Patents

Literature

110results about "Furnace-tube steam boilers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

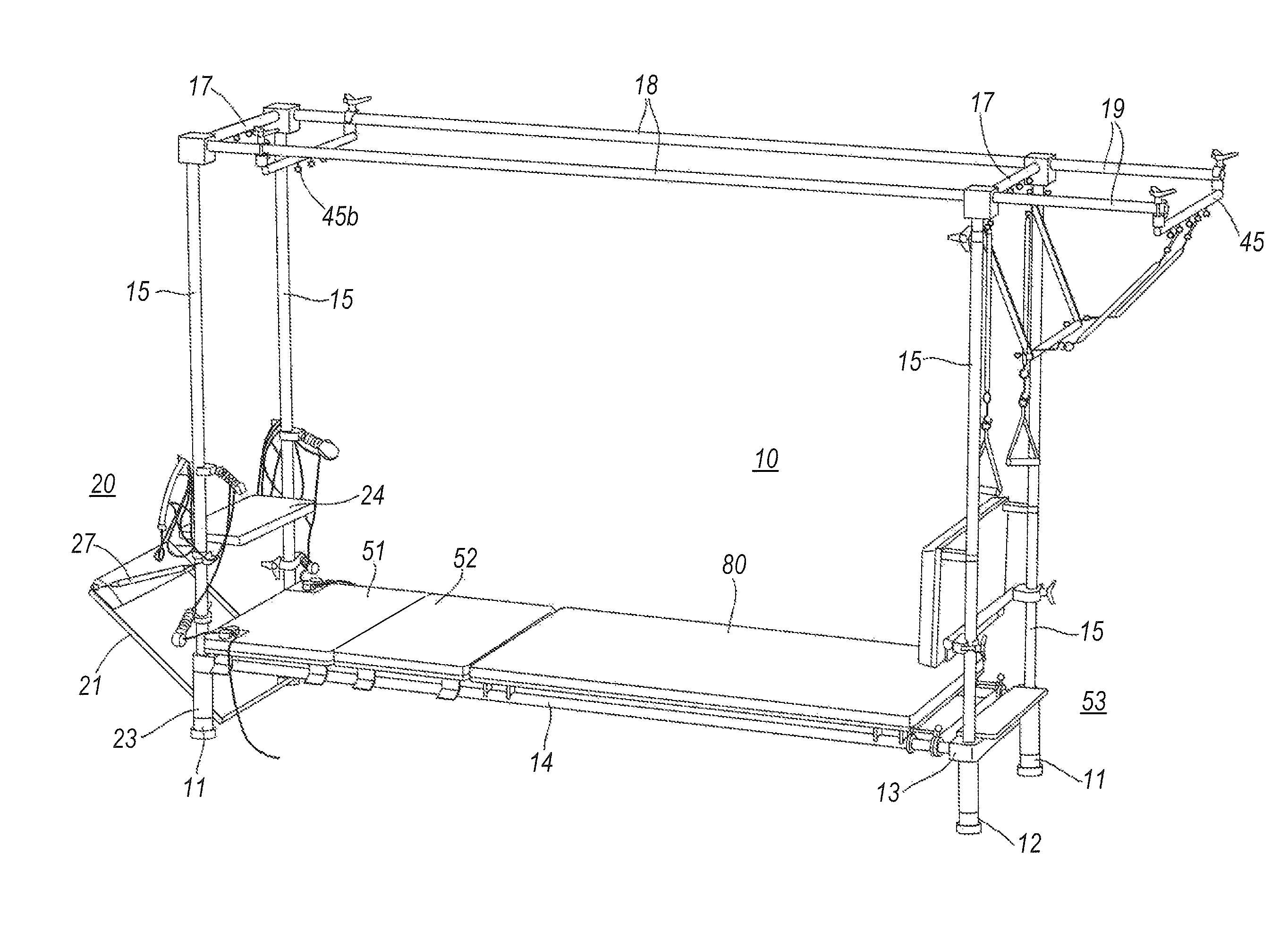

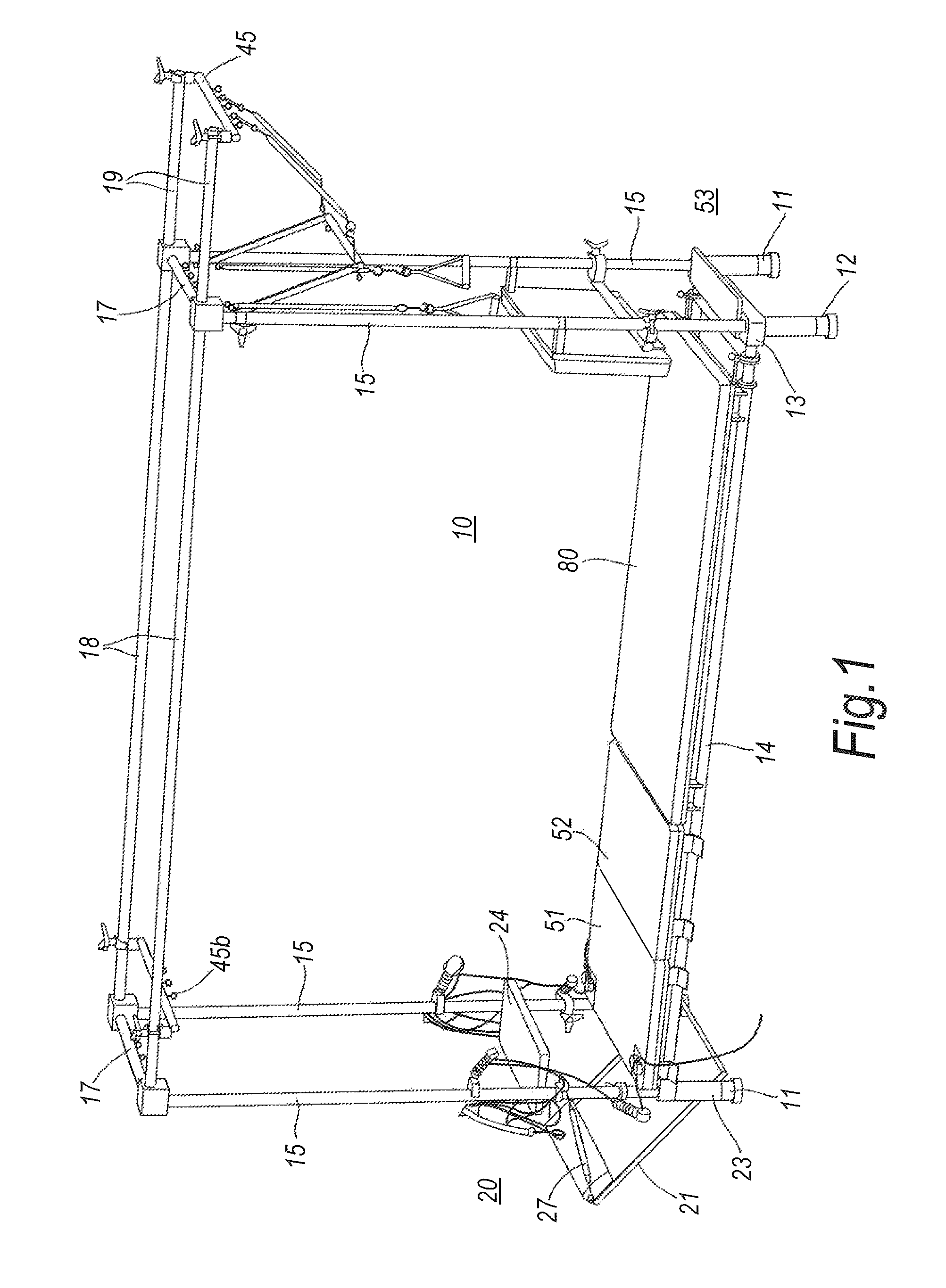

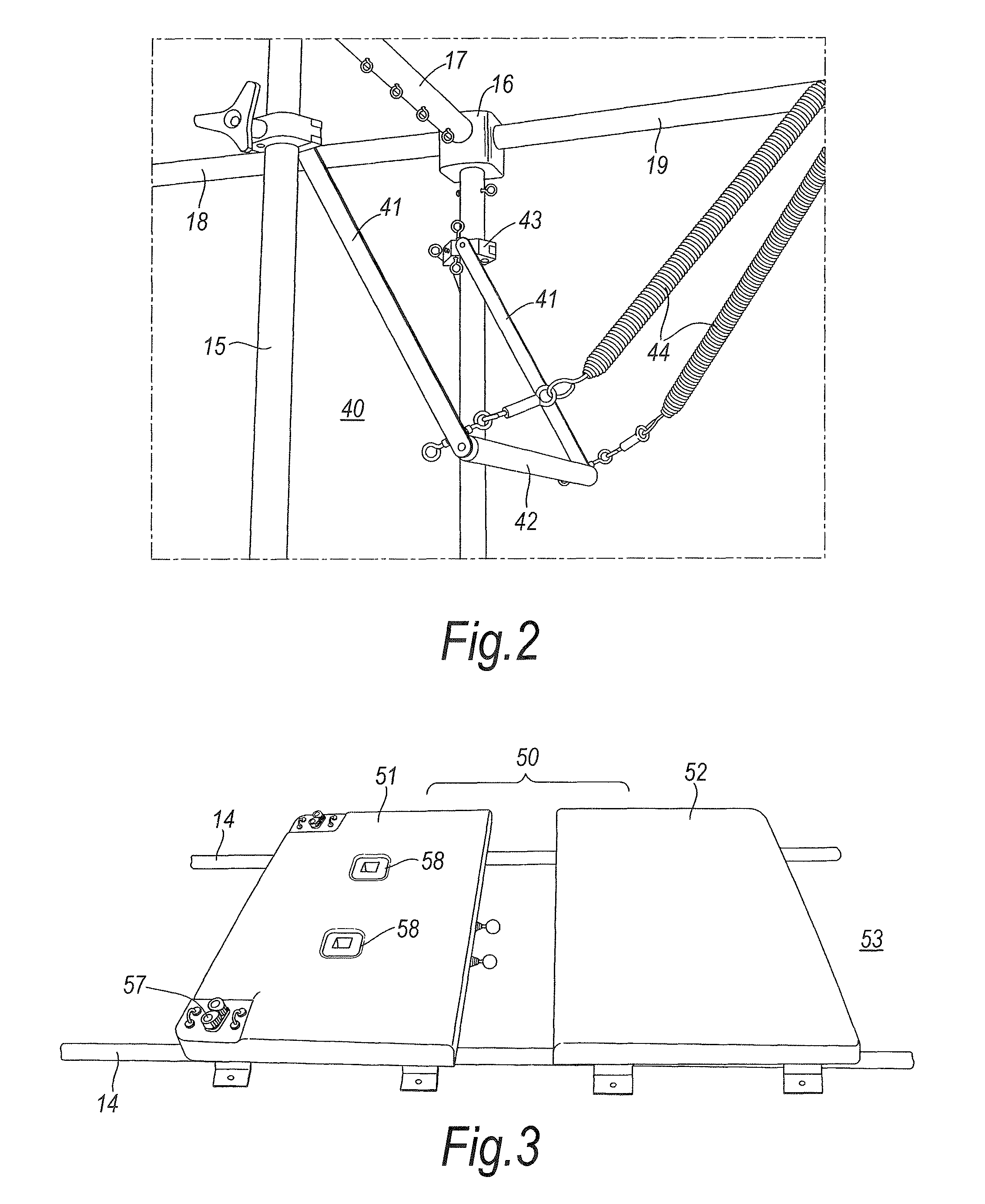

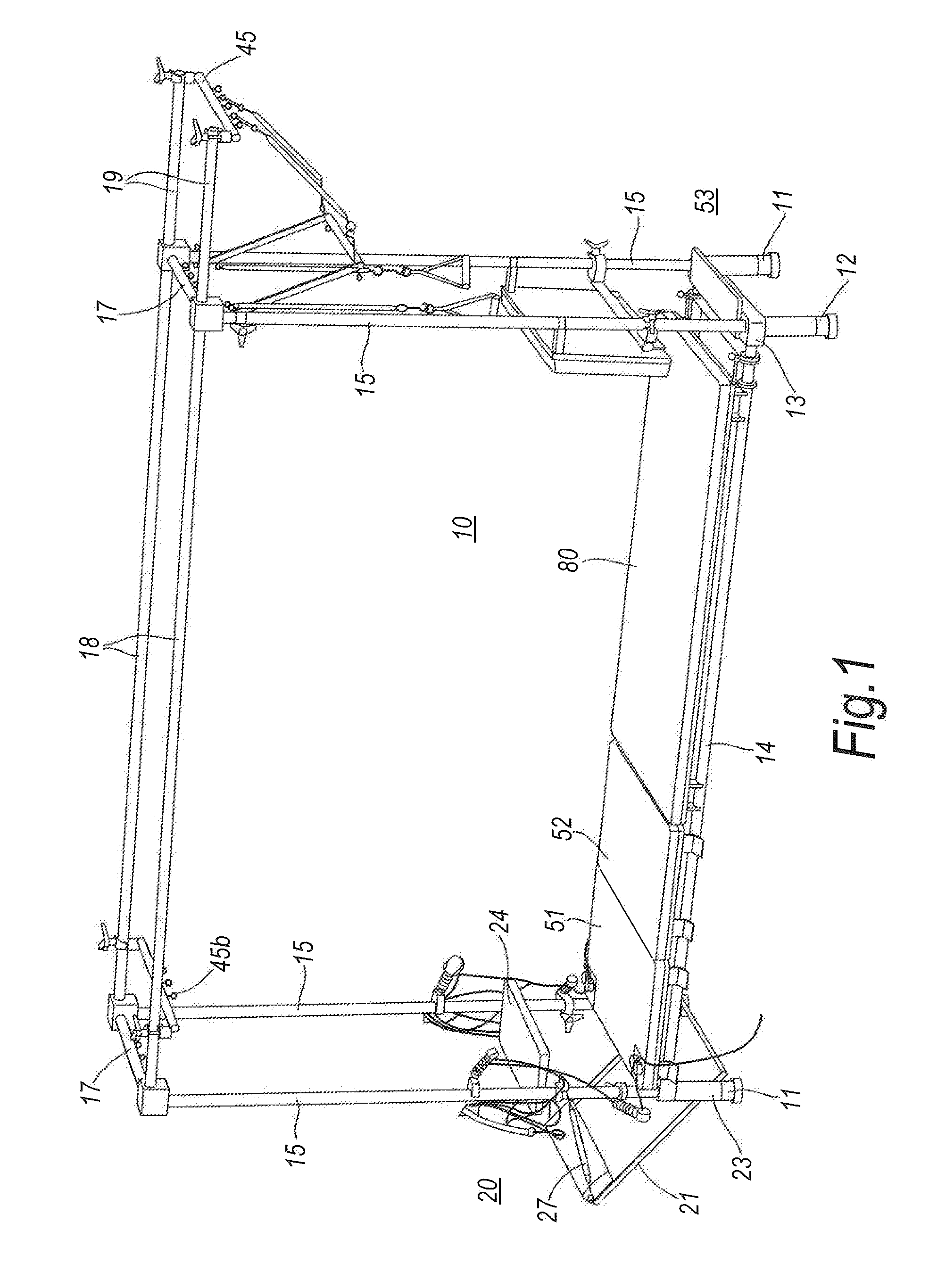

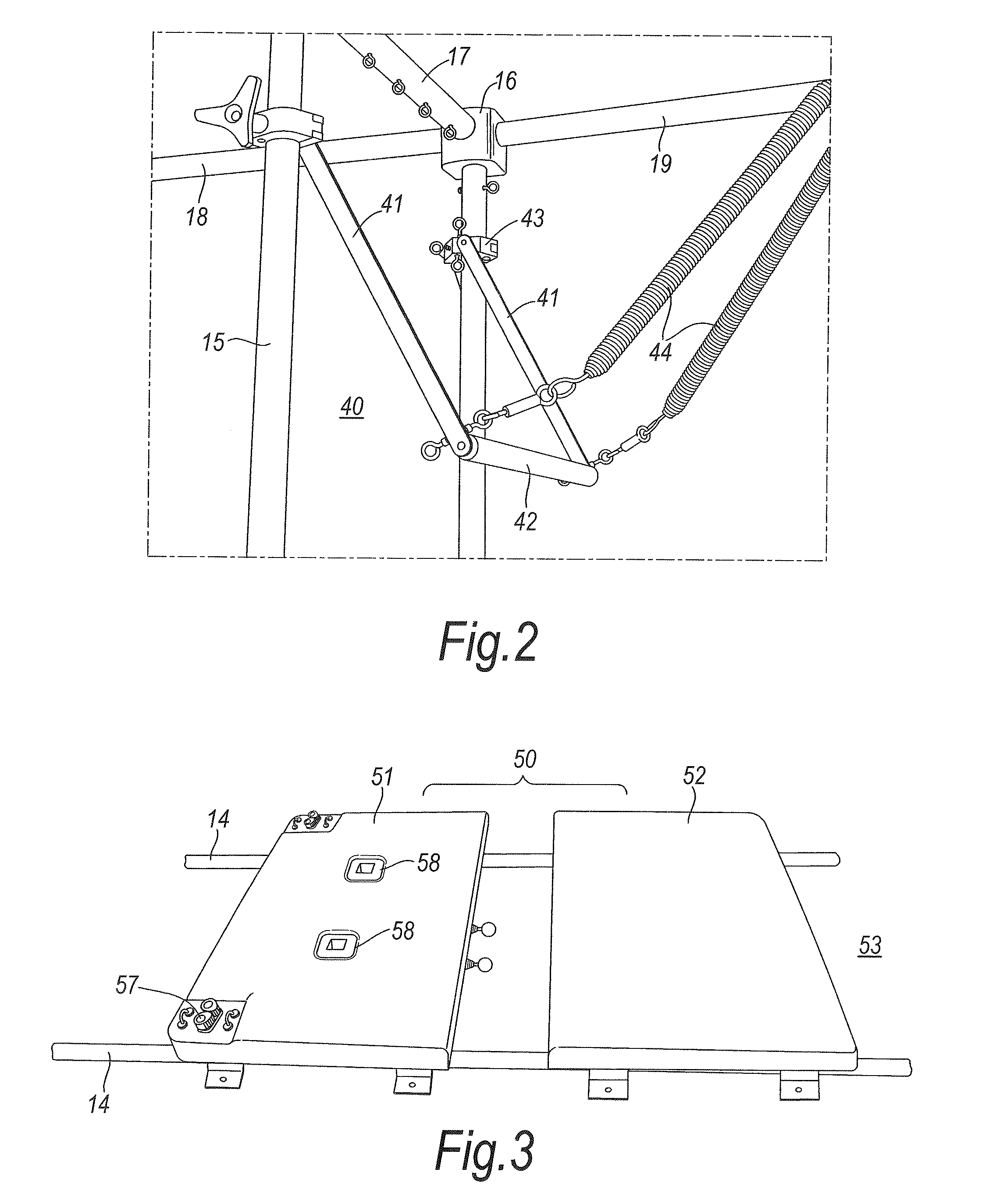

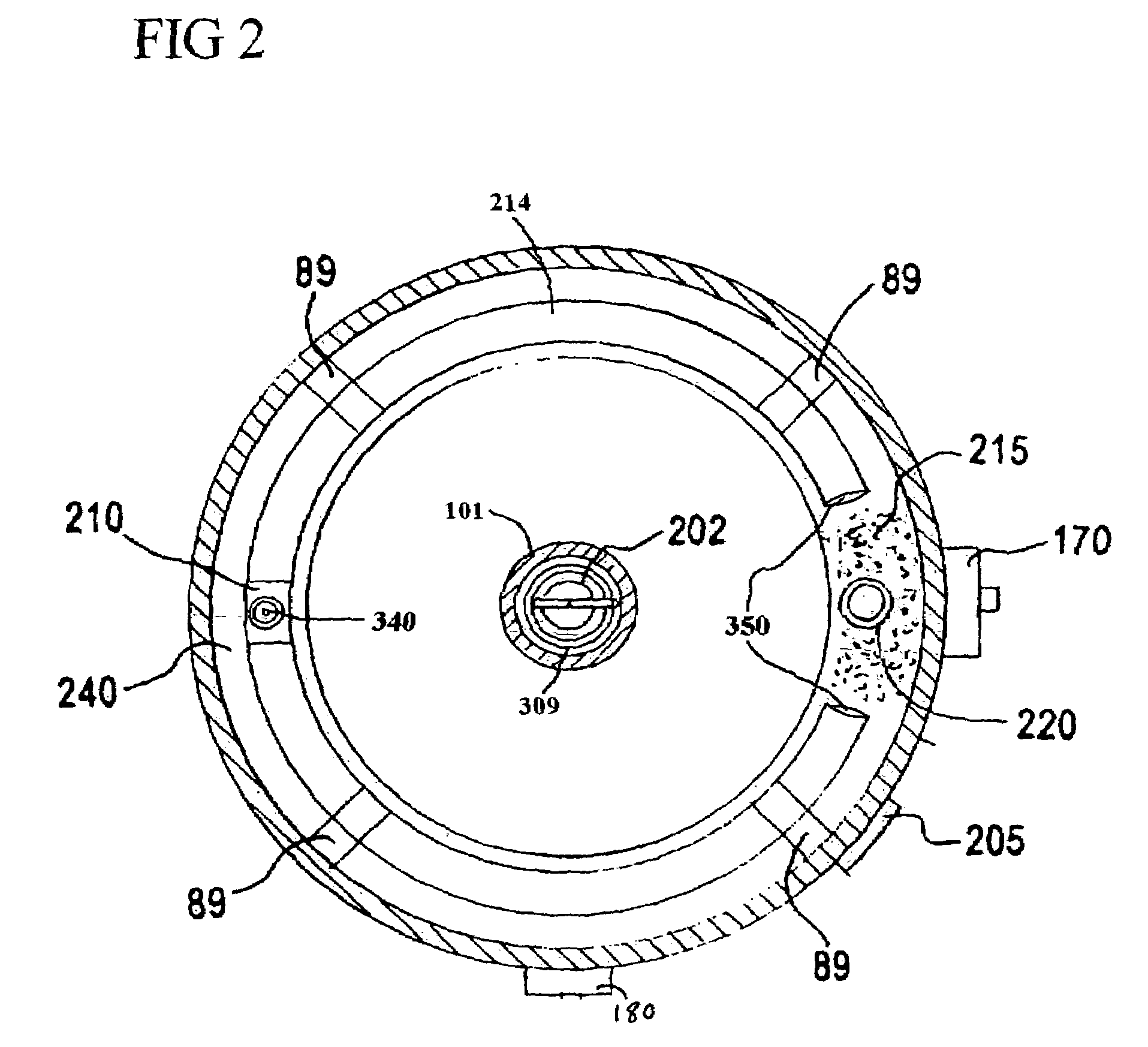

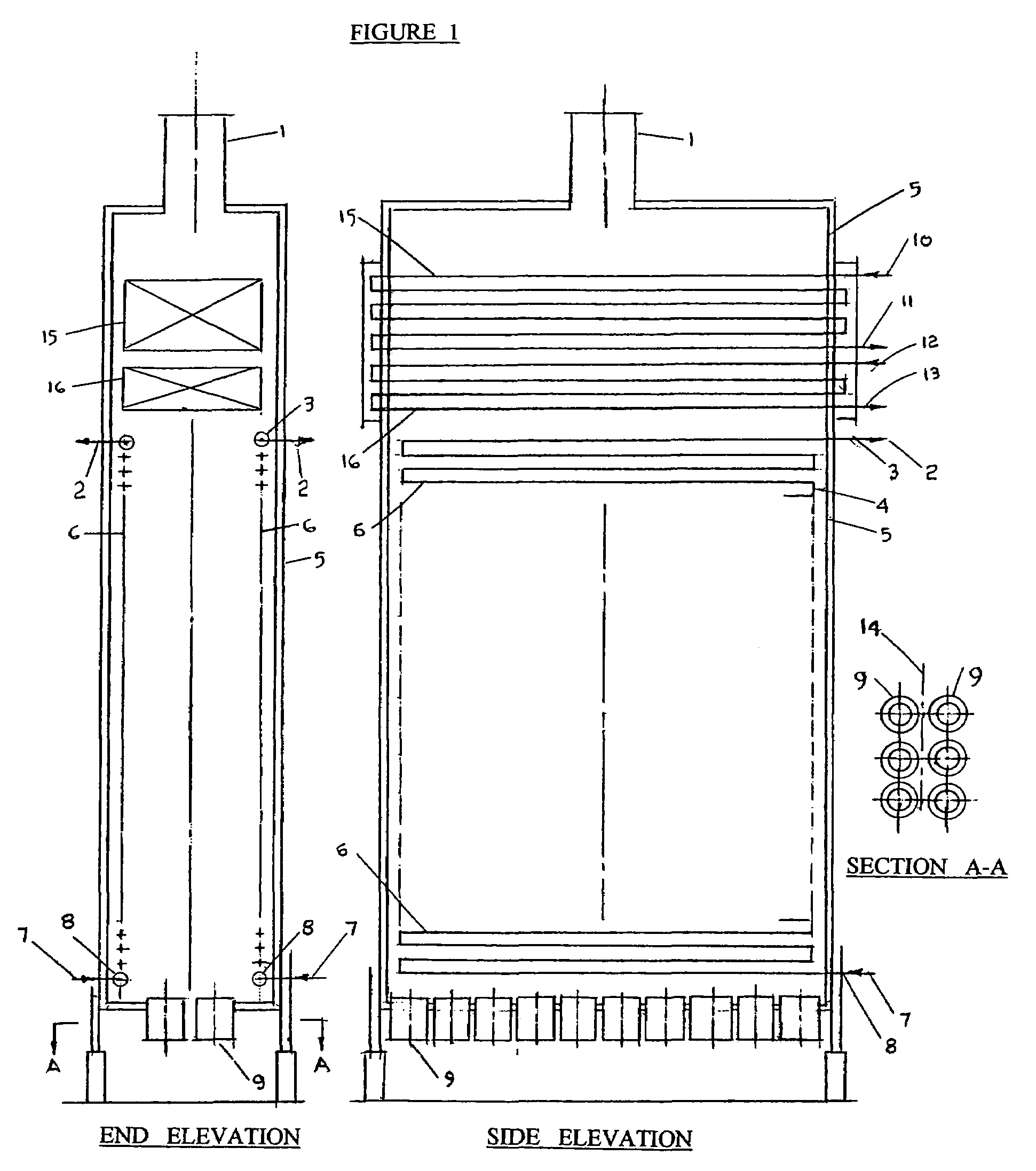

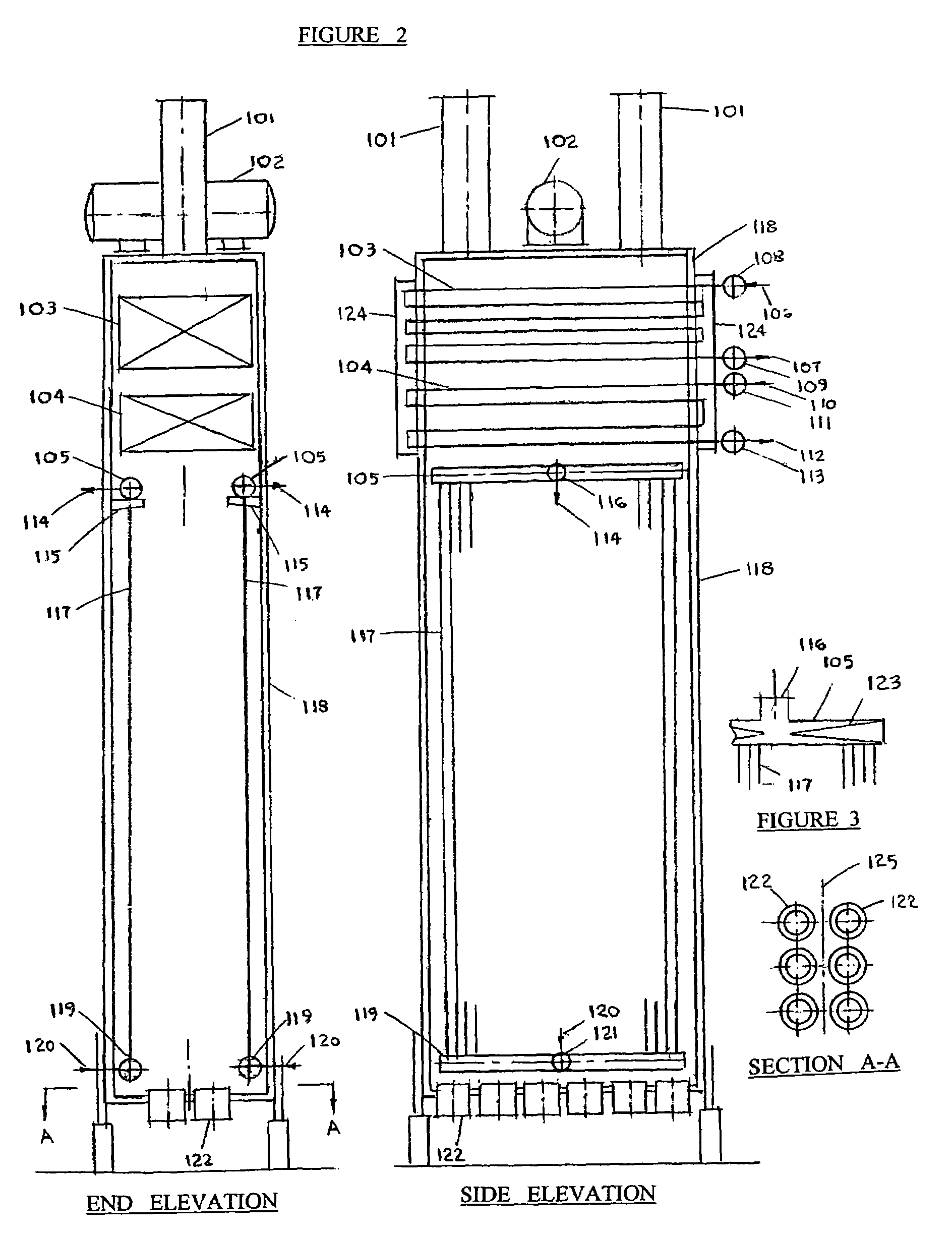

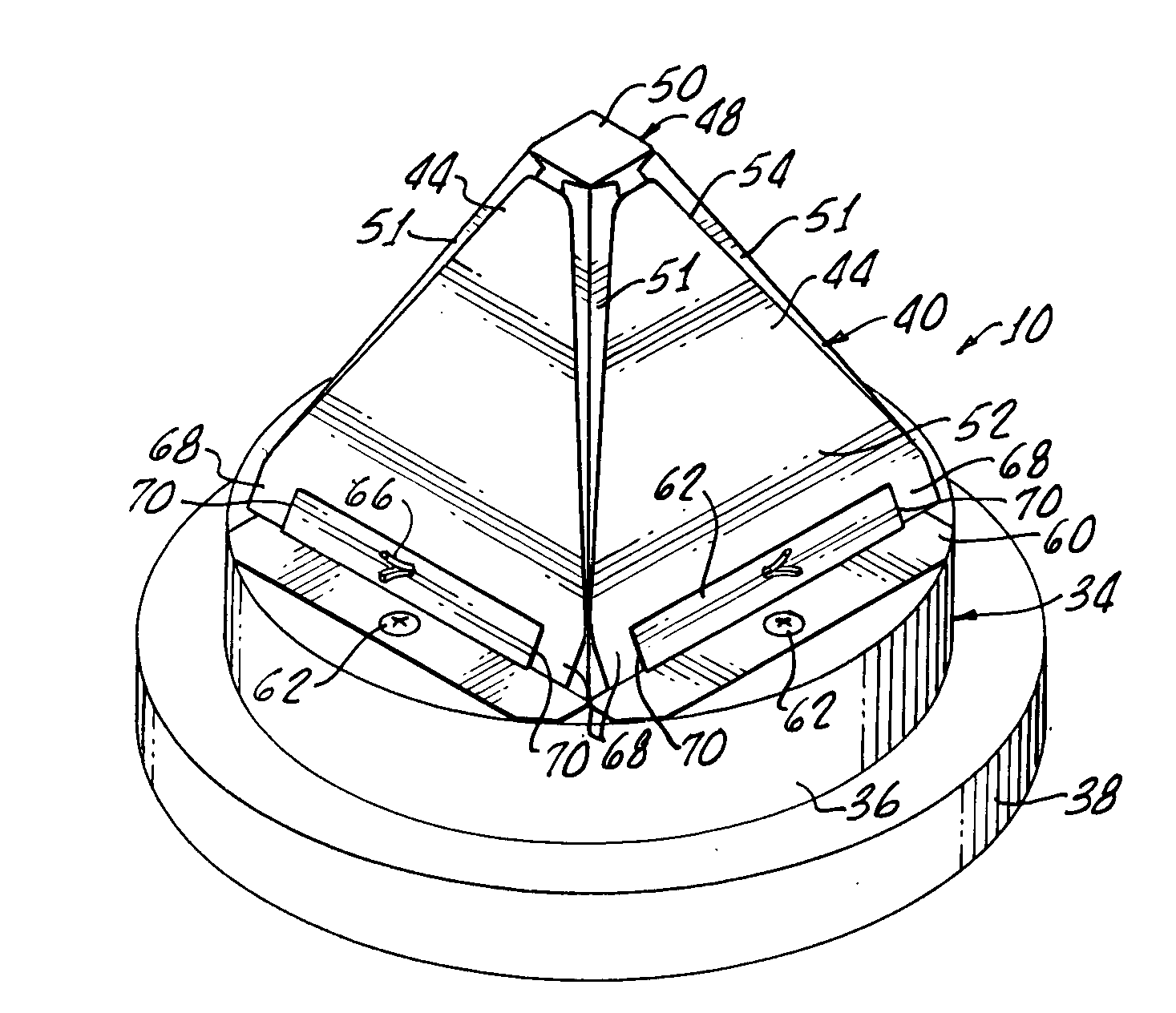

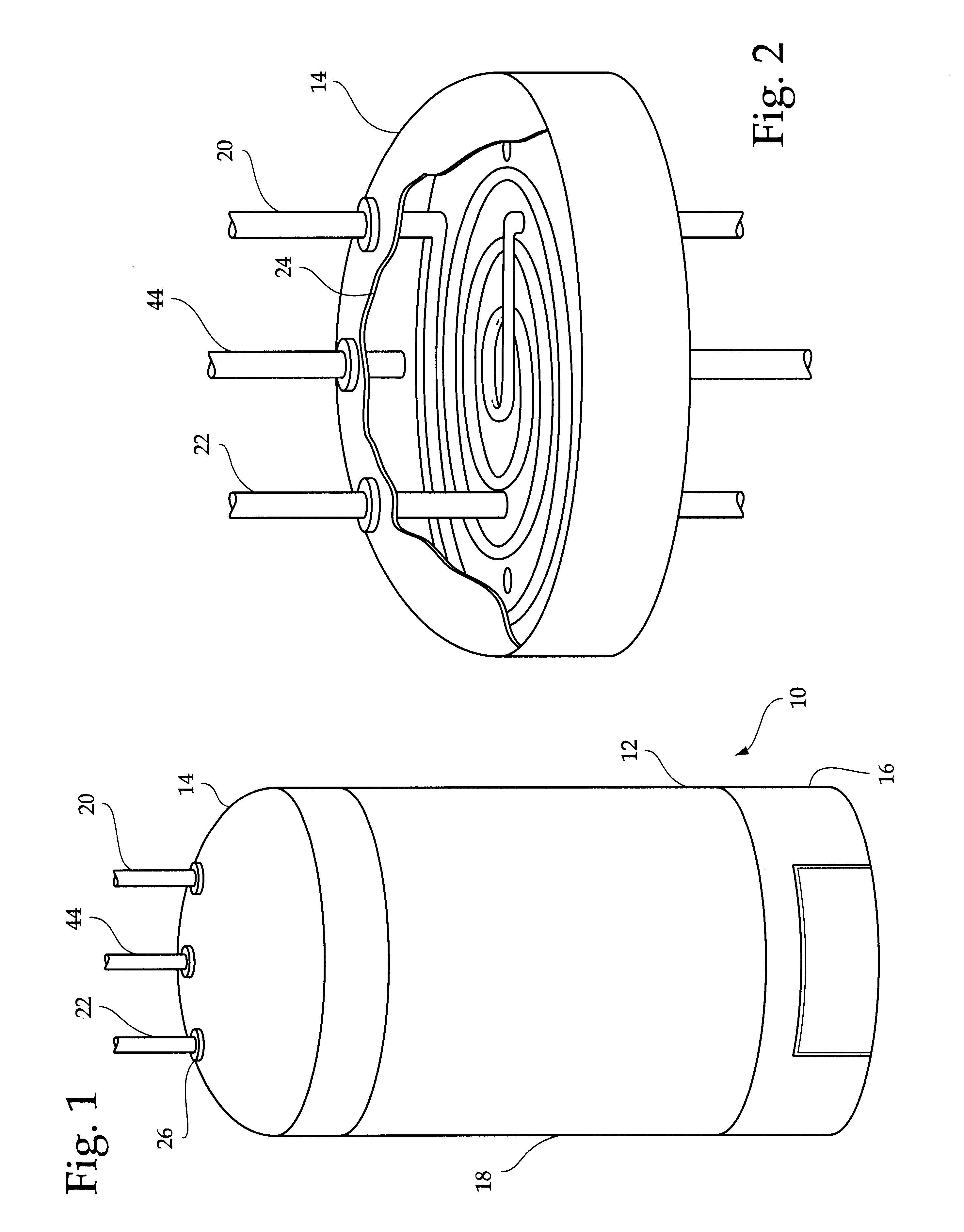

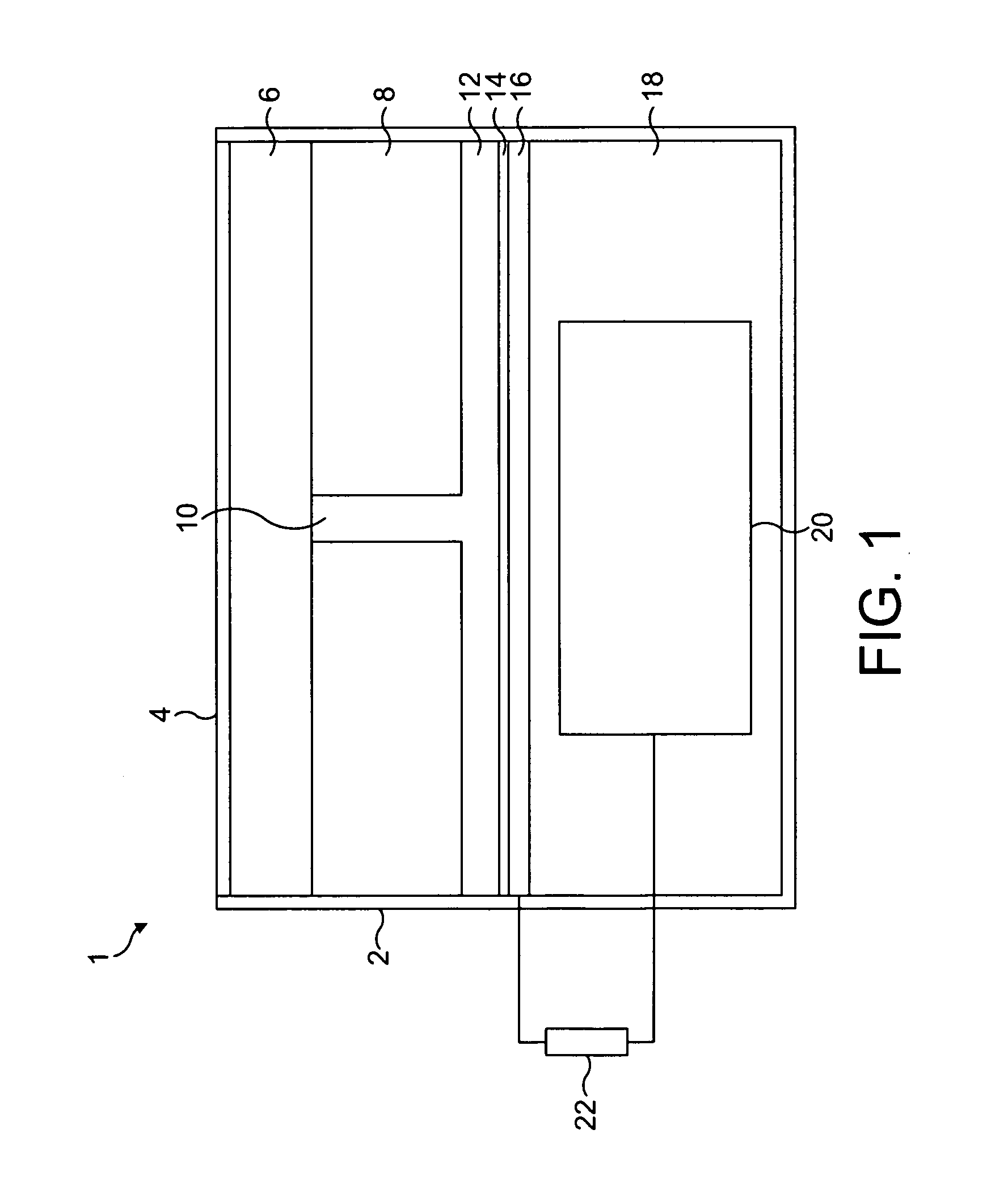

Exercise apparatus

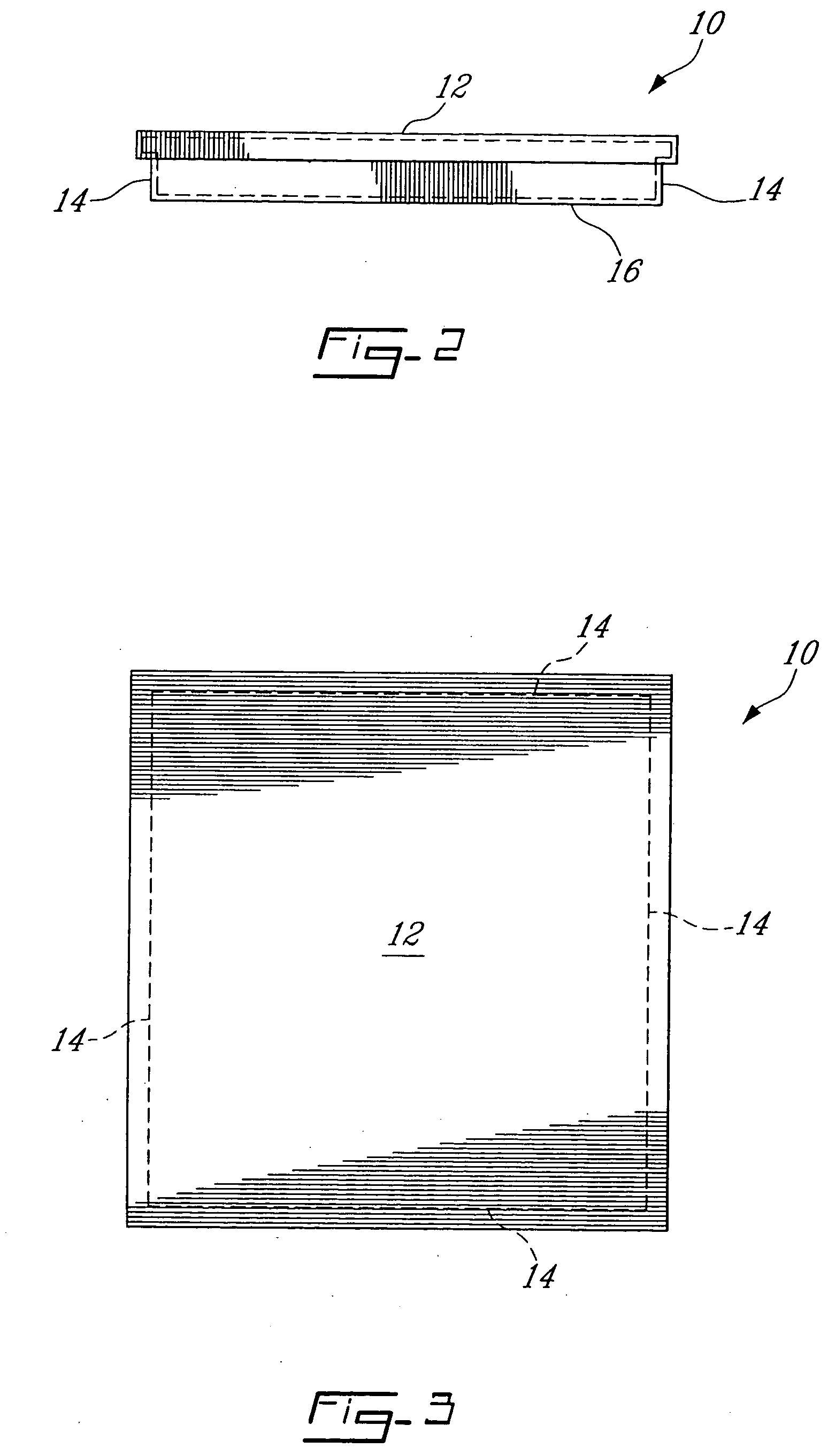

ActiveUS7967736B2Reduce impactPrecise positioningResilient force resistorsFurnace-tube steam boilersEngineeringPhysical exercise

Apparatus suitable for pilates and other exercise comprises rails, supported on a box-like frame and an exercise carriage, mounted on the rails, wherein the carriage comprises a first carriage section and a second carriage section which sections can be (i) connected together to form a single exercise carriage which slides forwards and backwards on the rails, or (ii) disconnected to form two exercise carriages which independently slide forwards and backwards on the rails. The apparatus also has a seat with a spring-biased foot pedal and a spring-biased trapeze bar.

Owner:DSILVA LTD

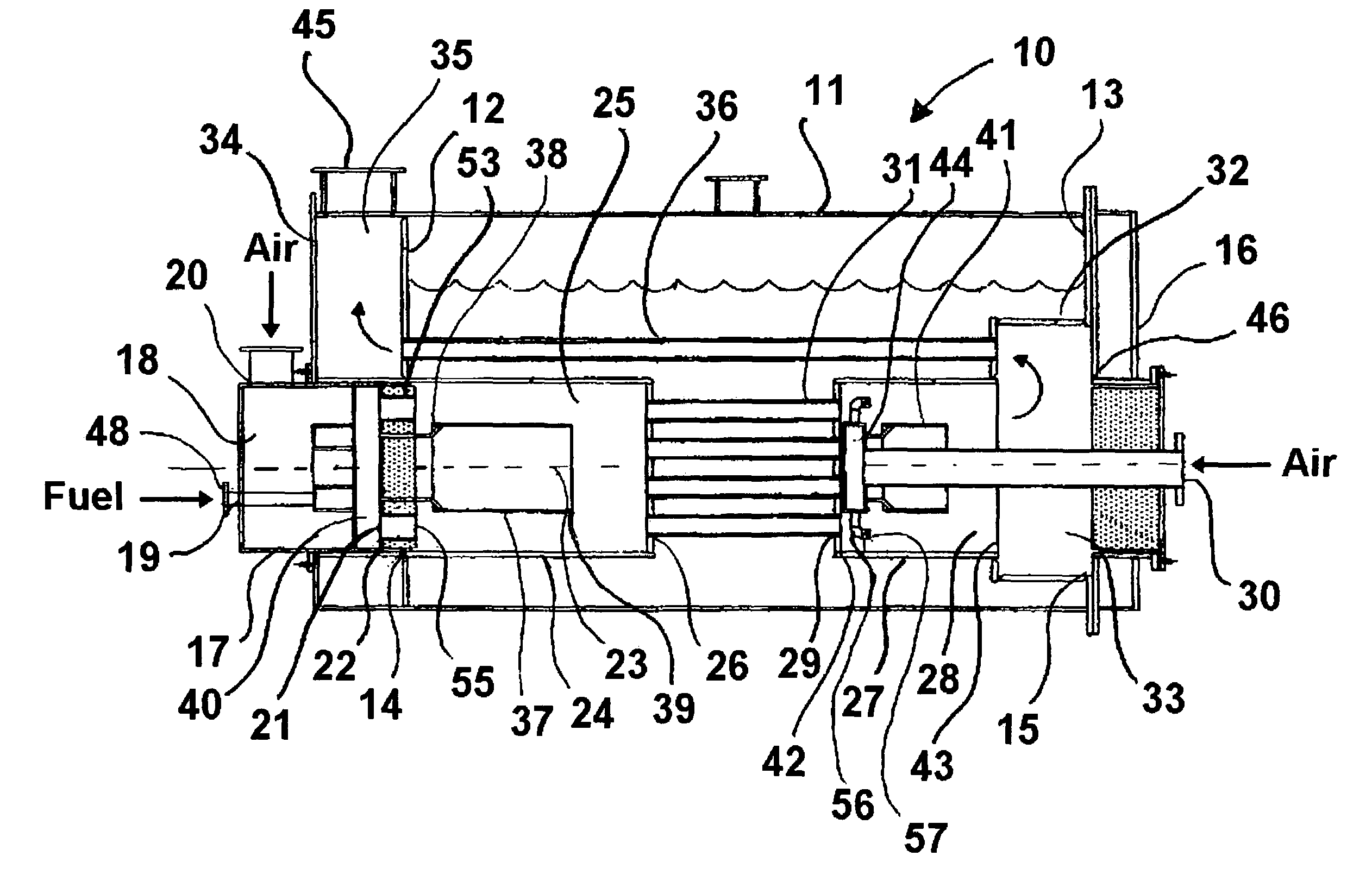

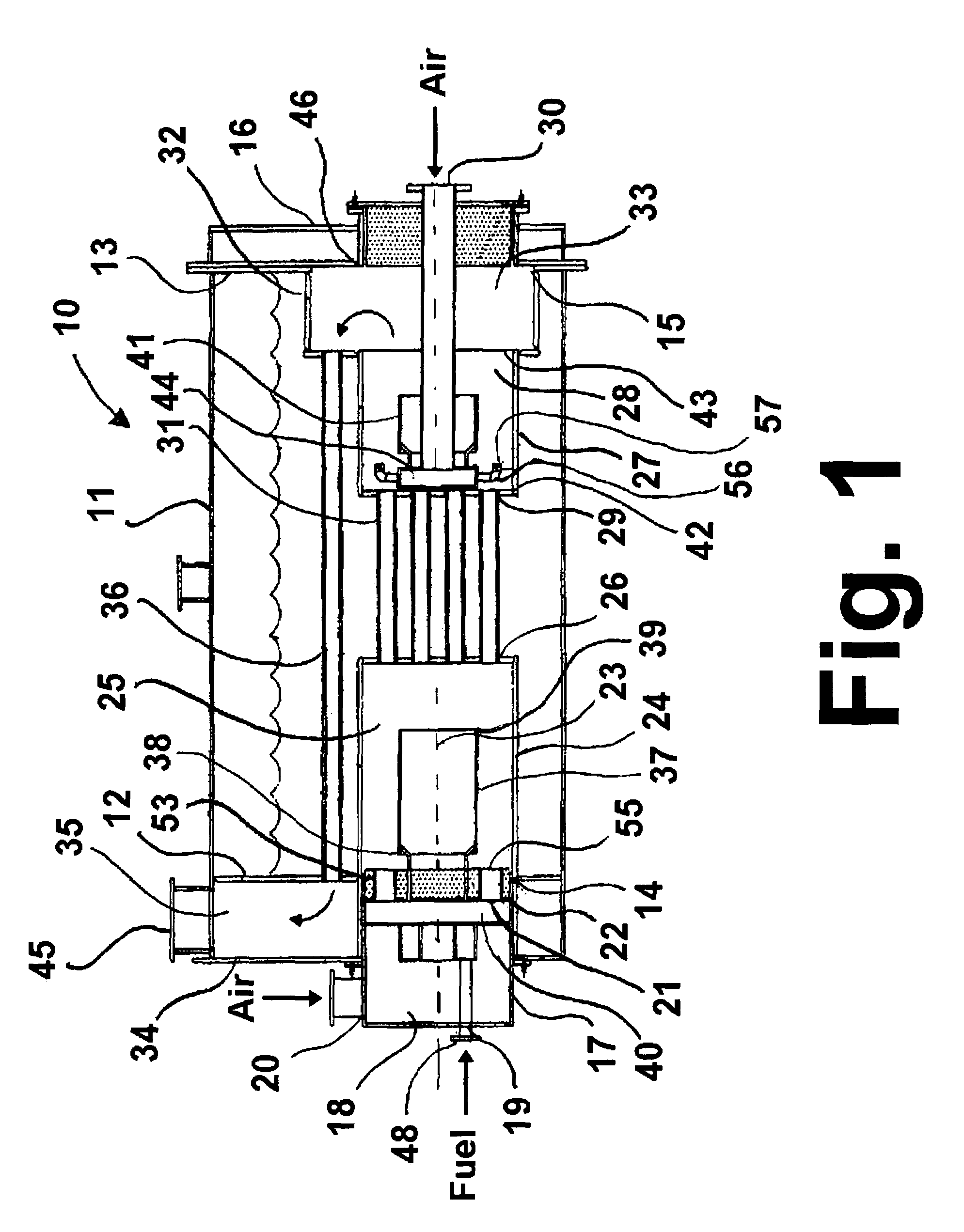

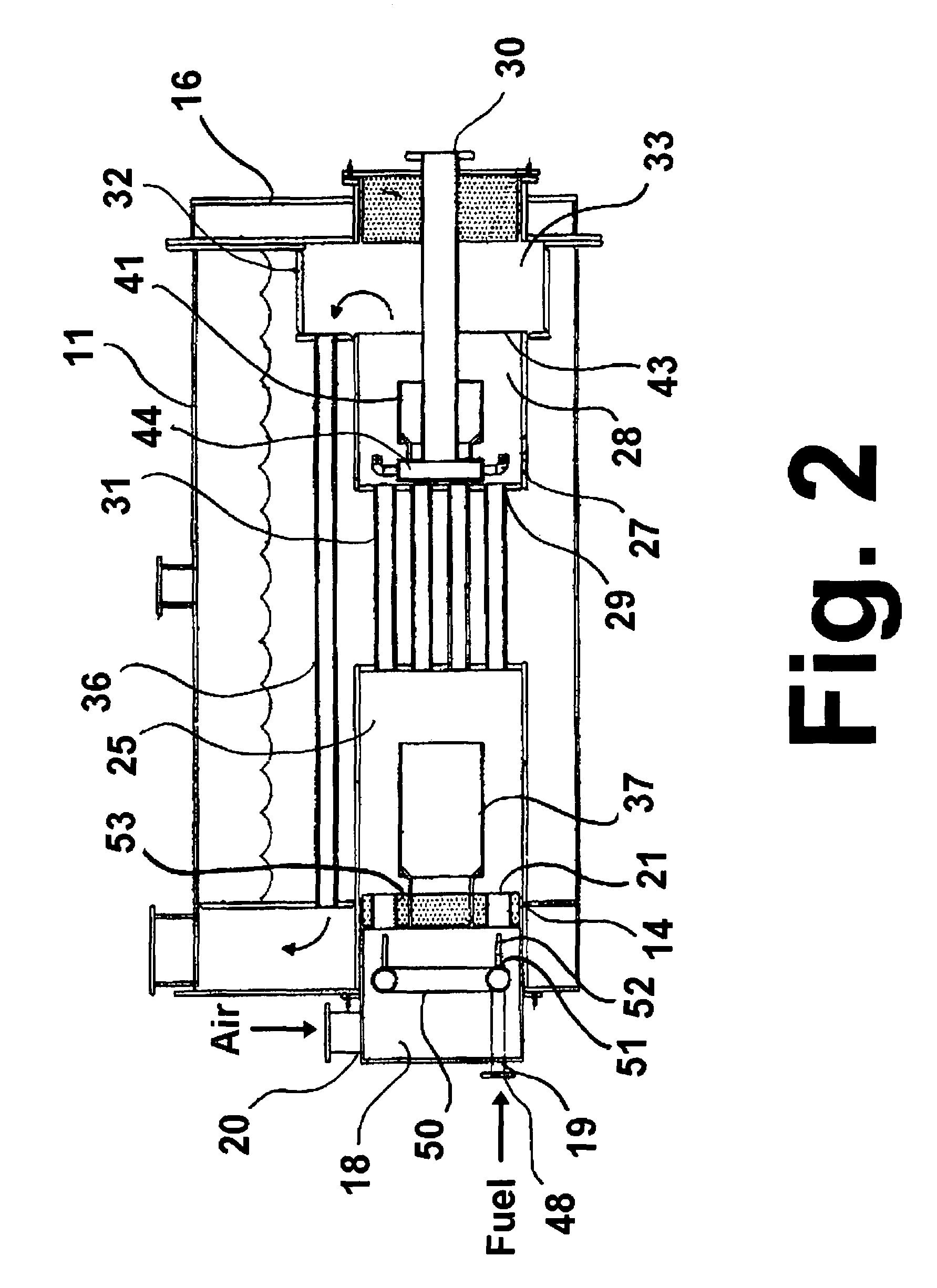

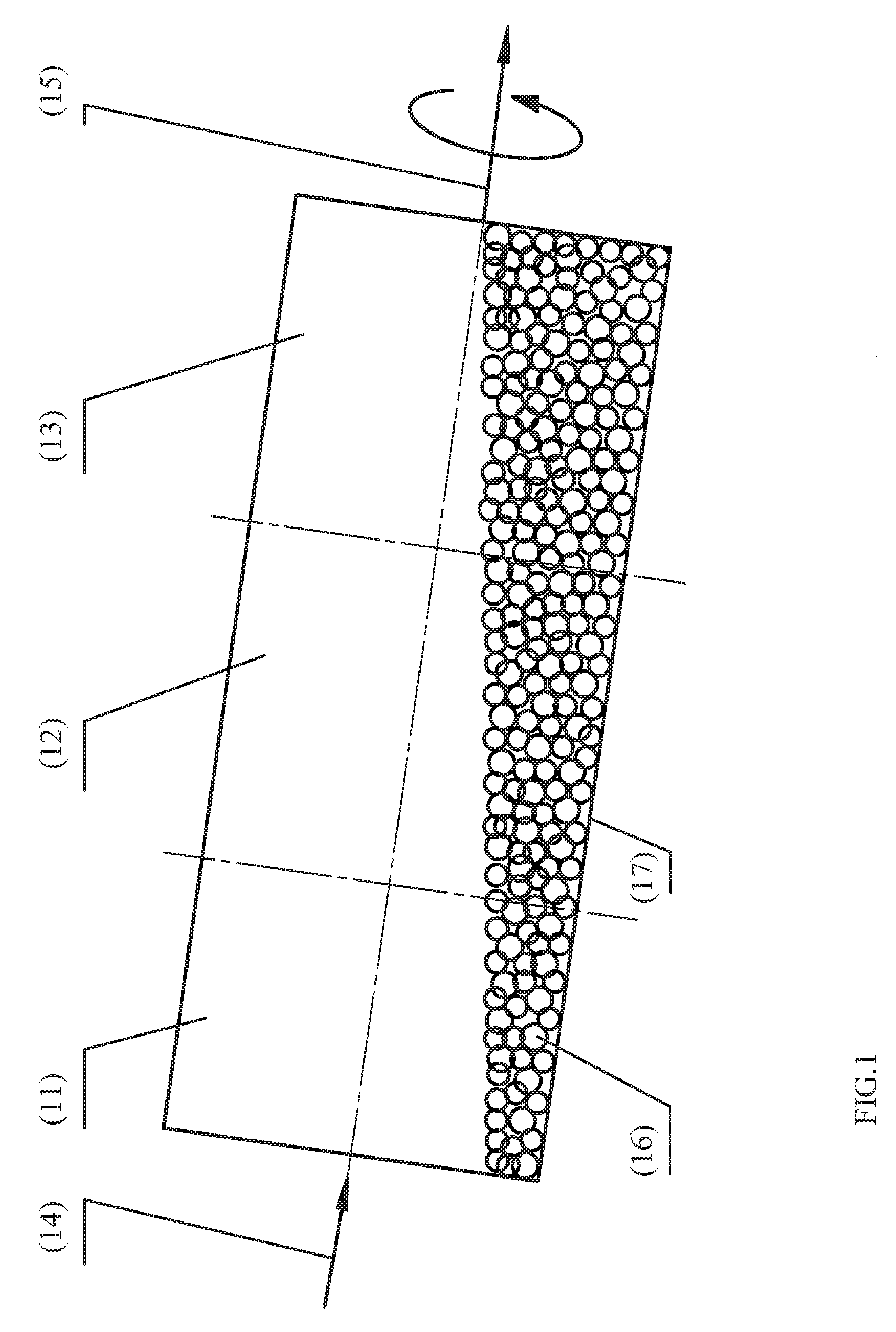

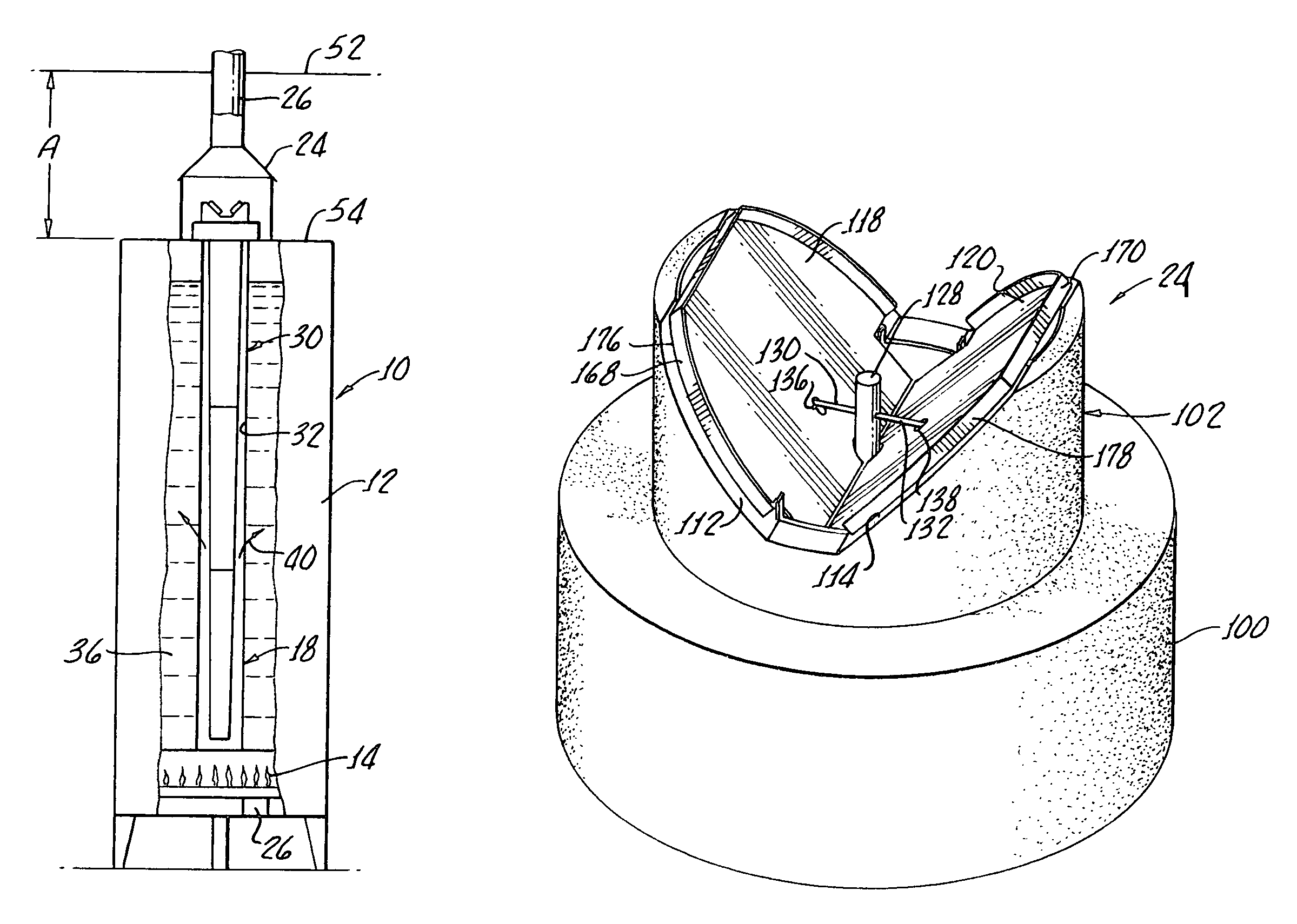

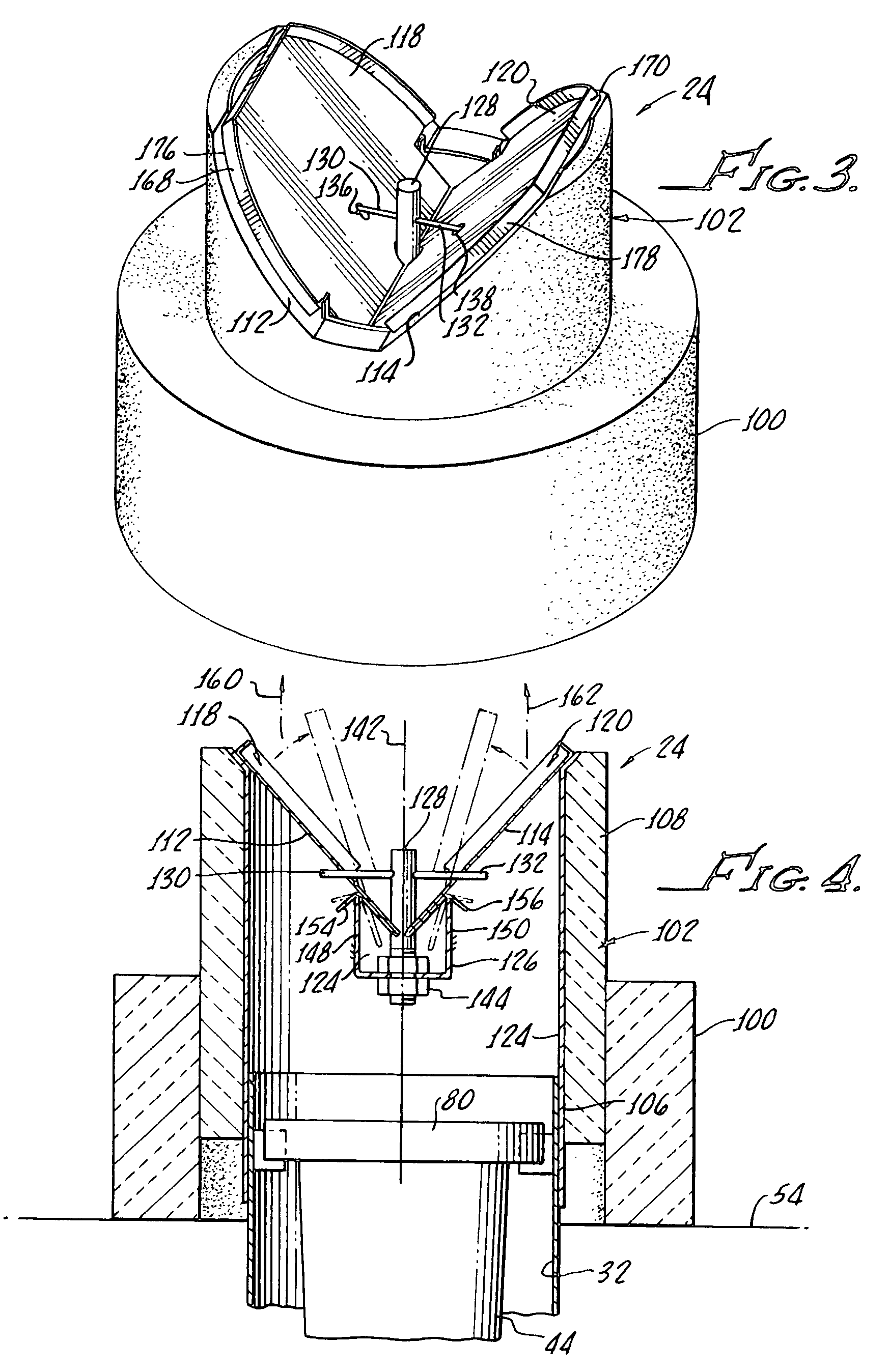

Graphite rotary tube furnace

InactiveUS6042370AMinimizing radiation heat lossStable temperatureRotary drum furnacesCharge supportsRadiative heat lossRadiant heat

A rotary tube furnace suitable for operation in controlled atmospheres at temperatures in the range of 1500 DEG to 2800 DEG comprises a generally horizontal rotatable graphite tube slidably supported on water-cooled split ring graphite bearings. The graphite tube is rotated by means of a stainless steel drive plate and is contained within a flexible atmospheric sealing assembly and enclosure for the containment of a selected atmosphere around and within the tube and allows for the co-current or counter-current flow of gas during operation. Radiation baffles in the interior of the graphite tube inhibit radiant heat loss at the ends of the tube. The graphite tube may be constructed in two or more sections having threaded ends for ease of installation as well as removal or replacement for maintenance purposes. A heating section of the tube is heated by a plurality of graphite electrical heating elements contained within an insulated heating chamber.

Owner:HARPER INT CORP

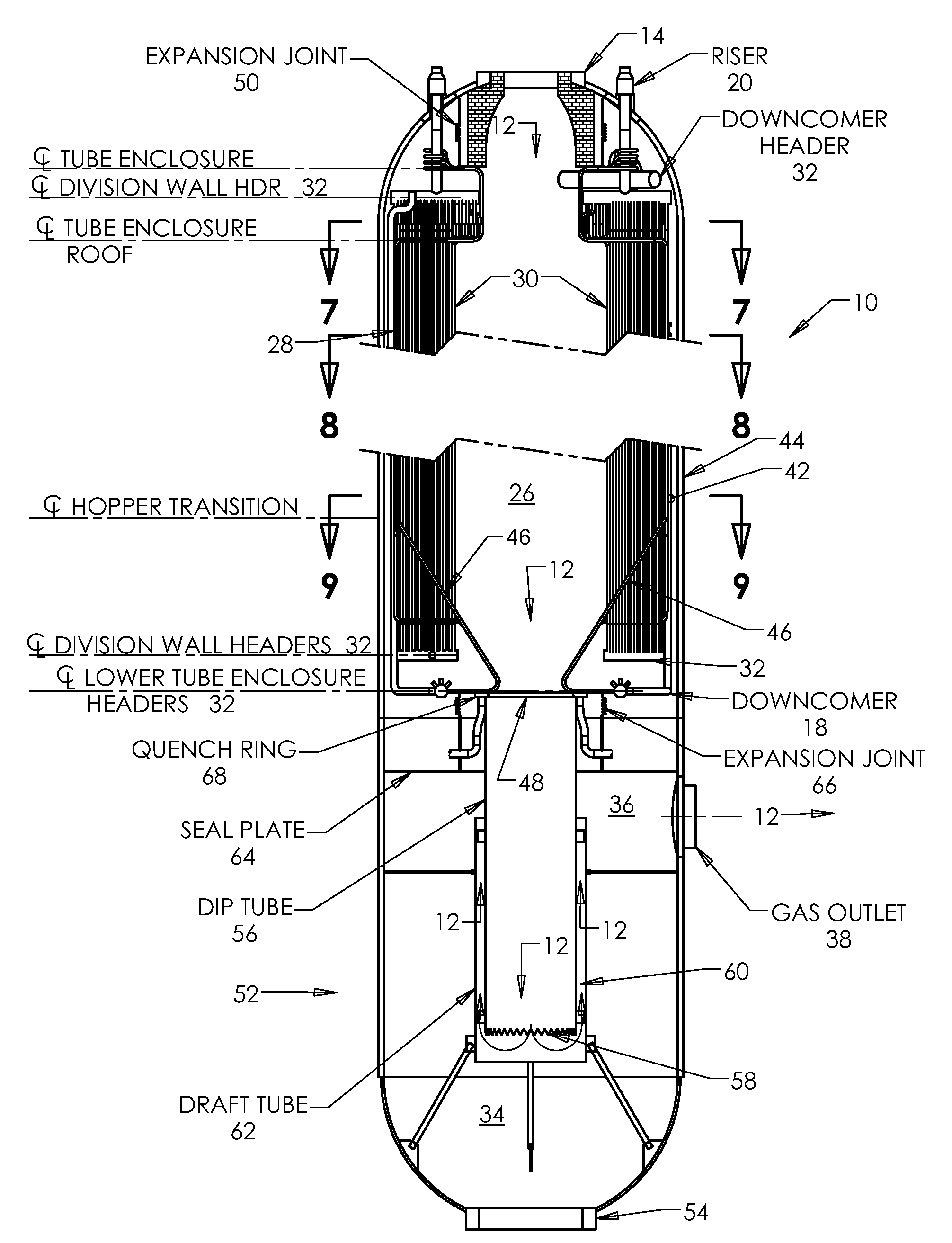

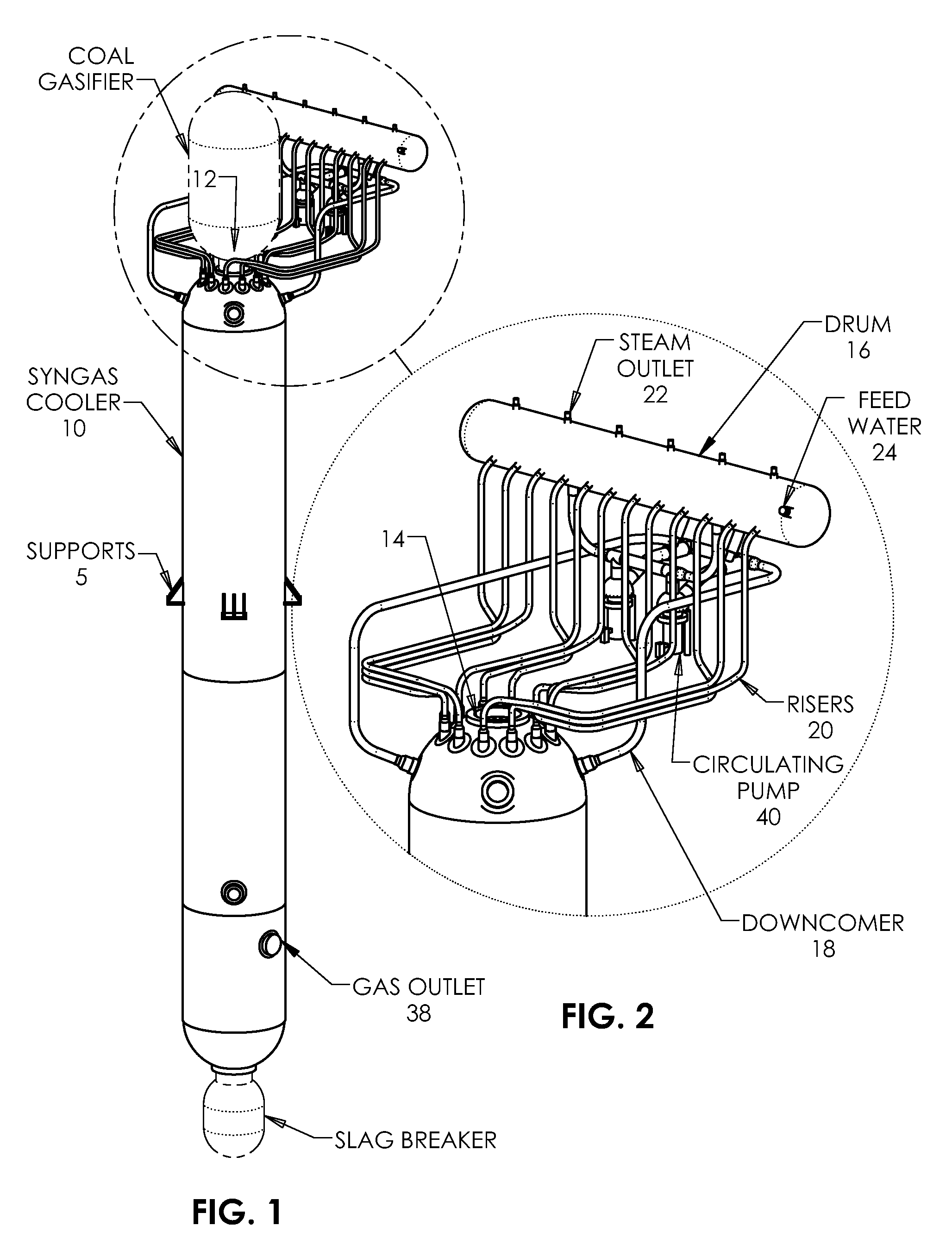

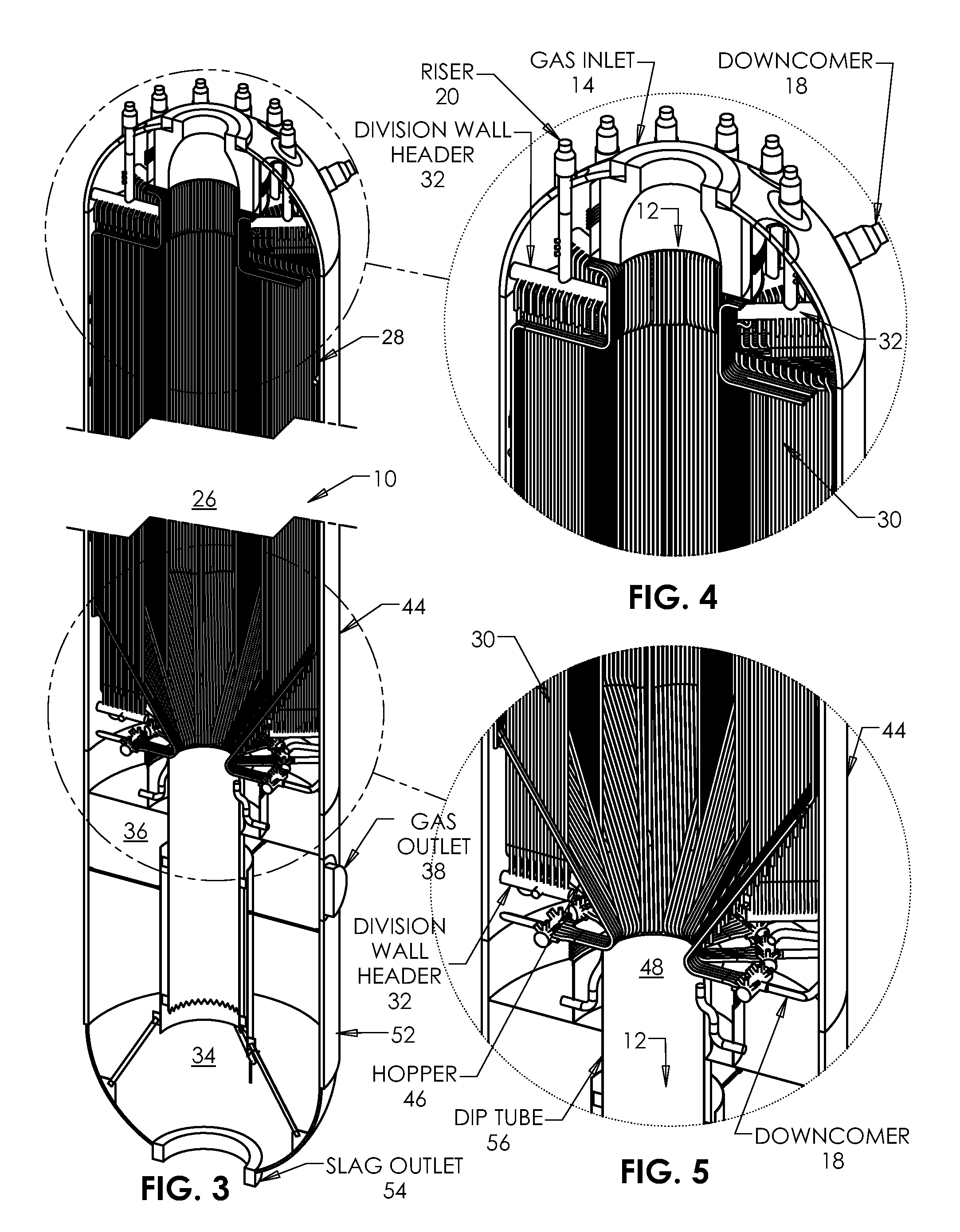

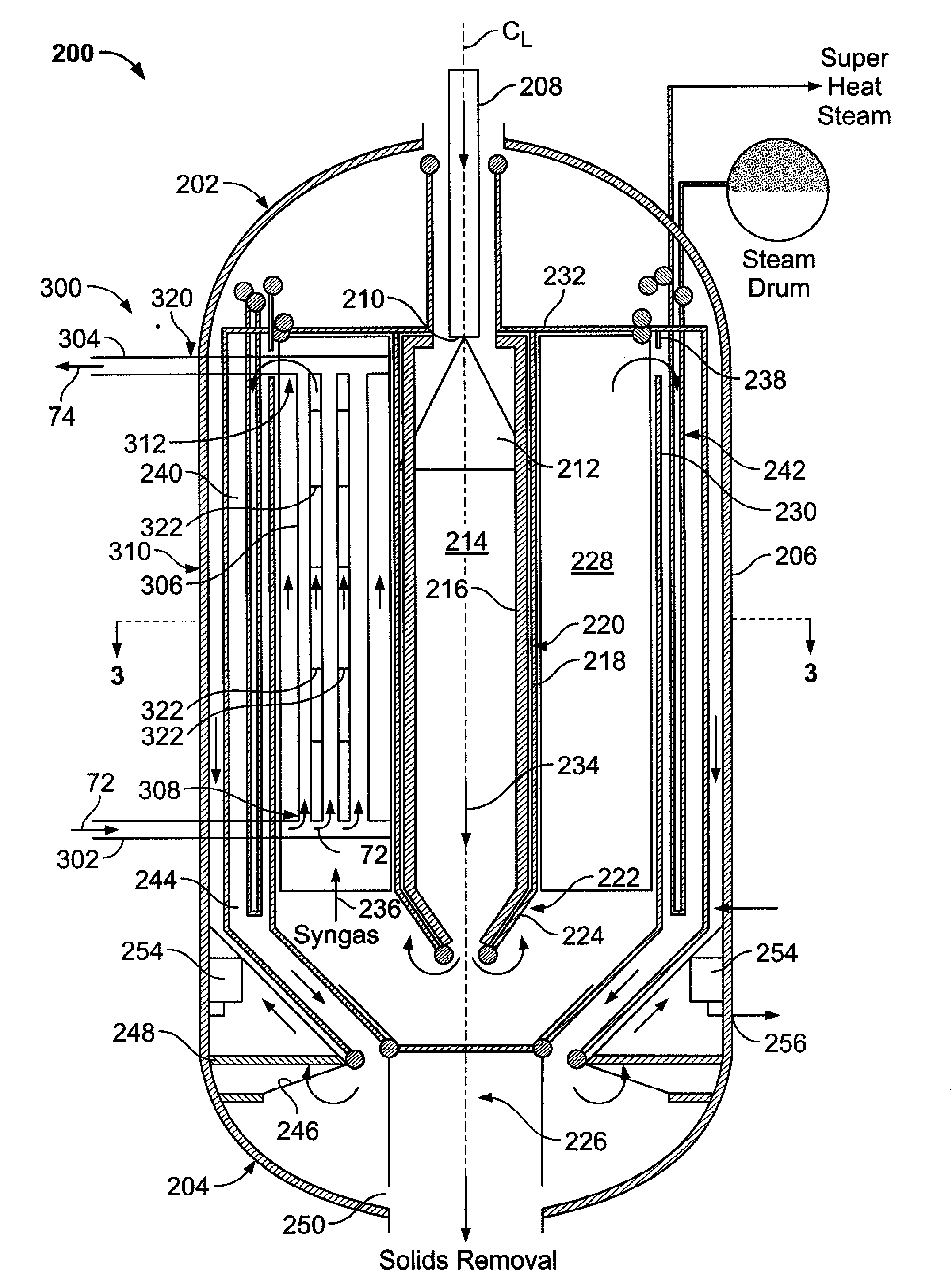

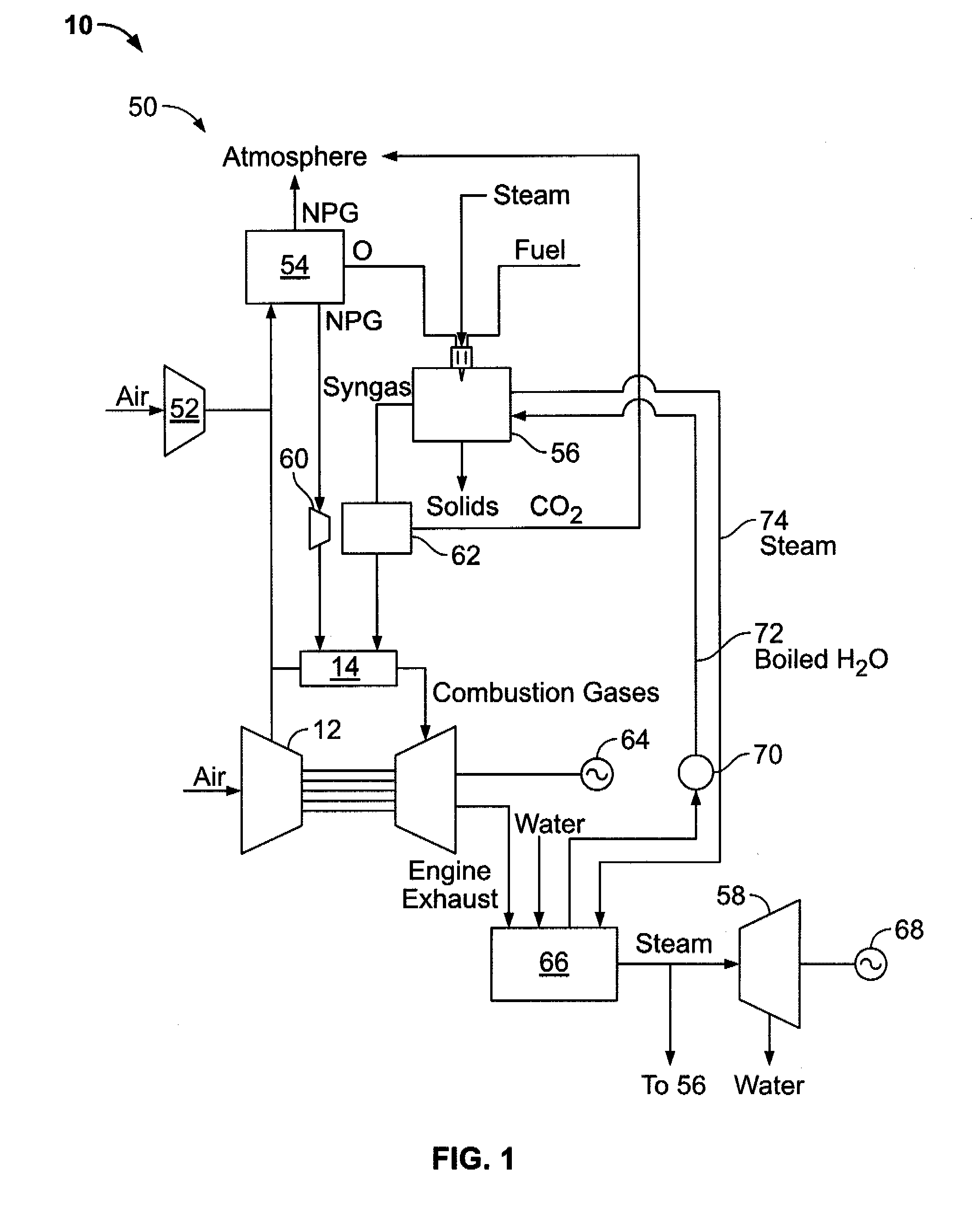

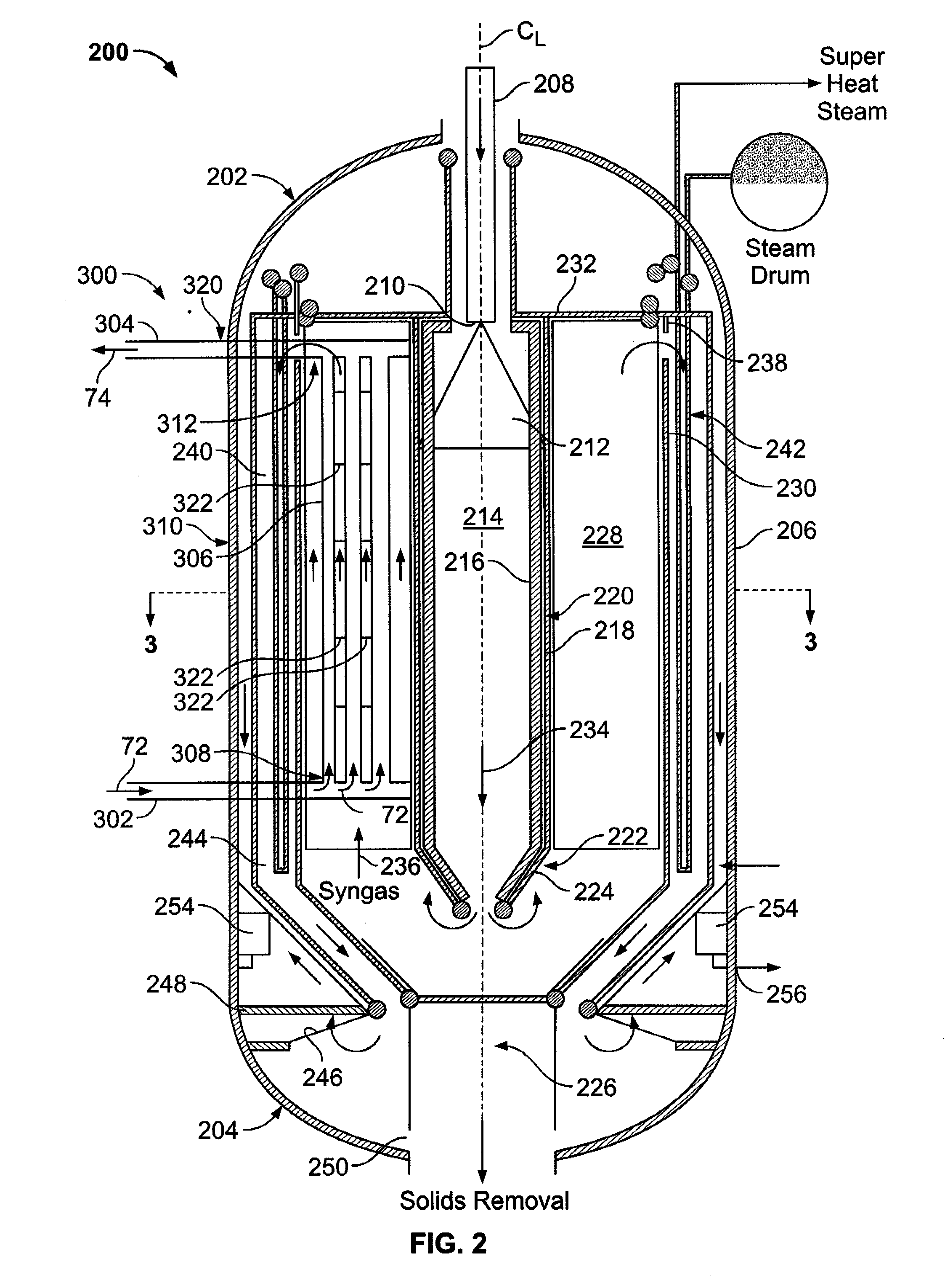

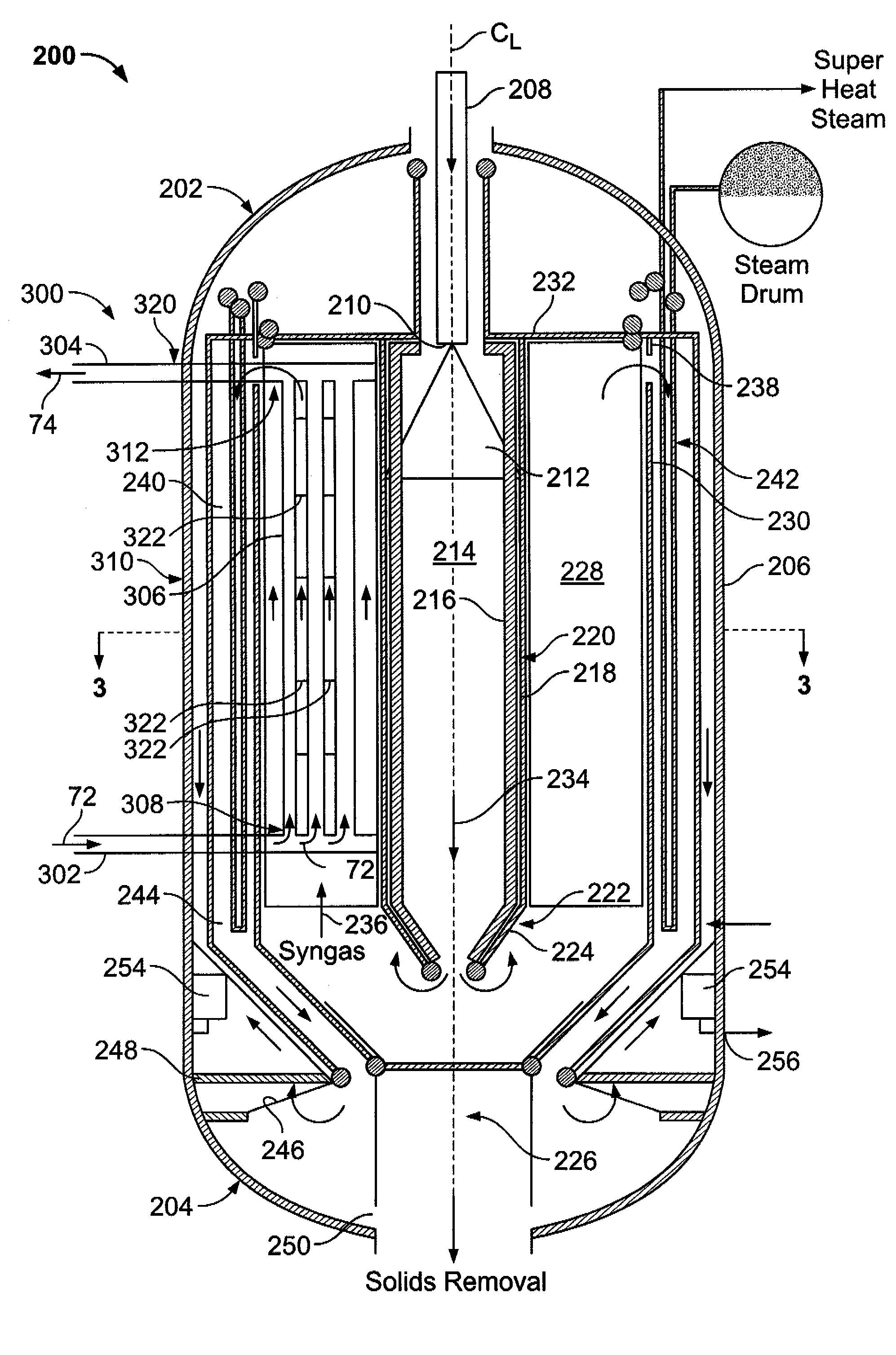

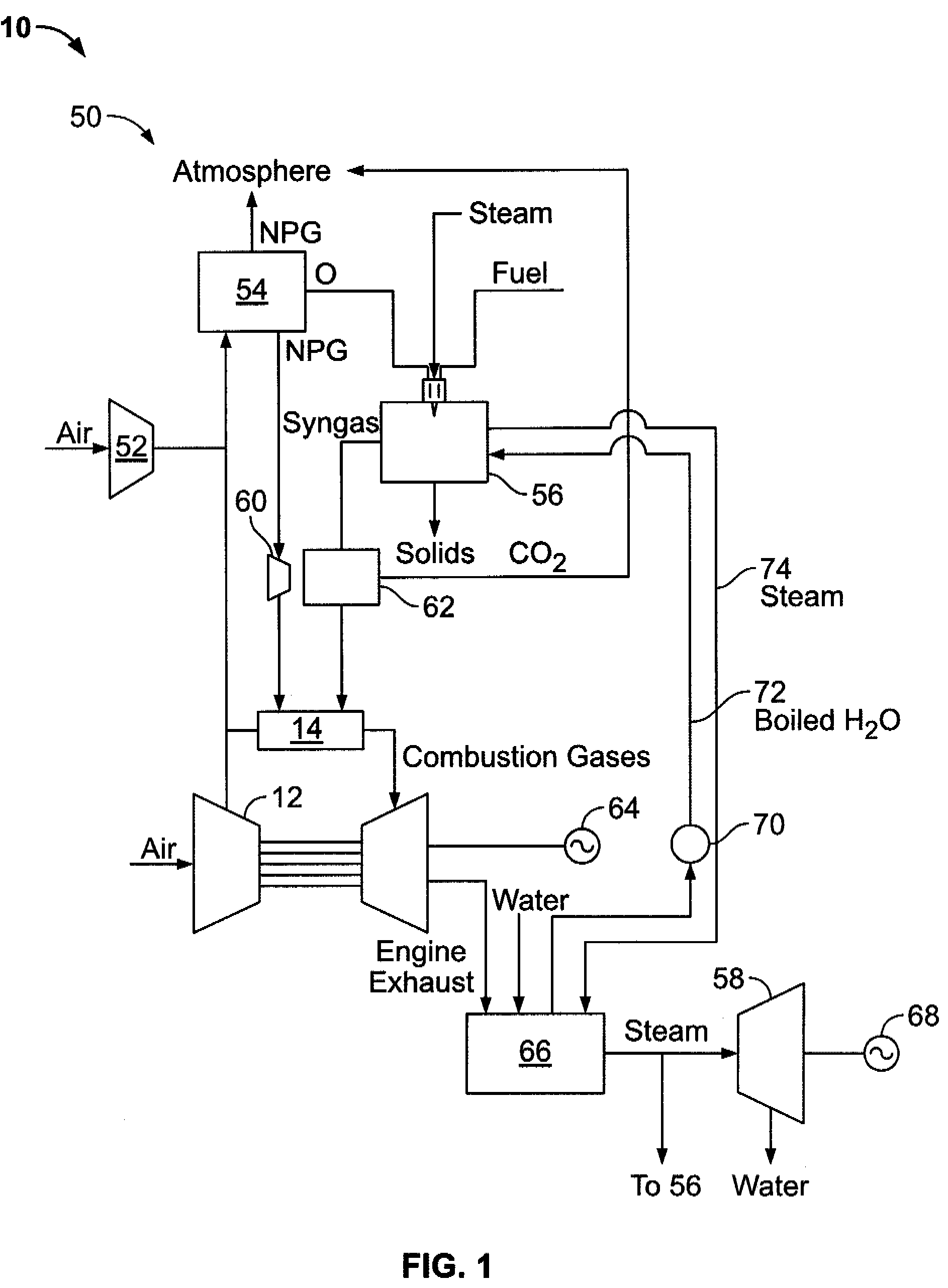

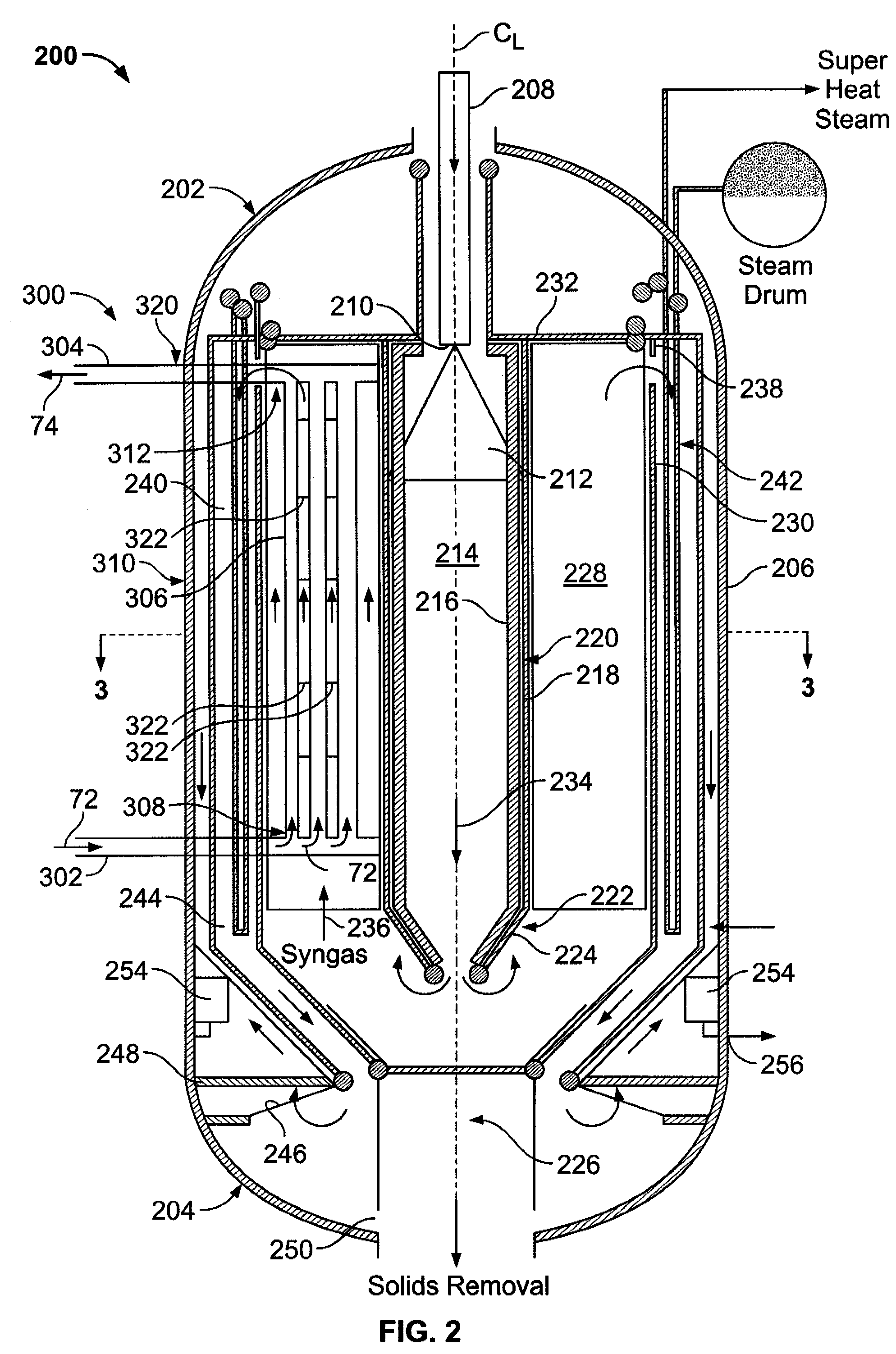

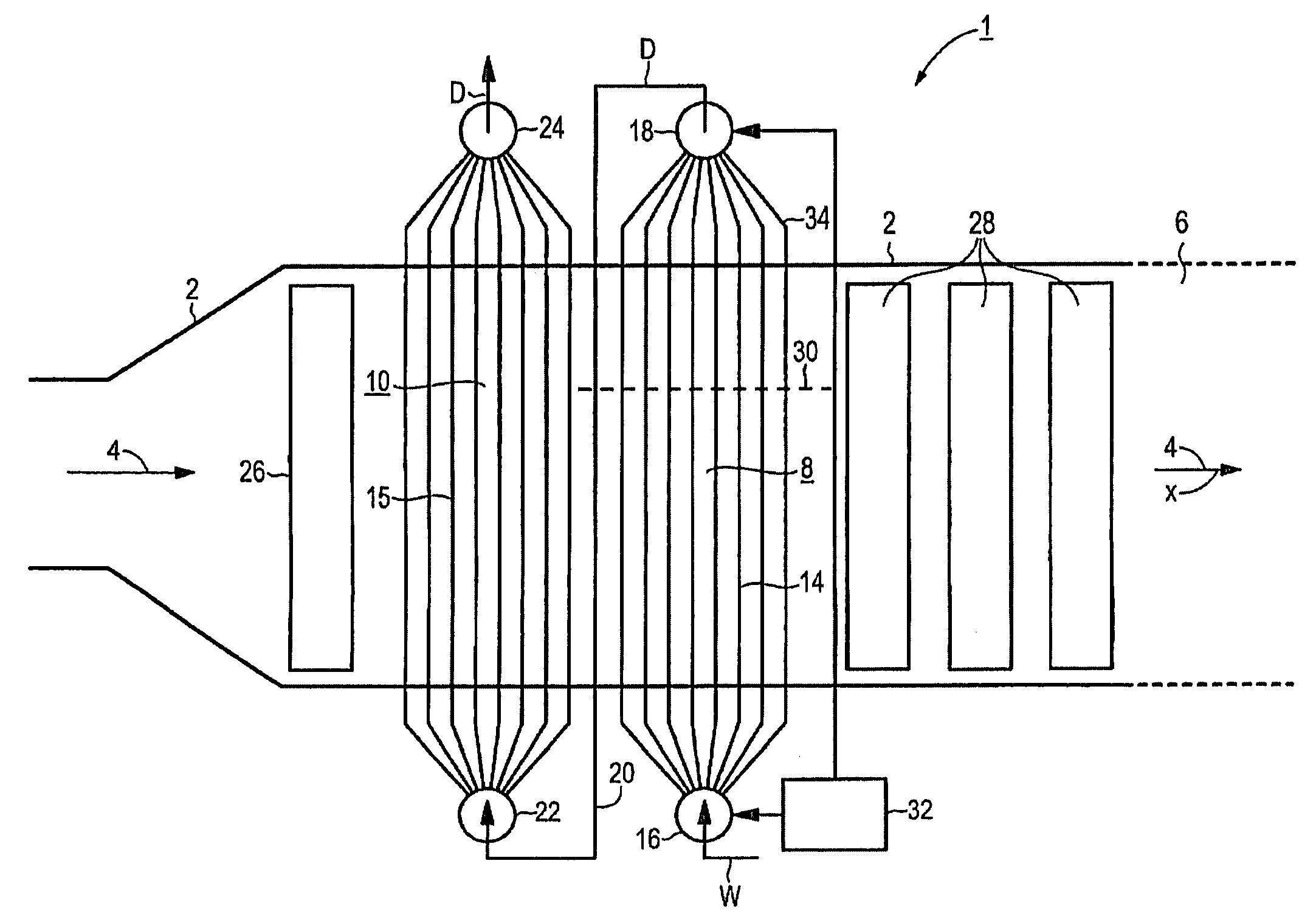

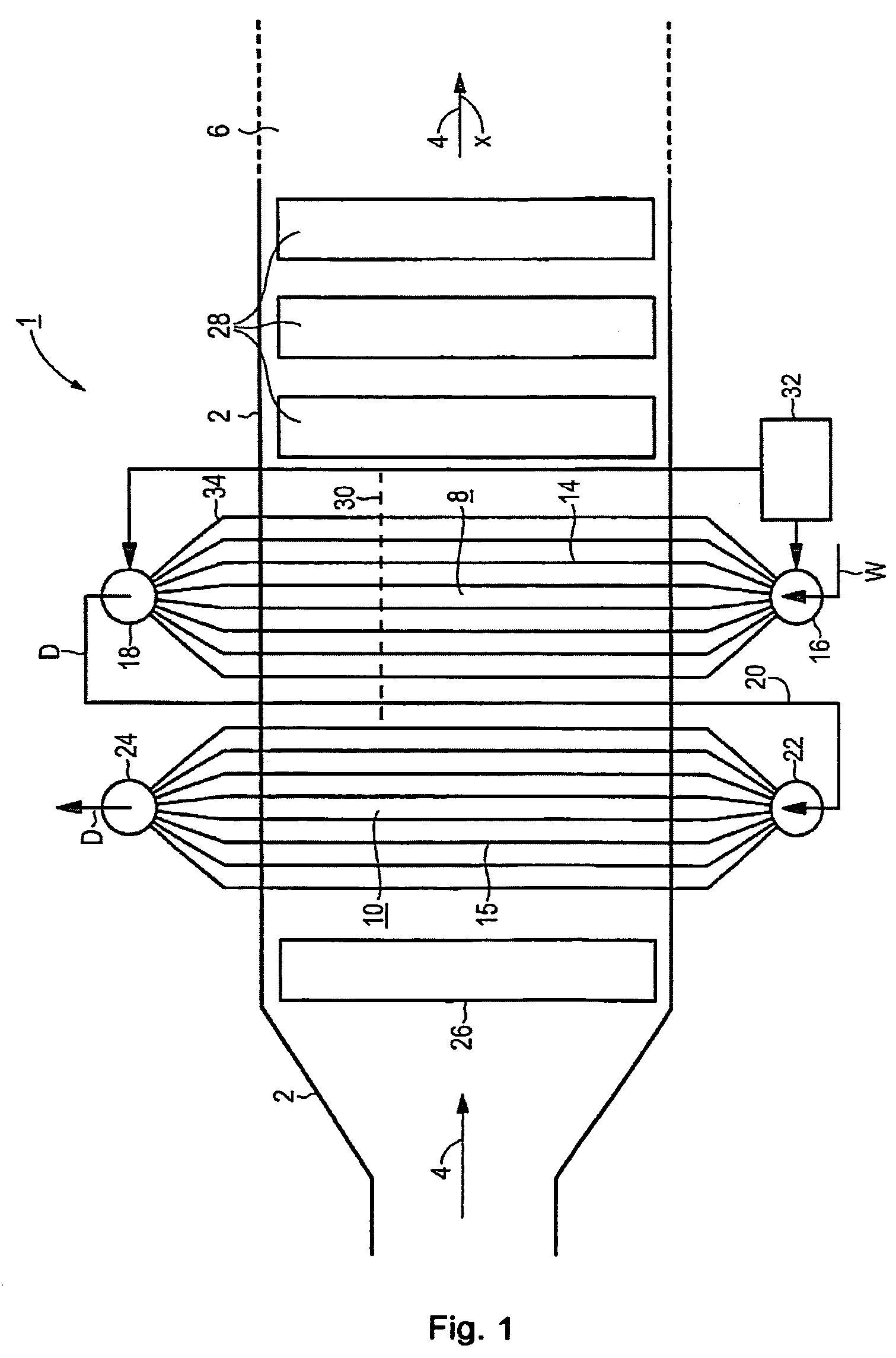

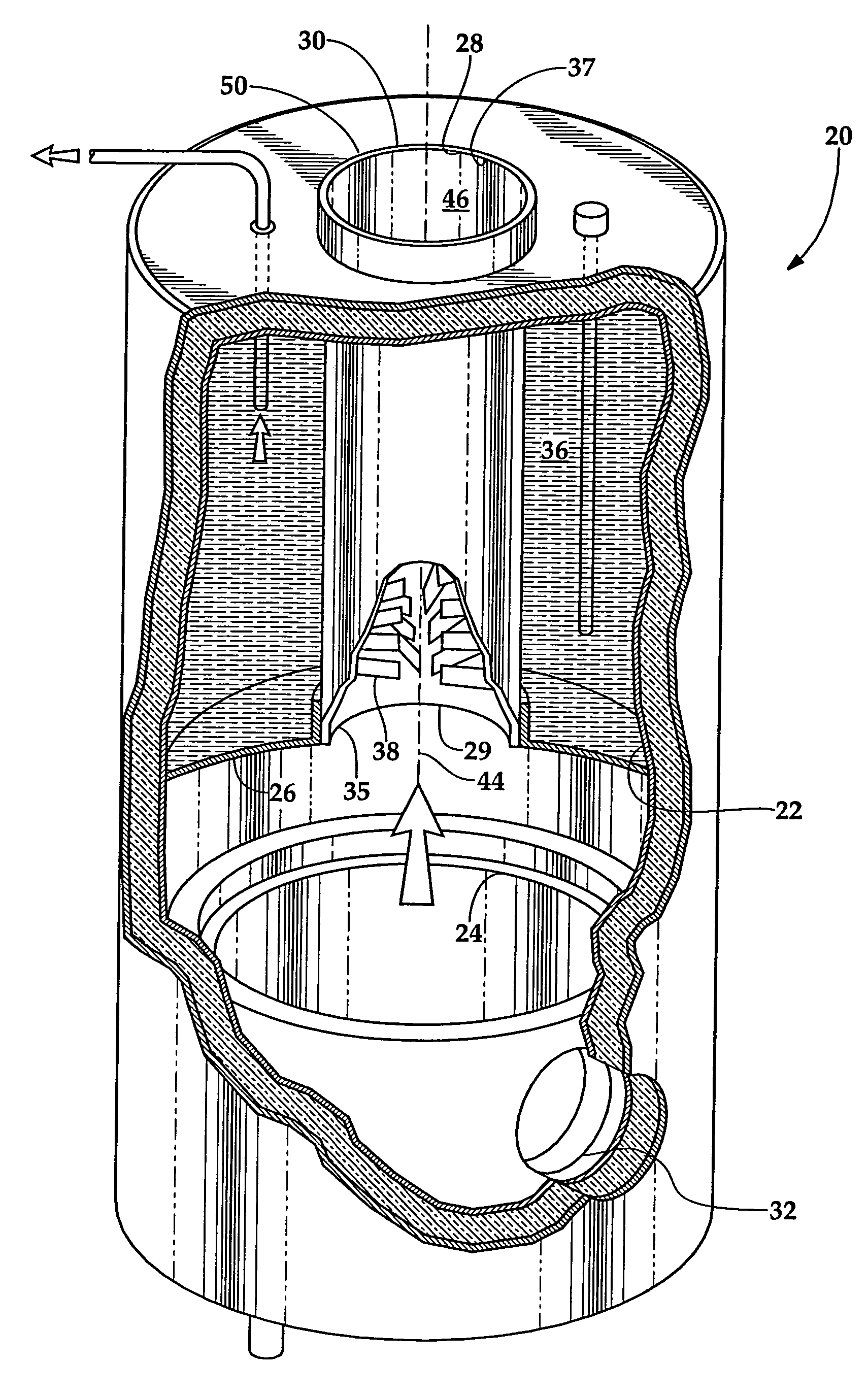

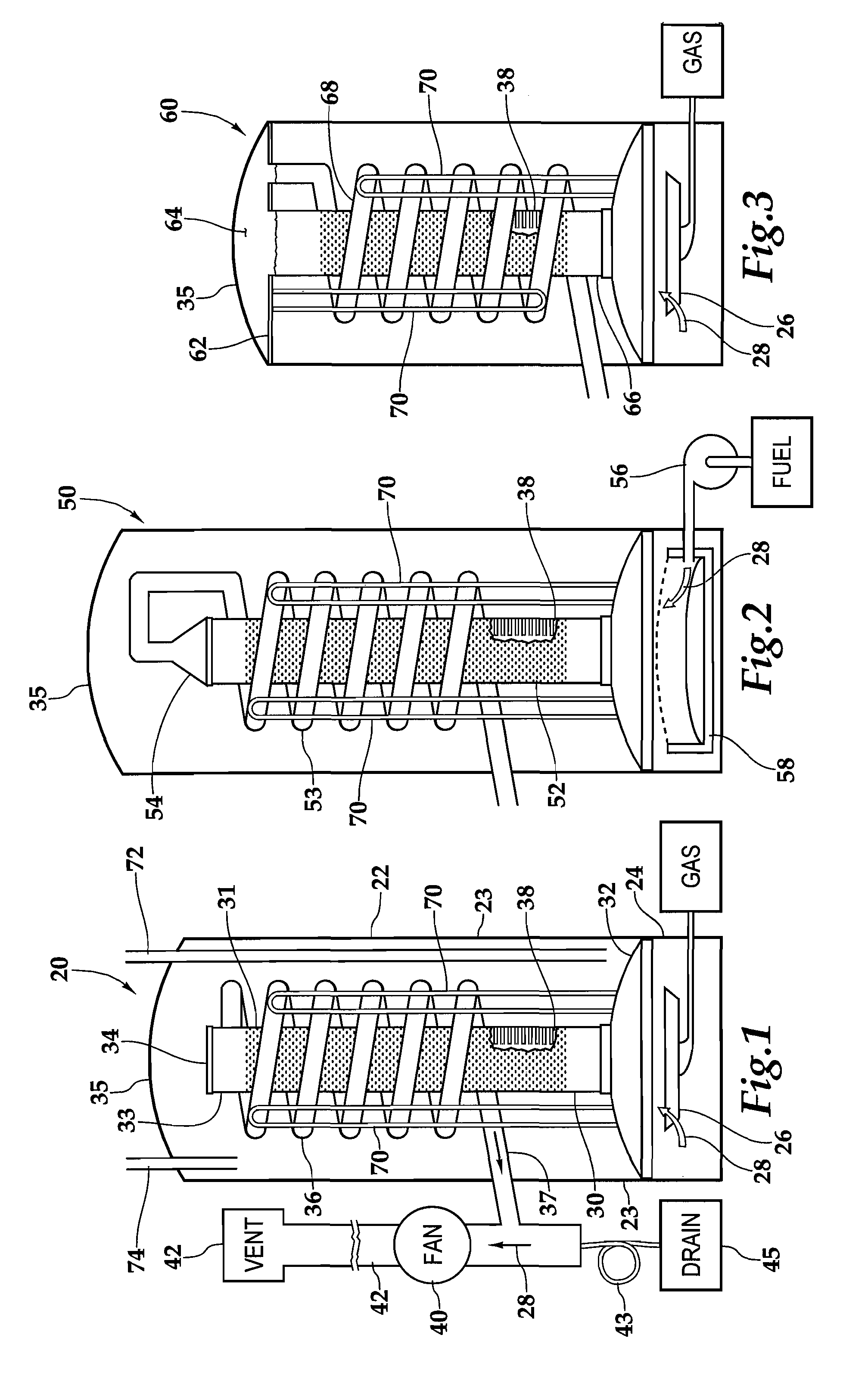

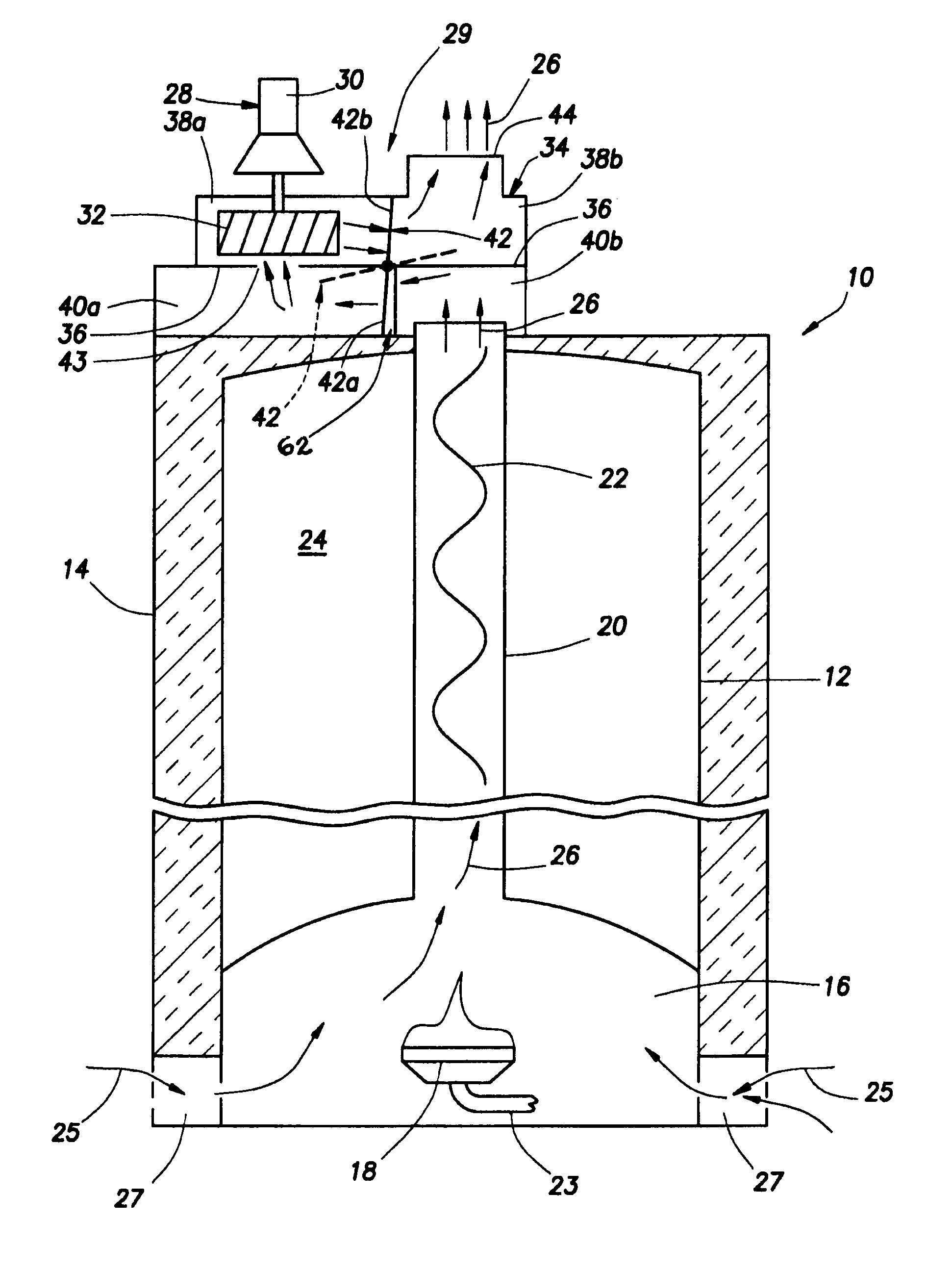

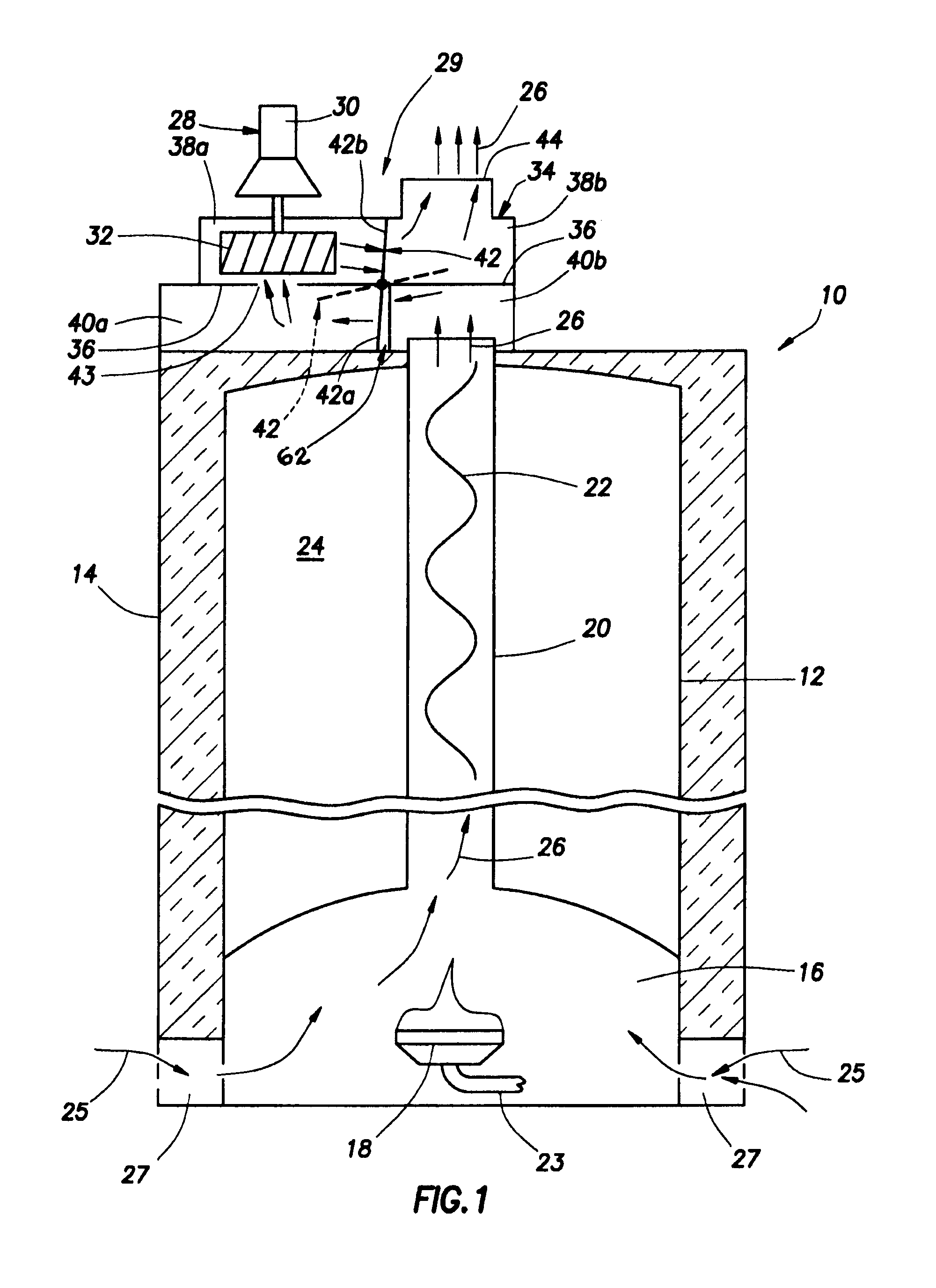

Methods and apparatus to facilitate cooling syngas in a gasifier

ActiveUS20080175770A1Improve heat transfer performanceMuffle furnacesGasifier mechanical detailsSyngasEngineering

A method of cooling syngas in a gasifier is provided. The method includes channeling cooling fluid through at least one platen that extends at least partially through a reaction zone of the gasifier, and circulating reactant fluid around the at least one platen to facilitate heat transfer from the reactant fluid to the cooling fluid.

Owner:AIR PROD & CHEM INC

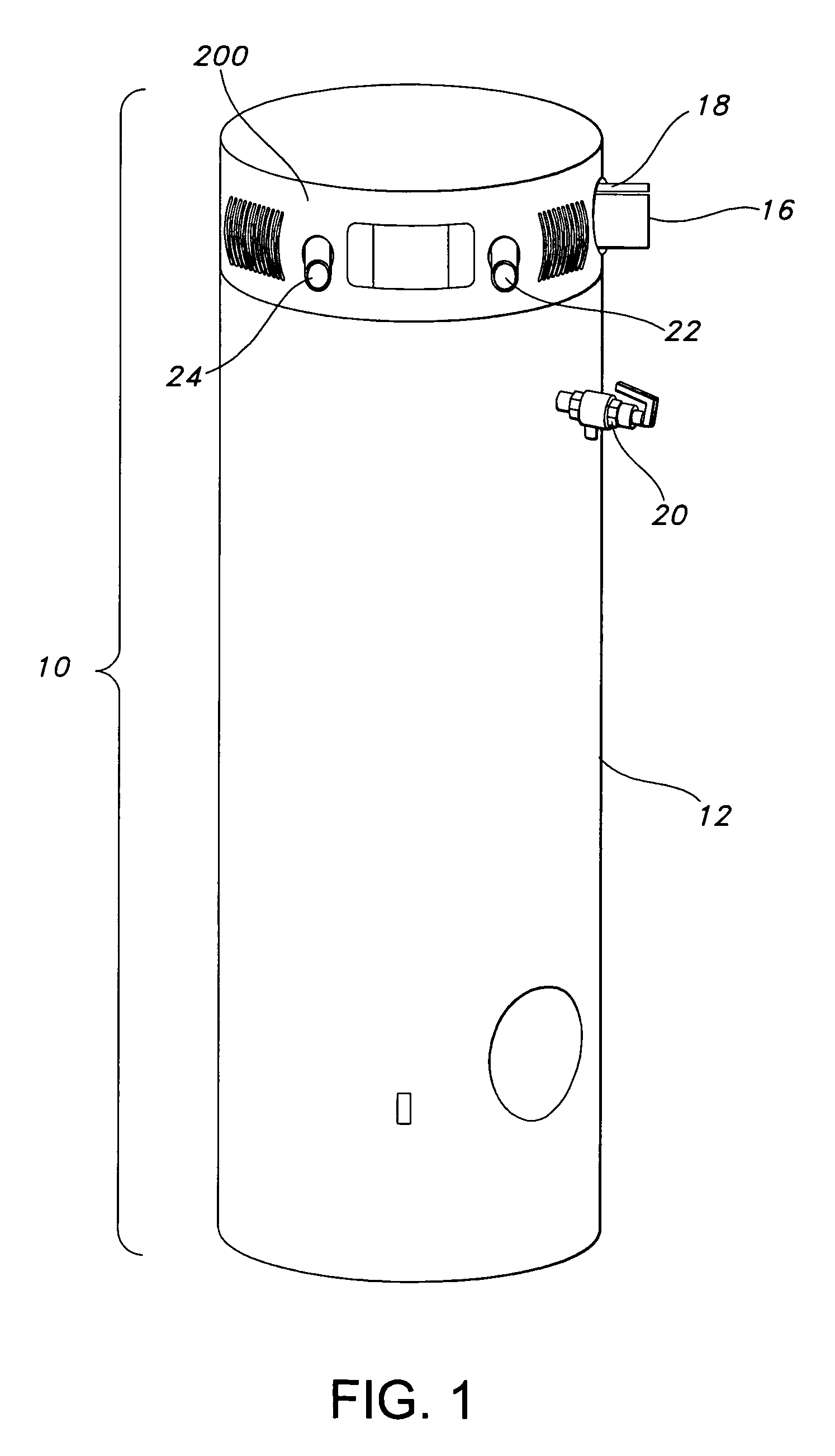

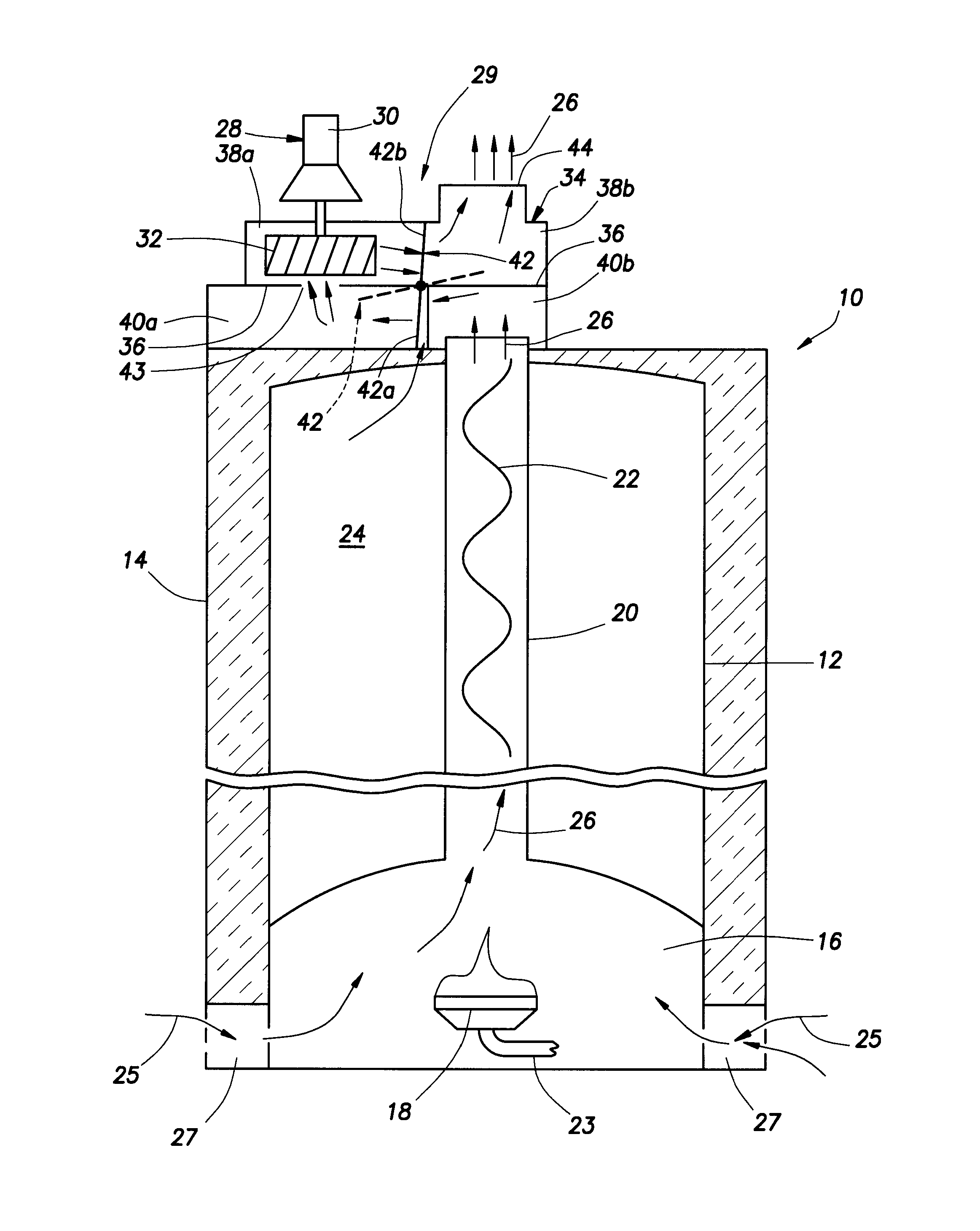

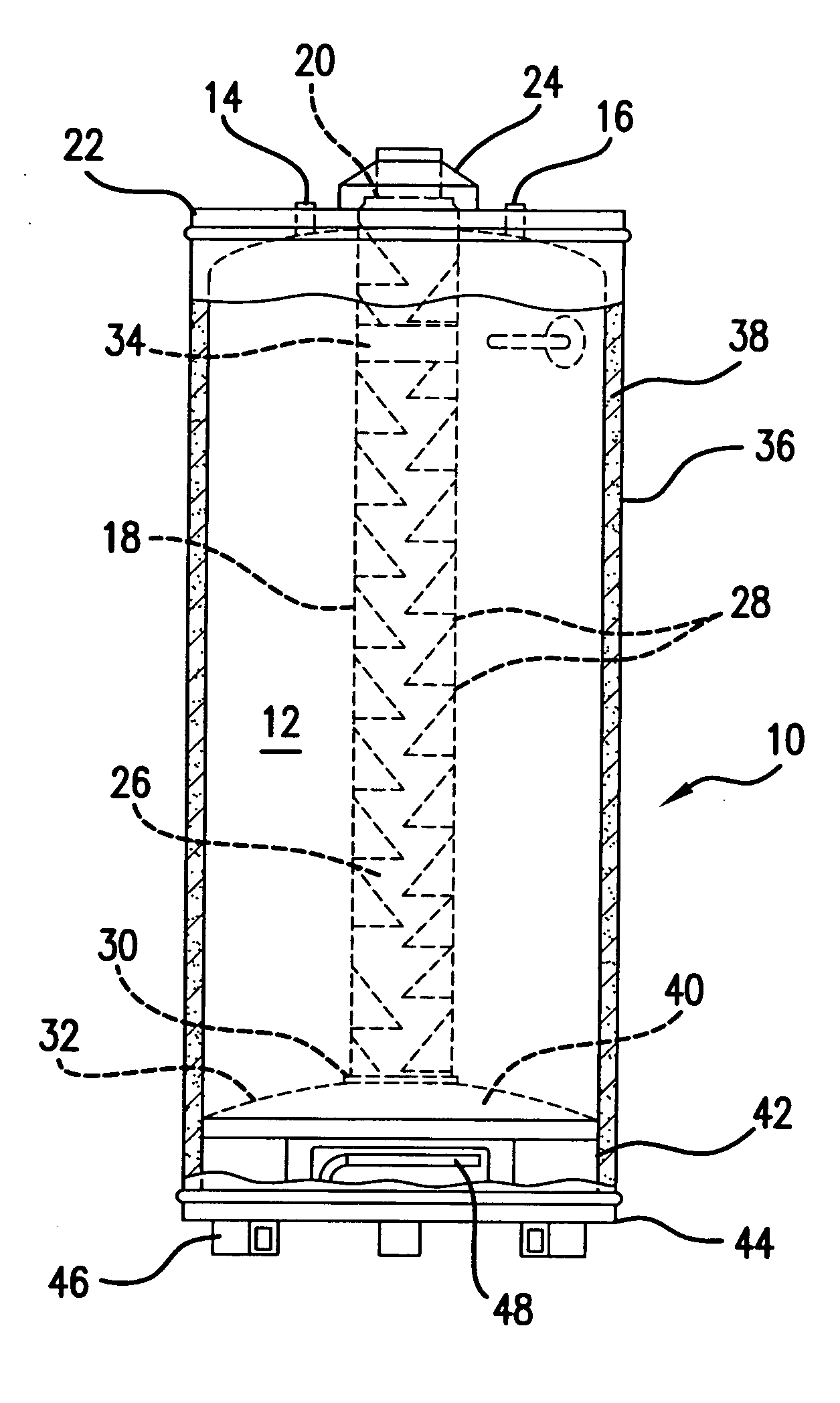

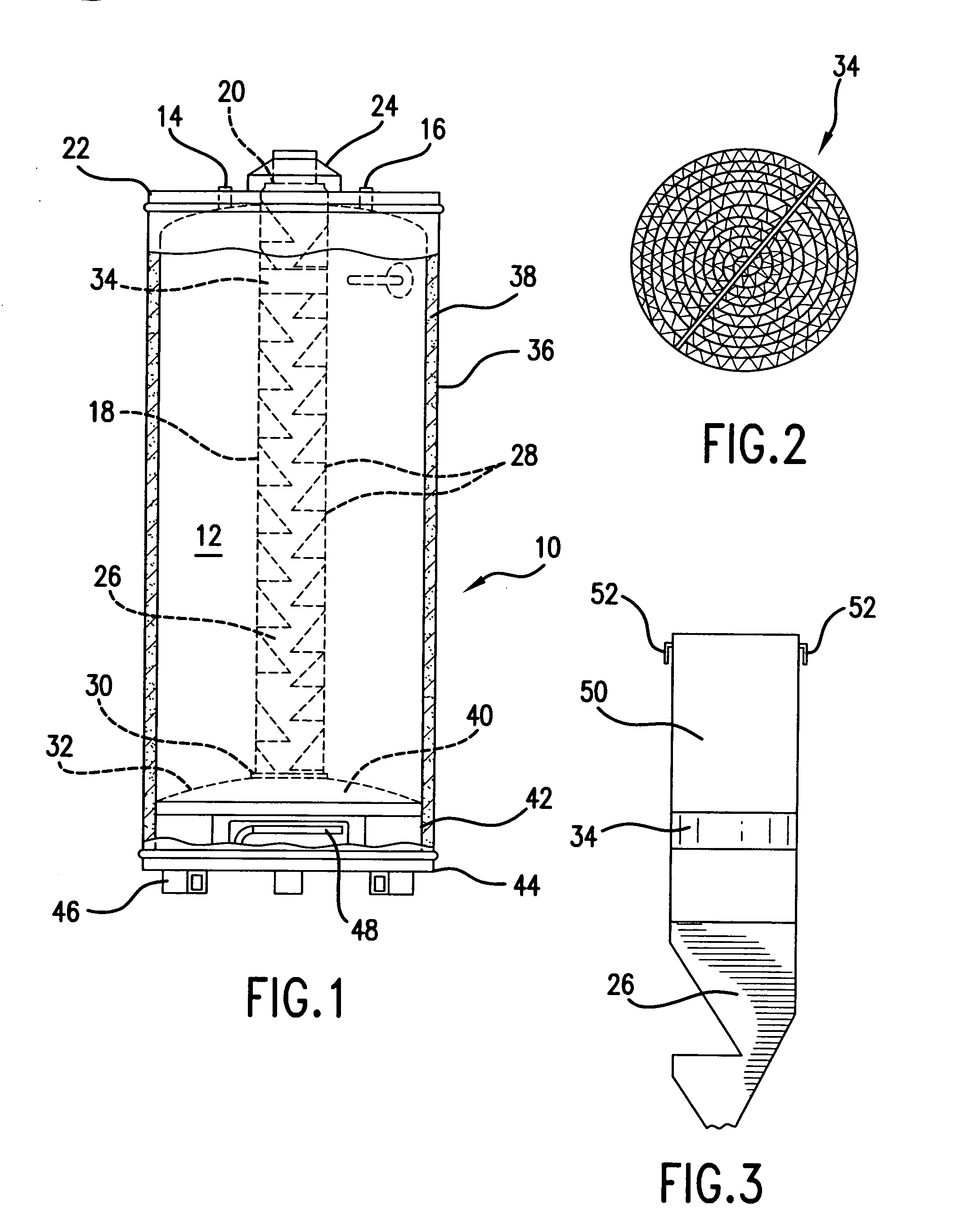

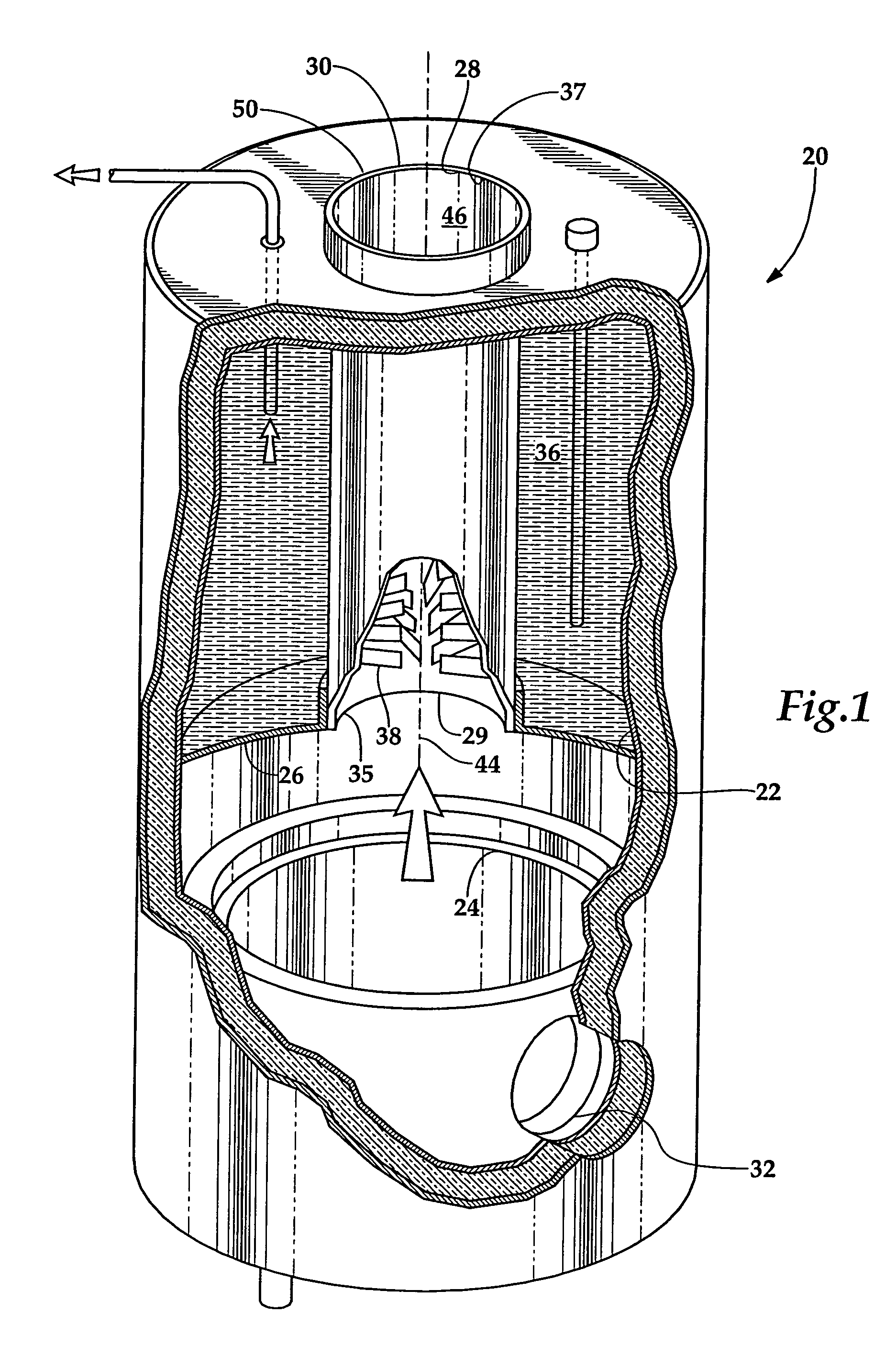

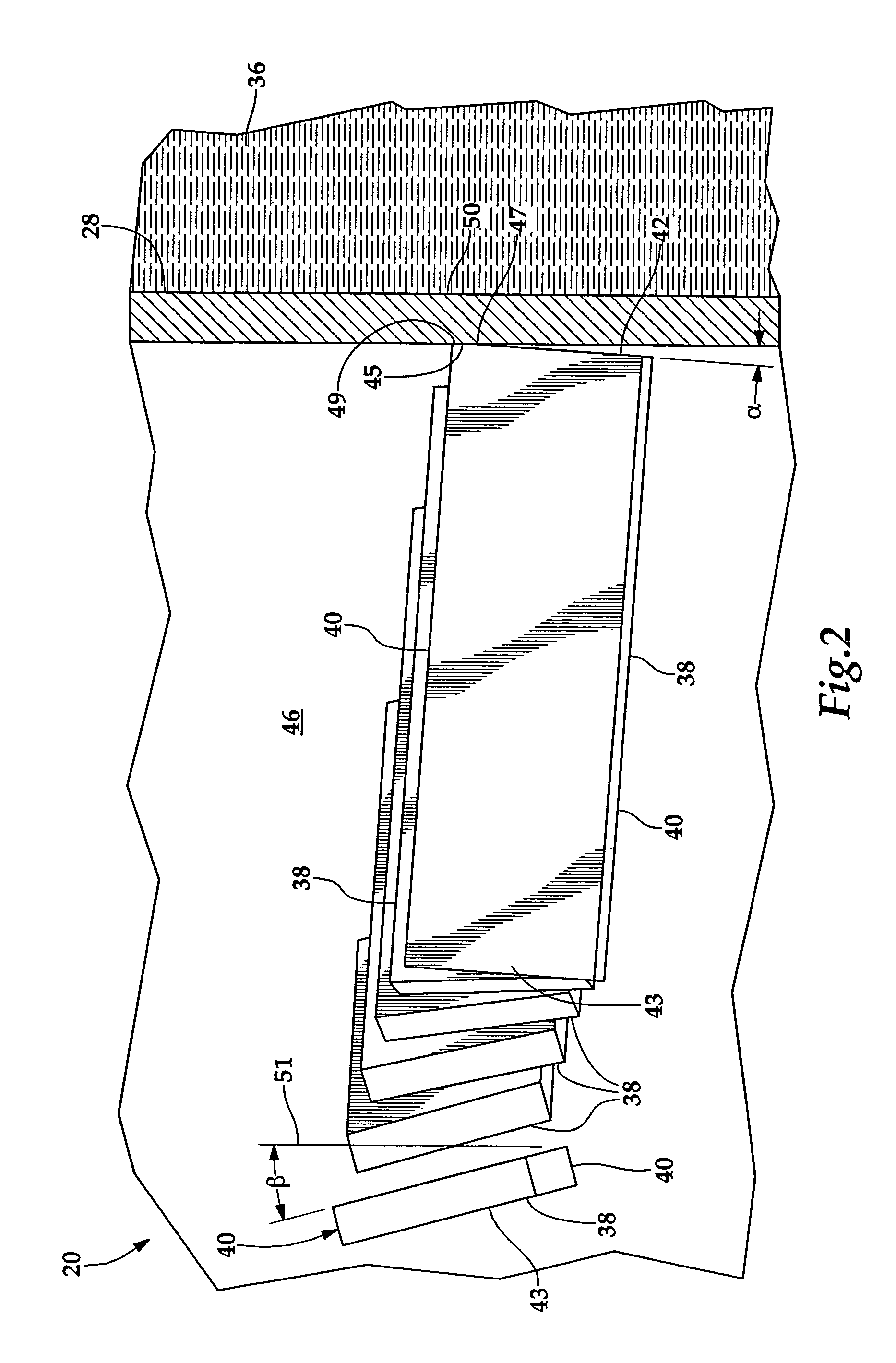

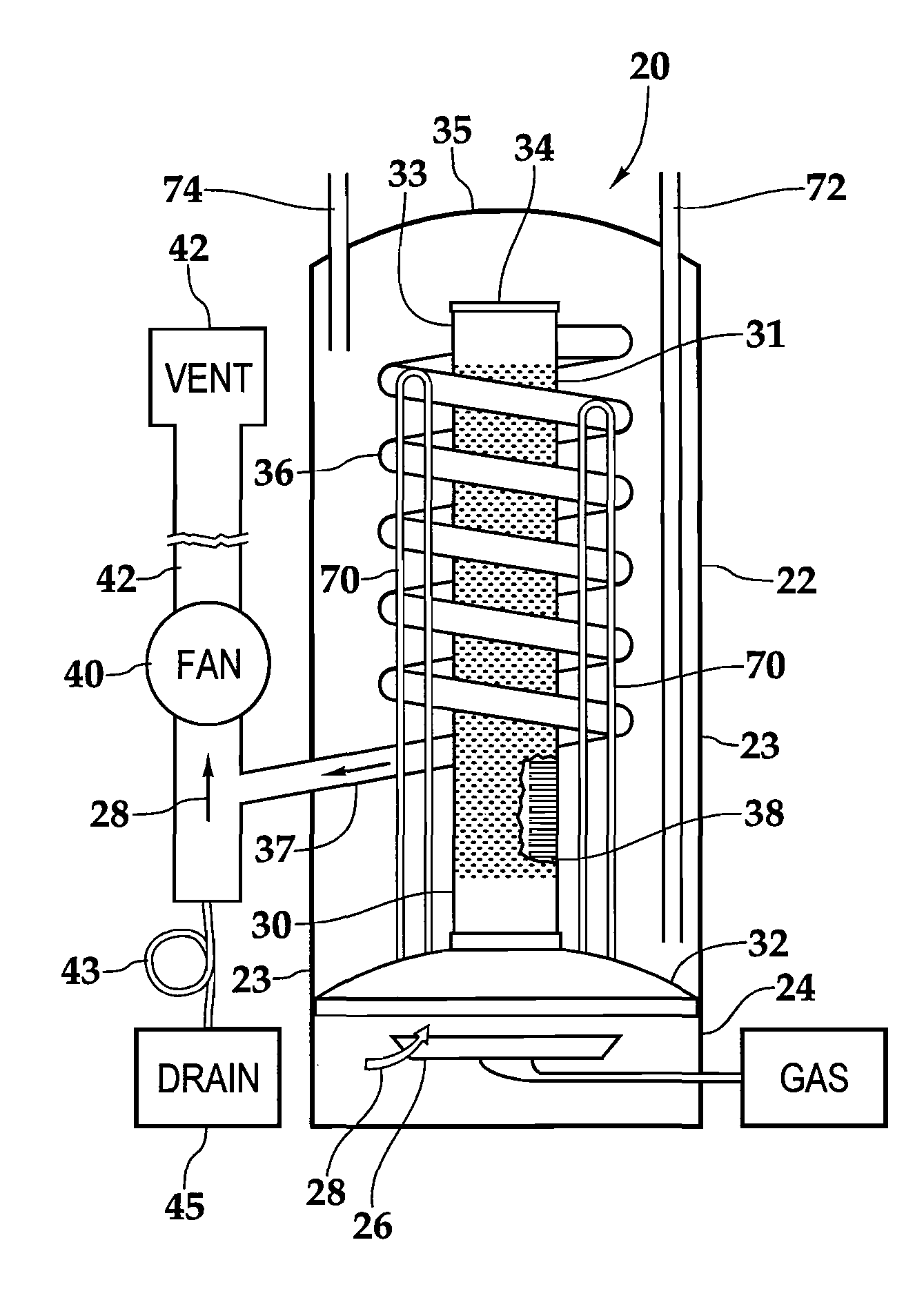

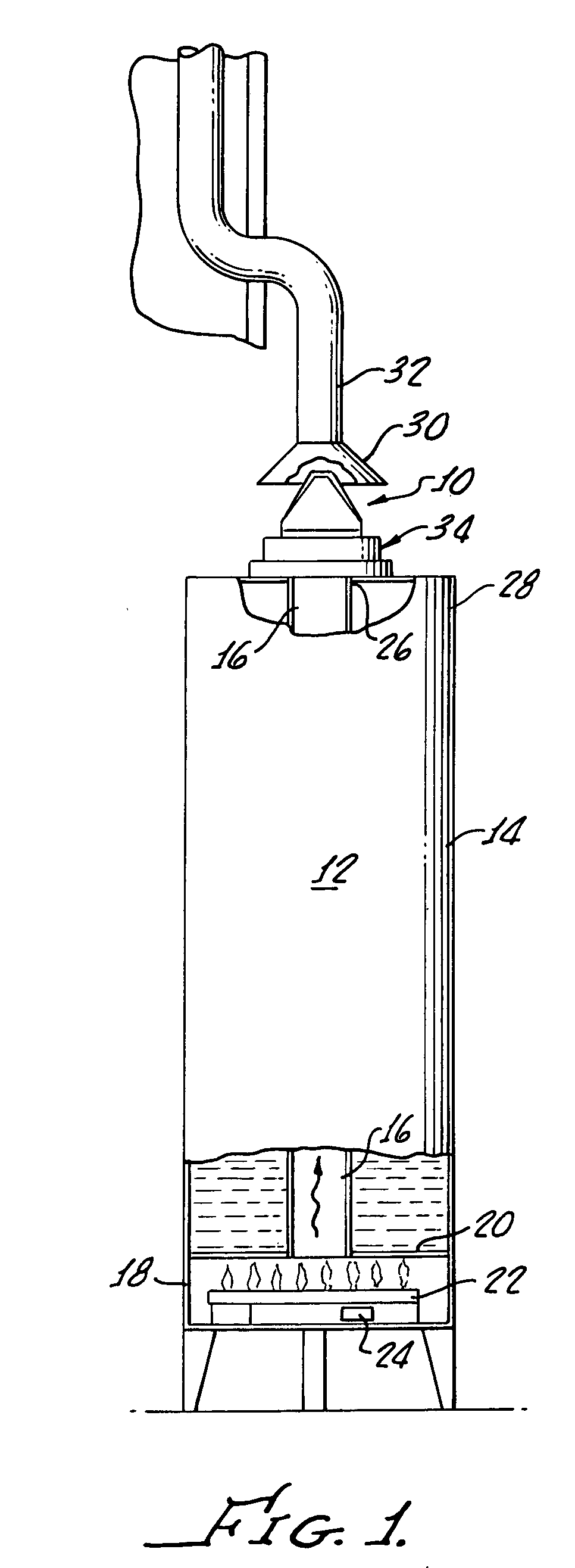

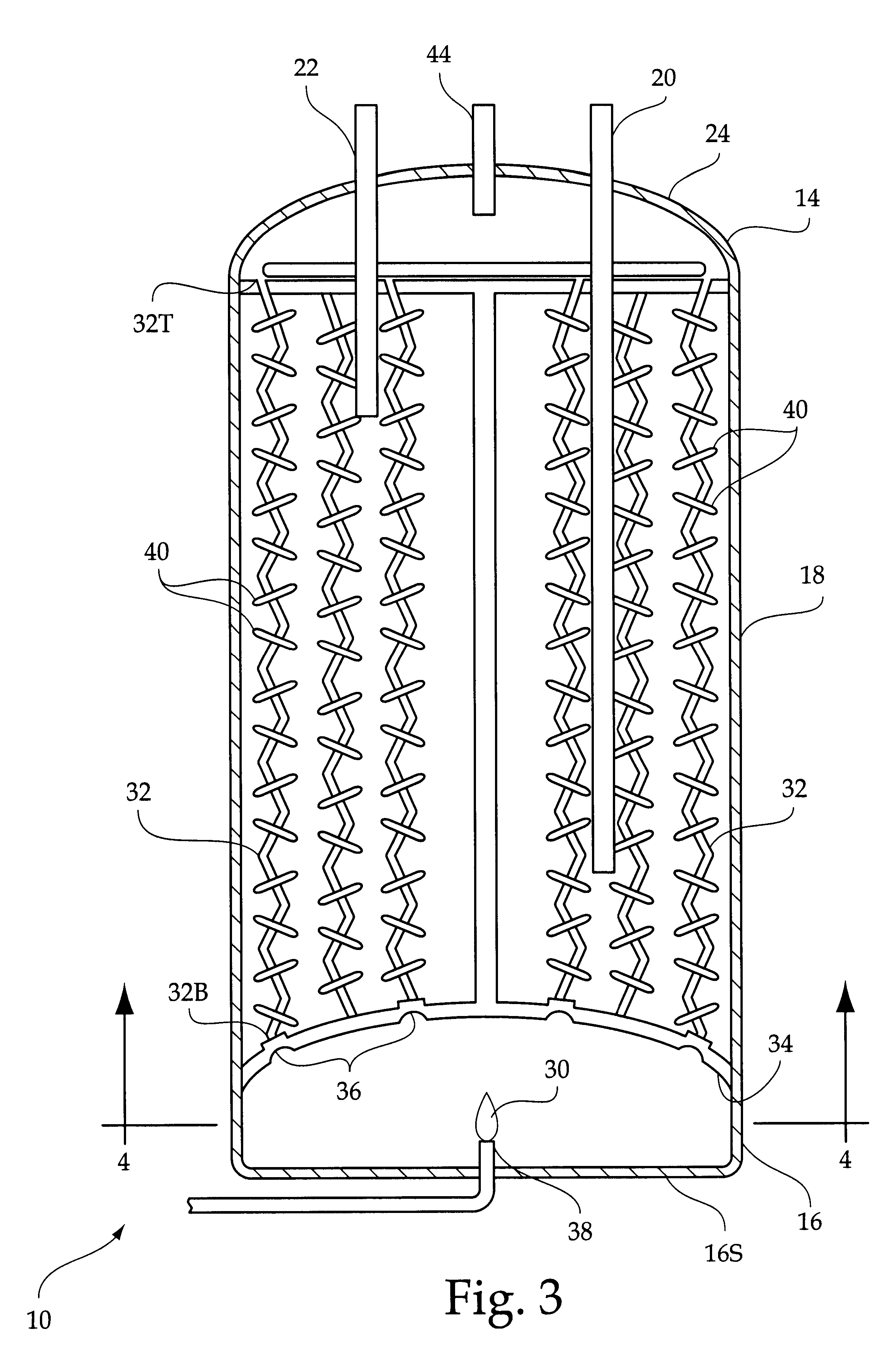

High efficiency water heater

InactiveUS7559293B2Improve heat transfer efficiencyReduce corrosionFurnace-tube steam boilersWater heatersEngineeringFlue

A flue system is provided for a water heater having improved heat exchange efficiency. The flue system includes an upstream heat exchange portion having at least one substantially vertical flue tube. The flue system also includes a downstream heat exchange portion having at least one substantially vertical flue tube. The upstream heat exchange portion provides a first pass for heat exchange with water in a water heater. The downstream heat exchange portion provides a second pass for heat exchange with water in the water heater.

Owner:BRADFORD WHITE

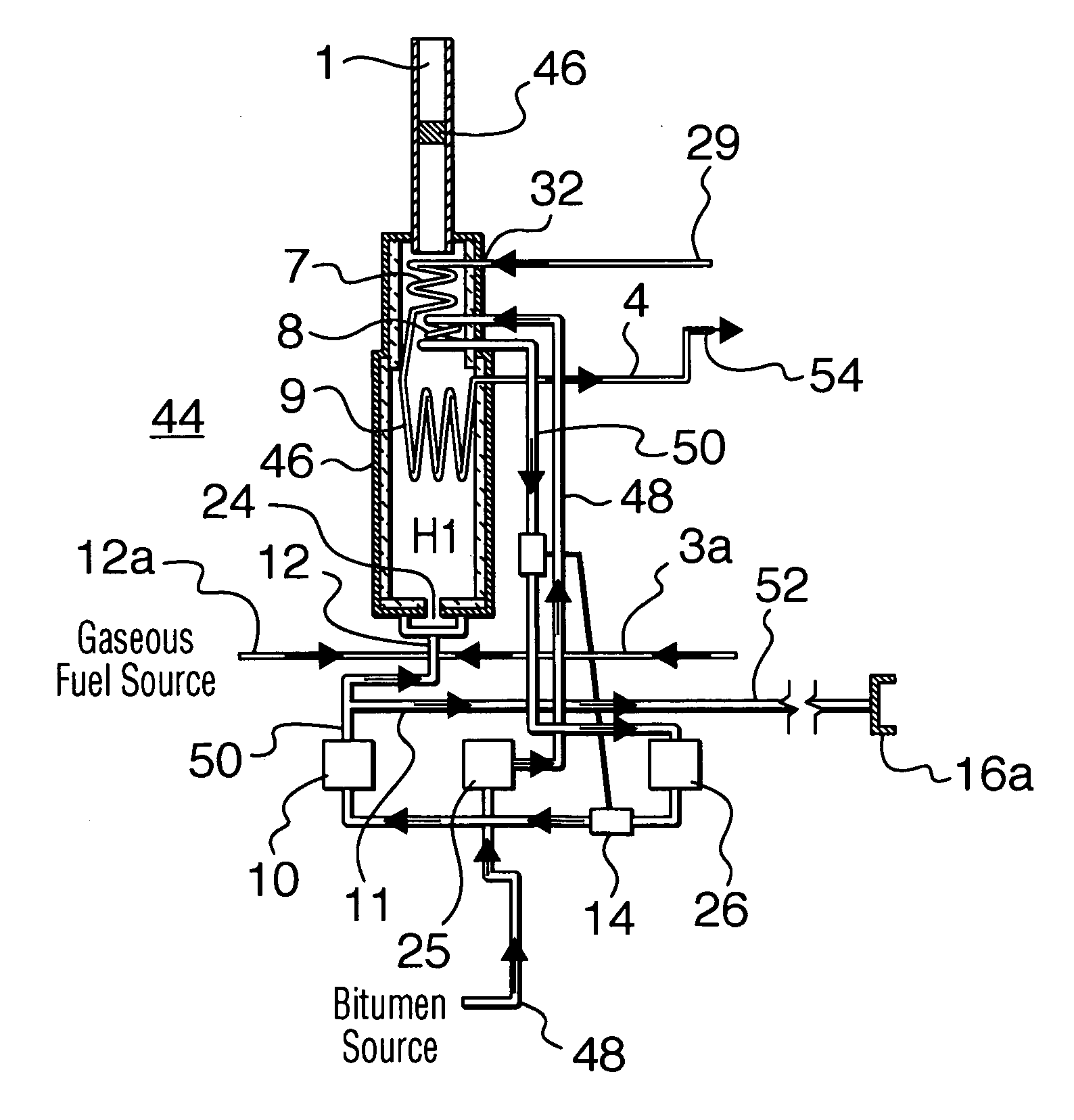

Steam generation apparatus and method

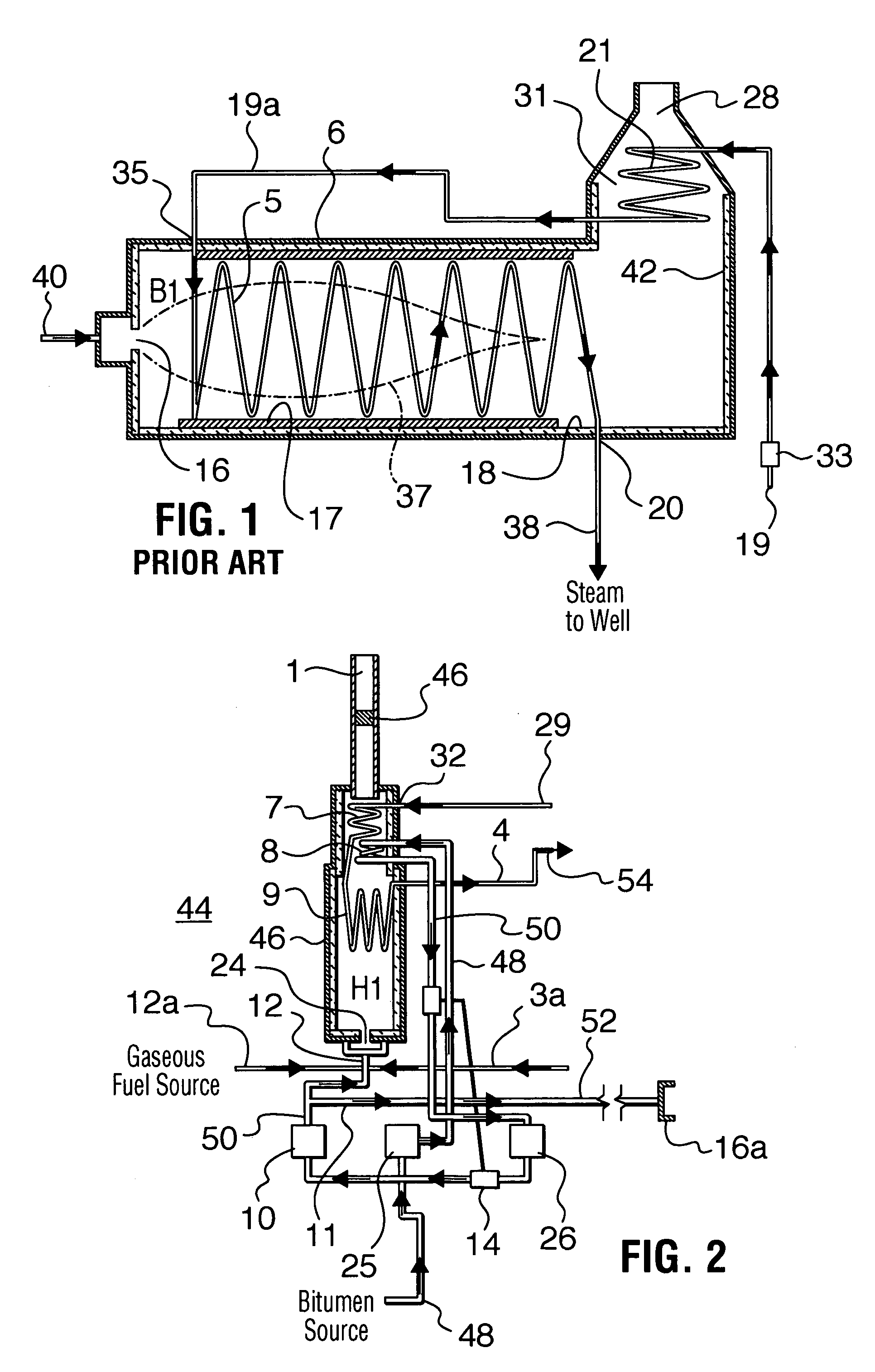

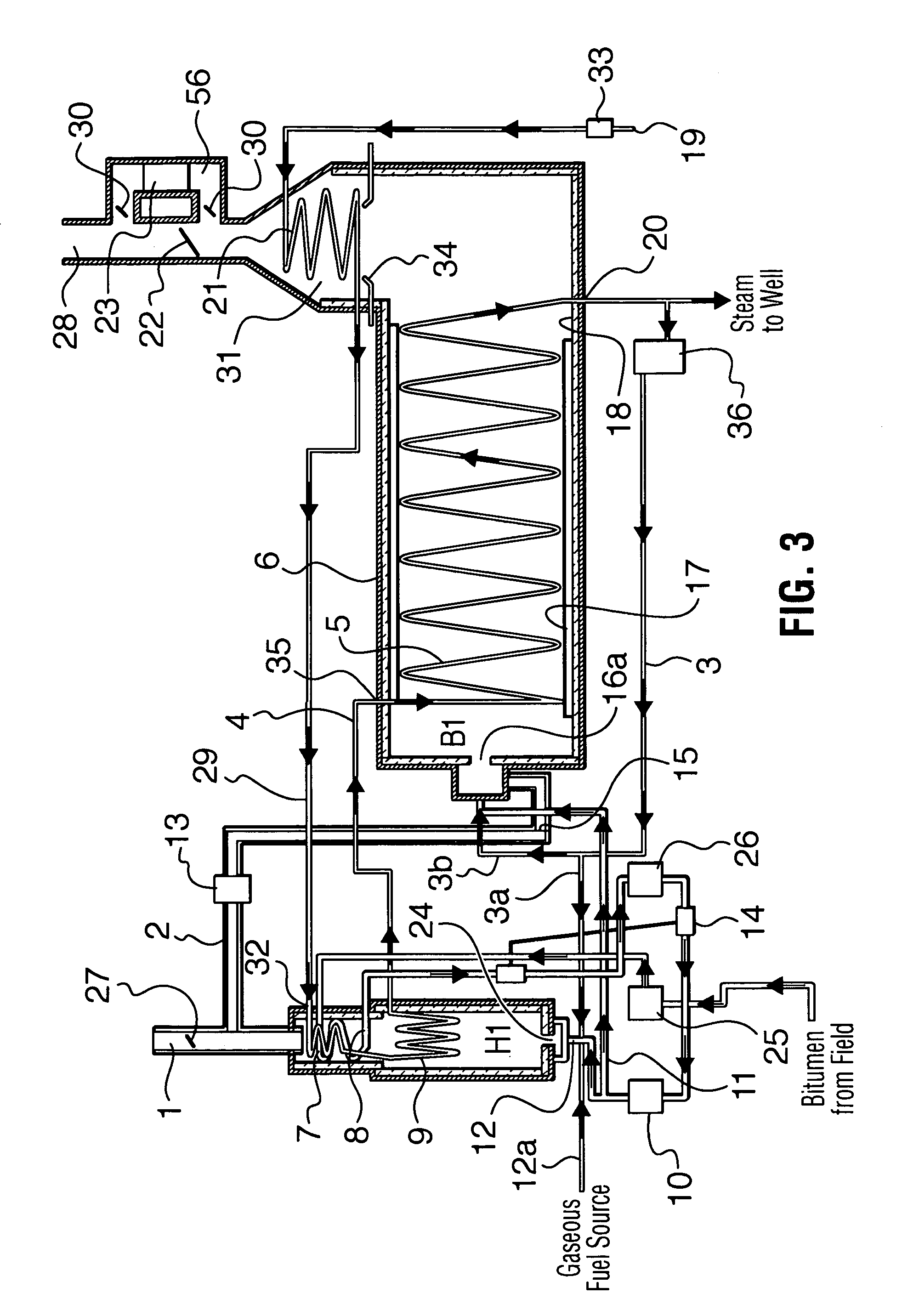

InactiveUS6990930B2Improve steaming qualityEasy to carryFurnace-tube steam boilersSteam/vapor condensersEngineeringLiquid fuel

In one aspect, the invention provides a steam generation apparatus that is liquid fuel fired and addresses conversion of gaseous fuel SIB units to operate with liquid fuel. The invention also relates to a conversion unit for a steam injection boiler, a method for converting a steam injection boiler from gas firing to possible liquid fuel firing and a method for generating steam from a liquid fuel source. The invention employs a fired heater for heating the liquid fuel to a temperature suitable for firing and preheats the water to compensate for the shortfall in heat liberation when a gas boiler is converted to use liquid fuel. In another aspect of the invention, production of steam is achievable consistently by employing step-up heaters with a steam injection boiler. The heaters being connected in parallel to continue heating the water / steam to achieve a higher quality steam over that produced in the boiler while minimizing consideration as to the adverse effects of coil fouling in the boiler.

Owner:ACS ENG TECH

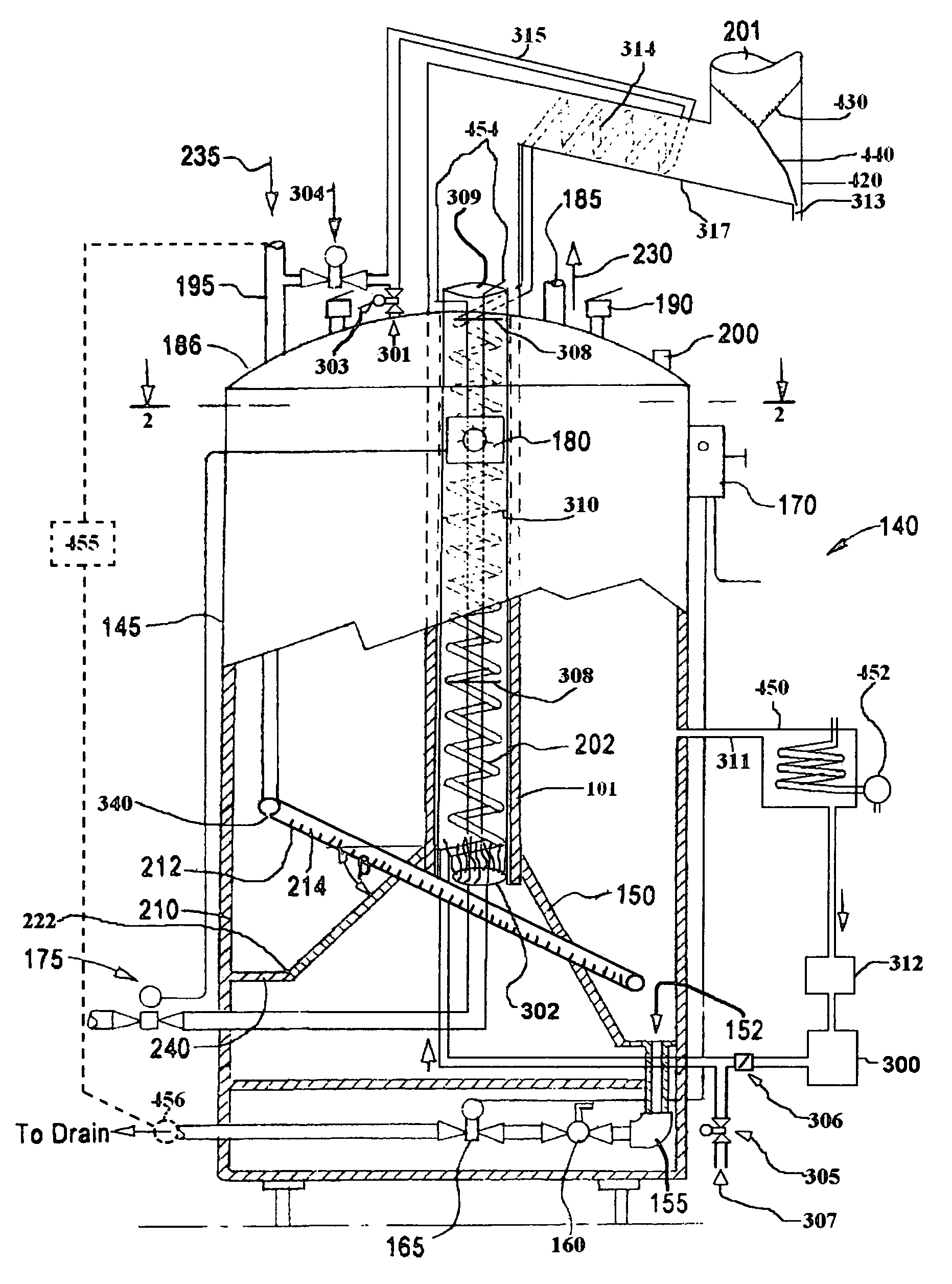

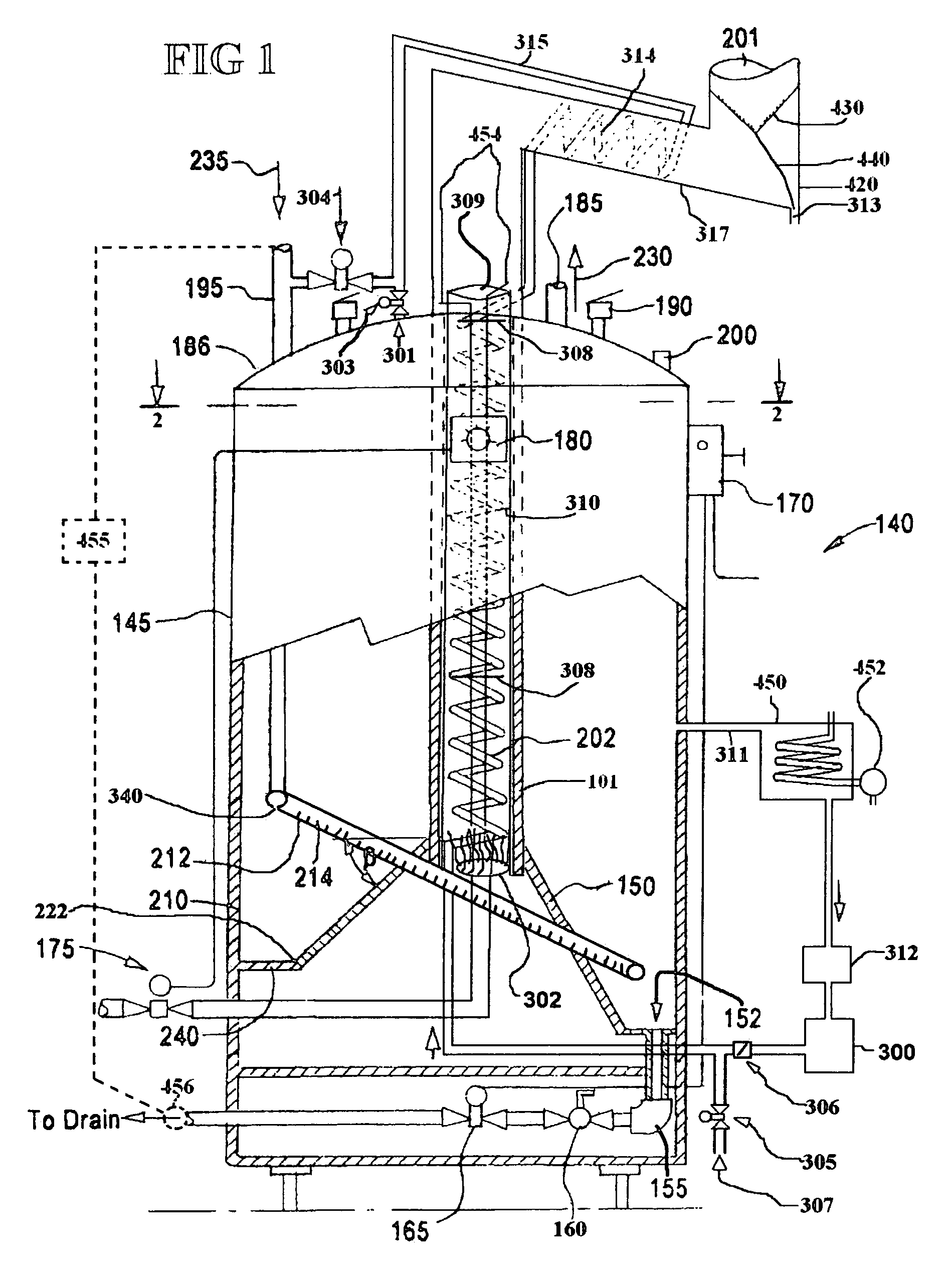

Water Heater with Condensing Flue

ActiveUS20090151653A1Reduce resistanceImprove heat transfer performanceEnergy efficient heating/coolingFurnace-tube steam boilersCombustorEngineering

A water heater has a burner positioned below a vertical centrally located flue with heat exchange capacity enhanced by a multiplicity of rectangular metal fins which are welded on the inside of the vertical central flue. The central flue extends upwardly within a water tank. The central flue transitions to a smaller diameter downwardly draining helically coiled condensing flue. Approximately 80% of the heat from the combustion gases is transferred to the water within the water tank through the wall of the central flue without condensation. An additional 10% or more of the combustion heat is transferred to the water accompanied by condensation of water in the coiled flue. A fan draws the combustion gases through the central flue and the coiled condensing flue and supplies the combustion gases to an exterior vent.

Owner:BOCK WATER HEATERS

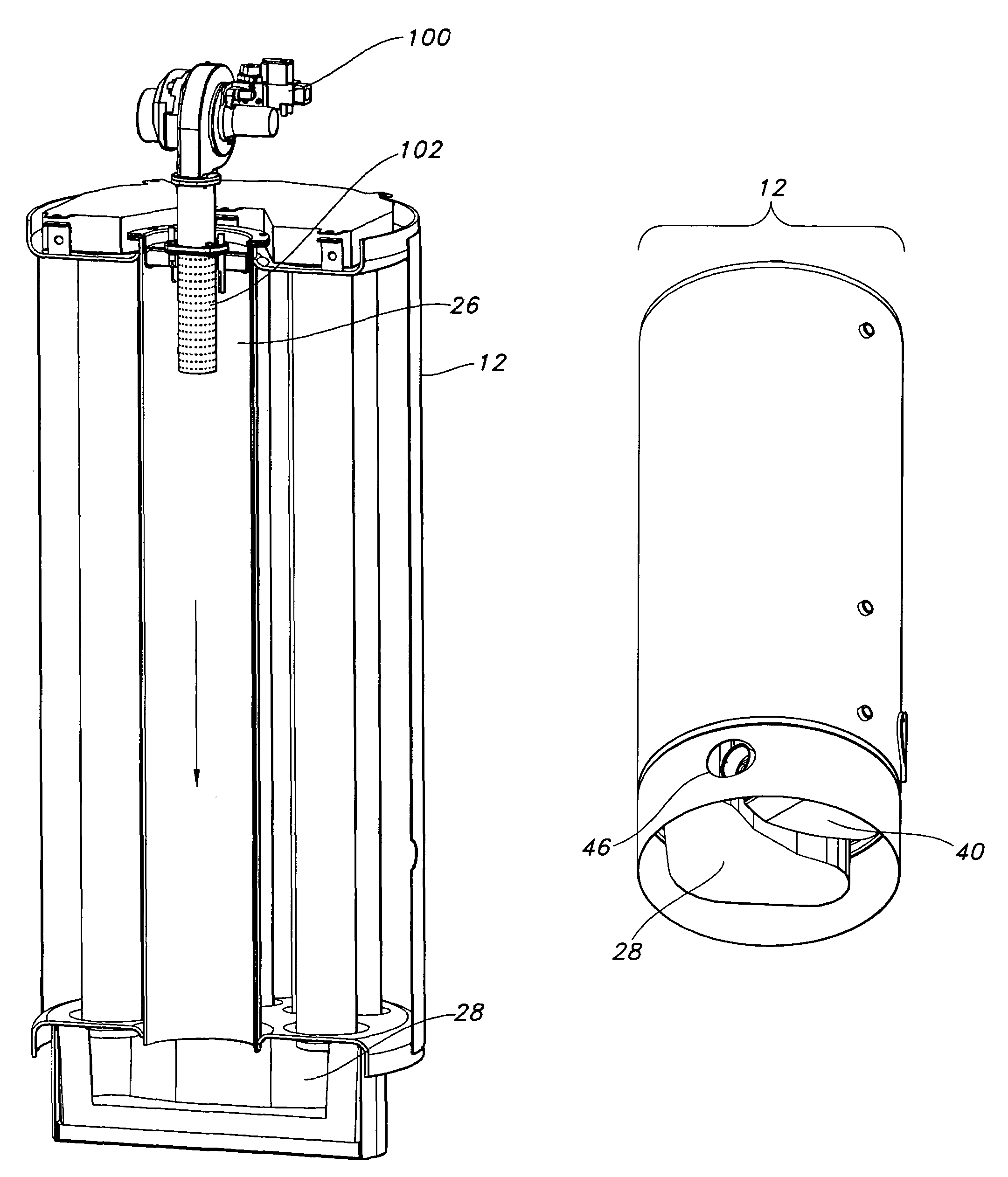

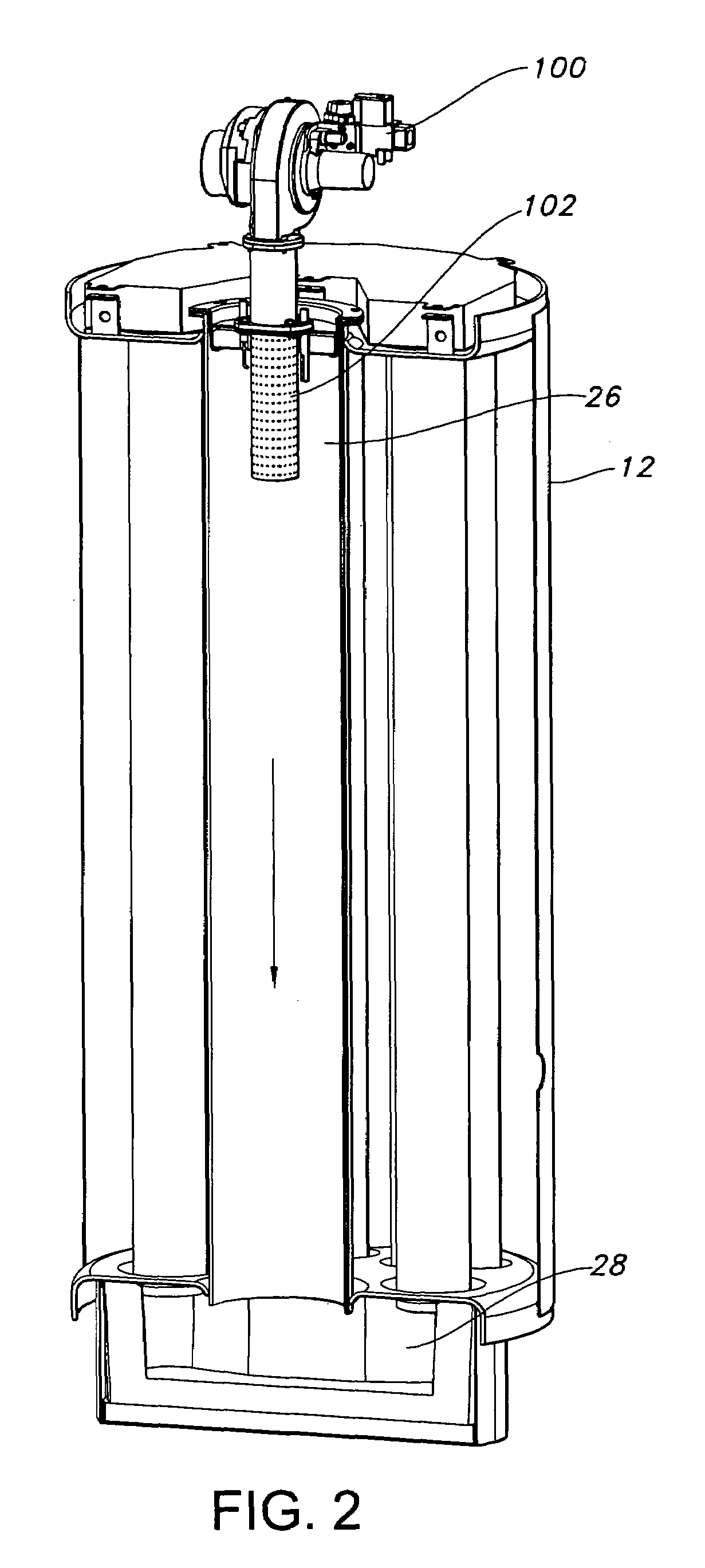

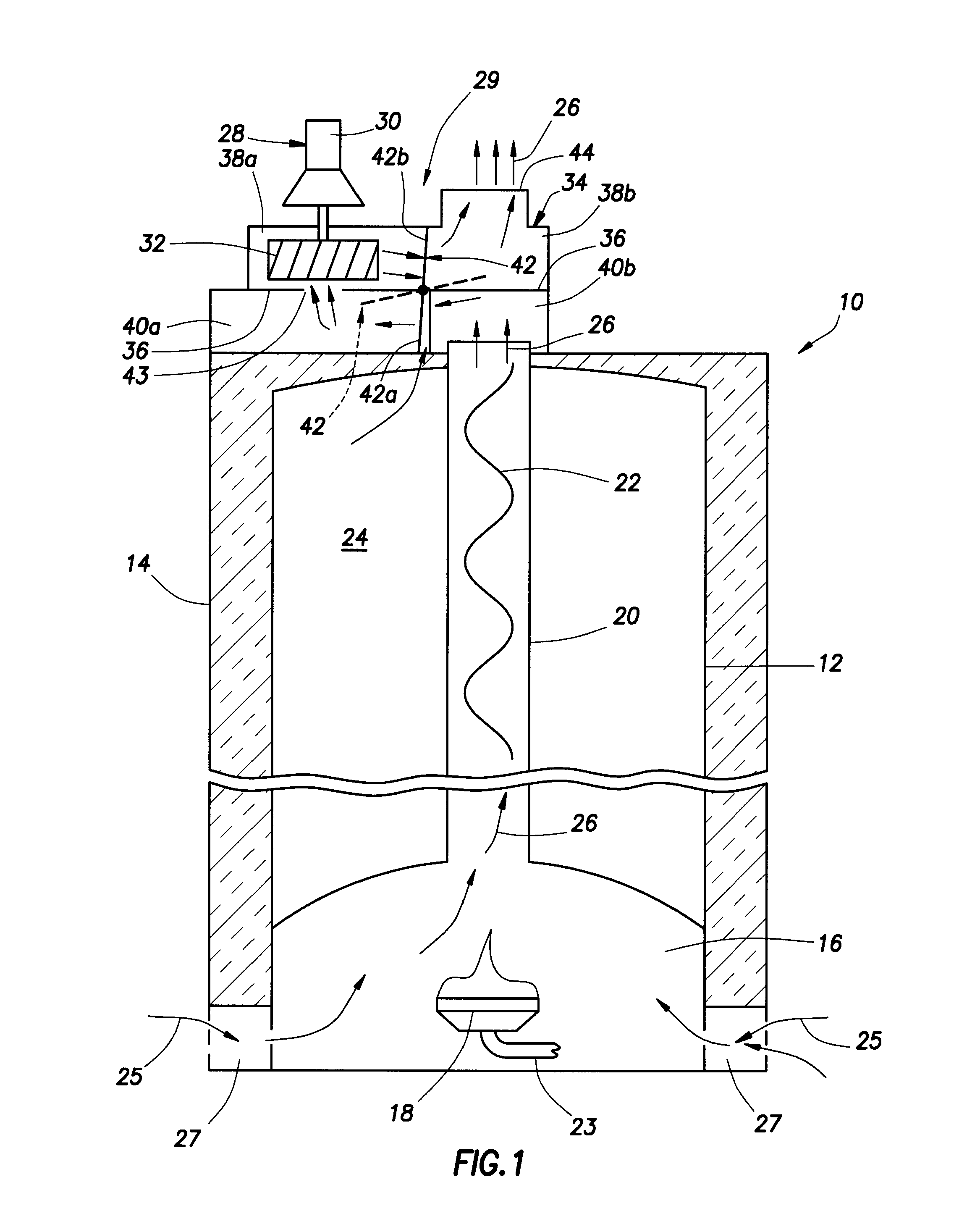

Fuel-fired, power vented high efficiency water heater apparatus

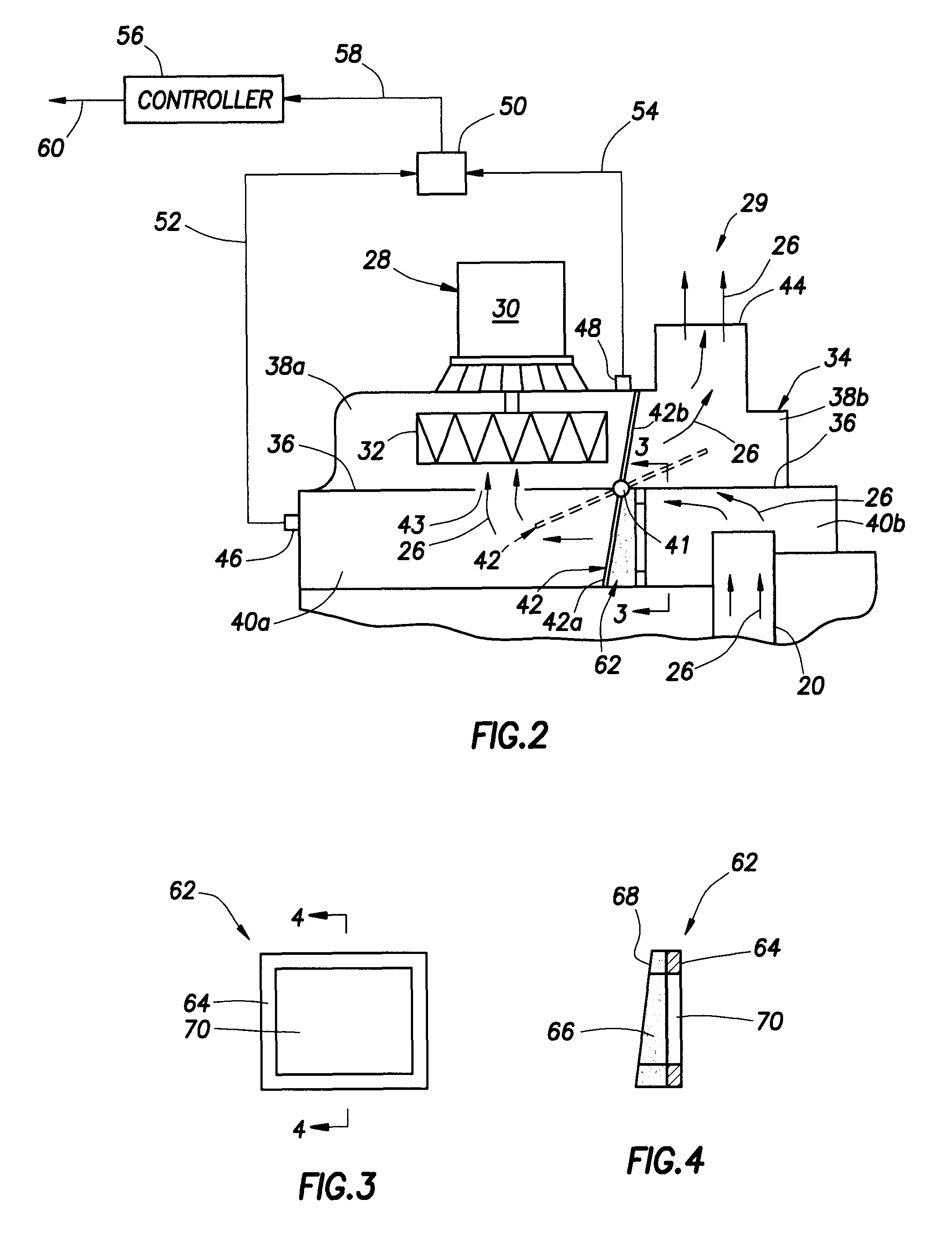

ActiveUS20090211540A1Improve energy efficiencyAvoid flowFurnace-tube steam boilersWater heatersCombustionFlue

A fuel-fired water heater has a draft inducer fan assembly with a housing having an inlet for receiving hot combustion gases discharged from the water heater, and an outlet for discharging the combustion gases. A normally closed damper member within the housing is openable by fluid pressure force created by operation of a draft inducer fan portion of the assembly. With the damper in its open position the fan exhausts the received combustion gases through a housing outlet. When the damper closes it prevents convective outflow through the housing outlet of flue-heated air. In alternate embodiments of the assembly the fan is operative to also draw in dilution air that cools the fan motor and the discharged combustion gases, with the assembly having an internal configuration preventing convective outflow of flue-heated air through the housing dilution air inlet during standby periods of the water heater.

Owner:RHEEM MFG CO

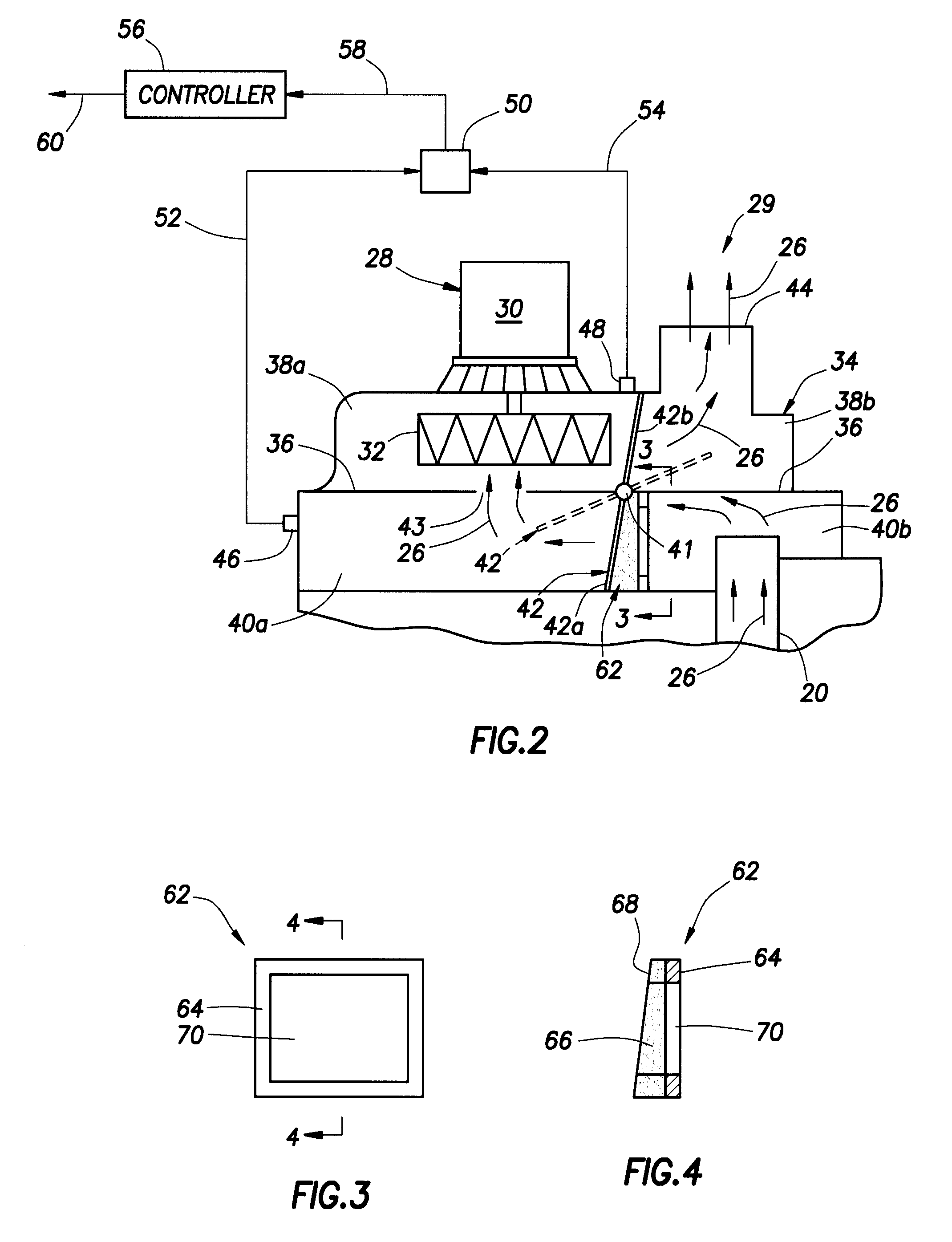

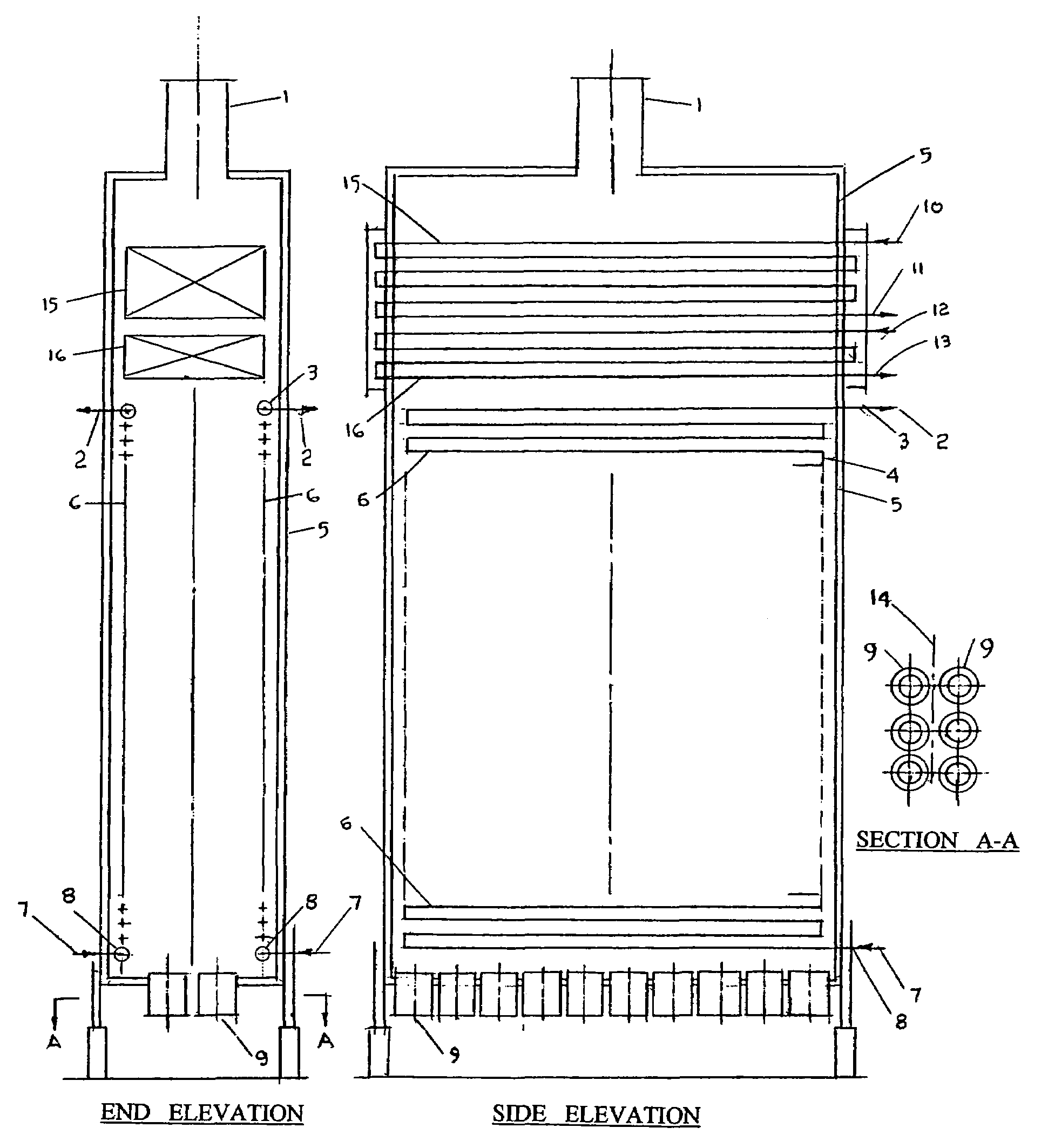

Super low NOx, high efficiency, compact firetube boiler

ActiveUS6971336B1Reduce nitrogen oxide emissionsReducing NO<sub>Furnace-tube steam boilersCombustion enginesCombustion chamberBoiler furnace

A firetube boiler furnace having two combustion sections and an in-line intermediate tubular heat transfer section between the two combustion sections and integral to the pressure vessel. This design provides a staged oxidant combustion apparatus with separate in-line combustion chambers for fuel-rich primary combustion and fuel-lean secondary combustion and sufficient cooling of the combustion products from the primary combustion such that when the secondary combustion oxidant is added in the secondary combustion stage, the NOx formation is less than 5 ppmv at 3% O2.

Owner:GAS TECH INST

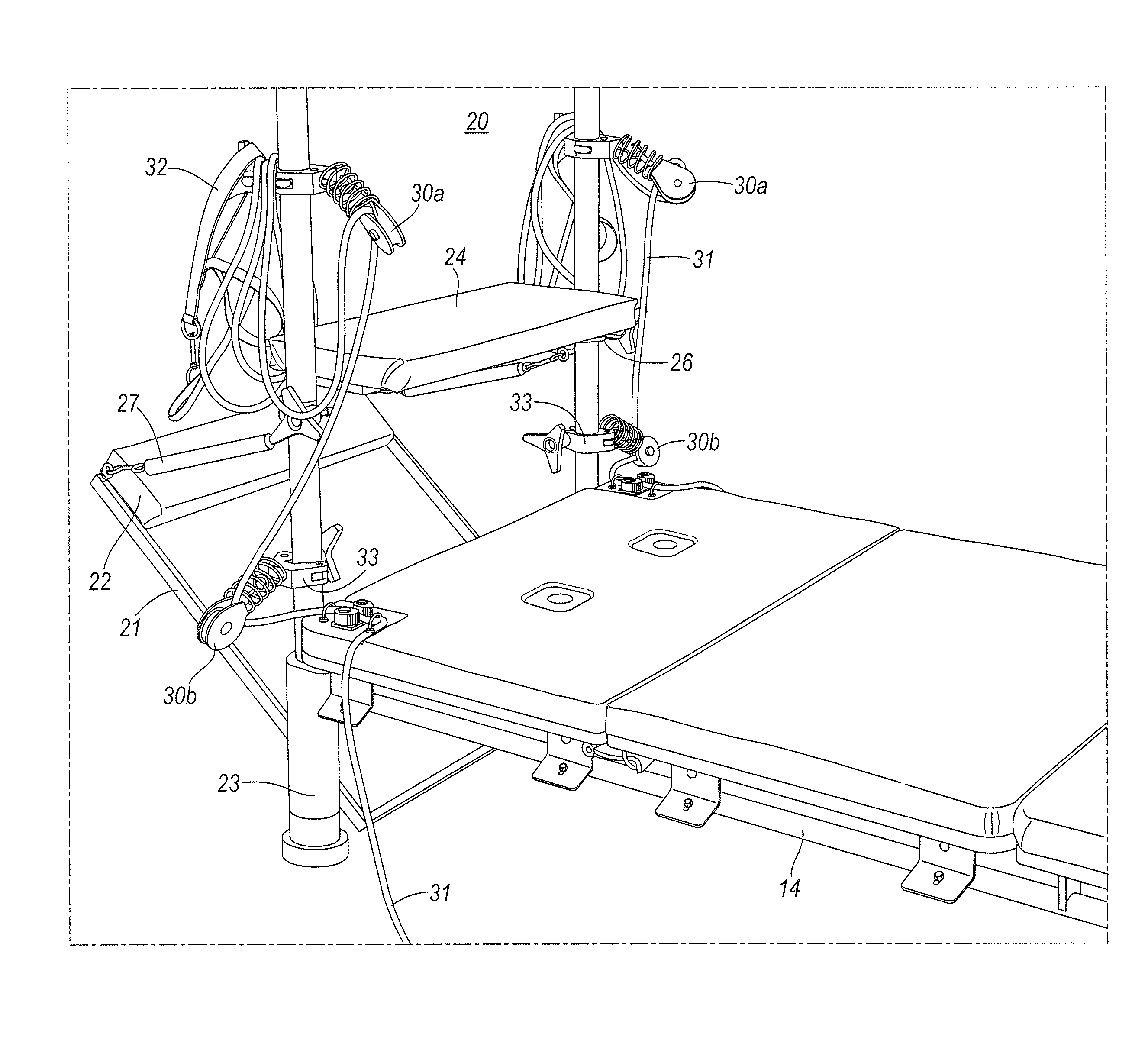

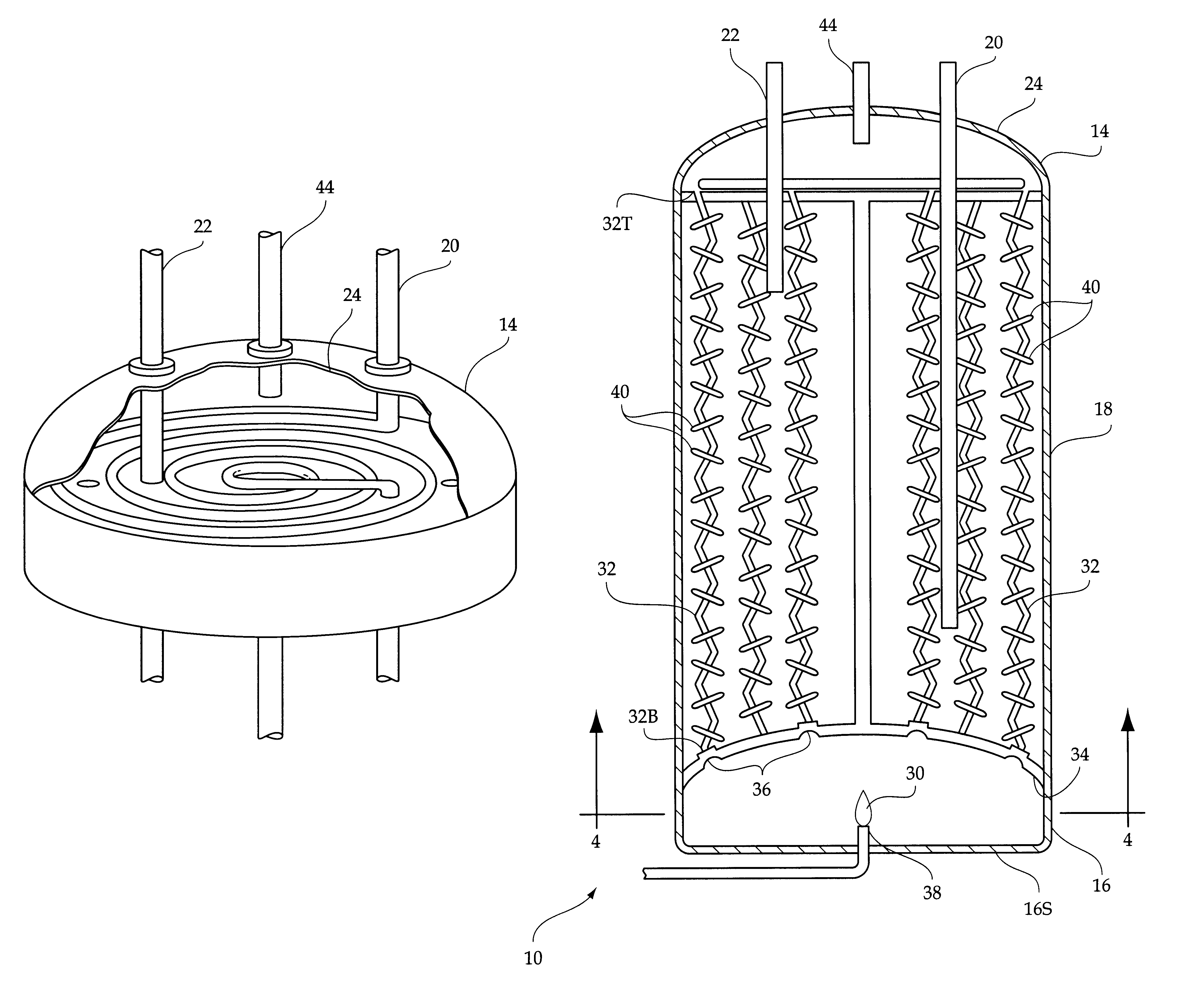

Exercise Apparatus

ActiveUS20100323857A1Improve instabilityReduce impactResilient force resistorsFurnace-tube steam boilersPhysical medicine and rehabilitationEngineering

Apparatus suitable for pilates and other exercise comprises rails, supported on a box-like frame and an exercise carriage, mounted on the rails, wherein the carriage comprises a first carriage section and a second carriage section which sections can be (i) connected together to form a single exercise carriage which slides forwards and backwards on the rails, or (ii) disconnected to form two exercise carriages which independently slide forwards and backwards on the rails. The apparatus also has a seat with a spring-biased foot pedal and a spring-biased trapeze bar.

Owner:DSILVA LTD

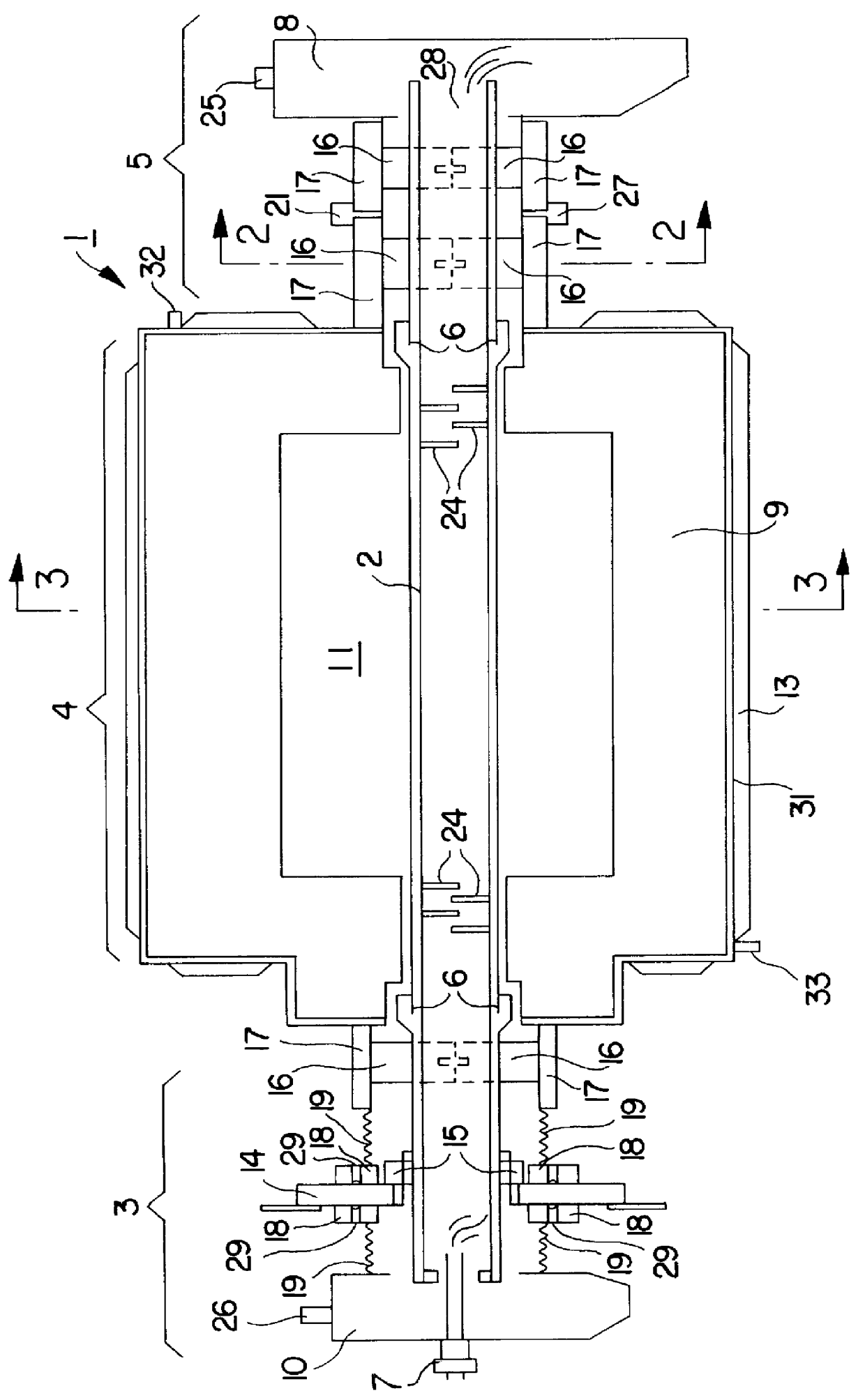

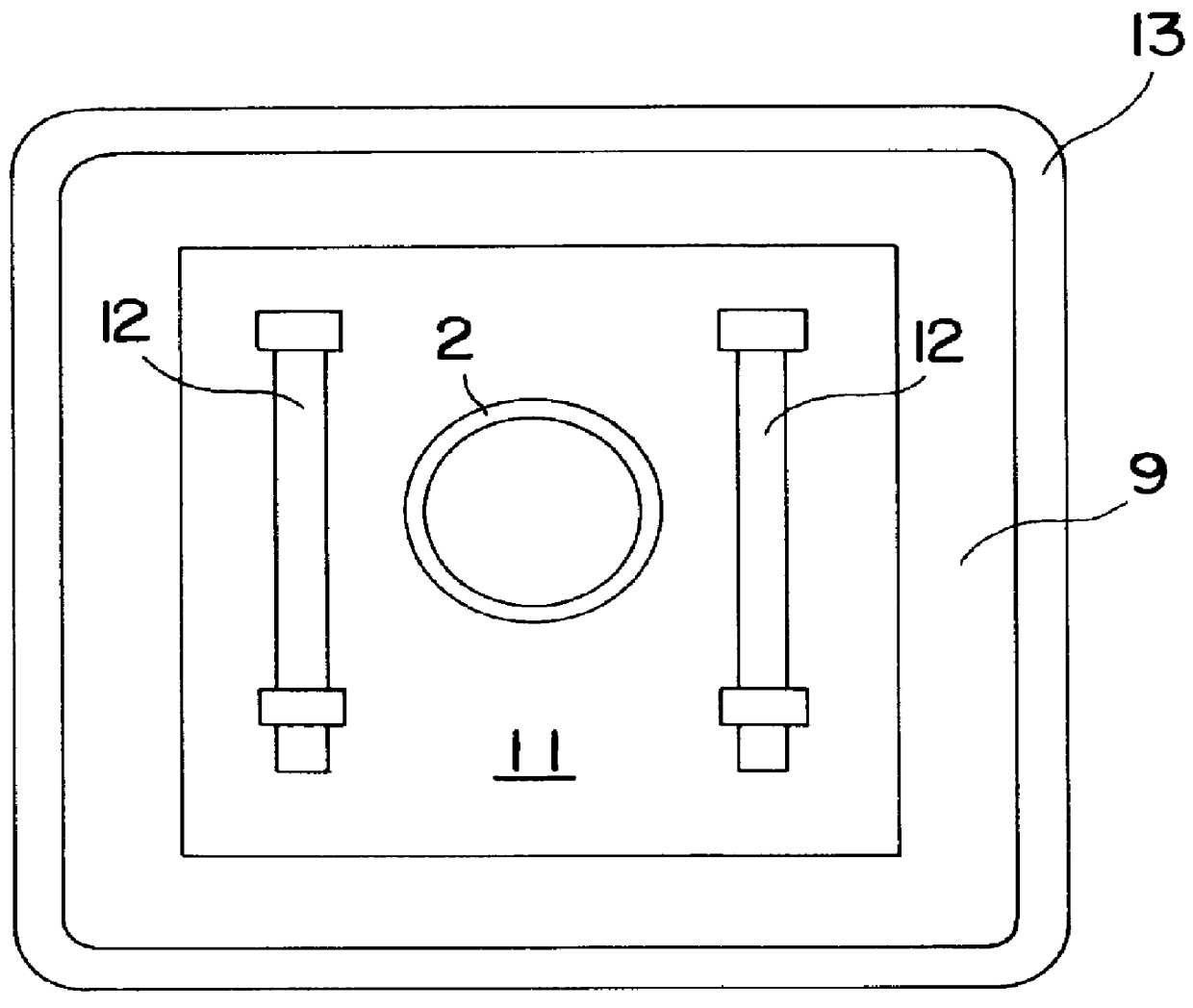

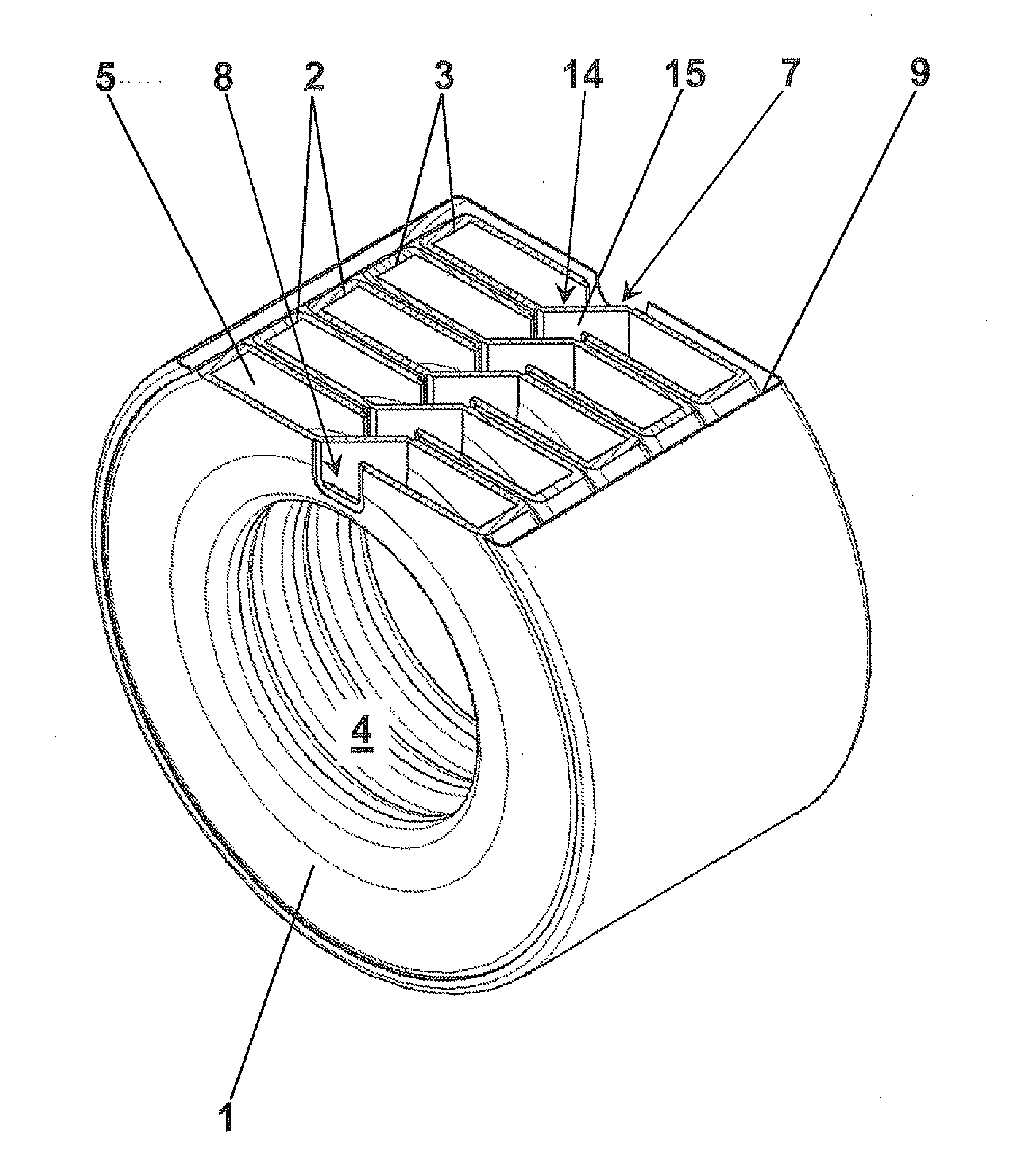

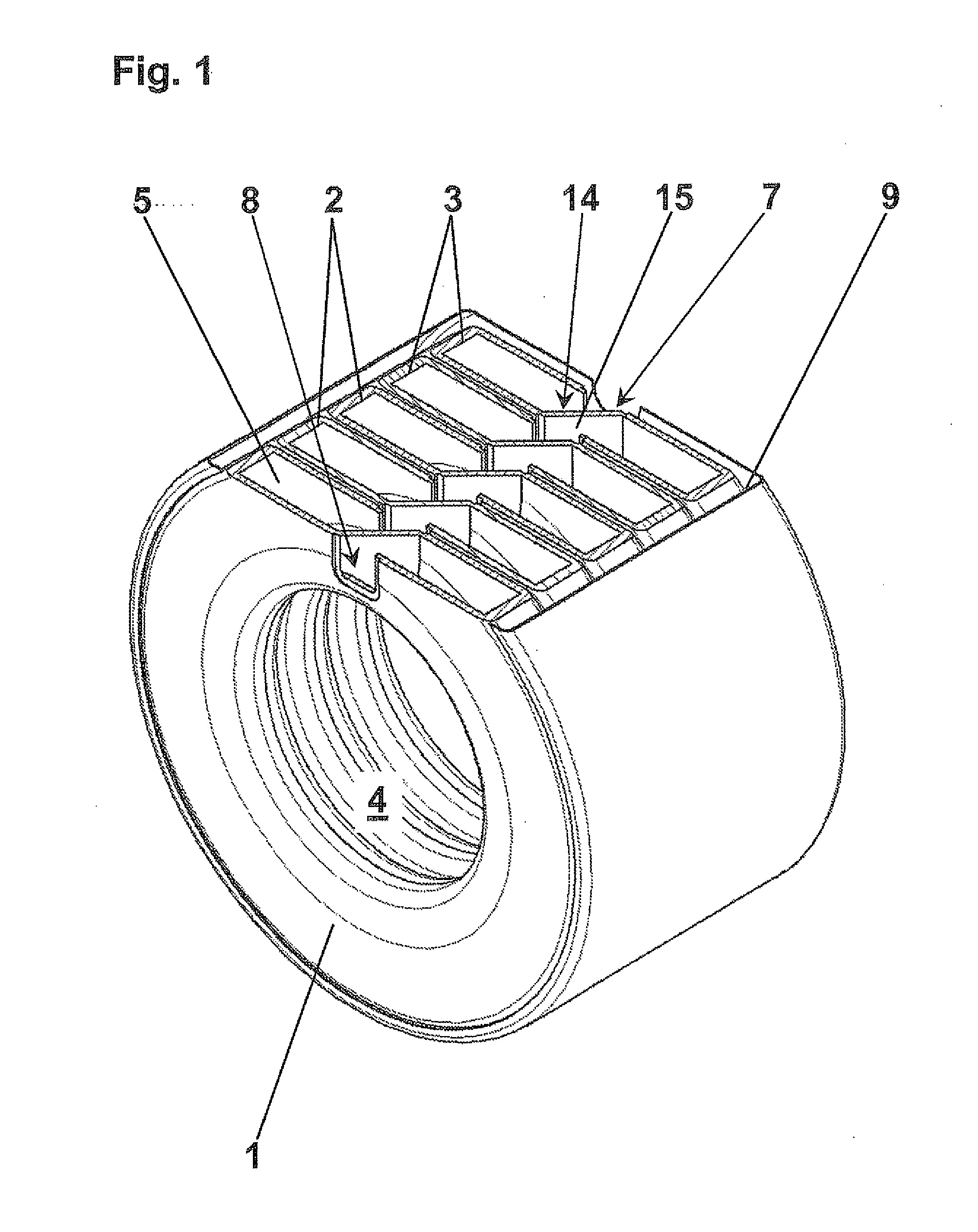

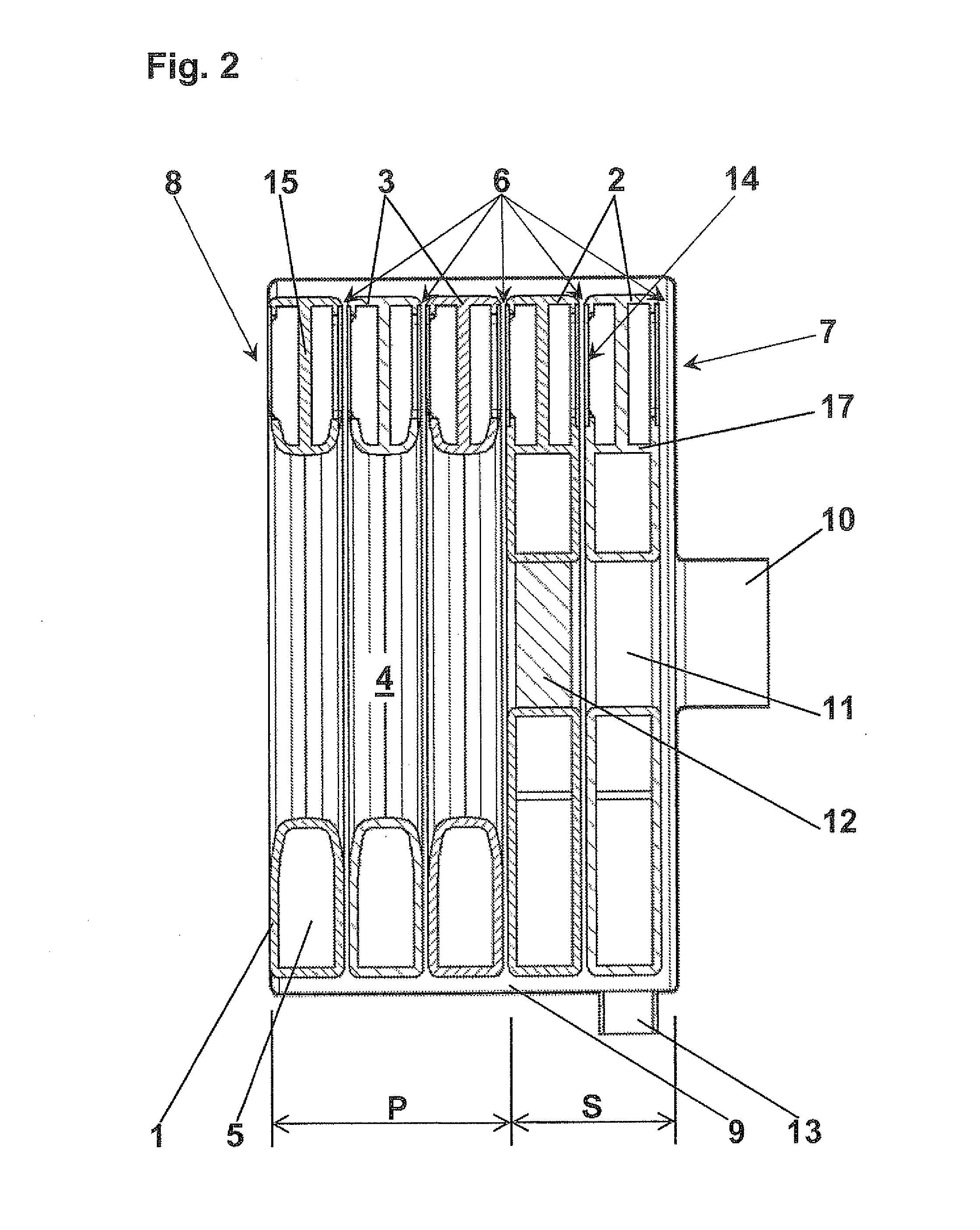

Sectional Boiler

InactiveUS20120055421A1Improve applicabilityPositive material propertiesEnergy efficient heating/coolingFurnace-tube steam boilersCombustion chamberMechanical engineering

A sectional boiler is described as made of cast iron or aluminum, in particular a condensing boiler, having essential annular sections, a front section, at least one rear section and at least one center section being provided, which form a combustion chamber having an essentially surrounding heat exchanger made of a sectional block, whose annular water chambers are connected to one another and which has gap-like heating gas flues, which extend between two adjacent sections with a mutually adapted geometry approximately radially and empty into an exhaust gas collection chamber, and having a return port and a feed port. The present system is based on the objective of optimizing a sectional boiler made of cast iron or aluminum as a condensing boiler particularly with respect to compactness and robustness. The present system provides that the return port and the feed port are located on opposite sides of the sectional block, the flow passes through the water chambers of the sections in series starting from the return port, and the individual sections are respectively provided hydraulically with overflow openings in only one place on the periphery and are connected by these on at least one side with an adjacent section.

Owner:ROBERT BOSCH GMBH

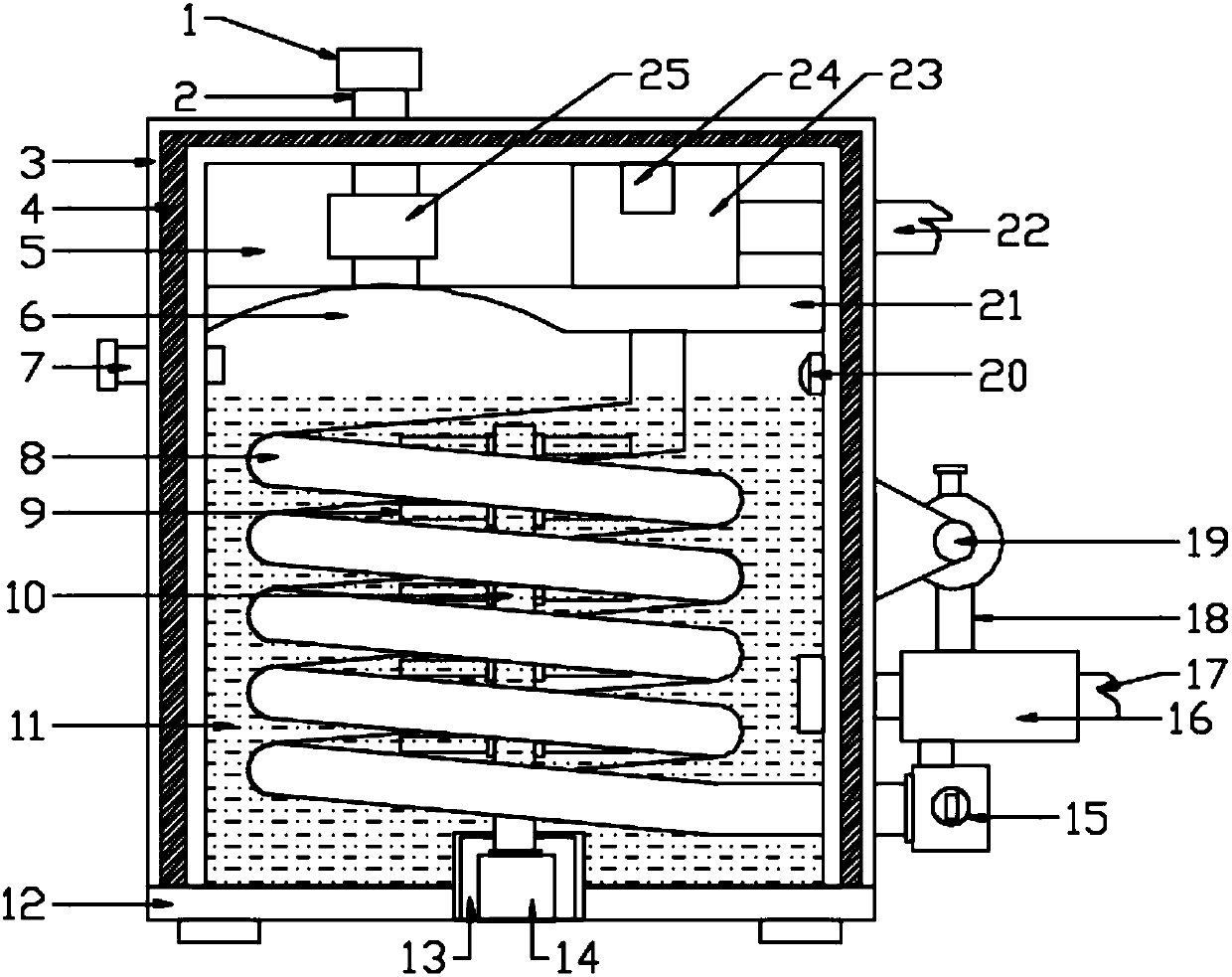

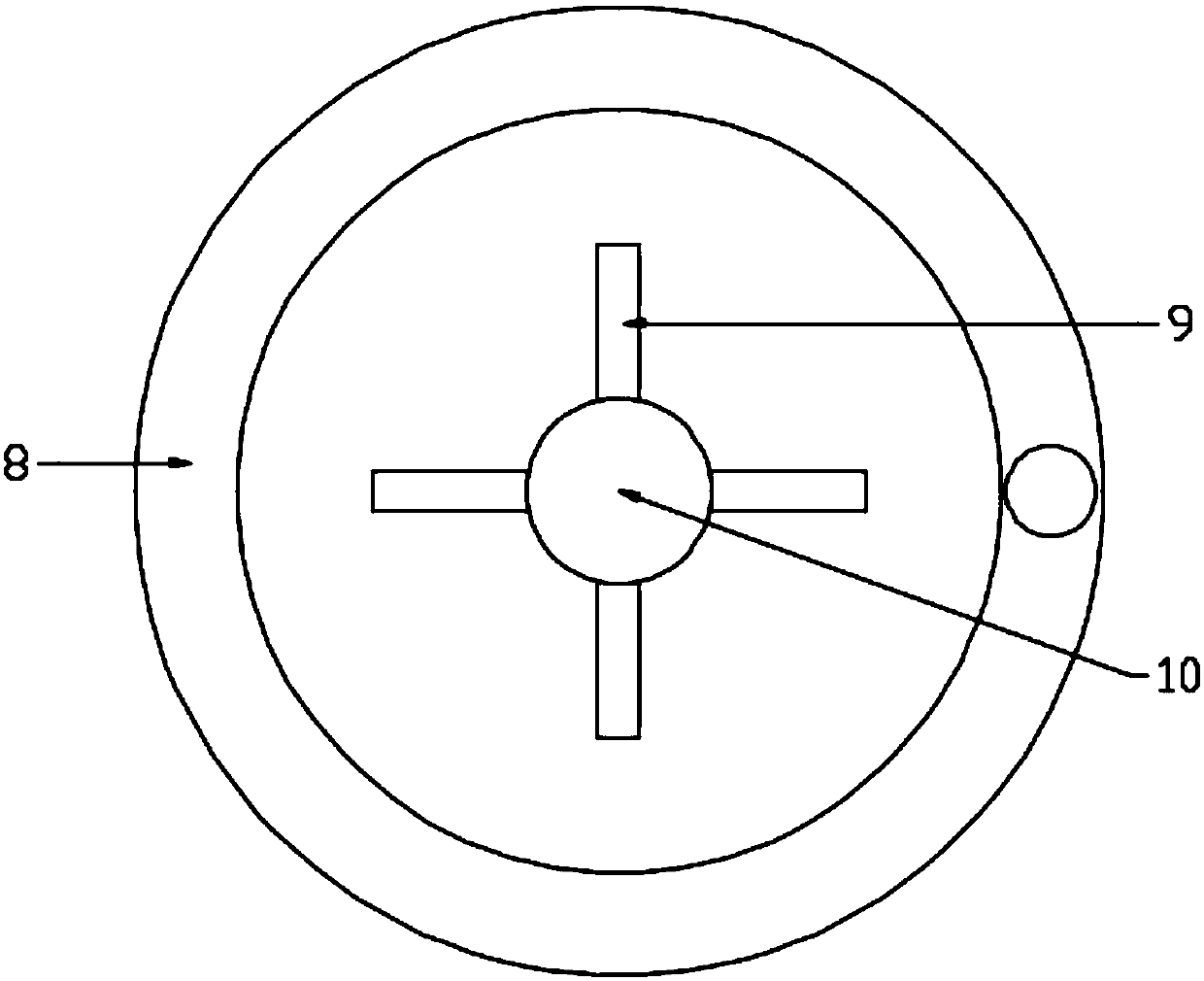

Energy-saving and environment-friendly heating furnace capable of generating steam in spiral pipe

InactiveCN108050502AExtended burn lengthIncrease contact areaFurnace-tube steam boilersEnvironmental resistanceEvaporation

The invention discloses an energy-saving and environment-friendly heating furnace capable of generating steam in a spiral pipe. The energy-saving and environment-friendly heating furnace comprises a containing cavity and a water storing cavity, and the water storing cavity is arranged at the lower end of the interior of a furnace body; the spiral pipe is arranged in a water filling pipe, a rotation shaft is arranged in the spiral pipe, and stirring rods are distributed on the rotation shaft in an array mode; a first fixing pipe is connected to the lower end of the spiral pipe, the right side of the first fixing pipe communicates with a control pipe, a control valve is arranged on the control pipe, the upper end of the control pipe is connected to a waste heat recycling pipe through a connecting pipe, and a condensate water inlet pipe is inserted into the waste heat recycling pipe; and a partition plate is arranged between the containing cavity and the water storing cavity, and a steamguiding cover is arranged on the left side of the lower end of the partition plate. According to the energy-saving and environment-friendly heating furnace capable of generating the steam in the spiral pipe, by adopting the spiral structure, the flame burning time is effectively prolonged, the fire source and fuel gas contact area is effectively increased, burning is more sufficient, the heat dissipation area is increased, and the heat transfer efficiency is high; and through stirring, the water heating rate is increased, the evaporation efficiency is high, and waste heat of exhaust gas generated after burning can be reutilized.

Owner:ZHENGZHOU YUANRAN BIOLOGY TECH CO LTD

Low CO water heater

InactiveUS20070186872A1Promote conversionReduce accumulationFluidized bed combustionFurnace-tube steam boilersForeign matterCombustor

A water heater including a water container, a combustion chamber adjacent the water heater, a burner associated with the combustion chamber and arranged to combust fuel to heat water in the water container, a flue having an upper portion and a lower portion operatively connected to the combustion chamber and extending through at least a portion of the water container, and a catalytic converter located in the upper portion of the flue. The water heater may also reduce NOx and CO emissions generated by a water heater having a radiant burner including activating the burner in response to the temperature of water in the water heater as needed, and substantially removing accumulated foreign matter on the burner by periodically activating the burner irrespective of the water temperature for a selected amount of time.

Owner:AMERICAN WATER HEATER

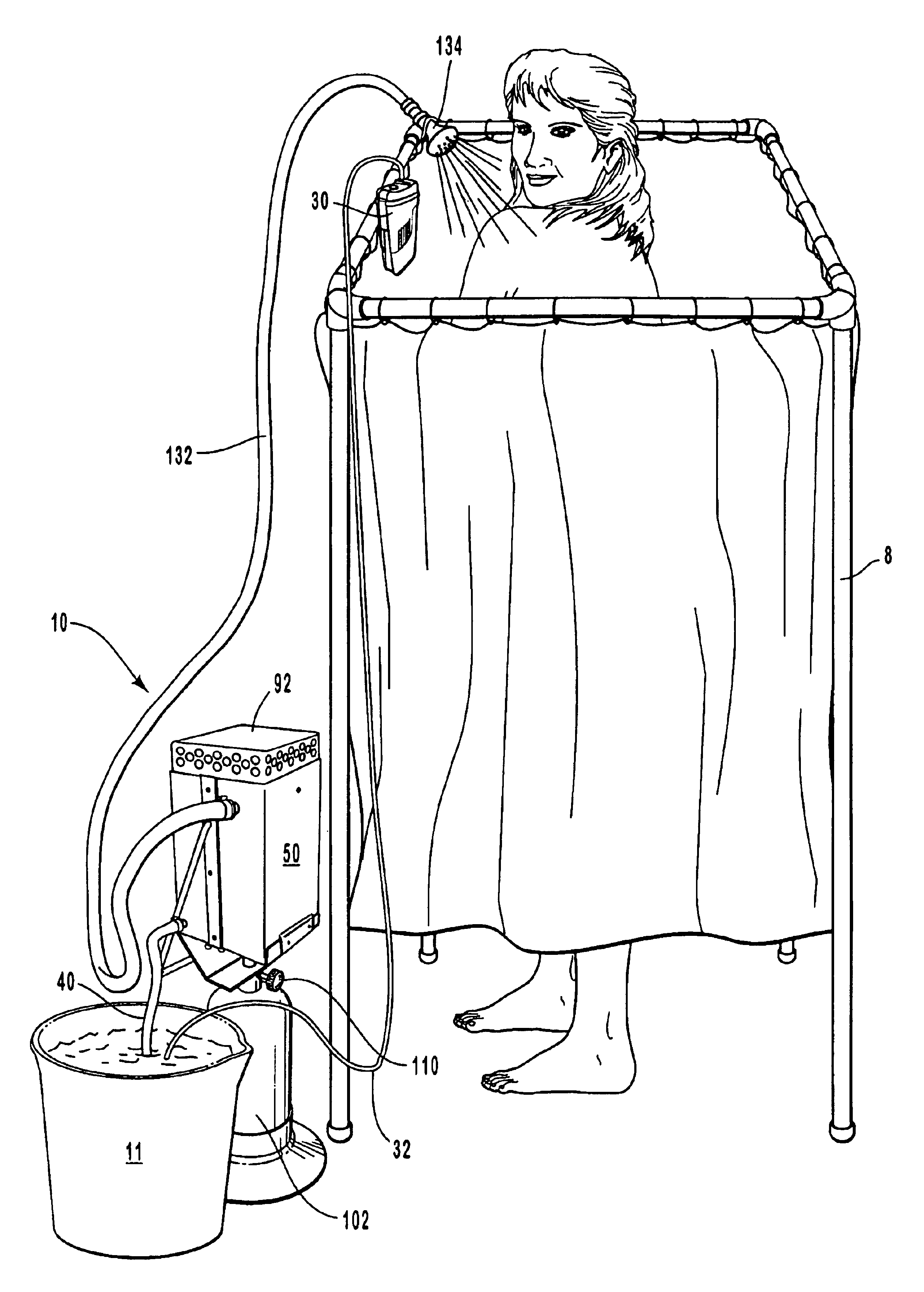

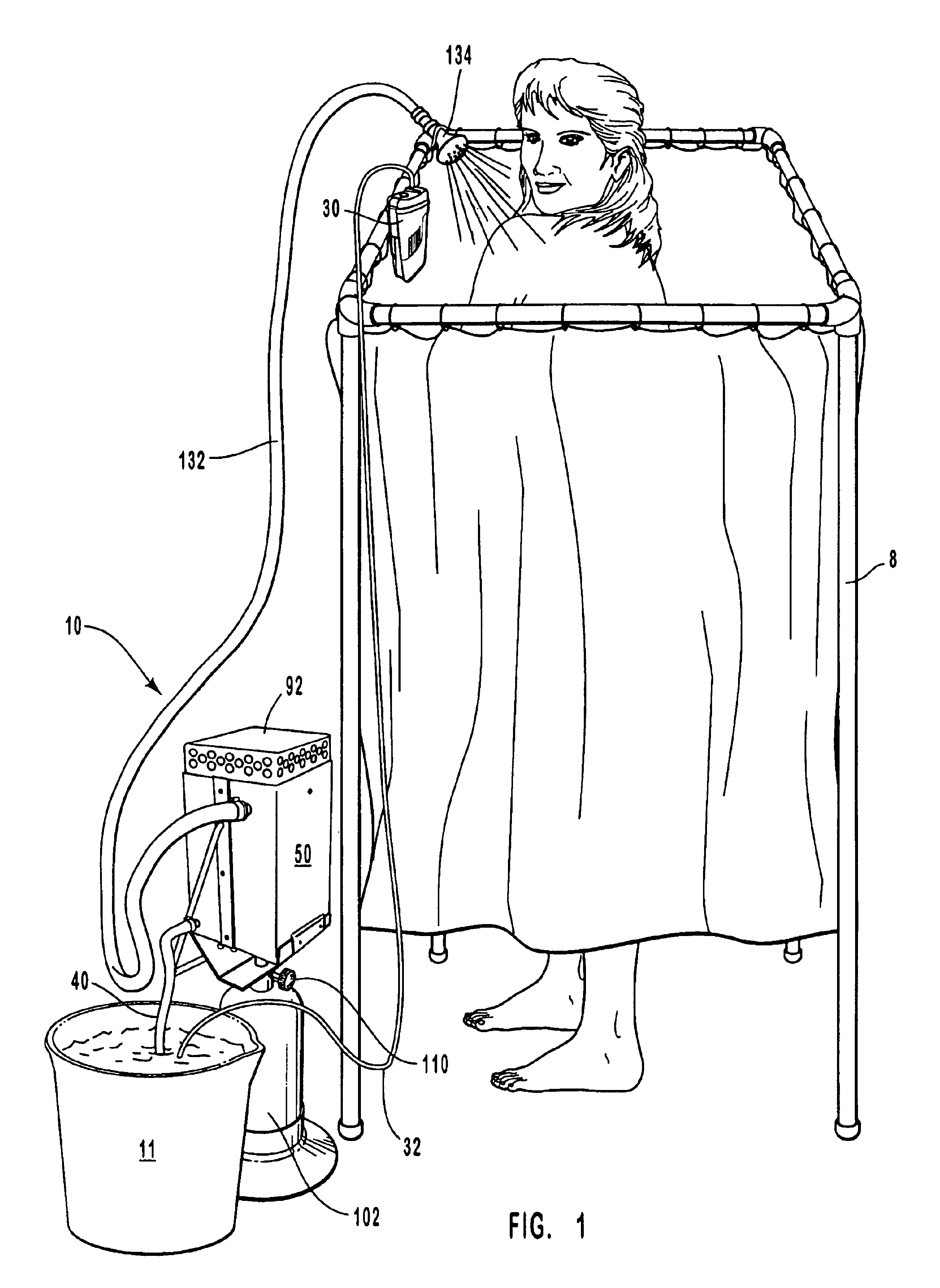

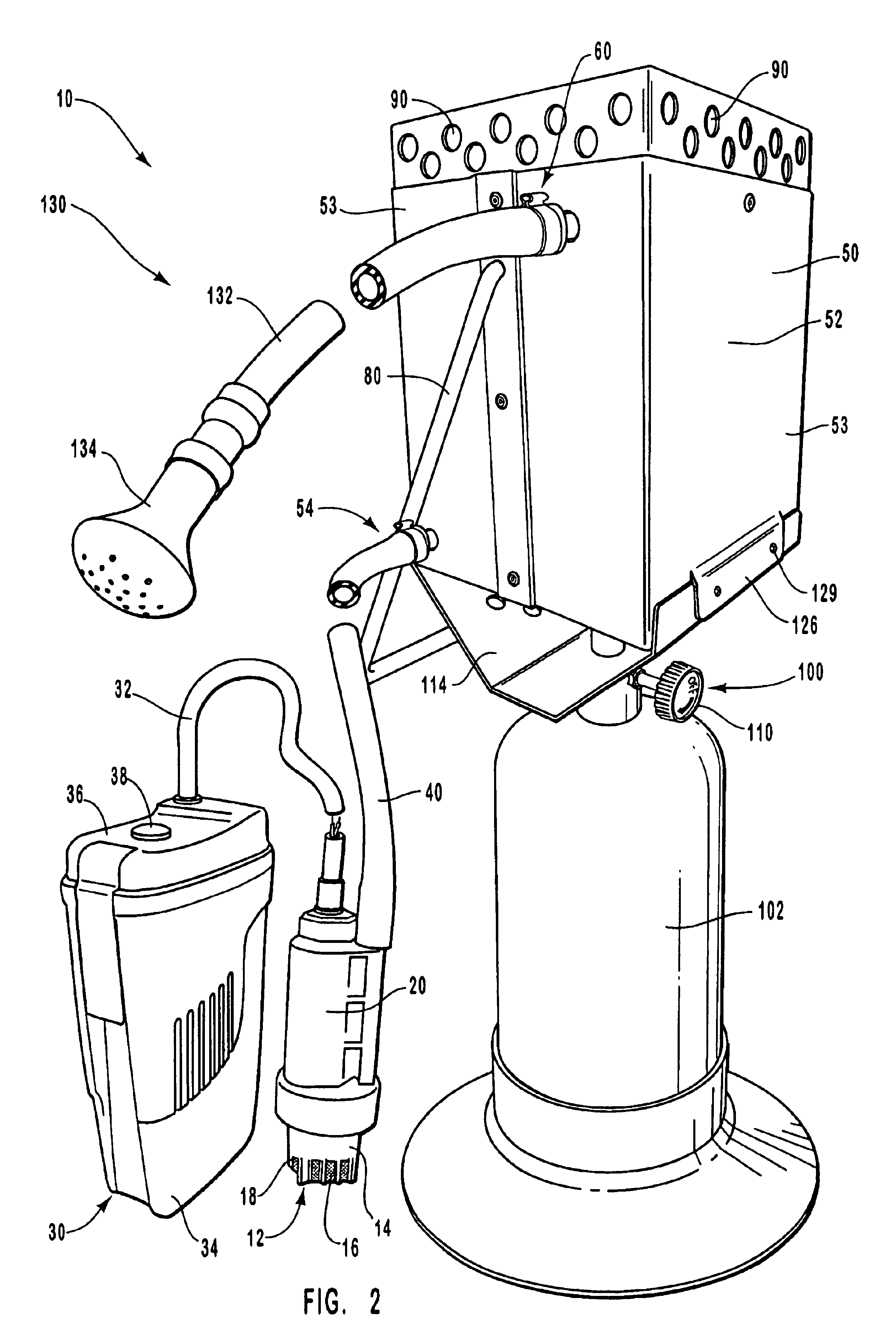

Portable water heater

InactiveUS6978496B2Minimal heat lossProvides heated quickly and efficientlyBathsDouchesWater sourceEngineering

A portable hot water heater for use during camping, boating, hunting, hiking, fishing, backpacking, etc. The hot water heater advantageously efficiently and rapidly heats large quantities of water for hot showers, cooking and cleaning. The hot water heater includes a pump that can draw water from any suitable water source, a power source, a heating assembly that quickly and efficiently heats the water as it flows through the heating assembly. The heating assembly is attached to a shower head or other fixture.

Owner:TAPH

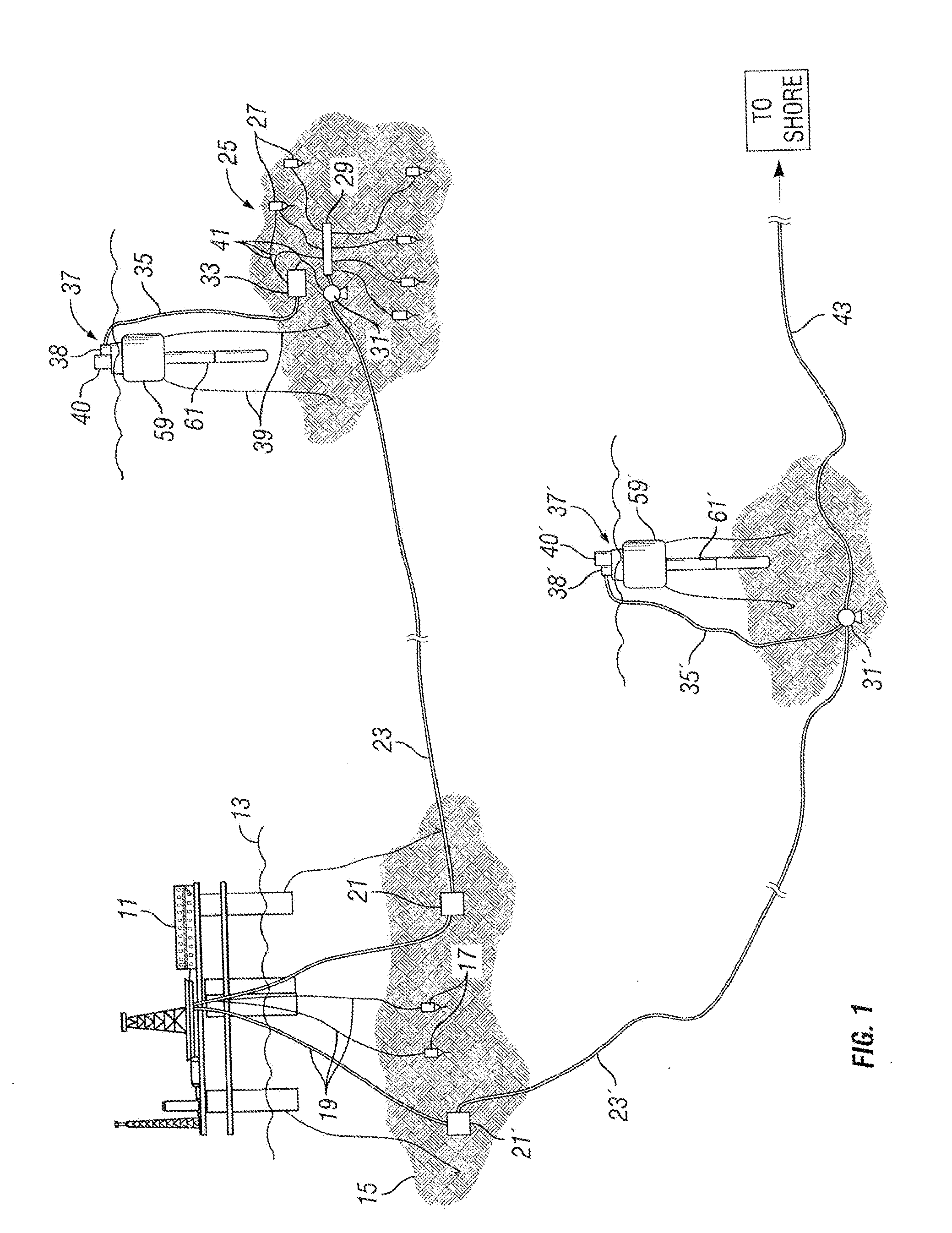

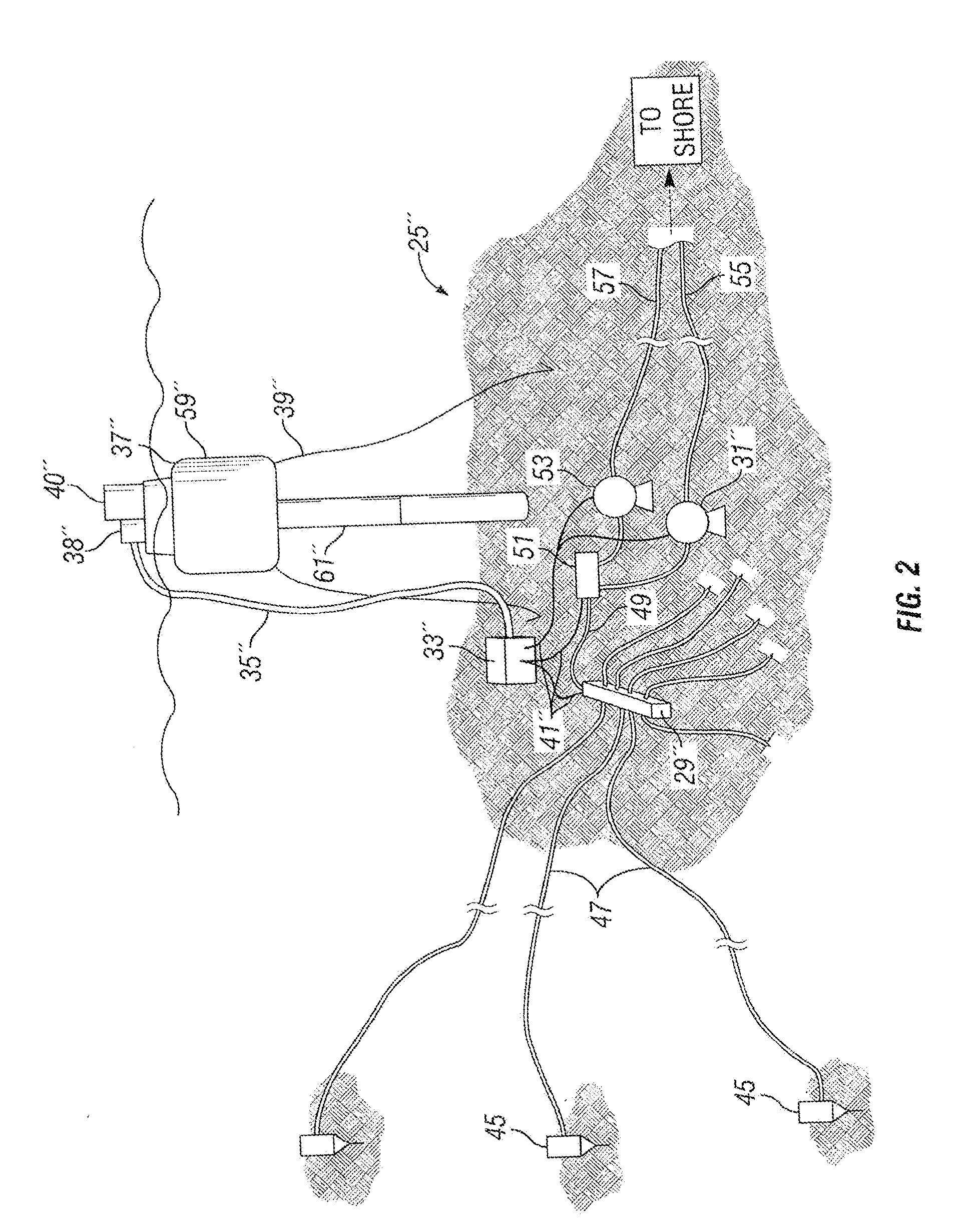

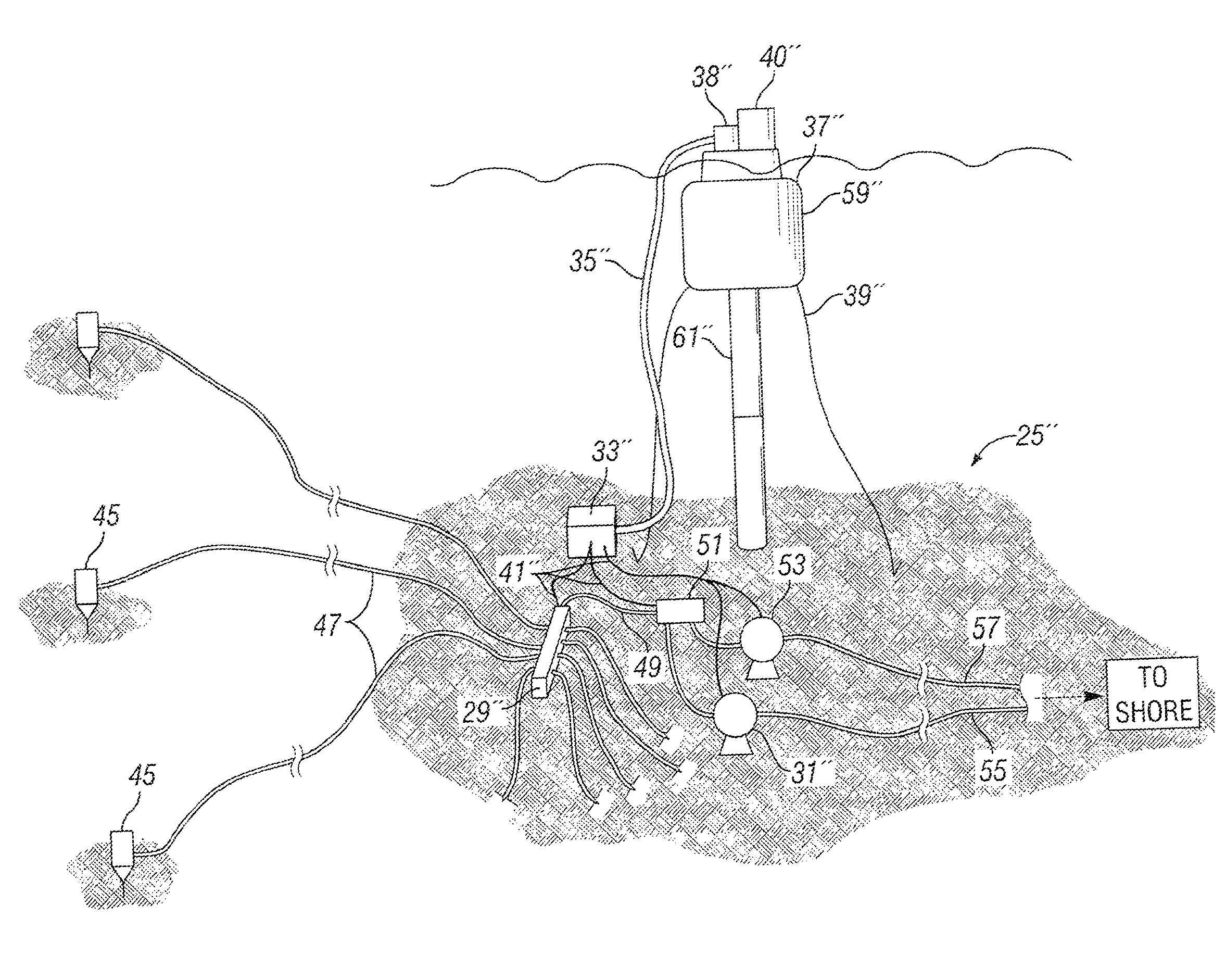

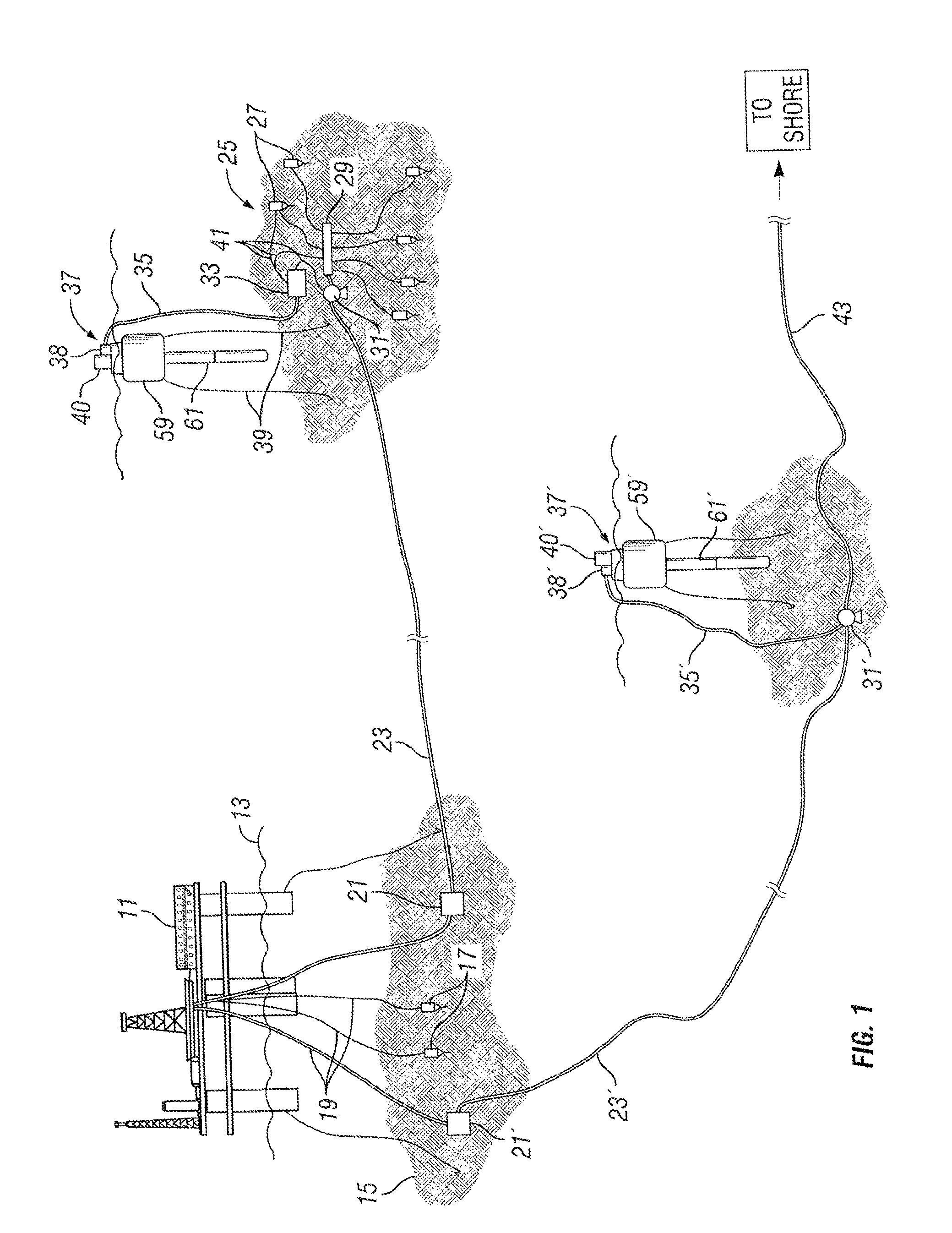

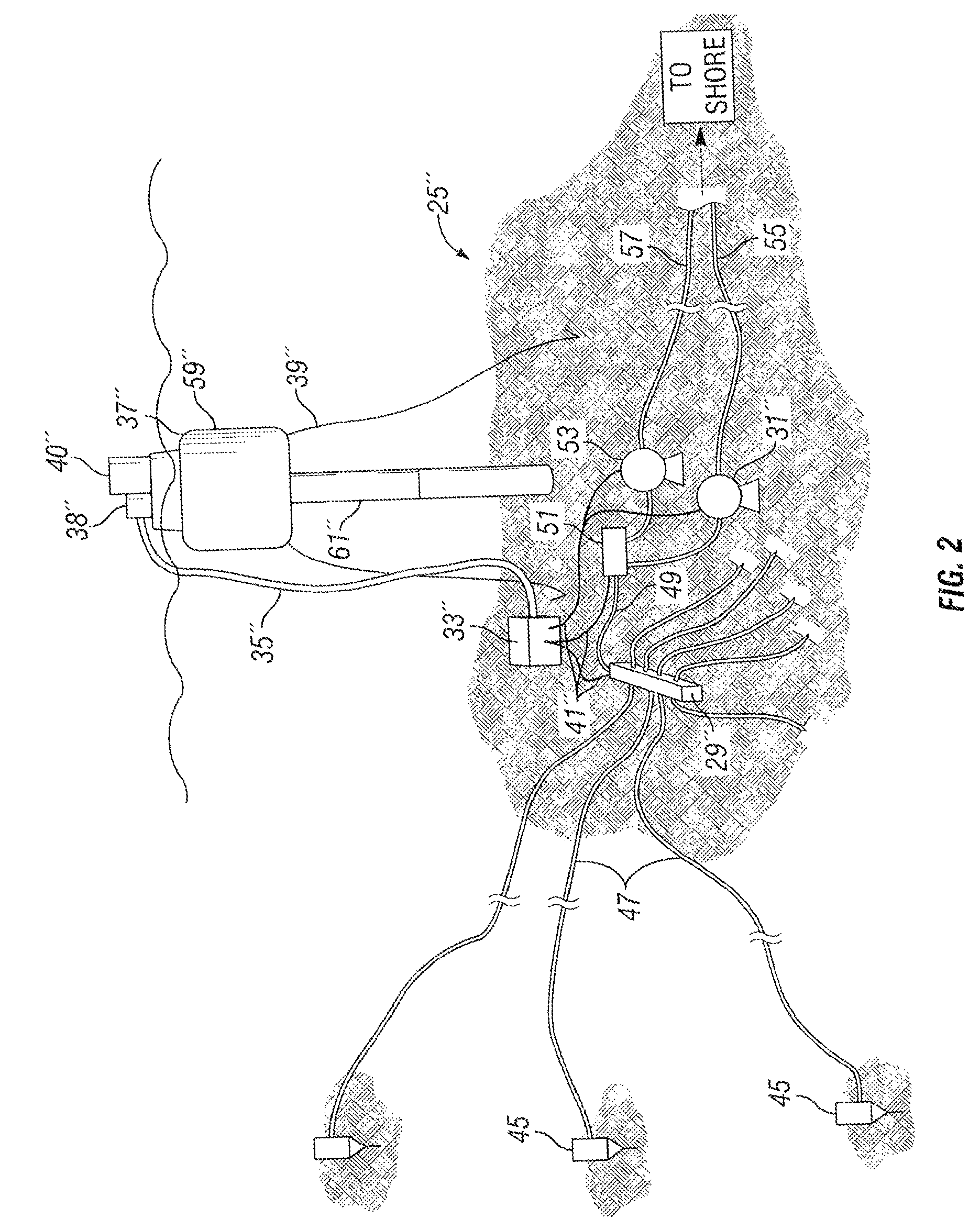

Remote power-generating assembly

InactiveUS20090152868A1Reduce spacingReduce weightFluid couplingsWaterborne vesselsTurbineElectric power

A remote power supply system associated with offshore hydrocarbon production and transportation operations includes an expansion turbine that generates power for the system. The remote power supply system also has a support structure that supports the expansion turbine. A cooling section is supported by the support structure, and is in fluid communication with the expansion turbine to receive the vapor therefrom and to condense it to liquid. A downcomer and boiler section is in fluid communication with the cooling section to receive the liquid condensed from the vapor. An ignition assembly is positioned toward a lower end portion of the downcomer and boiler section. The ignition assembly ignites a fuel and air mixture and causes the liquid received by the downcomer and boiler section from the cooling section to boil into vapor. A return passage conveys vapor from the downcomer and boiler section to the inlet of the expansion turbine.

Owner:CHEVROU USA INC

Methods and apparatus to facilitate cooling syngas in a gasifier

ActiveUS7749290B2Improve heat transfer performanceMuffle furnacesGasifier mechanical detailsSyngasEngineering

Owner:AIR PROD & CHEM INC

High efficiency tank type continuous flow and self cleaning water heater

InactiveUS7100541B2Reduce condensationAvoid overall overheatingFurnace-tube steam boilersWater heatersCombustorContinuous flow

A water heater comprising a closed tank having a water inlet for connection with a water supply, and a hot water outlet connected to the tank interior; a flue pipe extending vertically through the tank and having an upper portion for connection with a vent pipe; a cylinder having a lower end and upper open end with means for opening disposed within the flue pipe, and spaced from inner walls of the flue pipe, and extending substantially the length of the flue pipe; a burner disposed in a lower region of the cylinder and above the lower end thereof, such that combustion products from the burner rise through the cylinder; and a water conducing coil disposed within the cylinder connected with the interior of the tank.

Owner:FRASURE CHARLES J +3

Method for starting a steam generator comprising a heating gas channel that can be traversed in an approximately horizontal heating gas direction and a steam generator

InactiveUS7281499B2High degreeEasy constructionWater circulationFurnace-tube steam boilersProduct gasEngineering

The invention relates to a steam generator comprising a heating gas channel, which can be traversed in an approximately horizontal heating gas direction and in which at least one continuous heating surface is located, configured from a number of approximately vertical evaporator tubes, connected in parallel to allow the passage of a flow medium. The aim of the invention is to provide a method for starting a generator, which guarantees a high degree of operational safety, even for a steam generator with a particularly simple construction. According to the invention, to achieve this, at least several evaporator tubes are partially filled to a predeterminable desired level with unevaporated flow medium, prior to the impingement of the heating gas channel by a heating gas.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

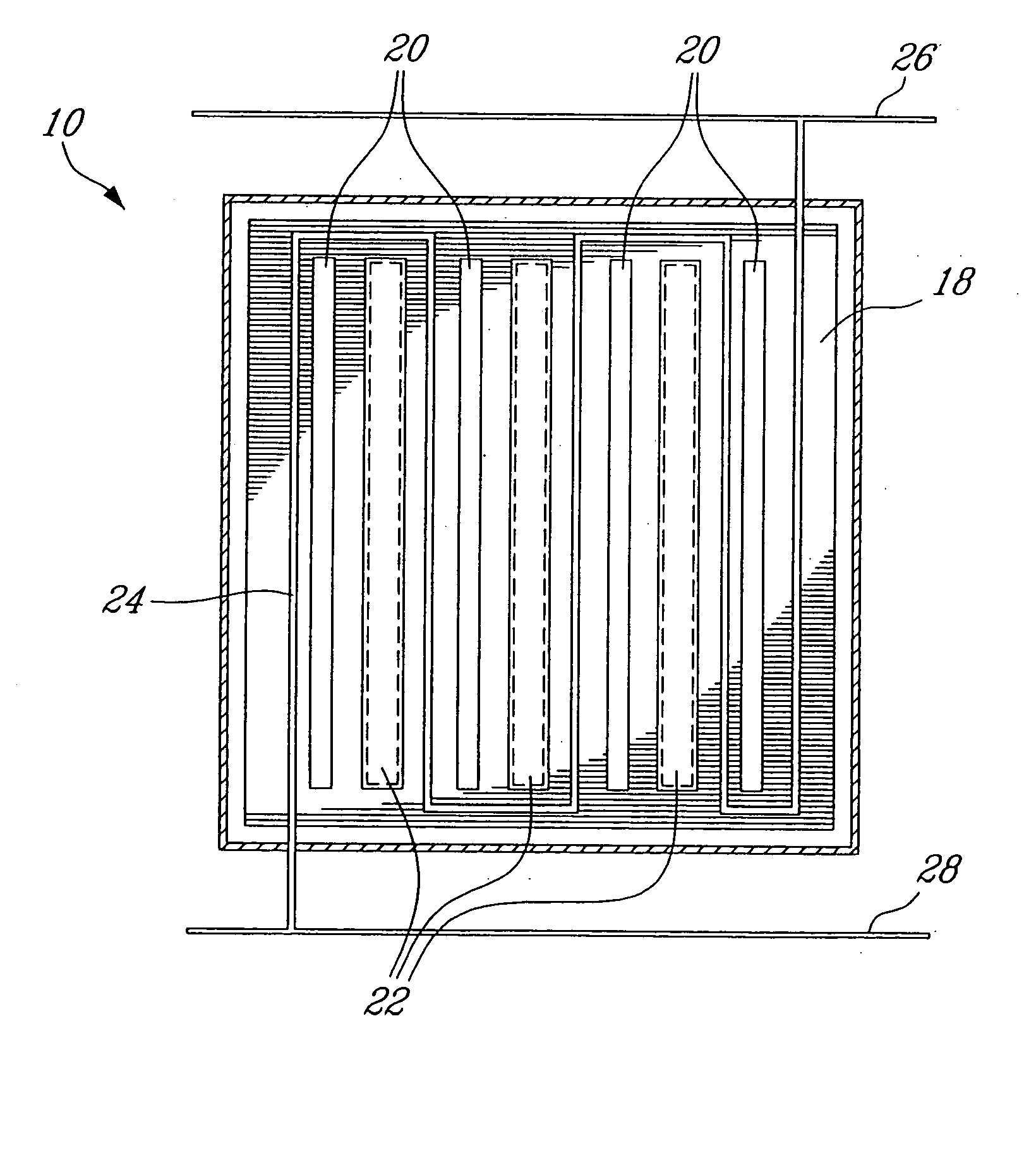

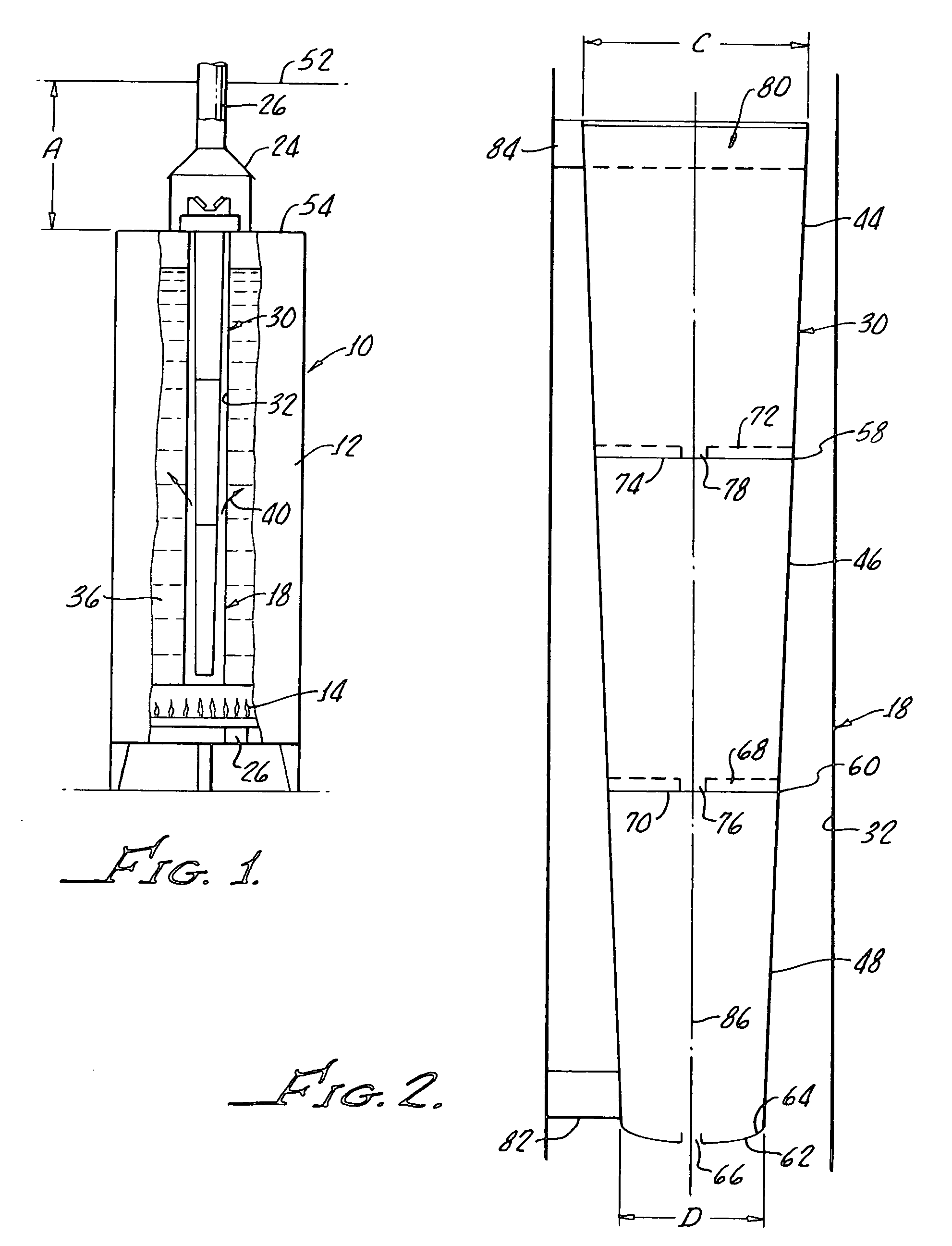

Water heater flue with improved heat transfer

ActiveUS6957629B1Improve water efficiencyFurnace-tube steam boilersWater heatersMechanical engineeringFlue

A water tank has a central flue to which clips are welded. The clips define baffles and are welded to have a greater heat transfer area where they are joined to the central flue. The individual clips are rectangular and are welded to the flue wall along one side at an angle of 4° rather than the 9° of the prior art so that the clip has a greater weld area. This greater weld area increases the thermal path between the clip and the wall of the central flue.

Owner:BOCK WATER HEATERS

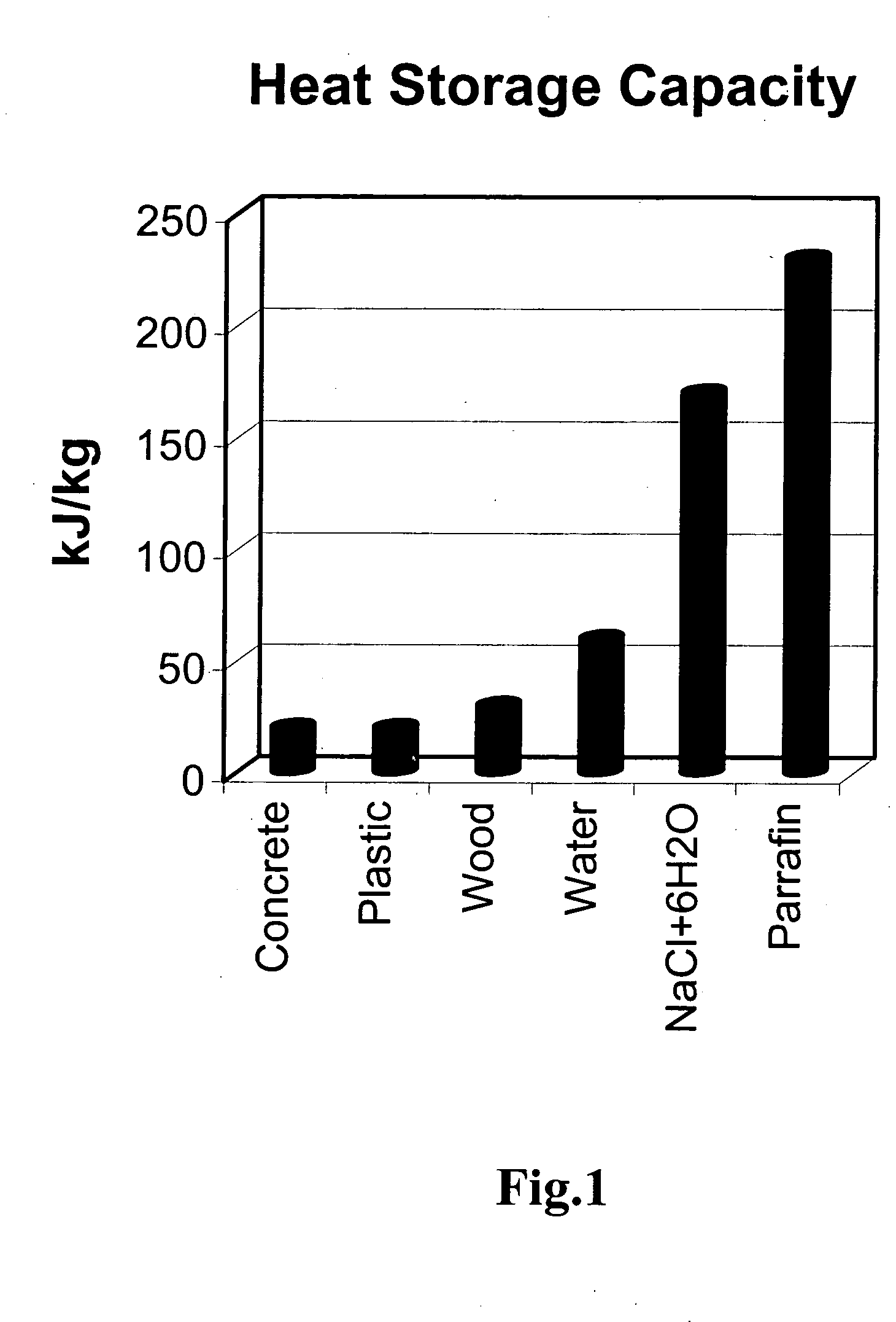

Surface heating system

InactiveUS20050281547A1Lower heating costsFluid heatersCentral heating with accumulated heatHeat conductingEngineering

A surface heating system comprising a sealed enclosure formed by connected top, bottom and side walls, at least one of the walls being in heat exchange relationship with a surface to be heated, a heat source connected in heat exchange relationship with the enclosure, at least one heat absorbing body located within the enclosure, and a heat conducting fluid filling the enclosure and surrounding the at least one heat absorbing body, the heat conducting fluid transferring heat from the heat source to the top wall and to the at least one heat absorbing body, the at least one heat absorbing body using at least part of the heat received from the heat conducting fluid to store energy such as to be able to release the energy over an extended period of time in the form of heat transferred to the top wall through the heat conducting fluid.

Owner:SAUVAGEAU YVAN

Water heater with condensing flue

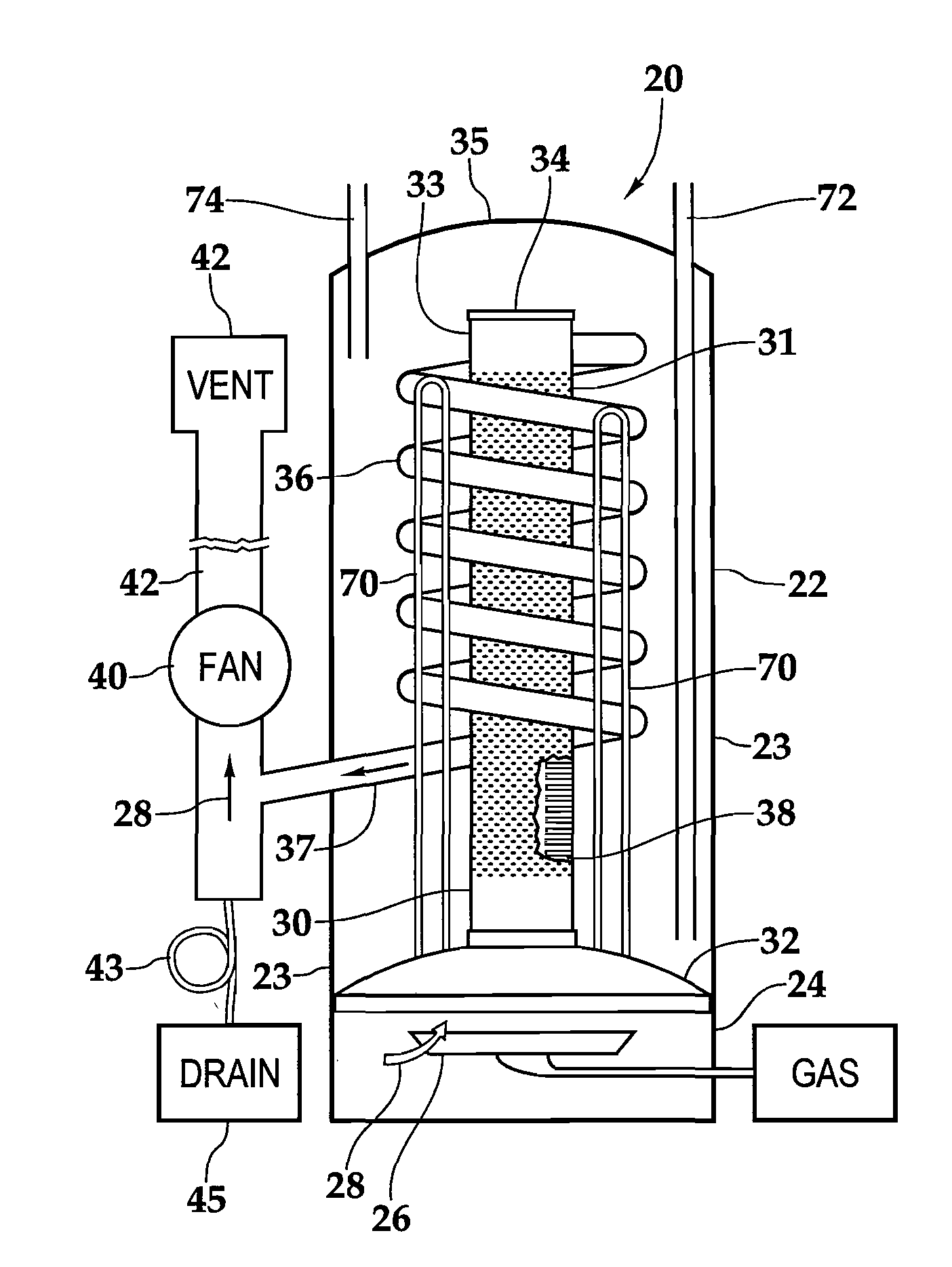

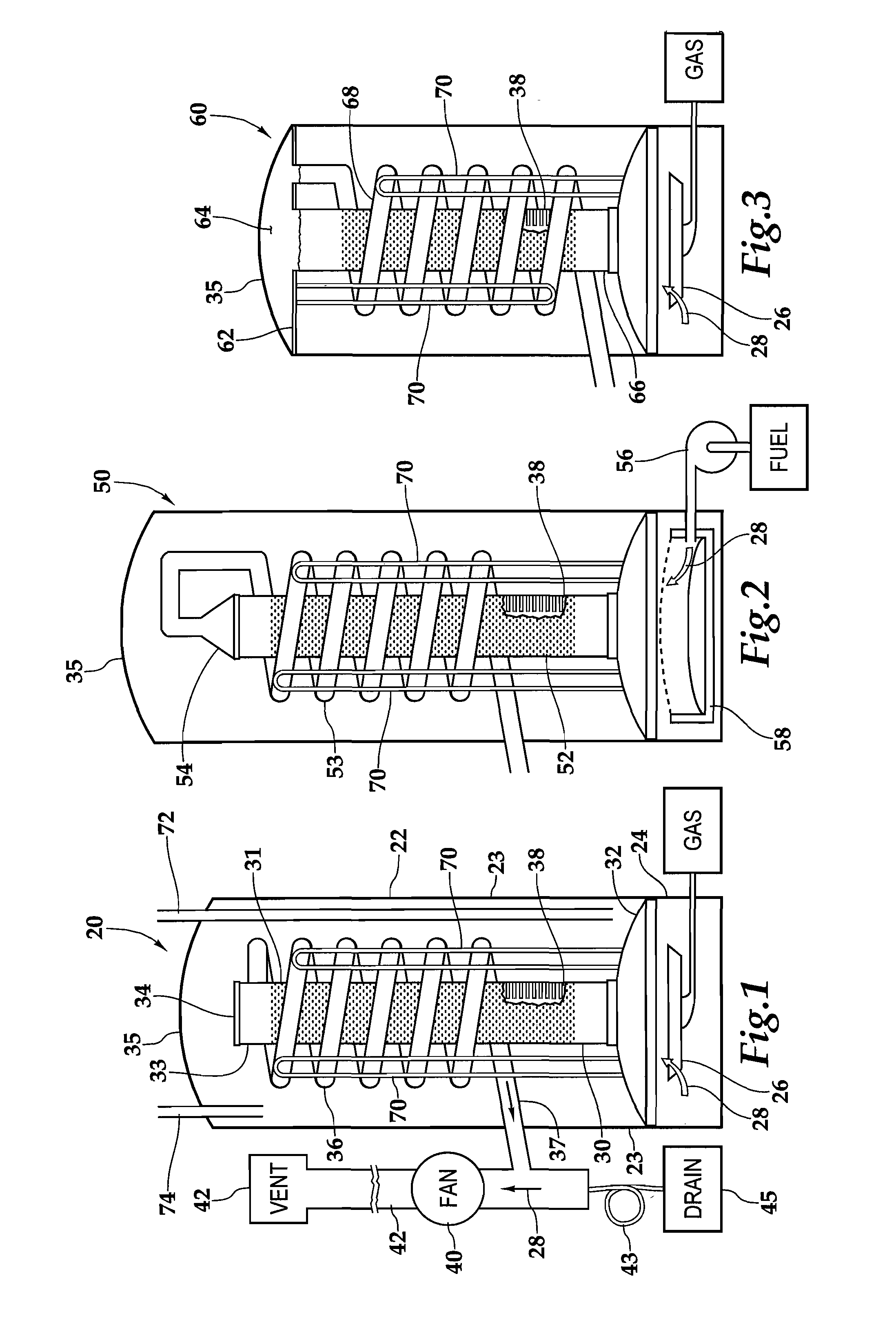

ActiveUS7836856B2Reduce resistanceImprove heat transfer performanceEnergy efficient heating/coolingFurnace-tube steam boilersCombustorEngineering

A water heater has a burner positioned below a vertical centrally located flue with heat exchange capacity enhanced by a multiplicity of rectangular metal fins which are welded on the inside of the vertical central flue. The central flue extends upwardly within a water tank. The central flue transitions to a smaller diameter downwardly draining helically coiled condensing flue. Approximately 80% of the heat from the combustion gases is transferred to the water within the water tank through the wall of the central flue without condensation. An additional 10% or more of the combustion heat is transferred to the water accompanied by condensation of water in the coiled flue. A fan draws the combustion gases through the central flue and the coiled condensing flue and supplies the combustion gases to an exterior vent.

Owner:BOCK WATER HEATERS

Reducing heat transfer surface area requirements of direct fired heaters without decreasing run length

InactiveUS7395785B1Small sizeLow costThermal non-catalytic crackingFurnace-tube steam boilersCombustion chamberContinuous flow

This invention relates to the design of direct fired heaters which consist of vertically oriented refractory lined enclosures containing tubular heat transfer elements, the elements partially surrounding a cluster of burners. The burners fire gaseous fuel and generate high temperature combustion products which allow for the transfer of heat, by radiation and convection, from the combustion products to the heat transfer elements and the continuous flow of process fluid contained therein. The transferred heat raises the temperature of the fluid from the design temperature at the inlet to the design temperature at the outlet, at a heat transfer rate commensurate with the temperature differential existing at any given location. The surface area requirements of the heat transfer elements and that of the enclosure surrounding the heat transfer elements is significantly reduced by limiting firebox recirculation of burner generated combustion products, thereby increasing overall temperature differentials and heat transfer rates between combustion products and process fluid. Gains in heating surface reduction are not accompanied by losses in heater run length because low process fluid temperatures and high inside heat transfer coefficients are provided, which minimize process fluid film temperature in areas where high heat transfer rates prevail.

Owner:CROSS ALAN

Fuel-fired, power vented high efficiency water heater apparatus

ActiveUS7814868B2Improve energy efficiencyAvoid flowFurnace-tube steam boilersFire-tube steam boilersCombustionEngineering

A fuel-fired water heater has a draft inducer fan assembly with a housing having an inlet for receiving hot combustion gases discharged from the water heater, and an outlet for discharging the combustion gases. A normally closed damper member within the housing is openable by fluid pressure force created by operation of a draft inducer fan portion of the assembly. With the damper in its open position the fan exhausts the received combustion gases through a housing outlet. When the damper closes it prevents convective outflow through the housing outlet of flue-heated air. In alternate embodiments of the assembly the fan is operative to also draw in dilution air that cools the fan motor and the discharged combustion gases, with the assembly having an internal configuration preventing convective outflow of flue-heated air through the housing dilution air inlet during standby periods of the water heater.

Owner:RHEEM MFG CO

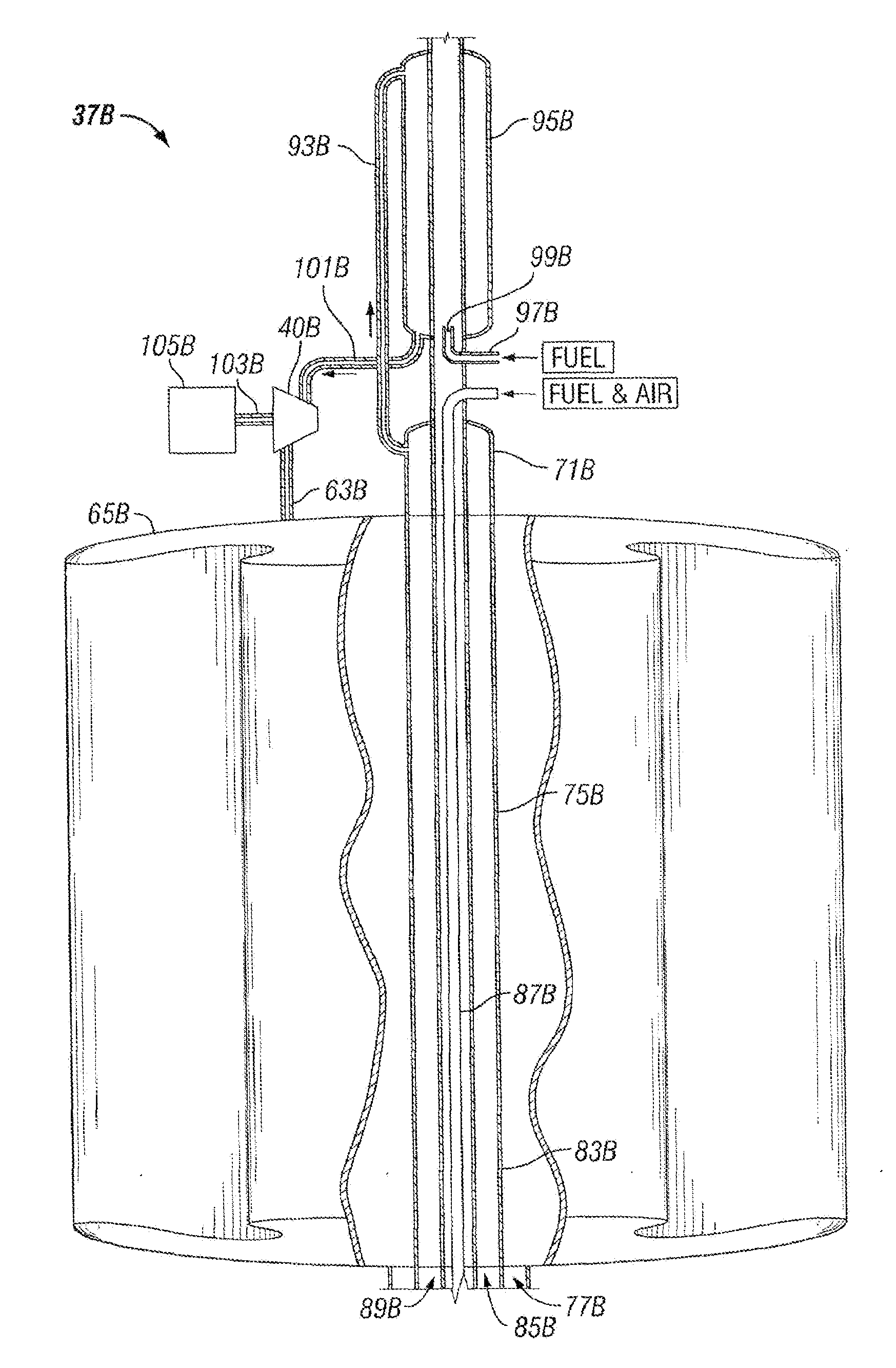

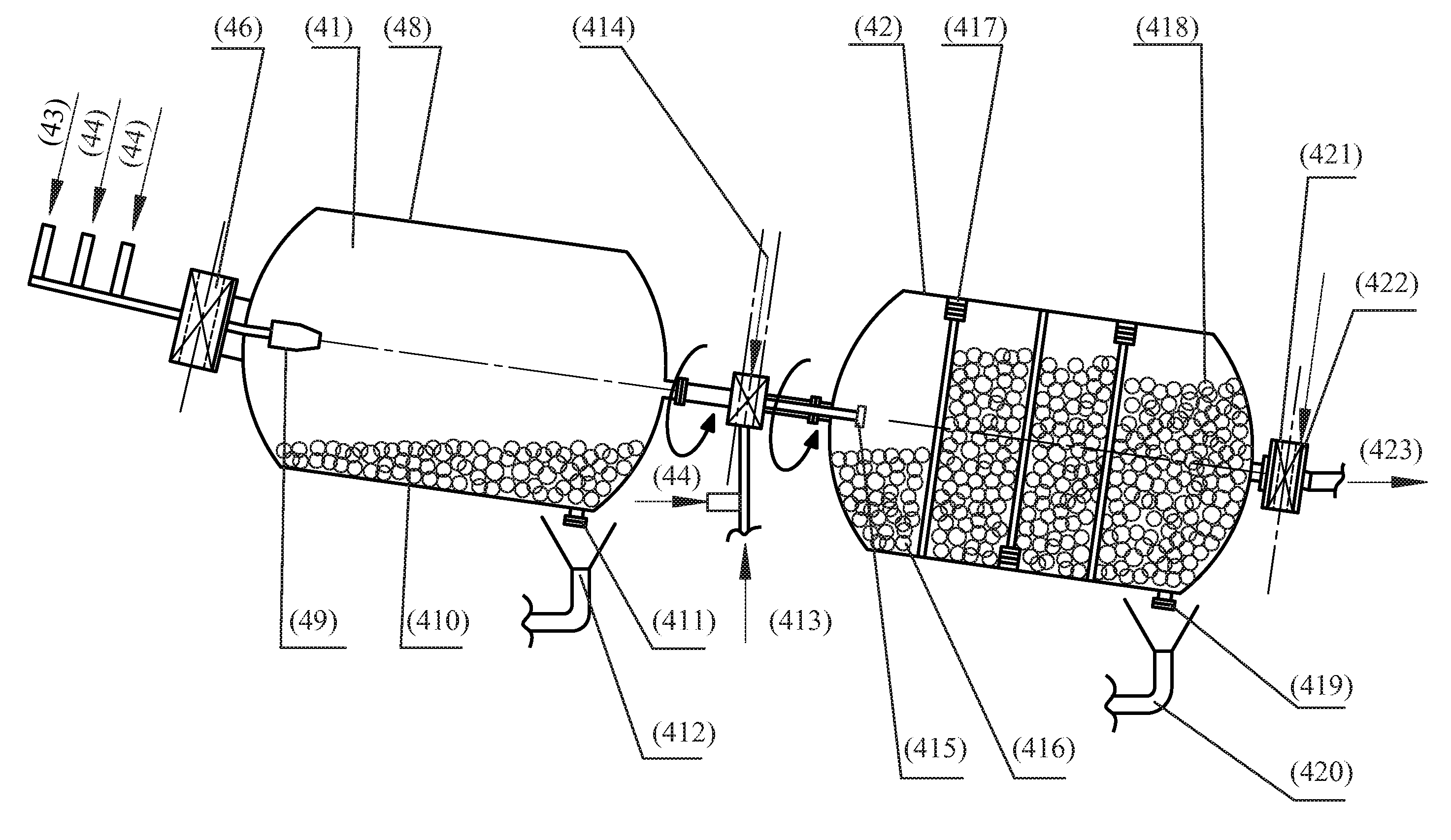

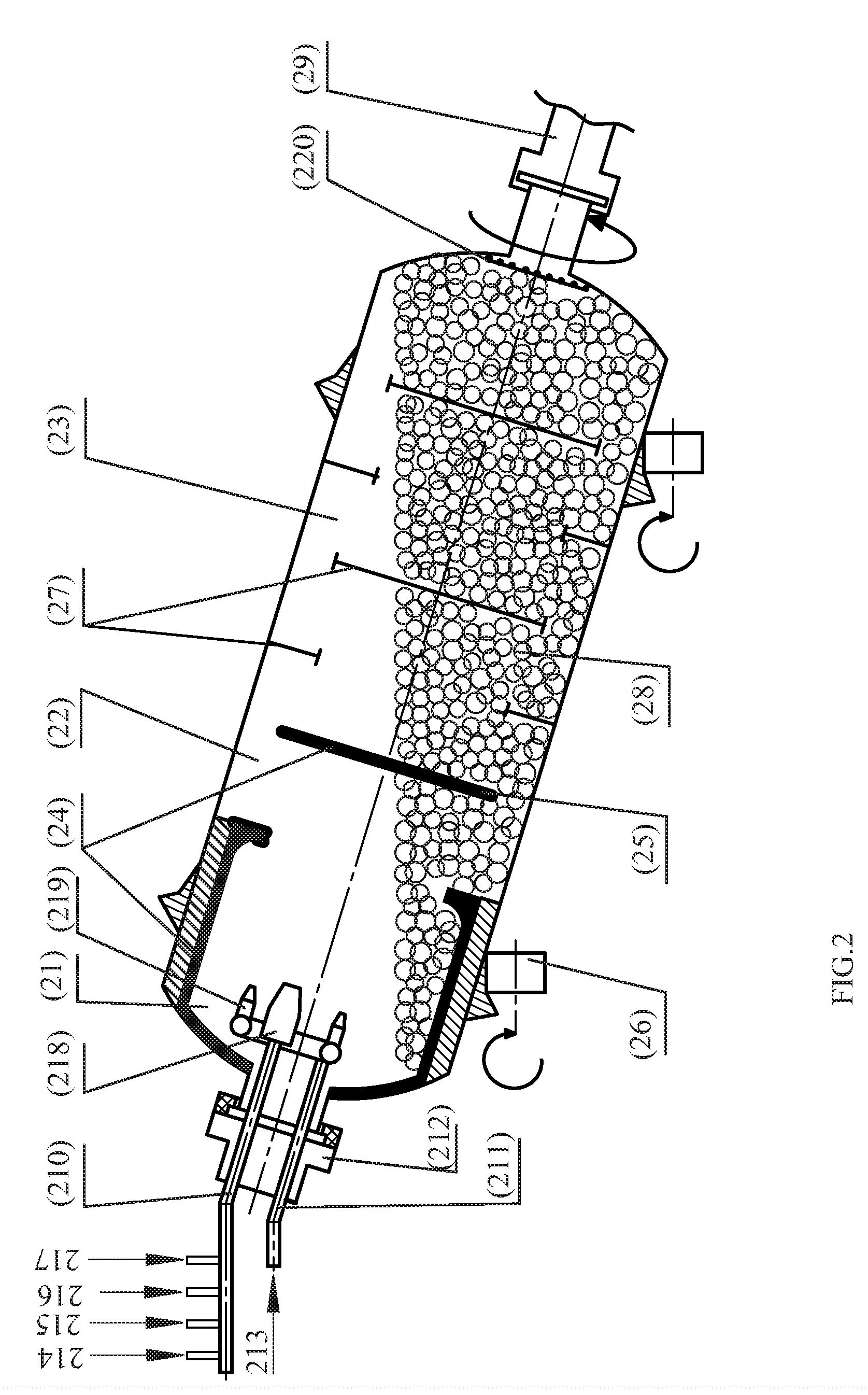

Reaction chamber for a direct contact rotating steam generator

InactiveUS20090211539A1Lower the volumeAvoid wastingBoiler water tubesRotary drum furnacesCombustionProduct gas

The present invention is an apparatus and method for producing a steam and CO2 mixture, as a super heated dry steam mixture. The apparatus includes a rotatable vessel having a combustion section and a steam producing section. There may also be a dry solid removal, a steam production and solid scrubbing vertical vessel, and a heat exchanger. The vessel is partially filled with spherical bodies, and the sections are partially separated by a partition. A discharge section is located at an end of the steam producing section. A homogenizing section has at least one partition wall guiding flow of gases. The process for producing the steam mixture includes mixing a low quality fuel with an oxidation gas, combusting in a rotating drum filled with spherical bodies, and mixing low quality water with a controlled temperature to generate steam. All liquids convert to gas so that there is no liquid discharge.

Owner:EX TAR TECH

Remote power-generating assembly

InactiveUS7770394B2Easy to deployHighly availableGas turbine plantsFire-tube steam boilersTurbineElectric power

A remote power supply system associated with offshore hydrocarbon production and transportation operations includes an expansion turbine that generates power for the system. The remote power supply system also has a support structure that supports the expansion turbine. A cooling section is supported by the support structure, and is in fluid communication with the expansion turbine to receive the vapor therefrom and to condense it to liquid. A downcomer and boiler section is in fluid communication with the cooling section to receive the liquid condensed from the vapor. An ignition assembly is positioned toward a lower end portion of the downcomer and boiler section. The ignition assembly ignites a fuel and air mixture and causes the liquid received by the downcomer and boiler section from the cooling section to boil into vapor. A return passage conveys vapor from the downcomer and boiler section to the inlet of the expansion turbine.

Owner:CHEVROU USA INC

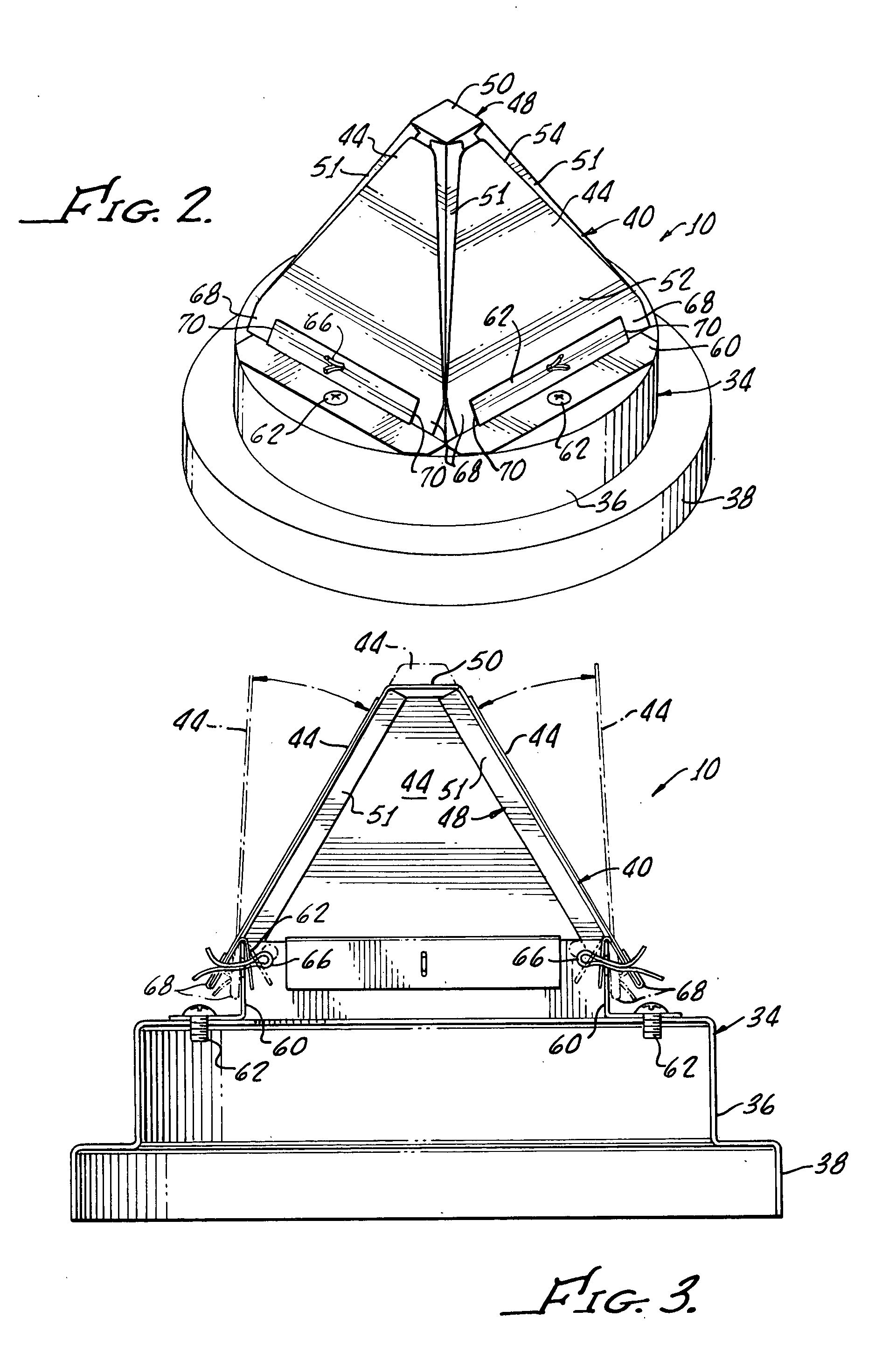

Vent damper apparatus

InactiveUS6868806B1Limited range of activitiesReduce generationDrum steam boilersFurnace-tube steam boilersAmbient airStreamflow

A vent damper apparatus provided for limiting flow of ambient air in a flue of a water heater. The apparatus generally includes a base structured to be connected to a water heater, and a damper assembly, extending from the base and structured to be responsive to a variable flow of exhaust gasses passing from a flue of the water heater. The damper assembly includes a plurality of independently movable dampers, and a frame structured to provide support to the plurality of independently movable dampers.

Owner:SCHIMMEYER WERNER

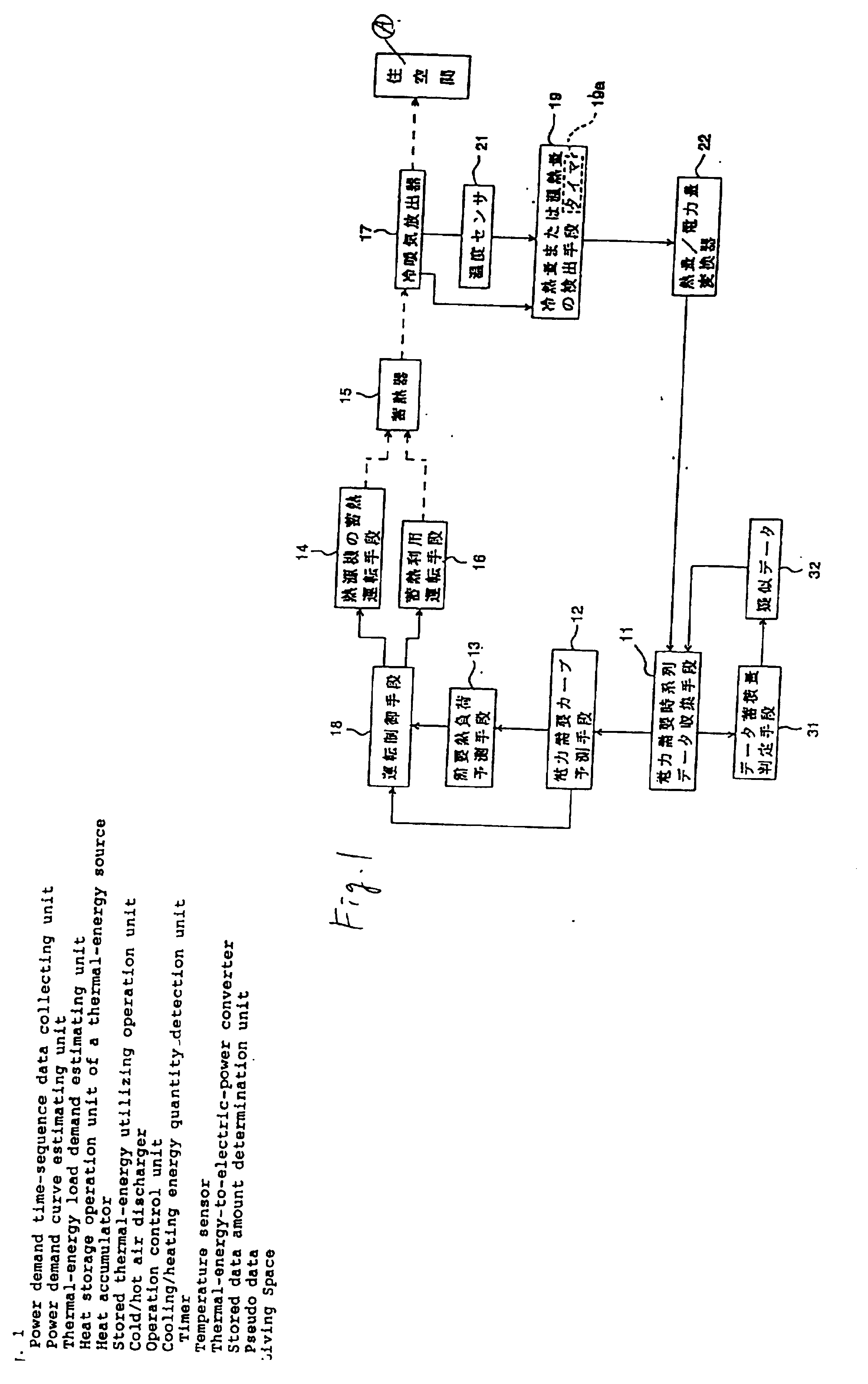

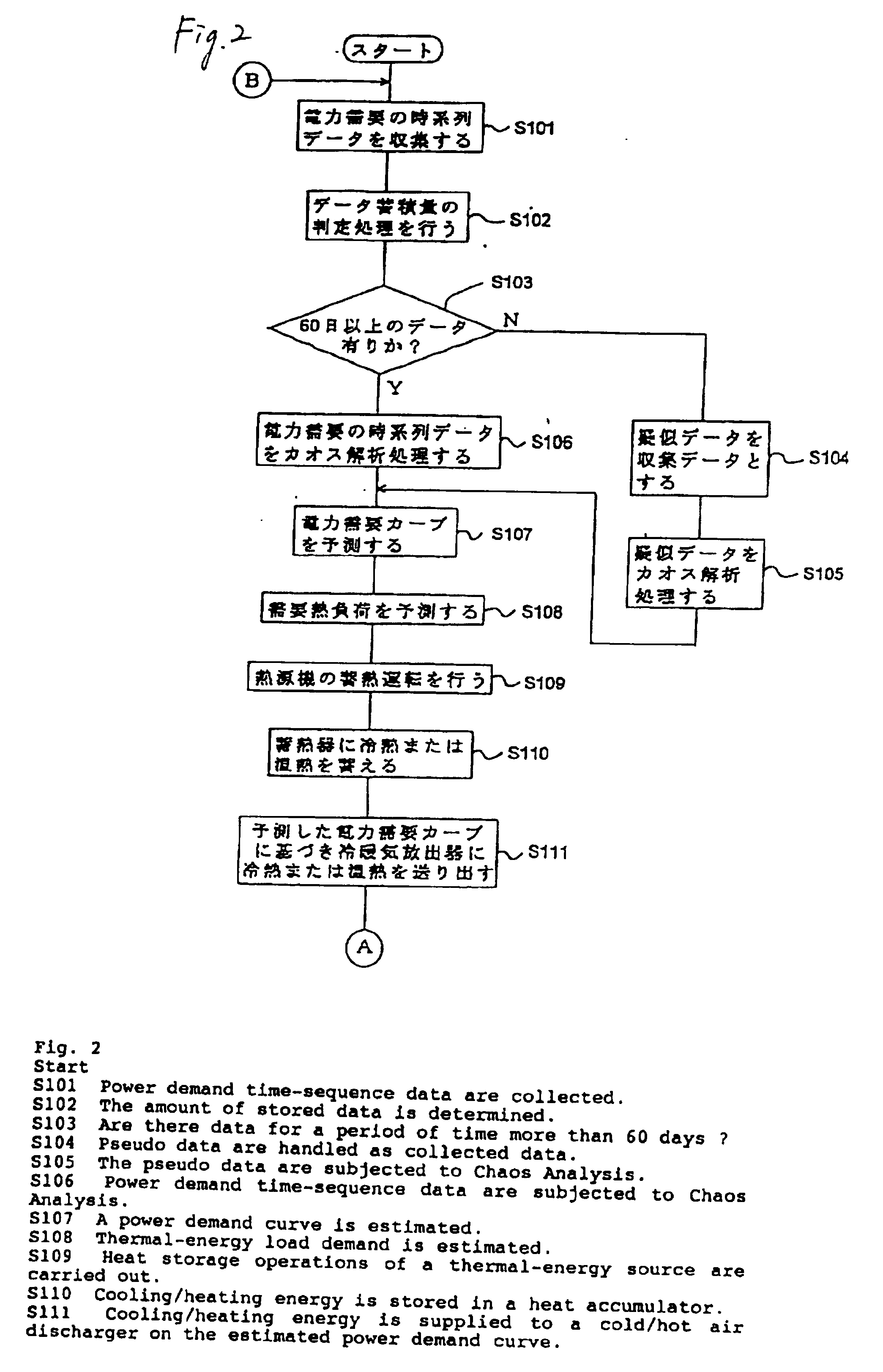

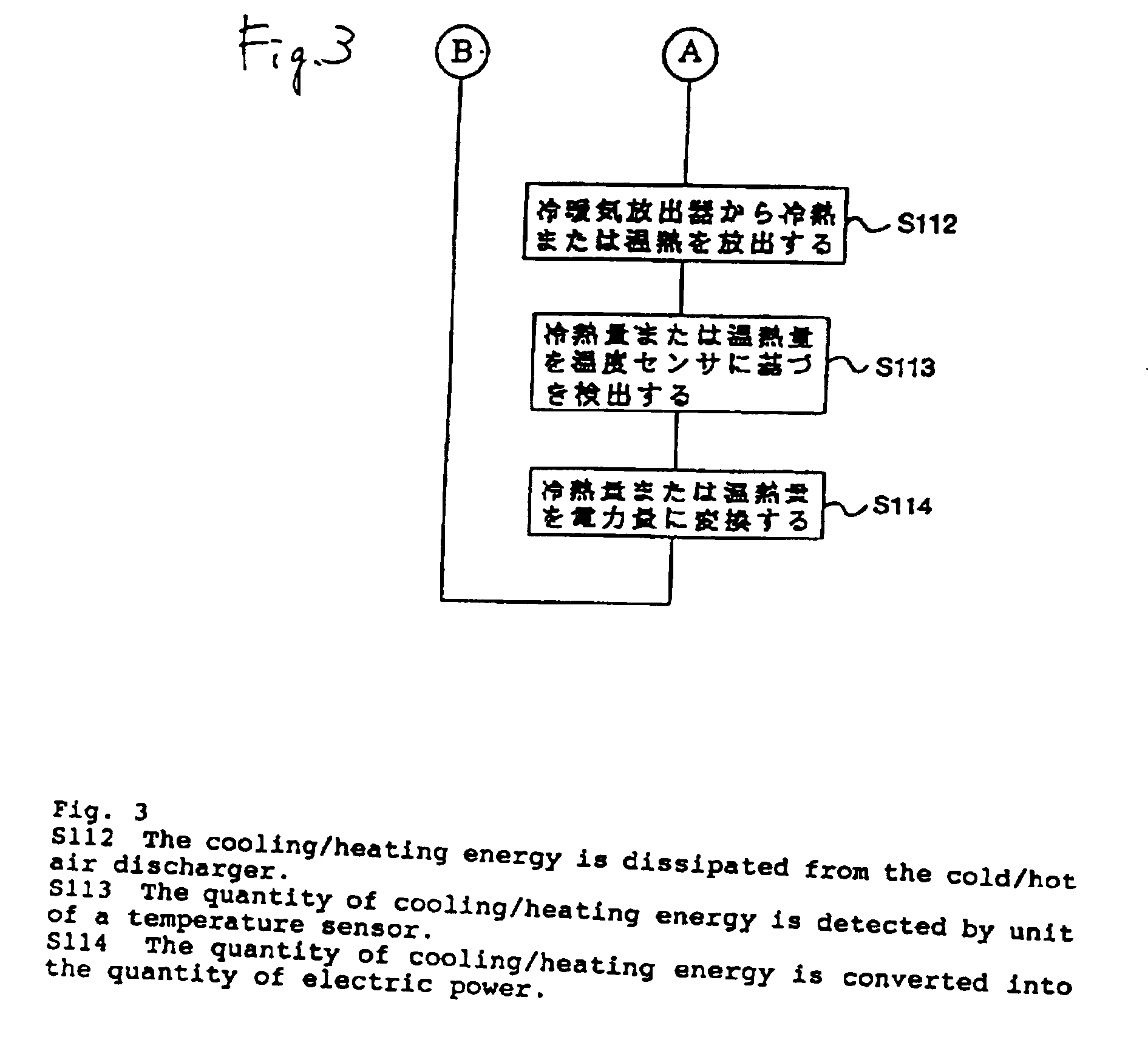

Heat storage air conditioning apparatus and heat storage estimating method

InactiveUS20010018971A1Central heating with accumulated heatElectric heatingThermal energyElectricity

In a heat storage air conditioning apparatus, a power demand time-sequence data collecting unit collects time-sequence data on demand for power; a power demand curve estimating unit estimates a power demand curve obtained as a result of analysis of the power demand time-sequence data collected by the power demand time-sequence data collecting unit; a thermal energy load demand estimating unit estimates thermal energy load demand from the power demand curve estimated by the power demand curve estimating unit; an operation unit of a thermal-energy source feeds cooling / heating energy; a heat accumulating unit stores the cooling / heating energy supplied from the operation unit therein; a cold / hot air discharging unit discharges the thermal energy stored in the heat accumulating unit; a cooling / heating energy quantity recognizing unit recognizes the quantity of cooling or heating energy dissipated from the cold / hot air discharging unit; and a converting unit converts the quantity of cooling / heating energy into the quantity of electric power, the converted quantity of electric power being supplied to the power demand time-sequence data collecting unit.

Owner:ELLEN MARCIE EMAS

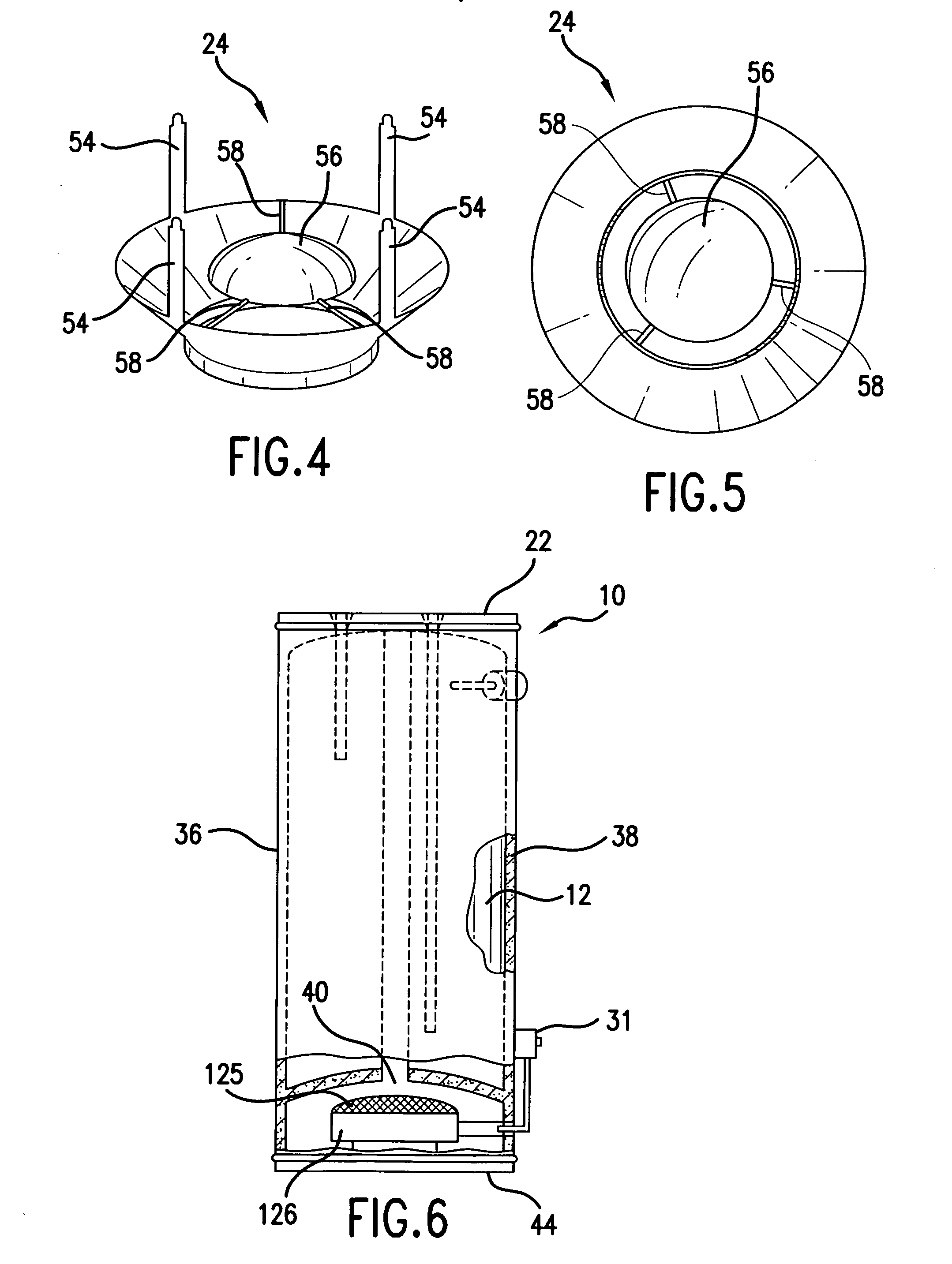

Gas water heater damper/baffle

InactiveUS7311064B2Improve gas efficiencyReduce generationFurnace-tube steam boilersWater heatersCombustorDirect combustion

Apparatus for improving the efficiency of a water heater includes a combination damper assembly and heat transfer baffle. The damper assembly includes a plurality of movable damper with each damper leaning outwardly from one another when the dampers are in a closed position. The baffle depends from the damper assembly and includes a truncated conical shape in this position within the flue of a water heater for directing combustion gases from the burner against a flue wall.

Owner:SCHIMMEYER WERNER K

Hot water heater

InactiveUS6311646B1Easy and efficient to manufactureDurable and reliable constructionBoiler water tubesFurnace-tube steam boilersCombustorEngineering

A hot water heater having a housing with a top chamber, a bottom chamber and a main tank. A cold water inlet pipe runs into the top chamber and extends into the tank. The cold water inlet pipe coils inward, beginning at circumference of the top chamber before extending into the tank, thus increasing the distance the water has to travel inside the heater. Contrastly, the hot water outlet pipe runs straight from the main tank through the top chamber and exits therefrom. The bottom chamber has a dome shaped ceiling with peaked apertures. A burner is positioned along the bottom surface and produces a flame that sends heated air upward, through the peaked apertures into connected heat distribution tubes which travel vertically through the tank. These tubes are angled along their length and have cylindrical fins attached. Once the heat from the flame rises through the apertures, it continues upward through the tubes, until it is released into the top chamber and exits trough an exhaust chimney.

Owner:SELMANI ASLLAN

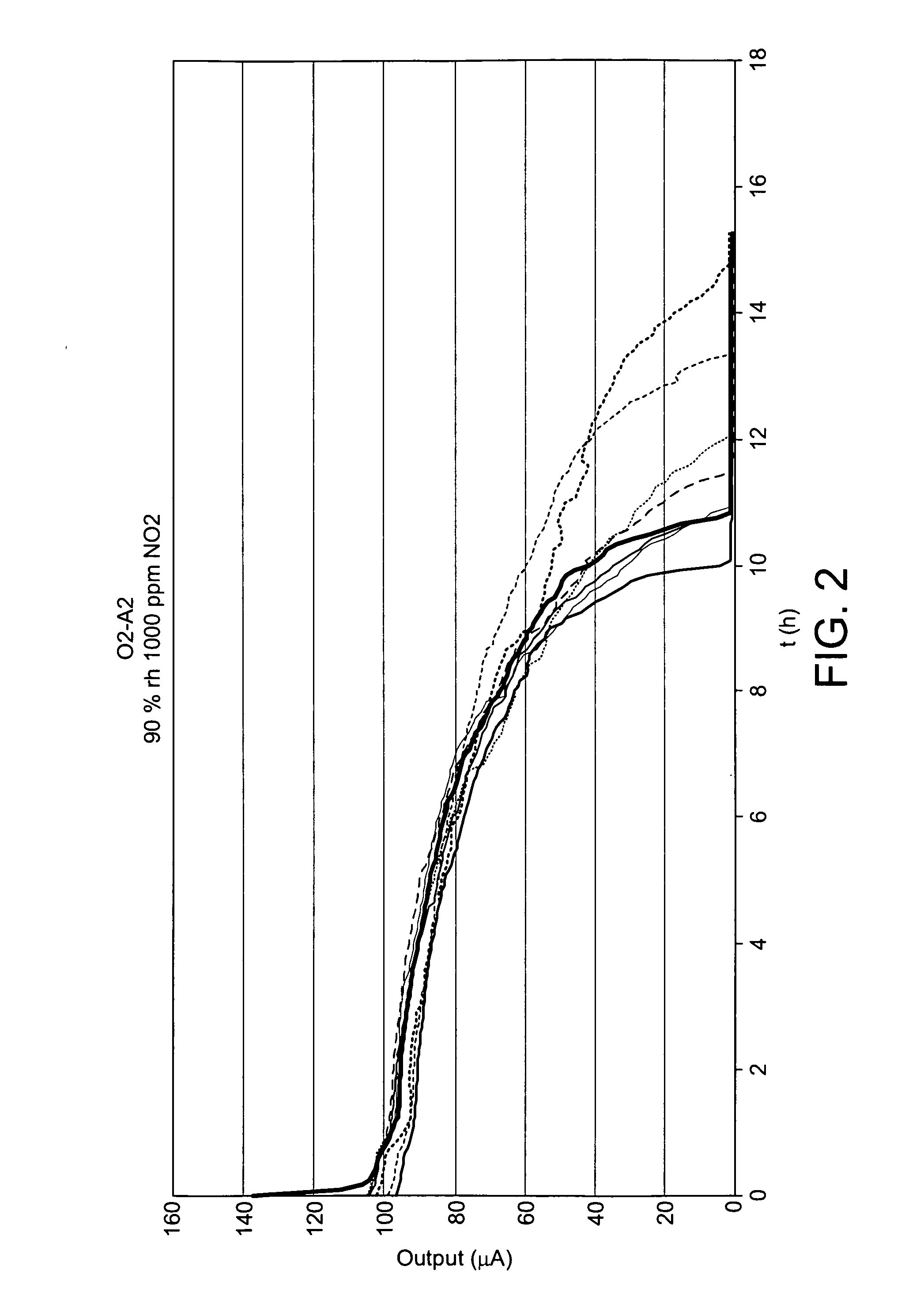

Flue gas analyser

InactiveUS20100065442A9Reduce humidityReduce harmWeather/light/corrosion resistanceVolume/mass flow measurementElectrochemical gas sensorNitrogen dioxide

A flue gas analyser for measuring the concentration of oxygen in flue gas, comprising an electrochemical oxygen sensor and water vapour removing means for reducing the relative humidity of received gas and / or nitrogen-containing-gas removing means for removing from received gas one or more gaseous species comprising nitrogen and oxygen which are either nitrogen dioxide, or formed from nitrogen dioxide in the presence of sufficient water vapour, which would otherwise lead to damage of the electrochemical oxygen sensor,

Owner:ALPHASENSE LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com