Patents

Literature

615results about "Steam separation arrangements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solar Thermal Power System

InactiveUS20090199557A1Simple efficiencyTechnology being suitableAuxillary drivesSteam separation arrangementsThermal energy storageEngineering

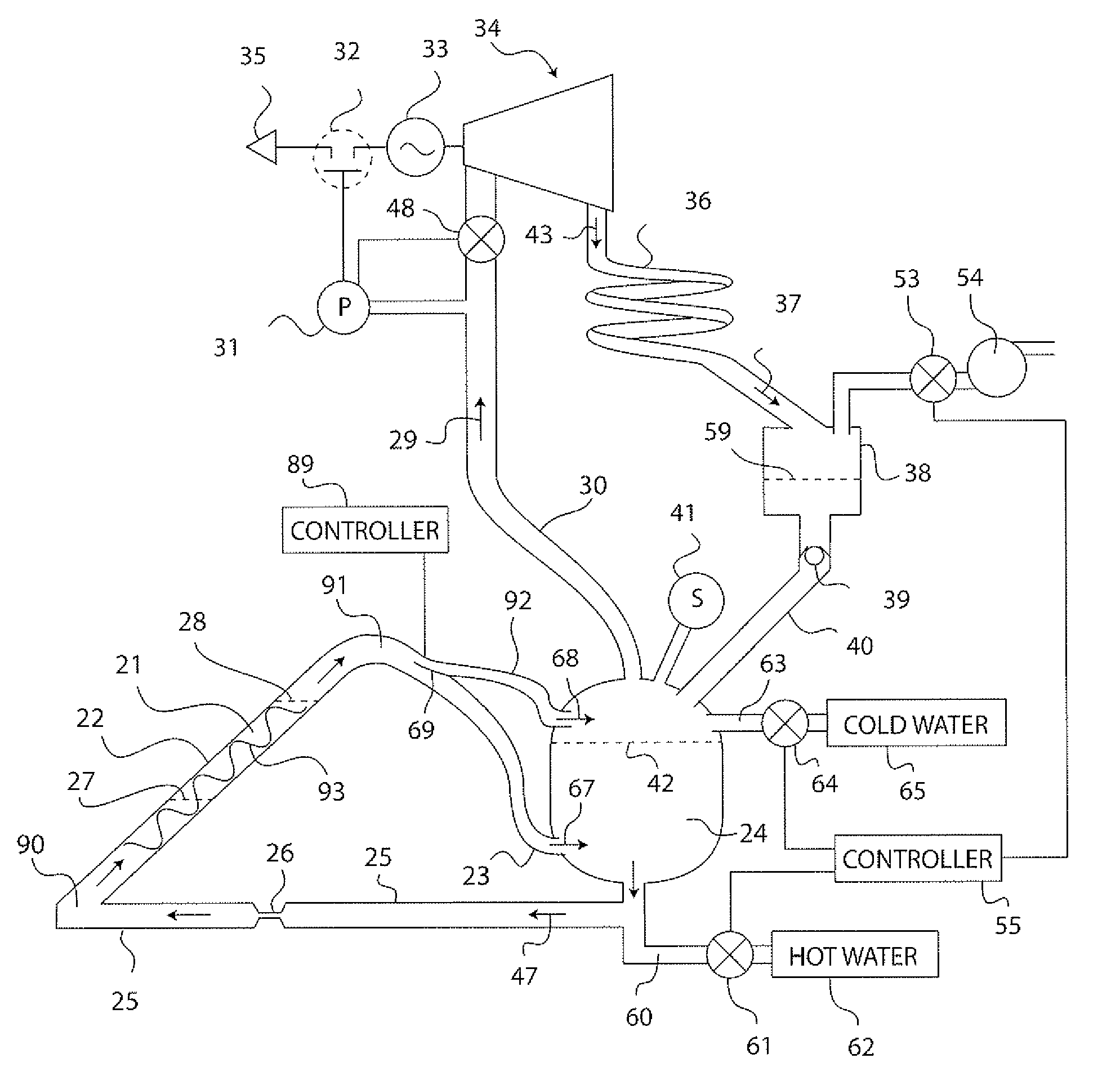

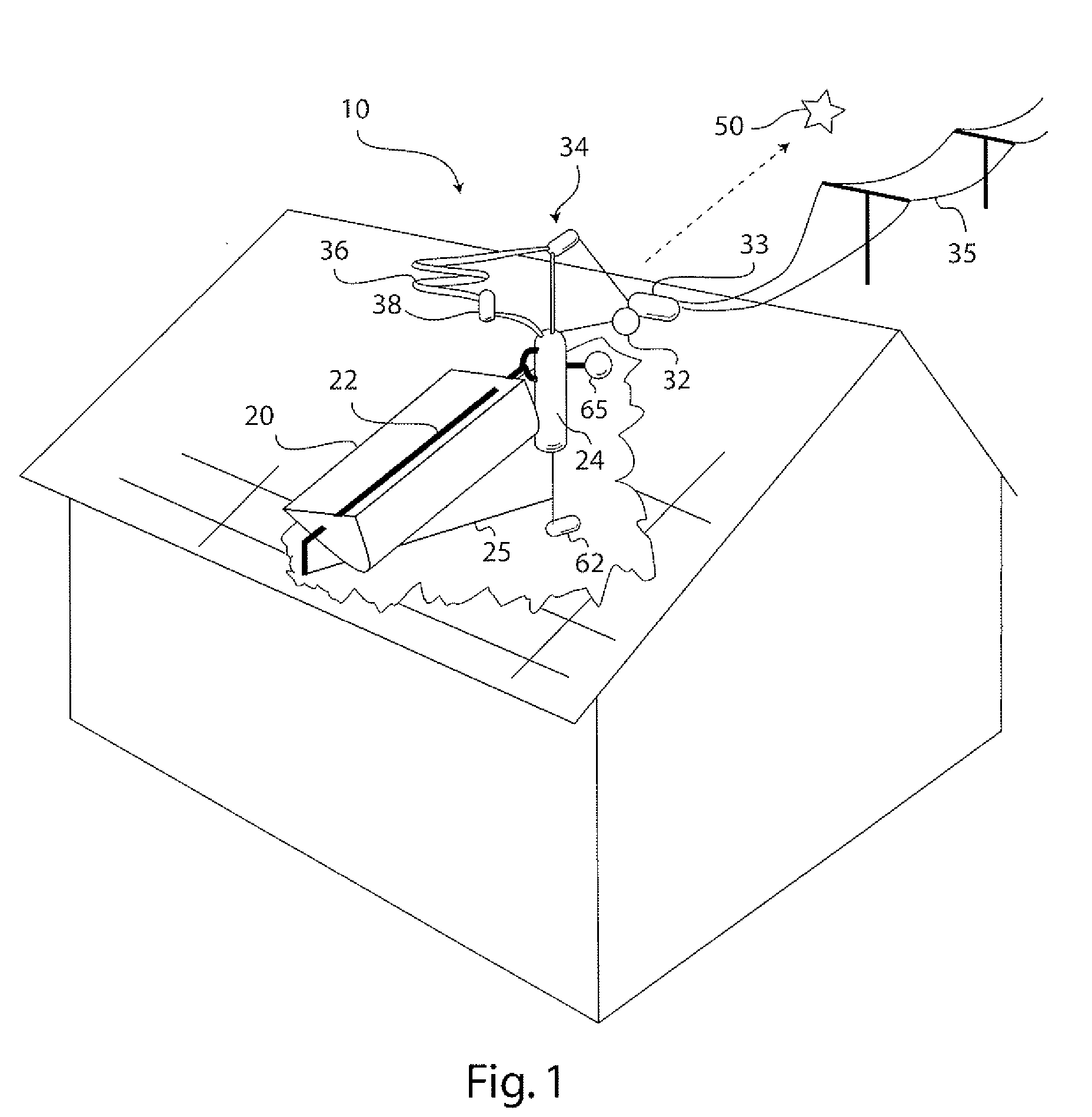

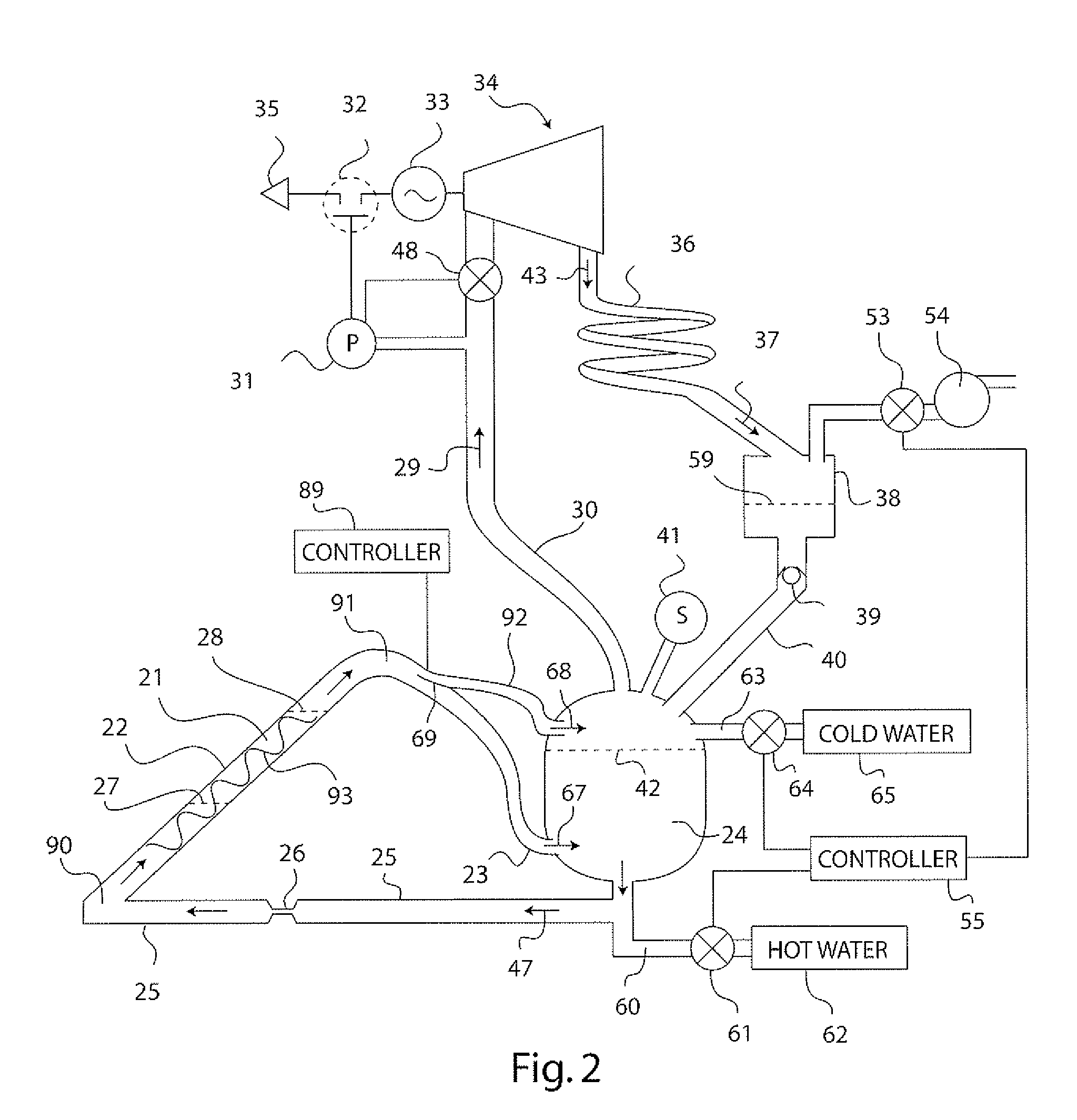

A solar thermal power generator includes an inclined elongated boiler tube positioned in the focus of a solar concentrator for generating steam from water. The boiler tube is connected at one end to receive water from a pressure vessel as well as connected at an opposite end to return steam back to the vessel in a fluidic circuit arrangement that stores energy in the form of heated water in the pressure vessel. An expander, condenser, and reservoir are also connected in series to respectively produce work using the steam passed either directly (above a water line in the vessel) or indirectly (below a water line in the vessel) through the pressure vessel, condense the expanded steam, and collect the condensed water. The reservoir also supplies the collected water back to the pressure vessel at the end of a diurnal cycle when the vessel is sufficiently depressurized, so that the system is reset to repeat the cycle the following day. The circuital arrangement of the boiler tube and the pressure vessel operates to dampen flow instabilities in the boiler tube, damp out the effects of solar transients, and provide thermal energy storage which enables time shifting of power generation to better align with the higher demand for energy during peak energy usage periods.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

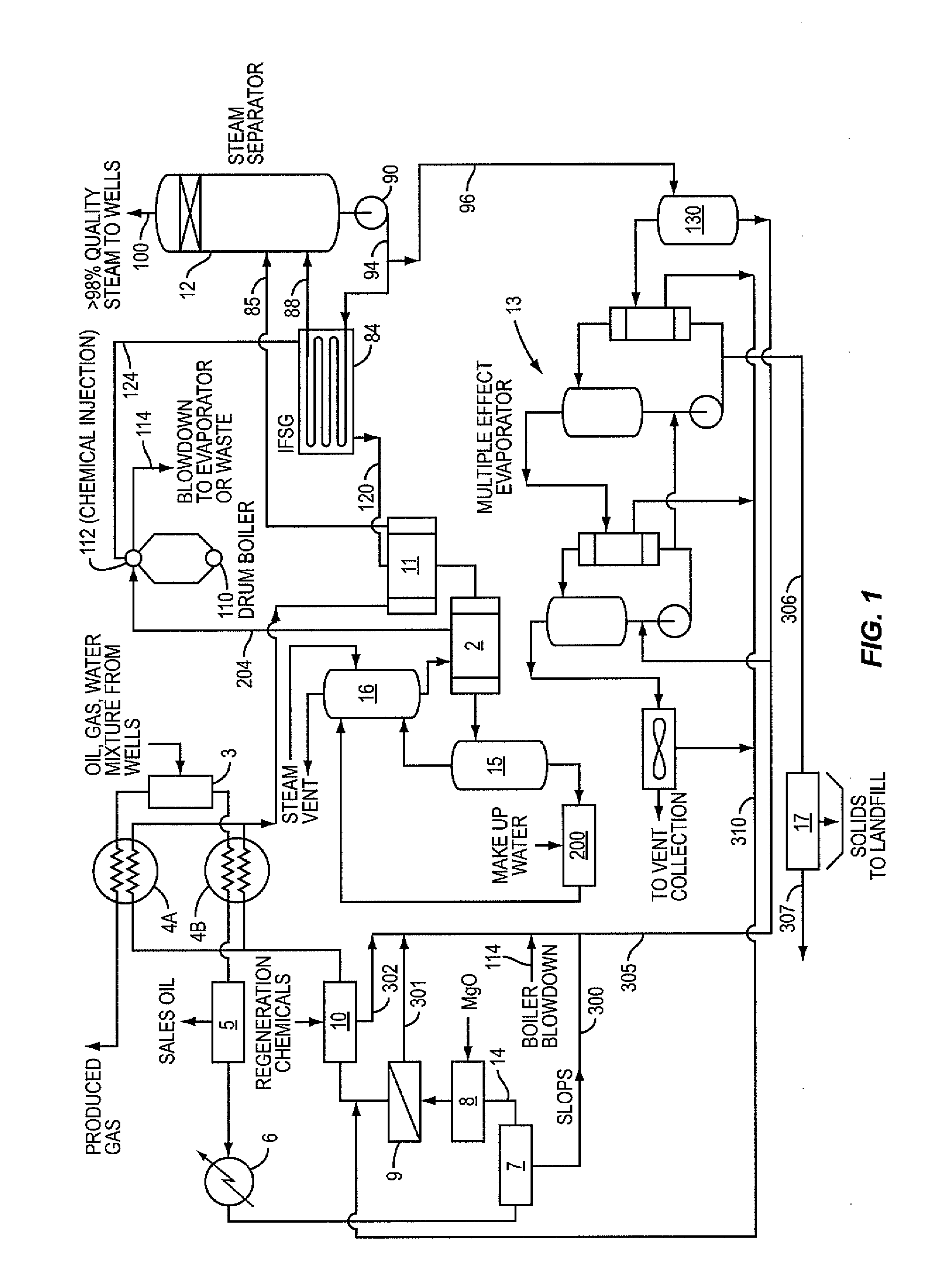

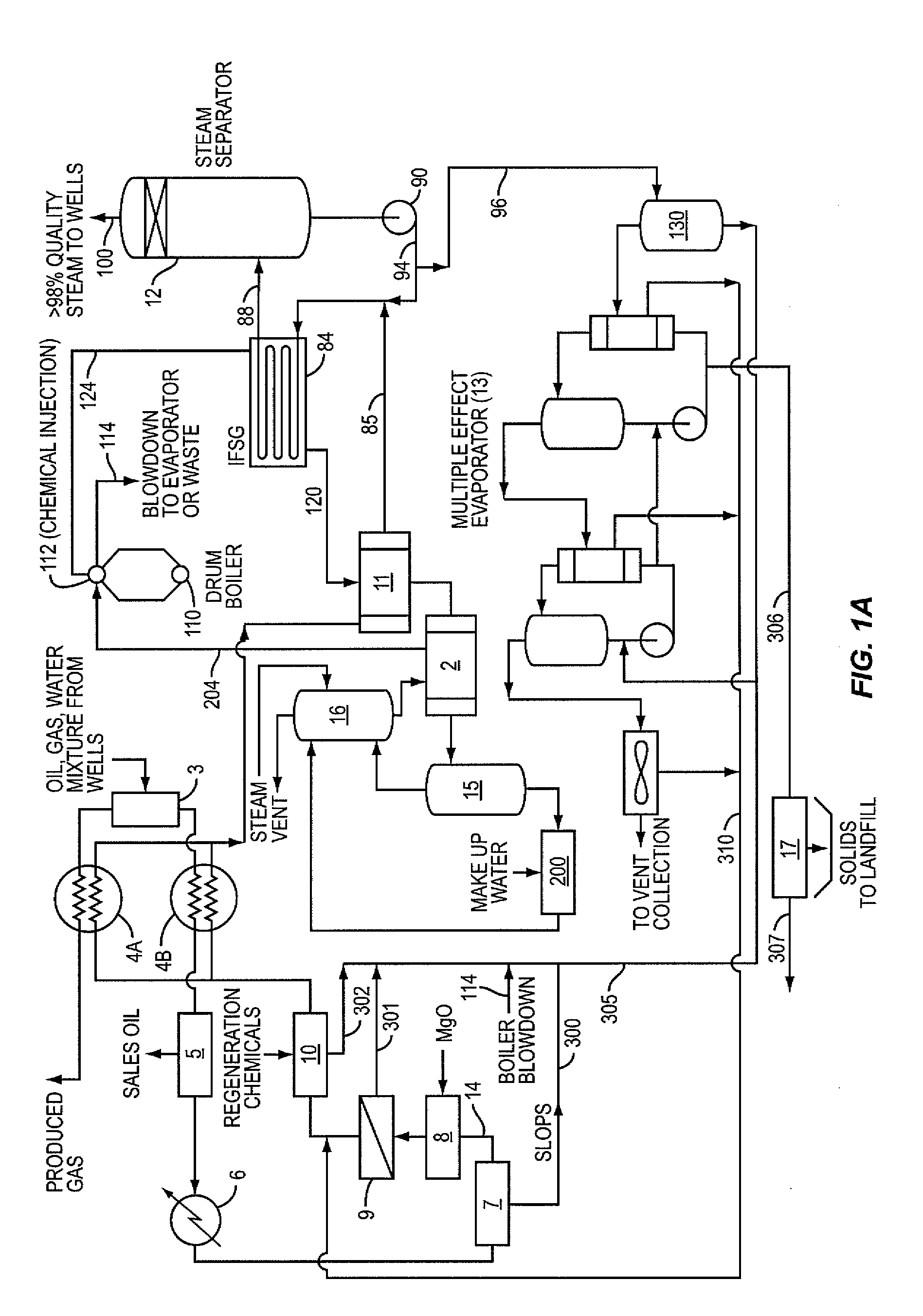

Method and System for Recovering Oil and Generating Steam from Produced Water

Owner:HIPVAP TECH INC

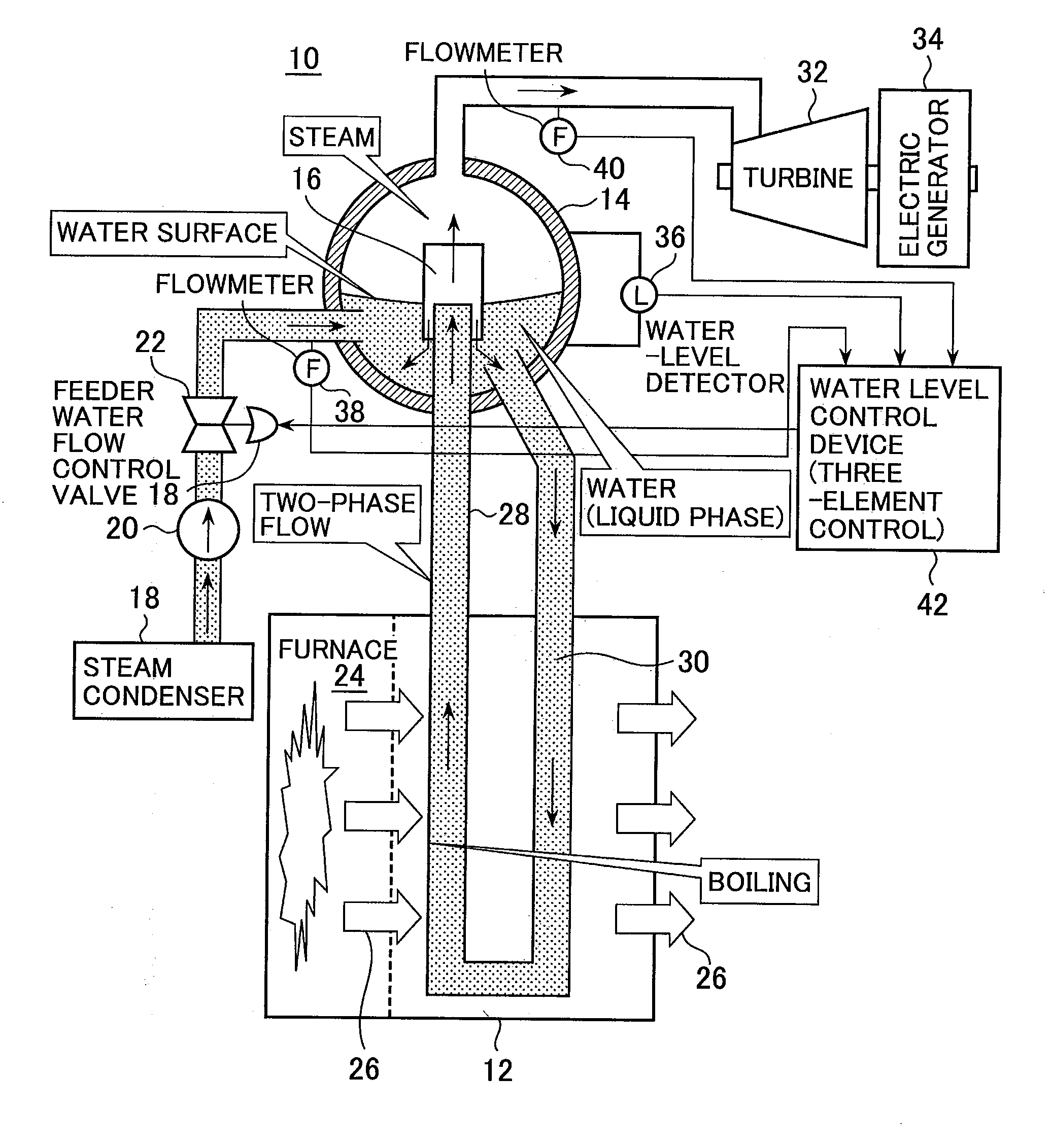

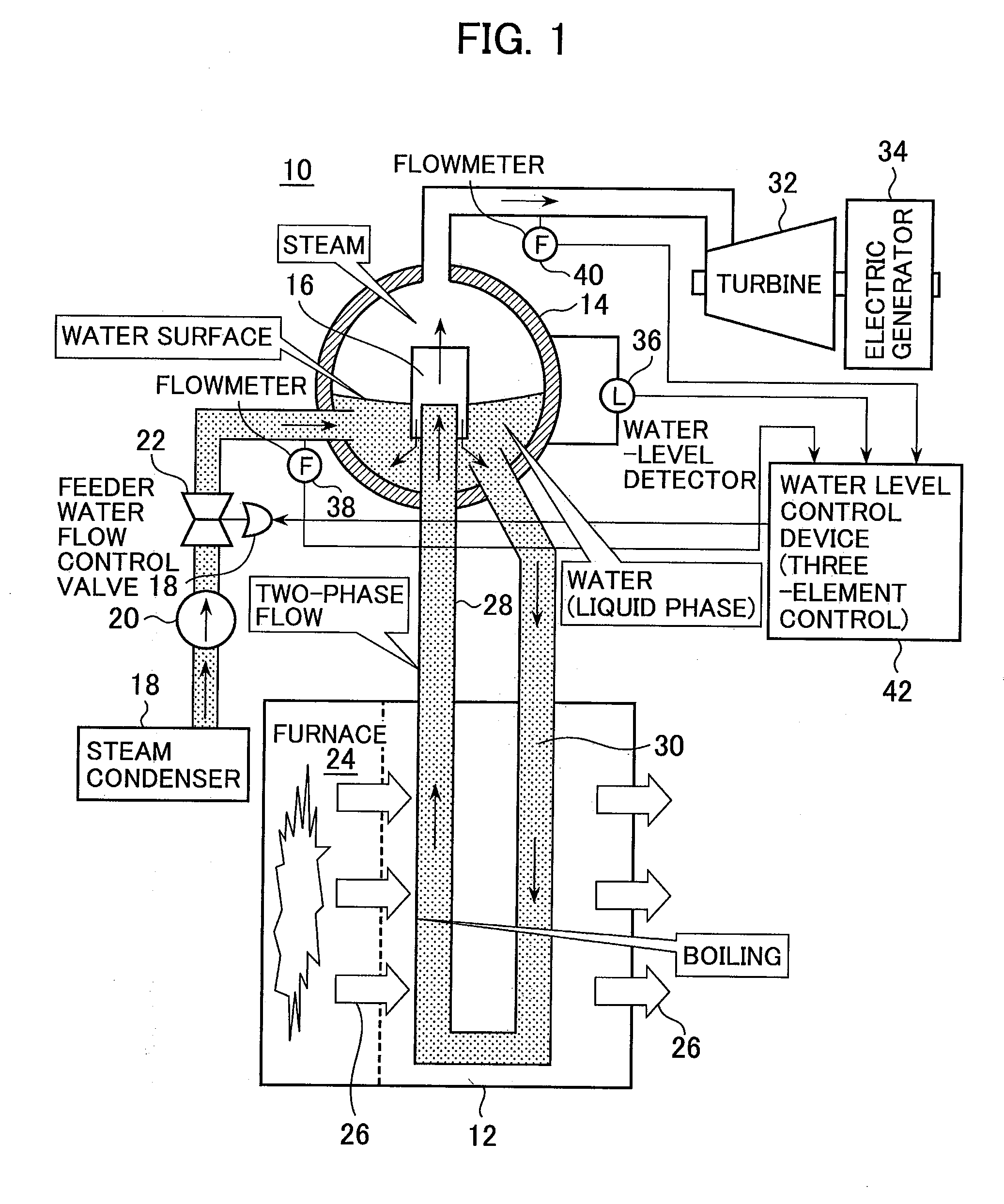

Liquid level control system

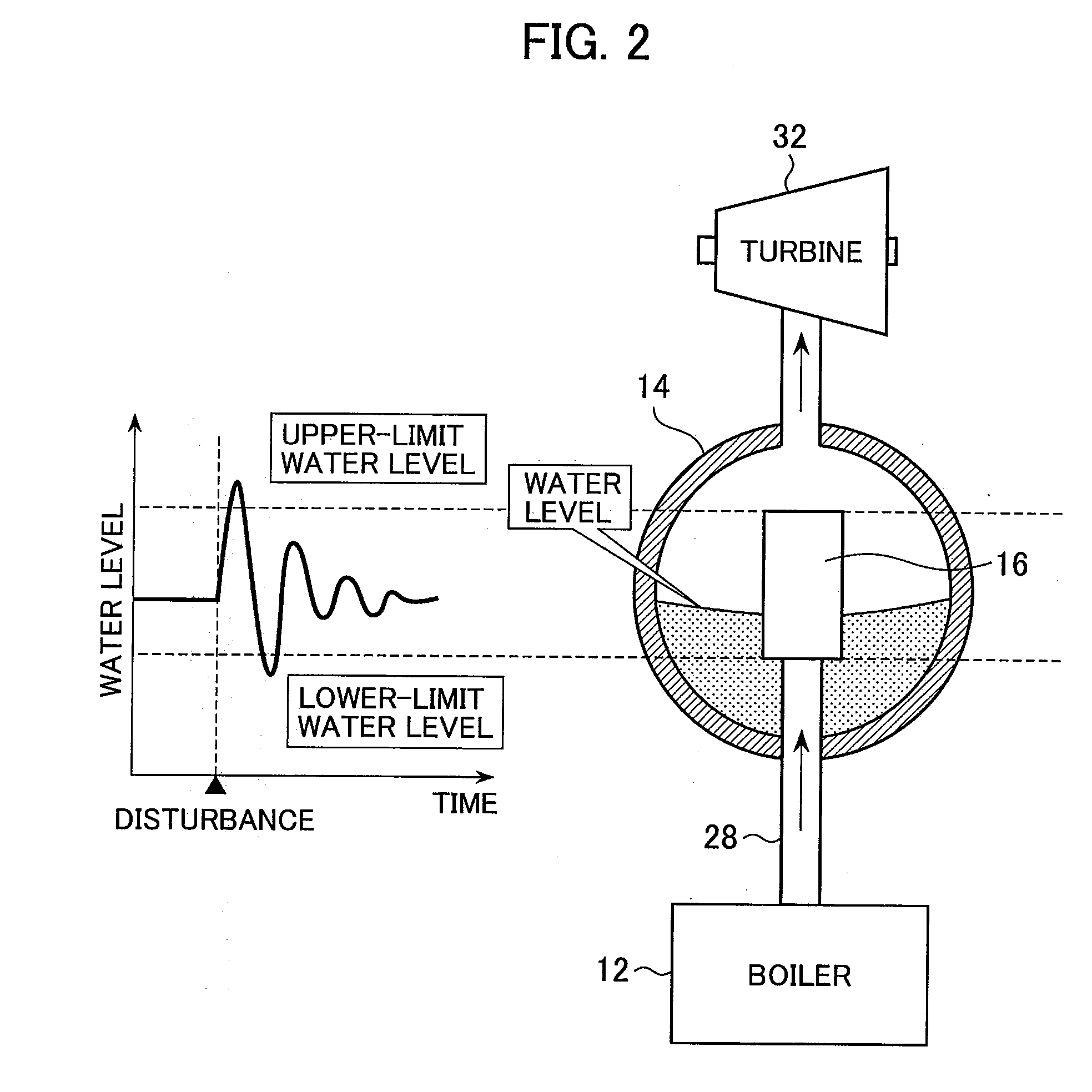

InactiveUS20100126433A1Improve controllabilitySteam separation arrangementsFuel injection apparatusEngineeringControllability

A water level control system for enhancing the controllability of the level of water retained in a steam drum. A water level control section of the system determines the volume of retained water in a steam-water separator from a detected steam flow rate signal by using a function operator and a first order lag circuit, determines a signal representing the mass flow rate balance of water in the steam-water separator by differentiating the volume of retained water with respect to time with a differentiator, generates a compensated signal by adding the signal to the difference between a detected feed water flow rate signal and the detected steam flow rate signal, and properly compensates a valve area demand for a feed water flow control valve.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

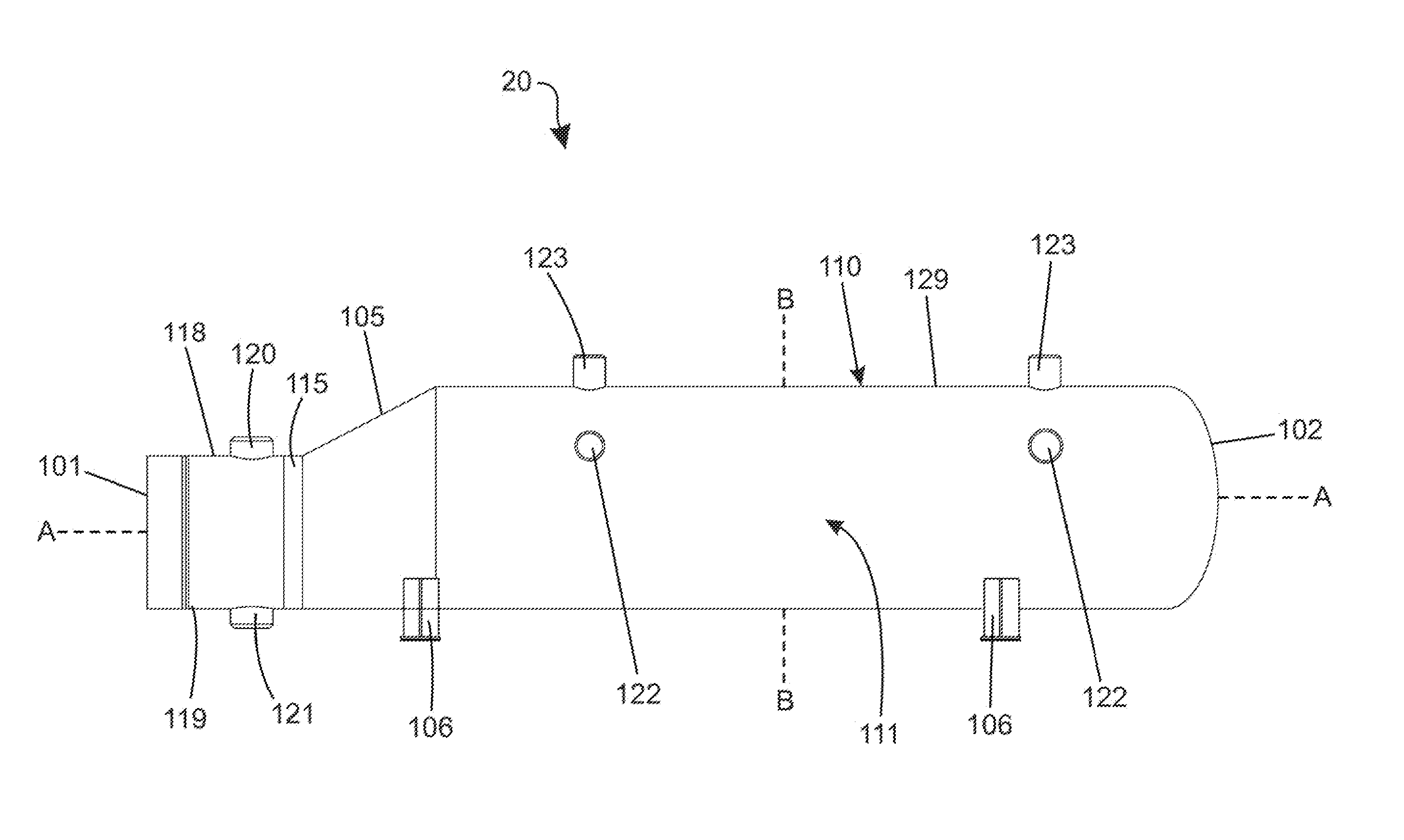

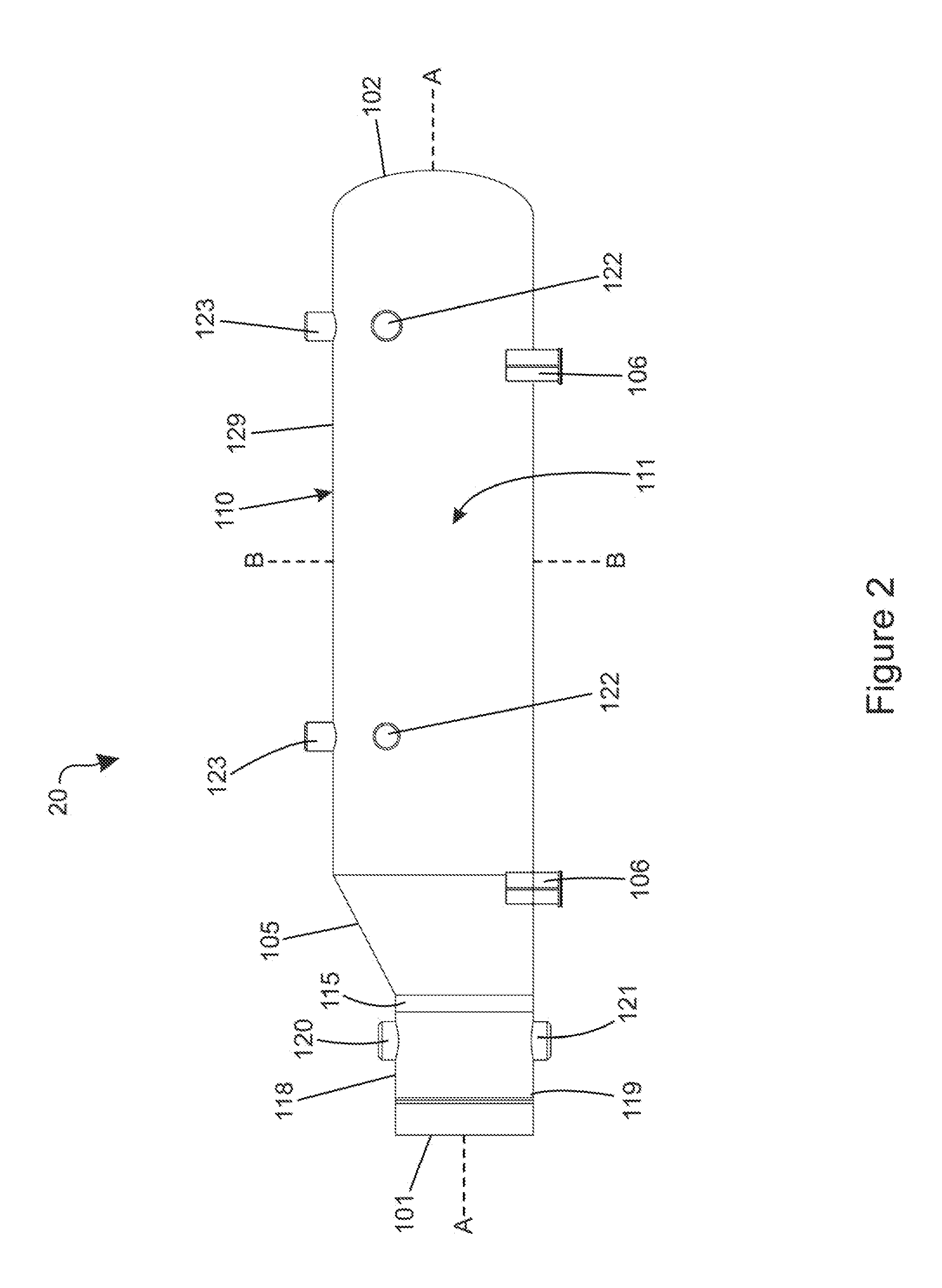

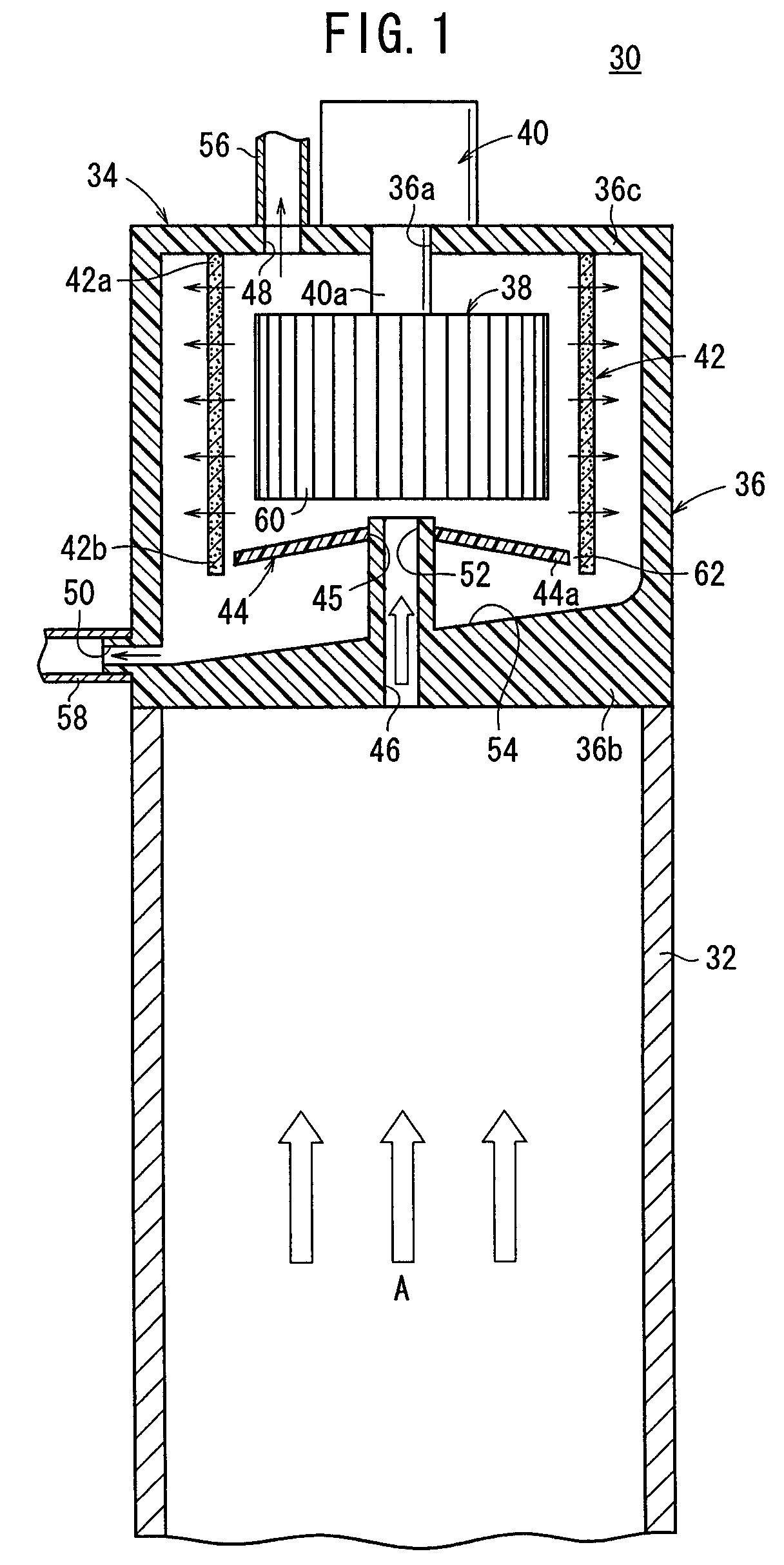

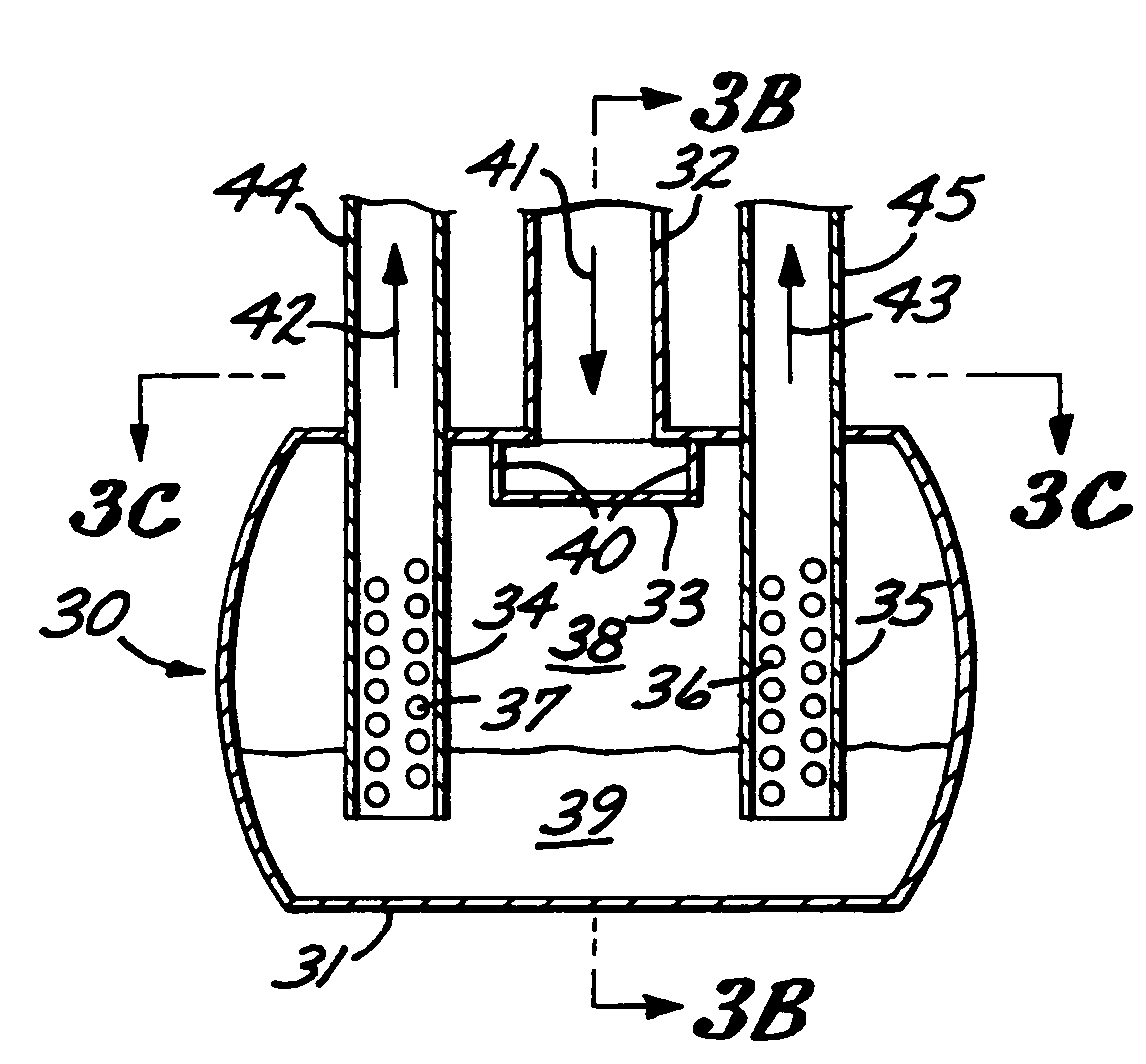

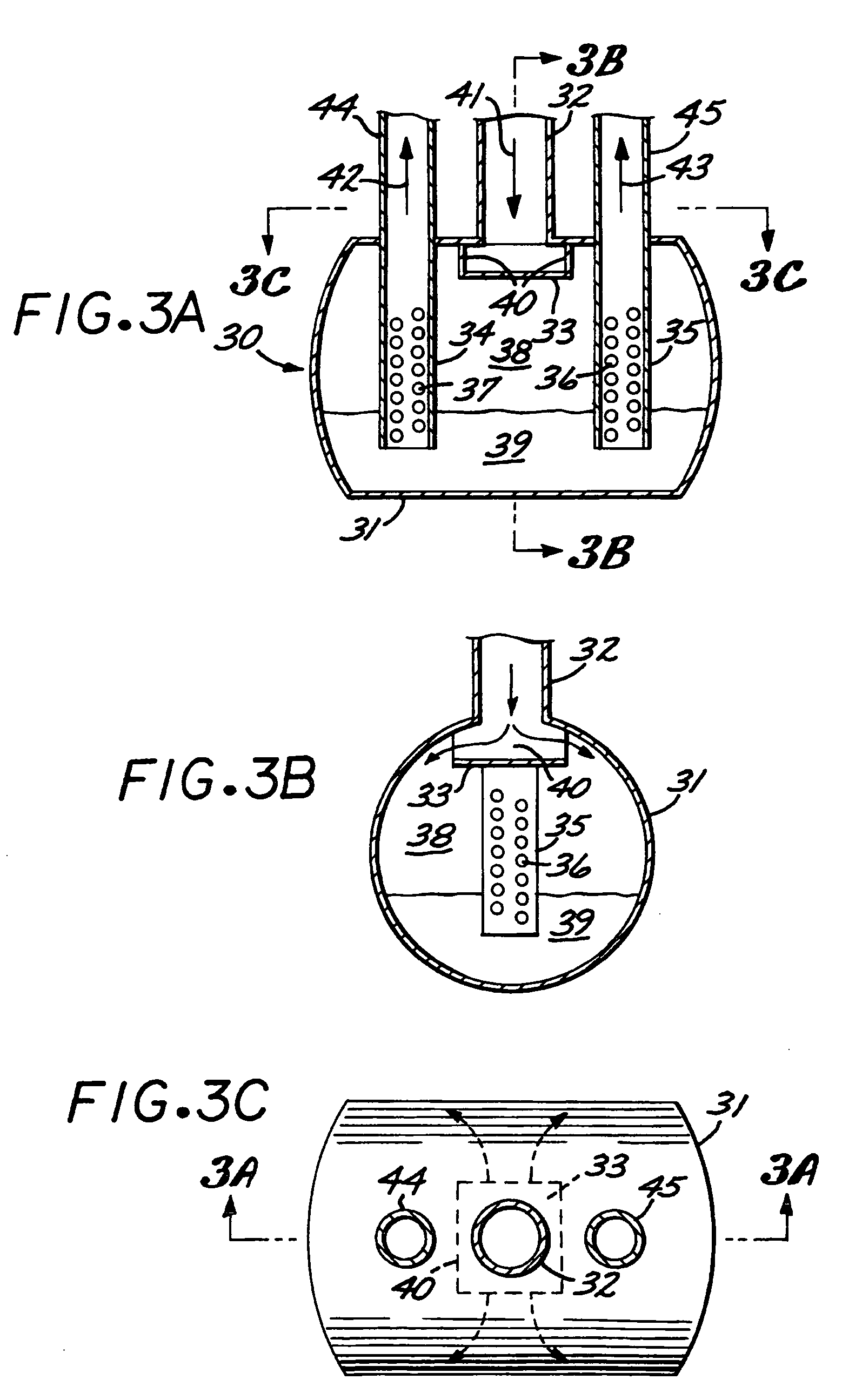

Heat exchanger apparatus for converting a shell-side liquid into a vapor

ActiveUS20100282448A1Eliminate and minimize occurrenceIncrease heat transfer rateThermal insulationSteam separation arrangementsEngineeringMechanical engineering

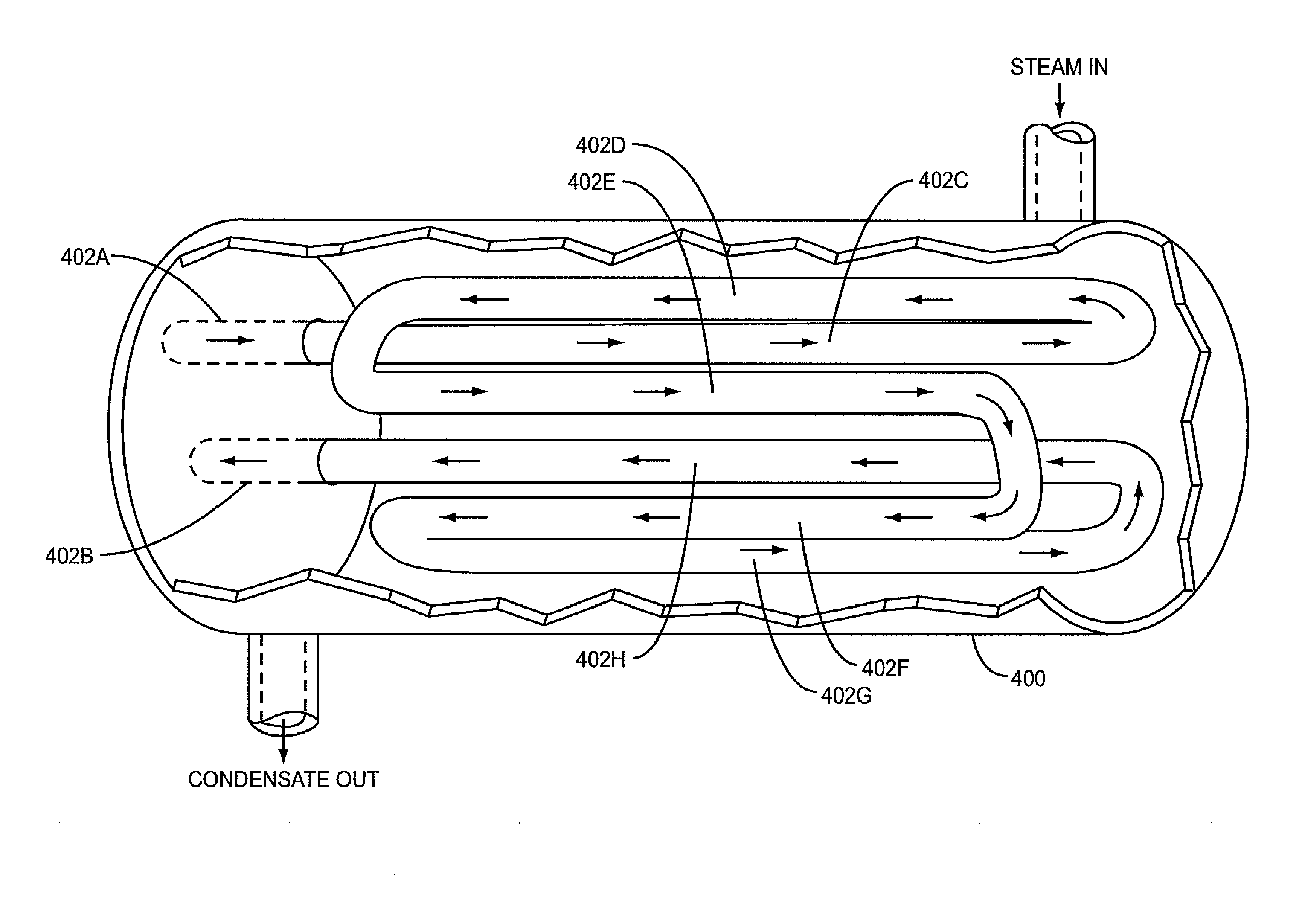

An apparatus for generating steam within a heat exchanger. In one aspect, the invention can be a heat exchanger comprising: a shell having an inner surface forming a cavity, the shell comprising an inlet for introducing the shell-side liquid into the cavity and an outlet for allowing the vapor to exit the cavity; a tube bundle comprising a plurality of tubes for carrying a tube-side fluid located in the cavity and having a longitudinal axis; a shroud circumferentially surrounding the tube bundle and positioned between the tube bundle and the inner surface of the shell so that an annular space exists between the shroud and the inner surface; an opening in a bottom portion of the shroud that forms a passageway between the annular space and the tube bundle; and an opening in a top portion of the shroud that forms a passageway between the annular space and the tube bundle.

Owner:HOLTEC INT

Heat exchanger having a counterflow evaporator

An evaporator including a lower drum, an upper drum, and at least one tube extending between the lower drum and the upper drum. The plurality of tubes have fluid passageways therein extending from the lower drum to the upper drum. A duct is provided having a heating gas passageway provided therein. The at least one tube extends through the heating gas passageway. The fluid passageways define an overall flow path from the lower drum to the upper drum extending in a direction substantially counter-current to an overall flow path defined by the heating gas passageway extending from a gas inlet of the heating gas passageway to a gas outlet thereof.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

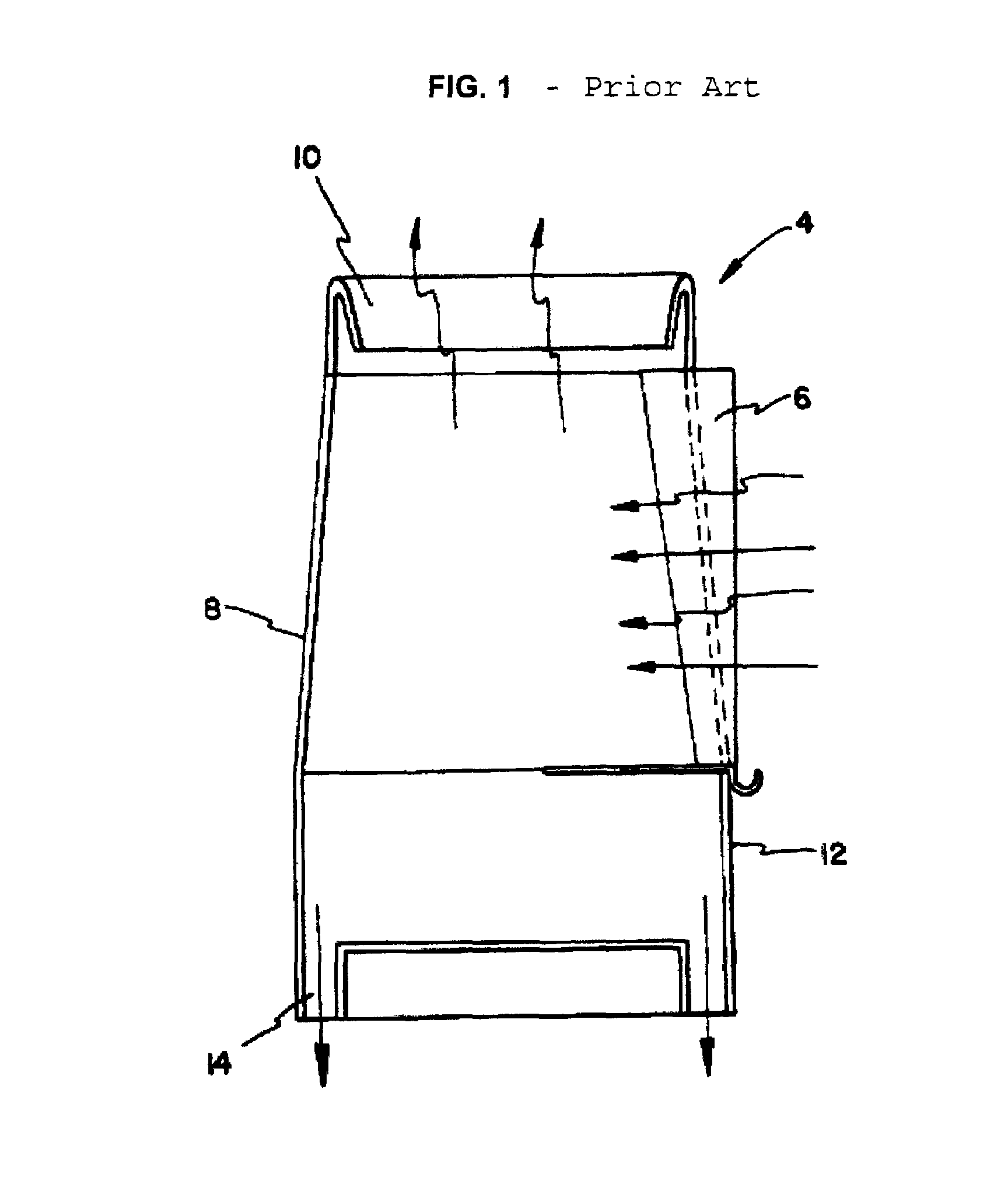

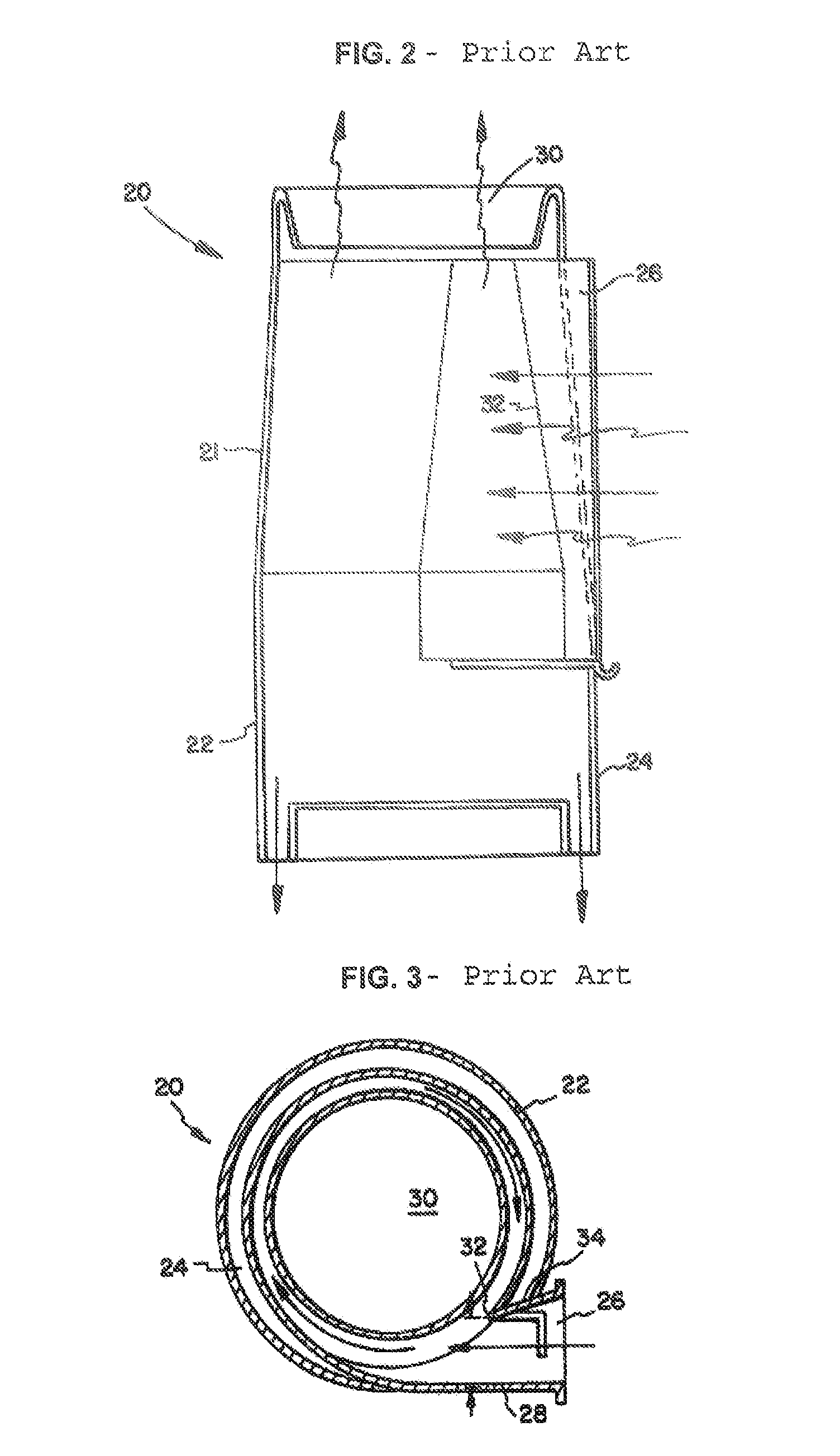

Steam/water conical cyclone separator

ActiveUS7637699B2Improve the cyclone separatorSmall diameterLiquid degasificationReversed direction vortexCycloneEngineering

A conical cyclone separator for separating steam from water in a steam / water mixture supplied to a steam drum of a boiler. A widened tangential inlet extends the axial length of the conical portion of the separator, increasing the width of the inlet while causing no derogation in steaming capacity and substantially lowering pressure drop. The inlet design of this separator is compatible with smaller diameter steam drums unable to currently utilize conventional separators.

Owner:THE BABCOCK & WILCOX CO

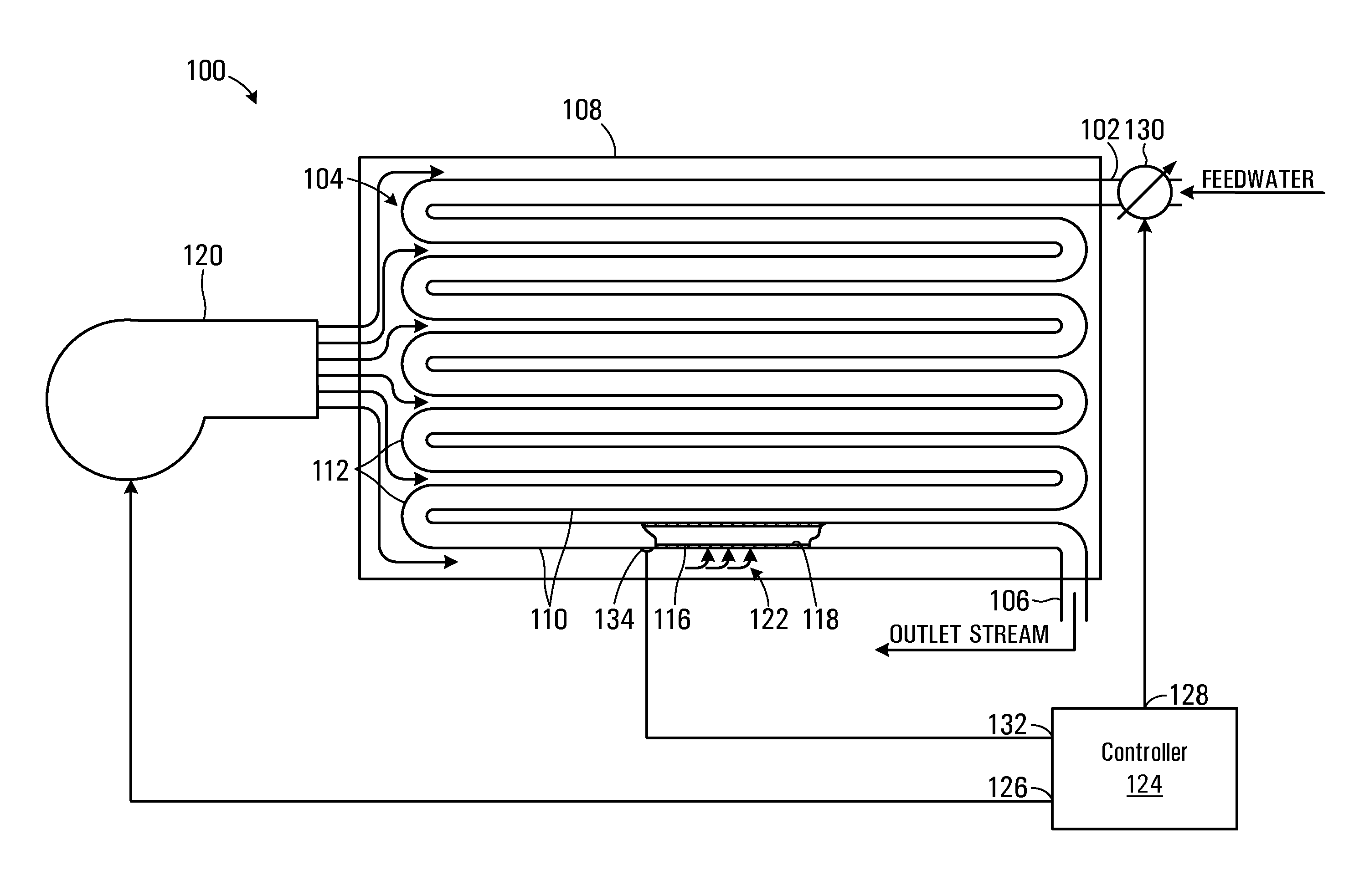

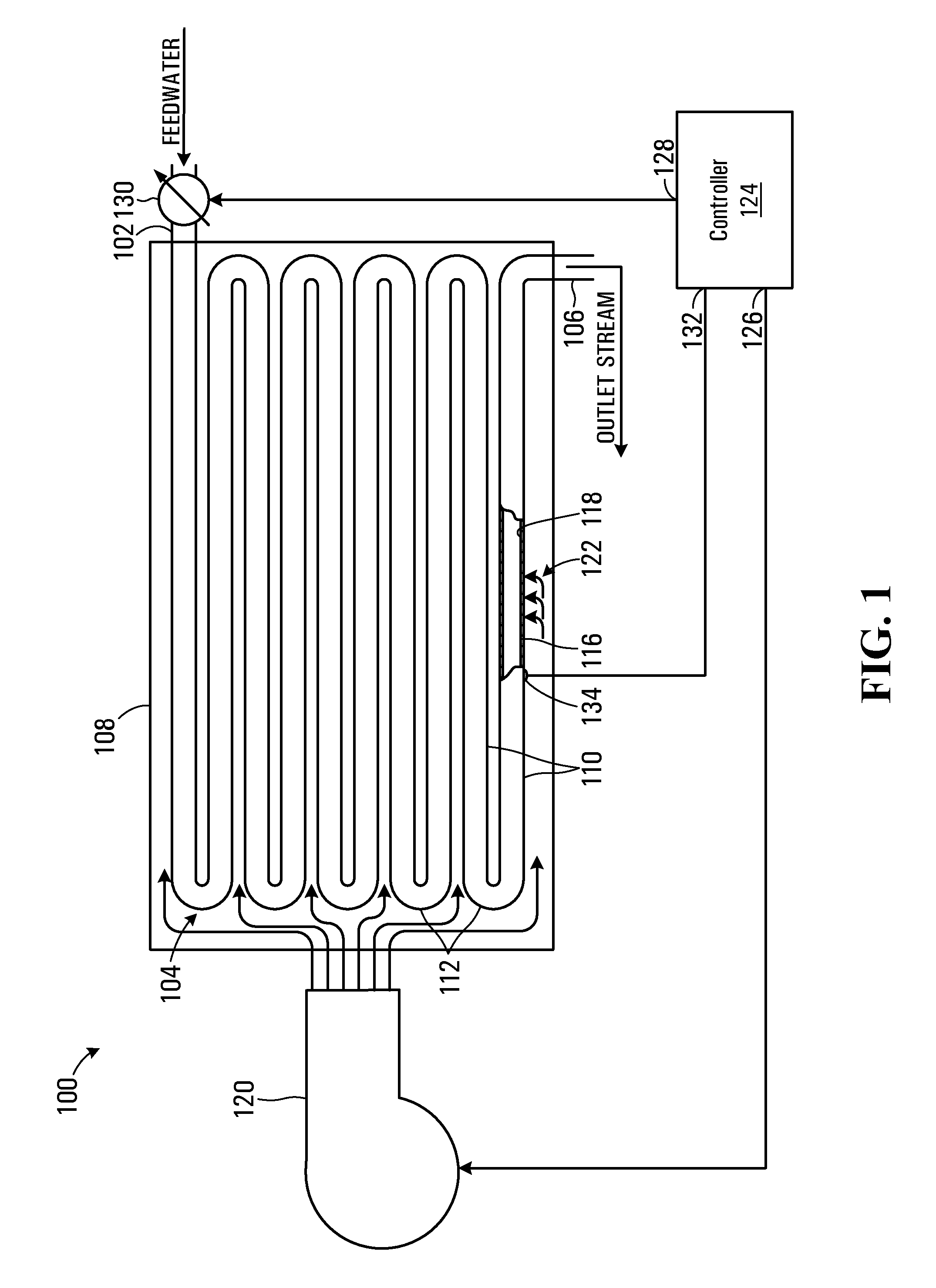

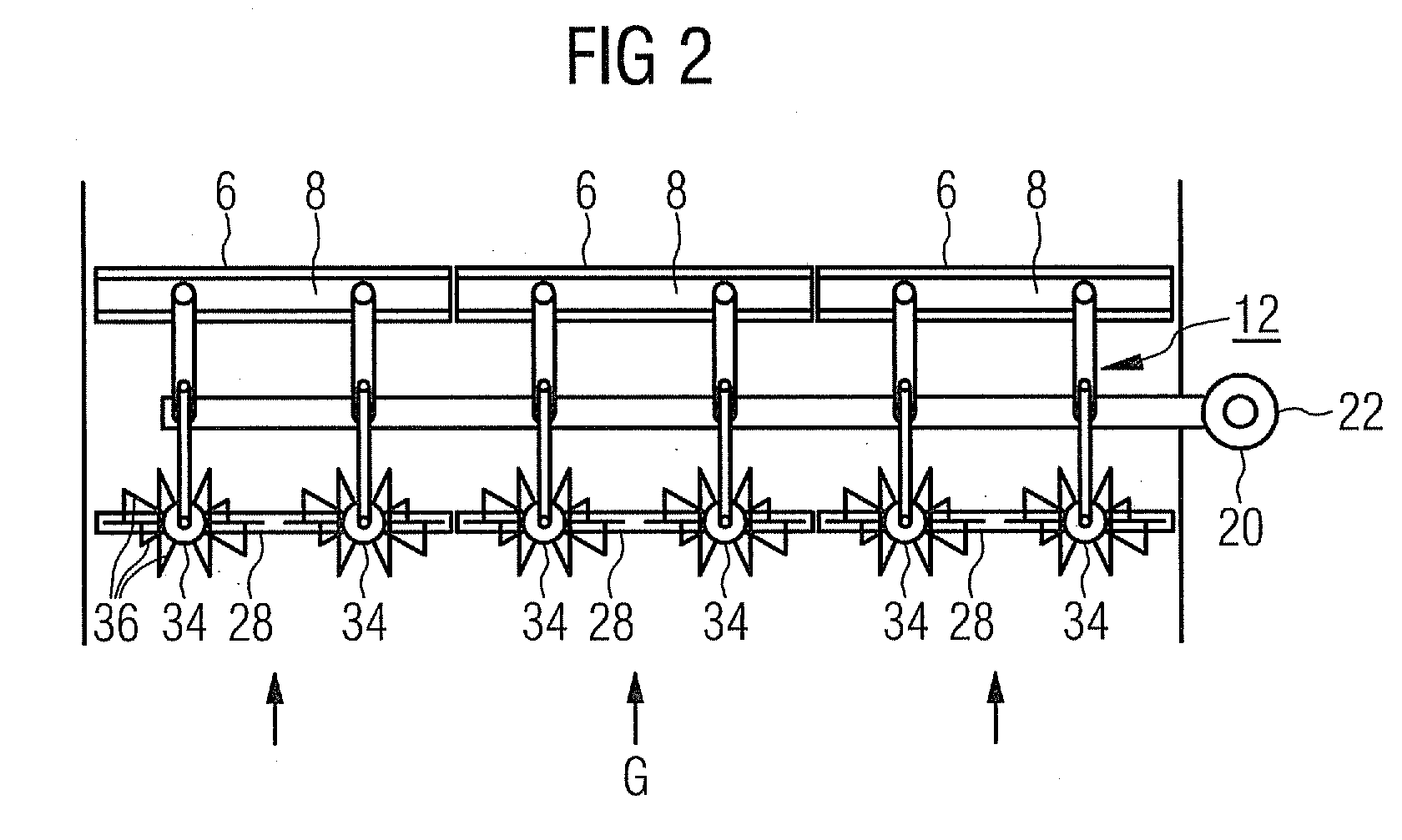

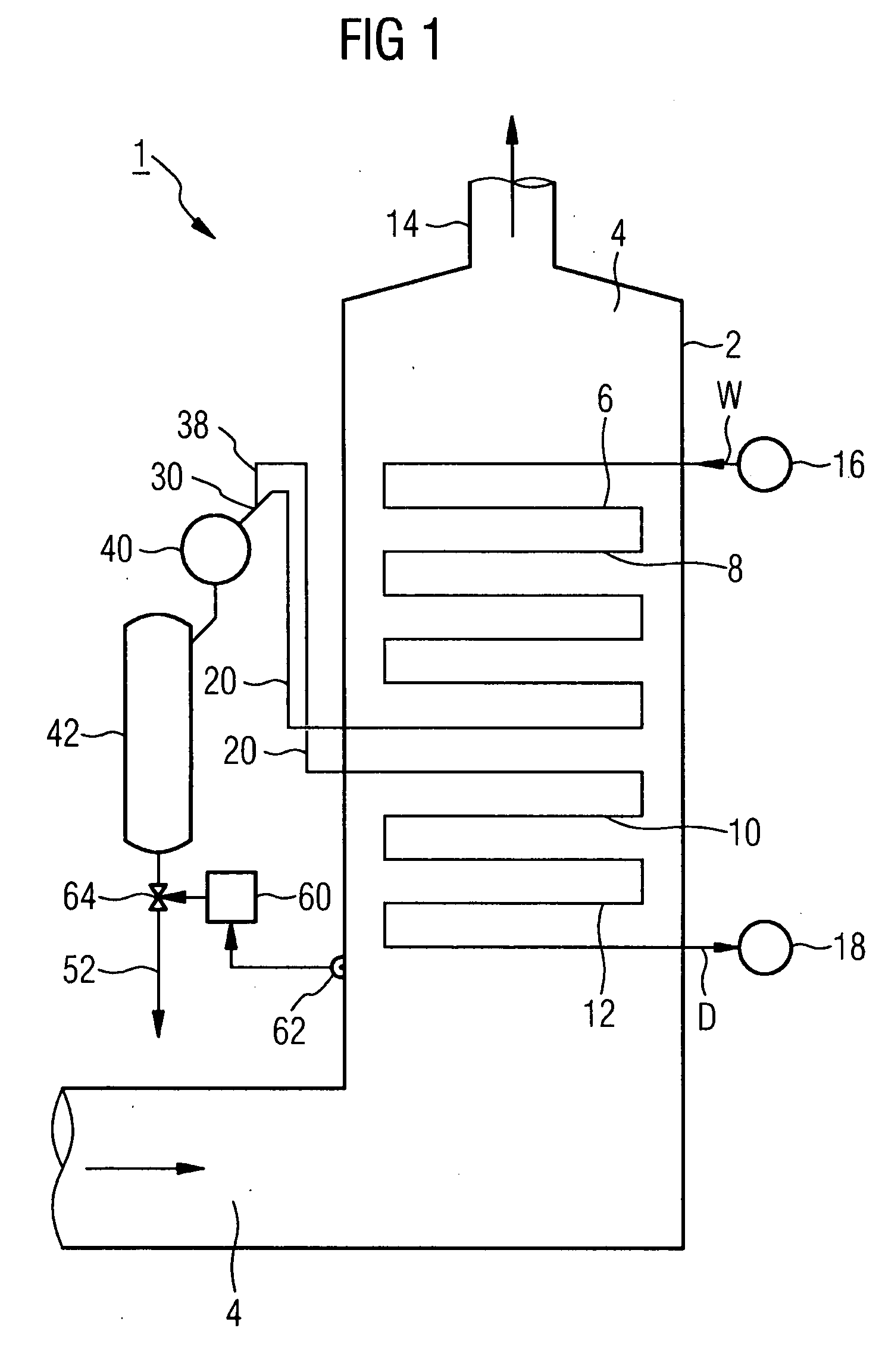

Steam generator and method for generating steam

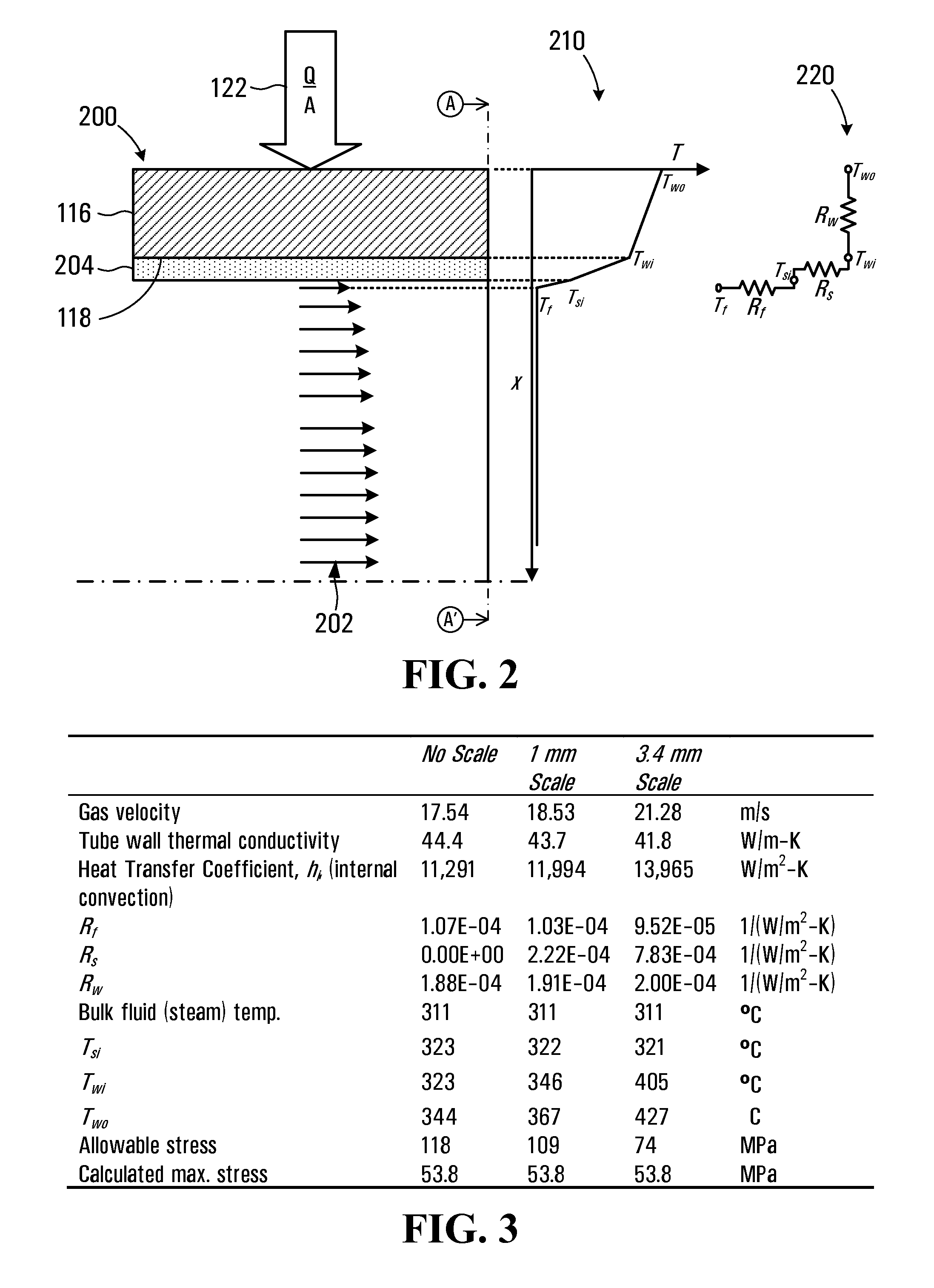

ActiveUS20130161009A1Improve cooling effectReduce problem sizeBoiler water tubesBoiler cleaning apparatusHeat fluxEvaporation

A method for generating steam from a feedwater inlet stream including impurities is disclosed. The method involves receiving the feedwater inlet stream at an inlet of a steam generator and causing the feedwater stream to flow through a tubing circuit to an outlet of the tubing circuit, the tubing circuit having a substantially un-rifled bore defined by a metal wall. The method also involves delivering a heat flux to the feedwater stream through the metal wall of the tubing circuit to generate steam by causing evaporation of feedwater within the tubing circuit, and controlling at least one of a flow rate of the feedwater stream and the heat flux to cause generation of an outlet stream at the outlet includes a steam portion and liquid phase portion, the steam portion being greater than about 80% of the outlet stream by mass. The steam portion provides sufficient cooling of the metal wall to maintain a wall temperature at less than a threshold temperature.

Owner:FCCL PARTNERSHIP

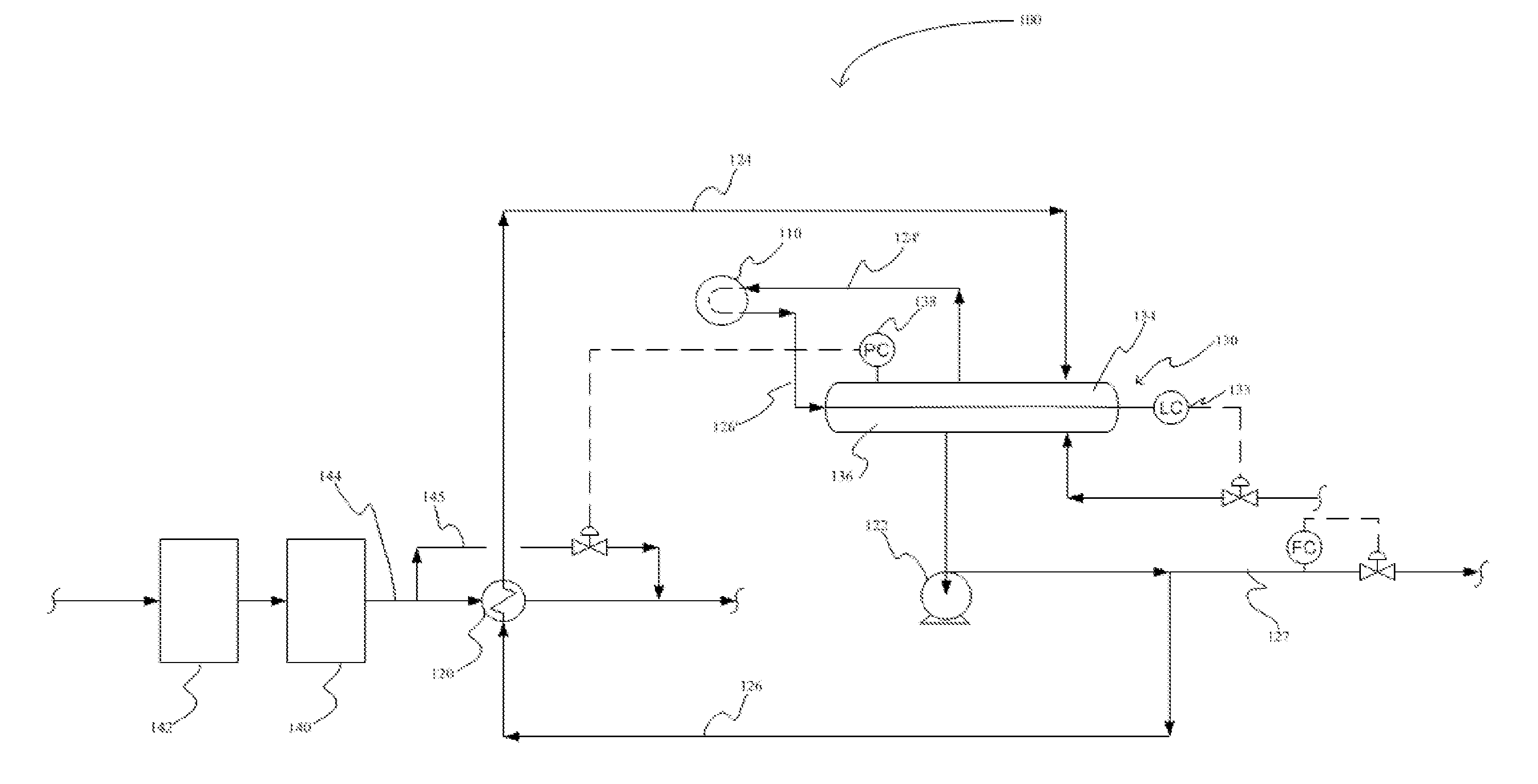

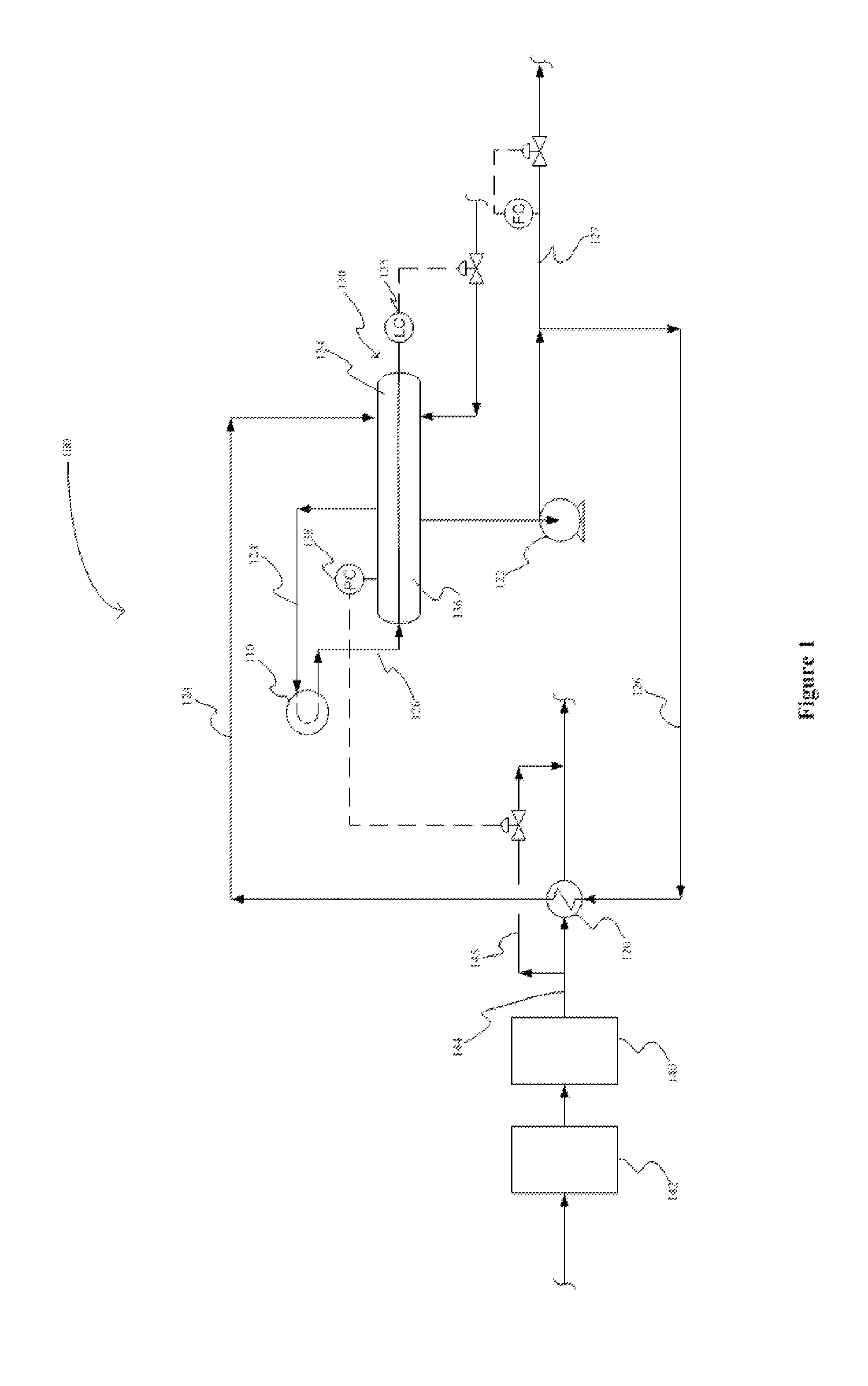

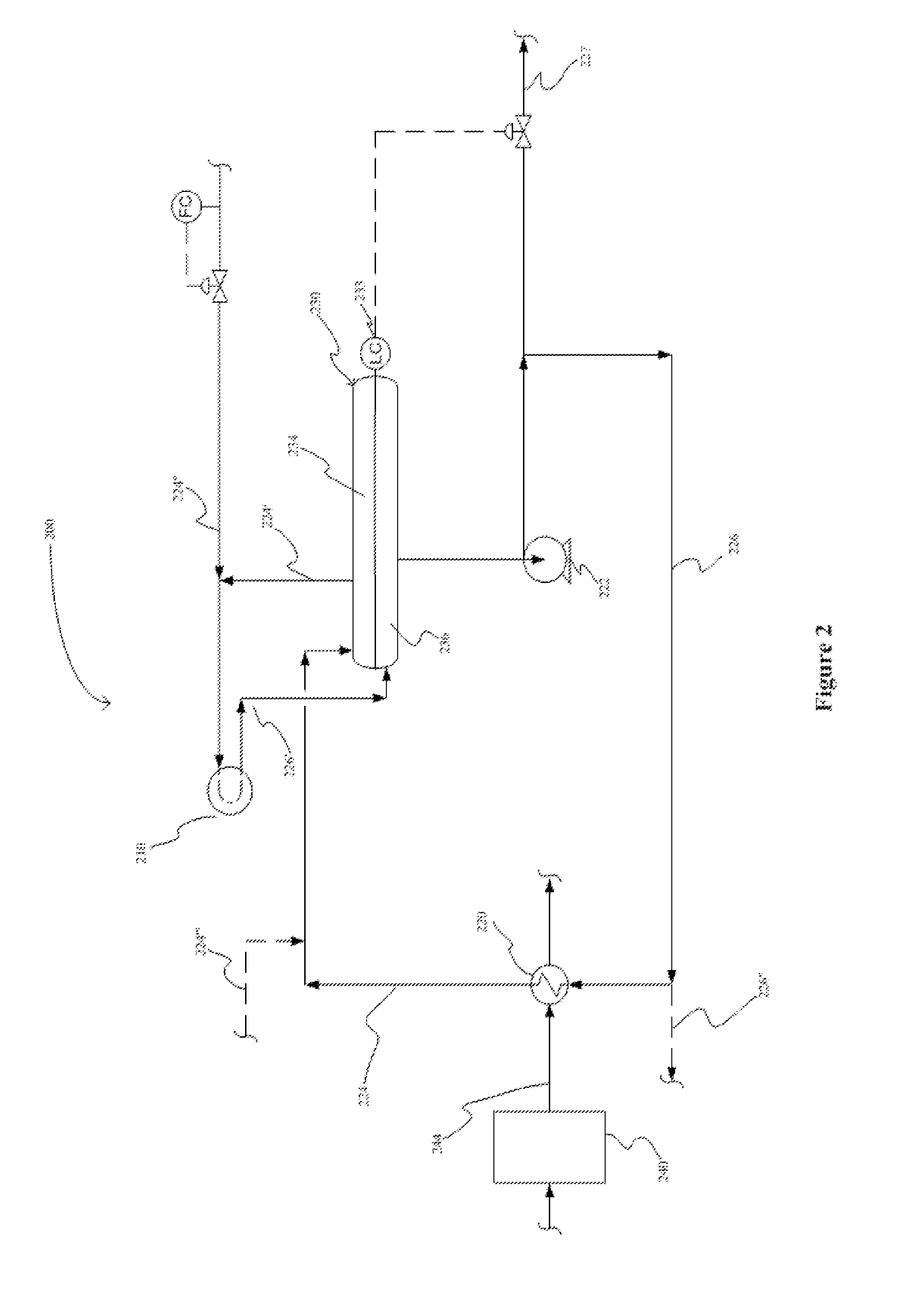

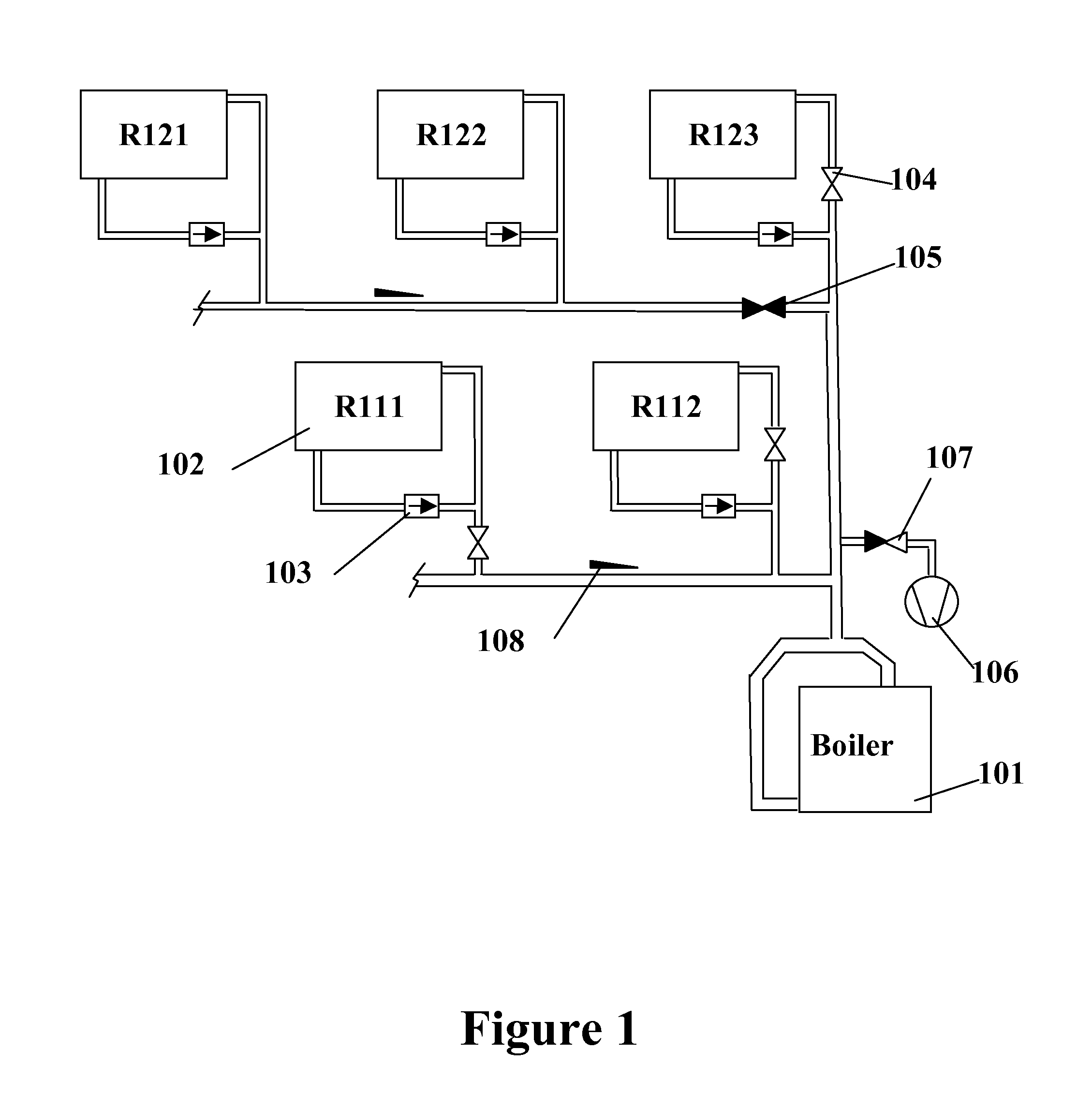

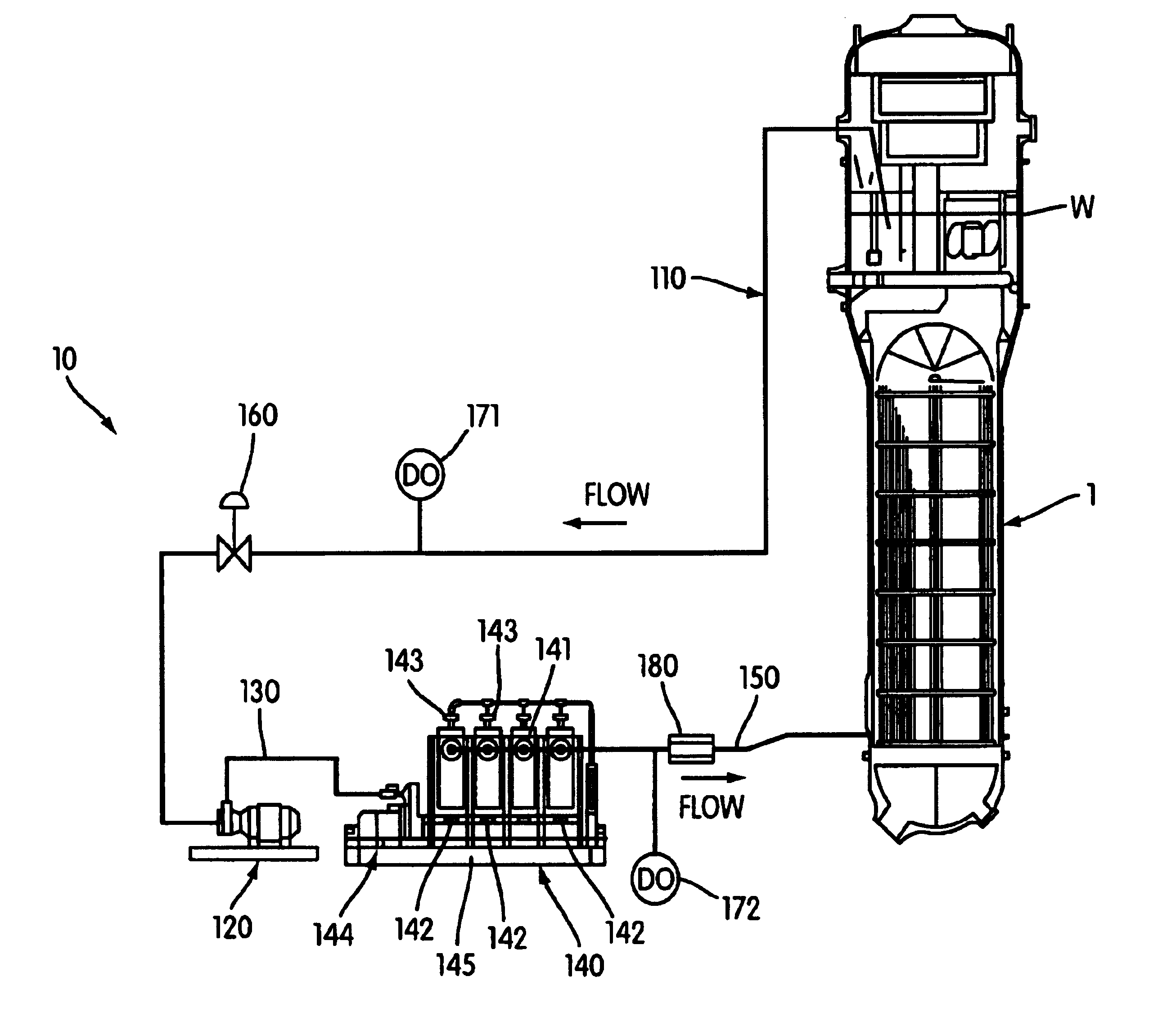

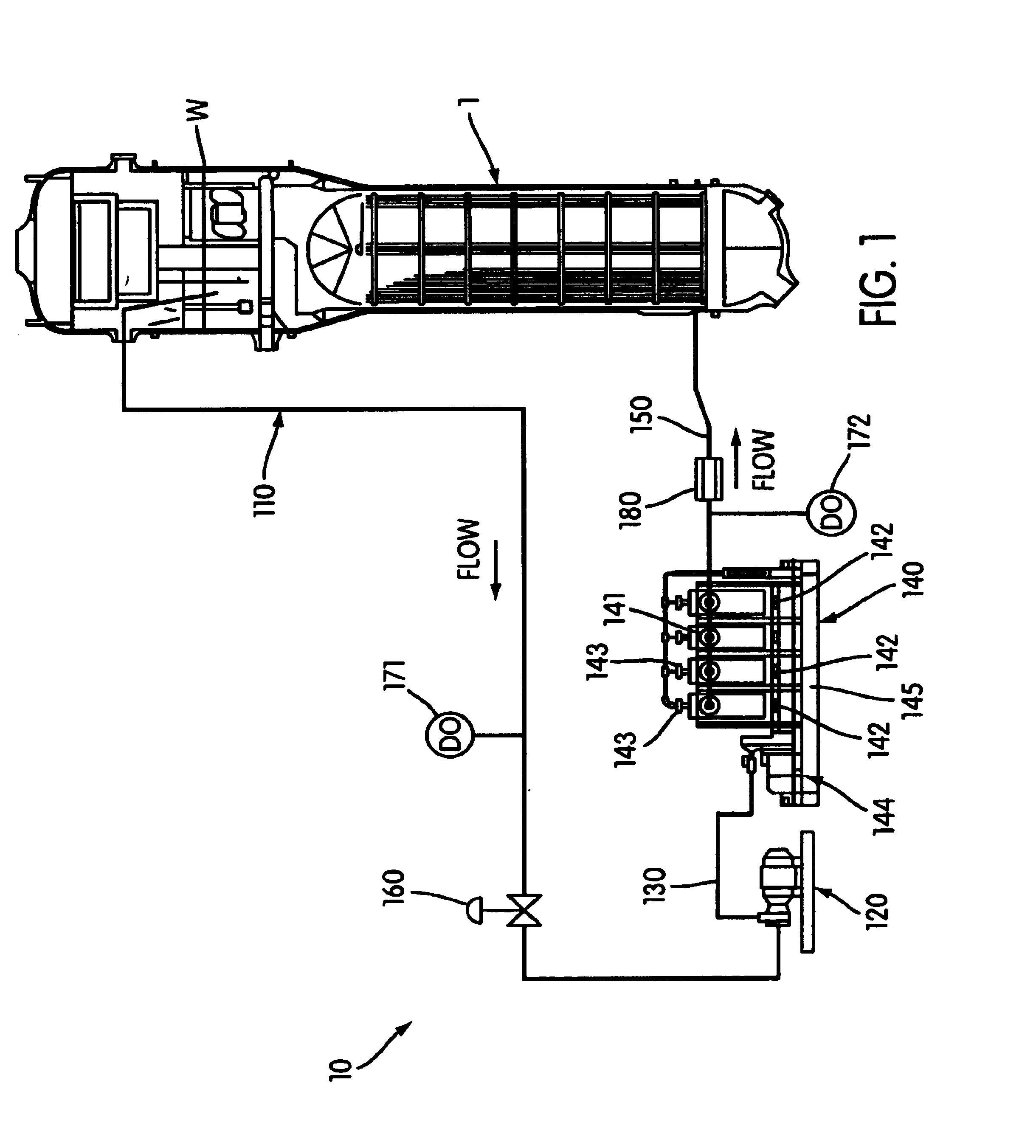

Method and apparatus for steam generation

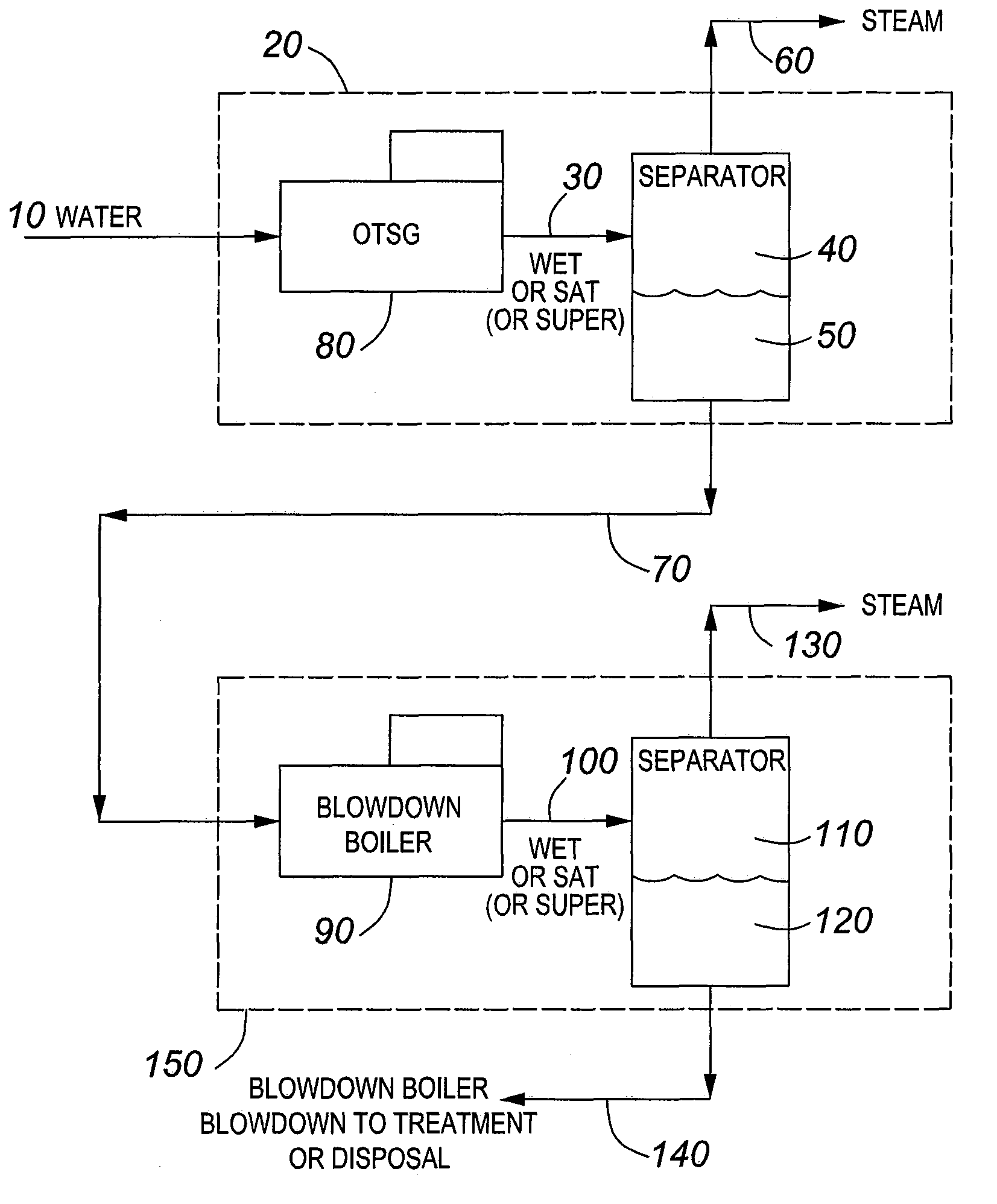

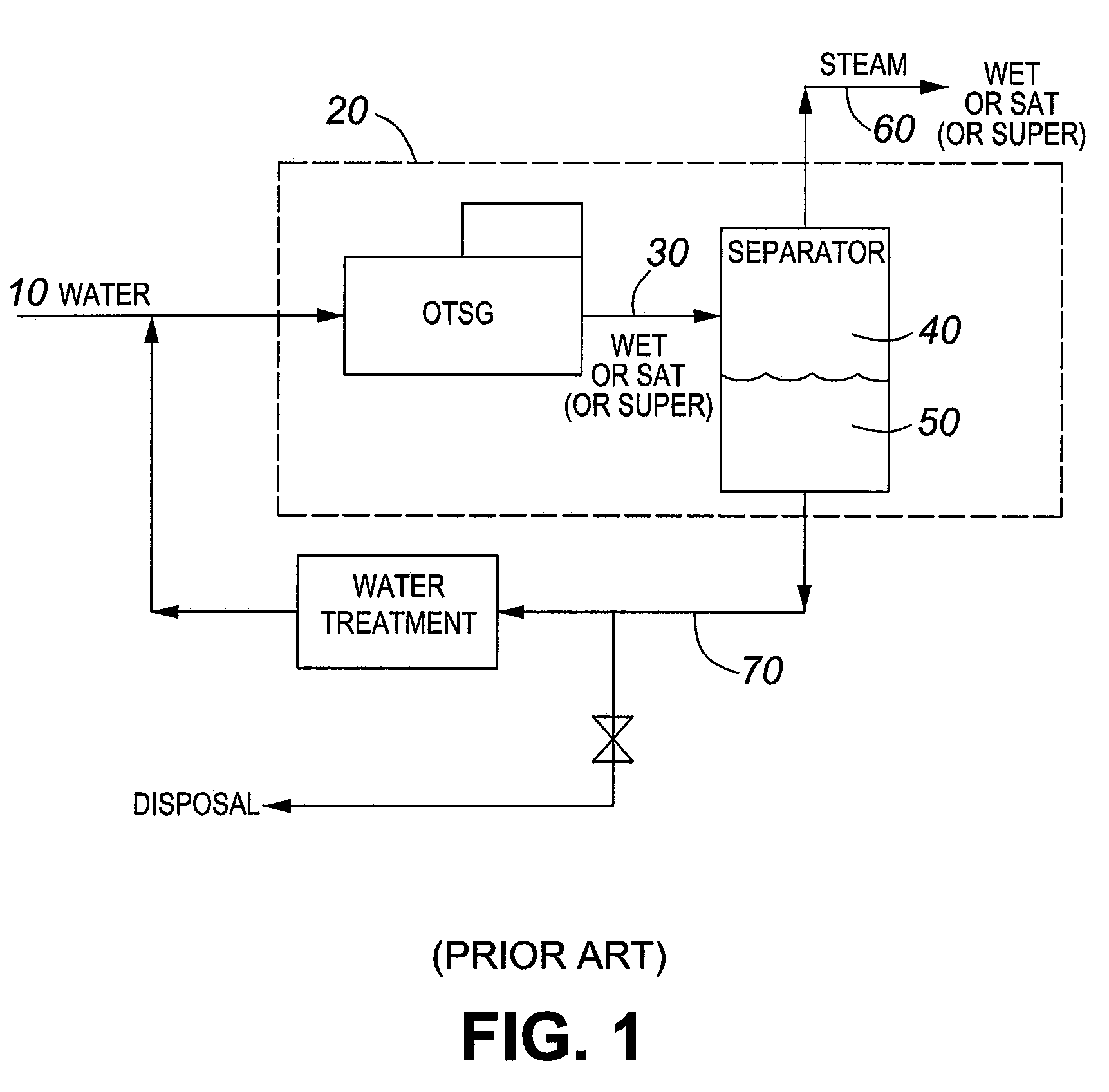

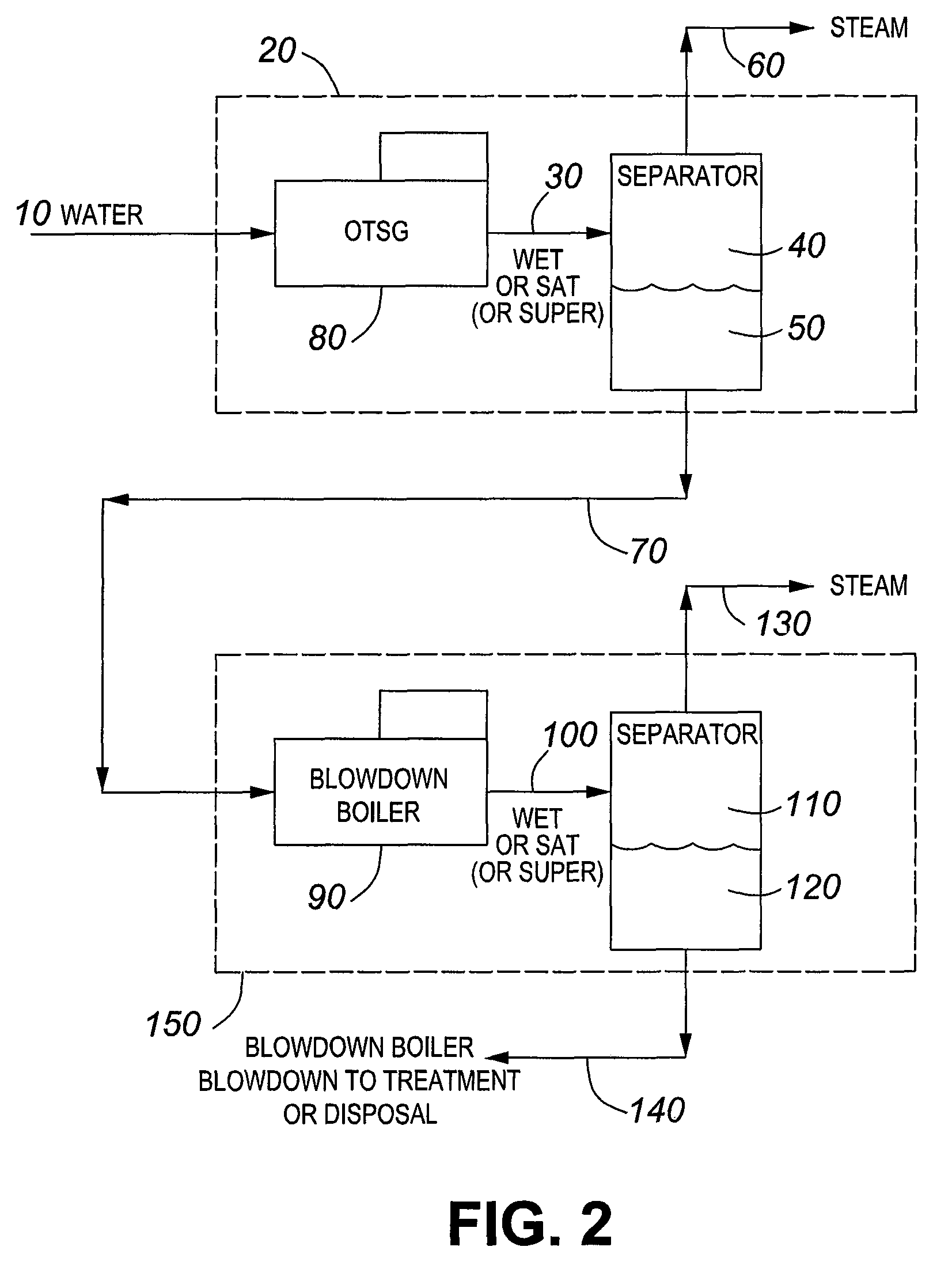

ActiveUS8166925B2Reduce in quantityIncrease volumeWater circulationFuel injection apparatusBoiler blowdownHardness

A method, apparatus, and system and operation of surface equipment to generate steam while reducing the quantity of boiler blowdown and thereby increasing the amount of feedwater that is re-used or re-cycled in generating said steam. The present invention teaches that, on a sustained basis, the blowdown stream at the outlet of a once-through steam generator can be routed to the inlet of a second once-through steam generator that is in series with the first, that blowdown stream can be used to generate additional steam in the second once-through steam generator and further reduce the amount of blowdown, and that this can be accomplished without need of any treatment that reduces hardness or silica levels of the blowdown stream prior to its entering or during its entry into the inlet of the second once-through steam generator. The output of this second steam generator is a substantially dry saturated steam vapor stream and, complementarily, a blowdown stream whose mass rate has been reduced substantially from that of the blowdown stream exiting the first steam generator.

Owner:FCCL PARTNERSHIP

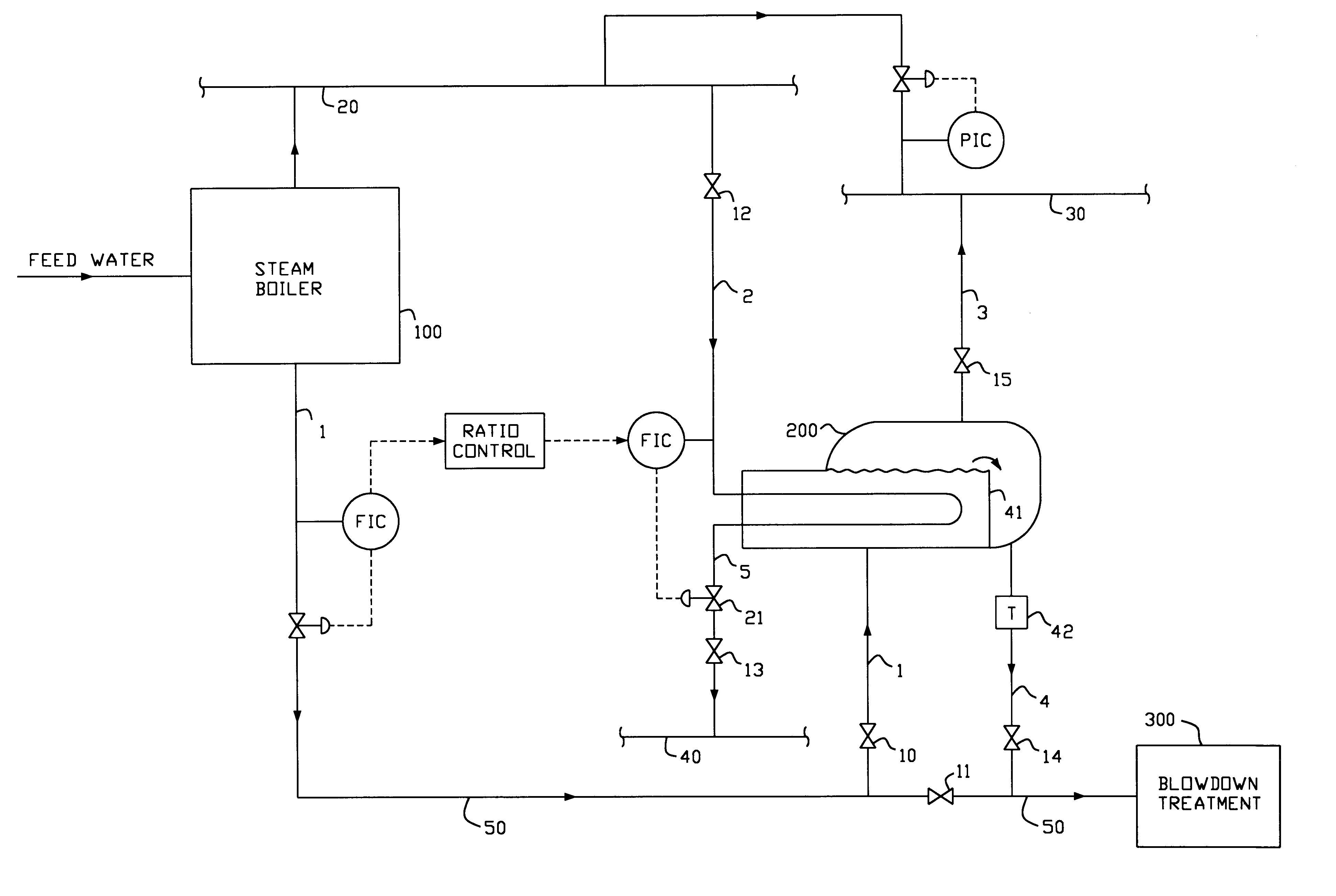

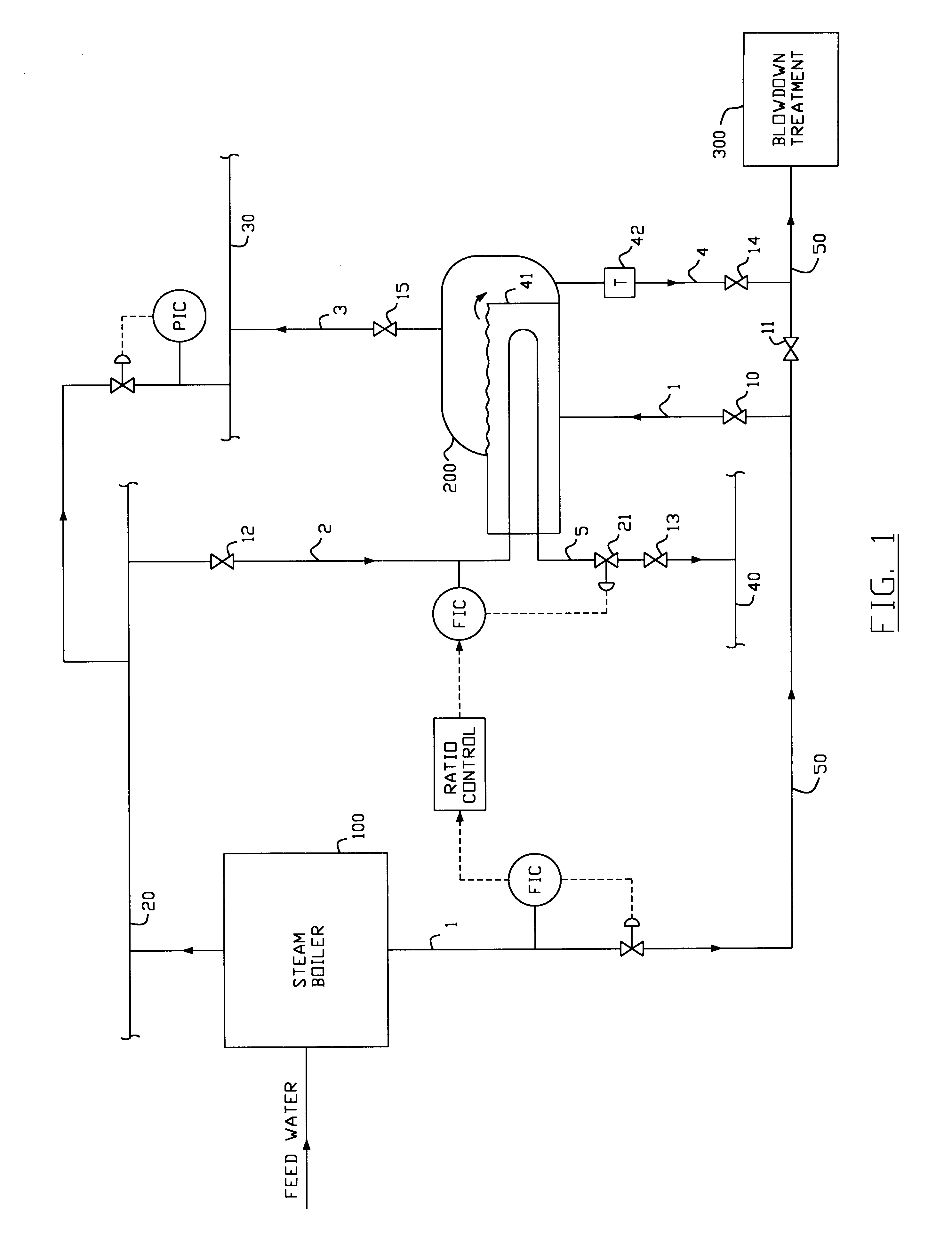

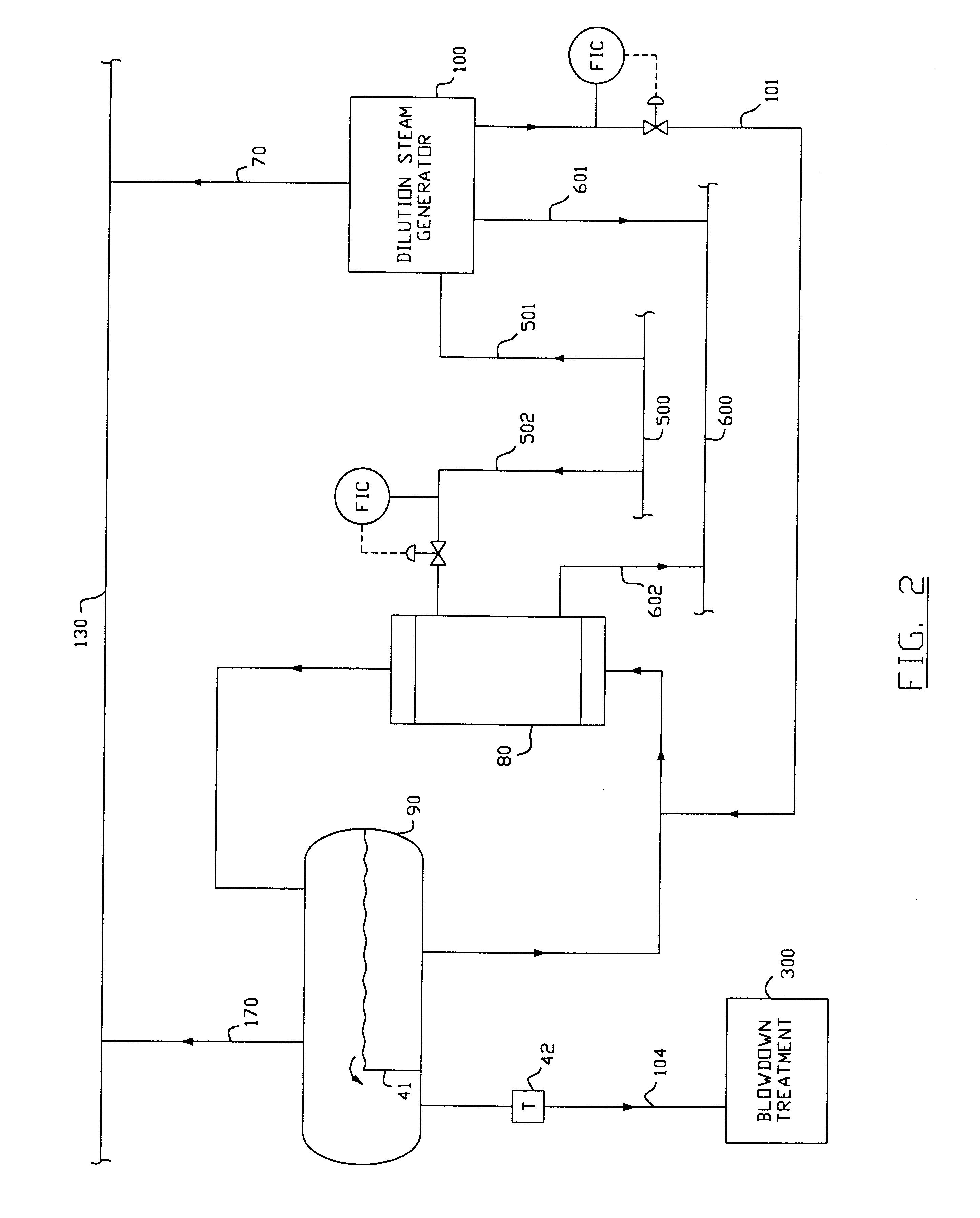

Methods for recycling process wastewater streams

InactiveUS6371058B1High mean blowdown rateChemical treatment costDrying using combination processesSteam separation arrangementsShell and tube heat exchangerWastewater

This invention provides cost-effective alternatives to reduce the cost associated with customary blowdown from steam generating equipment. By selectively recycling process blowdown streams using secondary vaporizers, the net result is a partial replacement of wastewater stream with almost an equivalent quantity of clean steam condensate. The heat transfer is carried out by indirect contact devices, such as shell and tube heat exchanger and the like, without mixing of the two process streams to allow condensate recovery while avoiding cross contamination. This invention carries economic as well as environmental credits. A condensate recovery apparatus can be designed to enable easy connection to existing equipment already in service, as well as easy removal, without causing process disruption.

Owner:TUNG PETER

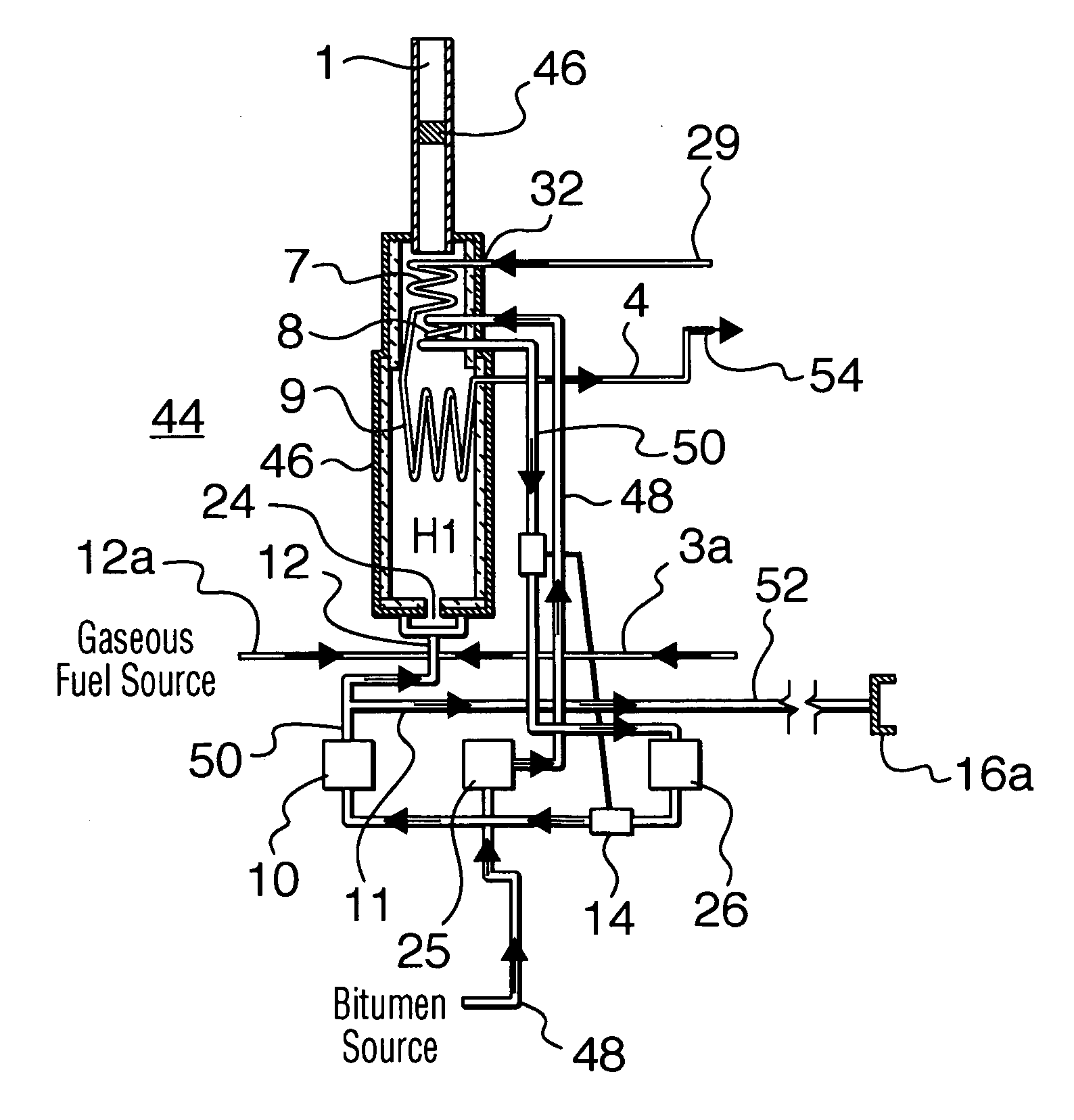

Steam generation apparatus and method

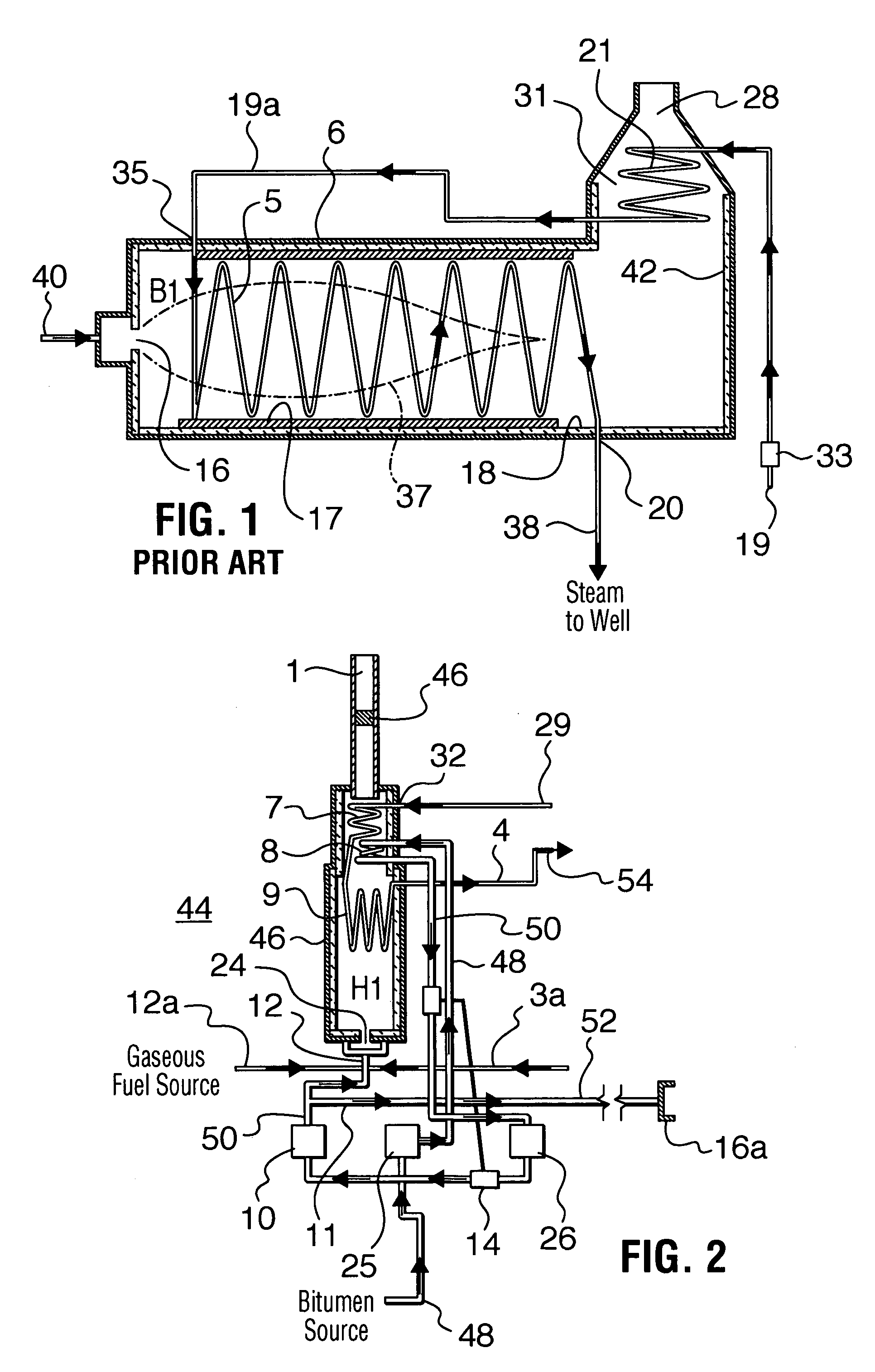

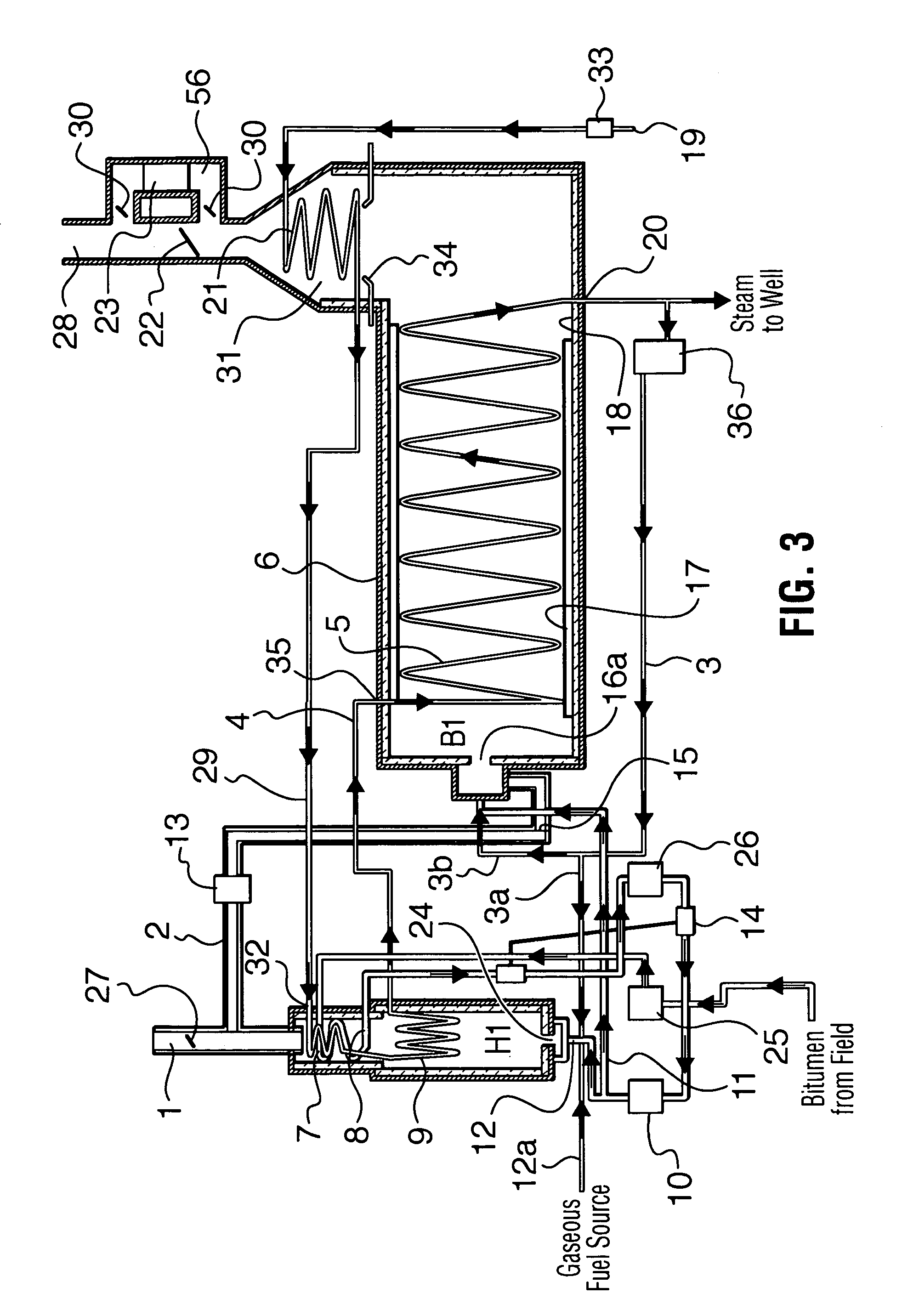

InactiveUS6990930B2Improve steaming qualityEasy to carryFurnace-tube steam boilersSteam/vapor condensersEngineeringLiquid fuel

In one aspect, the invention provides a steam generation apparatus that is liquid fuel fired and addresses conversion of gaseous fuel SIB units to operate with liquid fuel. The invention also relates to a conversion unit for a steam injection boiler, a method for converting a steam injection boiler from gas firing to possible liquid fuel firing and a method for generating steam from a liquid fuel source. The invention employs a fired heater for heating the liquid fuel to a temperature suitable for firing and preheats the water to compensate for the shortfall in heat liberation when a gas boiler is converted to use liquid fuel. In another aspect of the invention, production of steam is achievable consistently by employing step-up heaters with a steam injection boiler. The heaters being connected in parallel to continue heating the water / steam to achieve a higher quality steam over that produced in the boiler while minimizing consideration as to the adverse effects of coil fouling in the boiler.

Owner:ACS ENG TECH

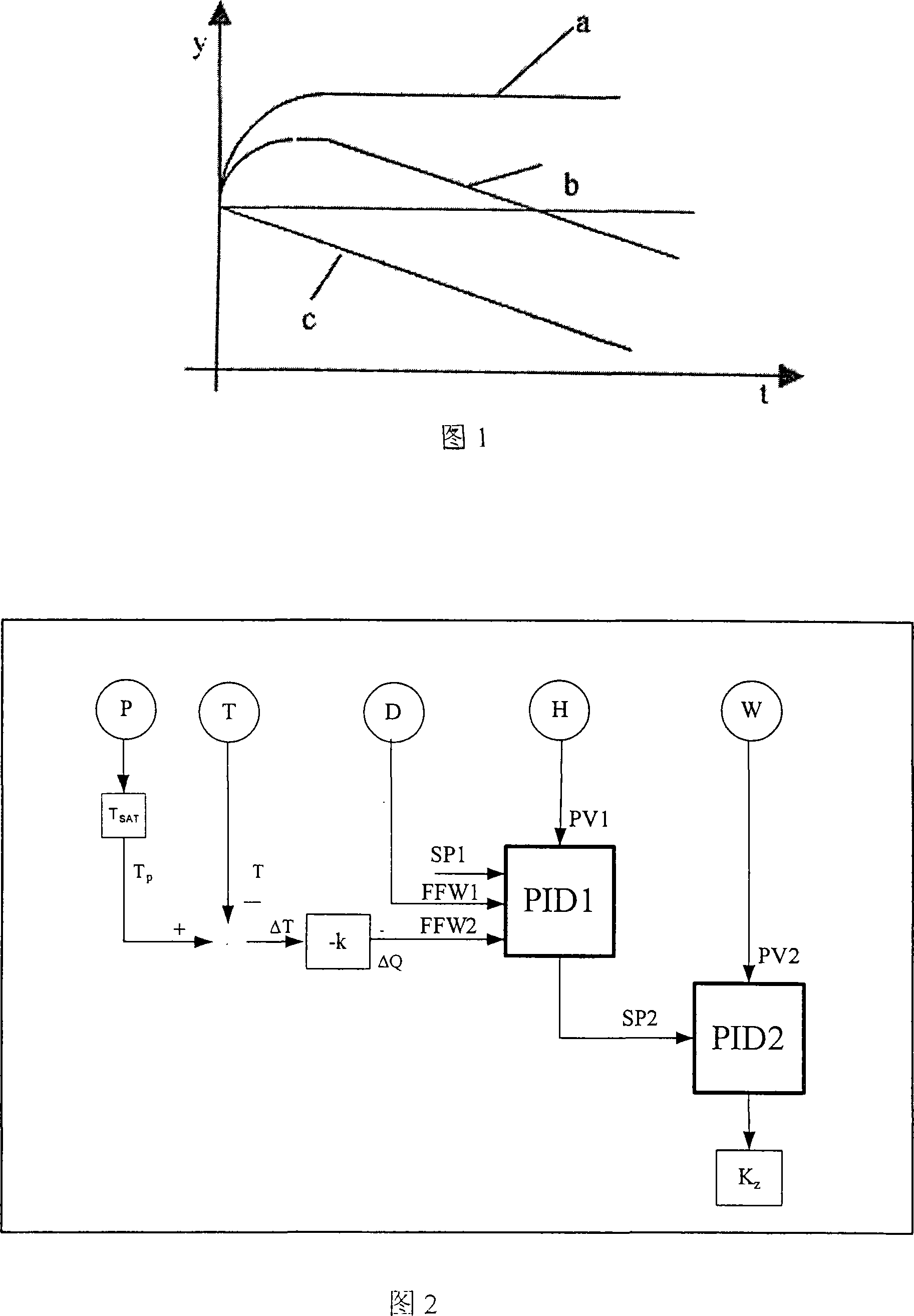

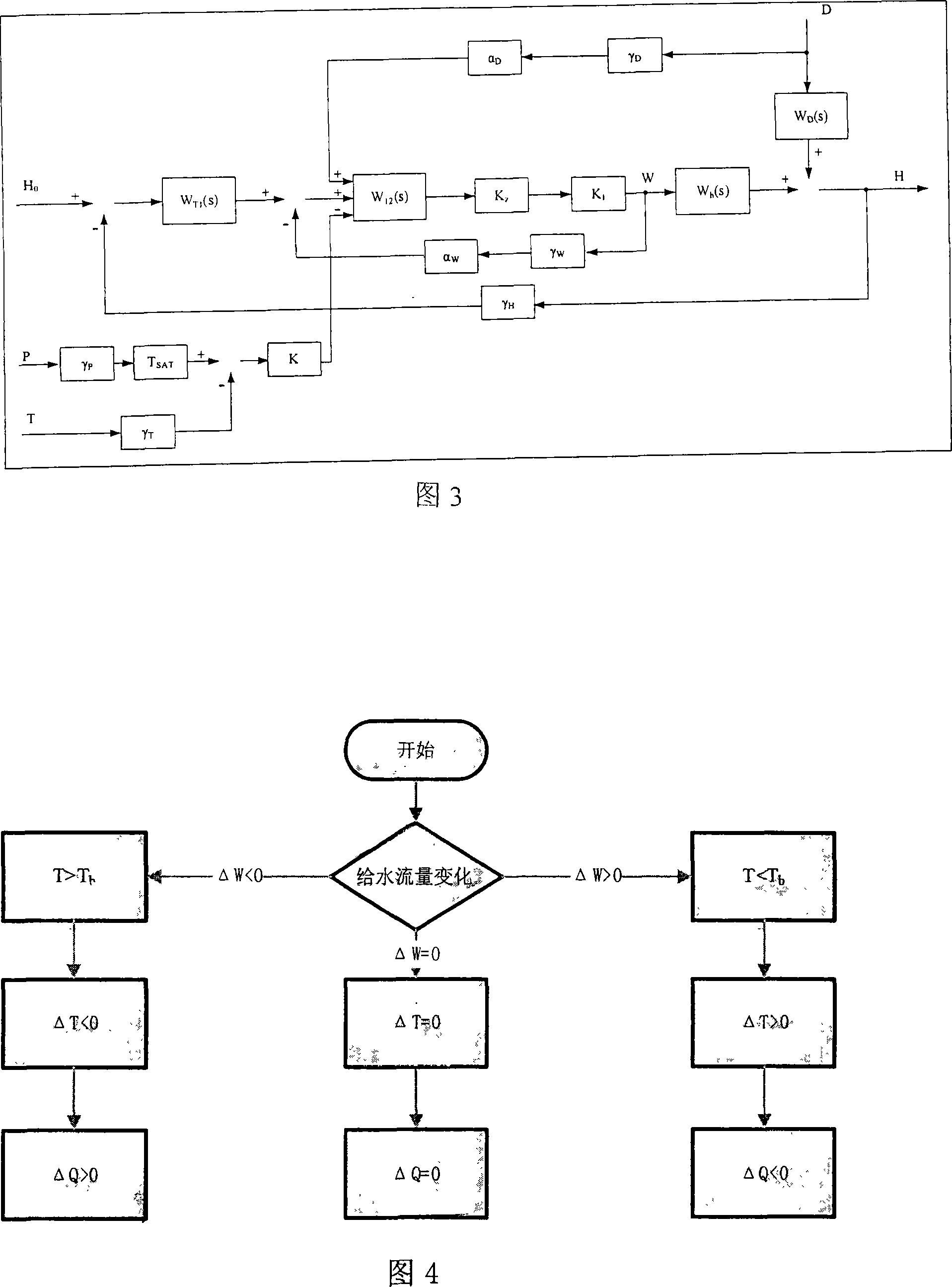

Method for correcting water level of steam drum based on temperature and pressure

ActiveCN101135438AImprove dynamic qualityGuaranteed uptimeSteam separation arrangementsWater feed controlEngineeringLinearity

This invention relates to a correctional method of water level in the steam drum based on the temperature and pressure that belongs to the heat process control field including the following steps: the temperature difference DeltaT is linear to the water supply flow increment in small range, DeltaQ=-kDeltaT, theDeltaQ is used as the feedforward value in the main circuit of the cascade control of the water level in the steam drum, to eliminate the adverse effect of 'false water level' on the water supply control. When the load increases,DeltaQ>0, and the steam drum working condition is nearly stable, the correctional value is 0; when the load decreases, the controlled water supply is suppressed, DeltaQ<0; when the water flow increases, the temperature T of the steam drum decreases and the water supply flow increment DeltaQ<0; when the water supply flow is nearly constant, the correctional value is 0; when the water supply flow decreases, the controlled supply flow increases, DeltaQ>0. This method introduces the effect of steam drum pressure and water temperature on the steam bubble in the steam drum water to correct the water level control, which suppresses the overshoot phenomenon and ensures the steady operation of the boiler.

Owner:CHINA ELECTRIC POWER RES INST +1

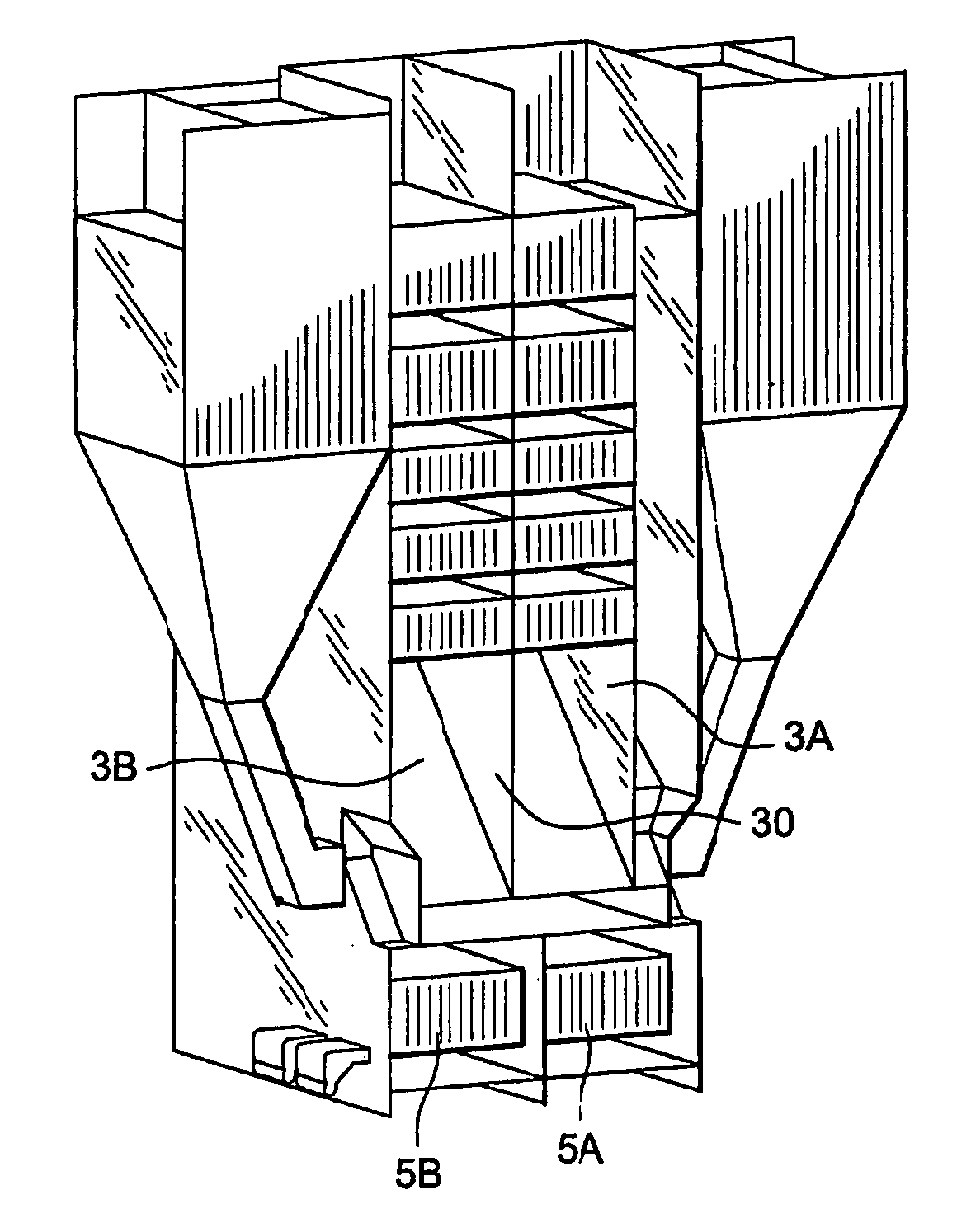

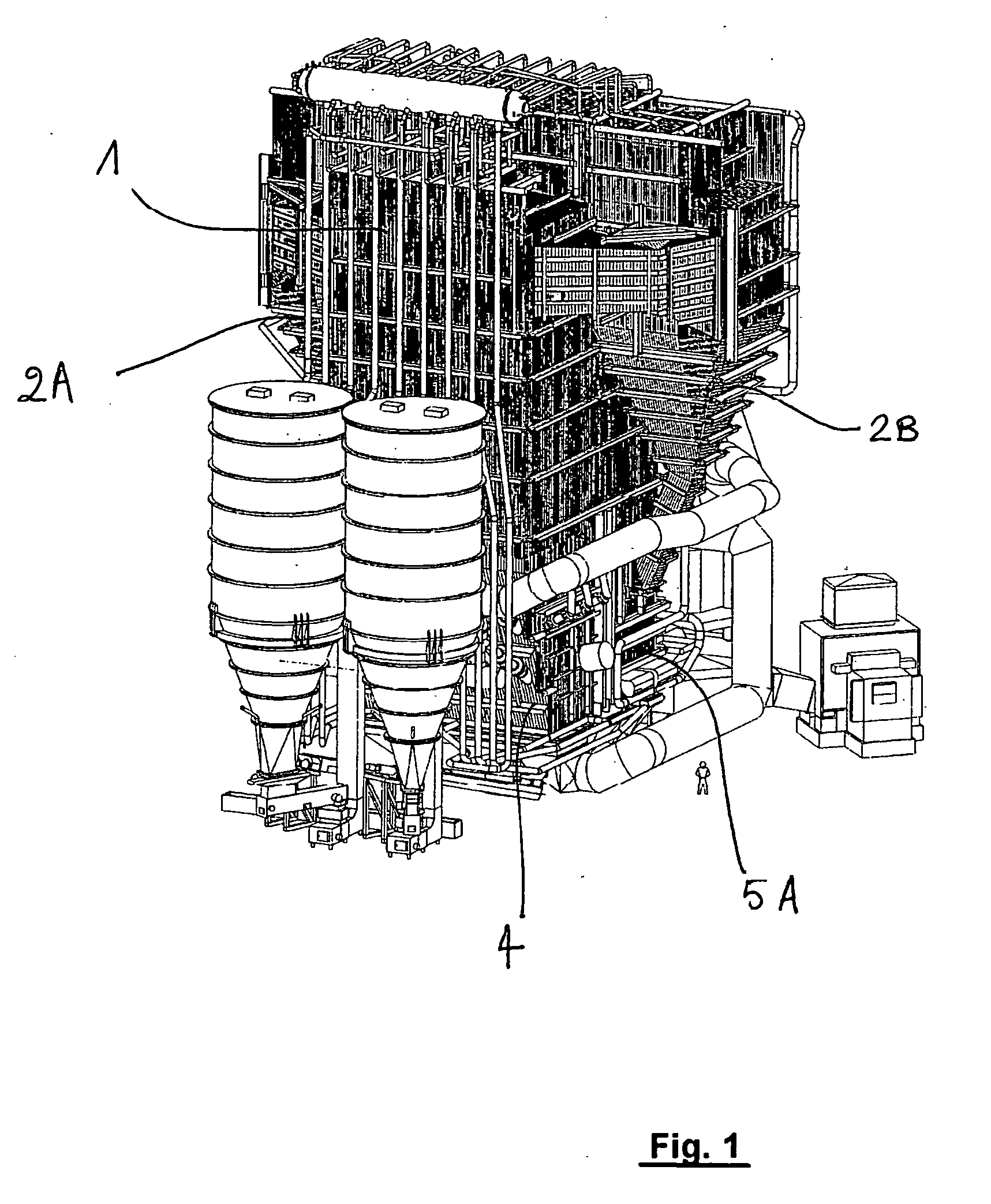

Circulating fluidized bed reactor with a convertible combustion method

InactiveUS20070079773A1Easy to operateFluidized bed combustionSteam/vapor condensersCombustionFlue gas

The invention relates to a circulating fluidized bed reactor designed to be fed with air and convertible to operate with an oxygen-rich mixture, comprising a reaction chamber (1) horizontally bounded by vertical walls, at least two centrifugal separators (2A, 2B) and a heat recovery element called a heat exchanger cage (3), a reactor also comprising means for introducing a fluidization gas into the reaction chamber using at least one wind box (4) placed under the reaction chamber, and for maintaining a circulating fluidized bed of particles in said chamber, means for transferring gas which must be dedusted from the chamber to the separators, means for discharging the particles separated from the separators and means for transferring the dust-free gases from the separators to the exchanger cage. According to the invention: said reaction chamber comprises at least one partially internal vertical partition wall (10) forming two subchambers (1A, 1B) communicating together and each communicating with at least one separator, said exchanger cage (3) comprises a partially internal vertical partition wall (30) forming two subcages (3A, 3B) communicating together and each communicating with at least one separator, these partition walls being arranged in order to create a passage for the flow of the flue gases into one of said subchambers and into one of said subcages corresponding to operation by oxygen feed in the reaction chamber.

Owner:GENERAL ELECTRIC TECH GMBH

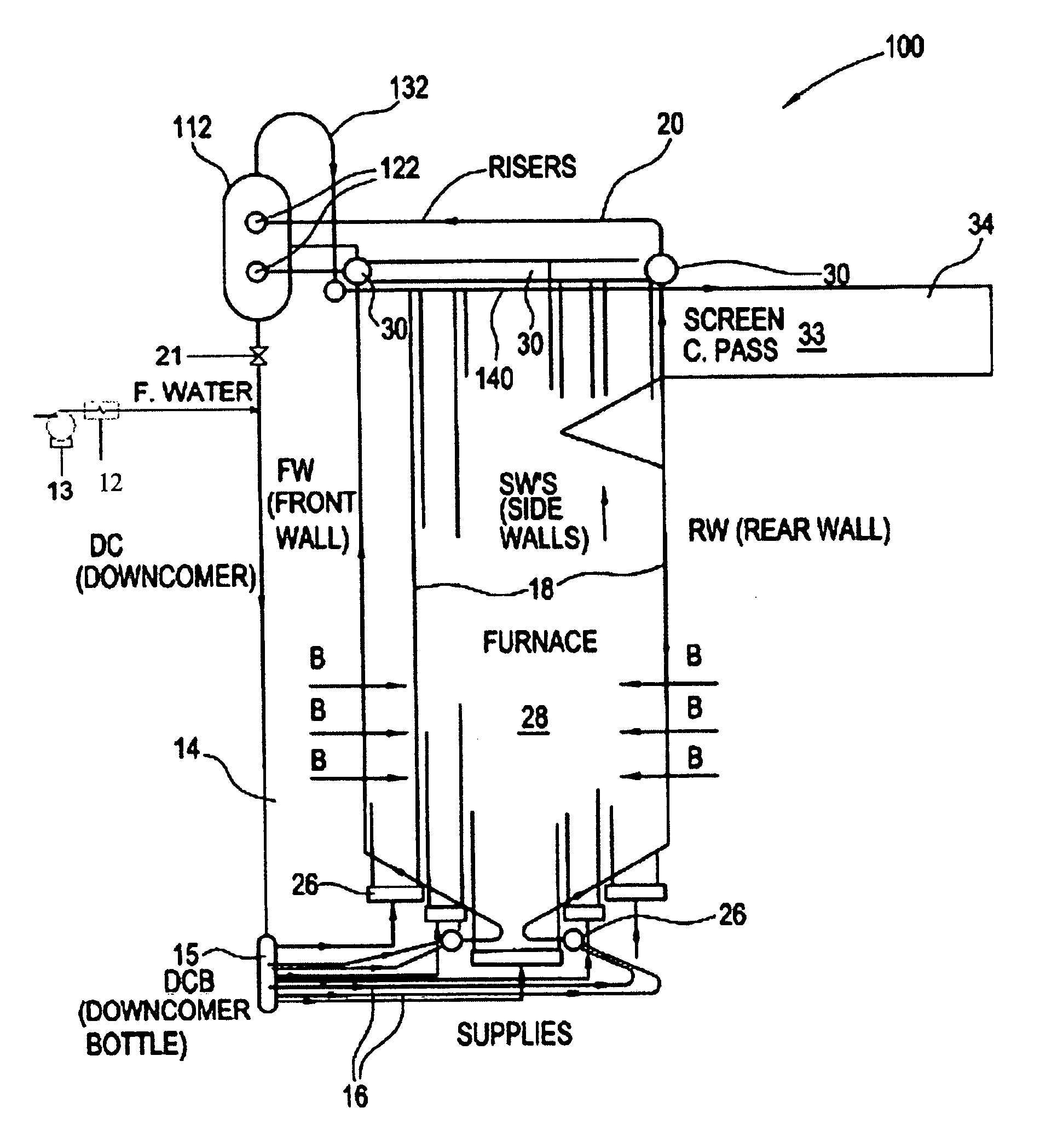

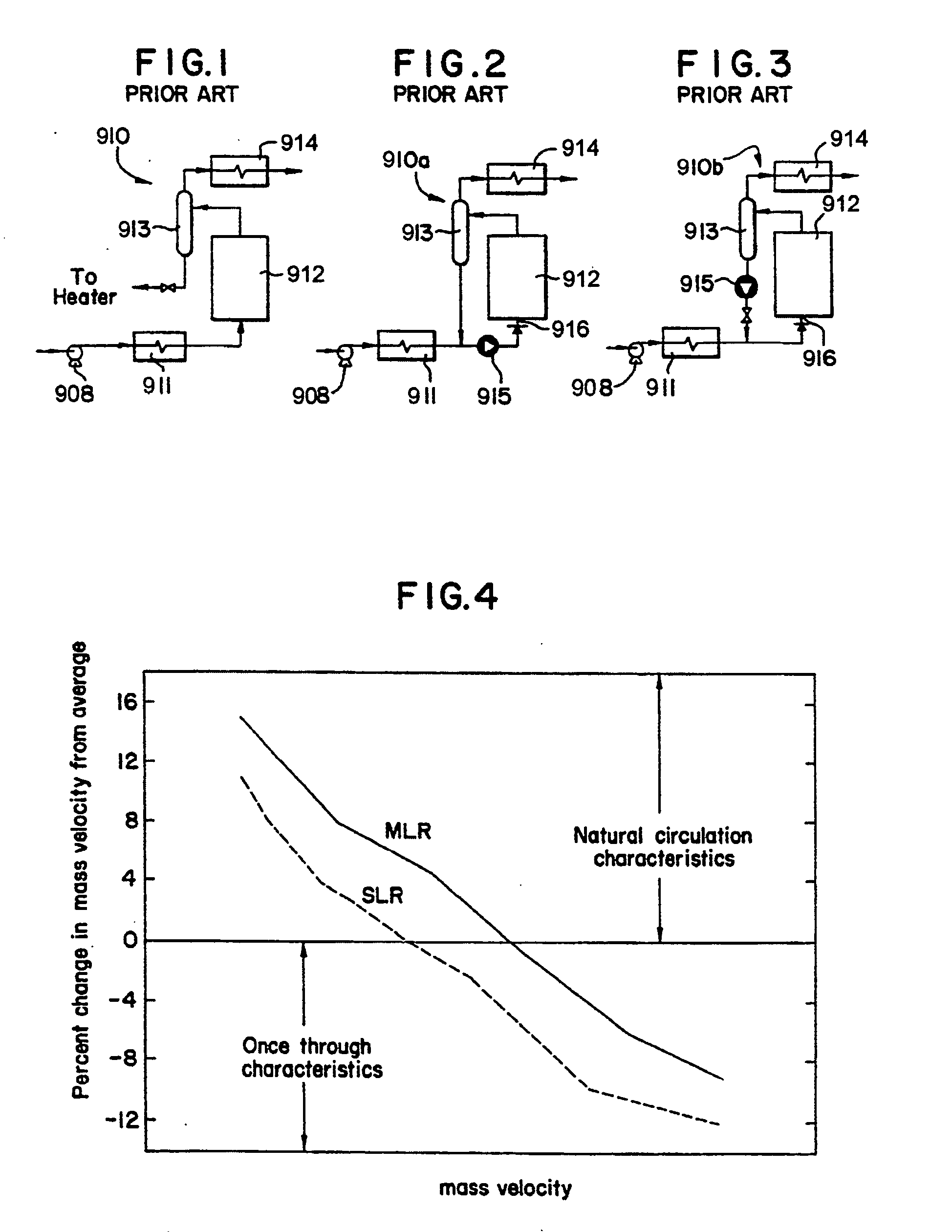

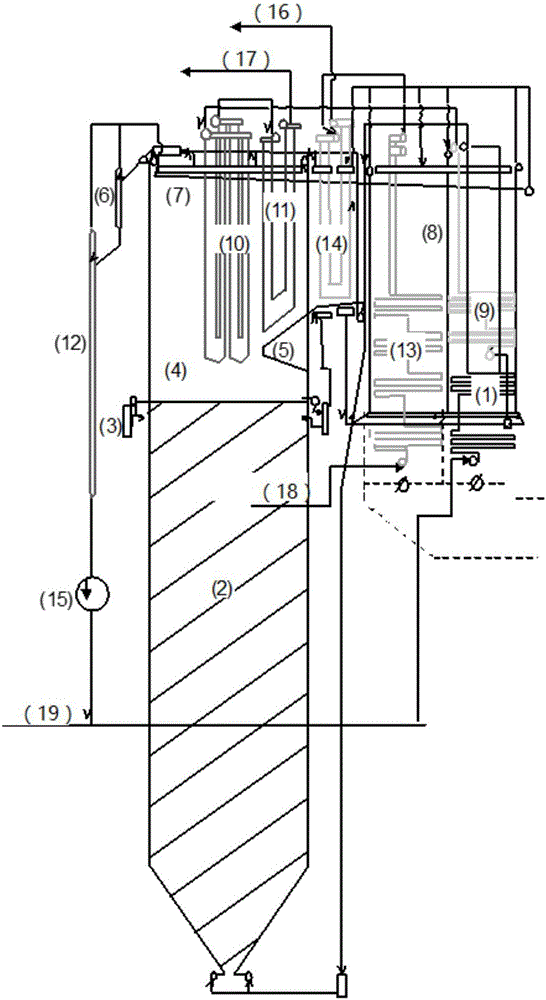

Circulation system for sliding pressure steam generator

InactiveUS20070283906A1High densityImprove abilitiesWater circulationFuel injection apparatusBoiler feedwater pumpEngineering

A steam generator circulation system is provided and includes a boiler feed pump for forcing water through an economizer, and through the waterwall tubes of an evaporator. A separator receives a mixture of steam and water and sends the steam to a steam utilization unit such as a superheater. A valve is provided below the separator. If the valve is open, the saturated water from the separator is mixed with feedwater and recirculated through the tubes of the evaporator. If the valve is closed, recirculation is terminated. At loads below the critical point, the valve below the separator system would be open and the boiler would operate like a natural circulation drum boiler. At loads above the critical point, the valve below the separator system would be closed resulting in a boiler that operates like a once-through boiler.

Owner:THE BABCOCK & WILCOX CO

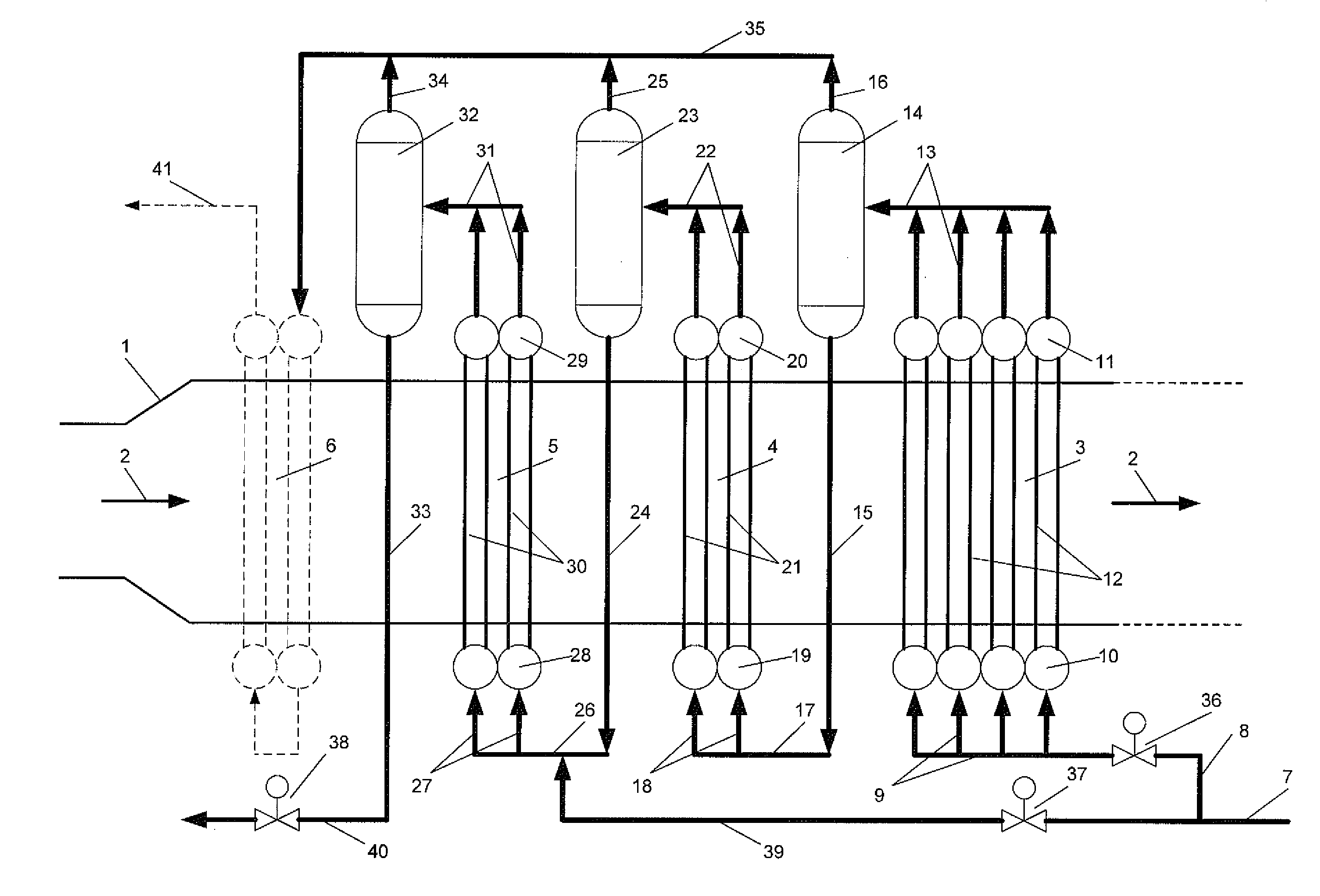

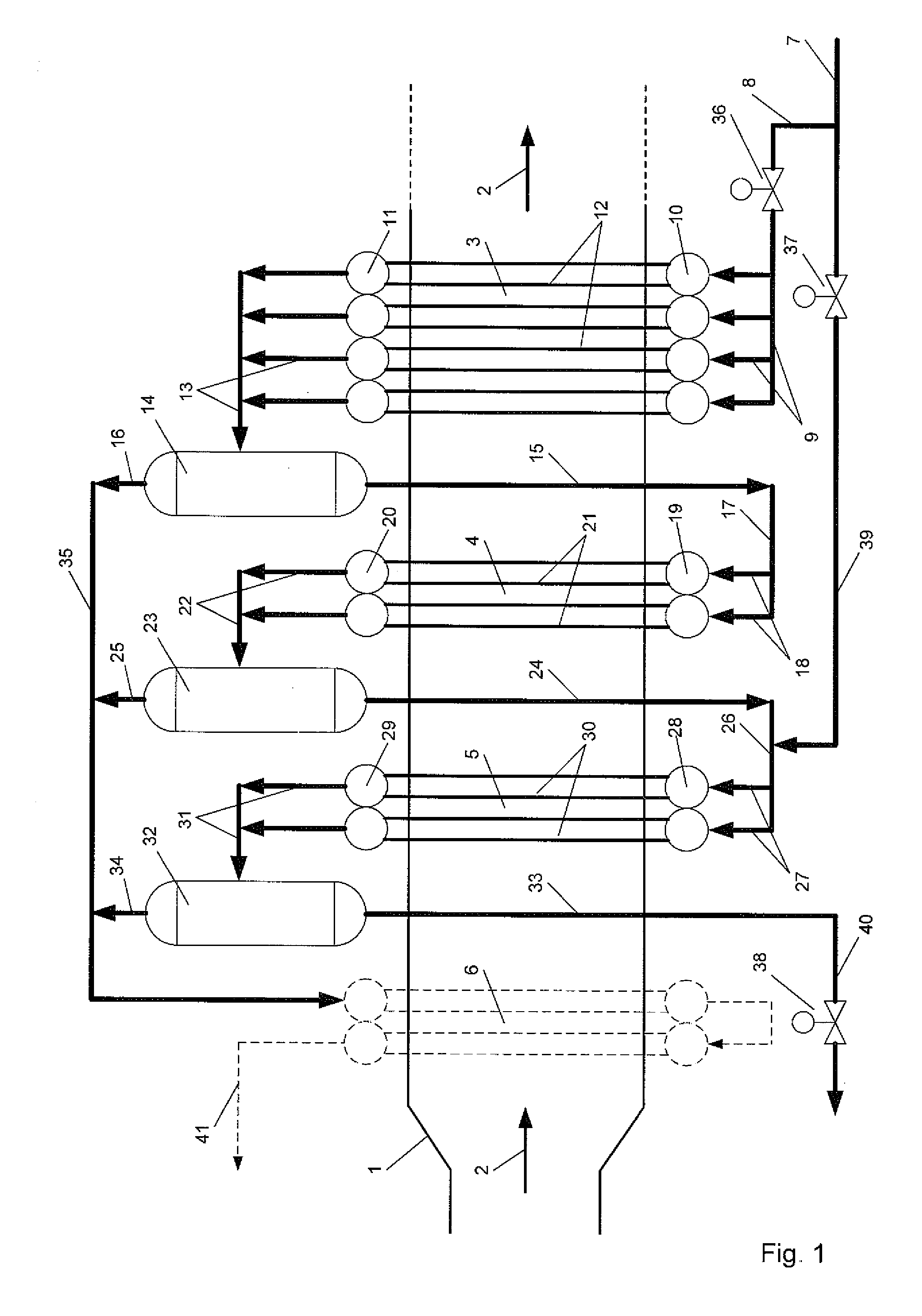

Cascading once through evaporator

ActiveUS20120180739A1Simple configurationLess susceptible to and failureSteam separation arrangementsSteam engine plantsEngineeringHeat transfer

A steam generator includes a substantially horizontal gas conduit (1) to guide a heating gas flow (2) and an evaporator unit positioned at least partially in the horizontal gas conduit for transferring heat from the heating gas to a flow medium which flows through the evaporator unit. The heat transfer section of the evaporator unit of the steam generator is bottom fed, which means that the inlet conduit is arranged at a lower region of the heat transfer section. The outlet conduit is arranged at an upper region. The inlet conduit allows an once through operation of the evaporator section which is necessary to enable operation under supercritical circumstances. The evaporator unit includes at least two evaporator stages (3, 4) which are arranged in a cascade. Each evaporator stage includes a heat transfer section (12, 21) and a separator (14, 23). The presence of the separators (14, 23) subdivides the evaporator unit into evaporator stages (3, 4).

Owner:NEM ENERGY

Drain separator

ActiveUS7662220B2Simple structureCombination devicesAuxillary pretreatmentEngineeringCentrifugal force

Owner:SMC CORP

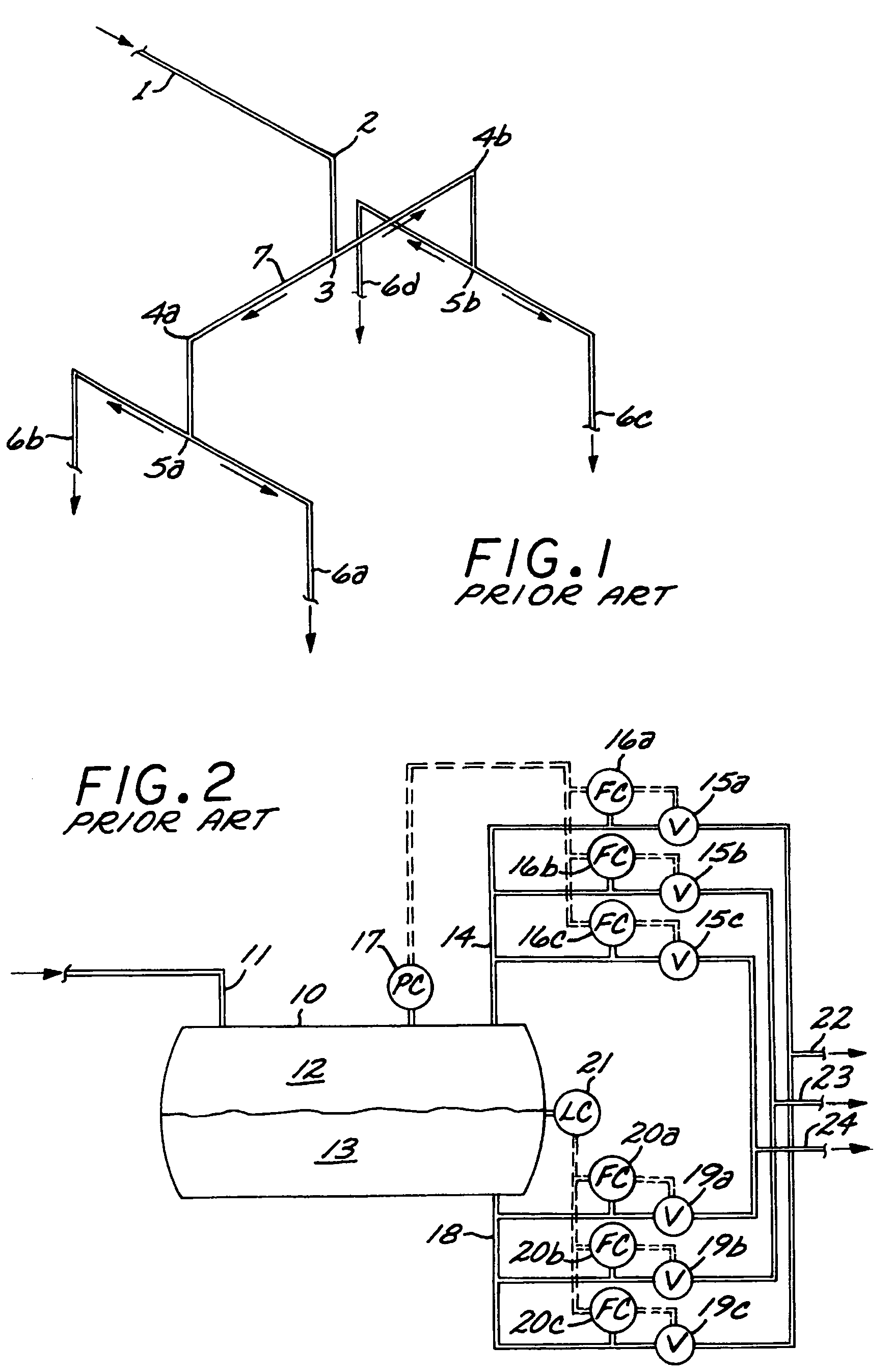

Device for splitting a two-phase stream into two or more streams with the desired vapor/liquid ratios

ActiveUS7261120B2Achieve separationPressure pumpsDispersed particle separationLiquid ratioEngineering

A stream splitting device splits a two-phase inlet stream into two or more outlet streams having nearly identical vapor-to-liquid ratios. The inlet stream is directed into a separator vessel containing an impingement plate to decrease the velocity of the stream and direct it toward the inner walls of the vessel, where it impinges, separating the liquid from the vapor. Inside the vessel, each of two vertical suction channels with side wall apertures is in fluid communication with an outlet pipe. The lower ends of the suction channels are submerged in the liquid phase. Vapor flows though the apertures that are above the liquid surface in the vessel, thereby generating a pressure drop across the walls of the suction channels. Consequently, liquid is lifted up into the suction channels, where it is mixed with the vapor. The two-phase mixture then leaves the vessel and stream splitter through the outlet pipes.

Owner:MORTEN MULLER LTD APS

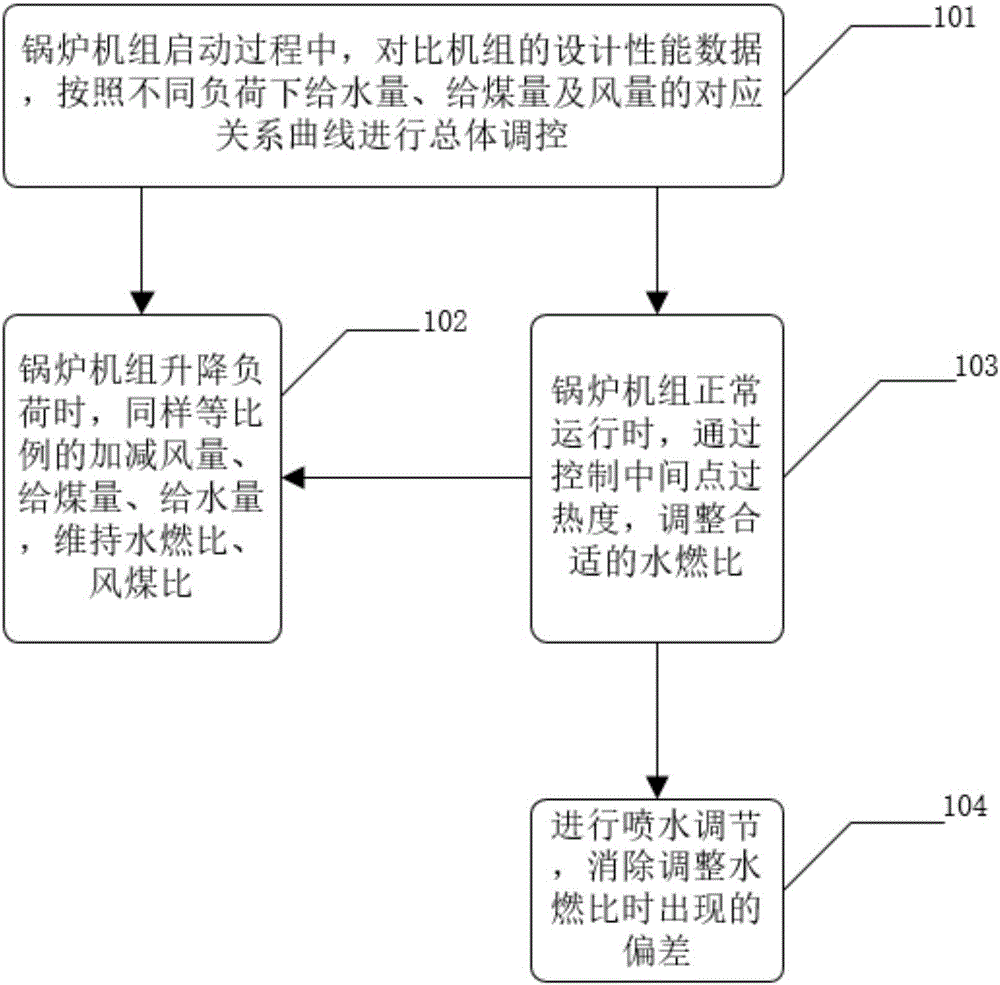

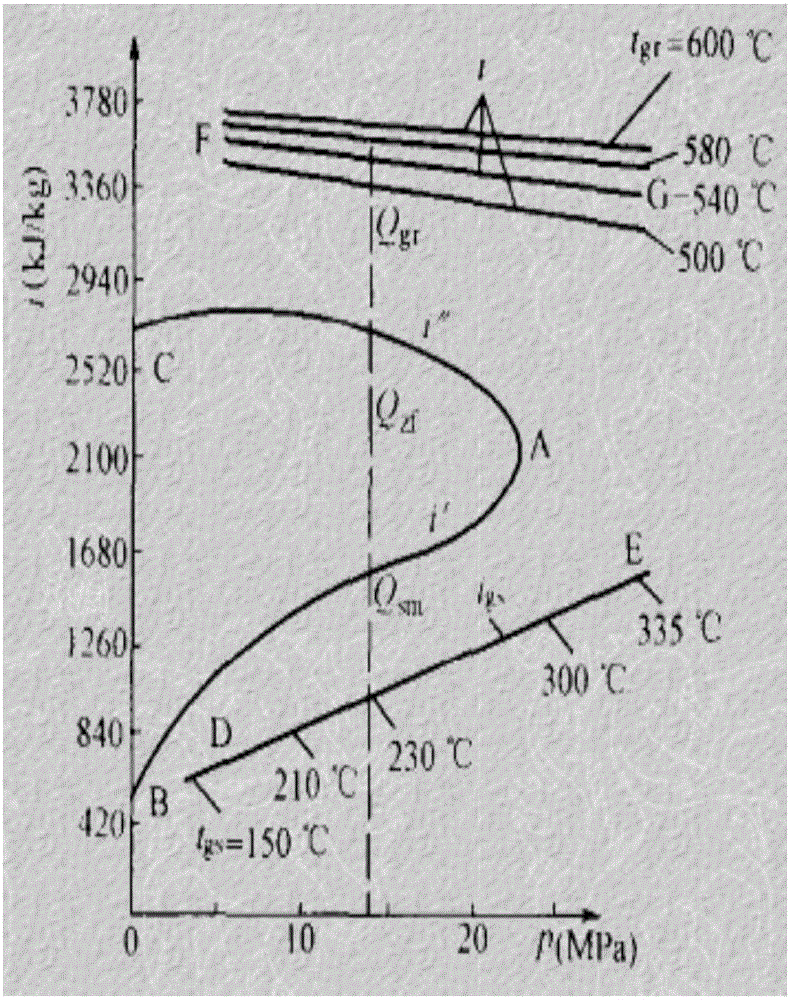

Control method for steam temperature of meager coal boiler of 1045MW ultra supercritical unit

ActiveCN106439770AGuaranteed uptimeEliminate biasSuperheating controlSteam separation arrangementsSupercritical steam generatorAir volume

The embodiment of the invention discloses a control method for the steam temperature of a meager coal boiler of a 1045MW ultra supercritical unit. The control method is used for solving the technical problems that because mature ultra supercritical steam temperature control technologies capable of being applied to actual production fields lack currently, heating surface over-temperature pipe explosion is frequently caused by unreasonable steam temperature control of a field ultra supercritical boiler, large potential safety hazards are caused to safe and stable operation of a power plant, and severe economic loss of a large thermal power plant is caused. The control method includes the steps that in the boiler unit starting process, design performance data of the unit are compared, and overall regulation and control are conducted according to the corresponding relation curve of water supply quantity, coal supply quantity and air volume under different loads; when the load of the boiler unit is increased or decreased, the air volume, coal supply quantity and water supply quantity are increased or decreased with the same ratio; when the boiler unit normally operates, the superheat degree of the intermediate point is controlled to regulate the water-fuel ratio to be proper; and water spraying adjustment is carried out, so that deviation in regulation of the water-fuel ratio is eliminated.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

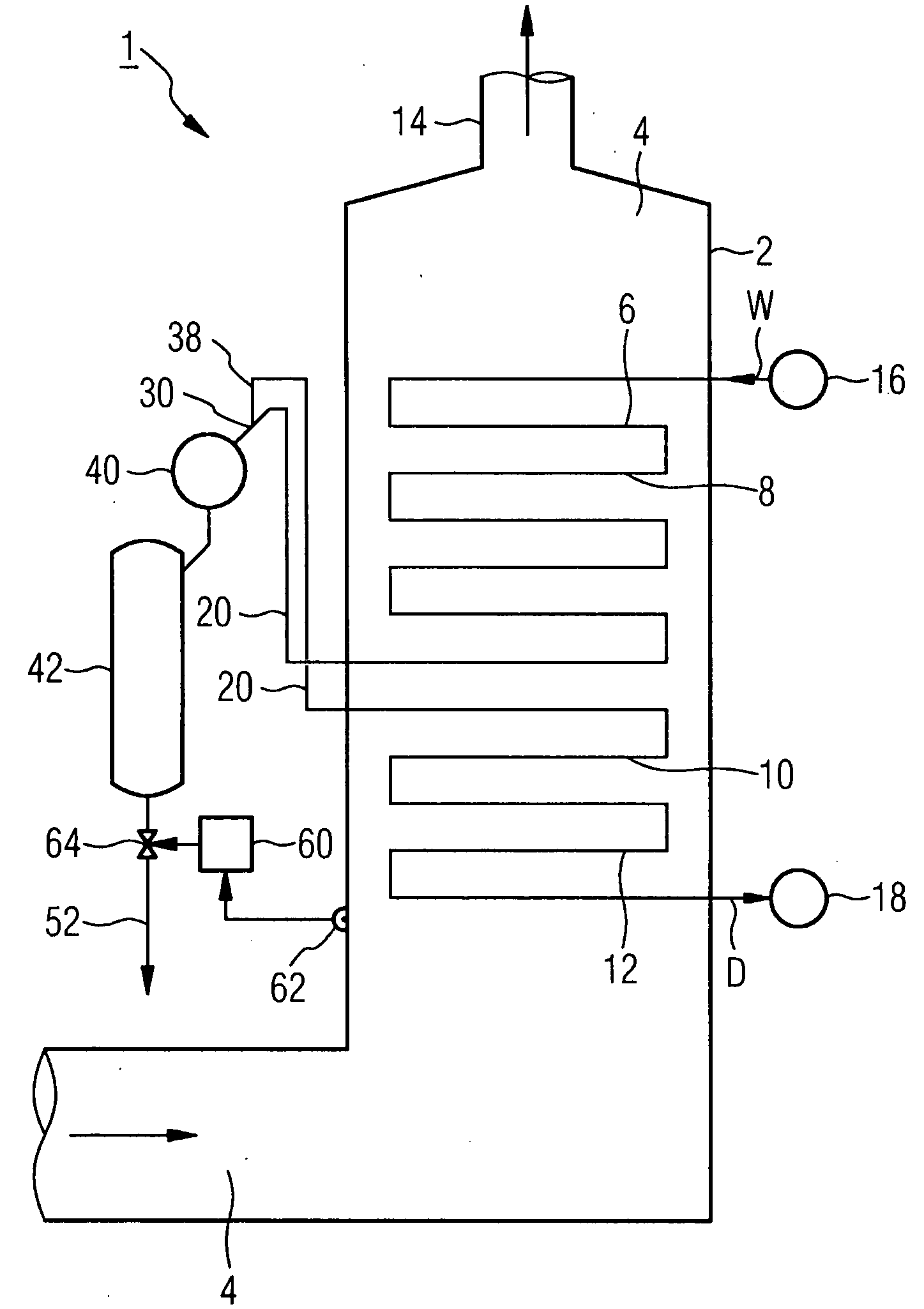

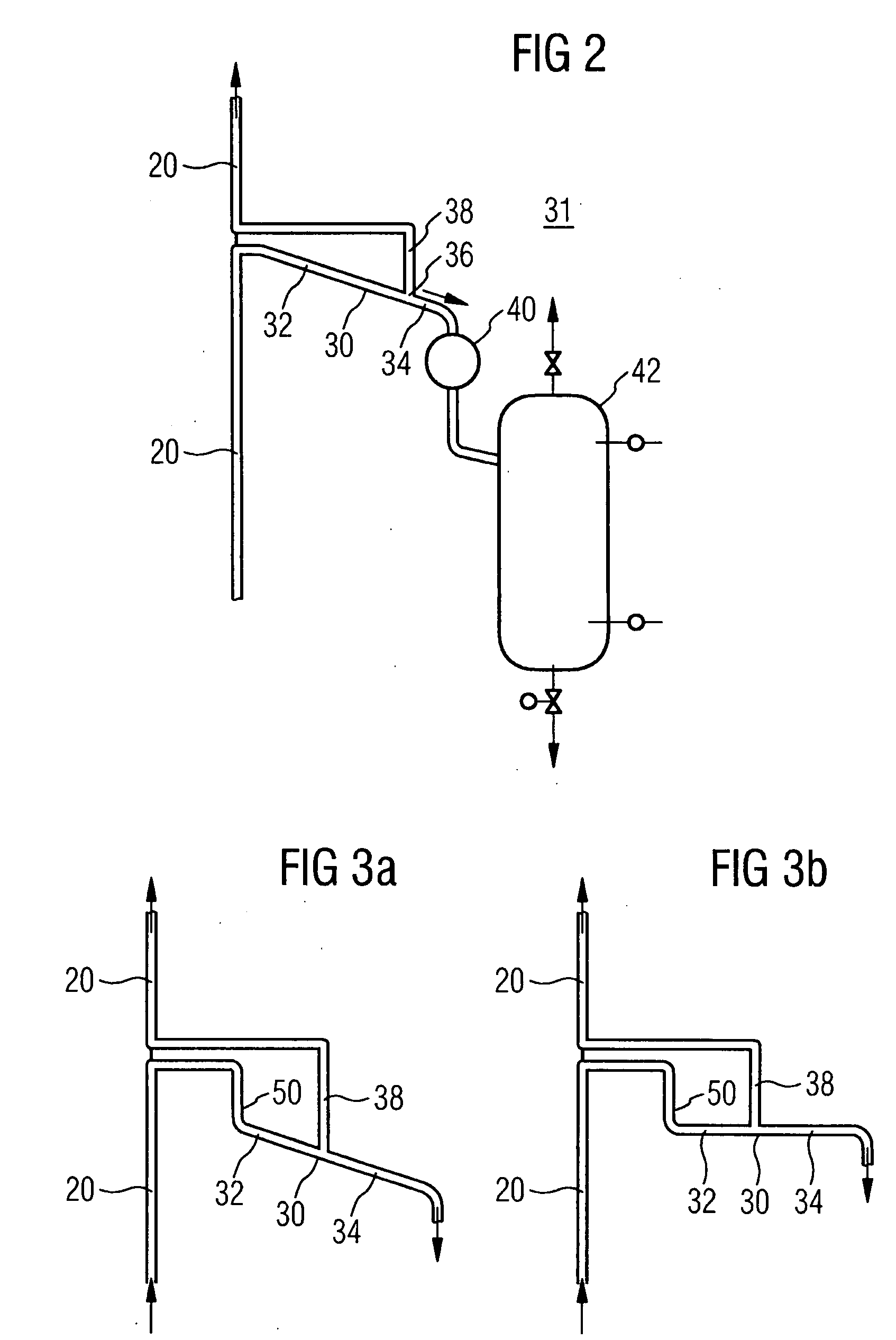

Waste Heat Steam Generator

ActiveUS20110162594A1Reduce stepsEasy constructionSteam generation heating methodsSteam separation arrangementsSeparation systemWaste heat

A waste heat steam generator including evaporator tubes is provided. The evaporator tubes are connected in parallel on the flow medium side, a plurality of overheating tubes are mounted downstream of the evaporator tubes using a water separation system. The water separation system includes water separation elements, each water separation element being respectively mounted downstream of the plurality of evaporator tubes and / or upstream of a plurality of overheating tubes. Each water separating element includes an inlet pipe which is respectively connected upstream to the evaporator tubes, the inlet pipe extending into a water evacuation pipe when seen in the longitudinal direction. A plurality of outflow pipes branch off in the transitional area, the pipes being connected to an inlet collector of the overheating tubes which are respectively connected downstream. A distribution element is arranged on the steam side between the respective water separating element and the inlet collector.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

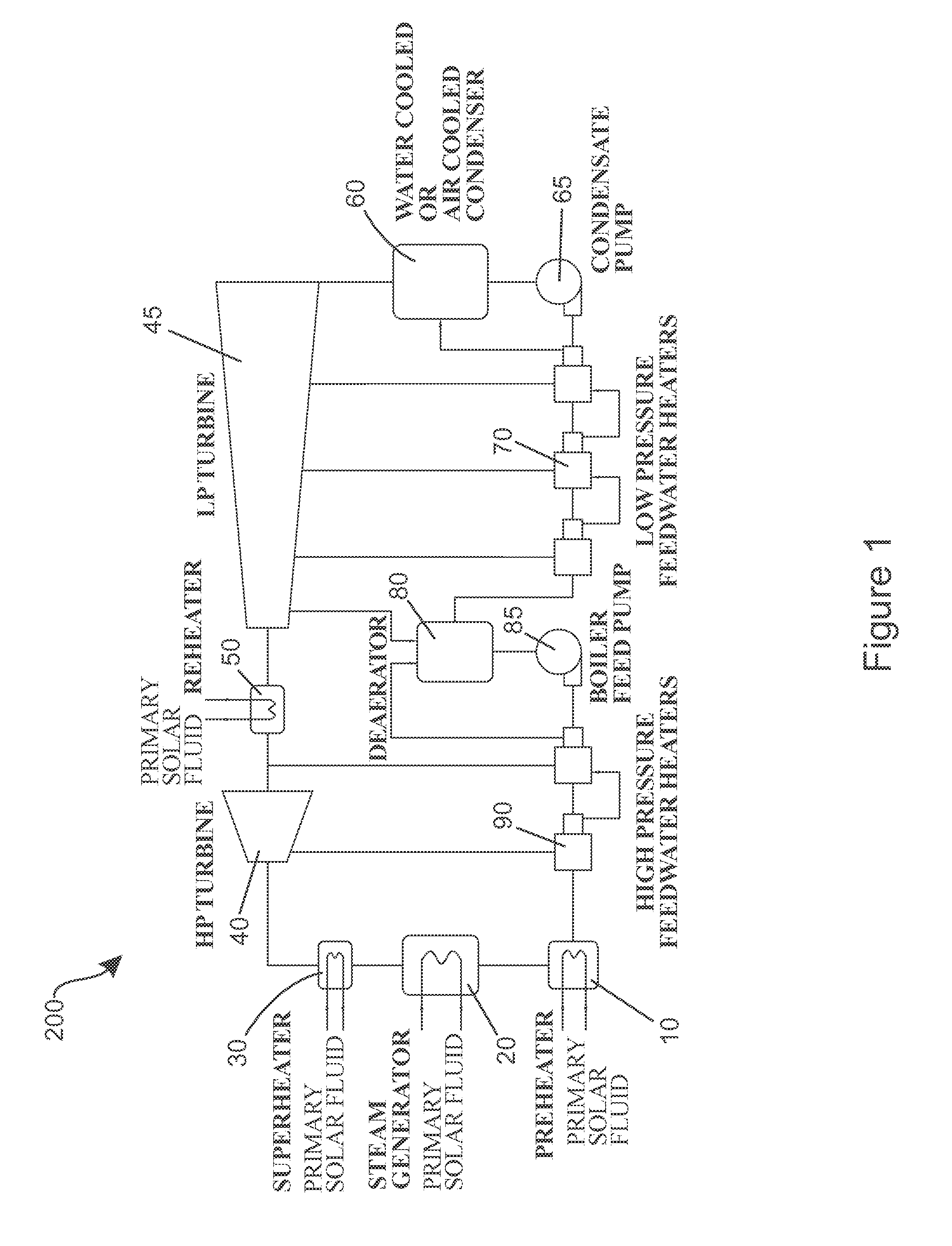

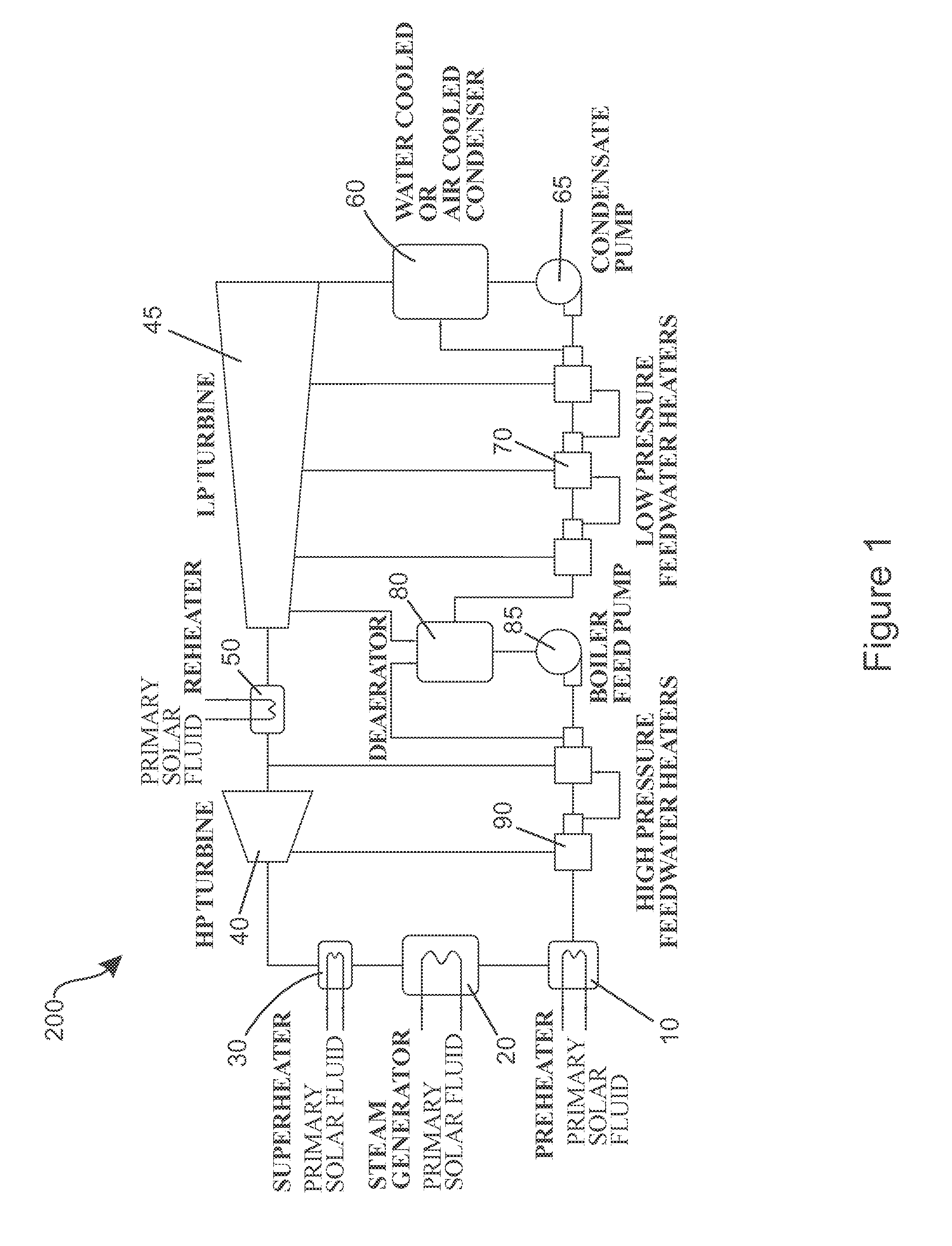

Configurations and methods of generating low-pressure steam

ActiveUS20120204817A1Heat recoverySteam generation heating methodsEnergy industryReboilerEngineering

Low-pressure steam for a steam consuming device, and particularly a steam reboiler, is generated at the steam consumption pressure to maximize the heat recovery from a utility fuel and / or waste heat source. Most preferably, steam is generated at the lowest possible pressure by fluidly coupling the steam generator to the steam consuming device (e.g., by integrating the condensate drum with the steam drum). Therefore, it should be appreciated that the steam generator pressure in such configurations and methods will ride on the reboiler pressure.

Owner:FLUOR TECH CORP

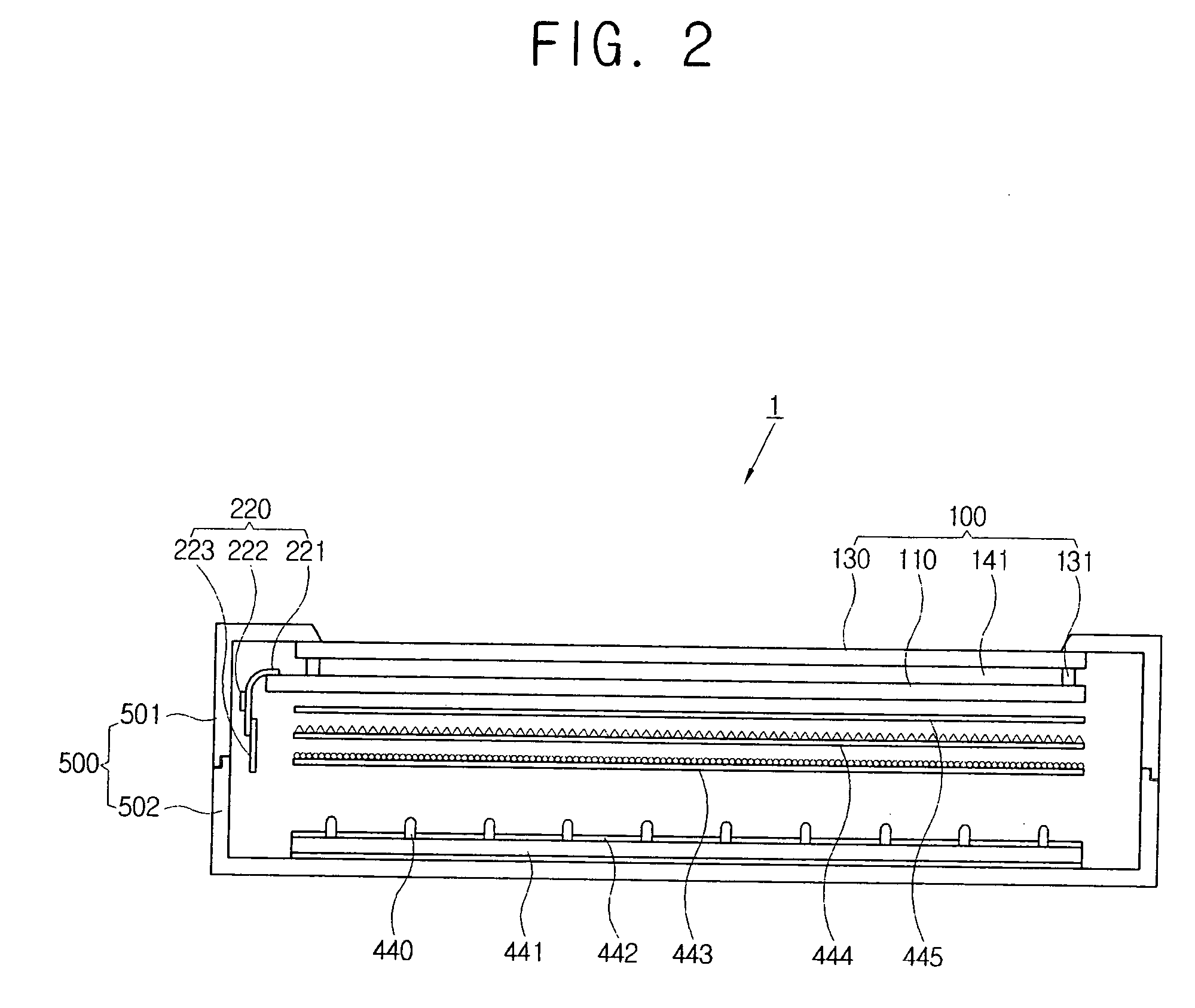

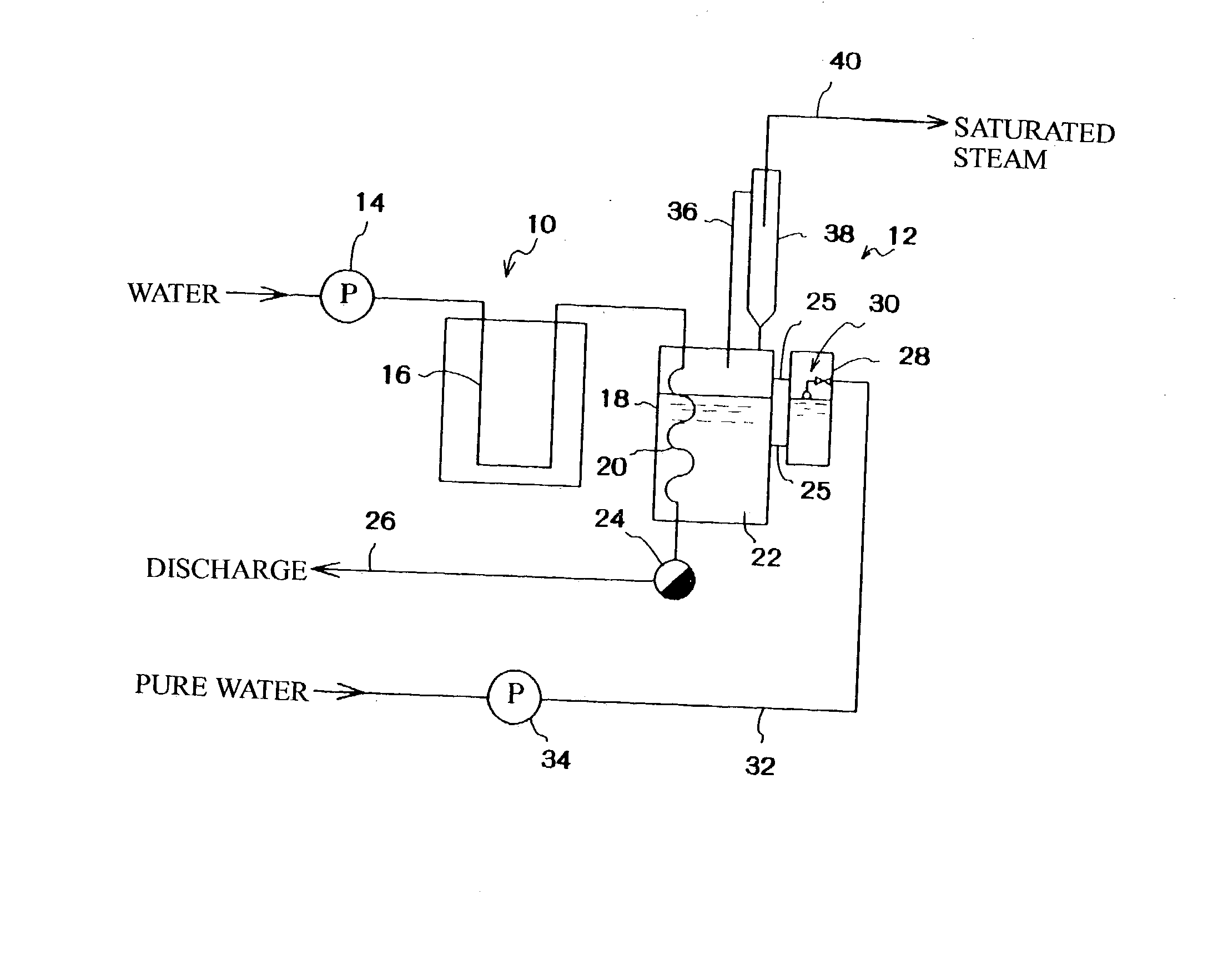

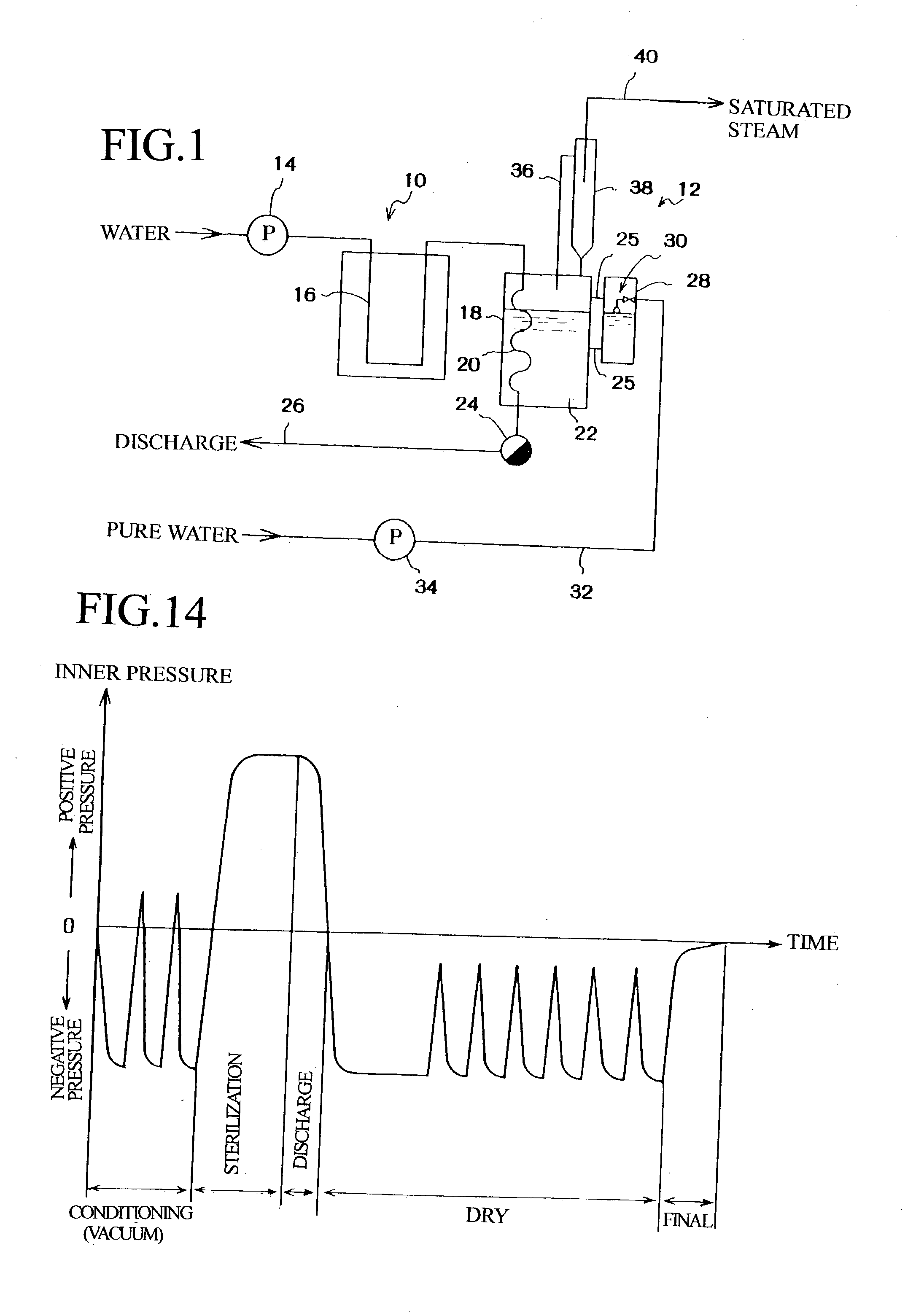

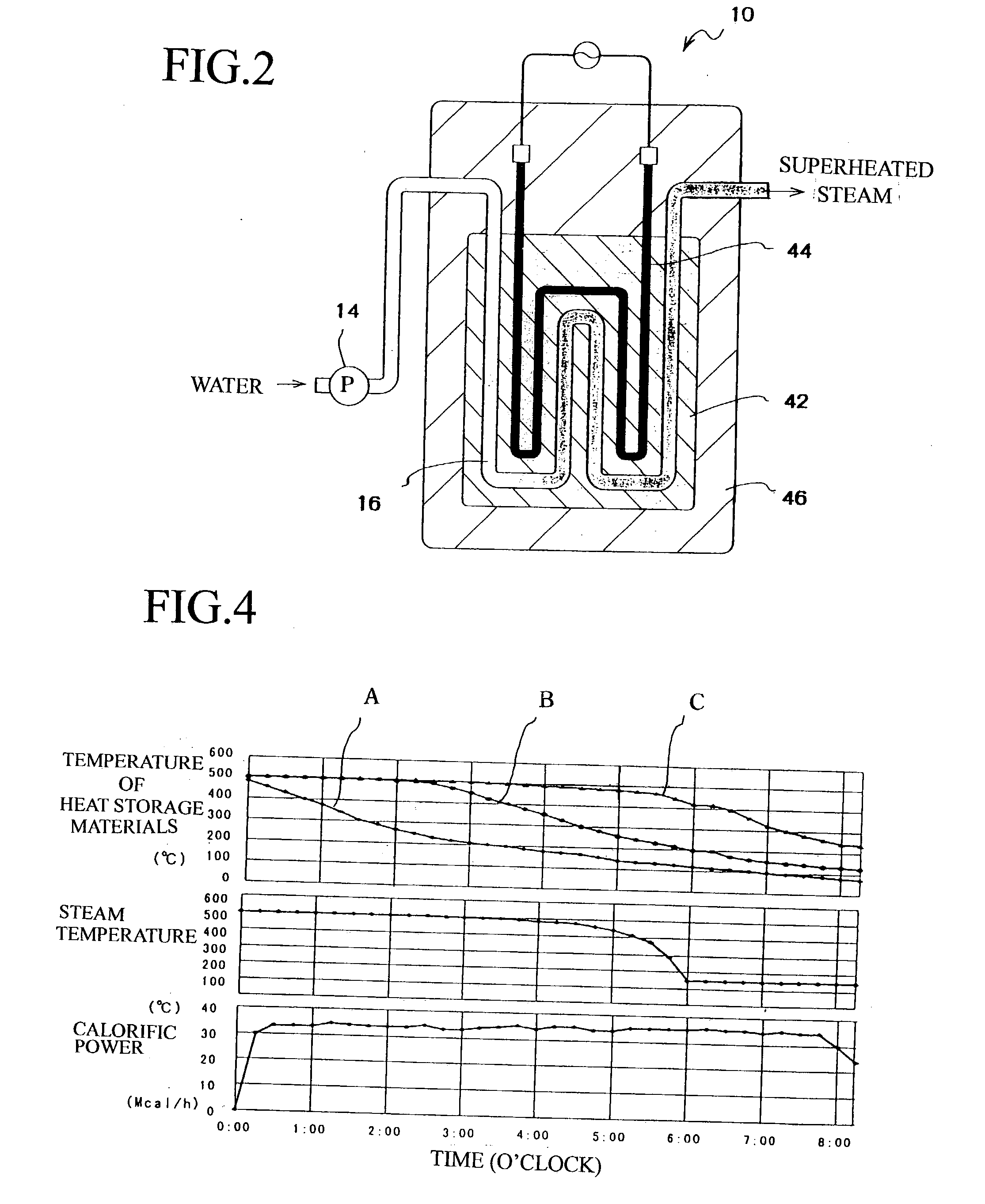

Saturated steam generator, steam sterilizer, and steam sterilization method

InactiveUS20030145806A1Liquid surface applicatorsSteam/vapor condensersHeat transmissionHeat storage material

A saturated steam generator which is provided with a heat source for heating water to generate saturated steam and which can be small-sized. A saturated steam generator for generating saturated steam by heating water with superheated steam resulting from being superheated in a heat transmission tube (16) inserted into a heat storage tank (10), characterized by the provision of a saturated steam generator tank (12), wherein in the heat storage tank (10), disposed in a heat storage section composed by having a solid heat storage material and a liquid heat storage material filled therein are a heat transmission tube (16) and a heater (44), which heats the solid heat storage material and the liquid heat storage material, it being arranged that superheated steam resulting from passing through the heat transmission tube (16) is used as a heat source to heat stored water (22) so as to generate saturated steam.

Owner:SAKURA SEIKI

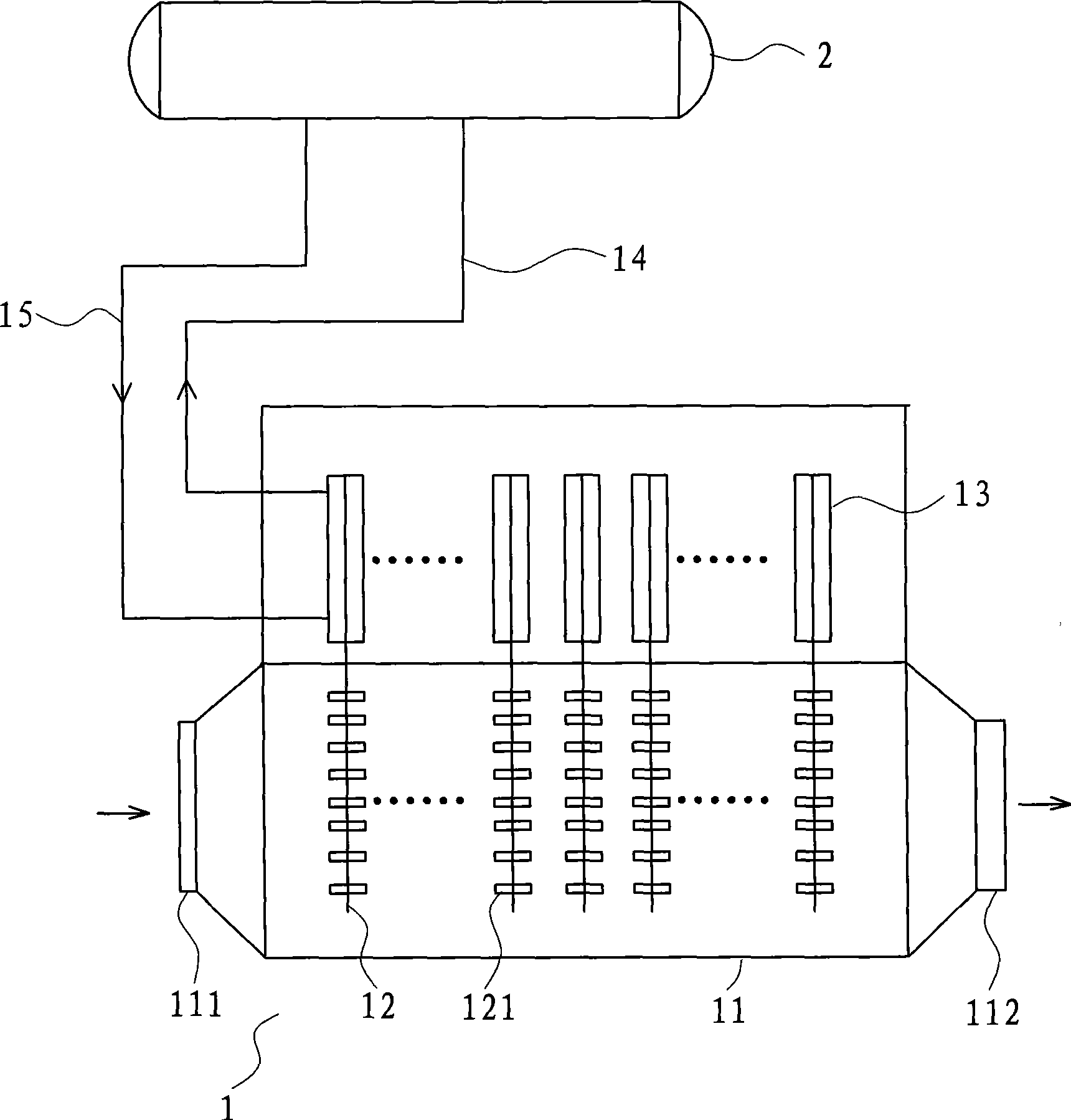

Residual heat reclaiming apparatus for boiler vent gas

InactiveCN101498437ARelieve pressureReduce qualitySteam separation arrangementsIndirect heat exchangersEngineeringLiquid metal

The invention provides a boiler end-gas waste-heat recovering device which comprises a steam generator and a steam-water separating device, wherein the steam generator comprises a box body, a plurality of heat pipes and sleeve pipes with the number corresponding to the number of the heat pipes; the box body is of a hollow structure, and is provided with an air inlet and an air outlet; one end of each heat pipe is respectively vertically arranged in the inner side of the box body; the other end of each heat pipe is respectively positioned above the box body; each heat pipe is of a sealing hollow structure; liquid absorption materials are fixed on the inner side wall of the heat pipe; proper amount of liquid metal is filled in the heat pipes; the outer side wall of each heat pipe positioned on the outer side of the box body is respectively provided with the sleeve pipe; the upper end and the lower end of each sleeve pipe are respectively communicated with the steam-water separating device; and saturated water is filled in each sleeve pipe. The invention is mainly used for heat recovering recycle of smoke gas and the end gas of a boiler.

Owner:石狮市亿祥染整有限公司

System for collecting concentrated solar radiation

InactiveUS20130047610A1Unlimited capacityLittle to no carbon dioxide emissionSolar heating energySolar heat devicesEvaporation heat transferEngineering

The present invention is directed to a solar energy system including a tower having a solar radiation receiver, the solar radiation receiver including a plurality of tubes carrying a heat-transfer medium and a drum, the drum in thermal communication with the tubes, and one or more mirrors configured to reflect solar radiation onto the receiver, wherein the receiver receives the reflected solar radiation from the mirrors, thereby heating the heat transfer medium and vaporizing the heat transfer medium.

Owner:CHEVROU USA INC

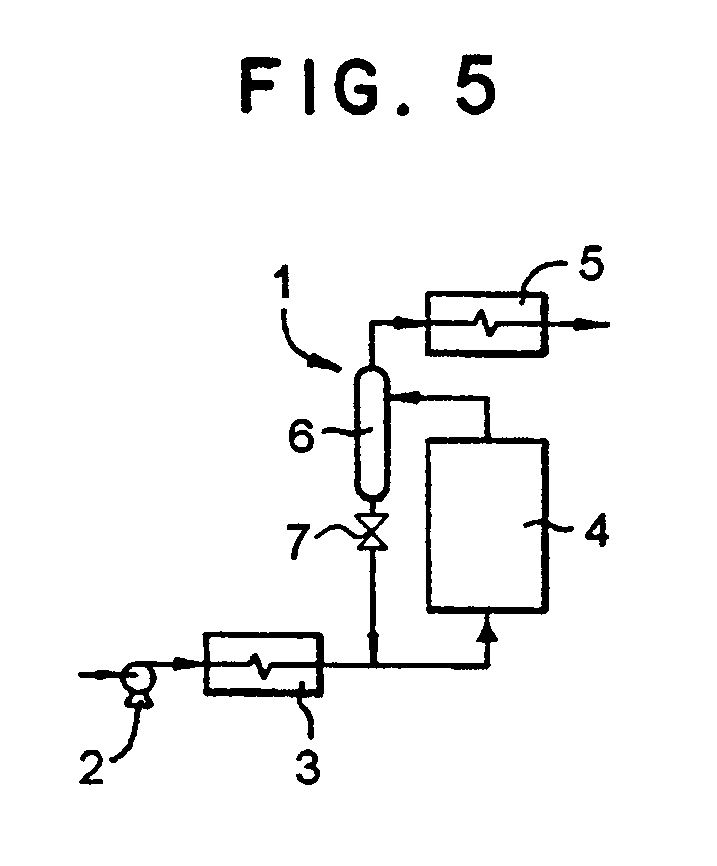

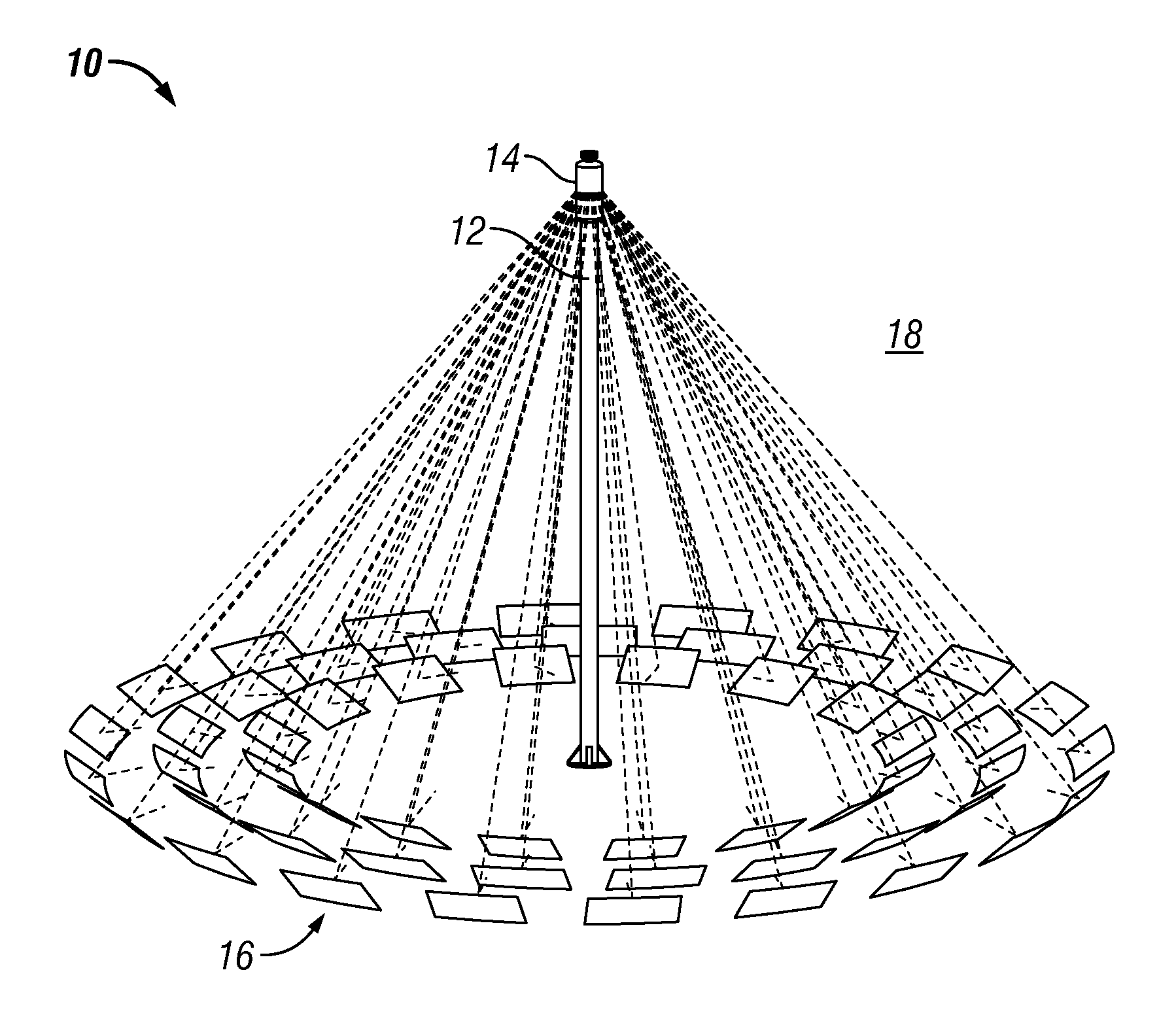

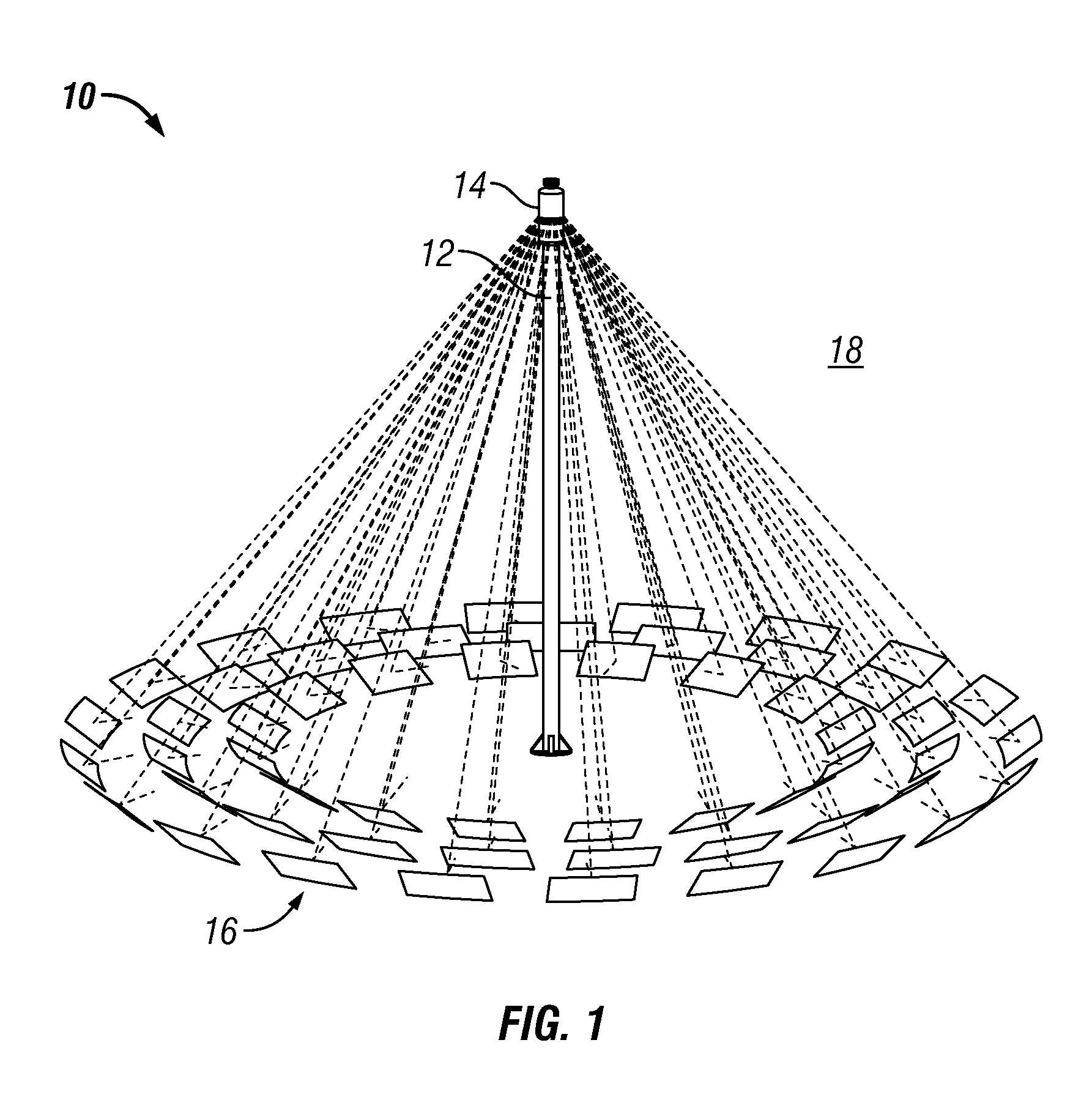

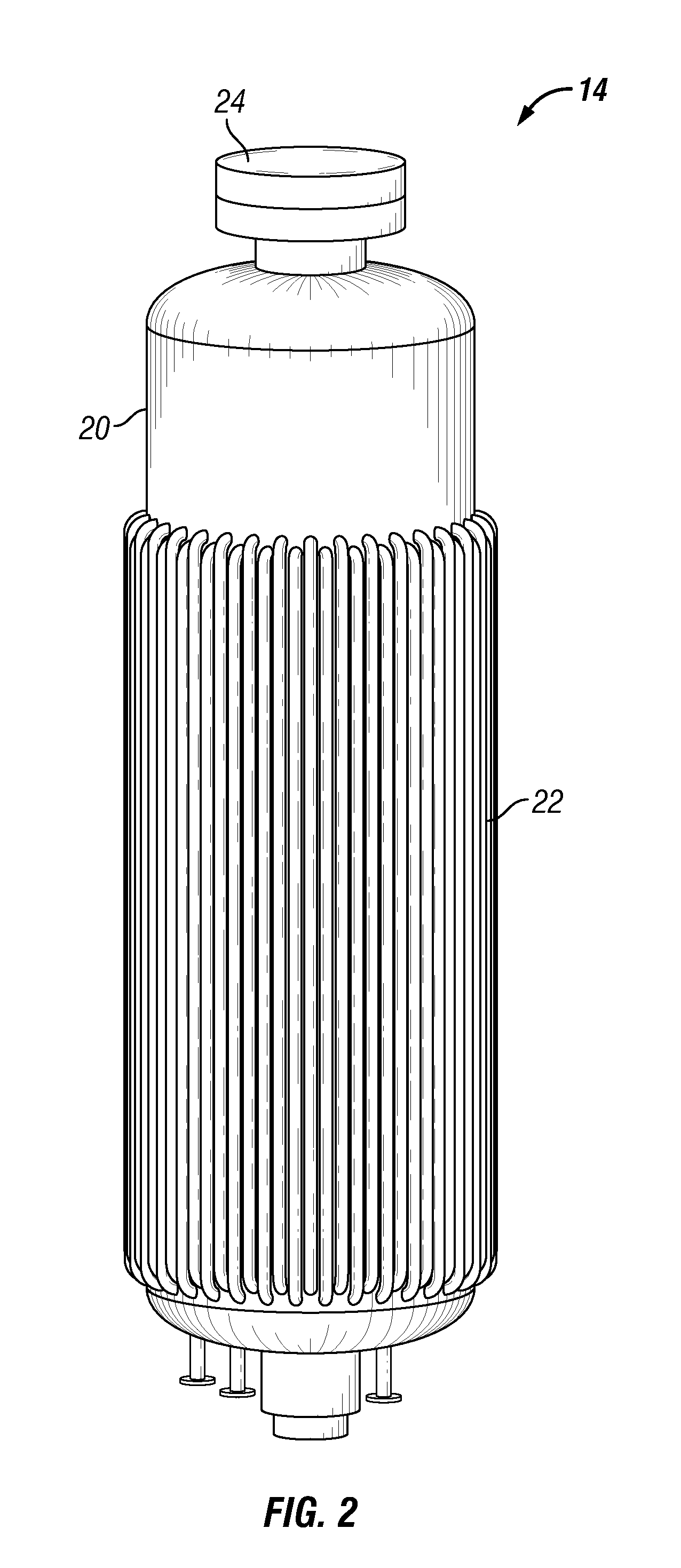

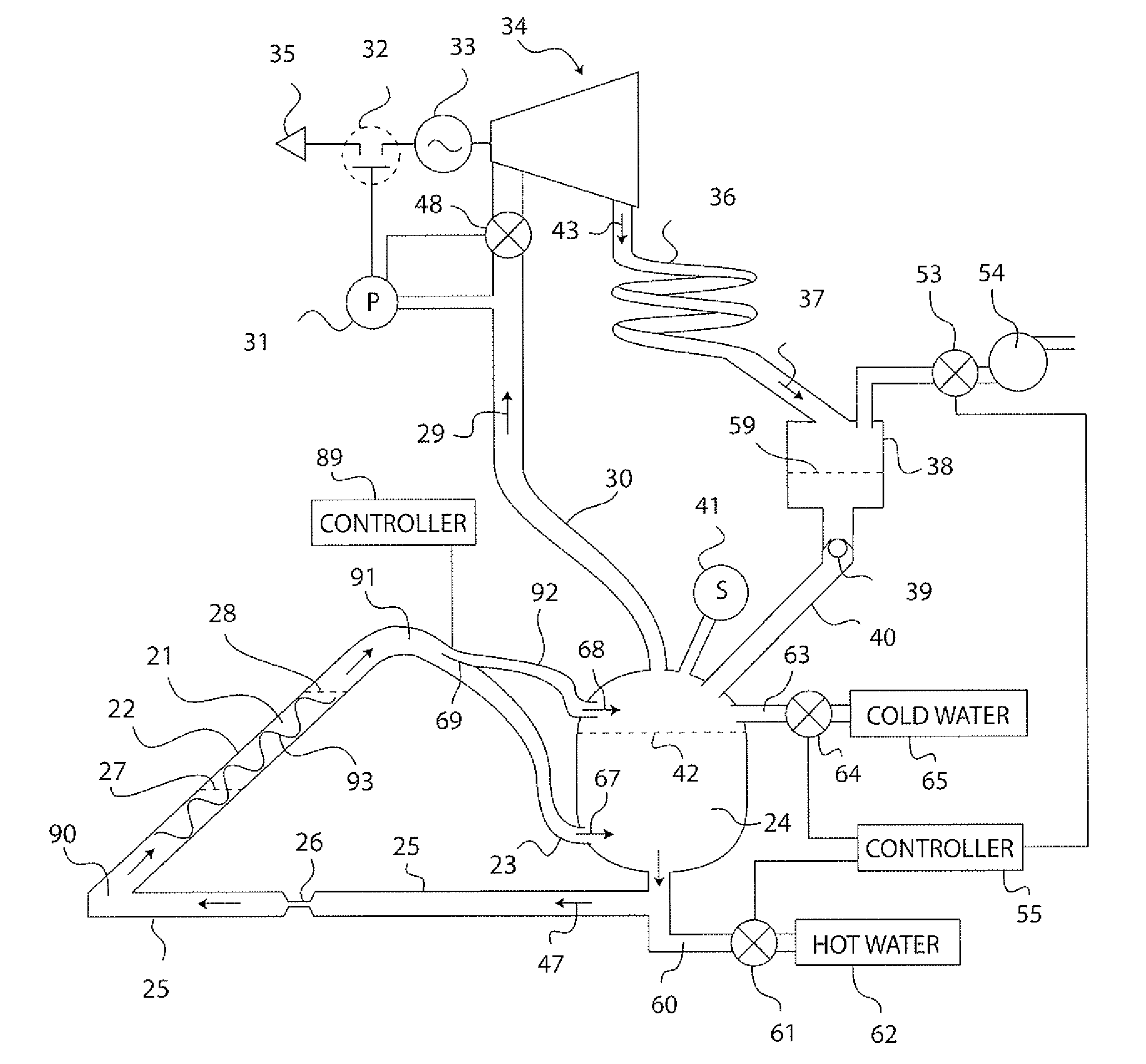

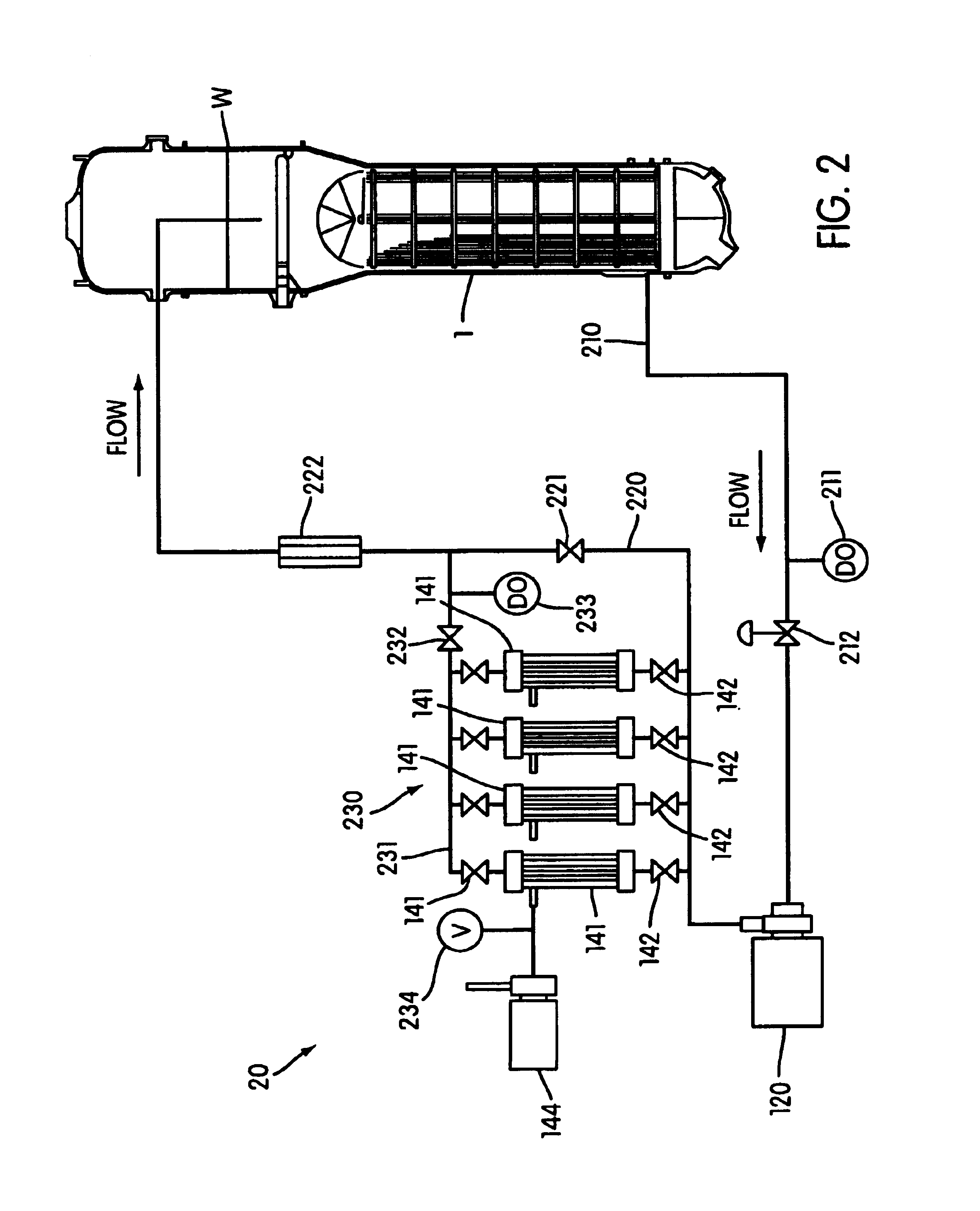

Solar thermal power system

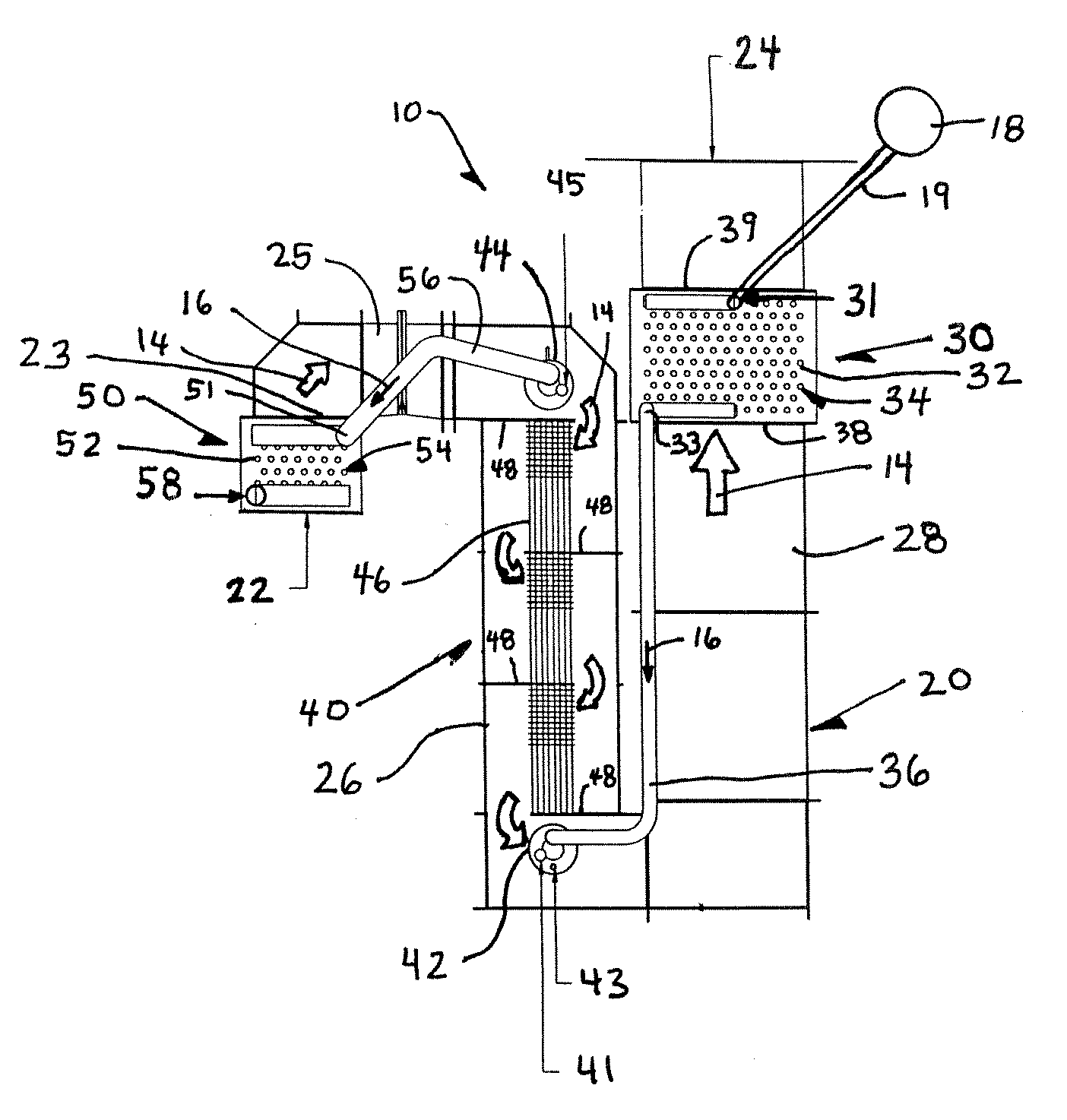

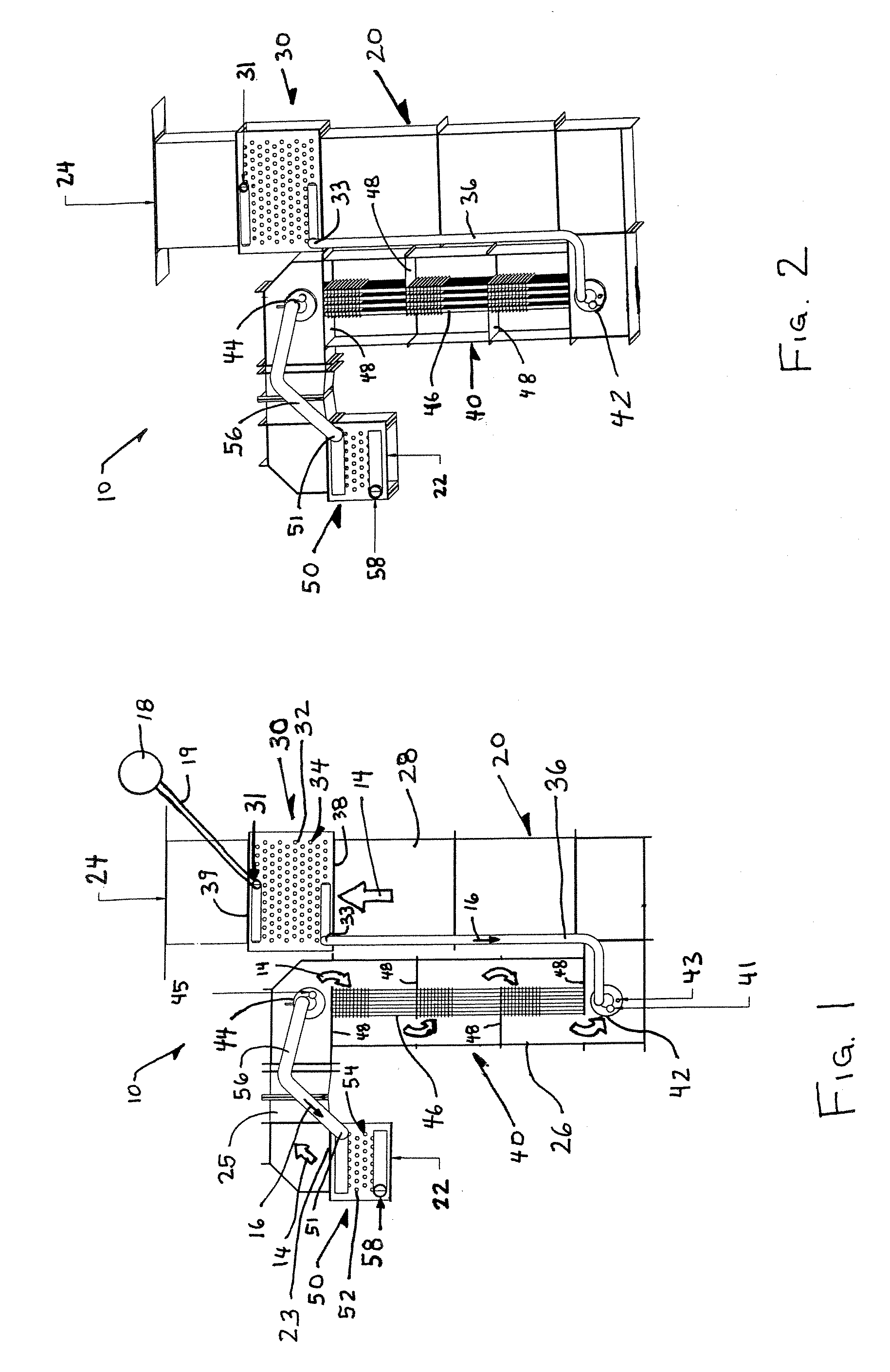

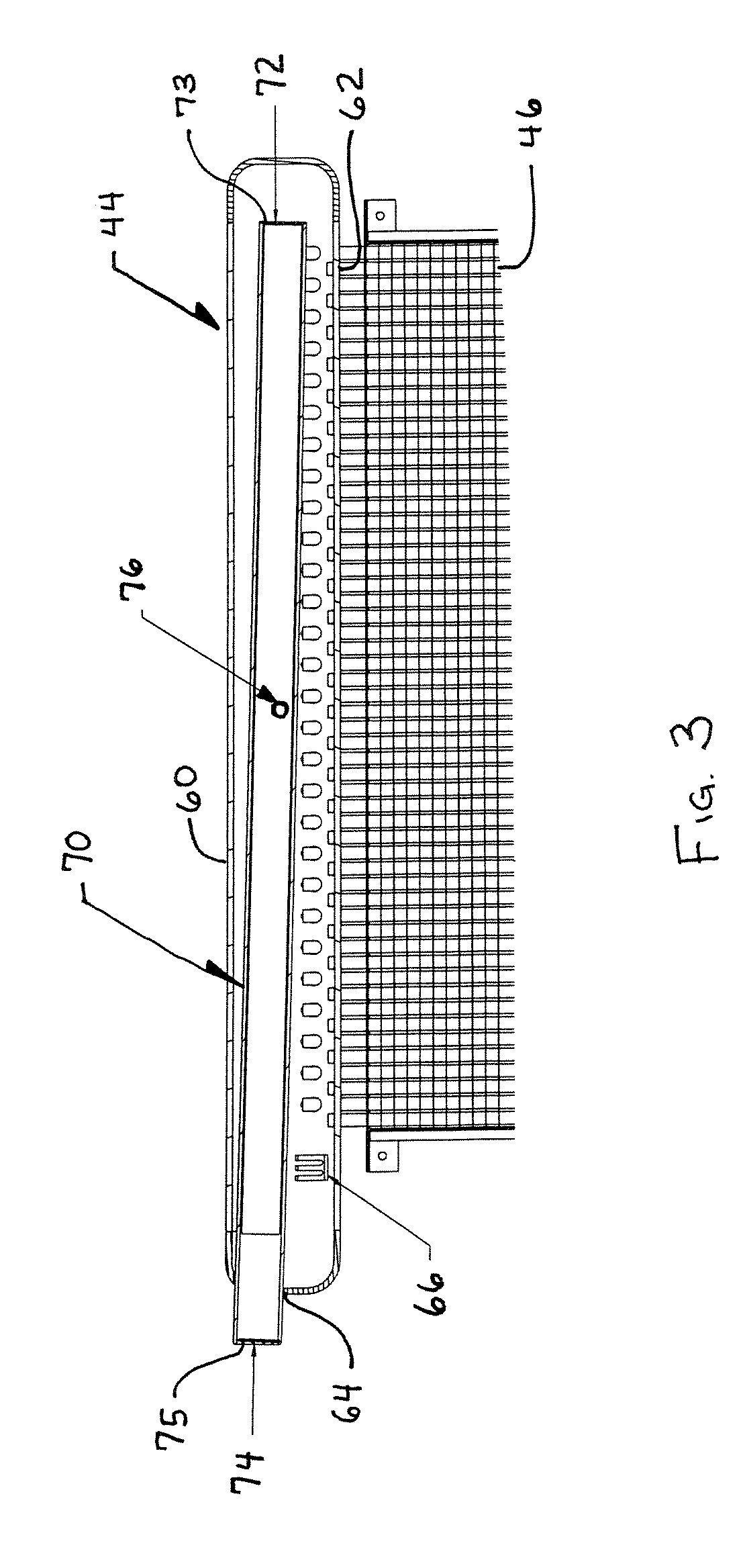

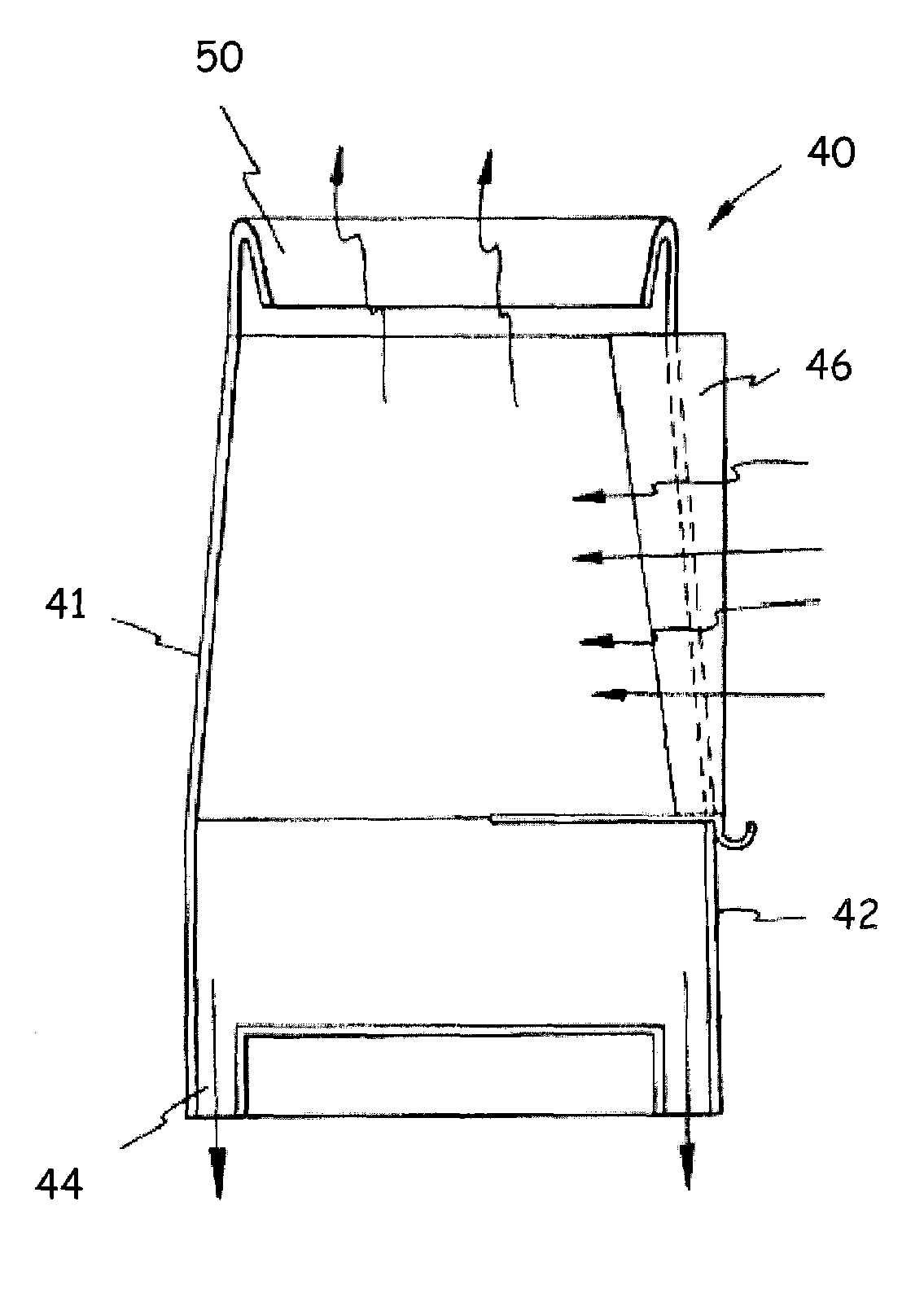

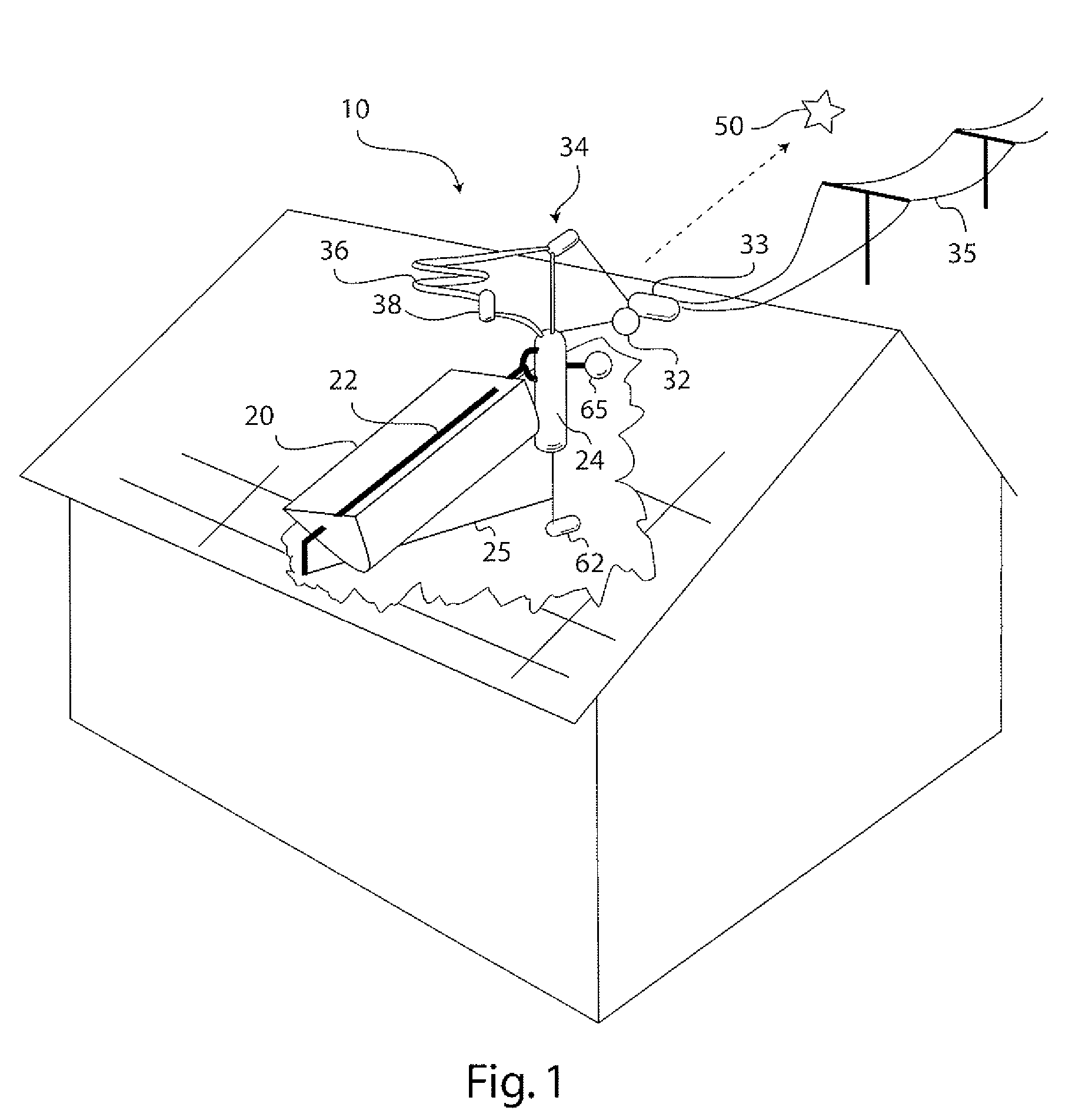

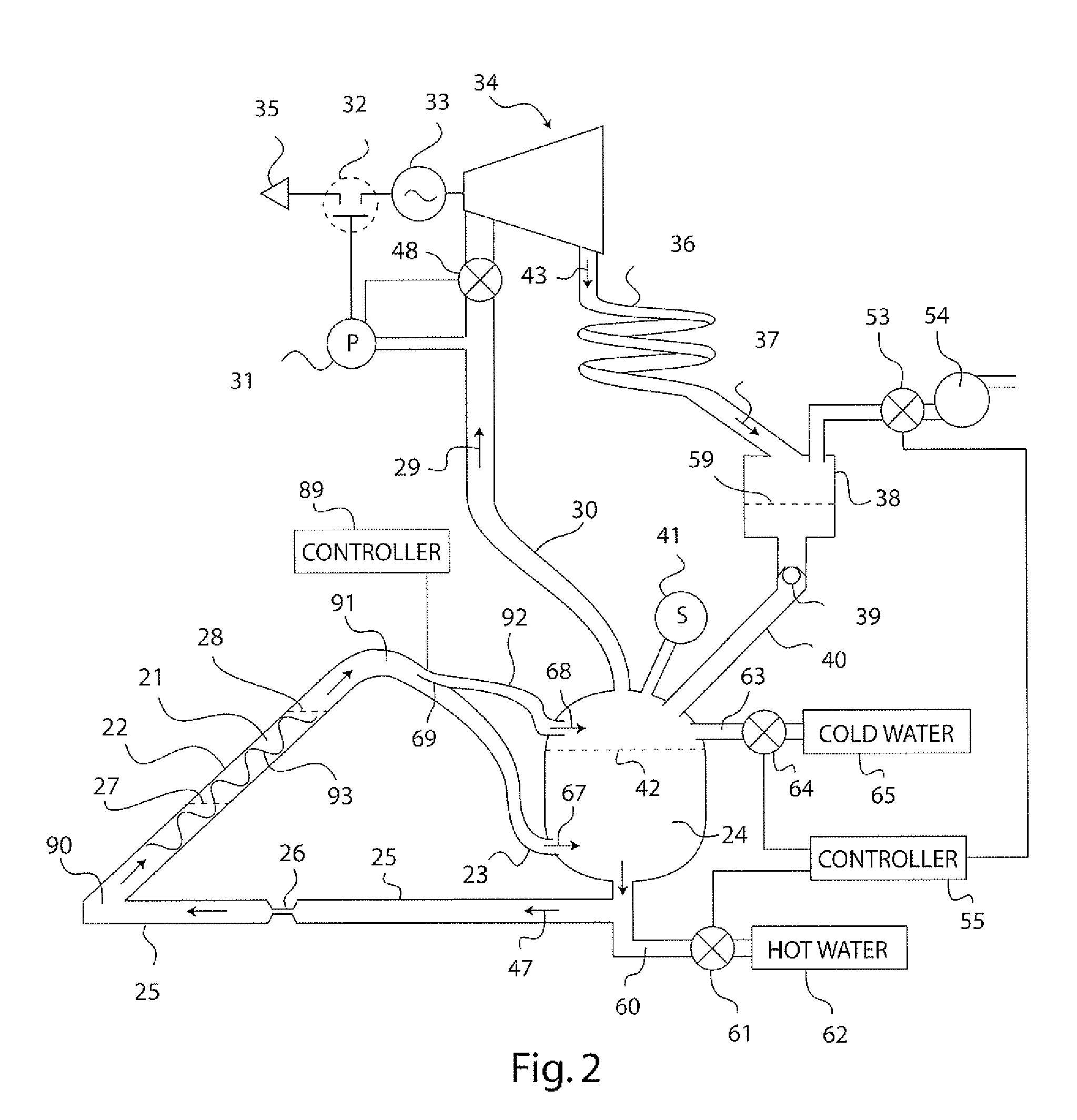

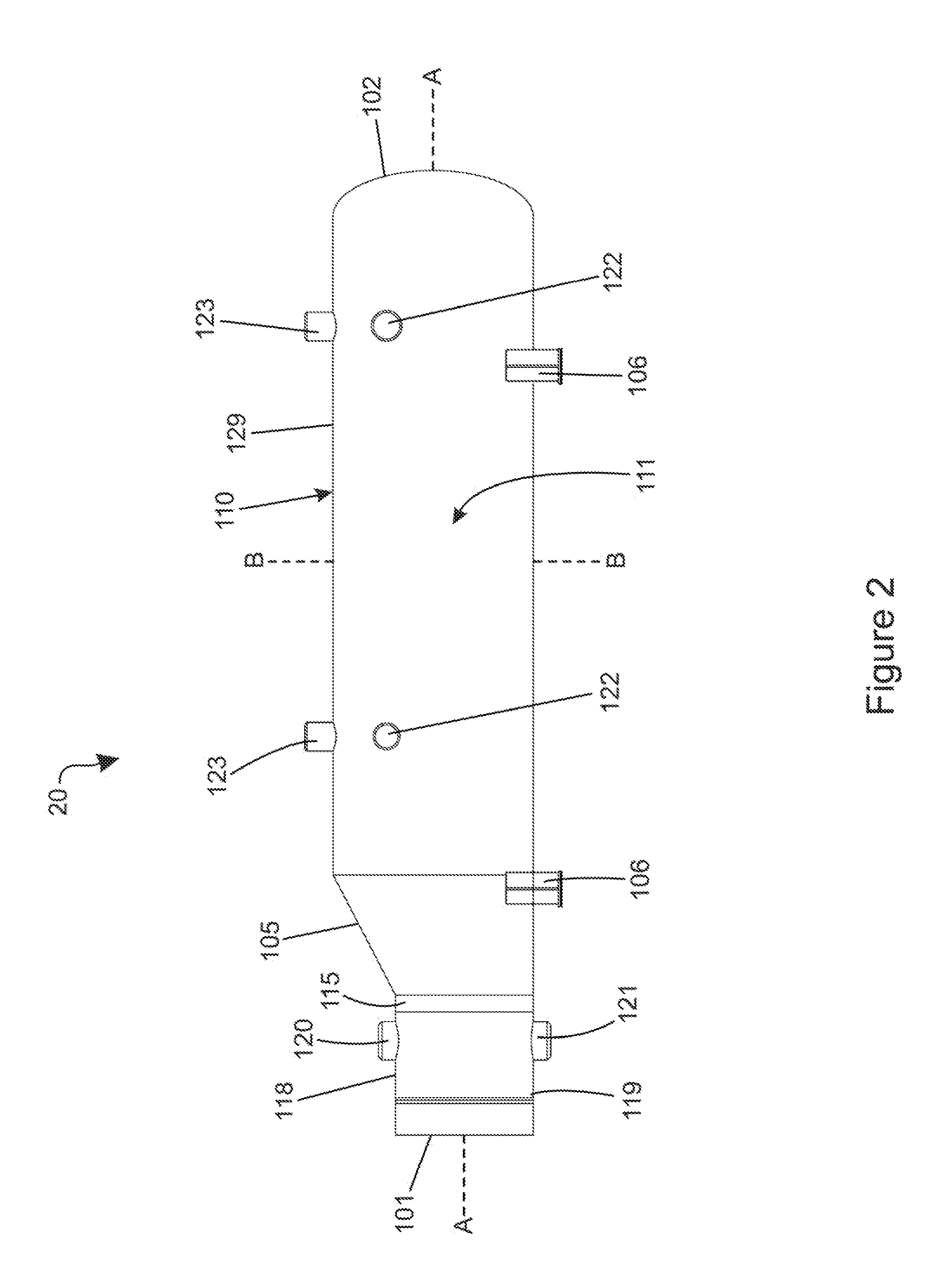

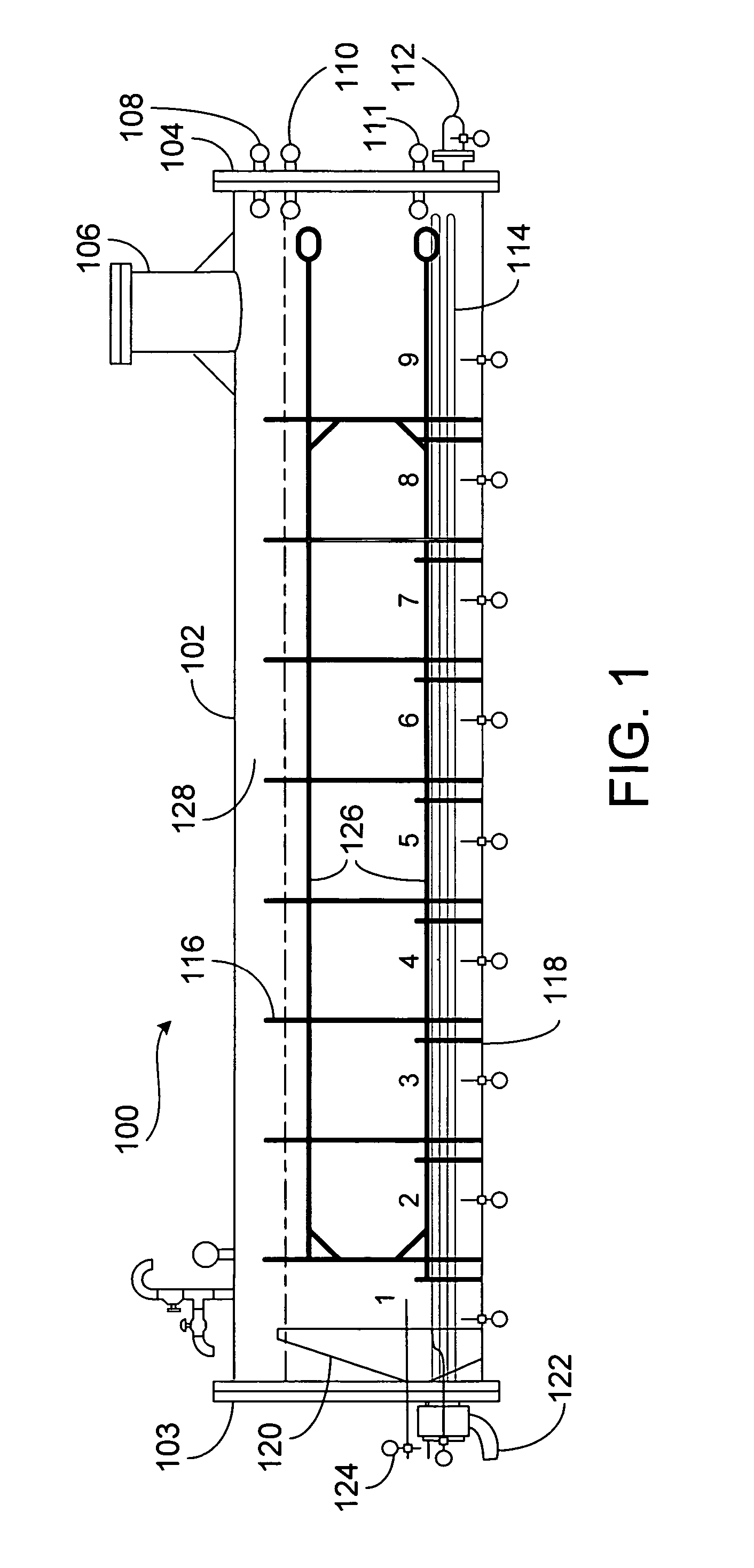

InactiveUS7735323B2Dampening flow instabilitySimple efficiencyAuxillary drivesSteam separation arrangementsThermal energy storageEngineering

A solar thermal power generator includes an inclined elongated boiler tube positioned in the focus of a solar concentrator for generating steam from water. The boiler tube is connected at one end to receive water from a pressure vessel as well as connected at an opposite end to return steam back to the vessel in a fluidic circuit arrangement that stores energy in the form of heated water in the pressure vessel. An expander, condenser, and reservoir are also connected in series to respectively produce work using the steam passed either directly (above a water line in the vessel) or indirectly (below a water line in the vessel) through the pressure vessel, condense the expanded steam, and collect the condensed water. The reservoir also supplies the collected water back to the pressure vessel at the end of a diurnal cycle when the vessel is sufficiently depressurized, so that the system is reset to repeat the cycle the following day. The circuital arrangement of the boiler tube and the pressure vessel operates to dampen flow instabilities in the boiler tube, damp out the effects of solar transients, and provide thermal energy storage which enables time shifting of power generation to better align with the higher demand for energy during peak energy usage periods.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

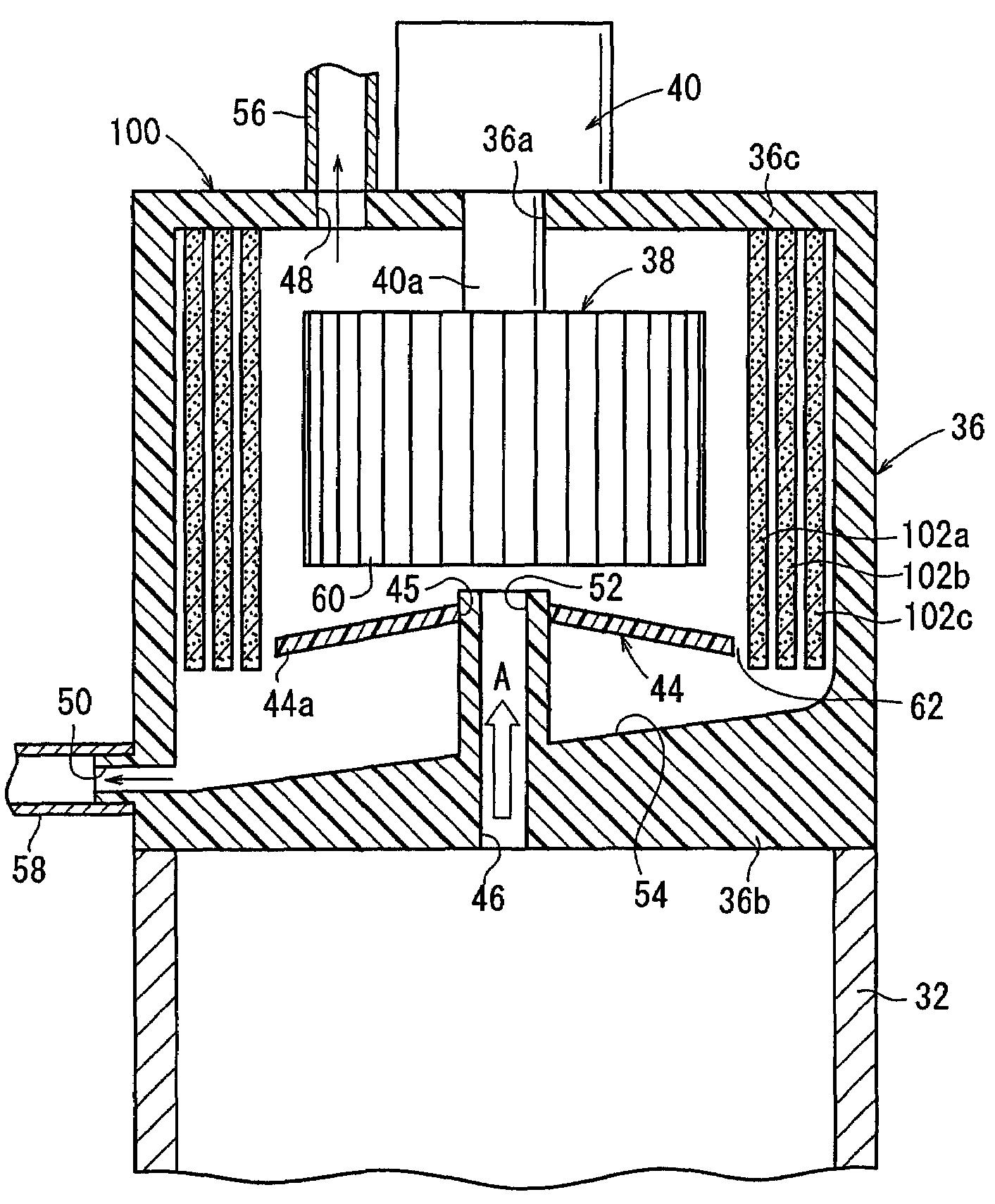

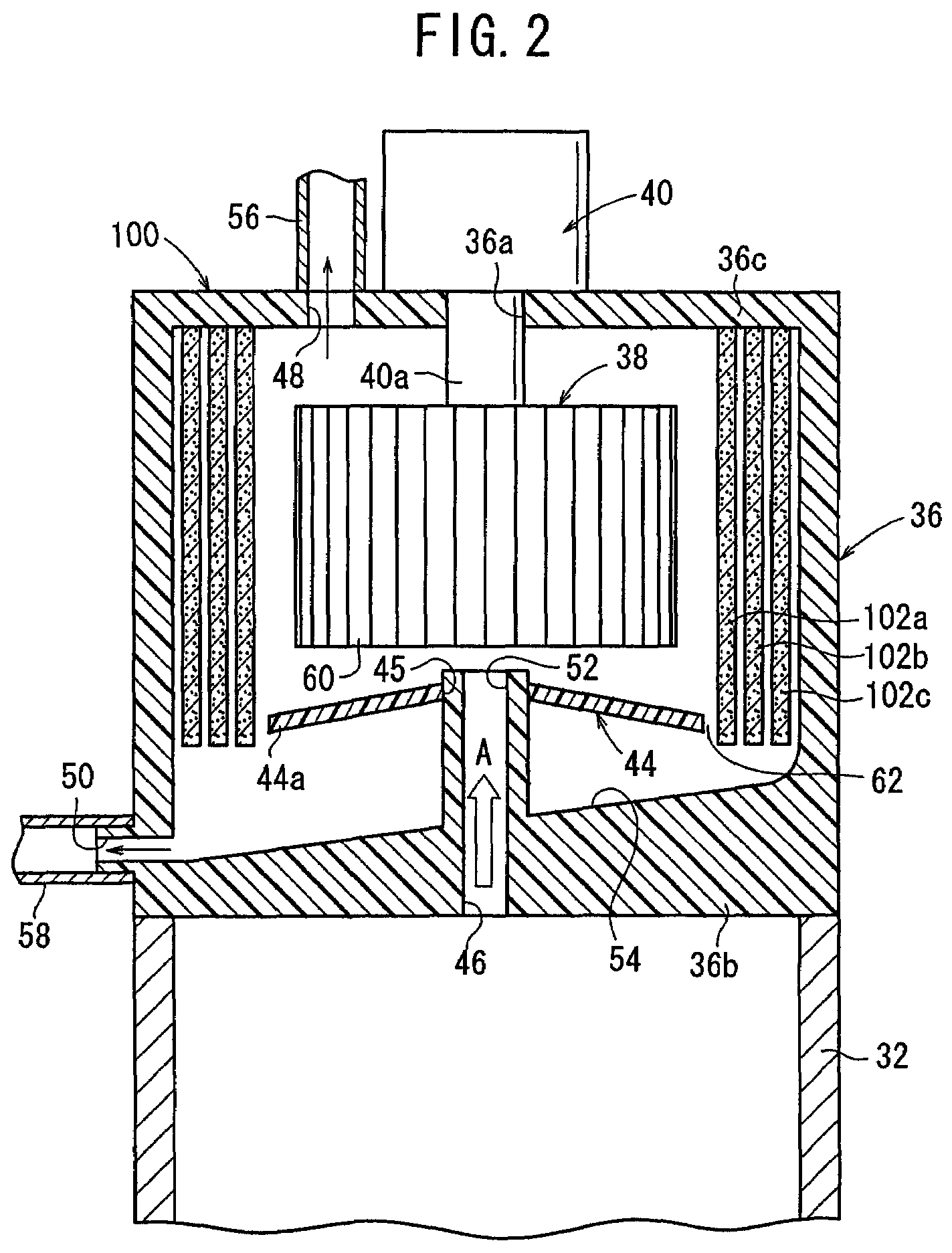

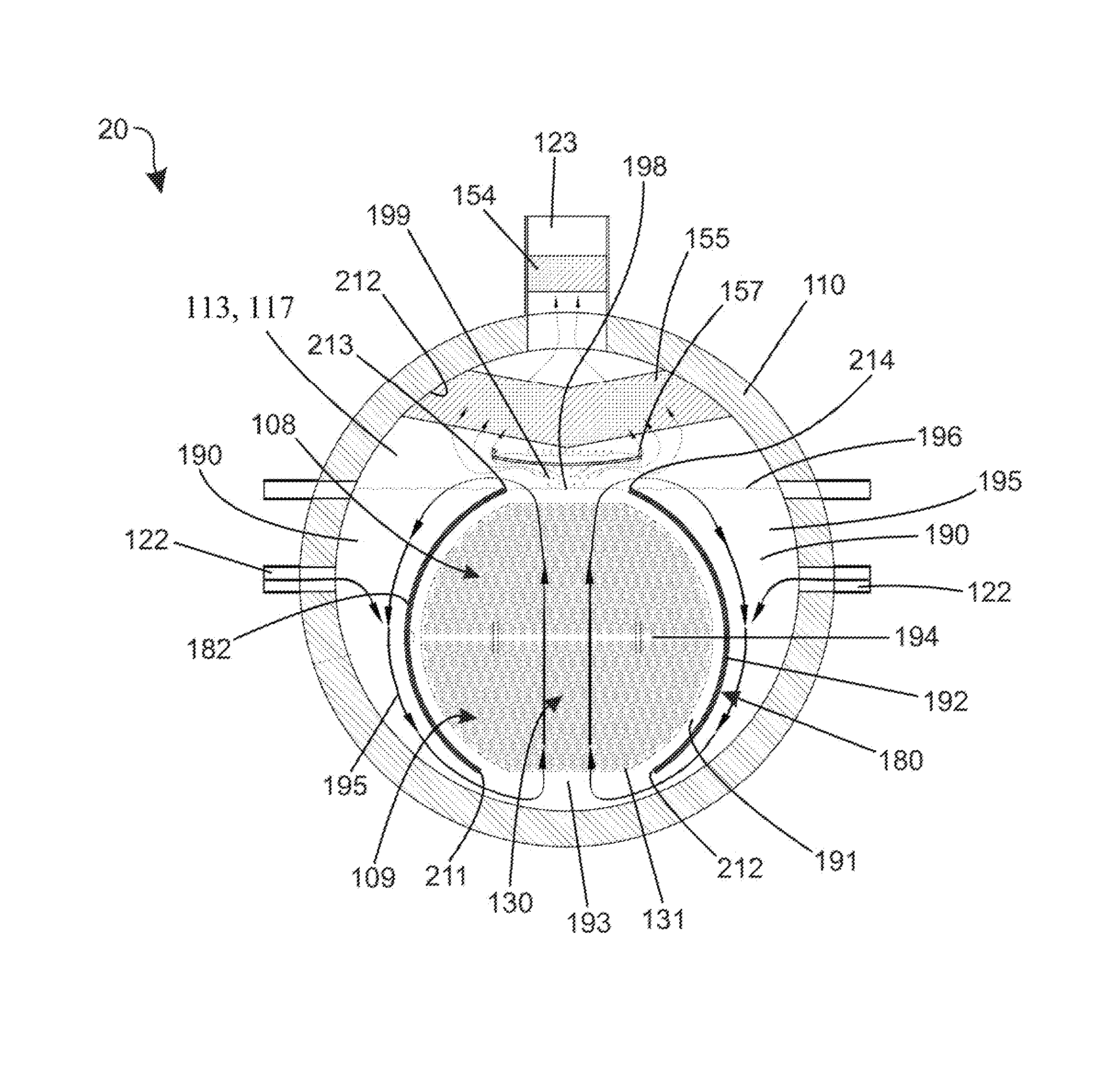

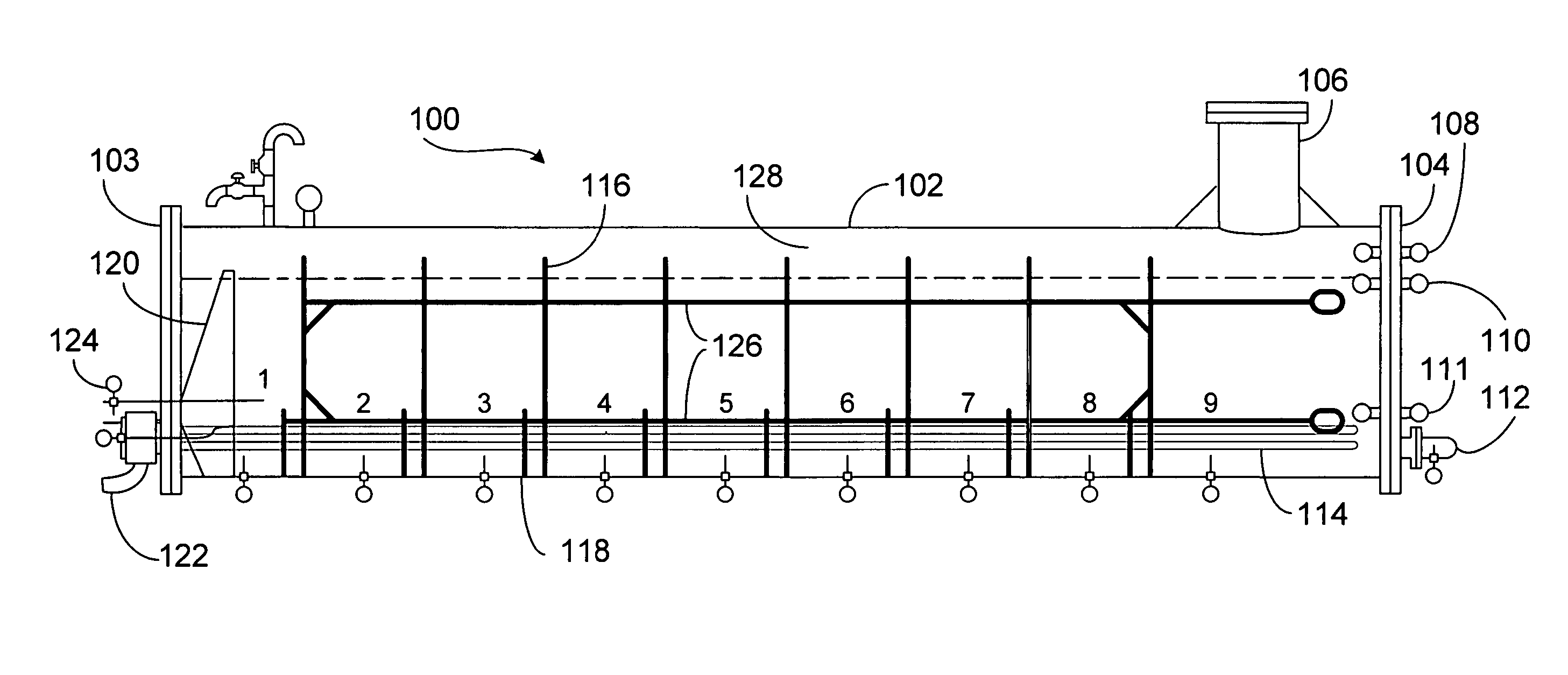

Heat exchanger apparatus for converting a shell-side liquid into a vapor

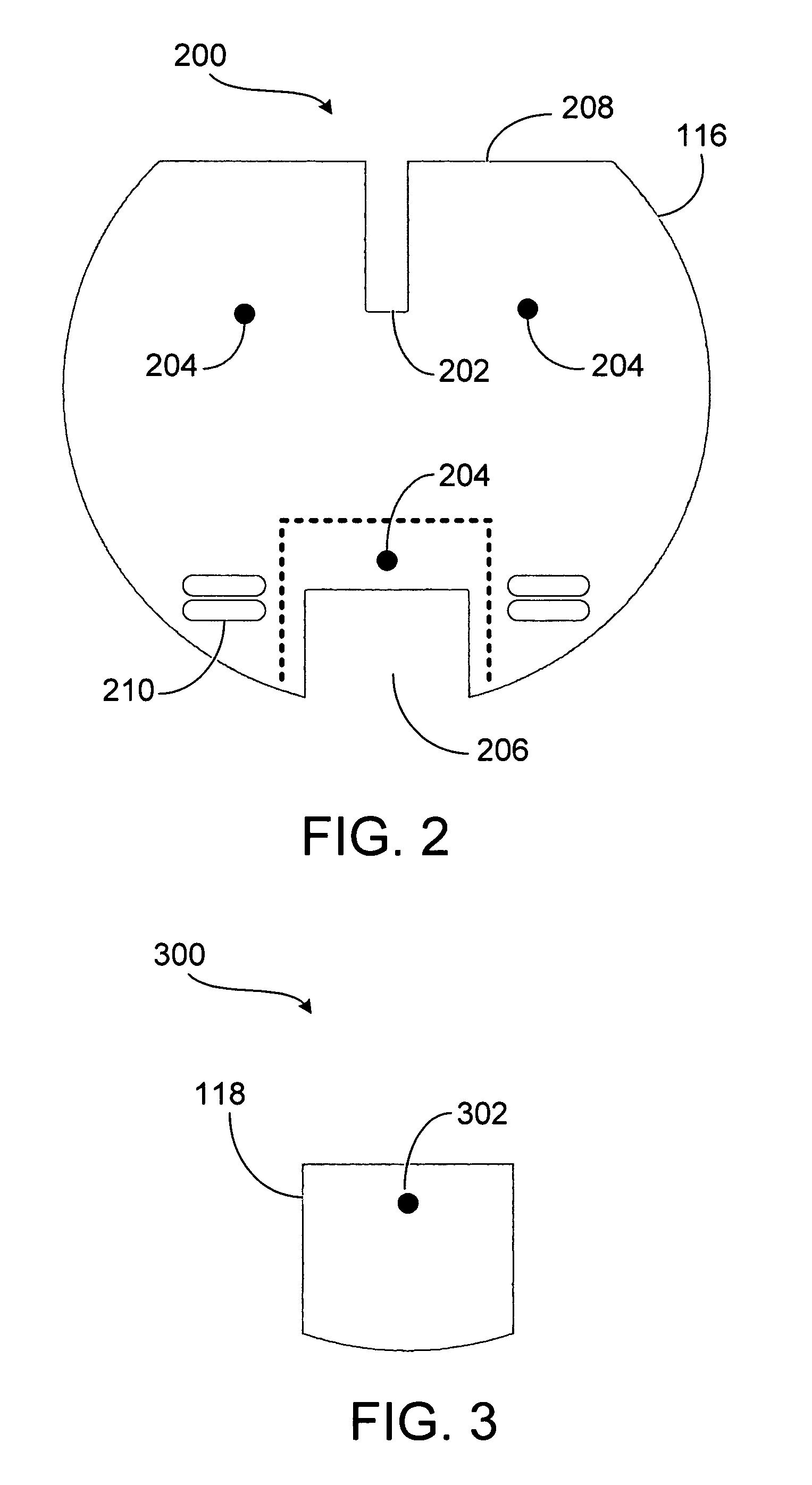

ActiveUS8833437B2Eliminate and minimize occurrenceBig ratioSteam/vapor condensersSteam separation arrangementsEngineeringMechanical engineering

An apparatus for generating steam within a heat exchanger. In one aspect, the invention can be a heat exchanger comprising: a shell having an inner surface forming a cavity, the shell comprising an inlet for introducing the shell-side liquid into the cavity and an outlet for allowing the vapor to exit the cavity; a tube bundle comprising a plurality of tubes for carrying a tube-side fluid located in the cavity and having a longitudinal axis; a shroud circumferentially surrounding the tube bundle and positioned between the tube bundle and the inner surface of the shell so that an annular space exists between the shroud and the inner surface; an opening in a bottom portion of the shroud that forms a passageway between the annular space and the tube bundle; and an opening in a top portion of the shroud that forms a passageway between the annular space and the tube bundle.

Owner:HOLTEC INT

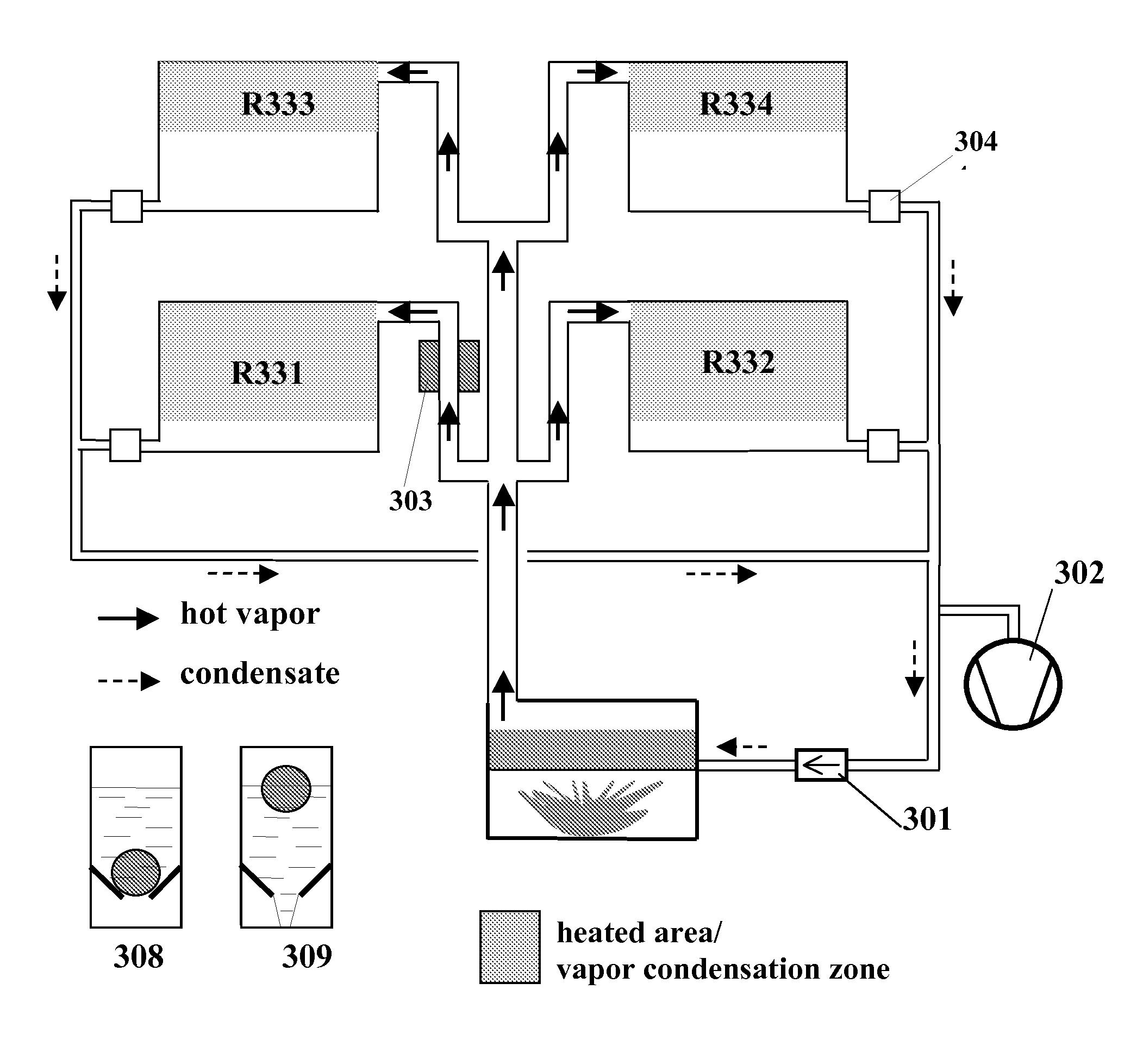

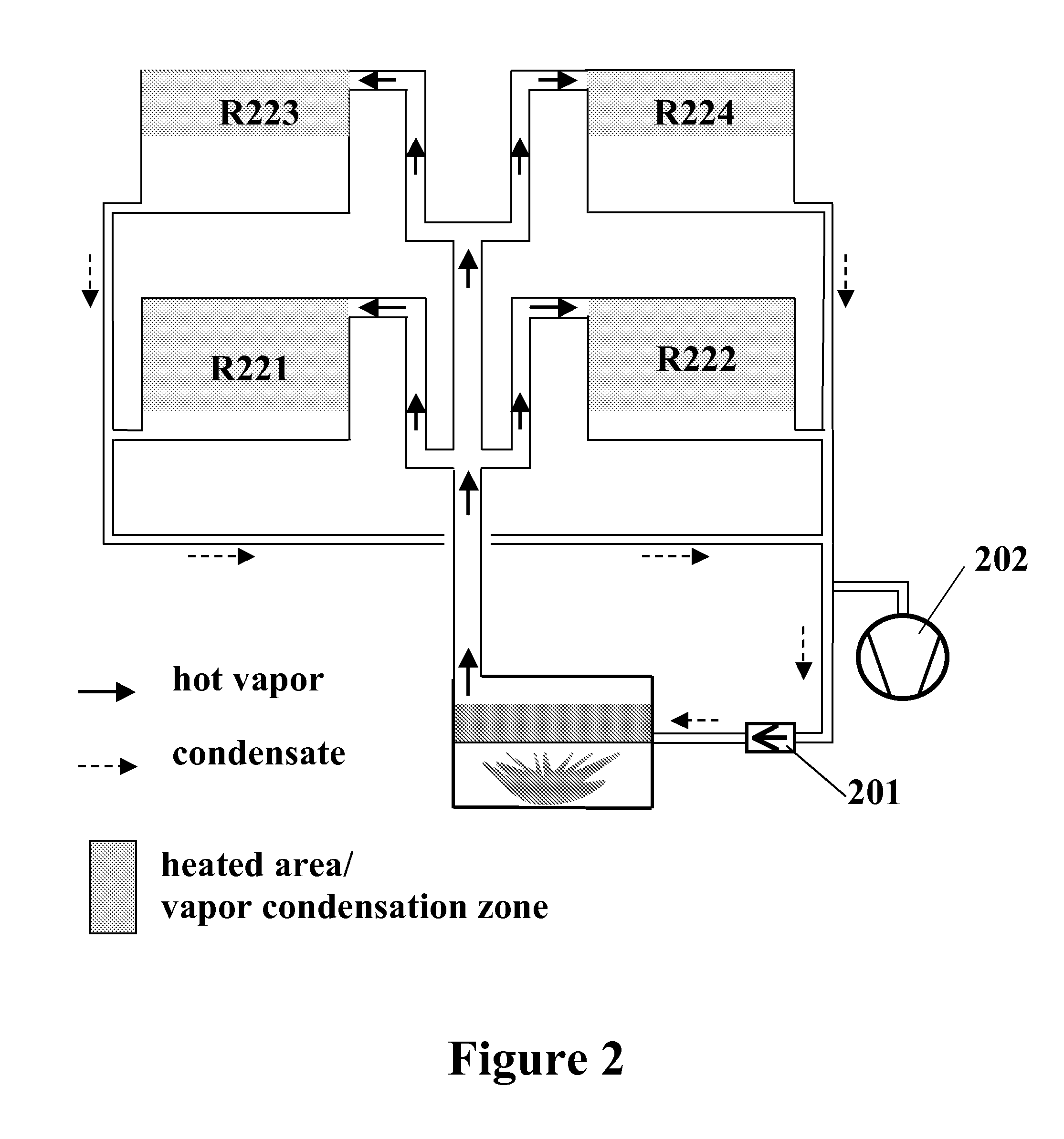

Vacuum sustaining heating systems and methods

ActiveUS20150076241A1Prevent condensate floodingPrevent condensate hammeringSteam separation arrangementsWater heatersField testsProcess engineering

In order to solve the numerous problems with existing steam, vacuum, and hot water heating systems, presented are novel systems and methods of vapor vacuum heating having several improvements over the prior art, including: condensate return which can operate without steam traps; naturally-induced vacuum; improved vacuum pump operation for sustaining vacuum in such systems; liquid lift apparatus for use with such systems; and other improvements. All innovations presented herein make vapor vacuum heating more efficient and economical for industrial, commercial, and home applications. A field test conducted with these innovations show results of about 26-50% reduced energy usage, implying significant energy savings from the use of the present invention over current heating systems.

Owner:ZHADANOVSKY IGOR

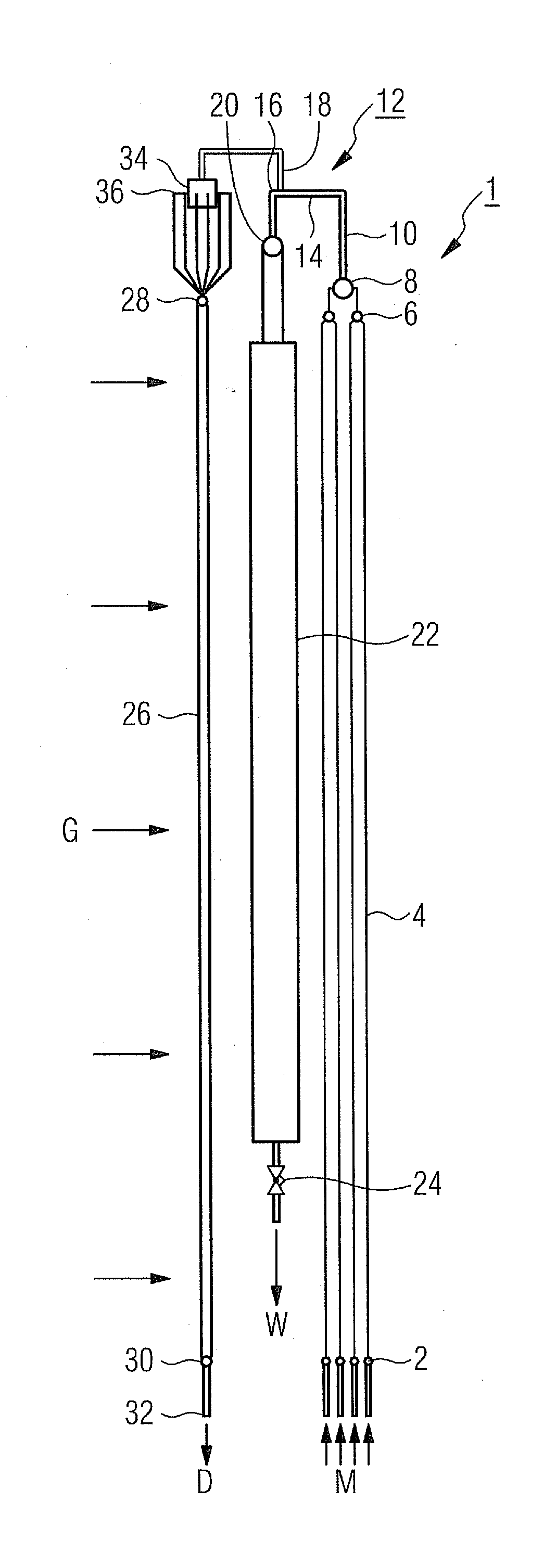

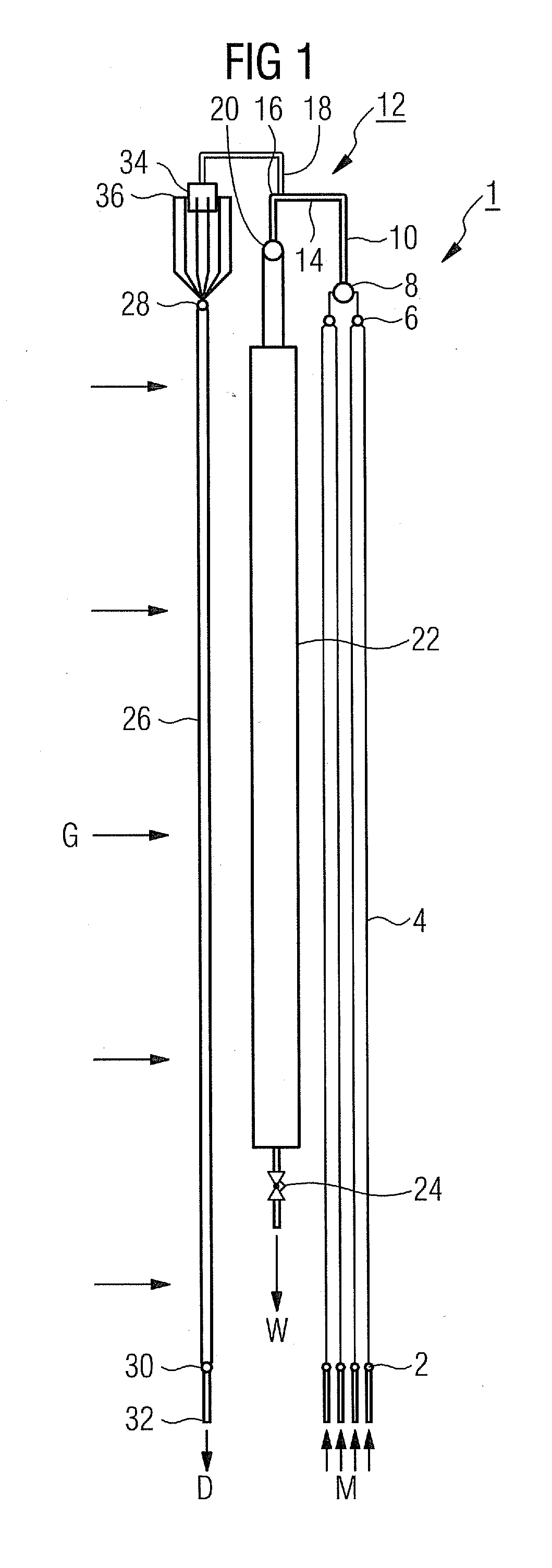

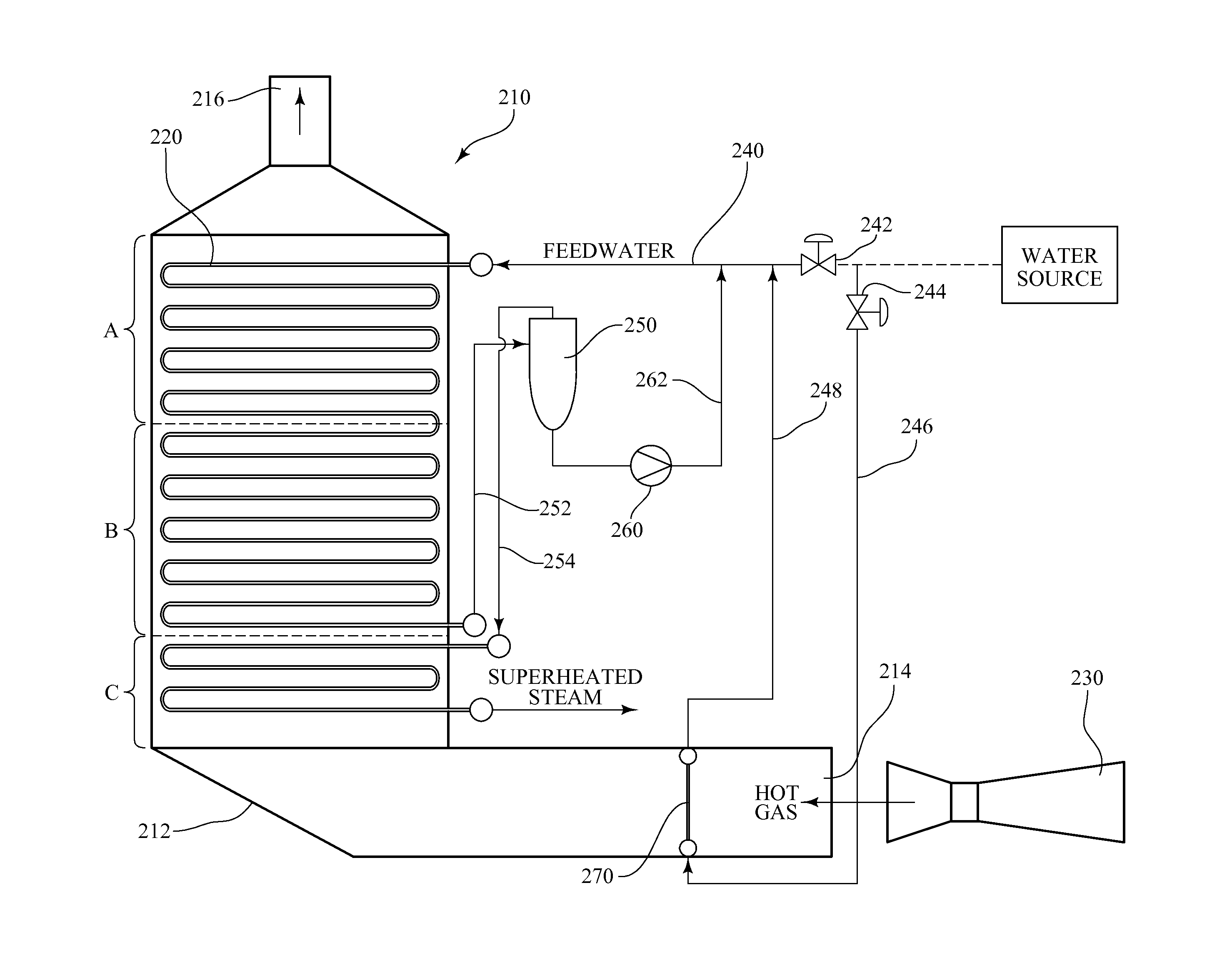

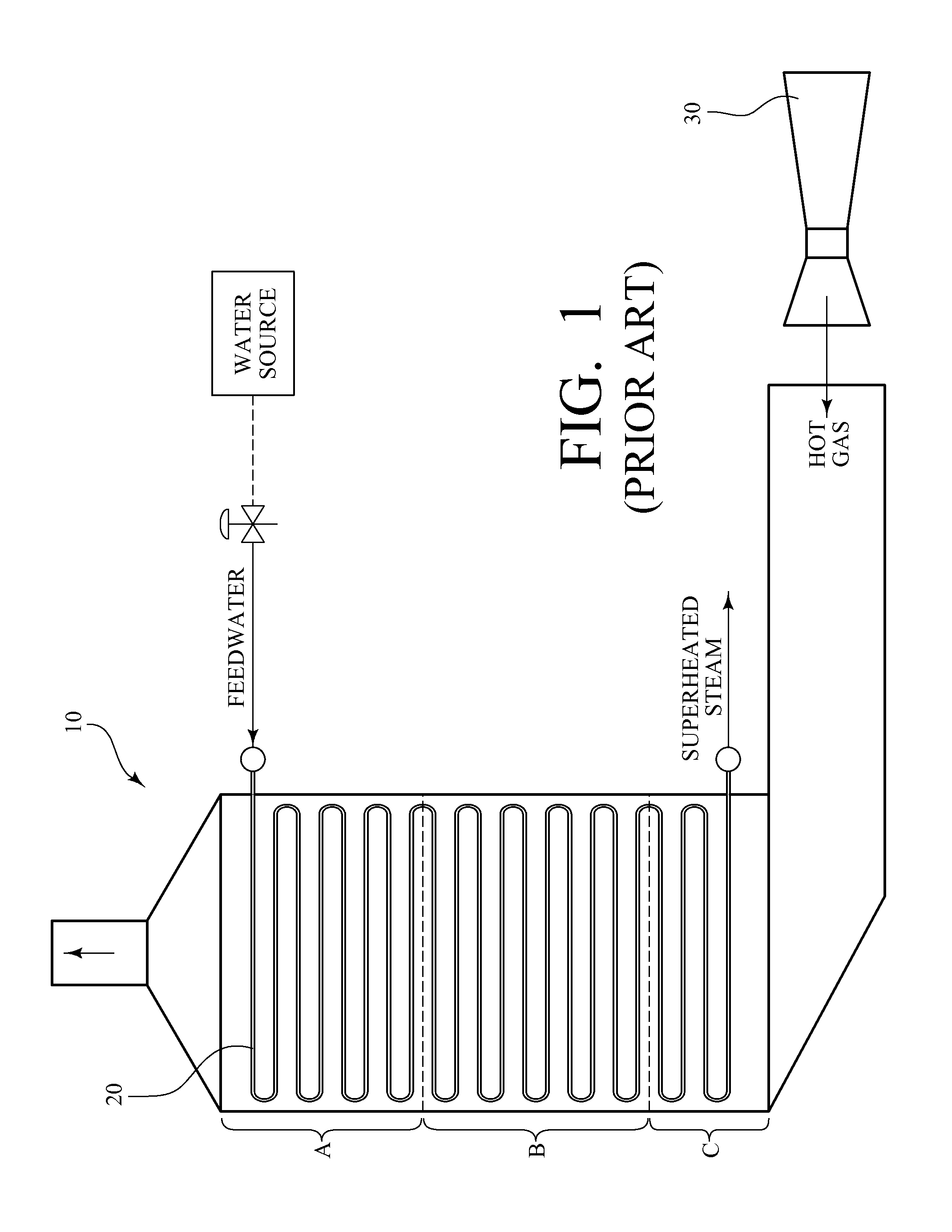

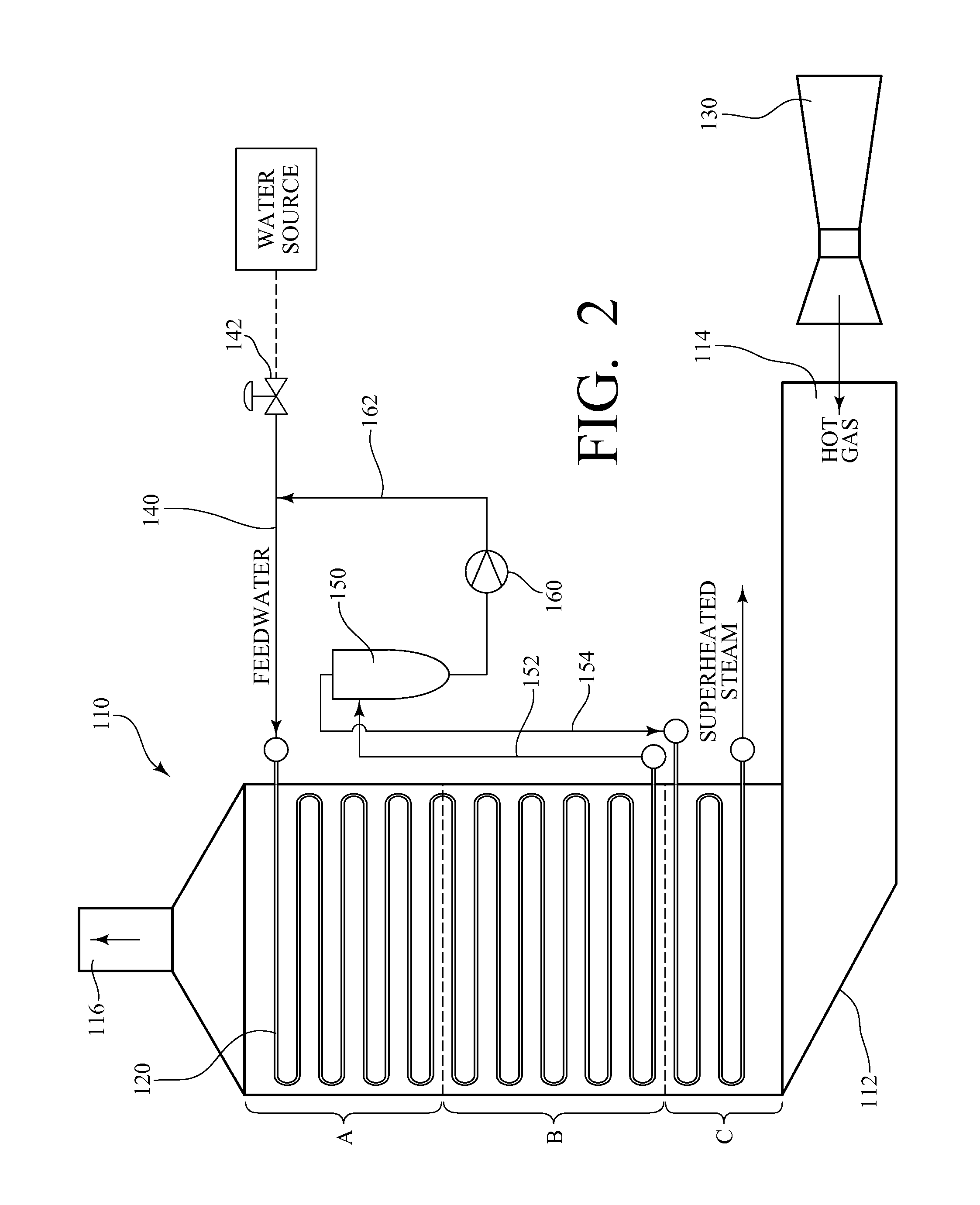

Once-through steam generator

InactiveUS20140123914A1Minimizes problemControl changesControlling ratio of multiple fluid flowsSteam separation arrangementsEngineeringSuperheater

A once-through steam generator comprises a duct having an inlet end in communication with a source of a hot gas; and a tube bundle installed in the duct and comprising multiple heat transfer tubes. The tube bundle has an economizer section, an evaporator section, and a superheater section. A steam separating device may be positioned between the evaporator section and the superheater section, wherein, as part of a wet start-up, hot water collected by the steam separating device is delivered from the steam separating device to mix with cold feedwater before it is introduced into the economizer section. A start-up module may be positioned in the duct near the inlet end, wherein, as part of a dry start-up, cold feedwater is delivered into the start-up module to generate hot water that is then mixed into the feedwater stream before it is introduced into the economizer section.

Owner:VOGT POWER INT

Steam Generator

ActiveUS20090071419A1Improve operational flexibilityShort reaction timeWater circulationSteam separation arrangementsElectric generatorEvaporator

The invention relates to a steam generator wherein a continuous heating panel of a generator, which is formed from a number of evaporator tubes, and an overheating panel, which is formed from a number of over-heating tubes which are arranged downstream from the evaporator tubes and on the flow side, are arranged in a heating gas channel. According to the invention, a water separating element is integrated into a number of over-flow tubes which are connected on the flow side of one of several evaporator tubes to one or several overheating tubes.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

Liquid degassing system for power plant system layup

InactiveUS6955706B2Easy to monitorDispersed particle filtrationSteam separation arrangementsPower stationVacuum pressure

A system for producing and maintaining high purity degassed layup water for use in a power plant system during a layup period is disclosed. The liquid degassing system includes a degassing assembly for removing a predetermined amount of the undesired gases under vacuum pressure from the layup solution such that the amount of desired gases within the layup solution remains at or below standard values.

Owner:DOMINION ENG

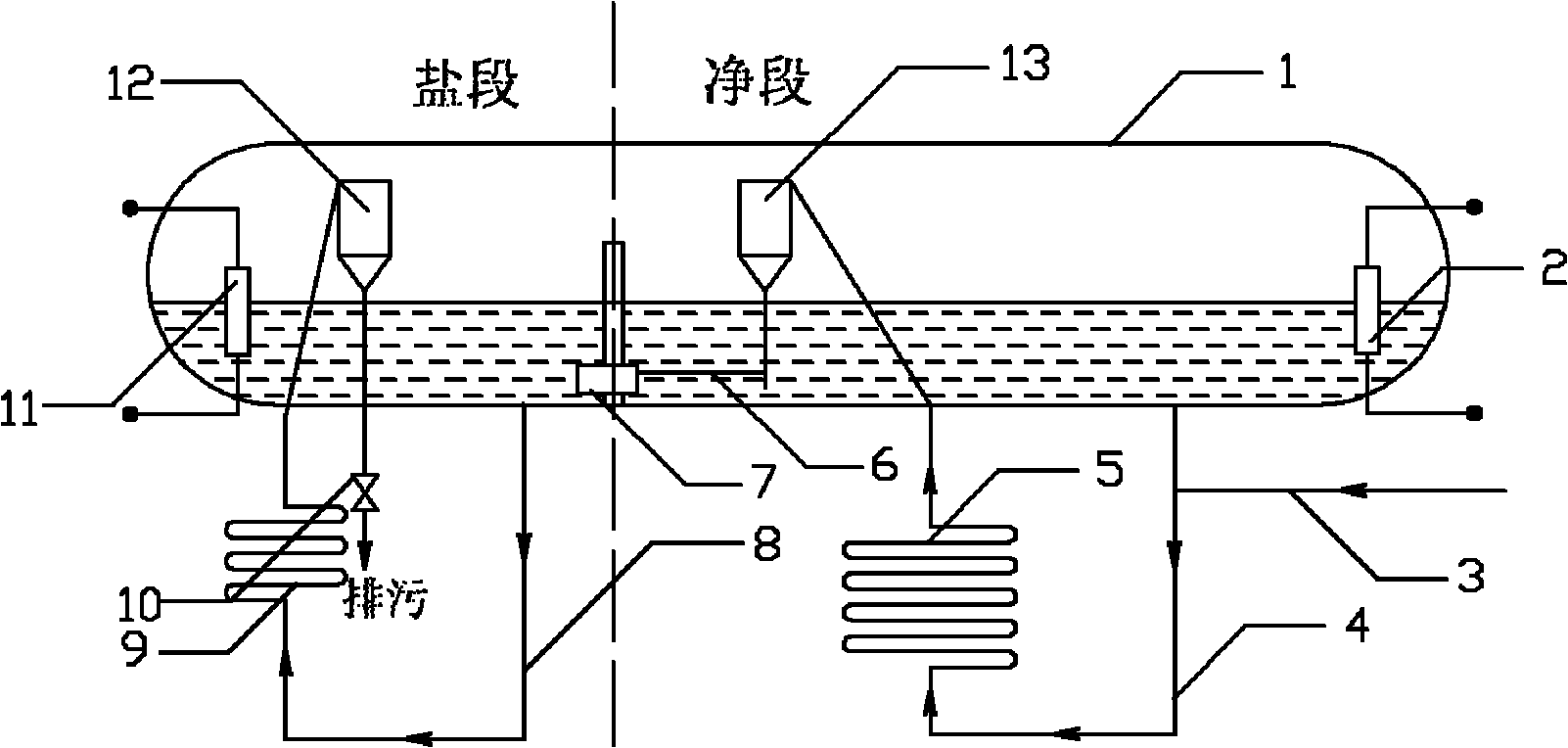

Natural circulating steam injection boiler fed with high salt-containing softened water and water circulating method

ActiveCN101979917ASmooth circulationReduced hydrodynamic safetyBoiler drums/headersBoiler cleaning apparatusBoiler blowdownSoftened water

The invention discloses a natural circulating steam injection boiler fed with high salt-containing softened water and a water circulating method, and belongs to the fields of natural circulating steam pocket water power technology and stage evaporation technology. A steam pocket is divided into a net section and a salt section, boiler feed water is directly introduced into a vertical down pipe of the net section of the steam pocket, and the evaporation heating surface of the net section is arranged on the heating surface of a hearth. The feed water of the salt section of the steam pocket is supplied by the boiler water of the net section, the evaporation heating surface of the salt section is arranged in a flue at the tail of the boiler, and the sewerage is directly led out by a steam-water separation device on the salt section of the boiler. The blow-down rate of the boiler is 5 to 15 percent, and the evaporation capacity of the salt section is 5 to 40 percent of the total evaporation capacity. Under the same blow-down rate, the boiler water of the net section and salt section heating surfaces of the boiler has low salt content; the heating surfaces have good corrosion resistance, hydrodynamic characteristic and safe heat transfer; and the heating surface of the salt section is convenient for overhauling. The fuel of the boiler can be coal, oil, natural gas and other combustible solids, and is suitable for high-capacity thick oil thermal recovery steam injection boilers.

Owner:TSINGHUA UNIV

Ethanol continuous flow boiler

An improved boiler that allows distillation of ethanol from a continuous flow of a hydrous feedstock compound, which may be beer or other semi-solid substance. The internal compartment of the boiler is separated into different zones by a plurality of primary baffle plates and secondary baffle plates. The hydrous feedstock compound is heated as it passes from one zone to another zone and ethanol inside the hydrous feedstock compound vaporizes. The ethanol rich vapor is channeled through a collector column and then collected for further processing. The temperature of the hydrous feedstock compound is slightly different from one zone to another zone because of ethanol concentration changes as the hydrous feedstock compound moves from one zone to another. At the last zone, where most of ethanol is removed, the remaining hydrous feedstock compound is removed from the boiler.

Owner:LING MICHAEL R

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com