Patents

Literature

205results about "Water circulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

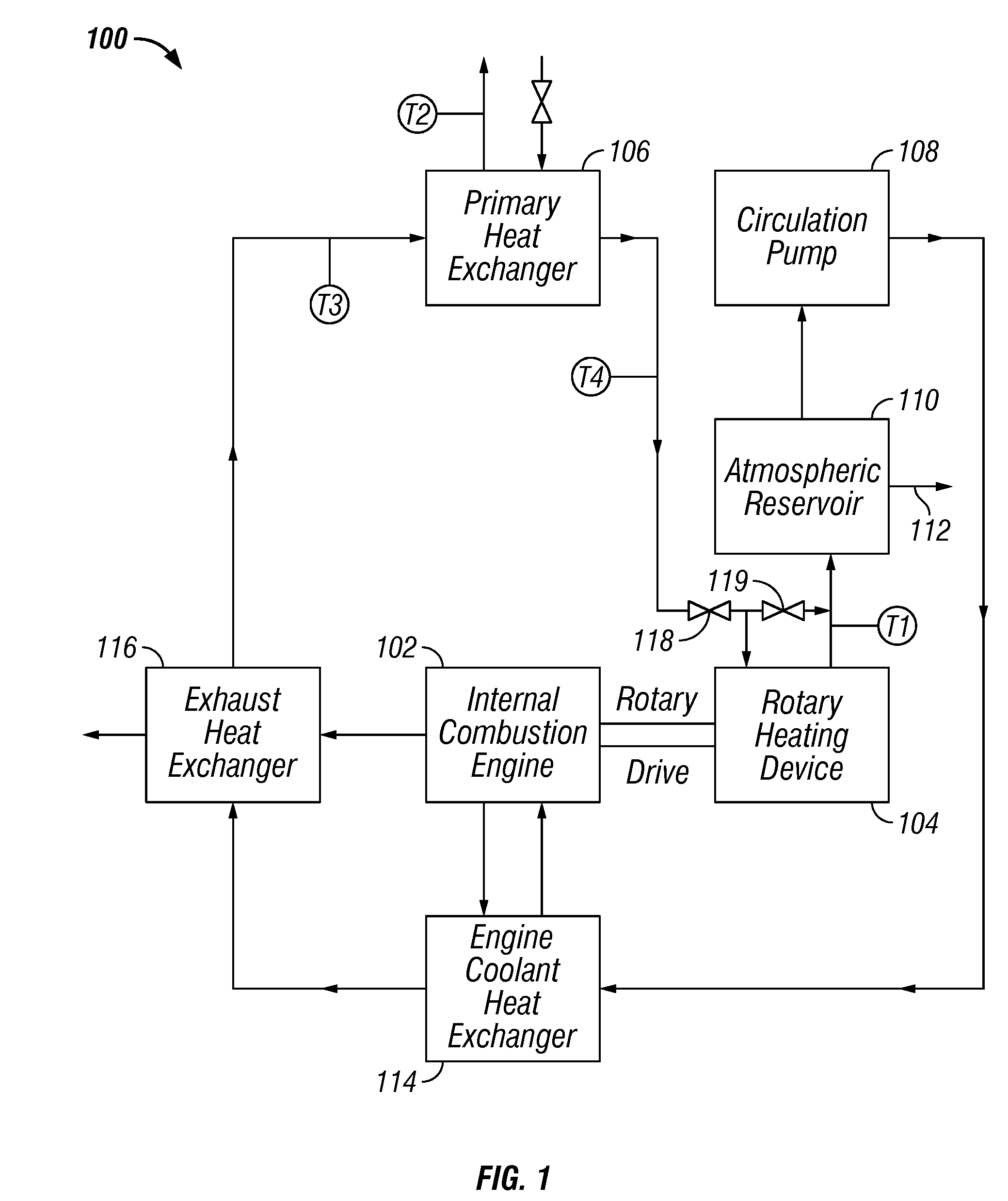

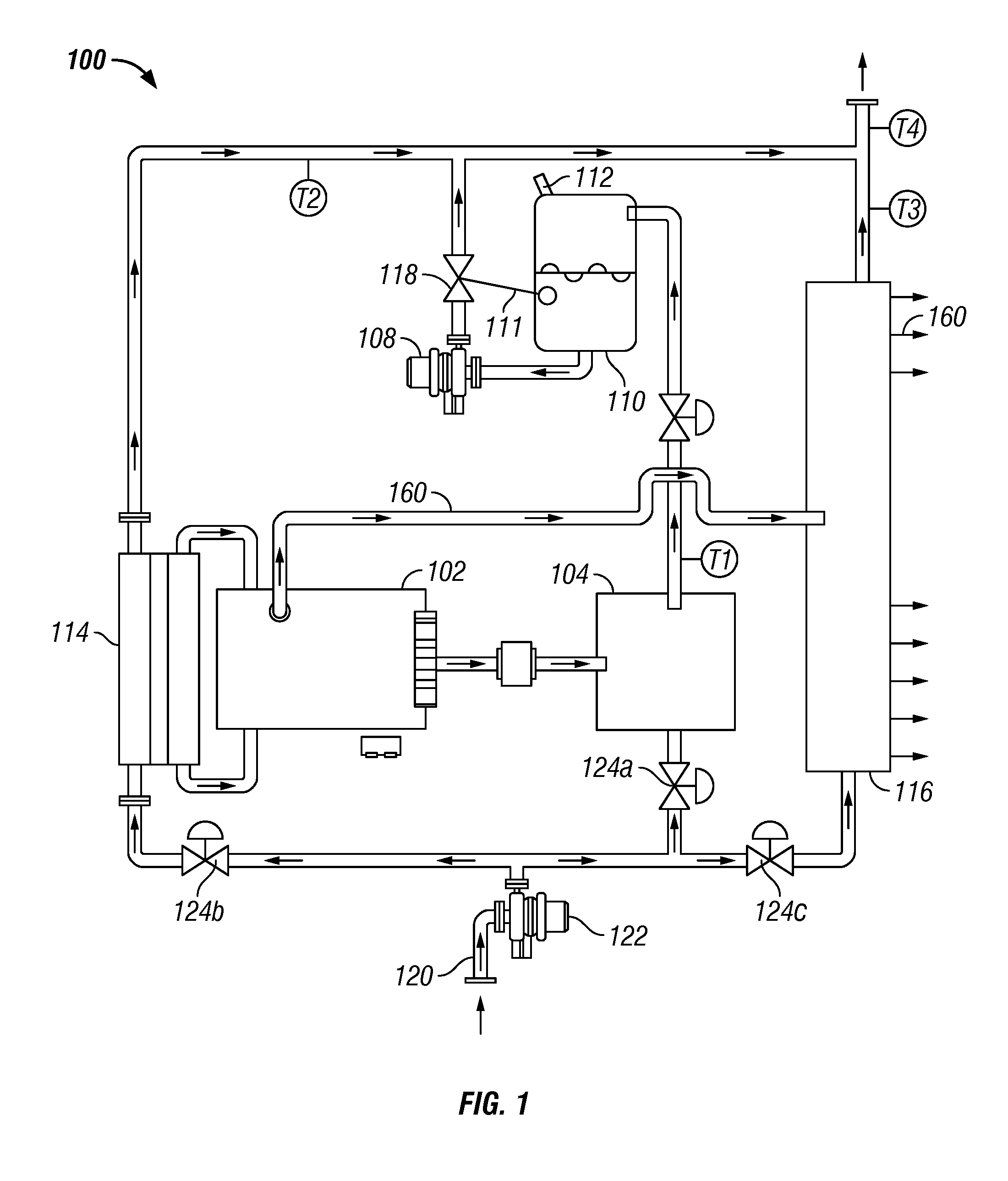

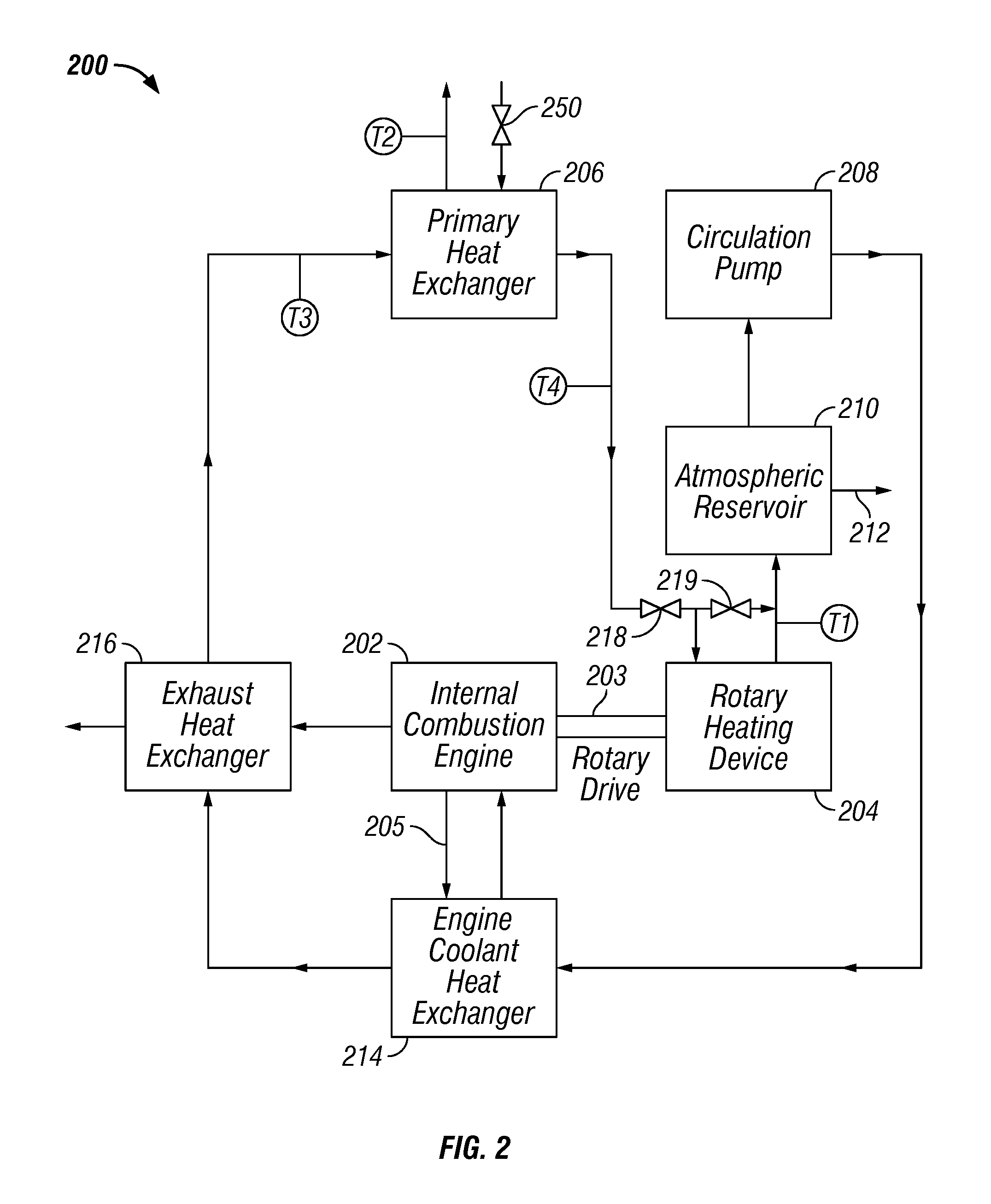

Method and apparatus for heating, concentrating and evaporating fluid

InactiveUS7614367B1Steam generation using mechanical energyAir-treating devicesWater brakeEvaporation

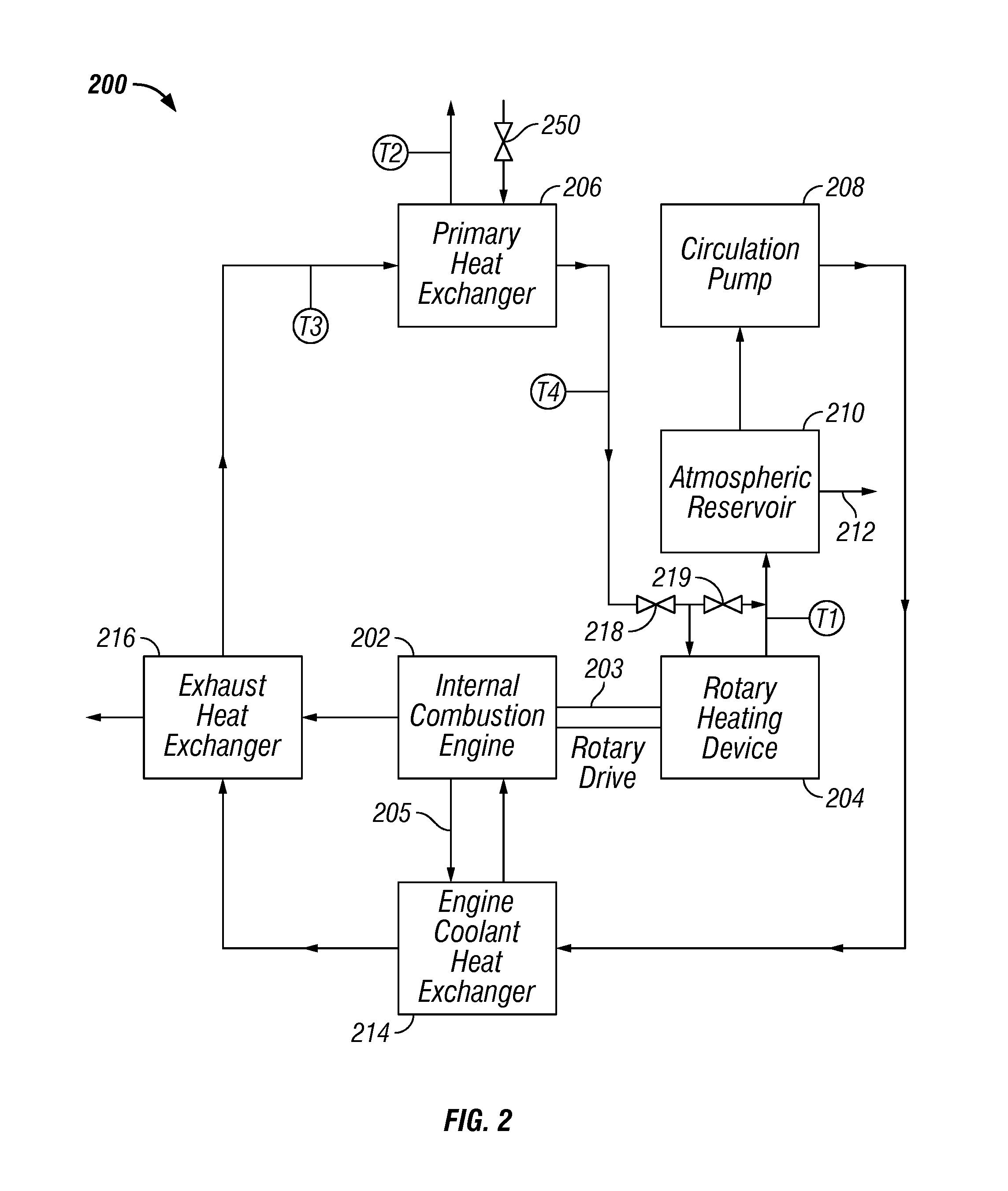

A system and method are provided for heating, concentrating and / or evaporating a fluid by heating the fluid in a heating subsystem comprising a rotary heating device, such as a water brake dynamometer, and then evaporating all or a portion of the fluid in an evaporation subsystem and / or concentrating the fluid in a concentration subsystem.

Owner:PHOENIX CALIENTE INC

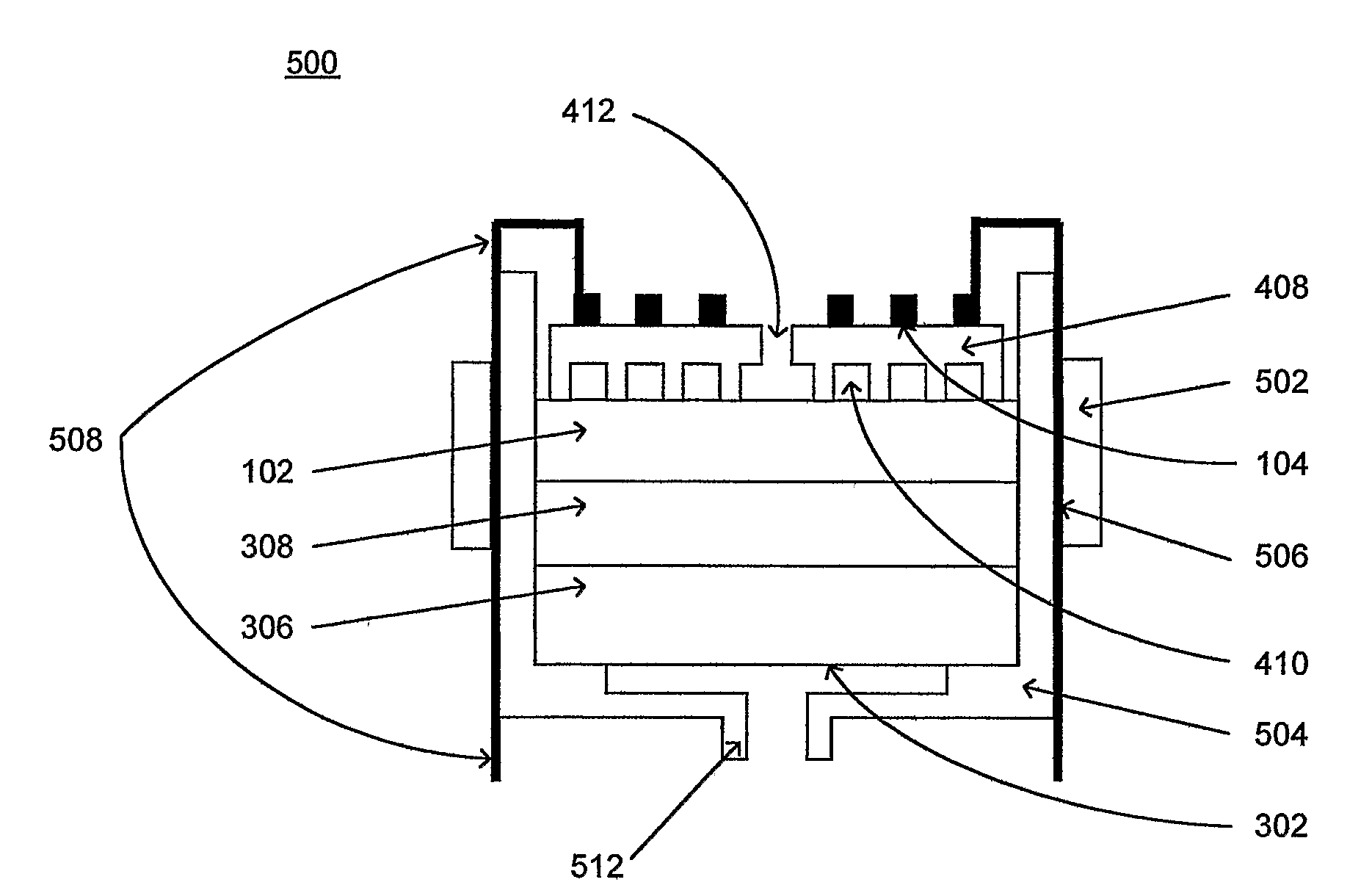

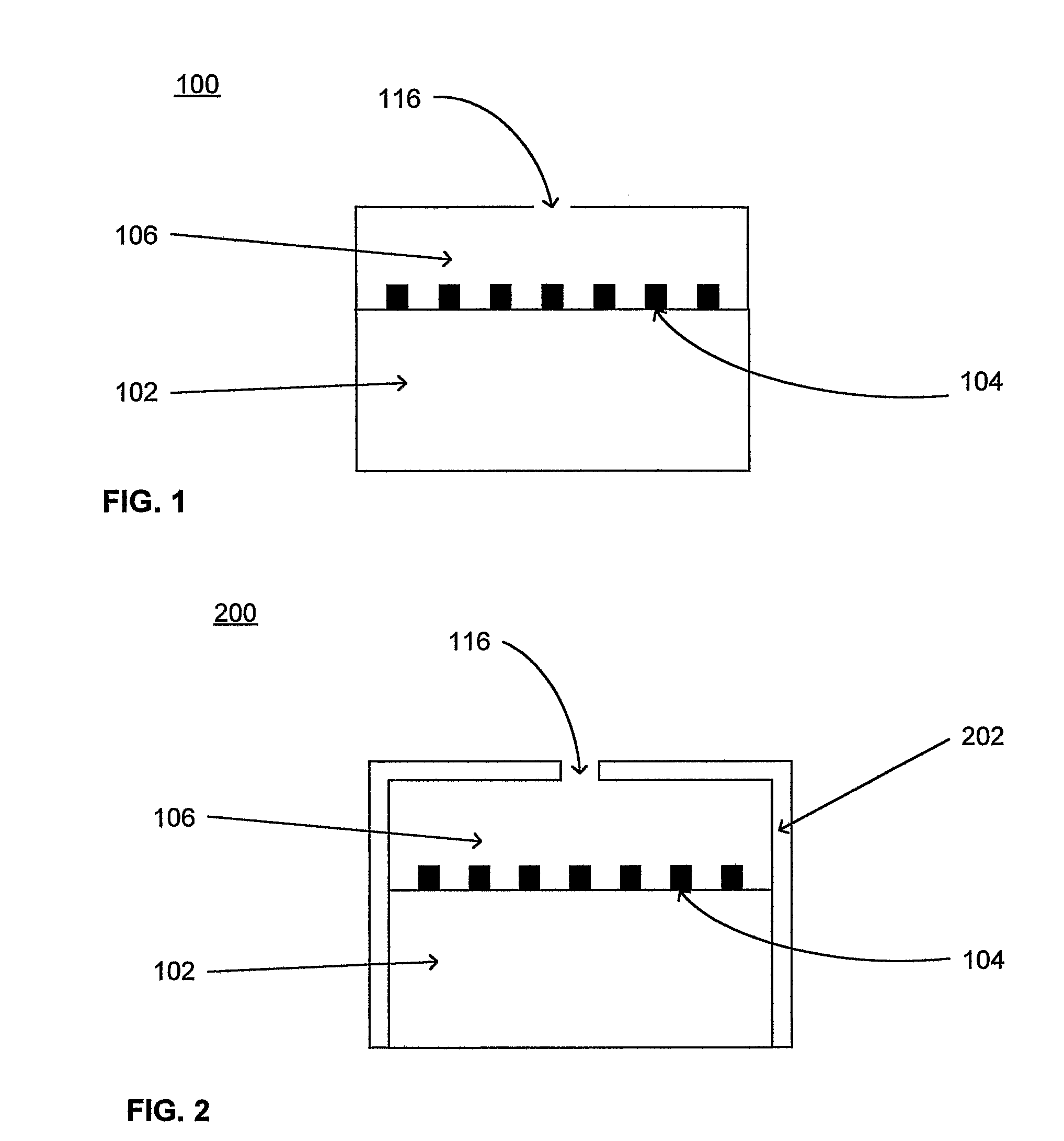

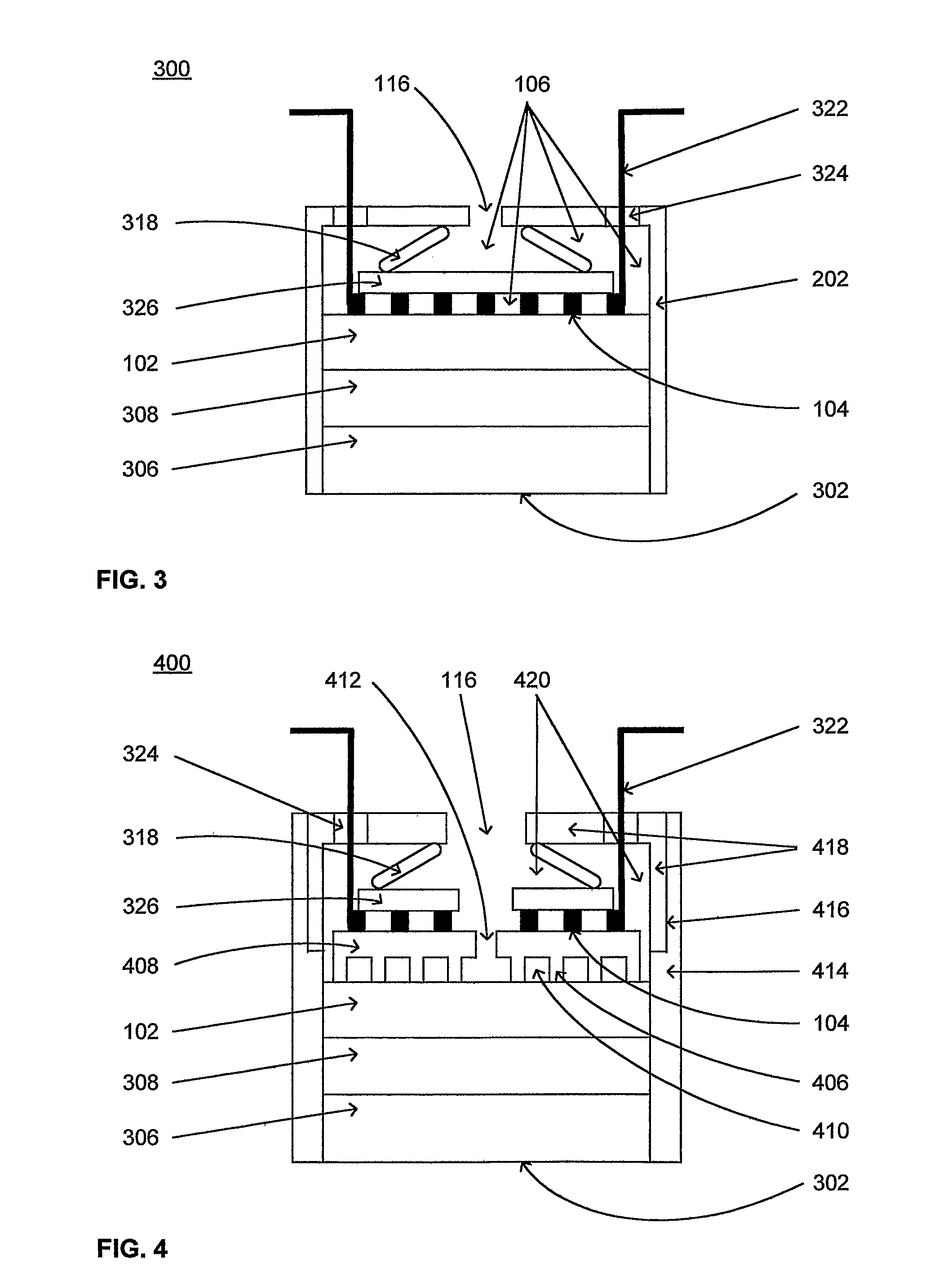

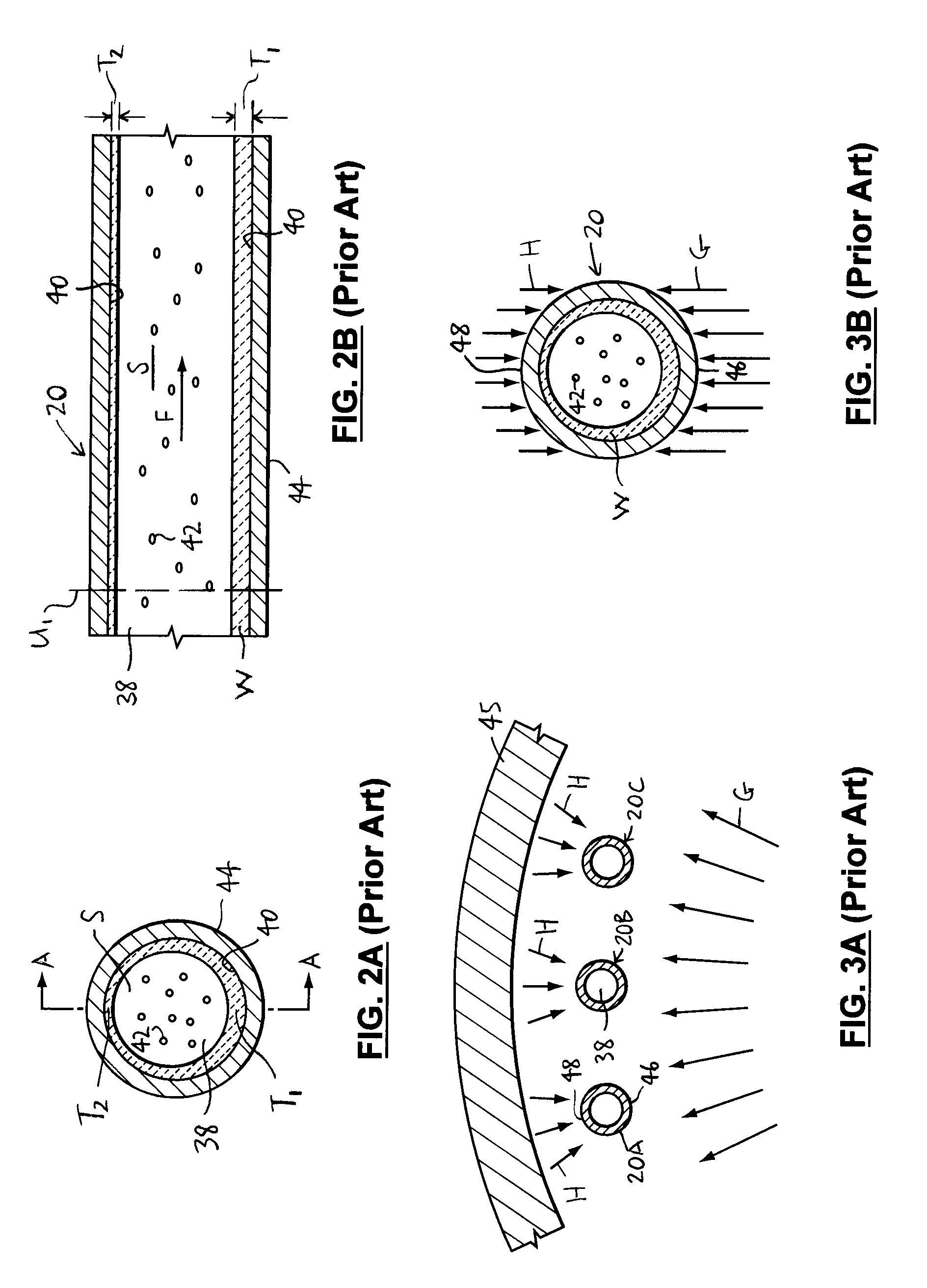

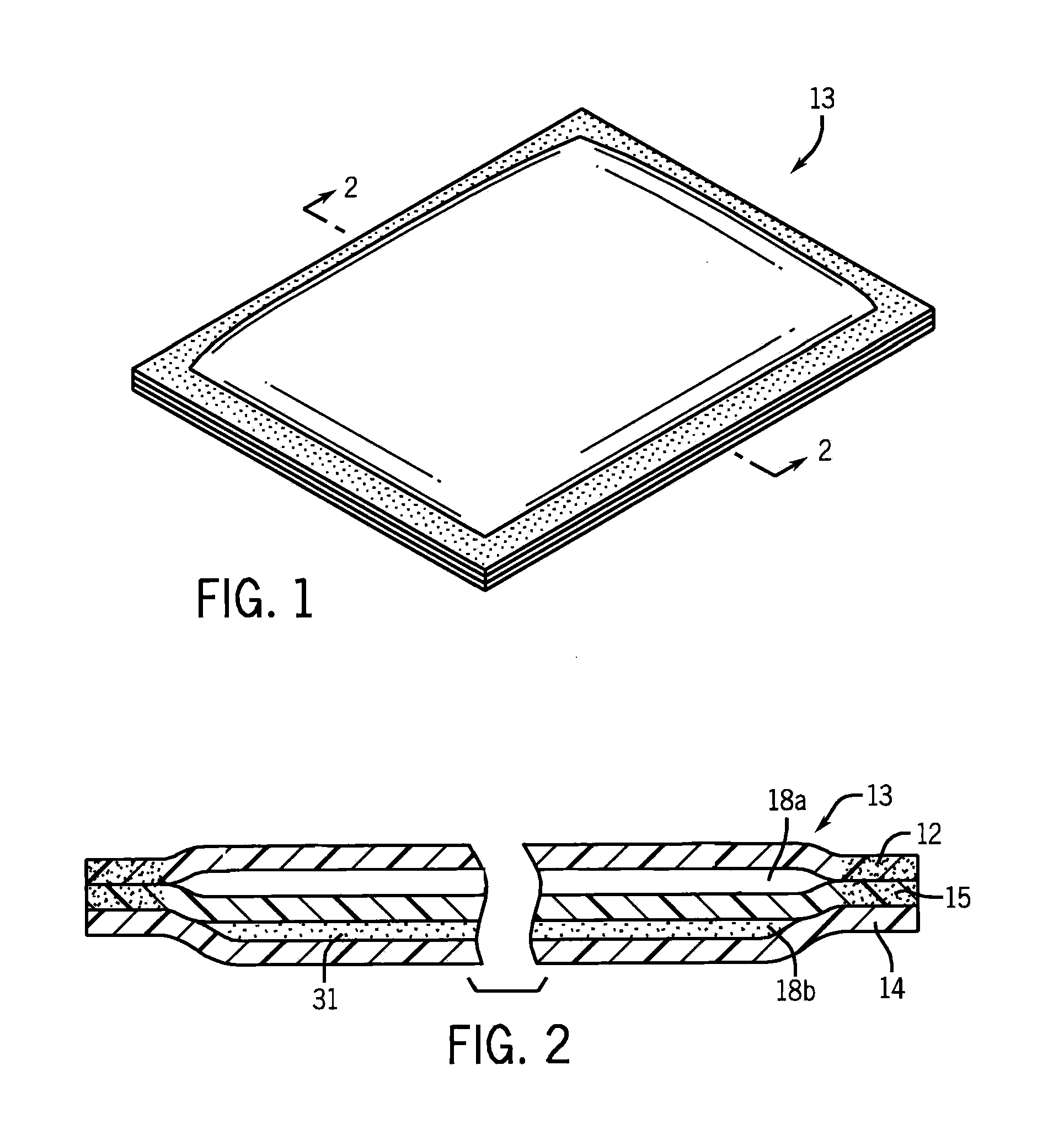

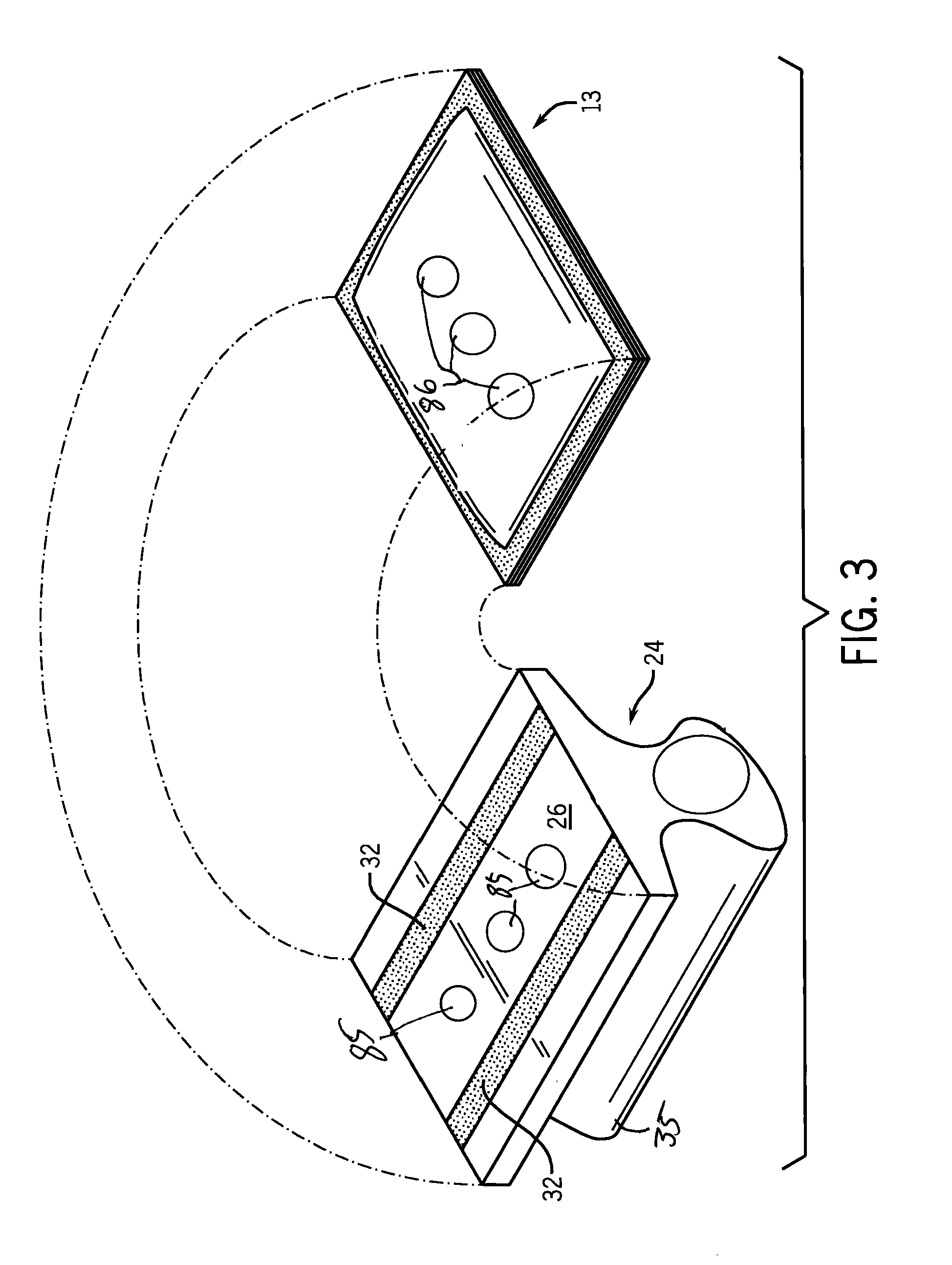

Capillary force vaporizers

ActiveUS20090220222A1Easy to assembleEliminate needSpace heating and ventilationMedical devicesCapillary networkEngineering

The present invention concerns capillary force vaporizers for use in vaporizing liquids and emitting pressurized vapors. In one embodiment, the inventive capillary force vaporizer includes a porous member, a heater component to convey heat to the porous member, and a vapor containment region. The porous member further includes a capillary network, a surface for receiving liquid and a vaporization area in which vapor is produced from the liquid. The vapor is collected and pressurized within the vapor containment region, which includes one or more openings for the release of vapor at a velocity greater than zero. Several different embodiments for capillary force vaporizers and systems comprising capillary force vaporizers are disclosed along with methods for their use.

Owner:VAPORE

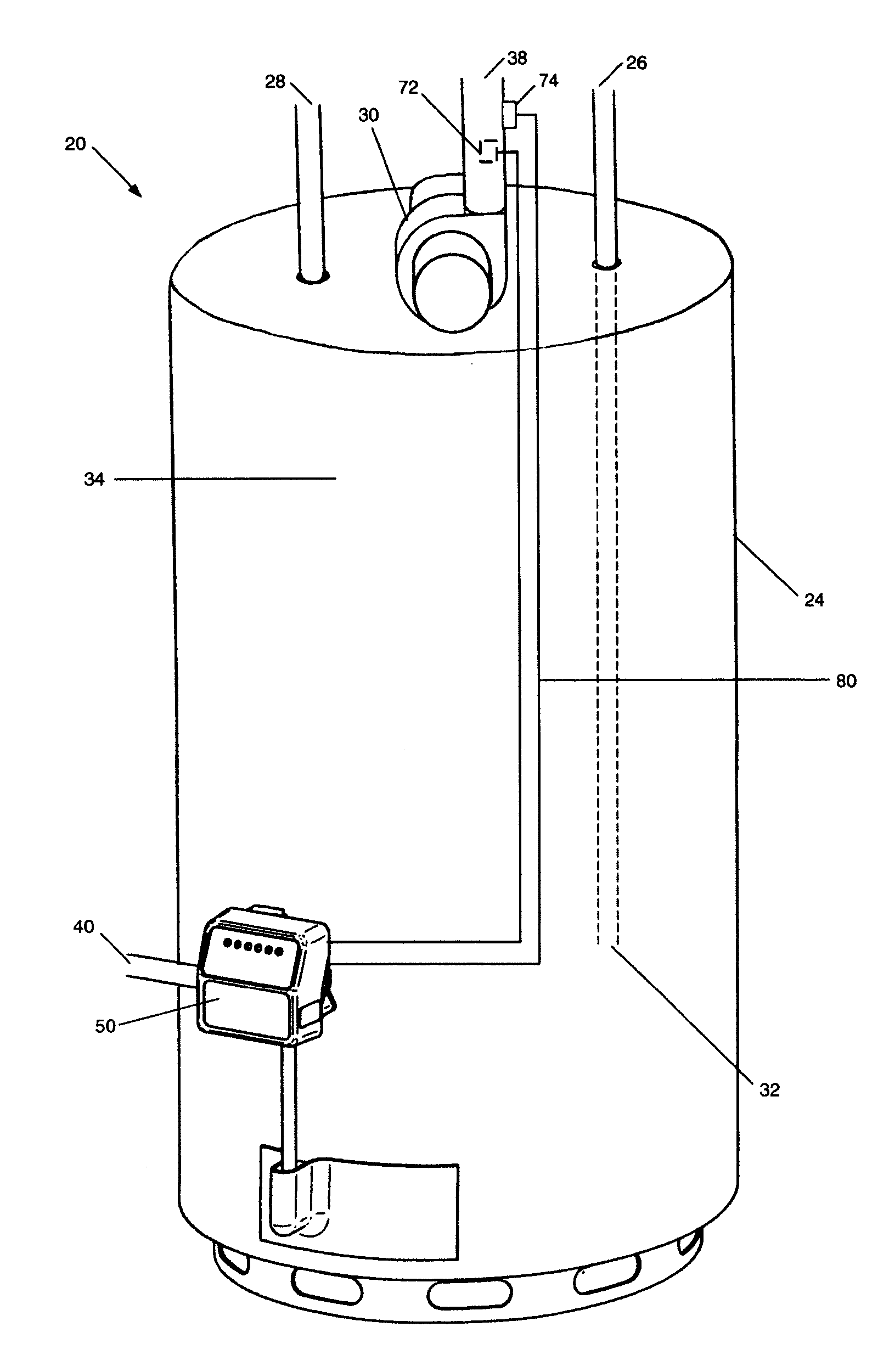

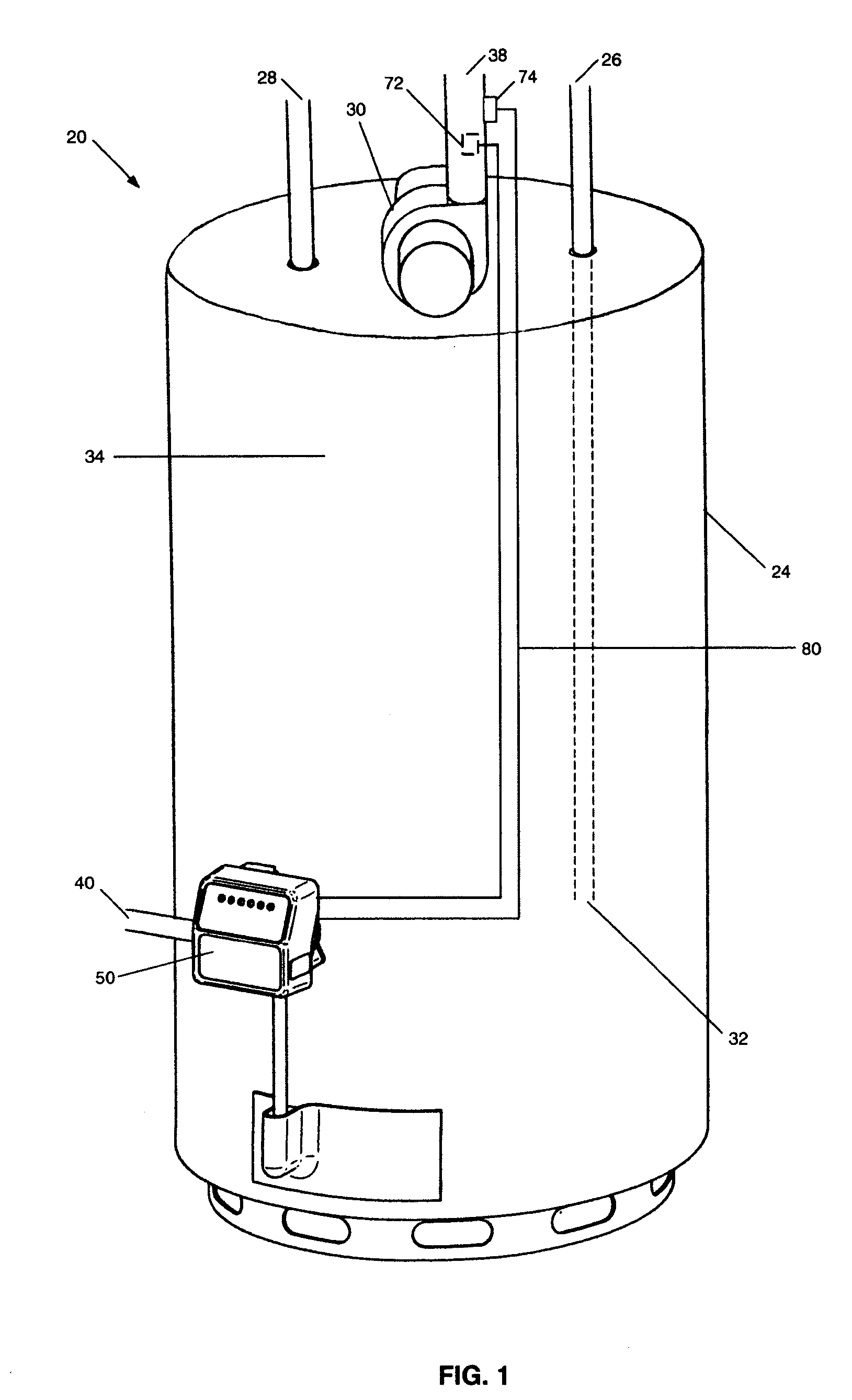

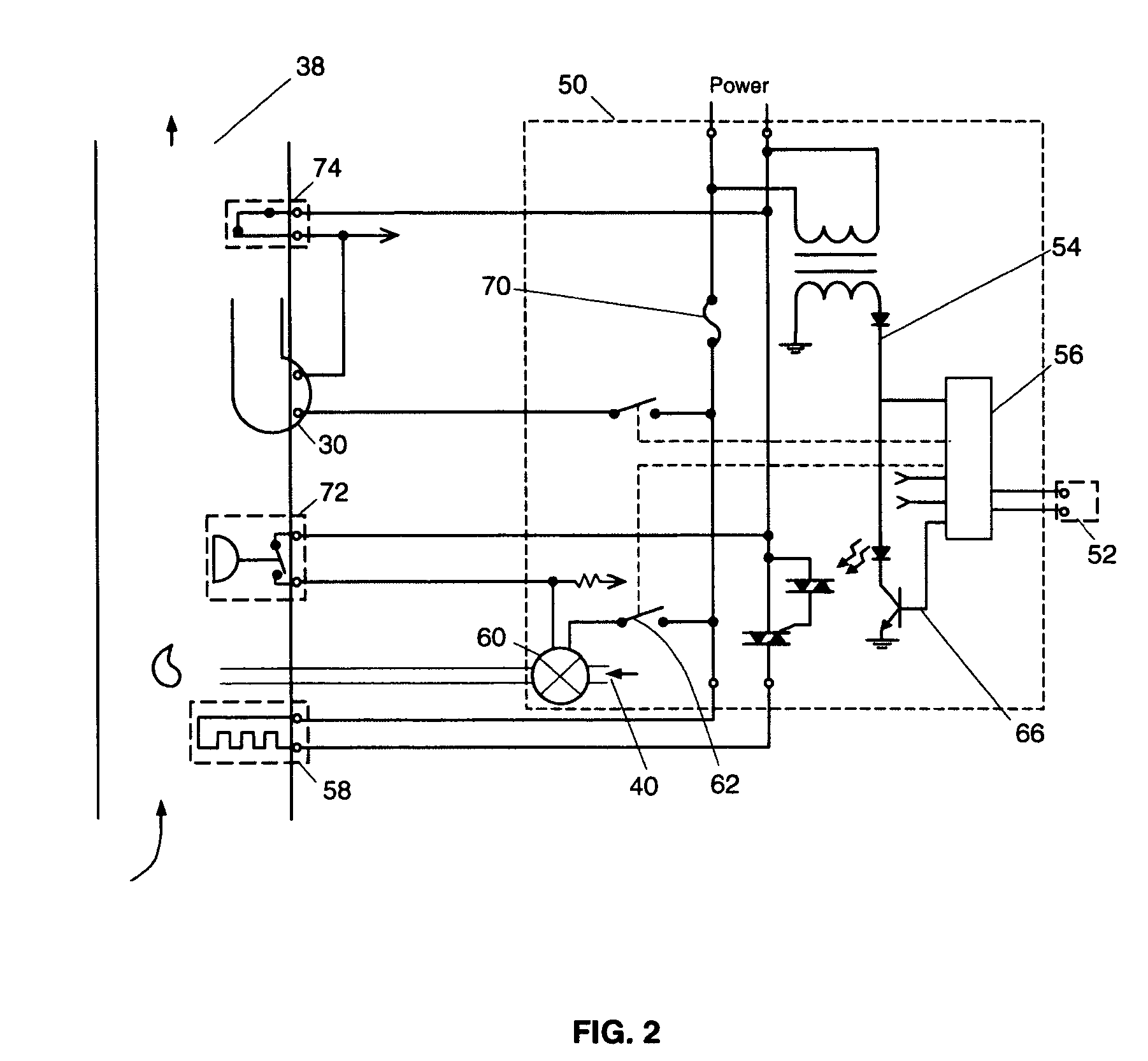

System and methods for controlling a water heater

A control for a water heater is provided that comprises a pressure switch for sensing a predetermined level of airflow sufficient for maintaining proper burner operation, and a temperature sensing means for sensing the temperature of the water in the tank. The control further comprises a processor for controlling the operation of the burner to maintain the water temperature above a predetermined value. When the processor receives a signal from the pressure switch indicating an insufficient level of airflow, the processor shuts down the burner and subsequently attempts to restart the burner. The processor will also lock-out further burner operation after a predetermined number of consecutive shut downs occurs before the water is heated to a desired temperature during a single call for heating.

Owner:COPELAND COMFORT CONTROL LP +1

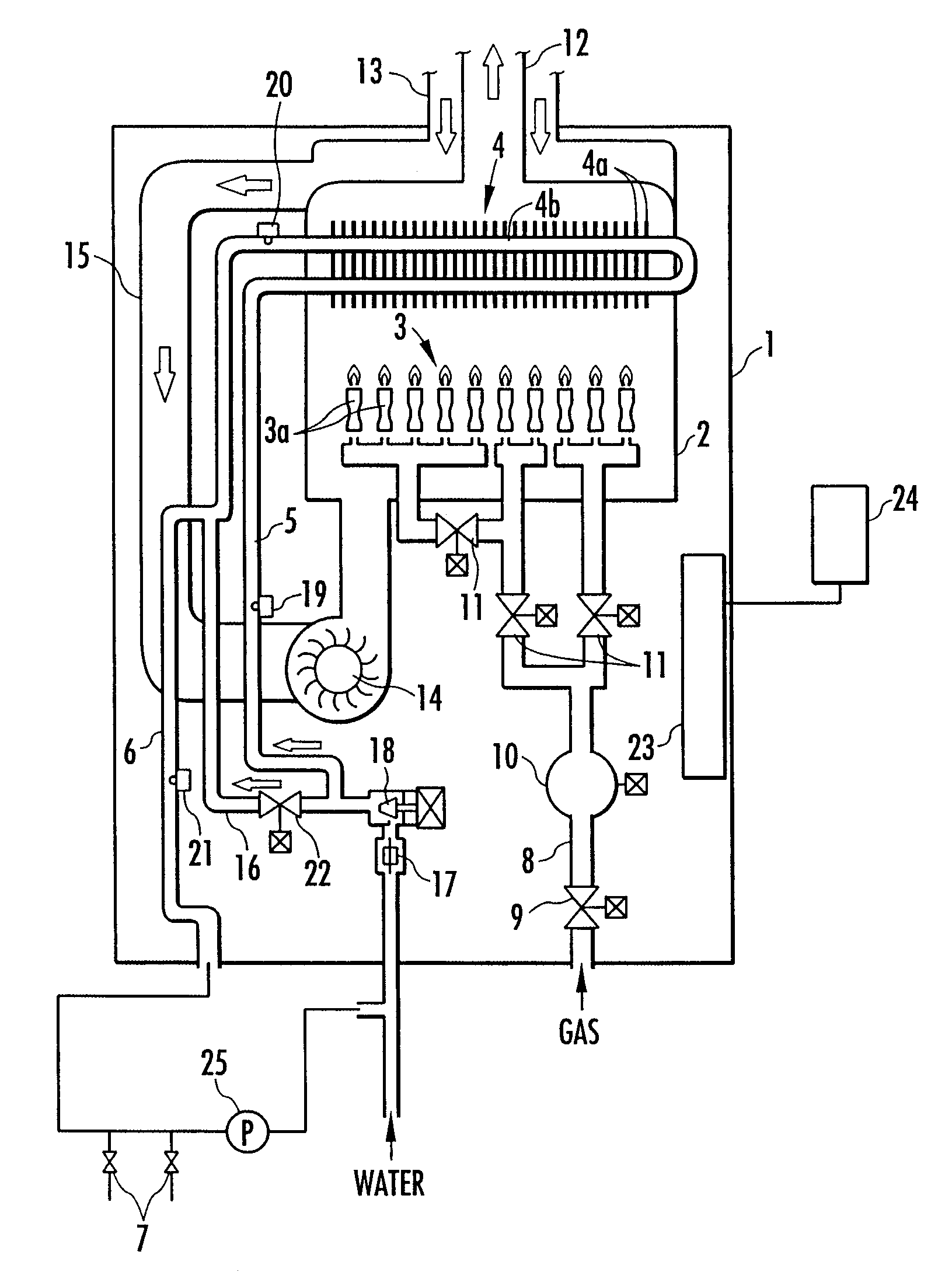

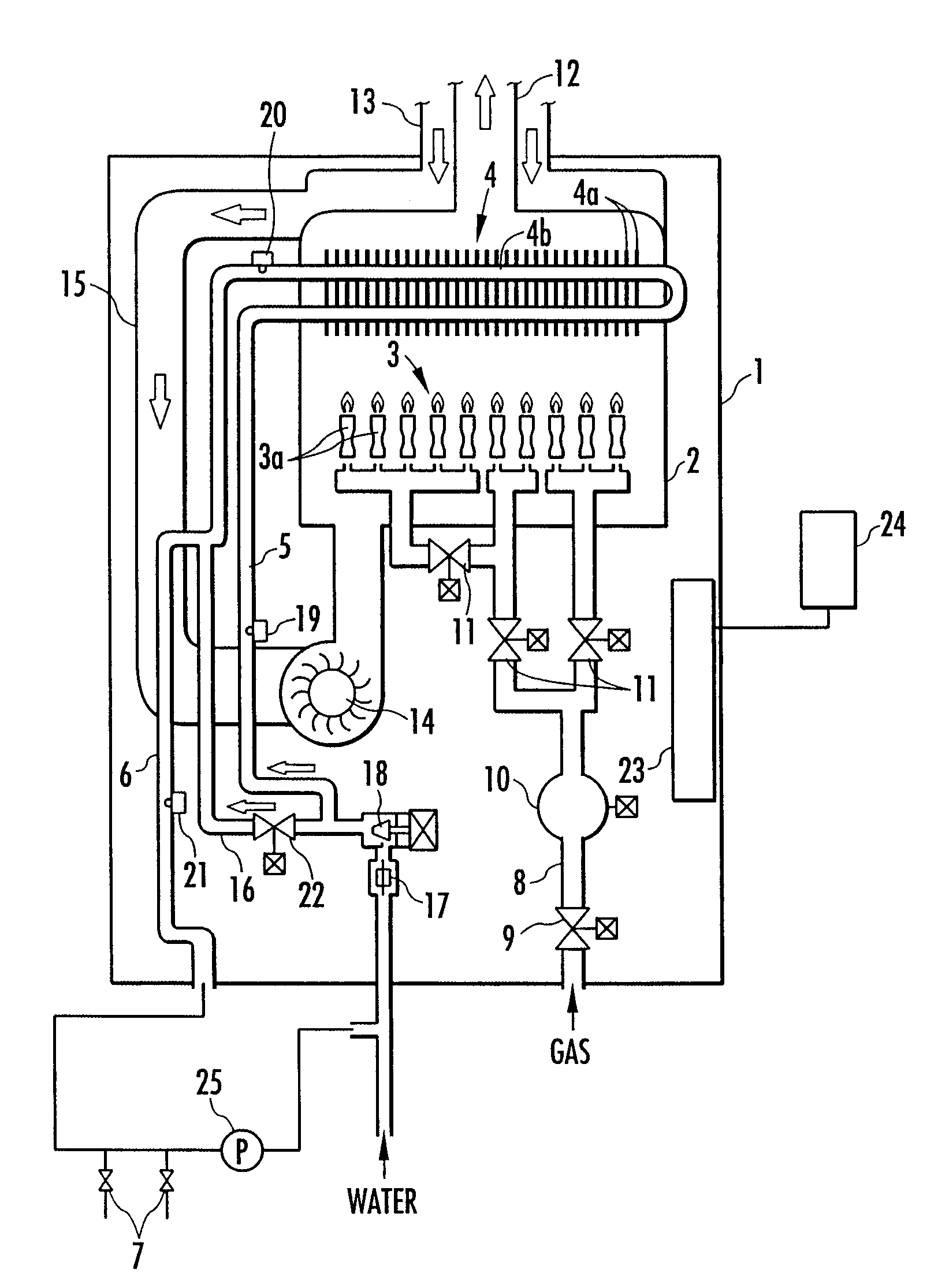

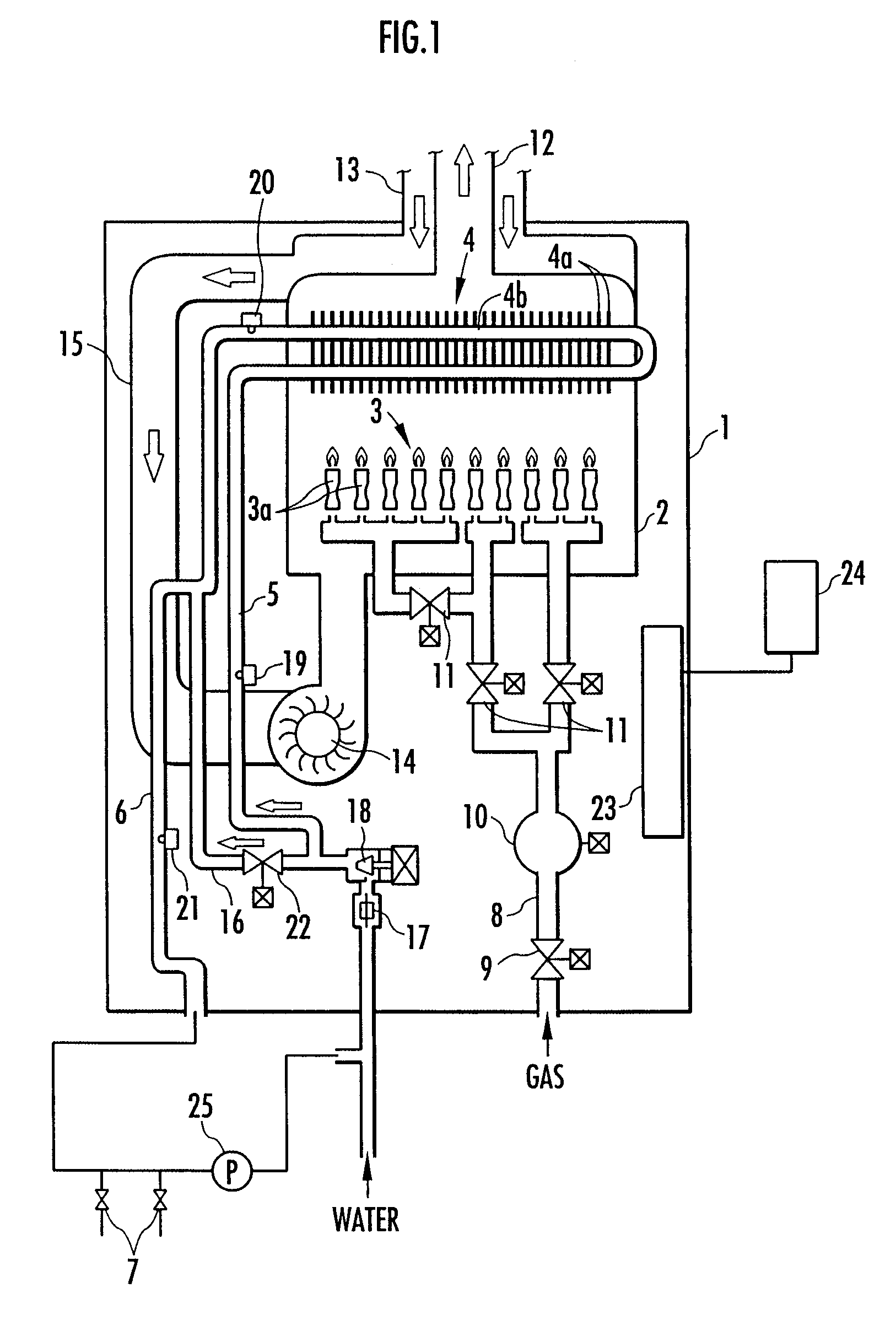

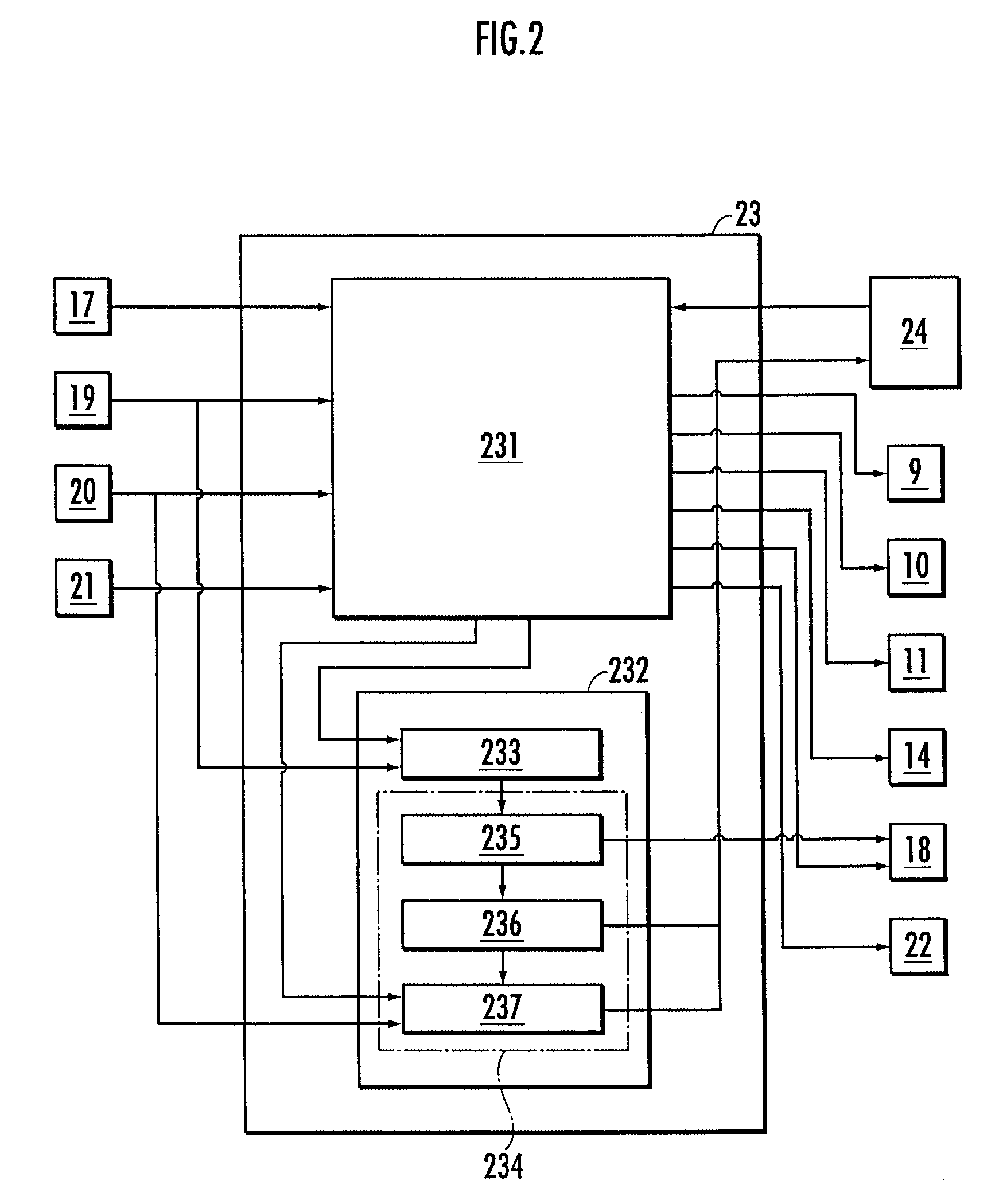

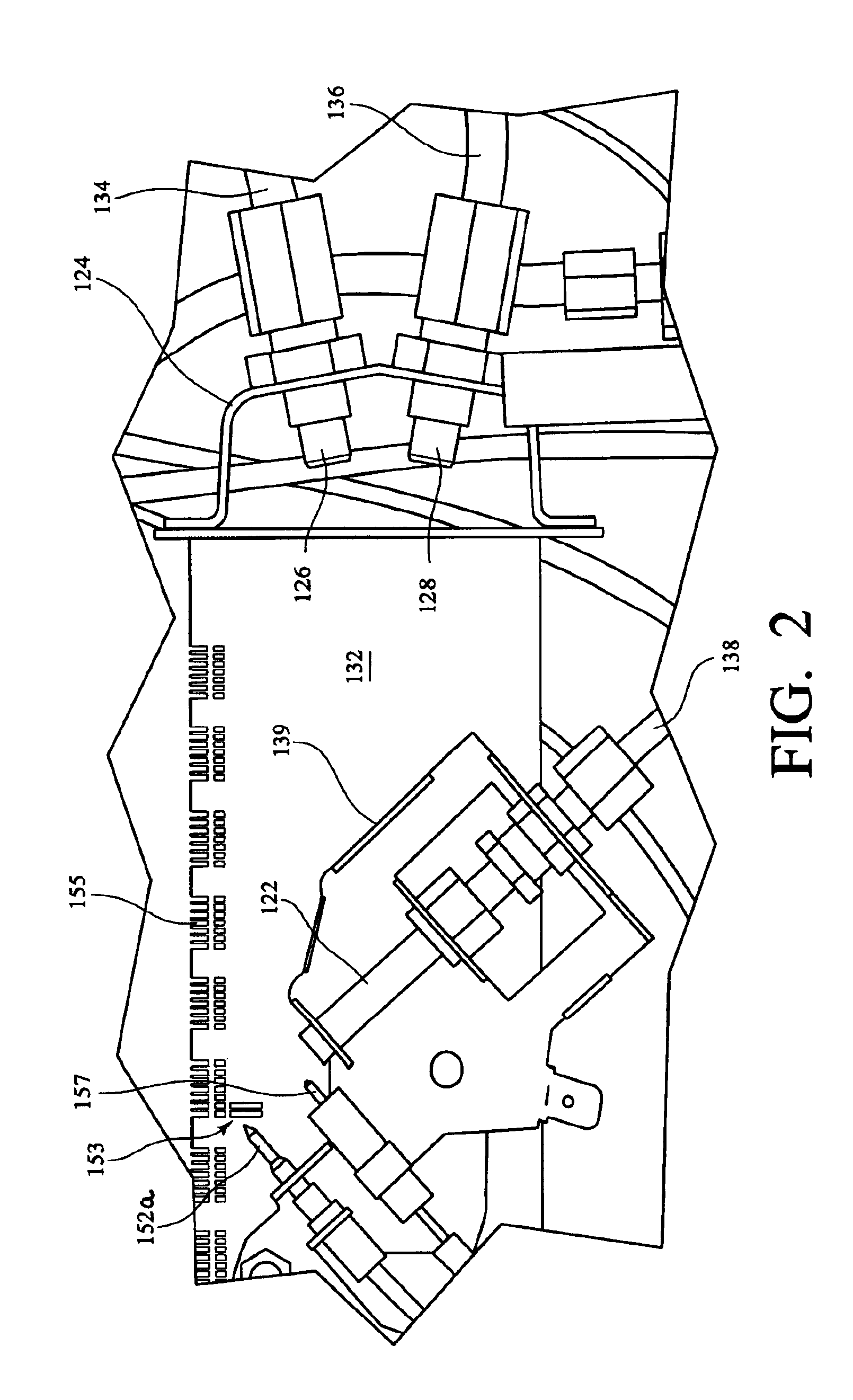

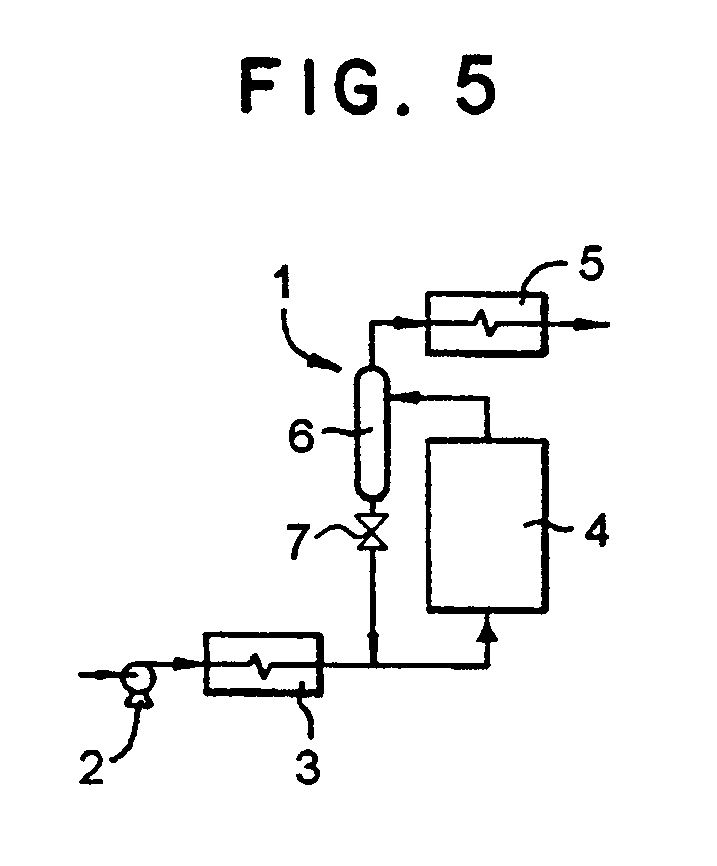

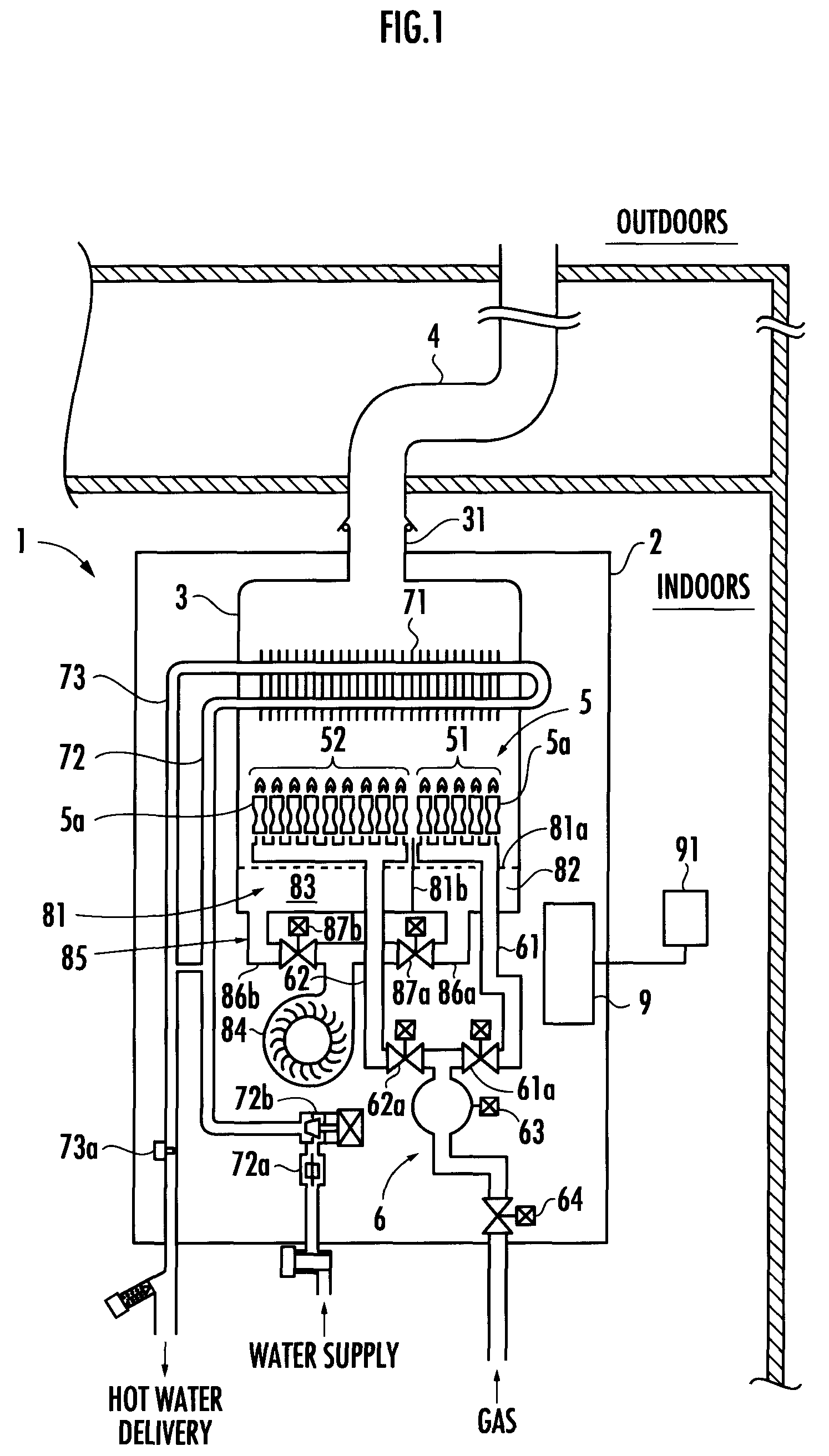

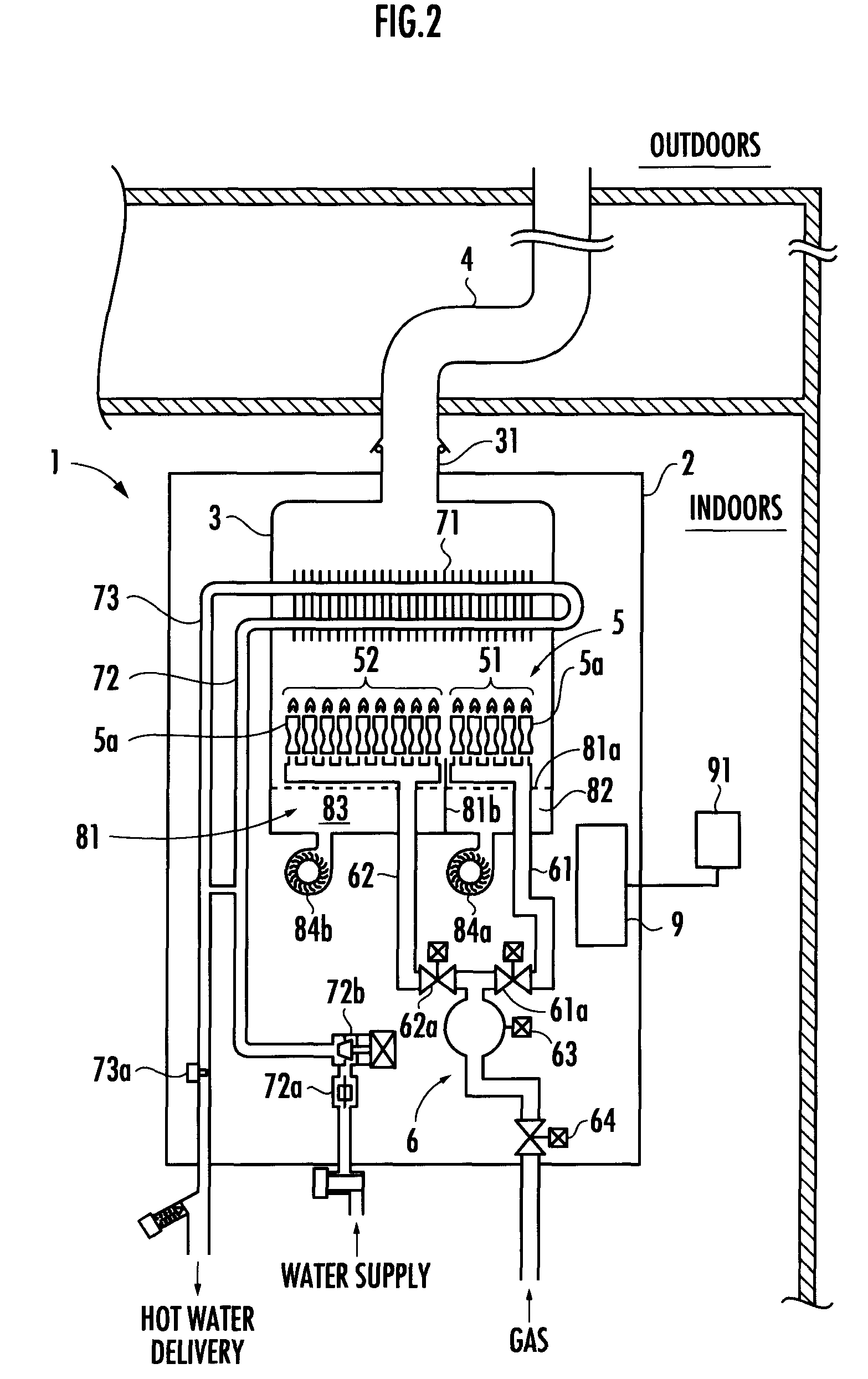

Circulation type hot water supply device

InactiveUS20070257122A1Reduce heat exchange efficiencyIncrease water temperatureFuel supply regulationWater circulationEngineeringWater supply

There is provided a circulation type hot water supply device in which a downstream end of a hot water delivering channel 6 connected to a heat exchanger 4 of a water heater 1 is connected to a water supply channel 5 upstream of the heat exchanger, and a circulating pump 25 that returns hot water fed from the heat exchanger to the hot water delivering channel to the heat exchanger through the water supply channel is provided in the hot water delivering channel. The device can reliably identify an abnormality when it occurs, such as adhesion of a deposit to an inner surface of a heat absorbing pipe 4b to reduce heat exchange efficiency. A diagnosis is started when a hot water delivering tap 7 is closed and a burner 3 is subjected to combustion. In the diagnosis, supply of water to the heat exchanger 4 is first stopped to shut down the burner 3. Then, the presence of an abnormality is determined when an amount of increase of a detection temperature from a hot water delivering temperature sensor 20 reaches a predetermined threshold value or more.

Owner:RINNAI CORP

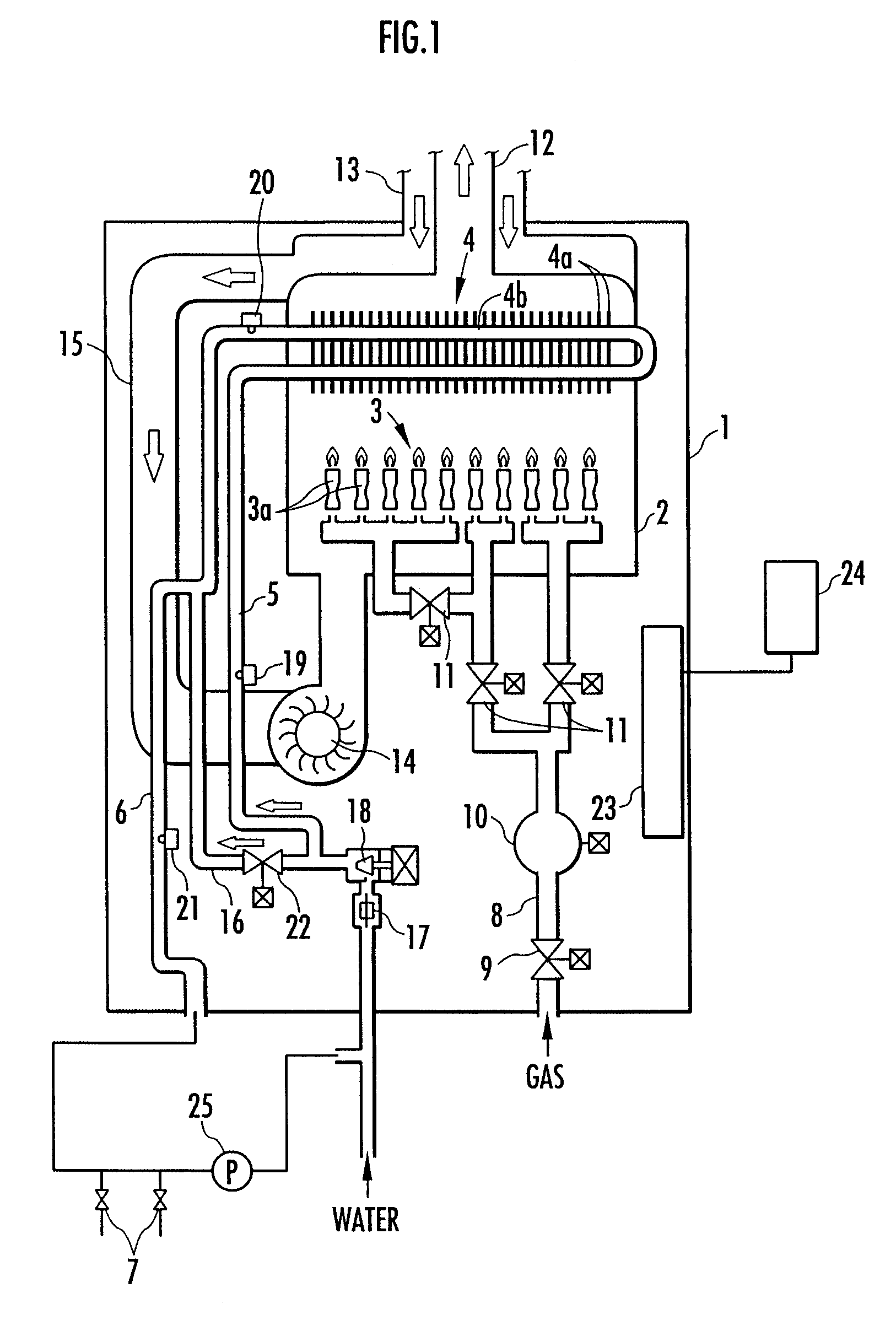

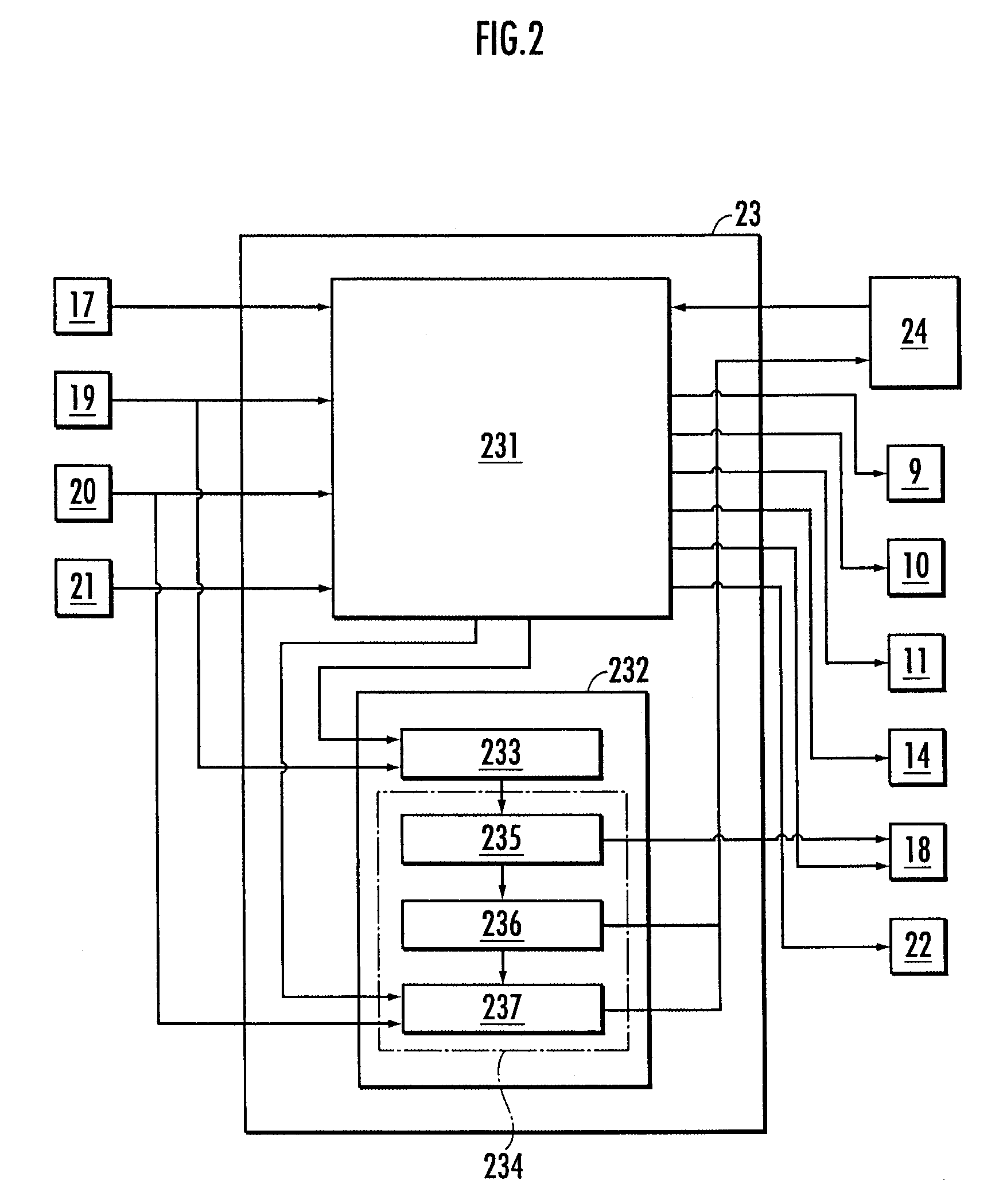

Circulation type hot water supply device

InactiveUS7597066B2Reduce heat exchange efficiencyReliable identificationFuel supply regulationWater circulationCombustorPlate heat exchanger

There is provided a circulation type hot water supply device in which a downstream end of a hot water delivering channel 6 connected to a heat exchanger 4 of a water heater 1 is connected to a water supply channel 5 upstream of the heat exchanger, and a circulating pump 25 that returns hot water fed from the heat exchanger to the hot water delivering channel to the heat exchanger through the water supply channel is provided in the hot water delivering channel. The device can reliably identify an abnormality when it occurs, such as adhesion of a deposit to an inner surface of a heat absorbing pipe 4b to reduce heat exchange efficiency. A diagnosis is started when a hot water delivering tap 7 is closed and a burner 3 is subjected to combustion. In the diagnosis, supply of water to the heat exchanger 4 is first stopped to shut down the burner 3. Then, the presence of an abnormality is determined when an amount of increase of a detection temperature from a hot water delivering temperature sensor 20 reaches a predetermined threshold value or more.

Owner:RINNAI CORP

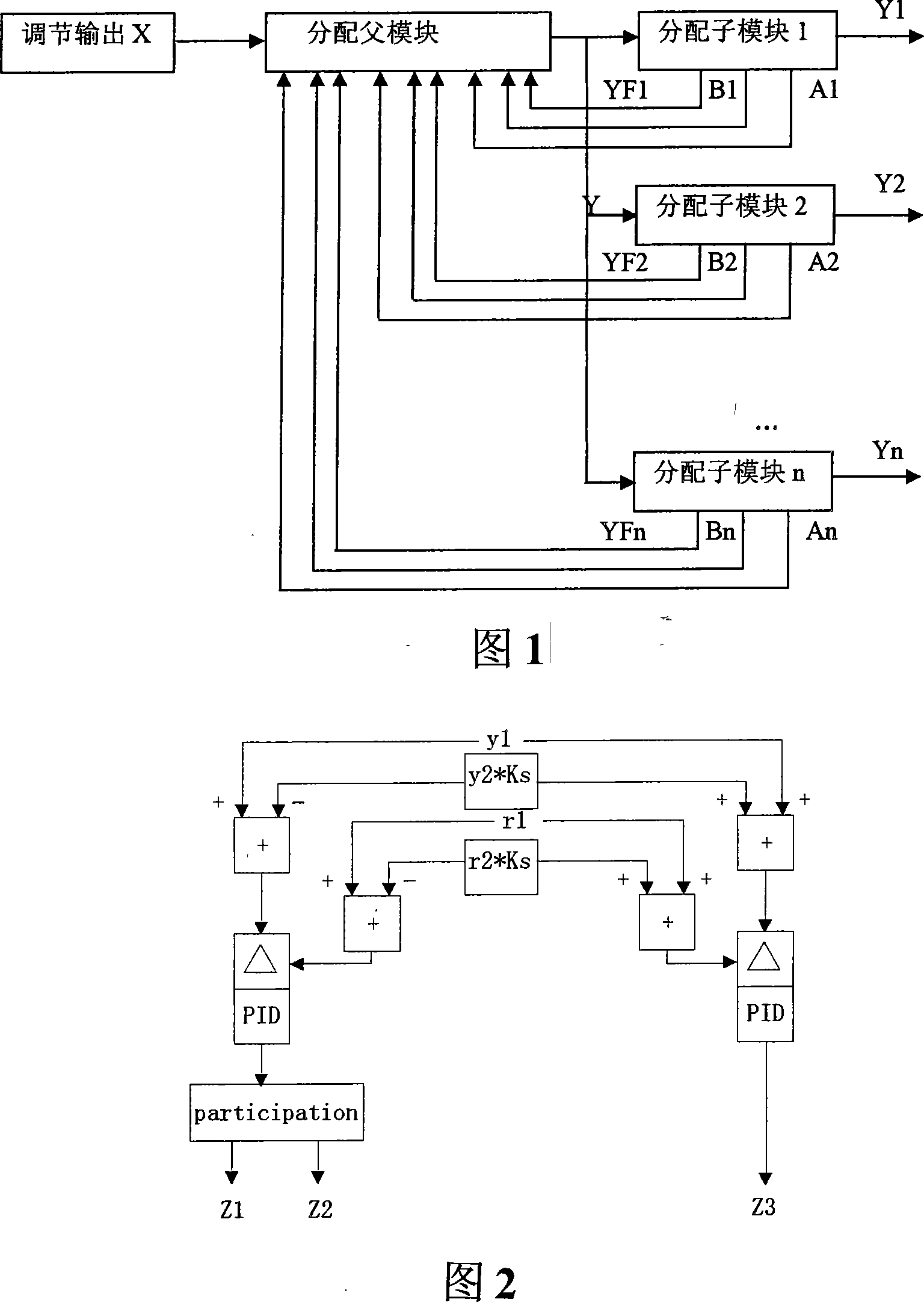

Automatic control method of 300 MW grading circulating fluidized bed units

ActiveCN101225955AKeep the economy runningAvoid cokingFluidized bed combustionLiquid fuel feeder/distributionAir volumeAutomatic control

The invention relates to an automatic control method of 300MW grade circulating fluid bed unit, which sets the automatic control methods for the coordination of machine and furnace, the deviation of single bed pressure and double bed pressure, the water level of the deaerator and the condenser, the secondary air quantity / oxygen quantity and the secondary air pressure, the boiler bed temperature, the fuel flow and the limerock feeding during making the first 300 MW circulating fluid bed unit as the localization of manufactures, meanwhile, the 300 MW circulating fluid bed unit has the advantages of stable operation, safety, reliable and remarkable economic operation passing through the coordination and control for the system.

Owner:云南电力试验研究院(集团)有限公司

Dual fuel vent free gas heater

ActiveUS8057219B1Enhanced natural convectionDomestic stoves or rangesLiquid heating fuelControl systemControl valves

A dual fuel vent free gas heater having at least one gas burner with a plurality of gas outlet ports. The gas outlet ports are in flow communication with at least one pilot flame burner. At least one fuel injector feeds fuel to the burner providing for introduction of more than one fuel to the burner. Optionally, an oxygen detection system, manual control valve, linkage, and / or shut off control system may be incorporated into the dual fuel vent free heater.

Owner:COPRECITEC

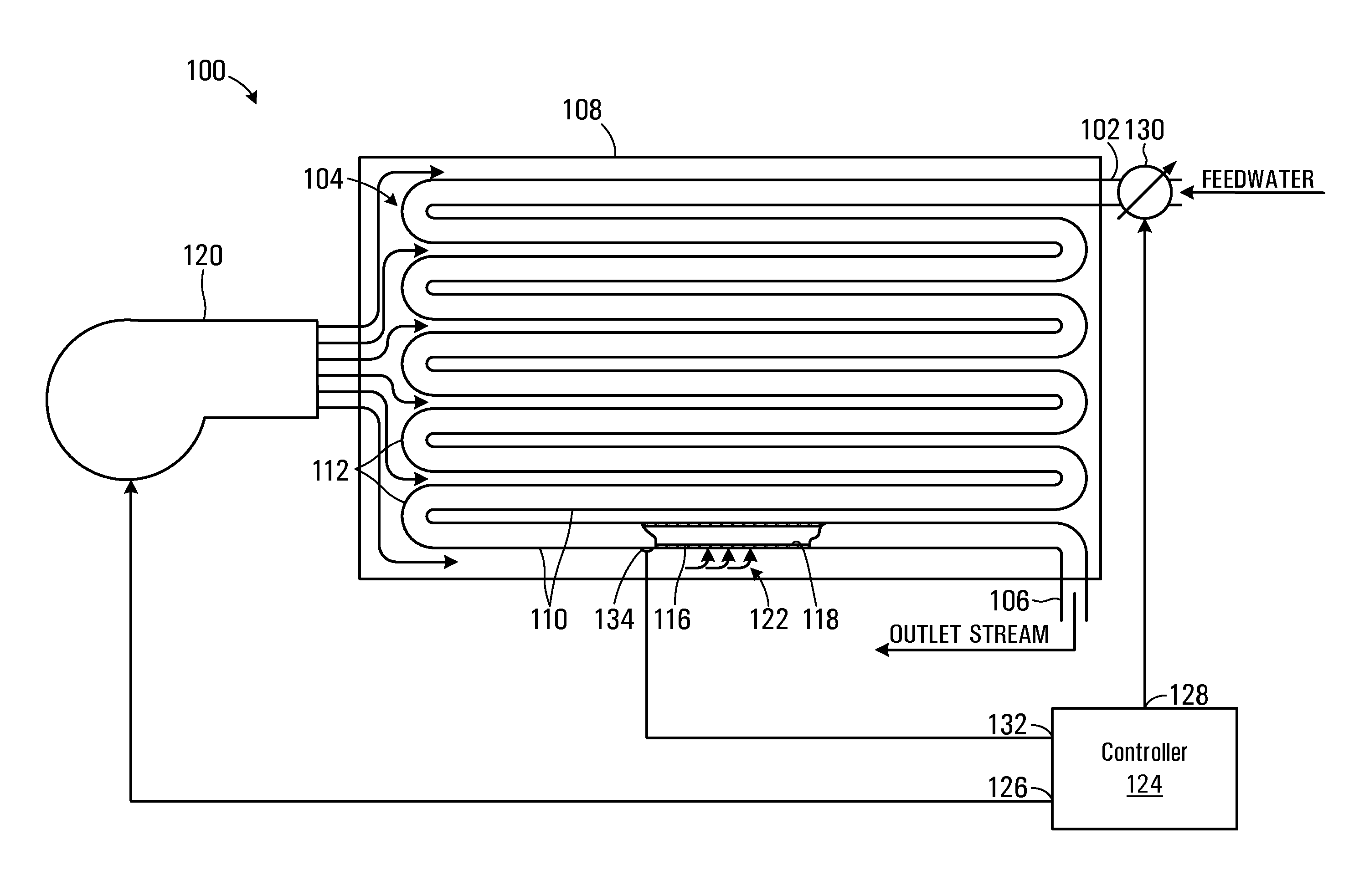

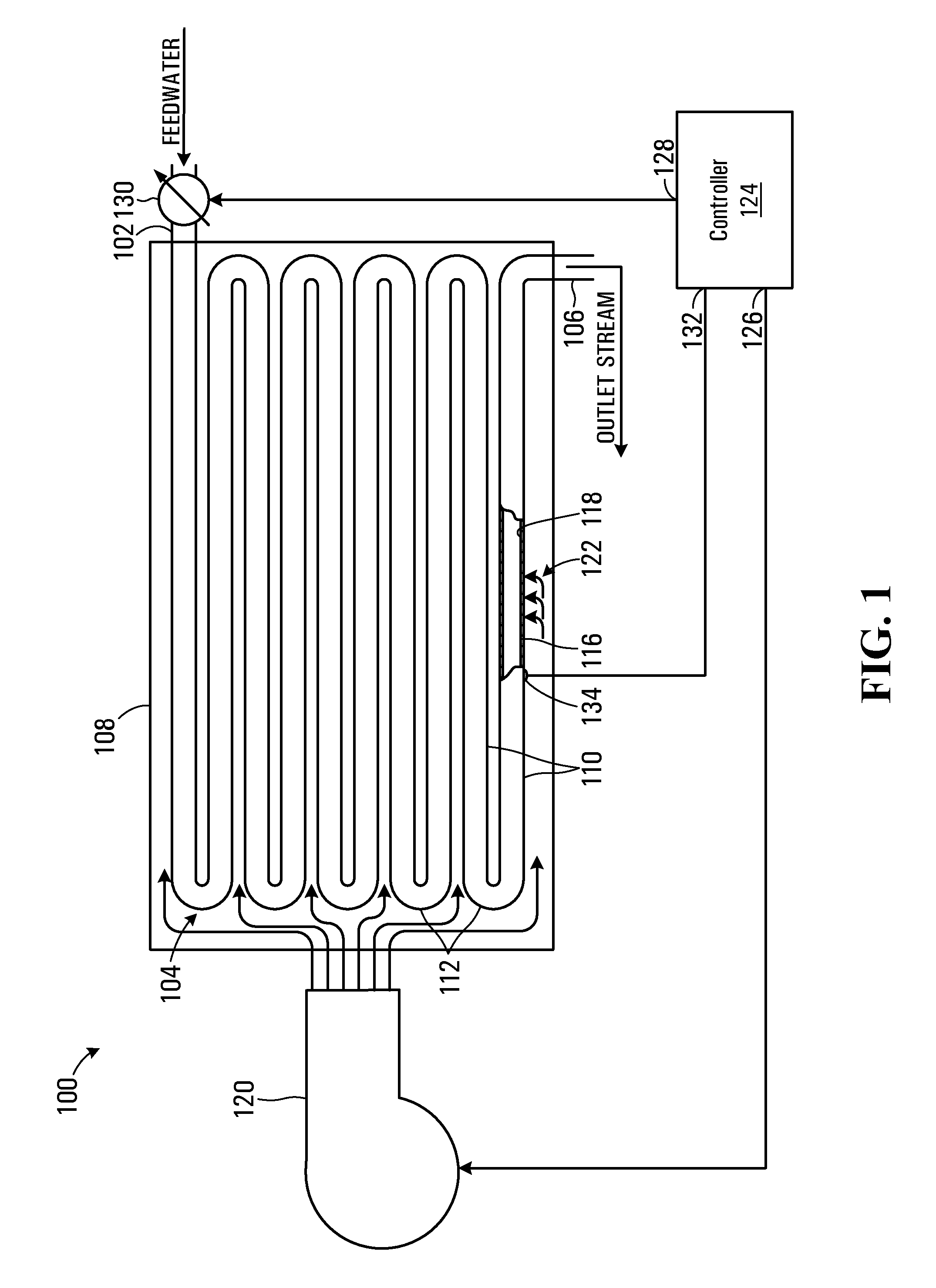

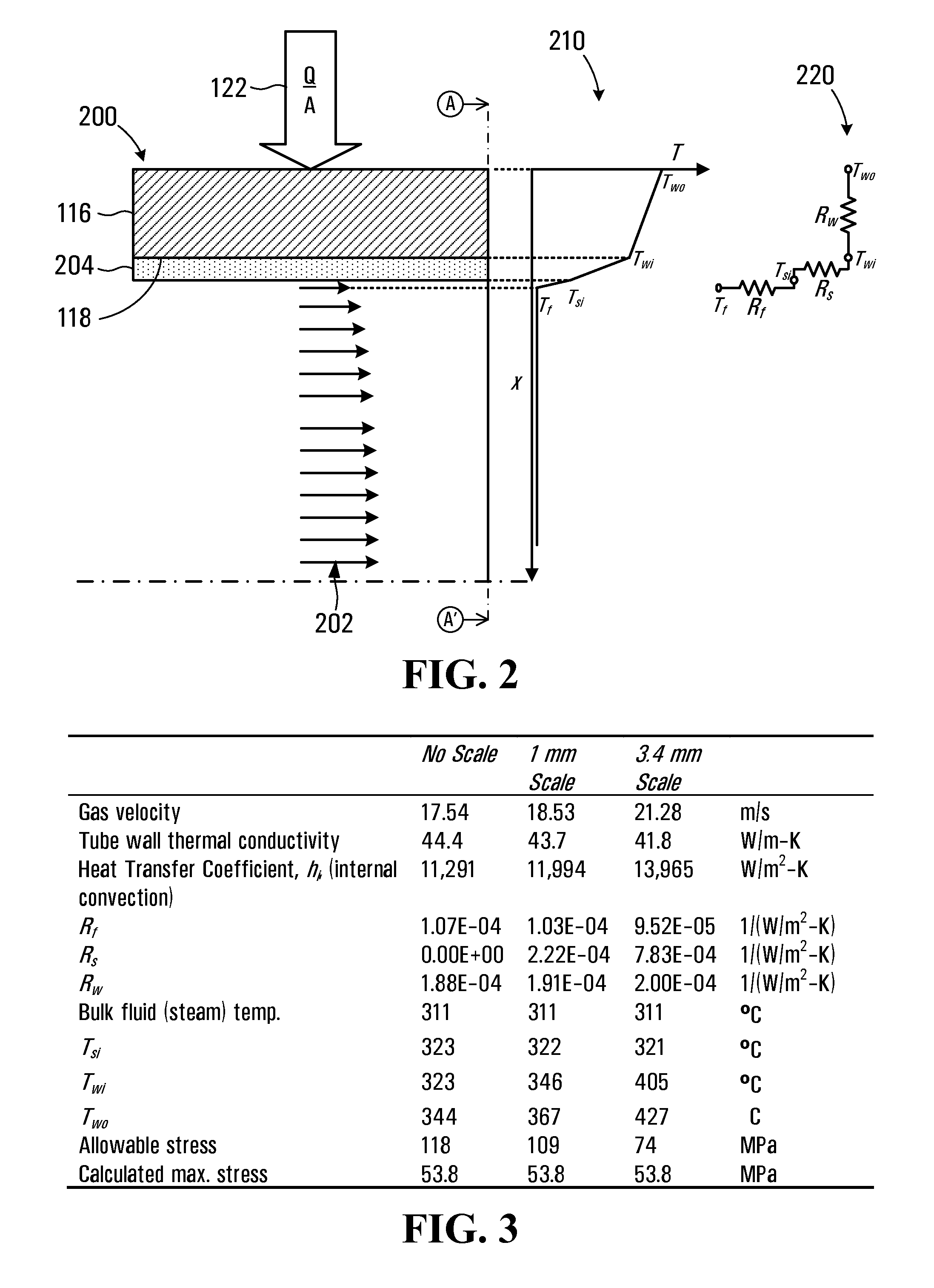

Steam generator and method for generating steam

ActiveUS20130161009A1Improve cooling effectReduce problem sizeBoiler water tubesBoiler cleaning apparatusHeat fluxEvaporation

A method for generating steam from a feedwater inlet stream including impurities is disclosed. The method involves receiving the feedwater inlet stream at an inlet of a steam generator and causing the feedwater stream to flow through a tubing circuit to an outlet of the tubing circuit, the tubing circuit having a substantially un-rifled bore defined by a metal wall. The method also involves delivering a heat flux to the feedwater stream through the metal wall of the tubing circuit to generate steam by causing evaporation of feedwater within the tubing circuit, and controlling at least one of a flow rate of the feedwater stream and the heat flux to cause generation of an outlet stream at the outlet includes a steam portion and liquid phase portion, the steam portion being greater than about 80% of the outlet stream by mass. The steam portion provides sufficient cooling of the metal wall to maintain a wall temperature at less than a threshold temperature.

Owner:FCCL PARTNERSHIP

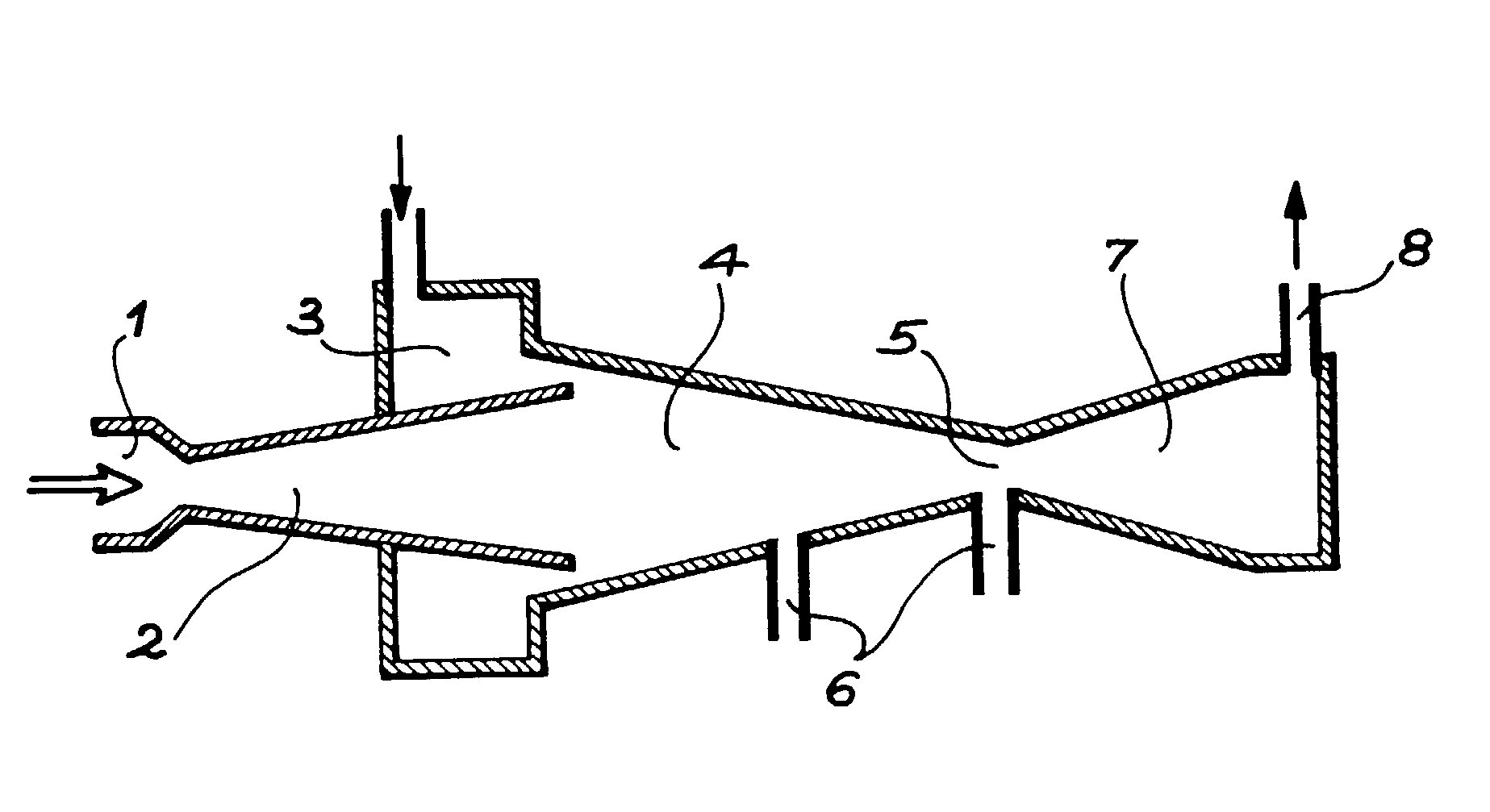

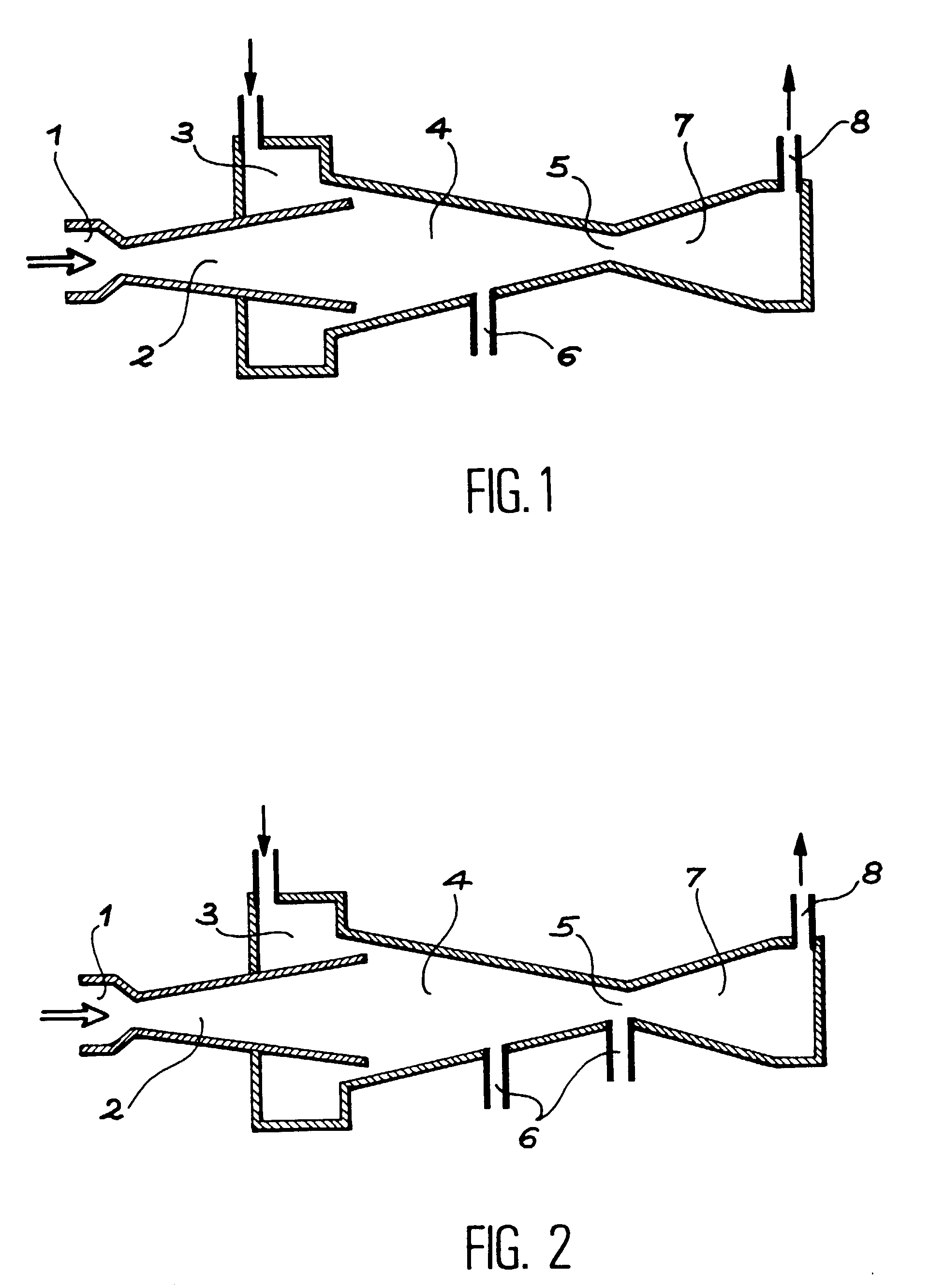

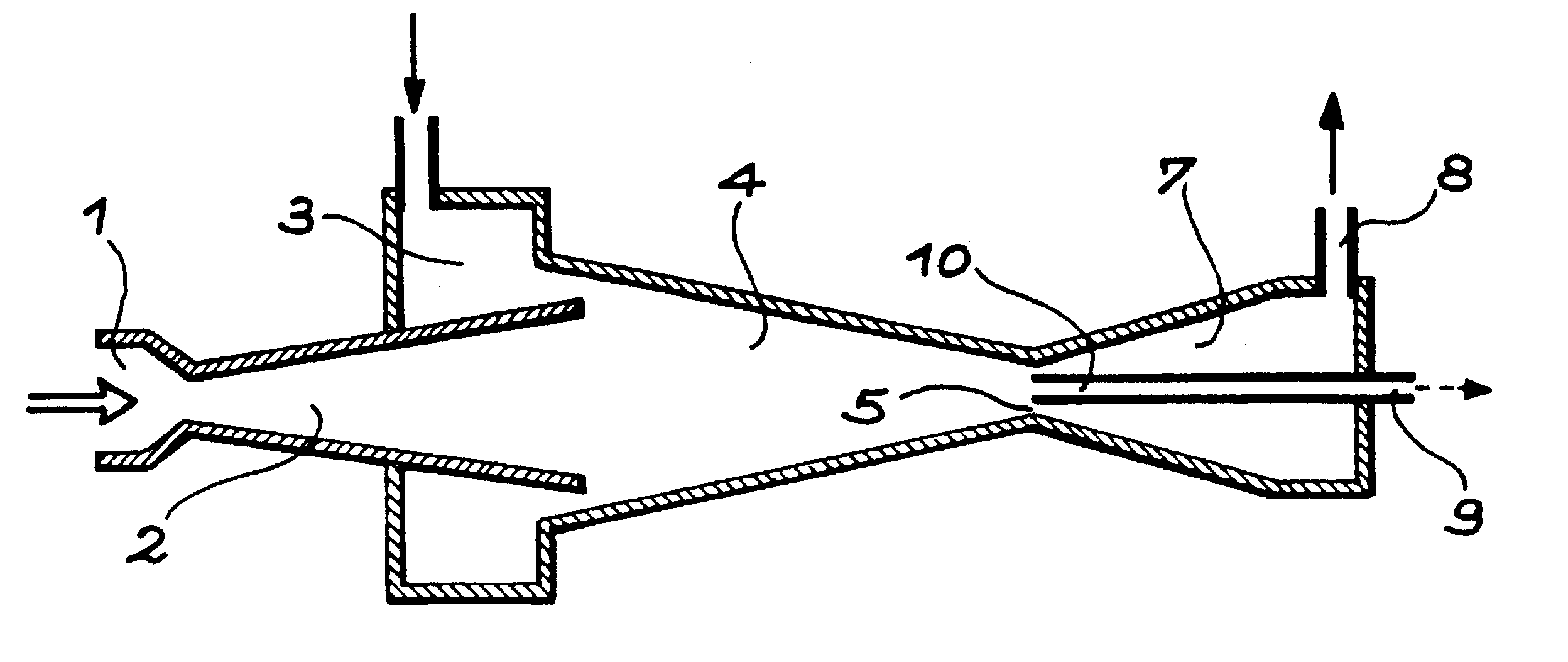

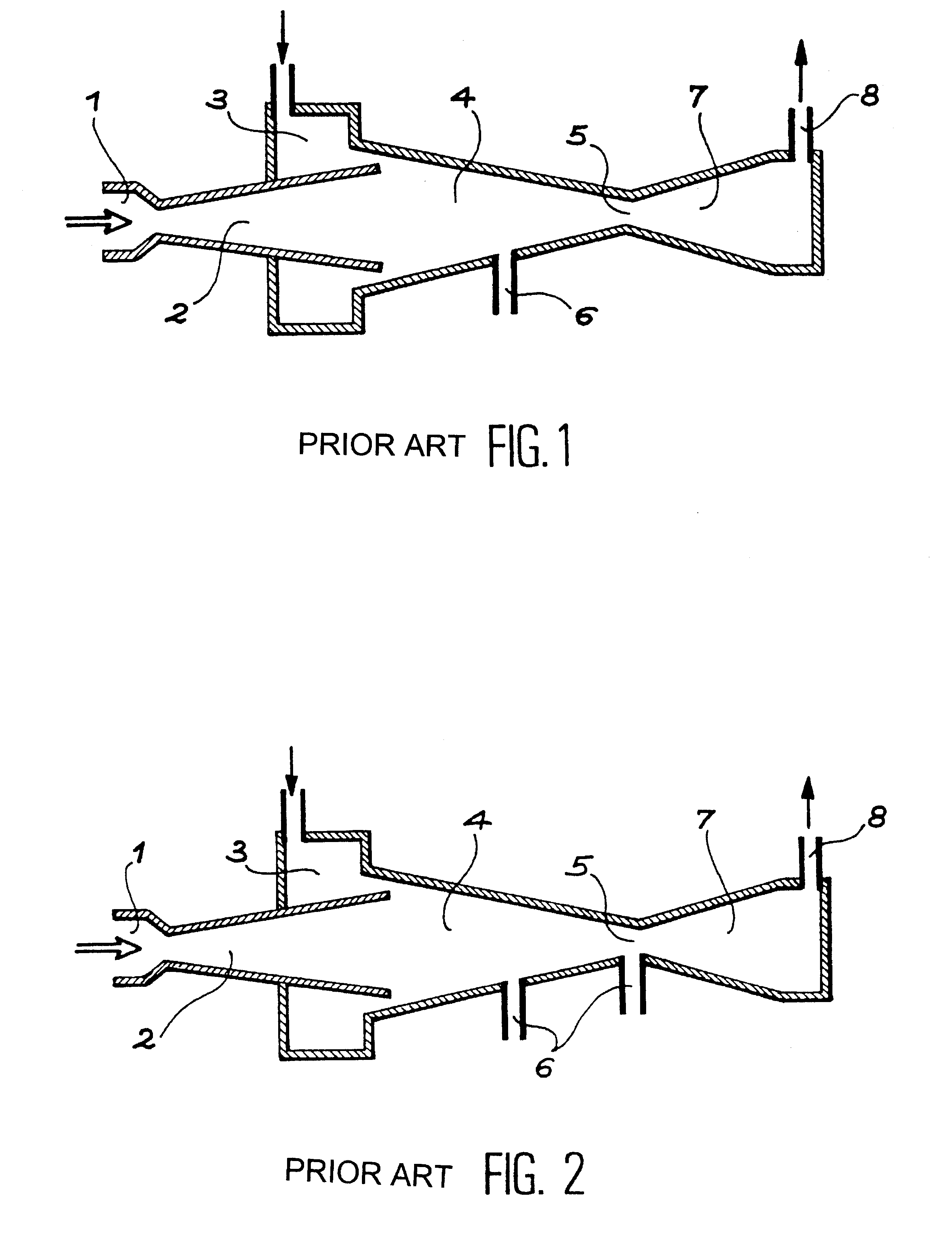

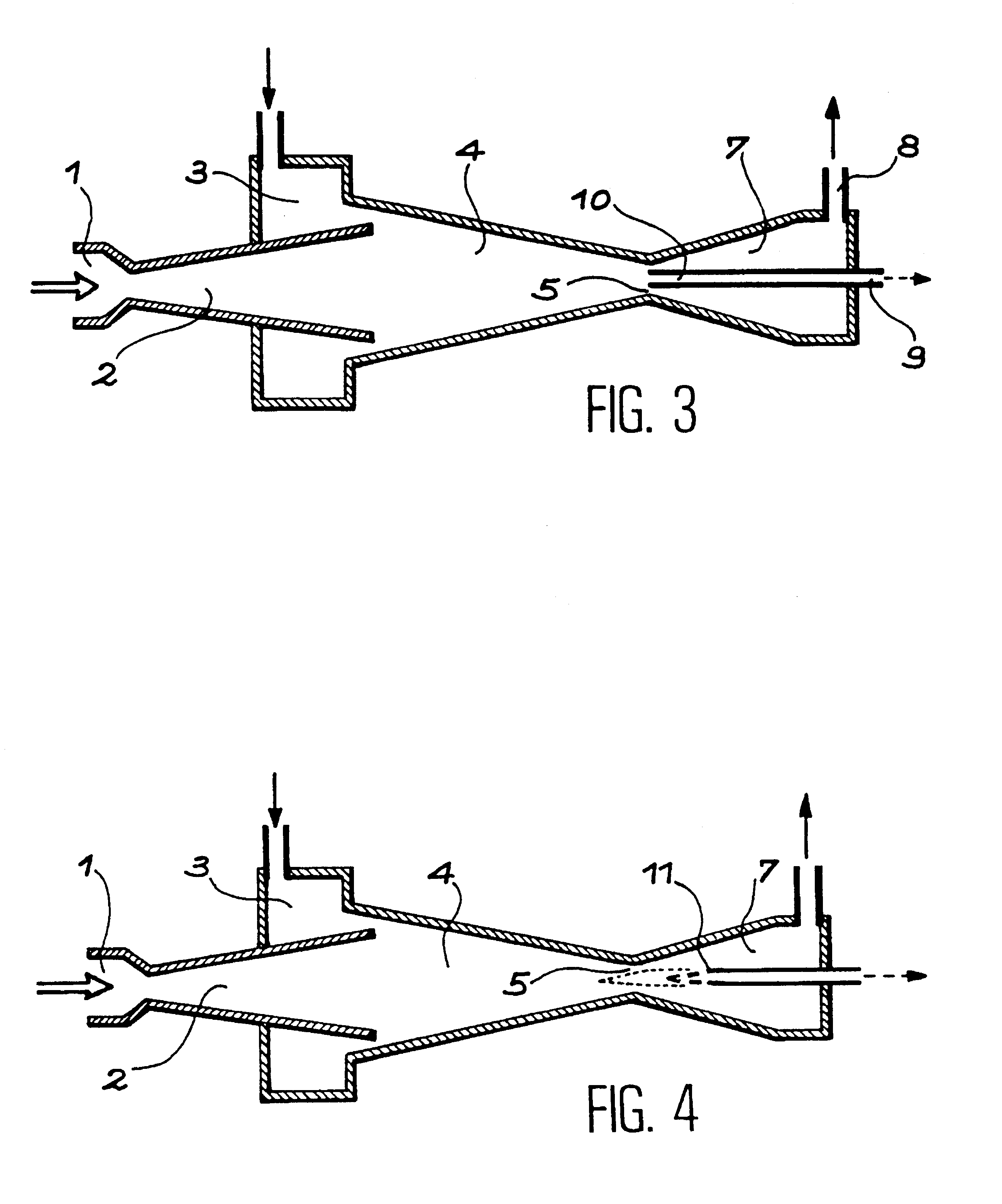

High pressure steam water injector comprising an axial drain

InactiveUS20020162518A1Increase the maximum pressureLow sectionFlow mixersWater circulationNuclear reactorHigh pressure

The steam injector is characteristic in its high pressure and improved start-up. It uses an axial drain (10) positioned in the centre of the neck (5) downstream from the mixing chamber (4) and inserted in the diffuser (7) for the purpose of narrowing the section of the neck (5) and evacuating a large part of the steam which has not been condensed. The axial drain (10) may be mounted so that it is axially mobile. Application to the water supply for steam generators in pressurized water nuclear reactors.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

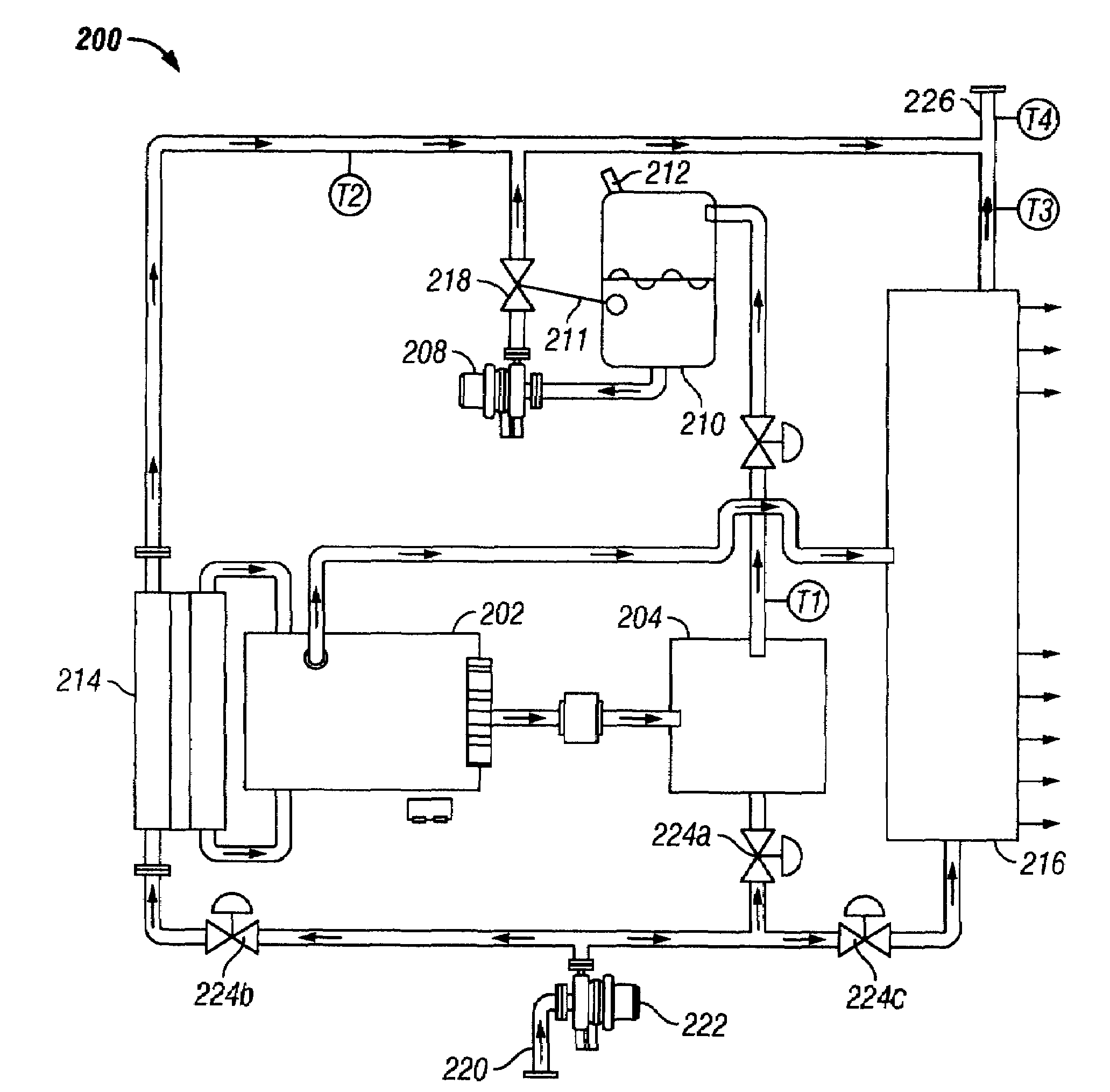

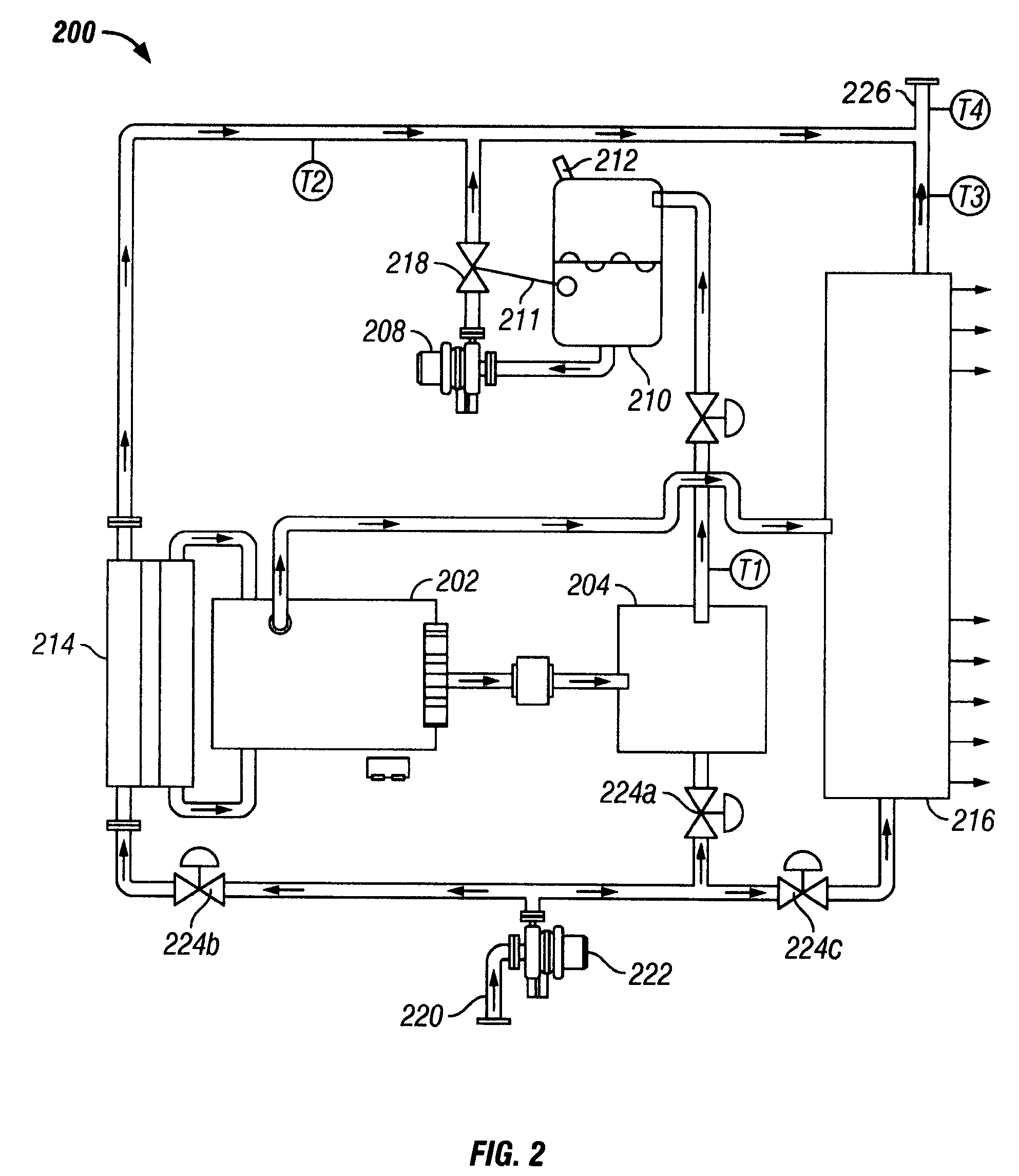

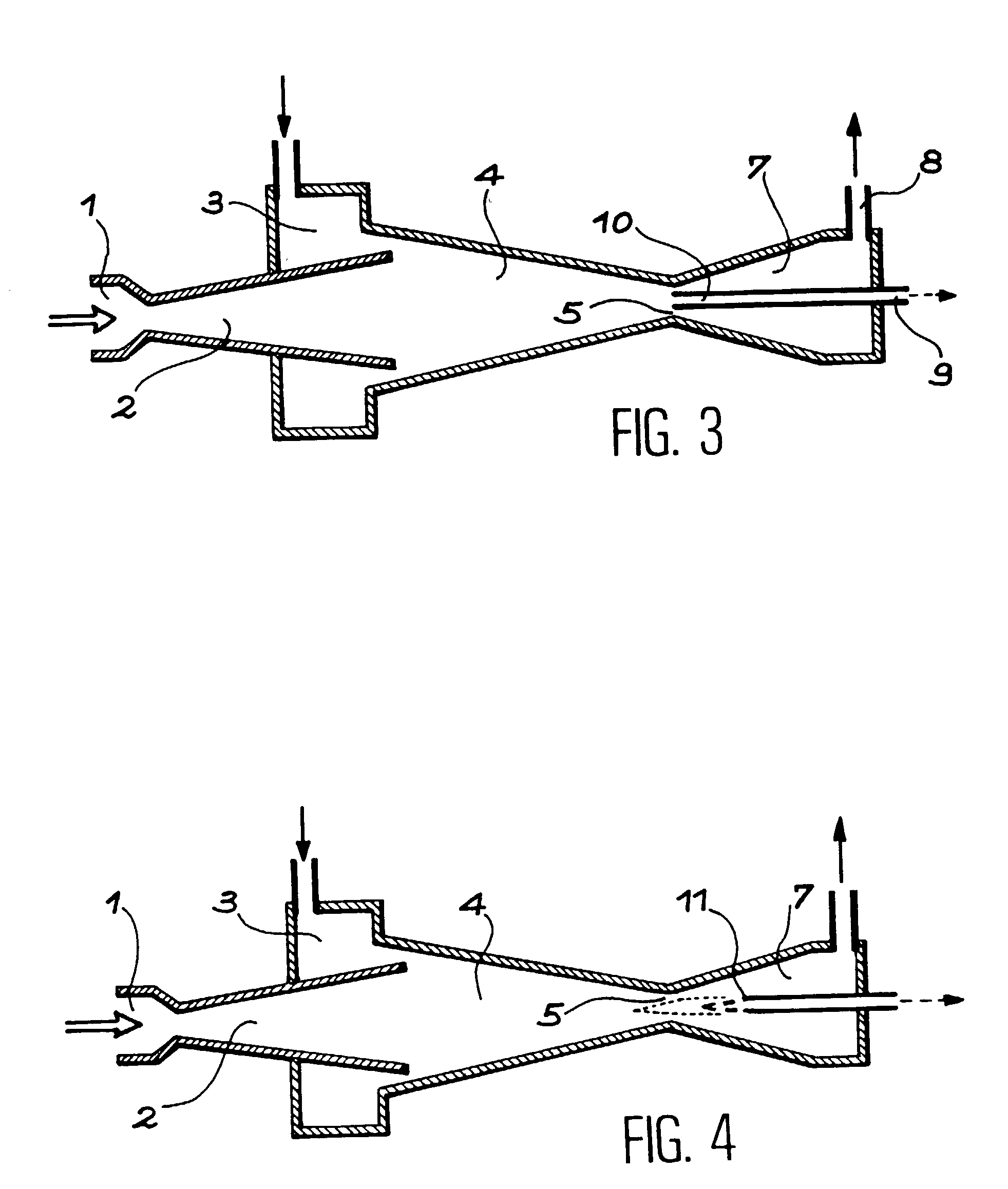

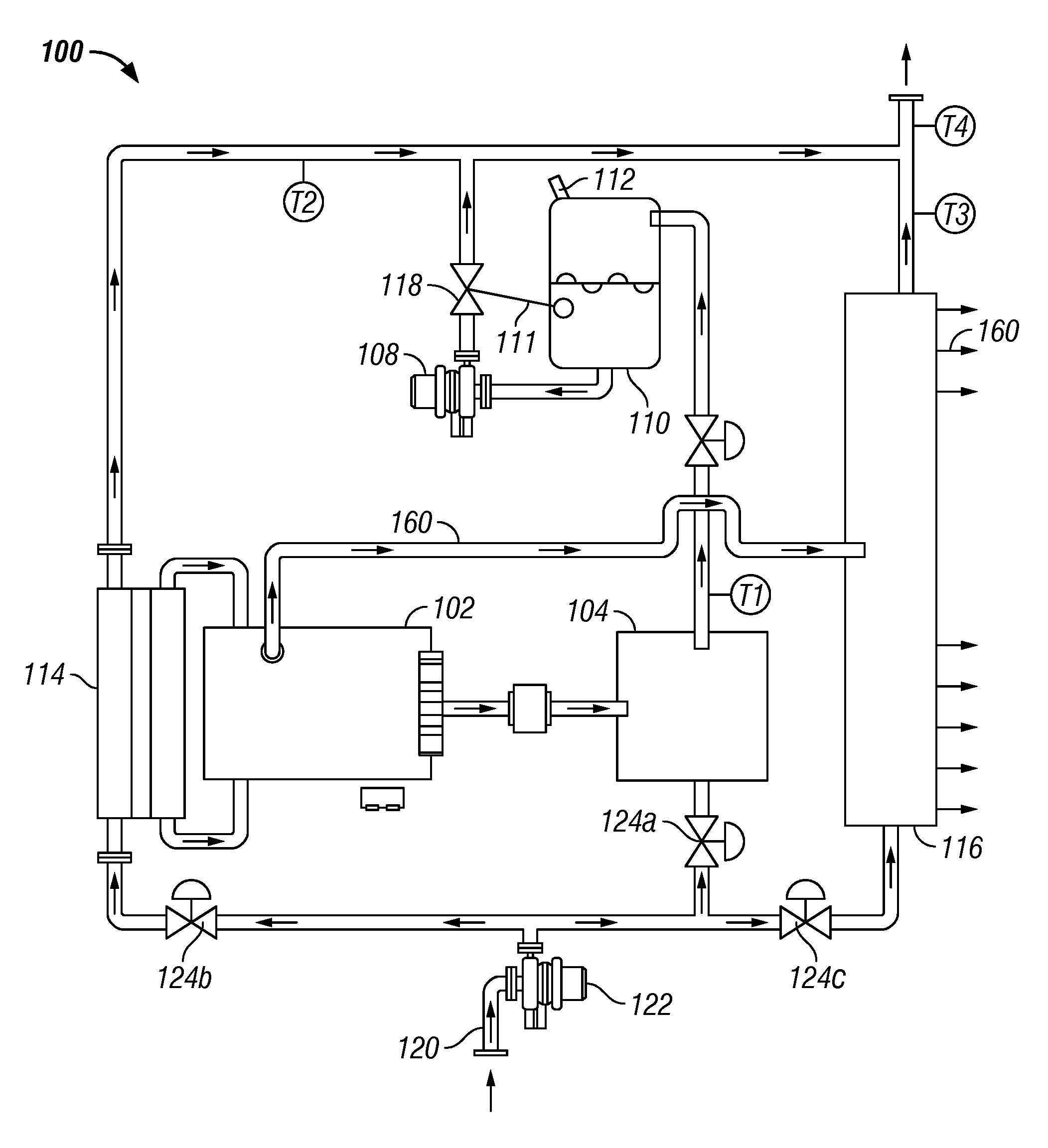

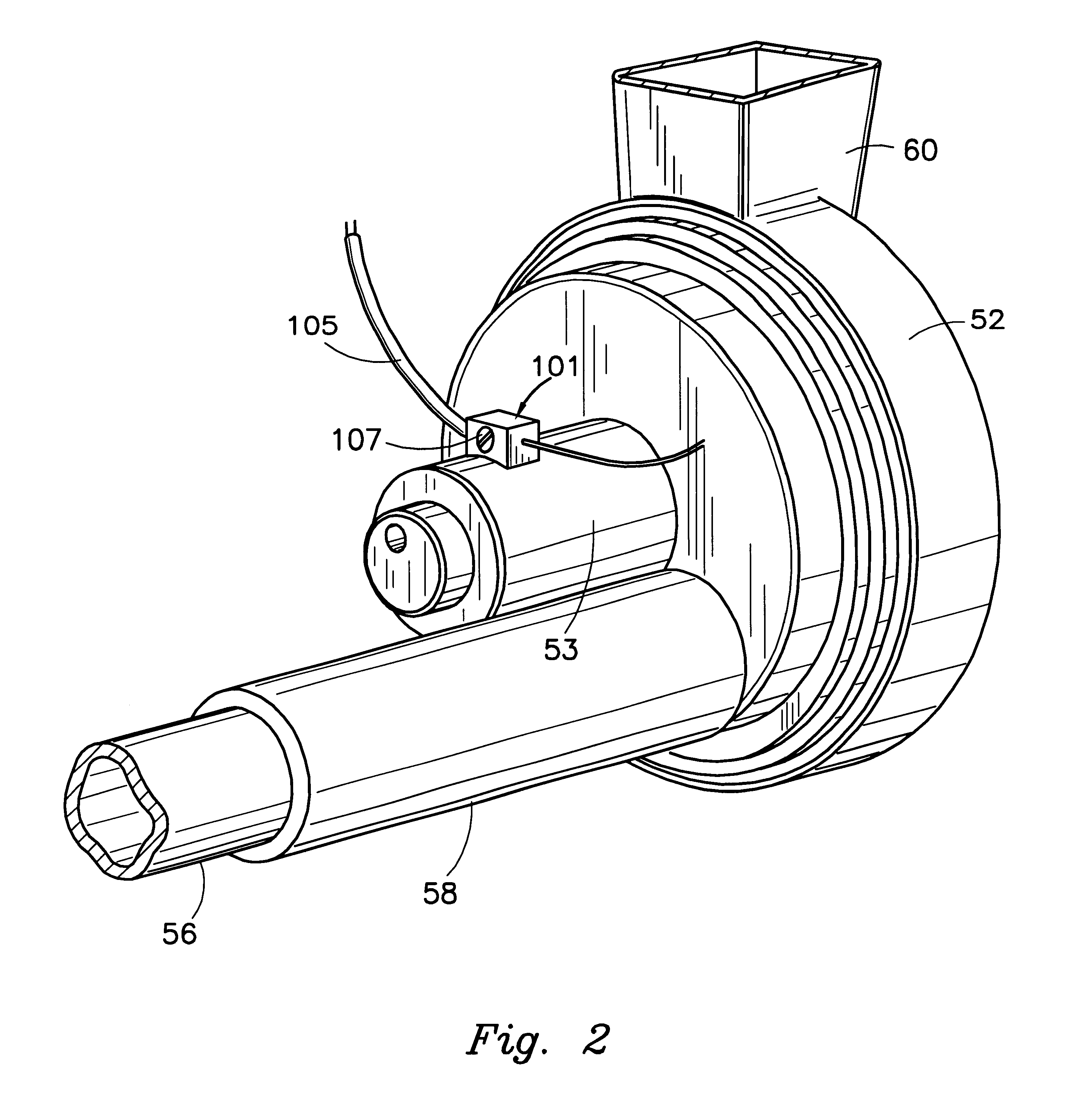

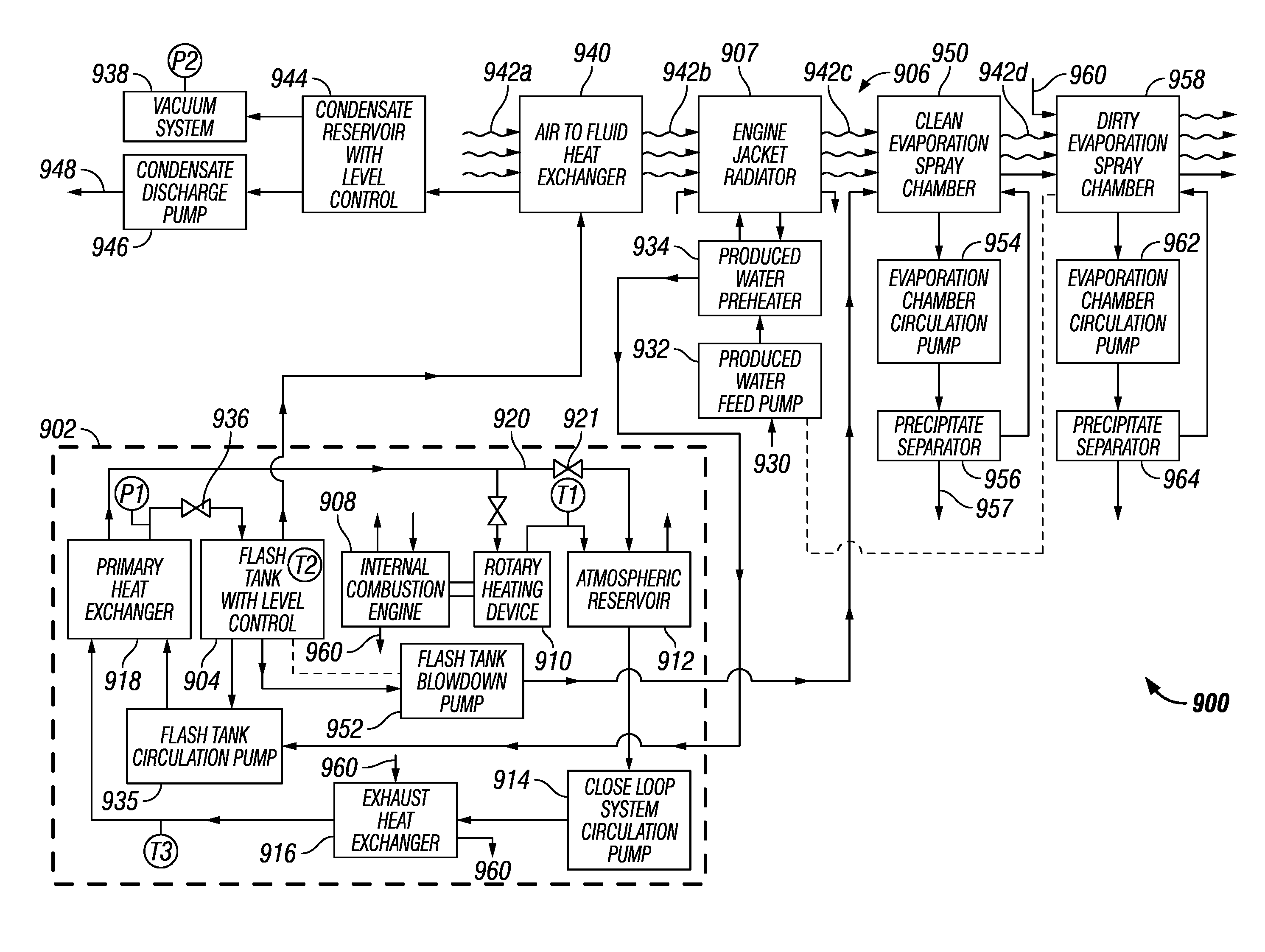

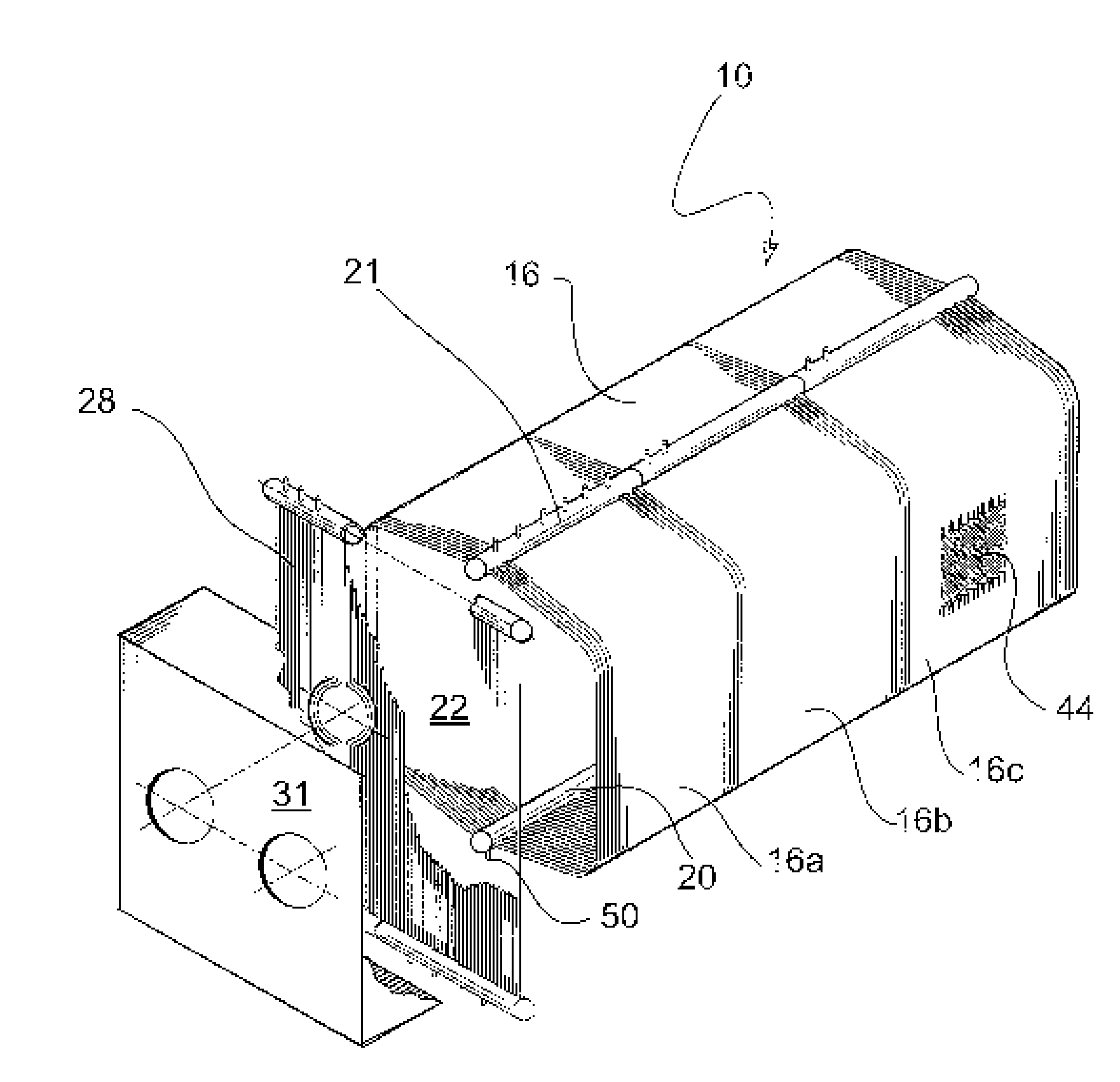

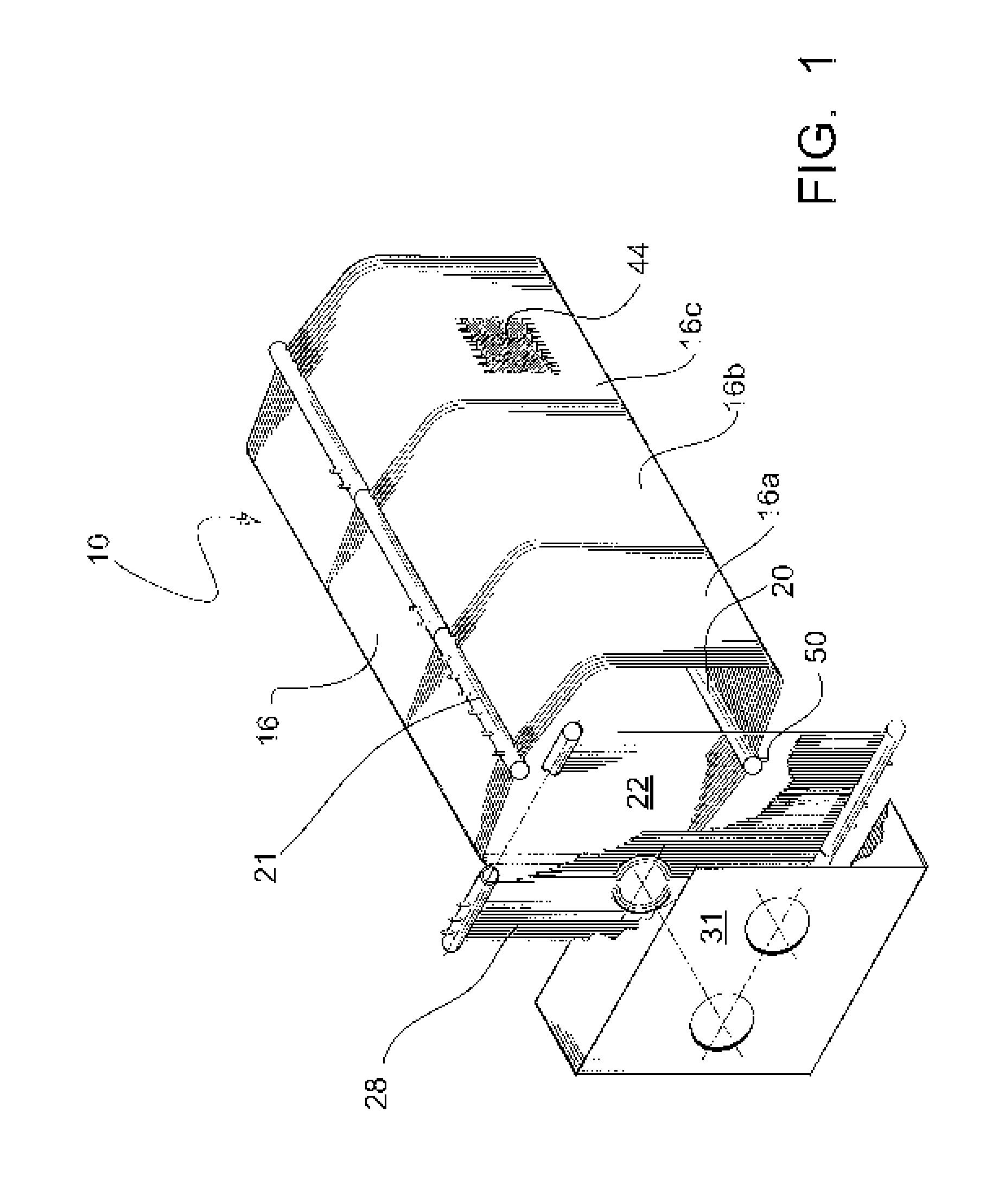

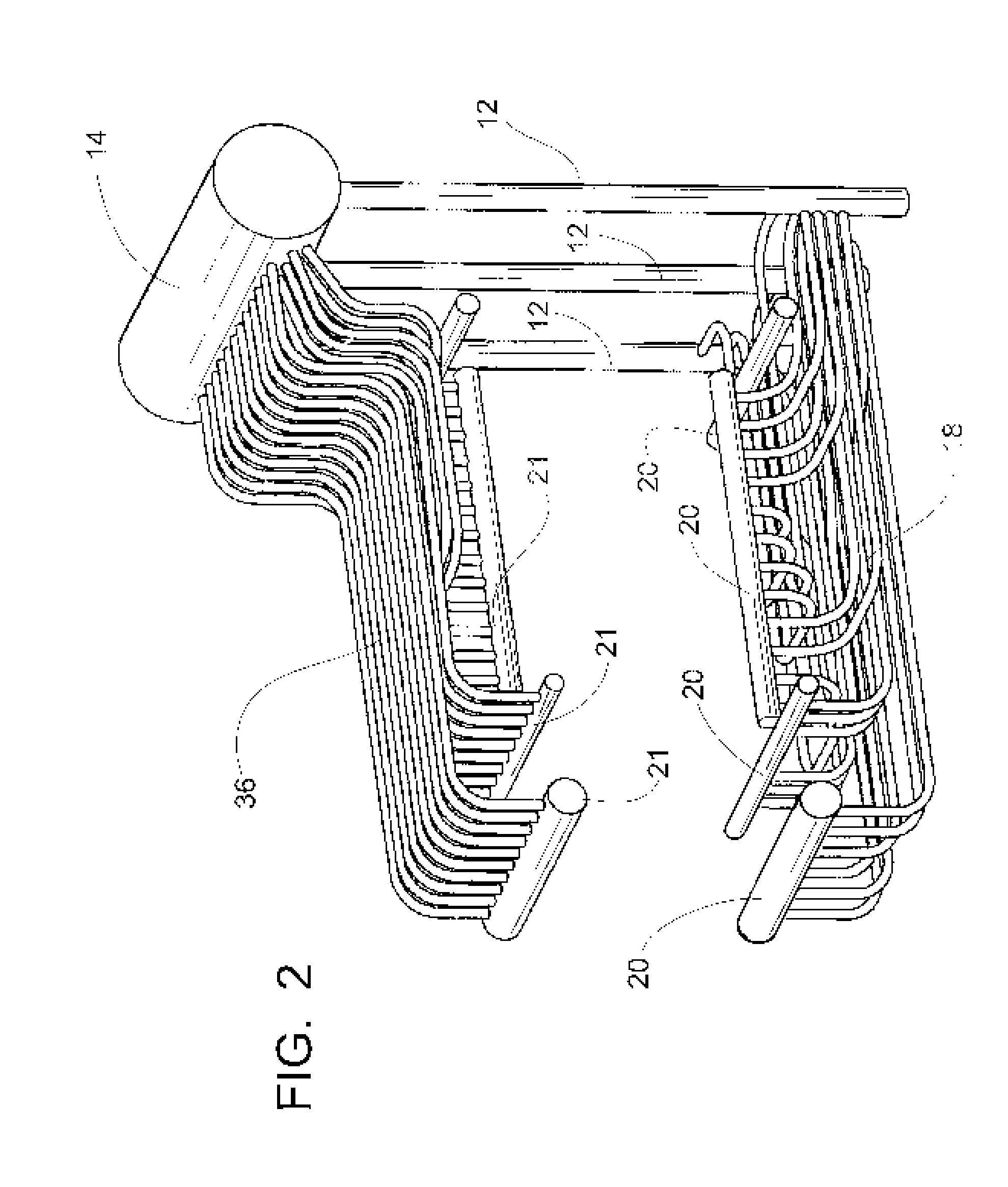

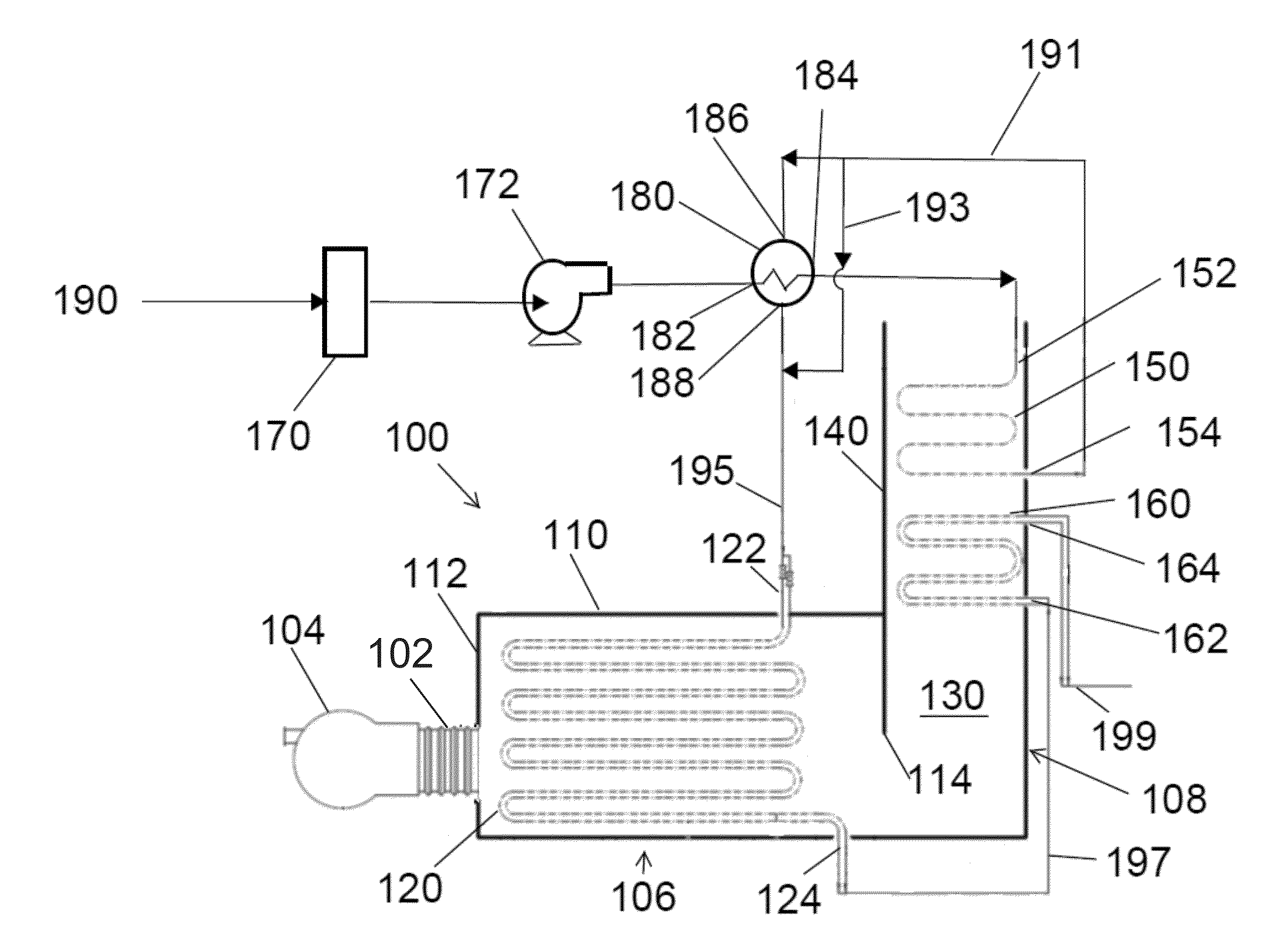

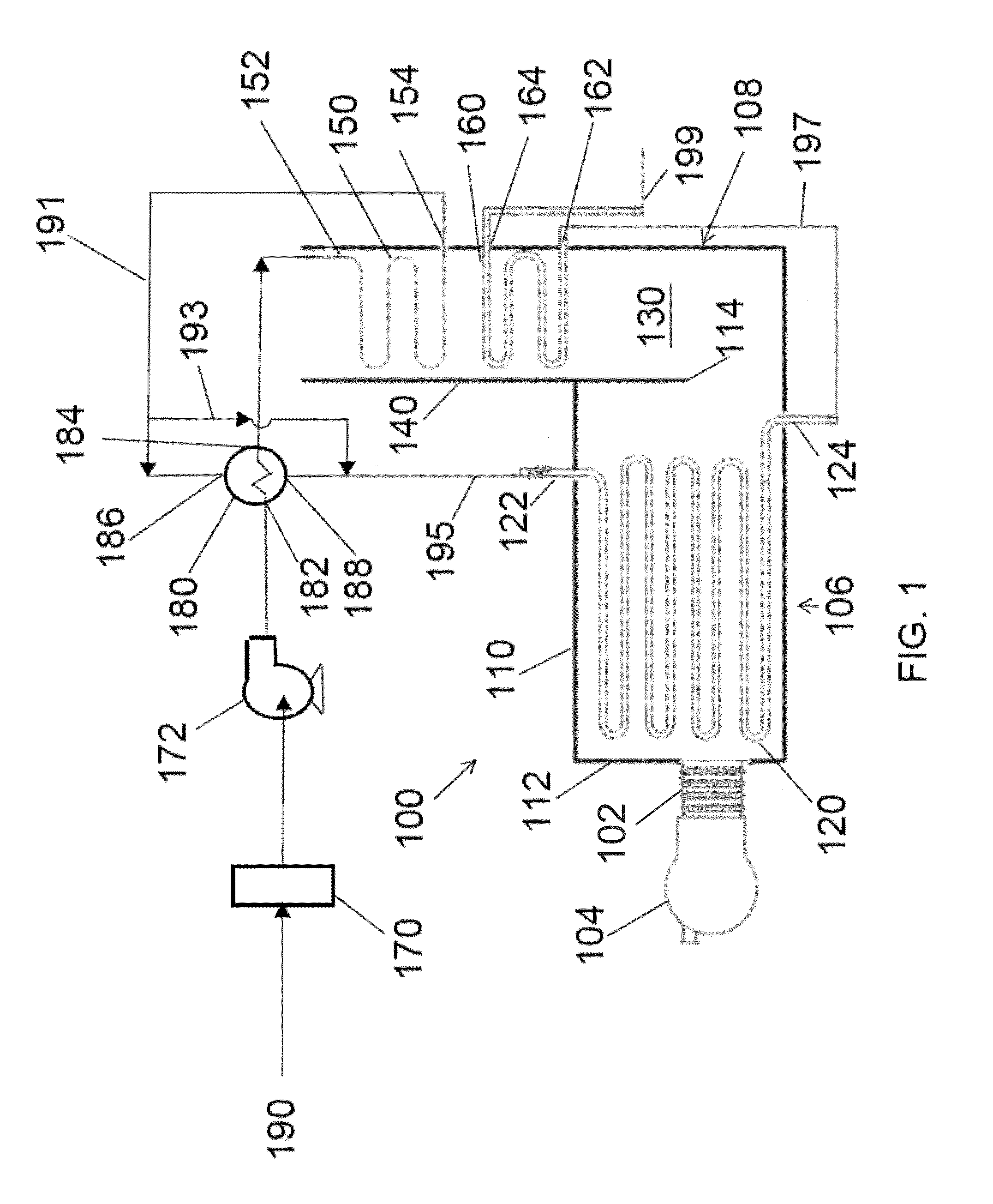

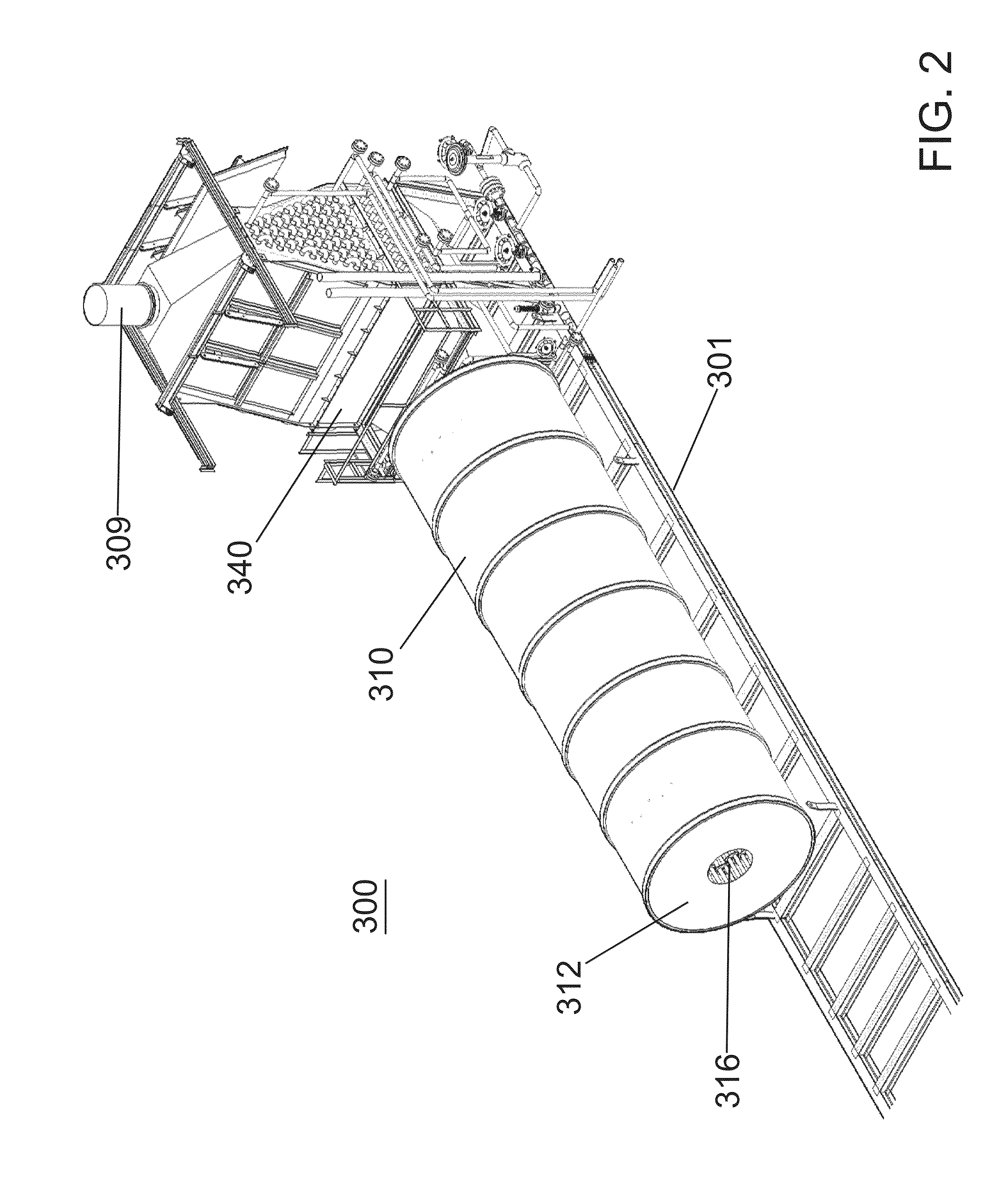

Methods and apparatuses for heating, concentrating and evaporating fluid

InactiveUS20100154395A1Steam generation using mechanical energyAir-treating devicesWater brakeClosed loop

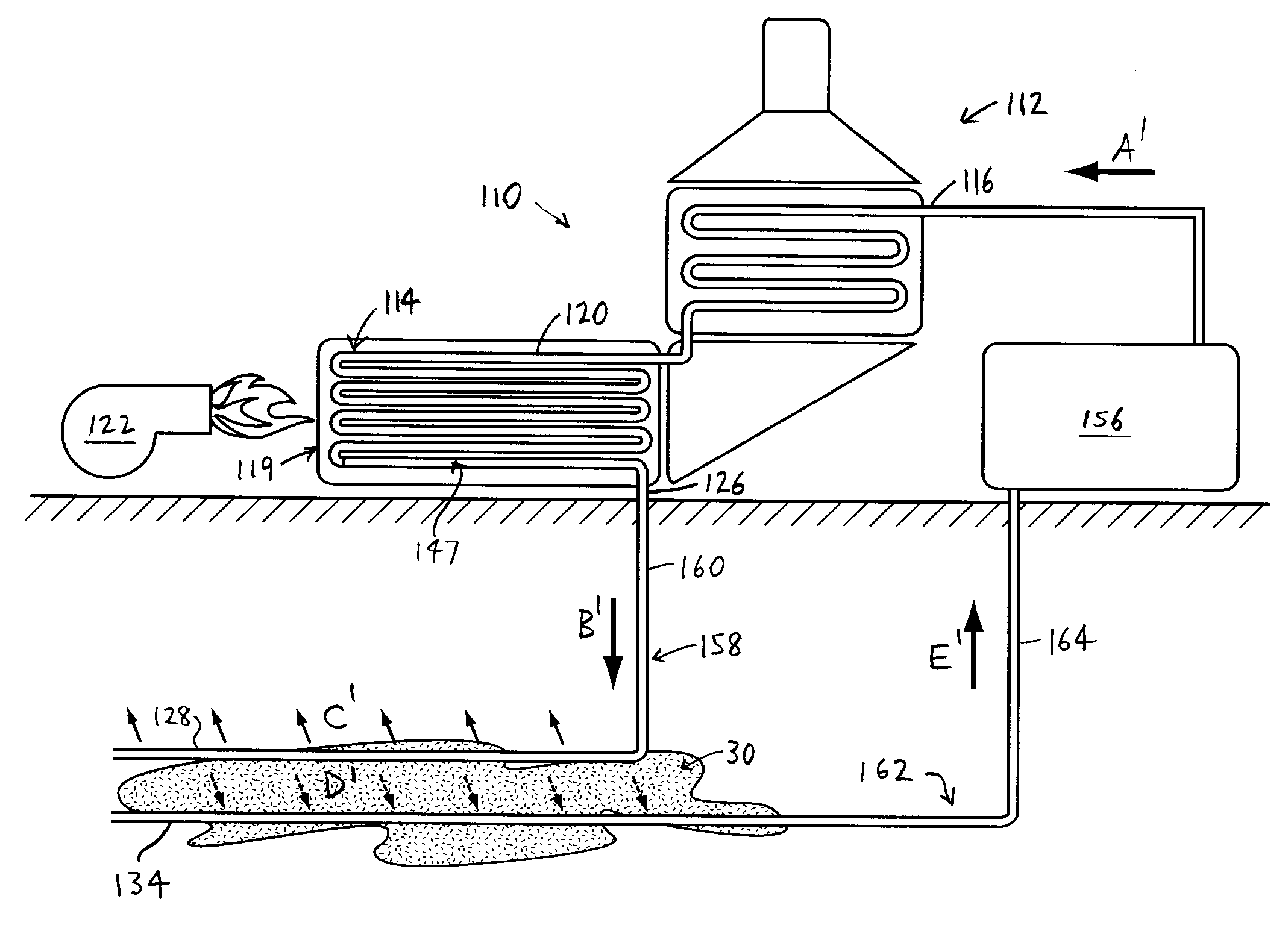

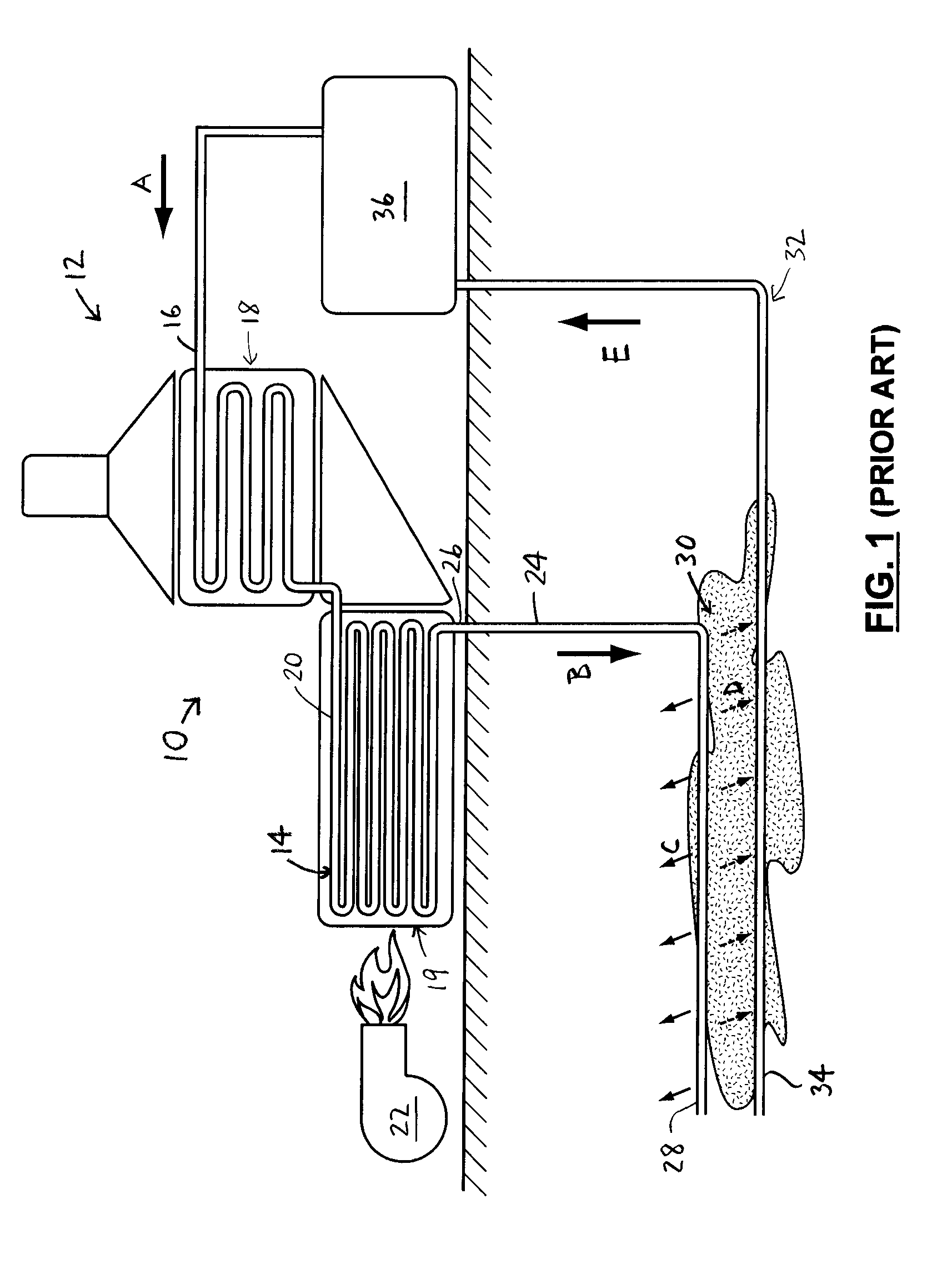

Systems and methods are provided for heating a fluid comprising an opened-loop heating circuit or a closed-loop heating circuit both comprising a rotary heating device, such as a water brake, and a closed-loop direct-fired boiler heating circuit; and systems and methods for evaporating a fluid and systems and methods for concentrating a fluid based on these heating circuits.

Owner:PHOENIX CALIENTE INC

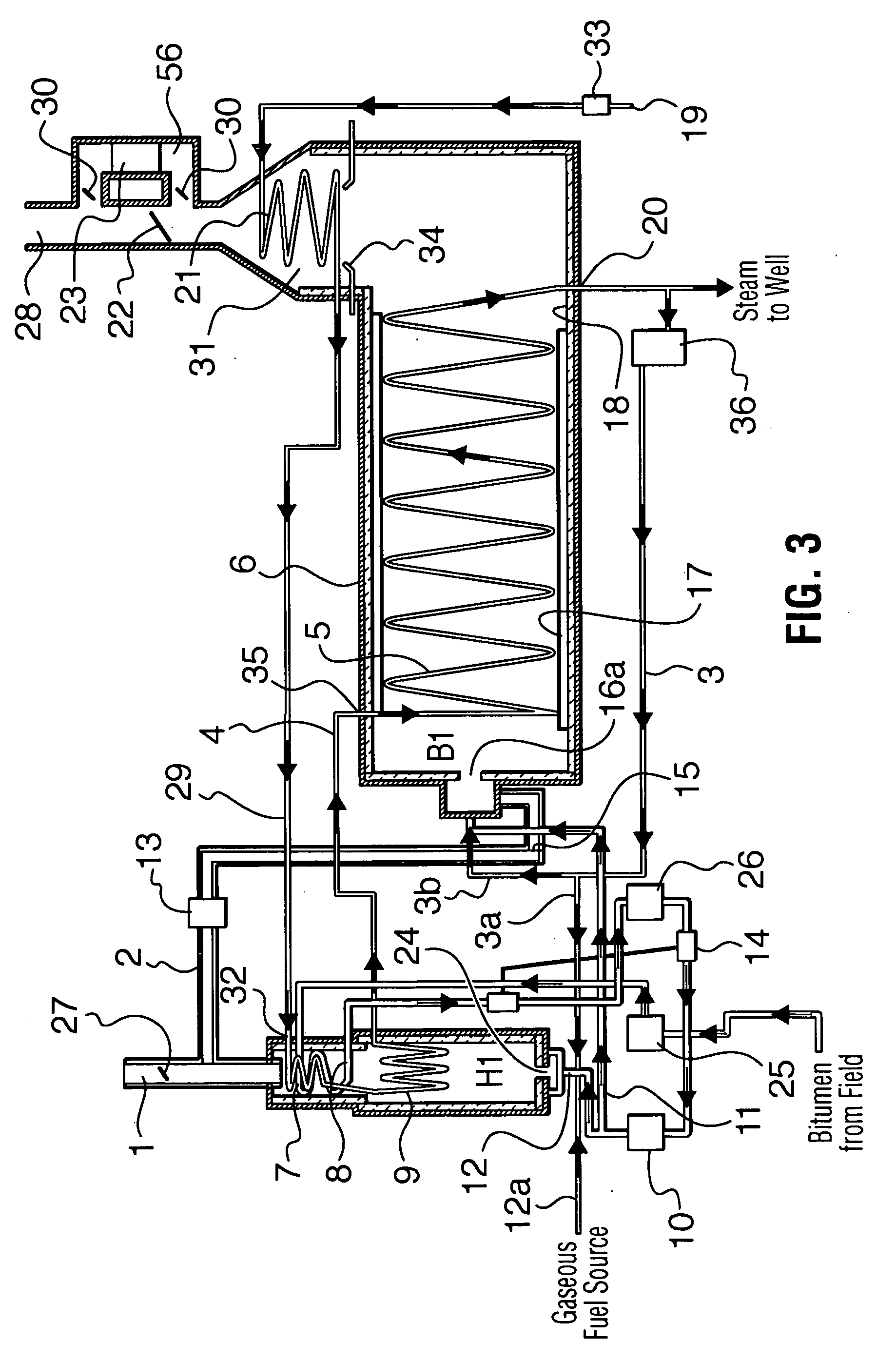

System and method for enhanced oil recovery with a once-through steam generator

ActiveUS20110017449A1High exit steam qualityEnhanced overall recoveryWater circulationInsulationEngineeringImpurity

A once-through steam generator including one or more steam-generating circuits extending between inlet and outlet ends thereof and including one or more pipes, the steam-generating circuit having a heating segment at least partially defining a heating portion of the once-through steam generator, and one or more heat sources for generating heat to which the heating segment is subjected. The steam-generating circuit is adapted to receive feedwater at the inlet end, the feedwater being subjected to the heat from the heat source to convert the feedwater into steam and water. The pipe has a bore therein at least partially defined by an inner surface, and at least a portion of the inner surface has ribs at least partially defining a helical flow passage. The helical flow passage guides the water therealong for imparting a swirling motion thereto, to control concentrations of the impurities in the water.

Owner:PROPAK SYST

High pressure steam water injector comprising an axial drain

InactiveUS6595163B2Increase the maximum pressureLow sectionFlow mixersWater circulationNuclear reactorHigh pressure

The steam injector is characteristic in its high pressure and improved start-up. It uses an axial drain (10) positioned in the centre of the neck (5) downstream from the mixing chamber (4) and inserted in the diffuser (7) for the purpose of narrowing the section of the neck (5) and evacuating a large part of the steam which has not been condensed. The axial drain (10) may be mounted so that it is axially mobile.Application to the water supply for steam generators in pressurized water nuclear reactors.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

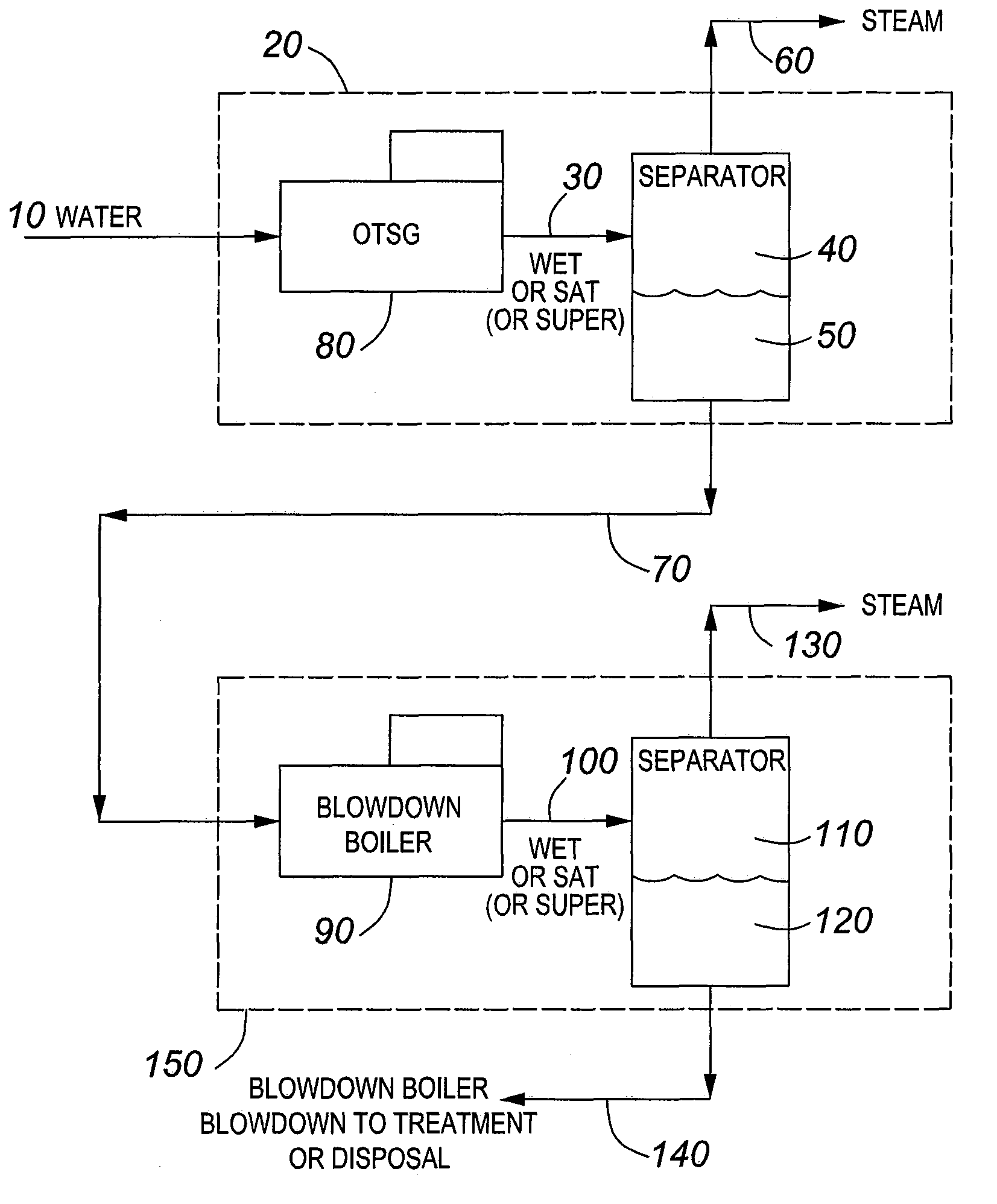

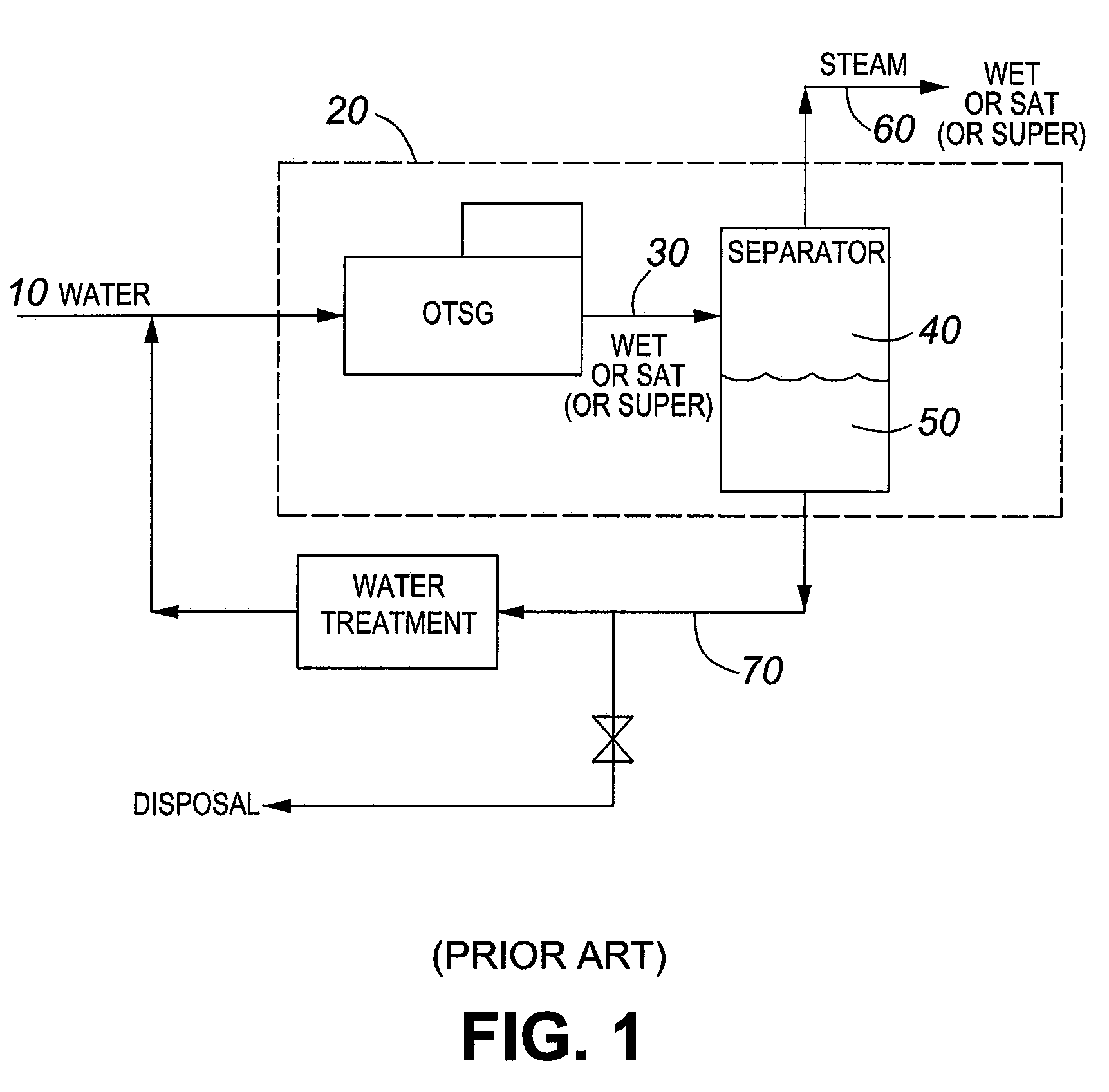

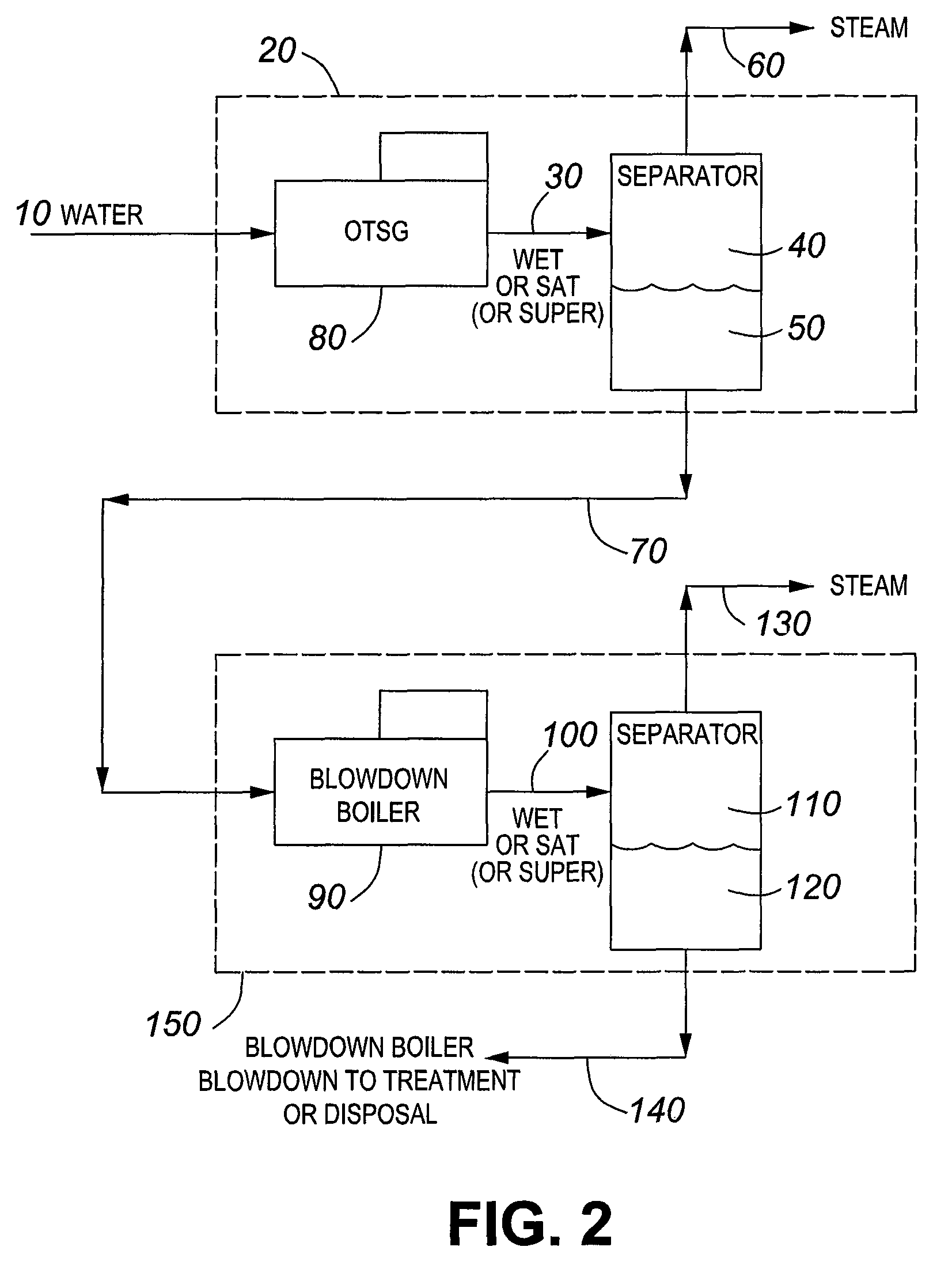

Method and apparatus for steam generation

ActiveUS8166925B2Reduce in quantityIncrease volumeWater circulationFuel injection apparatusBoiler blowdownHardness

A method, apparatus, and system and operation of surface equipment to generate steam while reducing the quantity of boiler blowdown and thereby increasing the amount of feedwater that is re-used or re-cycled in generating said steam. The present invention teaches that, on a sustained basis, the blowdown stream at the outlet of a once-through steam generator can be routed to the inlet of a second once-through steam generator that is in series with the first, that blowdown stream can be used to generate additional steam in the second once-through steam generator and further reduce the amount of blowdown, and that this can be accomplished without need of any treatment that reduces hardness or silica levels of the blowdown stream prior to its entering or during its entry into the inlet of the second once-through steam generator. The output of this second steam generator is a substantially dry saturated steam vapor stream and, complementarily, a blowdown stream whose mass rate has been reduced substantially from that of the blowdown stream exiting the first steam generator.

Owner:FCCL PARTNERSHIP

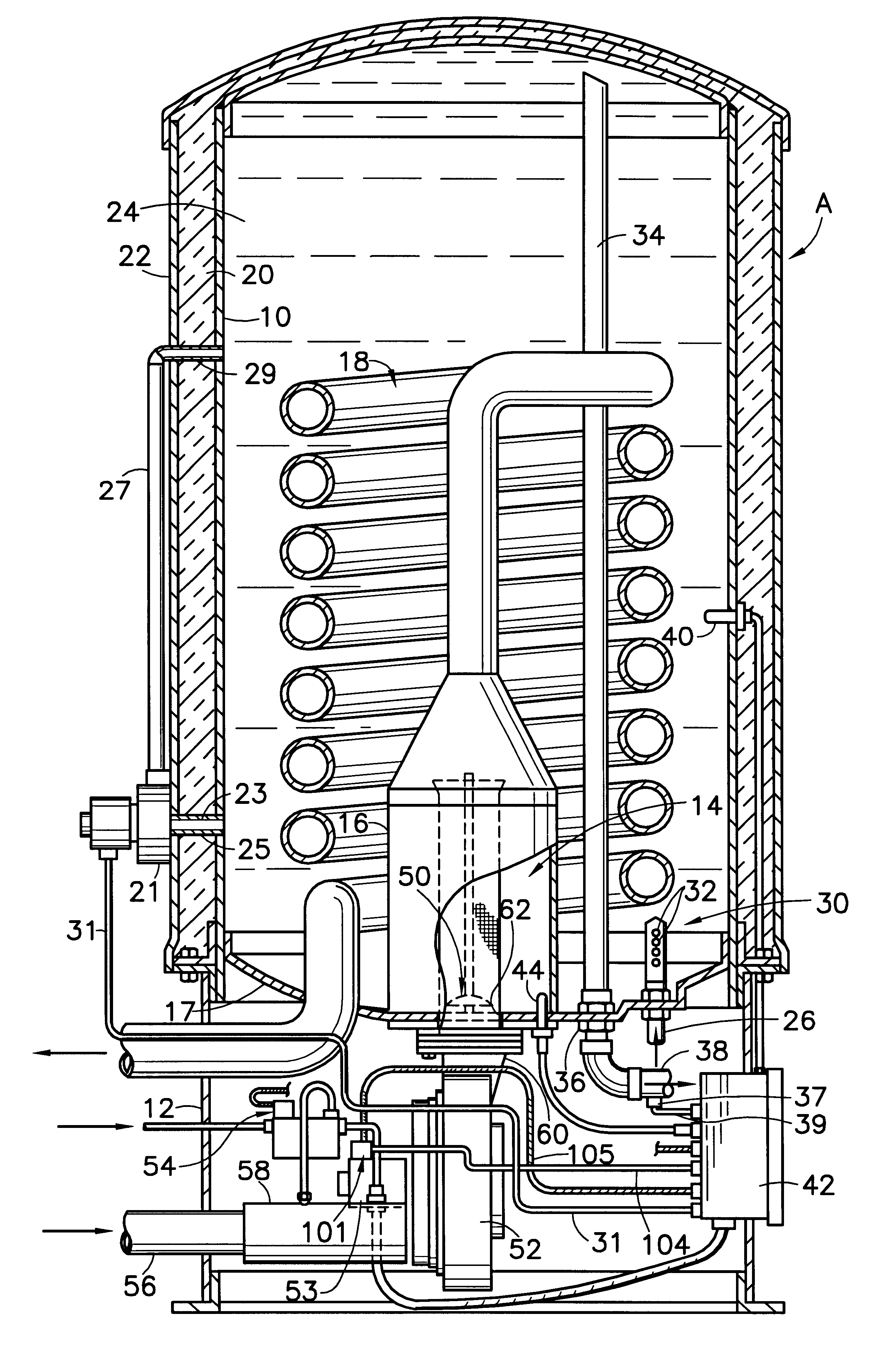

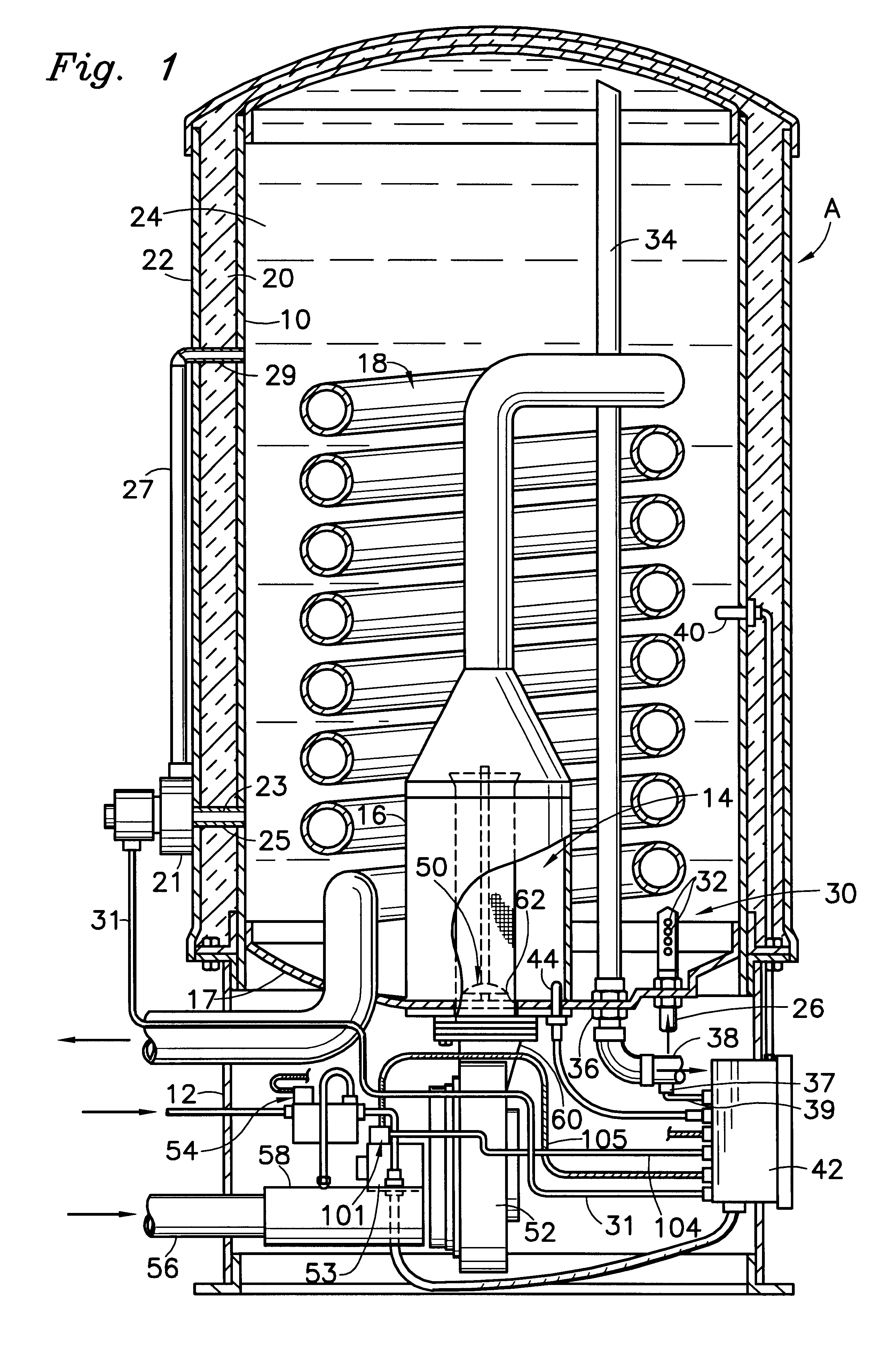

Water heater with reduced localized overheating

InactiveUSRE37240E1Reduce the effect of temperatureWater heating stoves/rangesBoiler cleaning apparatusWater cyclingEnvironmental engineering

A water and / or space heater is provided in which water is circulated to prevent the localized overheating or vaporization thereof.

Owner:FLEET CAPITAL CORPORATION

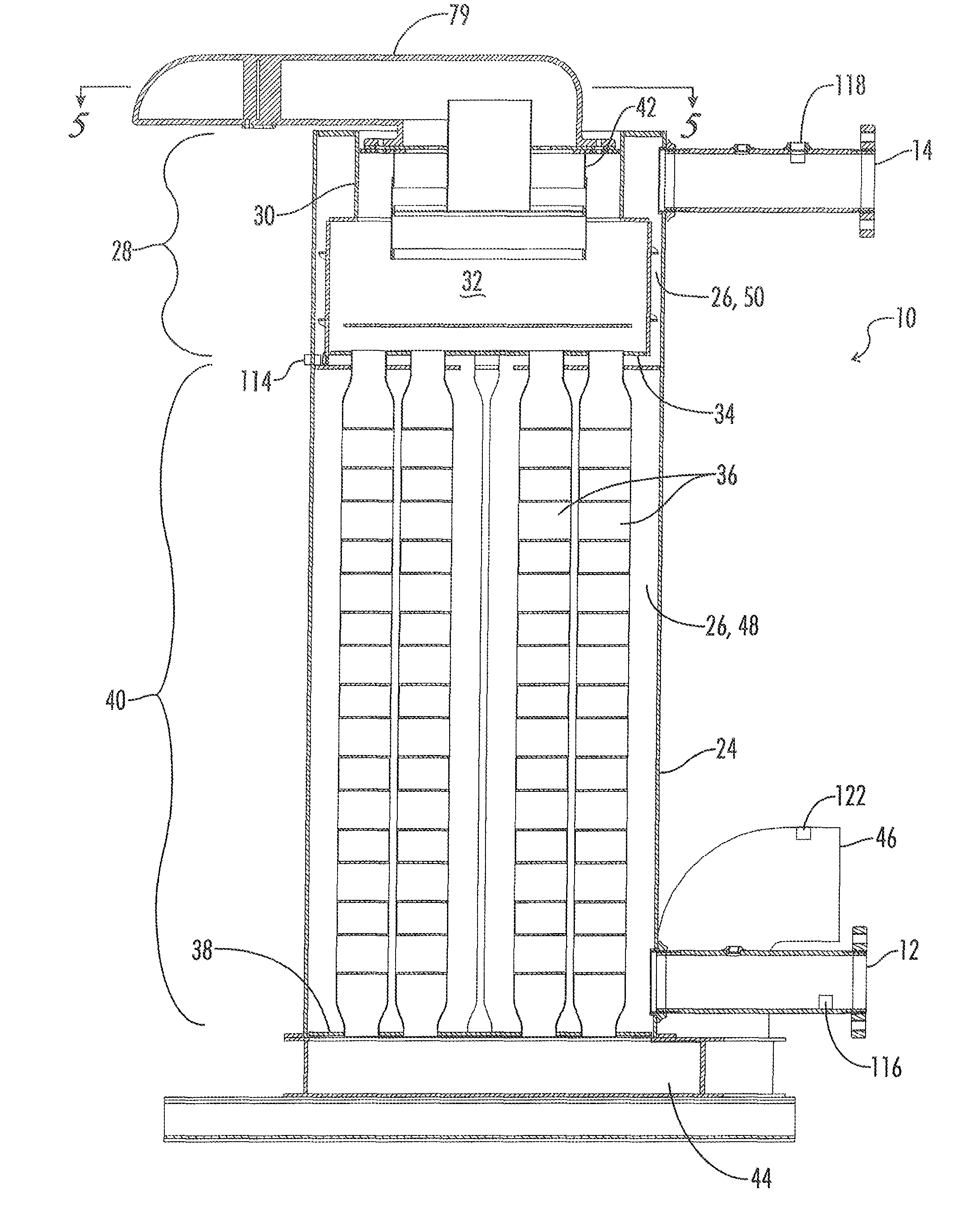

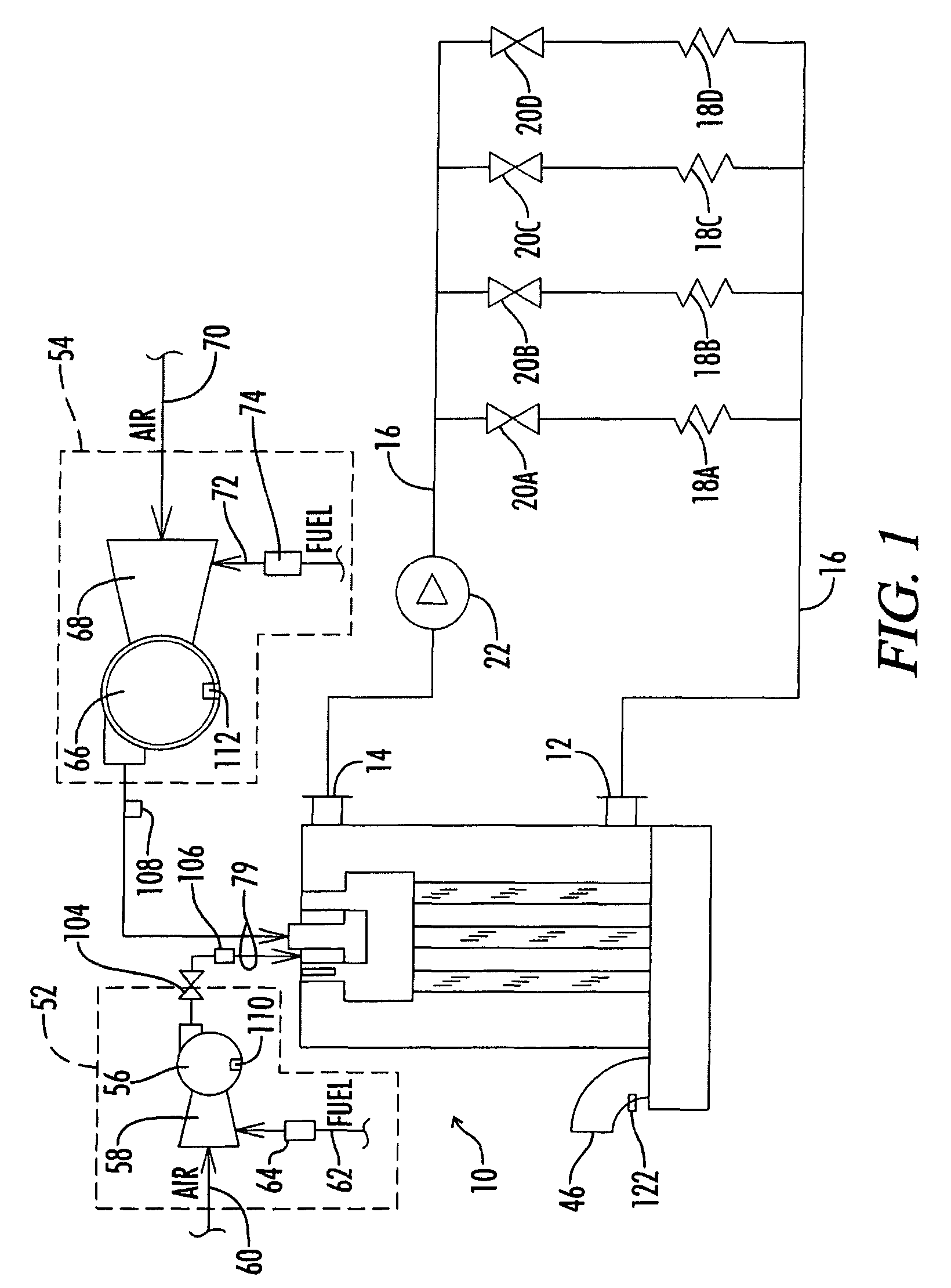

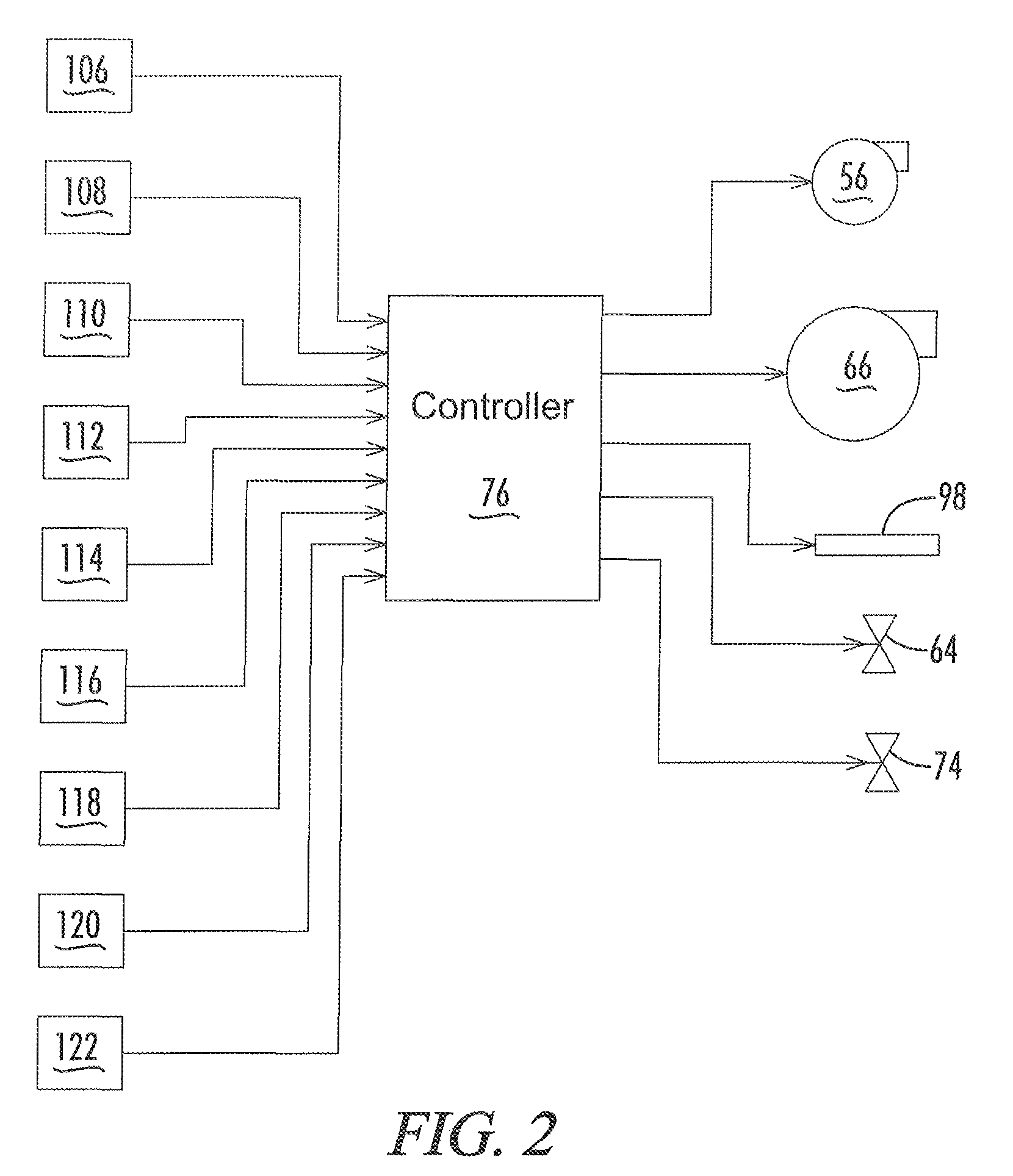

Gas fired modulating water heating appliance with dual combustion air premix blowers

ActiveUS8286594B2Avoid condensationIncrease the turndown ratioWater circulationEnergy efficient heating/coolingCombustorEngineering

A water heating apparatus uses a low range blower assembly and a high range blower assembly, each providing a variable flow of premixed fuel and air to a burner assembly. Appropriate choice of the operating ranges of the blower assemblies can provide a high turndown ratio approximately equal to the product of the turndown ratios of each of the individual blower assemblies. Turndown ratios as high as 25:1 are achievable.

Owner:LOCHINVAR

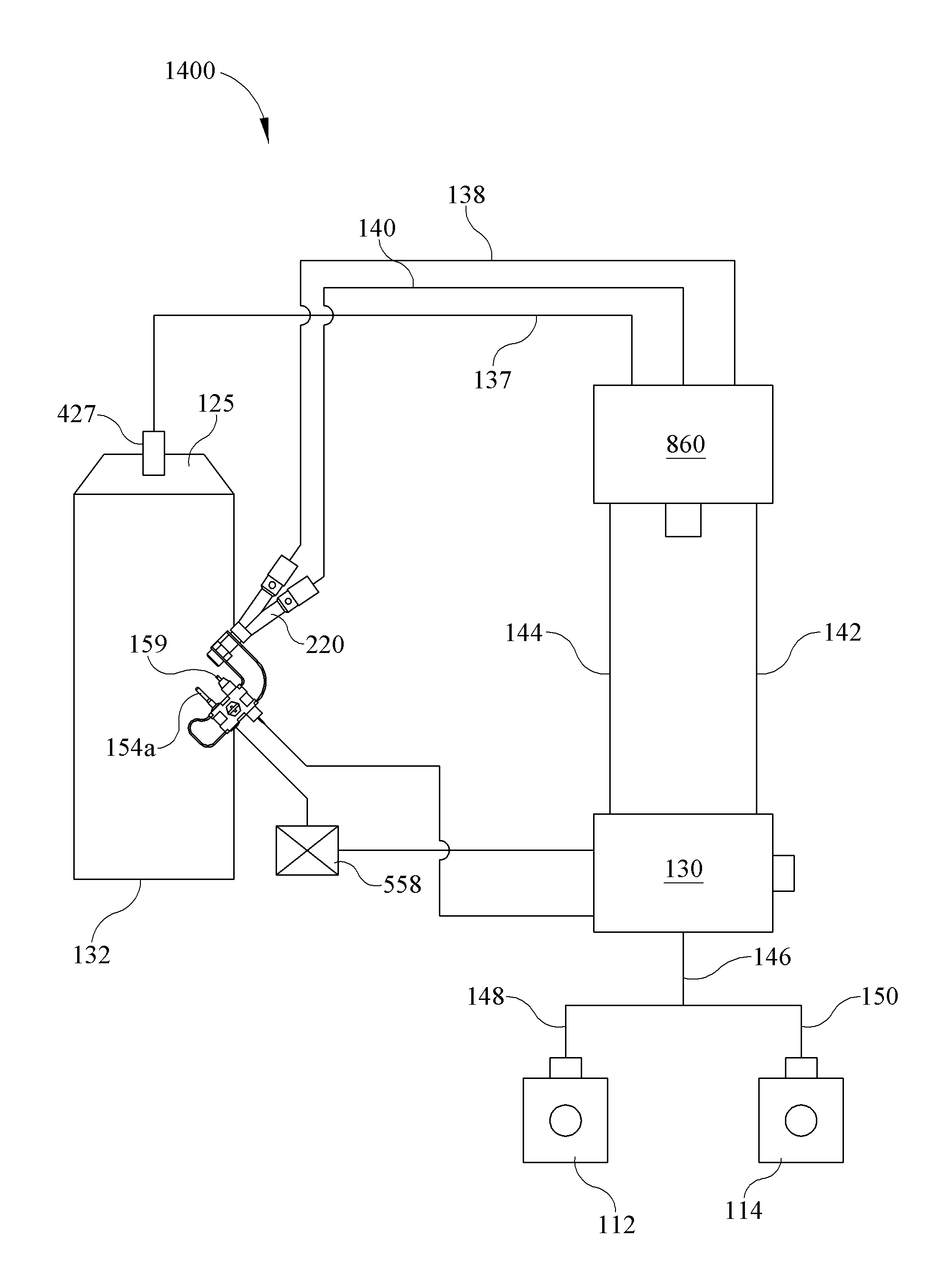

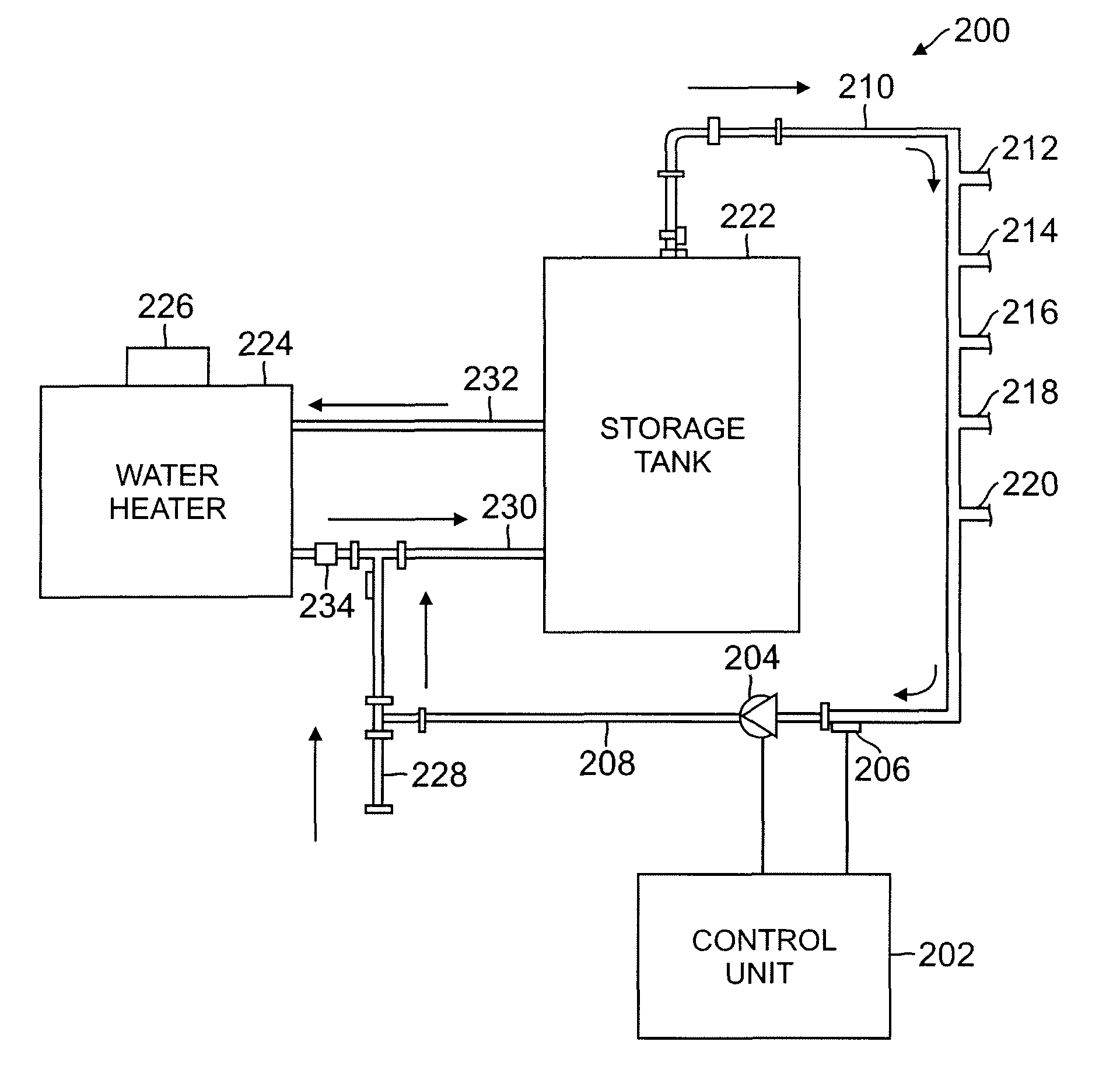

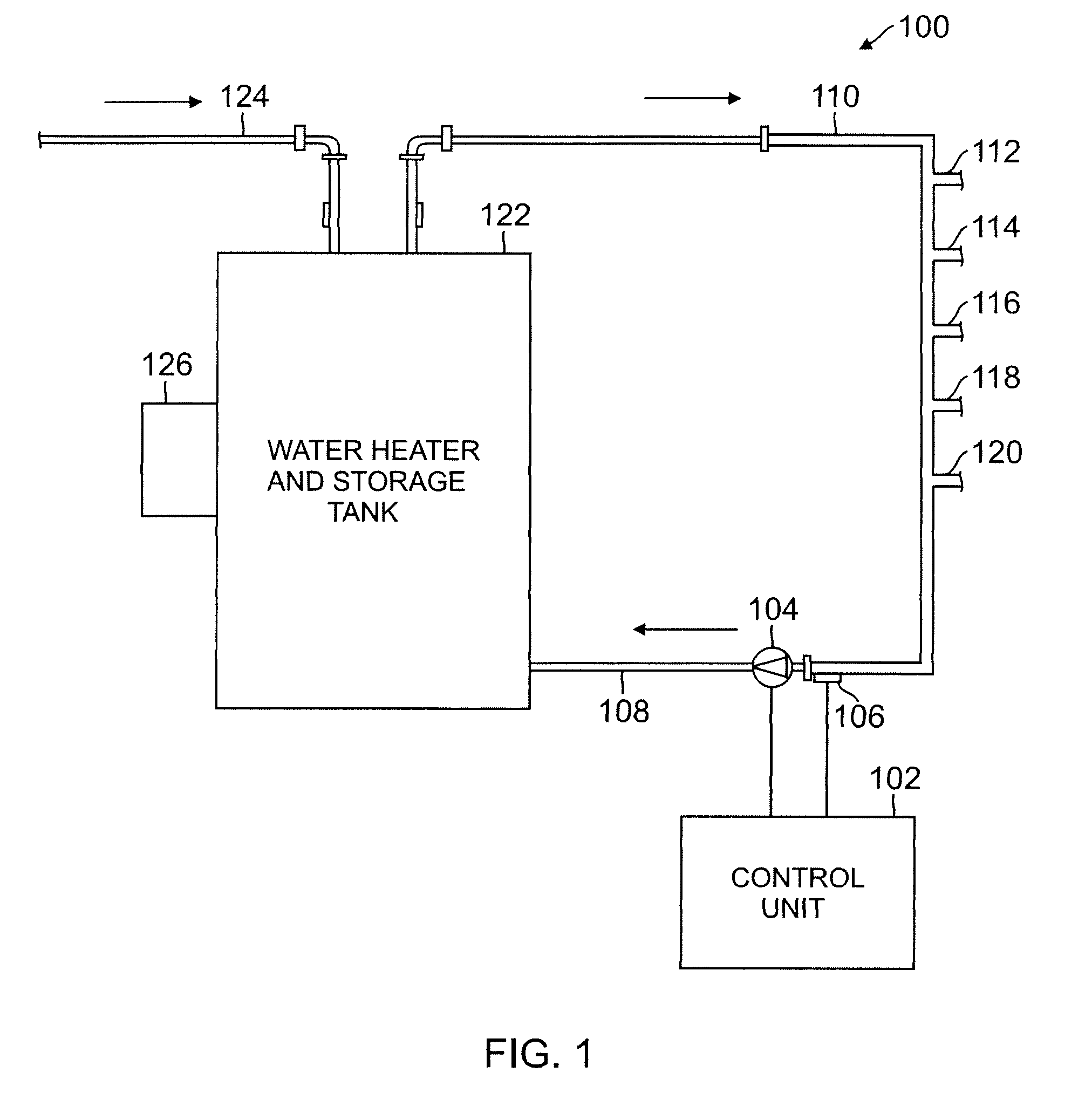

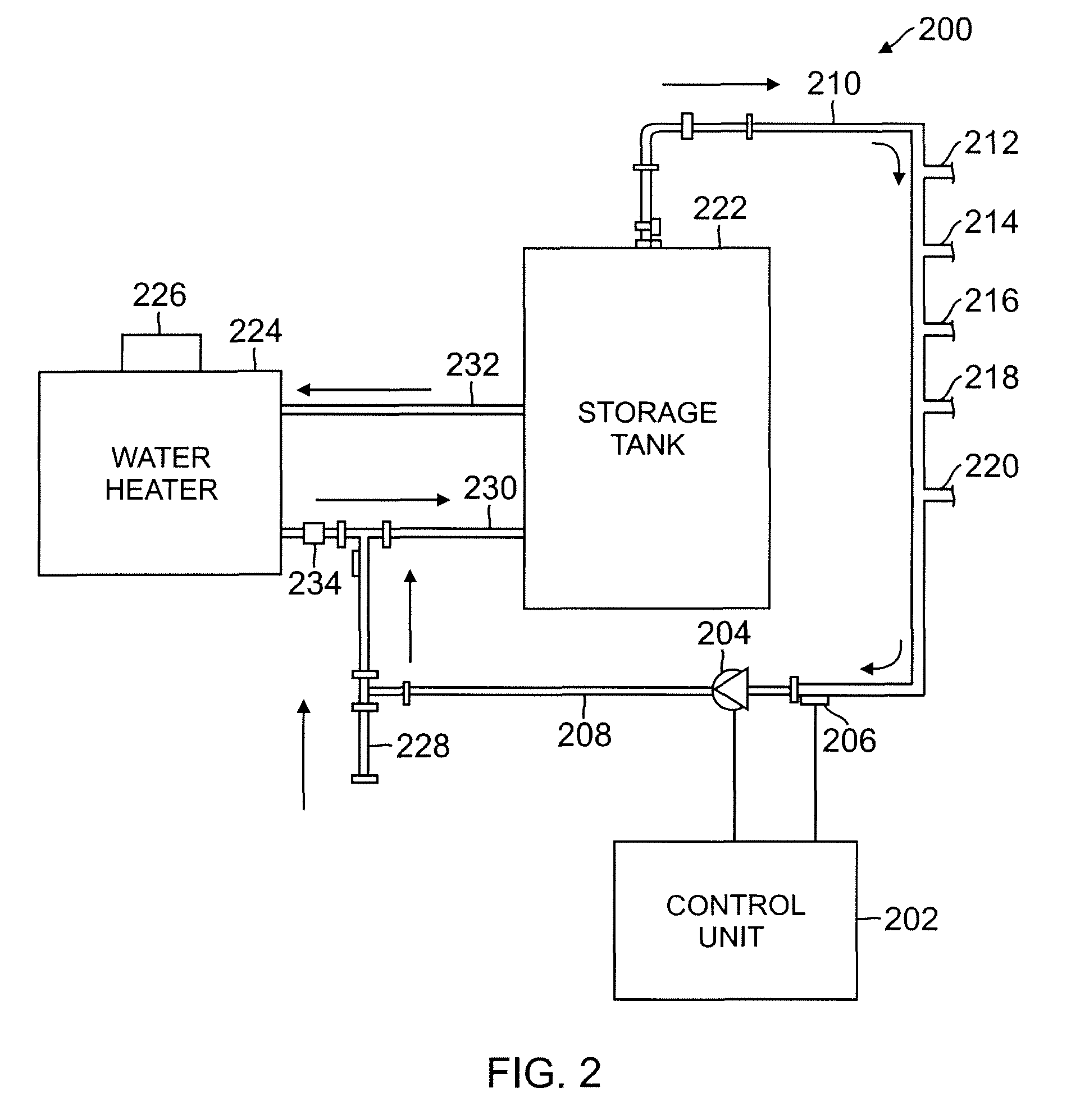

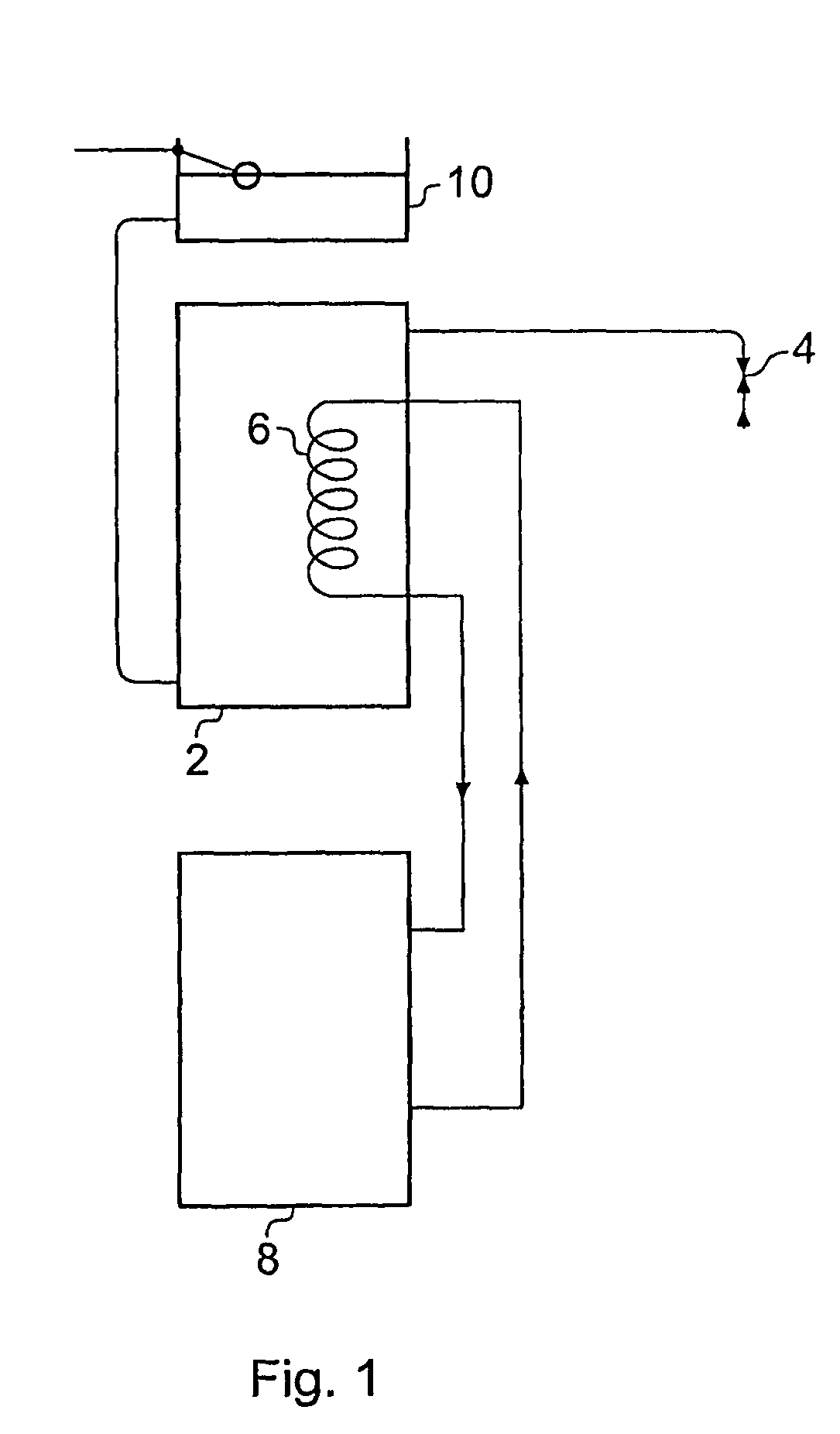

System and method for controlling a pump in a recirculating hot water system

InactiveUS8191513B2Efficient regulation technologiesMachines/enginesTemperature controlWater cycling

A system and a method for controlling a pump in a recirculating hot water system is provided. In one embodiment, the invention relates to a method for controlling a temperature of water in a recirculating hot water system including a storage tank for storing heated water, a recirculation conduit including a supply conduit for supplying the heated water to users via a plurality of outlets having a first outlet and a last outlet and a return conduit for returning an unused portion the heated water to the storage tank, a pump for circulating the heated water, the pump disposed along the return conduit, the method including measuring, at a point along the recirculation conduit, a temperature of the heated water provided from the storage tank, and controlling a speed of the pump, disposed along the return conduit, based on the measured temperature.

Owner:TDK FAMILY PARTNERSHIP

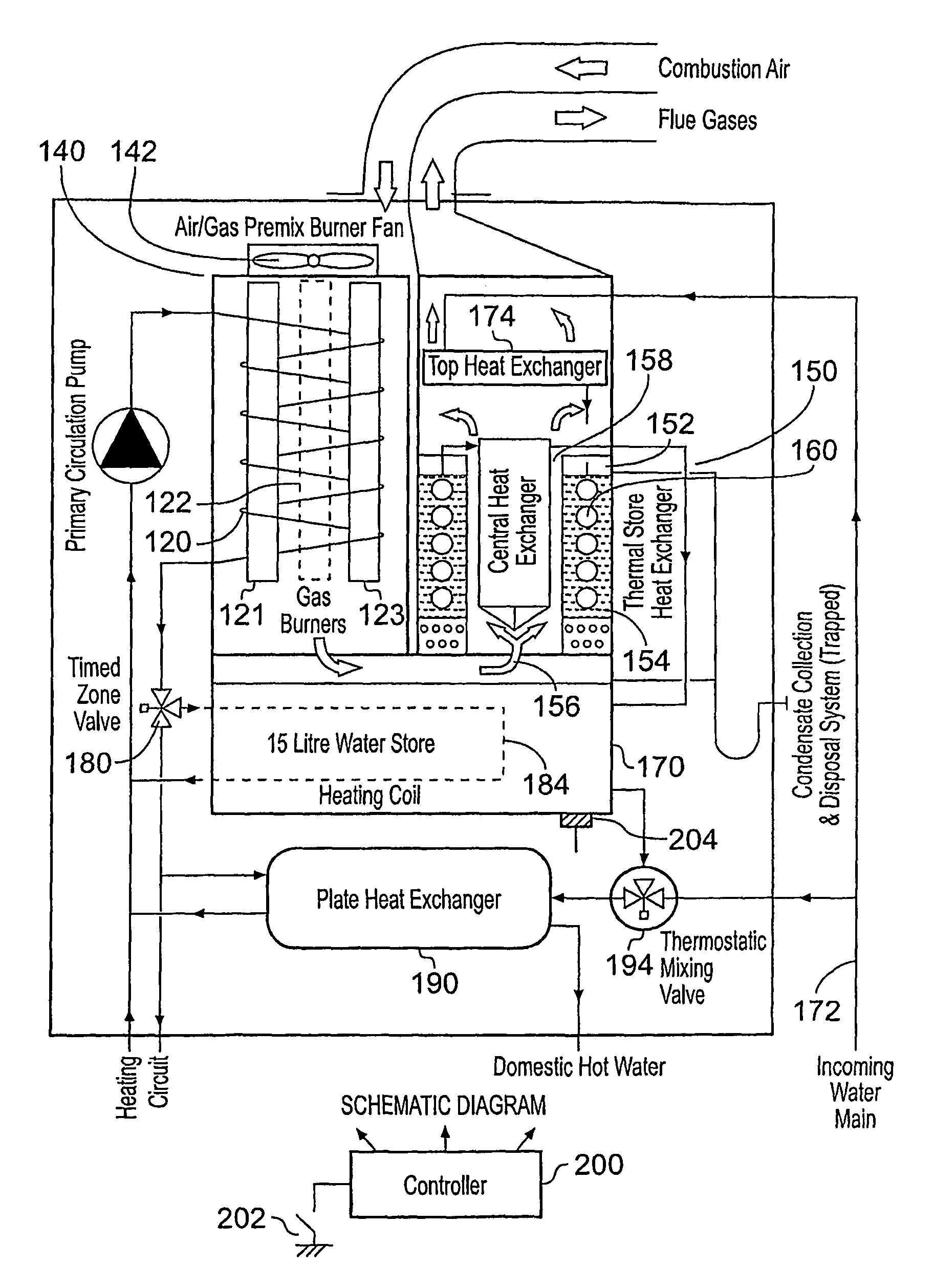

Heating system

InactiveUS8910880B2Speed up heat transferVarying amountSolar heating energySpace heating and ventilation detailsPlate heat exchangerEngineering

A heating system comprising a fuel burner in co-operation with a primary heat exchanger, a reservoir for storing warmed water in, and a blending valve, and a controller wherein in use a user can signal to the controller to warm the water in the water store using a heater or by the primary heat exchanger, and when hot water is required water is removed from the water store and mixed with water from a cold main prior to being or after the water from the cold main has been admitted to a further heat exchanger for heating the water.

Owner:CANETIS HLDG LTD

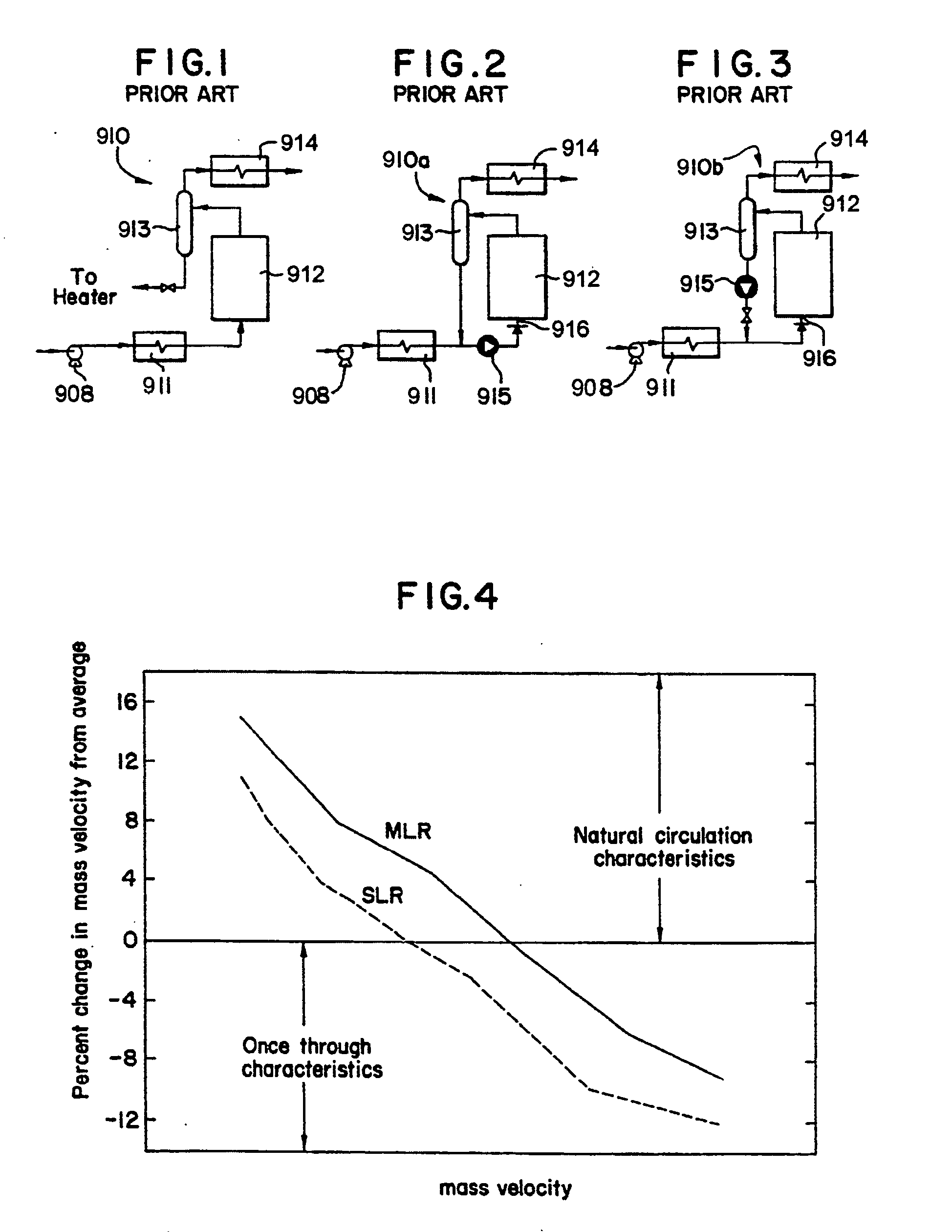

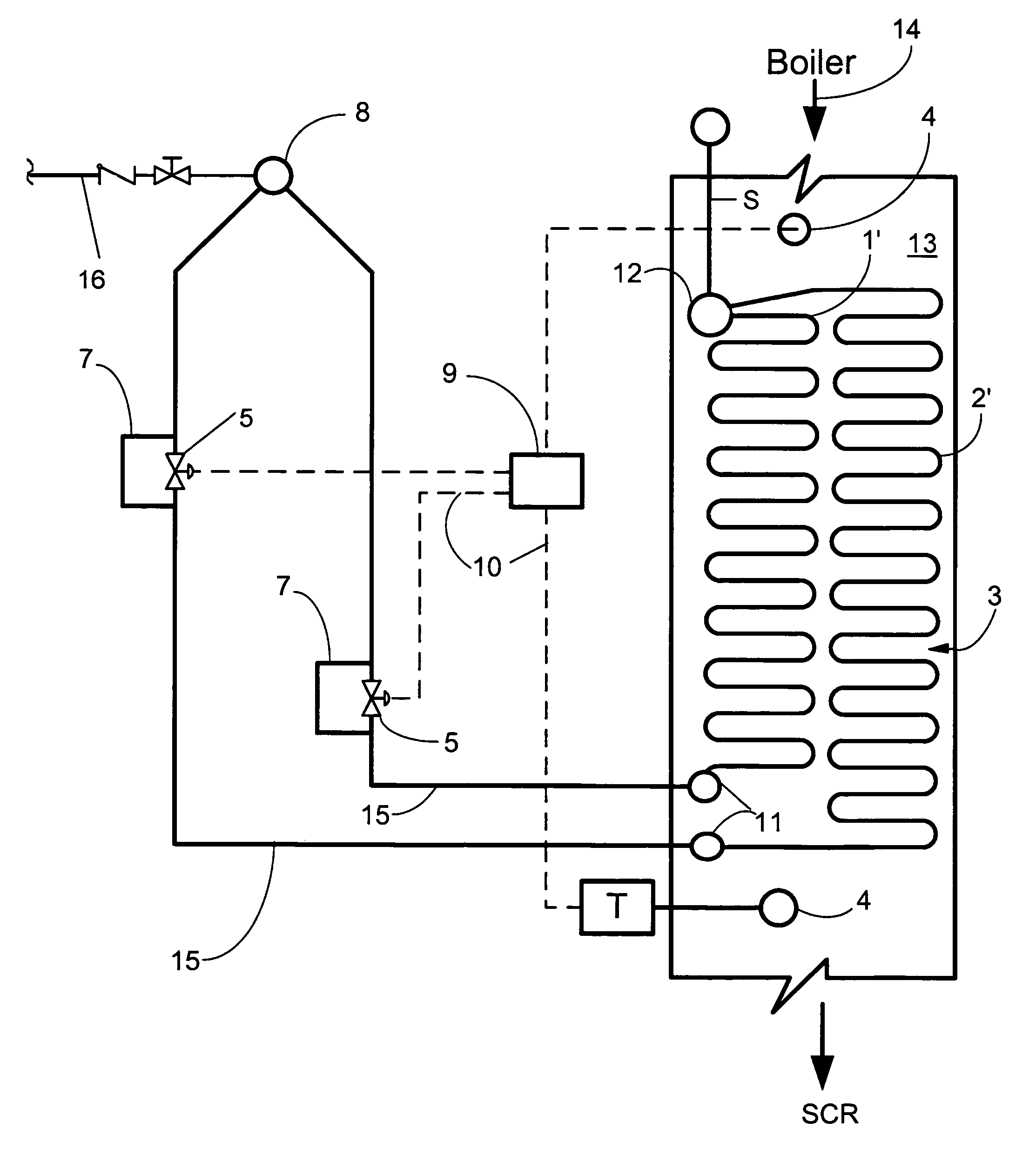

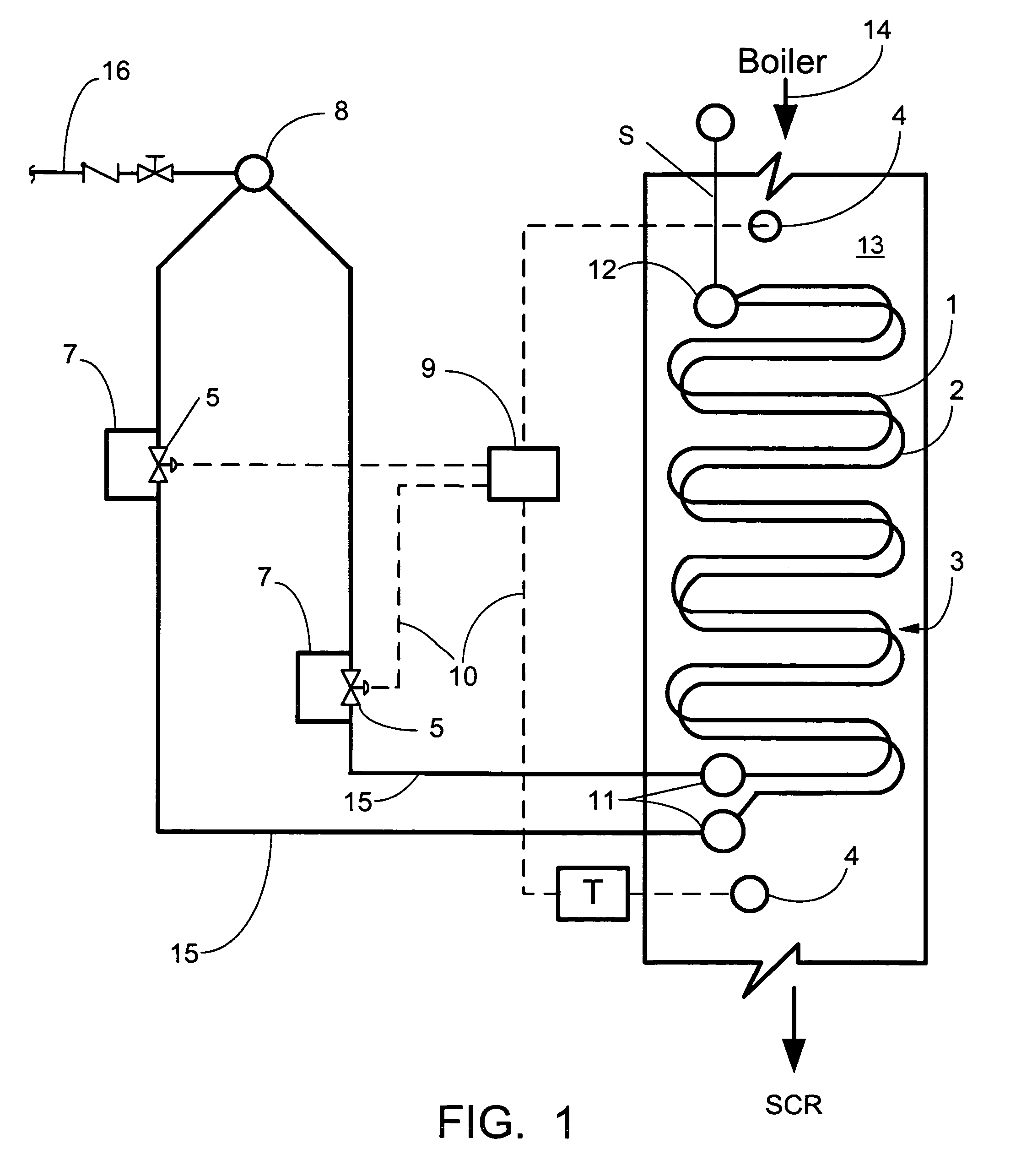

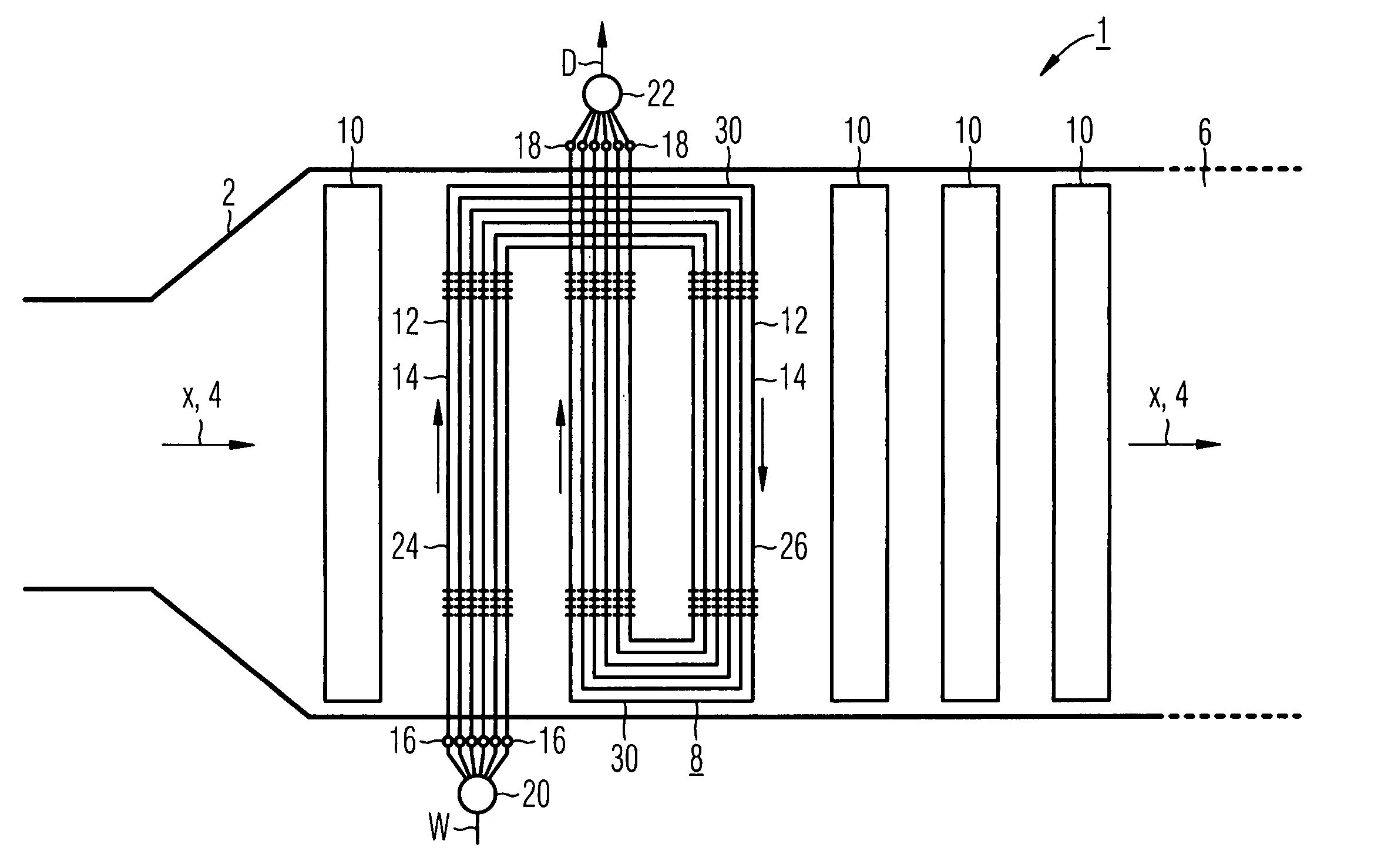

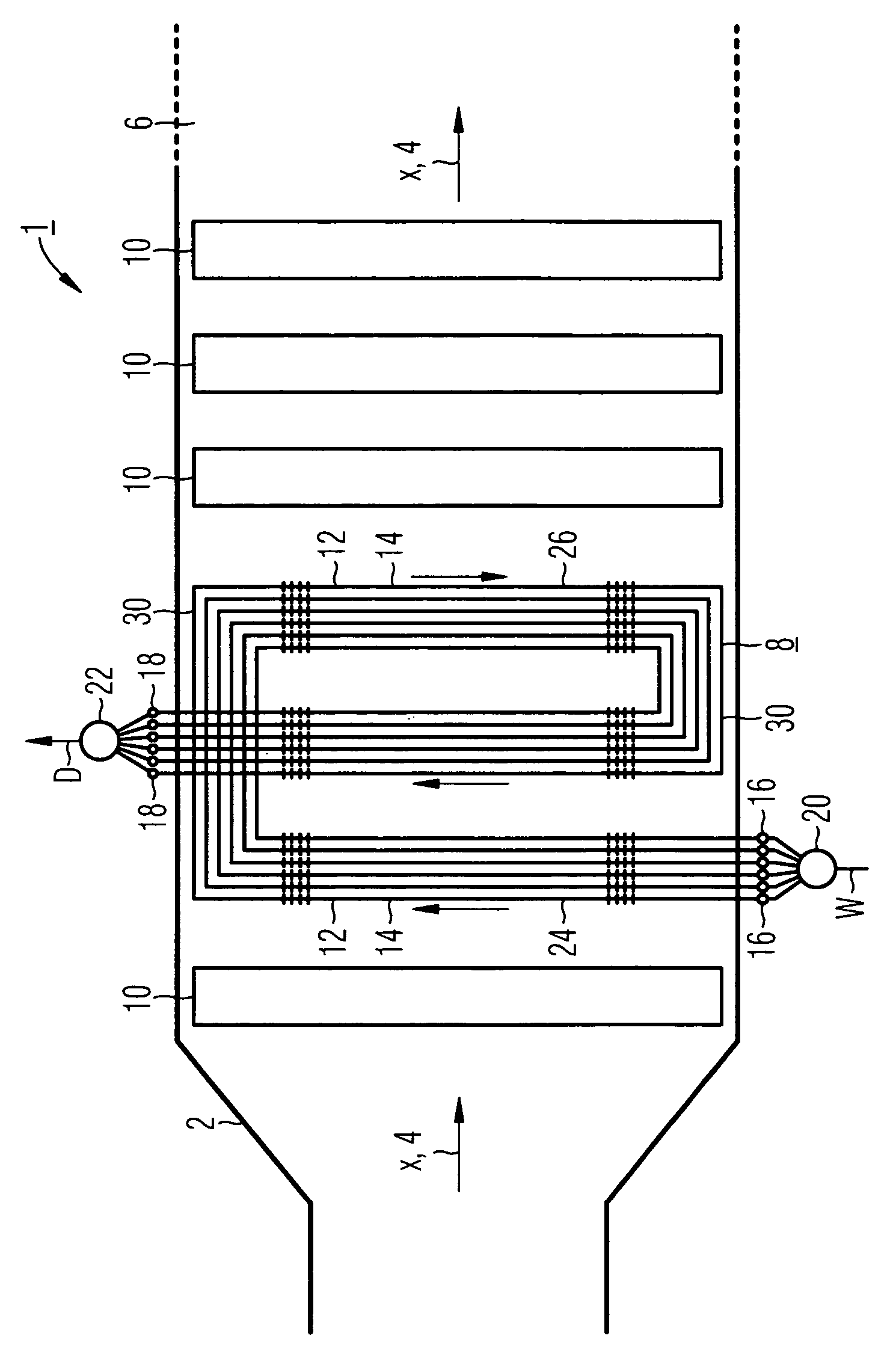

Circulation system for sliding pressure steam generator

InactiveUS20070283906A1High densityImprove abilitiesWater circulationFuel injection apparatusBoiler feedwater pumpEngineering

A steam generator circulation system is provided and includes a boiler feed pump for forcing water through an economizer, and through the waterwall tubes of an evaporator. A separator receives a mixture of steam and water and sends the steam to a steam utilization unit such as a superheater. A valve is provided below the separator. If the valve is open, the saturated water from the separator is mixed with feedwater and recirculated through the tubes of the evaporator. If the valve is closed, recirculation is terminated. At loads below the critical point, the valve below the separator system would be open and the boiler would operate like a natural circulation drum boiler. At loads above the critical point, the valve below the separator system would be closed resulting in a boiler that operates like a once-through boiler.

Owner:THE BABCOCK & WILCOX CO

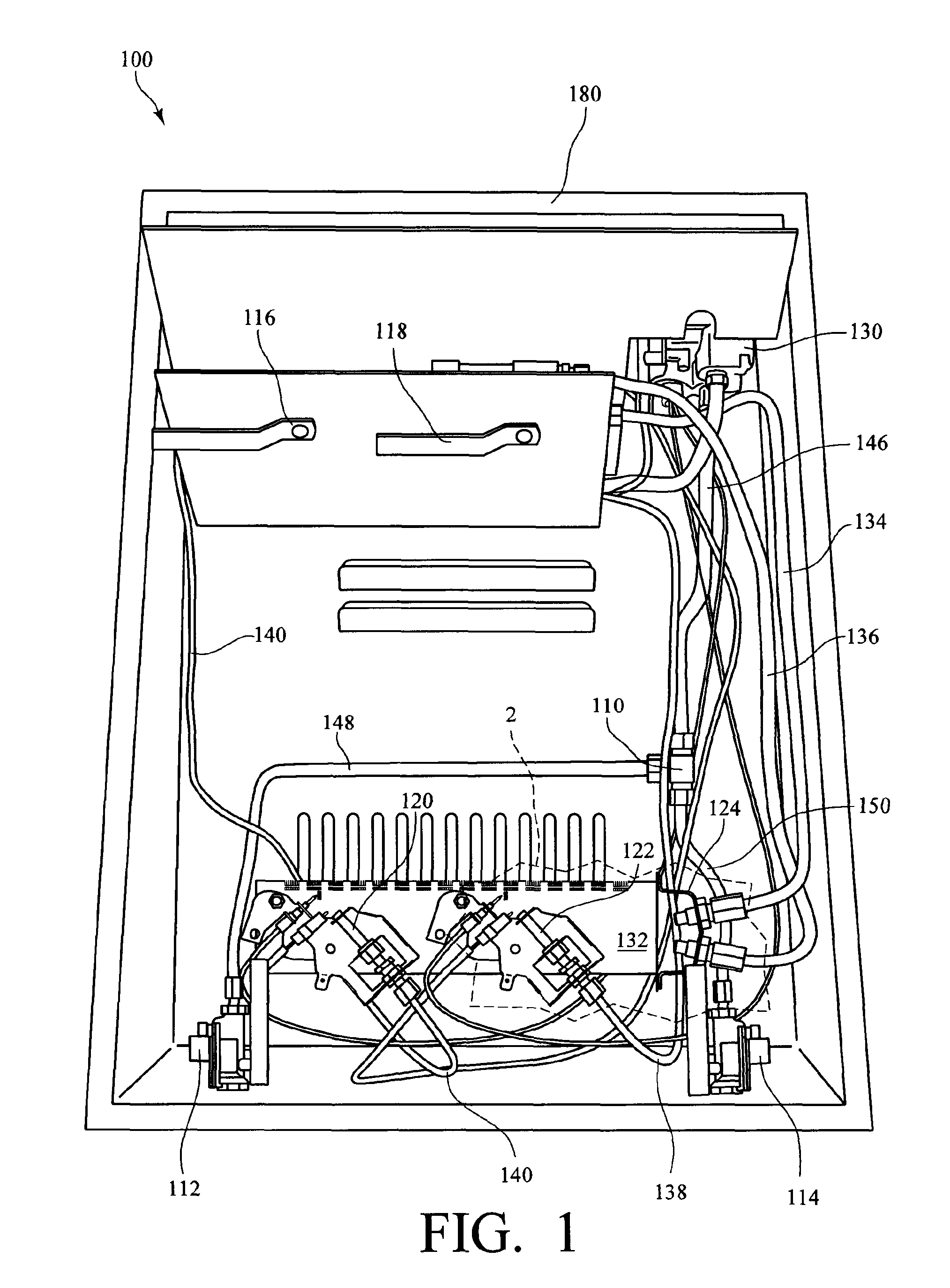

Methods and apparatuses for heating, concentrating and evaporating fluid

InactiveUS8371251B2Steam generation using mechanical energyAir-treating devicesWater brakeClosed loop

Systems and methods are provided for heating a fluid comprising an opened-loop heating circuit or a closed-loop heating circuit both comprising a rotary heating device, such as a water brake, and a closed-loop direct-fired boiler heating circuit; and systems and methods for evaporating a fluid and systems and methods for concentrating a fluid based on these heating circuits.

Owner:PHOENIX CALIENTE INC

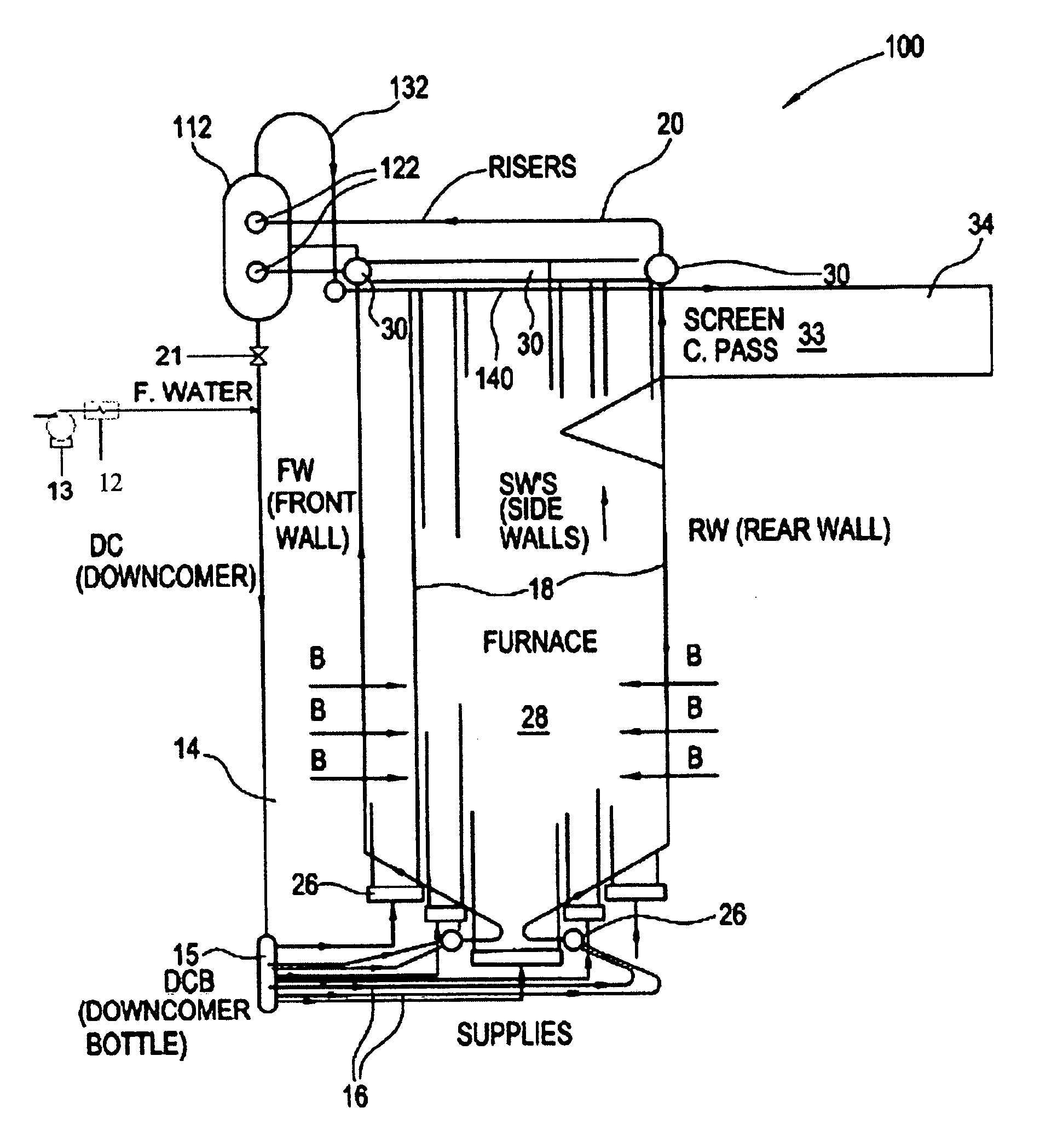

Natural Circulation Industrial Boiler for Steam Assisted Gravity Drainage (SAGD) Process

A gravity feed, natural circulation boiler for an SAGD process using low quality feedwater for carbonatious material recovery, has a large diameter steam drum with downcomers. A furnace of the boiler has individually replaceable membrane wall modules, each with upper and lower headers and membrane roof, wall and floor parts connected to the drum and defining a fire box having an inlet end and an outlet end. The furnace includes a membrane front wall connected to the drum with a windbox upstream of the front wall. Burners at the inlet end of the firebox heat the firebox and riser pipes are connected between the steam drum and the upper header for supplying steam to the steam drum when the firebox in heated, the downcomer pipes being connected to the lower header for supplying water from the stream drum under gravity feed so that each module defines a single circuit. Furnace outlet screen bank and subsequent generating banks each with upper and lower headers and associated feeder and riser tubes complete the boiler.

Owner:BABCOCK & WILCOX CANADA LIMITED

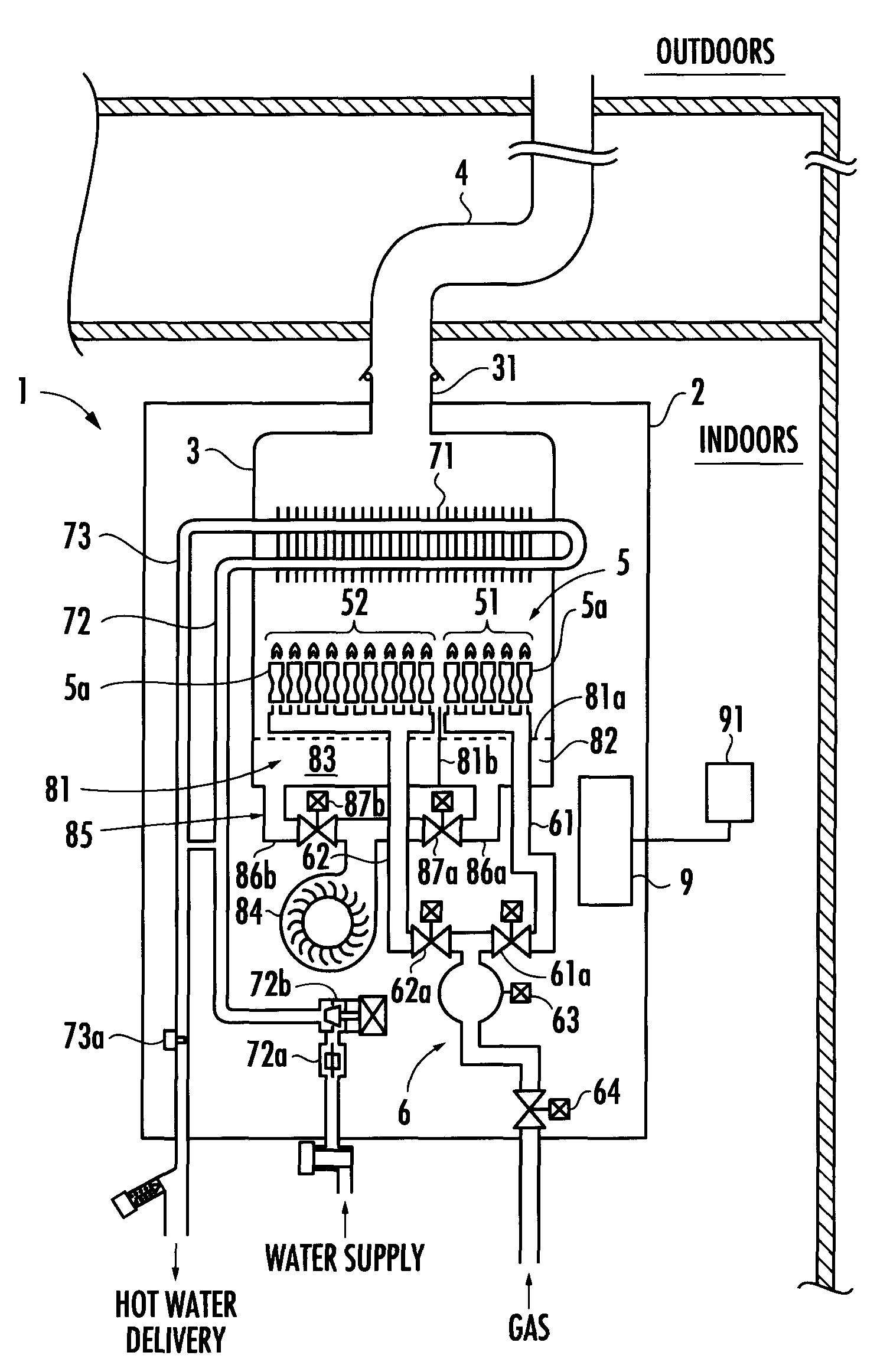

Water heater

ActiveUS8267051B2Improve heating efficiencyReduce the temperatureHeating fuelAir supply regulationCombustionCombustor

There is provided an indoor mounting water heater in which combustion exhaust gas is discharged to the outdoors via an exhaust duct, wherein a decrease in draft force caused when the number of burner groups to be burned is reduced by a capacity changeover mechanism to decrease the combustion capacity can be prevented, and the heat efficiency can be improved. An air supply chamber 81 is divided into a plurality of parts 82 and 83 corresponding to a plurality of burner groups 51 and 52. The air sent from an air supply fan 84 is supplied to only a part of the air supply chamber corresponding to a burning burner group.

Owner:RINNAI CORP

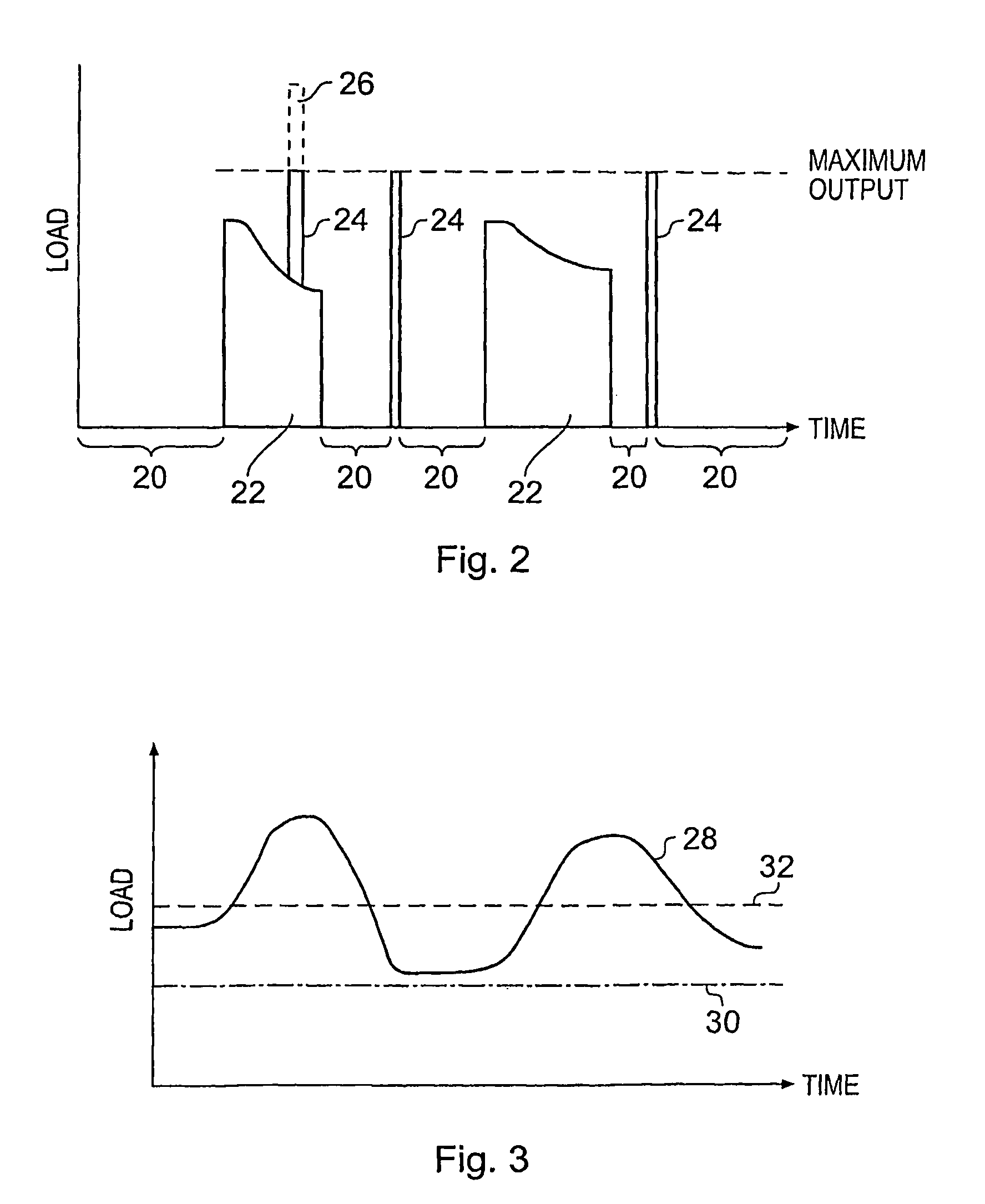

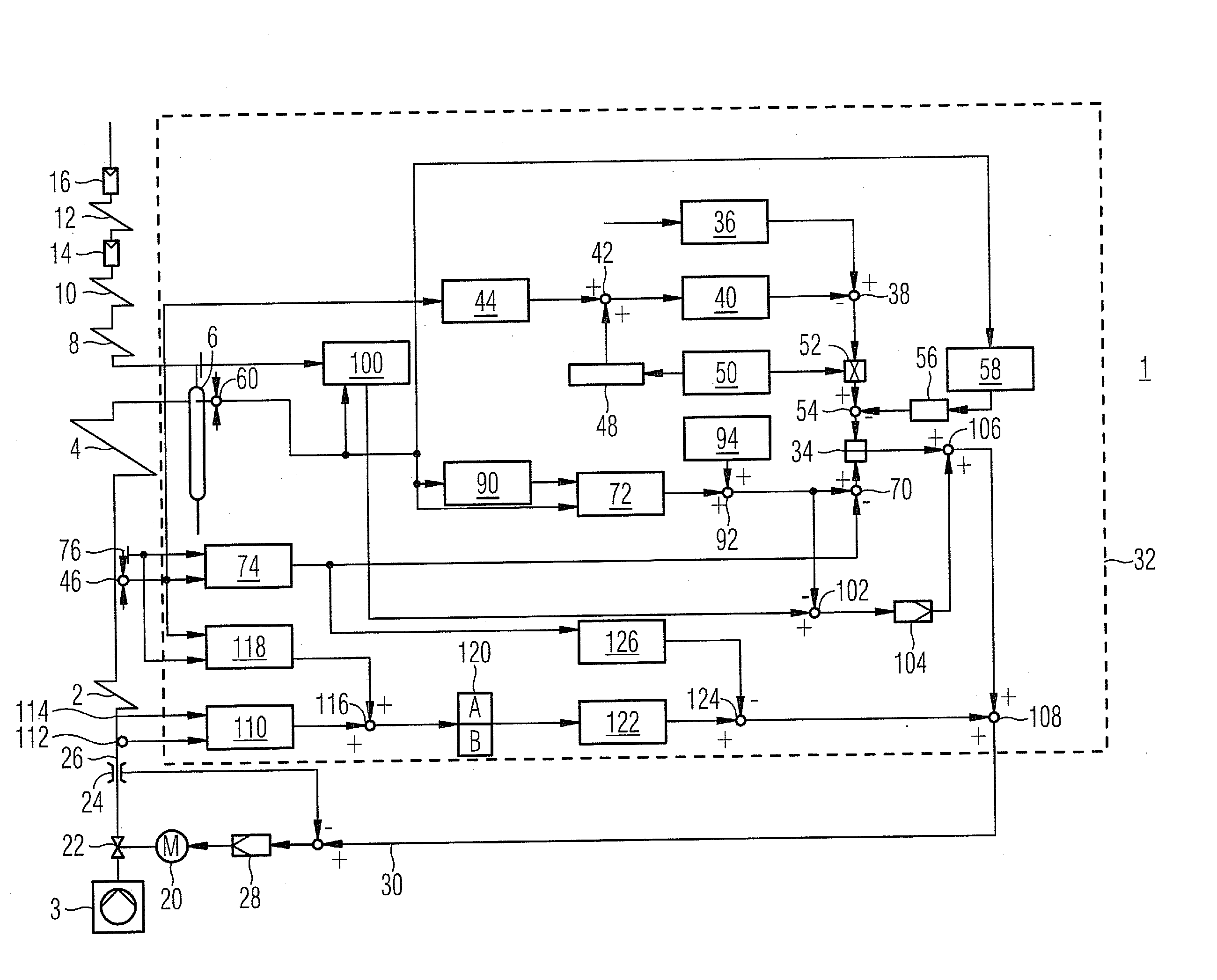

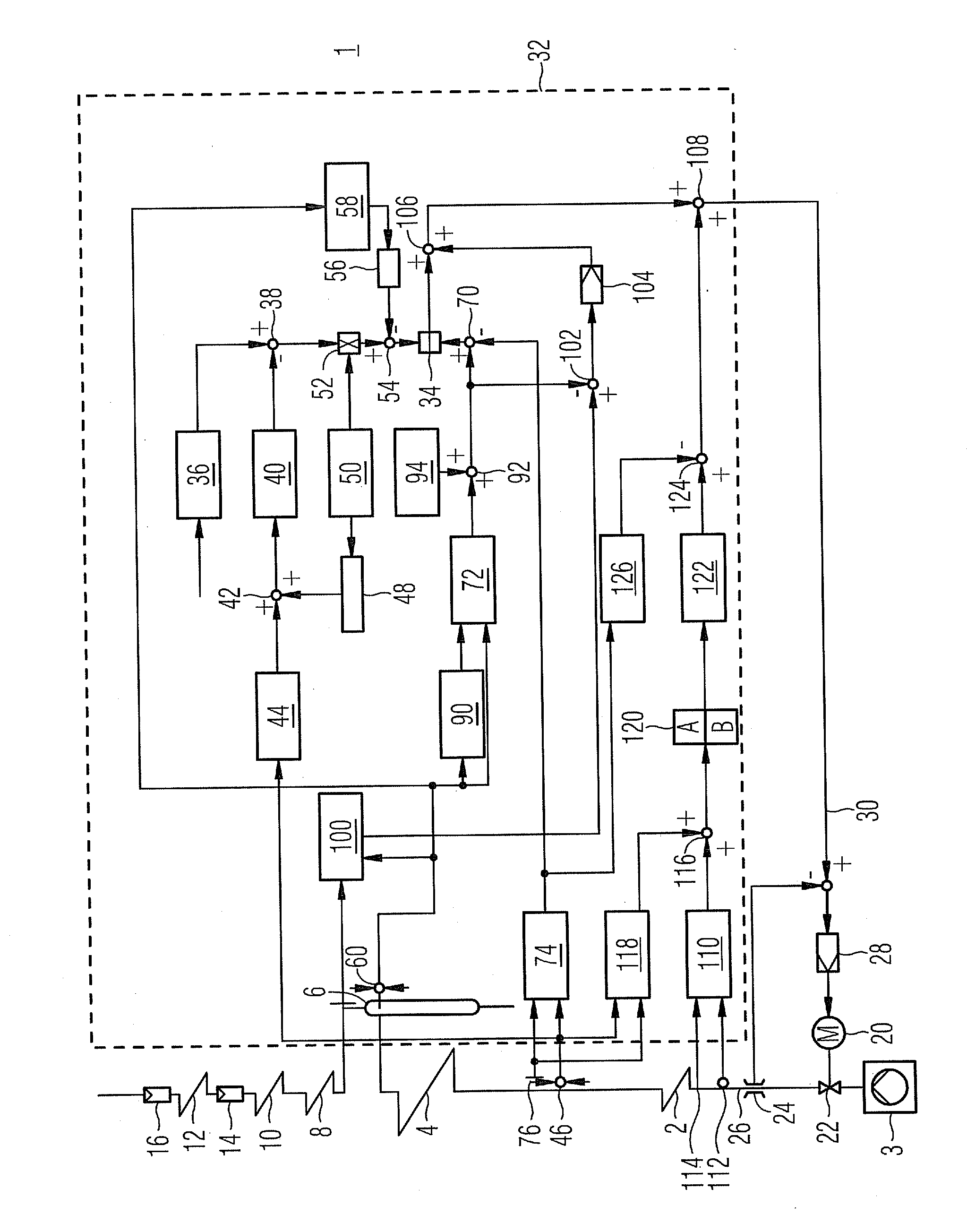

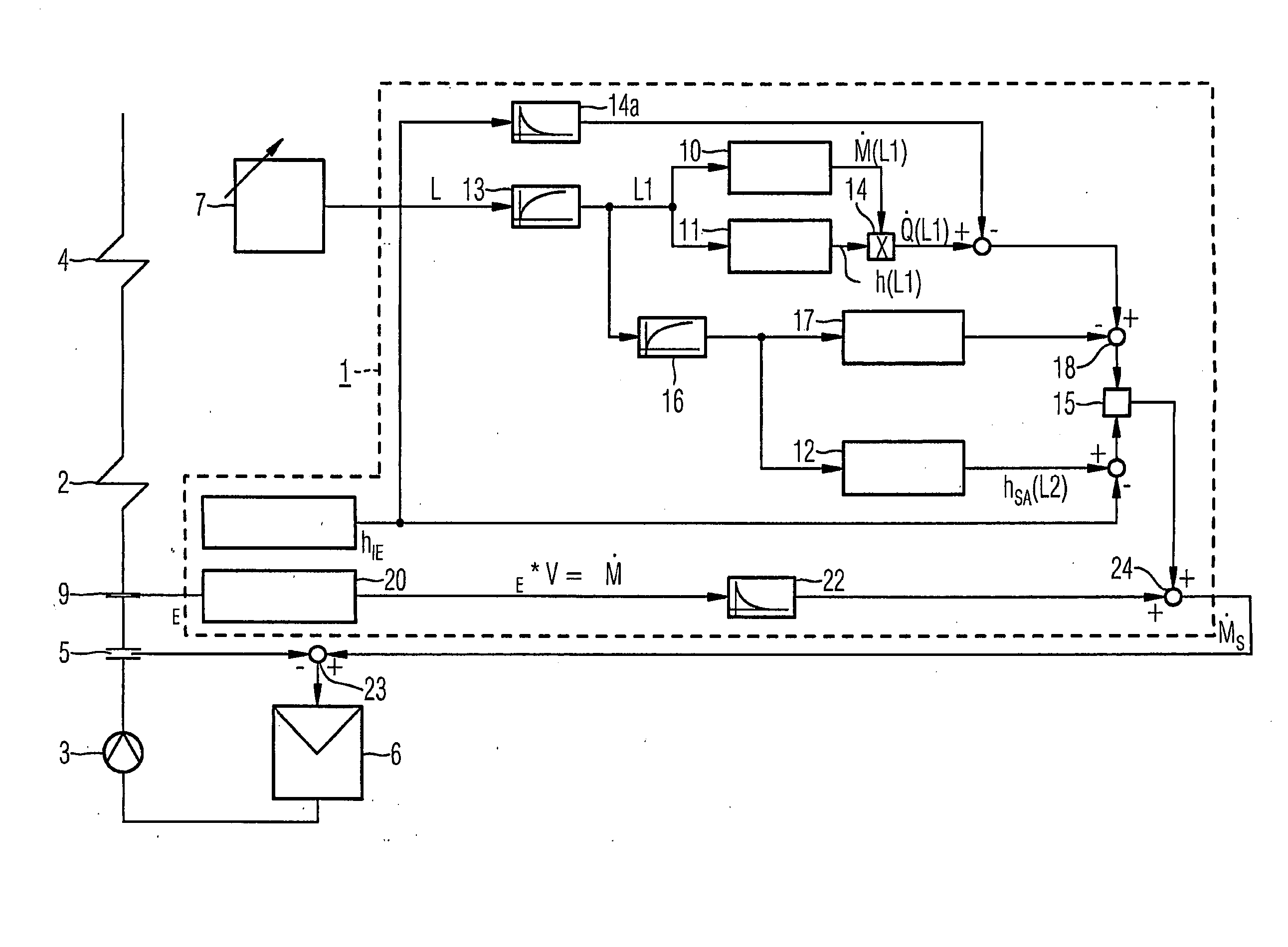

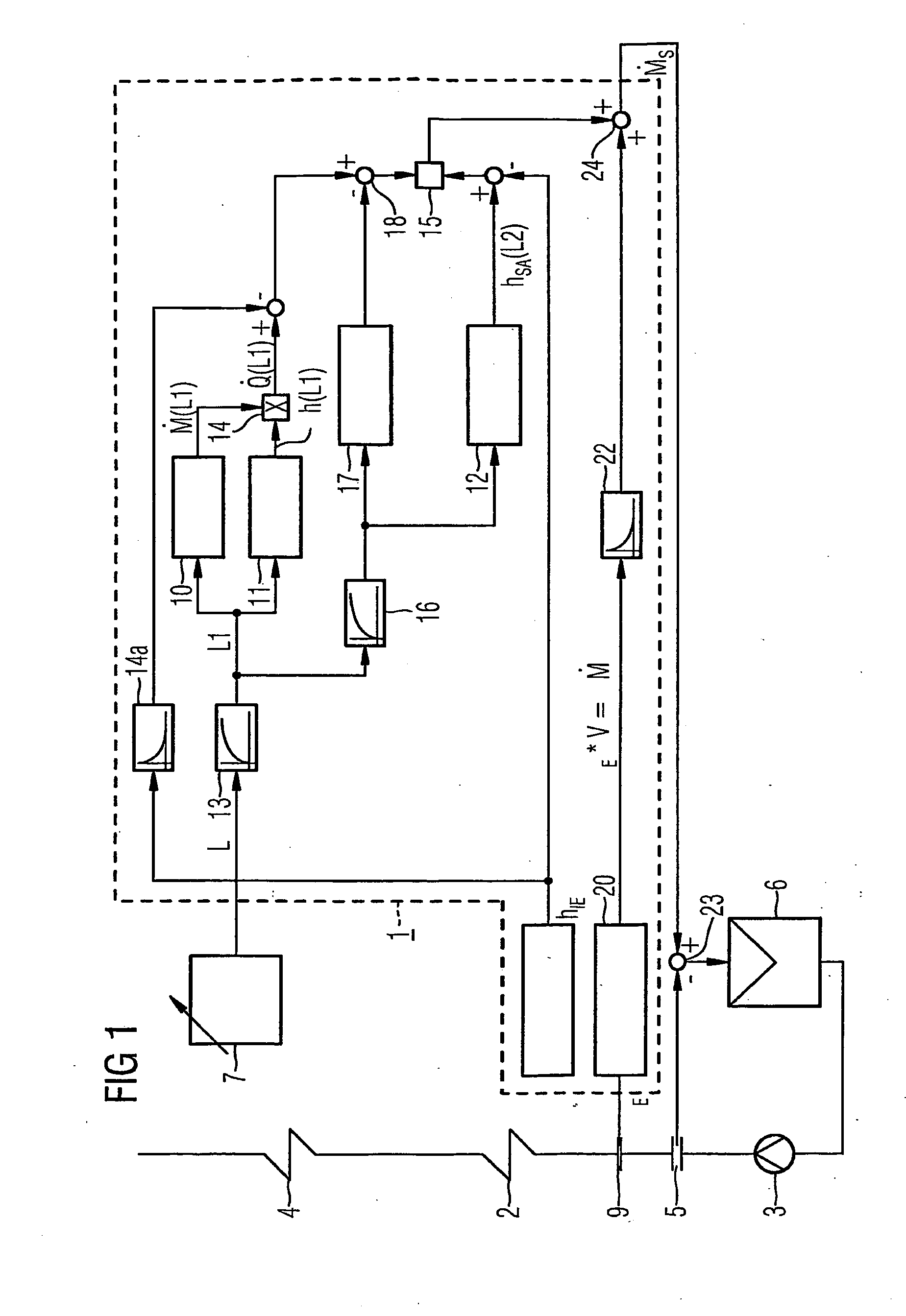

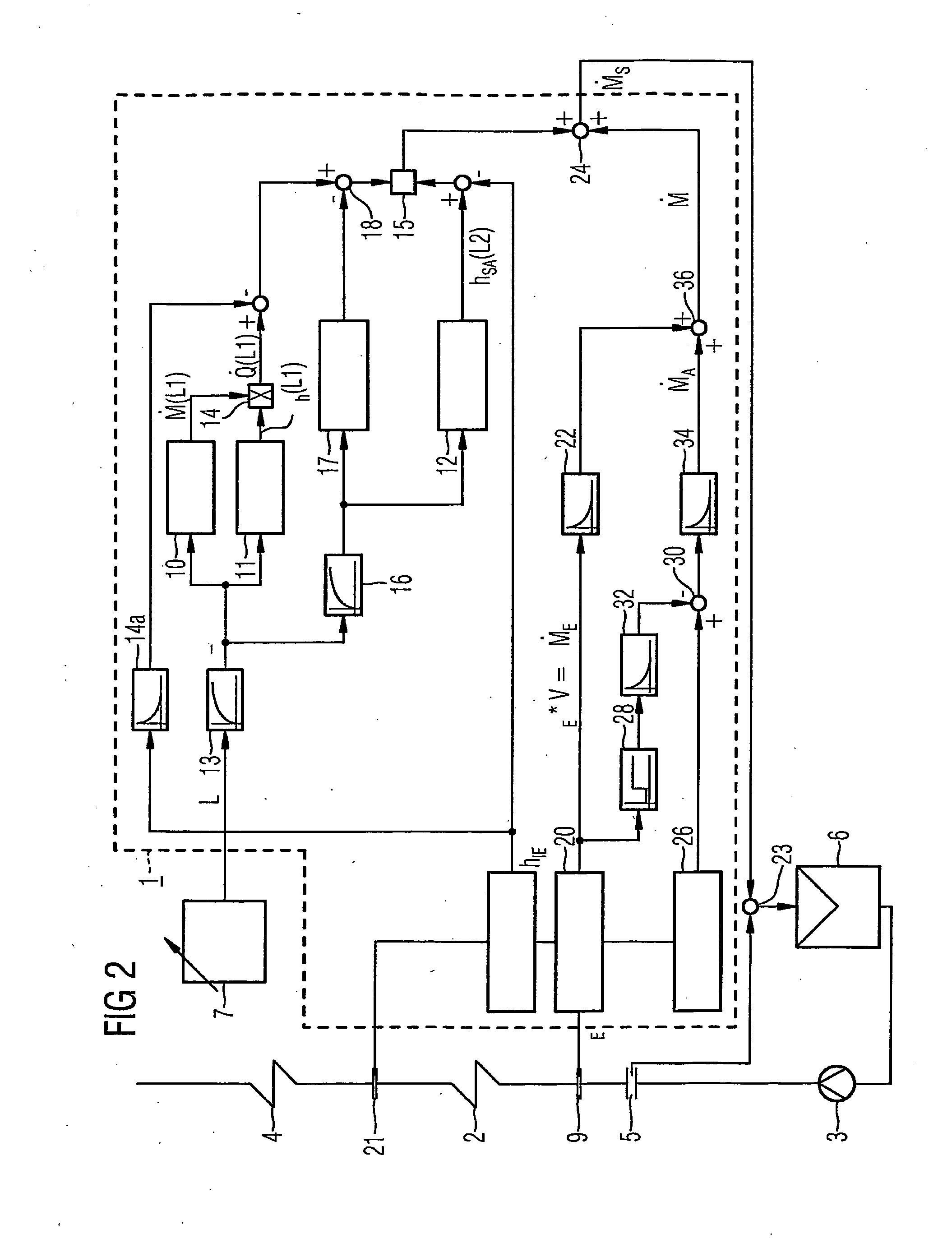

Method for operating a continuous flow steam generator

ActiveUS20110139094A1Increase valueWater circulationBoiler controlEngineeringVolumetric Mass Density

A method for operating a continuous flow steam generator with an evaporator heating surface is provided. A target value for a supply water mass flow is fed to a device for adjusting the supply water mass flow. In order to improve the quality of a predictive supply water or mass flow control and to maintain the enthalpy of the flow medium at the evaporator outlet particularly stable especially when load changes occur, a correction factor is taken into consideration during production of the target value for the supply water mass flow. The correction factor is a characteristic of the temporal derivative of enthalpy or the density of the flow medium at the input of one or more heating surfaces.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

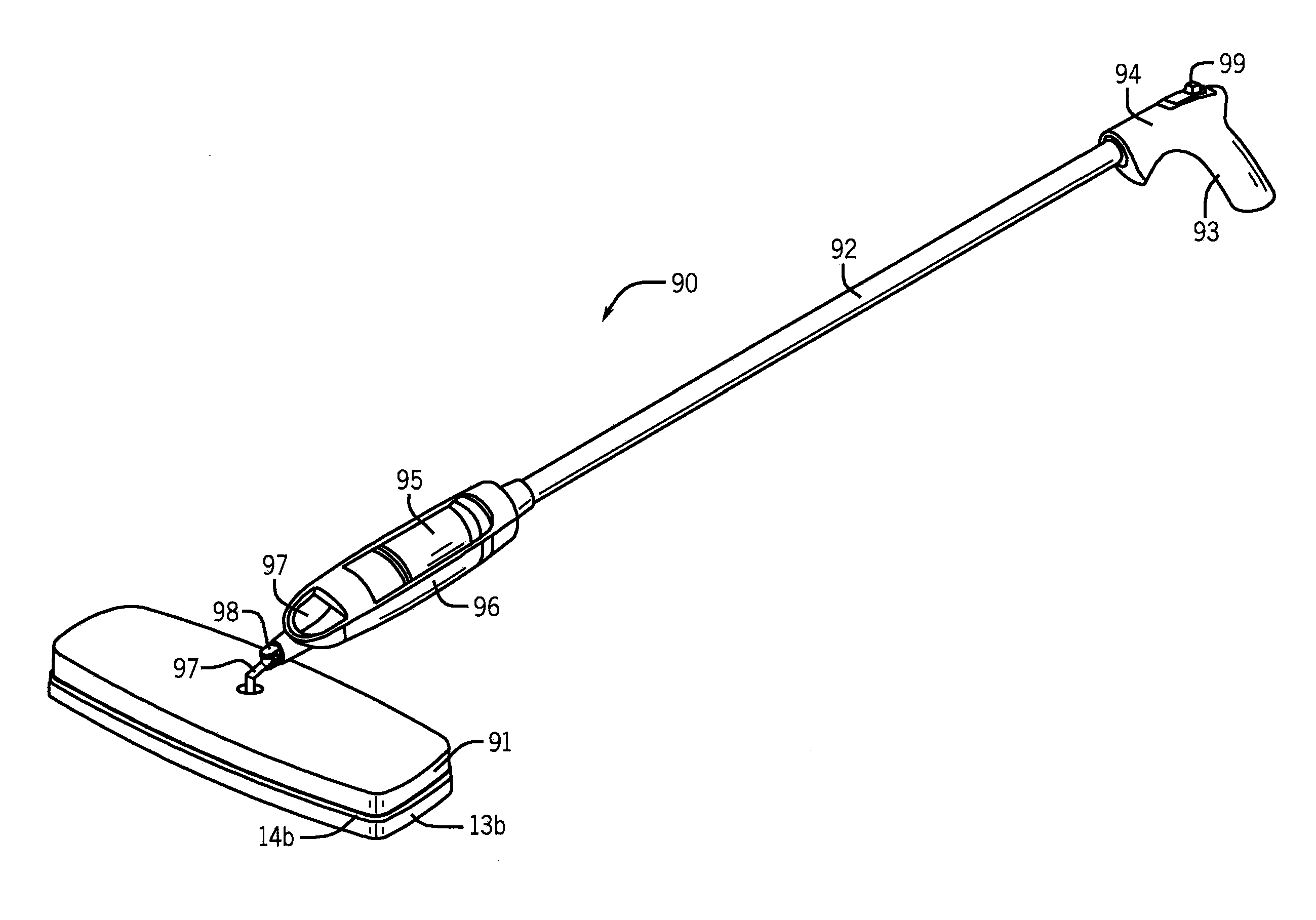

Portable Steam Generating Device

ActiveUS20130312212A1Easy to cleanSteam generation heating methodsReversing gearInterior spaceEngineering

A steam generating device has a handle and a nozzle or pad attached to the handle for treating a surface. The handle includes a heat exchanger, a water reservoir, a fluid conduit in fluid communication with the water reservoir and heat exchanger, and a fluid delivery system for moving water from the water reservoir, through the fluid conduit, and into the heat exchanger. A fuel powered heater is positioned on a side of the wall of the heat exchanger opposite the interior space of the heat exchanger. A first section of the wall of the heat exchanger transfers heat from the heater to water located in the heat exchanger for generating steam from the water located in the heat exchanger. A second section of the wall of the heat exchanger includes an opening that allows steam to exit the heat exchanger and handle and flow through the nozzle or pad.

Owner:SC JOHNSON & SON INC

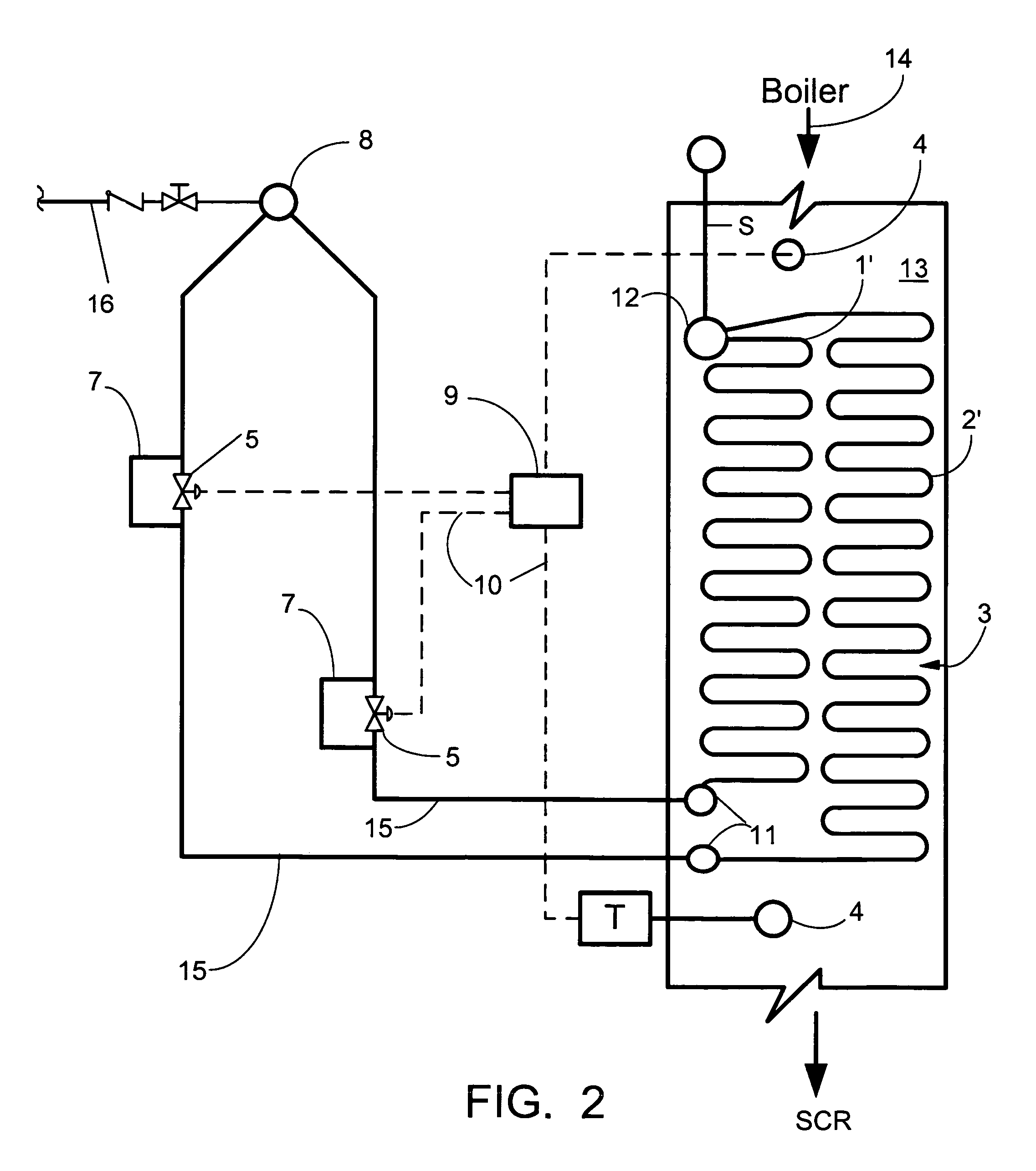

Multiple pass economizer and method for SCR temperature control

InactiveUS7637233B2Raise the outlet temperatureReduce water flowWater circulationFuel injection apparatusTemperature controlFlue gas

A control system for maintaining a desired heat exchanger outlet flue gas temperature across a range of boiler loads. The heat exchanger includes a plurality of tubular configurations in heat exchange contact with the flue gas with each tubular configuration having a separate feedwater inlet. Flue gas temperature control is achieved by modulating the feedwater flow rates through the tubular configurations. In a system having two tubular configurations, the overall heat transfer capacity of the heat exchanger may be reduced to maintain the desired heat exchanger outlet flue gas temperature by reducing feedwater flow through one tubular configuration and overflowing the other, while maintaining the total flow of feedwater through the heat exchanger substantially constant.

Owner:THE BABCOCK & WILCOX CO

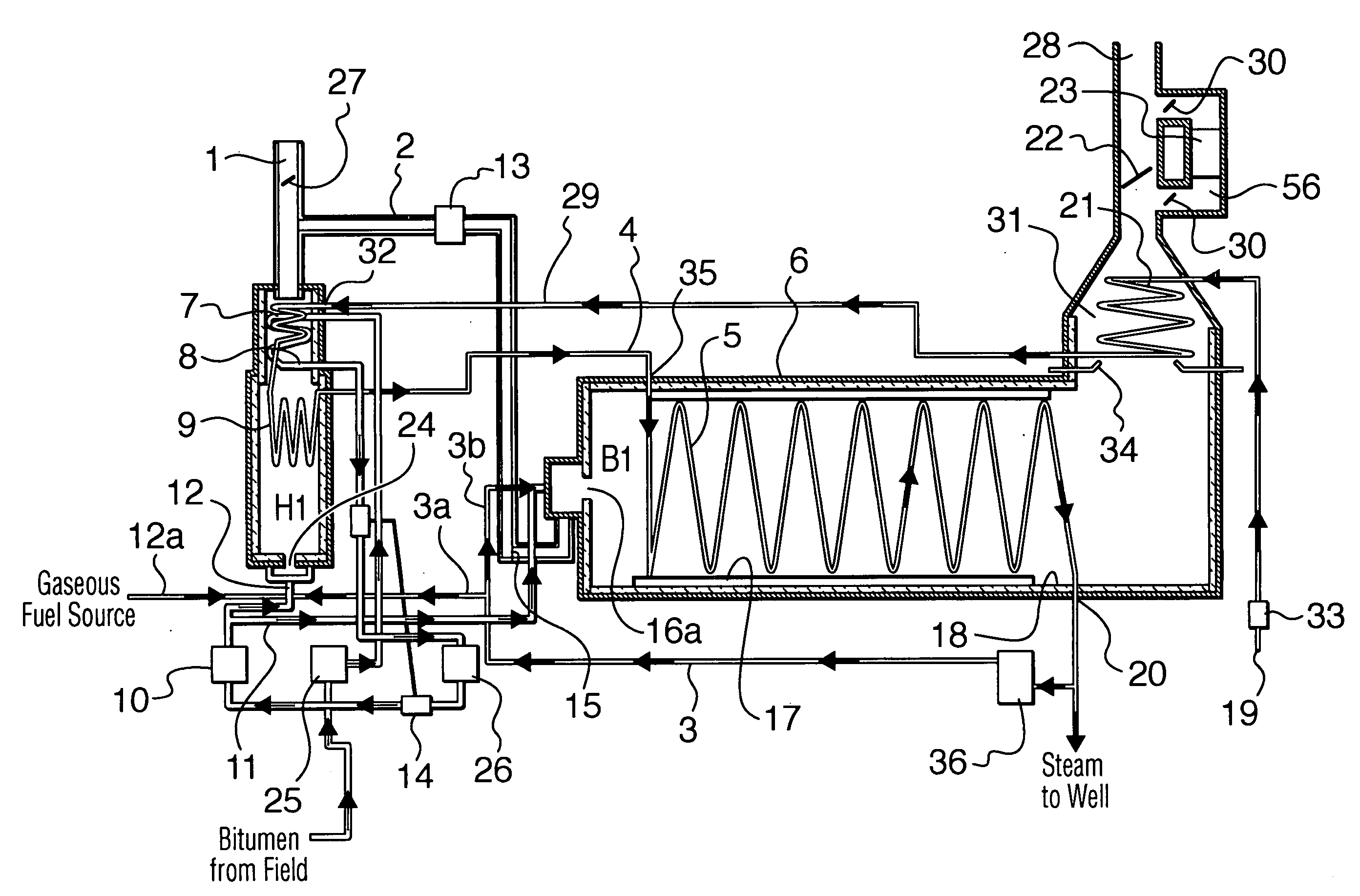

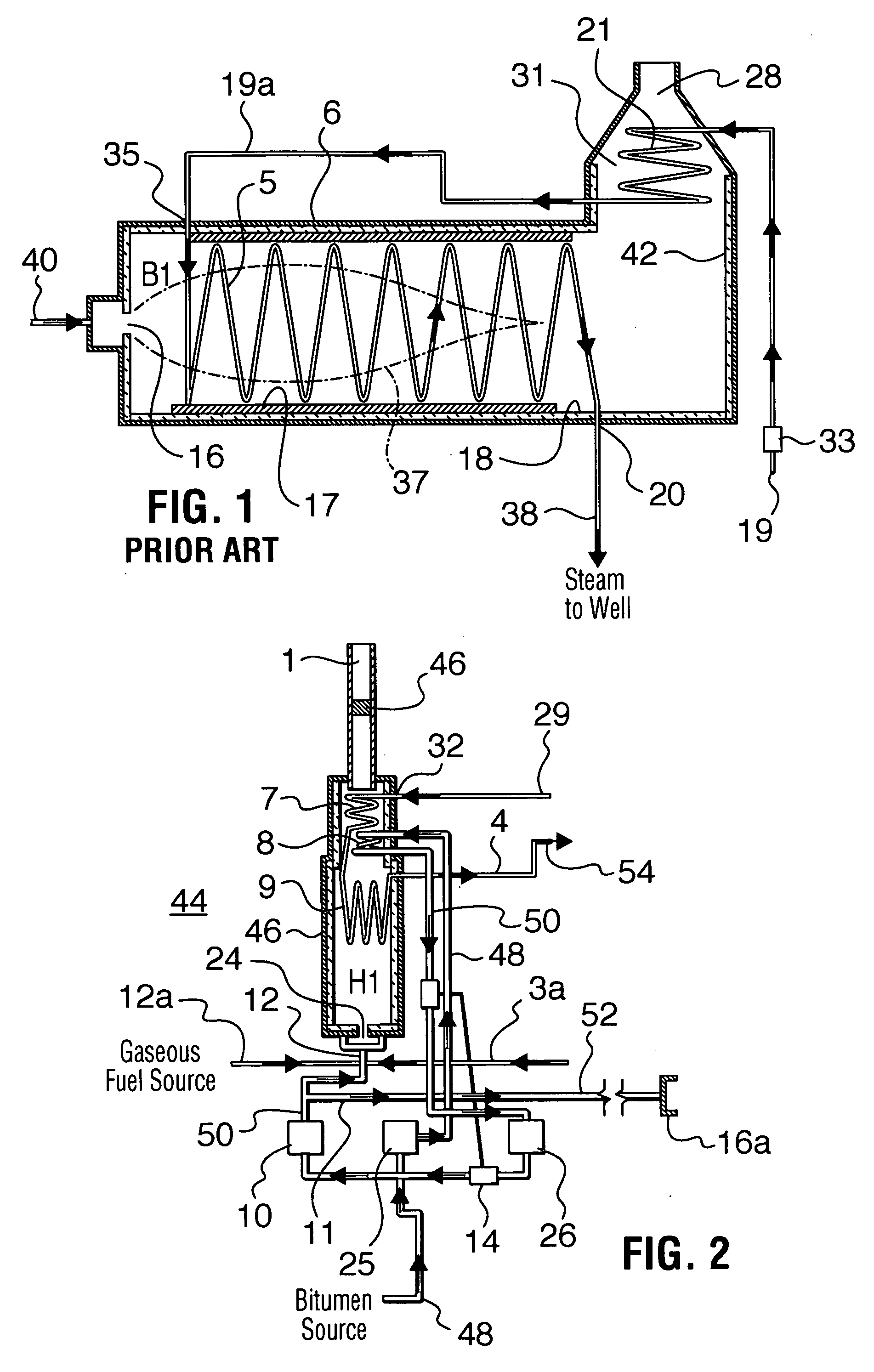

Steam generation apparatus and method

InactiveUS20060065213A1Easy to carryImprove steaming qualityWater circulationSteam boilersEngineeringLiquid fuel

In one aspect, the invention provides a steam generation apparatus that is liquid fuel fired and addresses conversion of gaseous fuel SIB units to operate with liquid fuel. The invention also relates to a conversion unit for a steam injection boiler, a method for converting a steam injection boiler from gas firing to possible liquid fuel firing and a method for generating steam from a liquid fuel source. The invention employs a fired heater for heating the liquid fuel to a temperature suitable for firing and preheats the water to compensate for the shortfall in beat liberation when a gas boiler is converted to use liquid fuel. In another aspect of the invention, production of steam is achievable consistently by employing step-up heaters with a steam injection boiler. The heaters being connected in parallel to continue heating the water / steam to achieve a higher quality steam over that produced in the boiler while minimizing consideration as to the adverse effects of coil fouling in the boiler.

Owner:ACS ENG TECH

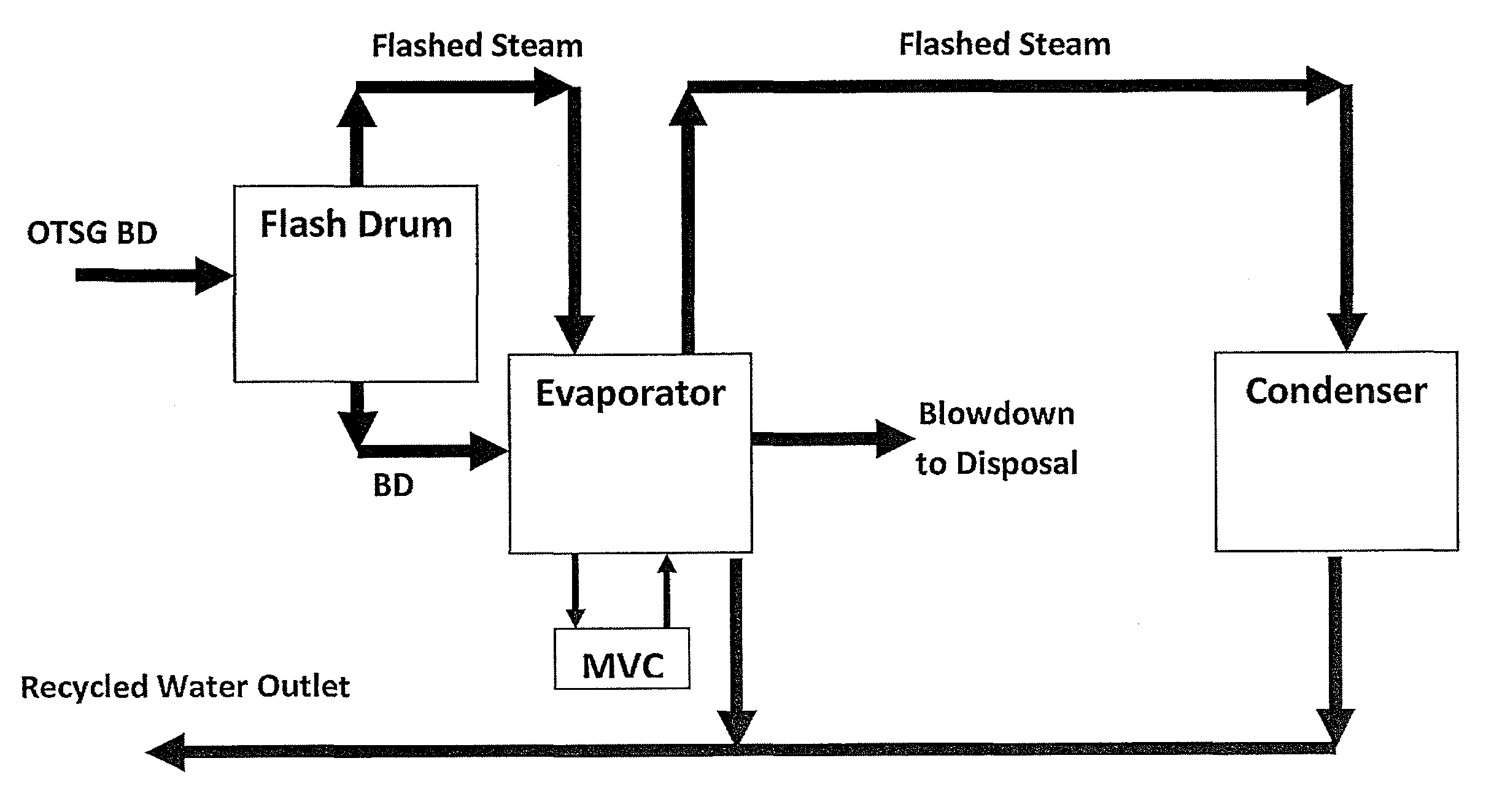

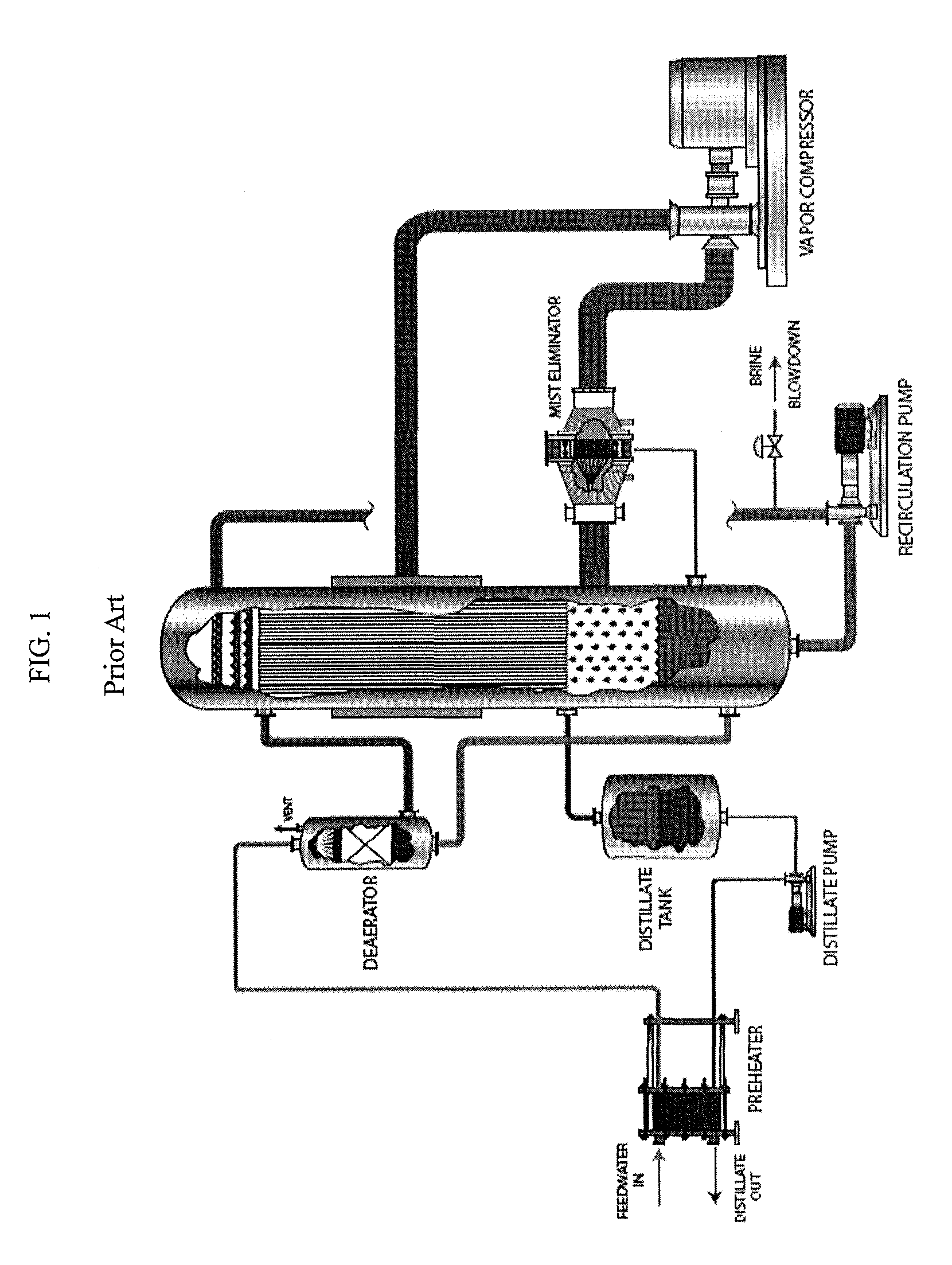

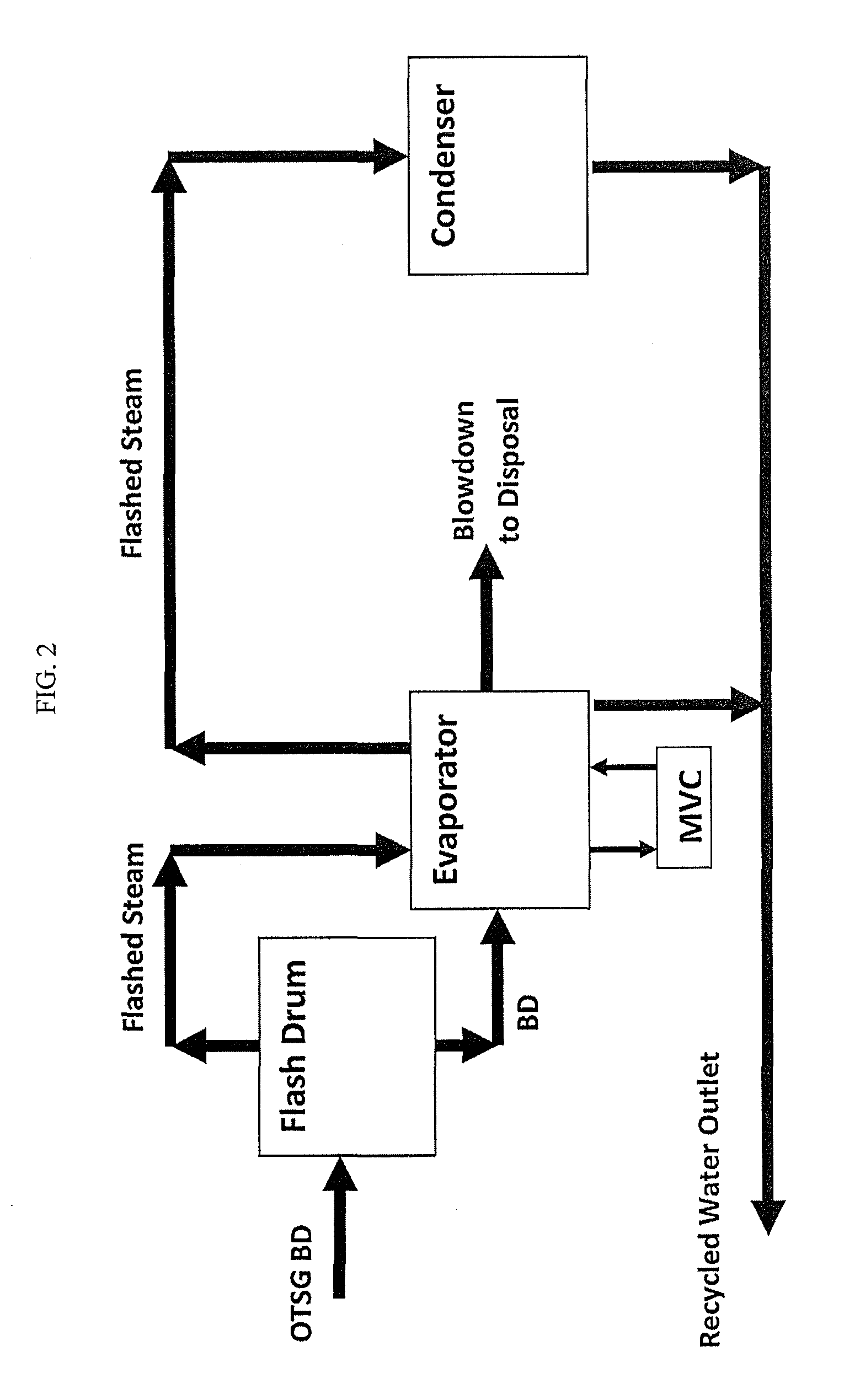

Method and apparatus for recycling water

ActiveUS9085471B2Improve economyReduce power consumptionWaste water treatment from quariesWater circulationLiquid wasteEvaporation

We provide an evaporation based zero-liquid discharge method for generation of steam for enhanced oil recovery (EOR) processes utilizing once-through steam generators (OTSGs). The method includes feeding the OTSG(s) with produced water, vaporizing a fraction of this water for steam injection and blowing down the balance of the water. This water, referred to as OTSG blowdown, can be flashed to produce a vapor stream and a liquid that is fed to a mechanical vapor compression (MVC) evaporative process. The latent energy contained in the vapor stream generated by the upstream flash is beneficially recycled to substantially reduce or eliminate the energy consumption of the MVC process. The evaporative process can be used to reduce the liquid waste for disposal or eliminate the need for liquid disposal by achieving zero liquid discharge.

Owner:AQUATECH INT LLC

Steam generator

InactiveUS20060075977A1Stable and reliable throughflowLow friction pressure lossWater circulationCombustion enginesPipe fittingMechanical stability

A stream generator wherein a continuous evaporating heating surface is disposed in a heating gas duct through which a heating gas flows in an approximately horizontal manner. The continuous evaporating heating surface comprises a plurality of steam-generating pipes which are connected in a parallel manner enabling flowthrough of a flow medium, and is configured in such a manner that a steam-generating pipe which is heated more than another stream-generating pipe of the same continuous evaporating heating surface has a higher throughput of a flow medium compared to the other steam-generating pipe. An object is to produce a particularly low-cost steam generator exhibiting particularly high mechanical stability with different thermal loads. The steam-generating pipe respectively comprises a riser pipe piece which can be cross-flown in an upward direction and which is arranged in an approximately vertical manner in relation to the flow medium; a down pipe piece which can be cross-flown in a downward direction downstream from said flow medium side and another riser pipe piece which can be cross-flown in an upward direction by a flow medium and which is arranged in an approximately vertical manner downstream from the latter flow medium side. Preferably, the other riser pipe piece of the respective steam-generating pipe is arranged in the heating gas duct, when seen in the direction of the heating gas, between the riser pipe piece associated therewith and the down pipe piece associated therewith.

Owner:SIEMENS AG

Small supercritical once-thru steam generator

A small supercritical once-through steam generator (OTSG) includes a radiant section with a furnace coil, and a convection section downstream of the radiant section that includes a superheater which is fluidically connected to the furnace coil. Optionally, the OTSG is devoid of a steam separator. An economizer can also be included downstream of the superheater. Supercritical steam can be generated using the OTSG, for use, among other things, in enhanced oil recovery applications.

Owner:THE BABCOCK & WILCOX CO

Process for Operating a Continuous Steam Generator

ActiveUS20080066695A1The method is simple and reliableRelieve pressureWater circulationGas pressure propulsion mountingWater qualityEngineering

The invention relates to a process for operating a continuous steam generator. The aim of the invention is to provide, with little technical complexity and for any operating state, a synchronous variation of the feed-water mass flow passing through the evaporator heating surface and of the heat input into the evaporator heating surface. To this end, a regulating device for the discharge of feed-water is allocated to a device for adjusting the feed-water mass flow. The control variable of said regulating device is the feed-water mass flow, while its set-point value in relation to the feed-water mass flow depends on the set-point value associated to the power of the steam generator. The actual value of the feed-water density at the entry of the pre-heater is fed to the regulating device for the discharge of feed-water as one of the input values.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

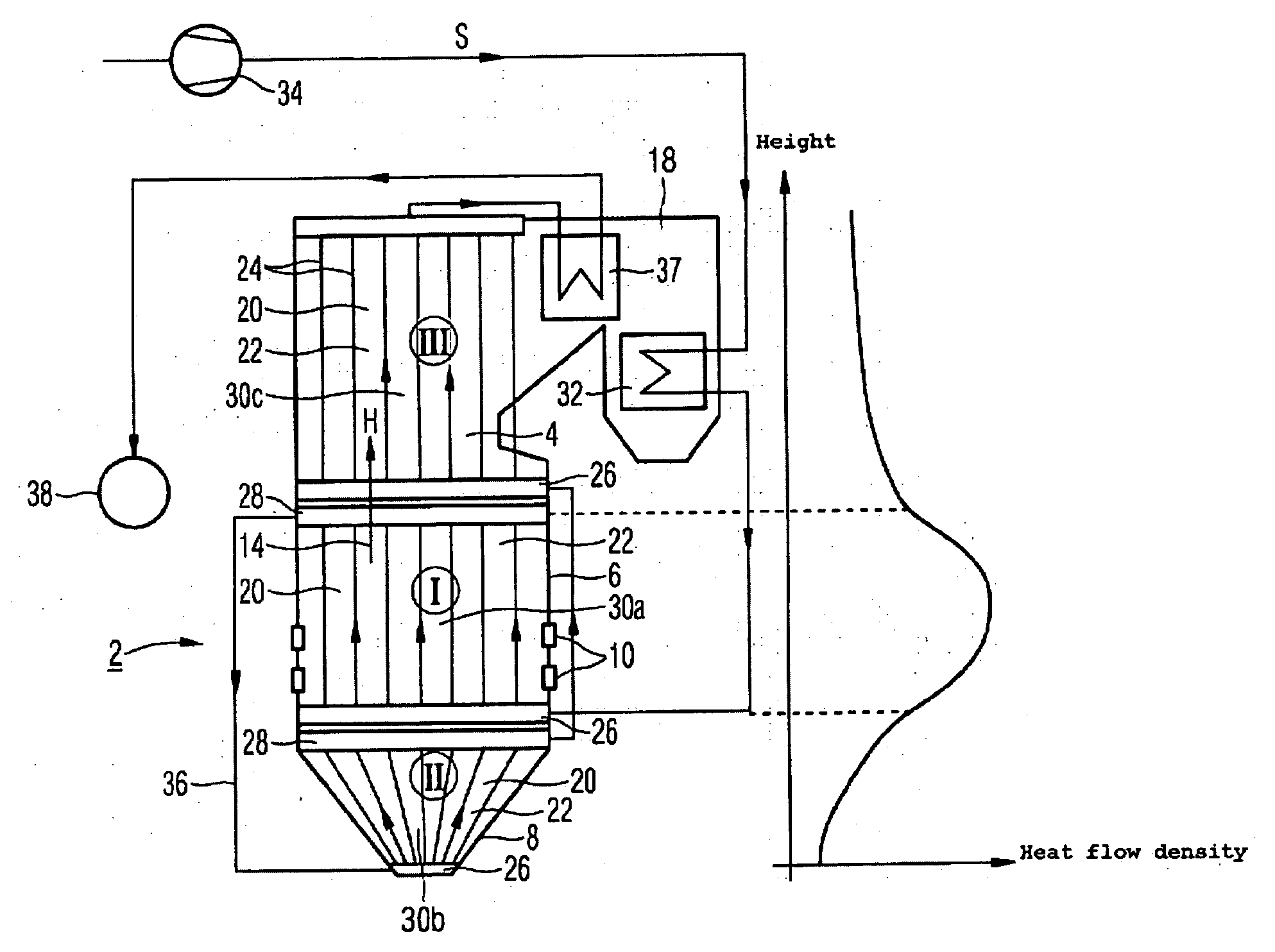

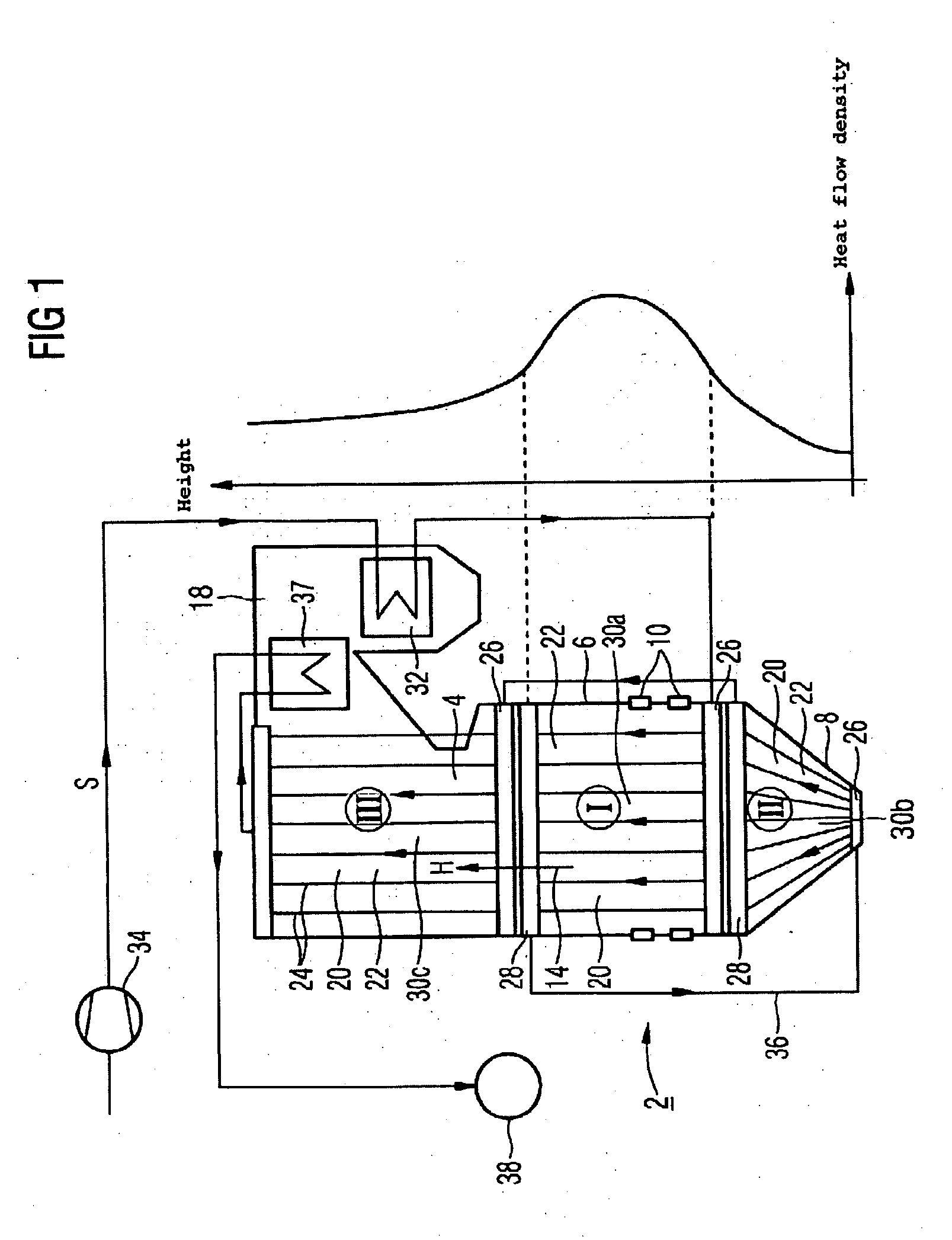

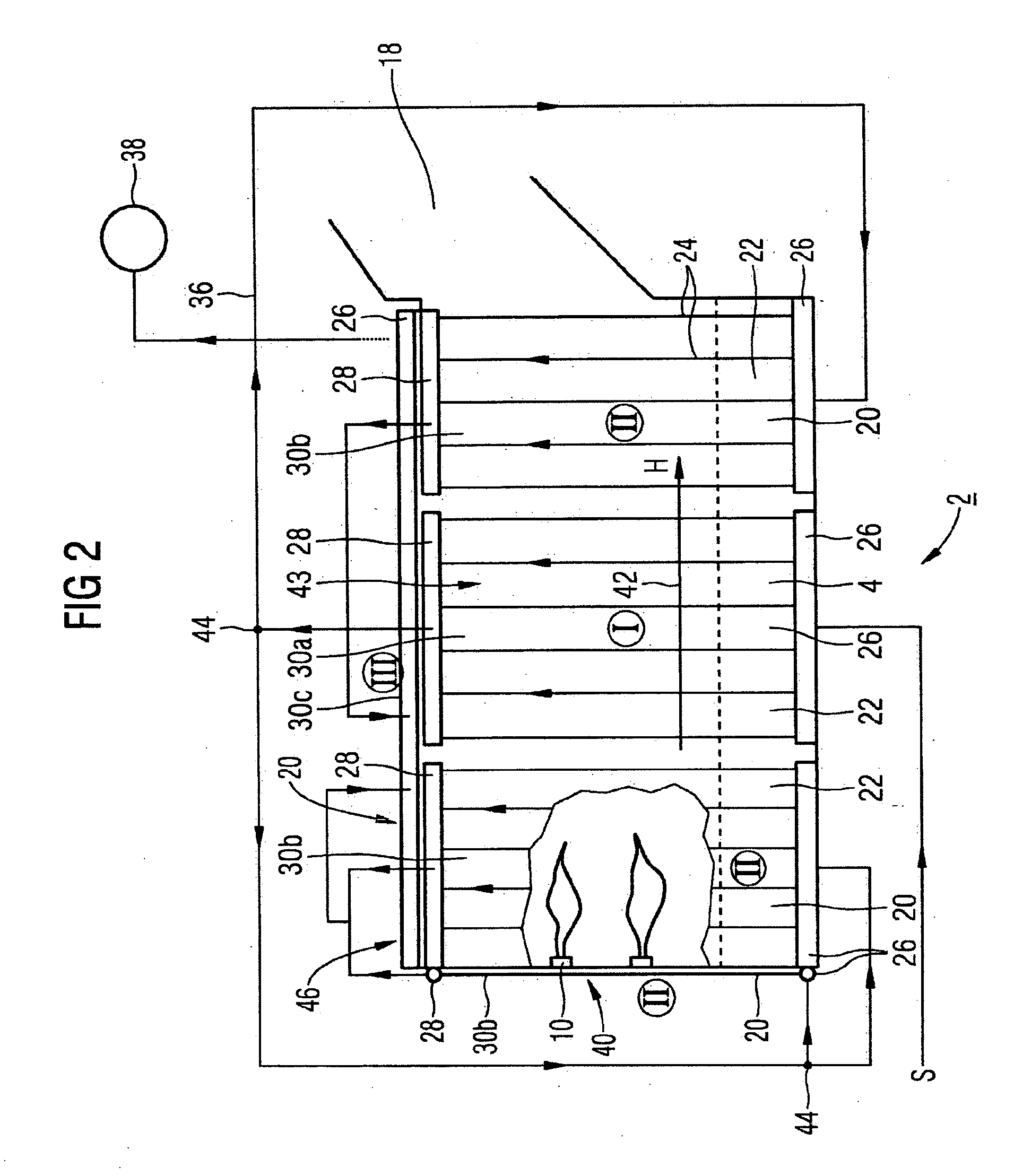

Fossil-Fuel Heated Continuous Steam Generator

InactiveUS20080257282A1Simple structureWater circulationFuel injection apparatusCombustion chamberEngineering

The invention relates to a fossil-energy heated continuous steam generator, whereby the at least one combustion chamber, viewed in the flow direction of the hot gases, is divided into at least two throughflow segments, formed by evaporator heating surfaces, whereby the evaporator heating surfaces each comprise steam generation tubes welded to each other in a gastight manner and pressurized in parallel with a flow medium. According to the invention, said generator is suitable for operation with high fresh steam parameters, such as for example, steam temperatures of approximately 700° C., with a simple construction and particularly simple assembly, whereby a throughflow segment, arranged after the first through flow segment, viewed in the direction of flow of the hot gases, forms the first evaporator stage for the flow medium, such that the injection of particularly cold flow medium can occur in the region of maximum heating.

Owner:SIEMENS AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com