Patents

Literature

237 results about "Ultrasonic propagation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

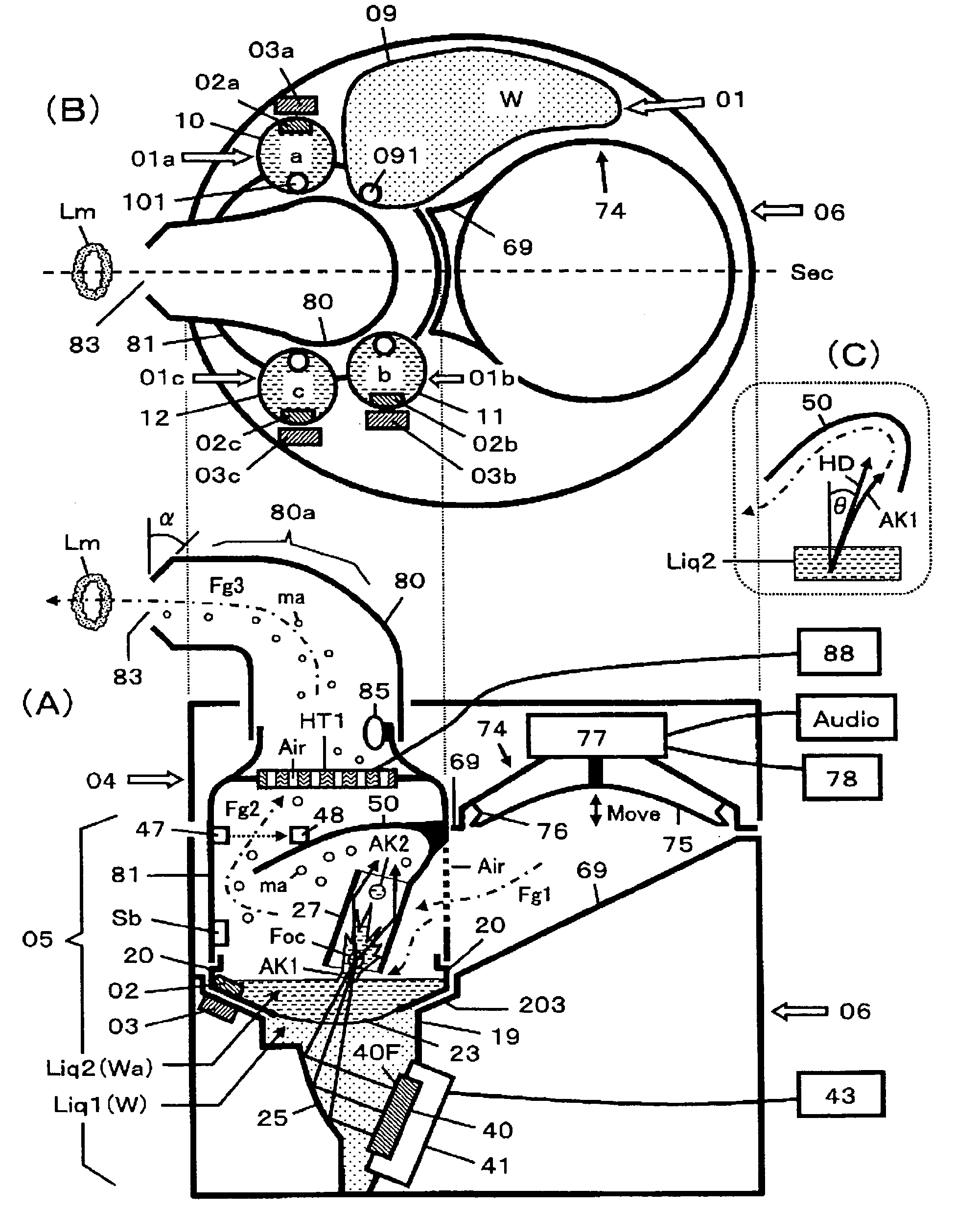

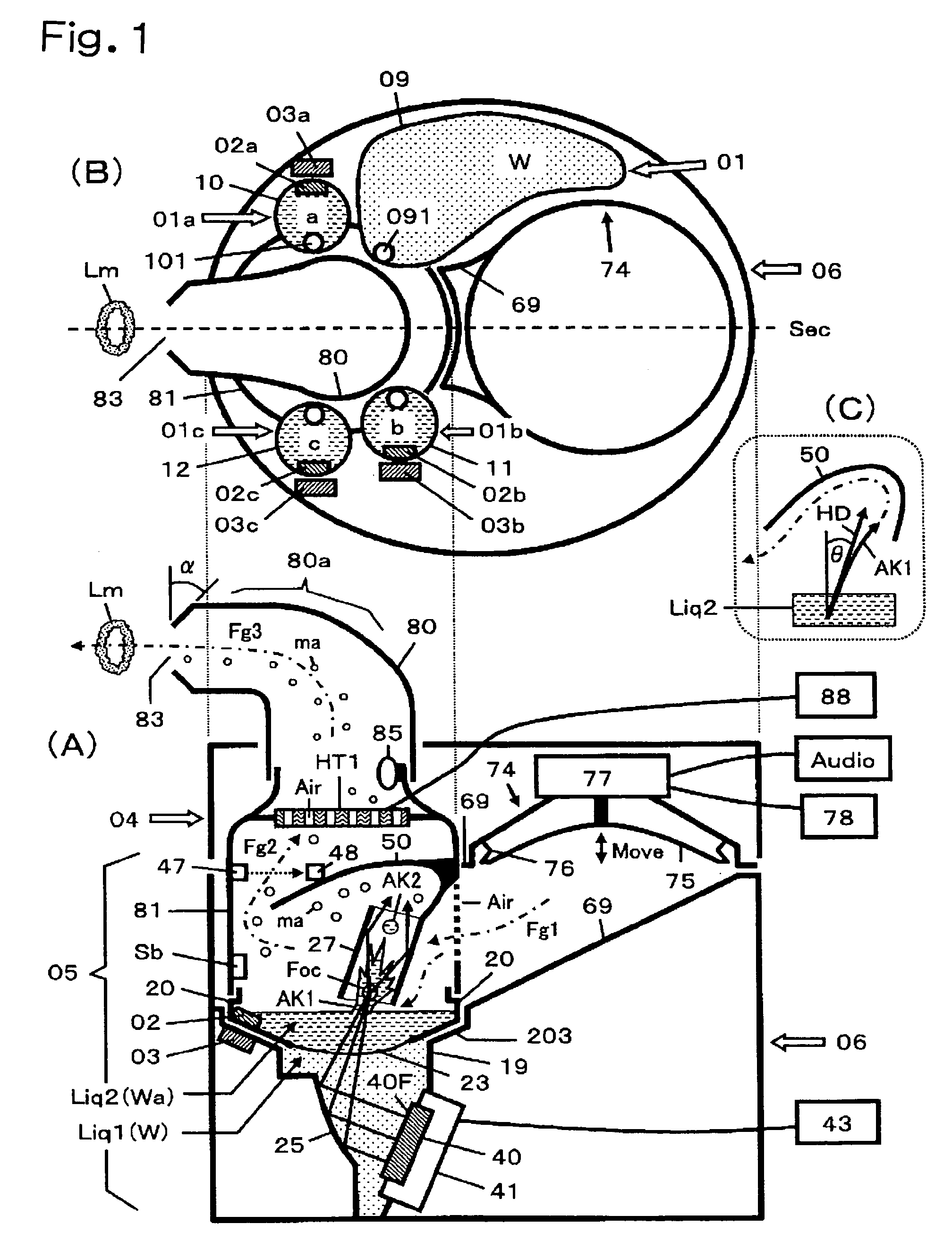

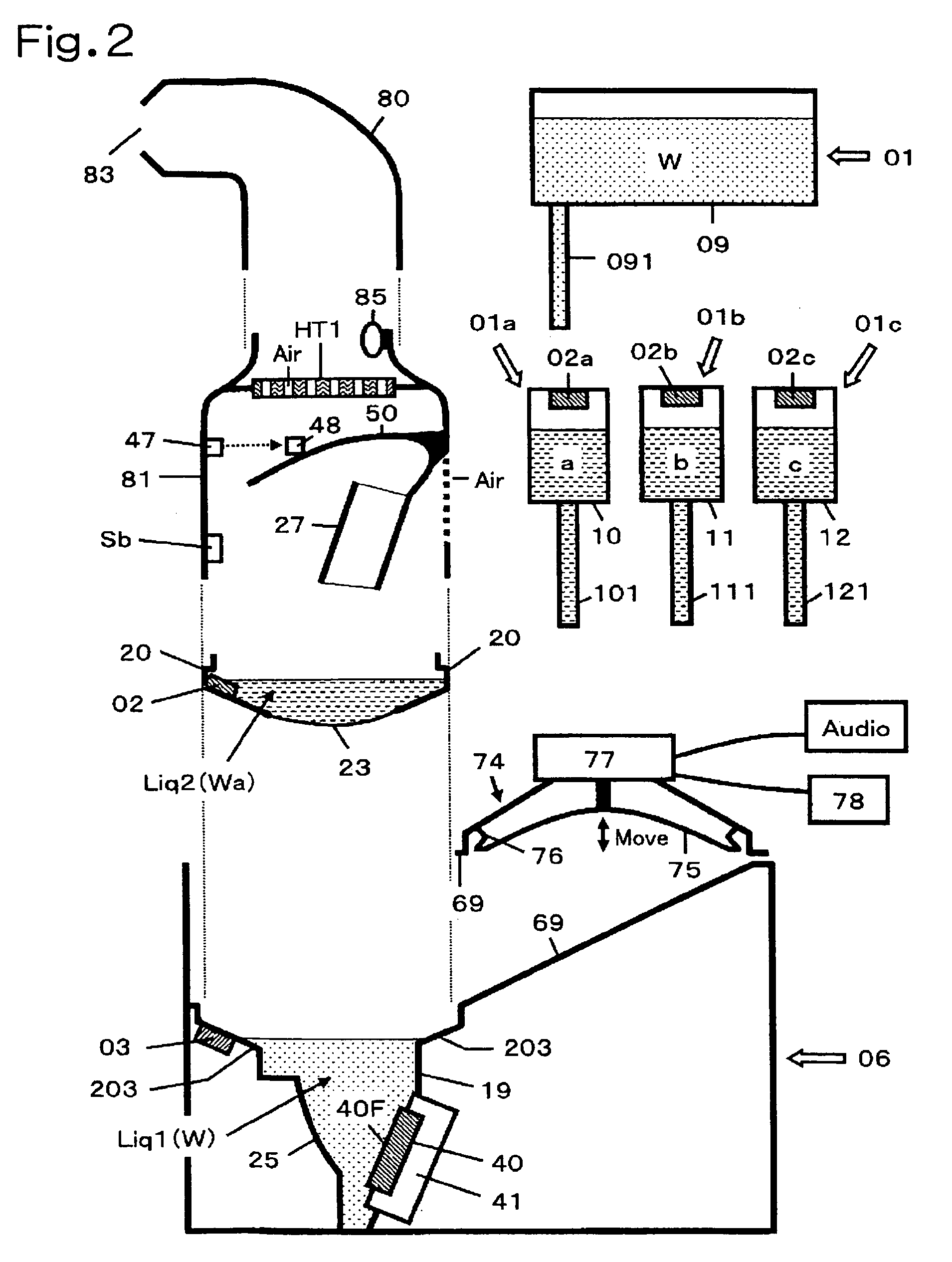

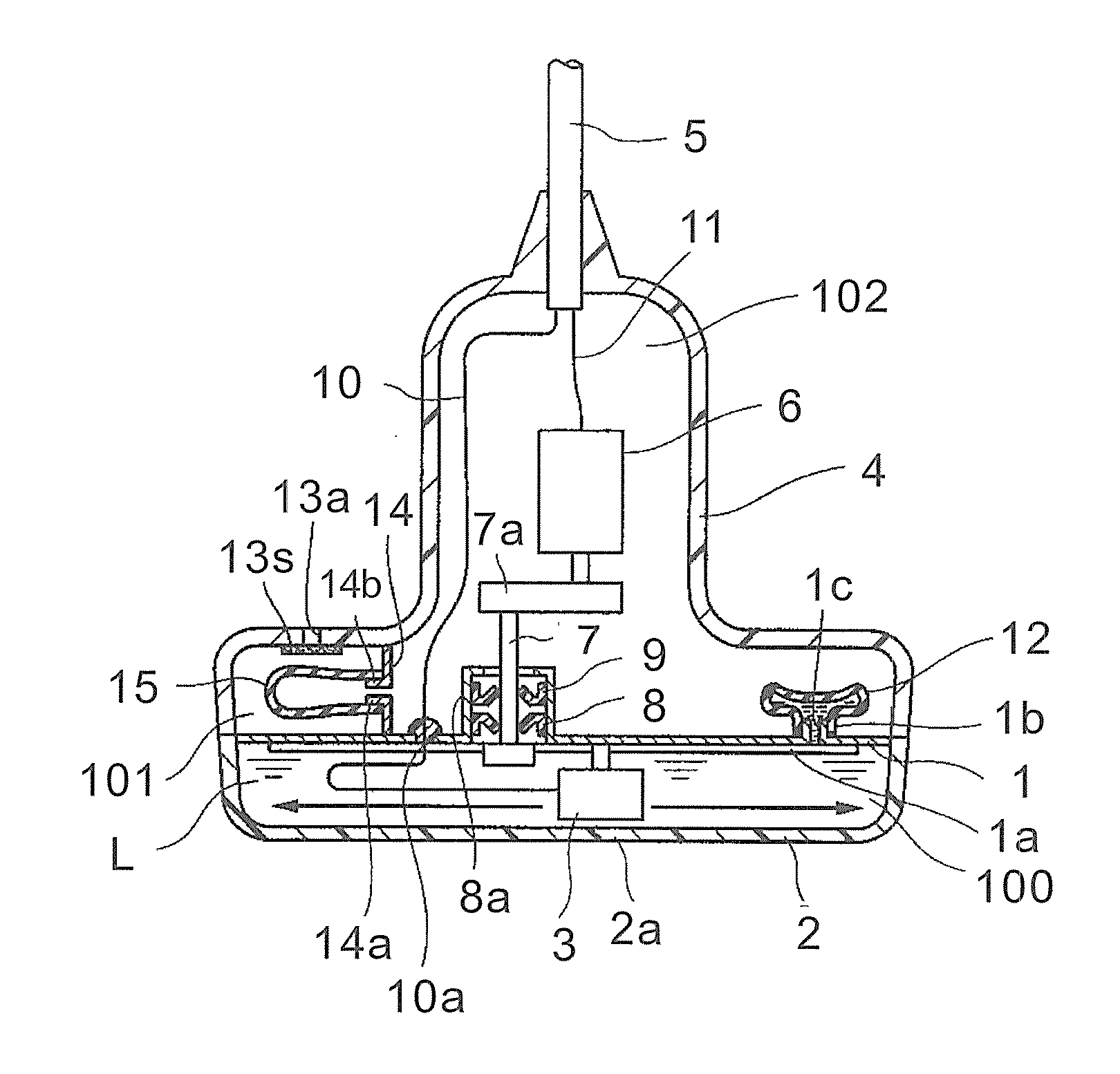

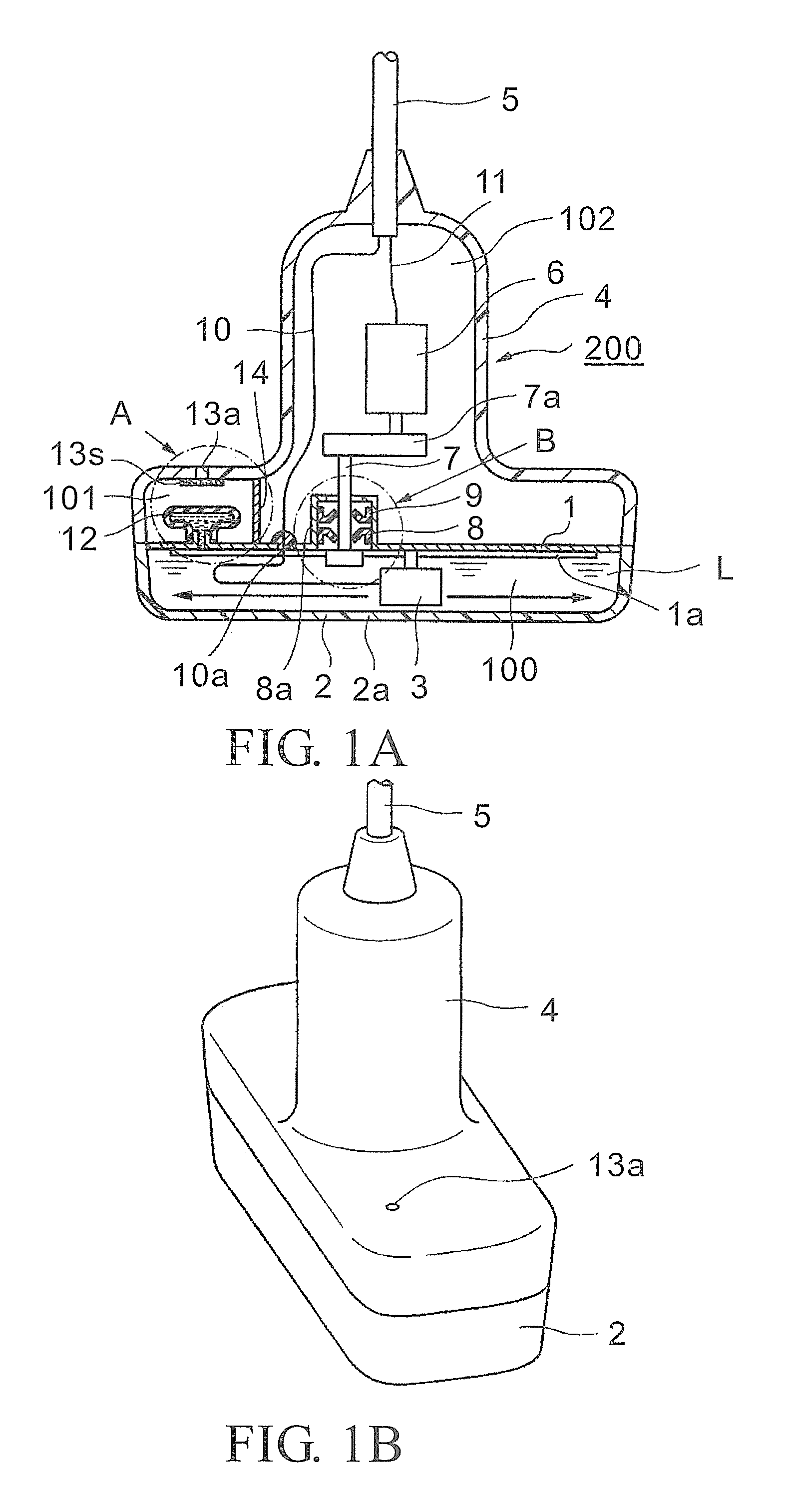

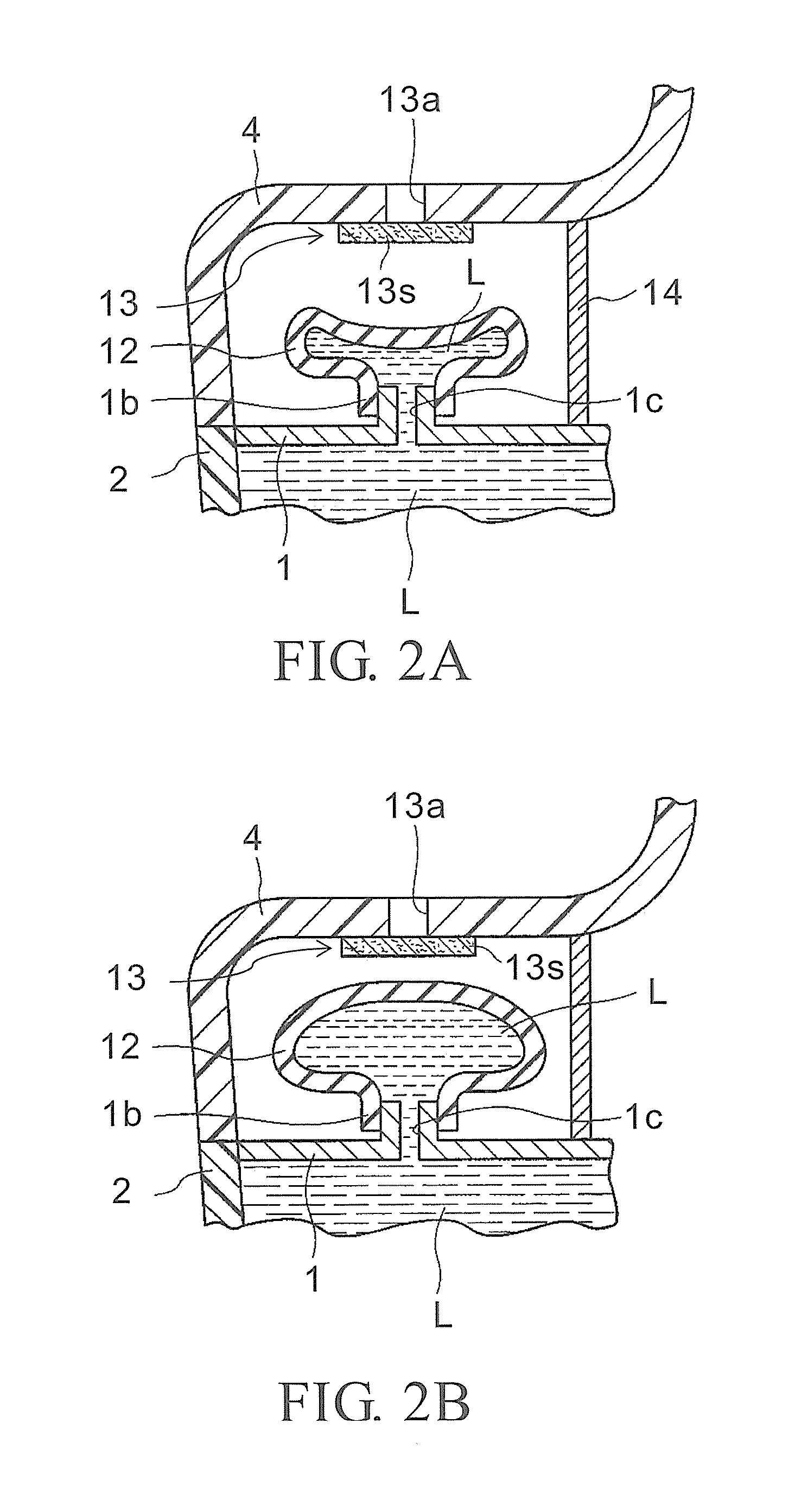

Mist Generator and Mist Emission Rendering Apparatus

InactiveUS20080223953A1Improve atomization efficiencyImprove overall utilizationLighting and heating apparatusUltrasonic humidifiersHeat flowMaintainability

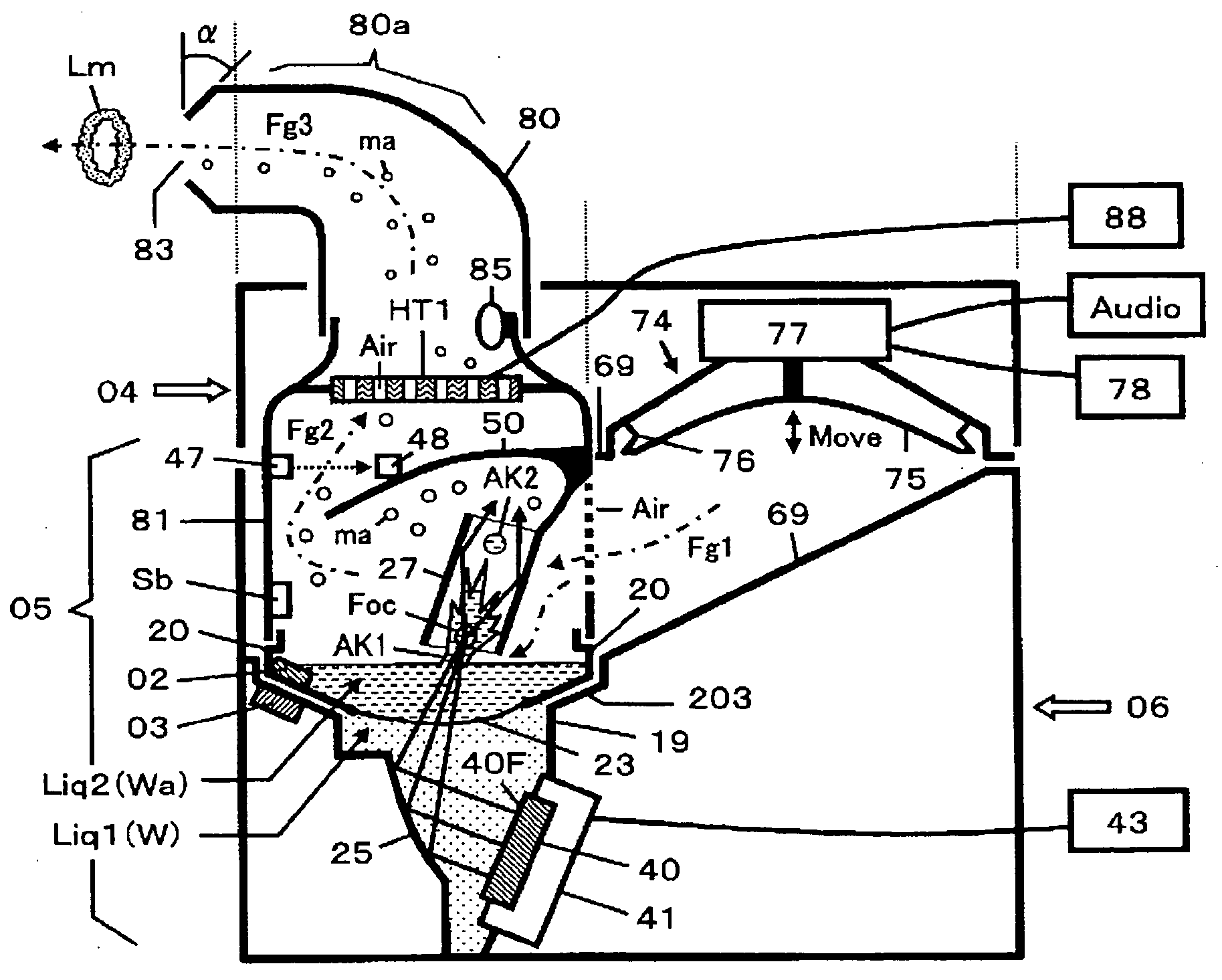

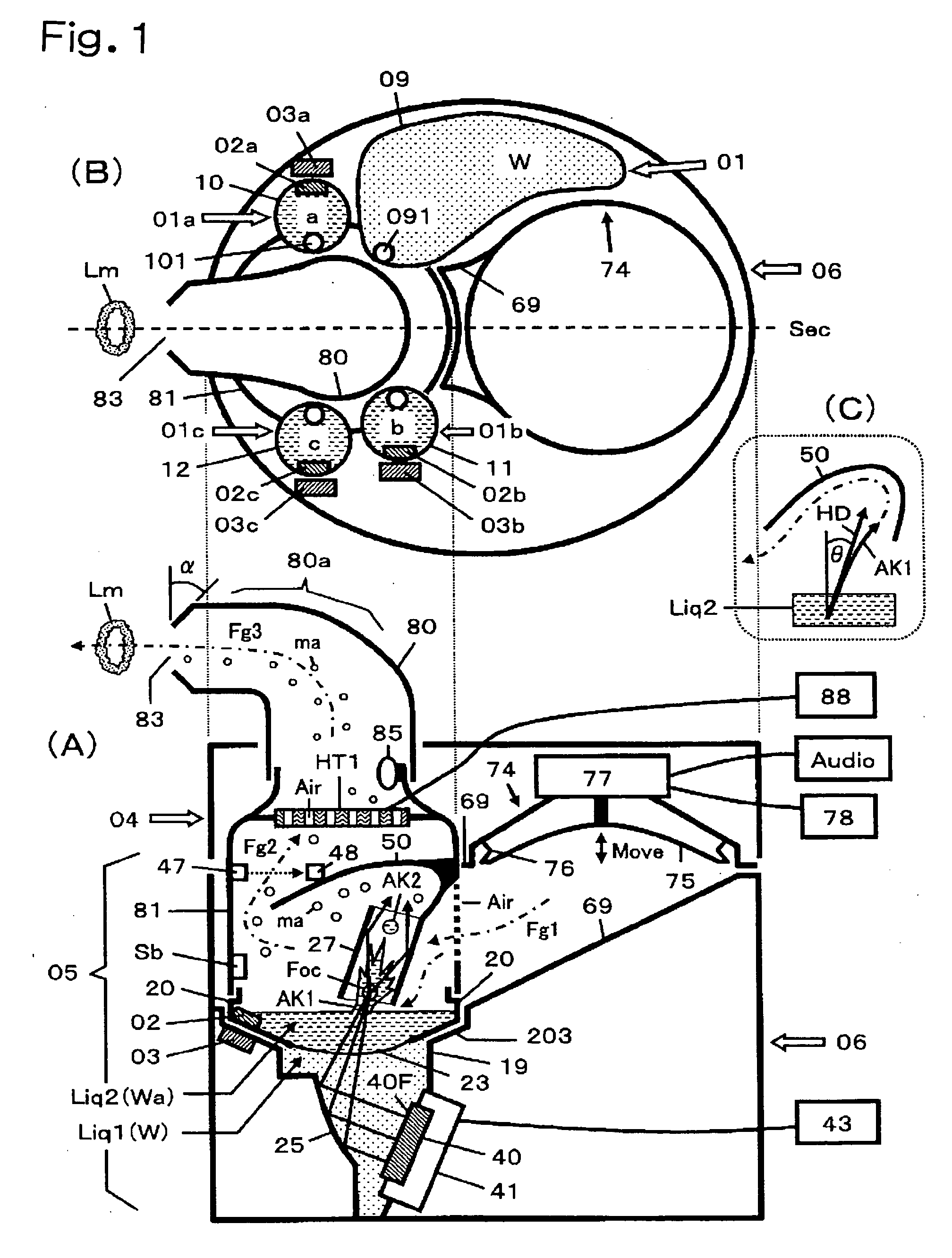

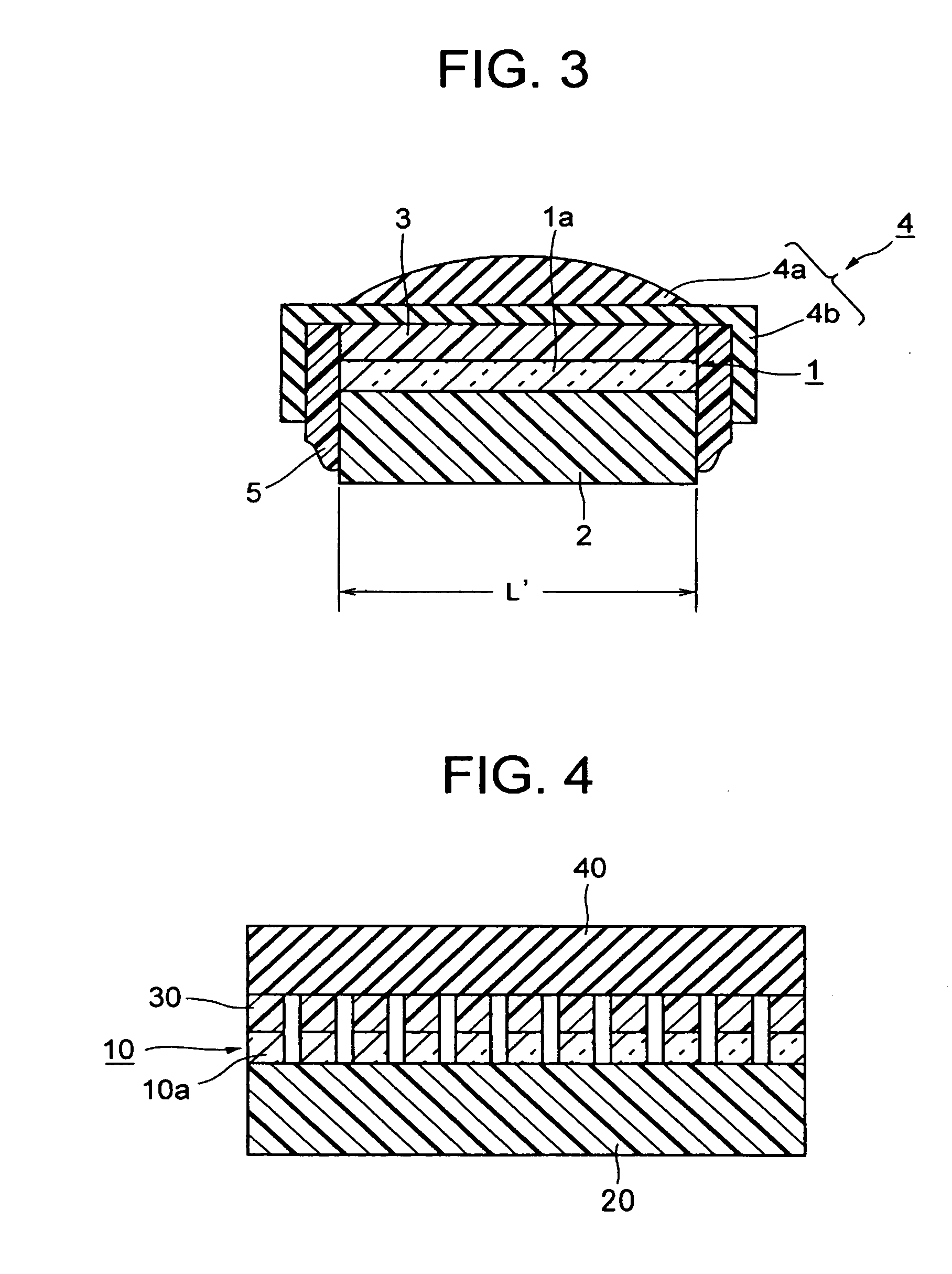

[OBJECTS AND PROBLEMS] Relating to a mist generator capable of emitting any of chemical substances used in life, such as perfumes, pharmaceuticals and pesticides, in the form of fog or vapor. An object of the invention is to attain means for efficiently atomizing liquid, means for easily and rapidly switching the type of chemical substance emitted and a compact apparatus of good maintainability. [MEANS FOR SOLVING PROBLEMS] An apparatus comprises an ultrasonic transducer; an ultrasonic propagation medium disposed so as to fill a plane of vibration of the transducer; liquid retaining means disposed so as to be in contact with an end face of the medium; and an ultrasonic focusing reflecting mechanism (concave reflection mirror) disposed in an ultrasonic propagation path, thereby the apparatus attains discharging into air and atomization of the liquid by means of ultrasonic waves. Atomization efficiency is enhanced by the use of an ultrasonic reflection tube, and mist emission is carried out. Use is made of a compact liquid container equipped at its bottom with an ultrasonic transmission membrane. Various types of liquids can be atomized by changing the direction of ultrasonic course. Mist can be emitted by means of a thermal current as heating means. IC tag is attached to the liquid retaining means or liquid injection means.

Owner:TOMONO AKIRA

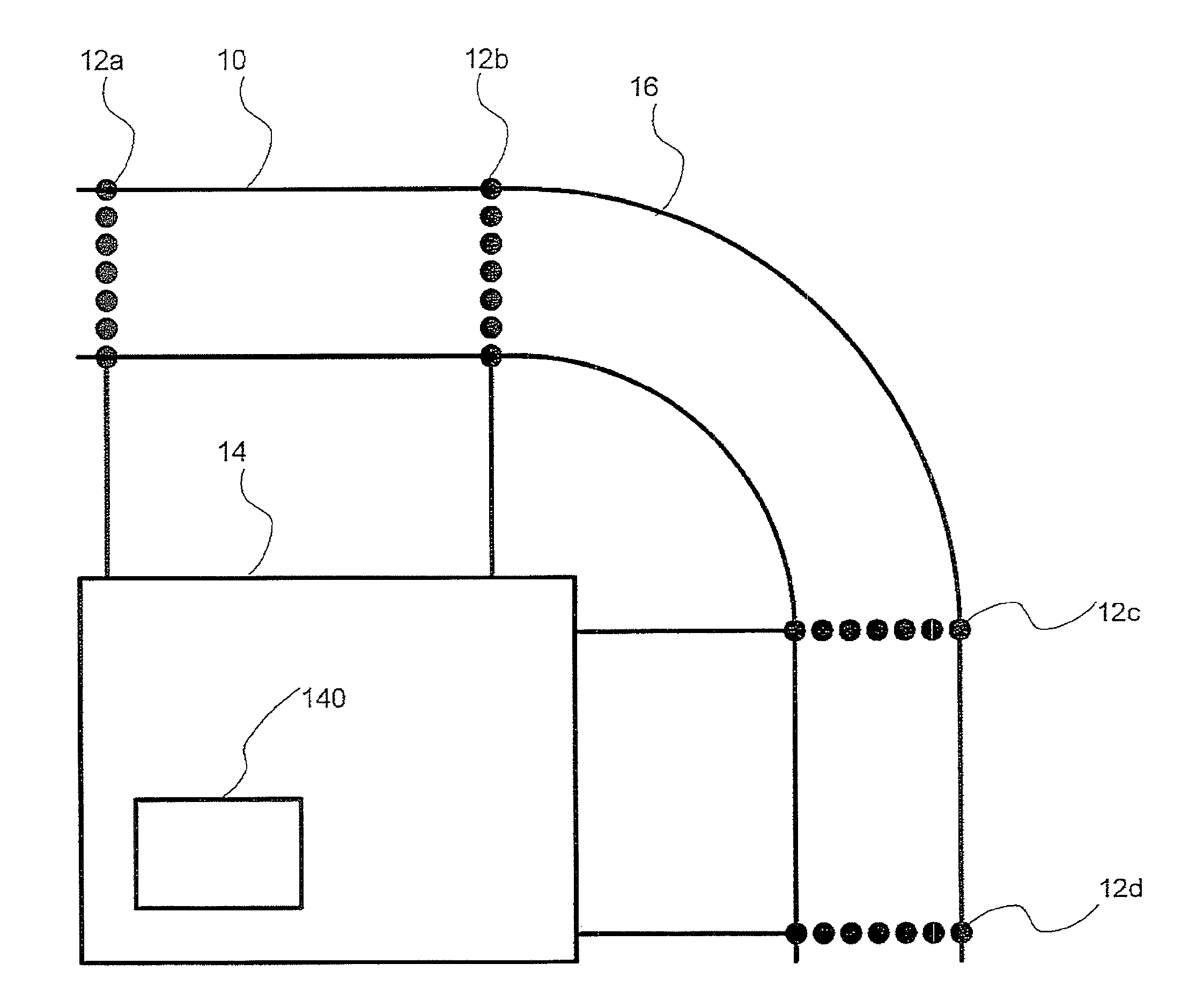

Flow measuring apparatus

ActiveUS20110271769A1Reliable and accurate measurementImprove energy transferFlow propertiesVolume flow measuring devicesPropagation timeUltrasonic radiation

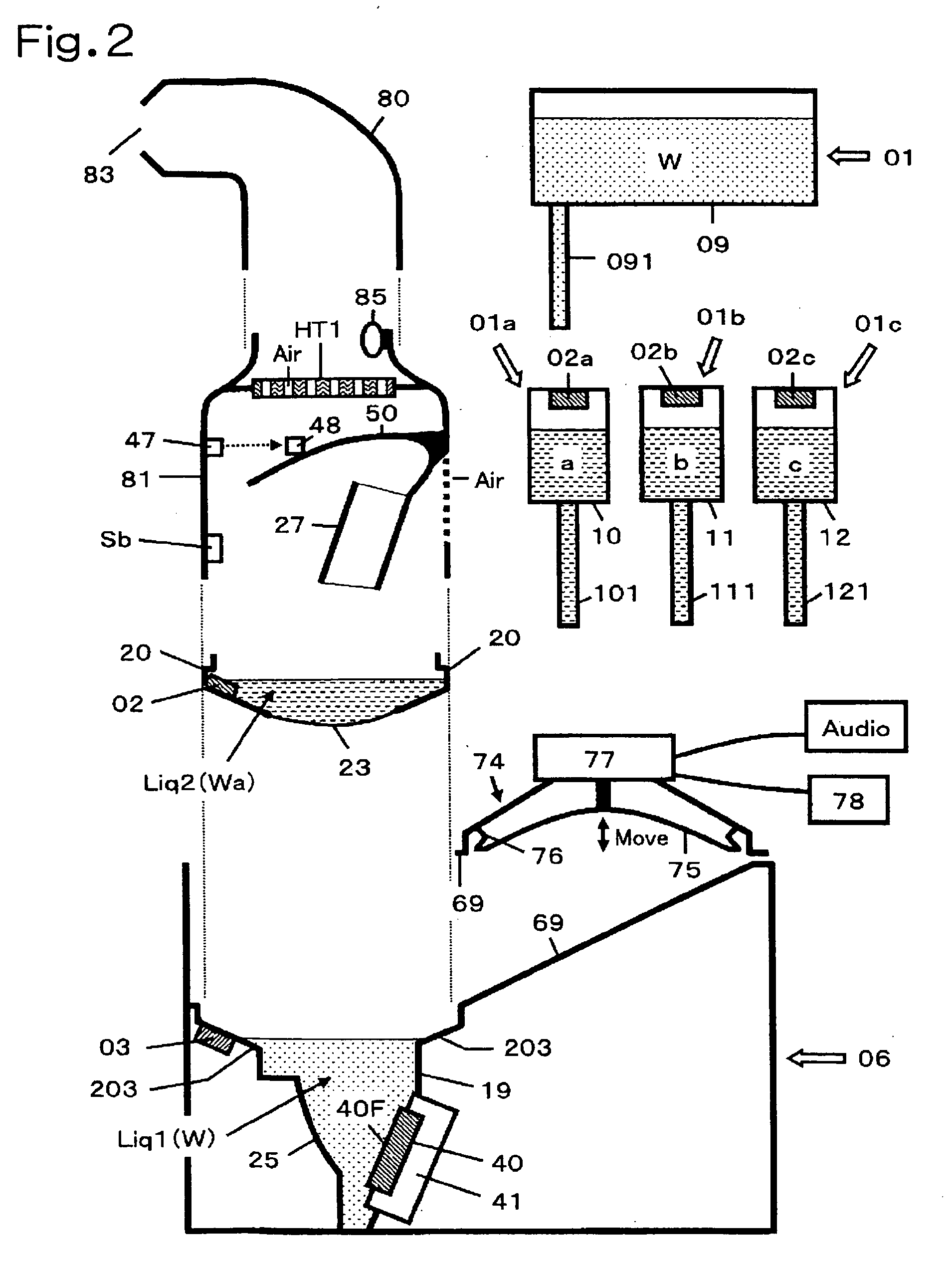

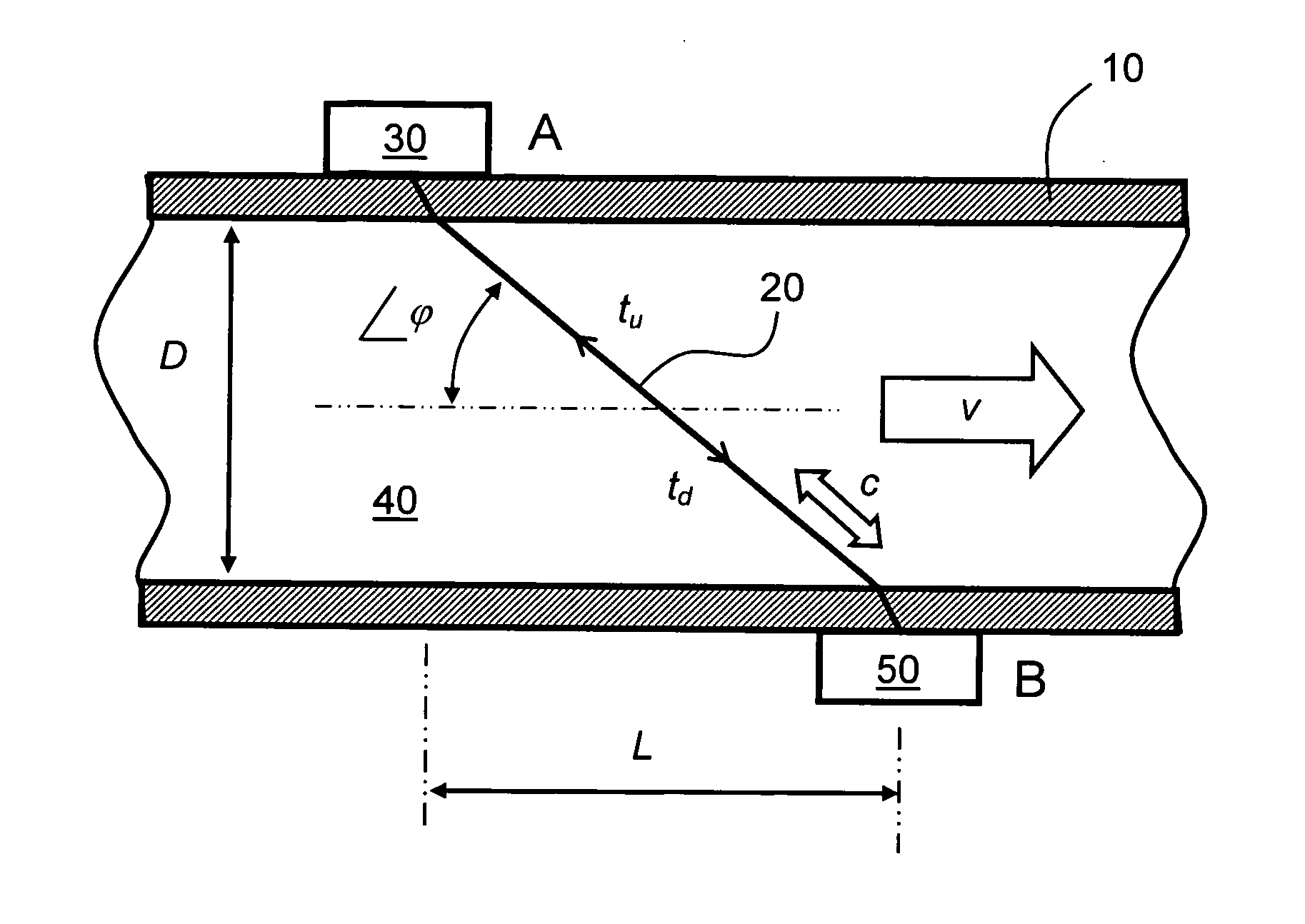

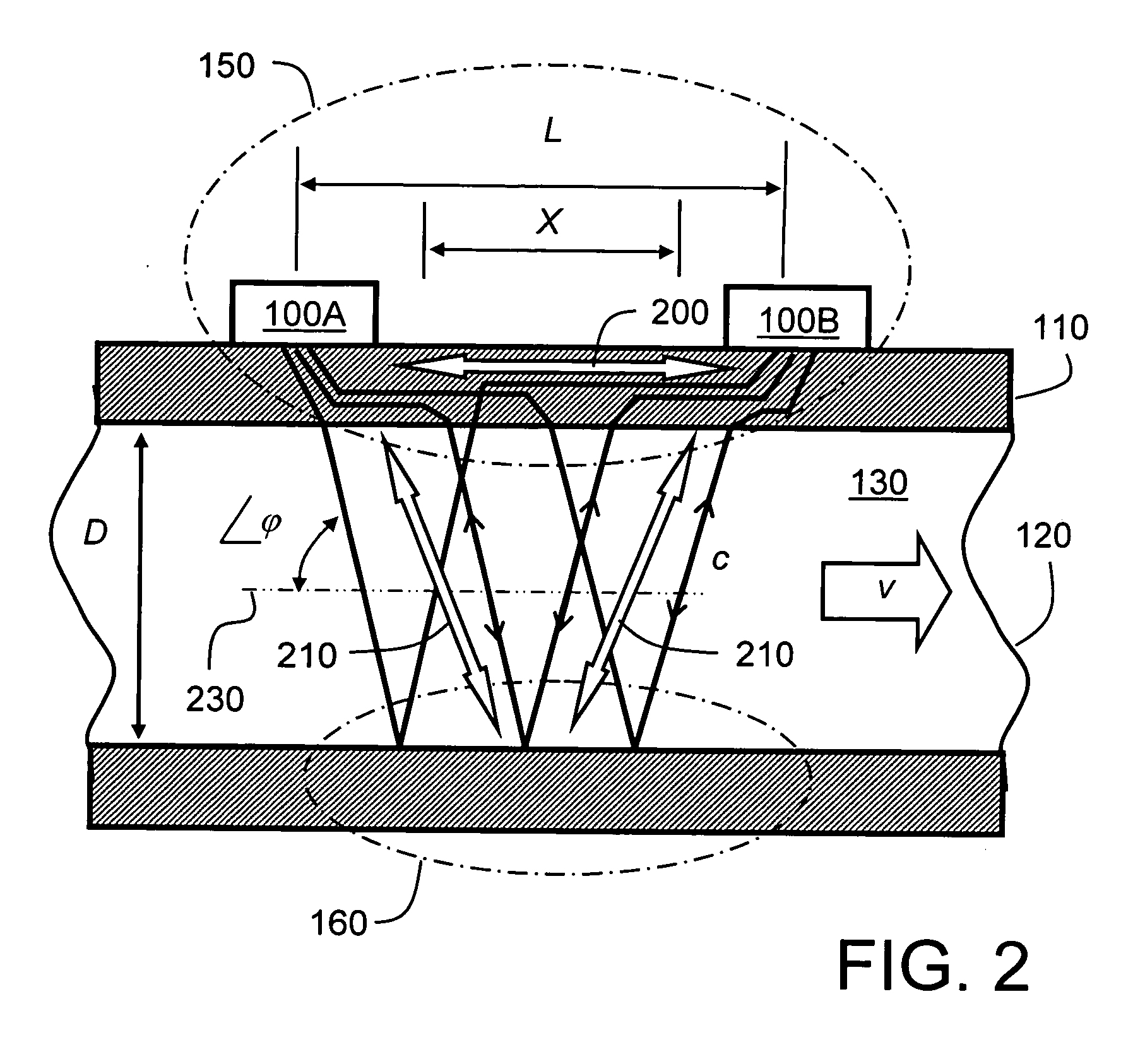

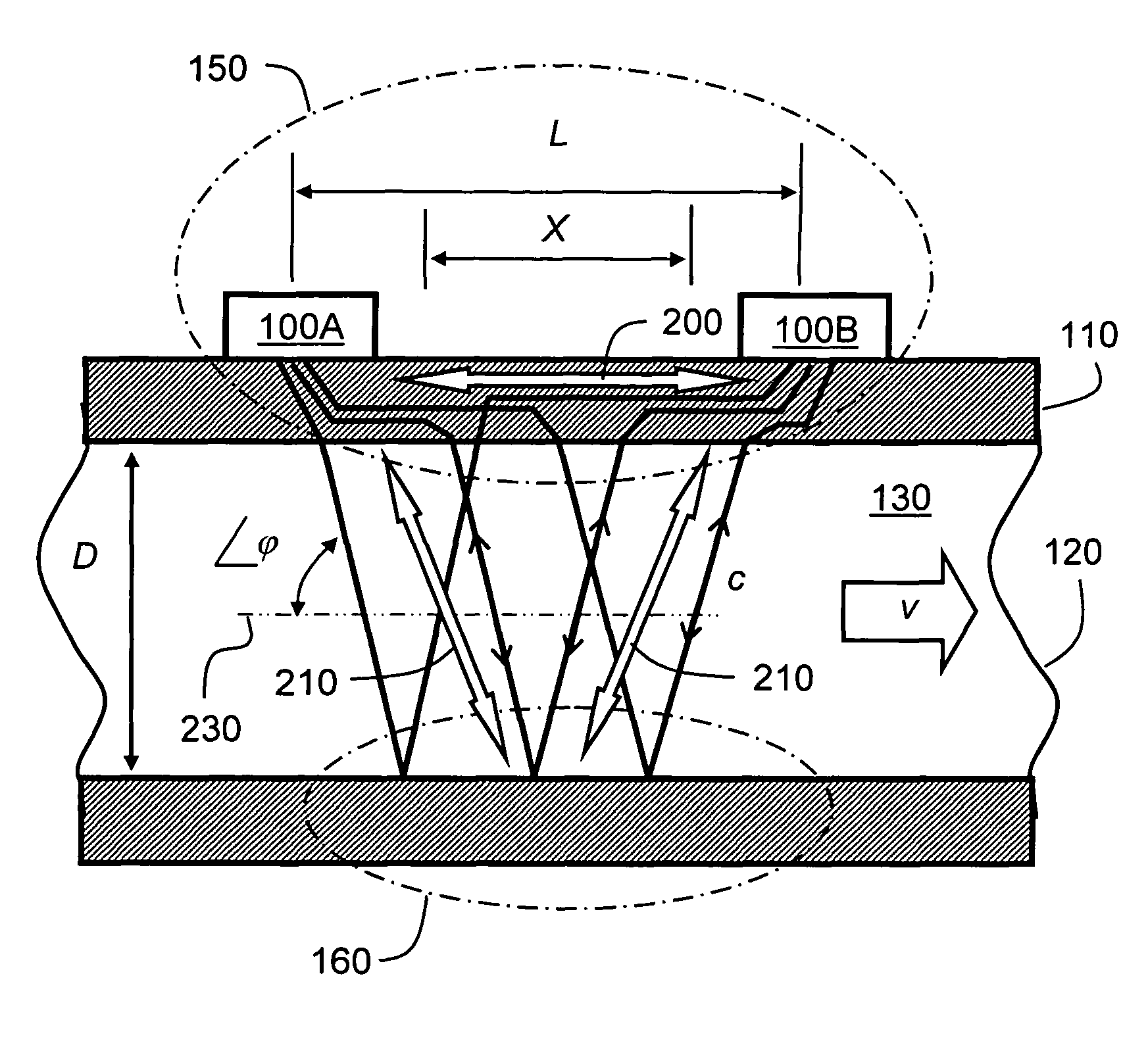

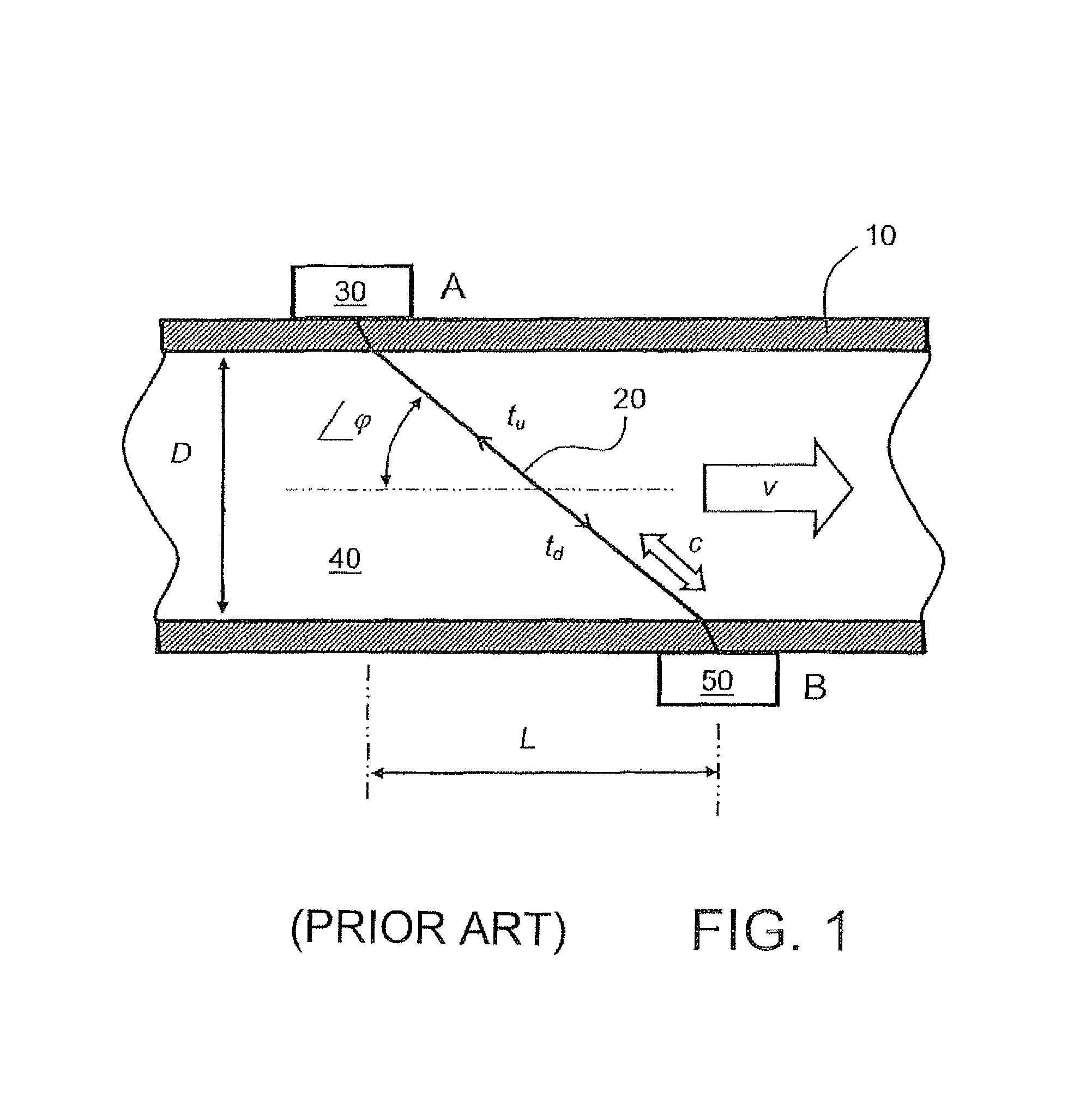

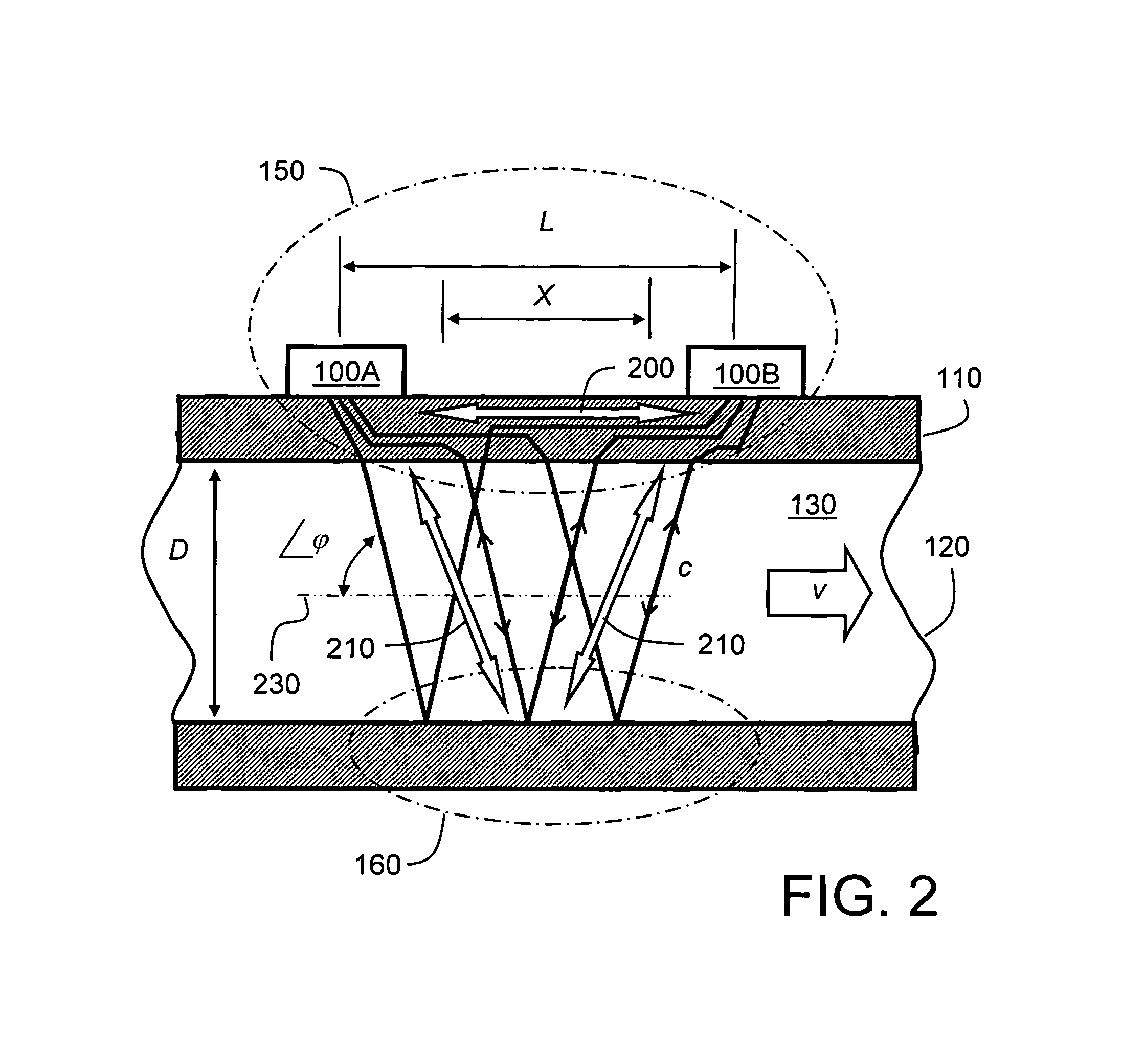

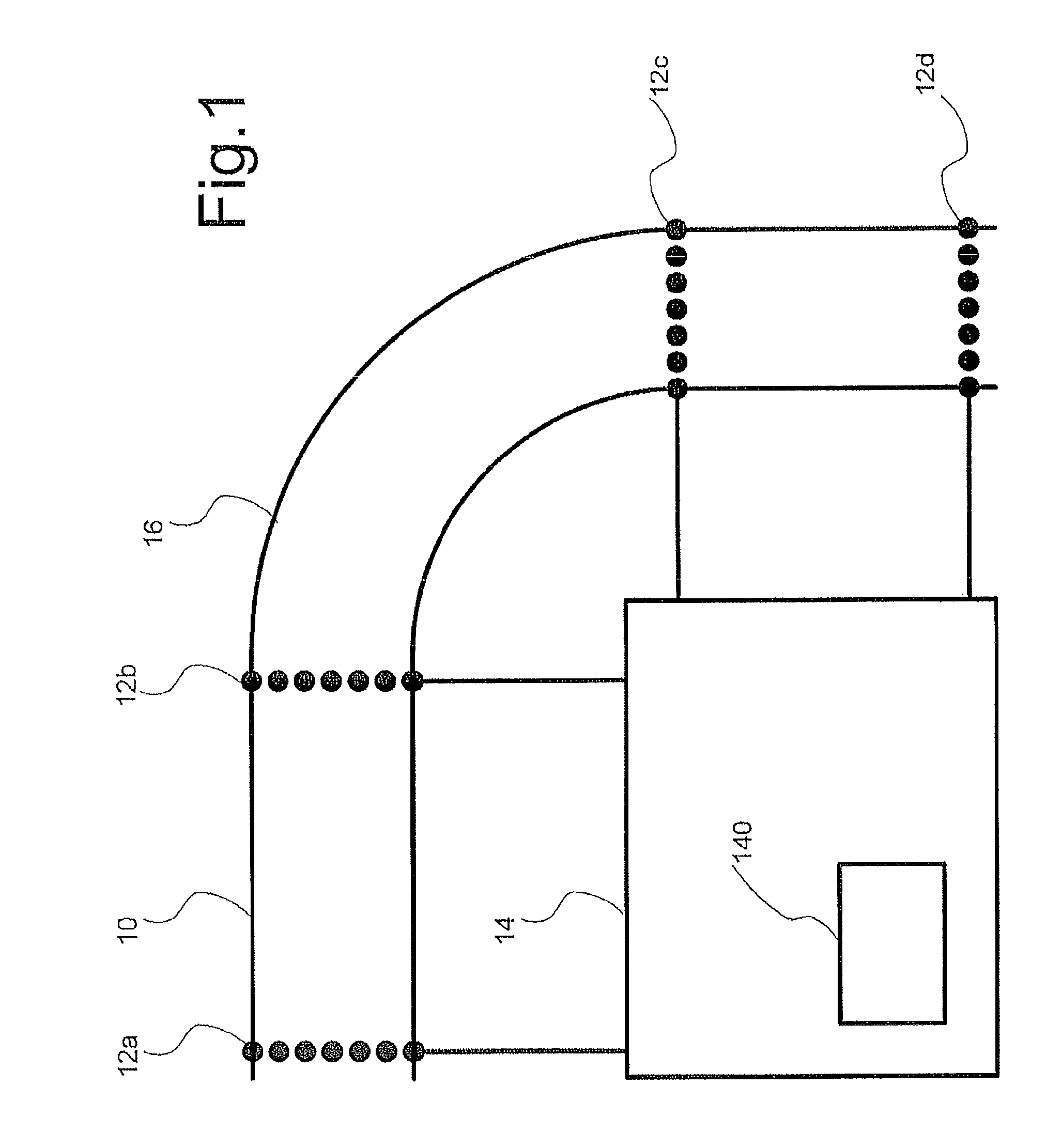

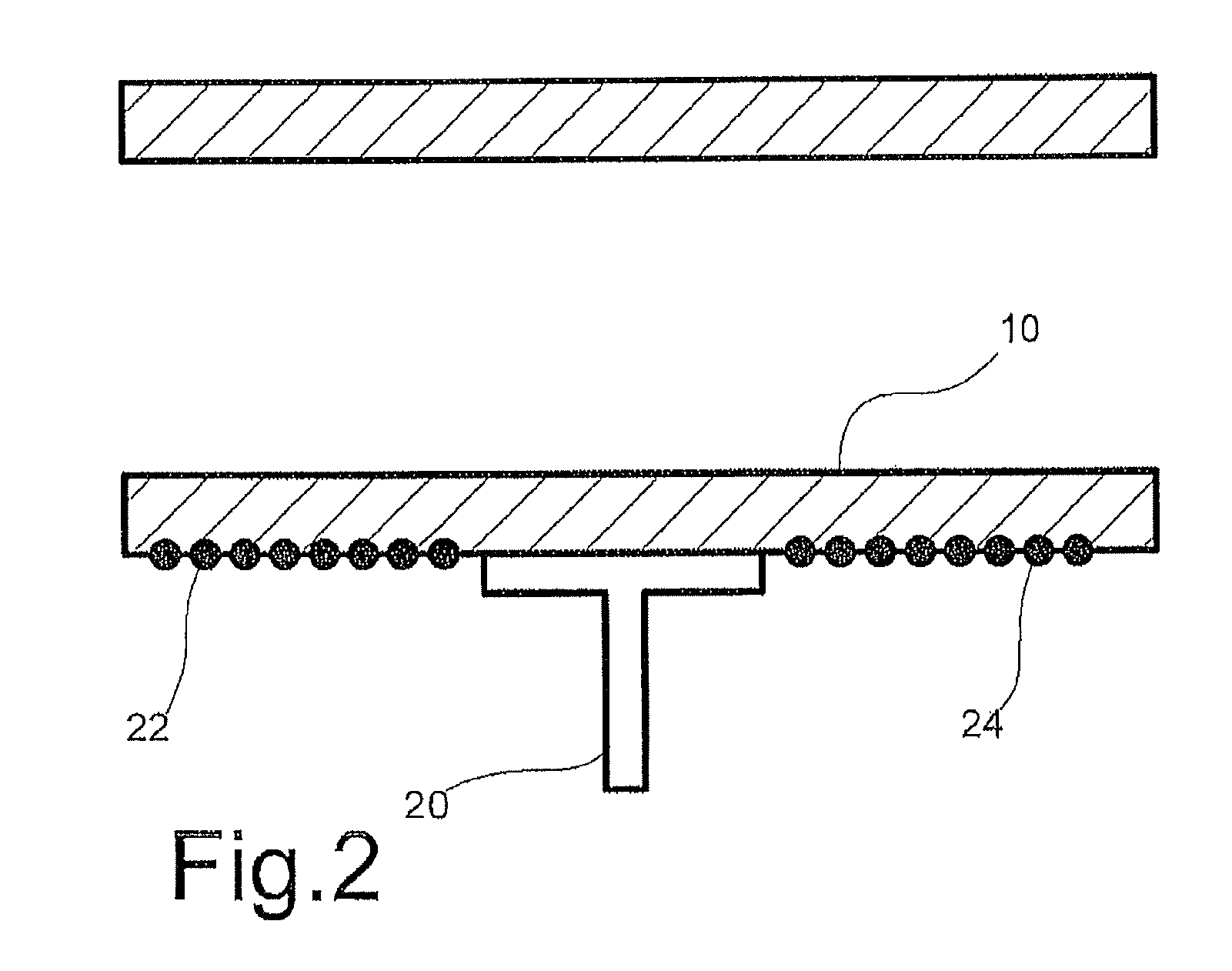

A flow measuring apparatus (300, 500) measures a fluid flow (130) within a conduit (120) including a wall (110). The apparatus (300, 500) includes a transducer arrangement including at least two transducers (100A, 100B) for alternately emitting and receiving ultrasonic radiation through the conduit wall (110) and the flow (130). The apparatus (300, 500) also includes a signal processing arrangement (310) for generating signals to excite the transducer arrangement (100A, 100B) and for processing received signals provided by the transducer arrangement (100A, 100B) for generating output signals from the signal processing arrangement (310) indicative of properties of the flow. The transducer arrangement (100A, 100B) in cooperation with the conduit (120) provides a first path (200) for Lamb-wave ultrasonic radiation coupling directly from a first of the at least two transducers (100A, 100B), to a second of said at least two transducers to generate a first received signal. The transducer arrangement (100A, 100B) in cooperation with the conduit (120) provides at least one second path (210) for ultrasonic propagation along the wall (100) via Lamb waves coupling to at least a portion of the flow (130) from a first of the at least two transducers (100A, 100B) to a second of the at least two transducers (100A, 100B) to generate a second received signal. The signal processing arrangement (310) determines from said first and second received signals ultrasonic radiation propagation time periods through the first path (200) and through the at least one second path (210), and to perform computational operations on the propagation time periods to determine properties of the flow including, but not limited to, at least one of: fluid flow velocity (v) in the conduit (120), a sound velocity (c) through the fluid (130).

Owner:XSENS

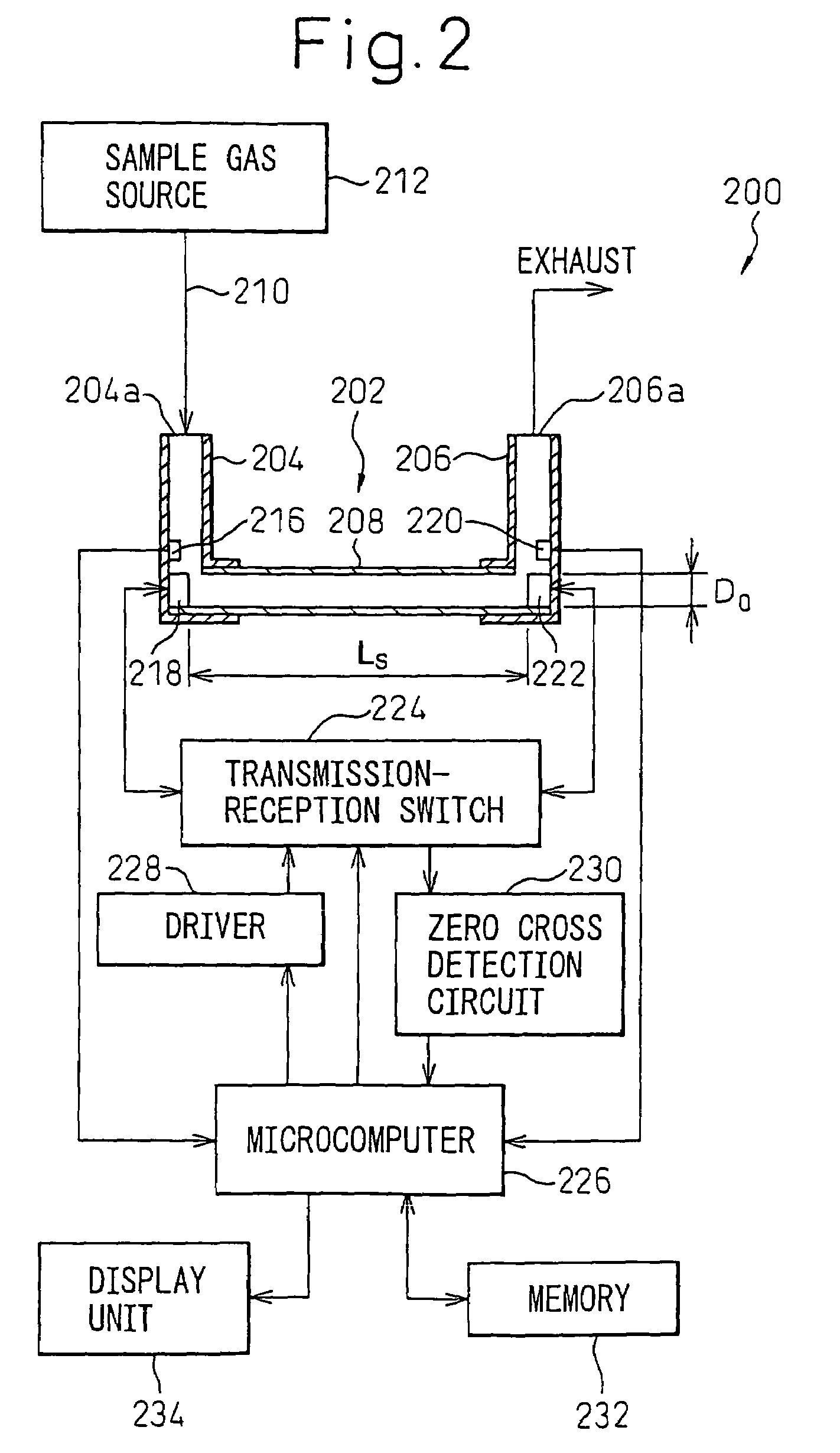

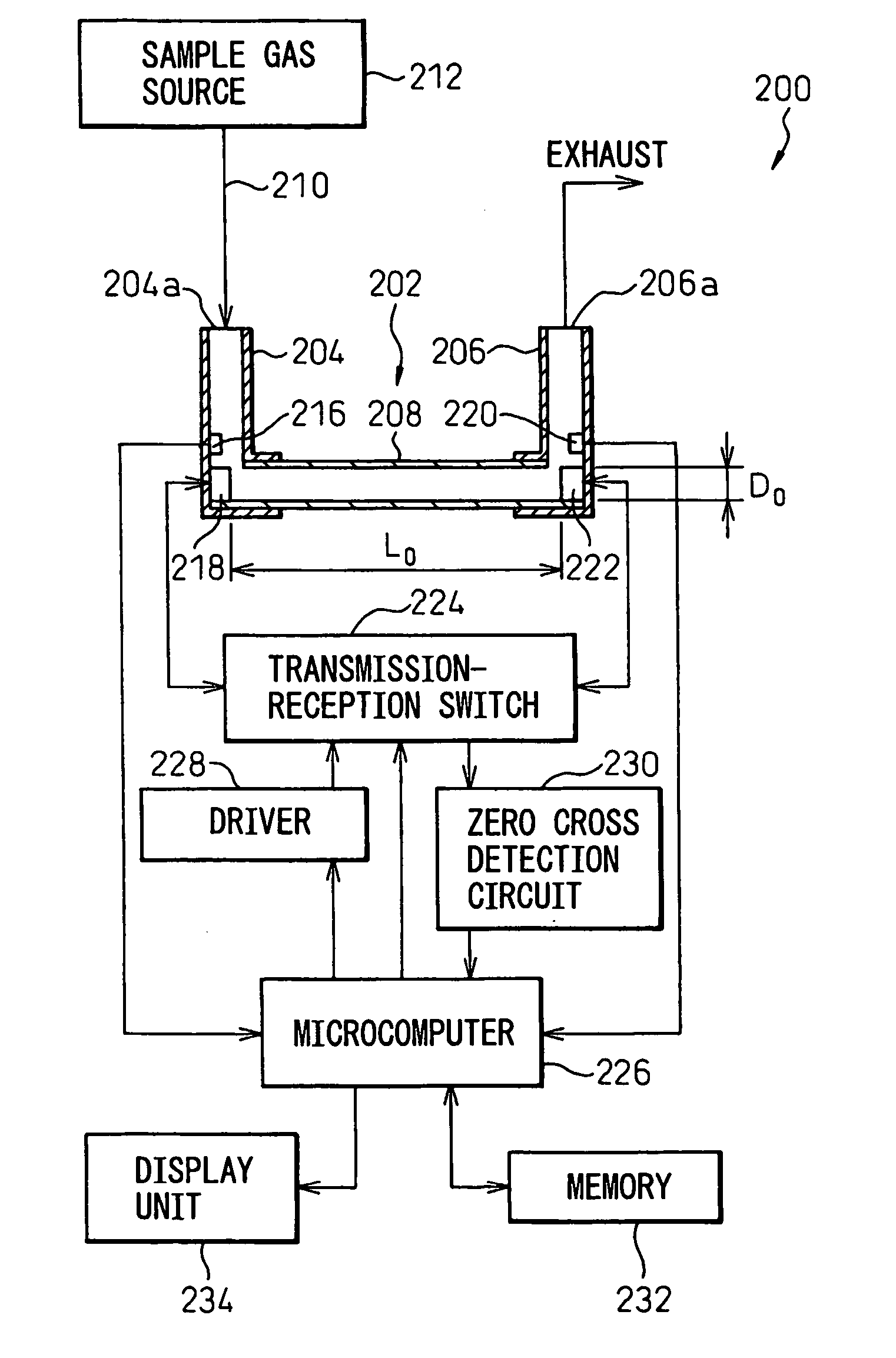

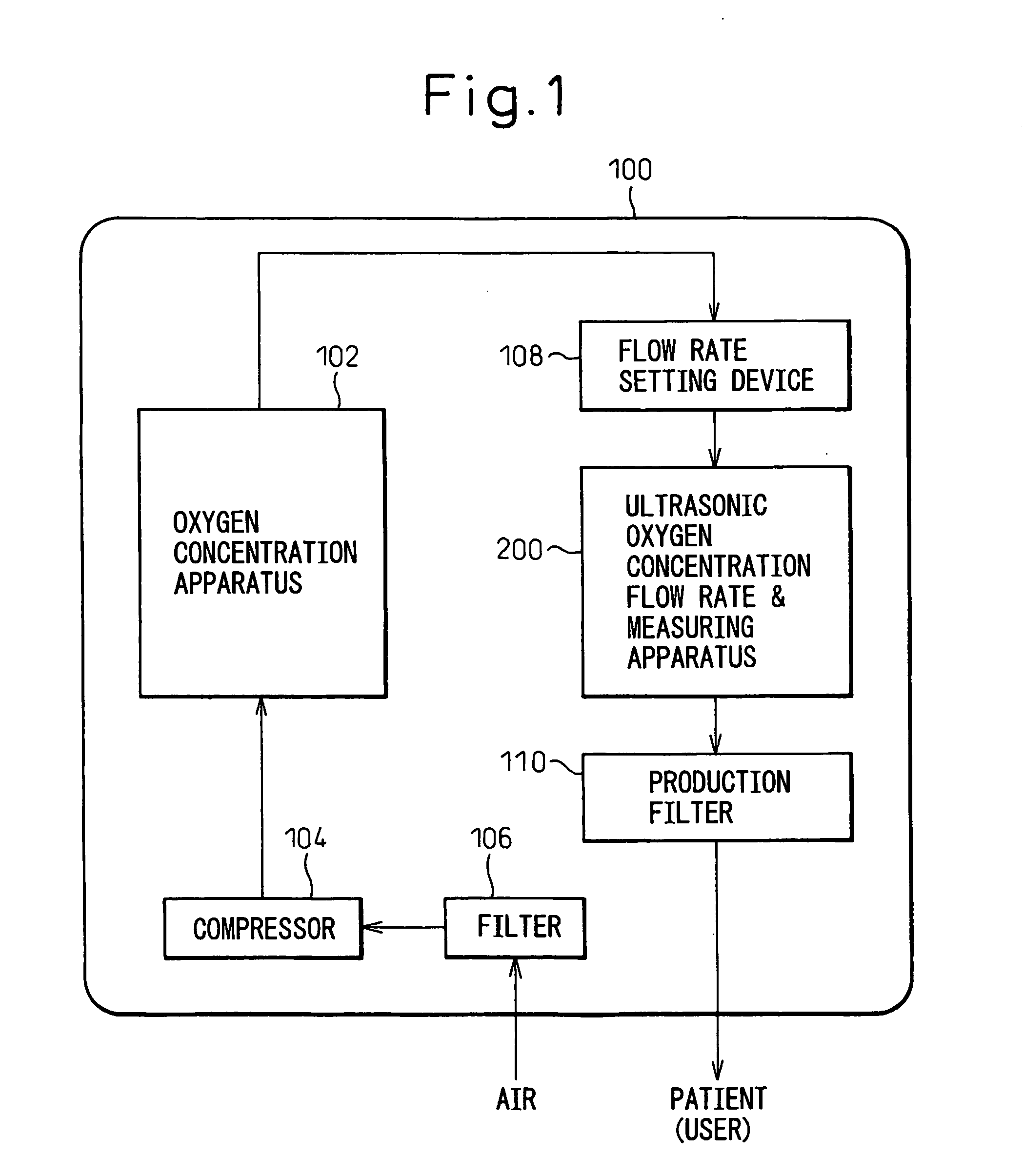

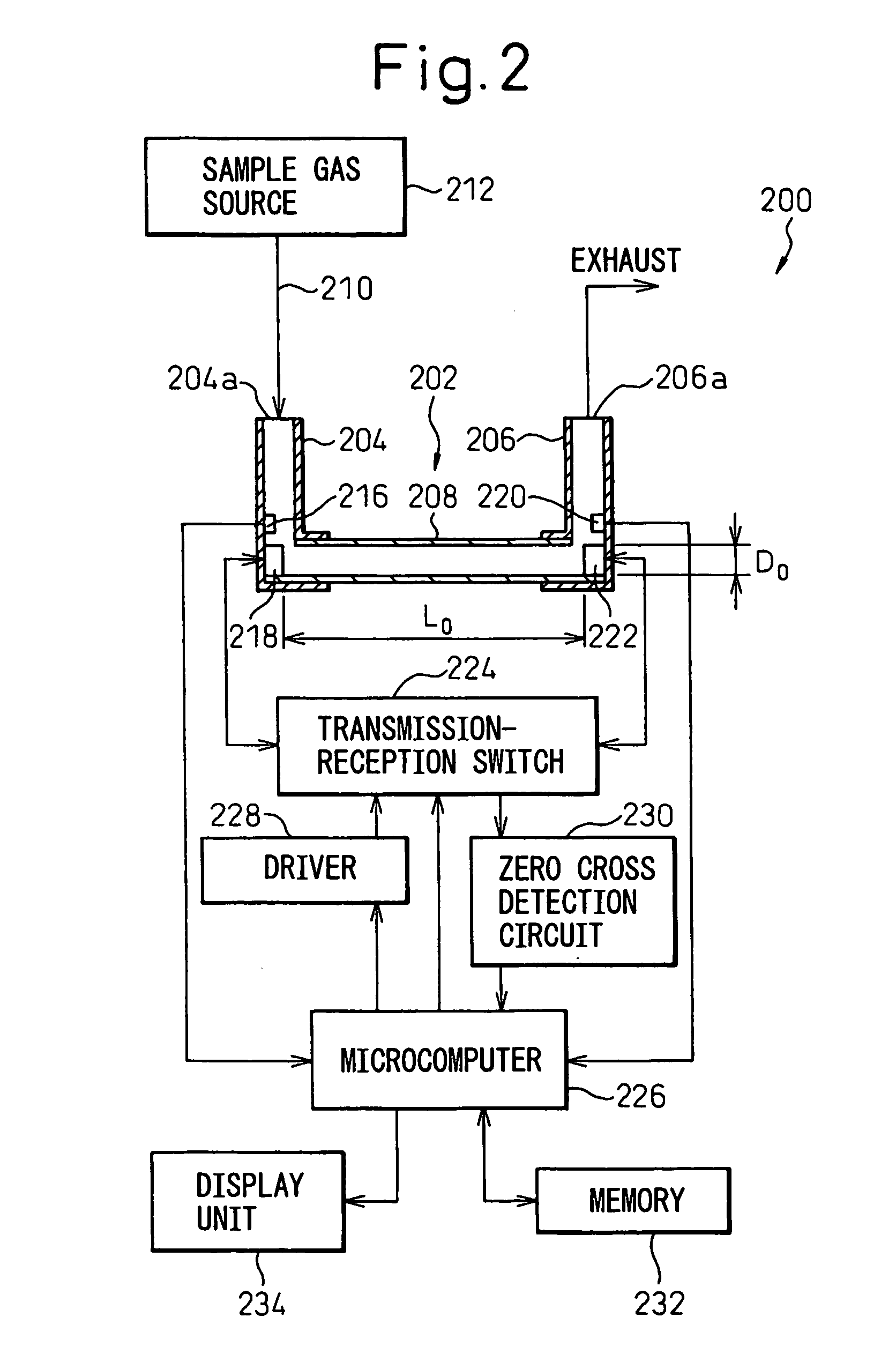

Ultrasonic apparatus and method for measuring the concentration and flow rate of gas

ActiveUS7213468B2Accurate measurementAnalysing solids using sonic/ultrasonic/infrasonic wavesVolume/mass flow measurementUltrasound devicePropagation time

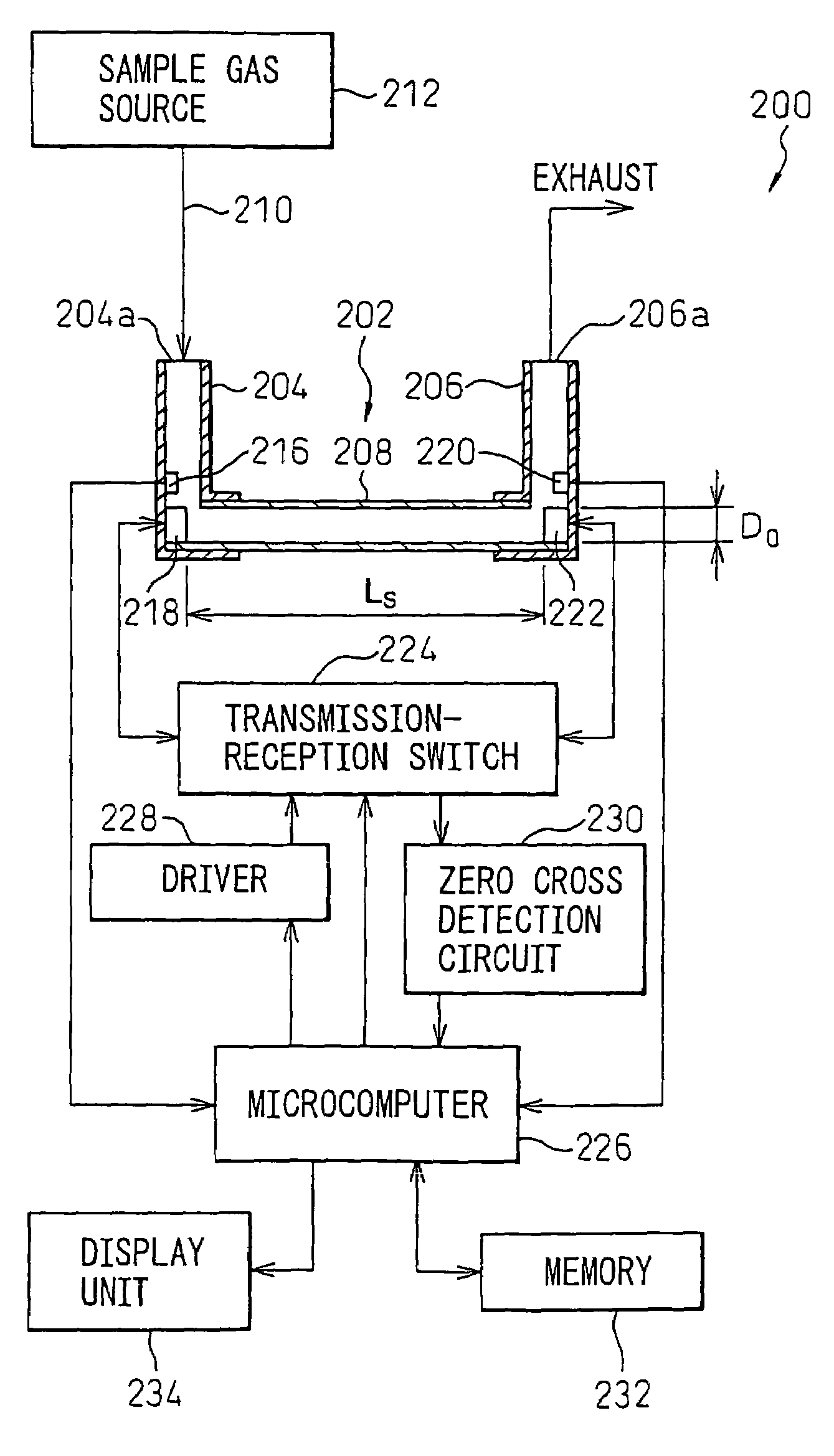

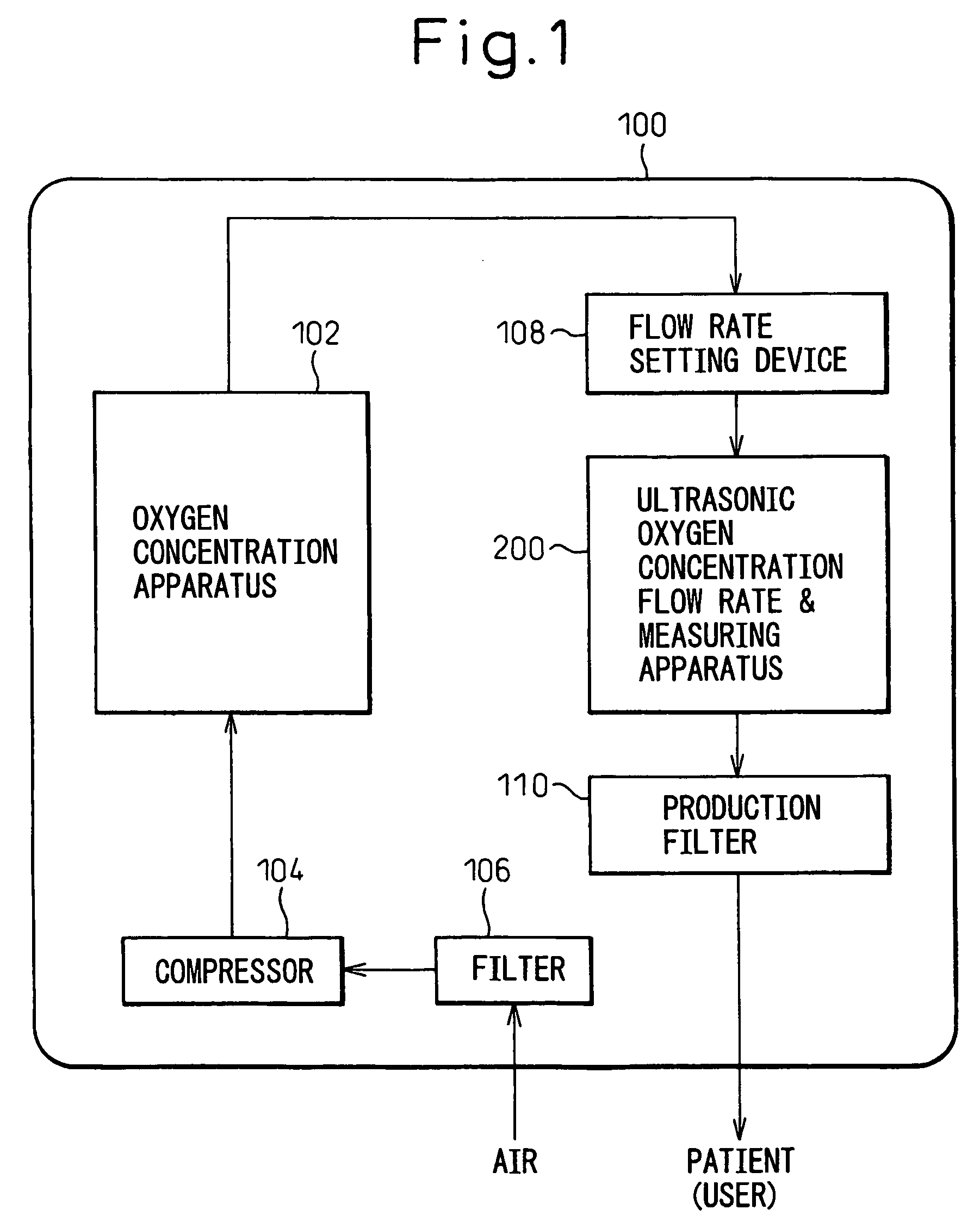

An ultrasonic apparatus measures the concentration and flow rate of a sample gas by calculating a possible propagation time range on the basis of the gas temperature, determining whether or not the phases at which two first trigger signals, respectively generated on the basis of forward and backward waveforms of the ultrasonic waves, coincide with each other, processing the zero-cross signals so that the phases coincide with each other, obtaining reference zero-cross time instant by calculating mean value of the forward and backward zero-cross time instants, obtaining an ultrasonic reception point by subtracting an integral multiple of the cycle of the ultrasonic waves so that the results of the subtraction falls into a possible propagation time range and estimating the ultrasonic propagation time on the basis of the ultrasonic reception point.

Owner:TEIJIN LTD

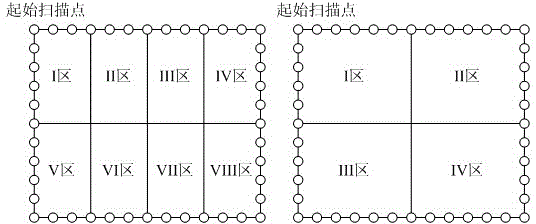

Laser ultrasonic detection method and laser ultrasonic detection system for rapidly locating defects

InactiveCN104634741AReduce data processingReduce processingOptically investigating flaws/contaminationGalvanometerLaser light

The invention relates to a laser ultrasonic detection method and a laser ultrasonic detection system for rapidly locating defects. The laser ultrasonic detection method comprises the following steps: a laser emits pulse laser light, and a galvanometer scanning system is adopted to act on a workpiece to be detected; an air coupling surface wave probe is arranged at the same side of the workpiece to be detected and is used for receiving a scattered signal generated by the defect of a detected part; a subarea where the defect is located in the detected part is judged according to the received scattered wave, and the defect area can be rapidly located; and the defect of the defect area can be accurately located along with gradual reduction of the defect area according to the ultrasonic propagation imaging principle. According to the method and the system, the defect can be rapidly located, the data processing load is small and the detection efficiency is high.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

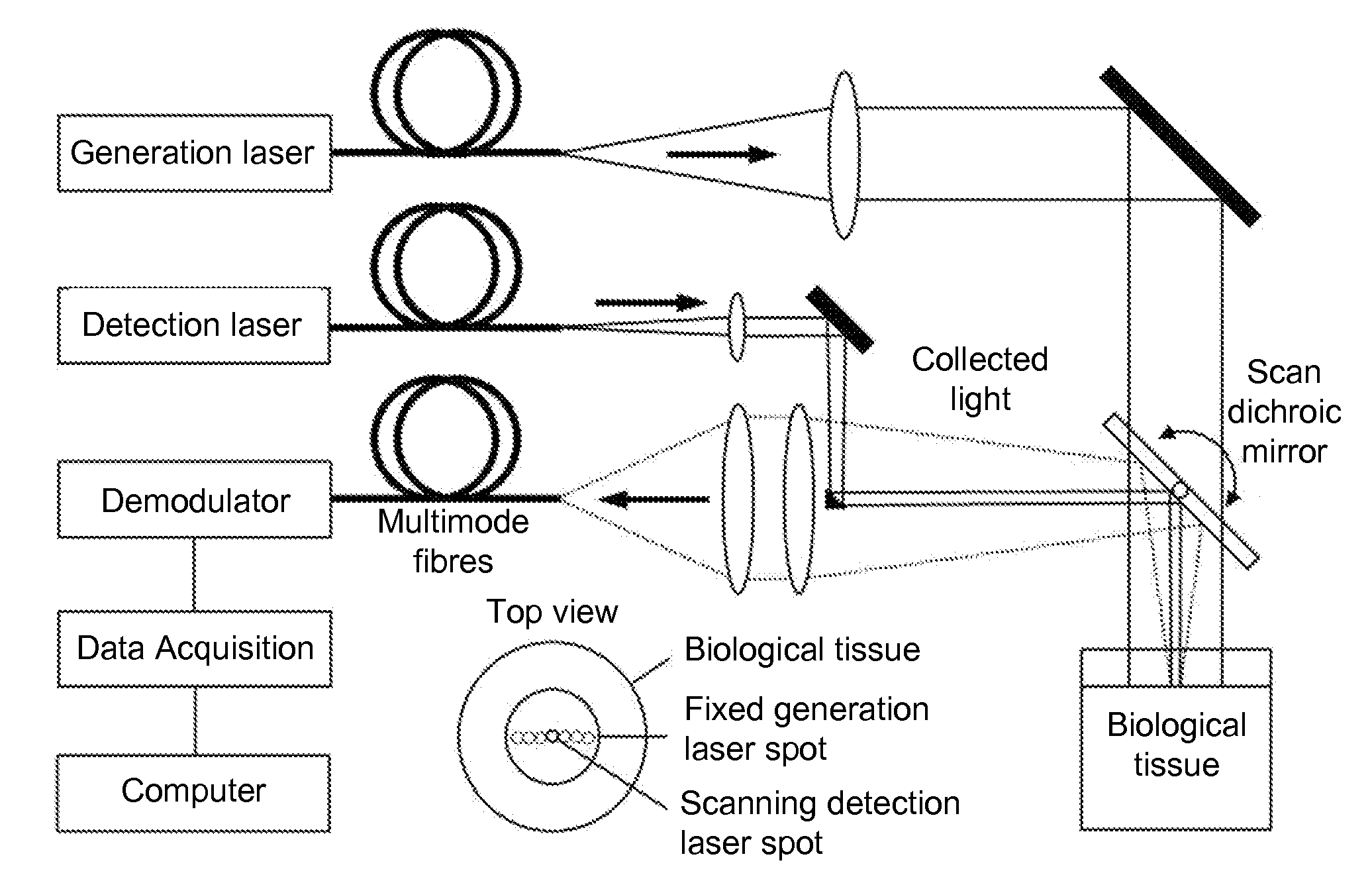

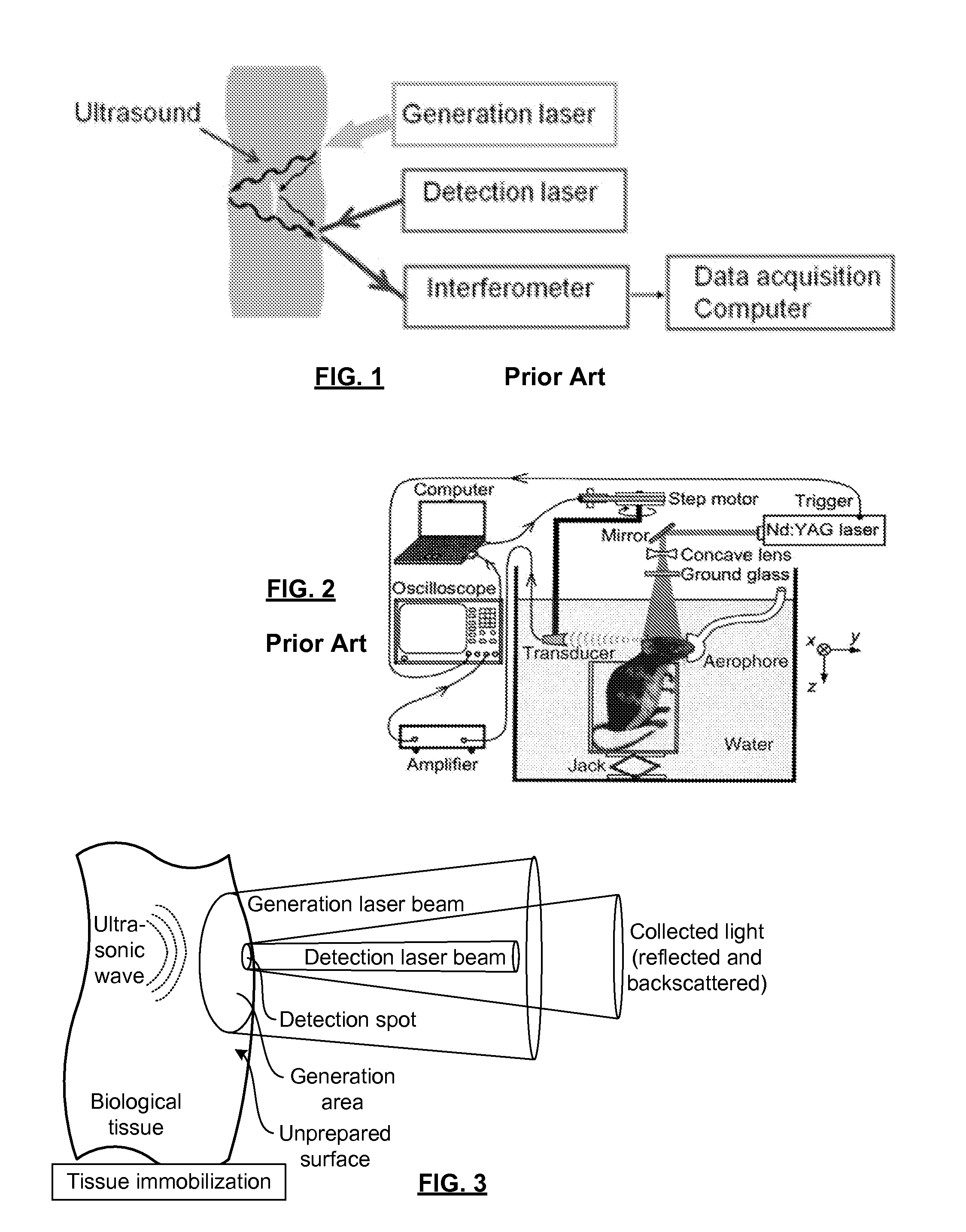

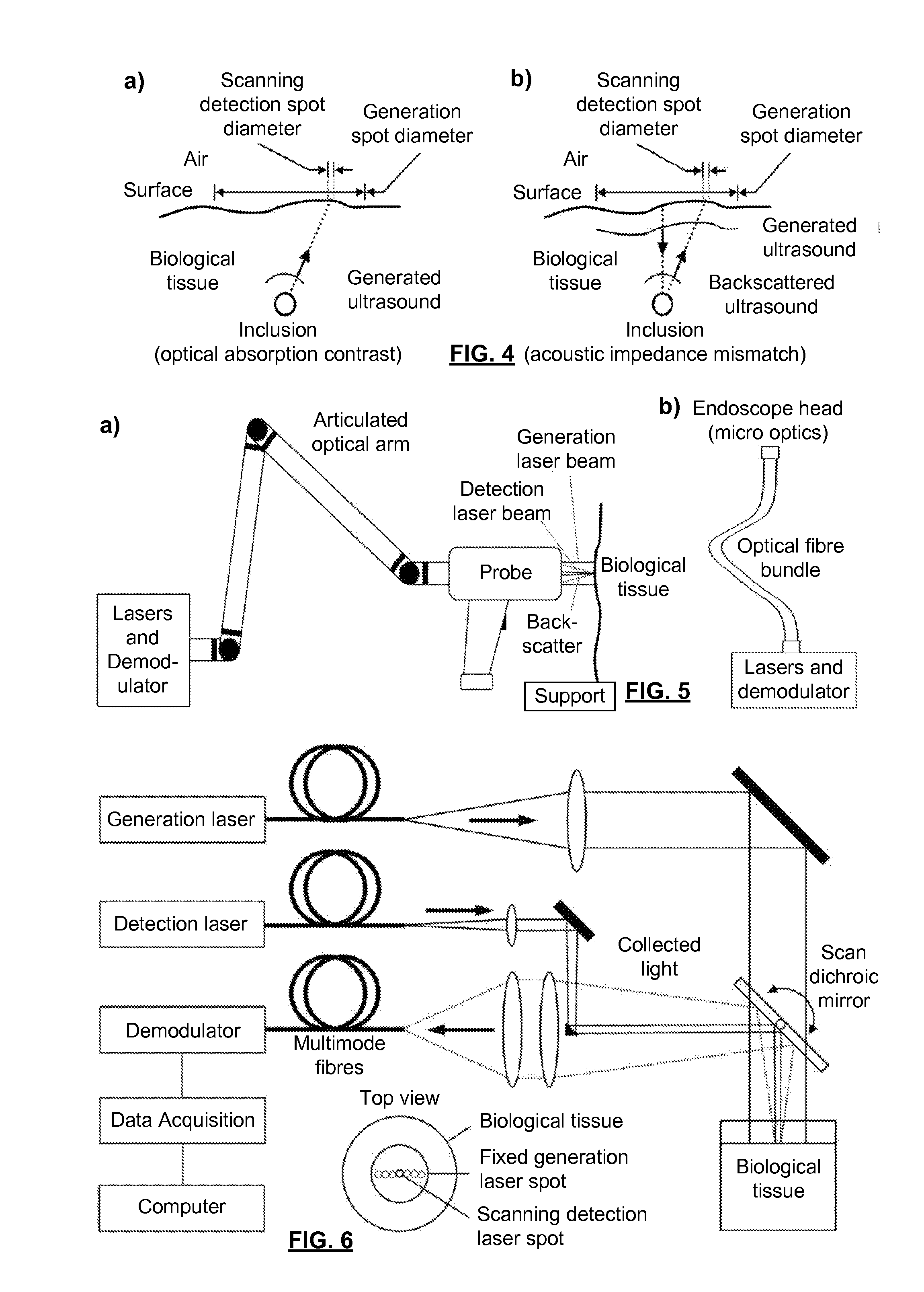

Biological tissue inspection method and system

InactiveUS20120200845A1Avoid large absorptionProvide powerMaterial analysis using sonic/ultrasonic/infrasonic wavesDiagnostics using lightPulsed laser beamLength wave

A method and system for inspecting biological tissue that has no applied coatings or treatments to improve reflectivity comprises an optical detection system with an exposed surface for inspection by an optical detection system; and a laser for exciting an ultrasonic wave within the tissue, which wave propagates within the tissue at least near the surface. The optical detection system includes: a laser to emit a pulsed detection laser beam onto the surface at a detection spot, the pulsed laser beam having a wavelength at which there is large scattering and little absorption by the tissue, and a pulse duration is chosen to correspond with ultrasonic propagation times associated with a range of depths of the scan, whereby the fluence of the detection laser is not applied unless ultrasonic information regarding a given depth is being obtained; and large étendue collection optics for collecting reflected and backscattered light from the detection spot; and a demodulator to extract information from the ultrasonic wave from the collected light.

Owner:NAT RES COUNCIL OF CANADA

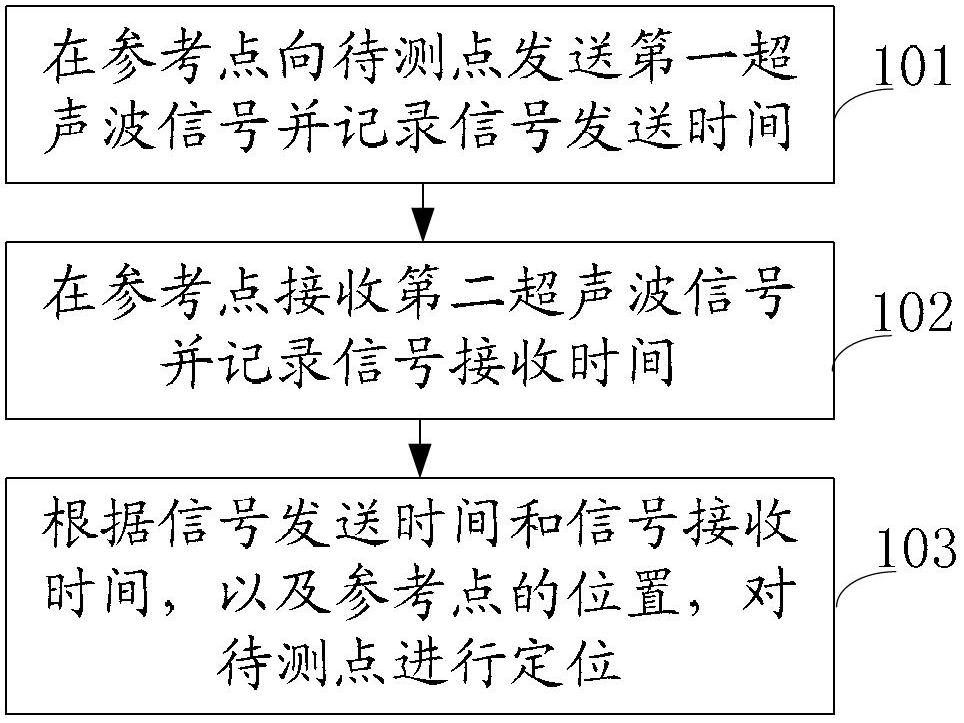

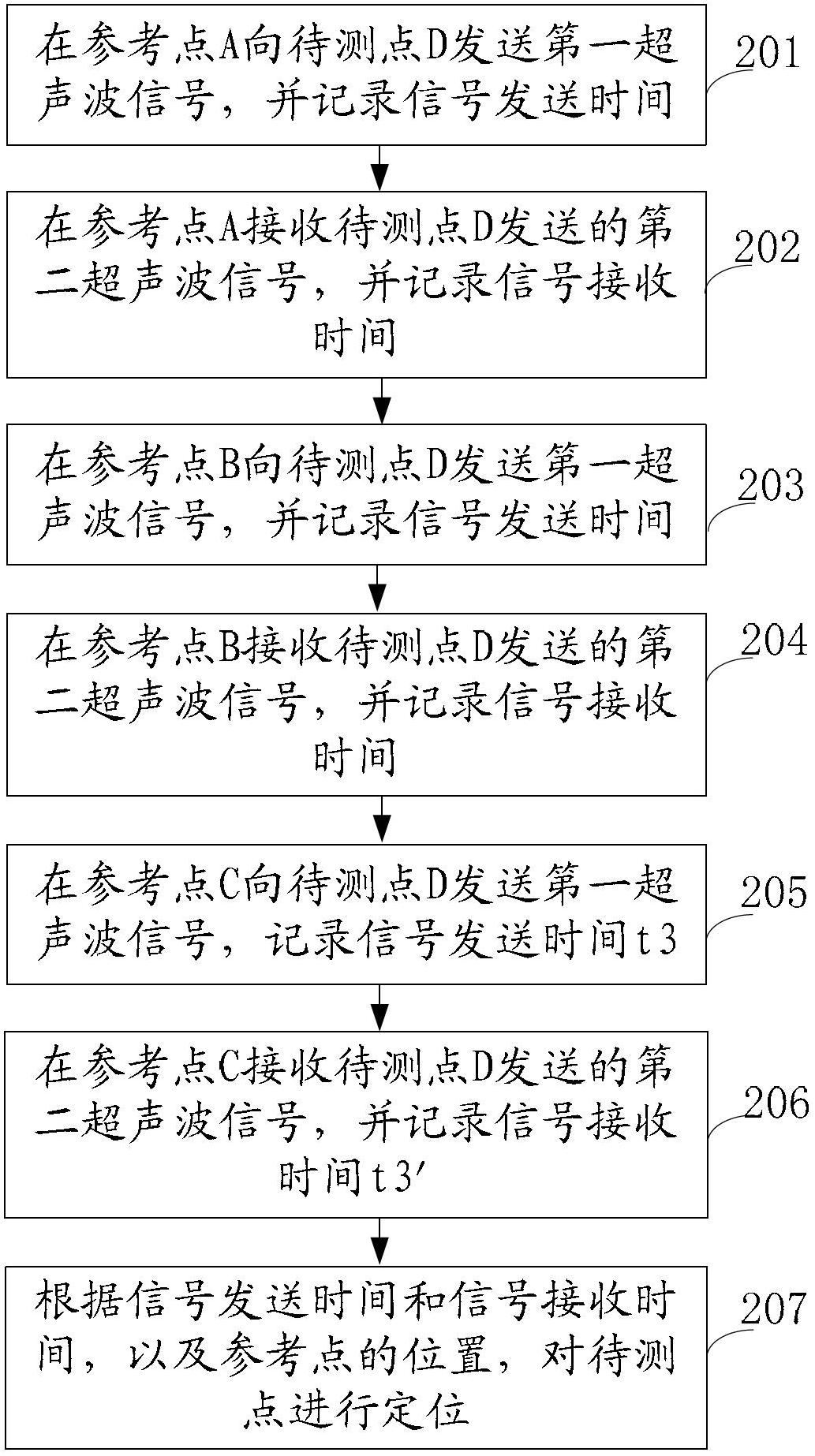

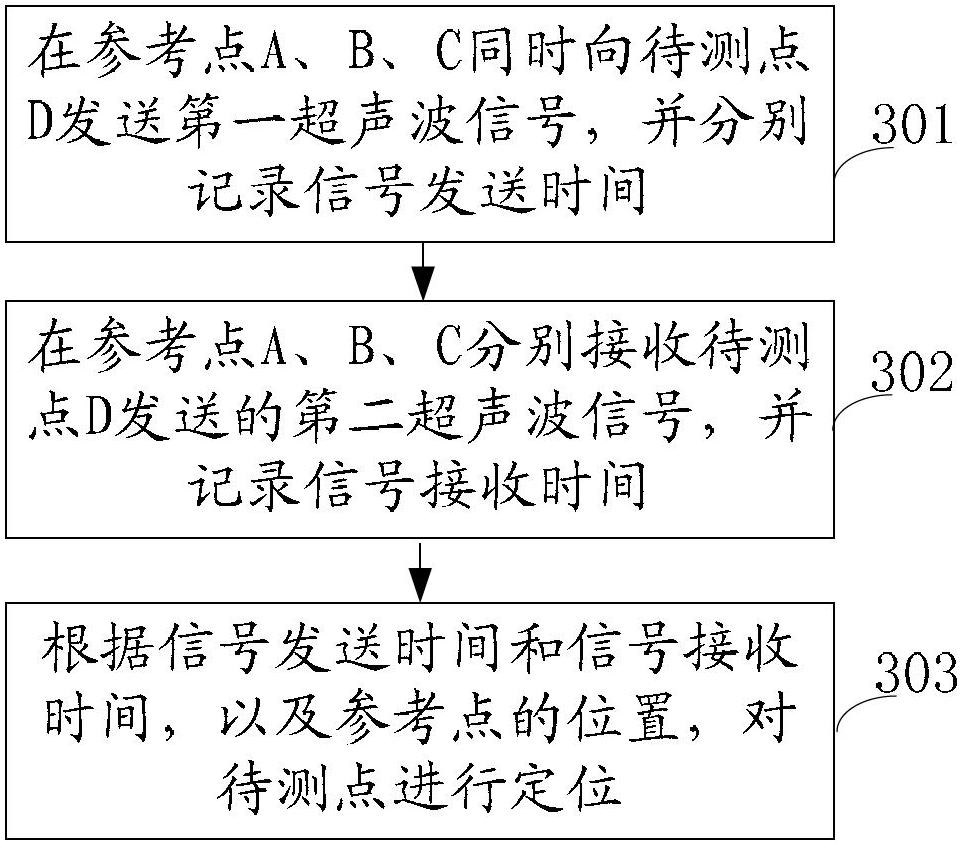

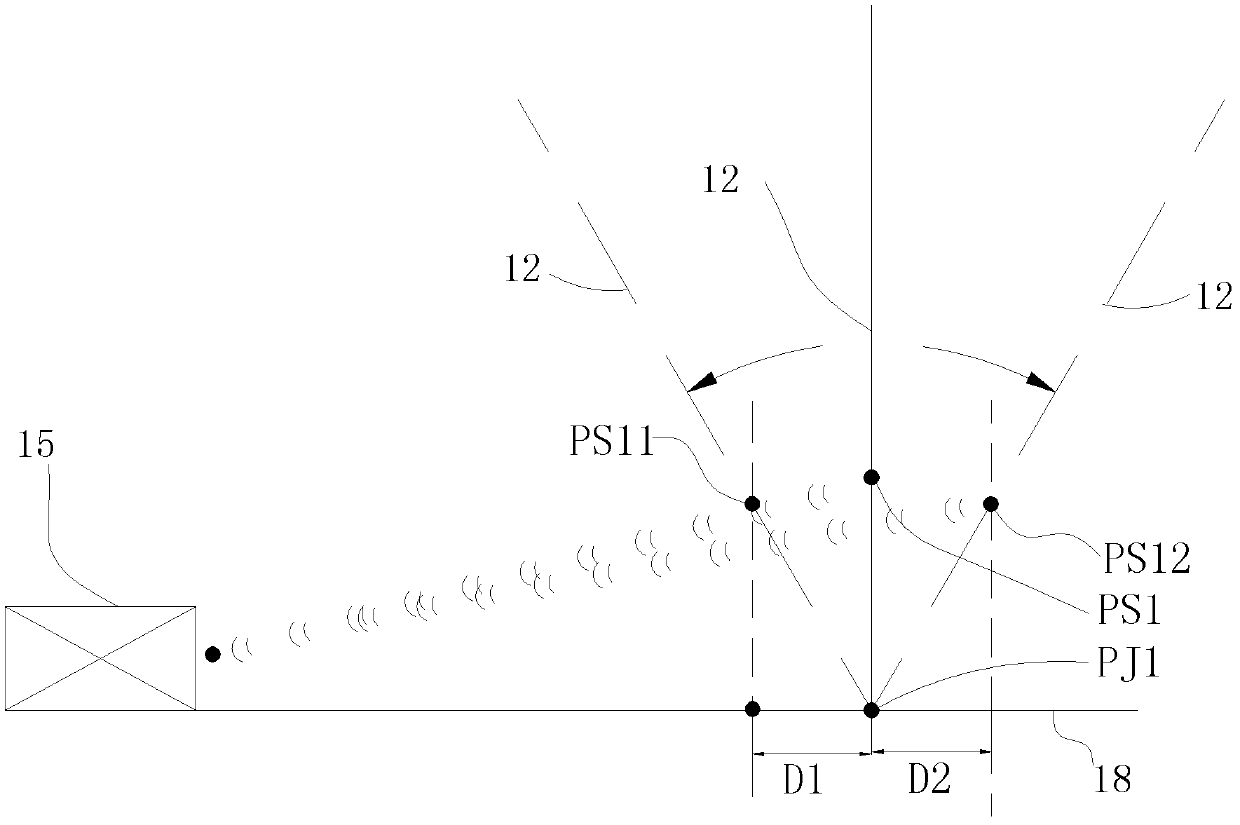

Ultrasonic positioning method, device and system

InactiveCN102680944AHigh precisionOvercoming multipath effectsPosition fixationMultipath effectUltrasonic propagation

An embodiment of the invention provides an ultrasonic positioning method, device and system. The ultrasonic positioning method comprises sending a first ultrasonic signal from a reference point to a point to be measured, and recording signal sending time; receiving a second ultrasonic signal at the reference point, recording signal receiving time, enabling the second ultrasonic signal to be a responding signal after the first ultrasonic signal is received at the point to be measured, and enabling the frequency of the first ultrasonic signal and the frequency of the second ultrasonic signal to be different; and positioning the point to be measured according to the signal sending time, the signal receiving time and the position of the reference point. By enabling the frequency of the ultrasonic signal sent at the reference point to be different from the frequency of the frequency fed back by the point to be measured, the multipath effect in the ultrasonic propagation process and positioning disturbance caused by the ultrasonic wave reflected by other subjects are avoided, and the accuracy of ultrasonic positioning is improved.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

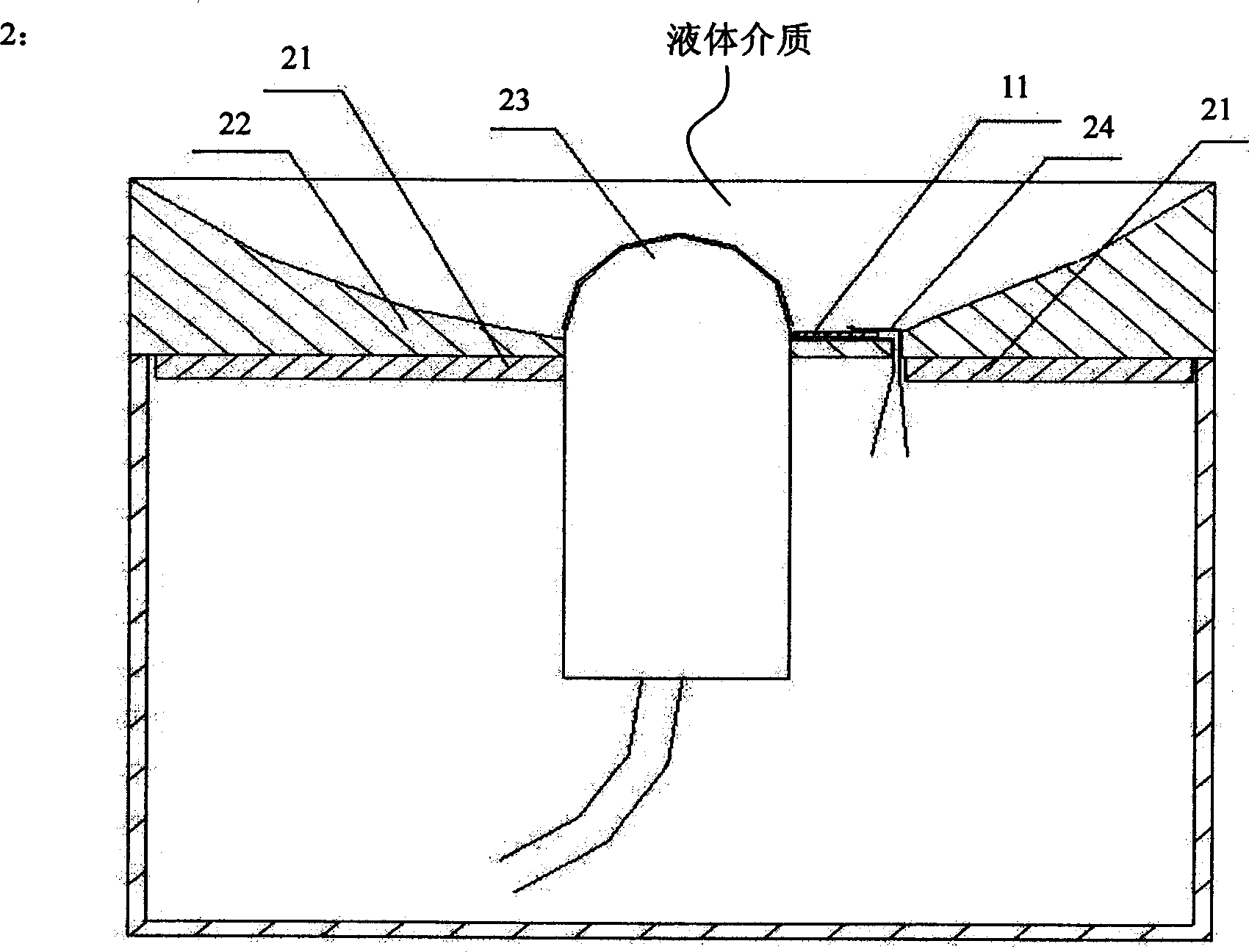

Mist generator and mist emission rendering apparatus

InactiveUS7934703B2Improve atomization efficiencyImprove overall utilizationSpace heating and ventilationMixing methodsTransducerEngineering

An apparatus includes an ultrasonic transducer; an ultrasonic propagation medium disposed so as to fill a plane of vibration of the transducer; liquid retaining means disposed so as to be in contact with an end face of the medium; and an ultrasonic focusing reflecting mechanism disposed in an ultrasonic propagation path, thereby the apparatus attains discharging into air and atomization of the liquid by use of ultrasonic waves. Atomization efficiency is enhanced by the use of an ultrasonic reflection tube, and mist emission is carried out. Use is made of a compact liquid container equipped at its bottom with an ultrasonic transmission membrane. Various types of liquids can be atomized by changing the direction of ultrasonic course.

Owner:TOMONO AKIRA

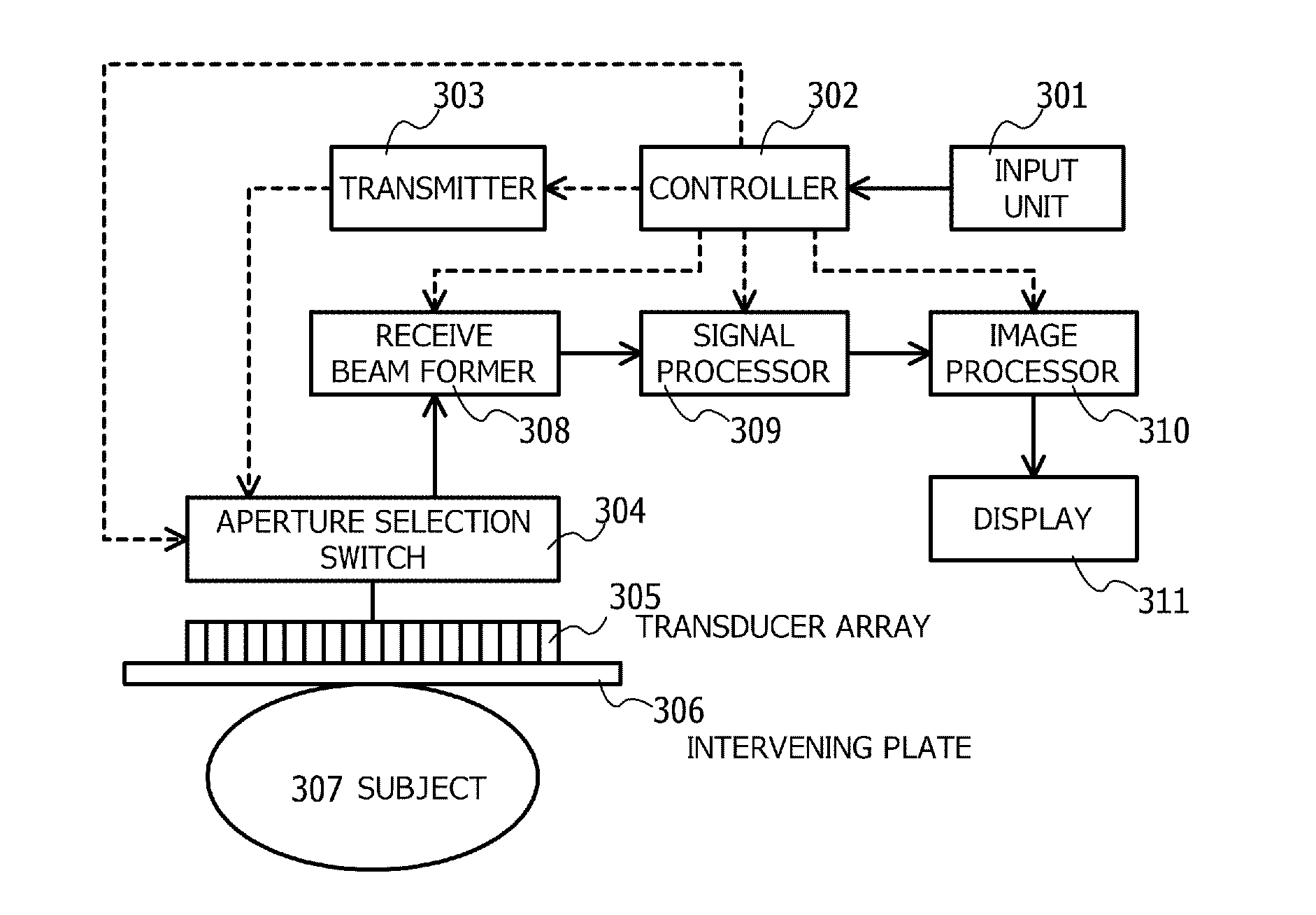

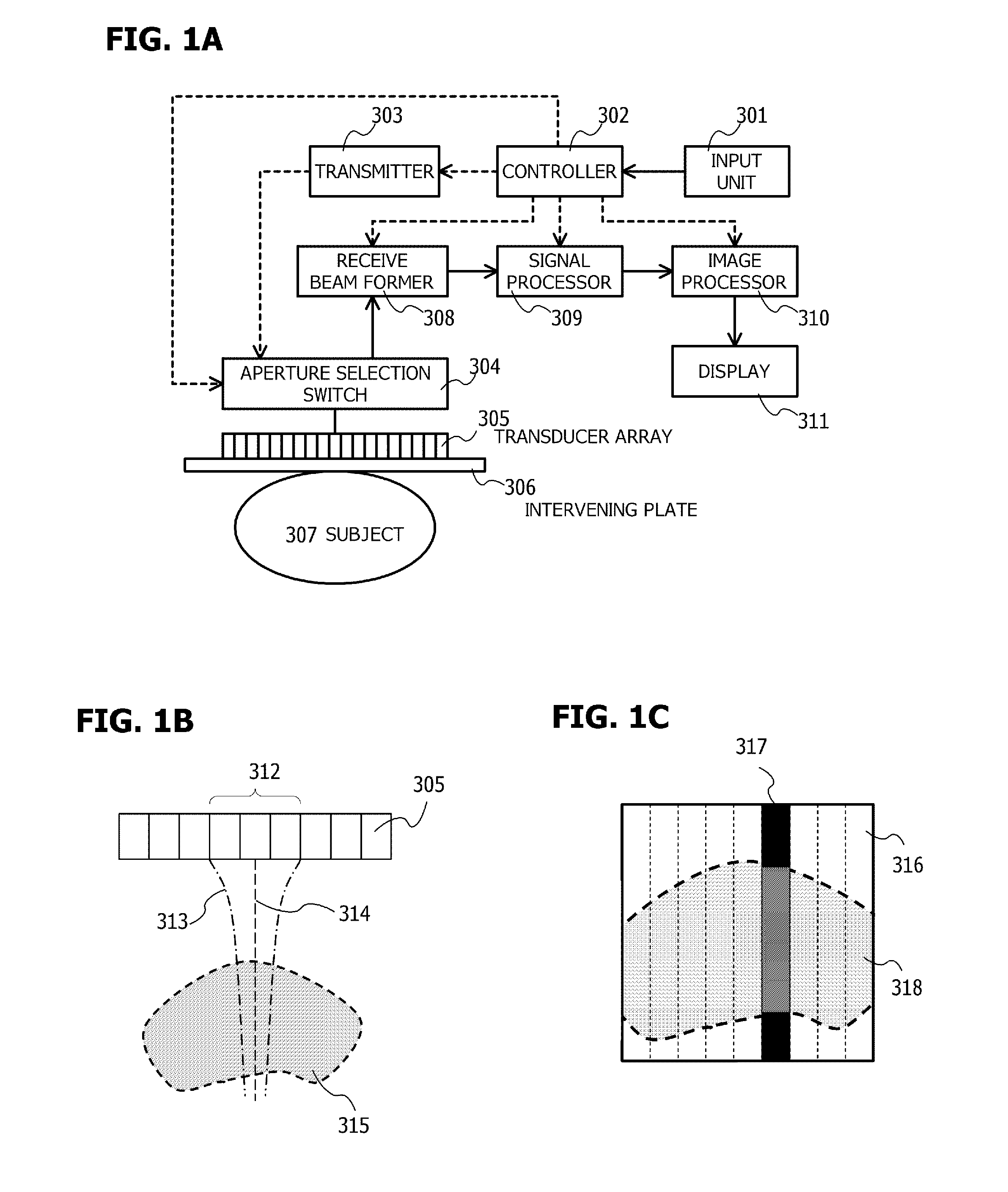

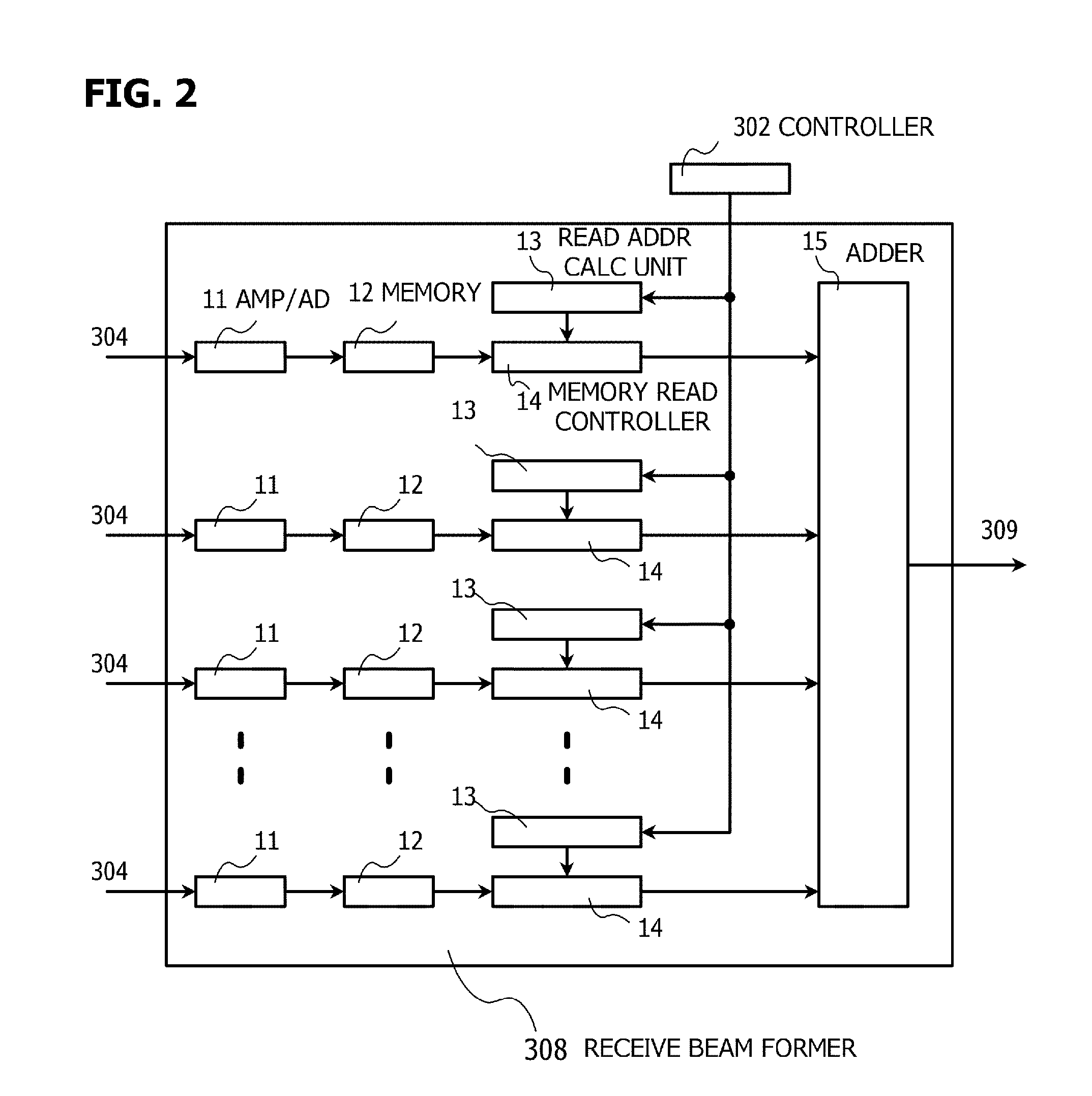

Ultrasonic imaging apparatus and method of controlling delay

ActiveUS20120281902A1Easy to installEasy to packWave based measurement systemsCharacter and pattern recognitionSonificationPropagation time

The present invention enables ultrasonic propagation time values after correction of refraction to be calculated in parallel for each receive channel, by using a recurrence relation in the depth direction. Moreover, accumulation of errors can be avoided by using an accurate propagation time value obtained in advance at a reference depth to correct the propagation time value each time the reference depth is reached. For this error correction, the recurrence relation to calculate the propagation time value can be an approximate expression. For example, the propagation time value can be calculated using the inclination of reference propagation time values between reference depths. In an actual circuit, received signals are sequentially stored in a memory, and a receive beam is formed by calculating an address position corresponding to the propagation time value of the ultrasonic wave, and adding the received signals stored in the calculated addresses.

Owner:CANON KK

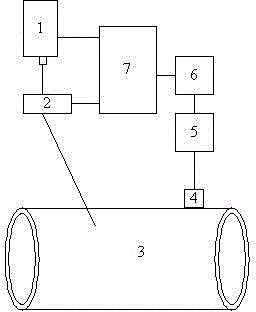

Flow measuring apparatus

ActiveUS8141434B2Reliable and accurate measurementImprove energy transferFlow propertiesVolume flow measuring devicesPropagation timeUltrasonic radiation

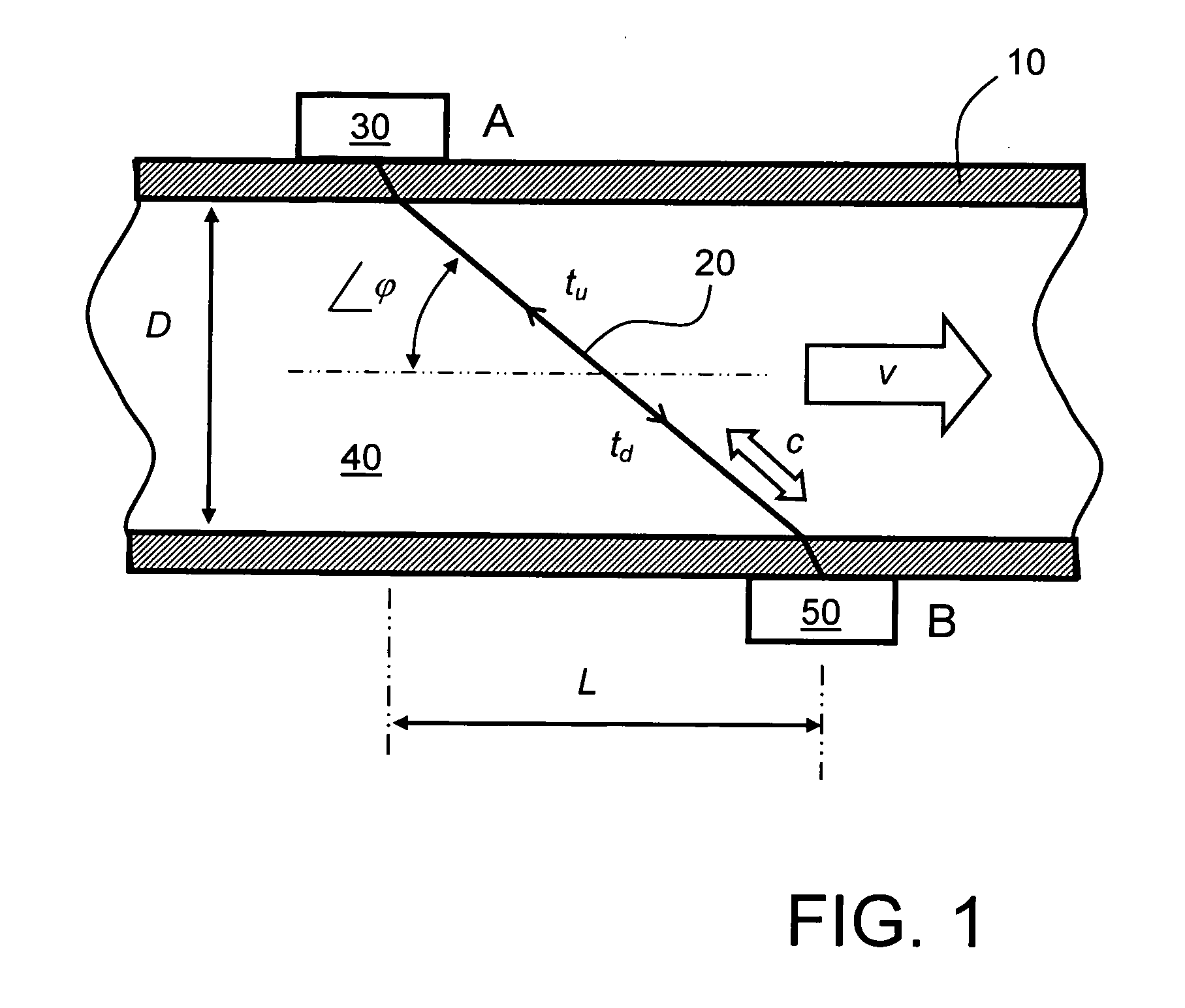

A flow measuring apparatus measures a fluid flow within a conduit including a wall. The apparatus includes a transducer arrangement including at least two transducers for alternately emitting and receiving ultrasonic radiation through the conduit wall and the flow. The apparatus also includes a signal processing arrangement for generating signals to excite the transducer arrangement and for processing received signals provided by the transducer arrangement for generating output signals from the signal processing arrangement indicative of properties of the flow. The transducer arrangement in cooperation with the conduit provides a first path for Lamb-wave ultrasonic radiation coupling directly from a first of the at least two transducers, to a second of said at least two transducers to generate a first received signal. The transducer arrangement in cooperation with the conduit provides at least one second path for ultrasonic propagation along the wall via Lamb waves coupling to at least a portion of the flow from a first of the at least two transducers to a second of the at least two transducers to generate a second received signal. The signal processing arrangement determines from said first and second received signals ultrasonic radiation propagation time periods through the first path and through the at least one second path, and to perform computational operations on the propagation time periods to determine properties of the flow including, but not limited to, at least one of: fluid flow velocity (v) in the conduit, a sound velocity (c) through the fluid.

Owner:XSENS

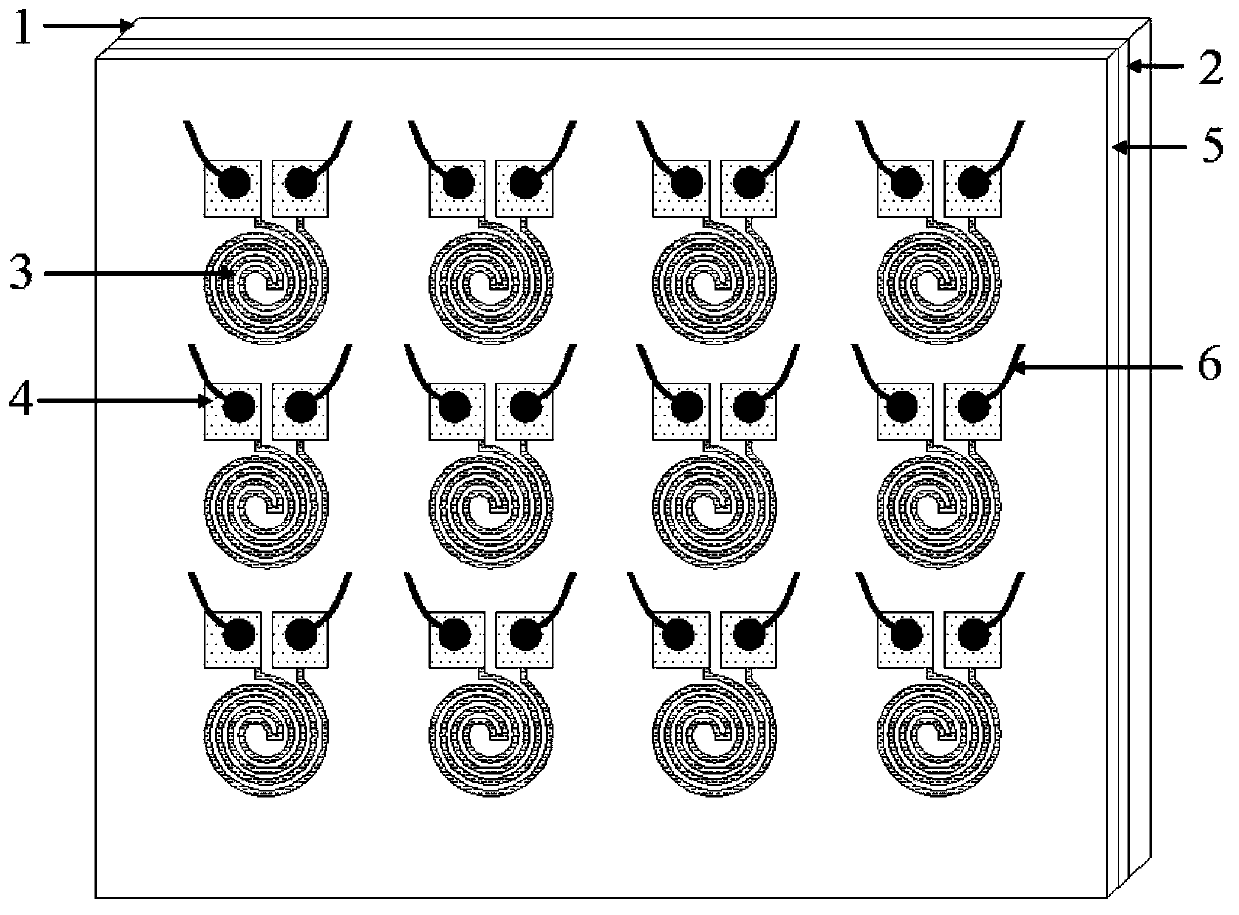

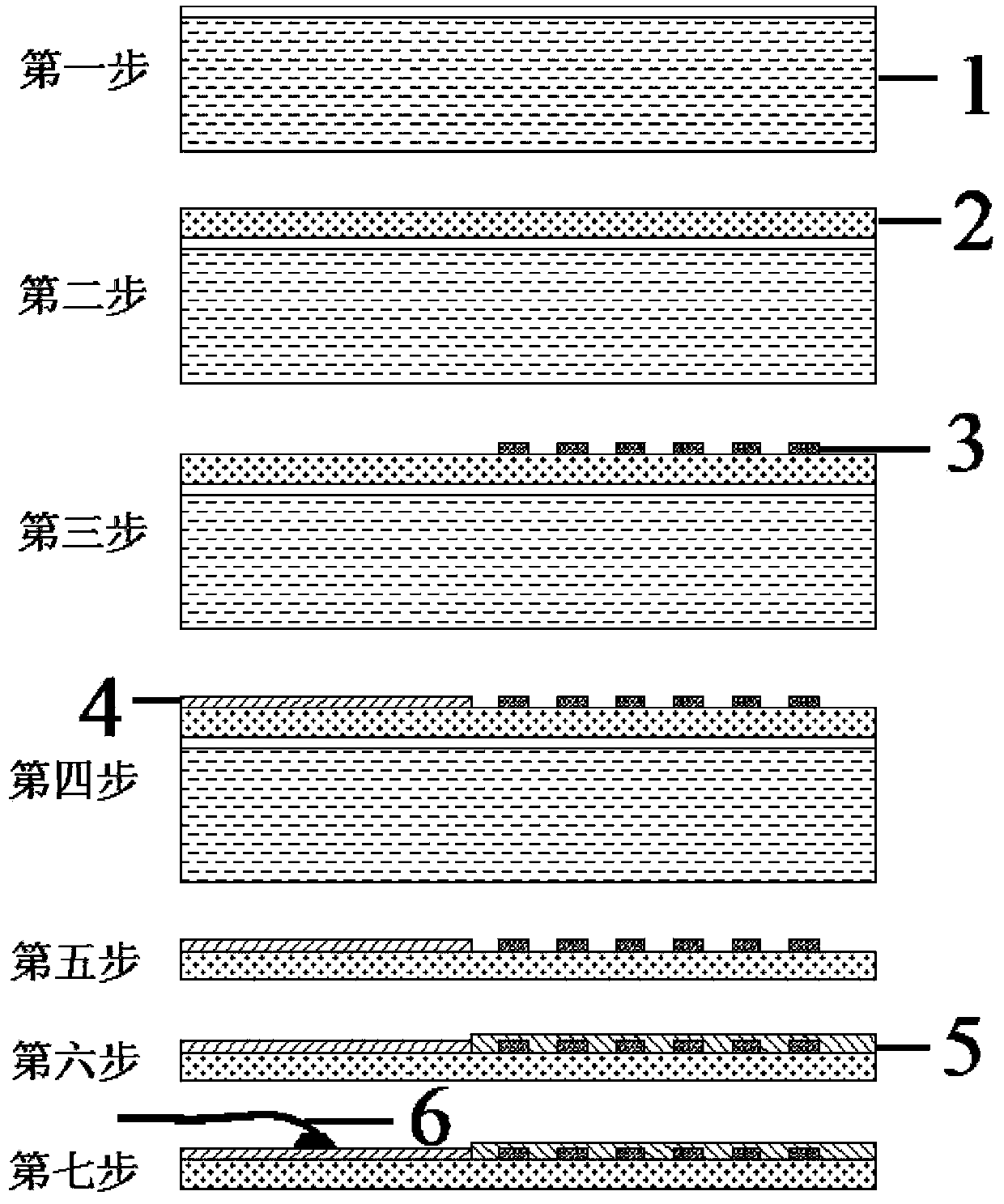

Flexible resistance-type MEMS (micro-electro-mechanical systems) temperature sensor array and preparation method thereof

ActiveCN103385699AAvoid measuringHigh ultrasonic propagation velocityDiagnostic recording/measuringSensorsSensor arrayElectrical conductor

The invention provides a flexible resistance-type MEMS (micro-electro-mechanical systems) temperature sensor array and a preparation method thereof. The sensor array comprises a fixed substrate, a flexible substrate film, a temperature sensitive film, sensor electrodes, a flexible covering layer and electrical conductors. A preparation method for the sensor array comprises the following steps of forming a metal sacrificial layer on the upper surface of a fixed substrate material in a sputtering or thermal evaporation manner, performing spin coating on the sacrificial layer with PI (polyimide), preparing the temperature sensitive film, preparing sensor electrode arrays, preparing the covering layer PI film, imaging the covering layer PI film, peeling off flexible sensors and welding the electrical conductors. The sensor array provided by the invention has biocompatibility, stronger mechanical property, high-temperature resistance, high temperature impact resistance and higher ultrasonic propagation speed. Sizes and shapes of the sensitive film and sensor electrode points can be controlled by exposure, and the temperature field distribution of a skin surface can be measured in real time. The preparation method for the sensor array is simple and reliable and low in cost, and can be realized by adopting a micromachining process.

Owner:SHANGHAI JIAO TONG UNIV

Ultrasonic apparatus and method for measuring the concentration and flow rate of gas

ActiveUS20060185443A1Accurate measurementAnalysing solids using sonic/ultrasonic/infrasonic wavesVolume/mass flow measurementUltrasound devicePropagation time

An ultrasonic apparatus measures the concentration and flow rate of a sample gas by calculating a possible propagation time range on the basis of the gas temperature, determining whether or not the phases at which two first trigger signals, respectively generated on the basis of forward and backward waveforms of the ultrasonic waves, coincide with each other, processing the zero-cross signals so that the phases coincide with each other, obtaining reference zero-cross time instant by calculating mean value of the forward and backward zero-cross time instants, obtaining an ultrasonic reception point by subtracting an integral multiple of the cycle of the ultrasonic waves so that the results of the subtraction falls into a possible propagation time range and estimating the ultrasonic propagation time on the basis of the ultrasonic reception point.

Owner:TEIJIN LTD

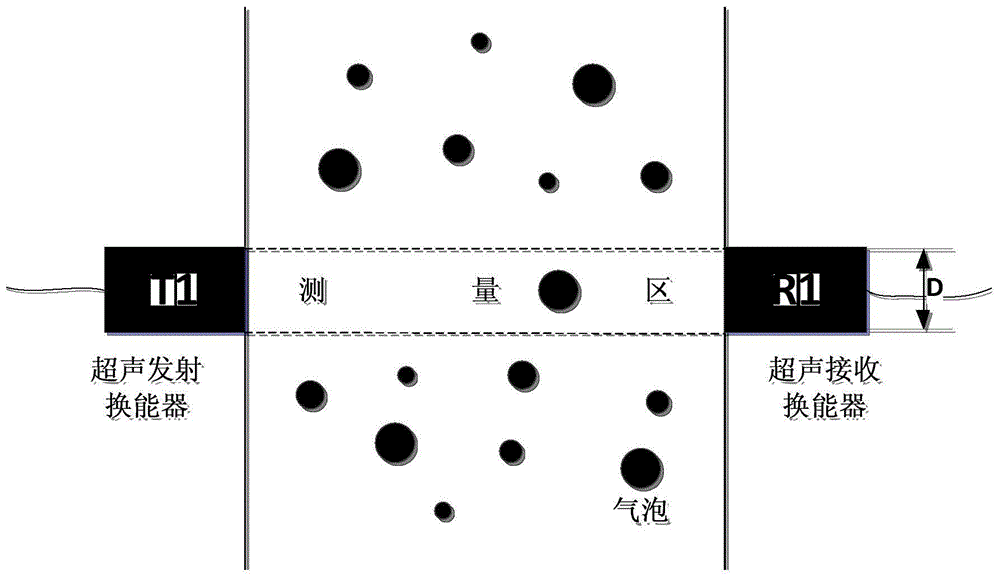

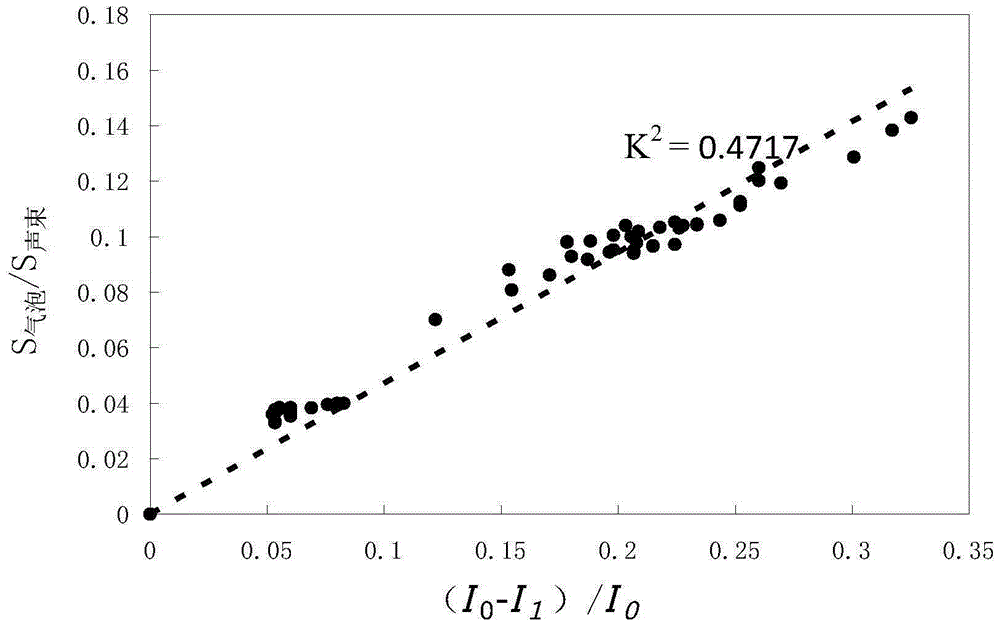

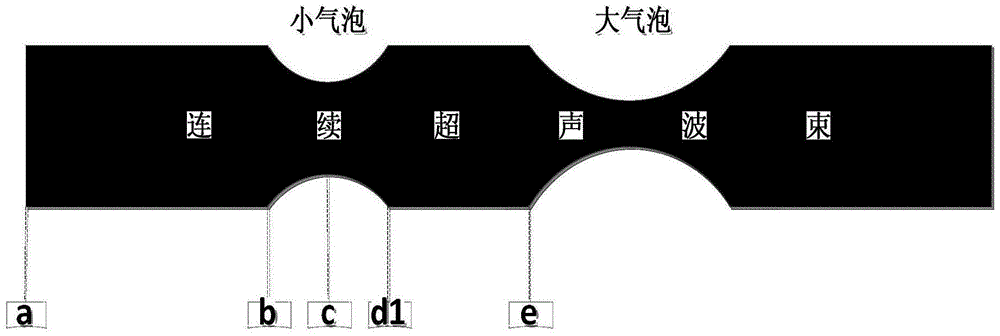

Method for measuring bubble size, bubble number and bubble movement velocity in gas-liquid two-phase flow

InactiveCN105222833ARealize detectionSimple structureMeasurement devicesCapacitanceUltrasound attenuation

The invention relates to a method for measuring the bubble size, the bubble number and the bubble movement velocity in a gas-liquid two-phase flow. During the ultrasonic propagation process in the fluid, no significant energy attenuation occurs during the propagation process. During the ultrasonic propagation process in the gas-liquid two-phase flow, the acoustic impedance of the gas is much smaller than that of the liquid, so that the energy loss is caused. Through detecting the attenuation degree and the attenuation time of ultrasonic waves, the particle size of gas bubbles and the movement velocity of gas bubbles can be determined. In this way, the number of gas bubbles in a measurement region within a certain period of time can be obtained. The measurement system is simple in structure and low in equipment cost, which can realize the on-line measurement. The method is applied to the scientific research in a laboratory, and is particularly applicable to applications at an industrial site. Compared with gas bubble measurement methods based on other principles, such as the capacitance method, the photoelectric method and the like, ultrasonic waves are stable in performance, free from being interfered by the circuit, strong in penetrating power and capable of being propagated in optically opaque media. The above method is fast in measurement speed, easy to measure and good in data automation, thus having significant advantages.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

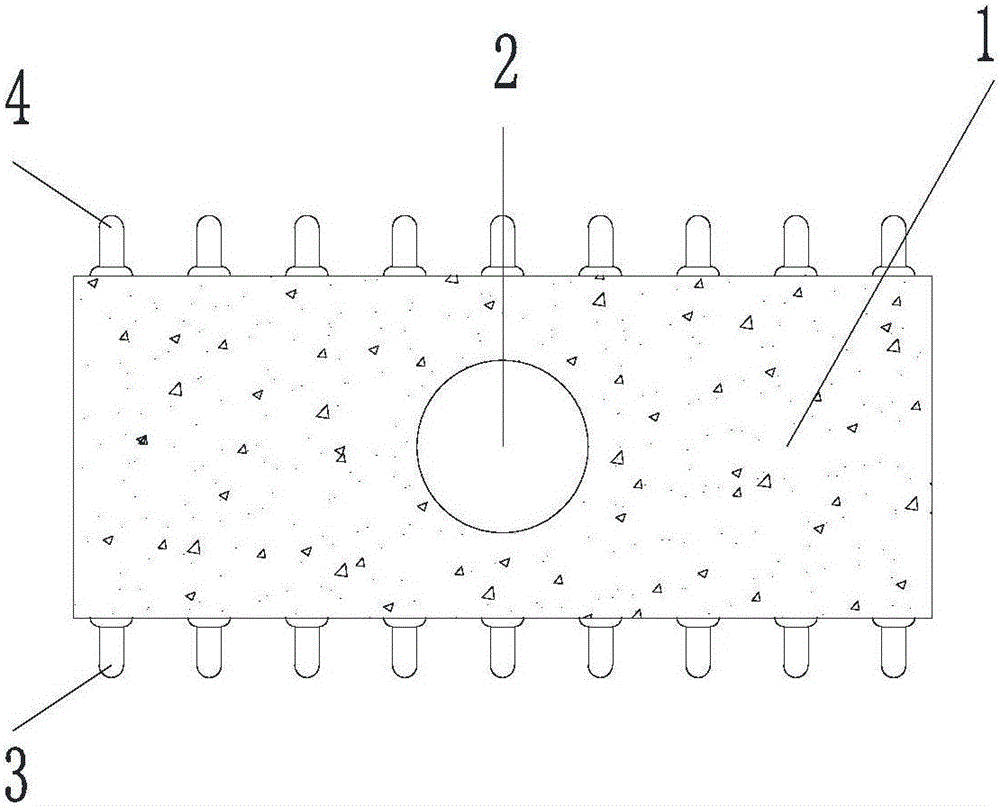

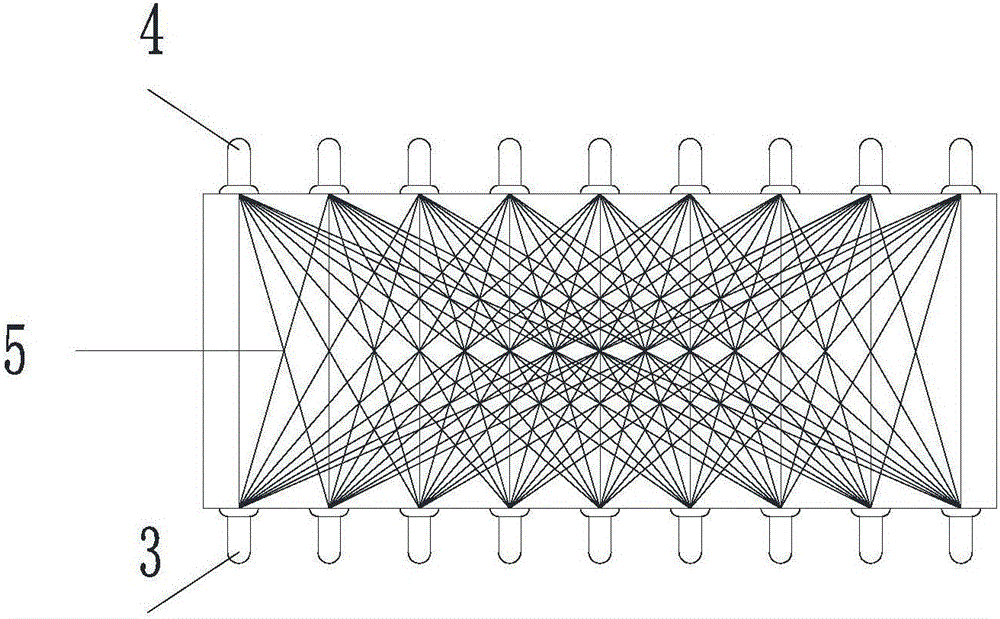

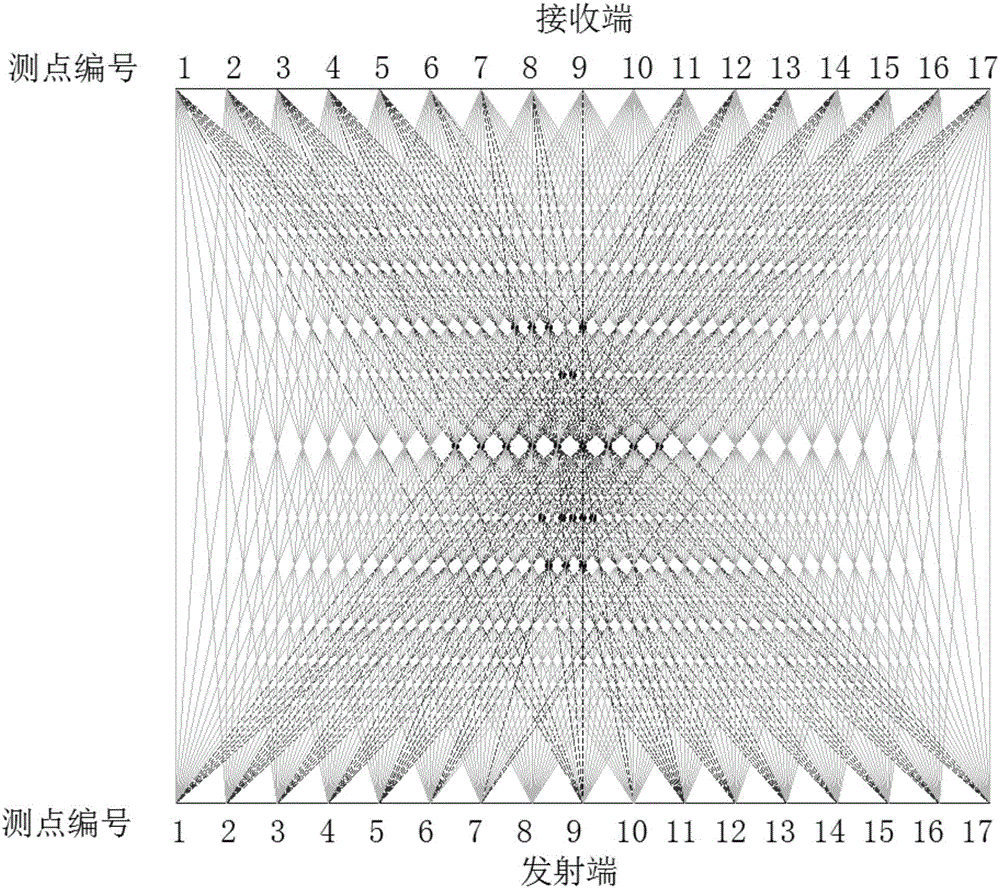

Ultrasonic wave based concrete density assessment method

ActiveCN106124632AAccurate Wave Velocity DistributionAchieve losslessAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalUltrasonic attenuationQuantitative assessment

The invention discloses an ultrasonic wave based concrete density assessment method. When first wave sound at a detection point set for ultrasonic detection is utilized, a distribution diagram of the sound velocity inside concrete is then determined, suspected voids or non-dense zones in the distribution diagram are marked, an ultrasonic CT forward simulation model is established, an ultrasonic propagation path is obtained based on a shortest-path ray tracing method, inversion is performed for quantitative assessment of the sizes of the voids or the non-dense zones inside the concrete. Compared with a traditional ultrasonic CT method, the testing accuracy of the method is higher, a two-dimensional image is introduced, the internal defects of the concrete is reflected clearly, and the ultrasonic wave based concrete density assessment method has wide popularization prospect.

Owner:SHANDONG UNIV +1

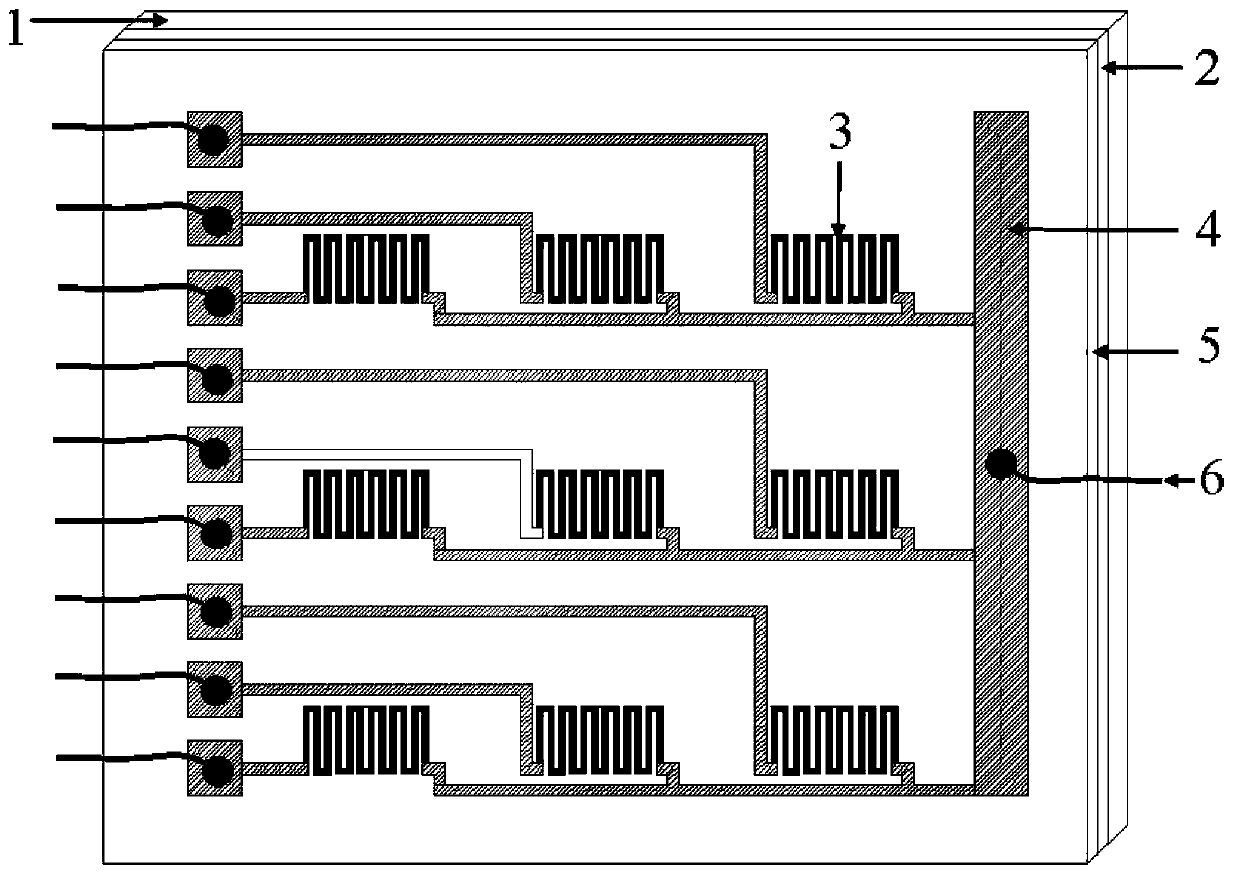

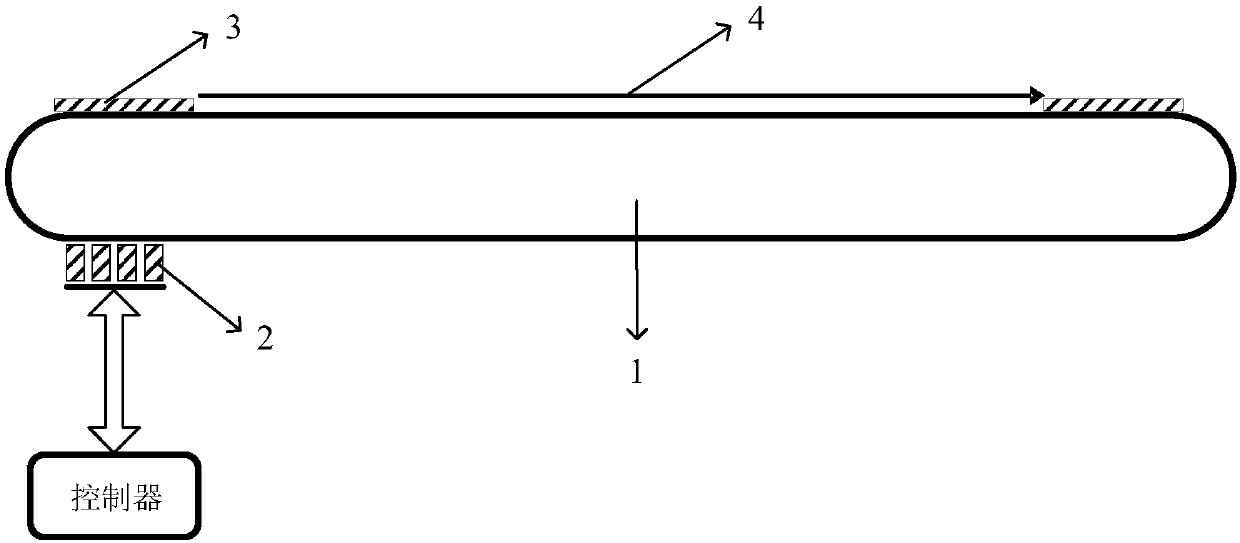

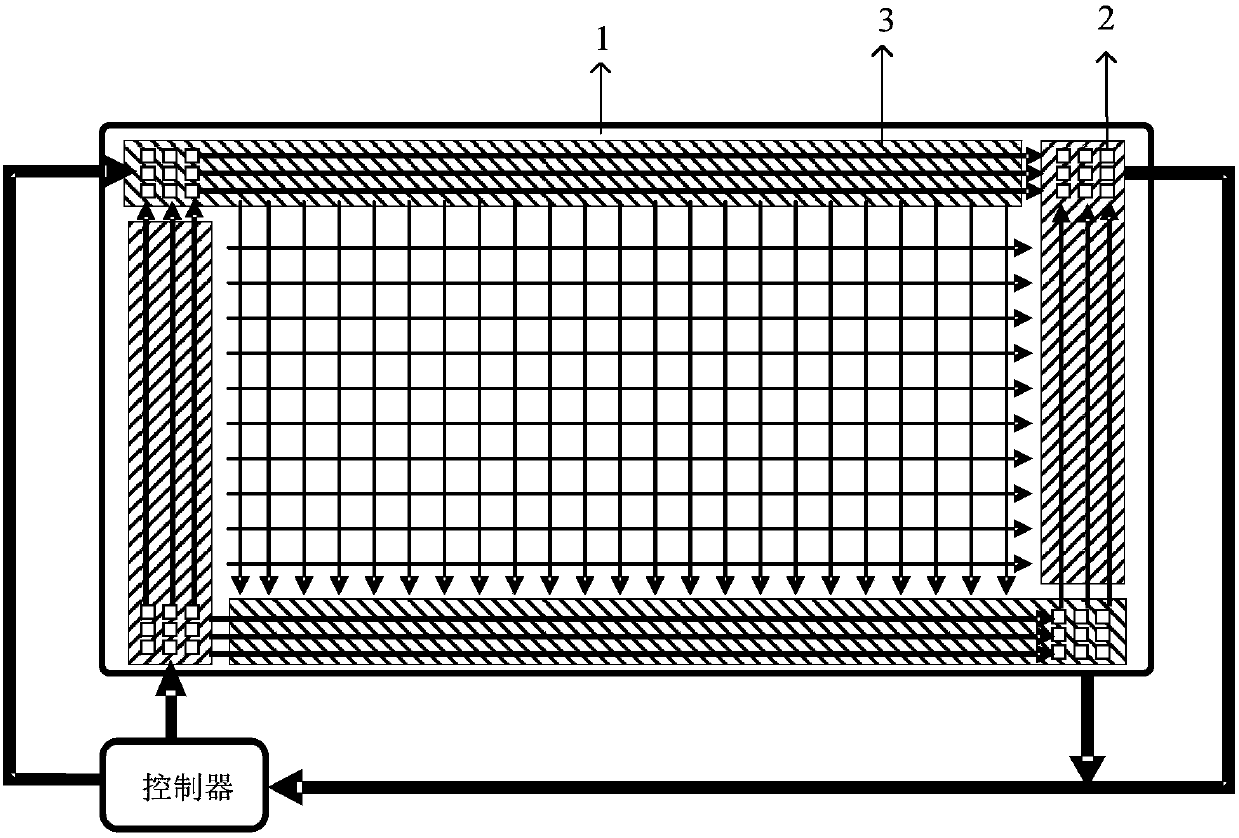

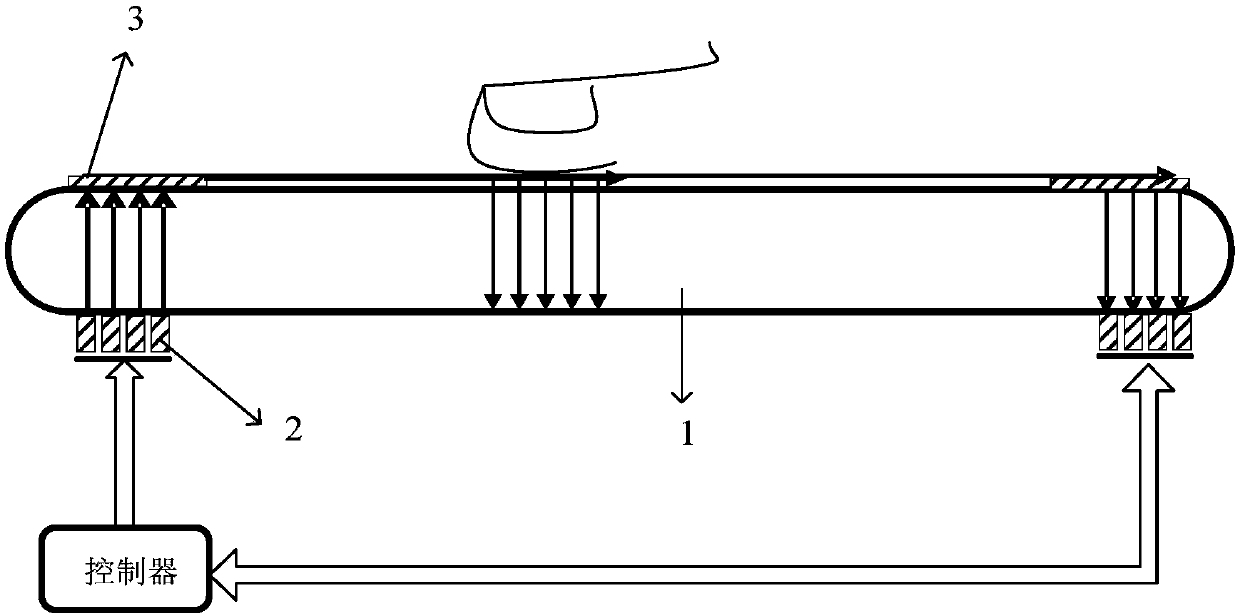

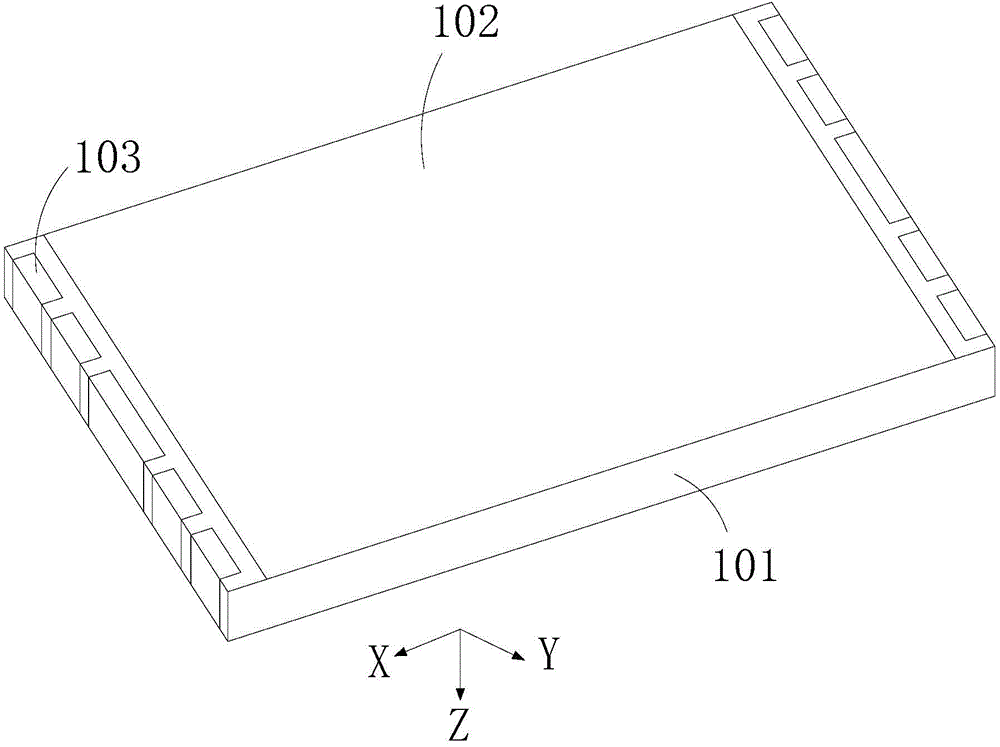

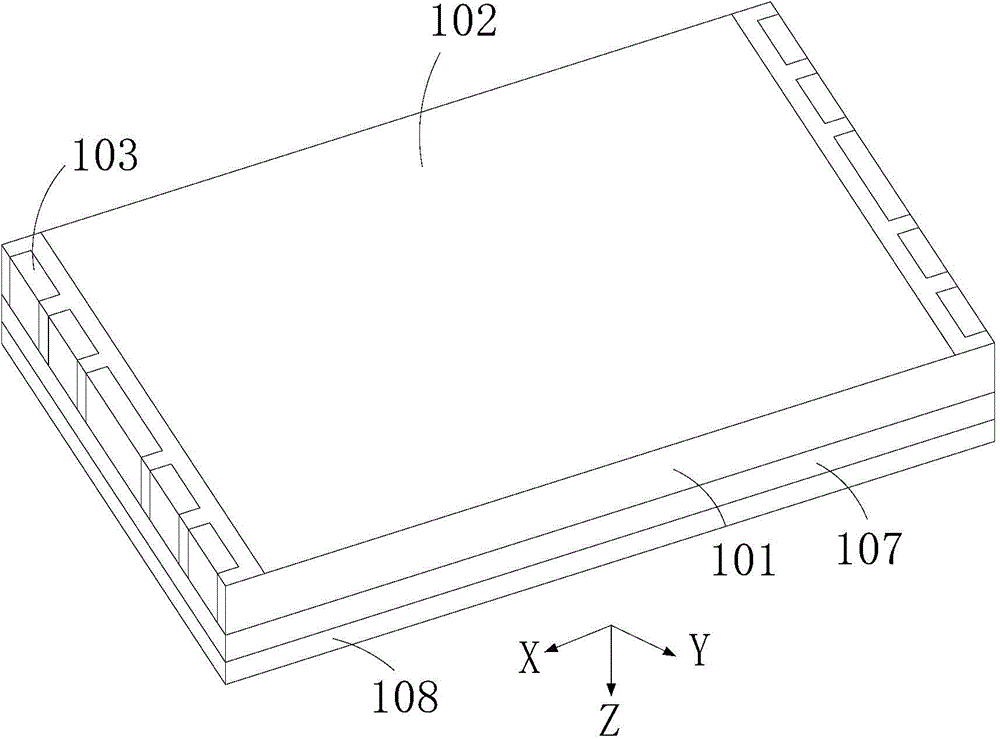

Ultrasonic touch screen system

PendingCN107665068AIncrease fingerprint biometric identification functionEnsure safetyInternal/peripheral component protectionDigital data authenticationFingerprintElectricity

The invention provides an ultrasonic touch screen system. The system comprises a substrate used for propagating ultrasonic, at least one transducer located on the upper side or the lower side of the periphery of the substrate, reflection fringes and a controller; the same transducer is used for receiving and emitting the ultrasonic, wherein the ultrasonic propagated along the surface of the substrate is used for touch recognition and / or fingerprint recognition, and the ultrasonic of which the propagation direction is perpendicular to the substrate is used for fingerprint recognition; the reflection fringes are located on the upper side of the periphery of the substrate and used for changing the ultrasonic propagation direction; the controller is electrically connected with the transducersand used for driving the transducers to vibrate so as to generate the ultrasonic, the transducers convert the received ultrasonic into electric signals, and the controller is used for processing the electric signals.

Owner:成都睿联创想科技有限责任公司

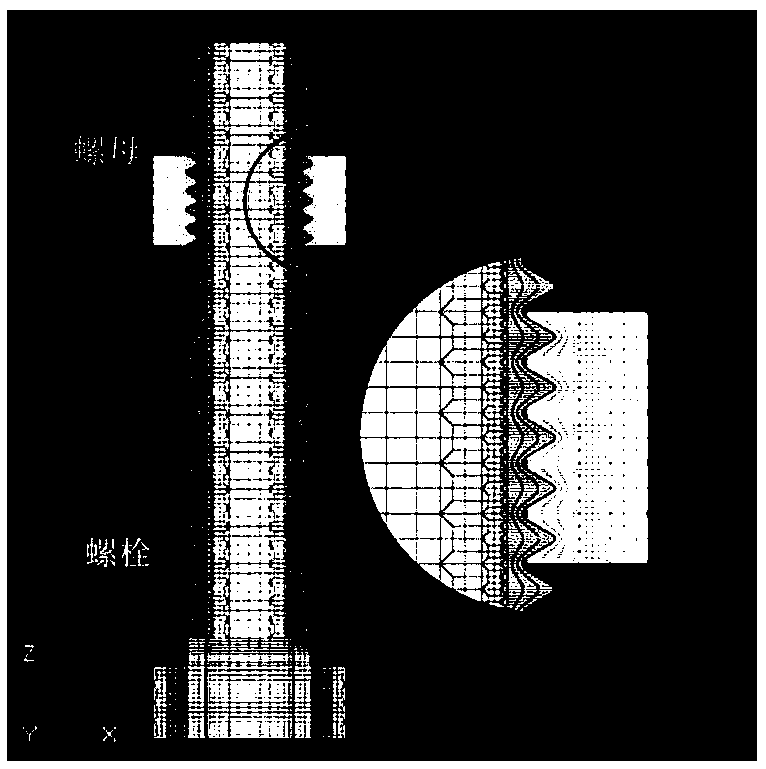

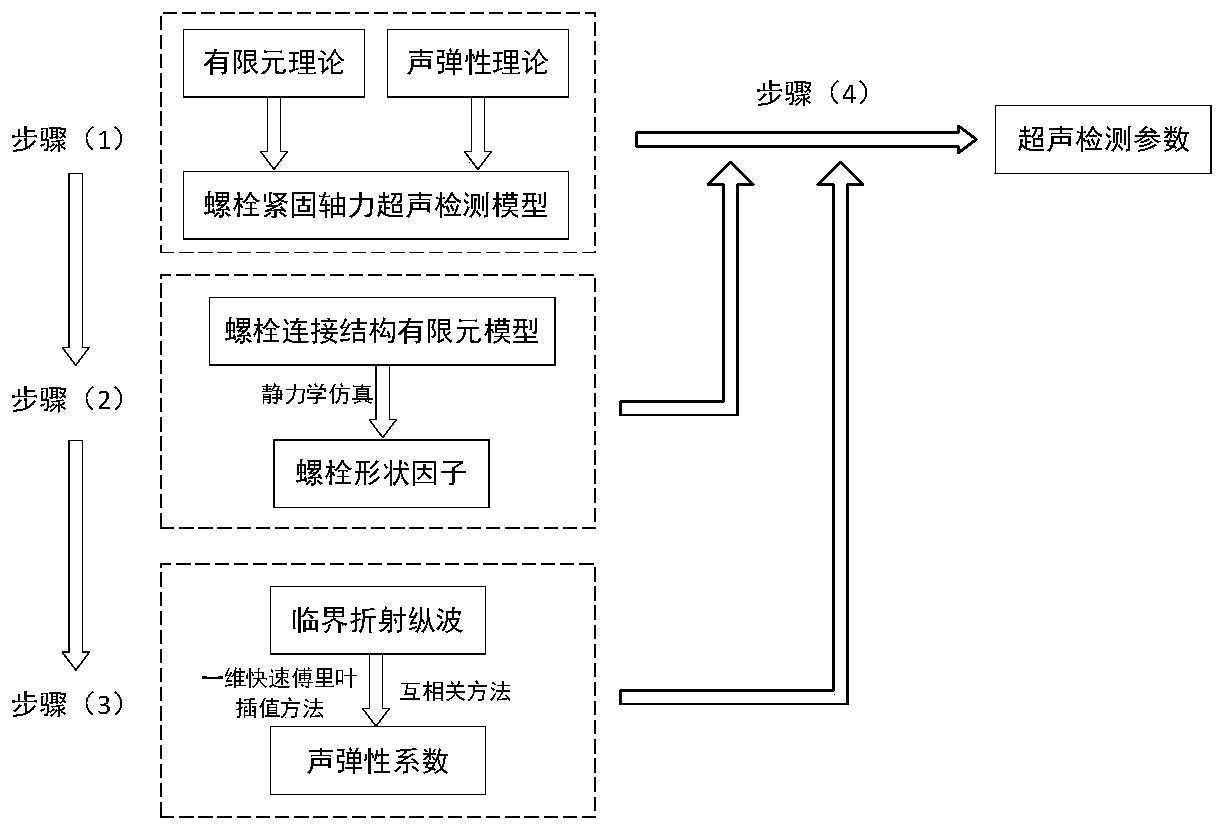

Bolt fastening force ultrasonic detection and key detection parameter determination method based on finite elements

ActiveCN108896230AAccurate detectionImprove practicalityMeasurement of torque/twisting force while tighteningStress distributionElement model

The invention provides a bolt fastening force ultrasonic detection and key detection parameter determination method based on finite elements. The method is suitable for bolting force ultrasonic soundtime nondestructive measurement. The finite element theory and the acoustic elasticity principle are combined, and a bolt fastening force ultrasonic detection principle model is established. A bolt finite element model and a static simulation are established, the bolt axial stress distribution rule on the ultrasonic propagation path is obtained, so that the shape factor of the bolt is determined.The ultrasonic detection coefficient of the bolt fastening force is calculated by combining the acoustic elasticity coefficient of the bolt material measured by the critical refraction longitudinal wave. The method is low in cost and good in adaptability, and the detection coefficient can be accurately and quickly determined.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

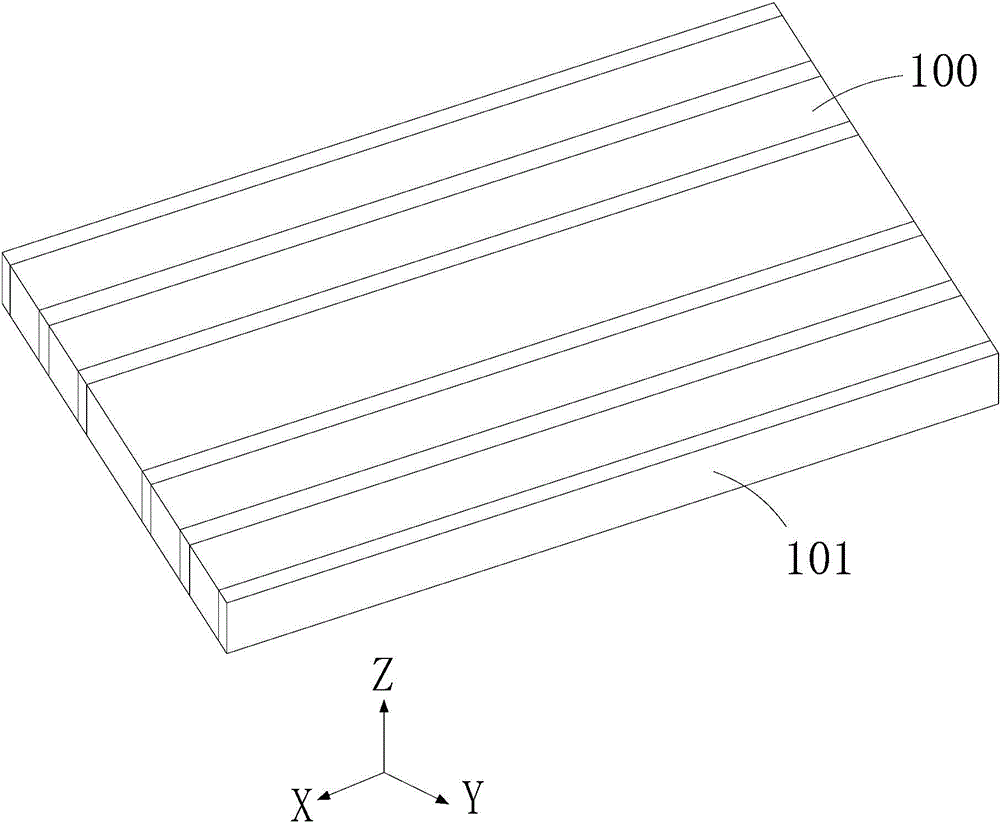

Ultrasonic probe and manufacturing method for ultrasonic probe

ActiveCN104586430ASimple structureIncrease productivityUltrasonic/sonic/infrasonic diagnosticsMaterial analysis using sonic/ultrasonic/infrasonic wavesElectricityUltrasonic imaging

The invention relates to the technical field of ultrasonic imaging equipment and discloses an ultrasonic probe and a manufacturing method for the ultrasonic probe. The ultrasonic probe comprises a piezoelectric crystal plate, wherein row electrodes are arranged on the front surface of the piezoelectric crystal plate; matching layers are pasted to a plurality of rows of electrodes; each row electrode passes through the side wall of the piezoelectric crystal plate and extends to two sides of the rear surface of the piezoelectric crystal plate to form an edge-covering electrode; column electrodes are arranged on the rear surface of the piezoelectric crystal plate; transverse cutting grooves are formed between adjacent row electrodes; longitudinal cutting grooves are formed between adjacent column electrodes; the edge-covering electrodes and the column electrodes are connected to leads; the leads are connected to a circuit board. The ultrasonic probe is simple in structure; the cost and the process difficulty are reduced; the production efficiency of the ultrasonic probe is improved; the batch production is achieved; the condition that the process difficulty of the ultrasonic probe is additionally increased by the introduction of a conductive component can be avoided; the positions of the leads connected to the edge-covering electrodes and the column electrodes are not located on the ultrasonic propagation path; the reduction of the acoustic performance of the probe caused by the introduction of structures such as an electric connection plate is avoided; the imaging effect of the ultrasonic probe is improved.

Owner:EDAN INSTR

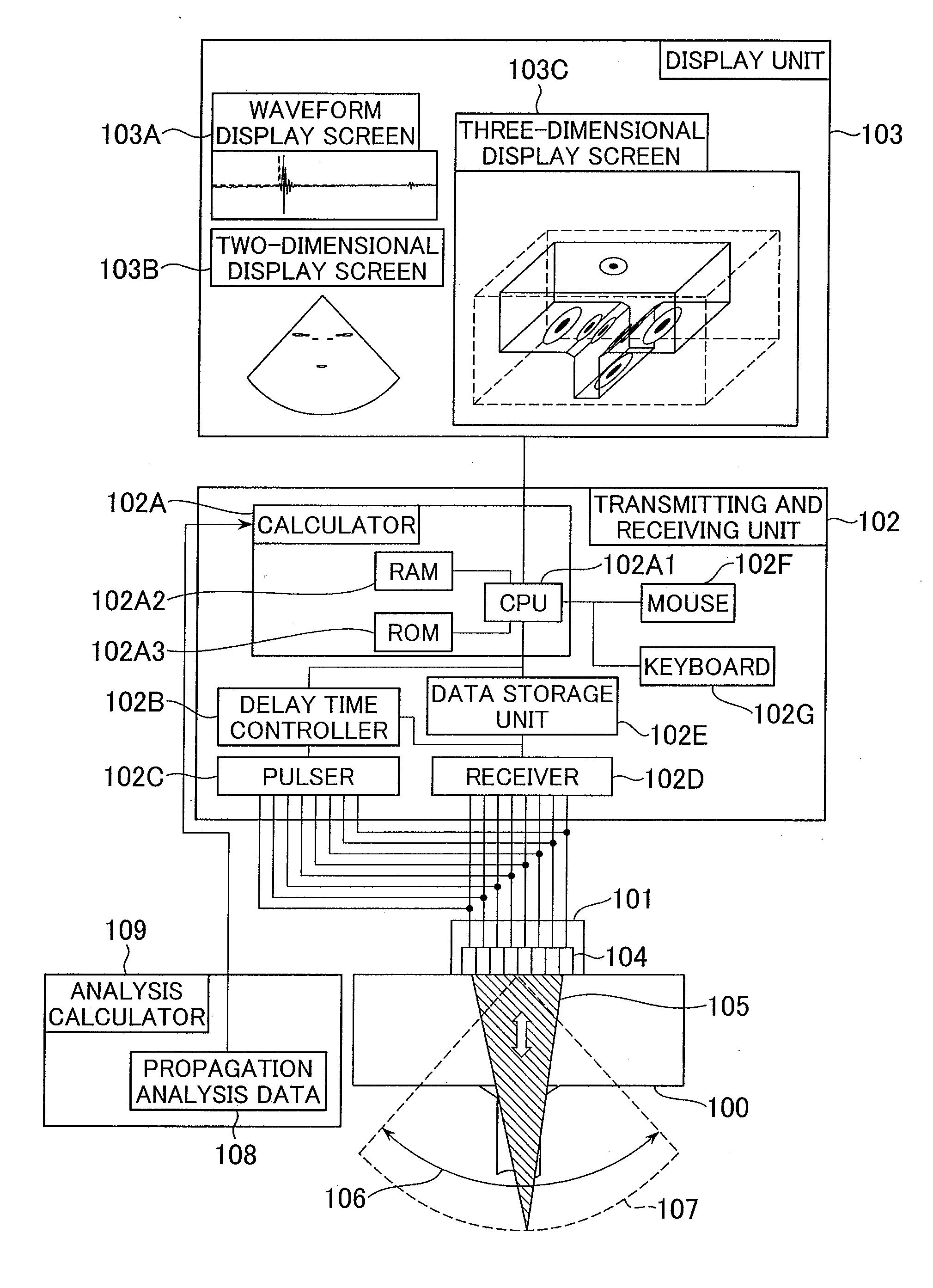

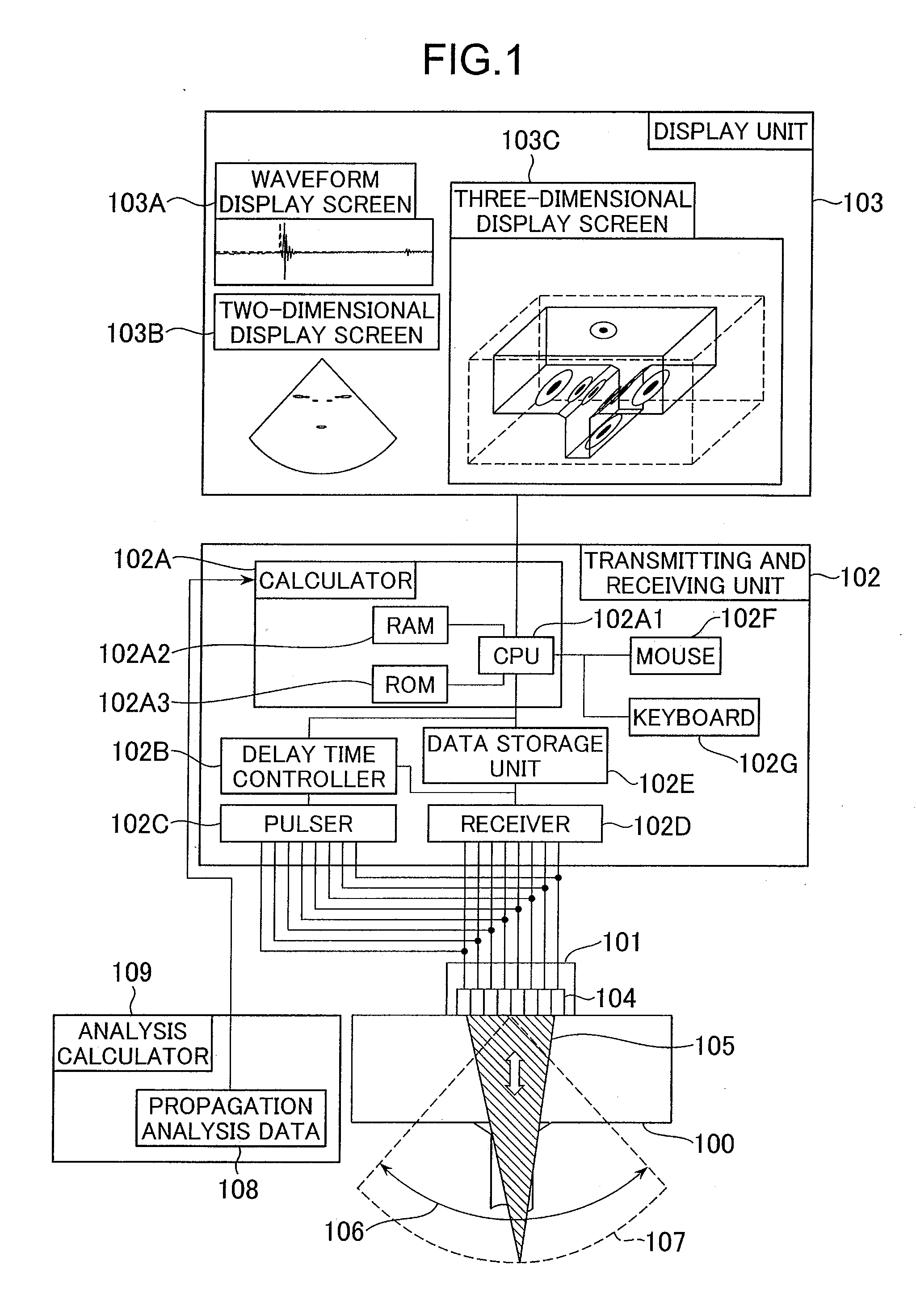

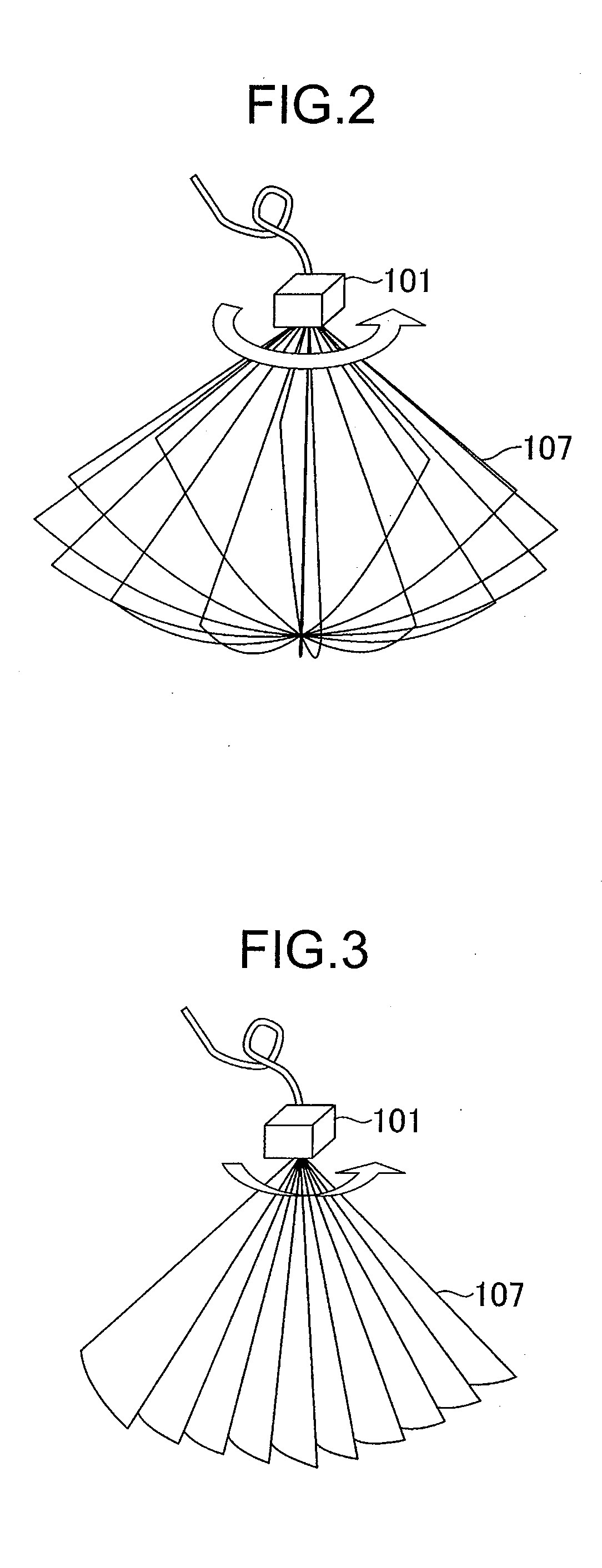

Ultrasonic inspection method and ultrasonic inspection device

ActiveUS20110166807A1Quick identificationAppropriate performanceMaterial analysis using sonic/ultrasonic/infrasonic wavesFlow propertiesThree dimensional shapeUltrasonic propagation

An ultrasonic inspection method and an ultrasonic inspection device allow three-dimensional inspection data and three-dimensional shape data to be appropriately positioned on a display screen and allow a defect echo and a shape echo to be quickly identified even when information on the relative positions of a probe and an object to be inspected is not provided. The ultrasonic inspection data that is generated from the waveforms of ultrasonic waves received by an ultrasonic probe is compared with a plurality of ultrasonic propagation data pieces calculated by a ray tracing method on the basis of the three-dimensional shape data on an object to be inspected. The position of the three-dimensional inspection data or the three-dimensional shape data is moved relative to the other data position on the basis of the comparison results, thereby displaying the three-dimensional inspection data and the three-dimensional shape data while overlapping each other.

Owner:HITACHI-GE NUCLEAR ENERGY LTD

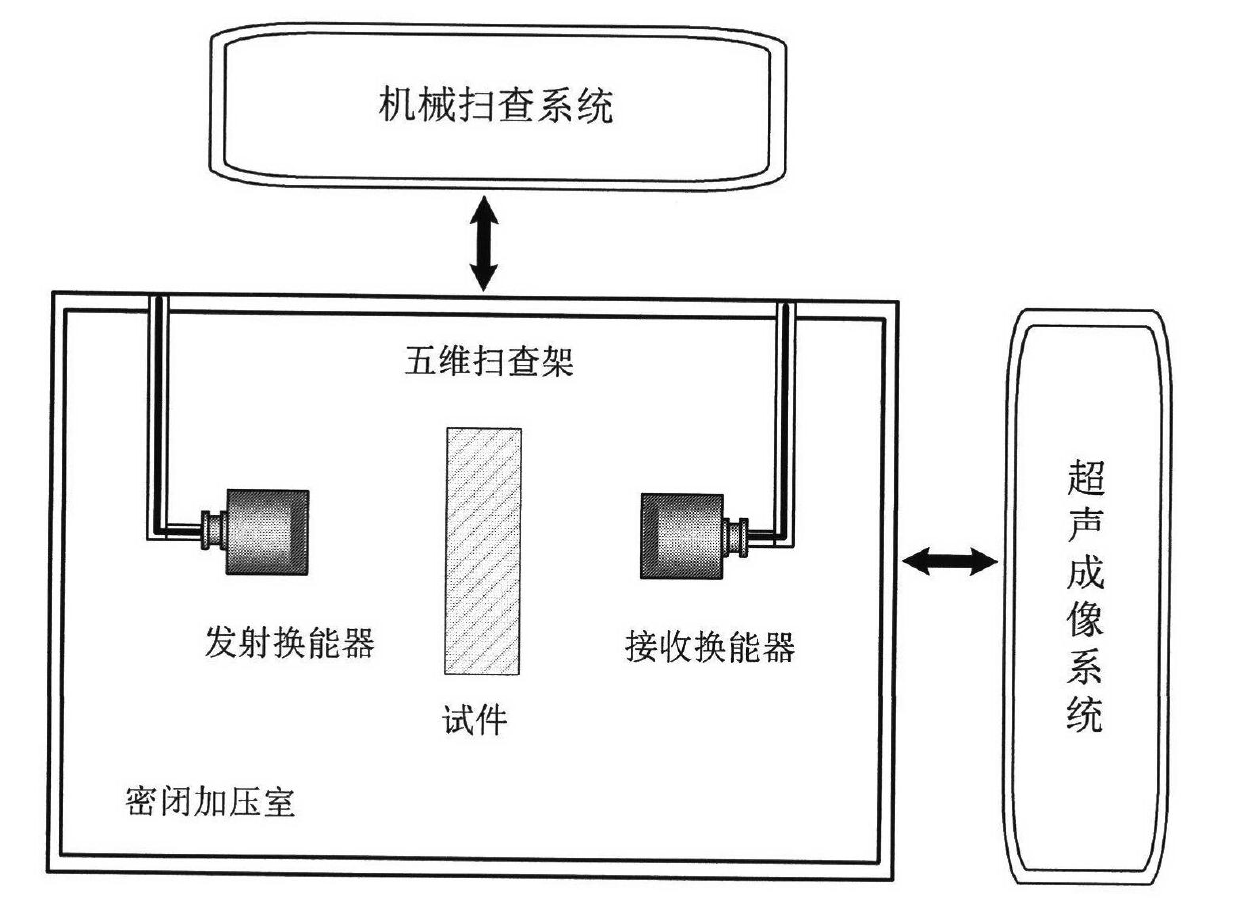

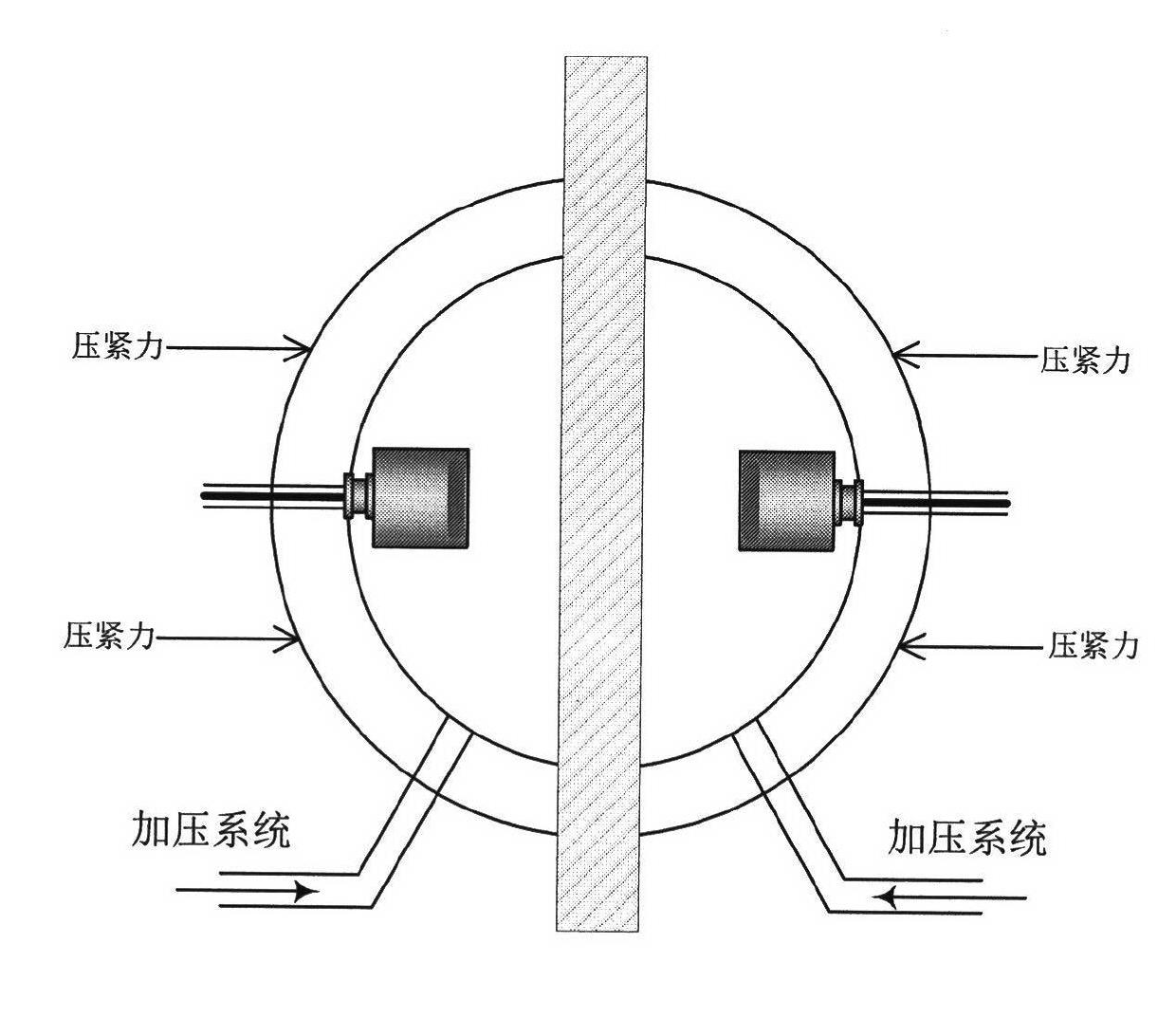

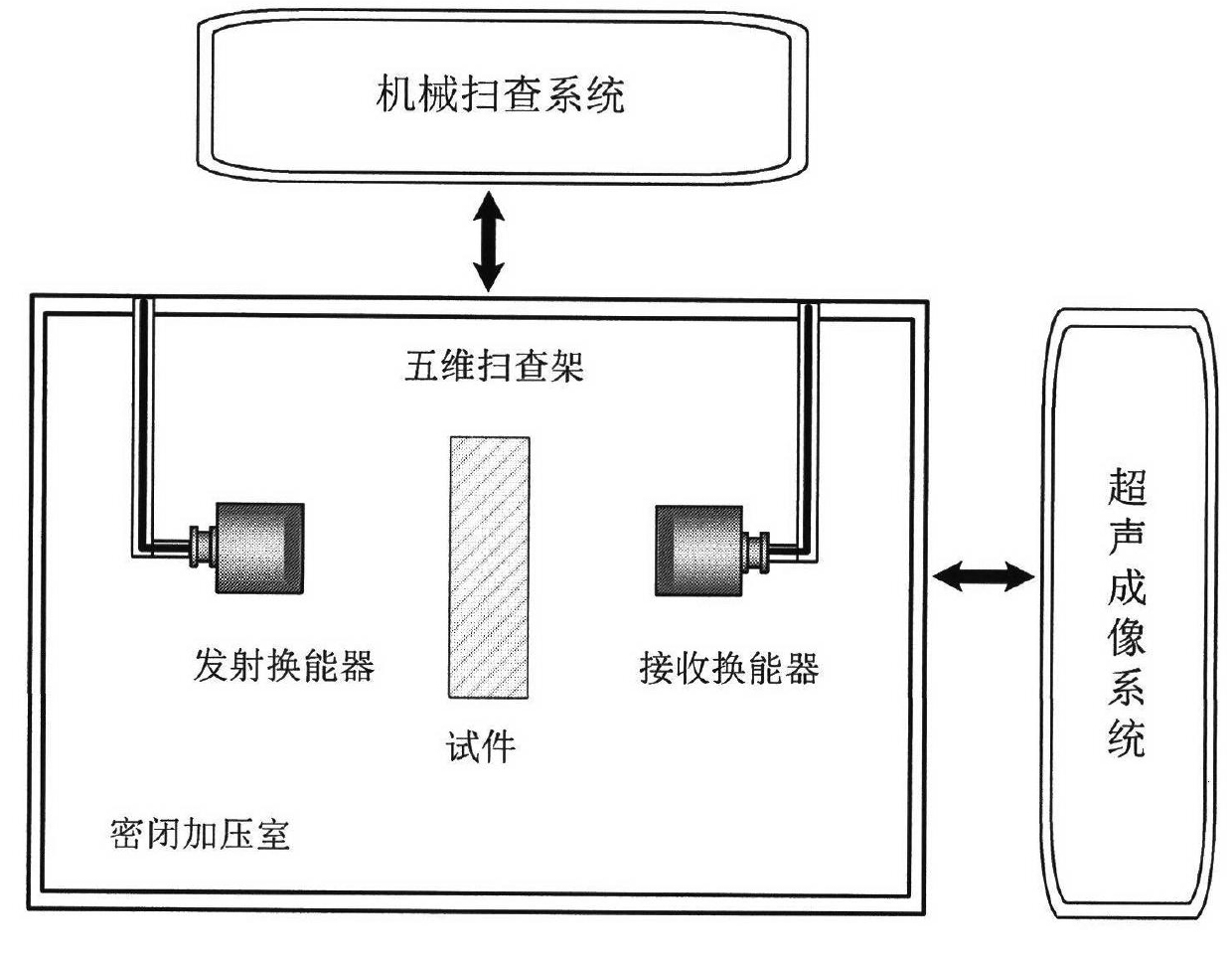

High-pressure-gas-coupled ultrasonic detection method for flaw of composite material

InactiveCN102608214AAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasound attenuationHigh pressure

The invention discloses a high-pressure-gas-coupled ultrasonic detection method for a flaw of a composite material. The high-pressure-gas-coupled ultrasonic detection method for the flaw of the composite material is mainly characterized in that: the attenuation degree in ultrasonic propagation is lowered through changing the pressure intensity of a detection environment (increasing the density of coupled gas in the detection environment) so as to improve the accuracy and the sensitivity in flaw detection. The method has the characteristics of no contact, no penetration and complete no destruction, is flexible and convenient to use, can realize quick online scanning, and has very good application prospects.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

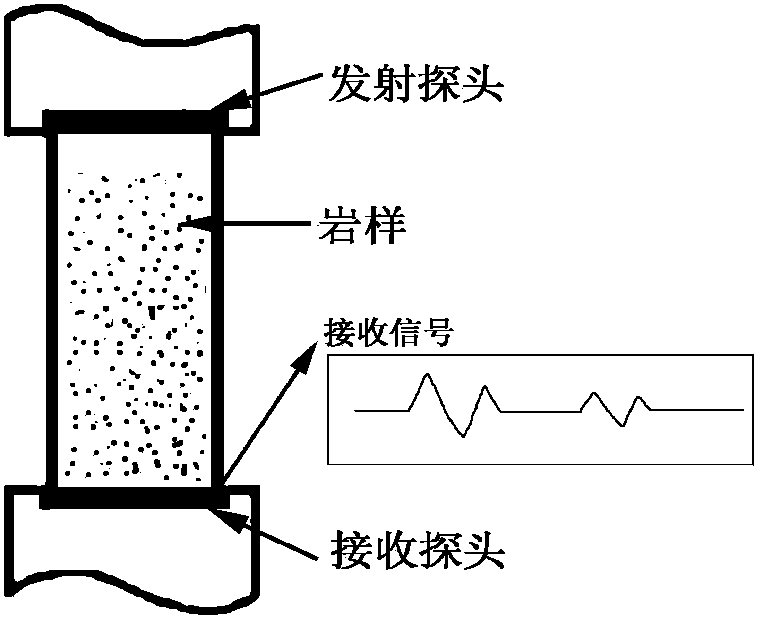

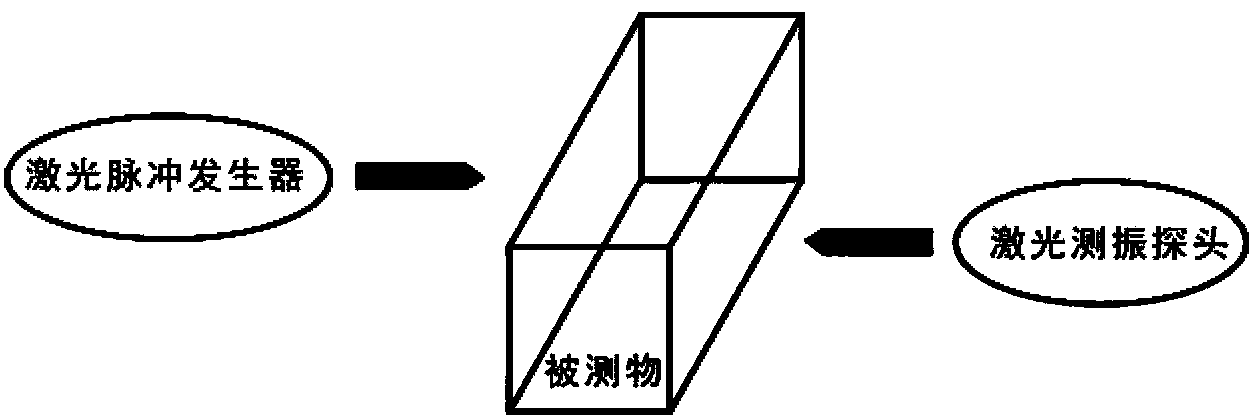

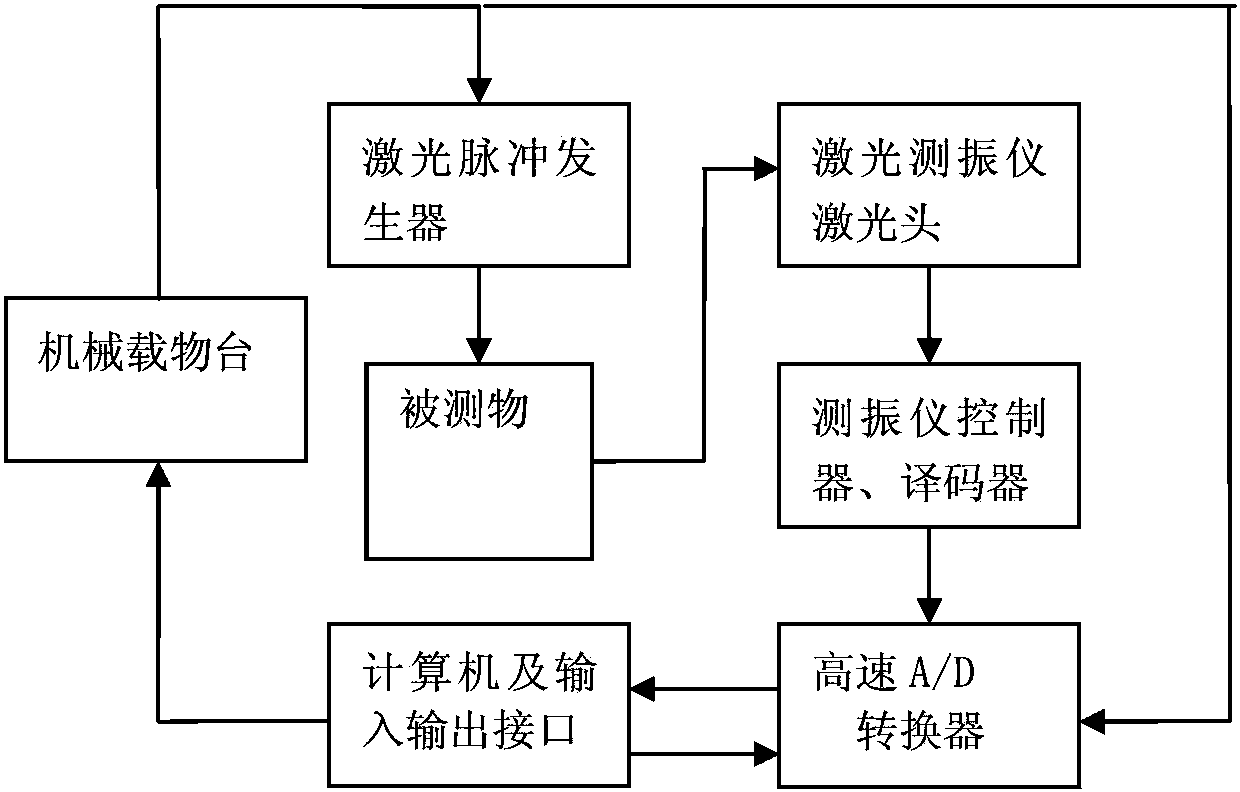

Non-contact rock sound wave speed detection method

InactiveCN104251883AObtaining Sonic Velocity DataHigh reuse rateAnalysing solids using sonic/ultrasonic/infrasonic wavesSignal onUltrasonic propagation

The invention provides a non-contact rock sound wave speed detection method belonging to rock physics research field. The method is as follows: laser pulses produced by a laser pulse generator bombard the surface of a to-be-measured object to form ultrasonic wave in the to-be-measured object, at the same time, a laser vibration measurement instrument laser head is used for detecting vibration signals on the surface of the to-be-measured object on the other side of the to-be-measured object and converting the vibration signals into electrical signals, then ultrasonic wave waveform is drawn according to the electrical signals, and finally, the ultrasonic propagation speed in the to-be-measured object can be calculated according to the first arrival time of the ultrasonic wave. By use of the non-contact rock sound wave speed detection method, laser vibration experiments on a variety of core samples can be performed, rock core sound wave speed data can be obtained without damages to rock core, the rate of repeated use of the rock core is improved, the number of repeated core mining is reduced; sound wave speed value of any position of the rock core can be calculated by the method, a rock core speed field can be established according to the results, and study on anisotropic characteristics of the rock core can be facilitated.

Owner:CHINA PETROLEUM & CHEM CORP +1

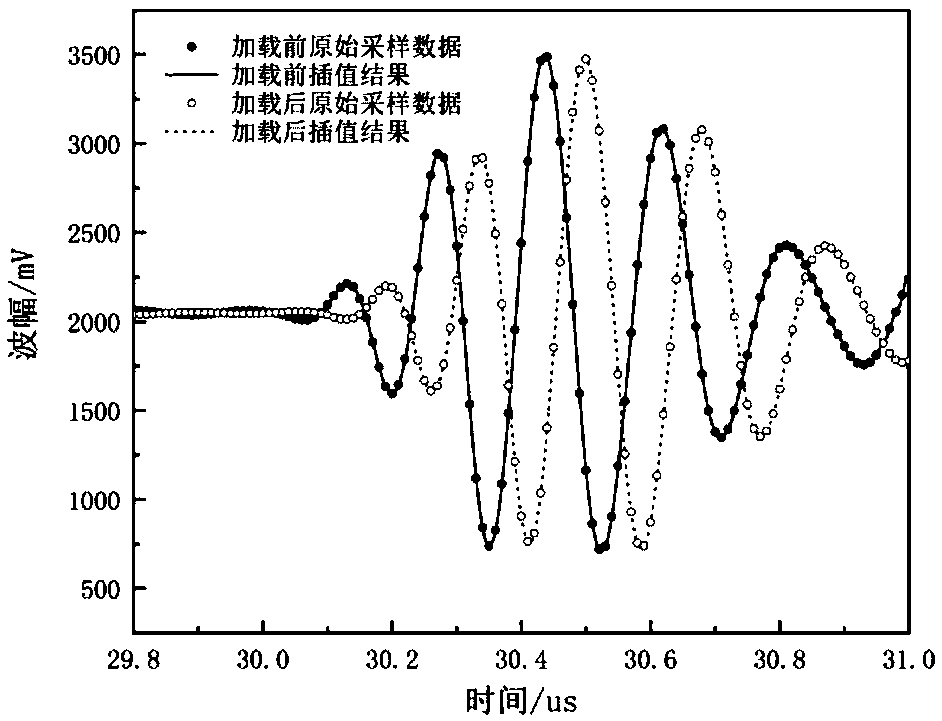

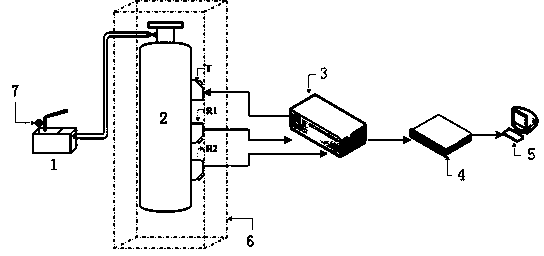

Method for pressure detection of pressure container and based on reflected P-waves and measuring system

The invention discloses a method for pressure detection of a pressure container and based on reflected P-waves and a measuring system. The measuring system comprises the cylindrical pressure container, a manual booster pump, a thermostat, an ultrasonic excitation and receiving device, a high-speed oscilloscope and a computer. The fundamental principle of the method for pressure detection is characterized in that based on the ultrasonic sound elastic principle and the theory of plates and shells, after deduction and simplification, a pressure measuring model based on the reflected P-waves is established, and in other words, the relation between the internal pressure of the pressure container and ultrasonic propagation time delay is acquired; then accurate propagation time delay is acquired based on an FIR digital filter and a cross-correlation algorithm; finally in order to reduce temperature interference, a measuring model with the temperature compensating function is provided, and pressure measuring errors are controlled within a small range. The measuring result shows that compared with other similar measuring methods, flexibility and accuracy are higher, and interference resistance is stronger.

Owner:ZHEJIANG UNIV

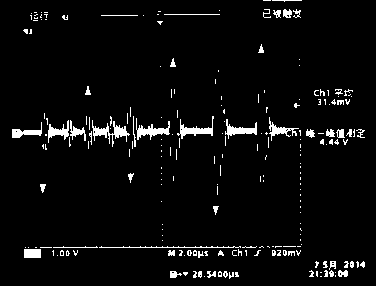

Method for accurately estimating propagation time of ultrasonic flowmeter under noise background

ActiveCN104897248AFast convergenceHigh precisionTesting/calibration apparatusGenetic modelsSonificationPropagation time

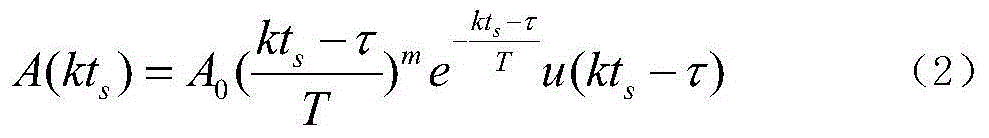

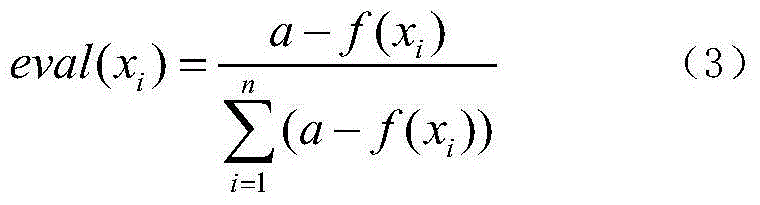

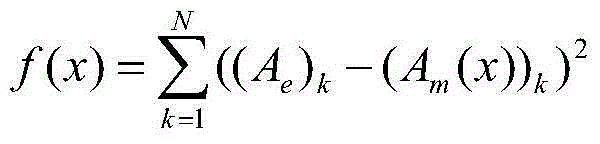

The invention relates to a method for accurately estimating propagation time of an ultrasonic flowmeter under a noise background. The method comprises the steps of experimenting the ultrasonic flowmeter; building an ultrasonic pulse receiving signal discrete model according to the experiment result; determining parameter vectors x including the ultrasonic propagation time; determining target functions according to an ultrasonic receiving signal and a model signal obtained by sampling in the experiment; creating a fitness function; performing the genetic algorithm; iterating to obtain an optimal solution to obtain the initial pheromone condition of the subsequent ant colony algorithm; initializing the ant colony pheromone through the optimal solution obtained by the genetic algorithm; determining the variation range of the parameter vectors x according to the ultrasonic receiving signal obtained in the experiment; determining whether ants are transferred and new optimal solution is obtained; volatilizing and updating the pheromone; iteratively calculating to obtain the optimal estimation value of the ultrasonic propagation time. The method can increase the accuracy of the parameter estimation.

Owner:TIANJIN UNIV

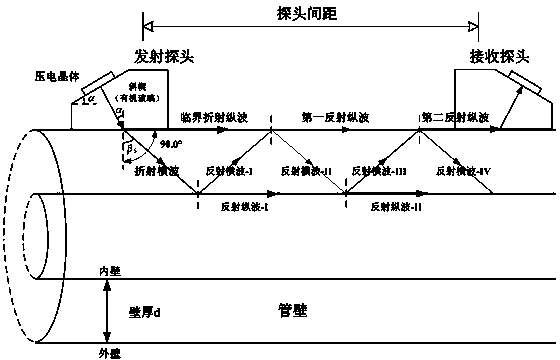

System and method for performing ultrasonic pipeline wall property measurements

ActiveUS9255910B2Analysing solids using sonic/ultrasonic/infrasonic wavesUsing subsonic/sonic/ultrasonic vibration meansSonificationImage resolution

Pipeline wall thickness is measured as a function of position using ultrasound propagation. A series of predictive models is used, which define predictions of the ultrasound response signals as a function of different sets of parameters. The different sets that are determine of position dependent ultrasound speed at different sound frequencies and different spatial resolution. Successive iterative fitting process are executed, each fitting a combination of values of a successive set of parameters to the detected ultrasound response signals according to a respective model, using the values fitted values from the previous fitting process to initialize the next set of parameters for iterative fitting. At least the first model defines predictions of wave vector values as a function of circumferential position in successive rings around the pipe as sums of wave vector value for a plurality of circumferential positions in a preceding one of the rings multiplied by propagation coefficients, using propagation coefficients that depend on a first set of parameters.

Owner:NEDERLANDSE ORG VOOR TOEGEPAST-NATUURWETENSCHAPPELIJK ONDERZOEK (TNO)

Acoustic lens and ultrasonic probe using the lens

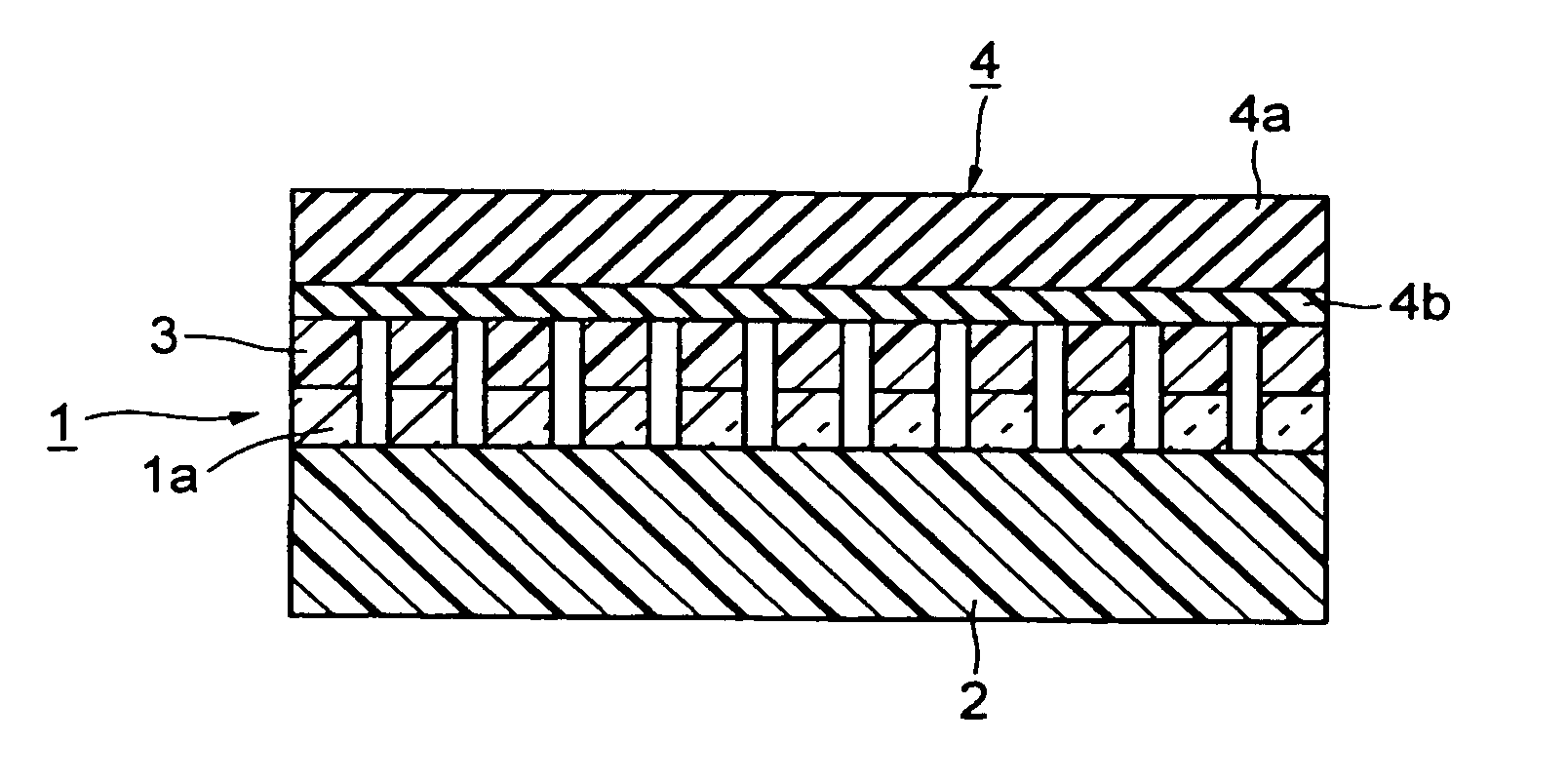

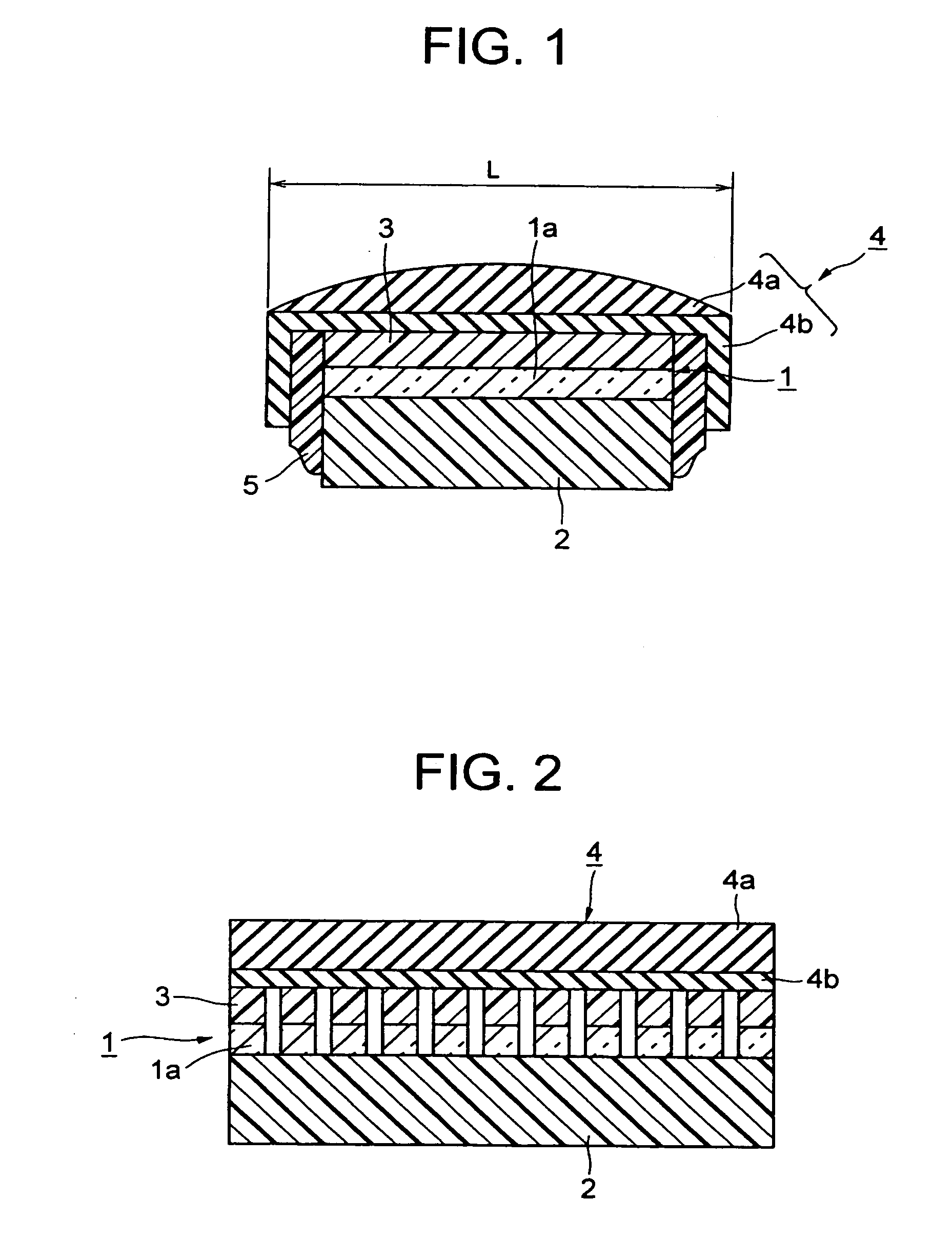

InactiveUS20050245829A1High sensitivitySmall propagation lossUltrasonic/sonic/infrasonic diagnosticsAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasound attenuationCamera lens

The invention has a structure, in an acoustic lens for an ultrasonic probe comprising leg portions which are connected by a planar shape, and a lens portion which is provided on the leg portions and has curvature in the lengthwise direction, wherein the leg portions are made from an attenuation prevention material having the less ultrasonic propagation loss than for the lens portion. Moreover, the leg portions of the acoustic lens are formed with opposite end sides thereof in a bent L-shape. Furthermore, an ultrasonic probe is constructed by adhering onto a piezoelectric element group where a plurality of piezoelectric elements are arranged side by side, an acoustic lens provided with curvature in the lengthwise direction.

Owner:NIHON DEMPA KOGYO CO LTD

Device and method for ultrasonic transmission of audio

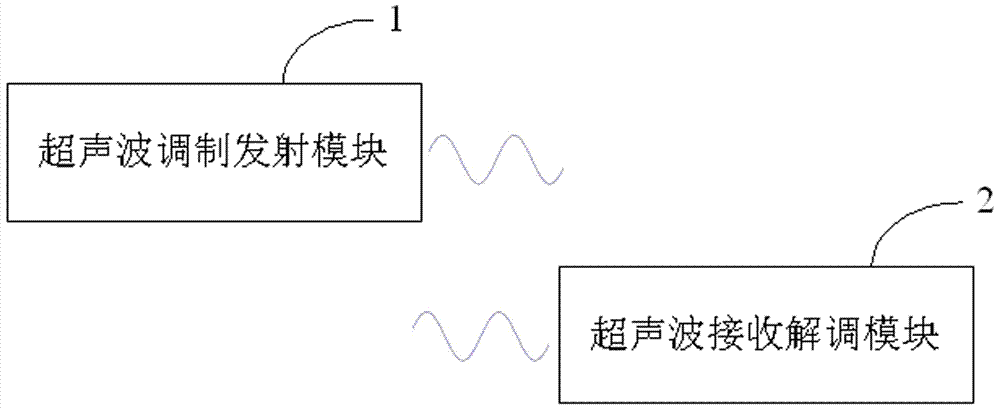

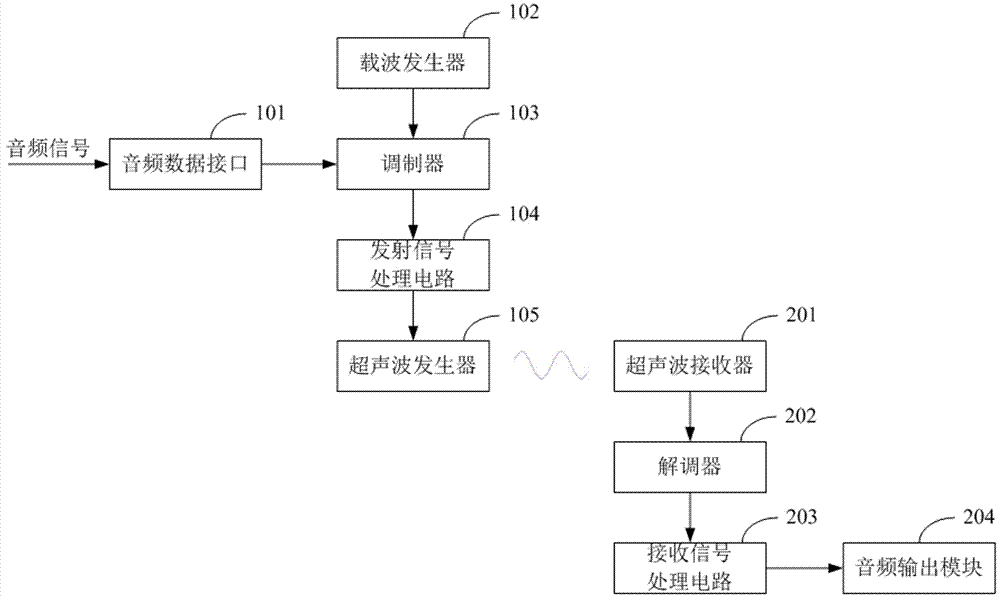

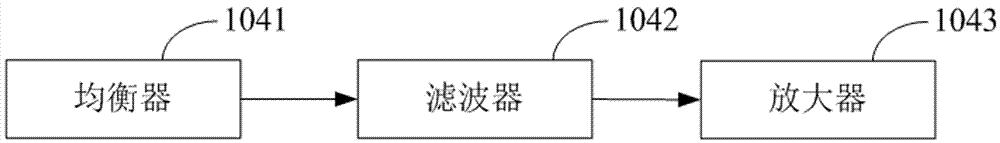

PendingCN107171738AAvoid noise pollutionSimple planSonic/ultrasonic/infrasonic transmissionMultiple carrier systemsSignal processing circuitsCarrier signal

A device and a method for ultrasonic transmission of audio are provided. A modulator modulates an audio signal extracted by an audio data interface to a high-frequency oscillation signal generated by a carrier generator. A transmitted signal processing circuit processes a signal output by the modulator. An ultrasonic generator generates an ultrasonic signal containing audio information under the drive of the high-frequency oscillation signal. An ultrasonic receiver receives the ultrasonic signal from the ultrasonic generator. A demodulator demodulates an audio signal from the ultrasonic signal. A received signal processing circuit processes the audio signal. An audio output module plays audio. Based on the characteristics of ultrasonic, an audio signal generated by audio generation equipment is loaded to an ultrasonic signal for transmission, and a user needing to receive the audio signal demodulates the ultrasonic signal to get the audio signal. Noise pollution to the environment in the process of transmission is avoided, and other people are not disturbed. The scheme is simple, easy to implement, highly practical, and wide in range of application.

Owner:SHENZHEN TRANSSION HLDG CO LTD

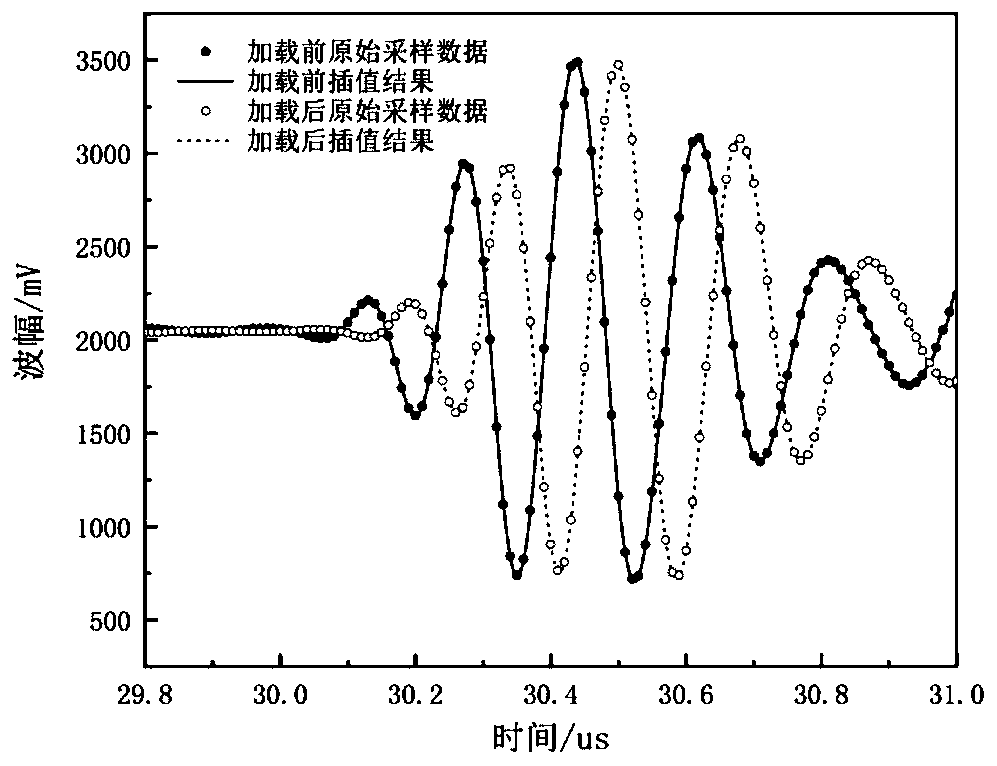

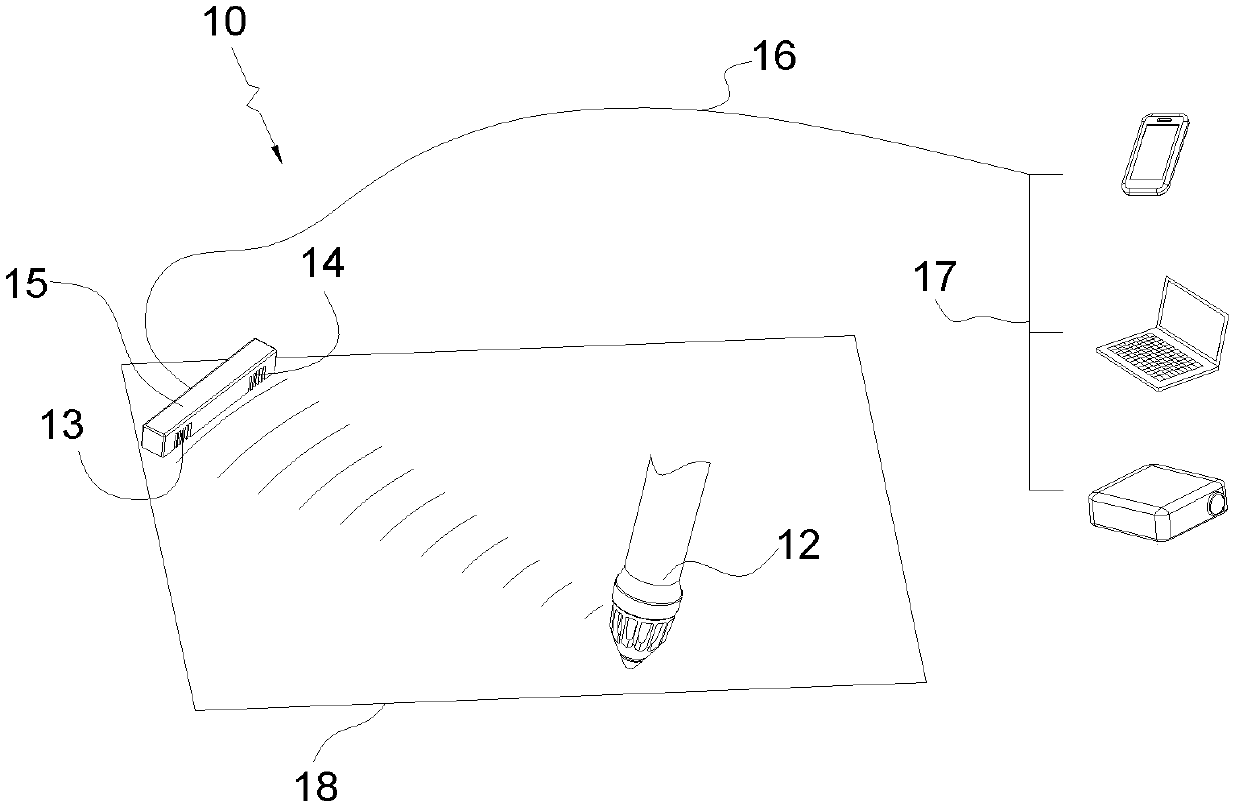

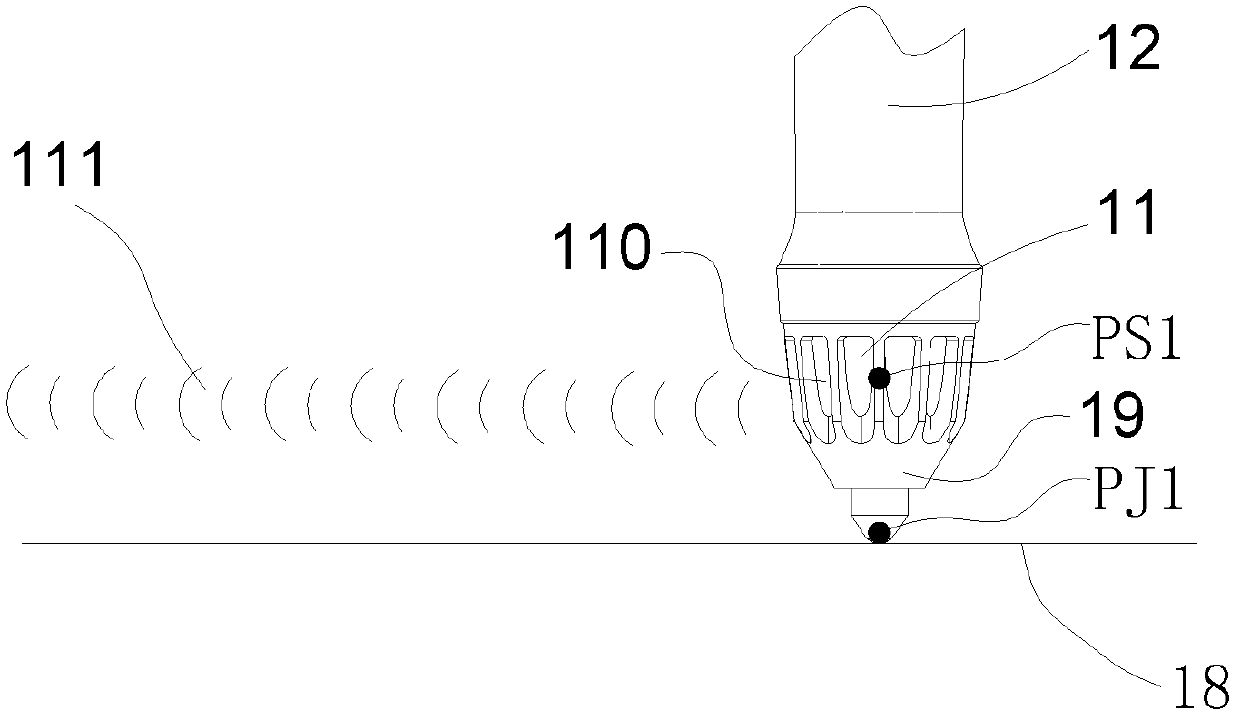

Bolt fastening axial force ultrasonic detection method based on differential method

InactiveCN111307357AImprove adaptabilityImprove practicalityMeasurement of torque/twisting force while tighteningDesign optimisation/simulationElement modelLongitudinal wave

The invention provides a bolt fastening axial force ultrasonic detection method based on a differential method, which comprises the following steps: (1) establishing a mathematical relationship between bolt fastening axial force and ultrasonic propagation time difference, and establishing a bolt fastening axial force ultrasonic detection principle model; (2) establishing a finite element model ofthe bolt connection structure, carrying out static simulation, obtaining axial stress data on the central axis of the bolt, and calculating to obtain a bolt shape factor; (3) carrying out a loading test in combination with the critical refraction longitudinal wave, and carrying out linear fitting on the loading stress and the measured time difference to obtain the acoustic elastic coefficient of the bolt material; and (4) substituting the bolt shape factor, the acoustic elastic coefficient and other bolt material attribute parameters into the detection principle model, and determining the boltfastening axial force ultrasonic detection coefficient. According to the method, the adaptability of a detection model is improved, and ultrasonic detection coefficients of the bolt under different specifications and different connection states are obtained; the method is low in cost and good in adaptability, and accurate and quick determination of ultrasonic detection parameters is achieved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Ultrasonic handwriting input system

InactiveCN103294285ARelatively small errorInput/output processes for data processingHandwritingSonification

The invention is applicable to the technical field of ultrasonic sensing, and provides an ultrasonic handwriting input system. The ultrasonic handwriting input system at least comprises a handwriting input working plane, an ultrasonic handwriting pen and at least two ultrasonic receiving sensors, wherein the ultrasonic handwriting pen moves on the working plane; the at least two ultrasonic receiving sensors receive ultrasonic sent by the ultrasonic handwriting pen and are mutually separated; the ultrasonic handwriting pen comprises a casing and an ultrasonic sending sensor, an ultrasonic outlet is formed in a pen point part of the casing, and the ultrasonic sending sensor is arranged in the casing and sends the ultrasonic to the working plane through the ultrasonic outlet; and effective ultrasonic received by the ultrasonic receiving sensors is ultrasonic reflected by the working plane. The effective ultrasonic enters the ultrasonic receiving sensor through reflection of the working plane, so that an ultrasonic propagation path has the advantage as follows: when the ultrasonic handwriting pen tilts, calculation errors caused by tilting are less smaller when compared with tilting errors in the prior art.

Owner:MEASUREMENT SPECIALTIES CHINA

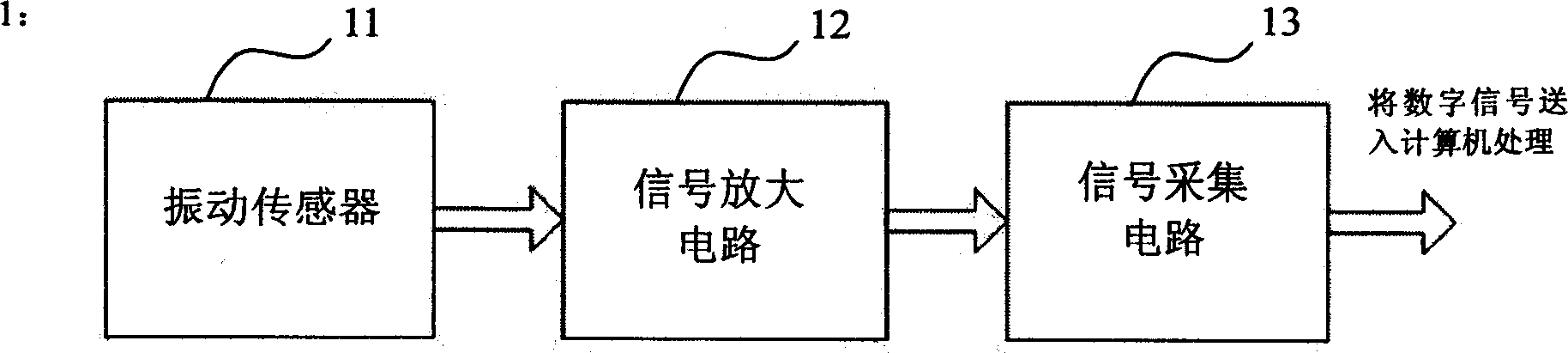

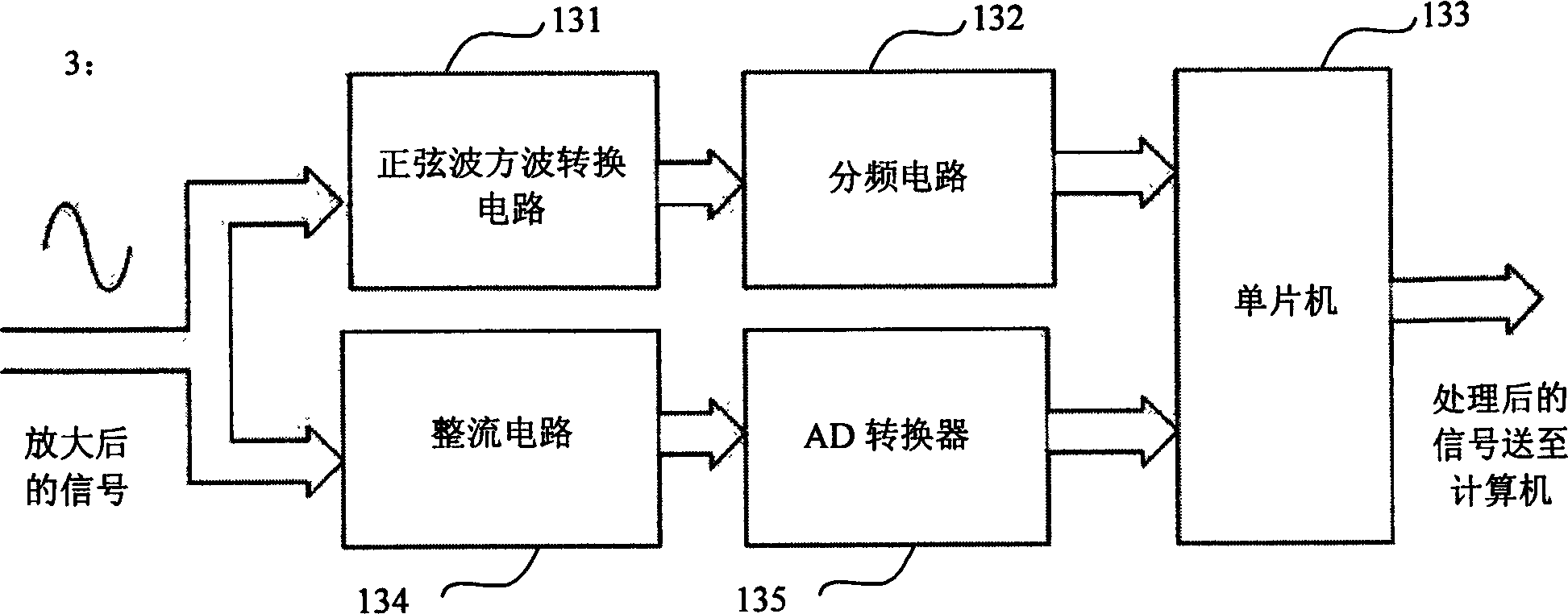

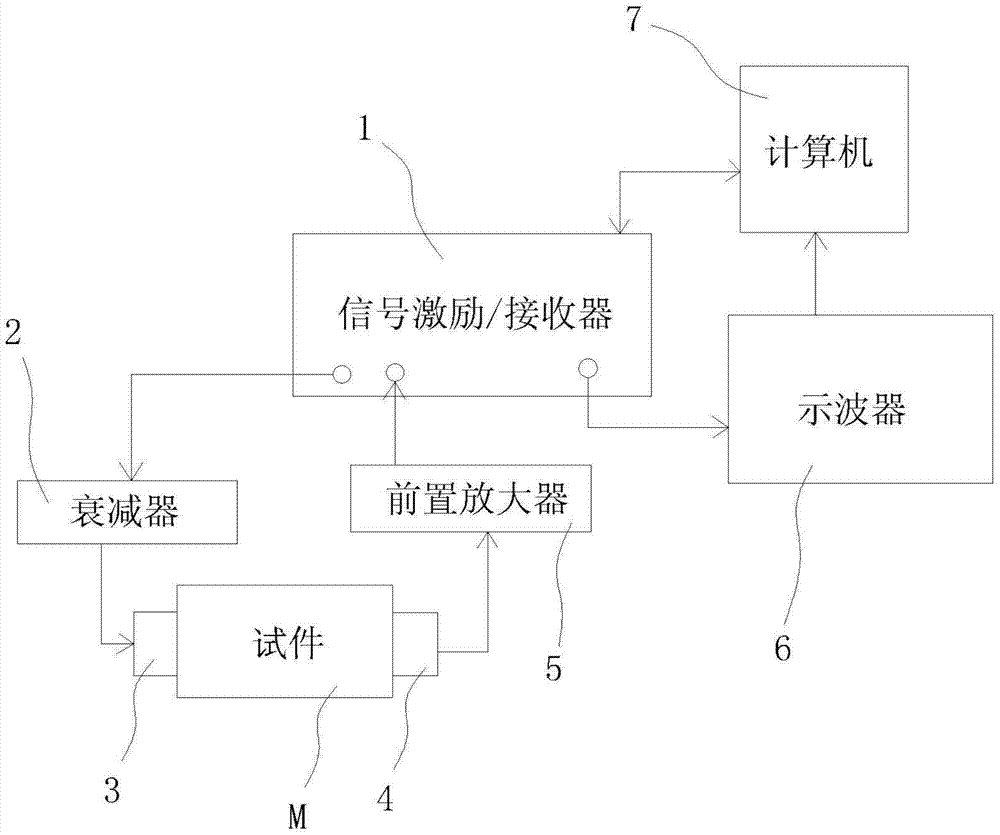

Real-time ultrasonic energy monitoring apparatus and method

ActiveCN1804562AUltrasonic/sonic/infrasonic diagnosticsSubsonic/sonic/ultrasonic wave measurementSonificationHigh-intensity focused ultrasound

The invention provides a real-time ultrasonic energy monitor and method used in real-time monitoring the work condition of the ultrasonic generator during high strength focus ultrasonic treating course. It comprises a vibration sensor, a vibration press fixed on the ultrasonic generator or the ultrasonic propagation sound field used to test the vibration press of the ultrasonic and transfer it into electric signal and output it, a signal amplifying circuit which is connected with the vibration sensor and is used to amplify and output the electric signal of the vibration sensor and a signal collecting circuit which is connected with the signal amplifying circuit and is used to test the frequency of the ultrasonic and the frequency and voltage value of the amplitude from the electric signal of the signal amplifying circuit and output it to the computer so that the computer can quote the work condition of the ultrasonic generator by the tested frequency and amplitude.

Owner:重庆微海软件开发有限公司

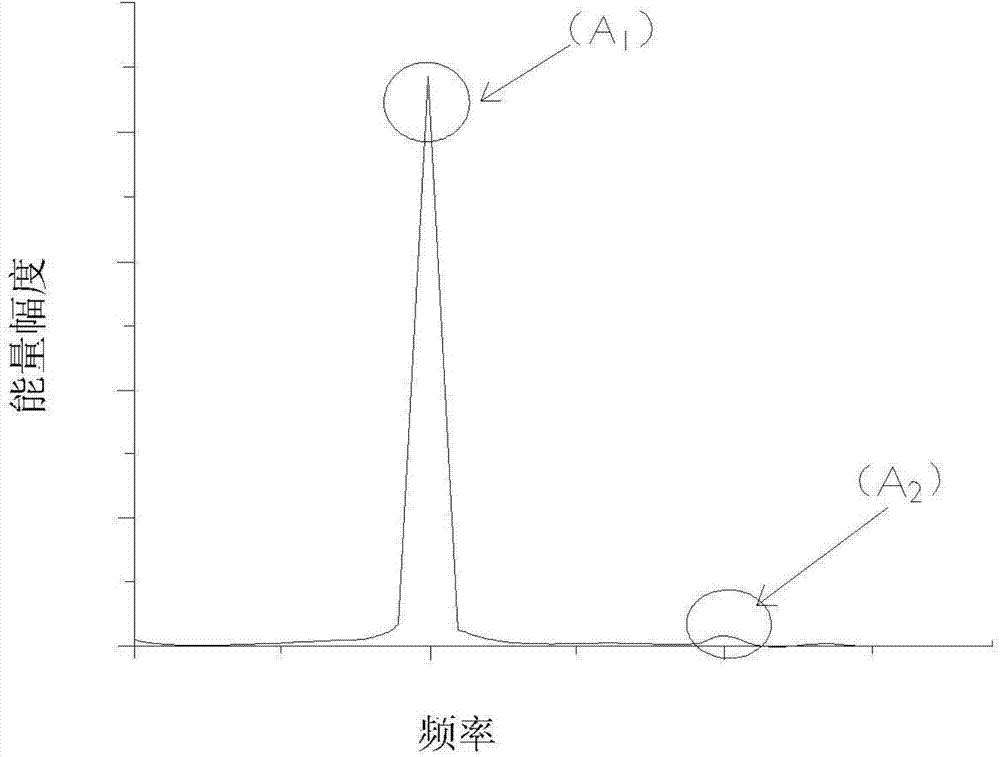

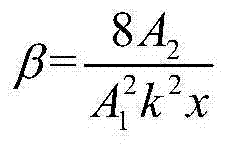

Nonlinear ultrasonic heat treatment process evaluation and optimization method and device

ActiveCN103940910AImprove performanceUniform structureAnalysing solids using sonic/ultrasonic/infrasonic wavesHarmonicNonlinear ultrasound

The invention discloses a nonlinear ultrasonic heat treatment process evaluation and optimization method and device. The method comprises the following steps: acquiring an ultrasonic baseband signal A1 propagated in a test piece and amplitude A2 of second harmonics, and calculating a nonlinear acoustic parameter beta' of the test piece, wherein the expression is as shown in the specification; and comparing the difference between nonlinear acoustic parameters of an untreated material and a material subjected to different heat treatment processes based on the obtained relative nonlinear acoustic parameter beta'. The better the heat treatment process is, the more uniform the interior structure of the material subjected to heat treatment is, the performance is greatly improved, and the acoustic nonlinear response of ultrasonic propagation is low. The microstructure of the material can be changed based on heat treatment, a direct correlation exists between the nonlinear response of ultrasonic propagation and the microstructure of the material. According to the method, the heat treatment process effects can be nondestructively, rapidly and effectively evaluated, and the related parameters of heat treatment process are optimized and perfected.

Owner:XIAMEN UNIV

Ultrasonic transducer

ActiveUS20130207517A1Prevent movementUltrasonic/sonic/infrasonic diagnosticsMaterial analysis using sonic/ultrasonic/infrasonic wavesElectricityEngineering

An ultrasonic transducer includes an ultrasonic transmitting and receiving portion, a housing, a driving device, a casing, a first volume compensation mechanism, a ventilating portion, a diaphragm, and a component. The housing houses the ultrasonic transmitting and receiving portion, and the housing seals ultrasonic propagation liquid. The driving device is configured to drive the ultrasonic transmitting and receiving portion. The casing houses the driving device. The first volume compensation mechanism is configured to absorb a volume change of the ultrasonic propagation liquid. The diaphragm divides an internal space of the casing into at least a first internal space and a second internal space. The ventilating portion is configured to ventilate the first internal space to outside of the casing. The component is disposed in a space other than the first internal space in the internal space and includes a frame ground that electrically connects to an electrical circuit.

Owner:NIHON DEMPA KOGYO CO LTD

Self-calibration ultrasonic wind speed measurement method

InactiveCN103018480AAccurate measurementIndication/recording movementTesting/calibration of speed/acceleration/shock measurement devicesPropagation timeAtmospheric sciences

The invention discloses a self-calibration ultrasonic wind speed measurement method capable of accurately measuring the wind speed and the wind direction. The self-calibration ultrasonic wind speed measurement method is characterized by orderly comprising the steps of carrying out initialization, absorbing ultrasonic waves by a pair of ultrasonic probes positioned in the same dimension to obtain the bi-directional ultrasonic propagation time Tab and Tba between the ultrasonic probes, collecting the ultrasonic environment temperature C, calculating the propagation time Vs of the ultrasonic waves in the air according to a formula of Vs=331.3+0.607*C, calculating the distance D between the ultrasonic probes in the same dimension according to the formula, calculating the wind speed Vw and the wind direction Theta according to the formula, and outputting the wind speed and the wind direction.

Owner:DALIAN JINTIAN TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com