Patents

Literature

4472results about "Testing/calibration apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

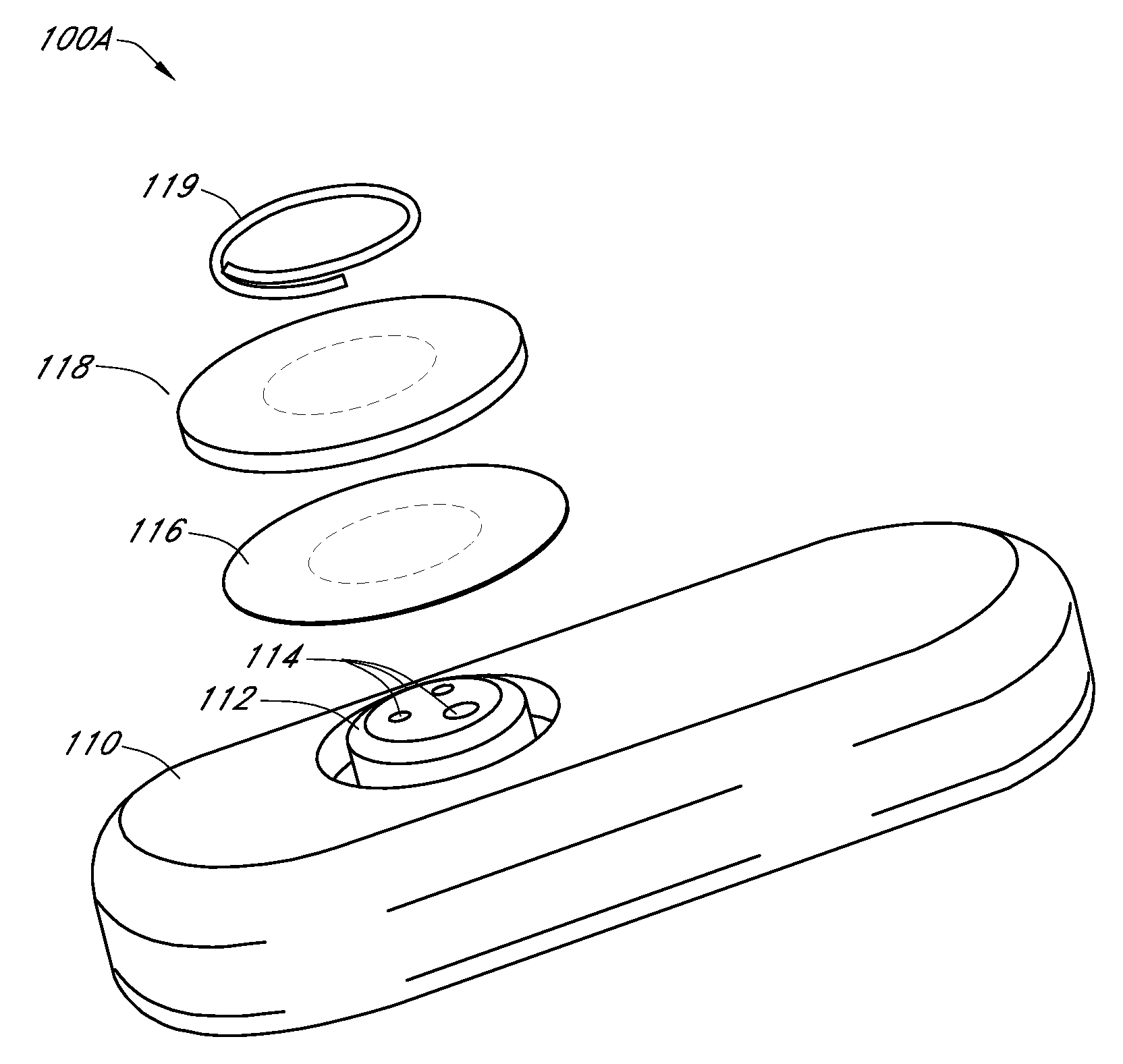

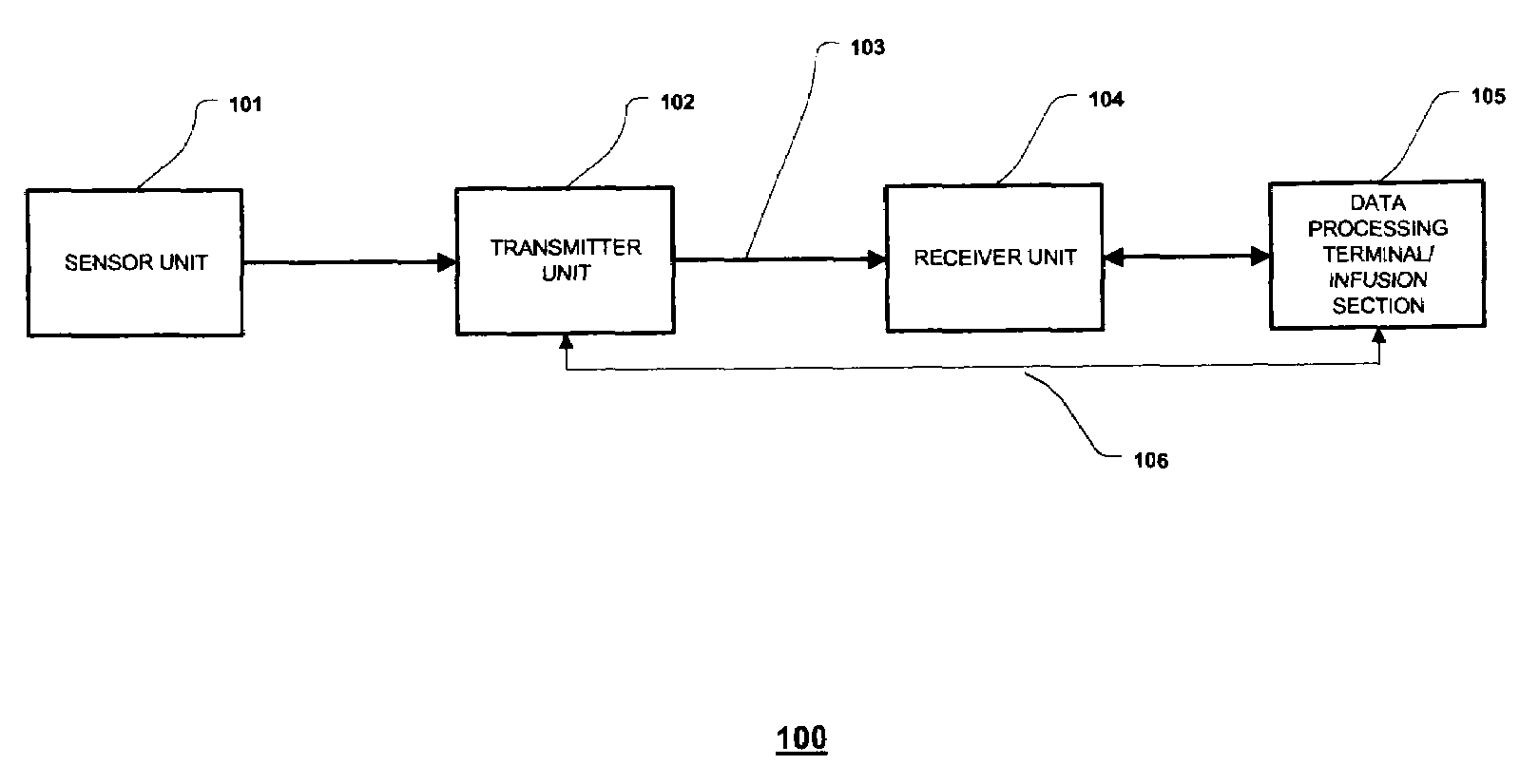

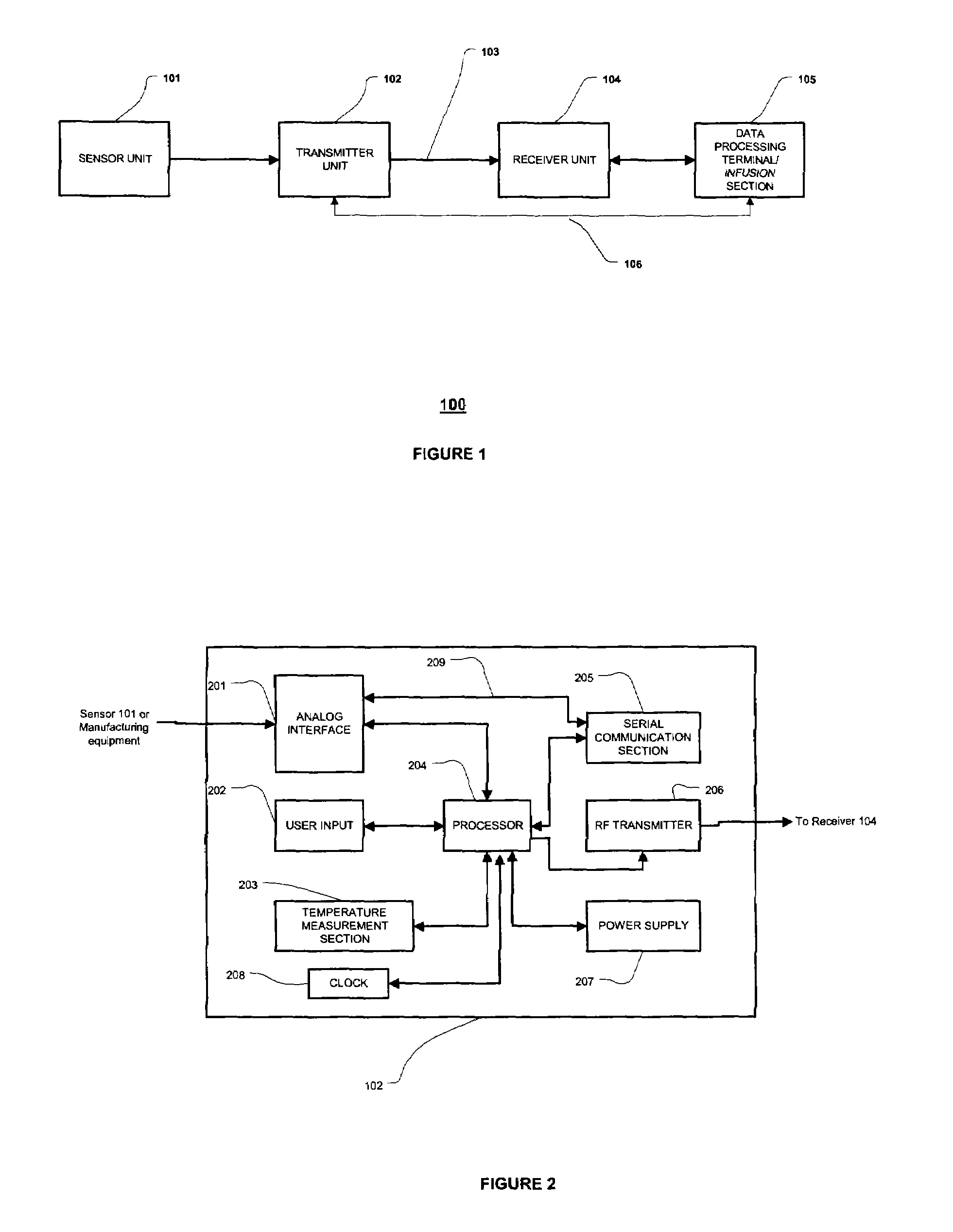

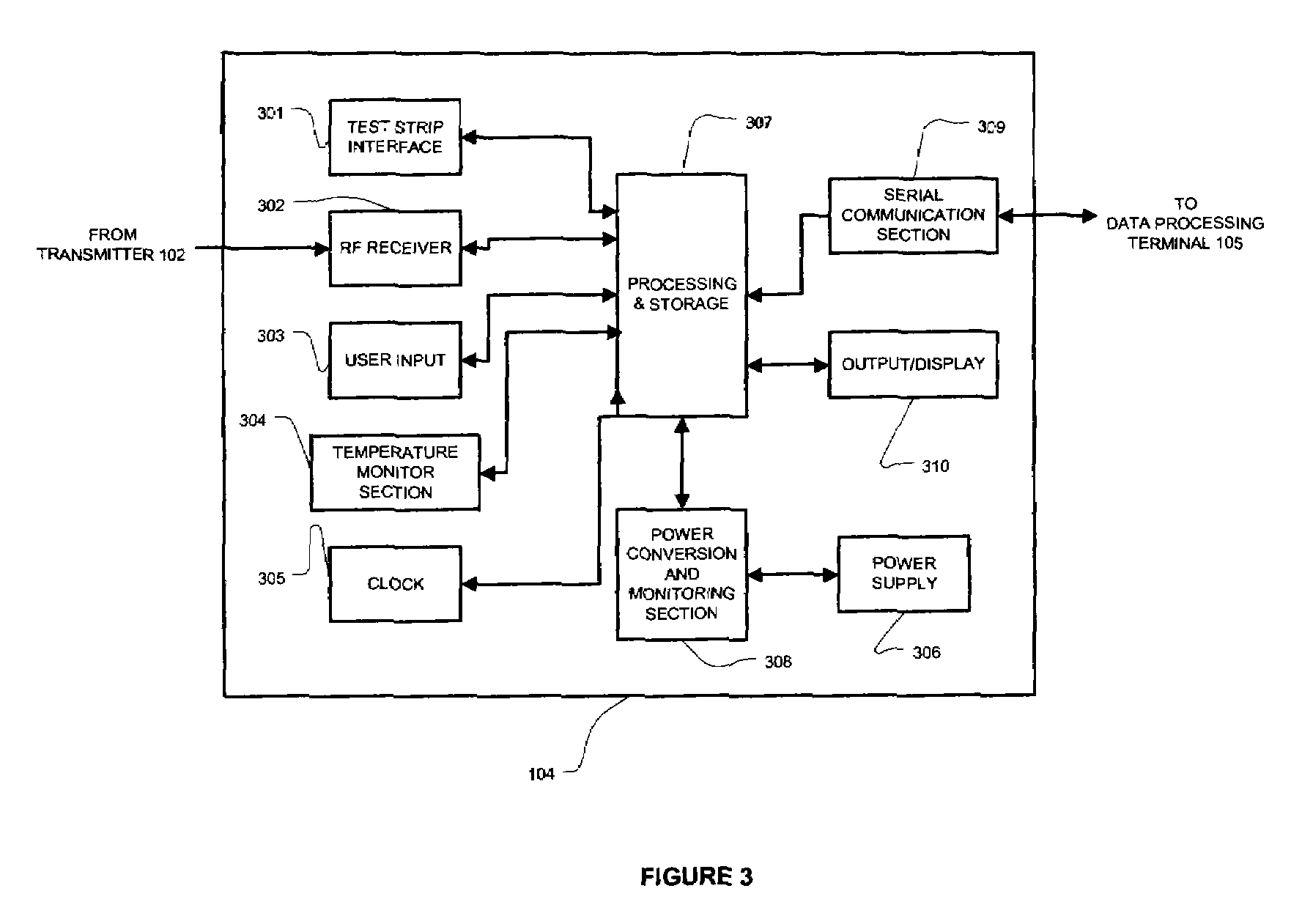

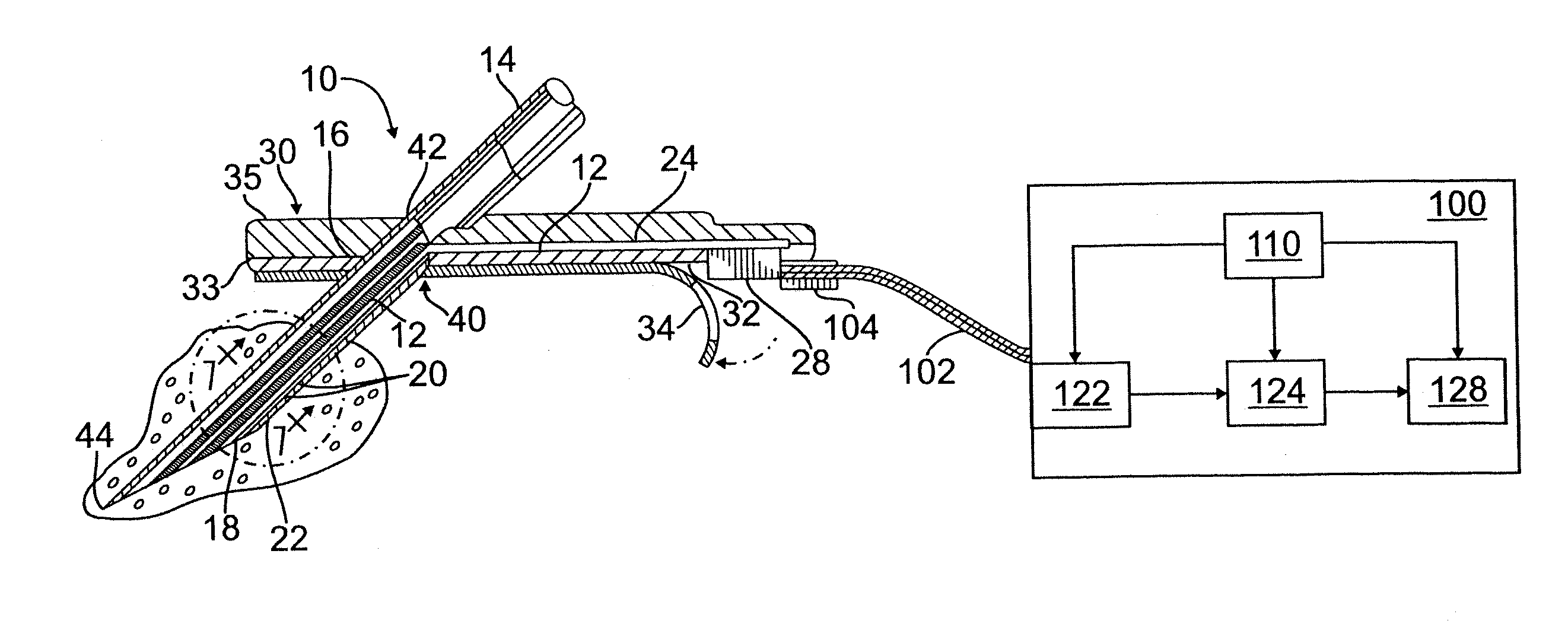

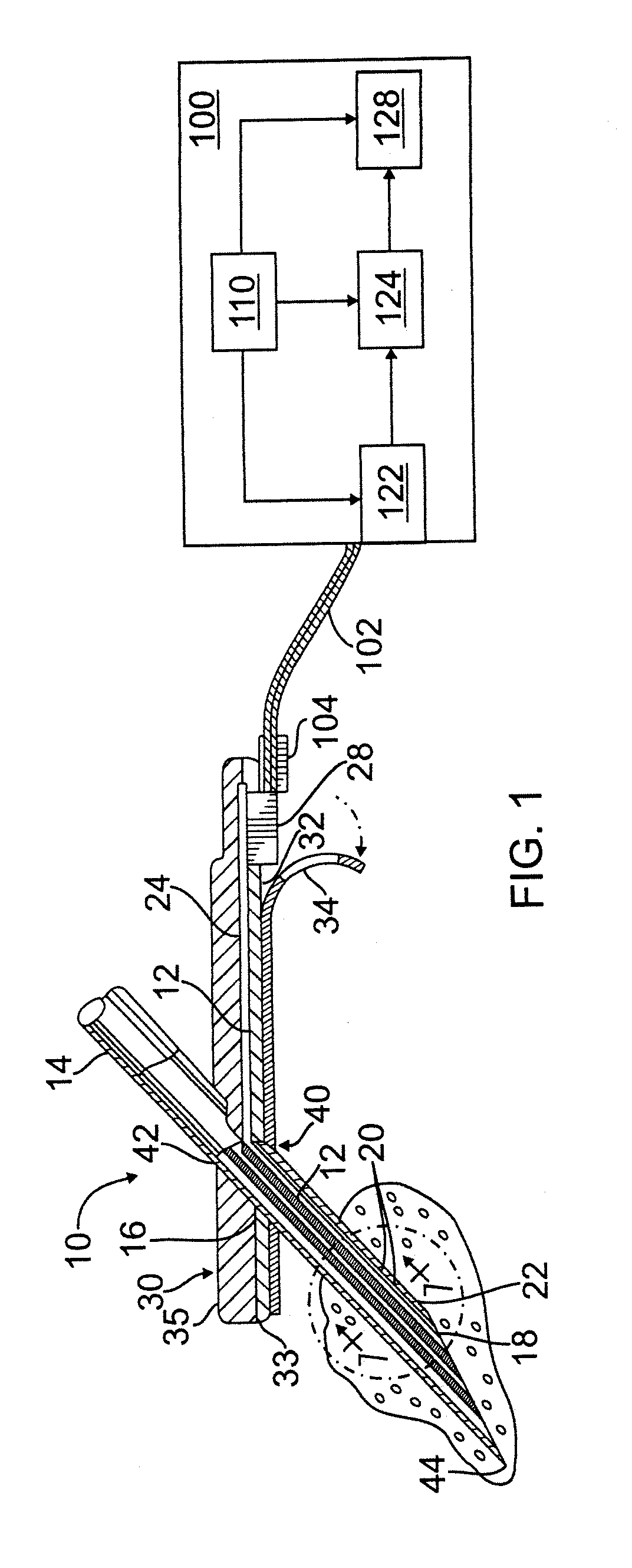

Systems and methods for processing sensor data

ActiveUS20090192751A1Testing/calibration apparatusMaterial analysis by electric/magnetic meansAnalyteConcentrations glucose

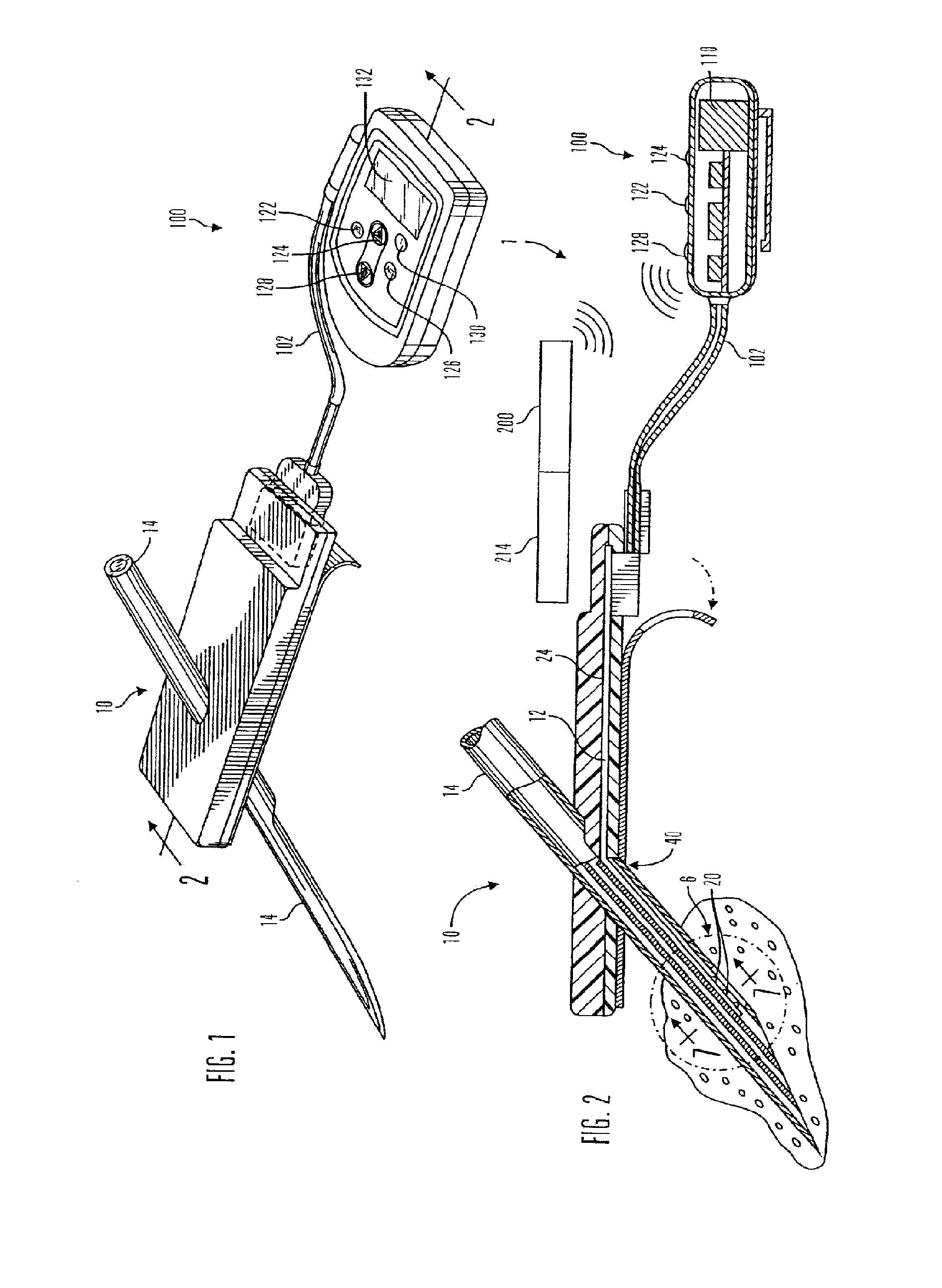

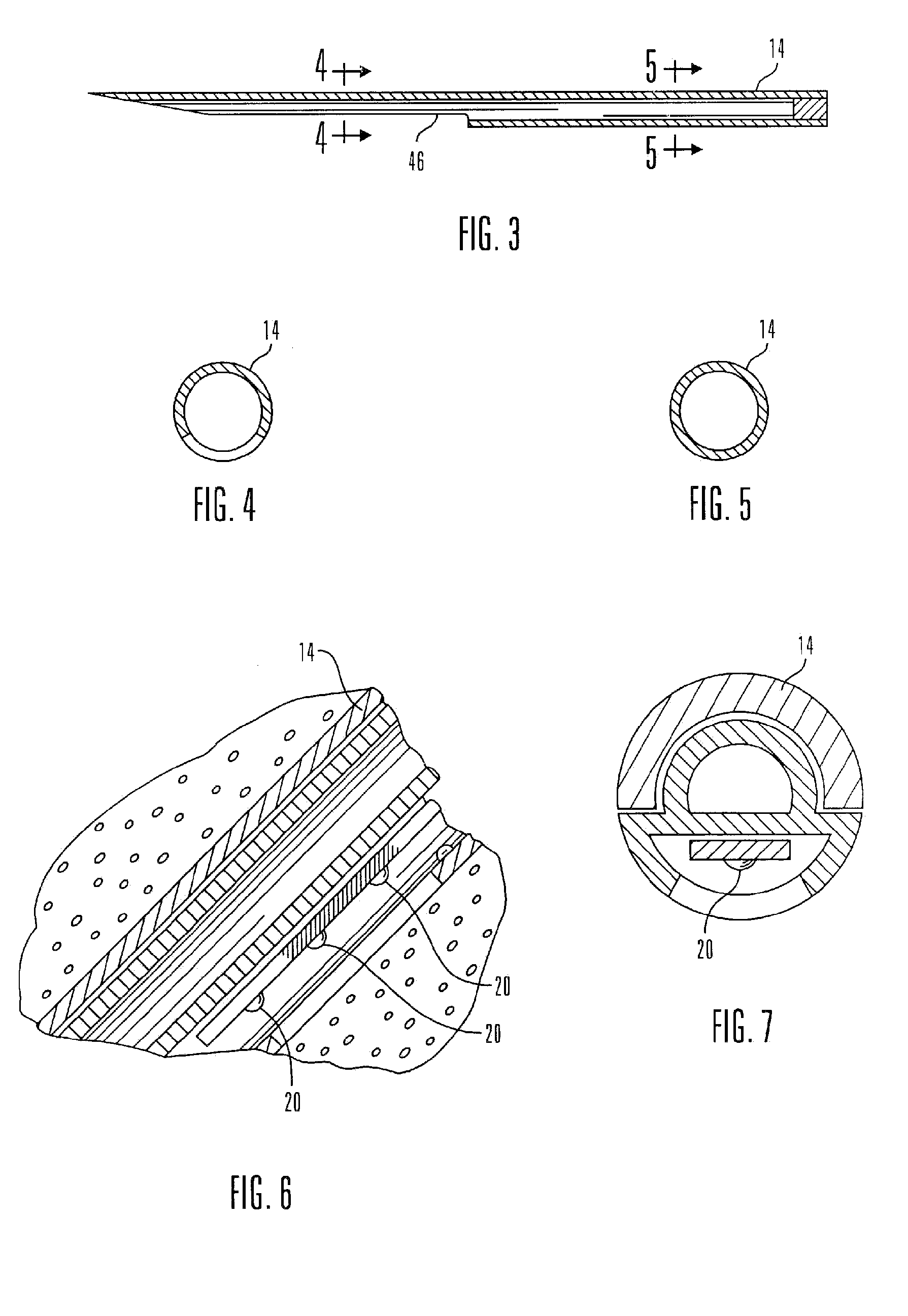

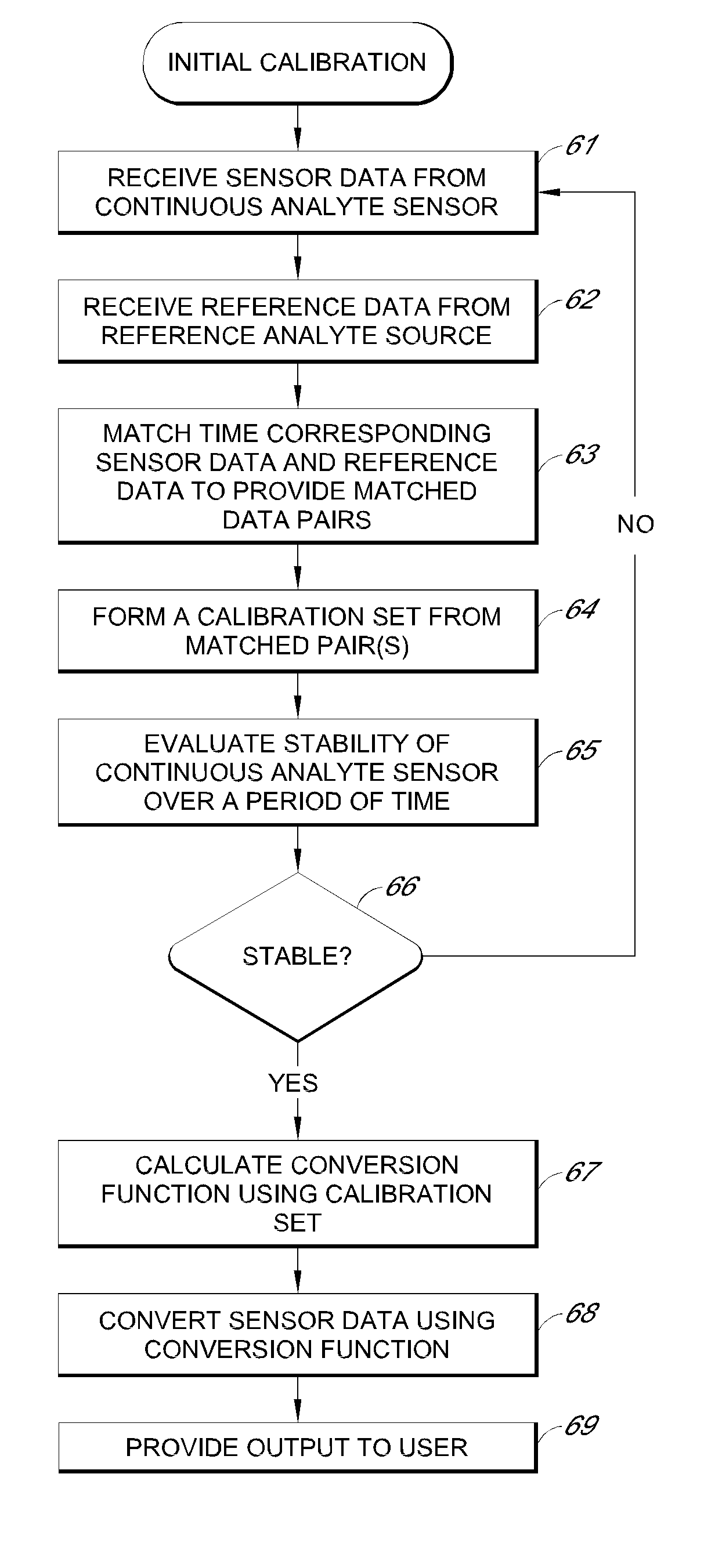

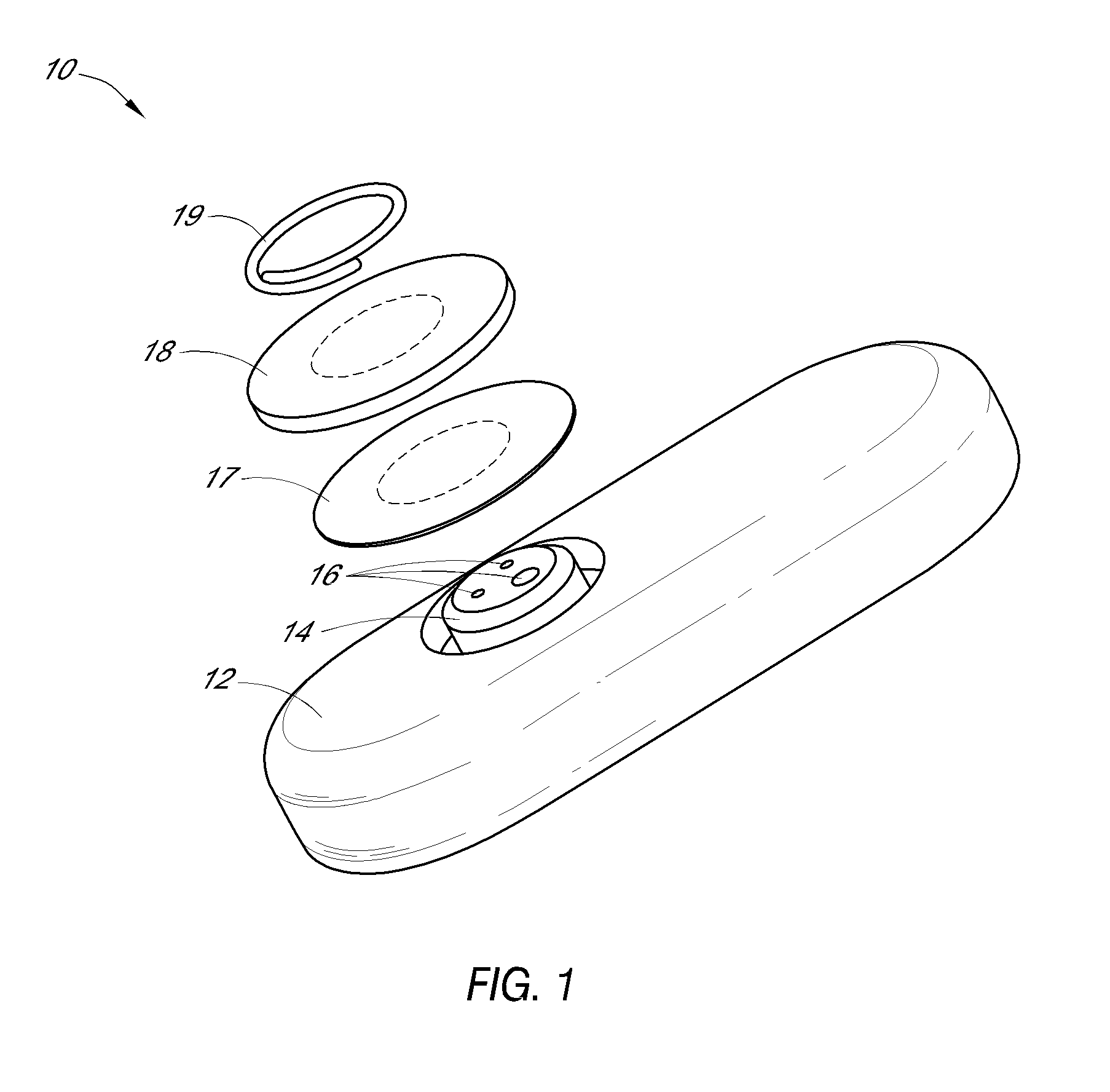

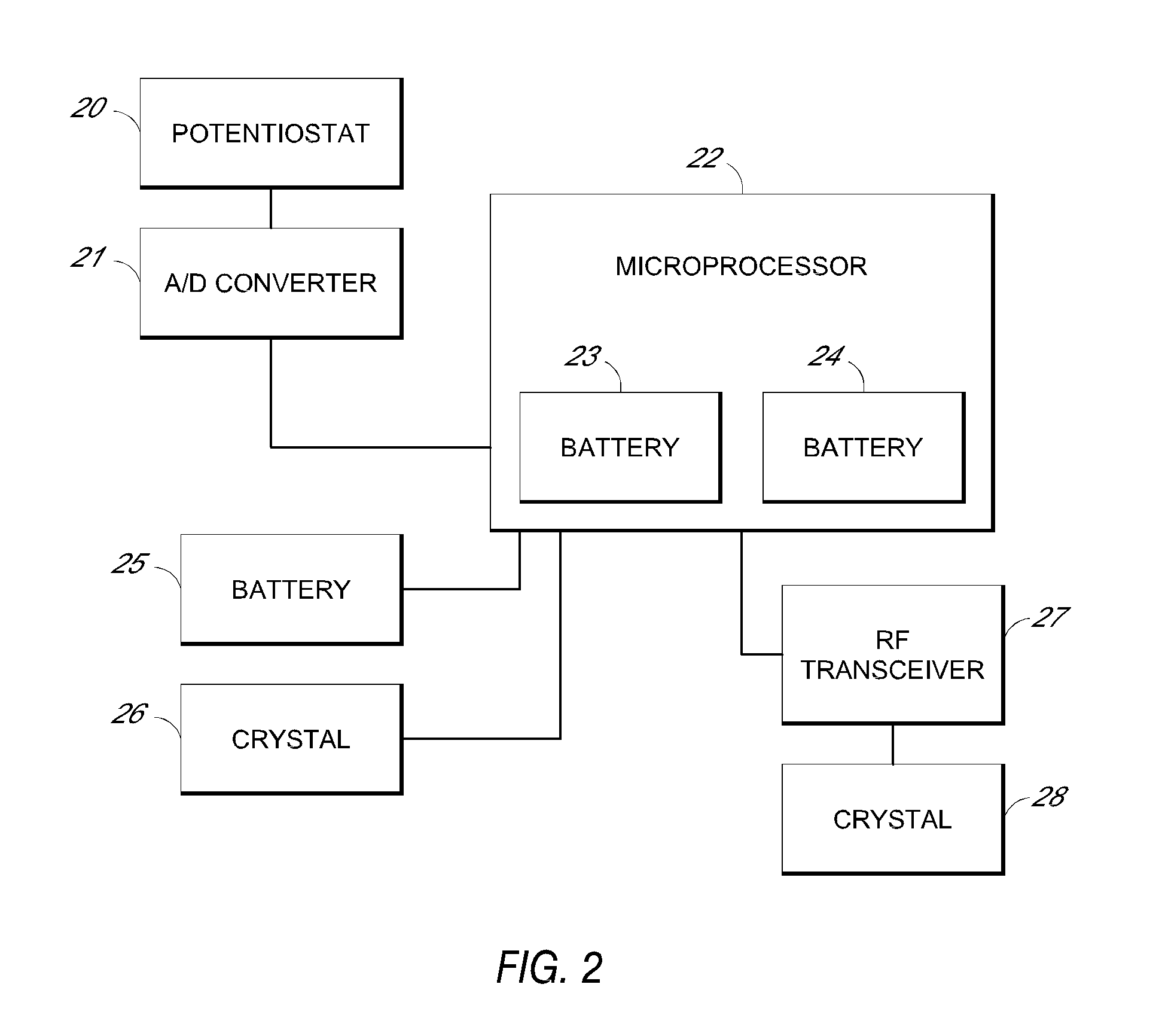

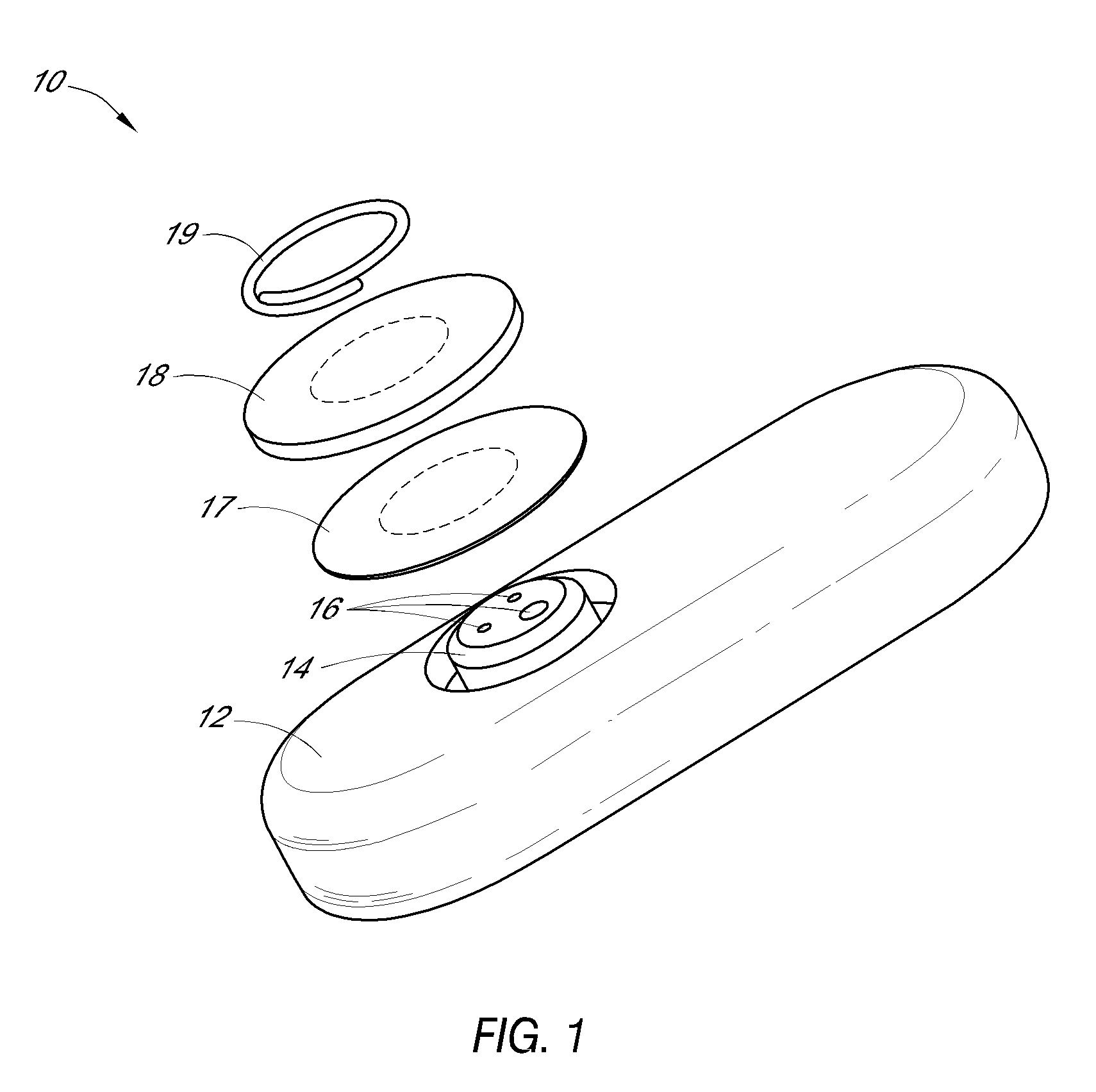

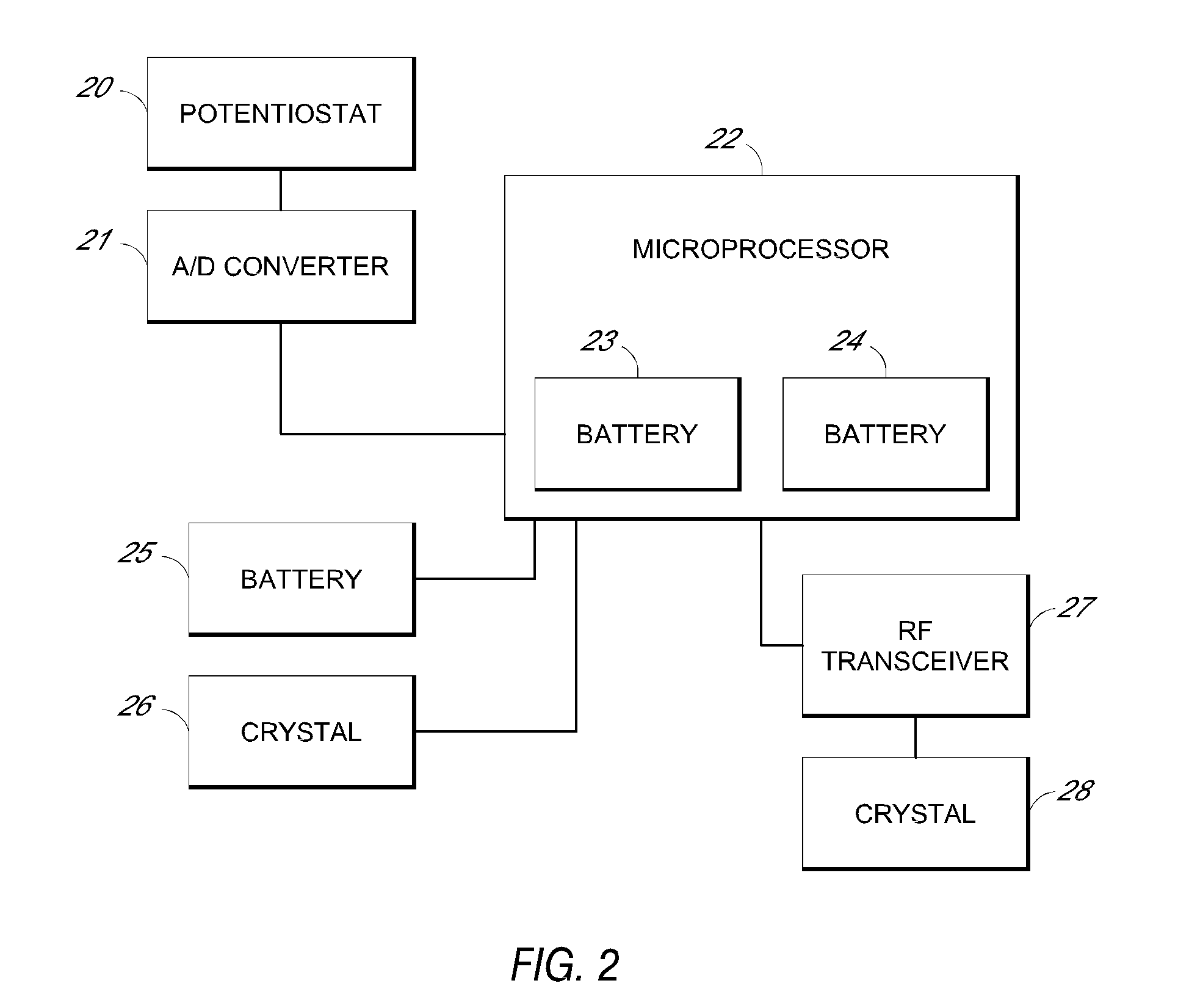

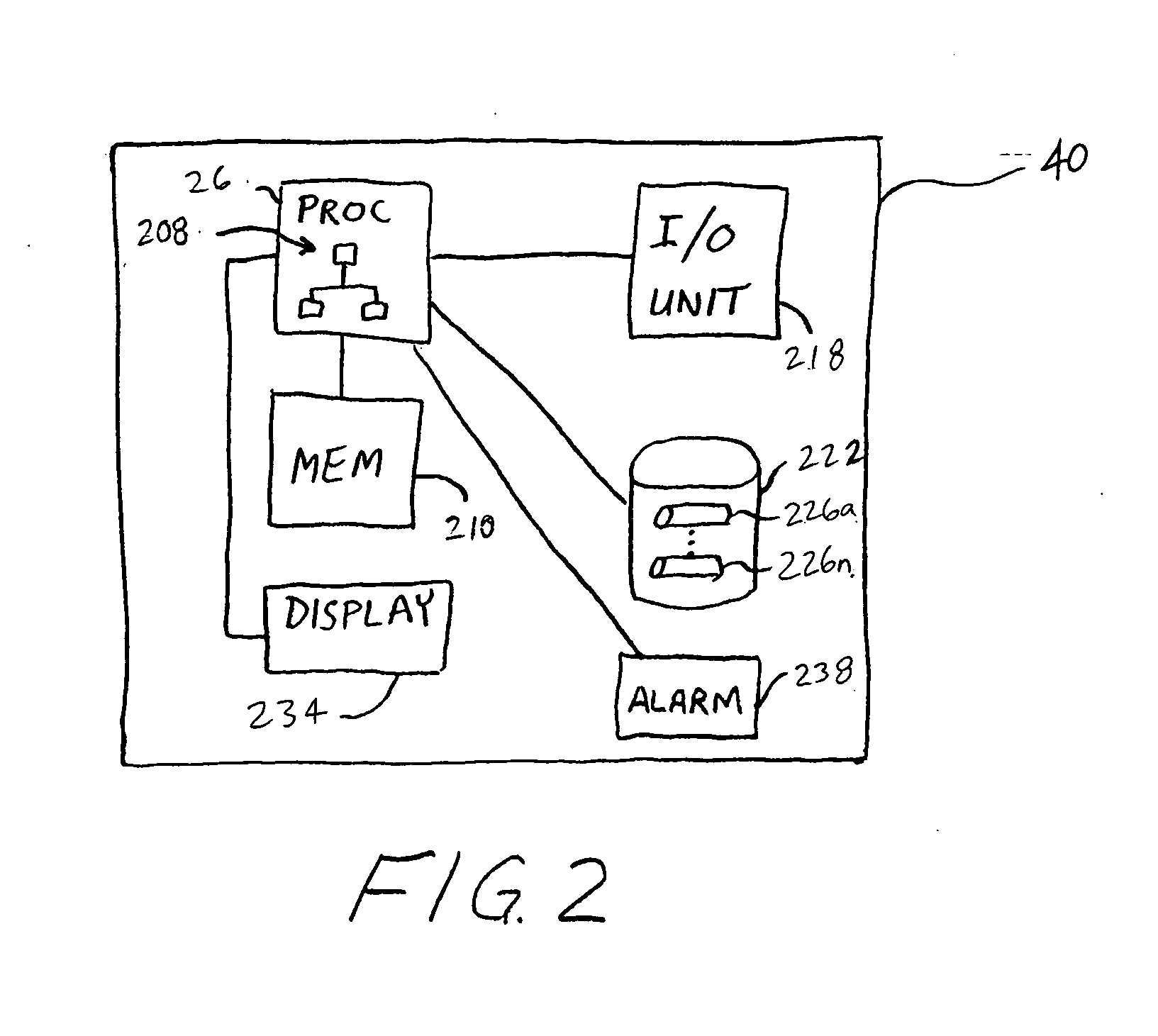

Systems and methods for processing sensor data are provided. In some embodiments, systems and methods are provided for calibration of a continuous analyte sensor. In some embodiments, systems and methods are provided for classification of a level of noise on a sensor signal. In some embodiments, systems and methods are provided for determining a rate of change for analyte concentration based on a continuous sensor signal. In some embodiments, systems and methods for alerting or alarming a patient based on prediction of glucose concentration are provided.

Owner:DEXCOM

Device and method employing shape memory alloy

InactiveUS6916159B2Low costSmall size and weightTesting/calibration apparatusVolume/mass flow measurementShape-memory alloyEngineering

Owner:THERASENSE

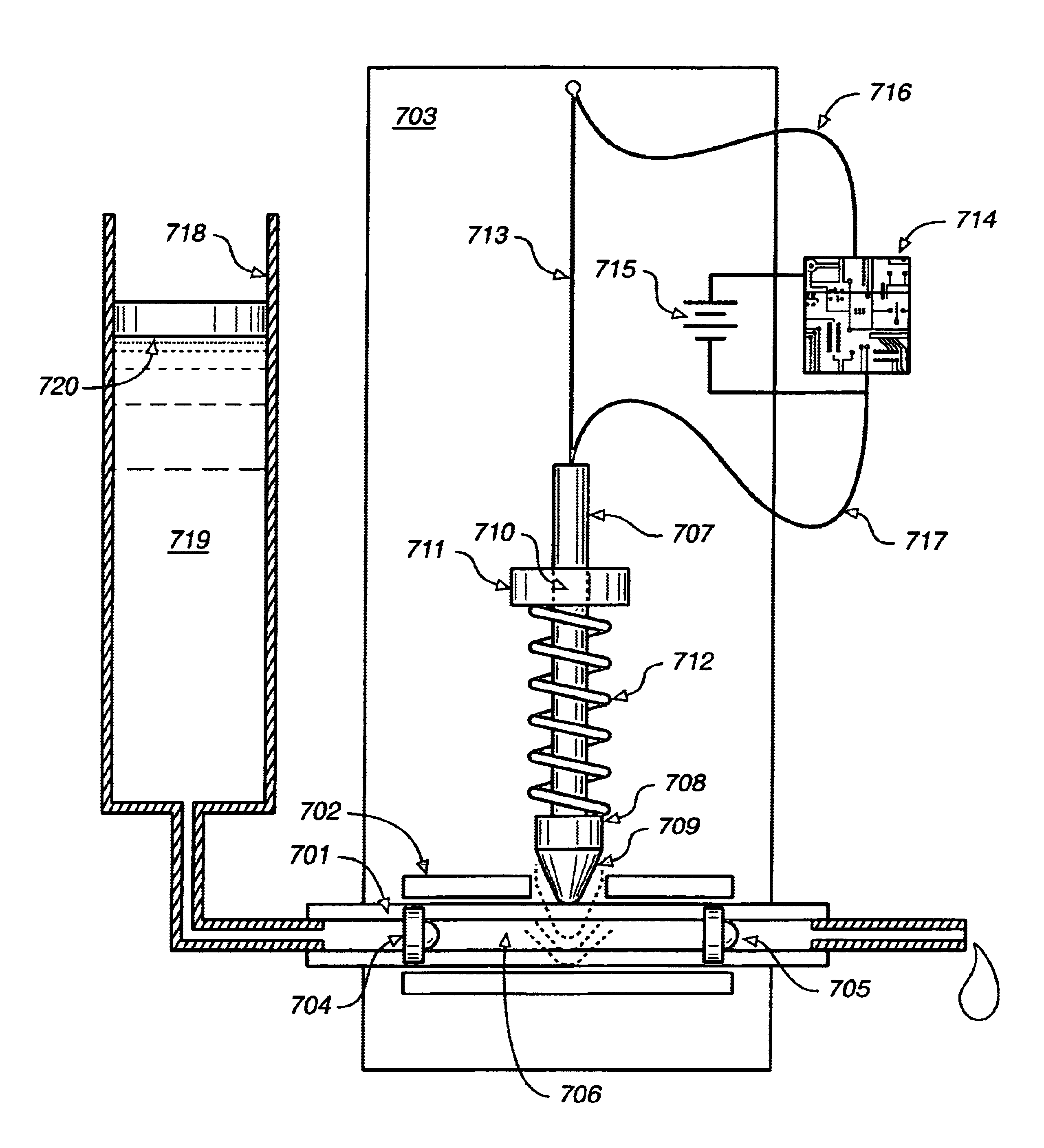

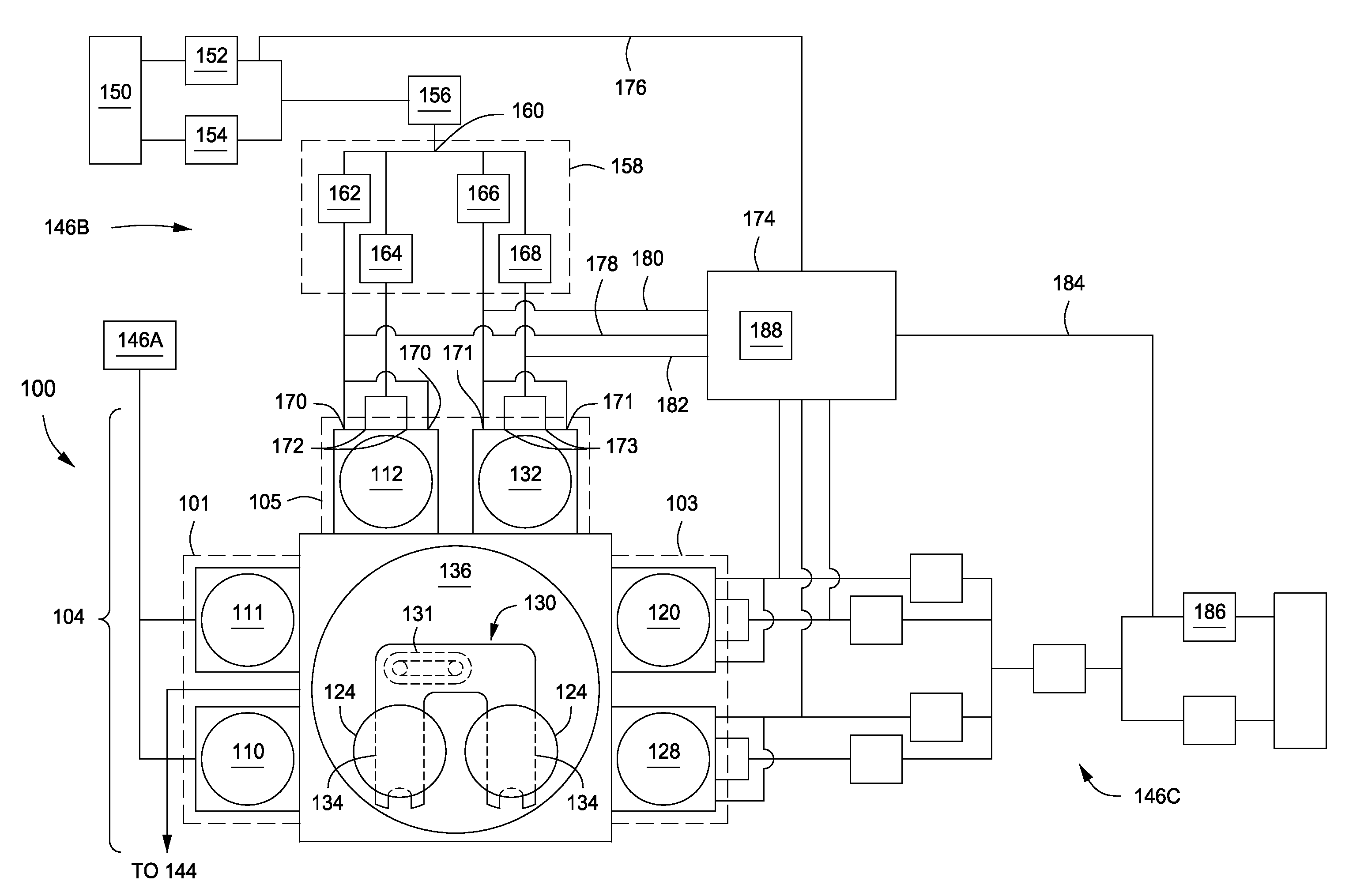

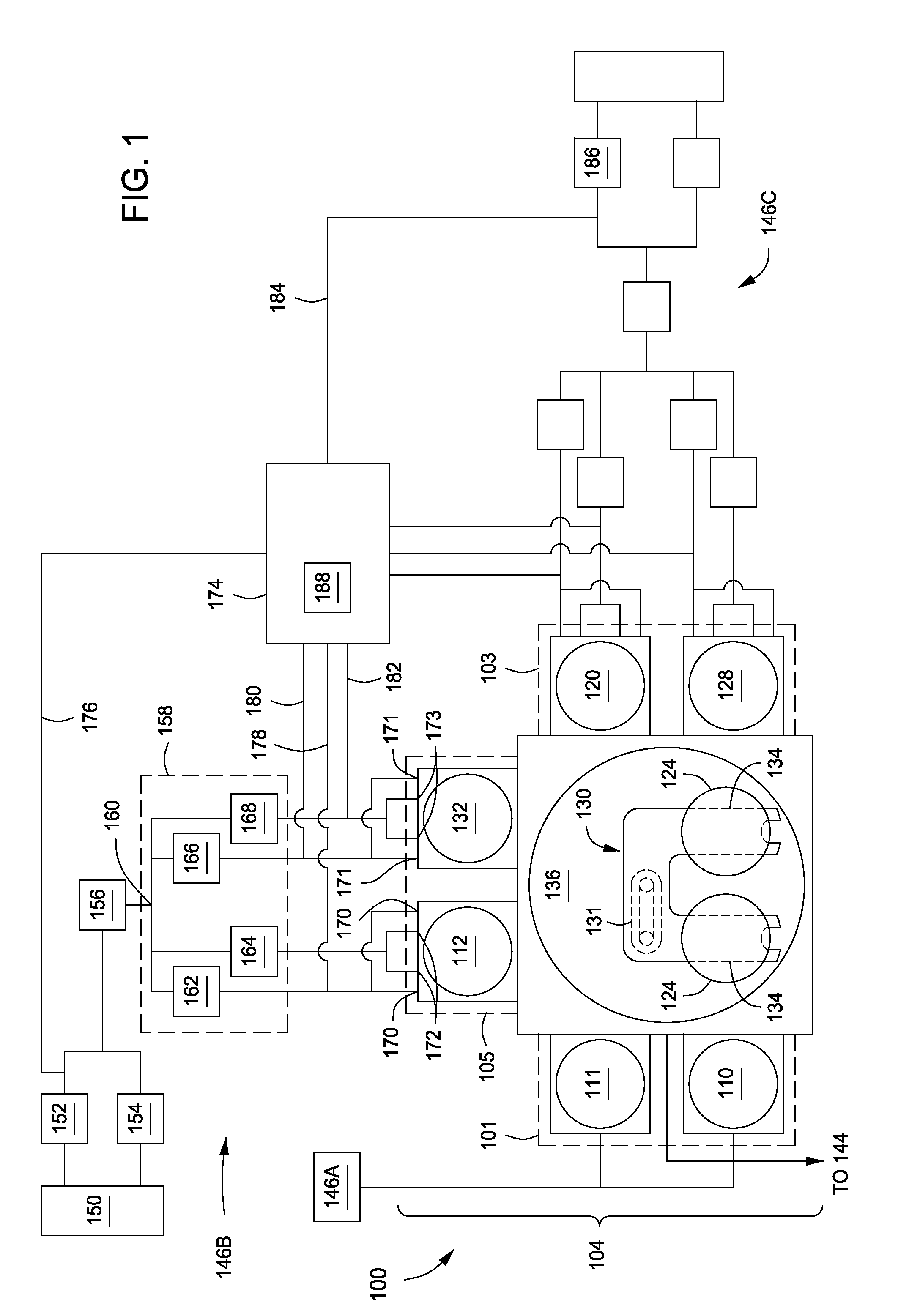

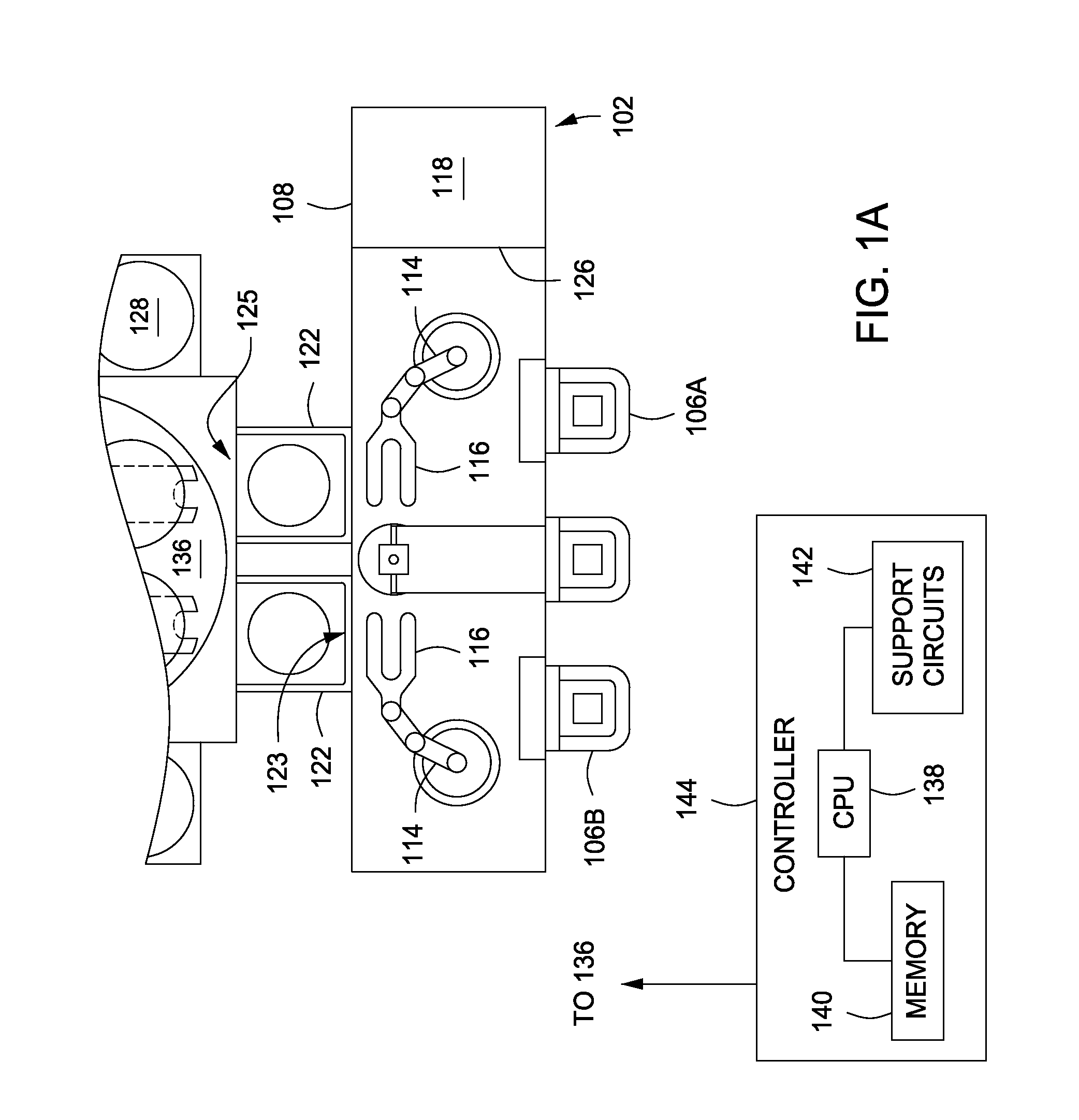

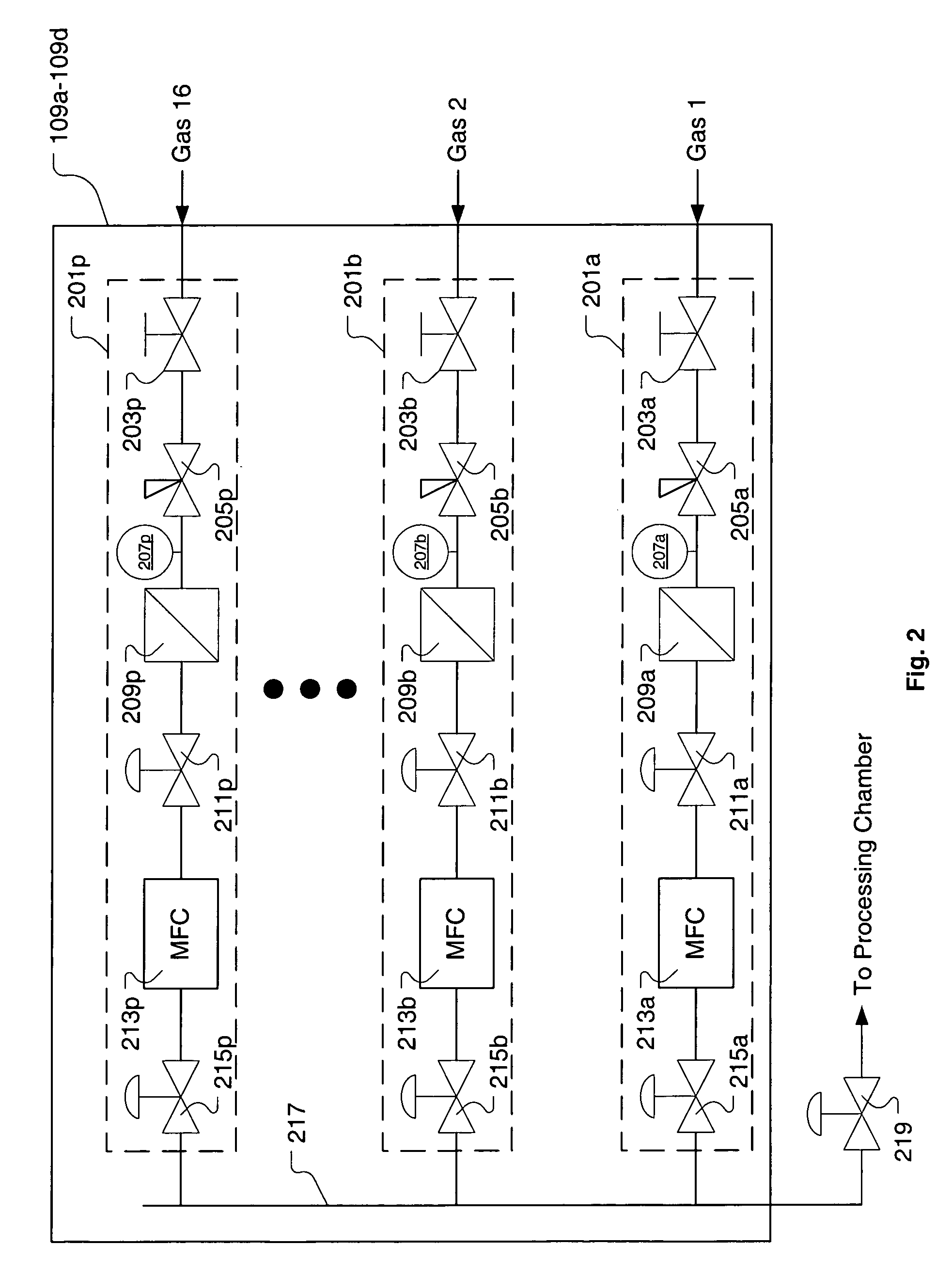

Methods and apparatus for calibrating flow controllers in substrate processing systems

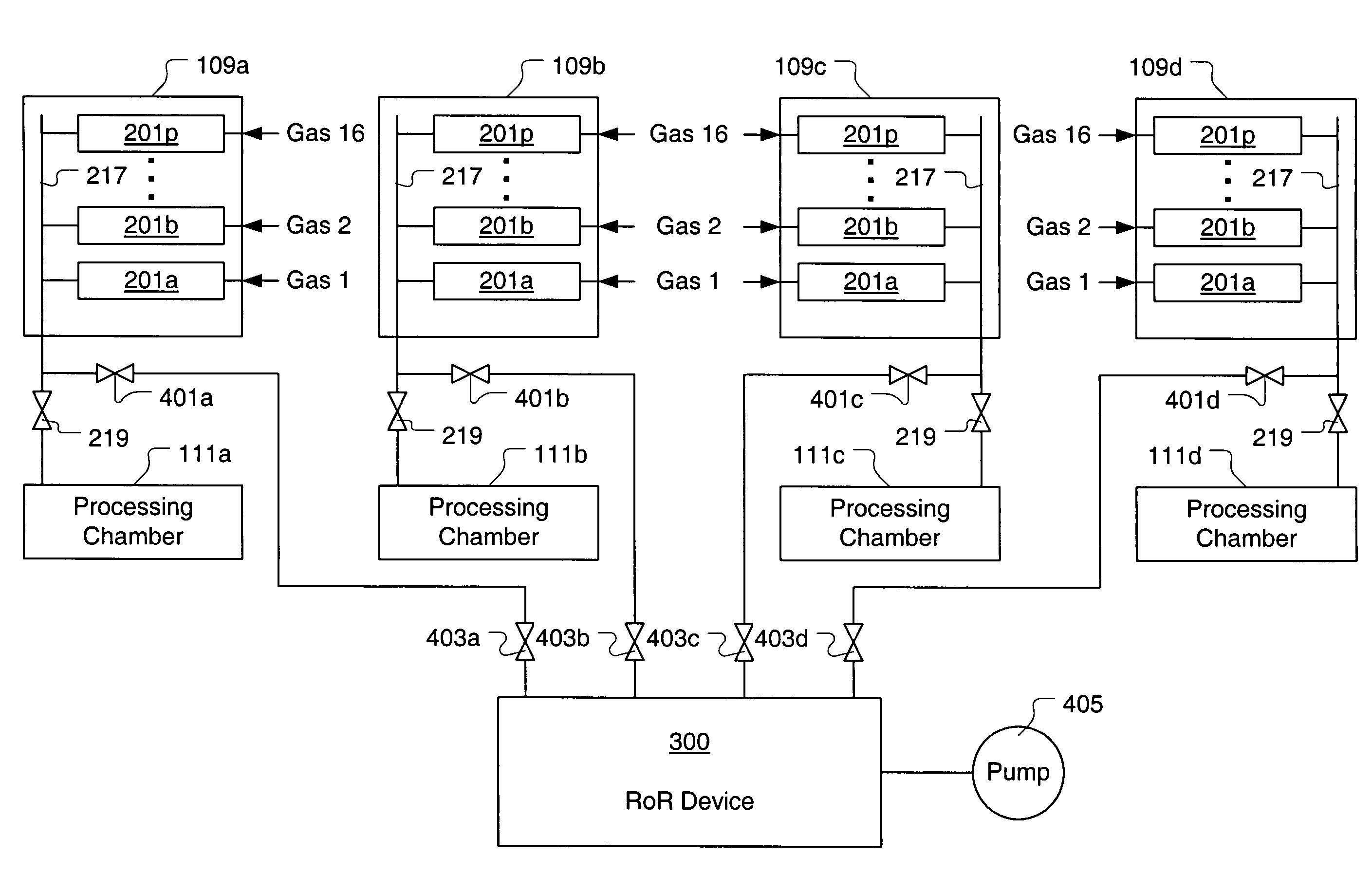

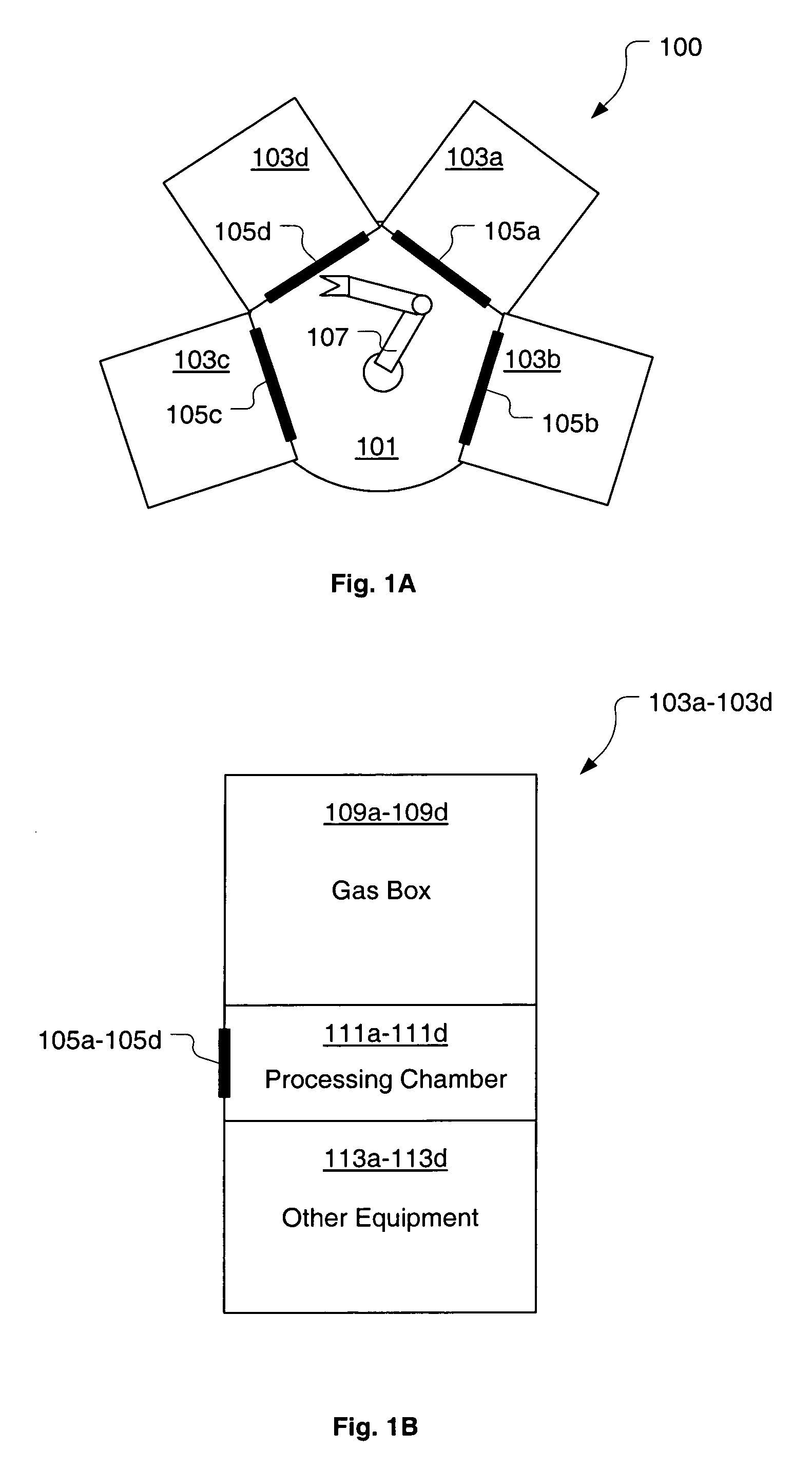

Methods and apparatus for calibrating a plurality of gas flows in a substrate processing system are provided herein. In some embodiments, a substrate processing system may include a cluster tool comprising a first process chamber and a second process chamber coupled to a central vacuum transfer chamber; a first flow controller to provide a process gas to the first process chamber; a second flow controller to provide the process gas to the second process chamber; a mass flow verifier to verify a flow rate from each of the first and second flow controllers; a first conduit to selectively couple the first flow controller to the mass flow verifier; and a second conduit to selectively couple the second flow controller to the mass flow verifier.

Owner:APPLIED MATERIALS INC

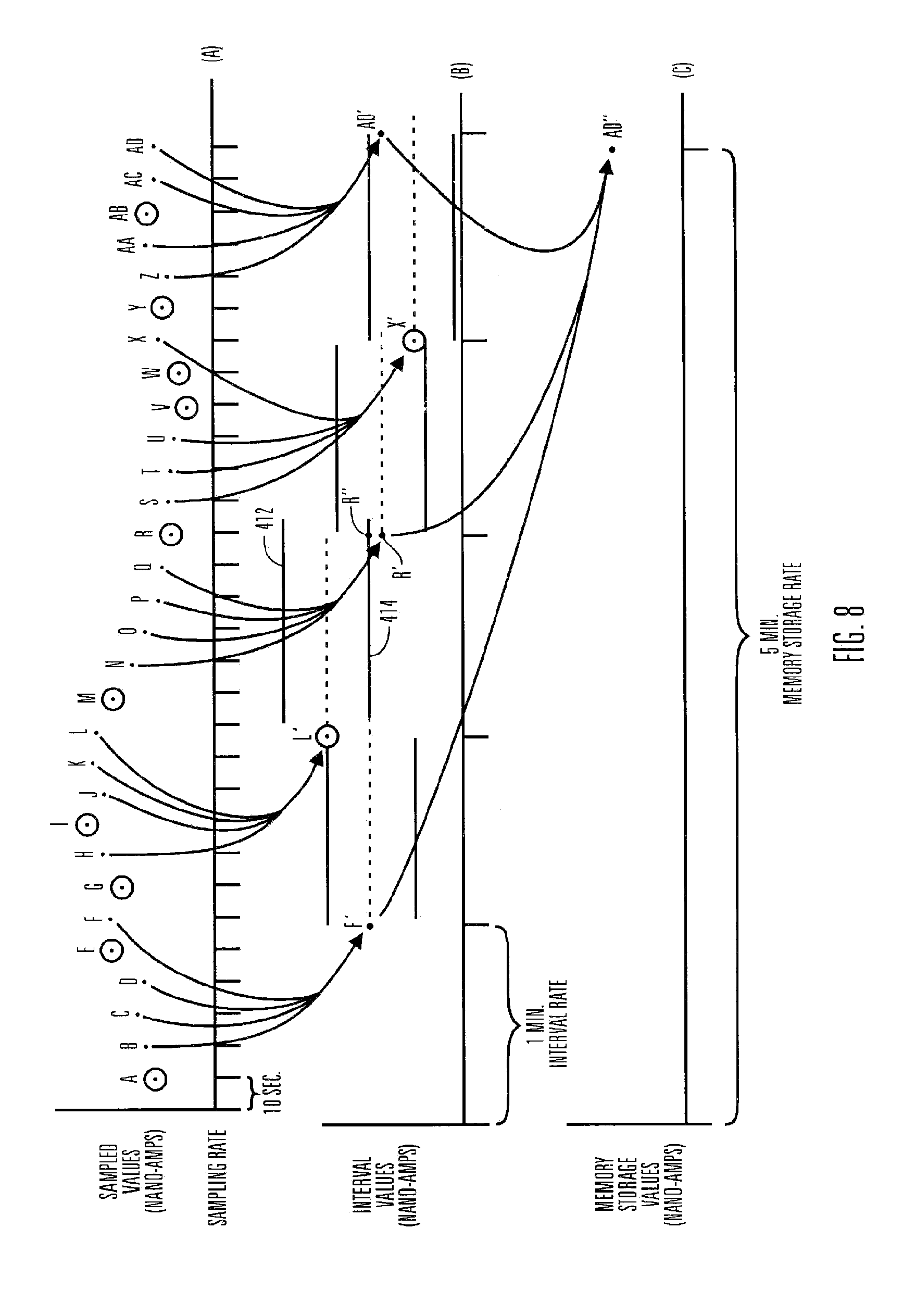

Modified Sensor Calibration Algorithm

ActiveUS20090112478A1Reduce weightQuick changeTesting/calibration apparatusSpeed measurement using gyroscopic effectsData integrityGlucose polymers

A method of calibrating glucose monitor data includes collecting the glucose monitor data over a period of time at predetermined intervals, obtaining reference glucose values from a reference source that temporally correspond with the glucose monitor data obtained at the predetermined intervals, calculating the calibration characteristics using the reference glucose values and corresponding glucose monitor data to regress the obtained glucose monitor data, and calibrating the obtained glucose monitor data using the calibration characteristics. In additional embodiments, calculation of the calibration characteristics includes linear regression and, in particular embodiments, least squares linear regression. Alternatively, calculation of the calibration characteristics includes non-linear regression. Data integrity may be verified and the data may be filtered. Further, calibration techniques may be modified during a fast rate of change in the patient's blood glucose level to increase sensor accuracy.

Owner:MEDTRONIC MIMIMED INC

System and methods for processing analyte sensor data

InactiveUS20110231140A1Testing/calibration apparatusSpeed measurement using gyroscopic effectsAnalyteData system

Owner:DEXCOM INC

System and methods for processing analyte sensor data

ActiveUS20110231142A1Testing/calibration apparatusSpeed measurement using gyroscopic effectsAnalyteData system

Owner:DEXCOM INC

System and method for gas flow verification

A gas flow rate verification apparatus is provided for shared use in a multiple tool semiconductor processing platform. The gas flow rate verification apparatus is defined to measure a pressure rate of rise and temperature within a test volume for determination of a corresponding gas flow rate. The apparatus includes first and second volumes, wherein the second volume is larger than the first volume. The apparatus also includes first and second pressure measurement devices, wherein the second pressure measurement device is capable of measuring higher pressures. Based on the target gas flow rate to be measured, either the first or second volume can be selected as the test volume, and either the first or second pressure measurement device can be selected to measure the pressure in the test volume. Configurability of the apparatus enables accurate measurement of gas flow rates over a broad range and in an time efficient manner.

Owner:LAM RES CORP

Method and system for providing calibration of an analyte sensor in an analyte monitoring system

Owner:ABBOTT DIABETES CARE INC

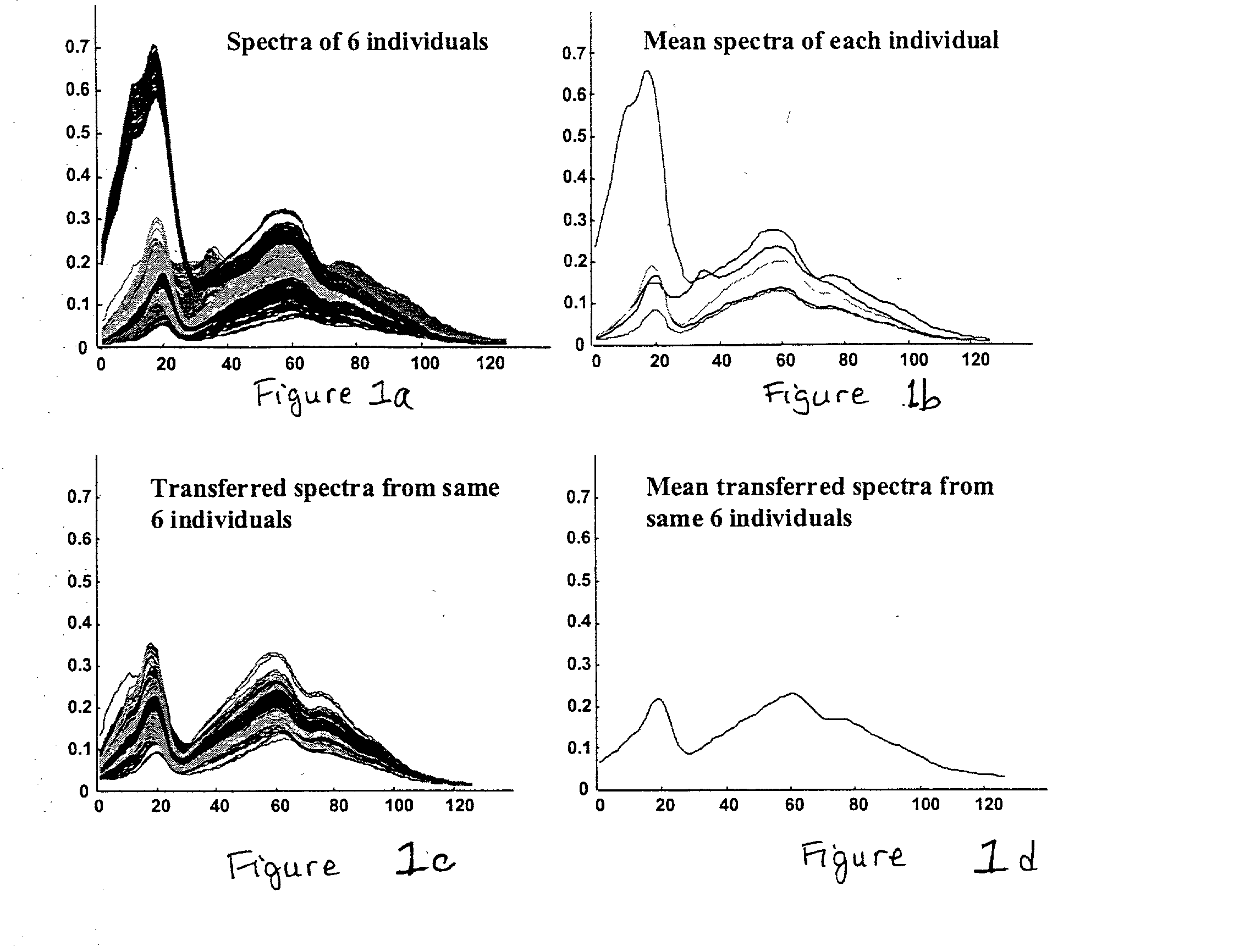

Reduction of inter-subject variation via transfer standardization

InactiveUS20010039483A1Testing/calibration apparatusSpeed measurement using gyroscopic effectsComputer scienceStandardization

This invention relates to the reduction of inter-subject variation via transfer standardization. According to the method, the effects of inter-subject variation on the analysis of spectra collected from the skin of two or more different subjects is reduced by correcting for the differences between spectra collected from said two or more subjects.

Owner:ARGOSE

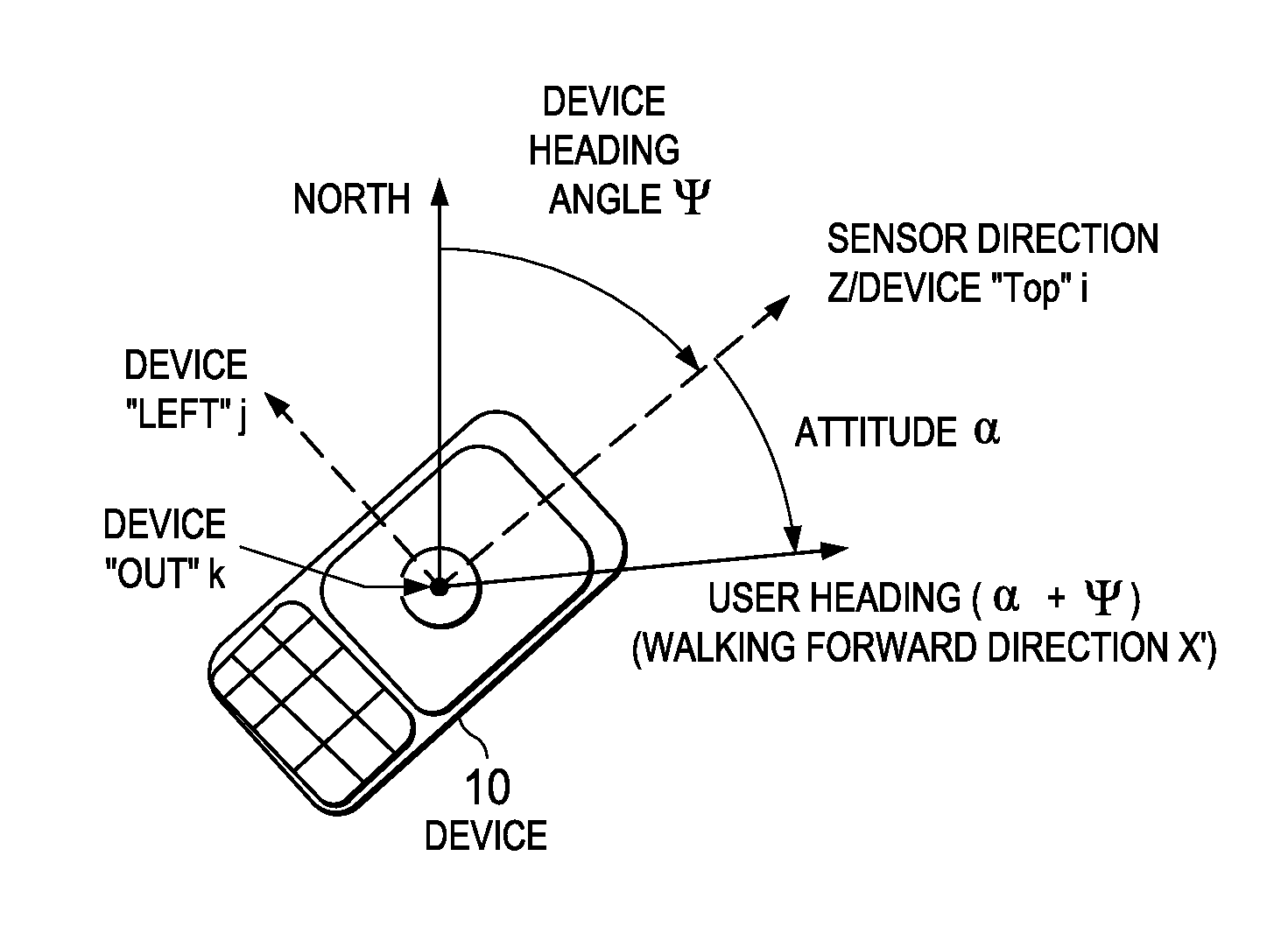

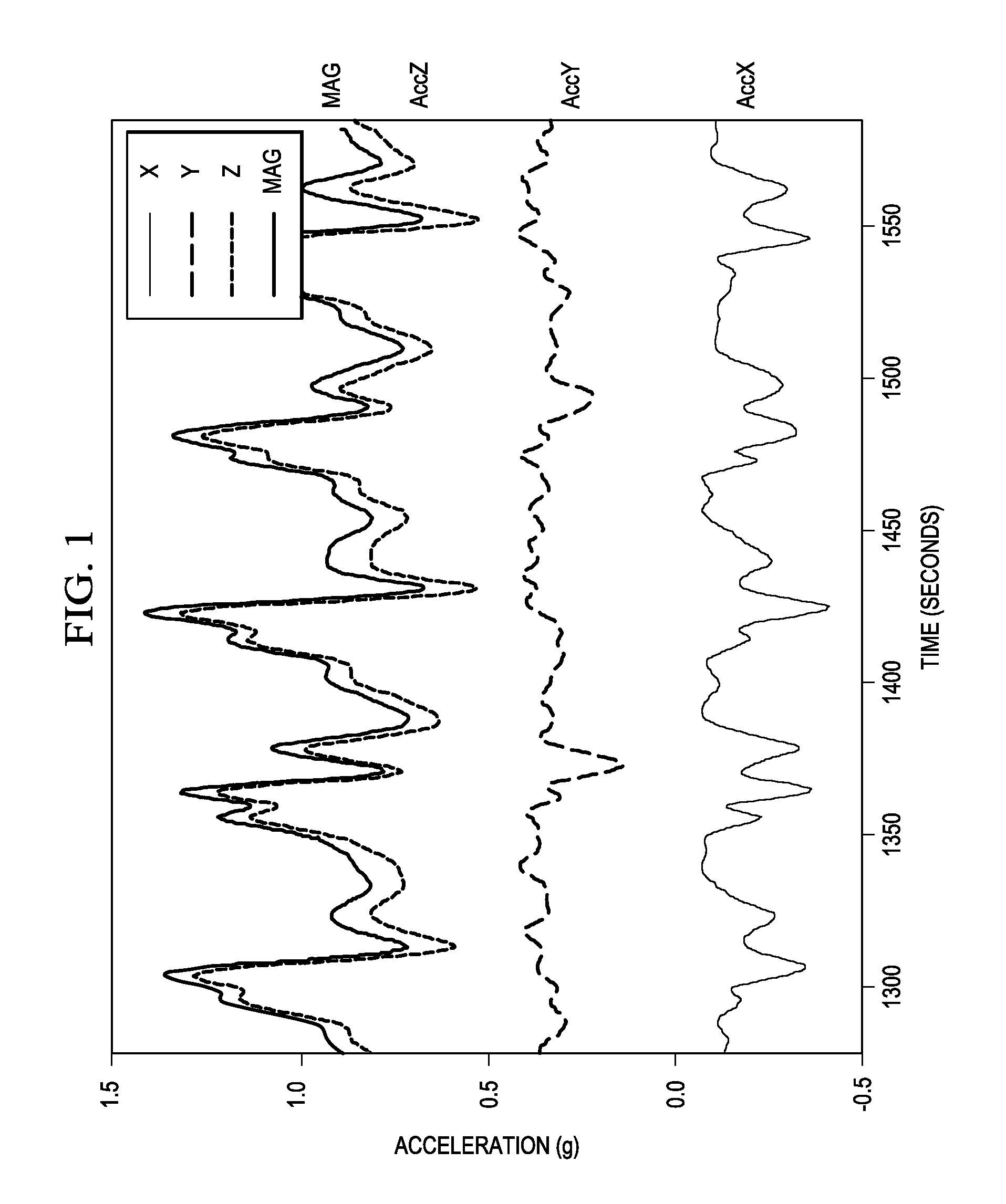

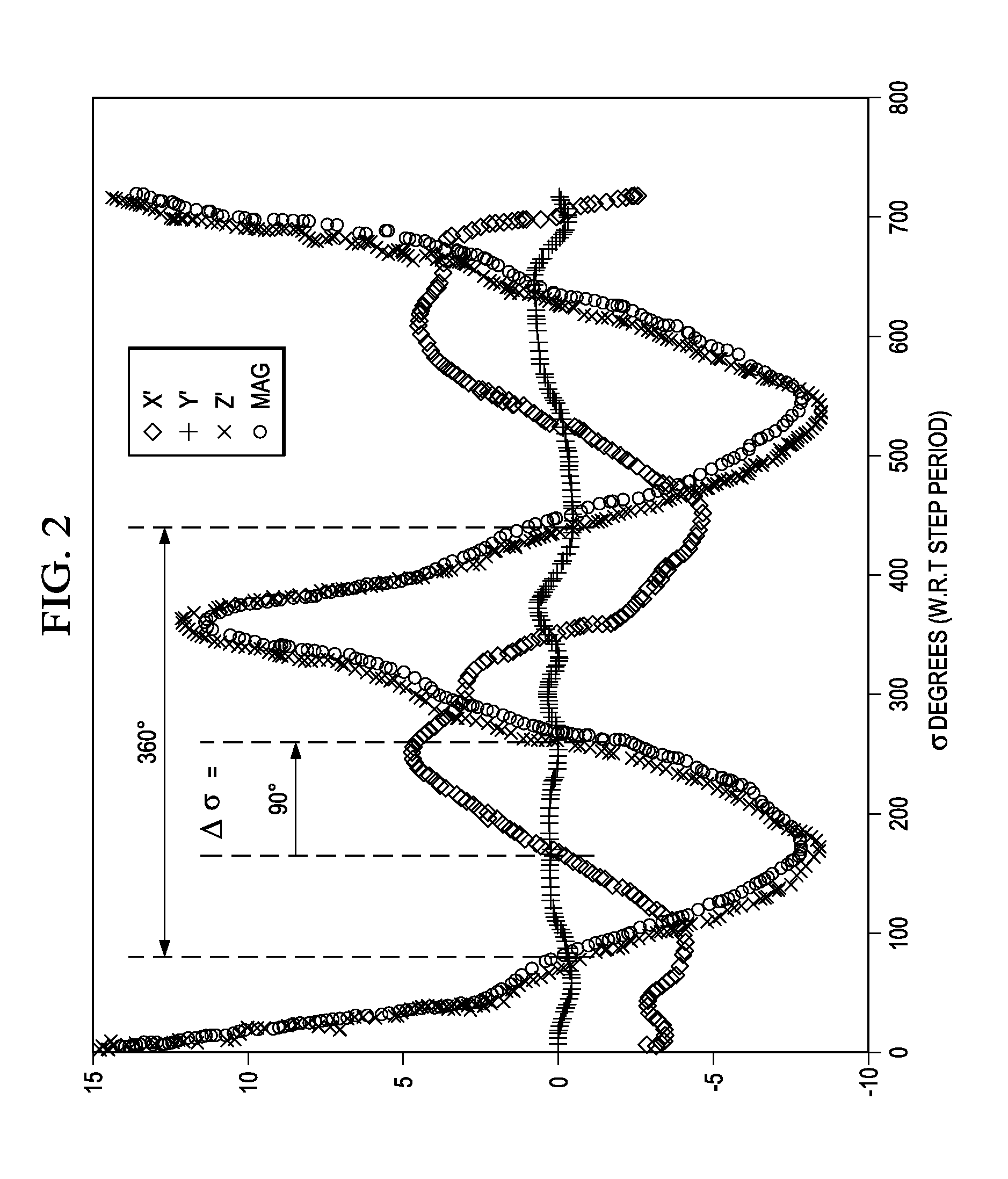

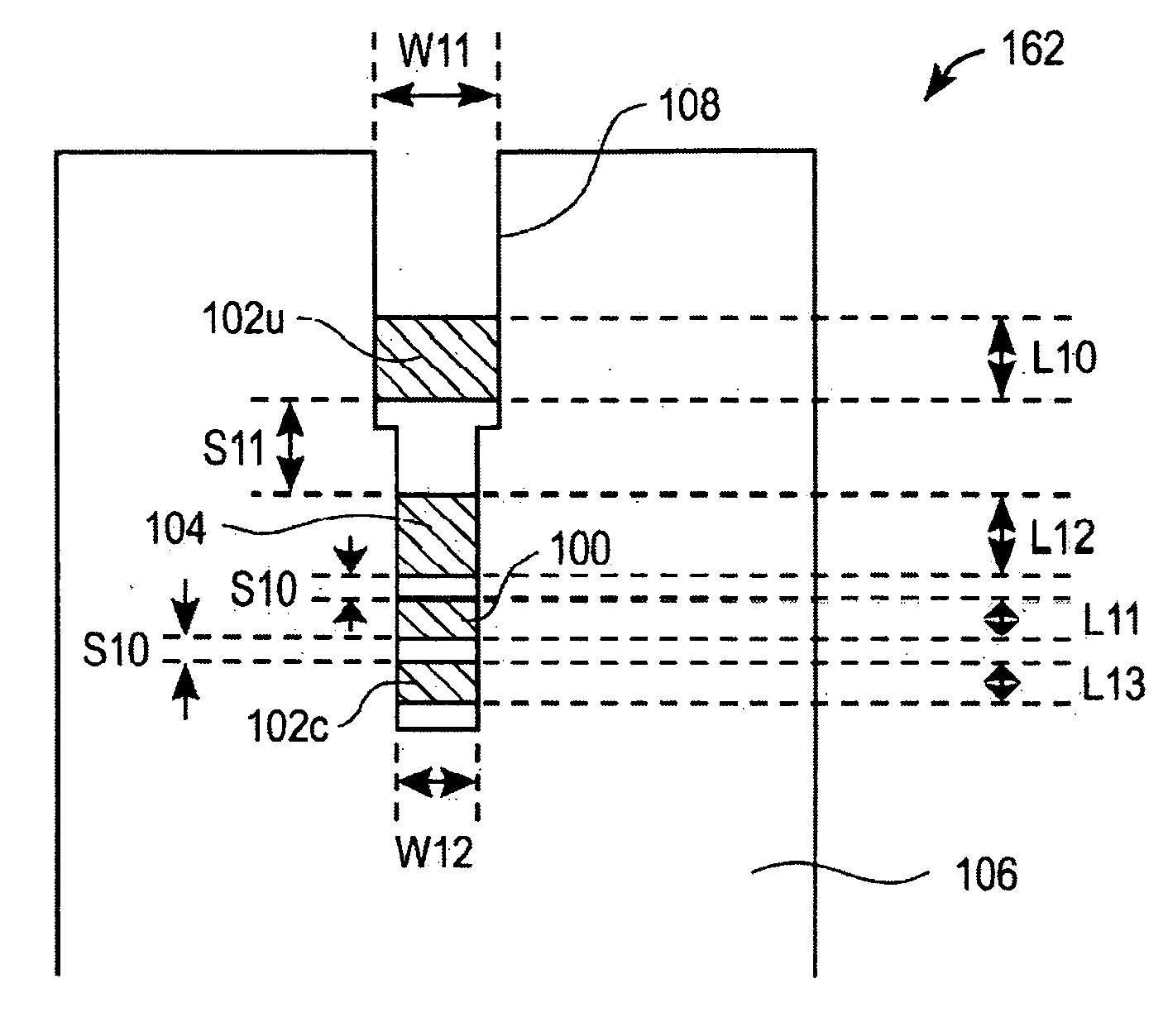

Robust step detection using low cost MEMS accelerometer in mobile applications, and processing methods, apparatus and systems

ActiveUS20130090881A1Testing/calibration apparatusNavigation by speed/acceleration measurementsAccelerometerSlide window

A system (10) for pedestrian use includes an accelerometer (110) having multiple electronic sensors; an electronic circuit (100) operable to generate a signal stream representing magnitude of overall acceleration sensed by the accelerometer (110), and to electronically correlate a sliding window (520) of the signal stream with itself to produce peaks at least some of which represent walking steps, and further operable to electronically execute a periodicity check (540) to compare different step periods for similarity, and if sufficiently similar then to update (560) a portion of the circuit substantially representing a walking-step count; and an electronic display (190) responsive to the electronic circuit (100) to display information at least in part based on the step count. Other systems, electronic circuits and processes are disclosed.

Owner:TEXAS INSTR INC

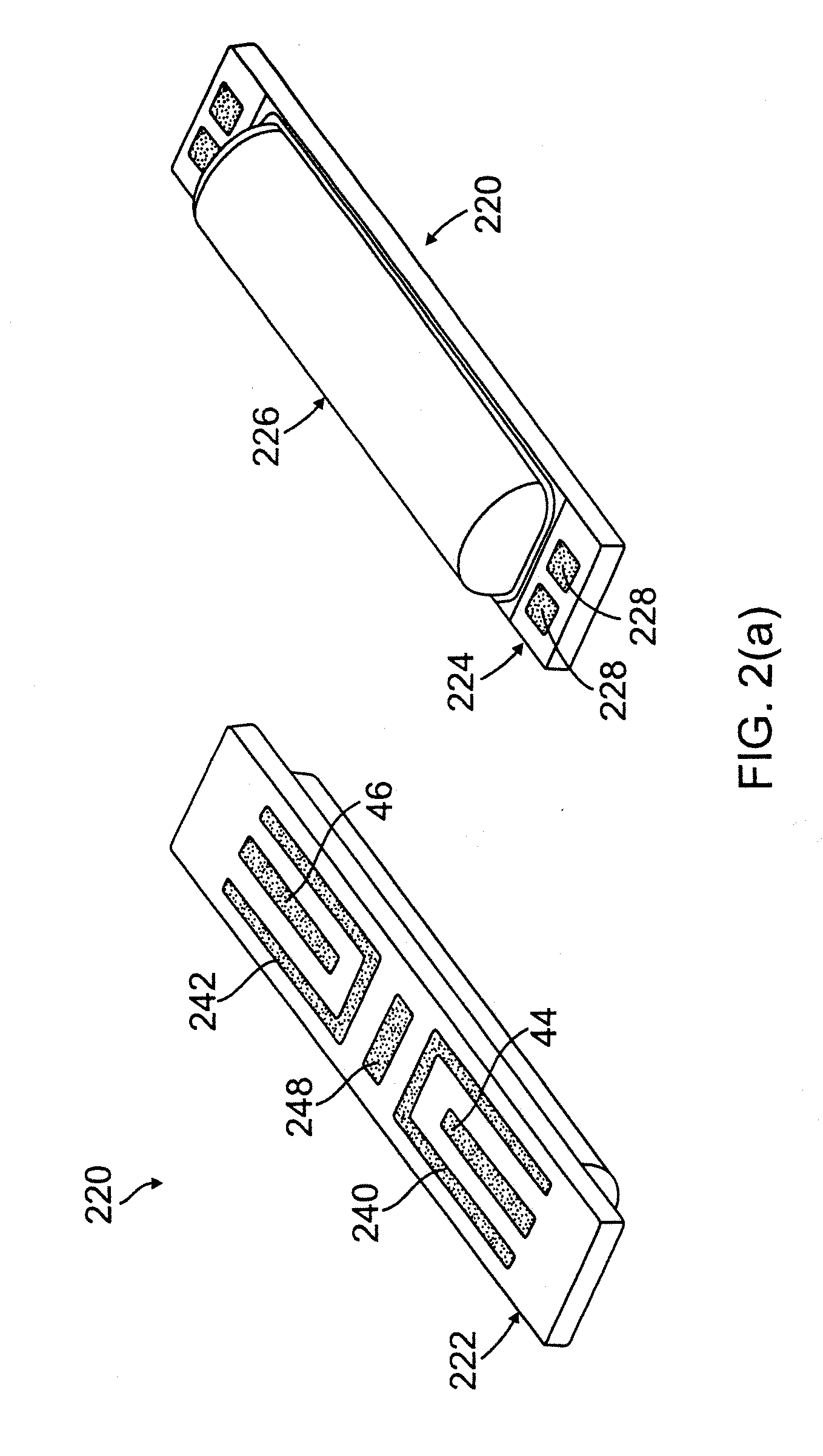

Optical sensor and method of operation

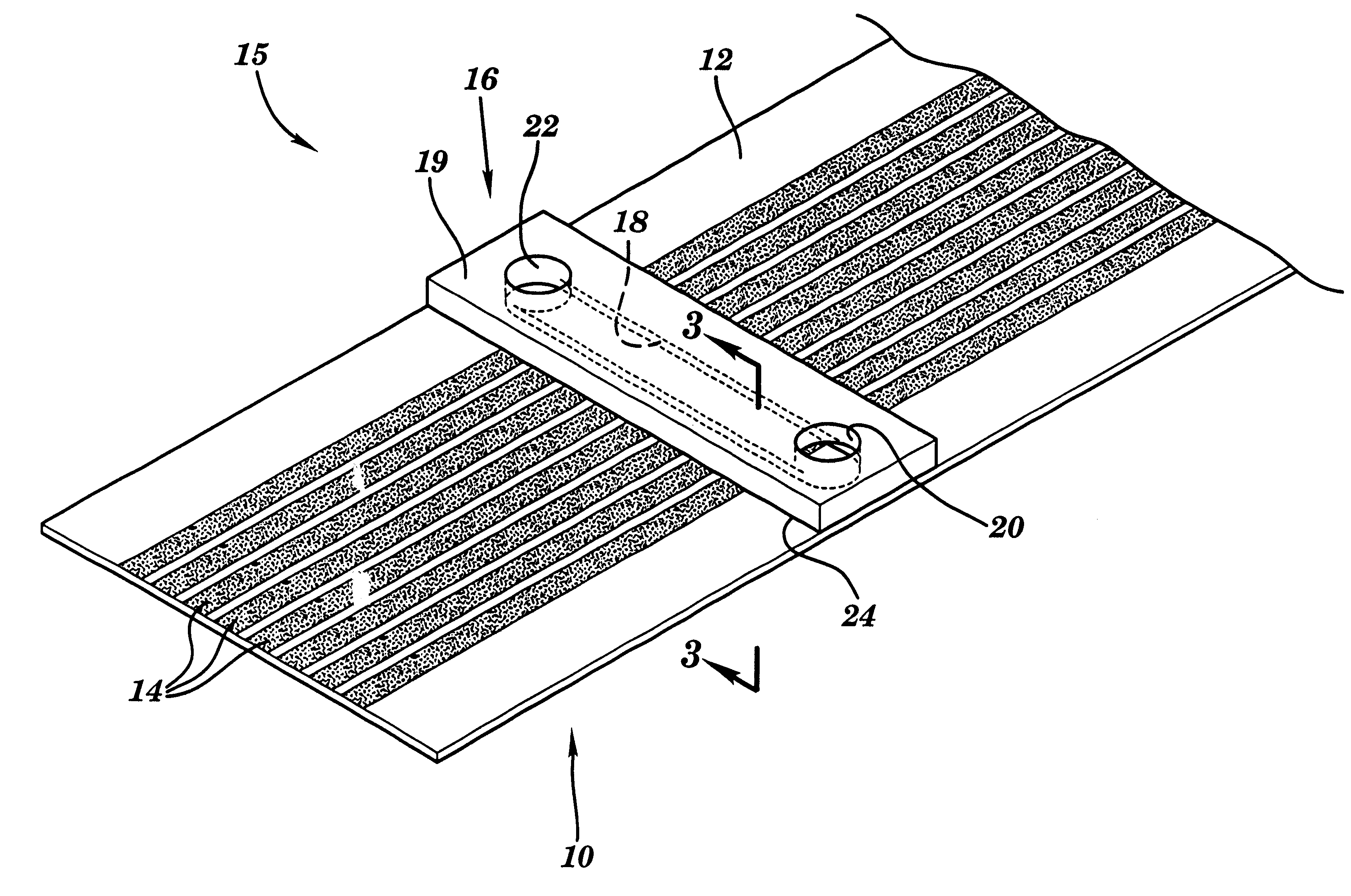

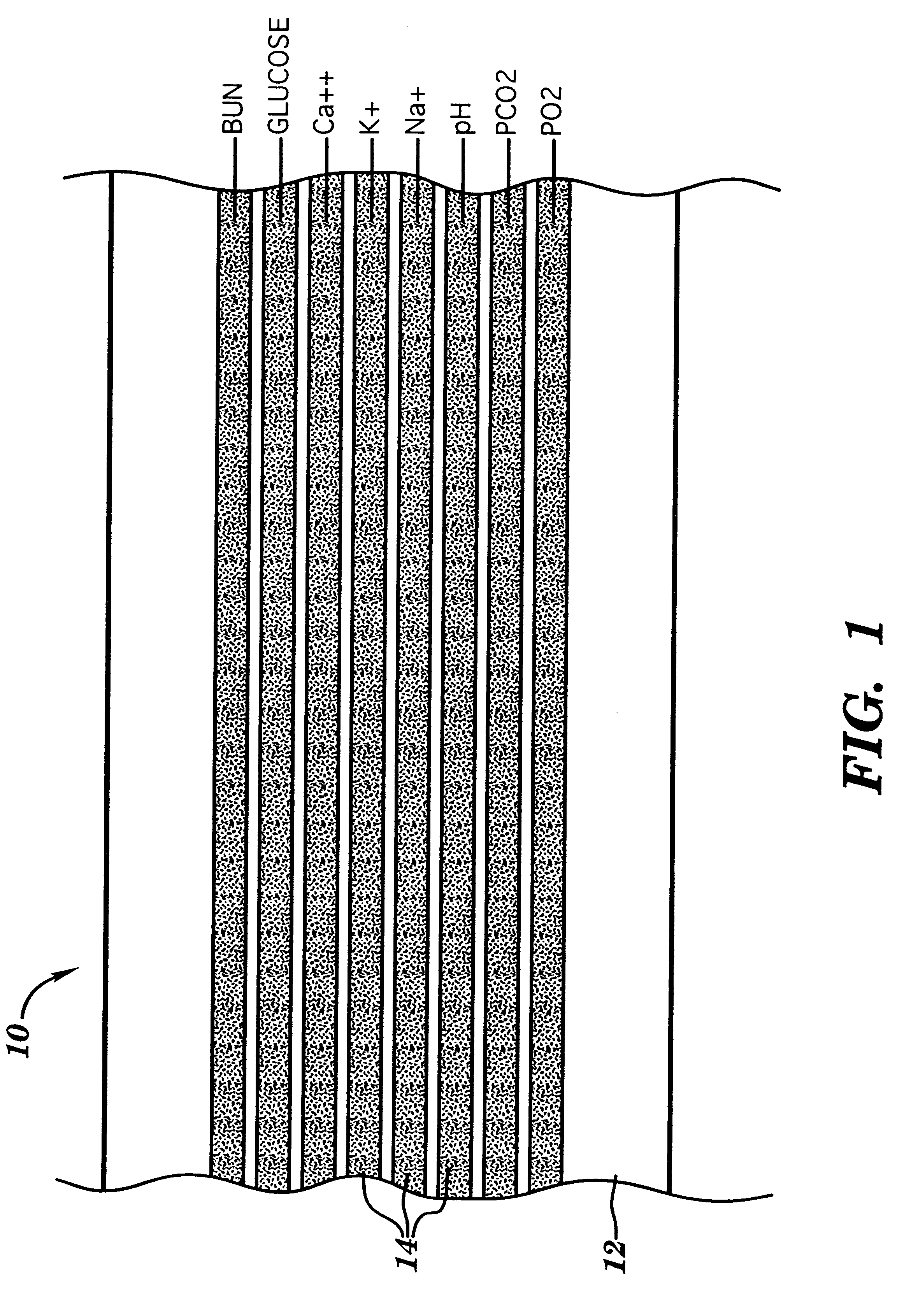

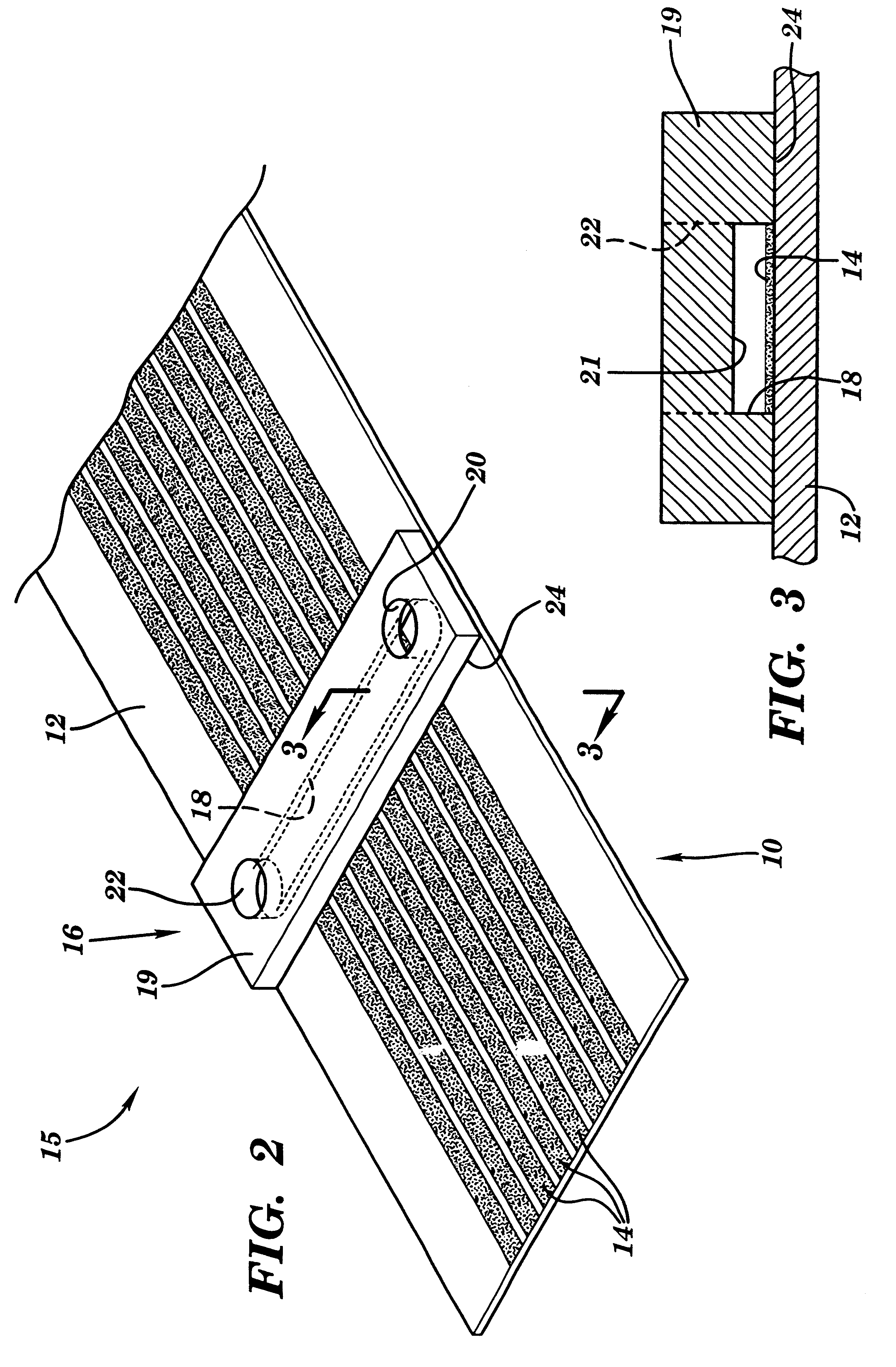

InactiveUS6488891B2Analysis using chemical indicatorsTesting/calibration apparatusOptical transducersSample chamber

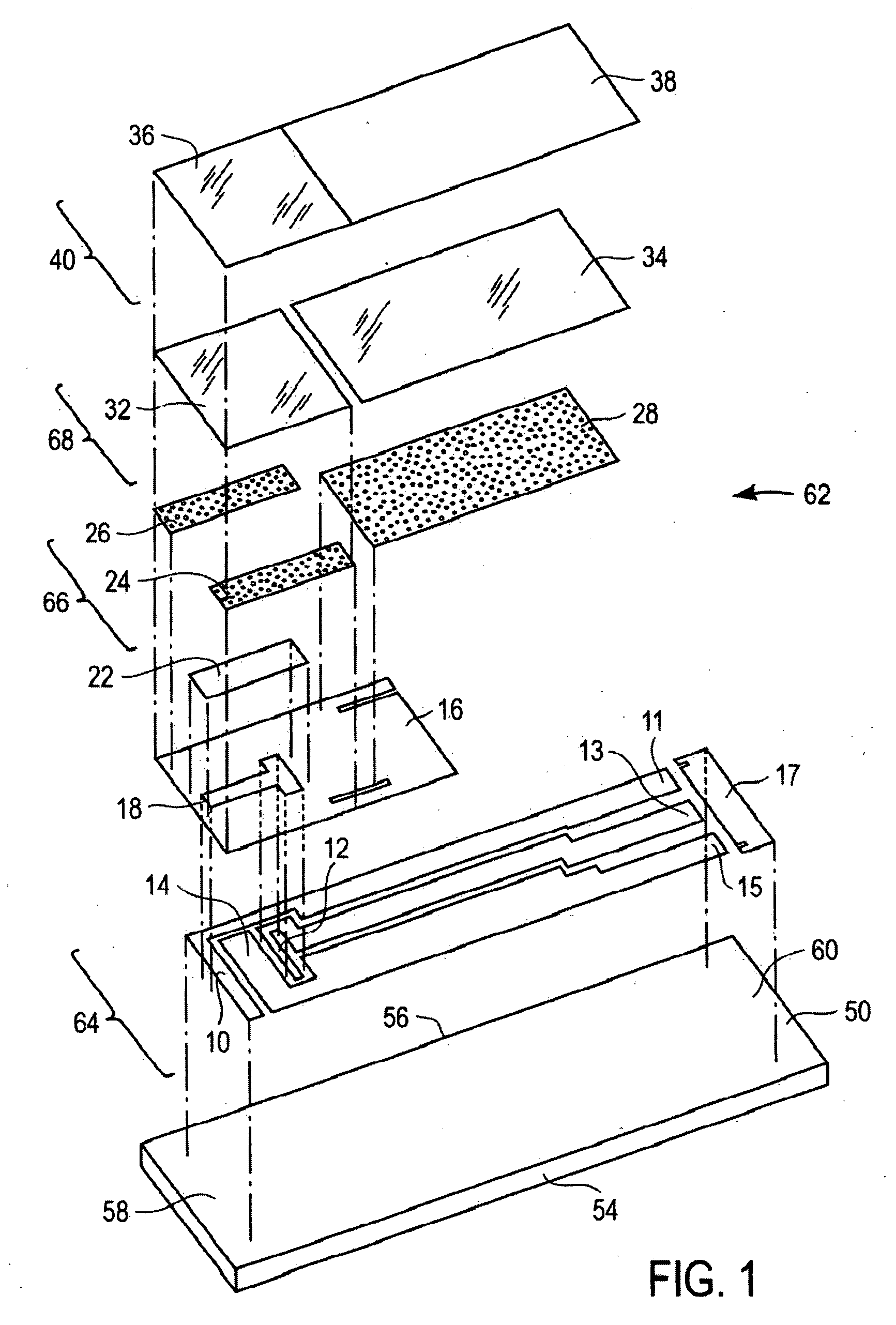

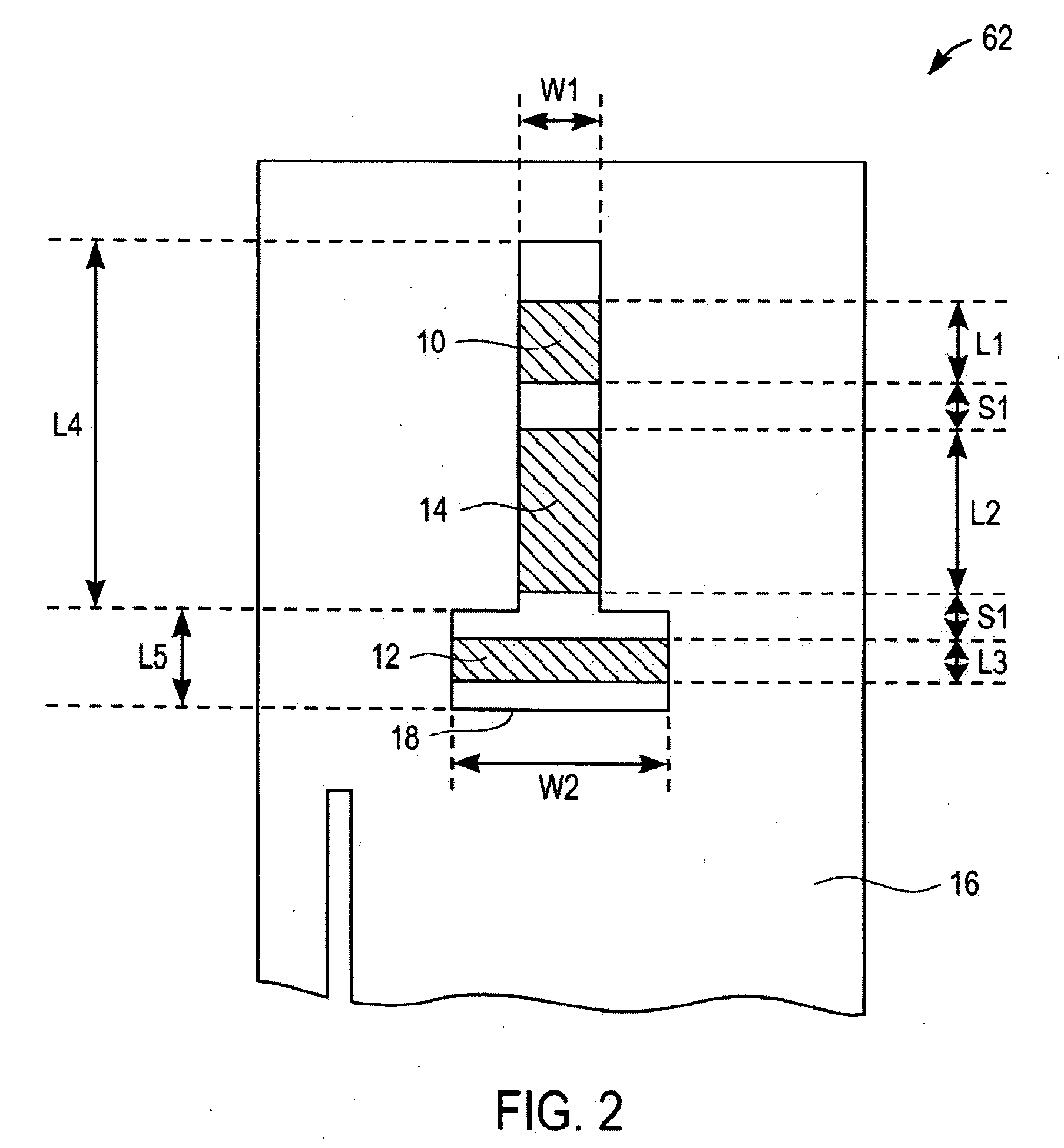

A multiple single use optical sensor includes a series of continuous sensor stripes deposited on a substrate web. At least one sample chamber is adapted to extend transversely across a discrete portion of the series of sensor stripes to facilitate analysis of a sample disposed therein. The sample chamber may be moved, or additional sample chambers provided to enable subsequent measurements of additional samples at unused discrete portions of the sensor stripes. The continuous nature of the sensor stripes provides consistency along the lengths thereof to enable calibration data obtained from one discrete portion of the sensor stripes to be utilized for testing an unknown sample an other discrete portion of the sensor stripes. This advantageously eliminates the need for any particular discrete portion of the sensor stripes to be contacted by more than one sample, for improved sensor performance.

Owner:SIEMENS HEALTHCARE DIAGNOSTICS INC

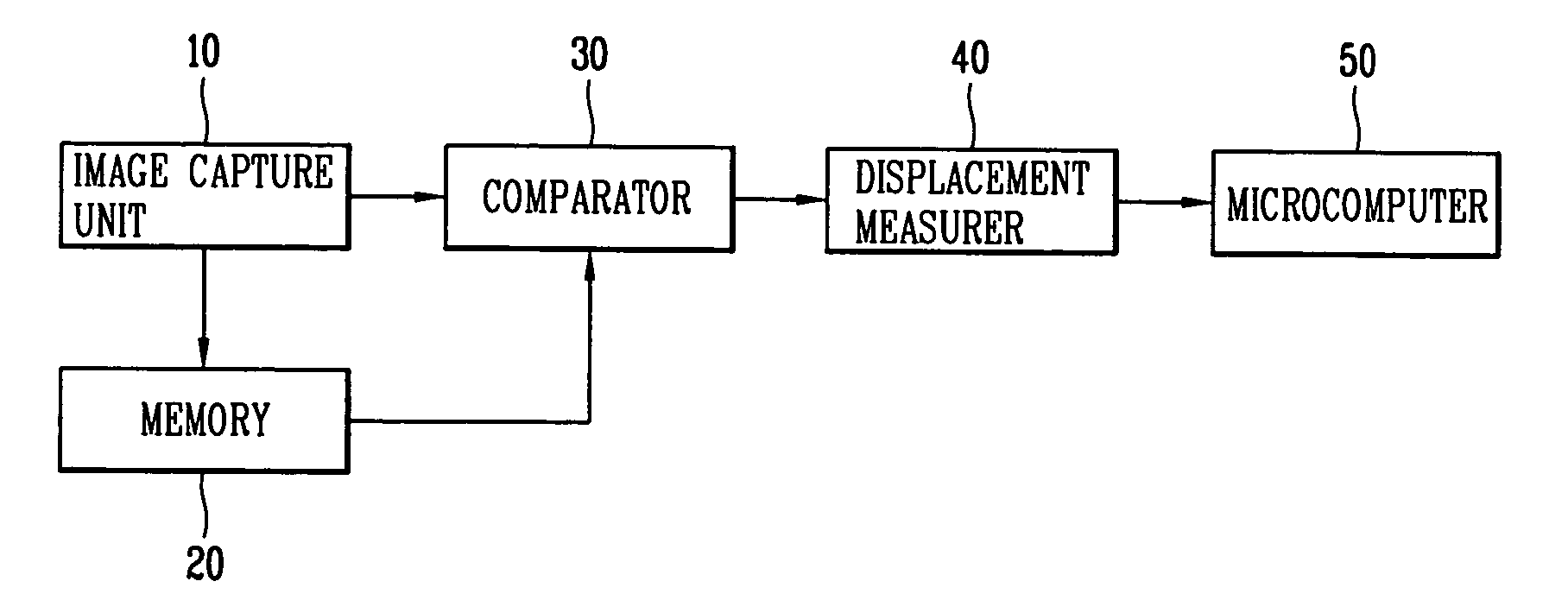

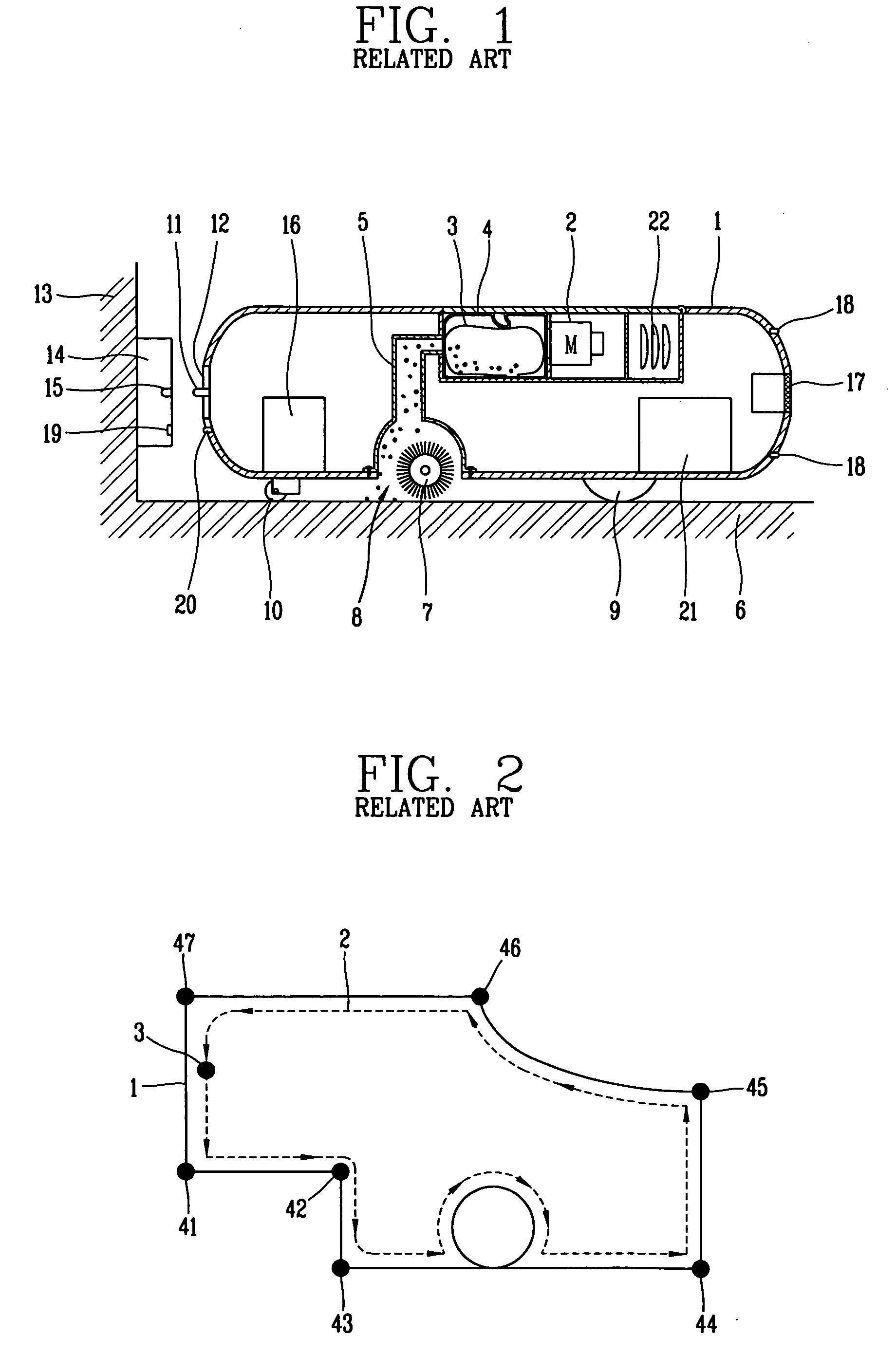

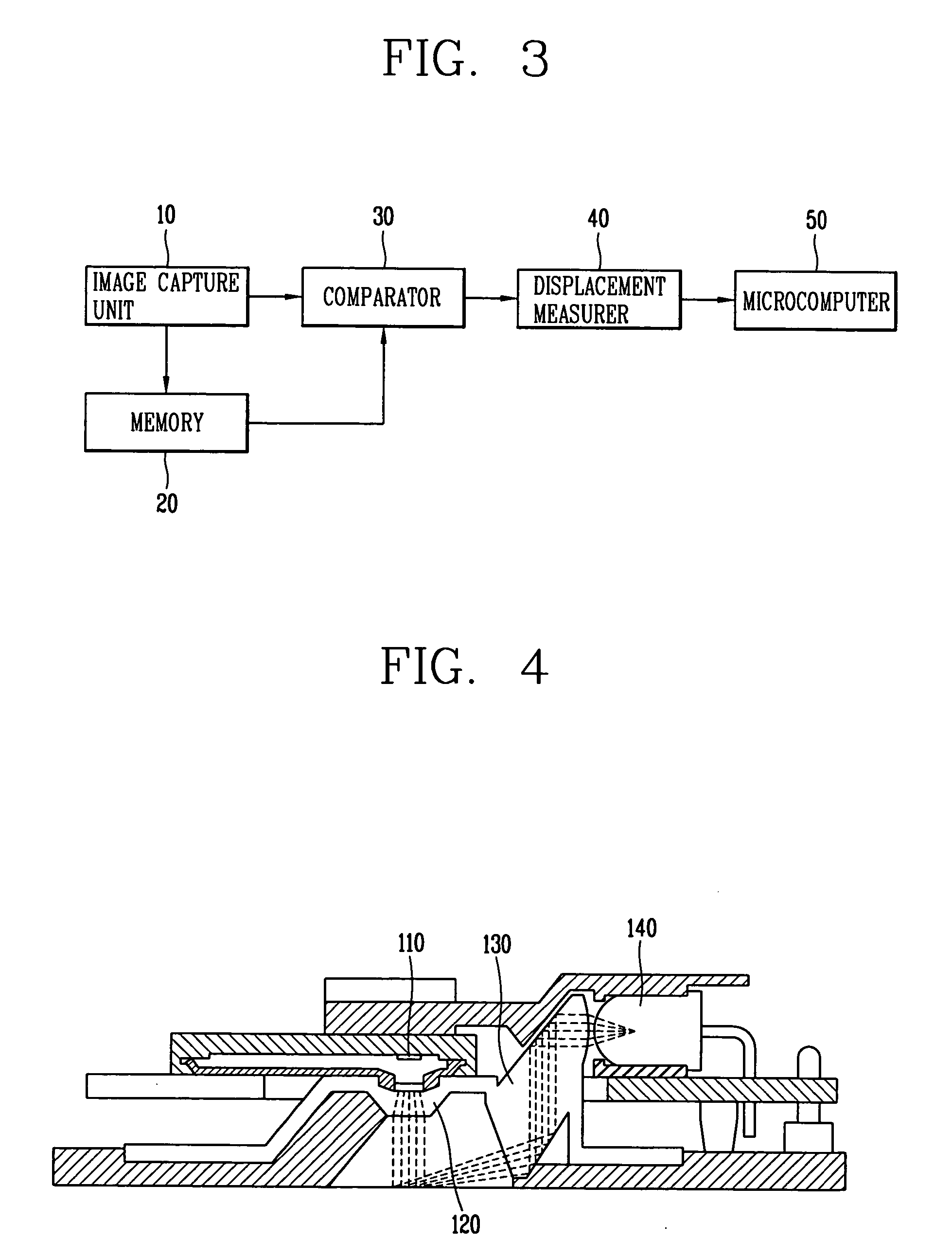

Mobile robot using image sensor and method for measuring moving distance thereof

ActiveUS7171285B2Accurate movement distanceAccurate calculationVehicle testingAutomatic obstacle detectionMicrocomputerComputer science

In a mobile robot and a method for measuring a moving distance thereof, by including an image capture unit for photographing the bottom surface according to motion of a mobile robot at a certain intervals and capturing images; a displacement measurer for measuring displacement about the captured image; and a microcomputer for outputting an actual moving distance by direction and motion of the mobile robot on the basis of the measured displacement value, it is possible to measure an accurate moving distance of the mobile robot with only one image sensor installed at the center of a body of the mobile robot, and accordingly it is possible to simplify a mechanical structure and facilitate maintenance and repairing.

Owner:LG ELECTRONICS INC

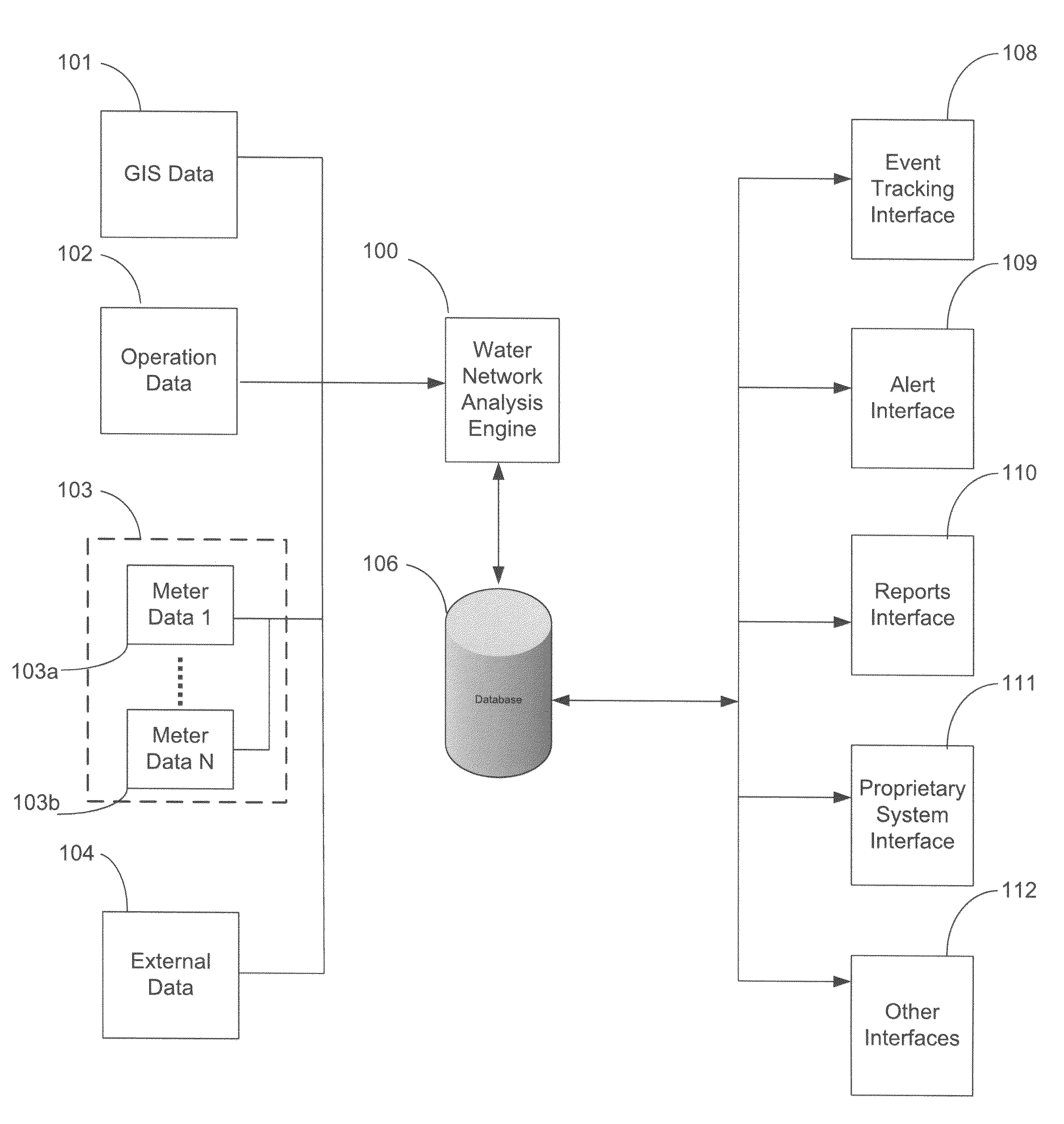

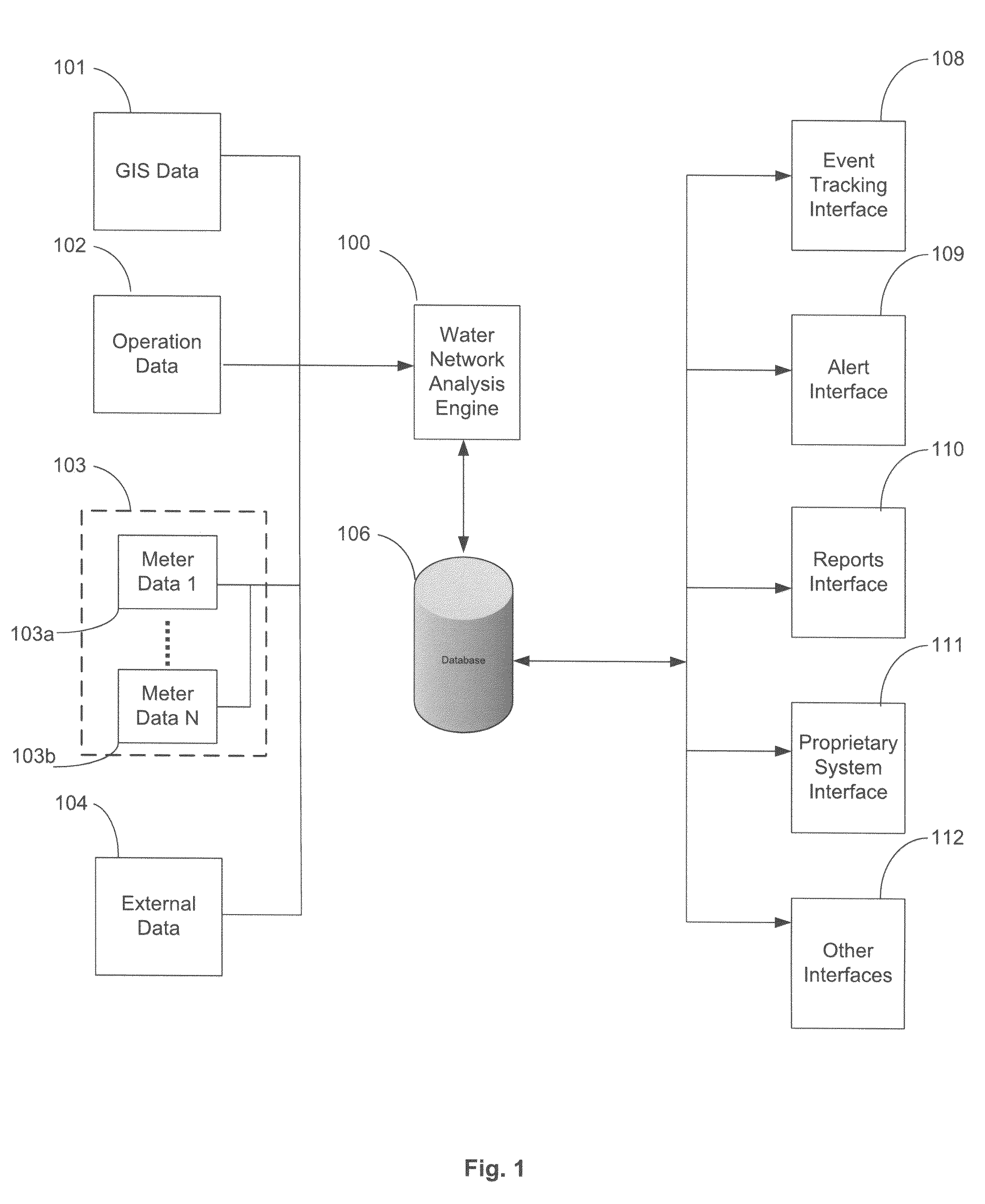

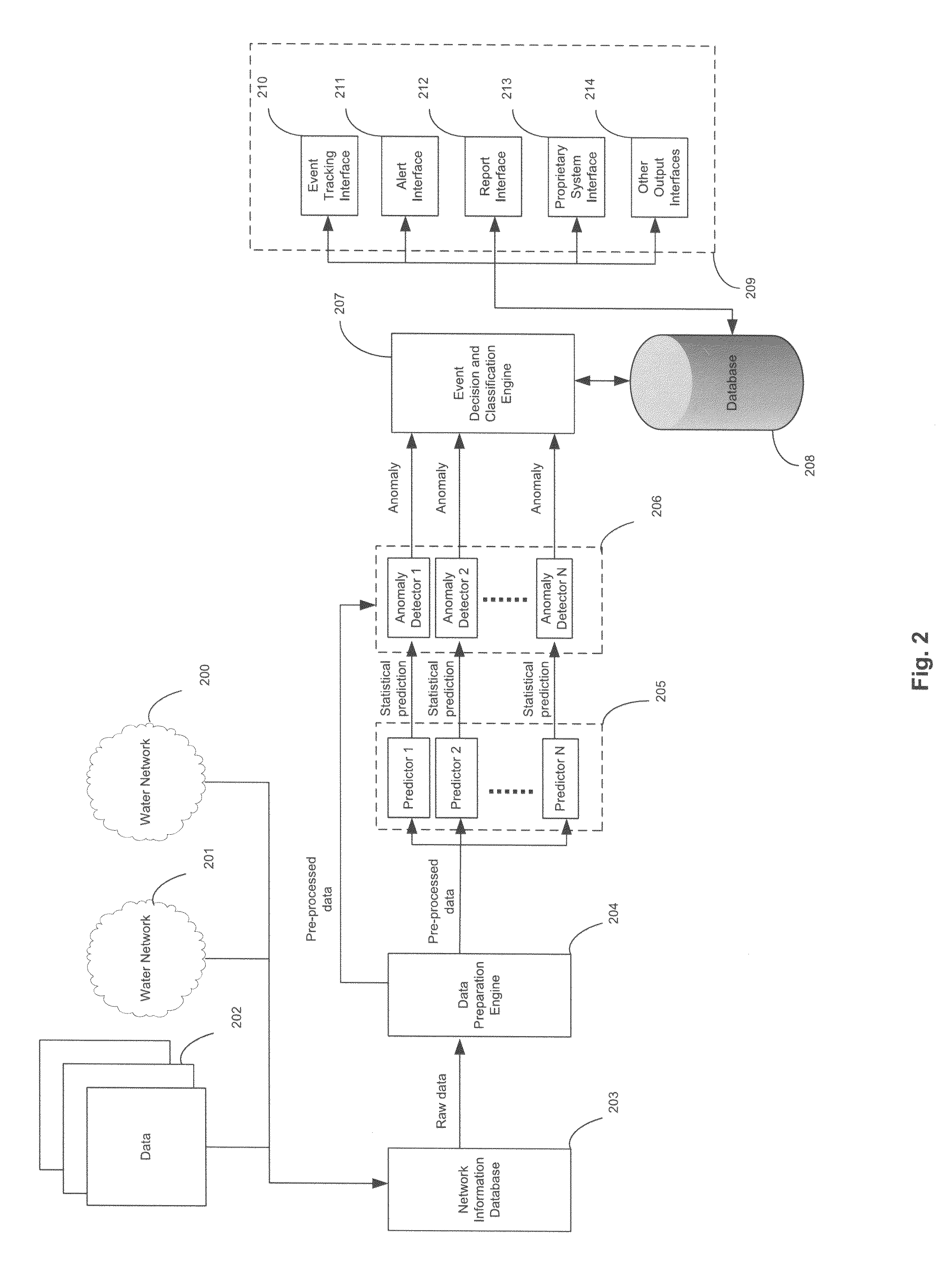

System and method for monitoring resources in a water utility network

ActiveUS7920983B1Easy to detectIncrease consumptionElectric signal transmission systemsTesting/calibration apparatusWater utilityUtility industry

A computerized method for monitoring a water utility network, the water utility network comprising a network of pipes for delivering water to consumers and a plurality of meters positioned within the pipes across the water distribution network. The method includes receiving meter data representing parameters measured by the meters, such as flow, pressure, chlorine level, pH and turbidity of the water being distributed through the pipes. The method also includes receiving secondary data from sources external to the meters and representing conditions affecting consumption of water in a region serviced by the water utility network such as weather and holidays. The meter and secondary data is analyzed using statistical techniques to identify water network events including leakage events and other events regarding quantity and quality of water flowing through the pipes and operation of the water network. The events are reported to users via a user interface.

Owner:TAKADU

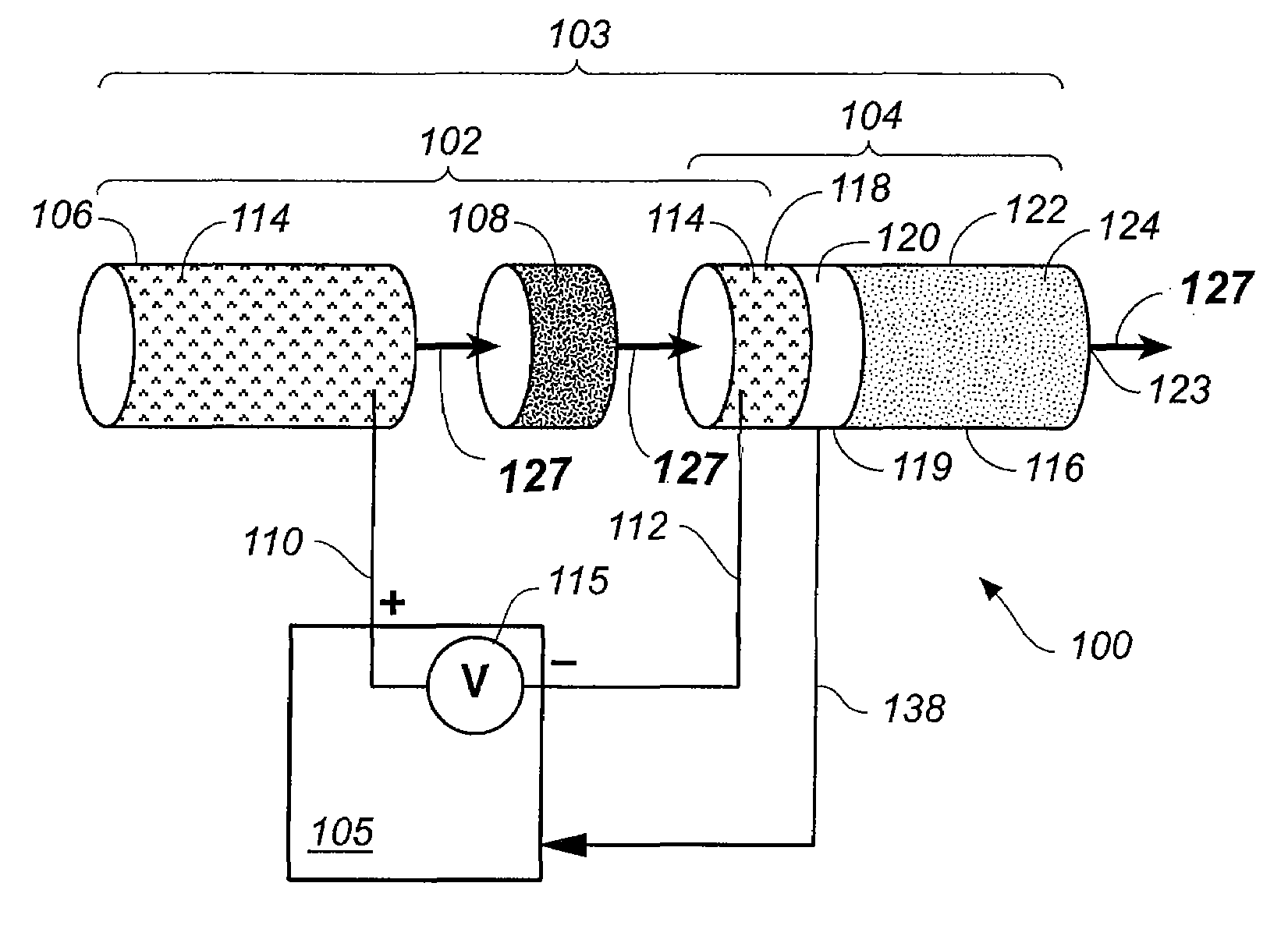

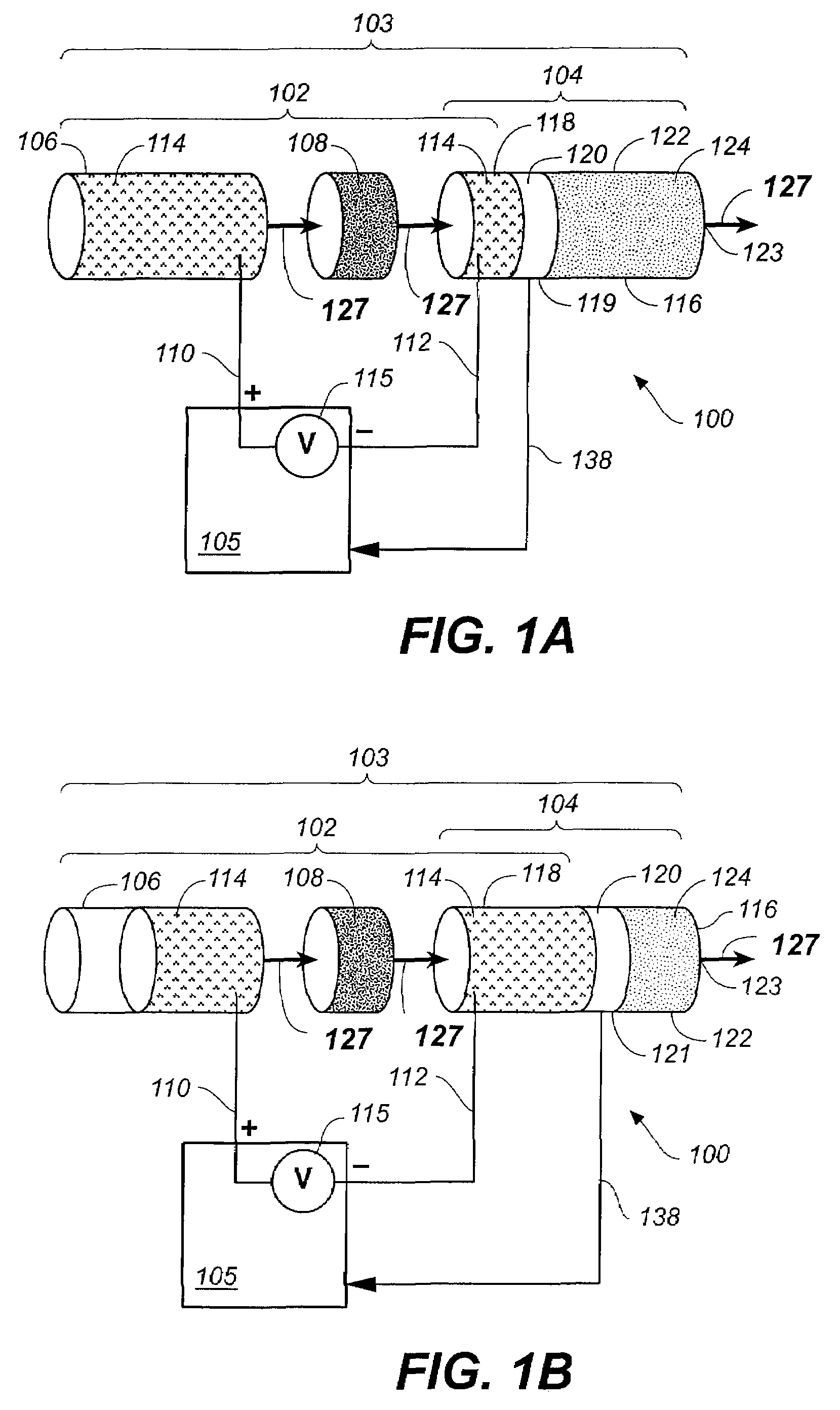

Malfunction detection in infusion pumps

The present application is directed to systems and methods associated with infusion pumps, which can optionally utilize an electrokinetic driving mechanism. Infusion pumps, including electrokinetically-driven pumps, are discussed, along with schemes for controlling their operation. As well, systems and methods of detecting malfunctions in infusion pumps are discussed. Any number of malfunctions can be detected including the presence of occlusions and / or leaks. In some instances, a measurement associated with some aspect of electrokinetic phenomena (e.g., an electrode measurement such as voltage or current) is compared with one or more sample values, the comparison allowing an indication of pump malfunction to be determined. A variety of such measurements and comparison techniques are discussed in the present disclosure.

Owner:LIFESCAN IP HLDG LLC

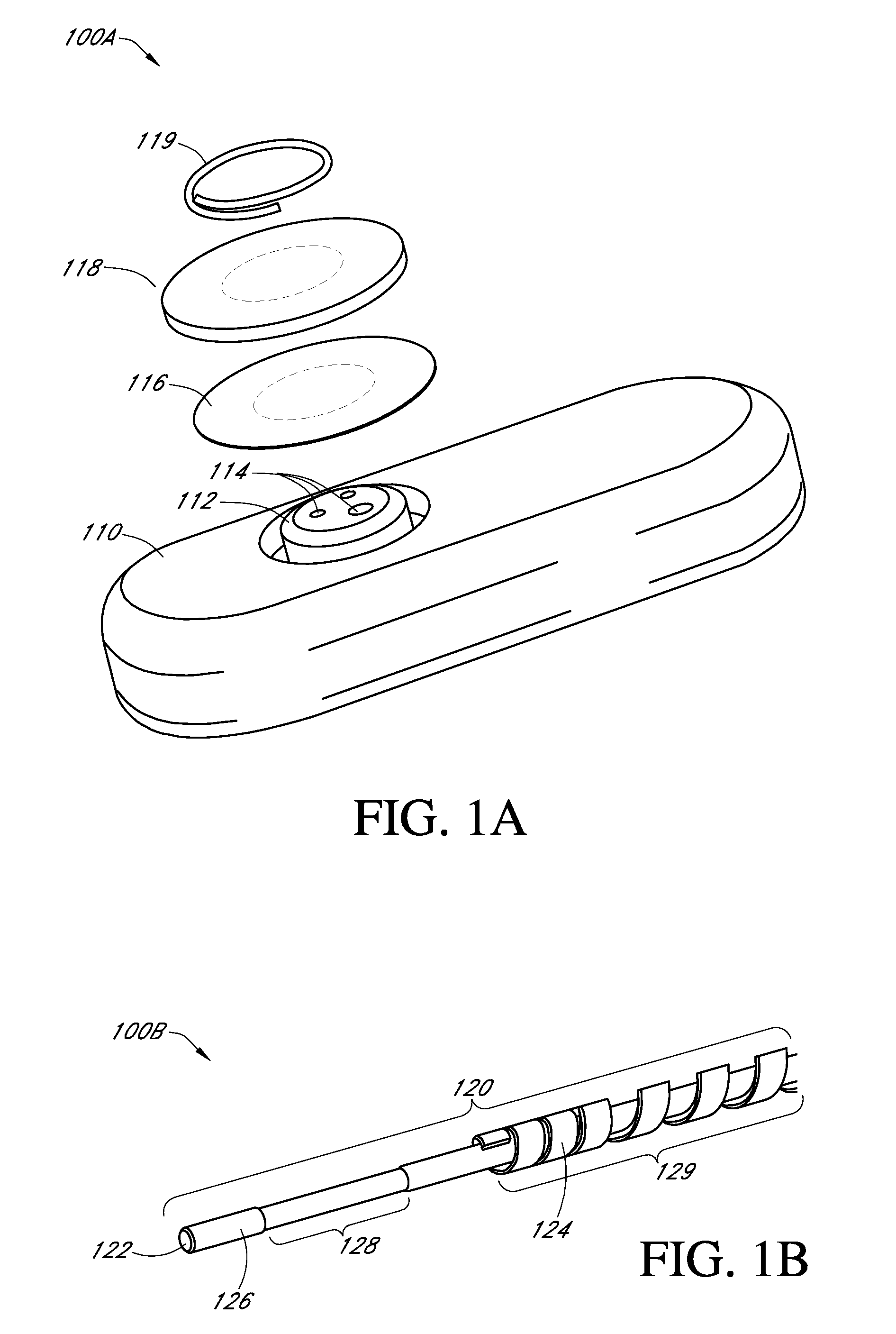

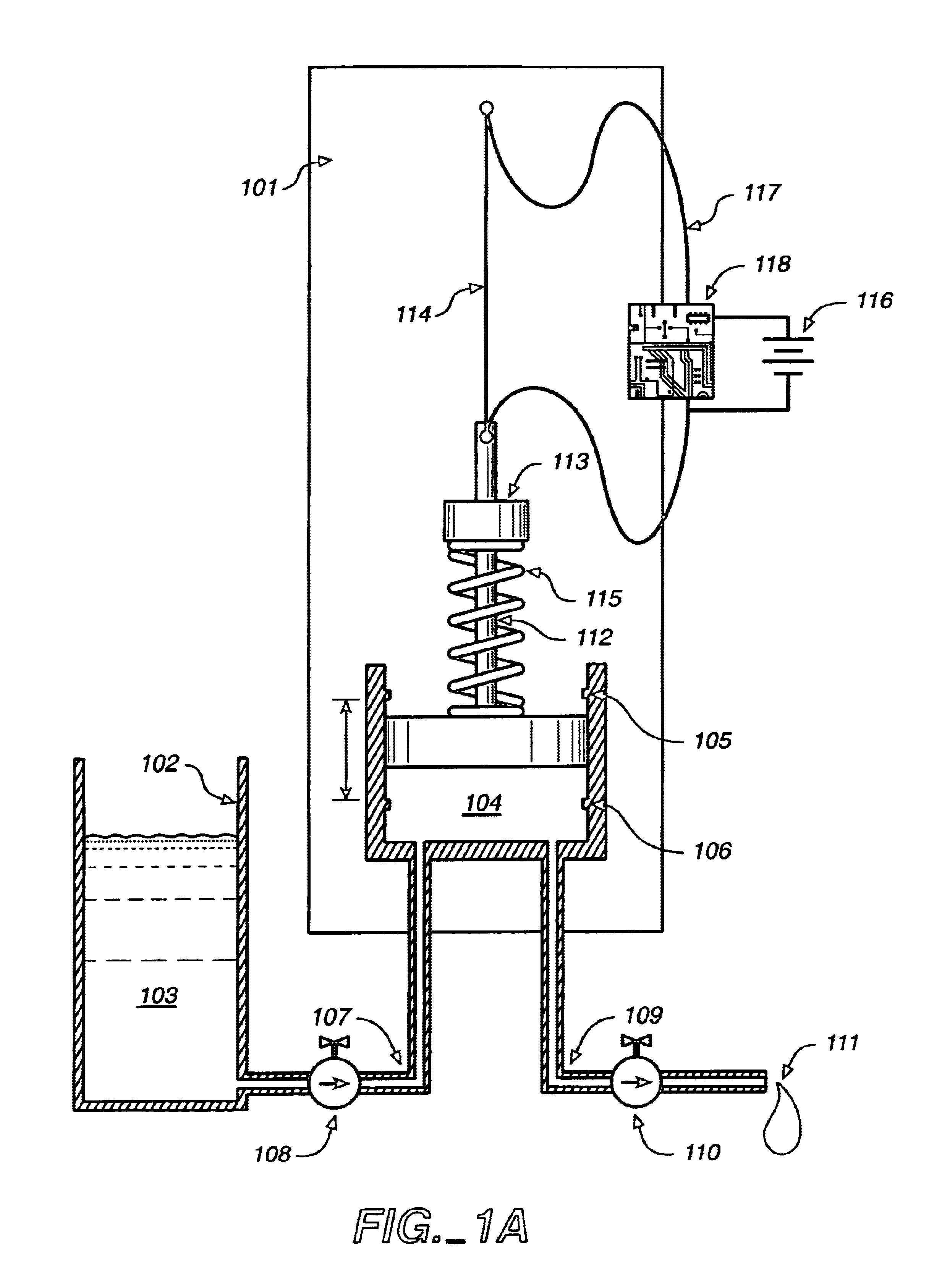

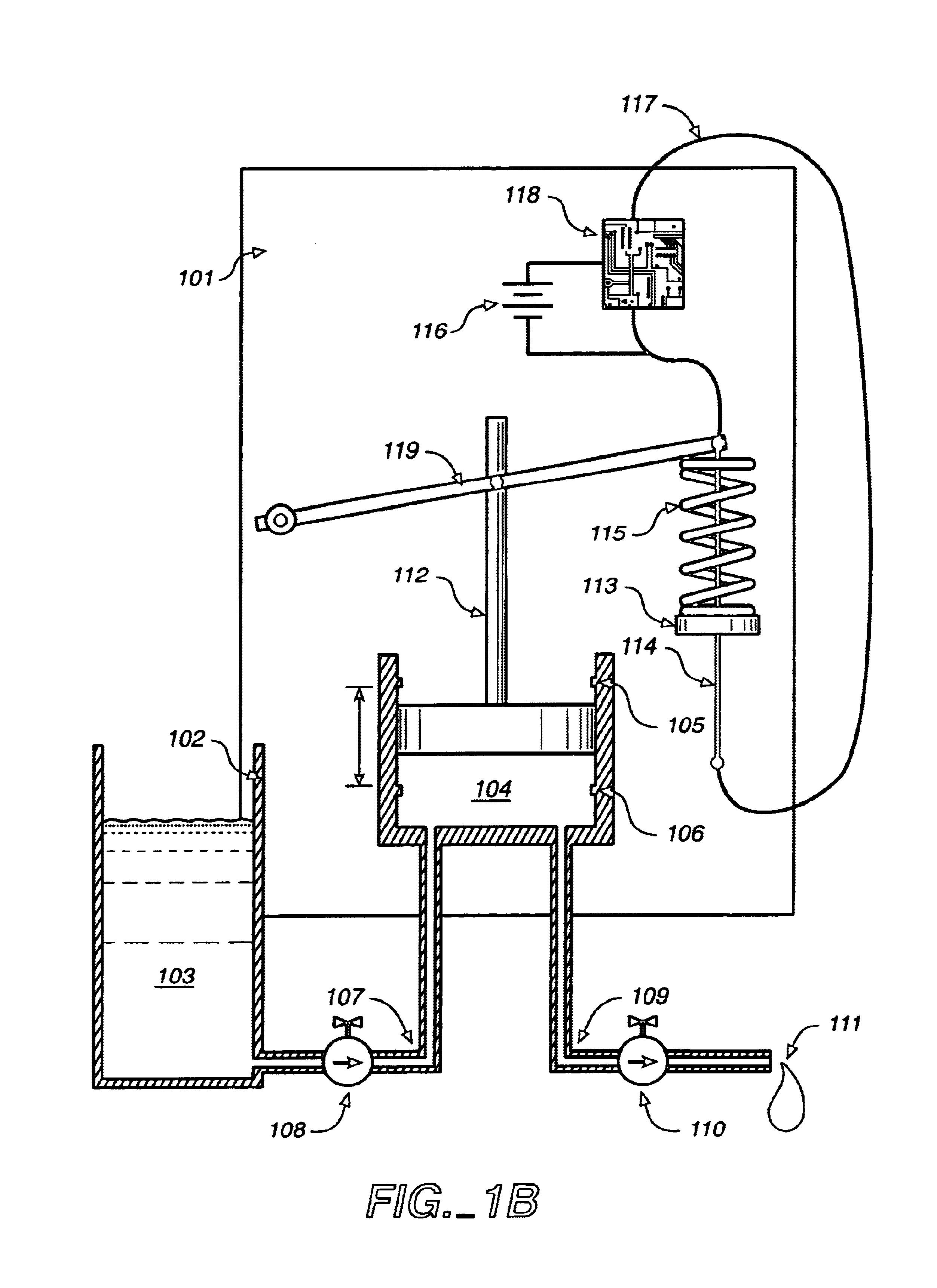

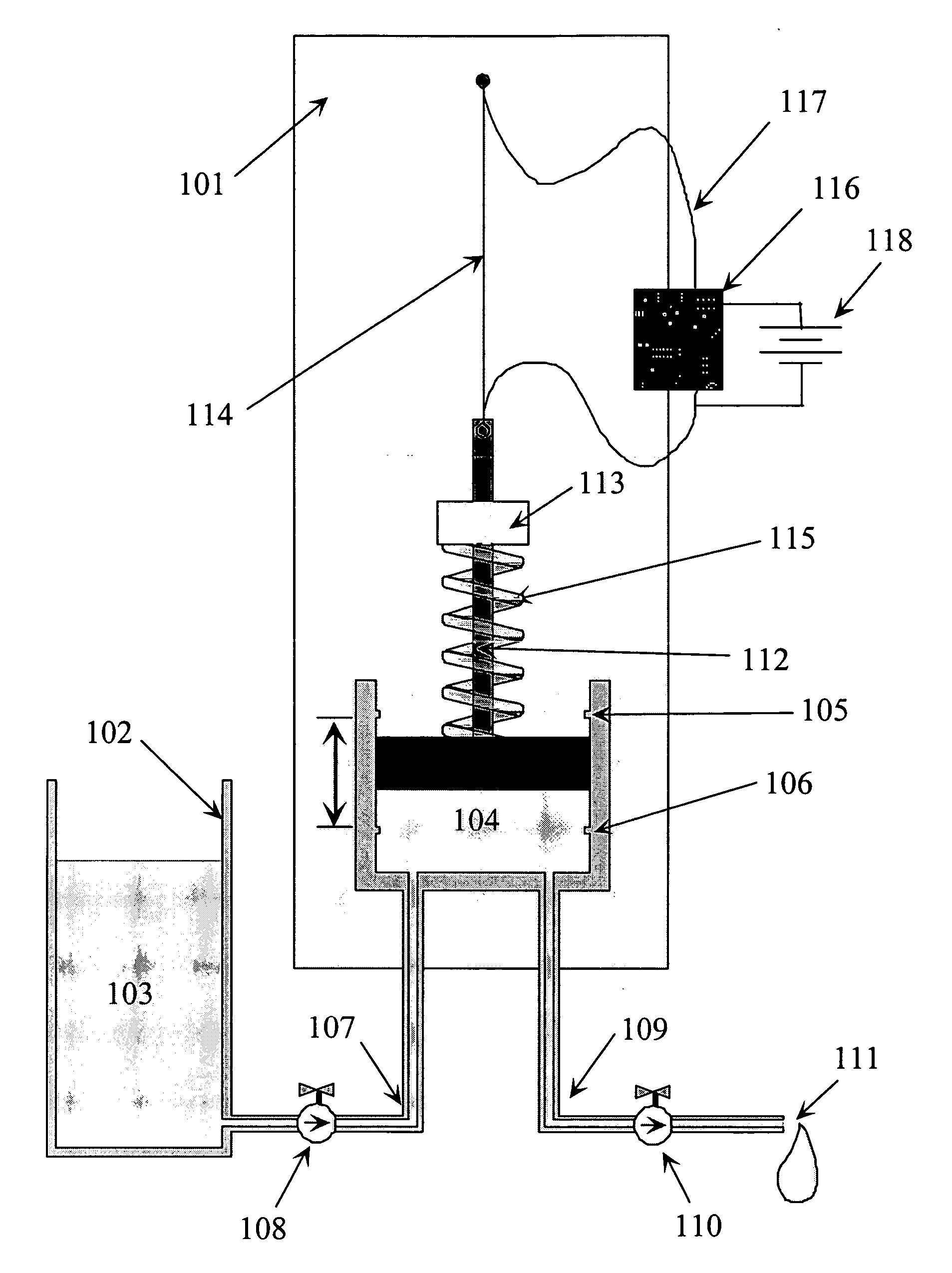

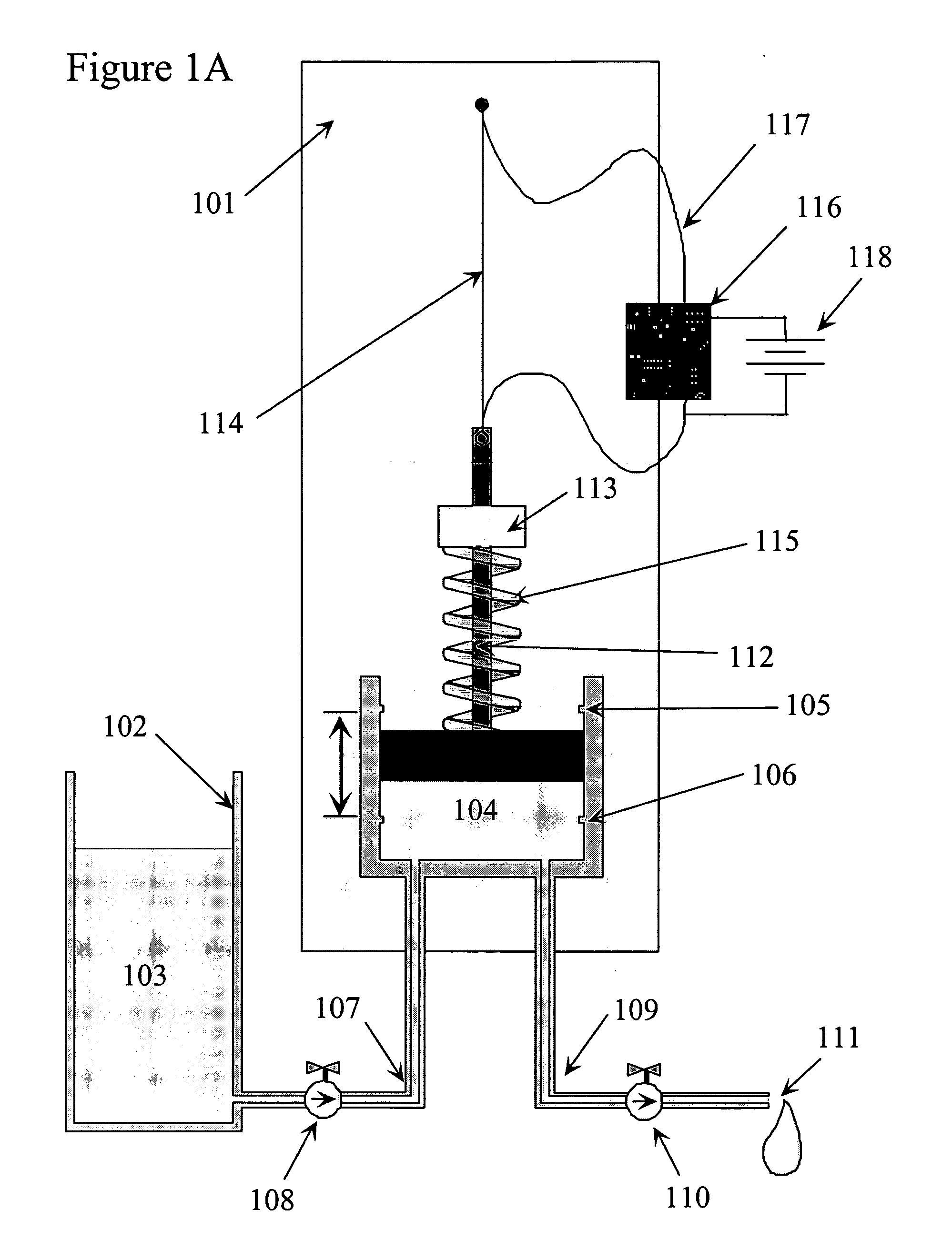

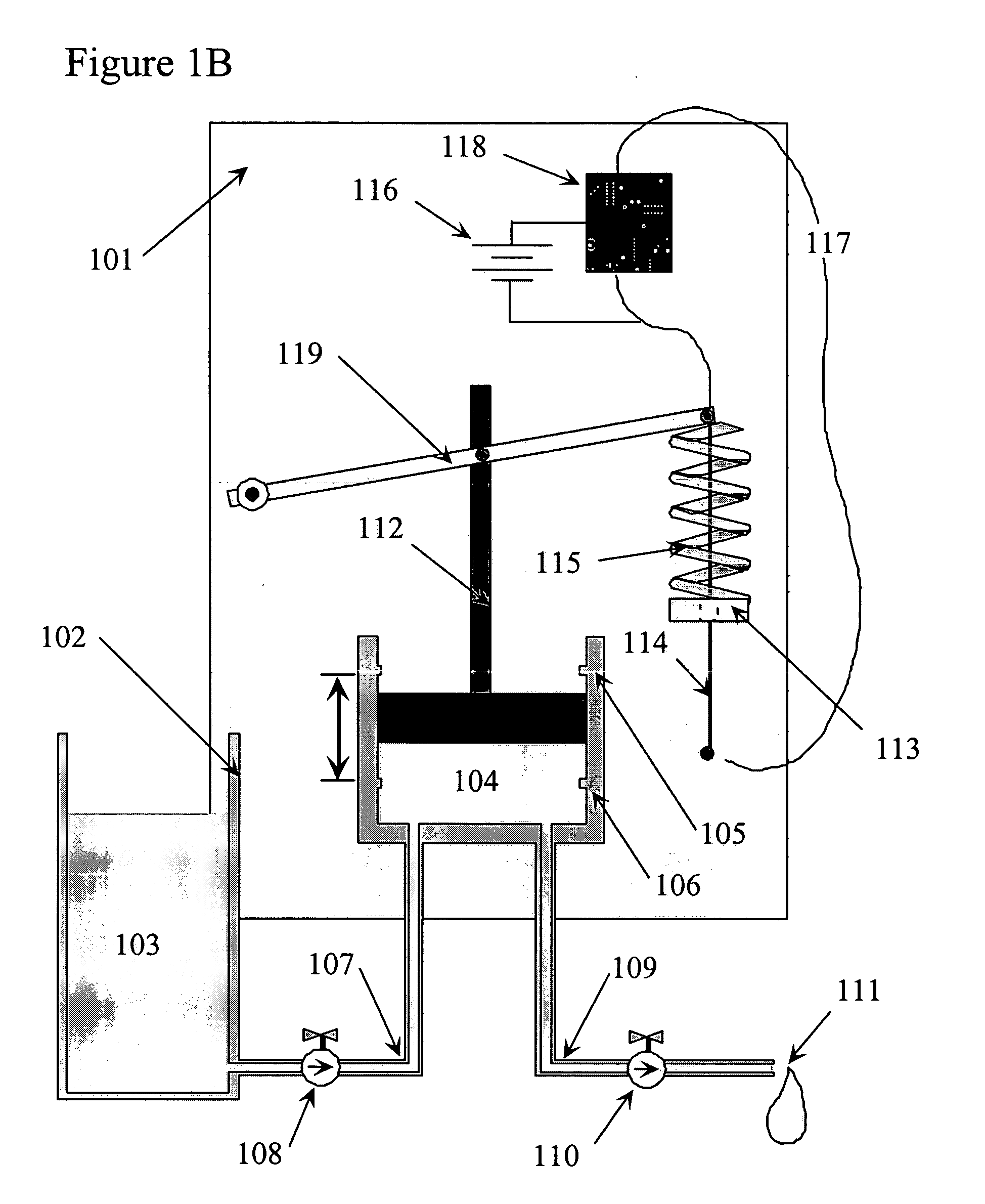

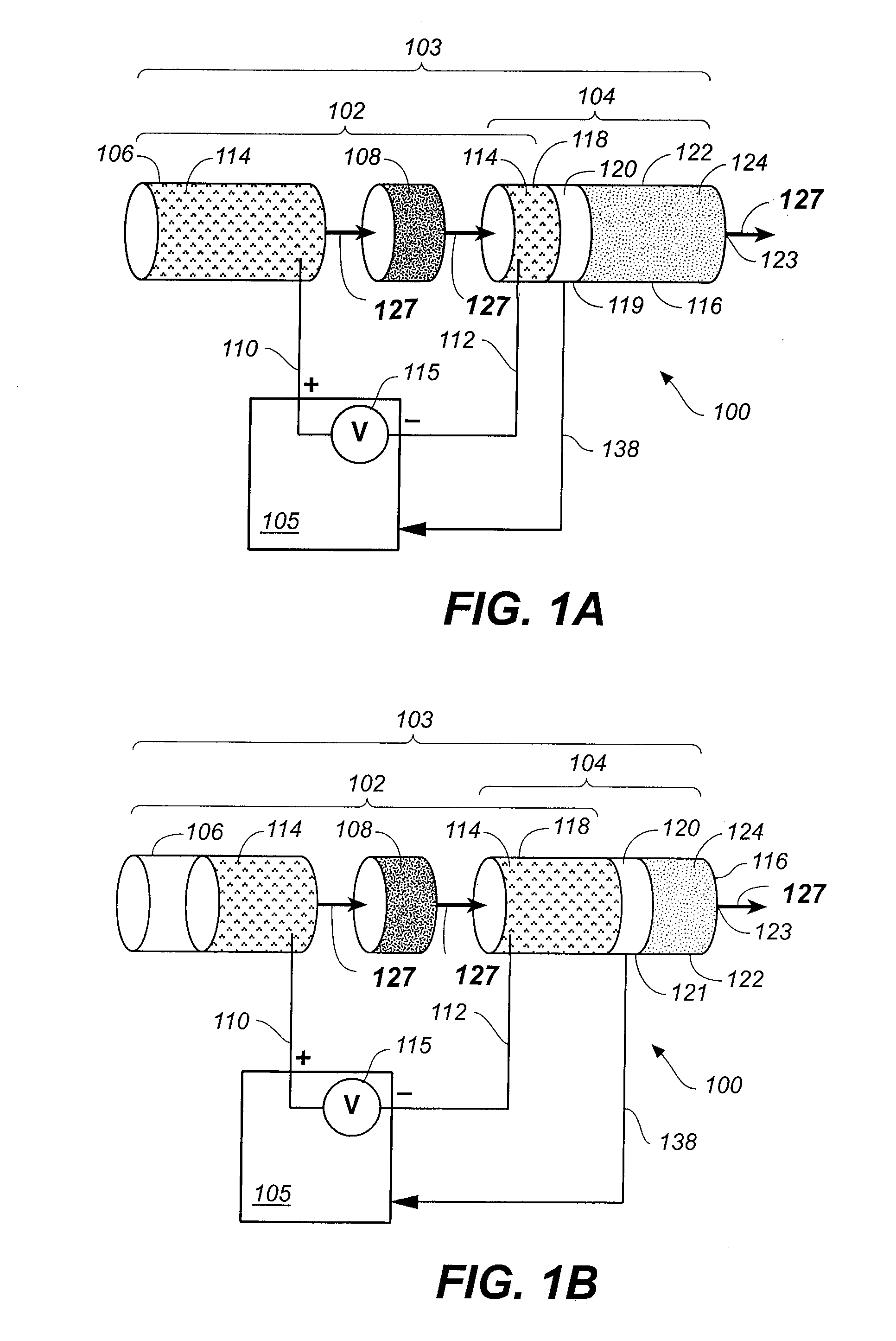

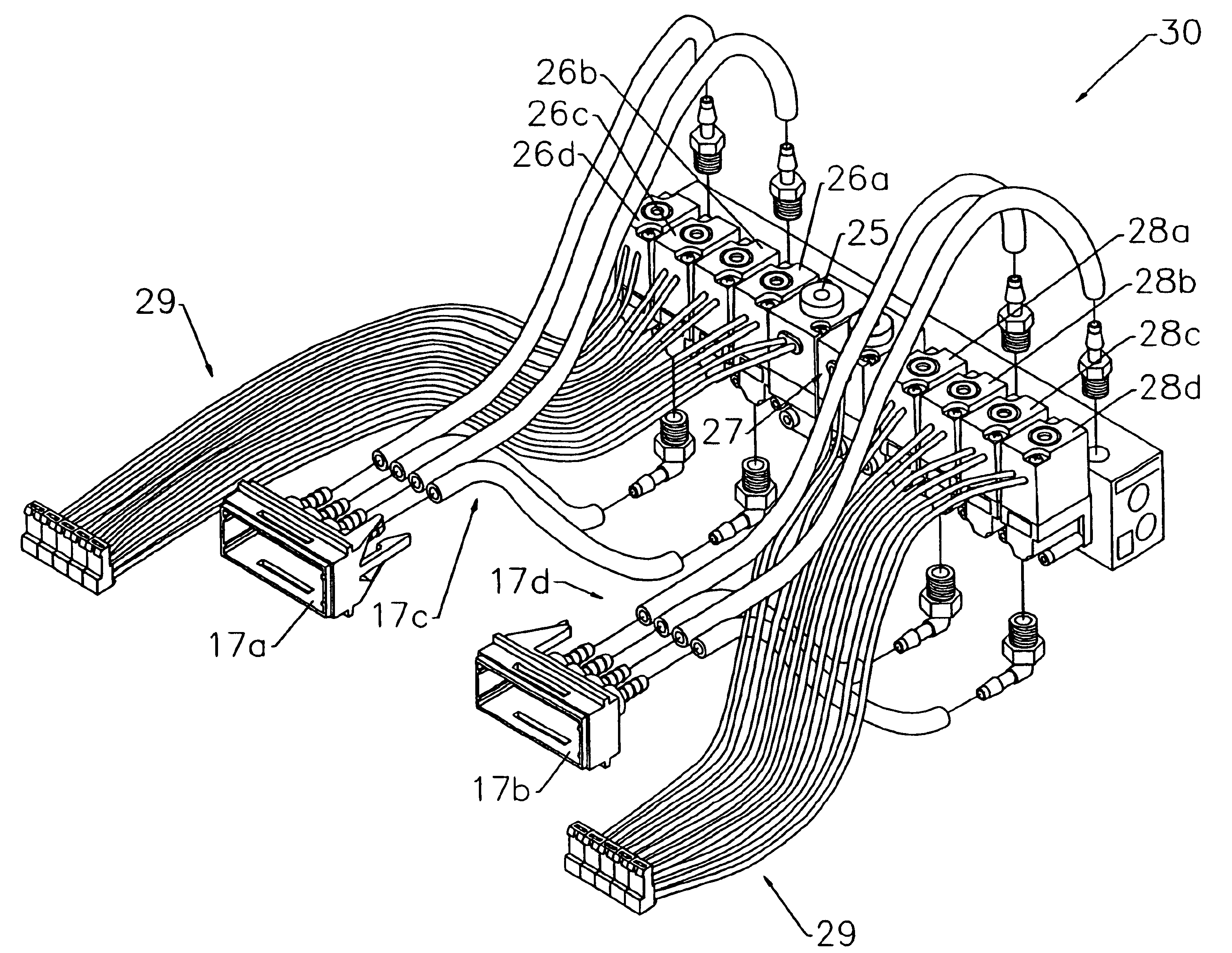

Fluid delivery device, system and method

ActiveUS20040115067A1Low costSmall sizeTesting/calibration apparatusVolume/mass flow measurementShape-memory alloyAlloy

A system for the metering and delivery of small discrete volumes of liquid is comprised of a small or minimal number of inexpensive components. One such component is a movable member, such as a miniature precision reciprocating displacement pump head, which is driven by an actuator that comprises a shape memory alloy material. The operating mechanism of the system is of little or minimal complexity. The system facilitates the precise metering and delivery of the small discrete volumes of liquid. Potential applications for the system include subcutaneous, long-term, automated drug delivery, for example, the delivery of insulin to a person with diabetes. In such an application, the small, simple and inexpensive nature of the invention would allow for its use as both a portable and a disposable system.

Owner:THERASENSE

Methods and systems for observing sensor parameters

ActiveUS20110230741A1Testing/calibration apparatusResistance/reactance/impedenceVoltage pulseMonitors blood glucose

The invention disclosed herein provides methods and materials for observing the state of a sensor, for example those used by diabetic patients to monitor blood glucose levels. Typically a voltage such as a voltage pulse is applied to the sensor in order to solicit a current response from which for example, factors such as impedance values can be derived. Such values can then be used as indicators of a sensor's state, for example the state of sensor hydration, sensor noise, sensor offset, sensor drift or the like.

Owner:MEDTRONIC MIMIMED INC

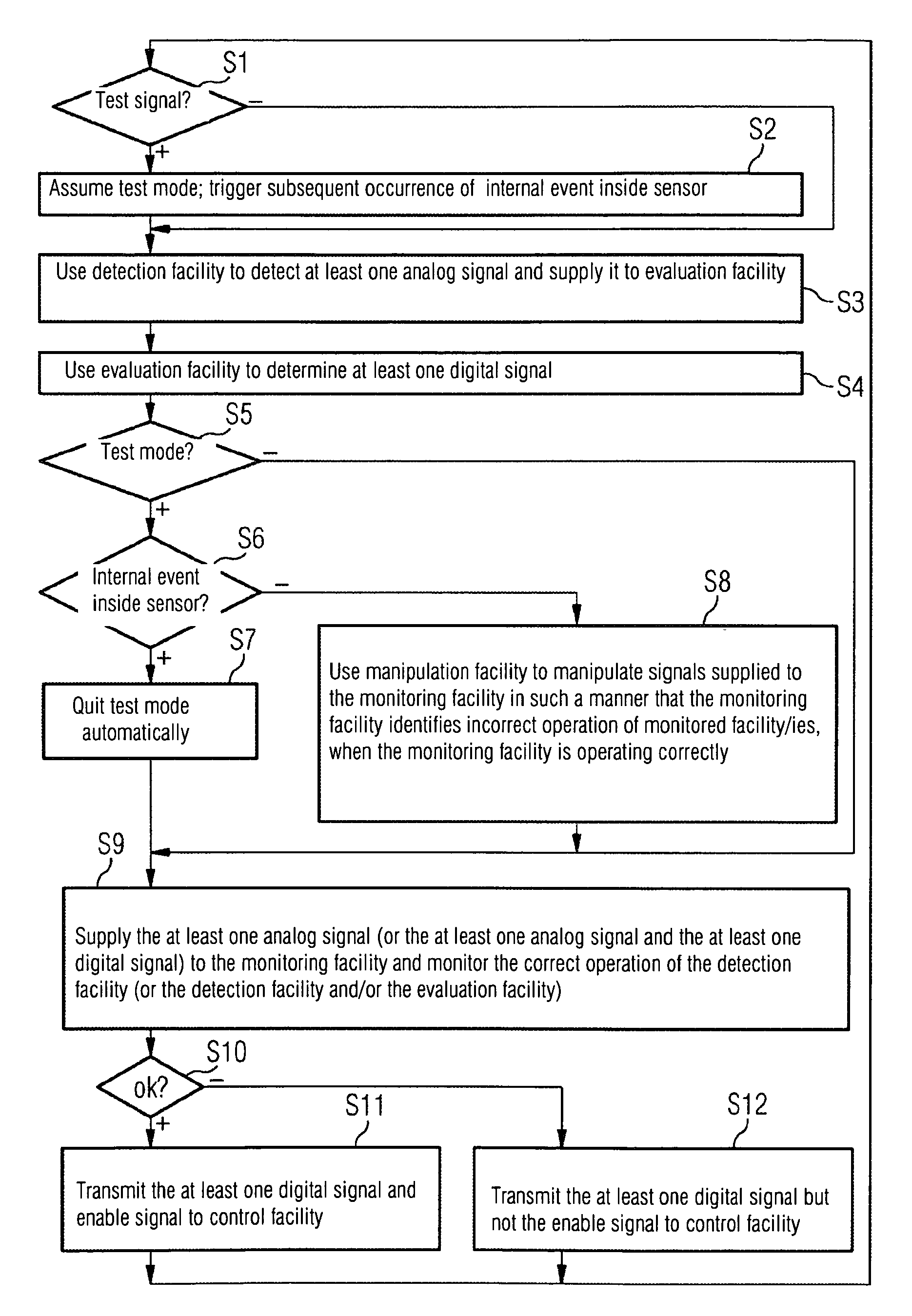

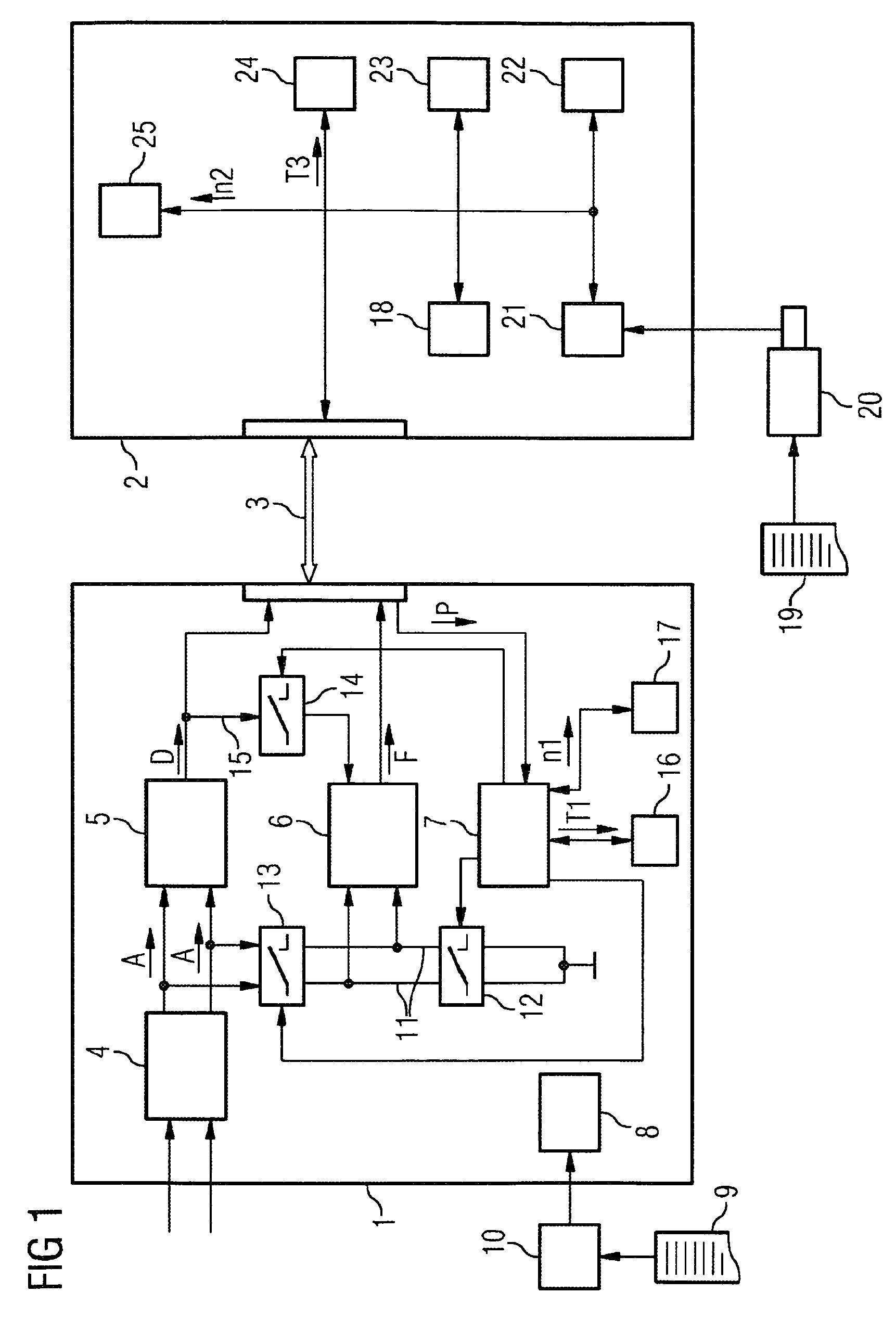

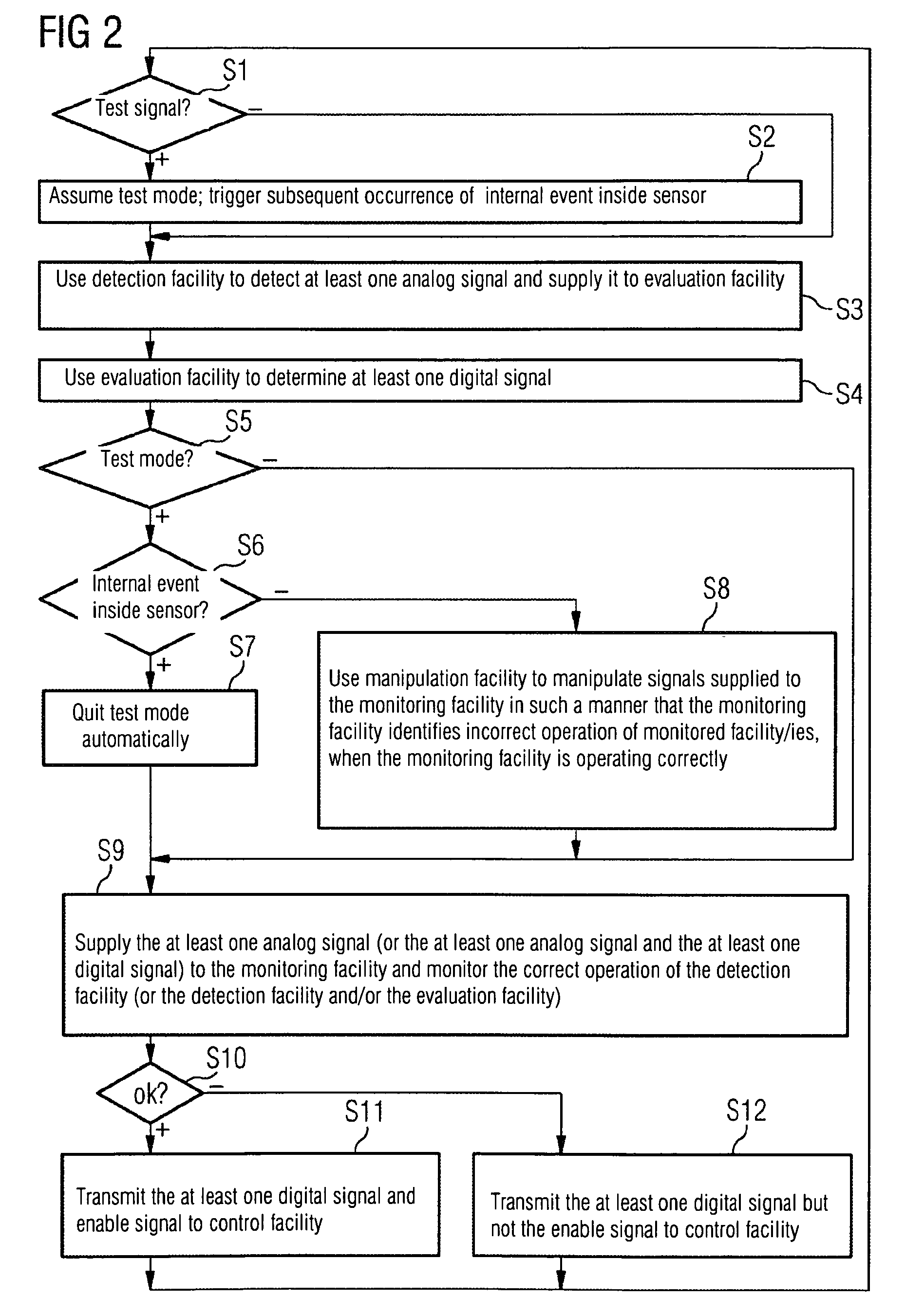

Operating method for a sensor and a control facility communicating with the sensor

InactiveUS8140299B2Minimize timeAvoid testingTesting/calibration apparatusDigital computer detailsComputer hardwareEngineering

Owner:SIEMENS AG

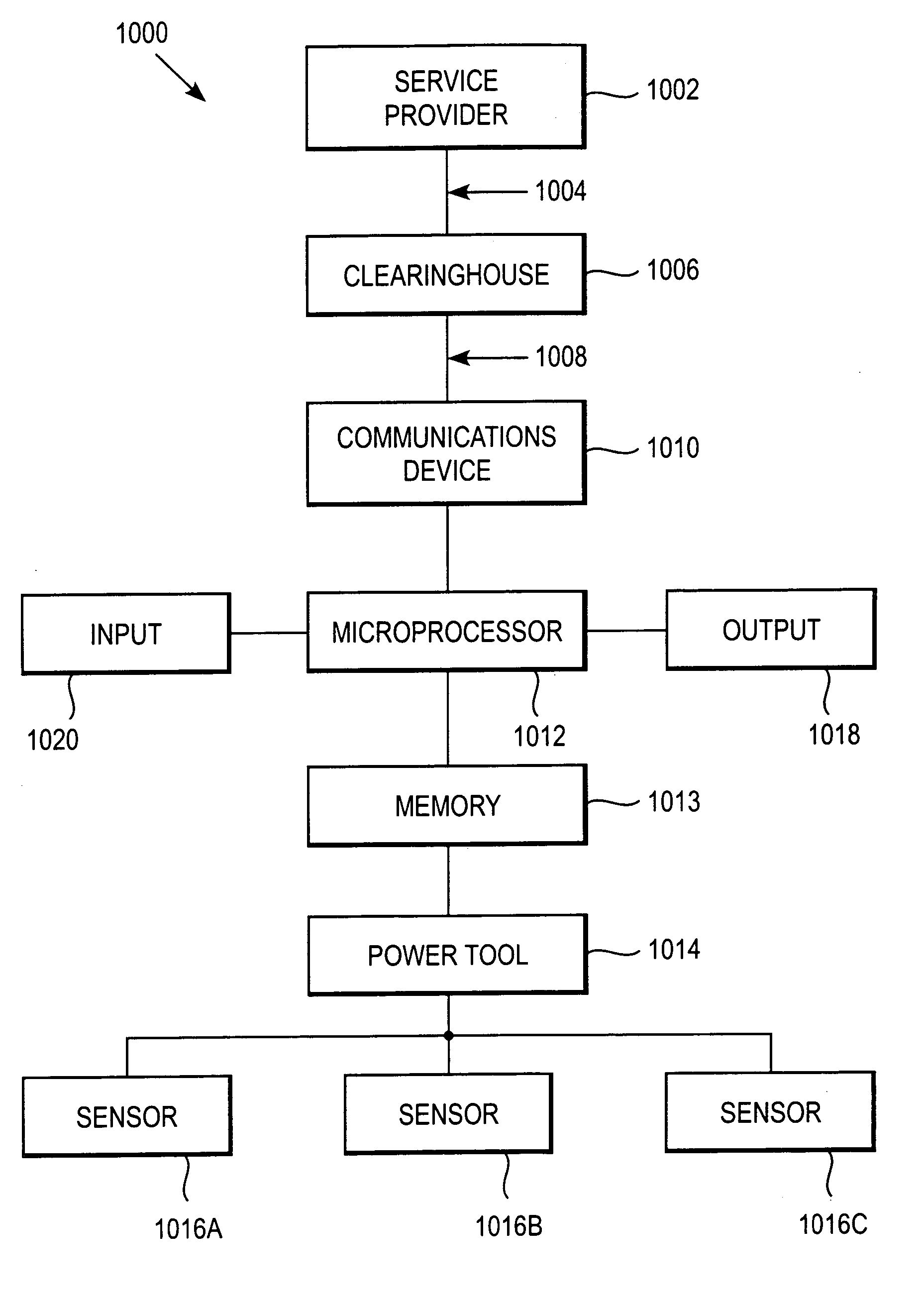

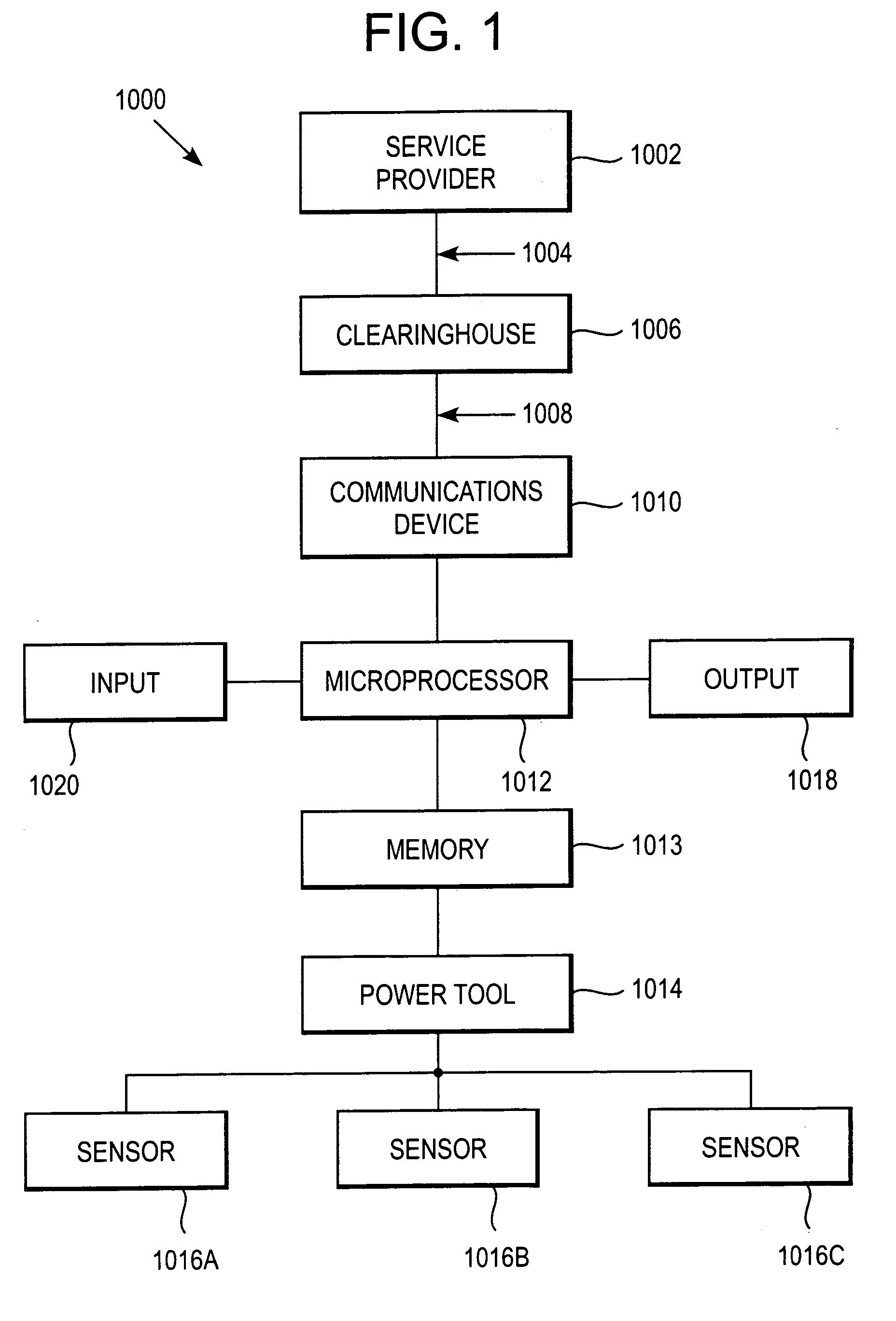

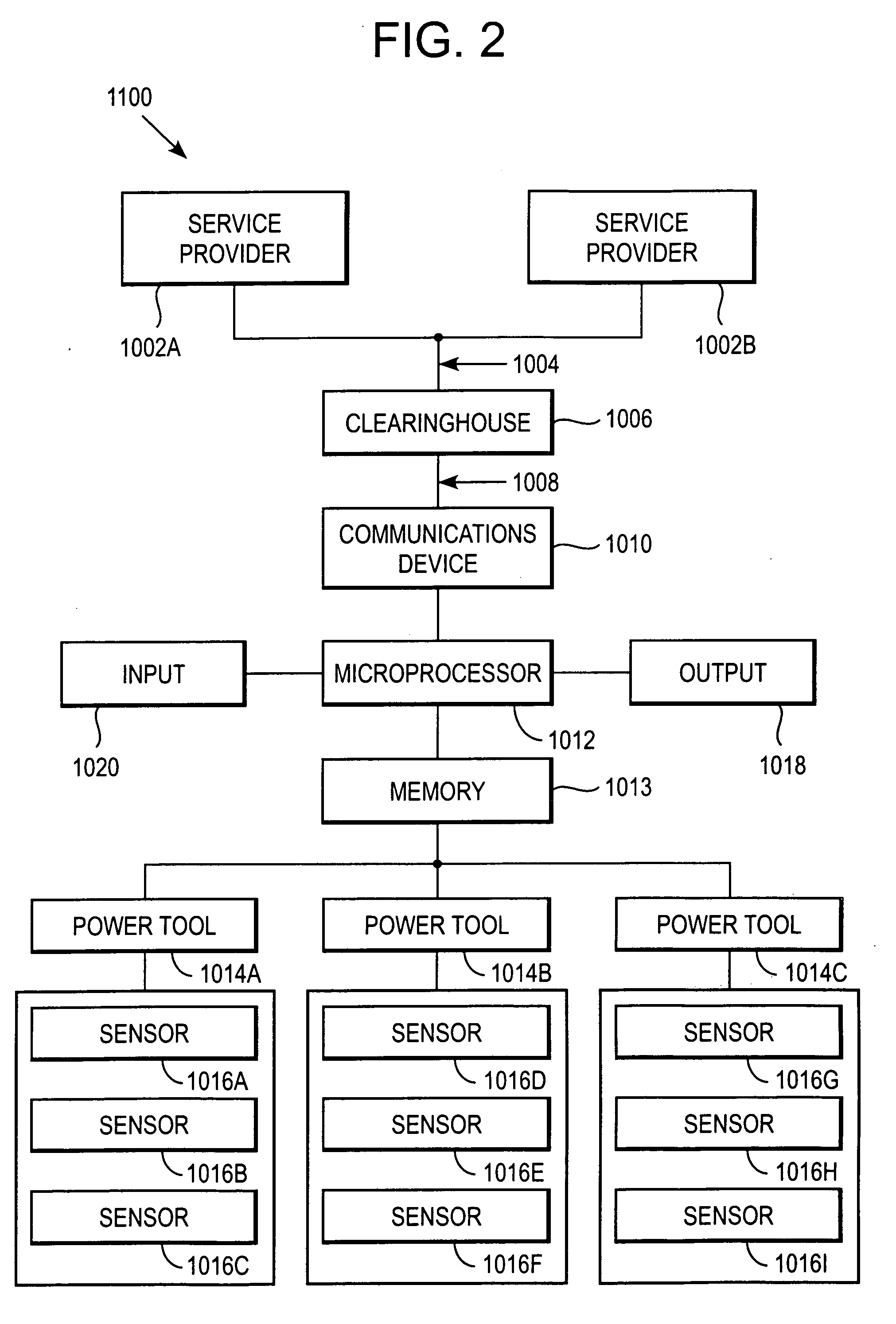

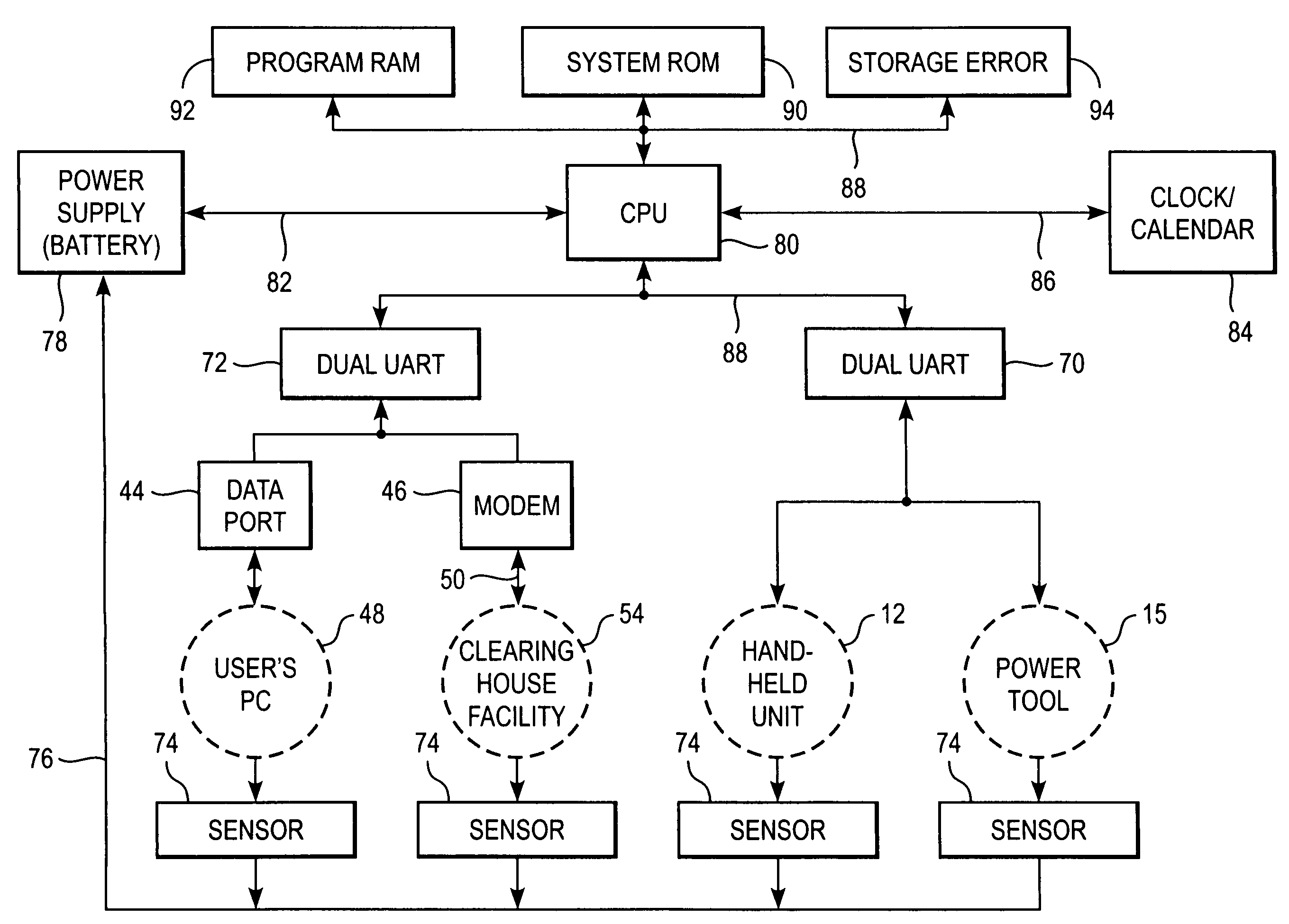

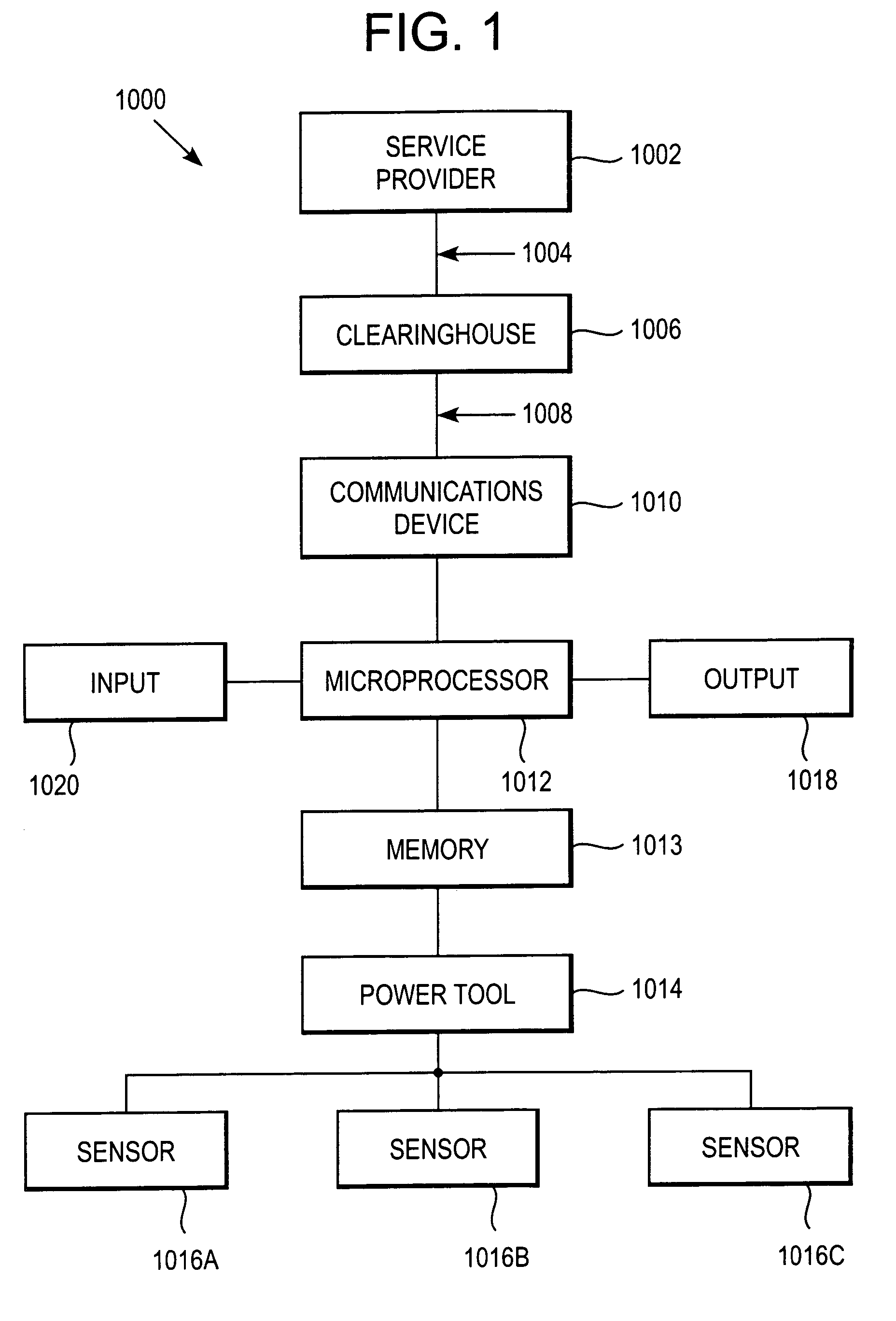

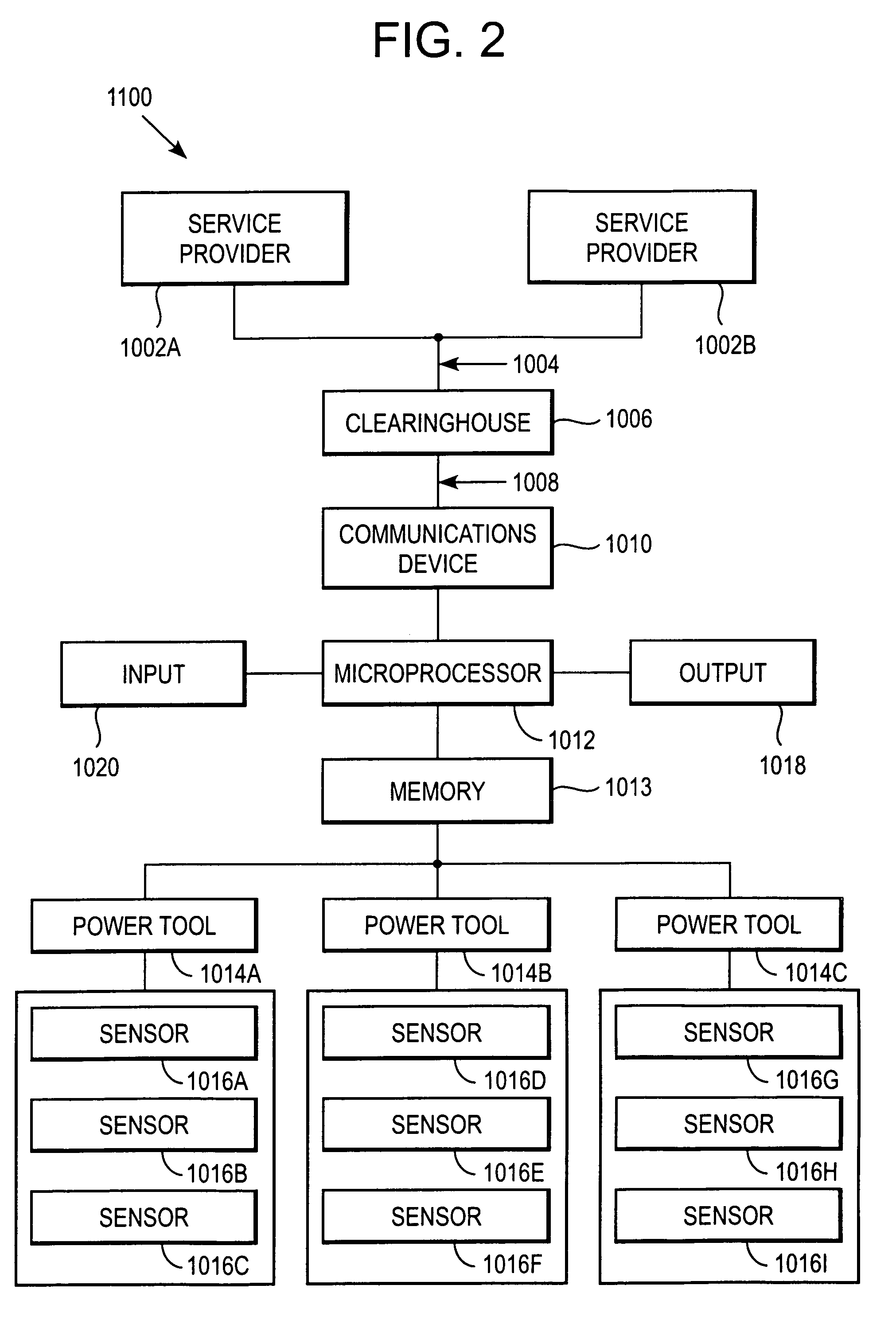

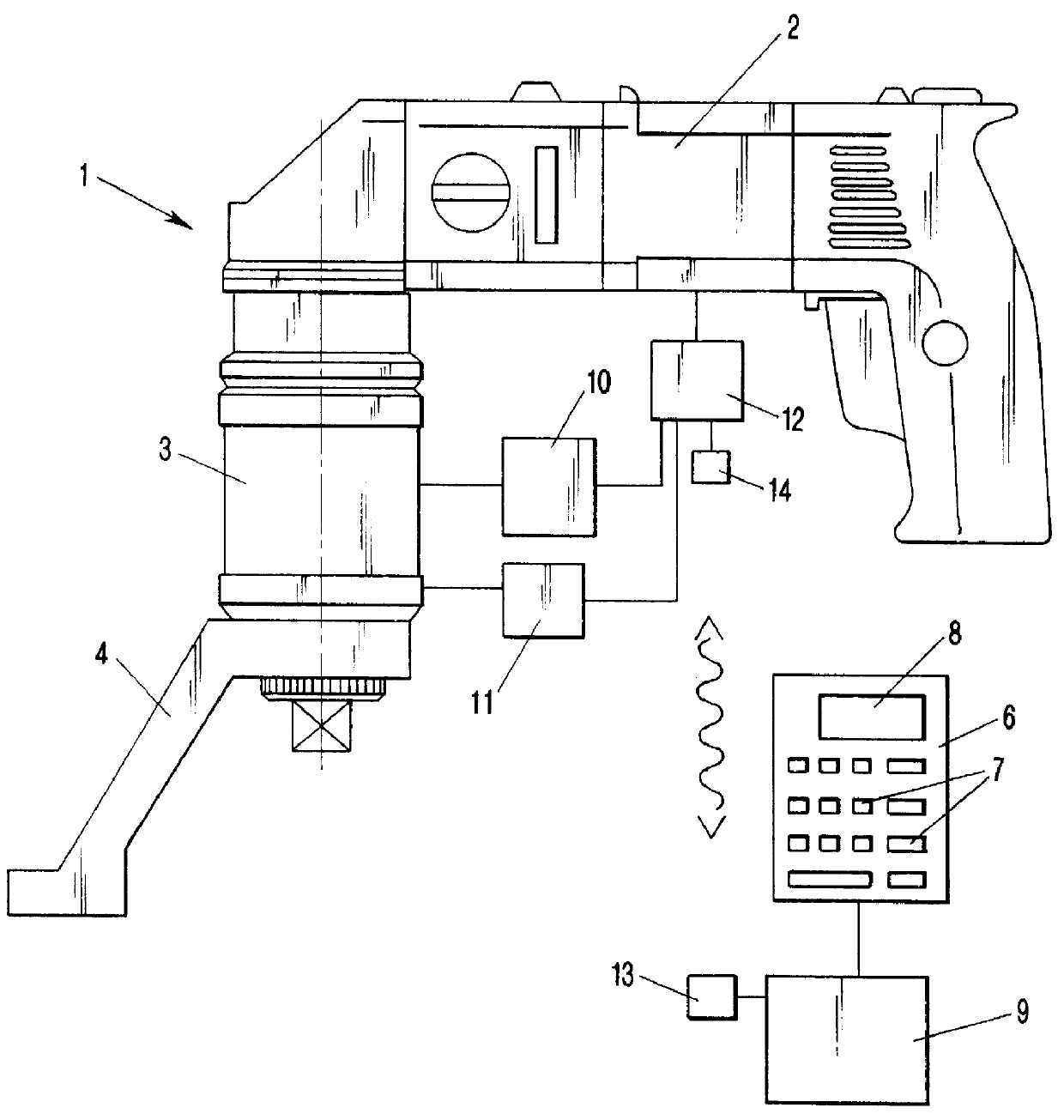

Modular microprocessor-based power tool system

InactiveUS20060155582A1Testing/calibration apparatusTurning machine accessoriesProgram instructionDisplay device

A power tool system and method of using the same is provided. The system can include a programmable microprocessor device including at least one input mechanism, and a memory having instructions and / or other information. The system can also include a display; at least one power tool having at least one sensor operable for monitoring a parameter associated with operation of the power tool. The system can further include a communications device connectable in signal communication with both the programmable microprocessor device and the at least one sensor and program instructions. The method can include the steps of (i) using stored program instructions to generate power tool related information on at least one display and (ii) collecting power tool related data using a programmable microprocessor.

Owner:HEALTH HERO NETWORK

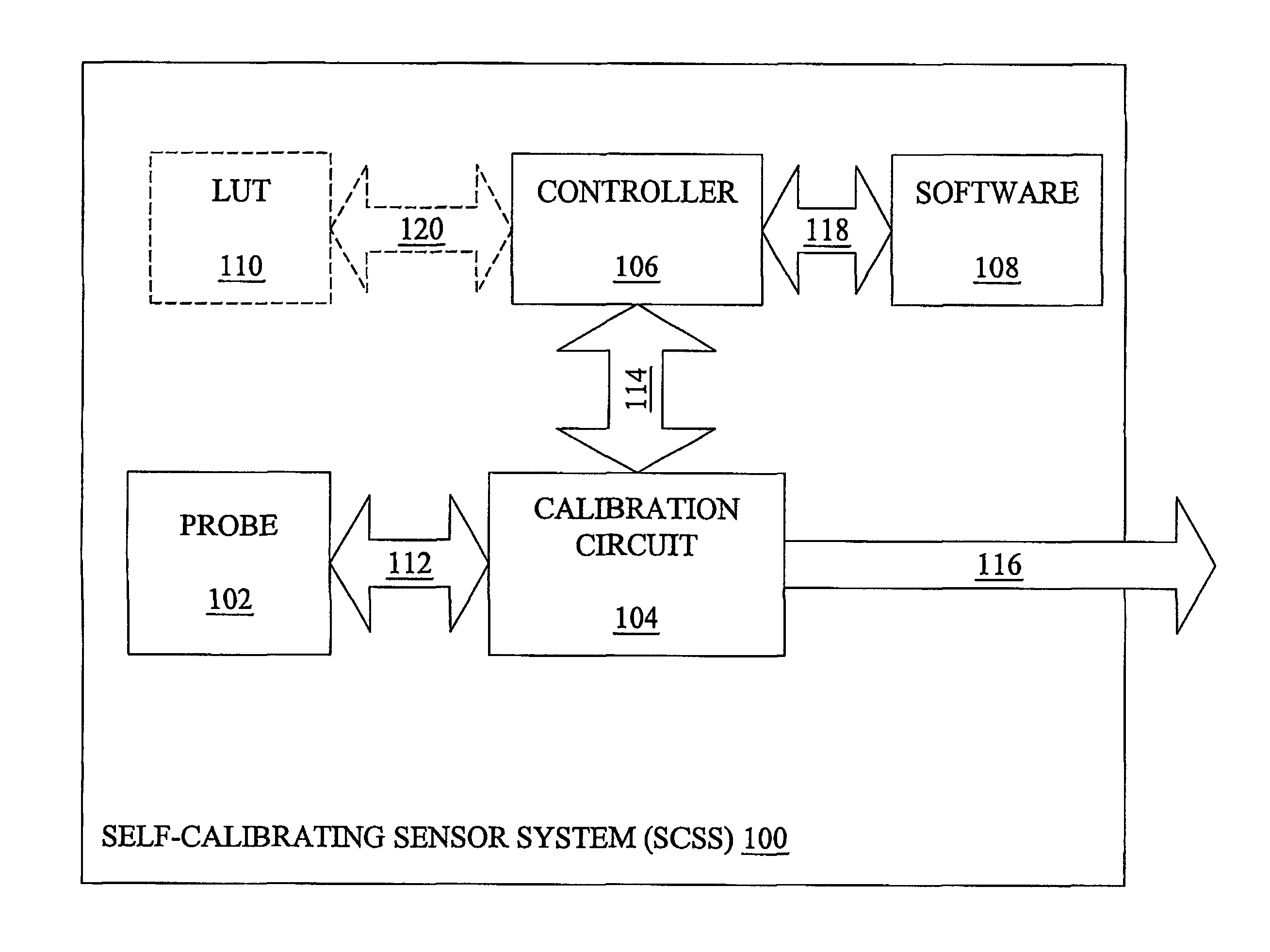

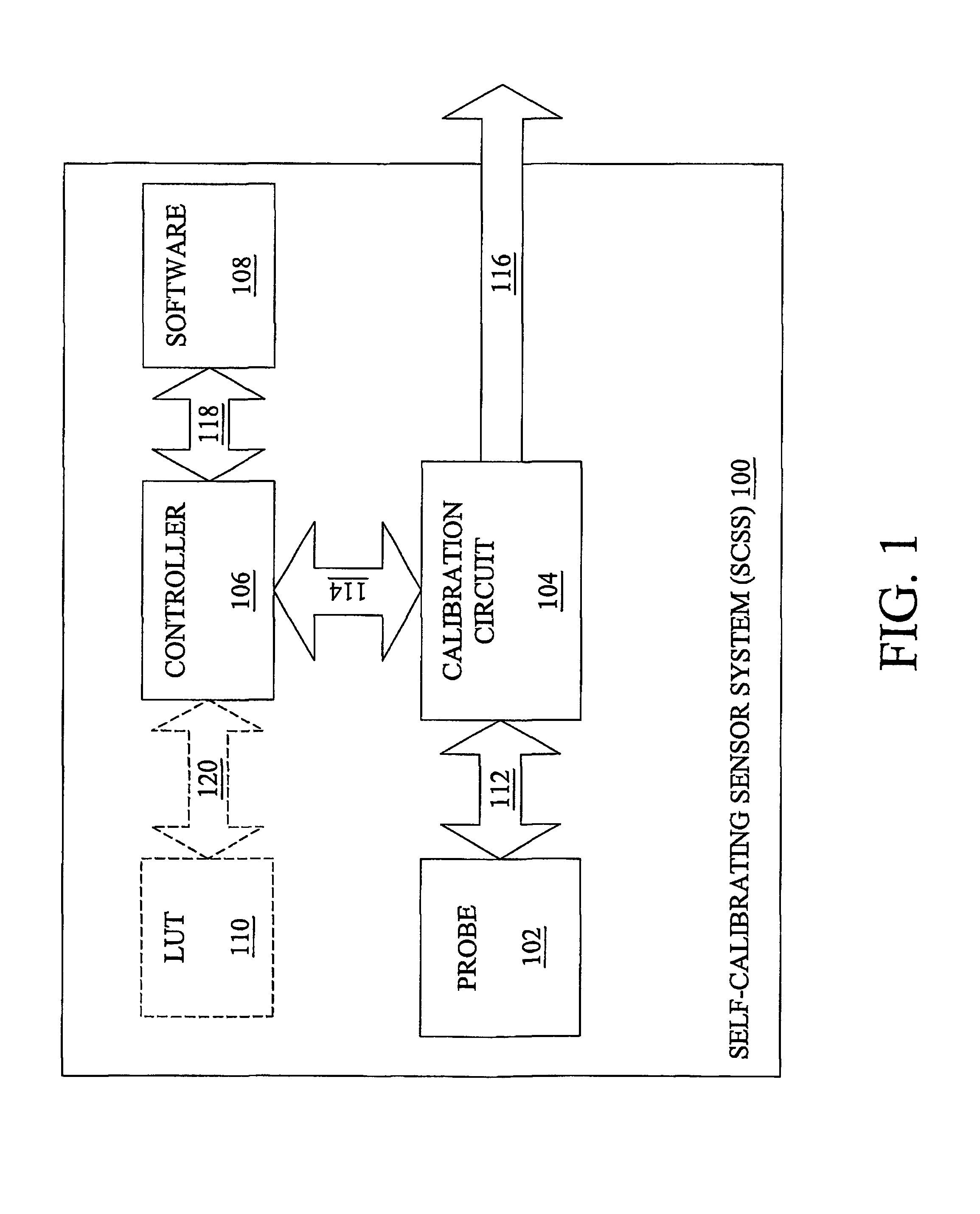

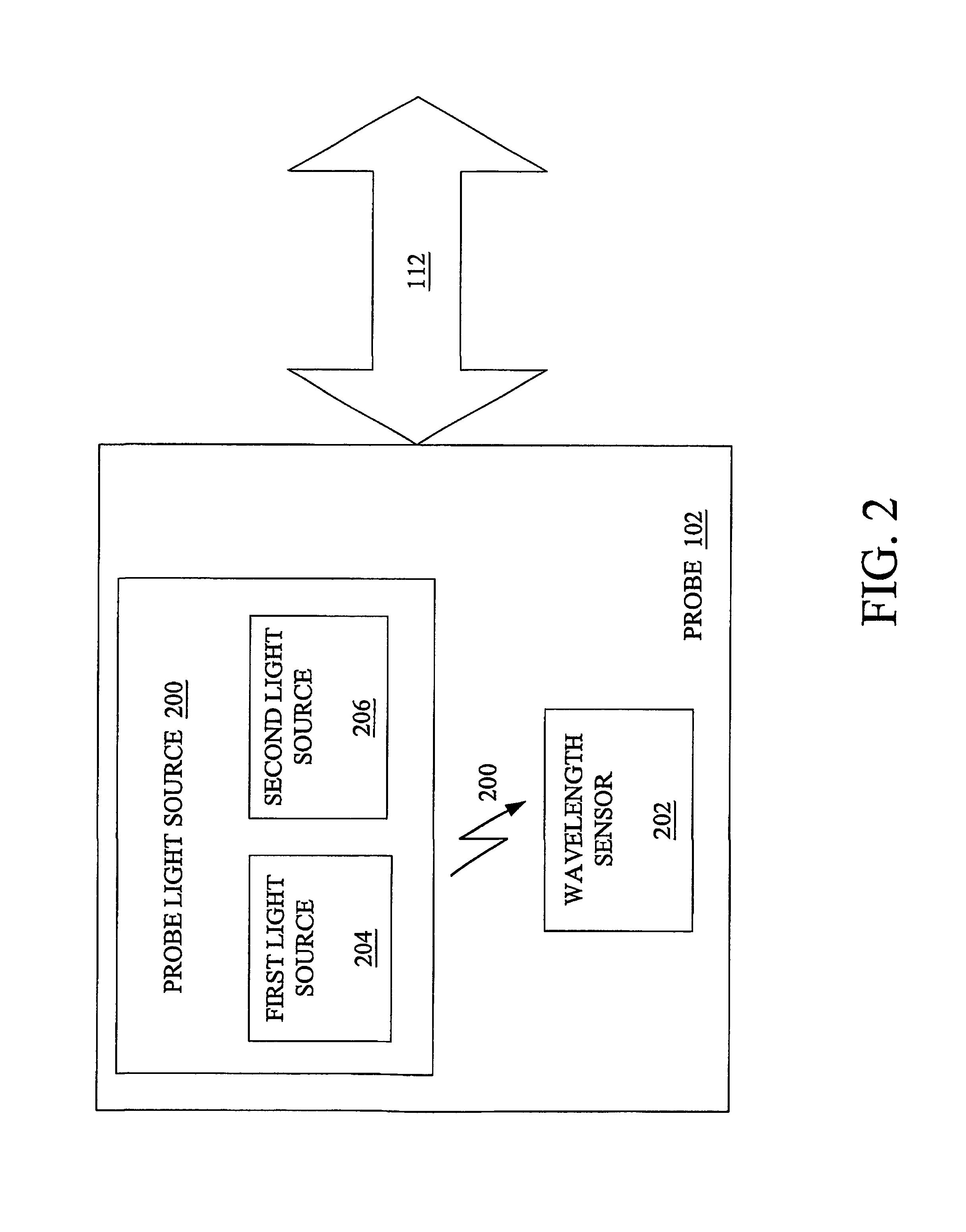

System and method for a self-calibrating non-invasive sensor

A non-invasive emitter-photodiode sensor which is able to provide a data-stream corresponding to the actual wavelength of light emitted thereby allowing calibration of the sensor signal processing equipment and resulting in accurate measurements over a wider variation in emitter wavelength ranges.

Owner:MEDTOR INC

Modular microprocessor-based power tool system

InactiveUS7613590B2Turning machine accessoriesTesting/calibration apparatusProgram instructionDisplay device

A power tool system and method of using the same is provided. The system can include a programmable microprocessor device including at least one input mechanism, and a memory having instructions and / or other information. The system can also include a display; at least one power tool having at least one sensor operable for monitoring a parameter associated with operation of the power tool. The system can further include a communications device connectable in signal communication with both the programmable microprocessor device and the at least one sensor and program instructions. The method can include the steps of (i) using stored program instructions to generate power tool related information on at least one display and (ii) collecting power tool related data using a programmable microprocessor.

Owner:HEALTH HERO NETWORK

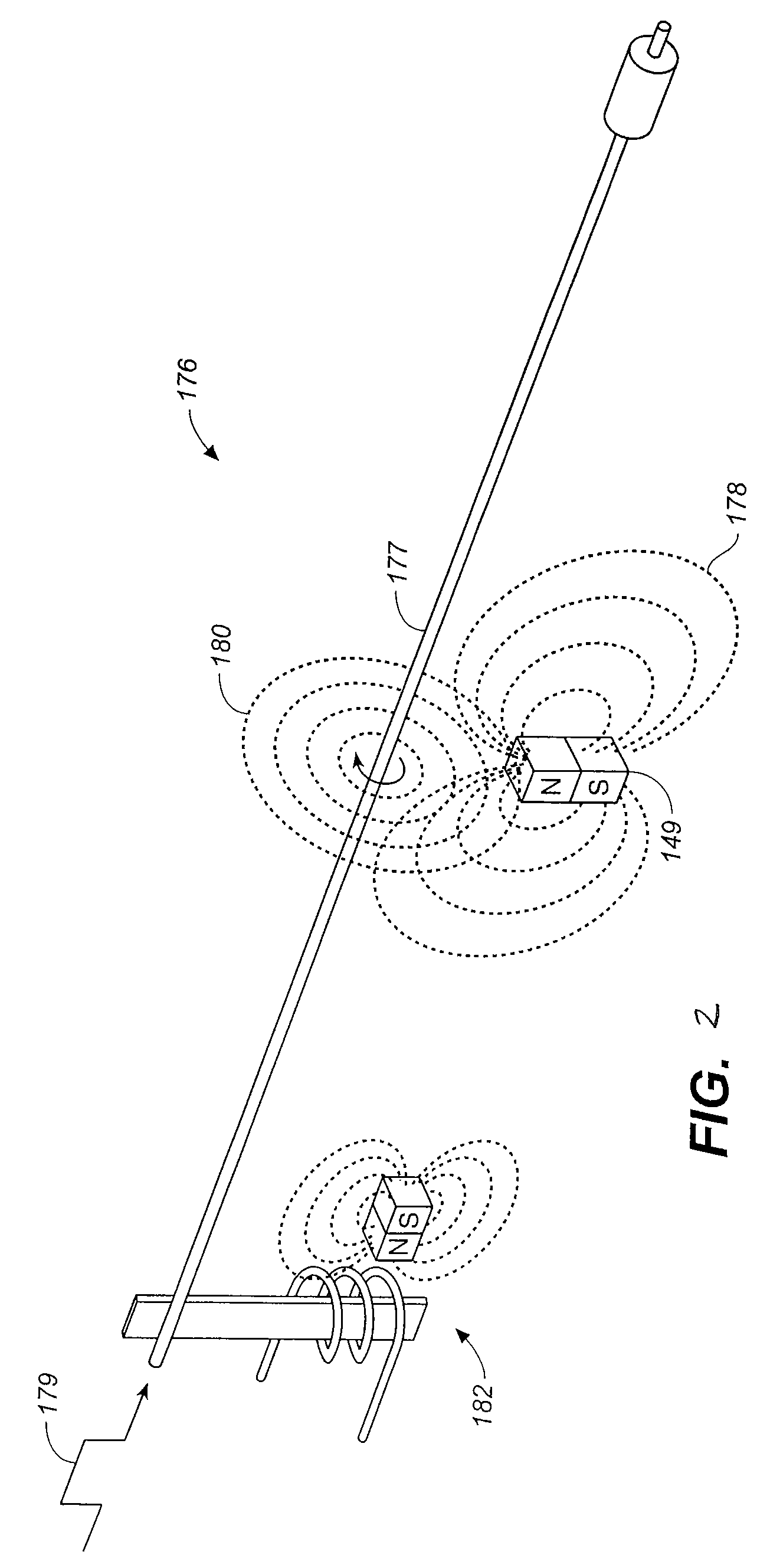

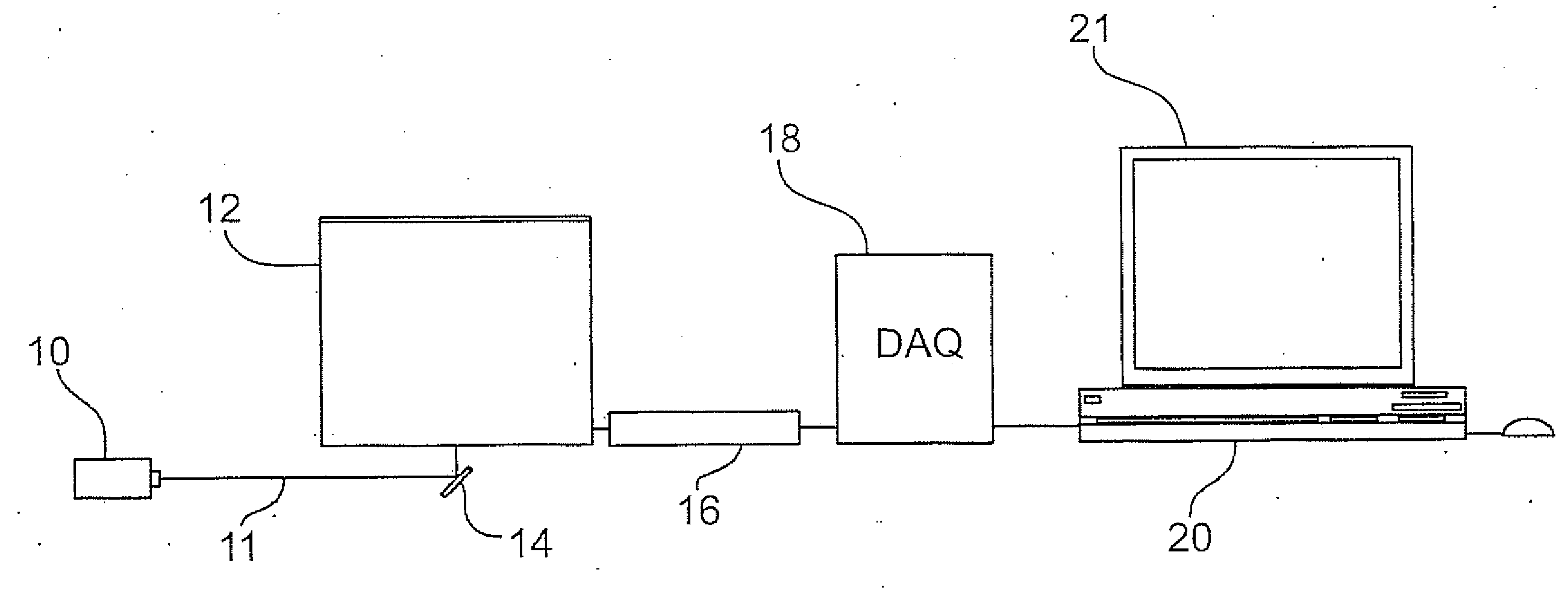

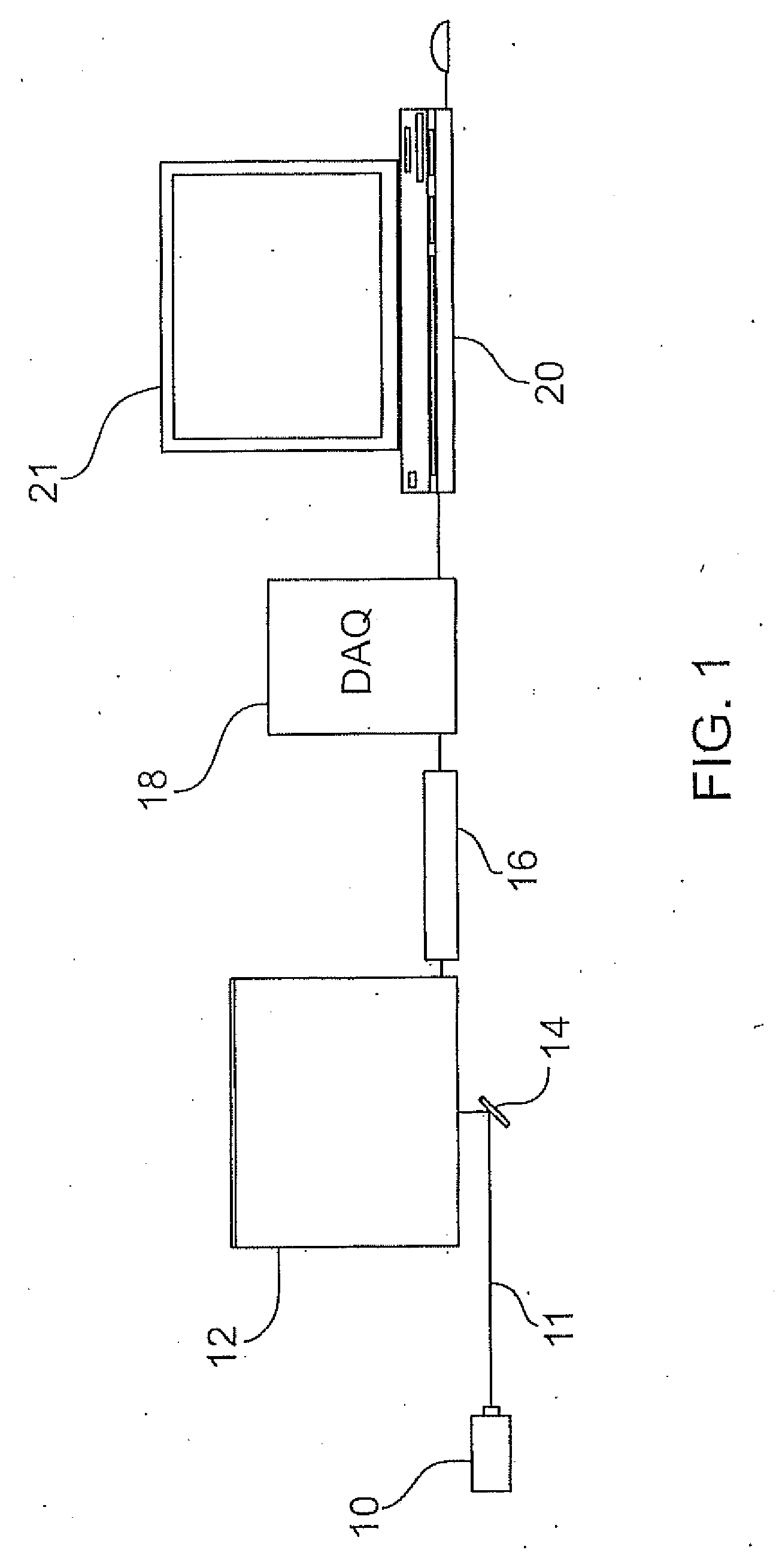

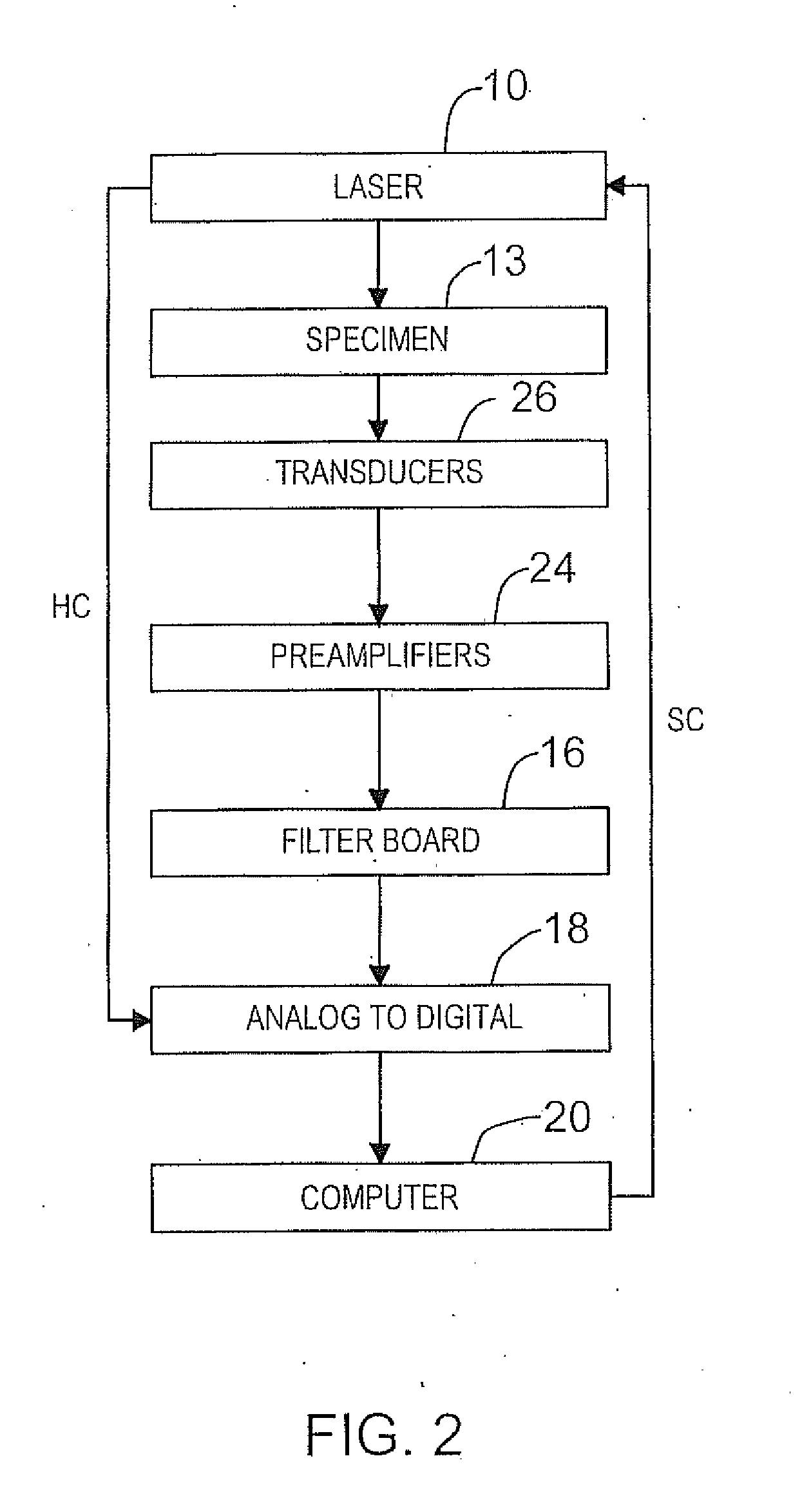

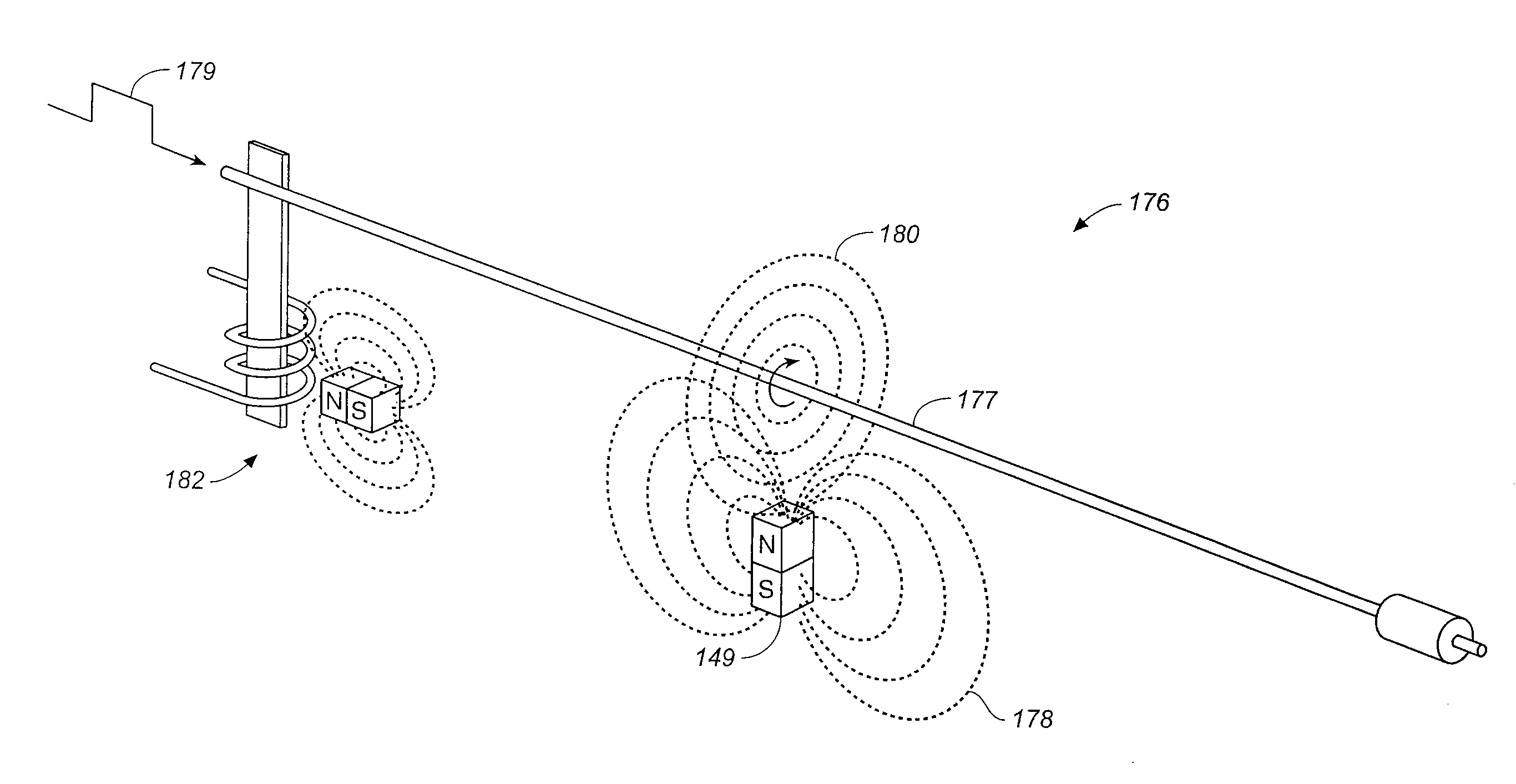

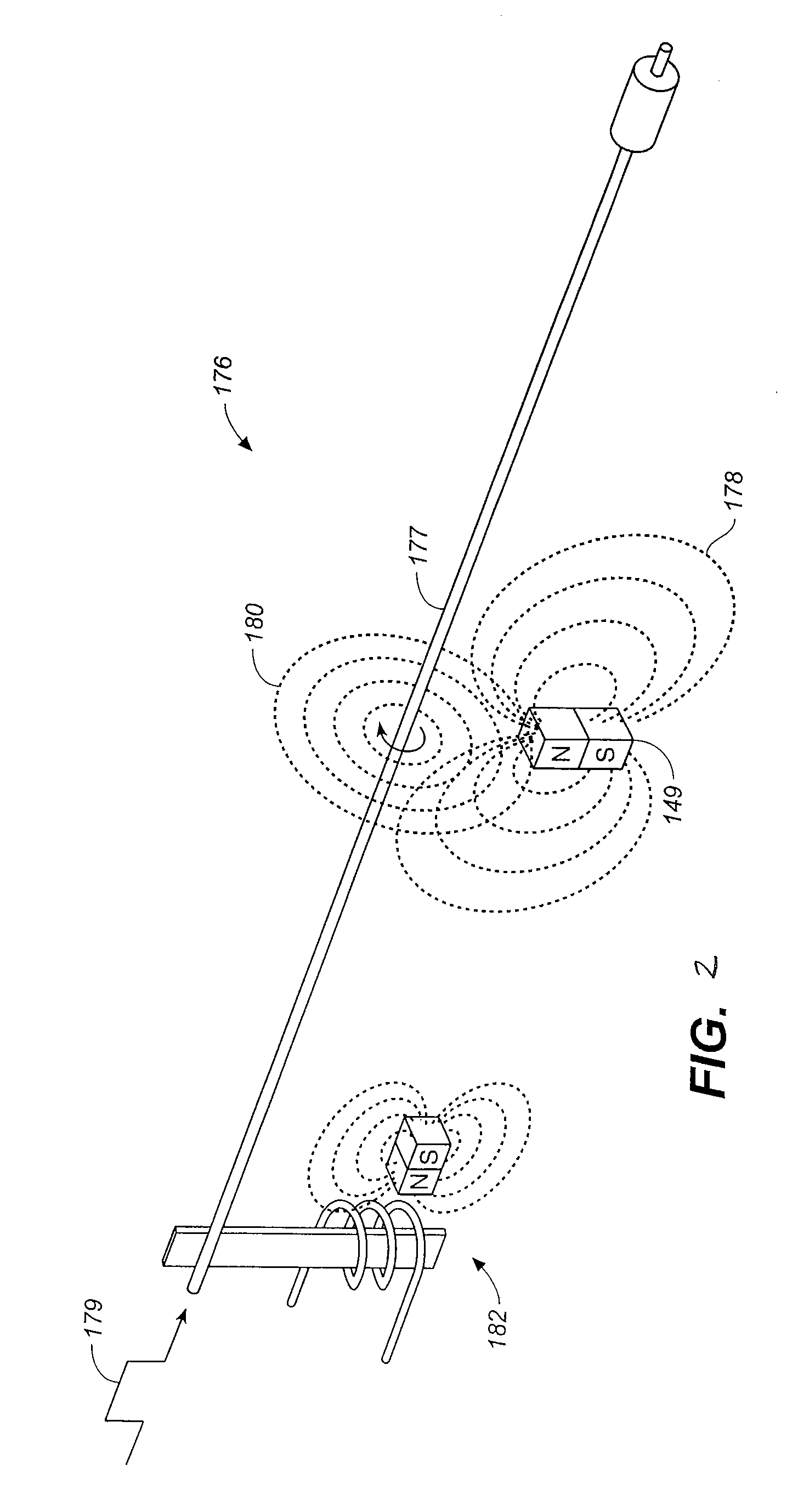

Three-dimensional photoacoustic imager and methods for calibrating an imager

InactiveUS20100249570A1Illuminating subjectUltrasonic/sonic/infrasonic diagnosticsMaterial analysis using sonic/ultrasonic/infrasonic wavesData acquisitionReconstruction algorithm

A photoacoustic imaging apparatus is provided for medical or other imaging applications and also a method for calibrating this apparatus. The apparatus employs a sparse array of transducer elements and a reconstruction algorithm. Spatial calibration maps of the sparse array are used to optimize the reconstruction algorithm. The apparatus includes a laser producing a pulsed laser beam to illuminate a subject for imaging and generate photoacoustic waves. The transducers are fixedly mounted on a holder so as to form the sparse array. A photoacoustic (PA) waves are received by each transducer. The resultant analog signals from each transducer are amplified, filtered, and converted to digital signals in parallel by a data acquisition system which is operatively connected to a computer. The computer receives the digital signals and processes the digital signals by the algorithm based on iterative forward projection and back-projection in order to provide the image.

Owner:MULTI MAGNETICS

Malfunction detection in infusion pumps

The present application is directed to systems and methods associated with infusion pumps, which can optionally utilize an electrokinetic driving mechanism. Infusion pumps, including electrokinetically-driven pumps, are discussed, along with schemes for controlling their operation. As well, systems and methods of detecting malfunctions in infusion pumps are discussed. Any number of malfunctions can be detected including the presence of occlusions and / or leaks. In some instances, a measurement associated with some aspect of electrokinetic phenomena (e.g., an electrode measurement such as voltage or current) is compared with one or more sample values, the comparison allowing an indication of pump malfunction to be determined. A variety of such measurements and comparison techniques are discussed in the present disclosure.

Owner:LIFESCAN IP HLDG LLC

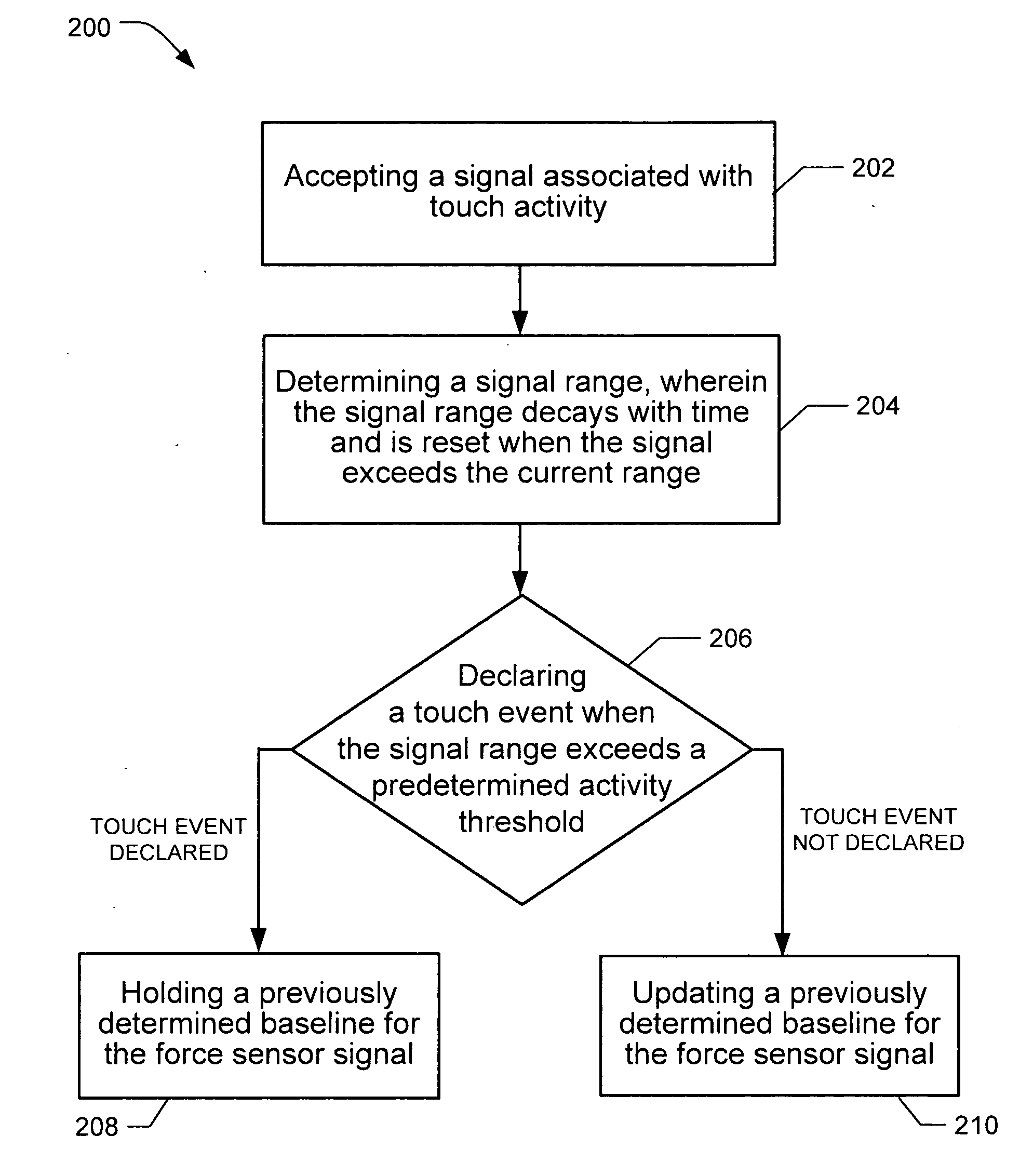

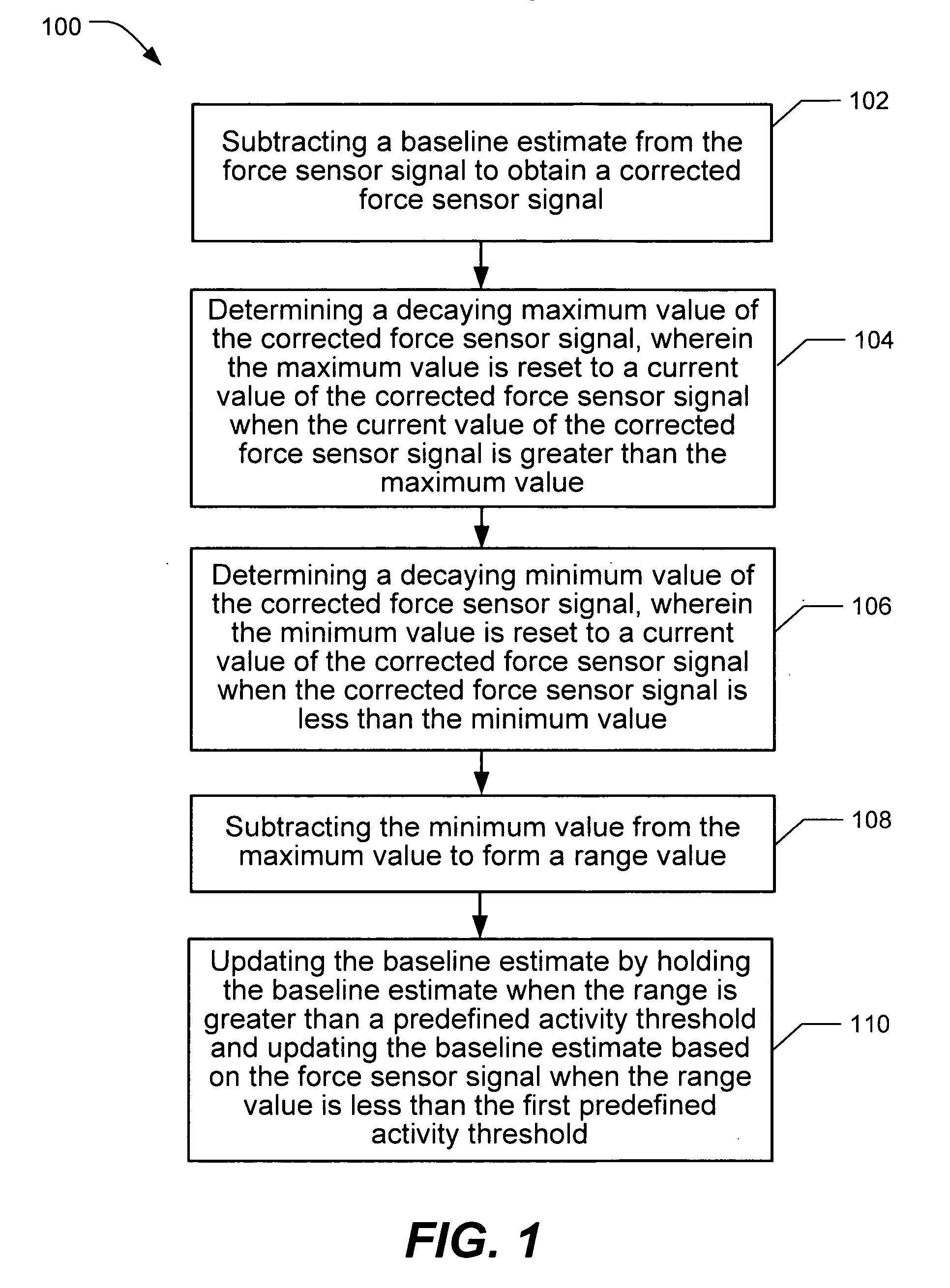

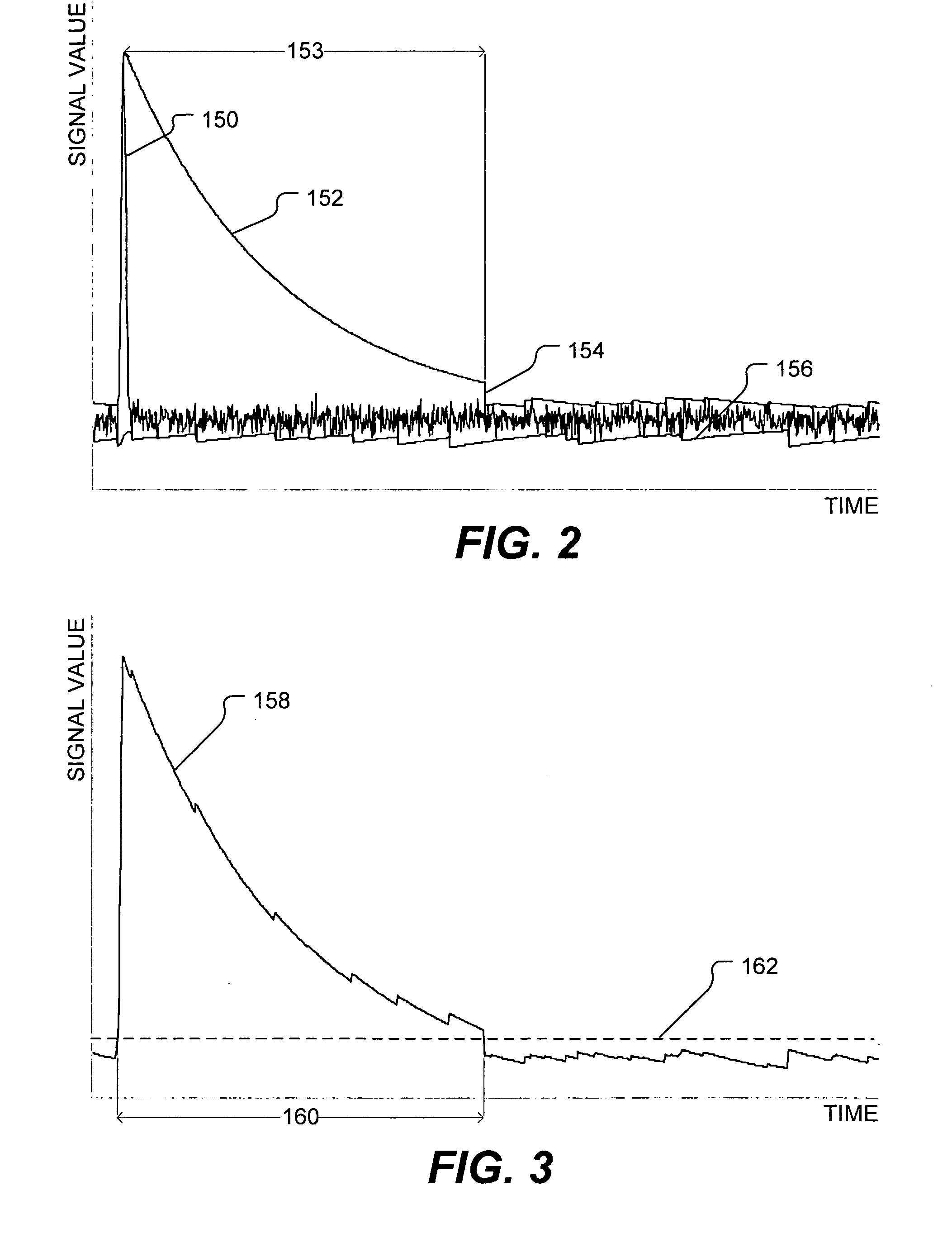

Sensor baseline compensation in a force-based touch device

InactiveUS20060293864A1Improve accuracyTesting/calibration apparatusSpeed measurement using gyroscopic effectsEngineeringControl theory

Disclosed is method and device for compensating a force sensor signal for baseline error in a force-based touch screen. In one embodiment, baseline compensation includes determining a decaying maximum value and a decaying minimum value of the force sensor signal, and subtracting these values to obtain a range value. When the range value is less than a predetermined activity threshold, updating of the baseline is disabled. The decaying maximum value and decaying minimum value are reset to the current value of the force sensor signal when exceeded by the current value of the force sensor signal.

Owner:QSI CORPORATION

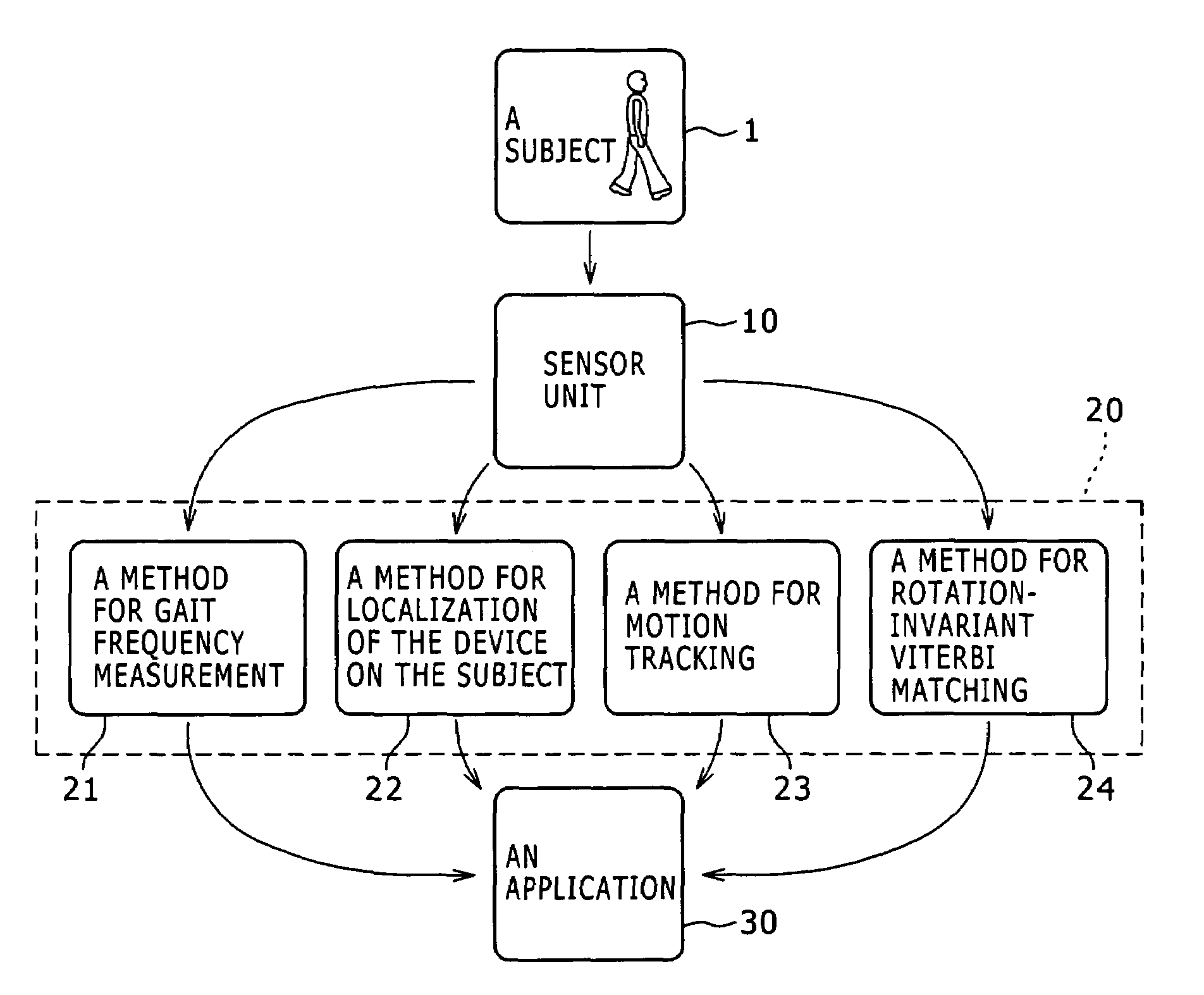

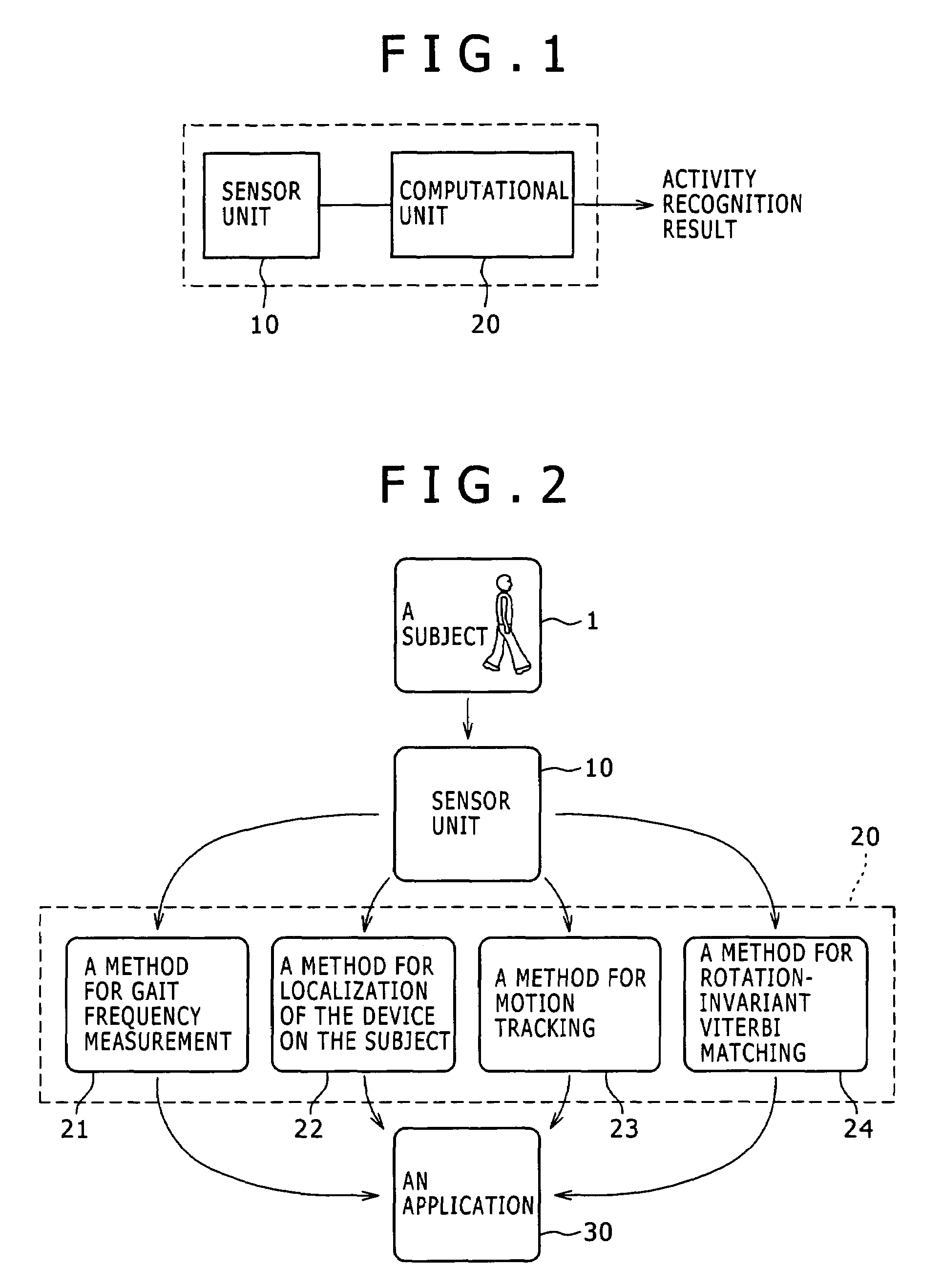

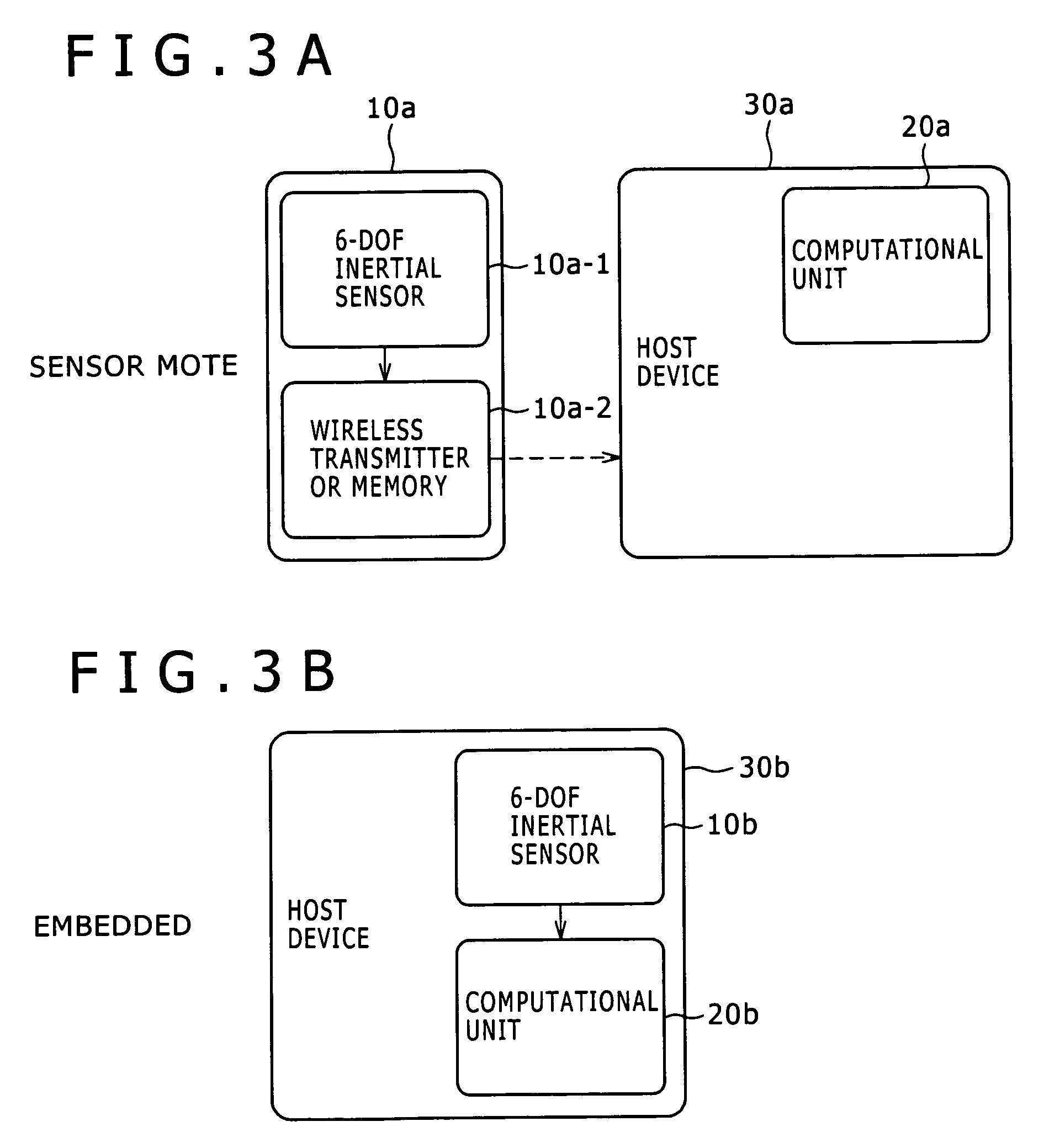

Activity recognition apparatus, method and program

ActiveUS7421369B2Flexibility of implementationAvoid less flexibilityVehicle testingTesting/calibration apparatusLinear motionComputer science

There is provided an activity recognition apparatus for detecting an activity of a subject. The apparatus includes: a sensor unit including a plurality of linear motion sensors configured to detect linear motions and a plurality of rotational motion sensors, the linear motions being orthogonal to each other, the rotational motions being orthogonal to each other; and a computational unit configured to receive and process signals from the sensors included in the sensor unit so as to detect an activity of the subject. The sensor unit is directly or indirectly supported by the subject with an arbitrary orientation with respect to the subject. The computational unit performs a calculation that uses the signals from both linear motion sensors and rotational motion sensors to determine the activity of the subject independent of the orientation of the sensor unit.

Owner:SONY CORP

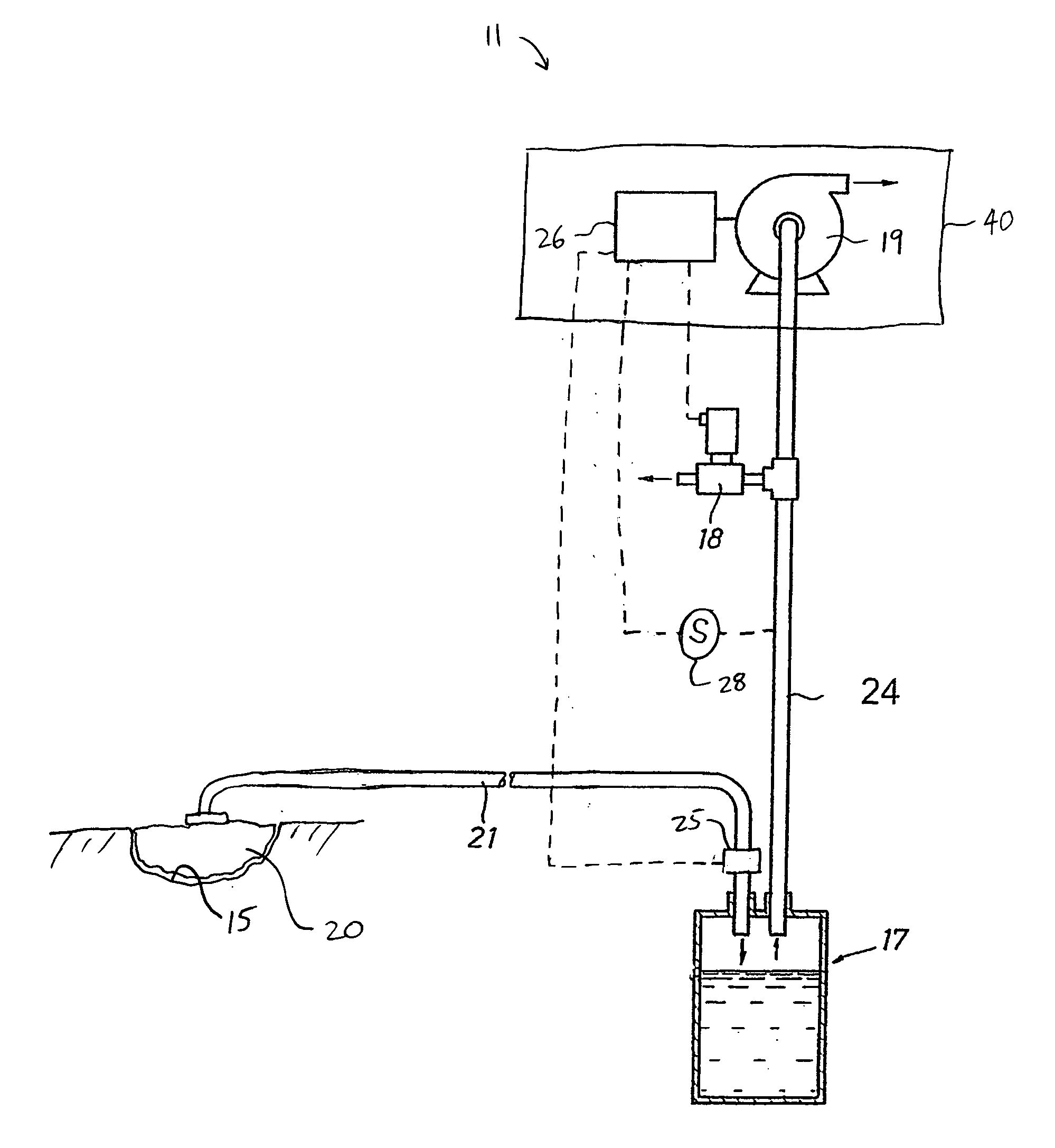

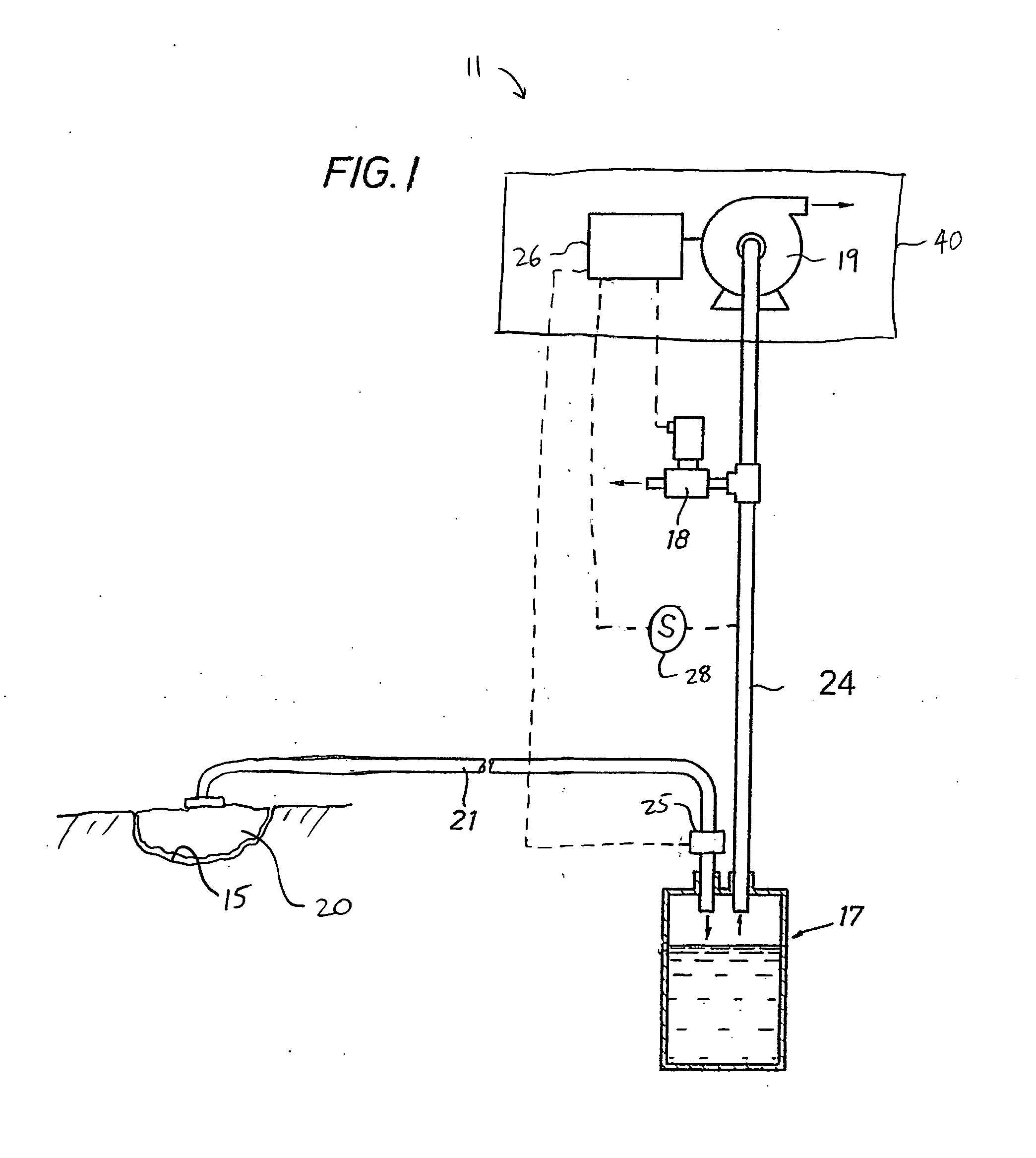

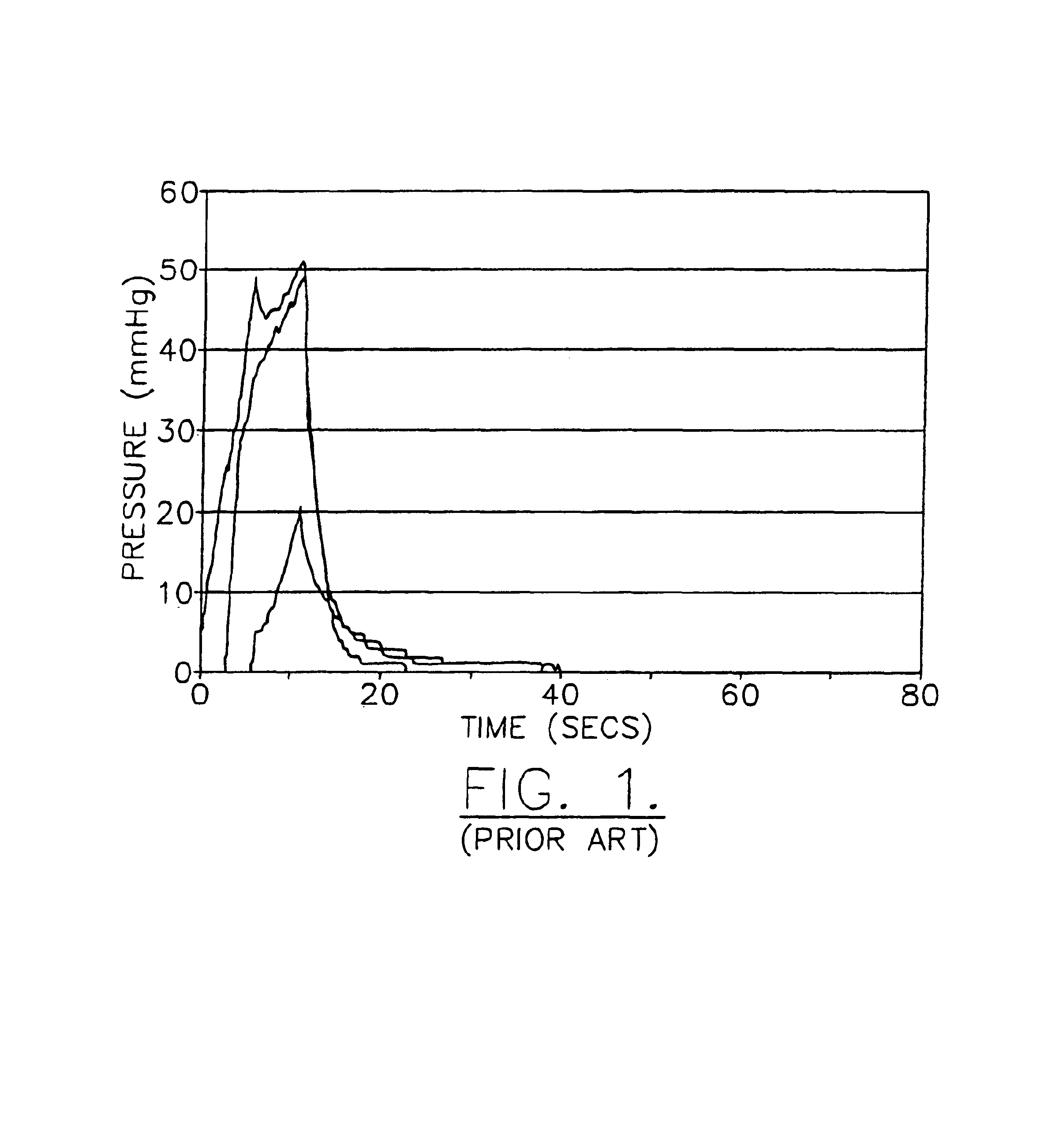

System and method for determining a fill status of a canister of fluid in a reduced pressure treatment system

ActiveUS20080071235A1Reduce pressureElectrotherapyTesting/calibration apparatusCatheterBiomedical engineering

A reduced pressure treatment system is provided that includes a canister that is fluidly connected to a tissue site and is configured to receive fluid drawn from the tissue site under the influence of a reduced pressure. A reduced pressure source provides the reduced pressure and is fluidly connected to the tissue site by a fluid communication path, which may include a source conduit, the canister, and a target conduit. A sensing device communicates with the source conduit and is configured to sense a pressure in the source conduit. A valve communicates with the source conduit and is configured to vent the reduced pressure. A processing unit communicates with the sensing device and the valve and is configured to open the valve for a selected amount of time, determine a decay of reduced pressure, and determine a fill status of the canister based on the decay of reduced pressure.

Owner:KCI LICENSING INC

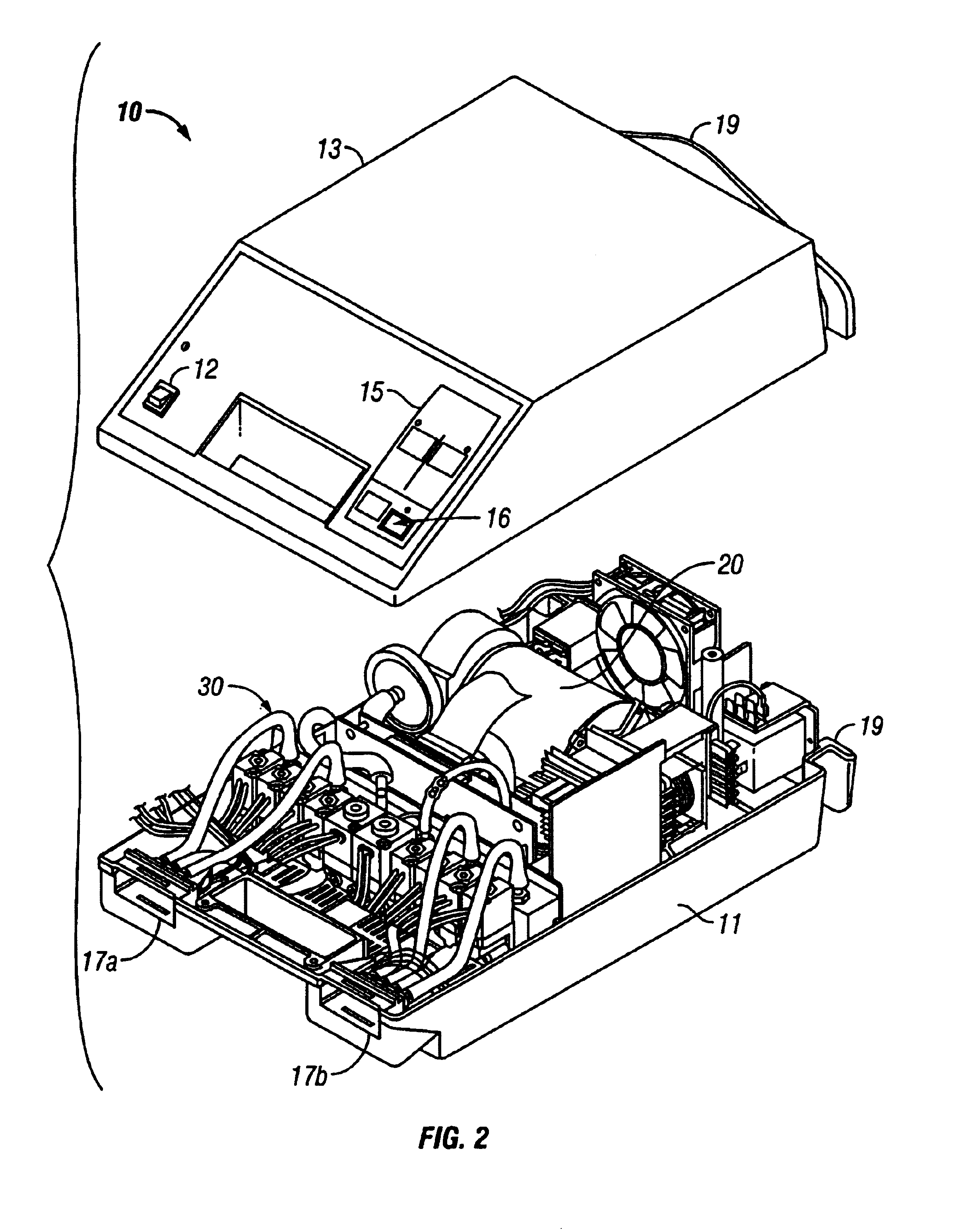

Universal connecting device that designates an operational mode

InactiveUS6988423B2Avoid it happening againPrevent escapeWave based measurement systemsTesting/calibration apparatusEngineeringOperation mode

A controller for a gradient sequential compression system is provided for inflating a plurality of inflatable chambers of one or more compression sleeves according to several different modes of operation. A mode of operation may define the number and selection of chambers to be inflated, the pressurization levels, the pressurization time, or the sequence of chamber inflation. To enable the controller to automatically perform a designated mode of operation based on the type of compression sleeve connected, a new and improved connecting device is provided. An indicator on an interface connector associates a predetermined mode of operation with the interface connector. A sensor associated with a complementary connector identifies the mode of operation associated with the interface connector. It is contemplated that the universal connecting device can be used for any type of system, not just controllers for a gradient sequential compression system.

Owner:HUNTLEIGH TECH LTD

Method and apparatus for calibration over time of histological and physiological biometric markers for authentication

InactiveUS7133792B2Easy CalibrationIncrease capacityTesting/calibration apparatusSpeed measurement using gyroscopic effectsData setBiometric trait

The present invention is directed toward a method for calibrating a biometric authentication device over time. The method of the present invention involves obtaining an authenticating biometric value from a biometric measurement. The biometric value is then weighted and integrated into the authentication data set or template.

Owner:HALO WEARABLES LLC

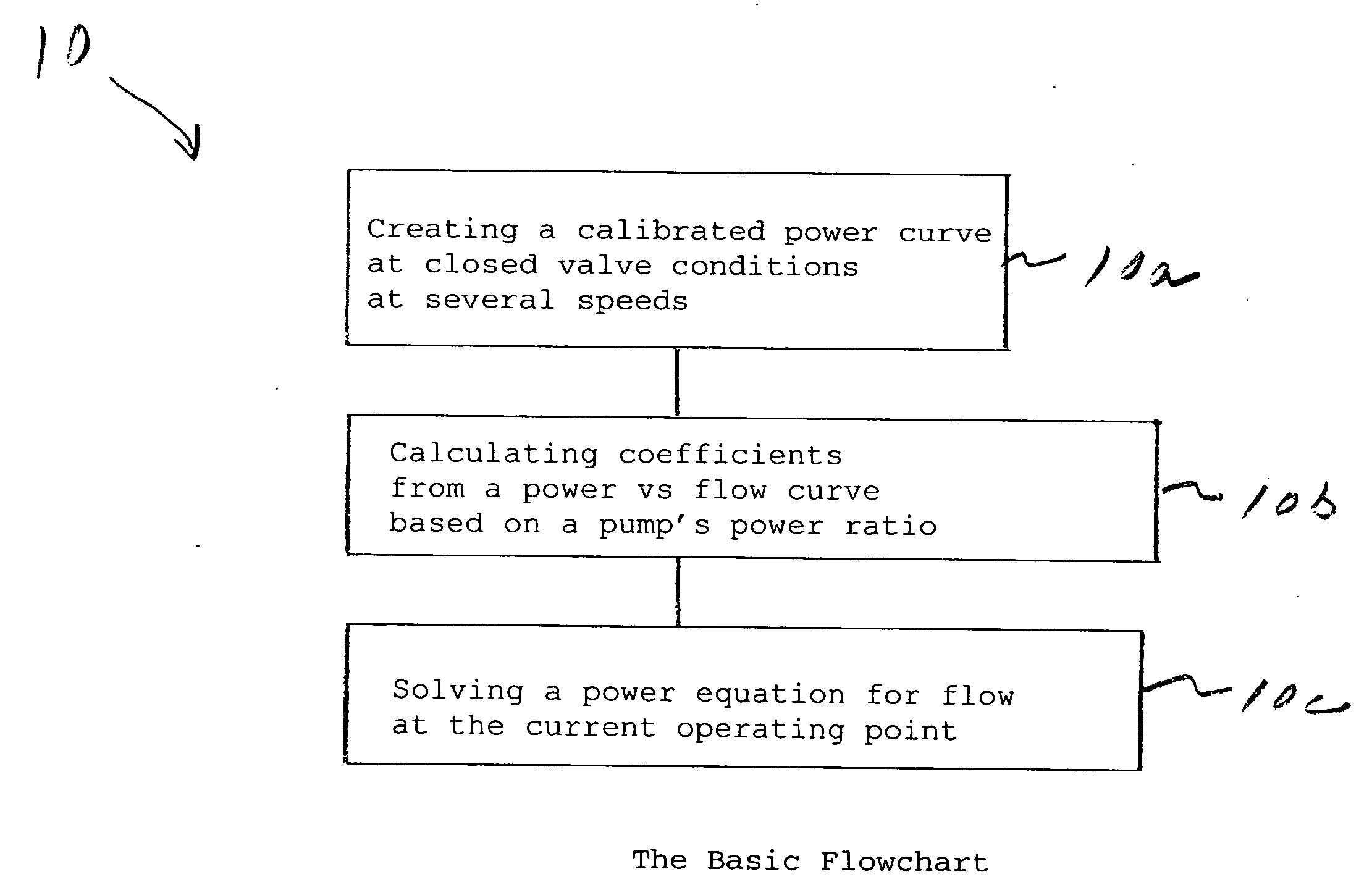

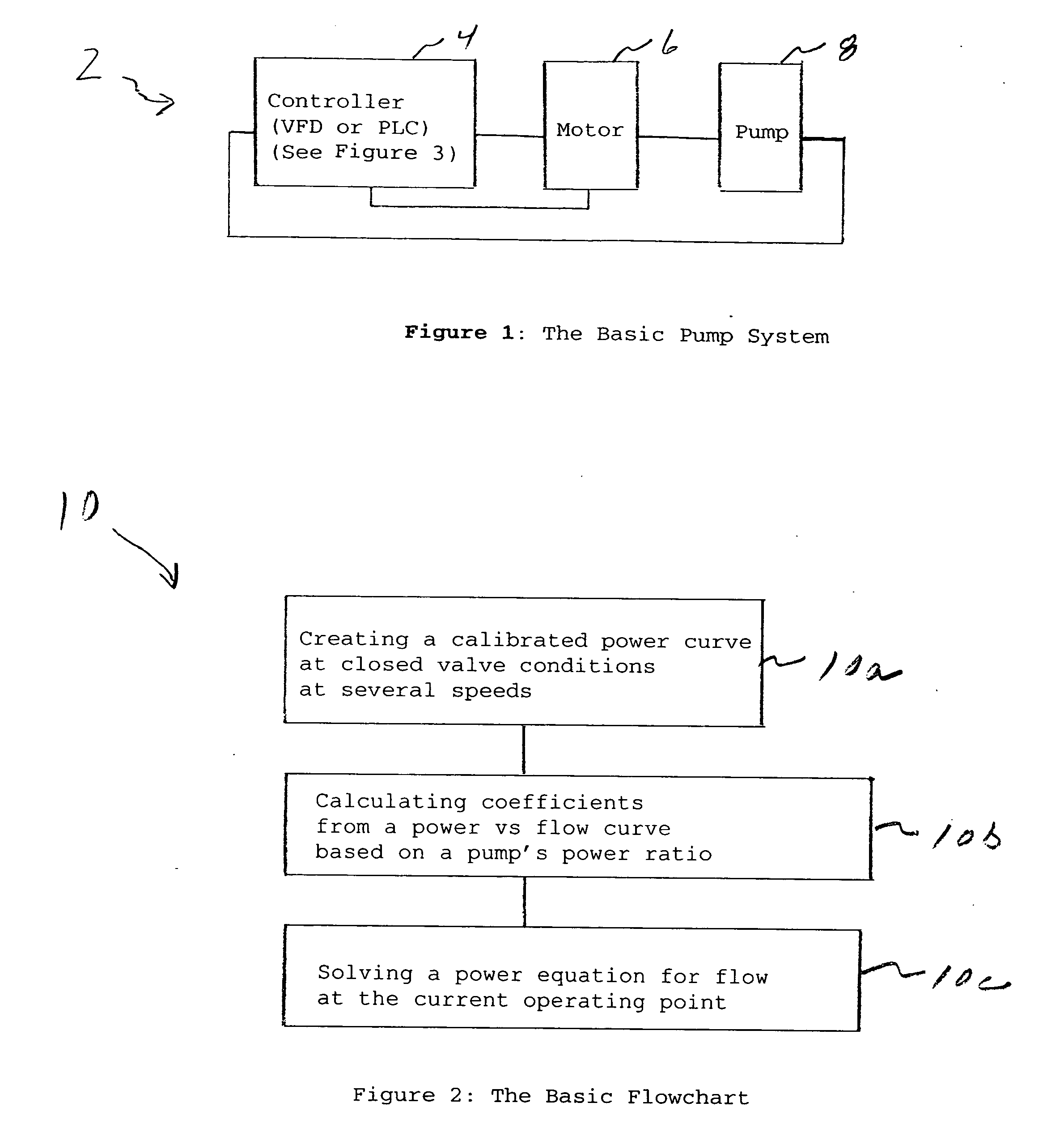

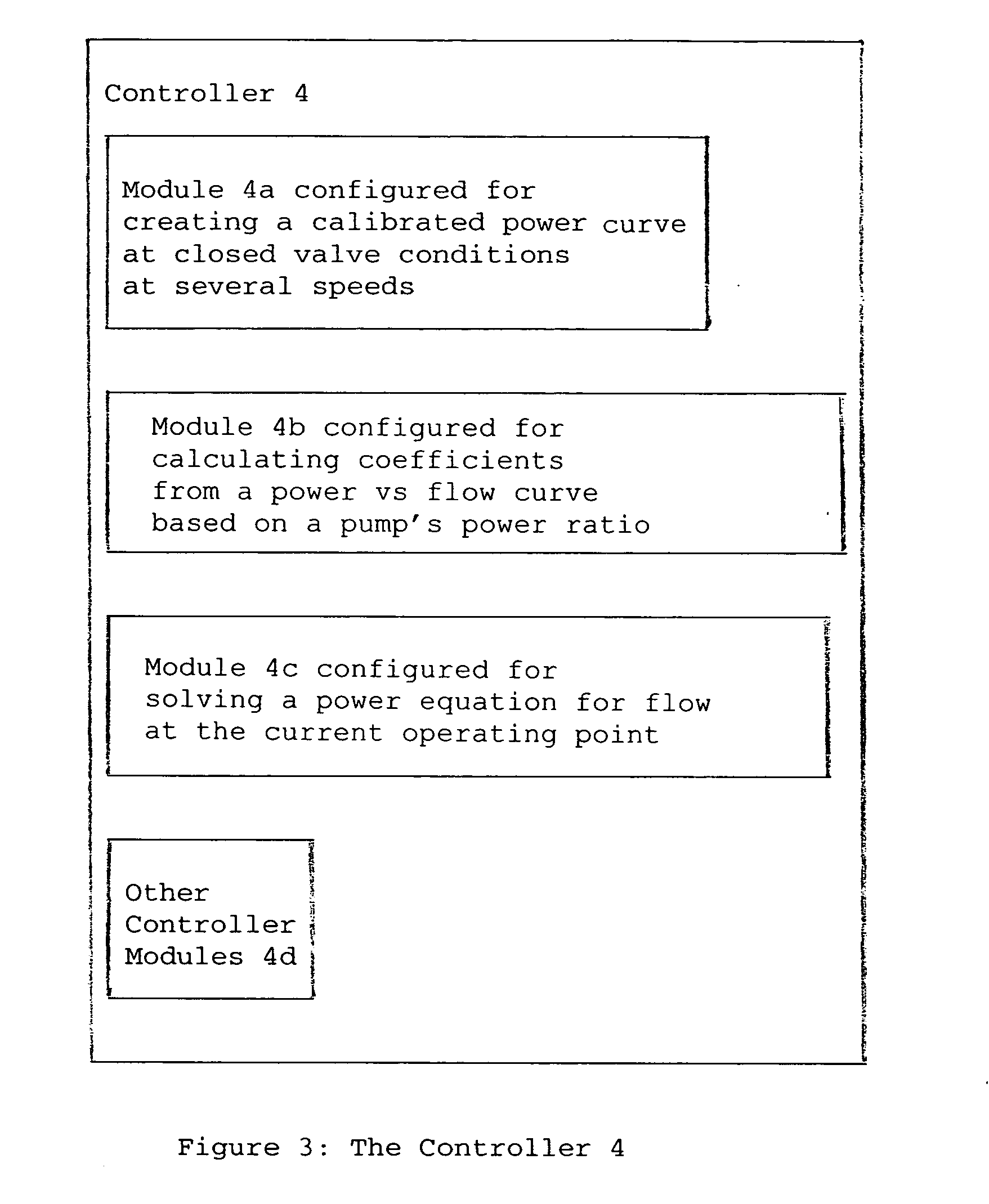

Method for determining pump flow without the use of traditional sensors

ActiveUS20070212210A1Testing/calibration apparatusAmplifier modifications to reduce noise influenceOperating pointMuller's method

A technique for determining pump flow without using traditional sensors features steps and modules for creating a calibrated power curve at closed valve conditions at several speeds; calculating coefficients from a normalized power curve based on a pump's power ratio; and solving a polynomial power equation for flow at the current operating point. The calibrated power curve may be created by increasing the speed of the pump from a minimum speed to a maximum speed and operating the pump with a closed discharge valve. This data is used to correct published performance for shutoff power and best efficiency point power at rated speed in order to determine the pump's power ratio. It is also used to accurately determine closed valve power at the current operating speed. The pump's power ratio is determined by the equation: Pratio=Pshutoff @100% / PBEP<sub2>—< / sub2>corr. The polynomial power equation may, for example, include a 3rd order polynomial equation developed using coefficients from the normalized power versus flow curve, and corrections may be made for speed, hydraulic efficiency and specific gravity in the polynomial power equation. Complex roots may be determined to solve the 3rd order polynomial equation using either Muller's method or some other suitable method, and the calculated actual flow may be determined for a specific operating point.

Owner:ITT MFG ENTERPRISES LLC

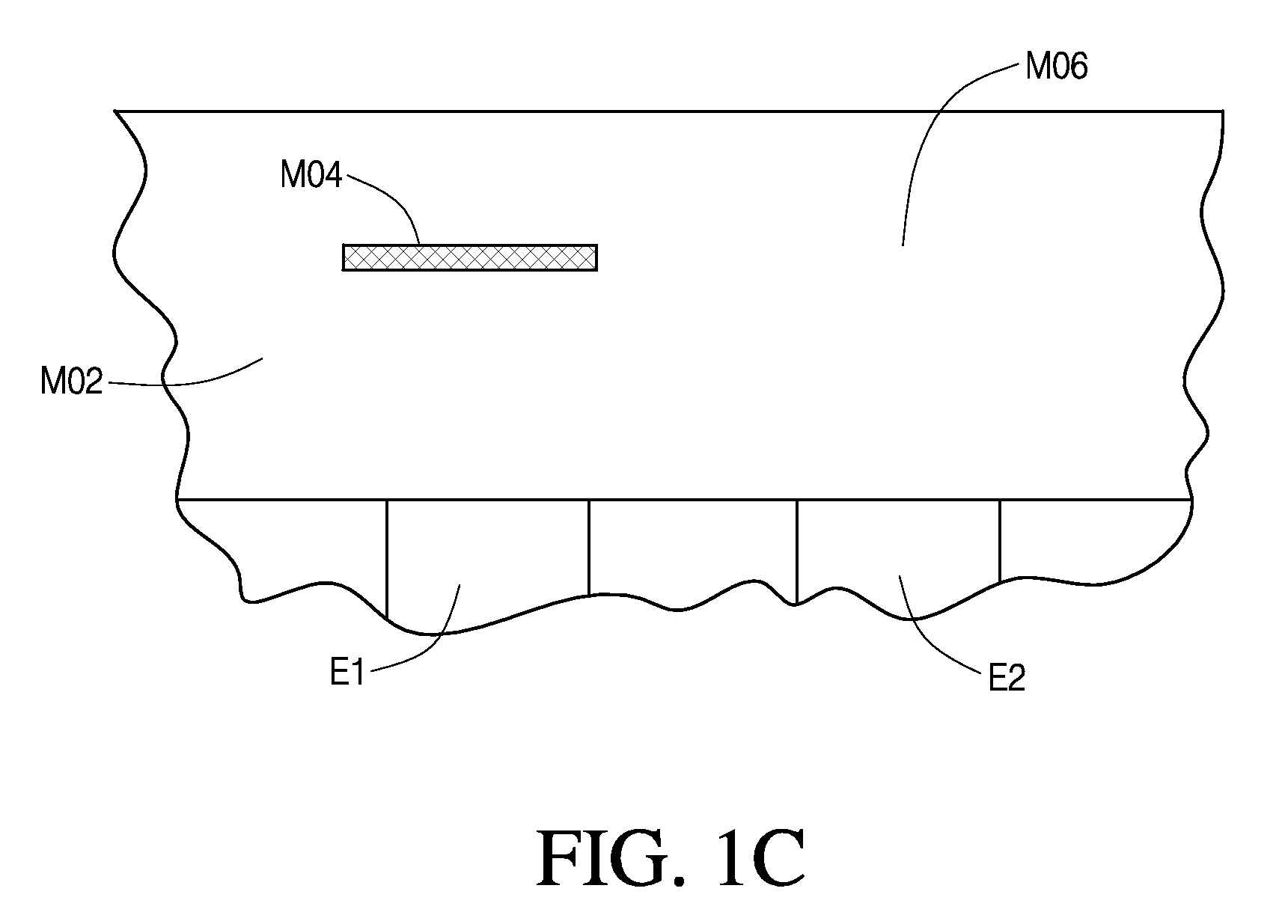

Method of reducing the effect of direct interference current in an electrochemical test strip

InactiveUS20050114062A1The result is accurateFully filledTesting/calibration apparatusMicrobiological testing/measurementPresent methodAnalyte

This invention describes a method of reducing the effect of interfering compounds in a bodily fluid when measuring an analyte using an electrochemical sensor. In particular, the present method is applicable to electrochemical sensors where the sensor includes a substrate, first and second working electrodes, and a reference electrode and either the first and second or only the second working electrode include regions which are bare of reagent. In this invention, an algorithm is described with mathematically corrects for the interference effect using the test strip embodiments of the present invention.

Owner:LIFESCAN SCOTLAND

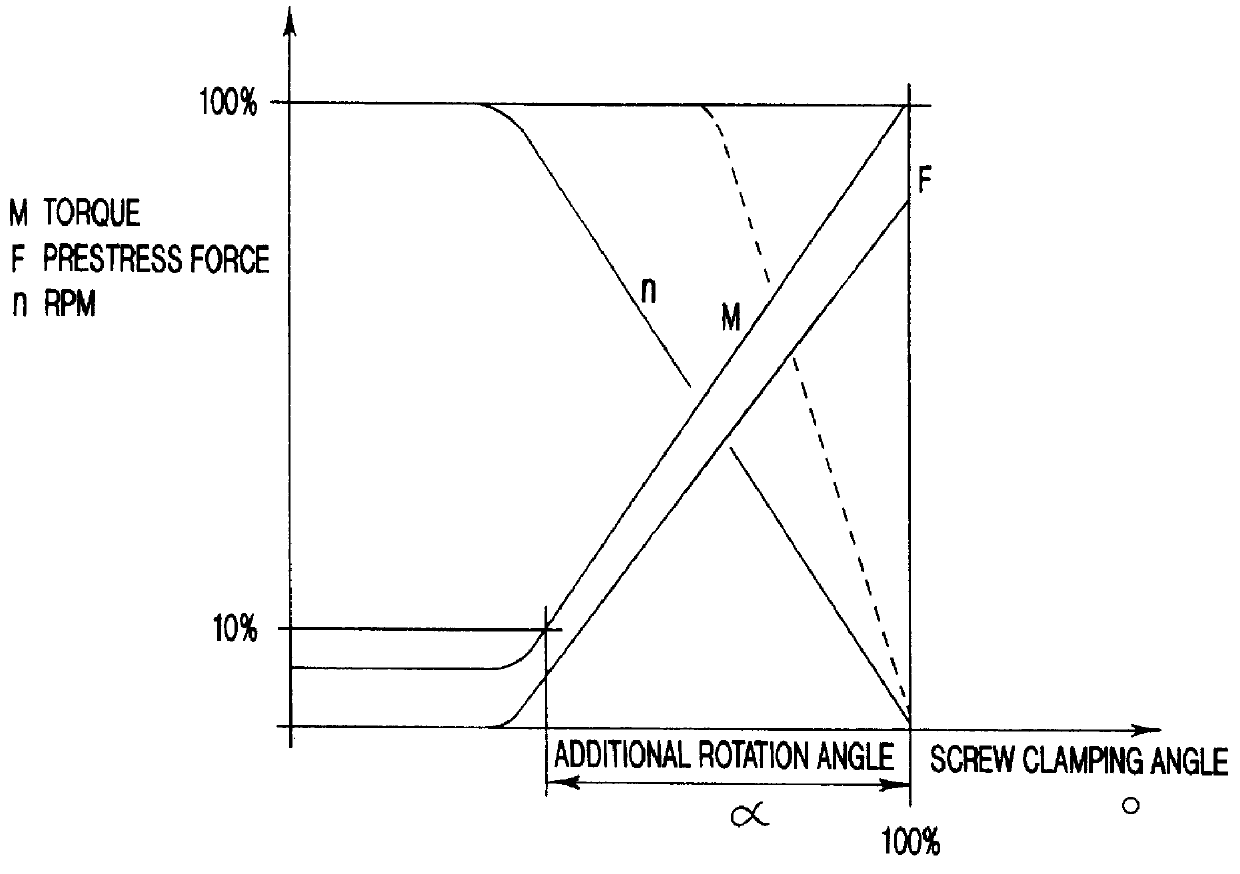

Power wrench

PCT No. PCT / EP97 / 05974 Sec. 371 Date Jul. 16, 1999 Sec. 102(e) Date Jul. 16, 1999 PCT Filed Oct. 29, 1997 PCT Pub. No. WO98 / 22263 PCT Pub. Date May 28, 1998A power screwdriver has a drive unit and an input circuit for inputting screw size, material quality, pitch, and clamping length of a screw. An evaluation circuit is provided for determining a nominal prestress force based on input screw size, material quality, and clamping length, for determining a nominal torque based on the nominal prestress force and the pitch, and for determining the screw clamping angle resulting from the nominal prestress force and the pitch. A sensing device for sensing the actual torque is provided, and a further sensing device for sensing the actual screw clamping angle is present. A control and switch-off device controls further rotation of the drive unit when the actual torque coincides with the nominal torque and switches off the drive unit when the actual screw clamping angle coincides with the nominal screw clamping angle. The nominal torque, based on which the additional rotation o f the drive unit is controlled until the nominal screw clamping angle is reached, is set to a value which is smaller than the torque corresponding to the nominal pretension force. An additional rotation angle of the drive unit, for reaching the nominal screw clamping angle corresponding to the nominal prestress force, is determined based on the difference between the nominal screw clamping angle and the adjusted screw clamping angle corresponding to the preset nominal torque and is used for switching off the drive unit.

Owner:HOHMANN JORG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com