Staple detection mechanism of electric stapler

A detection mechanism and technology for staples, applied in staple tools, staple staple tools, manufacturing tools, etc., can solve problems such as reduced reliability, damage, and obstruction of staple cassette insertion and extraction operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

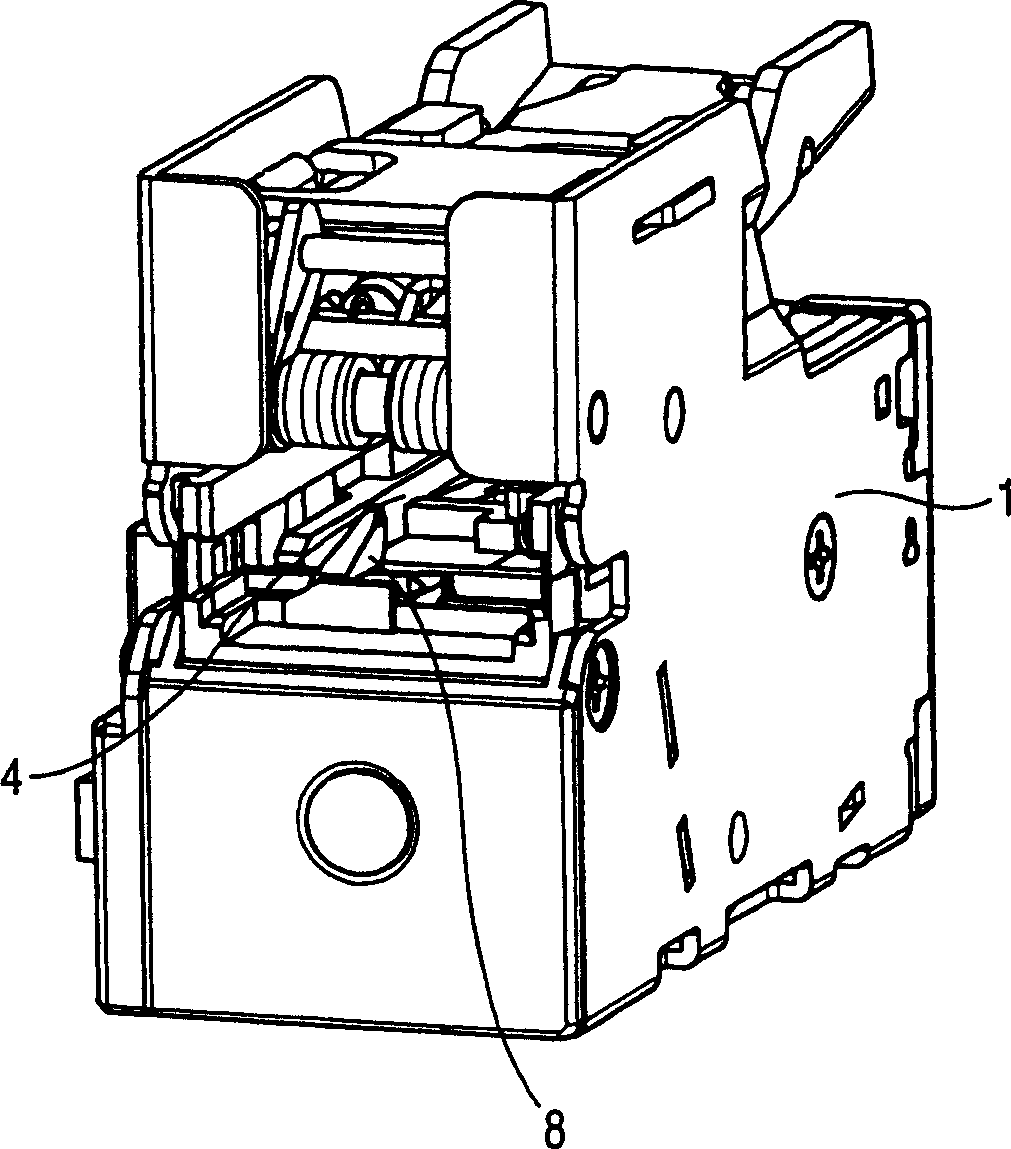

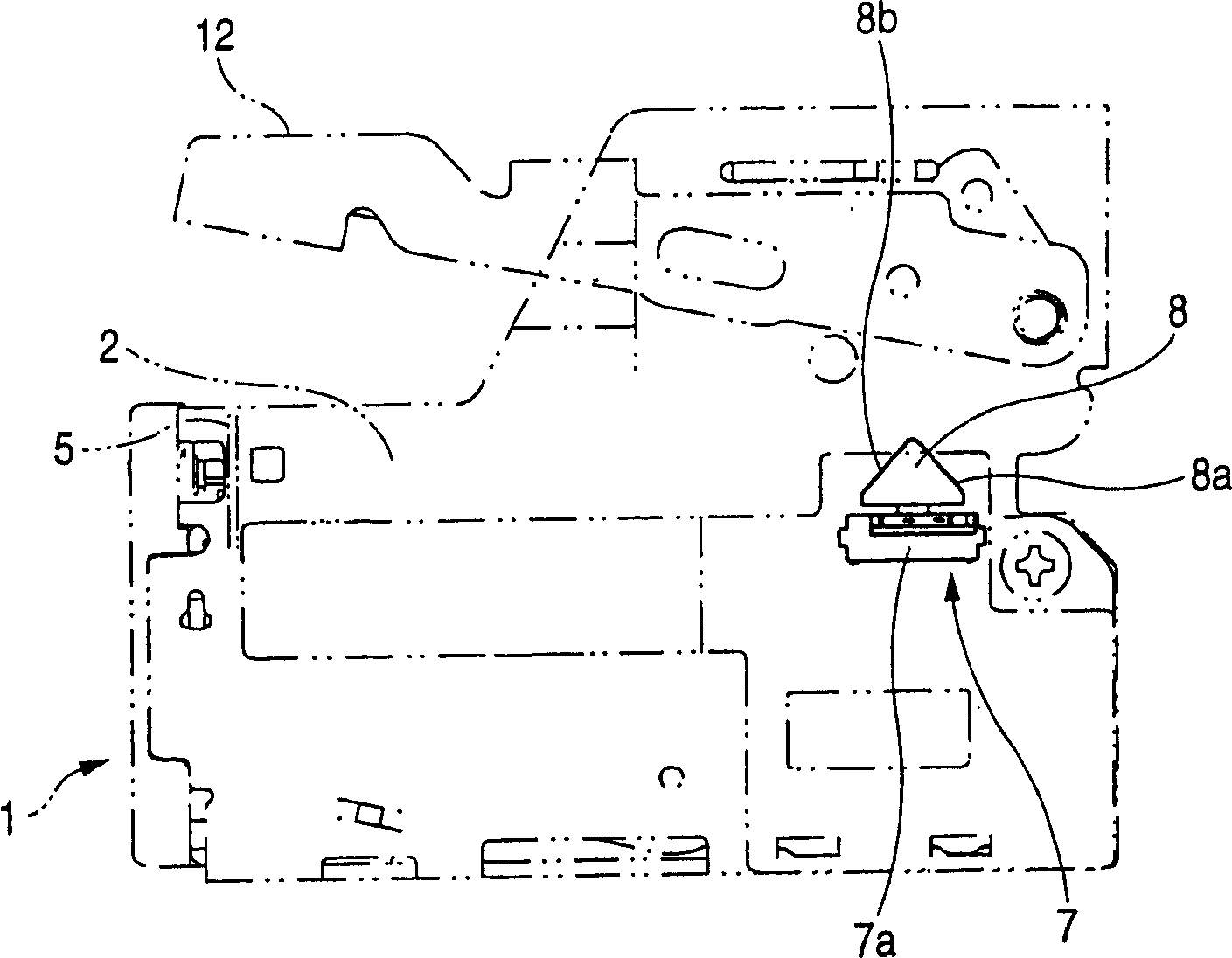

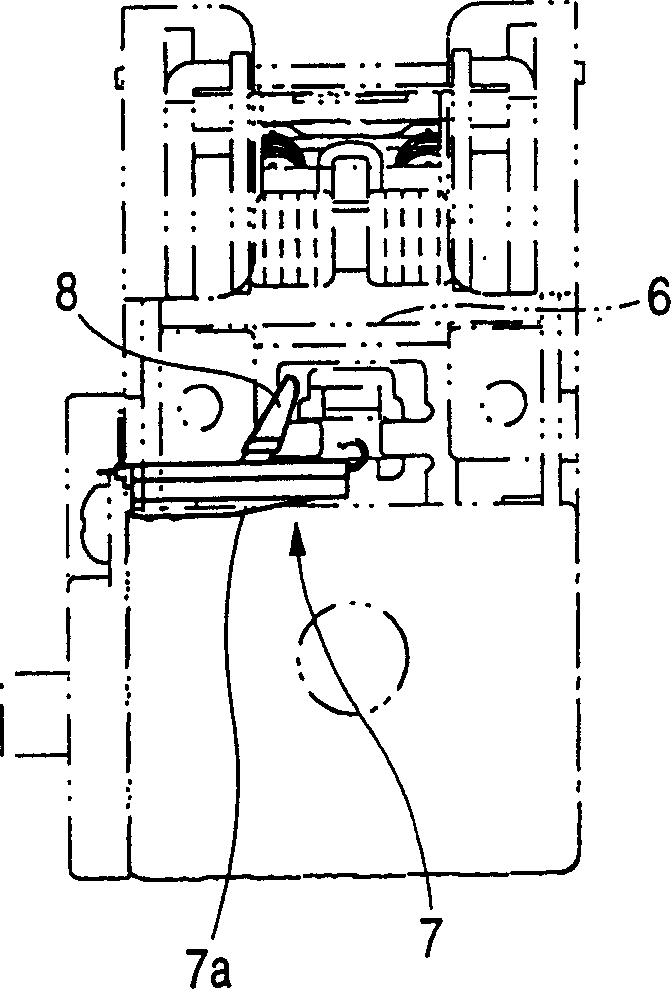

[0017] figure 1 It is a perspective view of the stapler main body of the electric stapler, figure 2 is a schematic diagram of its side, image 3 is the rear view.

[0018] The above-mentioned electric stapler is installed in the feeding part 2 of the stapler main body 1 so that it can be inserted and pulled out freely. Figure 4 and Figure 5 The staple cassette 3 shown, as Figure 6 As shown, in the staple cassette 3, the staple row a (refer to Figure 6 ). In addition, a passage 4 for installing a cassette is formed in the feeder 2 of the stapler main body 1 . And, insert and install the staple cassette 3 in the passage 4, drive the drive plate 5 provided on the stapler main body 1 upwards after the installation, and make the staple at the front end of the staple row a penetrate the bound material (paper) ), and drive the upper arm 12 downwards to bend both sides of the penetrating staple. Delivers the staple row in preparation for the next staple. Next, repeat thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com