Patents

Literature

889results about How to "Fully filled" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

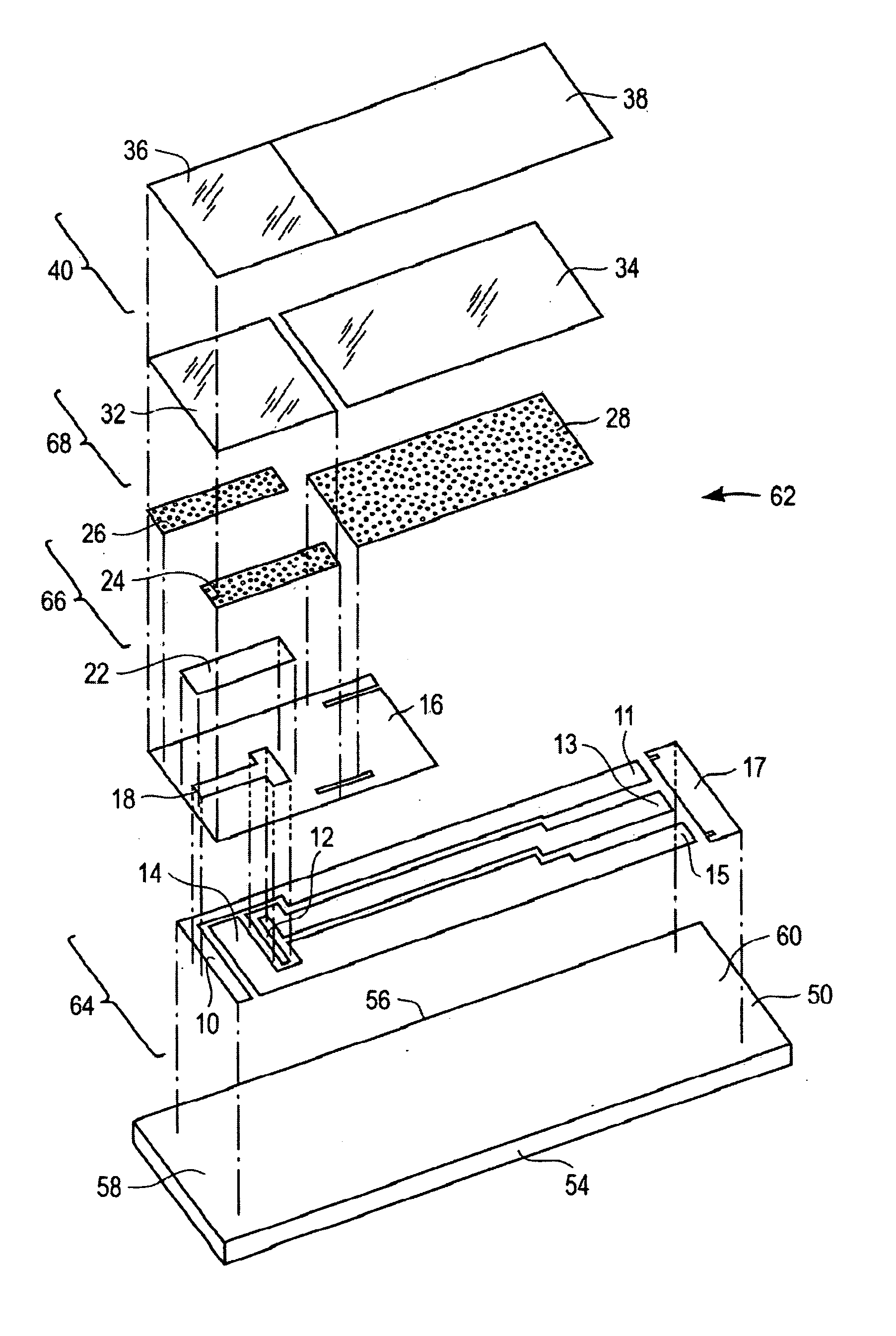

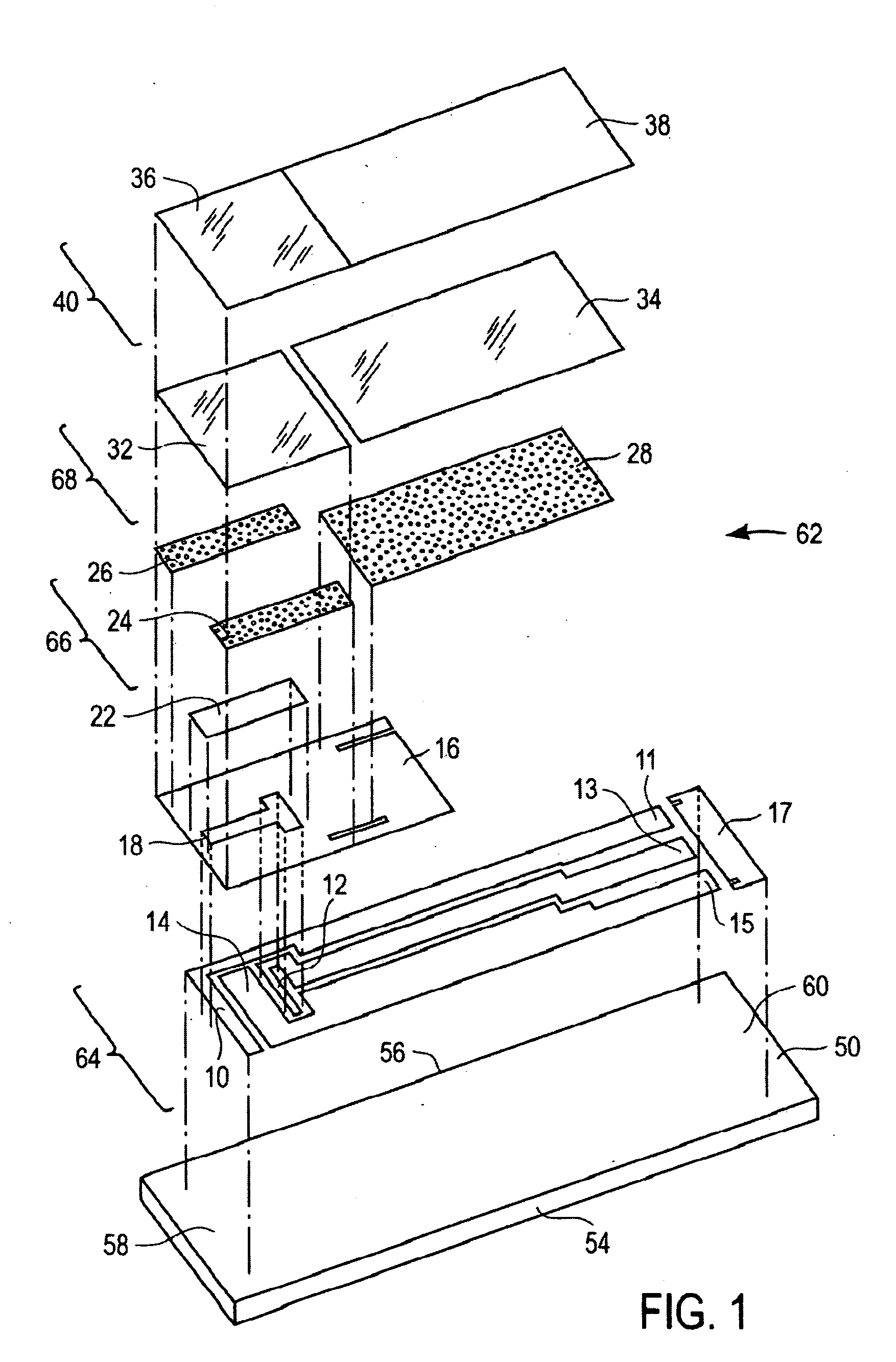

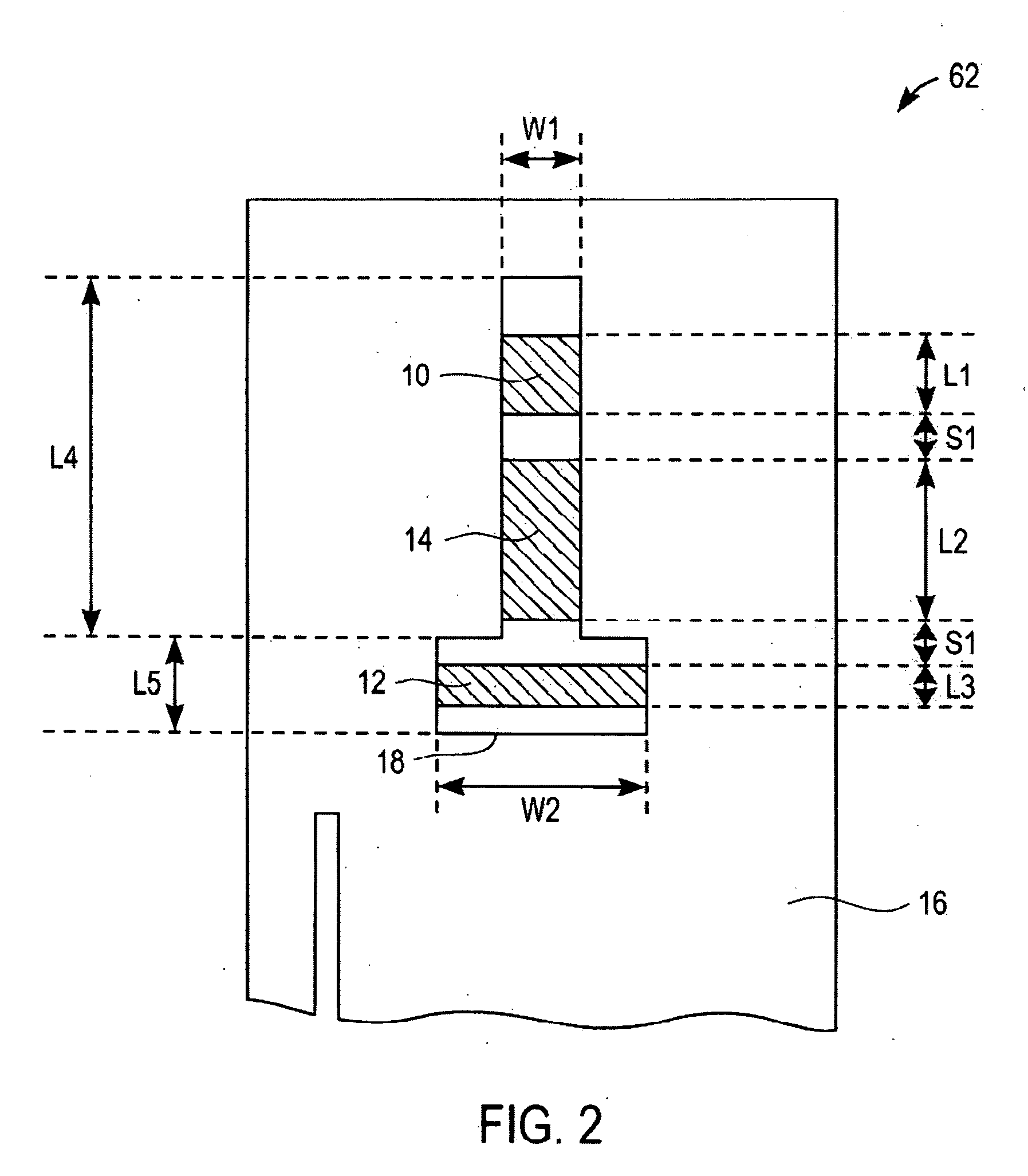

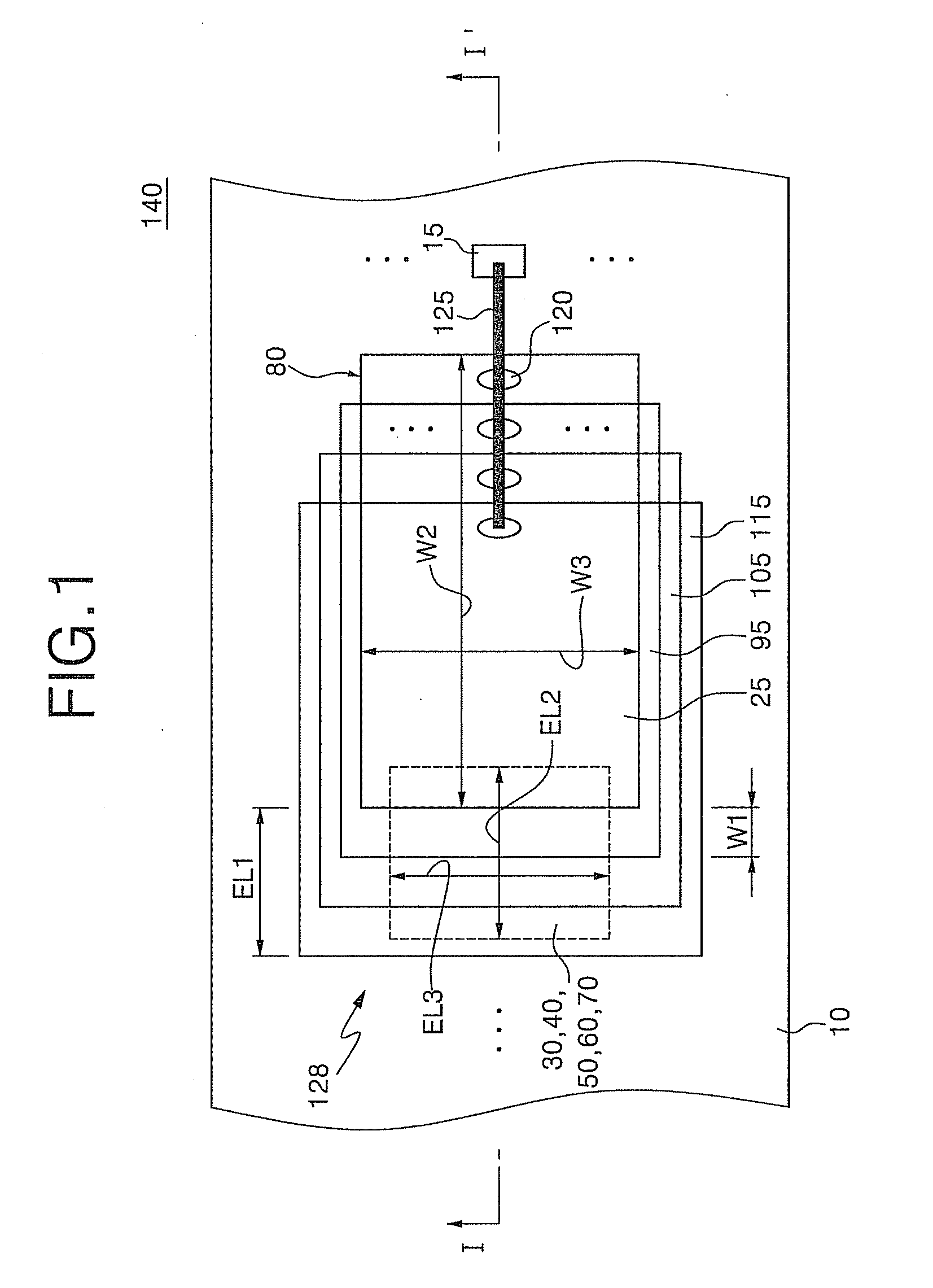

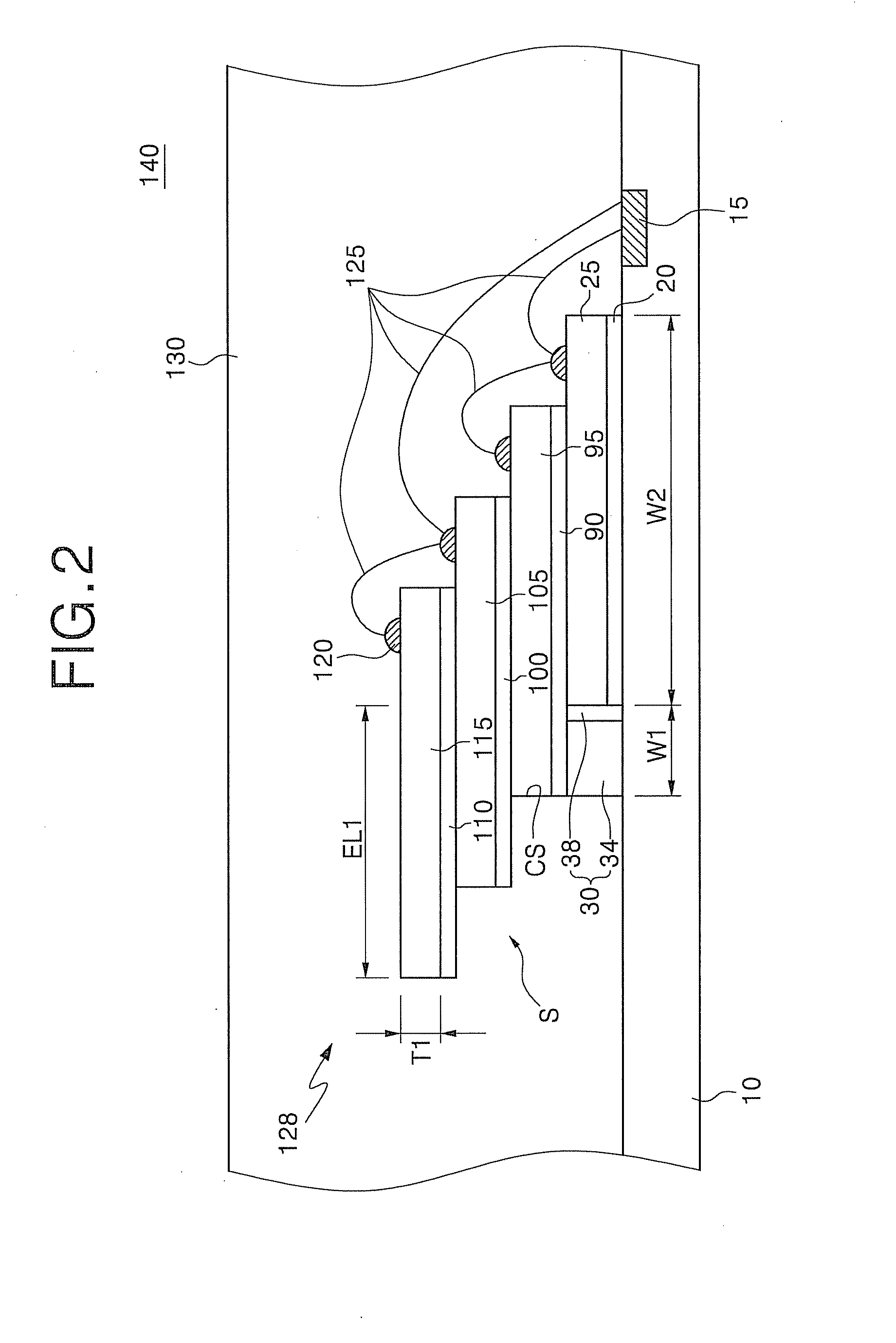

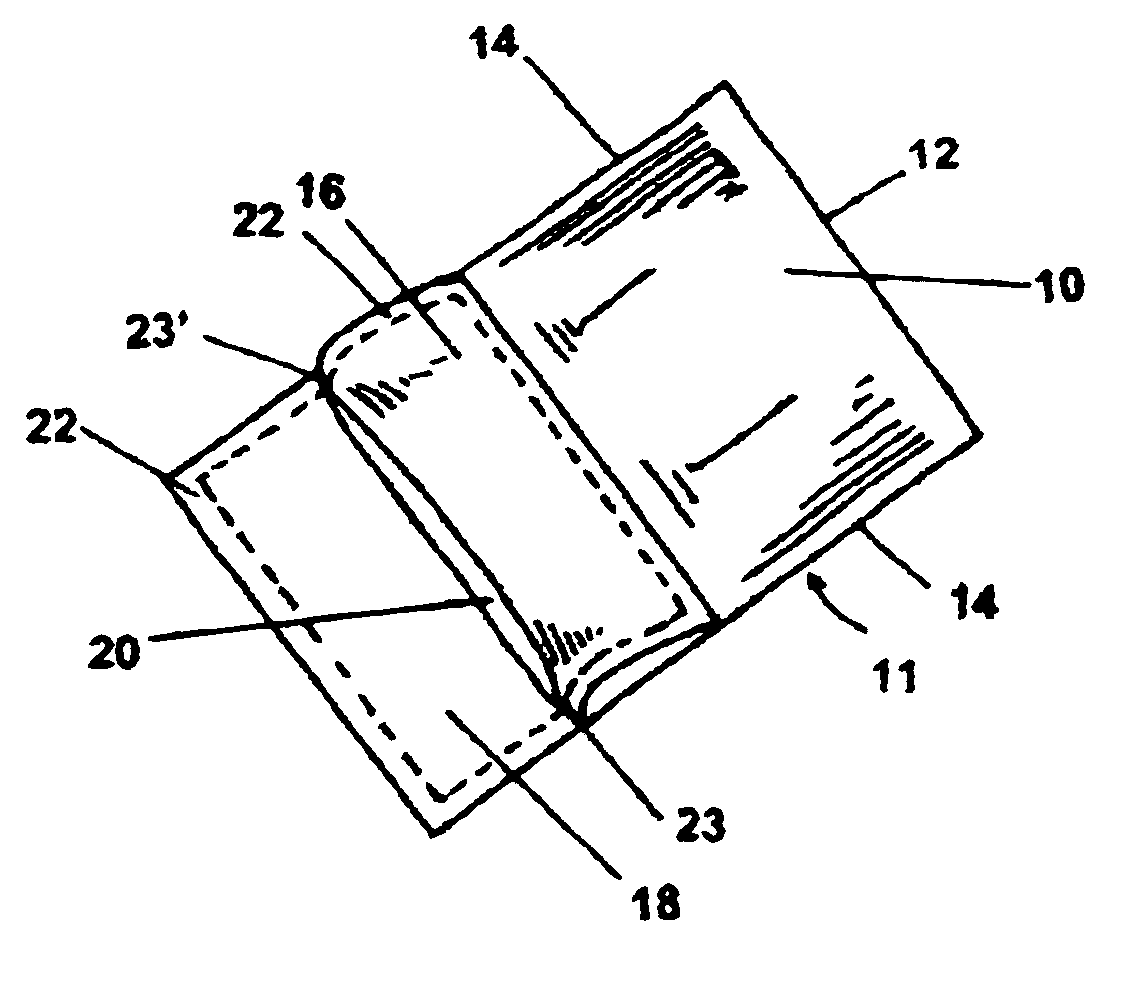

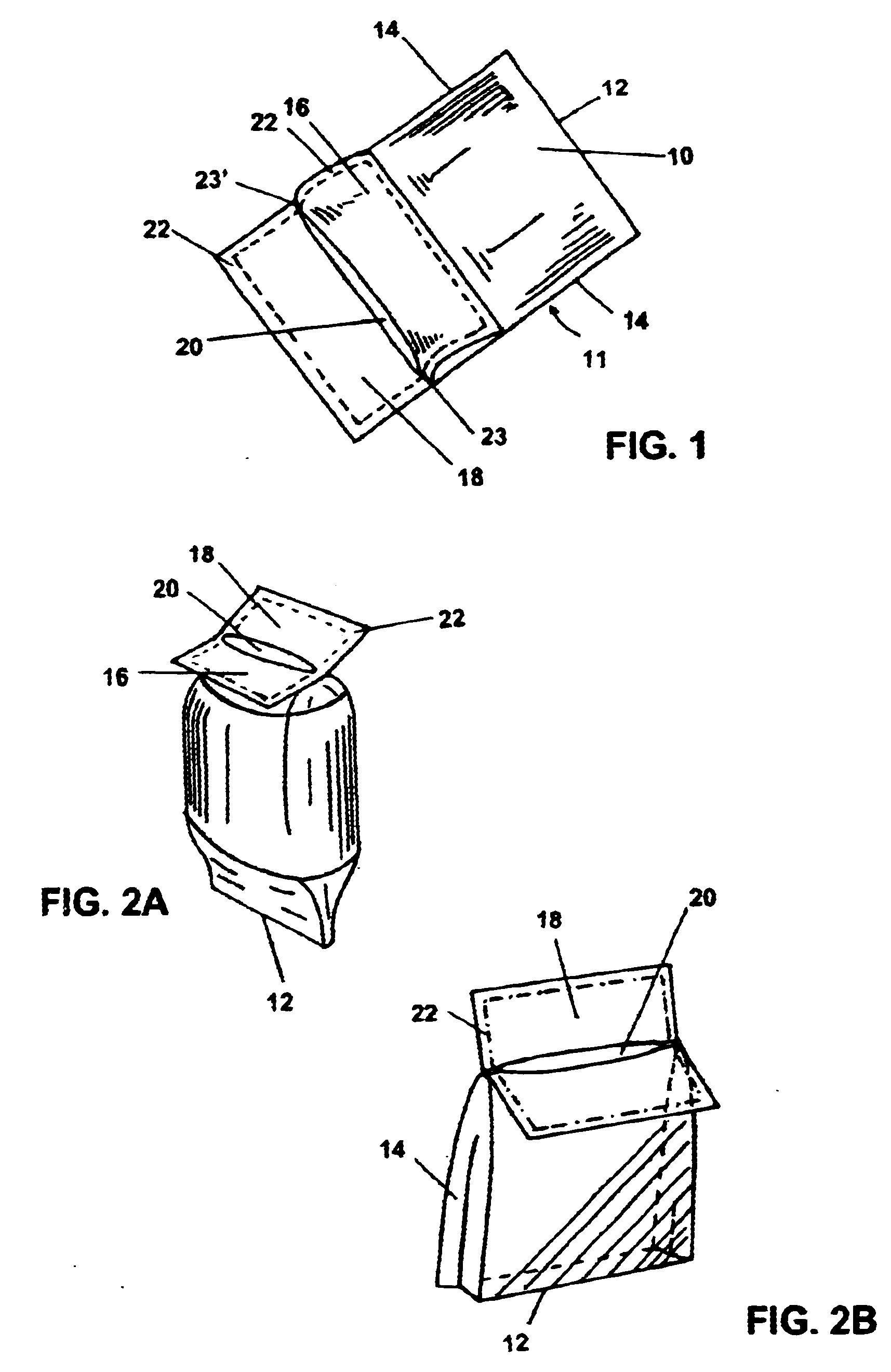

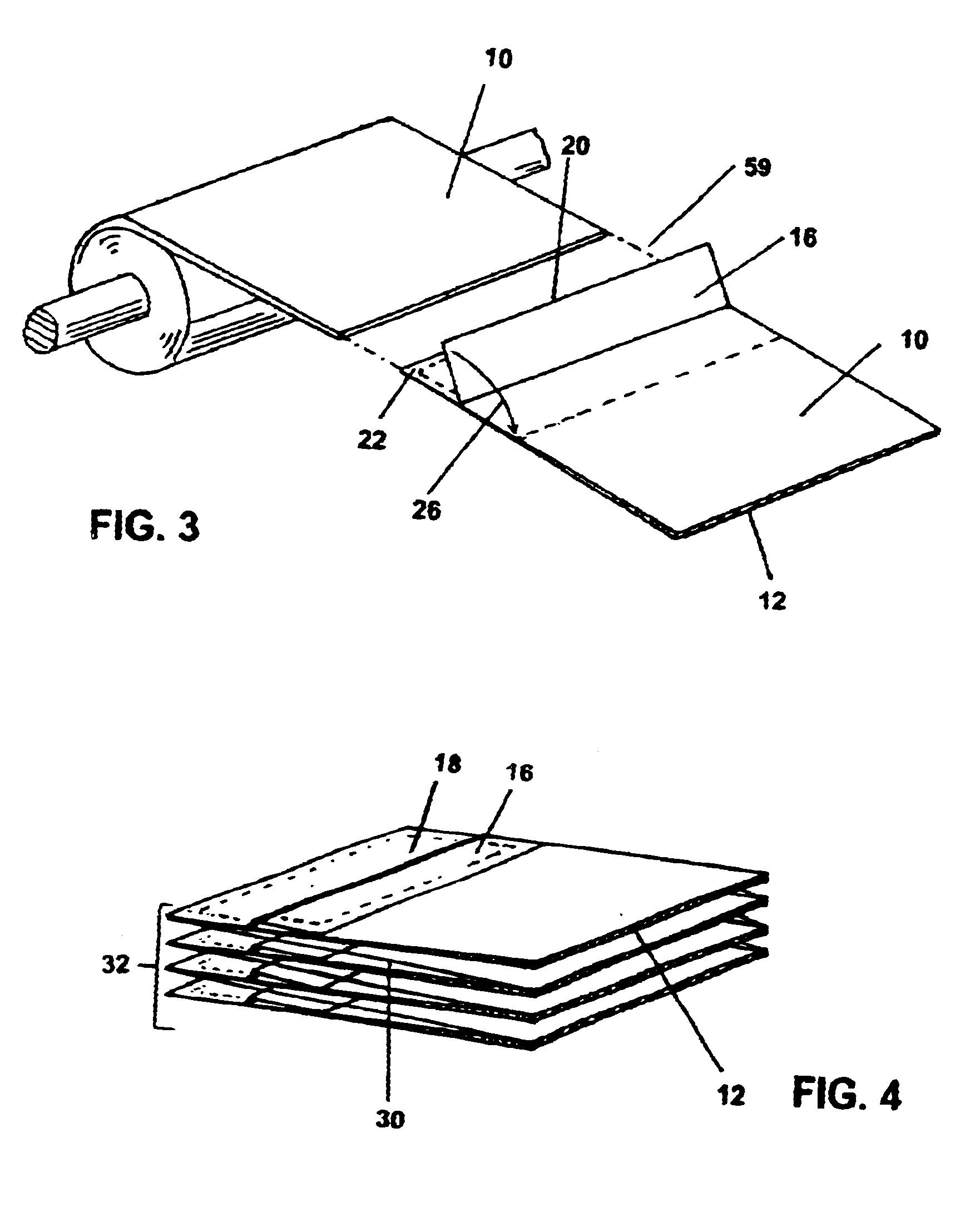

Electrochemical test strip for reducing the effect of direct interference current

InactiveUS20050133368A1The result is accurateFully filledImmobilised enzymesBioreactor/fermenter combinationsAnalyteEngineering

This invention describes an electrochemical sensor which is adapted to reduce the effects of interfering compounds in bodily fluids when measuring an analyte in such fluids using an electrochemical strip. The sensor includes a substrate, a first and second working electrodes, and a reference electrode. A reagent layer is disposed on the electrodes such that, in one embodiment it completely covers all of the first working electrode, but only partially covers the second working electrode and, in a second embodiment, it only covers a portion of the first and the second working electrode. The portion of the working electrodes not covered by the reagent layer and is used to correct for the interference effect on the analyte measurement.

Owner:LIFESCAN SCOTLAND

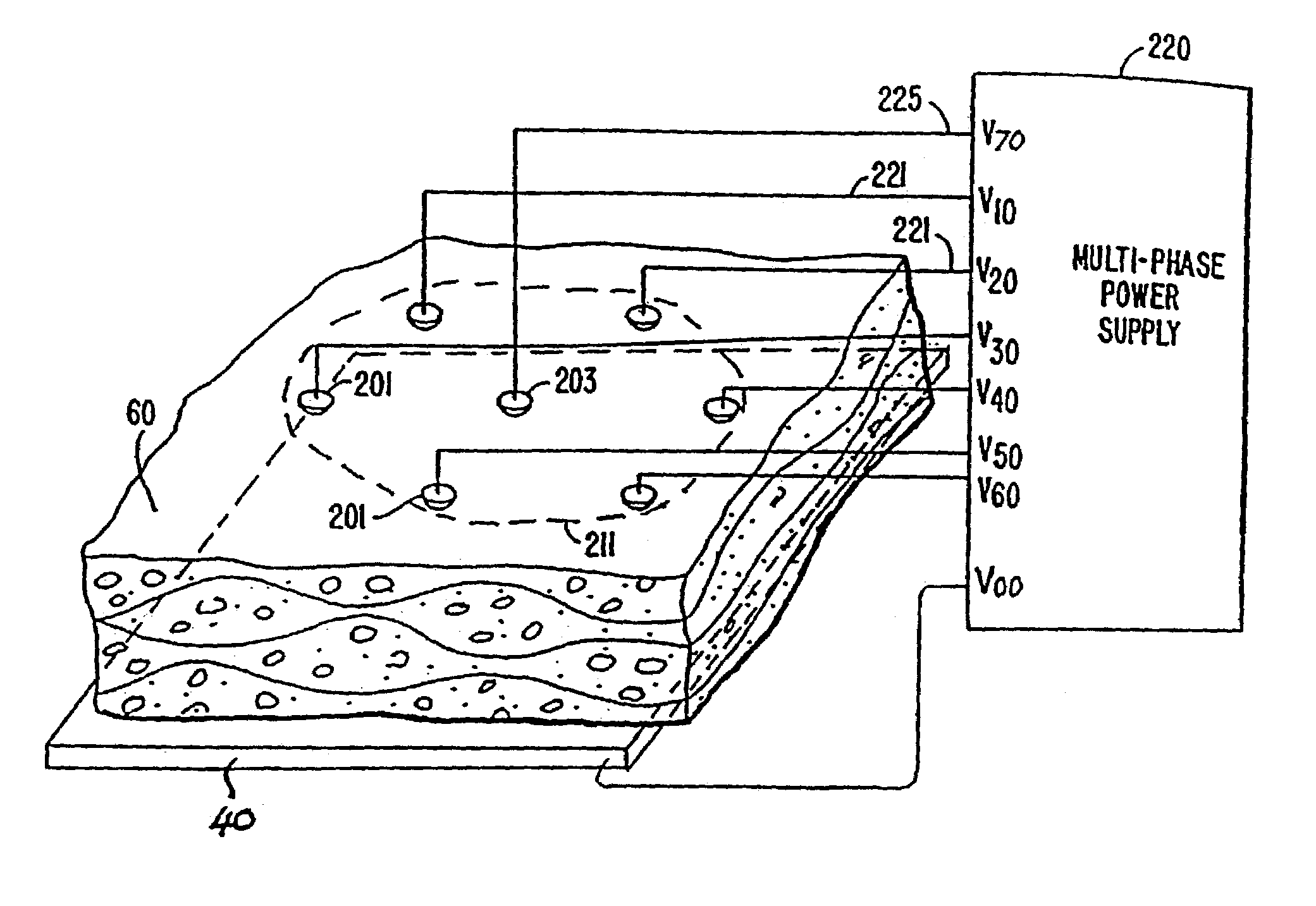

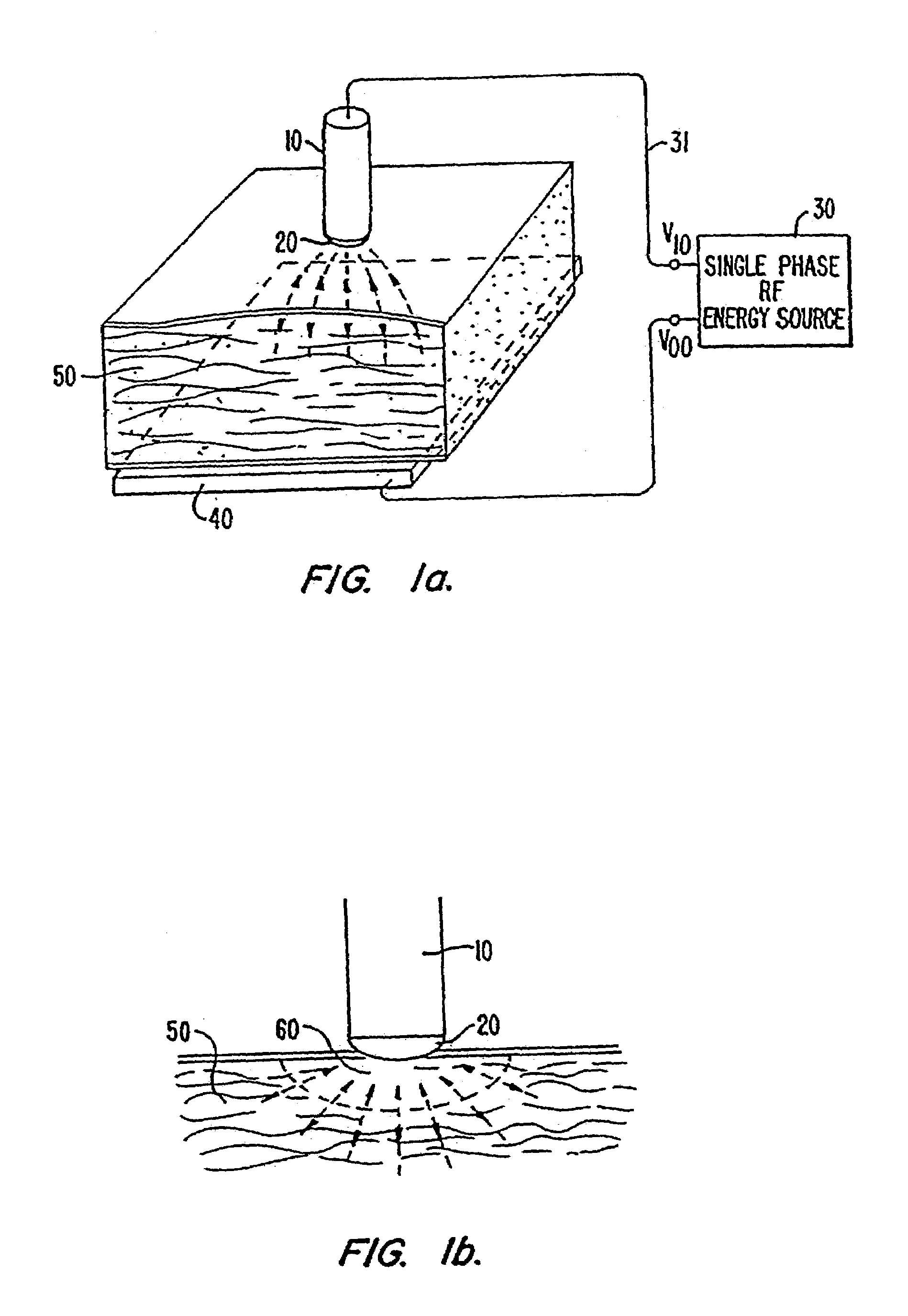

Device and method for multi-phase radio-frequency ablation

InactiveUS7151964B2Simple power connectionFully filledControlling energy of instrumentInternal electrodesAblation zoneAuxiliary electrode

Multi-phase RF ablation employing a two-dimensional or three-dimensional electrode array produces a multitude of currents paths on the surface of the ablation zone. This results in a uniform lesion with a size defined by the span of the electrode array. An orthogonal electrode catheter array suitable for cardiac ablation is used in conjunction with a two-phase RF power source to produce uniform square-shaped lesions of size 1.2 cm2. Lesions of larger size are created by successive adjacent placement of the square-shaped lesions. A temperature sensor at the electrode tip allows monitoring of ablation temperature and regulation of thereof to minimize the electrode tips from being fouled by coagulum. In another embodiment, an external auxiliary electrode is used in combination with the catheter electrodes. This also produces lesions of greater depth. In yet another embodiment, ablation is performed with a sequence of elementary electrode-electrical configurations.

Owner:MORVIL TECH LLC

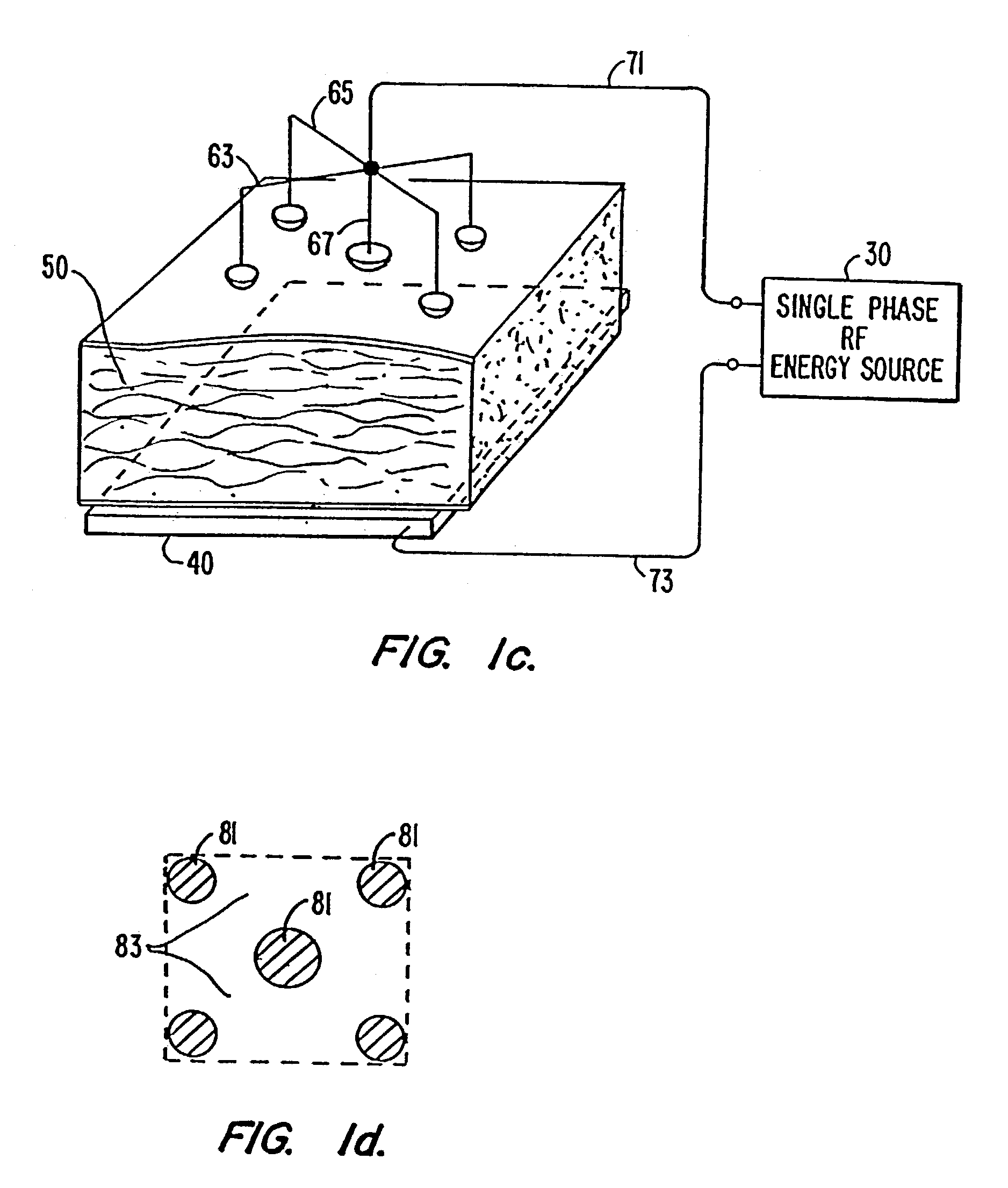

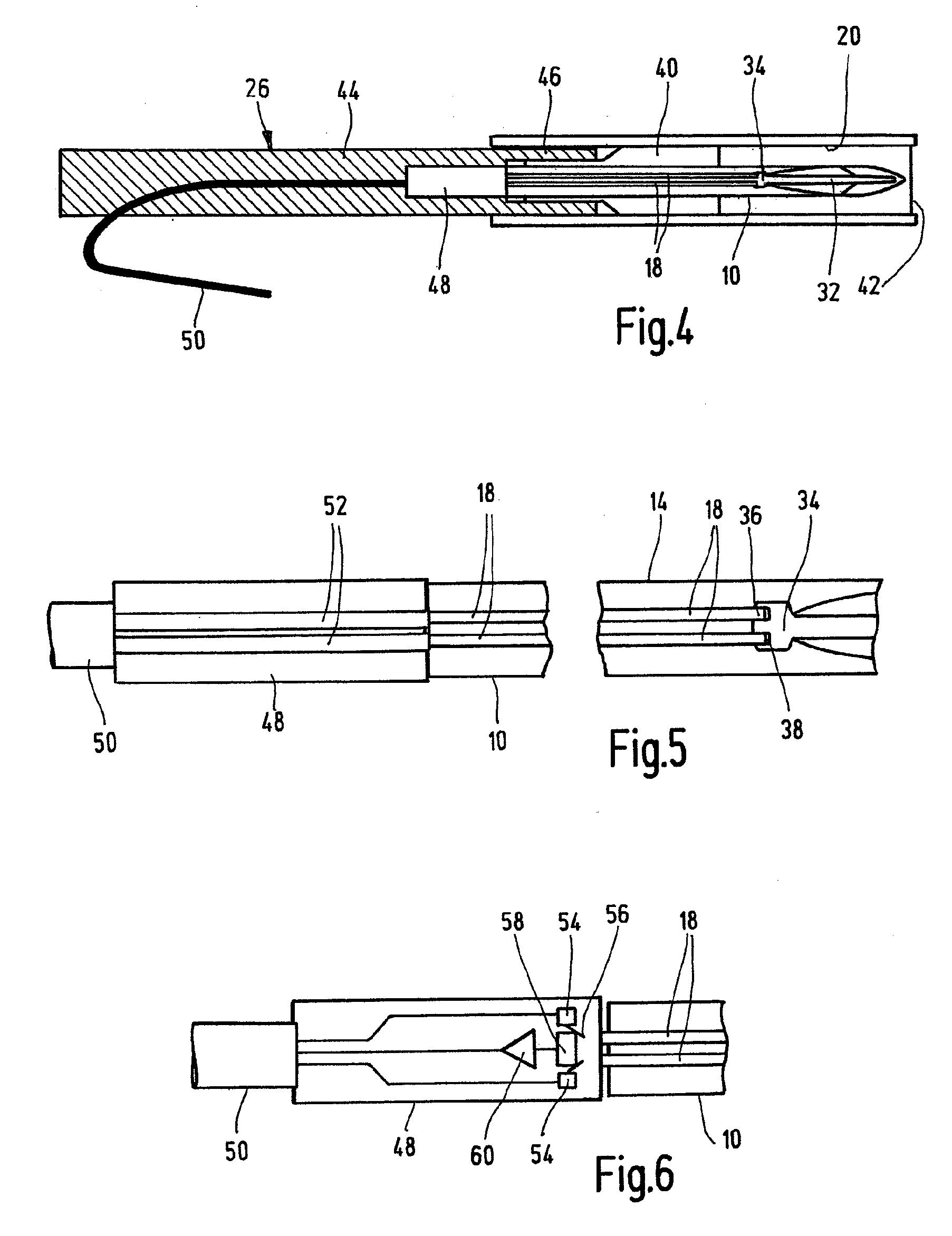

Test element and test system for examining a body fluid

ActiveUS20080249435A1Improve user friendlinessEasy to integrateMaterial analysis by optical meansCatheterLight guideOptical measurements

The invention relates to a test element as a single-use article for examining a body fluid, comprising a lancing member that can be inserted into a body part, a collecting area configured thereon for body fluid obtained by the lancing and at least one light guide for an optical measurement in the collecting area. The collecting area is formed by a collection recess of the lancing member which extends in the lancing direction and the light guide is integrated into the lancing member such that it is secure against displacement and the distal end thereof is arranged in a proximal measurement zone of the collection recess.

Owner:ROCHE DIABETES CARE INC

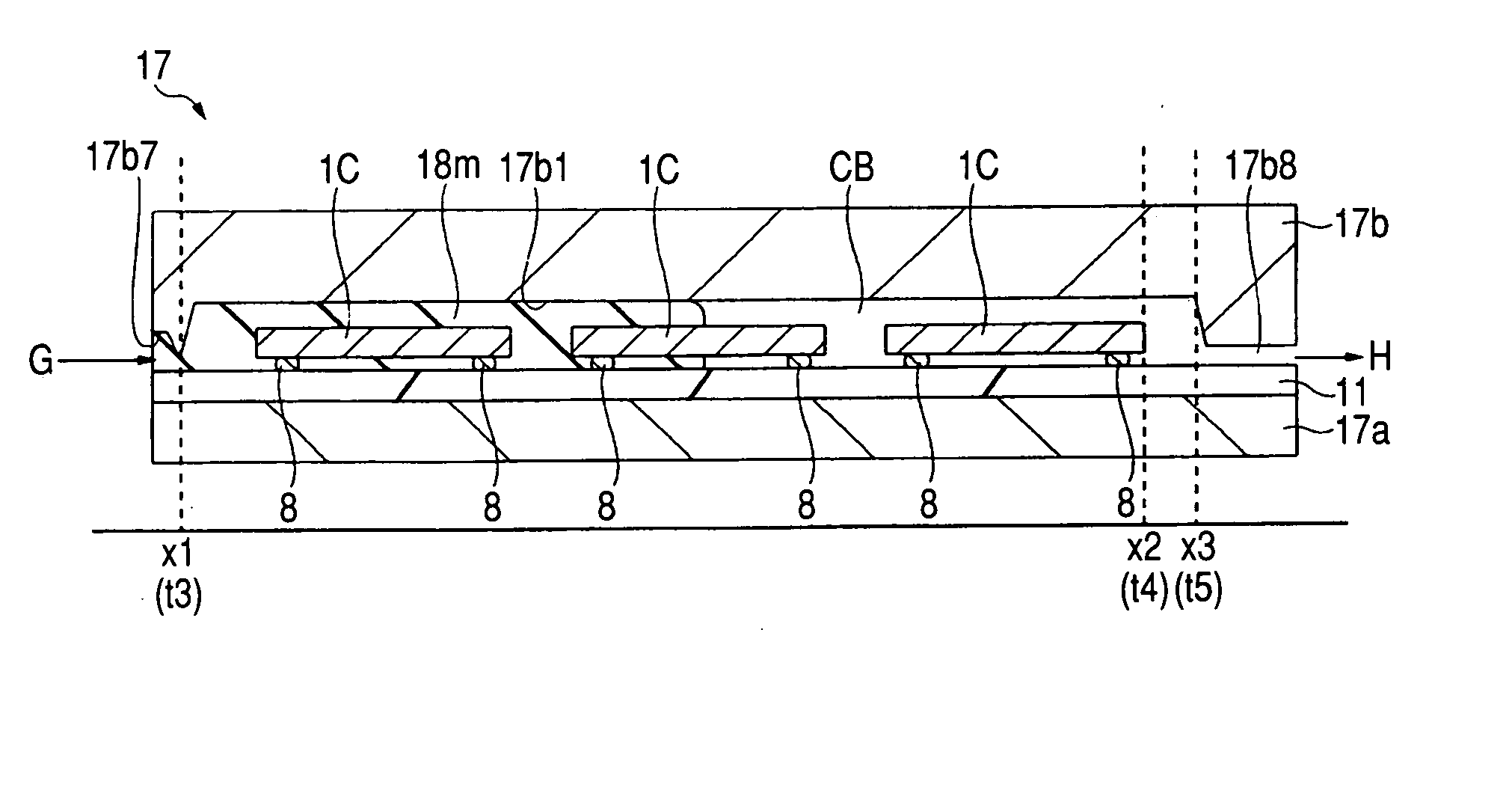

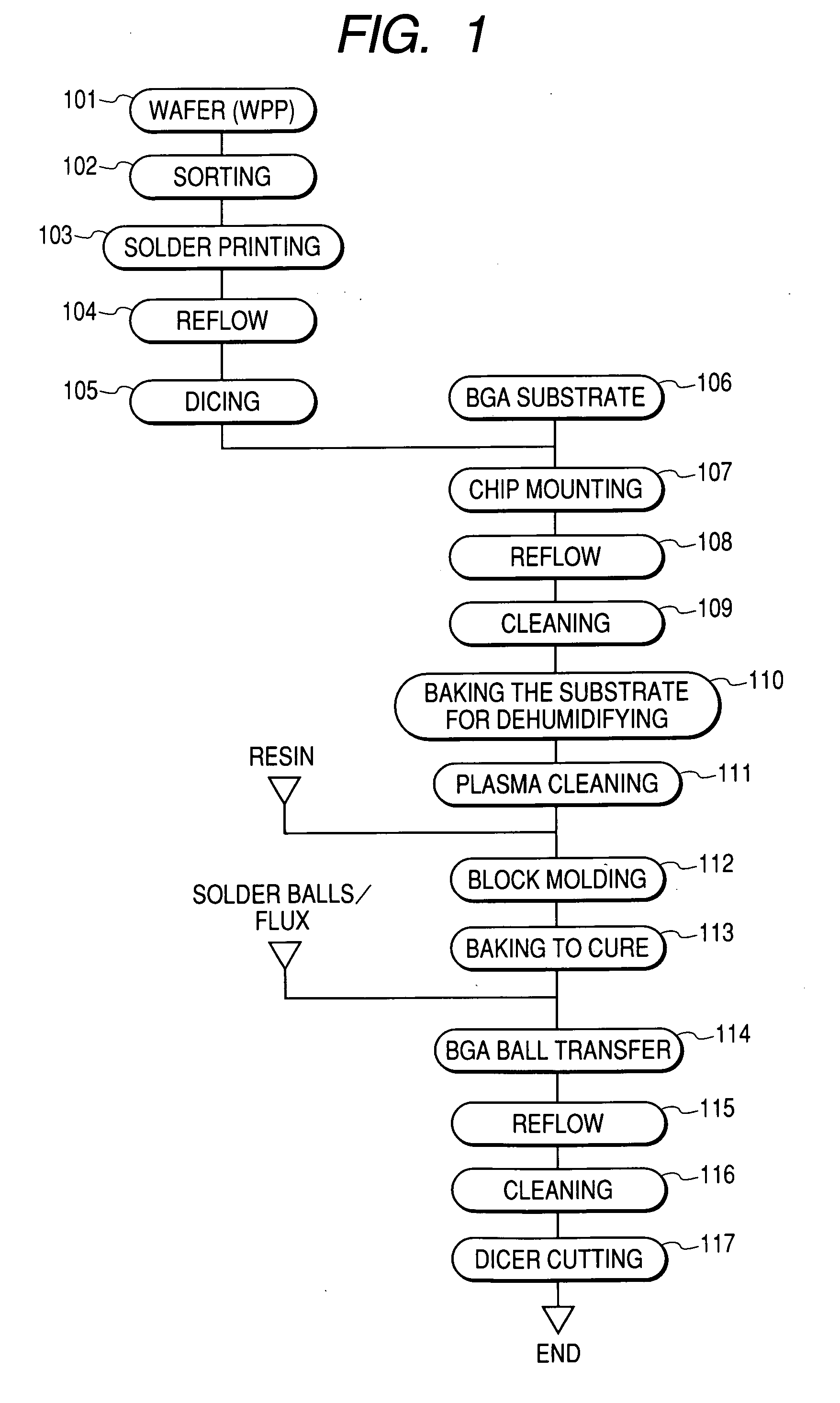

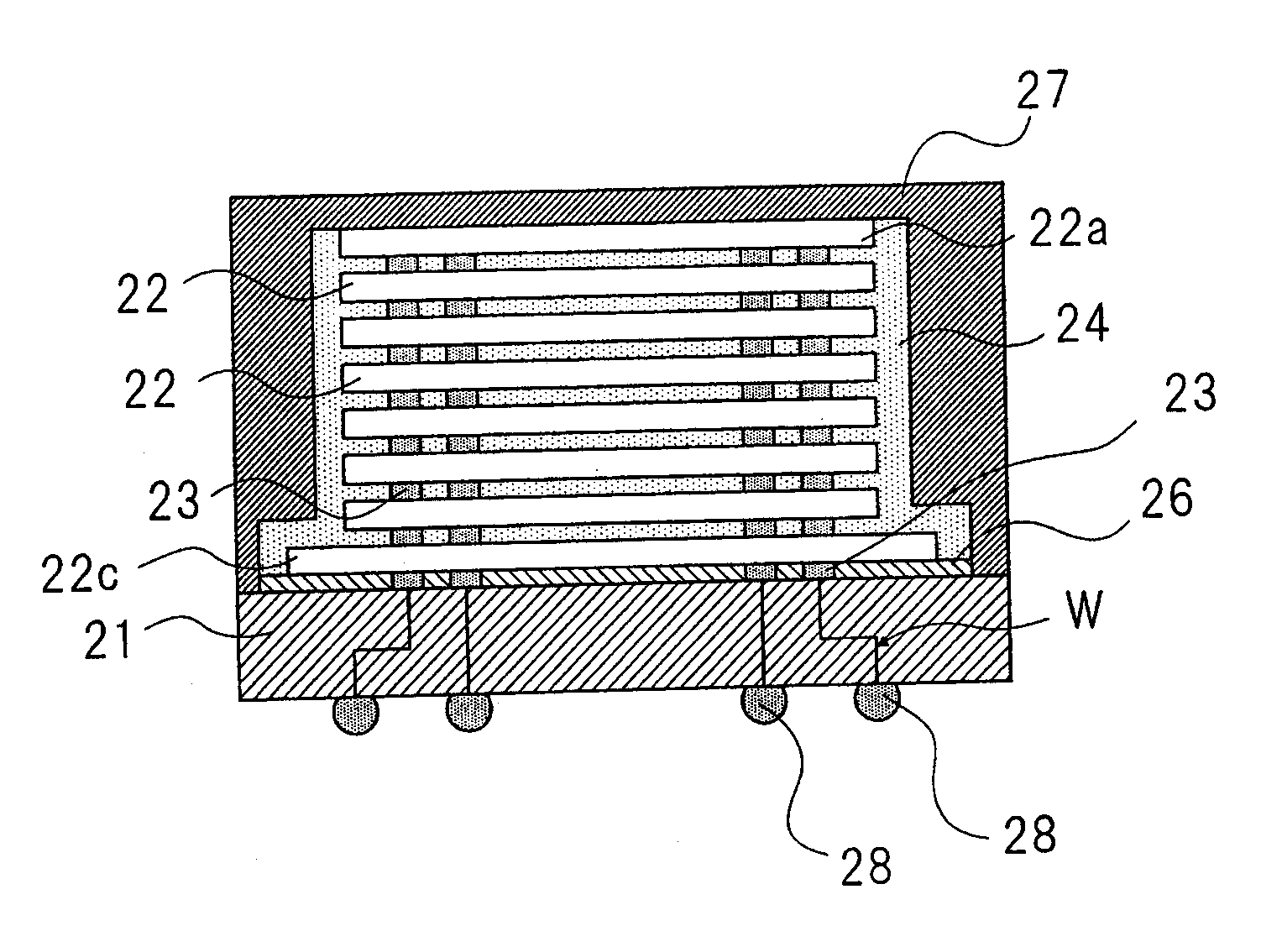

Manufacturing method of a semiconductor device

InactiveUS20050133895A1Increase productionReduce internal pressureSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsInternal pressureDevice material

The yield of a sealing process for a semiconductor device which adopts a flip-chip mounting method is to be improved. In a molding process wherein plural semiconductor chip ICs mounted on a parts mounting surface of a substrate matrix through bump electrodes are to be sealed all together with a sealing resin in a reduced state of the internal pressure of a cavity of a molding apparatus, a clamping pressure at the time of clamping the substrate matrix by both a lower die and an upper die of a molding die is set at a relatively low pressure in an initial stage of injection of the sealing resin and is changed to a relatively high pressure when the sealing resin has covered the semiconductor chip ICs located in a final stage in the resin injecting direction.

Owner:RENESAS ELECTRONICS CORP

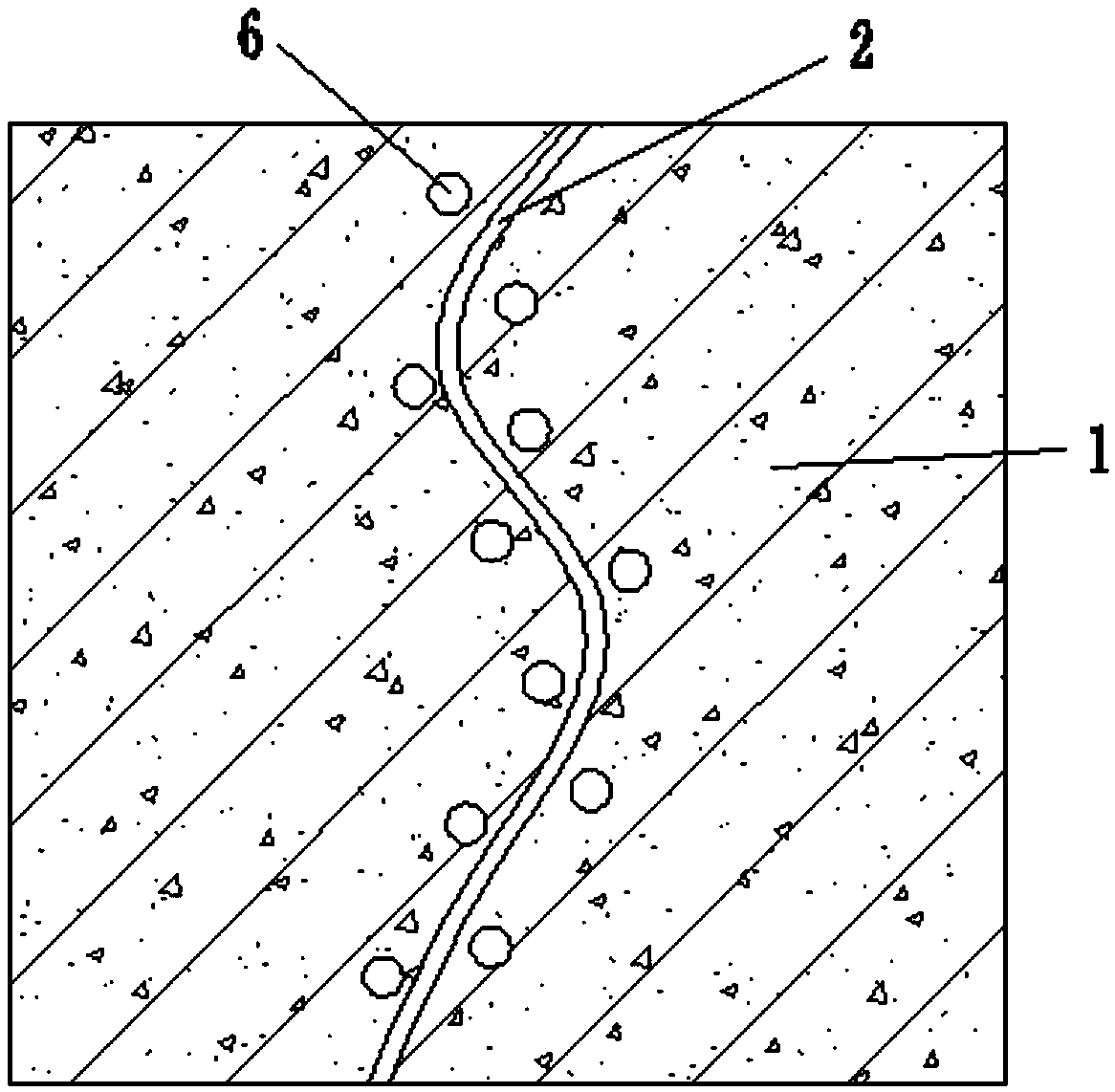

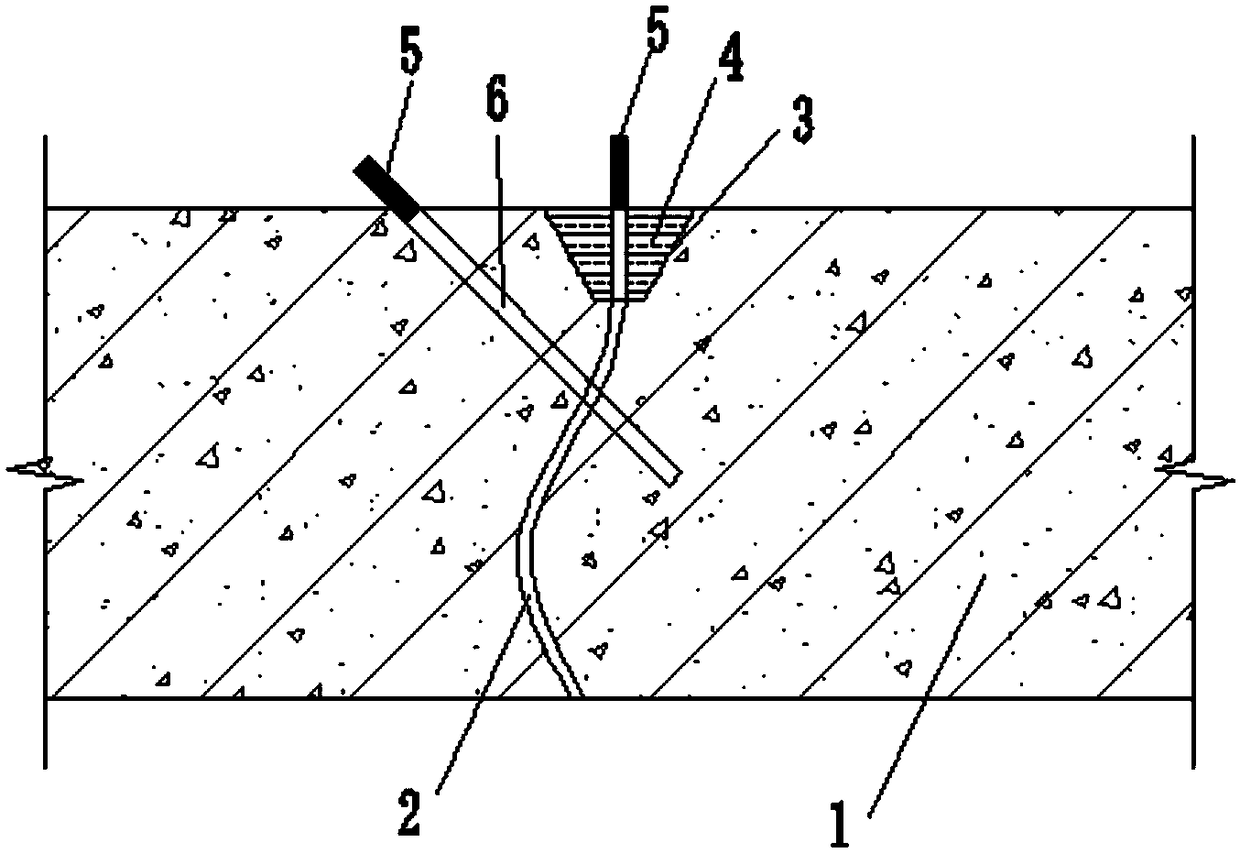

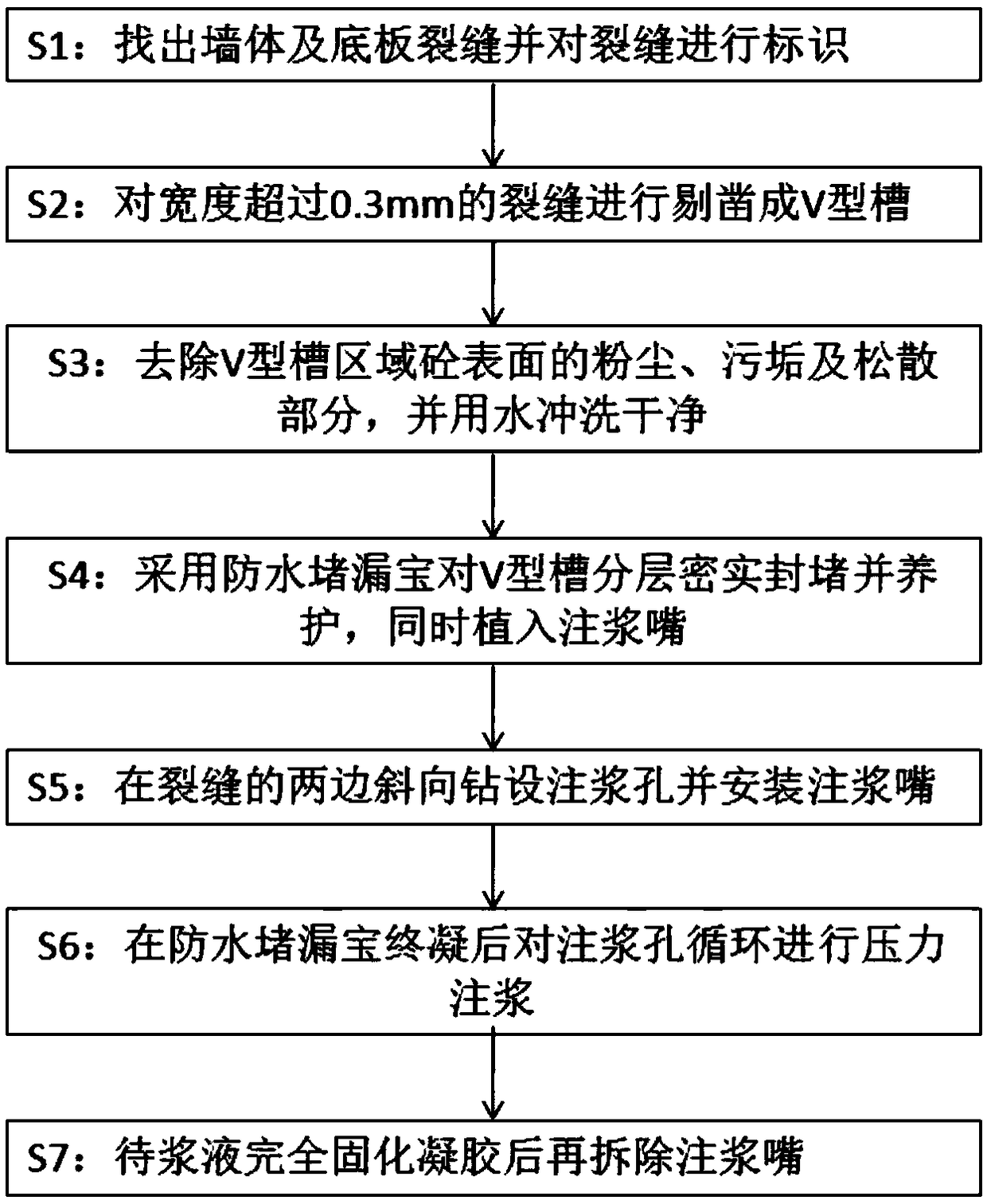

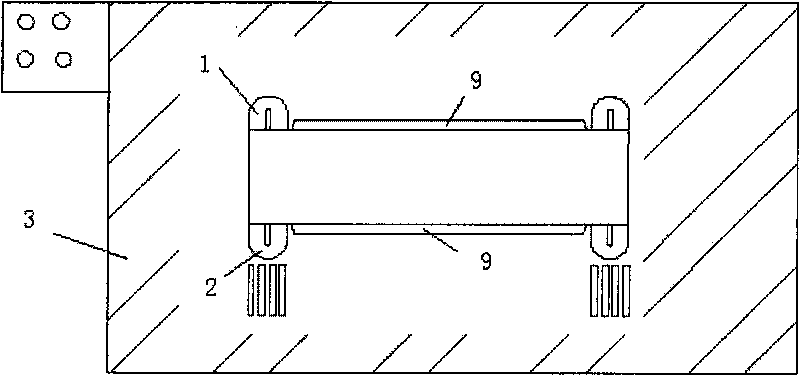

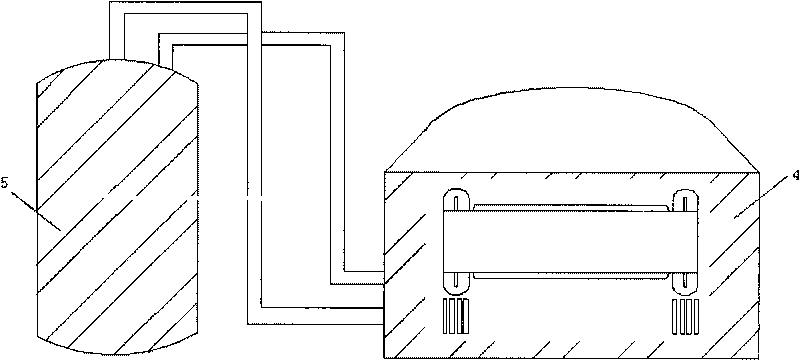

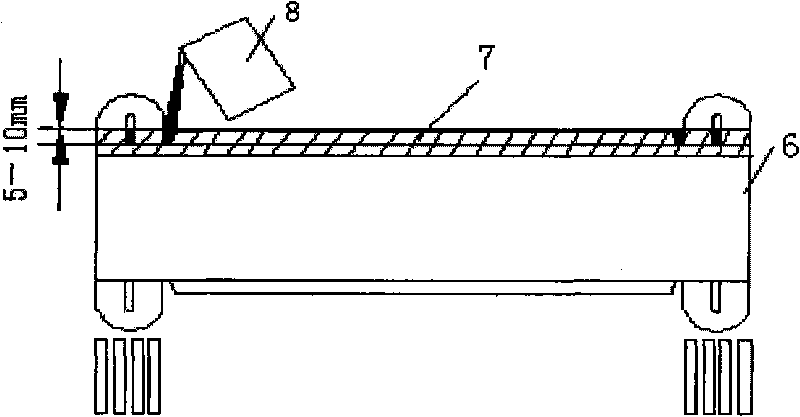

Concrete wall and bottom plate water seepage crack repair method

ActiveCN109457735AAvoid water leakage accidentsReduce water pressureArtificial islandsProtective foundationSlurryPressure grouting

The invention discloses a concrete wall and bottom plate water seepage crack repair method. The method comprises the following steps that wall and bottom plate cracks are found out and marked; the crack of which the width is larger than 0.3 mm is subjected to digging into a V-shaped groove; dust, dirt and loose parts of the surface of concrete in the V-shaped groove area are removed and washed with water; layered dense blocking and maintenance are conducted on the V-shaped groove through a waterproof leaking stoppage part, and meanwhile, a grouting nozzle is implanted; grouting holes are obliquely drilled in the two sides of the crack, and a grouting nozzle is installed; and after final set of the waterproof leaking stoppage part, the grouting holes are circularly subjected to pressure grouting; and after grout is completed solidified, the grouting nozzles are disassembled. According to the method, by obliquely drilling the grouting holes in the two sides of the crack and installing the grouting nozzle, a plurality of channels communicating with the interior of the crack are formed, the water pressure of the interior of the crack can be reduced, grout can be injected into the crackconveniently in the later period, through permeation of the grout, the water seepage crack is sealed after the grout is solidified, and accordingly, the water seepage crack leaking stoppage effect isachieved so that underground construction water seepage accidents can be avoided.

Owner:中铁二十三局集团第四工程有限公司

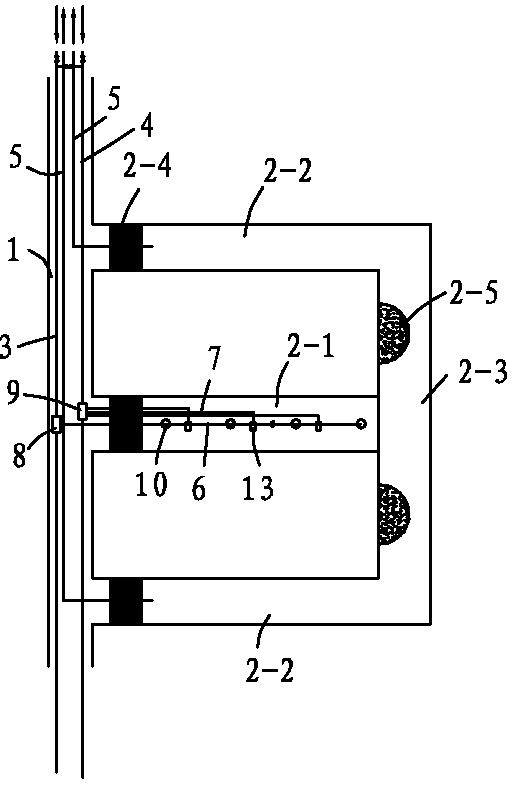

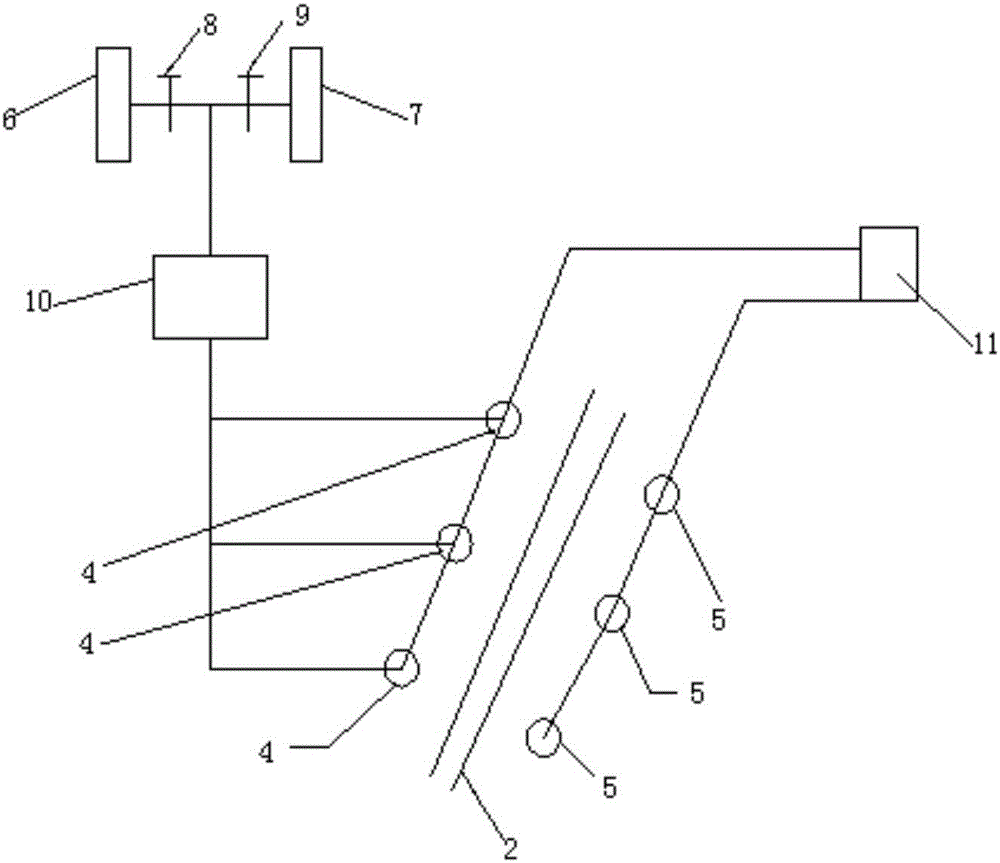

Gas injection point retreating type coal underground gasification system and process

InactiveCN103277082AAvoid cloggingPrevent backflowConstructionsCoal gasificationThermodynamicsCombustion

The invention discloses a gas injection point retreating type coal underground gasification system and process. The gas injection point retreating type coal underground gasification system comprises an airway arranged in a coal layer and multiple coal underground gasification units, wherein the airway is connected to the multiple coal underground gasification units; and the technical steps are sequentially as follows: a step of cold-state testing, a step of ignition on a gasification working surface, a step of debugging of the gasification working surface and a step of gasification normal production process. According to the invention, mud can be prevented from blocking the gas injection point efficiently, and the coal layer can be exploited to the maximum extent, so that possibility of thoroughly cutting off the leakage of a gasification agent to a combustion space area is realized while safe retreating in the coal underground gasification process is realized, filling of the combustion space area is realized, collapse of the ground surface caused by the gasification is removed, stability of the gasification channel structure is guaranteed, problem of the short circuit of the gasification agent caused by a channel which is resulted from collapse of a coal layer plate in the gasification area in the early stage and the gasification channel at the later stage of the underground gasification is solved, the quality of the coal gas is improved, and safe and reliable coal gas production and high gasification rate are achieved.

Owner:HENAN ZHONGKUANG KENENG COAL CHEM

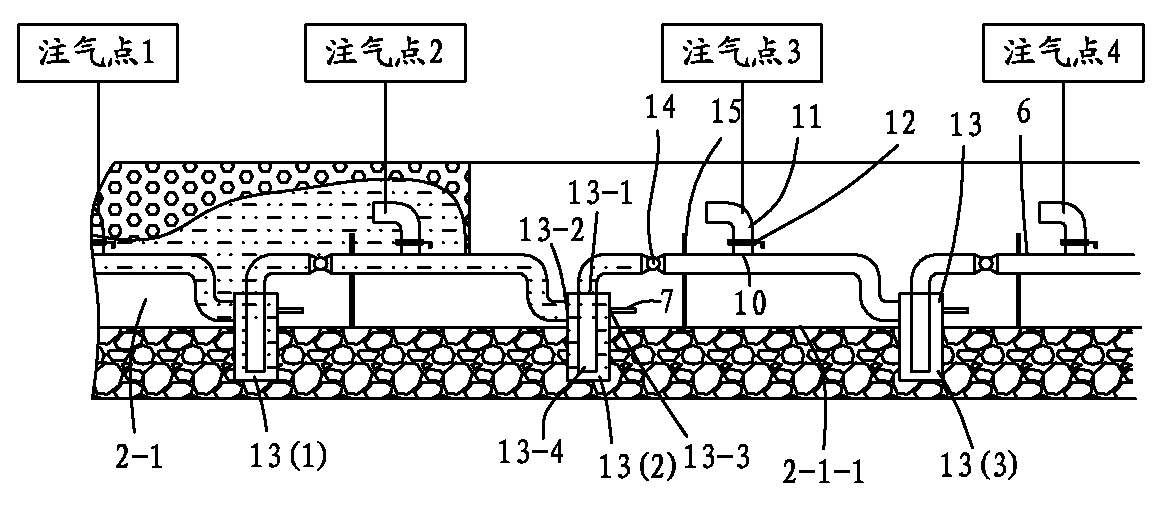

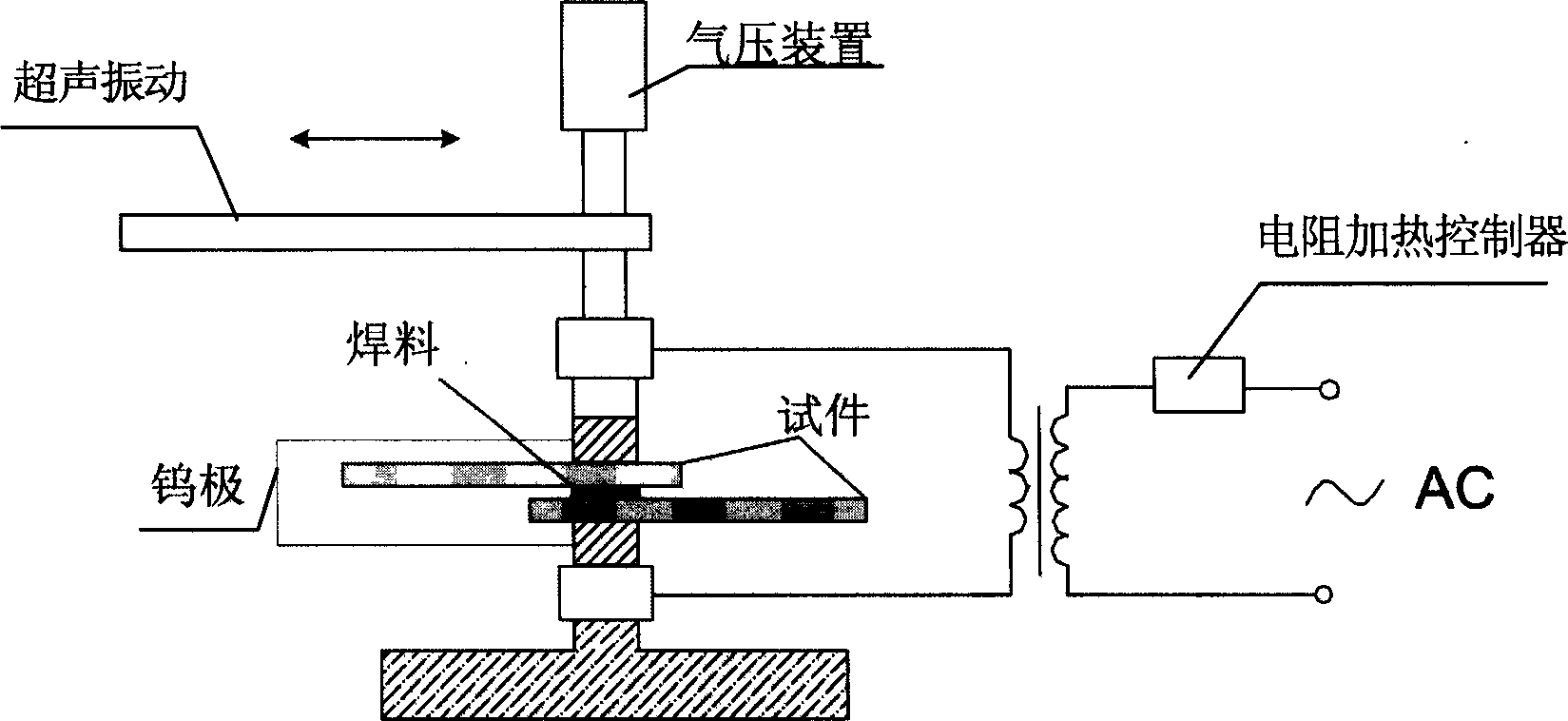

Aluminium base composite material ultra sonic electrical resistance welding method

InactiveCN1686659AEasy to operateStrong designWelding apparatusElectrical resistance and conductanceMegasonic cleaning

An ultrasonic-resistance welding method for the Al-based composition includes grinding the surfaces of Al-based compositions, ultrasonic cleaning, putting the flux between two surfaces to be welded, heating by electric resistance, decreasing the thickness of liquid film between two surfaces, ultrasonic vibrating, pressing and natural cooling.

Owner:HARBIN INST OF TECH

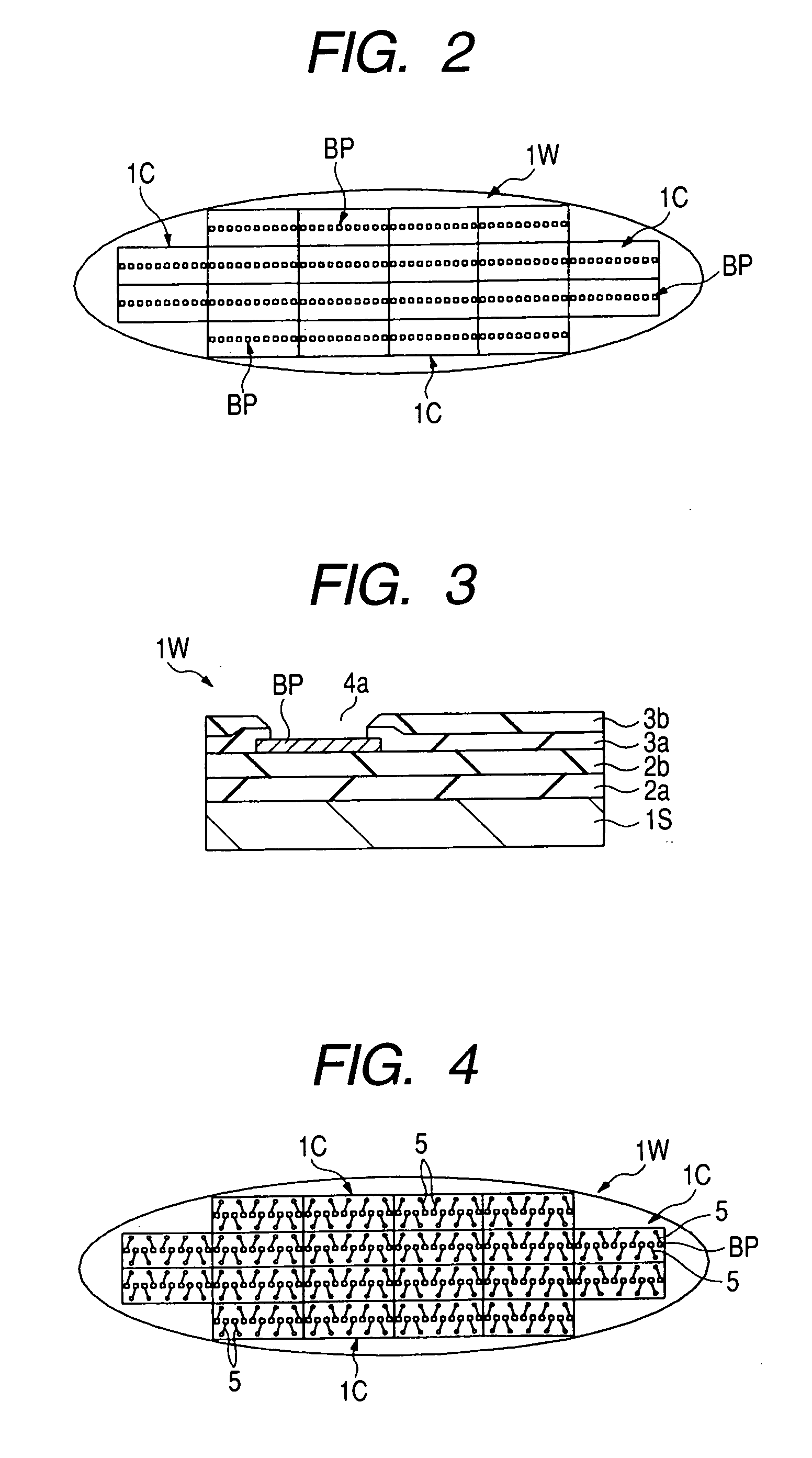

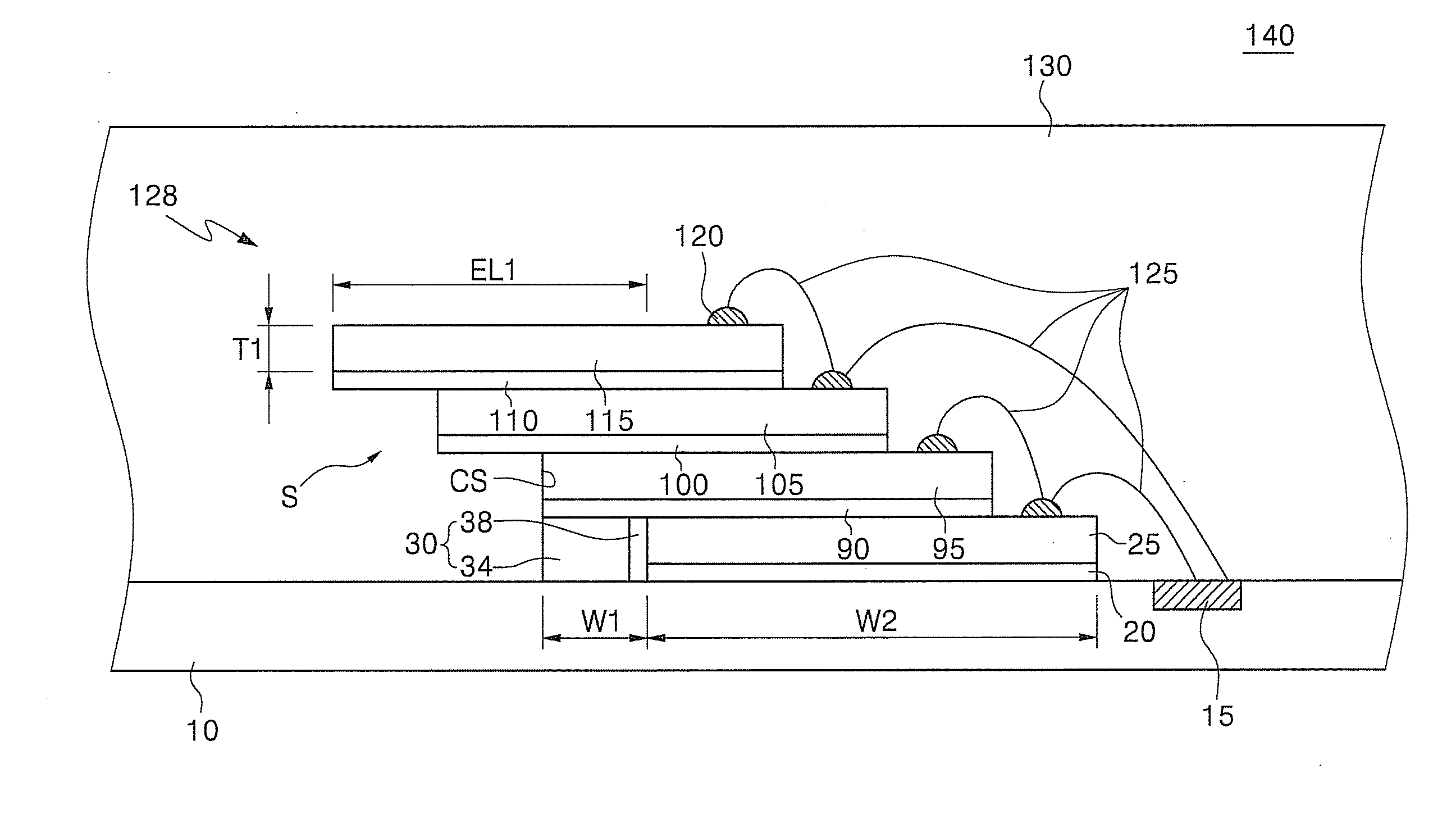

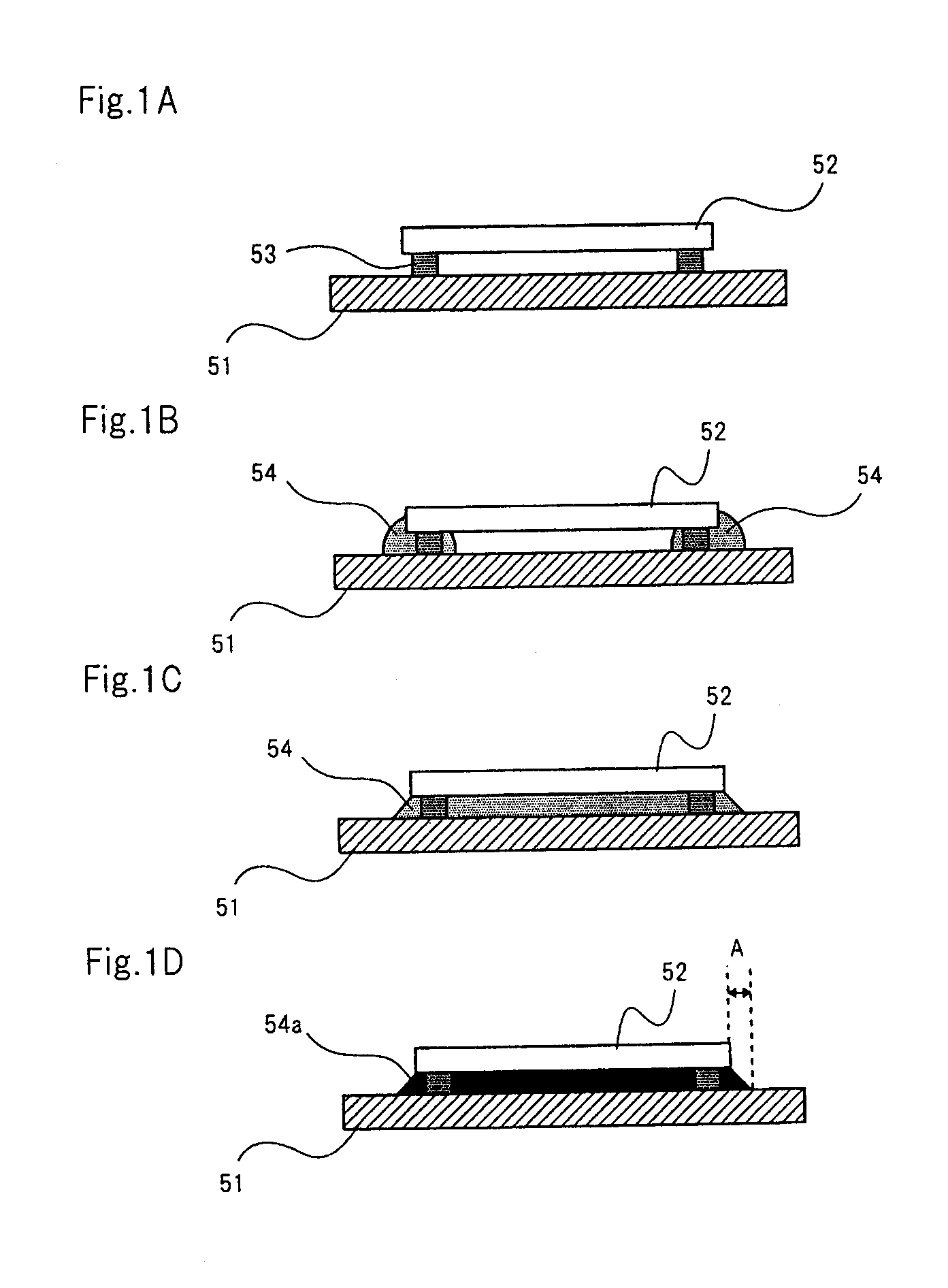

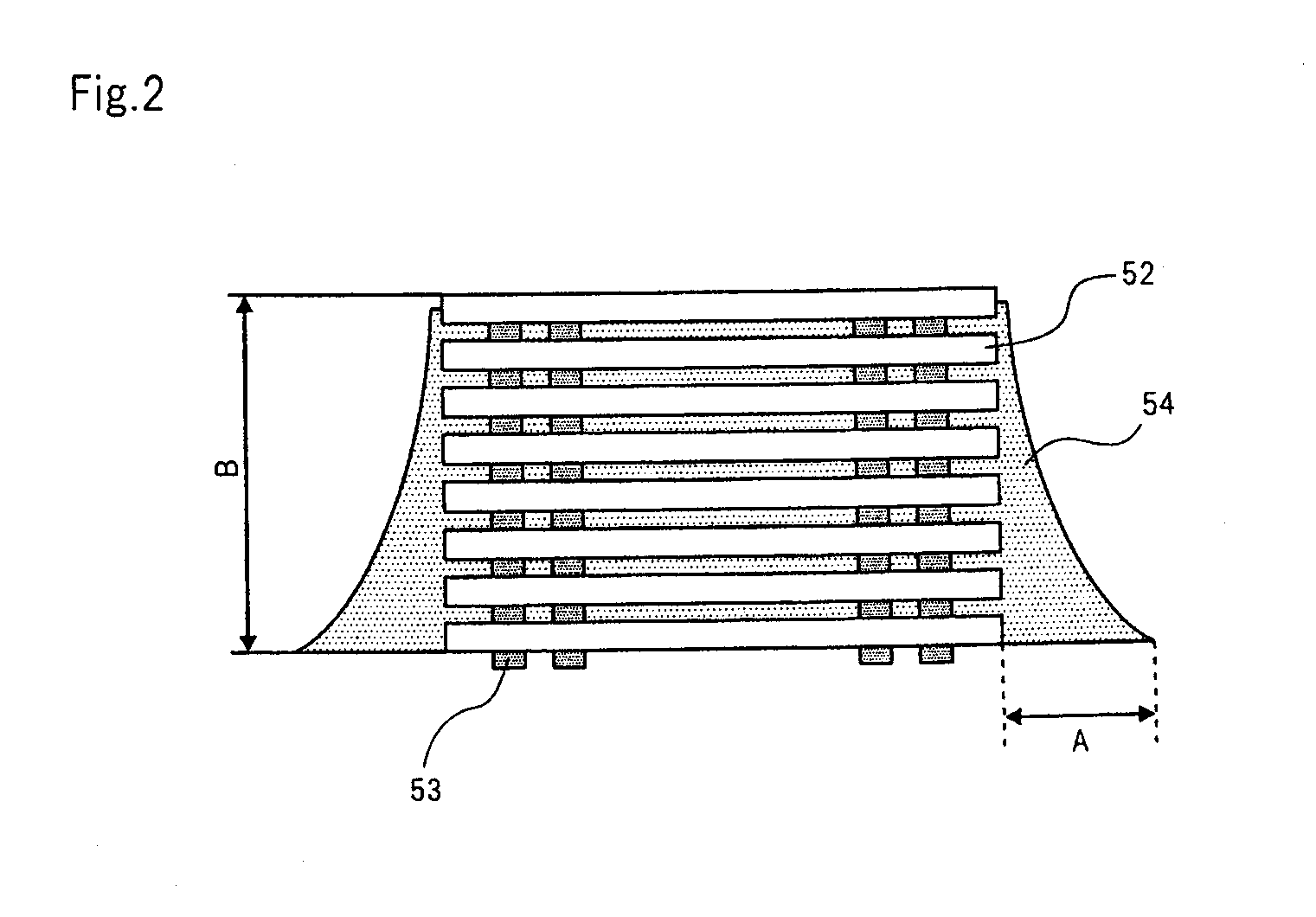

Semiconductor package, semiconductor package structure including the semiconductor package, and mobile phone including the semiconductor package structure

ActiveUS20110079890A1Fully filledSemiconductor/solid-state device detailsSolid-state devicesFirst FillSemiconductor chip

Provided is a semiconductor package. The semiconductor package may include a first semiconductor package having first semiconductor chips sequentially stacked on a substrate. In example embodiments, the first semiconductor chips may have a cascaded arrangement in which first sides and second sides of the semiconductor chips define cascade patterns. The cascaded arrangement may extend in a first direction to define a space between the first sides of the first semiconductor chips and the substrate. The semiconductor package may also include at least one first connection wiring at the second sides of the semiconductor chips, the at least one first connection wiring being configured to electrically connect the substrate with the first semiconductor chips. In addition, the semiconductor package may further include a first filling auxiliary structure adjacent to the first sides of the first semiconductor chips.

Owner:SAMSUNG ELECTRONICS CO LTD

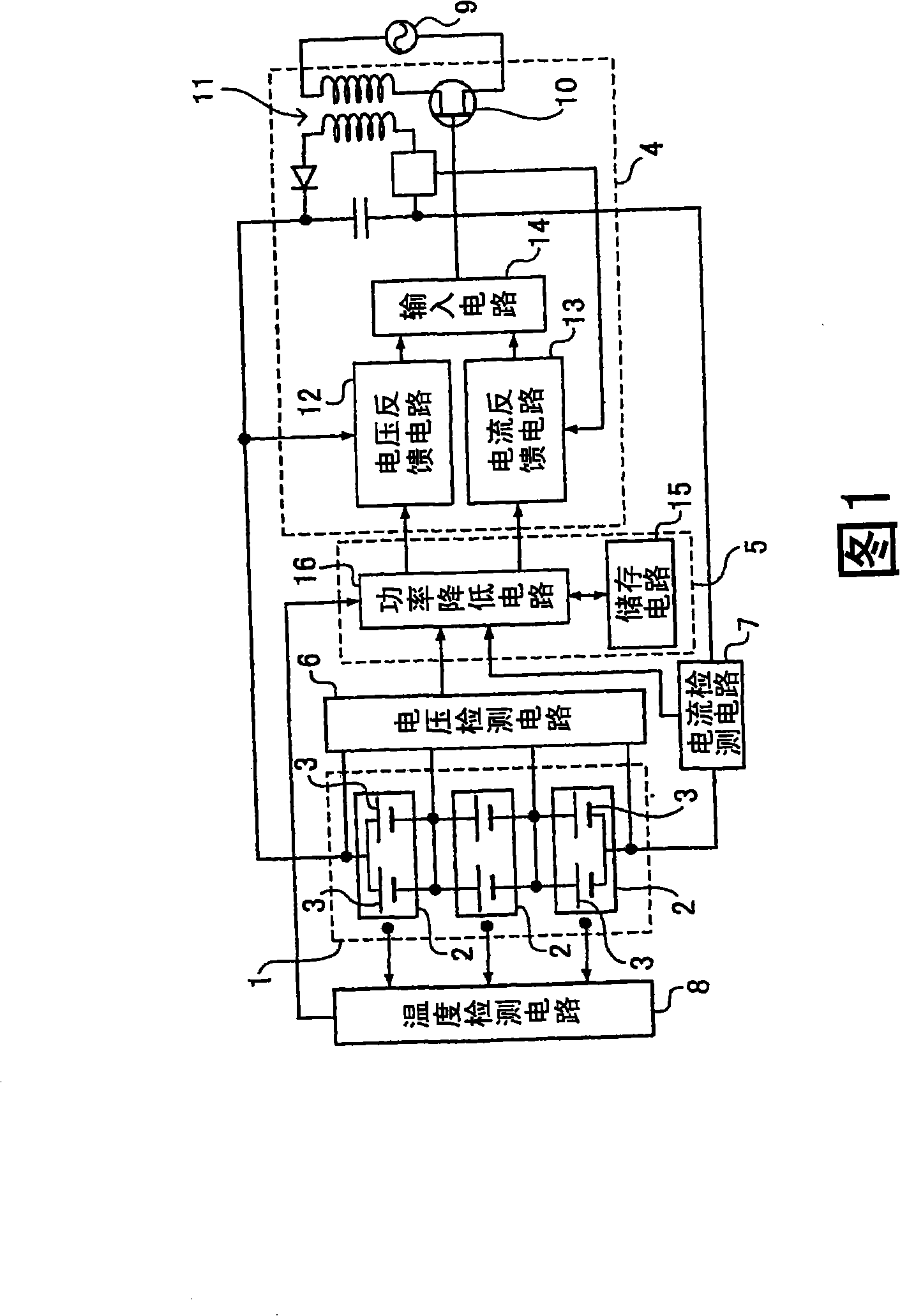

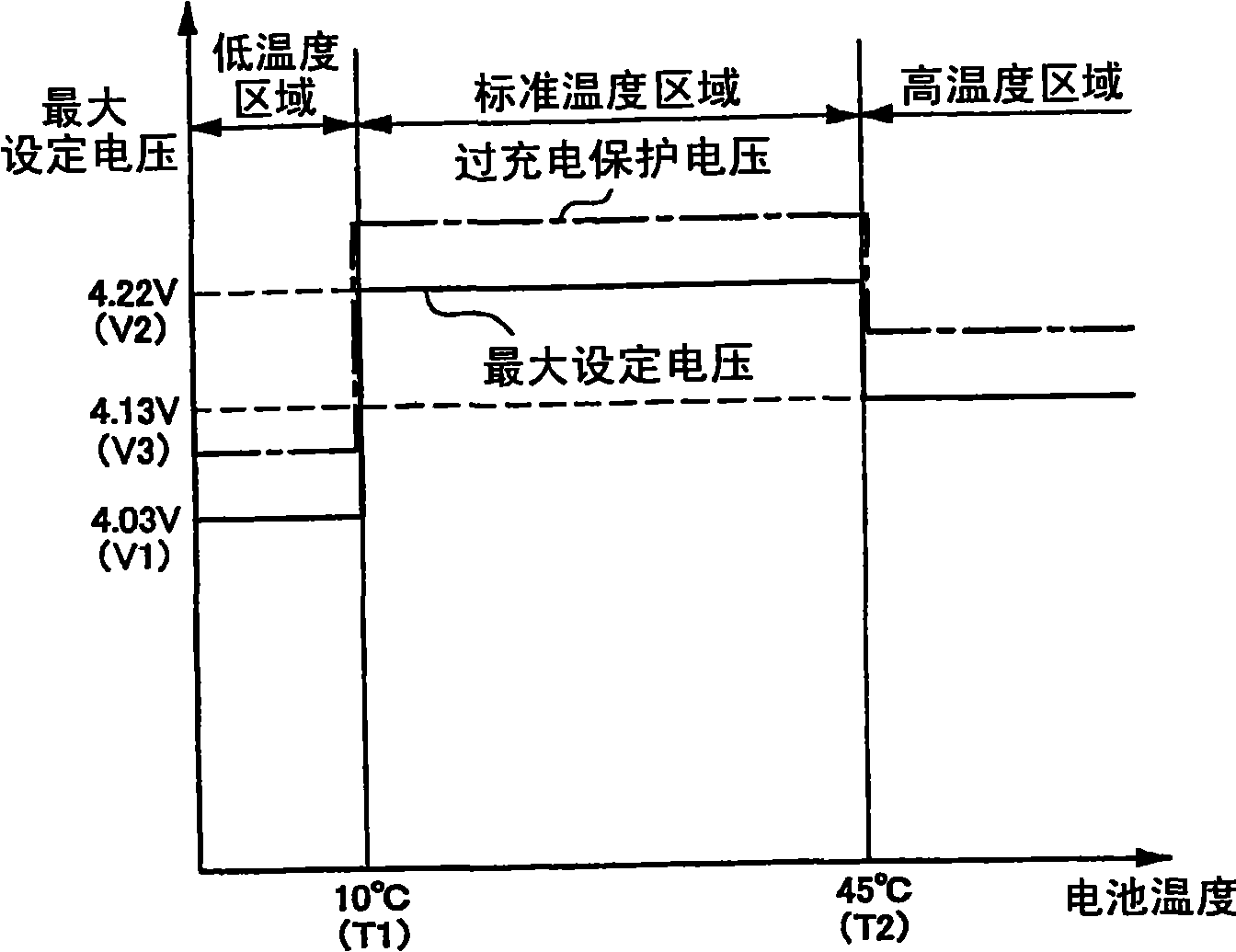

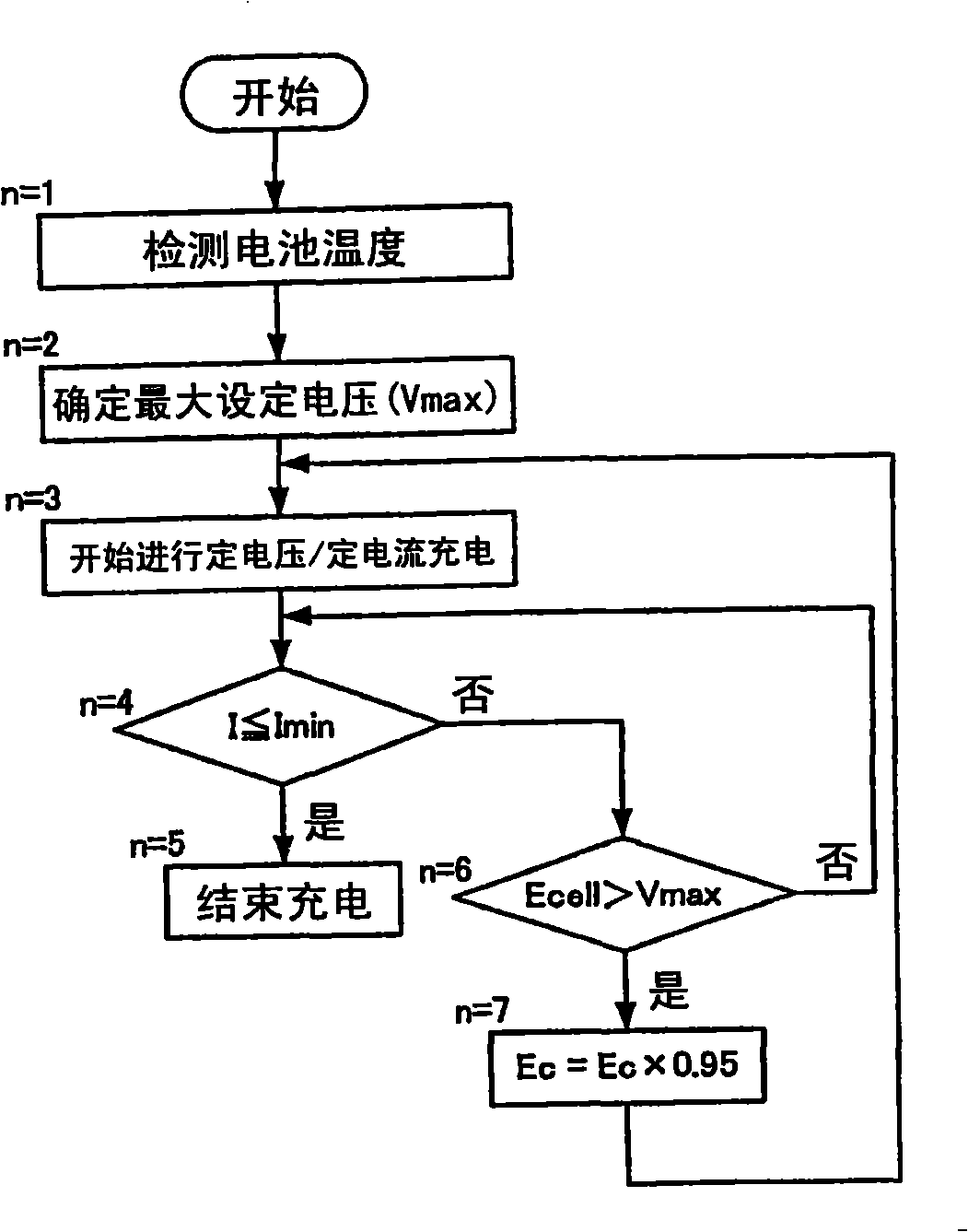

Method of charging a battery array

ActiveCN101345432AReduce performanceCharging Power ControlBatteries circuit arrangementsSecondary cells charging/dischargingEngineeringBattery cell

The invention provides a charging method which can increase the charging capacity of a battery array while controlling the voltage of each battery at or below the maximum specified voltage. The method of charging a battery array performs constant current, constant voltage charging of a battery array while detecting the voltage of each battery. The battery array is a plurality of series connected batteries. The charging method detects the voltage of each battery cell at a prescribed sampling rate. When the voltage of any battery cell exceeds a preset maximum specified voltage, charging power is reduced for constant current, constant voltage charging of the battery array.

Owner:SANYO ELECTRIC CO LTD

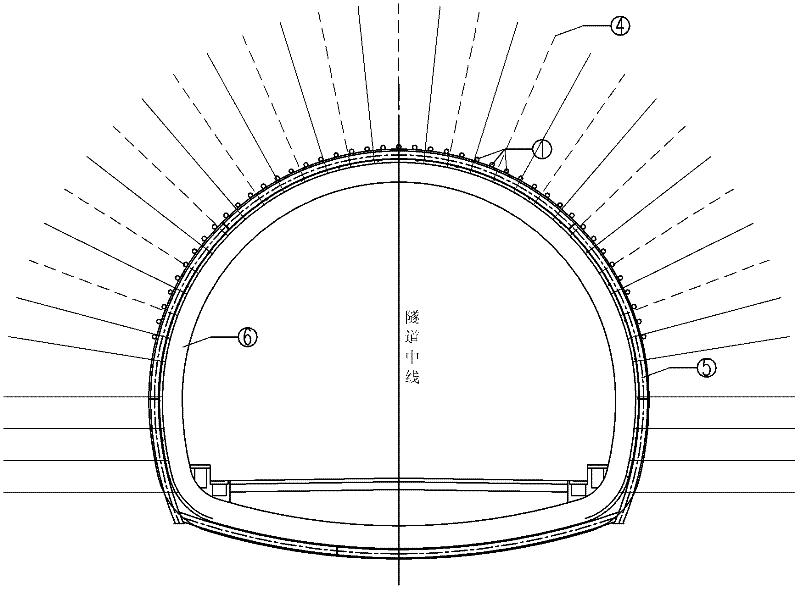

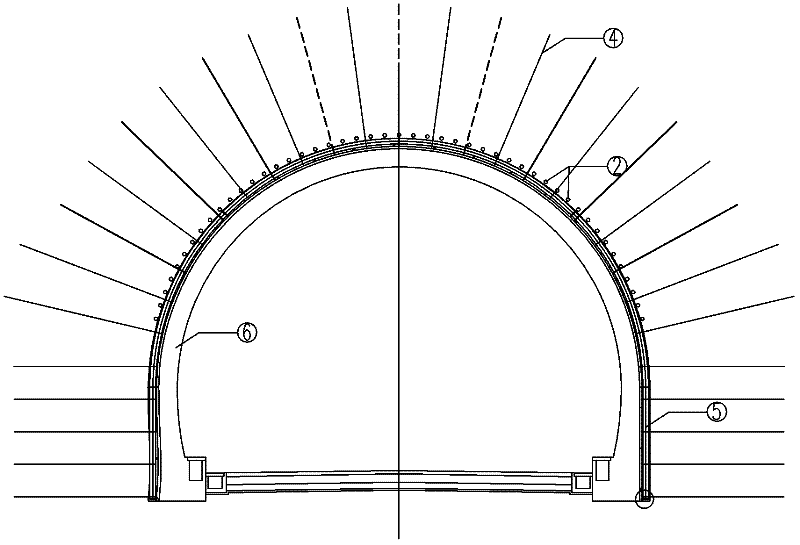

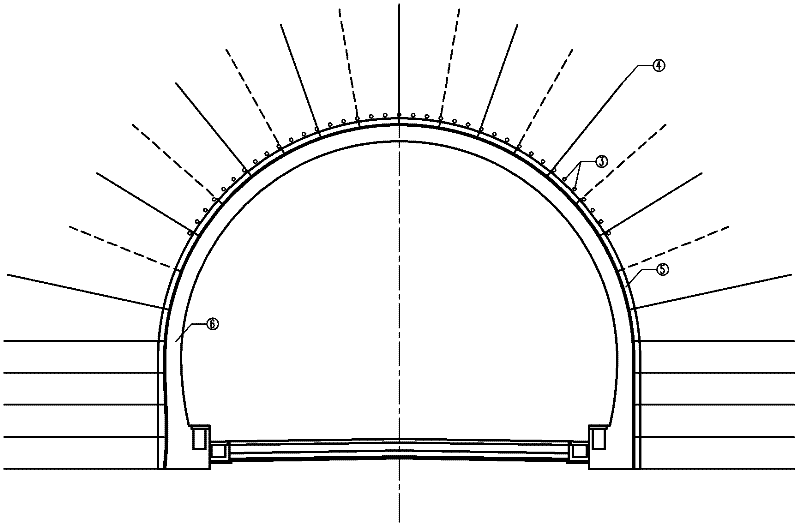

Method for designing long-distance small-spacing tunnel

InactiveCN102287196AFully filledGrouting requirements are fullUnderground chambersTunnel liningRebarReinforced concrete

The invention discloses a method for designing a long-distance small-spacing tunnel. In the method, before the tunnel is excavated, different advanced support modes are selected according to different grades of surrounding rocks; for V-grade surrounding rock, a large pipe-shed advanced support mode is adopted, for IV-grade surrounding rock, a small duct advanced support mode is adopted; for III-grade surrounding rock, a longitudinal anchor rod advanced support mode is adopted; different steel arch models and spaces are selected for primary support according to the grades of the surrounding rocks; a reinforced concrete mode and a plain concrete mode are adopted; and a linear presplitting blasting and weak blasting technology is adopted for tunnel blasting. By the method, the limitation of a specification on the space of the small-spacing tunnel is broken, support parameters are constantly adjusted in the construction process, and corresponding reliable support systems are established according to different grades of the surrounding rocks to guide designs and construction. By the method, the minimum spacing between tunnels is 4.5 meters.

Owner:DALIAN MUNICIPAL DESIGN & RES INST

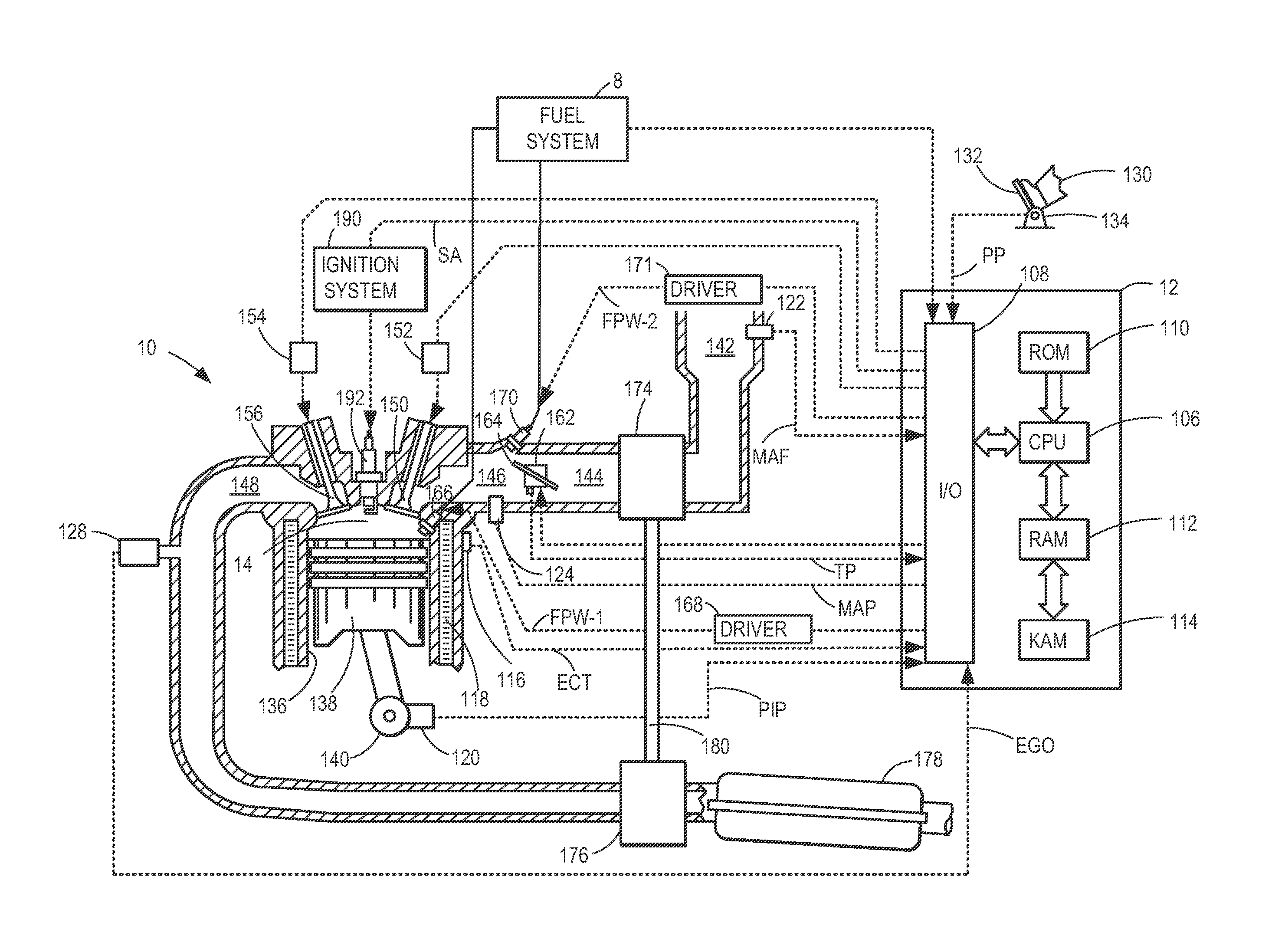

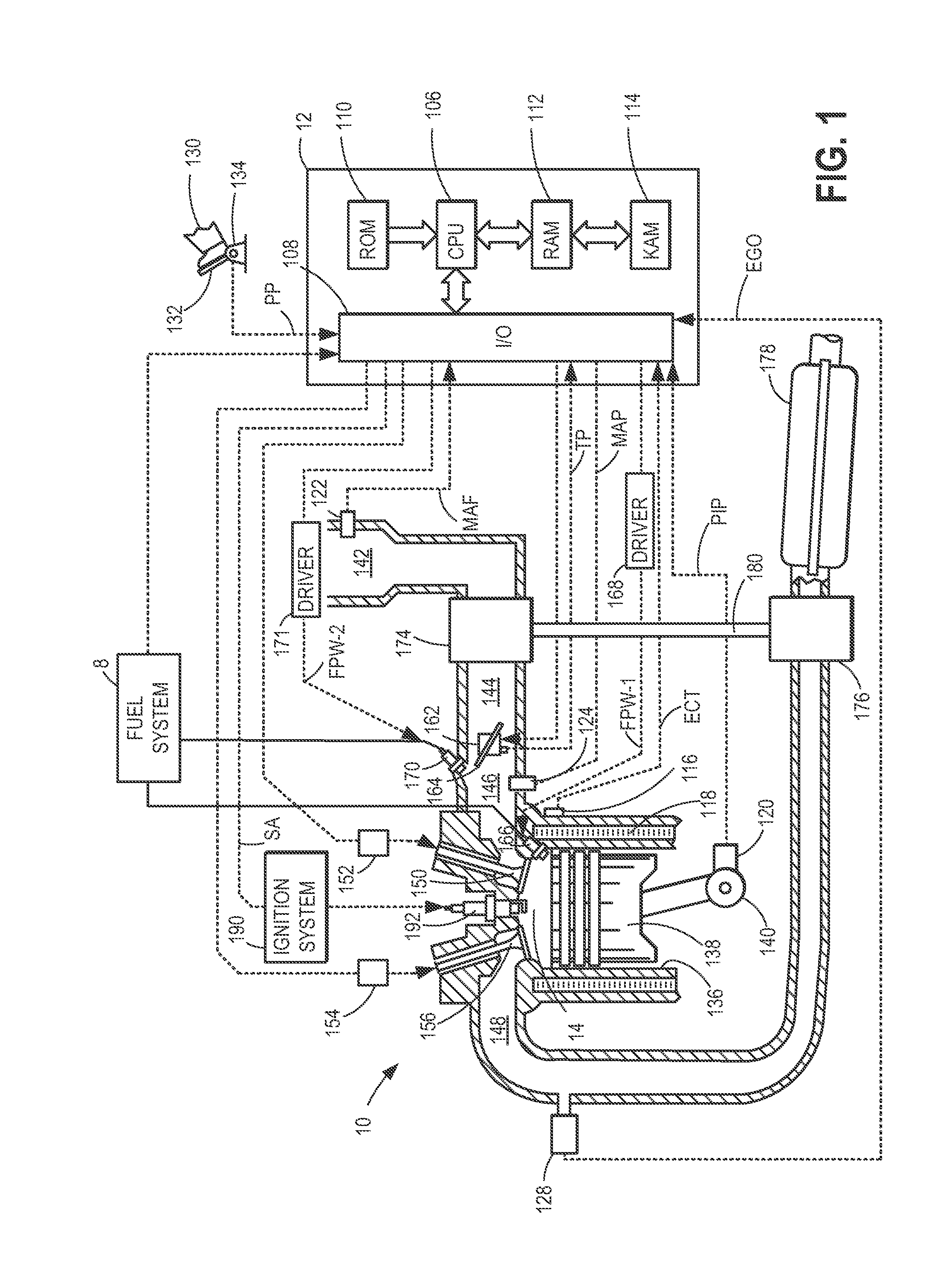

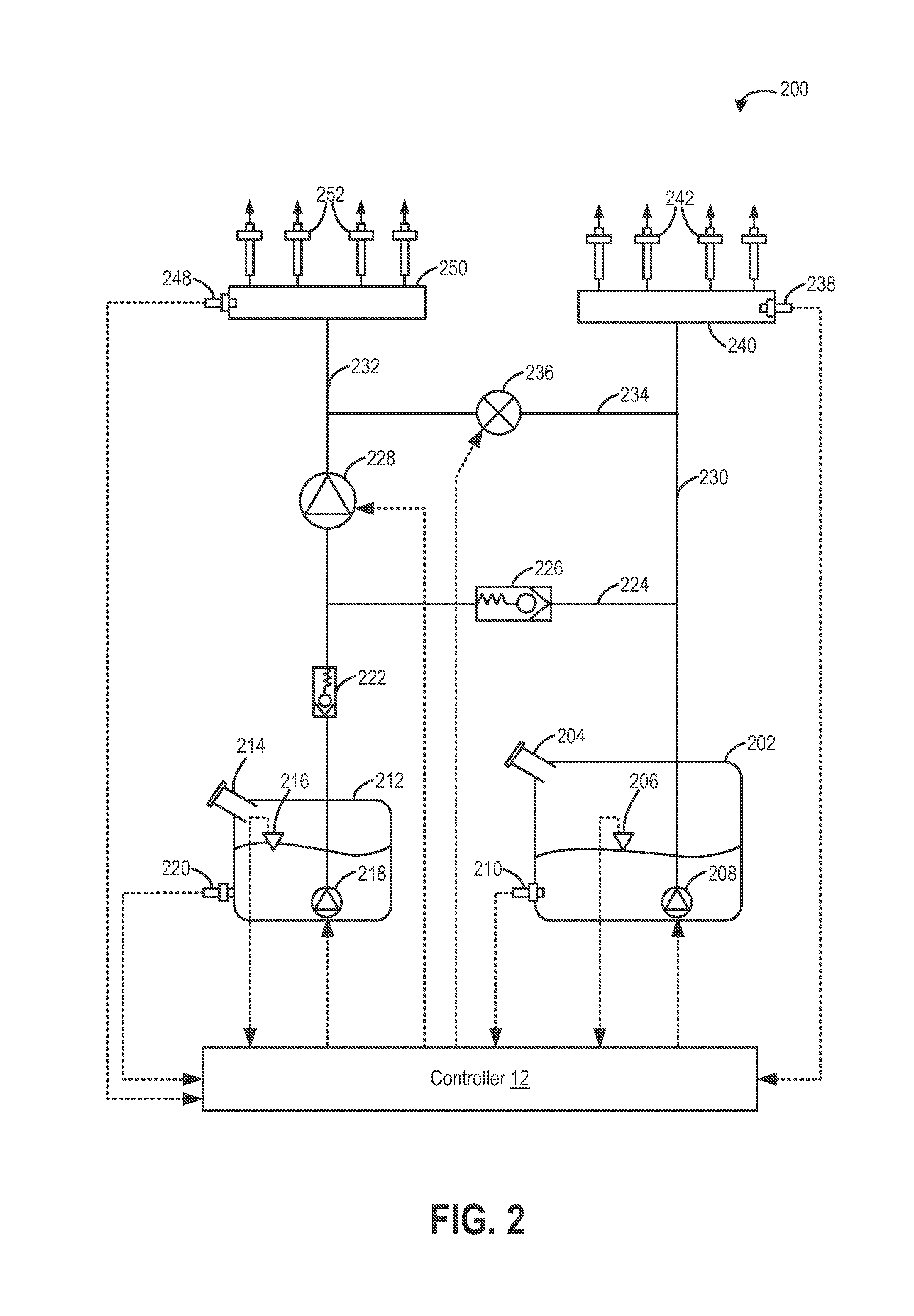

Fuel system for a multi-fuel engine

ActiveUS8776764B2Improve fuel vaporizationEmission reductionInternal combustion piston enginesLow pressure fuel injectionRail pressureFuel oil

Methods and systems are provided for operating an engine fuel system including a low pressure pump and a high pressure pump. During conditions when direct injection is not requested, a fuel rail pressure is maintained by the low pressure pump and fuel is port injected. Further, a stroke amount of the high pressure pump is adjusted to maintain an outlet pressure of the high pressure pump just below the fuel rail pressure. By maintaining fuel flow within the high pressure pump when high pressure pump operation is not required, and without flowing fuel from the high pressure pump outlet into the fuel rail, the high pressure pump may be cooled and lubricated without affecting the fuel rail pressure.

Owner:FORD GLOBAL TECH LLC

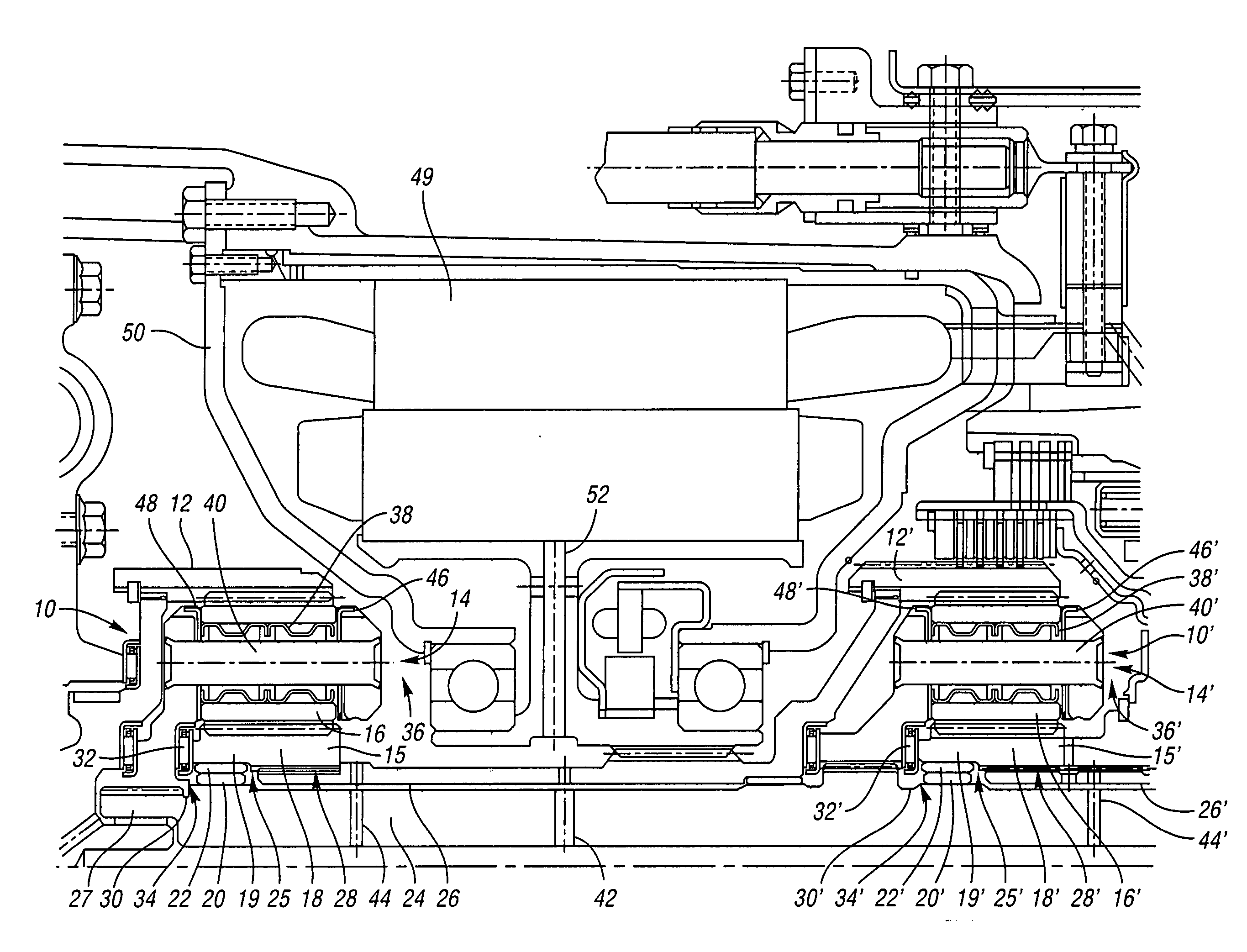

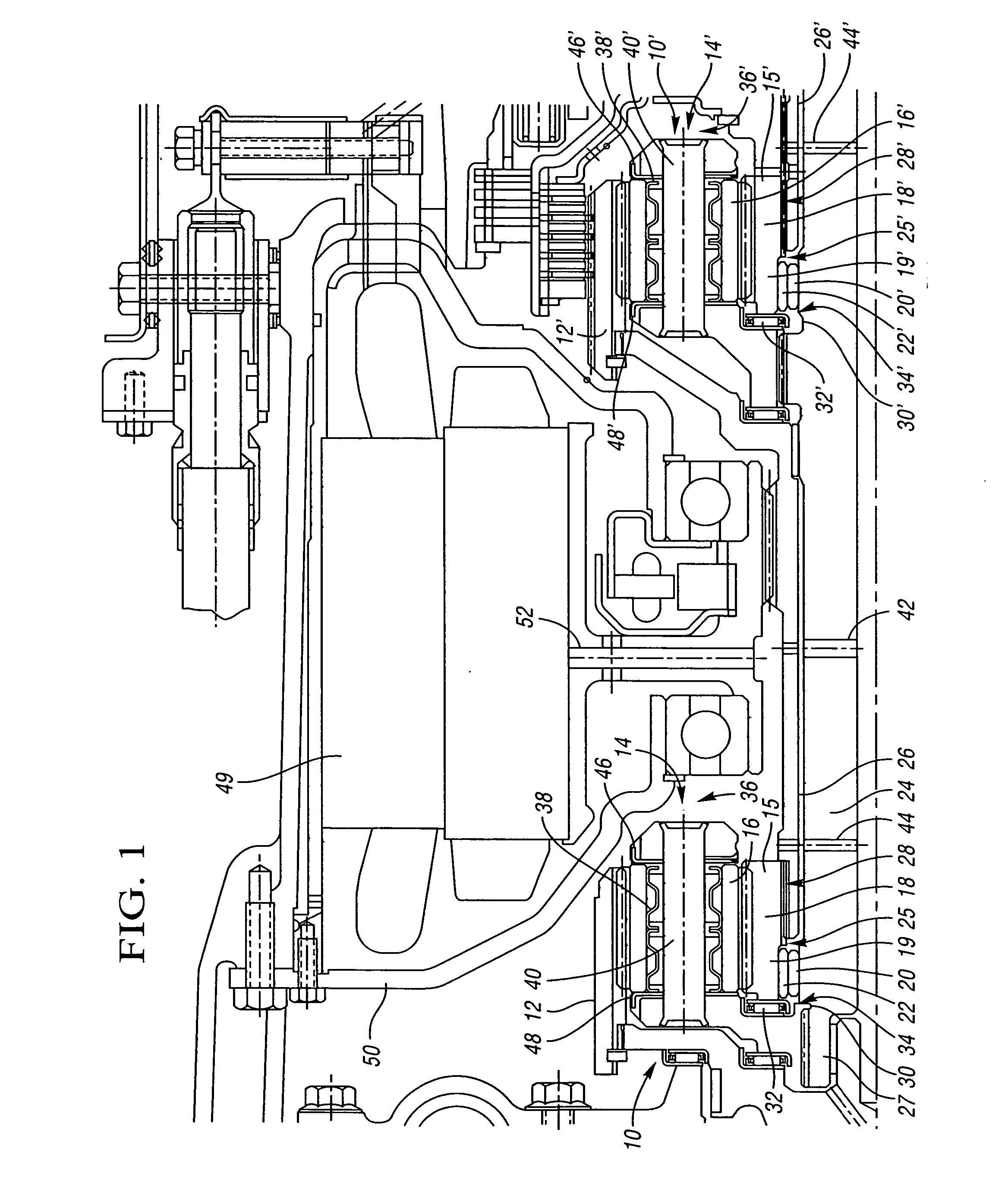

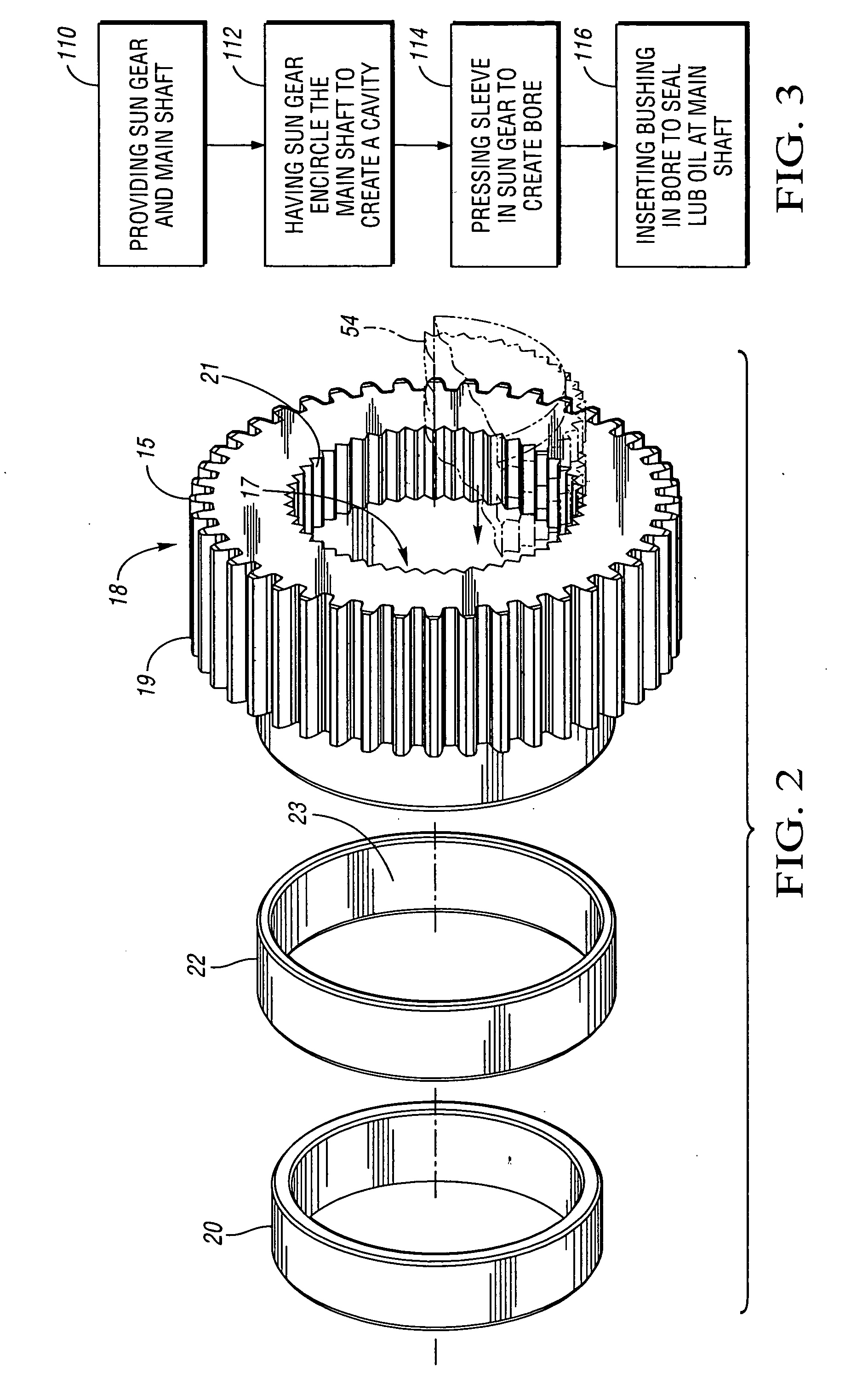

Sun gear bushing and sleeve and method for sealing in a hybrid electromechanical automatic transmission

InactiveUS20050209038A1Easy to assembleEfficient and cost-effective processHybrid vehiclesGear lubrication/coolingAutomatic transmissionGear wheel

The present invention details a sleeve and bushing of an electromechanical automatic planetary transmission. The sleeve and bushing operate to confine the desired flow of transmission lubricant through the components of the planetary gear arrangement. Additionally, the sleeve and bushing assist in maintaining a sufficient pressure level in the cavity of the planetary carrier to enable the lubricant to reach the bearings of the pinion gear. Moreover, the radius or size of the bushing / sleeve arrangement can be adjusted to occupy the radial clearance or cavity between the sun gear and main shaft for an automatic transmission with axially separable splined sun gear and sun gear shaft.

Owner:GM GLOBAL TECH OPERATIONS LLC

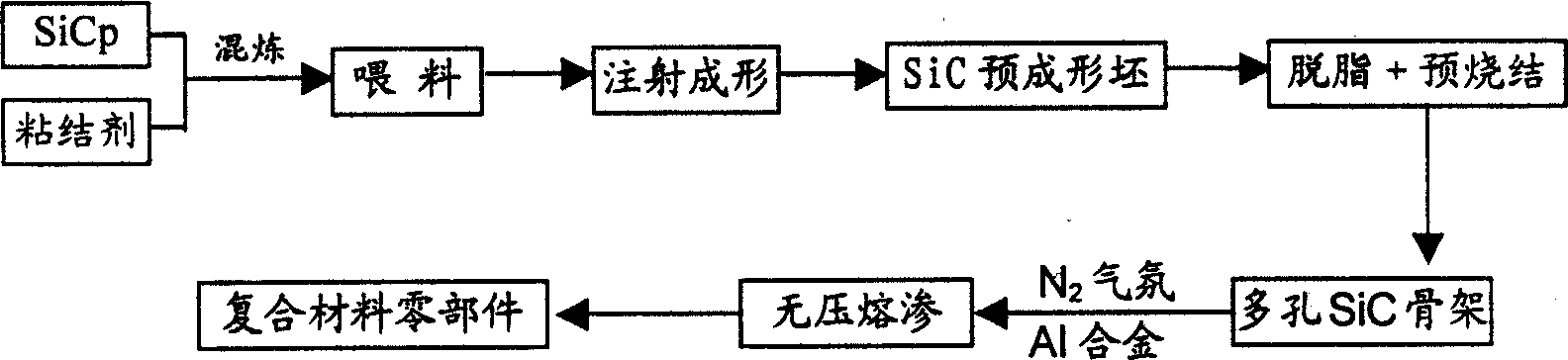

Method for producing high-volume fractional silicon-carbide particle reinforced aluminium-base composite material member

A technology for preparing the silicon carbide particles reinforced Al-based workpiece (SiCp / Al) with high volume fraction includes such steps as proportionally mixing SiC particles with paraffin wax based multi-polymer adhesive, stirring, granulating, injection moulding, thermal defatting in solvent, presintering at 1000-1150 deg.C, and osmosizing the molten Al alloy into SiC skeleton at 1100-1200 deg.C in N2 atmosphere.

Owner:UNIV OF SCI & TECH BEIJING

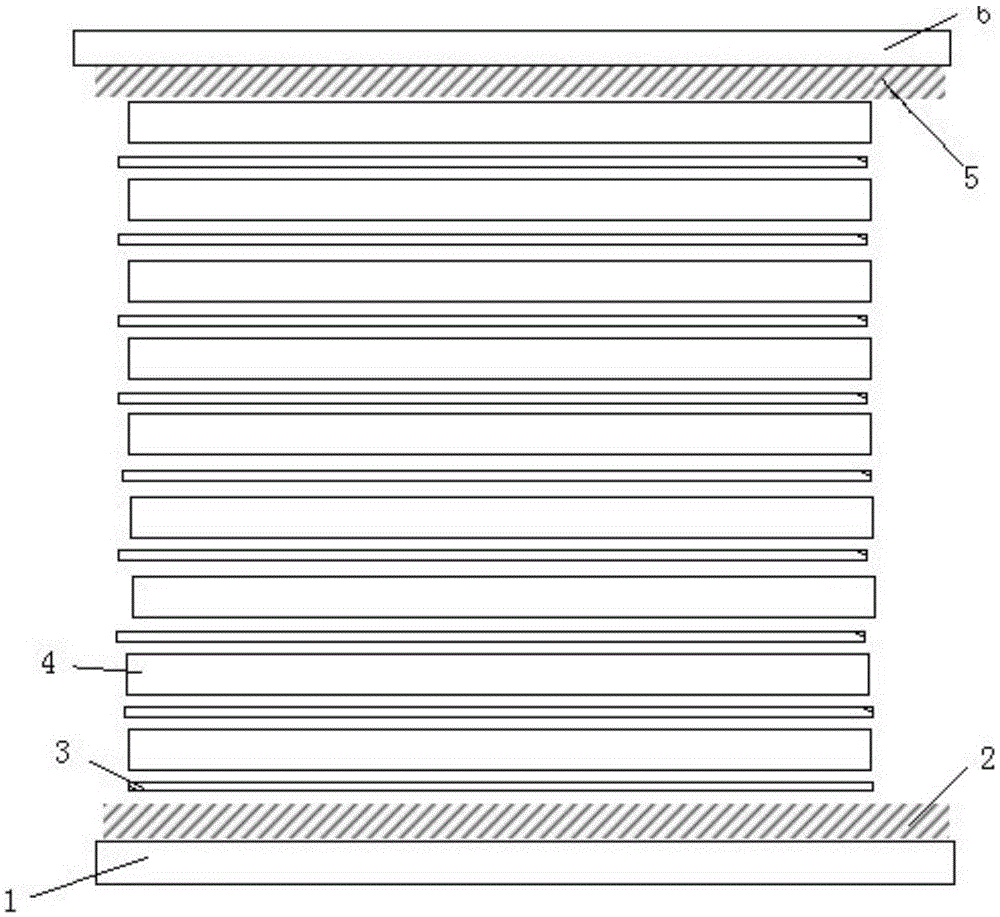

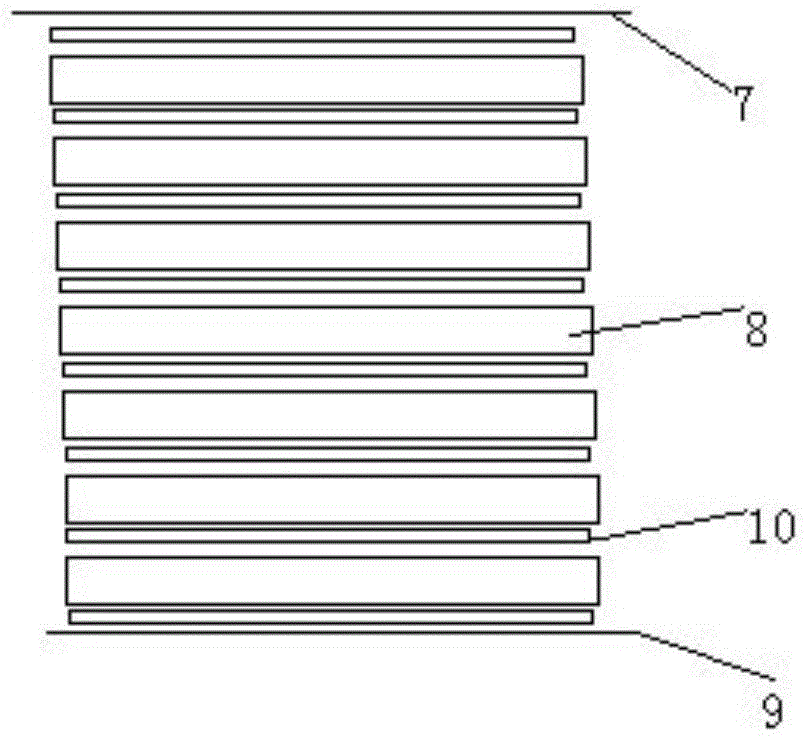

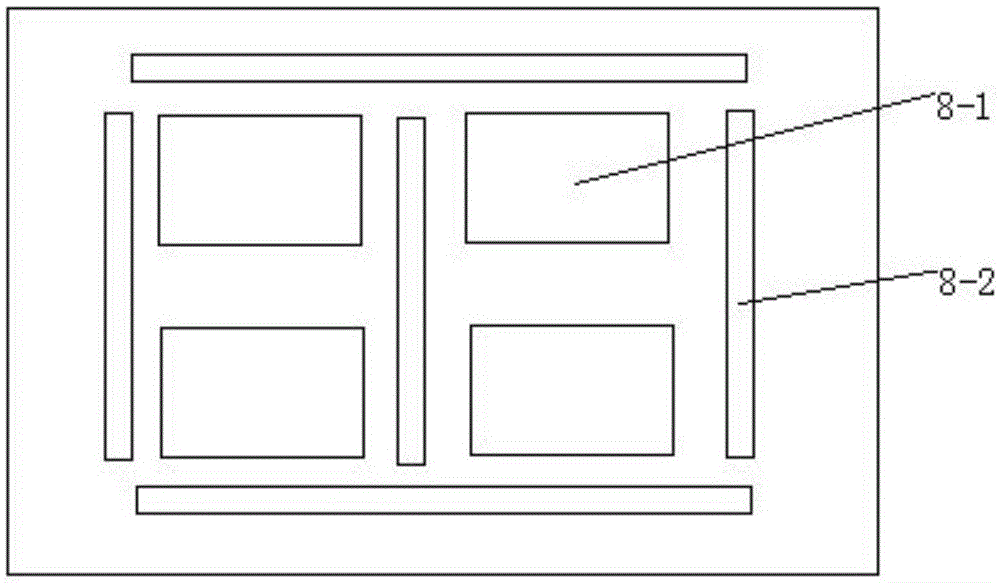

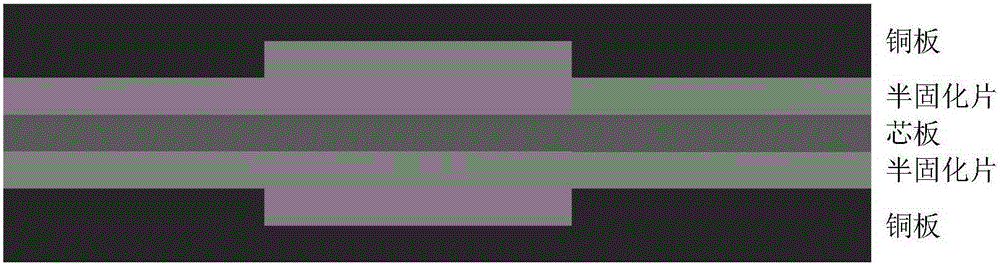

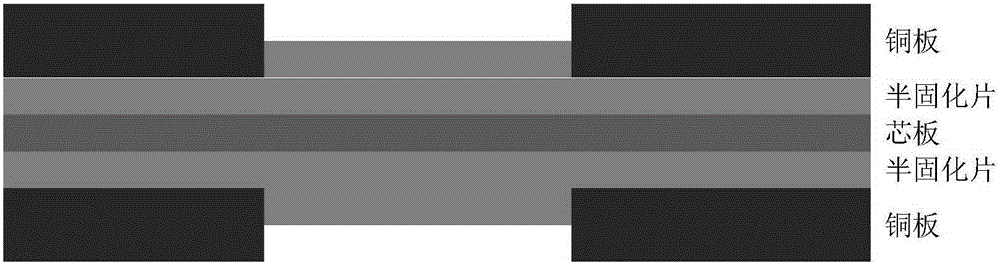

Control method for uniformly laminating multi-layered PCB

A control method for uniformly laminating a multi-layered PCB is disclosed. The control method comprises the steps of PCB laminating and pressing. The control method is simple, convenient, and easy to operate and master; the layers are aligned accurately and the PCB is pressed uniformly; board sliding and decompression can be avoided, and high product quality can be achieved; the lamination process is easy to control, and easy machining and low cost are realized as well; the relatively consistent uniformity of the thickness of each laminated board among different layers can be accurately ensured; sufficient and uniform flowing adhesive in all directions is supplied; the thickness and the impedance of a laminated dielectric layer are moderate; the board edge is designed in a choked-flow manner; the overall uniformity of the laminated PCB is high; the fused flowing time of resin in a prepreg is prolonged, so that sufficient stuffing among the multiple core plate layers is ensured, uniform fused resin flowing is realized, and the efficiency is greatly improved; and in addition, the service life of equipment is prolonged, the lamination quality is effectively ensured, and the production cost is lowered.

Owner:AOSHIKANG TECH CO LTD

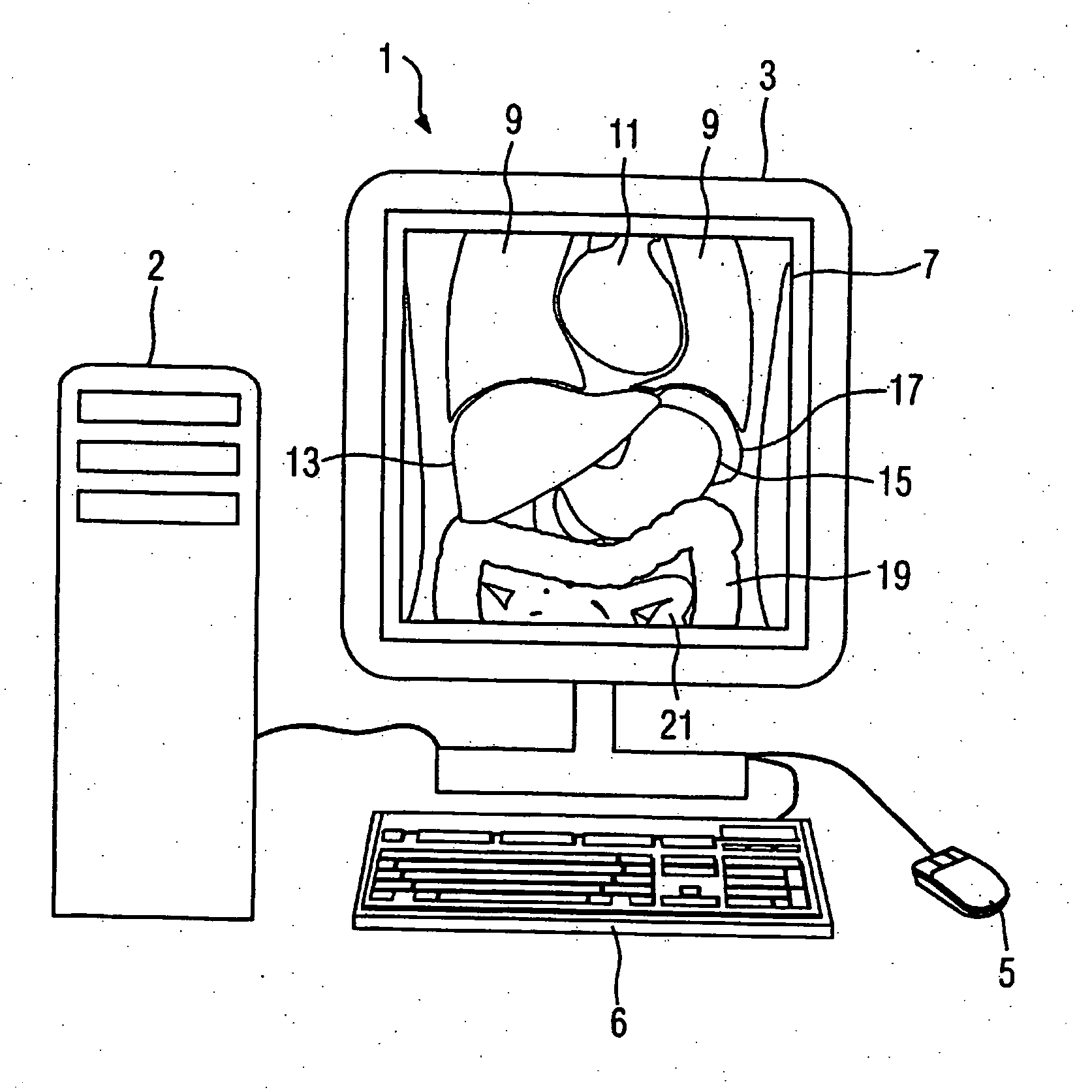

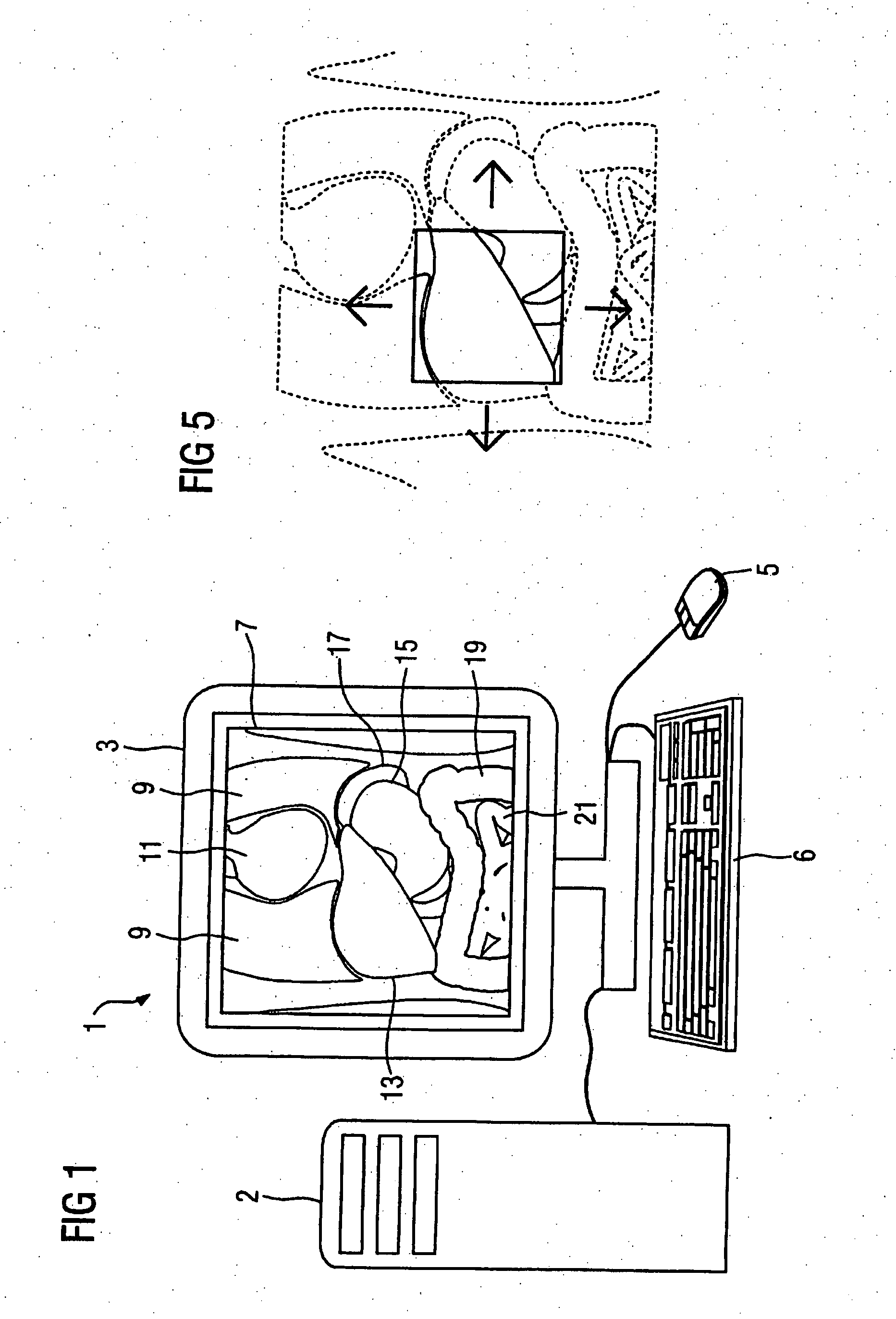

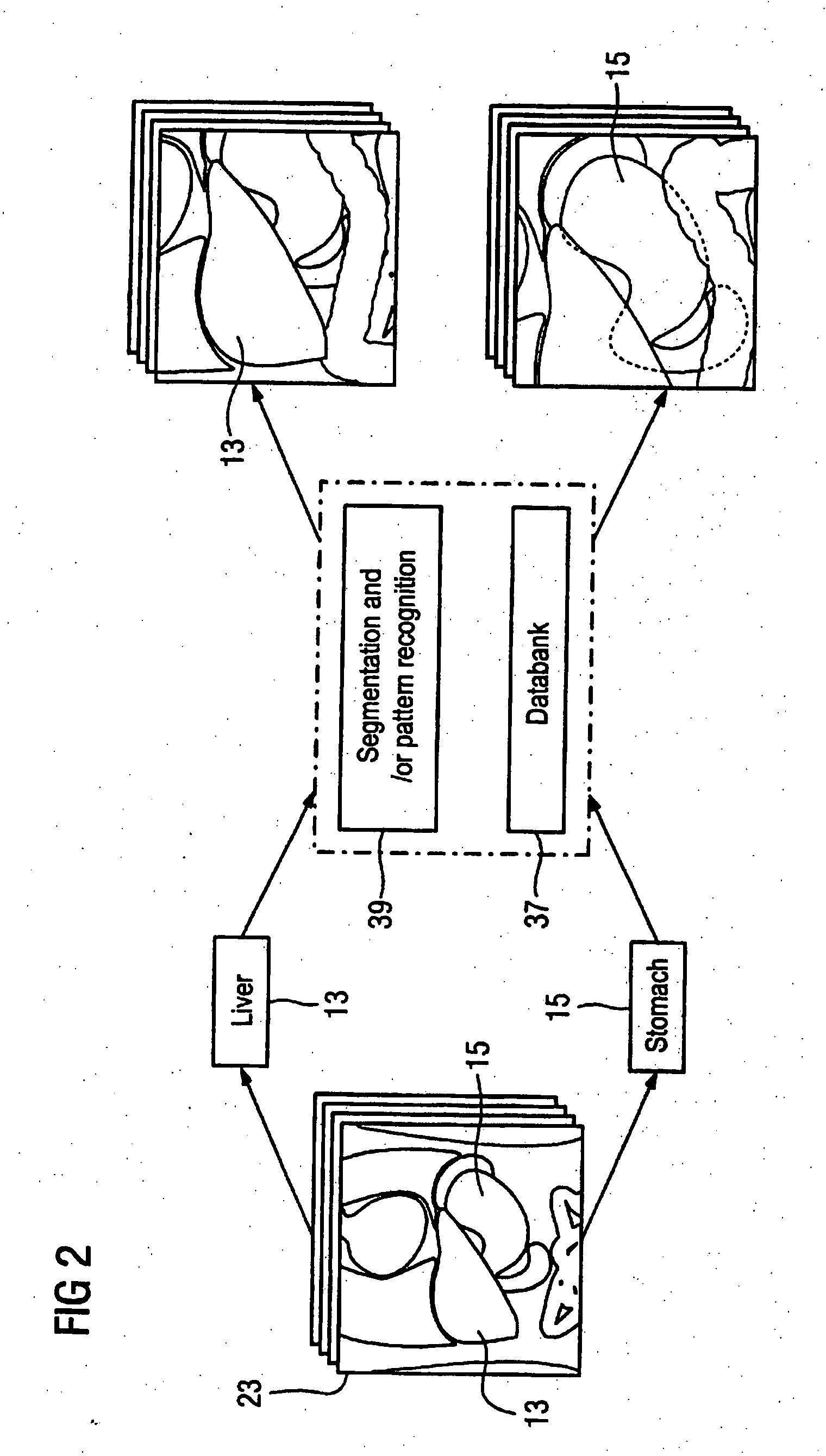

Method and processor for generating a medical image

ActiveUS20080037850A1Accurately image processing imageImprove precisionImage enhancementImage analysisData processingSoftware

In a method for generation of a medical image, starting from an acquired data set of an organ to be depicted, a magnification factor and / or an image section to be depicted are automatically determined dependent on the organ to be depicted. Based on this a medical image is generated from the data set. A data processing unit for medical images is fashioned for implementation of such a method and computer software implements such a method when it is executed on a data processing unit.

Owner:SIEMENS HEALTHCARE GMBH

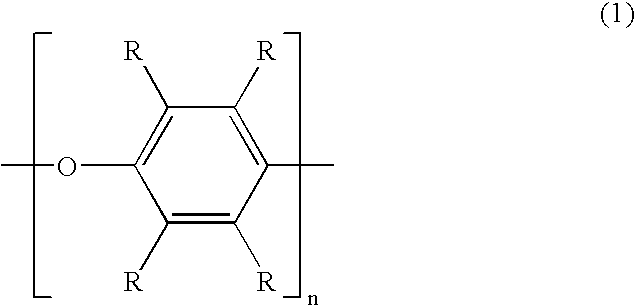

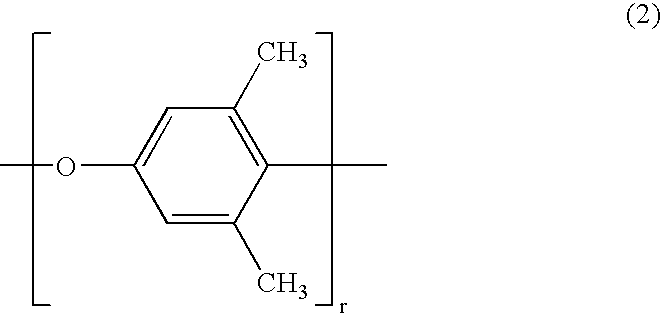

Poly(phenylene oxide) resin composition, prepreg, laminates sheet, printed wiring board, and multilayer printed wiring board

InactiveUS7288587B2Improve electrical performanceHigh glass transition temperatureSynthetic resin layered productsThin material handlingHeat resistanceTriallyl isocyanurate

The poly(phenylene oxide) resin composition of the invention is a poly(phenylene oxide) resin composition containing poly(phenylene oxide) and triallyl isocyanurate, wherein the poly(phenylene oxide) has a number average molecular weight in a range from 2,000 to 12,000 and the IPN structure can be formed in a cured product of the poly(phenylene oxide) and triallyl isocyanurate to provide a high heat resistance, and at the same time by using a poly(phenylene oxide) with a relatively low molecular weight, the fluidity of the melt resin can be made desirable at the time of molding to result in high molding properties.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Sandbag with spring-like self-closing opening

A new sandbag that has a spring-like collar attached to the inside of the sandbag's mouth that forces the mouth closed. In order to fill the bag with sand the flaps that form the mouth have to be pulled apart. The self-closing feature of this sandbag can be used to automate sandbagging by having the bags packaged with one mouth flap in the open position. As the bags are removed from the stack, roll or similar packaging, the mouth flap clamps around the open-end of the source of sand, which can be similar to a funnel. After the bags are filled, they are removed, sealed shut and the next bag is put in place. The self-closing feature of this sandbag first allows for the sand to be guided into the bag, and then forces the mouth of the bag to close. The mouth can be further secured by a sealing means such as staples, thread or fiber, or hook-and-loop fastening surfaces.

Owner:HORNE JAMES

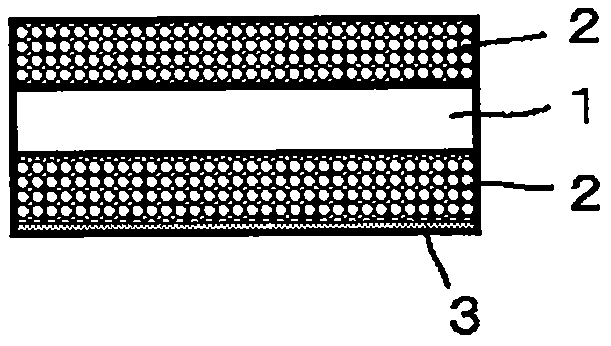

Adhesive sheet

InactiveCN106414640AGood flexibilityImprove featuresWindings insulation materialWindings insulation shape/form/constructionEpoxyFoaming agent

Disclosed is an adhesive sheet comprising a base member (1) and an expansive adhesive agent layer (2) formed on one surface or both surfaces of the base member 1, wherein the expansive adhesive agent layer (2) comprises: an epoxy resin that comprises a polyfunctional epoxy resin; a phenolic resin that serves as a curing agent; an imidazole compound that serves as a curing catalyst; and a temperature-sensitive foaming agent. The adhesive sheet particularly has a good balance among properties including rapid curability, heat resistance and adhesion properties. The adhesive sheet also has satisfactory filling properties, and therefore has excellent various properties associated with the satisfactory filling properties, including heat conductivity.

Owner:TERAOKA SEISAKUSHO

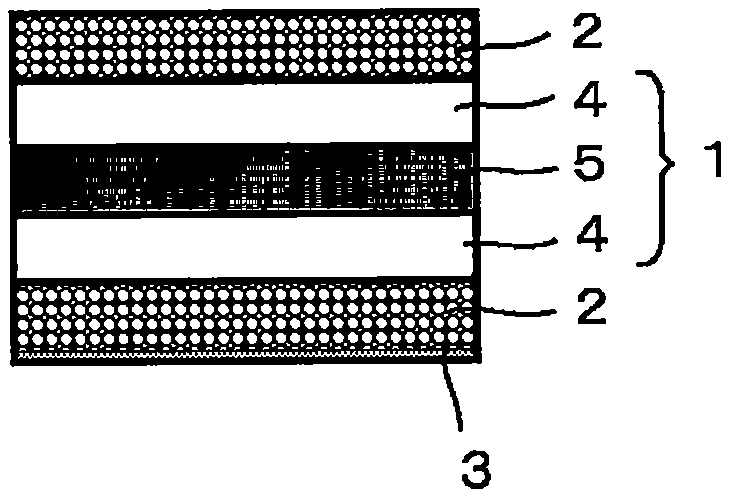

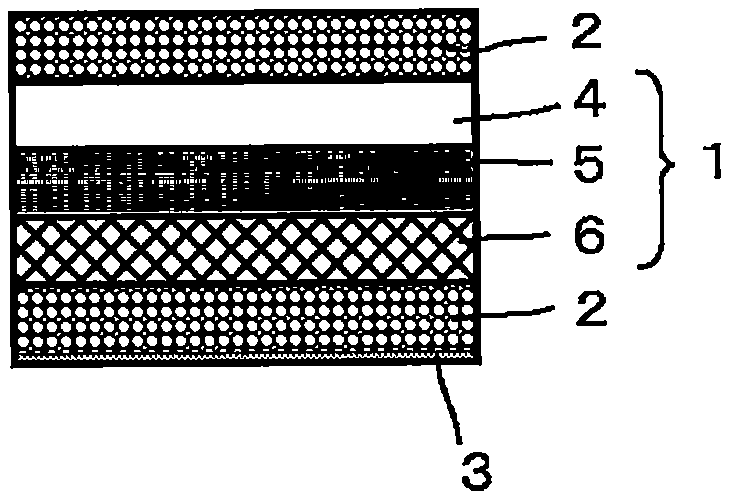

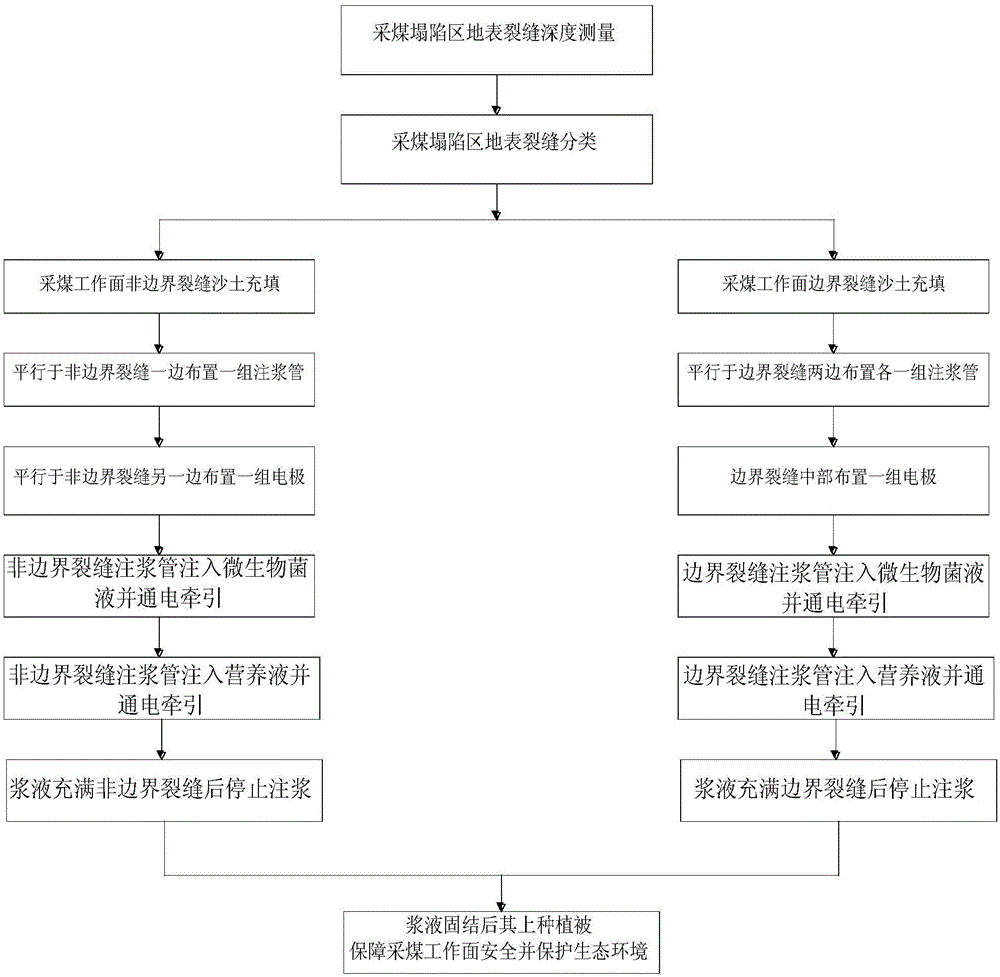

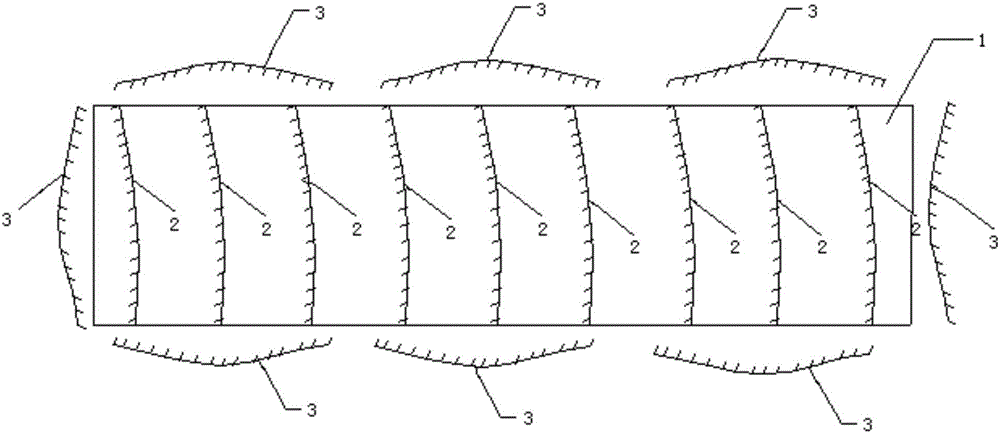

Device and method for repairing ground cracks of coal mining loess subsidence area

InactiveCN106368207AGood against soil lossGood effectSoil preservationCoal miningEnvironmental geology

The invention relates to a device and a method for repairing ground cracks of a coal mining loess subsidence area. The method comprises the steps of during repairing, firstly, detecting the depth of all the ground cracks formed on a coal mining working surface and judging the type; filling the ground cracks with a filler, and arranging grouting pipes and electrodes at the ground cracks; adding a microorganism bacterial liquid into the grouting pipes, and introducing a direct current between the grouting pipes and the electrodes; adding a nutrient solution into the grouting pipes; when the ground cracks are filled with mixed size of the microorganism bacterial liquid and the nutrient solution, stopping grouting; and after the injected mixed size is solidified, planting plants on the ground. According to the invention, the method is simple and easy to implement, the method is more environment-friendly through microorganism grouting, the distribution of microorganism products can be made more uniform through electric traction, as a renewable matter, microorganisms can be continuously utilized on a large scale, different prevention methods are utilized for cracks in different coal mining positions, and the limitation of one method is avoided.

Owner:陕西省地质环境监测总站

Rapid preparation method of low-cost carbon/carbon composite material

The invention relates to a rapid preparation method of a low-cost carbon / carbon composite material, and belongs to the field of composite materials. The method is mainly used for reducing the preparation cycle and the cost of the high-density carbon / carbon composite material. A low-density carbon / carbon composite material is formed through compounding fixed carbon fiber fabric in fiber bundles, the carbon fiber bundles are filled with carbon particles to make macro-pores become micro-pores, and low-pressure liquid impregnation carbonization or chemical vapor infiltration and high temperature thermal treatment are carried out to obtain the high-density carbon / carbon composite material. Compared with traditional methods, the preparation method of the carbon / carbon composite material, disclosed in the invention, has the advantages of greatly shortened preparation cycle and greatly reduced preparation cost.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

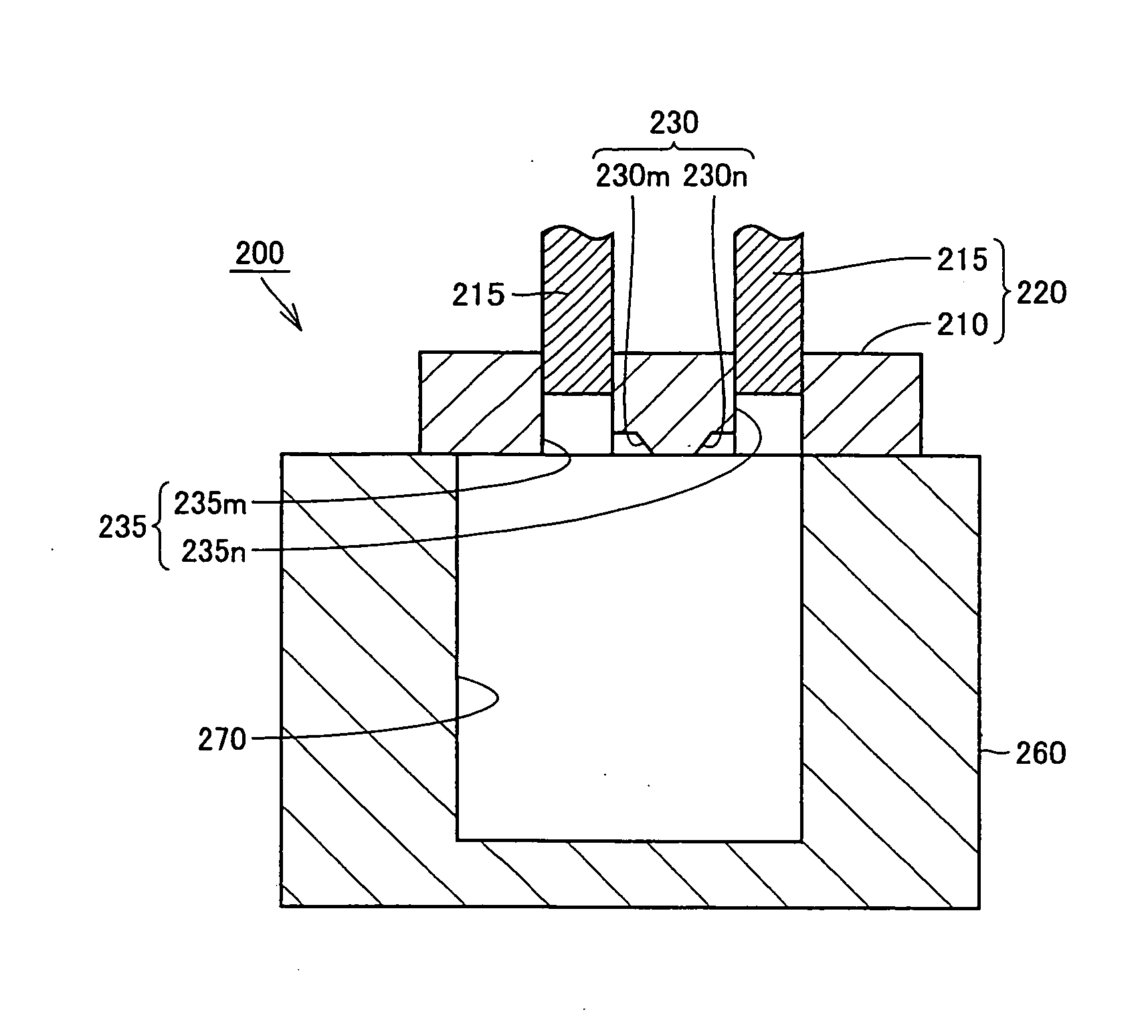

Method of manufacturing semiconductor device

InactiveUS20110244628A1Obstruction is producedFully filledSemiconductor/solid-state device detailsSolid-state devicesFilling materialsSemiconductor chip

A method of manufacturing a semiconductor device includes: supplying a supercritical fluid mixed with an under-fill material to a stacked unit, which has a plurality of stacked semiconductor chips; and filling the under-fill material in the space between the plurality of the semiconductor chips, by heating the stacked unit placed in the inside of the high-pressure vessel and curing the under-fill material flowing in the space between the plurality of the semiconductor chips by a polymerization reaction, while the supercritical fluid is being supplied.

Owner:LONGITUDE SEMICON S A R L

Paint immersing method of stator of outdoor open-type motor

ActiveCN101707423AIncrease the amount of remnantsImprove the dipping effectManufacturing dynamo-electric machinesChemistryLacquer

The invention provides a paint immersing method of a stator outdoor of an open-type motor, which is characterized by comprising the steps of: firstly, potting the end part of one end of the stator subject to primary vacuum paint immersion (VPI) with a potting adhesive, and then overturning, wherein a semi-closed surface is formed at the end part of the potting adhesive and immersion paint on the surface of the stator; and secondly, carrying out secondary paint immersion, wherein since the potting adhesive at the lower end exists, the immersion paint can not be lost because of the gravity during the secondary paint immersion, which not only can obviously increase the remain amount of paint in a stator slot and remarkably enhancing the paint immersion effect, and can lead the motor to operate more safely and reliably. The invention has broader application range, and is especially suitable for the outdoor open-type motor.

Owner:XINJIANG GOLDWIND SCI & TECH +1

Ultra-thick copper circuit board and manufacturing method thereof

ActiveCN105188269AGuaranteed stabilityAvoid over erosionPrinted circuit aspectsConductive material chemical/electrolytical removalPrinting inkCopper

The invention relates to an ultra-thick copper circuit board and a manufacturing method thereof. The manufacturing method comprises the following steps: (1) etching partial thickness of a non-circuit-pattern area copper plate on one side of the copper plate by adopting an etching process to form a groove, and carrying out the lamination step on the side by virtue of a binding layer; (2) drilling, metalizing the hole, etching the rest thickness of the non-circuit-pattern area copper plate on the other side of the copper plate by adopting the etching process to obtain a circuit pattern; (3) carrying out the printing resistance soldering steps: printing resin onto the non-circuit-pattern area, drying, and then printing ink onto the entire circuit board; and (4) carrying out the subsequent procedures. By adopting the method, the copper plate of 80Z or more is realized, and the blank that a multilayer ultra-thick copper circuit board cannot be manufactured in the industry is filled; moreover, the manufacturing method is simple, the manufacturing method can be realized by adopting a circuit board conventional device, and the manufactured ultra-thick copper circuit board is good in yield and reliable in performance.

Owner:GCI SCI & TECH

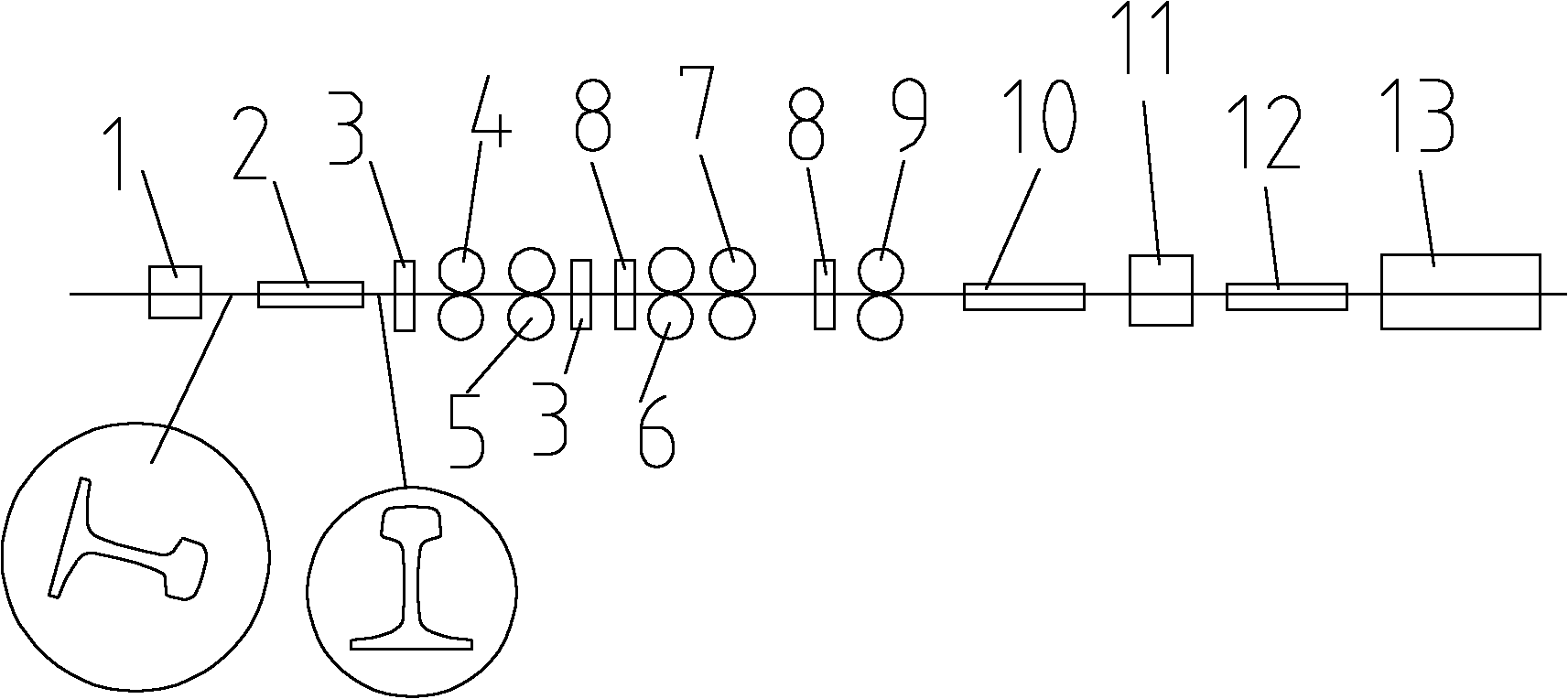

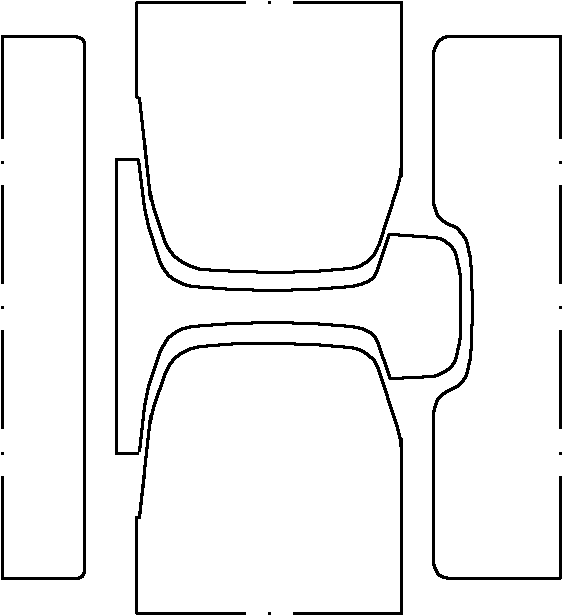

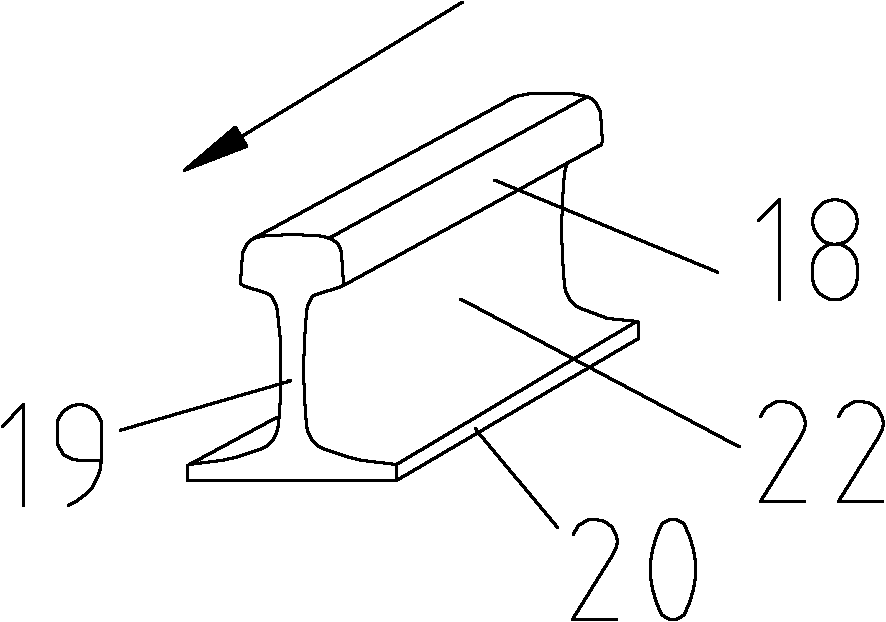

Universal rolling technology for rails

The invention discloses a universal rolling technology for rails, which can prevent the head of a rail-shaped rolled piece from being suspended in a rolling process. The technology comprises the following steps: a billet is cogged in a BD region to form a rail-shaped rolled piece; after the rail-shaped rolled piece is rolled out of a pilot hole of the BD region and before the rail-shaped rolled piece enters a universal region, the waist of the rail-shaped rolled piece is changed into a vertical state through the overturning of a turnover device; then, the rail-shaped rolled piece is conveyed into the universal region for intermediate rolling and fine rolling through a vertical universal mill and a vertical edging mill; in the rolling process of the universal region, the waist of the rail-shaped rolled piece is in the vertical state, the abdominal cavity of the rail-shaped rolled piece is rolled through a left vertical roller and a right vertical roller of the vertical universal mill, and the head of the rail-shaped rolled piece is supported by the left vertical roller and the right vertical roller of the vertical universal mill; and the rail-shaped rolled piece is conveyed into a rail printer for printing, and the rail-shaped rolled piece after printing is conveyed into a cooling bed for cooling. By adopting the technology, the final finished rail has the advantages that the head is fully filled, the abdominal cavity has better processing quality, and the working tread is better filled and has better symmetry.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

Low silver copper base medium temperature brazing filler metal

ActiveCN101524798AConserve limited resourcesReduce use costWelding/cutting media/materialsSoldering mediaUltimate tensile strengthFiller metal

The invention relates to a low silver copper base medium temperature brazing filler metal applicable to braze welding of workpieces such as copper and copper alloy, copper and steel, belonging to the field of medium temperature brazing material. The formula and content of the low silver copper base medium temperature brazing filler by weight percentage is as follows: Ag: 1.8-5%, P: 5.5-7.5%, In: 0.5-2.5%, Ni: 0.01-1%, the rest: Cu. The invention has the advantages of rational design of formula, low manufacture cost, relatively low melting temperature of the brazing filler metal when welding copper and copper alloy and copper and bundy tubes, good wetting property and fluidness, smooth and bright surface of soldered connection, high mechanical strength, fine processing property of braze welding, stable quality and good uniformity and capability of replacing noble metal silver brazing filler metal BAg25CuZnSn.

Owner:HANGZHOU HUAGUANG ADVANCED WELDING MATERIALS CO LTD

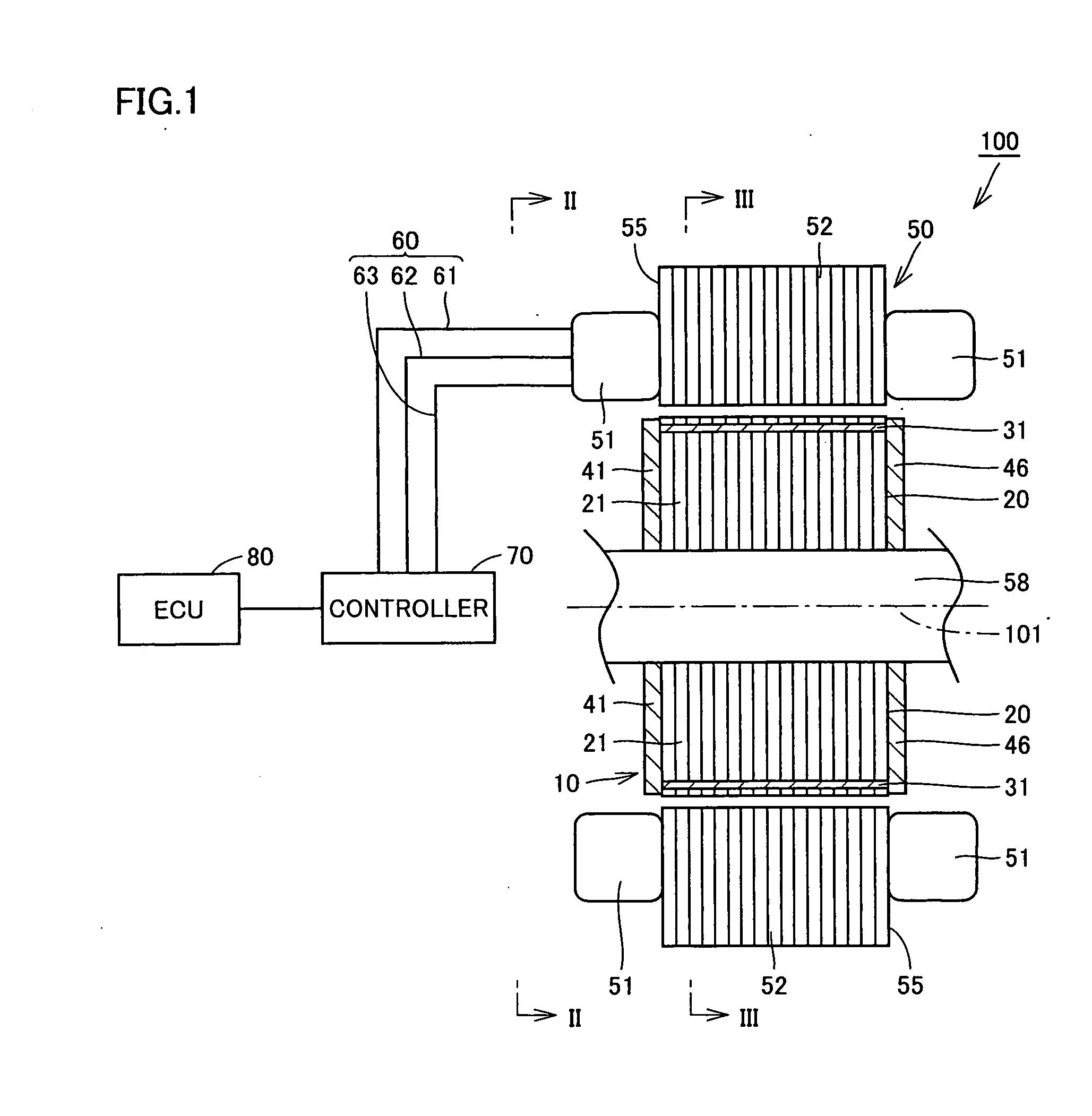

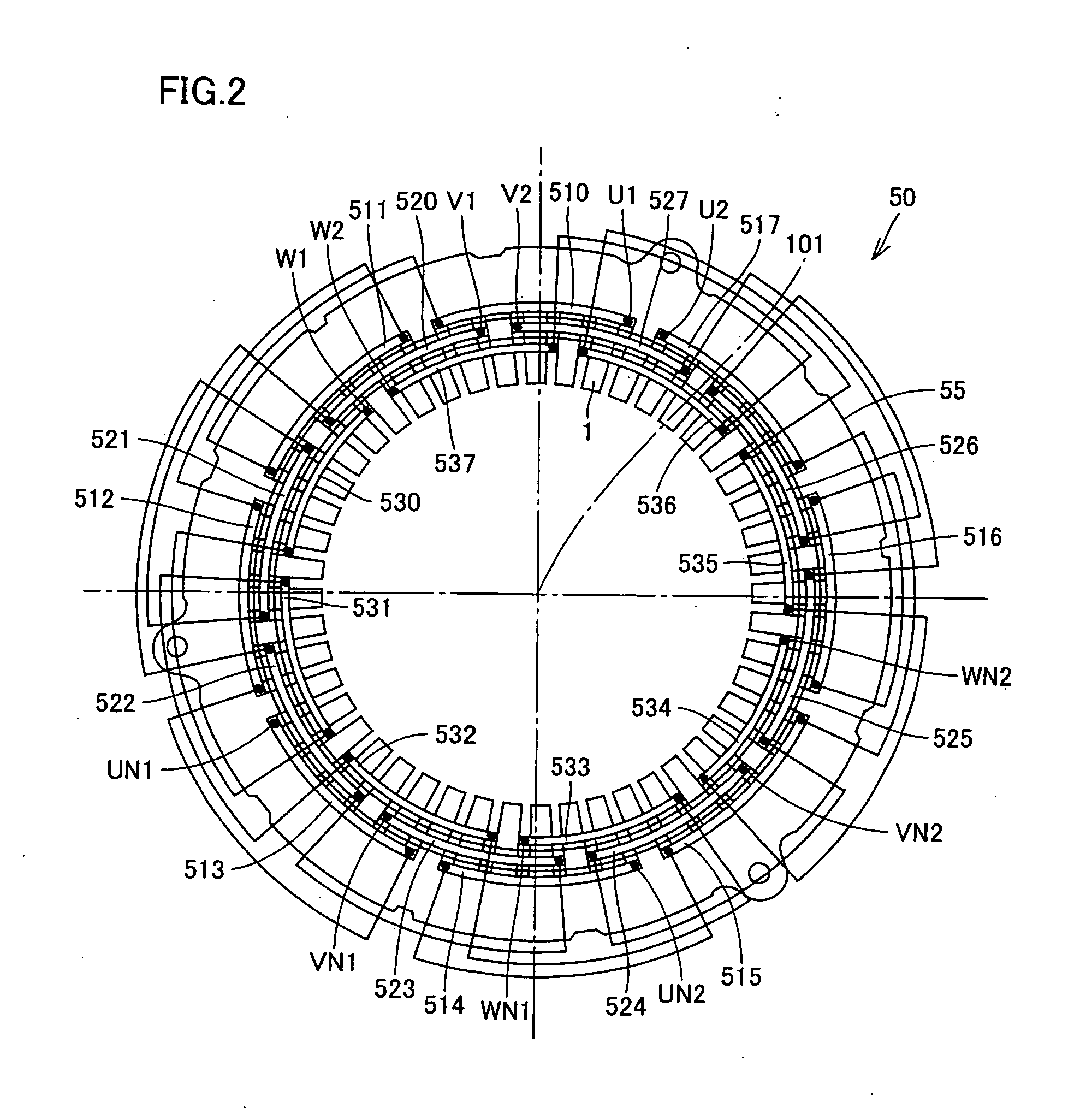

IPM Rotor, IPM Rotor Manufacturing Method and IPM Rotor Manufacturing Apparatus

ActiveUS20090278417A1Coupling rigidityImprove featuresMagnetic circuit rotating partsManufacturing stator/rotor bodiesManufactured apparatusEngineering

An injection apparatus includes a gate for injecting a filler to a gap between an inner wall of a slot and a permanent magnet. A plurality of gates are provided for one slot. An IPM rotor with improved NV characteristics, and method and apparatus for manufacturing such an IPM rotor can be provided by such a structure.

Owner:TOYOTA JIDOSHA KK

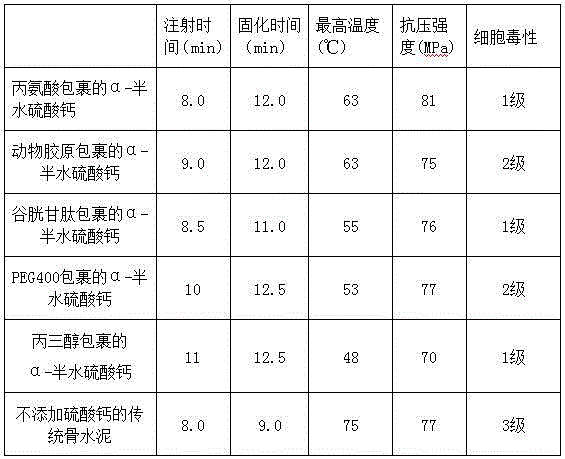

Biological bone cement

InactiveCN106390192AReduce viscosityLow reaction temperatureTissue regenerationProsthesisDiseaseMicrosphere

The invention discloses biological bone cement. Calcium sulfate hemihydrate is coated by an absorbable hydrophilic biological material to form micro-spheres, and the micro-spheres are added into acrylic bone cement according to a certain proportion; and in vivo, the calcium sulfate hemihydrate with a surface coated by the absorbable hydrophilic biological material between a tissue and the bone cement is gradually degraded, then a micro-porous structure is formed on the surface of the bone cement, and the biological tissues around continuously fill the micro-pores, so that the contact area between the bone cement and the human body tissue is greatly increased, the fixation strength of the bone cement is enhanced, the incidence of 'bone cement disease' is further reduced, and clinical advantages are obvious.

Owner:爱本斯南京医疗器械有限公司

Brazing filler metal for brazing W-Cu composite and Fe-based alloy, method and brazing technique

ActiveCN105081597AModerate melting temperatureFacilitated Diffusion and Interfacial ReactionsWelding/cutting media/materialsWelding/soldering/cutting articlesAlloy elementMicrometer

The invention discloses brazing filler metal for brazing a W-Cu composite and Fe-based alloy, a method and a brazing technique. The brazing filler metal is in a foil piece strip shape. The thickness of the brazing filler metal ranges from 50 micrometers to 100 micrometers. The brazing filler metal comprises, by weight, 6.0%-9.0% of Mn, 3.5%-5% of Co, 0.3%-1.7% of Ni, 2.0%-5.0% of Zr, 1.2%-2.8% of Ti, and the balance Cu. The brazing temperature of the brazing filler metal ranges from 1000 DEG C to 1050 DEG C, the melting temperature of the brazing filler metal is moderate, and the brazing filler metal is uniformly melted; diffusion and the interface reaction of alloy elements in the brazed connection process can be promoted through a brazing filler metal foil piece, and the wetting and spreading capacity of the brazing filler metal on the surfaces of the W-Cu composite and the Fe-based sintered alloy is improved; crystal particles are refined, residual stress is reduced, and the mechanical performance of joints is improved; the brazing technique for connecting the W-Cu composite and the Fe-based sintered alloy through the brazing filler metal is stable and reliable, vacuum brazed connection is used, a component is in a vacuum state in the heating process, the whole component does not deform, the defects such as microscopic cracks, air holes and inclusions are avoided, and the wetting and spreading capacity of the surface of the brazing filler metal is good.

Owner:JIANGSU UNIV OF SCI & TECH

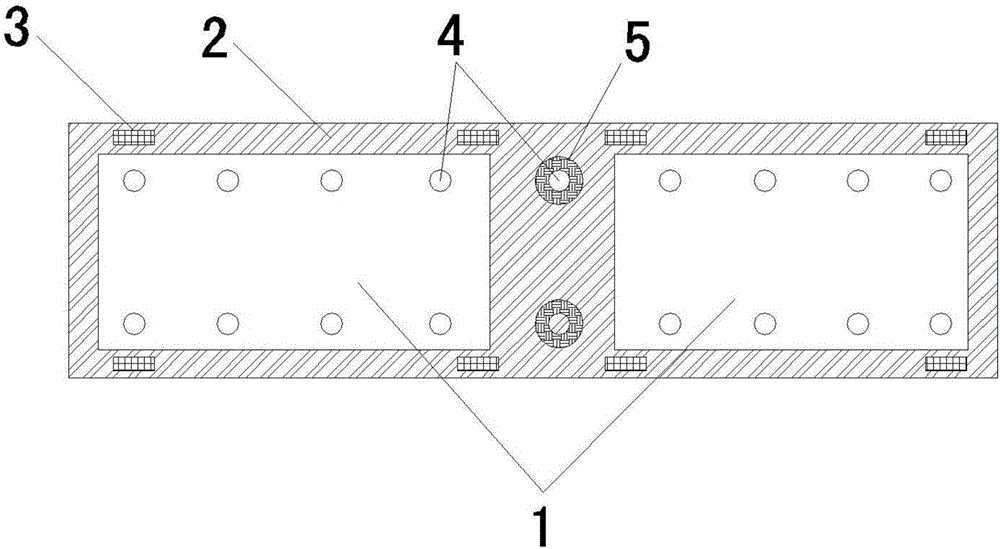

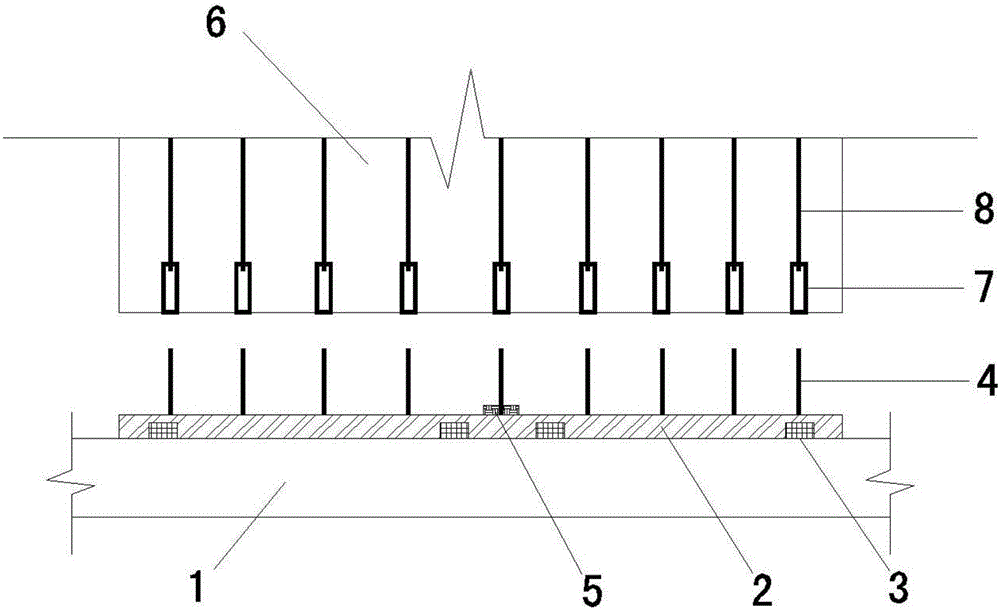

Semi-bedding and semi-grouting vertical connection construction method of prefabricated wall plate

InactiveCN105821978AGuaranteed elevation positionFully filledBuilding constructionsFloor slabEngineering

The invention discloses a construction method for vertical connection of prefabricated wall boards with semi-grouting and semi-grouting. At the same time, install the rubber pad in the sitting slurry; after the sitting slurry is wiped, put a rubber gasket thinner than the rubber pad on the vertical connection reinforcement of the floor at the sitting slurry; hoist the prefabricated wallboard, After aligning the grouting sleeve at the bottom of the prefabricated wall panel with the vertical steel bars of the floor, lower the prefabricated wall panel so that the vertical steel bars of the floor slab are inserted into the grouting sleeve at the bottom of the prefabricated wall panel one by one; when the prefabricated wall panel is completely put down Support on the rubber pad, then adjust the position of the prefabricated wall panel and fix it temporarily; after the prefabricated wall panel is fixed, perform grouting construction on the grouting sleeve so that the prefabricated wall panel is fixed on the floor through the curing connection of the grouting material and the sitting grout superior. This method can make the structure firm and stable.

Owner:天津住宅集团建设工程总承包有限公司

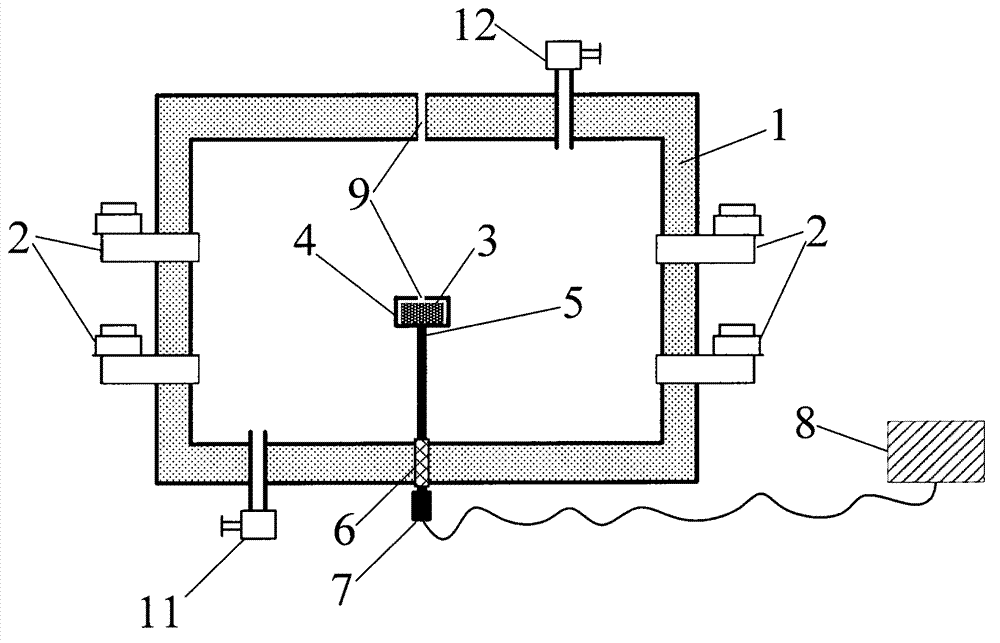

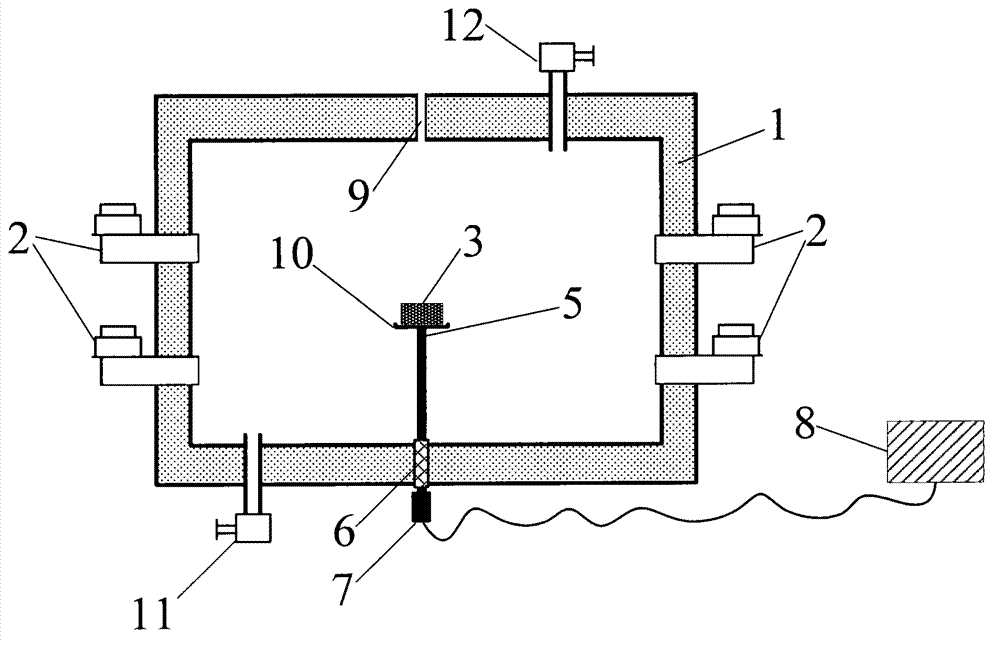

Ultrasonic vibration activation assisted microwave sintering furnace

The invention aims at designing an ultrasonic vibration activation assisted sintering microwave sintering furnace according to the practical needs of new material research and development for the sintering technology and the advantages of the ultrasonic technology. The ultrasonic vibration activation assisted microwave sintering furnace is composed of a microwave source, magnetrons, a waveguide tube, a wave leading crucible or a common high-temperature crucible, an amplitude-change pole, an amplitude-change pole supporting frame, an ultrasonic generator, an ultrasonic transducer and the like. Electric signals generated by the ultrasonic generator are converted into ultrasonic vibration through the ultrasonic transducer, the ultrasonic vibration is transmitted to a sample to be sintered in the wave leading crucible or the common high-temperature crucible through the amplitude-change pole and the crucible, the sample to be sintered is in the ultrasonic vibration state in the microwave sintering process, material particles of the sample to be sintered are vibrated at a high speed under the microwave sintering temperature through the microwave radiation action, crystalline grains of the sample to be sintered are promoted to be quickly and evenly nucleated and grow or part of matter is evenly melted for quickly filling a gap. By means of the ultrasonic vibration activation assisted microwave sintering furnace, the sintered microstructure of a block sample can be more uniform and more compact, and the sample is better in the microstructure.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com