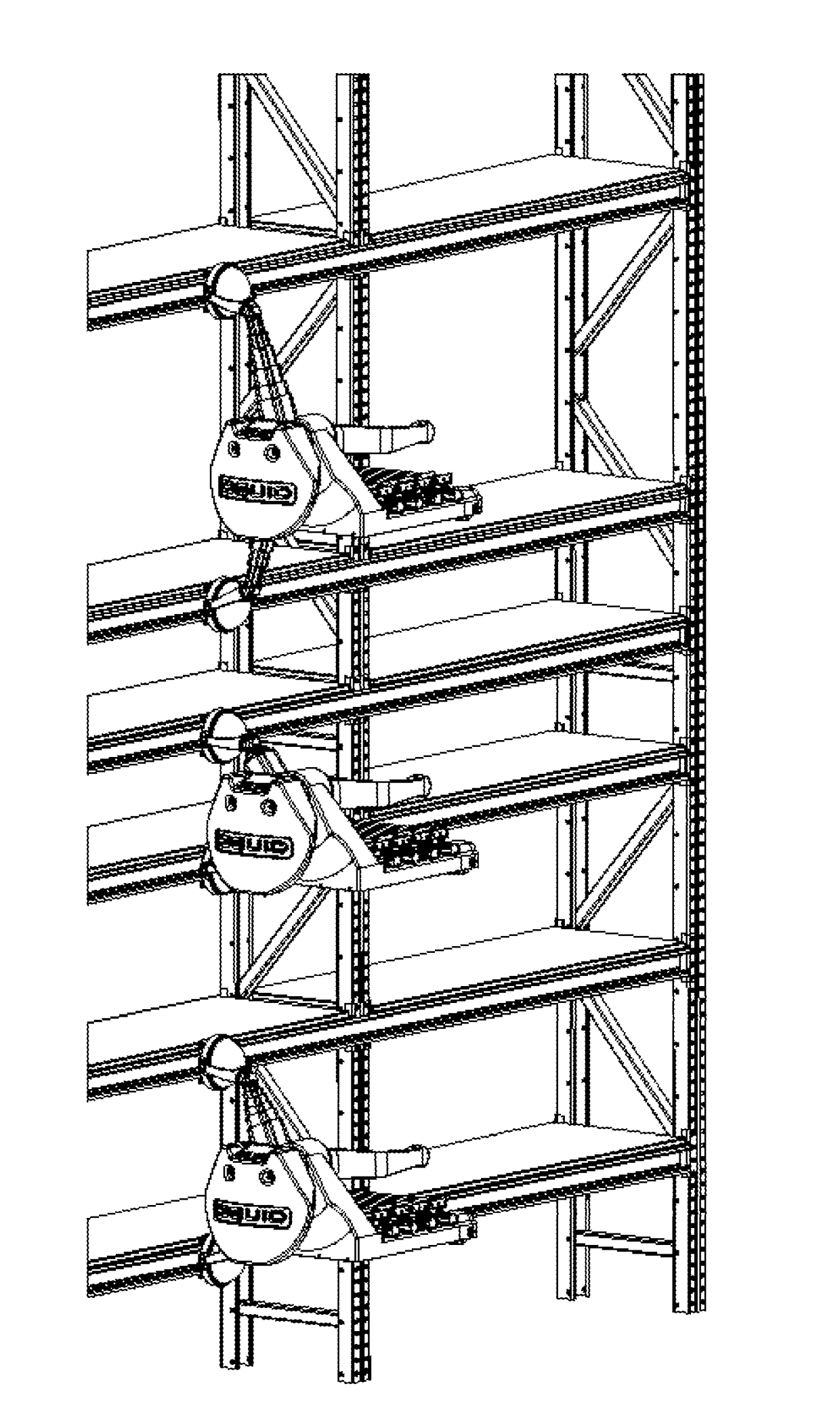

A material handling system for use in storing and moving goods within multi-level storage warehouses, ocean going vessels and the like wherein storage areas are provided on at least one of the levels and wherein goods are automatically transferred to and from the storage areas and between the various levels by self-propelled load transfer vehicles. The load transfer vehicles move across the surface of the various levels and deliver are also movable within open vertical trunks between the levels to thereby move goods to any desired area.

Owner:GEBRR BECKER

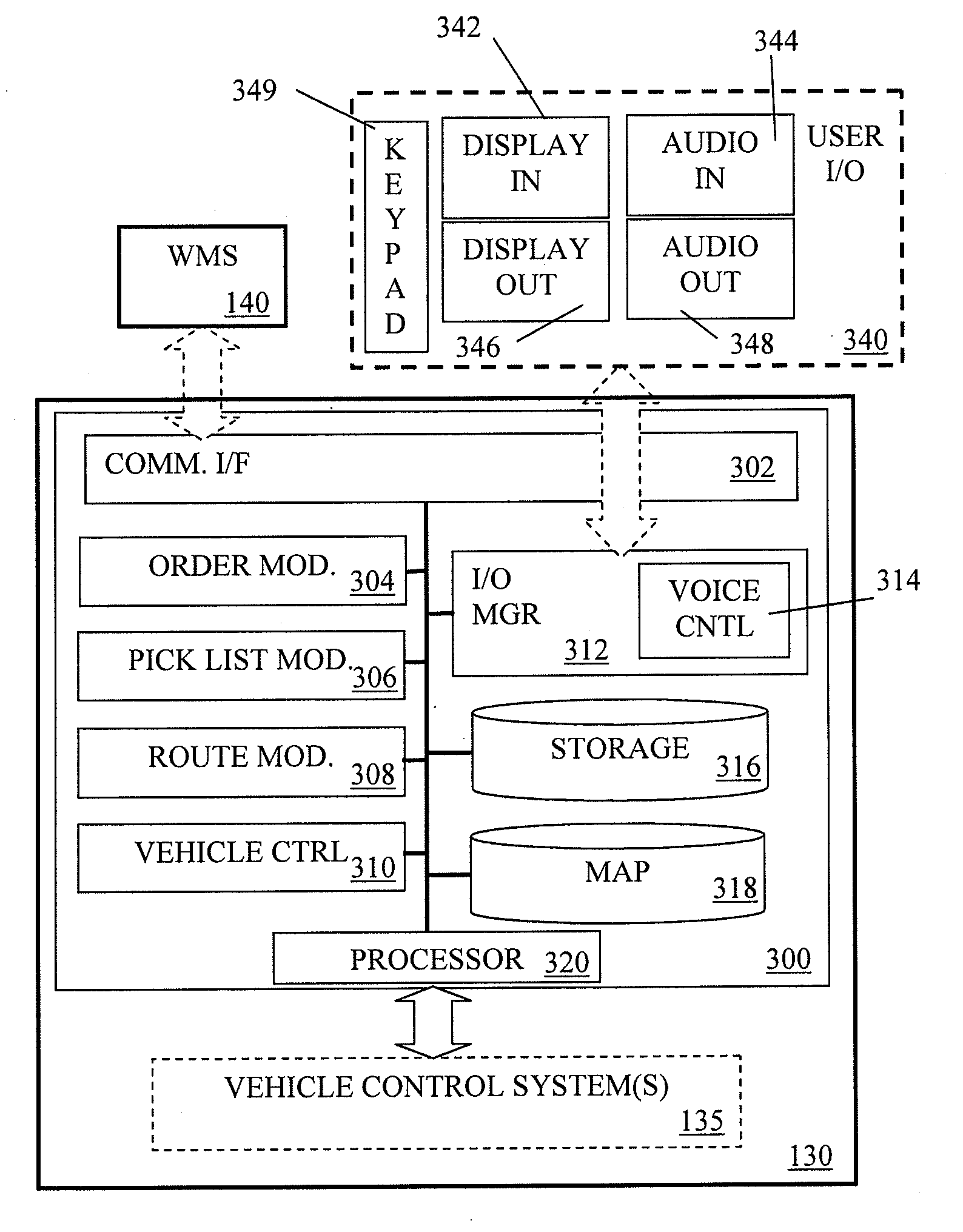

Robot-enabled case picking

ActiveUS20120330458A1Minimize travel distanceMinimize order distanceProgramme controlDigital data processing detailsUser inputOutput device

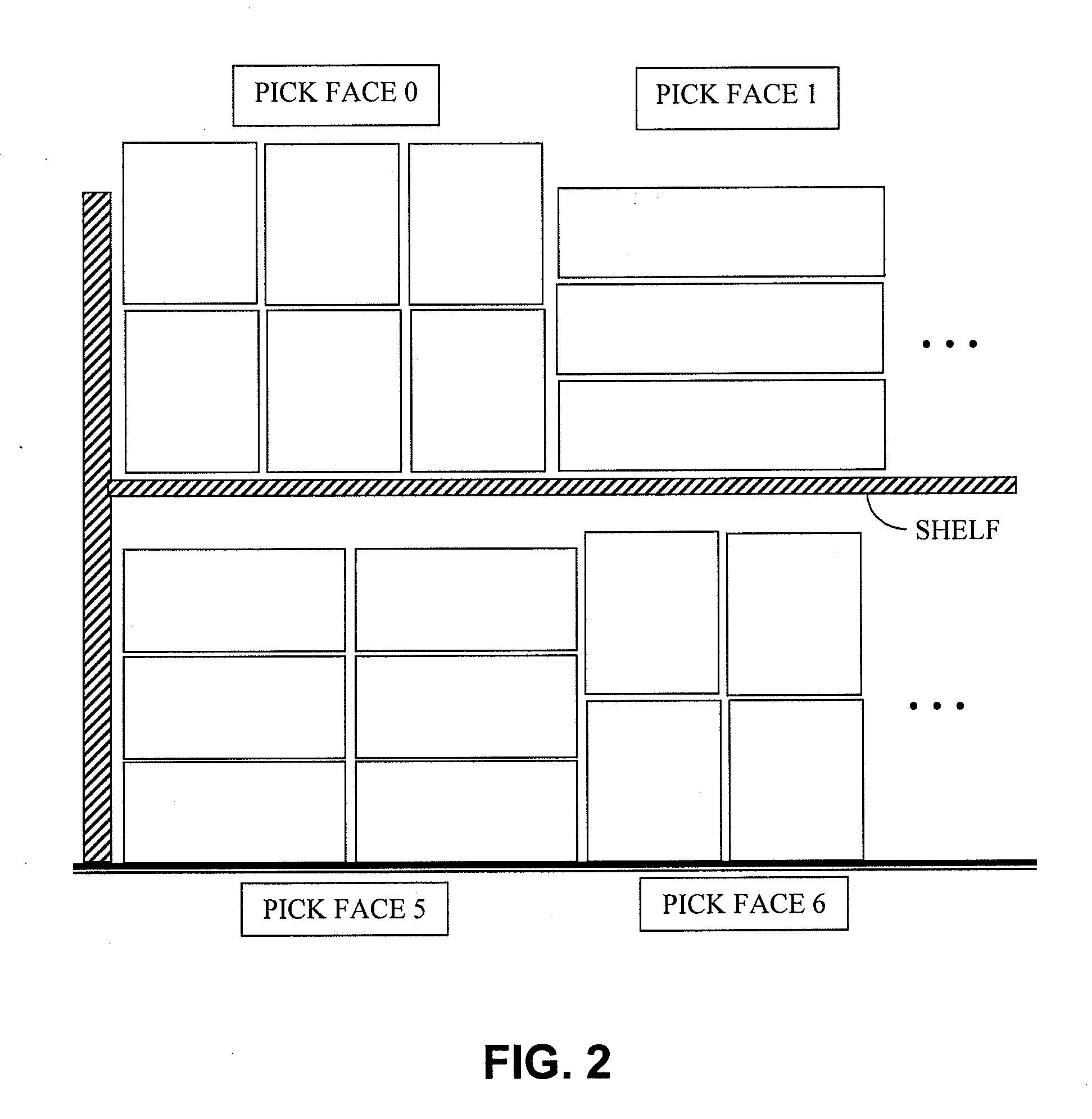

A robot-enabled method of picking cases in a warehouse is provided. A robotic vehicle includes a processor configured to access a memory, a user input device, an output device, and a load platform, and has access to an electronically stored representation of a warehouse. The representation includes a map that defines aisles for storing items arranged as pick faces within the warehouse. A pick list is generated from an order; the pick list provides identifications of items to be picked to fulfill the order. Determined from the pick list is a plurality of stops at pick faces associated with the items. A route within the map is generated that includes the plurality of stops. The robotic vehicle iteratively guides itself along the route and automatically stops at each of the plurality of stops to enable loading of the items from the pick list onto the load platform.

Owner:SEEGRID CORPORATION

Battery Exchange Station

ActiveUS20100141206A1Keep for a long timeReduce dependenceHybrid vehiclesBatteries circuit arrangementsRobotic systemsElectrical battery

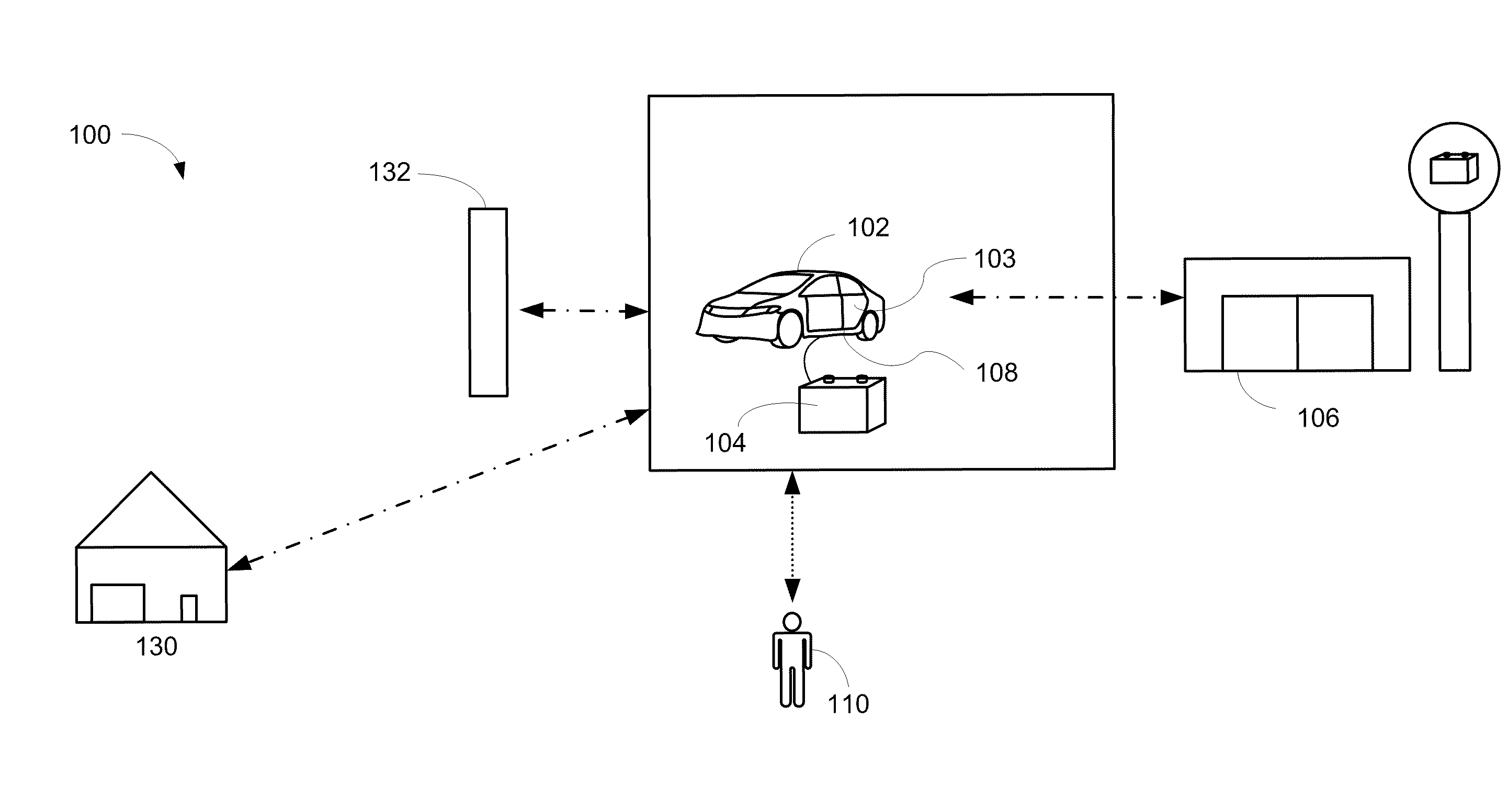

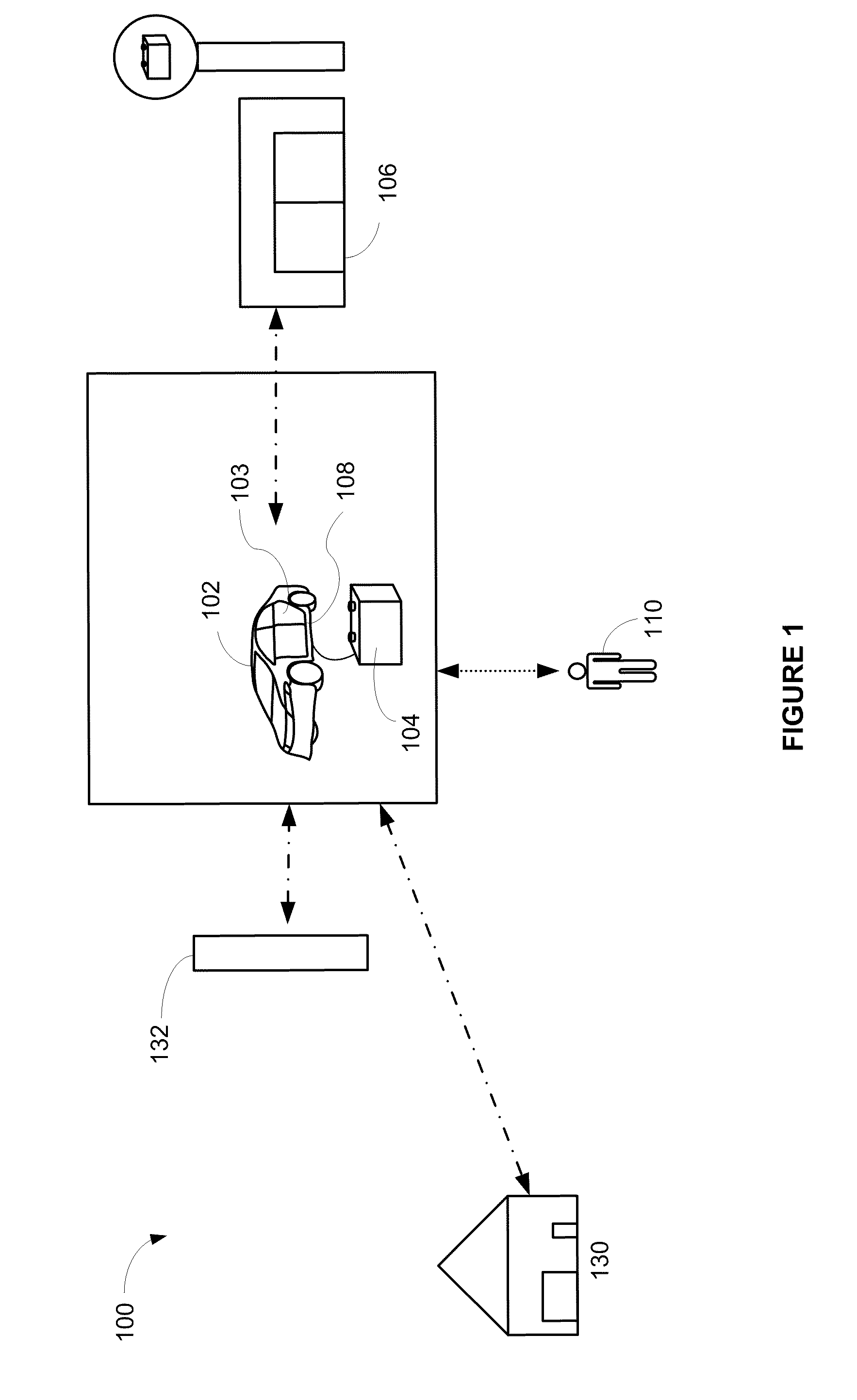

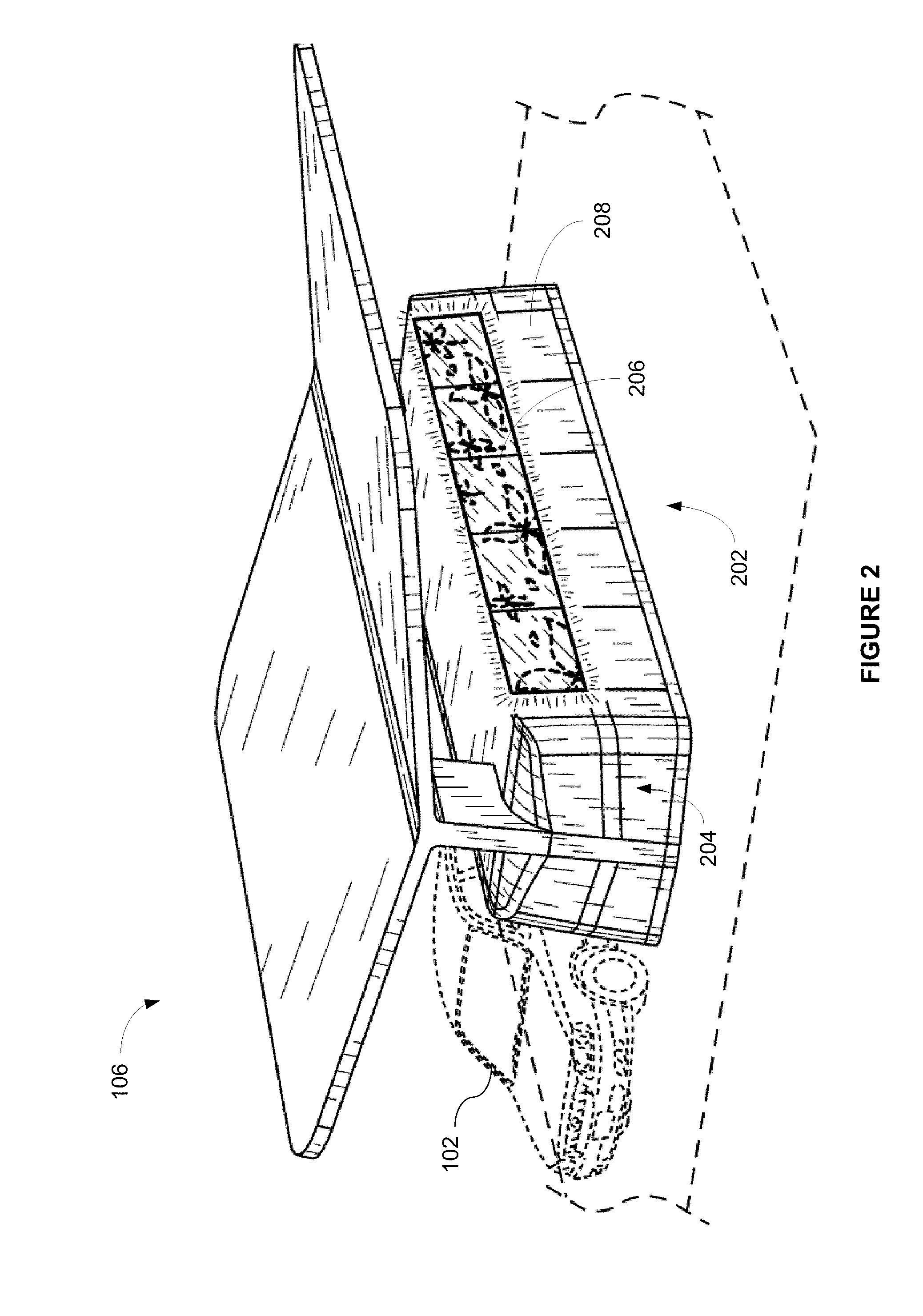

At a battery exchange station a discharged battery is removed and a charged battery is inserted into an electric vehicle. The battery exchange station has various mechanisms to make this exchange. In some embodiments, the batteries are stored in a warehouse, where they are given an appropriate amount of charge. The charged batteries are moved from the warehouse by an automated robotic mechanism. The automated robotic system provides the charged battery to a battery exchange system which inserts the charged battery into the vehicle after it removes the discharged battery from the vehicle. The insertion and removal of the battery is done vertically, i.e., into and out of the bottom of the vehicle. The battery exchange system is located in a service bay under the vehicle. A sliding door system creates an opening above the service bay. The opening is of variable size depending on the size of the vehicle.

Owner:CHARGE PEAK

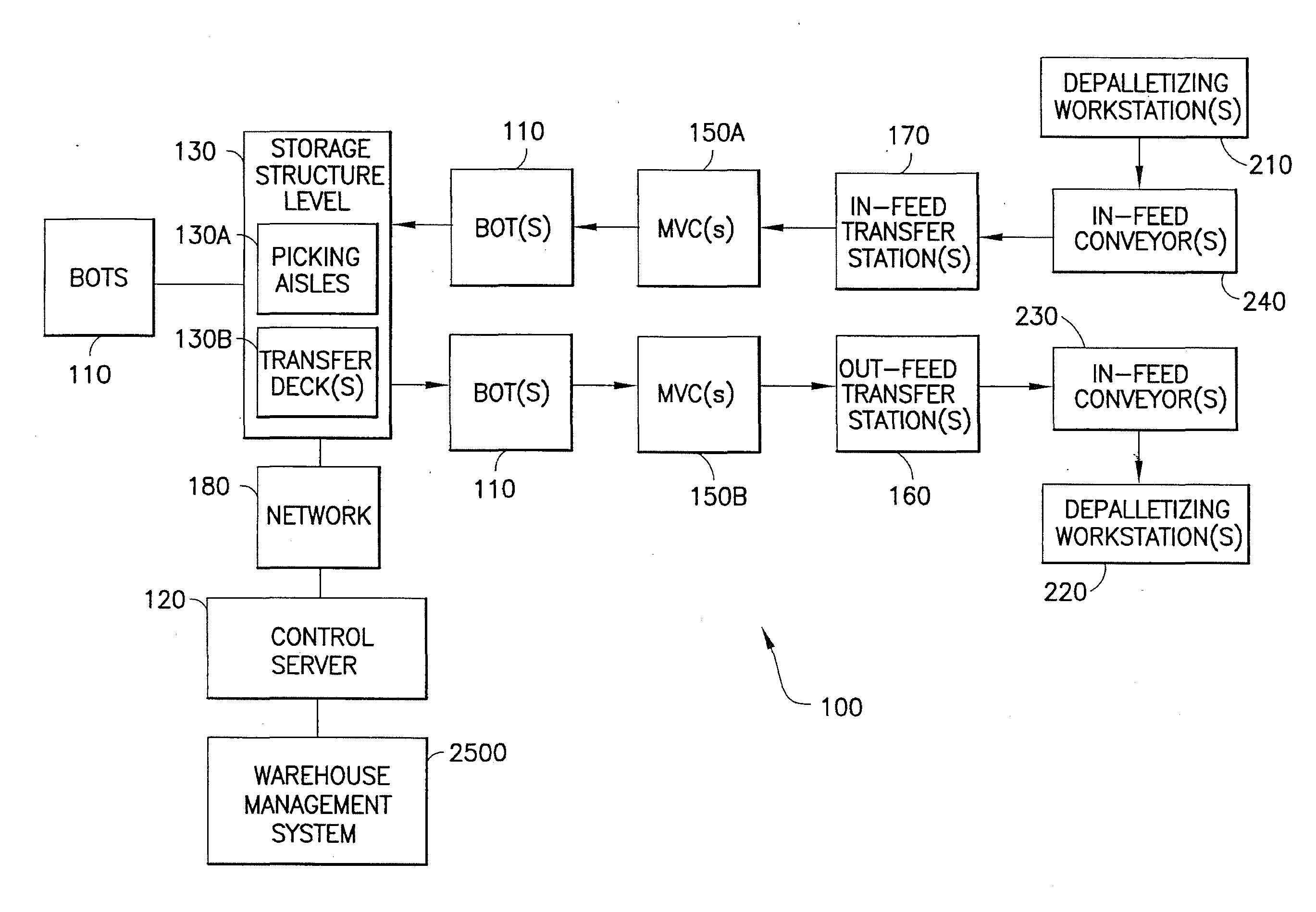

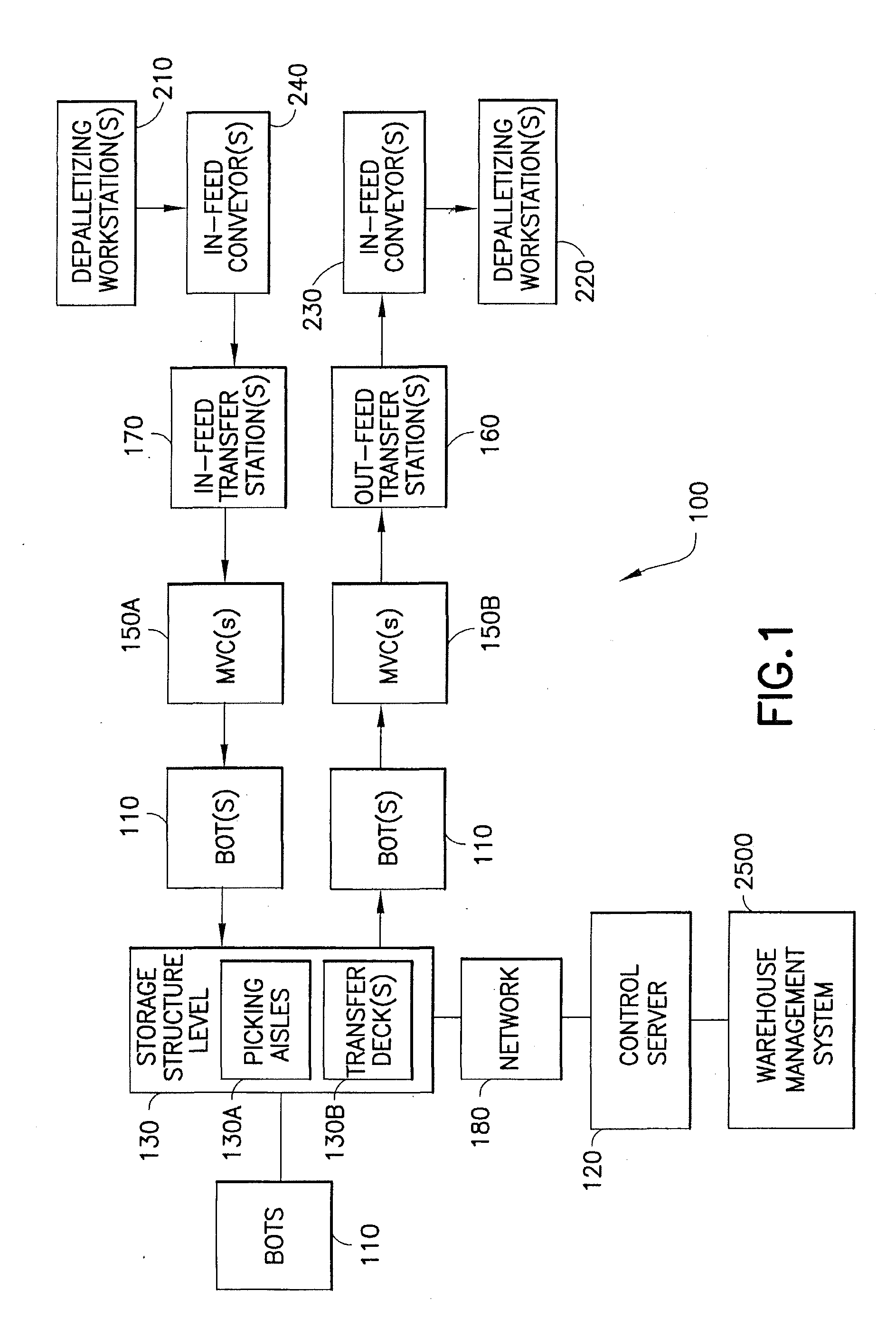

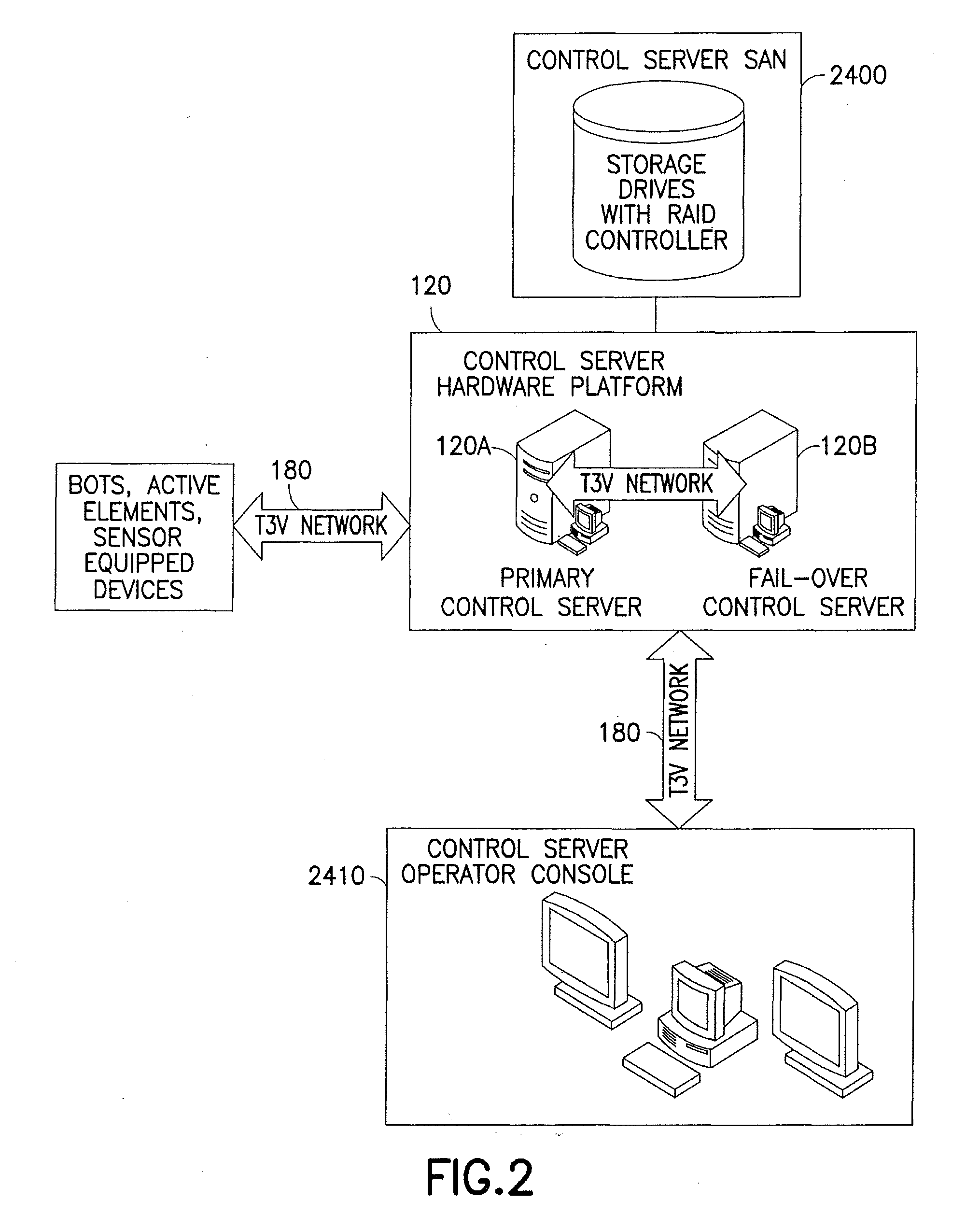

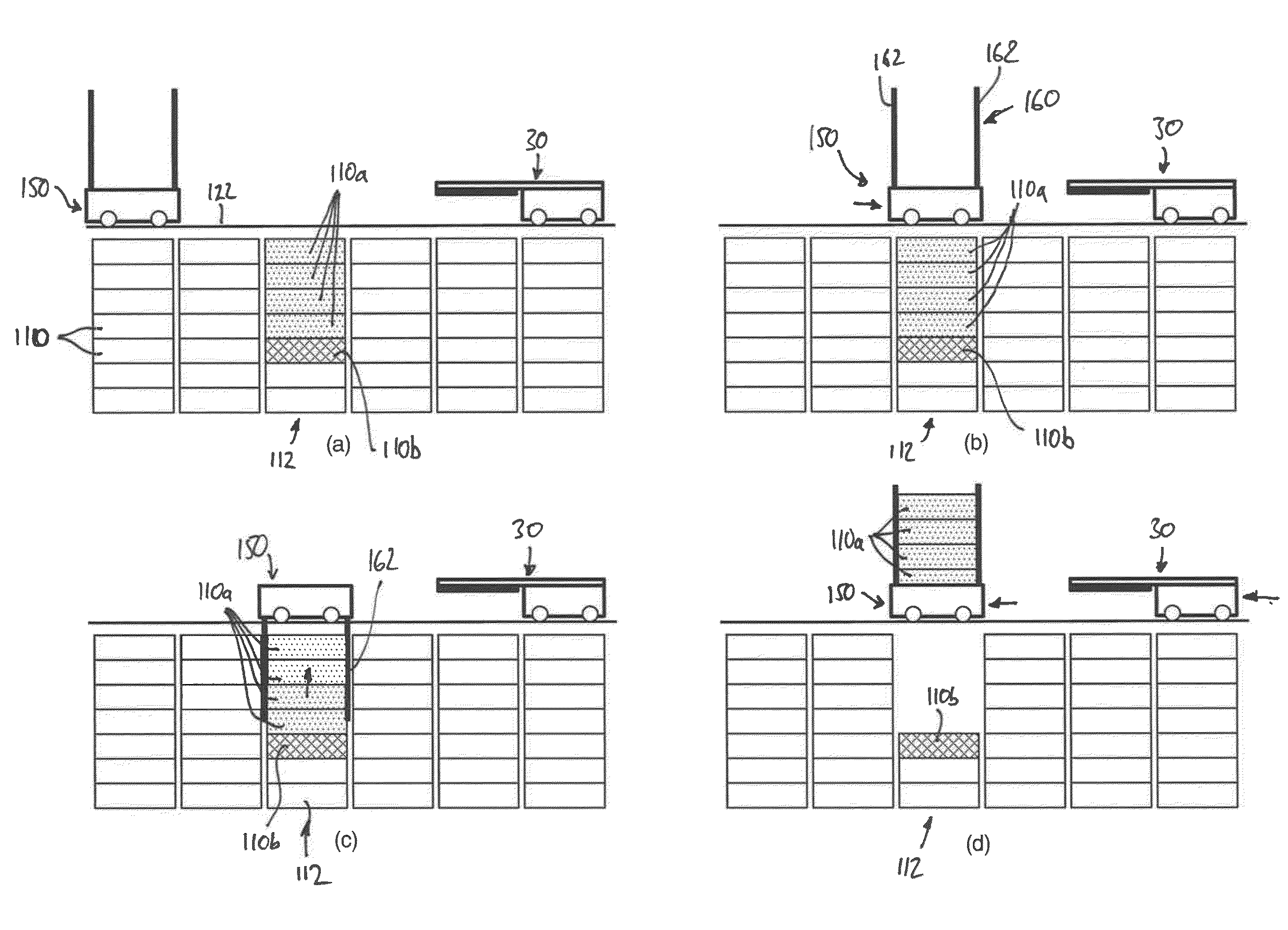

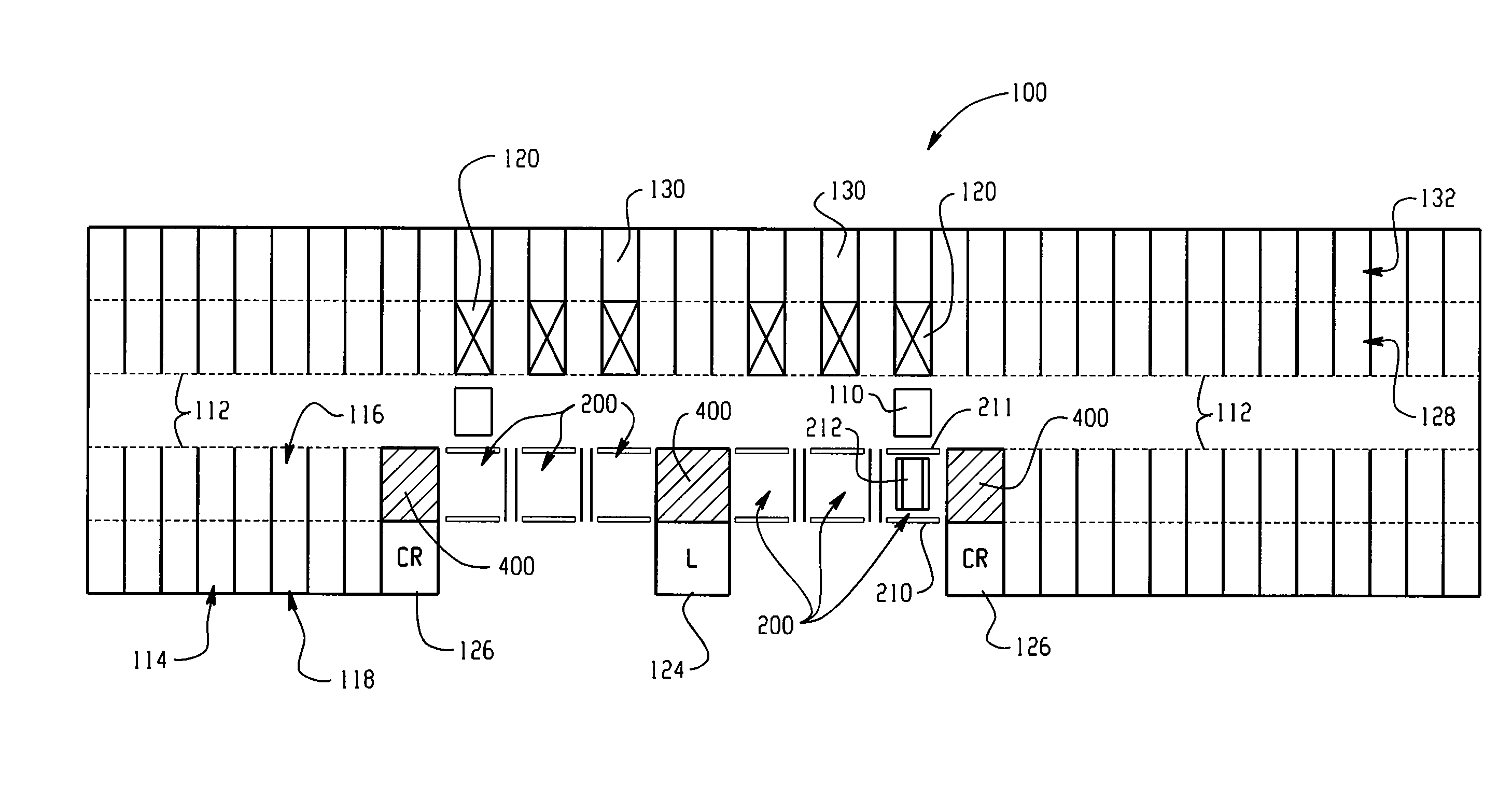

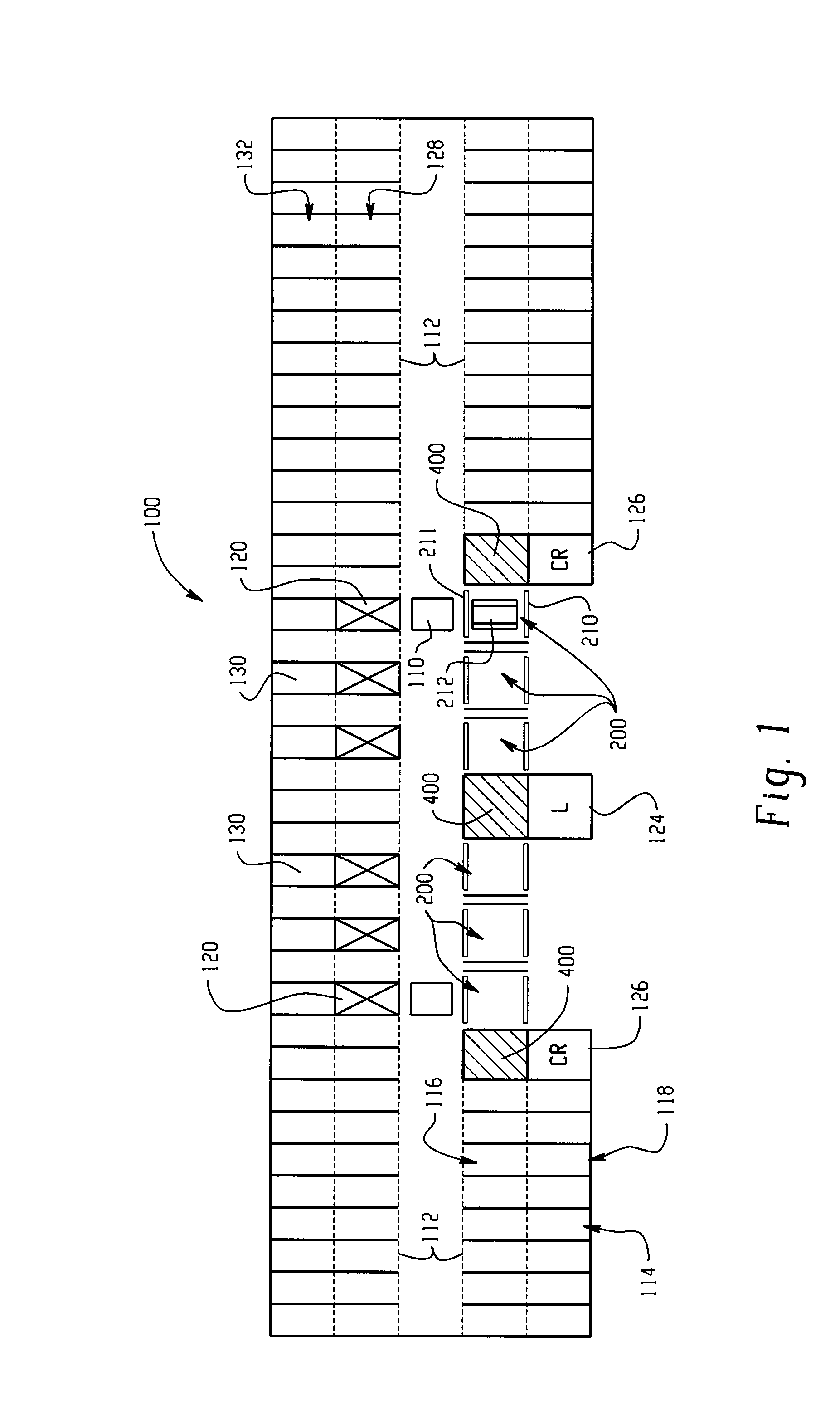

Control system for storage and retrieval systems

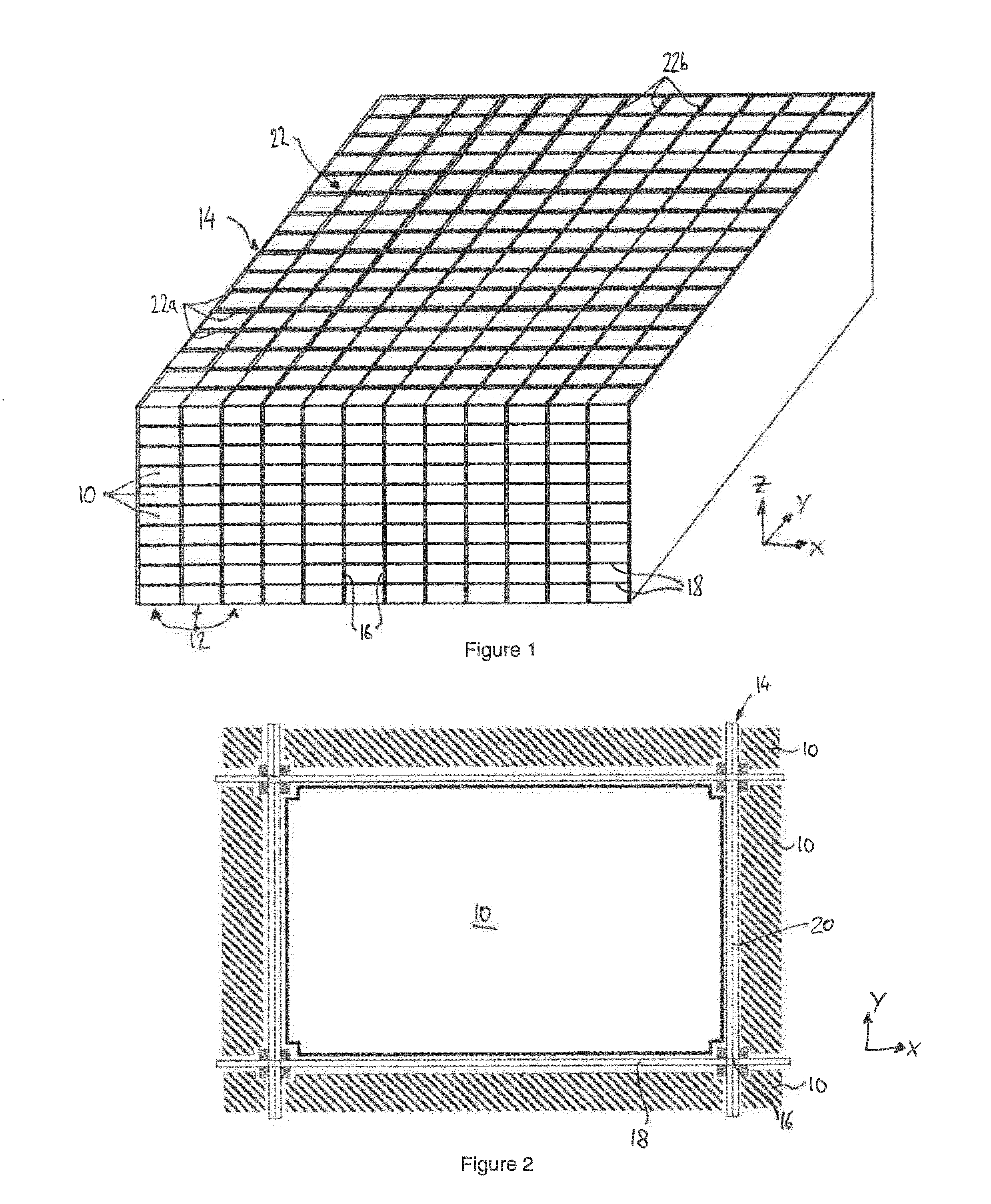

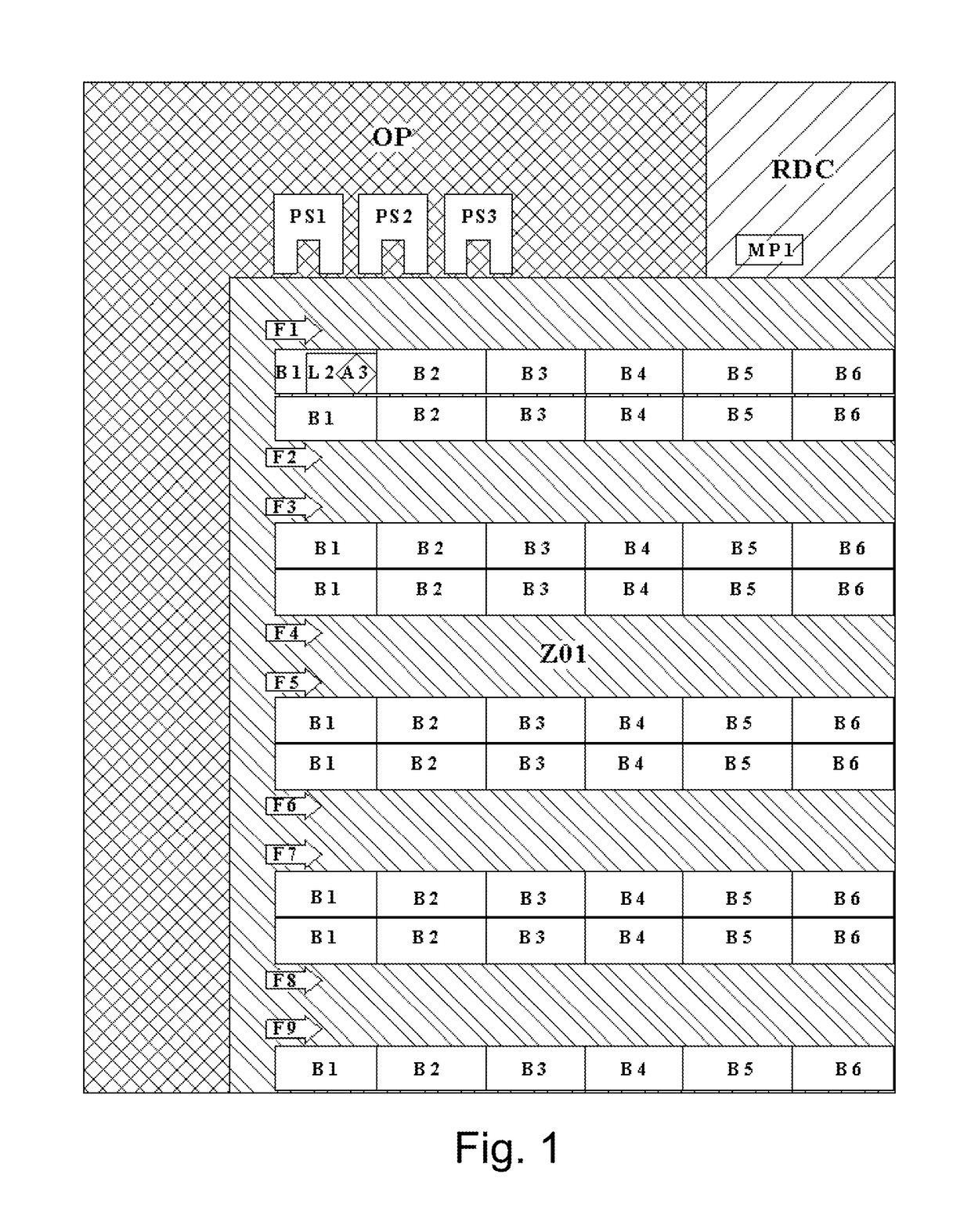

A warehouse storage and retrieval system including an array of multilevel storage racks having at least one transfer deck, picking isles and storage areas disposed along picking isles, the storage areas being configured to hold differing loads, and a controller including a management module configured to variably size the storage areas of the array of multilevel storage rack modules and assign each of the variably sized storage areas to a corresponding one of the differing loads, wherein the storage and retrieval system is arranged to transport the differing loads for placement in the variably sized storage areas assigned by the controller.

Owner:SYMBOTIC LLC

Storage systems and methods for retrieving units from a storage system

ActiveUS20150127143A1Efficient retrievalEasy to solveComputer controlDigital data processing detailsProduction lineEngineering

A system and method suitable for storing multiple product lines in an automated warehouse environment are disclosed. The storage system includes a frame containing a plurality of stacks of containers, a first handling device capable of lifting a plurality of containers from a stack in a single operation, and a second independently moveable handling device capable of lifting a single container and moving the container laterally. The first and second handling devices can work together to remove a target container quickly and with minimum use of resources.

Owner:OCADO INNOVATION

Automatic warehouse system

ActiveUS20170158430A1Improve the level ofOngoing scalabilityLogisticsStorage devicesOn boardExact location

The invention is an automatic system for picking and placing boxes on shelves in a warehouse. The system comprises a set of autonomous mobile robots; a network of vertical and horizontal rails that are parallel to the vertical support posts and horizontal shelves of the shelving system in the warehouse; and a Real Time Traffic Management (RTTM) server, which is a central processing server configured to communicate with the robots and other processors and servers in the warehouse. The system is characterized in that the robots comprise a set of on-board sensors, a processor, software, and other electronics configured to provide them with three-dimensional navigation and travel capabilities that enable them to navigate and travel autonomously both along the floor and up the vertical rails and along the horizontal rails of the network of rails to reach an exact location on the floor or shelving system of the warehouse.

Owner:BIONICHIVE

Warehouse storage system

ActiveUS20080075569A1Maximize storage spaceReduce areaTravelling cranesLoading/unloadingEngineeringStorage cell

A system and method for the safe storage of items wherein a storage structure is provided having a first section in which storage units are stored in vertically oriented cells with each storage unit being stacked one upon another and wherein at least one transfer vehicle is provided for selectively engaging and conveying the storage units along an overhead grid track system between the first section and a second section wherein the at least one transfer vehicle may be used to either lift or lower a storage unit and move the storage unit to and from a storage position in one of the vertical storage cells of the first section of the storage structure.

Owner:GEBRR BECKER

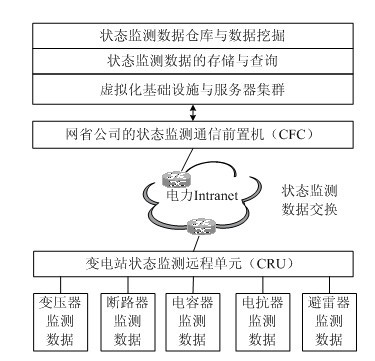

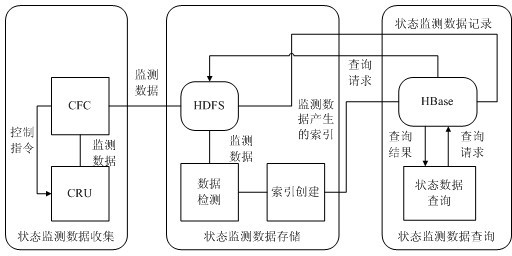

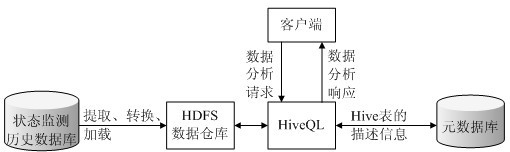

Distributed storage and parallel mining method for state monitoring data

InactiveCN102685221AEnsure operabilityReduce construction costsData switching networksService modelData warehouse

A distributed storage and parallel mining method for state monitoring data includes the steps: defining function service models of a remote substation state monitoring unit and a state monitoring communication front-end processor by means of Web service description language, and exchanging the state monitoring data of electric power equipment in an electric power wide area network environment by a simple object access protocol; storing large-scale state monitoring data redundancy in a distributed file system, creating an index table for a state monitoring data file, inserting the index table into a large-scale structural data table and querying the state monitoring data according to a query request; and generating basic data and multi-dimensional analytical data by extracting, converting and loading to built a data warehouse, and parallelly executing association rules, classification and clustered data mining algorithm by means of MapReduce task decomposition and result summary. The distributed storage and parallel mining method can be used for effectively realizing distributed data exchange, redundant storage and rapid parallel processing for state monitoring information of the mass electric power equipment in an intelligent power network environment.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Automated warehousing using robotic forklifts

ActiveUS8965561B2Low costReduce rateDigital data processing detailsLifting devicesOn boardEngineering

A system for automated inventory management and material handling removes the requirement to operate fully automatically or all-manual using conventional vertical storage and retrieval (S&R) machines. Inventory requests to place palletized material into storage at a specified lot location or retrieve palletized material from a specified lot are resolved into missions for autonomous fork trucks, equivalent mobile platforms, or manual fork truck drivers (and their equipment) that are autonomously or manually executed to effect the request. Automated trucks plan their own movements to execute the mission over the warehouse aisles or roadways sharing this space with manually driven trucks. Automated units drive to planned speed limits, manage their loads (stability control), stop, go, and merge at intersections according human driving rules, use on-board sensors to identify static and dynamic obstacles, and human traffic, and either avoid them or stop until potential collision risk is removed.

Owner:CYBERNET SYST

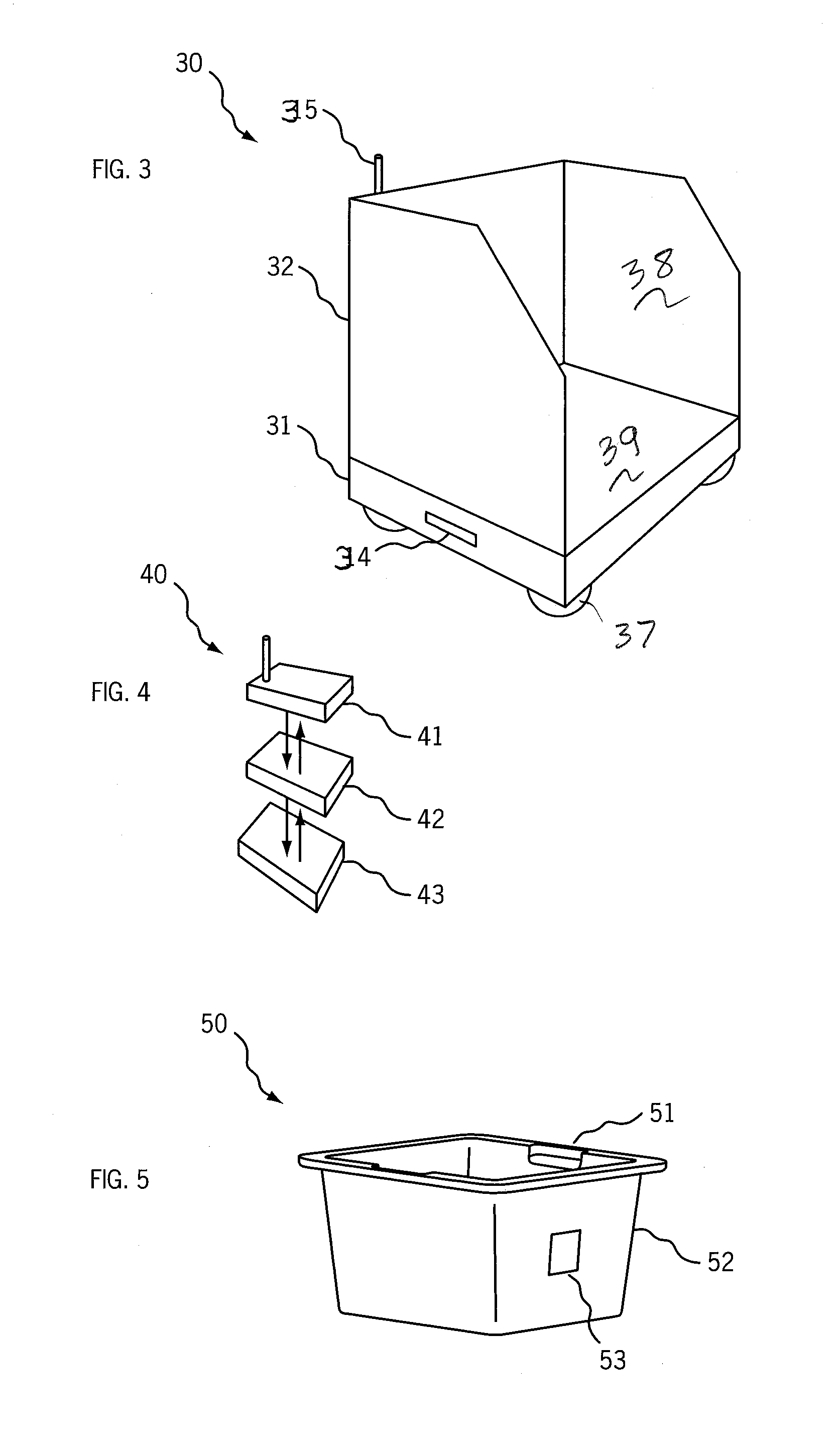

Robotic manipulator for warehouses

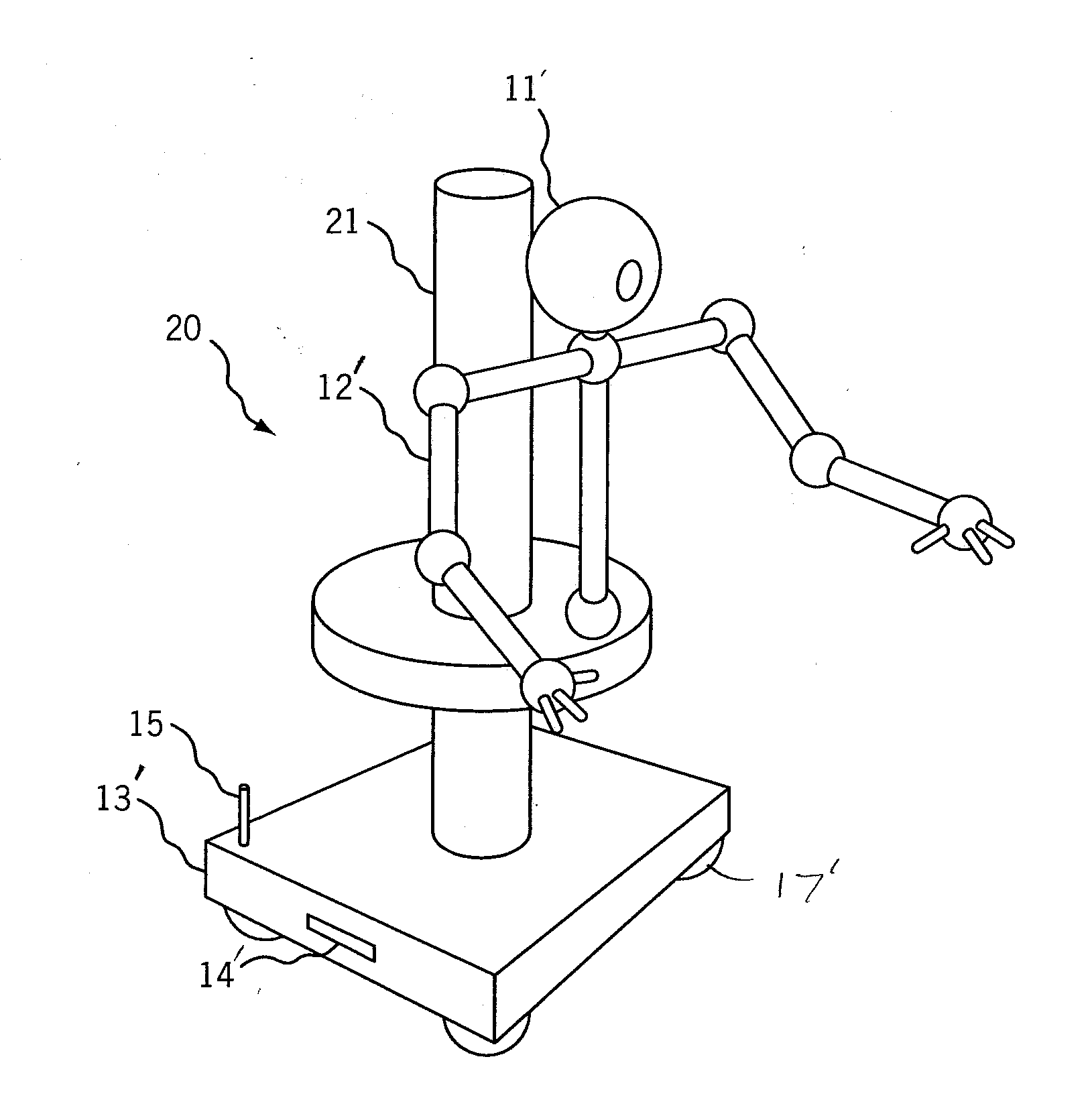

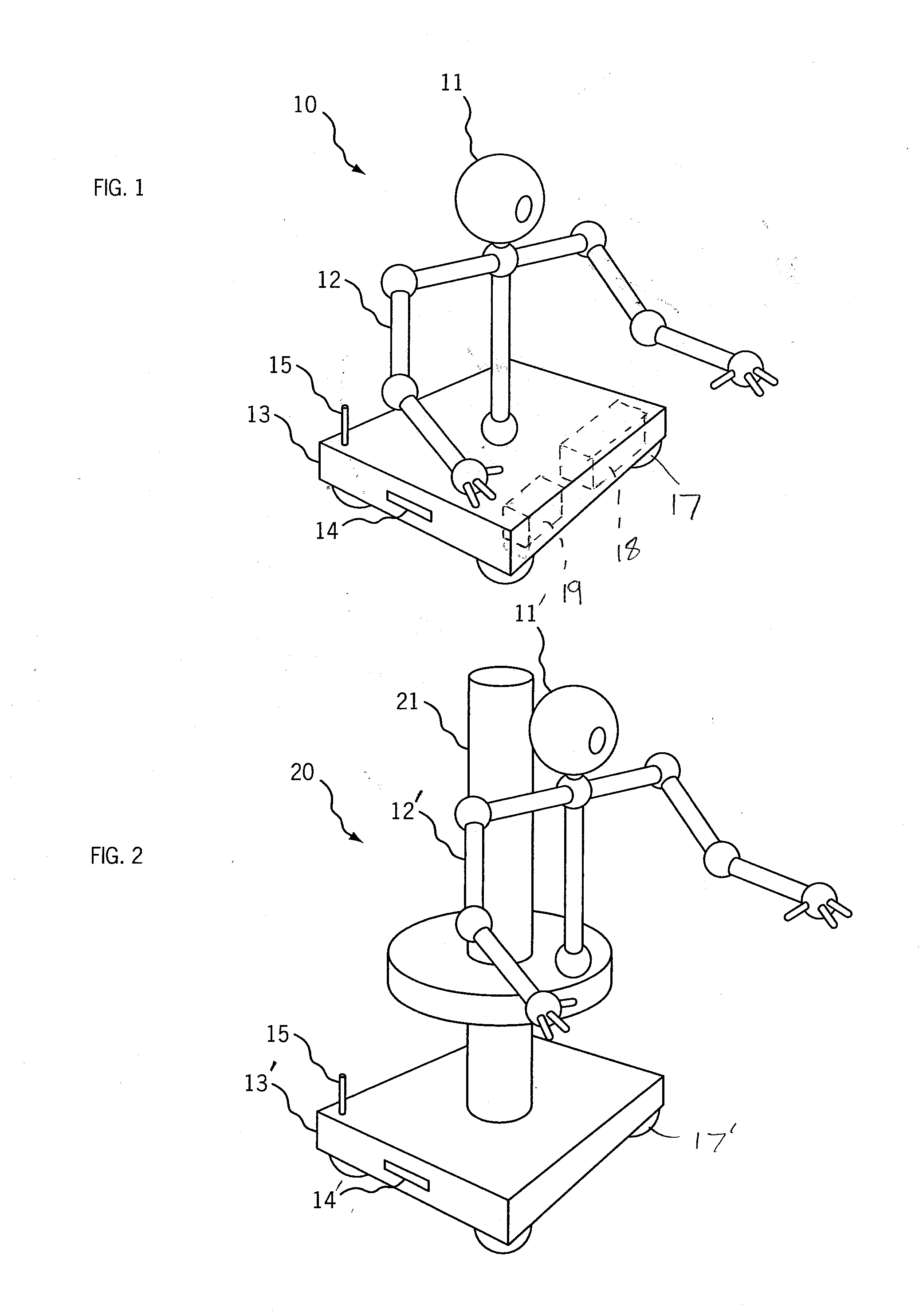

InactiveUS20150360865A1Programme-controlled manipulatorStorage devicesRobotic systemsCommunications system

A warehouse robotic system includes a picker robot, including a mobile base, an environment sensing system, a communications system and at least one manipulator. The picker robot can also include an object sensing system. The robotic system also includes a control system, including a communications system and a robot controller which communicates with the picker robot and is connected to an associated warehouse inventory system. The picker robot is adapted to maneuver to a first location, retrieve at least one associated object from the first location, transport the at least one associated object to a second location and place the at least one associated object at the second location. The system can also include a carrier robot and a storage container.

Owner:HDT EXPEDITIONARY SYST

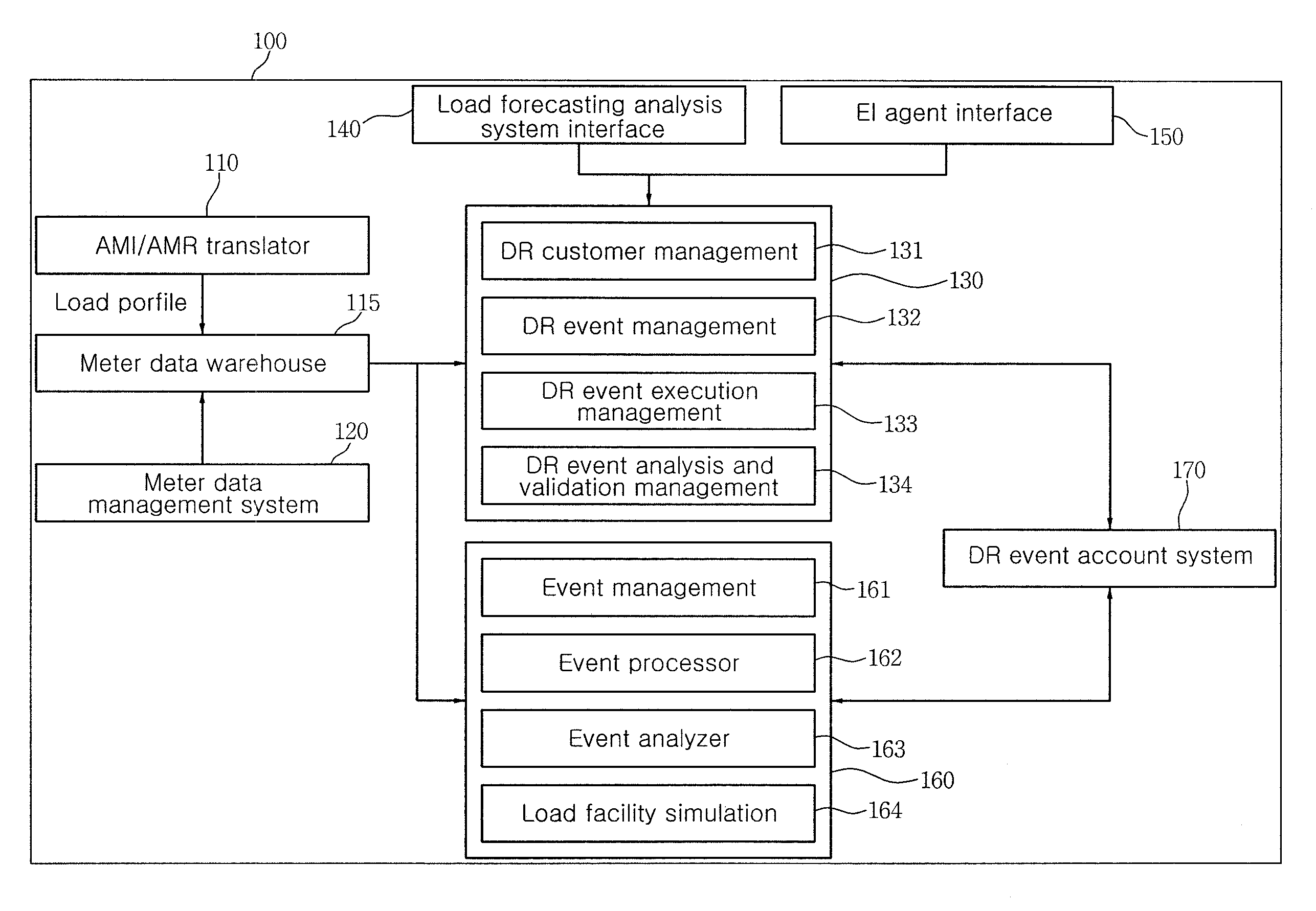

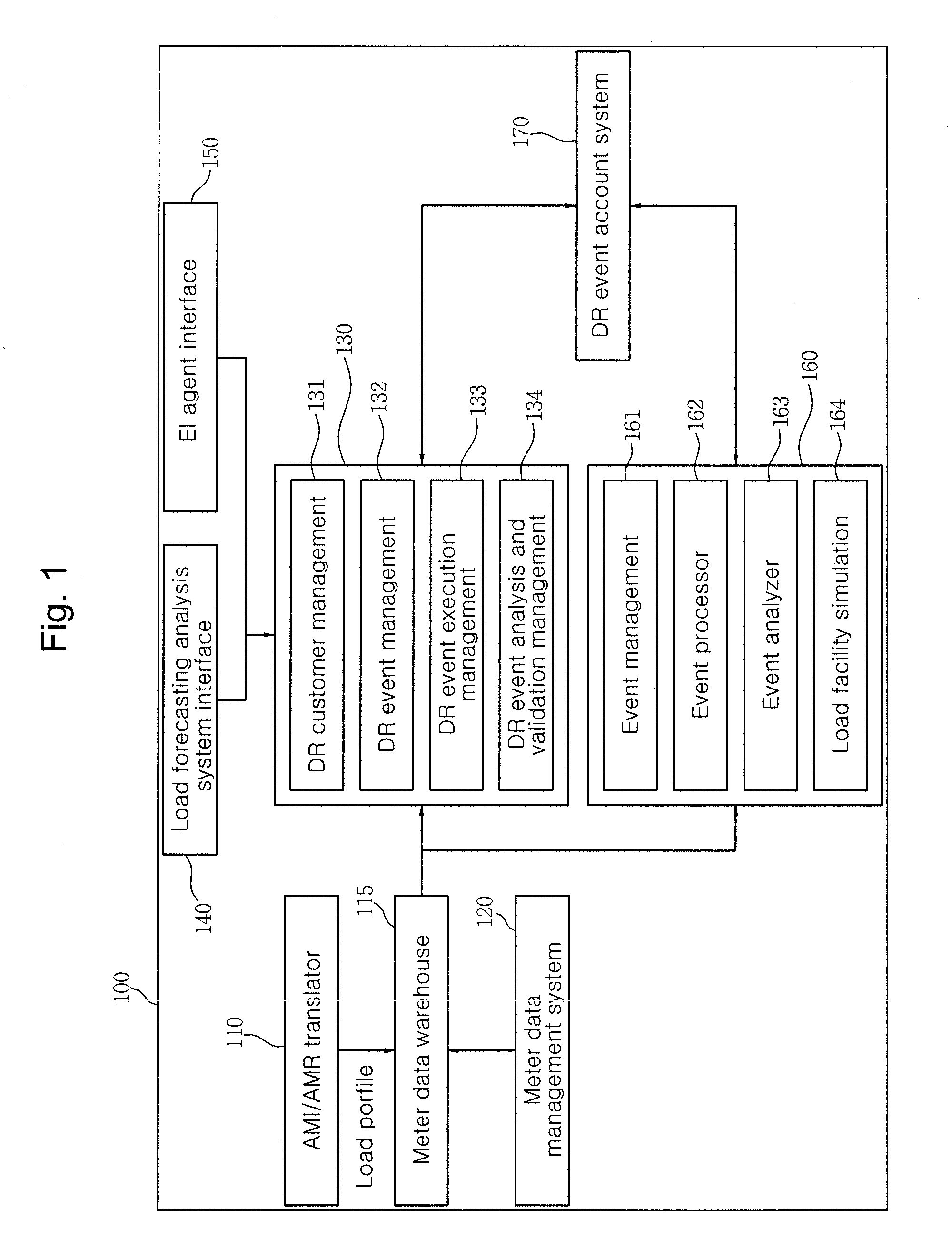

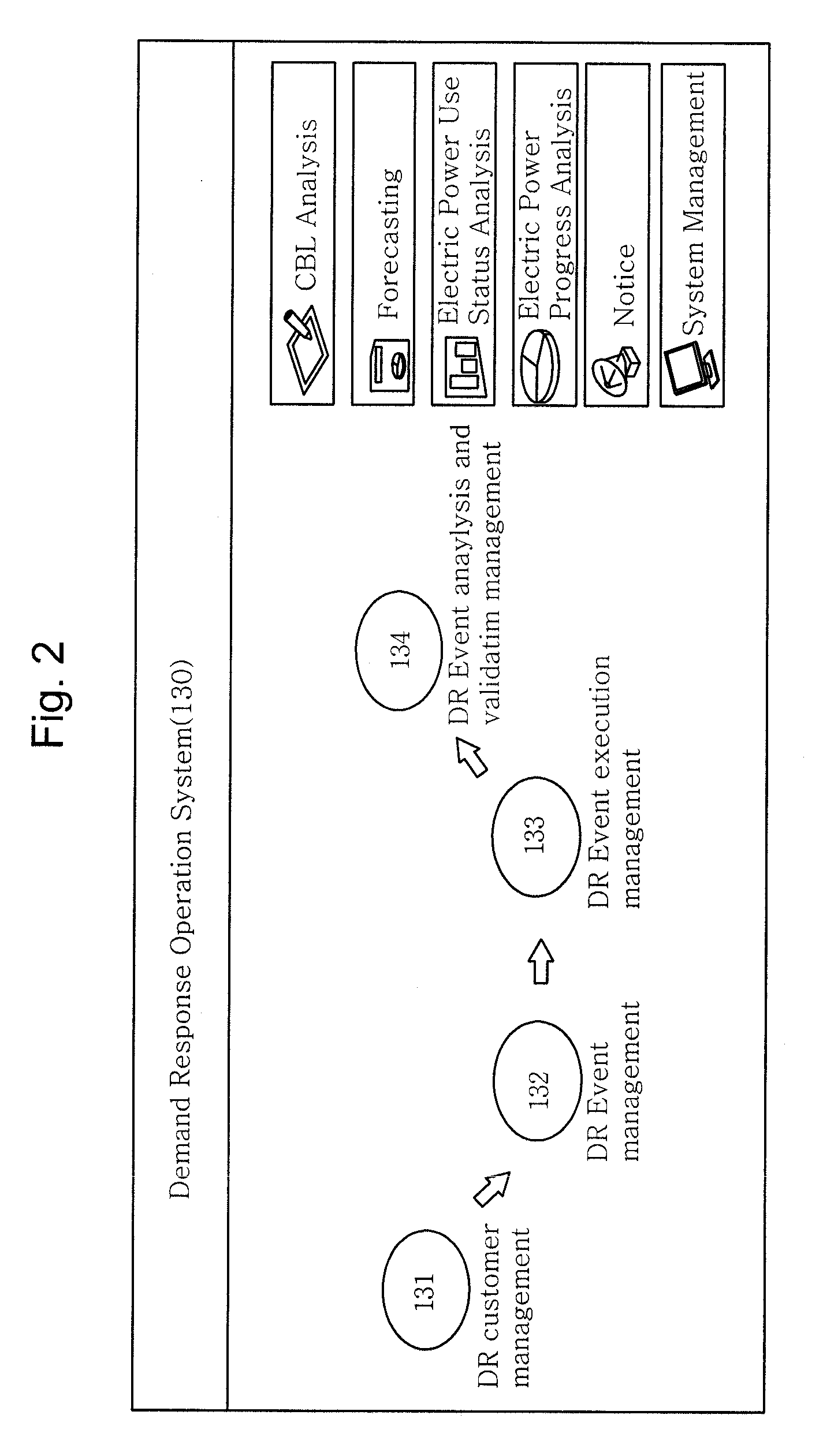

Day-ahead load reduction system based on customer baseline load

InactiveUS20100106342A1Efficient energy consumptionAddress rising pricesLevel controlLoad forecast in ac networkOperational systemData warehouse

Provided is a day-ahead load reduction system based on a customer baseline load for inducing a user to efficiently manage energy consumption by applying an incentive (user compensation according to load reduction) to achieve load reduction and load decentralization. The day-ahead load reduction system based on a customer baseline load operates in connection with a provider terminal and a user terminal through a network to induce a reduction in the load of a user and includes an AMI / AMR translator collecting load profile data of the user in real time, converting the load profile data and storing the load profile data in a meter data warehouse; a meter data management system monitoring and analyzing the load profile data stored in the meter data warehouse in real time; a demand response operation system managing the demand of the user by using the load profile data and performing overall management, analysis and verification of a day-ahead load reduction event; a customer energy management system operating in connection with the demand response operation system and providing information on the load to the user through the user terminal in real time to allow the user to control the load; and an account system operating in connection with the demand response operation system and the customer energy management system, calculating an incentive for the day-ahead load reduction event and notifying a provider and the user of the incentive through the provider terminal and the user terminal.

Owner:KOREA ELECTRIC POWER CORP

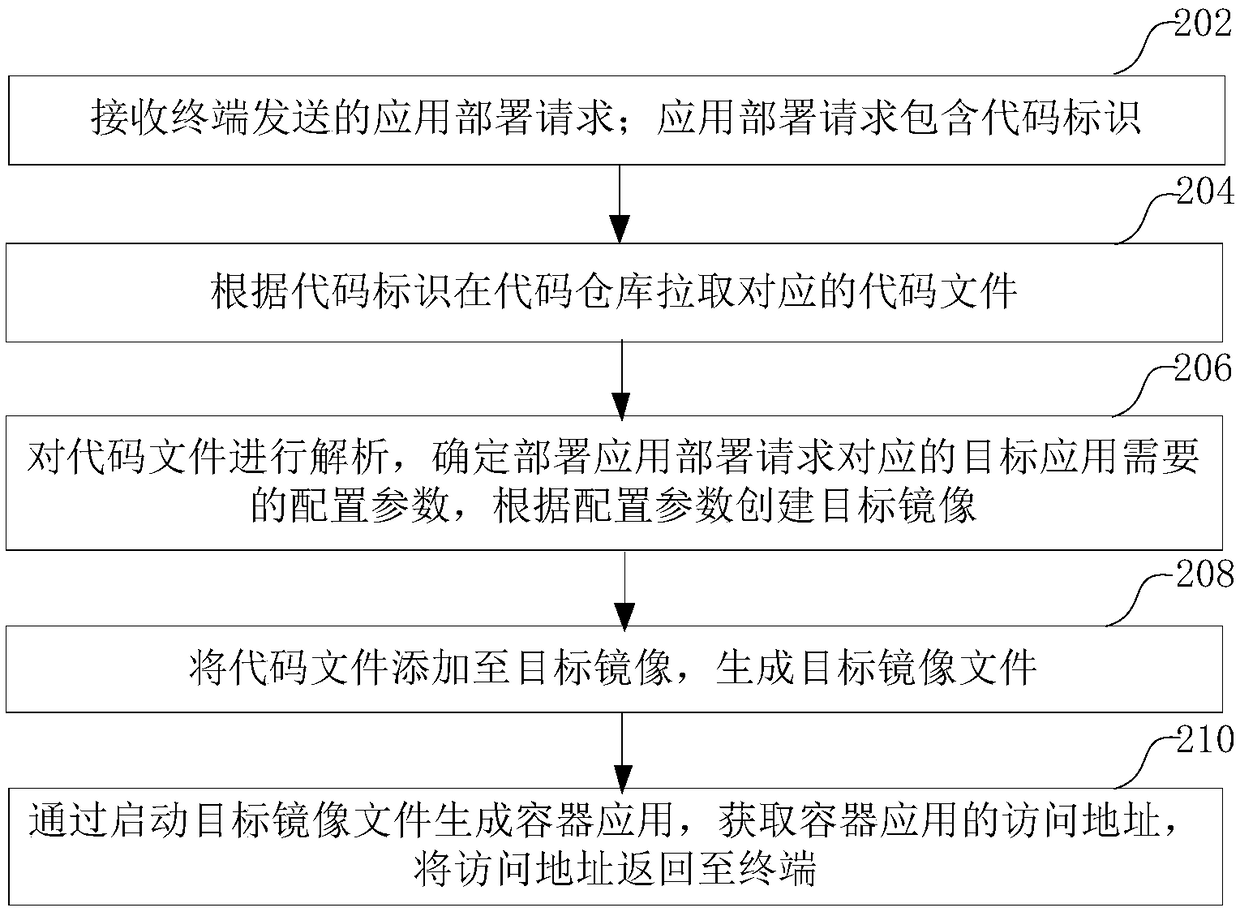

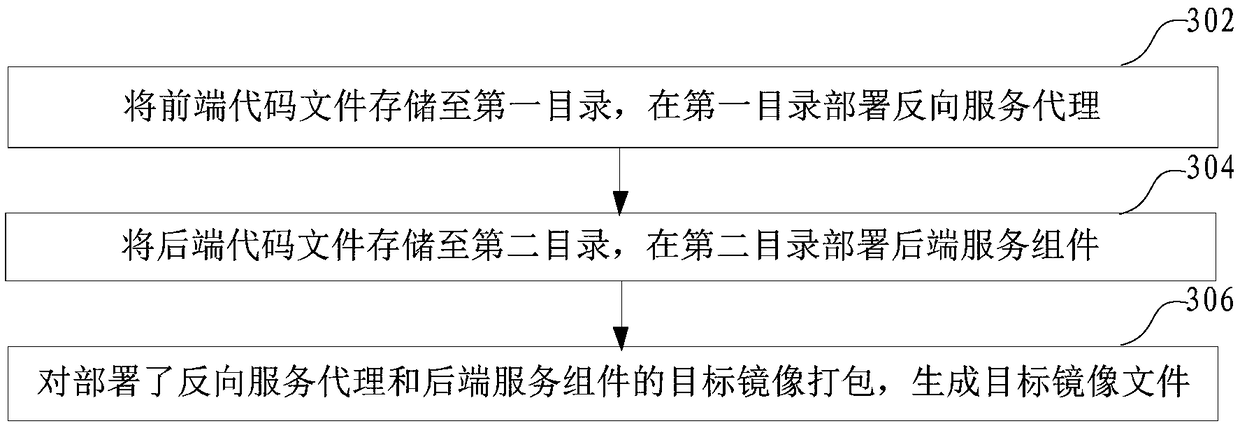

Container application deployment method and device, computer equipment and storage medium

ActiveCN108958927AReduce configuration operationsLower application thresholdResource allocationEnergy efficient computingComputer terminalMirror image

The application relates to a container application deployment method and device, computer equipment and a storage medium. The method includes the following steps: receiving an application deployment request sent by a terminal, wherein the application deployment request includes a code identifier; pulling a corresponding code file in a code repository according to the code identifier; parsing the code file, determining configuration parameters required to deploy a target application corresponding to the application deployment request, and creating a target mirror image according to the configuration parameters; adding the code file to the target mirror image to generate a target mirror image file; and starting the target mirror image file to generate a container application, acquiring an access address of the container application, and returning the access address to the terminal. By adopting the method, the deployment threshold of the container application can be lowered, and the deployment efficiency of the container application can be improved.

Owner:KANG JIAN INFORMATION TECH (SHENZHEN) CO LTD

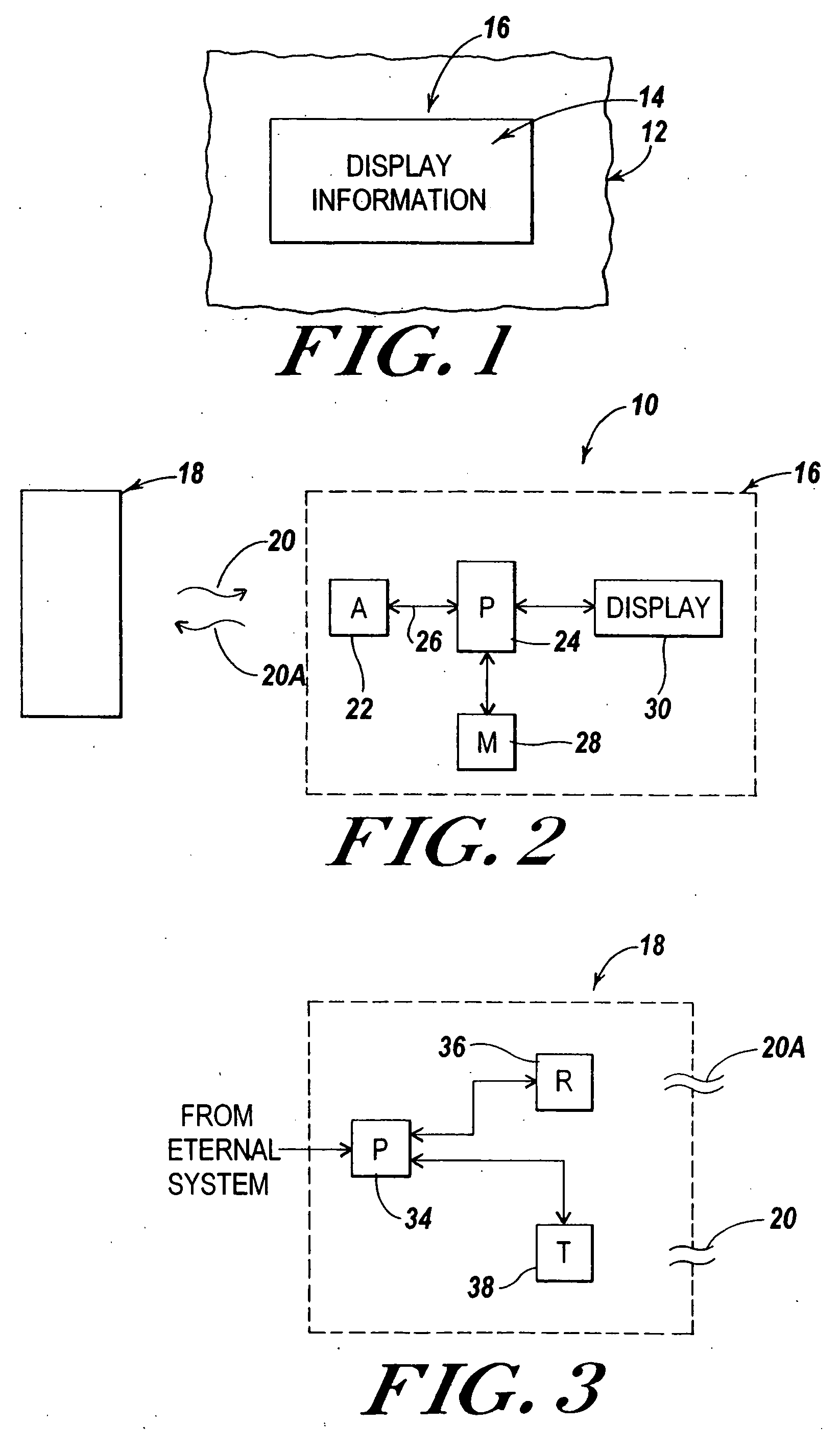

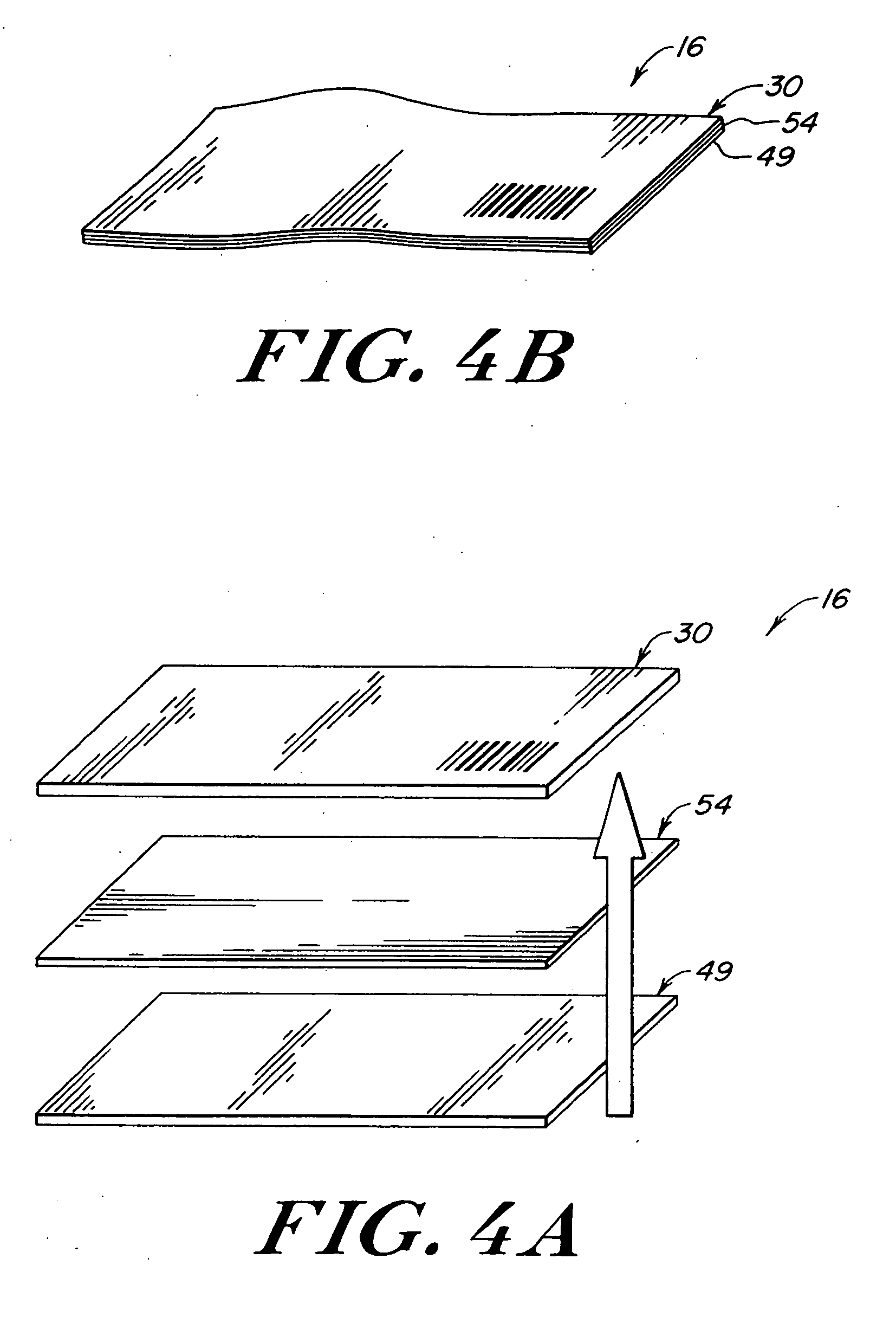

Smart electronic label employing electronic ink

The present invention provides for smart and dumb implementations of a standalone, remotely updateable, remotely alterable, flexible electronic label. The electronic label provides for displaying information, such as prices, bar codes, advertising messages and restocking information, in connection with a mammal, non-mammal, an item or location. The flexibility and form factor of the electronic label allow the label to fit into and conform to the shape of the molding used in retail store shelving to display merchandize and warehouse shelving. The label can be of various sizes, shapes and lengths to allow for multiple applications. The flexible, thin label includes a flexible display assembly having electronic ink disposed on a support, one or more antennas for sending or receiving signals corresponding to one of instructions, programs, data or selected indicia to be displayed by said display assembly, a storage element in circuit with the antenna for storing the instructions, programs, data and indicia, and one or more processors for intelligently determining the indicia to be displayed by the display assembly, for controlling and coordinating operation of the label, and for generating output signals for instructing the display assembly to display the indicia.

Owner:METROLOGIC INSTR

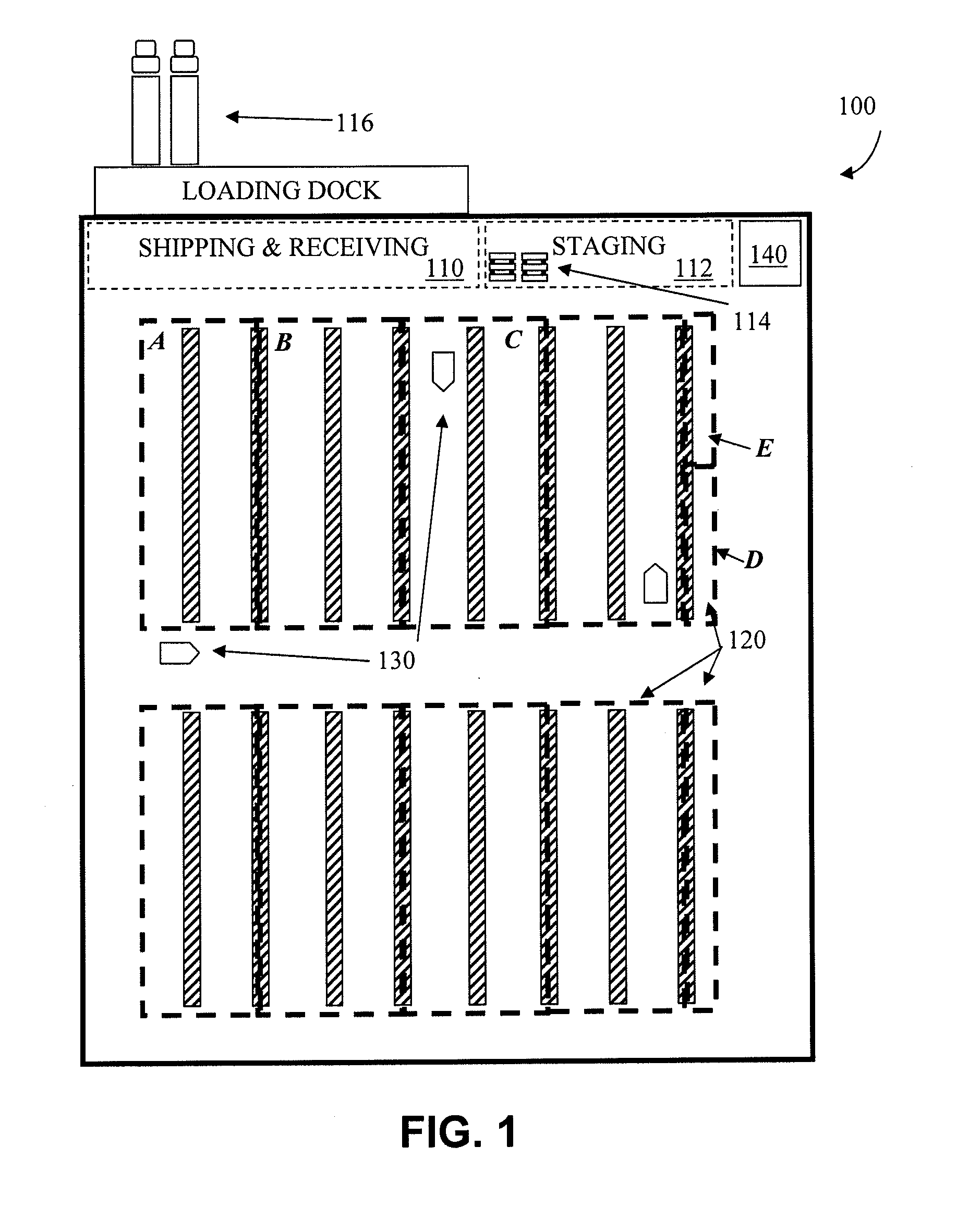

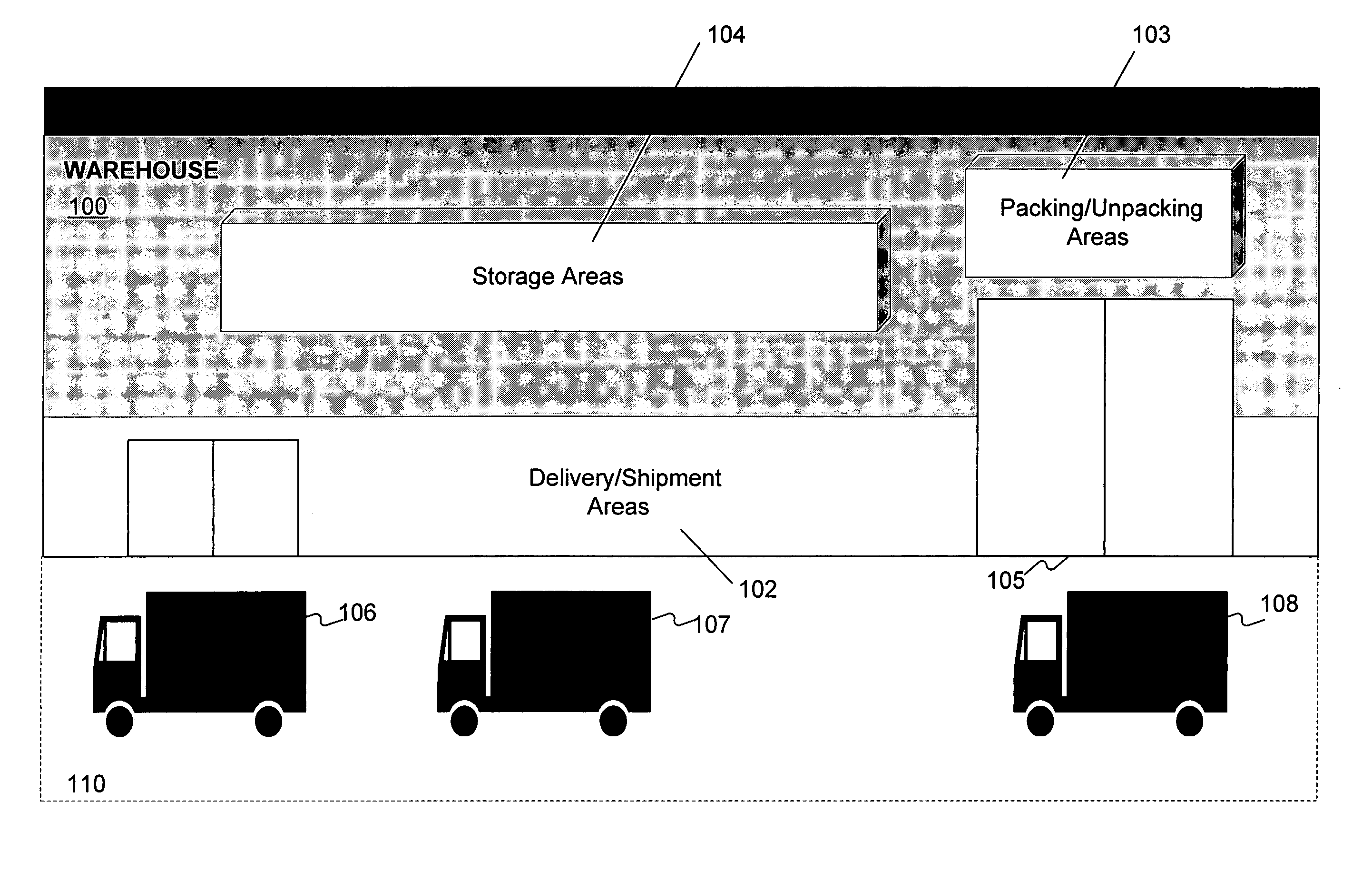

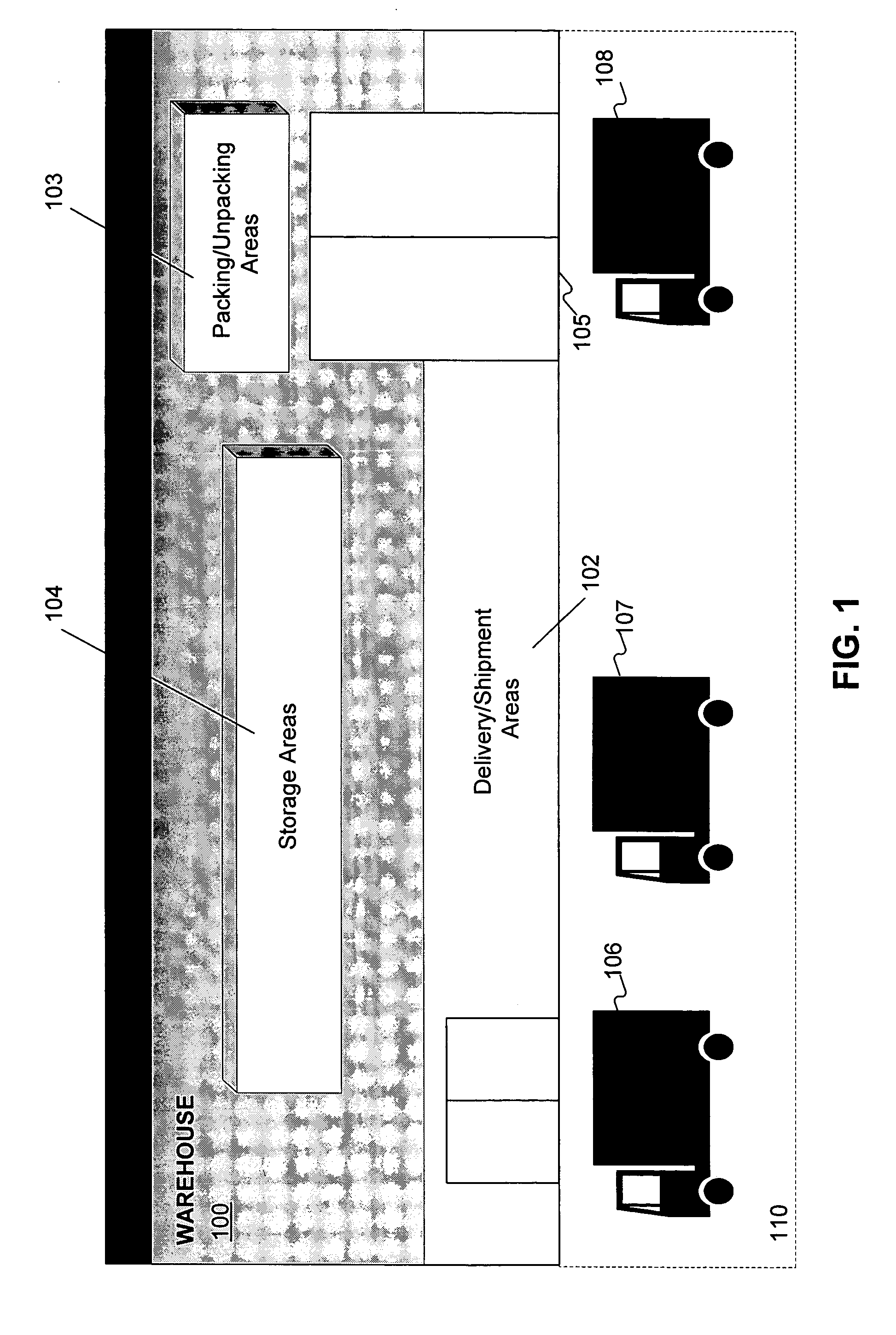

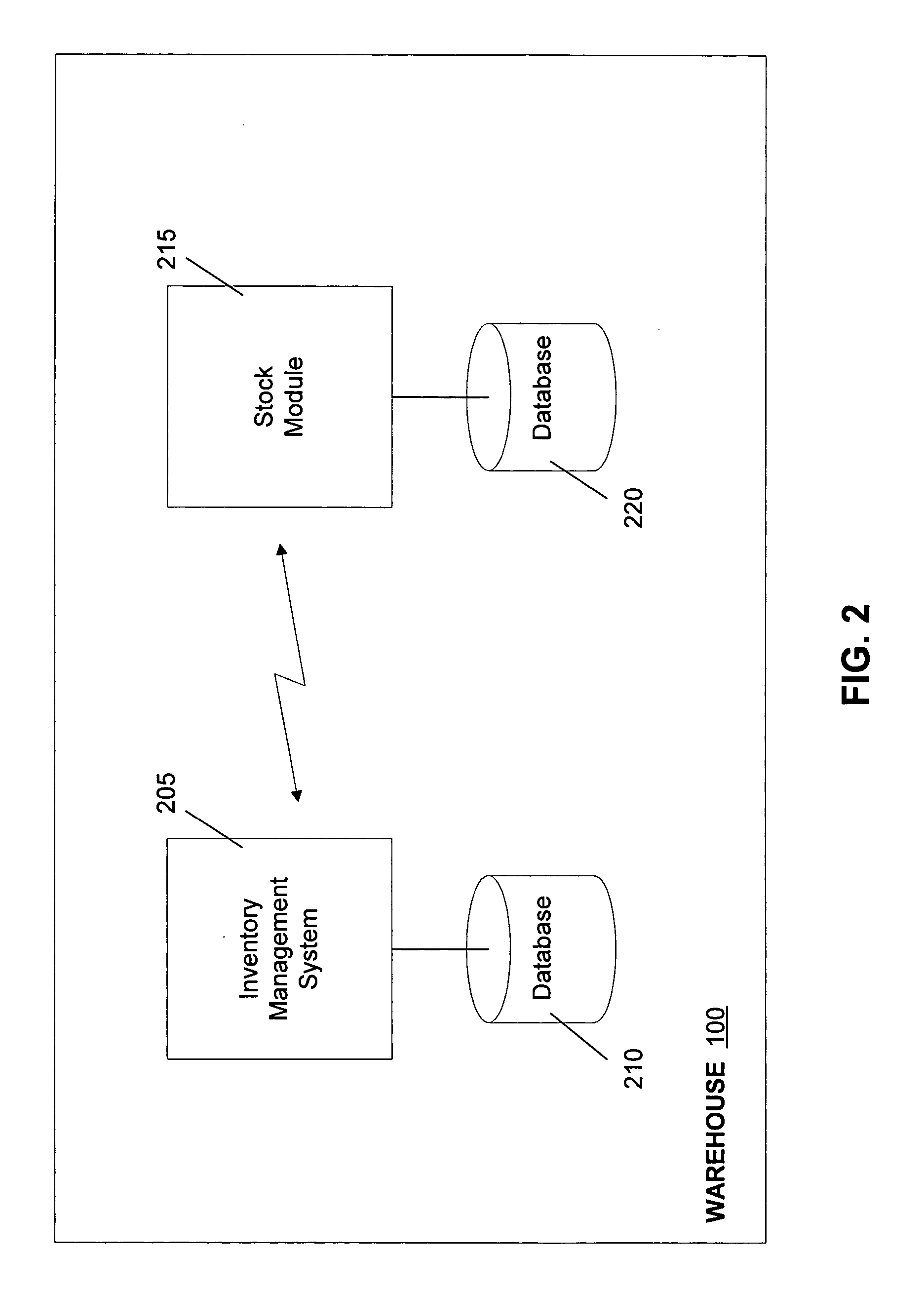

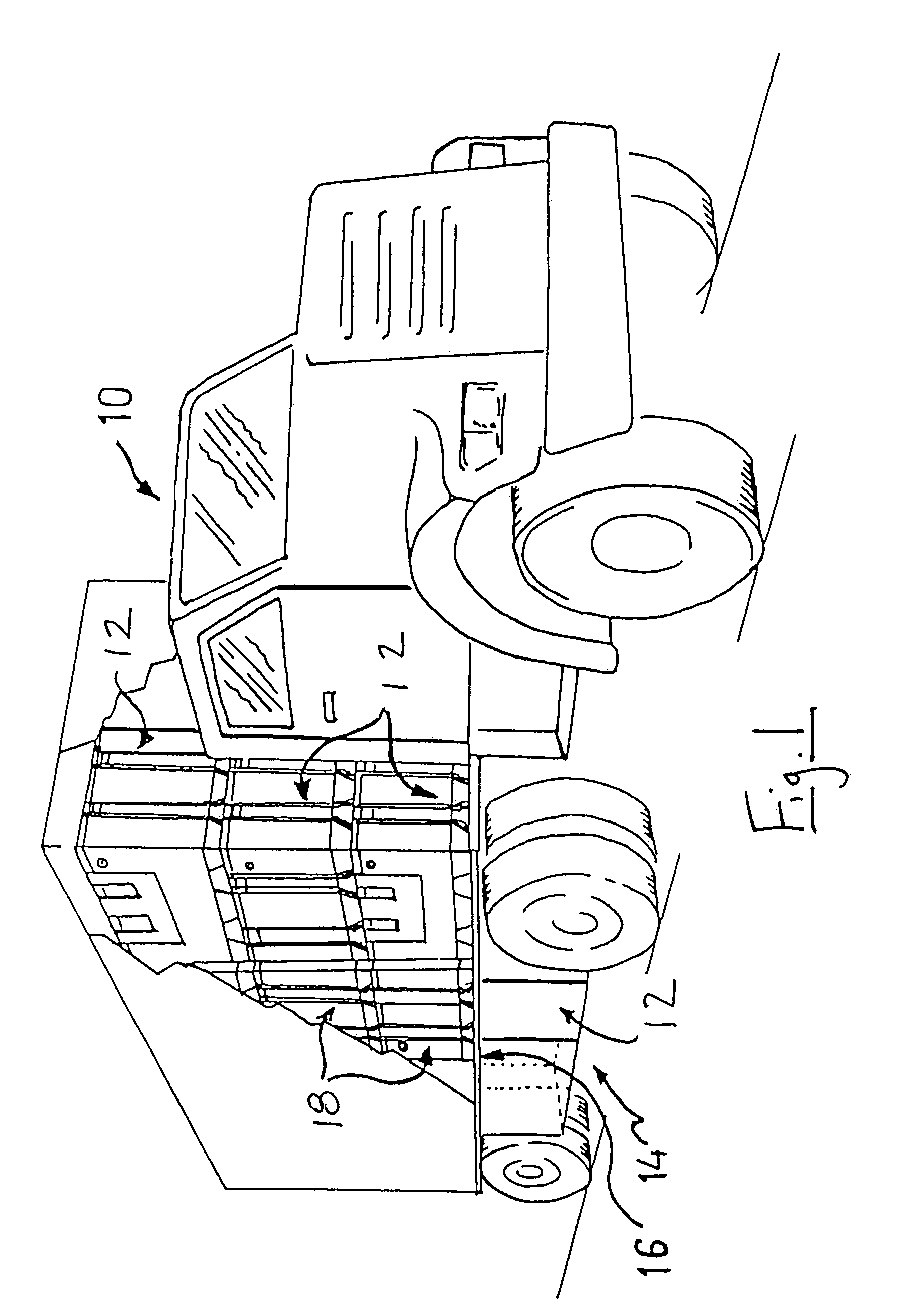

Methods and systems for managing stock transportation

ActiveUS20050289020A1Electric signal transmission systemsTicket-issuing apparatusVisibilityStorage garage

Systems and methods are disclosed for providing stock visibility during transportation of stock from between storage facilities. Such systems and methods can provide information identifying the location of stock while it is being transported to a new location and can provide the ability to alter the destination of stock while it is in transit to a new location. Upon the removal of stock from a warehouse, an inventory management system may be updated to indicate a transport unit of a vehicle that is being used to move the stock and, thus, provide visibility of the stock while it is in transit. In addition, through identification of the transport unit moving the stock to a new location, the vehicle transporting the stock may be rerouted to transfer the stock to an alternate location.

Owner:SAP AG

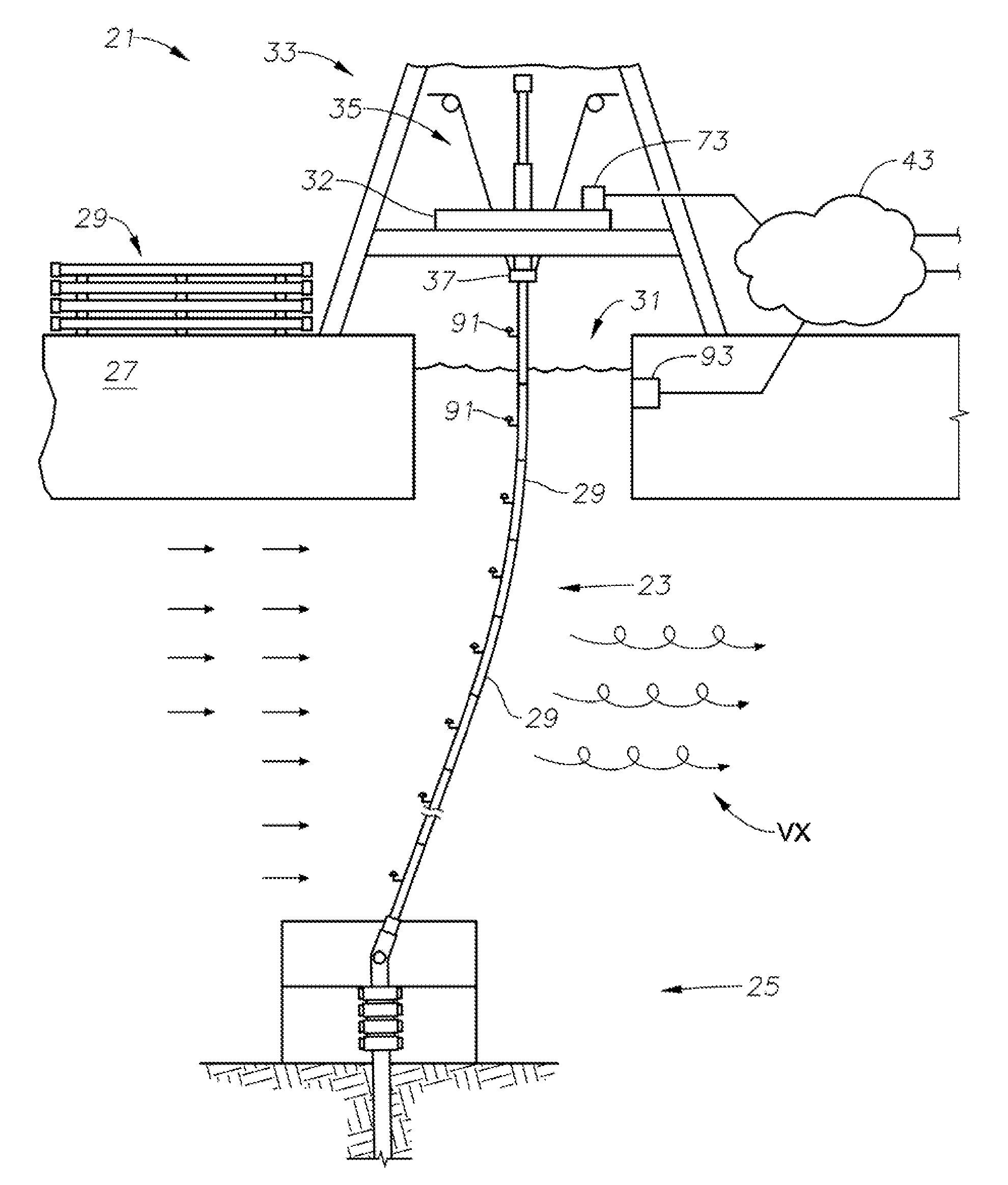

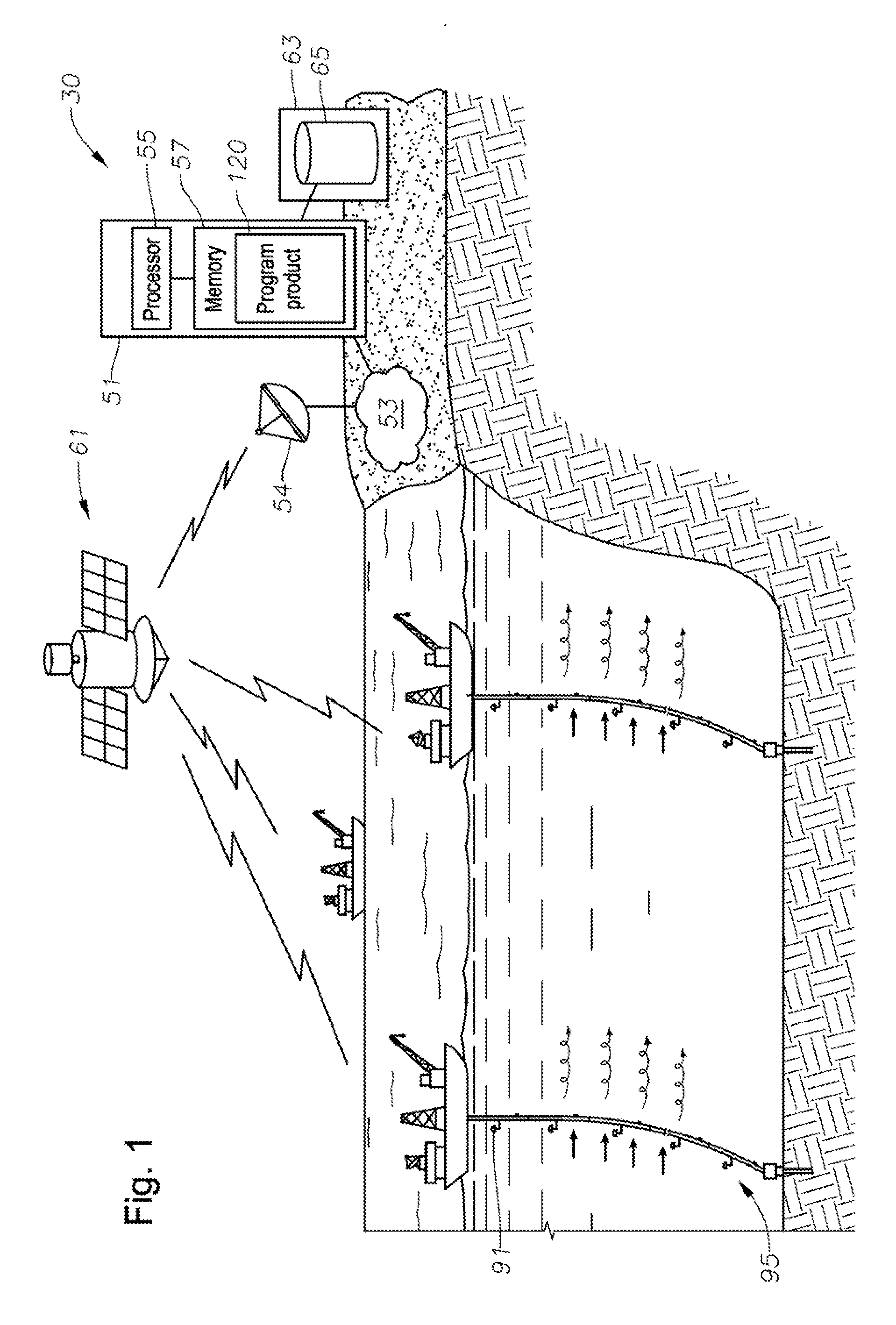

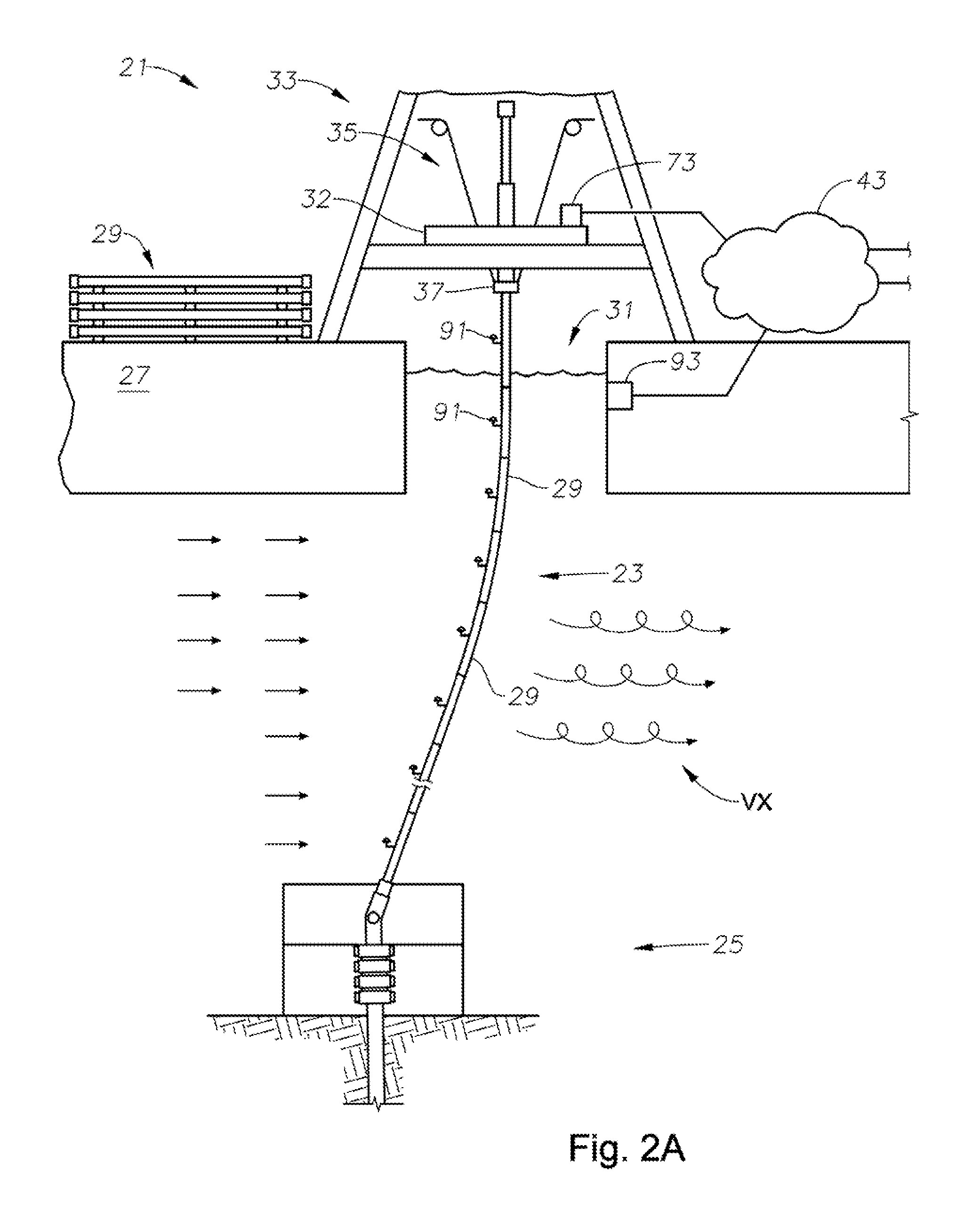

Riser lifecycle management system, program product, and related methods

ActiveUS20080128138A1Easy for daily maintenanceTechnology managementSensing record carriersData warehouseSystem configuration

Owner:HYDRIL USA DISTRIBUTION LLC

Method and apparatus for monitoring the flow of items through a store or warehouse

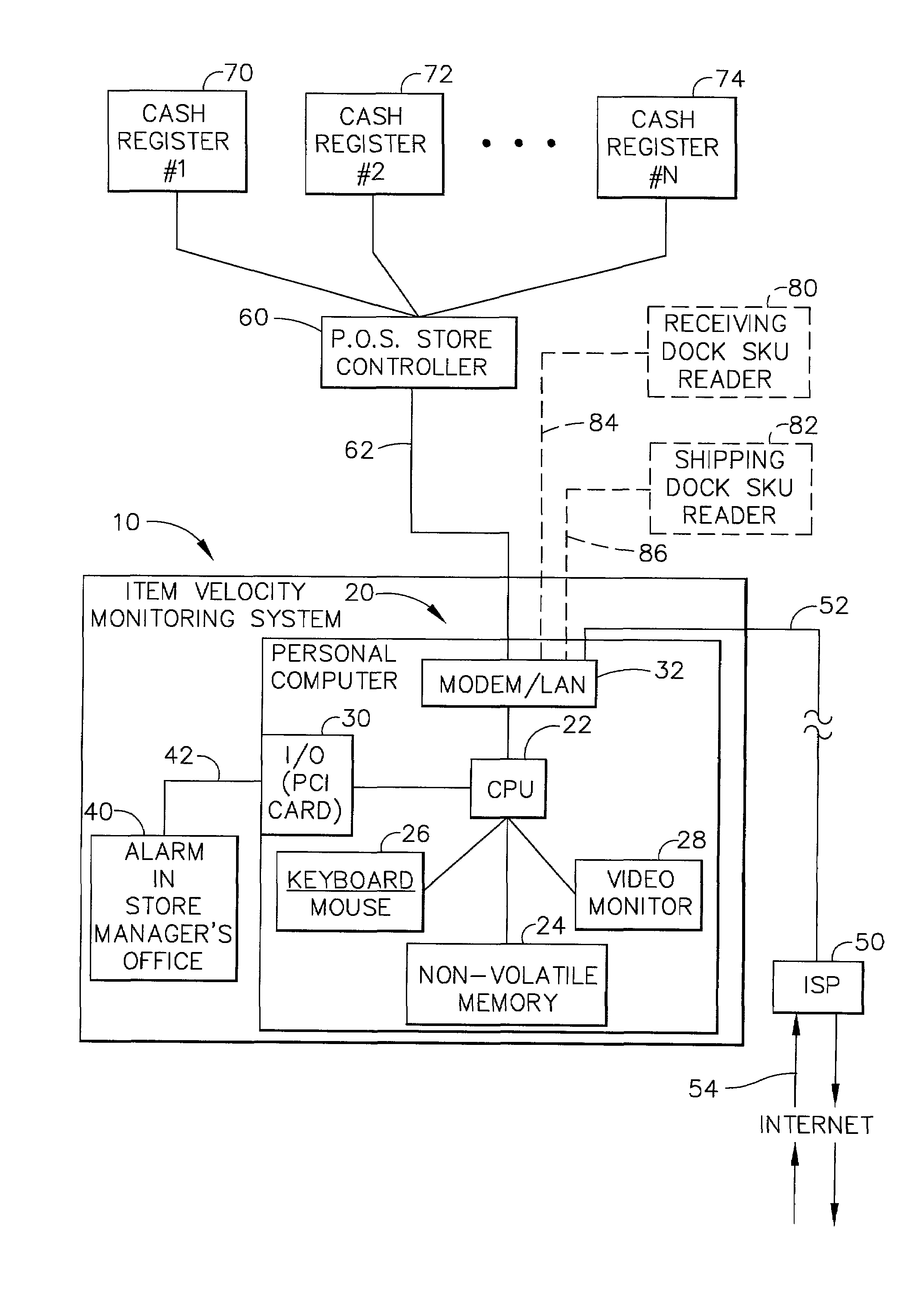

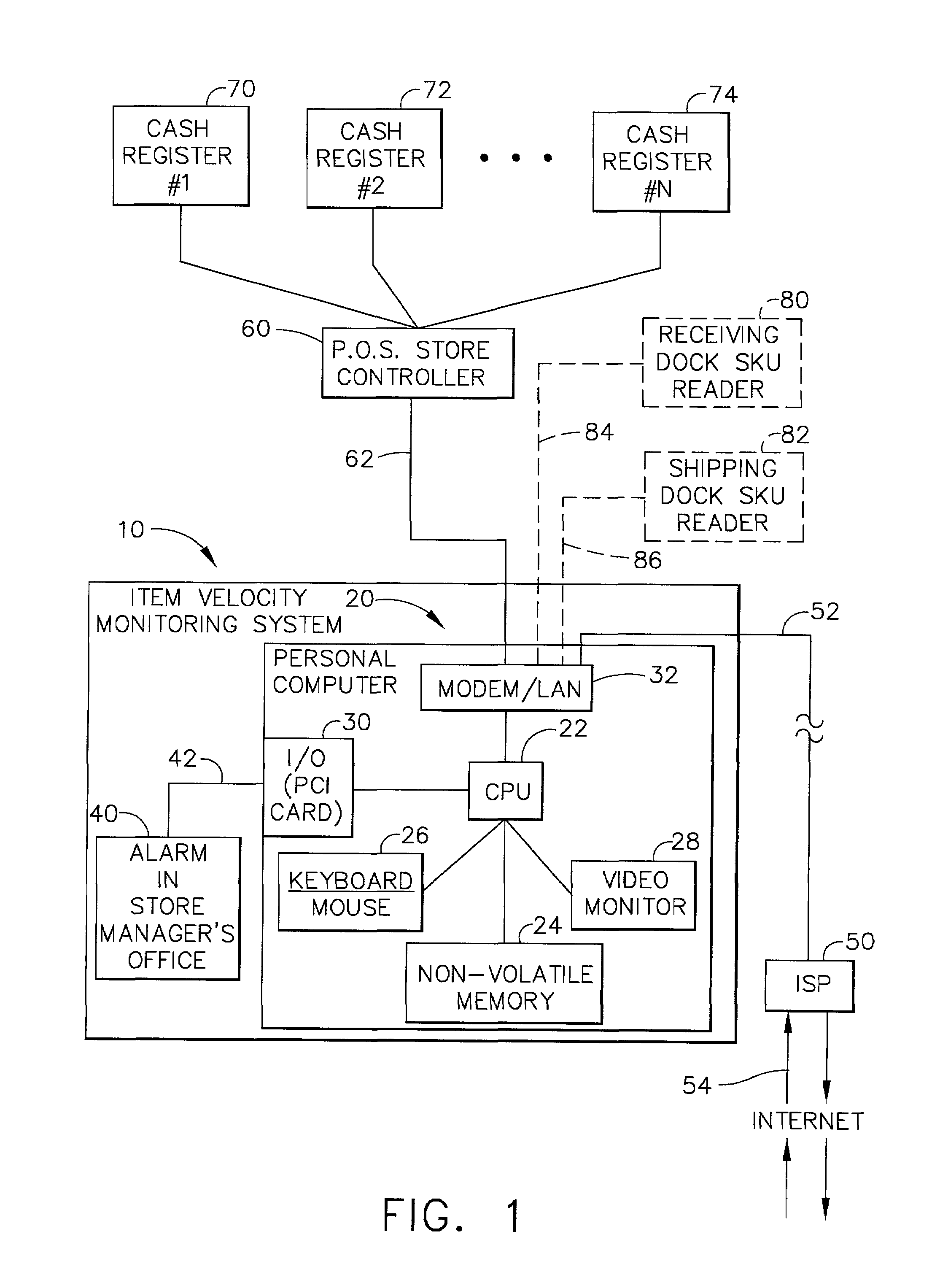

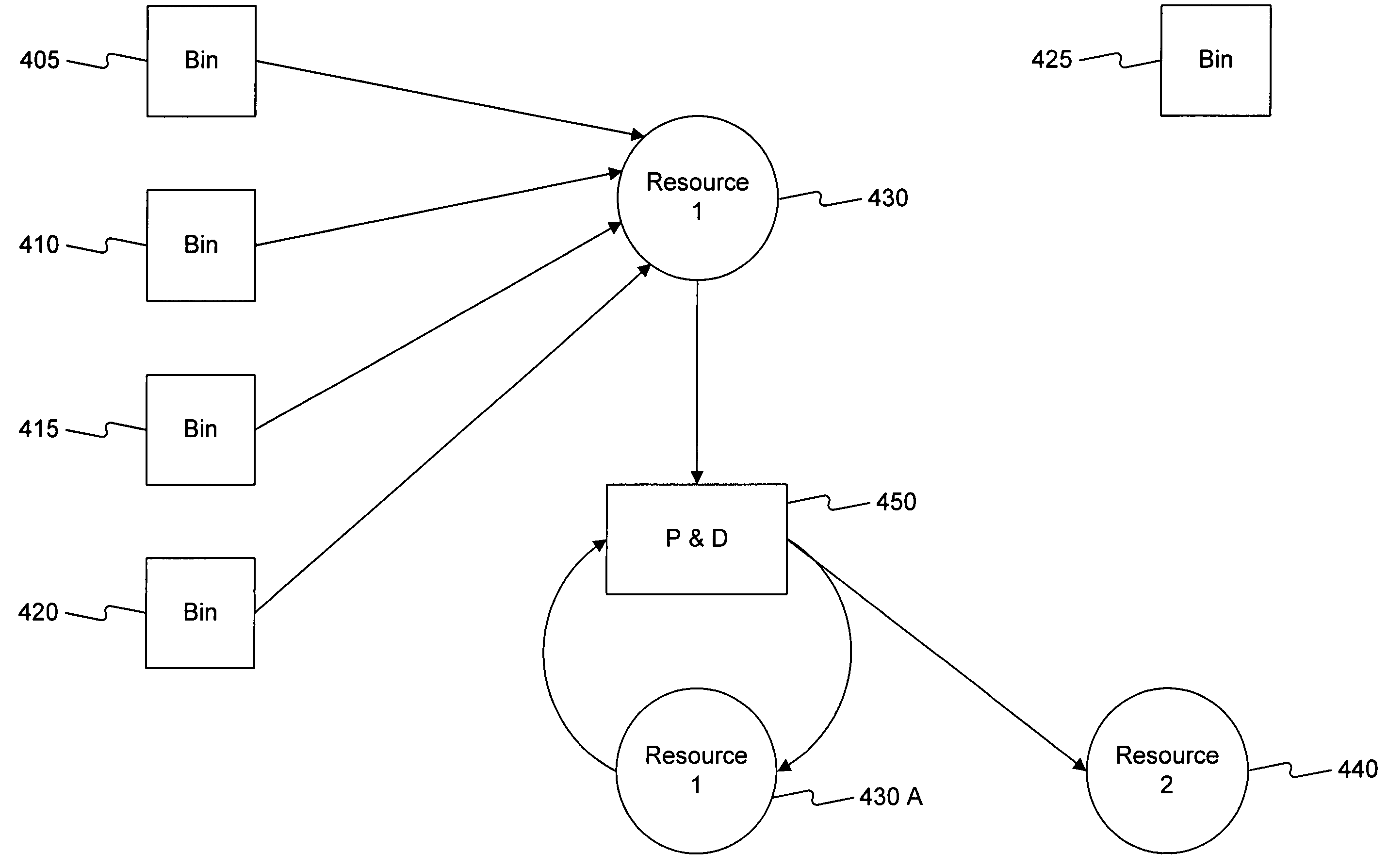

InactiveUS7240027B2Automatic detectionCoin-freed apparatus detailsCash registersThe InternetOperation mode

An item velocity monitoring system is provided which interfaces with a consumer retail store that has several cash registers that are tied into a “point of sale” store controller. The item velocity monitoring system is capable of detecting when sales (or other movement activities) of an item are occurring too quickly, or too slowly. The item velocity monitoring system is first “trained” in a learning mode of operations, during which item patterns and group patterns are evaluated and placed into a pattern database. The system then compares the observed item velocity to its model probability velocity, and if the observed item velocity deviates beyond the statistical model, a “velocity event” is generated, declaring one of the above selling “too quick” or “too slow” conditions. Once a velocity event is detected, an event handling routine displays the event, and can transmit the event information over a network (including the INTERNET) to a remote computer for additional analysis or record keeping. A “Loyalty Out-of-Stock System,” (LOSS) is incorporated in the above item velocity monitoring system which automatically detects when items for sale are out-of-stock (OOS), discovers the reasons for these “stock-outs,” and determines how customers react to these stock-outs. The LOSS operates on store data and models the expected item movement rate for each item under varying time-of-day, day-of-week, price, promotion, season, holiday, and market conditions; detects items that are moving abnormally slowly, thereby identifying items that may be improperly displayed; provides early warning that an item may go out-of-stock (OOS) by detecting items with abnormally high movement; detects and reports on items that are OOS at retail stores; summarizes OOS events for the store and retail chain management, and for suppliers, thereby identifying items that are over-stocked (too few OOS events), under-stocked (too many events), badly re-stocked (too long events); analyzes the OOS events to find patterns that explain why OOS's are occurring; and determines the impacts of these OOS events on store customers, thereby measuring losses to the retailer and supplier, and establishing the loyalty of consumers to the item, brand, and chain.

Owner:DUNNHUMBY LTD

Methods and system for managing stock

ActiveUS20050284934A1Provide visibilityElectric signal transmission systemsTicket-issuing apparatusVisibilityManagement system

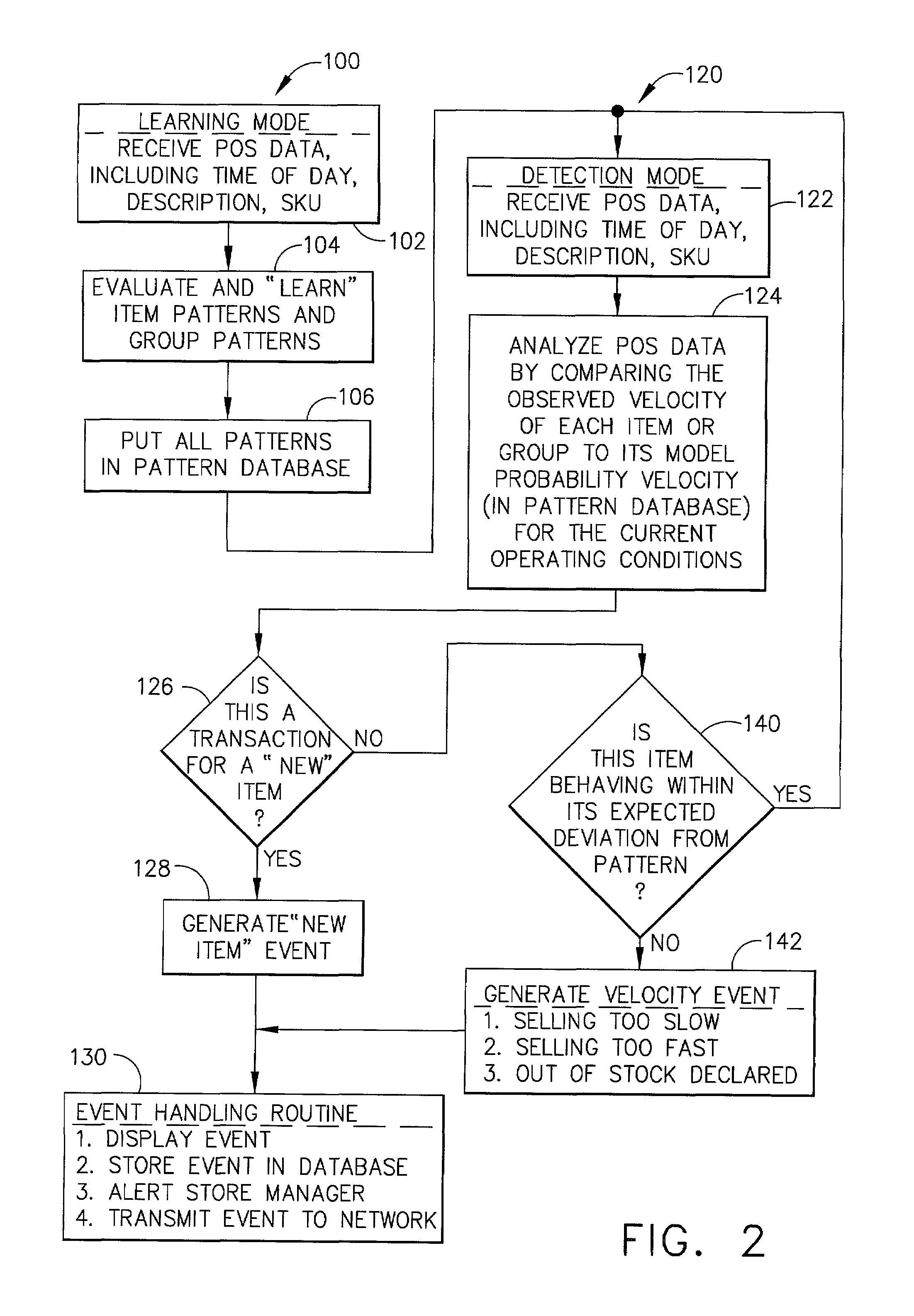

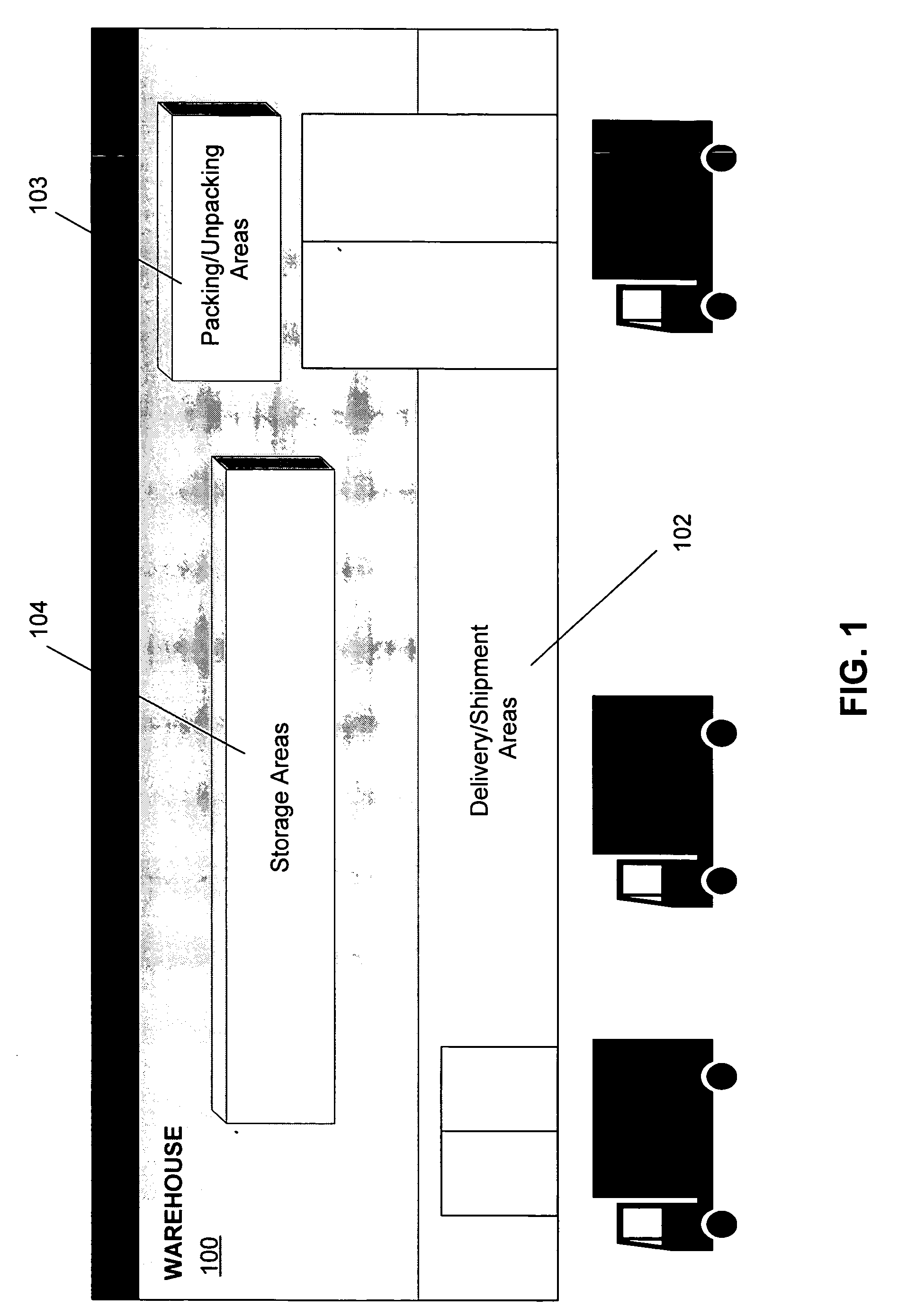

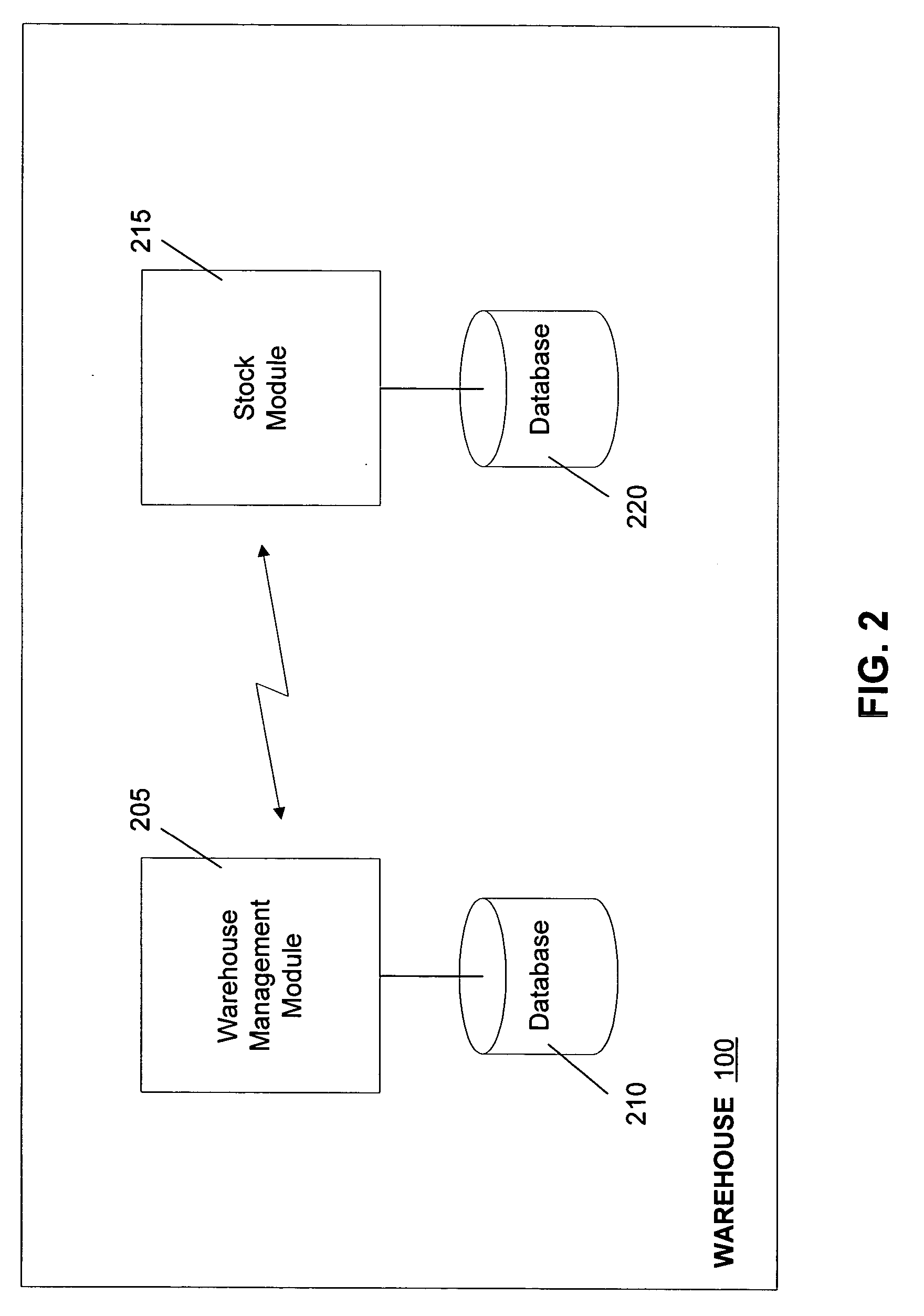

Systems and methods are disclosed for providing stock visibility in a storage facility, such as a warehouse. Such systems and methods may provide information identifying the location of stock while it is being transported to a new location, as well as may provide the ability to alter the destination of stock while it is in transit to a new location. Upon the removal of stock from a bin, a warehouse management system may be updated to indicate a resource that is being used to move the stock and, thus, provide visibility of the stock while it is in transit. In addition, through identification of the resource moving the stock to a new location, the resource can be rerouted to transfer the stock to an alternate location.

Owner:SAP AG

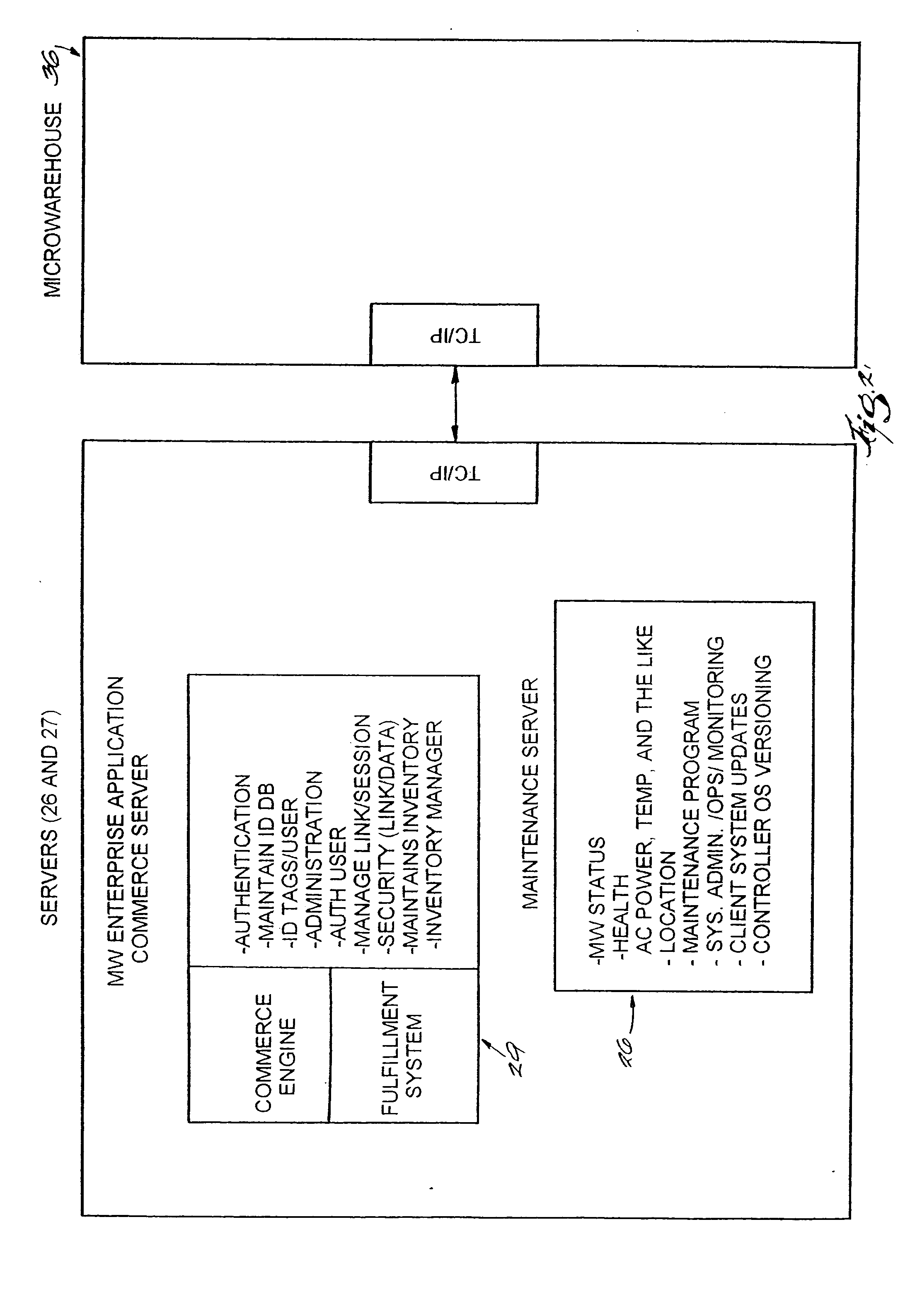

RF point of sale and delivery method and system using communication with remote computer and having features to read a large number of RF tags

InactiveUS20050125312A1Credit registering devices actuationLighting and heating apparatusShadowingsEngineering

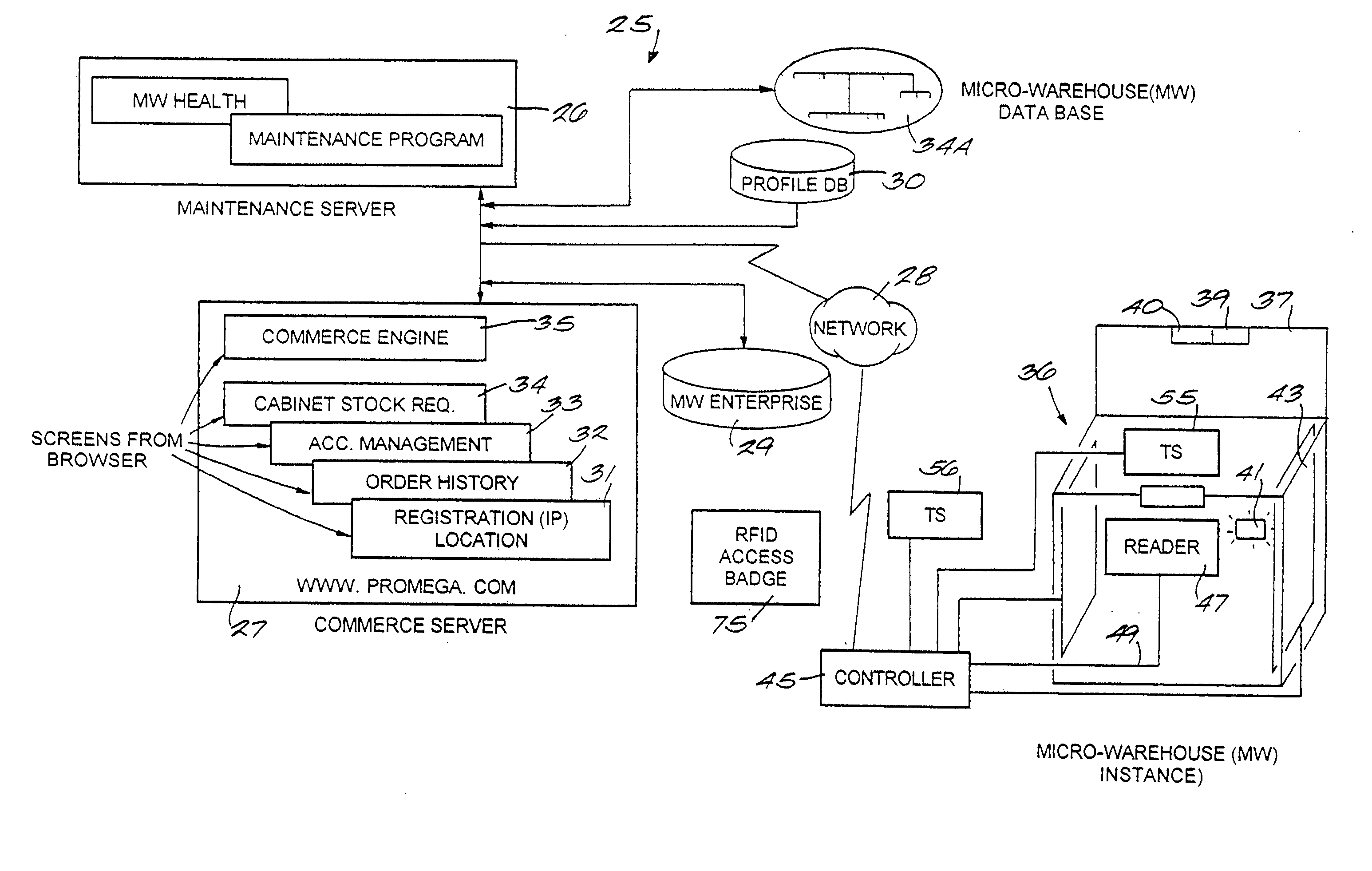

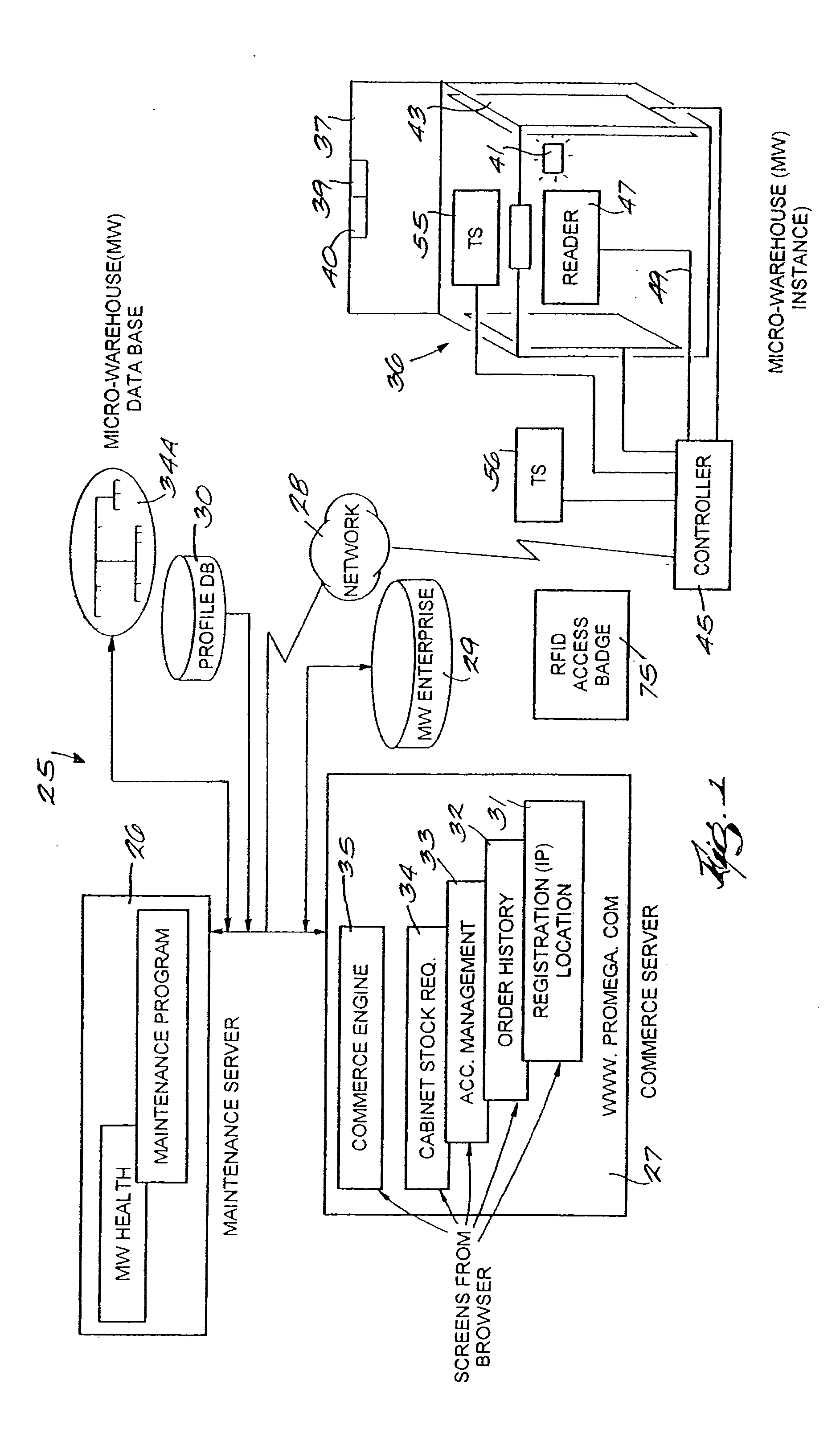

A method and system for providing point-of-sale and point-of-delivery and / or distribution of products in a restricted access unit near the customer. The method and system utilize products equipped with radio frequency tags and reduce the effects of energy sharing, shadowing, and nulls. In one embodiment, a plurality of RF tagged products are placed within a refrigerator, cabinet, or other micro-warehouse that has a door or opening that can detect access to the micro-warehouse. In one embodiment, one or more antennas are positioned within the door. Each antenna may have a transmission line of sight and be configured to emit a signal at predefined frequencies. Each antenna generates an electromagnetic field within the micro-warehouse. In one embodiment, the products are positioned in one or more bins, compartments, or similar devices located within the micro-warehouse such that at least two of the plurality of products are spaced a distance from each other to reduce energy sharing. The electromagnetic field is moved or altered within the micro-warehouse through the use of reflectors, devices that move the antennas, or other mechanisms.

Owner:PROMEGA CORP

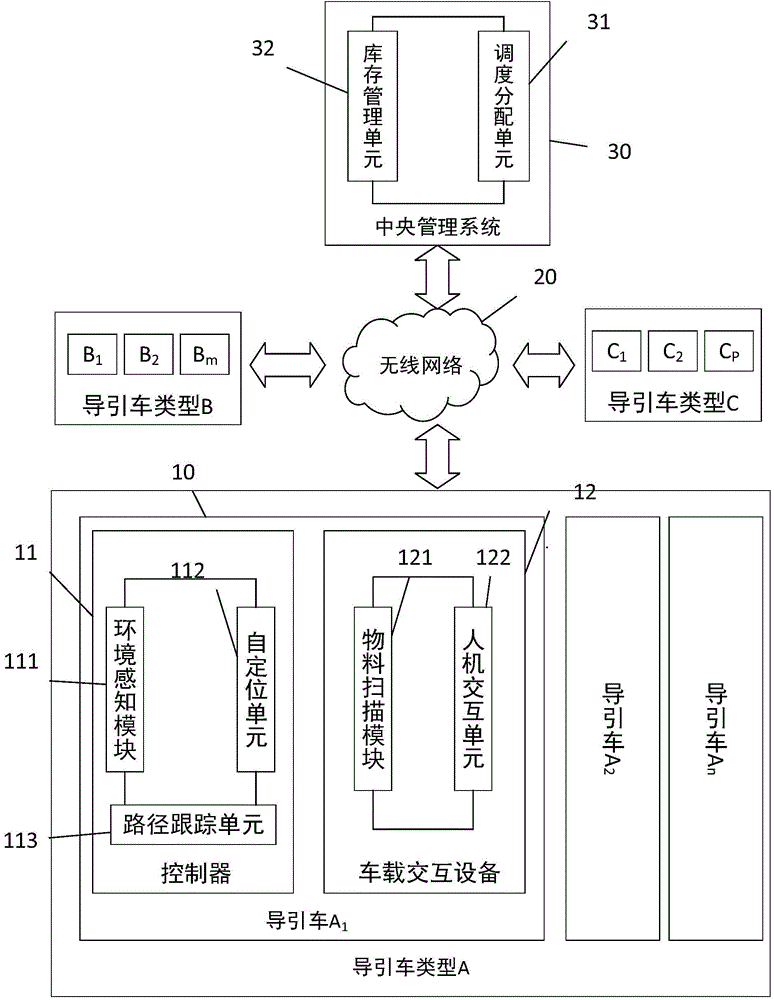

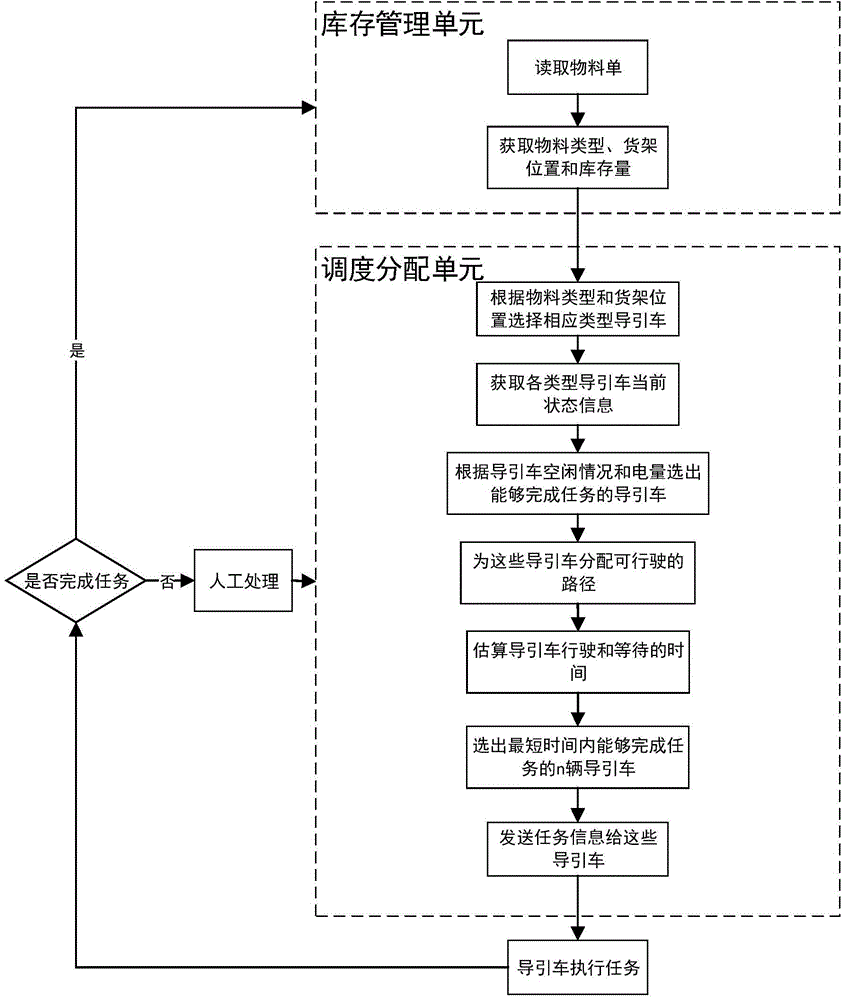

Warehouse management system with multi-guide-vehicle dispatching and distribution function

ActiveCN104809606AEasy way to workIncrease the level of automationLogisticsSelf positioningComputer science

The invention discloses a warehouse management system with a multi-guide-vehicle dispatching and distribution function. The warehouse management system comprises a central management system and guide vehicles. The central management system reads material lists to obtain the inventory and position information of materials, selects appropriate guide vehicle types and number according to task quantity and the material positions, distributes the traveling routes for the guide vehicles, and selects the guide vehicles and distributes material input and output tasks according to the shortest time principle. The guide vehicles travel in a warehouse along the routes distributed by the central management system and have functions of self-positioning and barrier avoiding. The guide vehicles complete material information scanning, map information displaying and task displaying and receiving through vehicular interaction equipment and transmit guide vehicle state information to the central management system. The warehouse management system has the advantages that the guide vehicles are dispatched according to the comprehensive material information and the state information of the guide vehicles, the guide vehicles travel along the distributed routes to target positions to complete material input and output, a traditional warehouse management manner is optimized, and warehouse management efficiency is increased.

Owner:SHANGHAI JIAO TONG UNIV

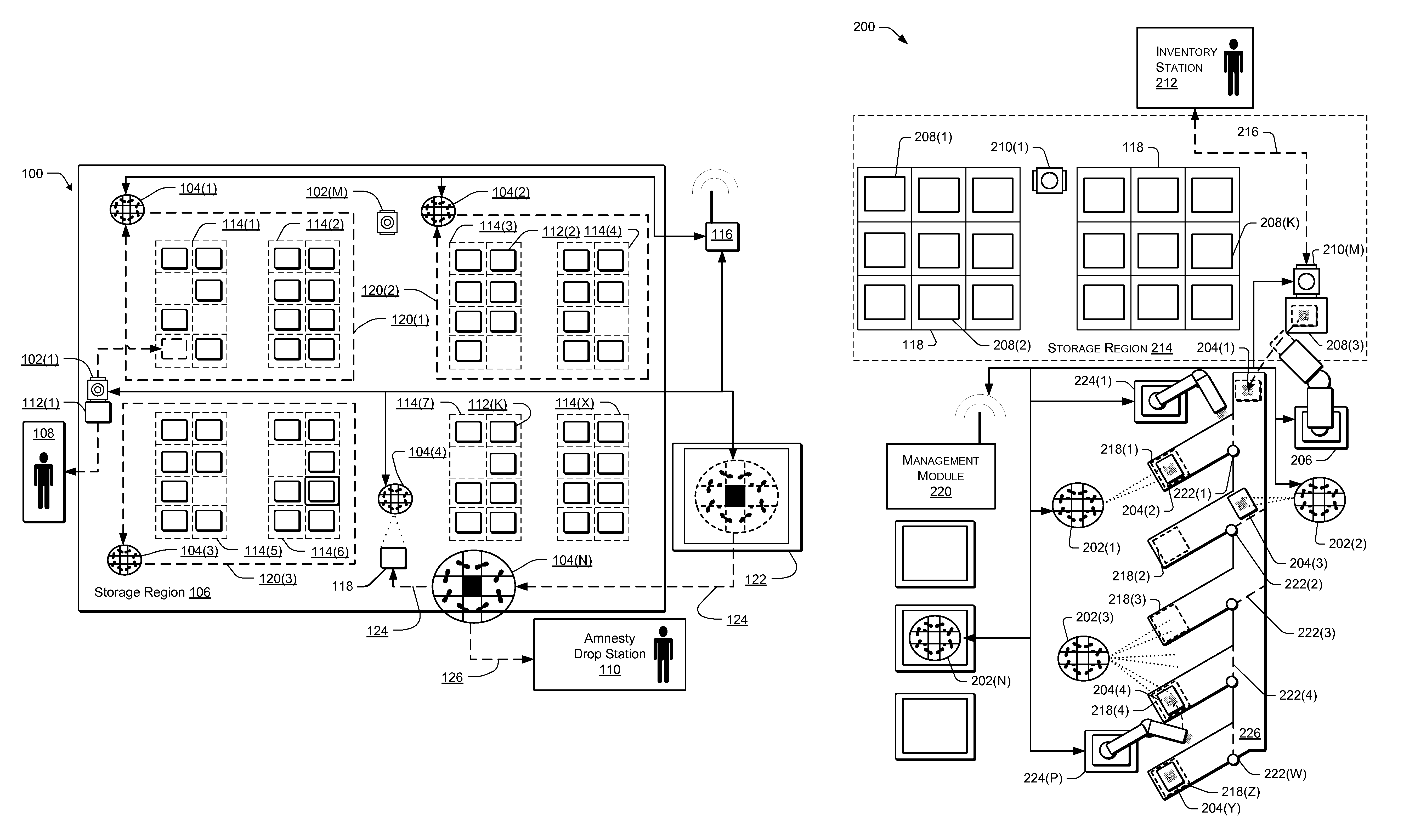

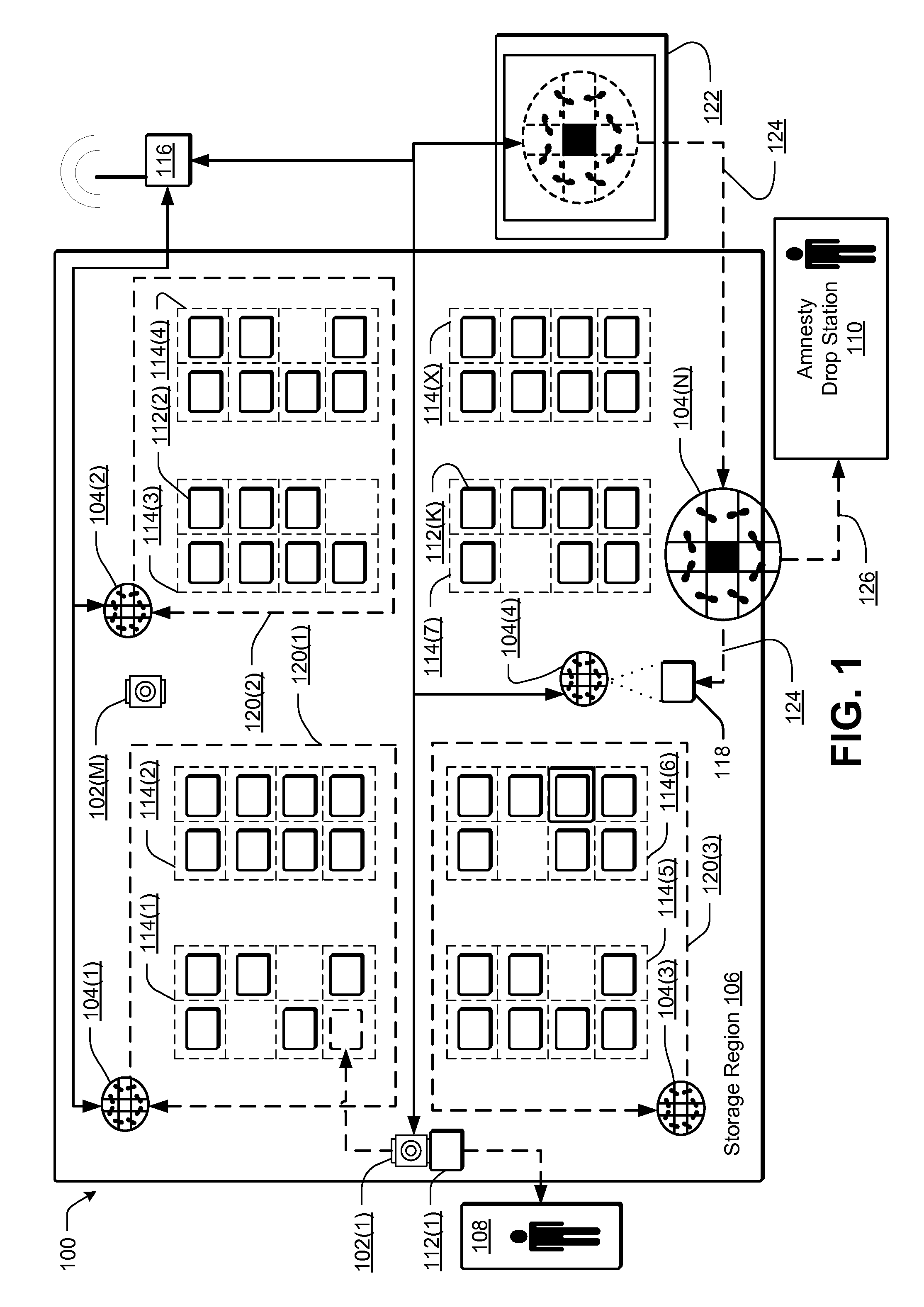

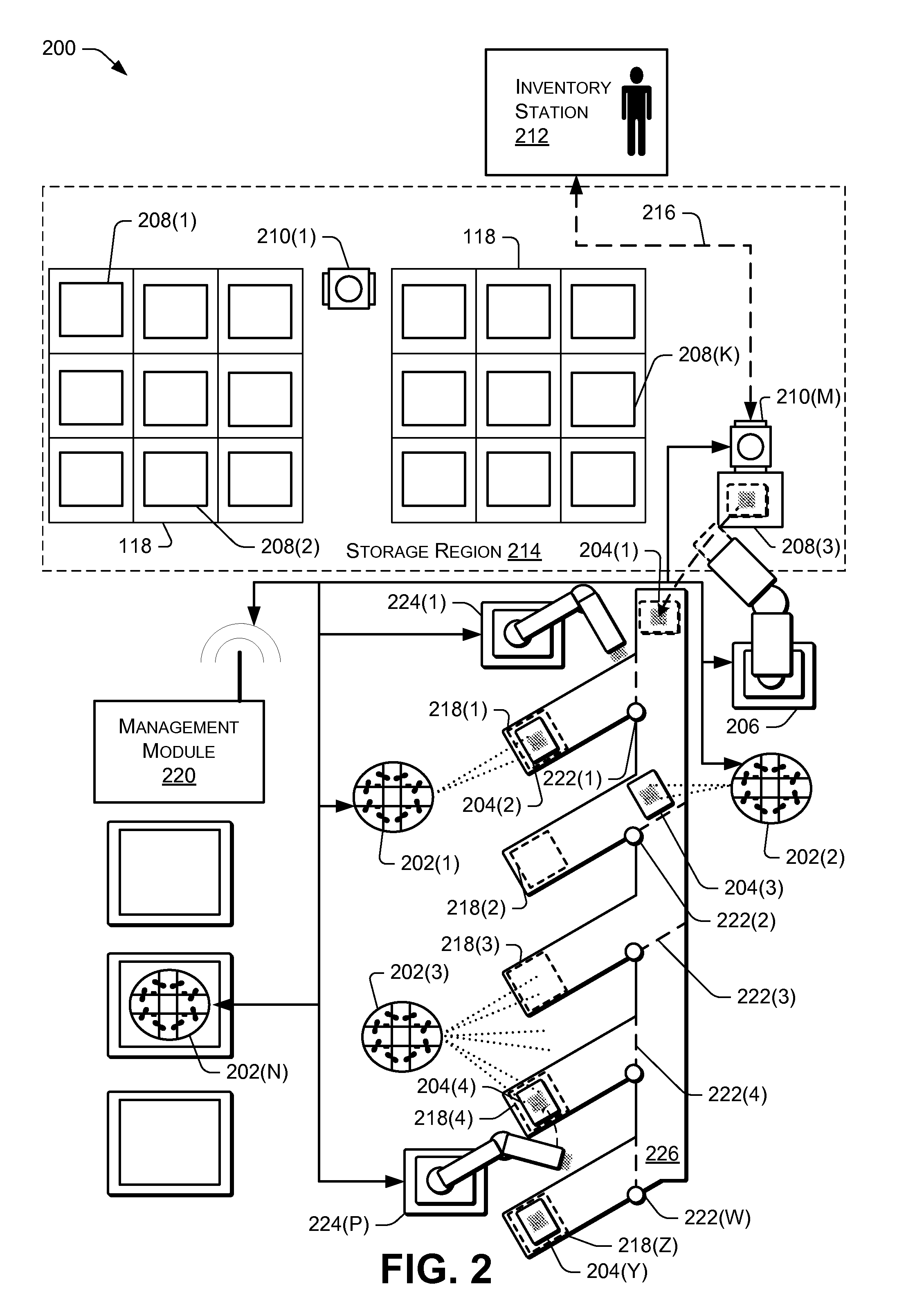

Automated inventory management system

Some examples include an inventory system having both mobile drive units remotely controllable to transport inventory items and holders within a warehouse and automated aerial vehicles remotely controllable to identify and remove amnesty items from the storage region. In some implementations, the automated aerial vehicles are equipped with imaging components to monitor the floor of the warehouse to identify and engagement mechanisms to secure and remove the amnesty items that may otherwise impede the movement of the mobile drive units.

Owner:AMAZON TECH INC

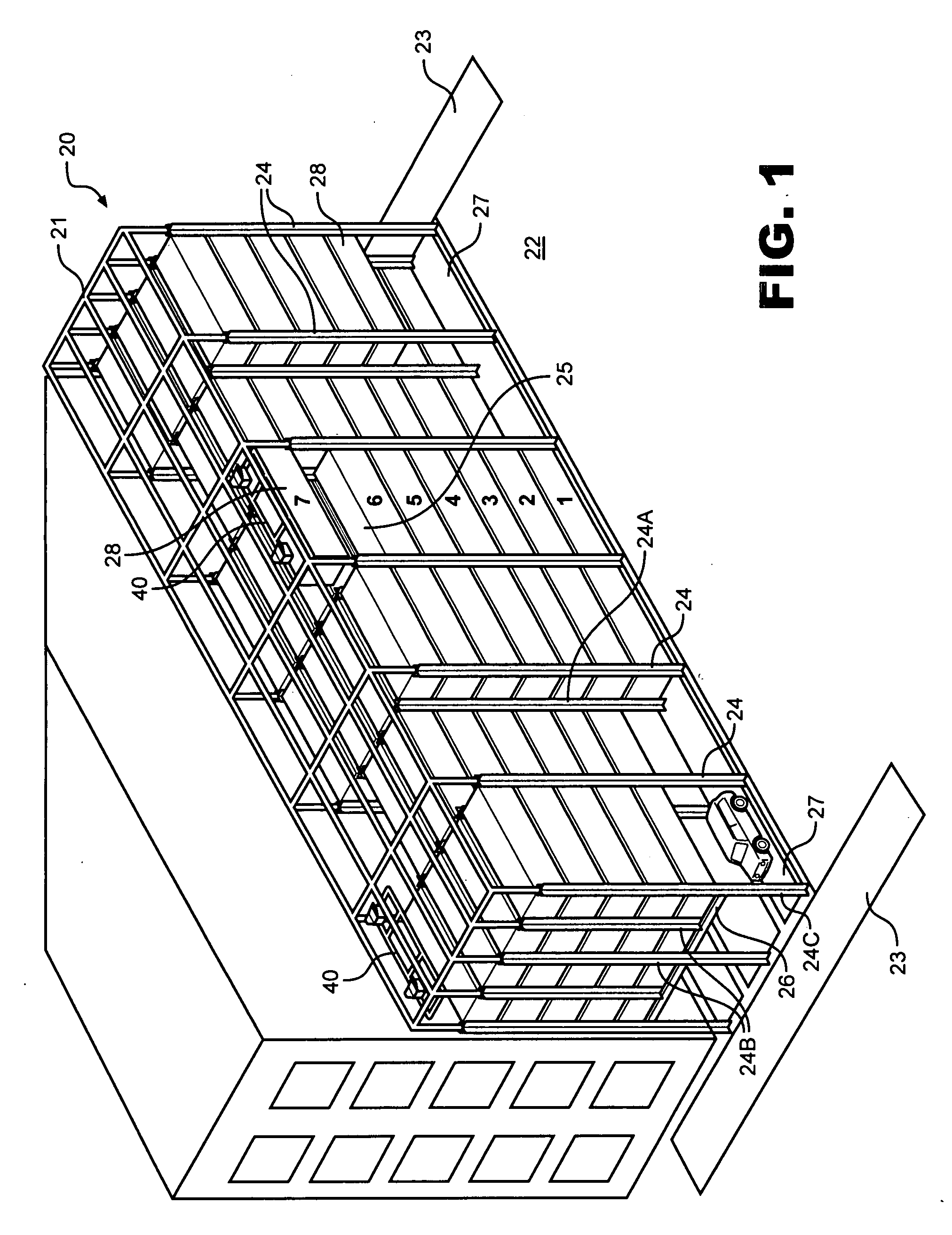

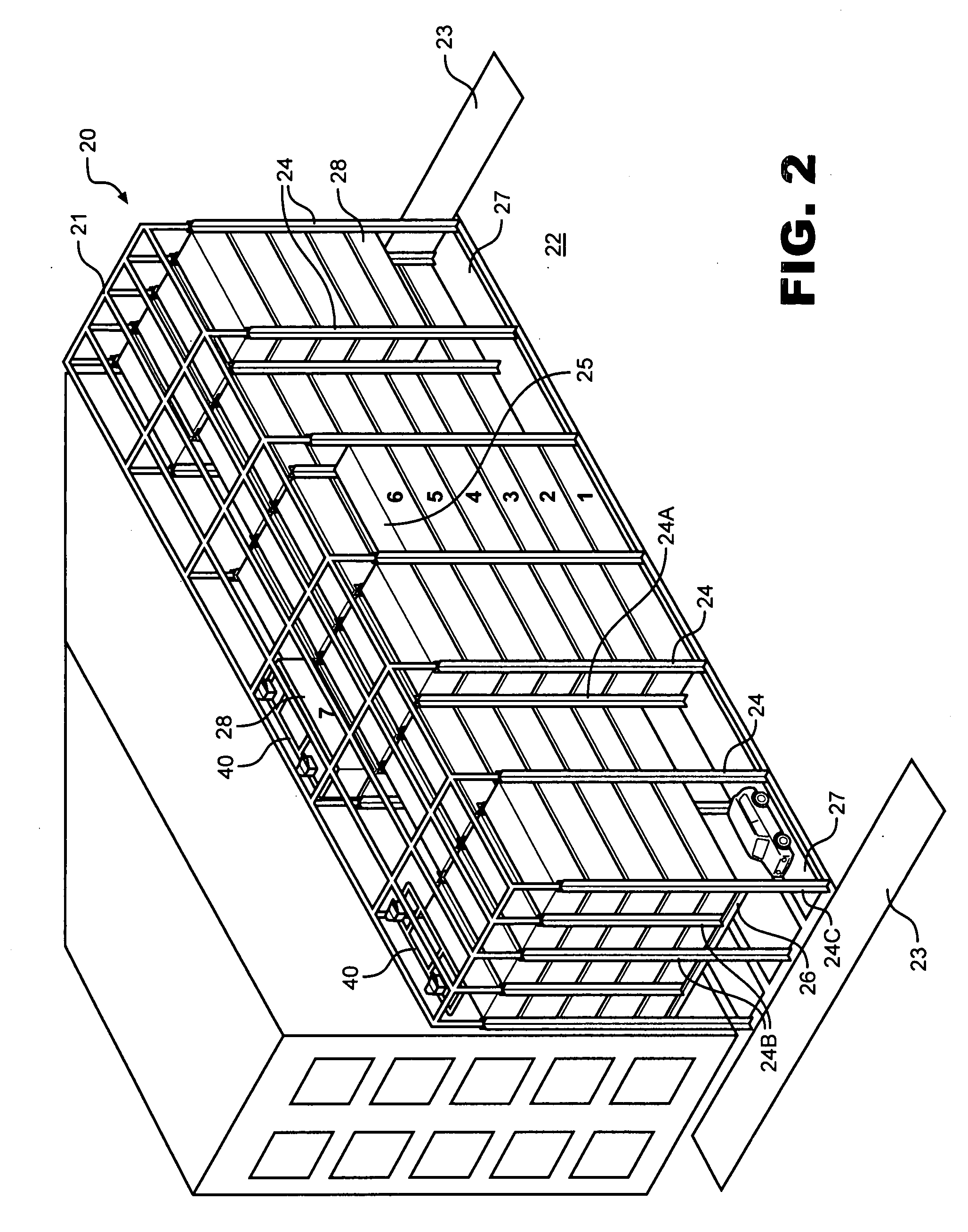

Automated warehouse facility

InactiveUS20070276535A1Improve efficiencyImprove performanceDigital data processing detailsStorage devicesTransport systemTransit system

An automated warehouse facility for warehousing and storing a plurality of items simultaneously in a plurality of varying levels, in which empty pallets circulate simultaneously with the main circulation of goods but separately from it without interfering with storing and retrieving goods on the all levels. The warehouse facility comprises a multi-level building having a plurality of storage racks for simultaneous and independent storing multiple loaded or unloaded pallets. An entrance-floor level of the building includes a terminal for receiving or releasing multiple items simultaneously through an exterior entrance. An interior entrance to the terminal provides access to the storage area and transportation of the loaded pallet. The warehouse facility includes a pallet stacking station for storing the unloaded pallet located over a shuttle aisle that extends under the terminal. A transport system provides simultaneous and independent transporting of the loaded pallet and unloaded items in the storage area.

Owner:ROBOTIC TECH ADMINISTRATION

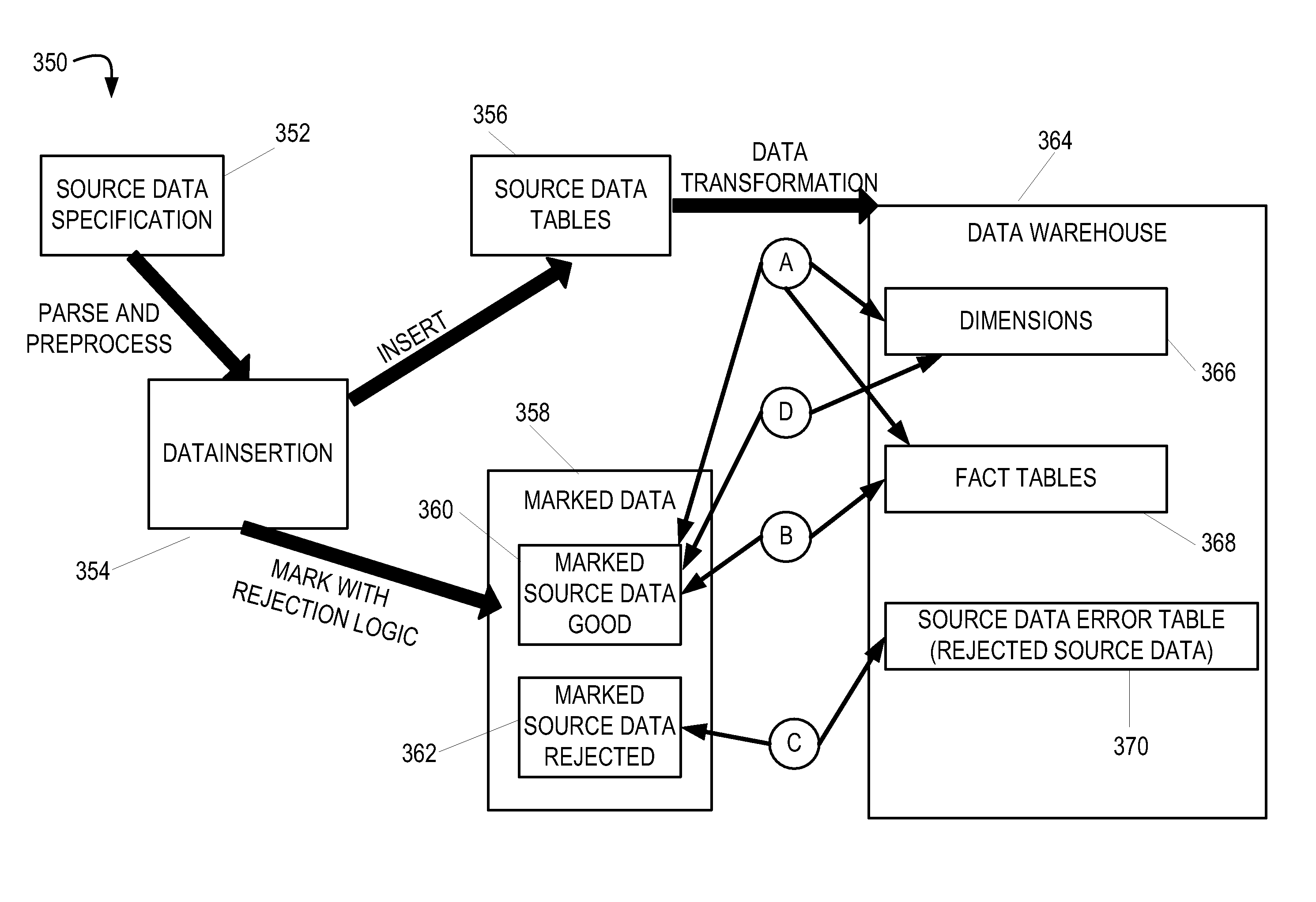

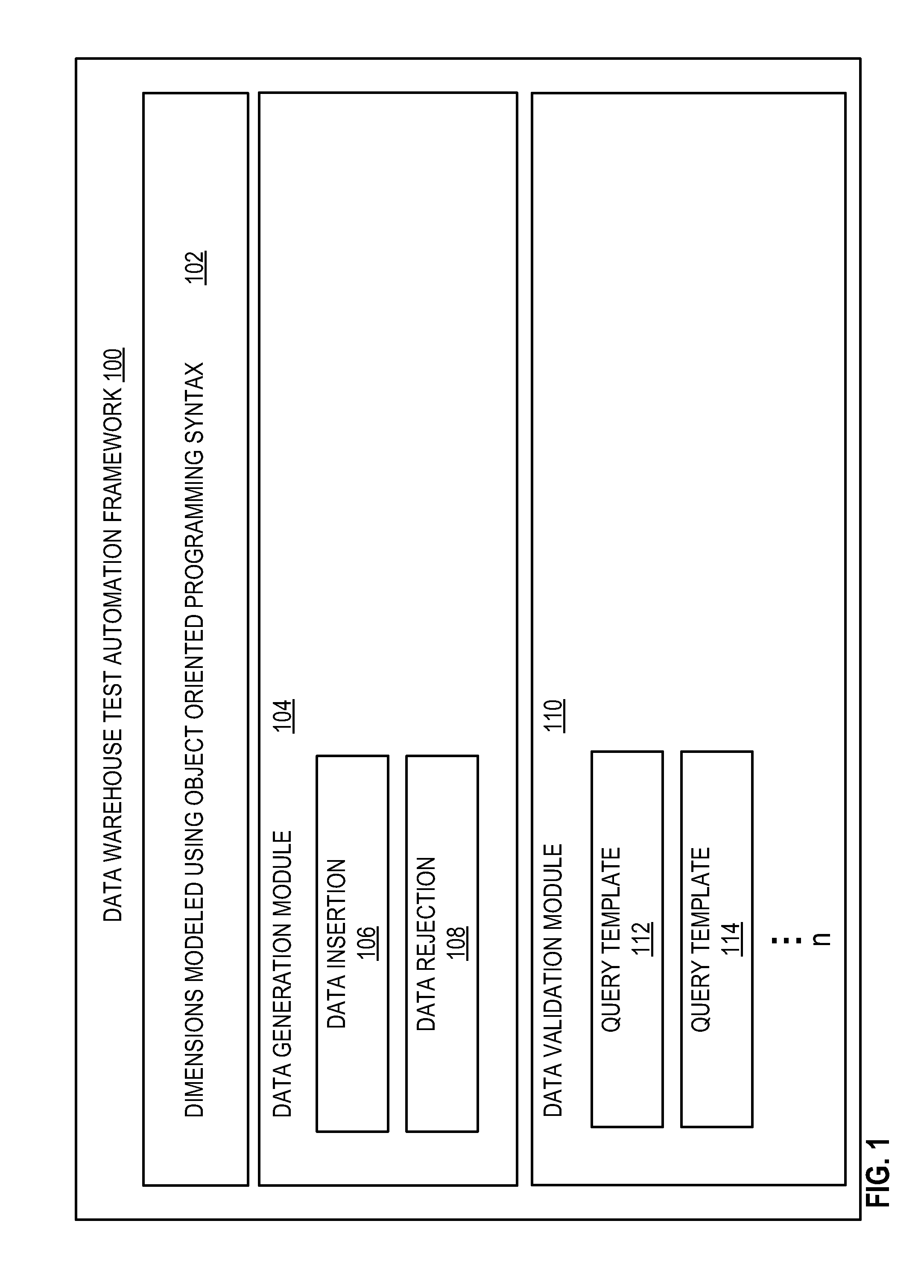

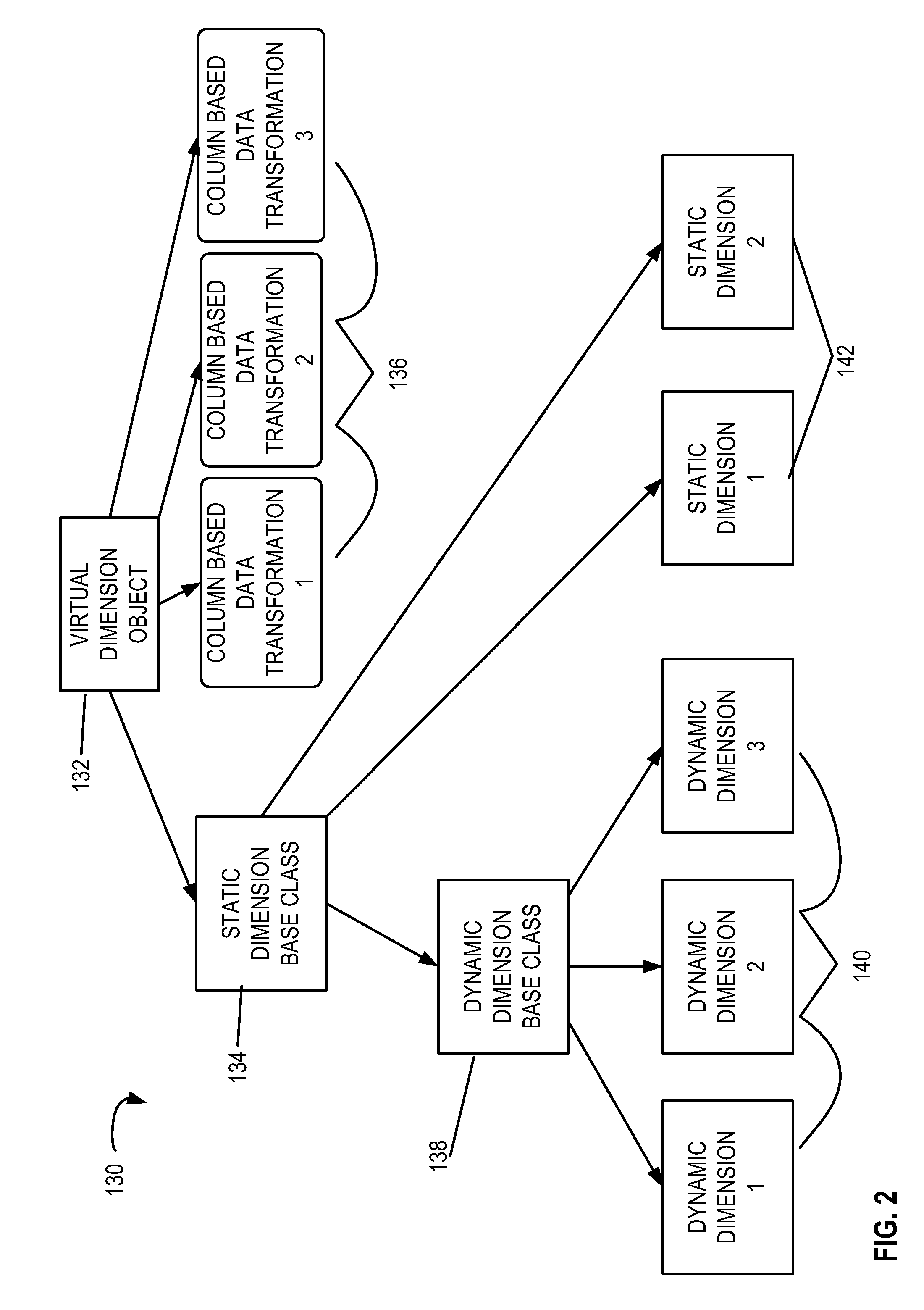

Data warehouse test automation framework

ActiveUS8019795B2Digital data processing detailsMulti-dimensional databasesData validationData warehouse

Various technologies and techniques are disclosed for providing a data warehouse test automation framework system. A data generation module is provided that is operable to generate data scenarios that ensure specific logic is being validated against a data warehouse. A data validation module is provided that has data validation blocks that provide a framework for validating data completeness and data integrity of a data warehouse. The data validation blocks are represented by query templates that provide specifications for how queries that perform the validating of the data completeness and the data integrity should be structured. Dimensions in the data warehouse are modeled using an object oriented programming syntax.

Owner:MICROSOFT TECH LICENSING LLC

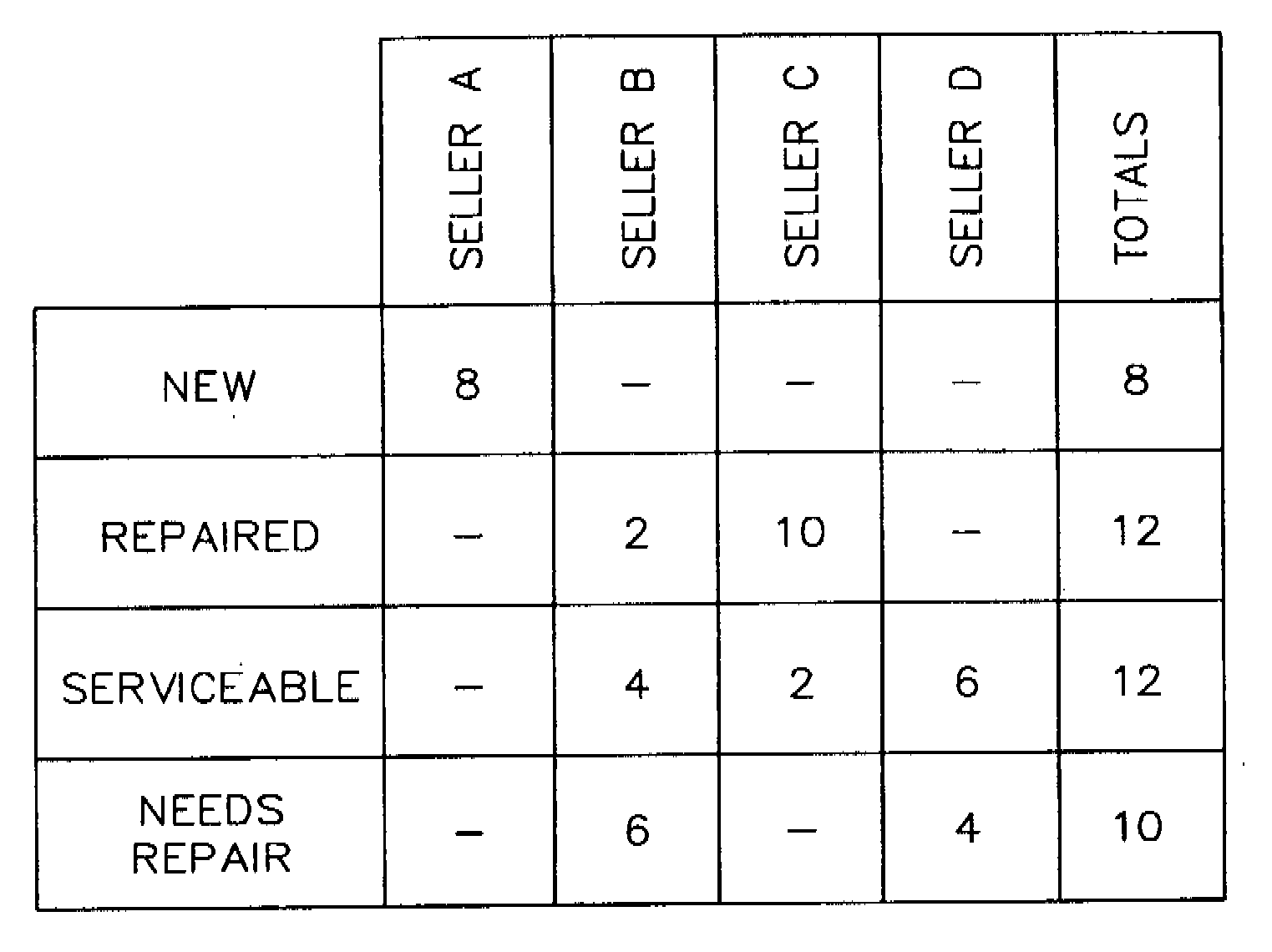

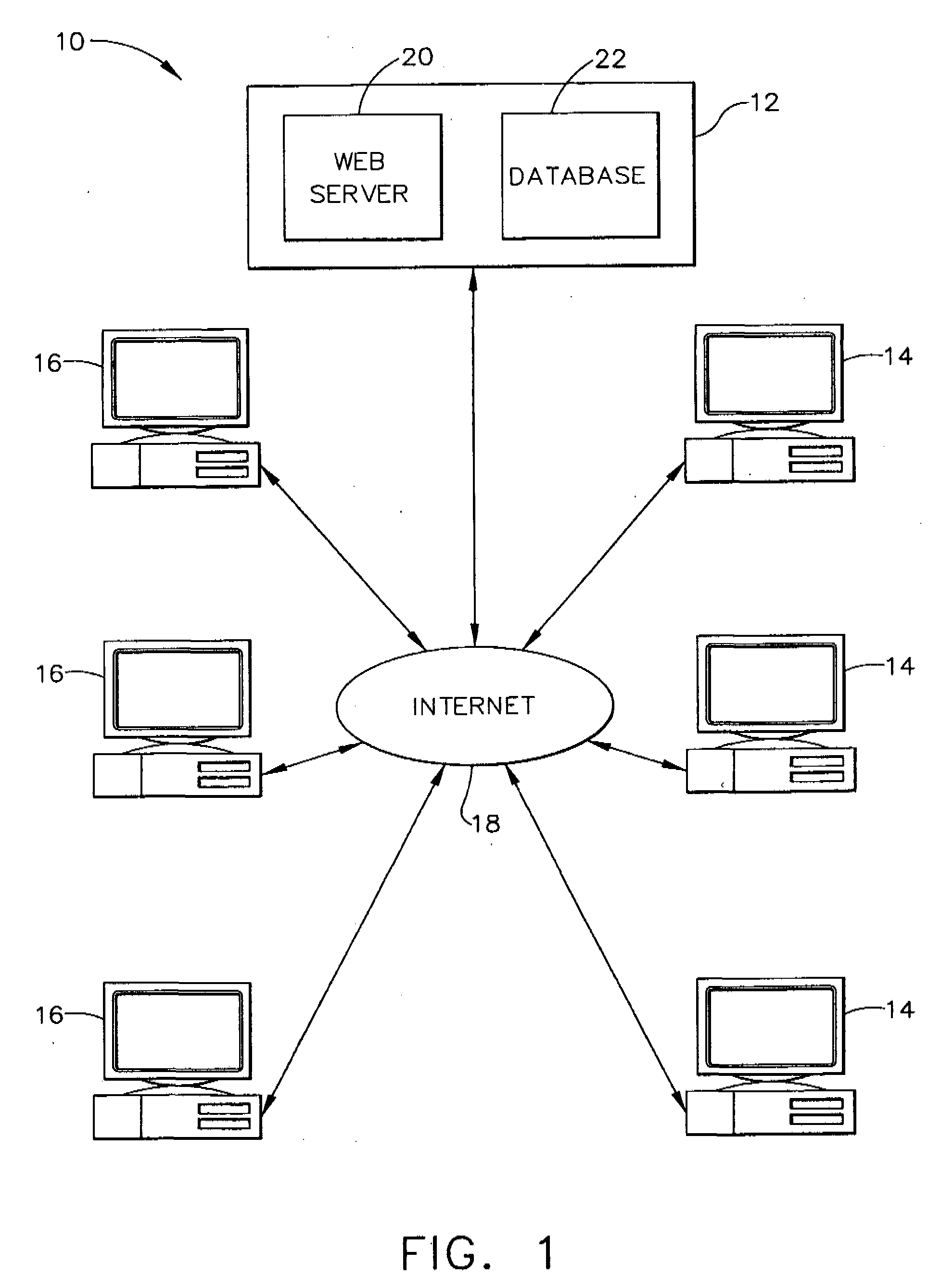

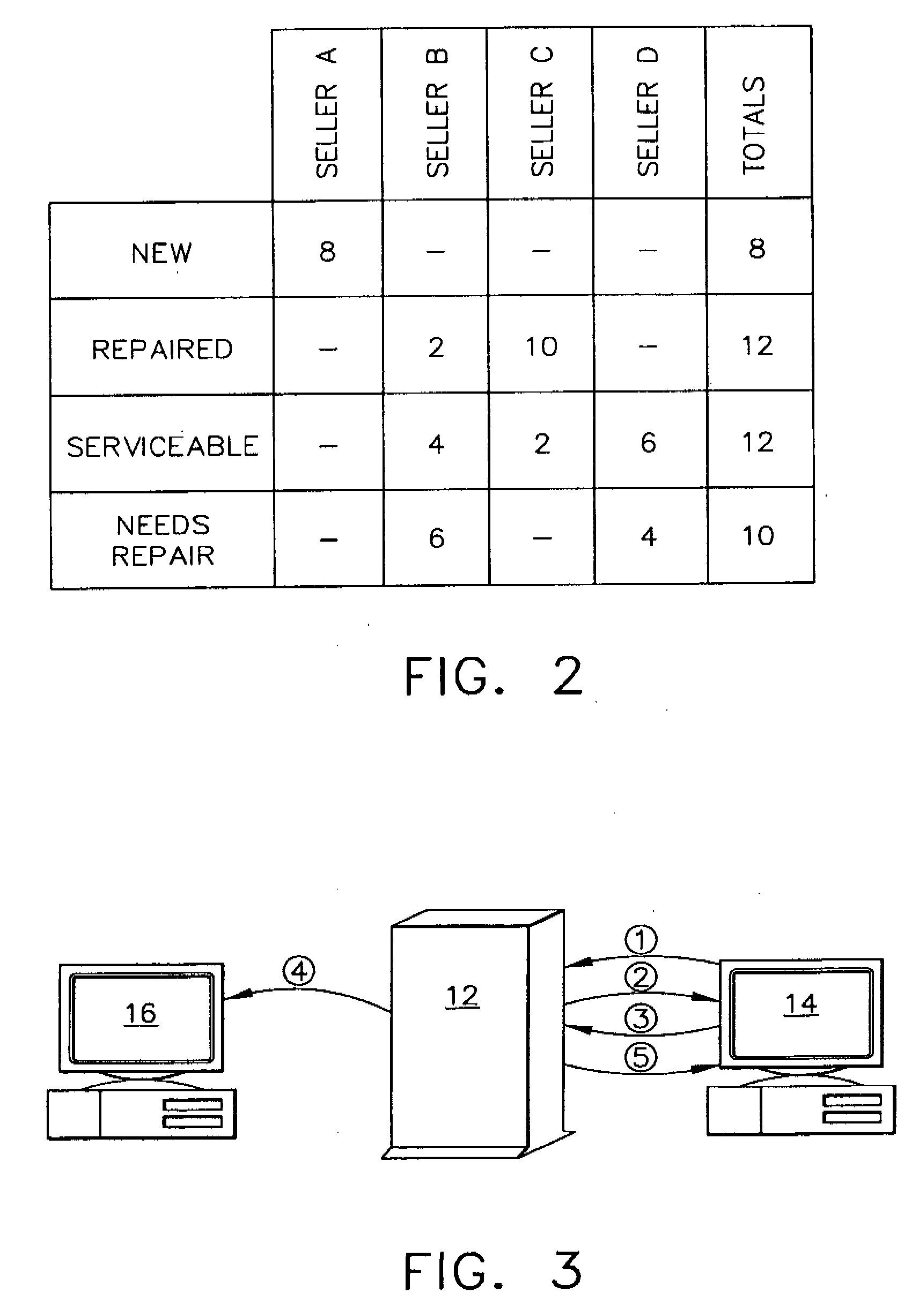

Virtual warehouse parts distribution system and process

A parts distribution system and process uses a computer network, particularly the Internet, to efficiently distribute spare parts in a cost-effective manner. The system includes a plurality of buyer computers for operation by a system participant desiring to obtain one or more parts, a plurality of seller computers for operation by a system participant desiring to sell one or more parts, and at least one server computer. The buyer computers, seller computers and server computer are interconnected as a computer network. In operation, the seller computers are used to input part related data to the server computer, and the server computer uses the data to maintain a database of all available parts. The buyer computers are used to transmit part requests to the server computer, and the server computer selecting one or more parts from the database in response to the requests.

Owner:GENERAL ELECTRIC CO

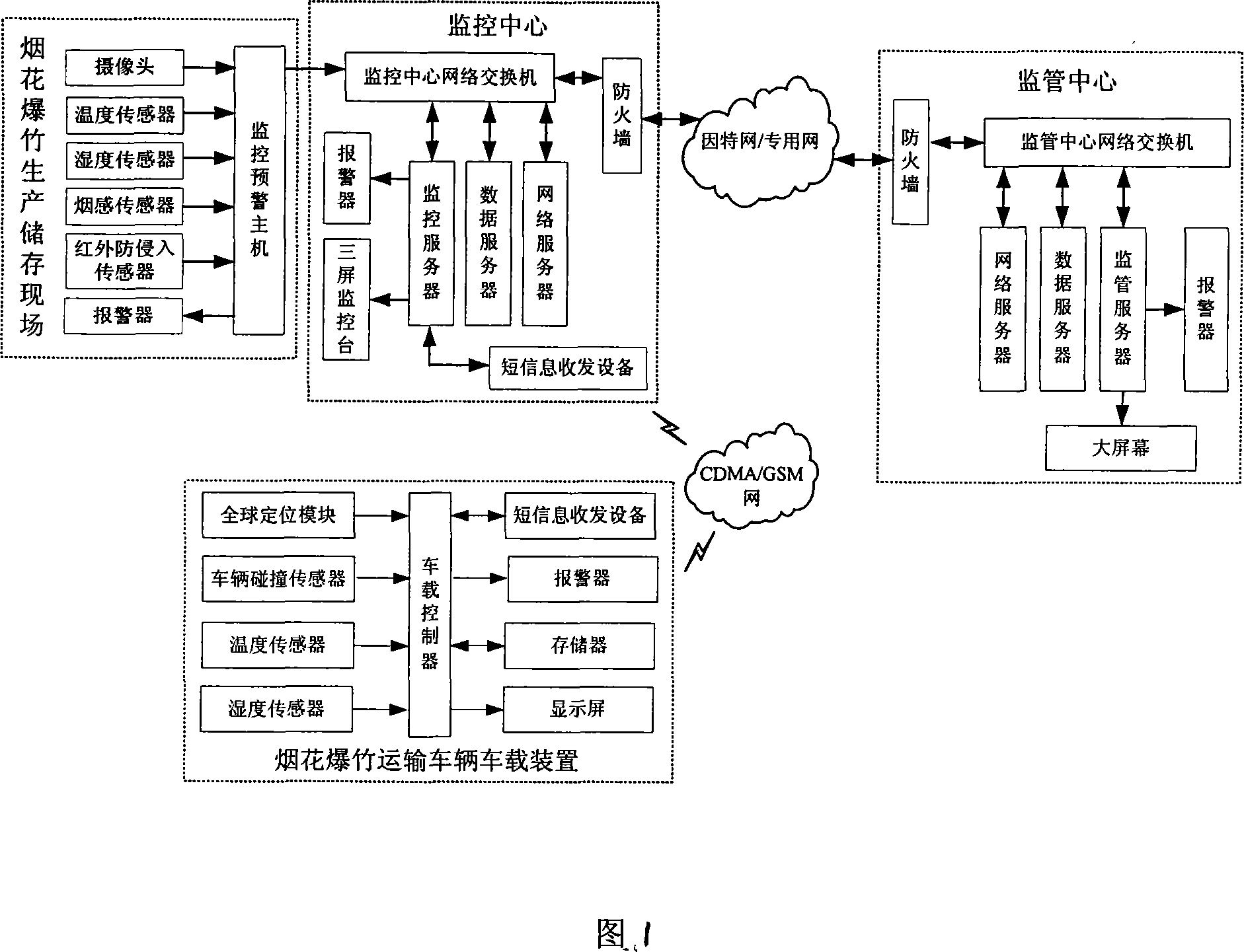

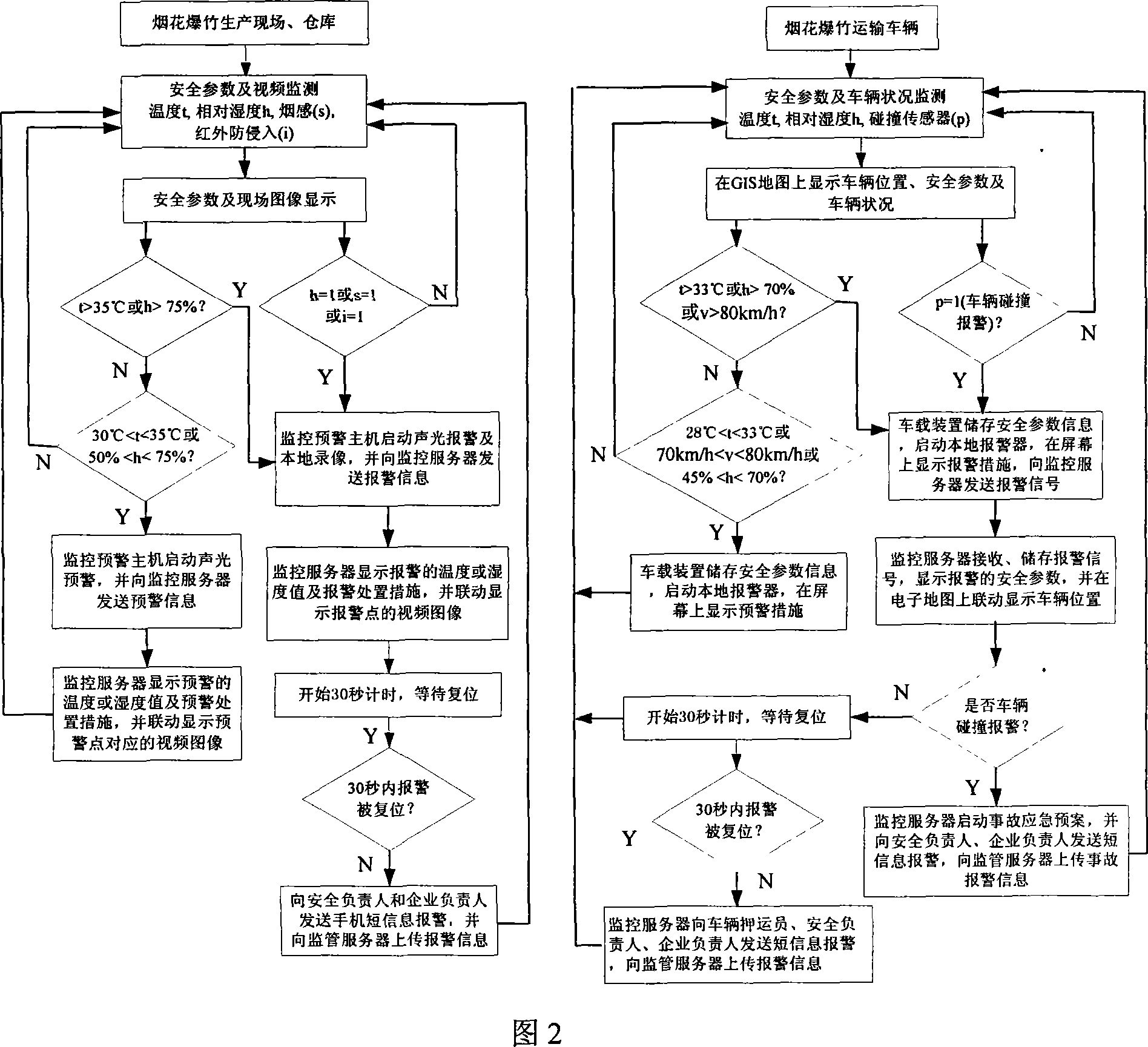

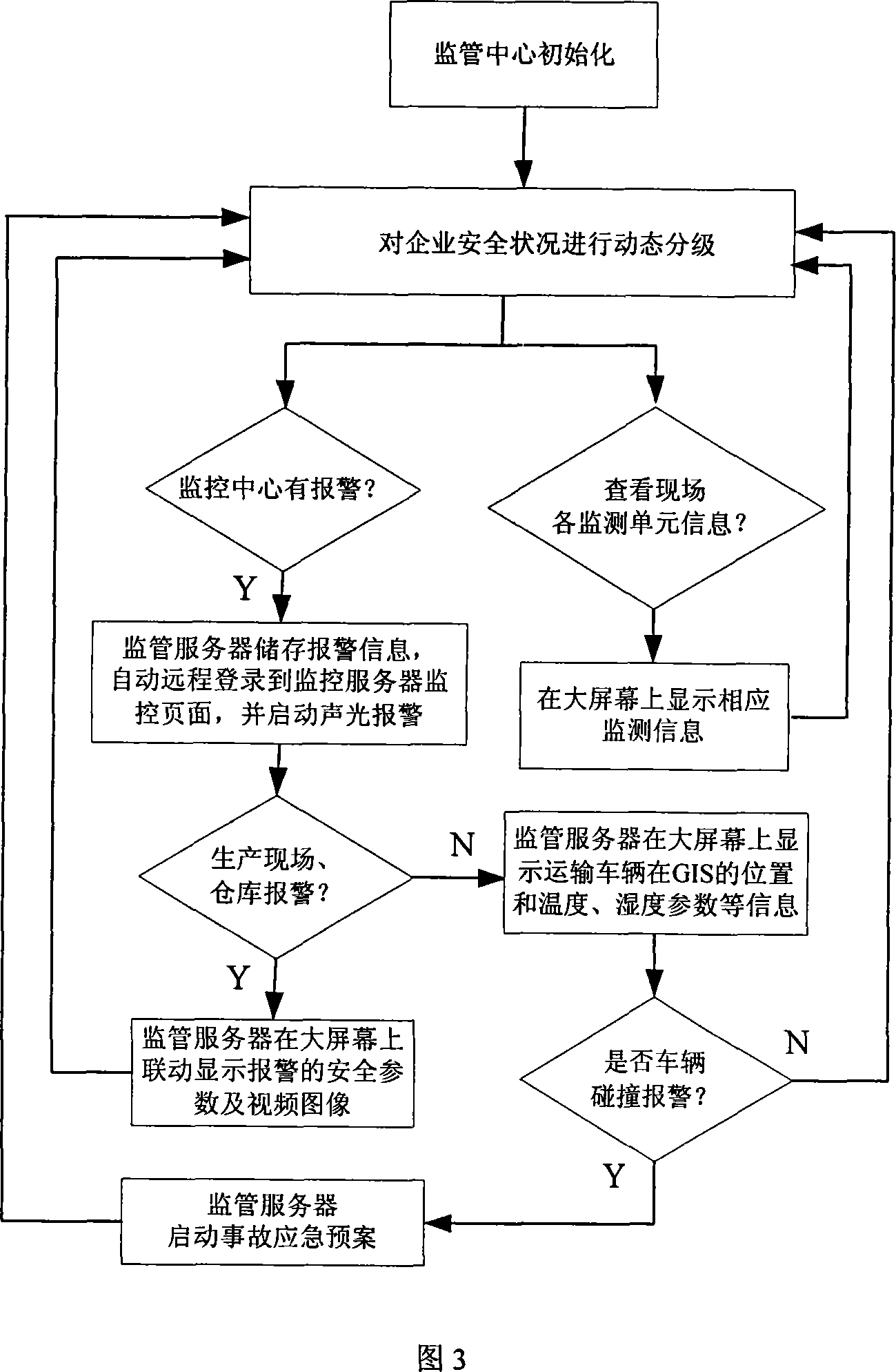

Dynamic monitoring system and method for fireworks and firecracks production storage and transportation process

InactiveCN101067744ARealize hierarchical alarmImprove work efficiencyComputer controlSimulator controlProcess dynamicsStatistical analysis

The invention relates to fireworks and crackers producing, storing, transporting process dynamic monitoring system and method. The method is formed by supervising and monitoring center systems. It includes that real time collecting and dynamically displaying safe parameter and video information for the firework and crackers production field, band and transportation vehicle; dynamically display the safe parameter, position information, speed information for the transportation vehicle; classing early-warning, warning, processing for the safe parameter; statistical analysis for corporation safety condition; searching corporation monitoring information and warning processing; when the transportation happens accident, the monitoring server will start corresponding emergency beforehand. The invention can prevent large malignancy accident from happening in firework and crackers producing, storing, and transporting to protect people life and property better.

Owner:CHINA ACAD OF SAFETY SCI & TECH

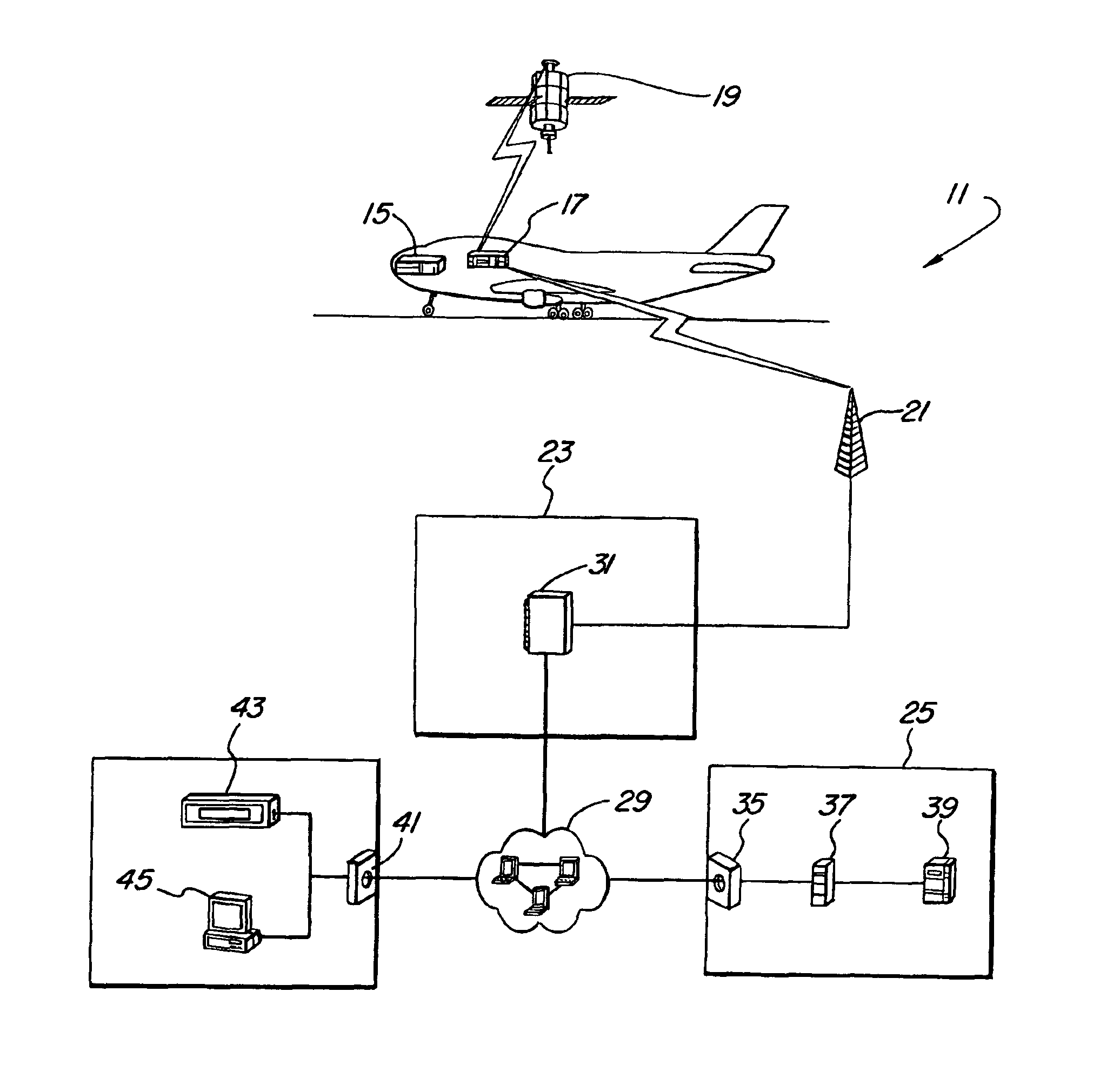

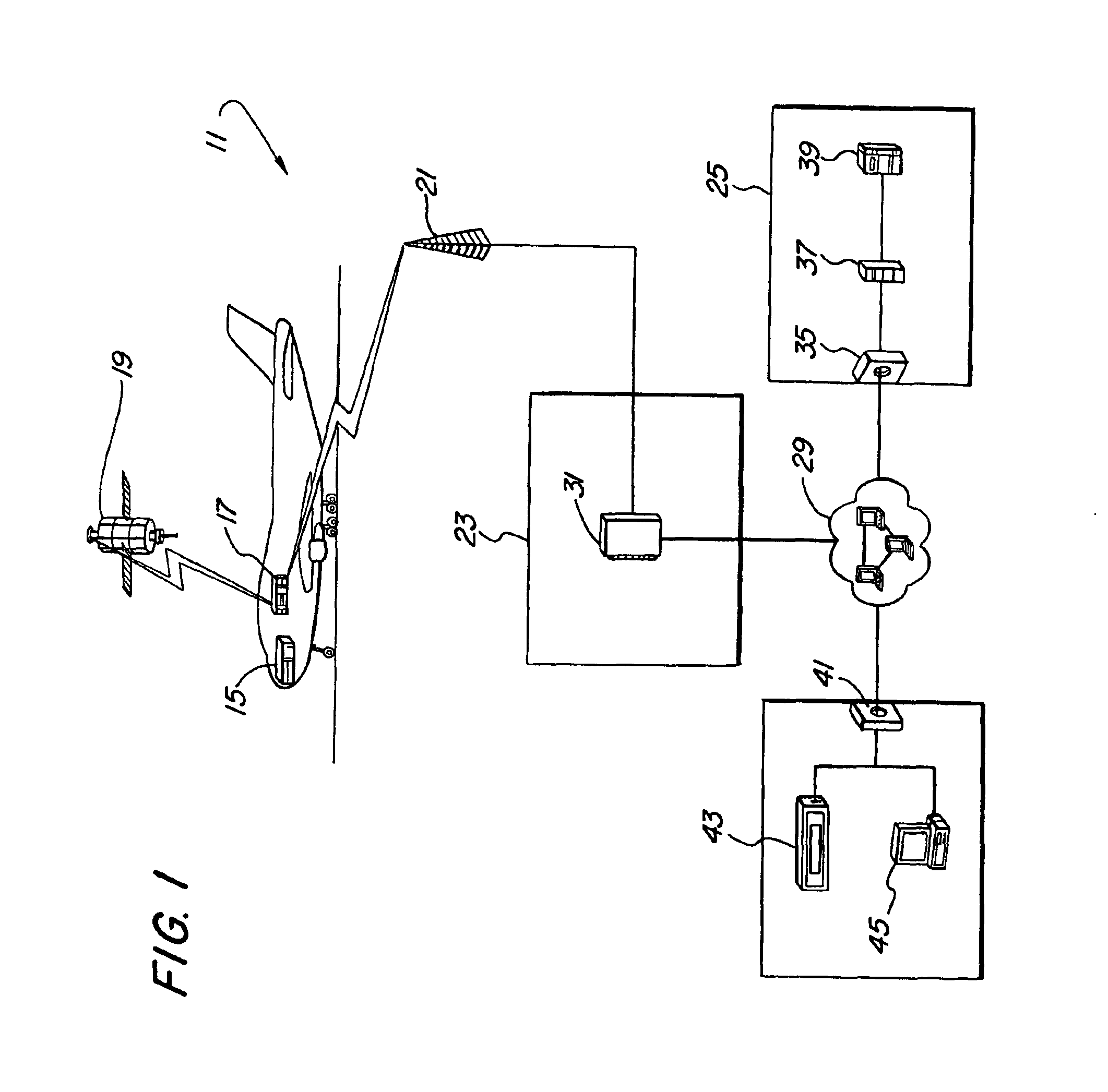

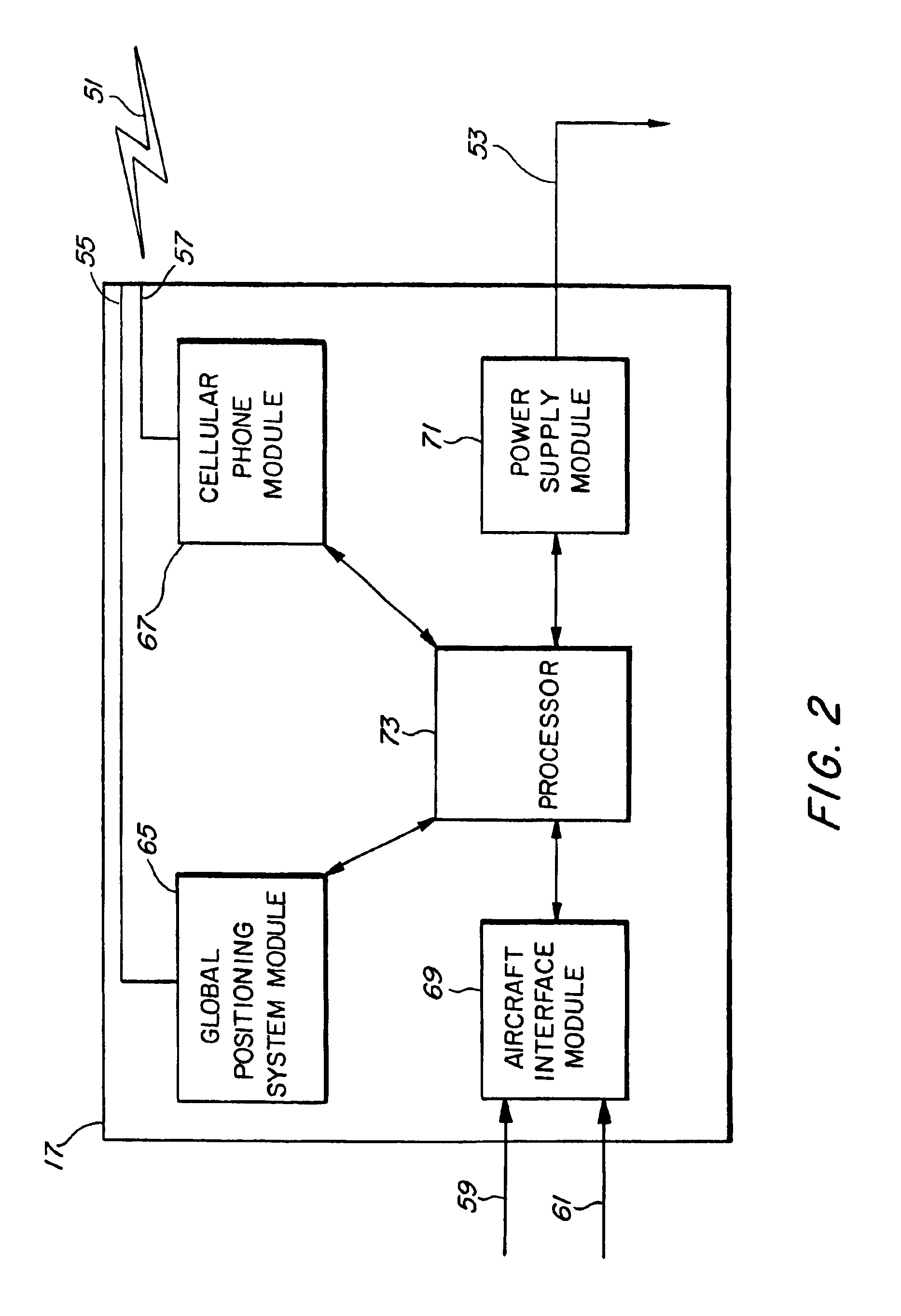

Aircraft data transmission system for wireless communication of data between the aircraft and ground-based systems

A device to enable automatic wireless communication with an aircraft after the aircraft has parked at a gate. A terminal cellular bridge (TCB) enables the retrieval of data from, and the sending of data to the aircraft by an internet service provider. The internet service provider uses the Internet to send data to and receive data from a remotely located network operation center and data warehousing center. The data warehousing center provides secure data storage and retrieval, and data processing. The network operations center provides for system control and monitoring.

Owner:SAFRAN PASSENGER INNOVATIONS LLC

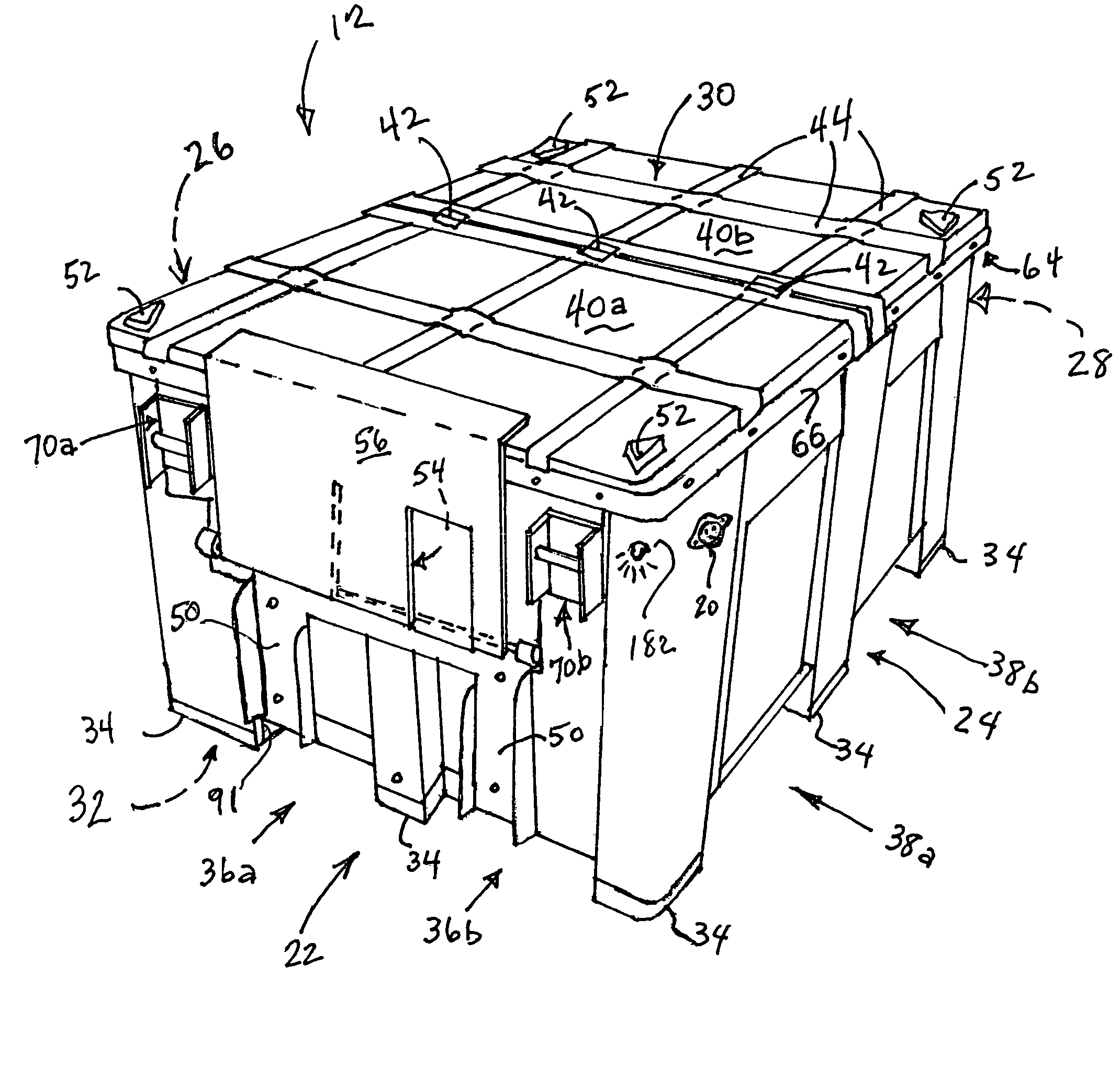

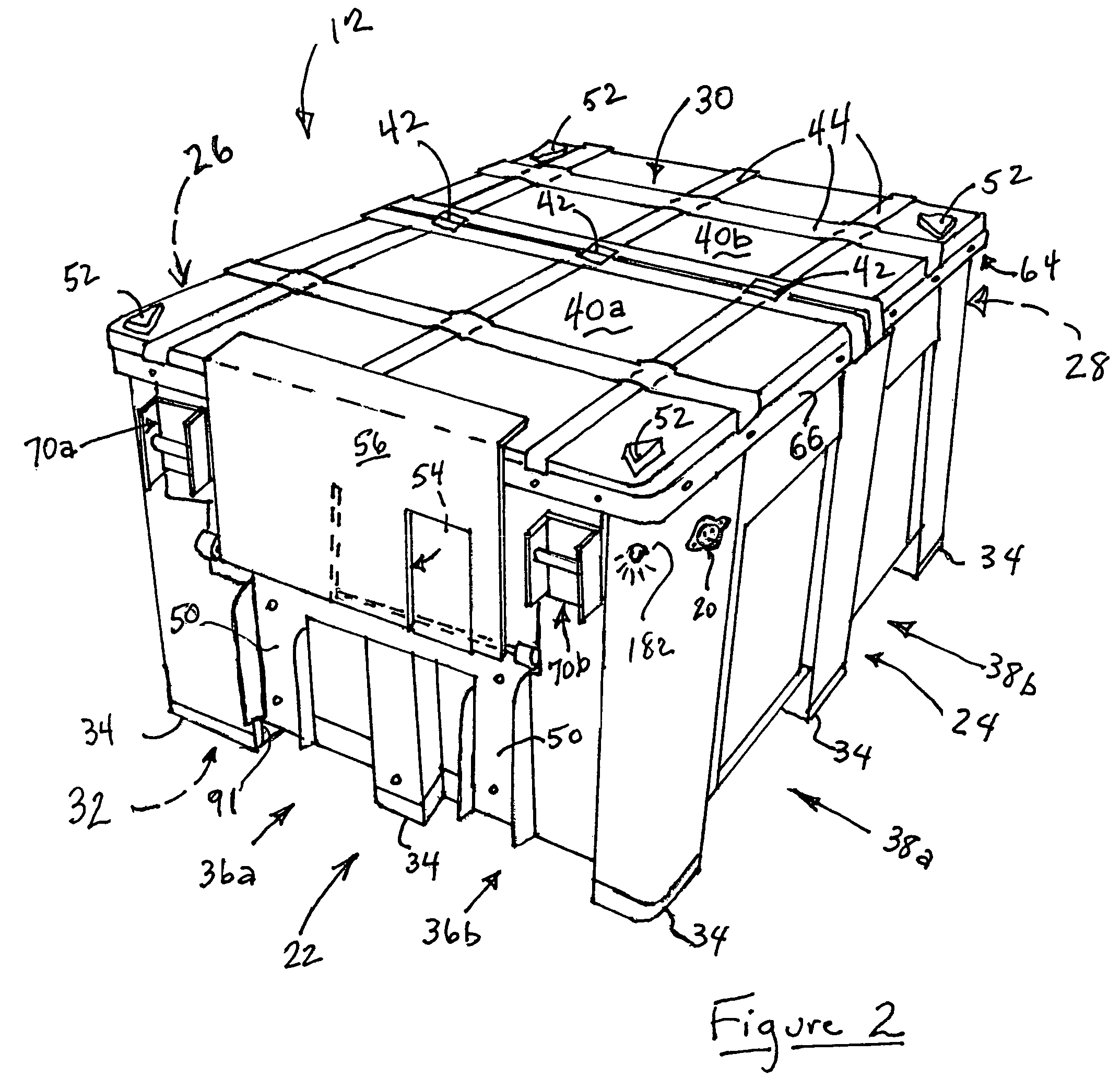

Smart pallet-box cargo container

Smart cargo container system comprising auditable, secure, sealable, stackable, trackable and pollable, universal, “pallet boxes” used: 1) auto-latchingly secured to the under-carriage transverse I-beams of over-the-road semi-trailers by means of a guiding latching system; and 2) stackable, up to three or more high, in the trailers or warehouses. Sophisticated battery-powered electronic locks, sensors and alarms are provided, as well as an RF communications and GPS locator module that radios to a base station the time, location and status of the inventive smart cargo container, and any anomalous events as they occur, including unauthorized attempts to open or break into the container, or potential damage events. In addition, both the locks and comm modules are programmable, and provide extensive, and selectably pollable and downloadable event, access and transport history and audit trails. The comm system permits remote tracking and real time status check via the Internet, LAN or WAN wireless networks.

Owner:VERDASEE SOLUTIONS

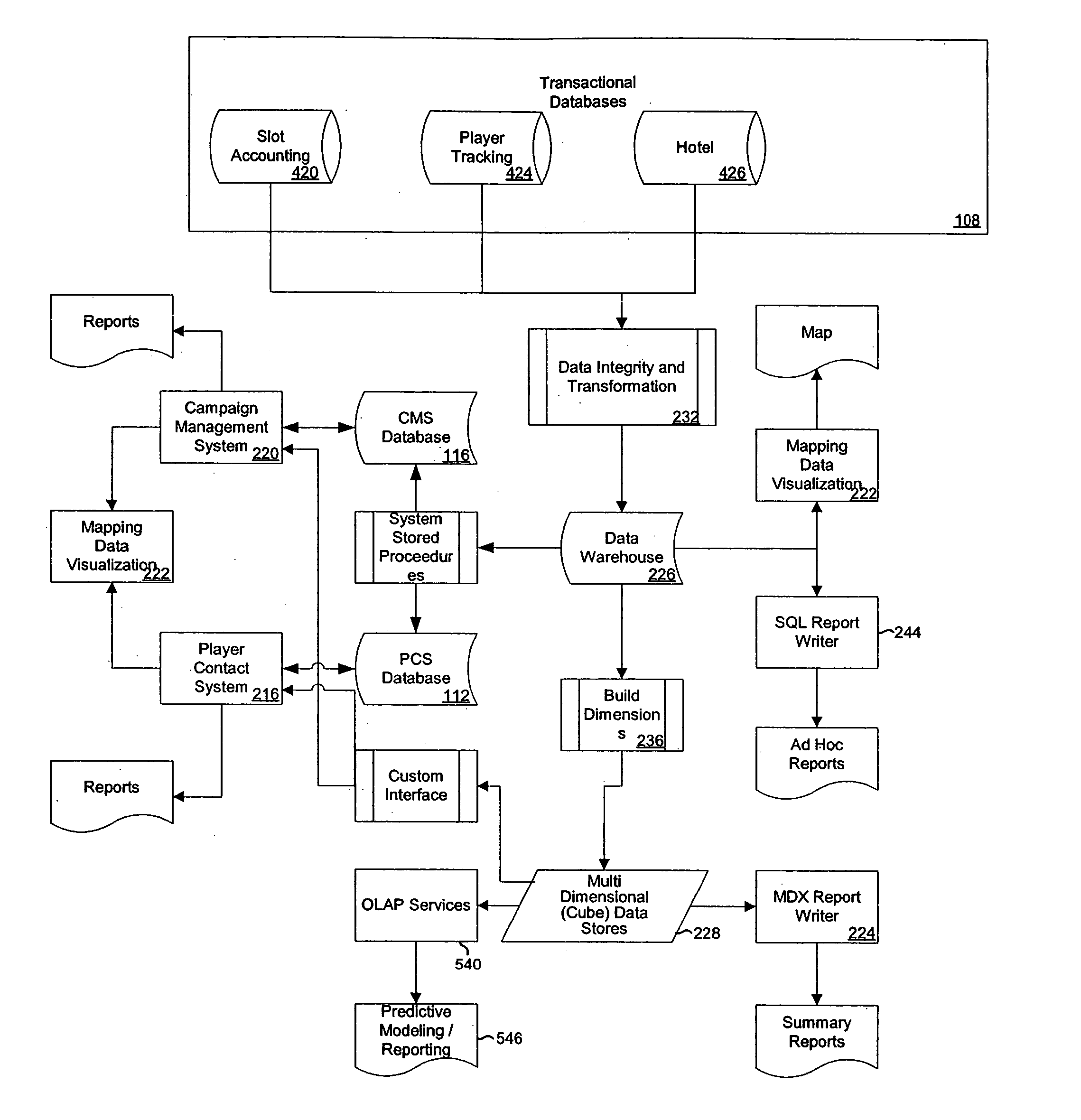

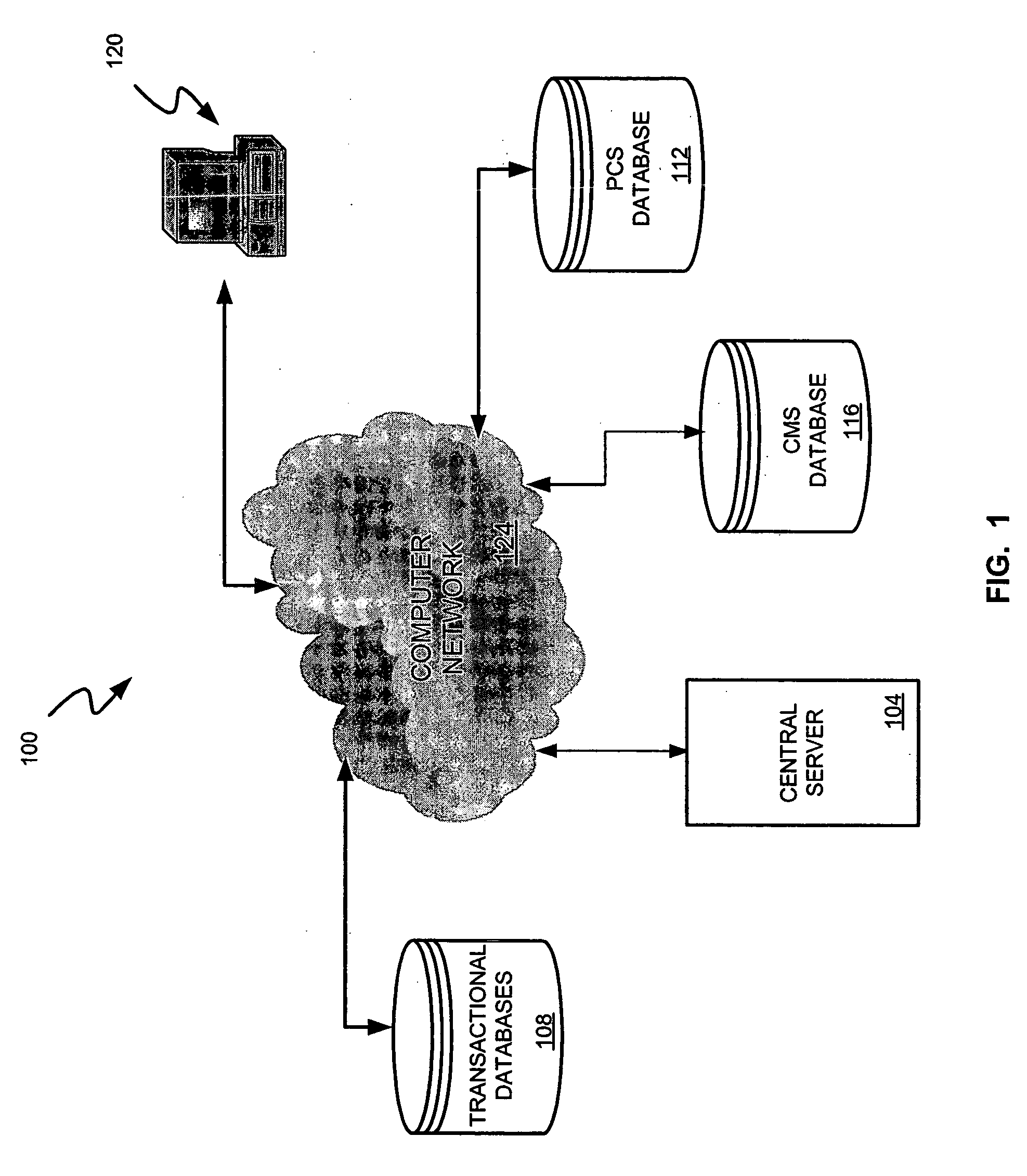

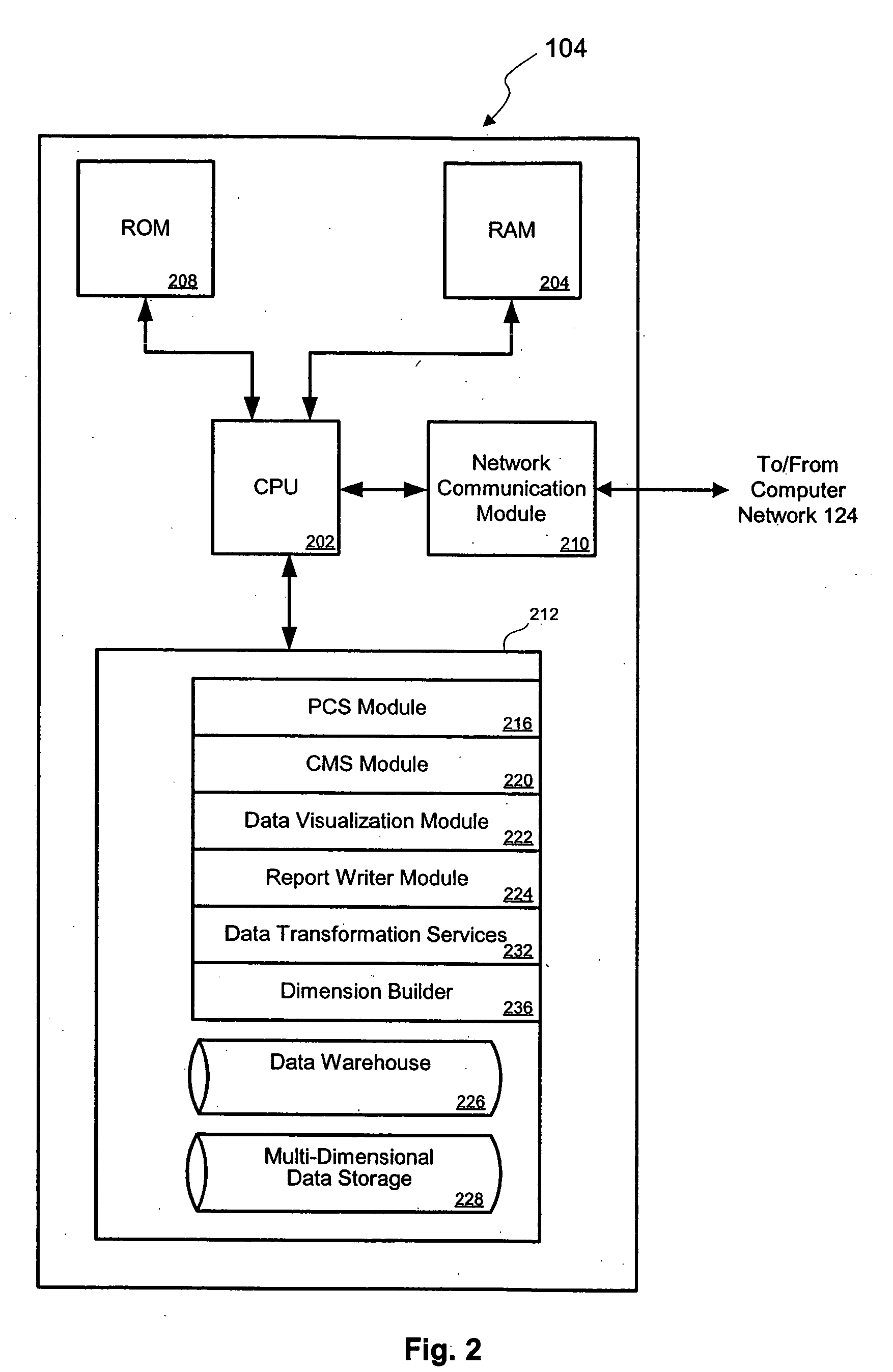

System and method for distributed data warehousing

A computer-implemented system and method for gathering data from a plurality of properties. The system includes a plurality of data warehouses and each of the warehouses is located at a corresponding one of the plurality of properties. A central server unit is operatively connected to the plurality of data warehouses, and is configured to receive patron data and gaming machine data from each of the plurality of data warehouses, and to combine the patron data and said gaming machine data with corresponding property characteristics from each of the plurality of warehouses so as to generate a combined dataset. In variations of the invention, the patron, machine and property data is organized into a multi-dimension data model so that combinations of the patron, machine and said property data to be displayed vis-á-vis one another.

Owner:IGT

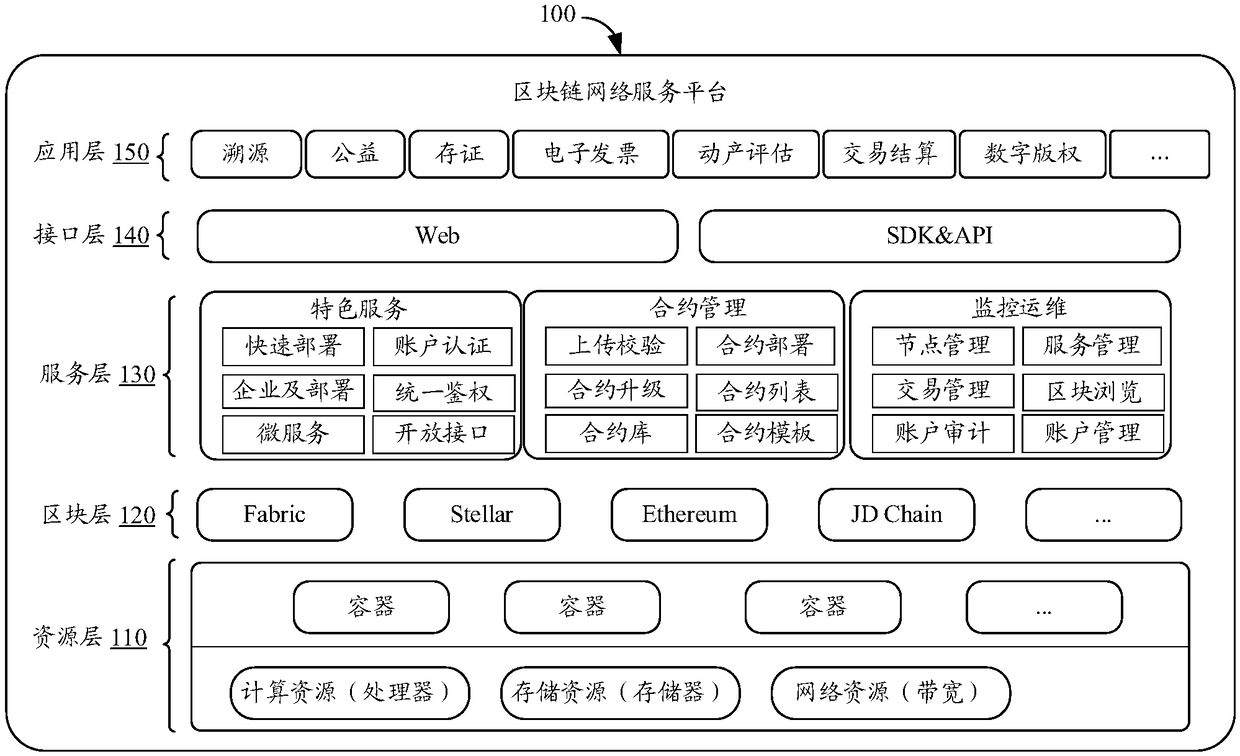

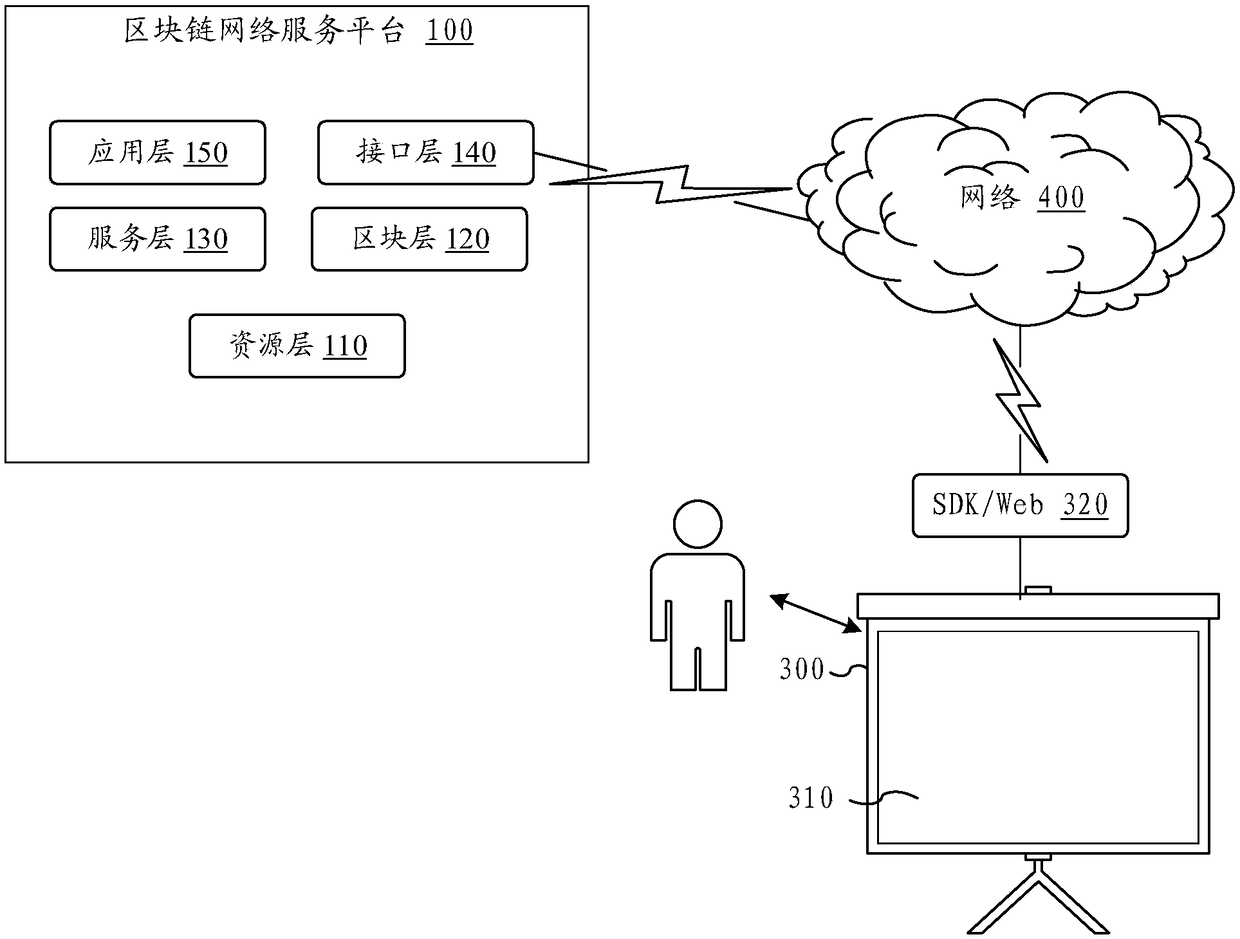

Block chain network service platform and chain code installing method thereof, storage medium

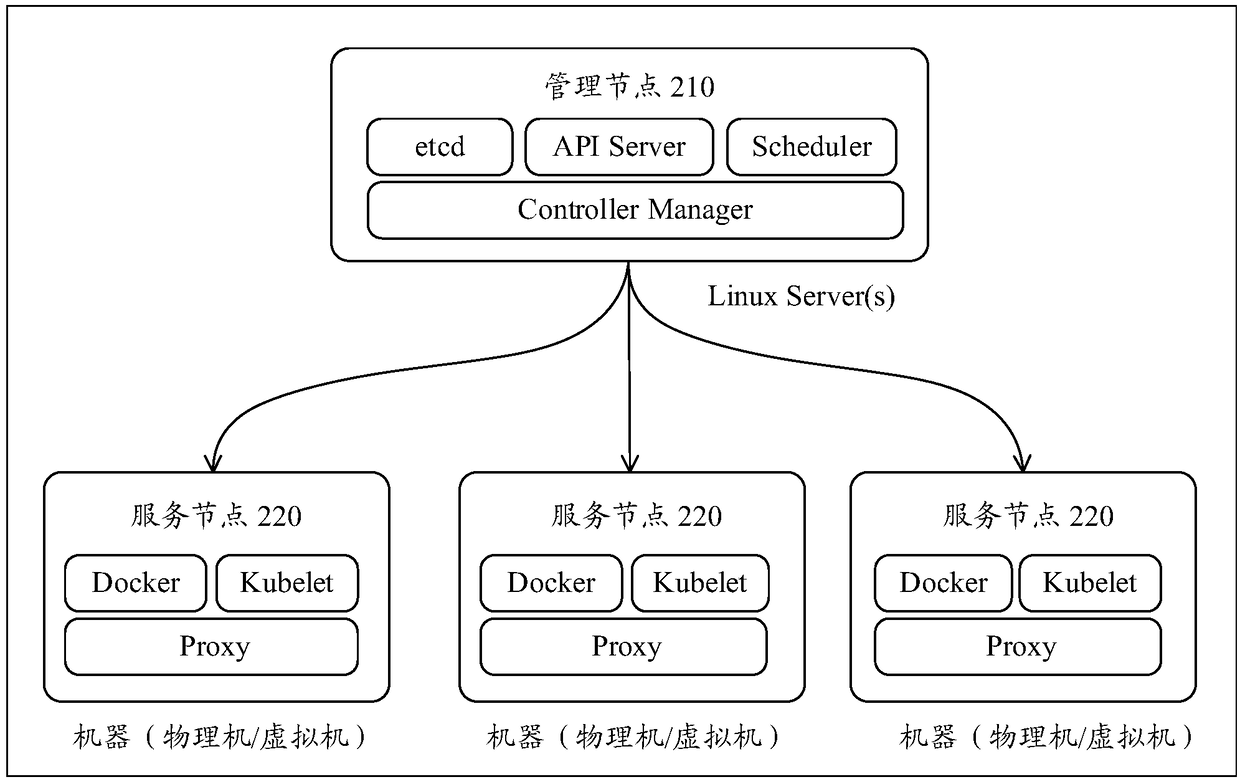

The embodiment of the invention provides a block chain network service platform and a chain code installing method, a storage medium. The method comprises the following steps: storing a chain code mirror image compiled by an endorsement node by calling a container engine, wherein the endorsement node is located at a first service node of a container cluster, and the endorsement node is deployed through a block chain network service platform; when the chain node is installed, calling an application program interface service module of a management node of the container cluster, and requesting the management node to schedule the chain code container through the endorsement node, wherein the chain code container is located at a second service node of the container cluster; and scheduling the chain code mirror image to accomplish the installing of the chain node in response to an operation of requesting to search the chain node mirror image corresponding to the chain node container from a mirror image warehouse.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

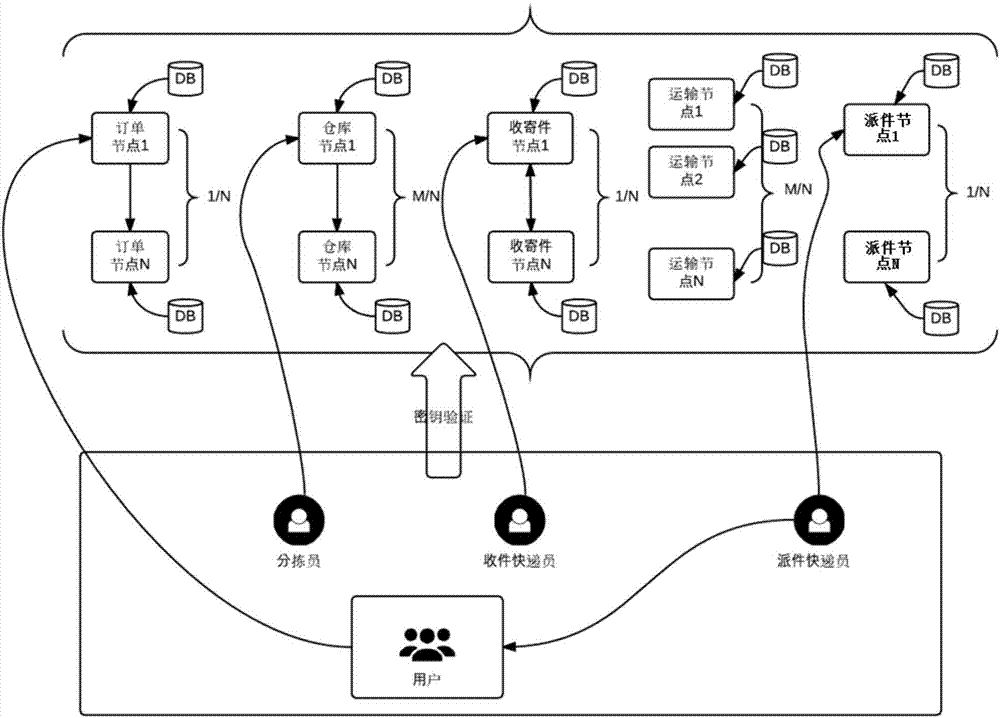

Block chain-based distributed logistic tracking method

InactiveCN106971288AGuaranteed privacyEnsure safetyForecastingDigital data protectionData streamEncryption

A block chain-based distributed logistic tracking method is disclosed and comprises the following steps: an order is placed by a user via a conventional information system, the order is distributed to an order node, and order information is generated; upper node private key decryption verification is adopted for a warehouse node, package information is generated and stored in a block chain after successful verification, and packaging operation is conducted by a sorter; the package is picked up via a package pickup and sending node, the upper node private key decryption verification is adopted, package pickup information is generated and stored in the block chain after successful verification, an optimal transport route is calculated, the upper node private key decryption verification is adopted for a transport node, transport information is generated and stored in the block chain after successful verification, the upper node private key decryption verification is adopted for a package delivery node, package delivery information is generated and stored in the block chain after successful verification, an express delivery worker sends the package to the user who places the order, the upper node private key decryption verification is adopted by the user, and signing information is generated and stored in the block chain after successful verification. Via the block chain-based distributed logistic tracking method, encryption performance and safety of data flows can be greatly improved, the optimal route is provided, and whole course data can be monitored and traced.

Owner:无锡井通网络科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com