Control method for uniformly laminating multi-layered PCB

A control method and PCB board technology, which is applied in multilayer circuit manufacturing, printed circuit manufacturing, electrical components, etc., can solve the problem of reduced pressure and temperature uniformity of the hot plate of the press, poor uniformity of the PCB board, and poor overall uniformity of the board and other problems to achieve the effect of optimizing pressing parameters, avoiding poor pressing uniformity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment includes the following steps:

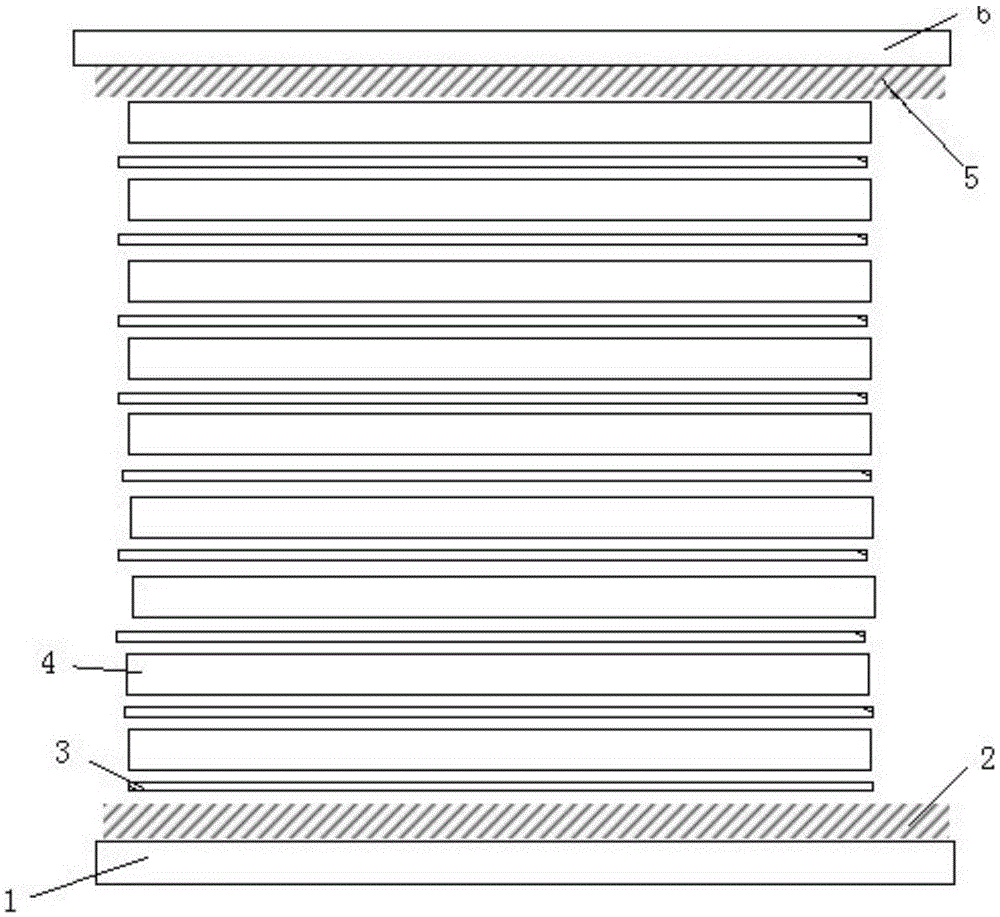

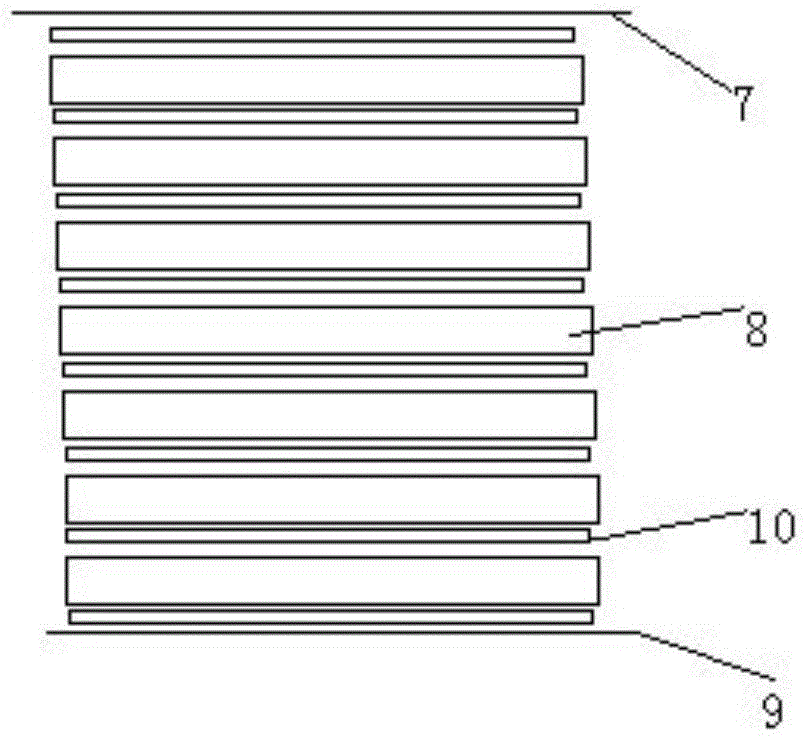

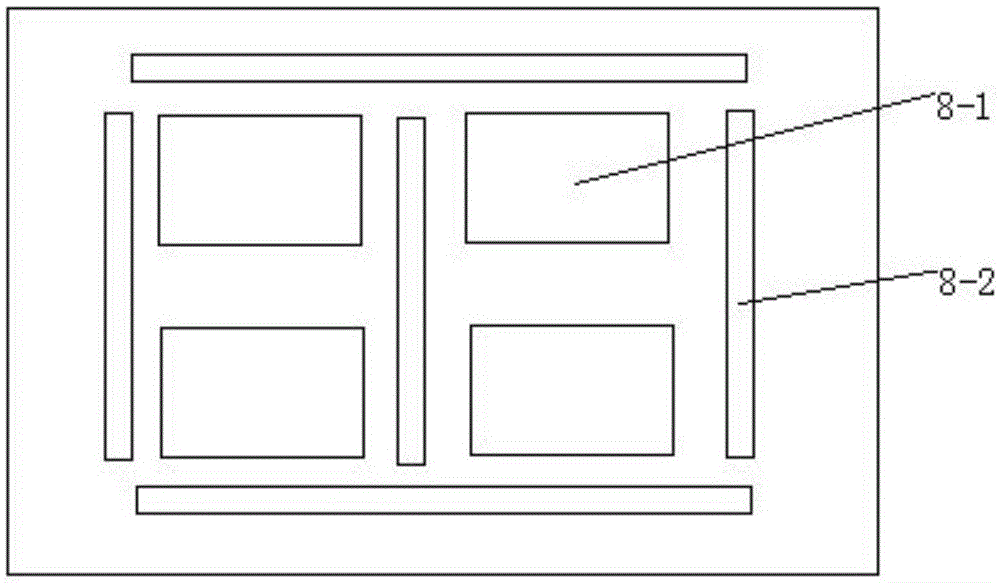

[0037] (1) PCB board stack: first place the carrier plate 1, place the lower buffer layer 2 on the carrier plate 1, place mirror steel plates 3 and PCB boards 4 alternately on the lower buffer layer 2, and the PCB board 4 is made of The upper copper foil 7, several core board layers 8 and the lower copper foil 9 are placed sequentially from top to bottom, and a prepreg 10 is placed between the upper copper foil 7 and the lower copper foil 9 and the adjacent core board layer 8, A prepreg 10 is placed between the core layer 8 and the core layer 8, and the placement positions of the core layer 8 and the prepreg 10 are positioned by an infrared positioning transmitter, and the number of the mirror steel plate 3 is the same as that of the PCB board 4 , the number of PCB boards 4 is adapted to the opening height of the hot plate of the pressing device, and then an upper buffer layer 5 is placed, and a cover plate 6 is placed abo...

Embodiment 2

[0052] This embodiment includes the following steps:

[0053] (2) PCB board stack: first place the carrier plate 1, place the lower buffer layer 2 on the carrier plate 1, and alternately place mirror steel plates 3 and PCB boards 4 on the lower buffer layer 2, and the PCB board 4 is made of The upper copper foil 7, several core board layers 8 and the lower copper foil 9 are placed sequentially from top to bottom, and a prepreg 10 is placed between the upper copper foil 7 and the lower copper foil 9 and the adjacent core board layer 8, A prepreg 10 is placed between the core layer 8 and the core layer 8, and the placement positions of the core layer 8 and the prepreg 10 are positioned by an infrared positioning transmitter, and the number of the mirror steel plate 3 is the same as that of the PCB board 4 , the number of PCB boards 4 is adapted to the opening height of the hot plate of the pressing device, and then an upper buffer layer 5 is placed, and a cover plate 6 is placed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com