Patents

Literature

2991results about How to "Uniform pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

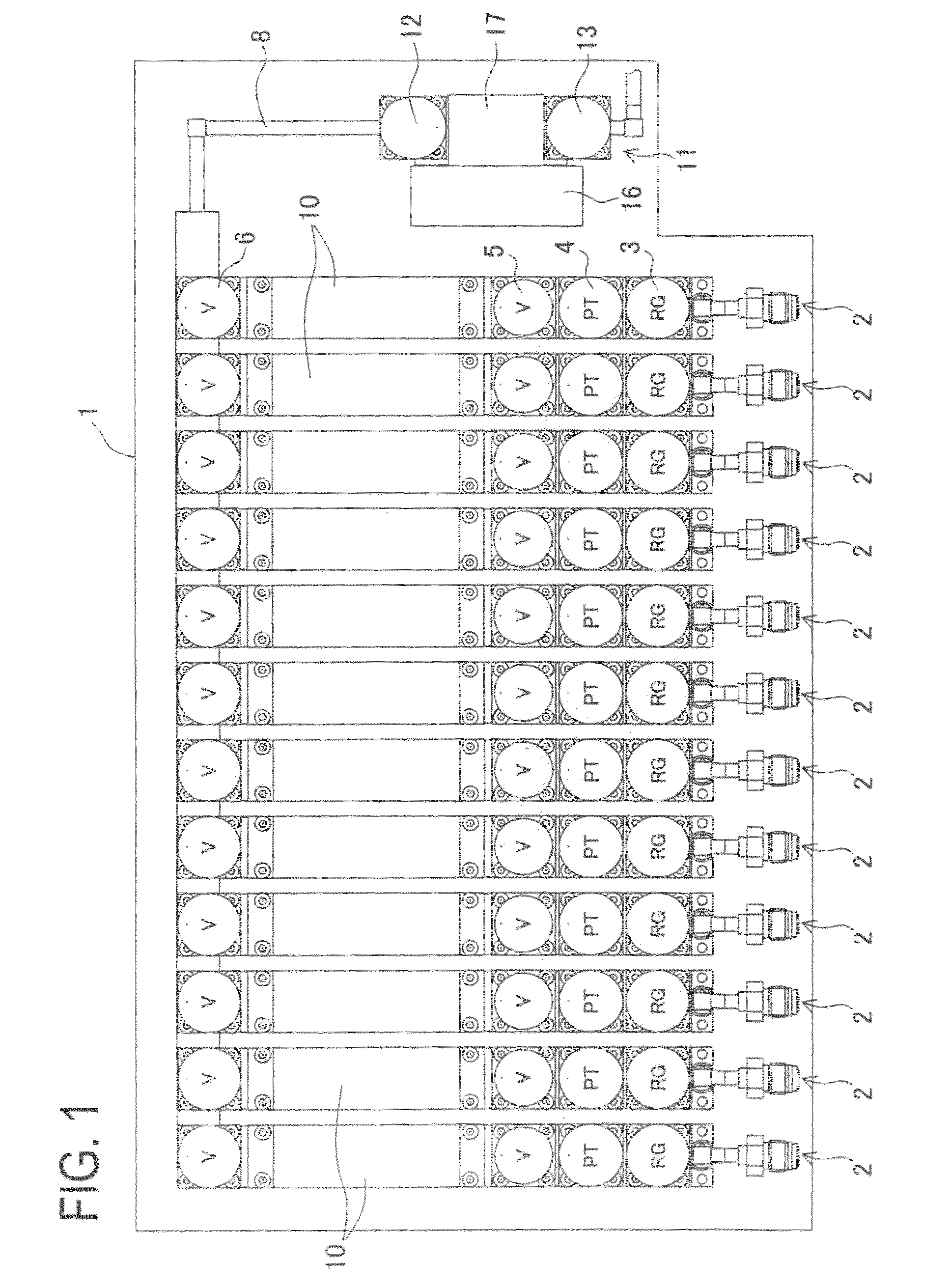

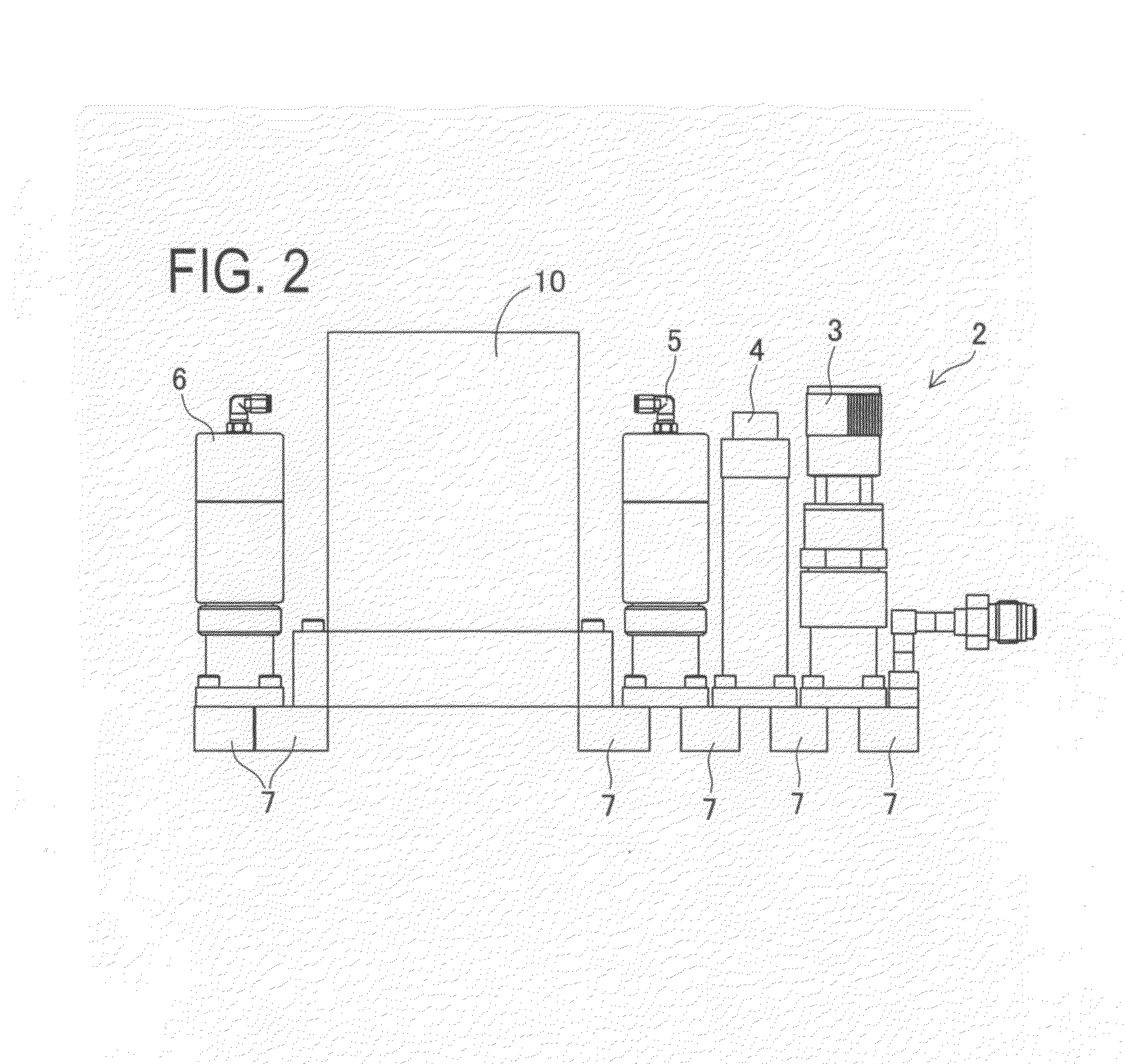

Gas flow rate verification unit

ActiveUS7716993B2Increase flow rateUniform pressureMultiple way valvesPipeline systemsEngineeringGas supply

A gas flow rate verification unit capable of enhancing reliability of gas flow rate verification. The gas flow rate verification unit has a first cutoff valve that is connected to a flow rate control device and to which gas is inputted, a second cutoff valve for discharging the gas, a communication member for allowing the first cutoff valve and the second cutoff valve to communicate with each other, a pressure sensor for detecting the pressure of the gas supplied between the first cutoff valve and the second cutoff valve, a temperature detector for detecting the temperature of the gas supplied between the first cutoff valve and the second cutoff valve, and a control means for verifying the flow of the gas flowing in the flow control device, the verification being performed by using both the result of the pressure detected by the pressure sensor and the result of the temperatures detected by the temperature detector. The volume (Vk) between the valve seat of the first cutoff valve and the valve seat of the second cutoff valve is equal to or less than the volume (Ve) between the outlet of the flow control device and the valve seat of the first cutoff valve.

Owner:CKD

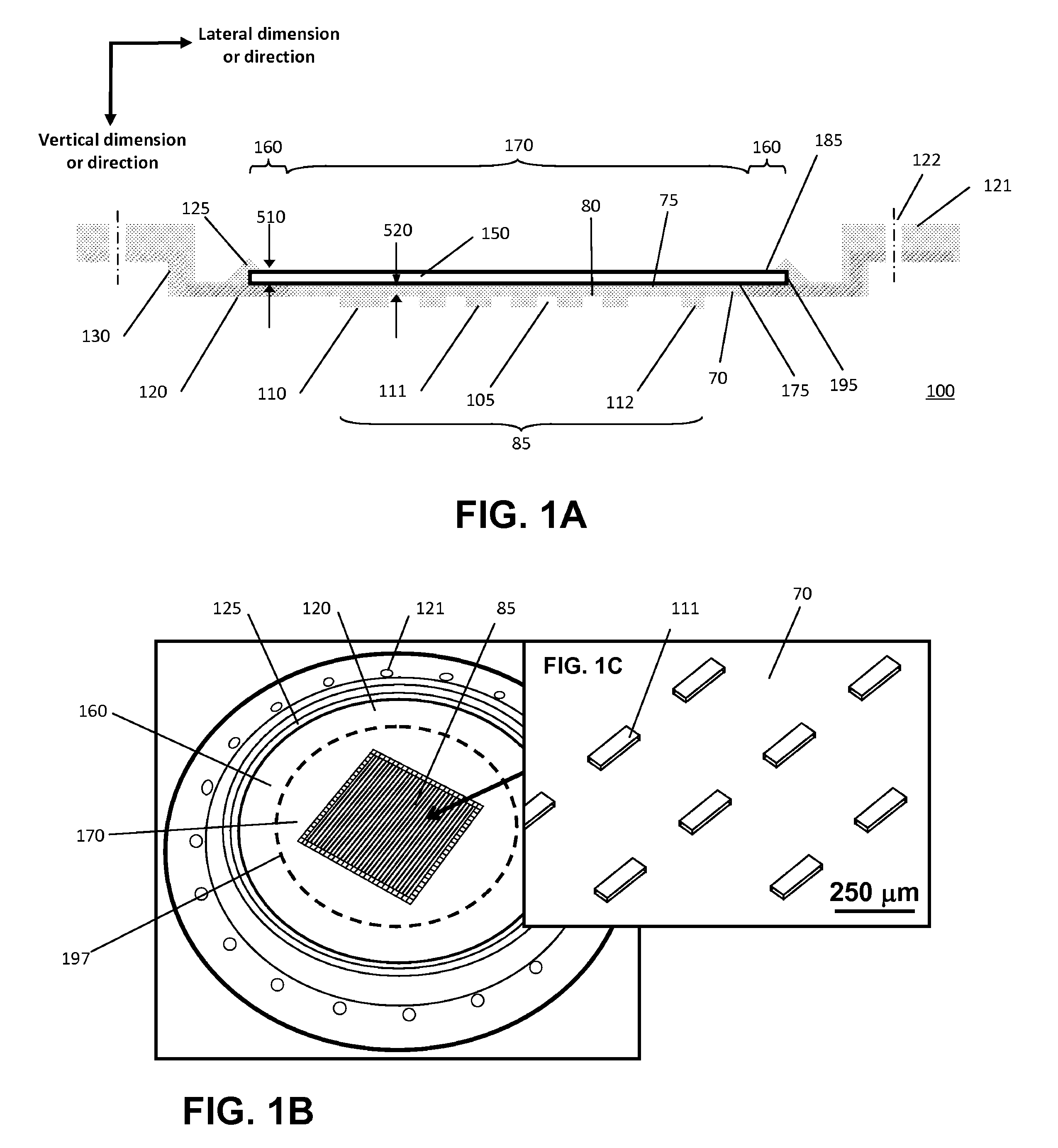

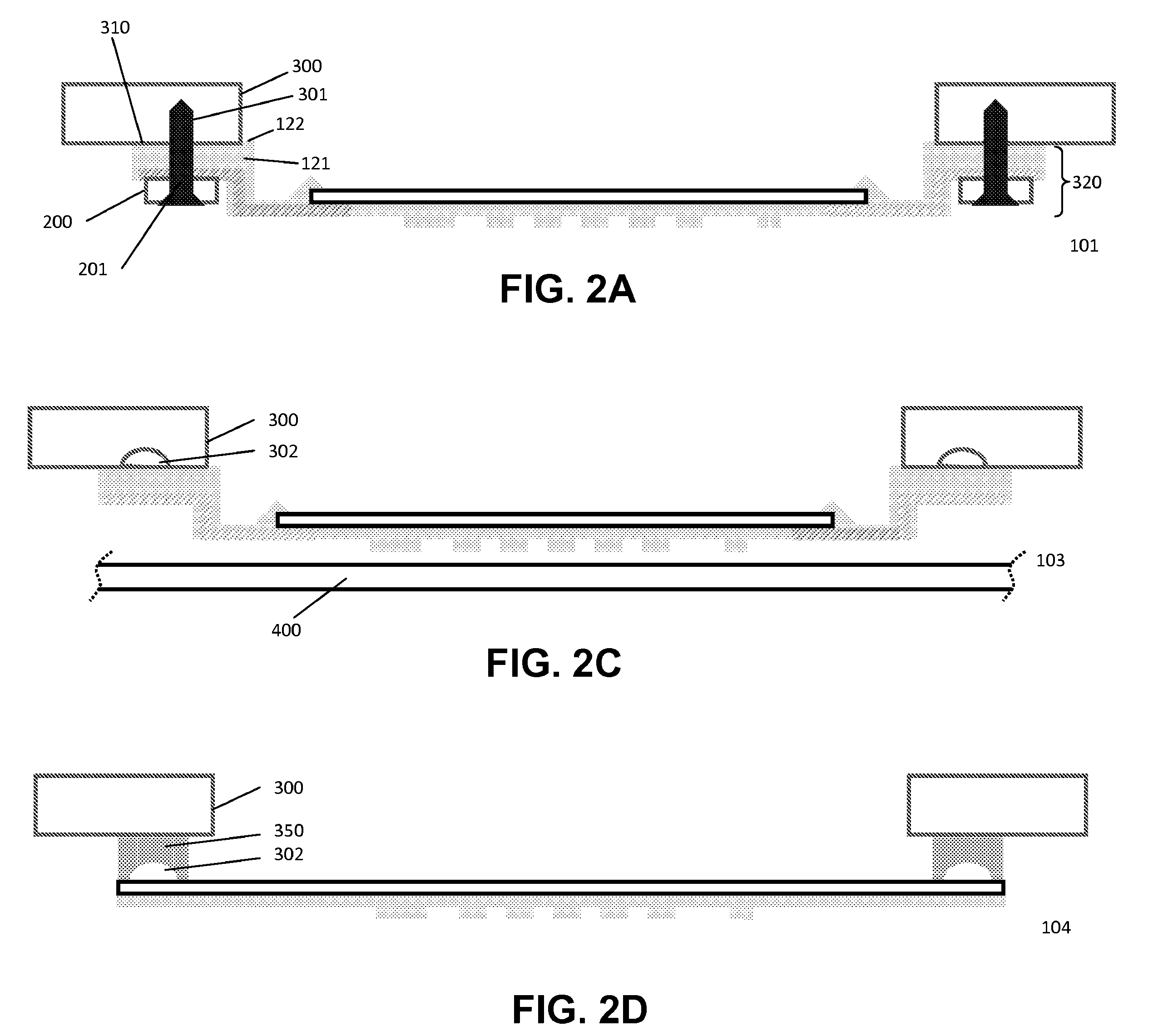

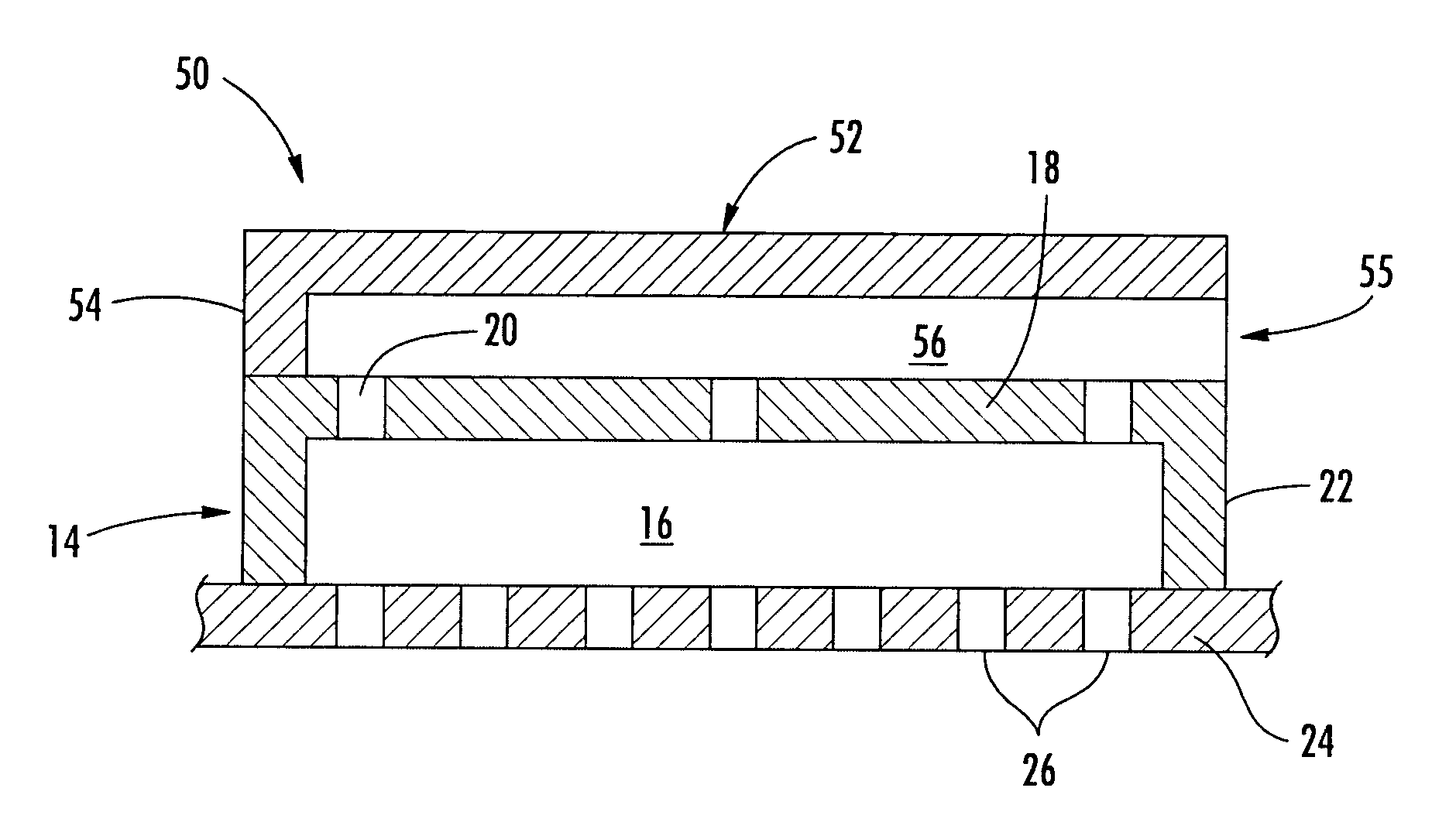

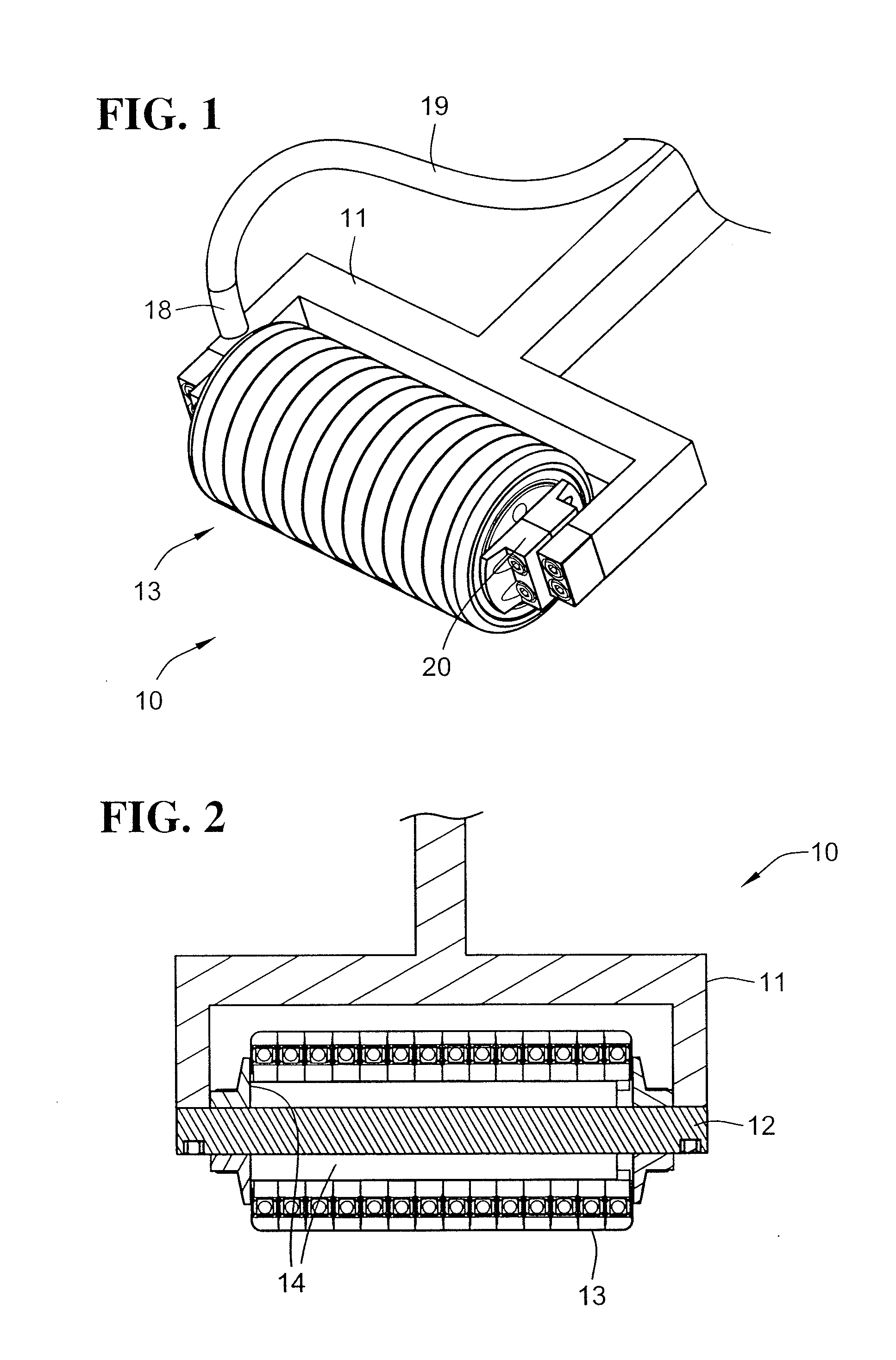

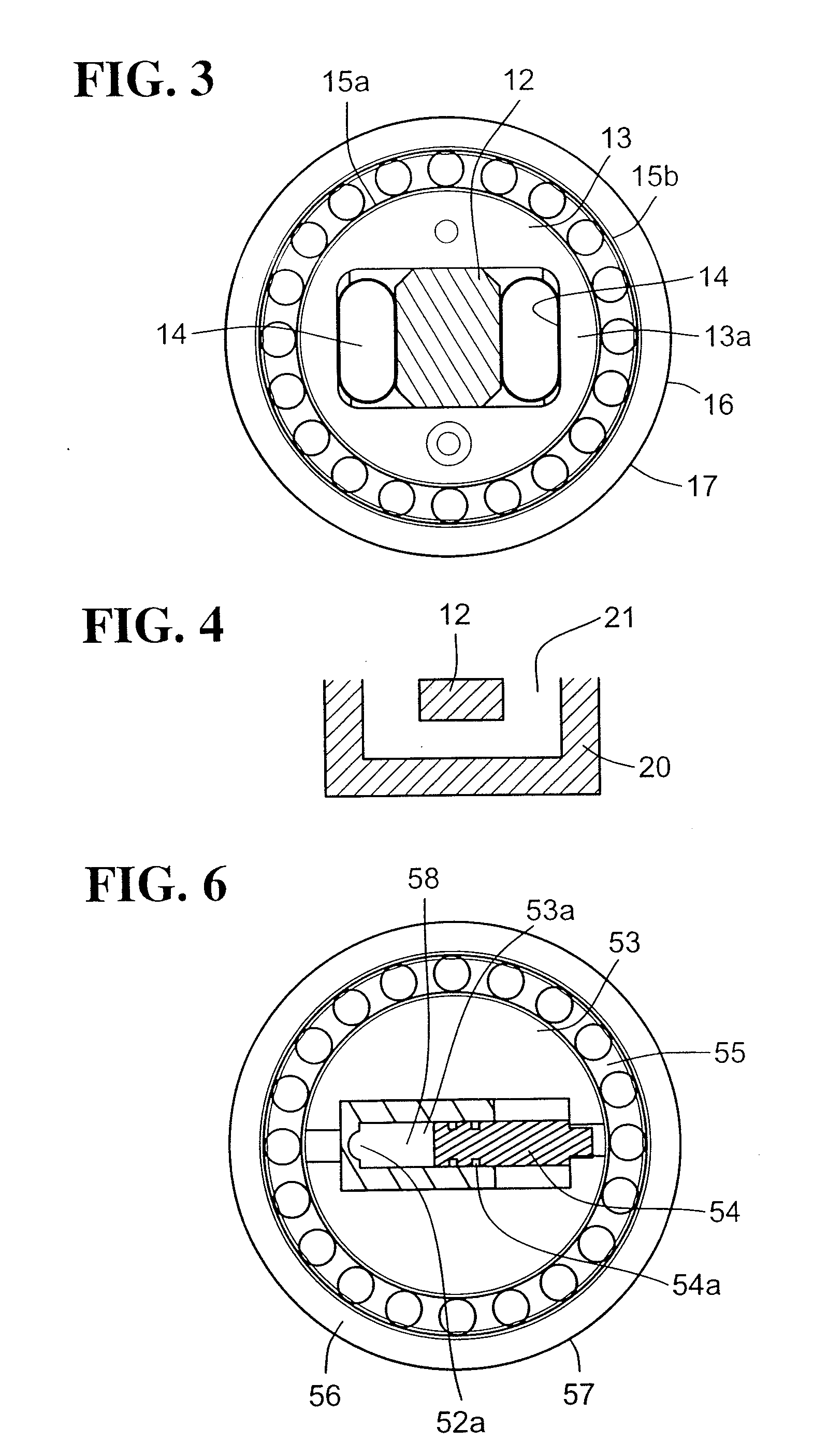

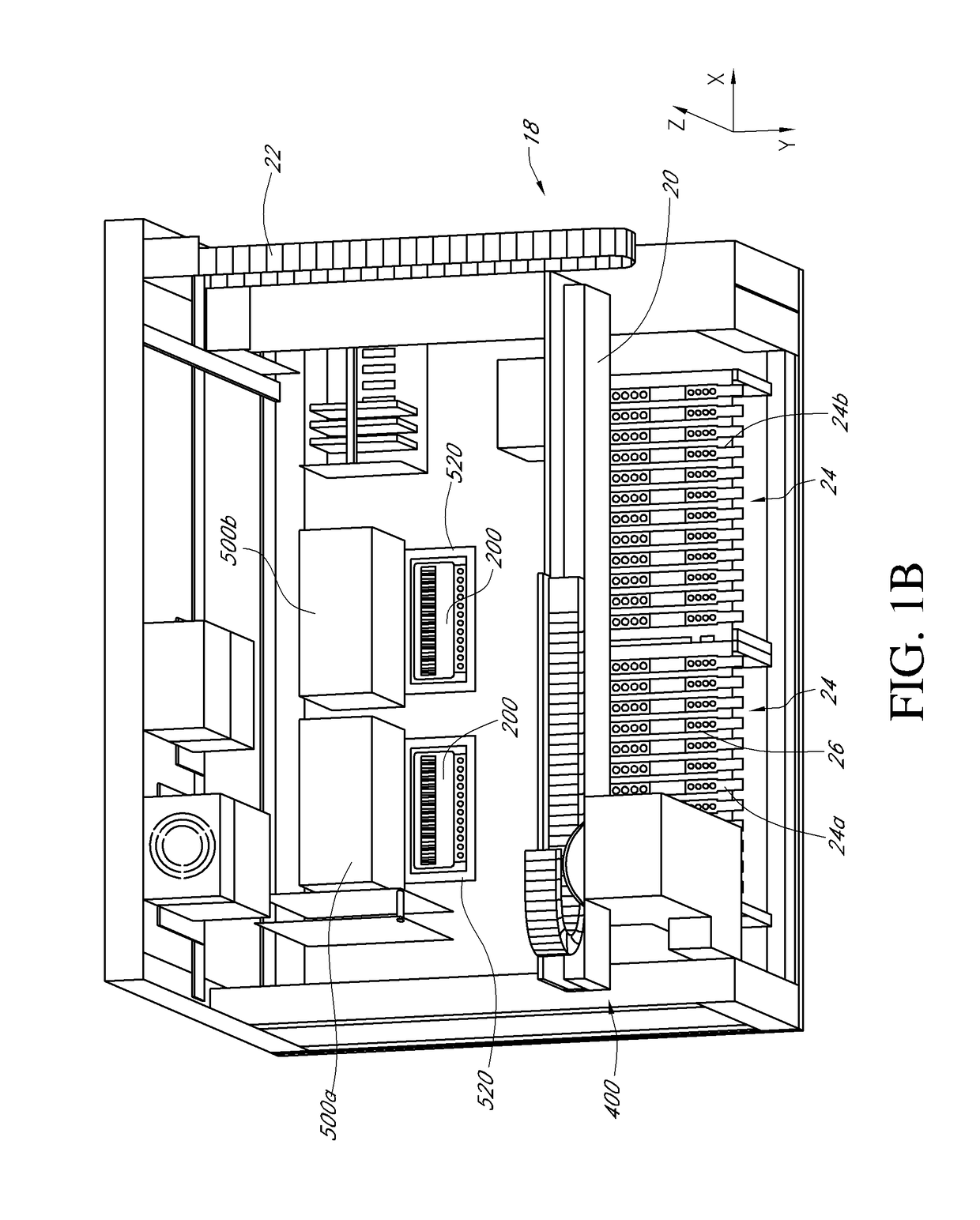

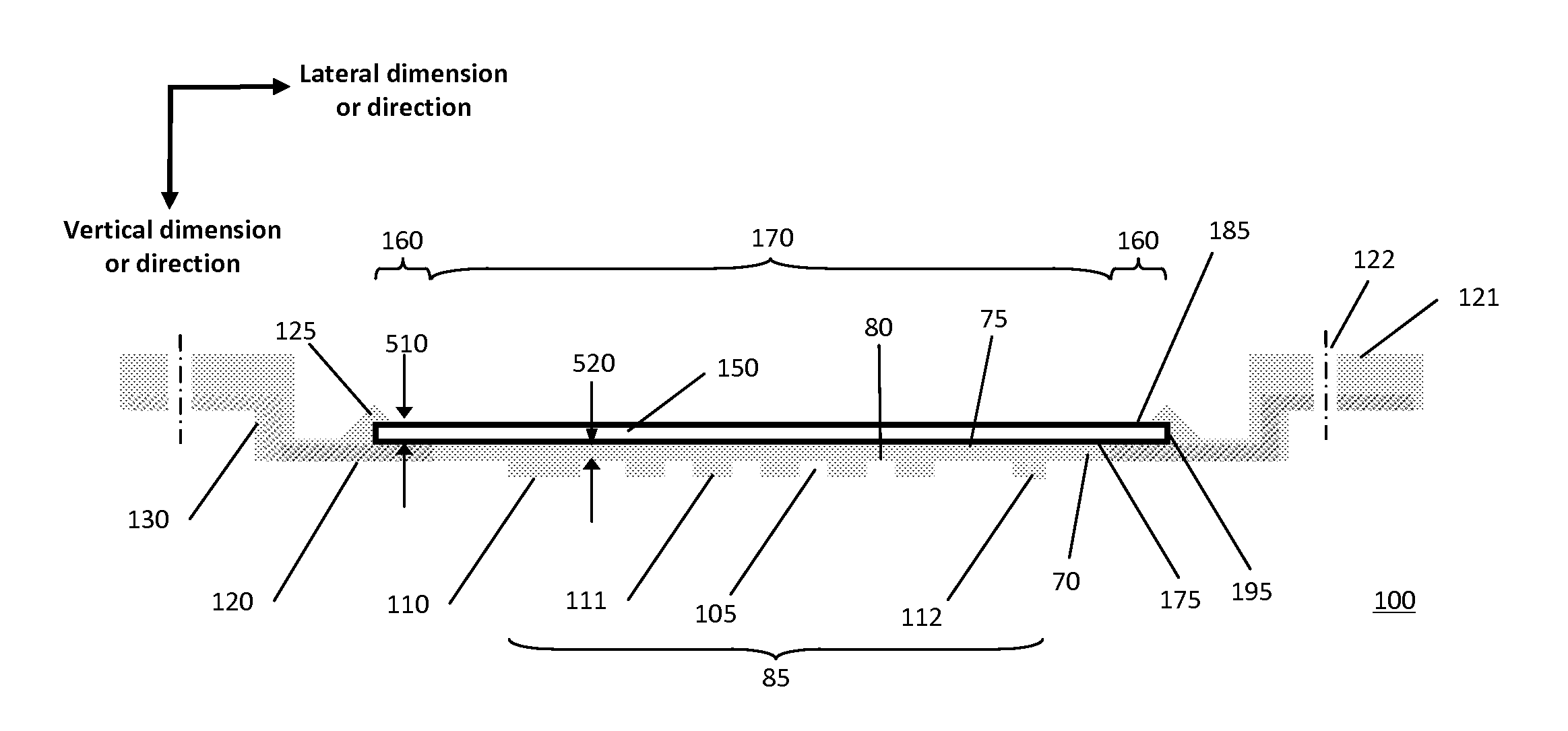

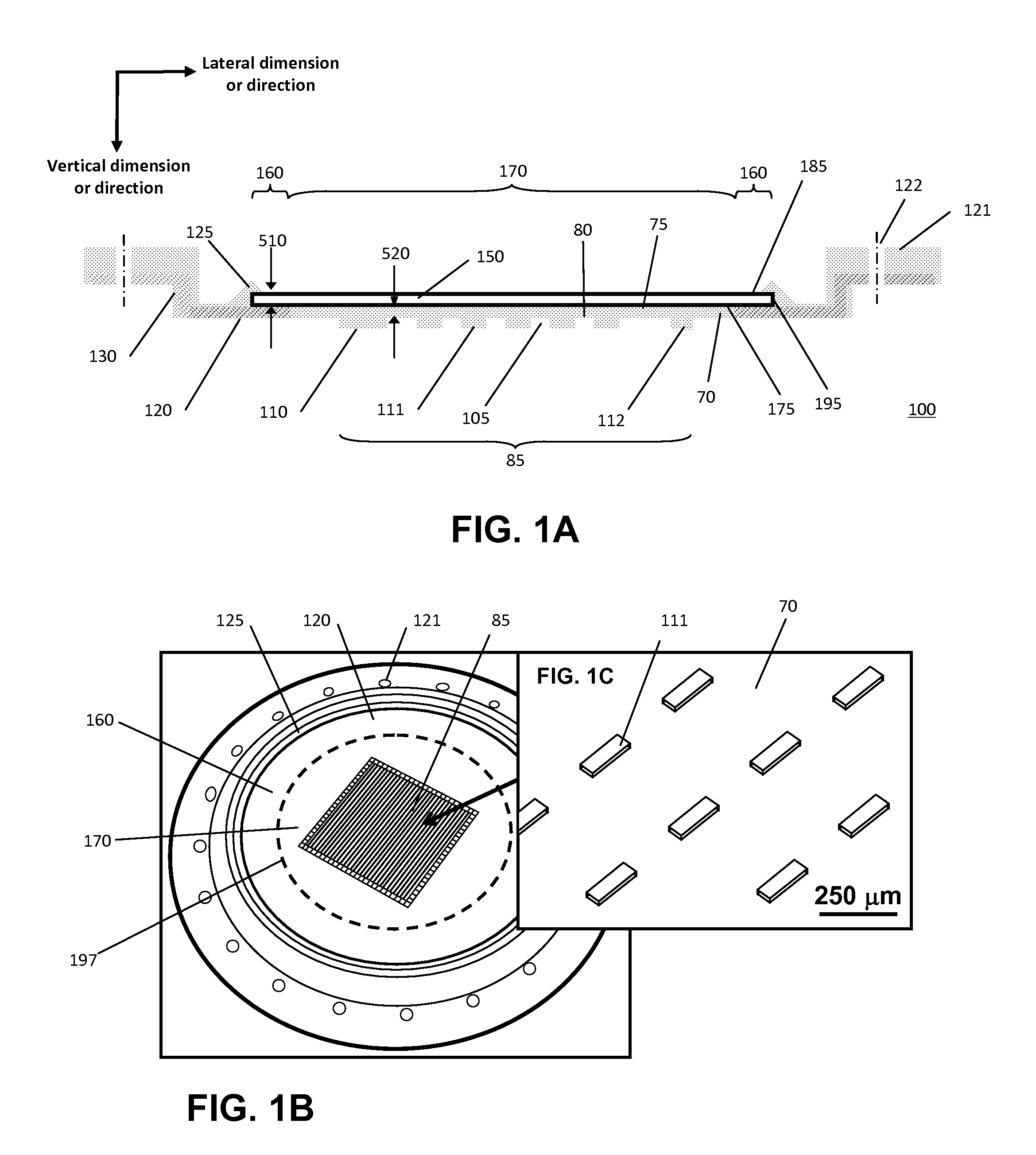

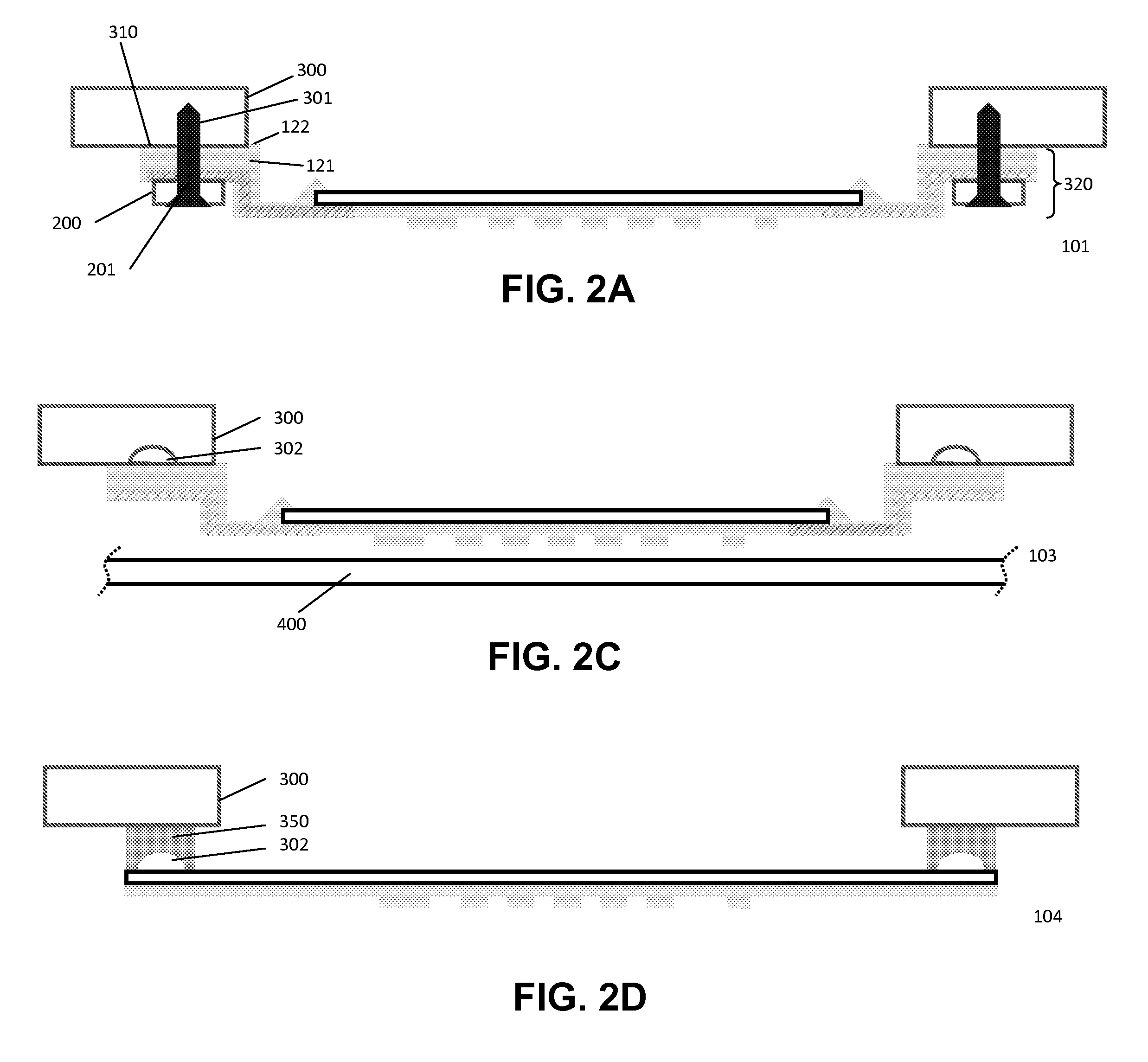

Reinforced composite stamp for dry transfer printing of semiconductor elements

ActiveUS7927976B2Easy to controlPrecise and repeatable vertical motionTurning machine accessoriesMouldsSemiconductor structureContact force

Provided are reinforced composite stamps, devices and methods of making the reinforced composite stamps disclosed herein. Reinforced composite stamps of certain aspects of the present invention have a composition and architecture optimized for use in printing systems for dry transfer printing of semiconductor structures, and impart excellent control over relative spatial placement accuracy of the semiconductor structures being transferred. In some embodiments, for example, reinforced composite stamps of the present invention allow for precise and repeatable vertical motion of the patterned surface of the printing apparatus with self-leveling of the stamp to the surface of a contacted substrate. Reinforced composite stamps of certain aspect of the present invention achieve a uniform distribution of contact forces between the printing apparatus patterned surface and the top surface of a substrate being contacted by the reinforced composite stamp of the printing apparatus.

Owner:X DISPLAY CO TECH LTD

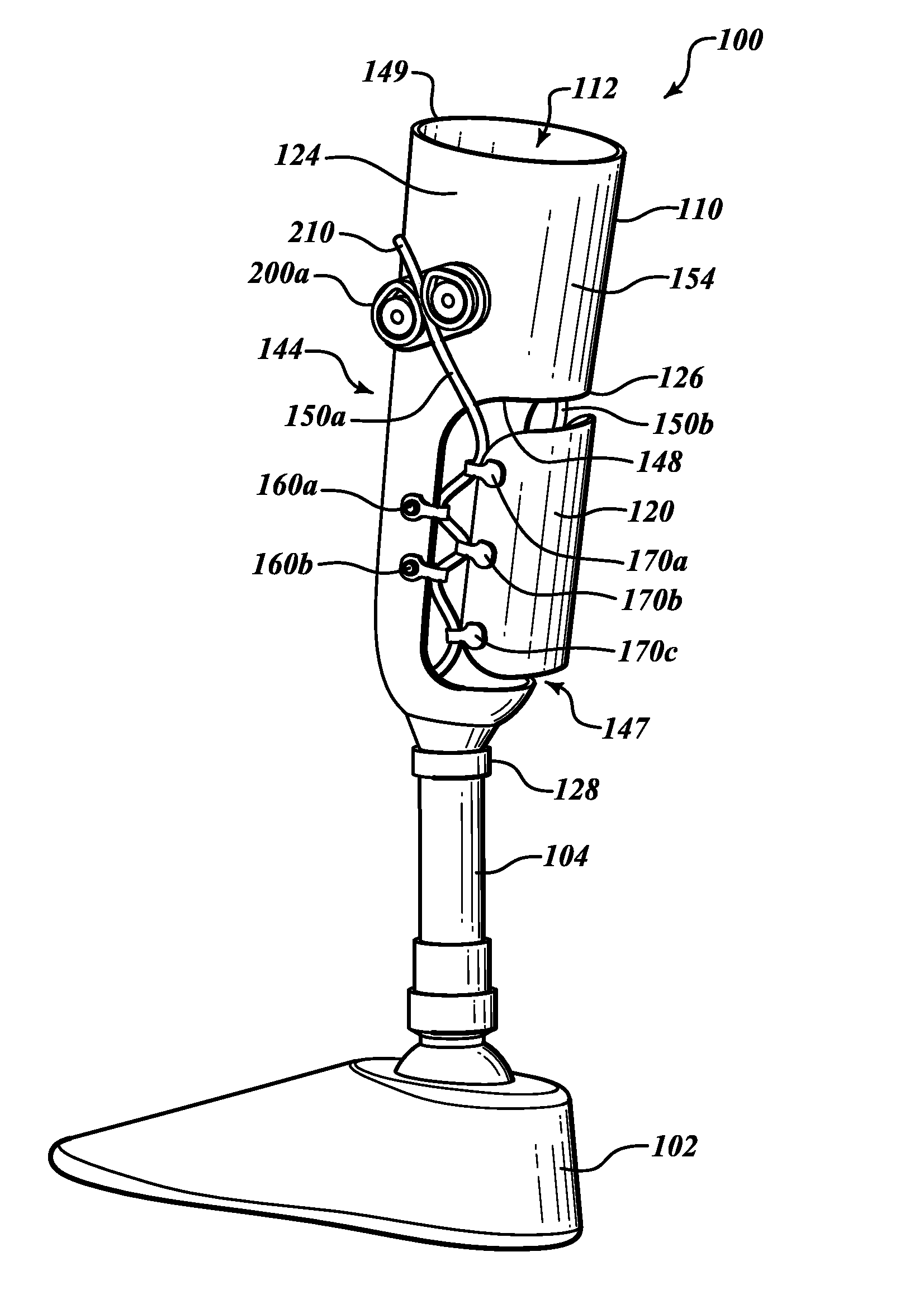

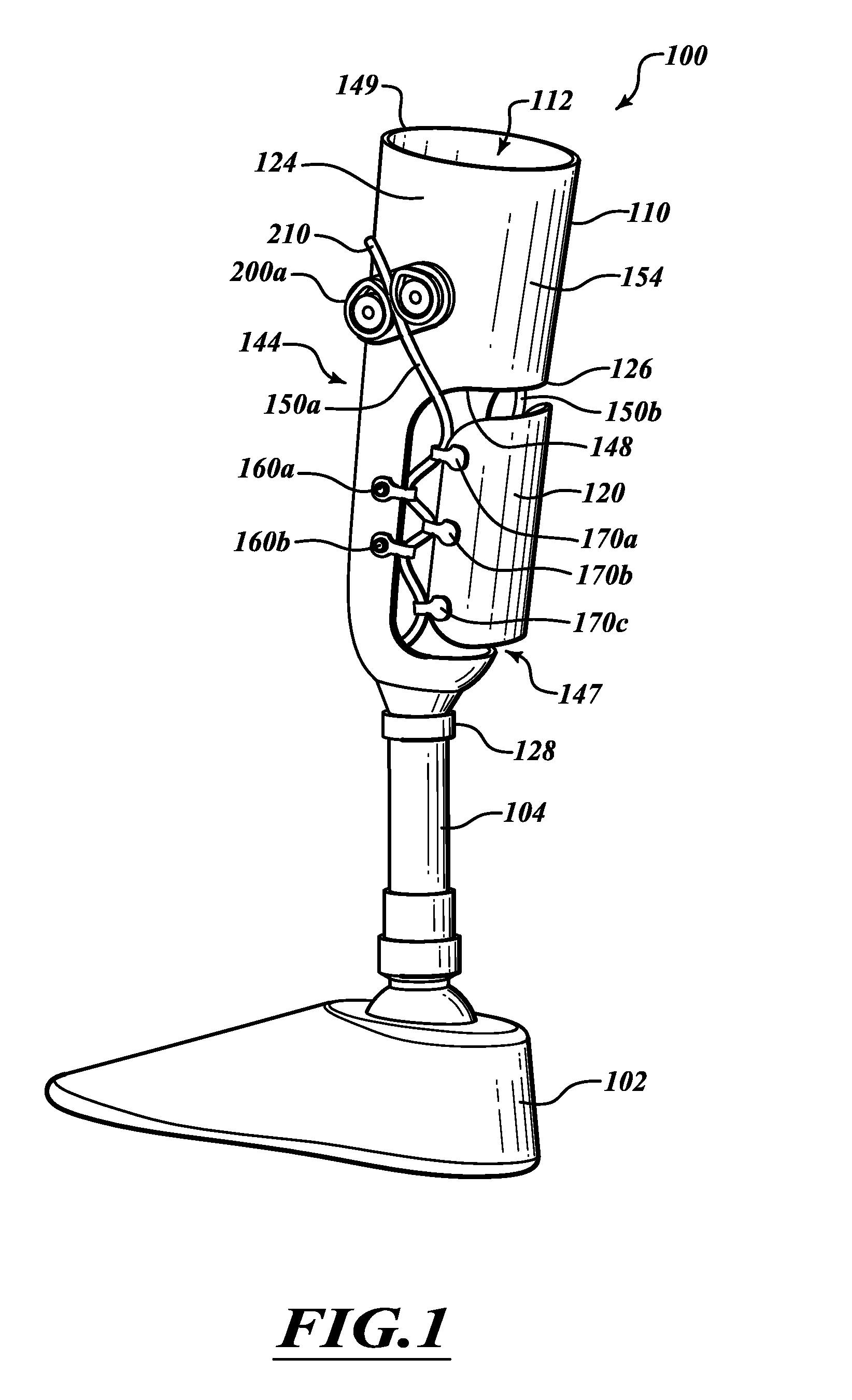

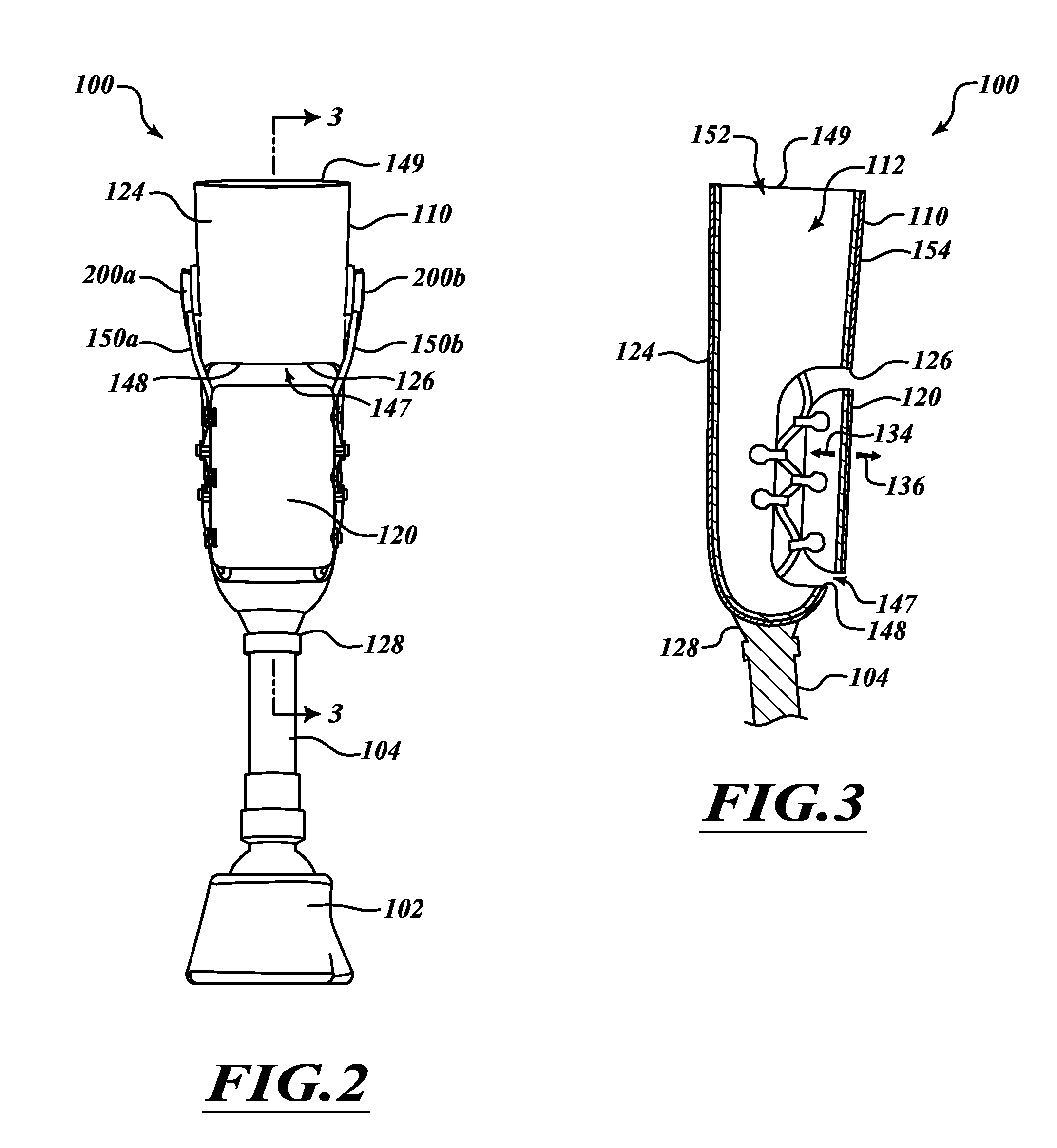

Adjustable prosthesis

InactiveUS20100274364A1Improve comfortInhibits and eliminates problemPerson identificationSensorsEngineeringResidual limb

A prosthesis system includes a reconfigurable socket. The socket changes configurations to adjust the socket fit. The socket includes a socket main body with a window and a panel positioned in the window. The panel and the socket main body cooperate to define a cavity for receiving a residual limb. A lacing system is coupled to both the socket main body and the panel and moves the panel with respect to the socket main body to adjust a volume of the cavity. A tensioning mechanism holds the lacing system to position the adjustment panel. The prosthesis system also allows for the escape of moisture from within the cavity.

Owner:CADENCE BIOMEDICAL

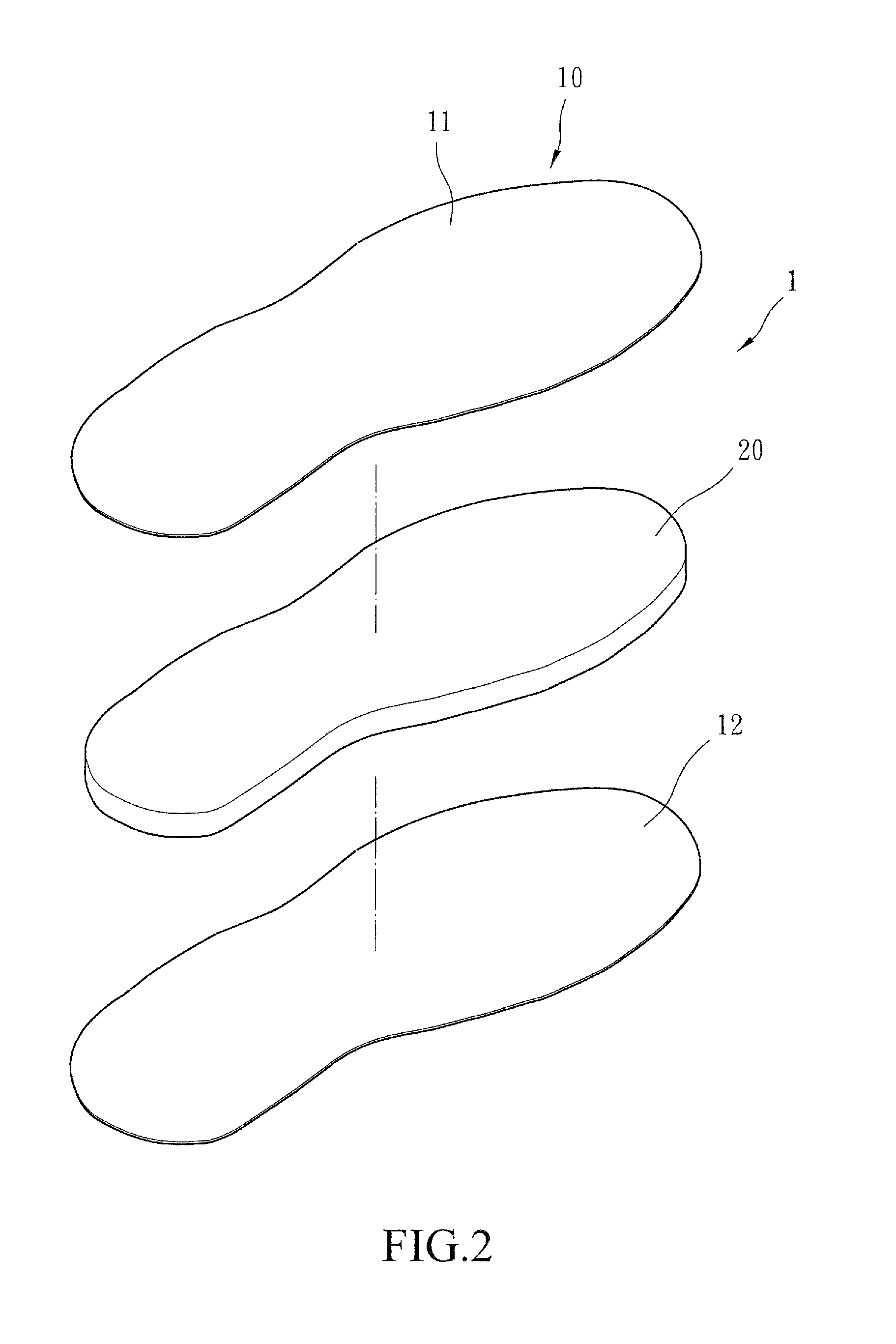

Structure of shoe sole

InactiveUS20100212186A1Add valueIncrease economic valueSolesInsolesComposite materialCustom made shoes

A structure of shoe sole is provided, which is a custom-made shoe sole that is formed according to a user's foot sole so as to improve the effects of support and wrapping of the shoe sole. The shoe sole includes an enclosure and a clay-like thermoplastic material. The enclosure includes upper and lower cover layers that are made of a material showing local stretchability and air permeability. The thermoplastic material is received between the upper and lower cover layers and is a thermoplastic mixture in the form of soft ceramic. With the shoe sole placed in a shoe and the shoe put on a user's foot, the thermoplastic material of the shoe sole may get deformed inside the enclosure according to the contour of the user's foot sole, making the shoe sole shaped to completely match the foot sole of the user.

Owner:CHENG FU YUAN +2

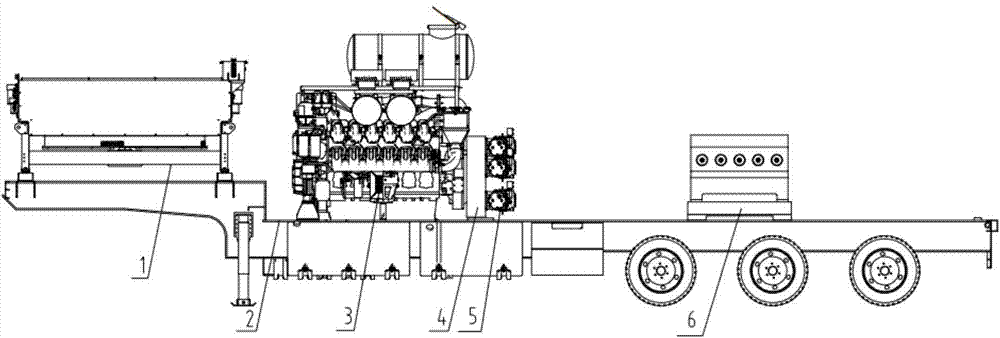

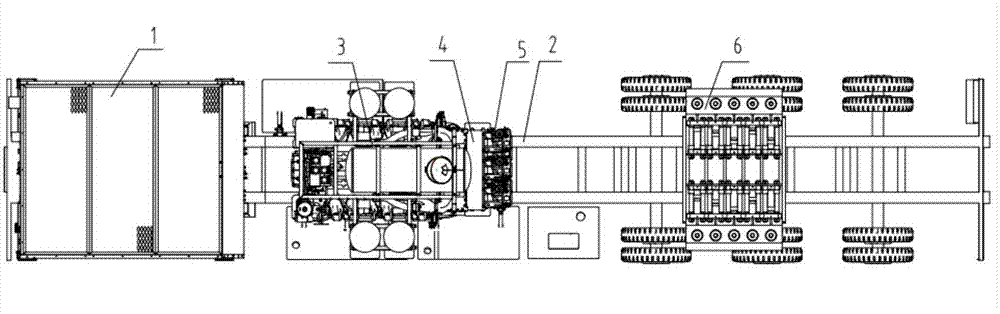

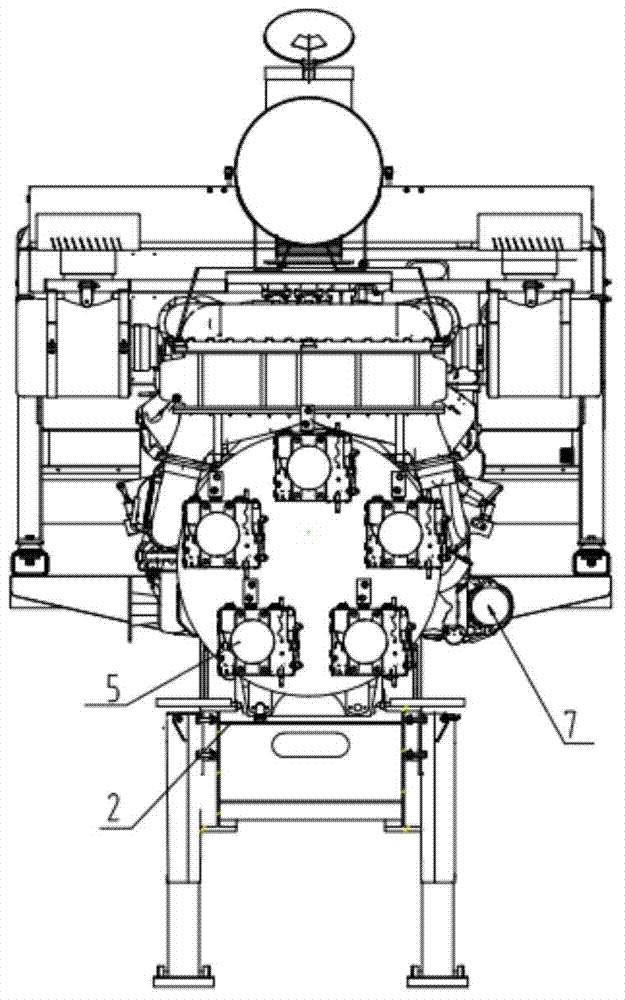

Fracturing transmission and high-pressure discharging system

InactiveCN104727797AExpand the range of selectionSave layout spaceFluid removalTransfer caseEngineering

The invention relates to a fracturing transmission and high-pressure discharging system. The fracturing transmission and high-pressure discharging system comprises a chassis and is characterized in that a high-power engine, a transfer case, a plurality of variable displacement plunger pumps and a double-acting fracturing pump are arranged on the chassis, the output end of the high-power engine is connected with the input end of the transfer case, the output end of the transfer case comprises a plurality of power take-off ports, and each power take-off port is connected with one variable displacement plunger pump; the variable displacement plunger pumps drive the double-acting fracturing pump through a hydraulic system. The fracturing transmission and high-pressure discharging system further comprises a system radiator and a heat dissipation plunger pump used for driving the system radiator, and the heat dissipation plunger pump is connected with one power take-off port of the transfer case. The power take-off ports of the transfer case and the variable displacement plunger pumps are arranged annularly. The fracturing transmission and high-pressure discharging system has the advantages that hydraulic driving replaces mechanical transmission, and working vibration is reduced; the layout space of a whole vehicle is saved, and meanwhile, operating efficiency and the stability of the whole vehicle are improved.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

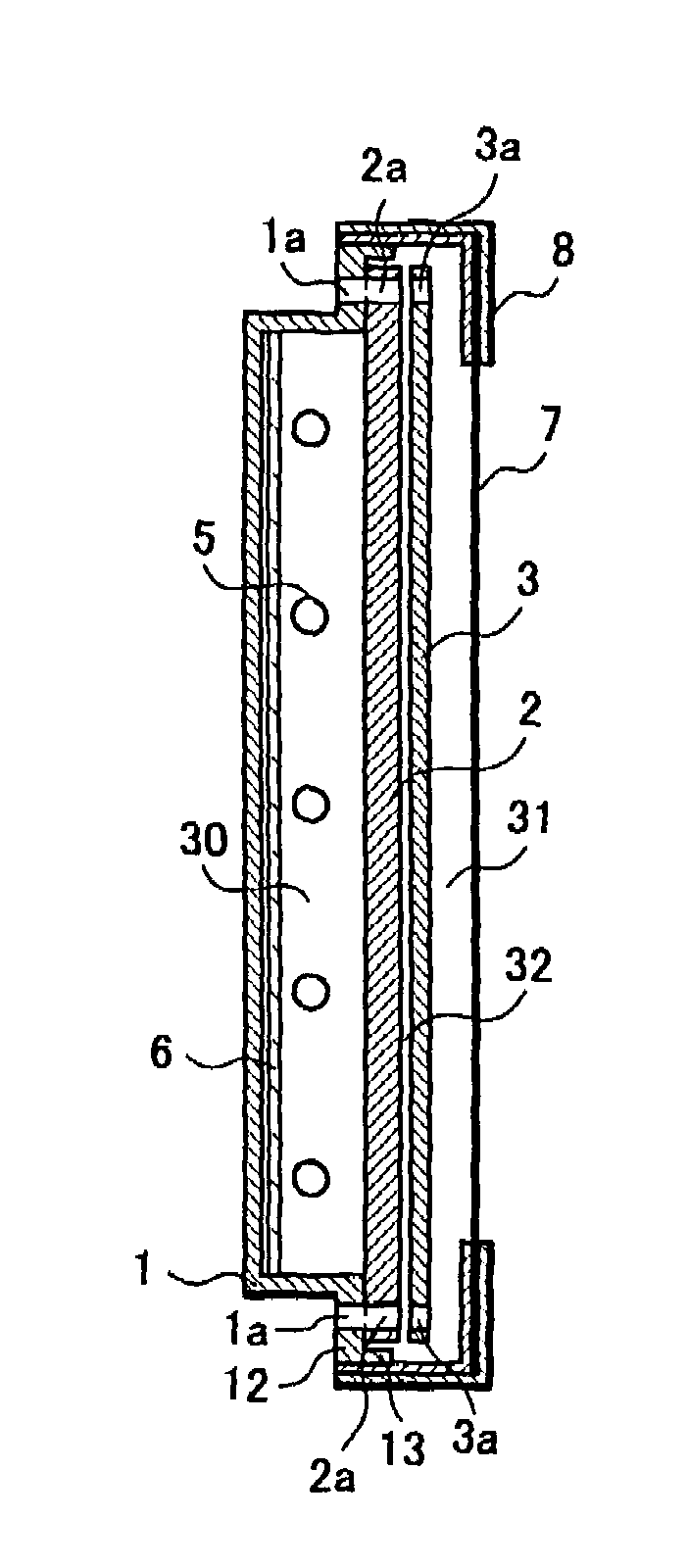

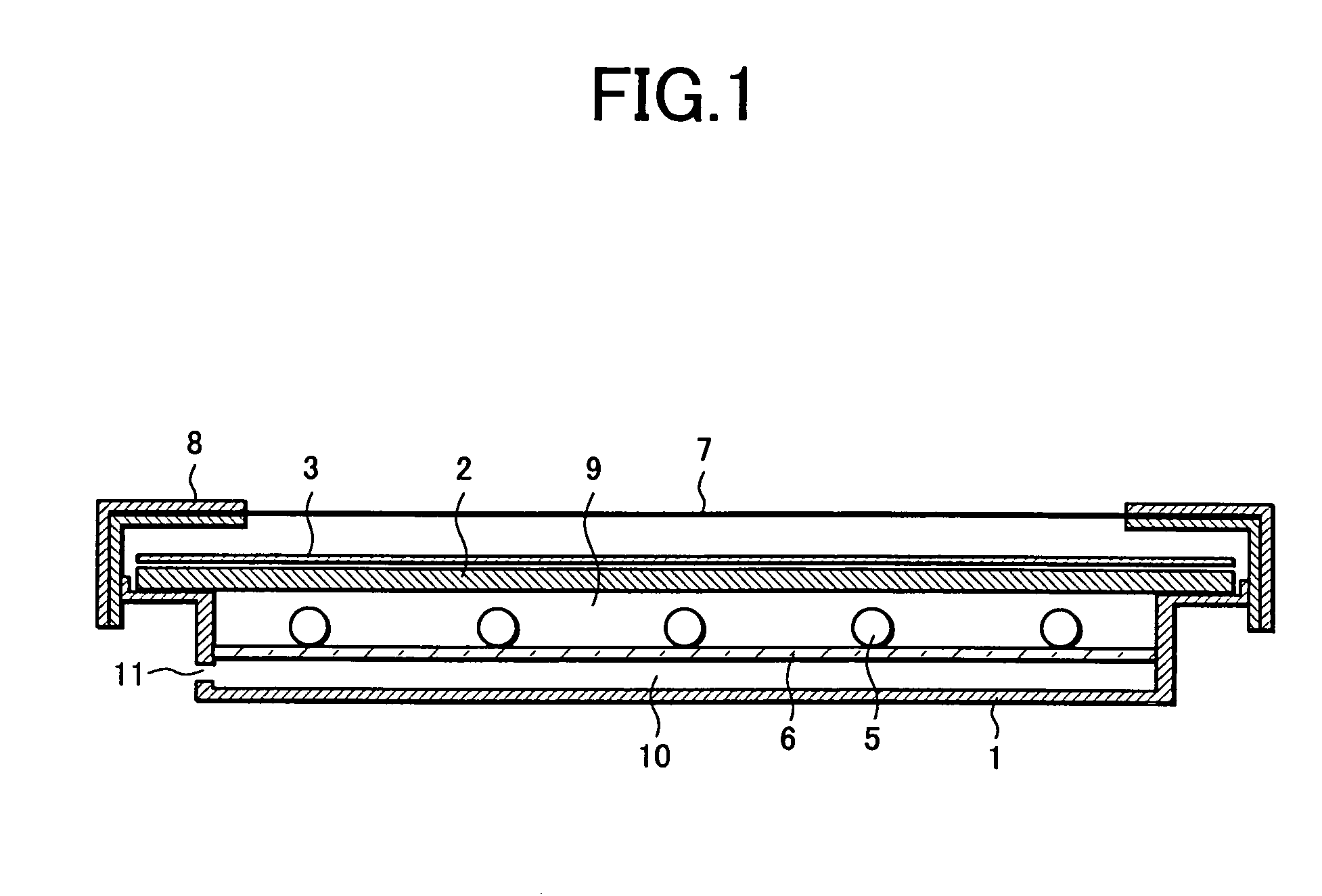

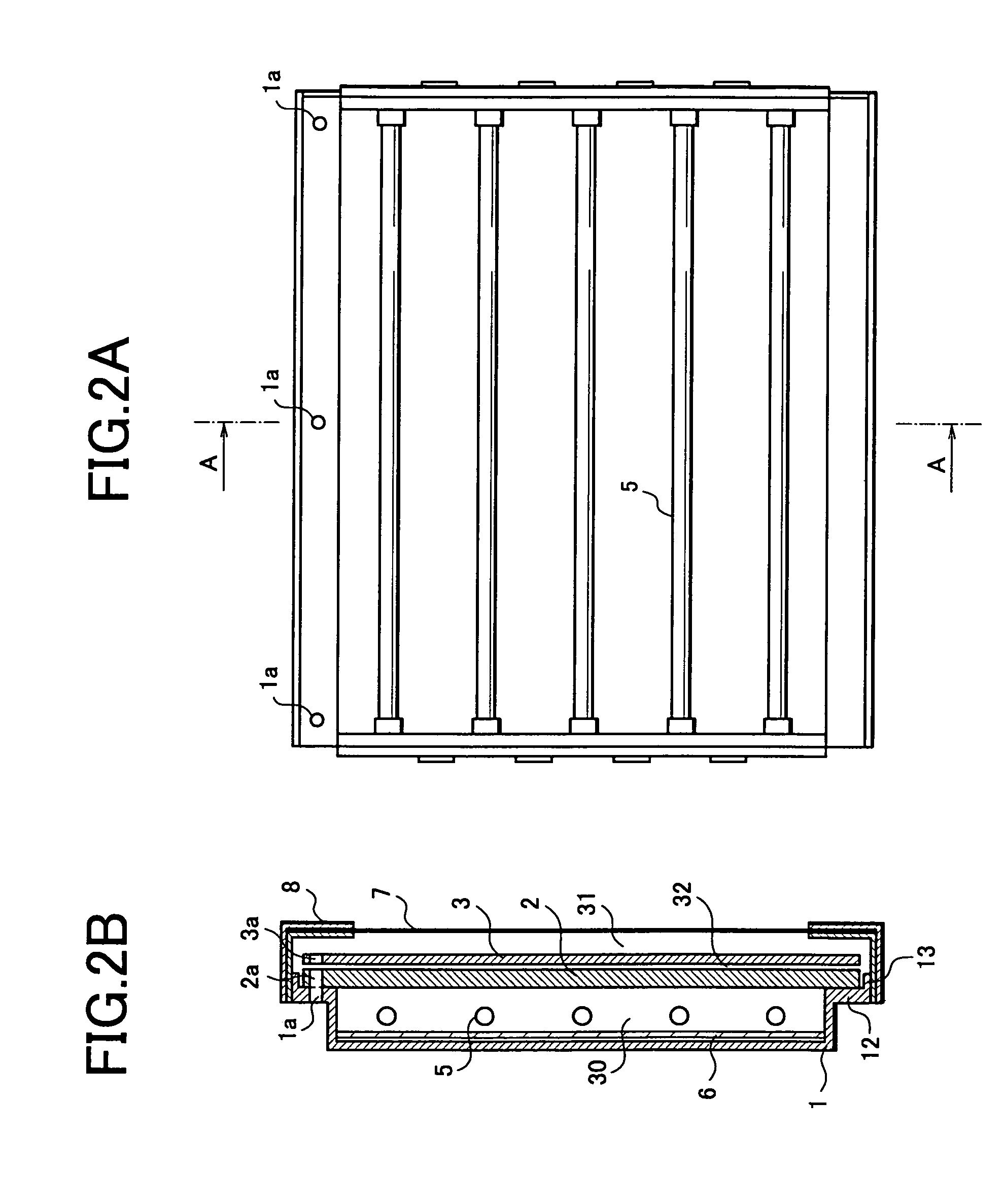

Liquid crystal display device

InactiveUS7059757B2Avoid deformationRule out the possibilityMeasurement apparatus componentsPoint-like light sourceLiquid-crystal displayEngineering

A liquid crystal display device has a plurality of lamps, a light diffusion plate and / or an optical sheet, a shield portion for accommodating the lamps, the light diffusion plate and / or the optical sheet. There is a liquid crystal display panel located opposite to one side of the light diffusion plate and / or the optical sheet opposed each with the other side to the lamps. The light diffusion plate and / or the optical sheet each have a vent, and a lamp chamber formed in the lamp-accommodating side of the light diffusion plate and / or the optical sheet. There is an LCD panel chamber formed in the LCD panel-disposing side of the light diffusion plate and / or an optical sheet that communicate with each other through the vent of the light diffusion plate and / or optical sheet.

Owner:SHARP KK

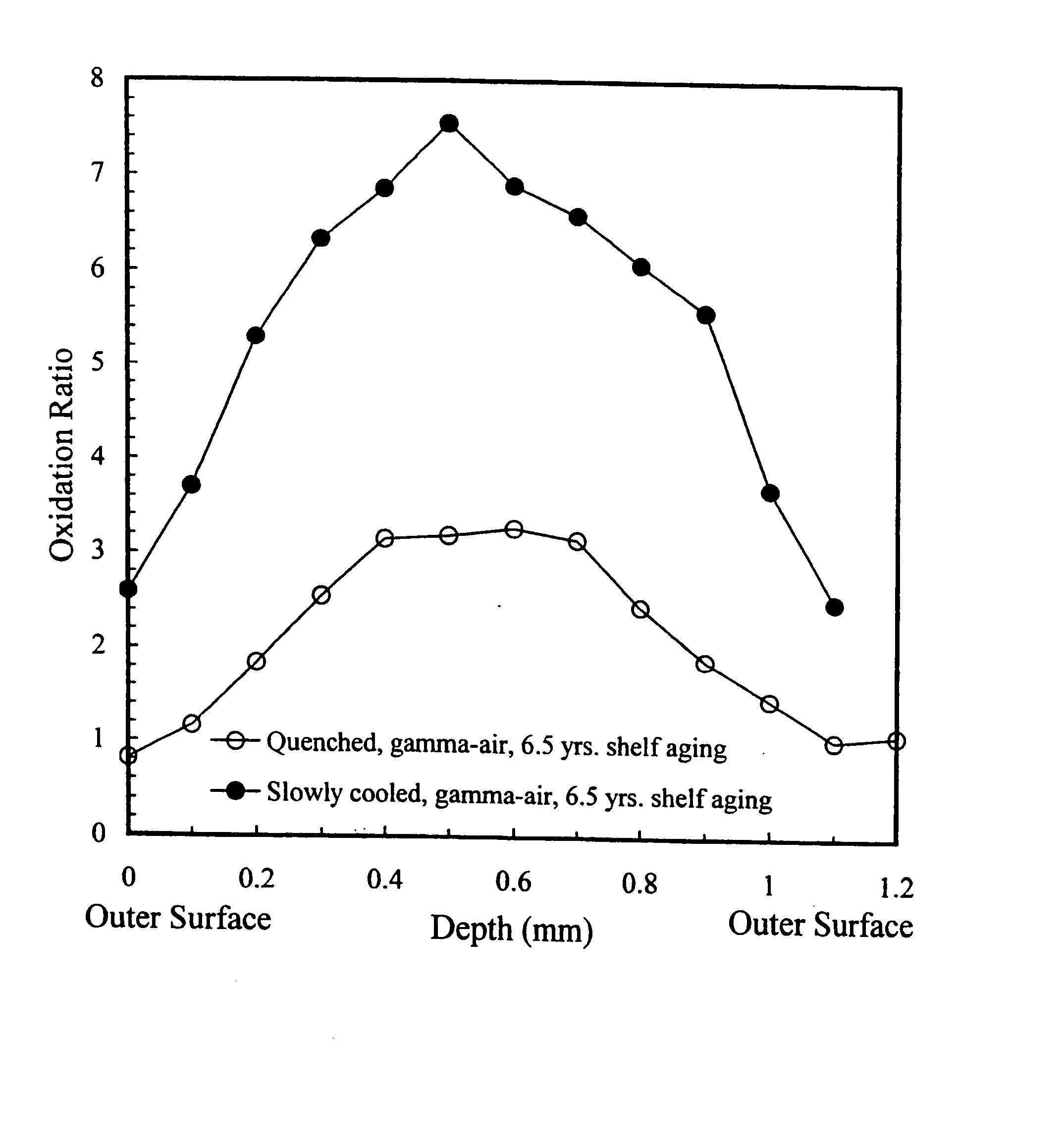

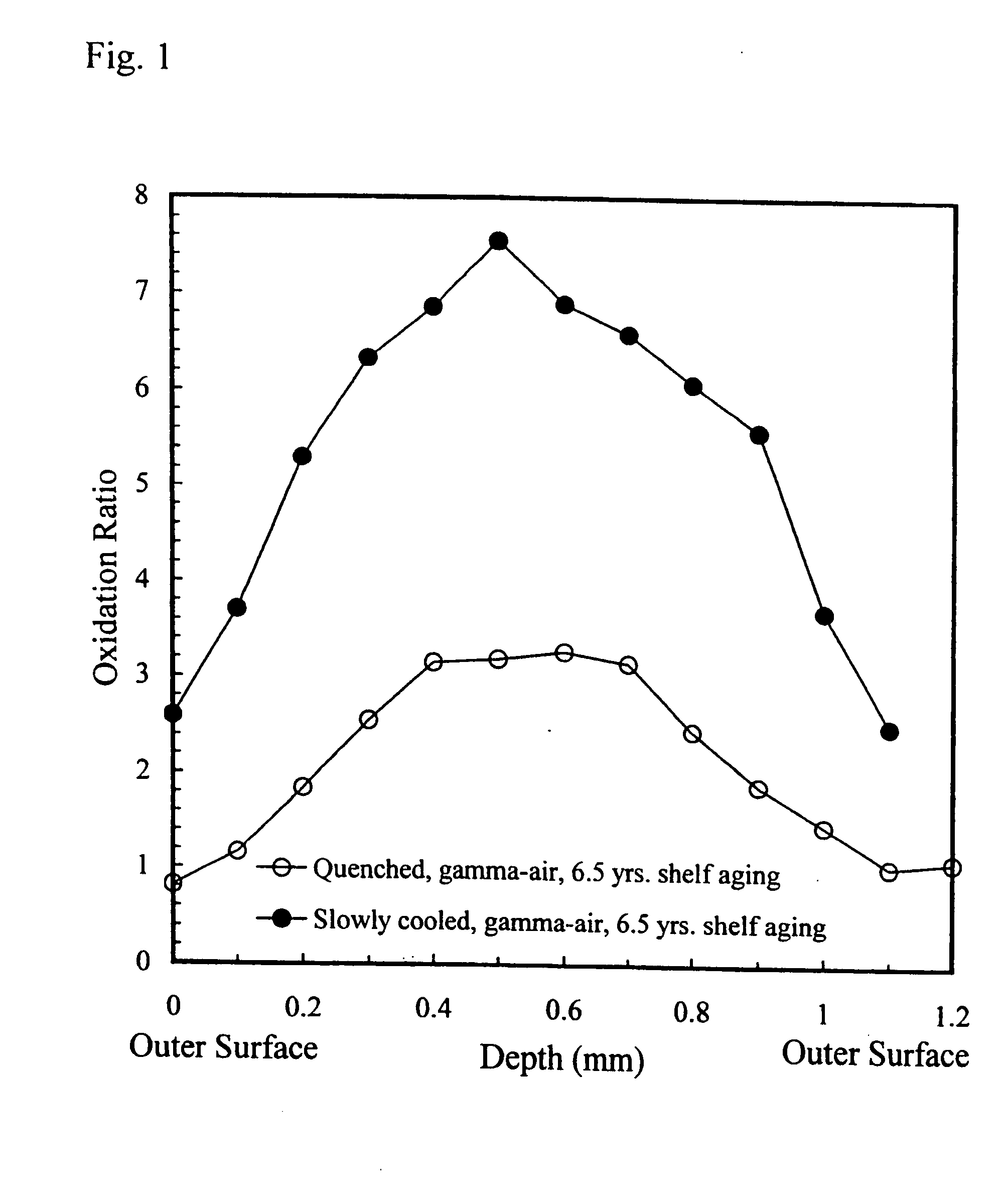

Oxidation-resistant and wear-resistant polyethylenes for human joint replacements and methods for making them

InactiveUS20070293647A1Improve wear resistanceImprove the immunitySurgeryPackage sterilisationPresent methodWear resistant

The present invention presents methods for making oxidation-resistant and wear-resistant polyethylenes and medical implants made therefrom. Preferably, the implants are components of prosthetic joints, e.g., a bearing component of an artificial hip or knee joint. The resulting oxidation-resistant and wear-resistant polyethylenes and implants are also disclosed.

Owner:THE ORTHOPAEDIC HOSPITAL

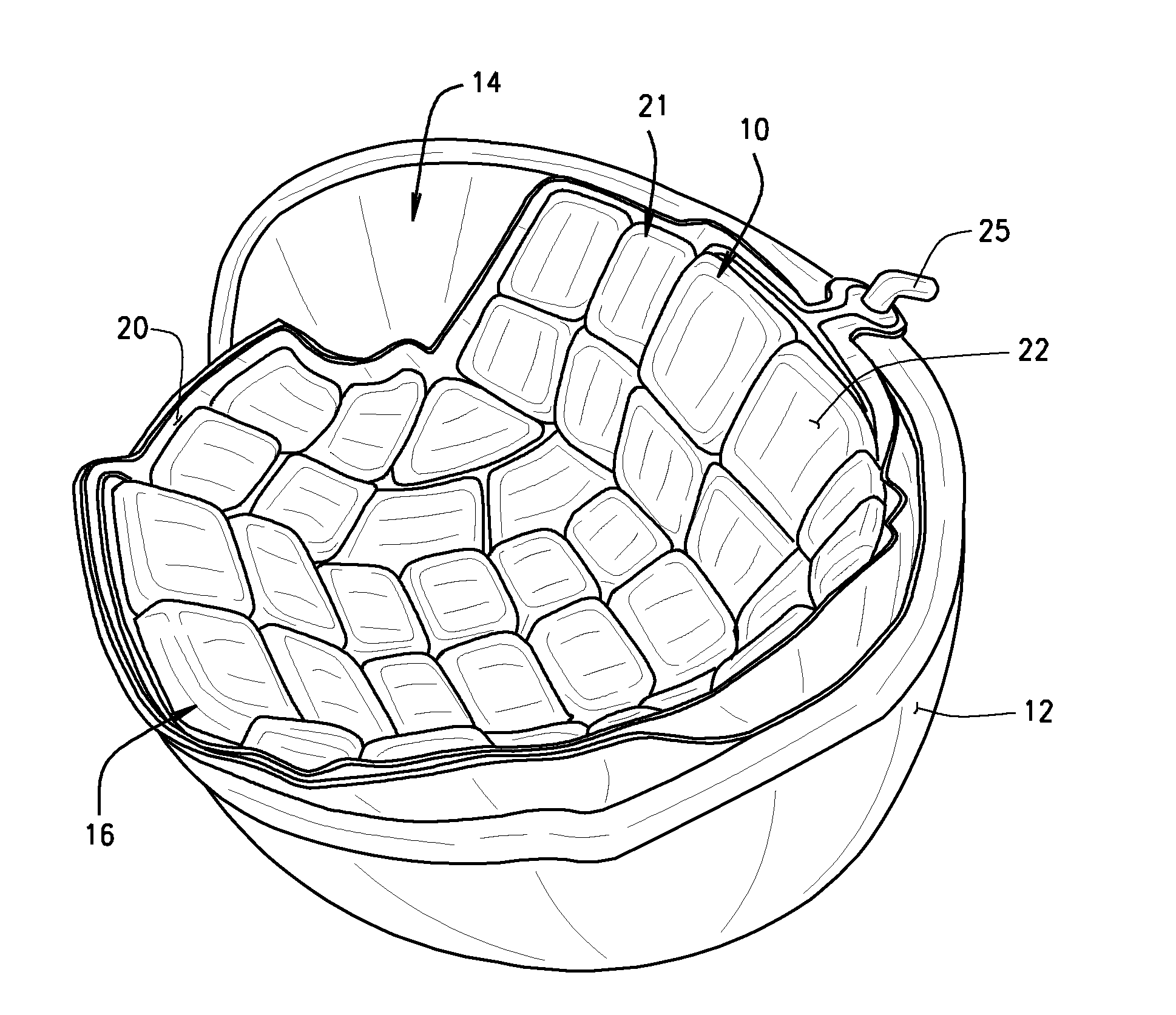

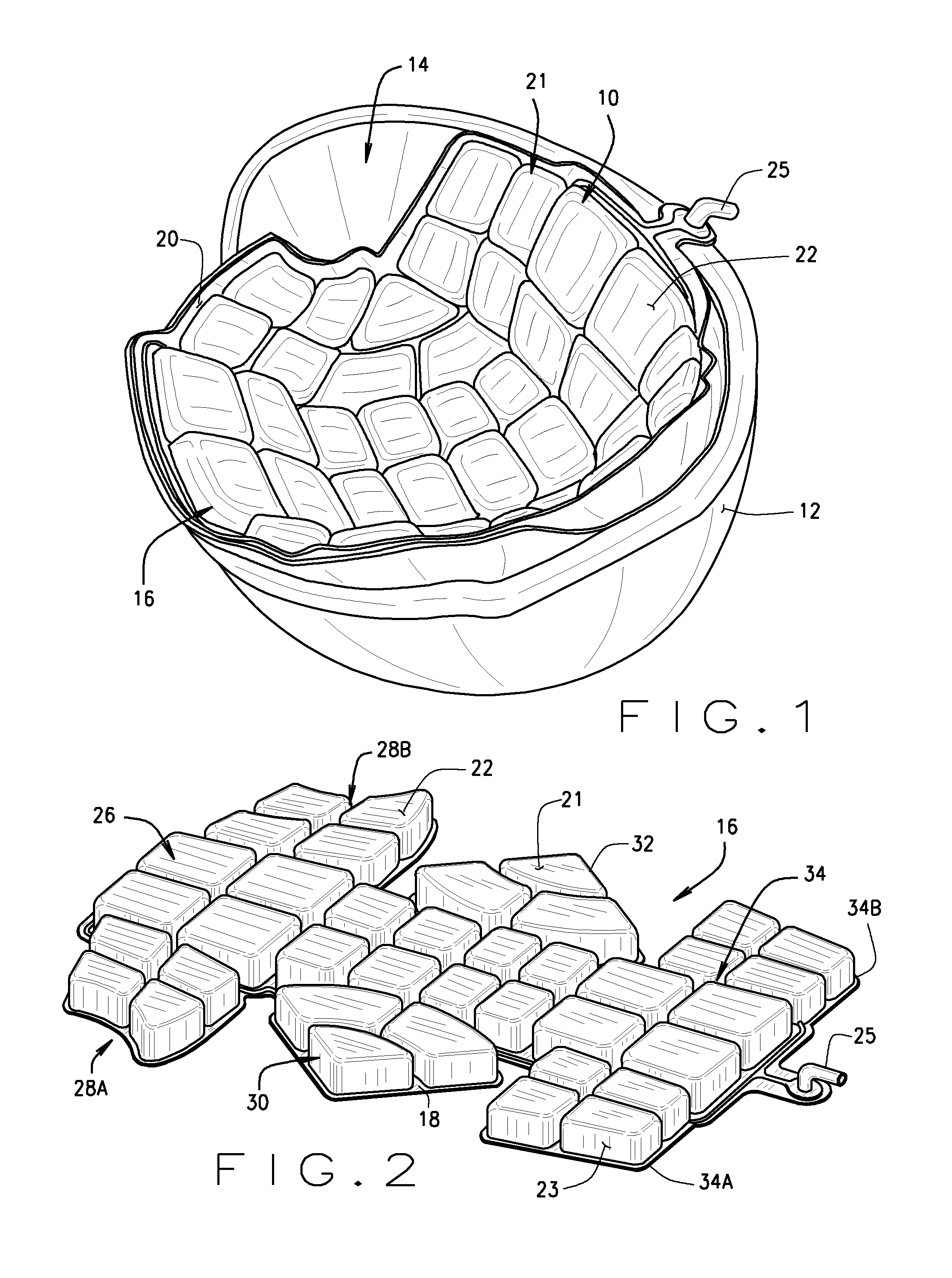

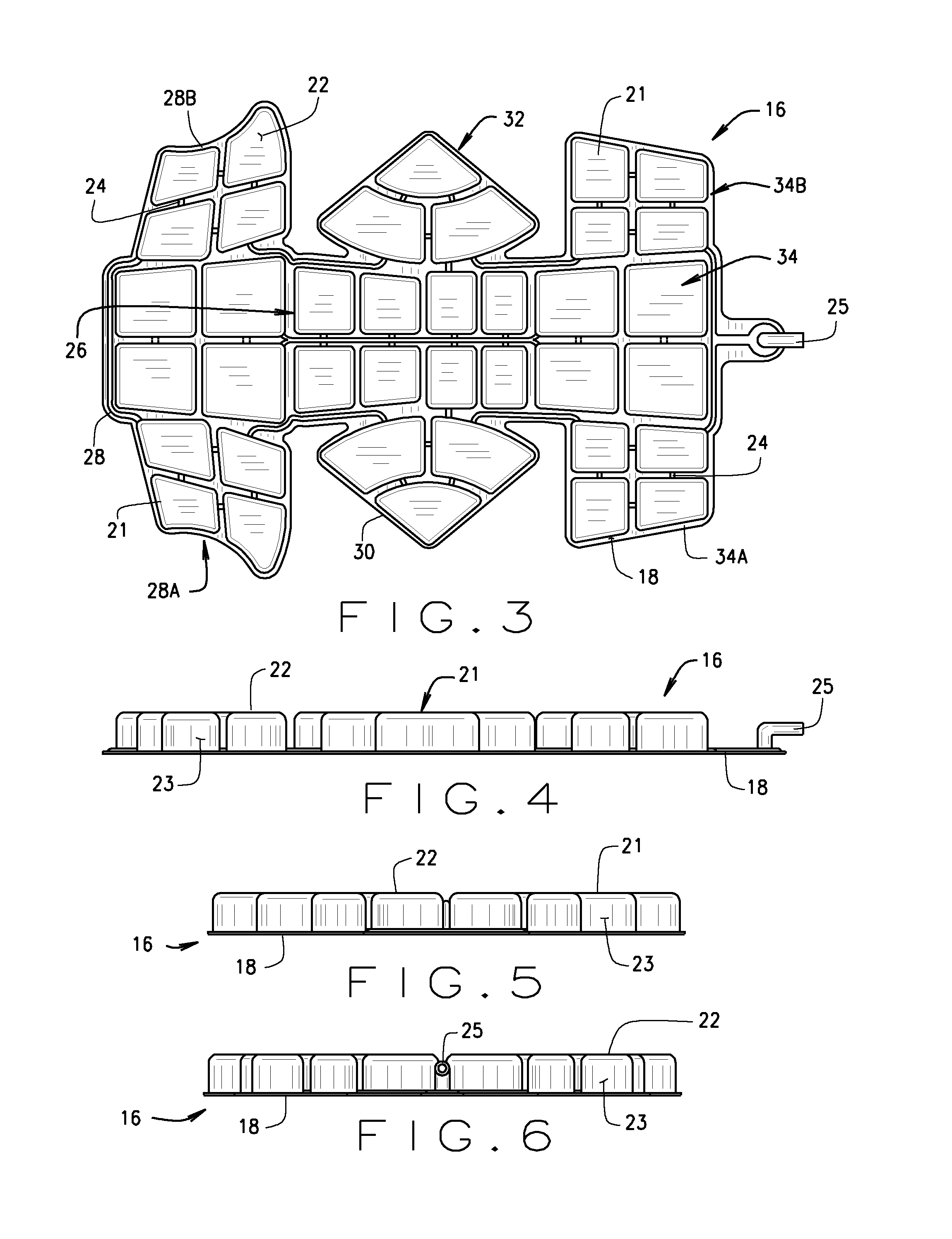

Multilayer impact attenuating insert for headgear

InactiveUS20140020158A1Improve propertiesControl impact attenuating characteristicHelmetsHelmet coversFiberEngineering

Impact attenuating liner for headgear and headgear employing the liner, the liner positionable inside the headgear and comprising a cellular layer having an array of individual impact attenuating cells, each individual impact attenuating cells including an impact attenuating medium. The impact attenuating cells can comprise a gas, liquid, visco-elastic gel, foam, fiber or combinations thereof as well other impact attenuating medium. In another aspect, the impact attenuating liner has at least two layers, a cellular layer of and an impact attenuating layer under the cellular. The liner can include a cover. The liner can be removable from the headgear.

Owner:AIRHAWK VENTURES

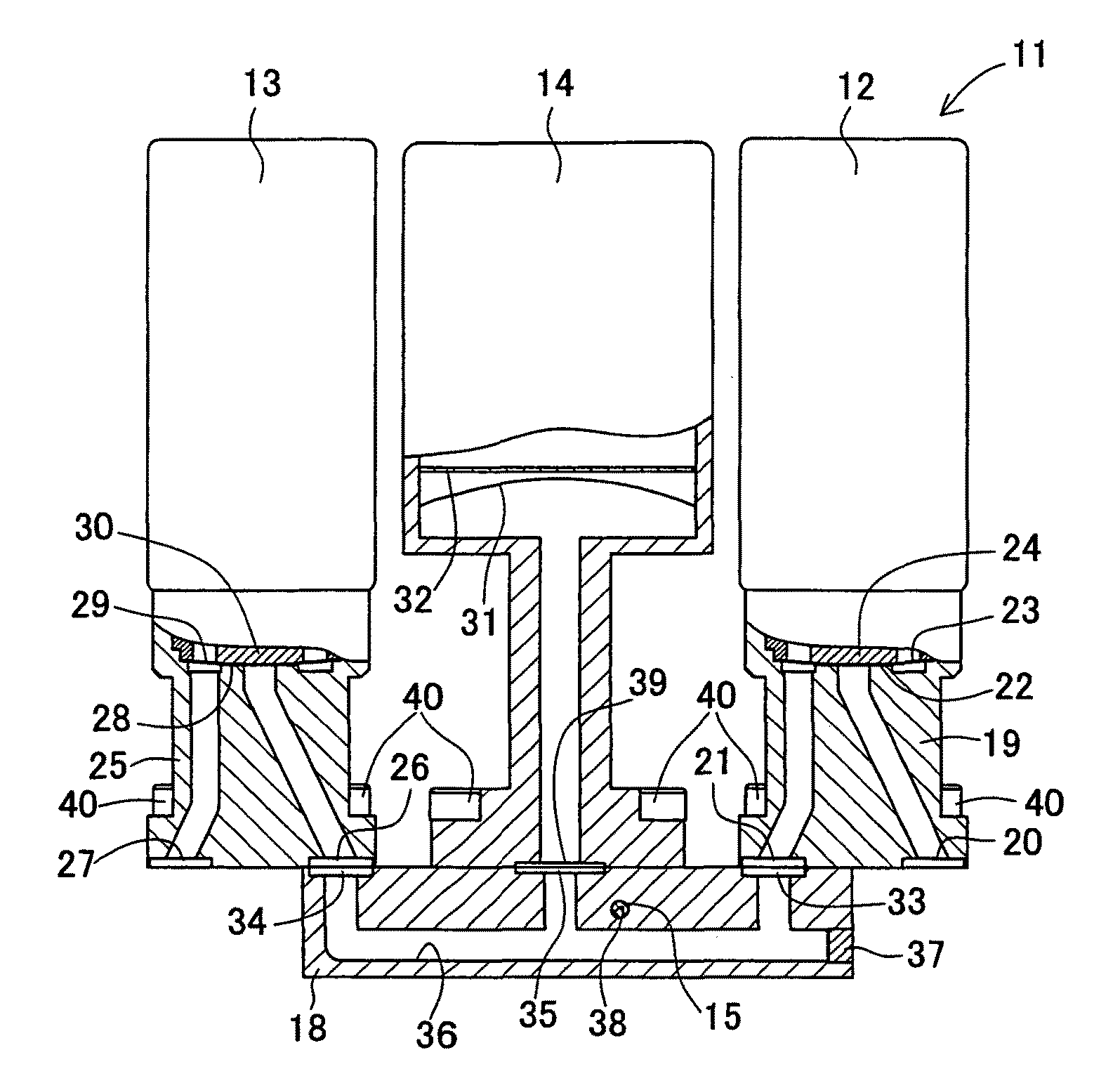

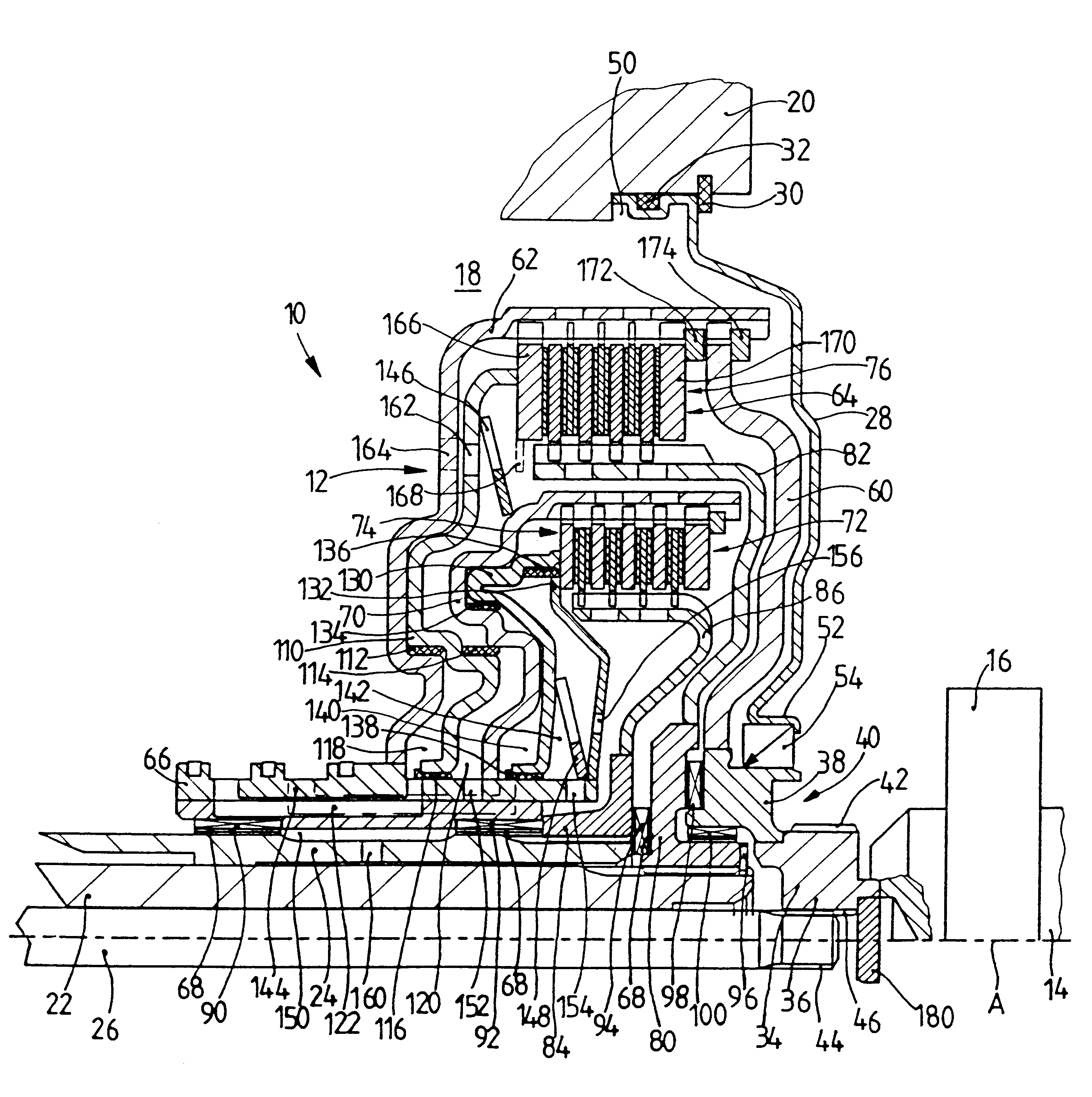

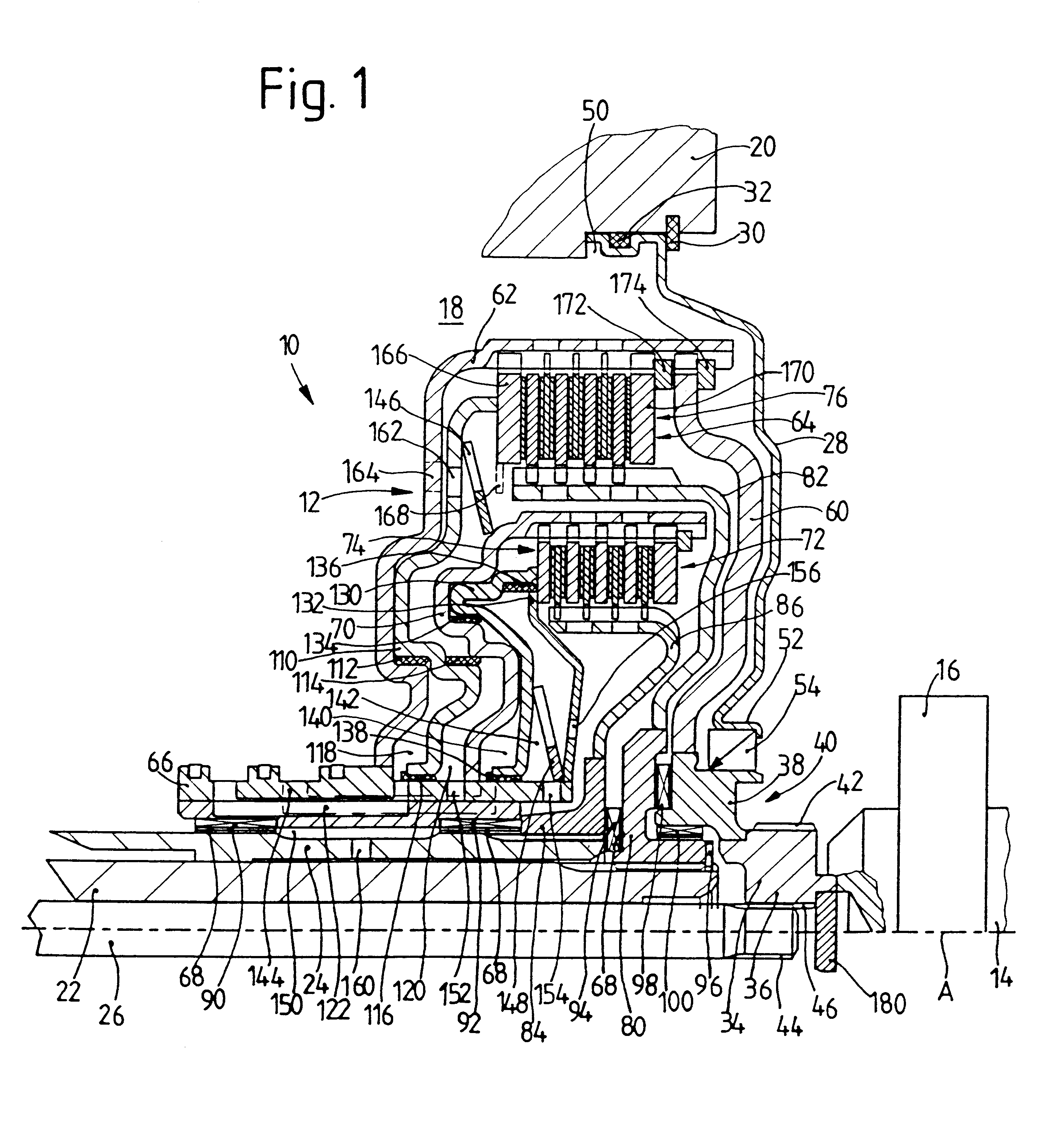

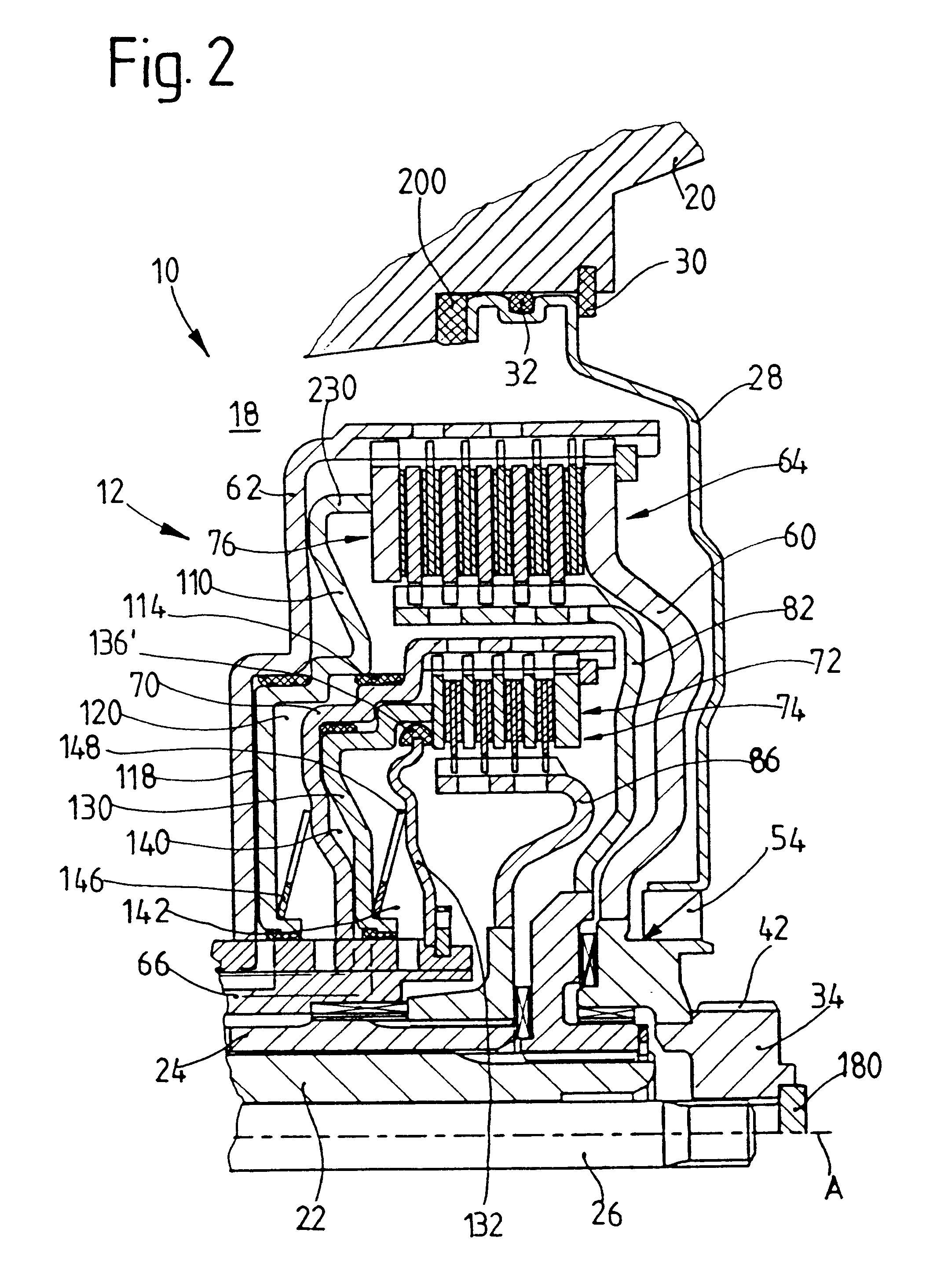

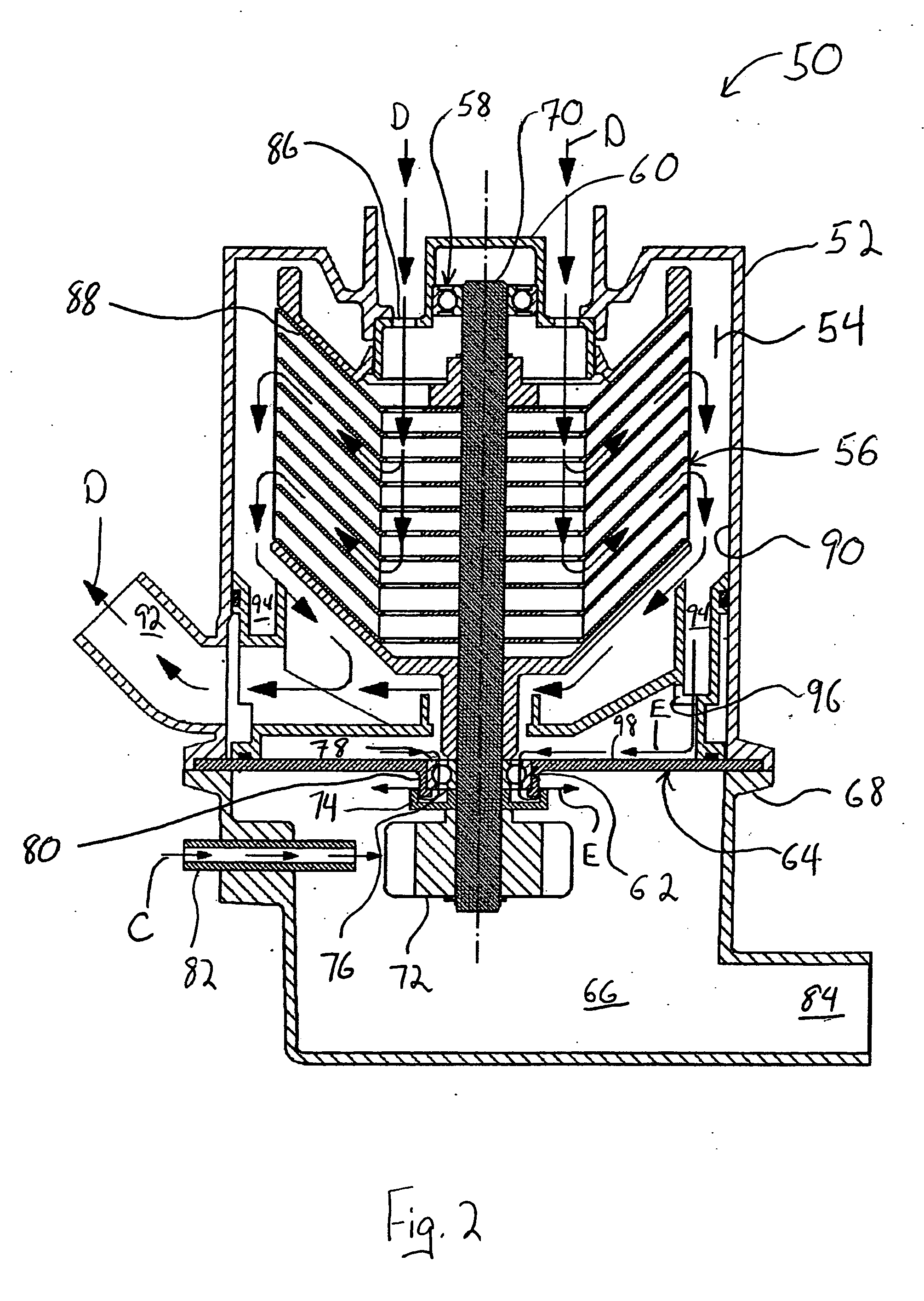

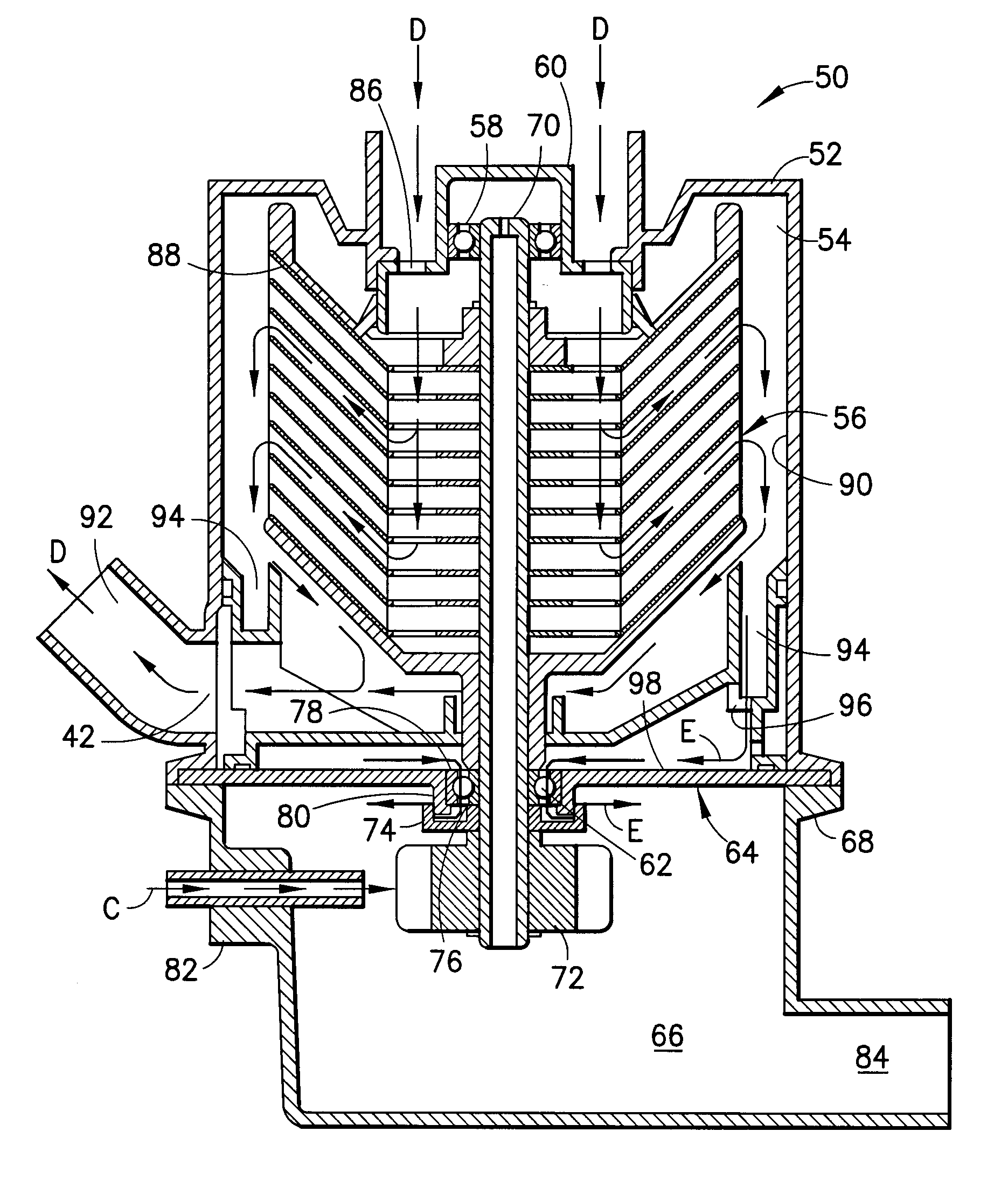

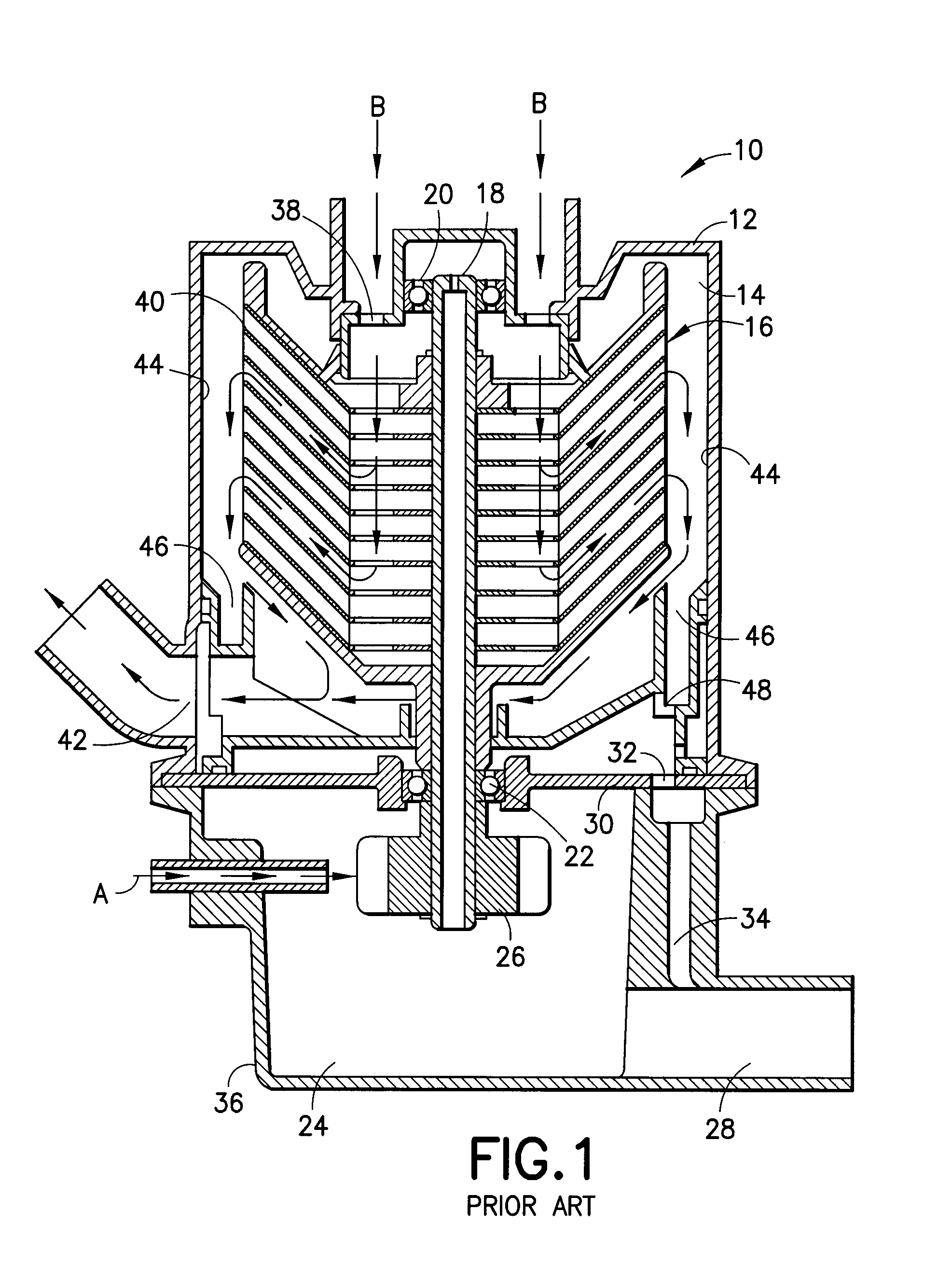

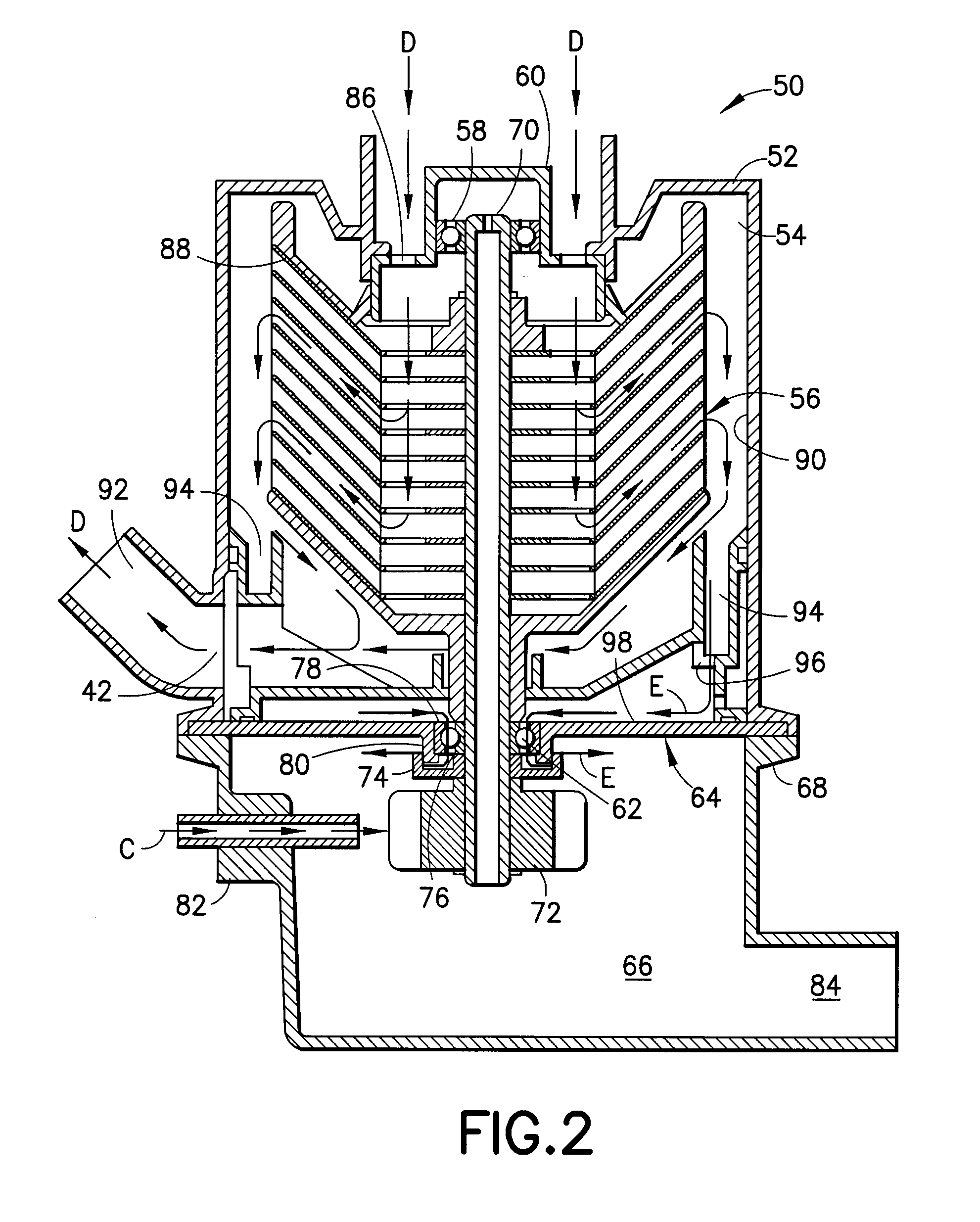

Multiple-clutch device

InactiveUS6523657B1Large massLarge heat capacityRoad transportFluid actuated clutchesMobile vehicleDrivetrain

The invention is directed to a multiple-clutch device, such as a double-clutch device, for arranging in a drivetrain of a motor vehicle between a drive unit and a transmission, wherein the clutch device has a first clutch arrangement associated with a first transmission input shaft of the transmission and a second clutch arrangement associated with a second transmission input shaft of the transmission for transmitting torque between the drive unit and the transmission. According to one aspect of the invention, it is suggested that plates in a plate stack of a clutch arrangement constructed as a plate clutch arrangement which have at least one friction facing can be brought into frictional engagement with plates having no friction facing, wherein at least one of the plates not having a friction facing is thicker in axial direction than friction facing carrying elements of adjacent plates having at least one friction facing. Alternatively or in addition, it is suggested that at least one plate which has at least one friction facing of sintered material and at least one plate which has at least one friction facing made of another friction facing material are provided in the plate stack, wherein the other friction facing material has a progressive frictional coefficient curve (dlambd / dDELTAN) in relation to a slip speed (DELTAN).

Owner:ZF FRIEDRICHSHAFEN AG +1

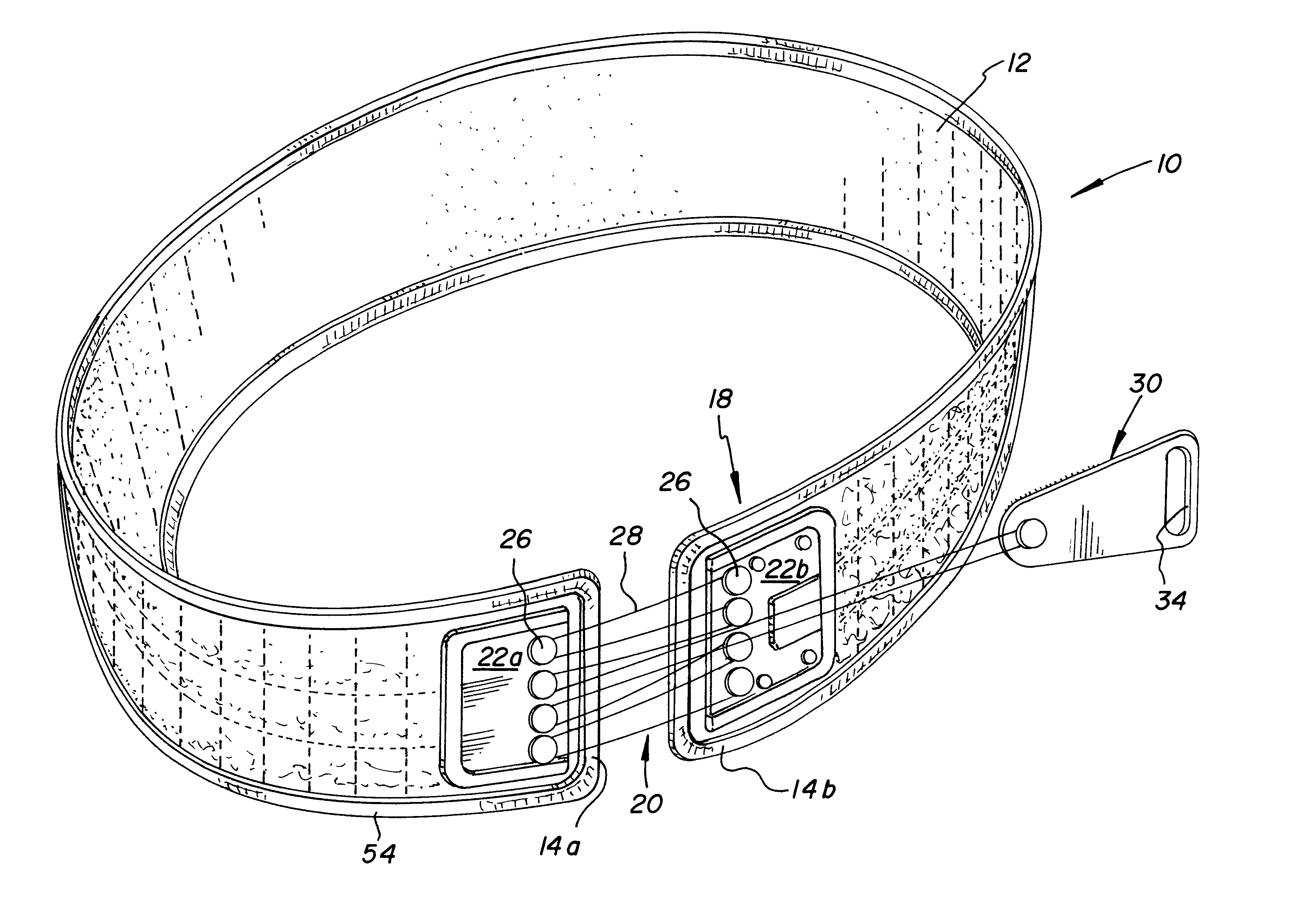

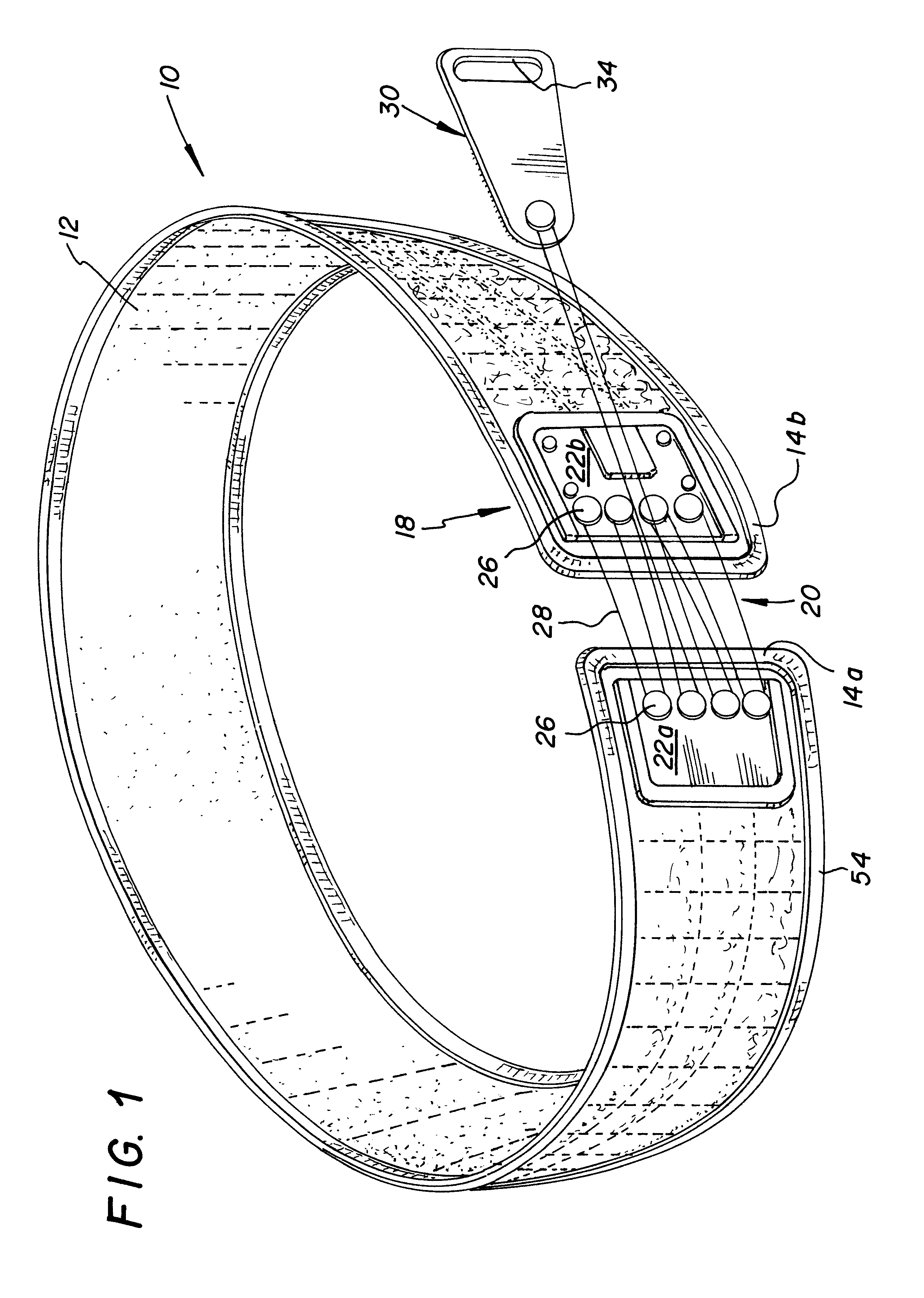

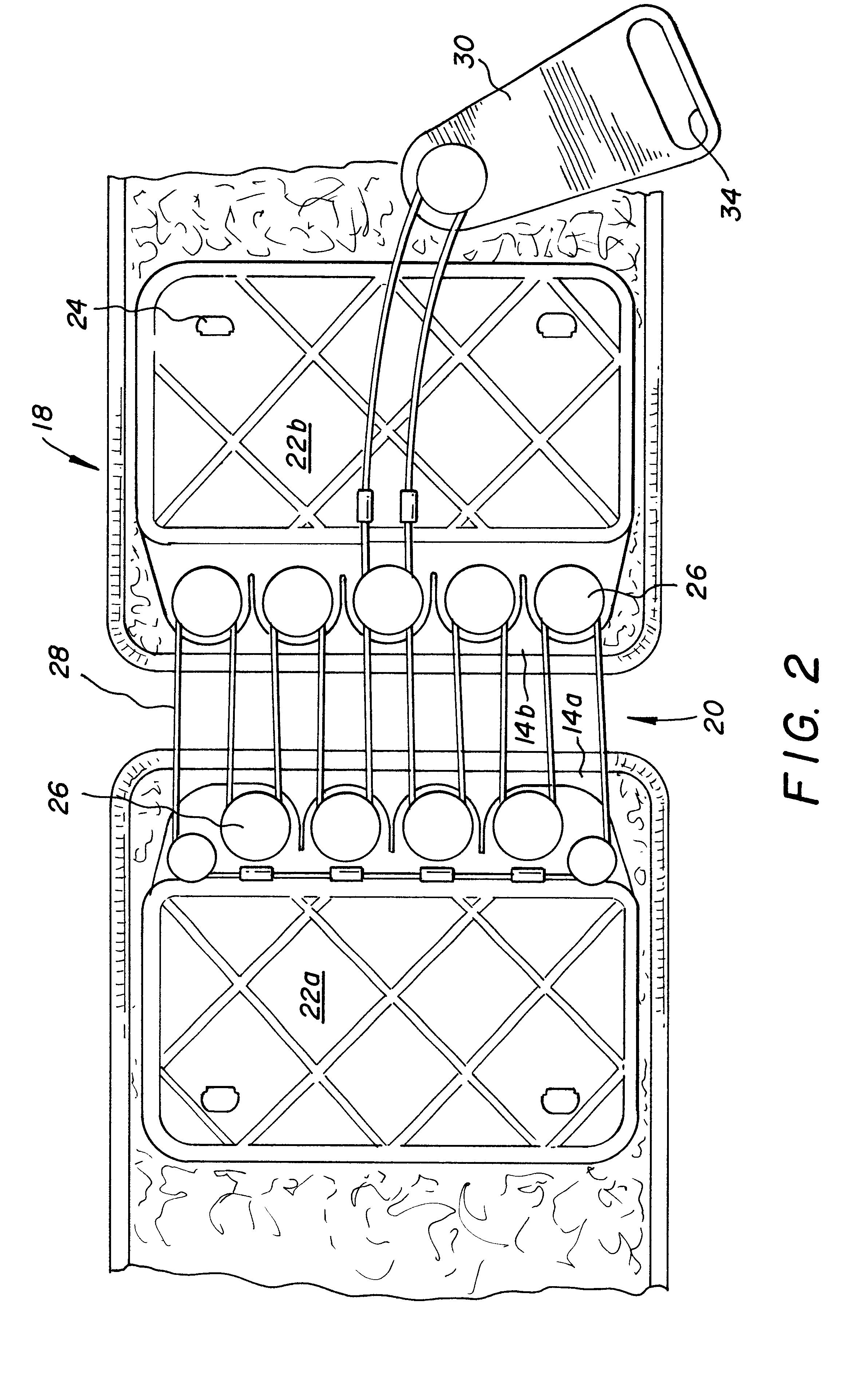

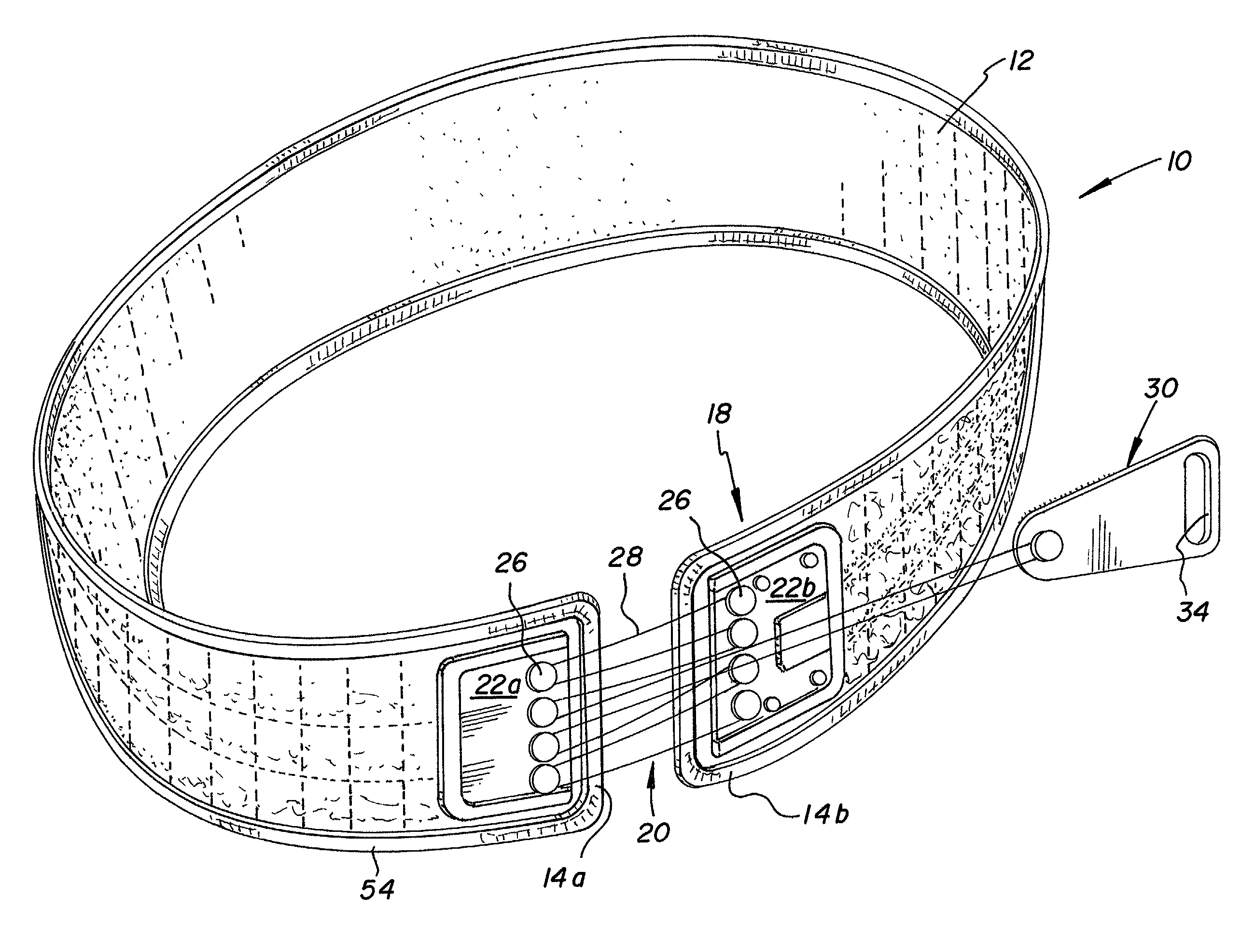

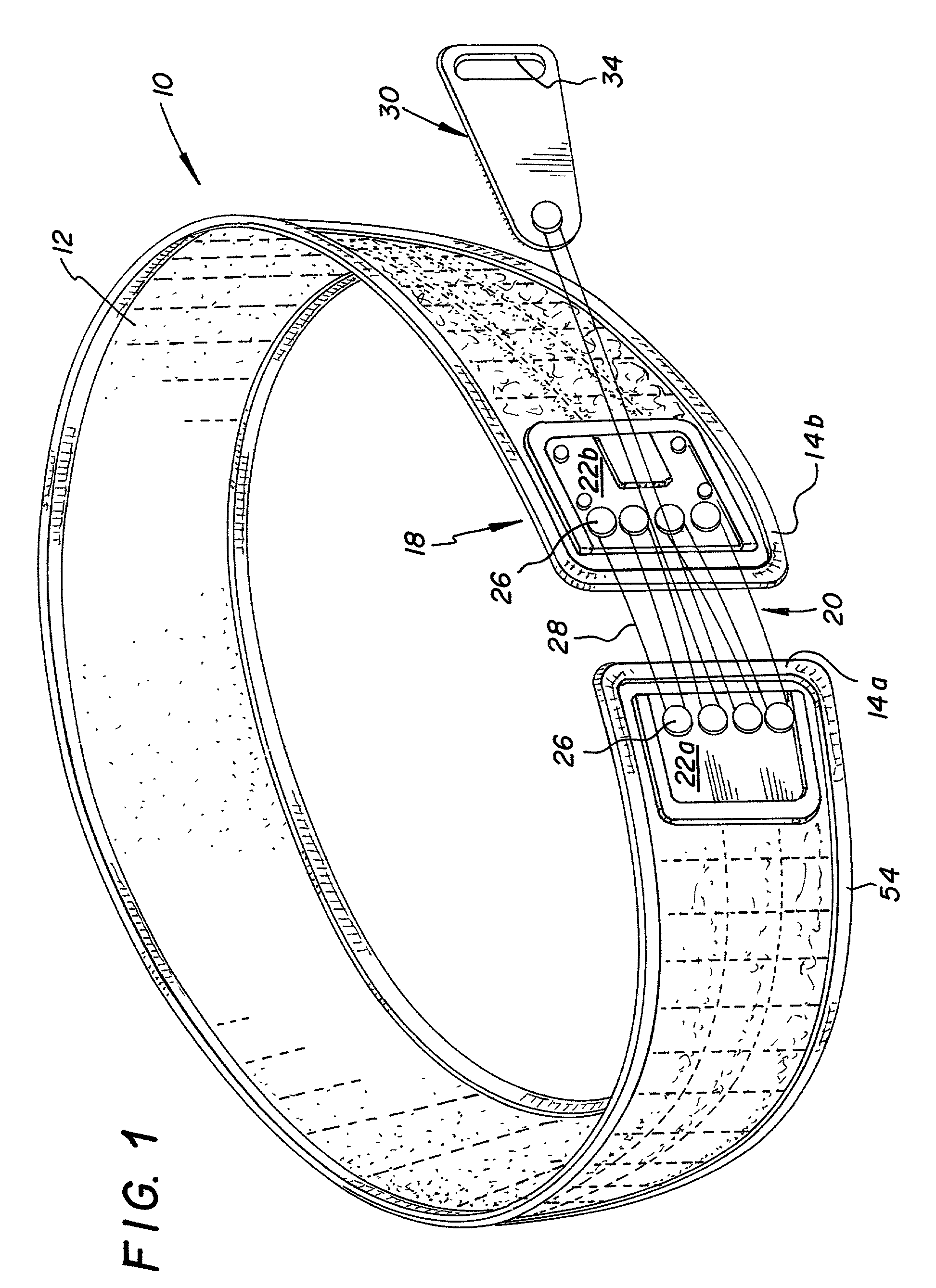

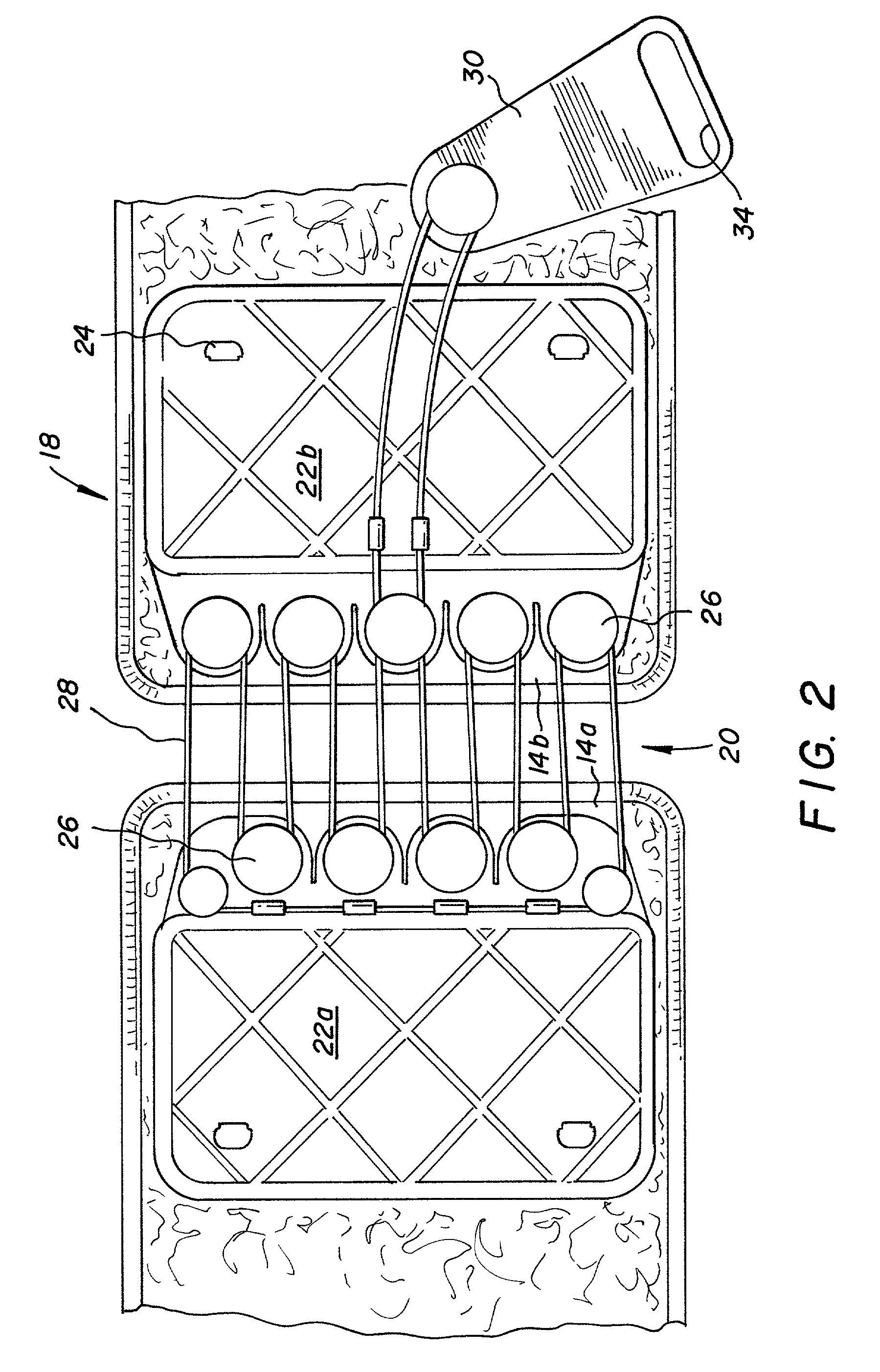

Orthotic trauma device

InactiveUS6602214B2Stabilizes broken boneReduce relative motionNon-surgical orthopedic devicesKnee orthosisEngineering

An orthotic trauma device is provided including an elongated orthosis body adapted to be wrapped around a portion of a body, the orthosis body being formed of a pliant material be easily cut with cloth-cutting scissors; a detachable fastening device provided at distal ends of the elongated orthosis body to releasably secure the distal ends to one another; and means for adjusting the tightness of the orthosis body operatively associated with the detachable fastening device. A pulley system for use in an orthotic device includes a pair of pulley banks arranged in a first and second of the pair of pulley banks detachably connected to a first distal end and a second distal end of the orthosis body respectively, a first bank of which is adapted to be detachably disposed on a first distal end of an elongated orthosis body and a second bank of pulleys adapted to be detachably disposed on a second distal end of the elongated orthosis body; and a cable interconnecting the two pulley banks and running through a pulley on each of the pulley banks in alteration, such that shortening of the cable pulls the pulley banks together and tightens the orthotic device with the aid of a mechanical advantage.

Owner:PYNG MEDICAL CORP

Orthotic trauma device

InactiveUS20020148461A1Stabilizes broken boneBlood lossNon-surgical orthopedic devicesKnee orthosisBlock and tackle

An orthotic trauma device is provided including an elongated orthosis body adapted to be wrapped around a portion of a body of a wearer of the device, the orthosis body being formed of a pliant material which is adapted to be easily cut with cloth-cutting scissors; a detachable fastening device provided at distal ends of the elongated orthosis body to releasably secure the distal ends to one another; and means for adjusting the tightness of the orthosis body operatively associated with the detachable fastening device. A pulley system for use in an orthotic device is also provided including a pair of pulley banks arranged in juxtaposed relationship, a first bank of which is adapted to be detachably disposed on a first distal end of an elongated orthosis body and a second bank of pulleys adapted to be detachably disposed on a second distal end of the elongated orthosis body; and a cable interconnecting the two pulley banks and running through a pulley on each of the pulley banks in alteration, such that shortening of the cable pulling the pulley banks together and tightening the orthotic device with the aid of a mechanical advantage dependent upon the number of pulleys mounted on each of the pulley banks.

Owner:PYNG MEDICAL CORP

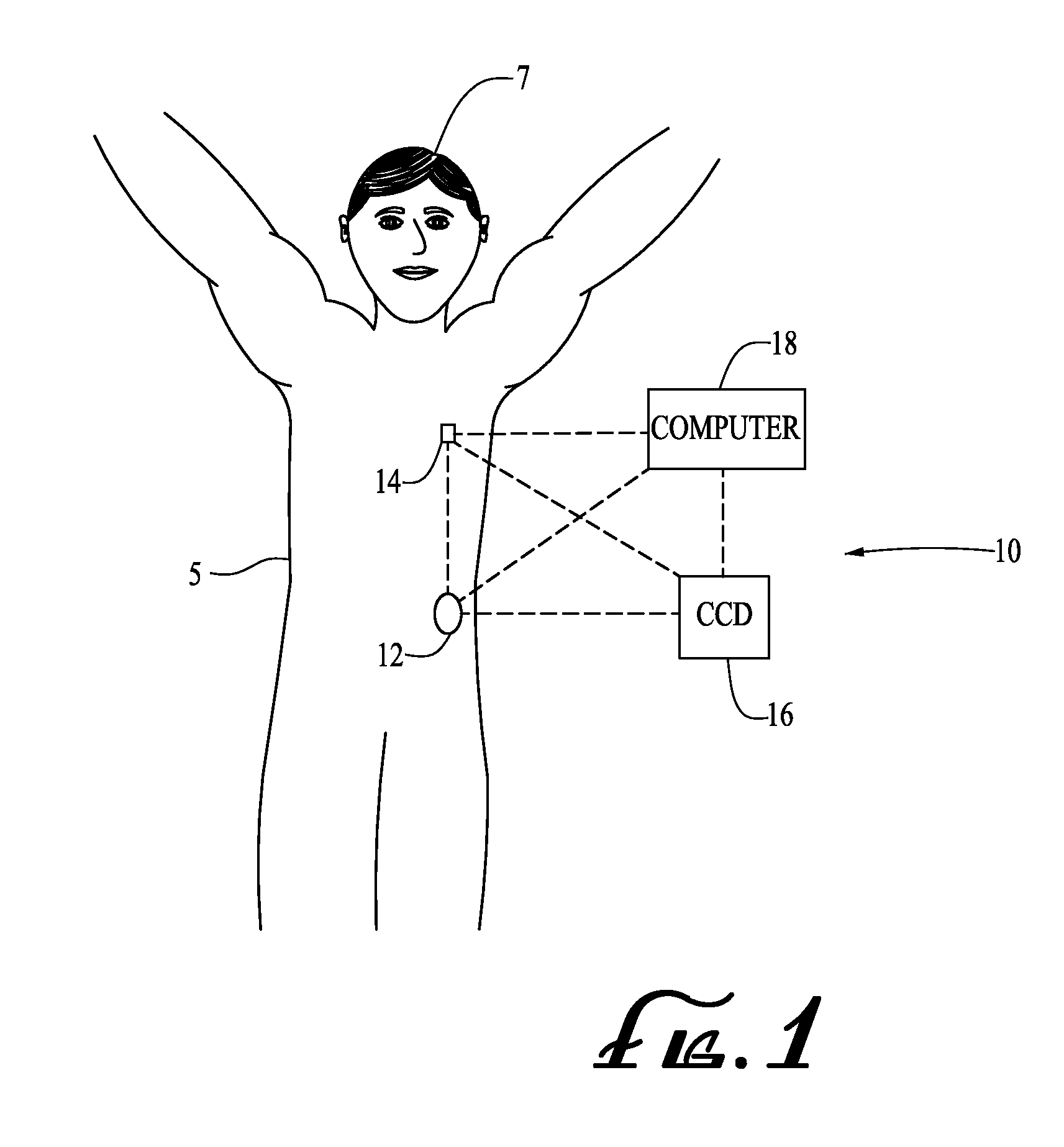

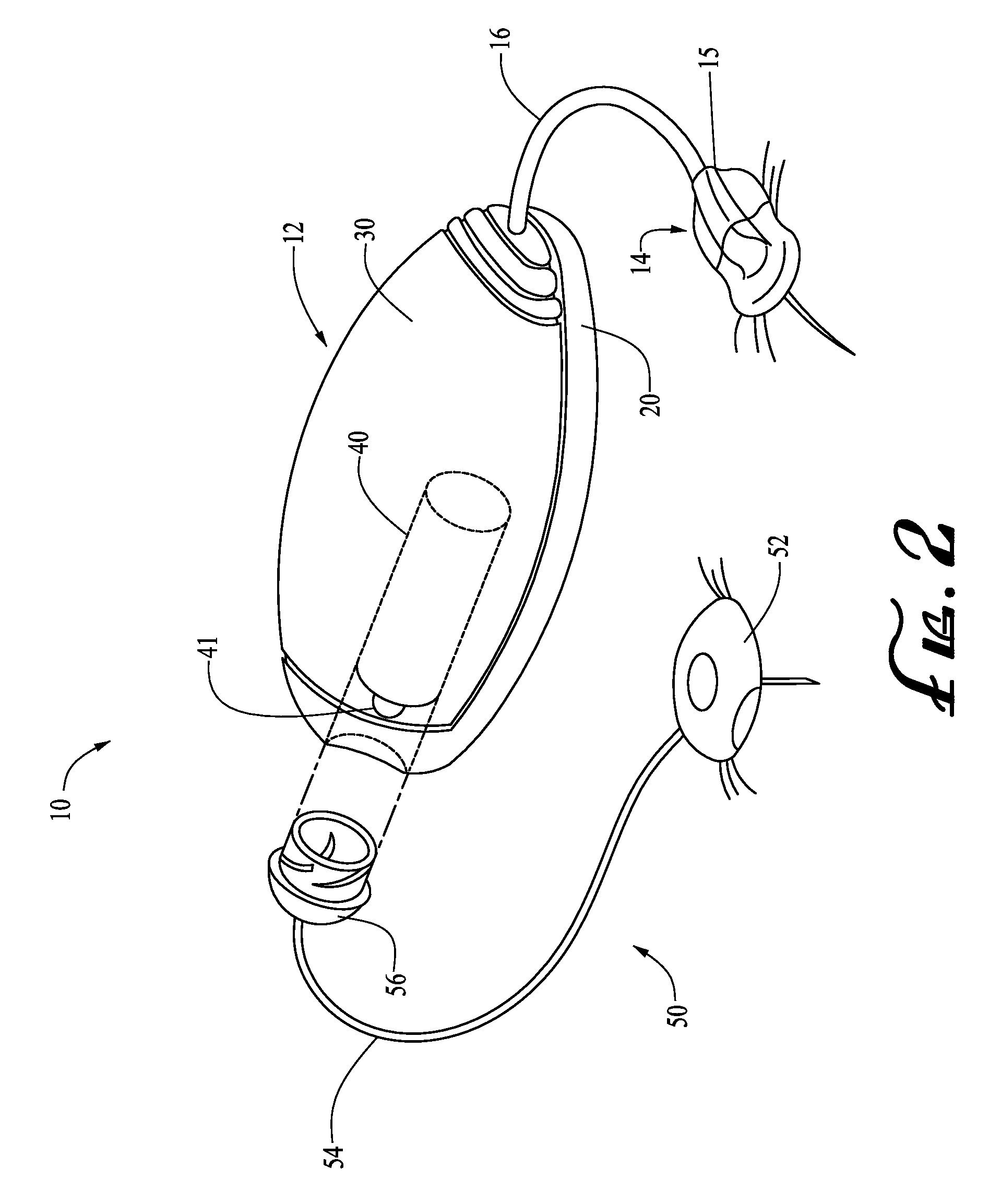

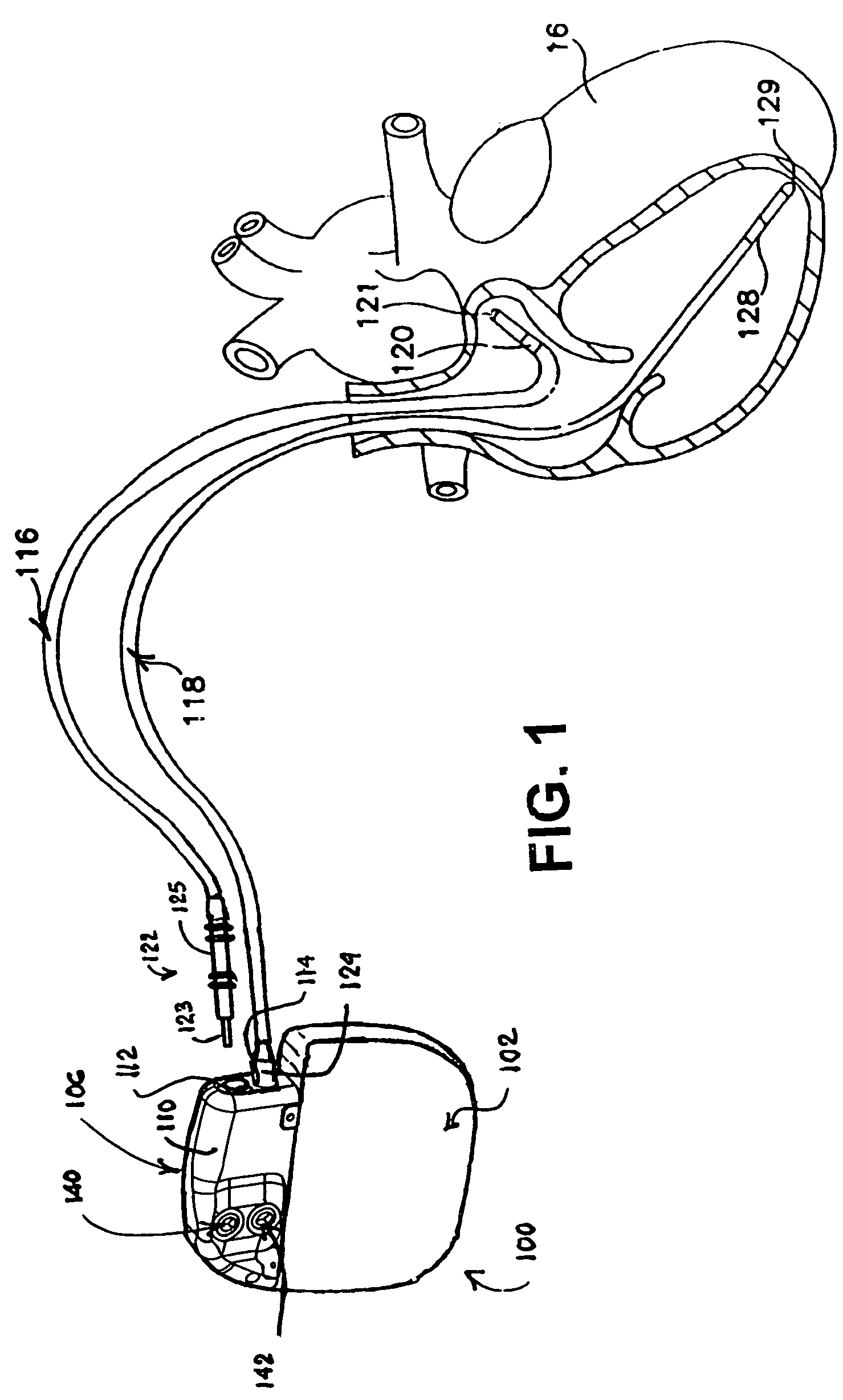

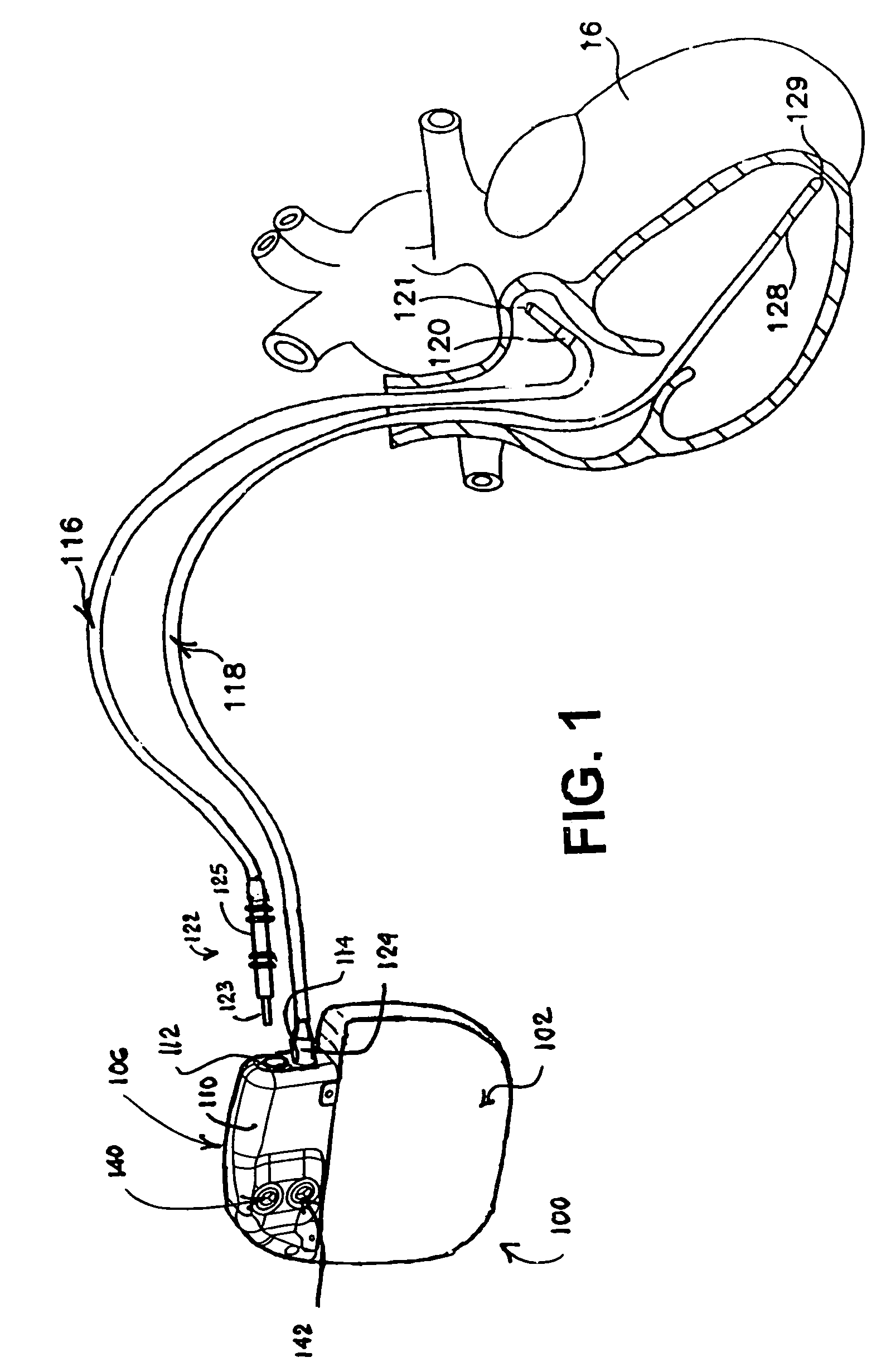

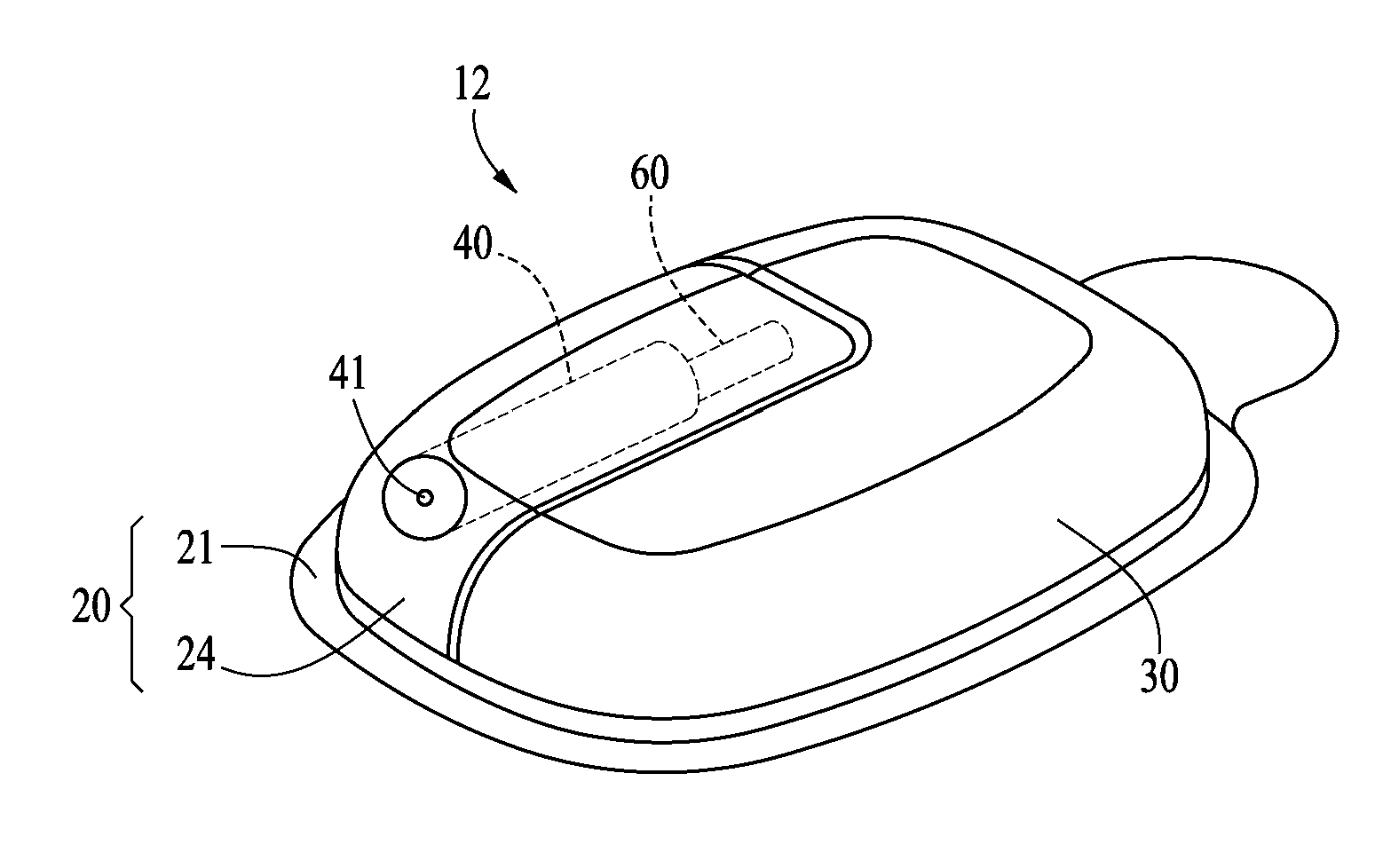

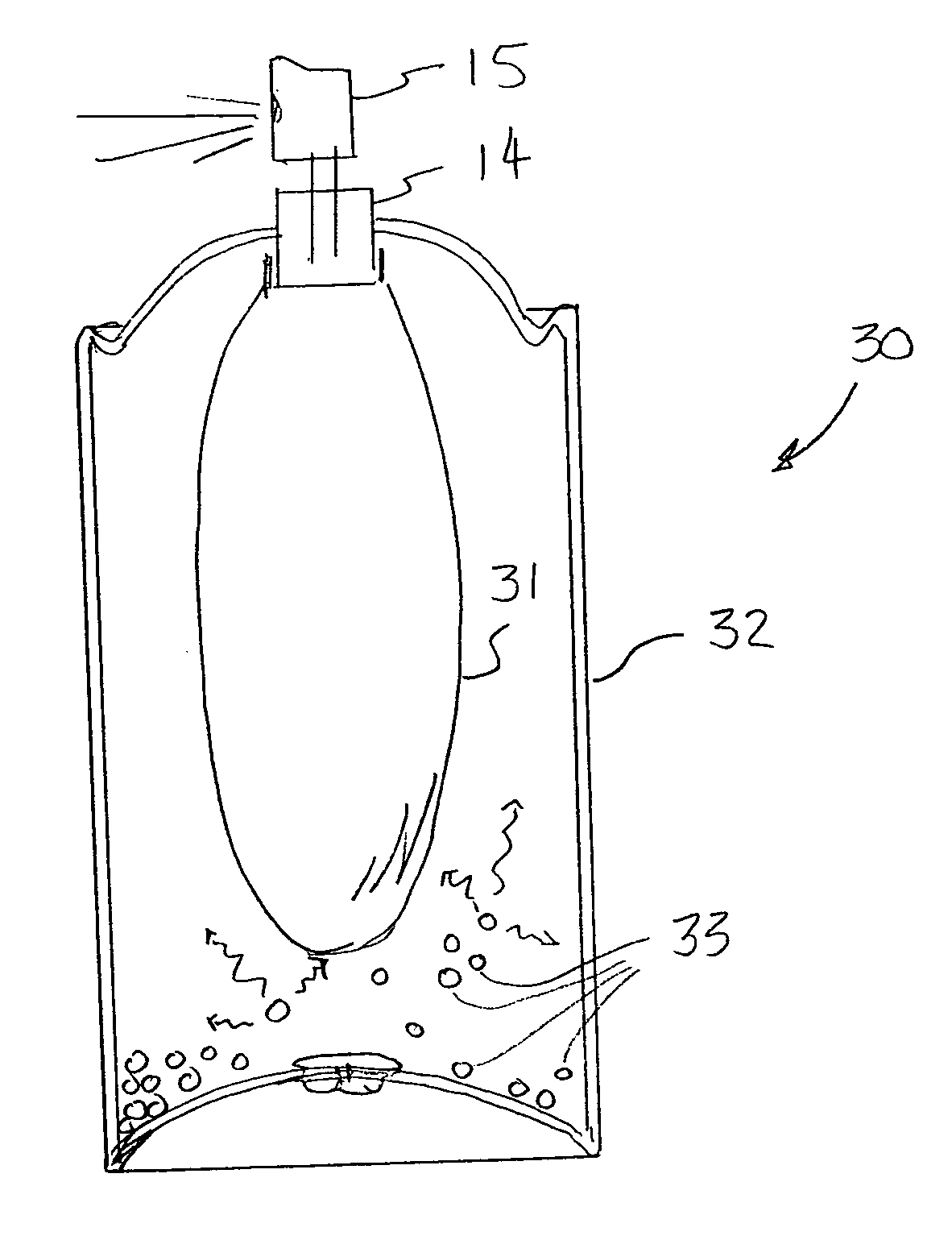

Reservoir Pressure Equalization Systems and Methods

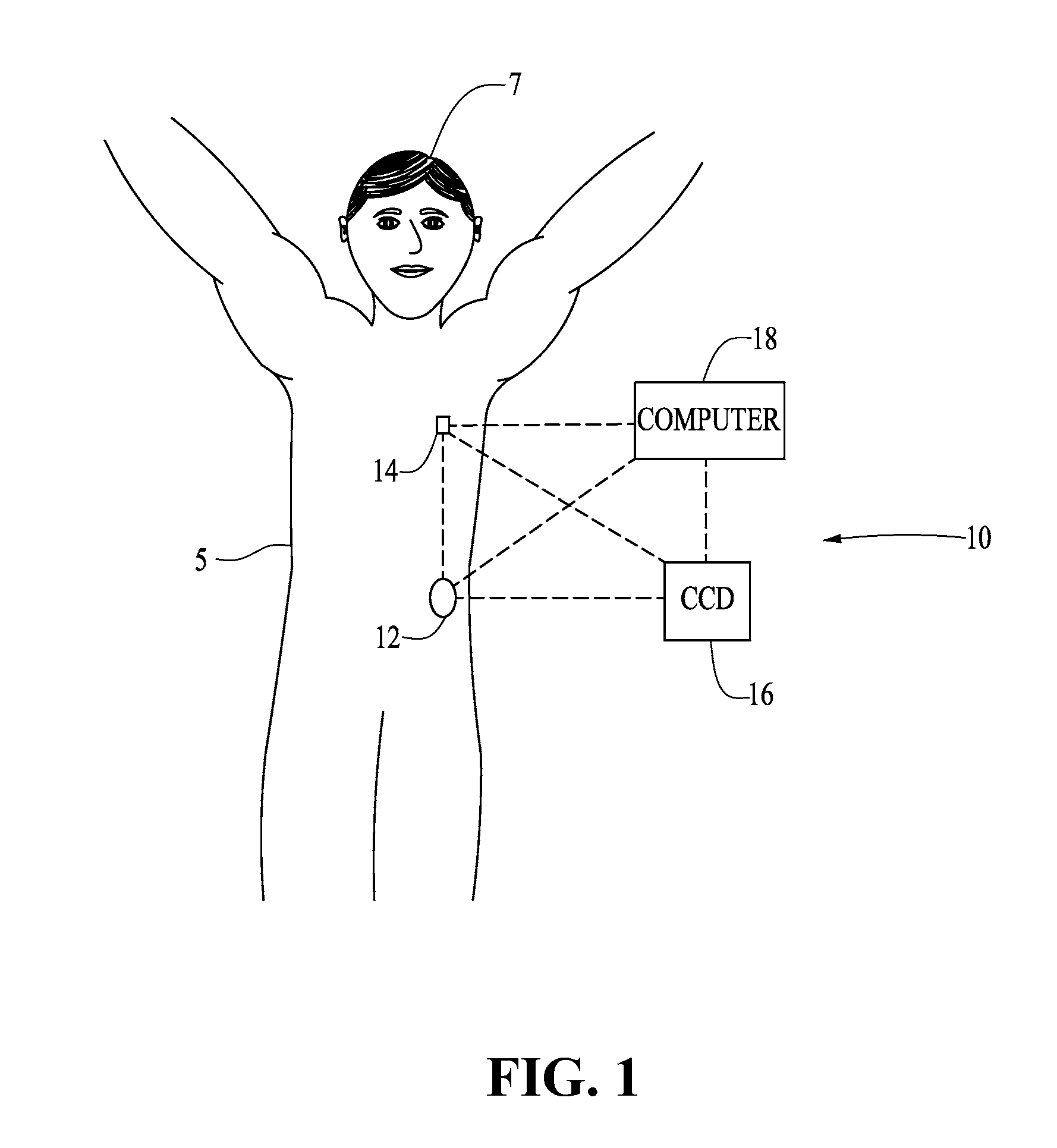

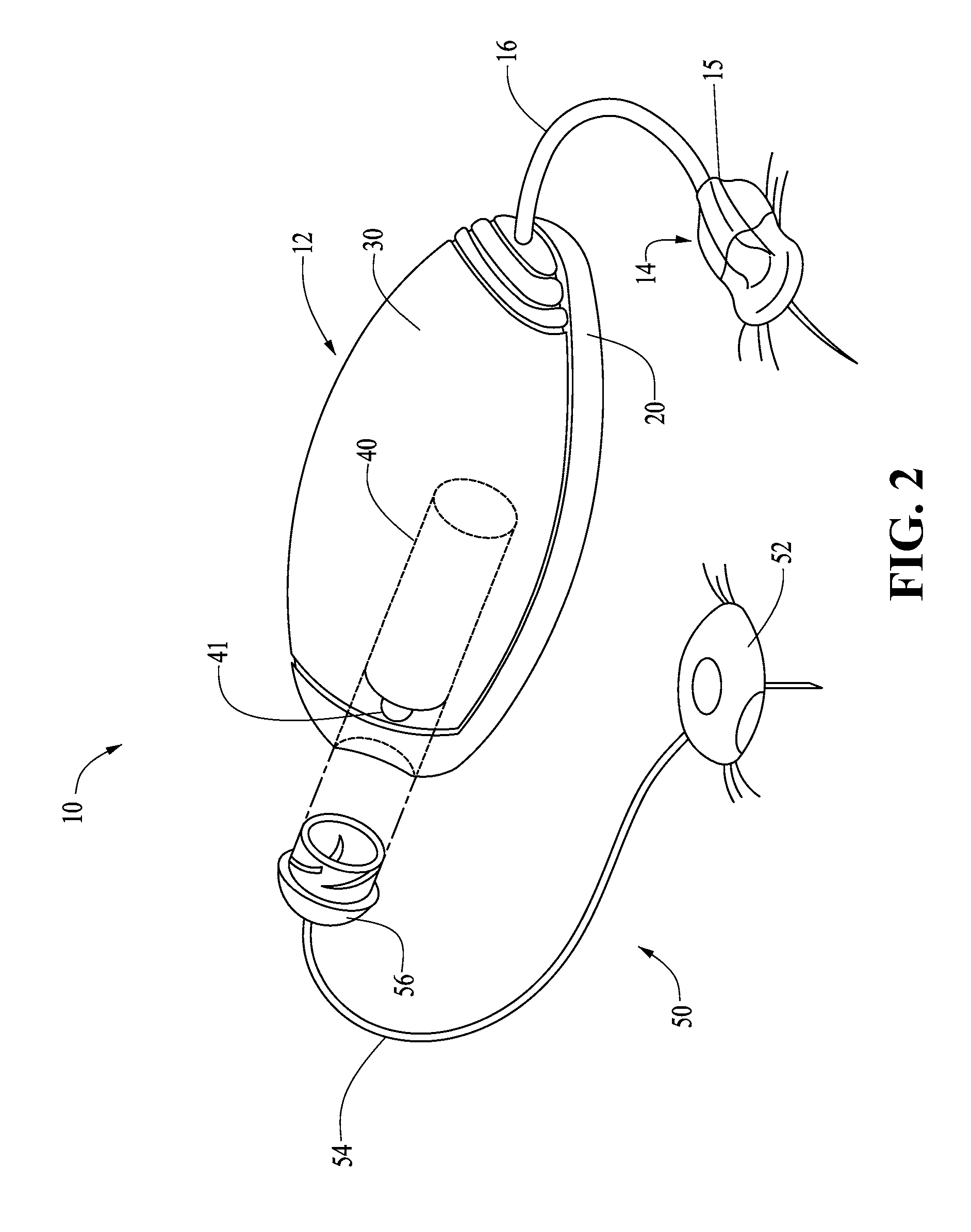

ActiveUS20090171324A1Increase pressureUniform pressureAmpoule syringesClosuresEqualizationBiomedical engineering

Various embodiments of the present invention are directed to equalizing pressure in a reservoir containing fluidic media, possibly due to imperfect installation of the reservoir or an external influence such as an altitude or a temperature change. In various embodiments, fluidic media may be expelled from the reservoir through a needle and contained in an interior volume of a pierceable member before the needle pierces the pierceable member to establish a flow path to a user. In other embodiments, fluidic media may be expelled through a port of the reservoir into a chamber. In further embodiments, fluidic media may be expelled through a channel in a plunger head and out a passage in the reservoir when the channel and passage are aligned. In other embodiments, fluidic media may be expelled through a valve, and the valve may be pierceable by a needle to establish a flow path to the user.

Owner:MEDTRONIC MIMIMED INC

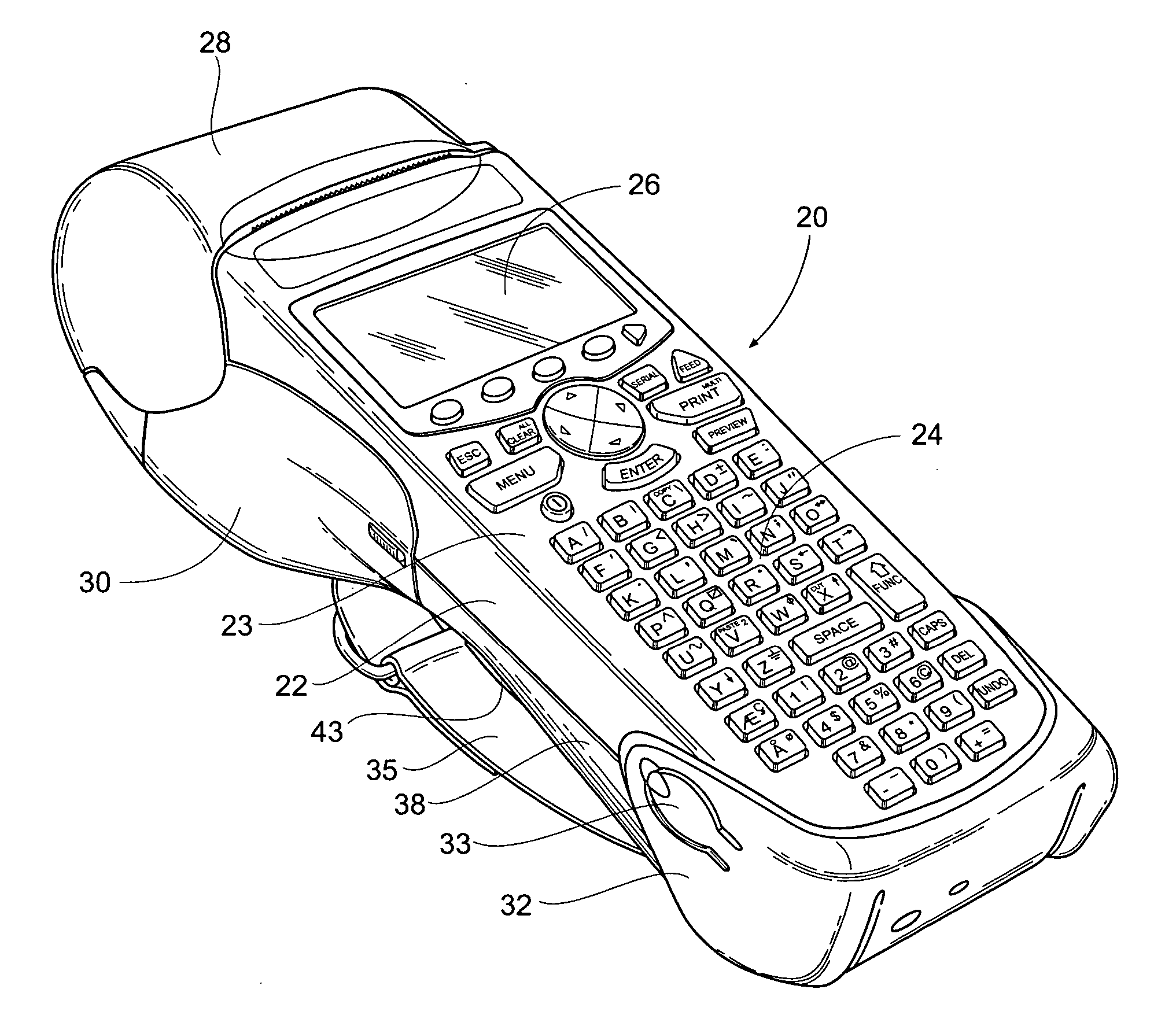

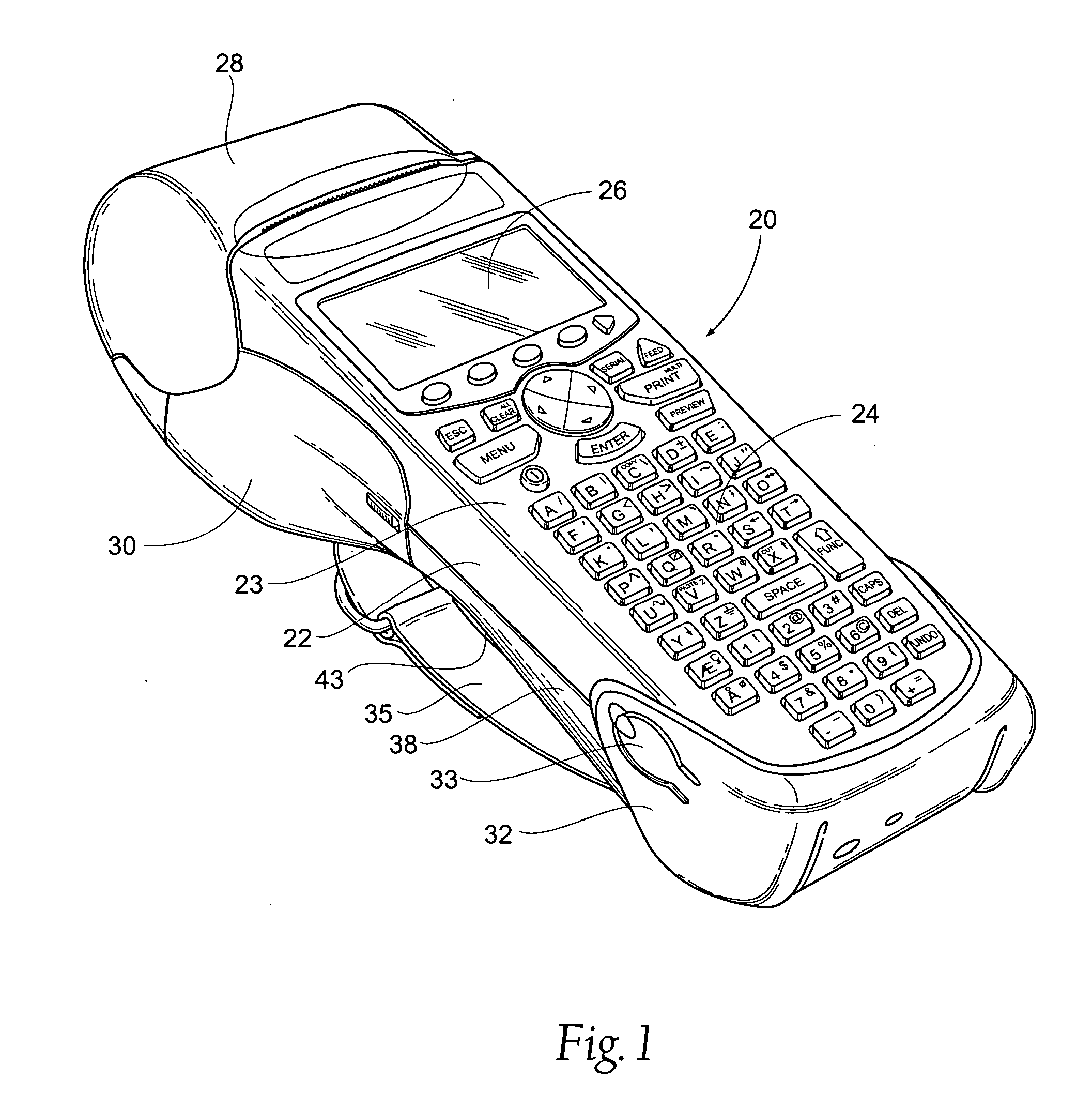

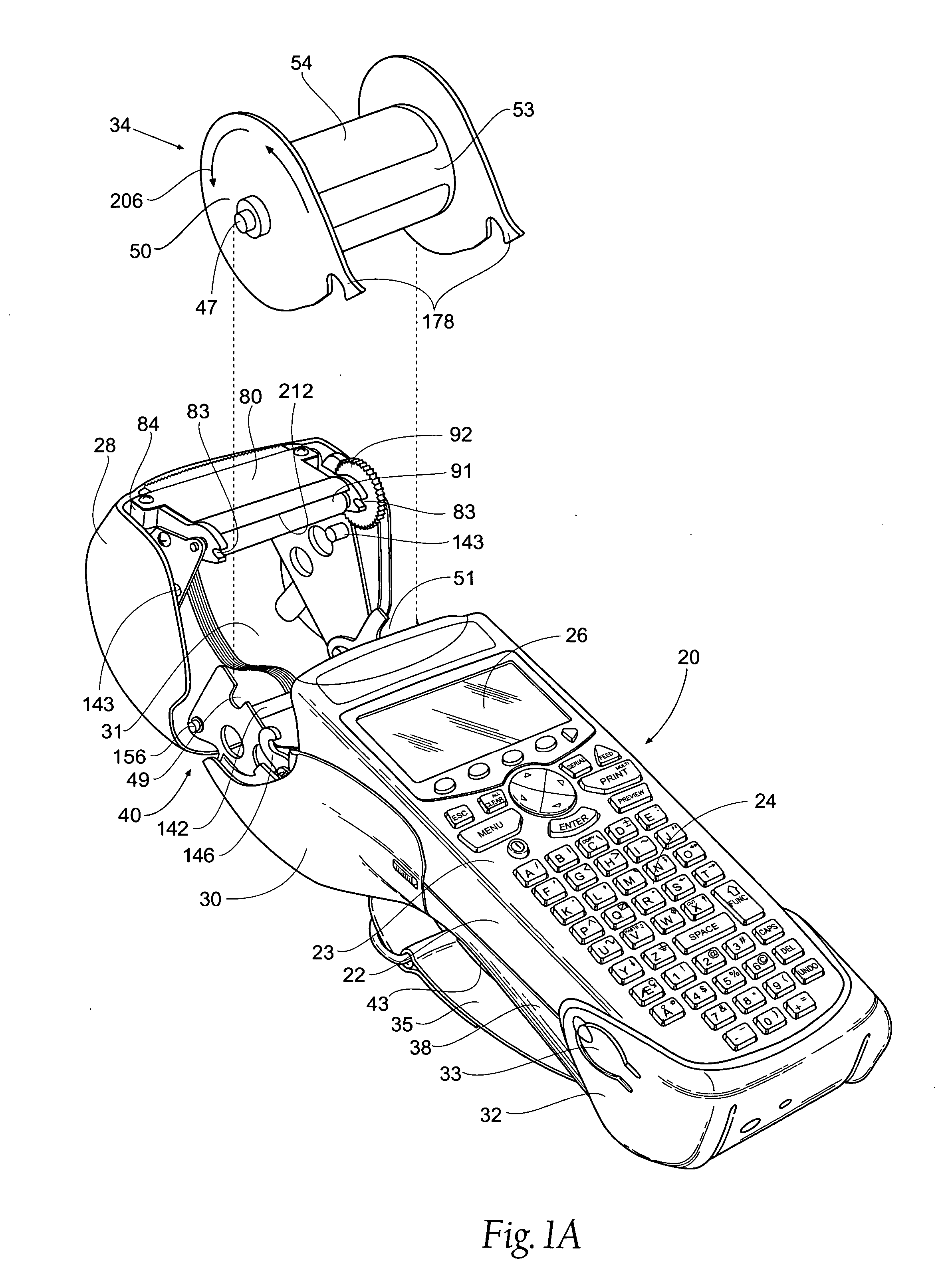

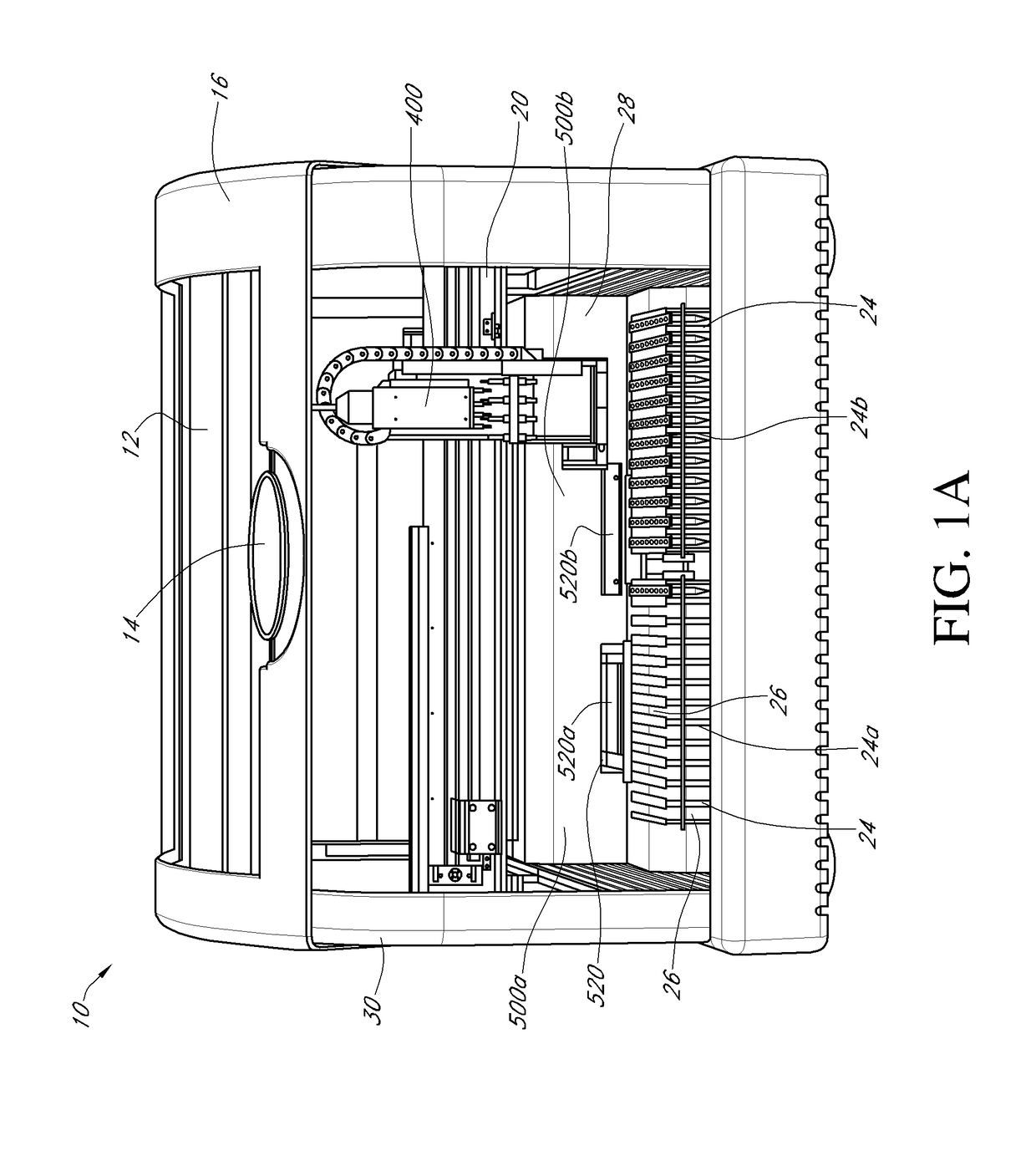

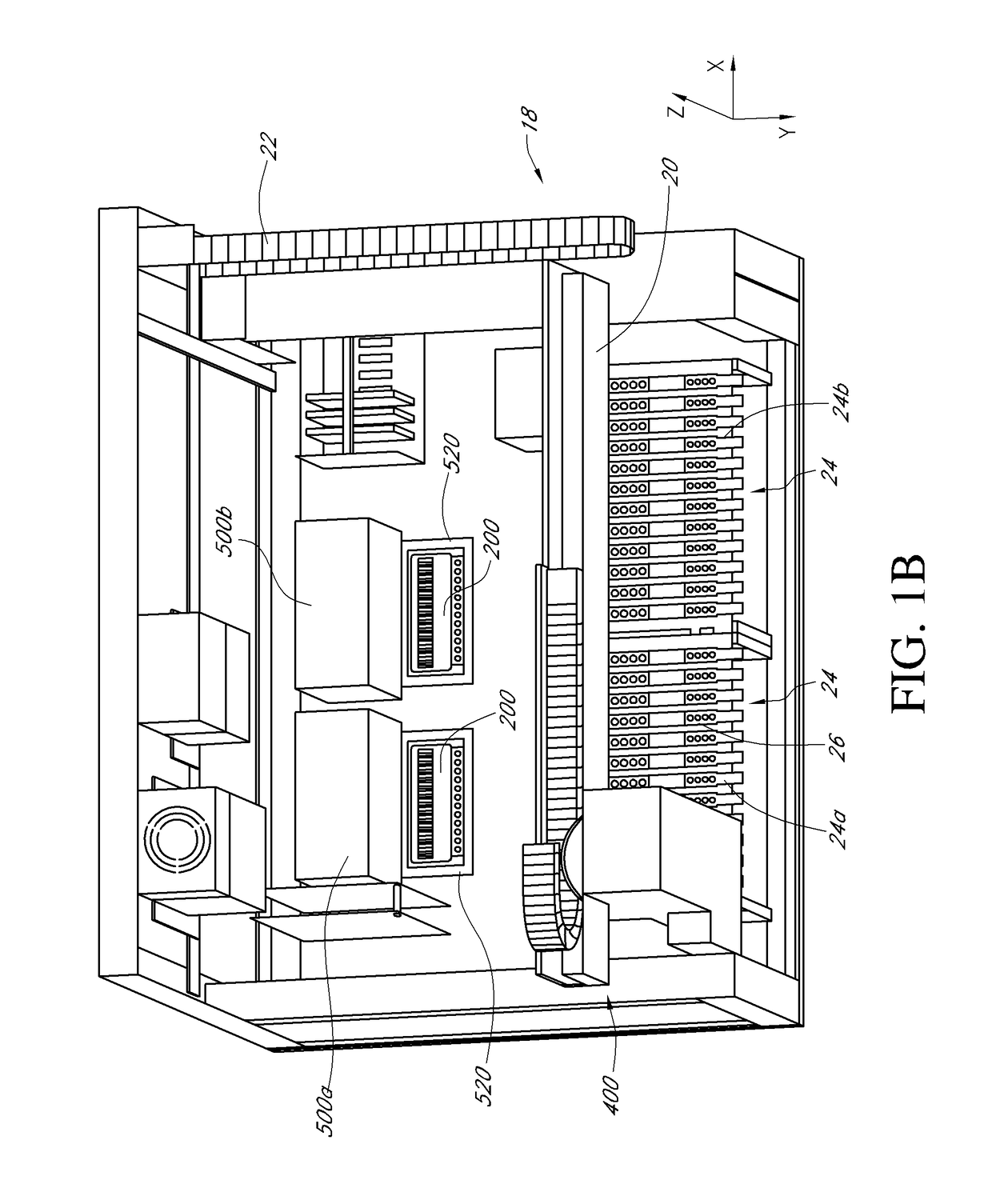

Portable printing system

ActiveUS20050002715A1Easy to changeNecessitating time consuming threading over spindlesTypewritersOther printing apparatusEngineeringSystem identification

A portable label printing system for printing on a variety of materials is disclosed. A retractable platen roller cooperates with a self-aligning print head in three planes cooperates for proper label printing registration. A display screen allows the user to view precisely what the actual label and associated indicia will look like when printed on a selected label. In addition, the printing system includes an optical sensor positioned to sense data marks on the backside of a label, located on a label supply roll, allowing the printing system to identify the label specifications and make necessary adjustments to affect print quality. Reverse feed of the label supply roll is possible. The label printing system further comprises a communication port for cooperation with various devices, such as online databases and computers.

Owner:HELLERMANNTYTON CORP

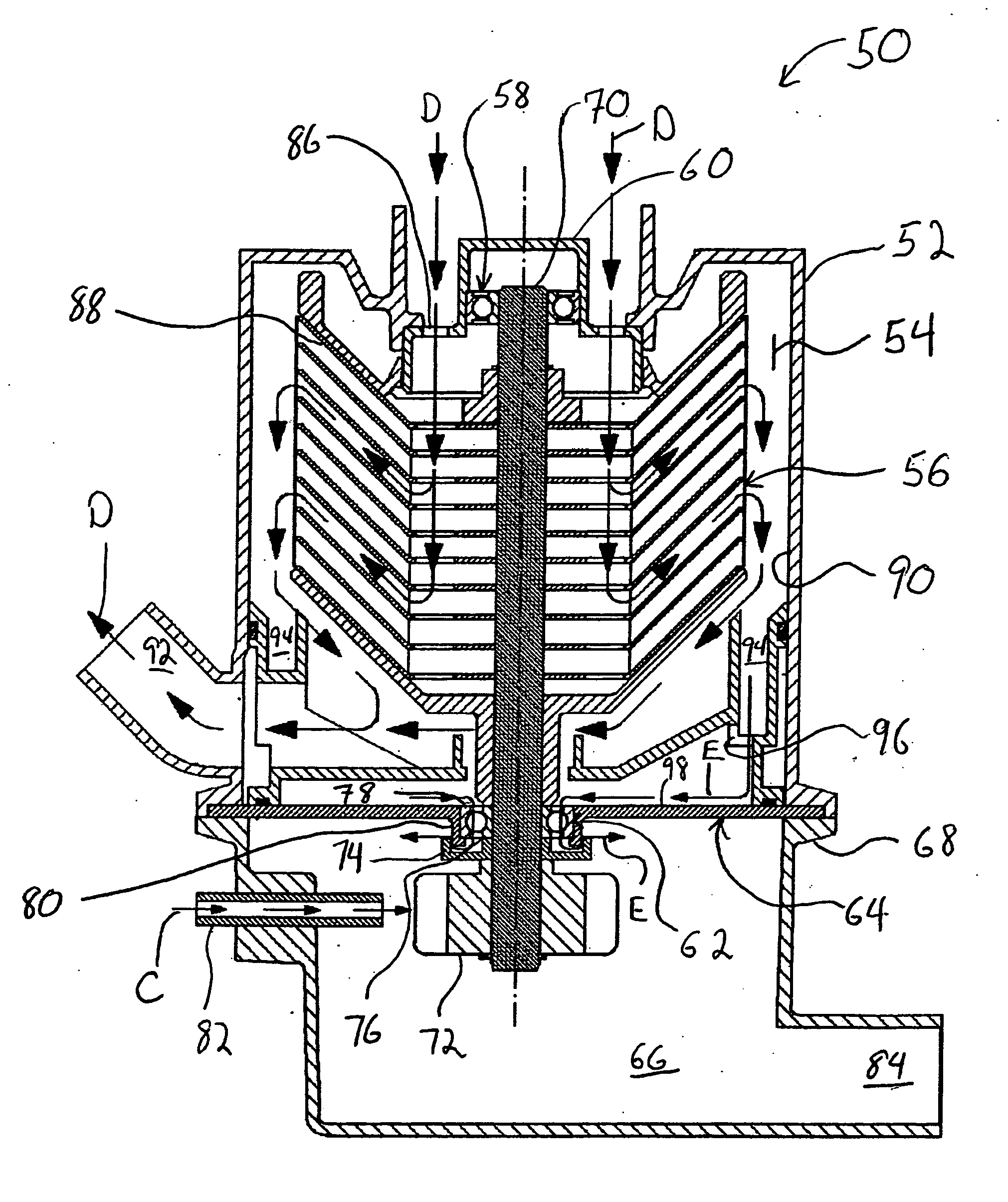

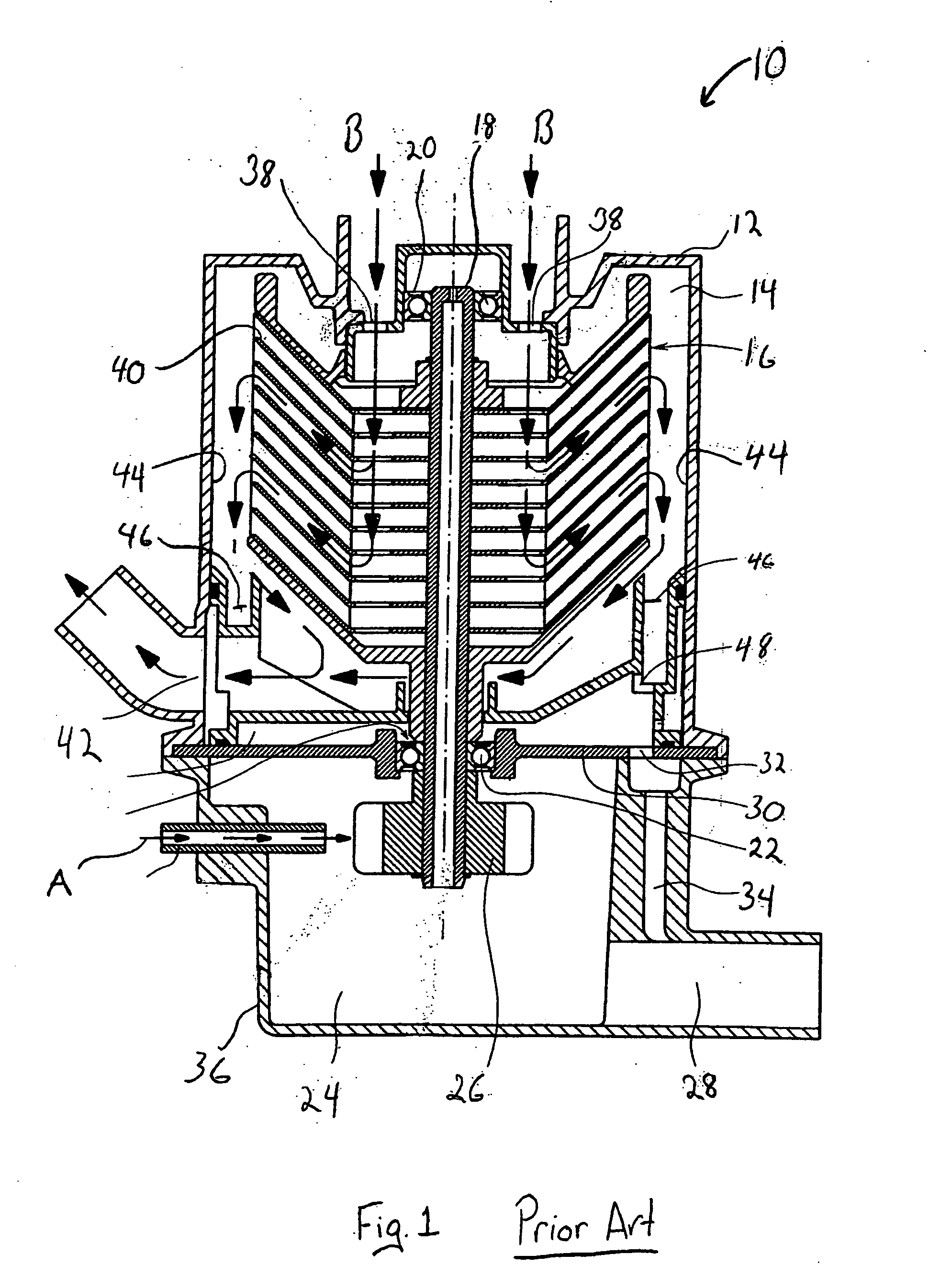

Centrifugal separator for cleaning gas generated by an internal combustion engine and a method for operating the same

ActiveUS20070249479A1Minimizes for egressMinimize potentialCombination devicesAuxillary pretreatmentEngineeringCentrifugal force

In a centrifugal separator for cleaning gases generated by an internal combustion engine a housing defines an interior separation chamber. A centrifugal rotor is coupled for rotation to the housing and extends into the separation chamber. A drainage chamber is positioned adjacent the separation chamber and is delimited therefrom by a partition wall. A flow path is provided through which oil, separated from gases generated by the internal combustion engine and collecting on the partition wall, can travel from the separation chamber to the drainage chamber. A pump wheel is coupled to a shaft portion defined by the rotor and extends radially outwardly therefrom. During operation the oil, upon exiting the separation chamber, contacts the pump wheel. Centrifugal forces generated due to the rotation of the pump wheel cause the oil to be thrown into the drainage chamber. The pump wheel also minimizes the potential for oil resident in the drainage chamber to re-enter the separation chamber.

Owner:ALFA LAVAL CORP AB

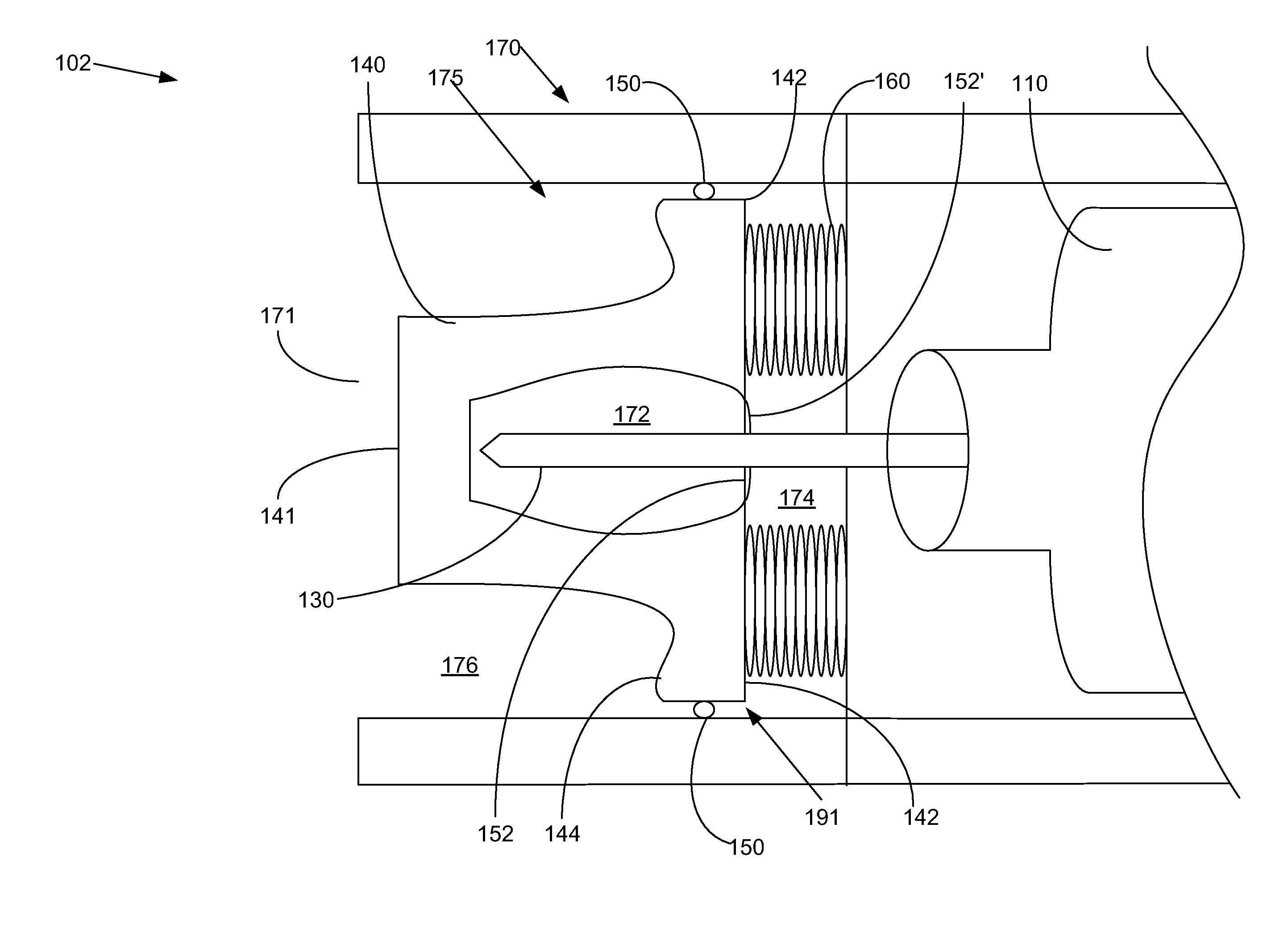

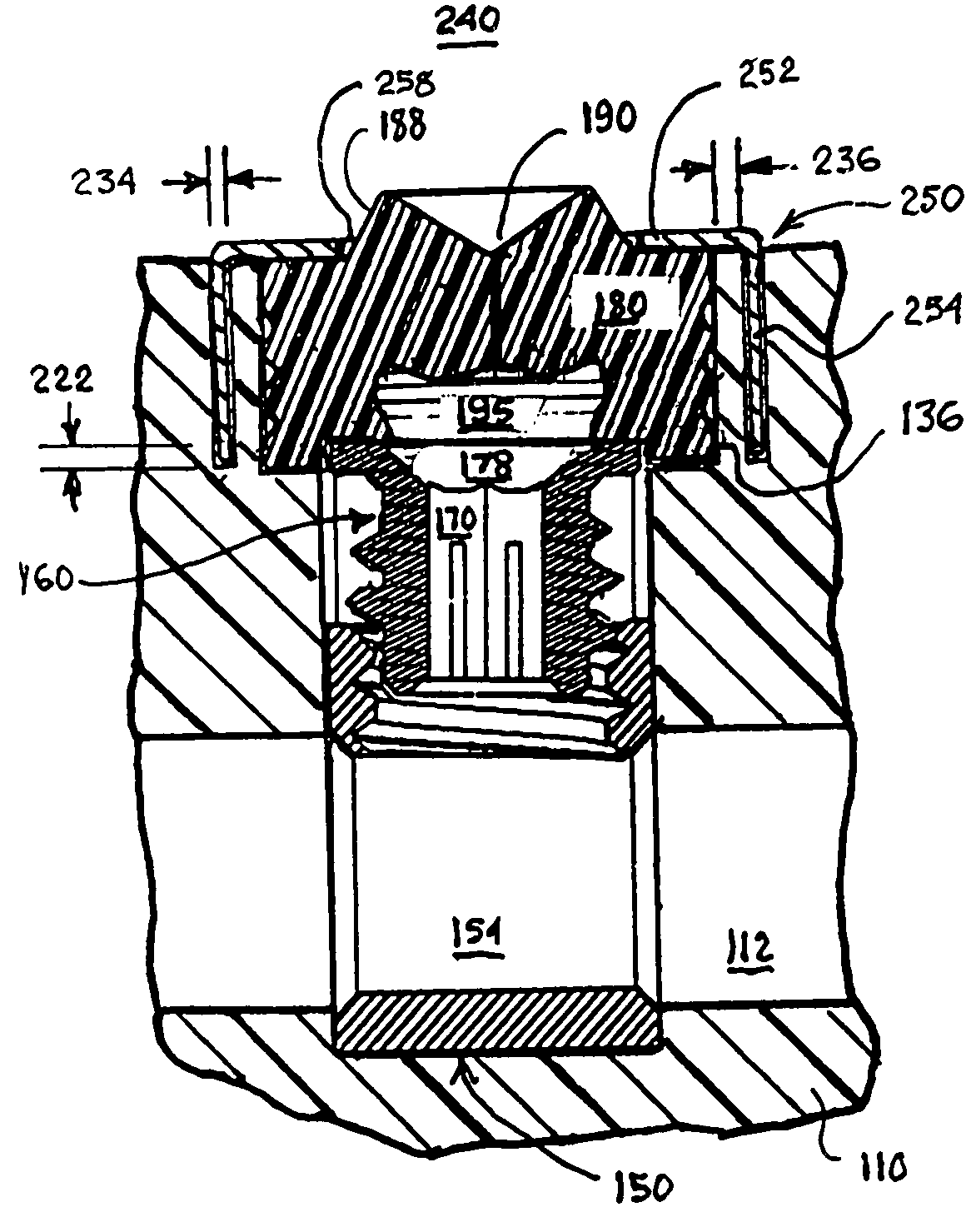

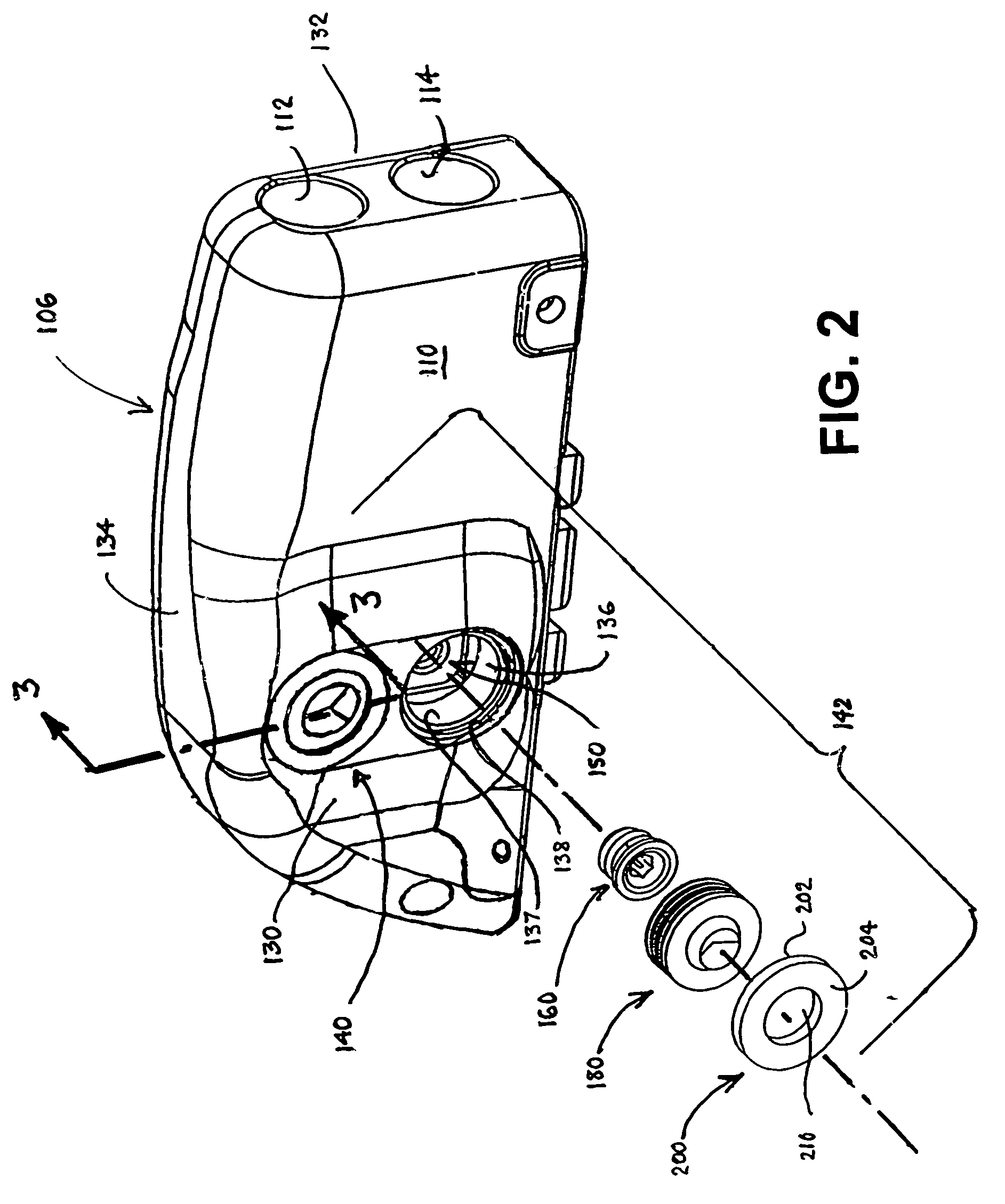

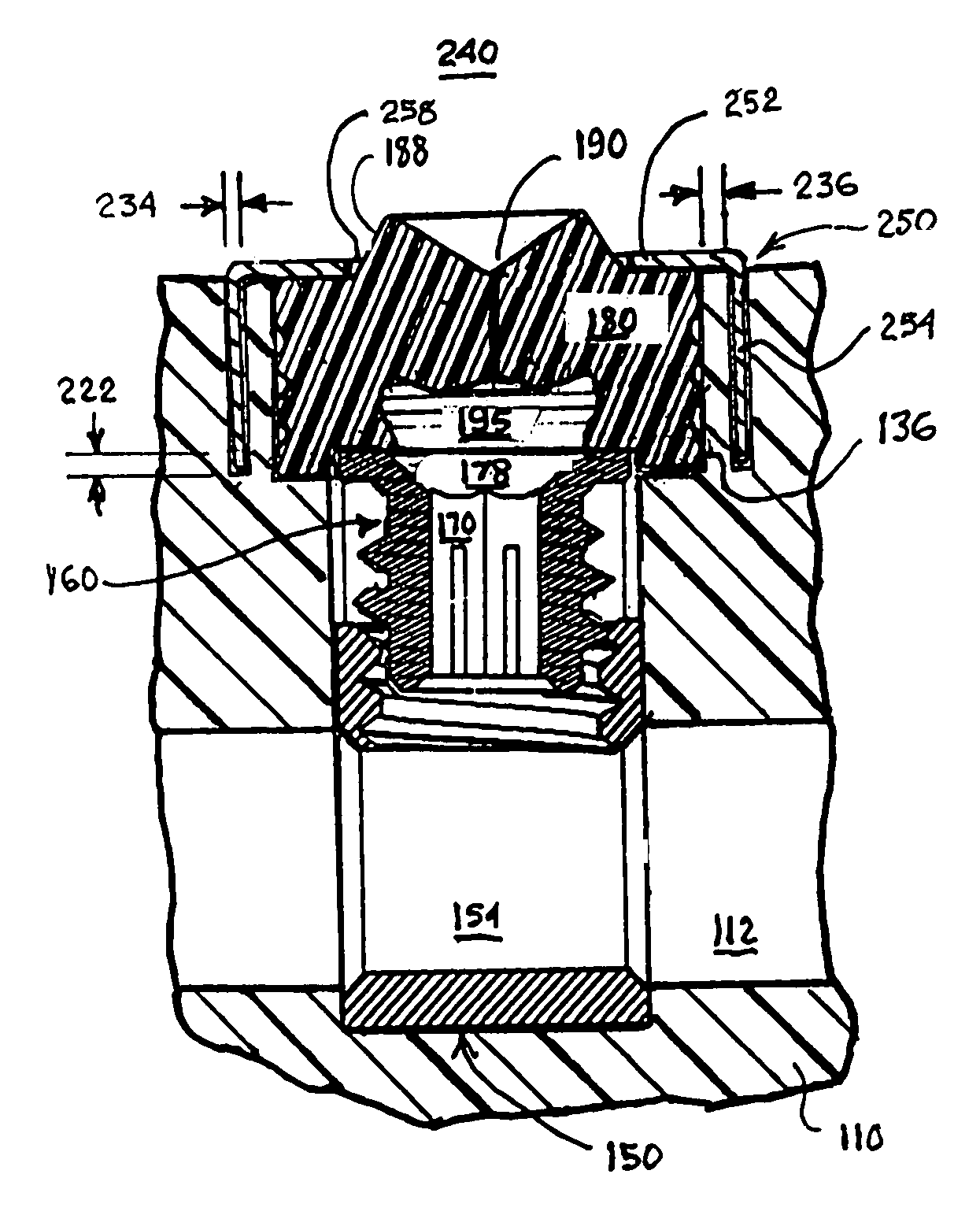

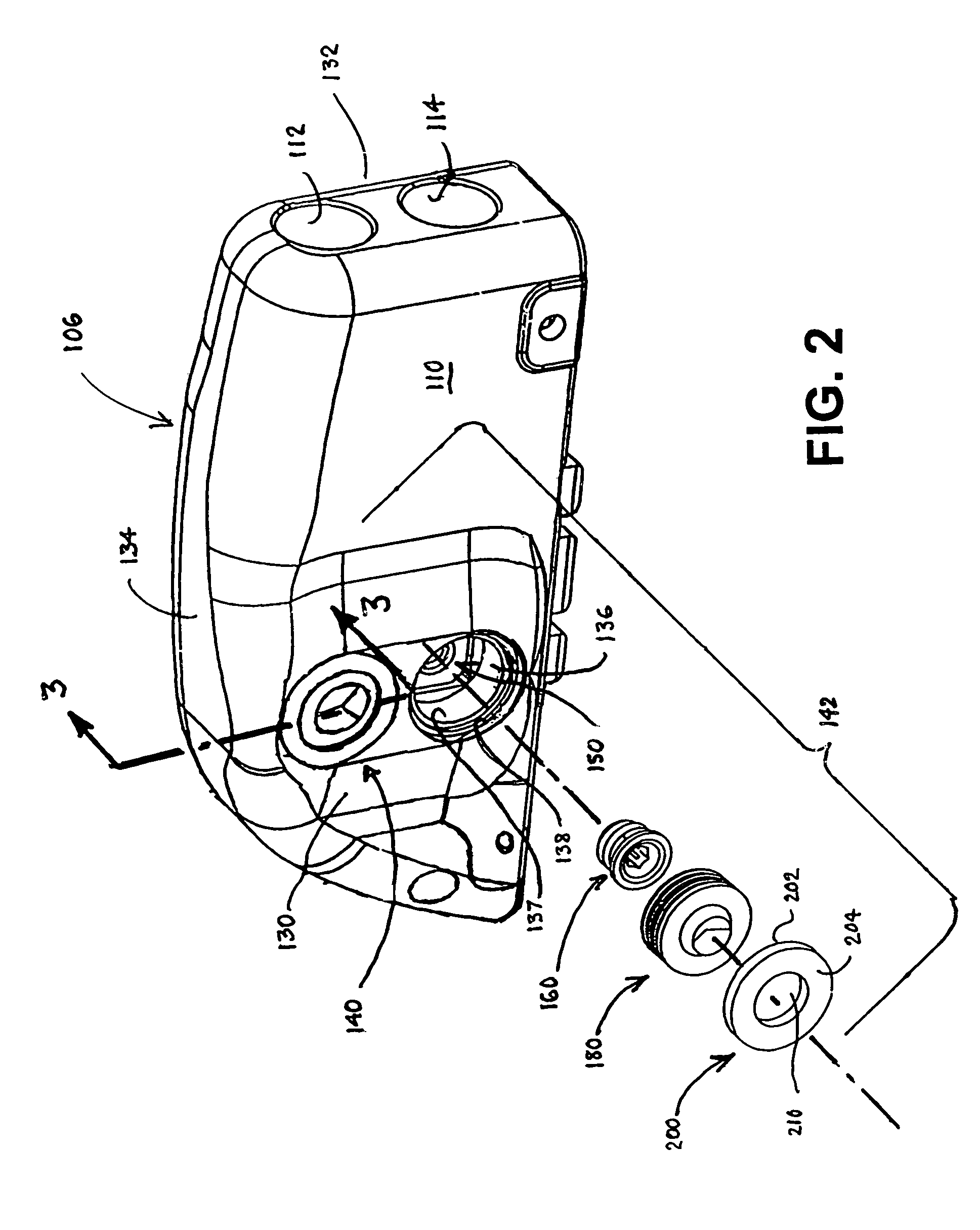

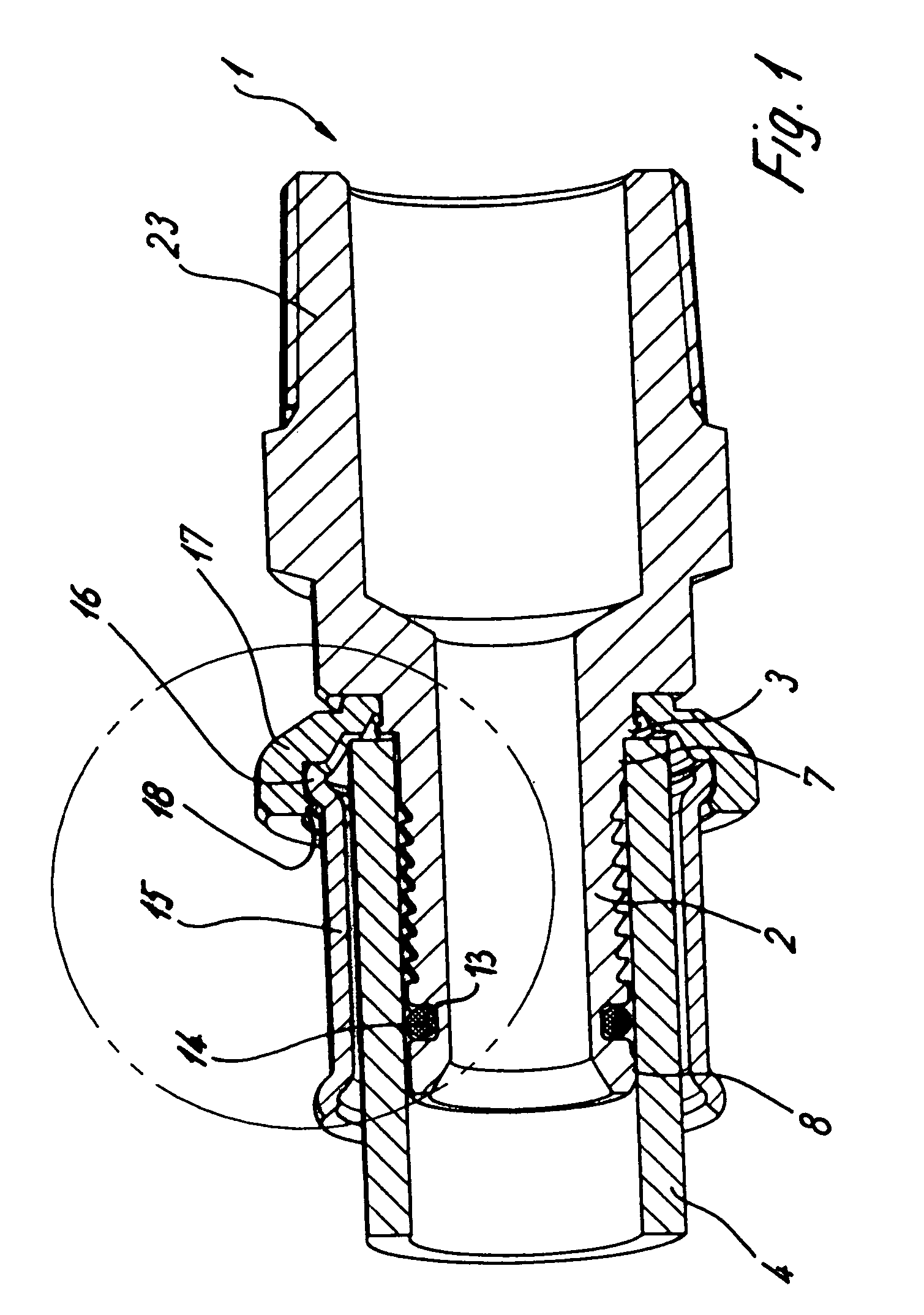

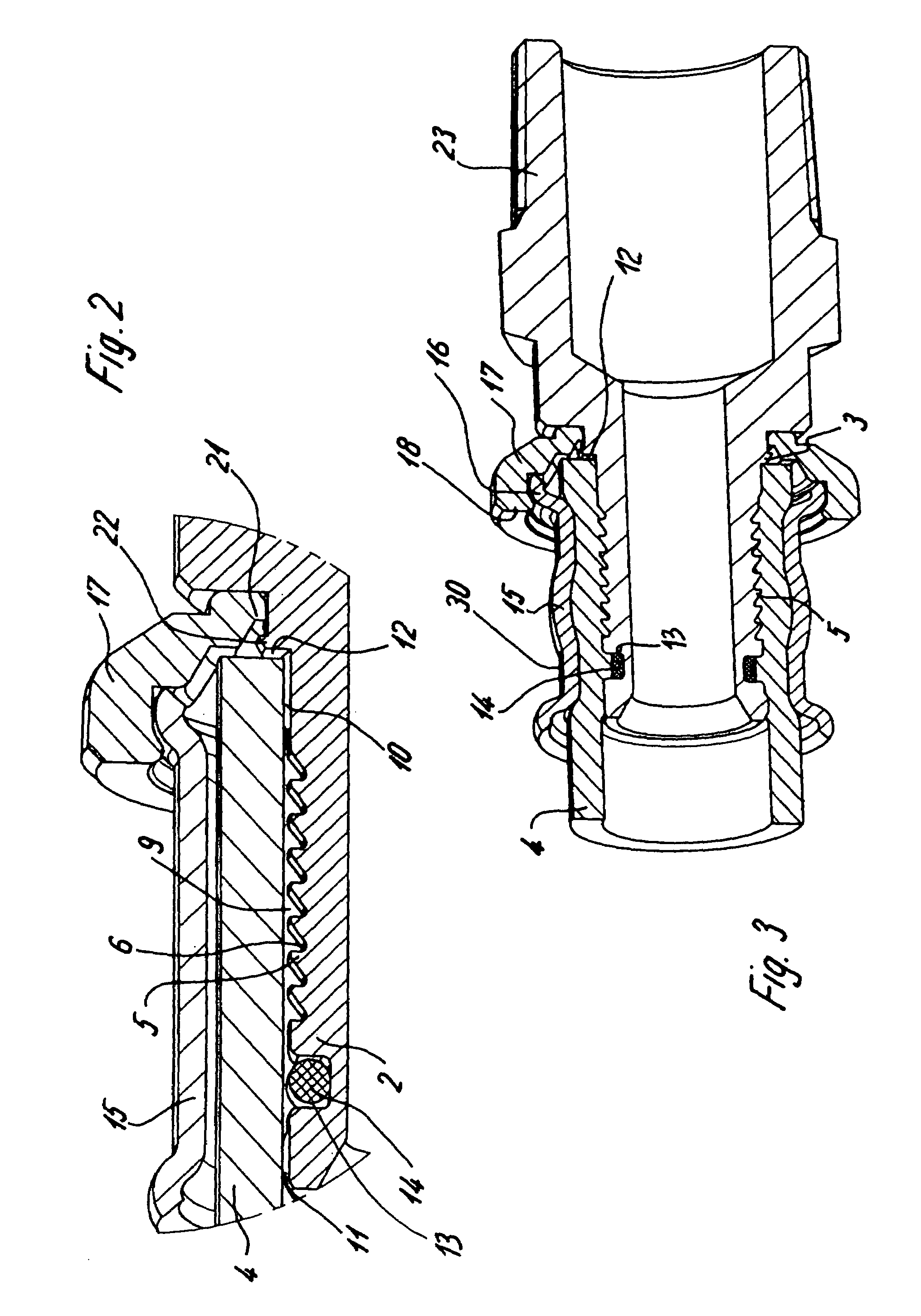

IMD connector header with grommet retainer

An implantable medical device (IMD) includes a connector header for making electrical and mechanical connections with a proximal connector assembly of an electrical medical lead and includes a retainer for retaining a penetrable grommet within a header grommet aperture. A connector block disposed within a header body of the connector header has a threaded bore aligned with a header grommet aperture and a connector block bore aligned with a header connector bore. The penetrable grommet is disposed within the header grommet aperture, and a setscrew is threaded into the threaded bore having a setscrew socket disposed to be engaged by a tool inserted through the penetrable grommet within the header grommet aperture to enable rotation of the setscrew within the threaded bore to tighten the setscrew against or to loosen the setscrew from a lead connector element received in the header connector bore.

Owner:MEDTRONIC INC

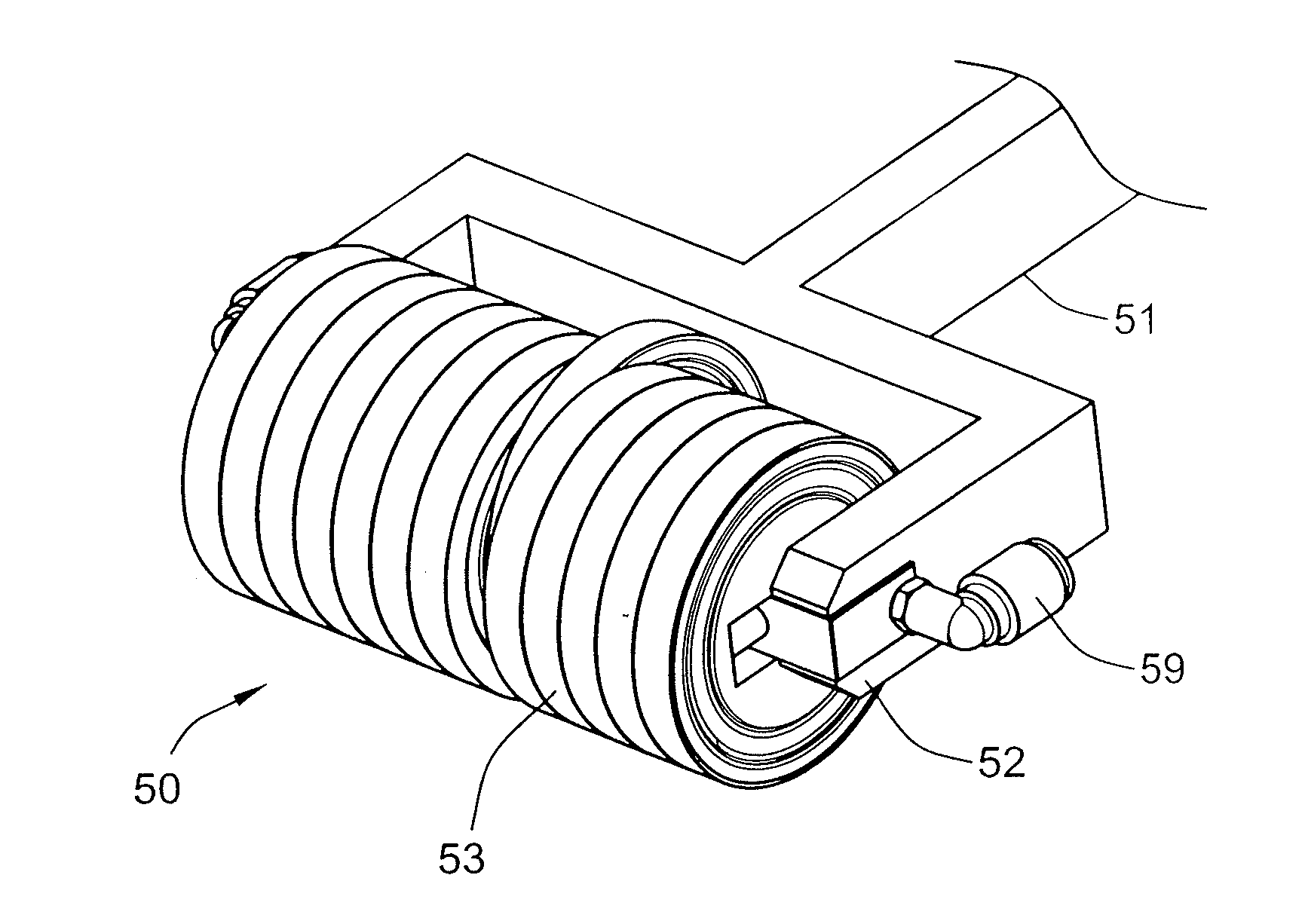

High frequency dynamics resonator assembly

ActiveUS7080514B2Uniform pressureContinuous combustion chamberEngine fuctionsMechanical engineeringResonator

Aspects of the invention relate to resonator assemblies for use in non-uniform flow environments. The resonator assemblies include one or more features, such as a box or a scoop, for substantially equalizing the pressure on the resonator. In the box configuration, a box is attached on top of the resonator. The box has a top plate with a plurality of openings and at least one side wall extending from the entire periphery of the top plate. A plenum is defined between the box and the resonator plate. In the scoop configuration, a scoop is attached to the top of the resonator such that the scoop substantially overhangs the resonator. The scoop includes at least one side wall extending substantially perpendicularly therefrom, except for one side without a side wall so as to provide an opening into a space defined between the scoop and the resonator.

Owner:SIEMENS ENERGY INC

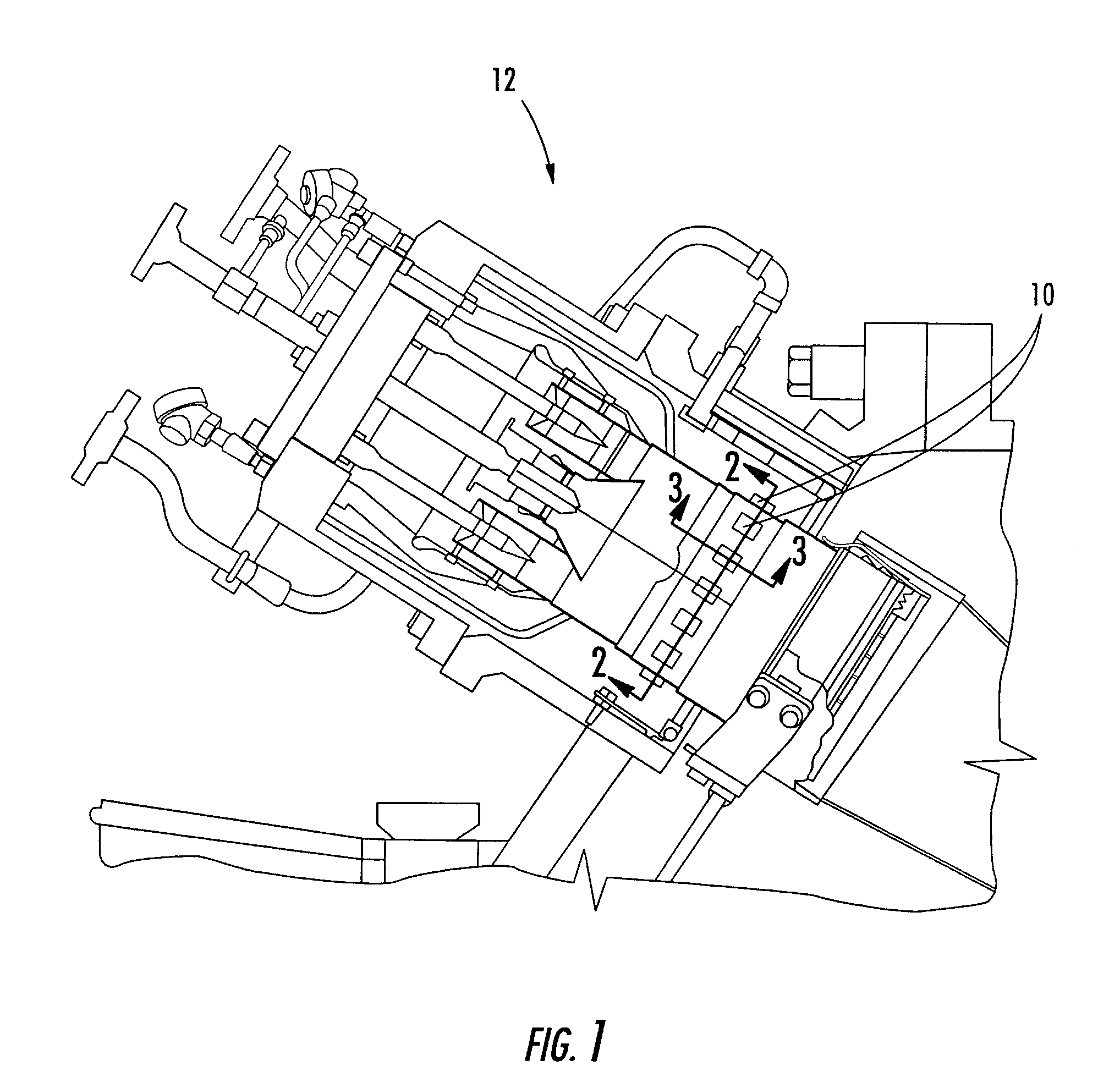

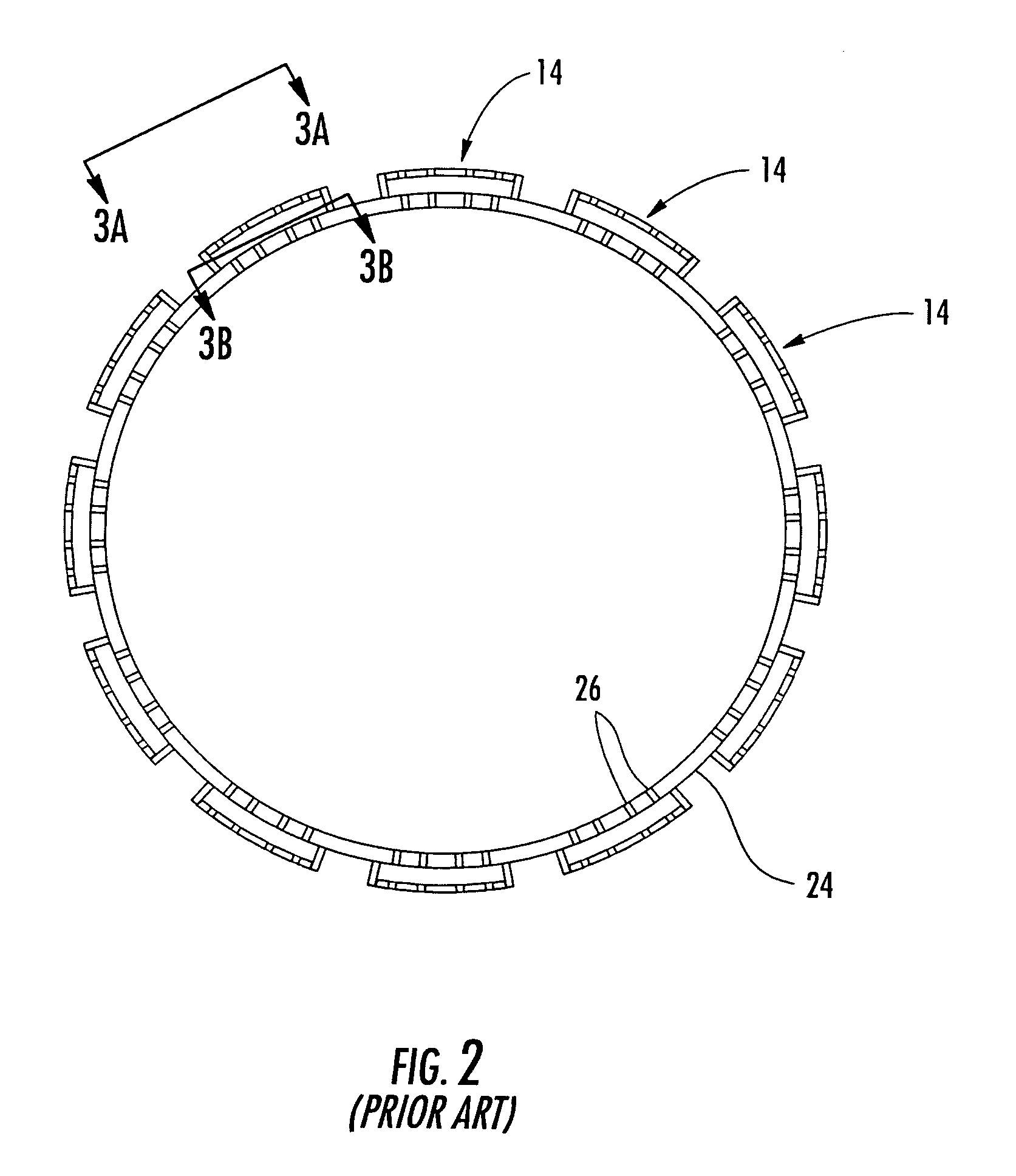

Compaction roller for a fiber placement machine

Tools for compacting composite parts are disclosed. These tools are used while layers of composite material, such as tows or laminae, are being deposited onto a fabricating surface, such as a mold or other forming tool. The compacting tool is typically divided into a series of narrow segments, each segment able to advance or retreat individually so as to conform to the surface of a composite part being formed. Pressurized fluid, such as air or hydraulic fluid, or non-pressurized internal bladders with incompressible fluid, are used to evenly apply pressure to the segments in order to compact the material with which the tool and the segments are in contact. The compacting tool thus helps eliminate voids and helps the material conform to the desired shape on the forming tool.

Owner:INGERSOLL MACHINE TOOLS

Centrifugal separator for cleaning gas generated by an internal combustion engine and a method for operating the same

ActiveUS7338546B2Minimize potentialUniform pressureCombination devicesAuxillary pretreatmentExternal combustion engineEngineering

In a centrifugal separator for cleaning gases generated by an internal combustion engine a housing defines an interior separation chamber. A centrifugal rotor is coupled for rotation to the housing and extends into the separation chamber. A drainage chamber is positioned adjacent the separation chamber and is delimited therefrom by a partition wall. A flow path is provided through which oil, separated from gases generated by the internal combustion engine and collecting on the partition wall, can travel from the separation chamber to the drainage chamber. A pump wheel is coupled to a shaft portion defined by the rotor and extends radially outwardly therefrom. During operation the oil, upon exiting the separation chamber, contacts the pump wheel. Centrifugal forces generated due to the rotation of the pump wheel cause the oil to be thrown into the drainage chamber. The pump wheel also minimizes the potential for oil resident in the drainage chamber to re-enter the separation chamber.

Owner:ALFA LAVAL CORP AB

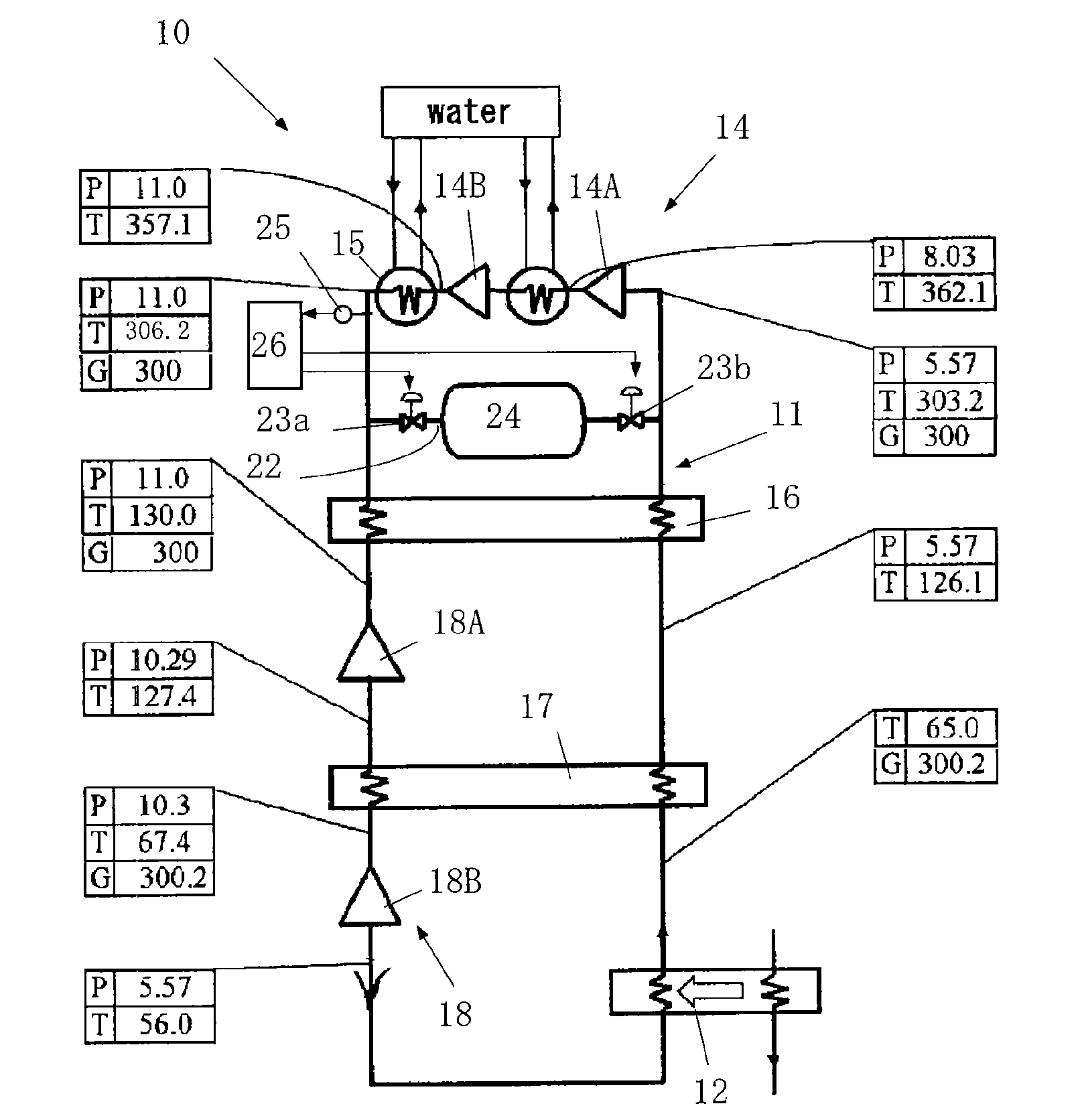

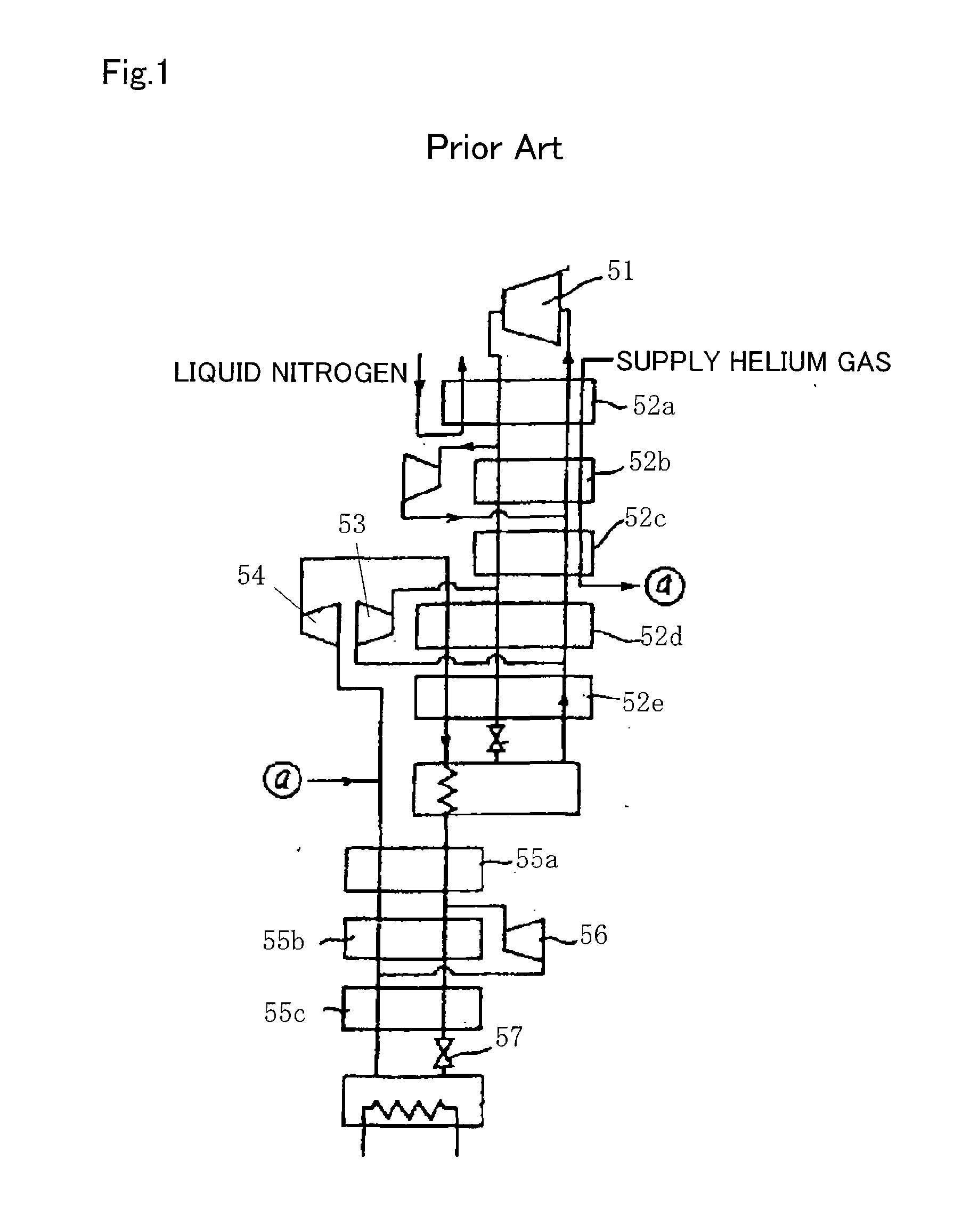

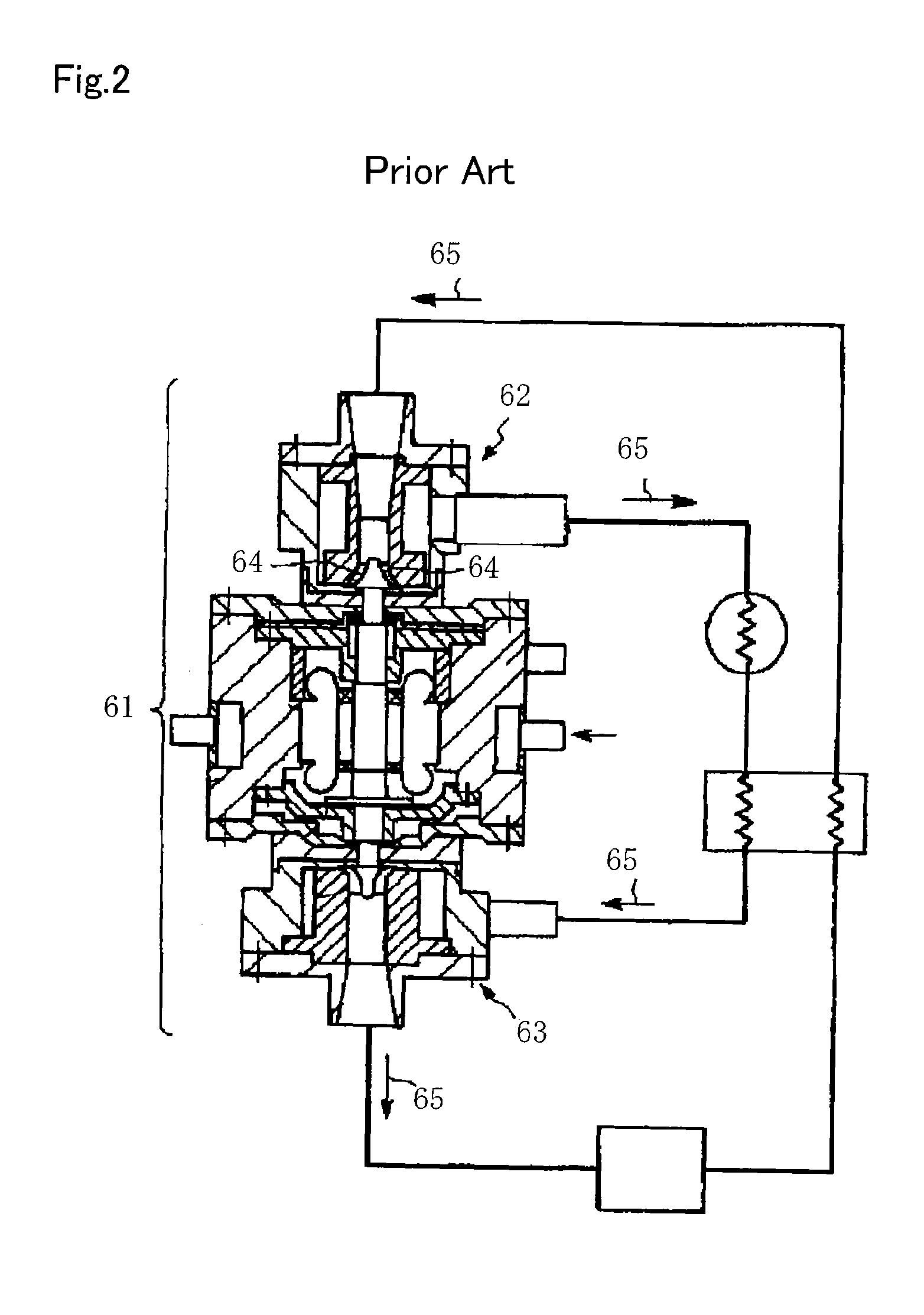

Cryogenic refrigerator and control method therefor

InactiveUS20100275616A1Smooth rotationPrevent reversalSolidificationLiquefactionClosed loopRoom temperature

A cryogenic refrigerator (10) which generates a cryogenic temperature by compressing and expanding a working gas in a closed loop (11). The cryogenic refrigerator comprises a bypass line (22) allowing a high-pressure portion and a low-pressure portion to communicate with each other, a gas storage tank (24) located midway in the bypass line and having pressure regulation valves (23a, 23b) on the high-pressure side and the low-pressure side, respectively, and a pressure control unit (26) controlling the pressure regulation valves. The pressure control unit (26) controls the pressure regulation valves (23a, 23b) so that the pressure in the gas storage tank (24) is equal to the pressure in the closed loop at room temperature and in a stopped state and so that the pressure in the gas storage tank (24) is between the pressures in the high-pressure portion and in the low-pressure portion and is close to the pressure in the low-pressure portion in an operating state.

Owner:IHI CORP

Connector header grommet for an implantable medical device

Improvements in connector headers of implantable medical devices (IMDs) for making electrical and mechanical connections with a connector element of a proximal connector assembly of an electrical medical lead and components thereof are disclosed. A connector block disposed within a header body of the connector header has a threaded bore aligned with a header grommet aperture and a connector block bore aligned with a header connector bore. A penetrable grommet is disposed within the header grommet aperture, and a setscrew is threaded into the threaded bore having a setscrew socket disposed to be engaged by the tool inserted through the penetrable grommet within the header grommet aperture to enable rotation of the setscrew within the threaded bore to tighten the setscrew against or to loosen the setscrew from a lead connector element received in the header connector bore.

Owner:MEDTRONIC INC

Reservoir pressure equalization systems and methods

ActiveUS20110282282A1Increase pressureUniform pressureClosuresMedical devicesEngineeringEqualization

Various embodiments of the present invention are directed to equalizing pressure in a reservoir containing fluidic media, possibly due to imperfect installation of the reservoir or an external influence such as an altitude or a temperature change. In various embodiments, fluidic media may be expelled from the reservoir through a needle and contained in an interior volume of a pierceable member before the needle pierces the pierceable member to establish a flow path to a user. In other embodiments, fluidic media may be expelled through a port of the reservoir into a chamber or to the outside environment. In further embodiments, fluidic media may be expelled through a channel in a plunger head and out a passage in the reservoir when the channel and passage are aligned. In other embodiments, fluidic media may be expelled through a valve, and the valve may be pierceable by a needle to establish a flow path to the user.

Owner:MEDTRONIC MIMIMED INC

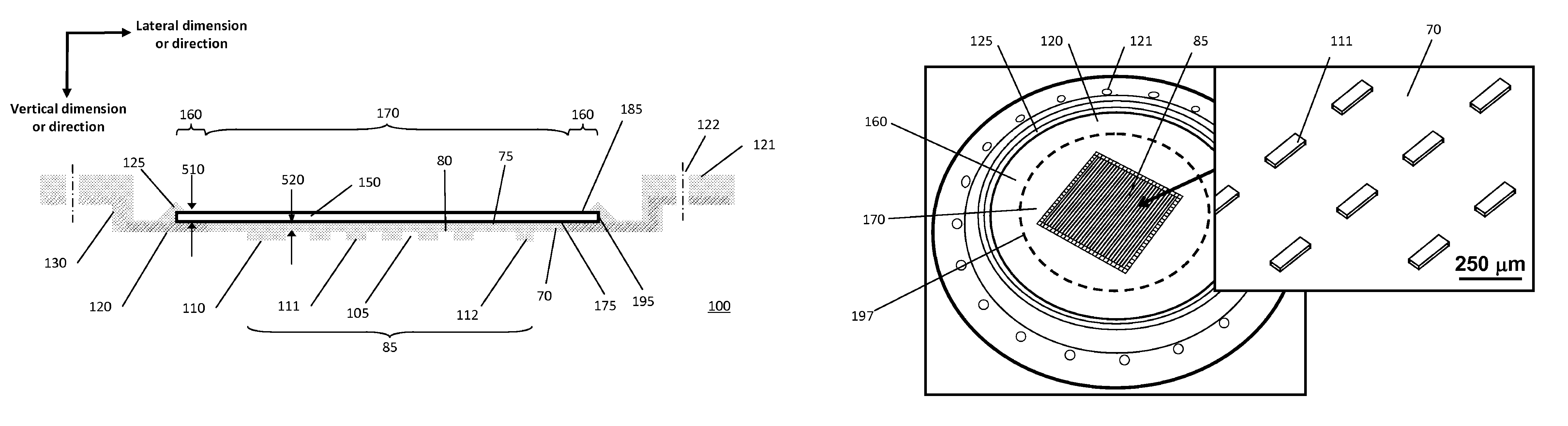

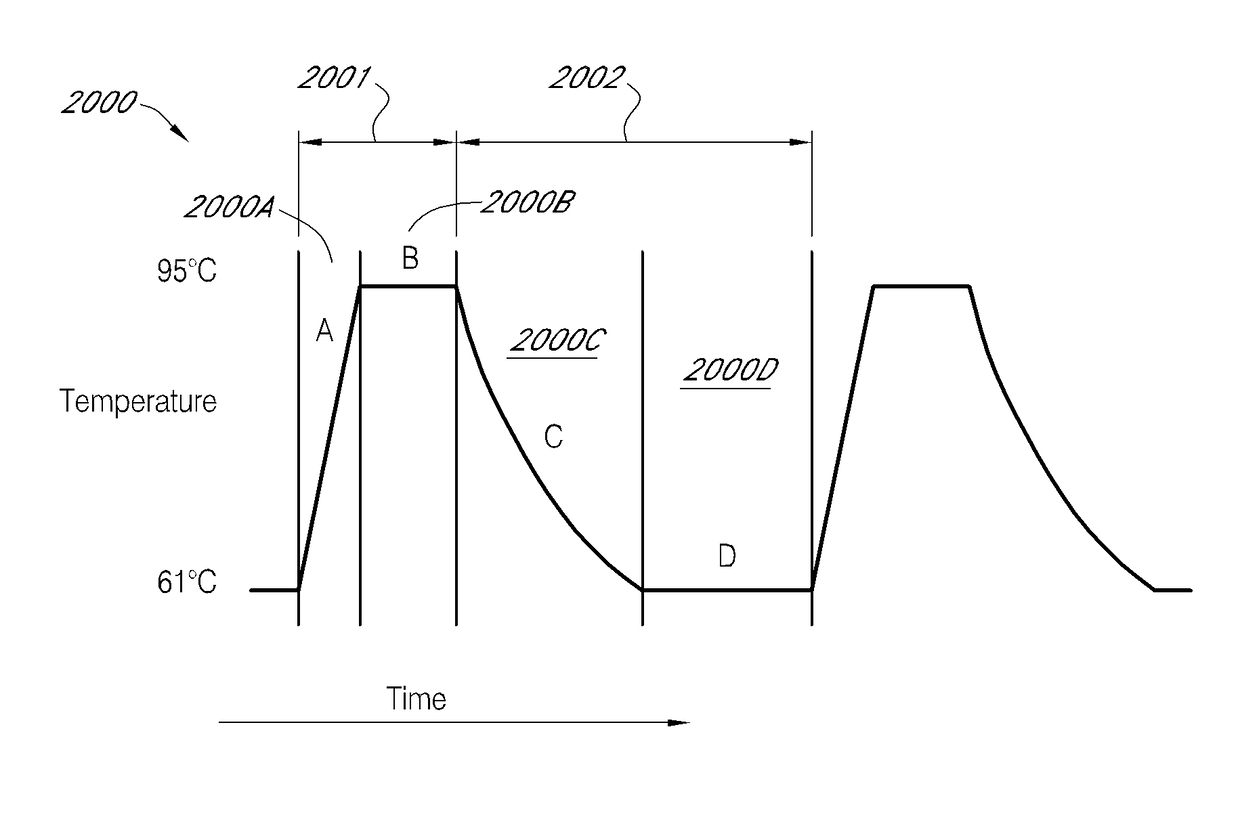

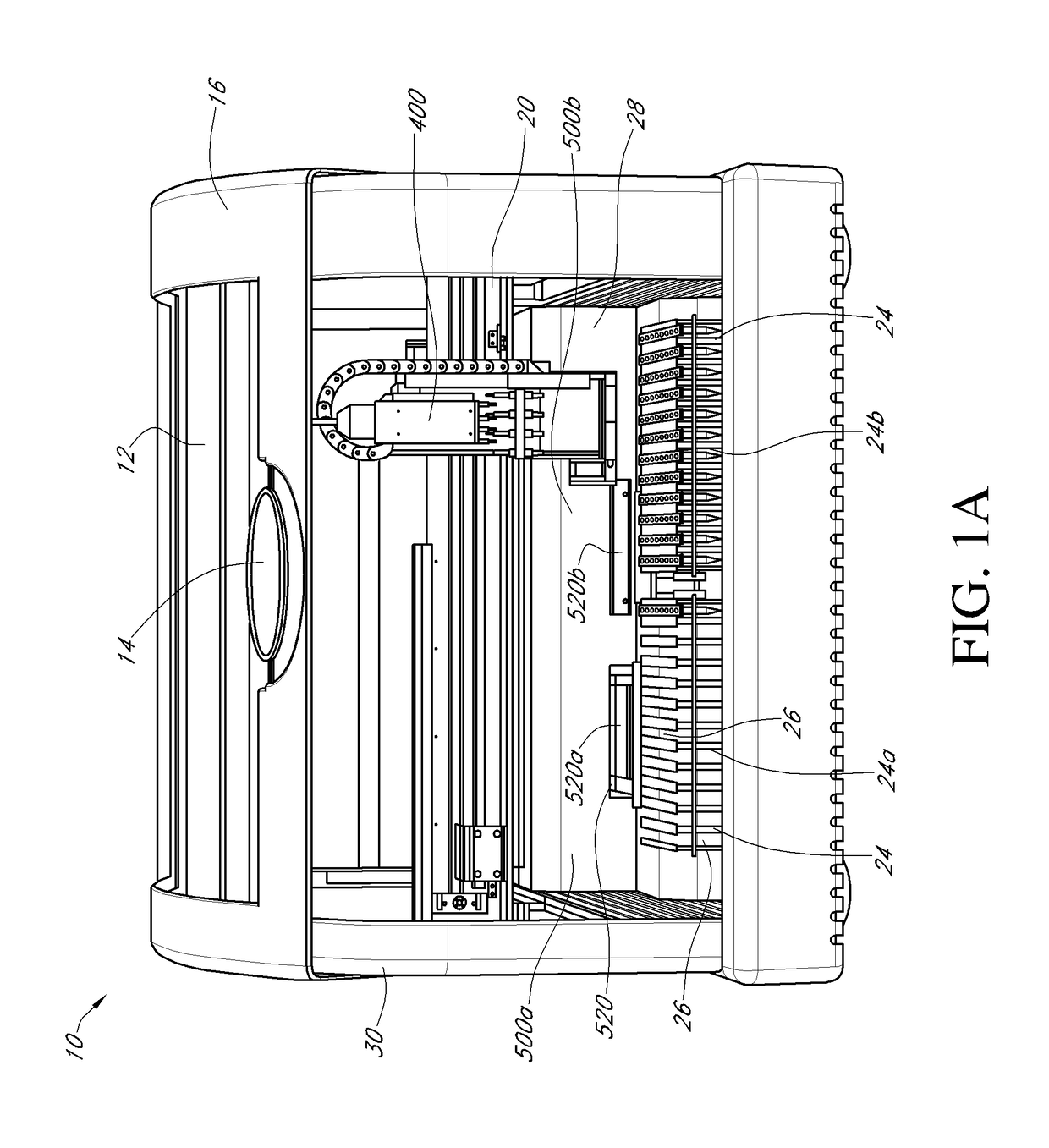

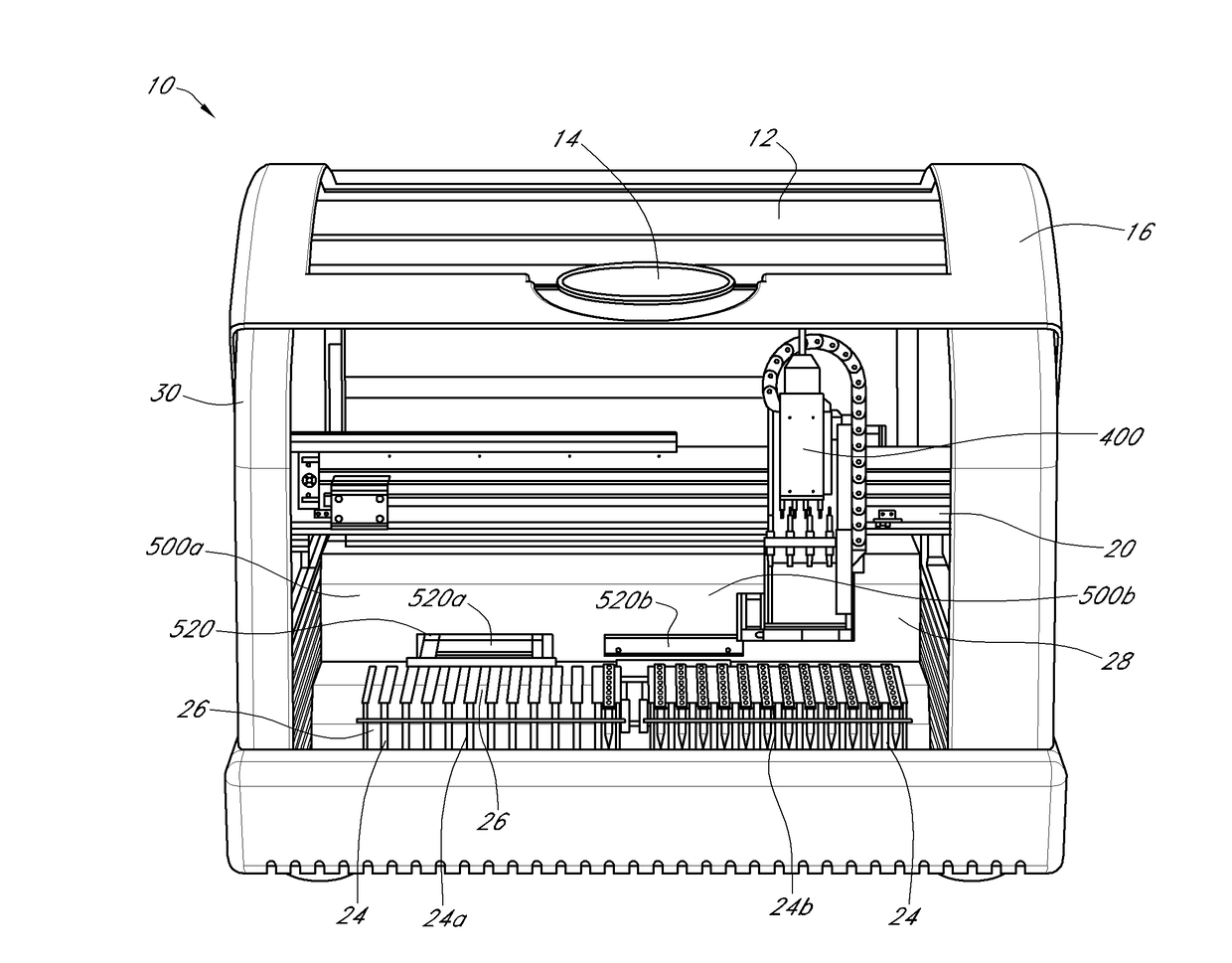

Scanning real-time microfluidic thermocycler and methods for synchronized thermocycling and scanning optical detection

ActiveUS9765389B2Facilitate substantially uniform thermal contactUniform pressureHeating or cooling apparatusMicrobiological testing/measurementSensor arrayComputer science

Systems and methods for performing simultaneous nucleic acid amplification and detection. The systems and methods comprise methods for managing a plurality of protocols in conjunction with directing a sensor array across each of a plurality of reaction chambers. In certain embodiments, the protocols comprise thermocycling profiles and the methods may introduce offsets and duration extensions into the thermocycling profiles to achieve more efficient detection behavior.

Owner:BECTON DICKINSON & CO

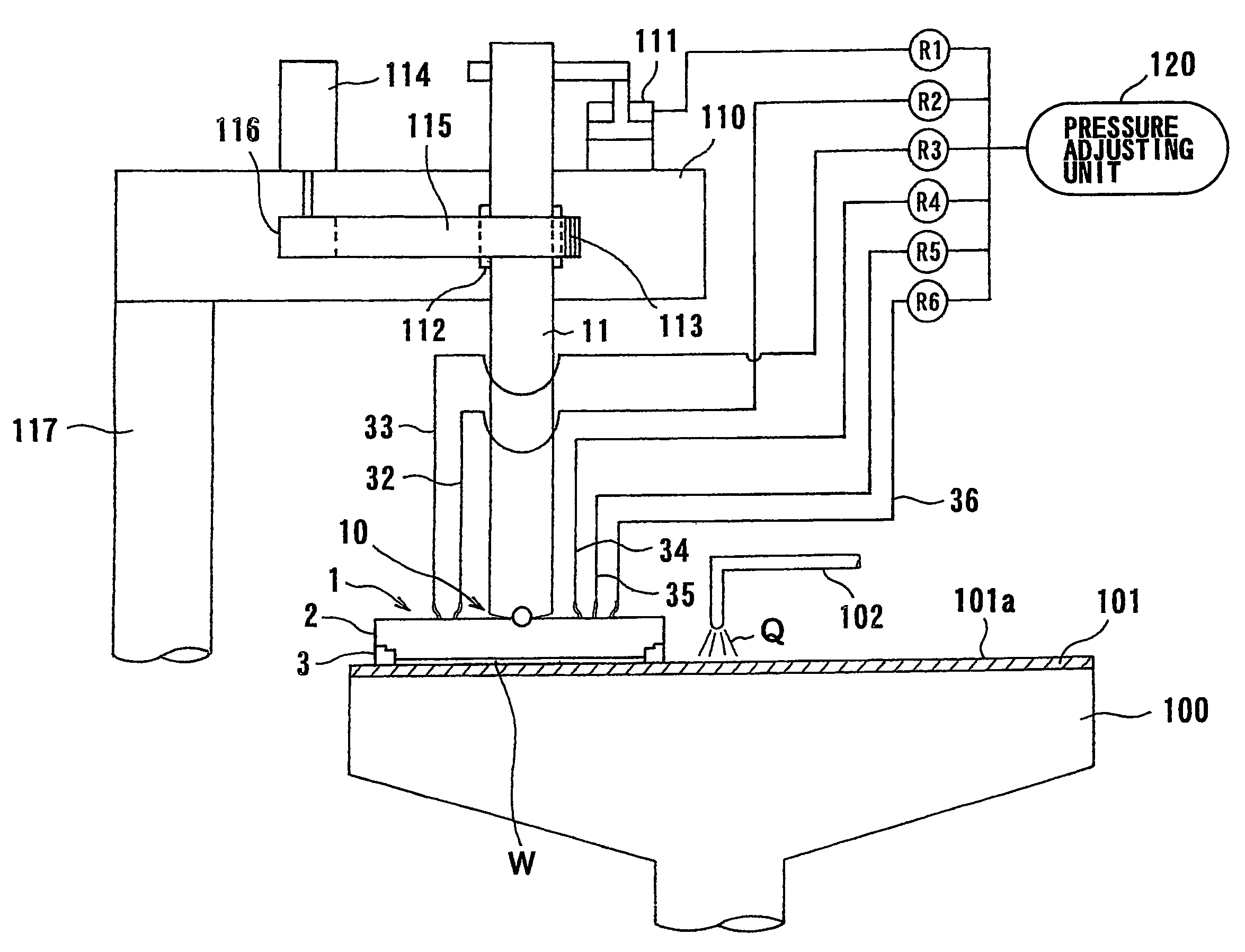

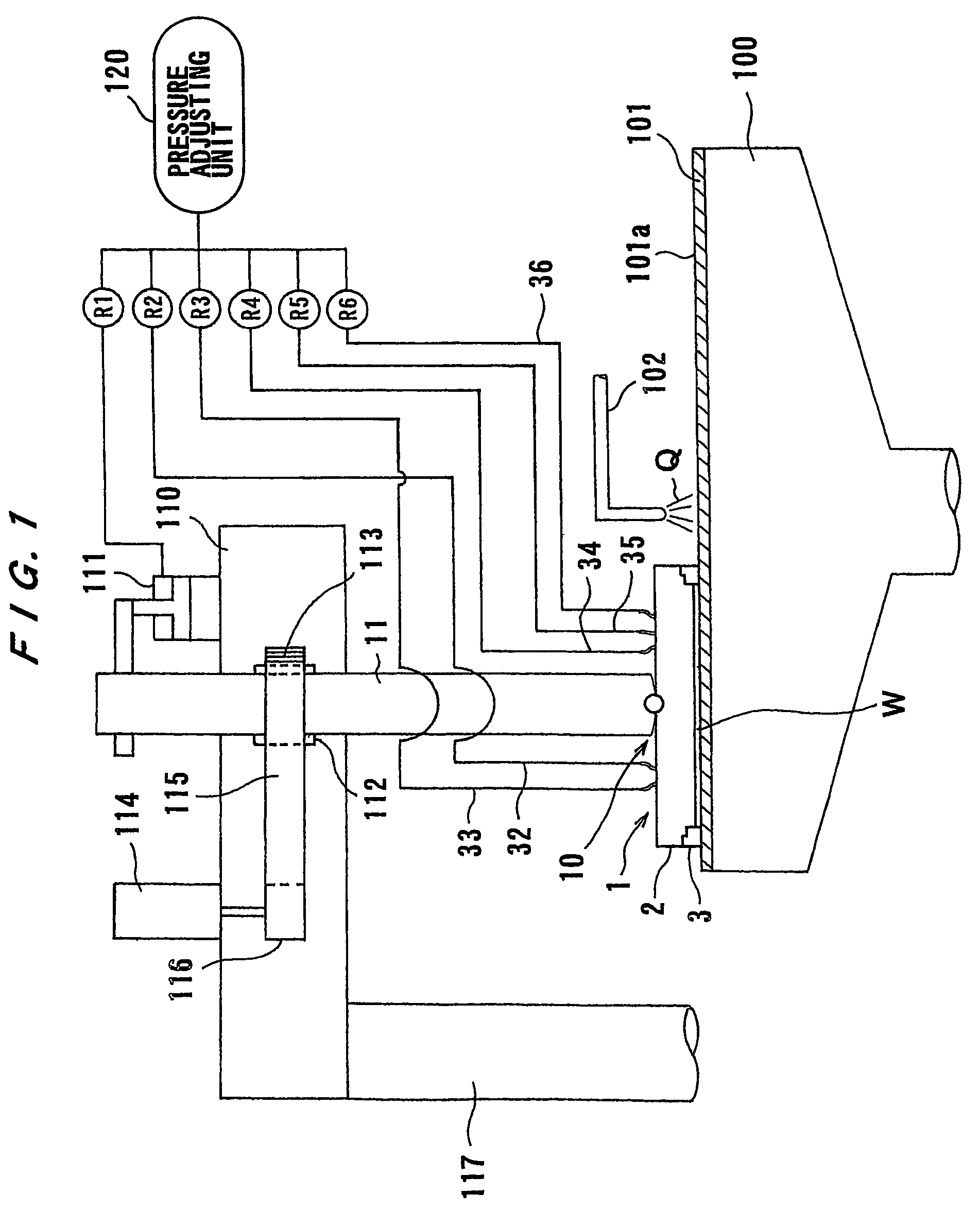

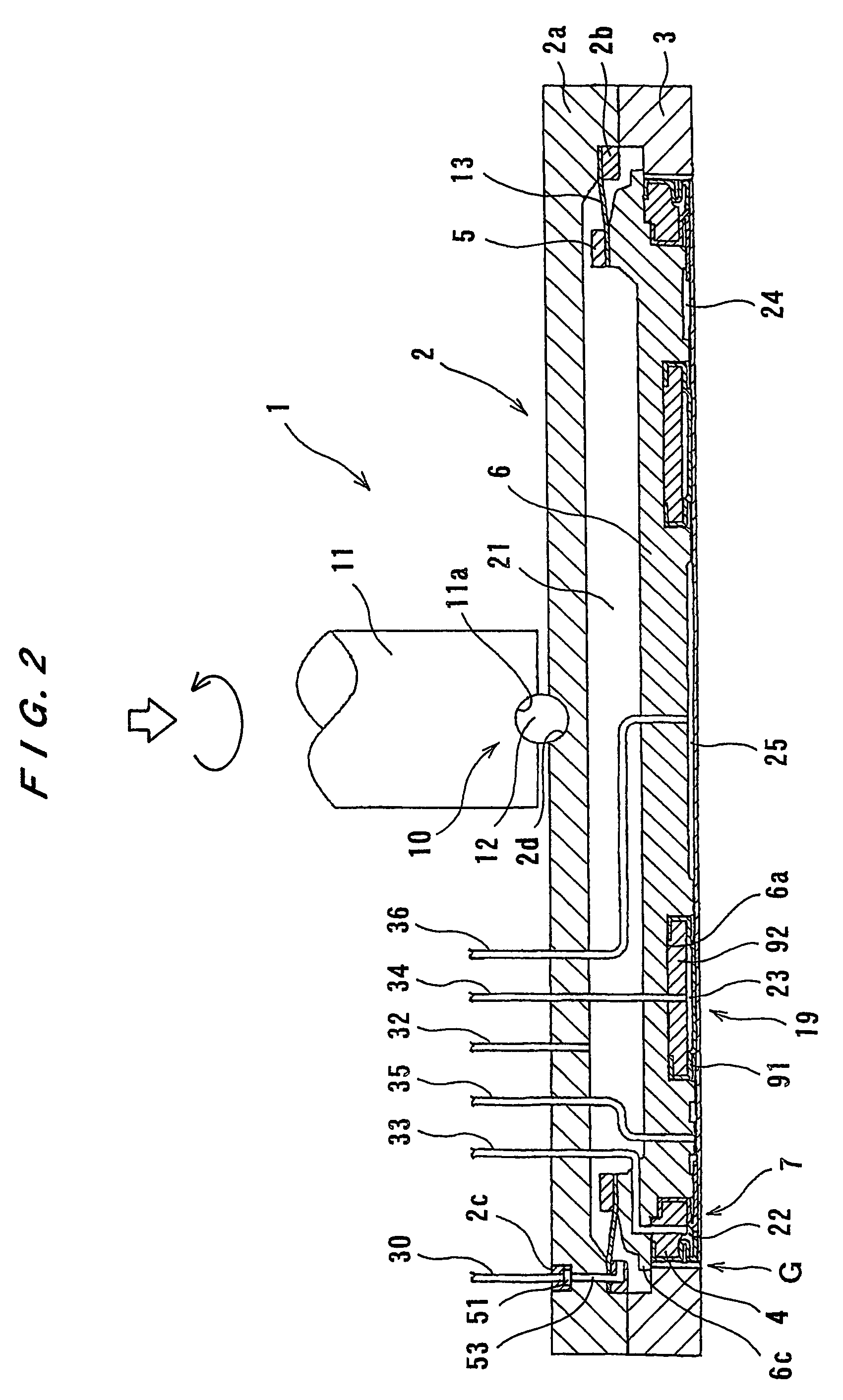

Substrate holding apparatus and polishing apparatus

ActiveUS7357699B2Uniform pressureStay in shapePolishing machinesRevolution surface grinding machinesEngineeringMechanical engineering

A substrate holding apparatus is for holding a substrate such as a semiconductor wafer in a polishing apparatus for polishing the substrate to a flat finish. The substrate holding apparatus comprises a vertically movable member, and an elastic member for defining a chamber. The elastic member comprises a contact portion which is brought into contact with the substrate, and a circumferential wall extending upwardly from the contact portion and connected to the vertically movable member. The circumferential wall has a stretchable and contractible portion which is stretchable and contractible vertically.

Owner:EBARA CORP

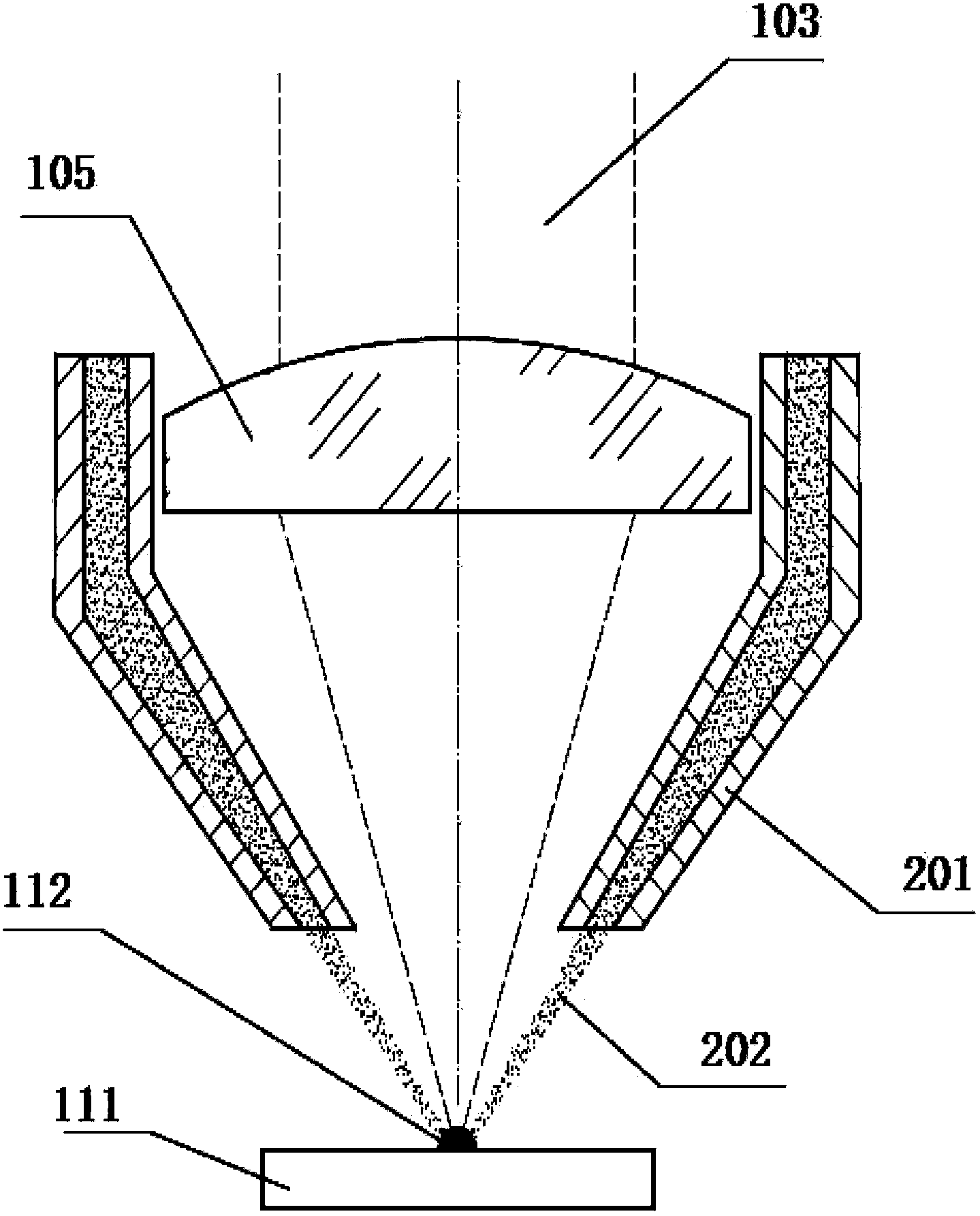

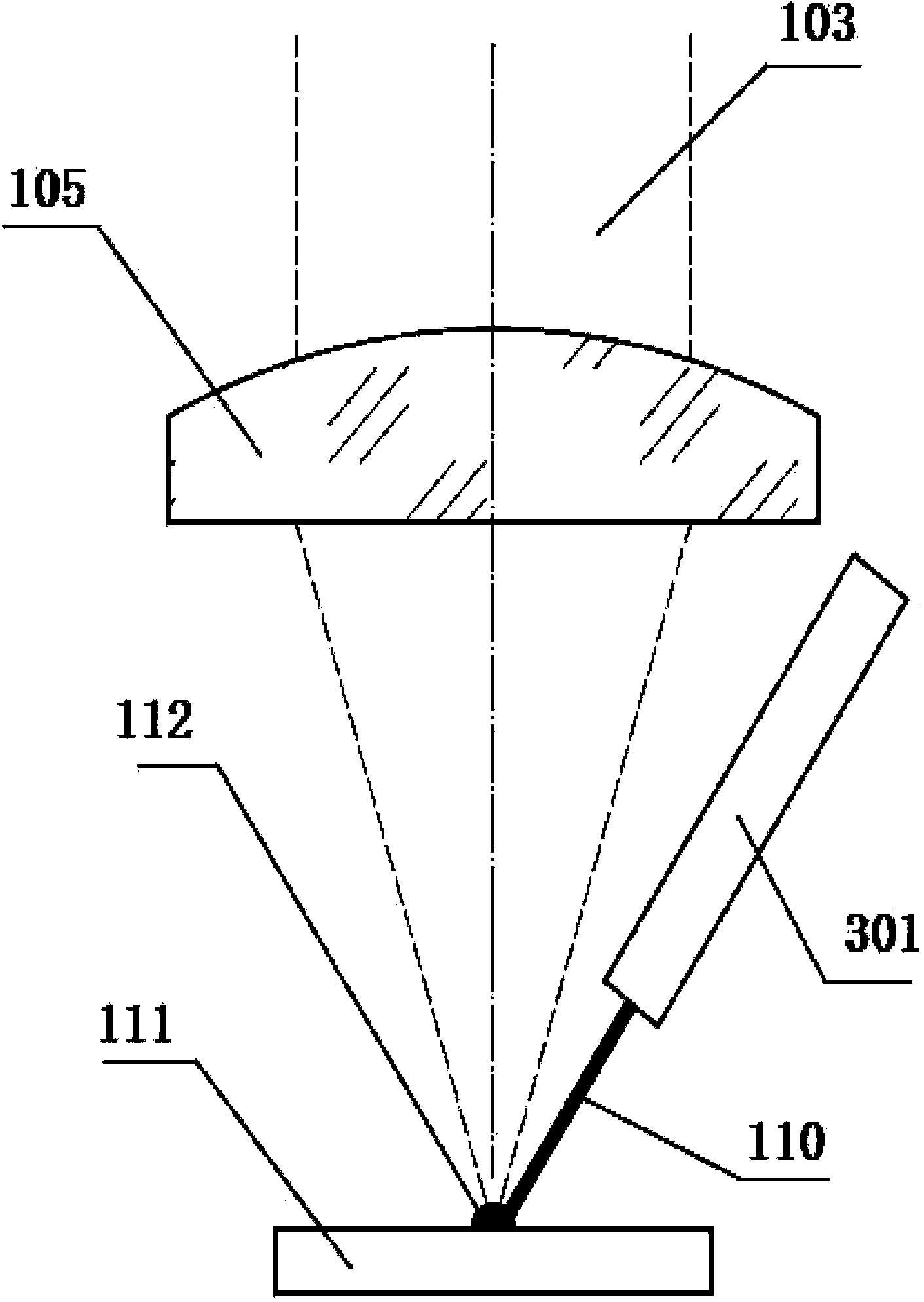

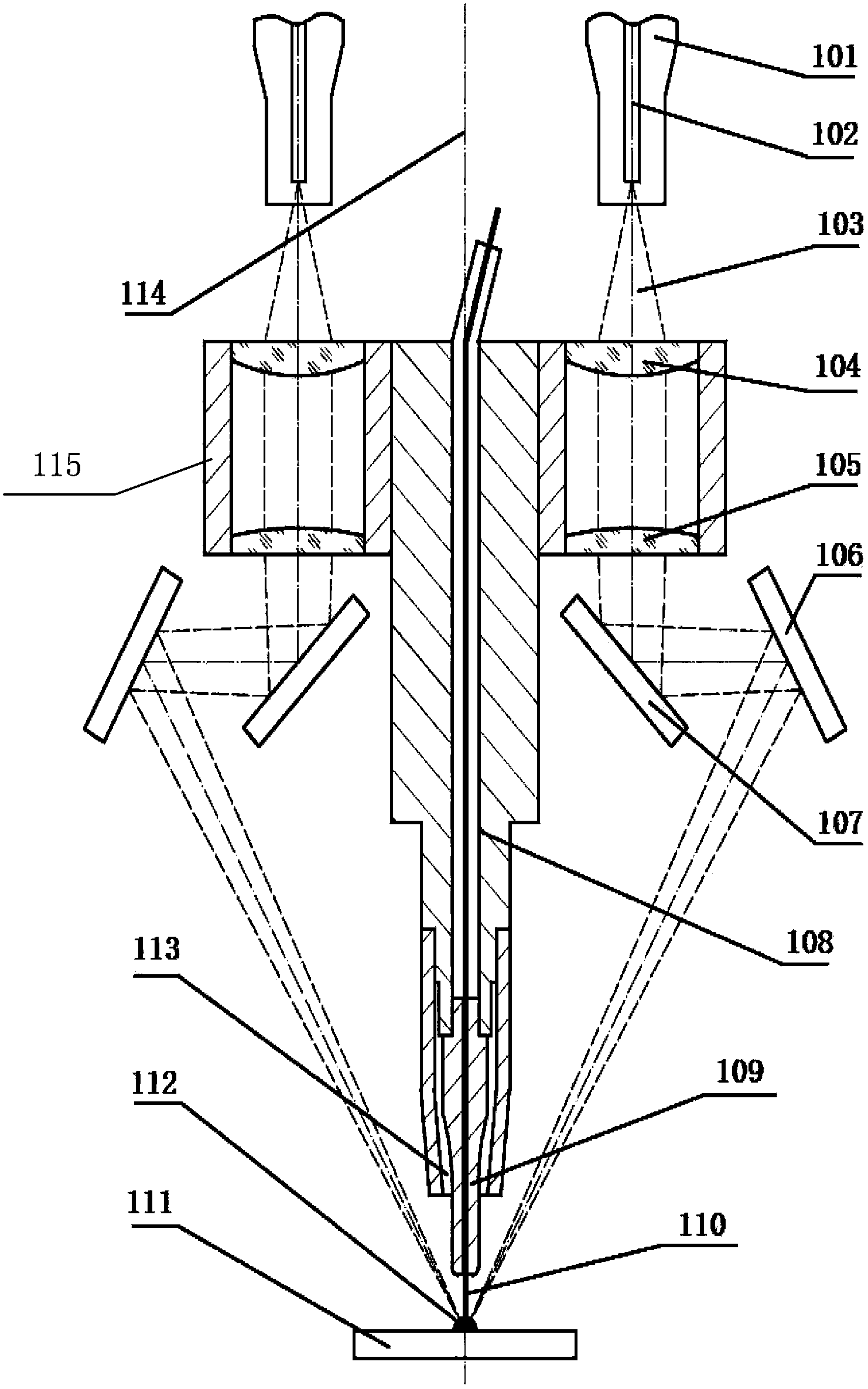

Multi-beam center wire feeding laser processing head and processing method thereof

InactiveCN104289811AEnsure consistencyEvenly heatedLaser beam welding apparatusOptical ModuleLaser processing

The invention belongs to the field of laser processing, in particular to a multi-beam center wire feeding laser processing head and a processing method of the multi-beam center wire feeding laser processing head. The laser processing head comprises a wire feeding tube, a wire feeding nozzle and a plurality of identical optical modules, wherein the wire feeding tube and the wire feeding nozzle are located on the center axis of the laser processing head, the optical modules are rotationally and symmetrically distributed around the center axis, each optical module comprises a collimating lens set, a focusing lens set and a reflecting mirror set, lasers are transmitted to the processing head through a plurality of paths of optical fibers, a plurality of laser beams are focused on one point of the surface of a workpiece to form a molten pool after being collimated, focused and reflected by the optical modules, a metal wire is perpendicularly fed into the molten pool on the surface of the workpiece through the fire feeding nozzle, and the laser processing head moves on the surface of the workpiece according to a certain track so that the center wire feeding laser processing process can be achieved. Through the multi-beam center wire feeding laser processing head, center wire feeding in laser focusing light spots in circular symmetry distribution is achieved, and the processing quality consistency is guaranteed when the laser processing head moves in different directions.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

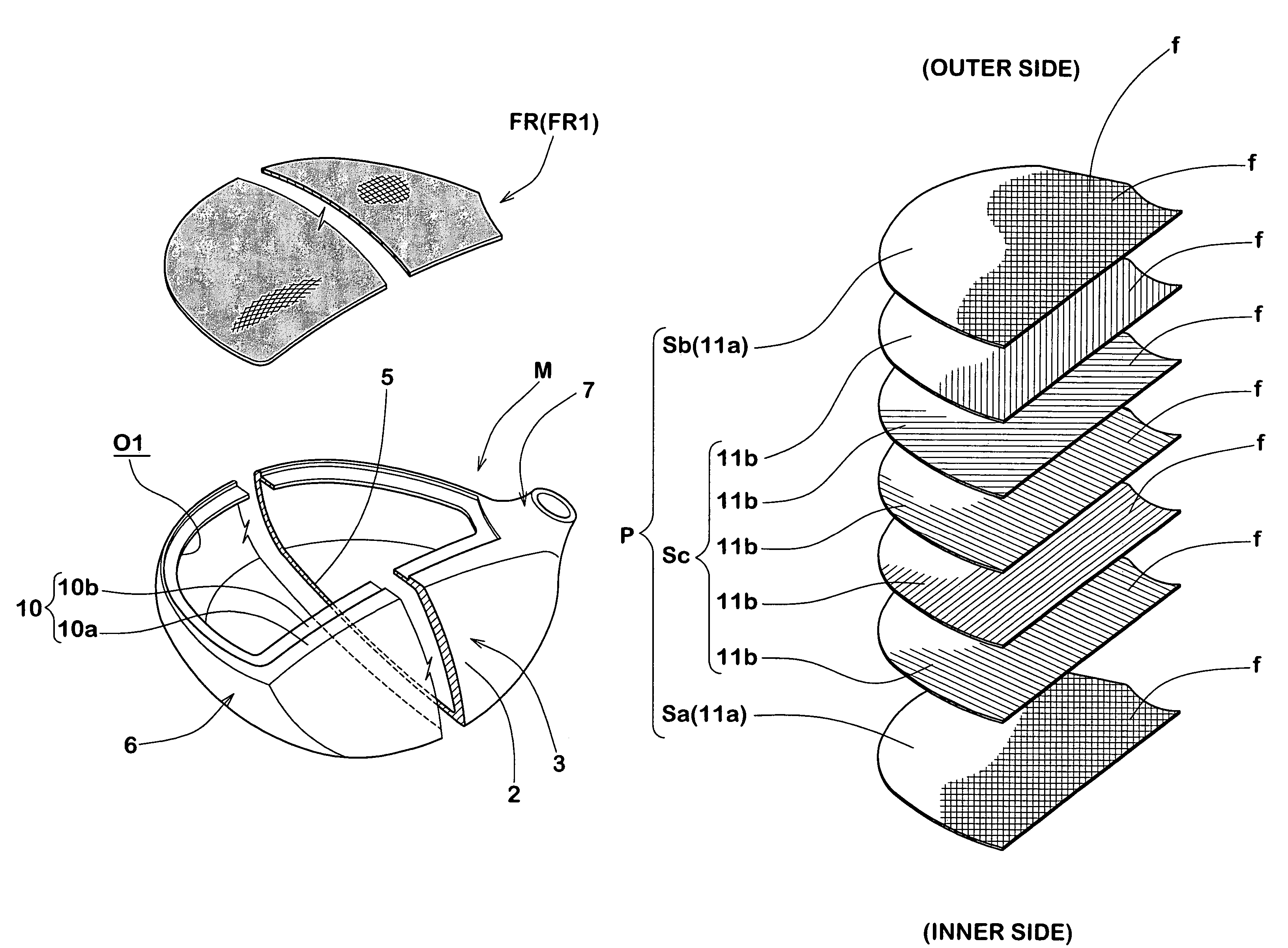

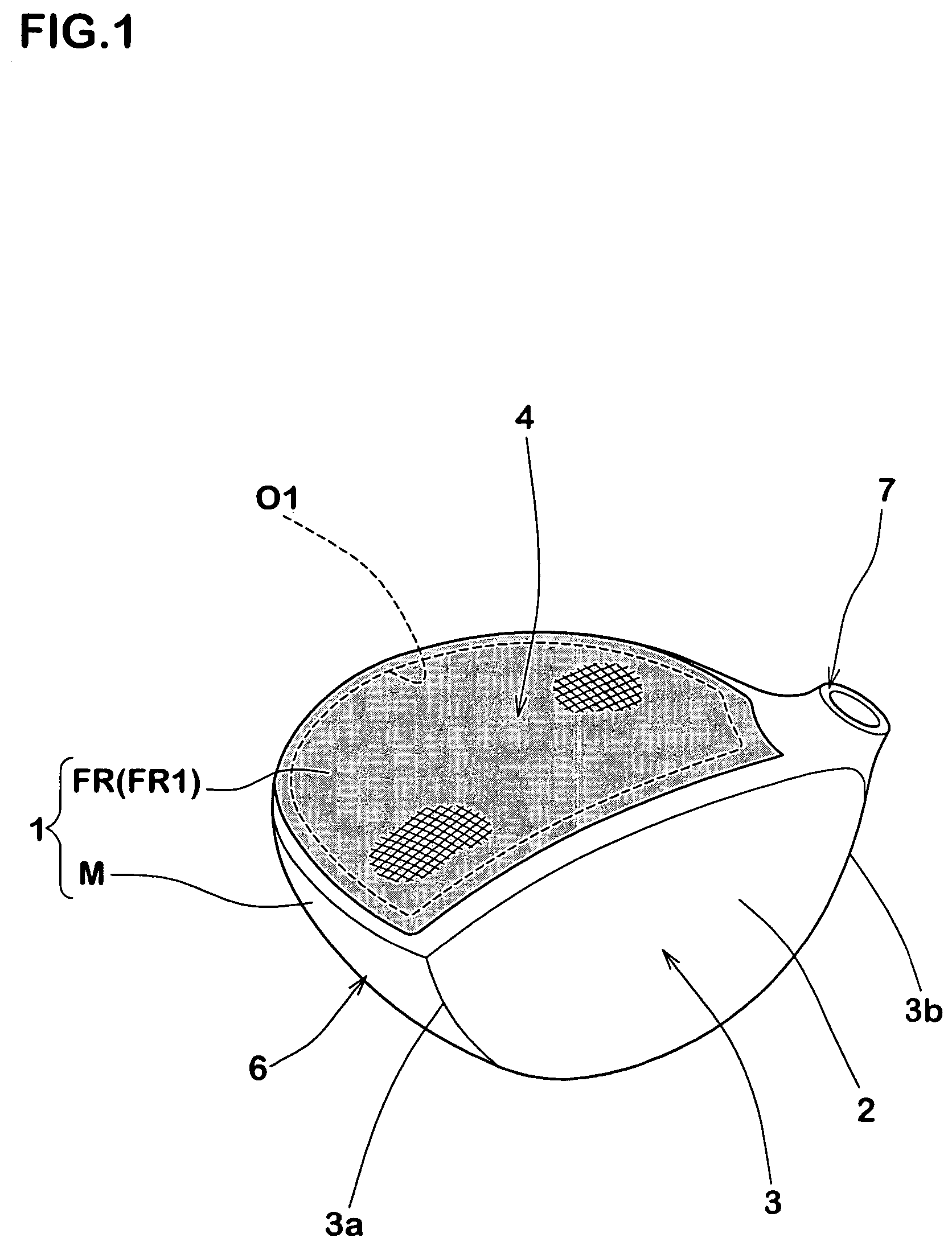

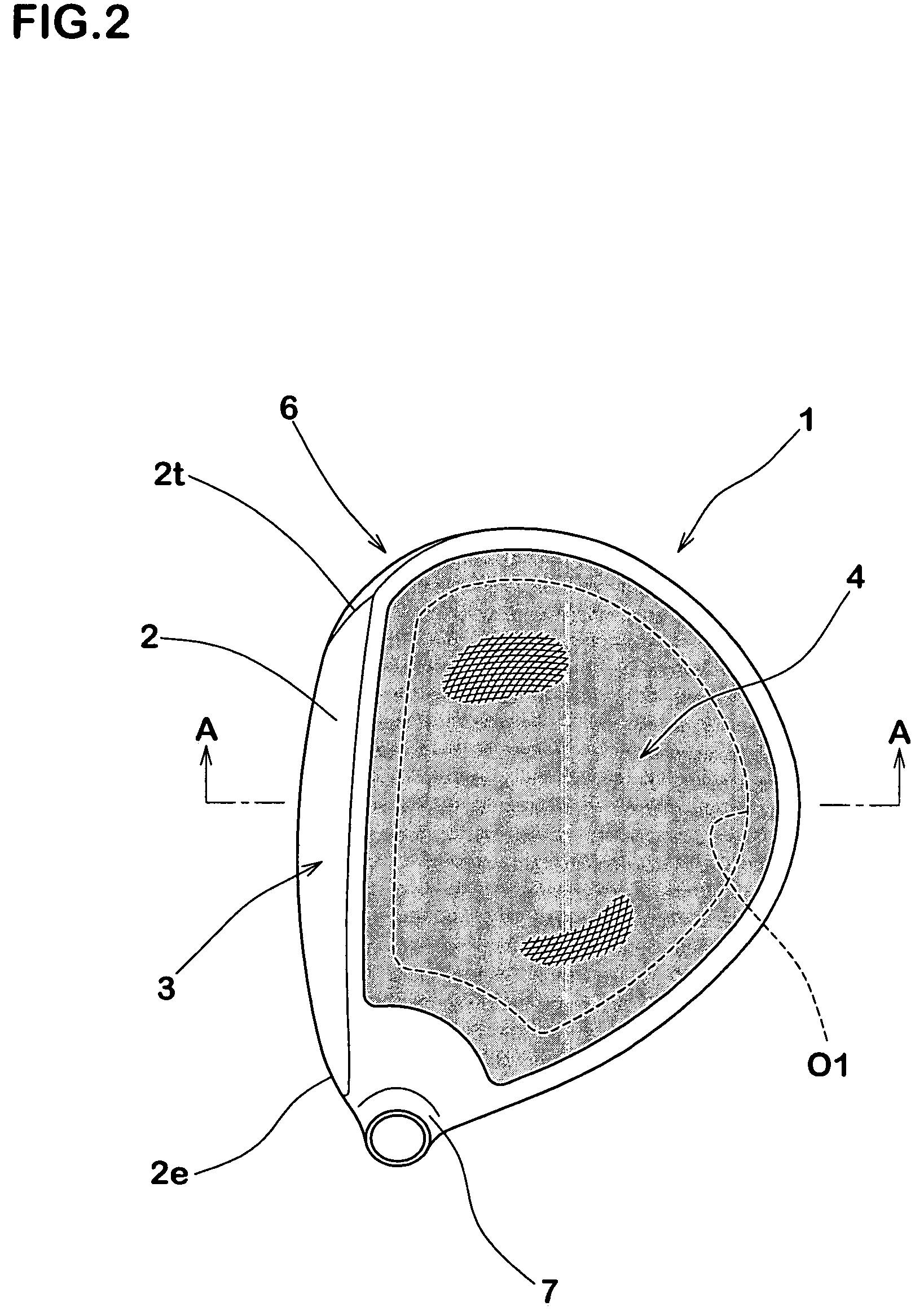

Golf club head and manufacturing method of the same

The invention prevents a crimple from being generated in a resin member. The invention provides a golf club head (1) including a head shell portion (M) made of a metal material and having an opening portion (O1), and a resin member (FR) made of a fiber reinforced resin arranged in the opening portion (O1), and provided with a hollow portion in an inner portion. The resin member (FR) is constituted by a molded body formed by integrally molding a laminated body of plural layers of prepregs having a magnitude covering the opening portion (O1) and having different resin percentage contents in the head shell portion in accordance with an internal pressure molding method. Further, the prepreg having the largest resin percentage content is used in an innermost layer of the laminated body closest to the hollow portion.

Owner:SUMITOMO RUBBER IND LTD

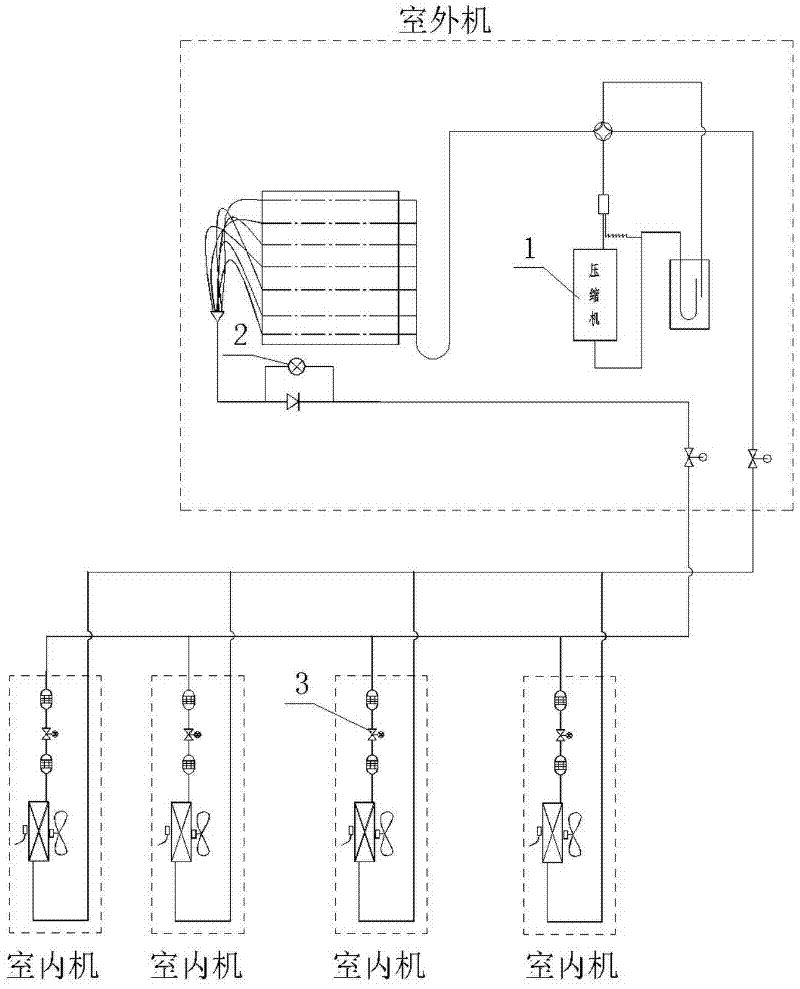

Oil returning method during heating of multi-split air-conditioning unit

InactiveCN102645057ATemperature does not dropEasy to useCompressorRefrigeration safety arrangementElectronic expansion valveElectron

The invention discloses an oil returning method during heating of a multi-split air-conditioning unit. The oil returning method comprises the following steps of: a, carrying out normal heating on the multi-split air-conditioning unit; b, adjusting an operation frequency of a compressor (1) to an oil returning frequency, adjusting aperture of an external unit electronic expansion valve (2) to an external unit oil returning aperture, adjusting apertures of internal unit electronic expansion valves (3) of all the indoor units to an internal unit oil returning aperture, and returning oil for 2.5-3.5 minutes by maintaining the oil returning frequency of the compressor (1), the external unit oil returning aperture of the external unit electronic expansion valve (2) and the internal unit oil returning aperture of the internal unit electronic expansion valves (3); c, adjusting the operation frequency of the compressor (1) to a normal frequency, and operating for 15-25 seconds; and d, adjusting the aperture of the external unit electronic expansion valve (2) to the normal aperture, and adjusting the apertures of all the internal unit electronic expansion valves (3) to the normal aperture. The oil returning method disclosed by the invention can guarantee good oil returning effect without liquid impact on the compressor, and indoor heating can be continuously carried out in an oil returning process.

Owner:NINGBO AUX ELECTRIC

Reinforced Composite Stamp for Dry Transfer Printing of Semiconductor Elements

ActiveUS20100018420A1Easy to controlPrecise and repeatable vertical motionTurning machine accessoriesNanoinformaticsSemiconductor structureContact force

Provided are reinforced composite stamps, devices and methods of making the reinforced composite stamps disclosed herein. Reinforced composite stamps of certain aspects of the present invention have a composition and architecture optimized for use in printing systems for dry transfer printing of semiconductor structures, and impart excellent control over relative spatial placement accuracy of the semiconductor structures being transferred. In some embodiments, for example, reinforced composite stamps of the present invention allow for precise and repeatable vertical motion of the patterned surface of the printing apparatus with self-leveling of the stamp to the surface of a contacted substrate. Reinforced composite stamps of certain aspect of the present invention achieve a uniform distribution of contact forces between the printing apparatus patterned surface and the top surface of a substrate being contacted by the reinforced composite stamp of the printing apparatus.

Owner:X DISPLAY CO TECH LTD

Scanning real-time microfluidic thermocycler and methods for synchronized thermocycling and scanning optical detection

ActiveUS20180135102A1Facilitate substantially uniform thermal contactUniform pressureHeating or cooling apparatusMicrobiological testing/measurementSensor arrayComputer science

Systems and methods for performing simultaneous nucleic acid amplification and detection. The systems and methods comprise methods for managing a plurality of protocols in conjunction with directing a sensor array across each of a plurality of reaction chambers. In certain embodiments, the protocols comprise thermocycling profiles and the methods may introduce offsets and duration extensions into the thermocycling profiles to achieve more efficient detection behavior.

Owner:BECTON DICKINSON & CO

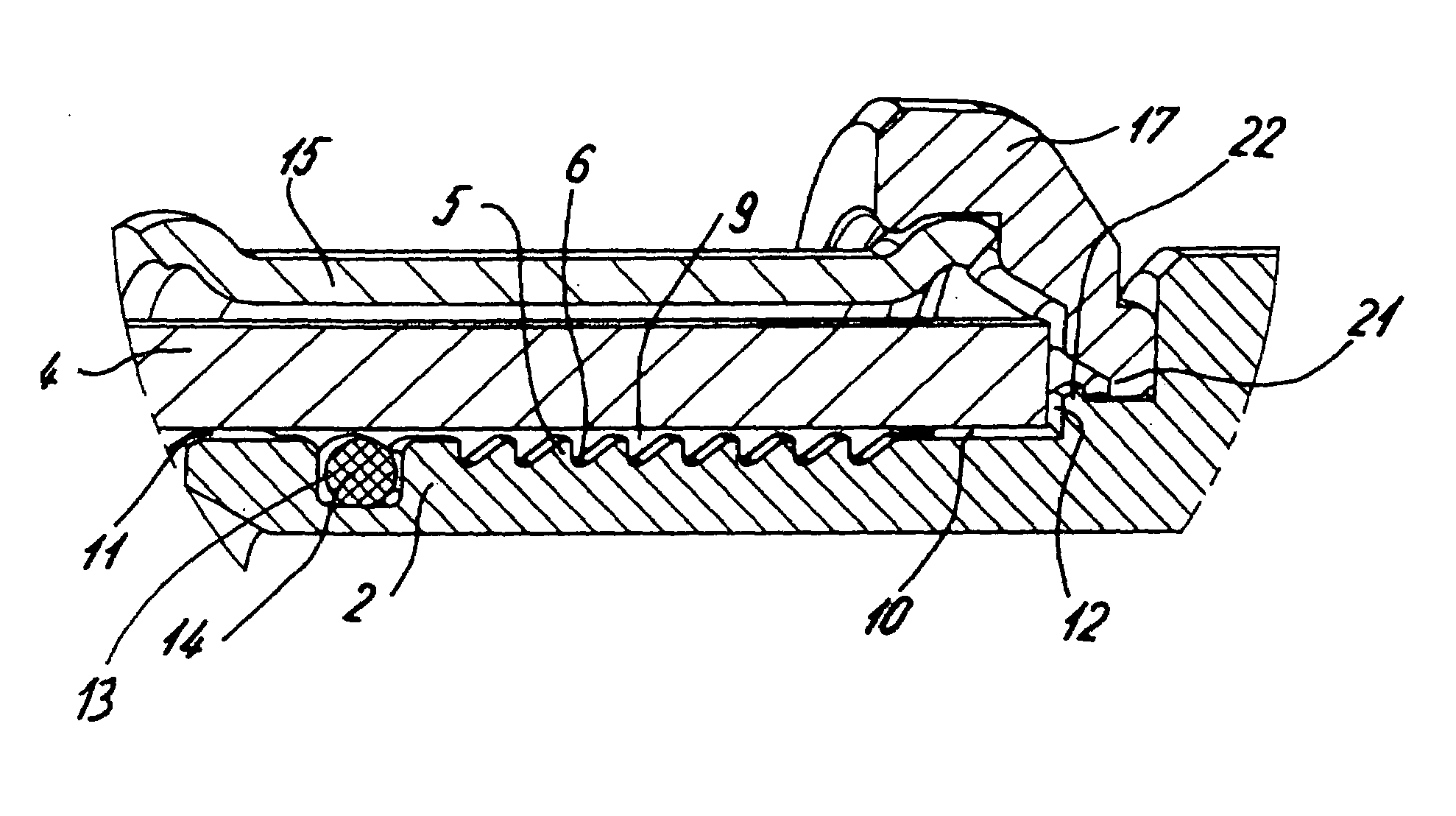

Connecting piece and connecting arrangement

InactiveUS6874823B2Durable pressed connectionPrevent movementJoints with sealing surfacesPipe couplingsEngineeringMechanical engineering

A connecting piece for establishing a connecting arrangement for a pipe which can be pressed together comprises a stub which can be inserted into a pipe. Profilings for the pressing-together with the pipe and a stop are on the stub. At least one radially projecting spacer is provided on the stub. The spacer defining a gap for forming a flow duct between the stub and the pipe. The spacer may have an interruption for forming part of the flow duct.

Owner:FRANZ VIEGENER II GMBH & CO KG

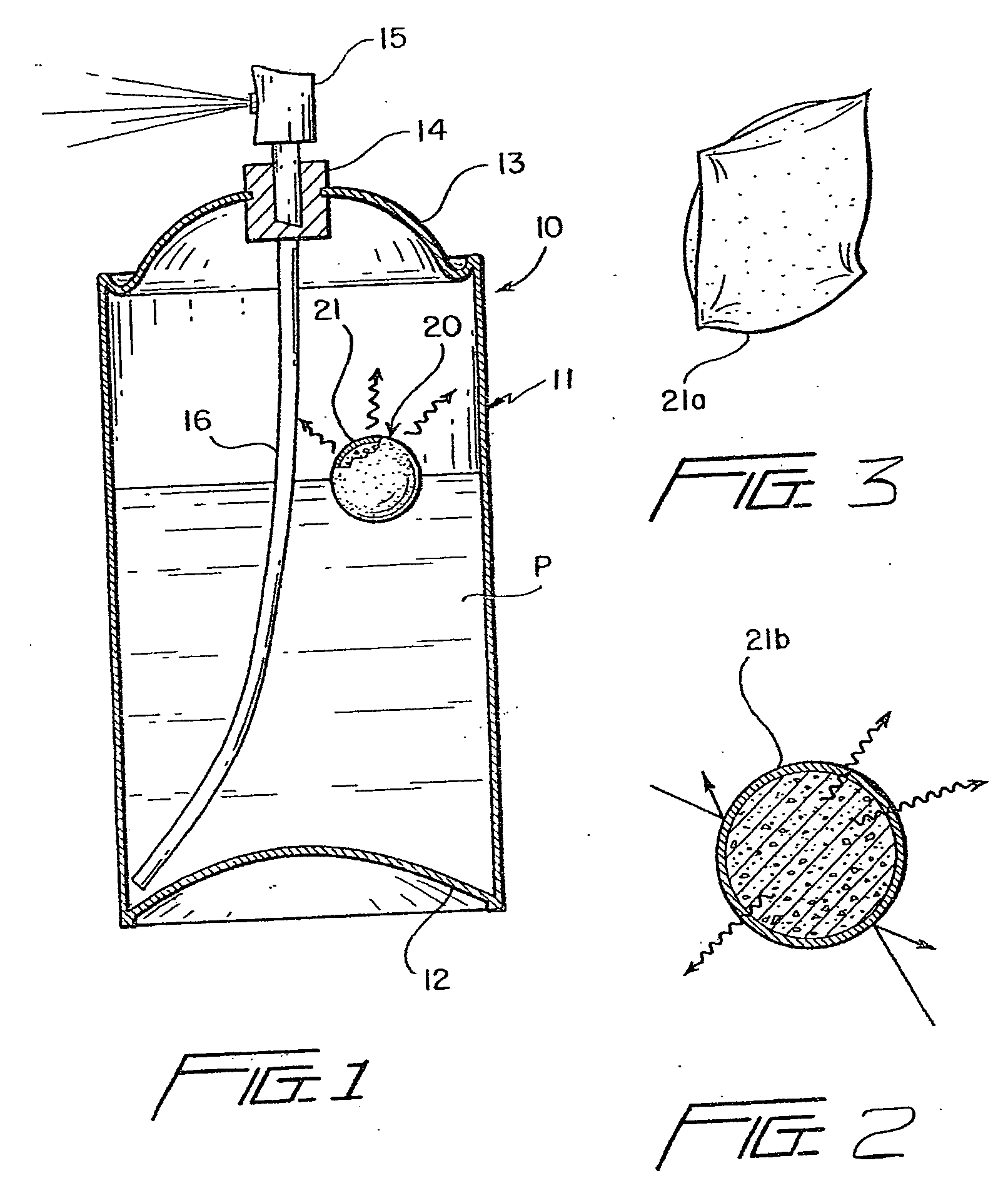

Gas storage and delivery system for pressurized containers

InactiveUS20050274737A1Consistent and uniform and acceptable spray patternFine foamOpening closed containersBottle/container closureSodium bicarbonateDesorption

A gas adsorption material containing a desired quantity of gas is placed in a pressurized container along with a product to be dispensed, and as pressure in the container is depleted during use, stored gas is released into the container to maintain pressure in the container within a predetermined range. The material may be in contact with the product, or it may be isolated from the product, and is known as a pressure swing adsorption (PSA) system, wherein adsorption of gas into the material occurs at a high pressure, and desorption of gas from the material occurs at a low pressure. Such devices are capable of storing under pressure a volume of gas 18 to 20 times the volume of the material. A preferred adsorbent gas storage material is granular activated carbon, or a carbon fiber composite molecular sieve (CFCMS). Other materials, such as zeolite, starch-based polymers, activated alumina, silica gel, and sodium bicarbonate, or mixtures thereof, may be used, although they generally are not as effective as activated carbon. The adsorbent material may be in granular, powdered, or pellet form, or a mass of the material may be formed into variously shaped cohesive bodies, such as balls, tubes, cubes or rods, or sheets or screens which may be flat or curved or folded into various shapes, such as, for example, an accordion-like fold.

Owner:LIM WALTER K

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com