Patents

Literature

21202results about "Efficient regulation technologies" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

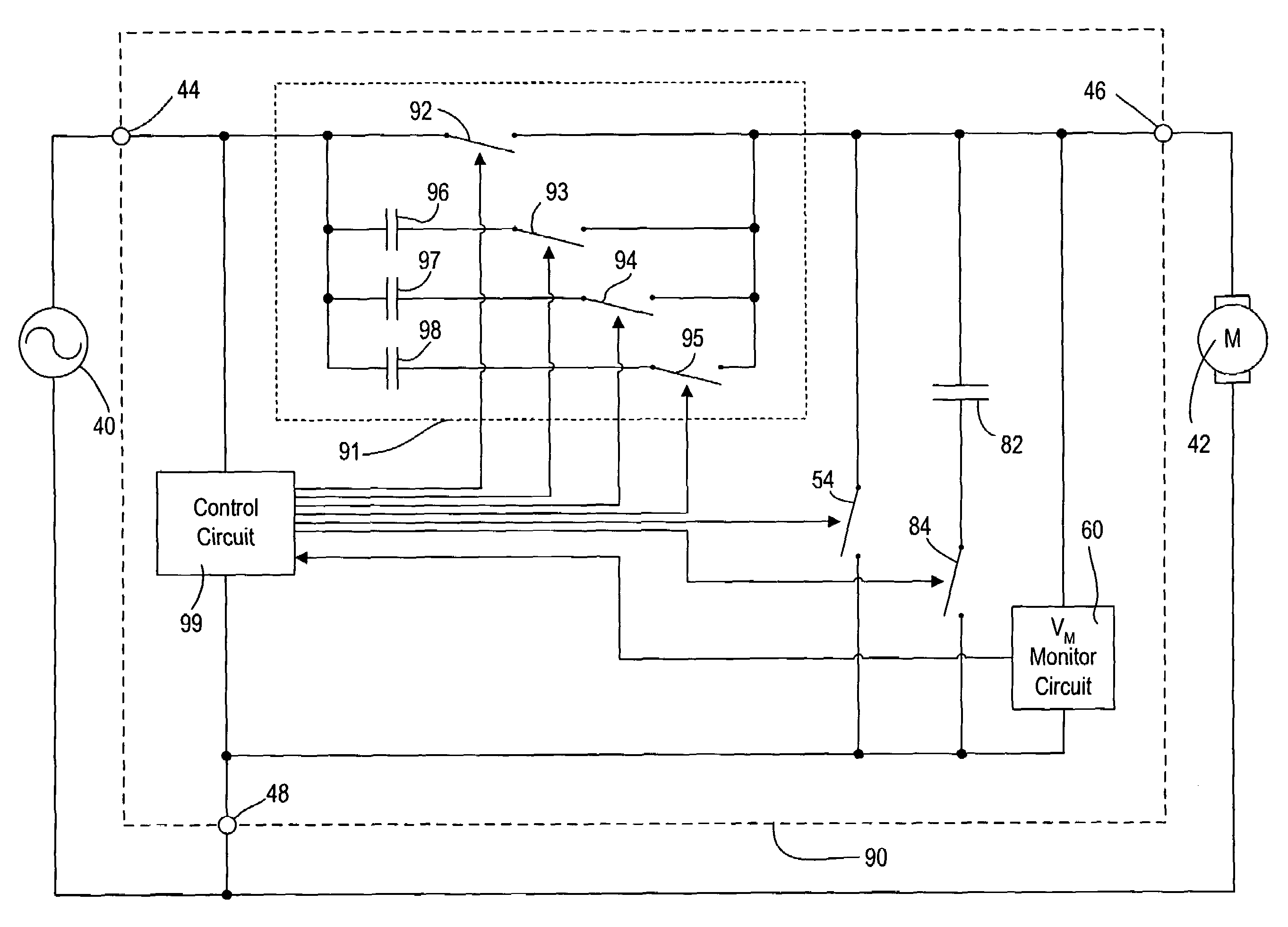

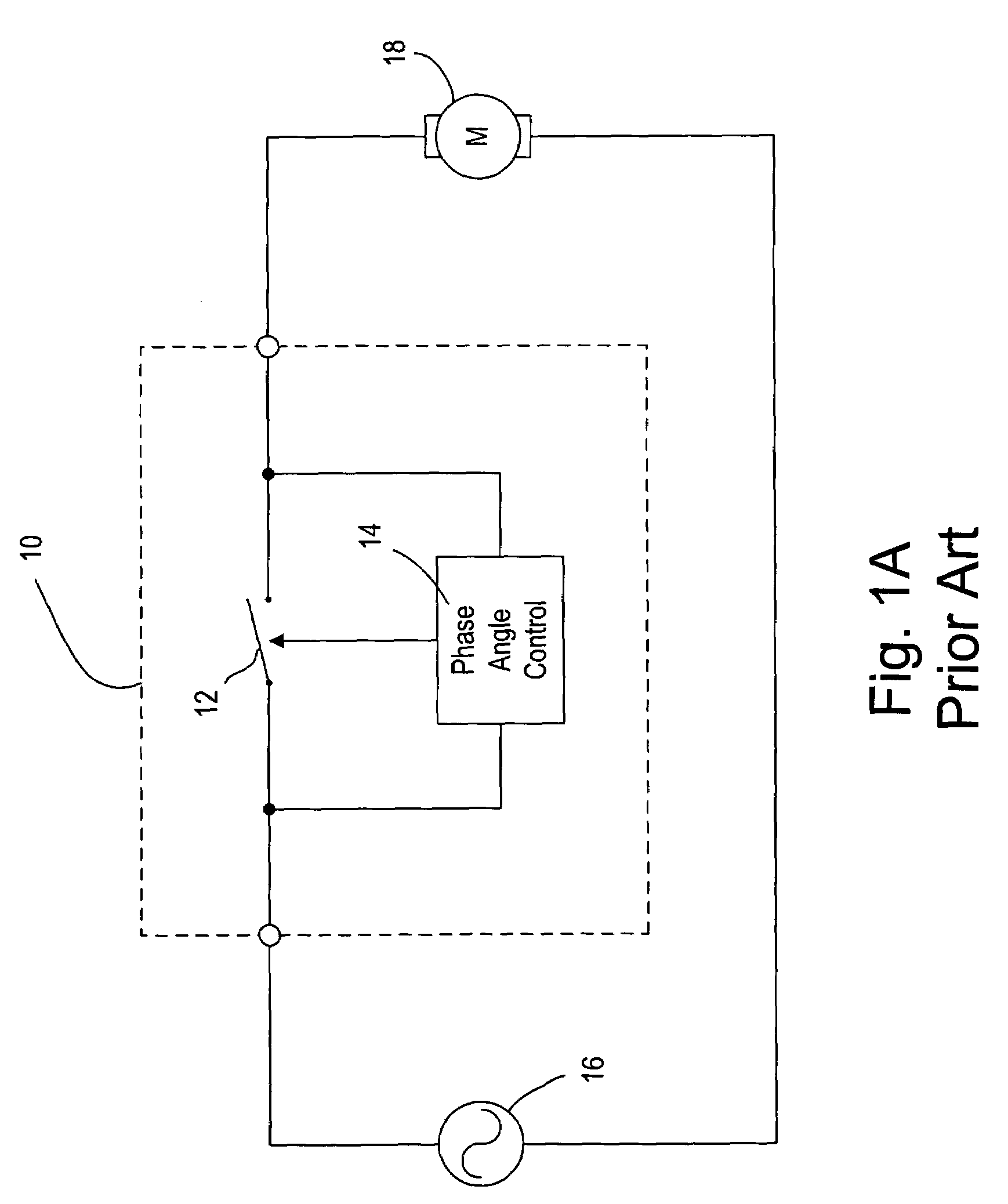

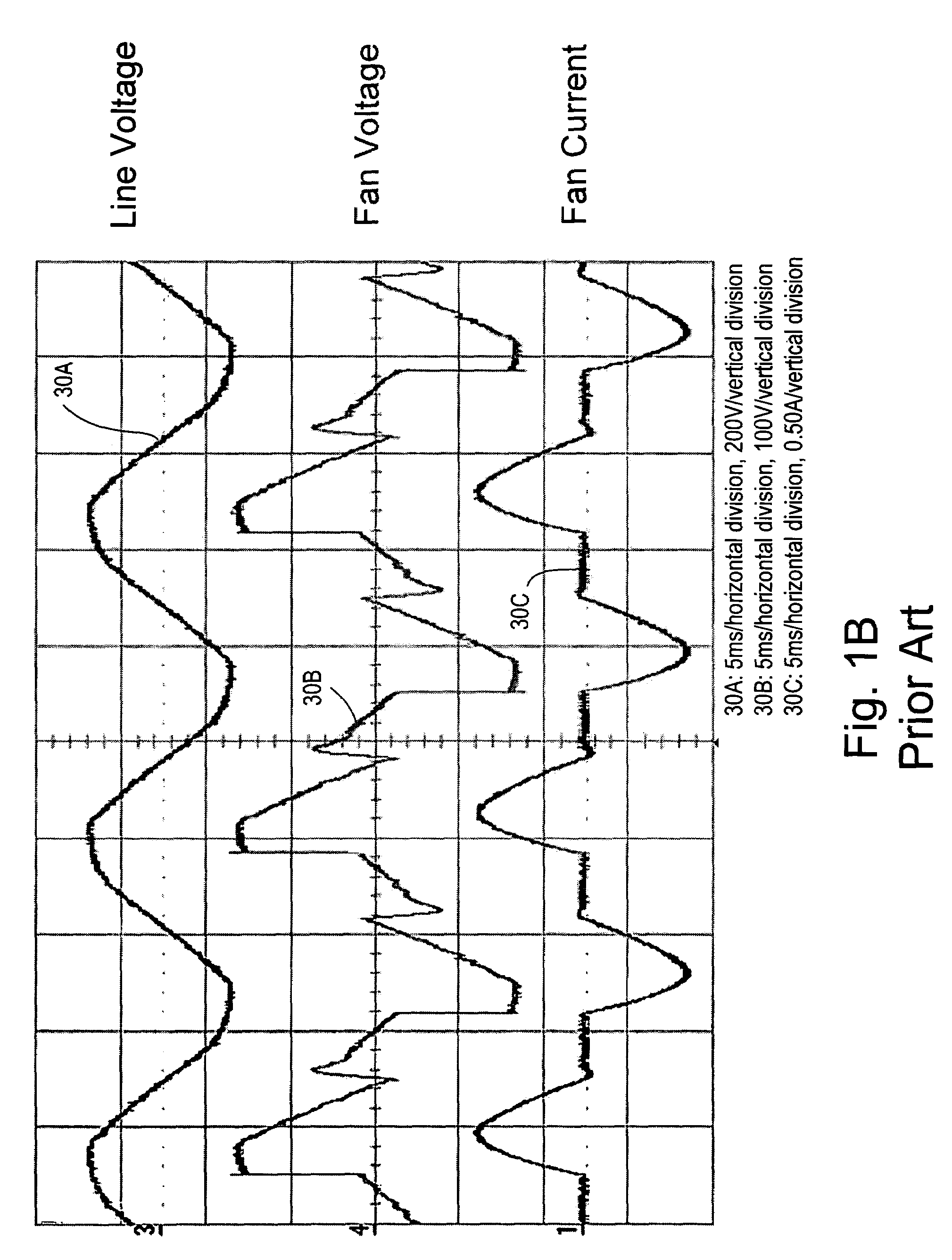

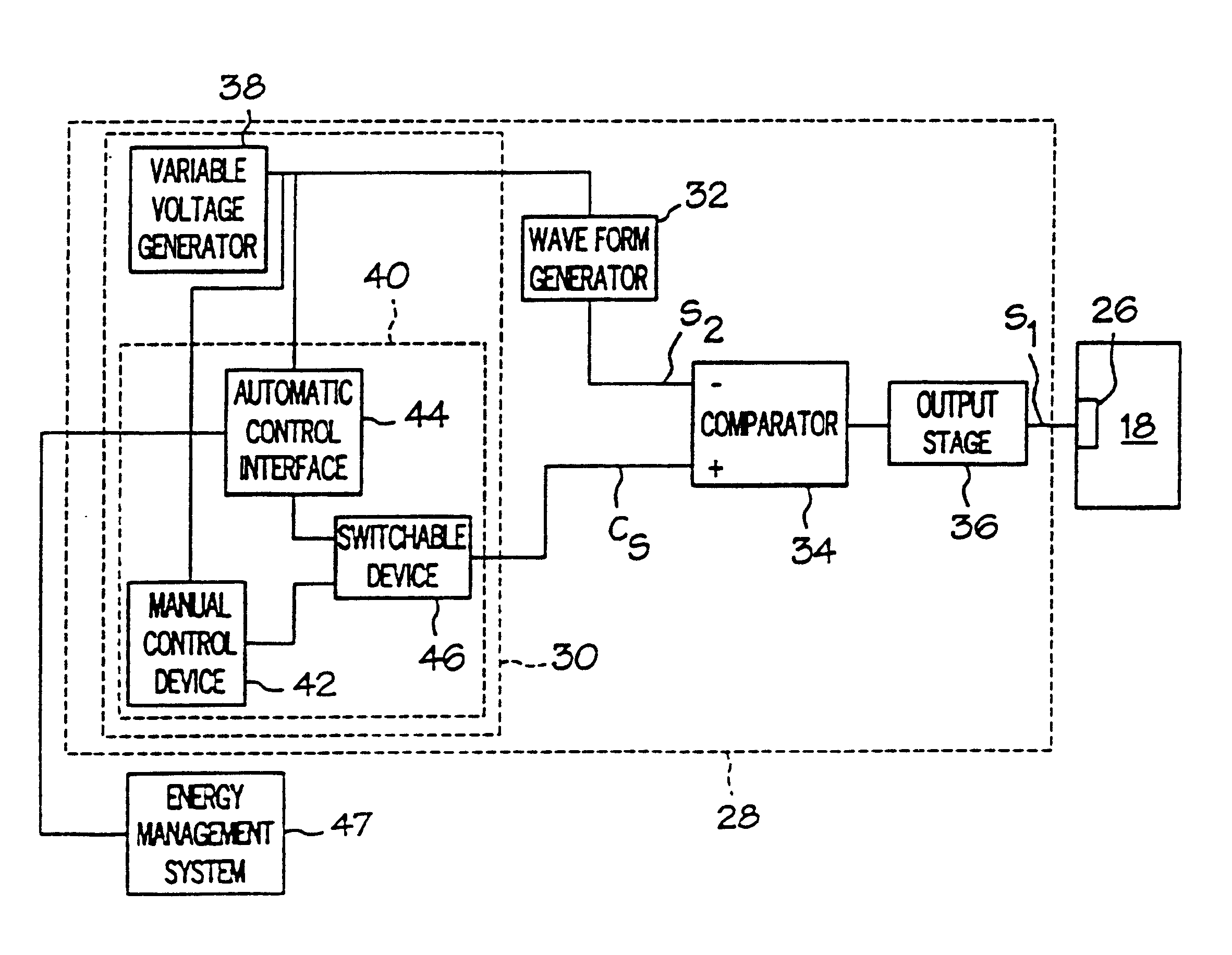

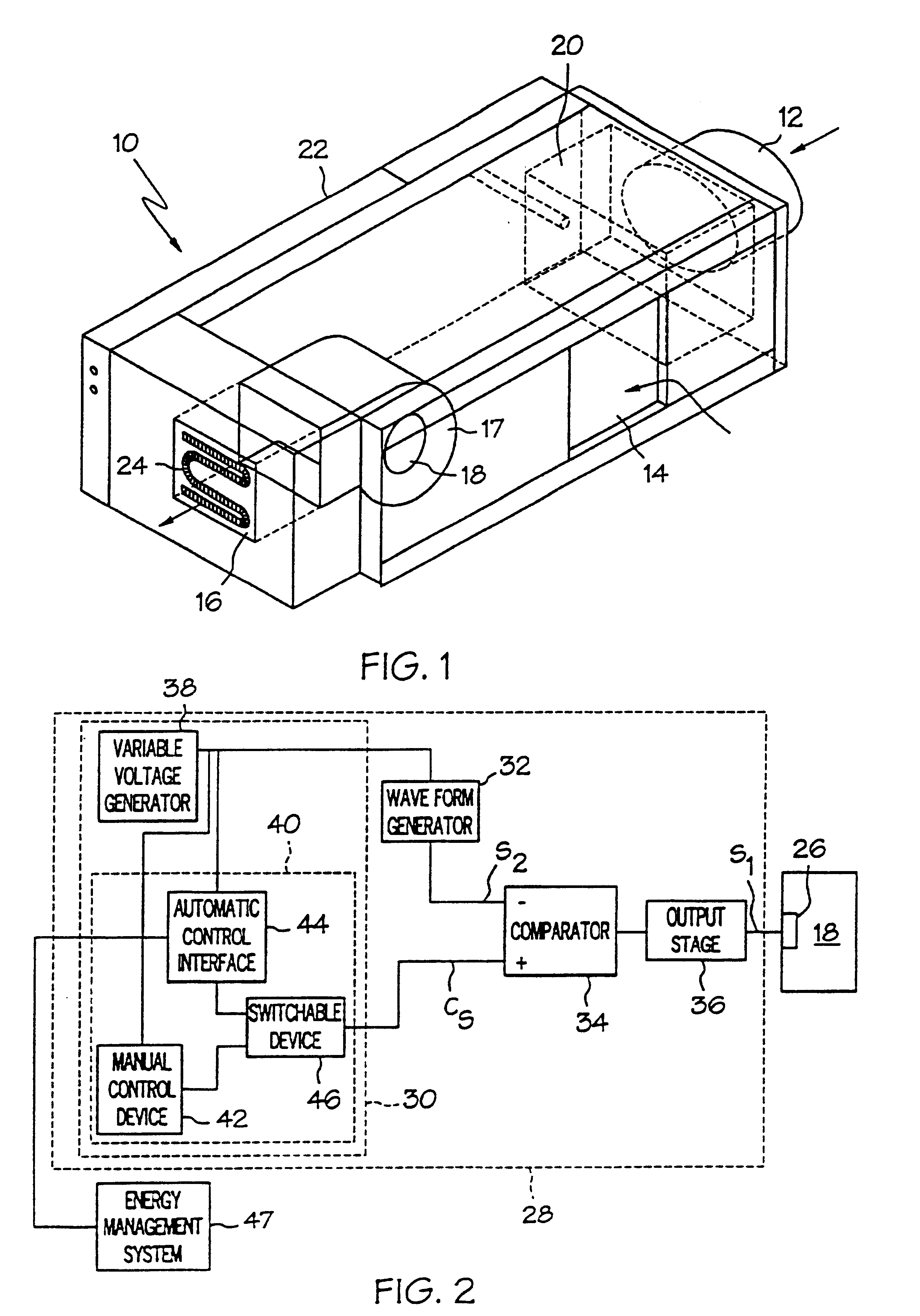

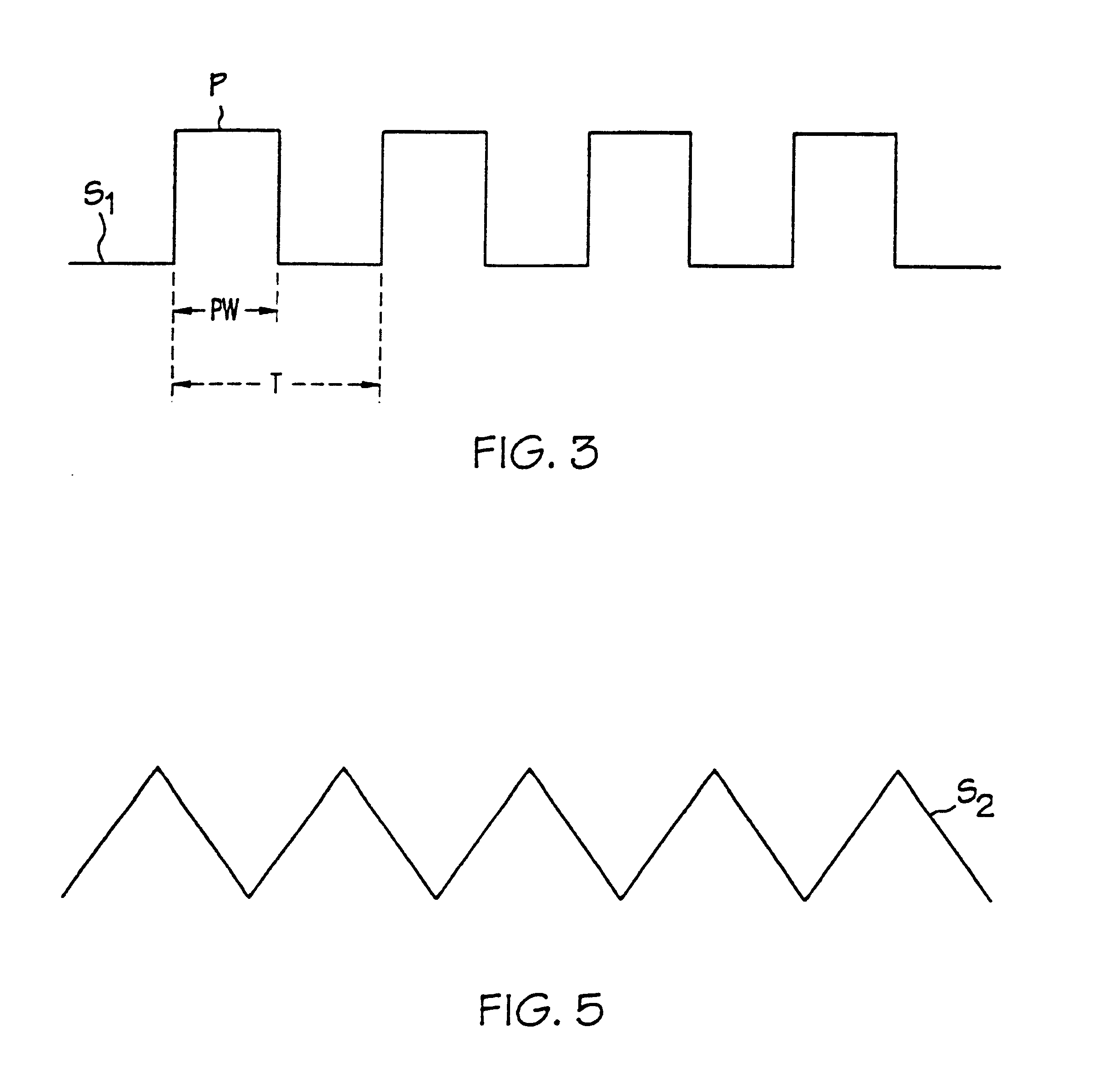

Method and apparatus for quiet variable motor speed control

ActiveUS7330004B2Single-phase induction motor startersMotor/generator/converter stoppersMotor speedEngineering

An apparatus for controlling the speed of an AC motor comprising a switch adapted to be coupled in parallel with power terminals for the AC motor; a capacitor coupled in series with the parallel combination of the switch and the motor; the capacitor adapted to provide an AC supply voltage from an AC source to the parallel circuit comprising the motor and the switch; and a control circuit for controlling the conduction time of the switch in order to vary the speed of the motor. The switch is preferably pulse-width modulated at a frequency twice the line frequency of the AC supply voltage, and the switch is turned on when the voltage across the AC motor is zero volts. The apparatus is operable to provide for continuously variable control of the motor speed while minimizing acoustic noise in the motor.

Owner:LUTRON TECH CO LLC

Refrigeration monitor unit

InactiveUS20070220907A1Food quality is not compromisedAvoid damageProgramme controlPower network operation systems integrationRefrigeration compressorControl system

A control unit is attached to or embedded within a refrigeration appliance to monitor electric power voltage and / or frequency supplied by the mains. If the unit detects a sag or peak in either the voltage or frequency, the control unit either separates any high demand elements of the appliance from the mains to reduce demand in a sag or energizes the elements in a peak. When the control system separates the refrigeration compressor from the mains, a food spoilage monitoring system monitors the food storage compartments. This system utilizes food industry temperature and time algorithms to ensure the food does not spoil. If food spoilage could occur, the unit re-energizes the compressor to allow it to lower the temperature provided the power is sufficient to operate the compressor unit without damaging it. Once the sensed temperature is restored to a safe level, the unit separates the compressor from the mains.

Owner:RANCO OF DELAWARE

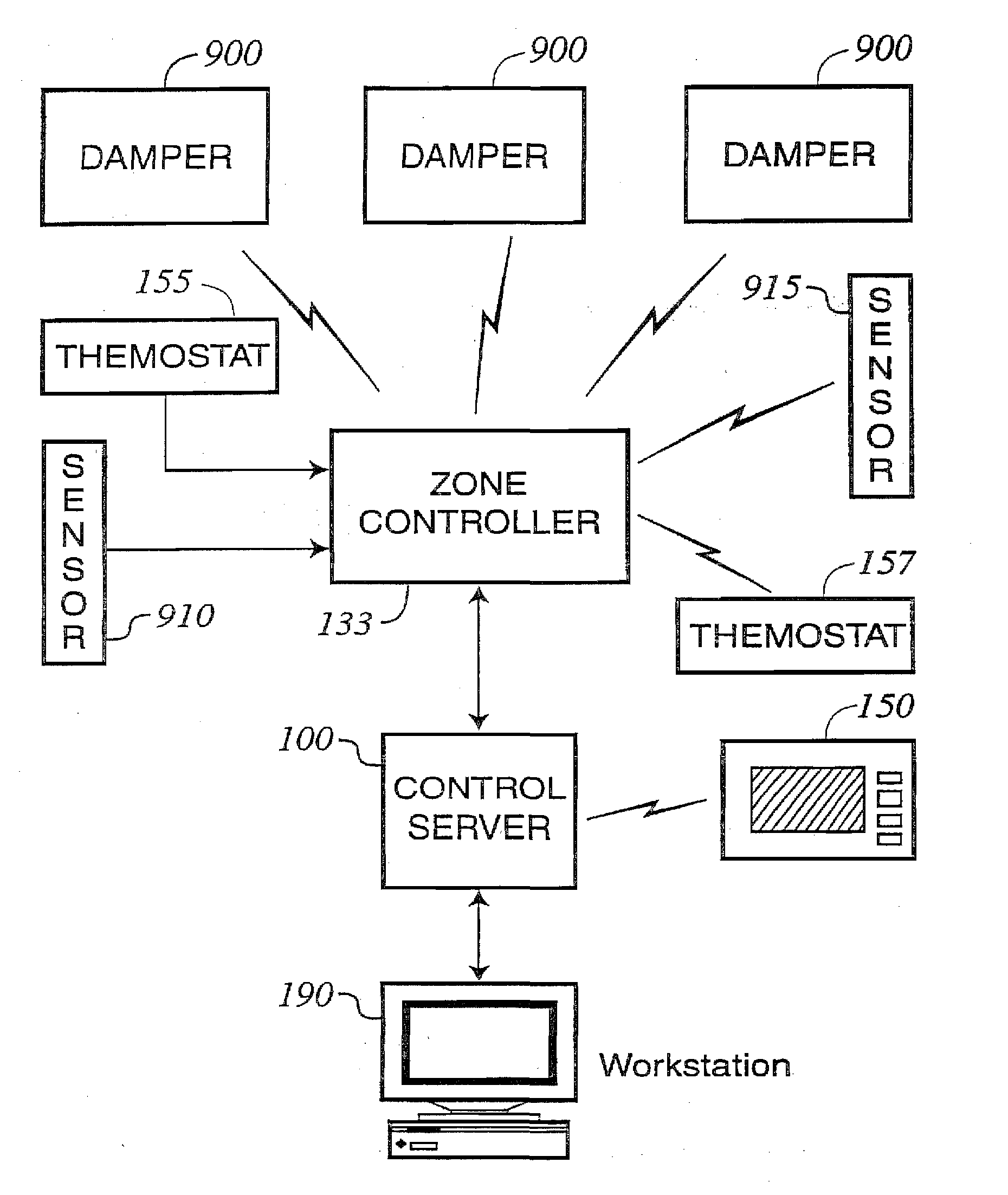

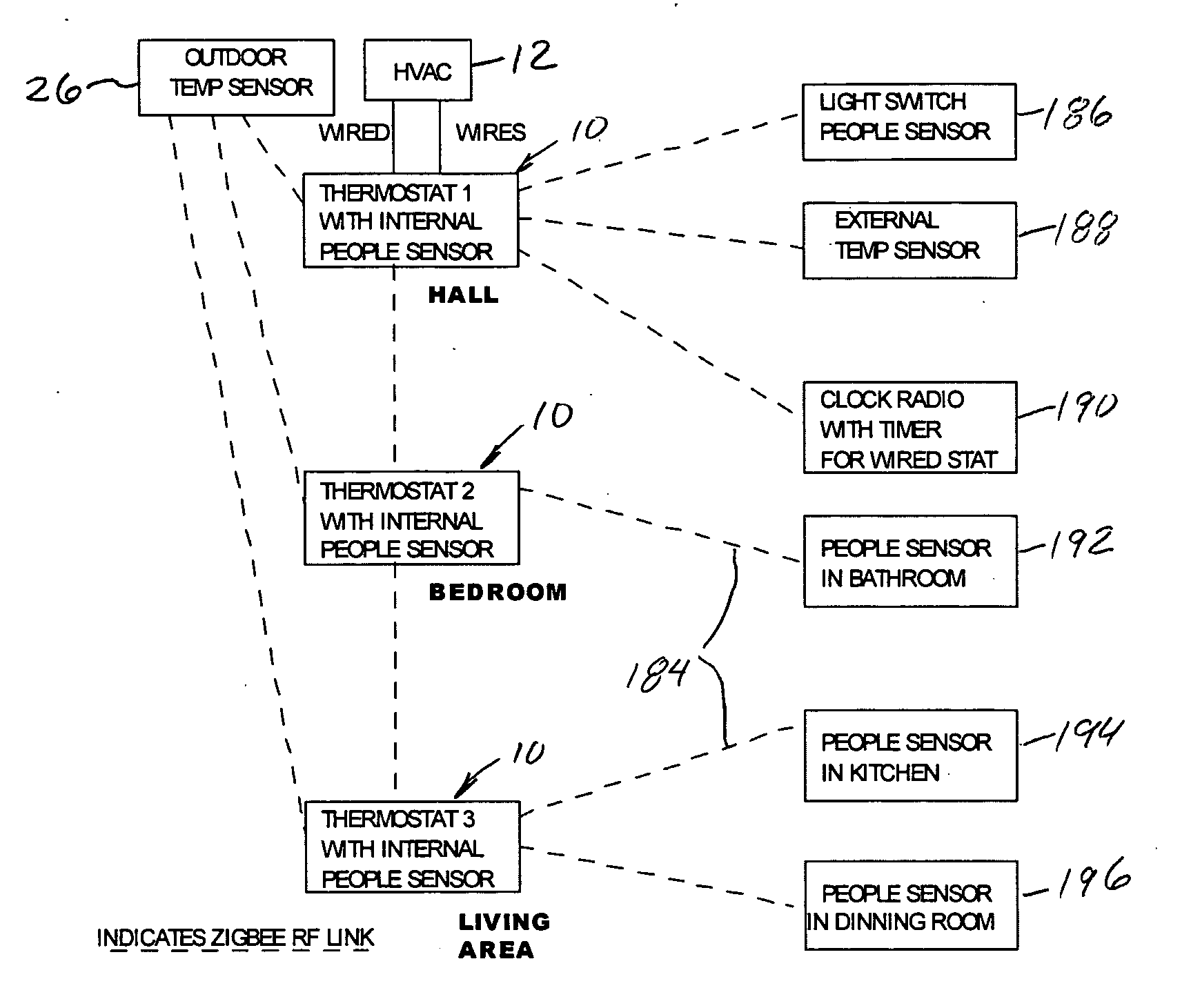

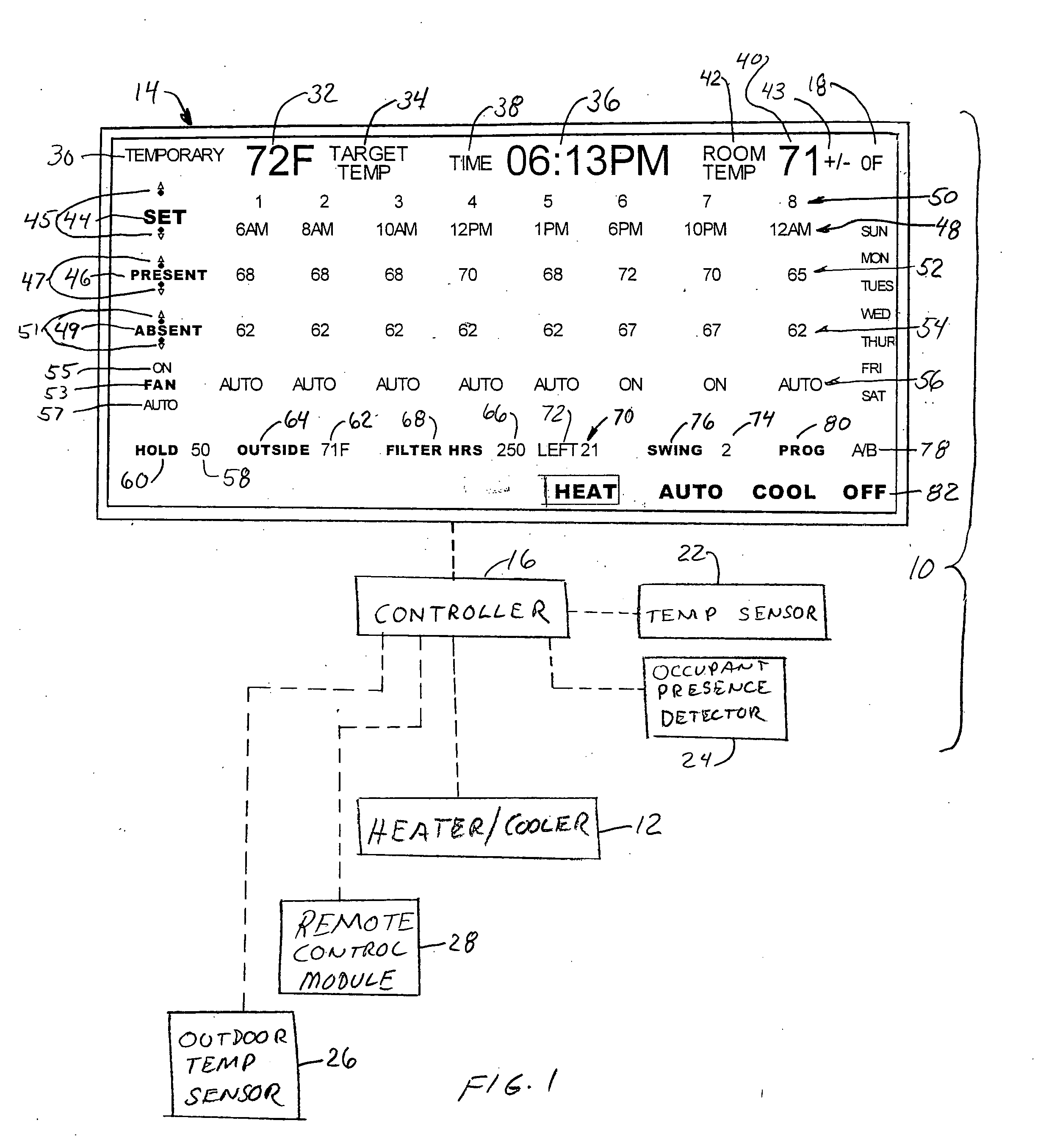

Multiple thermostat installation

At least first and second thermostats may be operably coupled to one another and are capable of sharing their target temperatures and their temperature signals. The first thermostat may provide a thermostatic control signal to the air temperature control system. In some embodiments at least one thermostat further comprises a target-temperature-modifying occupant presence detector. Some embodiments further comprise first and second air movement control devices operably coupled to and controlled by the first and second thermostats, respectively. The operation of the stages of a multistage air temperature control system may be controlled.

Owner:TIM SIMON

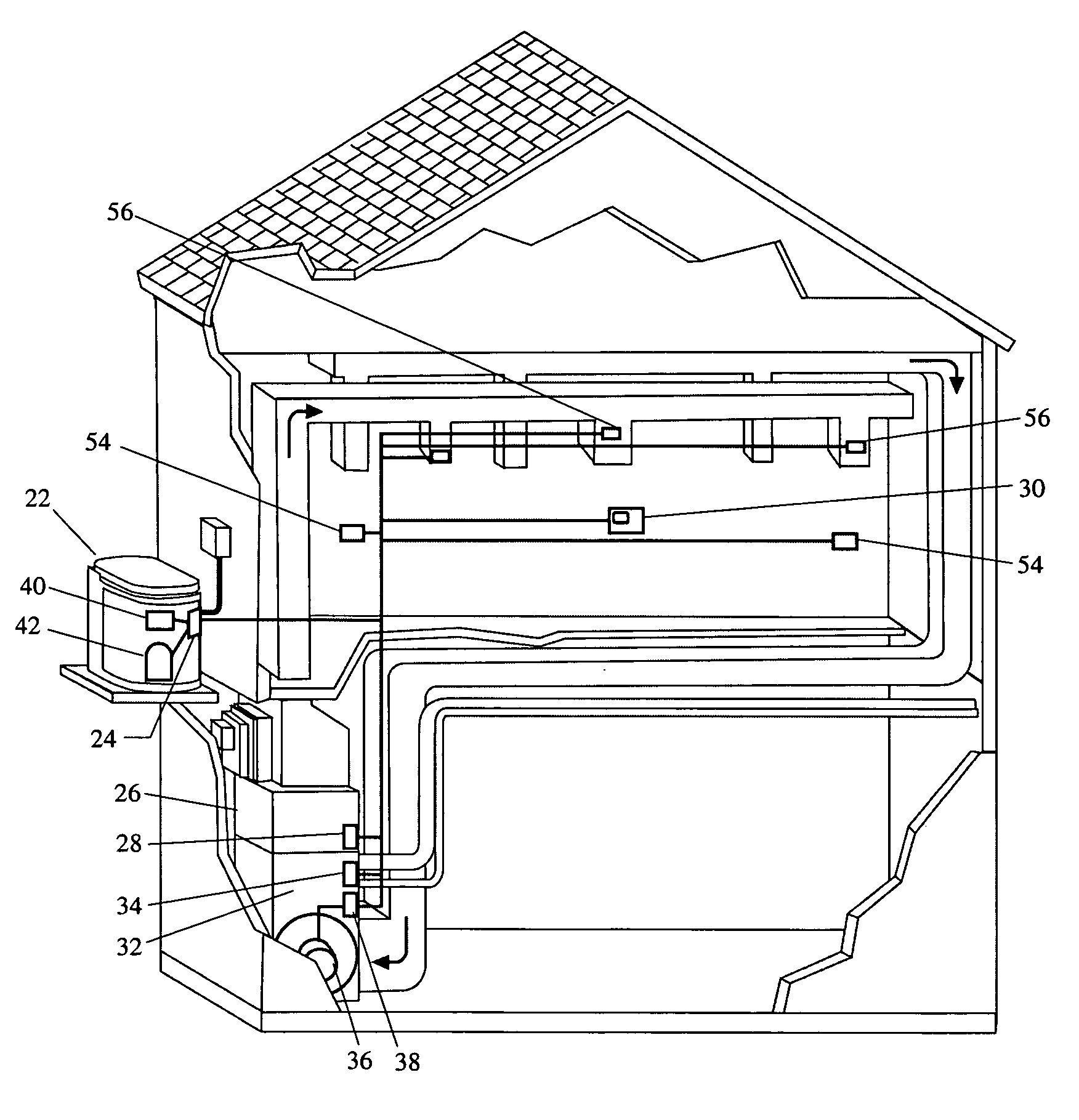

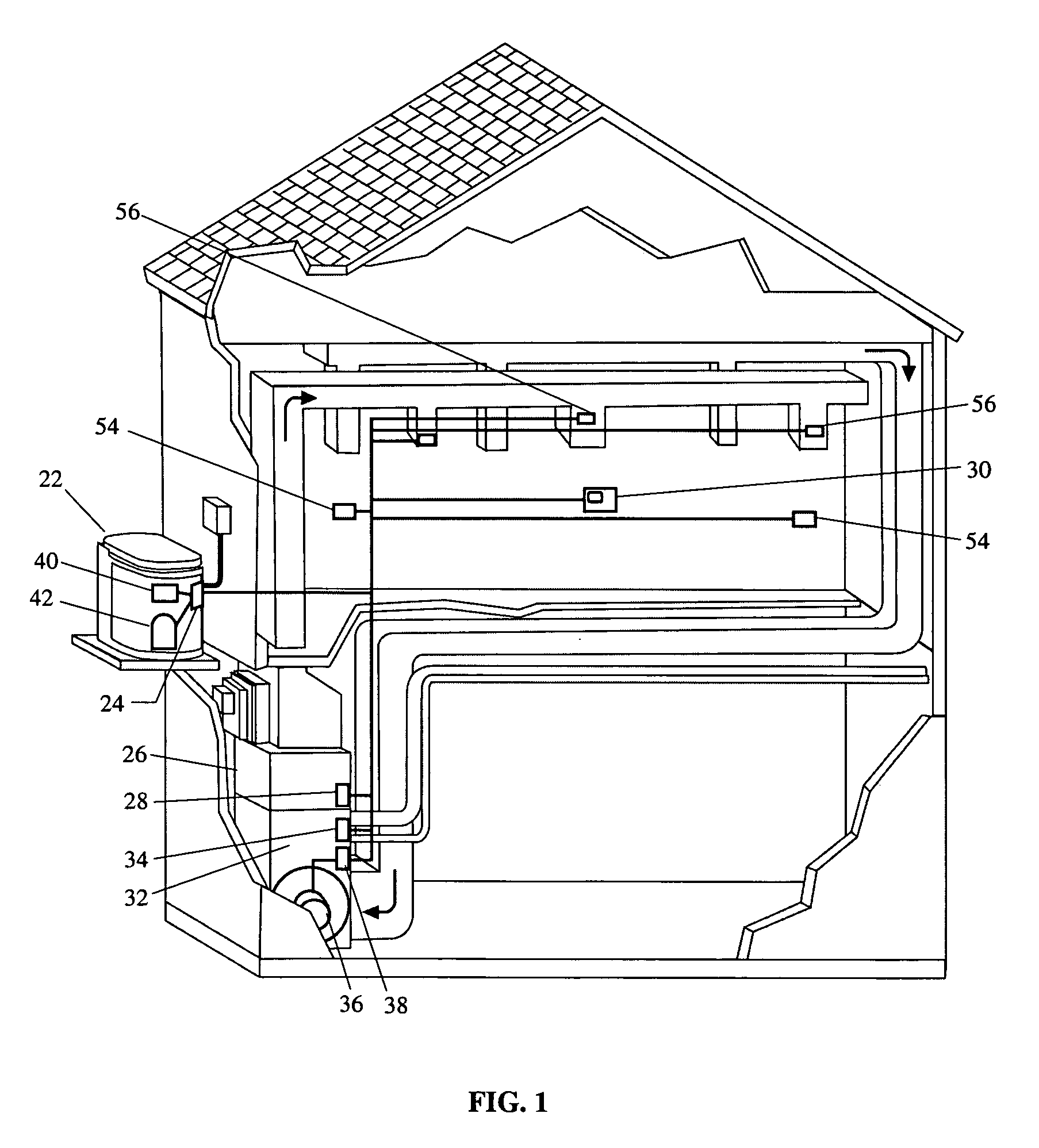

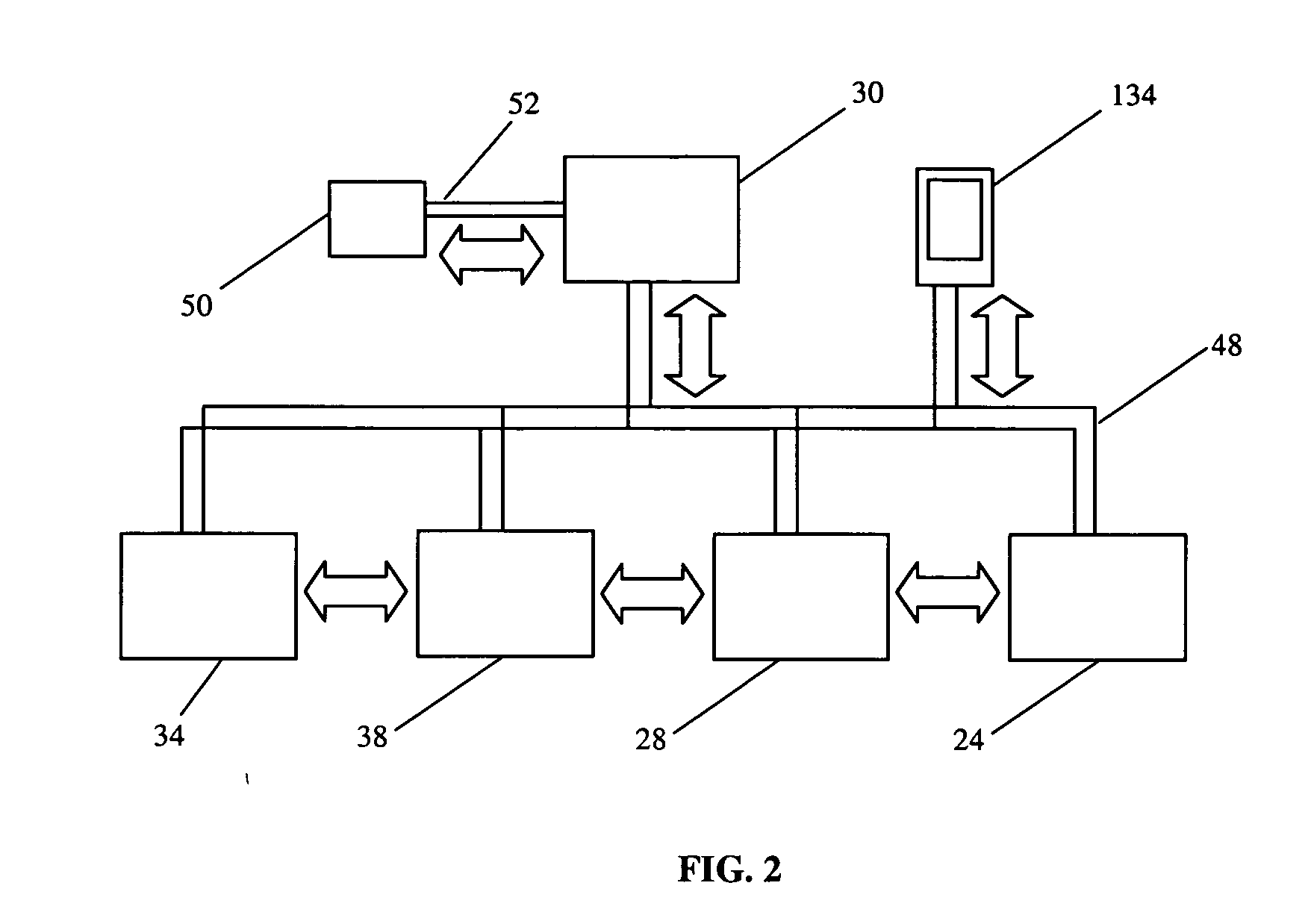

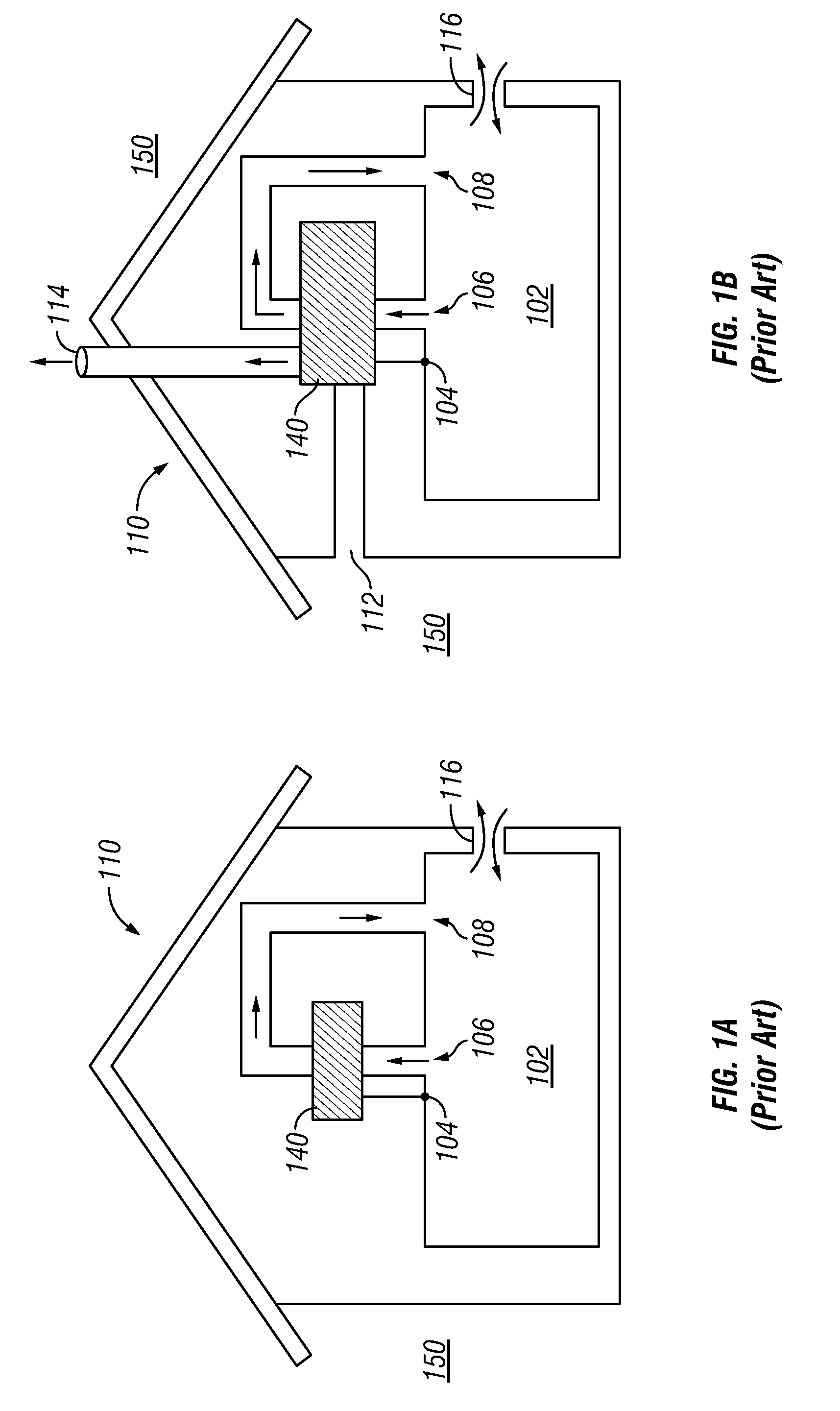

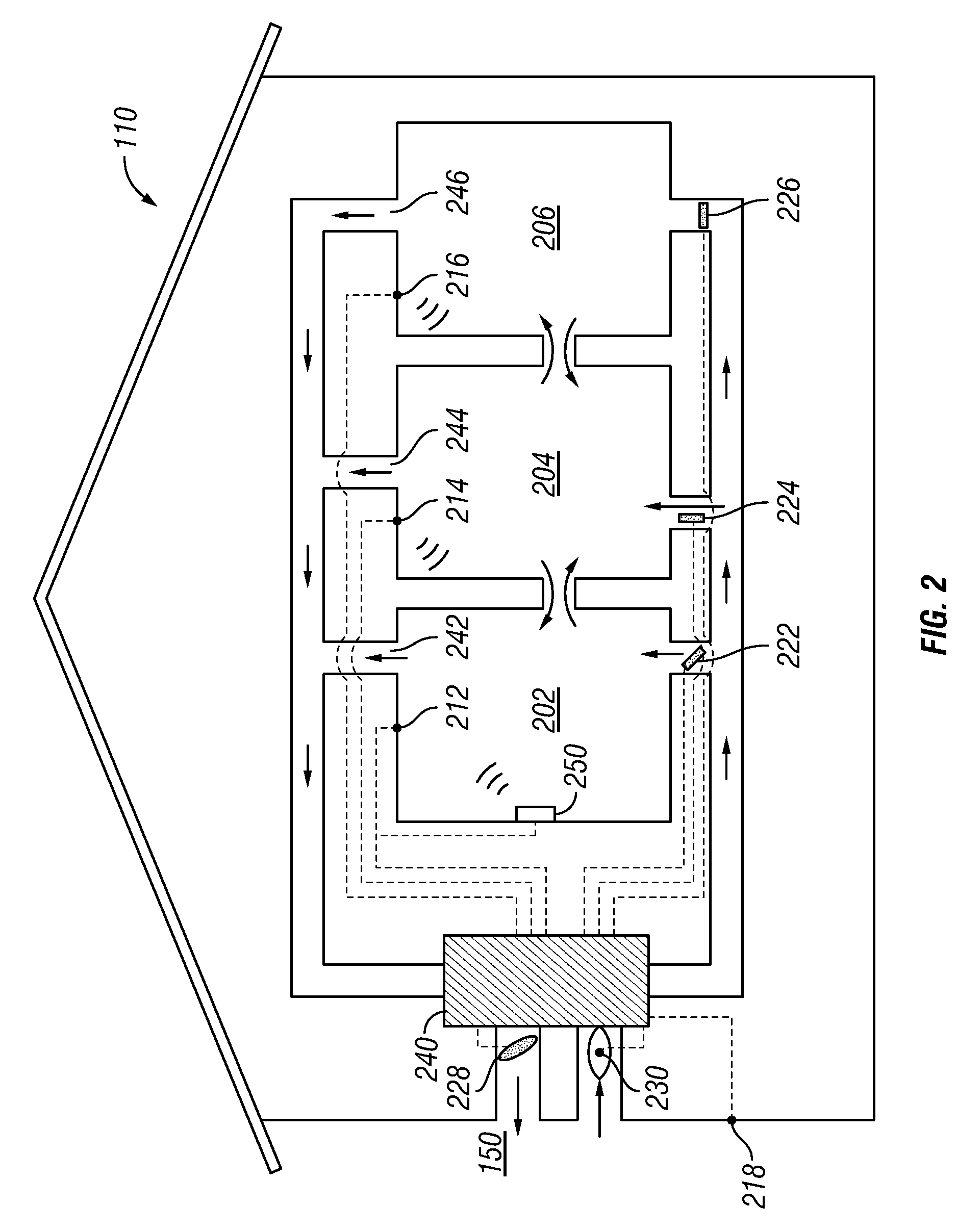

Interactive control system for an HVAC system

An interactive system for controlling the operation of an HVAC system is provide that comprises a thermostat for initiating the operation of the HVAC system in either a full capacity mode of operation or at least one reduced capacity mode of operation, and a controller for an outside condenser unit having a condenser fan motor and a compressor motor, the controller being capable of operating the compressor in a full capacity mode and at least one reduced capacity mode. The system also comprises a controller for an indoor blower unit having a blower fan motor, the controller being capable of operating the blower fan motor in a full capacity mode an at least one reduced capacity mode. The system further includes a communication means for transmitting information between the outside condenser unit controller and at least the indoor blower controller, where the information relates to the operation of the indoor blower and the outdoor condenser unit. The indoor blower controller responsively controls the operation of the blower fan motor in a full capacity mode or a reduced capacity mode based on the information received from the outdoor unit controller, and the outdoor unit controller responsively controls the operation of the compressor in a full capacity mode or a reduced capacity mode based on the information received from the indoor blower controller.

Owner:COPELAND COMFORT CONTROL LP

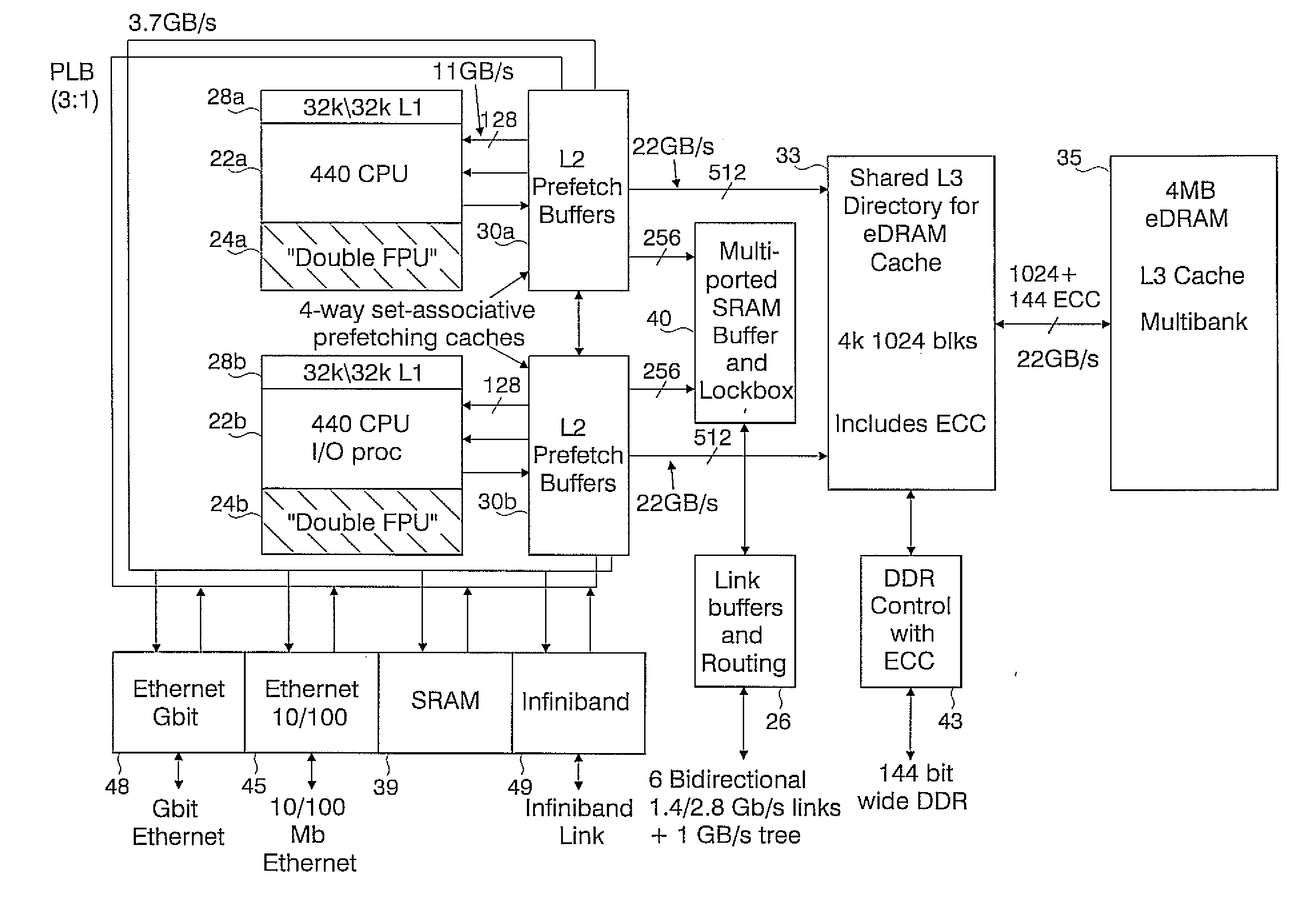

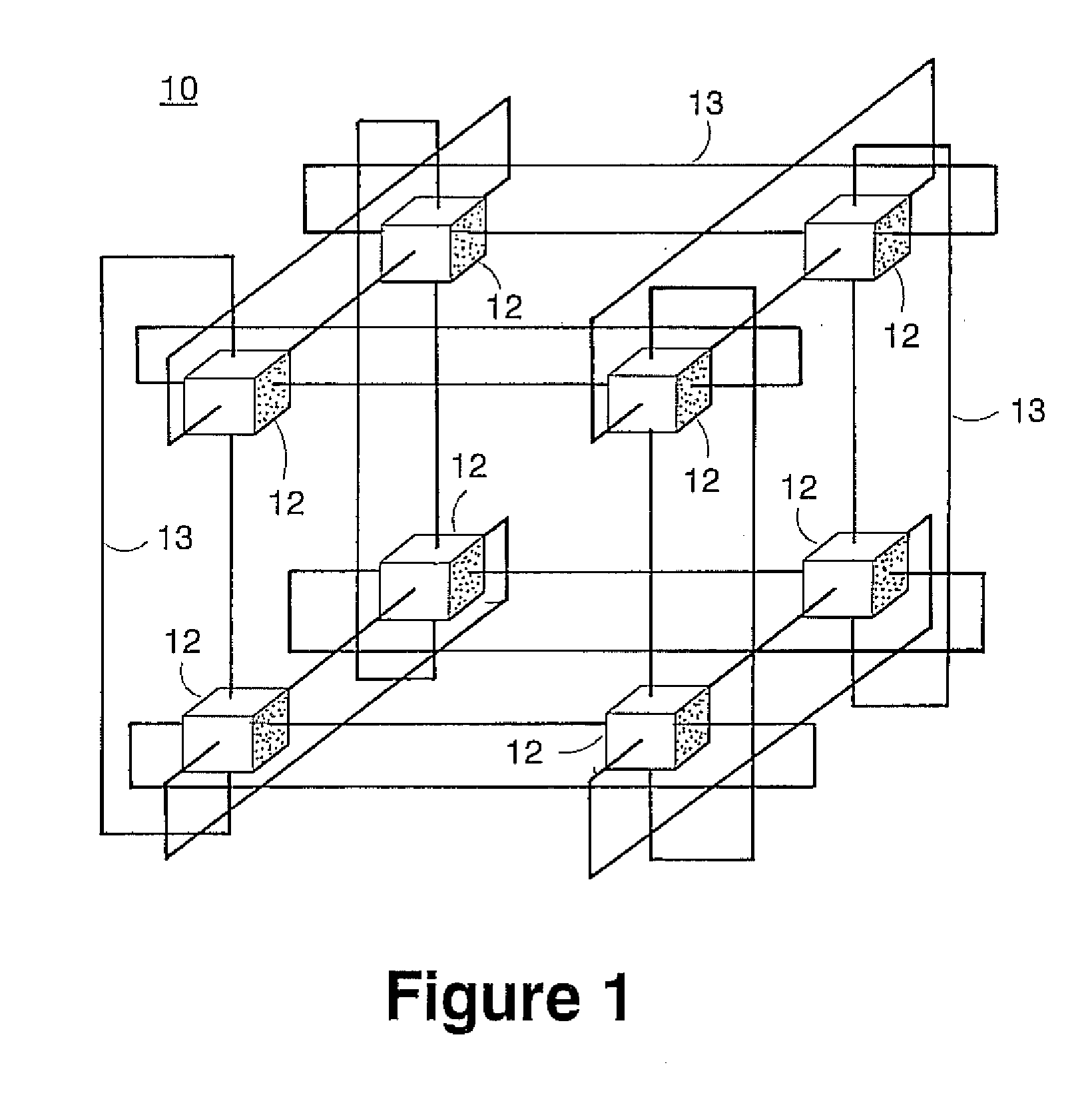

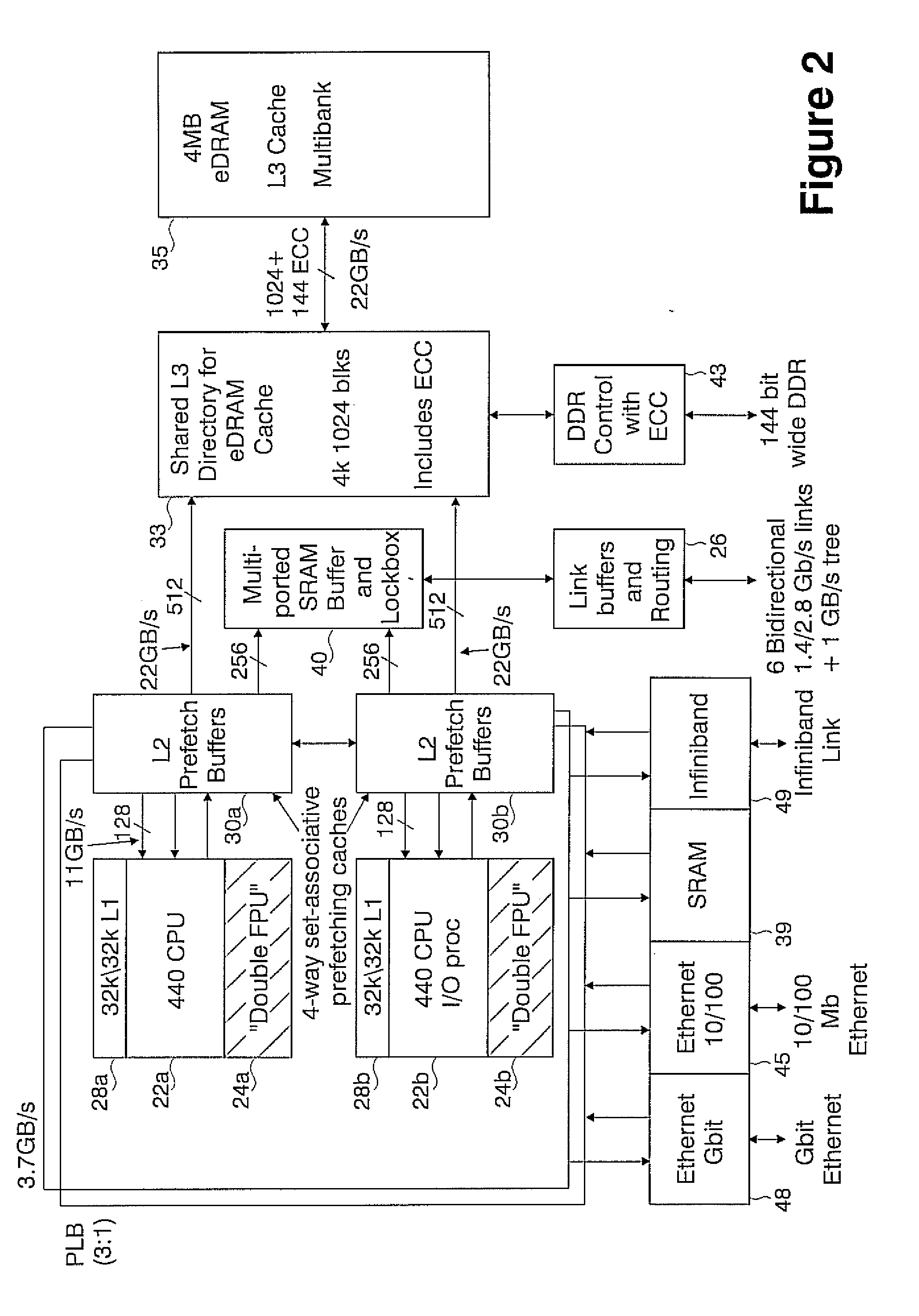

Novel massively parallel supercomputer

InactiveUS20090259713A1Low costReduced footprintError preventionProgram synchronisationSupercomputerPacket communication

Owner:INT BUSINESS MASCH CORP

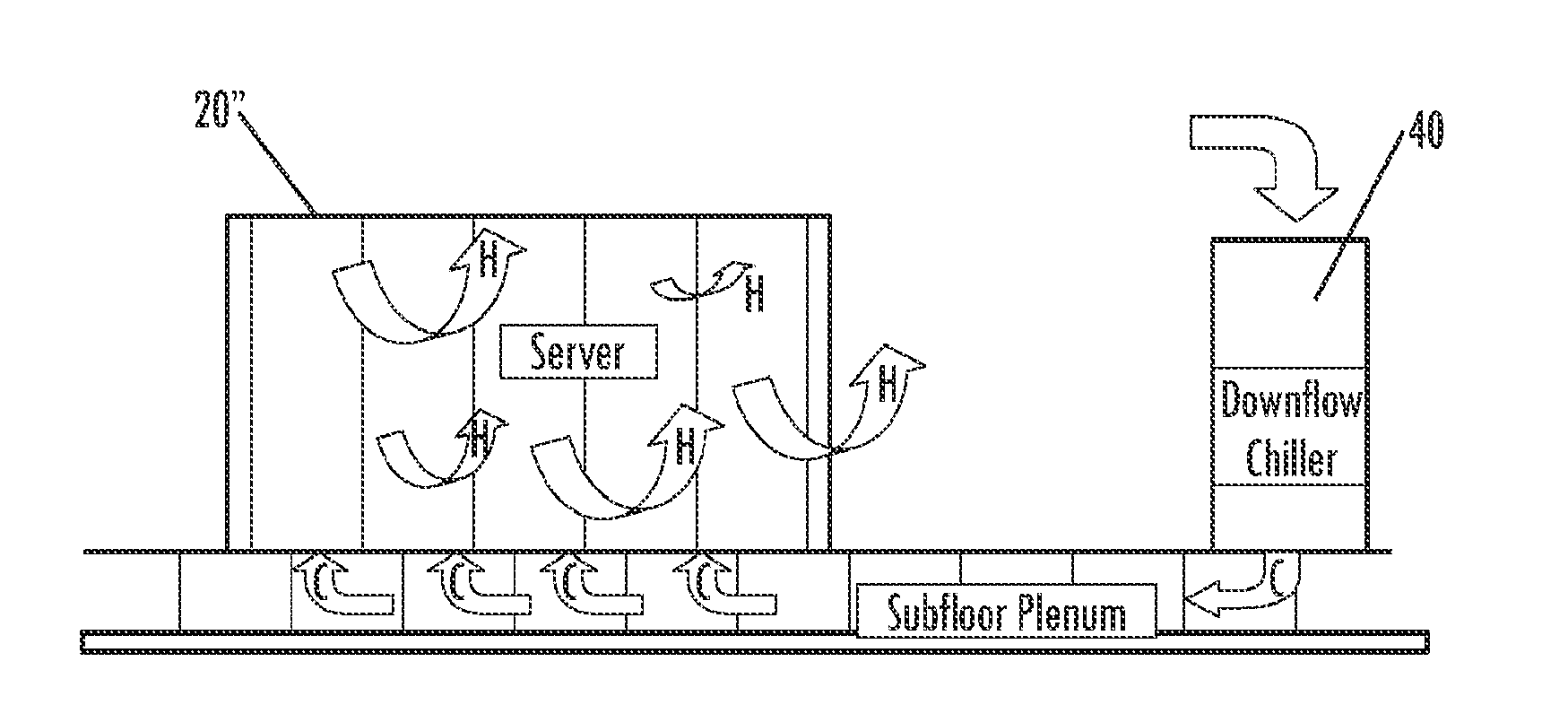

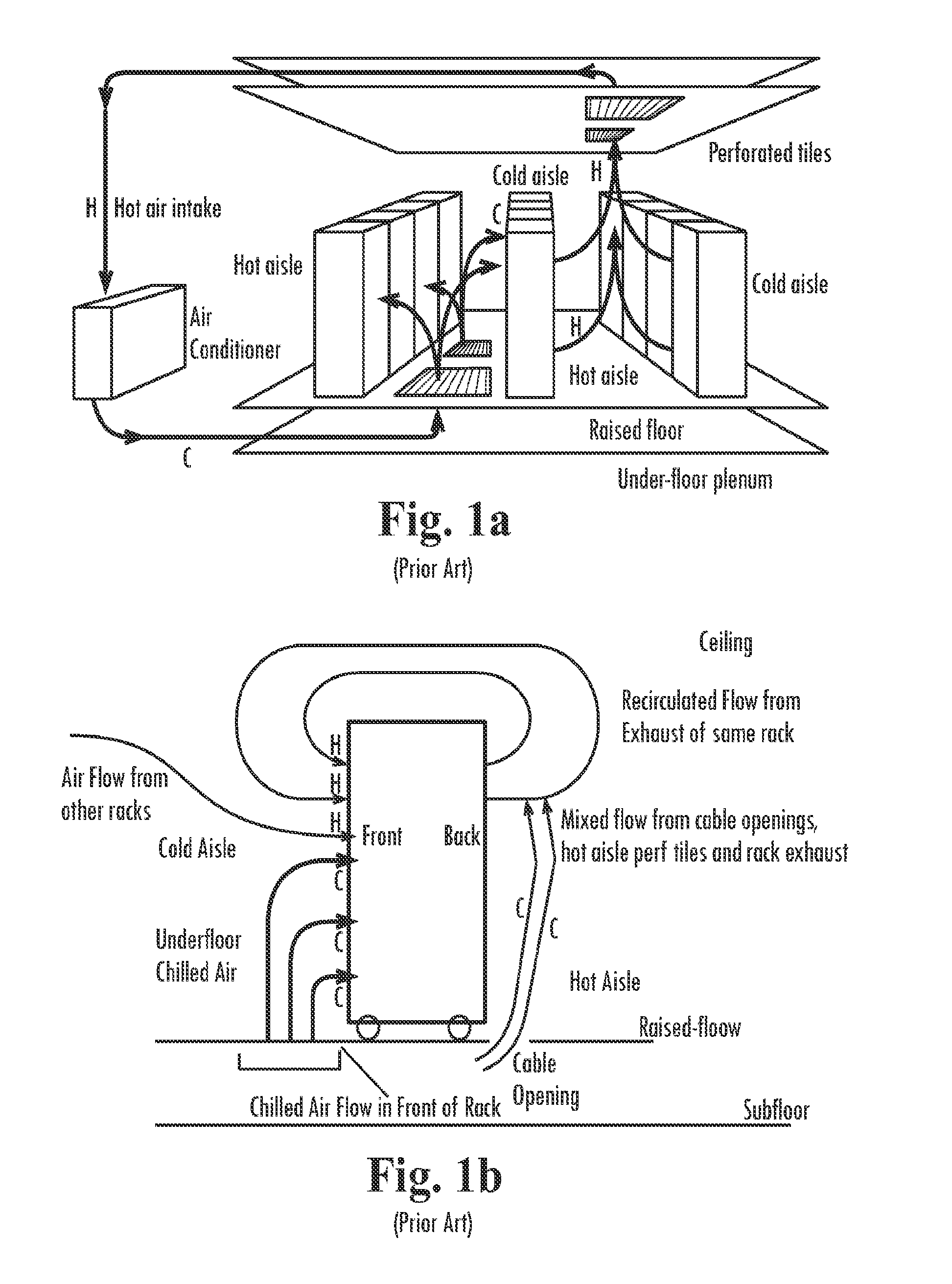

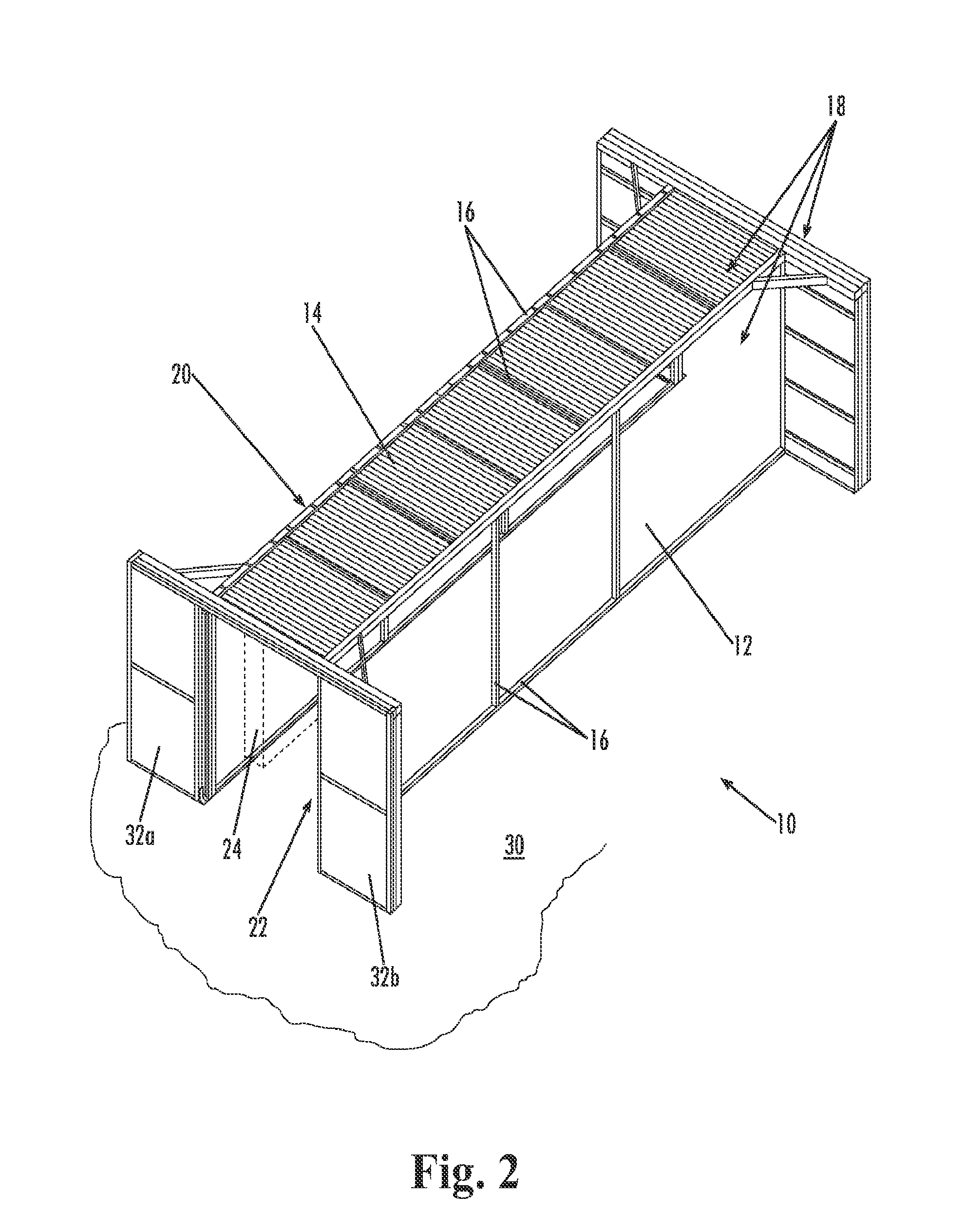

Energy saving system and method for cooling computer data center and telecom equipment

ActiveUS20090168345A1Avoid thermal failureEfficient cooling and heatingMechanical apparatusSpace heating and ventilation safety systemsElectricityData center

A system and method of reducing consumption of electricity used to cool electronic computer data center, networking, and telecommunications equipment, and to reduce the incidence of thermal failure of electronic components, includes provision of one or more partitions to reduce the volume of the cooled environment supplying coldest possible cooled air from air conditioning systems to a chamber adjacent to racks containing the electronic components, preventing dilution of the supplied cooling airflow by warmer air from outside of the reduced volume environment, and controlling the delivery of cooling air flow through the reduced volume of the cooled environment.

Owner:MARTINI VALAN R

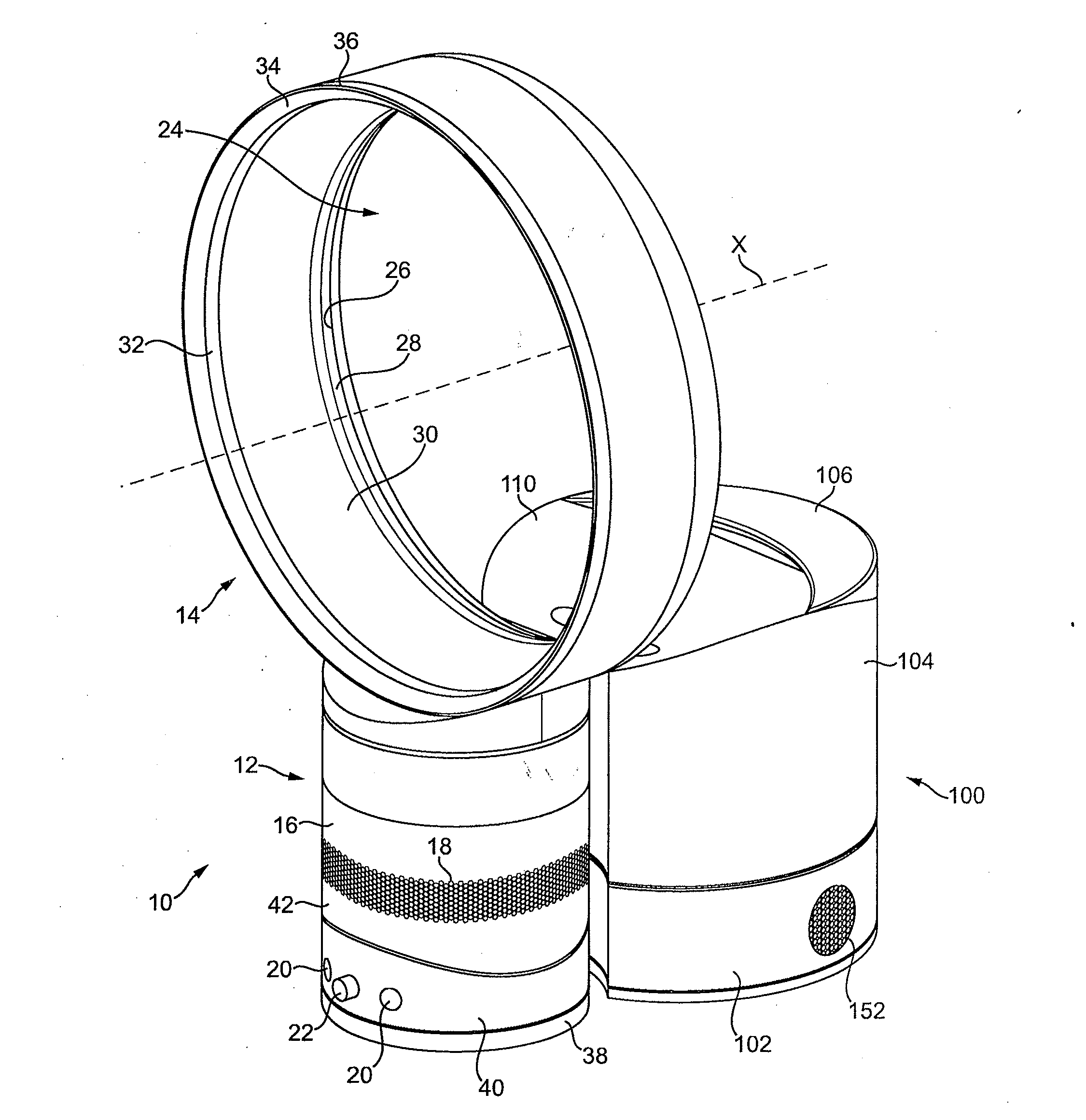

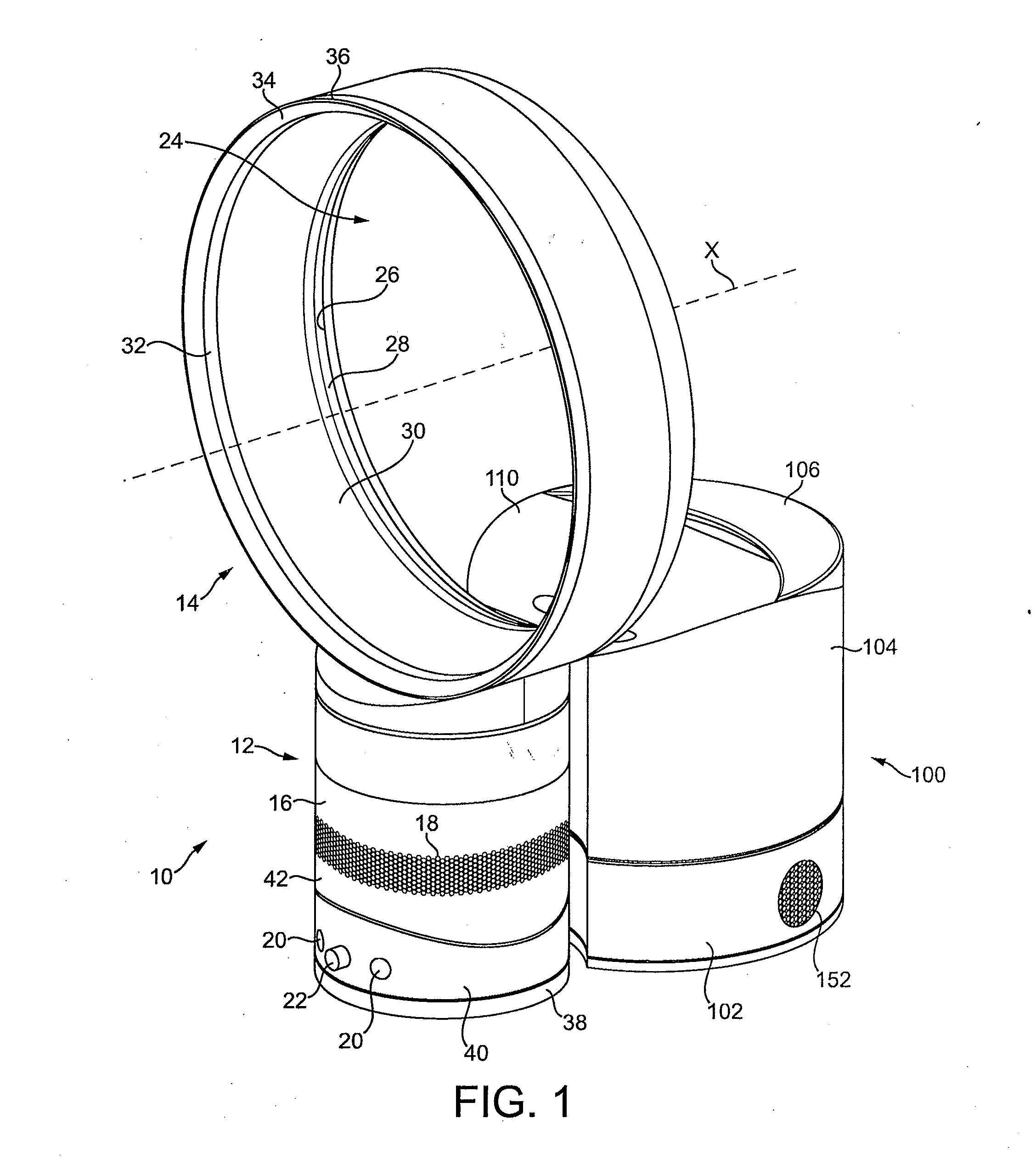

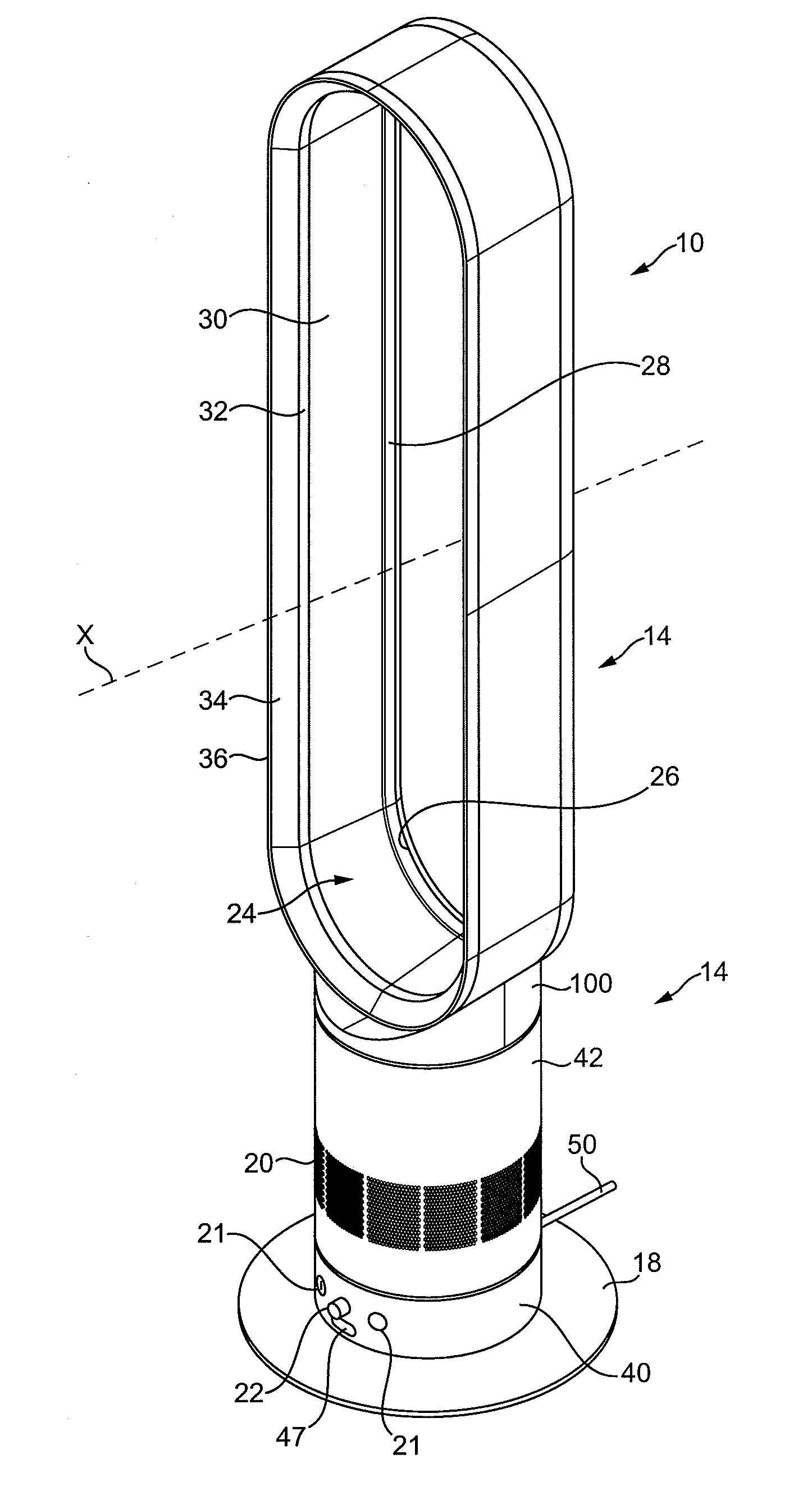

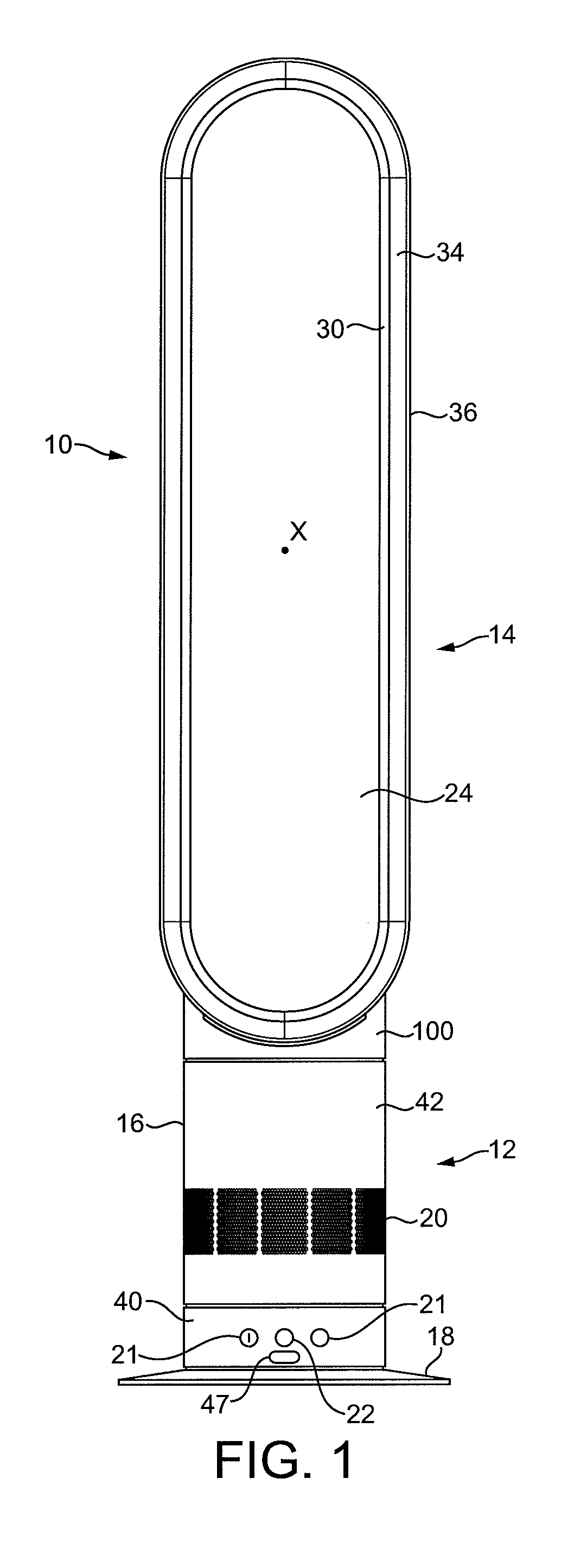

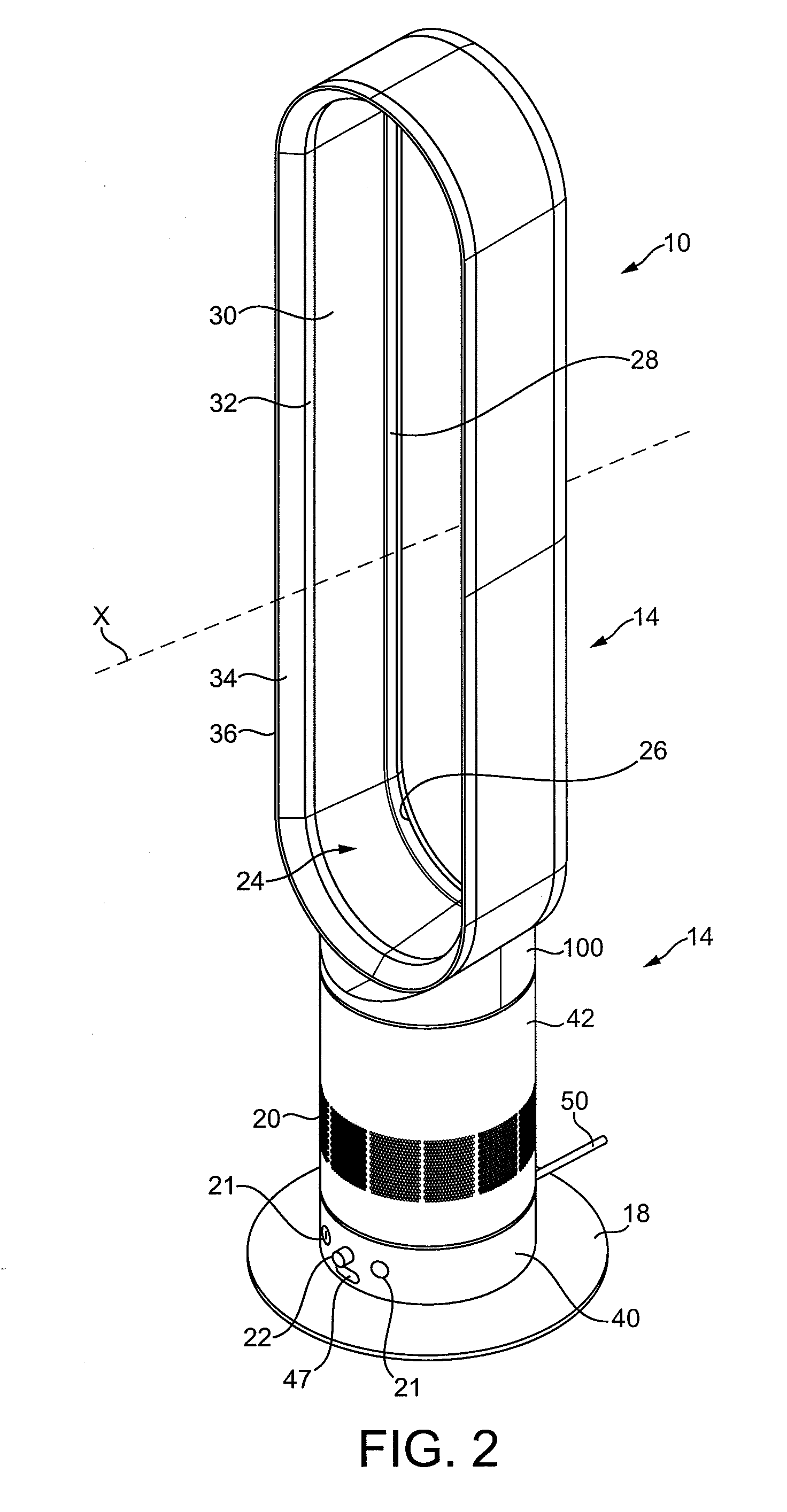

Humidifying apparatus

InactiveUS20100225012A1Rapid rise in relative humidityReduce the amount requiredFlow mixersSpace heating and ventilationEngineeringAirflow

Humidifying apparatus includes a humidifier for emitting moist air into an external environment, and a fan assembly for generating an air current within the external environment for conveying the emitted moist air away from the humidifier. The fan assembly includes a device for creating an air flow and a nozzle comprising an interior passage for receiving the air flow and a mouth for emitting the air flow. The humidifier is located behind nozzle, the nozzle extending about and defining an opening through which both air from outside the nozzle and the moist air emitted from the humidifier are drawn by the air flow emitted from the mouth.

Owner:DYSON TECH LTD

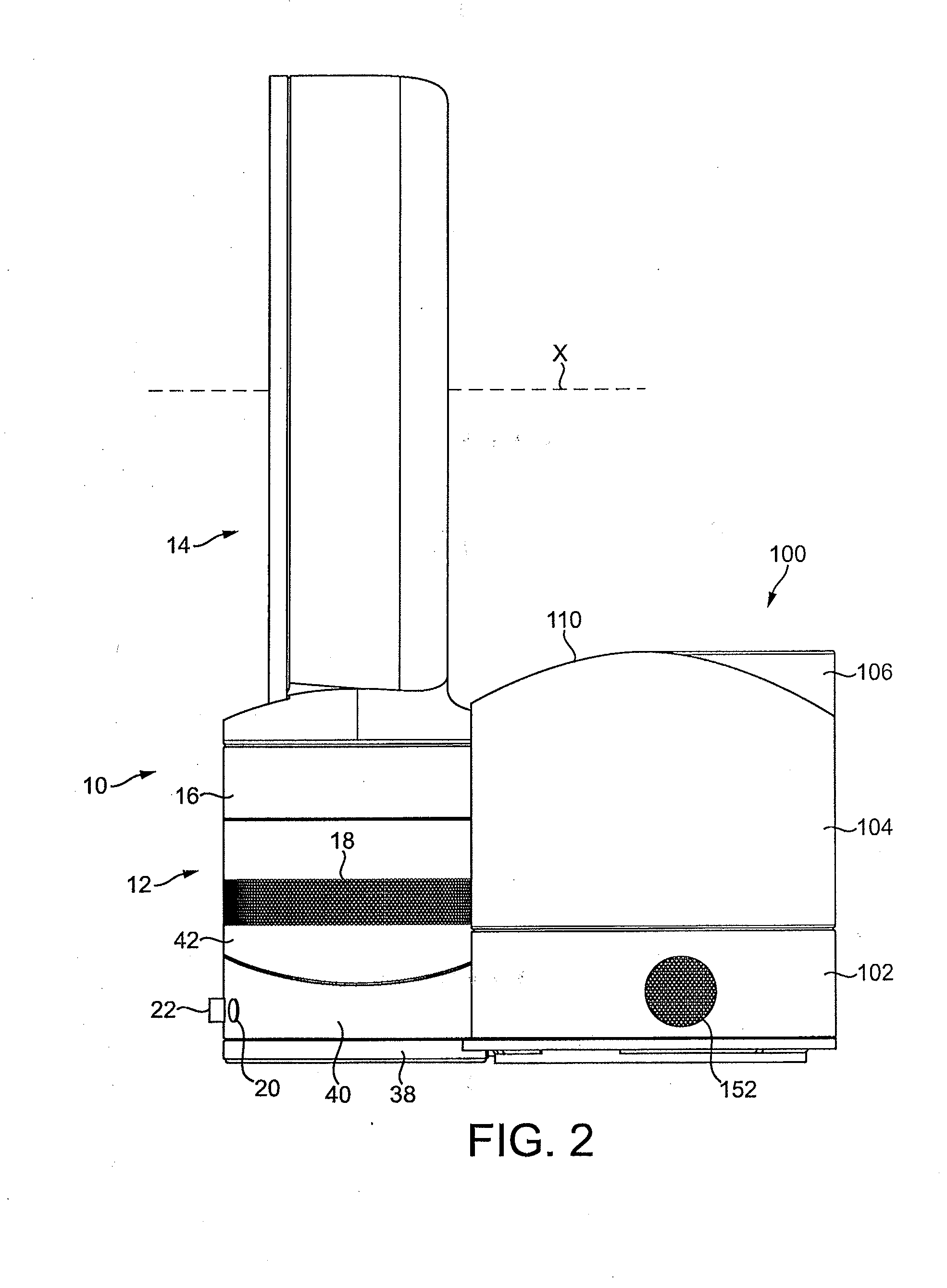

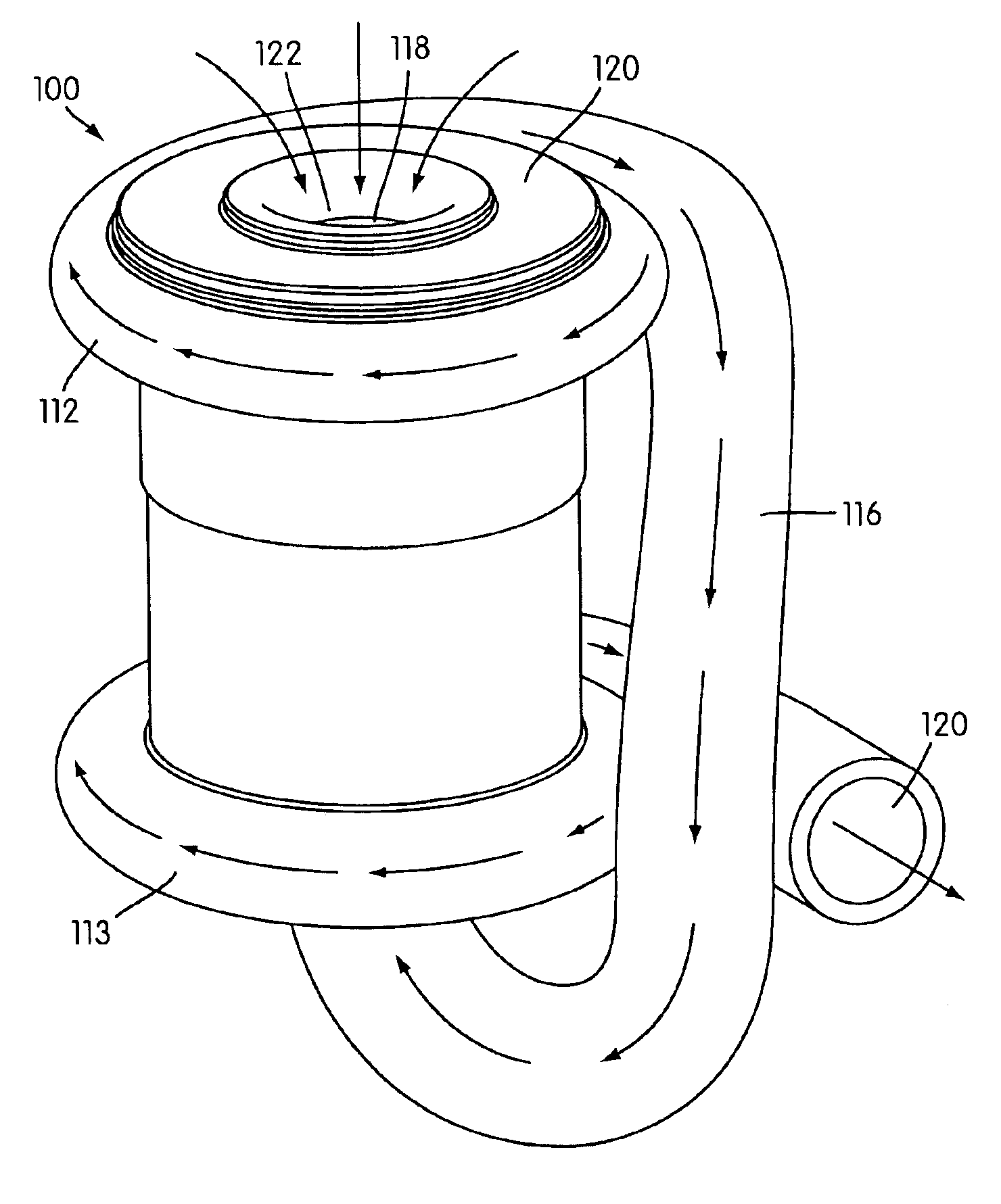

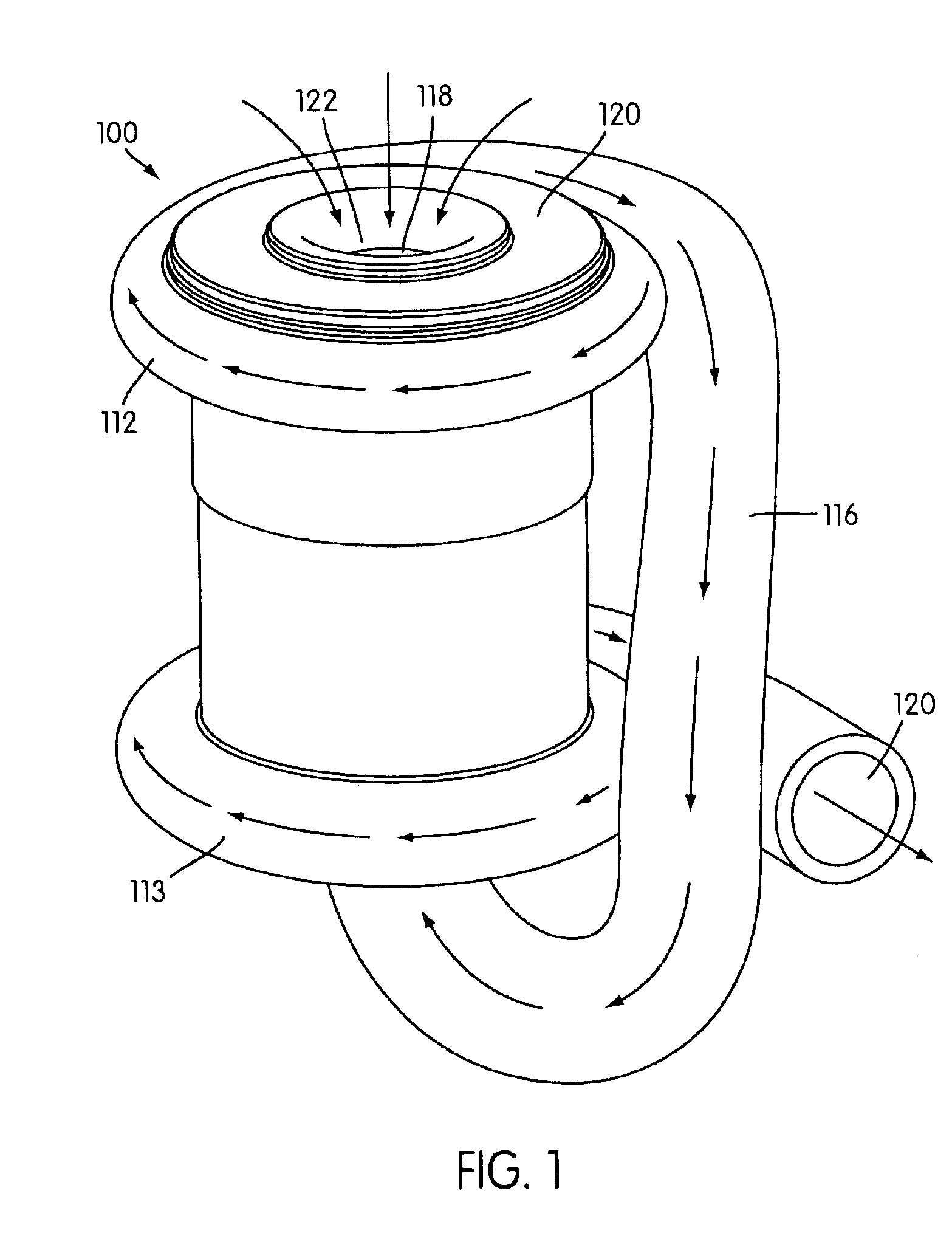

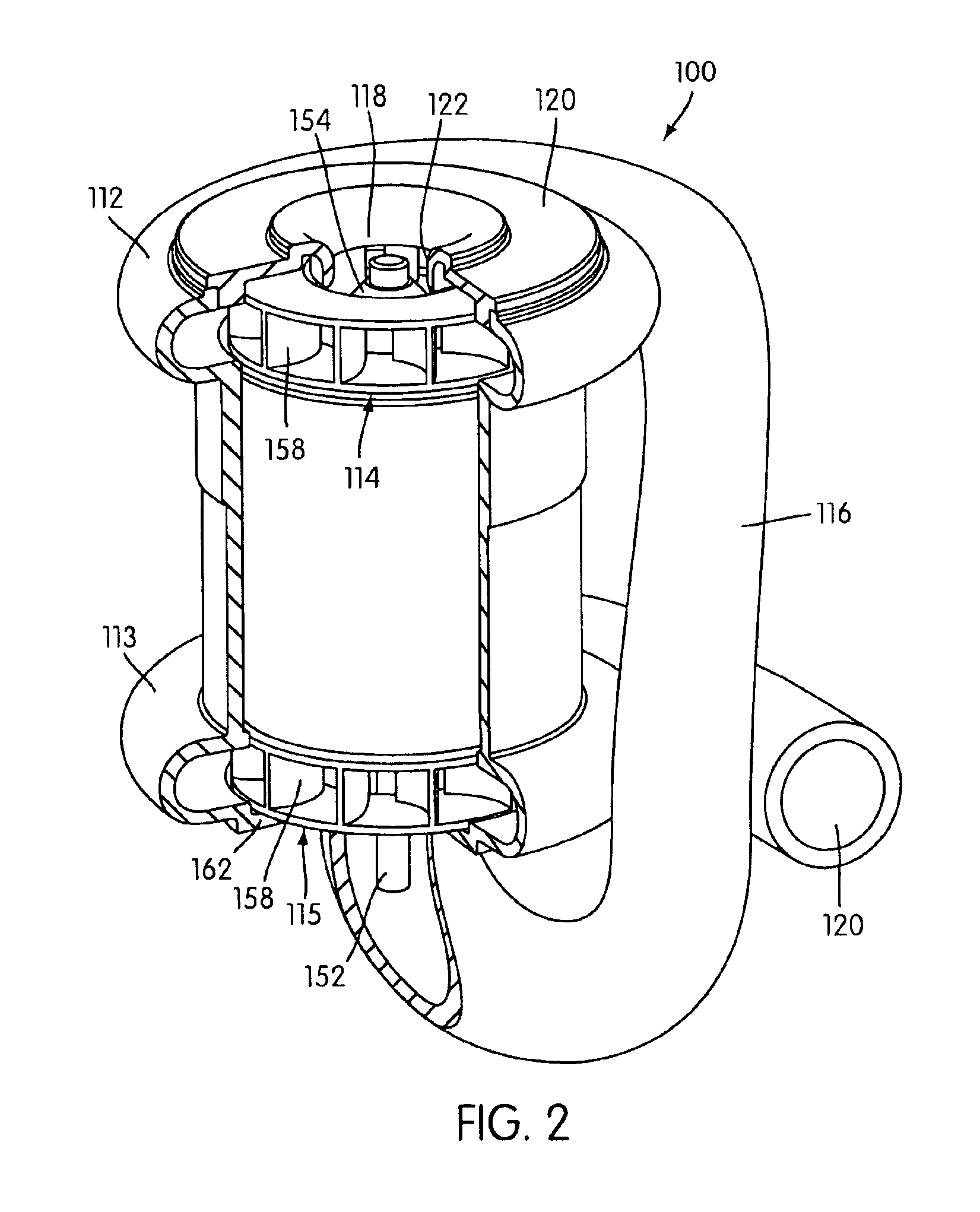

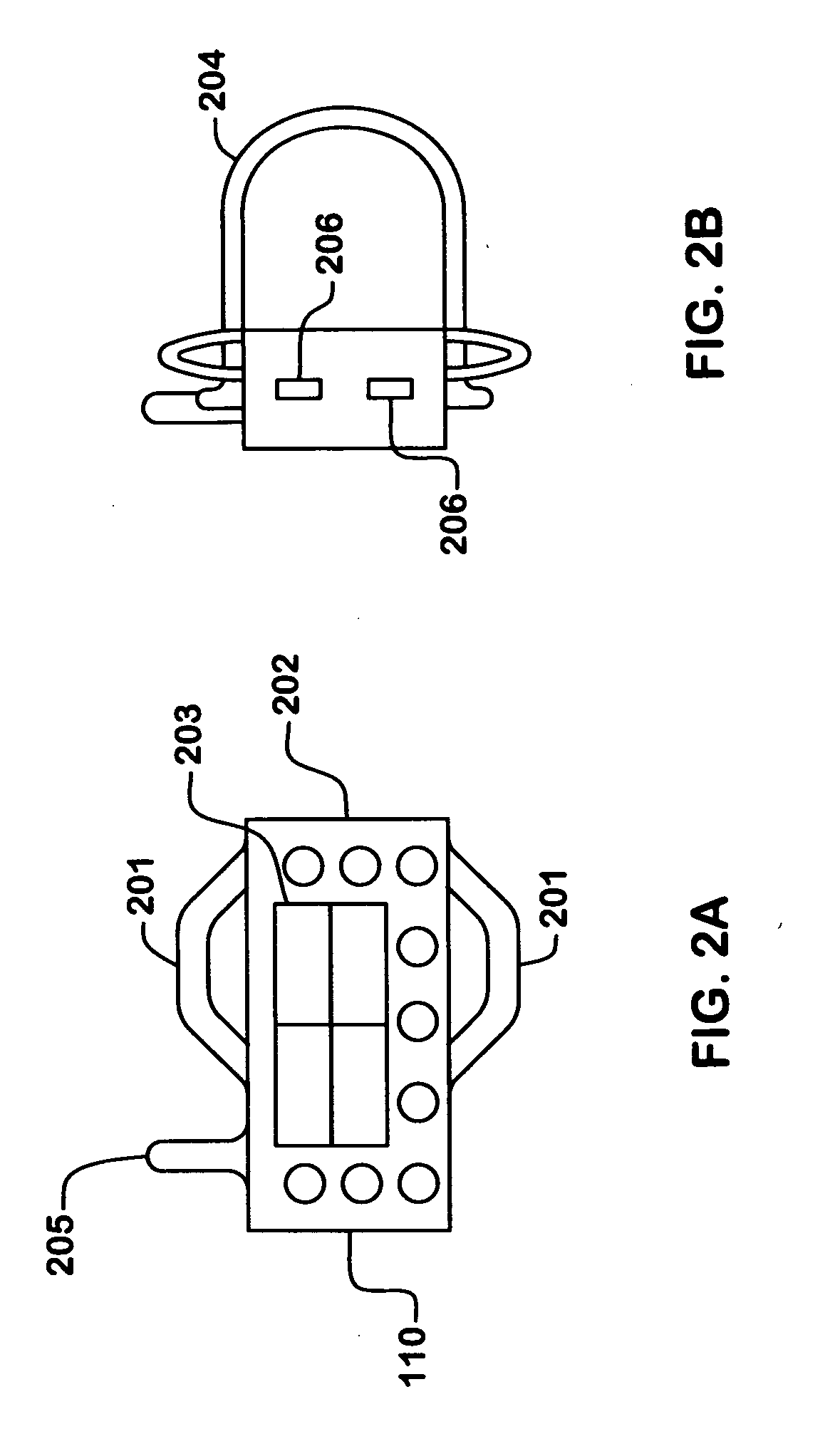

Double-ended blower and volutes therefor

InactiveUS6910483B2Faster pressure rise timeImprove reliabilityPropellersElement comparisonMotor speedImpeller

A double-ended variable speed blower for Continuous Positive Airway Pressure (CPAP) ventilation of patients includes two impellers in the gas flow path that cooperatively pressurize gas to desired pressure and flow characteristics. Thus, the double-ended blower can provide faster pressure response and desired flow characteristics over a narrower range of motor speeds, resulting in greater reliability and less acoustic noise.

Owner:RESMED LTD

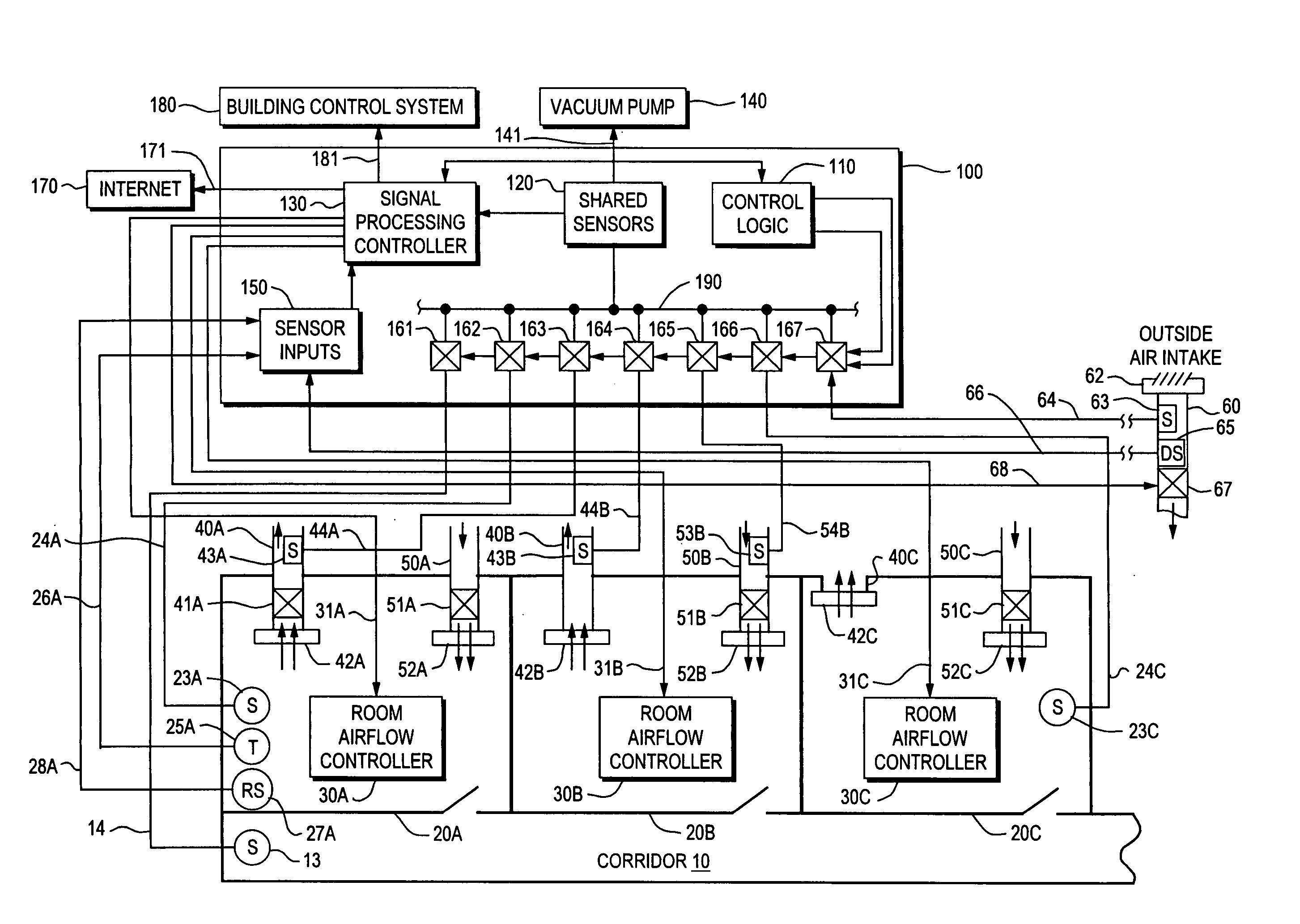

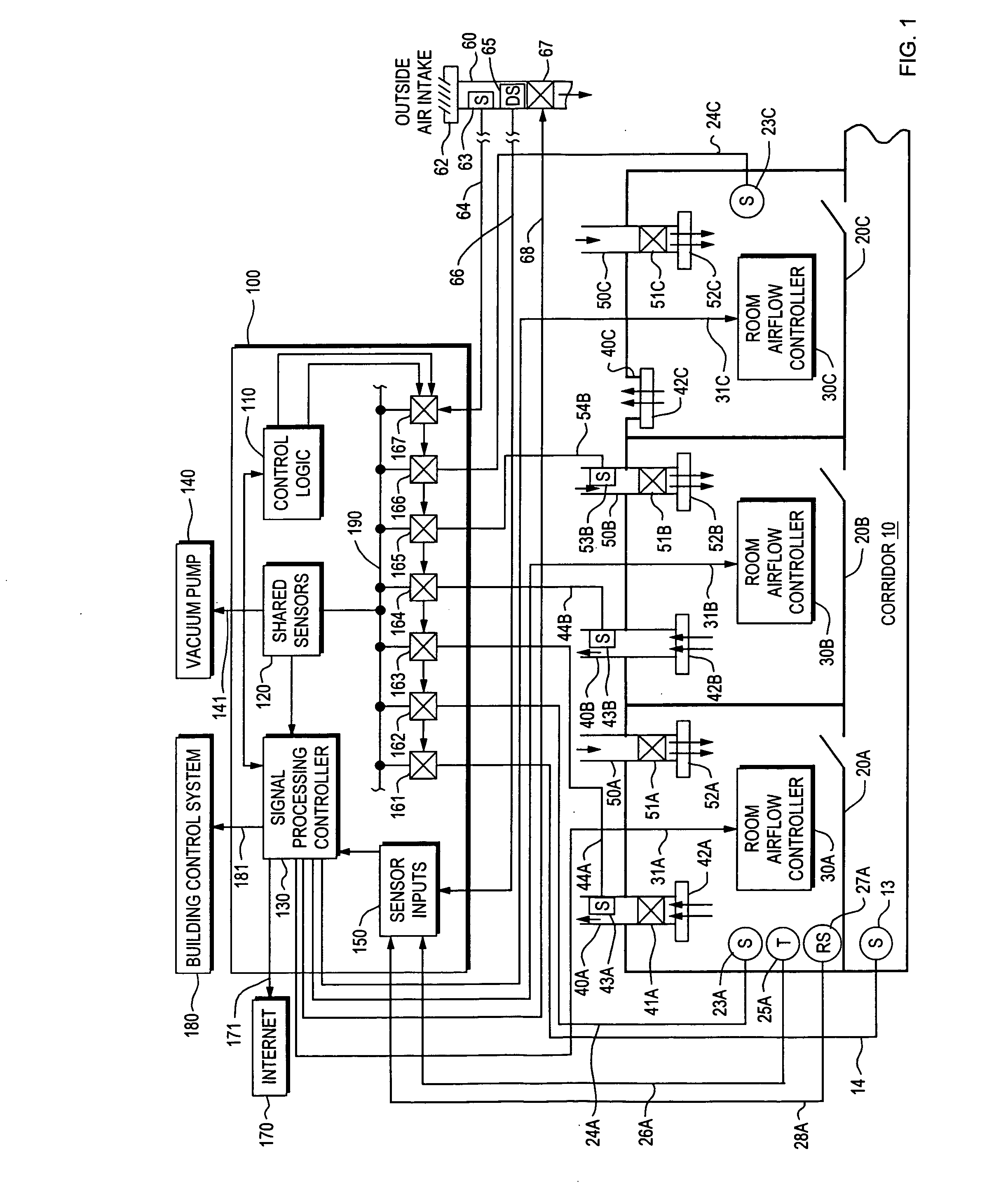

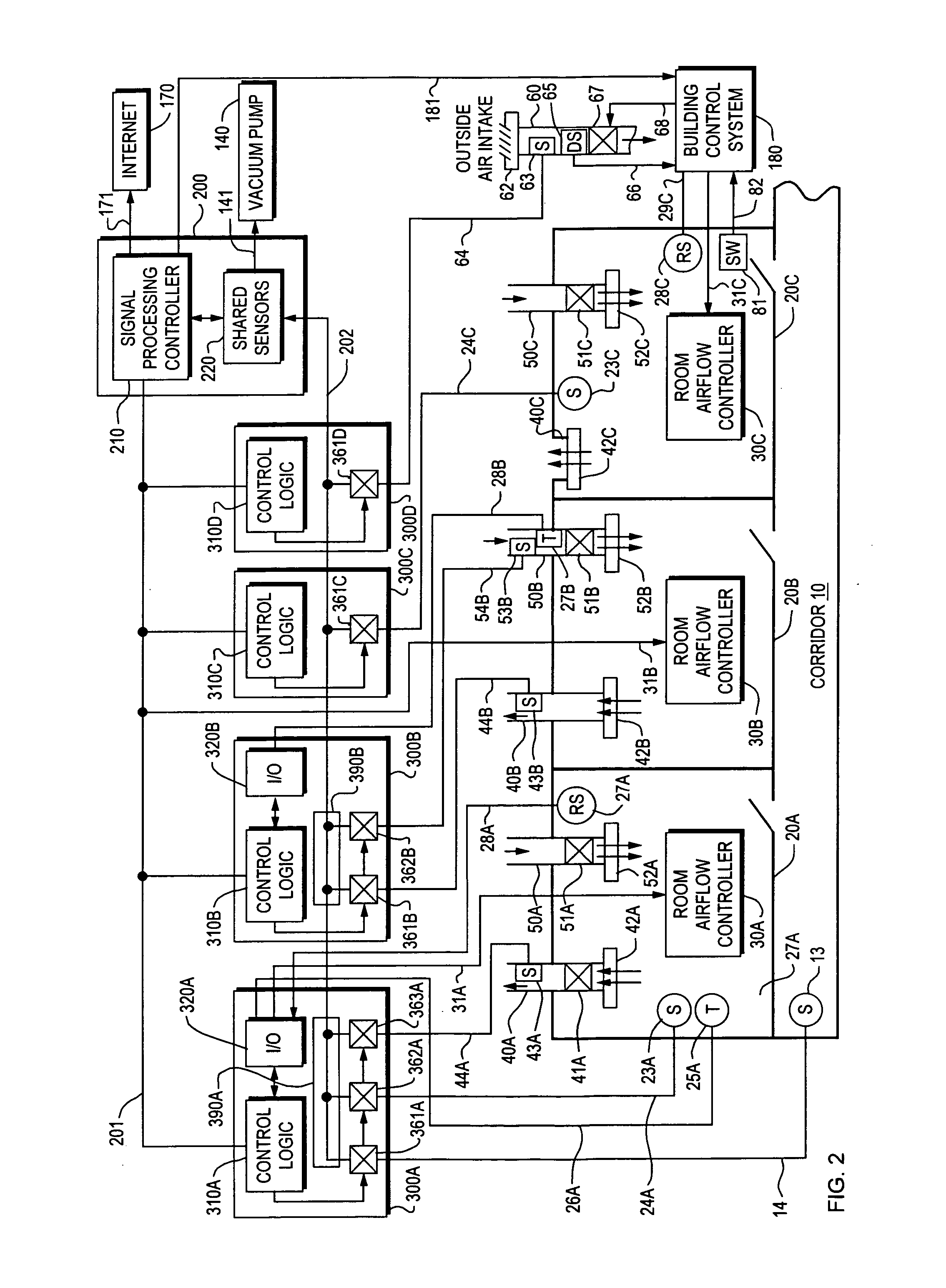

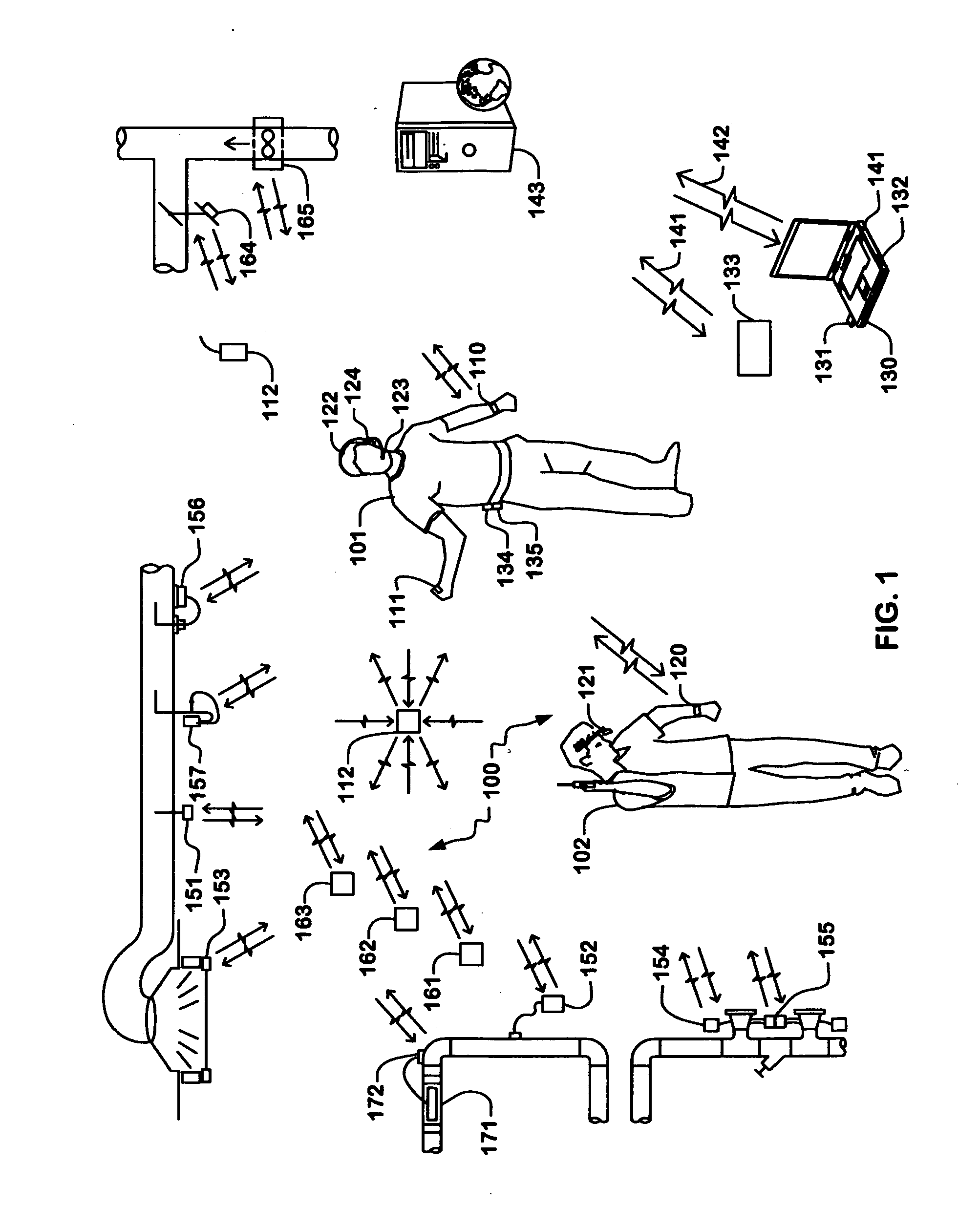

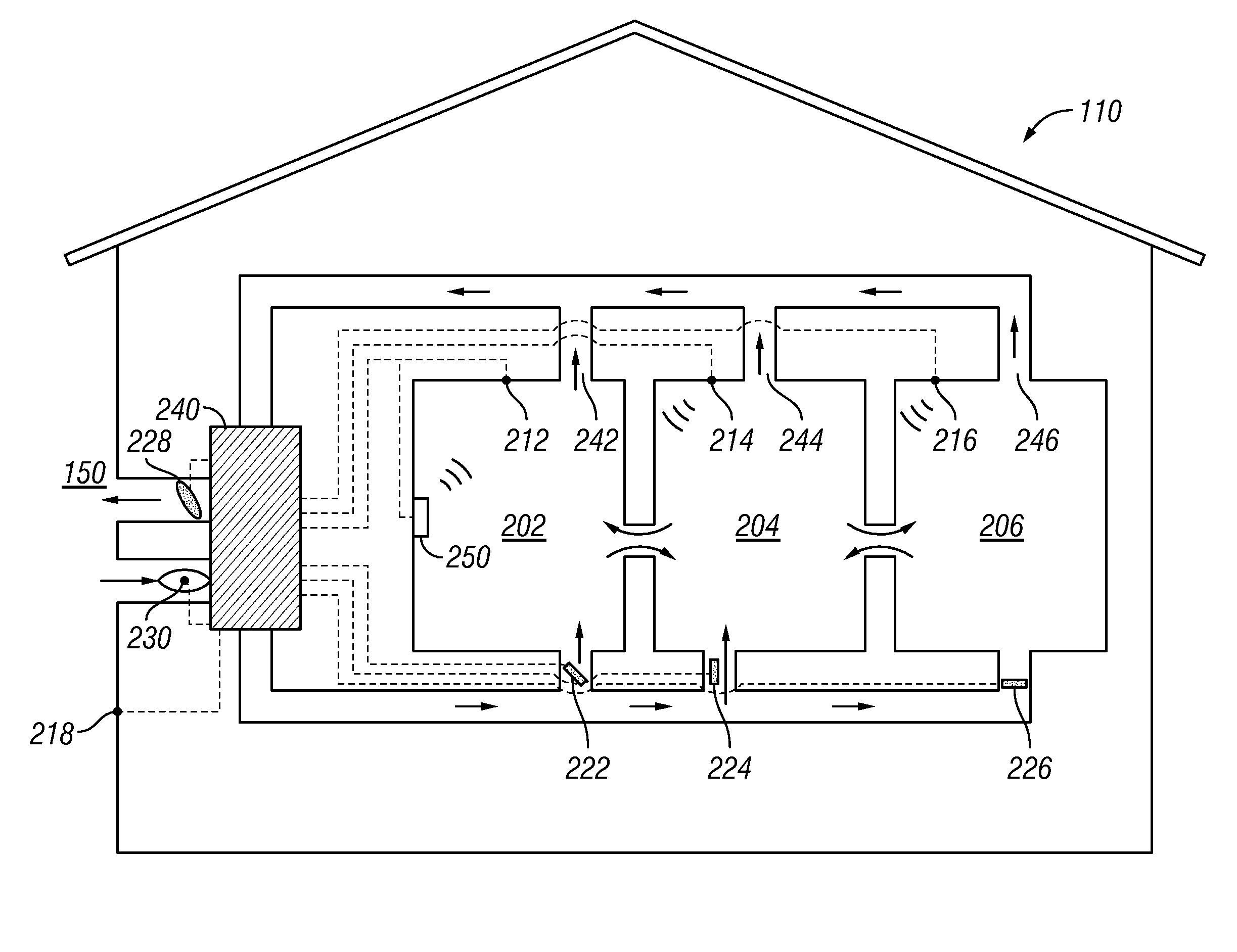

Multipoint air sampling system having common sensors to provide blended air quality parameter information for monitoring and building control

ActiveUS20060234621A1Improve accuracyMore accuratelySampled-variable control systemsSpace heating and ventilationAir monitoringQuality data

A system for monitoring air quality conditions, comprising, a multi-point air monitoring system comprising, a plurality of sensors for collecting air quality data from a plurality of at least partially enclosed areas; one or more data processing units for processing one or more air quality parameters based on the collected air quality data; and one or more communication devices for communicating the data from the sensor to the processing unit; and a signal processing controller that generates one or more blended air quality parameter signals via the multi-point air monitoring system based at least in part on one or more of the processed air quality parameters representative of data from a plurality of the sensors.

Owner:AIRCUITY

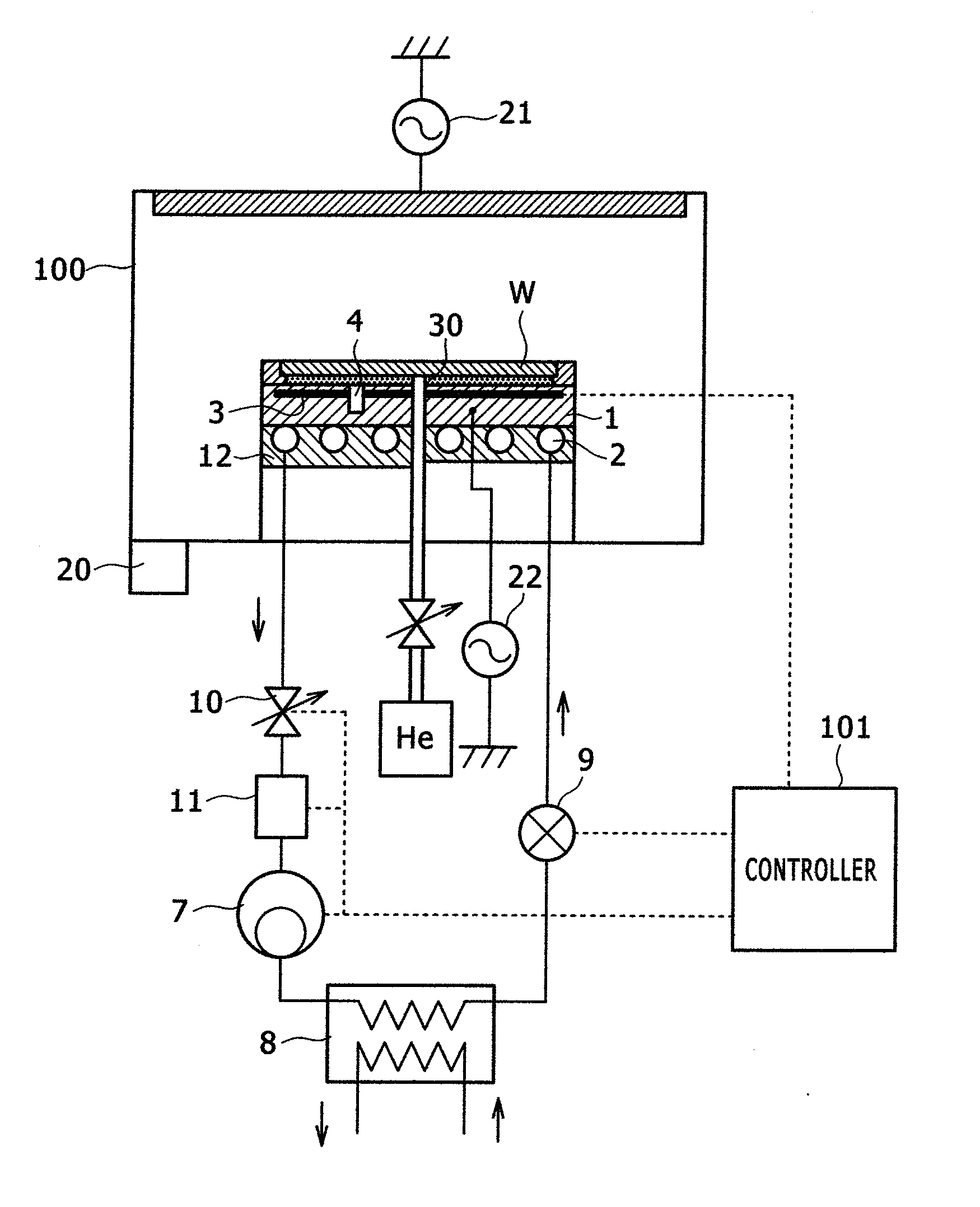

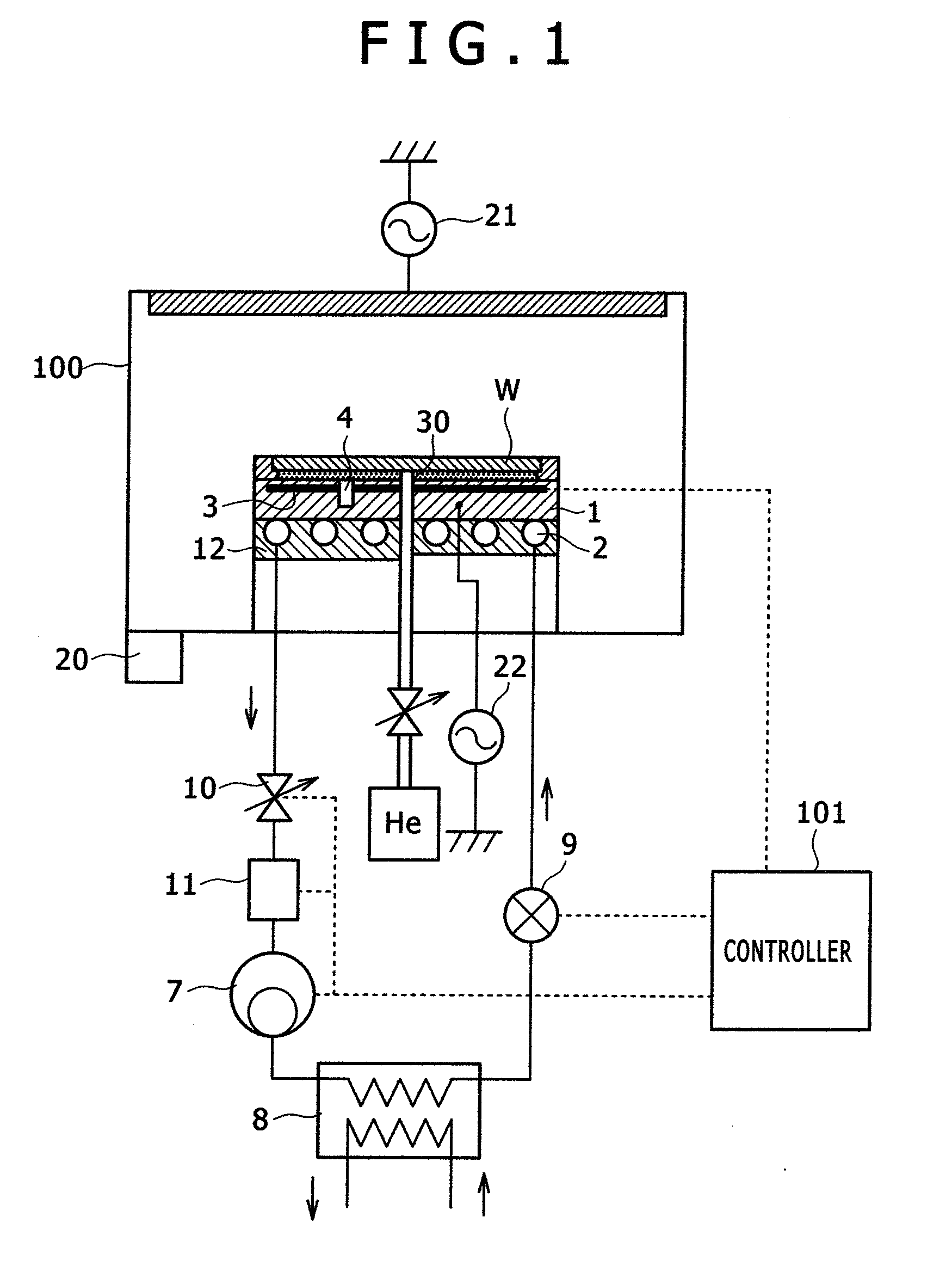

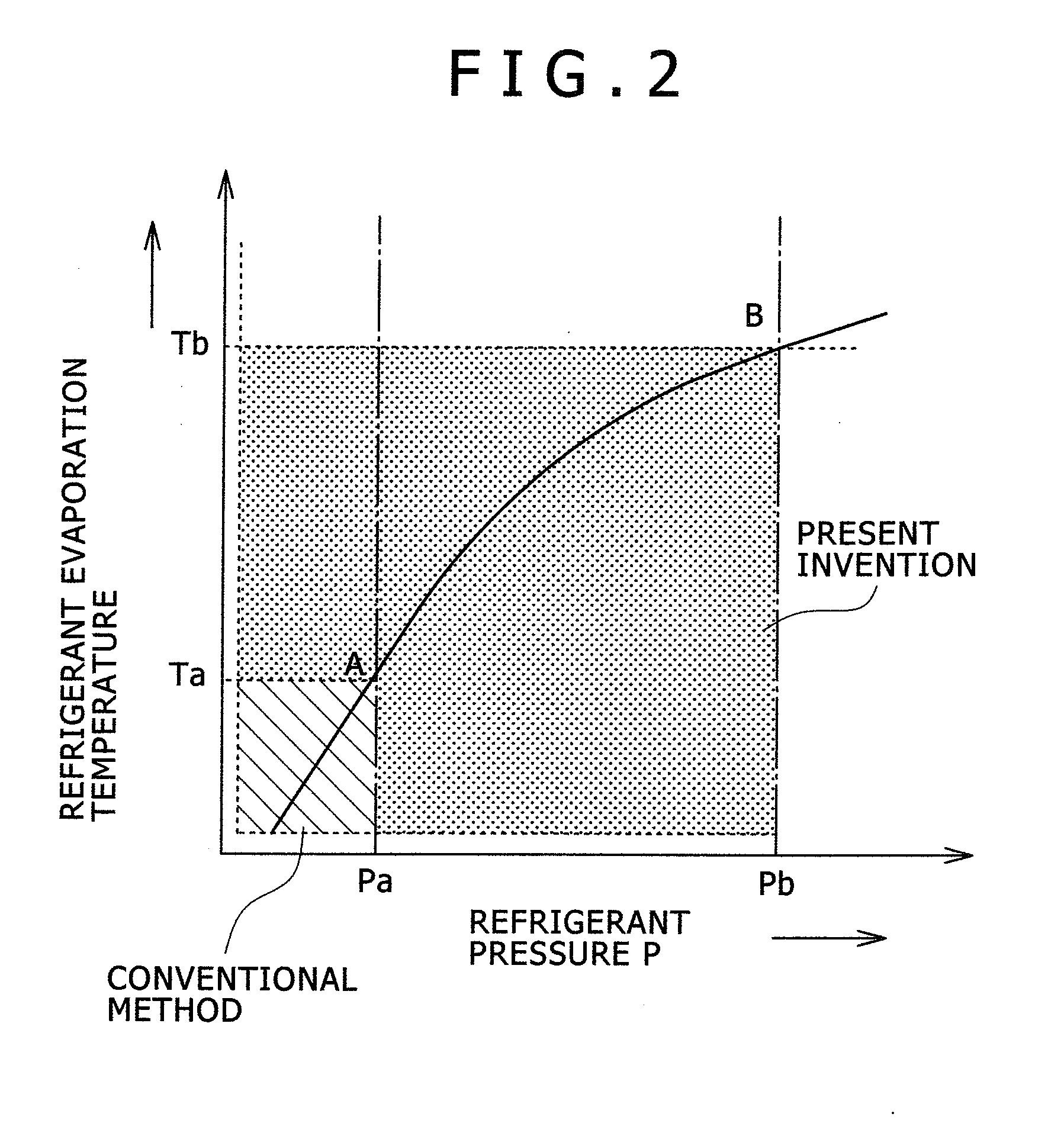

Plasma processing apparatus

ActiveUS20080289767A1High bias powerWide temperature rangeMechanical apparatusDomestic cooling apparatusIn planeEtching

The present invention provides a temperature control unit for an electrostatic adsorption electrode that is capable of controlling the wafer temperature rapidly over a wide temperature range without affecting in-plane uniformity while high heat input etching is conducted with high wafer bias power applied. A refrigerant flow path provided in the electrostatic adsorption electrode serves as an evaporator. The refrigerant flow path is connected to a compressor, a condenser, and a first expansion valve to form a direct expansion type refrigeration cycle. A second expansion valve is installed between the electrostatic adsorption electrode and the compressor to adjust the flow rate of a refrigerant. This makes it possible to compress the refrigerant in the refrigerant flow path of the electrostatic adsorption electrode and adjust the wafer temperature to a high level by raising the refrigerant evaporation temperature. Further, a thin-walled cylindrical refrigerant flow path is employed so that the thin-walled cylinder is deformed only slightly by the refrigerant pressure.

Owner:HITACHI HIGH-TECH CORP

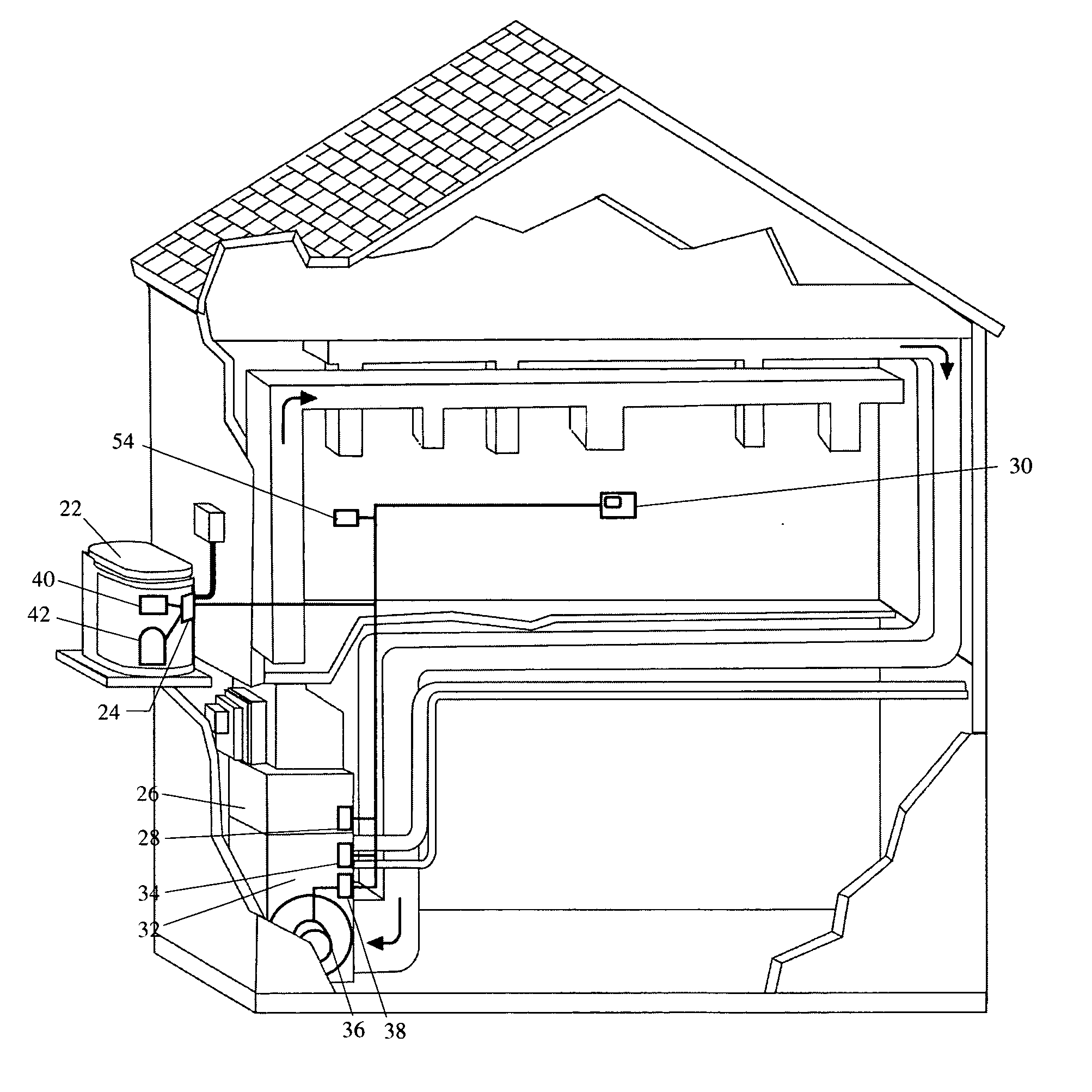

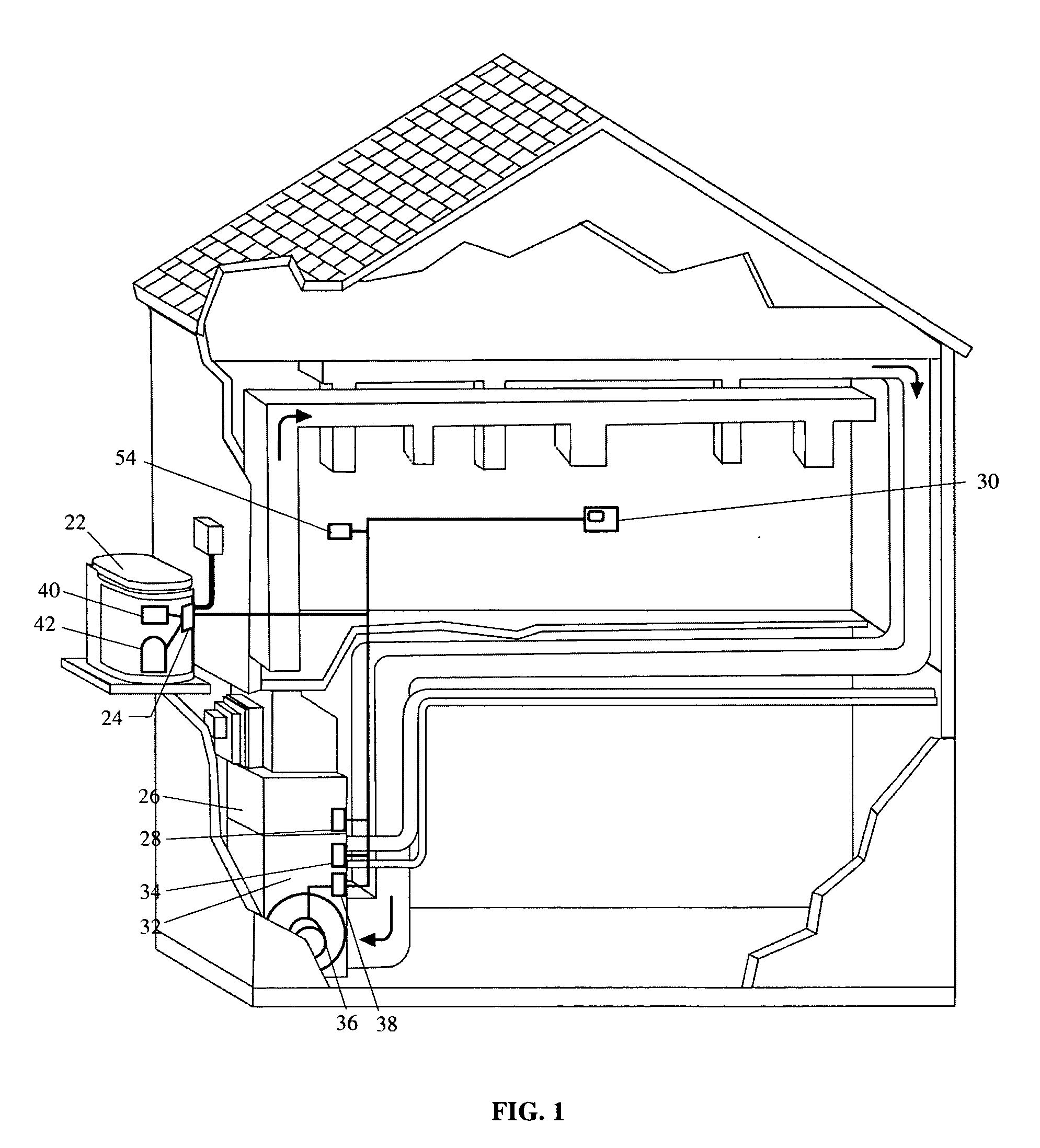

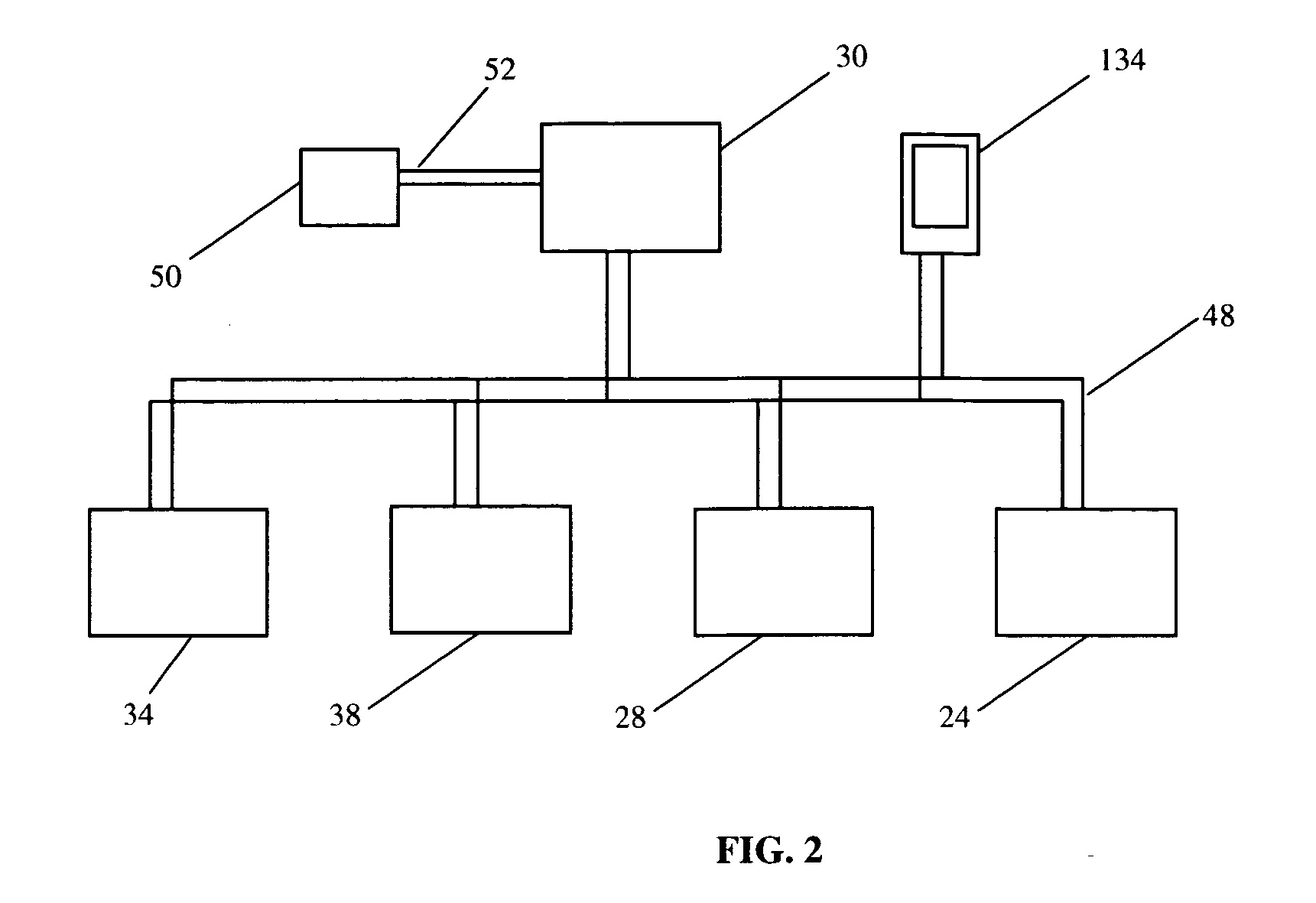

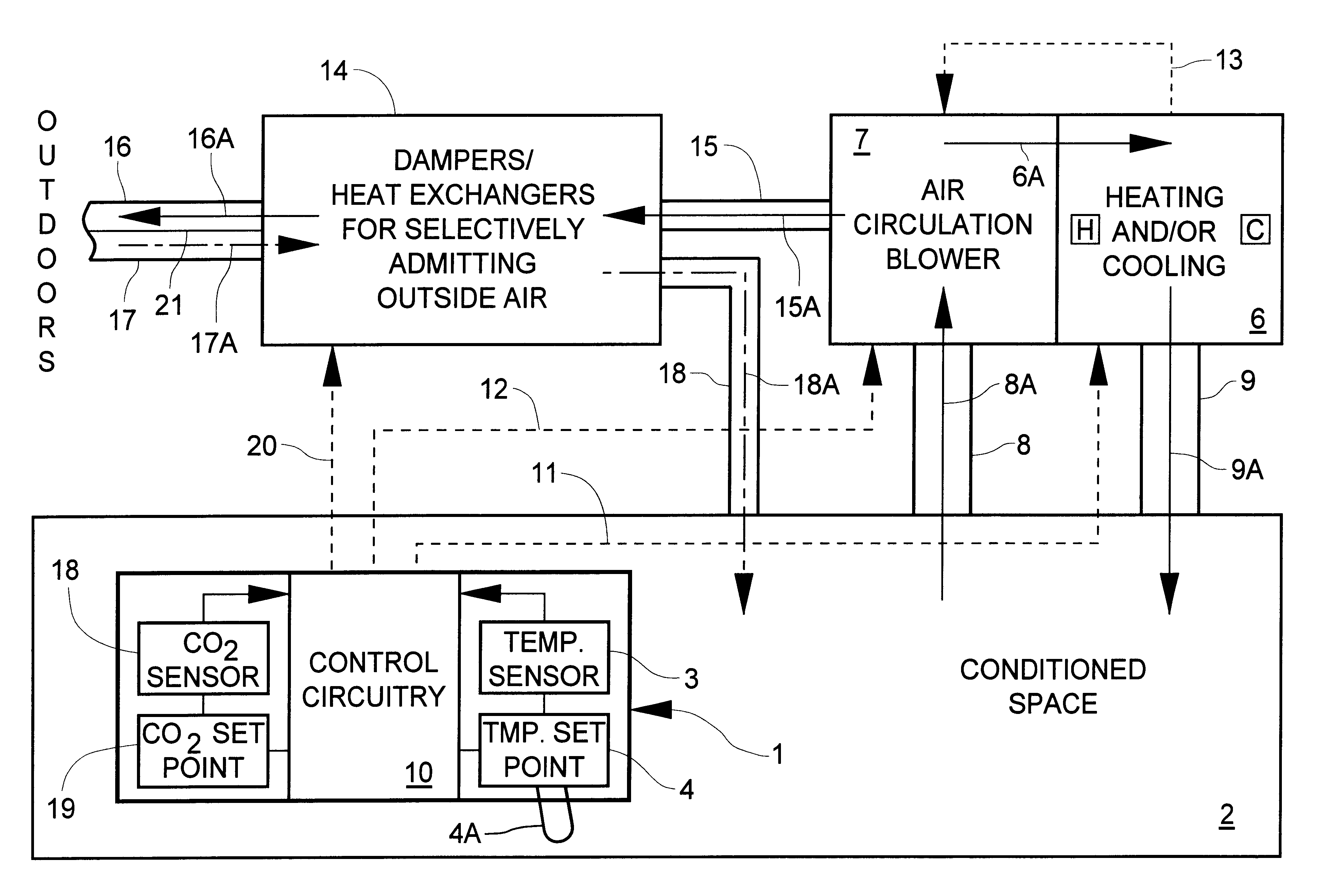

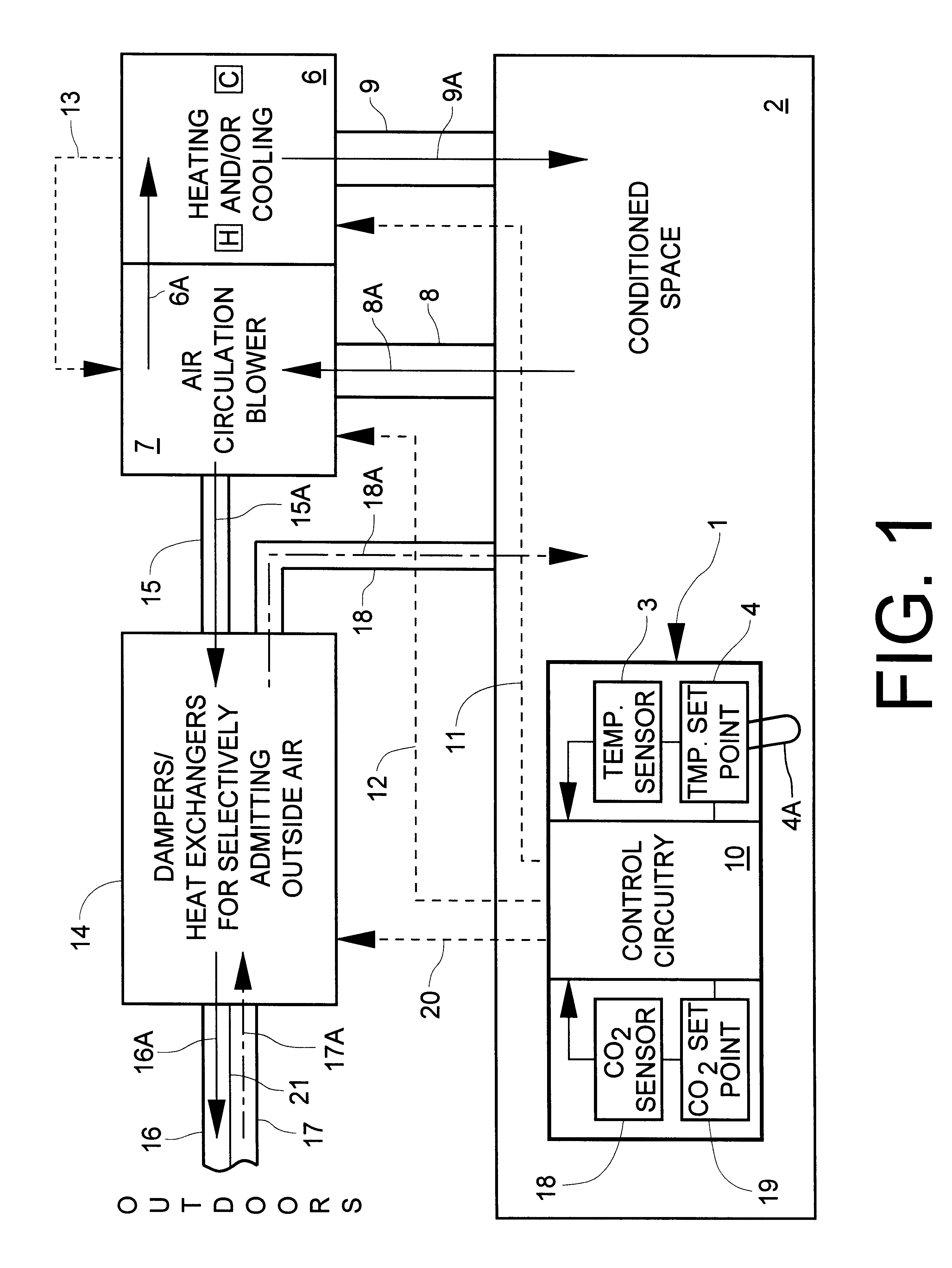

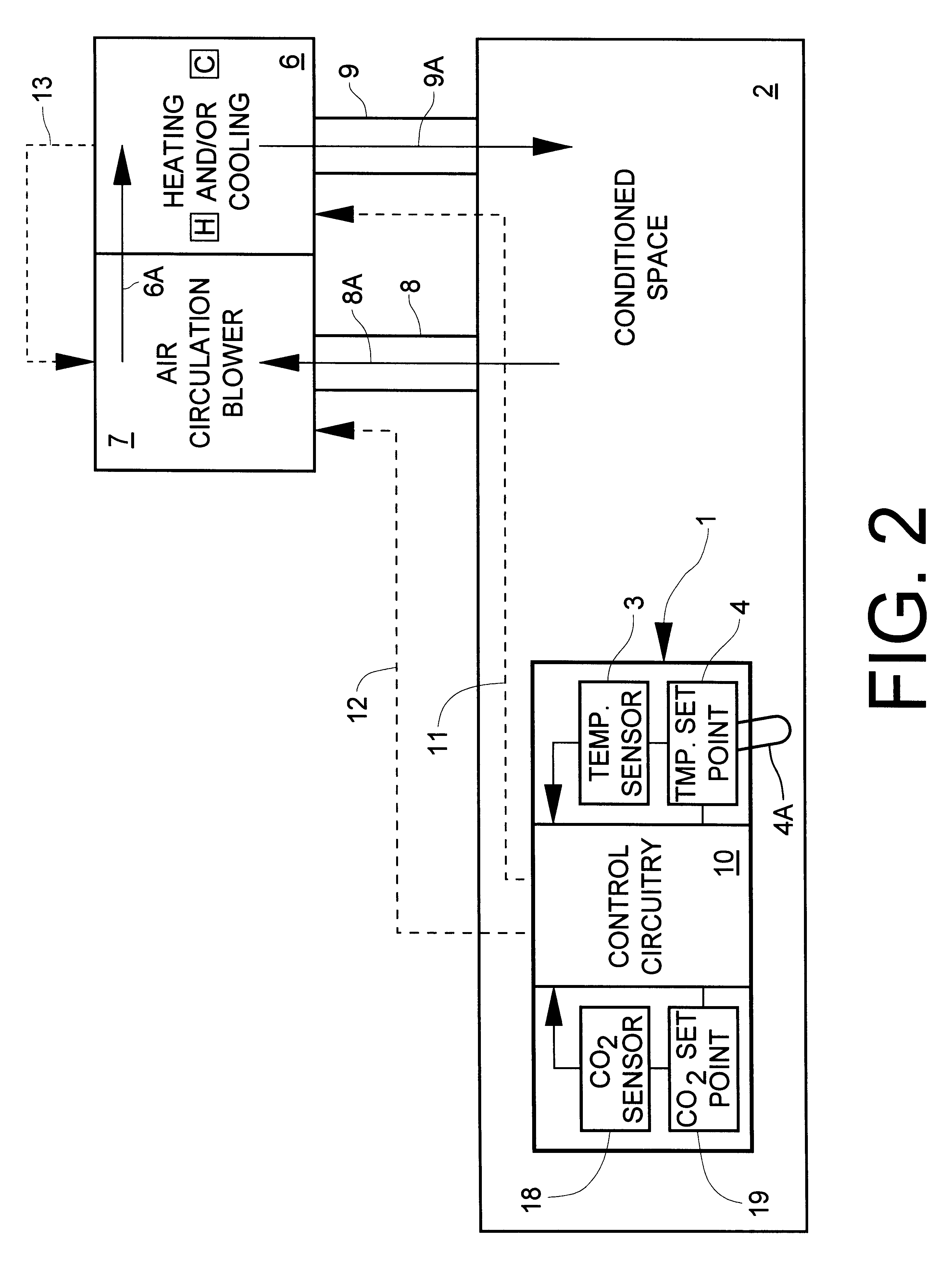

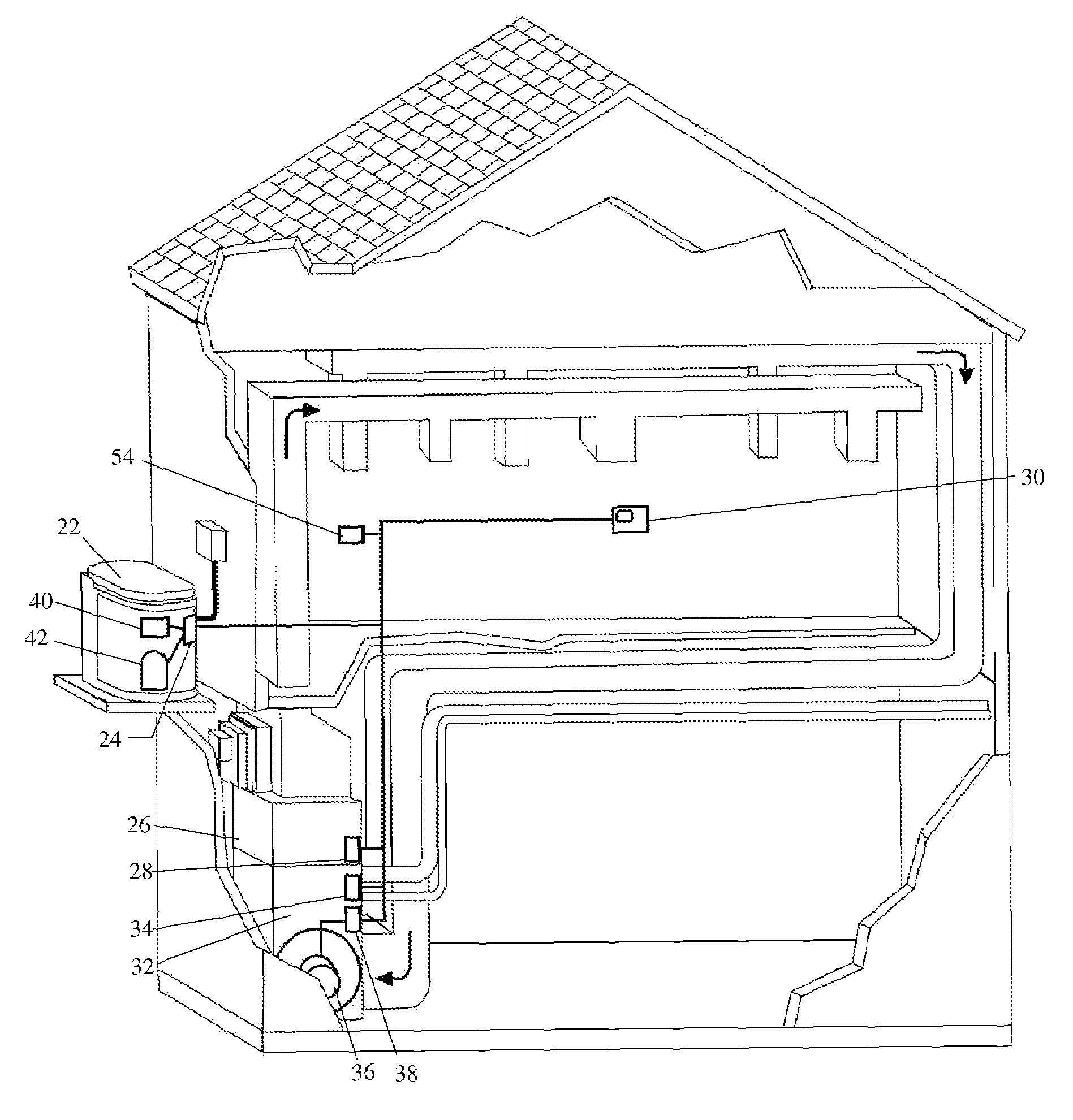

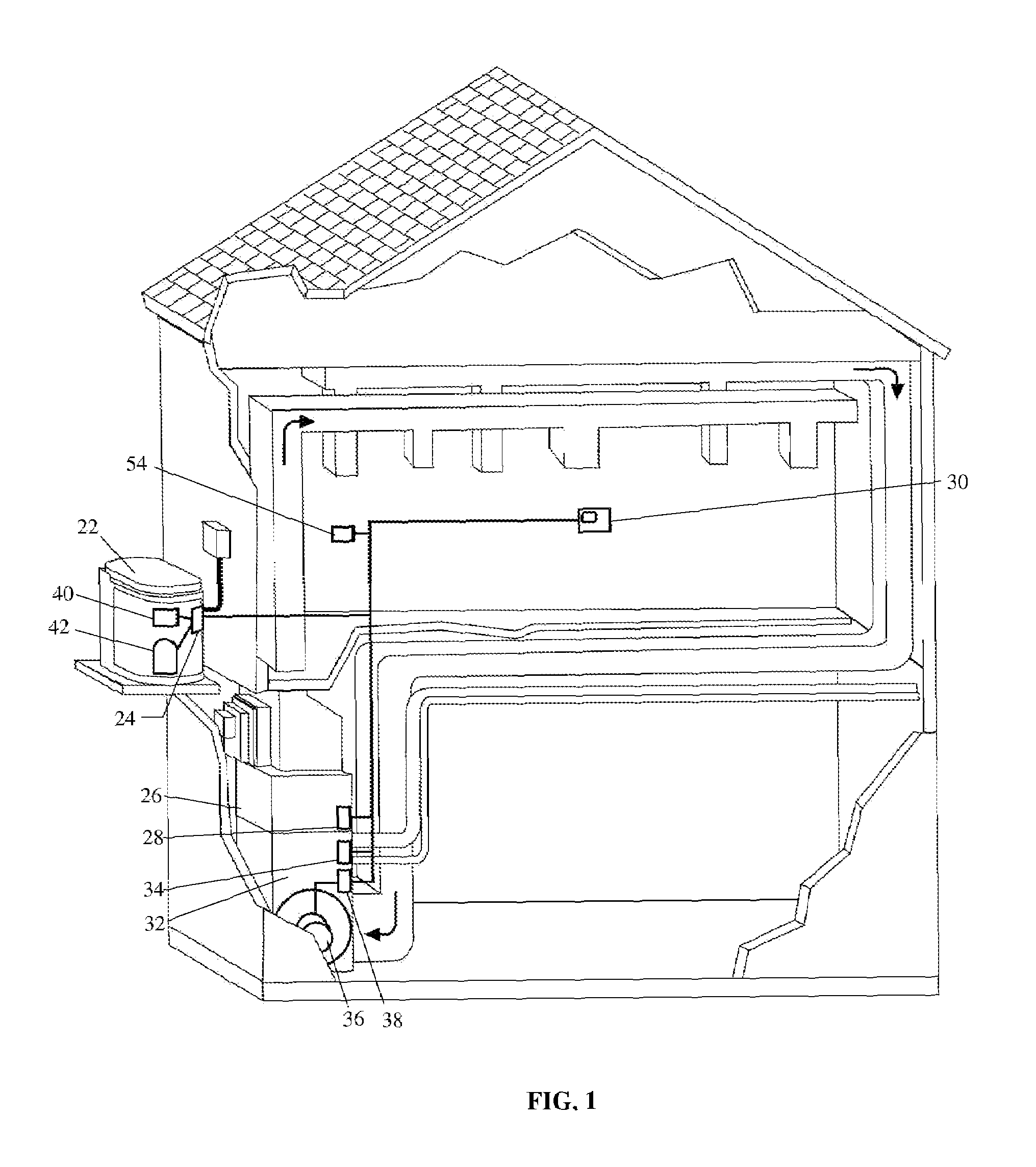

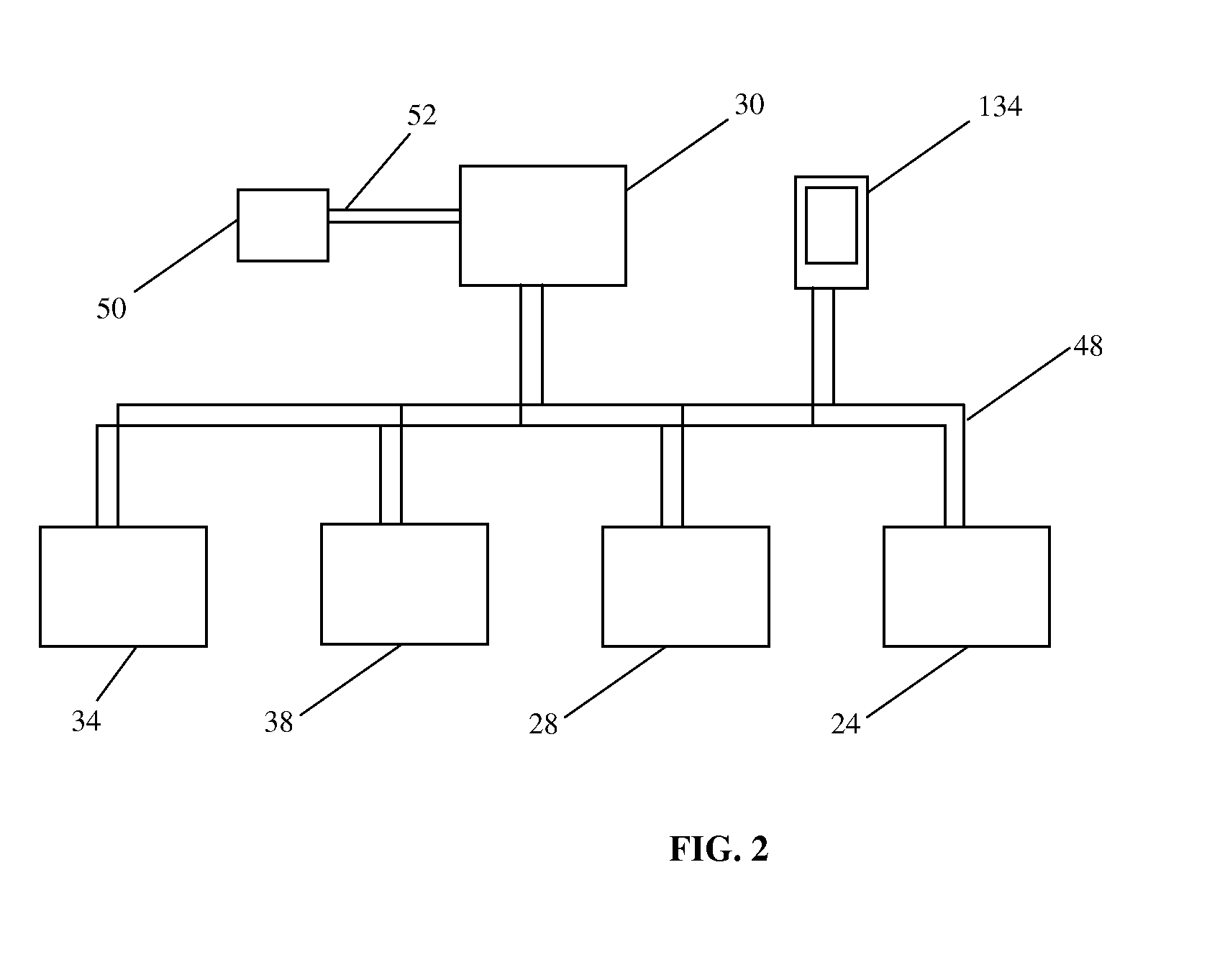

Thermostat incorporating thin film carbon dioxide sensor and environmental control system

InactiveUS6398118B1Sufficiently compactSimple enoughMechanical apparatusSpace heating and ventilation safety systemsThermostatEngineering

A system for monitoring and modifying the quality and temperature of air within a conditioned space includes a blower unit, a damper unit for selectively admitting outside air into the conditioned space, a temperature moderating unit and a control unit. The control unit includes a thermostat and conventional temperature control apparatus for selectively activating the temperature moderating unit to maintain the desired temperature in the conditioned space. The control unit also incorporates CO2 concentration measuring and control apparatus which includes a small CO2 sensor. The CO2 sensor includes a cathode, an anode and a solid electrolyte disposed intermediate and electrically in contact with each of the cathode and the anode to effect a primary electrical cell. A heater and a heater thermostat serve to maintain the temperature of the cell at about 250° C. The cathode and anode materials and the chemical composition of the electrolyte are further selected such that the voltage generated across the heated cell varies in accordance with the CO2 concentration. CO2 concentration modifying apparatus is responsive to sensing a first predetermined CO2 concentration for turning on the blower unit and to sensing a second, higher, predetermined CO2 concentration for actuating the damper unit to admit outside air.

Owner:ROSEN HOWARD B +1

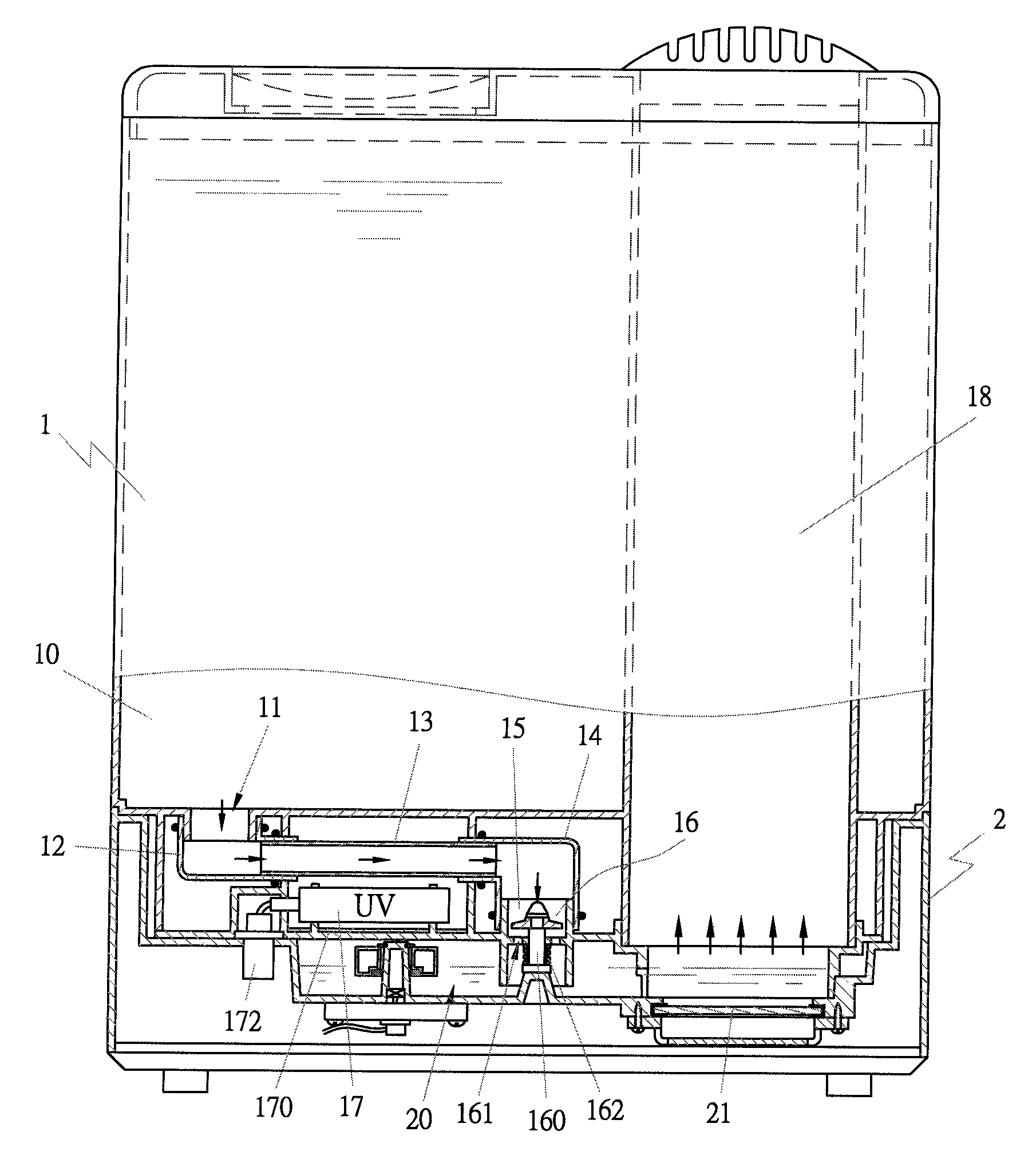

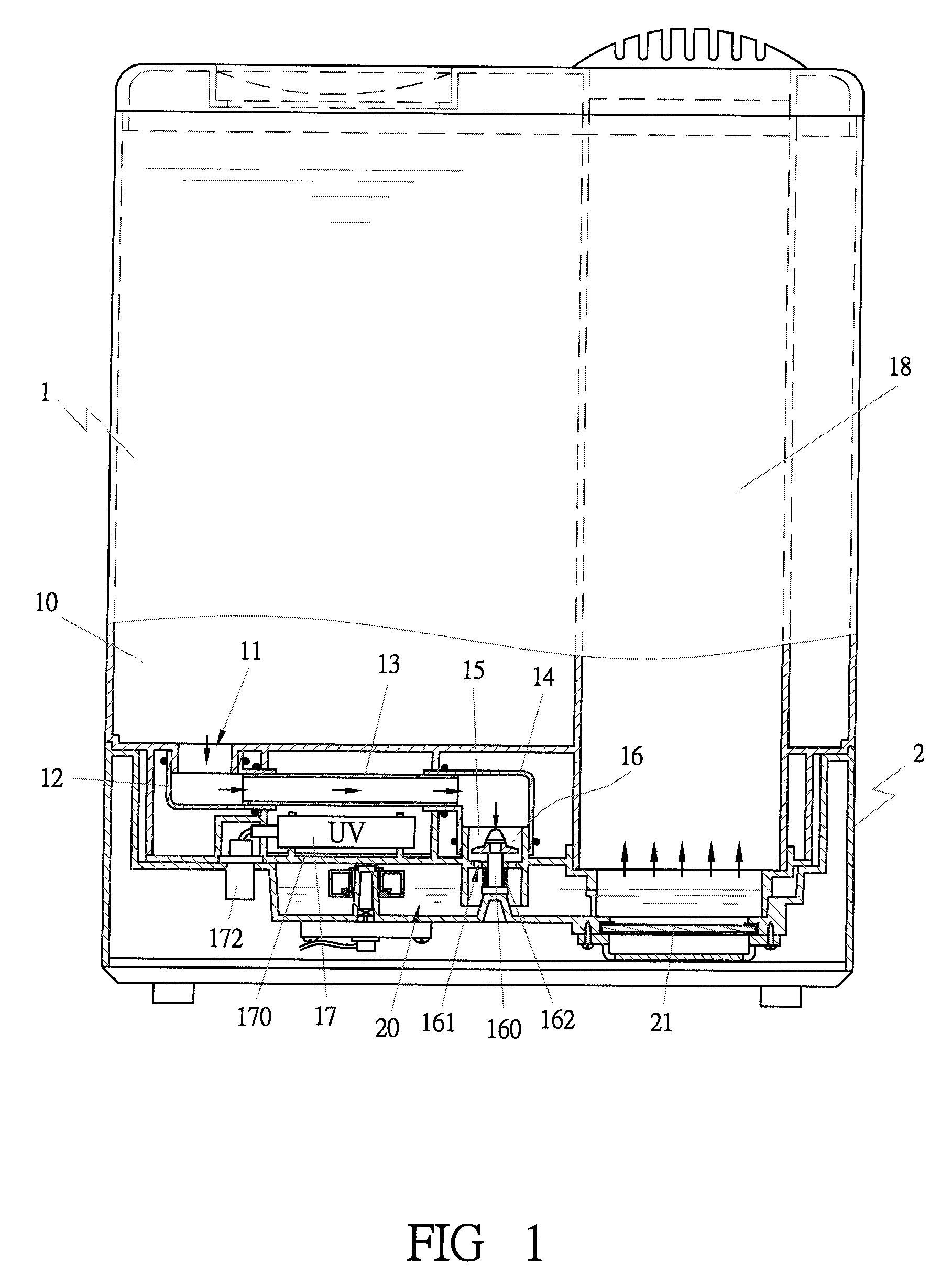

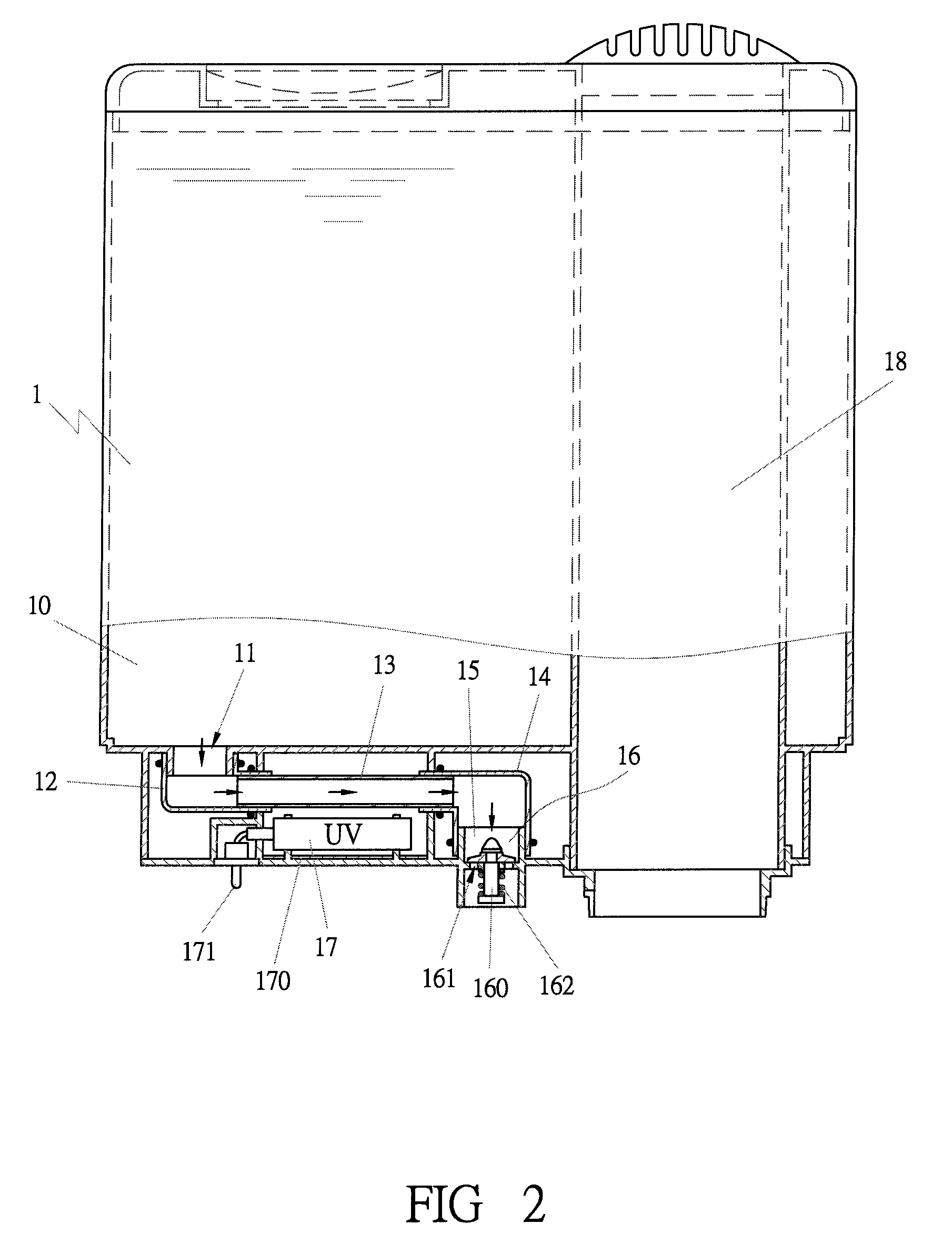

UV sterilizing humidifier

InactiveUS7540474B1Safe installationMechanical apparatusLighting and heating apparatusUv disinfectionEngineering

A UV sterilizing humidifier includes a water box body provided with a water-storing box bored with a water inlet fixed with a first silica tube connected with one end of a glass tube having another end connected with a second silica tube, which is connected with the inlet tube of the water-storing tank of a main body. The water box body is installed with a UV sterilizing lamp positioned under the glass tube and having its circumference provided with an isolating layer for preventing UV light from transmitting to the outer environment. The water box body further has an atomization chamber for receiving atomized substance. A main body is disposed with a water-storing tank for storing a proper amount of water, an oscillator for atomizing the water inside and a detecting element for detecting the water amount therein for insuring safety of using the humidifier.

Owner:HUANG CHUAN PAN +1

Interactive control system for an HVAC system

An interactive system for controlling the operation of an HVAC system is provide that comprises a thermostat for initiating the operation of the HVAC system in either a full capacity mode of operation or at least one reduced capacity mode of operation, and a controller for an outside condenser unit having a condenser fan motor and a compressor motor, the controller being capable of operating the compressor in a full capacity mode and at least one reduced capacity mode. The system also comprises a controller for an indoor blower unit having a blower fan motor, the controller being capable of operating the blower fan motor in a full capacity mode an at least one reduced capacity mode. The system further includes a communication means for transmitting information between the outside condenser unit controller and at least the indoor blower controller, where the information relates to the operation of the indoor blower and the outdoor condenser unit. The indoor blower controller responsively controls the operation of the blower fan motor in a full capacity mode or a reduced capacity mode based on the information received from the outdoor unit controller, and the outdoor unit controller responsively controls the operation of the compressor in a full capacity mode or a reduced capacity mode based on the information received from the indoor blower controller.

Owner:COPELAND COMFORT CONTROL LP

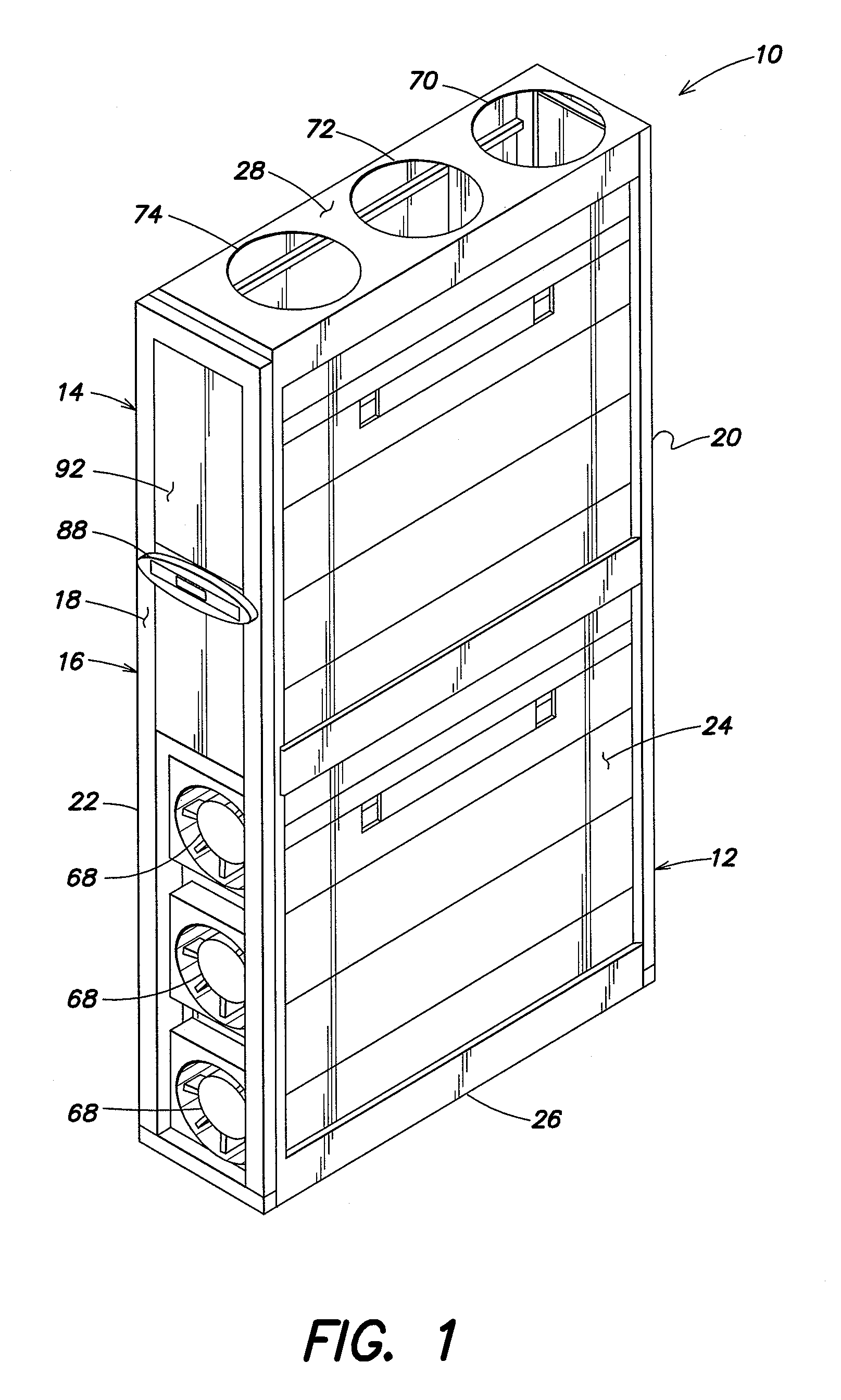

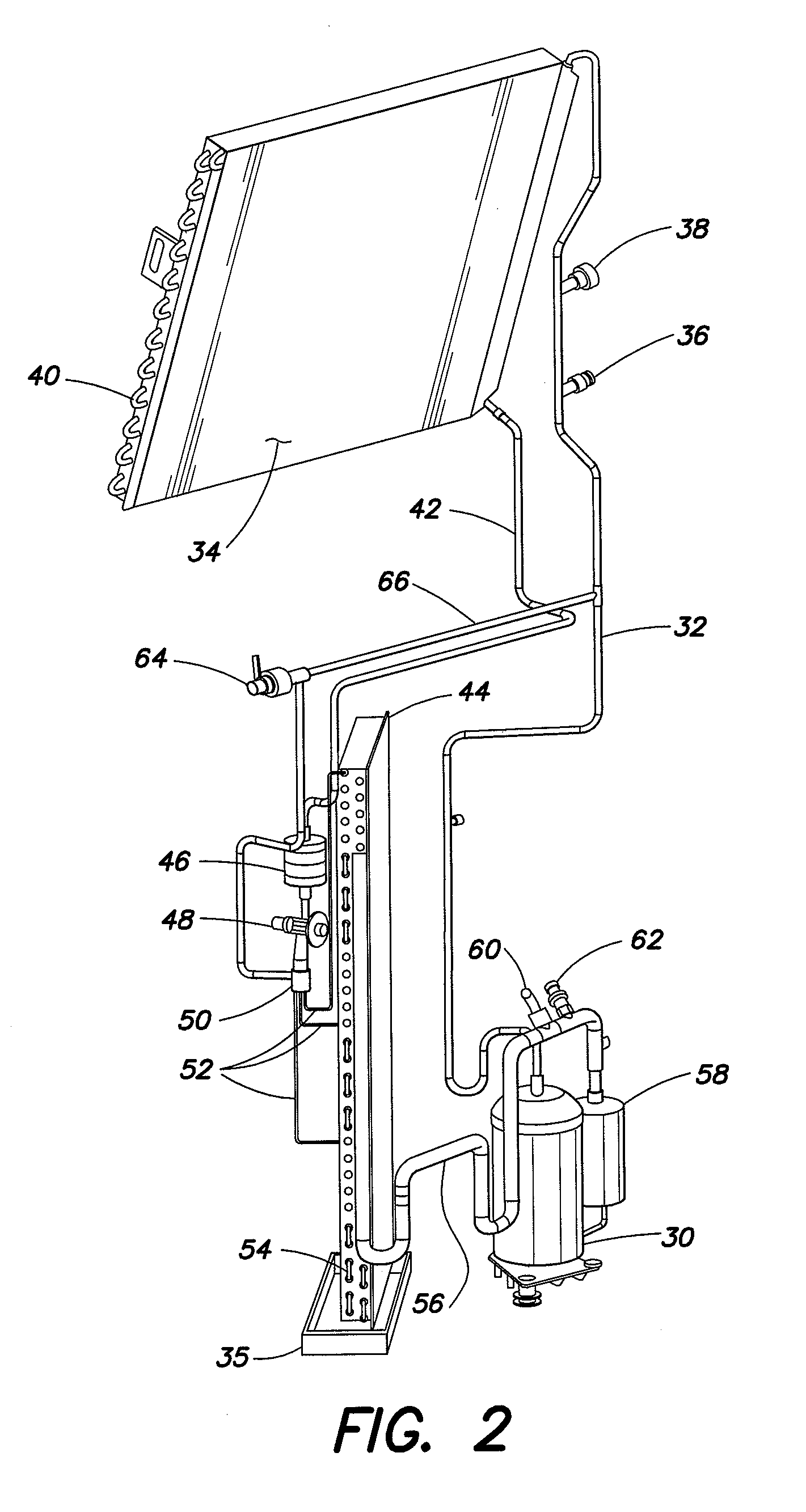

Method and apparatus for cooling

ActiveUS20080245083A1Increase loopHigh trafficMechanical apparatusTemperatue controlEngineeringCooling capacity

A method of calculating net sensible cooling capacity of a cooling unit includes measuring a discharge pressure from of fluid from a compressor and a suction pressure from an evaporator, calculating a condensing temperature of fluid flowing from the compressor and an evaporating temperature of fluid flowing from the evaporator, calculating a mass flow rate of fluid flowing from the compressor, calculating enthalpy of fluid flowing from the compressor, of fluid flowing from the thermal expansion valve, and of fluid flowing from the evaporator, calculating a mass flow rate of fluid flowing through the hot gas bypass valve, and calculating net sensible cooling capacity. Embodiments of cooling units and other methods are further disclosed.

Owner:AMERICA POWER CONVERSION CORP

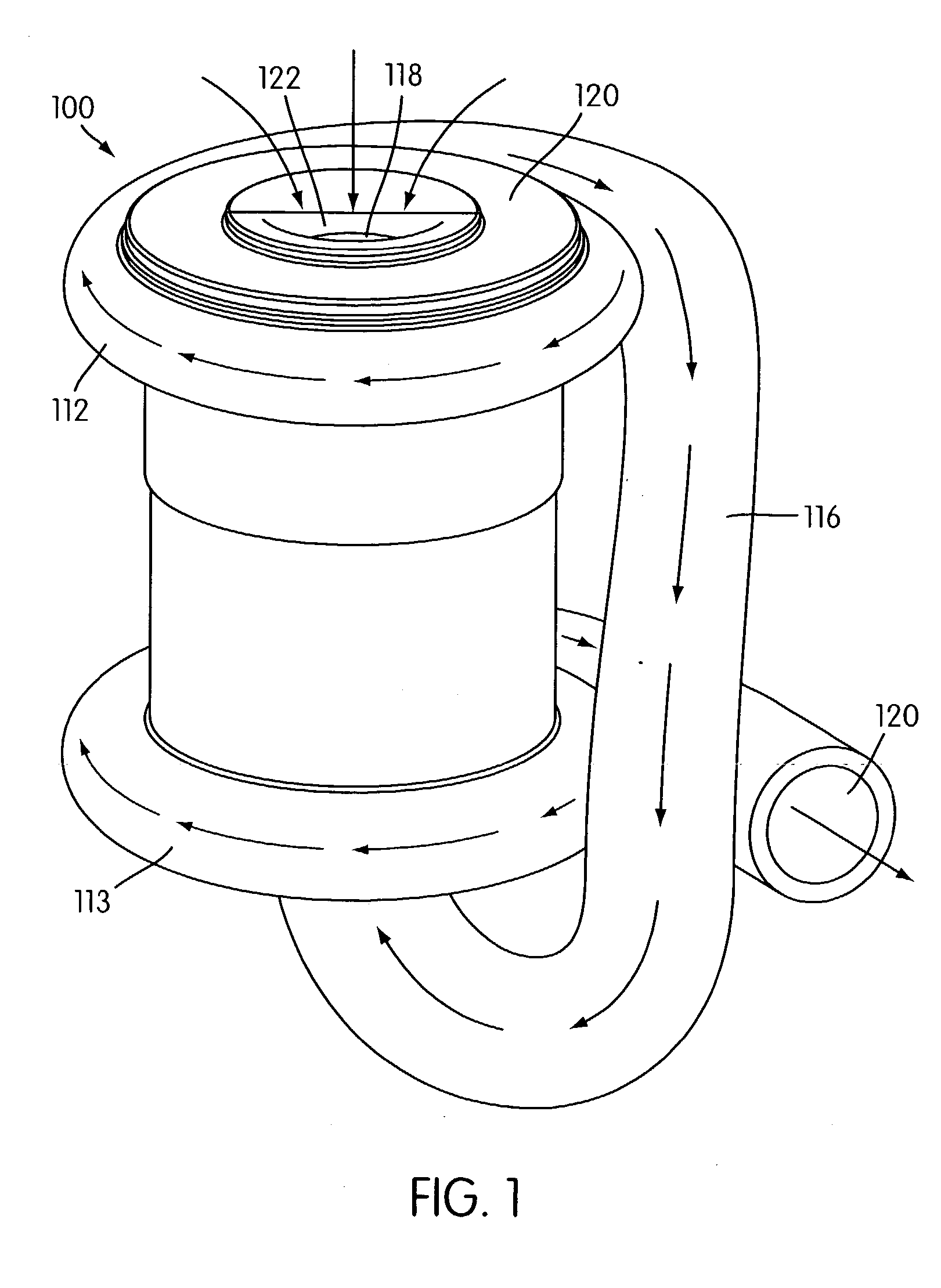

Double ended blower and volutes therefor

InactiveUS20030168064A1Faster pressure rise timeImprove reliabilityPropellersElement comparisonMotor speedImpeller

A double-ended variable speed blower for Continuous Positive Airway Pressure (CPAP) ventilation of patients includes two impellers in the gas flow path that cooperatively pressurize gas to desired pressure and flow characteristics. Thus, the double-ended blower can provide faster pressure response and desired flow characteristics over a narrower range of motor speeds, resulting in greater reliability and less acoustic noise.

Owner:RESMED LTD

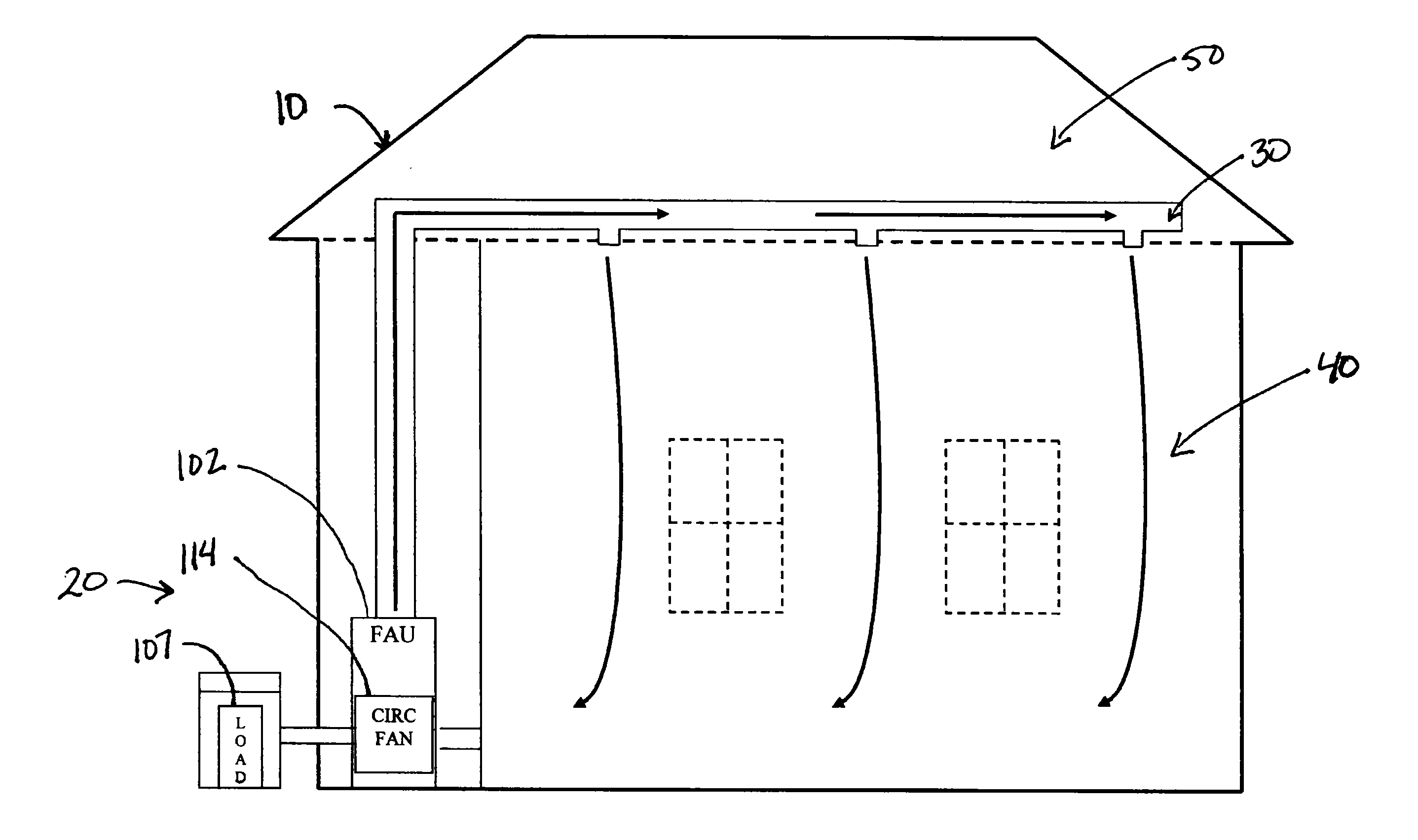

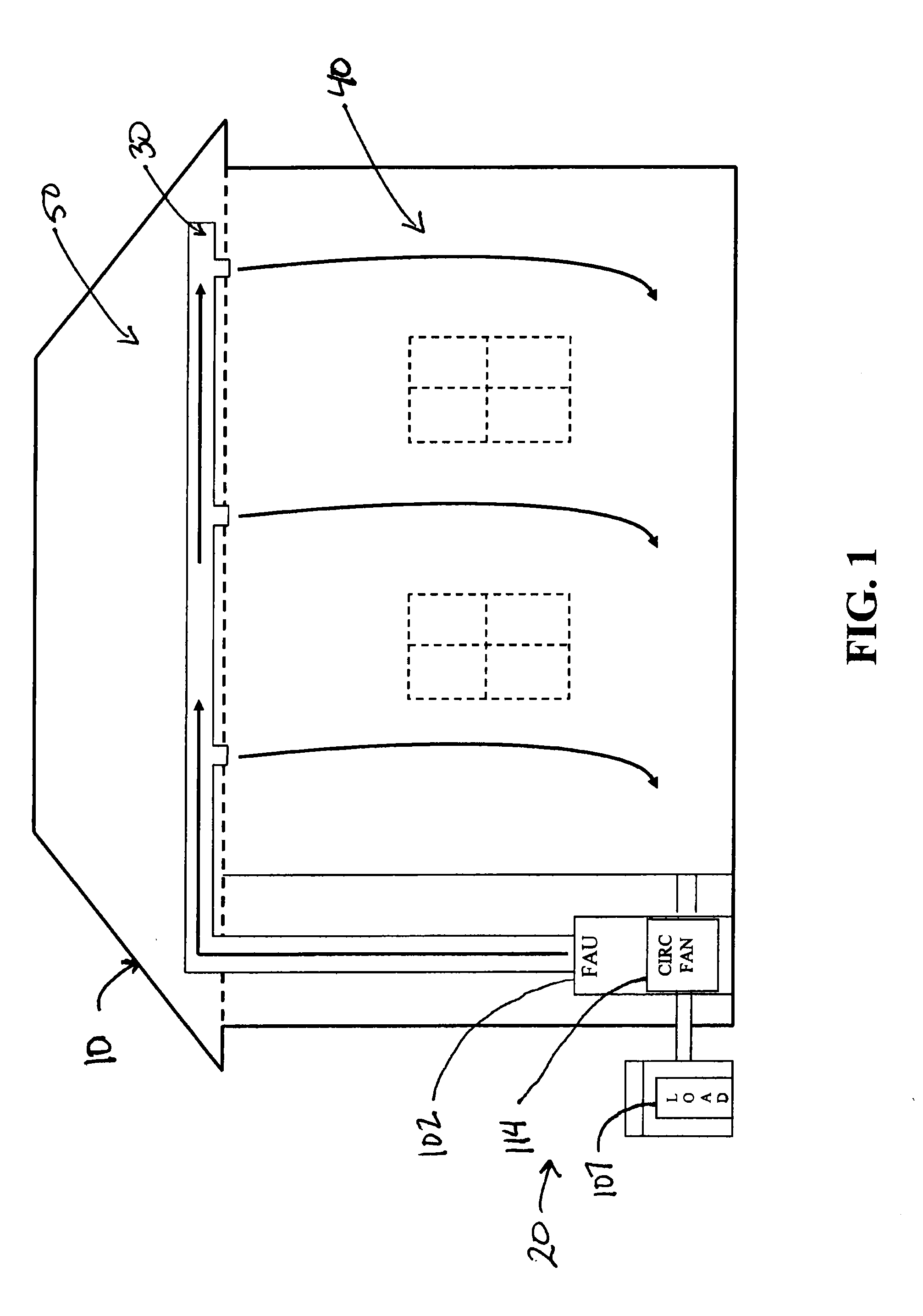

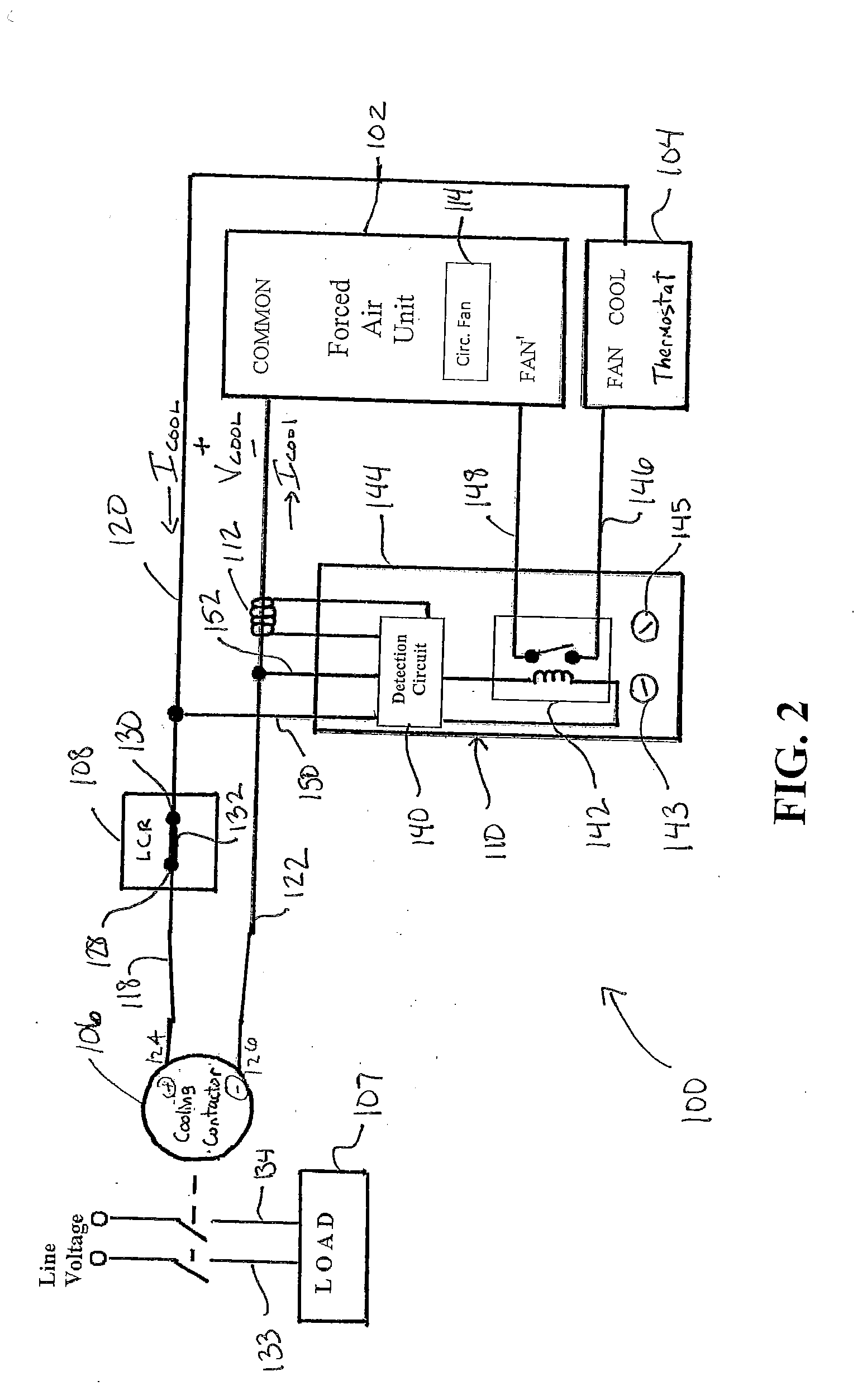

Load management aware fan control

InactiveUS20120017611A1Improve cooling efficiencyPower interruptionMechanical apparatusSpace heating and ventilation safety systemsPower flowControl theory

A fan-control device for overriding normal operation of a circulation fan delivering conditioned air through ductwork in an unconditioned space. The fan-control device includes a detection circuit and a fan relay. The detection circuit is configured to detect a cooling system control voltage and a cooling system control current and to output a fan control override signal when the cooling system control voltage is detected and the cooling system control current is absent.

Owner:COOPER TECH CO

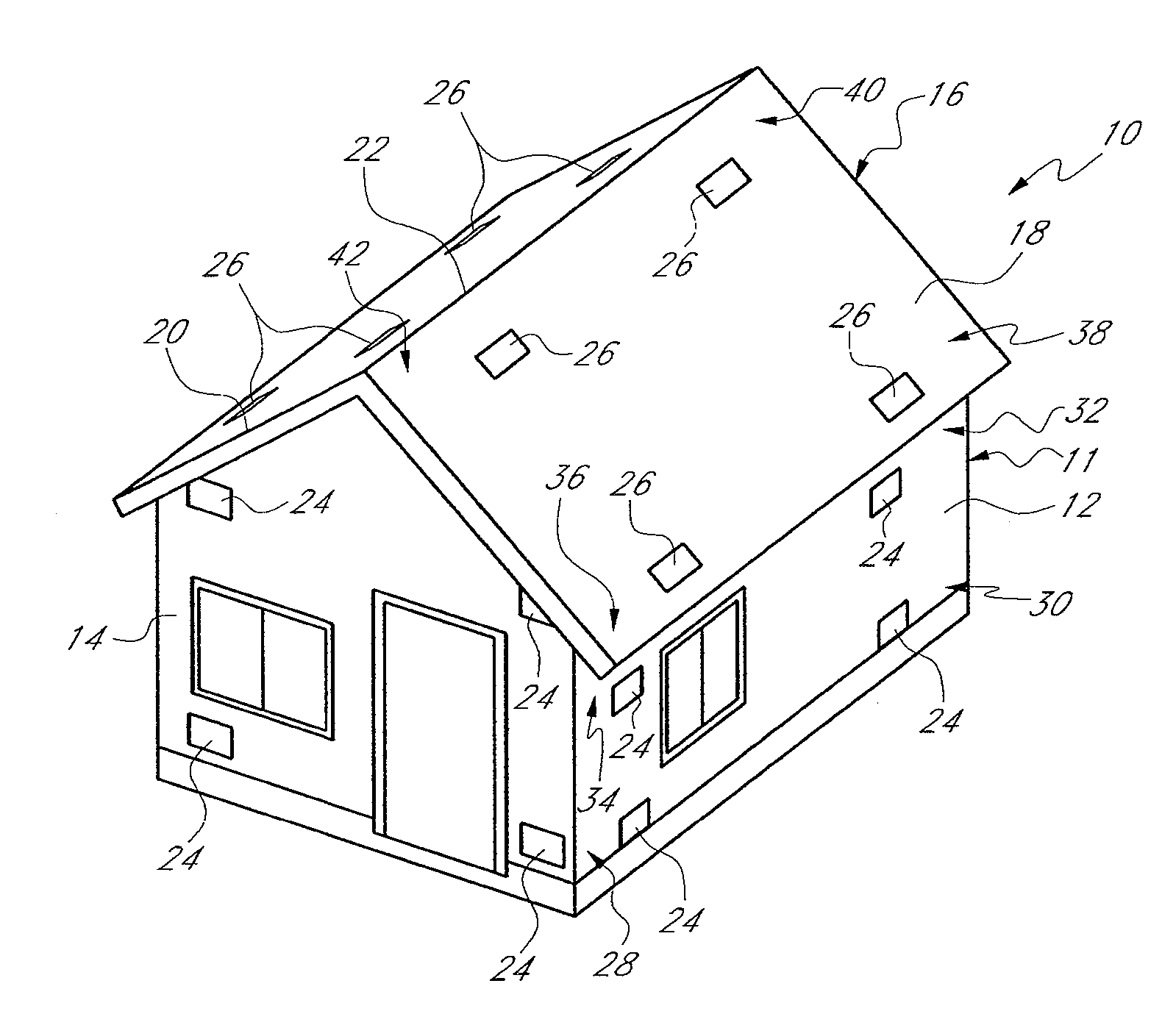

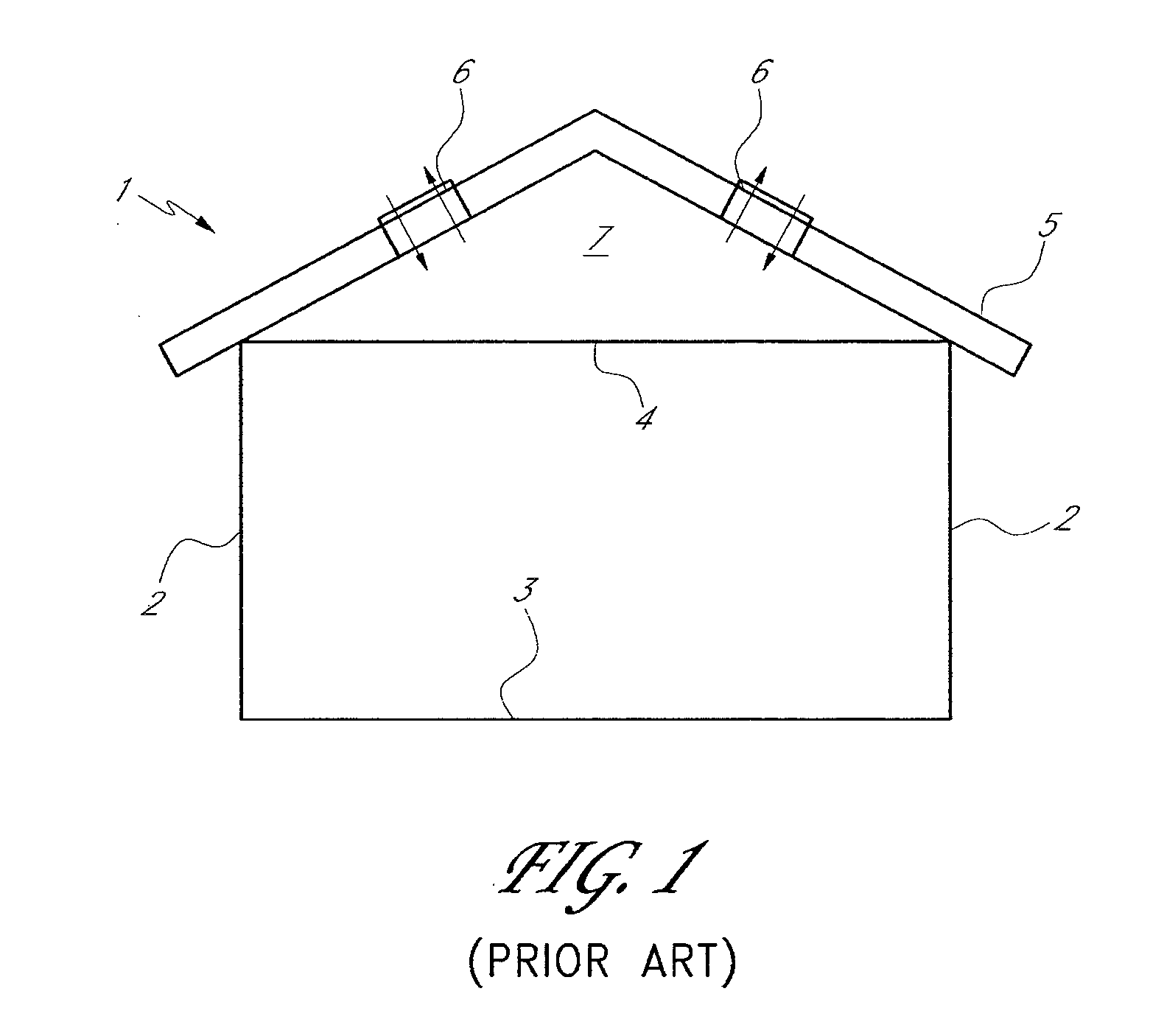

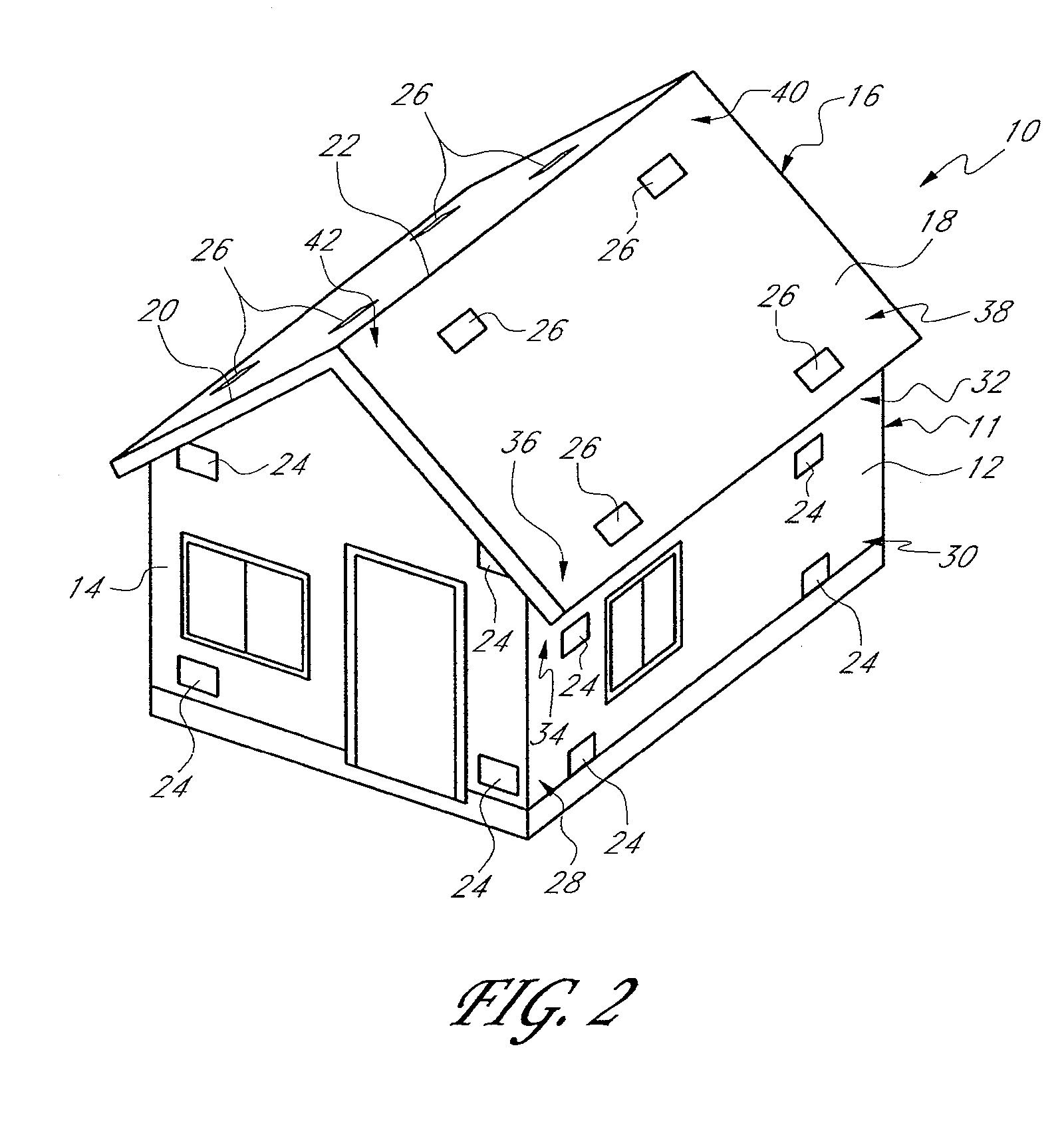

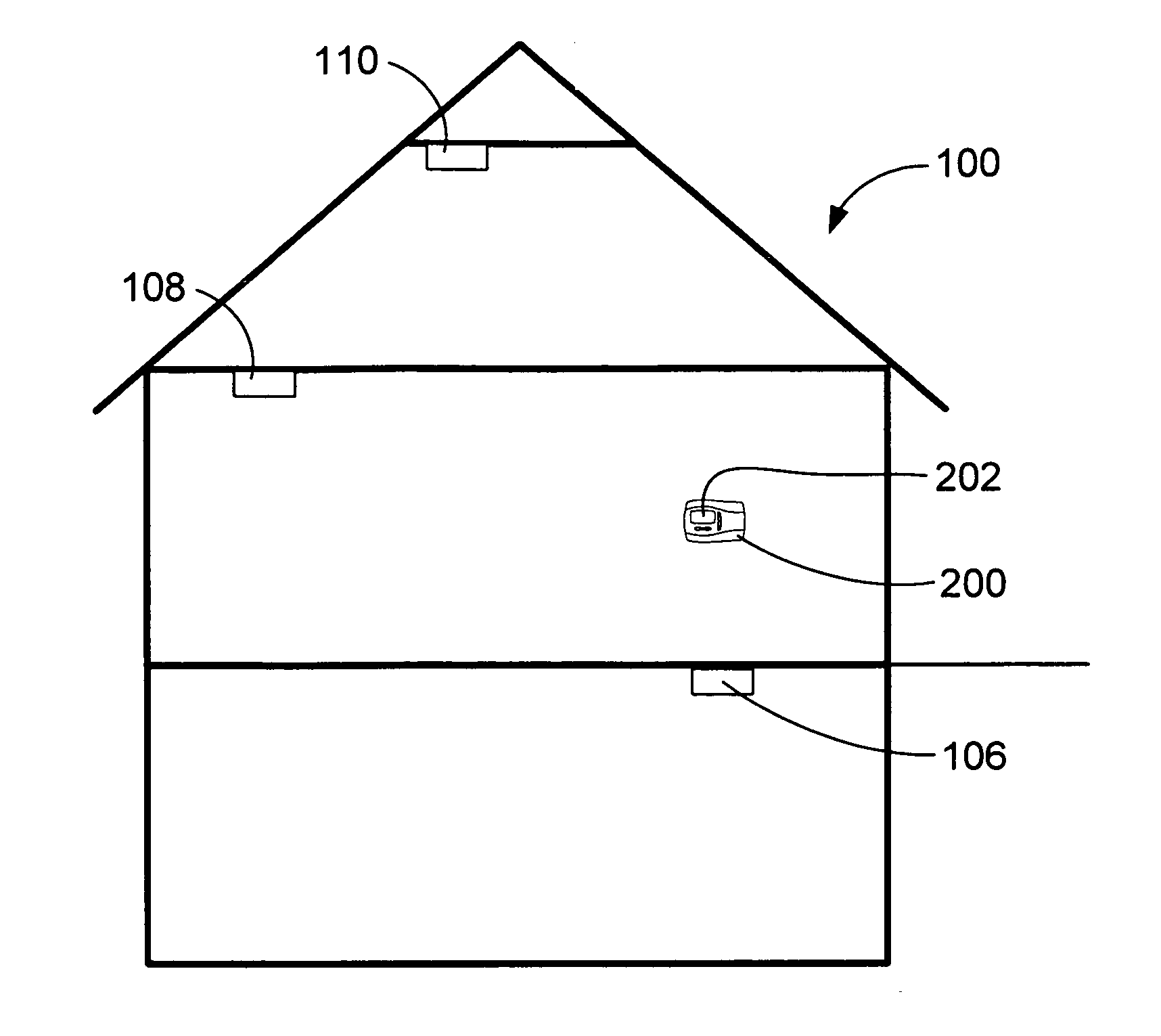

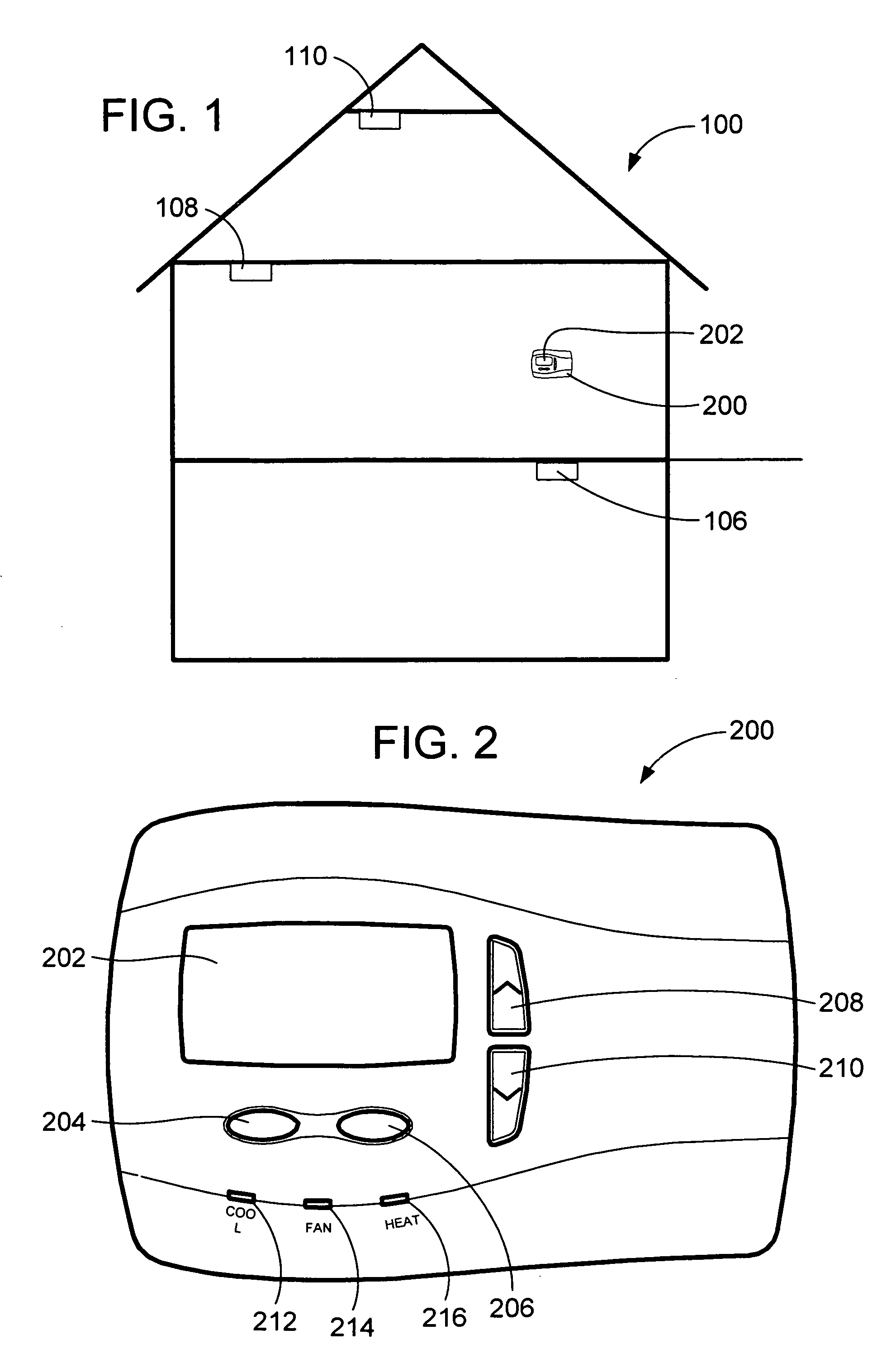

Passive ventilation control system

ActiveUS20070072541A1Mechanical apparatusSpace heating and ventilation safety systemsControl systemPassive ventilation

A passive ventilation control system and method. The system includes passive vents throughout a building. The vents may be arranged in multiple sets, with each set being substantially vertically aligned through multiple floors or the entire height of the building. Sensors are positioned inside and / or outside the building for sensing different environmental parameters or atmospheric conditions. The sensors send signals to a controller, which automatically adjusts airflow through the vents in response to the signals from the sensors.

Owner:DANIELS II WILLIAM B +1

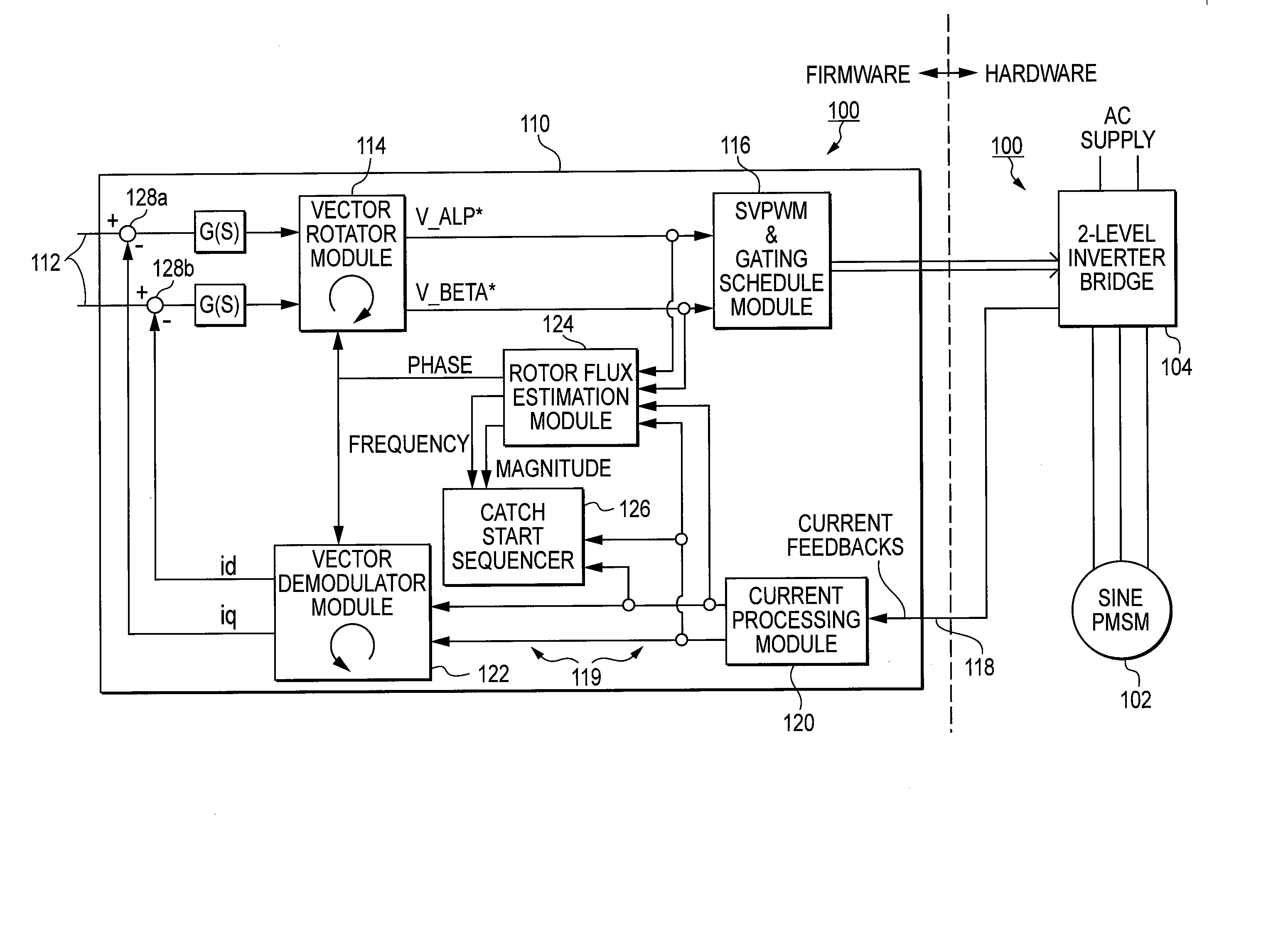

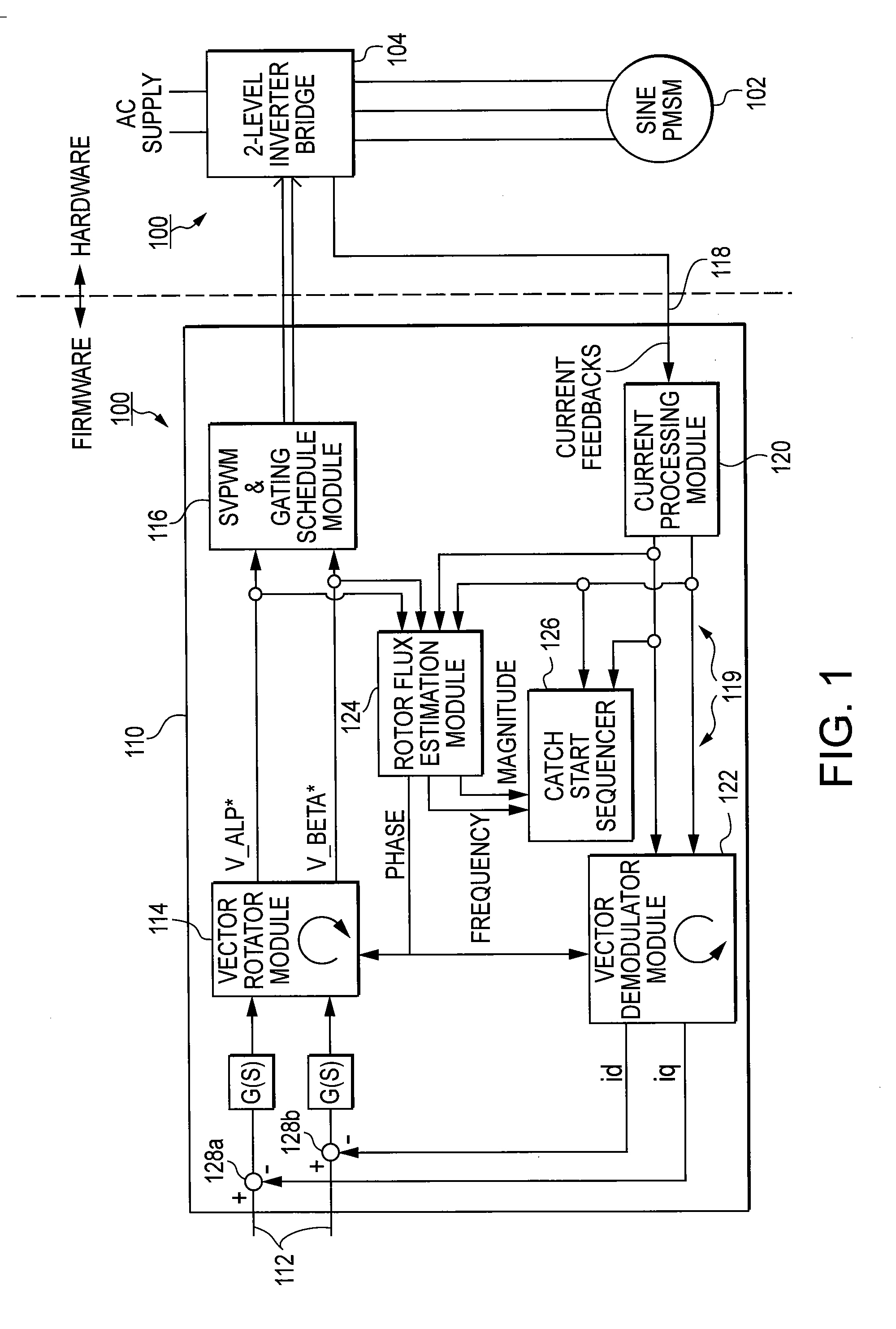

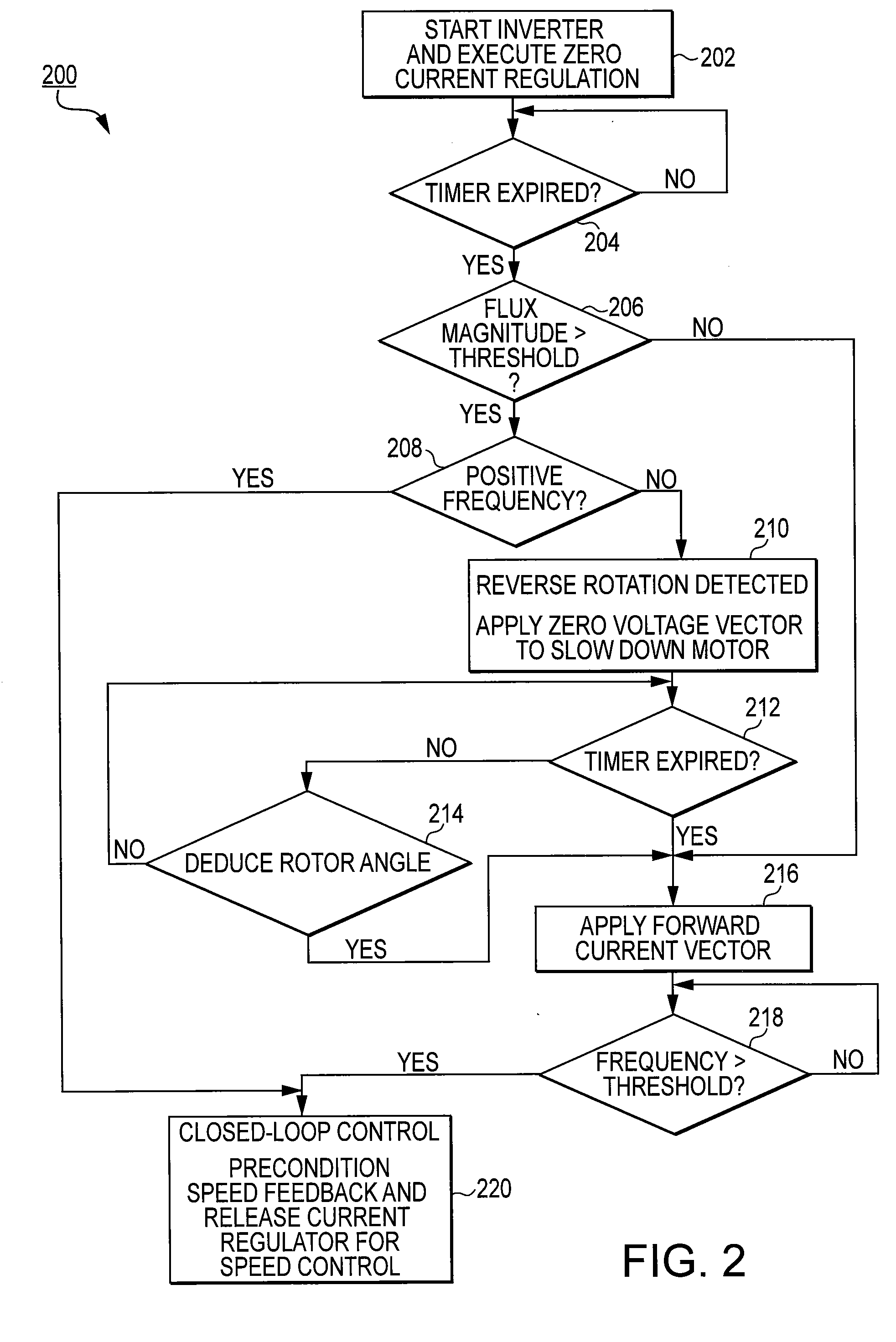

Method and system for starting a sensorless motor

ActiveUS20070001635A1Preventing over current shutdownHigh currentAC motor controlSynchronous motors startersMotor driveEngineering

A motor drive system for a sensorless motor includes a catch start sequencer that controls the motor drive system to robustly start the motor in the event the motor rotor is rotating in forward or reverse direction prior to activating the motor drive system. In particular, the catch start sequencer causes the motor drive system to initially find and track the rotor position, and then determines the speed and possibly the direction of rotation of the rotor. If the rotor is rotating in the reverse direction, the catch start sequencer controls the motor drive system to slow the speed of rotation and to then start the rotor rotating in the forward direction.

Owner:INFINEON TECH AMERICAS CORP

Interactive control system for an HVAC system

An interactive system for controlling the operation of an HVAC system is provide that comprises a thermostat for initiating the operation of the HVAC system in either a full capacity mode of operation or at least one reduced capacity mode of operation, and a controller for an outside condenser unit having a condenser fan motor and a compressor motor, the controller being capable of operating the compressor in a full capacity mode and at least one reduced capacity mode. The system also comprises a controller for an indoor blower unit having a blower fan motor, the controller being capable of operating the blower fan motor in a full capacity mode an at least one reduced capacity mode. The system further includes a communication means for transmitting information between the outside condenser unit controller and at least the indoor blower controller, where the information relates to the operation of the indoor blower and the outdoor condenser unit. The indoor blower controller responsively controls the operation of the blower fan motor in a full capacity mode or a reduced capacity mode based on the information received from the outdoor unit controller, and the outdoor unit controller responsively controls the operation of the compressor in a full capacity mode or a reduced capacity mode based on the information received from the indoor blower controller.

Owner:COPELAND COMFORT CONTROL LP

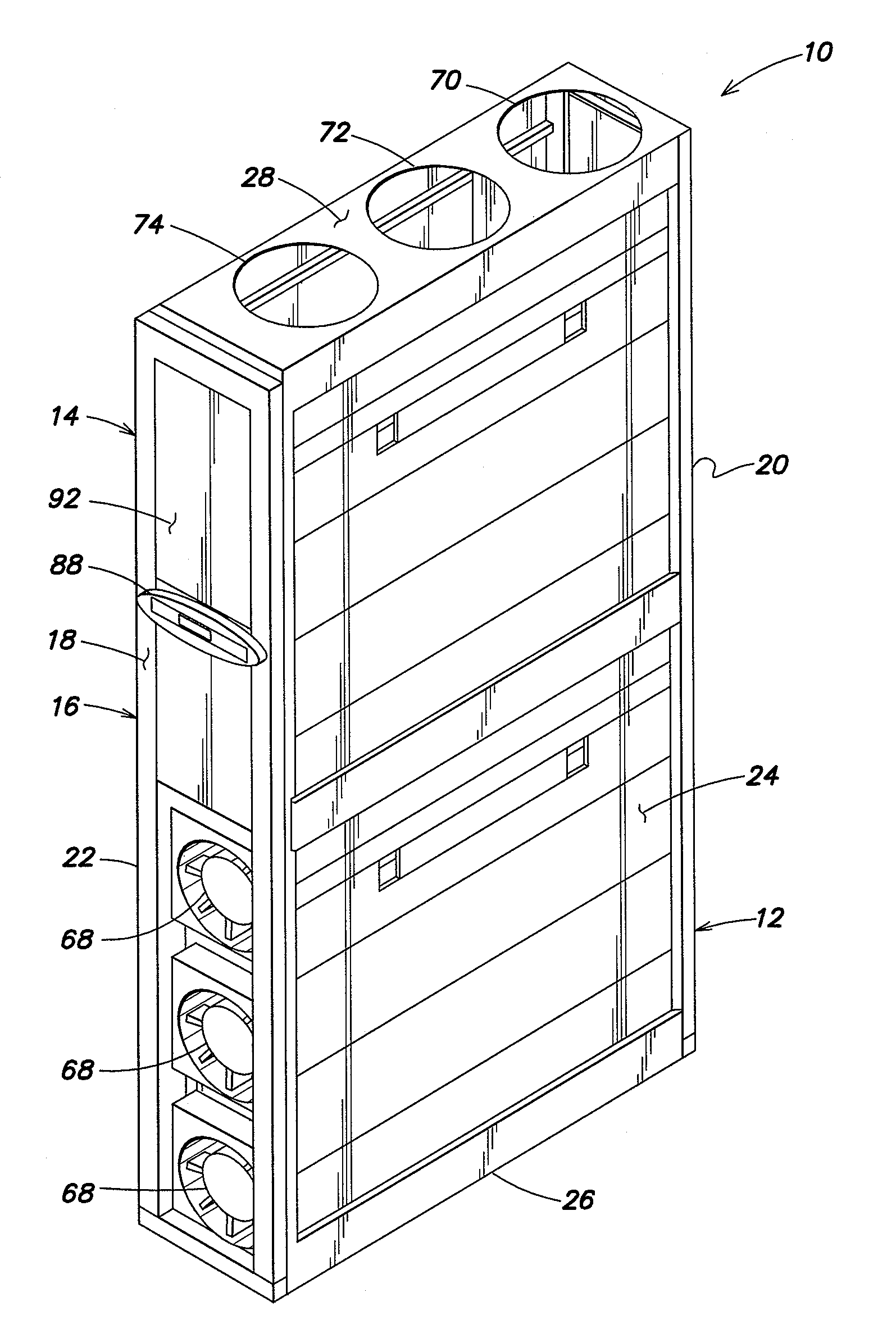

HVAC fan-powered terminal unit having preset fan CFM

InactiveUSRE38406E1Mechanical apparatusSpace heating and ventilation safety systemsVoltmeterEngineering

An arrangement is disclosed for controlling fan motors in fan-powered terminal units which permit the air flow of the terminal units to be factory preset and reset using a voltmeter. The fan motor is responsive to the pulse width of pulses of a pulse width modulated signal to provide an air flow which is proportional to the pulse width. By adjusting the pulse width, the air flow may be set as desired. A pulse width modulated signal having pulses with a set amplitude and frequency is generated. The dc voltage of the pulse width modulated signal is measured using a voltmeter. As the pulses have a set amplitude and frequency, the pulse width of the pulses may be adjusted by controlling the dc voltage of the pulse width modulated signal. The fan motor is programmed to deliver the set air flow over a range of static pressures.

Owner:NAILOR INDS OF TEXAS

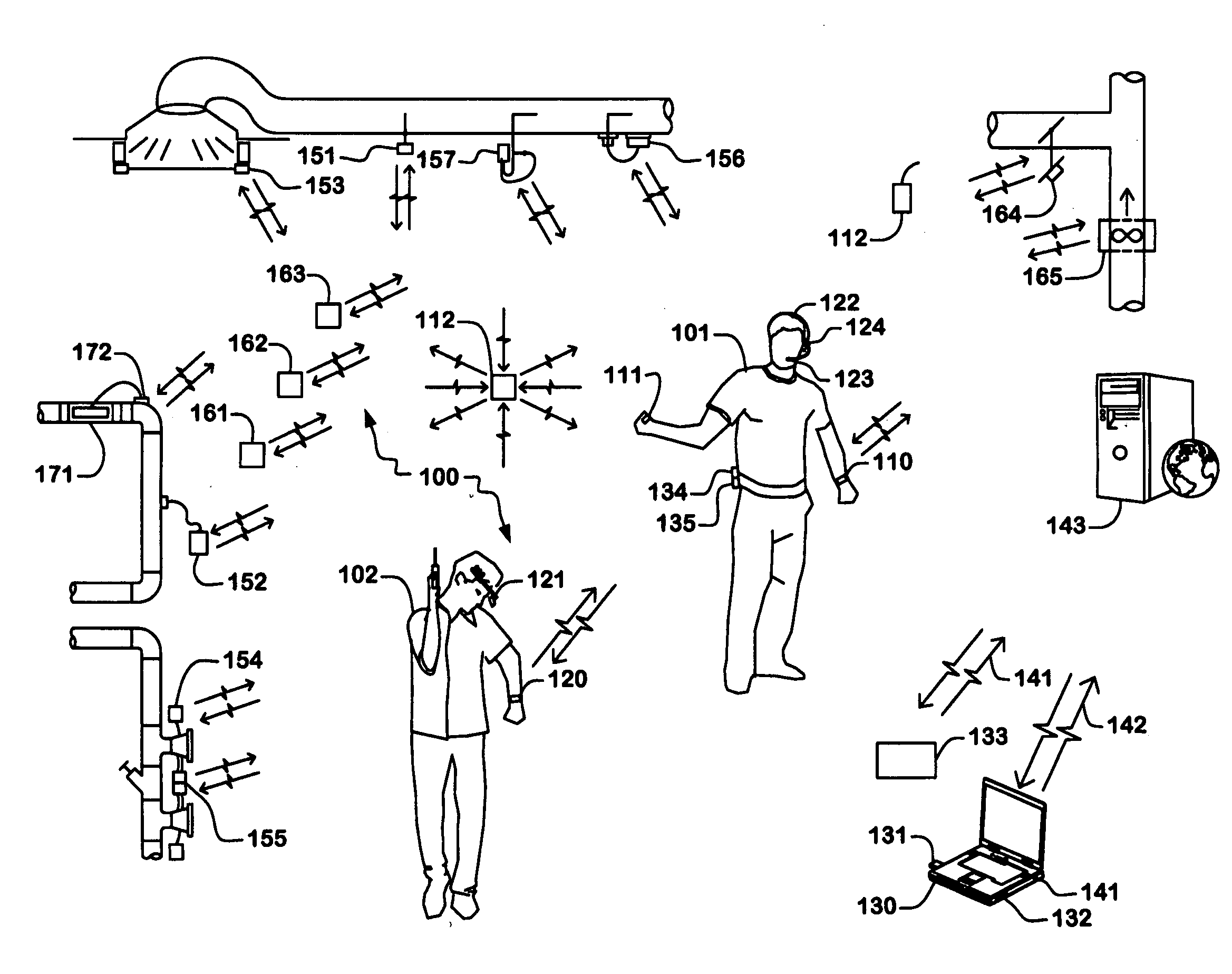

Wireless sensors system and method of using same

ActiveUS20120046792A1Improve understandingAct quicklySpace heating and ventilationTemperatue controlEngineeringWater temperature

An apparatus, system, and methods for measuring environmental parameters are disclosed. The apparatus, system, and methods can be used for a variety of applications, including HVAC air balancing and building commissioning. The system includes a variety of wireless sensing modules and wearable modules for control, display, and storage. Parameters measured include air and water temperature, pressure, velocity, and flow. Also included are sensors for light intensity, CO concentrations, and CO2 concentrations.

Owner:EVERGREEN TELEMETRY LLC

Fan assembly

InactiveUS20100226752A1Improve comfortReduce turbulenceCircumferential flow pumpsPump componentsImpellerEngineering

A fan assembly for creating an air current includes an air inlet, an air outlet, an impeller and a motor for rotating the impeller to create an air flow passing from the air inlet to the air outlet. The air outlet includes an interior passage for receiving the air flow and a mouth for emitting the air flow. The air outlet defines an opening through which air from outside the fan assembly is drawn by the air flow emitted from the mouth. The motor has a rotor which, in use, is capable of rotating at a speed of at least 5,000 rpm.

Owner:DYSON TECH LTD

Method for controlling multiple indoor air quality parameters

InactiveUS20080182506A1Mechanical apparatusSpace heating and ventilation safety systemsParticulatesIndoor air quality

The present invention provides an improved method and system for controlling an HVAC system for managing multiple indoor air quality (IAQ) parameters. An acceptable range is defined for each of the IAQ parameter. The parameters are then monitored by sensors within a controlled space. The parameters may comprise temperature, humidity, smoke, radon, VOCs, carbon dioxide, carbon monoxide, particulates, hydrocarbons, oxygen, ozone, and odors. The invention maintains the IAQ parameters within their respective acceptable ranges by automatically manipulating certain HVAC system functions including heating, cooling, humidification, dehumidification, ventilation, addition or removal of materials or compounds which affect IAQ parameters, airflow volume and air recirculation. In one embodiment of the invention, a non-HVAC-specific venting system is used to augment HVAC adjustment of airflow volume and air recirculation. This may include bathroom, kitchen and attic venting systems as well as whole-home vacuum systems.

Owner:LENNOX MFG

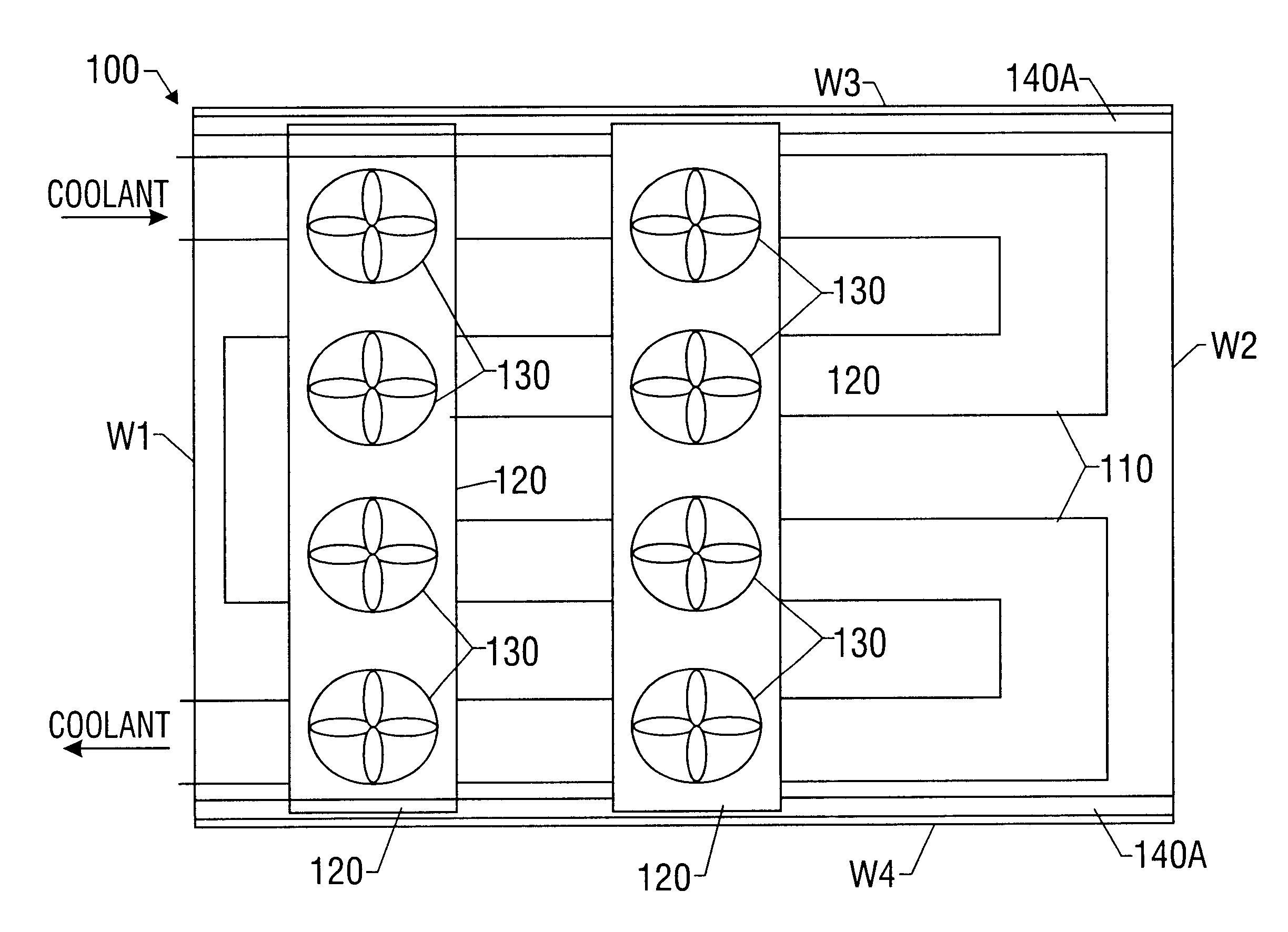

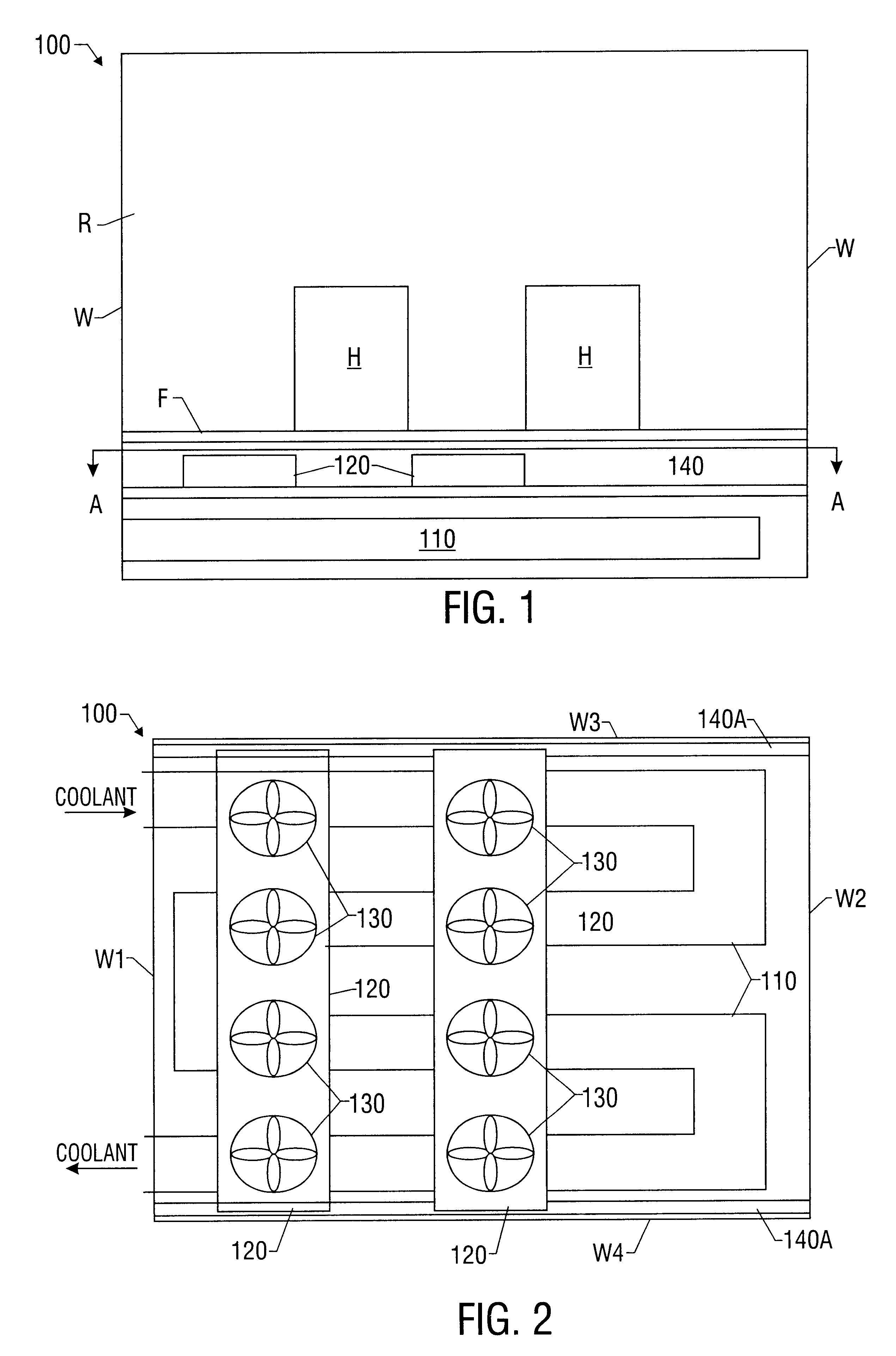

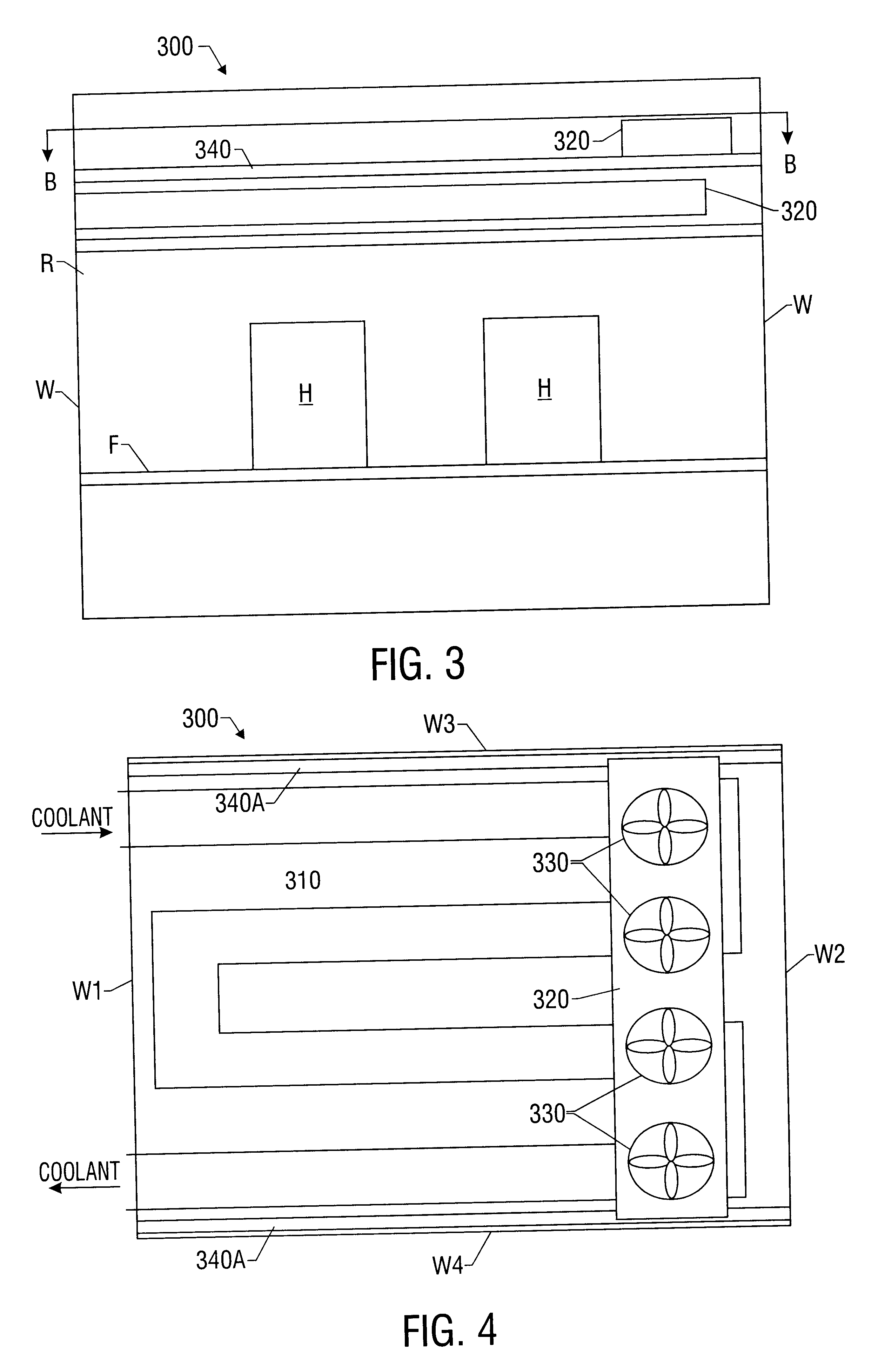

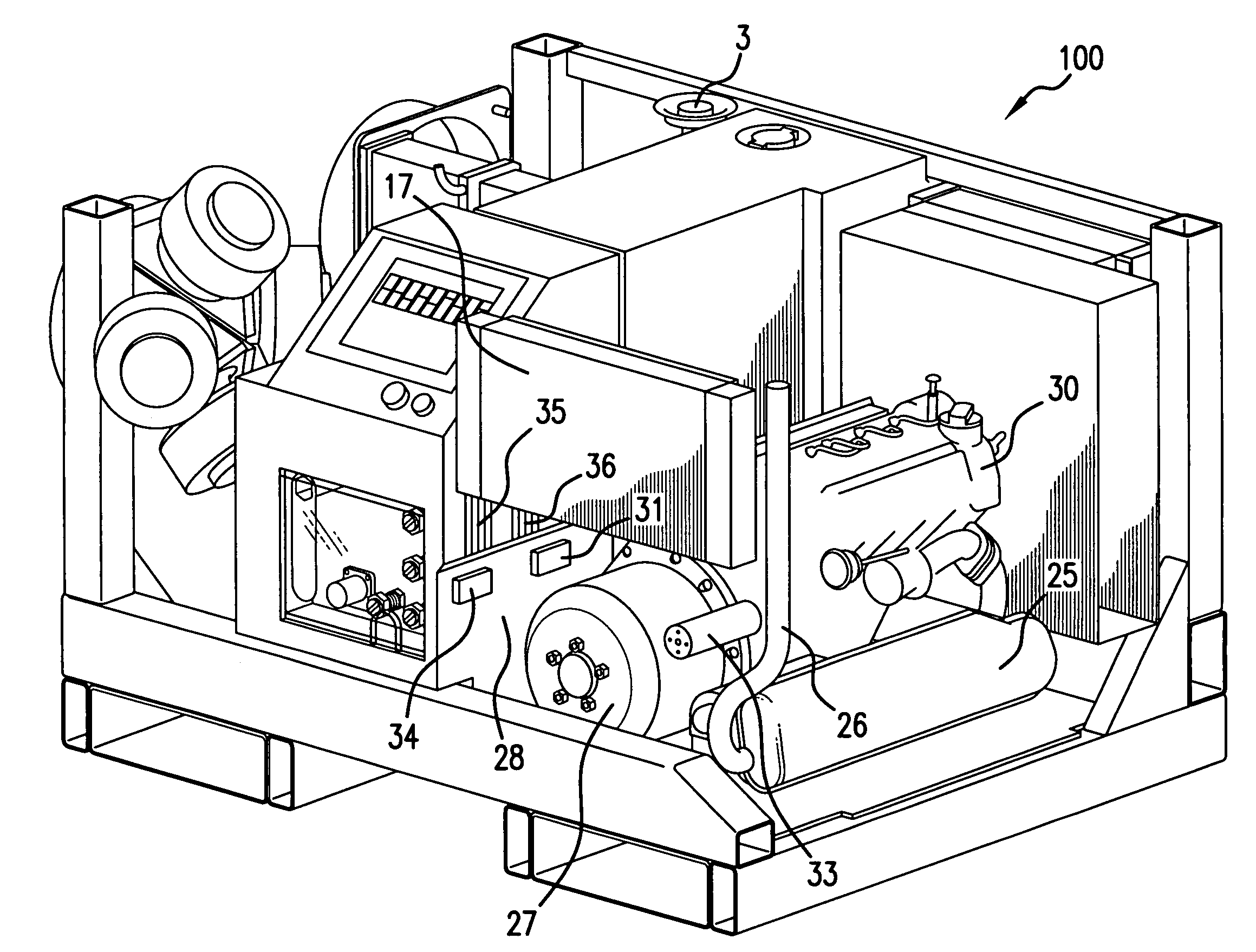

Configurable system and method for cooling a room

InactiveUS6557624B1Improve efficiencyReduce air pressureMechanical apparatusHot-air central heatingNuclear engineeringConfigurable systems

A method and system are disclosed for cooling a room having one or more heat generating objects. A number of heat exchangers are disposed adjacent a floor or ceiling and extends substantially entirely or partially between the walls of the room. A fan unit is disposed adjacent the heat exchanger and draws or blows cooled air from the heat exchanger and directs the drawn air into the room. The fan unit is capable of being repositioned along a different portion of the heat exchanger so as to redefine the flow of cooled air into the room. The cooling system components are modularized enabling configuration of a number of components to cool a room.

Owner:VERTIV CORP

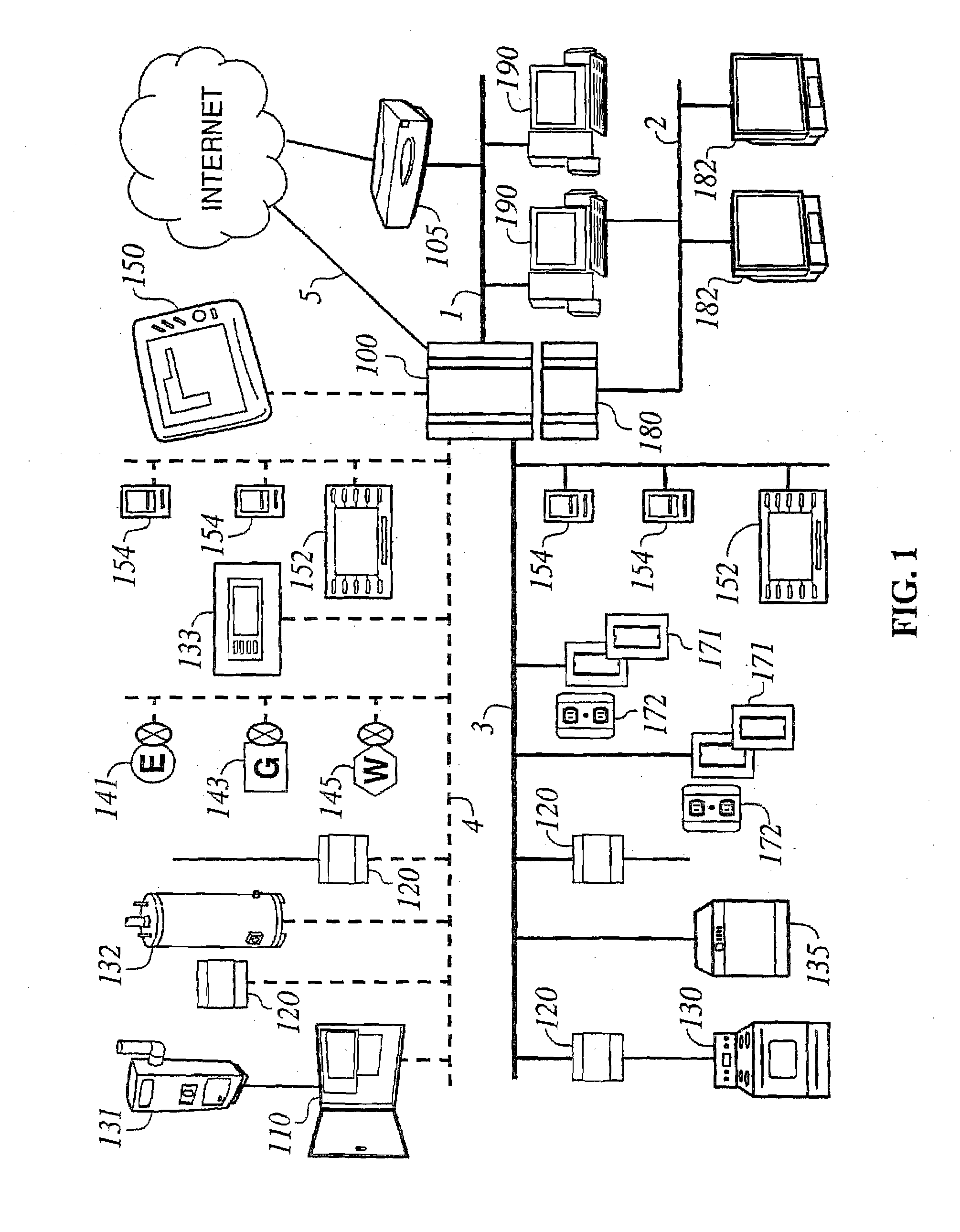

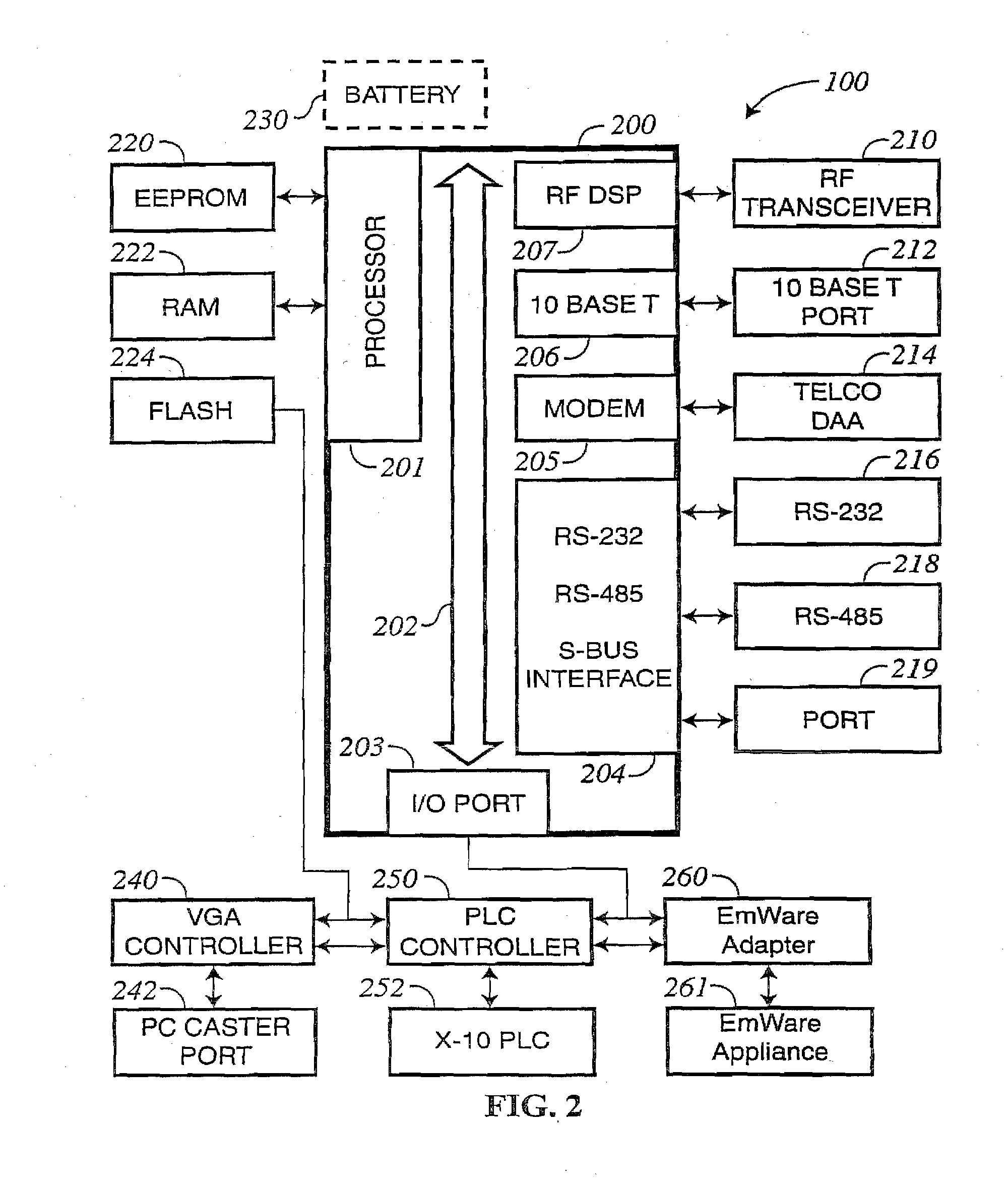

Environmental control and power system

InactiveUS20080161974A1Decrease external thermal signatureHeat dissipationStatic/dynamic balance measurementSpeed sensing governorsControl mannerElectric power system

A self-contained environmental control and power system (ECAPS) unit including an HVAC system with at least one variable-speed compressor driven by a DC motor, wherein the HVAC system is adapted to condition air and output the conditioned air and a variable-speed diesel engine connected to a generator. The generator is configured to vary in speed so as to output AC power at a variable frequency. The unit includes a rectification assembly which transforms the AC power from the generator and / or external AC power to DC power, and an inverter assembly which transforms the DC power to an export AC power. The ECAPS unit directs the DC power to the DC motor to drive the variable speed compressor and varies, in a controlled manner, at least one parameter of the outputted conditioned air from the HVAC system.

Owner:GLACIER BAY

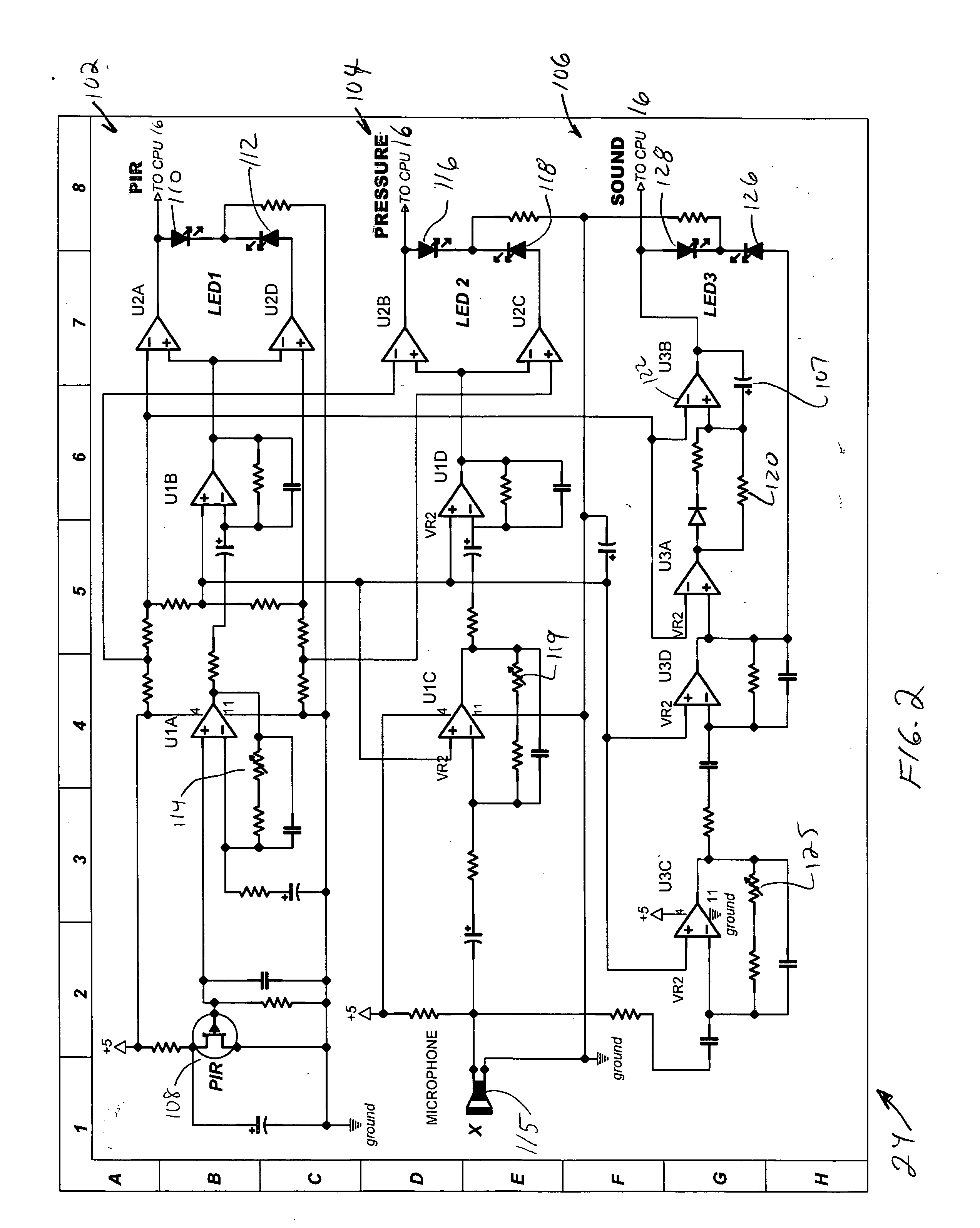

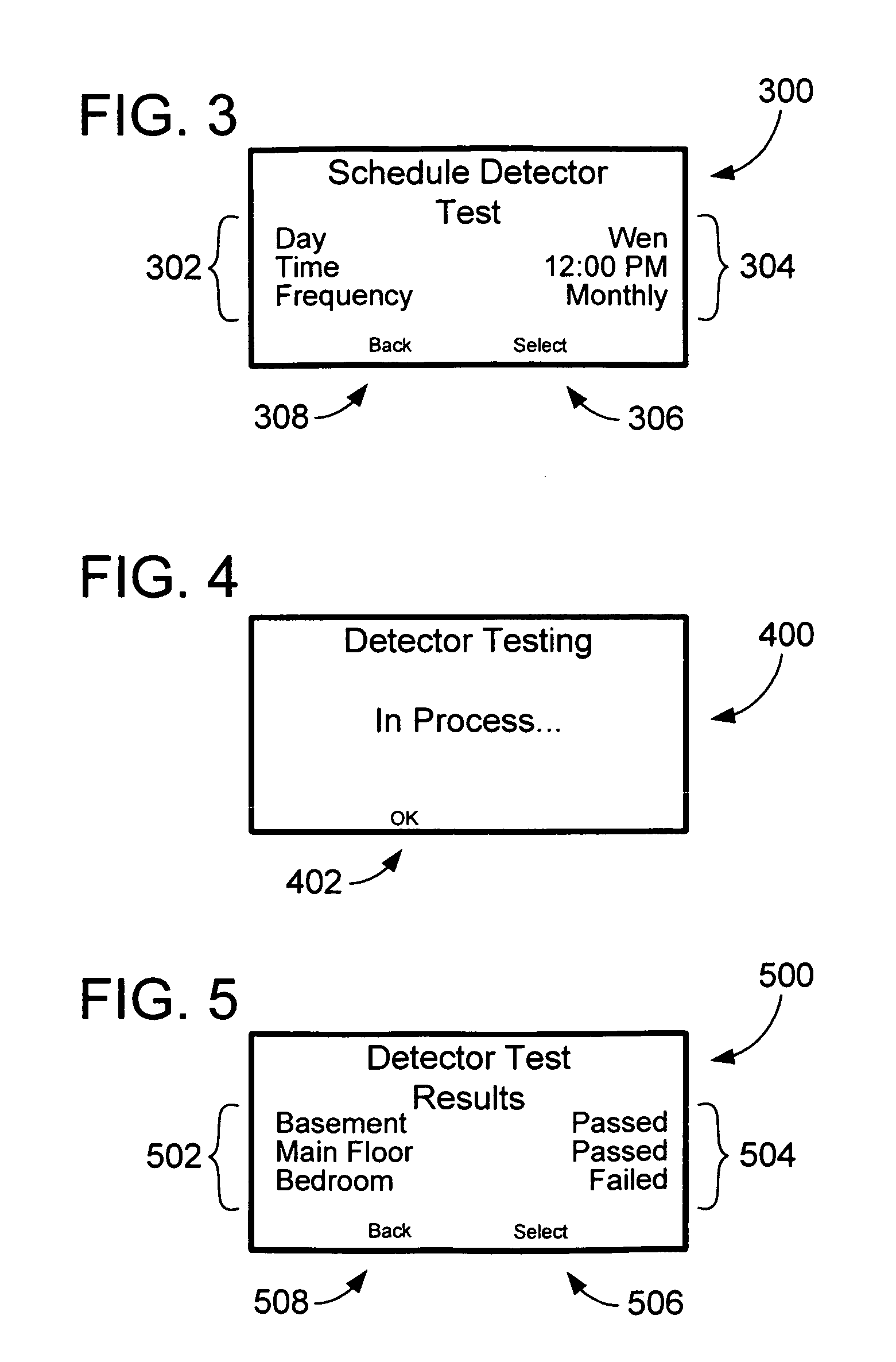

Hazardous condition detection system and method and thermostat for use therewith

ActiveUS7135965B2Electric signal transmission systemsMechanical apparatusReal-time clockControl signal

An intelligent thermostat communicates with threat detectors to allow periodic remote testing of the detector. The real-time clock and calendar functions of the thermostat allow the consumer to program the day, time, and frequency of the testing. The thermostat then communicates a test control signal to each of the detectors to initiate the self-test. The communication may be wired or wireless. During testing the thermostat displays a detector test screen. Upon completion of the self-test, the thermostat displays a test results screen for user confirmation. This results screen will indicate that the test passed or failed along with any diagnostic information provided by the detector. The thermostat also provides a test initiation screen from which the consumer may initiate a detector self-test manually. Loss of communications with a detector is also communicated to the user, as is the location of the detector that first identified a threat.

Owner:INVENSYS SYST INC

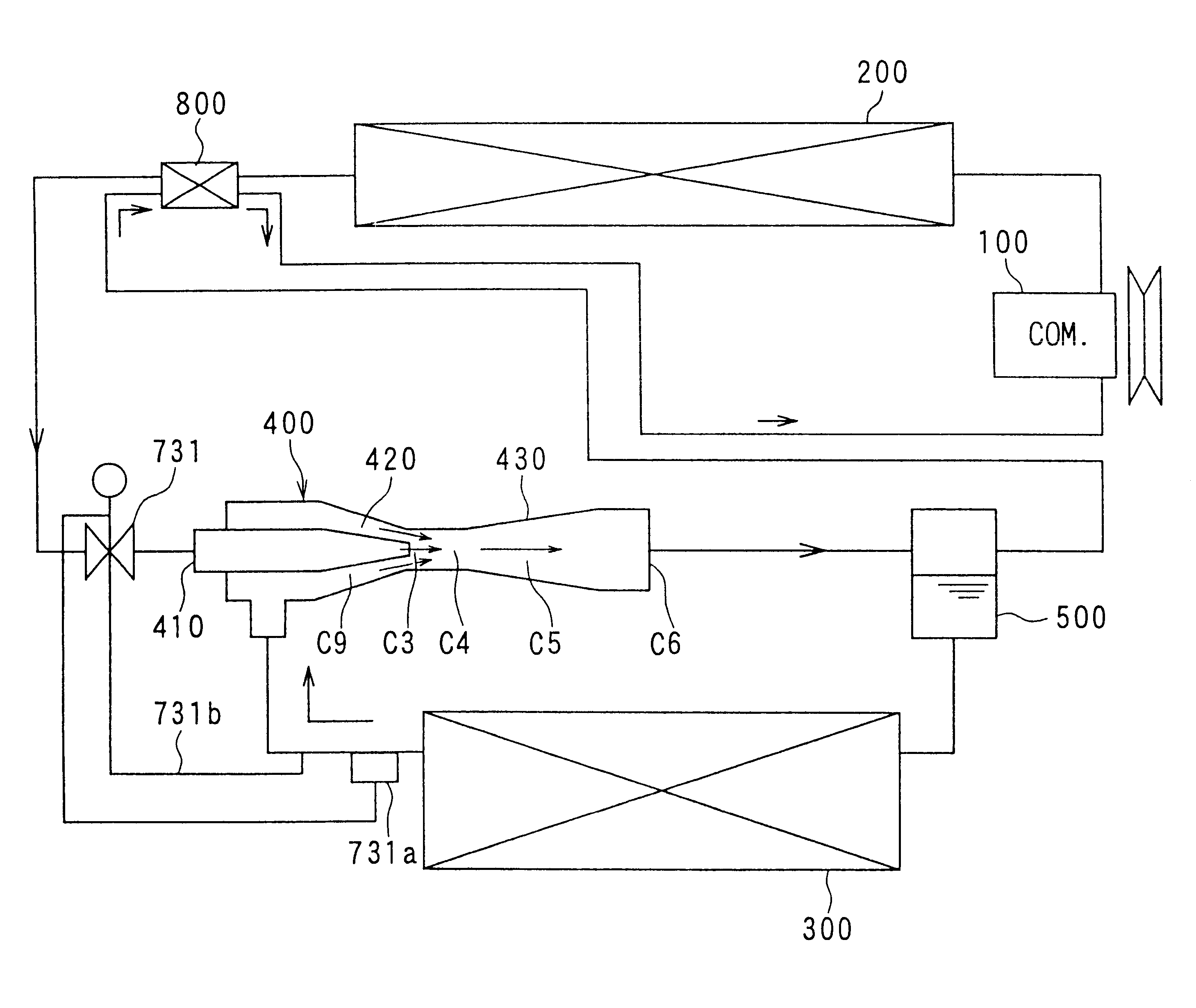

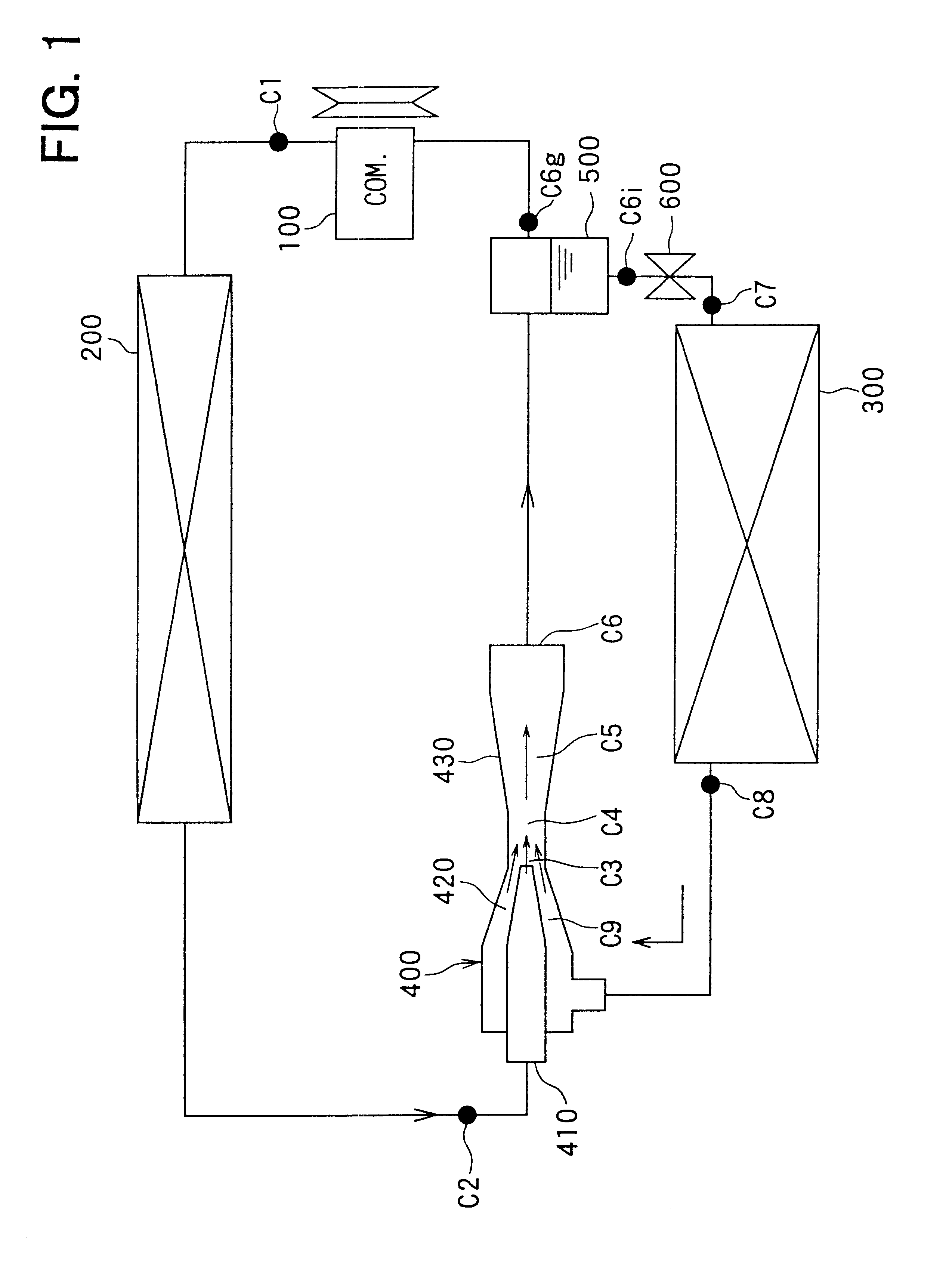

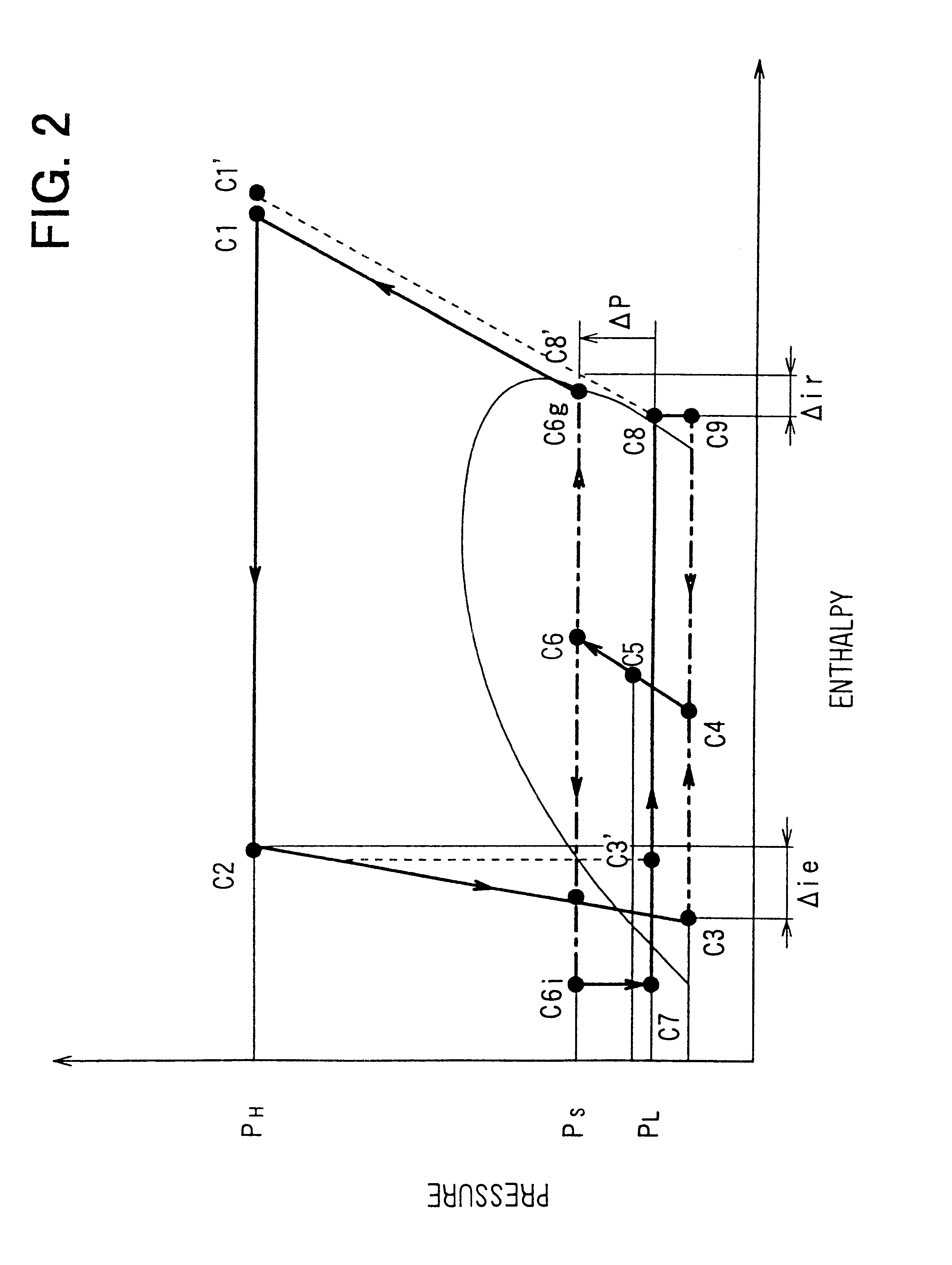

Ejector cycle system with critical refrigerant pressure

InactiveUS6477857B2Recover energyReduce power consumptionCompression machines with non-reversible cycleEvaporators/condensersEngineeringPressure difference

Owner:DENSO CORP

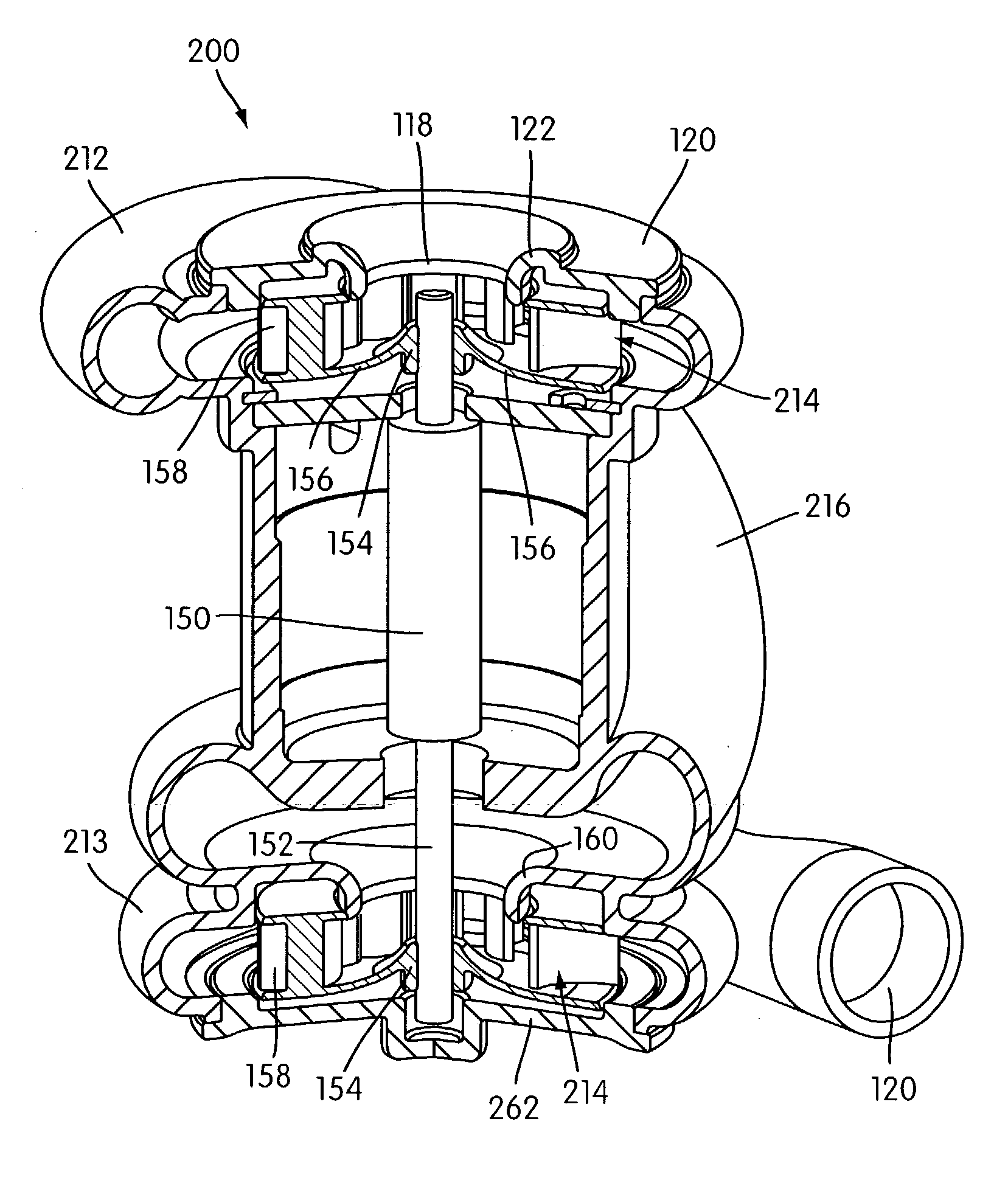

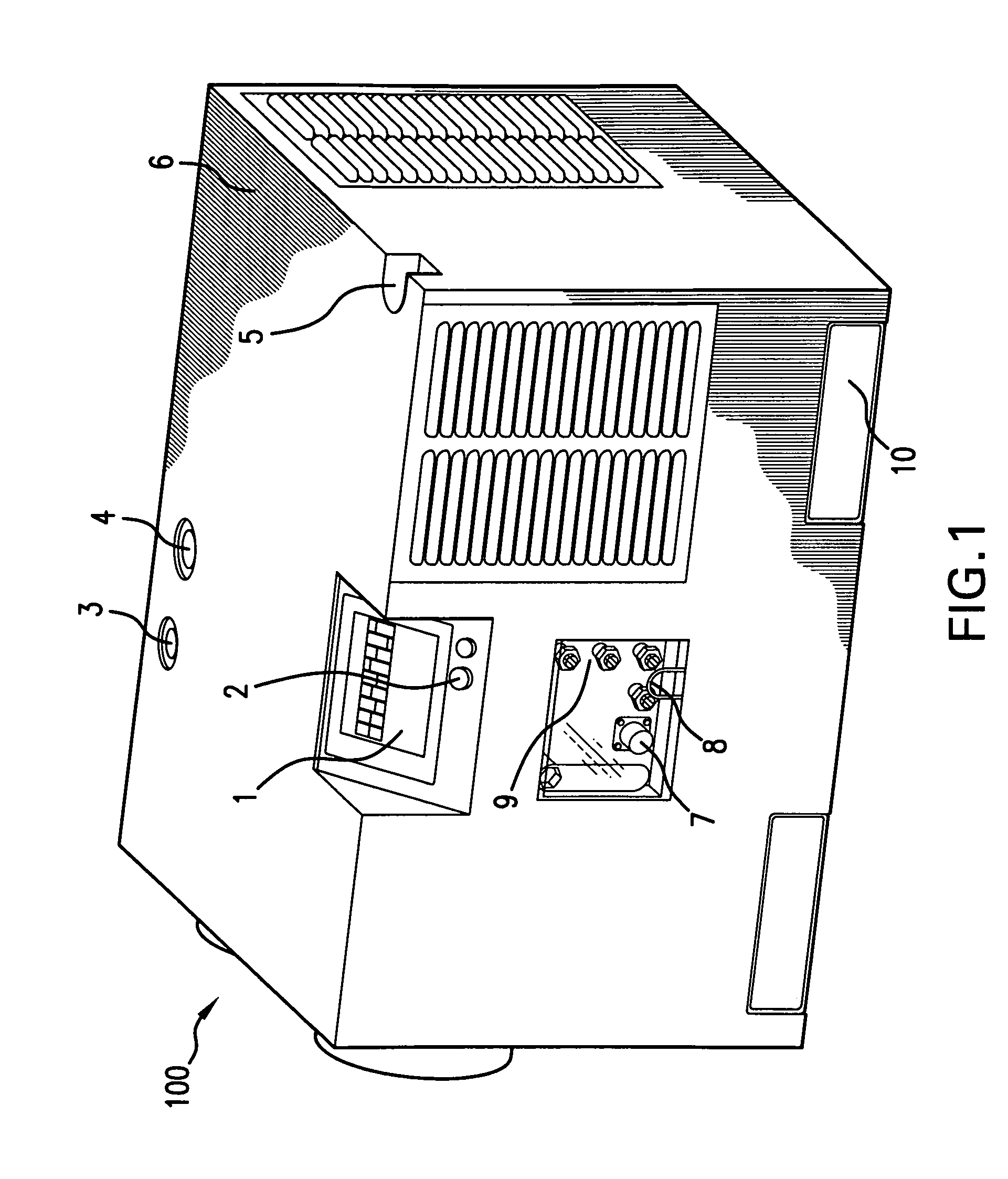

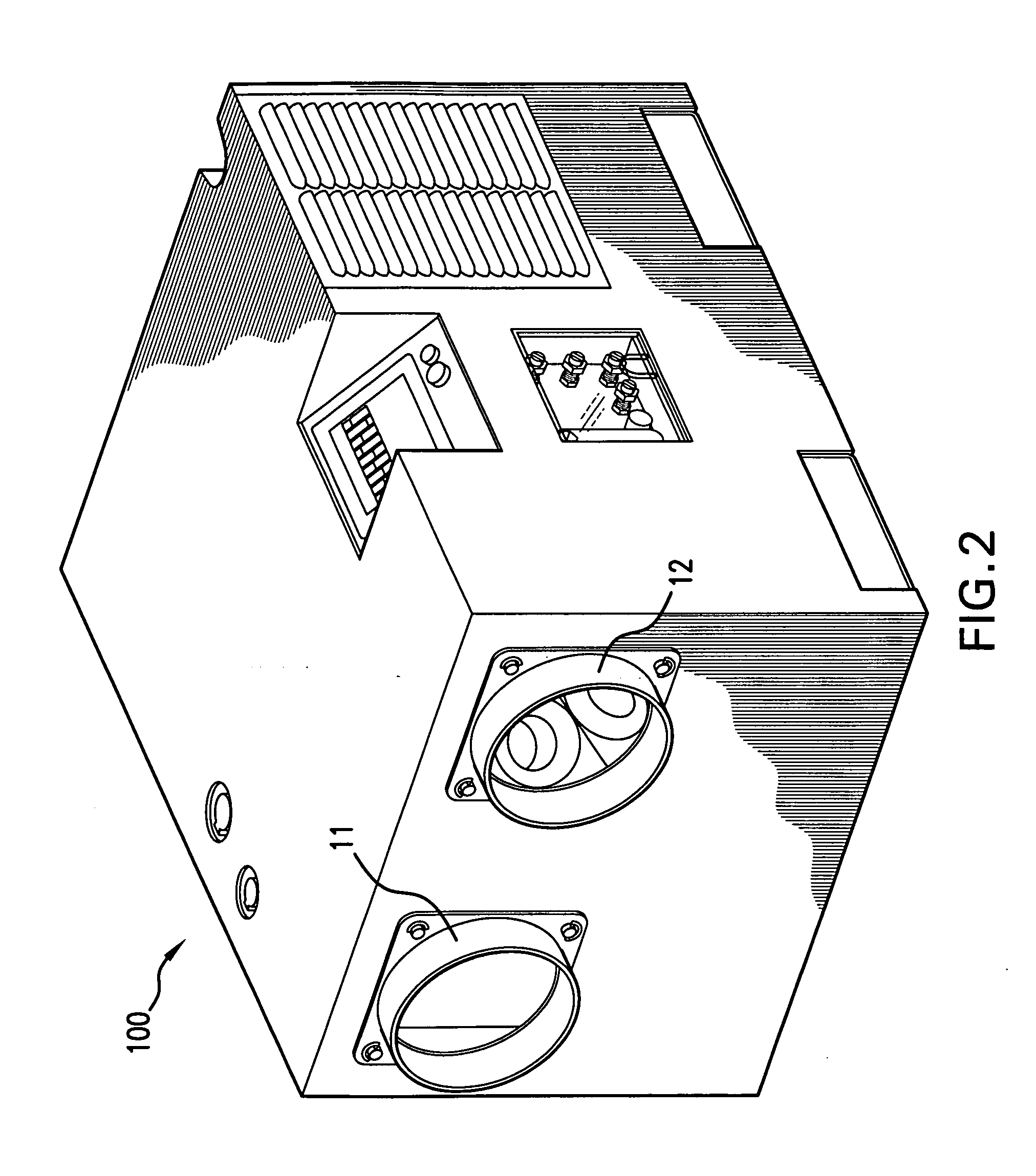

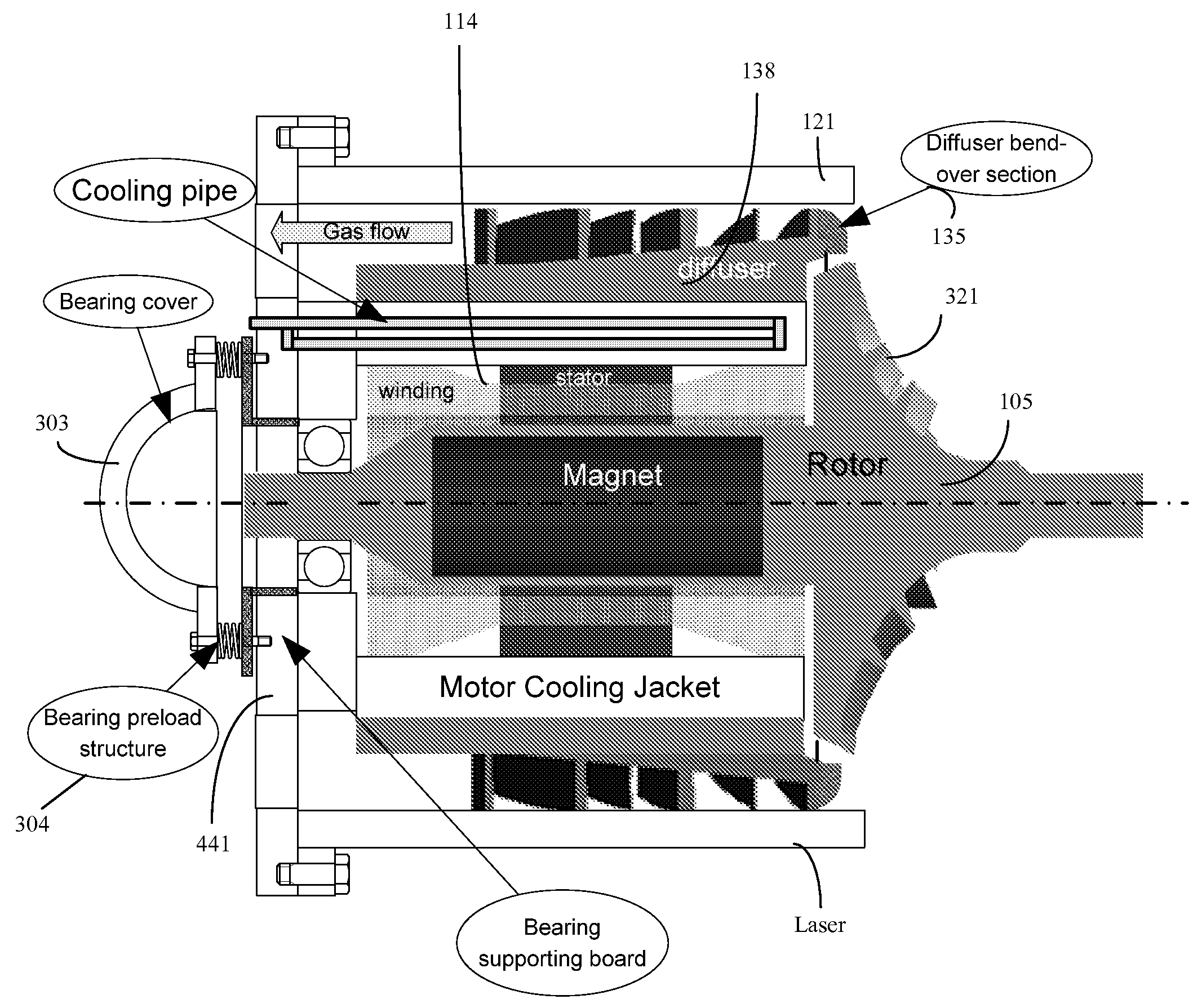

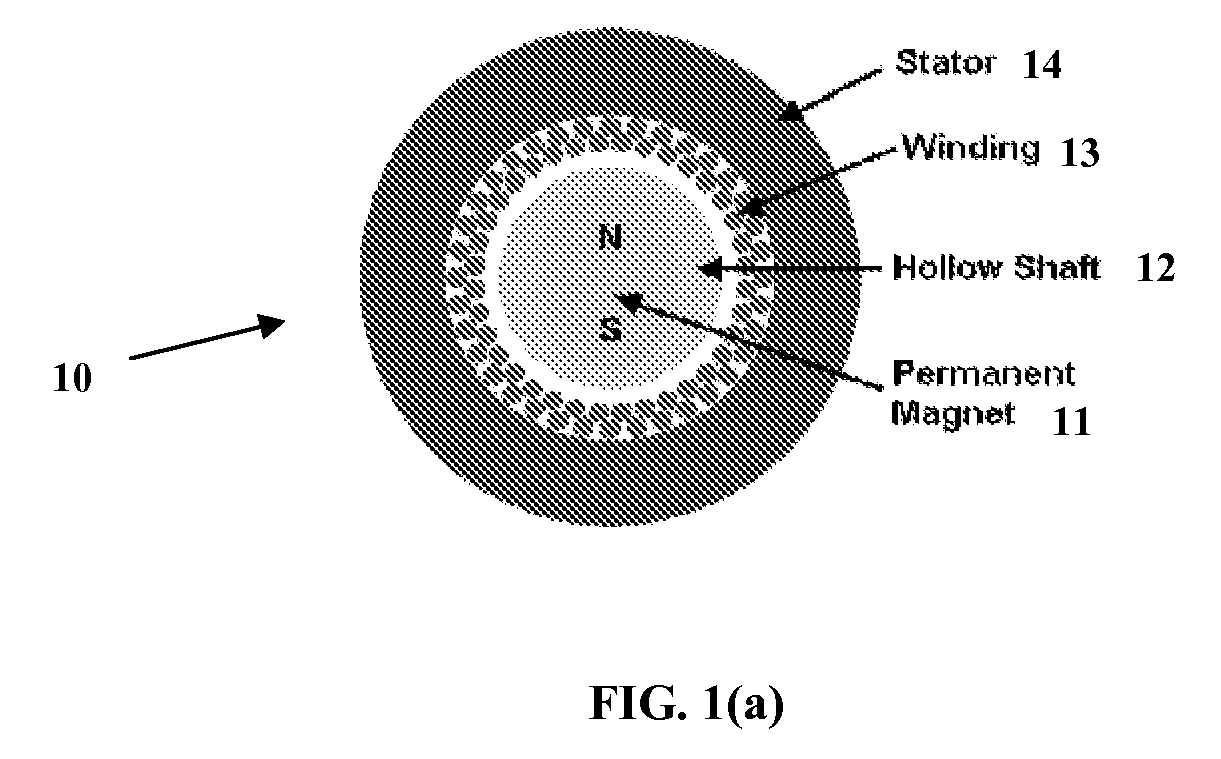

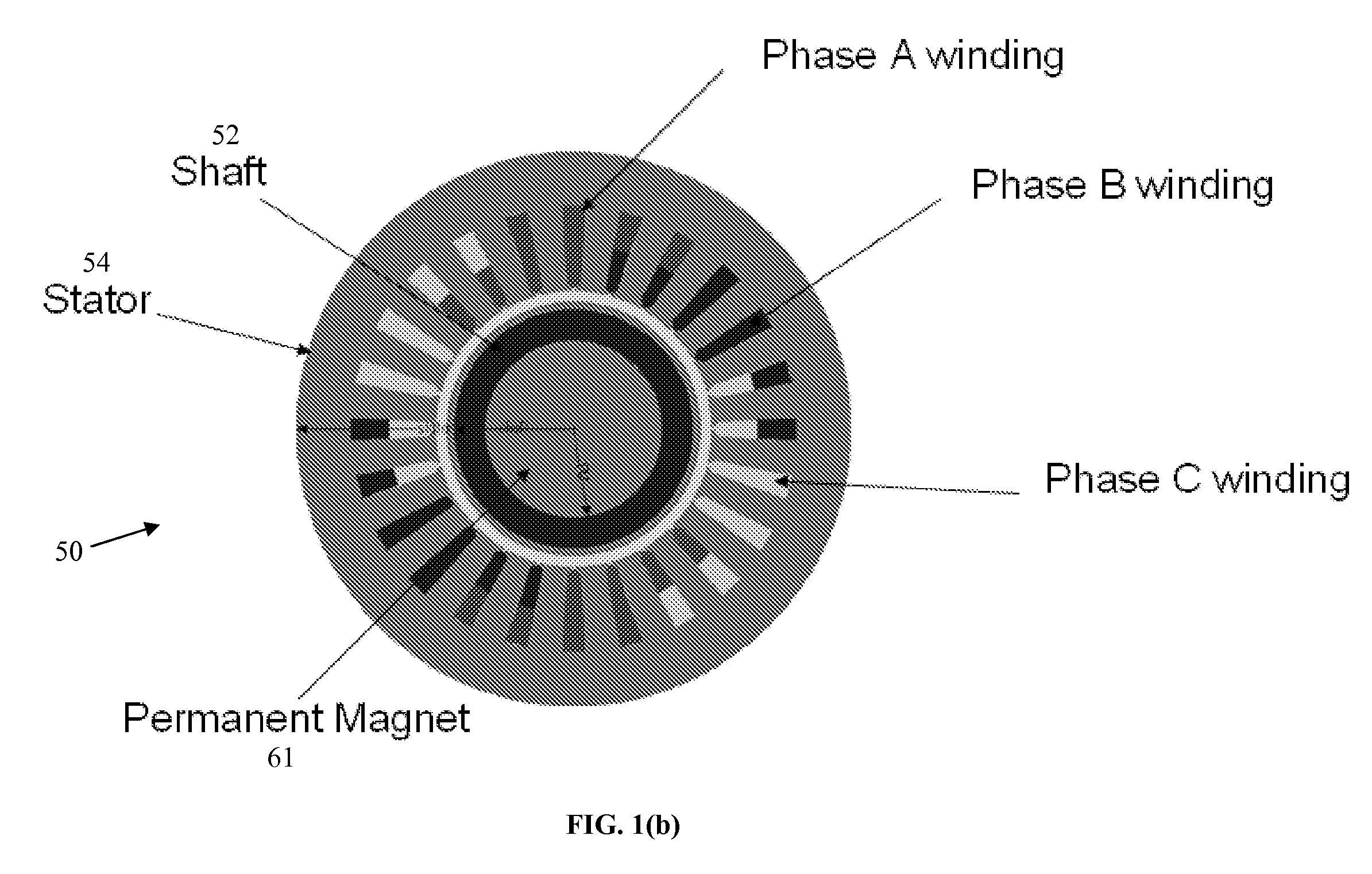

Miniature high speed compressor having embedded permanent magnet motor

InactiveUS20070269323A1Improve rigidityEasy to implementPositive displacement pump componentsEfficient regulation technologiesRigid rotorBall bearing

A high speed centrifugal compressor for compressing fluids includes a permanent magnet synchronous motor (PMSM) having a hollow shaft, the being supported on its ends by ball bearing comprising supports. A permanent magnet core is embedded inside the shaft. A stator with a winding is located radially outward of the shaft. The PMSM includes a rotor including at least one impeller secured to the shaft or integrated with the shaft as a single piece. The rotor is a high rigidity rotor providing a bending mode speed of at least 100,000 RPM which advantageously permits implementation of relatively low-cost ball bearing comprising supports.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

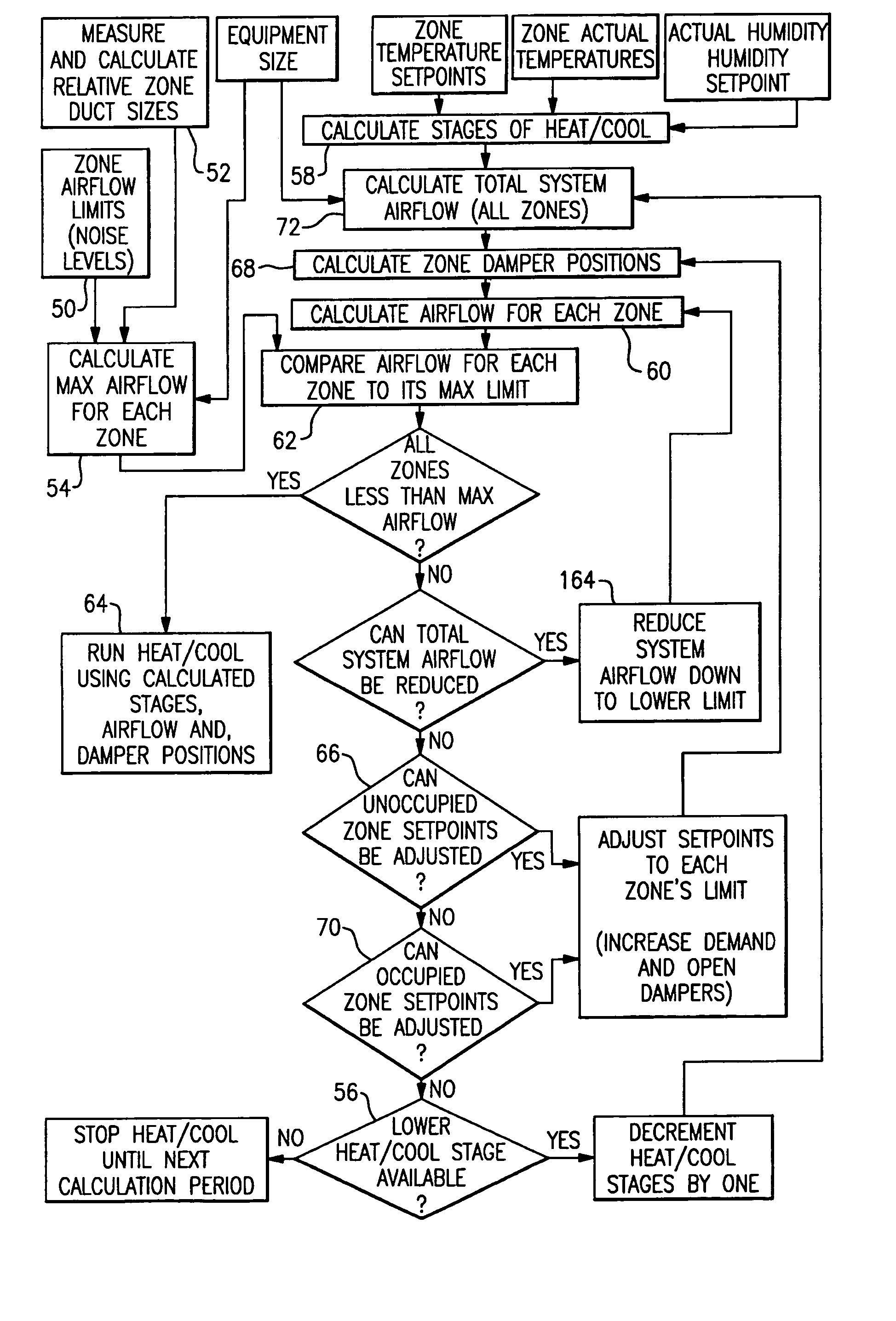

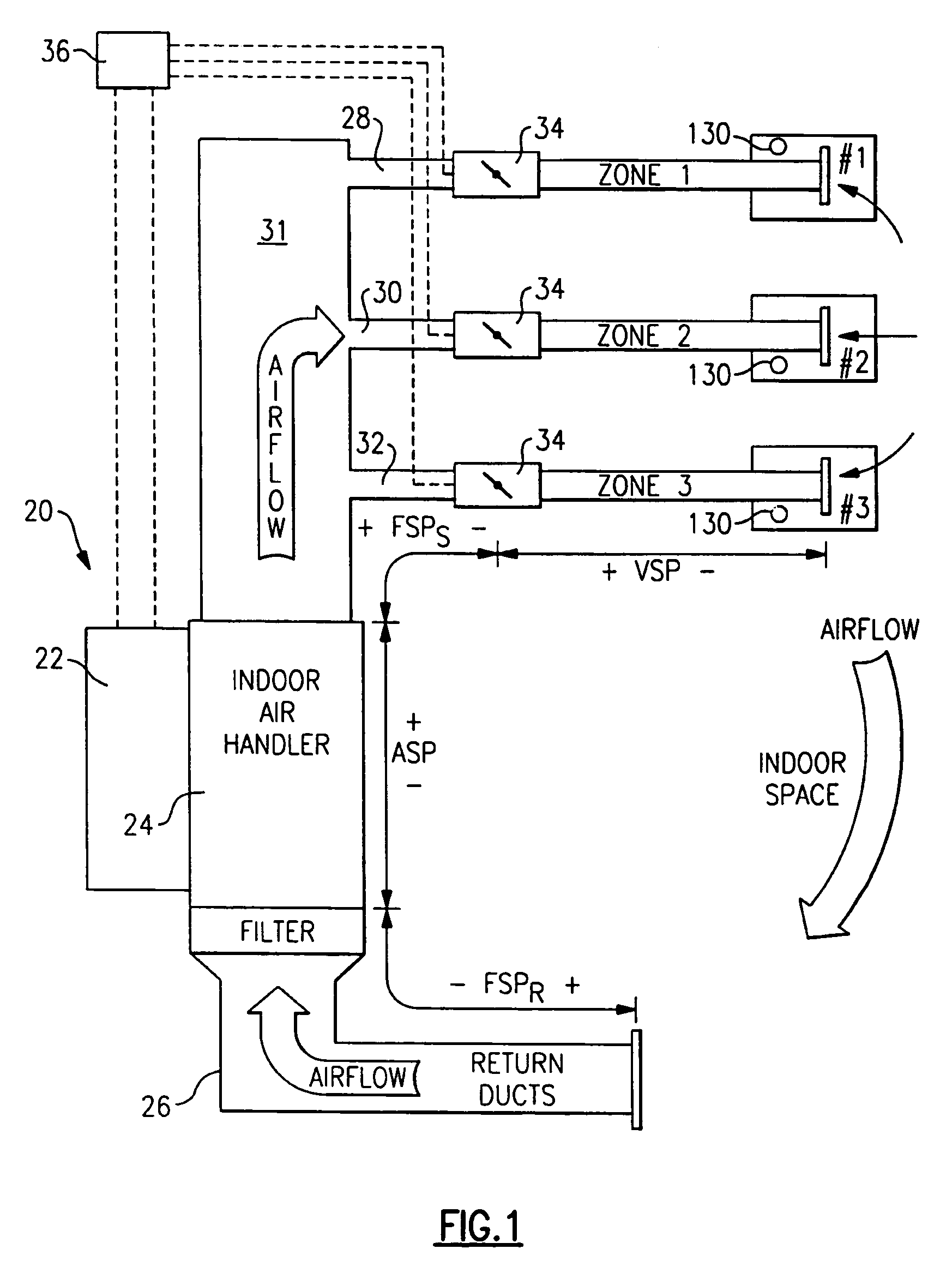

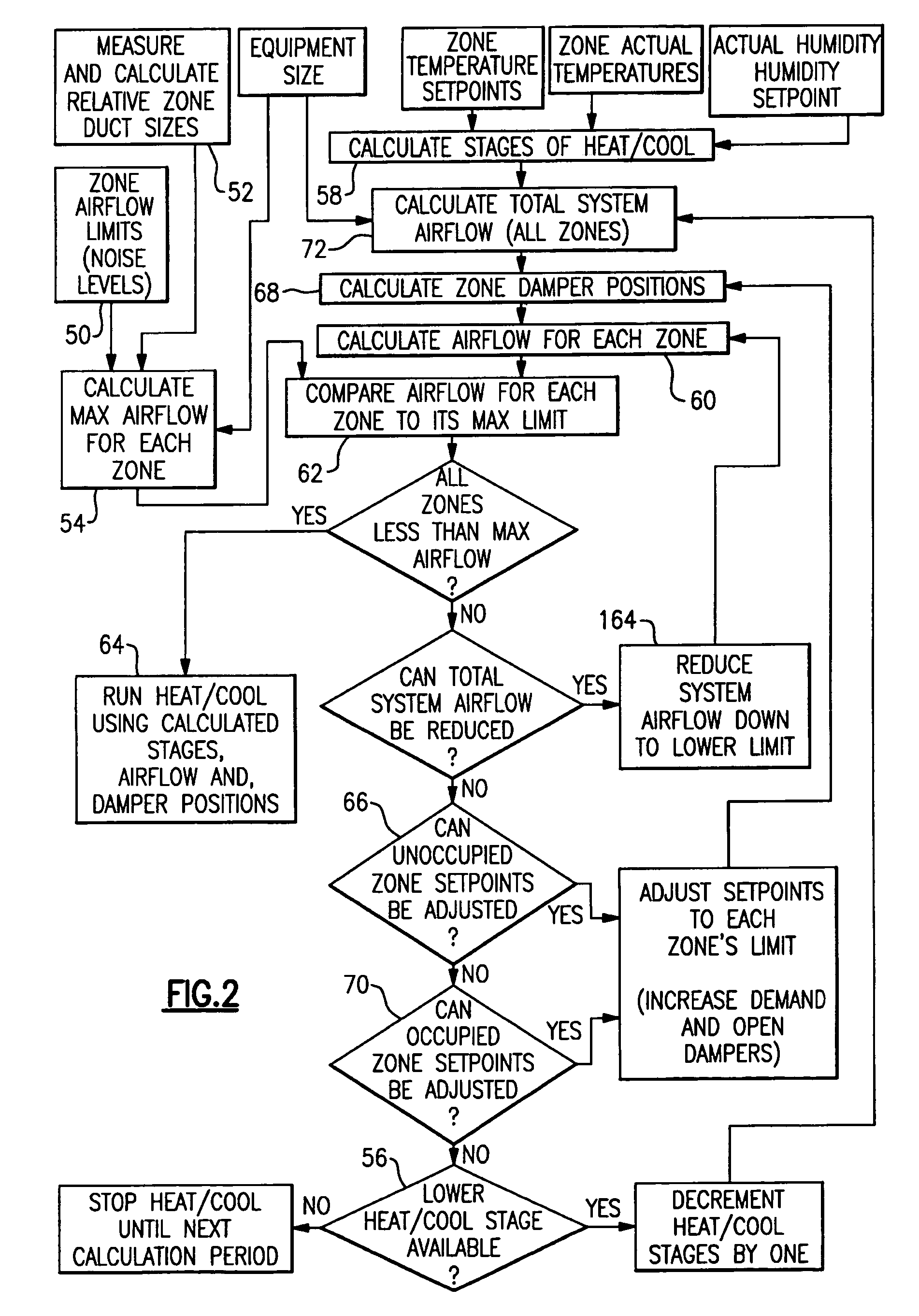

Method and system for automatically optimizing zone duct damper positions

A control is functional to perform a method of determining a maximum desired airflow for each of a plurality of zones in a multi-zone HVAC system, and an expected airflow to those zones. In part, these determinations are based upon an algorithm that calculates the relative size of the ducts leading to each of the zones. The expected and maximum airflows are compared for each of the zones, and if any zone has an expected airflow that exceeds its maximum airflow, certain steps are taken to reduce airflow to that zone.

Owner:CARRIER CORP

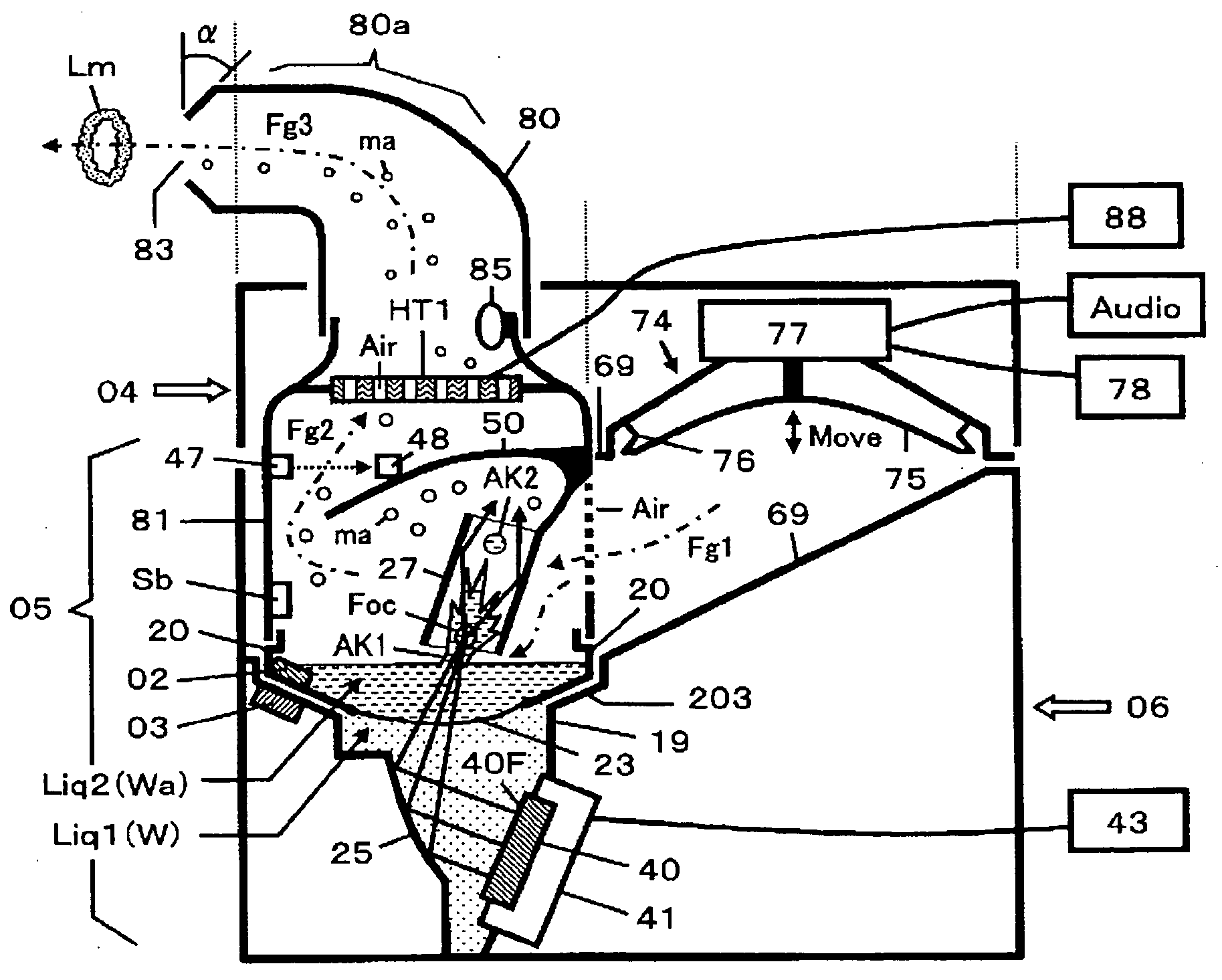

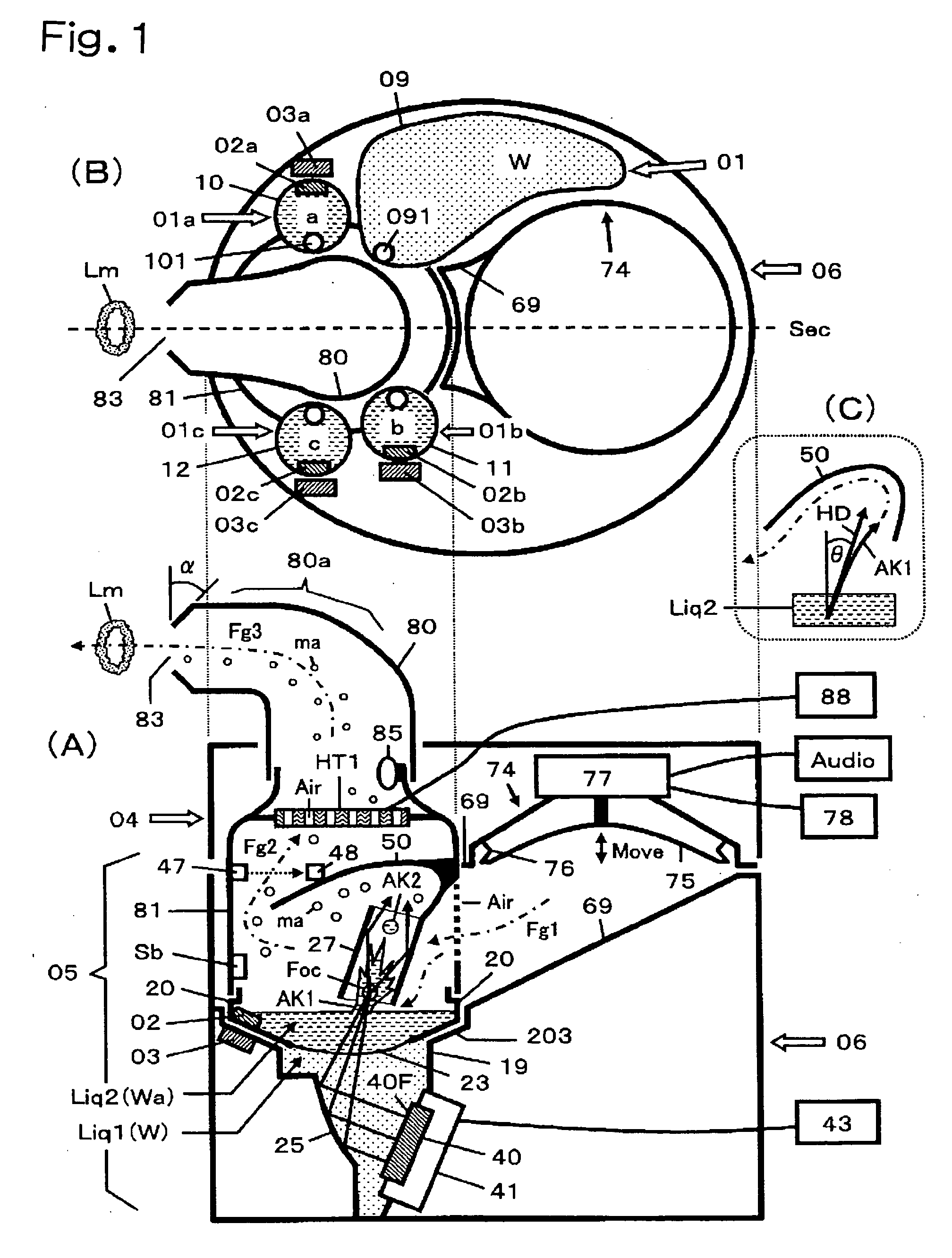

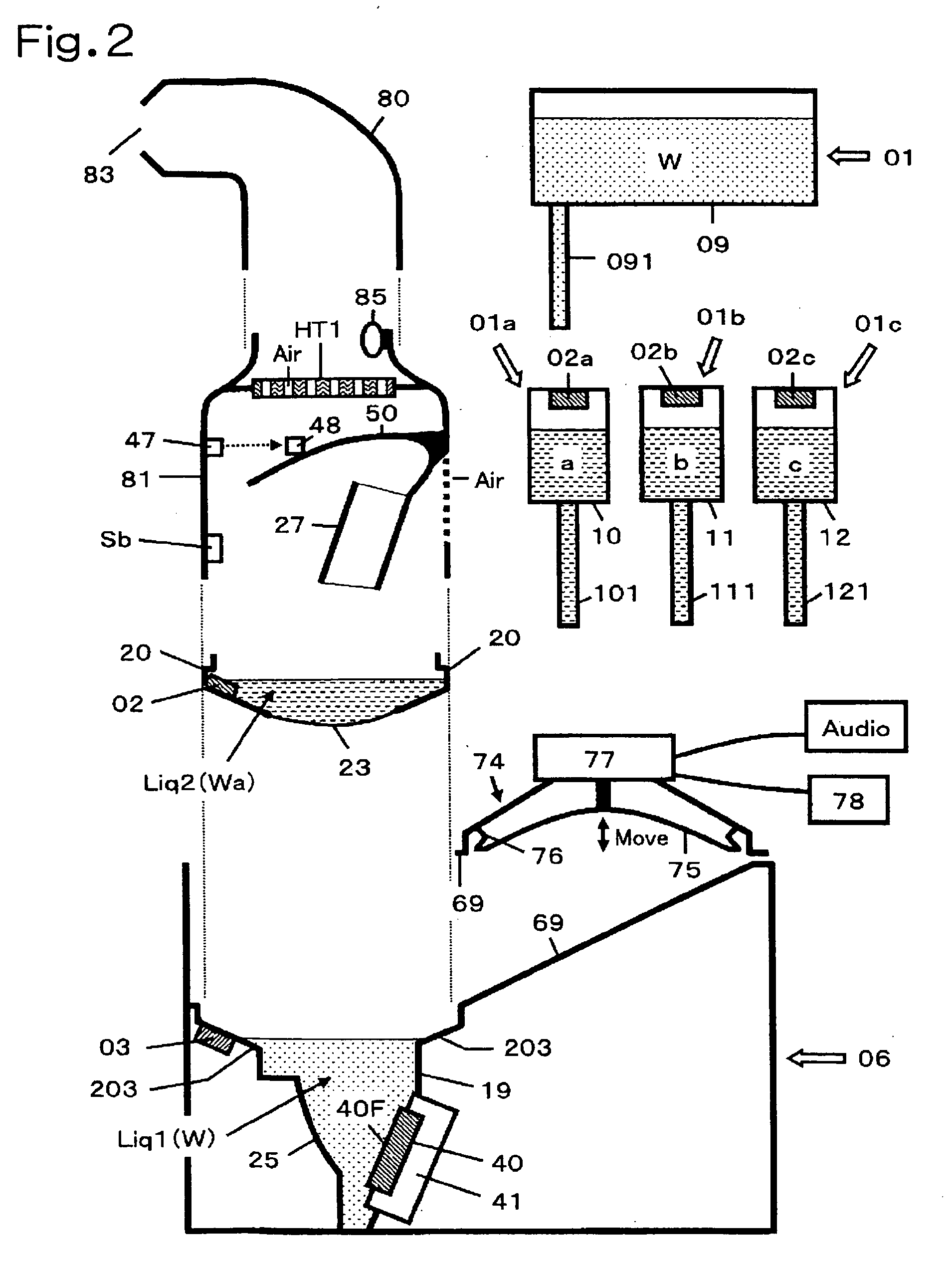

Mist Generator and Mist Emission Rendering Apparatus

InactiveUS20080223953A1Improve atomization efficiencyImprove overall utilizationLighting and heating apparatusUltrasonic humidifiersHeat flowMaintainability

[OBJECTS AND PROBLEMS] Relating to a mist generator capable of emitting any of chemical substances used in life, such as perfumes, pharmaceuticals and pesticides, in the form of fog or vapor. An object of the invention is to attain means for efficiently atomizing liquid, means for easily and rapidly switching the type of chemical substance emitted and a compact apparatus of good maintainability. [MEANS FOR SOLVING PROBLEMS] An apparatus comprises an ultrasonic transducer; an ultrasonic propagation medium disposed so as to fill a plane of vibration of the transducer; liquid retaining means disposed so as to be in contact with an end face of the medium; and an ultrasonic focusing reflecting mechanism (concave reflection mirror) disposed in an ultrasonic propagation path, thereby the apparatus attains discharging into air and atomization of the liquid by means of ultrasonic waves. Atomization efficiency is enhanced by the use of an ultrasonic reflection tube, and mist emission is carried out. Use is made of a compact liquid container equipped at its bottom with an ultrasonic transmission membrane. Various types of liquids can be atomized by changing the direction of ultrasonic course. Mist can be emitted by means of a thermal current as heating means. IC tag is attached to the liquid retaining means or liquid injection means.

Owner:TOMONO AKIRA

Popular searches

Electric motor control Dynamo-electric converter control DC commutator Ac commutator motor starters AC commutator Emergency protective arrangements for automatic disconnection Thermometer applications Refrigeration safety arrangement Ac network voltage adjustment Information technology support system

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com