Patents

Literature

87results about How to "Easy way to work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

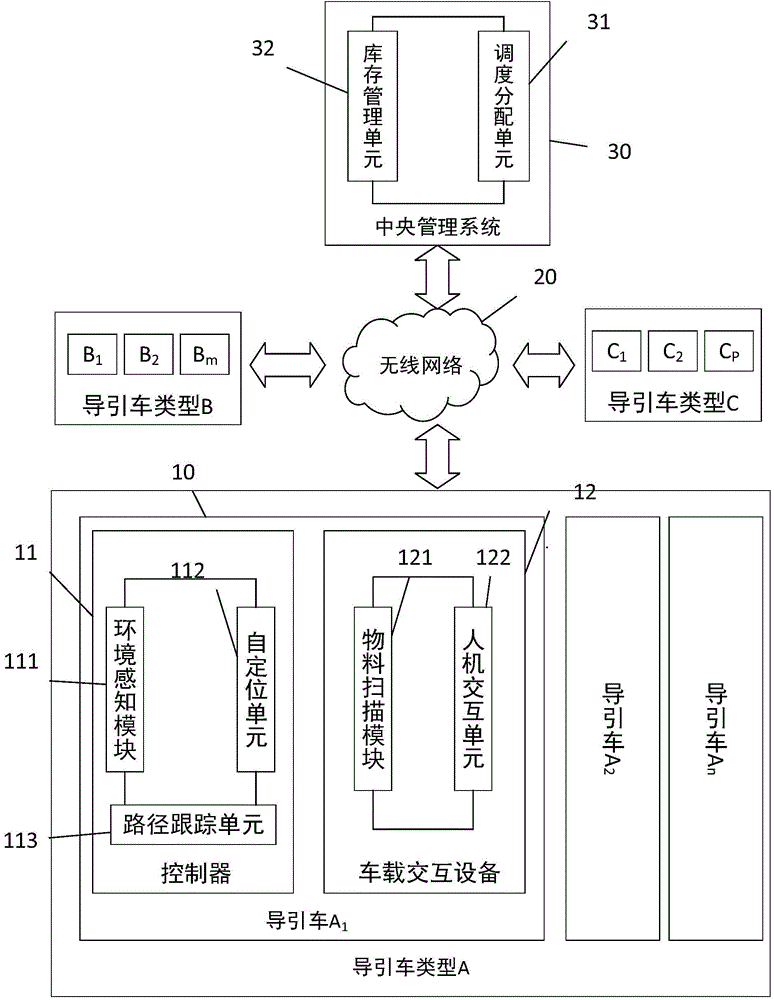

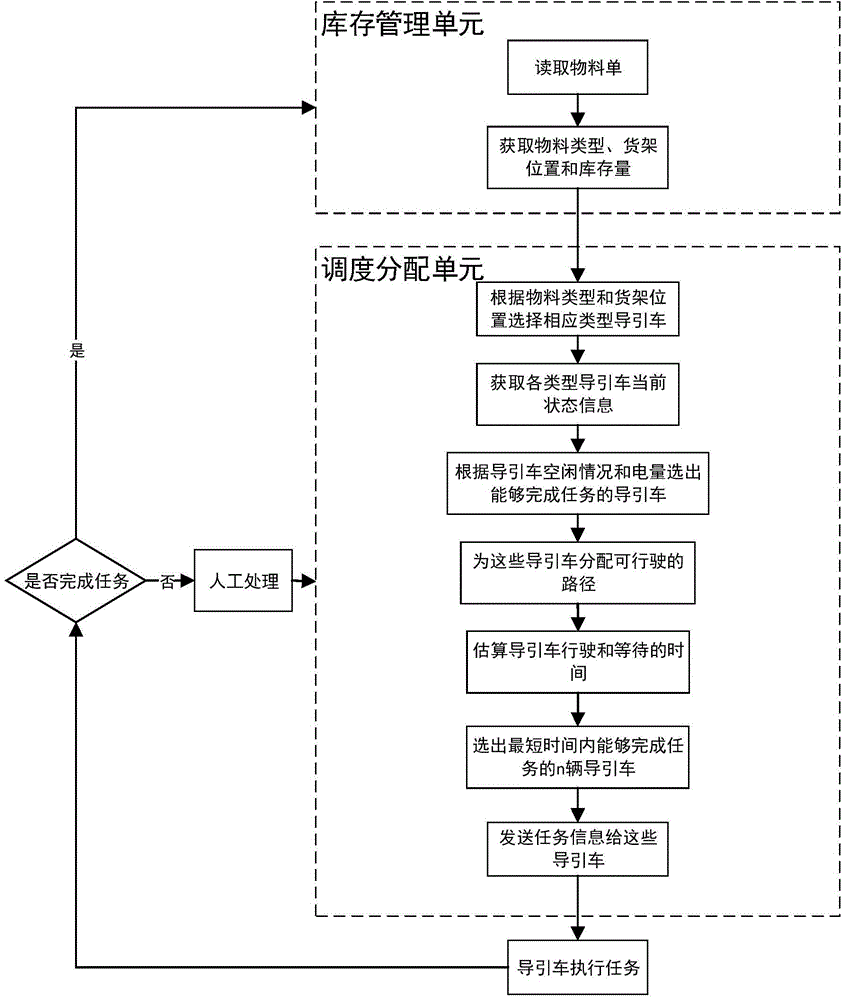

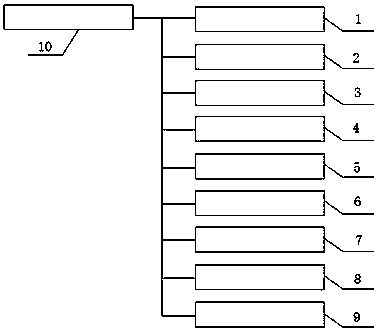

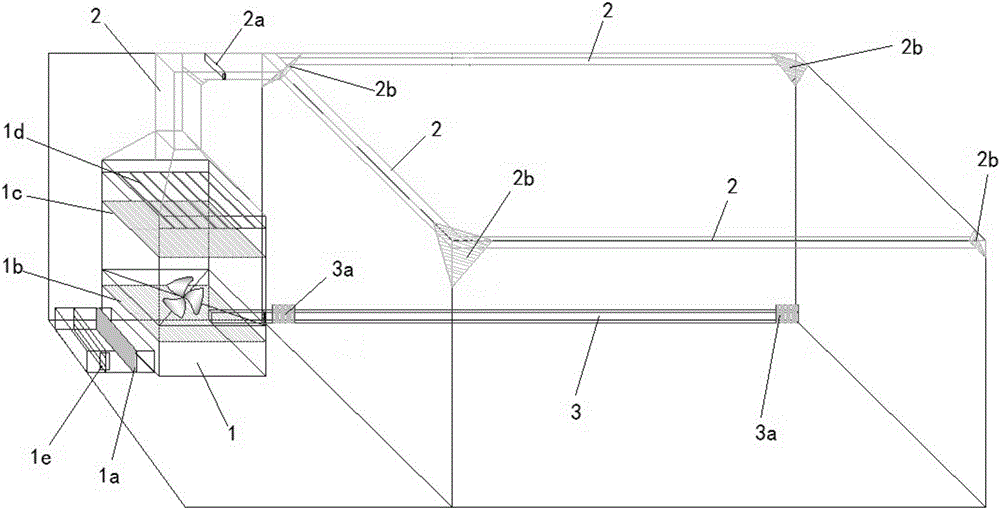

Warehouse management system with multi-guide-vehicle dispatching and distribution function

ActiveCN104809606AEasy way to workIncrease the level of automationLogisticsSelf positioningComputer science

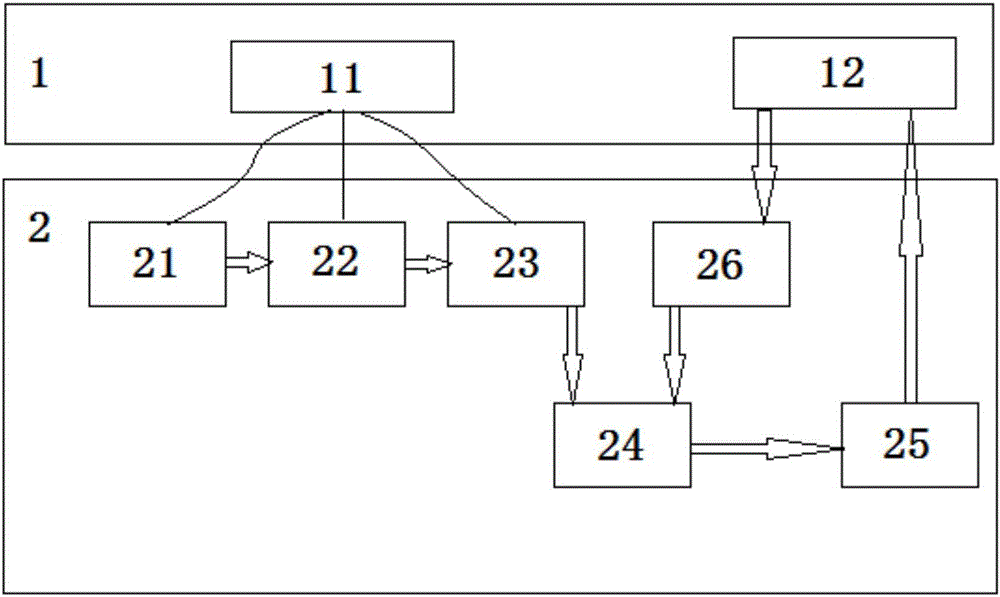

The invention discloses a warehouse management system with a multi-guide-vehicle dispatching and distribution function. The warehouse management system comprises a central management system and guide vehicles. The central management system reads material lists to obtain the inventory and position information of materials, selects appropriate guide vehicle types and number according to task quantity and the material positions, distributes the traveling routes for the guide vehicles, and selects the guide vehicles and distributes material input and output tasks according to the shortest time principle. The guide vehicles travel in a warehouse along the routes distributed by the central management system and have functions of self-positioning and barrier avoiding. The guide vehicles complete material information scanning, map information displaying and task displaying and receiving through vehicular interaction equipment and transmit guide vehicle state information to the central management system. The warehouse management system has the advantages that the guide vehicles are dispatched according to the comprehensive material information and the state information of the guide vehicles, the guide vehicles travel along the distributed routes to target positions to complete material input and output, a traditional warehouse management manner is optimized, and warehouse management efficiency is increased.

Owner:SHANGHAI JIAO TONG UNIV

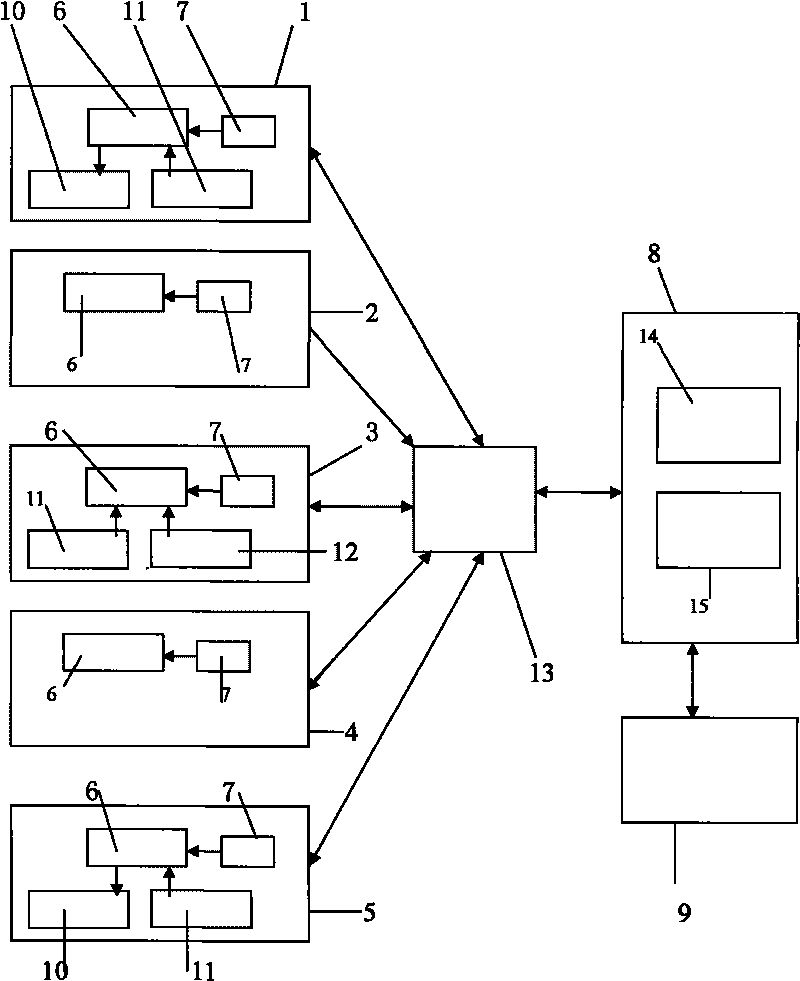

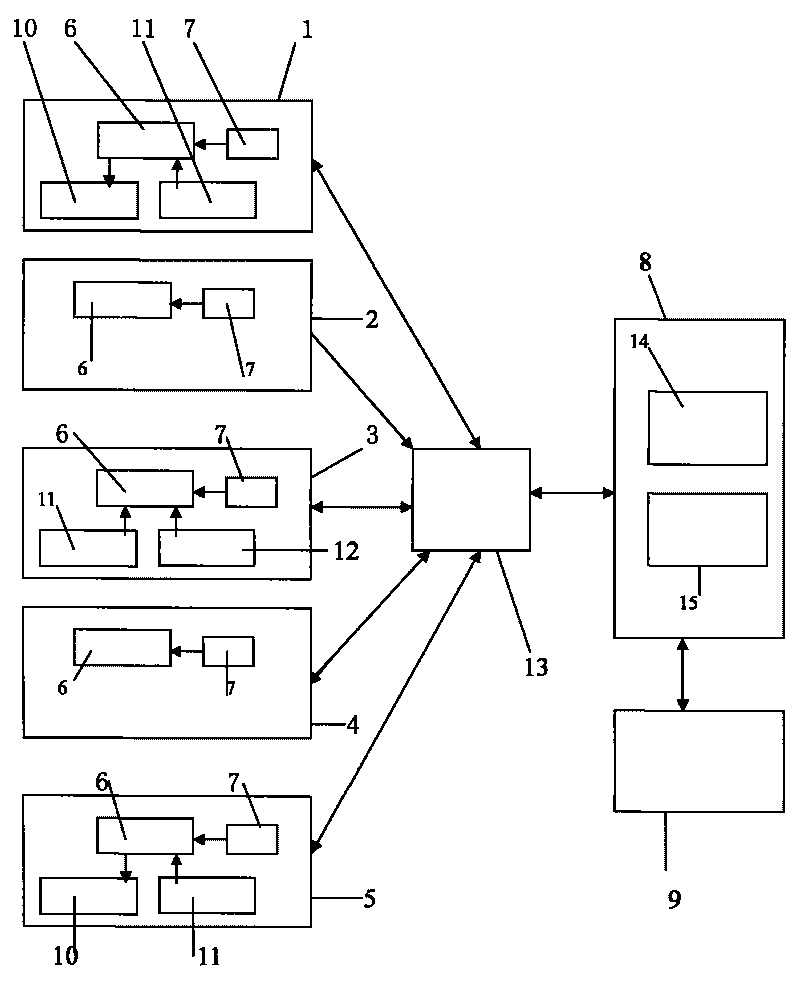

Comprehensive metering control system for coaler of coal mine

InactiveCN101763079ATimely and accurate processingEasy to handleProgramme total factory controlInformation CardControl system

The invention discloses a comprehensive metering control system for a coaler of a coal mine, belonging to the technical field of metering control systems. The system comprises the following structures of an entrance taring system, a coal loading system, a weighing system, a pricing system, an exit system, a server of a dispatch center monitoring room and a database, wherein the entrance taring system records the inert weight of the coaler, and transmits information of the coaler into the server of the dispatch center monitoring room; the coal loading system records the number of loaded coal of the coaler, and uploads the coal loading information to the server; the weighing system uploads the weighing information to the server of the dispatch center monitoring room in real time; the valuating system carries out valuation confirmation and financial settlement for the coaler through a coaler information card to complete sale transaction; the exit system transmits the information of the coaler information card to the server of the dispatch center monitoring room at the outlet; the server of the dispatch center monitoring room transmits a signal of going ahead or not to the entrance taring system and the exit system; and the database saves information of the coaler. The system accurately meters and calculates the coalers.

Owner:XIAN ZTE JINGCHENG COMM

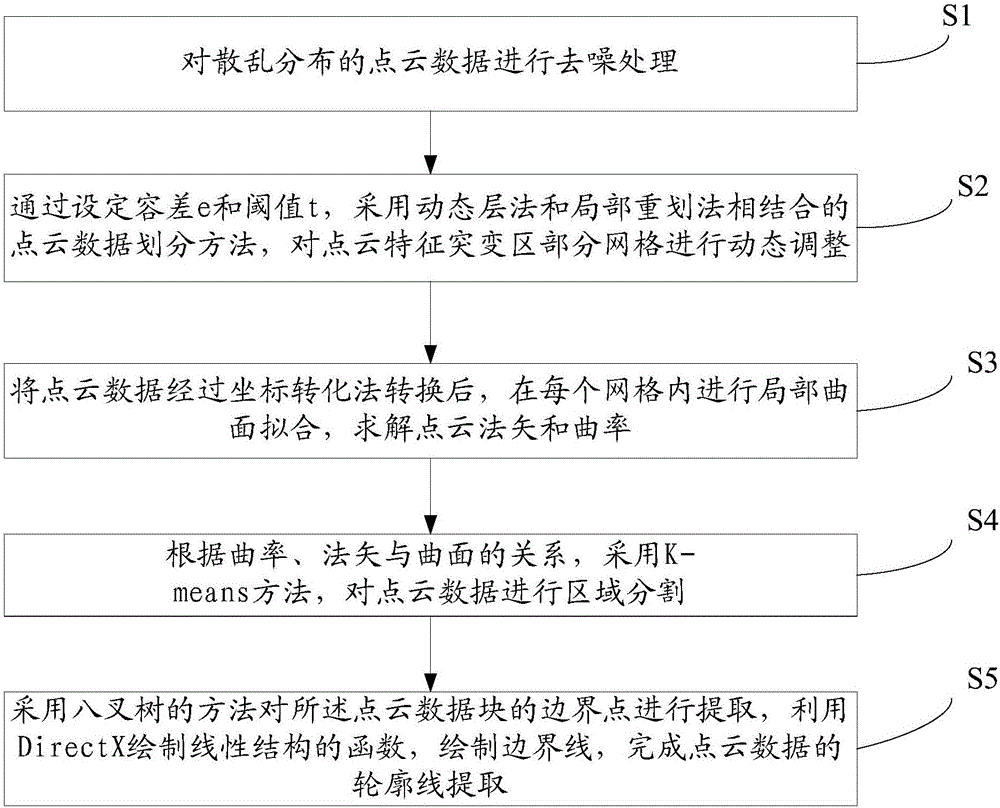

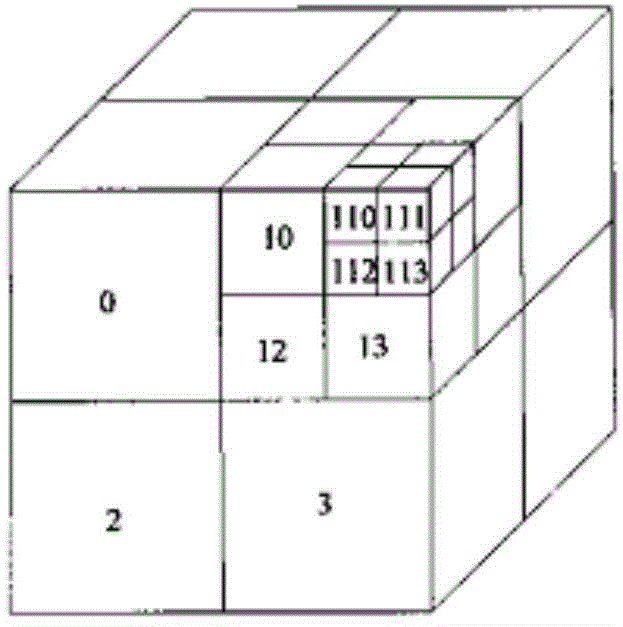

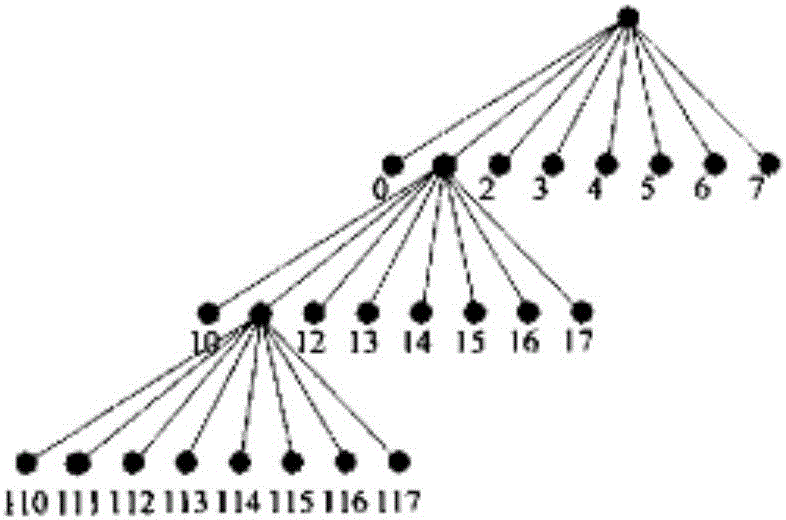

Method of extracting building contour line from Lidar point cloud data based on curvature

InactiveCN106600617AIncrease productivityEasy way to workImage enhancementImage analysisPoint cloudLidar point cloud

The invention, which relates to the technical field of the Lidar data processing, discloses a method of extracting a building contour line from Lidar point cloud data based on a curvature, wherein the method is applied to contour extraction during a digital city construction process and a production process of three-dimensional model establishment. The method comprises steps of denoising processing of point cloud data, dynamic mesh division of point cloud data, solution of point cloud normal vector and curvature, regional segmentation of point cloud data, and contour line extraction of point cloud data. According to the method disclosed by the invention, a reliable solution is provided for automatic calculation and extraction of a regular building contour line structure during the digital city contour line extraction and three-dimensional modeling process of the geographic information industry, so that a working way of purely manual building contour line extraction at this stage can be improved and the efficiency of the three-dimensional data production of the digital city can be enhanced.

Owner:MAPUNI TECH CO LTD

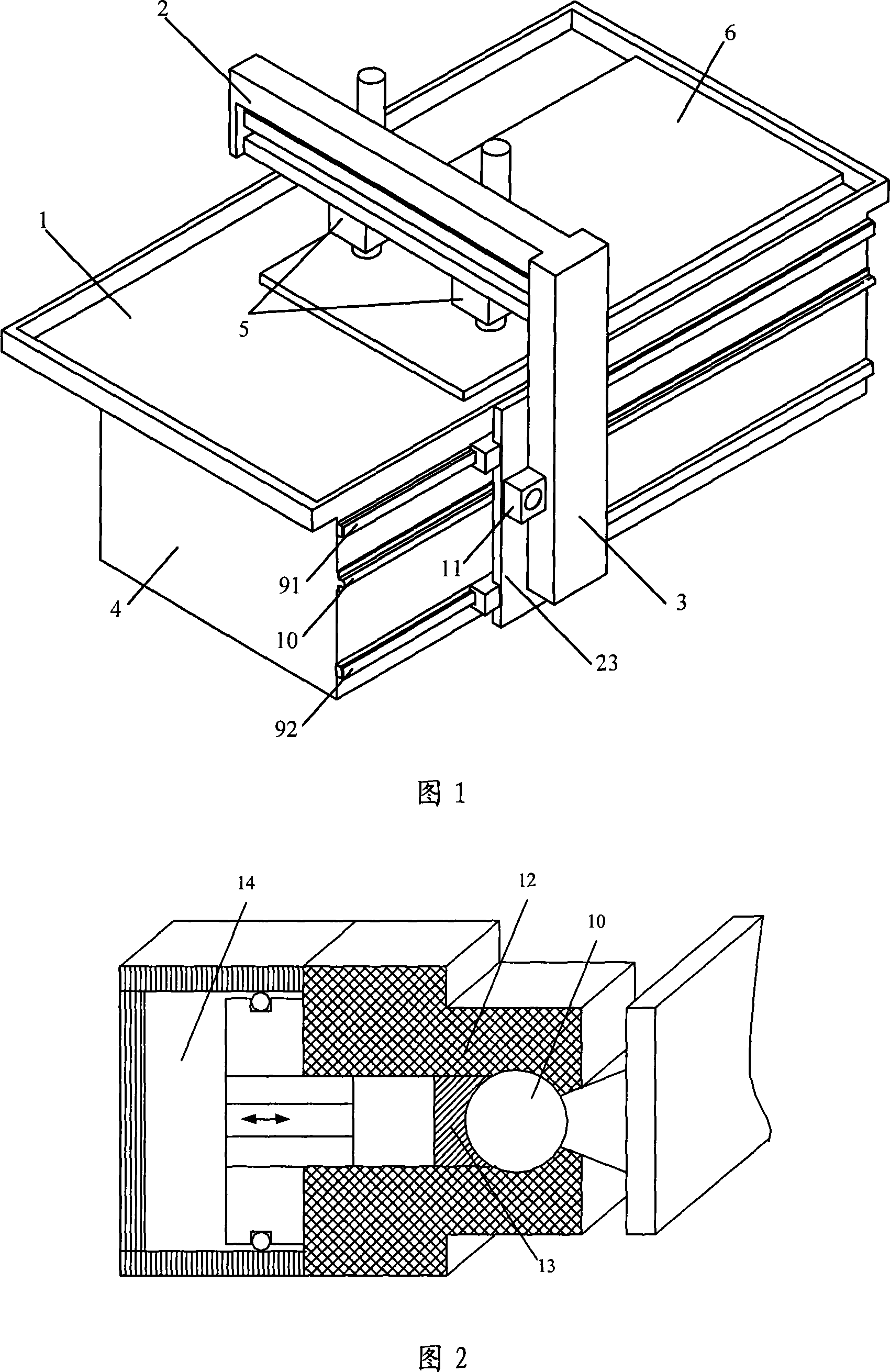

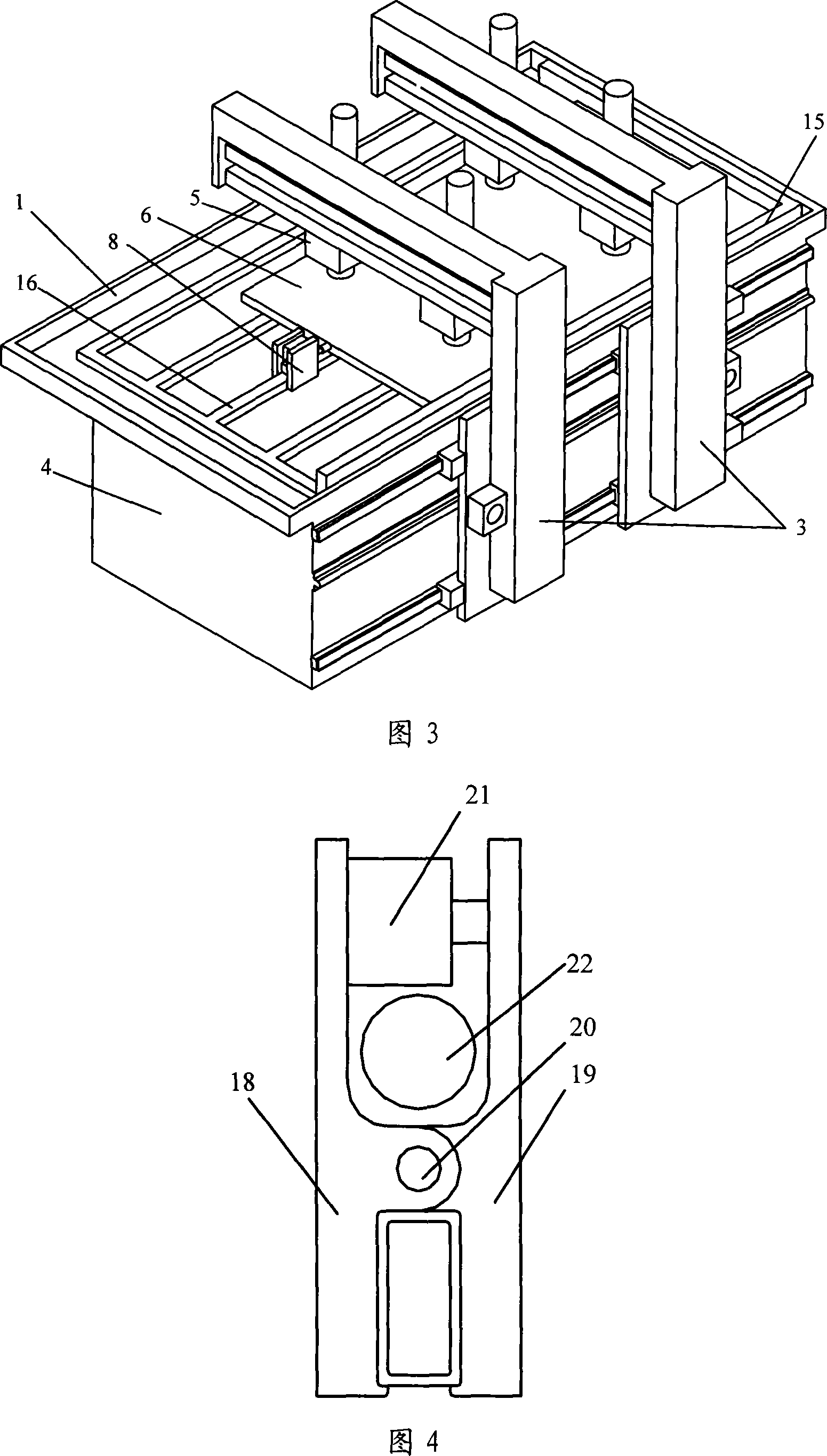

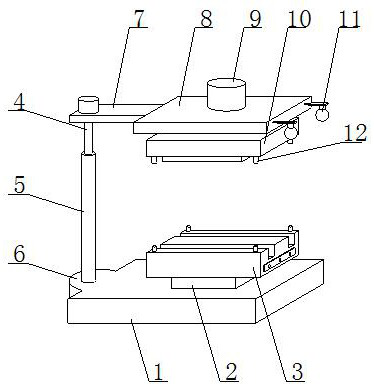

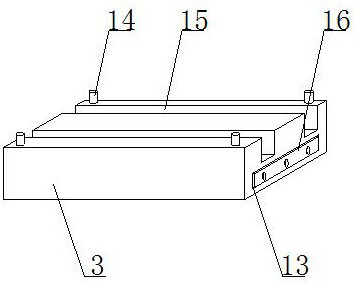

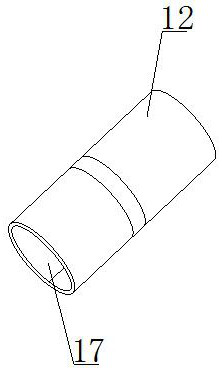

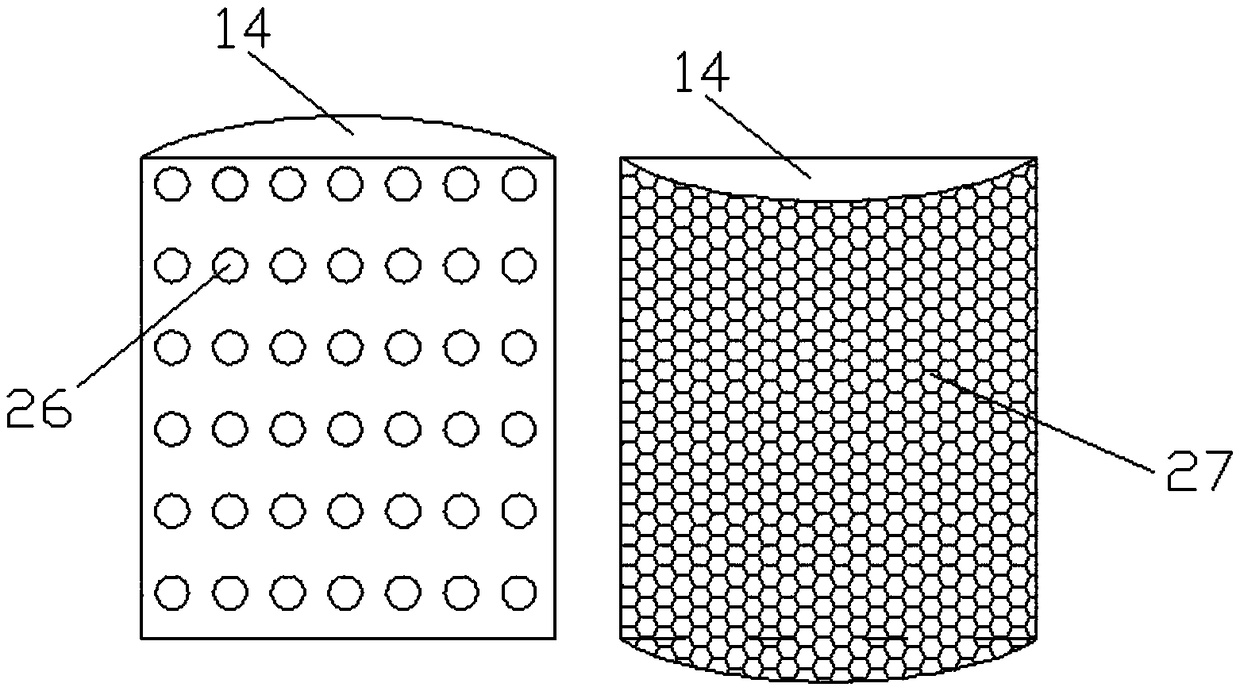

Board drilling equipment

InactiveCN101143467ATo overcome the complex processFast positioningStone-like material working toolsDrill holeMachine tool

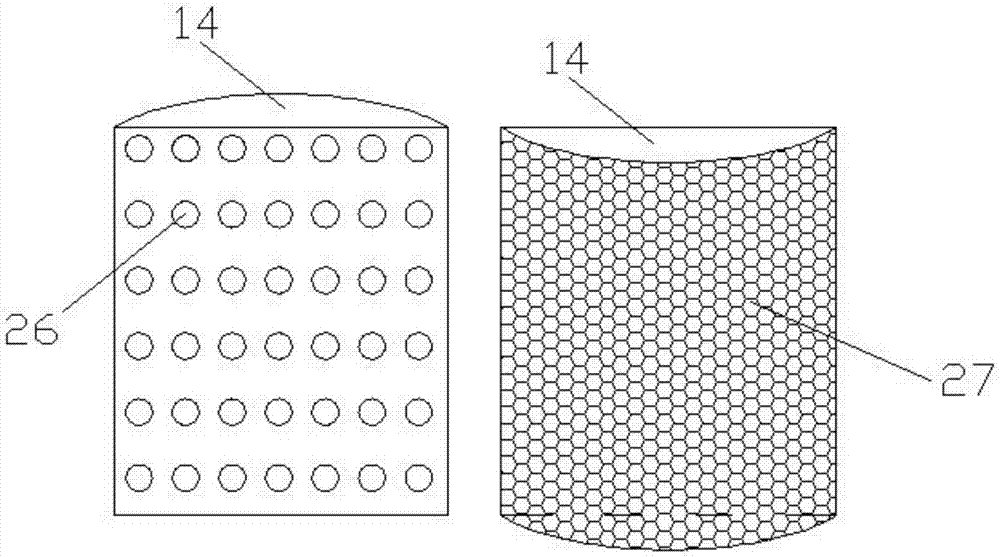

A plate drilling equipment of the invention comprises a machine tool body, an operating floor arranged on the machine tool body, a rack connected with the machine tool body and an operating head section connected with the rack, wherein the rack is an L-shape device and comprises a beam and a pillar. One side of the machine tool body is provided with at least two tracks parallel with the surface of the operating floor. The pillar is connected in sliding with the track. The machine tool body is provided with at least one locking track parallel with the track. The pillar is connected in sliding with the locking track. A locking device is arranged between the pillar and the locking track. The plate drilling equipment of the invention results in an accurate and fast positioning, reduces the required clamping process, improves the production efficiency and adapts to the complex requirement of drilling a plurality of holes in the plate at the same time.

Owner:裴庭胜

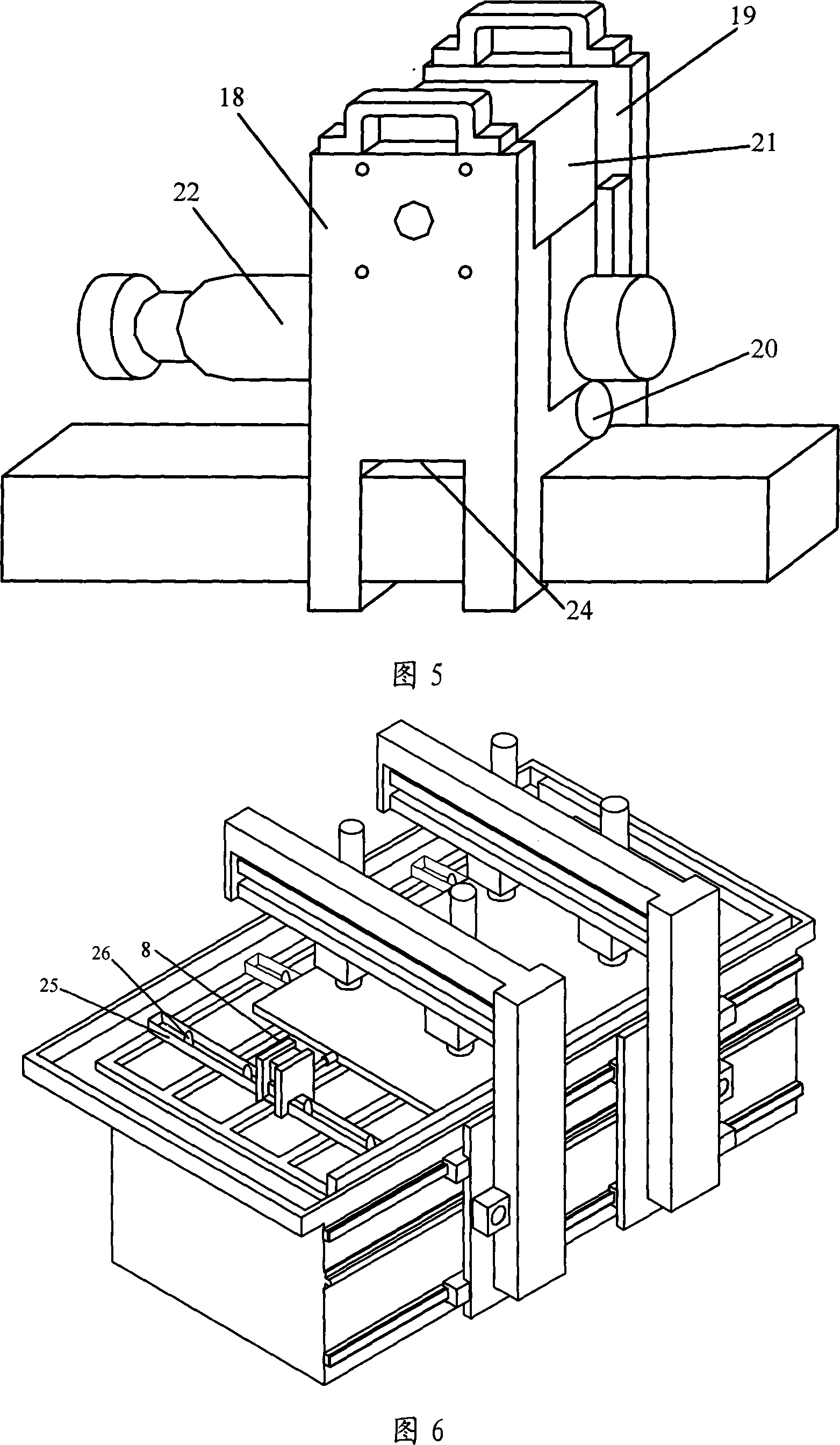

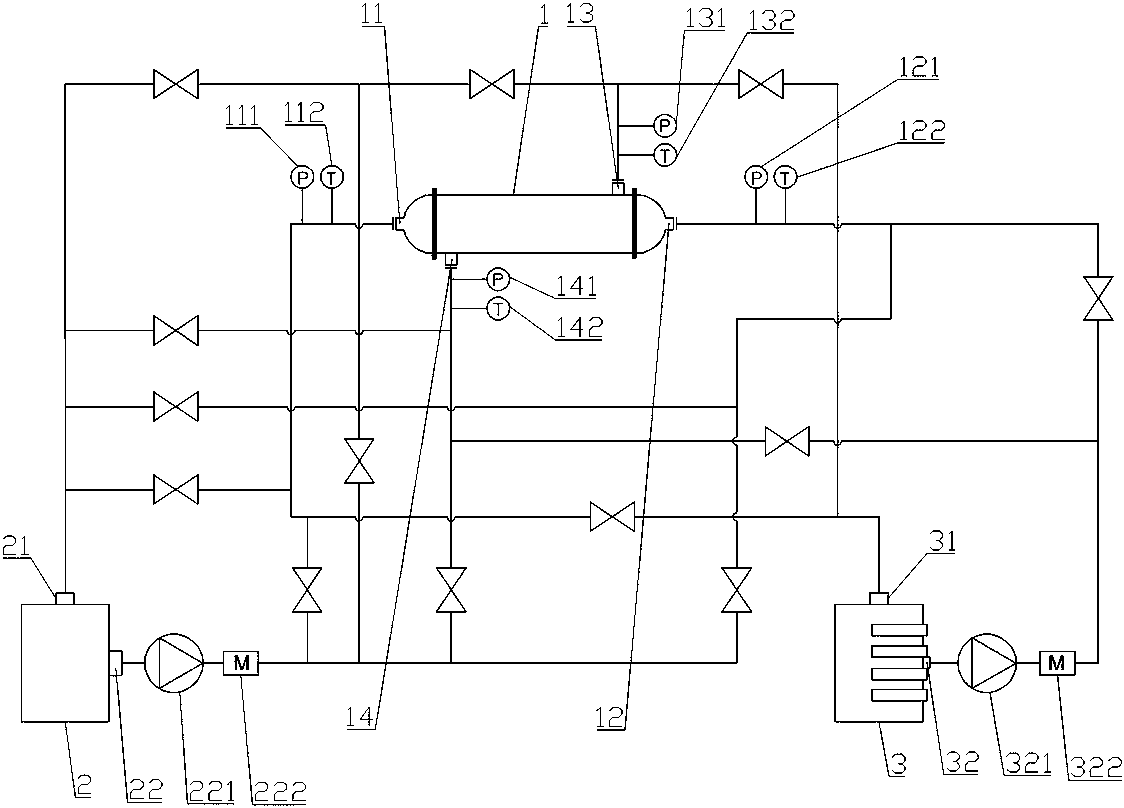

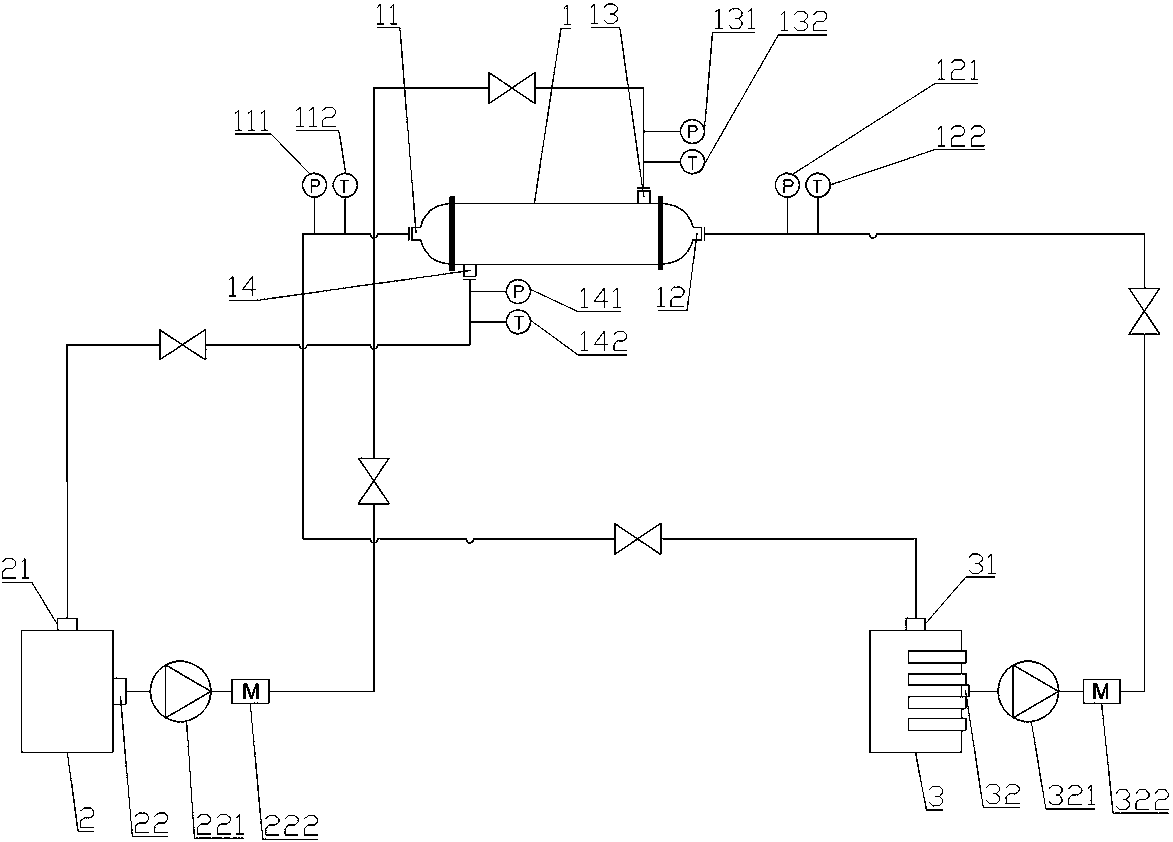

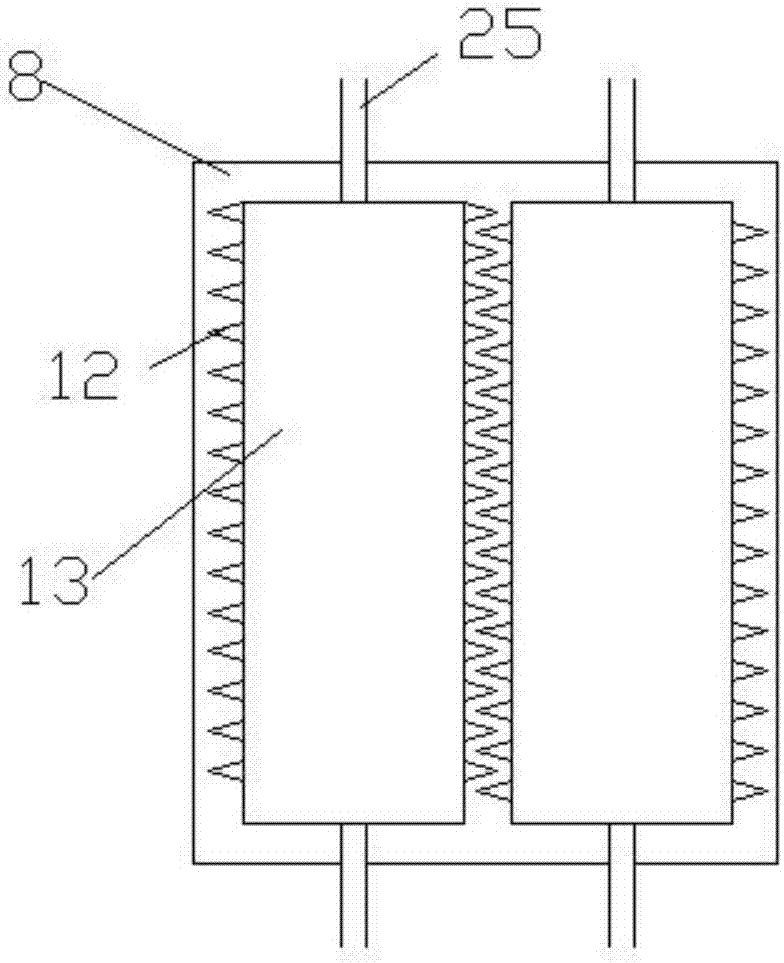

Shell-and-tube heat exchanger performance testing device and testing way

PendingCN108107075AUnderstand performanceEasy way to workMaterial heat developmentShell and tube heat exchangerEngineering

A shell-and-tube heat exchanger performance testing device comprises a shell-and-tube heat exchanger, a cold water tank, a hot water tank and a computer, wherein a tube pass cavity and a shell pass cavity are formed in the shell-and-tube heat exchanger; a water inlet and a water outlet are formed in the cold water tank; a water inlet and a water outlet are formed in the hot water tank. A shell-and-tube heat exchanger performance testing way comprises the following steps: 1, filling a pipe network and the shell-and-tube heat exchanger with a fluid; 2, selecting a specific pipeline in the pipe network to form a cold flow path and a hot flow path; 3, starting circulation of the cold flow path and the hot flow path; 4, acquiring data; 5, calculating the heat transfer performance and the resistance performance of the shell-and-tube heat exchanger. Multiple pipelines are arranged in the pipe network, each pipeline is equipped with a valve, through adjustment of opening and closing of each valve, different testing ways can be selected; altogether, four testing ways can be implemented, and in multiple testing ways, a user can more thoroughly understand the performance of the heat exchanger, so that the user can select a better working way on different occasions.

Owner:NANHUA UNIV

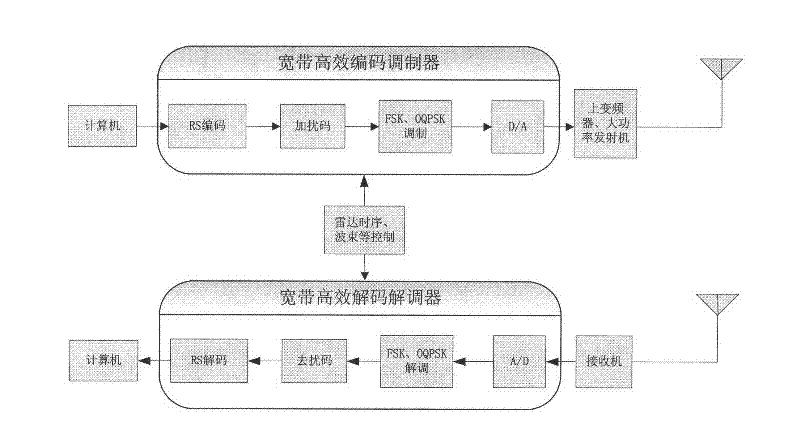

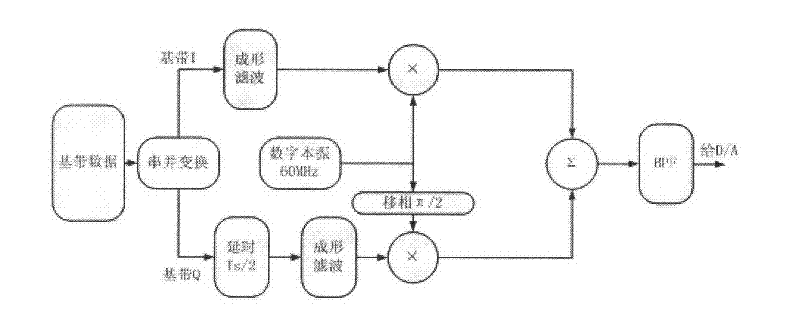

Remote high-efficiency data transmission technology of pulse radar

InactiveCN102466798AImprove the way you workLow linearity requirements for power amplifiersRadio wave reradiation/reflectionData transmissionImpulse radar

The invention relates to a remote high-efficiency data transmission technology of a pulse radar and a realization method thereof. In the method, a remote communication data transmission function is added in the conventional pulse radar. Through adding applications of a broadband efficient intermediate frequency coding modulator, a broadband efficient intermediate frequency decoding demodulator, radar sequence beam control, high-speed high-efficiency data transmission under a low duty ratio condition, Reed-Solomon coding and decoding under a deep saturated power amplifier, a FSK and OQPSK modulation demodulation technology and the like in the pulse radar, a multifunctional integration design based on the function of broadband efficient data transmission of the pulse radar, radar detection and communication information transmission can be realized.

Owner:THE 724TH RES INST OF CHINA SHIPBUILDING IND

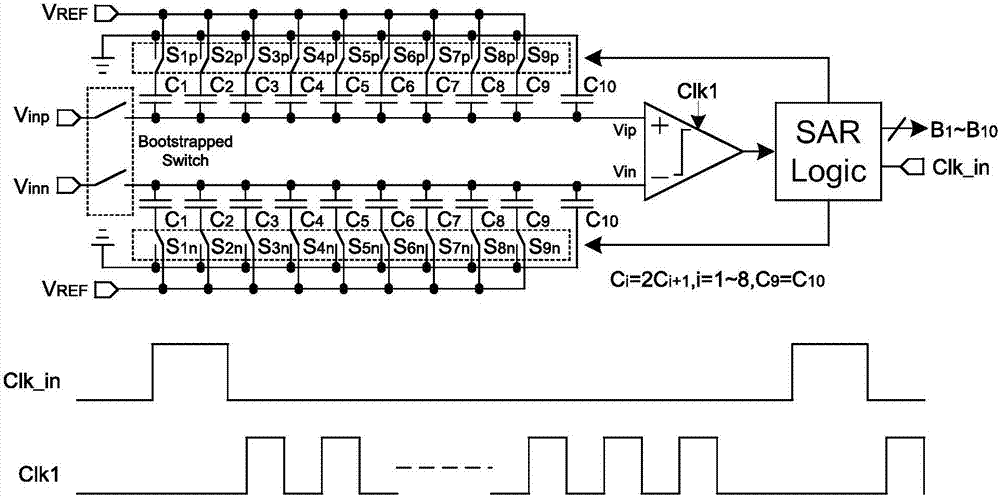

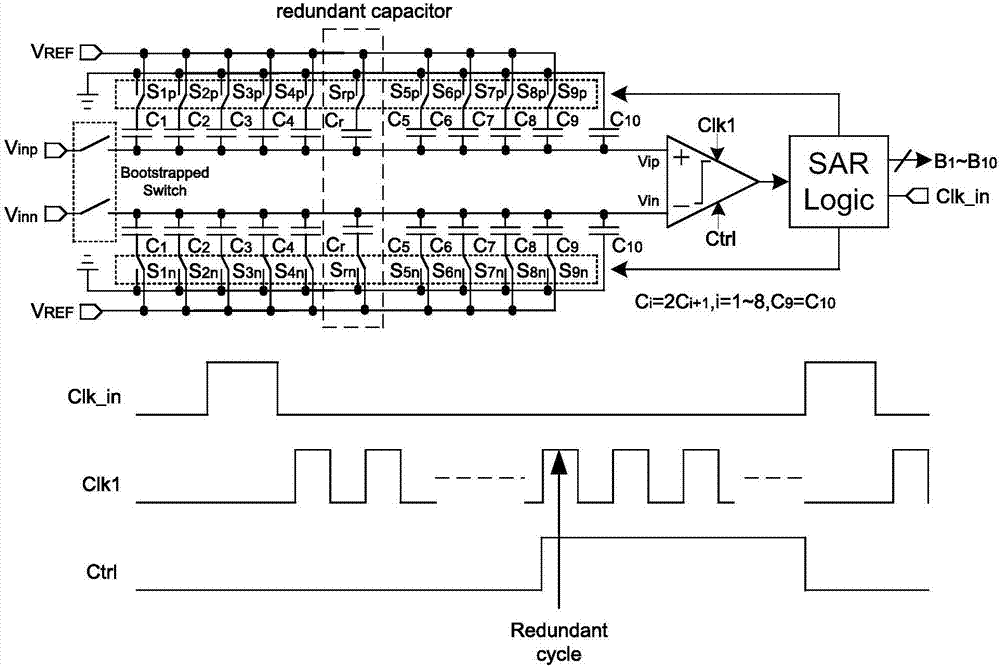

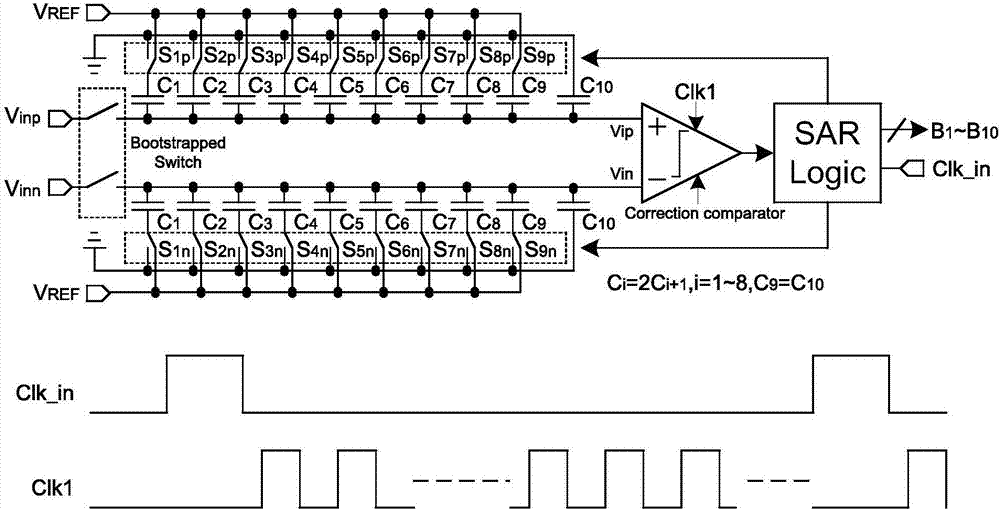

System-level error correction SAR analog-digital converter

ActiveCN106921391AEasy way to workImprove work efficiencyPhysical parameters compensation/preventionAnalogue/digital conversion calibration/testingDigital down converterDifferential signaling

The invention provides a system-level error correction SAR analog-digital converter comprising a bootstrapped sampling switch, a first capacitor array, a second capacitor array, a switch array, a comparator, a successive approximation register asynchronous logic module and an error correction comparator used for adjusting the working mode according to the change of an input differential signal. According to the system-level error correction SAR analog-digital converter provided by the invention, the comparator switches between two working modes, and the comparator can work in different working states according to the difference of the amplitudes of the input signals of the comparator, thereby optimizing the working mode of the comparator, improving the working efficiency of the comparator and further improving the performance of the whole SARADC. Moreover, the system-level error correction SAR analog-digital converter provided by the invention does not need to import an additional redundant bit to perform error correction, thereby simplifying the design difficulty and improving the working speed of the whole SARADC.

Owner:CHONGQING GIGACHIP TECH CO LTD

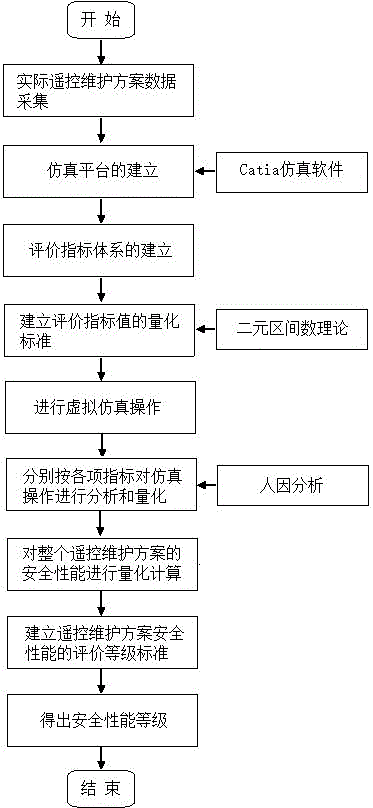

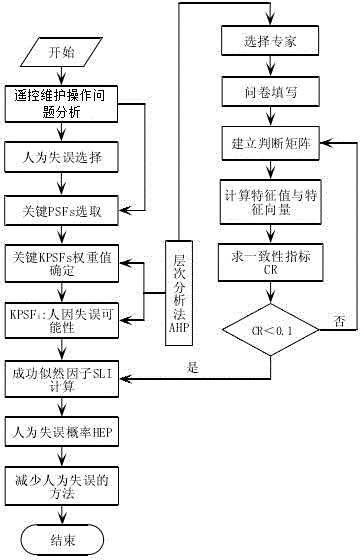

Remote control maintenance method and device based on human factor simulation analysis

The invention relates to a remote control maintenance method and device in a hot cell, especially a remote control maintenance method and device based on human factor simulation analysis in a mode of human factor simulation movement analysis and optimization maintenance. The method comprises the steps: 1) building a remote control maintenance device through Catia three-dimensional modeling software, and constructing a virtual three-dimensional remote control maintenance operation environment; 2) building a virtual human and simulation movement thereof; 3) setting an index inspection value interval of each index evaluation system as [0, 1], and setting the limits of the interval; 4) obtaining the value intervals of all indexes; 5) comprehensively evaluating the whole index of remote control maintenance according to interval vectors of all index factors and the evaluation indexes; 6) comprehensively improving a weak index in a process of maintenance operation. The method and device effectively prevent and control problems, demanding a prompt solution, of remote control maintenance, optimize the operation of remote control maintenance, improve the reliability and safety of the remote control maintenance, and improve the work efficiency and operation precision.

Owner:DONGGUAN UNIV OF TECH

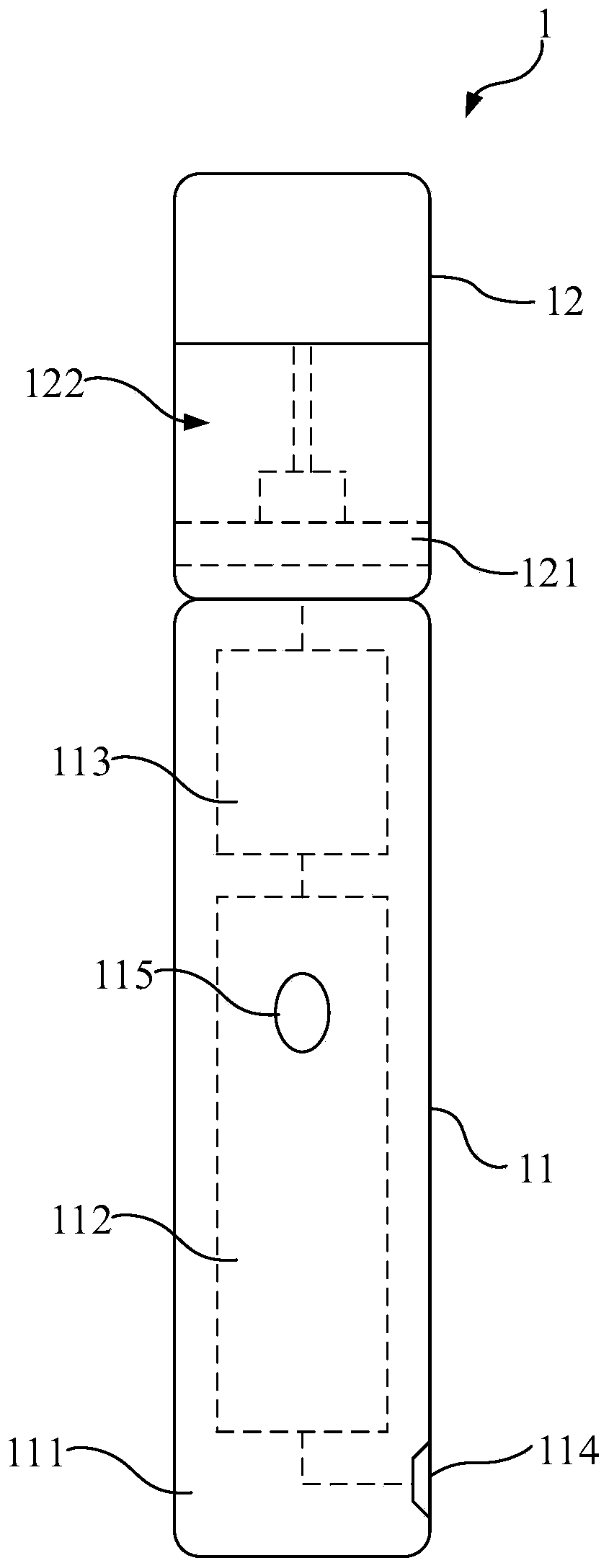

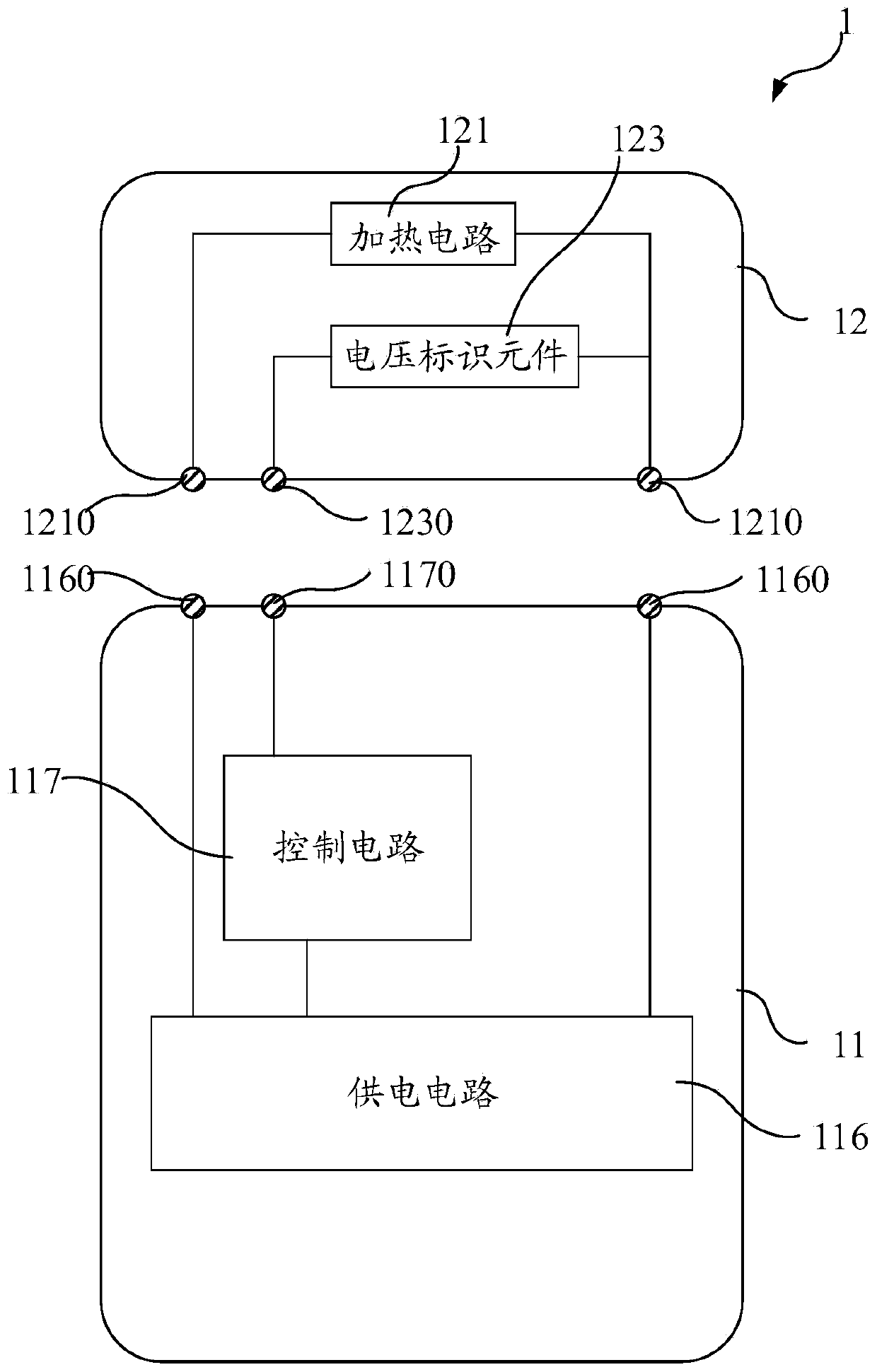

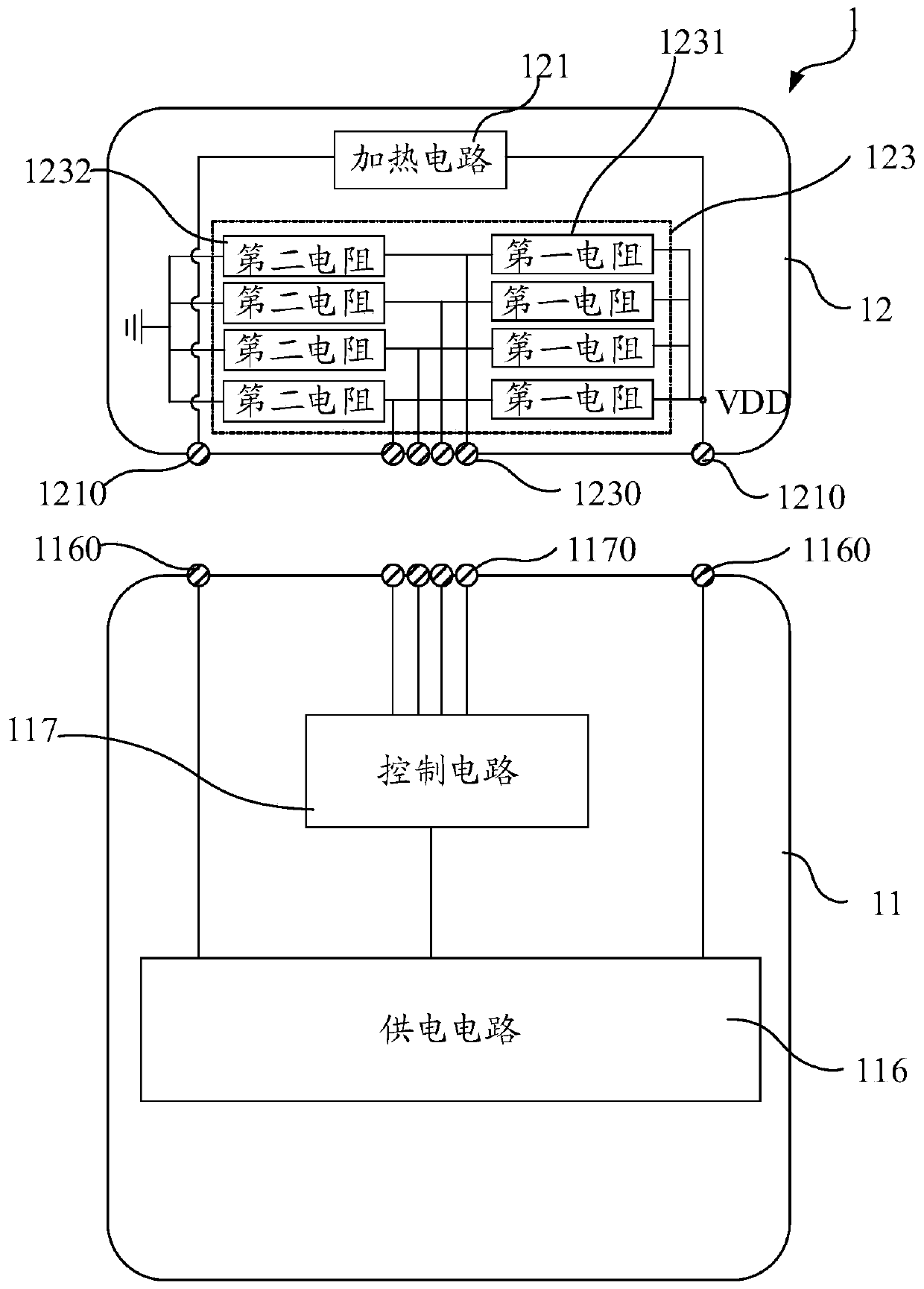

Electronic cigarette, cigarette utensil and cartridges

The invention discloses an electronic cigarette, a cigarette utensil and cartridges. The electronic cigarette comprises the cigarette utensil, the cartridges and one or more sets of voltage identification elements, and the voltage identification elements are used for identifying the cartridges; the cigarette utensil comprises a power supply circuit and a control circuit, the power supply circuit is provided with a power supply end, and the control circuit is provided with a signal end which is used for being connected with the voltage identification elements; the cartridges comprise heating circuits, and the heating circuits are provided with receiving ends which are used for being connected with the power supply end; and the control circuit is used for obtaining voltage signal values fromthe voltage identification elements through the signal end and judging the types of the cartridges according to the voltage signal values. In this way, the cartridges of the different types can be effectively identified.

Owner:JOUZ LTD

Online monitoring and management method for enterprise environment

InactiveCN108805401AMonitor emissionsEasy way to workResourcesReal-time dataApproaches of management

The invention relates to an online monitoring and management method for an enterprise environment, and belongs to the technical field of enterprise environment monitoring and management. According tothe technical scheme, an online monitoring and management platform for the enterprise environment is built; and each collected monitoring factor of each outlet of each area of a company is added to aninformation display module of the platform, and 24-hour real-time data of the monitoring factors are continuously updated. Different permissions are set for login users according to functions and posts of the platform users; and login time, an operation behavior and operation time of each user are recorded. The method breaks through the limitation of environment management time and regions, and provides real-time, objective and real environment monitoring information and environmental protection management information for enterprises to the largest extent, so that all levels of environmentalprotection managers can master the latest pollution source discharge condition and the environmental protection event disposal condition in first time, the current situation that the enterprise pollution discharge exceeds the standard and is not known and managed by persons is thoroughly eliminated, and the comprehensive decision and service management costs can be reduced.

Owner:WEIER AUTOMATION CO LTD TANGSHAN IRON & STEELGRP

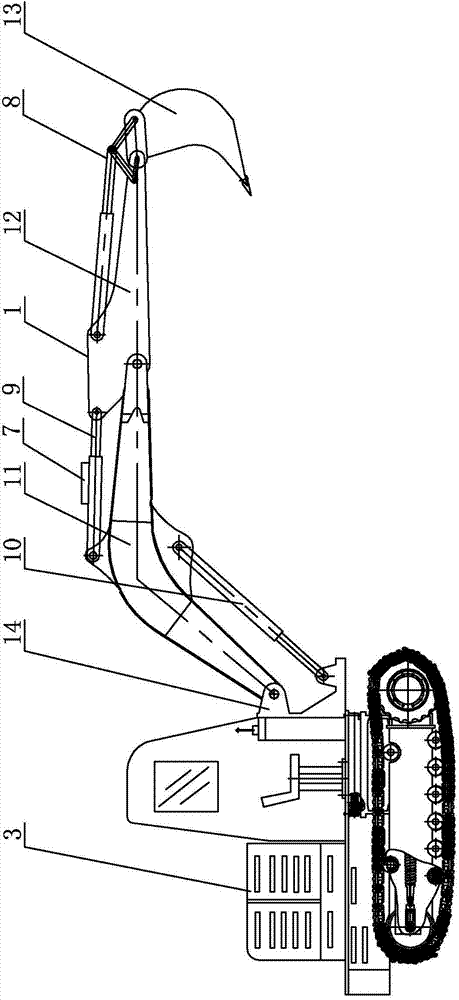

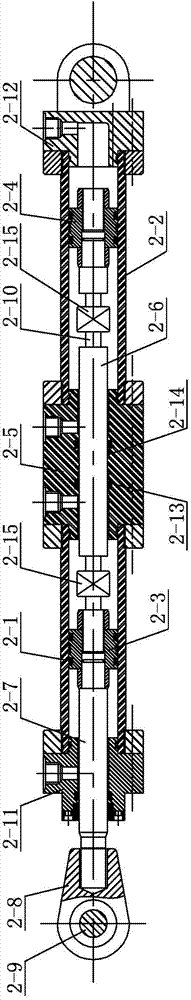

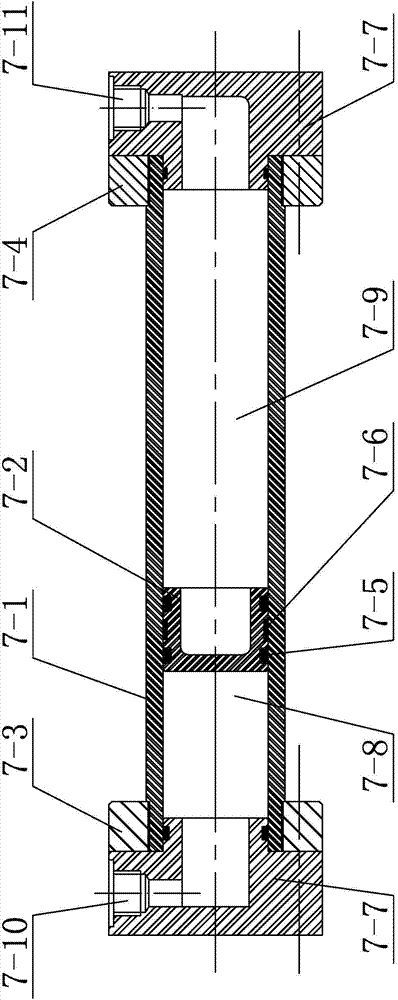

Automatic balance adjusting system of mechanical arms

InactiveCN104846863AReduce useless workReduce energy consumptionMechanical machines/dredgersFluid-pressure actuator componentsHydraulic cylinderControl signal

The invention provides an automatic balance adjusting system of mechanical arms, and relates to an automatic balance adjusting system. By the automatic balance adjusting system of the mechanical arms, the problems that the existing mechanical arm can apply idle work during movement due to the gravity of the existing mechanical arm, and the idle work can consume a large amount of mechanical power are solved. The automatic balance adjusting system comprises at least one mechanical arm, at least one hydraulic cylinder subassembly, a hydraulic driving system, an intelligent control system and a plurality of energy accumulators; a signal outputting end of the intelligent control system transmits a control signal to the hydraulic driving system; the hydraulic driving system controls movement of at least one hydraulic cylinder; each mechanical arm is matched with the corresponding hydraulic cylinder subassembly; each hydraulic cylinder subassembly moves to drive the corresponding mechanical arm to move; and the energy accumulators are arranged on the hydraulic cylinder subassemblies. Gravitational potential energy of the mechanical arms which work in a reciprocating manner is stored in the energy accumulators, and is released when the mechanical arms rise, power consumption on rising of the mechanical arms is reduced effectively, and the mechanical arms are prevented from applying idle work to a maximum extent. By the automatic balance adjusting system, ascending and descending of the mechanical arms can be adjusted.

Owner:QIQIHAR UNIVERSITY

Household automatic air purification system

InactiveCN105737359AEasy way to workIncrease carbon dioxide levelsMechanical apparatusSpace heating and ventilation safety systemsFresh airEngineering

The invention discloses a household automatic air purification system. The household automatic air purification system comprises an air purifier arranged outdoors, an air feeding pipeline and an air return pipeline. The air purifier is provided with a fresh air inlet used for sucking external atmosphere, an indoor air inlet used for sucking indoor air and an exhausting port used for exhausting purified clean air to the outside. The air feeding pipeline connects the air exhausting port of the air purifier with indoor space to feed the clean air exhausted by the air exhausting port of the air purifier into a room; the air return pipeline connects the indoor air inlet of the air purifier with the indoor space to feed the indoor air into the air purifier for purification. The use defect in the market that the purification effect can be improved only by closing doors and windows is overcome, the situation that the content of carbon oxide is increased and the content of oxygen is decreased indoors is prevented, the limitation that air can be purified only through a central air conditioning system is broken through, the purification area is increased, and loss of indoor useful space is reduced.

Owner:SHANGHAI DIANJI UNIV

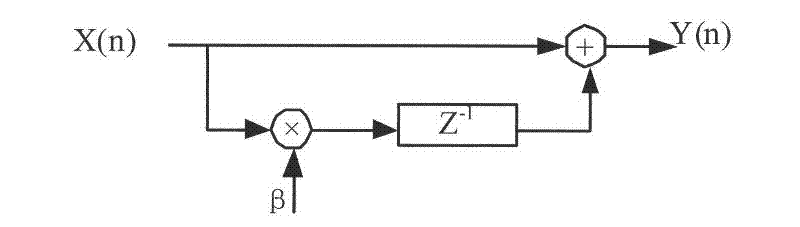

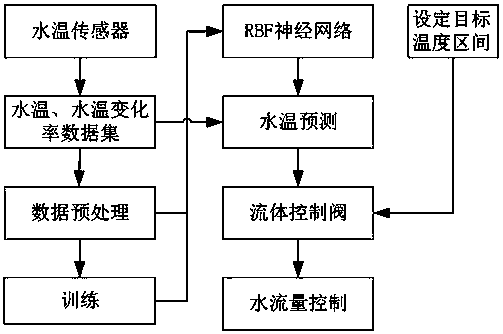

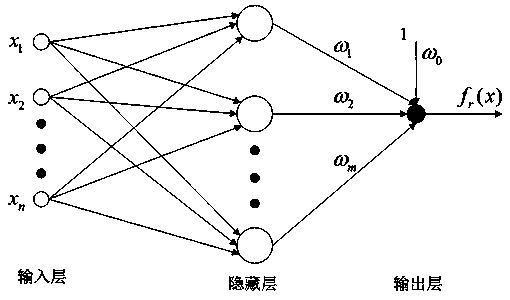

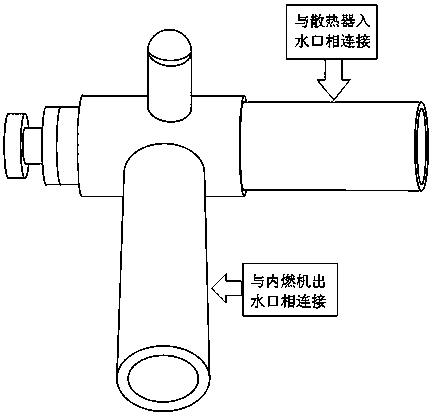

Internal combustion engine cooling water flow intelligent control method based on RBF neutral network

ActiveCN111456840AEasy way to workIncrease powerCoolant flow controlMachines/enginesInternal combustion engineElectronic information

The invention discloses an internal combustion engine cooling water flow intelligent control method based on an RBF neutral network. According to the method, an RBF neutral network model suitable forpredicting the water temperature of an internal combustion engine is designed, and the designed RBF neutral network model is trained and tested through a temperature data set, acquired through measurement, of the internal combustion engine; and the water temperature predicted temperature of the internal combustion engine is calculated through the RBF neutral network model, the temperature difference between the predicted temperature and the target water temperature is calculated, the cooling water flow is adjusted and controlled according to the temperature difference, the operating temperature of the internal combustion engine is subjected to temperature compensation, and therefore the operating water temperature of the internal combustion engine is within a target water temperature interval in real time. The modern electronic information technology is applied to control over a cooling circulation system of the internal combustion engine, it is guaranteed that the internal combustionengine always keeps or approaches the optimal temperature interval in any climatic environment for work, thus, part abrasion aggravation is truly achieved, tail gas emission is reduced, the working manner of the internal combustion engine is improved, and then the purposes of saving energy and reducing emission are achieved.

Owner:江苏隆信德科技有限公司

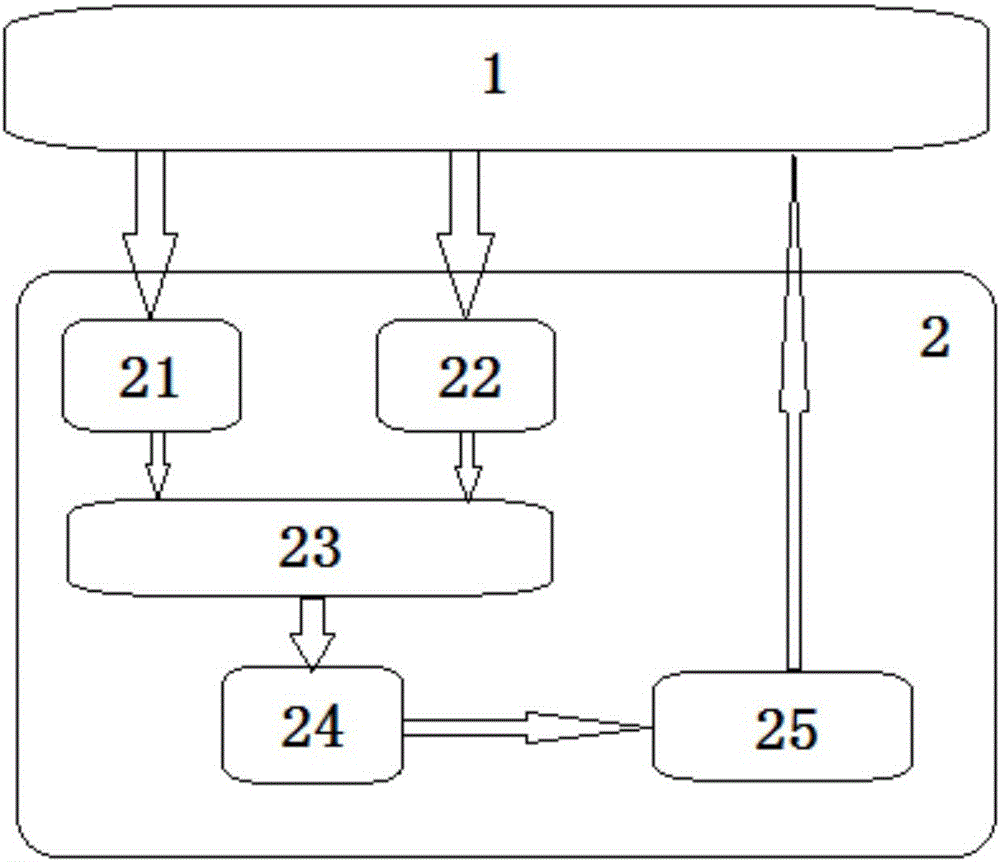

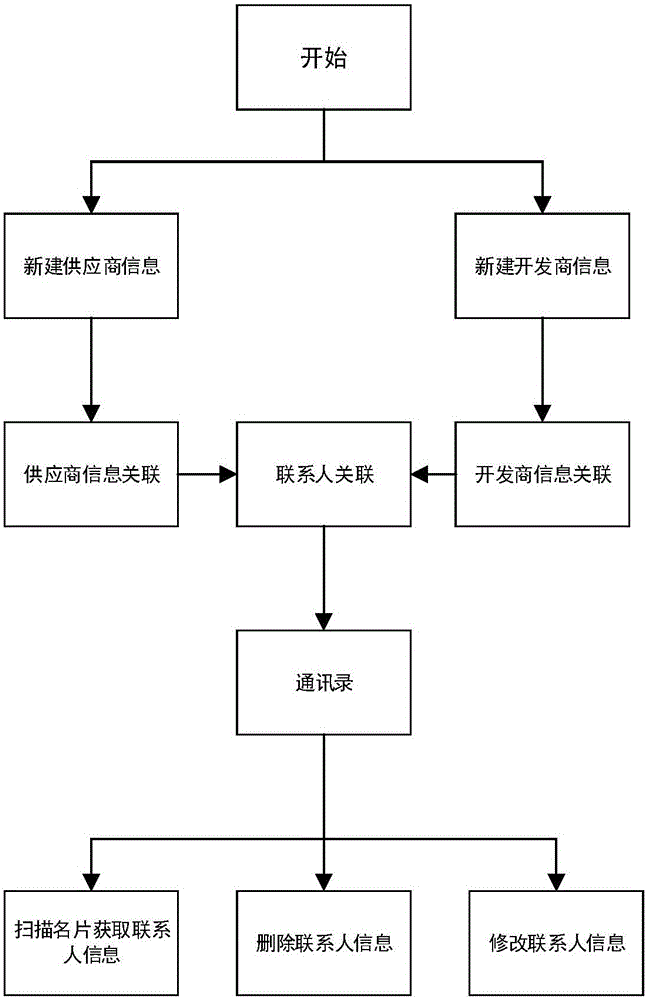

Human-computer interaction system for associating information of supplier, contact and enterprise library

InactiveCN106779617AImprove query efficiencyGood user experienceOffice automationLibrary scienceHuman system interaction

The invention relates to a human-computer interaction system for associating information of a supplier, a contact and an enterprise library. The system is used for classifying, querying and displaying the associated information of the supplier, the contact and the enterprise library. The system comprises a foreground subsystem and a background subsystem, wherein the foreground subsystem comprises multiple distributed operating terminals, and is used for acquiring the information of the supplier and the enterprise library and displaying the associated information of the supplier, the contact and the enterprise library as well as a query result; the background subsystem is a cloud data server connected with the operating terminals, and is used for creating, classifying and associating the information of the supplier, the contact and the enterprise library. Compared with the prior art, the system has the advantages of information sharing, applicability to multiple network environments, safety, reliability and the like.

Owner:蔡婷 +1

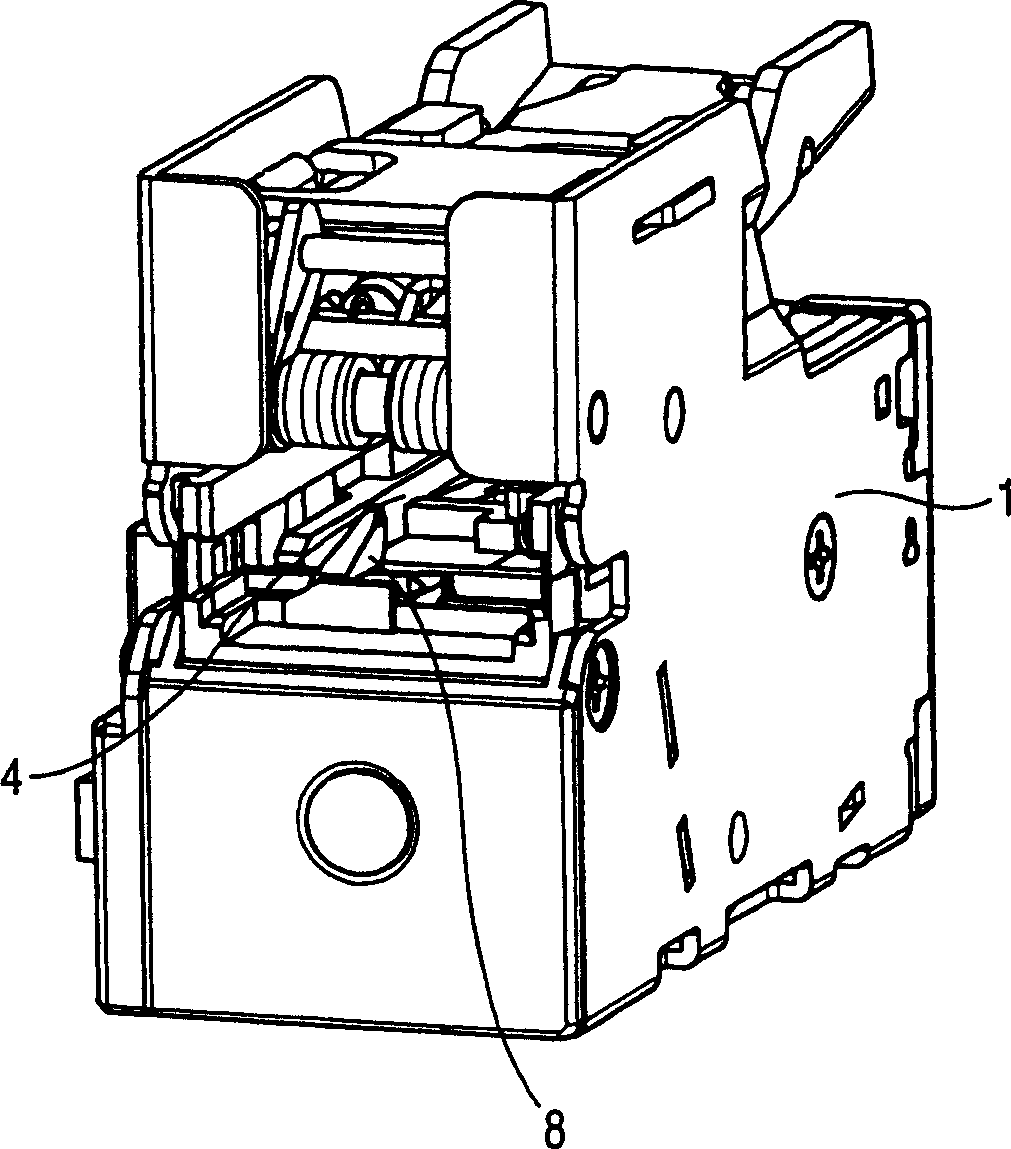

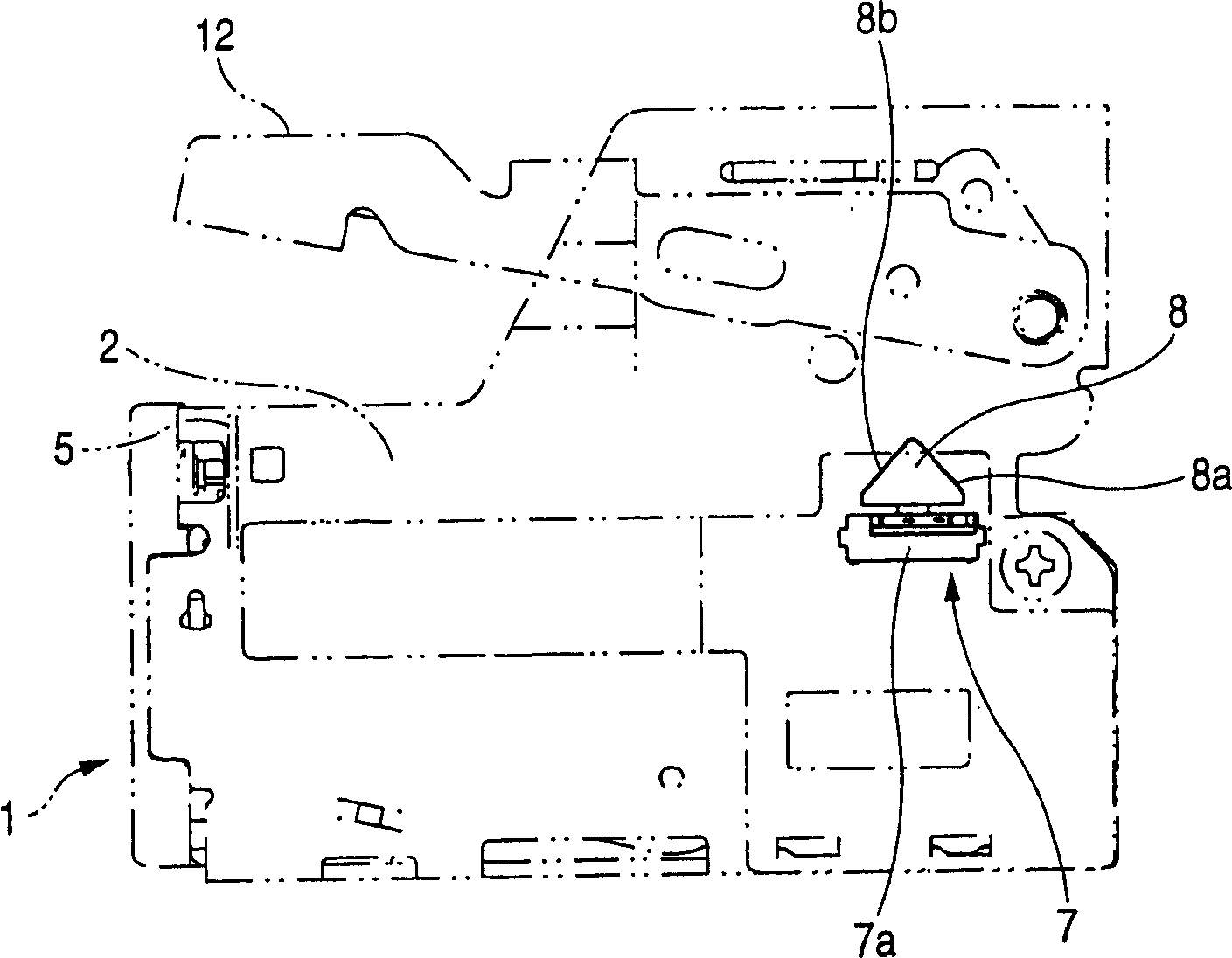

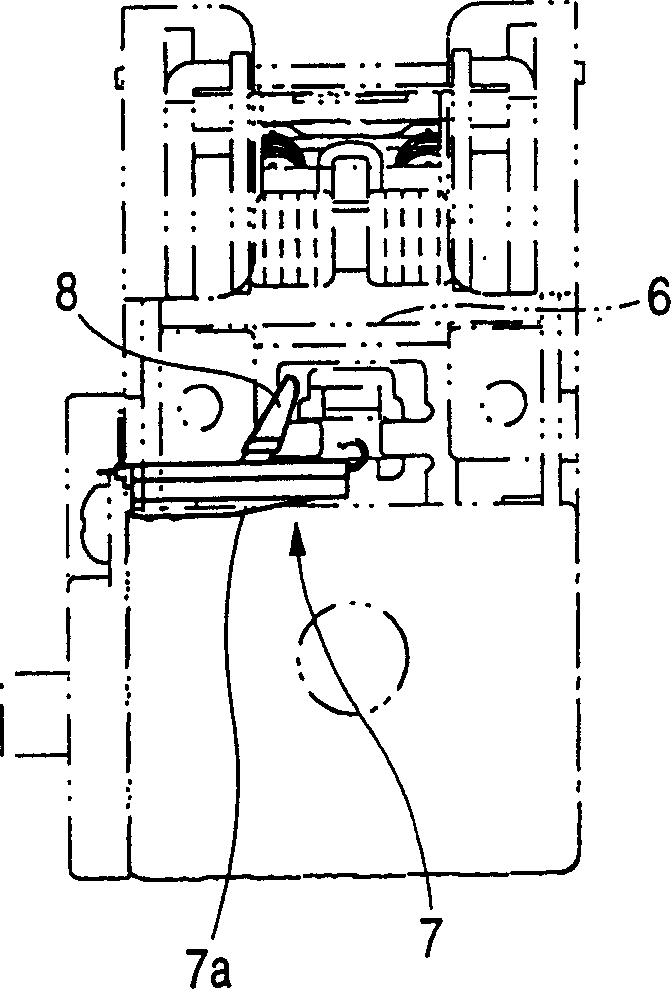

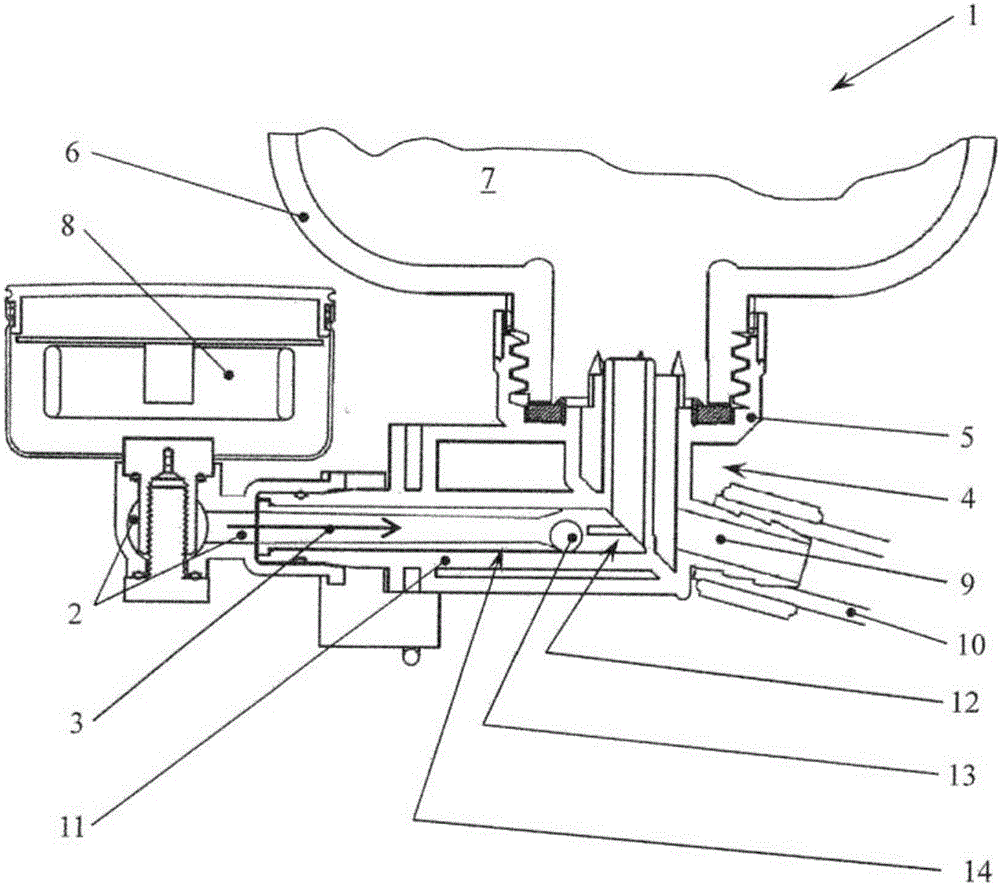

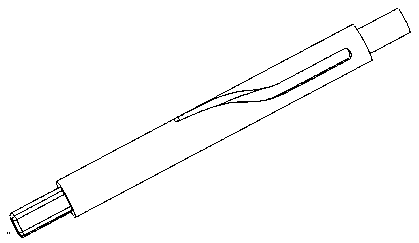

Staple detection mechanism of electric stapler

In an electric stapler which includes: a passage (4) formed in a magazine portion (2) of the stapler body (1), for attaching and detaching a staple cartridge (3); and sheet staples (a) accommodated in the staple cartridge (3), wherein both side portions of the lead staple (a1) and the following staples of the sheet staples (a) are successively bent and stricken, a staple detection sensor (7), both sides of the end of the actuator (8) of are tapered, is arranged so that both side portions can be directed to an entrance of the passage (4) and the end of the staple detection sensor (7) can be engaged with an upper or a lower face of the sheet staples (a) of the staple cartridge (3) attached into the passage (4). The actuator (8) is swung and tilted in the perpendicular direction to the longitudinal direction of the passage (4) and biased by a spring so that it can obliquely rise at all times.

Owner:MAX CO LTD

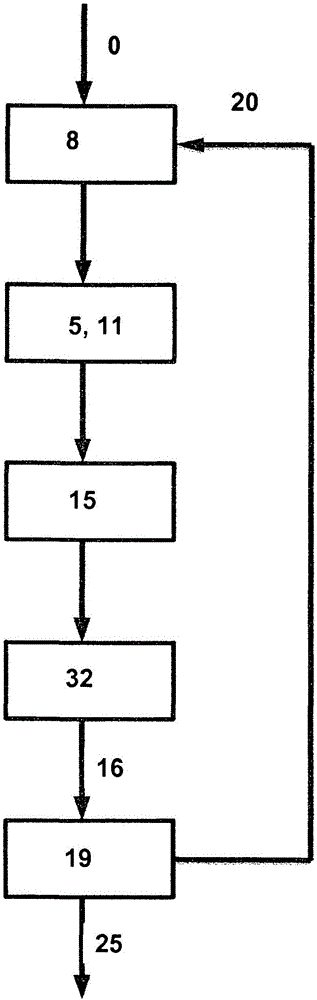

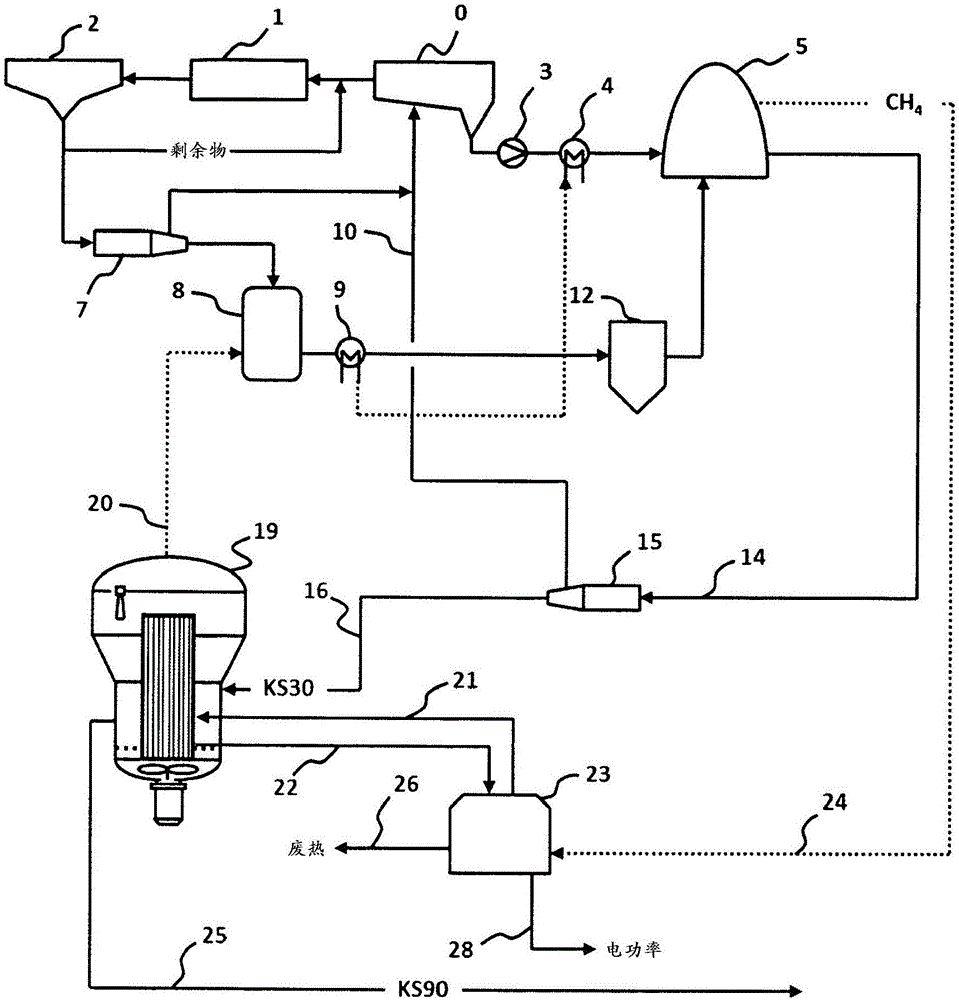

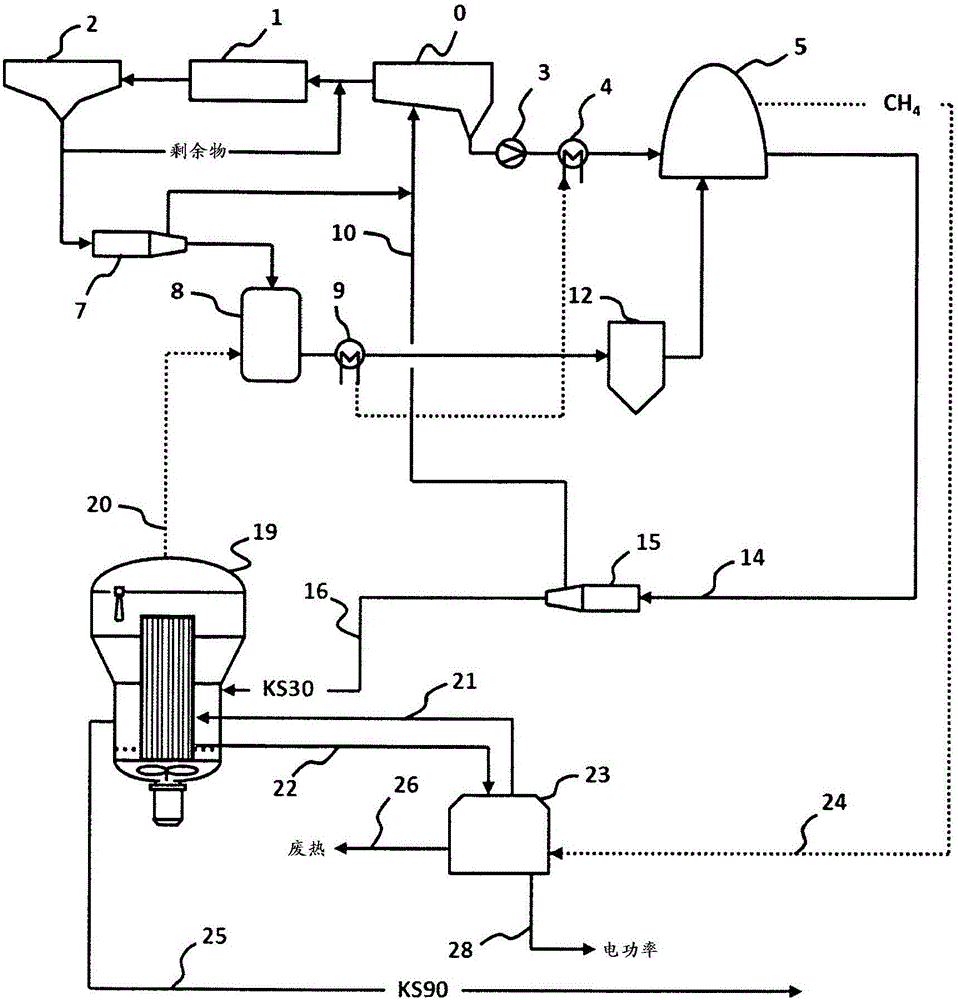

Method and arrangement for wastewater treatment

PendingCN106795023AReduce consumptionLow costByproduct vaporizationWaste based fuelSludgePositive pressure

The invention relates to a method and an arrangement for wastewater treatment, in which at least portions of the sewage sludge contained in the wastewater (0) are subjected to a hydrolysis (8). The hydrolysis (8) is carried out as a thermal hydrolysis. After the hydrolysis step (8), a drying process is (19) carried out. The drying process (19) is a process operating with positive pressure in the steam region. At least parts of the steam resulting from the drying process (19), which operates with positive pressure, are fed (20) to the portions of the sewage sludge in the thermal hydrolysis (8).

Owner:AWAMA

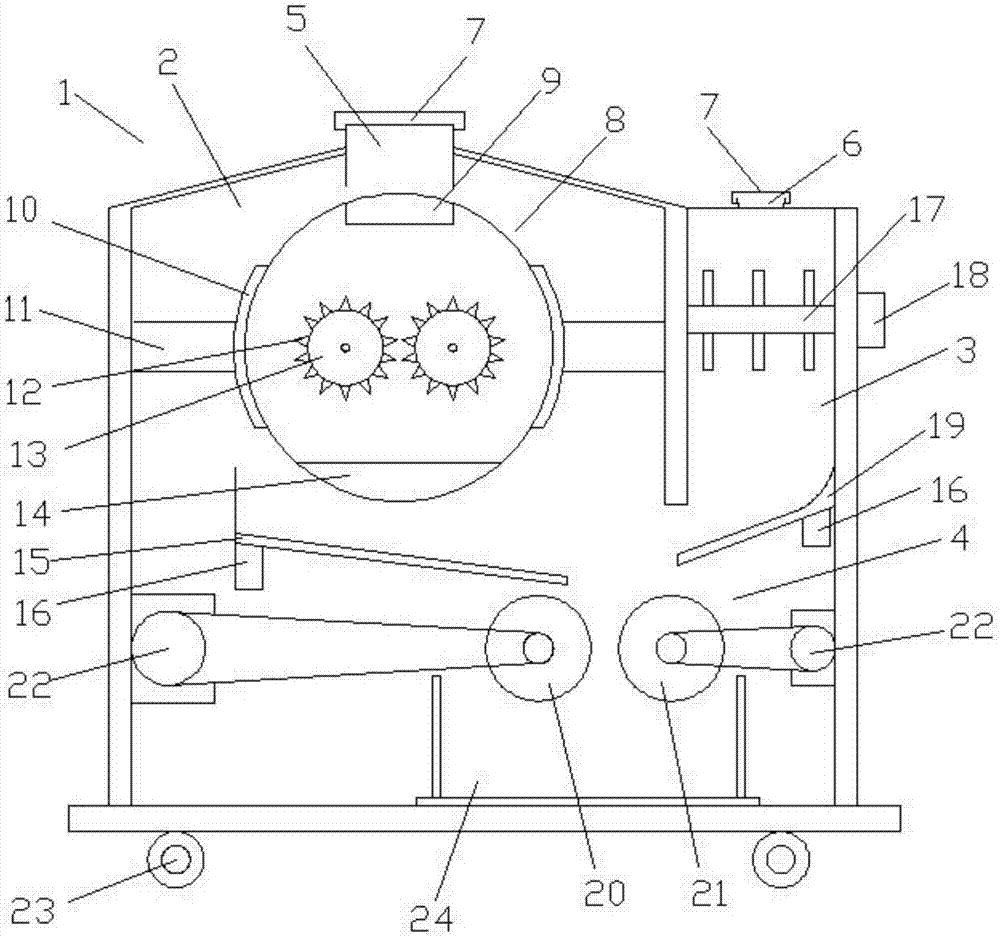

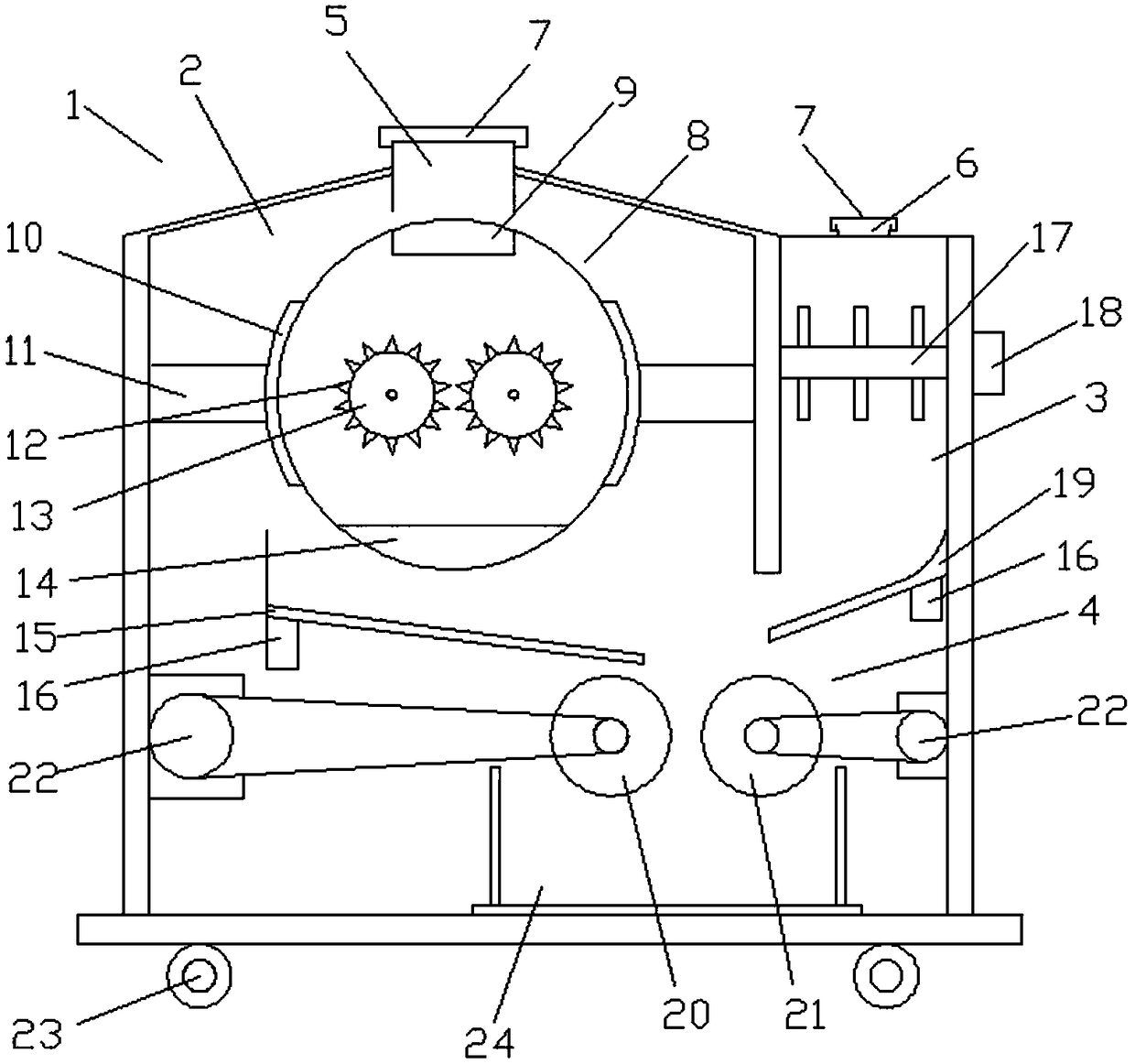

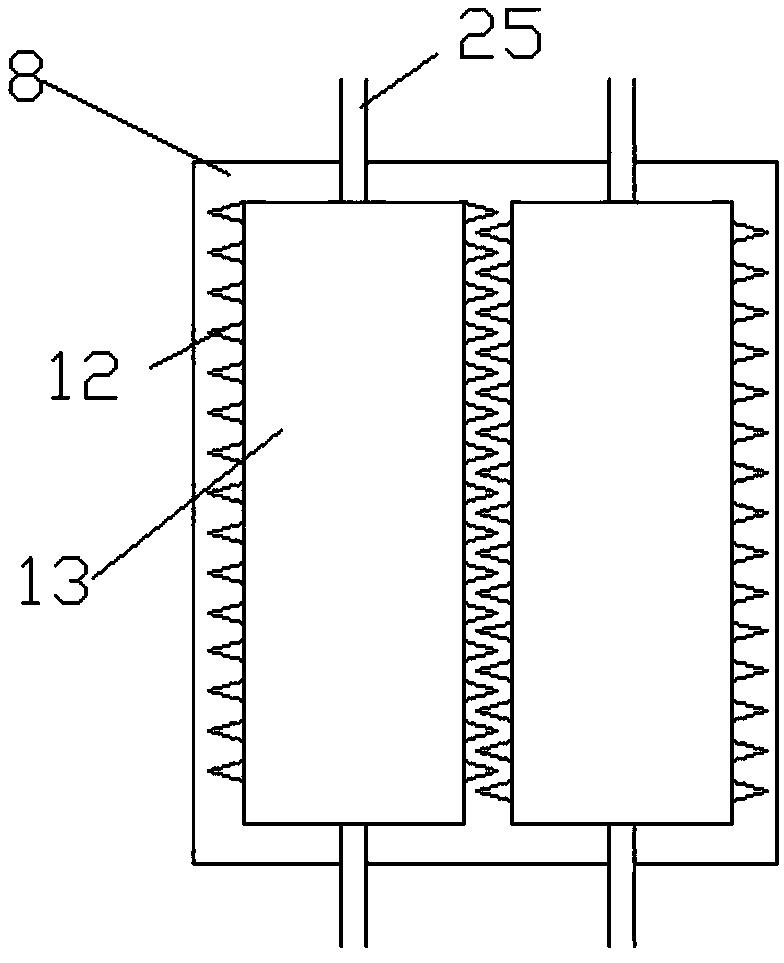

Smashing device for veterinary medicines

The invention relates to the technical field of veterinary medicine processing, in particular to a smashing device for veterinary medicines. The smashing device comprises a device body, a smashing chamber, a stirring chamber and a grinding chamber are arranged inside the device body, and a putting opening I and a putting opening II are formed in the upper side of the device body; the smashing chamber is arranged below the putting opening I; the stirring chamber is arranged below the putting opening II; the grinding chamber is arranged below the position between the smashing chamber and the stirring chamber; and a collecting box is arranged under a grinding roller. According to the smashing device, the smashing chamber and the stirring chamber are arranged, an operator can conveniently conduct processing in different manners according to the size of particles of the veterinary medicines, the working manner of the device is optimized, and the working efficiency is improved; and the rotary barrel is arranged, and therefore smashing of the veterinary medicines can be thorough, grinding through the grinding roller is facilitated successively, and the grinding speed is increased.

Owner:ANHUI HUANGHUAI VETERINARY MEDICINE

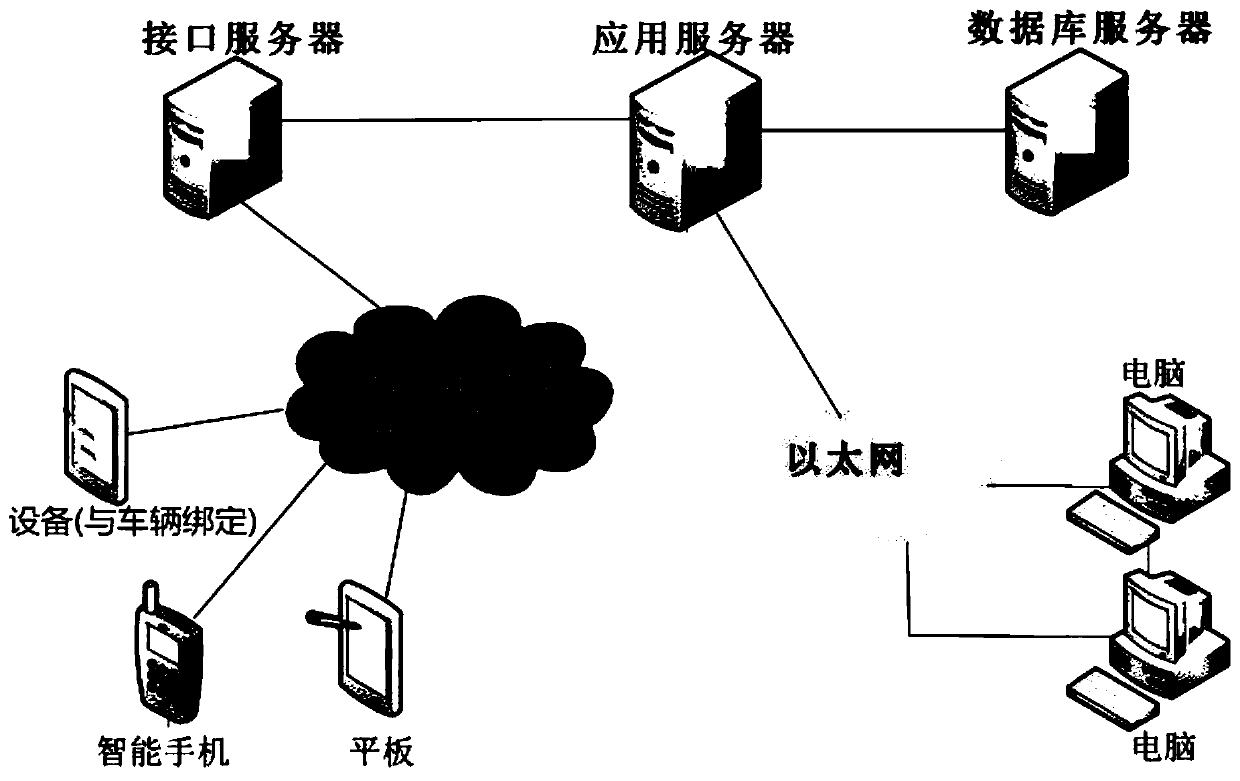

Cloud-based mechanical monitoring and order management mobile platform

PendingCN110852639AReduce cost and time overheadFlexible working styleOffice automationResourcesInformation technologyManagement system

The invention discloses a cloud-based mechanical monitoring and order management mobile platform, and belongs to the technical field of constructional engineering and information. The system comprisesan equipment vehicle system, an order management system, a map management system and a personal center system, the equipment vehicle system comprises a binding equipment module and a personnel vehicle module, binding equipment comprises binding, unbinding, learning and resetting between equipment and a vehicle, and the personnel vehicle module comprises a vehicle owner and addition, deletion, modification and check of vehicle information; the order management system comprises an initiating list, an approving list, a checking list, a tracking list and a history list. The mobile platform terminal displays part or all of the lists according to the authority of a login person. The map management system displays all vehicle information under the organization to which the login person belongs;and the personal center system comprises the functions of checking personal information, checking an updating log on line and downloading an operation manual. According to the invention, online detection of the position and the state of the vehicle equipment, online ordering and approval are realized, automatic calculation of working hours is realized, and a transparent operation mode is provided.

Owner:CHINA CONSTR EIGHTH ENG DIV

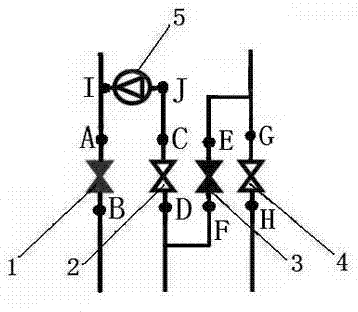

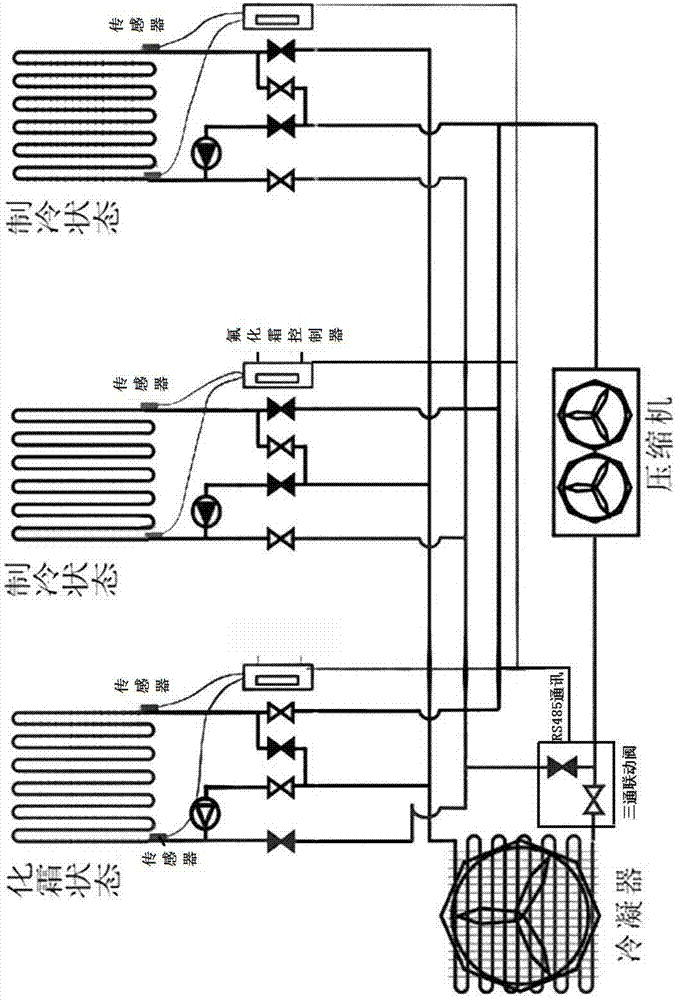

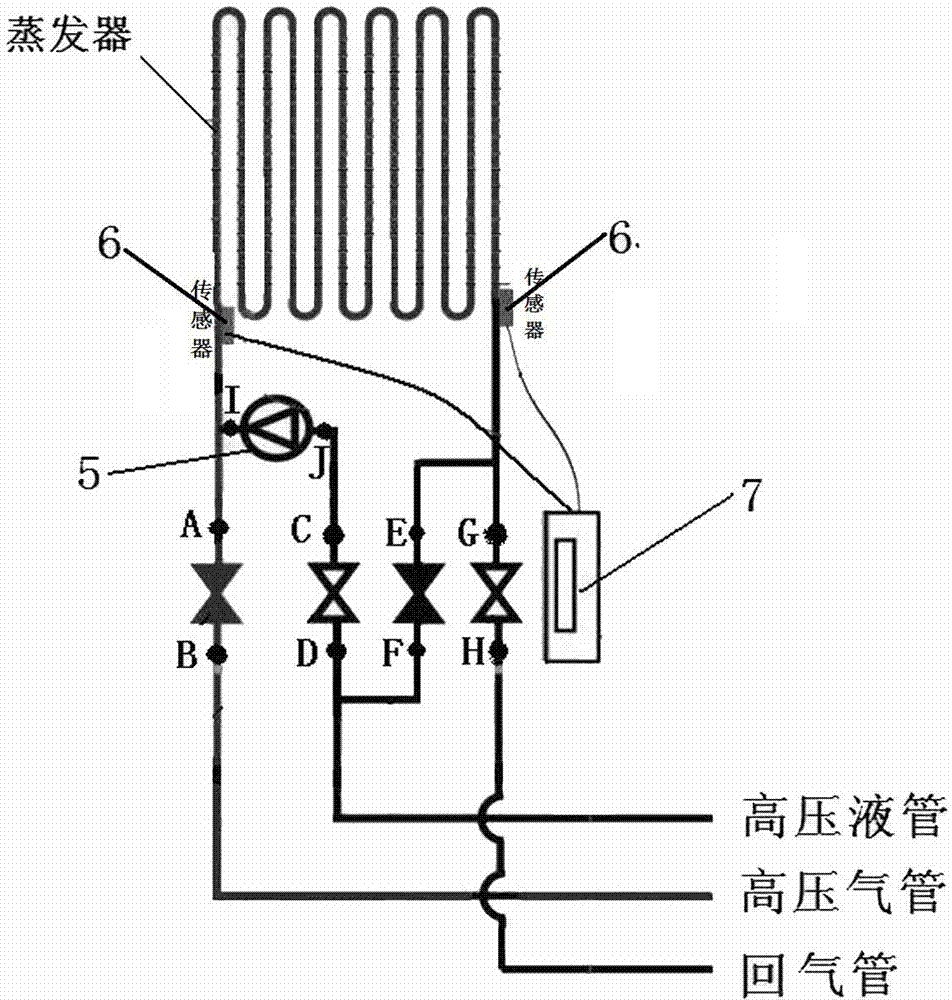

Freezer hot fluorine defrosting machine

InactiveCN104215017AEfficient use ofReduce consumptionLighting and heating apparatusDefrostingThermal energyEngineering

The invention discloses a freezer hot fluorine defrosting machine, which comprises a first control valve, a second control valve, a third control valve and a fourth control valve, wherein the end D of the second control valve is connected with a high pressure liquid pipe, the end C of the second control valve is connected with the end J of an expansion valve, the end I of the expansion valve is connected with an inlet of an evaporator, the end G of the fourth control valve is connected with an outlet of the evaporator, the end H of the fourth control valve is connected with an air return pipe, the end B of the first control valve is connected with a high pressure air pipe, the end A of the first control valve is connected with one end of the evaporator, the end E of the third control valve is connected with the other end of the evaporator, and the end F of the third control valve is connected with the high pressure liquid pipe. The defrosting device has the advantages that the heat generated by a compressor is used for defrosting, the energy consumption of defrosting is decreased, and the consumption of energy source is decreased; during defrosting, the high pressure gas is condensed to provide a refrigerant for the subsequent refrigerating of the evaporator, and the energy consumption is further saved; the defrosting is performed from interior to exterior, and the defrosting speed is high.

Owner:苏州新亚科技有限公司

Man-machine interactive system for real-time quote of construction suppliers

InactiveCN106846045AImprove quotation efficiencyFast communicationWeb data indexingMarketingMan machineComputer terminal

The invention relates to a man-machine interactive system for real-time quote of construction suppliers. The man-machine interactive system for real-time quote of construction suppliers is characterized by comprising foreground subsystems and a background subsystem, wherein the foreground subsystems are a plurality of distributed mobile terminals and are used for querying and displaying associated data of product information and quote information between the construction suppliers and developers; and the background subsystem is a data server, wirelessly communicates with the plurality of mobile terminal and is used for establishing association of quote data and product information between the construction supplies and the developers. Compared with the prior art, the man-machine interactive system has the advantages of accelerating the quote efficiency, and being comprehensive in association, convenient in statistical query and suitable for various network environments and information deposition.

Owner:蔡婷 +1

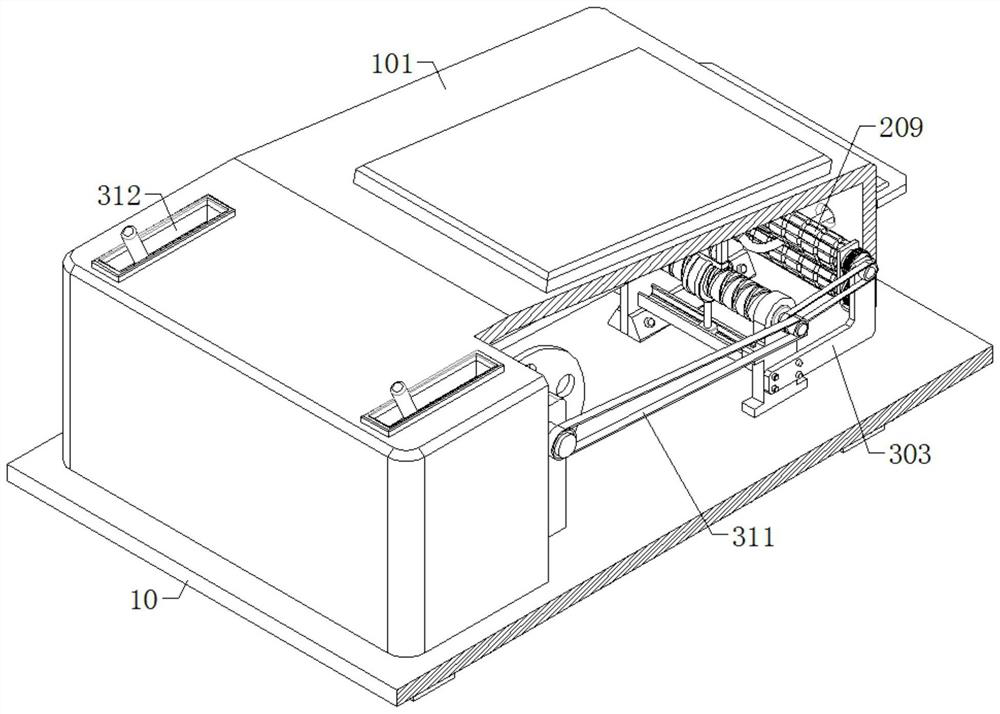

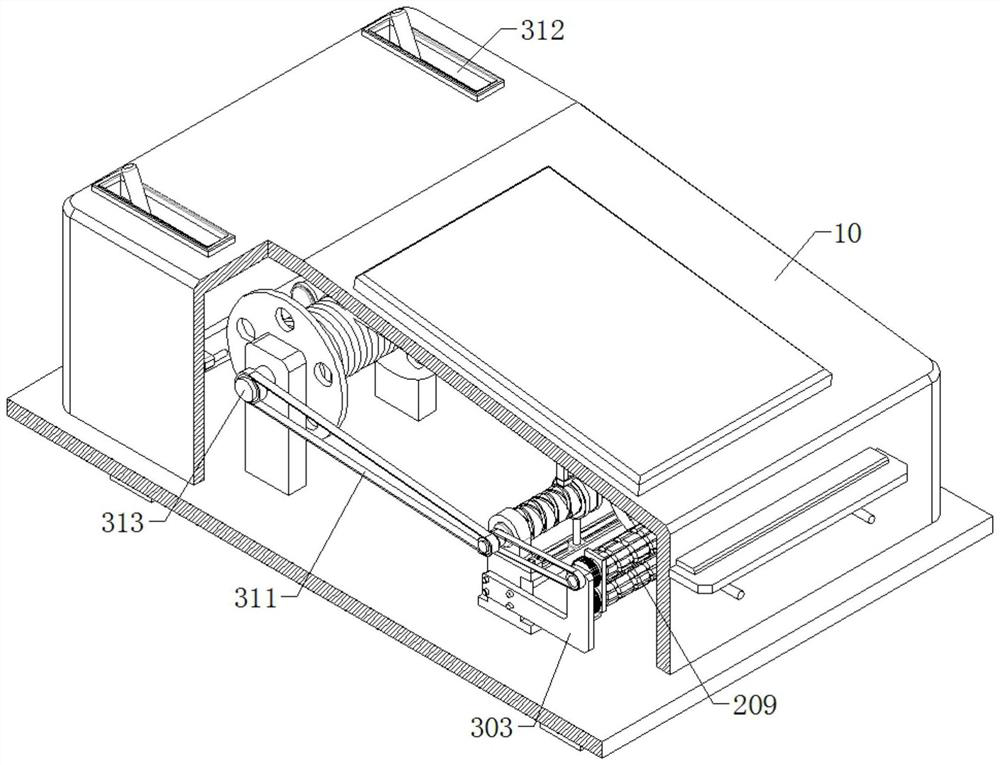

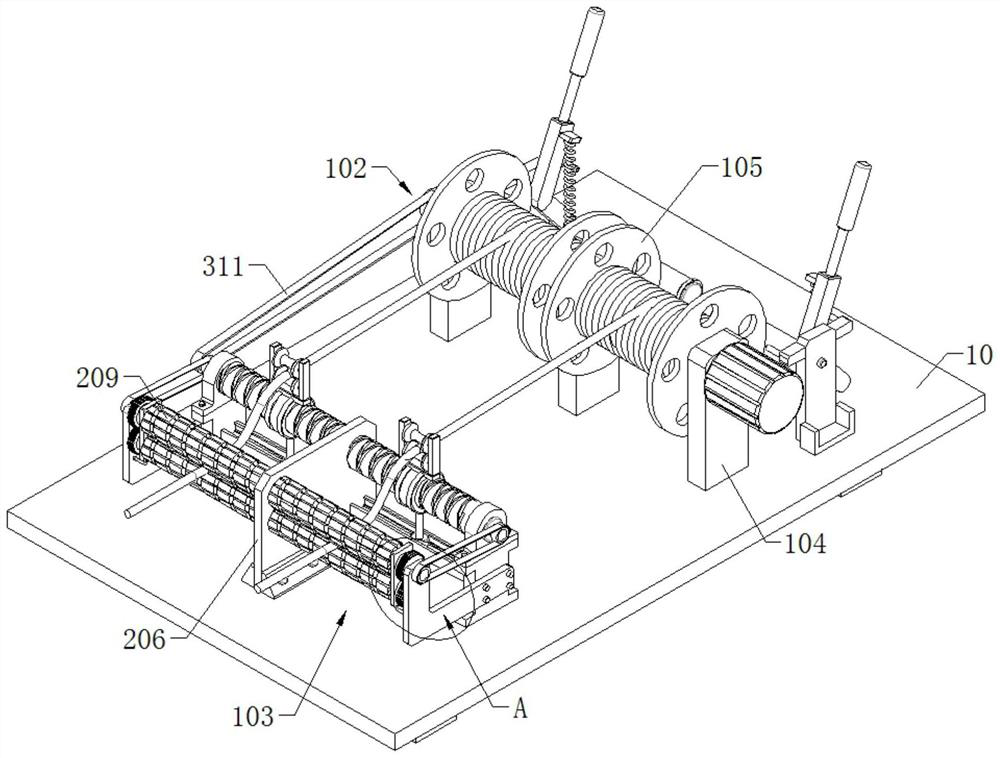

Wire frame for wire bundling machine and use method of wire frame

ActiveCN114455395AWind evenlyAvoid misaligned squeeze statesWeb rotation wrappingFilament handlingWinding machineWire rod

The invention provides a wire holder for a wire bundling machine and a using method thereof.The wire holder comprises a base and a box arranged at the top of the base, and further comprises a winding device fixedly connected to the top wall of the base and comprising a first winding mechanism and a second winding mechanism which are connected to the top of the base, each of the first winding mechanism and the second winding mechanism comprises a first connecting seat and an I-shaped plate which are connected to the top of the base station, the winding displacement device is fixedly connected to the top of the I-shaped plate, the winding displacement device is matched with the winding device through a first belt, an L-shaped plate and a second connecting seat are connected to the outer wall of the I-shaped plate, and the second connecting seat is fixedly connected to the top of the base station. The inner wall of the base table is connected with a film covering device. The end, away from the second connecting base, of the film covering device is matched with the winding device. The device is simple in structure and convenient to operate, oxidation reaction caused by contact between the wire and air can be avoided, it is guaranteed that the wire can be accurately wound around the winding roller, meanwhile, the working efficiency of the device is greatly improved, and automatic packaging and film covering of the wire are achieved.

Owner:无锡瑞进智能工程有限公司

Stamping device for hand shank of slide rail of automobile seat

PendingCN111804833AEasy way to workPrecise positioningShaping toolsMetal-working feeding devicesCar seatMechanical engineering

The invention discloses a stamping device for a hand shank of a slide rail of an automobile seat, and relates to the technical field of production of automobile seats. The stamping device comprises abase plate, wherein a bearing piece is welded to the center of the upper surface of the base plate, a lower mold base is fixed to the upper end of the bearing piece, a cavity which is through left andright is formed in the center inside the lower mold base, an electromagnetic suction cup is installed inside the cavity, an arc base is arranged at the left end of the base plate, a vertical rod is welded to the upper surface of the arc base, a first hydraulic telescopic rod is fixed to the top end of the vertical rod, a connecting plate is installed on the first hydraulic telescopic rod, a top plate is arranged at the other end of the connecting plate, and an upper mold base is arranged in the center of the lower surface of the top plate and is correspondingly arranged over the lower mold base. According to the stamping device, through the arrangement of the electromagnetic suction cup, the problem that the stamping device for the hand shank of the slide rail of the automobile seat has apoor positioning effect on workpieces, thus affecting the machining effect on the workpieces is solved.

Owner:无锡杰夫机械科技有限公司

Device for sealing and inflating inflatable objects

The invention concerns a device (1) for sealing and inflating inflatable objects, with a compressor, a connection (5) for a container (6) with sealant (7), a valve and distributor unit (4) for sealant and compressed gas and connection means between the valve and distributor unit and the inflatable object. Disposed in the valve and distributor unit is a valve which reversibly shuts off the connections (11) between the outlet of the sealant container and the compressor pressure line depending on the density and flow direction of the medium flowing through.

Owner:CONTINENTAL REIFEN DEUTSCHLAND GMBH

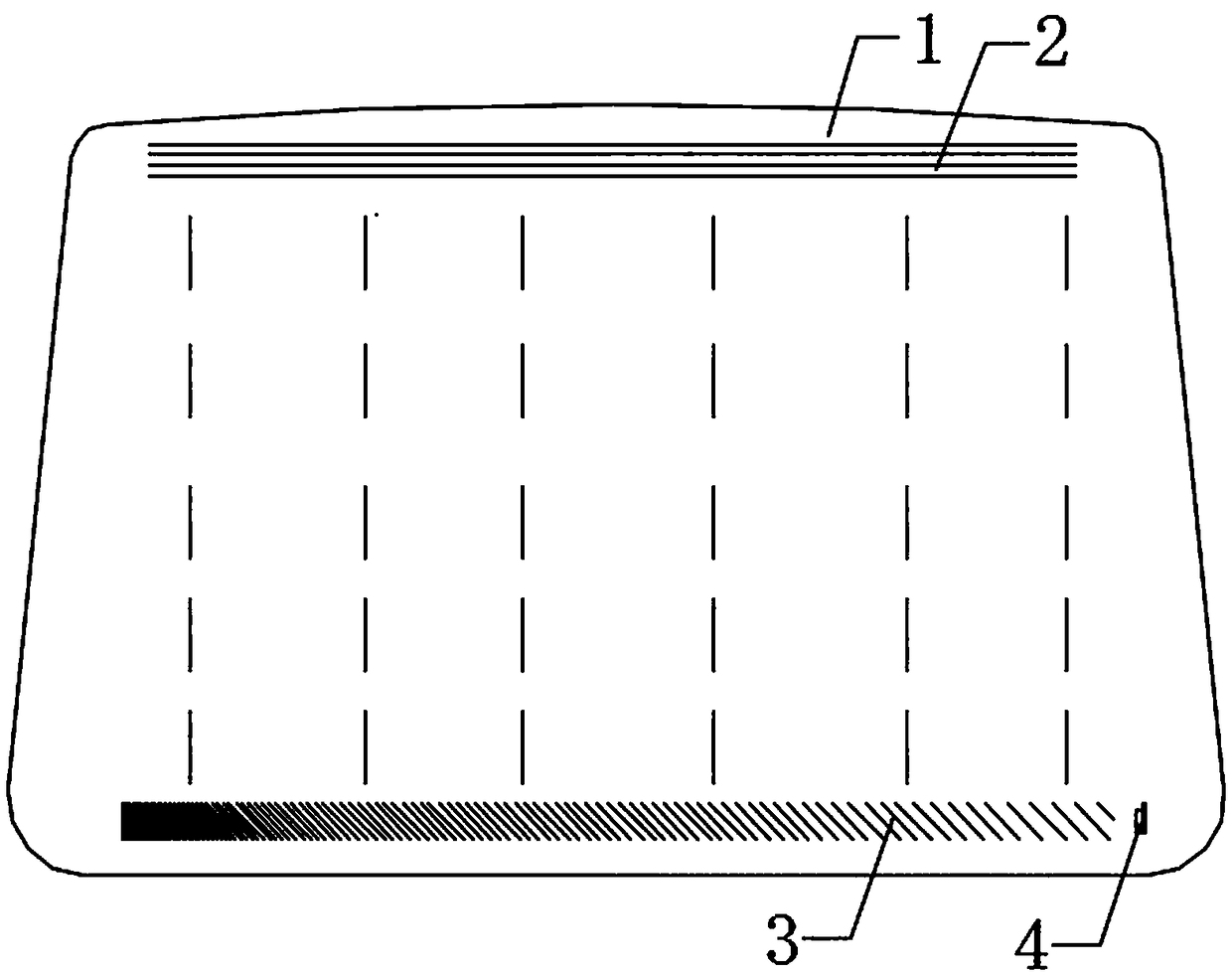

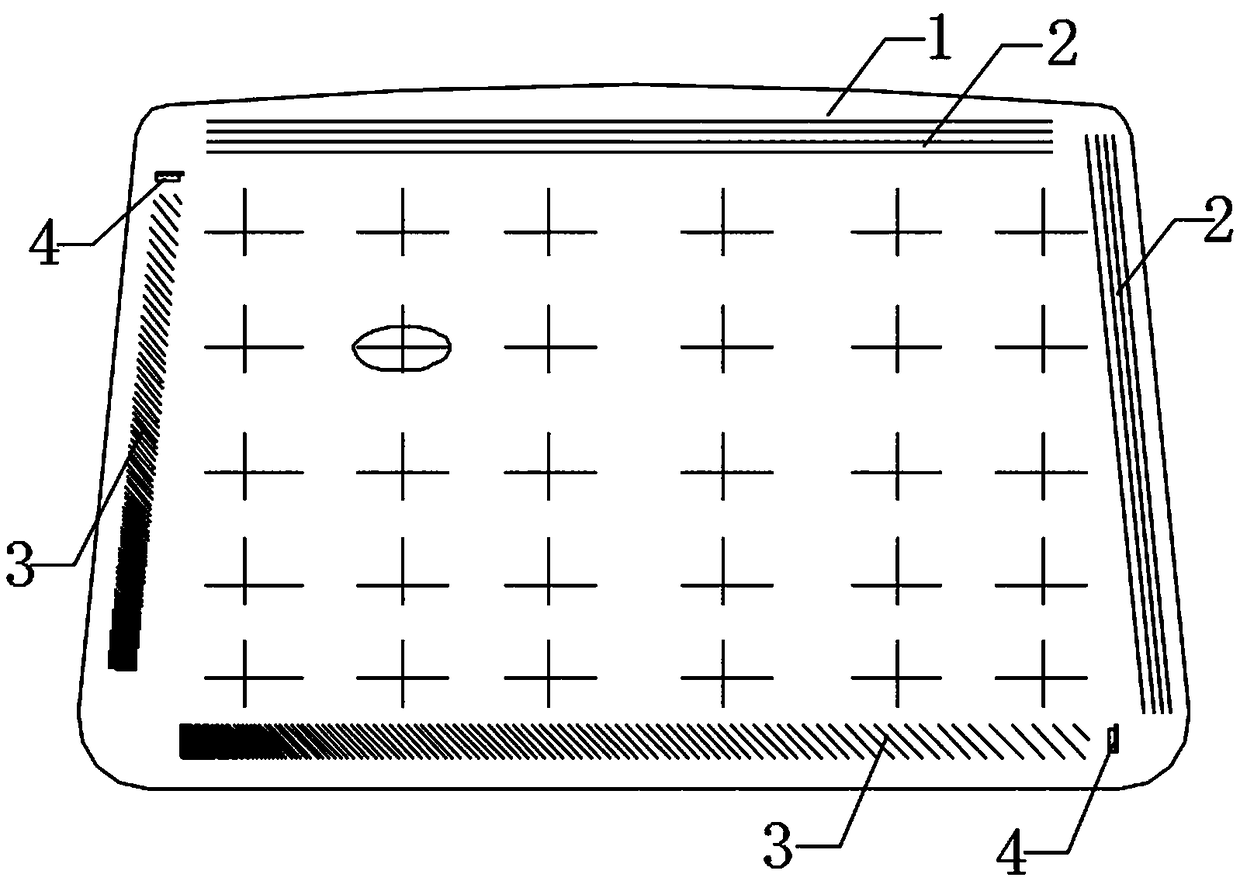

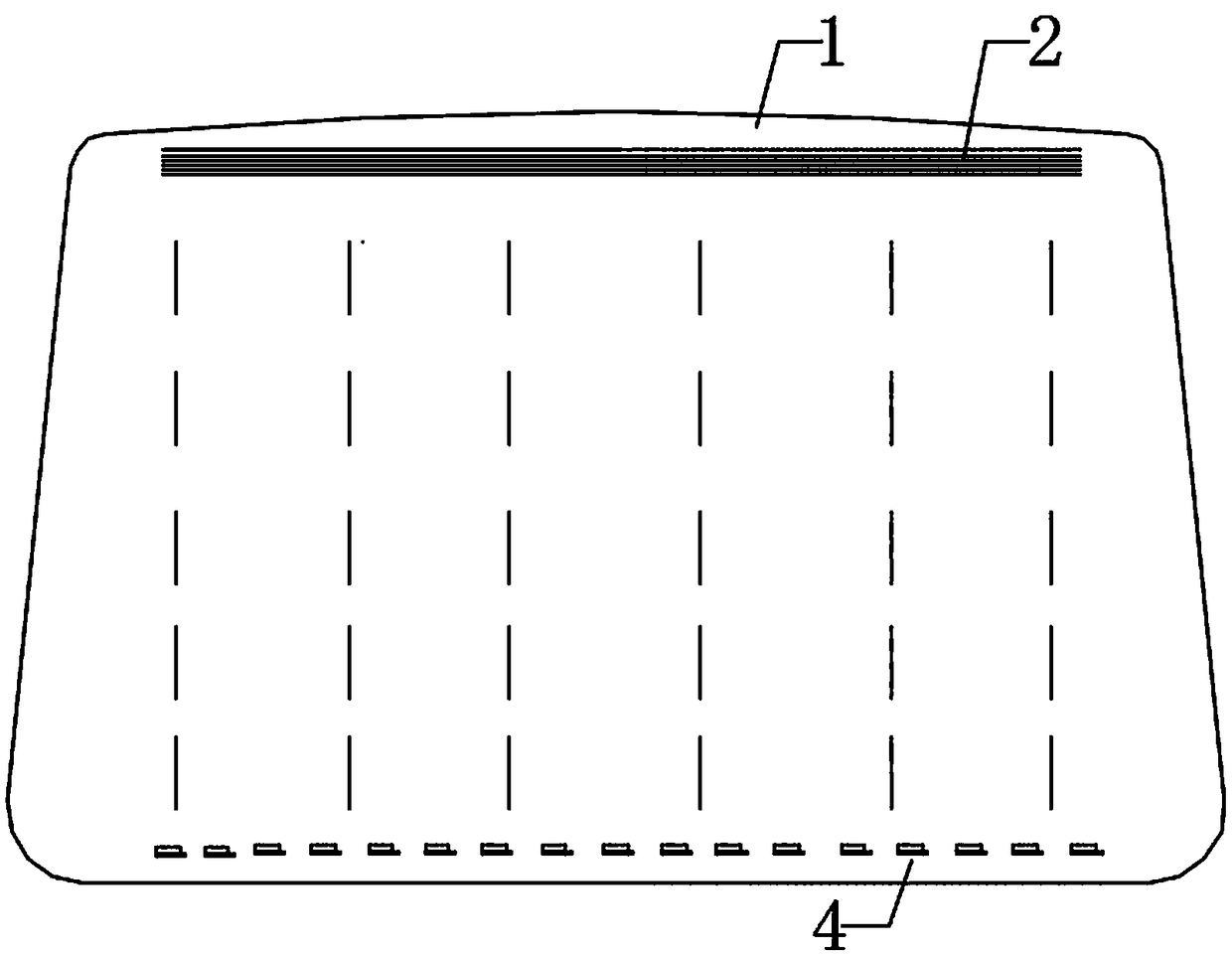

Method for detecting water mist on inner surface of windshield

InactiveCN109001298AStrong absorption attenuationMitigation of impairmentAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasoundWindshield

The invention discloses a method for detecting water mist on the inner surface of a windshield. The method mainly comprises the following steps of detecting water mist on the inner surface of the glass by utilizing surface ultrasonic waves. Water mist on the inner surface of the windshield can be accurately detected, and the specific position of a water mist area on the inner surface of the windshield can be recognized, so as to achieve the purpose of accurate defogging.

Owner:GENERAL TOUCH CO LTD

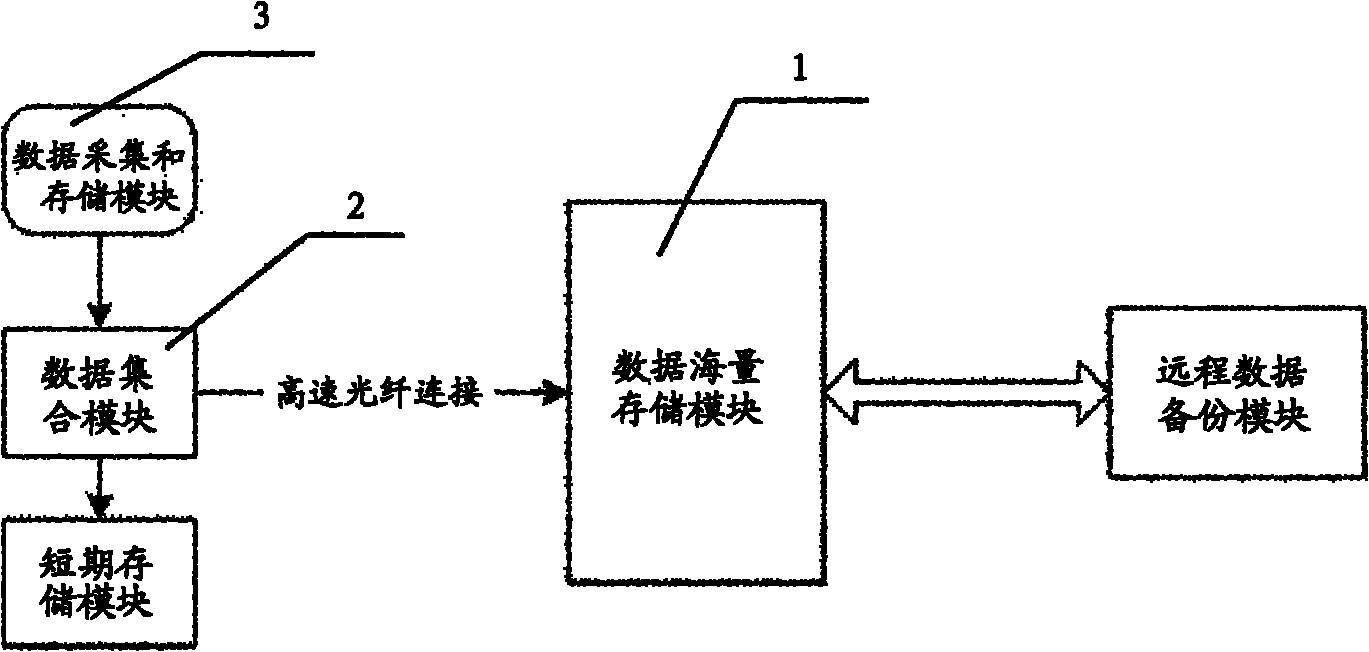

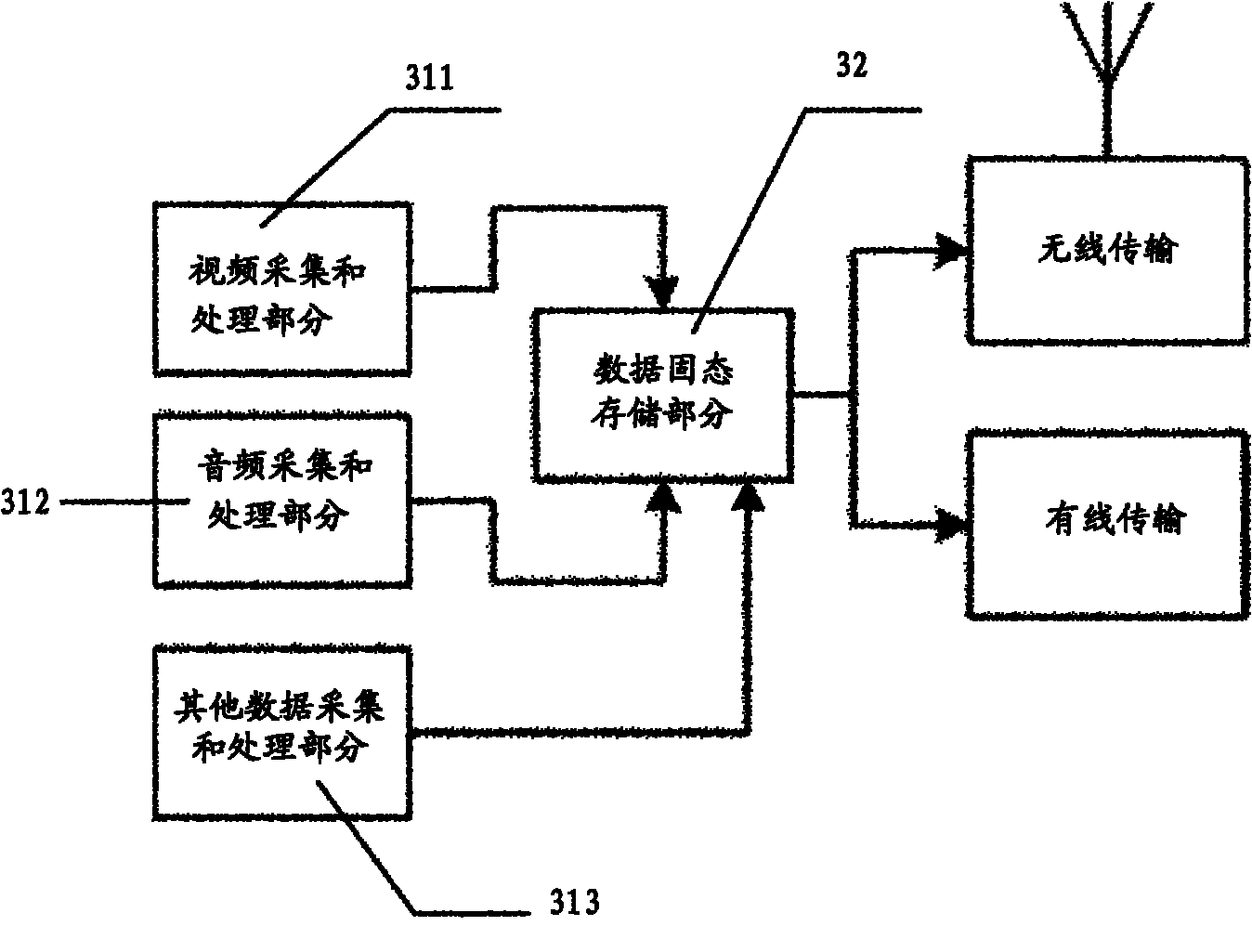

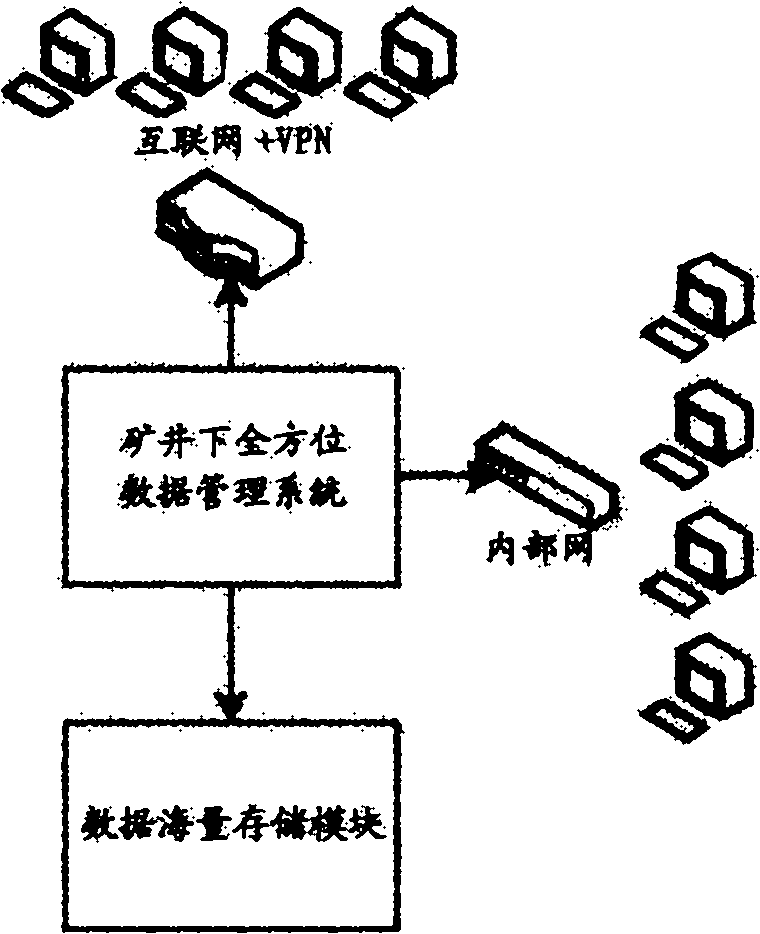

Underground omnibearing data acquisition system

InactiveCN102255936ANot lostOvercoming the defects of fixed-point data collectionMining devicesElectromagnetic transmissionSolid-state storageIp address

The invention discloses an underground omnibearing data acquisition system, which comprises a mass data storage module, a data integration collection module and data acquisition and storage modules convenient to carry, wherein the data acquisition and storage module comprises a data acquisition and processing part and a solid-state data storage part; the solid-state data storage part stores data acquired and processed by the data acquisition and processing part; the mass data storage module is in communication connection with the data collection module; the data collection module is in communication connection with each data acquisition and storage module, and performs node numbering and Internet protocol (IP) address mapping on the data acquisition and storage modules. The system overcomes the shortcomings of fixed point data acquisition in the prior art, processes and plays the acquired data in real time, and moreover, ensures that the data may not be lost for long and can be reserved after an accident in the most severe environment to greatly help to make safety responsibilities clear.

Owner:王永捷

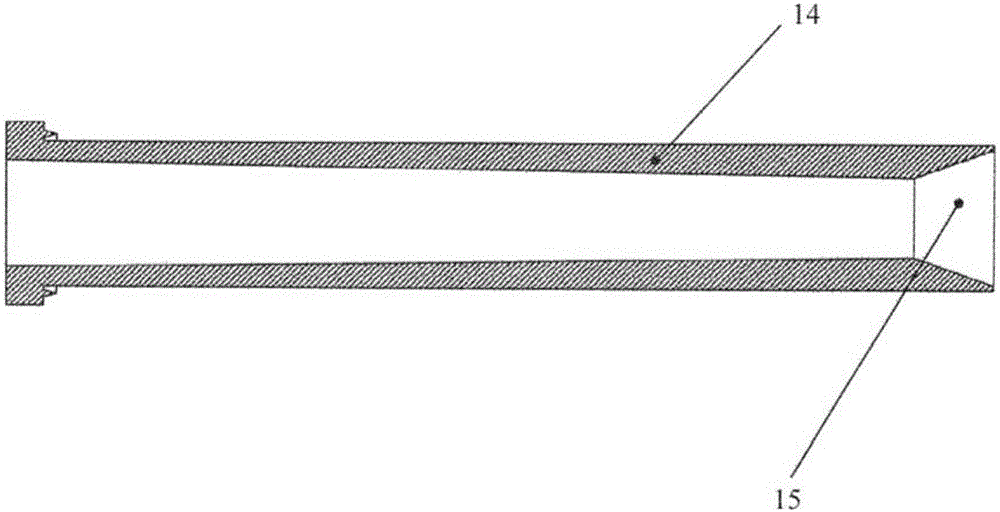

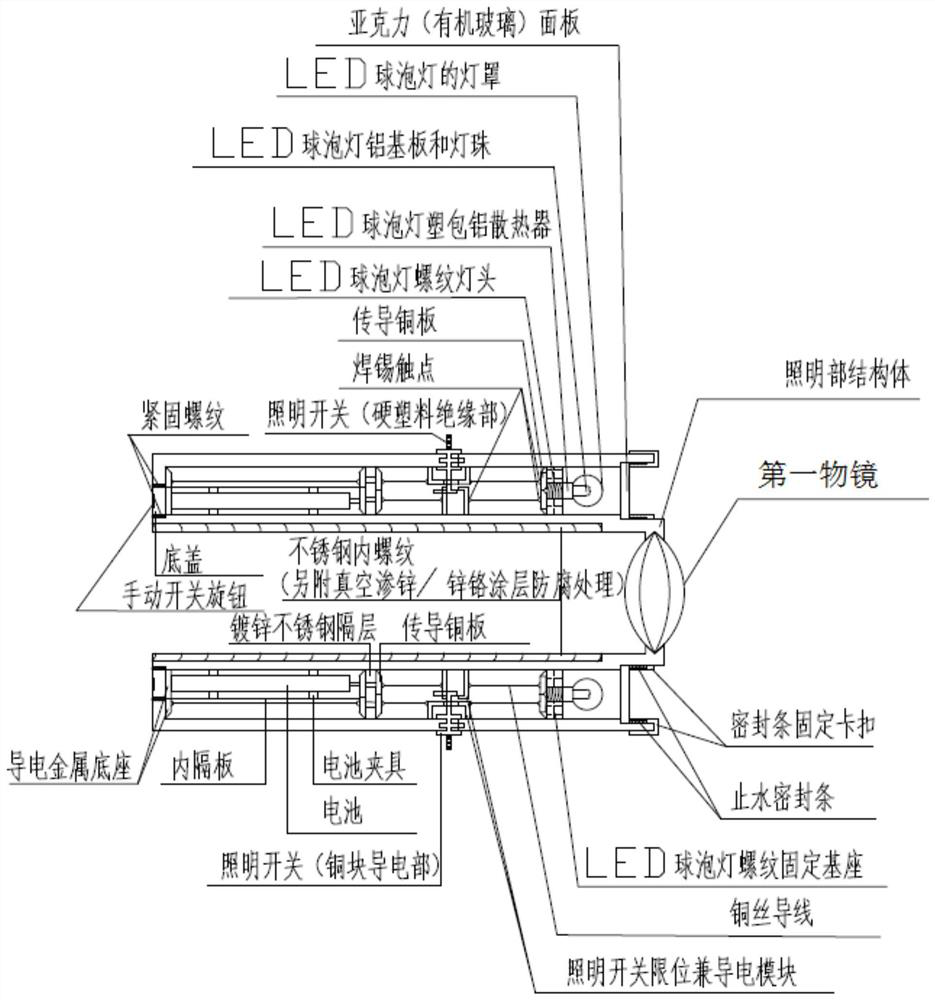

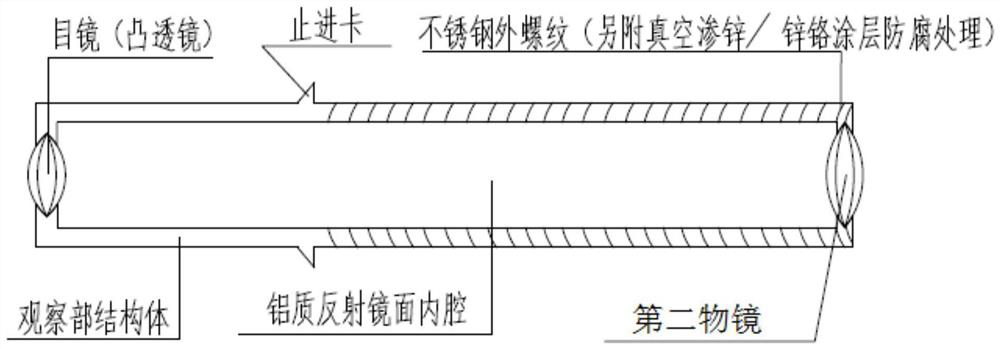

Handheld portable illumination observer for limited space and dark environment

PendingCN112987278AReliable technologyImprove reliabilityLighting elementsWith electric batteriesEyepieceVideo recording

The invention discloses a handheld portable illumination observer for a limited space and a dark environment. The handheld portable illumination observer comprises a tubular observation part, a lighting part axially arranged around the observation part, and an external connection part, the lighting part comprises a panel, an LED bulb lamp, a conduction copper plate, a soldering tin contact, a fastening thread, a bottom cover, a manual switch knob, a lighting part structural body, a first objective lens, a stainless steel internal thread, a sealing strip fixing buckle, a water stop sealing strip, an LED bulb lamp thread fixing base, a battery clamp, a battery, an inner partition plate and a conductive metal base; the observation part comprises an eyepiece, a stop card, an observation part structural body, an aluminum reflection mirror surface inner cavity and a second objective lens; and the external connection part is used for externally connecting an observation device, a detection device and a video recording device, so that additional detection and video recording functions besides illumination observation are realized, and corresponding activities are carried out. The observer has the advantages of small size, simple structure, convenience in prefabrication, less material consumption, short manufacturing and processing period and low processing cost, and the raw materials and parts are semi-finished products and are convenient to purchase.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

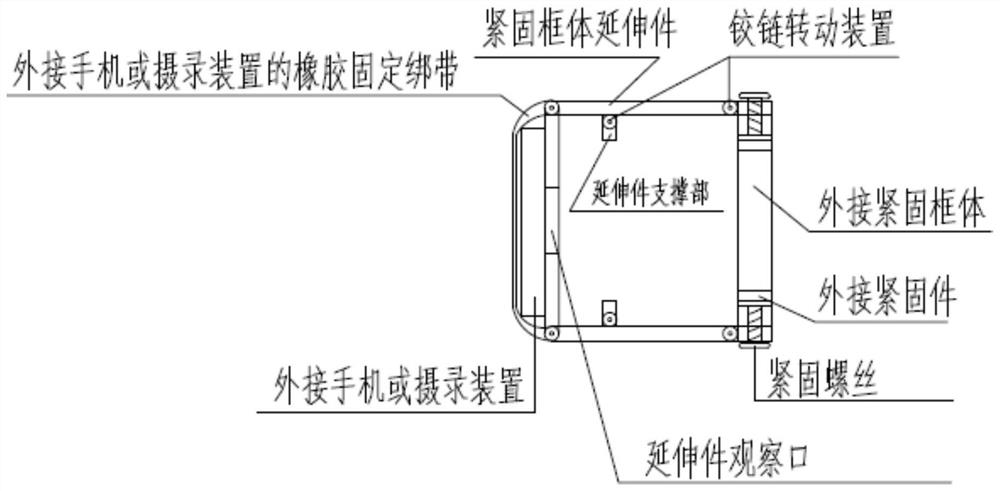

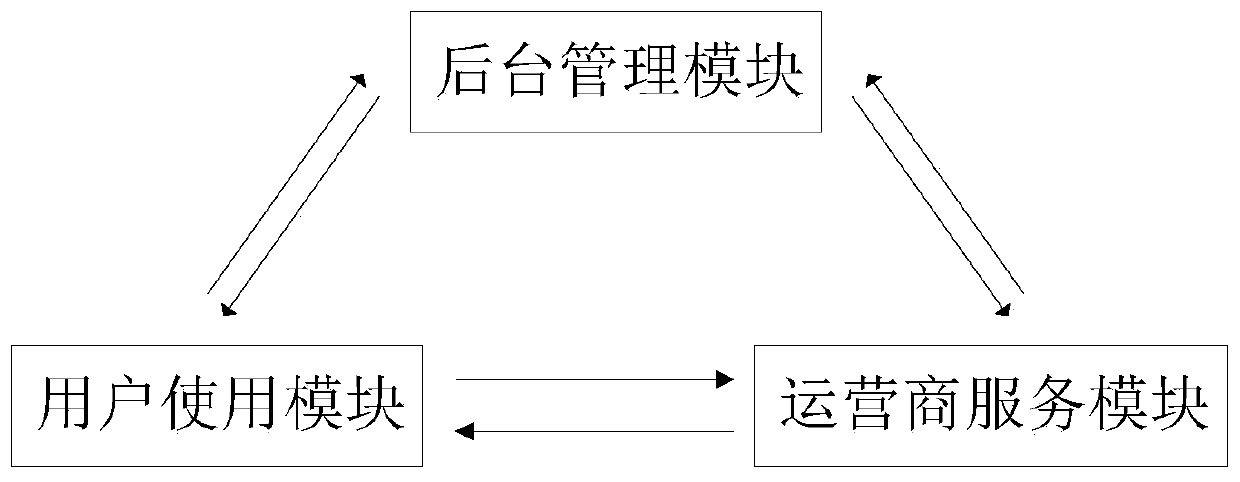

Garbage recycling system and garbage recycling method

InactiveCN110712900AImprove recycling efficiencyEasy way to workCo-operative working arrangementsRefuse receptaclesThe InternetGarbage collection

The invention provides a garbage recycling system and a garbage recycling method. The garbage recycling system comprises a user using module, an operator service module and a backstage management module. Signals of the user using module are transmitted to the operator service module and the backstage management module correspondingly. The backstage management module receives the signals of the operator service module and monitors operation of the operator service module. Through the garbage recycling system and the garbage recycling method provided by the invention, the problem that the offline garbage recycling efficiency is low is solved, the single operation mode is changed, the advantages of internet plus are represented, online garbage recycling is realized, and the operation mode isfast, convenient and efficient. The garbage recycling system conducts summarizing and counting on garbage recycling data and is beneficial to improving the self-operation mode and the social operationmode, improving and perfecting the operation level and improving the garbage recycling efficiency.

Owner:中晟泽邦(北京)再生资源回收技术有限公司

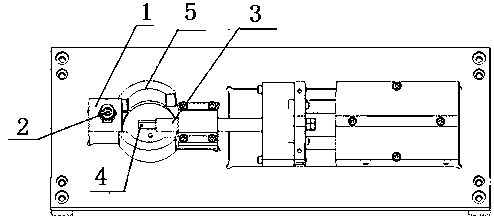

Automatic material taking mechanism for material particles

InactiveCN108974855ARealize automatic reclaiming processSimple structureConveyorsConveyor partsWorking environmentHorizontal axis

The invention discloses an automatic material taking mechanism for material particles, wherein a feeding bin, a discharging hopper and a material taking rod are sequentially arranged on the horizontalaxis of the same plane; the material feeding bin is provided with a through feeding channel along the direction perpendicular to the axis, a material taking port communicated with the feeding channelis arranged on the side surface of the feeding bin, a material taking groove is arranged on the material taking rod, the material taking rod reciprocates on the material taking port and the discharging hopper, along the direction of the horizontal axis,when the end part of the material taking rod is in the material taking port, the material taking groove faces upwards, and the material taking groove is downwards when the end part of the material taking rod is above the discharging hopper; according to the invention, compared with a prior mode, the automatic material taking process for the powder particles is realized through the reciprocating mechanical structure design, the structure is simple, independent program control is not needed, the two steps of material taking and discharging are realized through a simple positioning column, the current working environment and mode can be greatly improved.

Owner:MIANYANG TEACHERS COLLEGE +1

A crushing device for veterinary medicine

The invention relates to the technical field of veterinary medicine processing, in particular to a smashing device for veterinary medicines. The smashing device comprises a device body, a smashing chamber, a stirring chamber and a grinding chamber are arranged inside the device body, and a putting opening I and a putting opening II are formed in the upper side of the device body; the smashing chamber is arranged below the putting opening I; the stirring chamber is arranged below the putting opening II; the grinding chamber is arranged below the position between the smashing chamber and the stirring chamber; and a collecting box is arranged under a grinding roller. According to the smashing device, the smashing chamber and the stirring chamber are arranged, an operator can conveniently conduct processing in different manners according to the size of particles of the veterinary medicines, the working manner of the device is optimized, and the working efficiency is improved; and the rotary barrel is arranged, and therefore smashing of the veterinary medicines can be thorough, grinding through the grinding roller is facilitated successively, and the grinding speed is increased.

Owner:ANHUI HUANGHUAI VETERINARY MEDICINE

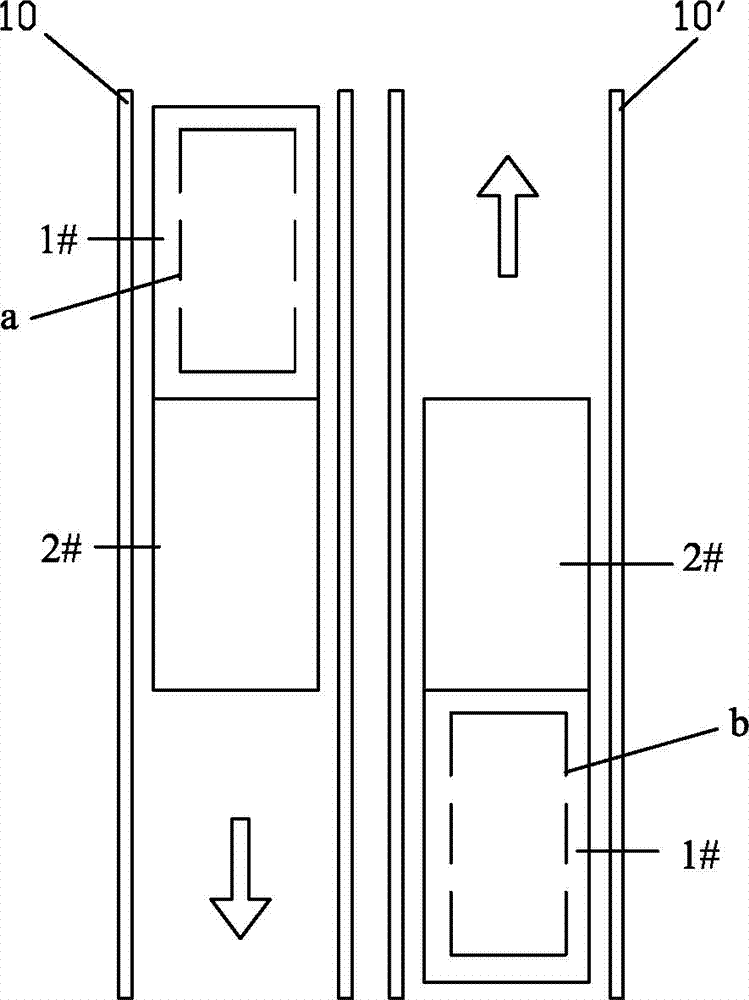

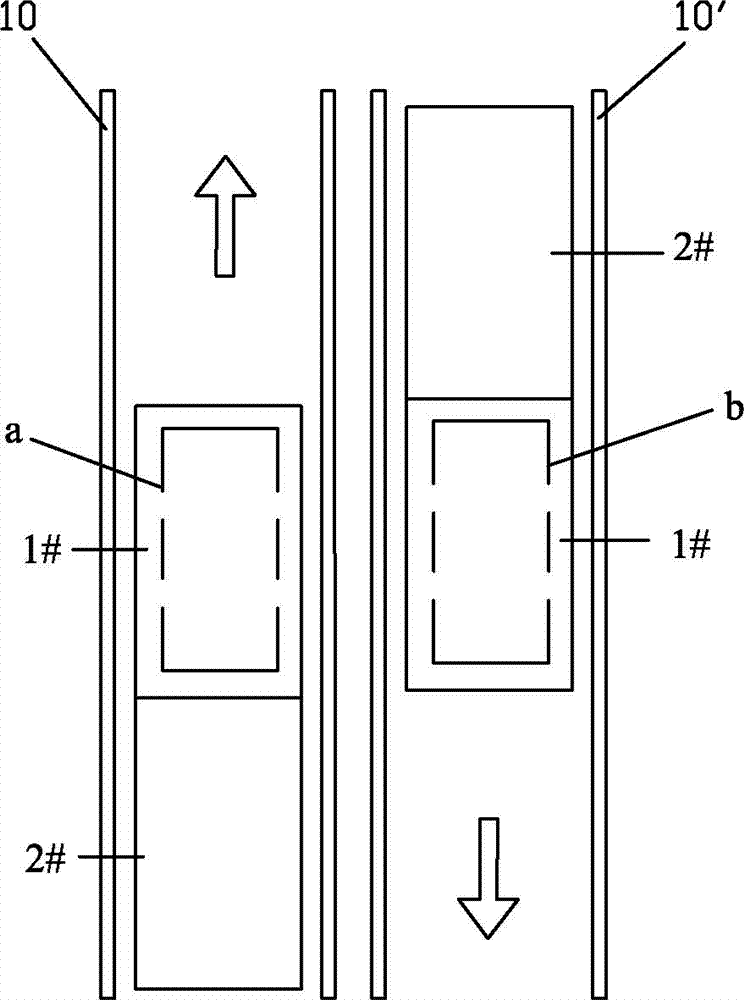

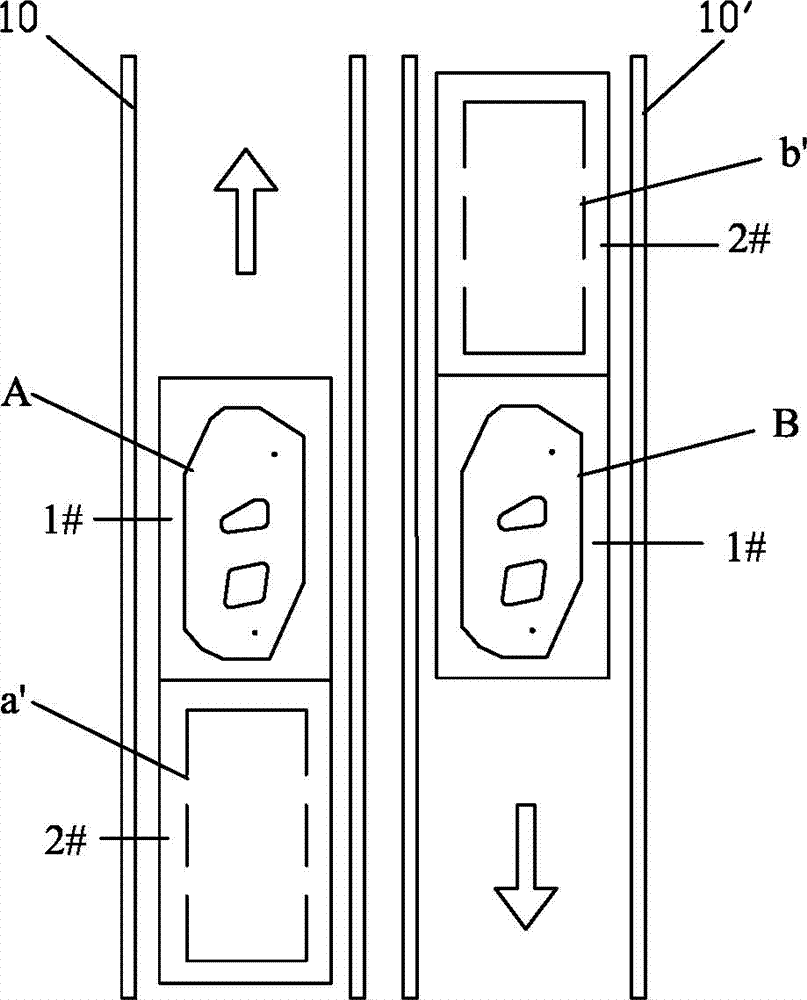

A method and system for loading, unloading and cutting a longitudinal metal plate

ActiveCN103600170BReduce in quantityCompact layoutWelding/cutting auxillary devicesAuxillary welding devicesProduction rateEngineering

A longitudinal metal plate loading, unloading and cutting method and system, which adopts two longitudinal moving loading and unloading and cutting operation lines set up in parallel. Each operation line includes an assembly loading position, a cutting station, and a sheet material unloading position. And a handling and stacking robot is located between the two operating lines; the two operating lines have opposite directions for assembling and loading materials; the assembly loading position and the sheet material discharging position are equipped with assembly trolleys, sheet trolleys and guide rails; cutting The workstation is equipped with at least two laser cutting heads and a mobile fast table; the mobile fast table moves longitudinally, feeds in and out of materials in two directions, and is equipped with two waiting positions and one cutting position; the external axes of the handling and stacking robot span the respective working lines. The assembly material loading position and the corresponding moving fast table and one waiting position are also across the sheet material lowering position of the opposite operating line and the corresponding moving fast table and another waiting position; each cutting station is equipped with A scrap conveyor system. The invention can effectively improve the cutting operation rhythm and output, and at the same time the system layout is more reasonable.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com