Patents

Literature

1561results about "Measurement of torque/twisting force while tightening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Power wrench

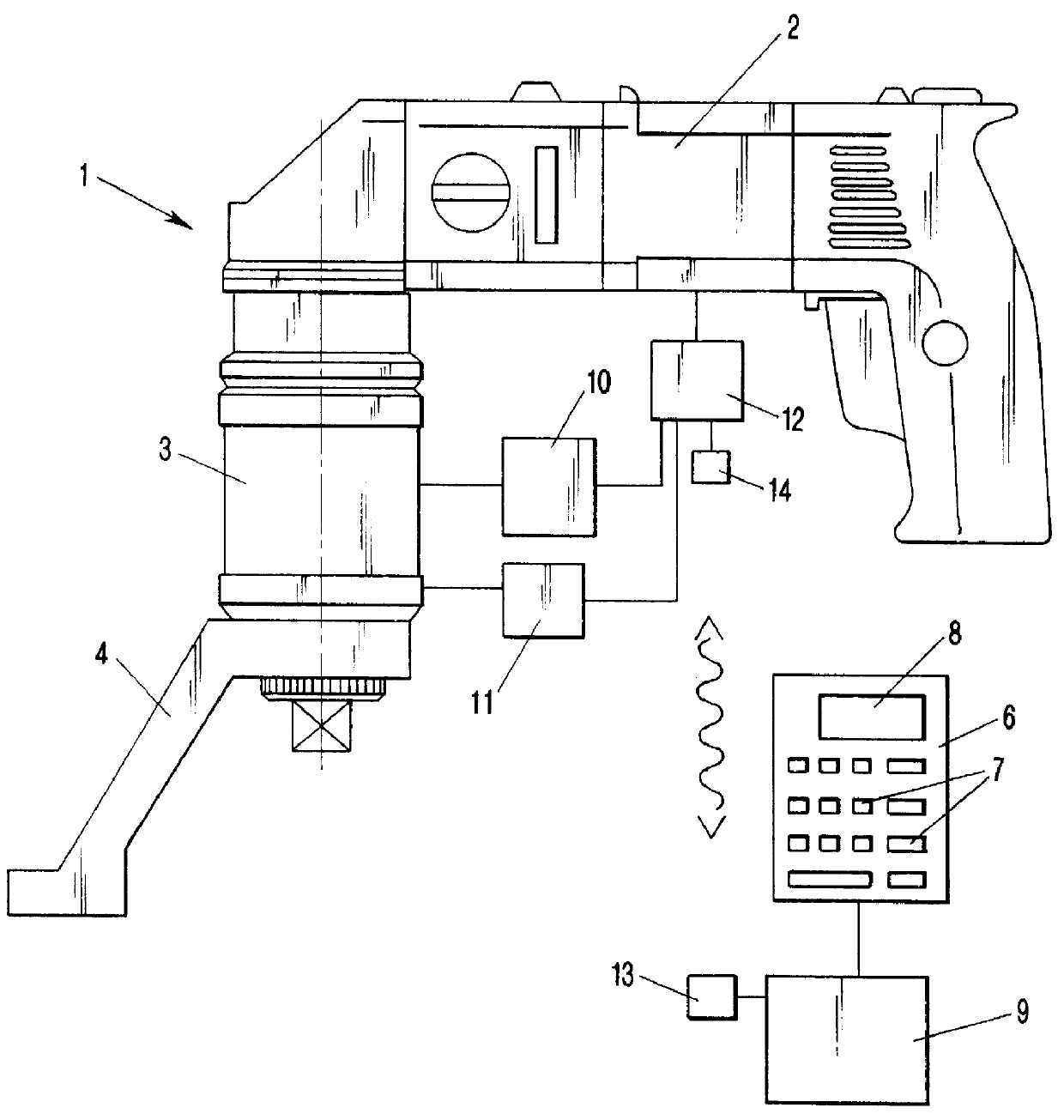

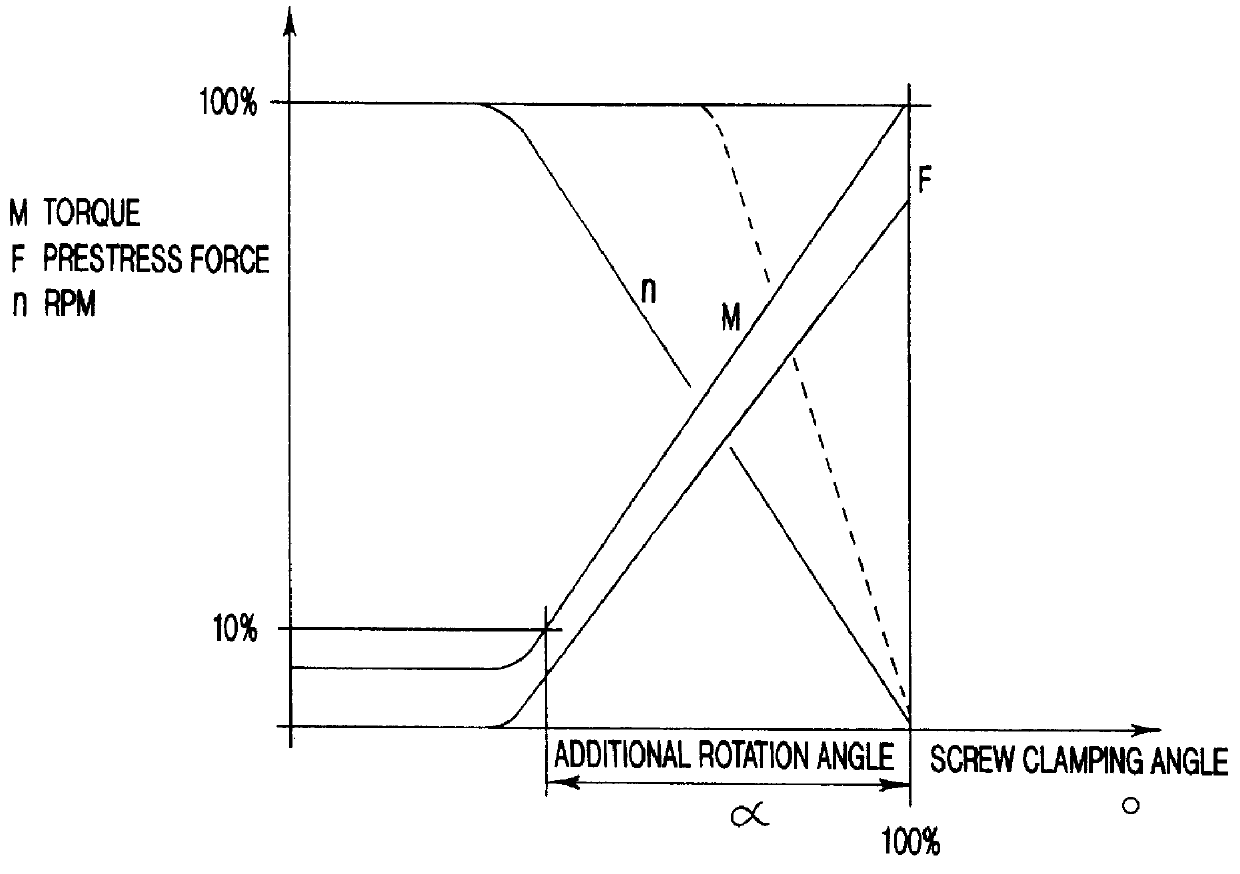

PCT No. PCT / EP97 / 05974 Sec. 371 Date Jul. 16, 1999 Sec. 102(e) Date Jul. 16, 1999 PCT Filed Oct. 29, 1997 PCT Pub. No. WO98 / 22263 PCT Pub. Date May 28, 1998A power screwdriver has a drive unit and an input circuit for inputting screw size, material quality, pitch, and clamping length of a screw. An evaluation circuit is provided for determining a nominal prestress force based on input screw size, material quality, and clamping length, for determining a nominal torque based on the nominal prestress force and the pitch, and for determining the screw clamping angle resulting from the nominal prestress force and the pitch. A sensing device for sensing the actual torque is provided, and a further sensing device for sensing the actual screw clamping angle is present. A control and switch-off device controls further rotation of the drive unit when the actual torque coincides with the nominal torque and switches off the drive unit when the actual screw clamping angle coincides with the nominal screw clamping angle. The nominal torque, based on which the additional rotation o f the drive unit is controlled until the nominal screw clamping angle is reached, is set to a value which is smaller than the torque corresponding to the nominal pretension force. An additional rotation angle of the drive unit, for reaching the nominal screw clamping angle corresponding to the nominal prestress force, is determined based on the difference between the nominal screw clamping angle and the adjusted screw clamping angle corresponding to the preset nominal torque and is used for switching off the drive unit.

Owner:HOHMANN JORG +1

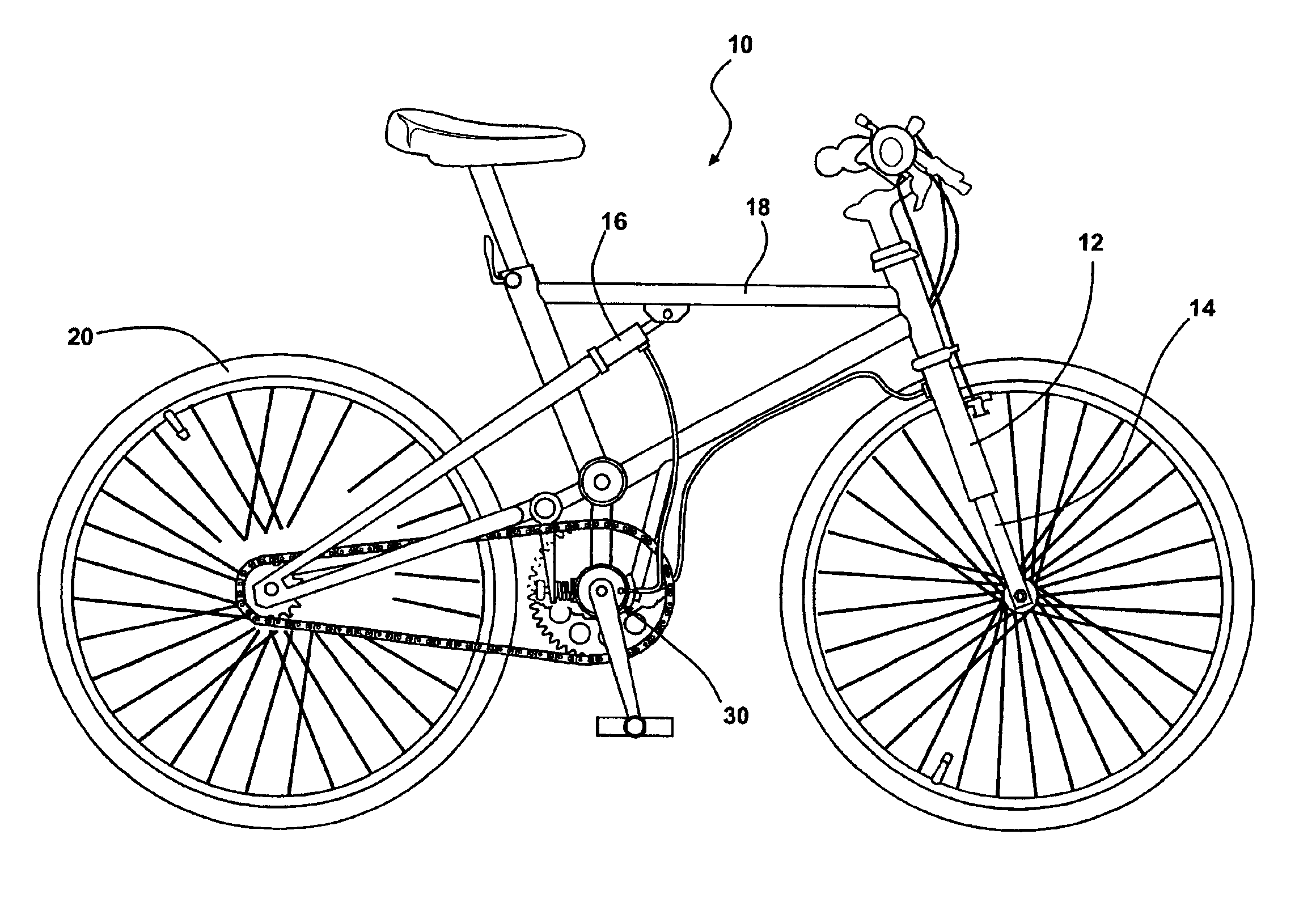

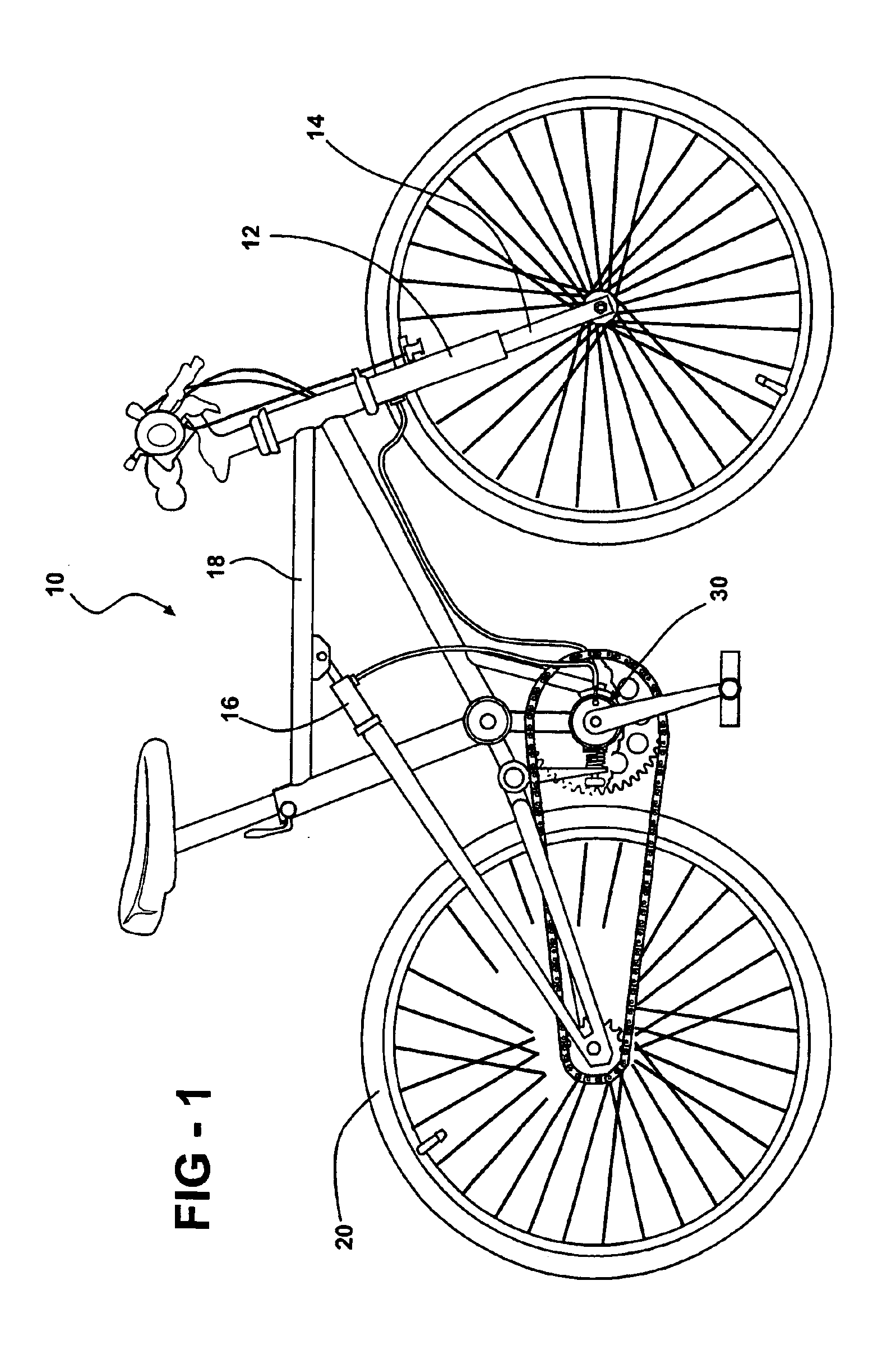

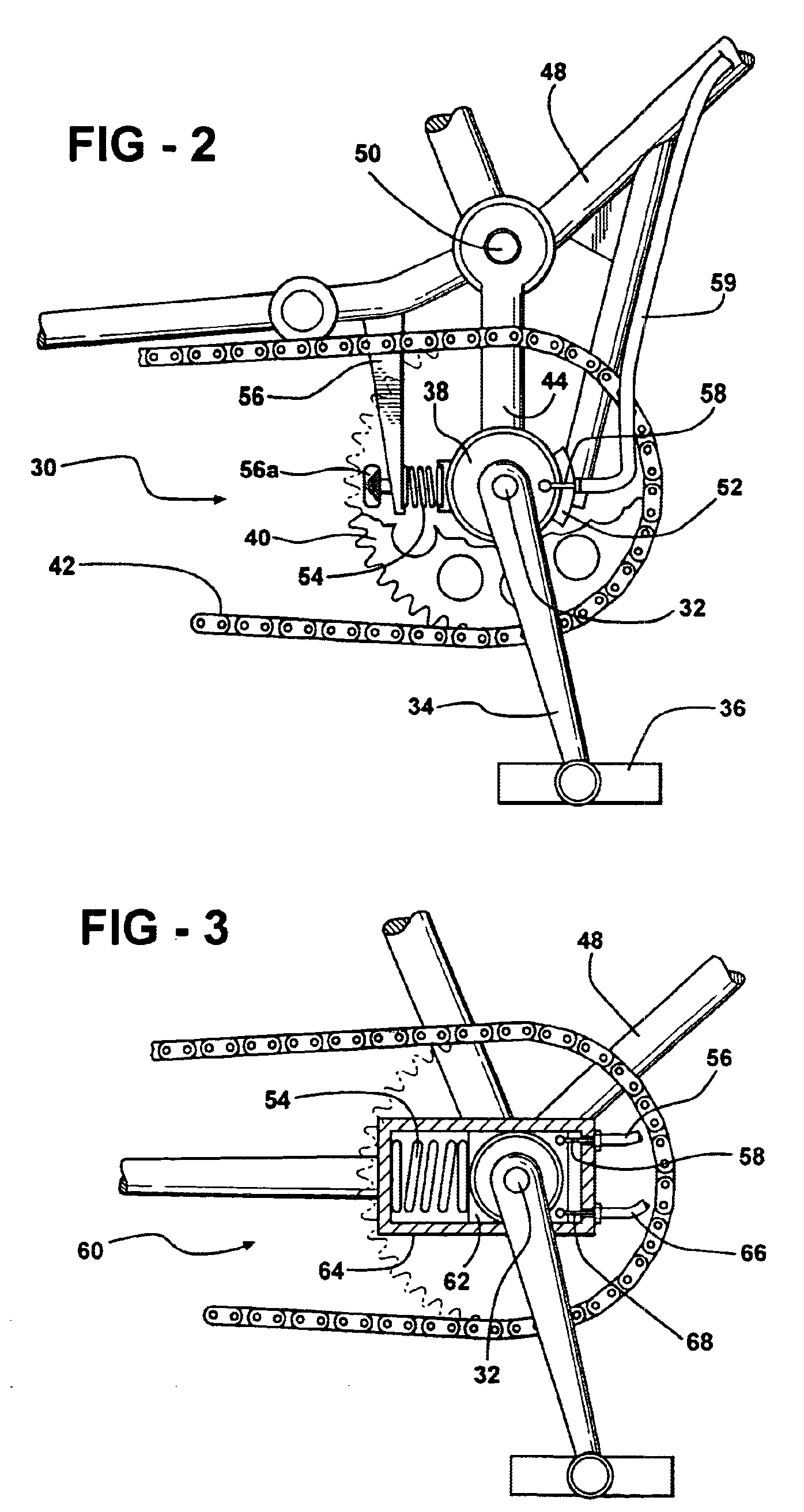

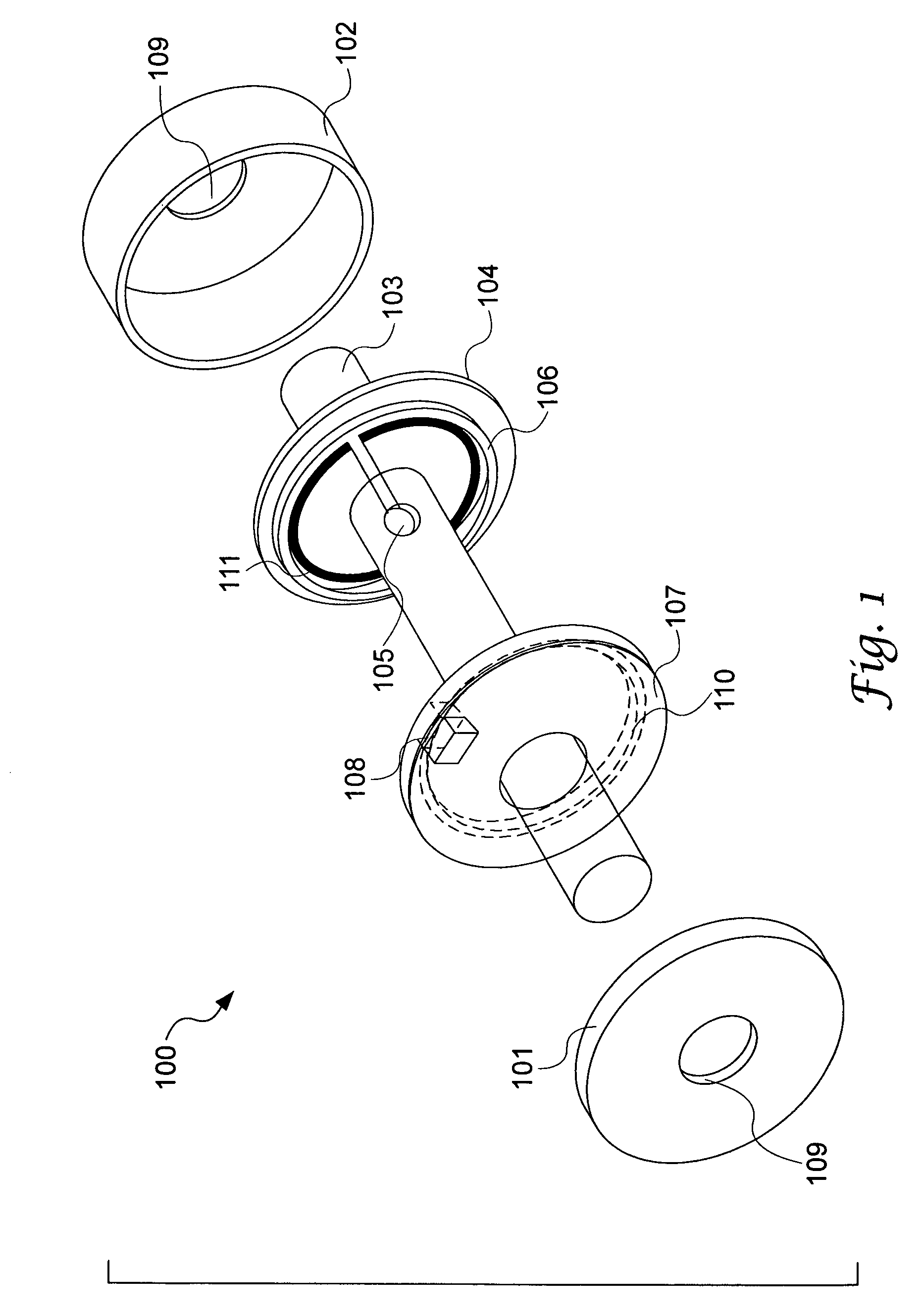

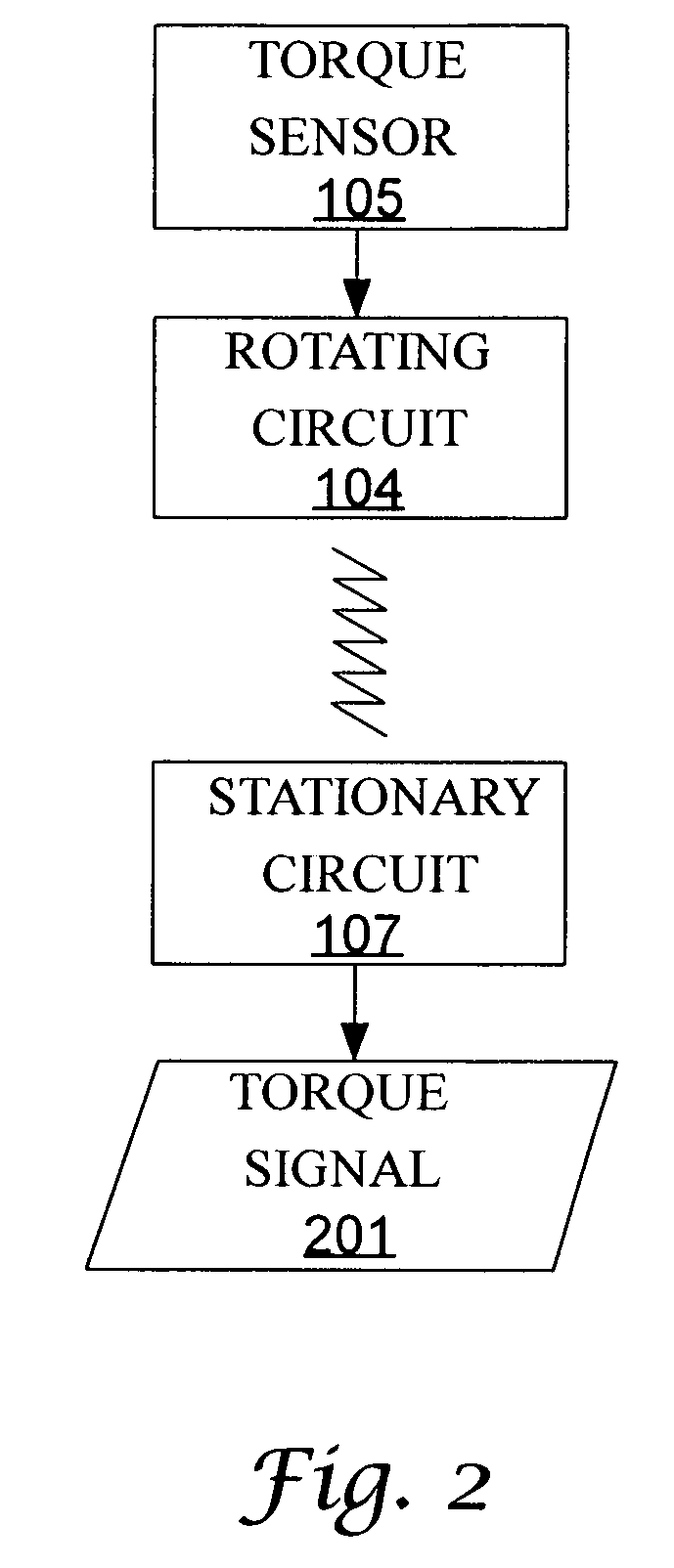

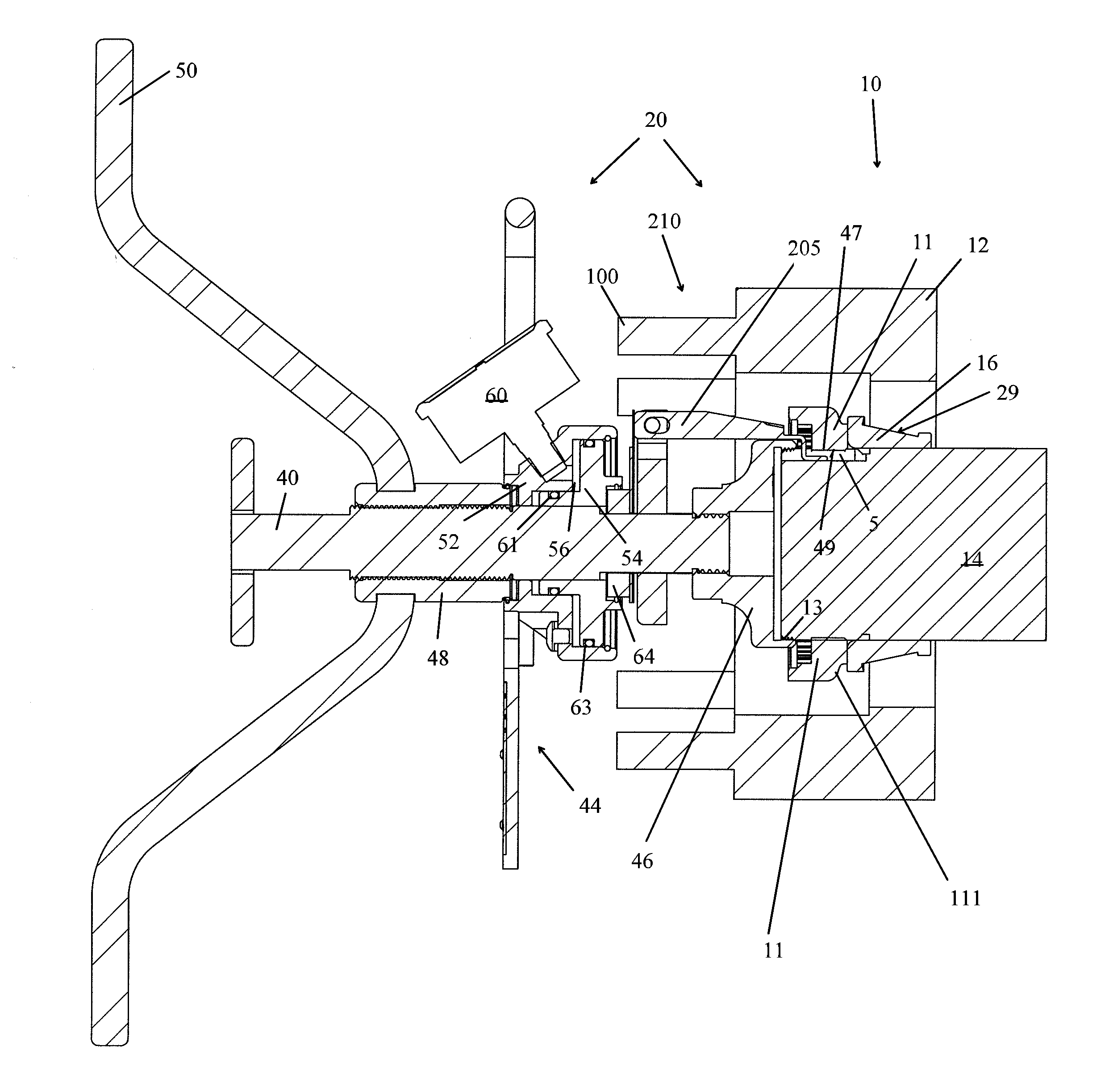

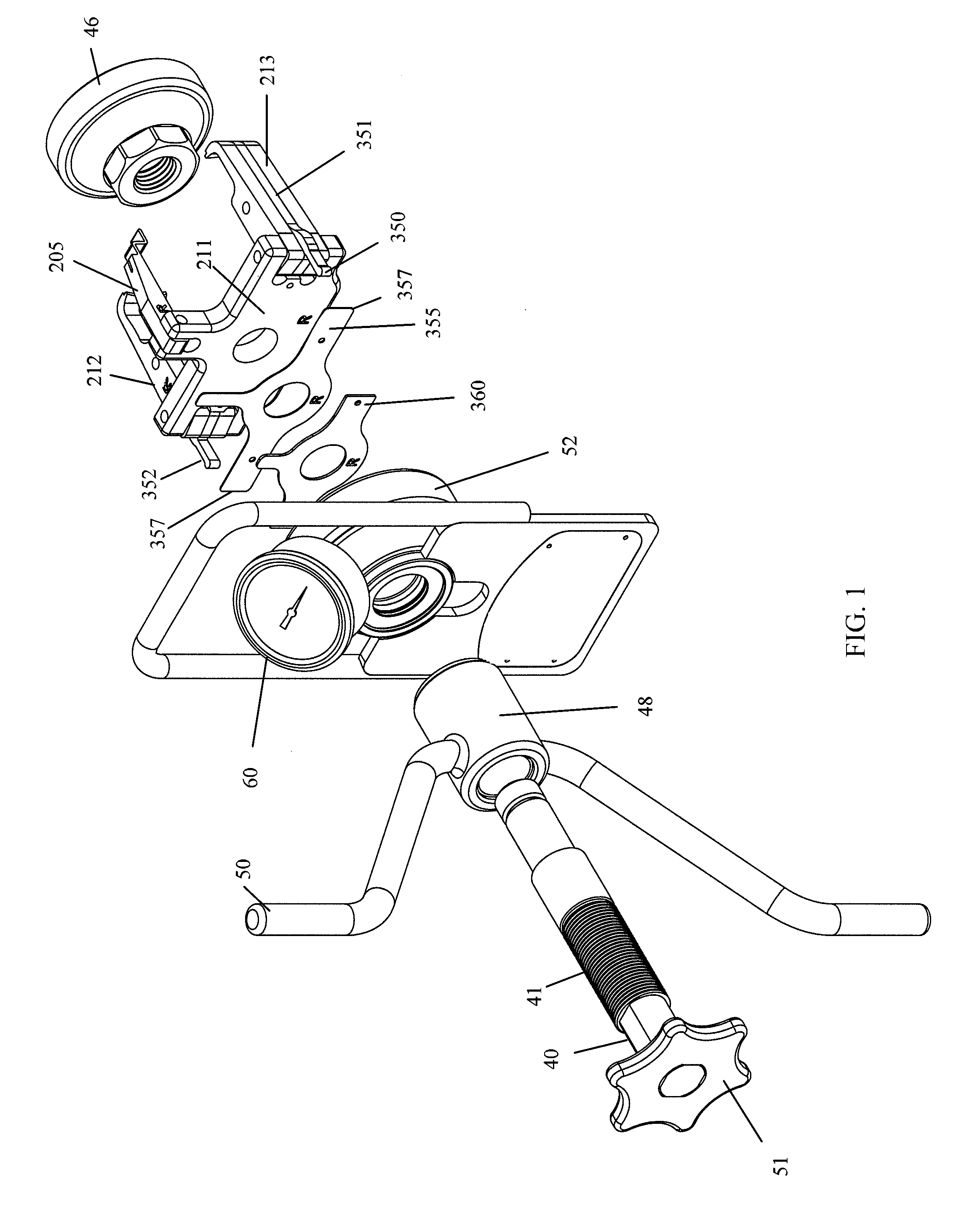

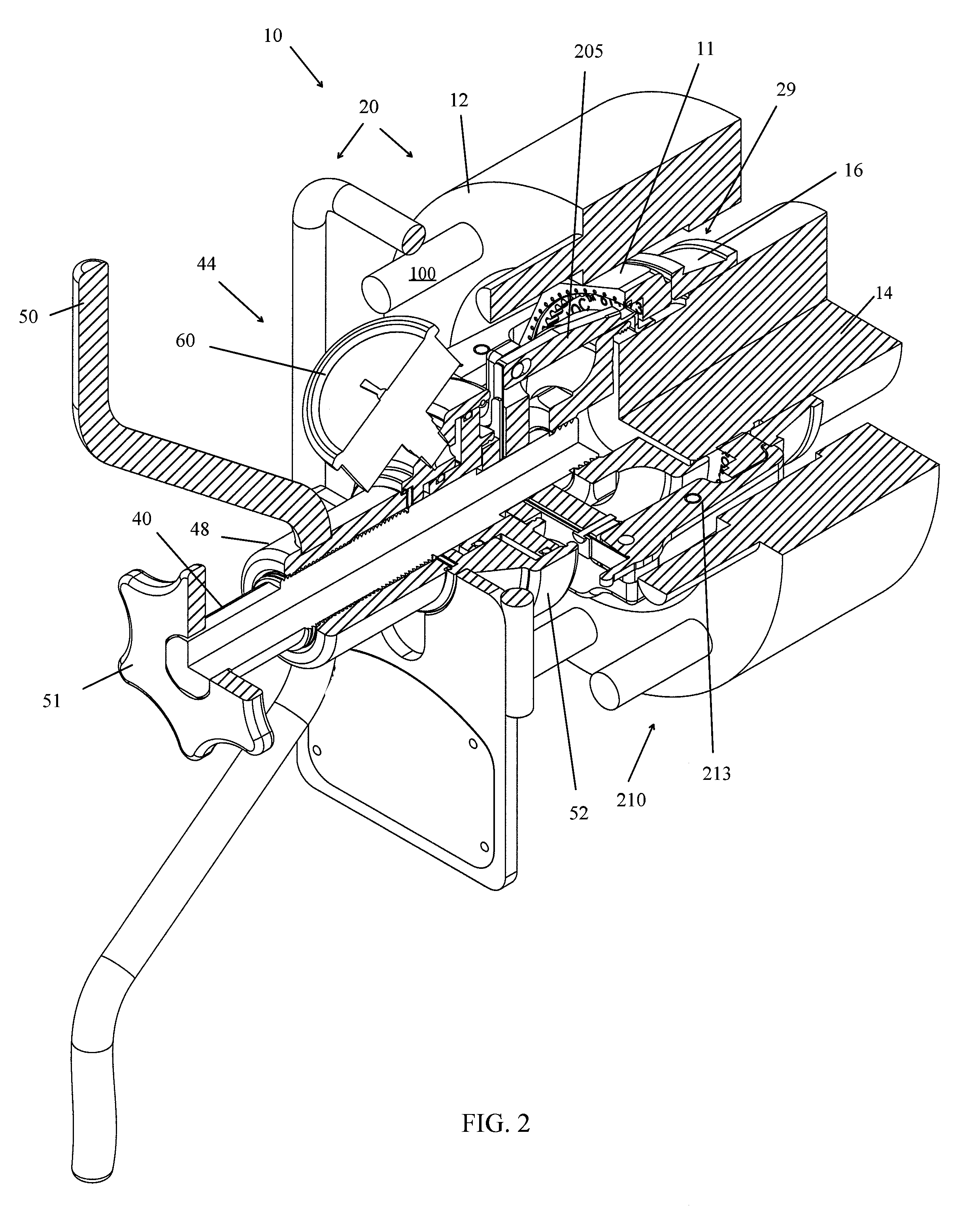

Anti-bob system for cycles

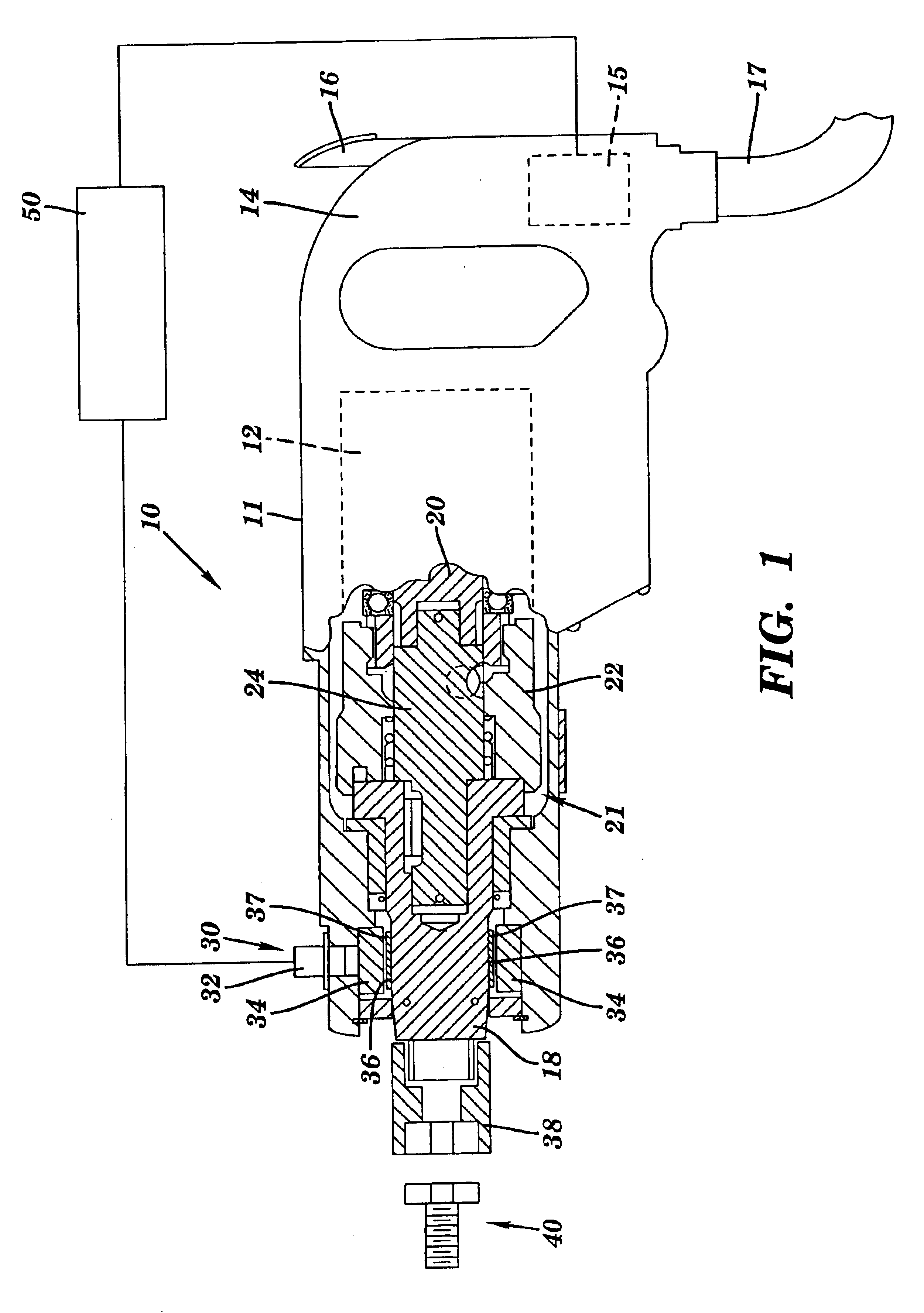

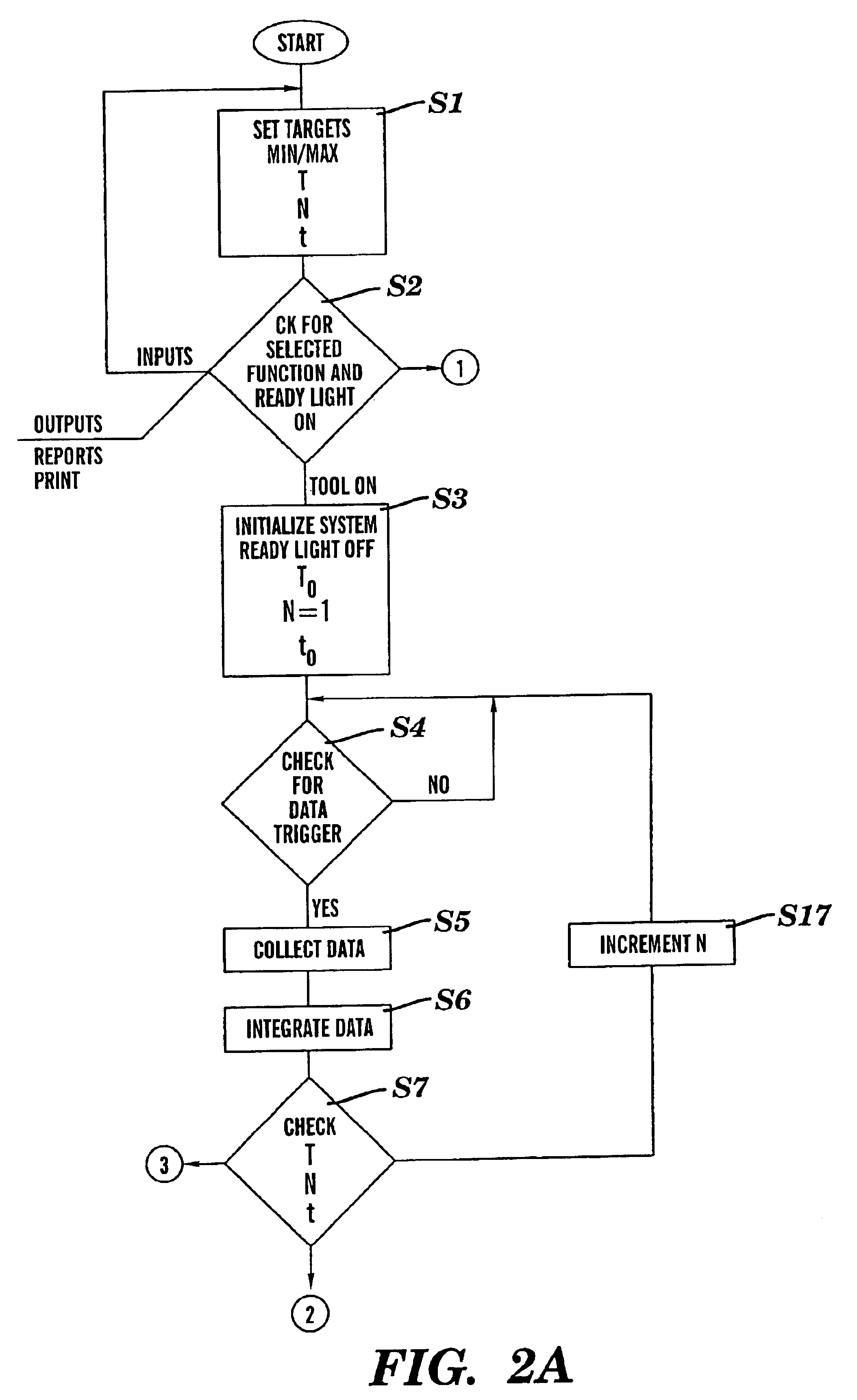

A control system is operable to selectably activate shock damping devices associated with a bicycle so as to eliminate bobbing encountered under extreme pedaling conditions. The system includes a crank axle torque detector which operates to detect a level of torque applied to a crank axle and provide a control signal corresponding to the level of torque. A shock damping device is coupled to the frame of the cycle, and functions to absorb and dampen mechanical shocks communicated to the frame. The shock damping device includes an activator for controlling its damping function. The activator is operable to receive the control signal from the crank axle torque detector and control the shock damping device in response thereto. The control signal may be an electrical or a mechanical signal.

Owner:THE LARRY D MILLER TRUST LARRY D MILLER & MARY L MILLER TRUSTEES DTD 06 12 98

Tool monitor and assembly qualifier

InactiveUS6055484AMeasurement of torque/twisting force while tighteningForce measurementPower flowDevice Monitor

This counting apparatus is a tool monitor and assembly qualifier that verifies that the correct number of fasteners have been properly installed into an assembly. When used in conjunction with a pressure tool, proper fastener torque and count can be verified. The device monitors internal tool pressures and has the ability to "learn" the pressure characteristics of the tool during the assembly process. This assembly qualifier is a device that monitors either the pressure of an air tool, the current of an electrical tool or the torque of a mechanical wrench to determine if the tool shut off at a target torque. The qualifier also determines if some unknown means shuts off the tool.

Owner:C P ELECTRONICS

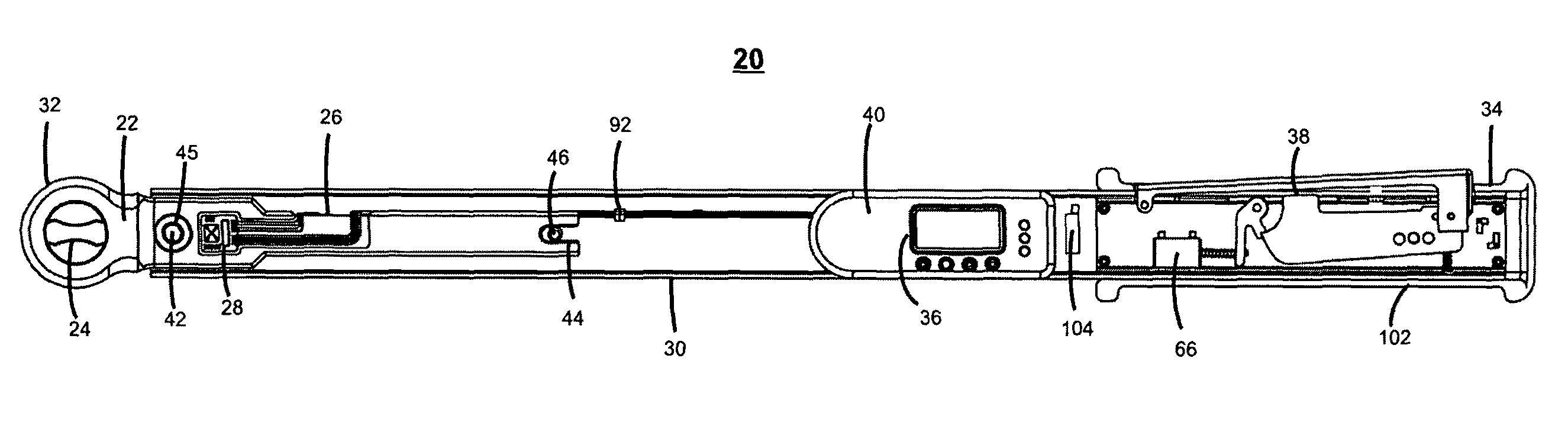

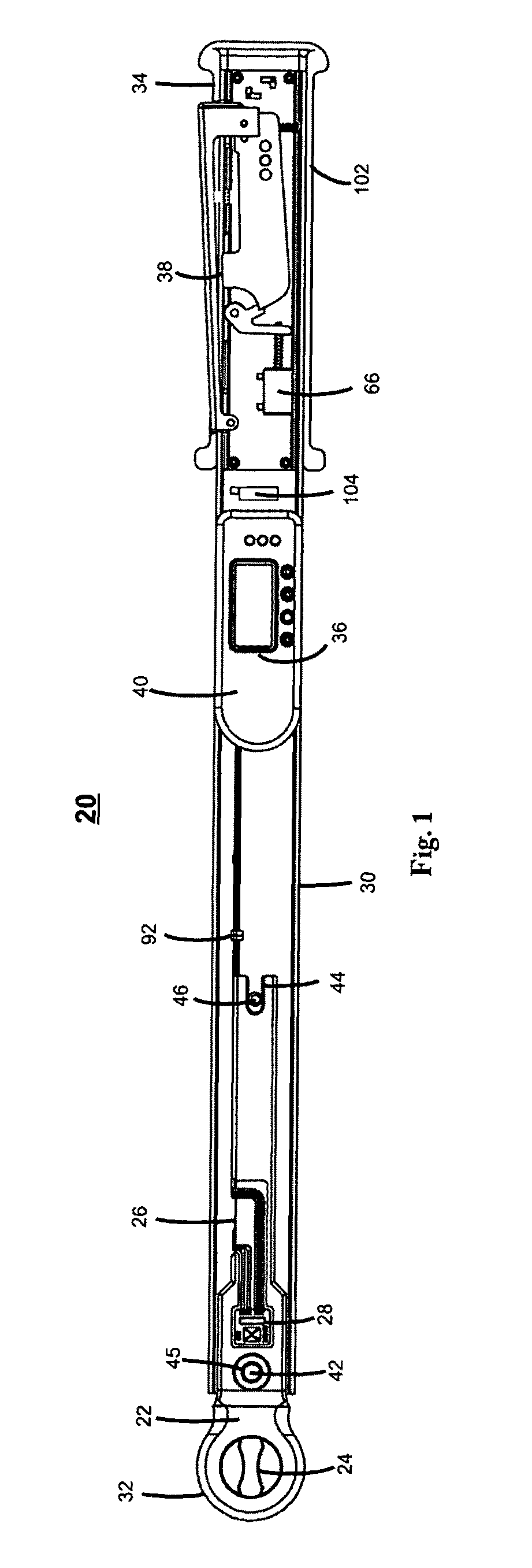

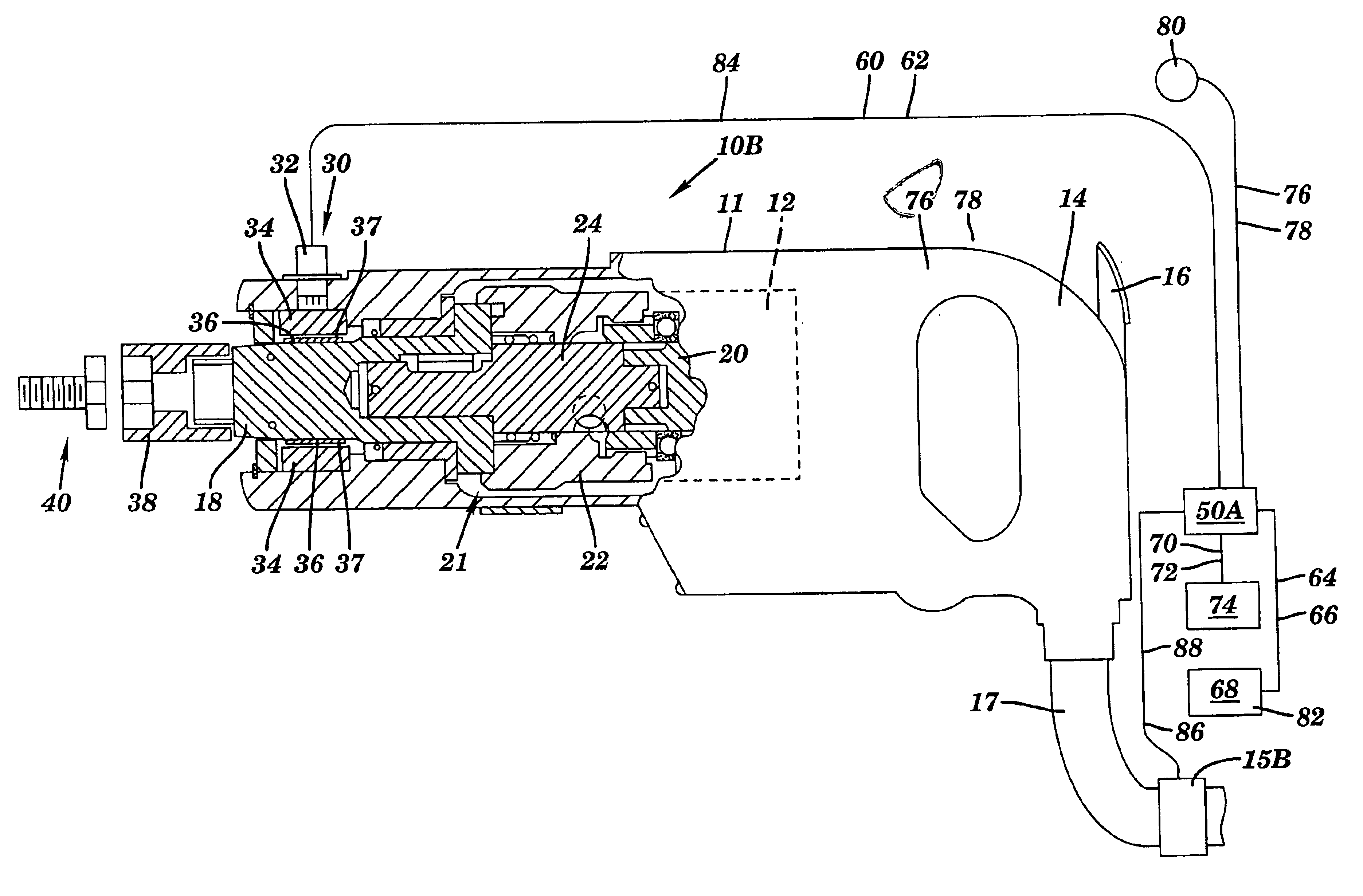

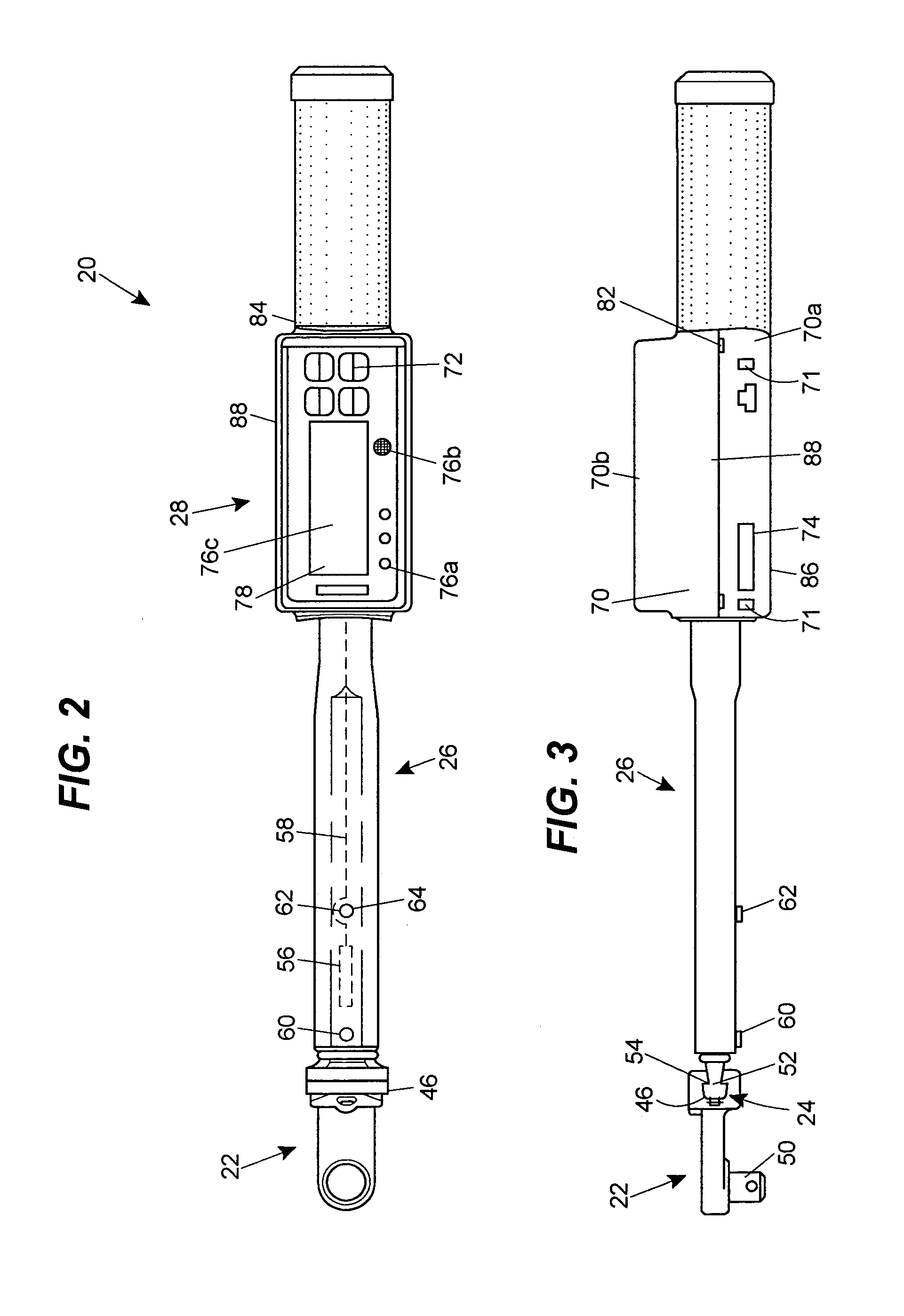

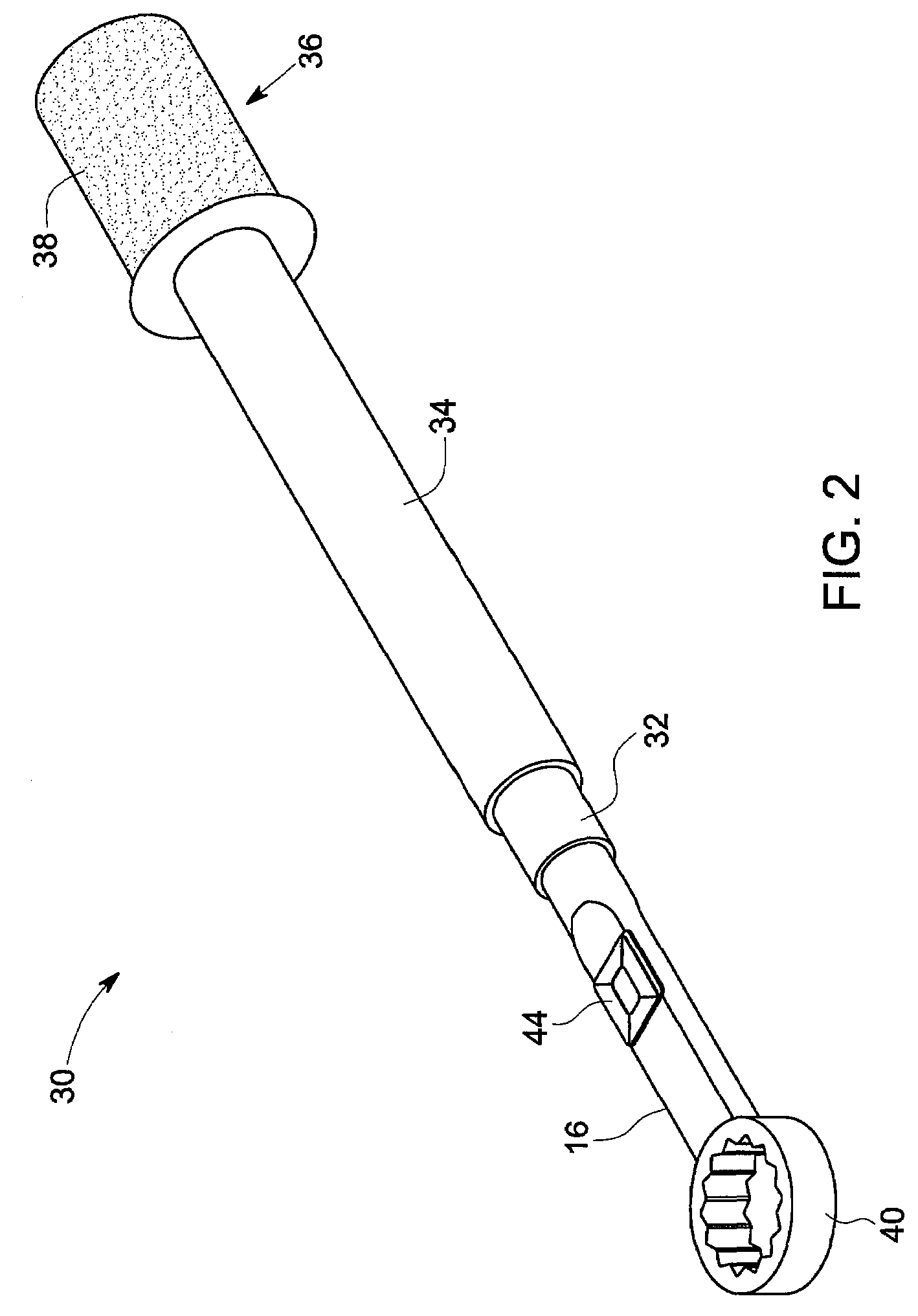

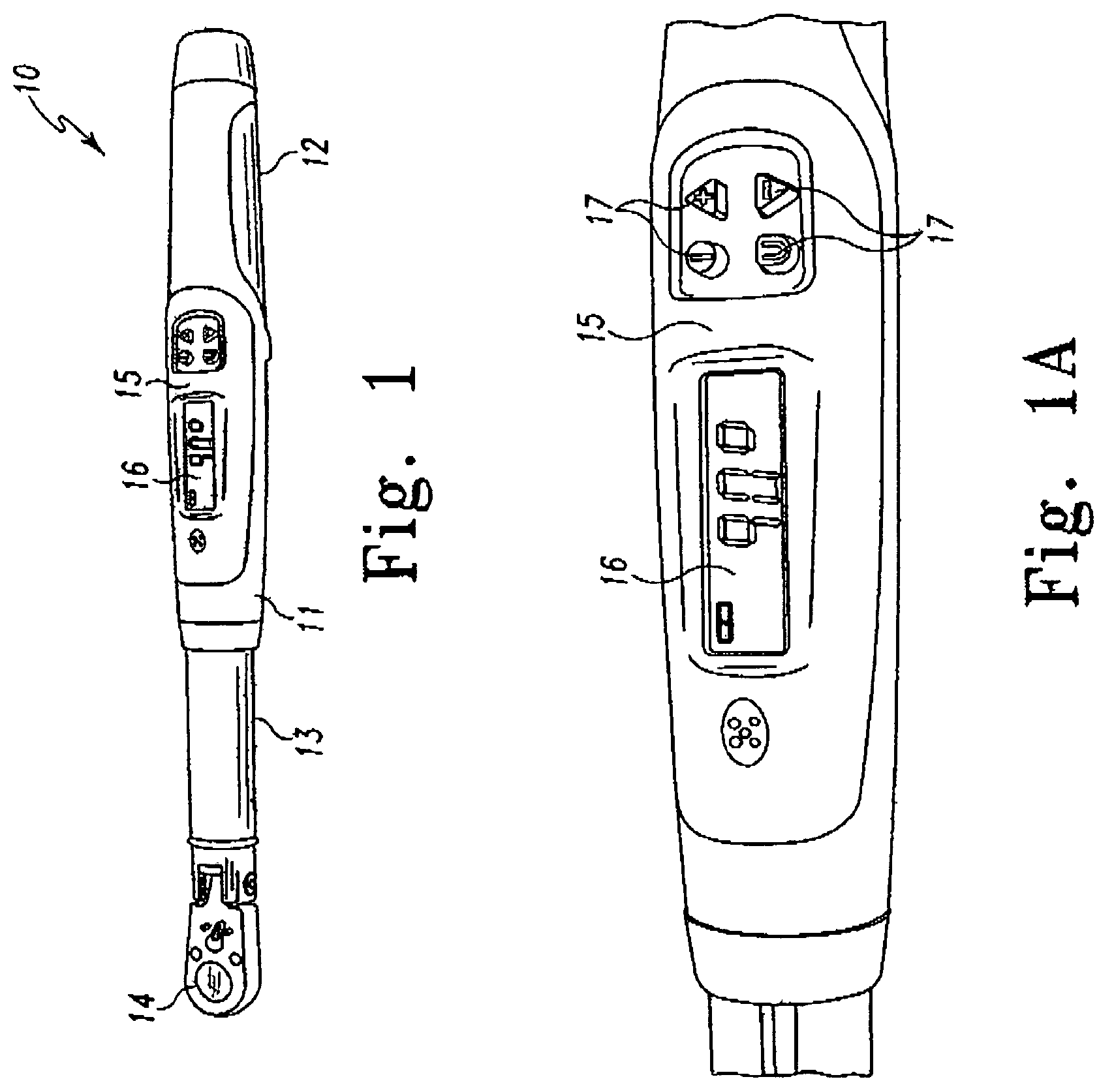

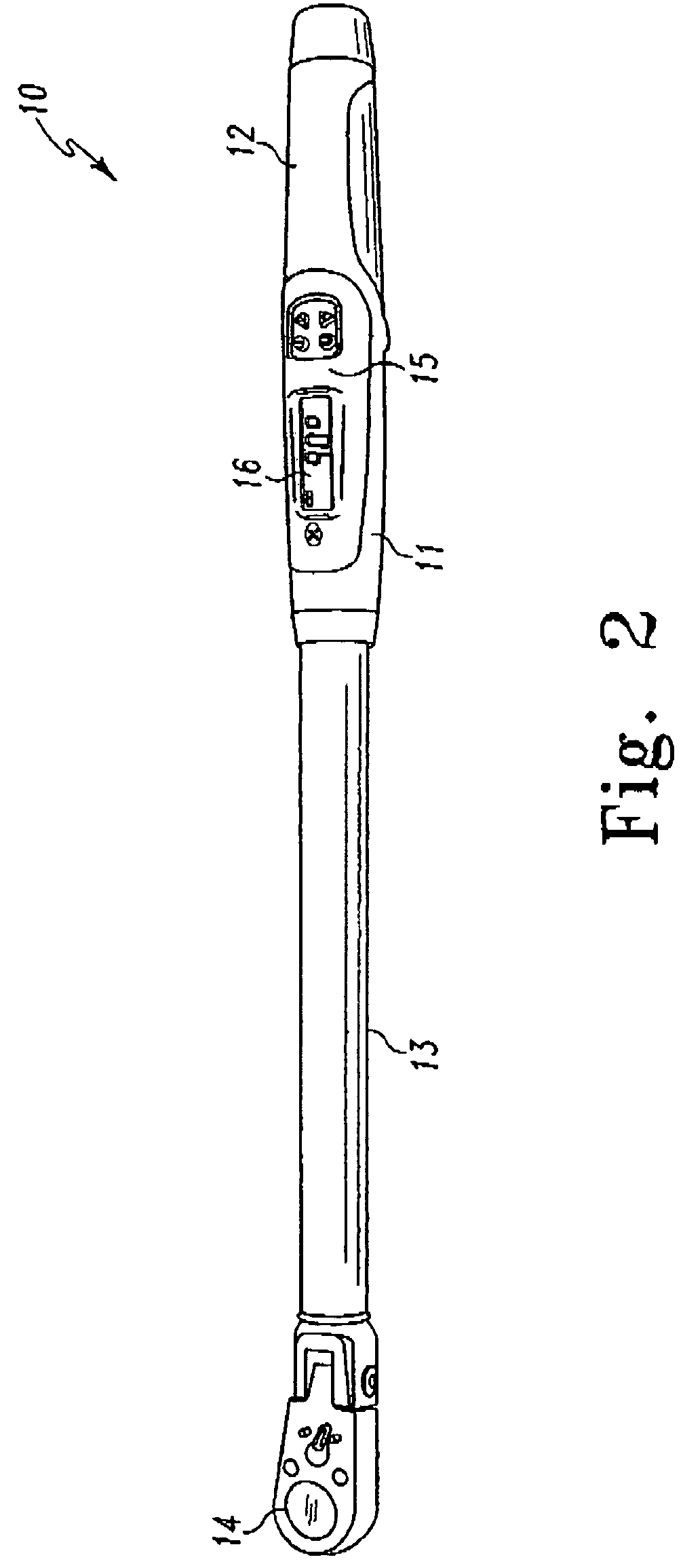

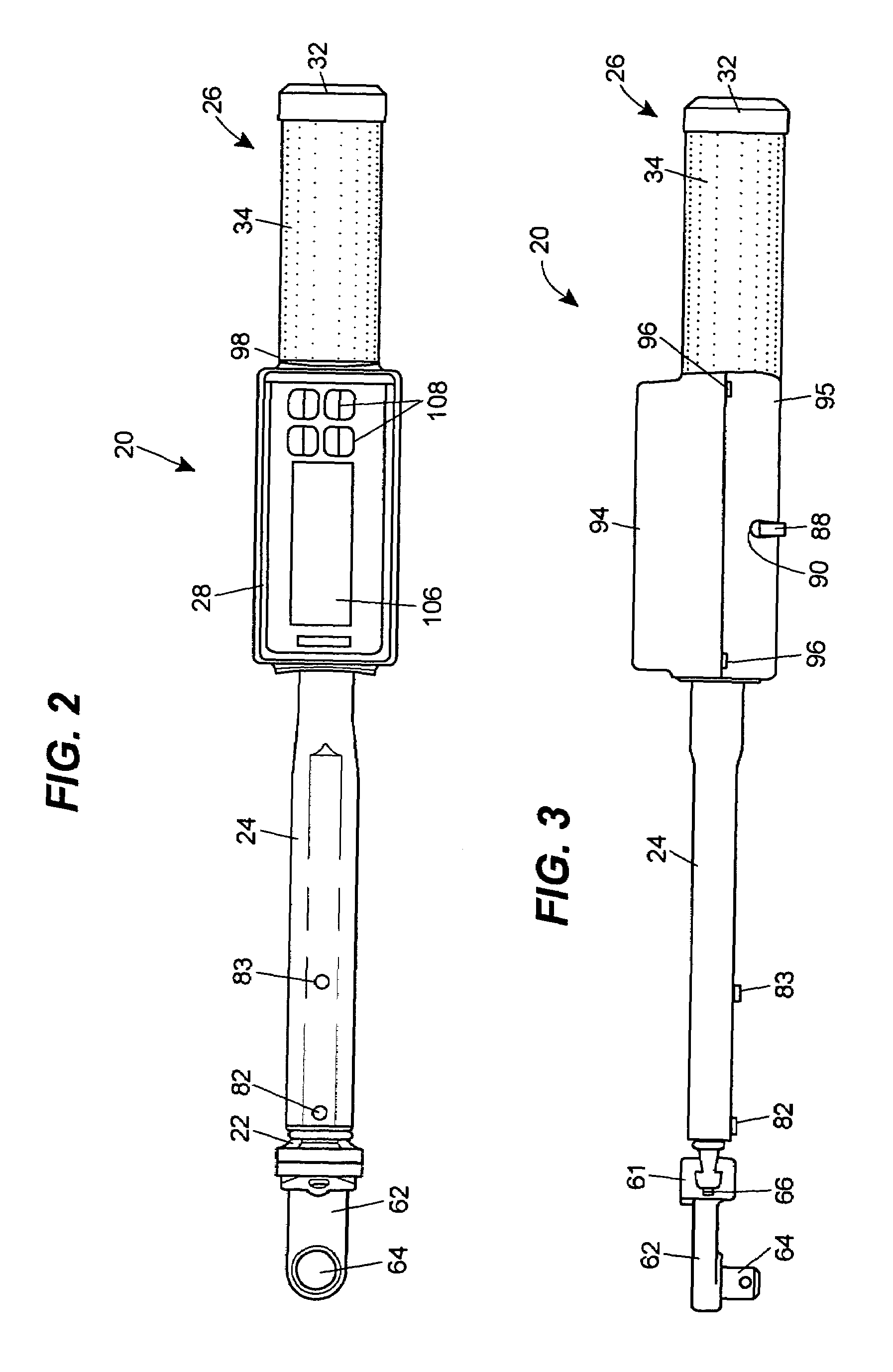

Electromechanical wrench

ActiveUS8171828B2Measurement of torque/twisting force while tighteningWork measurementRatchetEngineering

An electromechanical wrench has a housing that has a working end and a gripping end, with a driver positioned at the working end, and a handle positioned at the gripping end. The wrench further includes a click wrench emulator mechanism provided at the handle. A method of using an electromechanical wrench to secure a fastener using angular measurement without the need for establishing a zero reference point, and allowing for ratcheting, is also provided. A method of counting the number of fasteners secured by an electromechanical wrench during a wrenching job is further provided.

Owner:DIGITOOL SOLUTIONS

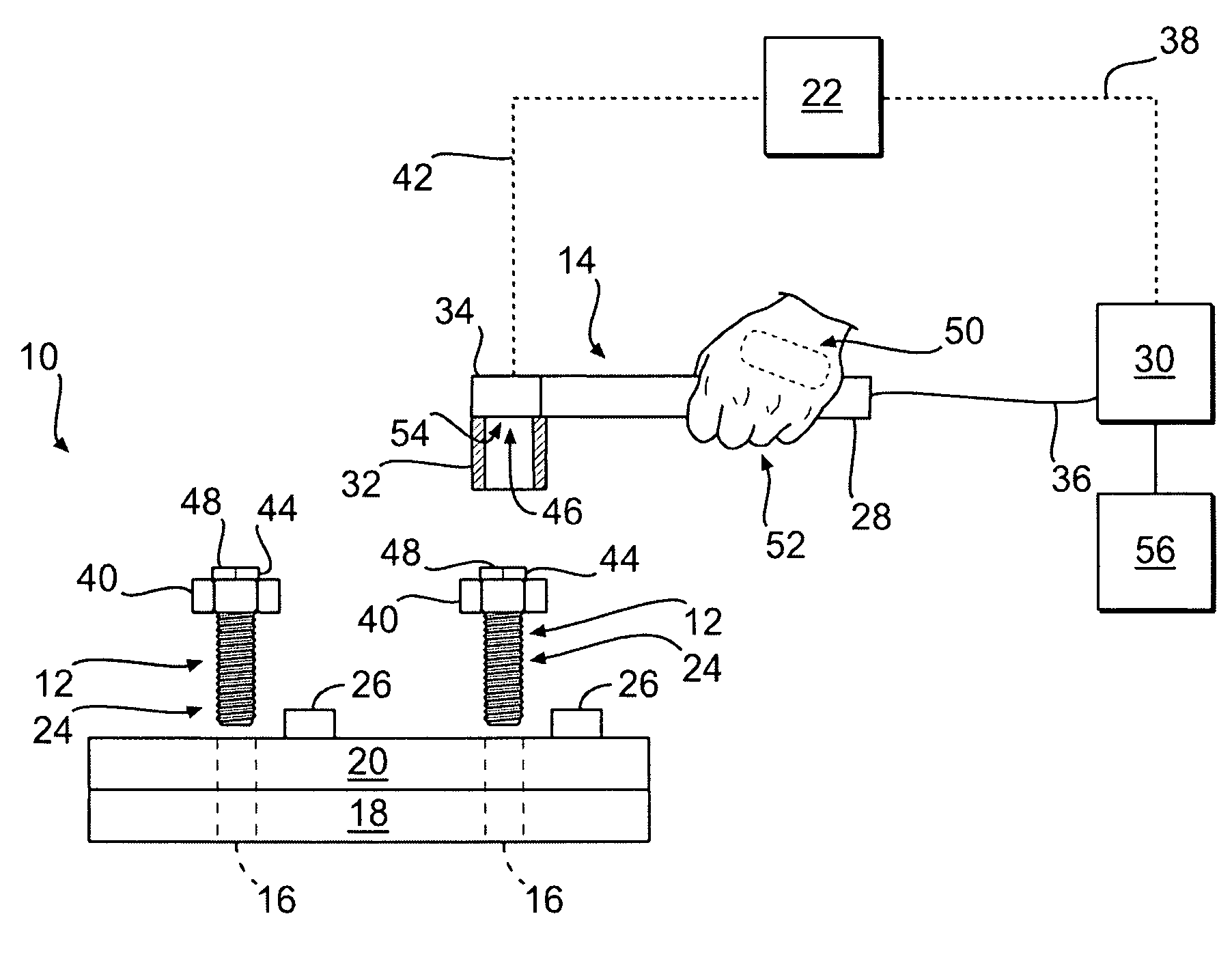

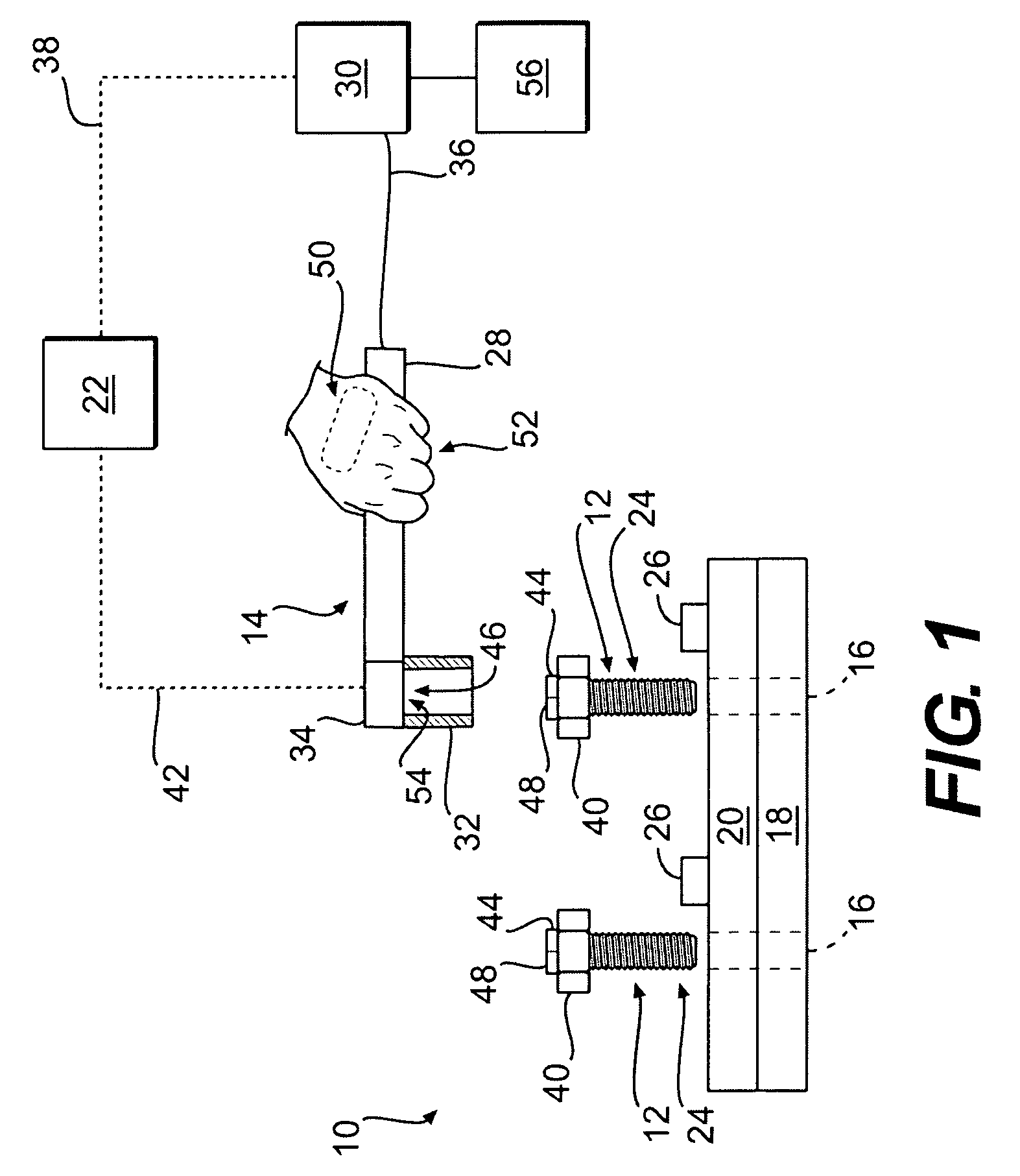

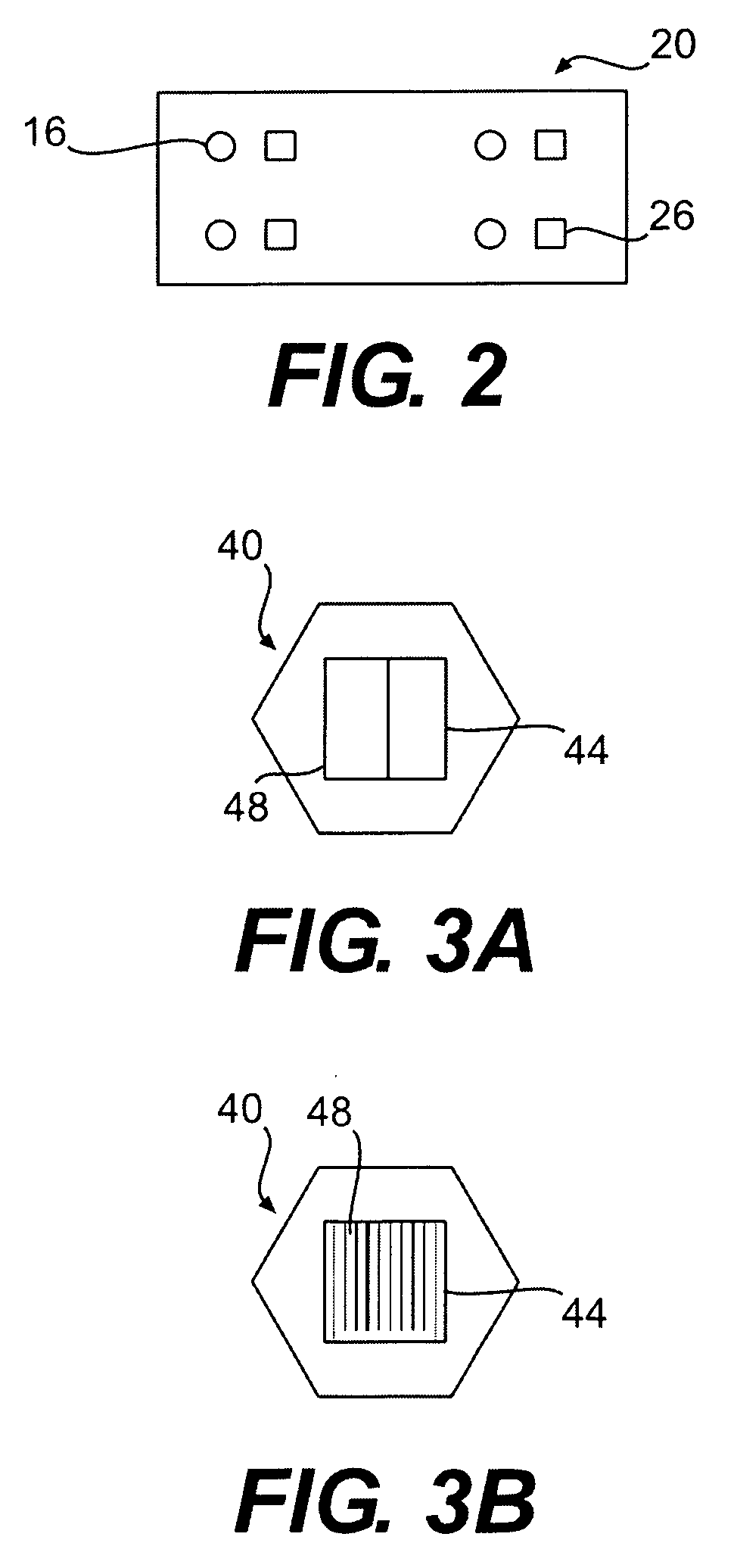

Fastener tightening system utilizing identification technology

InactiveUS20080178713A1Measurement of torque/twisting force while tighteningWork measurementSensing dataReliability engineering

In one aspect, the present disclosure is directed toward a fastener tightening system. The system has a tightening tool configured to apply a torque to a fastener. Additionally, the system has a fastener data storage device located on the fastener and configured to store data related to the associated fastener. The system further has at least one component data storage device located on a component receiving the fastener to store data related to a tightening process. A data sensor is also included and is configured to sense data stored on the fastener data storage device and the at least one component data storage device. The system also has a controller configured to regulate operation of the tightening tool based on the sensed data and the sensed parameter.

Owner:CATERPILLAR INC

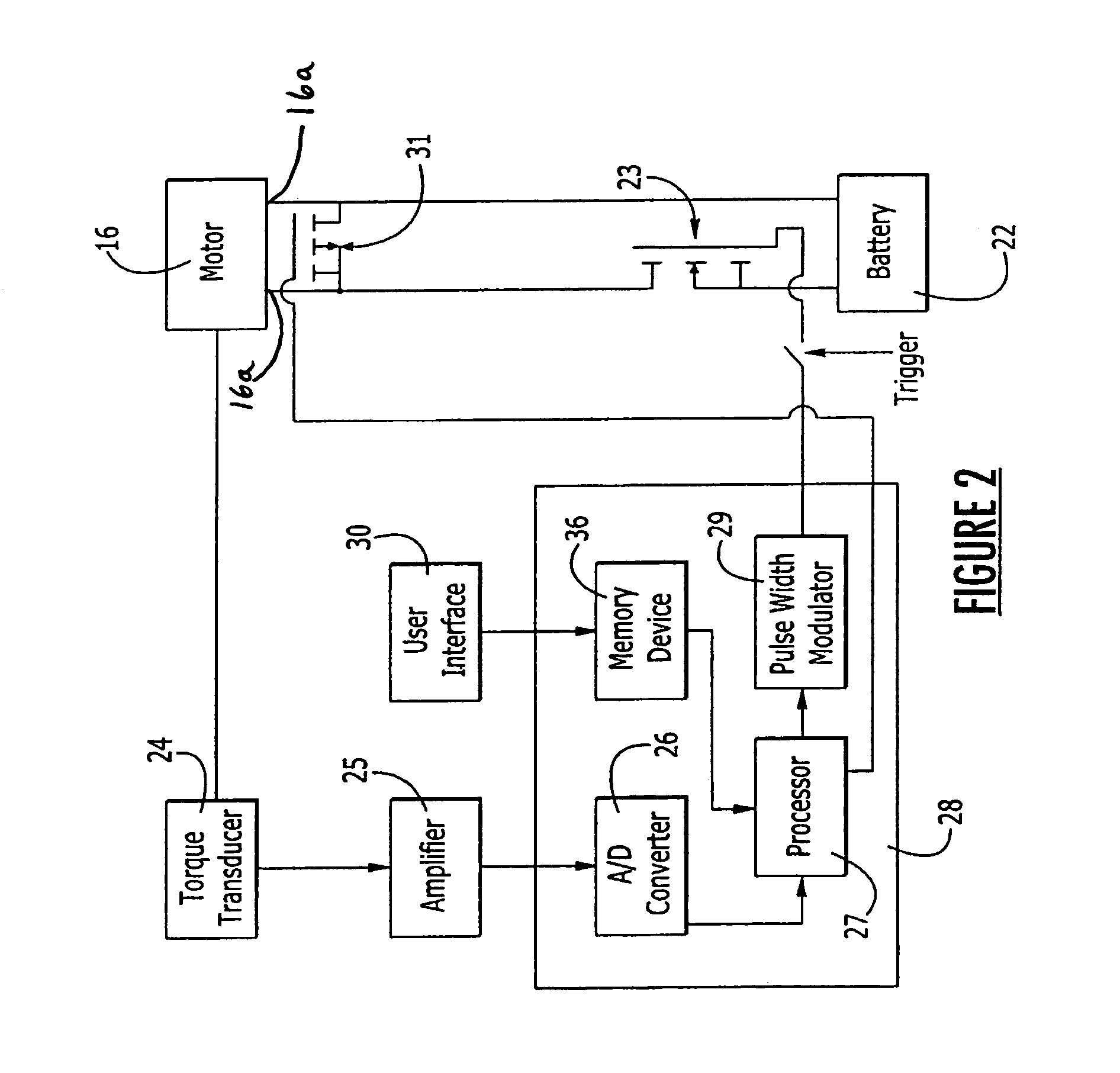

Processes of determining torque output and controlling power impact tools using a torque transducer

InactiveUS6848516B2Measurement of torque/twisting force while tighteningDerricks/mastsControl powerControl system

Owner:CHICAGO PNEUMATIC TOOL

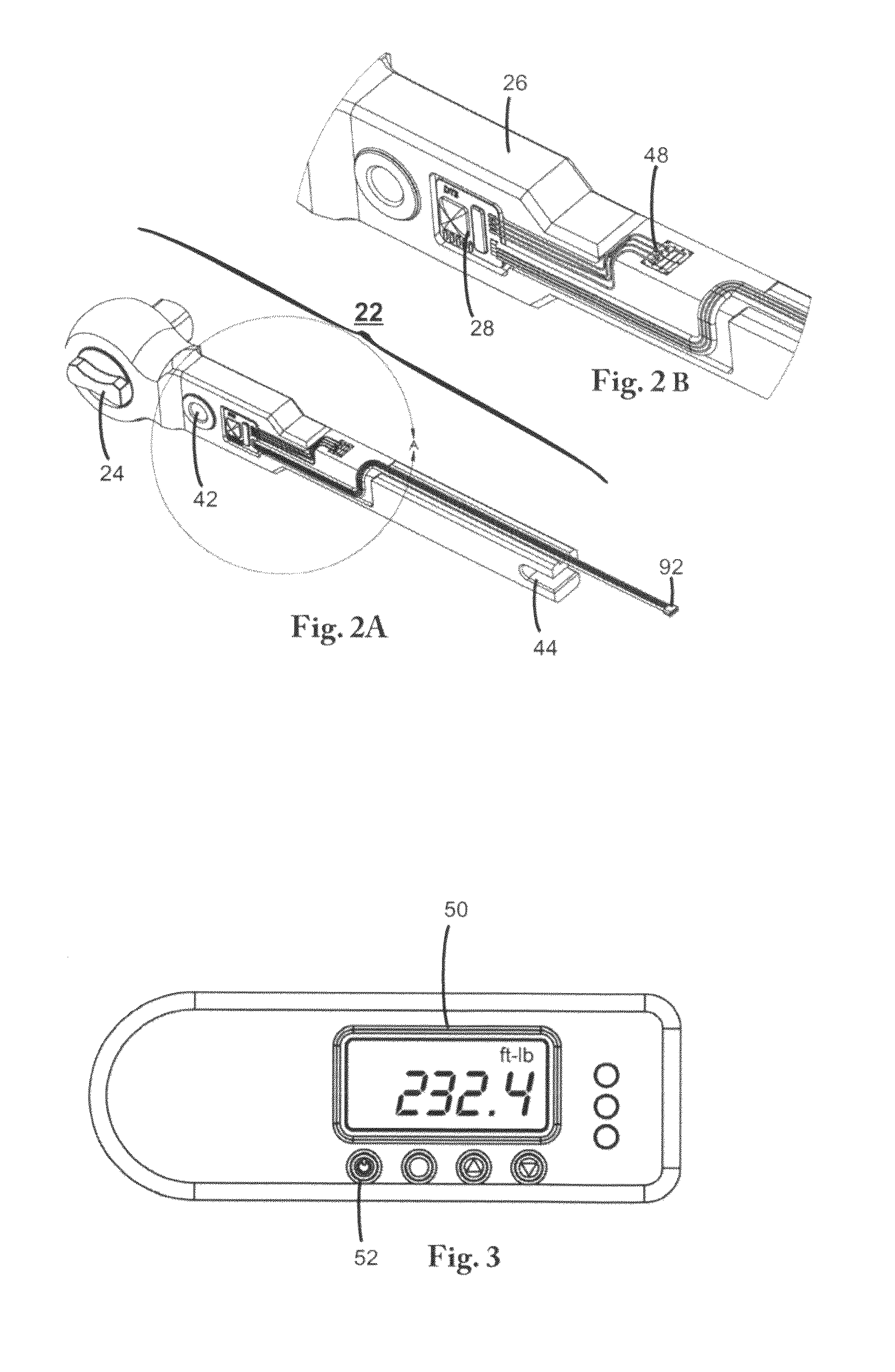

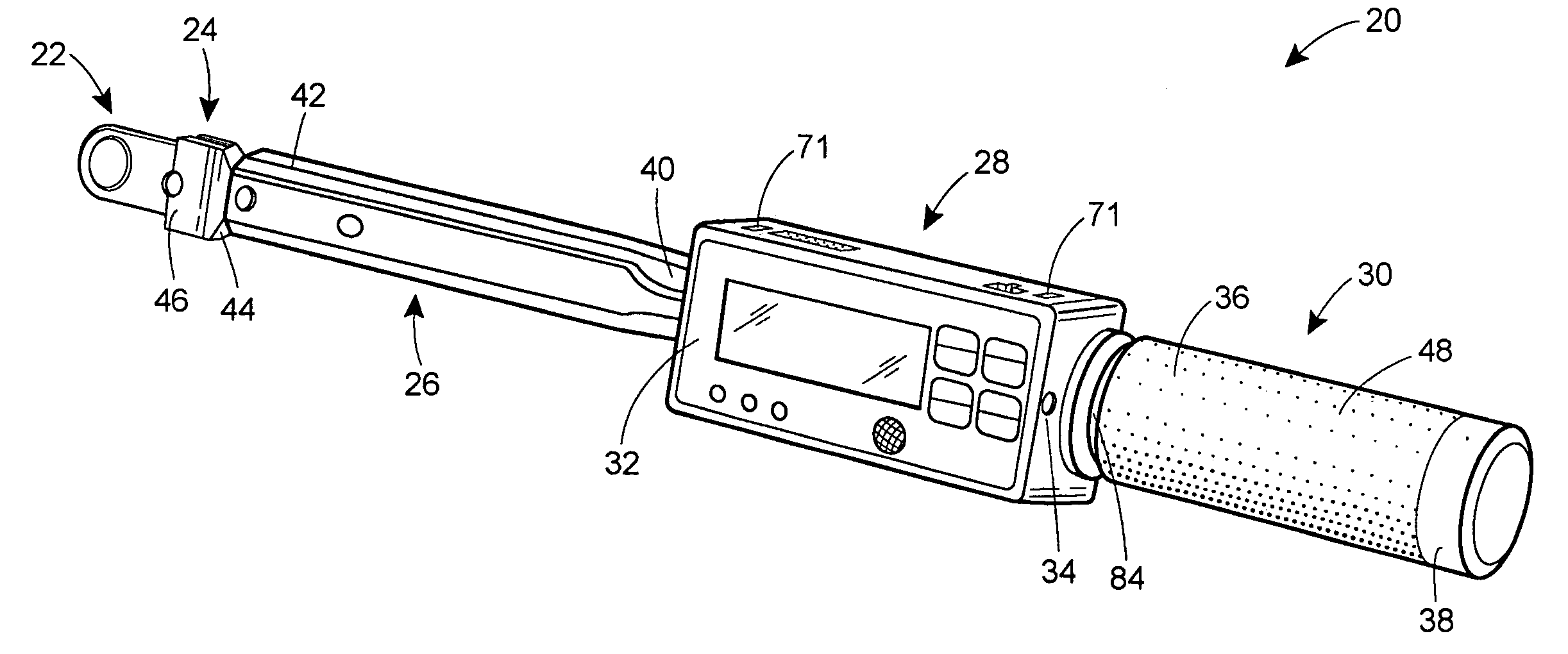

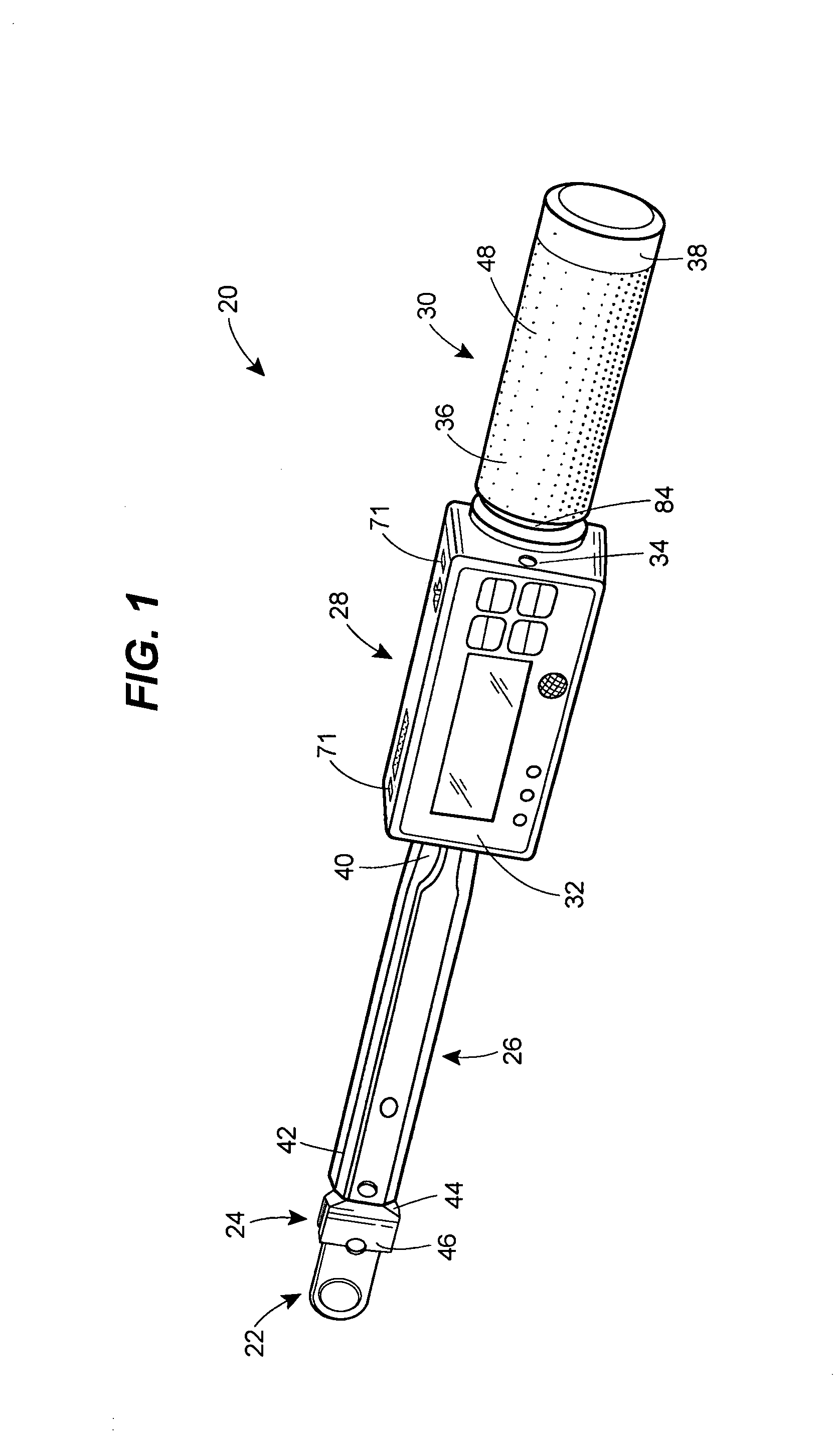

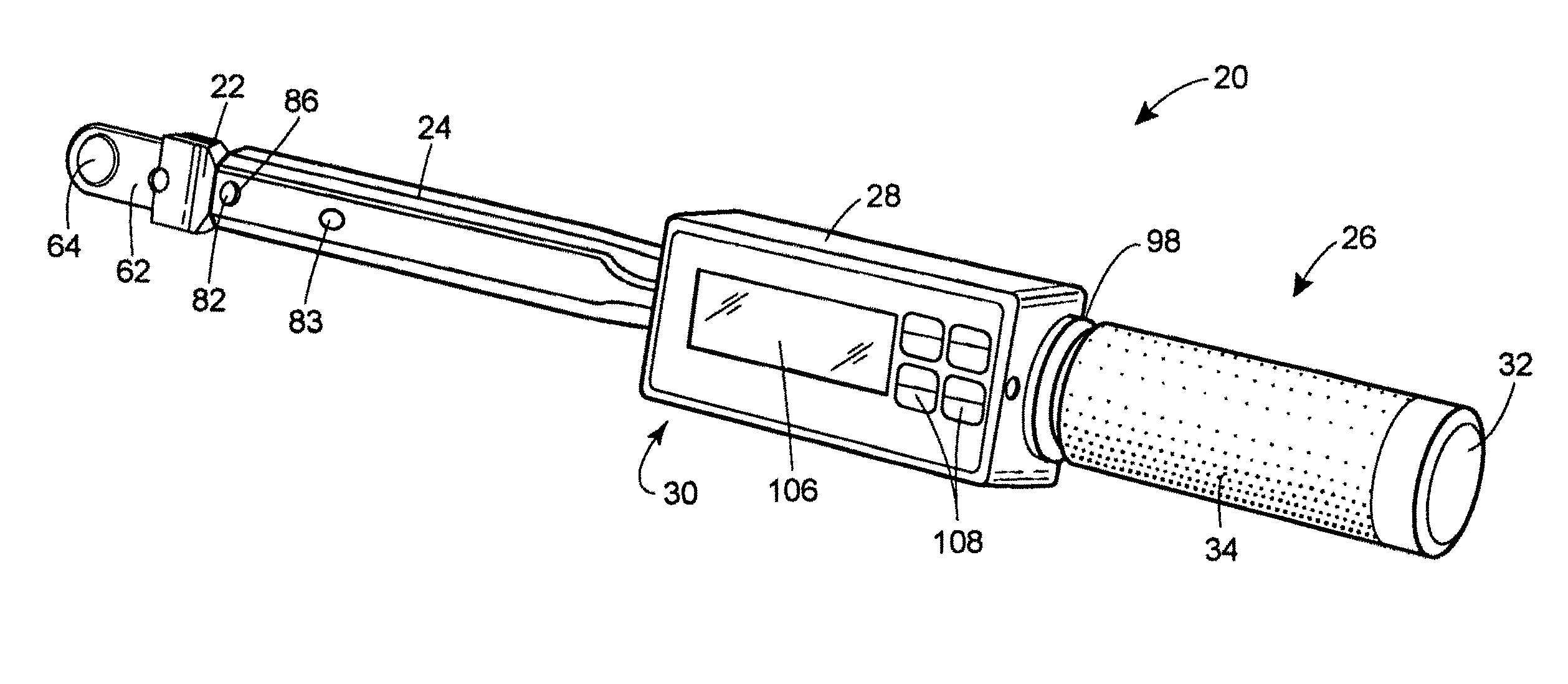

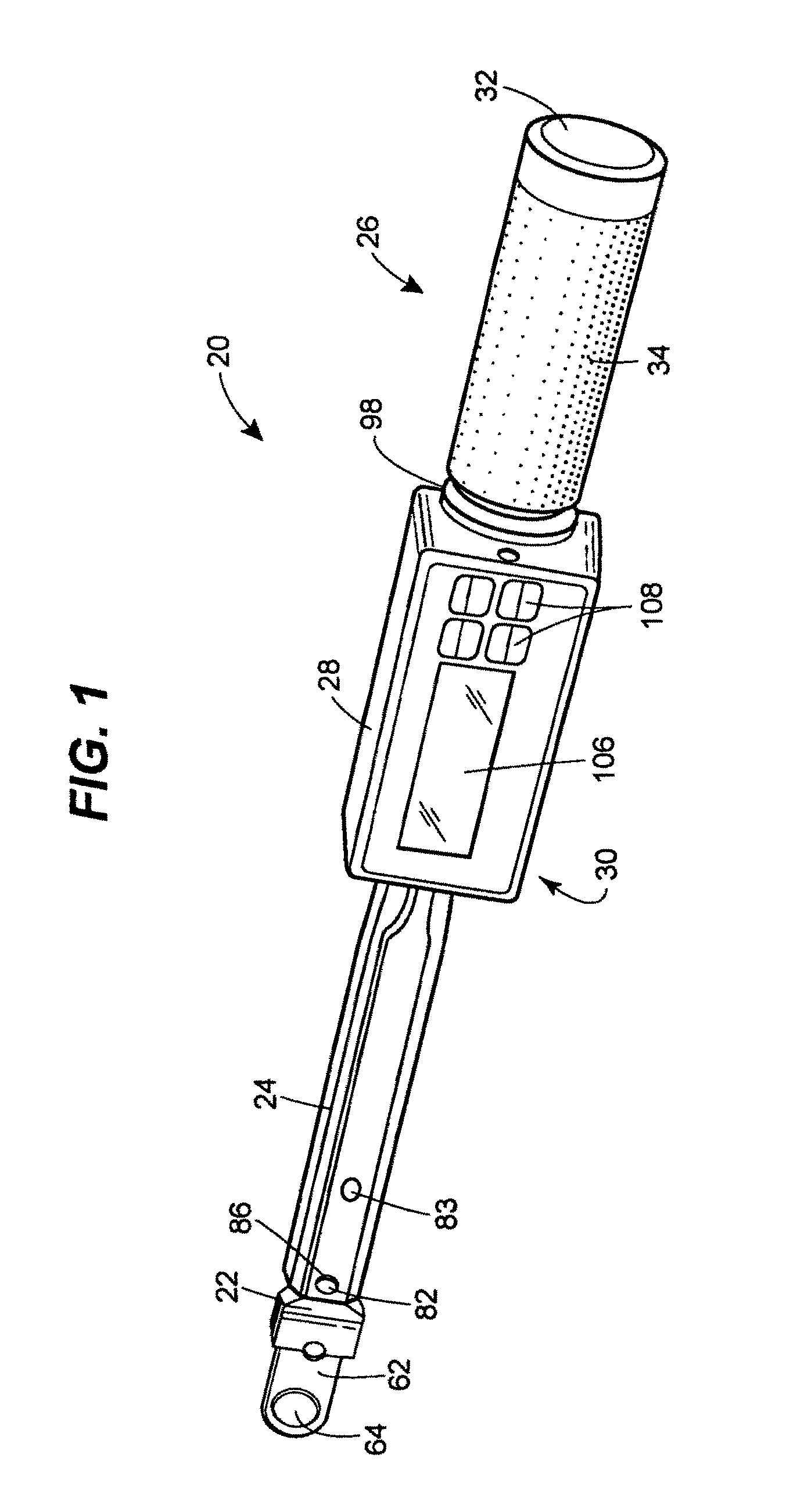

Torque wrench with torque range indicator and system and method employing the same

ActiveUS7089834B2Measurement of torque/twisting force while tighteningMeasurement arrangements for variableComputer moduleControl theory

A torque wrench is disclosed having torque range indicators. The torque wrench includes a handle, a torquing tool, a mounting bar and a programmable interface module. At least one torque sensor is communicatively coupled to the interface module. The interface module includes an input device able to receive at least one predetermined torque value, a torque value indicator, a torque range indicator, and a controller. The torque value indicator, the torque sensor, and the torque range indicator are communicatively coupled to the controller, and the controller is programmed to activate the torque range indicator based on a torque range calculated by comparing a torque value received from the torque sensor to the at least one predetermined torque value.

Owner:RYESON CORP

Independently calibrated wireless structural load sensor

InactiveUS8024980B2Testing/calibration apparatusMeasurement of torque/twisting force while tighteningStructural loadEngineering

A device includes a removable load element. The removable load element includes a pin portion and a housing portion. The pin portion extends from the housing portion. The pin portion includes a sensor. The housing portion includes an electronic circuit connected to the sensor.

Owner:LORD CORP

Smart fastener and smart insert for a fastener using fiber bragg gratings to measure strain and temperature

ActiveUS20100329602A1Accurate monitoringAccurate assessmentMeasurement of torque/twisting force while tighteningForce measurement by measuring optical property variationFiberMeasurement device

A measurement device including a fastener for use in attaching a first member to a second member, in which the fastener has an aperture extending through a length of the fastener, and a first optical fiber located within the aperture, in which the first optical fiber includes at least one fiber Bragg grating sensor. At least a portion of the first optical fiber can be secured within the aperture. A first end of the first optical fiber can be connected to an associated first optical connector and a second end of the first optical fiber can be connected to an associated second optical connector.

Owner:CLEVELAND ELECTRIC LAB

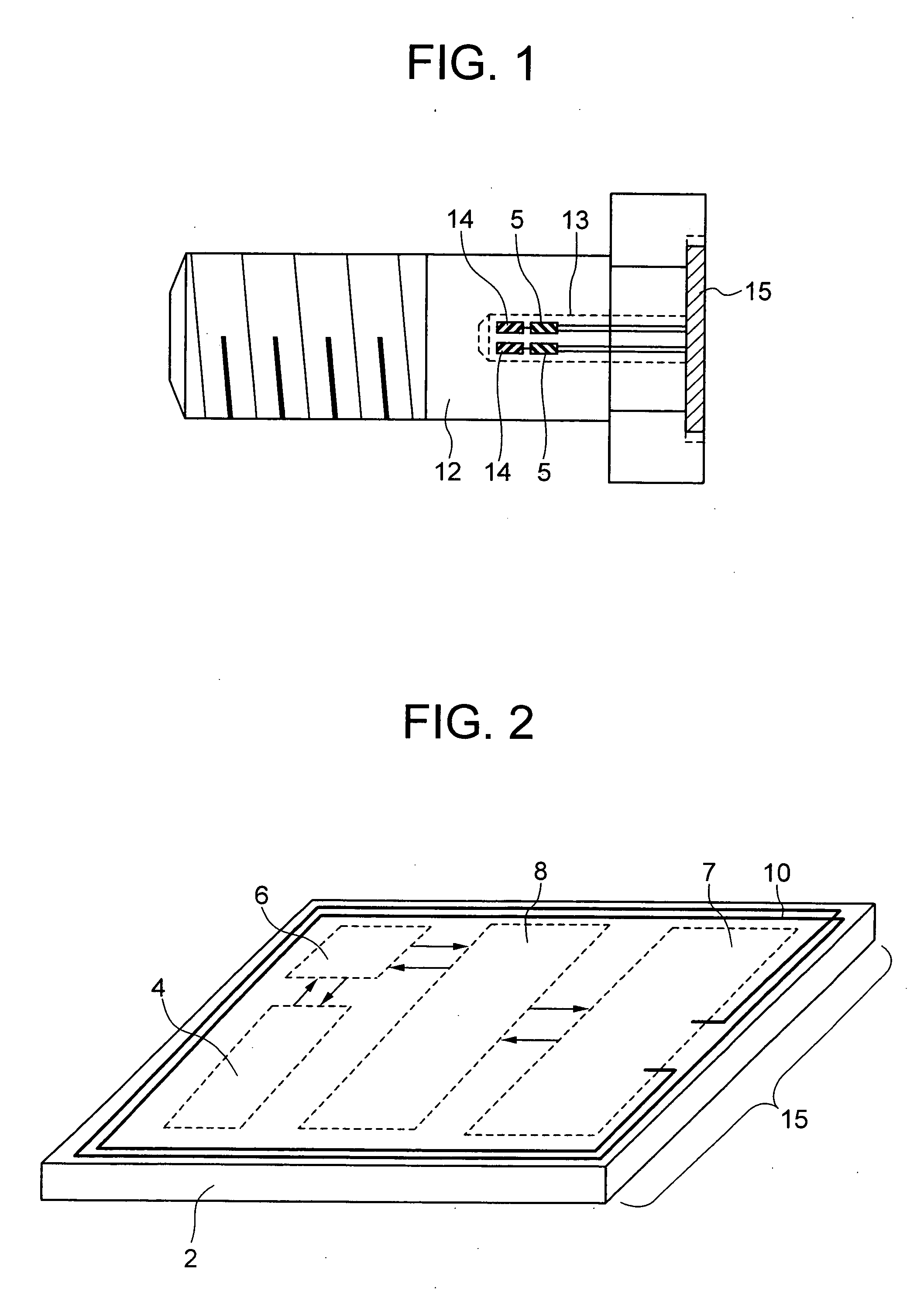

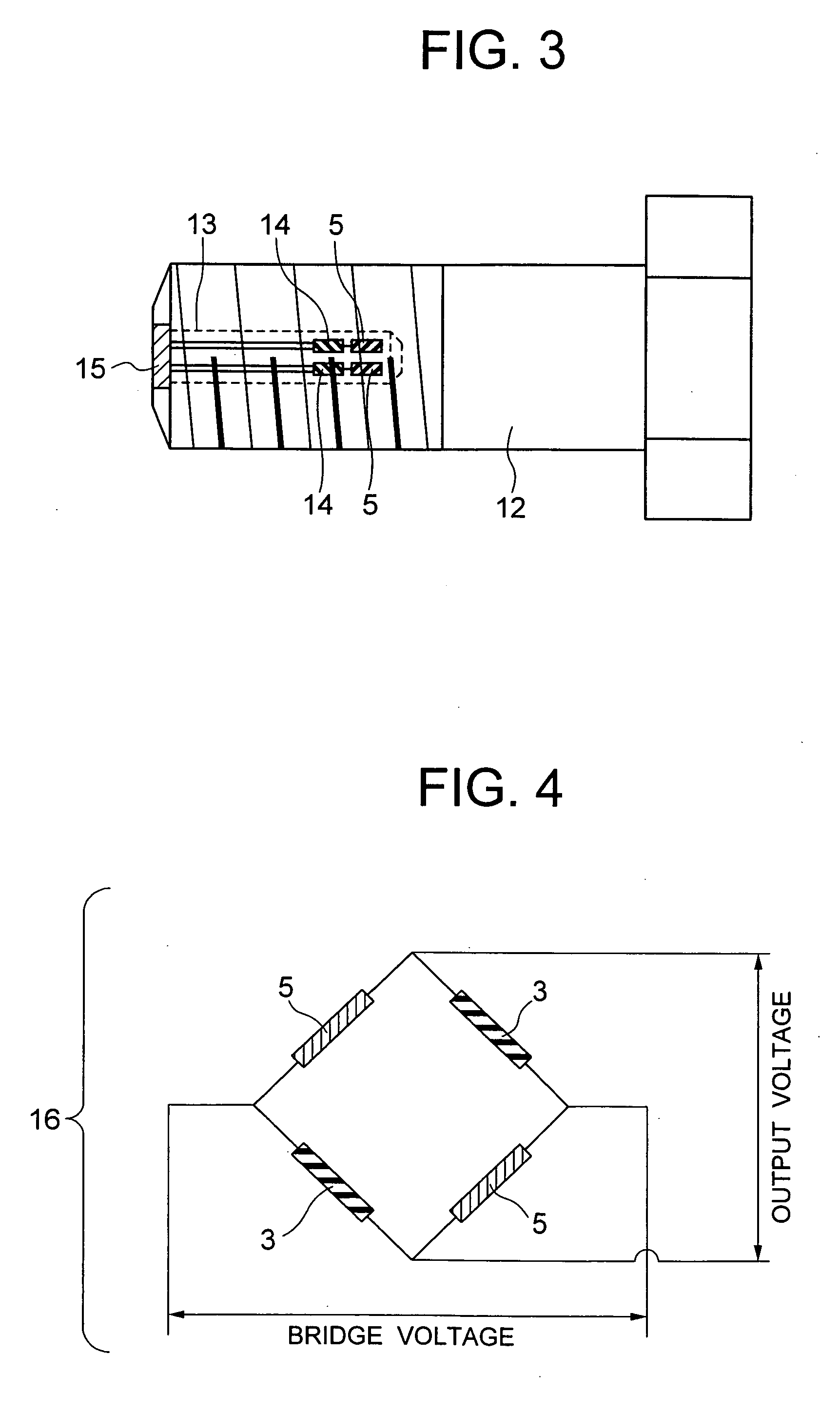

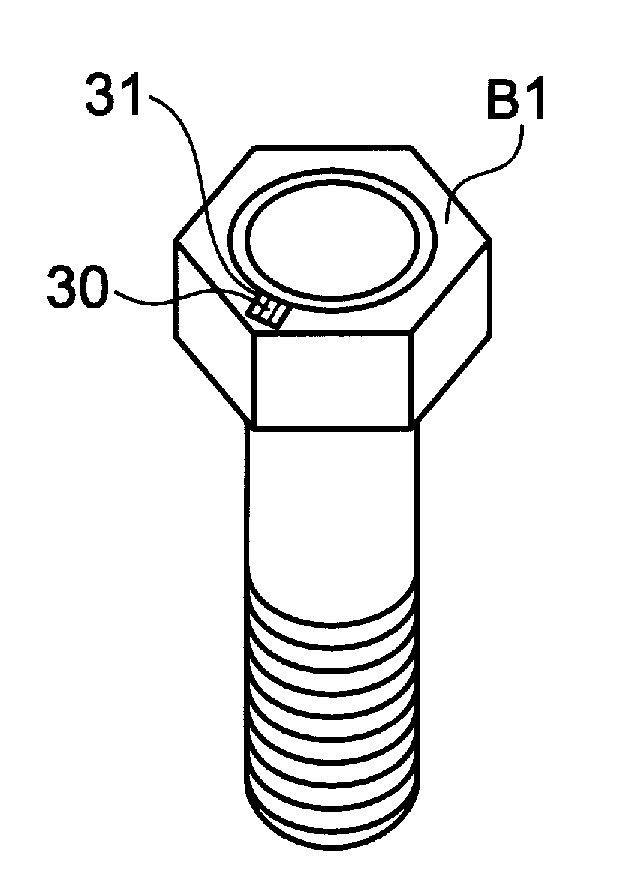

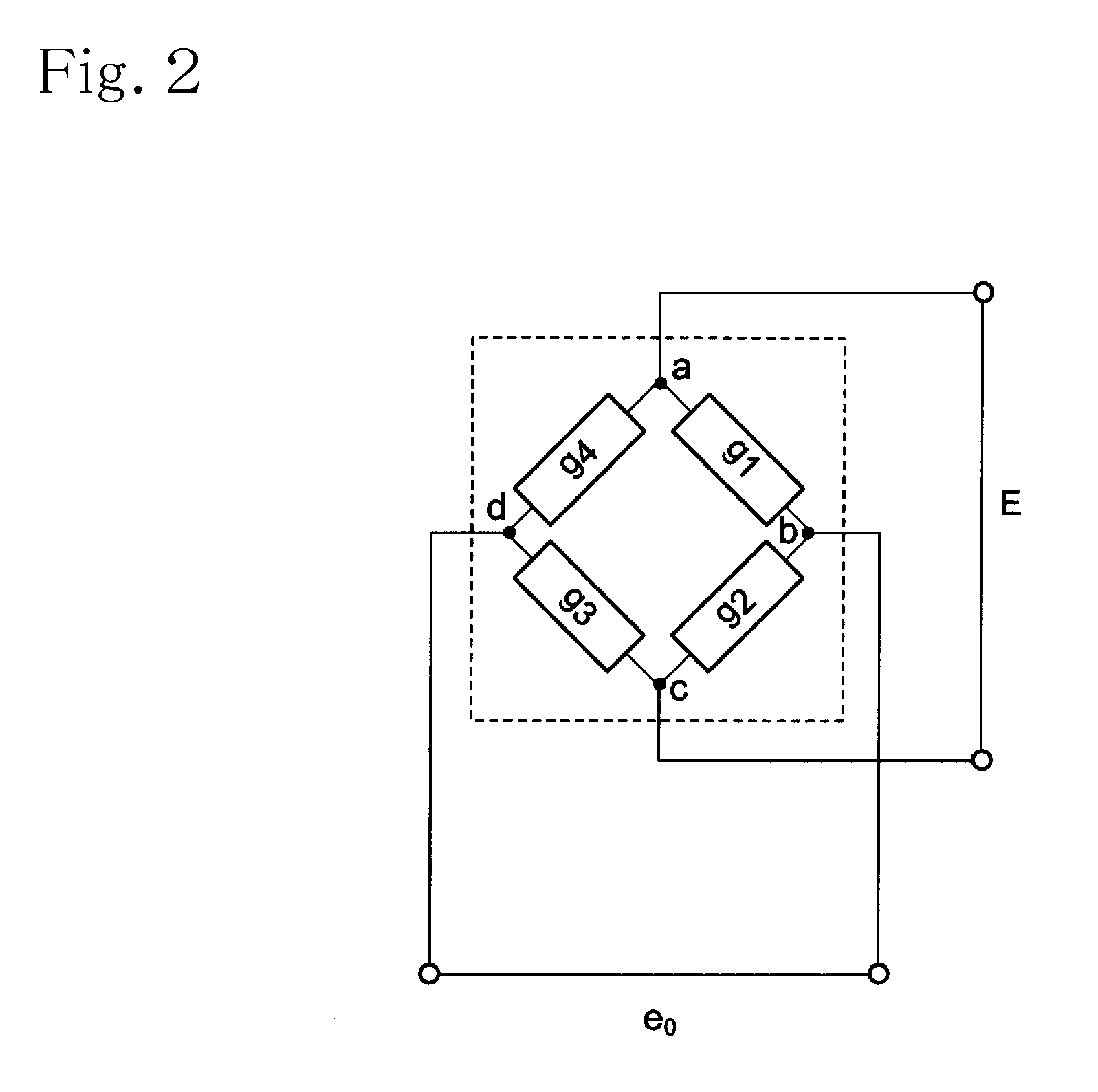

Bolt with function of measuring strain

ActiveUS20070017295A1Improve accuracyHigh precision measurementAcceleration measurement using interia forcesTesting/calibration apparatusElectrical resistance and conductanceEngineering

A bolt with a function of measuring strain, comprising a Wheatstone bridge circuit comprising a strain sensor and a dummy resistor, a translate circuit that amplifies a signal from the Wheatstone bridge circuit to convert the same into a digital signal, a transmitting circuit that transmits the digital signal outside the bolt, and a power circuit, by which electromagnetic wave energy received from outside the bolt is supplied as a power source for at least any one of the circuits.

Owner:HITACHI LTD

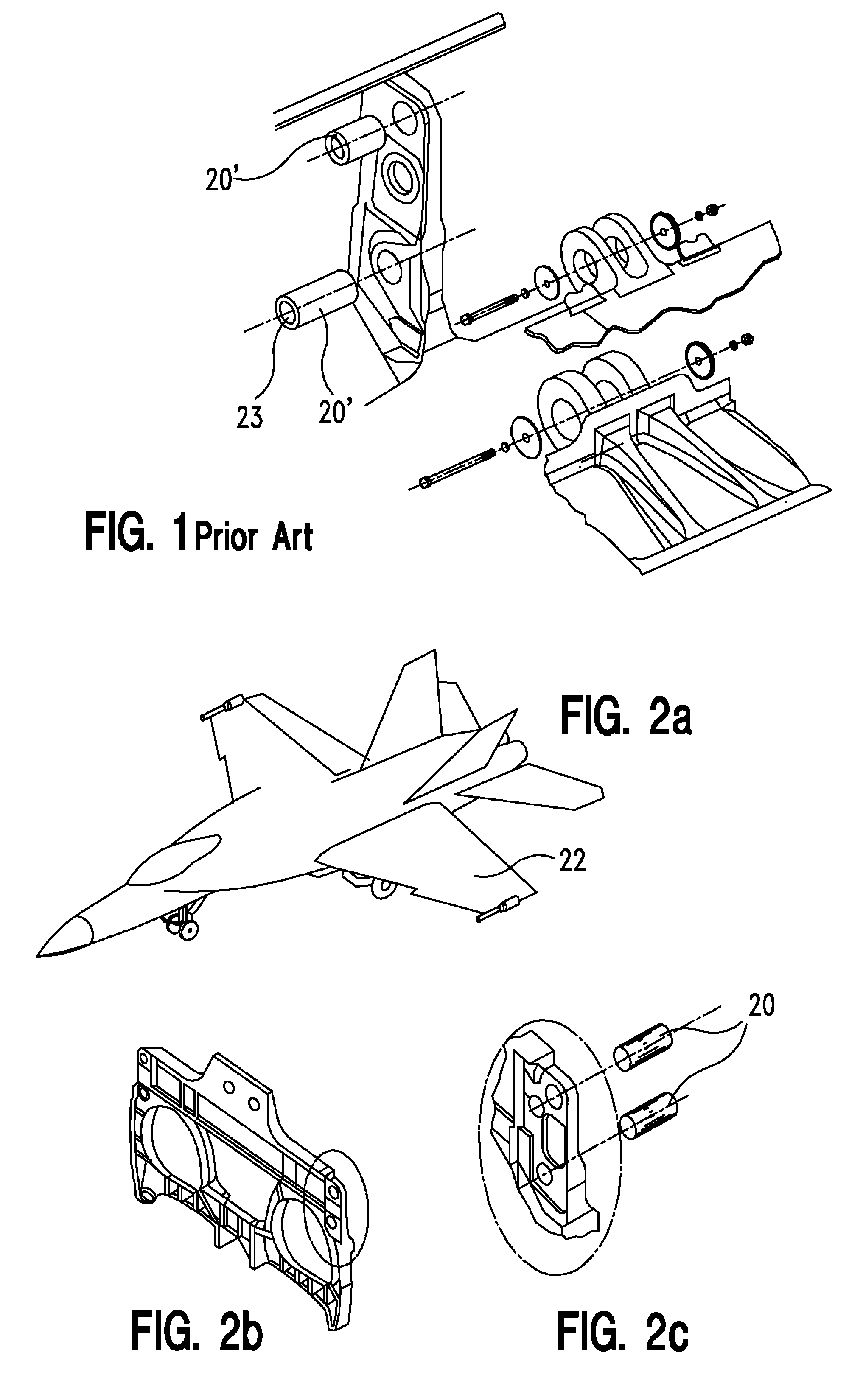

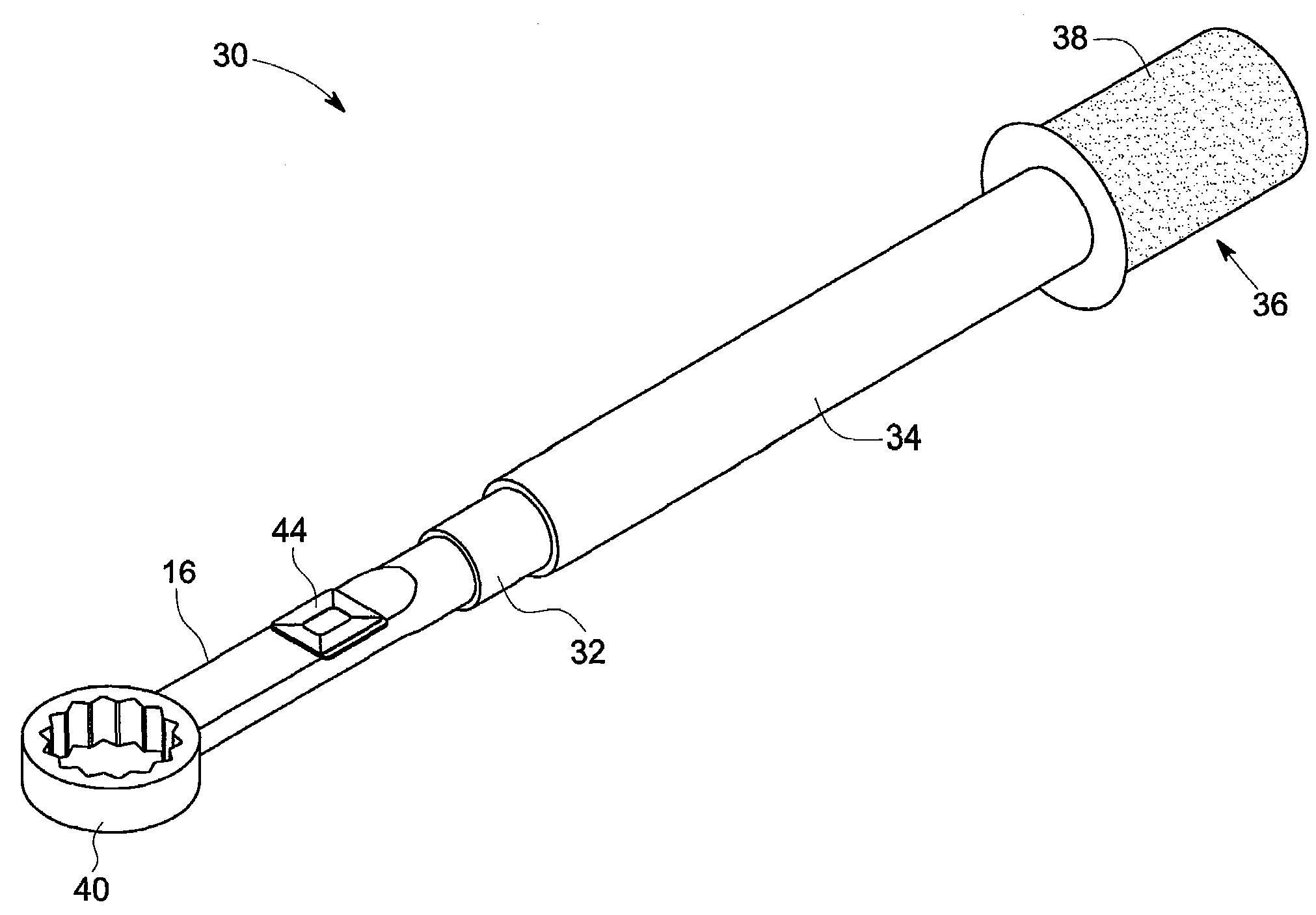

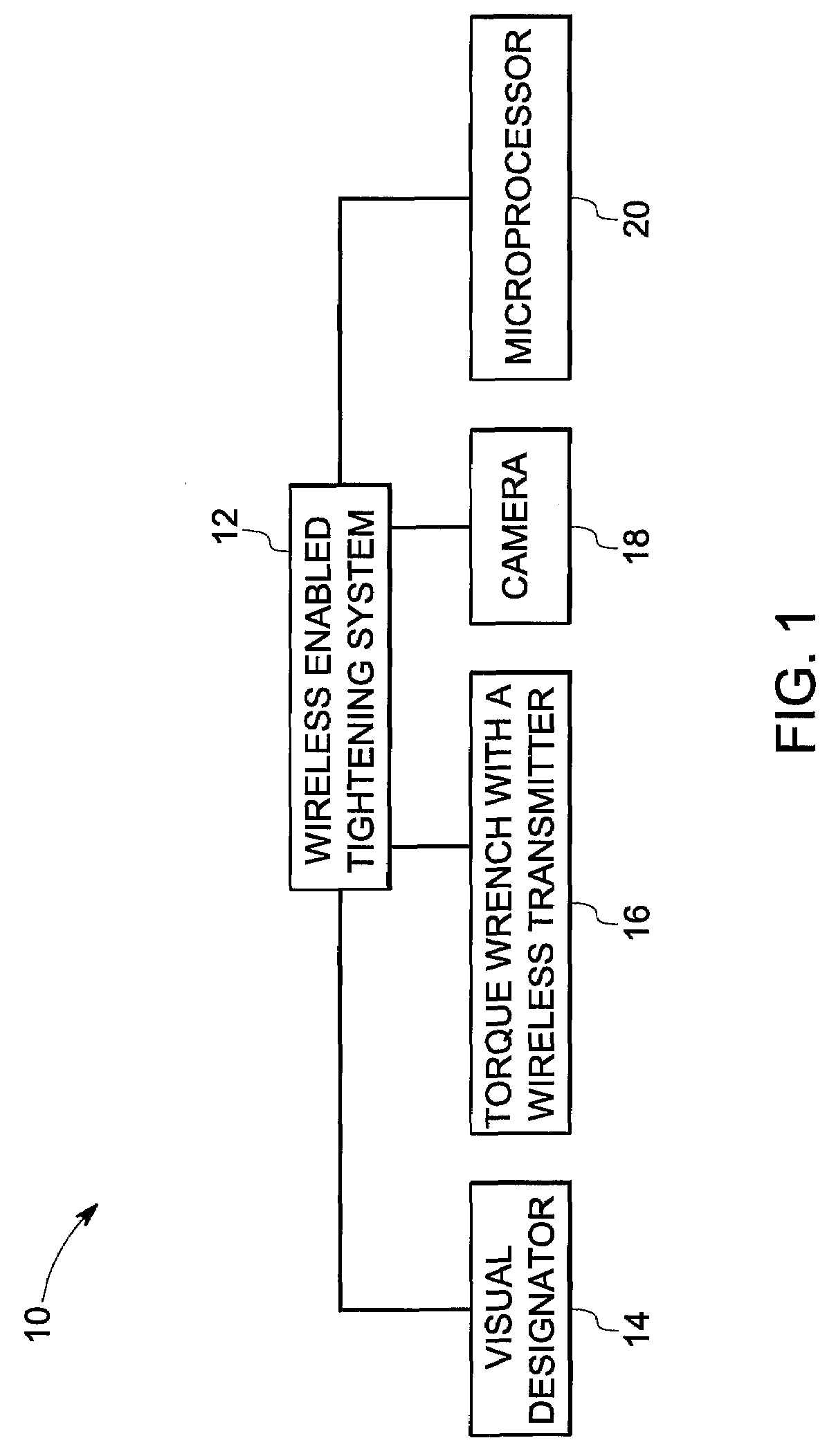

Wireless-enabled tightening system for fasteners and a method of operating the same

ActiveUS20080115589A1Measurement of torque/twisting force while tighteningLoad modified fastenersEngineeringVisual perception

A wireless-enabled tightening system for fasteners is disclosed. The system includes a visual designator configured to project an indicator onto a workpiece. The system also includes a torque wrench comprising a wireless transmitter and a means for identifying whether the correct torque has been applied to a fastener on the workpiece and configured to provide a feedback for a user. The system also includes a camera configured to capture an image of the workpiece when an appropriate amount of torque has been applied to the fastener. The system further includes a microprocessor for determining sequence of the fastener and identifying the tightened fastener.

Owner:GENERAL ELECTRIC CO

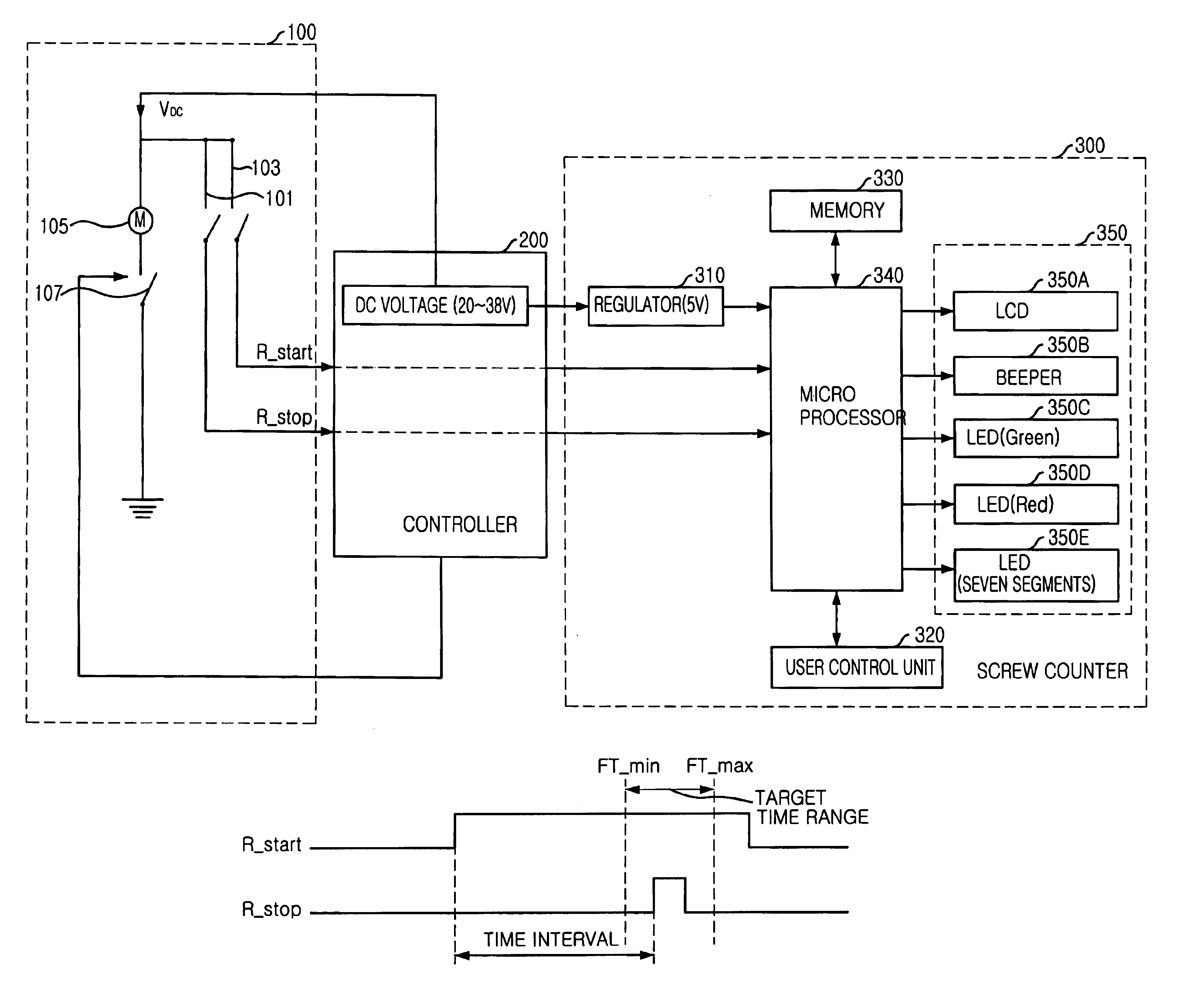

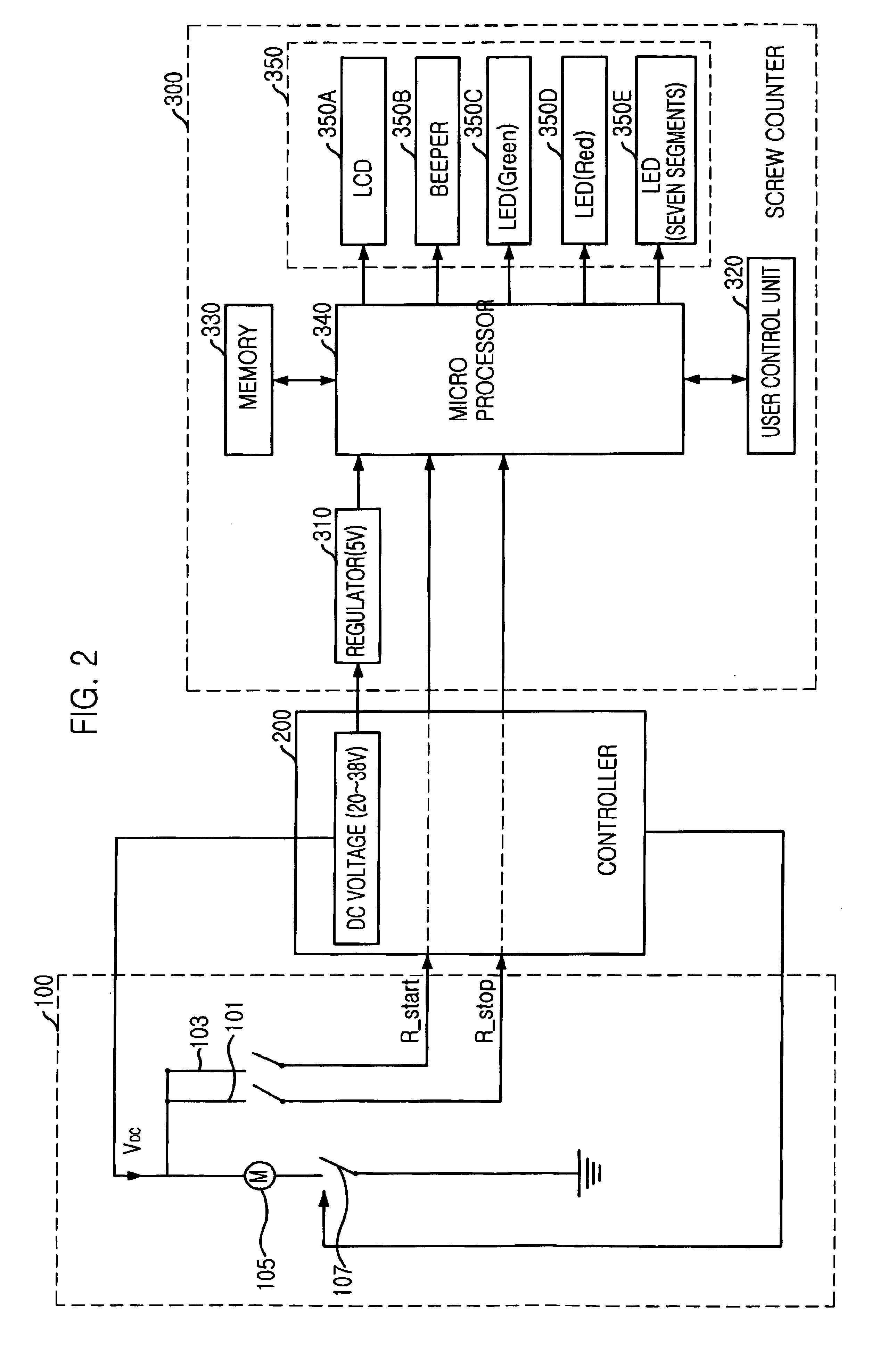

Apparatus for monitoring electric motor screw driver system

InactiveUS6954048B2Improve efficiencyDC motor speed/torque controlEmergency protective circuit arrangementsDriver/operatorInformation seeking

A driver monitor for a driver system. A driver monitor includes a driver monitoring unit for monitoring the fastening operation of the driver based on pre-determined fastening information. A rotation start signal and a rotation stop signal are used to determine whether the fastening operation is appropriately completed or not. An information signal is generated based on a result of monitoring. An operation processing unit outputs the result information signal from the driver monitoring unit to external peripheral apparatus and receives an operation information signal from the external peripheral apparatus in order to cooperate with the external peripheral apparatus. A display unit receives the information signal from the driver monitoring unit and displays the information signal.

Owner:SEHAN ELECTOOLS

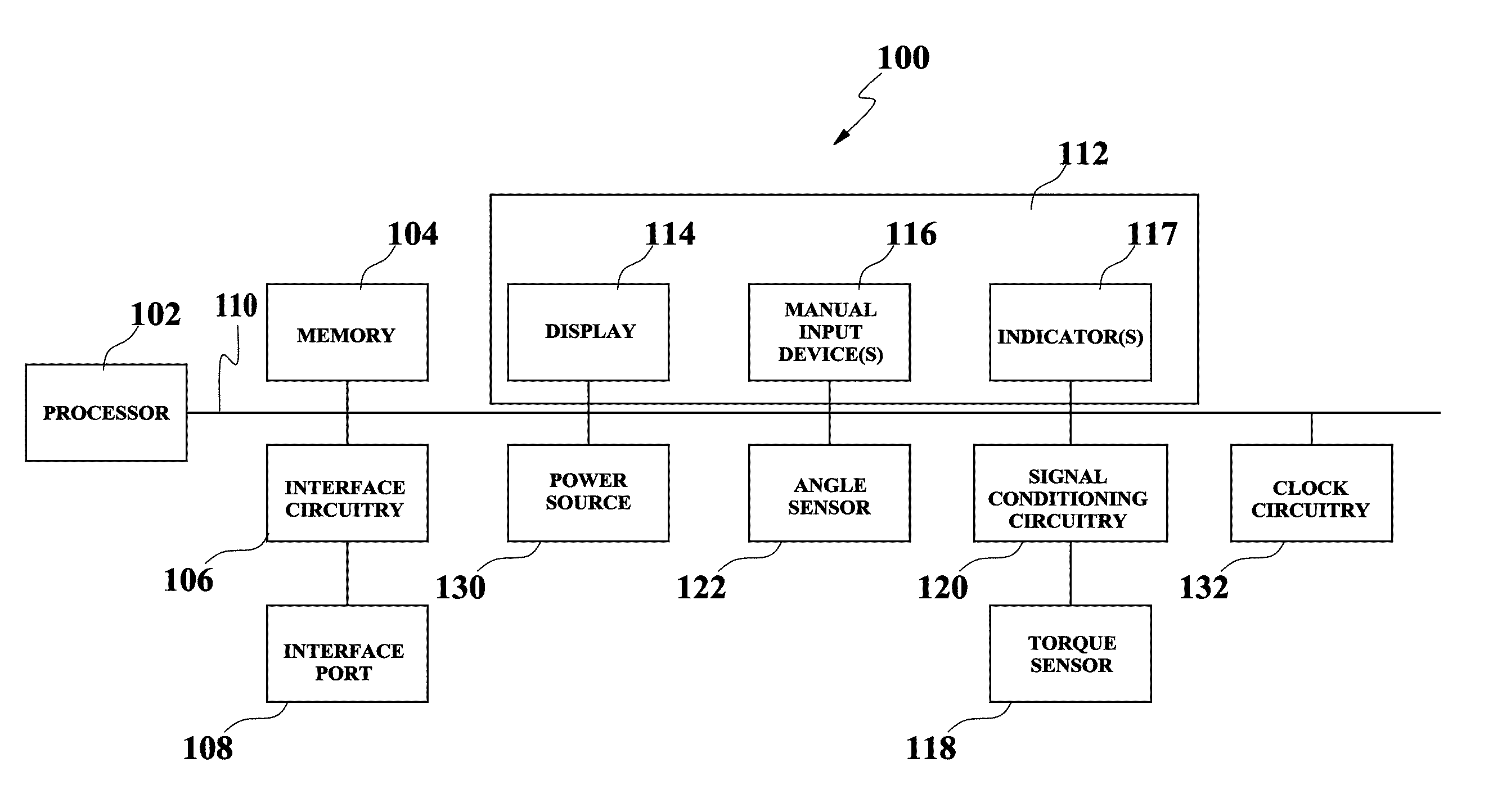

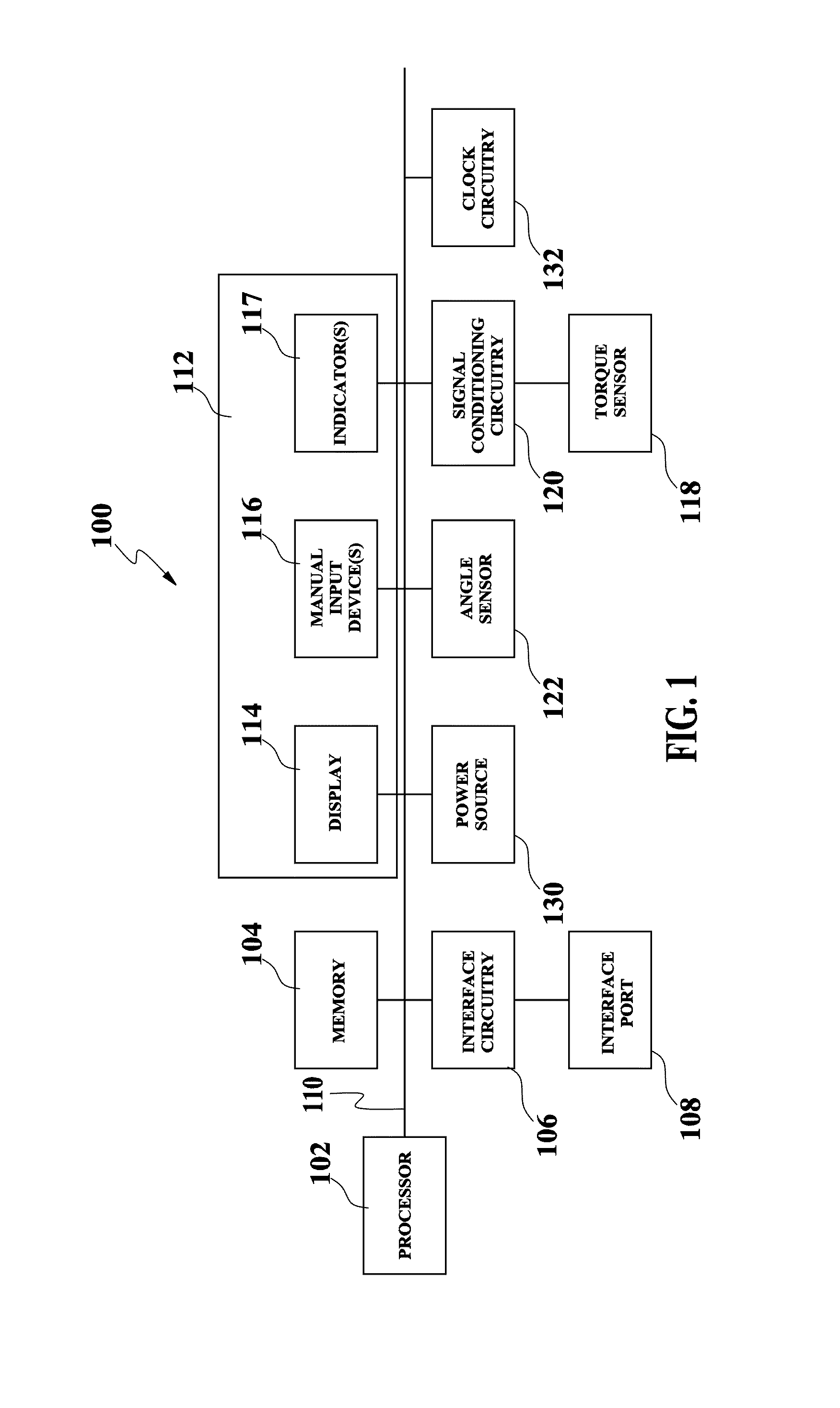

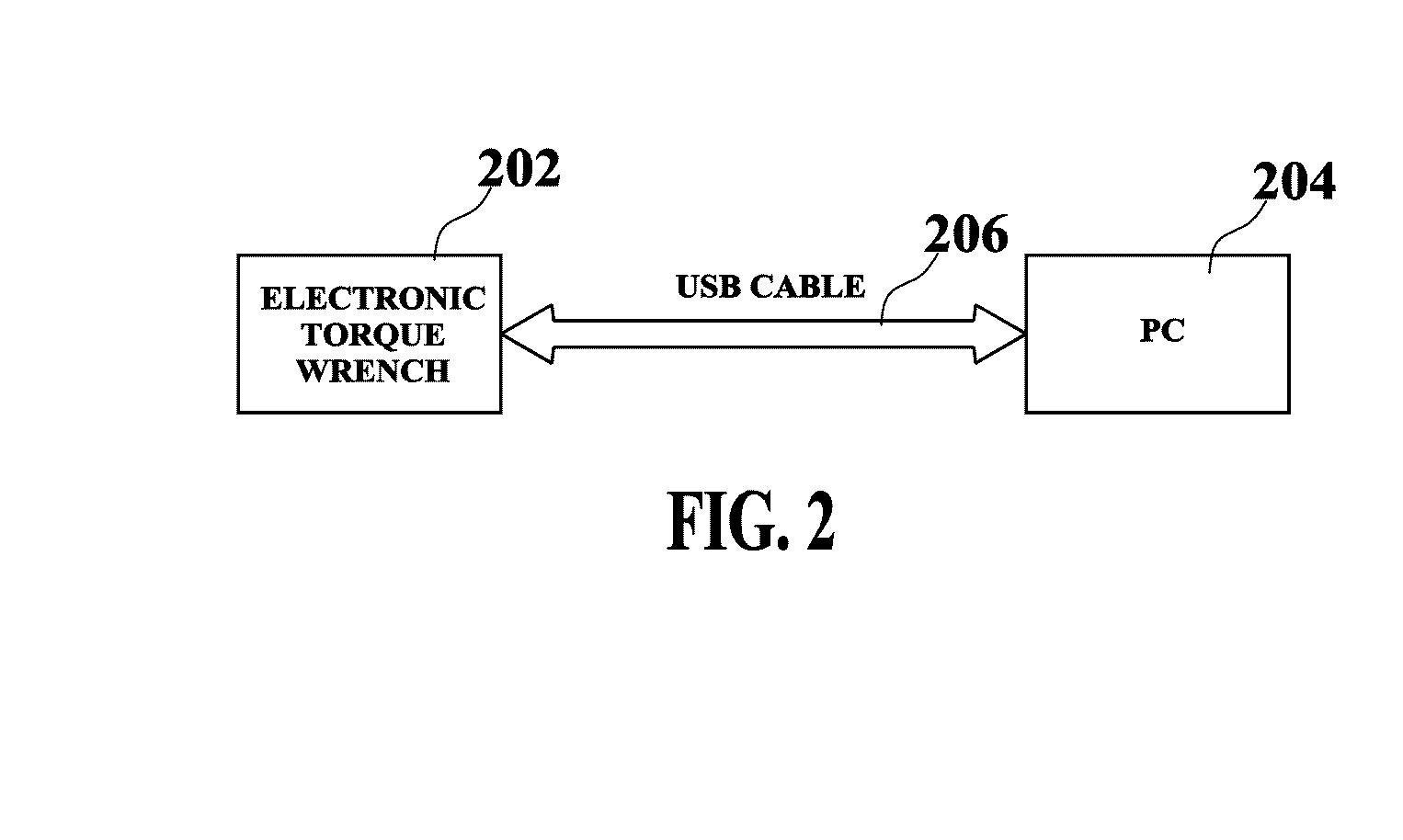

Electronic Torque Tool with Integrated Real-Time Clock

ActiveUS20140336955A1Easy to downloadMeasurement of torque/twisting force while tighteningForce measurementReal-time clockDisplay device

Real-time clock circuitry integrated in an electronic torque tool facilitates time-stamping of torque data acquired by the electronic torque tool. The time stamped torque data may be displayed on a display integrated in the electronic torque tool or may be communicated to an external device. The real-time clock circuitry may be adjusted based on information received from an external device or may be manually input to a keypad of the electronic torque tool. A calibration timer integrated in the electronic torque tool monitors time between calibrations of the tool and notifies a user upon expiration of a calibration interval. A secondary power source is coupled to the real-time clock circuitry to maintain power to the real-time clock circuitry during battery replacement.

Owner:SNAP ON INC

Speed sensor for a power sensor module

ActiveUS7095198B1Low costReduce assemblyDC motor speed/torque controlMeasurement of torque/twisting force while tighteningPower sensorComputer module

A power sensor module suitable for automotive and other high volume applications combines speed sensing and torque sensing operations into a single unit. A magnetic speed sensor is utilized for speed sensing. A power measurement can be derived from torque and speed. Combining torque sensing and speed sensing within a single module instead of using separate modules for each allows for reducing redundancies and lowering cost.

Owner:HONEYWELL INT INC

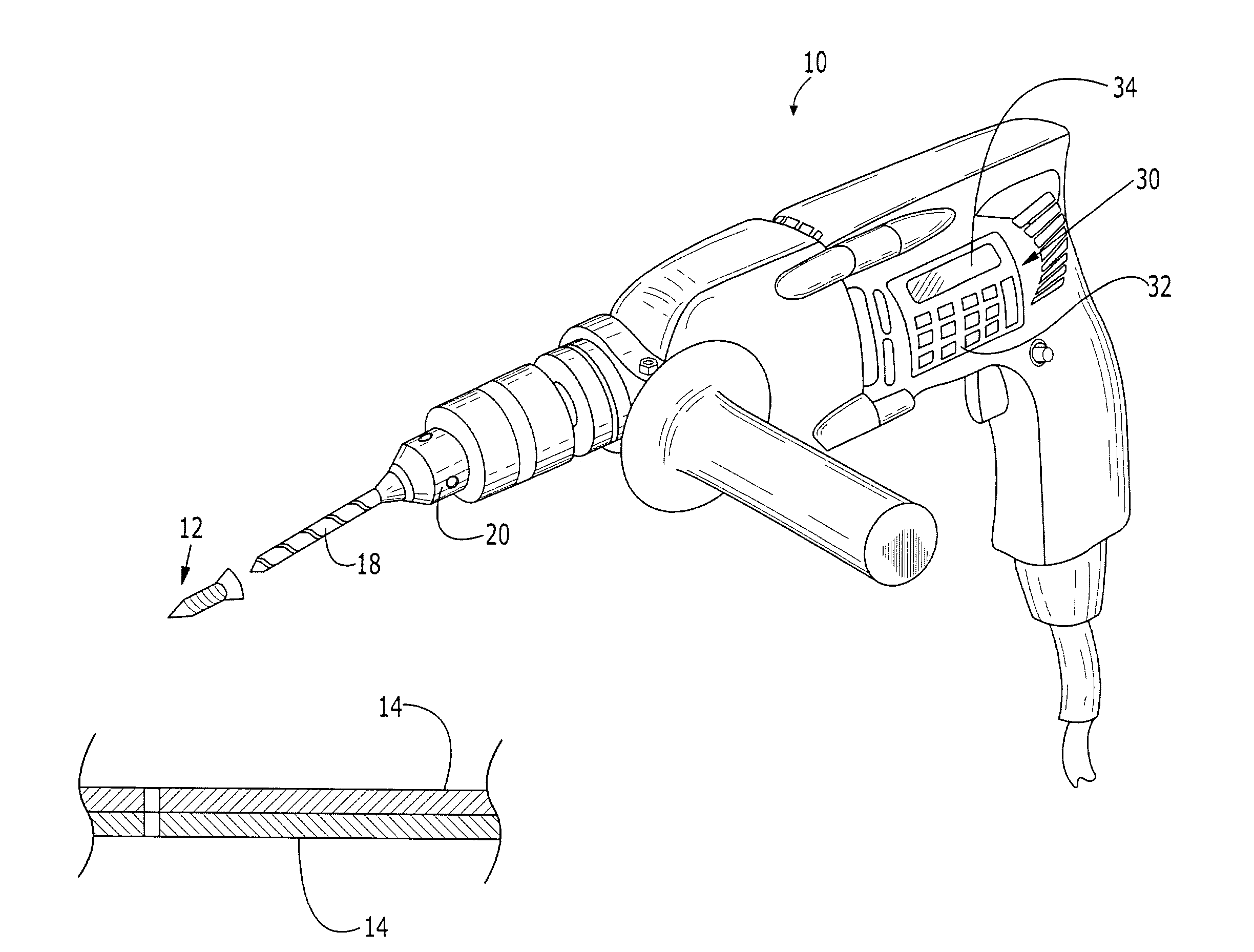

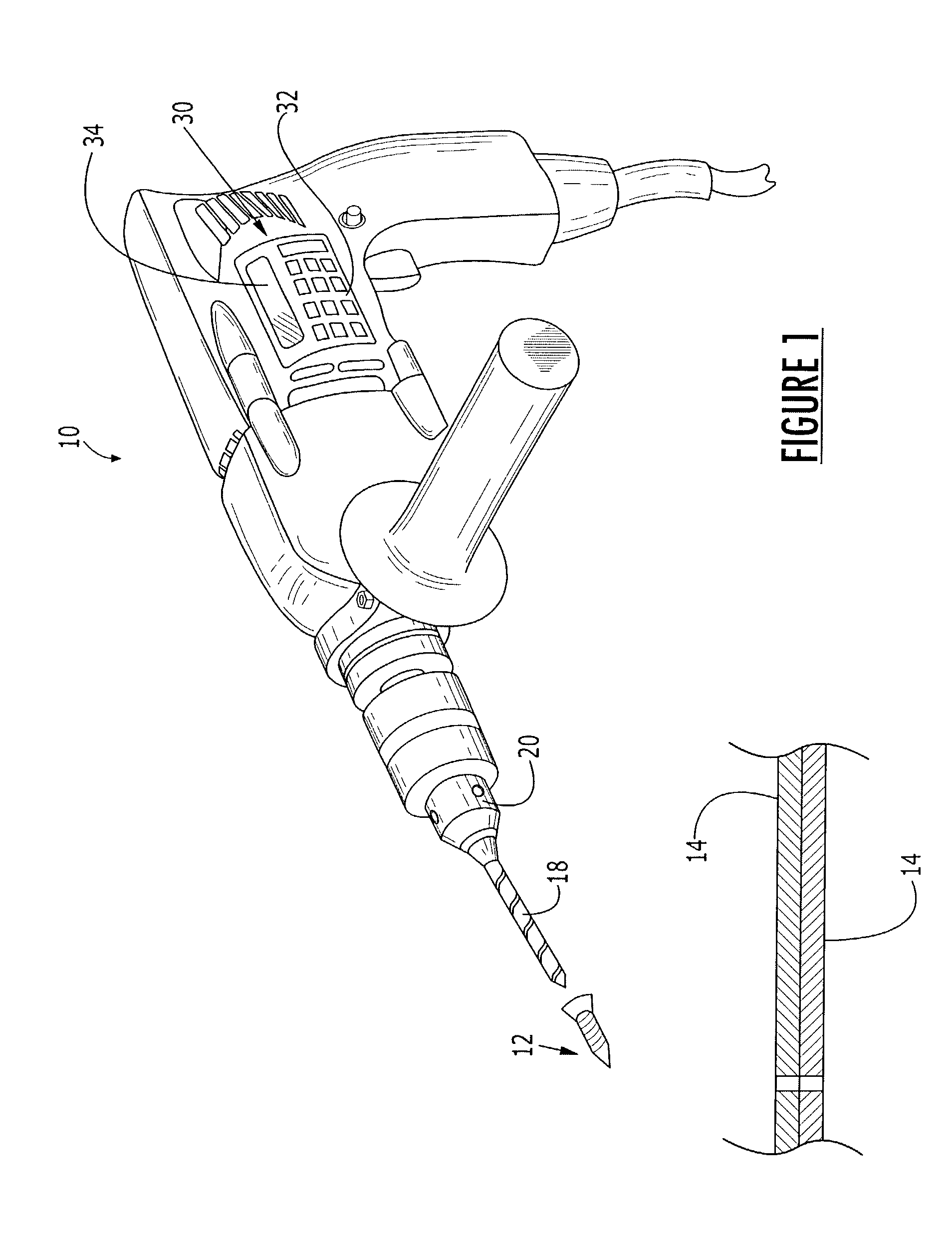

Tool and associated methods for controllably applying torque to a fastener

InactiveUS7062979B2Improve accuracyImprove consistencyMeasurement of torque/twisting force while tighteningWork measurementTransducerReference device

A torque tool and an associated method are provided which apply operator-defined levels of torque to a threaded fastener. In one aspect, a portable, battery powered torque tool controls the motor to slow further advancement of the threaded fastener once the torque that has been applied to the threaded fastener has reached a predefined threshold. In another aspect, a torque tool monitors a measure of torque applied to a threaded fastener more frequently once the torque applied to the threaded fastener has reached a predefined threshold. A method of defining a mathematical relationship between a first measure provided by a torque transducer of torque applied to a threaded fastener and a second measure provided by a torque measurement reference device of torque applied to the threaded fastener is also provided such that the measure of torque provided by the torque transducer can be calibrated.

Owner:THE BOEING CO

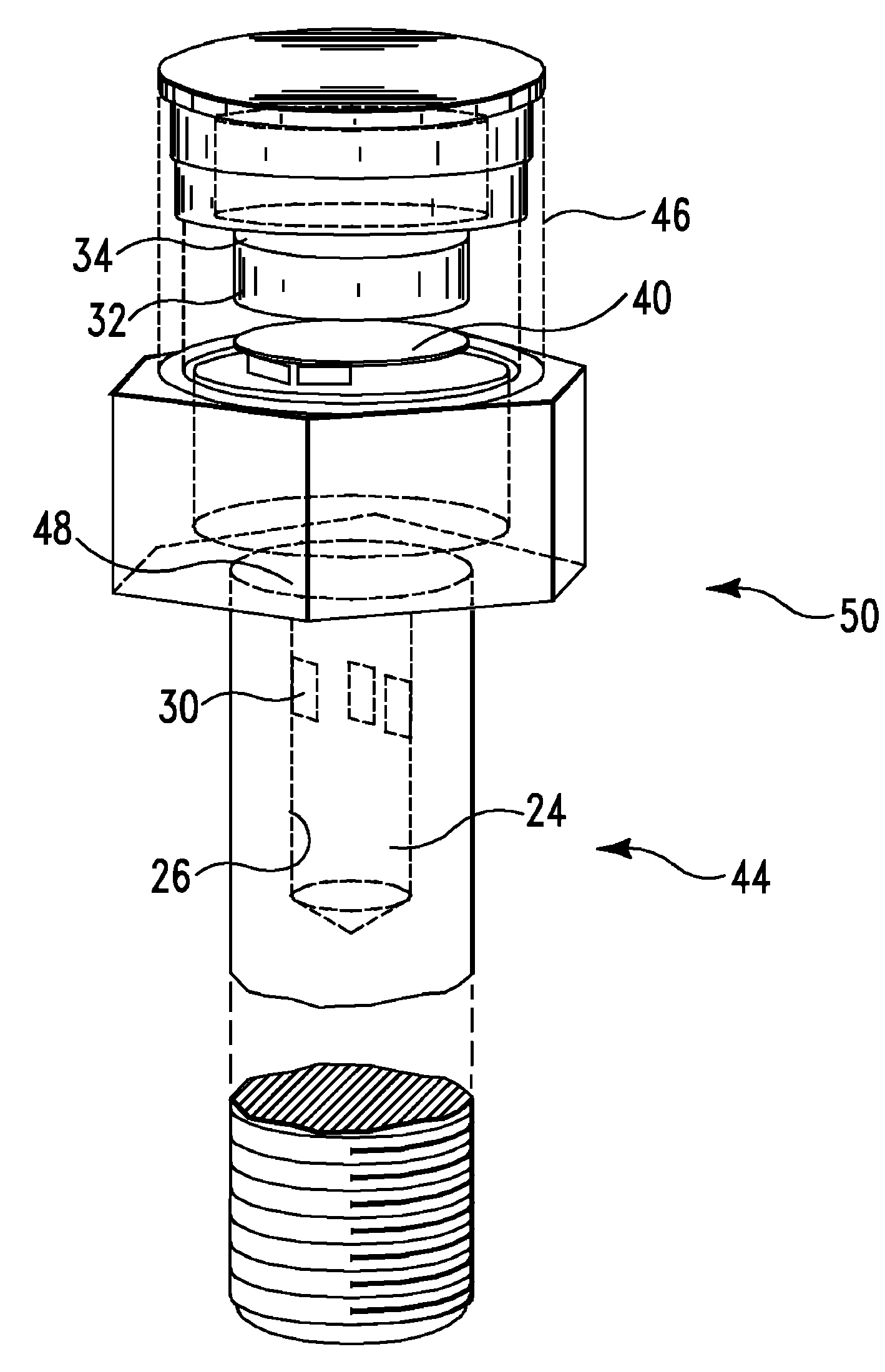

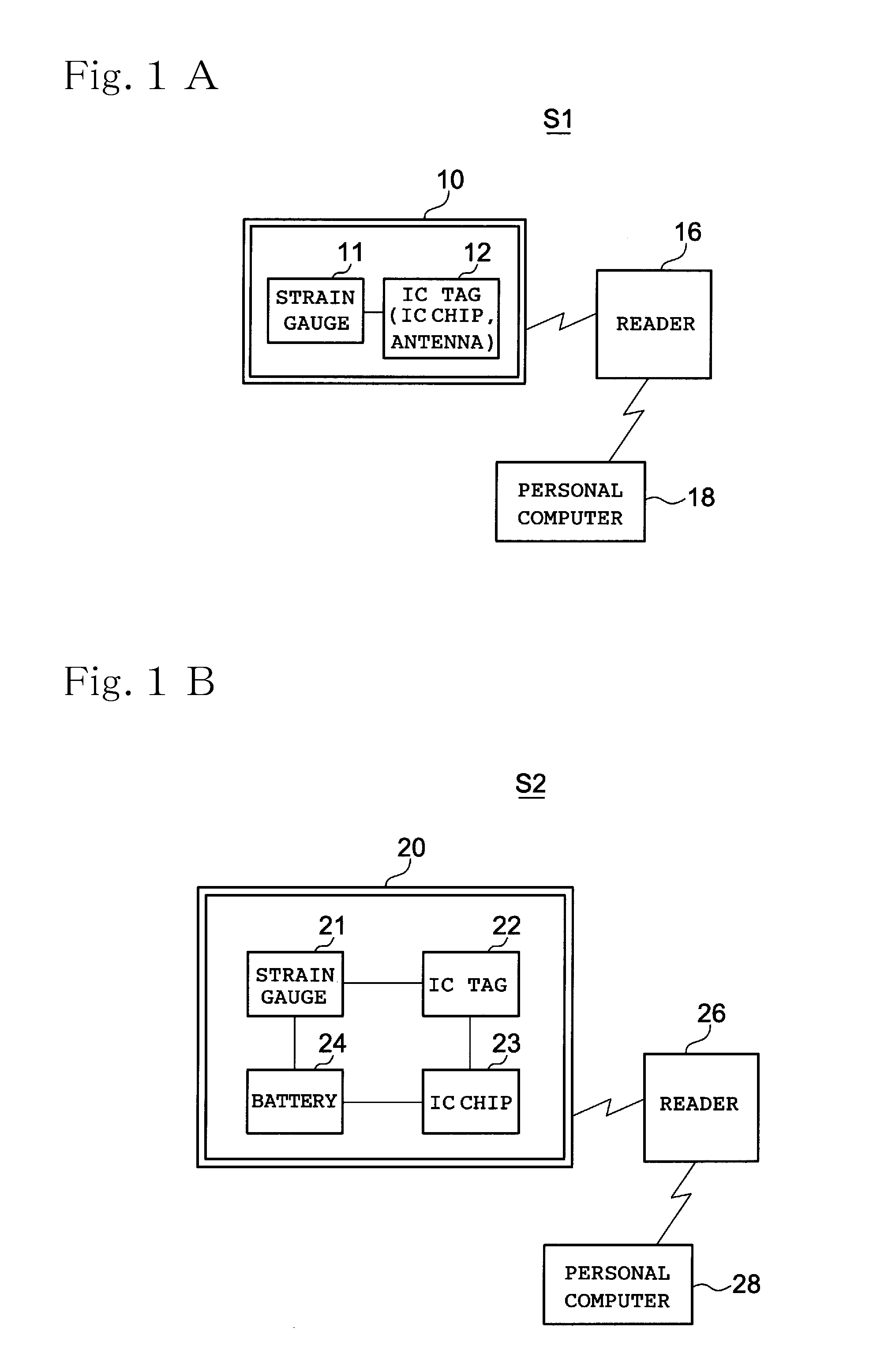

Fastening apparatus and system for detecting axial force thereof

InactiveUS20100054891A1Avoid accidentsLabor savingMeasurement of torque/twisting force while tighteningLoad modified fastenersAxial forceEngineering

A detecting system of a fastening apparatus that detects an axial force of the fastening apparatus including a bolt or a nut. The detecting system includes an axial force detector including a strain gauge and an IC tag, the strain gauge being provided at a predetermined location to detect an axial force value of the fastening apparatus, and the IC tag being connected to the strain gauge and wirelessly transmitting the detected axial force value and unique identification information. Power is supplied to the axial force detector. A reader reads data transmitted from the axial force detector.

Owner:FURUKAWA ELECTRIC POWER SYST

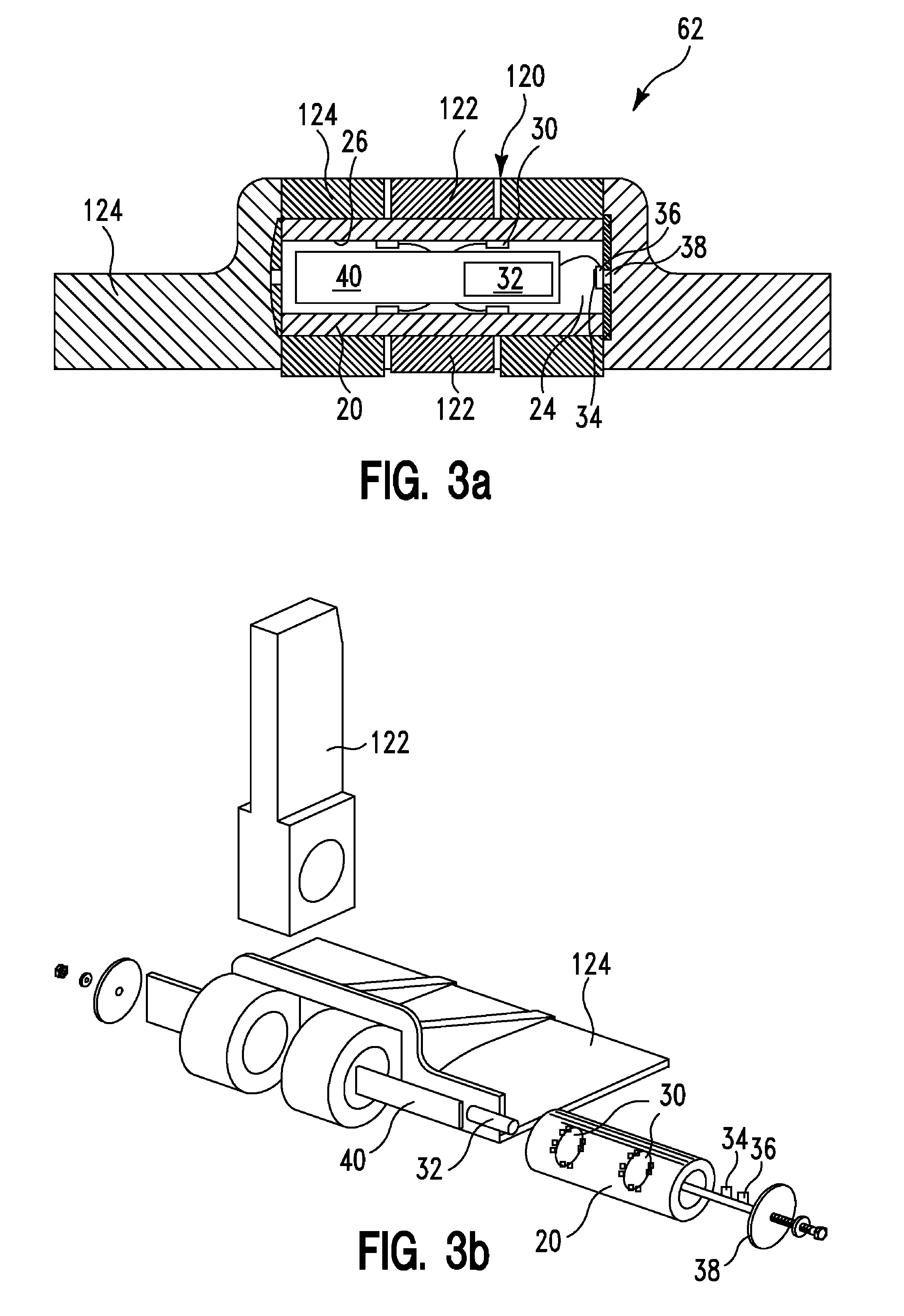

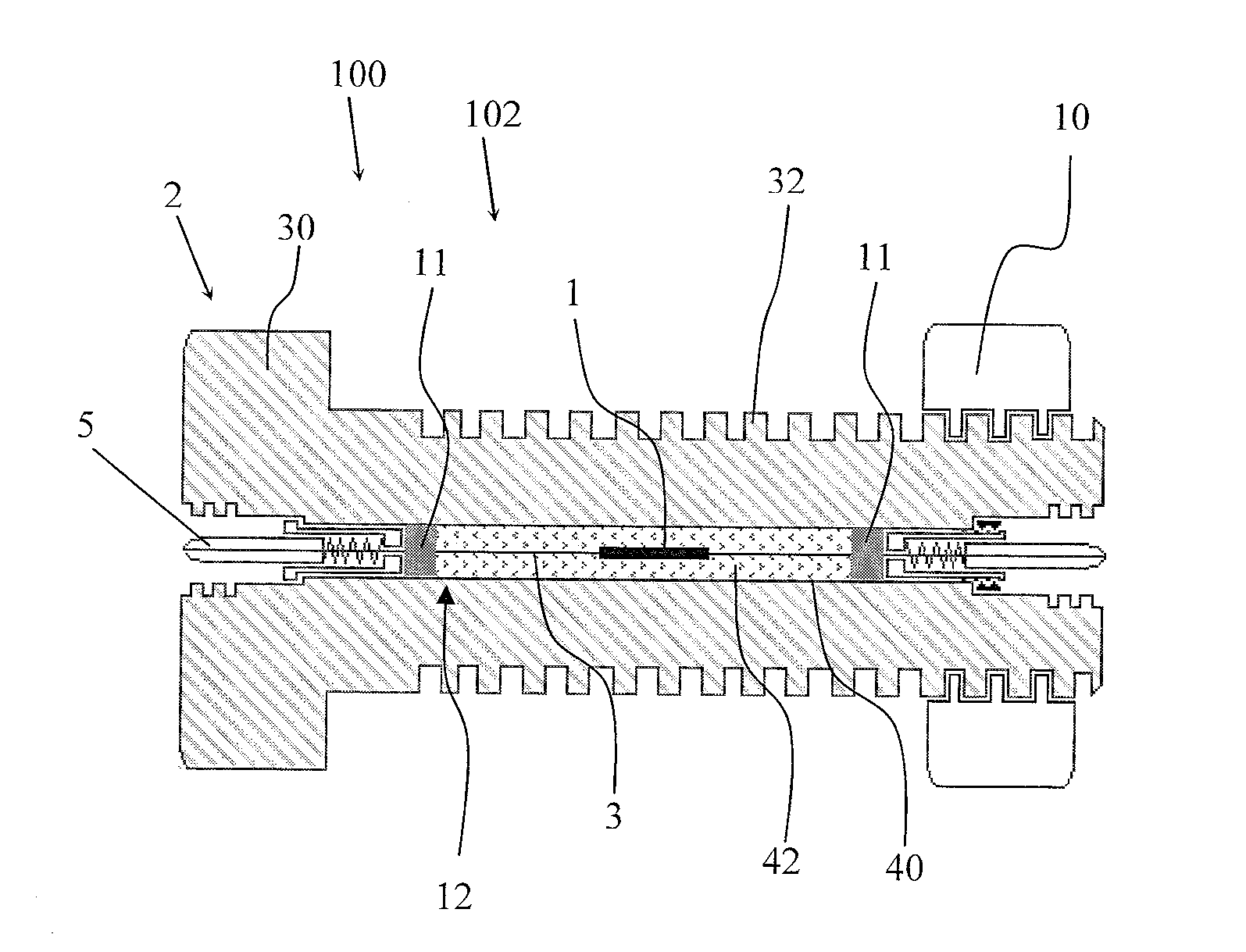

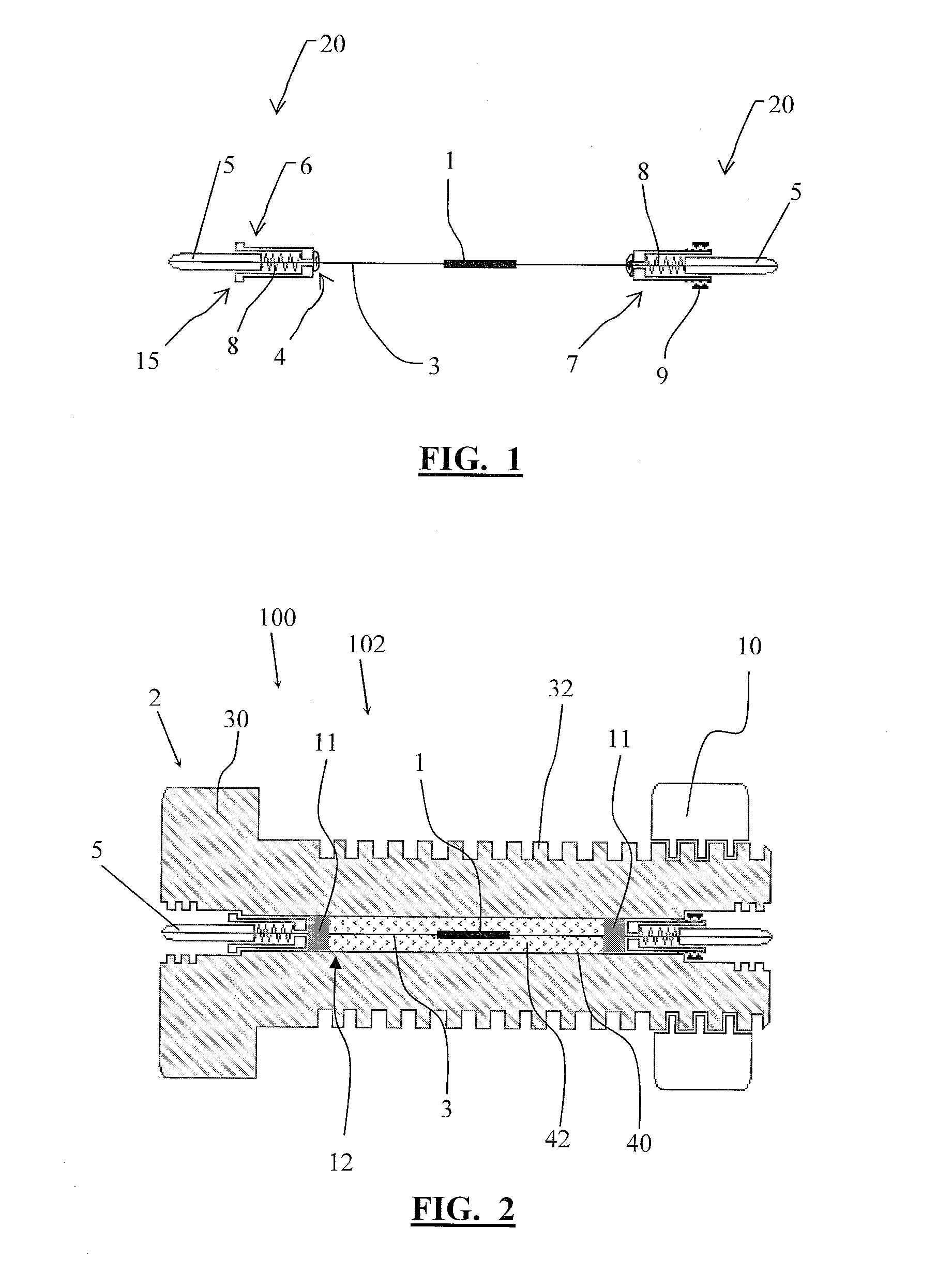

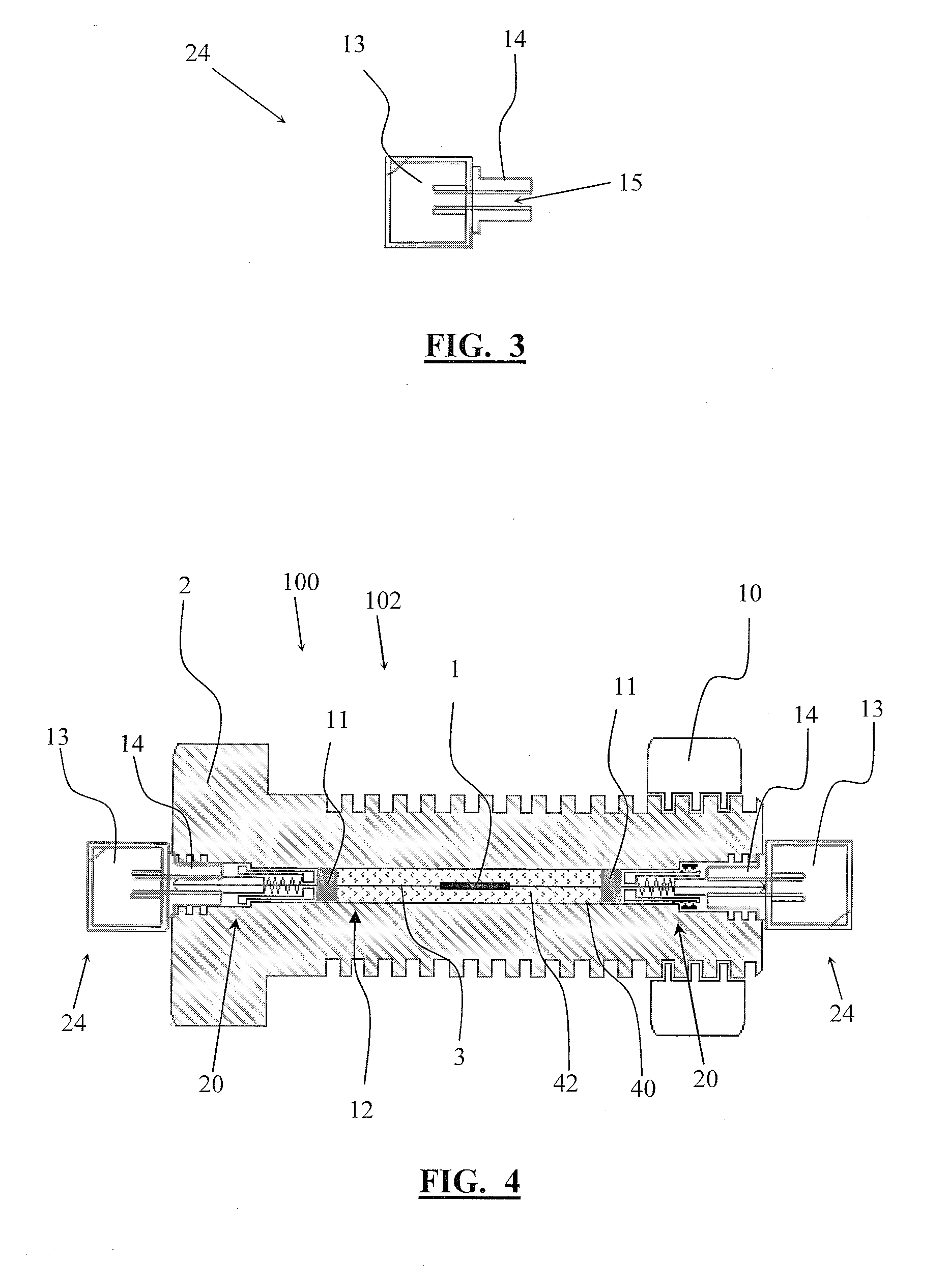

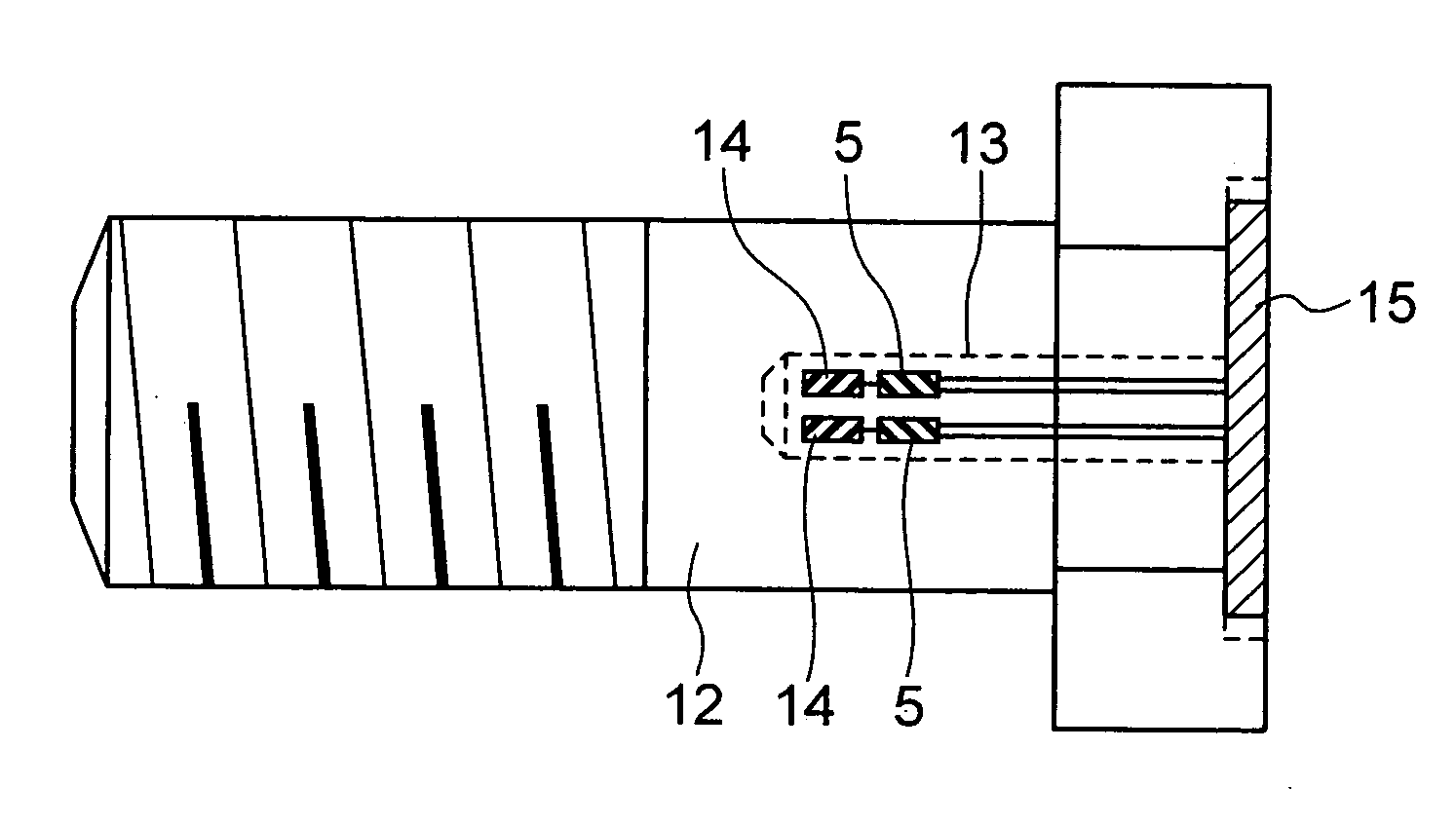

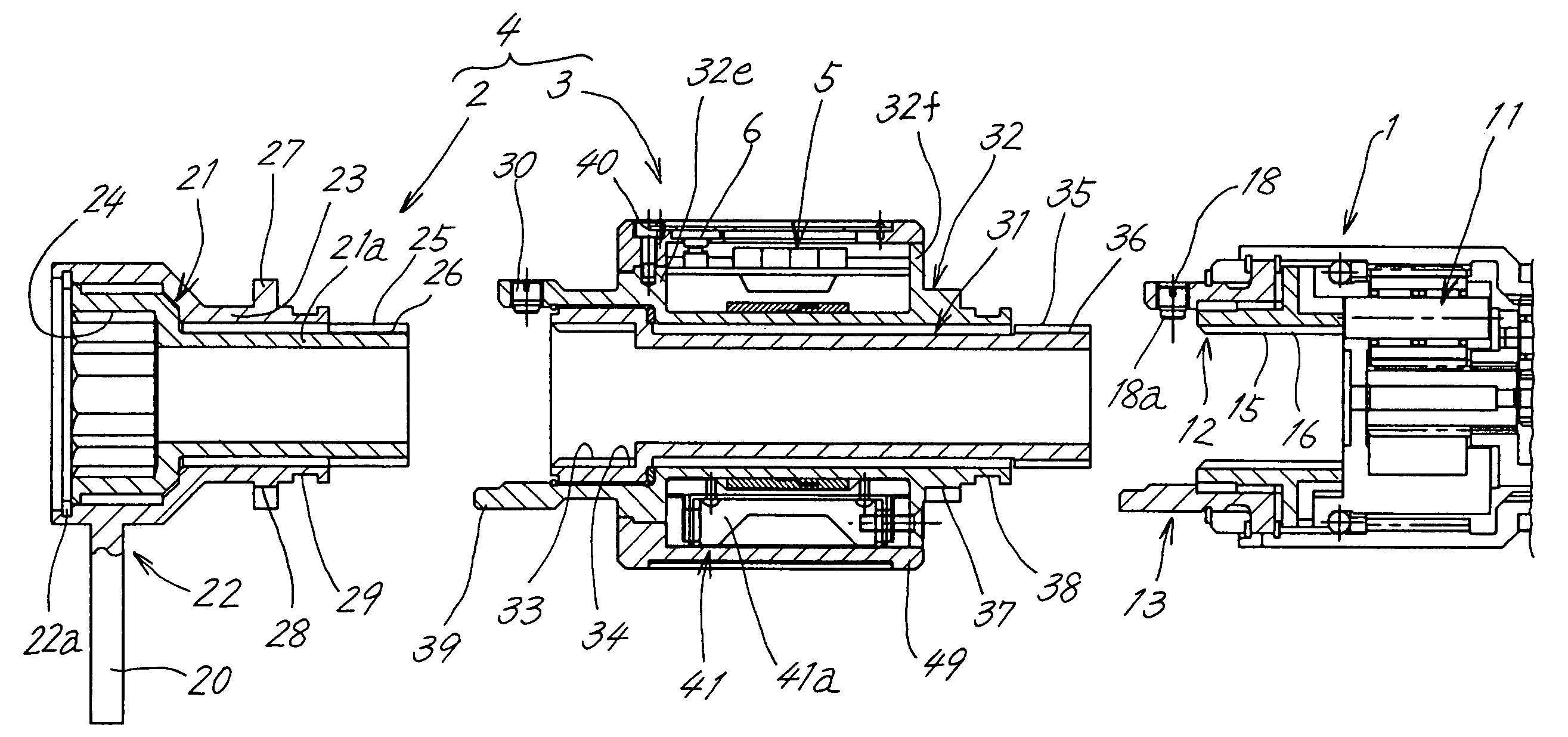

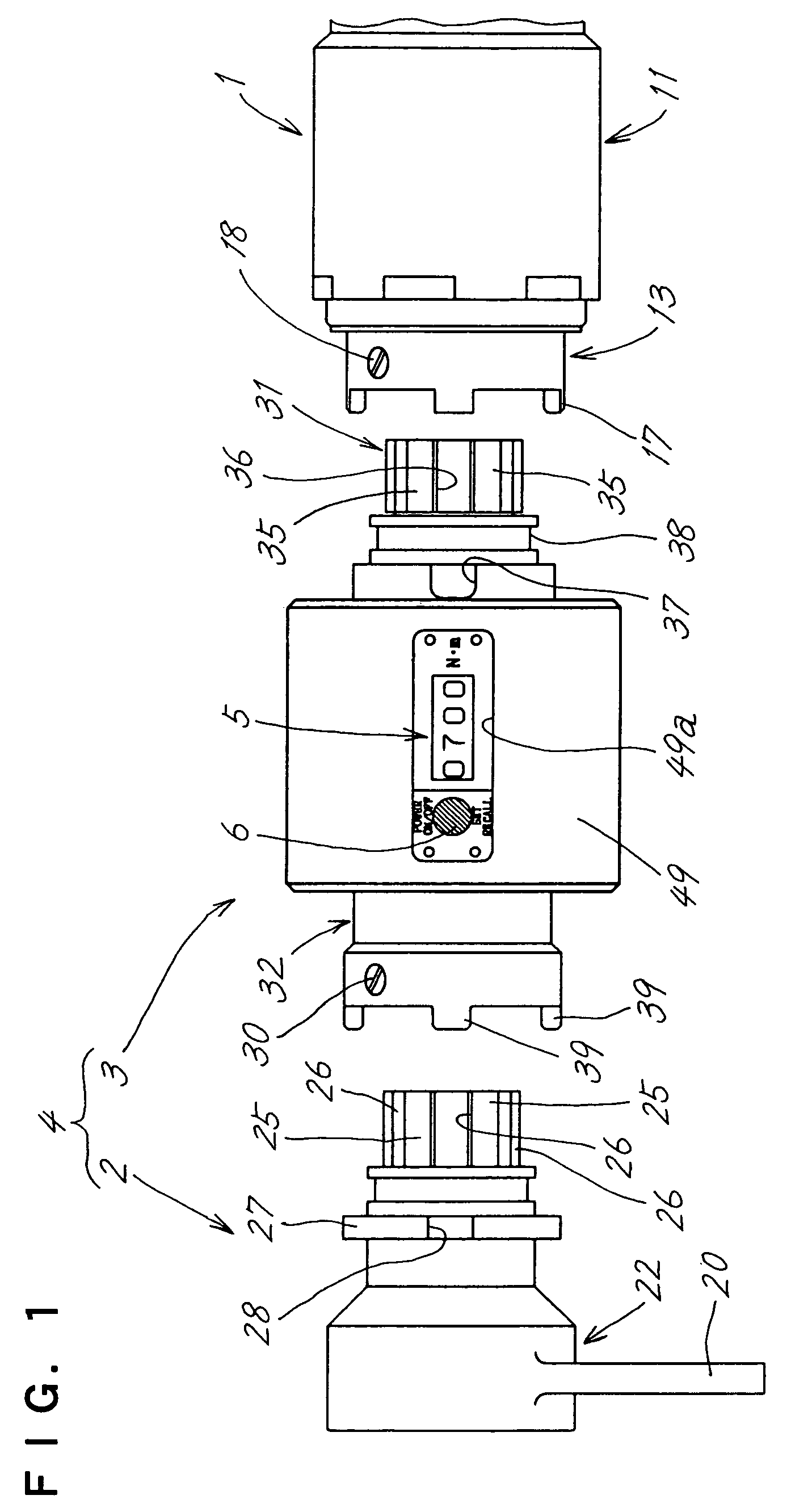

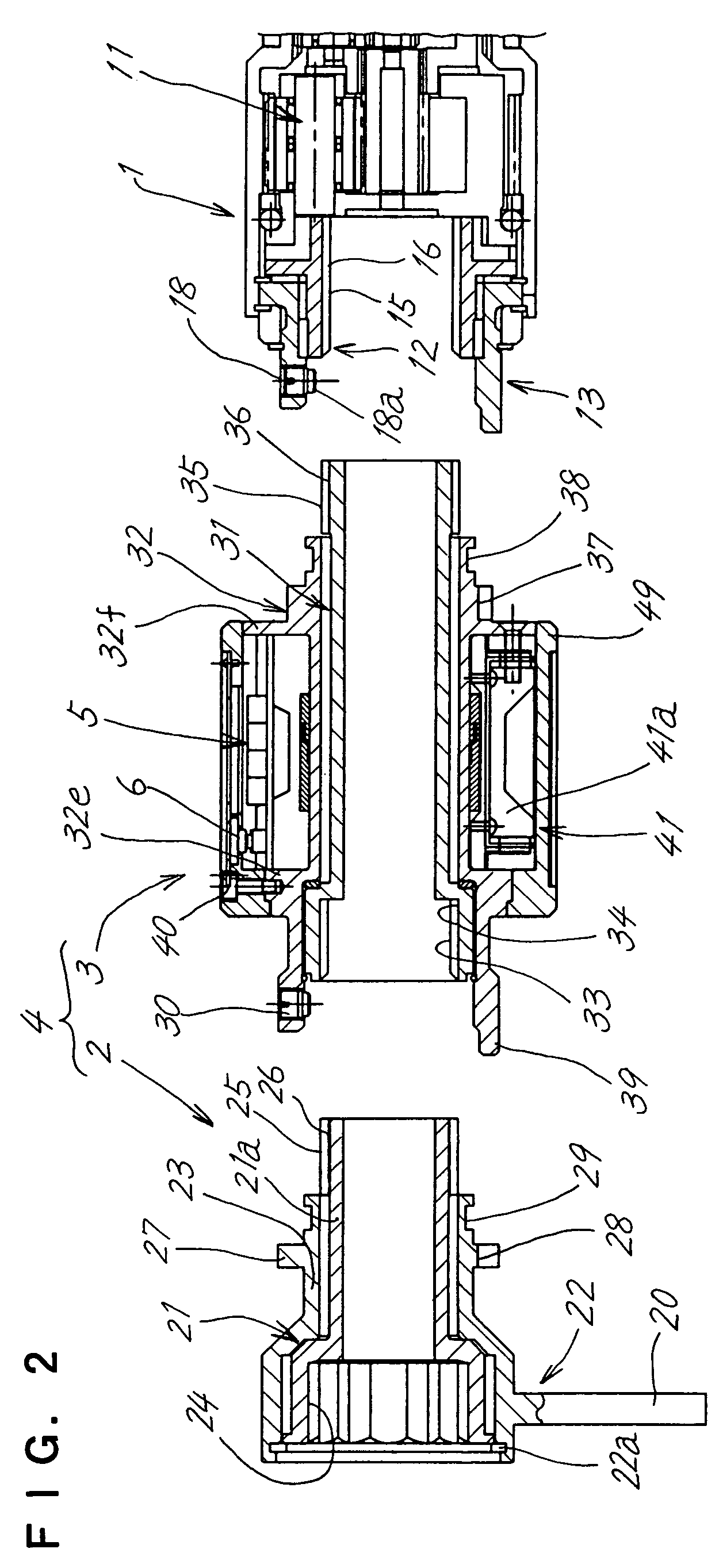

Tightening torque measuring unit and torque indicating tightening device

ActiveUS7275450B2Shorten the lengthMeasurement of torque/twisting force while tighteningWork measurementEngineeringStrain gauge

A tightening torque measuring unit (4) has an inner shaft (31) connectable to a first output shaft (12) of a tightening device main body (1) and an outer shaft (32) connectable to a second output shaft (13) of the body. The inner shaft (31) is provided with a tightening socket (21), and the outer shaft (32) with a reaction force receiver (22). The outer shaft (32) has strain gauges (47), and an indicator (5) for converting an amount of strain detected by the gauges into a corresponding tightening torque value. Since the reaction force receiver (22) can be attached to the measuring unit (4), the tightening reaction force is prevented from acting to knock down the receiver (22), enabling the unit (4) to measure tightening torque, with the device main body (1), the measuring unit (4) and the socket (21) positioned in alignment with the axis of the nut to be tightened.

Owner:MAEDA METAL IND LTD

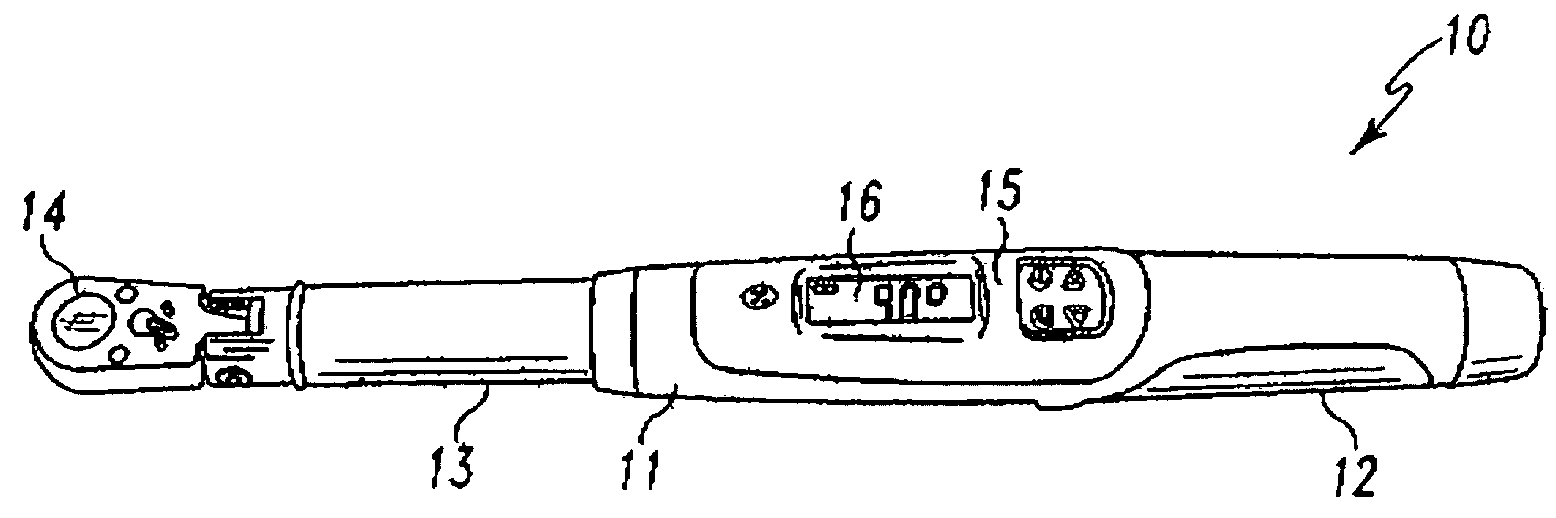

Torque-angle instrument

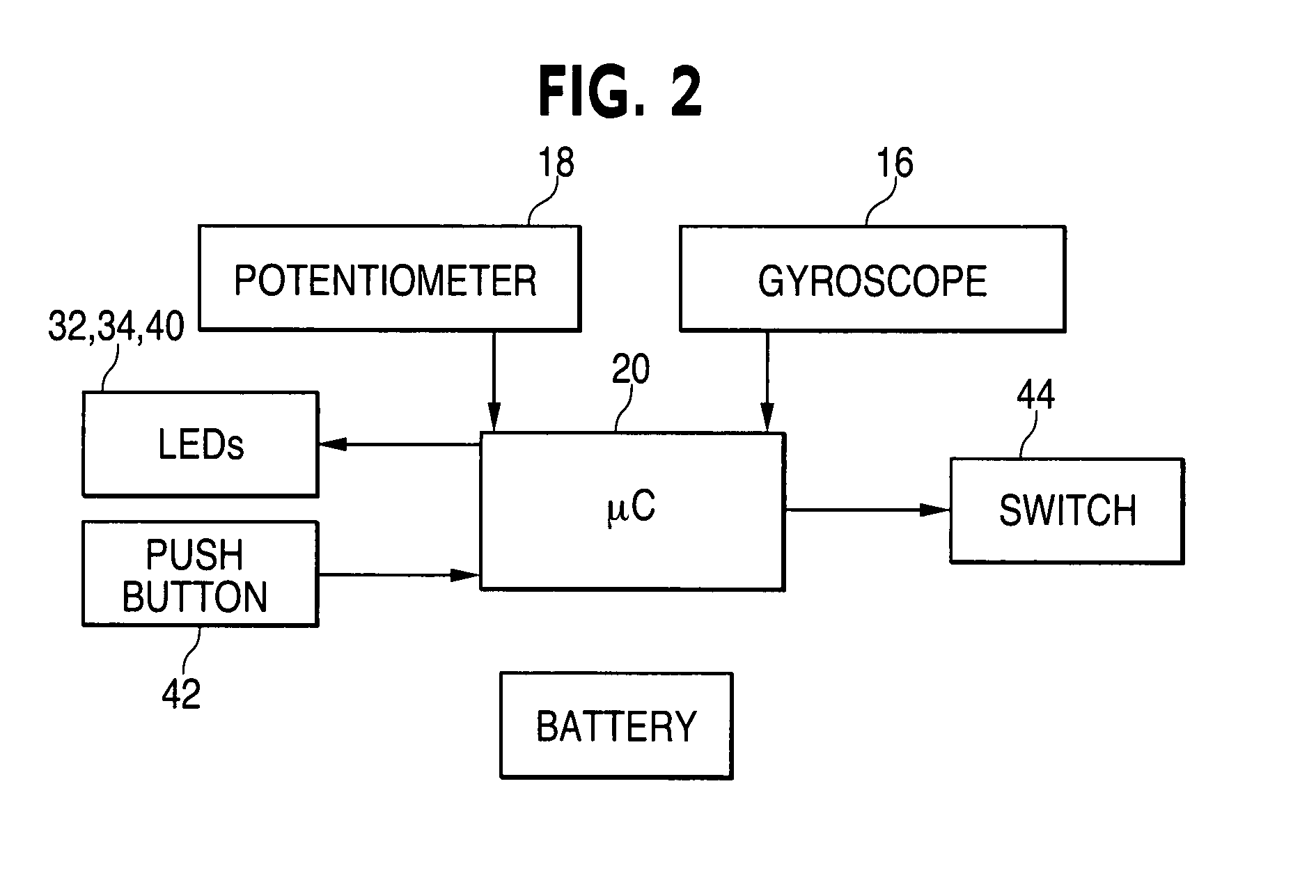

ActiveUS7565844B2Enhanced advantageAvoid disadvantagesMeasurement of torque/twisting force while tighteningWork measurementGyroscopeEngineering

An electronic torque-angle instrument including a generally tubular body having a gripping section and a pivoting head for engaging a workpiece, such as a nut or bolt, and a housing associated with the body and containing electronics, including a microprocessor, which permit individual or simultaneous measurement of torque and angle applied to the workpiece. The microprocessor includes stored programs which interpret a signal from an input, such as a gyroscopic sensor, and sends the interpreted signal to an output means. The signal is finally displayed as an accurate torque measure and / or angle measure from the output means.

Owner:SNAP ON INC

Digital torque wrench

ActiveUS7082865B2Measurement of torque/twisting force while tighteningMeasurement arrangements for variableShear stressDisplay device

A digital torque wrench is disclosed having a transducer beam with a reduced thickness web therein. At least one strain gauge sensor is mounted to the internal web to measure the shearing stress within the web as the wrench is rotated. By using such a reduced thickness web, mounting the sensors in opposed orientations, mounting the transducer beam to the torque wrench handle using first and second longitudinal flanking pins, and providing the transducer beam in a tapered shape, the resulting measurement of the torque wrench is very accurate. Moreover, a rotational interface module with digital display is provided to facilitate reading of the display by the user.

Owner:RYESON CORP

Systems for preloading a bearing and aligning a lock nut

Owner:TEMPER AXLE PROD +1

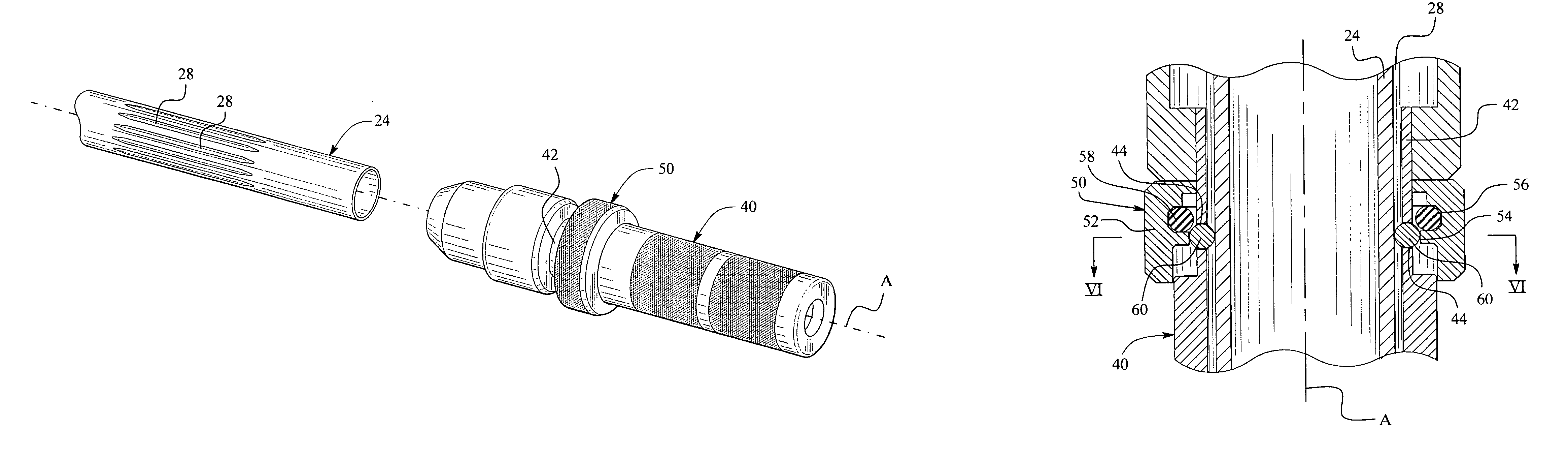

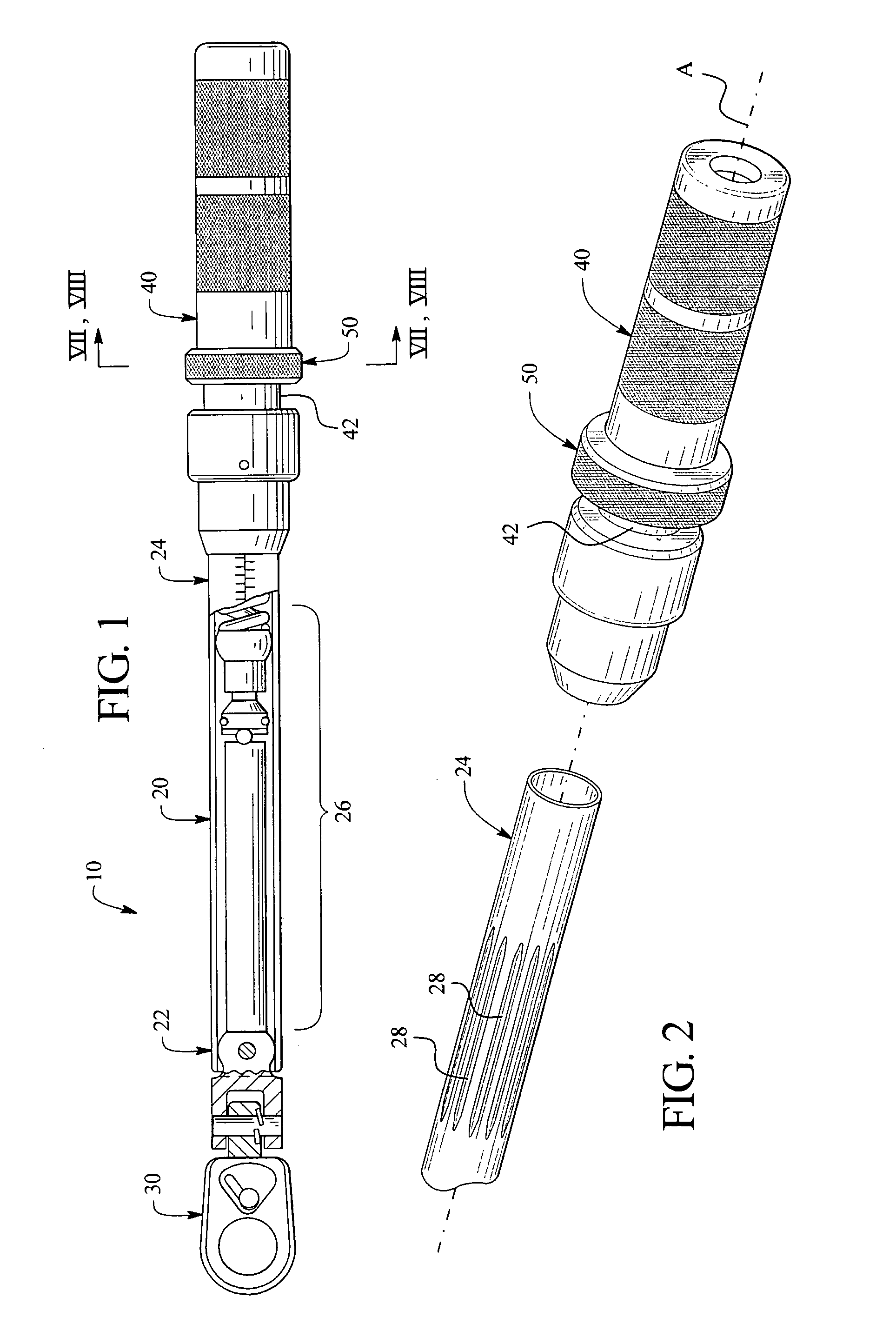

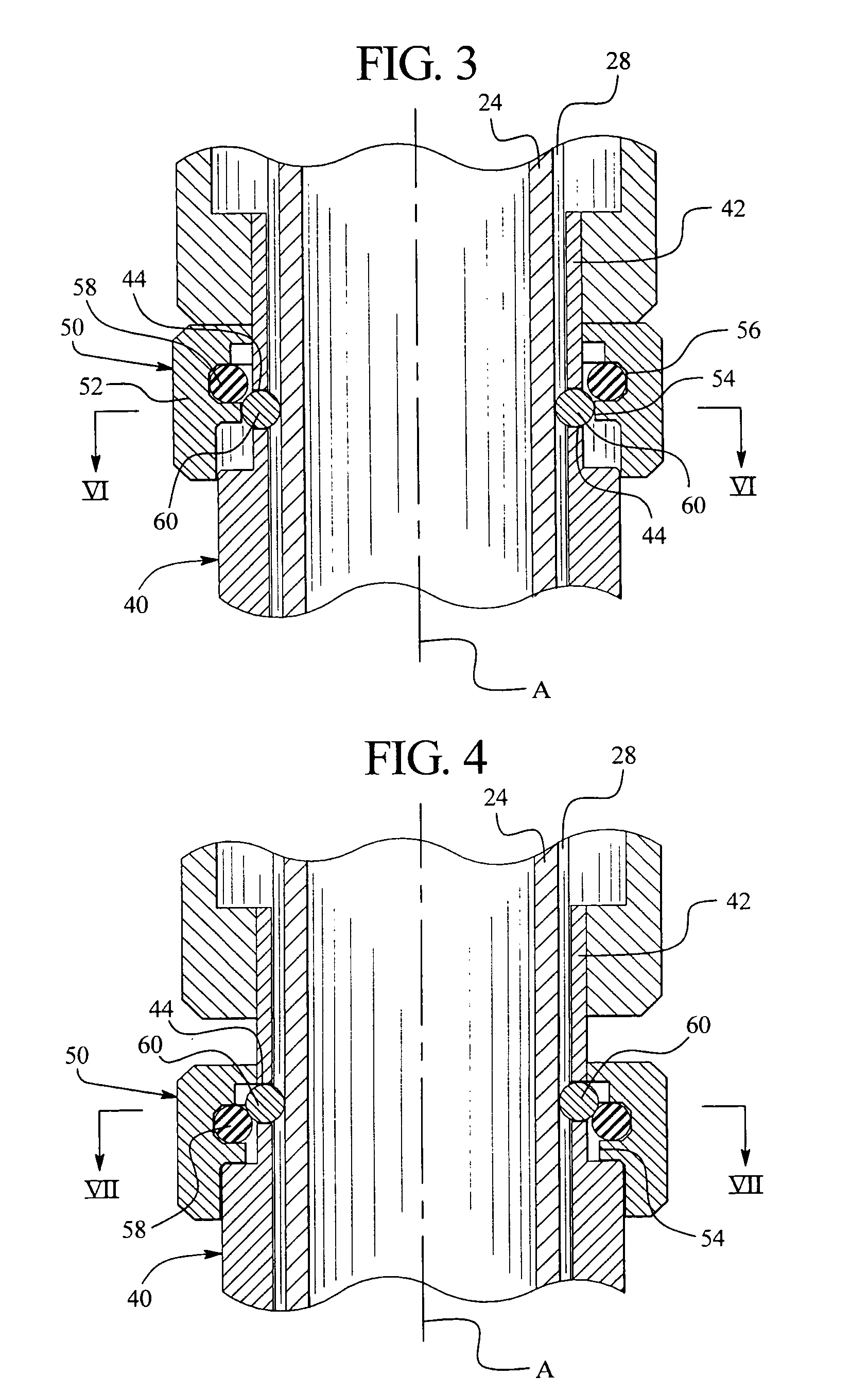

Torque wrench with sleeve for locking rotatable handle

InactiveUS6948410B1Improved locking mechanismReduce decreaseFurniture joining partsMeasurement arrangements for variableDetentTorque wrench

A torque wrench is provided having body and a handle that is rotatably mounted to the body for adjusting the torque setting, and an axially movable sleeve operable to selectively lock the handle. The sleeve includes a rigid member and an elastomeric member, such as an O-ring, and the sleeve is configured to act against a locking ball held in a bore of the handle. The sleeve is selectively movable between two positions: (a) a locked position wherein the rigid member firmly retains the locking ball seated in one of several detents in the body, thereby preventing rotation of the handle; and (b) an unlocked position wherein the elastomeric member biases the locking ball inwardly, deflecting when the locking ball unseats from the detent to permit handle rotation. When the sleeve is in the unlocked position, the locking ball can incrementally “click” over the detents during handle rotation.

Owner:PRECISION INSTR

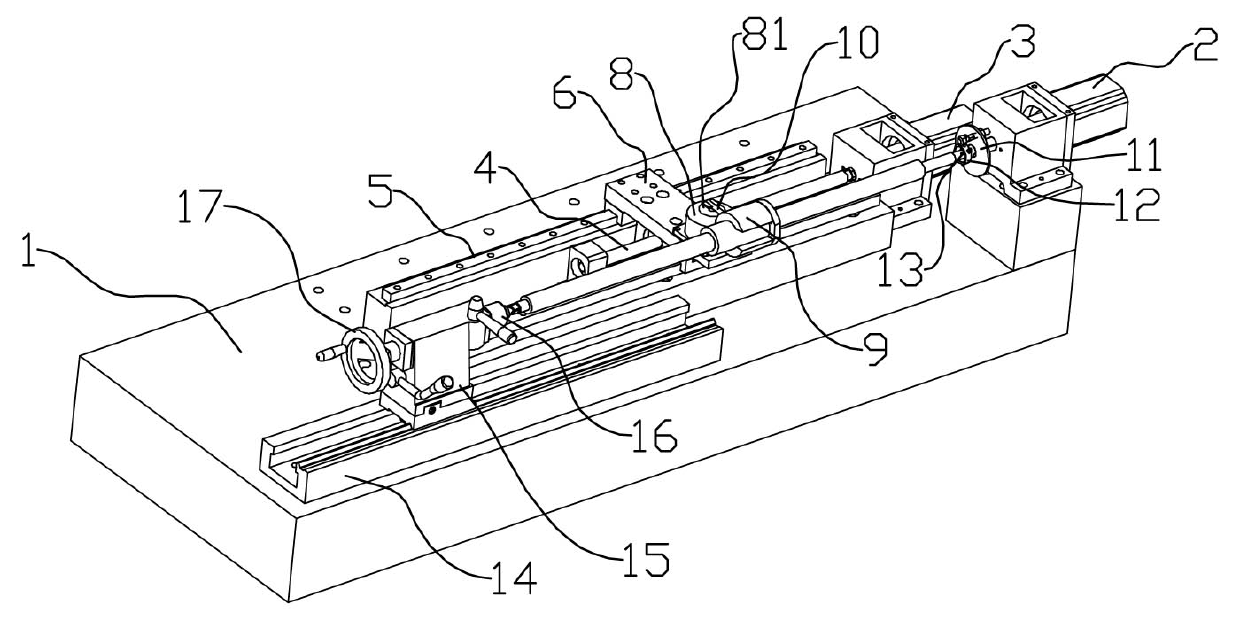

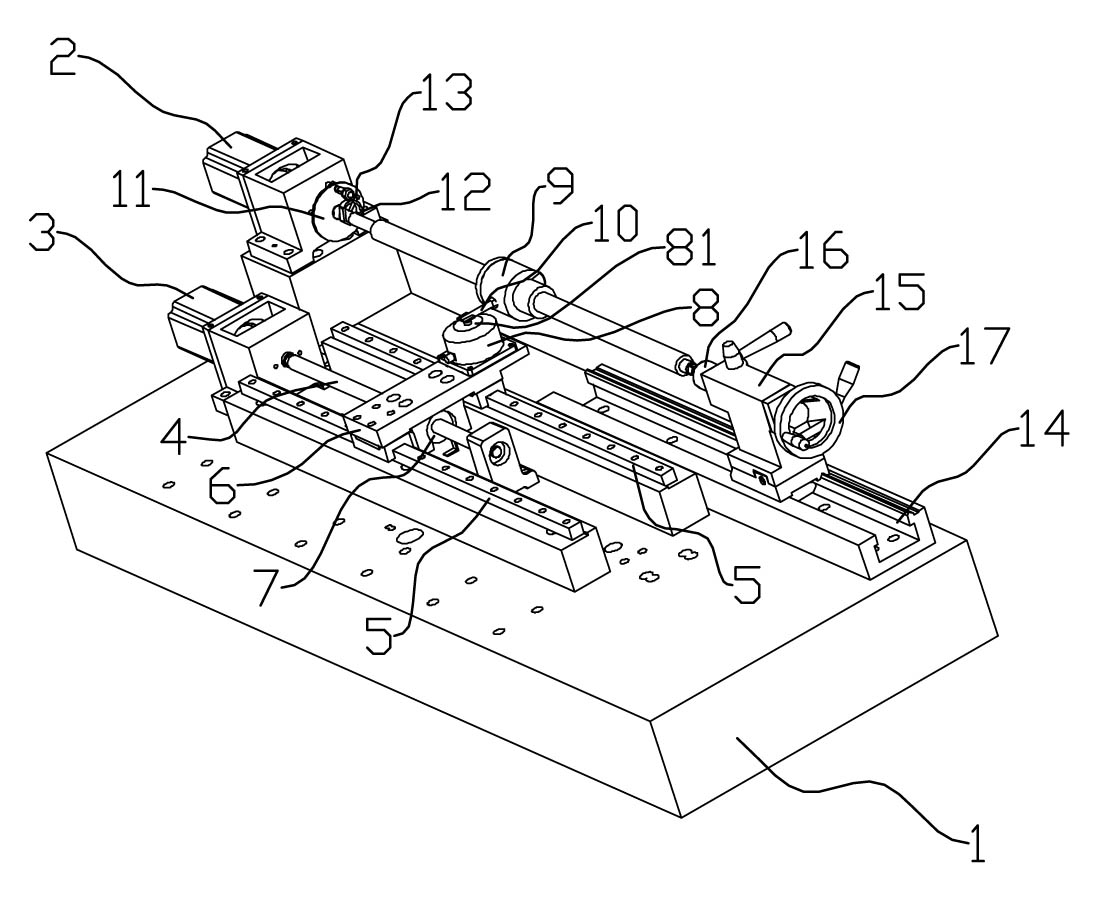

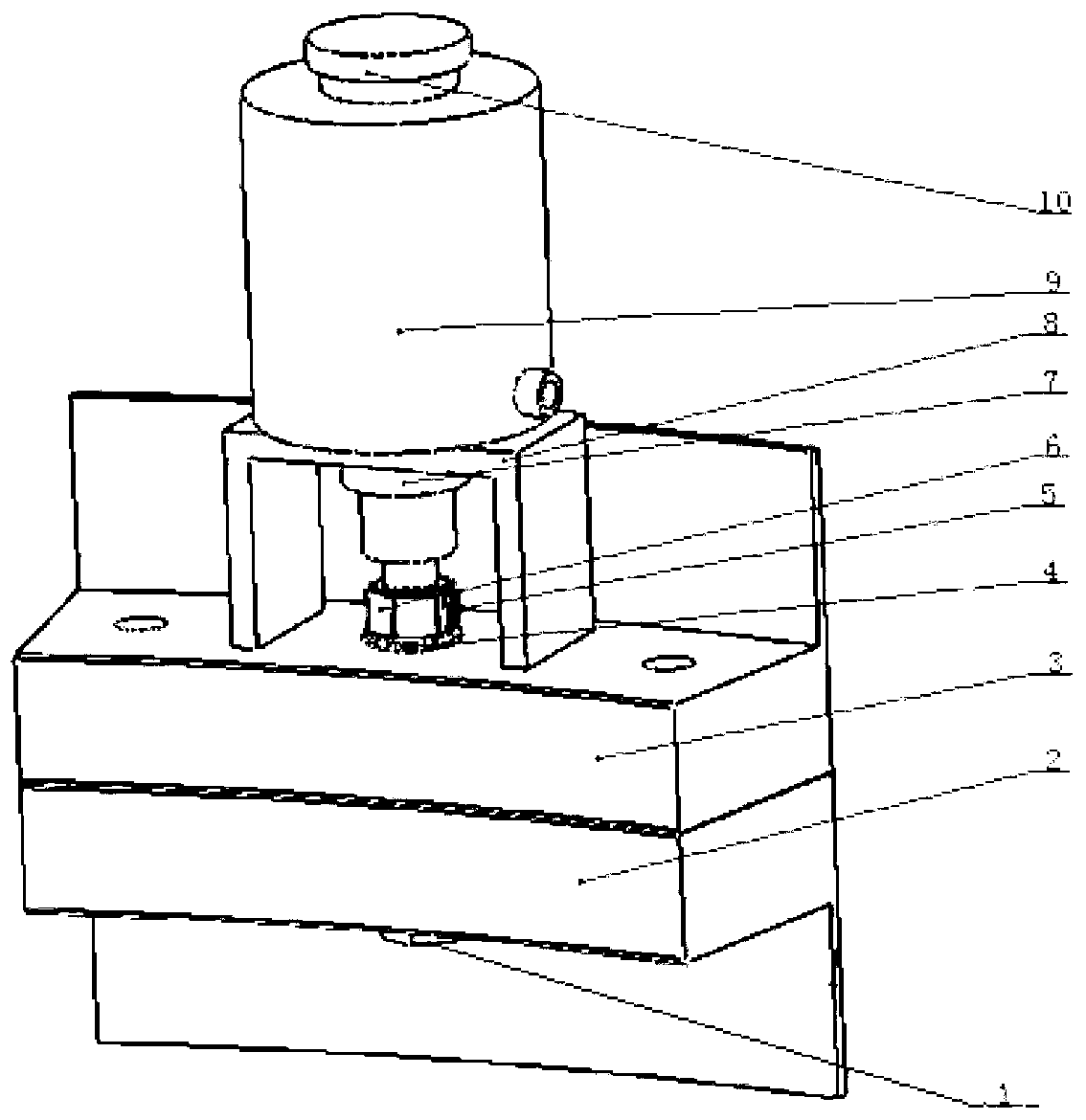

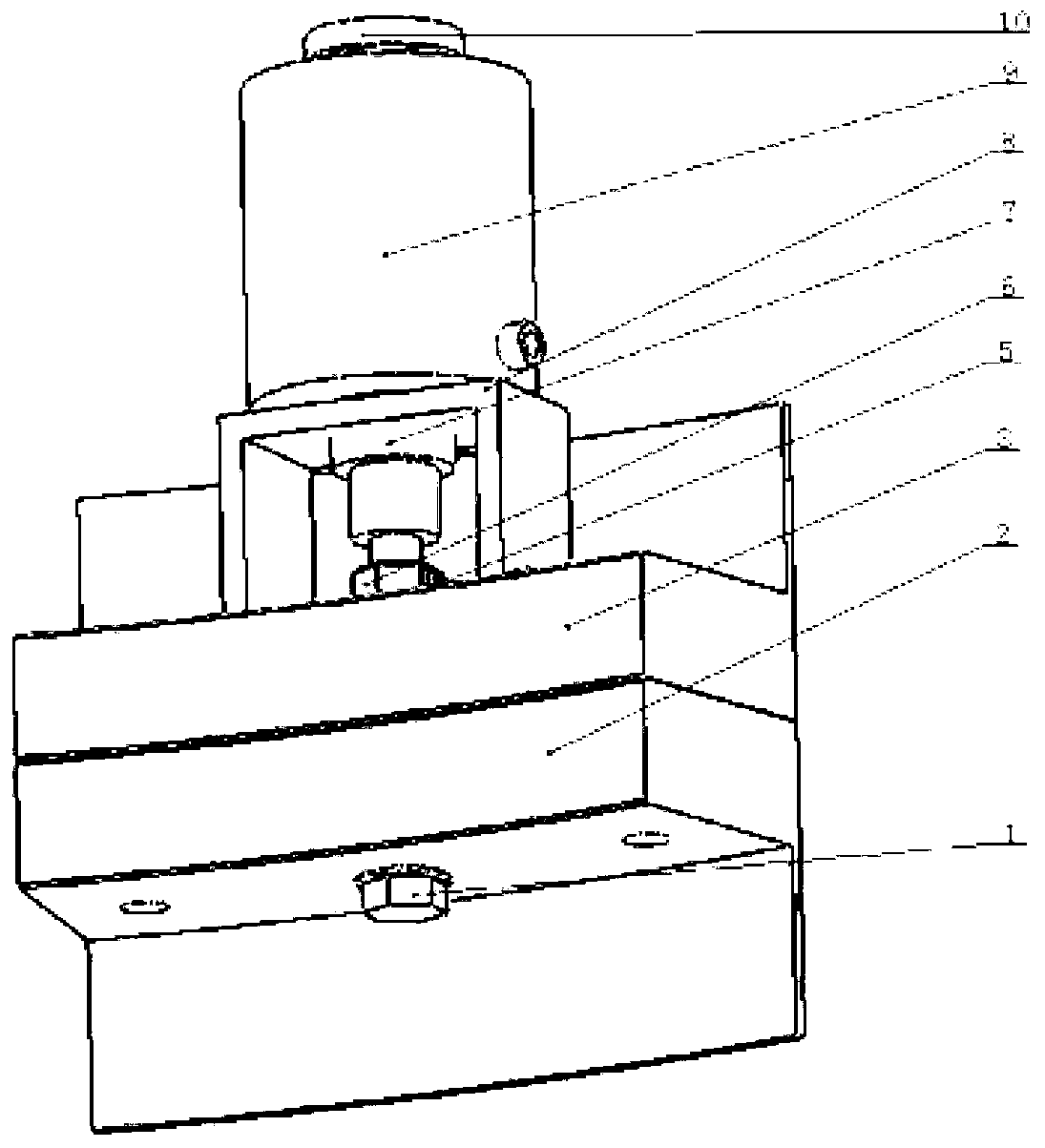

Test bed for testing friction torque property of double ball screws

InactiveCN101769805AQuality improvementImprove dynamic performanceMeasurement of torque/twisting force while tighteningMachine gearing/transmission testingNumerical controlFriction torque

The invention discloses a test bed for testing friction torque property of double ball screws, which comprises a base, and first and second servo motors which are arranged on the base and controlled by a control system, wherein the first servo motor is used for driving a ball screw to be tested; the second servo motor is used for driving a reference ball screw; two sides of the reference ball screw are provided with a linear guide rail respectively, and the upper parts of the two linear guide rails are provided with a workbench; the workbench is fixed with a reference nut on the reference ball screw; the workbench is provided with a force measuring sensor and a nut sleeve which is arranged on a nut of the ball screw to be tested; and the nut sleeve is provided with a cantilever contacted with a detection end of the force measuring sensor. After the ball screw to be tested is connected with the first servo motor, the size of friction torque of a ball screw pair can be effectively measured by using a corresponding signal of the friction torque of the ball screw to be tested acquired by the force measuring sensor so as to improve the quality of a ball screw pair product and promote the dynamic performance of a numerical control machine.

Owner:WUYI UNIV

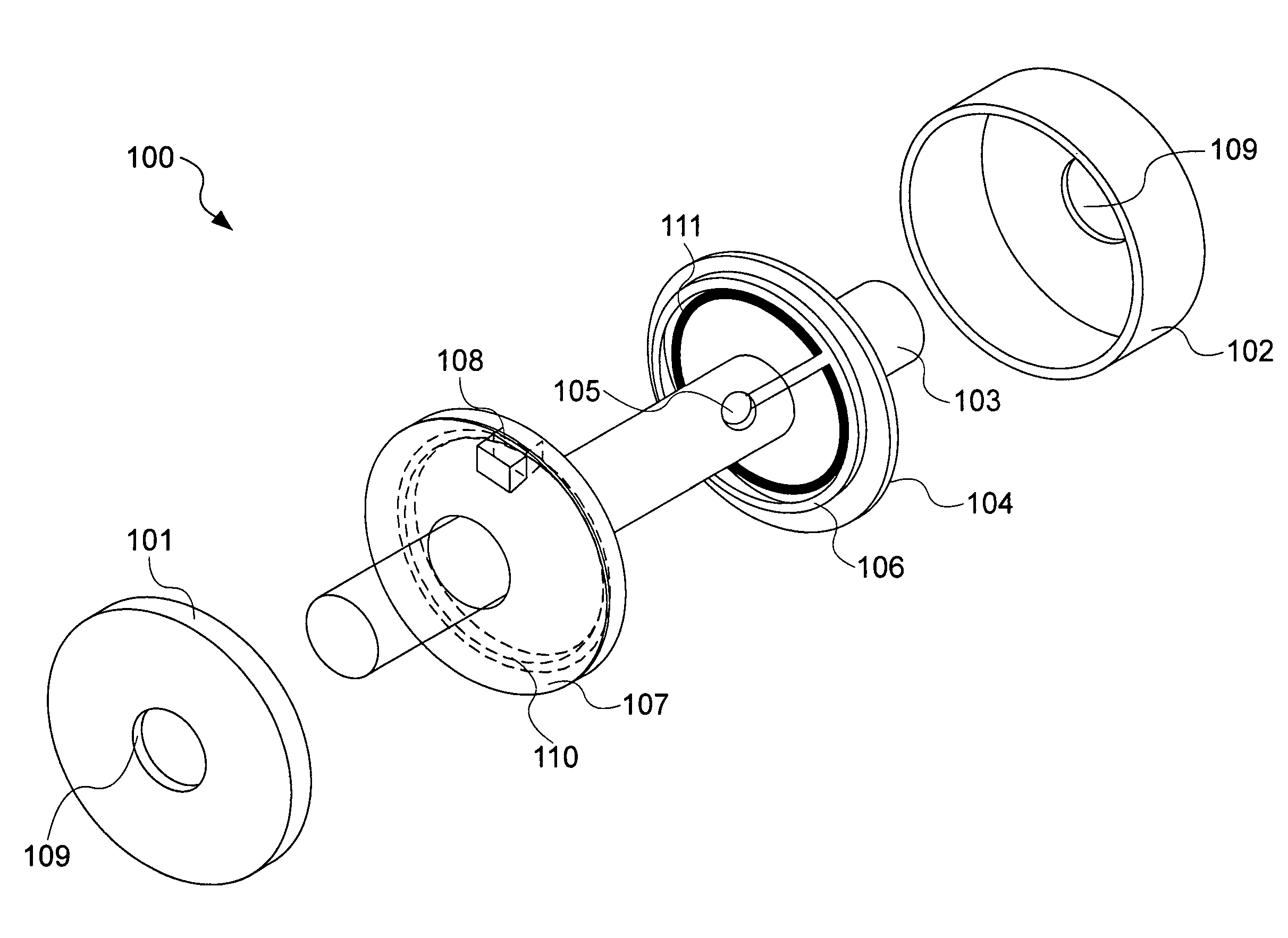

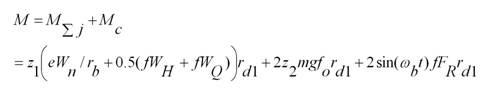

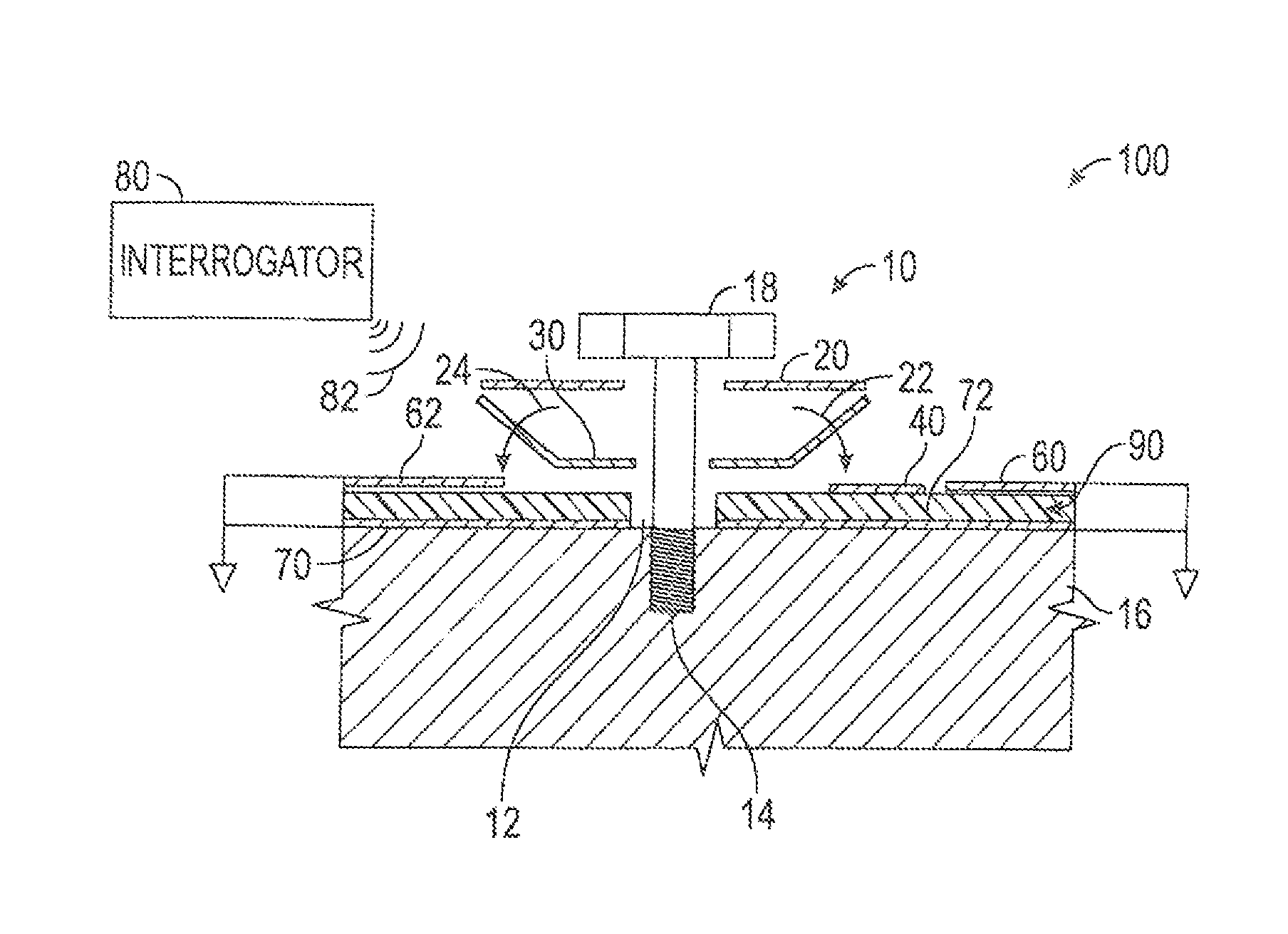

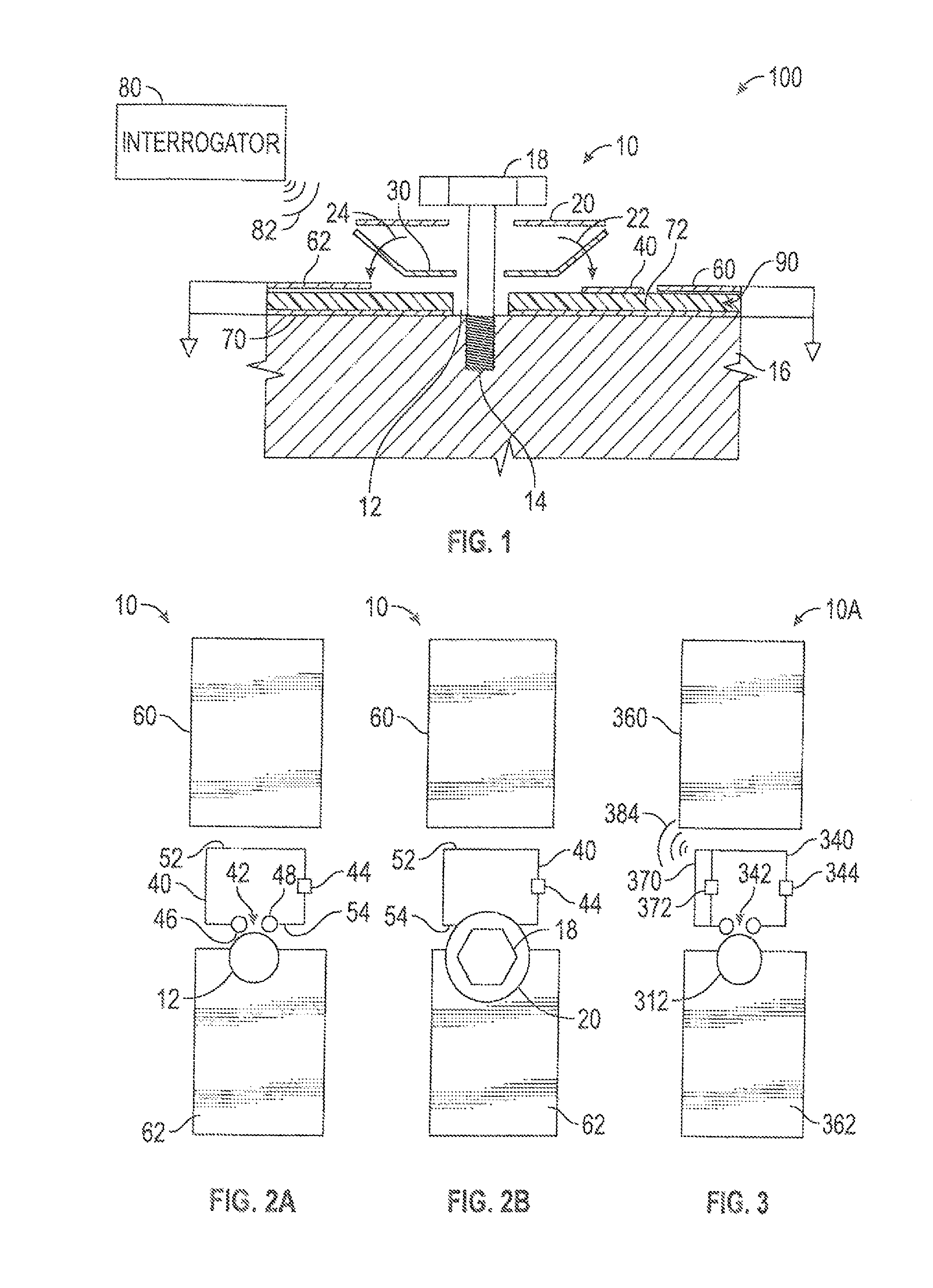

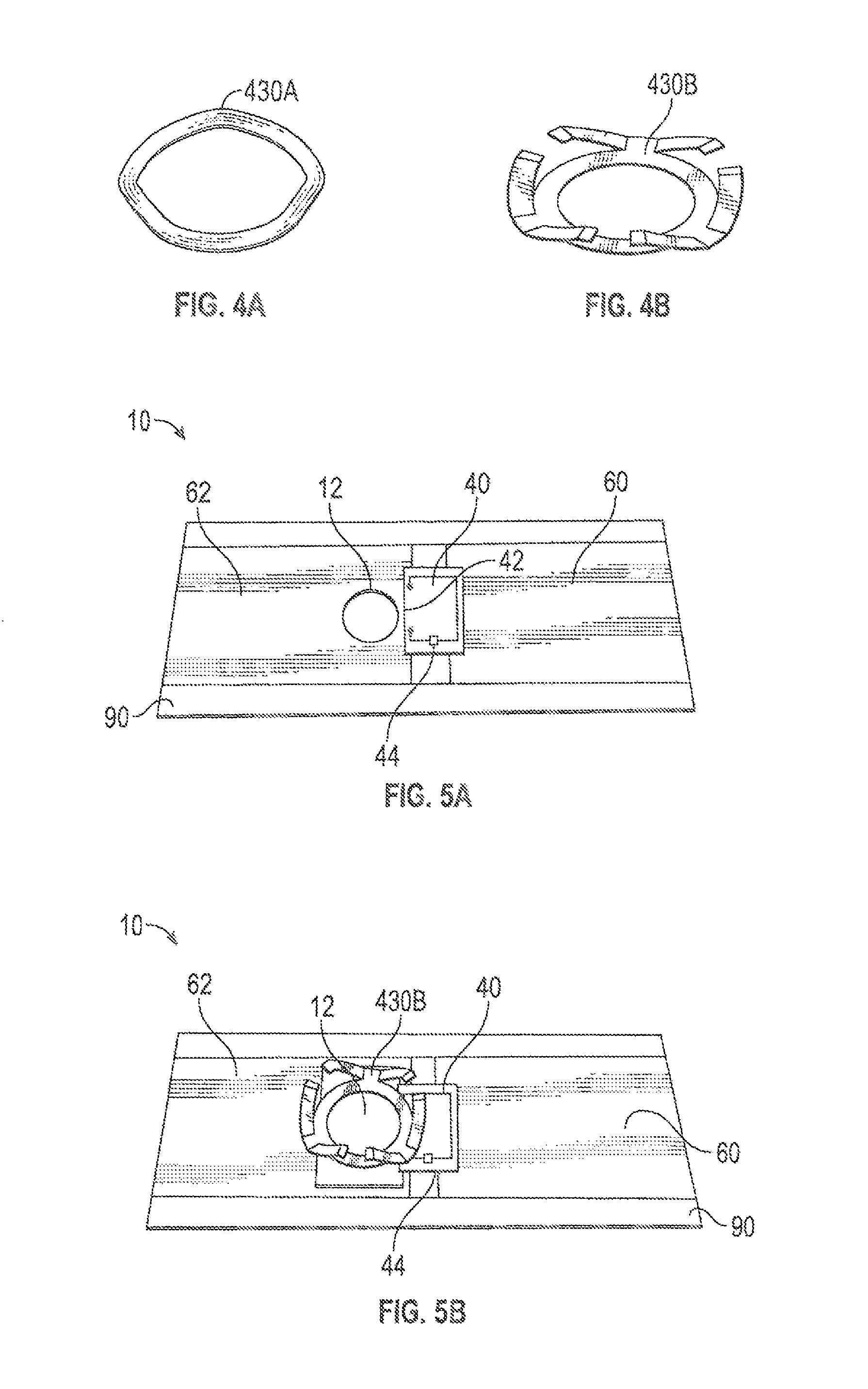

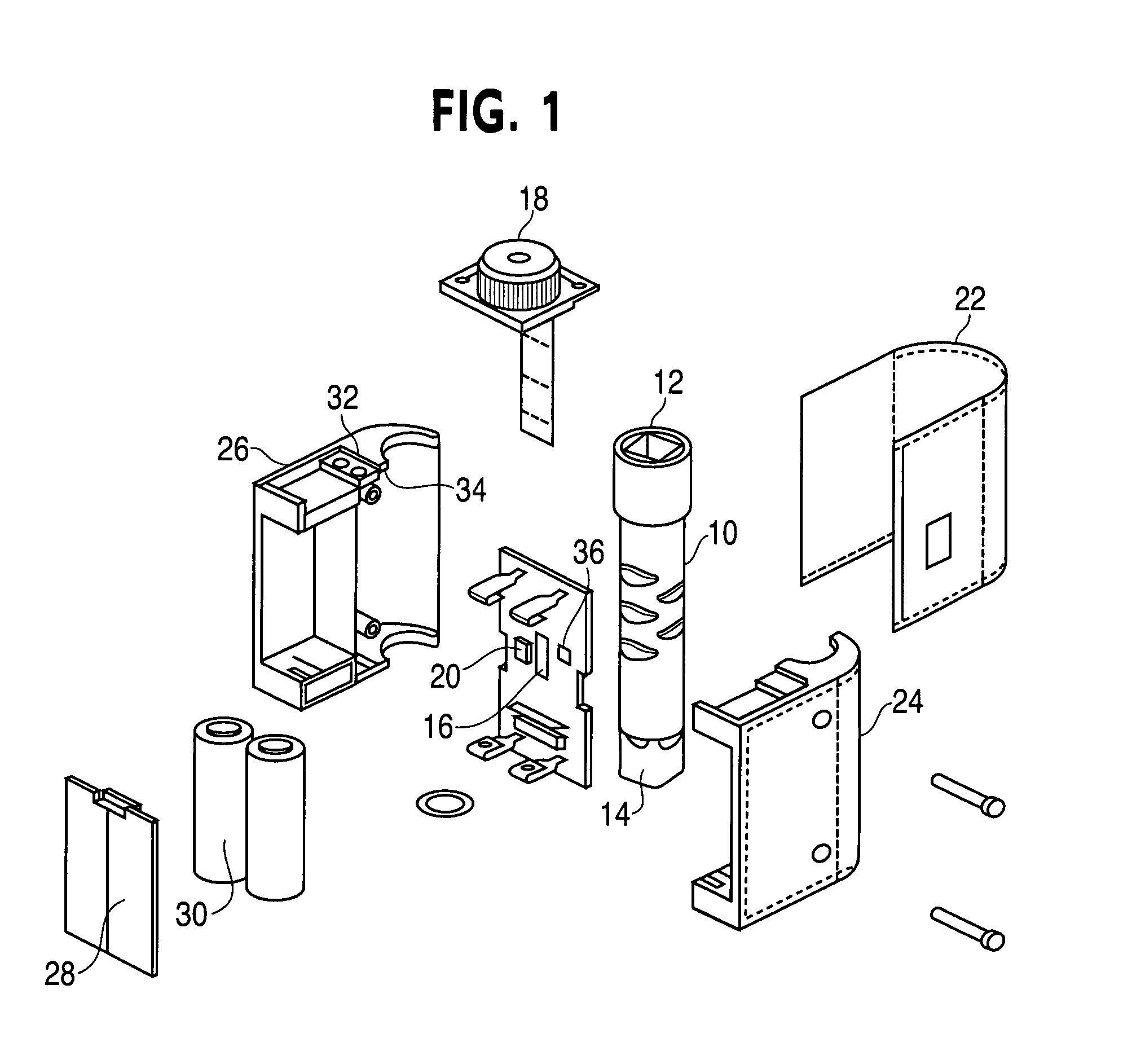

RFID torque sensing tag system for fasteners

ActiveUS9483674B1Reliable dataCost-effective meanMeasurement of torque/twisting force while tighteningLoad modified fastenersOff the shelfRadio frequency

The present invention provides an RFID-based torque sensor that can be used to quickly monitor off the shelf fasteners including fasteners that are used in expensive satellites or other uses where fastener failure can be very costly. In one embodiment, an antenna, RFID ring and spring comprise a sensor tag that can be interrogated with an interrogation signal produced by an interrogator device. When sufficient torque is applied to the fastener, an RFID circuit is connected, and produces a radio frequency (RF) signal that can be read by the interrogator. In one embodiment, the RFID circuit does not transmit when the spring member is not compressed, thereby indicating insufficient tensioning of the fastener. The present invention offers the ability to remotely, quickly, and inexpensively verify that any number of fasteners are torqued properly upon initial installation. Where applicable, the present invention allows low cost monitoring over the life of the fastener.

Owner:NASA

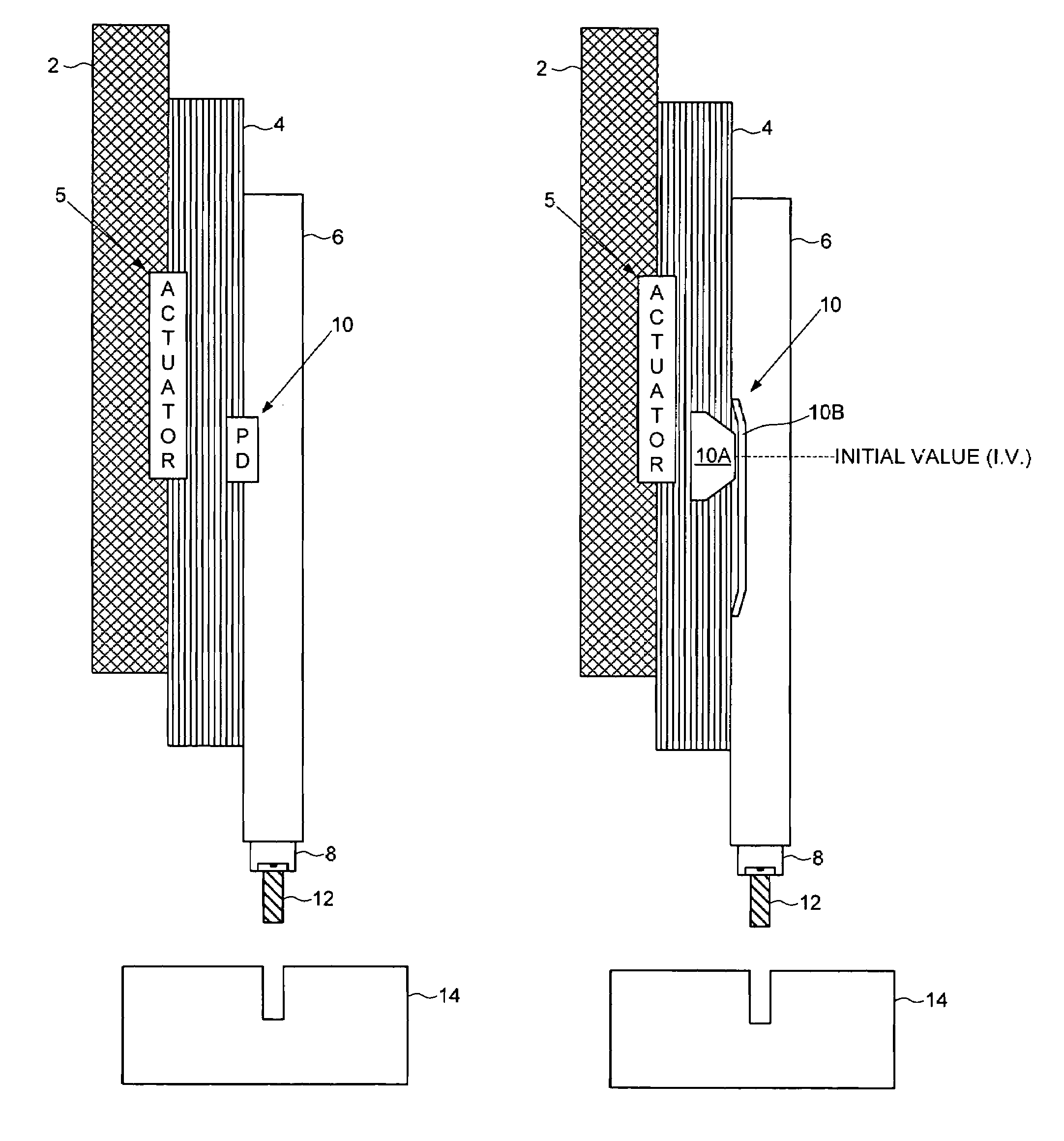

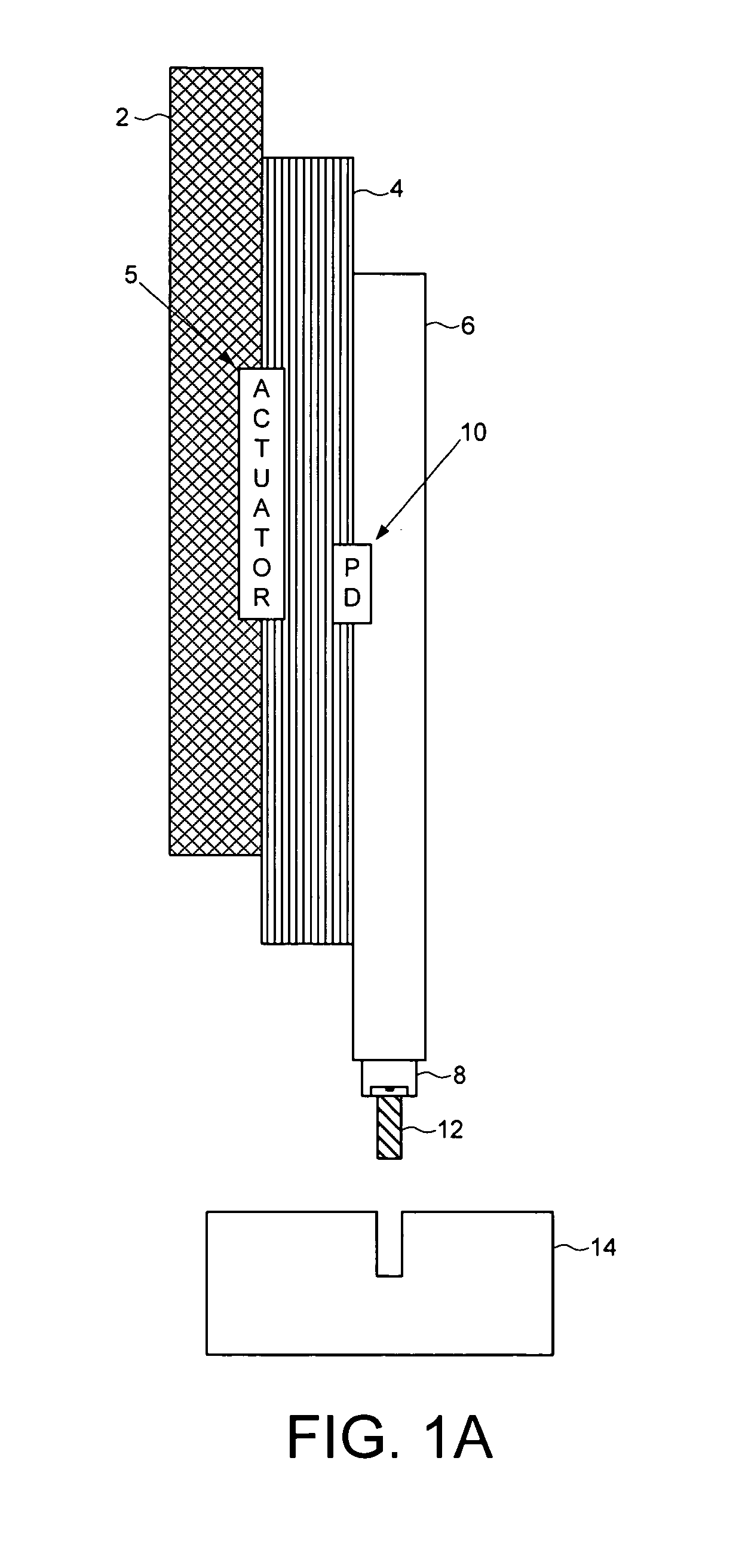

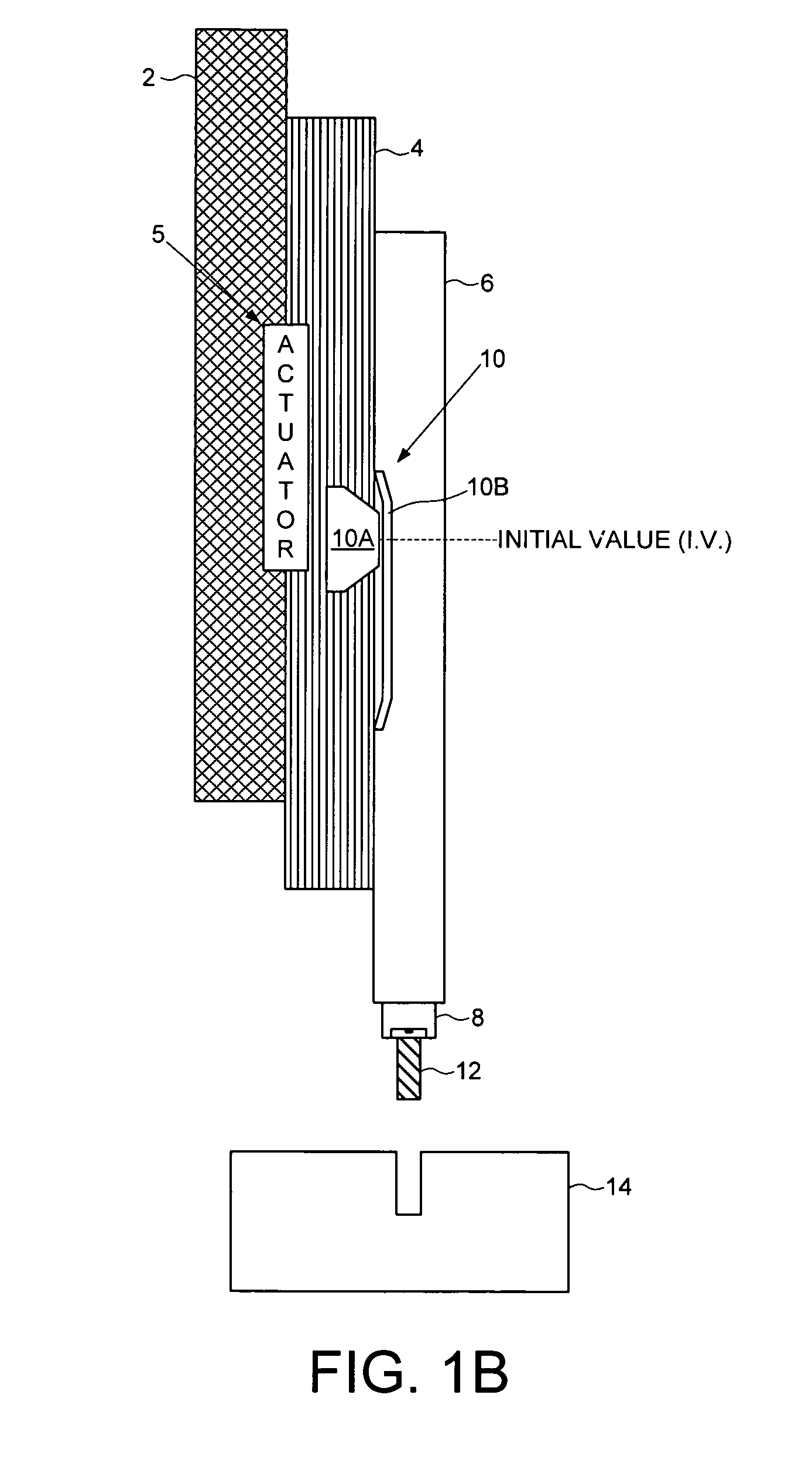

Screwdriver comprising a slider having an attached screw bit and a position detector for position feedback

ActiveUS7458282B1Measurement of torque/twisting force while tighteningMeasurement arrangements for variableEngineeringActuator

A screwdriver is disclosed comprising a base, a carriage moveably coupled to the base, an actuator operable to move the carriage relative to the base, and a slider comprising an attached screw bit, wherein the slider is coupled to the base through the carriage and the slider is moveably coupled to the carriage such that the slider and attached screw bit move together relative to the carriage. The screwdriver further comprises a position detector operable to detect a position of the slider relative to the carriage. In one embodiment, the carriage is moved relative to the base to move the screw towards the work surface. After the screw contacts the work surface, the carriage is moved further relative to the base causing the slider to move relative to the carriage, and the movement of the slider relative to the carriage is detected using the position detector.

Owner:WESTERN DIGITAL TECH INC

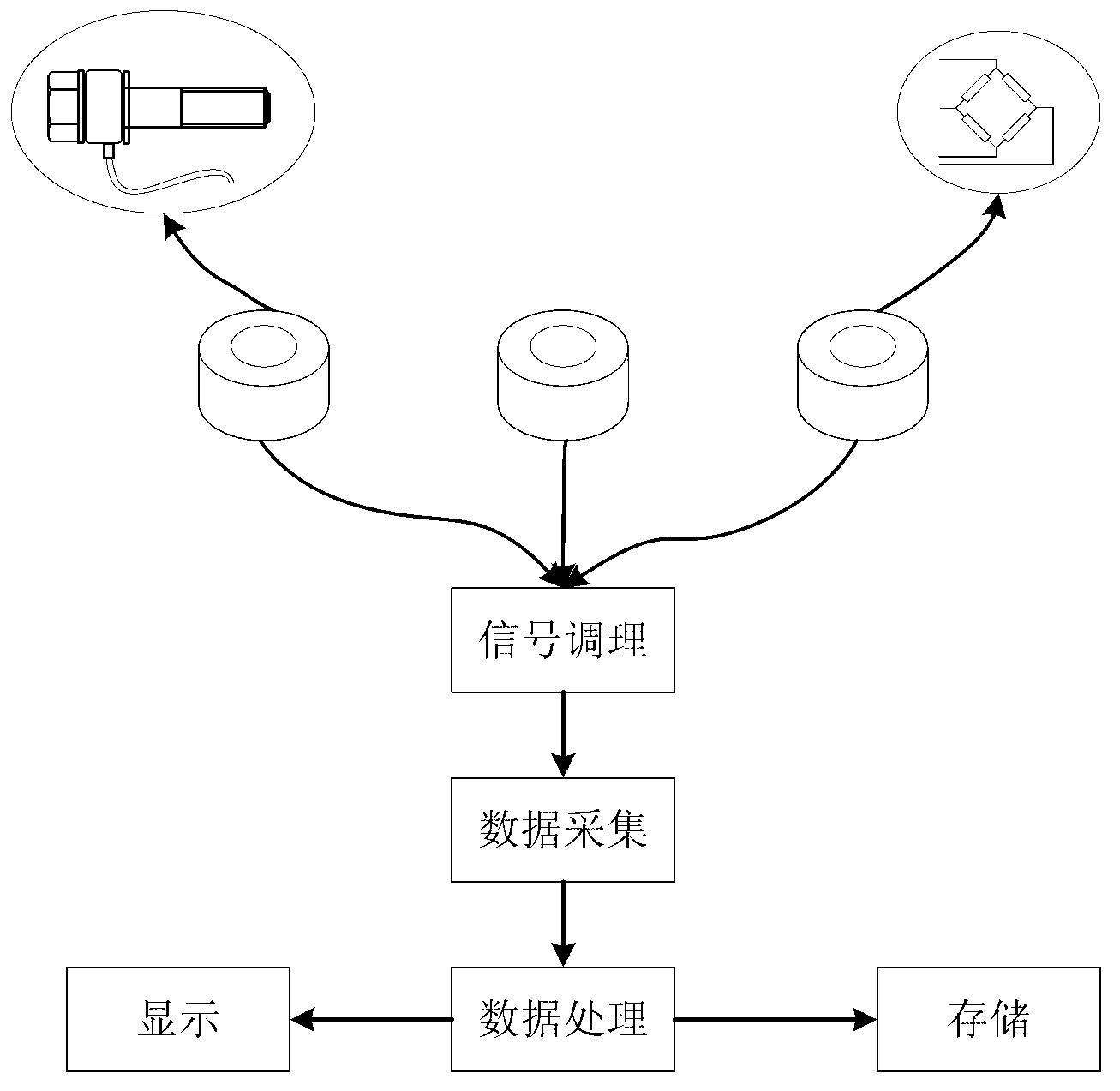

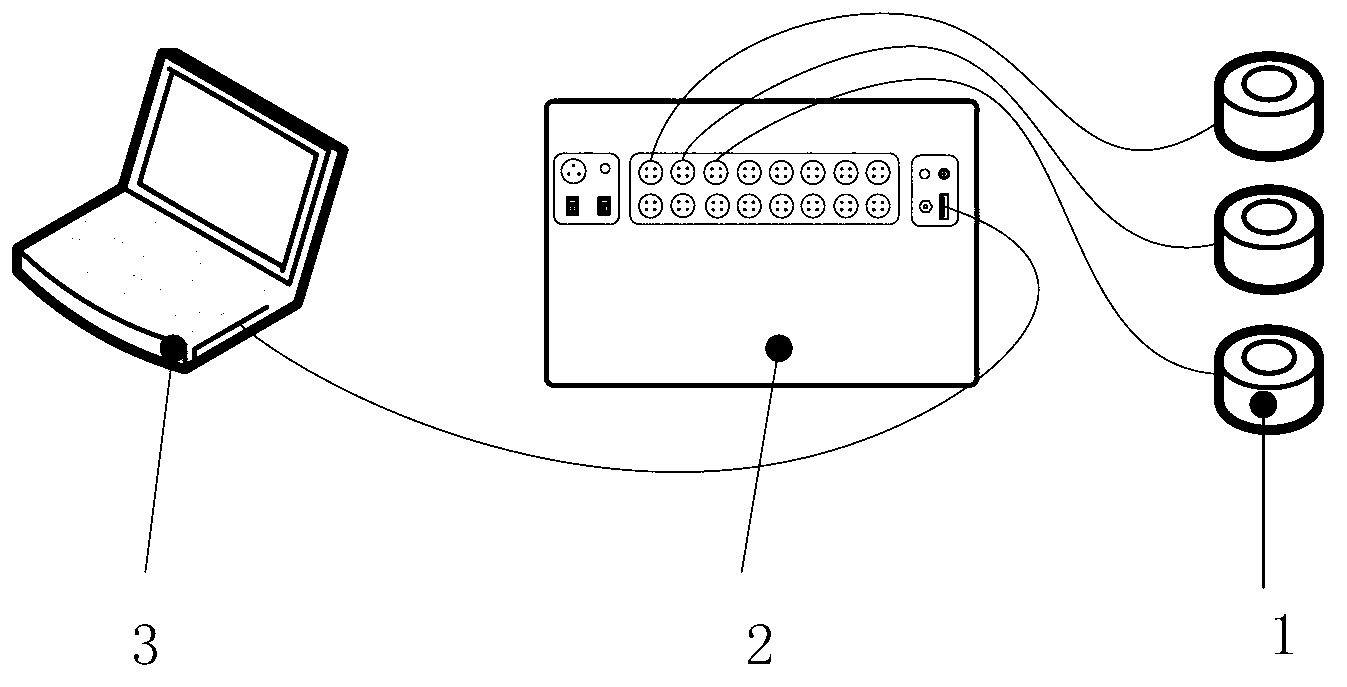

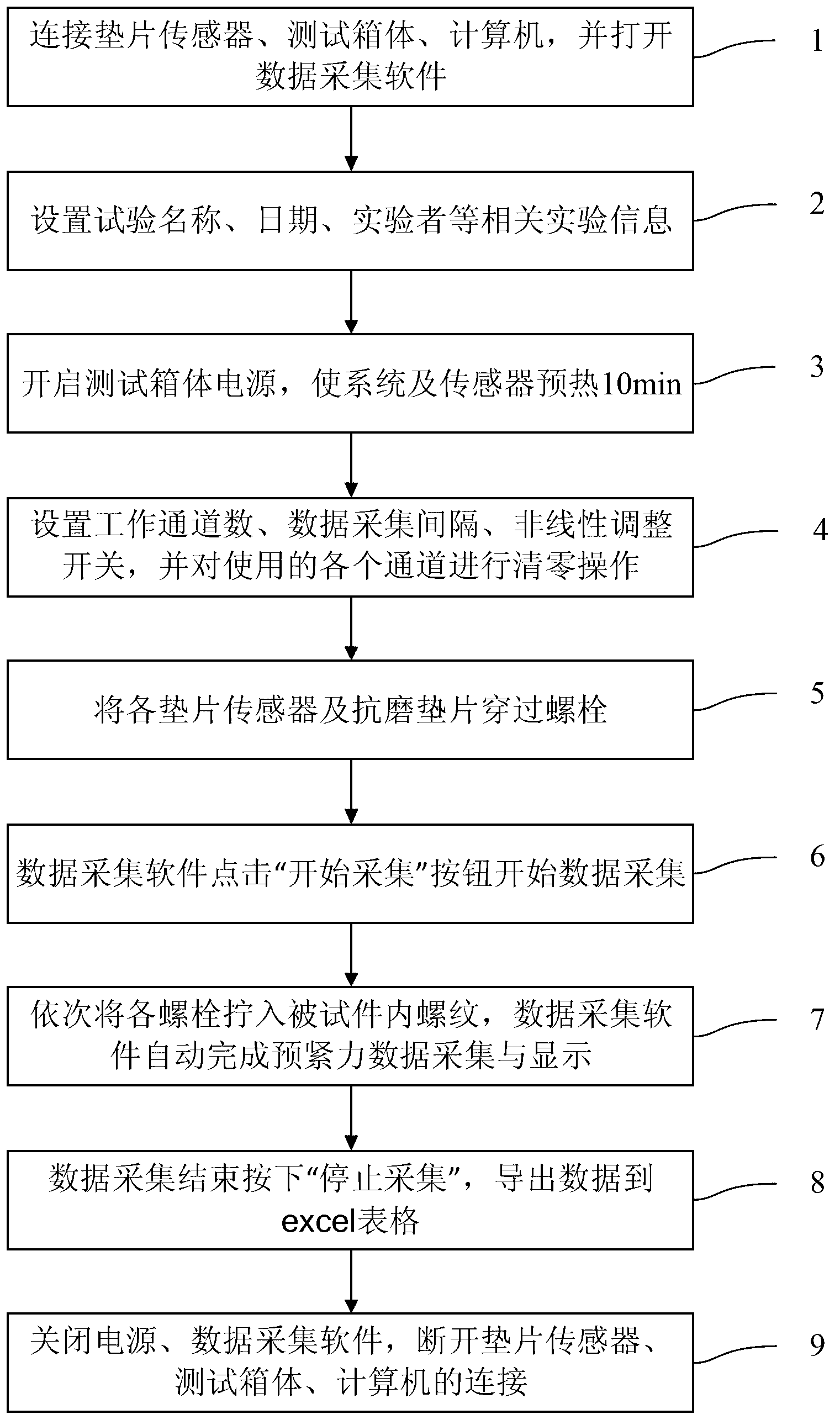

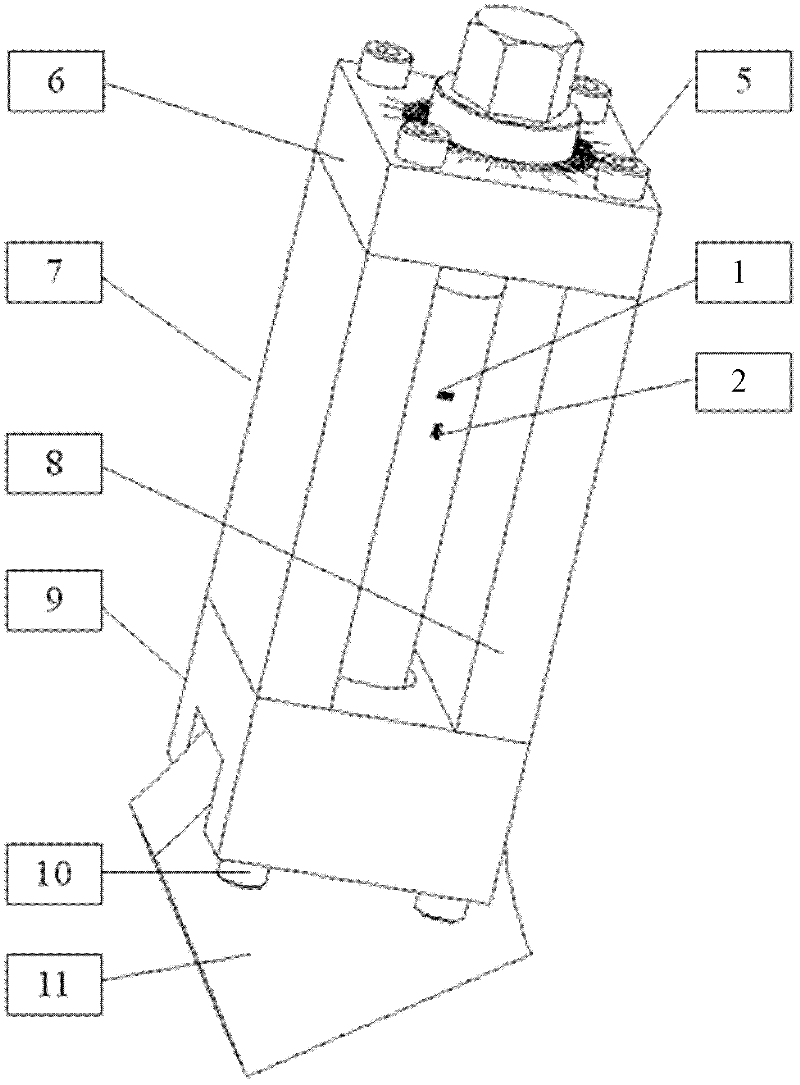

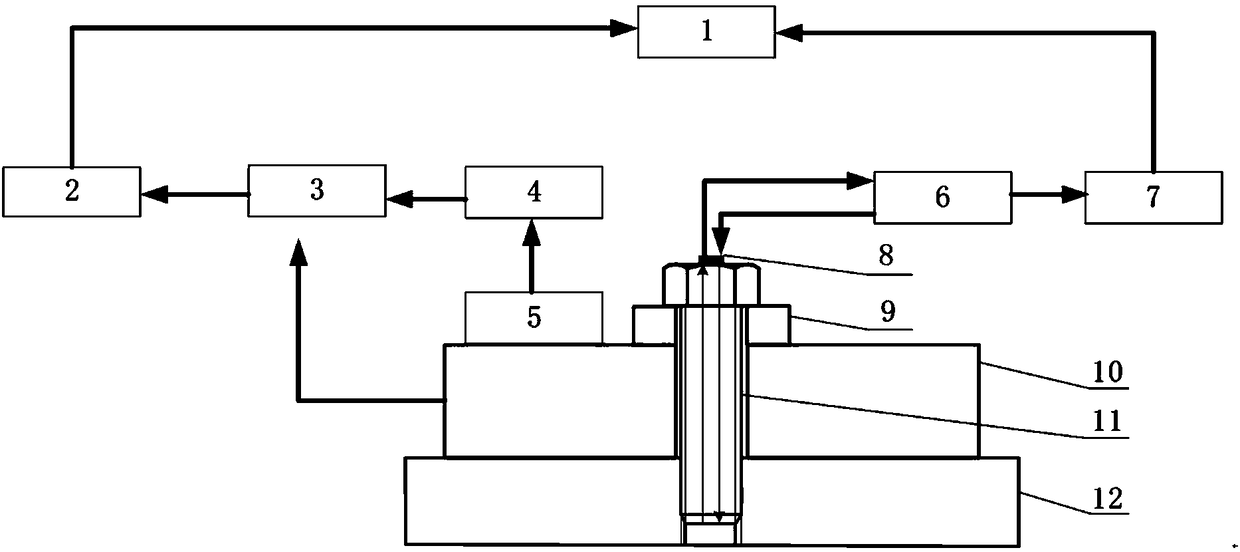

Pretightening force measuring system and method of bolt set connection

ActiveCN103323170AEasy to measure directlyEasy to measureMeasurement of torque/twisting force while tighteningSignal conditioningEngineering

The invention provides a pretightening force measuring system and method of bolt set connection. The system comprises a gasket type force sensor, a testing box connected with the gasket type force sensor, and processing equipment connected with the testing box, wherein the gasket type force sensor is provided with a hole for penetration of a bolt, when the bolt is screwed up, obtained pretightening force signals are transmitted to the testing box, signal conditioning is carried out on the pretightening force signals by the testing box, and the pretightening force signals after the conditioning are transmitted to the processing equipment to be processed. According to the pretightening force measuring system and method, measurement is convenient, the pretightening force in the screwing-up process of a bolt set and after the screwing-up process is monitored in on-site, shaking and other environments, and the pretightening force measuring system and method is portable to be used for measuring.

Owner:内蒙古第一机械集团股份有限公司 +1

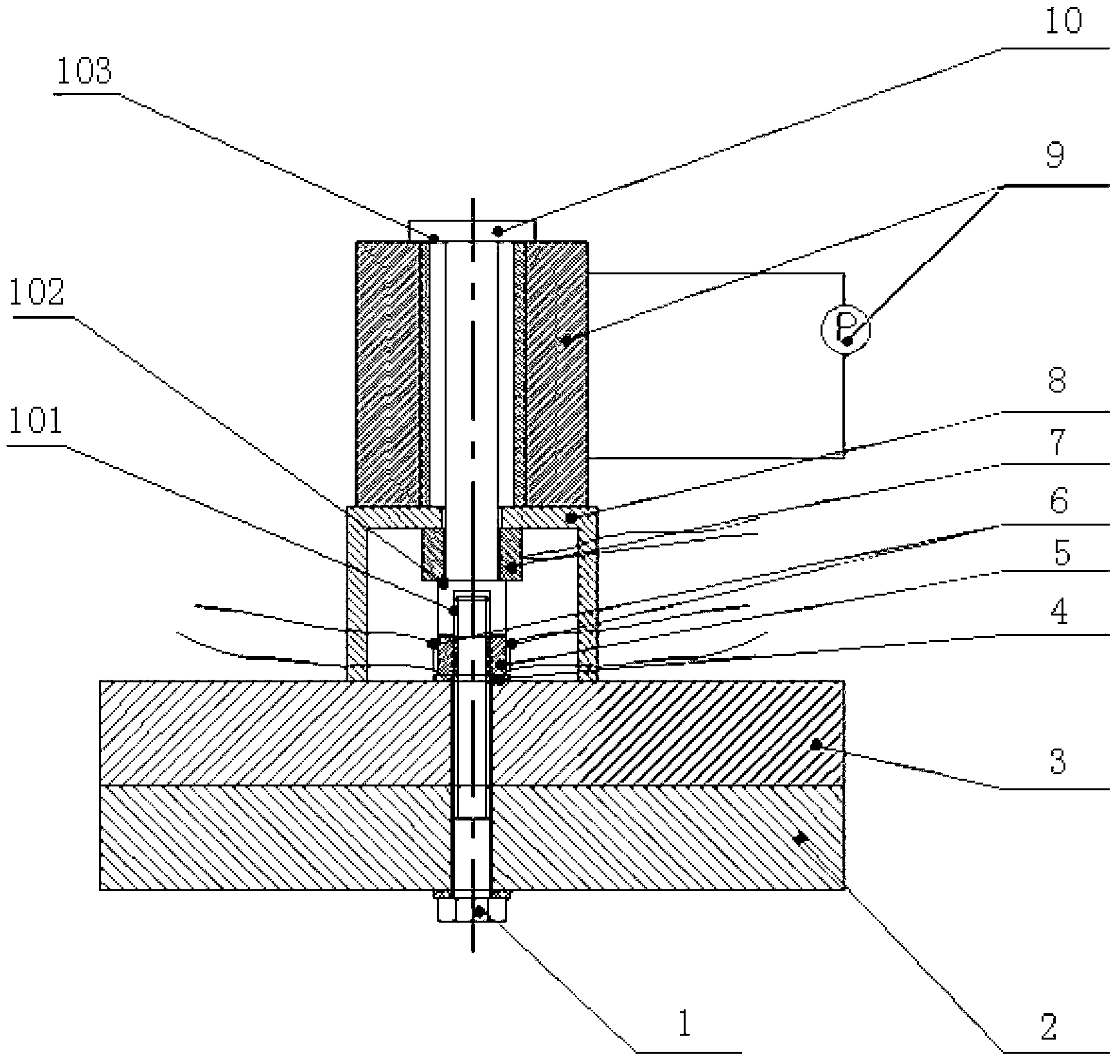

Bolt pre-tightening force testing device and control method thereof

ActiveCN102519652AMeet preload requirementsLow costMeasurement of torque/twisting force while tighteningHydraulic/pneumatic force measurementEngineering

Owner:TIANJIN UNIV

Torque angle sensing system and method with angle indication

A device used for measuring the angle of torque beyond a specific reference point. The device is comprised of a tool that applies torque to a fastener, an adapter that is attached to the fastener to transfer the torque from the tool, and an apparatus that connects a first end to the tool and a second end to the adapter. The apparatus comprises an angle selector that is adjustable to the desired torque angle, an angle rate sensor that measures the speed and direction of the torque applied, a processor which calculates the current angle from the rate sensor measurements, a zero point indicator that serves as the basis point for the processor to calculate the selected angle, and an angle indicator that indicates the current angle of rotation.

Owner:SPX CORP

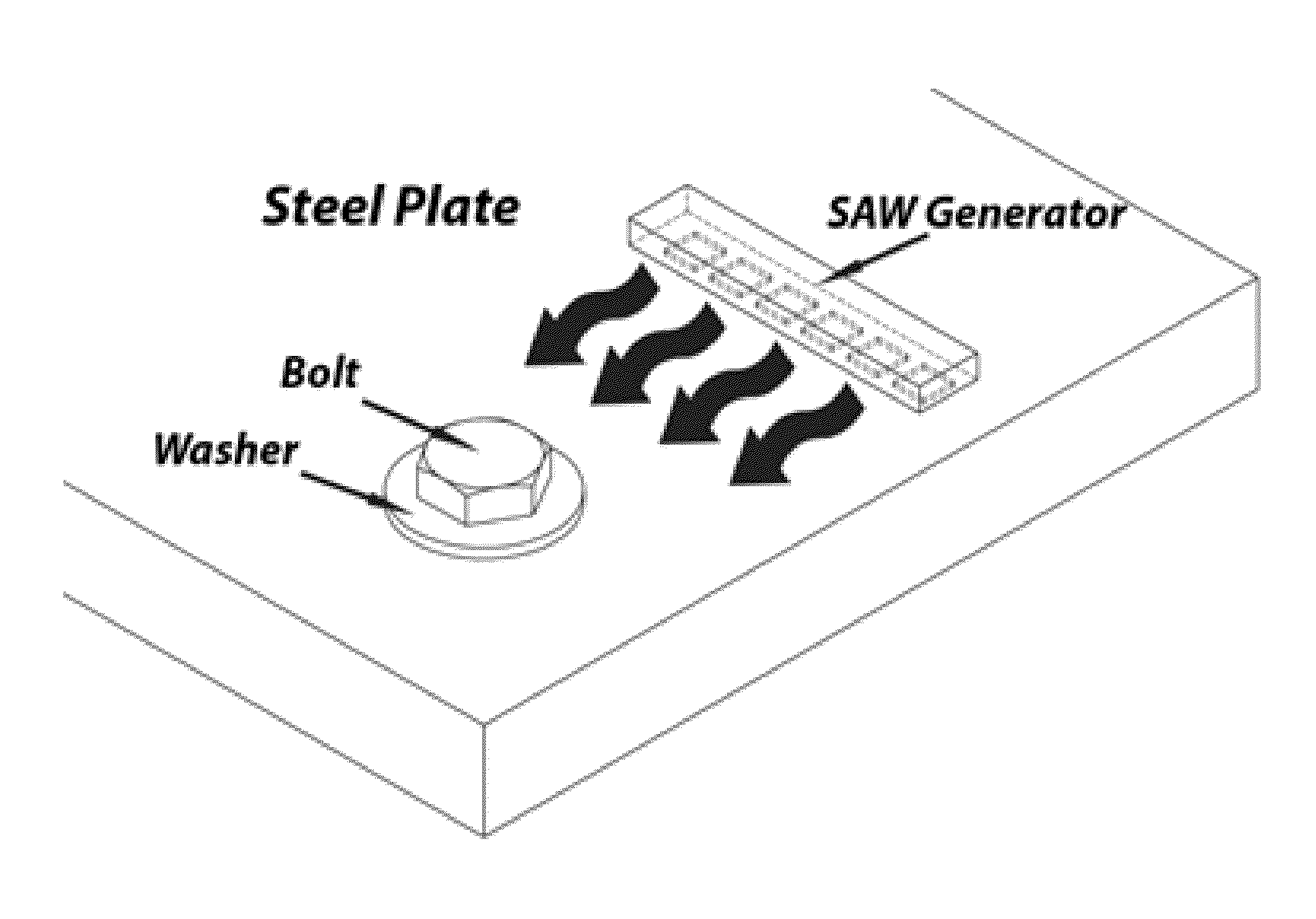

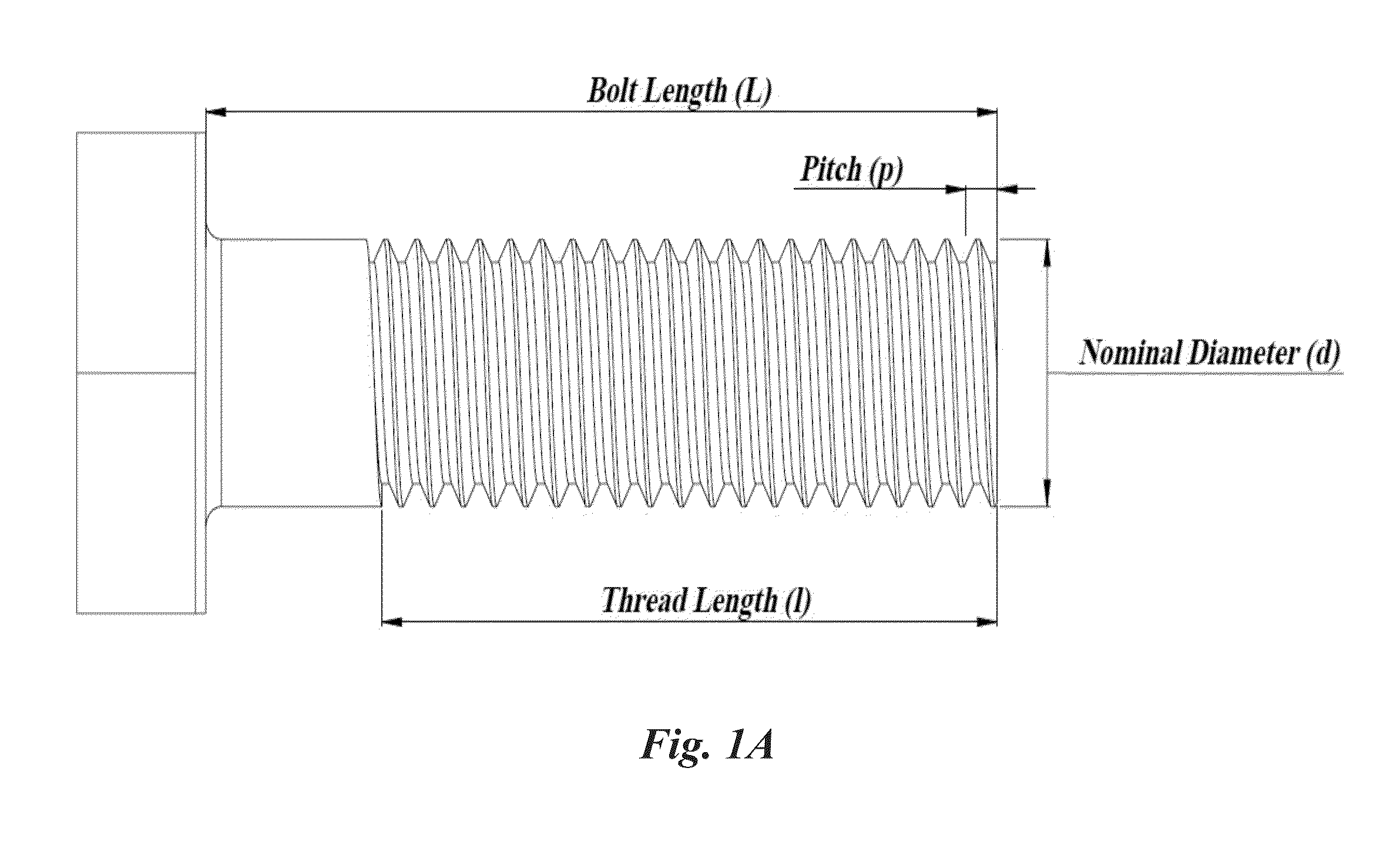

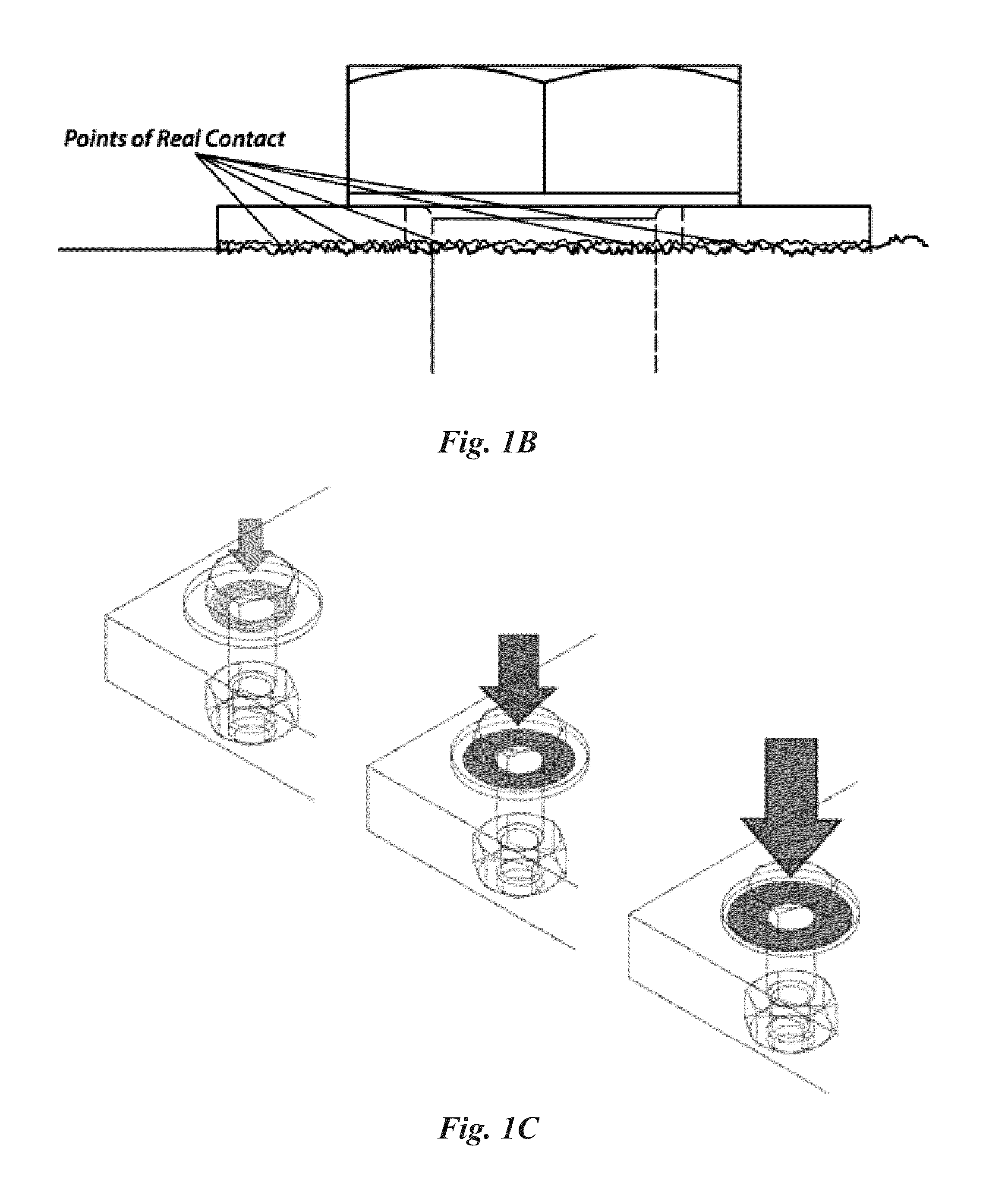

Active ultrasonic method of quantifying bolt tightening and loosening

ActiveUS9127998B1Problem in their useAnalysing solids using sonic/ultrasonic/infrasonic wavesMeasurement of torque/twisting force while tighteningSonificationInteraction point

A synthetic phased array surface acoustic wave sensor to quantify bolt tension and a method for determining or estimating the tension in bolts using surface acoustic waves (SAWs). The tension is determined or estimated by using the reflection of SAWs created by the bolt head interference with the underlying surface. Increments in the bolt tension raise the points of interaction between the waves and the bolt head (real area of contact), and hence the position of the reflective boundaries. The variations are estimated using known techniques (e.g., linear synthetic array imaging technique). A singular transducer is actuated from predefined positions to produce an array of signals that are subsequently arranged and added to construct an acoustic image.

Owner:UNIV OF SOUTH FLORIDA

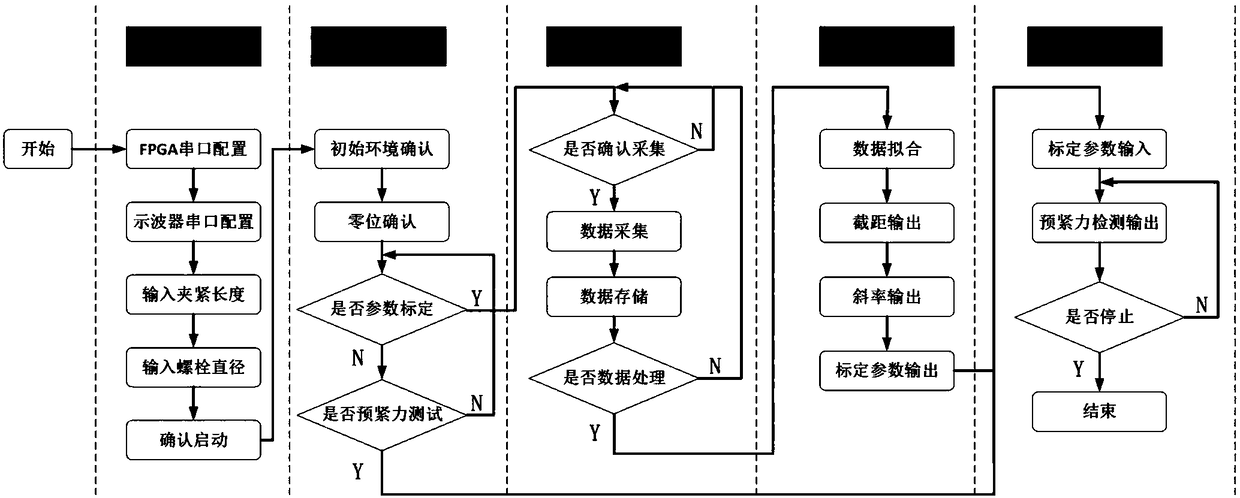

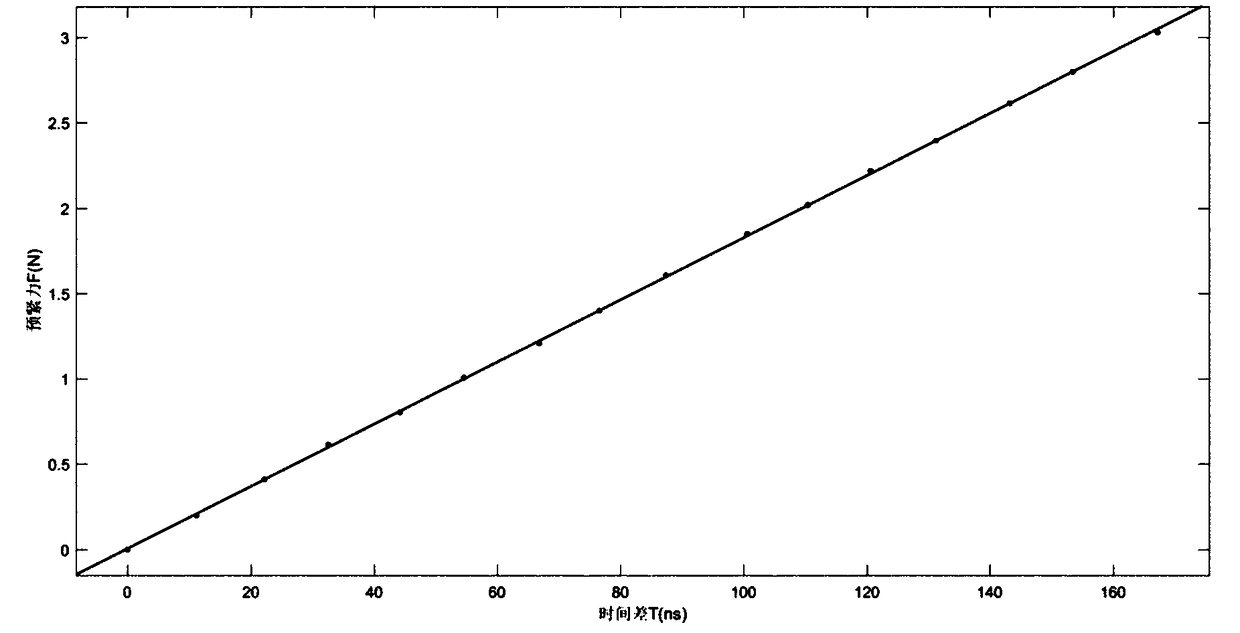

Real-time high-precision detection method and system for bolt pre-tightening force based on piezoelectric ultrasonic wafer

ActiveCN108387338AEliminate errorsHigh measurement accuracyMeasurement of torque/twisting force while tighteningForce sensorsElectricityEngineering

The invention discloses a real-time high-precision detection method and system for a bolt pre-tightening force based on a piezoelectric ultrasonic wafer. The piezoelectric ultrasonic chip is used as an ultrasonic excitation source to be attached to a bolt head, and a high-precision fitting relationship between an ultrasonic flight time difference and the bolt pre-tightening force is established byusing the change law of an ultrasonic single-wave time difference with the stress value; and real-time detection of the bolt pre-tightening force is achieved by using the mathematical relationship. Compared with the prior method using the ultrasonic probe, the method provided by the invention eliminates the error caused by the uncertainty of the thickness of the coupling agent, and further improves the measurement accuracy by using the single-wave time difference. Low-error-rate measurement of the bolt pre-tightening force is achieved at low cost and without influencing the structural performance.

Owner:DALIAN UNIV OF TECH

High-strength bolt axial force measuring device and measuring method

InactiveCN103245452AHigh measurement accuracyReduce adverse effectsMeasurement of torque/twisting force while tighteningMeasurement deviceProper time

The invention discloses a high-strength bolt axial force measuring device and measuring method. The measuring device comprises a pull rod, an axial force sensor, a force providing part and a support; the close end of the pull rod is provided with a connecting part for being connected with a high-strength bolt thread end, and the close and far ends of the pull rod are provided with a first match part and a second match part respectively; the first match part is in match contact with the close end face of the axial force sensor, the second match part and the far end of the force providing part act in a match mode, the far end of the support is mounted between the force providing part and the axial force sensor, and the close end of the support is used for being supported on a part connected with a high-strength bolt; and the high-strength bolt axial force measuring device also comprises a strain measuring part arranged on a nut. The measuring method comprises the steps of (1) mounting the strain measuring part on the axial outer face of the nut; 2, connecting the pull rod with the thread end of the high-strength bolt in the match mode; and 3 starting the force providing part to read the value of the axial force sensor at proper time according to the changing condition of the stain measuring part. The high-strength bolt axial force measuring device and method are accurate in measuring by directly measuring the axial force of the high-strength bolt.

Owner:LONGYUAN BEIJING WIND POWER ENG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com