Patents

Literature

980 results about "Shell and tube heat exchanger" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A shell and tube heat exchanger is a class of heat exchanger designs. It is the most common type of heat exchanger in oil refineries and other large chemical processes, and is suited for higher-pressure applications. As its name implies, this type of heat exchanger consists of a shell (a large pressure vessel) with a bundle of tubes inside it. One fluid runs through the tubes, and another fluid flows over the tubes (through the shell) to transfer heat between the two fluids. The set of tubes is called a tube bundle, and may be composed of several types of tubes: plain, longitudinally finned, etc.

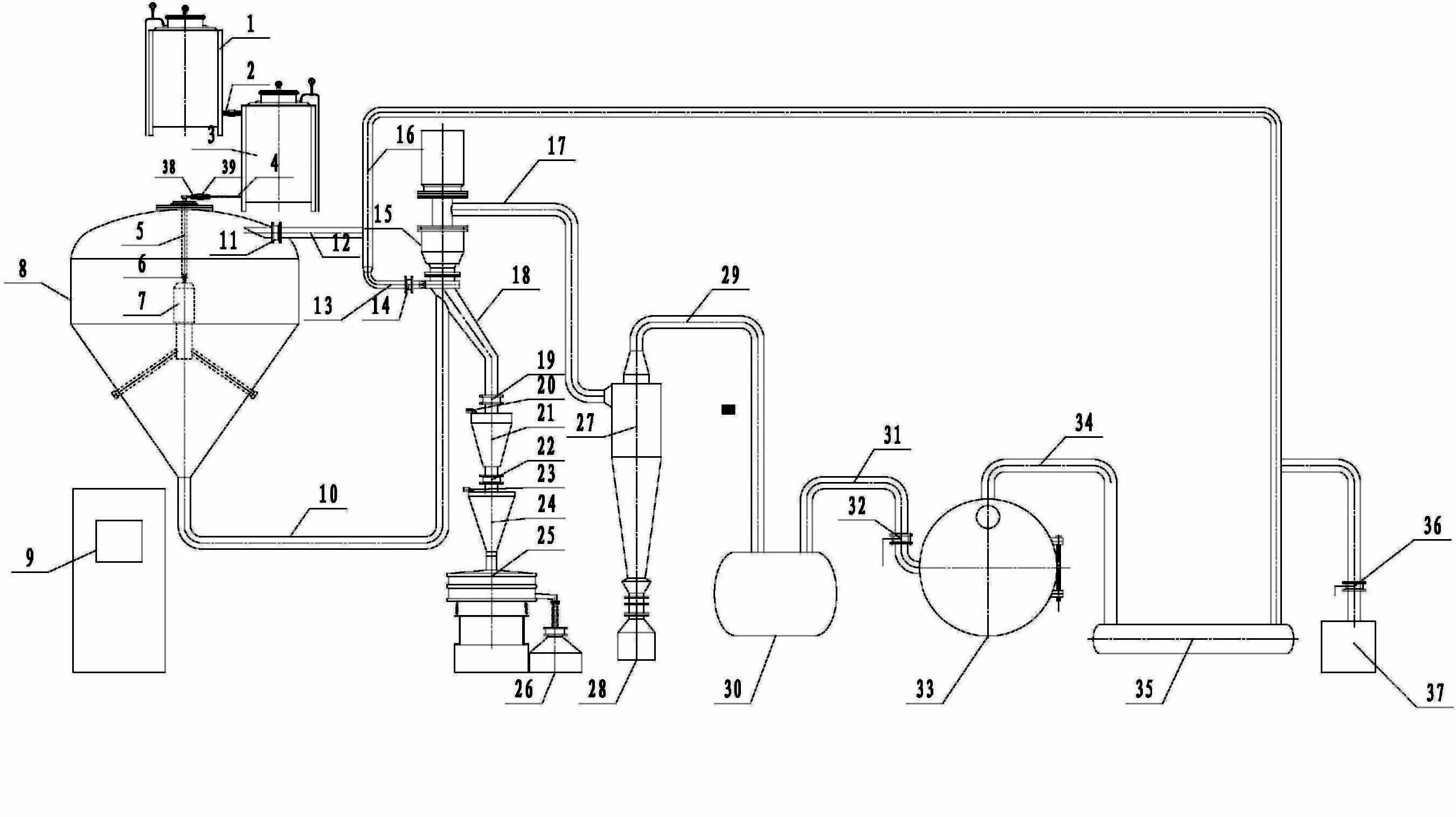

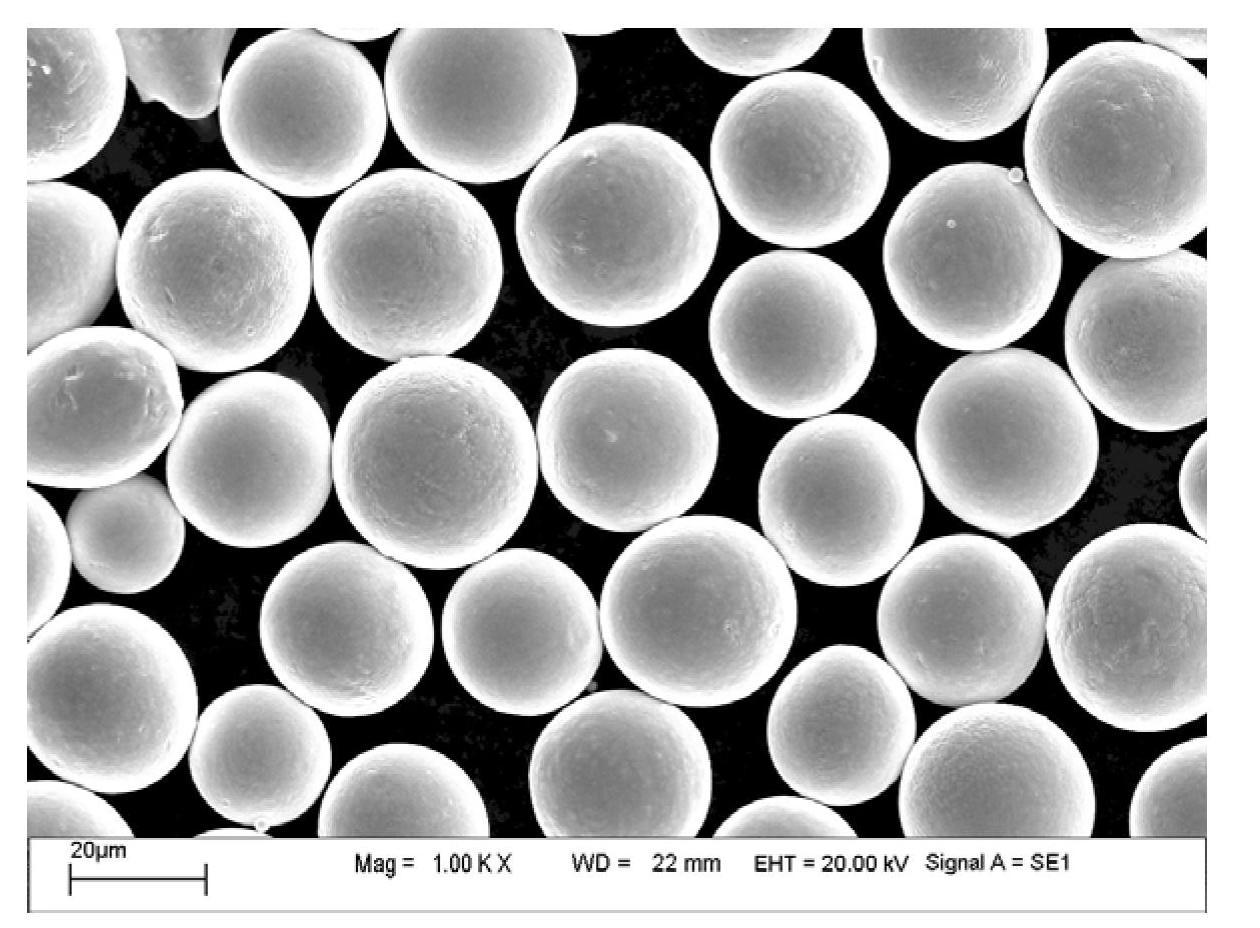

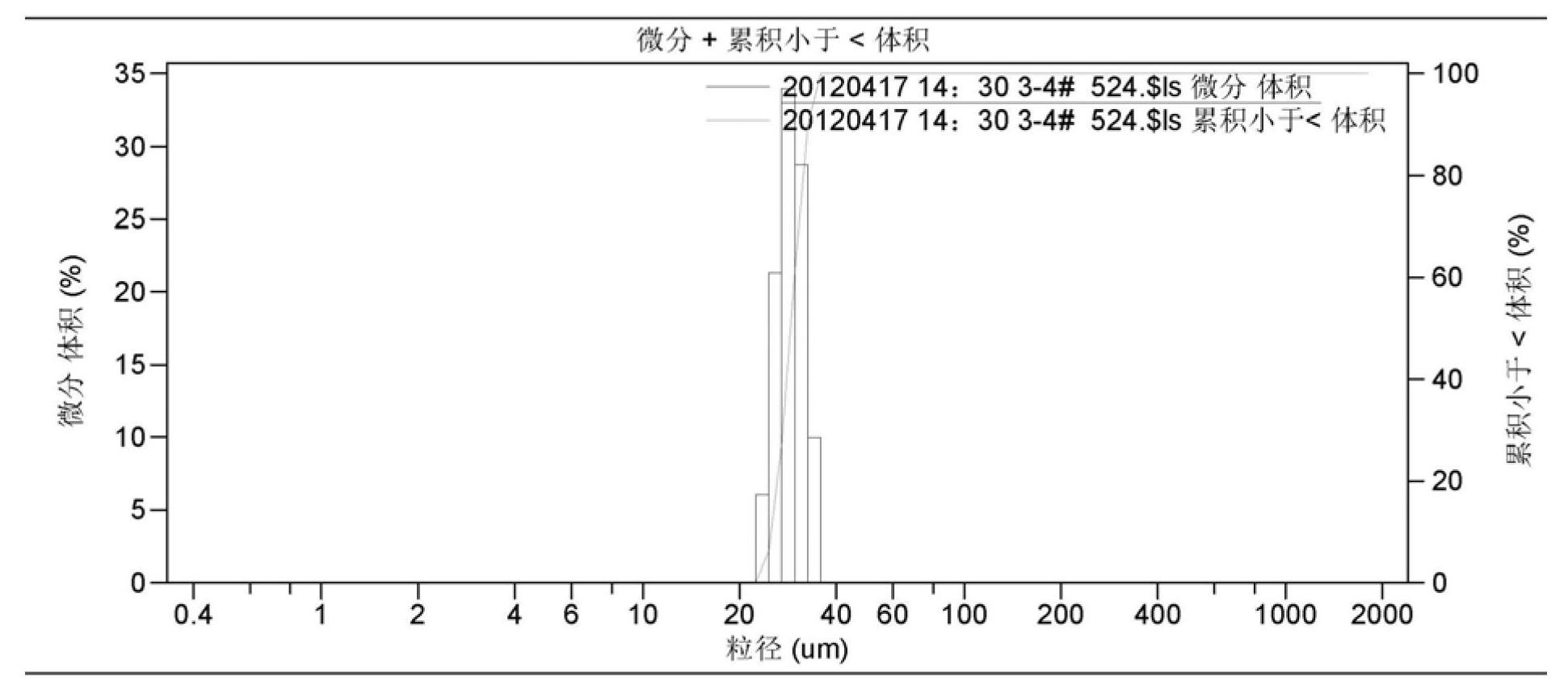

Metal powder preparation device and method therefor

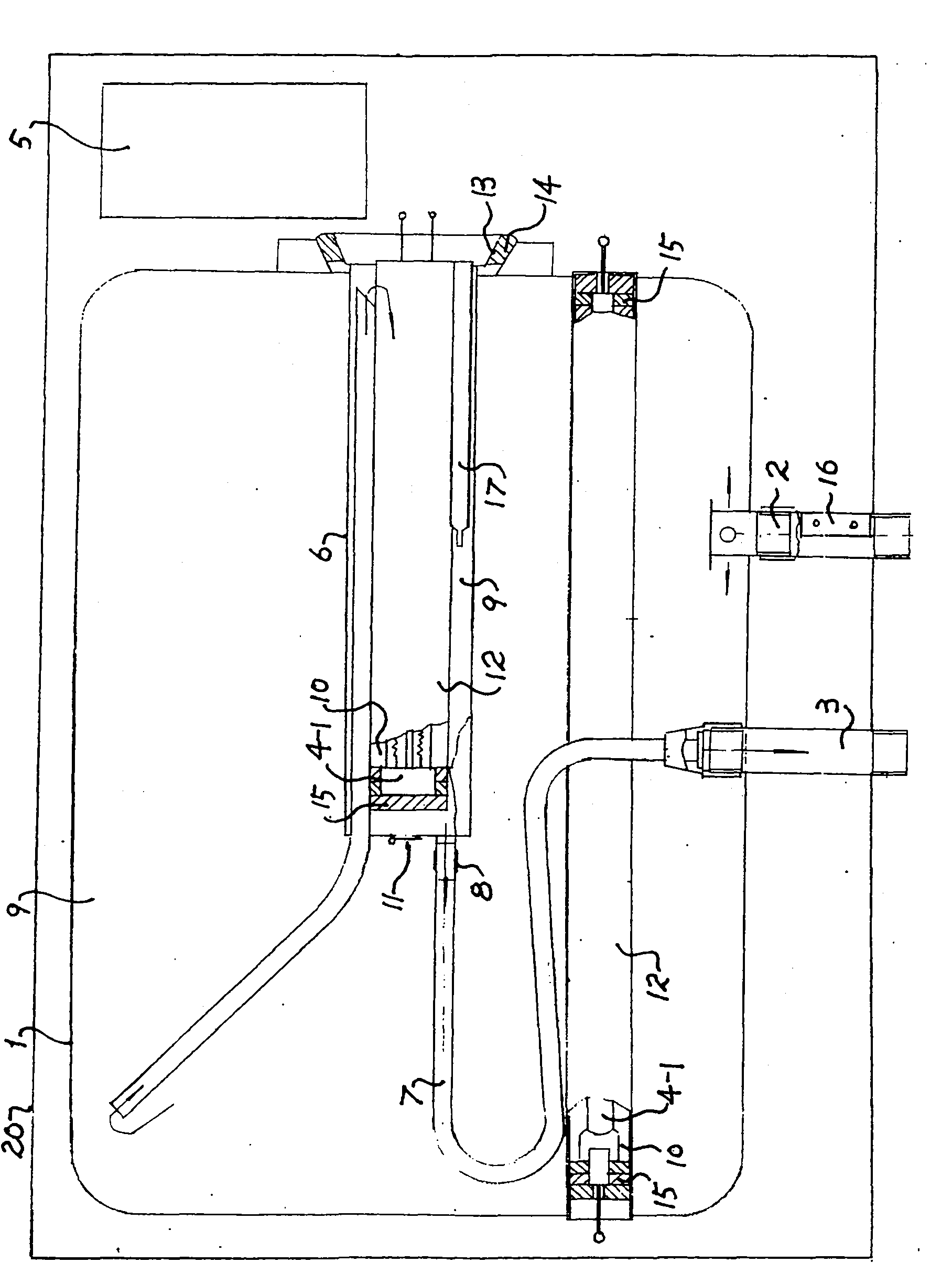

The invention relates to a metal powder preparation device and method therefor. The device comprises an atomization furnace, a heater, a cooler, an atomization chamber, an atomizer, a pneumatic classifier, a middle bin, a sieving funnel, a screening machine, a deduster, a balance tank, a shell-and-tube heat exchanger, a vacuum obtaining device, a control system, an infusion tube, a conduit, a pipeline, a gas channel, a pneumatic butterfly valve, an electromagnetic valve and the like. The method comprises atmosphere preparation, metal smelting, infusion, centrifugal atomizing, pneumatic classification, mechanical screening, gas purification, cooling and the like, the metal is smelted and treated so as to be poured onto the atomizer for centrifugal atomization to form powder, the powder is classified by the pneumatic classifier, after classification, rough powder is screened by the mechanical screening so as to obtain the finished powder, fine powder is sent into the deduster by airflow for purification, the purified gas is driven by a high pressure centrifugal fan so as to be speeded up to be atomized and classified again after being subjected to heat exchange through the shell-and-tube heat exchanger. The device can be used for continuous production of spherical powder below -320 meshes, and the oxygen content is less than or equal to 80ppm.

Owner:BEIJING COMPO ADVANCED TECH

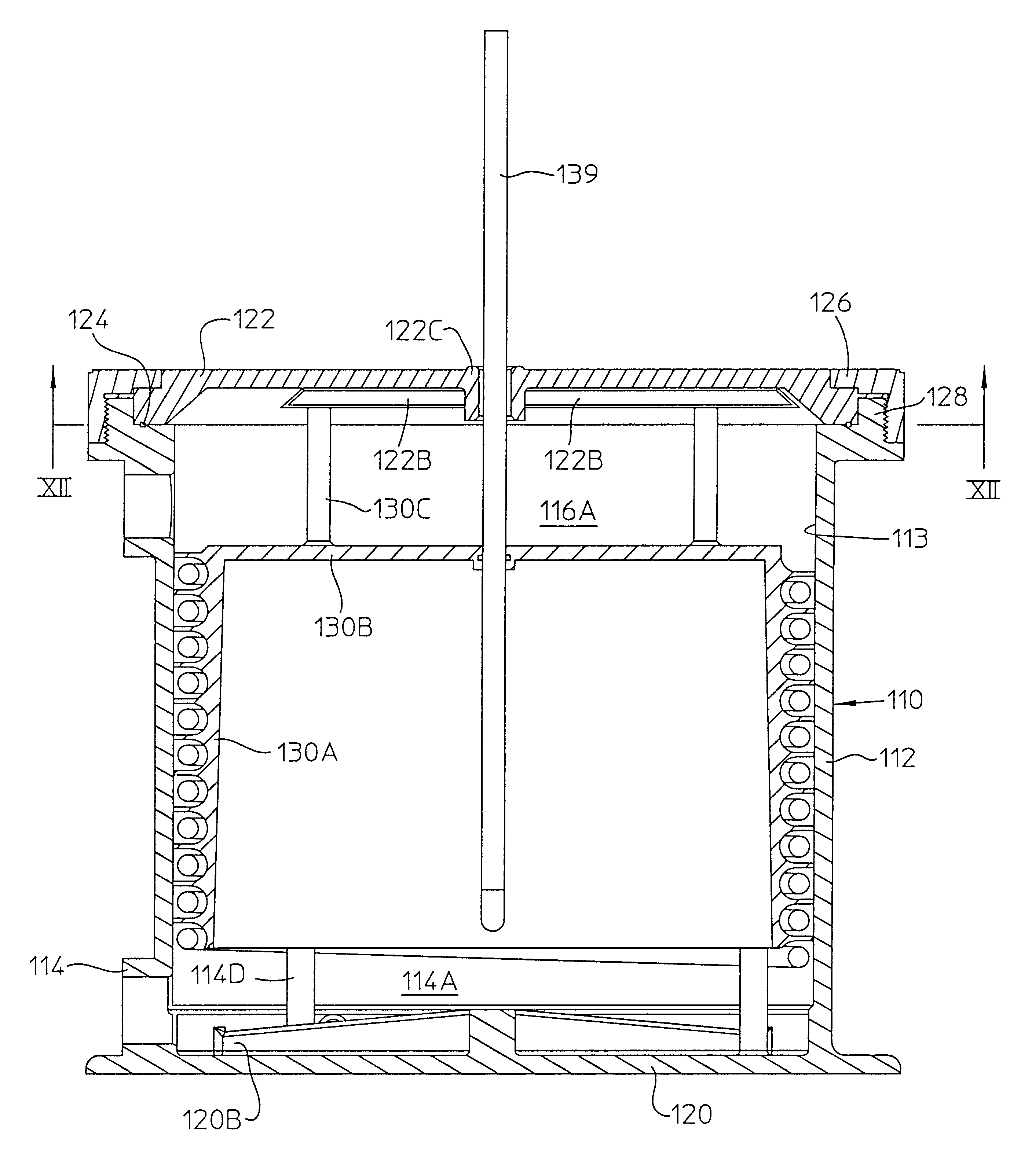

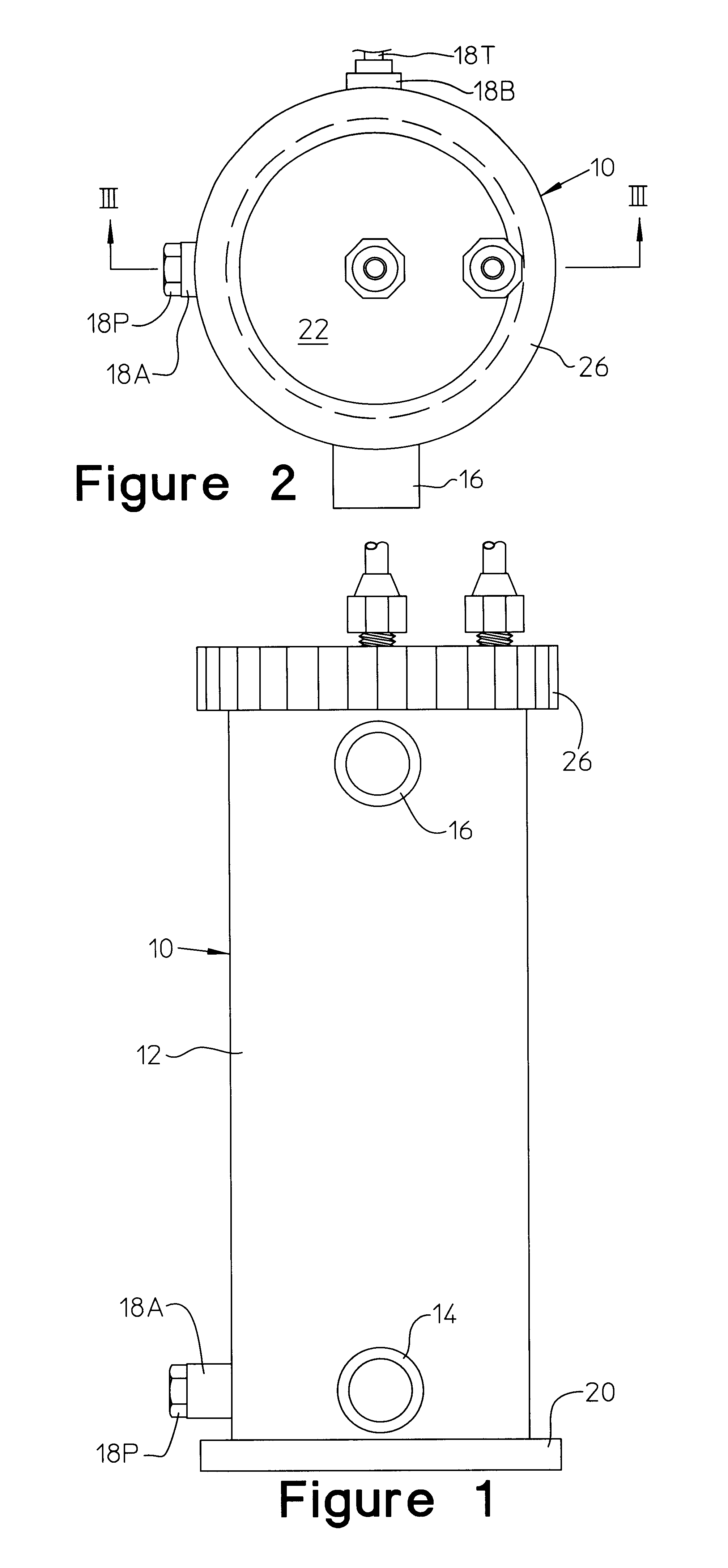

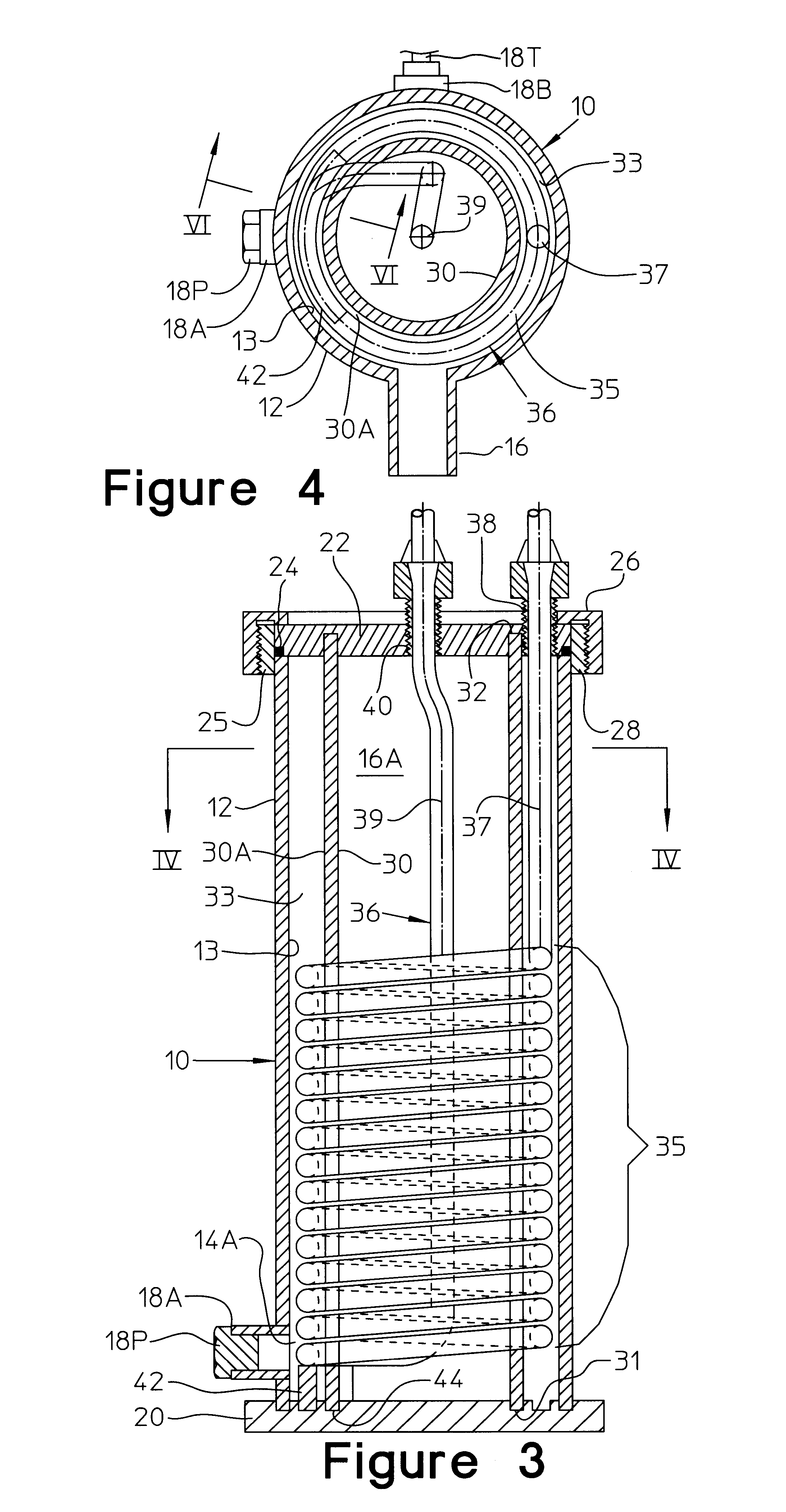

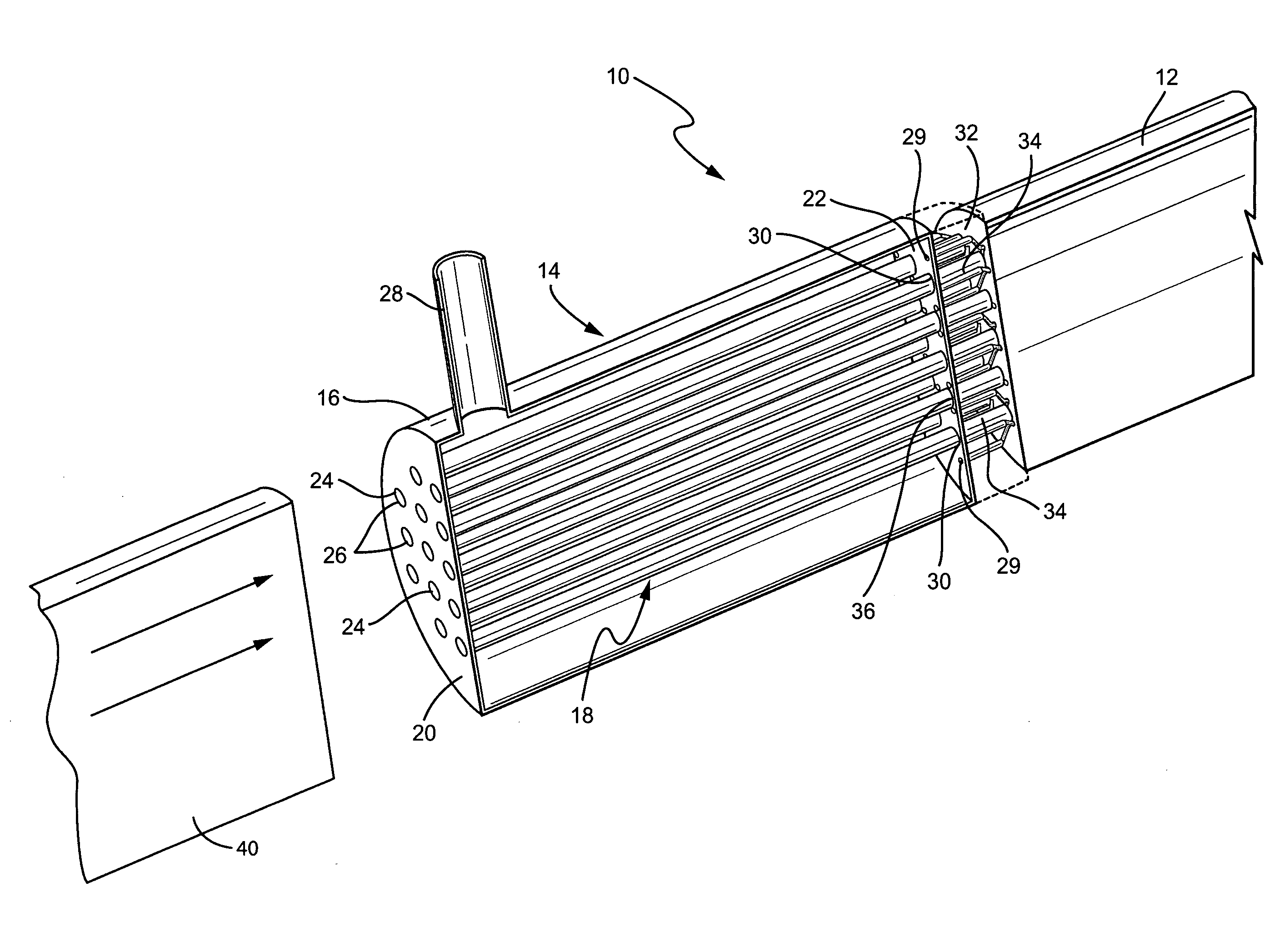

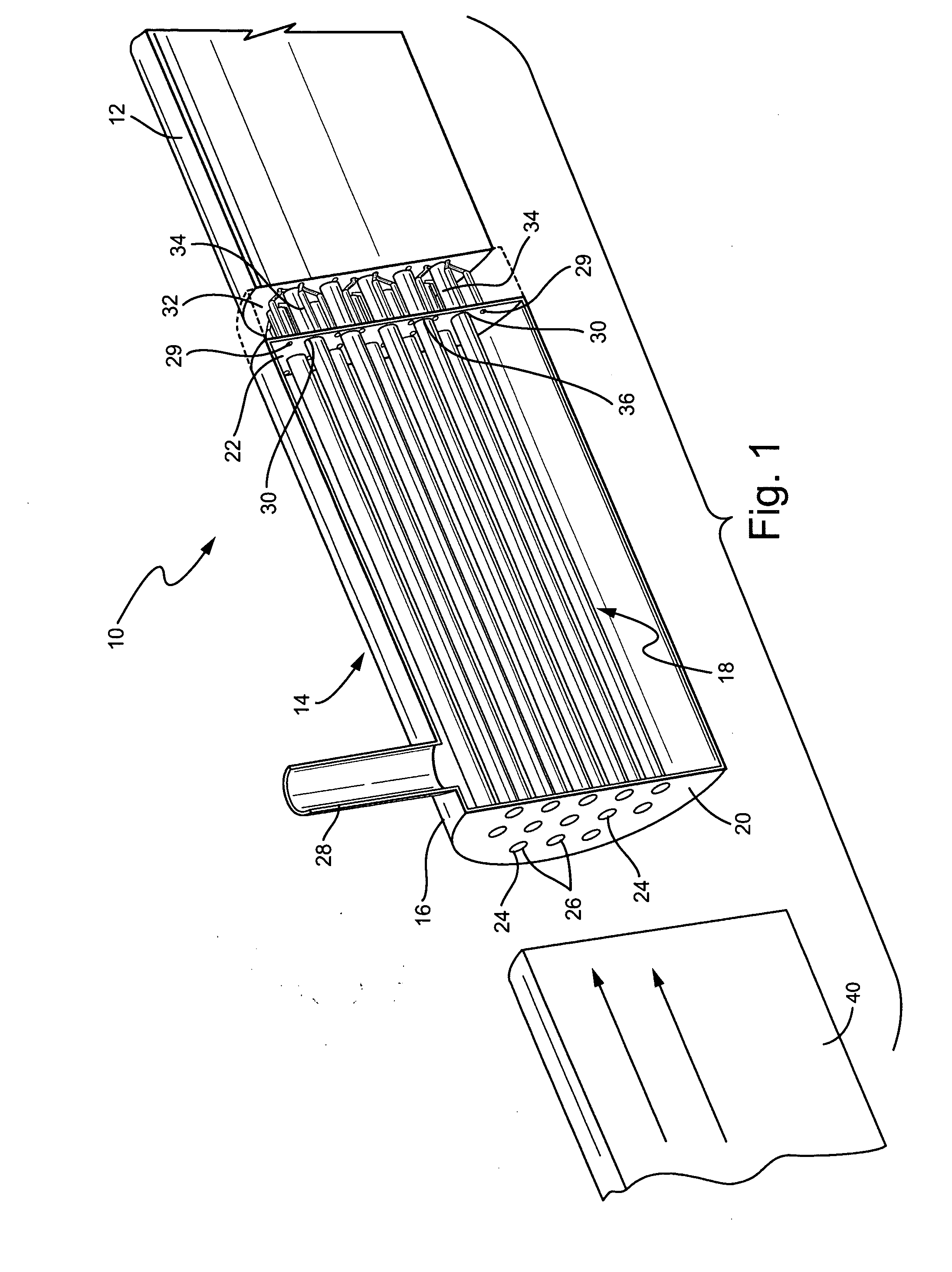

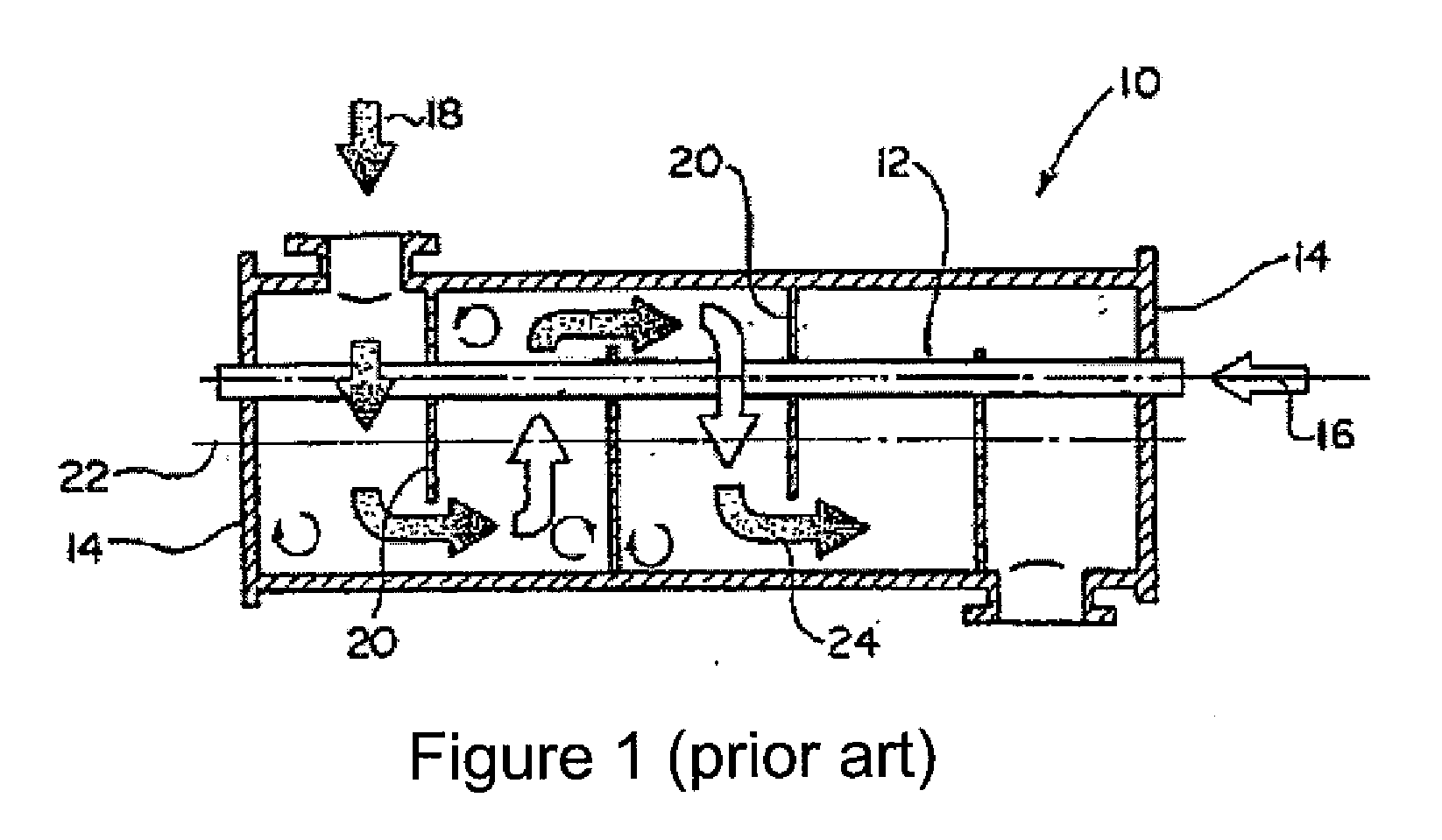

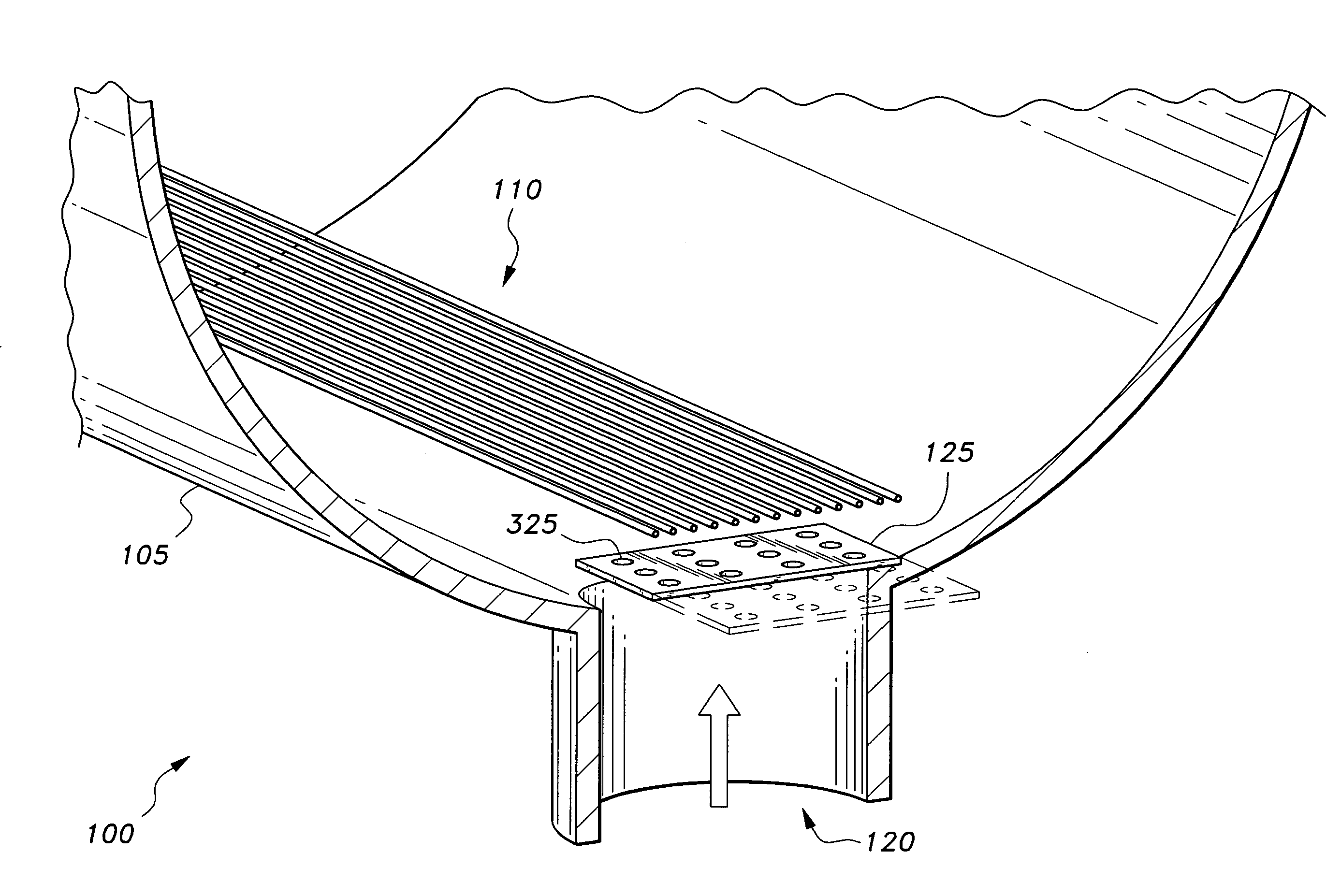

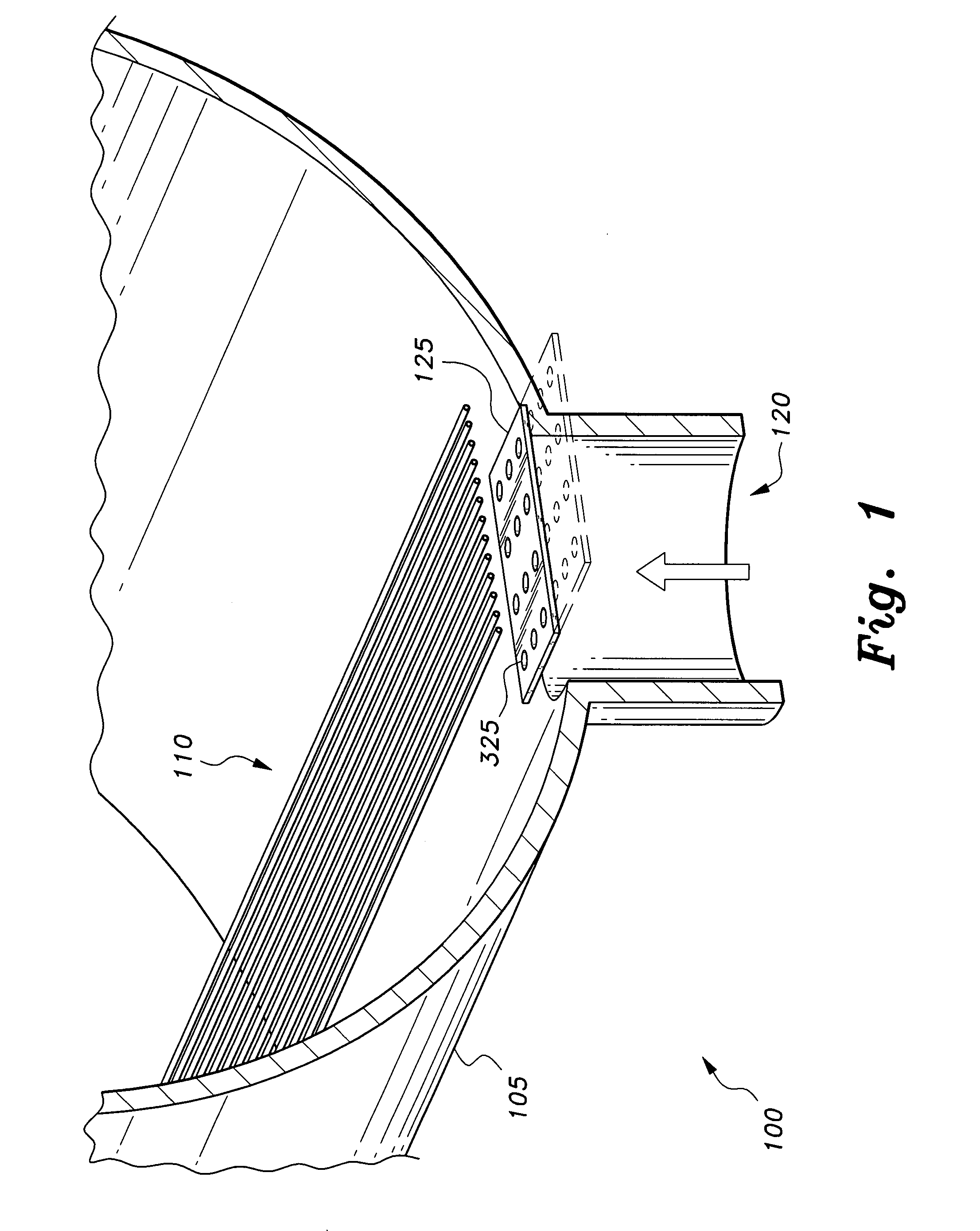

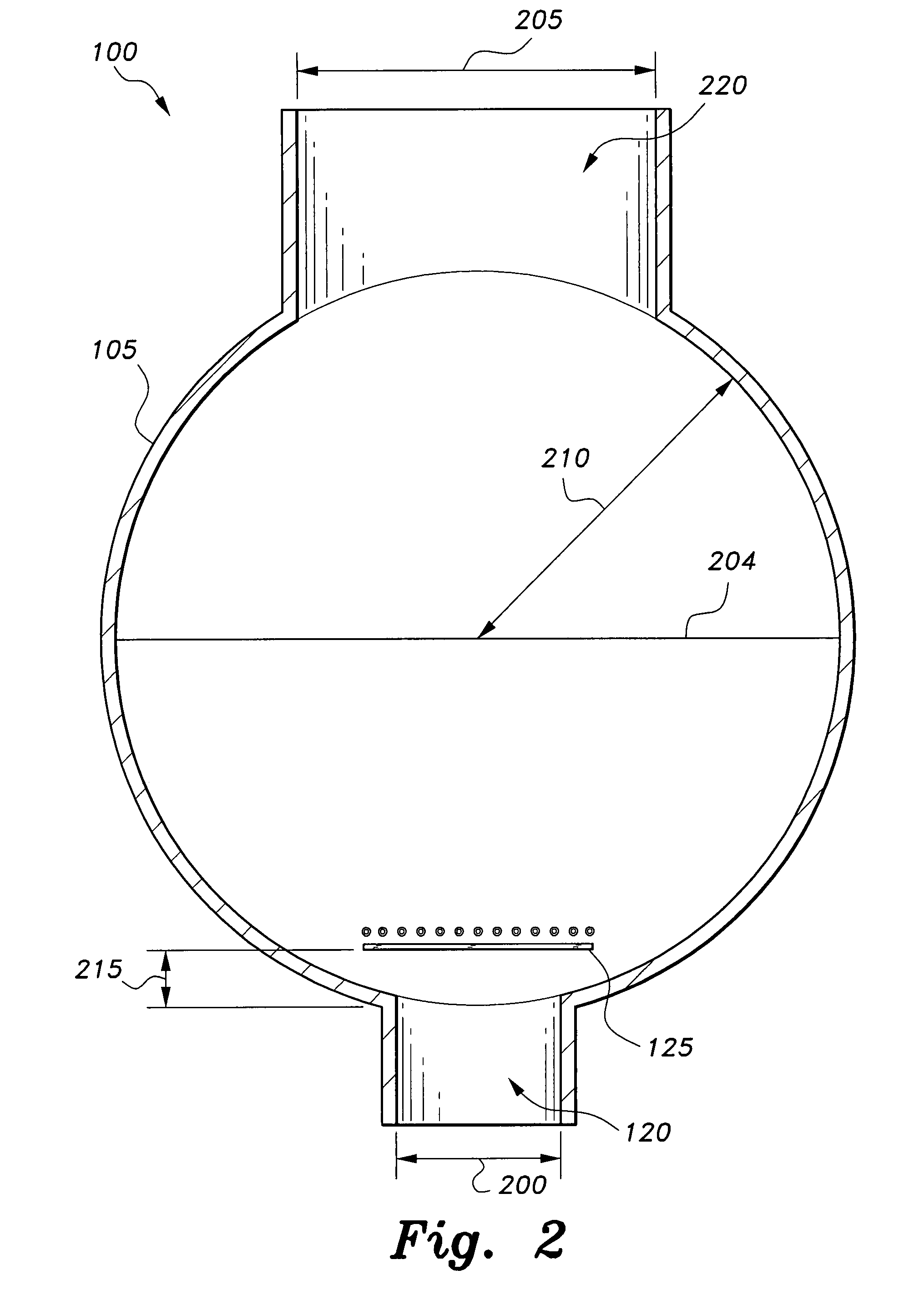

Method and apparatus for optimizing heat transfer in a tube and shell heat exchanger

InactiveUS6293335B1Increased turbulenceMaximize heat transferHeat exchanger casingsStationary tubular conduit assembliesPlate heat exchangerShell and tube heat exchanger

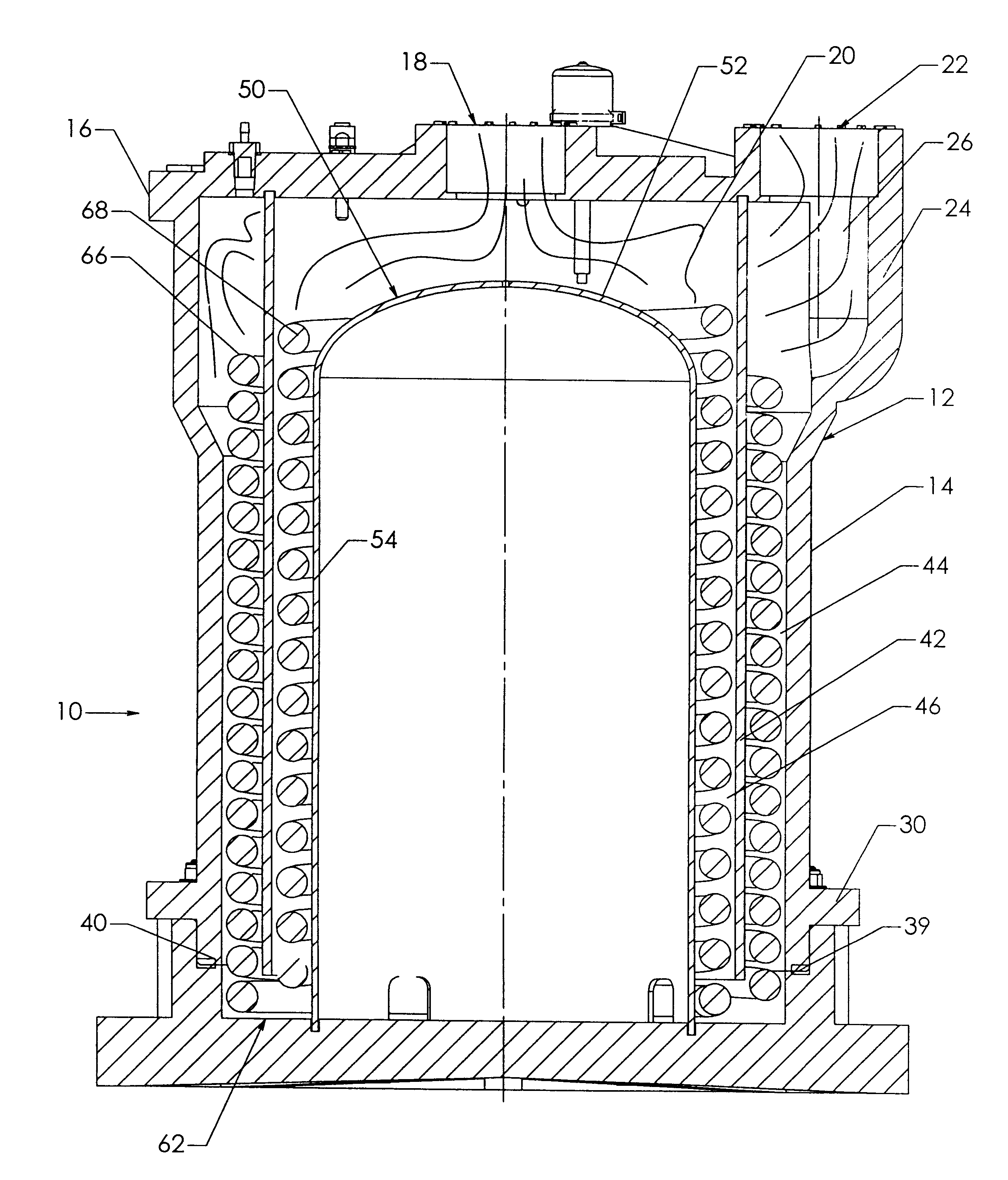

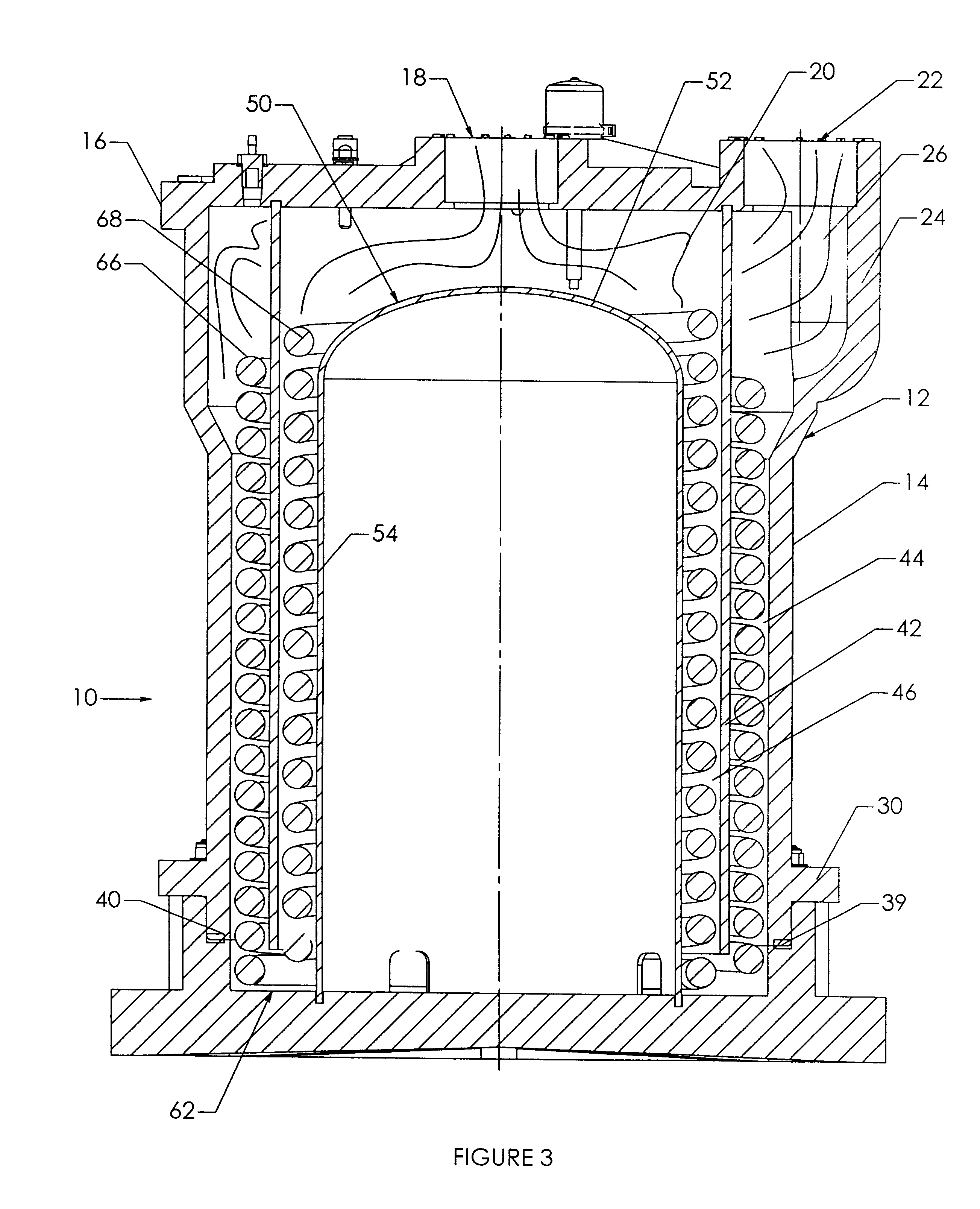

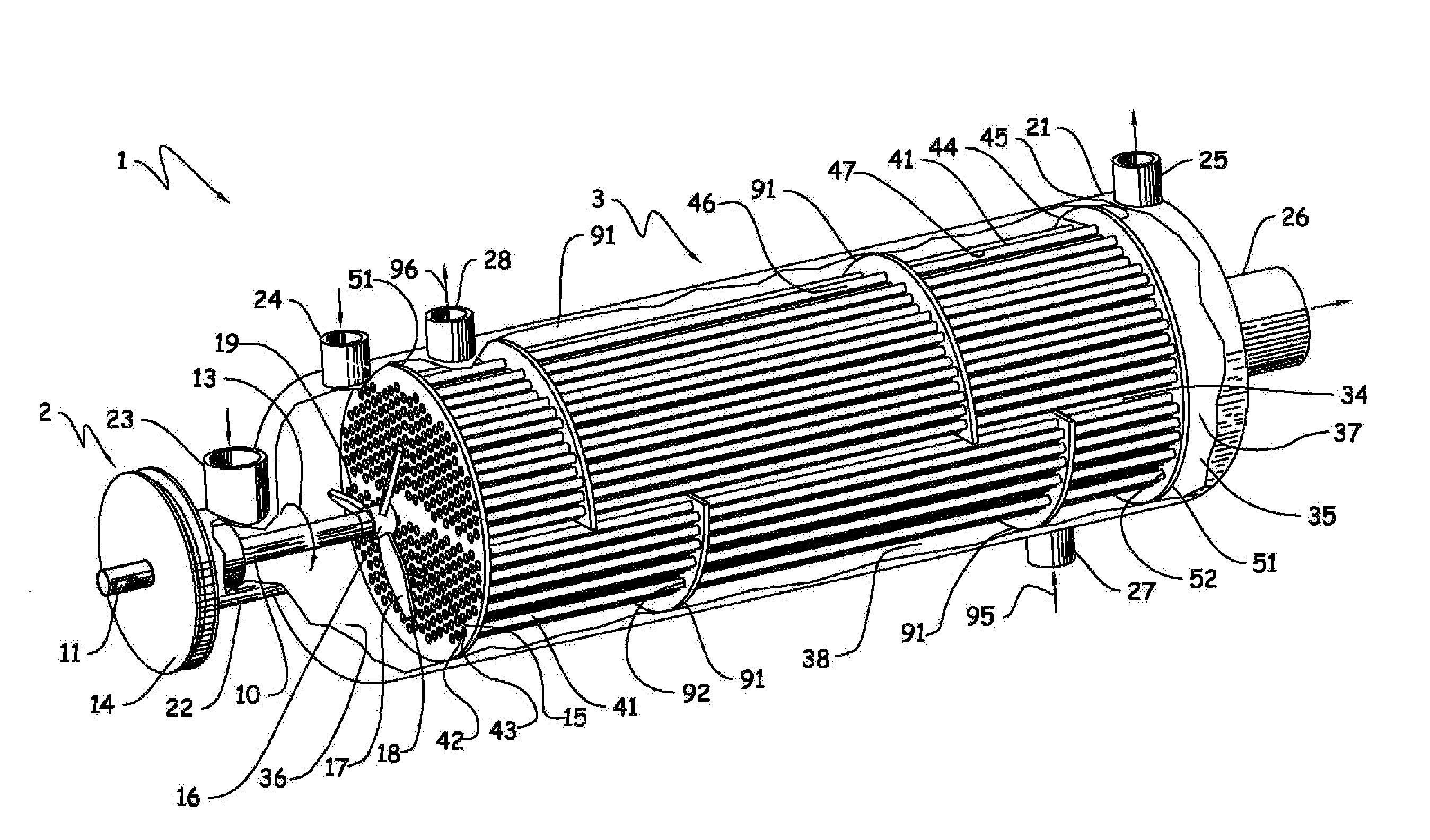

A tube and shell heat exchanger having a transversely oriented inlet port and a spirally coiled heat transfer tube contained within an arcuate chamber created by an internal baffle in which the water to be conditioned travels along a helical pathway in which the flow has minimized water depth and high turbulence. The tube and shell heat exchanger maximizes heat transfer capability in a relatively easy to assemble design to make feasible the use of a higher cost material for the tubing such as titanium in a wide range of applications.

Owner:AQUACAL

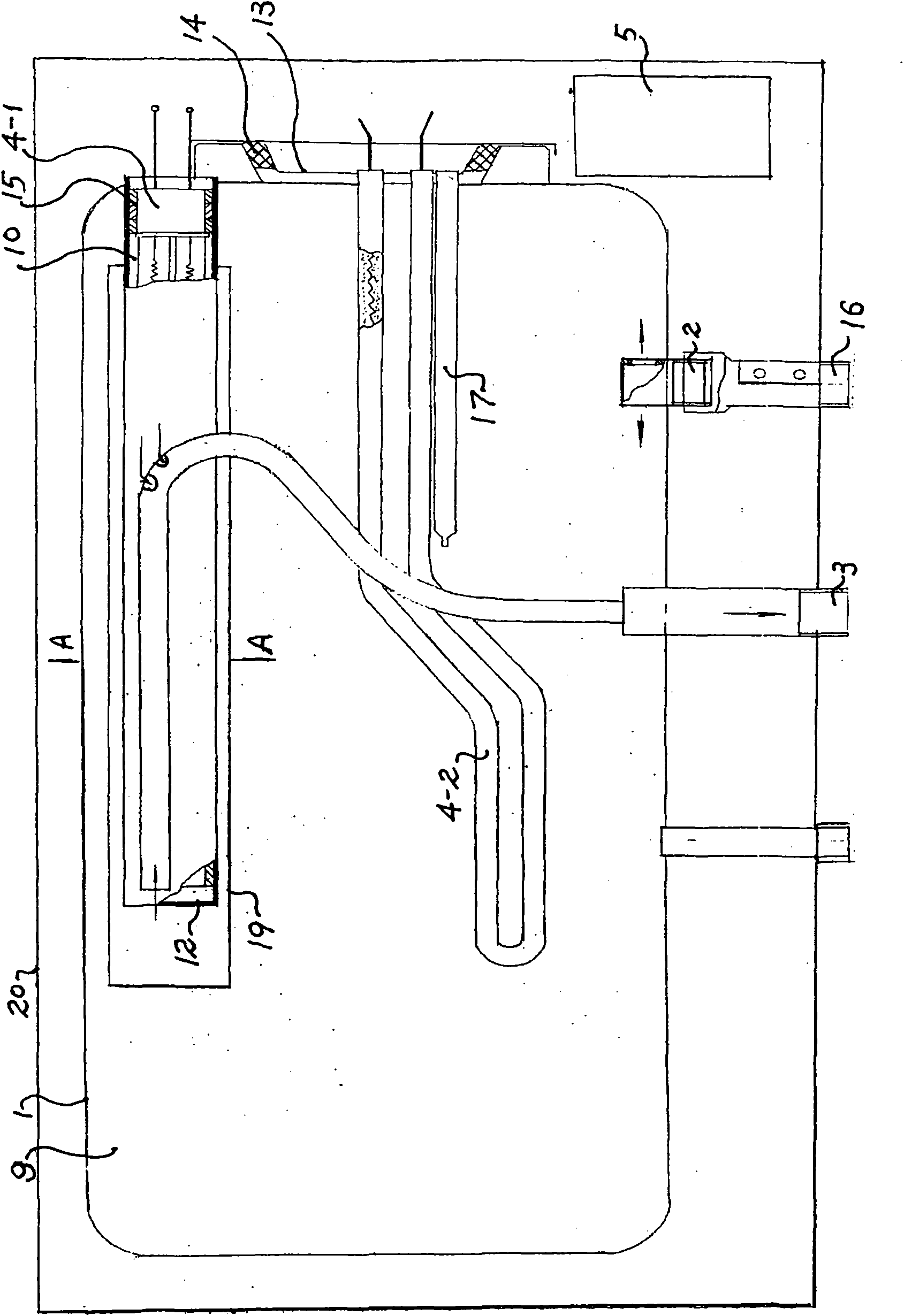

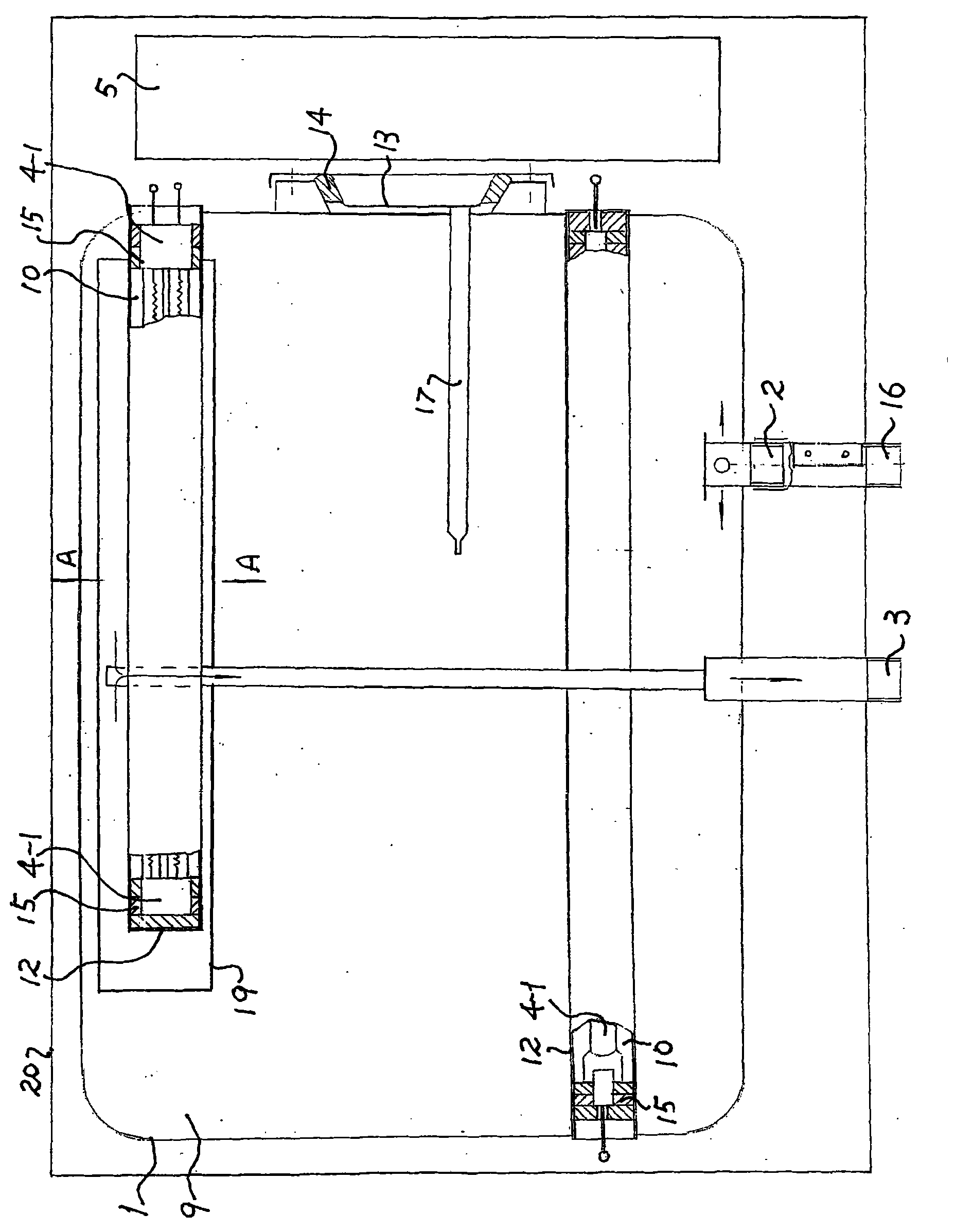

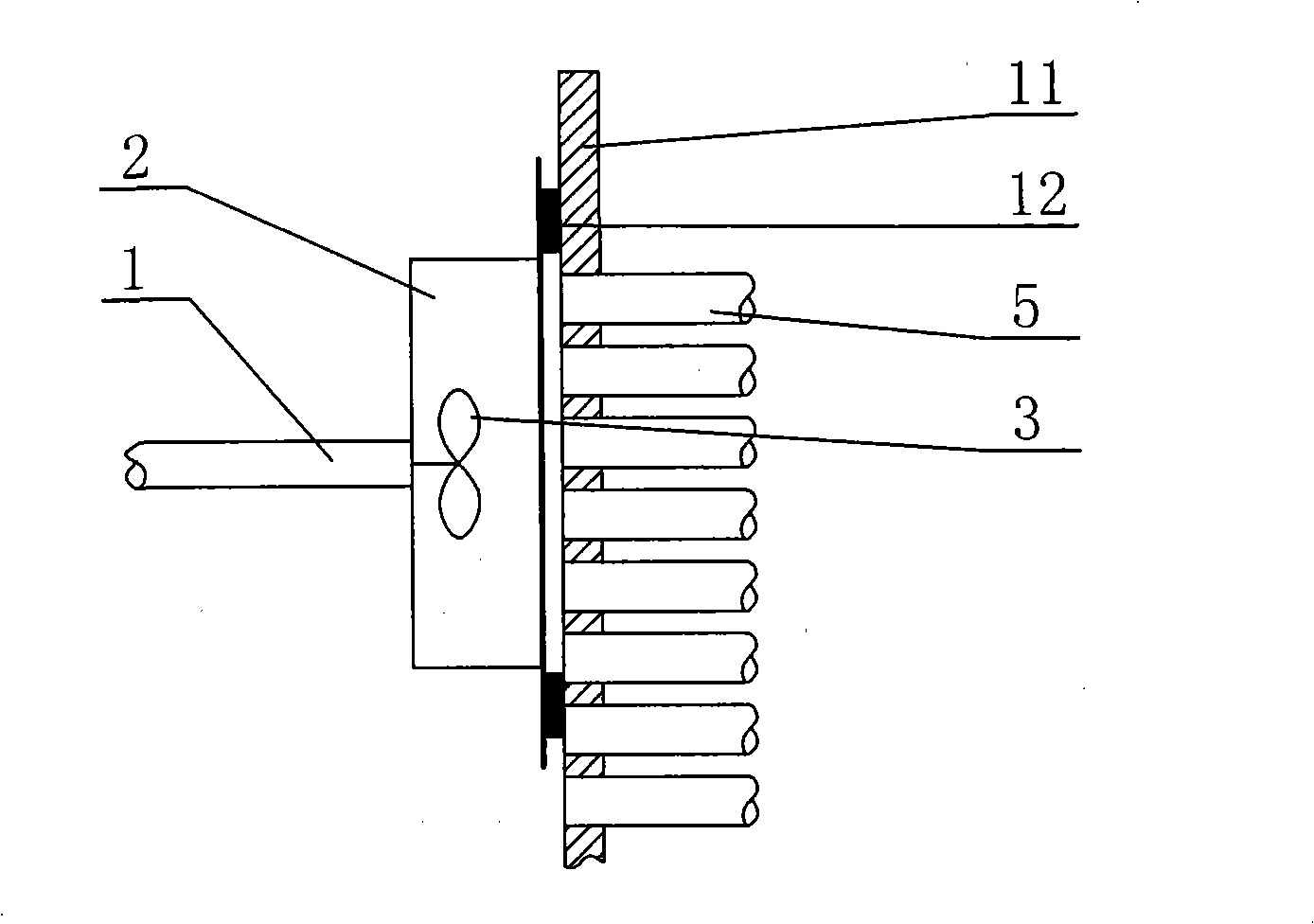

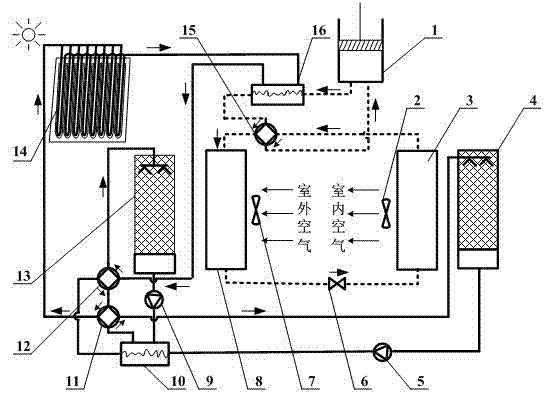

Water tank structure of electric energy, solar energy or air energy water heater

InactiveCN102147151AFast hotWater storage function hasFluid heatersSolar heat devicesEngineeringCheck valve

The invention relates to a water tank structure of an electric energy, solar energy or air energy water heater, which comprises a water tank, electric heating tubes, an energy accumulating cover or heating water tank, a connecting tube and a check valve and is characterized in that more than one circular or wing-shaped metallic or nonmetallic tubular body (12) is installed on the water tank (1) or flange (13) in a firm welding or mechanical connection mode, wherein each of two ends or one end of each tubular body (12) is opened outwards, an optical wave electric heating tube (4-1) is arranged in each tubular body (12), and the water tank needs to be sealed; the optical wave electric heating tubes (4-1) generate heat radiation after being powered on, so that the metallic or nonmetallic tubular bodies (12) are heated, and the water surrounding the tubular bodies (12) is heated through the heat transfer of tube walls; and simultaneously, more than one common stainless steel electric heating tube or silicon carbide tube (4-2) is arranged in the water tank and does not work when the hot water is released. A section of a vacuum tube heat accumulator is inserted into the water tank of a solar energy water heater; a condenser or metallic tube heat exchanger is arranged in the water tank of an air energy water heater; and for each of the solar energy water heater and the air energy water heater, an electric auxiliary heating device is also arranged in the water tank, i.e. the upper part is provided with a rapid-heating electric heating tube, the lower part is provided with a preheating electric heating tube, the heating water tank can also be manufactured on the flange or other parts, a water pump is connected to an end part, and the check valve is installed at the water outlet of the water pump.

Owner:刘运柳

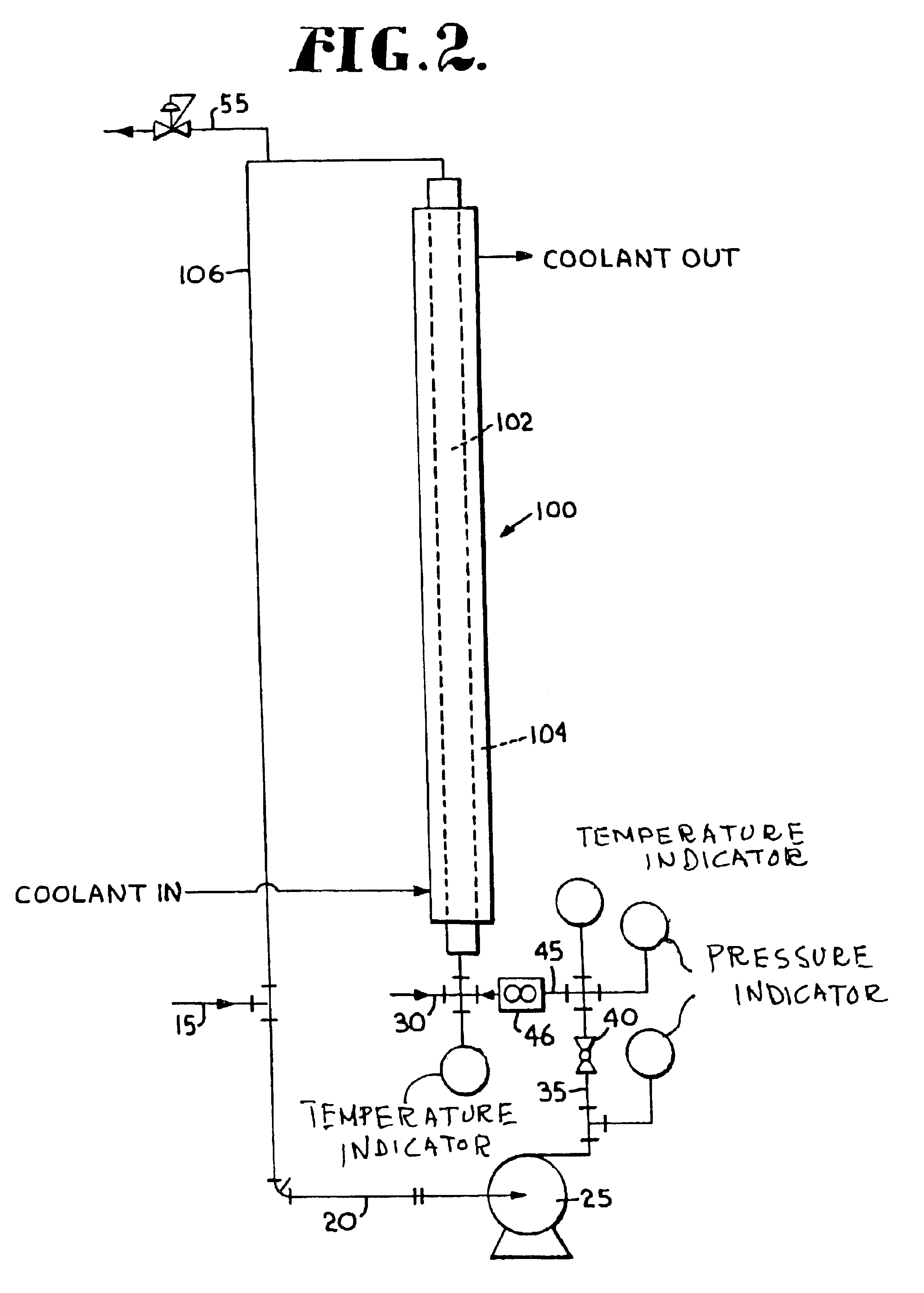

Heat exchanger with two-stage heat transfer

InactiveUS6499534B1Improve heat transfer performanceMinimize thermal losses to the atmosphereHeat exchanger casingsStationary tubular conduit assembliesPlate heat exchangerShell and tube heat exchanger

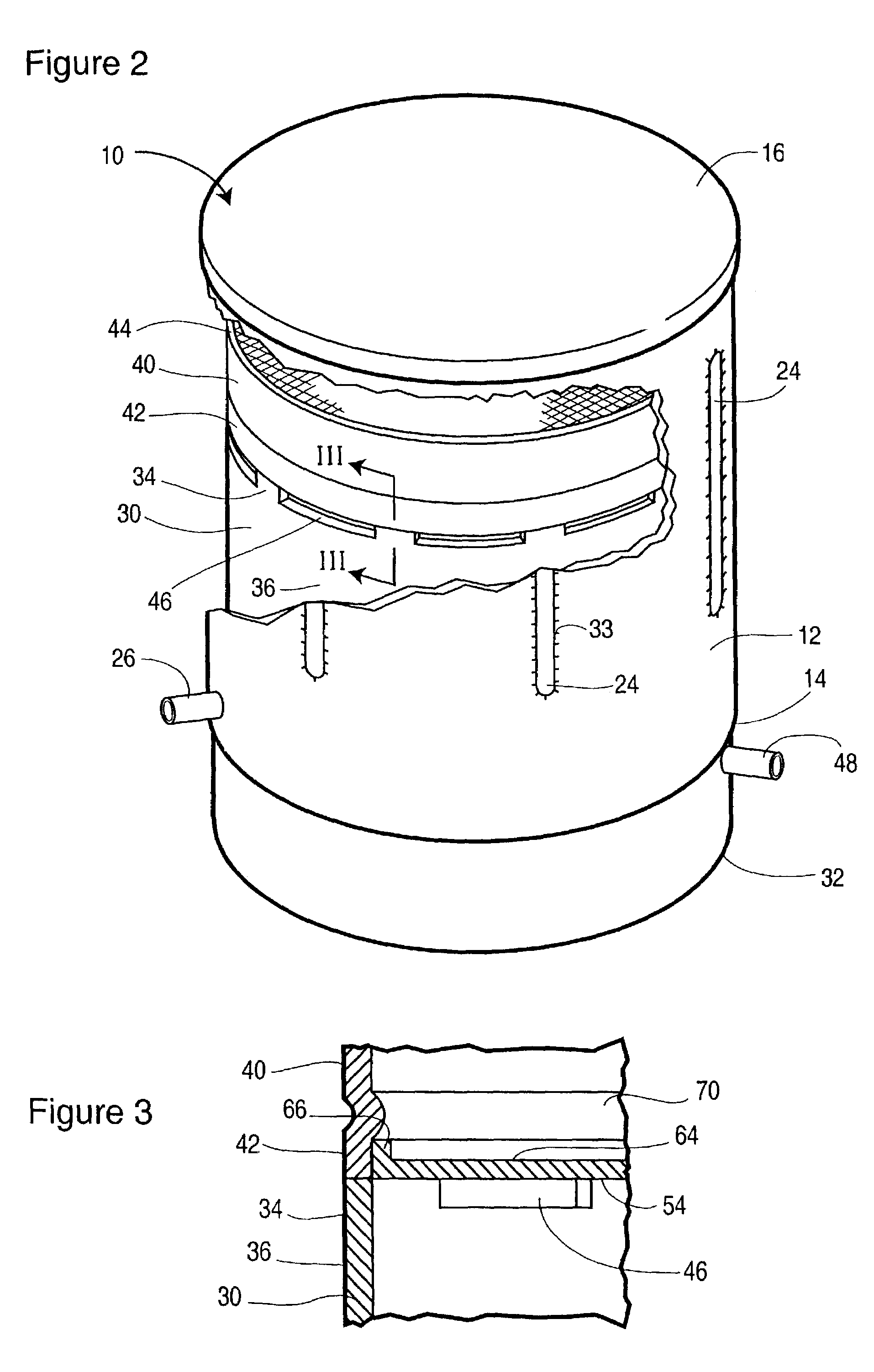

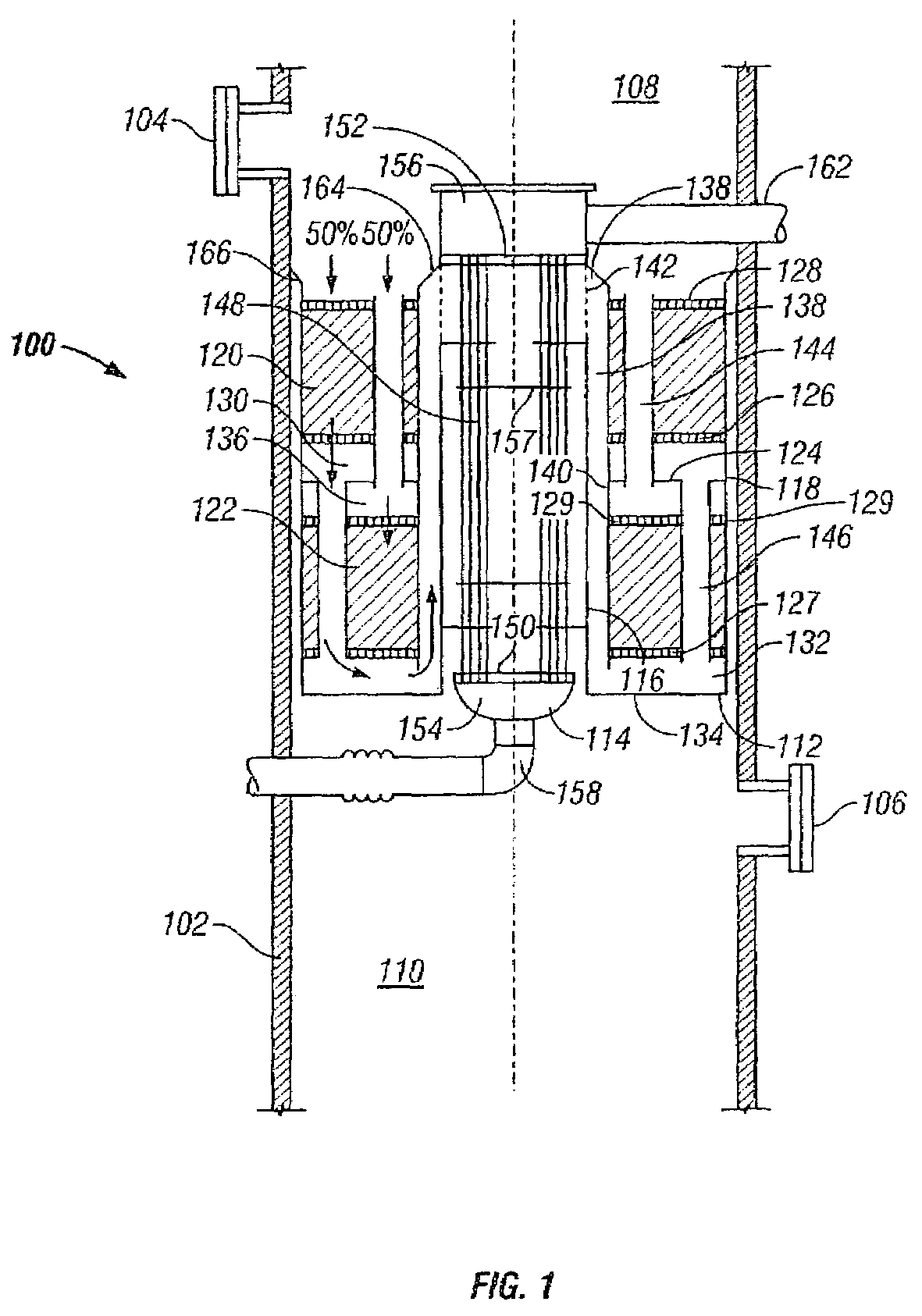

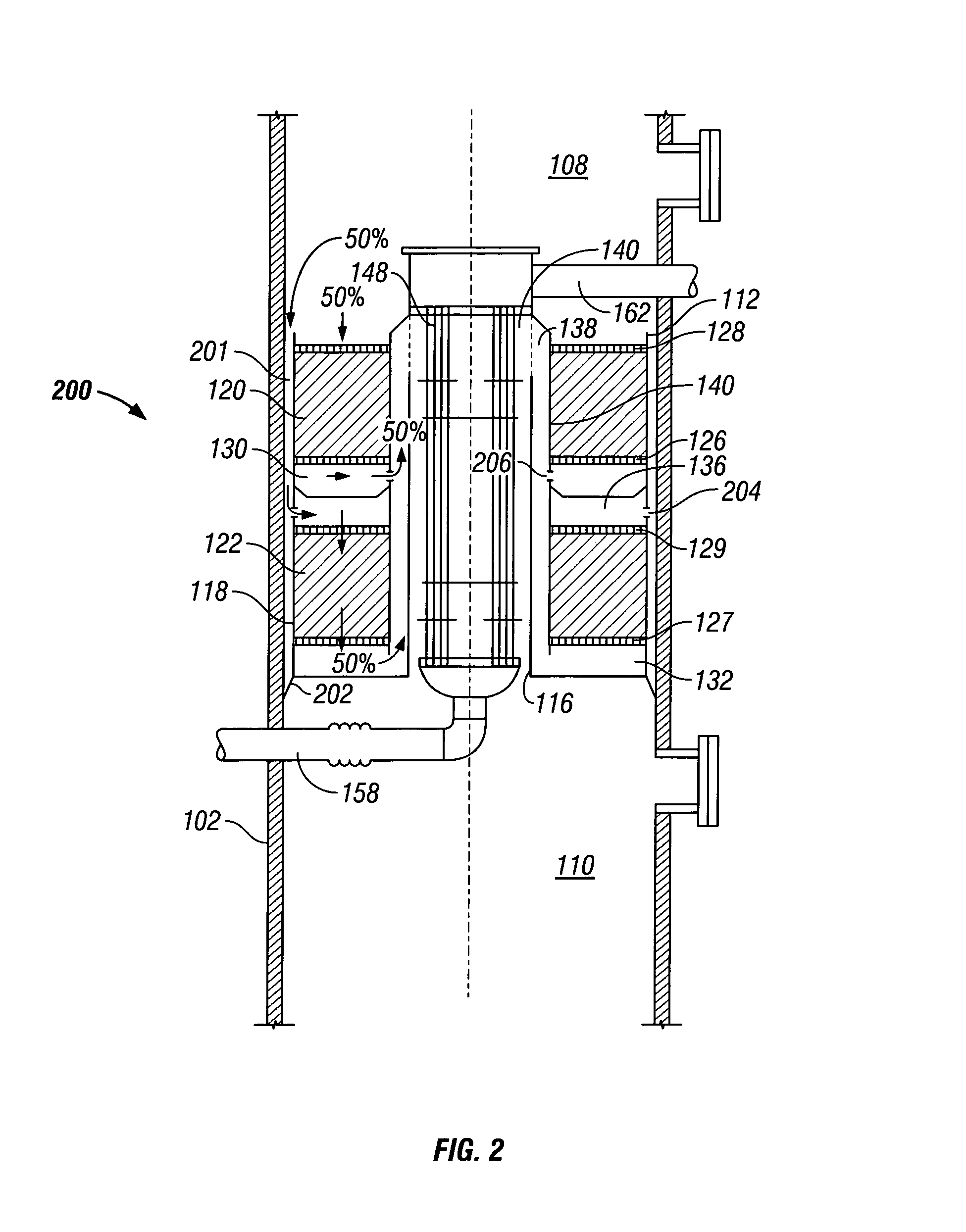

A tube and shell heat exchanger is formed by a shell enclosing an internal sidewall which in turn receives an internally located flow controller outer and inner heat exchange cavities are formed between the outer shell and the internal shell and the internal shell and the flow controller, respectively. Helical convolutions of the conduit are provided in each of the heat exchange cavities for counter concurrent flow of fluid medium from one cavity to another. A bottom wall closes off the outer shell.

Owner:AQUACAL

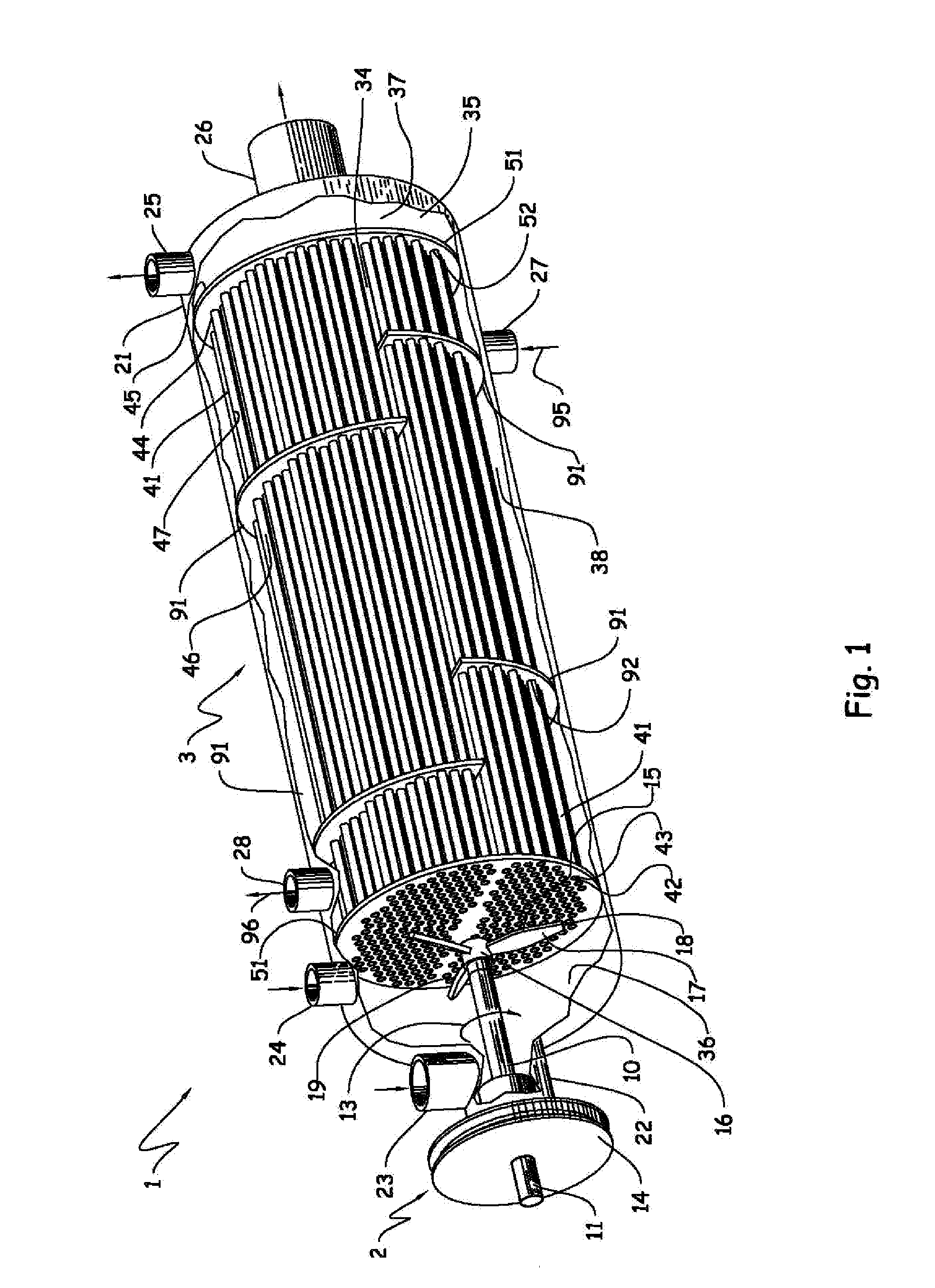

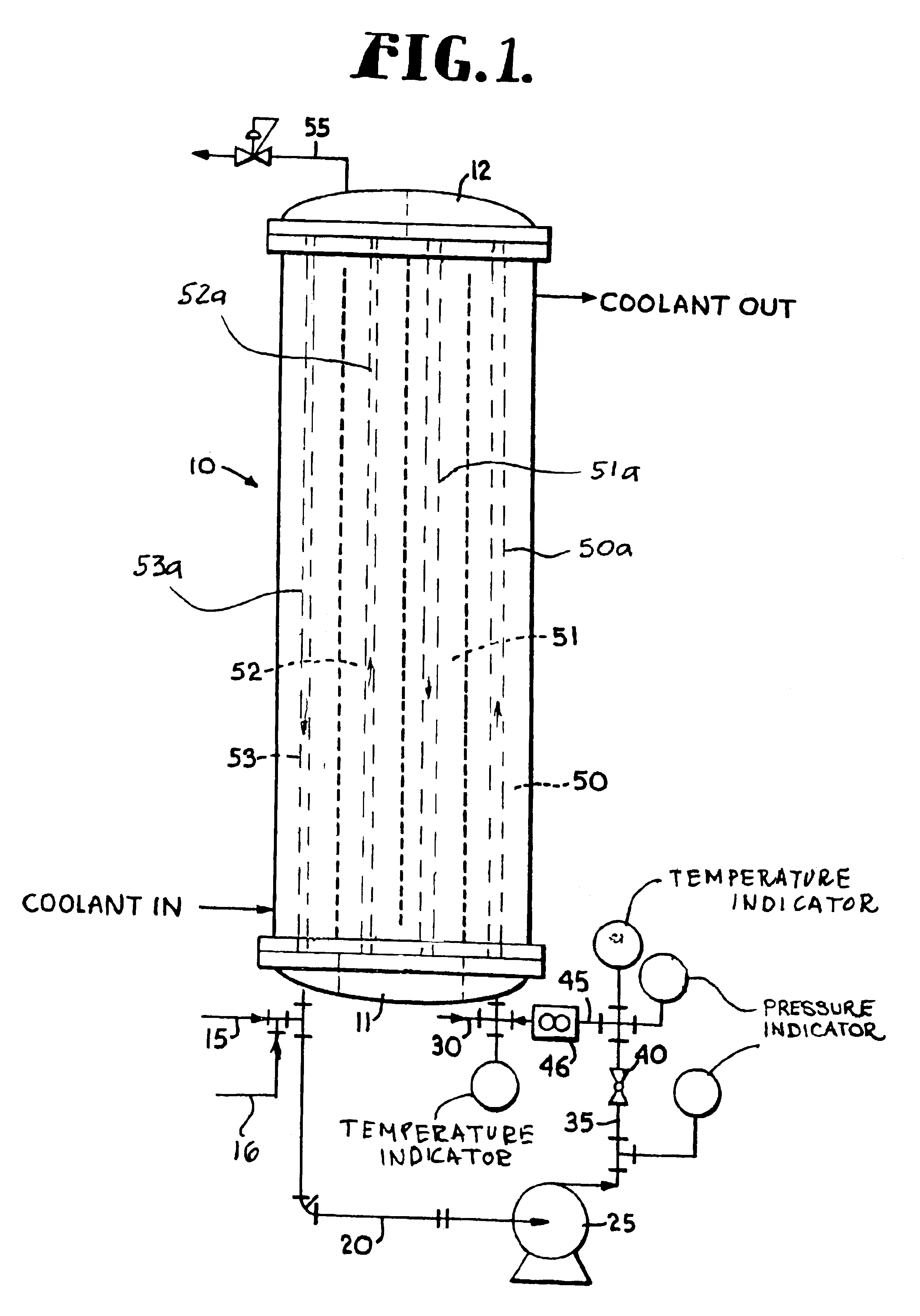

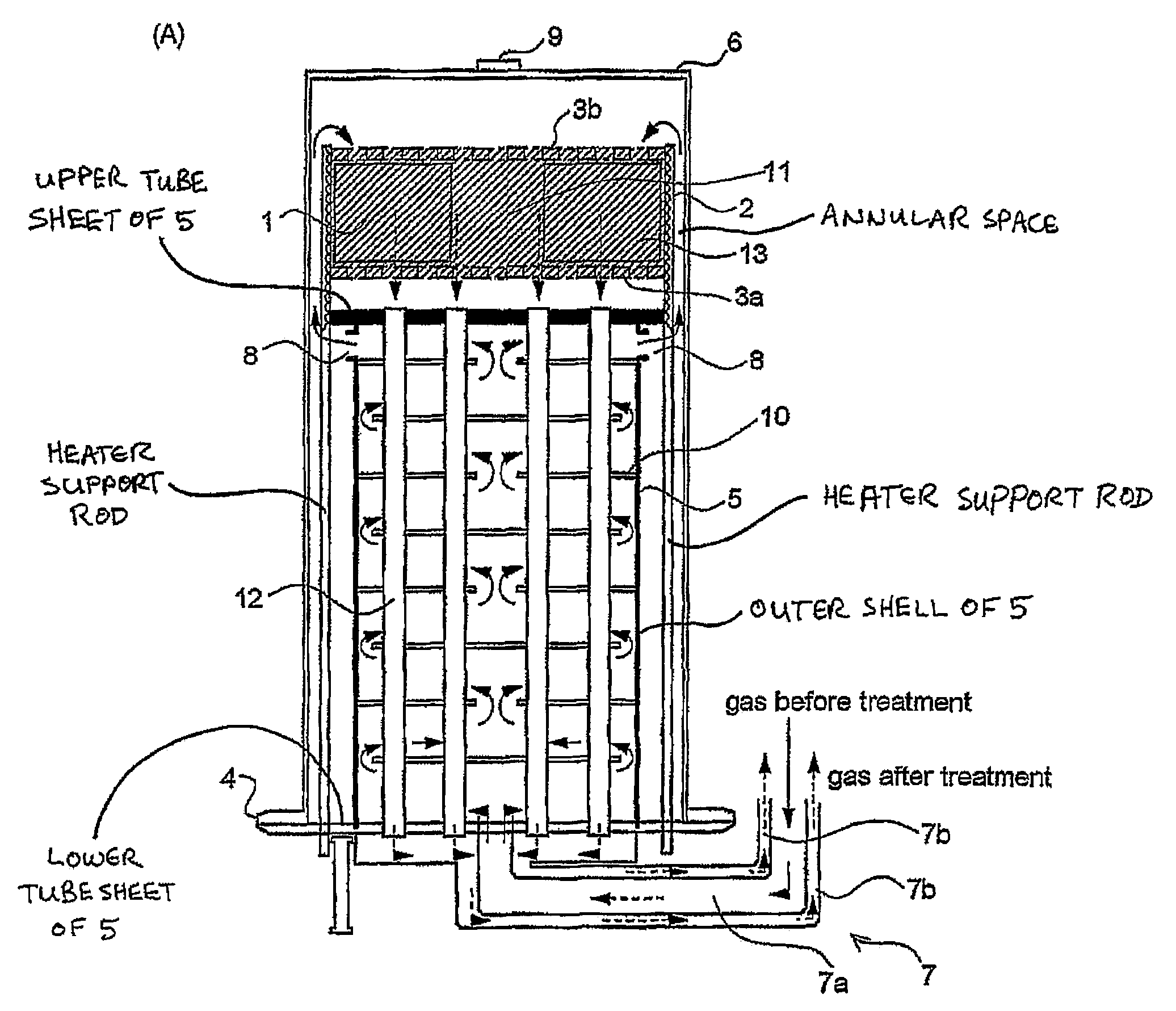

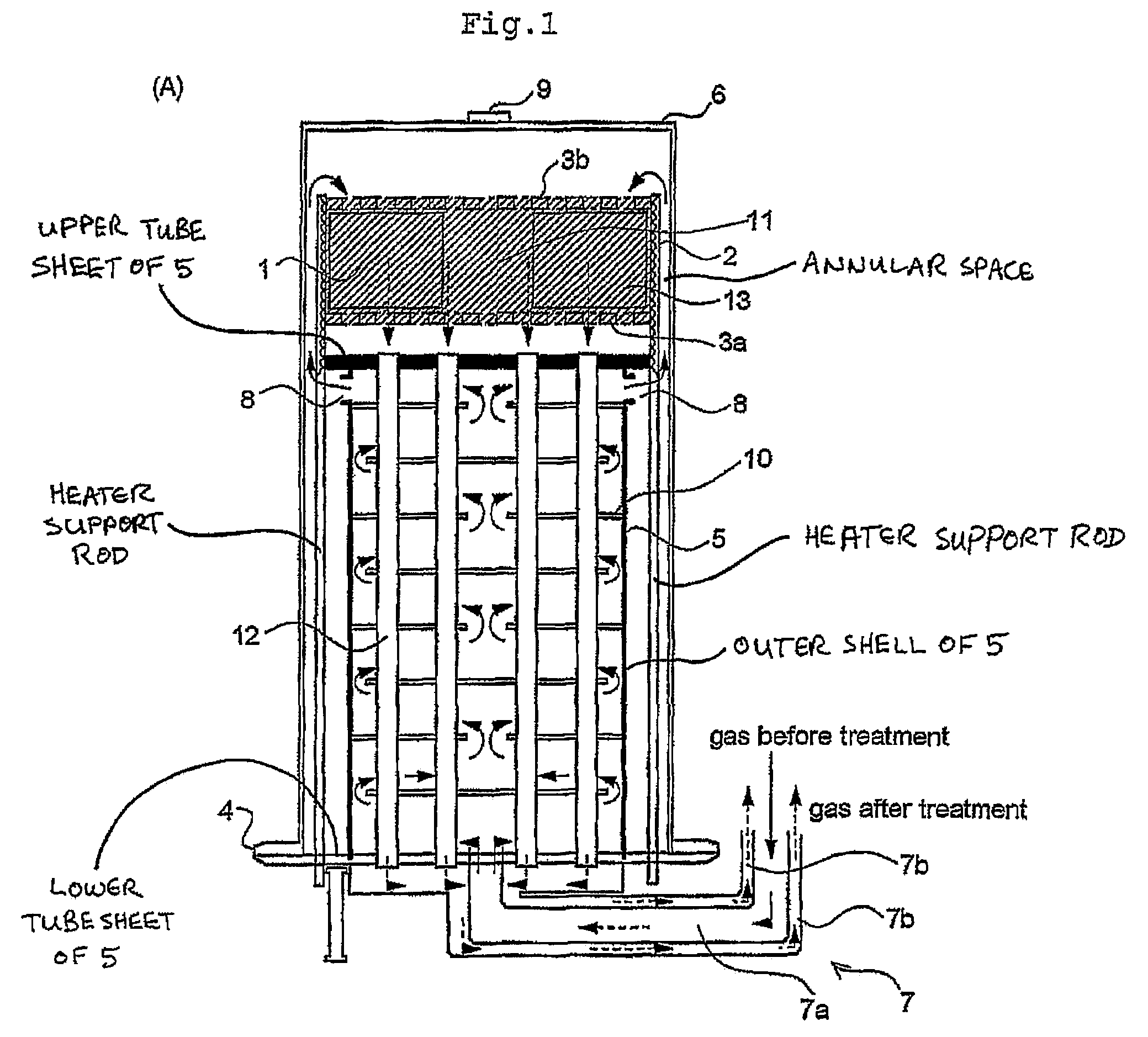

Vertical falling film shell and tube heat exchanger

InactiveUS6089312AMilk preservationEvaporators/condensersPlate heat exchangerShell and tube heat exchanger

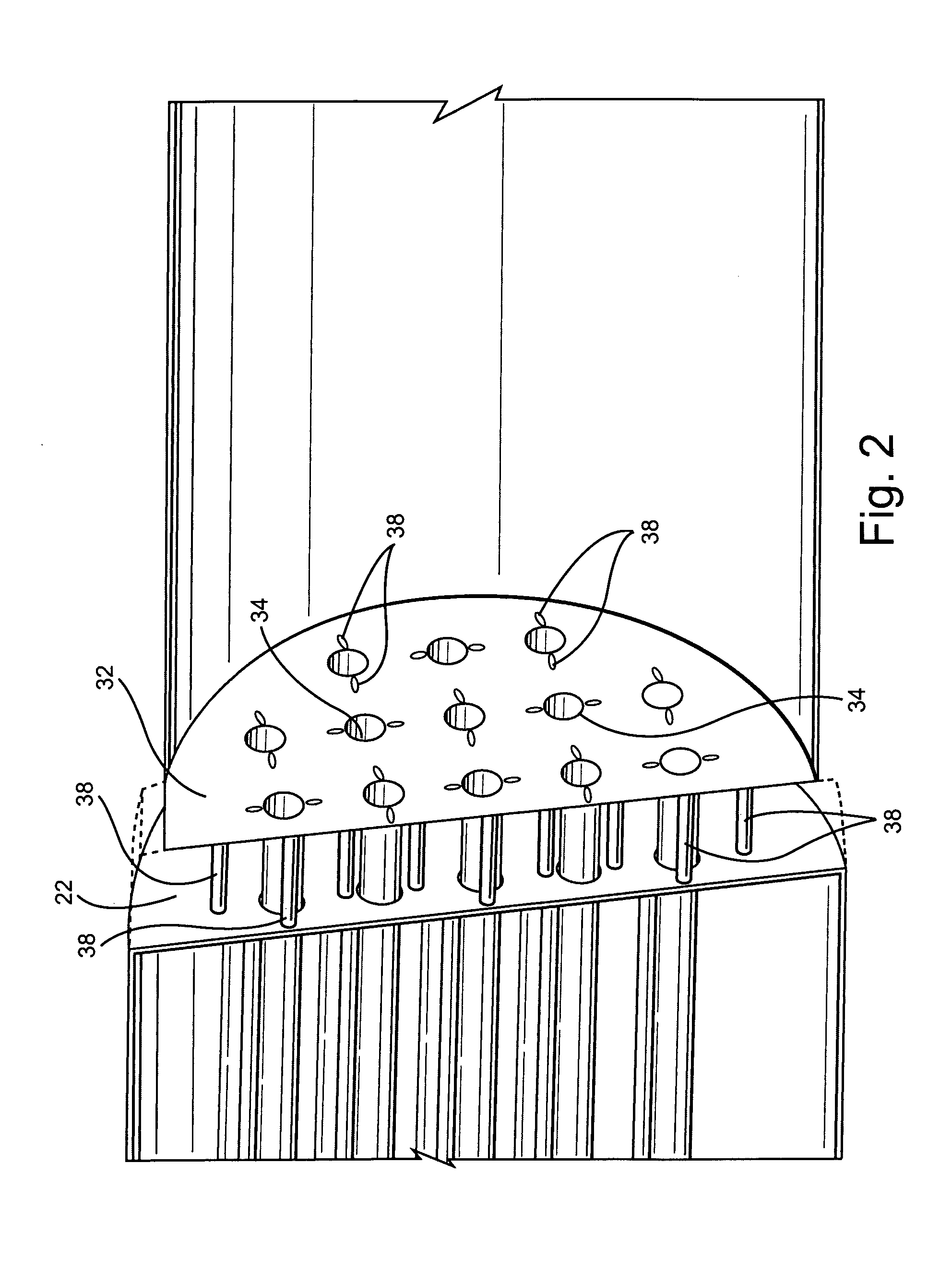

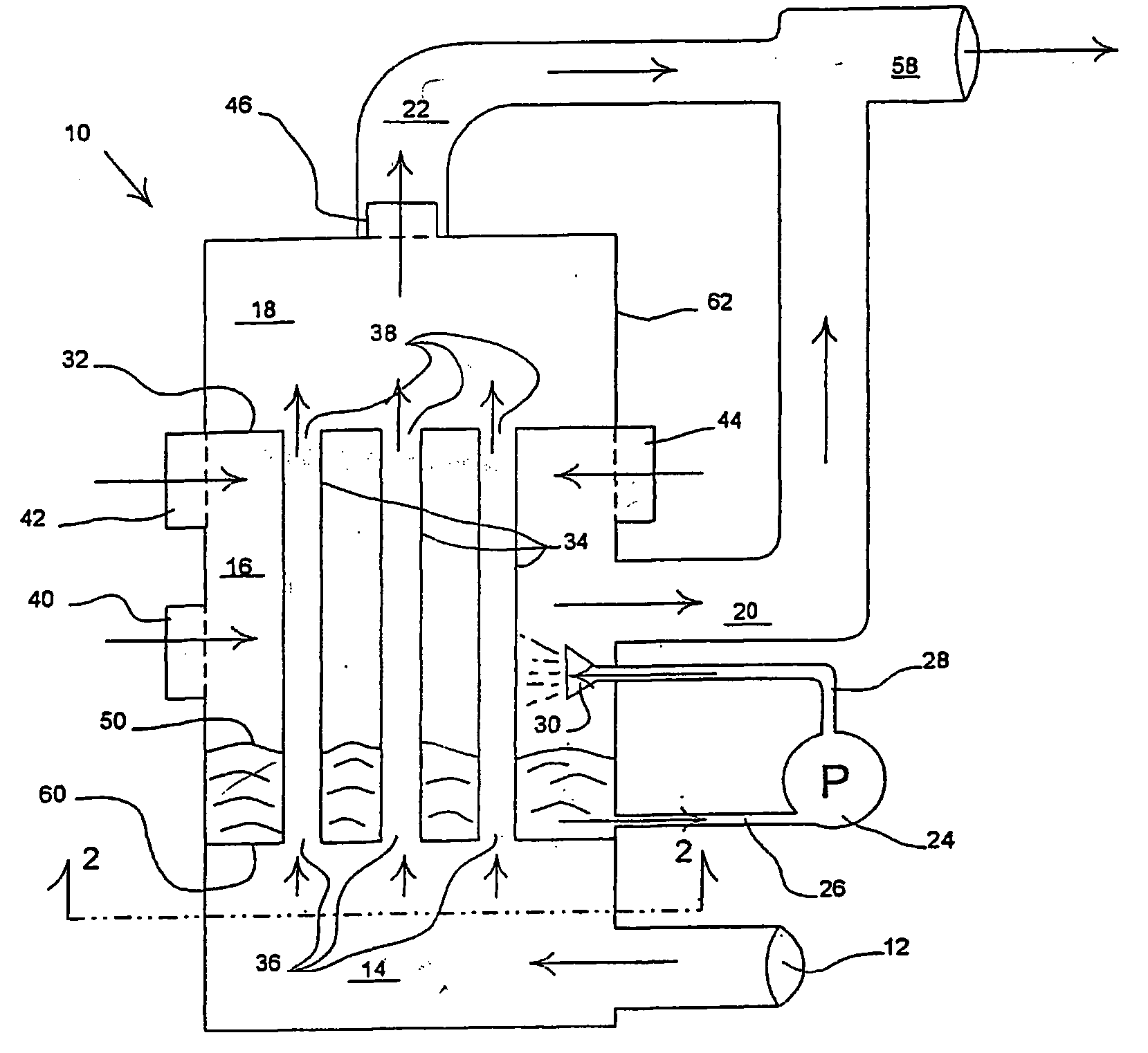

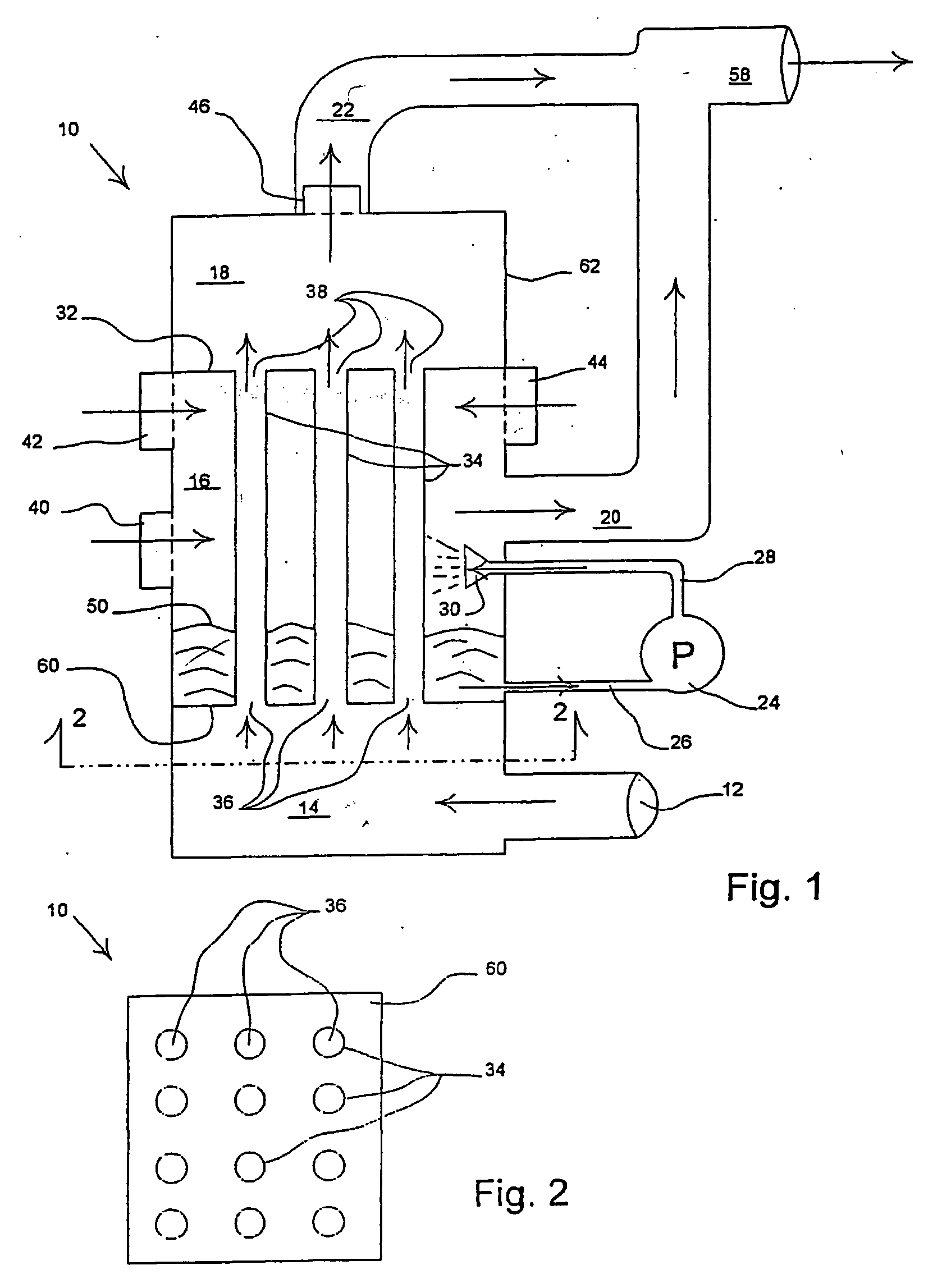

The present invention provides a vertical falling film shell and tube heat exchanger, where the falling film is formed on the exterior surface of the tubes. A distribution plate is provided below an upper tubesheet, and a sparger plate having sparger holes is provided between the upper tubesheet and the distribution plate. A plurality of vertical, parallel tubes pass through the distribution and sparger plates and are sealingly engaged with the upper tubesheet and the sparger plate. The distribution plate has oversized holes through which the tubes pass, an annular space being defined around each tube where the tube passes through the distribution plate. The first fluid passes one time through the tubes, and the second fluid is fed to the shell side as two streams, a liquid stream and a vapor stream. The liquid stream is introduced to the shell between the upper tubesheet and the sparger plate and drains downwardly onto the second distribution plate through the sparger holes. The liquid stream forms a falling film on the tubes as the liquid passes through the annular space around each tube. The vapor stream is introduced to the shell below the distribution plate and is condensed / absorbed into the falling film.

Owner:INT ENGINEERS & FABTORS CO

Plastic heat exchanger

ActiveUS6899169B1Safety devices for heat exchange apparatusHeat exchanger casingsPlate heat exchangerShell and tube heat exchanger

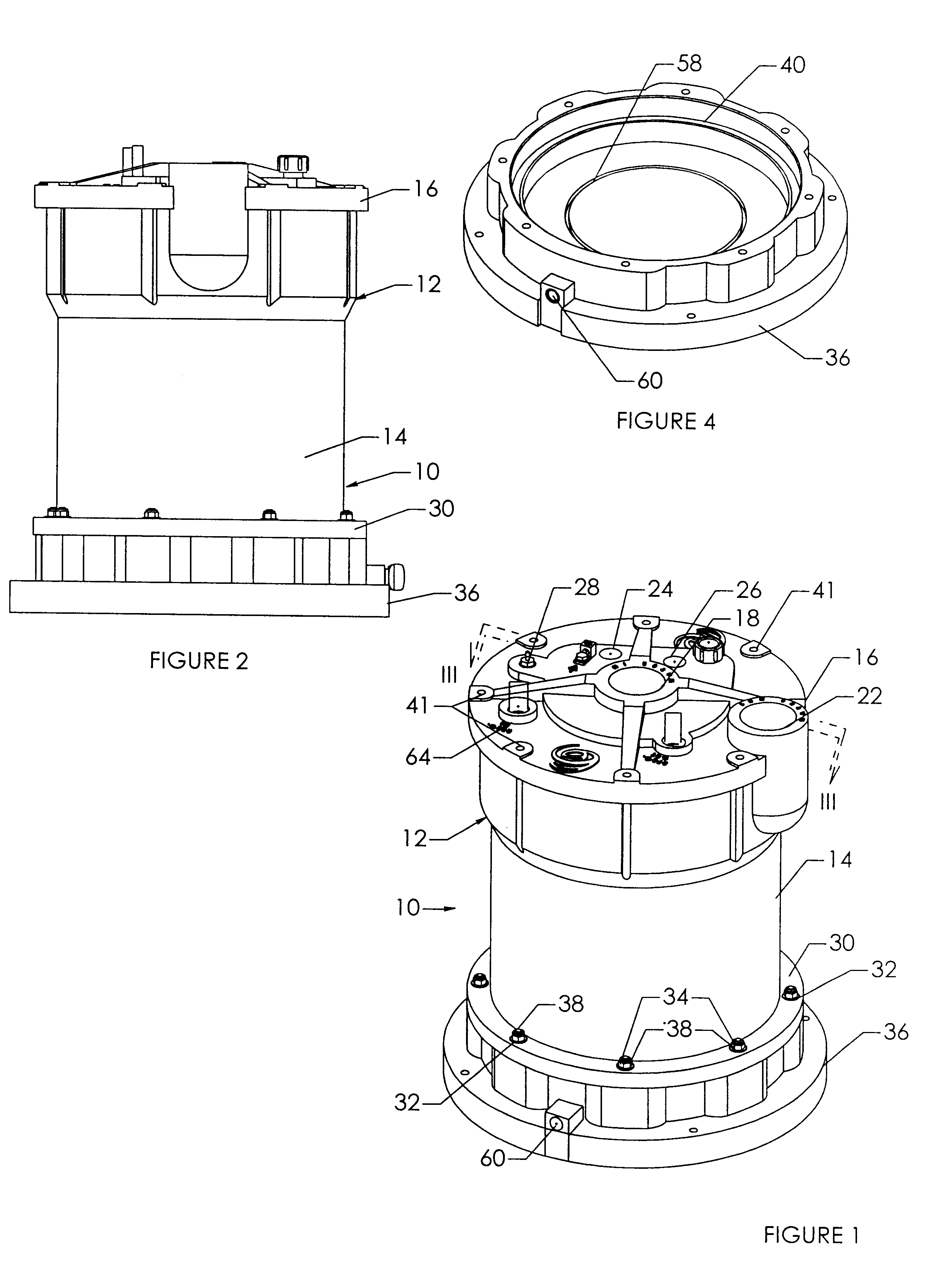

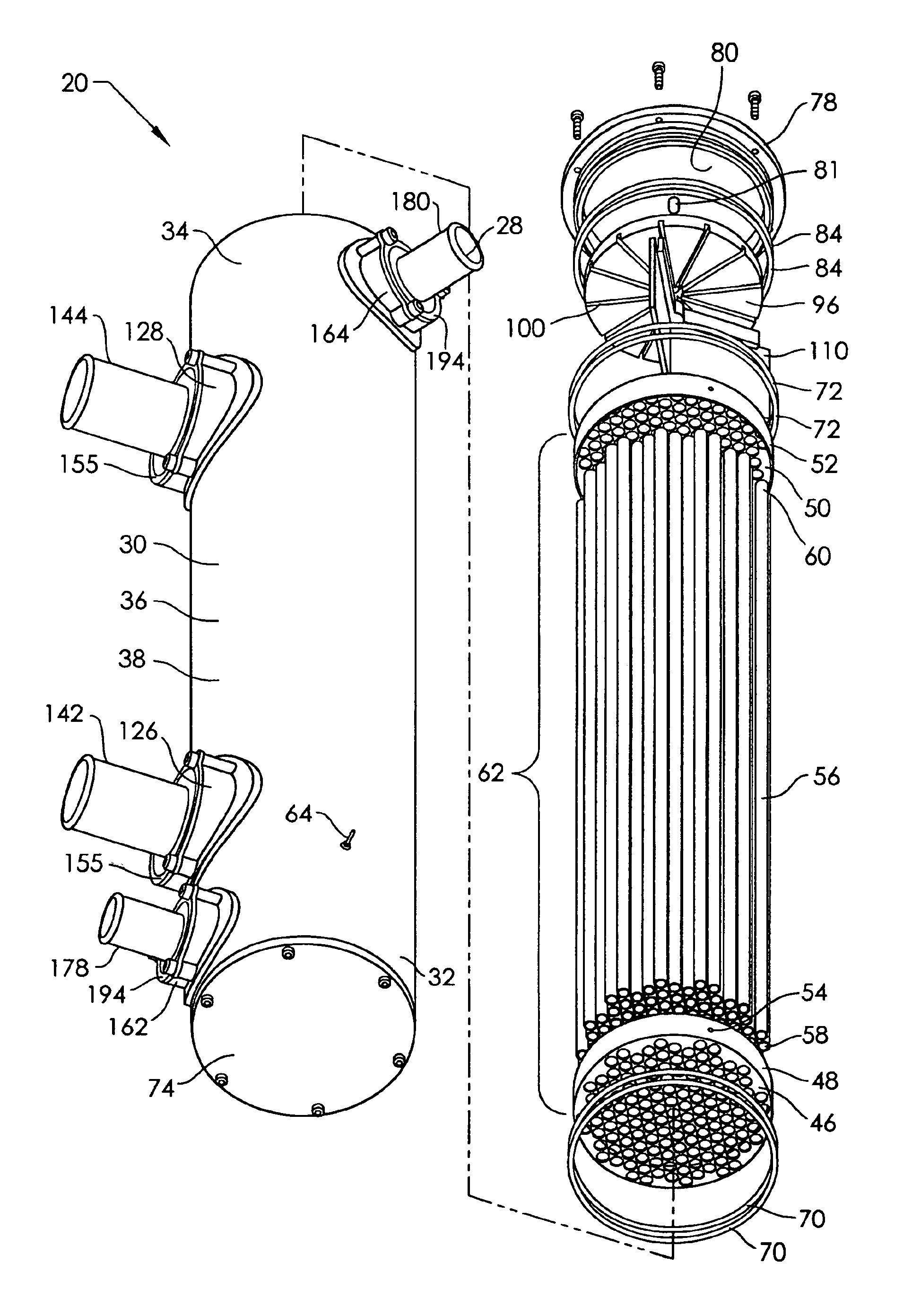

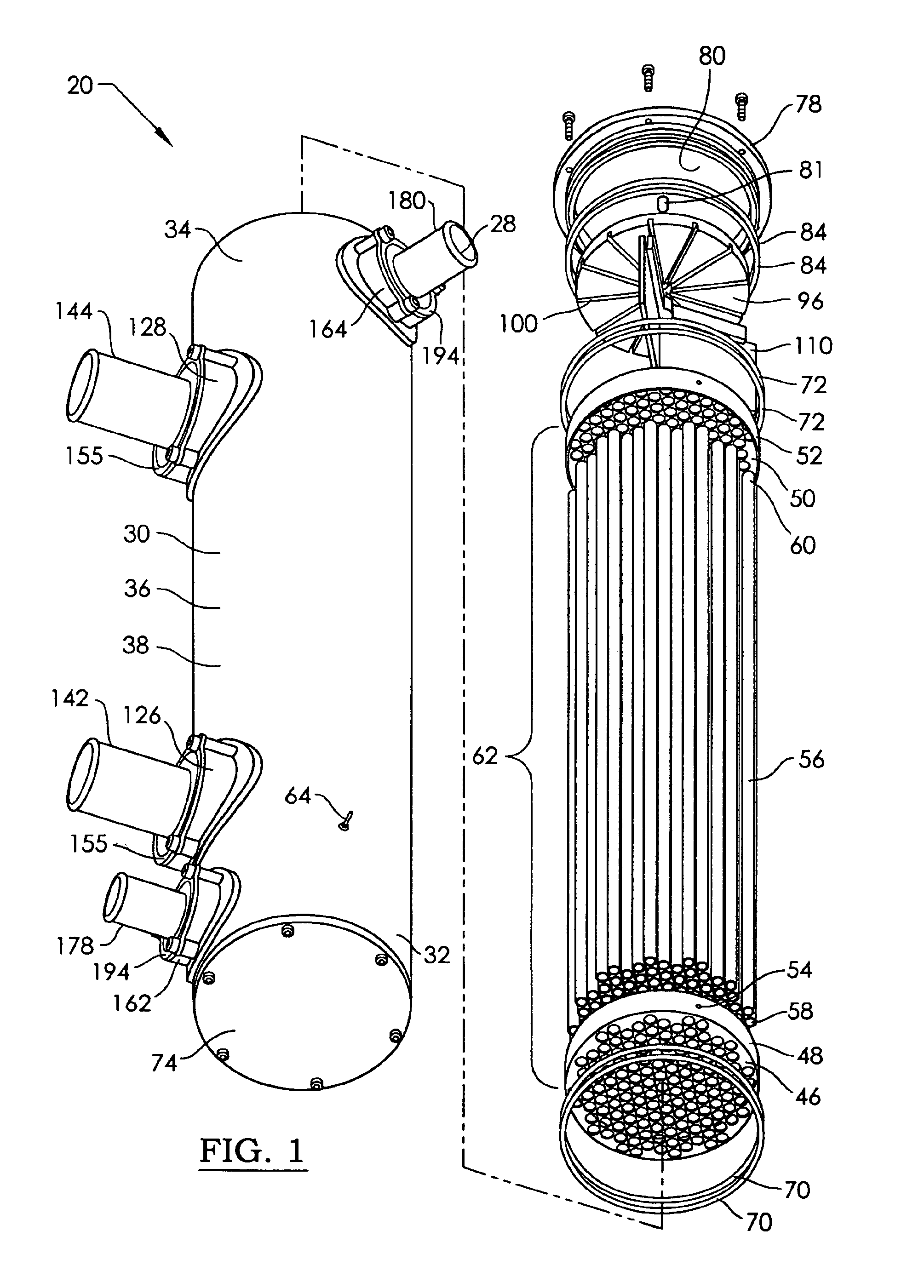

A shell and tube heat exchanger has two shell coolant and two tube coolant passageways communicating with a cavity in a shell. Removably received in the shell cavity is a tube bundle with tube headers. A locating screw extends through the shell to engage a locating recess in one tube header. The screw locates the tube bundle angularly about the central axis and longitudinally along the central axis, and is also used to electrically ground the tube bundle. An end cover, a flow separator, and resilient disc to take up thermal expansion are installed in each end of the shell to direct coolant through the tube bundle in multiple passes. Receivers with rotatable connectors are bonded to each shell coolant and tube coolant passageway. Angled connector nozzles can be connected to external conduits in any orientation.

Owner:R&D ENTERPRISES

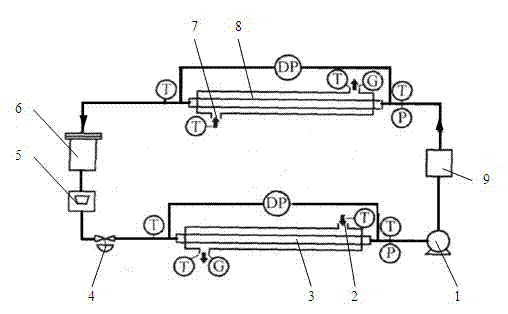

Tube-side sequentially pulsable-flow shell-and-tube heat exchanger appratus, system, and method

ActiveUS20100243208A1Increase heat exchange rateReduce dirtCorrosion preventionStationary tubular conduit assembliesChemical treatmentShell and tube heat exchanger

The present invention relates to a tube-side sequentially pulsable-flow, shell-and-tube heat exchanger apparatus and a chemical processing system comprising and methods of heat exchange employing the same.

Owner:DOW GLOBAL TECH LLC

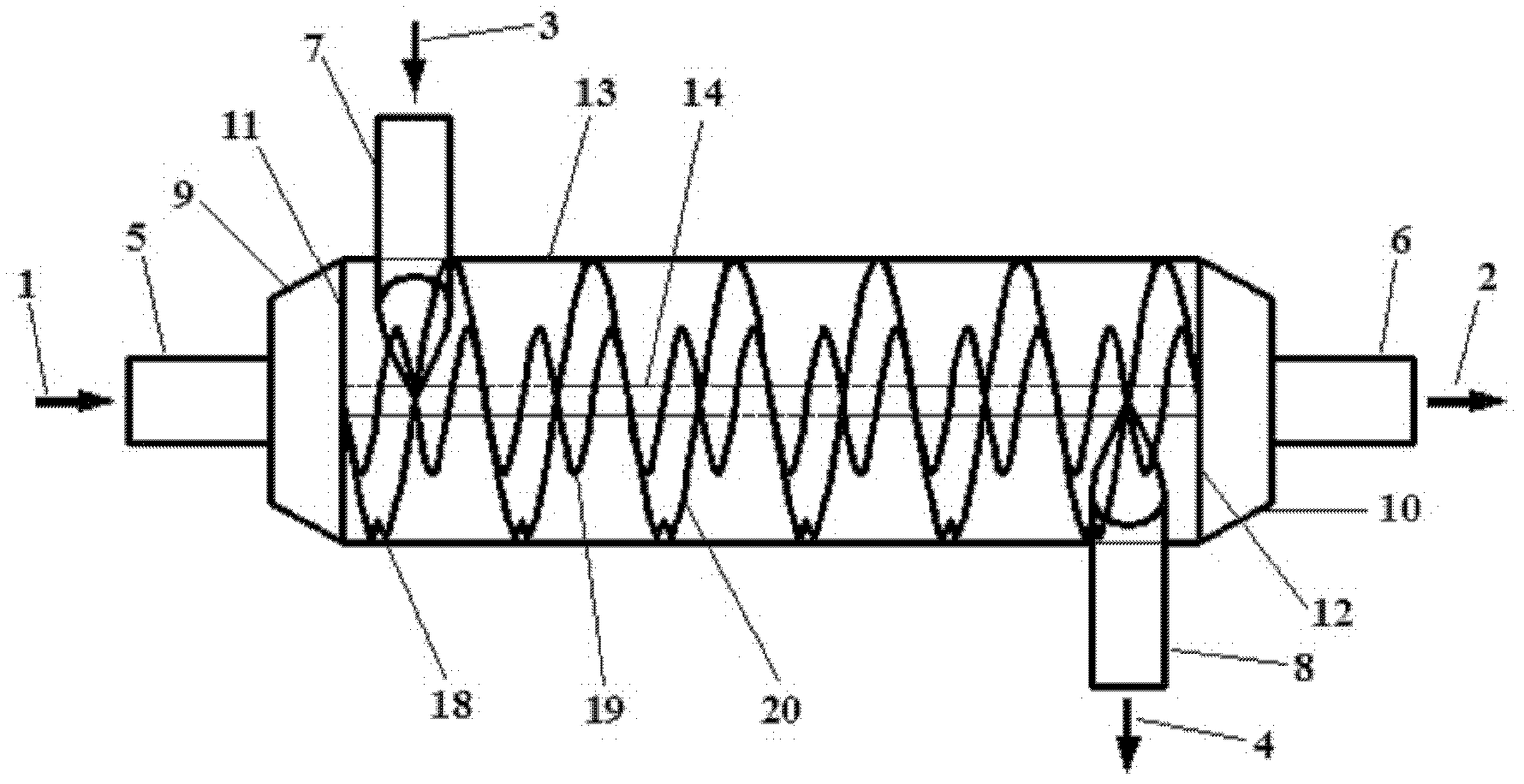

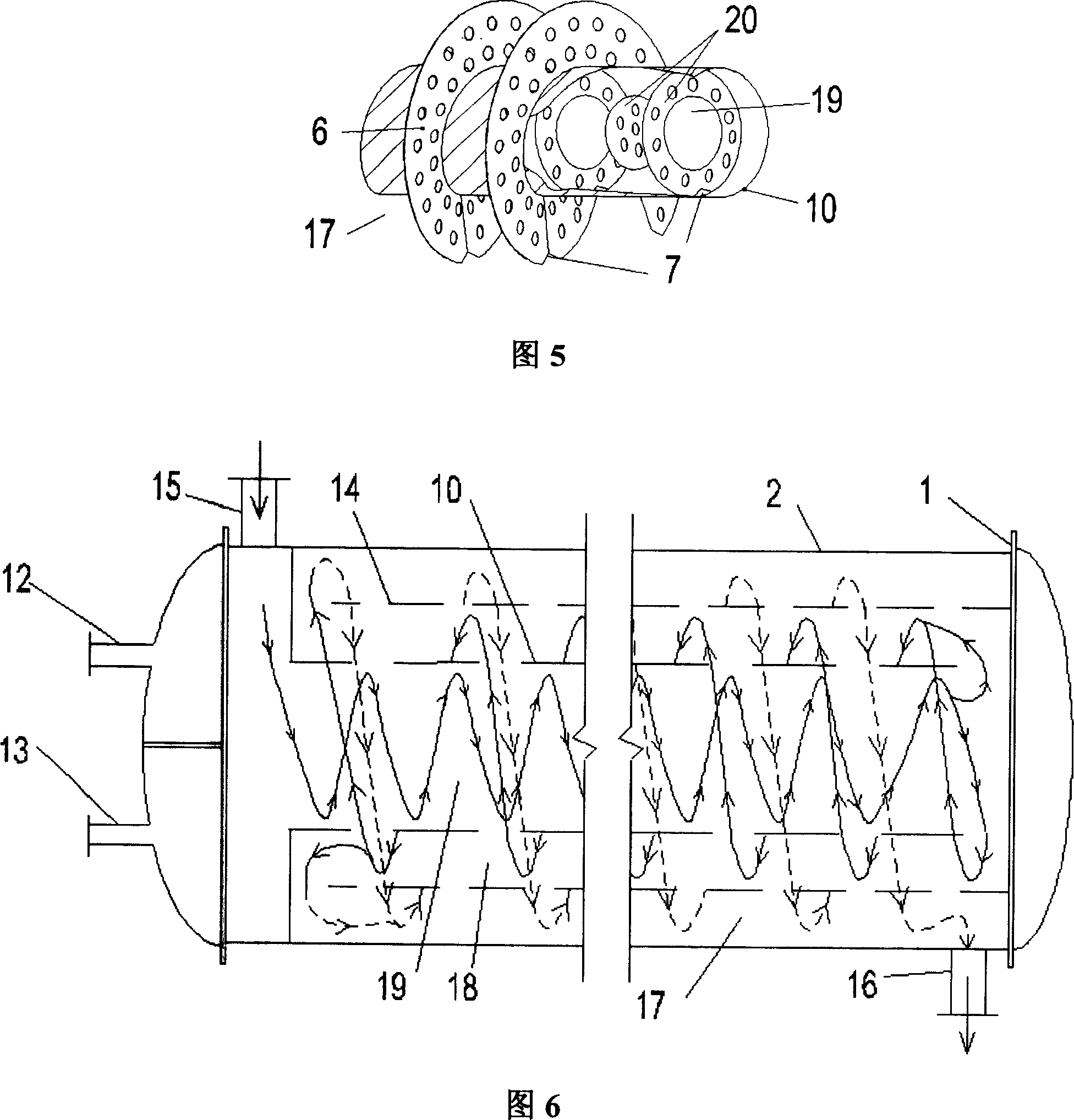

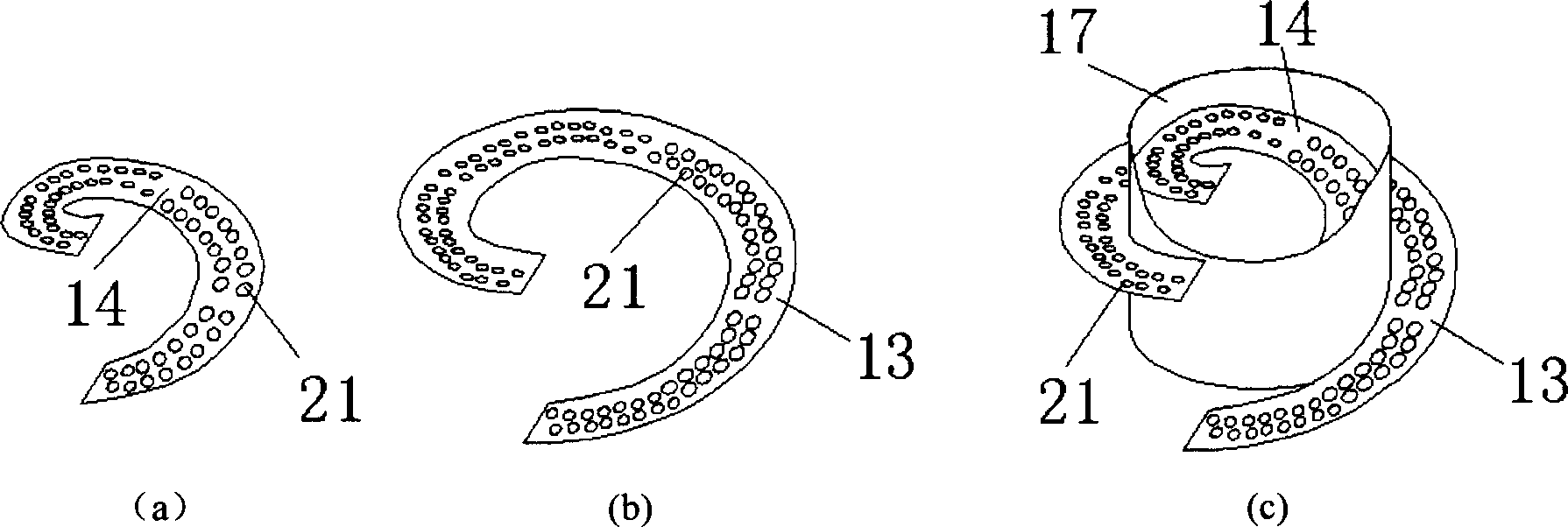

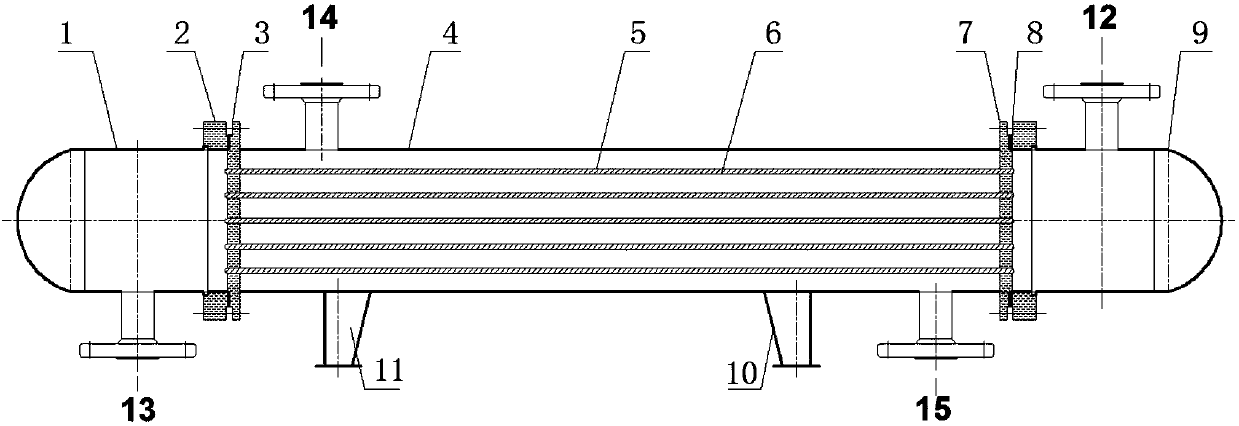

Shell-and-tube heat exchanger with combined type one-shell-pass continuous spiral baffles

ActiveCN102538562AIncrease the surface heat transfer coefficientIncreased turbulenceHeat exchanger casingsStationary tubular conduit assembliesShell and tube heat exchangerPlate heat exchanger

The invention relates to a shell-and-tube heat exchanger with combined type one-shell-pass continuous spiral baffles. The heat exchanger comprises a shell, a central tube, tube plates, a tube-side inlet tube, a tube-side outlet tube, a heat exchange tube bundle, a distance-setting tube, a distance-setting belt, a shell-side inlet tube and a shell-side outlet tube; and the spiral baffles comprise inner continuous spiral baffles and outer continuous spiral baffles. The heat exchange is characterized in that by utilization of different flow guiding actions of the inner continuous spiral baffles and the outer continuous spiral baffles, since cylinder partitioning plates are not arranged between the inner continuous spiral baffles and the outer continuous spiral baffles, the mixing of fluids at the center of the shell and the peripheral area of the center of the shell is enhanced, the flow state at the follow-wind side of the baffles is improved, the turbulent degree of the fluid in the heat exchanger is improved, and the shell-pass heat transfer is enhanced. The shell-and-tube heat exchanger has the advantages that the heat exchange efficiency of the heat exchanger is improved, the pressure loss is reduced, the bottleneck for limiting the heat exchanger with the spiral baffles to the large-flow operation is broken through, simultaneously, the structure is simple, the compactness is high, the vibration when the heat exchanger is operated is reduced, the scaling is not easy, the safety of the heat exchanger is improved and the service life is prolonged.

Owner:XI AN JIAOTONG UNIV

Friction-stir Weld-tool and Method

ActiveUS20110000952A1Welding/cutting auxillary devicesAuxillary welding devicesShell and tube heat exchangerEngineering

A method for joining a tube and tube plate for use in a tube-and-shell heat exchanger is disclosed. The method enables a joint between the tube and tube plate that is substantially hermetic and substantially corrosion-resistant. The method comprises providing an anvil inside the tube, wherein the anvil supports the tube wall during a friction-stir welding process used to join the tube and tube plate. The anvil facilitates formation of a reliable weld region and enables faster friction-stir welding.

Owner:LOCKHEED MARTIN CORP

Automotive adsorption heat pump

InactiveUS20110005267A1Efficient and reliableLess expensiveClimate change adaptationVehicle heating/cooling devicesSorbentFresh air

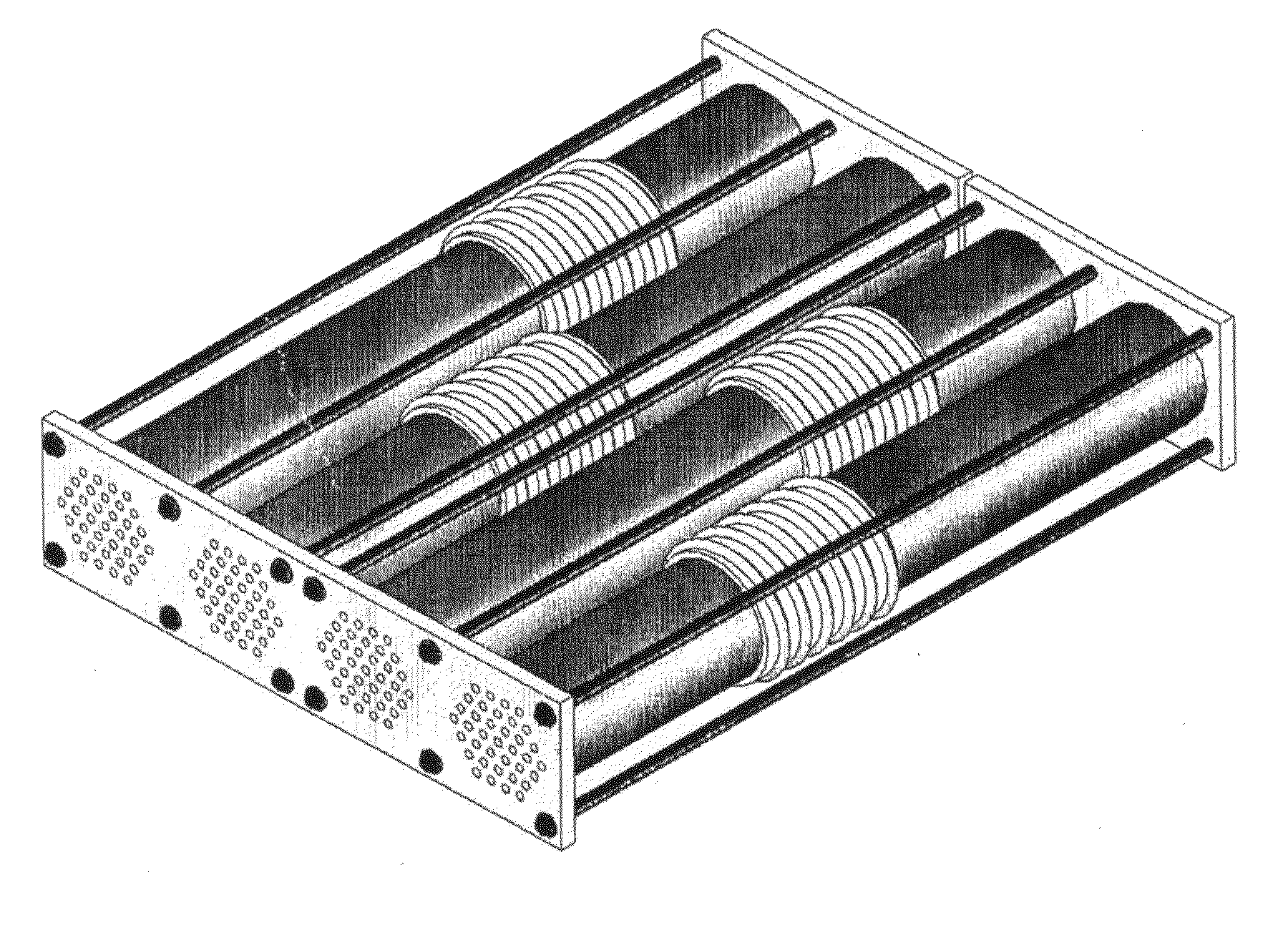

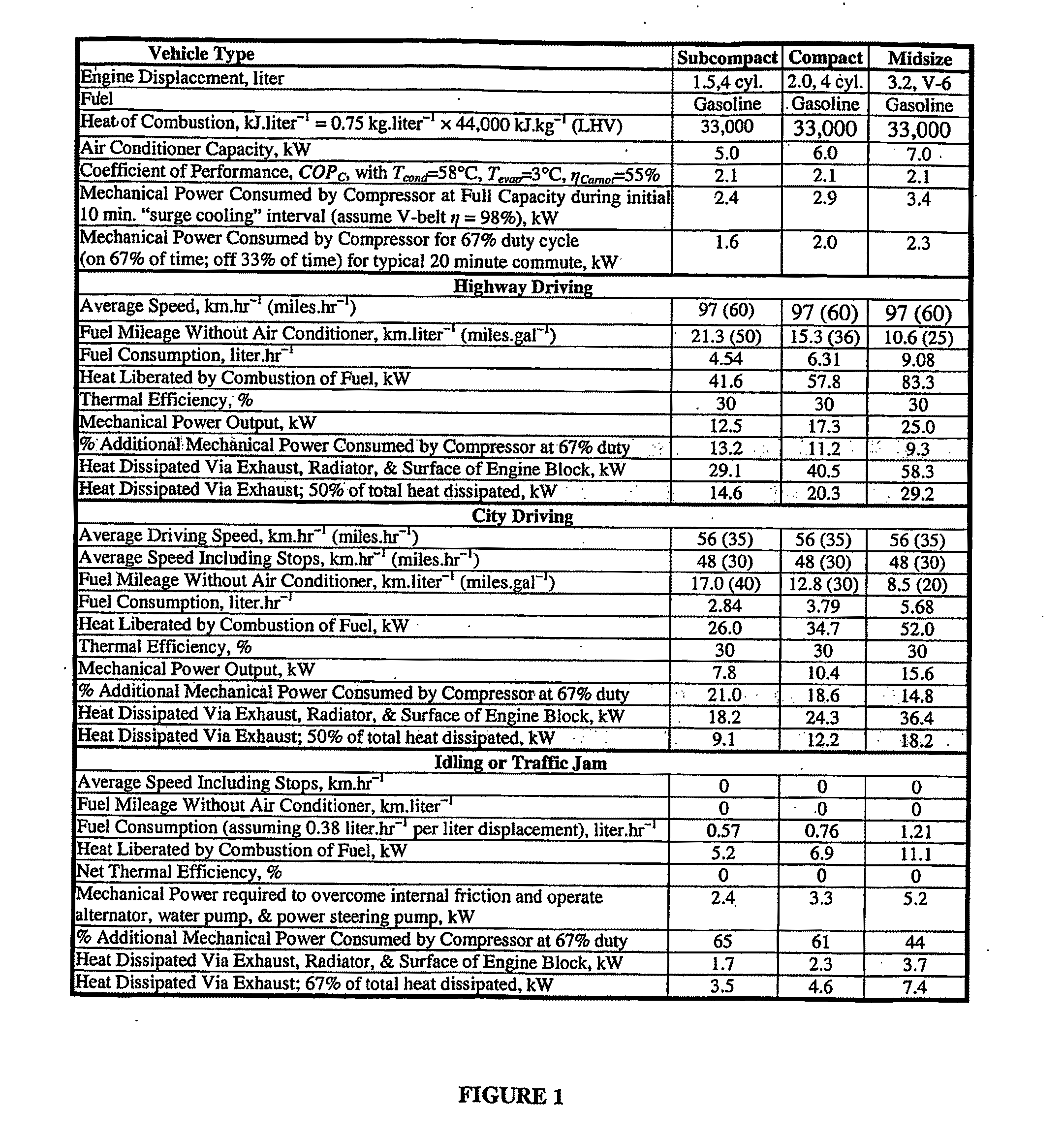

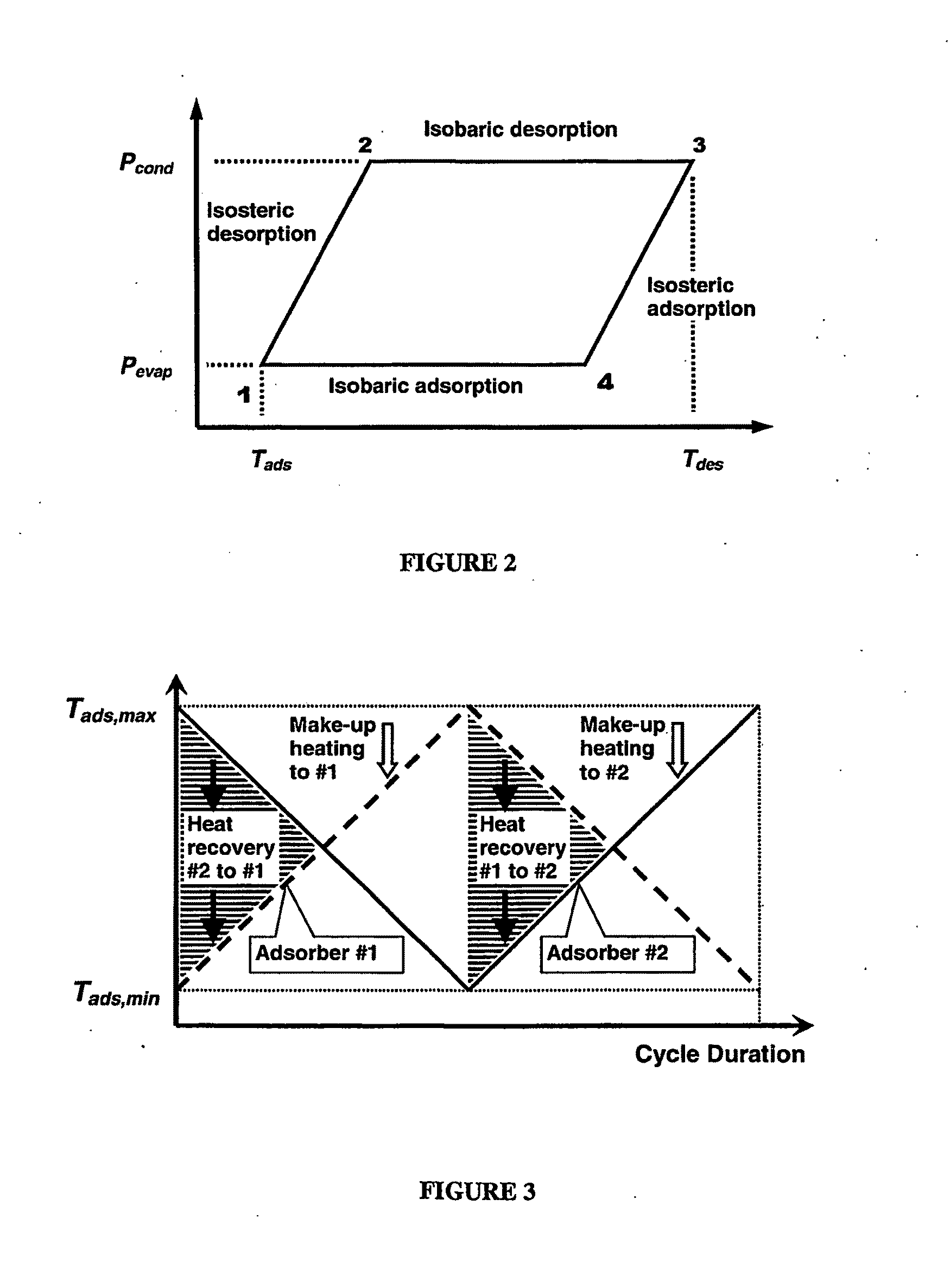

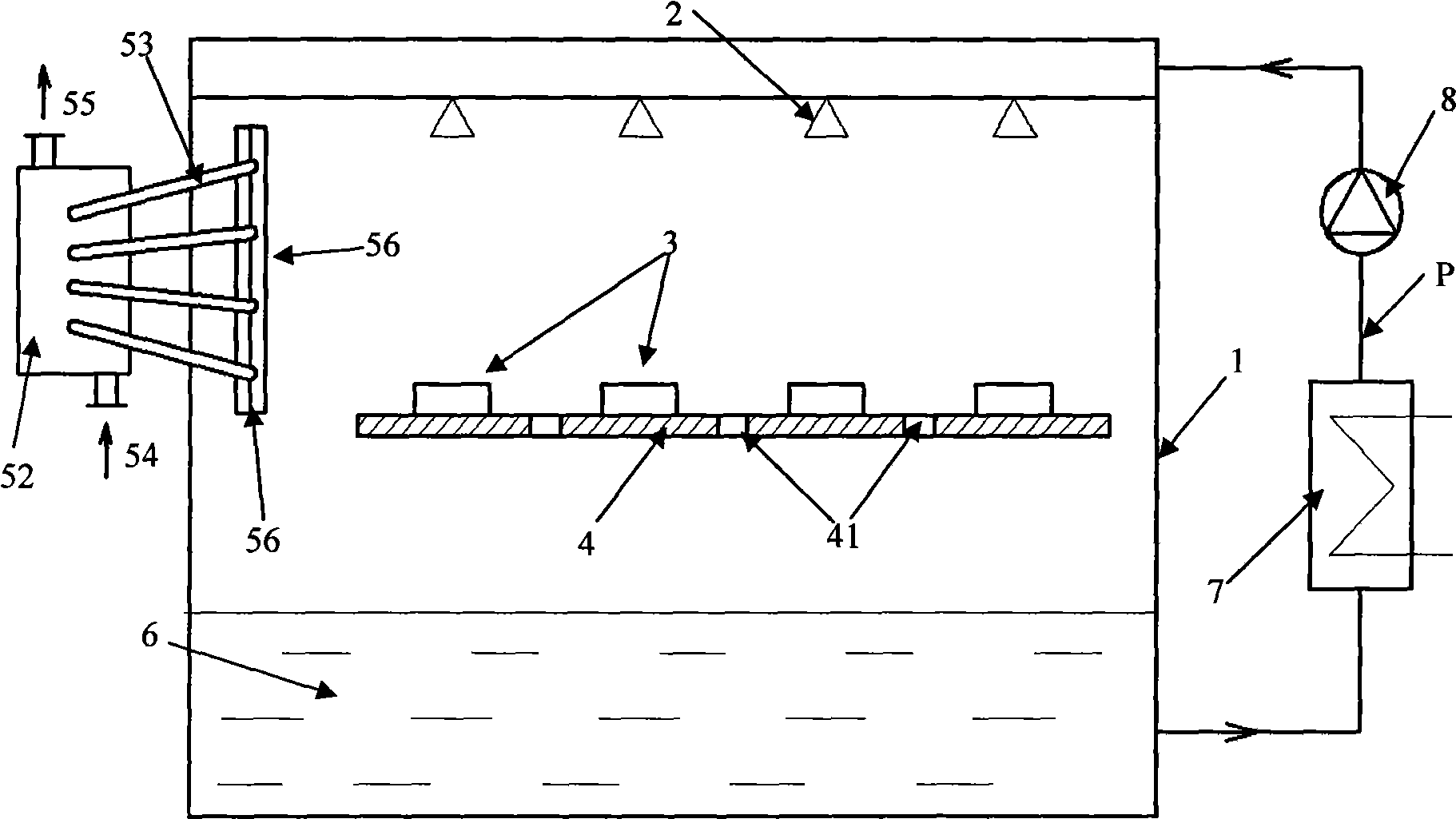

An adsorber unit has an outer shell, a plurality of internal tubes extending through the shell for carrying heat transfer fluid, each tube having outwardly projecting fins along its entire length, and a solid adsorbent material in the shell surrounding the tubes such that the fins project into the adsorbent material, the fins being of a material (e.g., metal) of higher thermal conductivity than the adsorbent material. Metal wool loosely packed inside the tubes, or internal radial fins swaged into the tubes, increase internal surface area thereby enhancing convective heat transfer. Metal wool loosely packed between the external fins, or fine wire metal coils lightly squeezed between the external fins, further increase external surface area of the heat exchanger in contact with the adsorbent thereby enhancing contact heat transfer. Performance is enhanced because the external fins and wool or wire coils transport heat more efficiently to all regions of the adsorbent, and permit less non-adsorbent heat exchanger material (e.g., metal) to be used for a given amount of adsorbent. Two or more such units are used in an adsorption heat pump. This design utilizes existing components (e.g., shell-&-tube heat exchanger, internally and externally finned tubing, and metal wool or wire coils) in a novel manner heretofore untried. In one exemplary embodiment, automobile air conditioning, exhaust heat is used to power such an air conditioner. The significant additional power used by the mechanical compressor of an automobile (12%-17% during commuting for subcompact to midsize cars) can be nearly eliminated by powering the air conditioner with otherwise wasted exhaust heat. The adsorbent is heated and cooled by light oil (called Heat Transfer Fluid, HTF) which in turn is heated and cooled by exhaust and fresh air. Such indirect heating and cooling achieves the required efficiency, and allows using phase change material (e.g., wax) to store and therefore fully utilize exhaust heat. A refrigerant reservoir is included which provides immediate cooling after start-up of a cold engine, while the exhaust system and heat pump are still heating up in order to start pumping refrigerant. Eliminating the mechanical compressor increases fuel mileage by 14-18% for midsize, compact, MS and subcompact cars, or 4.6-6.0% annually, given a four-month cooling season.

Owner:LAMBERT MICHAEL A +1

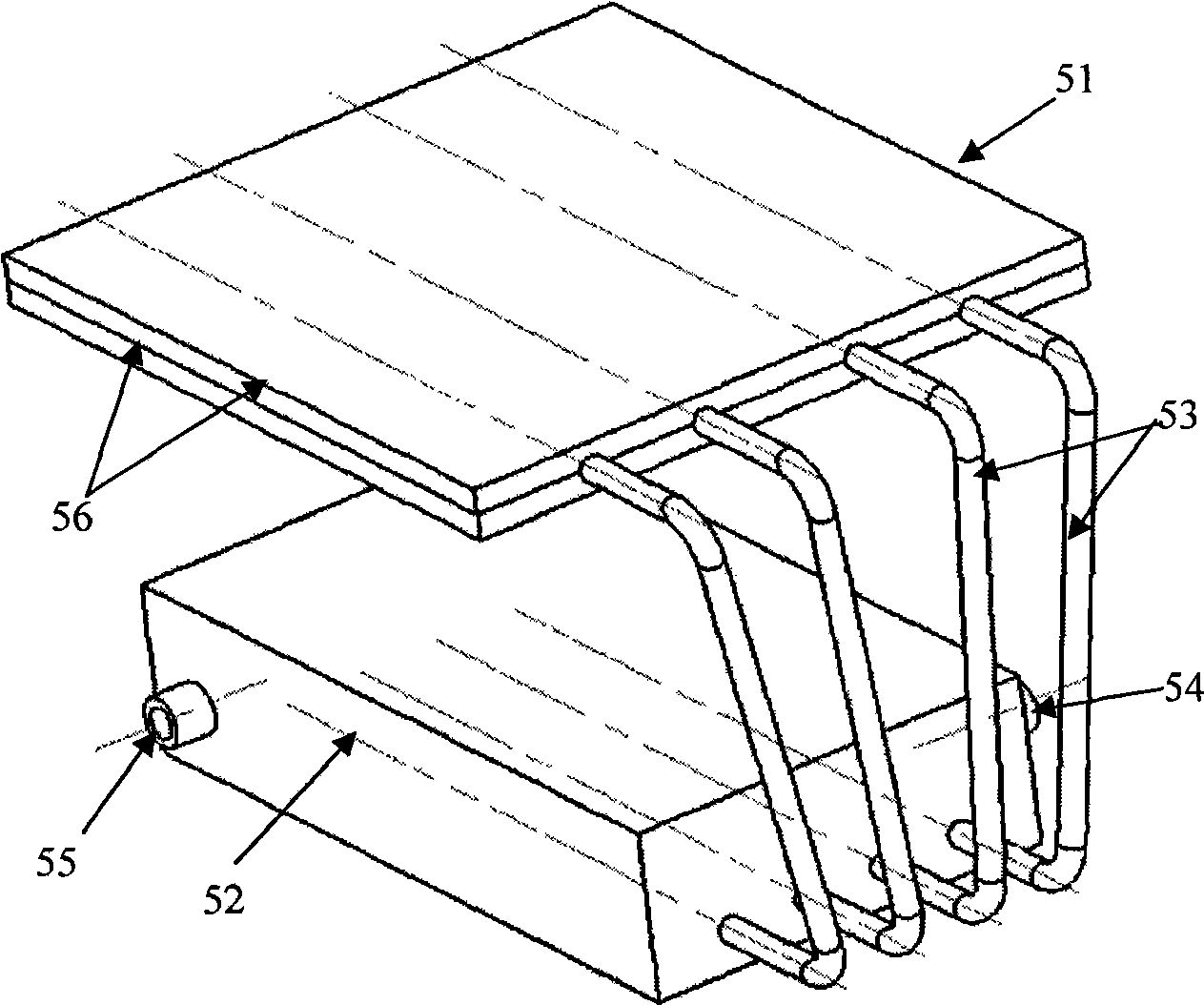

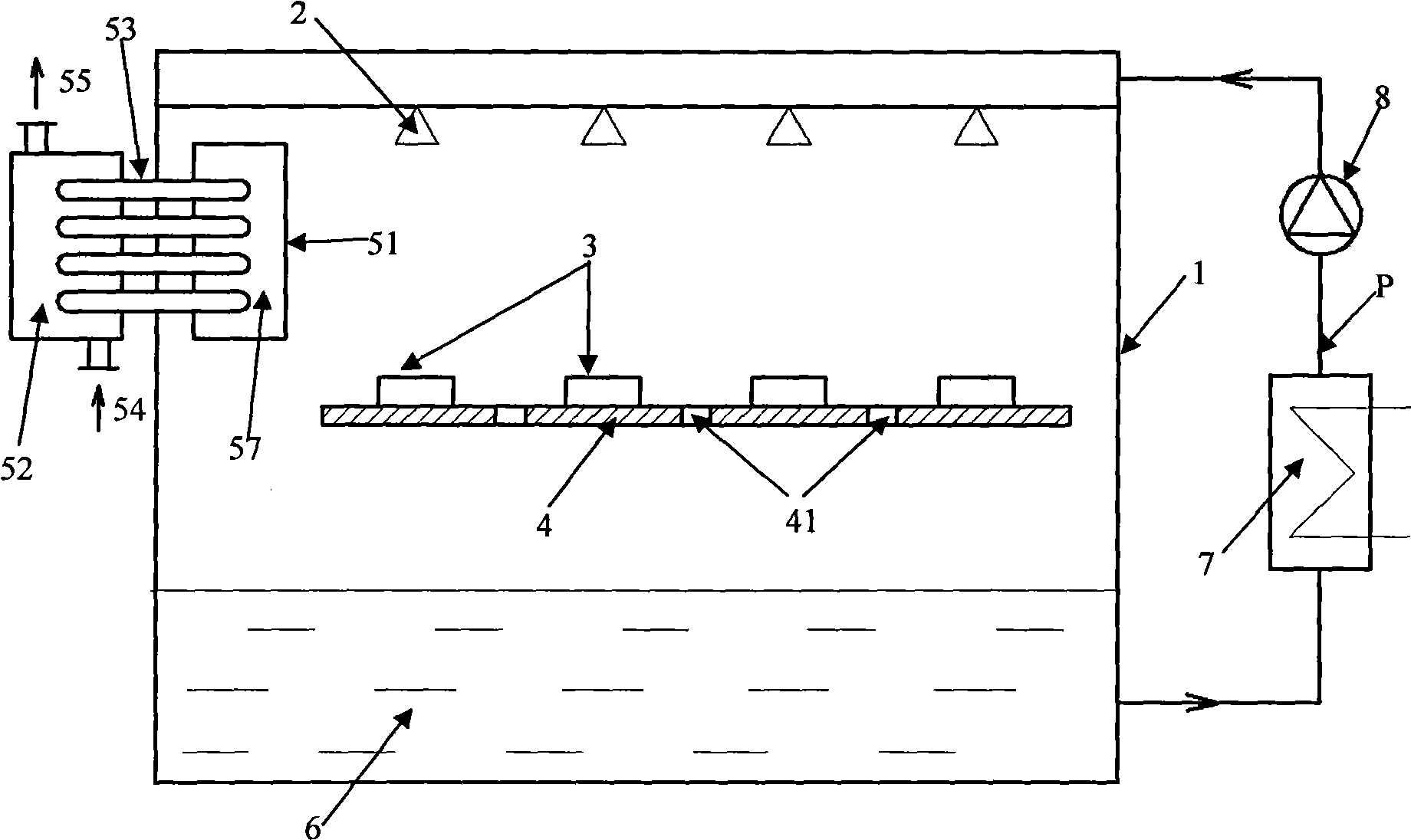

High-effective integral spray cooling system

InactiveCN101534627AReduce heat transfer areaCompact structureSemiconductor/solid-state device detailsSolid-state devicesEvaporationEngineering

The invention relates to a high-effective integral spray cooling system, which solves heat dissipation problem in field such as high power electron or laser system. The spray cooling system includes a spray cavity, a heat exchanger, a cooler, a circulating pump and a system working medium circulation pipeline, wherein the heat exchanger is a heat pipe heat exchanger; one end of the heat pipe of the heat pipe heat exchanger is a condensation end, and the other end is an evaporation end; the evaporation end is arranged in the spray cavity and is a steam condenser, and the condensation end is arranged in a water cooling shell-and-tube heat exchanger outside the spray cavity. The invention separates steam cooling and liquid cooling, which is beneficial to respectively increase heat transfer effect in condensation and cooling process; employs the heat pipe condenser to further increase heat transfer performance in condensation process and reduce heat exchange area of the condenser; and arranges the condenser in the spray cavity for making spray cooling structure more compact and reducing flow resistance of working medium steam, thereby reducing operating pressure of the spray cavity and being beneficial to increase general heat dispersion performance of spray cooling.

Owner:UNIV OF SCI & TECH OF CHINA +1

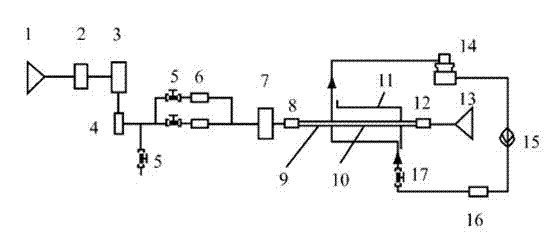

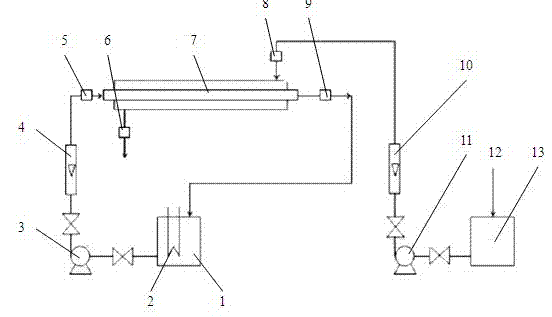

Method and device for detecting leakage of shell type heat exchanger

InactiveCN101408466AImprove detection accuracyImprove detection efficiencyFluid-tightness measurement using fluid/vacuumPlate heat exchangerShell and tube heat exchanger

The invention relates to a detection method and a device thereof, in particular to a leak detection method for a shell-and-tube heat exchanger and a device thereof. The detection device comprises a helium mass spectrometer leak detector and a vacuum pump, and is characterized in that an air inlet tube is arranged on an air intake hood which is hermetically connected with one end of the shell-and-tube heat exchanger, an exhaust hood is hermetically arranged on the other end of the shell-and-tube heat exchanger and is equipped with an exhaust tube on the exhaust hood, a vacuum pump clearance tube is arranged on the outer shell of the shell-and-tube heat exchanger, and an air inlet of the helium mass spectrometer leak detector is communicated with the outlet of the vacuum pump. The detection device can lock the leak situations of all the detected shells and tubes in the air intake hood and the exhaust hood which are respectively arranged on the shell-and-tube heat exchanger at one time, and can accurately determine the leaking shells and tubes by replacing hoods of different specifications, thus greatly enhancing the detection efficiency and lightening the labor intensity. Meanwhile, the helium mass spectrometer leak detector is used, thus enhancing the detection precision of the device and eliminates the external interference.

Owner:宁夏电力科技教育工程院

Process for preparing polyolefin products

InactiveUS6884858B2Efficient and economical productionDelayed reaction timeHydrocarbons from unsaturated hydrocarbon additionHydrocarbonsPolyolefinShell and tube heat exchanger

A novel liquid phase polymerization process for preparing a polyolefin product having preselected properties is disclosed. The process includes the steps of providing a liquid feedstock which contains an olefinic component and a catalyst composition consisting of a stable complex of BF3 and a complexing agent therefor. The feedstock may comprise any one or more of a number of olefins including branched olefins such as isobutylene, C3 to C15 linear alpha olefins and C4 to C15 reactive non-alpha olefins. The feedstock and the catalyst composition are introduced into a residual reaction mixture recirculating in a loop reactor reaction zone provided in the tube side of a shell and tube heat exchanger at a recirculation rate sufficient to cause intimate intermixing of the residual reaction mixture, the added feedstock and the added catalyst composition. The heat of the polymerization reaction is removed from the recirculating intimately intermixed reaction admixture at a rate calculated to provide a substantially constant reaction temperature therein while the same is recirculating in said reaction zone. The conditions in the reactor are appropriate for causing olefinic components introduced in said feedstock to undergo polymerization to form the desired polyolefin product in the presence of the catalyst composition. A product stream containing the desired polyolefin product is withdrawn from the reaction zone. The introduction of the feedstock into the reaction zone and the withdrawal of the product stream from the reaction zone are controlled such that the residence time of the olefinic components undergoing polymerization in the reaction zone is appropriate for production of the desired polyolefin product.

Owner:TPC GROUP

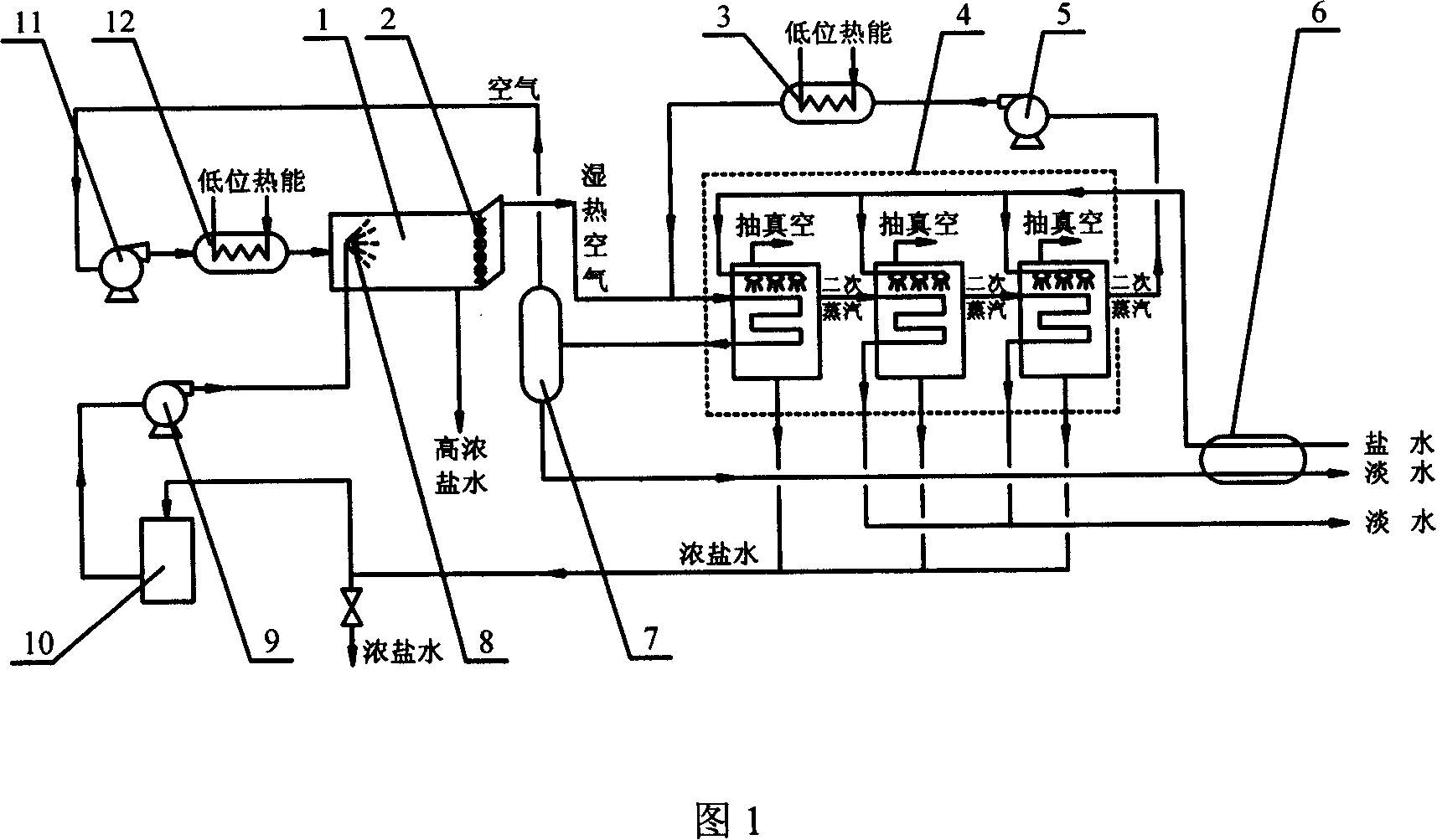

Low-position heat energy spray evaporation-multiple-effect distillation seawater desalination method and device

InactiveCN101113030ALow costIncrease productionGeneral water supply conservationSeawater treatmentThermal energyDistillation

The invention discloses a desalting method and device. The method is designed to desalt seawater through low heat energy spray vaporization and multiple-effect seawater distillation. The invention pertains to a desalting technical field of seawater or brackish water. The desalting device comprises a spray and vapor room which is provided with a nozzle and a demister. An air inlet is connected with a separator of air and water, a fan and a heater are positioned on a connection pipe. The inlet and outlet of the first effect heating steam of the multiple-effect distillation device are separately communicated with an outlet of wet and heat air of the spray and vapor room and with a middle part port in the vapor and water separator. The second steam of the every effect is used as the heating steam for the next heating steam, but after heated and pressurized of the second steam of the final effect, the second heating steam is interfused into hot and damp air discharged from the spray vapor room. The tops of the multiple-effect distillation device are communicated with the tube pass of a shell and tube heat exchanger, and the bottom of the multiple-effect distillation device is communicated with a heavy salt water tube. The invention takes the advantages of low heat energy as the energy recourse of desalting process to couple spray vapor and multiple-effect distillation technic and realizes comprehensive utilization of the energy and resources.

Owner:OCEAN UNIV OF CHINA

Method and device for predicting node temperature of shell and tube heat exchanger

InactiveCN102261968AEasy to installIncrease flexibilityTemperature measurement of flowing materialsShell and tube heat exchangerEngineering

The invention belongs to the technical field of heat transfer and discloses a method and a device for predicting the node temperature of a shell and tube heat exchanger. The invention relates to a single-tube heat exchange tube testing device; based on the device, the heat transfer characteristics of a single heat exchange tube can be acquired; and the node temperature of tube pass and shell passfluid of the shell and tube heat exchanger can be determined by matching the method for predicting the node temperature of the shell and tube heat exchanger. The method mainly comprises the followingsteps of: determining the length of a tested heat exchange tube section according to a space between baffles in the heat exchanger, determining a cylinder section number needed by constructing a shell pass cylinder, processing a heat exchange tube sealing plate, welding a tube flange, and assembling a testing device; determining testing parameters according to tube pass and shell pass inlet / outlet temperatures of the heat exchanger, testing the heat transfer performance of the heat exchange tube section, and establishing a mapping relationship between single tube inlet / outlet temperatures andupstream and downstream fluid temperatures outside the tube; and starting a computer program, inputting design data of the heat exchanger, executing an analysis command, and outputting a temperature value of each node inside the heat exchanger after the analysis is ended.

Owner:NANJING UNIV OF TECH

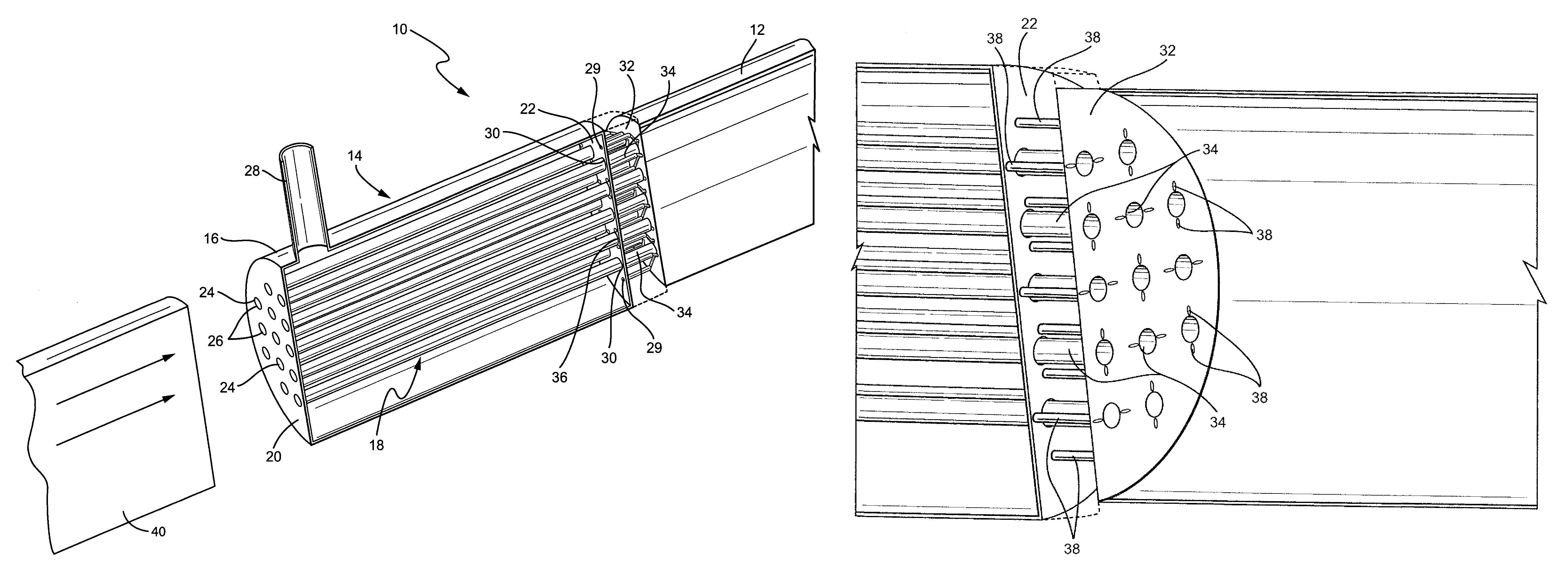

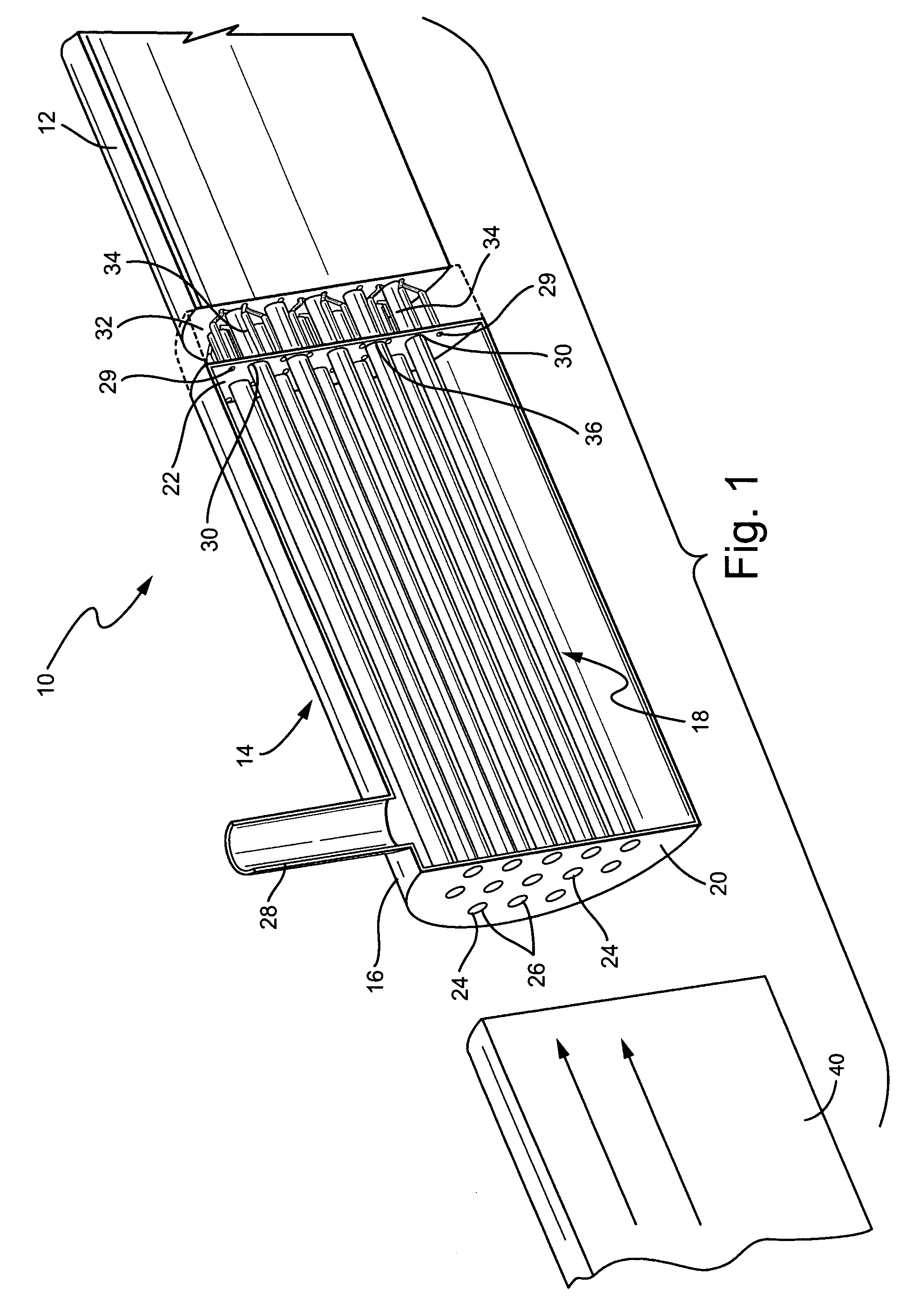

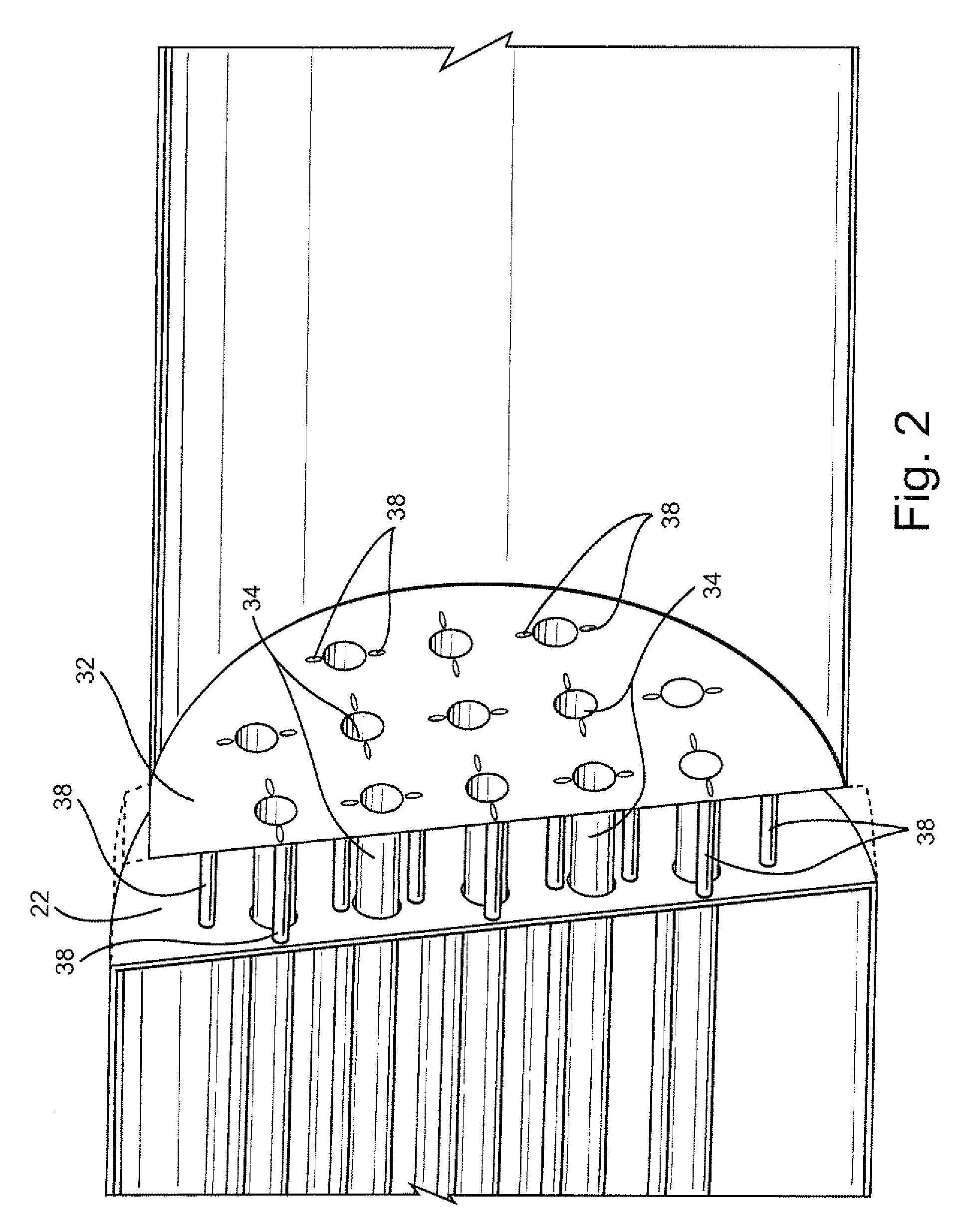

Lean direct injection combustion system

ActiveUS20090229269A1Continuous combustion chamberGas turbine plantsCombustion systemShell and tube heat exchanger

The present invention is directed to a lean direct injection (LDI) combustion system for a gas turbine using a shell and tube heat exchanger concept to construct a shell and tube lean direct injector (“LDI”) for the combustion system. One side of the LDI injector, either the shell side or the tube side, carries an oxidizer, such as air, to the combustor, while the other side of the LDI injector carries fuel to the combustor. Straight or angled holes drilled in an end plate of the combustor allow the fuel to enter the combustor and mix with air being injected into the combustor.

Owner:GENERAL ELECTRIC CO

Fin, method of fabricating the same and heat exchanger tube, heat exchanger and gas cooling apparatus

InactiveCN1755316ASpeed up heat exchangeImprove cooling efficiencyInternal combustion piston enginesNon-fuel substance addition to fuelShell and tube heat exchangerEngineering

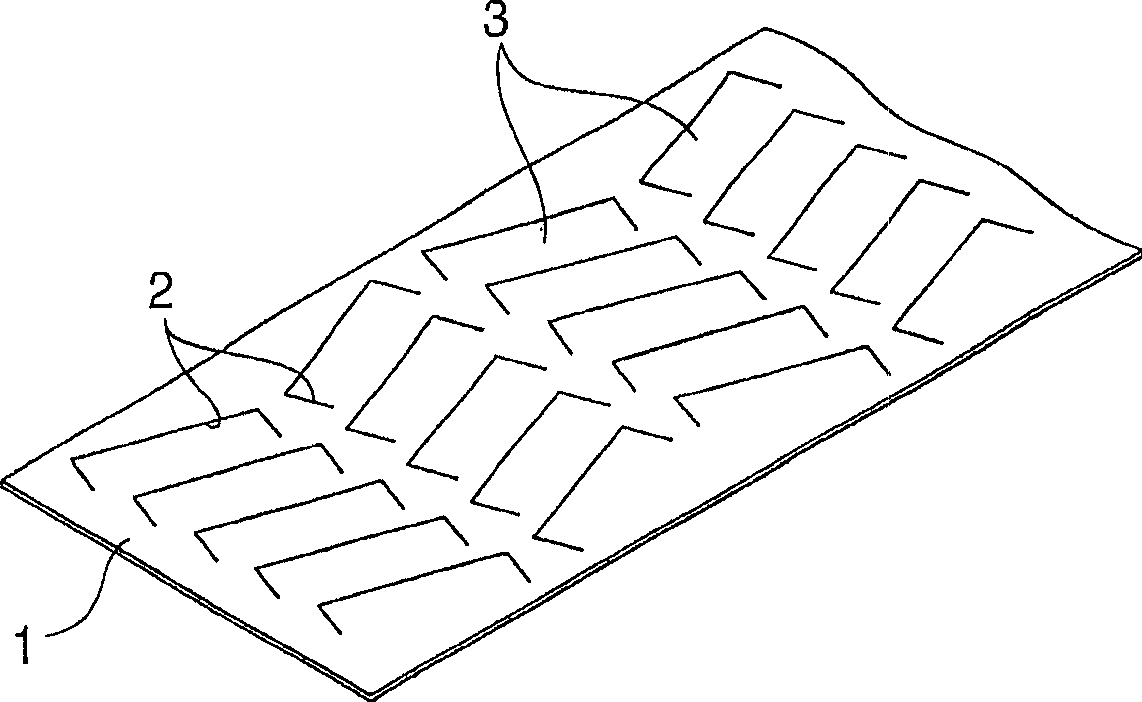

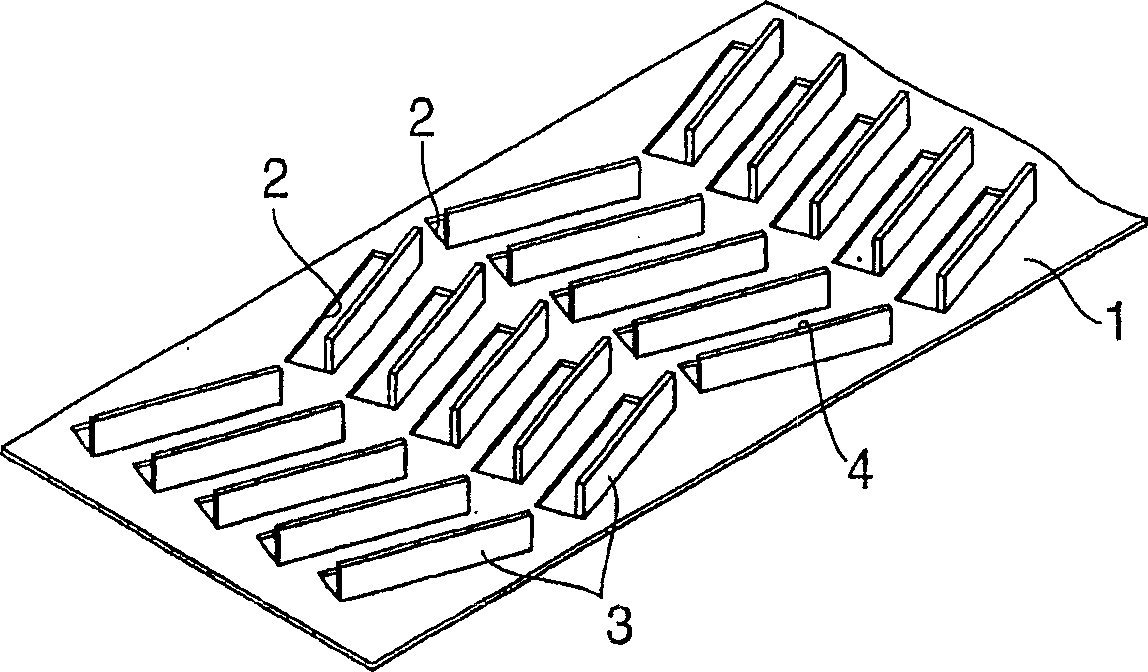

The invention relates to a shell and tube heat exchanger used as a coolant mechanism. The shell and tube heat exchanger comprises a plate-fin arranged inside or outside a heat exchanger tube, and at least one heat exchanger tube internally provided with the plate-fin. Through the heat exchanger has simple structure and easy manufacture, the heat exchanger can still limberly process fluid bodies with different shapes, promote the effective heat exchanging action of the fluid bodies, obtain good cooling efficiency, and can process a plurality of fluid bodies. The plate-fin that the invention relates to is the plate-fin for stirring liquid; the plate-fin is arranged inside or outside the heat exchanger tube to lead the fluid bodies which is composed of cooled medium or refrigeration medium to flow inside or outside the heat exchanger tube, thus impingiment flow or vortex flow with stirring action are generated; the plate-fin is arranged inside or outside the heat exchanger tube, and thus the blade edges of the plate-fin are butted and jointed up and down to enable the blade edges opposite to each other, and each butted and jointed blade edges are crossed with each other. The invention also relates to a method for manufacturing the plate-fin as well as the heat exchanger tube internally provided with the plate-fin, and the heat exchanger or an EGR gas cooling device provided with at least one heat exchanger tube.

Owner:USUI KOKUSAI SANGYO KAISHA LTD

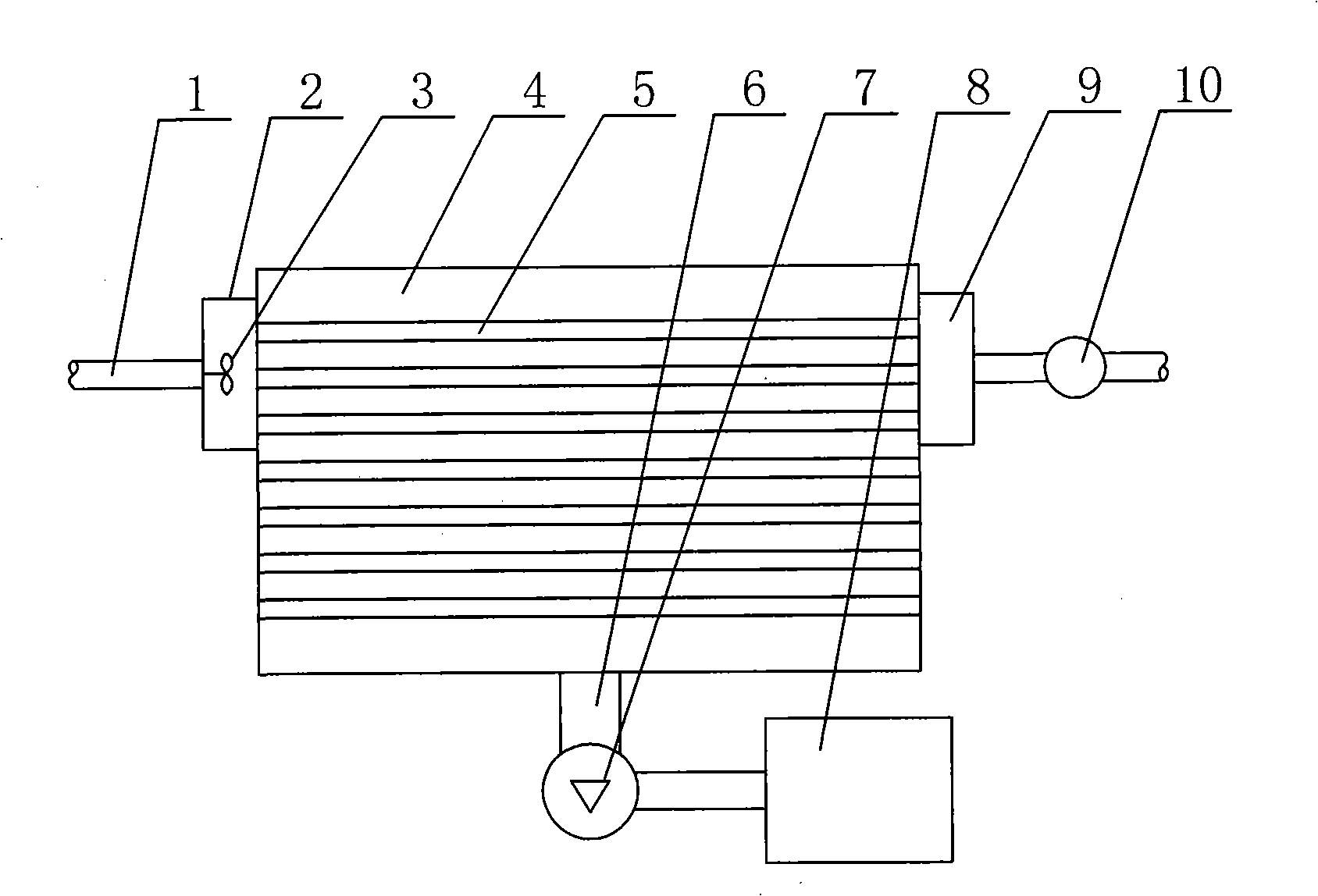

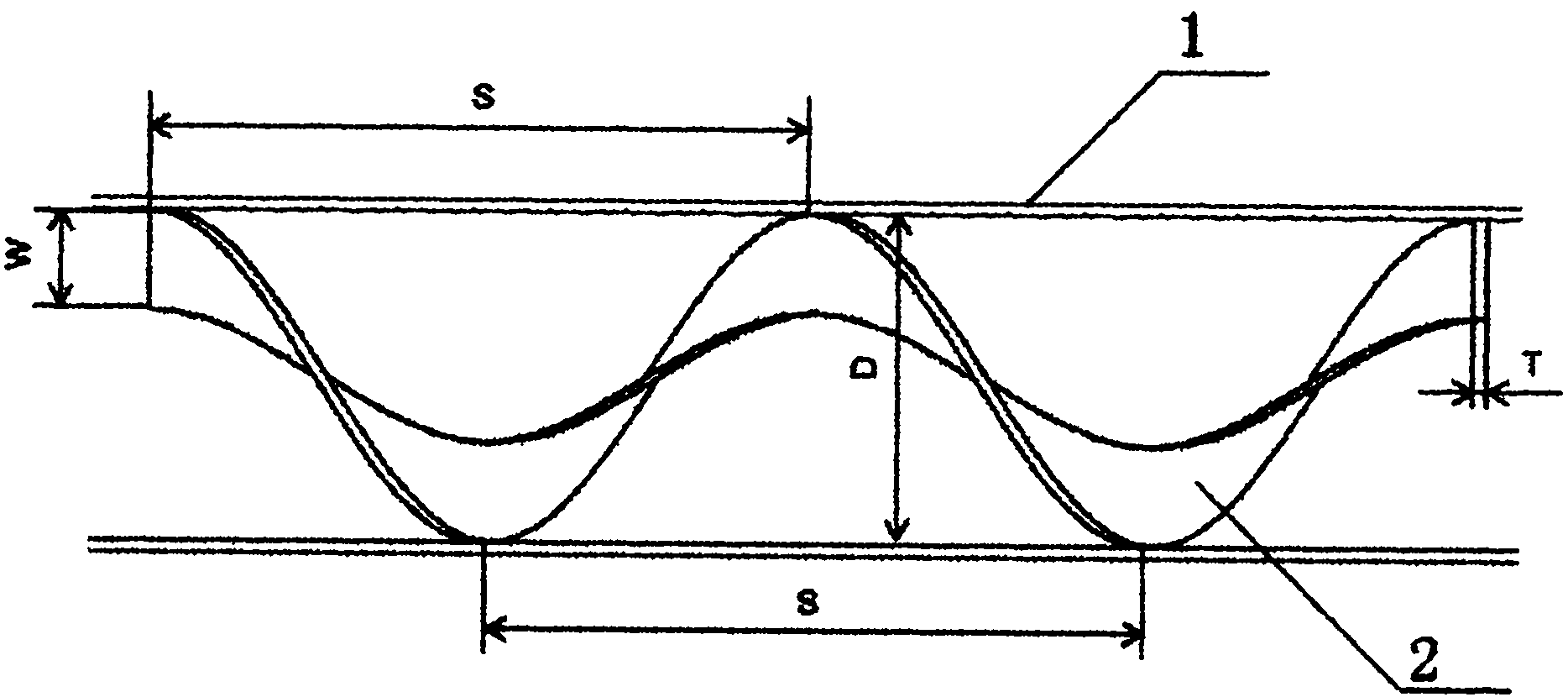

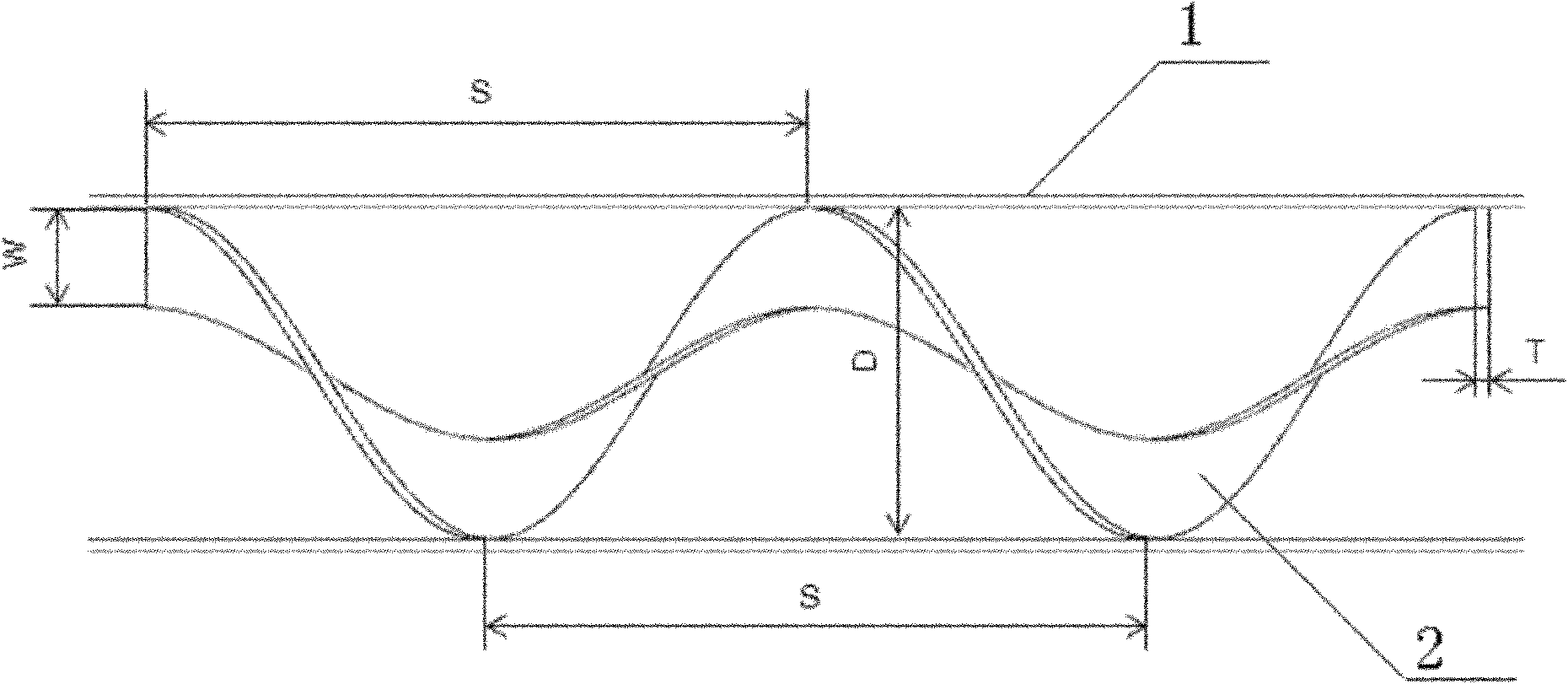

Heat exchange tube internally provided with spiral fins and application thereof

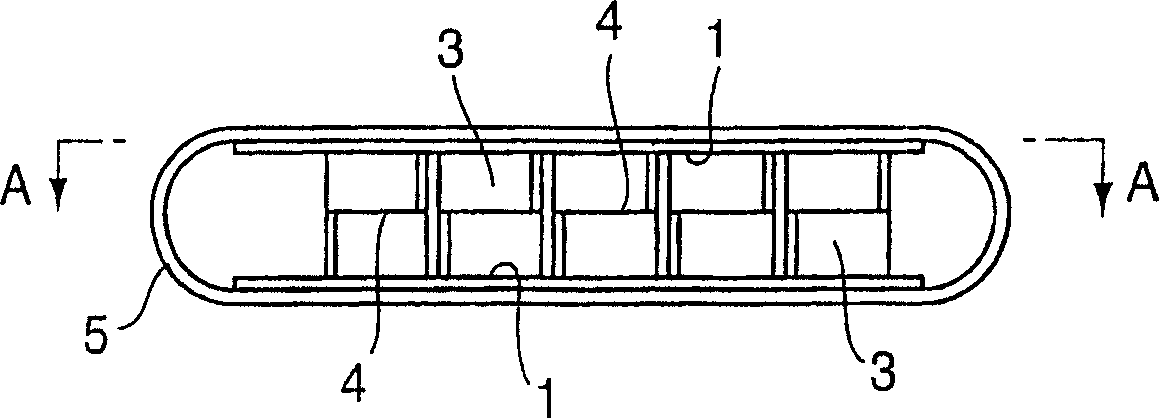

InactiveCN102095332AReduce scouring wearImprove heat transfer efficiencyThermal non-catalytic crackingHeat transfer modificationShell and tube heat exchangerHeat transfer efficiency

The invention relates to a heat exchange tube internally provided with spiral fins and application thereof. The heat exchange tube internally provided with the spiral fins comprises a heat exchange tube (1) and is characterized in that the heat exchange tube (1) is internally provided with the spiral fins (2) which are spiral; and the spiral fins (2) are distributed in the form of one or more sections along the axial direction at the inner side in the heat exchange tube (1). Meanwhile, the heat exchange tube internally provided with the spiral fins can be arranged in a radiation section furnace tube of an ethylene cracking furnace and can also be arranged in other heat exchangers, such as a shell-and-tube heat exchanger. The heat exchange tube achieves the purposes of increasing the heat transfer efficiency, strengthening the heat transfer effect, reducing coking, reducing the capacity consumption and increasing the life cycle of the equipment. Meanwhile, the spiral design also reduces the washing and abrading phenomena of high-speed fluid in the heat exchange tube to the interior of the tube body, thereby the heat transfer effect is further strengthened.

Owner:EAST CHINA UNIV OF SCI & TECH

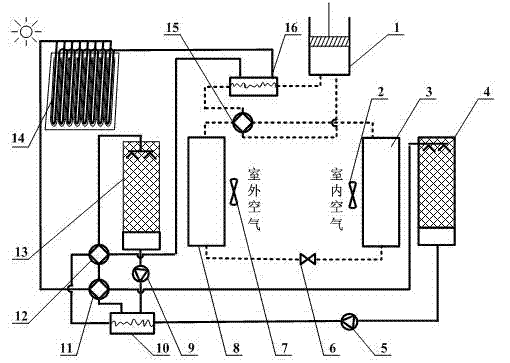

Method for heat humidity independent treatment of air by segmental utilization of condensation heat

InactiveCN102213471AImprove winter frost problemSave electricityEnergy recovery in ventilation and heatingLighting and heating apparatusShell and tube heat exchangerEngineering

The invention discloses a method for heat humidity independent treatment of air by segmental utilization of condensation heat. In the novel method for the heat humidity independent treatment of the air, solar energy and the condensation heat of a refrigerating system are comprehensively utilized as a solution circulation driving heat source, condensation waste heat is segmentally utilized, and solar energy accumulation is combined with solution energy accumulation. The method comprises the following steps of: pre-heating a solution by a solar heat collector / energy accumulator, absorbing thecondensation heat by a shell and tube heat exchanger; and continuously heating by outdoor air which absorbs the remained condensation heat of a condenser to make a temperature rise in a solution regenerator. In summer, indoor air is dehumidified by a solution dehumidifier to make the temperature rise and then passes through an evaporator of the refrigerating system to make an evaporating temperature rise, so the refrigerating coefficients of the system are effectively improved. In winter, the outdoor air passes through the solution dehumidifier and then passes through the evaporator of a heatpump system, so the total heat of outdoor humid air is fully utilized as a low-temperature heat source of the evaporator of the refrigerating system, energy source utilization ratio is improved, and the frosting problem of an outdoor machine in winter is effectively solved.

Owner:NANJING NORMAL UNIVERSITY

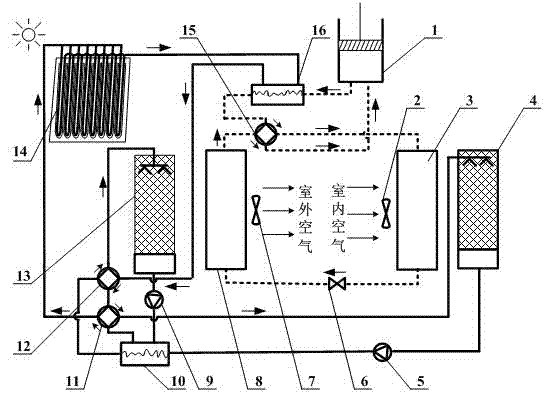

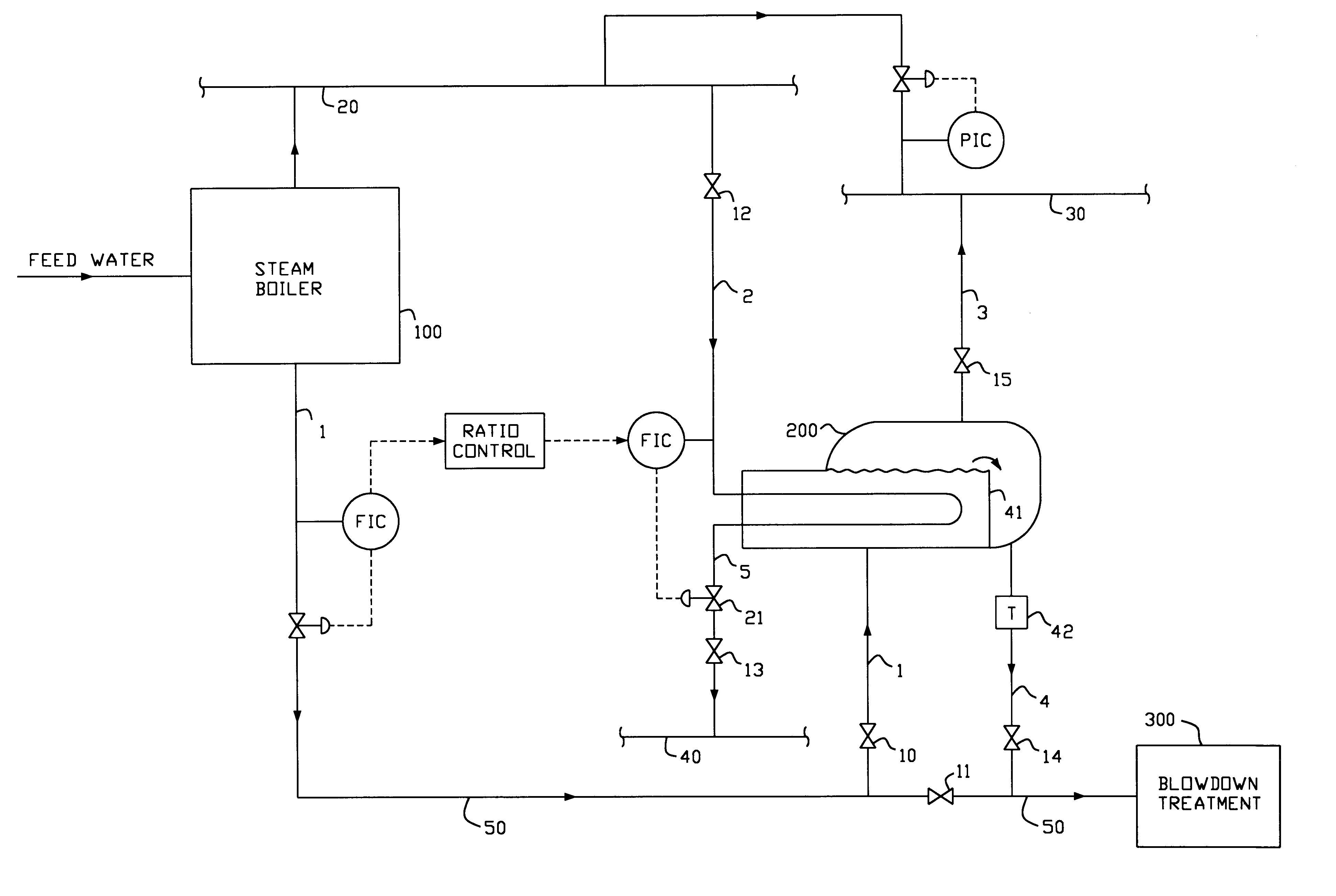

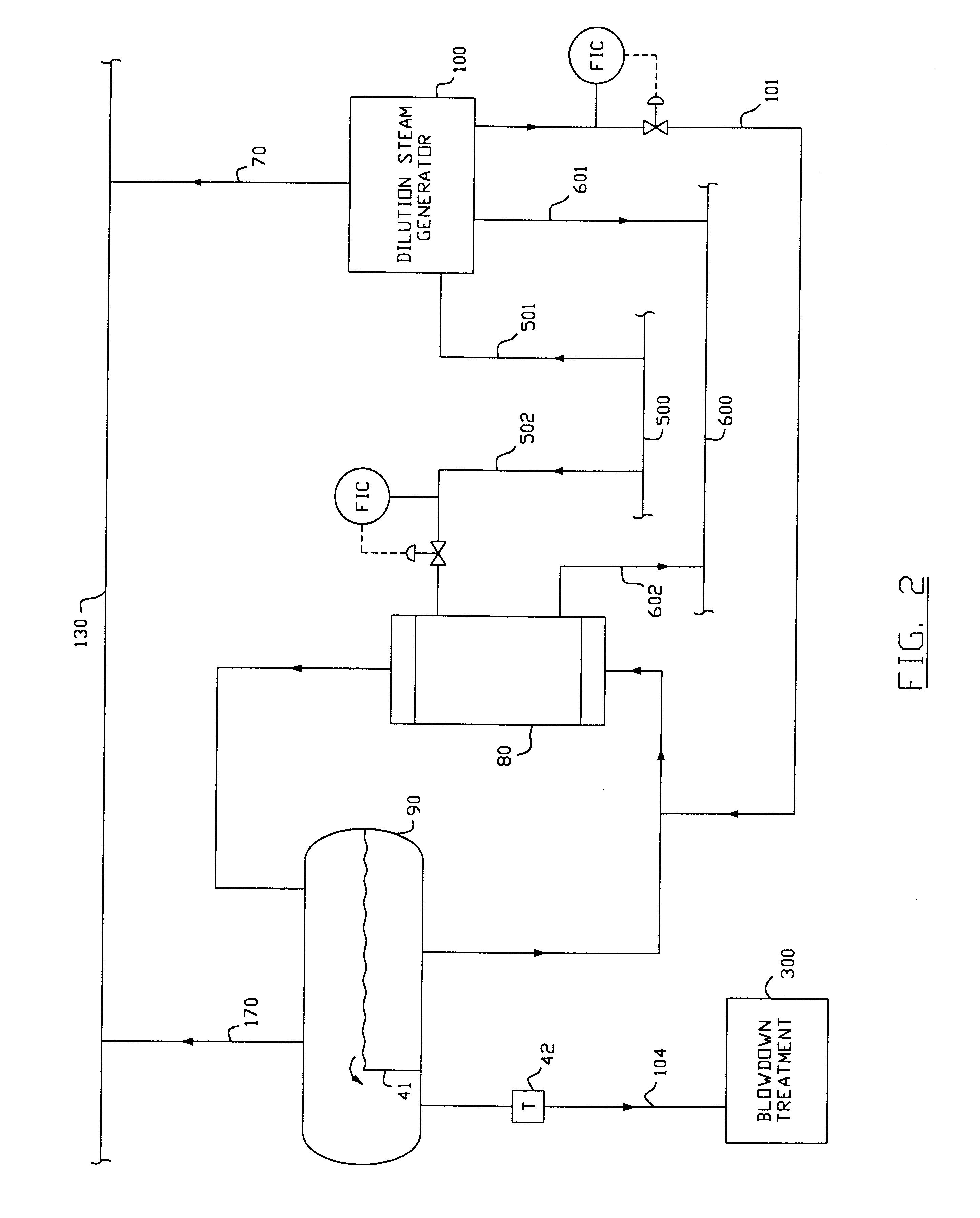

Methods for recycling process wastewater streams

InactiveUS6371058B1High mean blowdown rateChemical treatment costDrying using combination processesSteam separation arrangementsShell and tube heat exchangerWastewater

This invention provides cost-effective alternatives to reduce the cost associated with customary blowdown from steam generating equipment. By selectively recycling process blowdown streams using secondary vaporizers, the net result is a partial replacement of wastewater stream with almost an equivalent quantity of clean steam condensate. The heat transfer is carried out by indirect contact devices, such as shell and tube heat exchanger and the like, without mixing of the two process streams to allow condensate recovery while avoiding cross contamination. This invention carries economic as well as environmental credits. A condensate recovery apparatus can be designed to enable easy connection to existing equipment already in service, as well as easy removal, without causing process disruption.

Owner:TUNG PETER

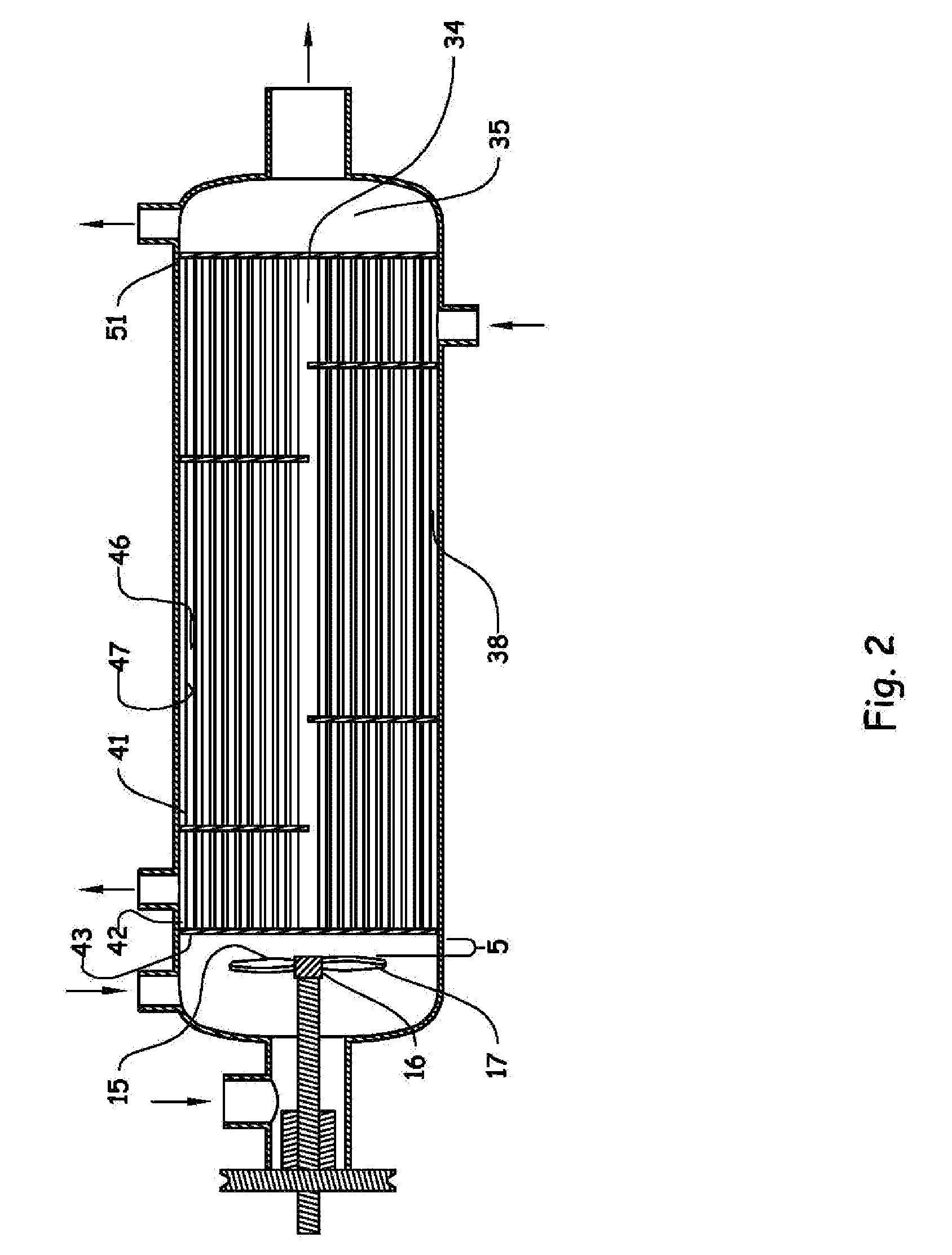

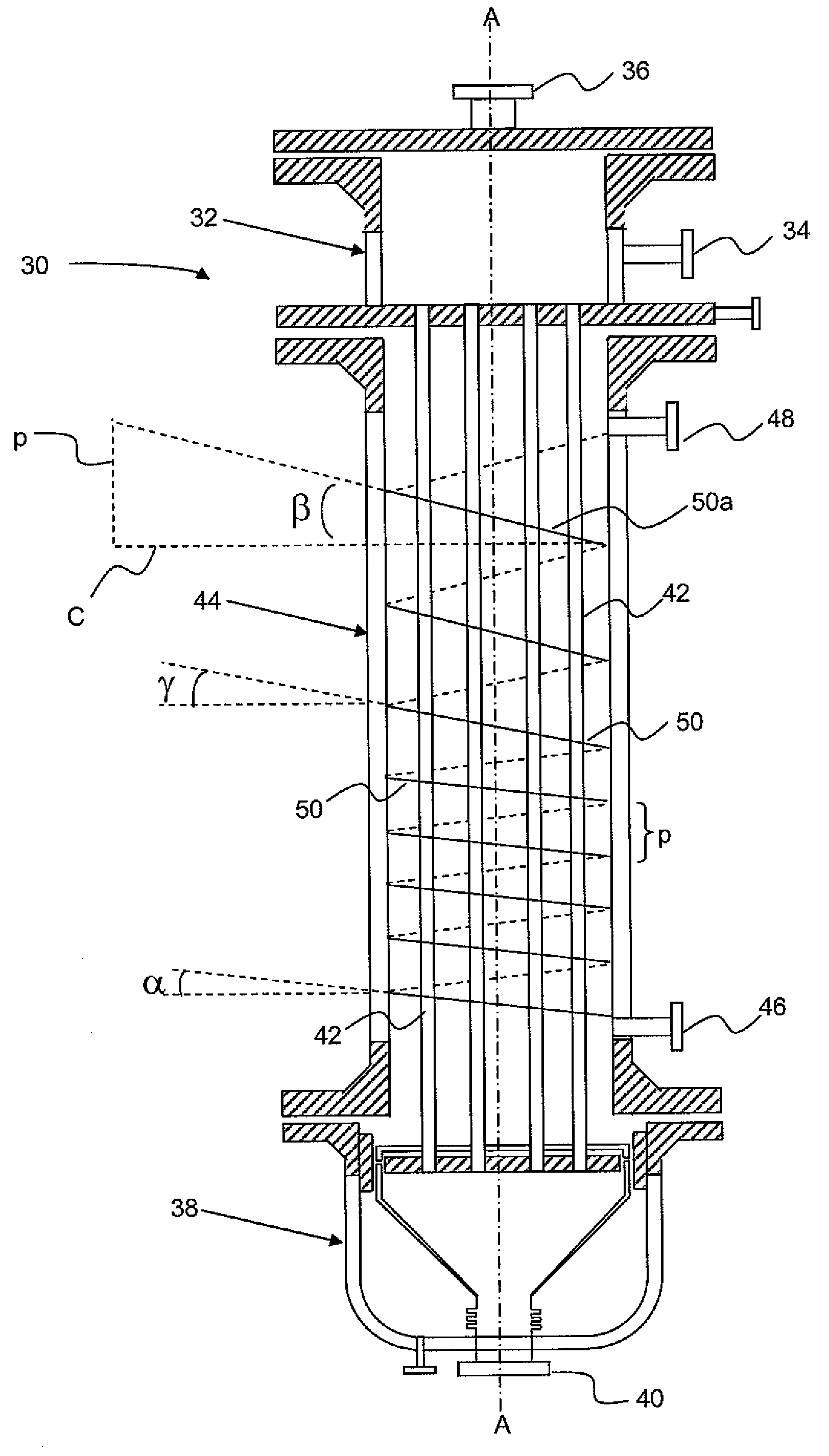

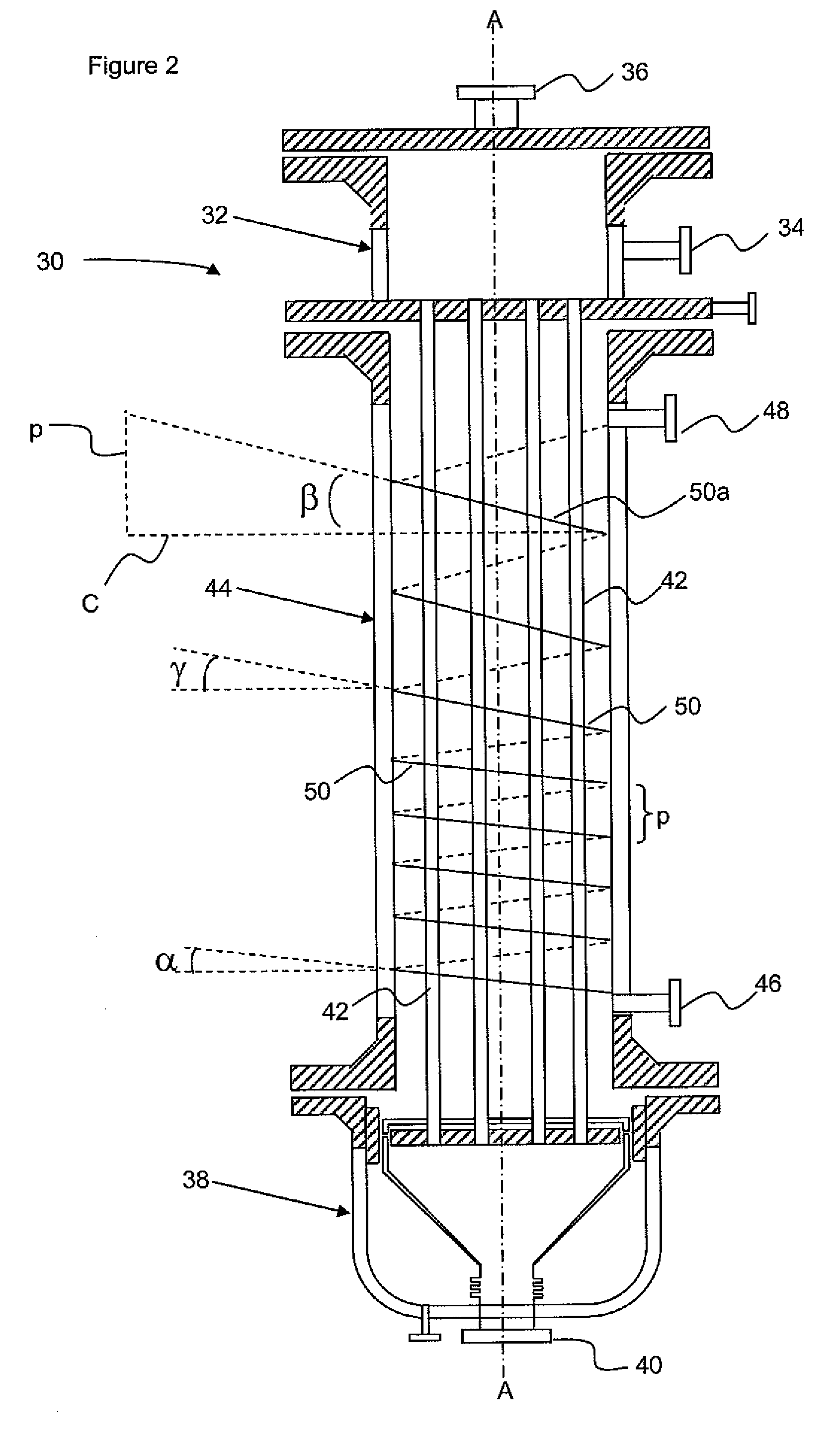

Vertical combined feed/effluent heat exchanger with variable baffle angle

InactiveUS20090301699A1Heat exchanger casingsStationary tubular conduit assembliesPlate heat exchangerShell and tube heat exchanger

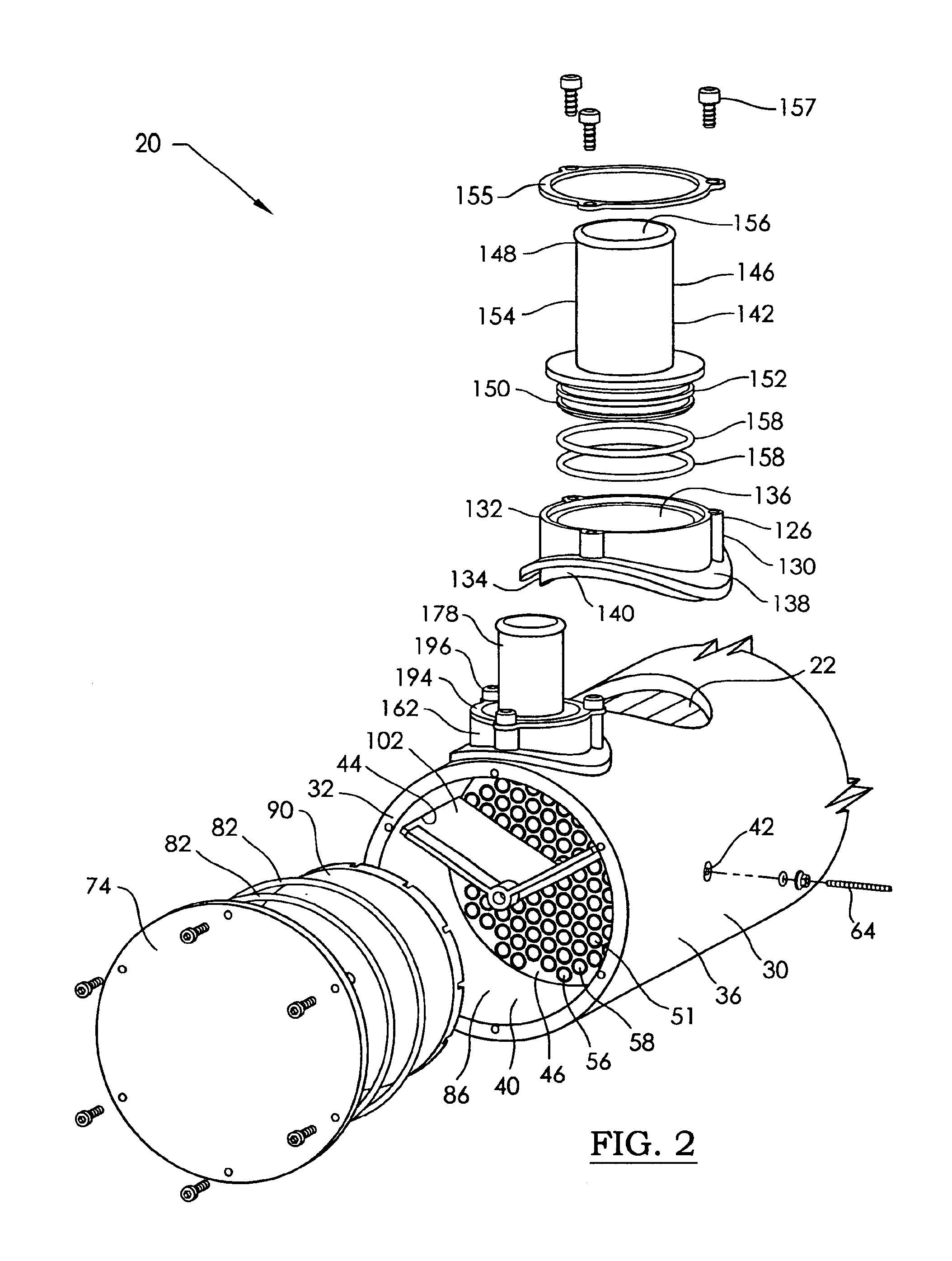

A shell and tube heat exchanger, such as a vertical combined feed / effluent heat exchanger (VCFE), including: a shell having a fluid inlet and a fluid outlet; a plurality of baffles mounted in the shell to guide the fluid into a helical flow pattern through the shell; wherein a helix angle α of a baffle proximate the inlet is different than a helix angle β of a baffle proximate the outlet.

Owner:LUMMUS TECH INC

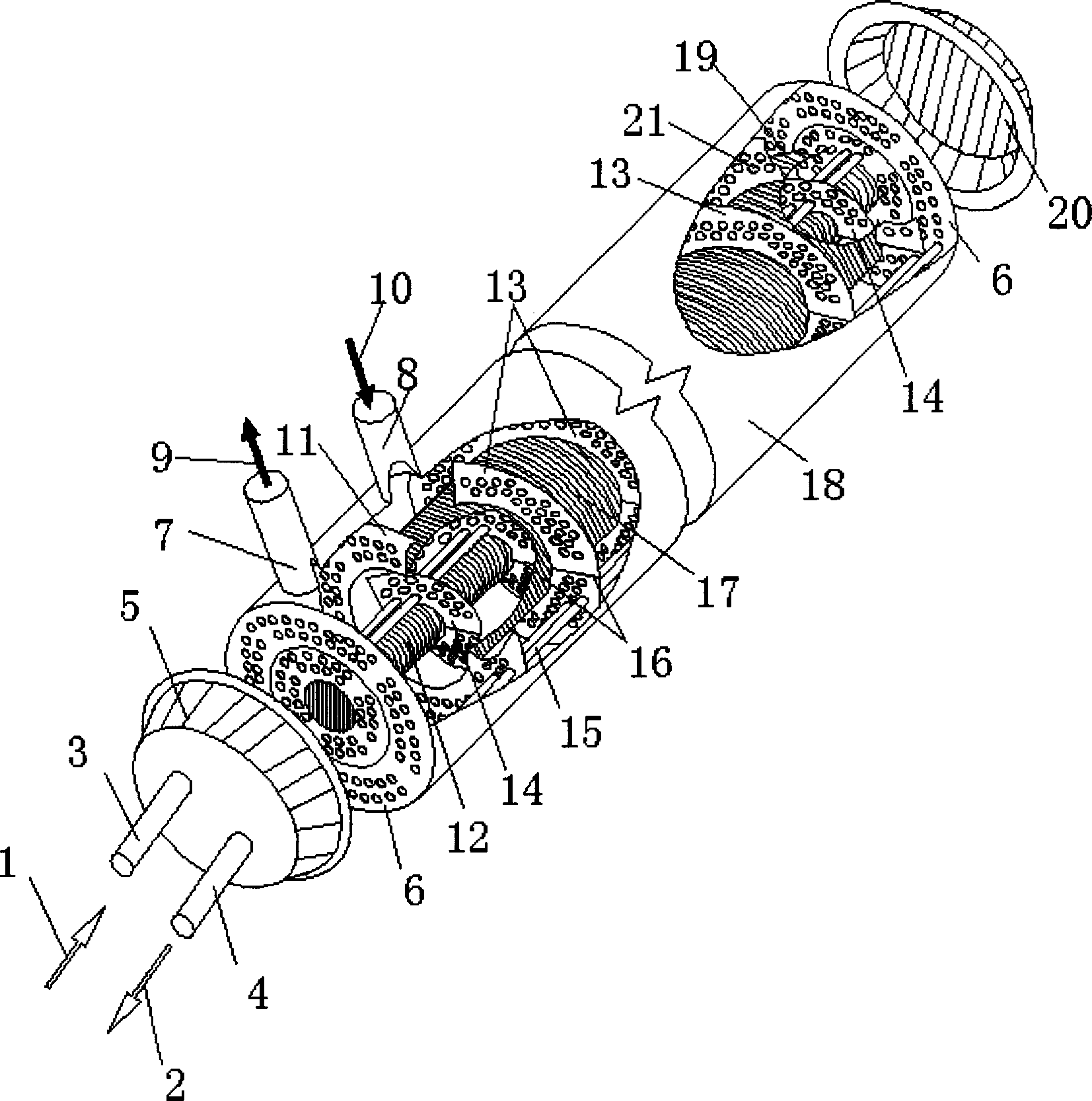

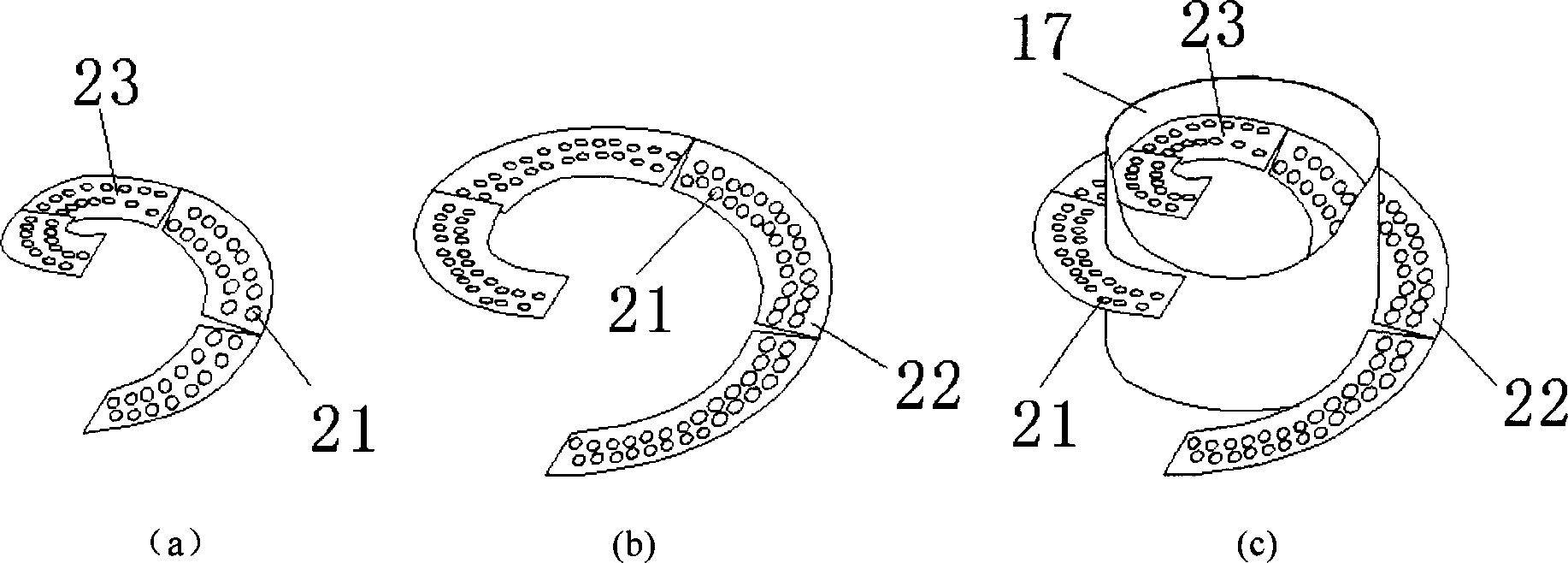

Combined multi-shell spiral baffle plate shell-and-tube heat exchanger

InactiveCN101021394ASmall pressure lossSimple processHeat exchanger casingsStationary tubular conduit assembliesCircular discPlate heat exchanger

The invention relates to the combined multi-shell spiral baffle board shell-and-tube exchanger, which includes the shell. One end of the shell is set with the pipe side inlet and the pipe side outlet. The heat exchanging bundle is through the baffle board and connected to the two pipe boards in two ends of the shell. The first internal bushing is set in the shell and the second is set out of the first internal bushing. One end of the second internal bushing is connected to the pipe board and one end of the first internal bushing is set with the clapboard; the shell is installed with the inlet pipe of the out shell and the outlet pipe of the inner shell. The out shell and the middle shell use the whole continuously spiral baffle board; the inner shell uses the non continuously spiral baffle board or bow baffle board or disc-ring baffle board or baffle pole or the whole round baffle board or not setting the baffle board; the baffle board of every shell has the self anti dirty hole. The invention has simplified the process and decreased the pressure loss but increased the compaction and self anti-dirty ability of the heat exchanger; also it decreases the cleaning cost and prolongs the using life.

Owner:XI AN JIAOTONG UNIV

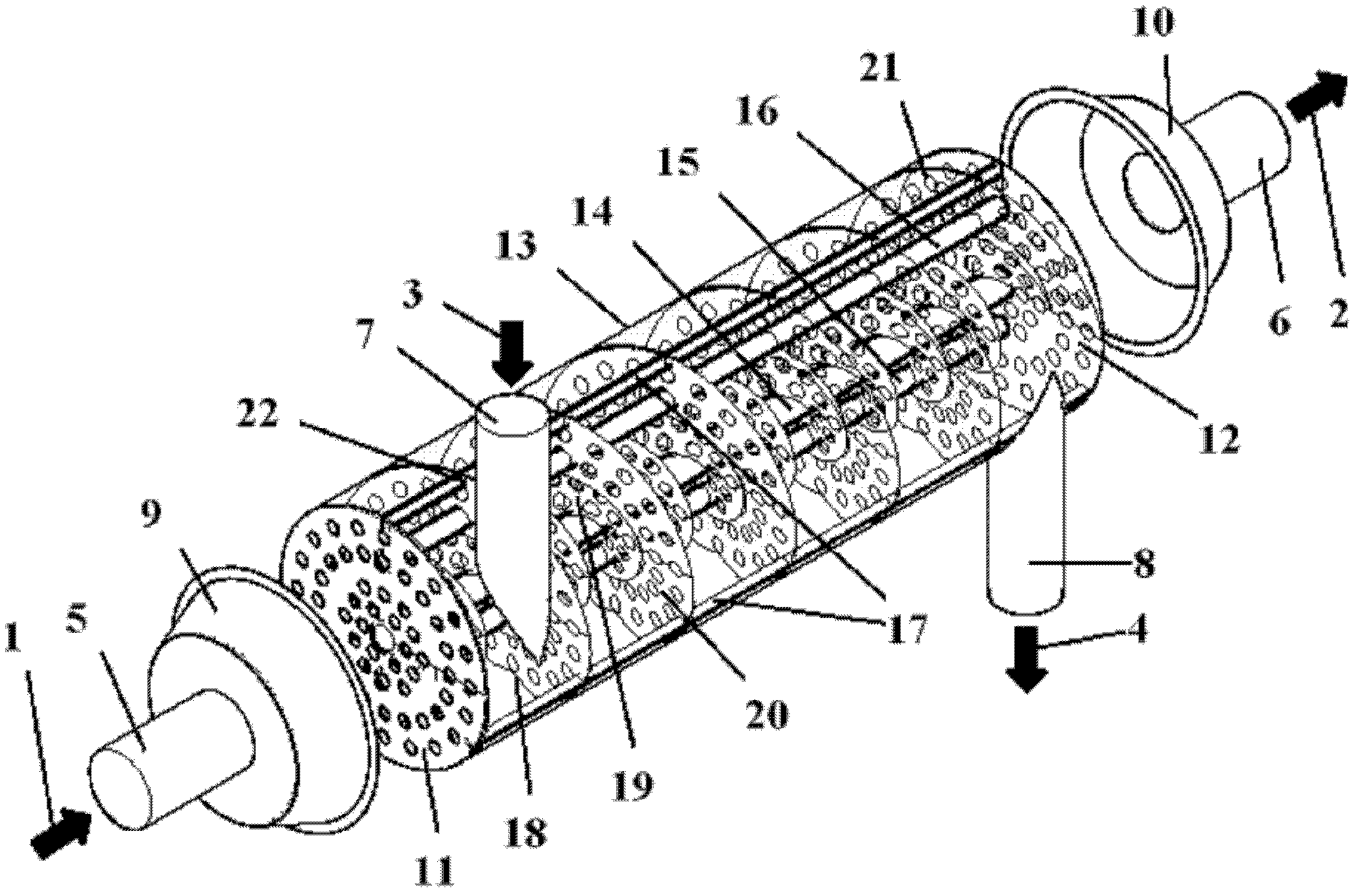

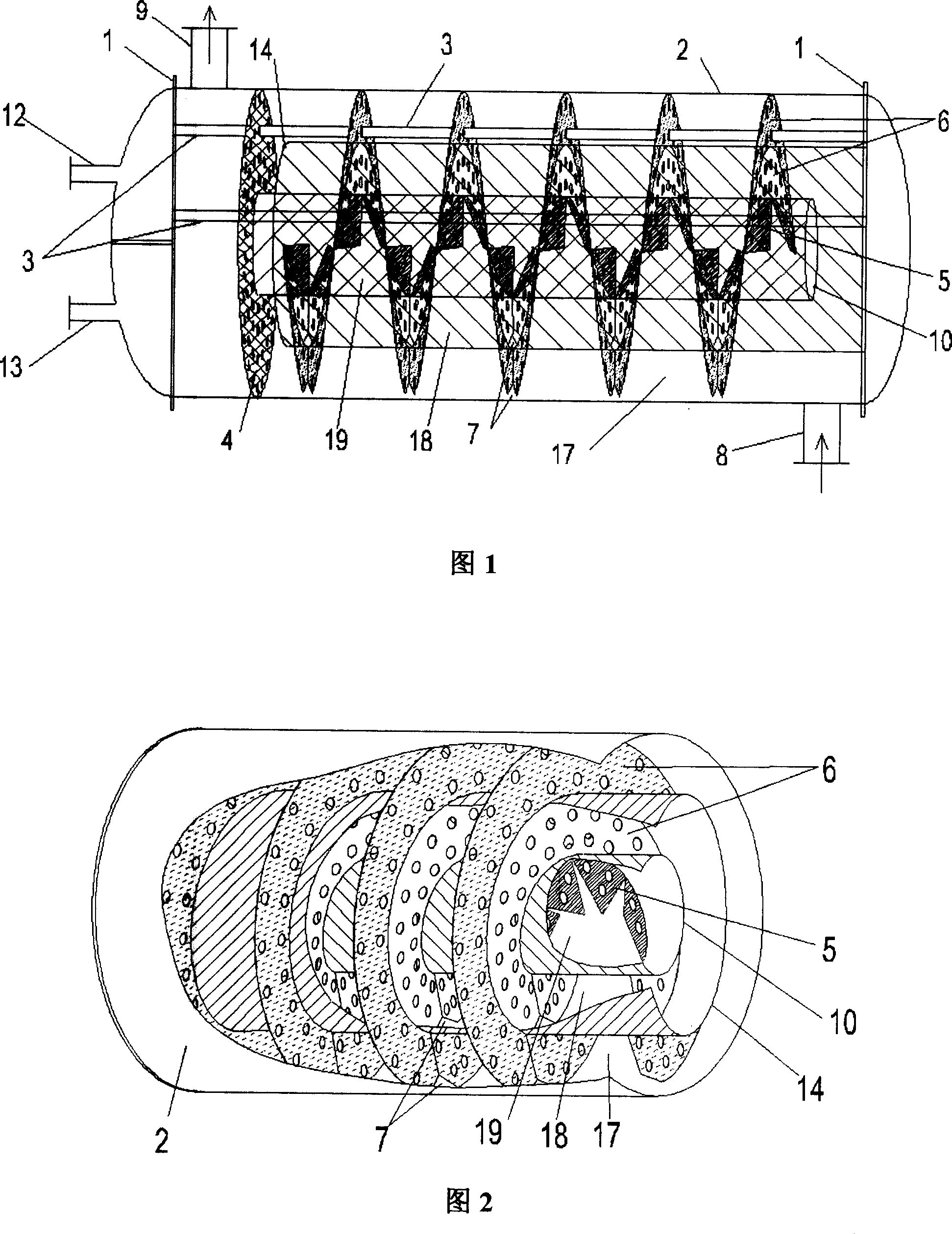

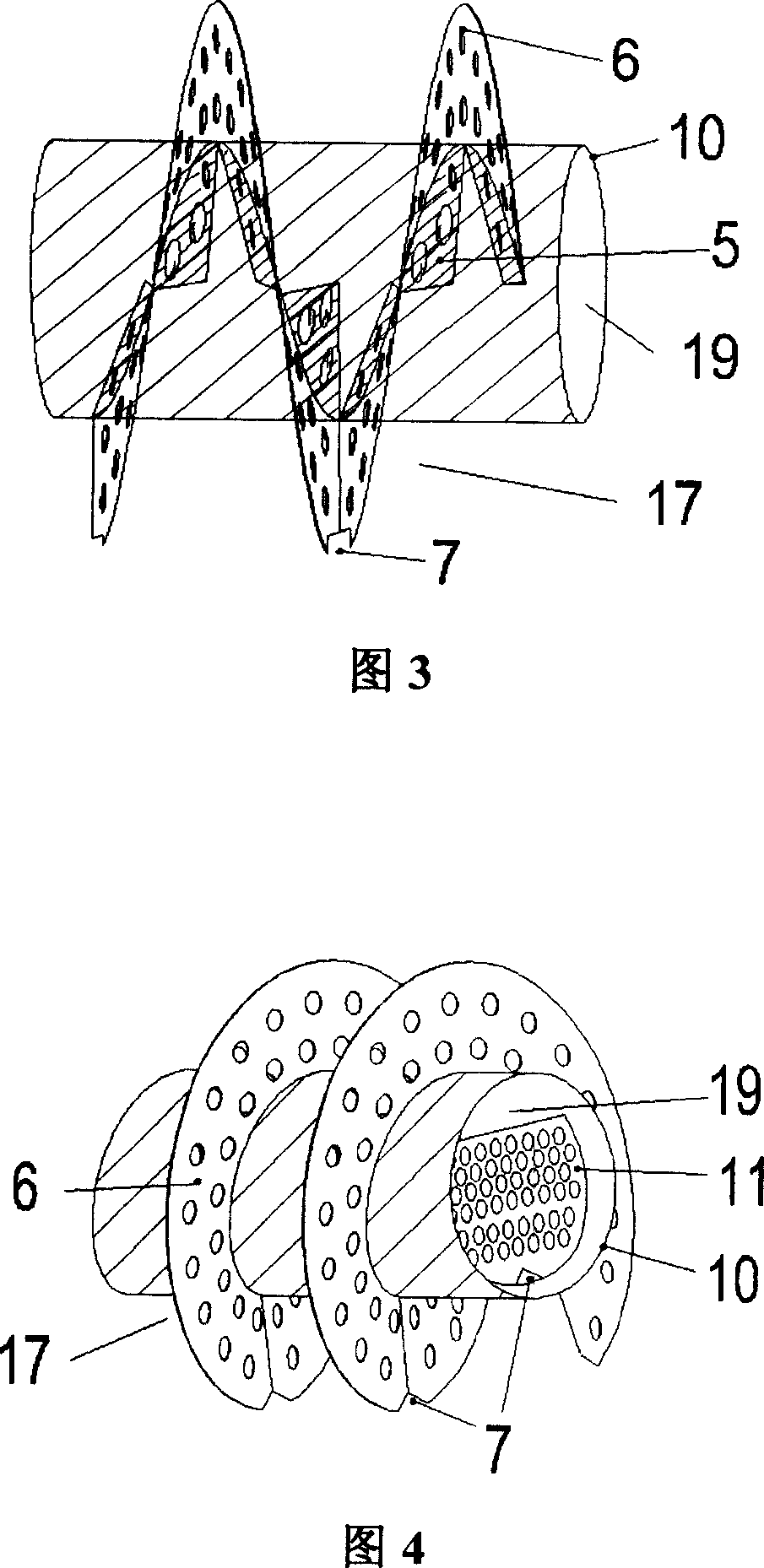

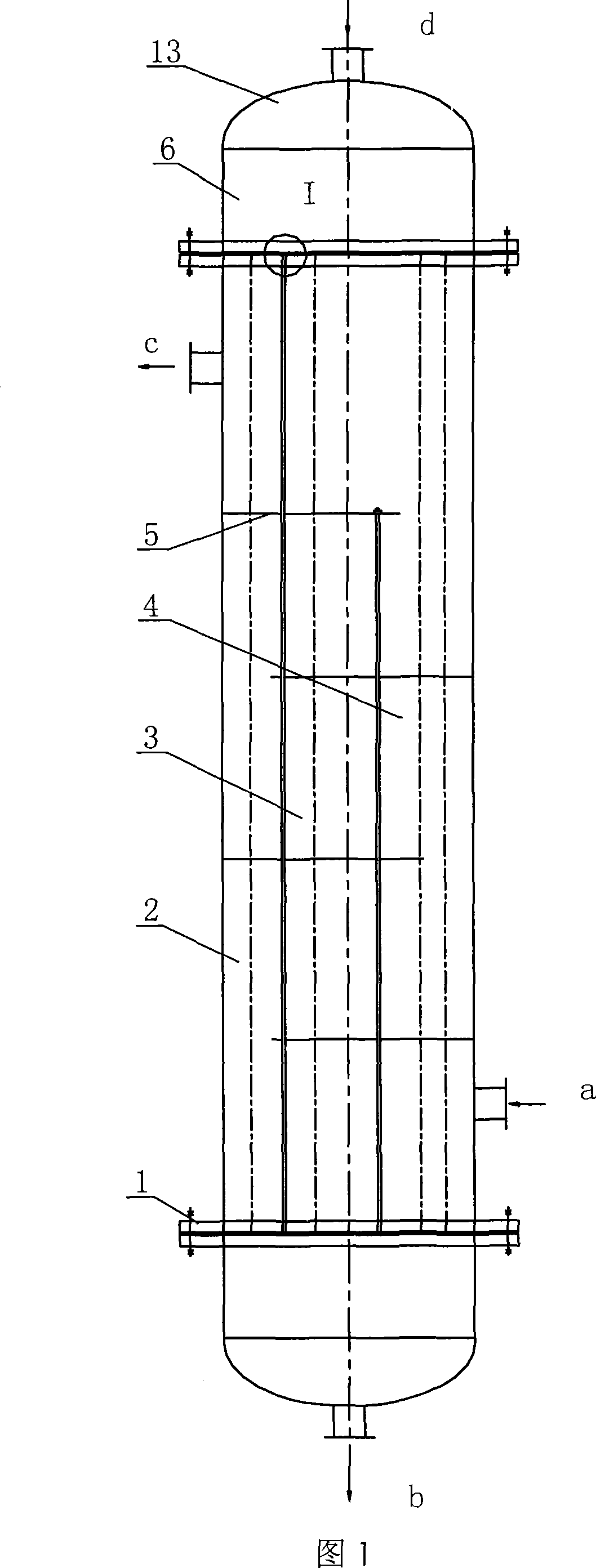

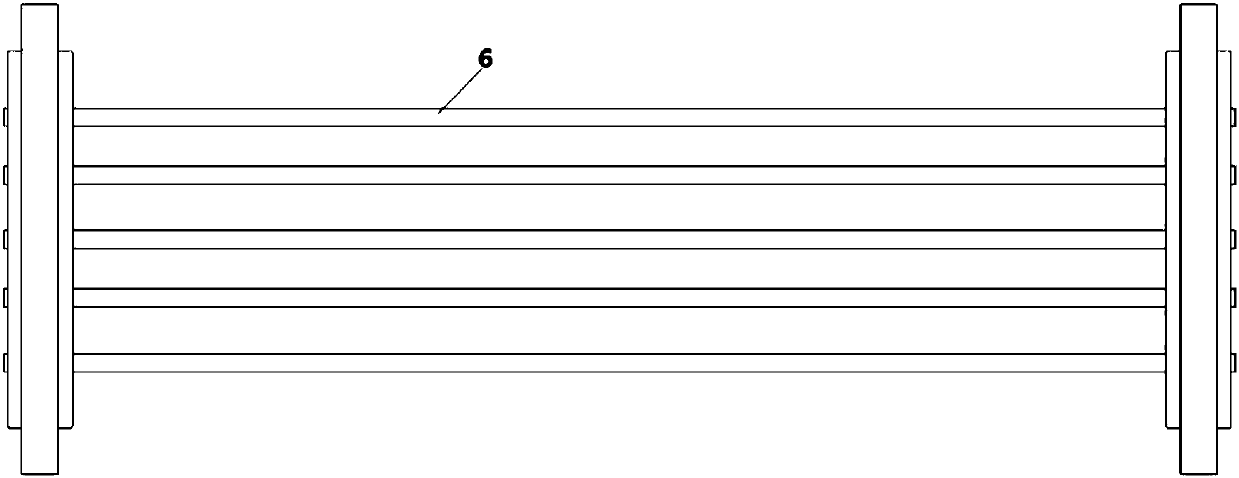

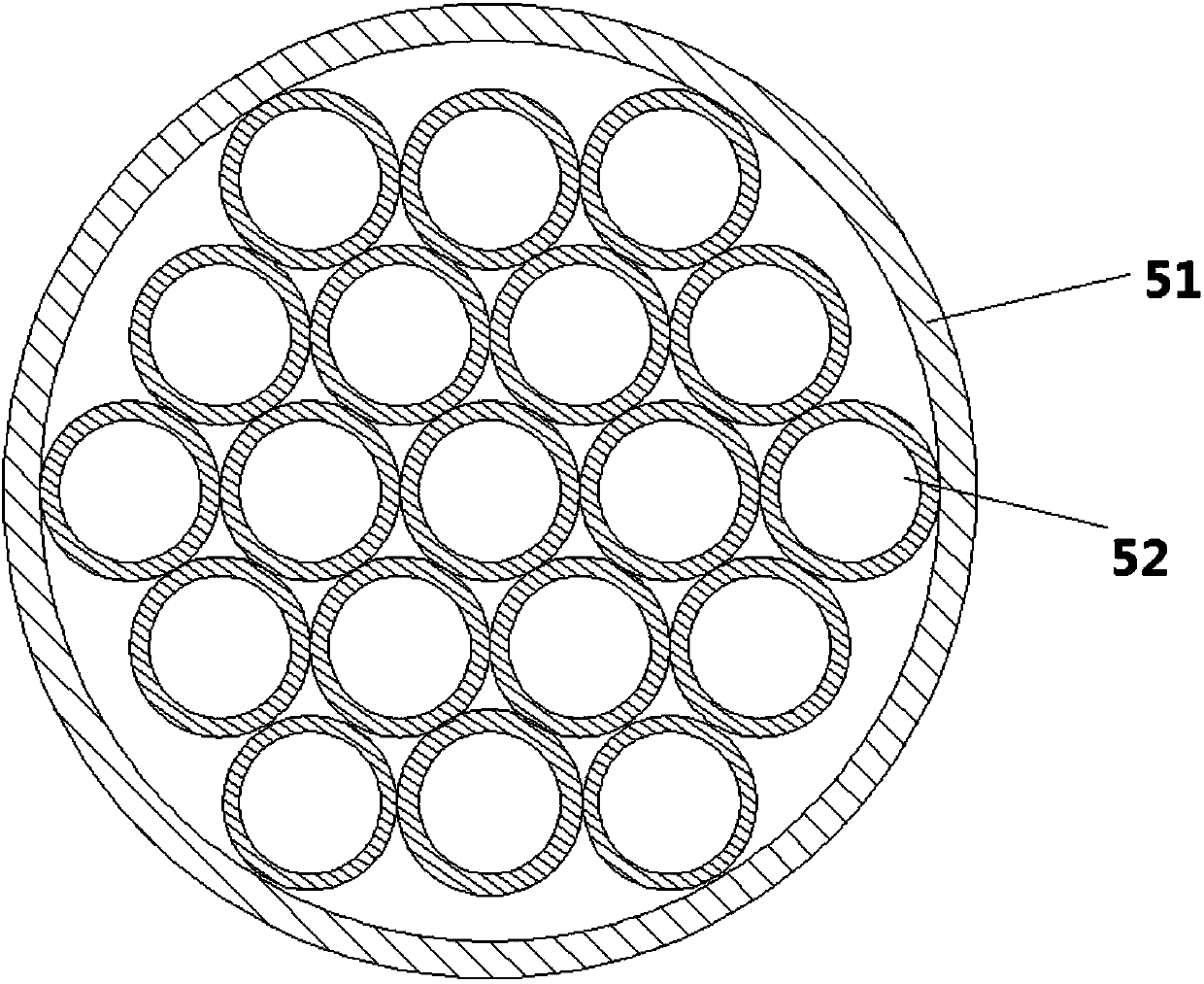

Multiple shell passes shell-and-tube helica-baffle heat exchangers

ActiveCN1821700ACompact structureExtended service lifeHeat exchanger casingsStationary tubular conduit assembliesPlate heat exchangerShell and tube heat exchanger

The multiple shell spiral baffle shell-and-tube heat exchanger includes one shell, one central tube in the center oft shell, two tube plates on ends of the shell and with separate end covers, one inlet pipe and one outlet pipe beside the tube, one heat exchange tube bundle, one inlet pipe and one outlet pipe beside the shell, one external spiral baffle plate and one internal spiral baffle plate, and one internal casing between the external spiral baffle plate and the internal spiral baffle plate. The shell, the external spiral baffle plate and the internal casing enclose one external spiral shell pass; and the internal casing, the internal spiral baffle plate and the central tube enclose one internal spiral shell pass, so that one two-shell pass spiral baffle plate shell-and-tube heat exchanger is formed. Adopting two or more internal casings can form multiple spiral shell pass. The present invention has raised heat exchange efficiency, compact heat exchanger structure, less vibration, high safety, less scaling and long service life.

Owner:上海益焓能源科技有限公司

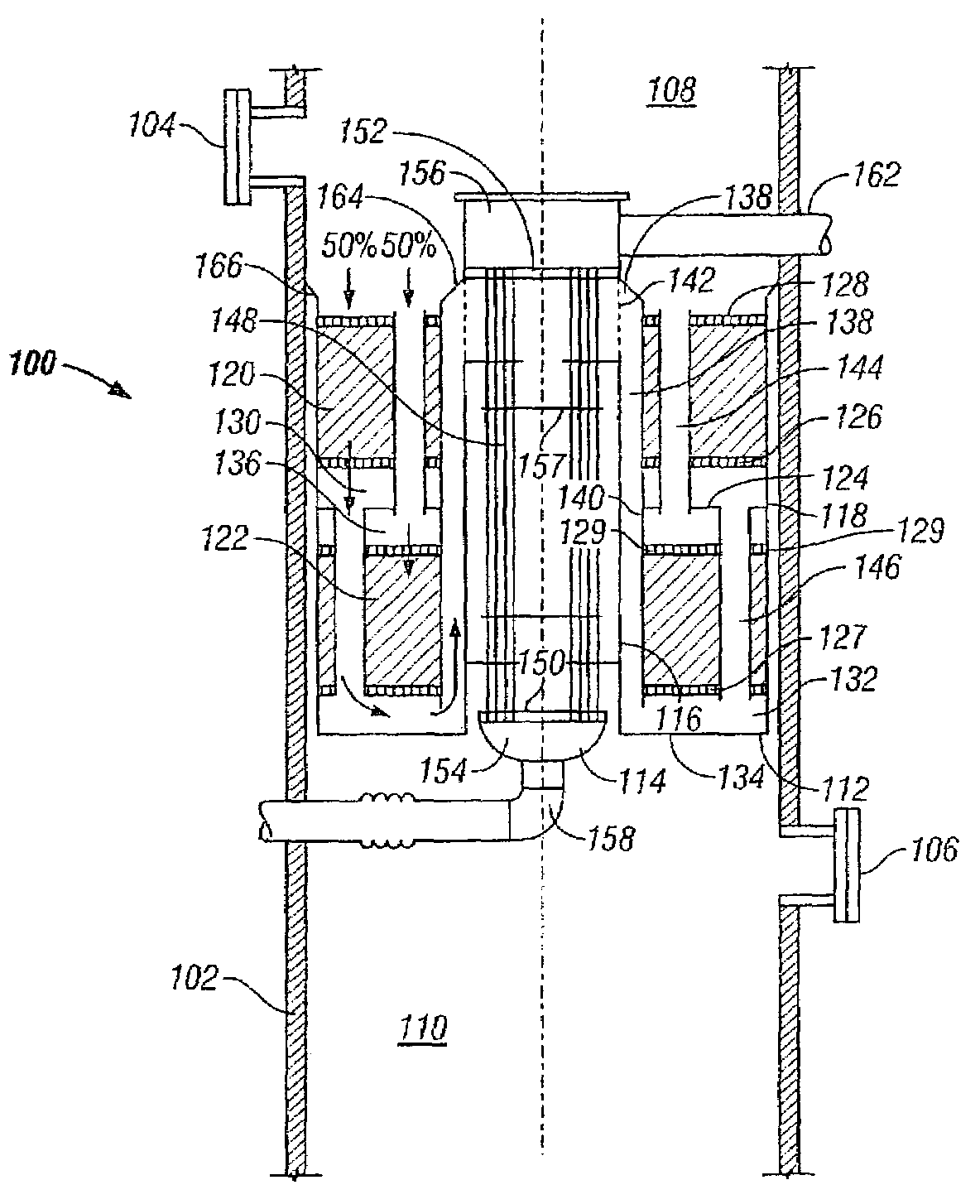

Fuel conversion reactor

ActiveUS7220392B2Hydrogen/synthetic gas productionHeat exchanger casingsPlate heat exchangerShell and tube heat exchanger

A fuel conversion reactor includes a shell-and-tube heat exchanger for controlling the temperature of a hot gaseous mixture produced by catalytic or non-catalytic reaction of a fuel with a gaseous fluid, and for controlling the temperature of the gaseous fluid and / or the fuel prior to the reaction. The reactor is either a catalytic or non-catalytic burner, or a fuel reformer for converting a fuel to hydrogen. A preferred reactor includes an outer shell having first and second ends and an inner surface, a primary inner shell extending into the outer shell, the primary inner shell defining a heat exchanging chamber and having primary and secondary ends, and a secondary inner shell having a first end located adjacent the secondary end of the primary inner shell. One or more outlet apertures are formed between the two inner shells for passage of the gaseous fluid out of the heat exchanging chamber. There are also a plurality of heat exchange tubes extending through the heat exchanging chamber between first and second tube sheets and connected to same. The first tube sheet is mounted in the primary inner shell while the second tube sheet is connected to the secondary inner shell. The tubes form passages for flow of the hot gaseous mixture in heat exchange contact with the gaseous fluid through the heat exchanging chamber, thereby preheating the gaseous fluid prior to reaction with the fuel. The adjacent ends of the inner shells form a disconnected joint and the secondary inner shell is free to move relative to the primary inner shell upon thermal expansion of the tubes.

Owner:DANA CANADA CORP

Cooling assembly

InactiveUS20050076665A1Easy to transportEfficient and reliable and economical and simple and effectiveFree-cooling systemsStationary conduit assembliesEvaporative coolerShell and tube heat exchanger

A process and the required apparatus for air conditioning the interior of a structure is shown which can be run entirely off a DC power source, such as a storage battery. A shell and tube heat exchanger is combined with a mechanical refrigeration system to provide a wet shell side and a dry tube side of the apparatus. In the operation of the air conditioner, a mass of distributed water is established on the wet shell side, and a flow of ambient air is passed through the wet shell side to form a resulting stream of moist air. A flow of ambient air is passed through the dry tube side and a resulting stream of dry cooled air is recovered. The streams of most and cooled air can either be combined or routed separately depending primarily upon the humidity of the surrounding environment to be cooled. The air conditioning unit is not hermetically sealed and the water consumption rate is generally less than that required for a conventional evaporative cooler.

Owner:GPM INC

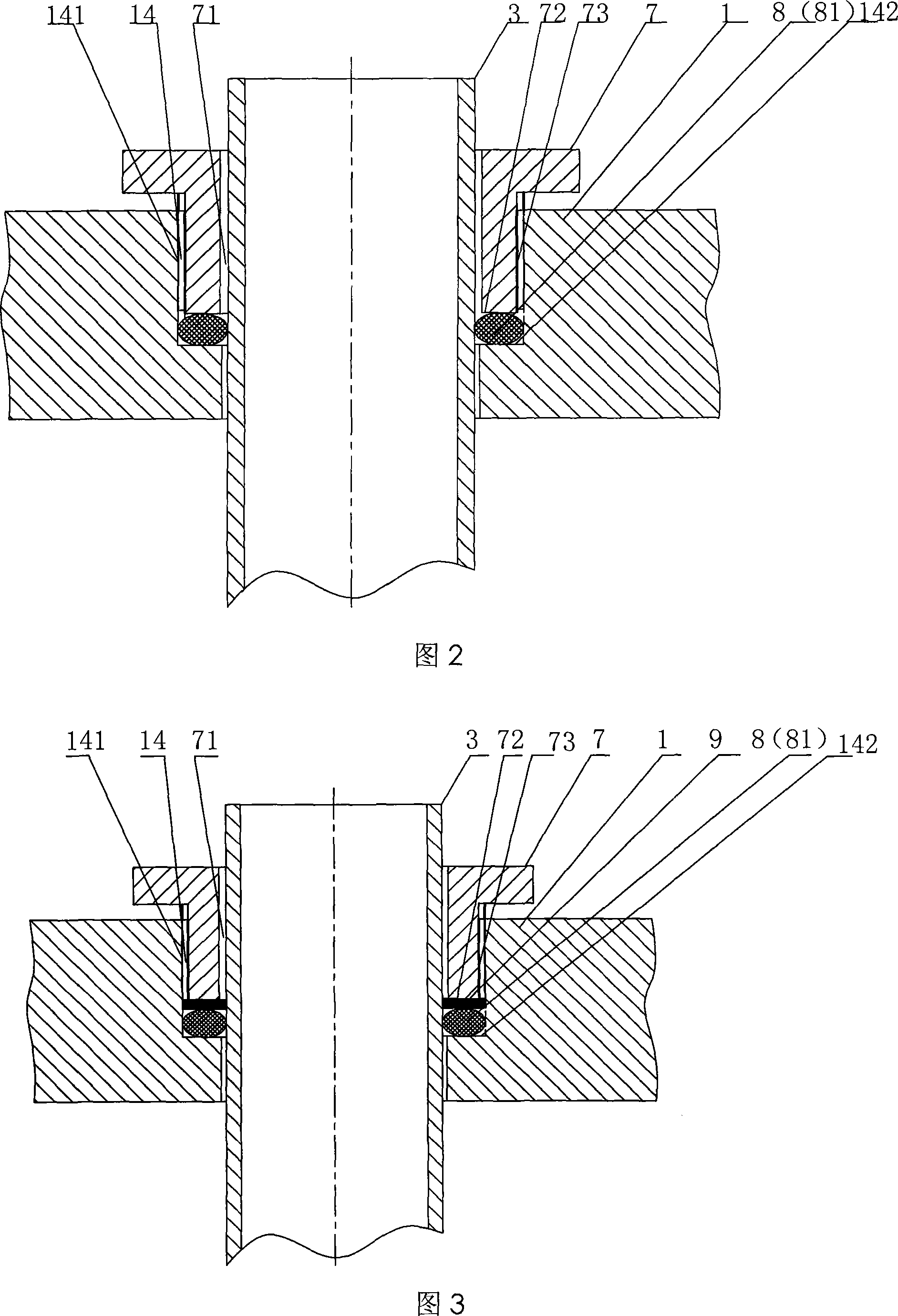

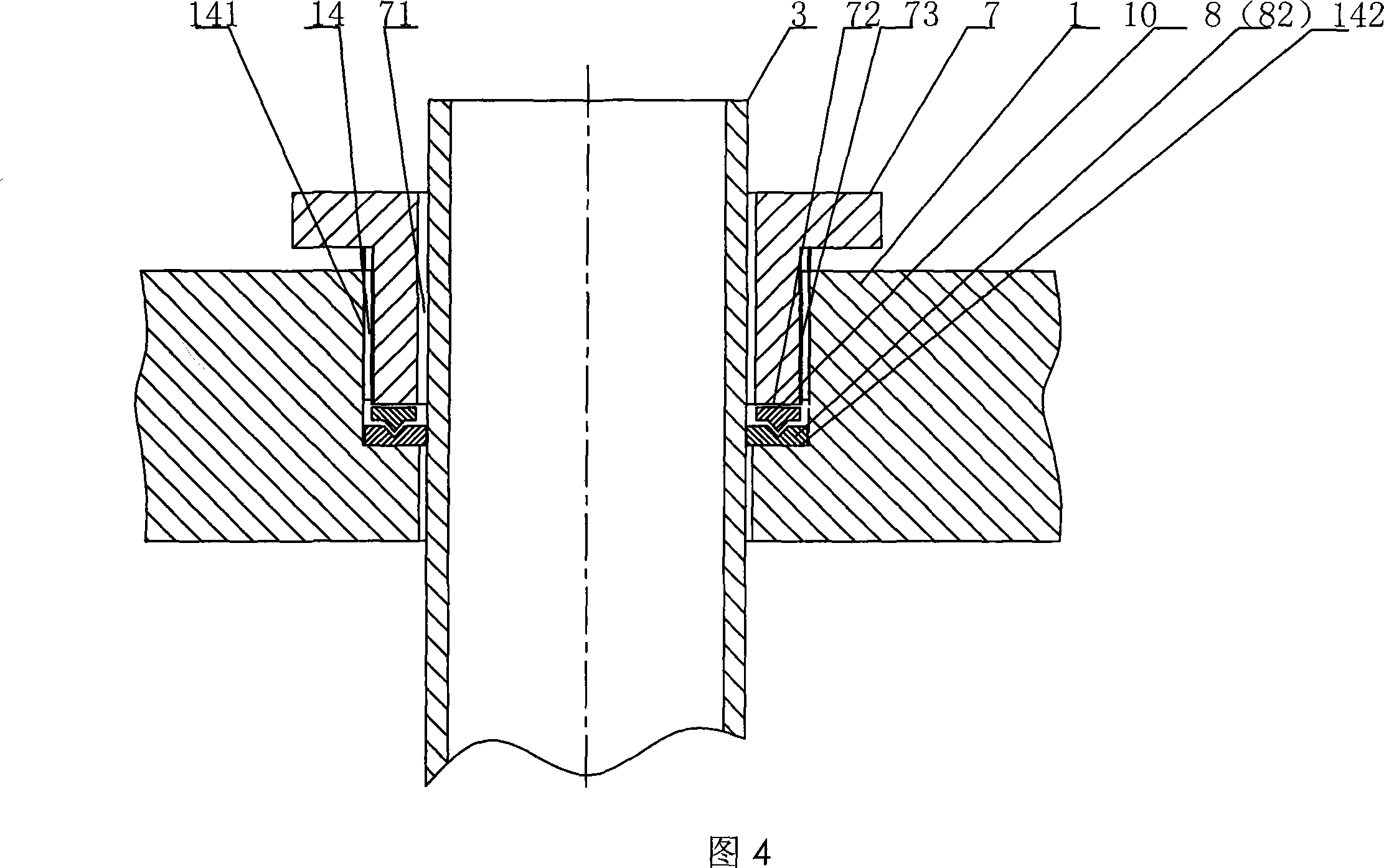

Pipe shell type heat-exchanger

InactiveCN101216263ALow costSolution to short lifeStationary tubular conduit assembliesShell and tube heat exchangerEngineering

The invention relates to a shell-and-tube heat exchanger, which comprises an outer shell, a header, tube plates, heat exchange tubes, baffle plates, a tension rod, and a channel that are assembled according to the conventional number and the method. The invention is characterized in that a trapezoid round hole is opened at the center of the tube plate, the large diameter site of the trapezoid round hole is provide with an internal thread, and the small diameter site is mated with the diameter of the heat exchange tube; the large diameter site of the trapezoid round hole is provide with a gland having an external thread, and the axial center of the gland is also opened with a round hole with diameter corresponding to that of the heat exchange tube; and a elastic sealing ring is disposed between the steps of the trapezoid round hole and the lower end surface of the gland.

Owner:HEBEI UNIV OF TECH

Split-flow, vertical ammonia converter

ActiveUS7081230B2Reduction in reactor sizeEasy alignmentStationary conduit assembliesHeat exchanger casingsShell and tube heat exchangerFixed bed

A vertical, fixed-bed ammonia converter wherein a fixed-bed catalyst zone is configured into two mechanically separated catalyst volumes and two gas streams that operate in parallel. The design maintains the ratio of gas flow to catalyst volume so that there is no catalyst effectiveness penalty. The catalyst beds and gas flow paths are configured so that gas flow is downward through each catalyst volume. Each fixed-bed catalyst zone in the present invention can hold the catalyst in an annular space formed between two concentric shrouds arranged around a shell and tube heat exchanger. The two catalyst beds associated with each zone are situated above one another along the length of an interstage heat exchanger. Pipes or conduits are disposed through the beds to effect the parallel gas flow configuration, or alternatively, annular flows are created via passages through the internal shrouds that contain the catalyst beds.

Owner:KELLOGG BROWN & ROOT LLC

Lean direct injection combustion system

ActiveUS8042339B2Continuous combustion chamberGas turbine plantsCombustion systemShell and tube heat exchanger

The present invention is directed to a lean direct injection (LDI) combustion system for a gas turbine using a shell and tube heat exchanger concept to construct a shell and tube lean direct injector (“LDI”) for the combustion system. One side of the LDI injector, either the shell side or the tube side, carries an oxidizer, such as air, to the combustor, while the other side of the LDI injector carries fuel to the combustor. Straight or angled holes drilled in an end plate of the combustor allow the fuel to enter the combustor and mix with air being injected into the combustor.

Owner:GENERAL ELECTRIC CO

Shell and tube heat exchanger

InactiveUS20090000775A1Preventing corrosionPreventing foulingCorrosion preventionHeat exchanger casingsPlate heat exchangerShell and tube heat exchanger

The shell and tube heat exchanger includes a shell having a fluid inlet and a fluid outlet, and a plurality of tubes disposed inside the shell, the tubes having a fluid inlet and a fluid outlet. An impingement baffle having a plurality of perforations is disposed in the shell between the shell fluid inlet and the tubes. The impingement baffle is configured to guide a heat exchanger fluid from the shell fluid inlet to distribute the heat exchanger fluid uniformly around the tubes. The perforations prevent recirculation and stagnation of fluid flow behind the baffle, thereby preventing fouling and corrosion with subsequent thinning of the tube walls.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com