Multi-beam center wire feeding laser processing head and processing method thereof

A laser processing head, multi-beam technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of continuity and the quality of the molten layer is difficult to guarantee, the structure of the optical wire feeding device is complex, and the optical path of the wire feeding tube Adverse effects and other problems, to avoid oxidation, good protection, and easy alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

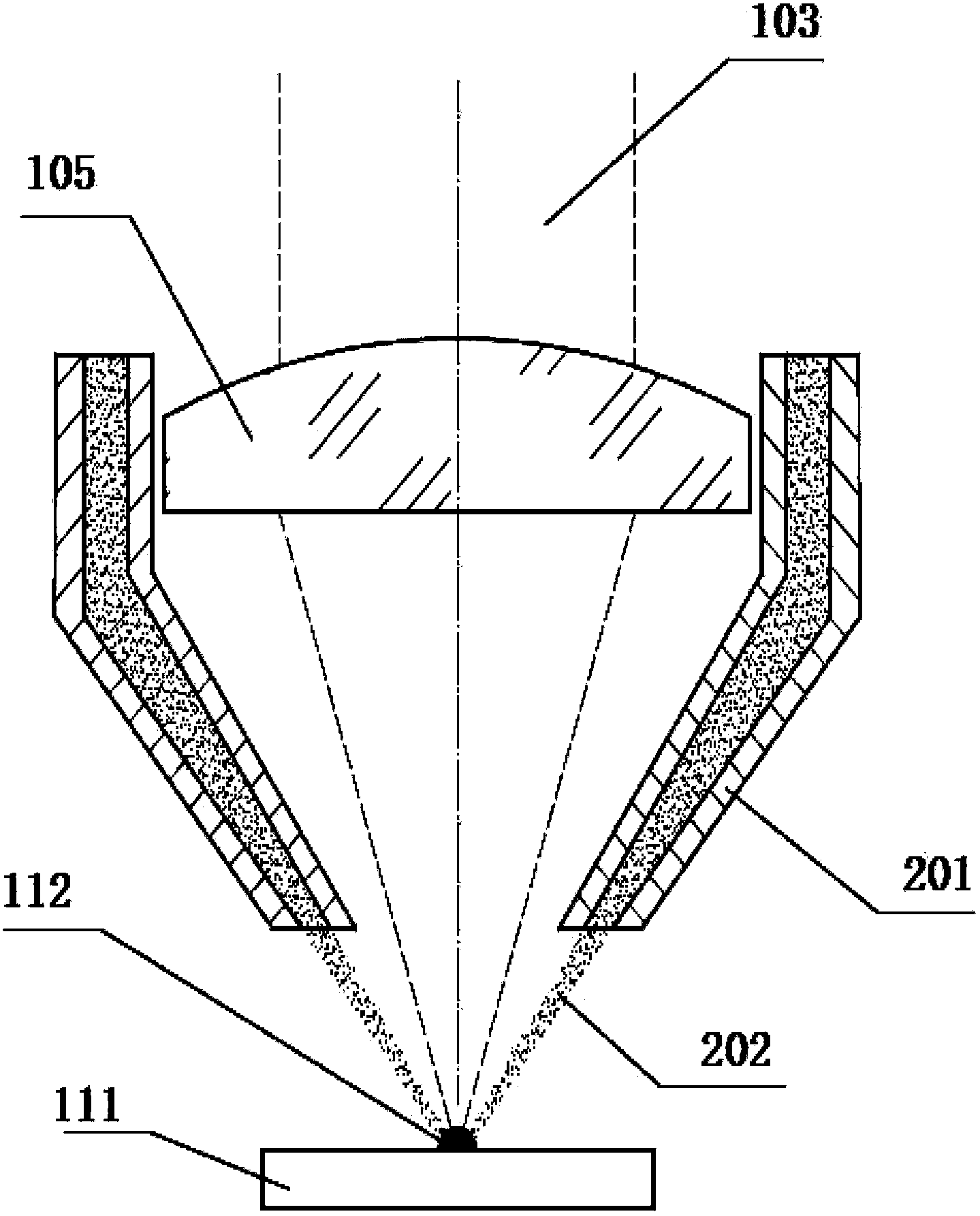

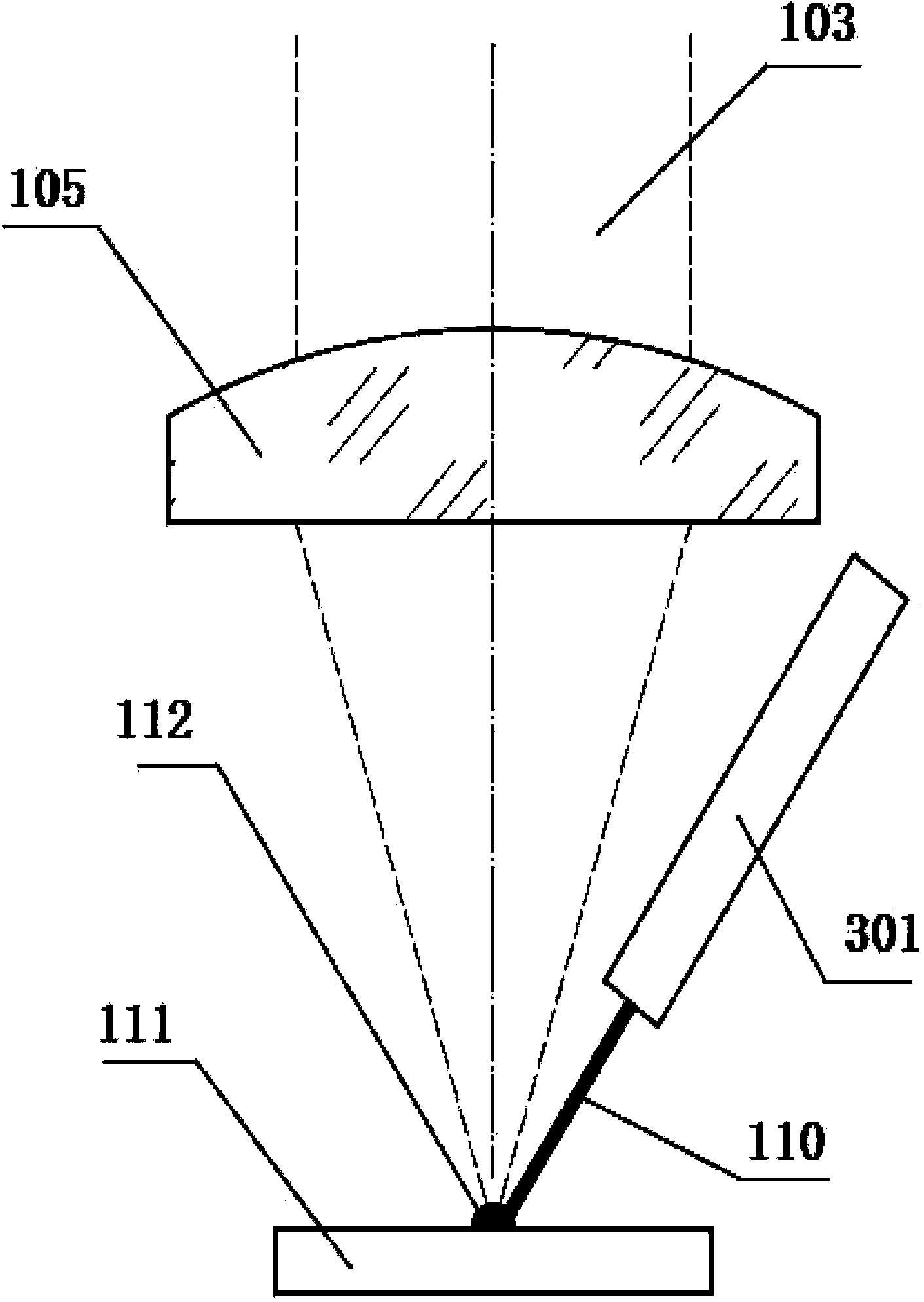

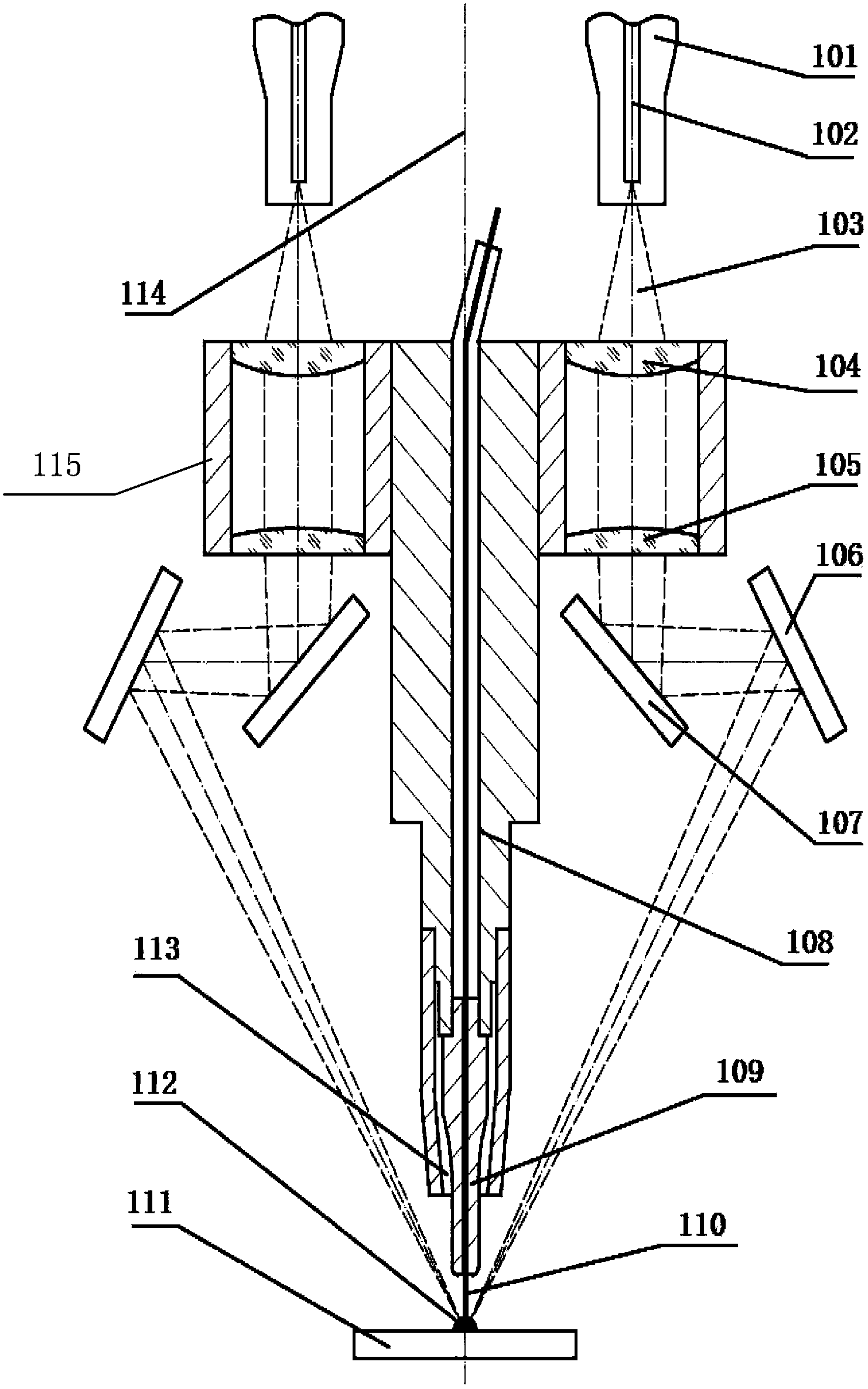

[0024] Such as image 3 As shown, the multi-beam center wire-feeding laser processing head of the present invention includes a wire feeding tube 108, a wire feeding nozzle 109 and a plurality of optical modules with the same structure, wherein the wire feeding tube 108 is installed on the housing 115 of the laser processing head, and the One end (lower end) of the wire tube 108 is connected to the wire feeding nozzle 109, and there are channels for the metal wire 110 to pass through the wire feeding tube 108 and the wire feeding nozzle 109, and the upper end of the inner channel of the wire feeding tube 108 passes through the wire feeding nozzle 109. The conduit 404 is connected to the wire feeder 403 . The wire feeding tube 108 and the wire feeding nozzle 109 are arranged coaxially, and the central axis of the wire feeding tube 108 and the wire feeding nozz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com