Patents

Literature

3738 results about "Molten pool" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

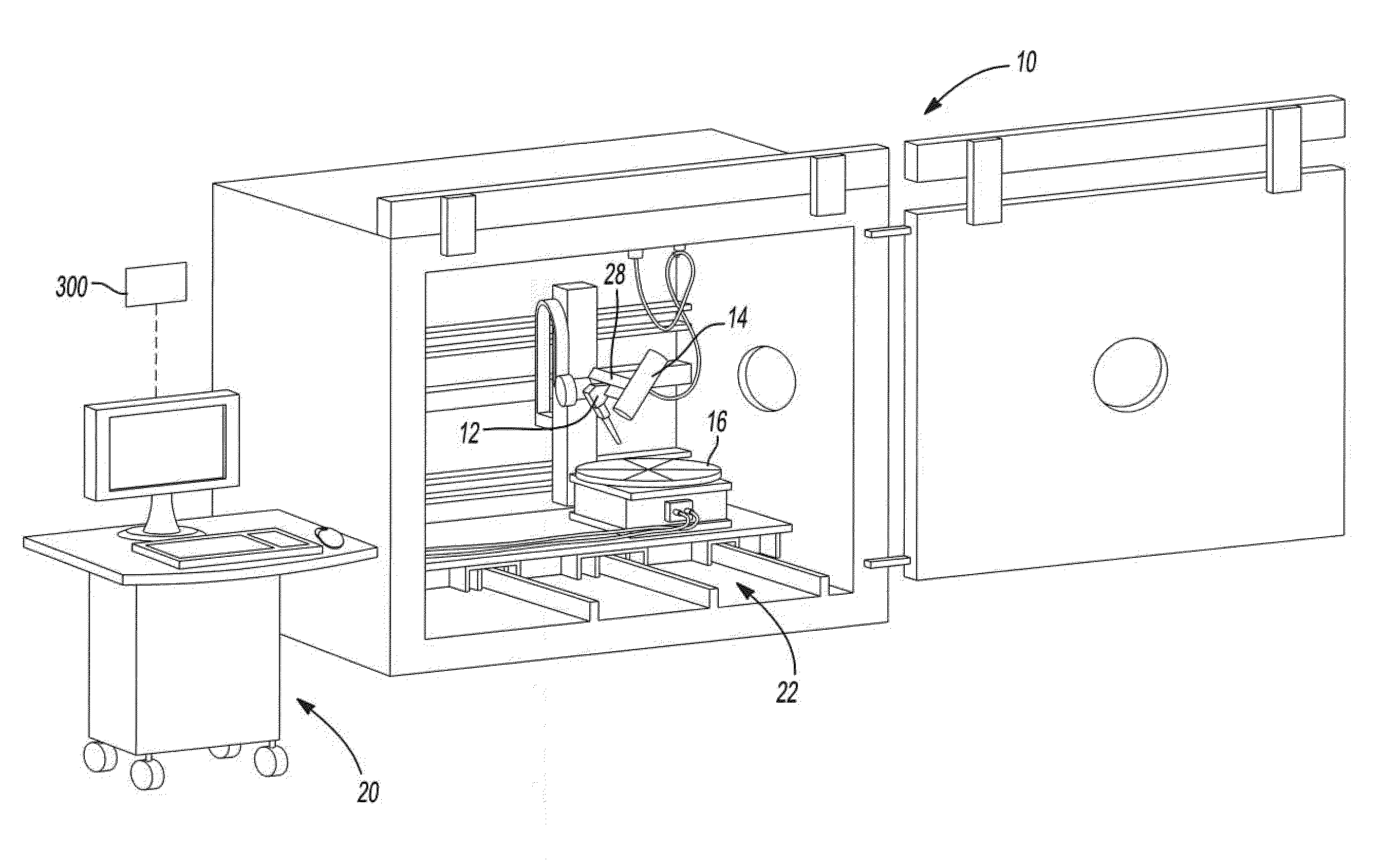

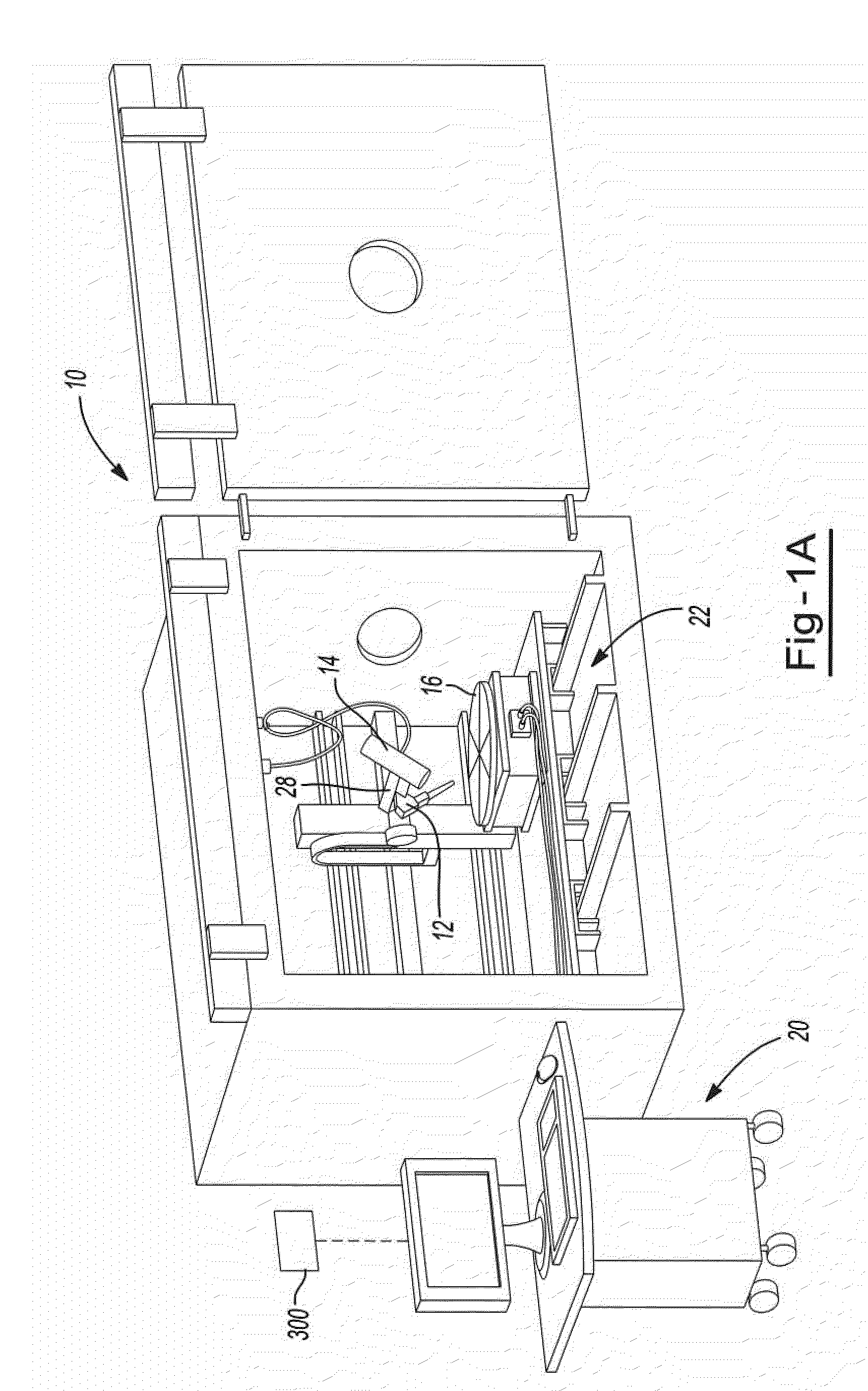

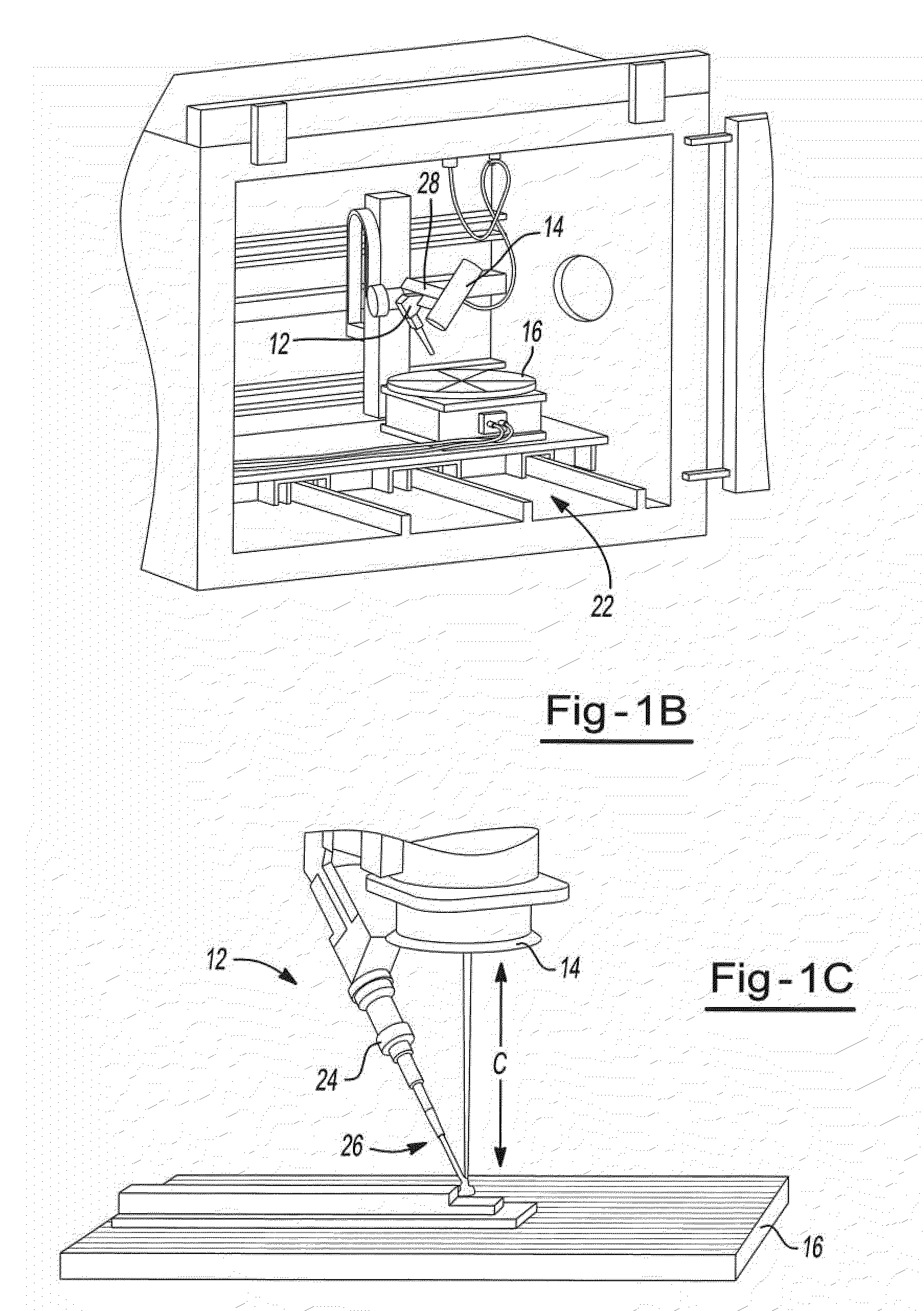

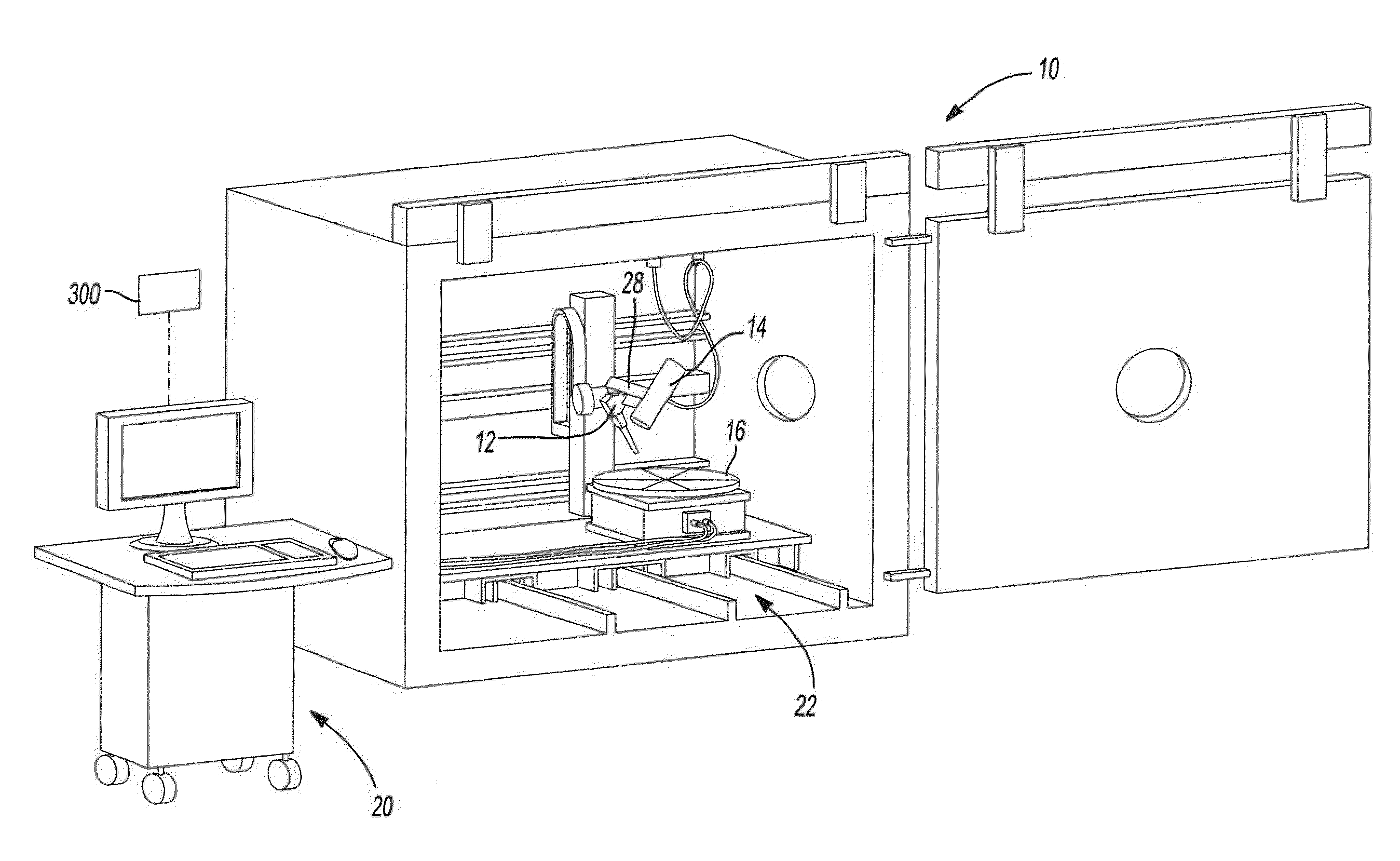

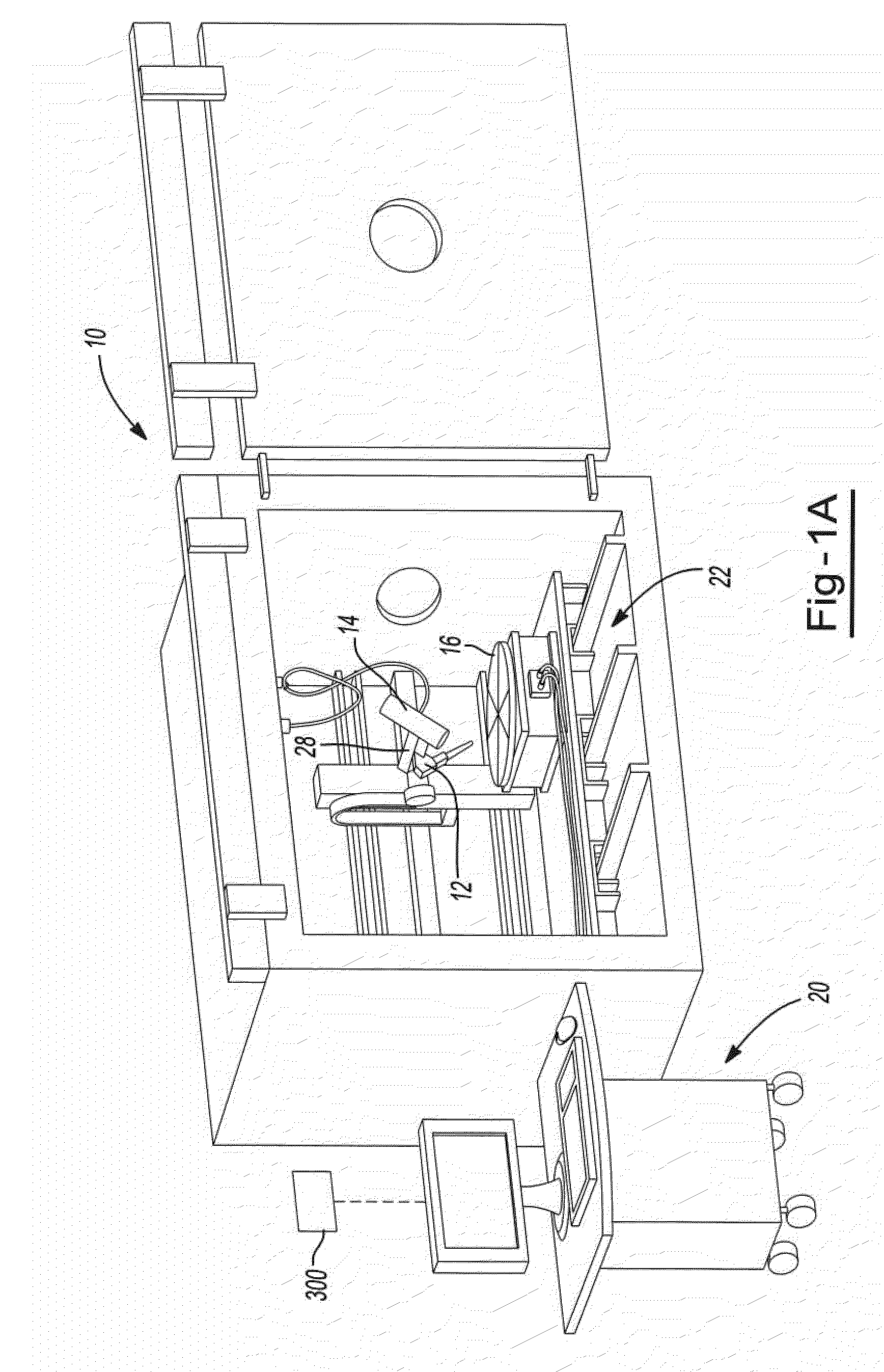

Electron beam layer manufacturing

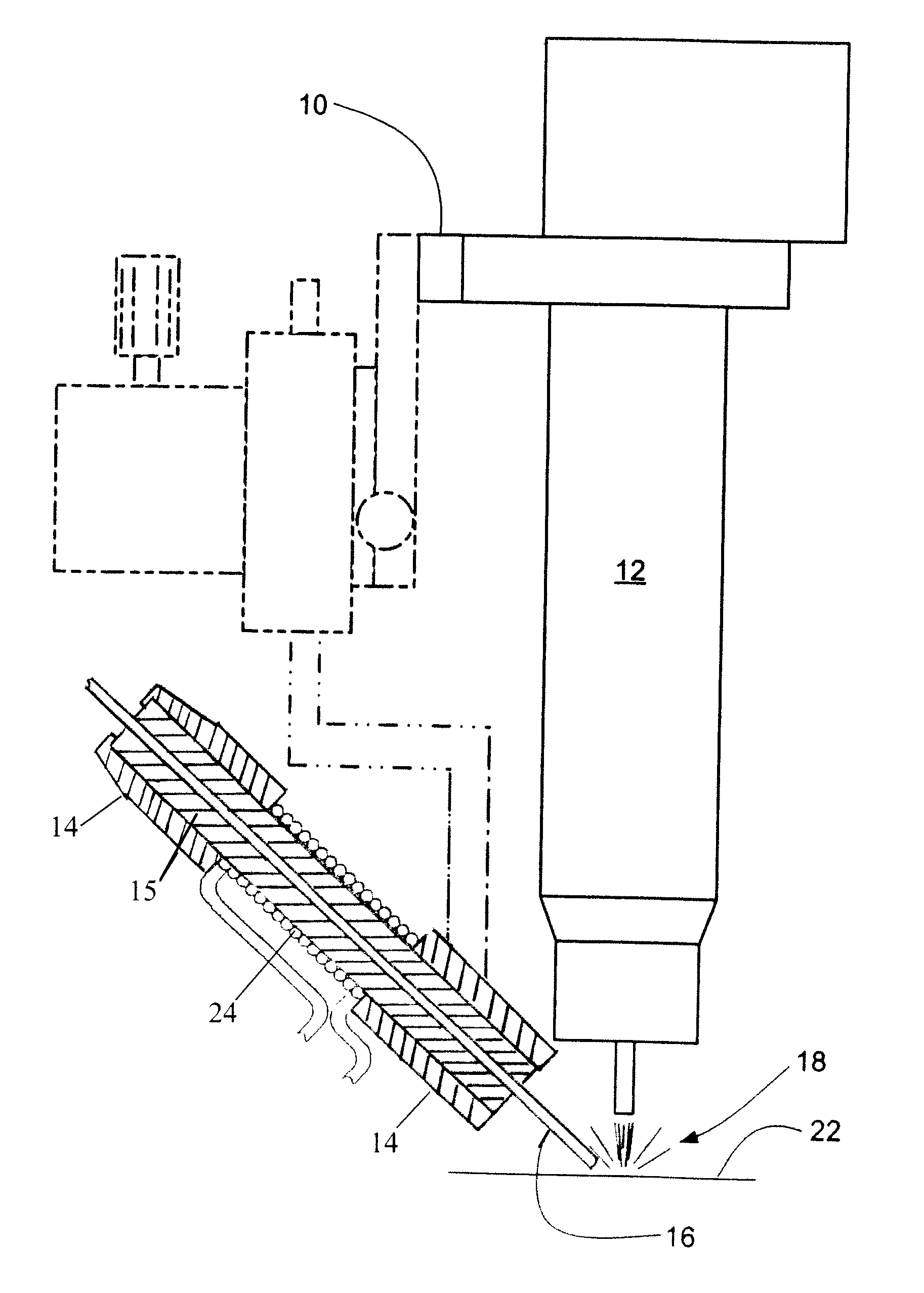

ActiveUS20110061591A1Obstruct passageProgramme controlAdditive manufacturing apparatusFree formClosed loop

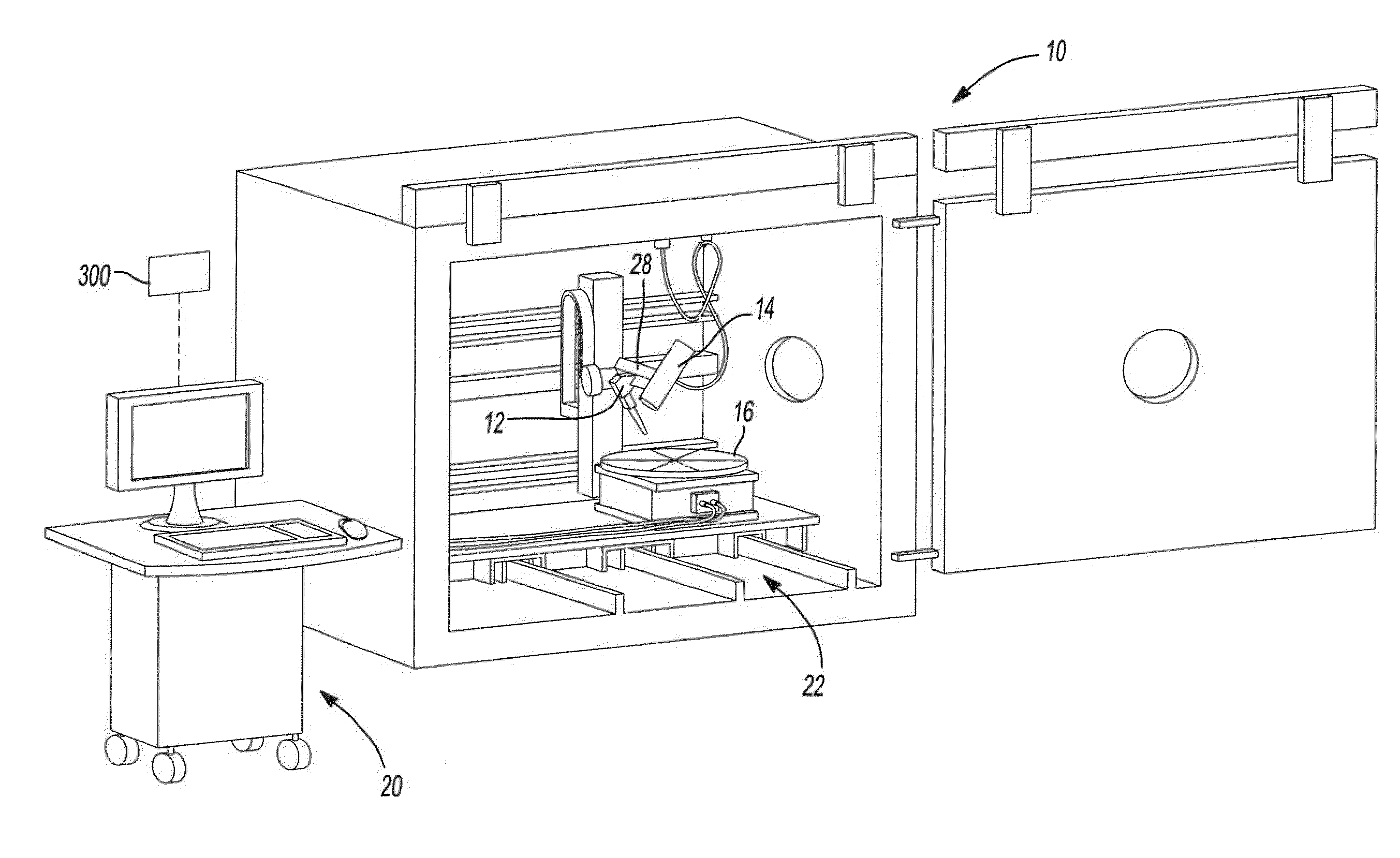

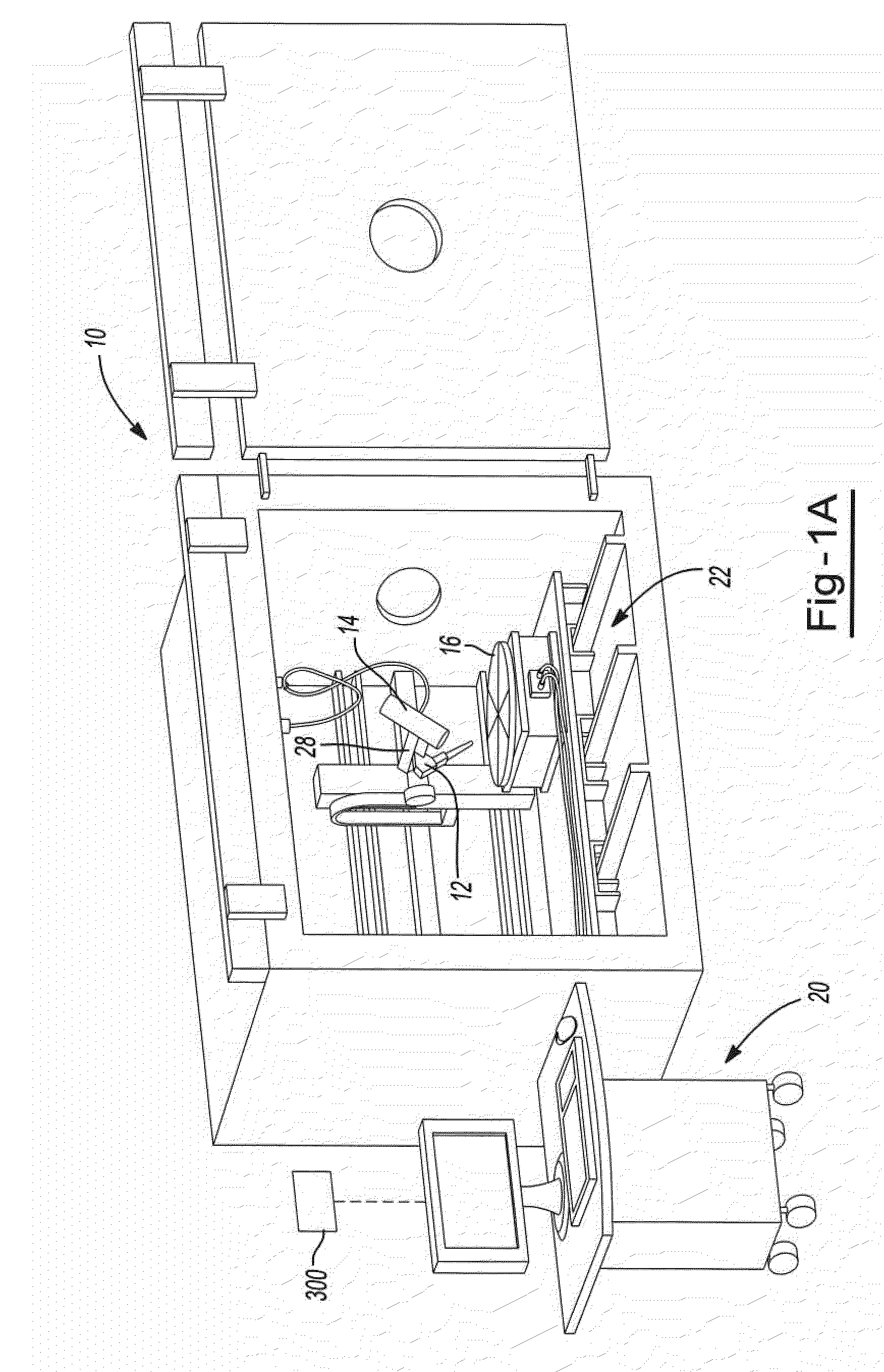

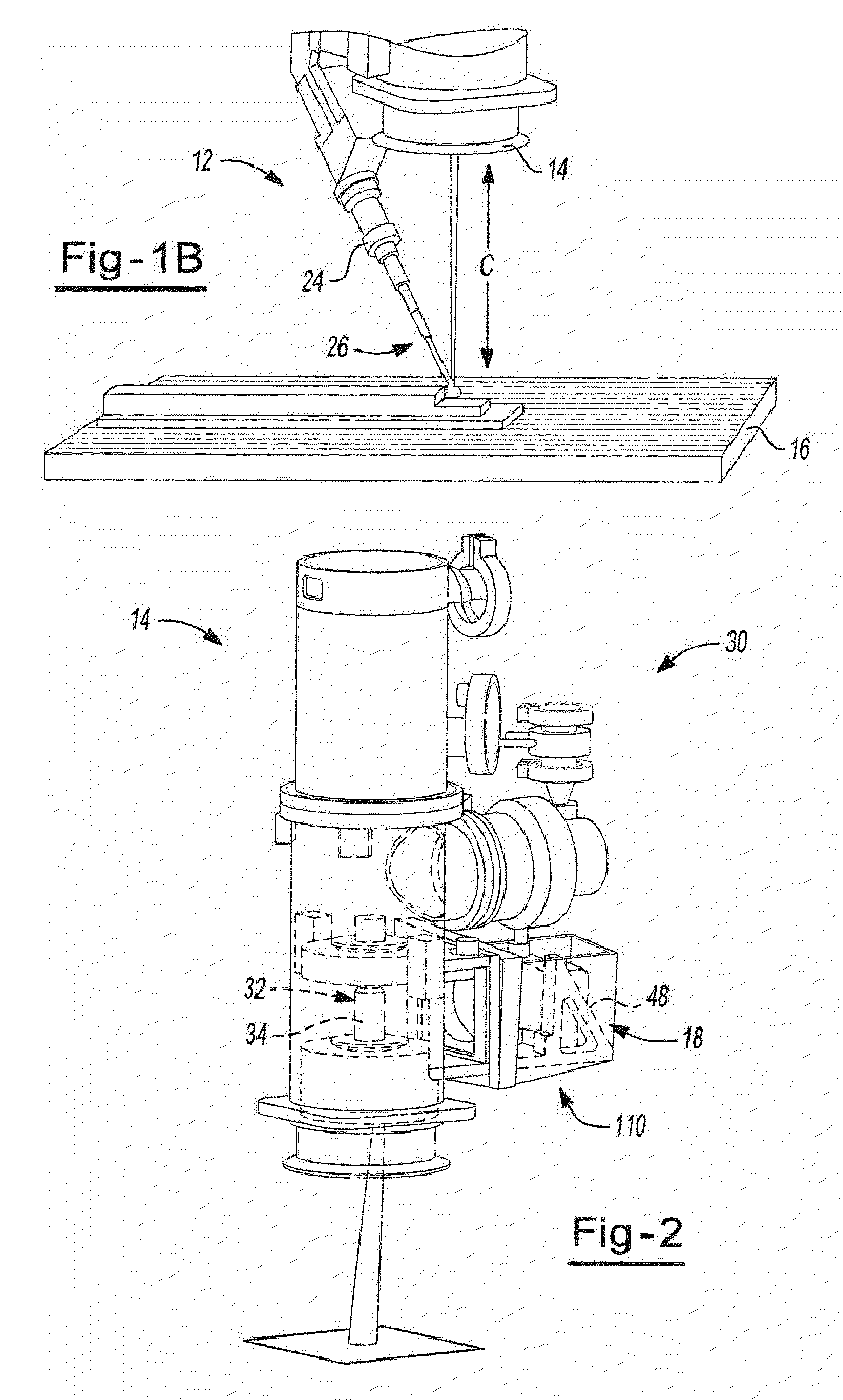

A process and apparatus for free form fabrication of a three-dimensional work piece comprising (a) feeding raw material in a solid state to a first predetermined location; (b) depositing the raw material onto a substrate as a molten pool deposit under a first processing condition; (c) monitoring the molten pool deposit for a preselected condition; (d) comparing information about the preselected condition of the monitored molten pool deposit with a predetermined desired value for the preselected condition of the monitored molten pool deposit; (e) solidifying the molten pool deposit; (f) automatically altering the first processing condition to a different processing condition based upon information obtained from the comparing step (d); and repeating steps (a) through (f) at one or more second locations for building up layer by layer a three-dimensional work piece. The apparatus is characterized by a detector that monitors a preselected condition of the deposited material and a closed loop electronic control device for controlling operation of one or more components of the apparatus in response to a detected condition by the detector.

Owner:SCIAKY SA

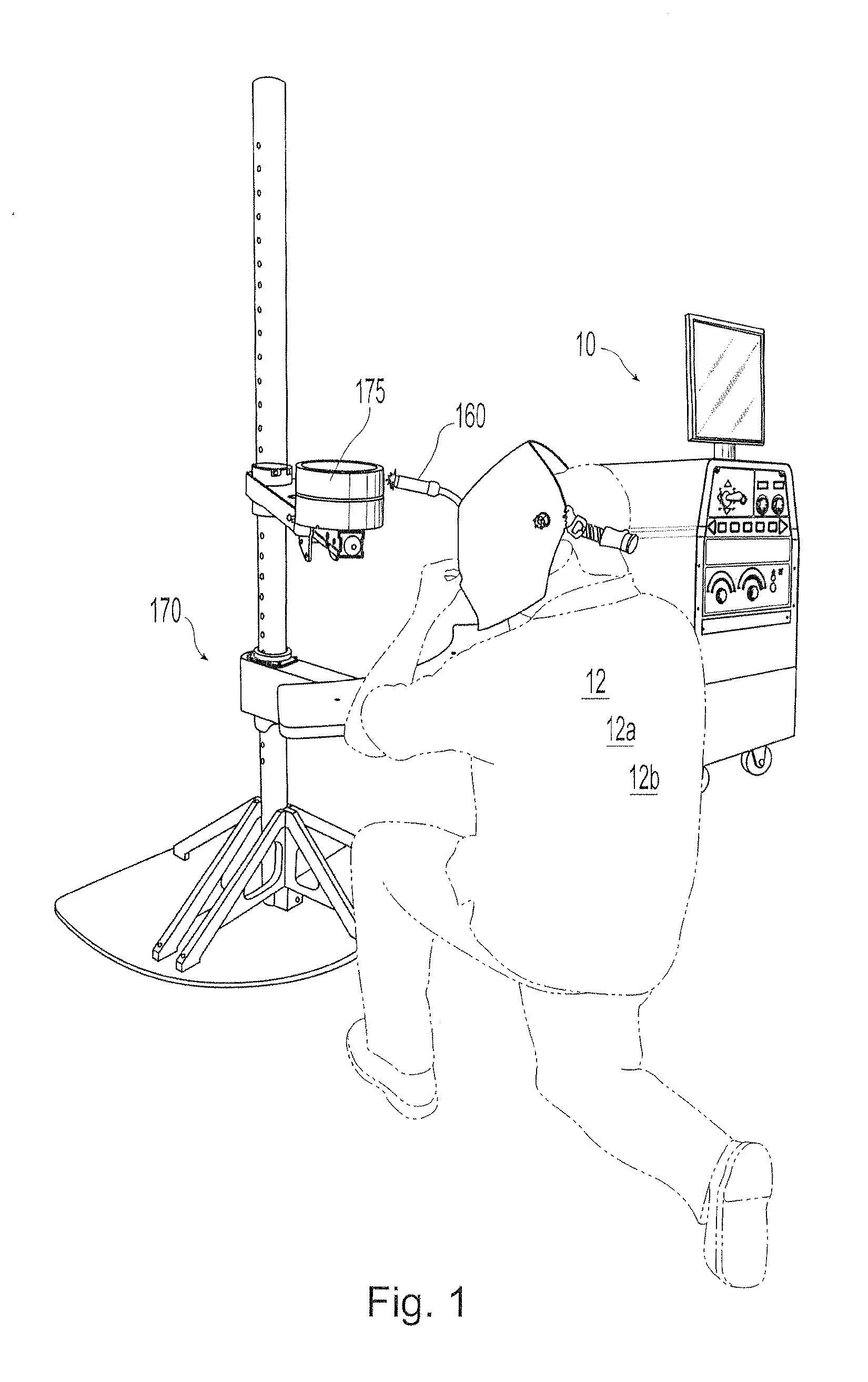

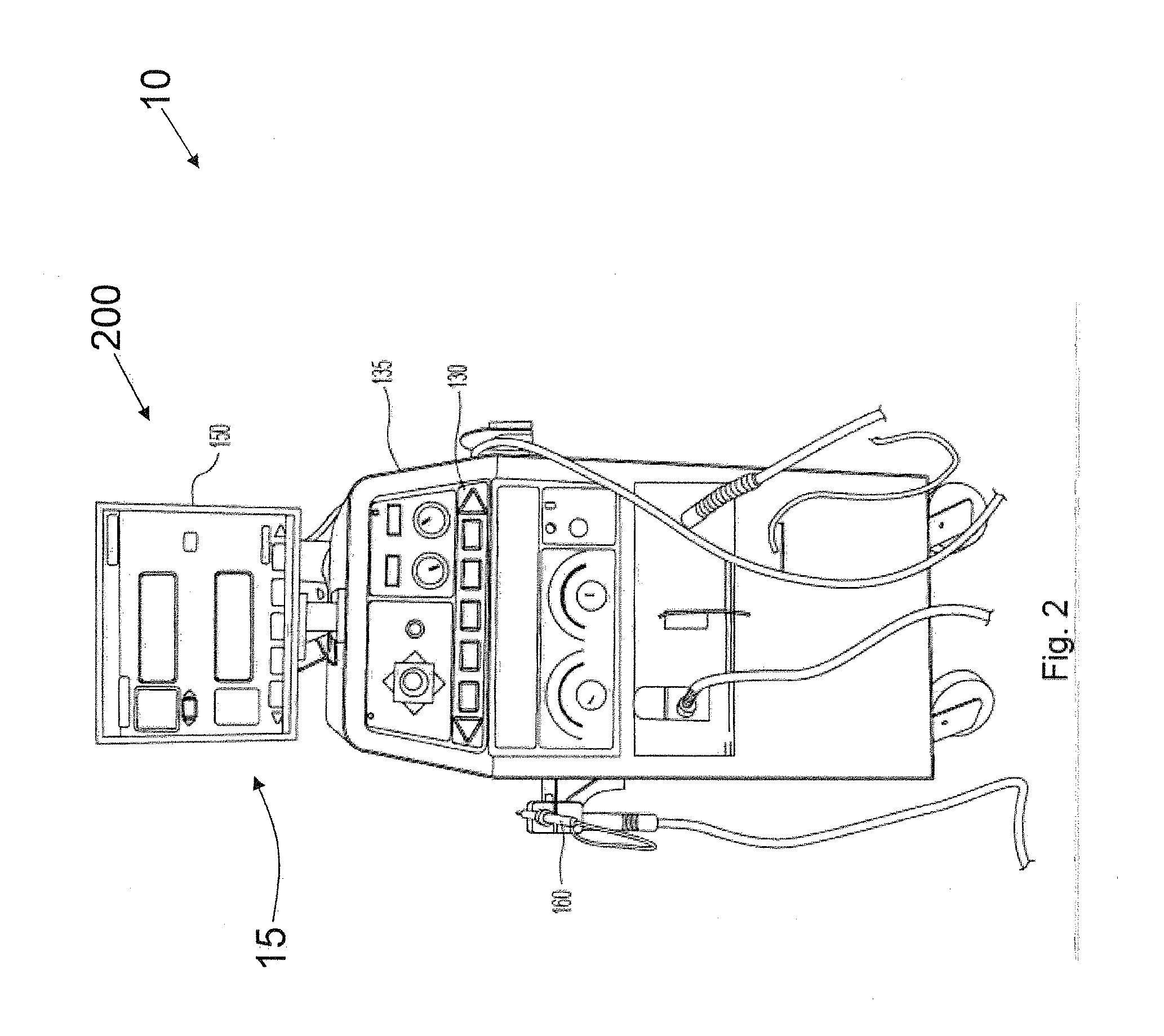

Virtual reality gtaw and pipe welding simulator and setup

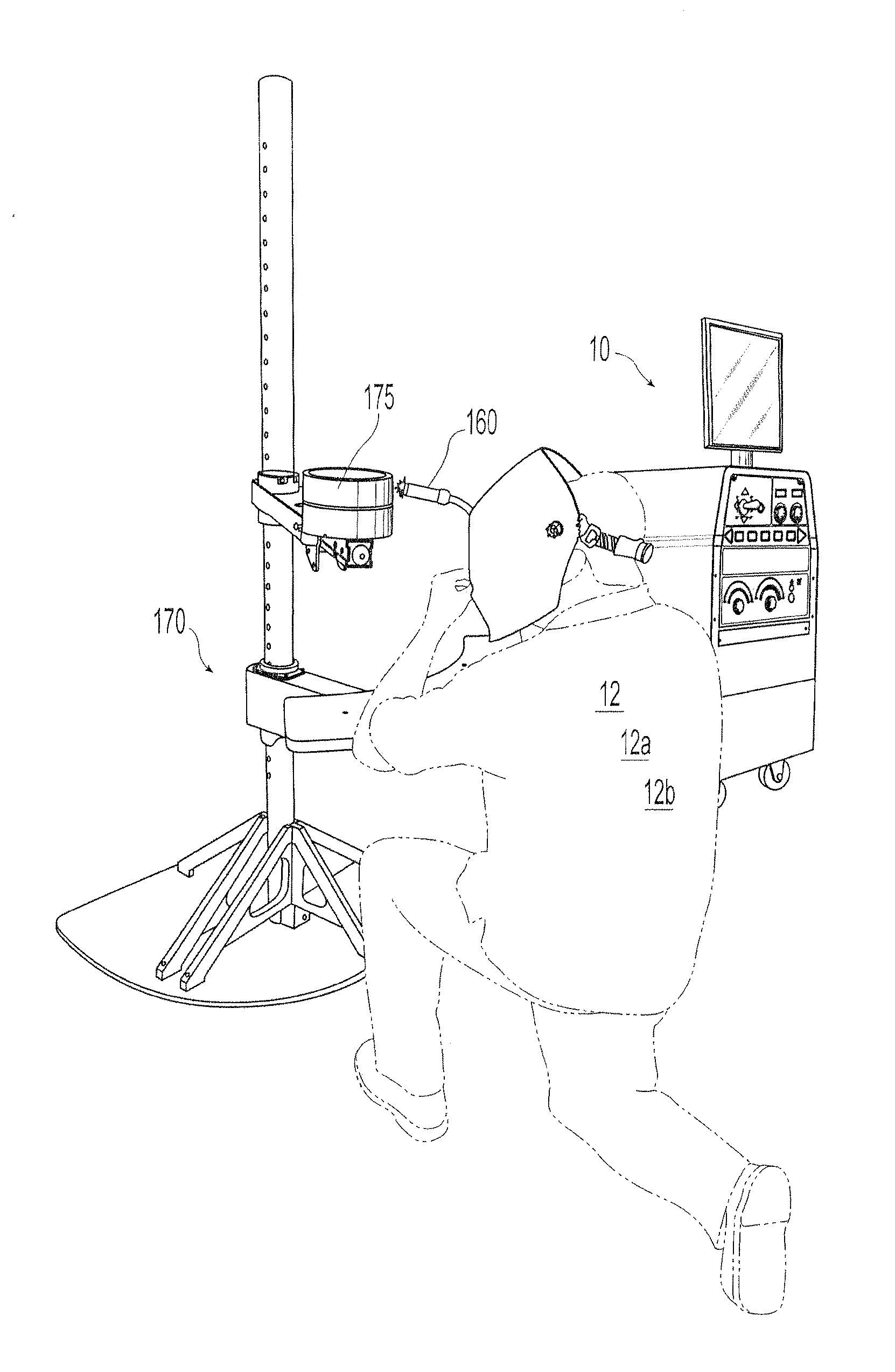

ActiveUS20130189657A1Affect characteristicArc welding apparatusEducational modelsSimulationClassical mechanics

Owner:LINCOLN GLOBAL INC

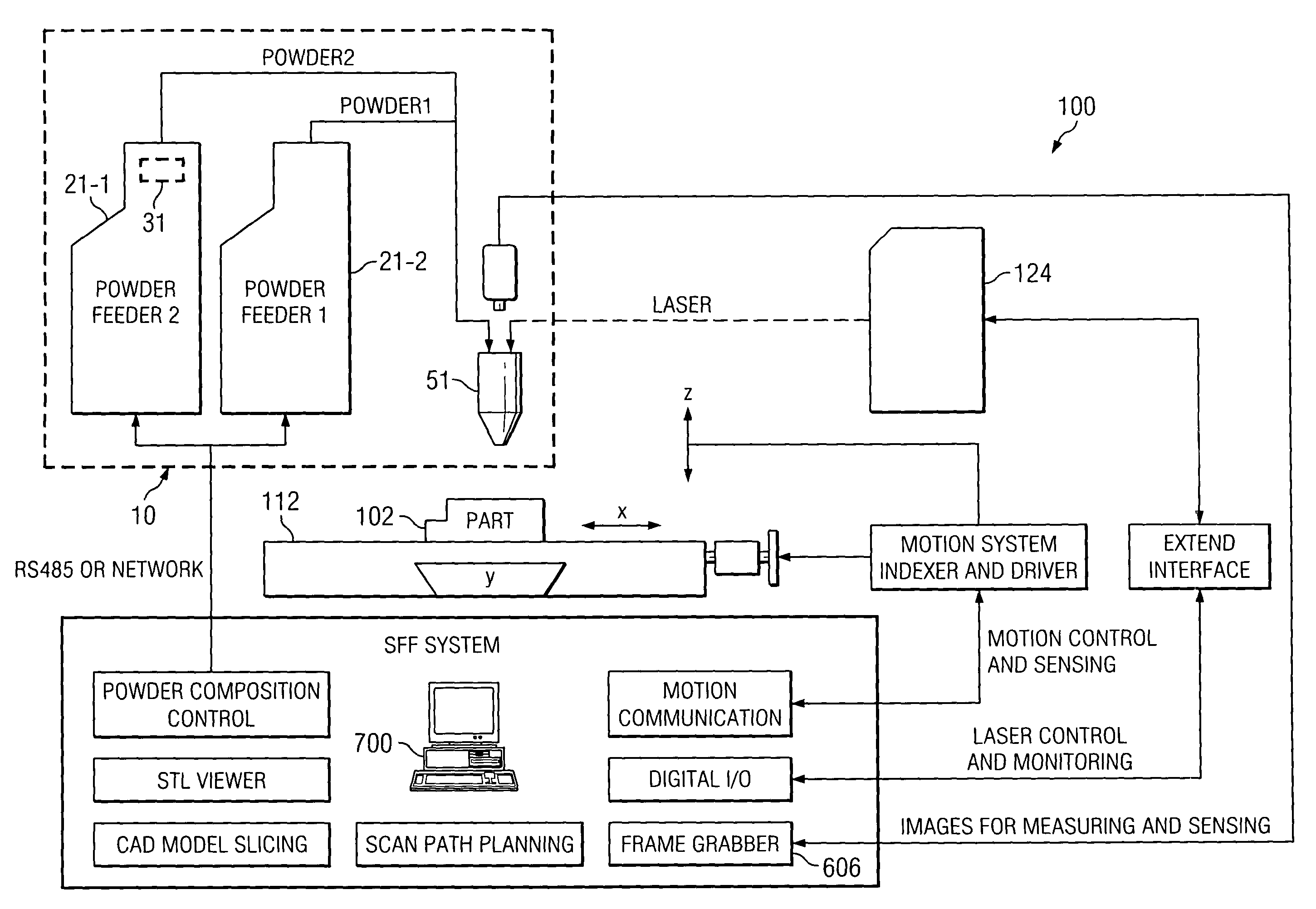

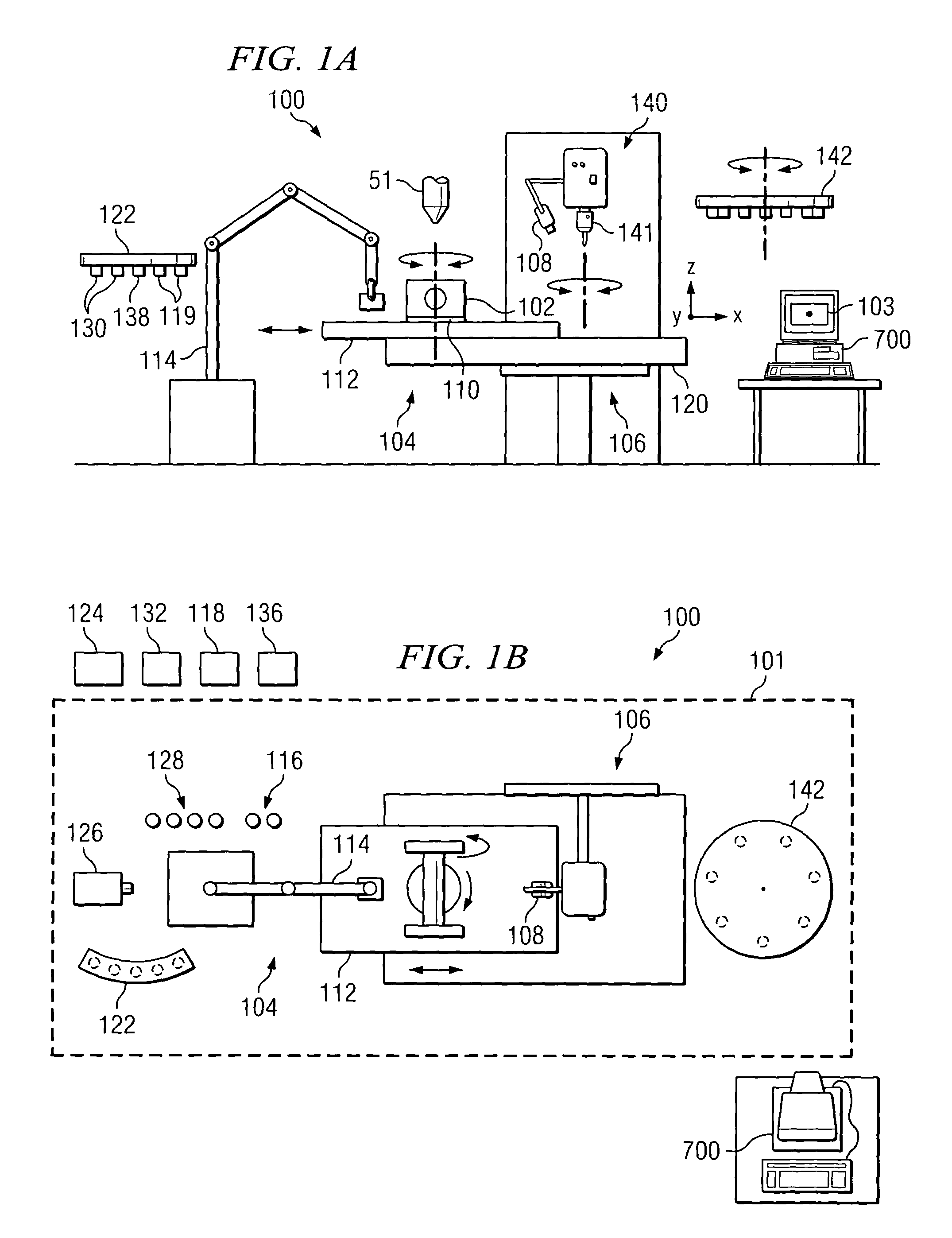

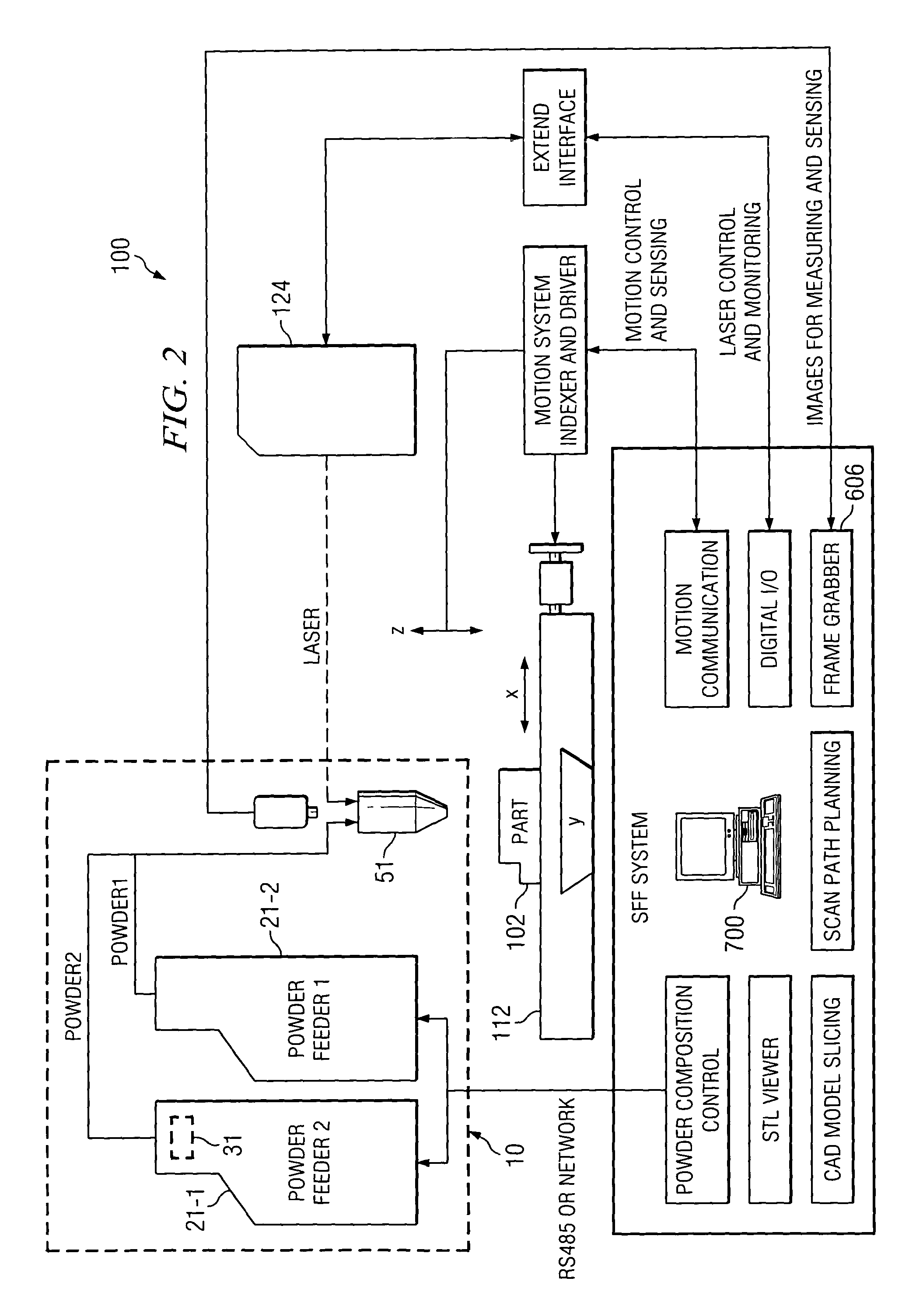

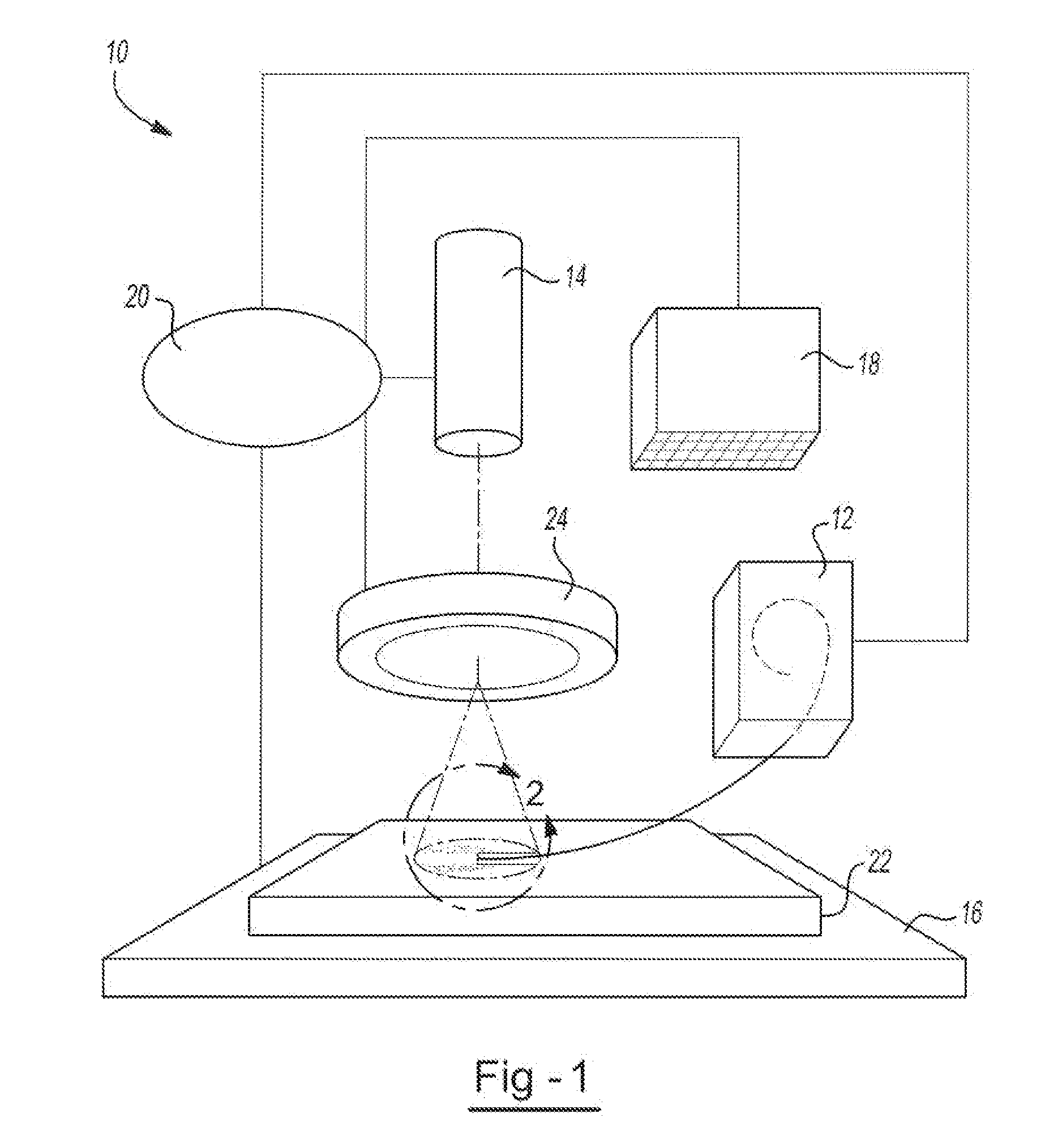

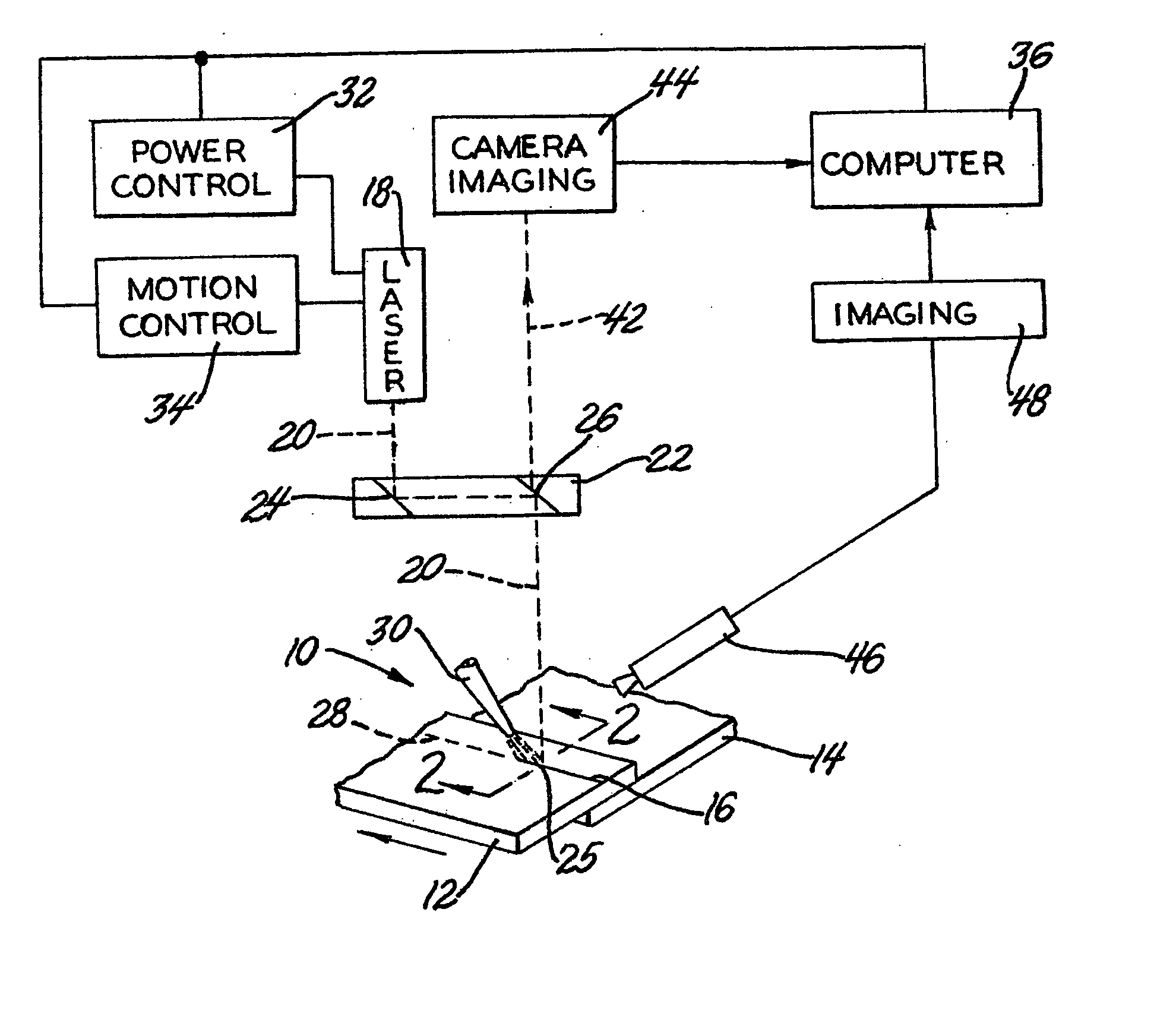

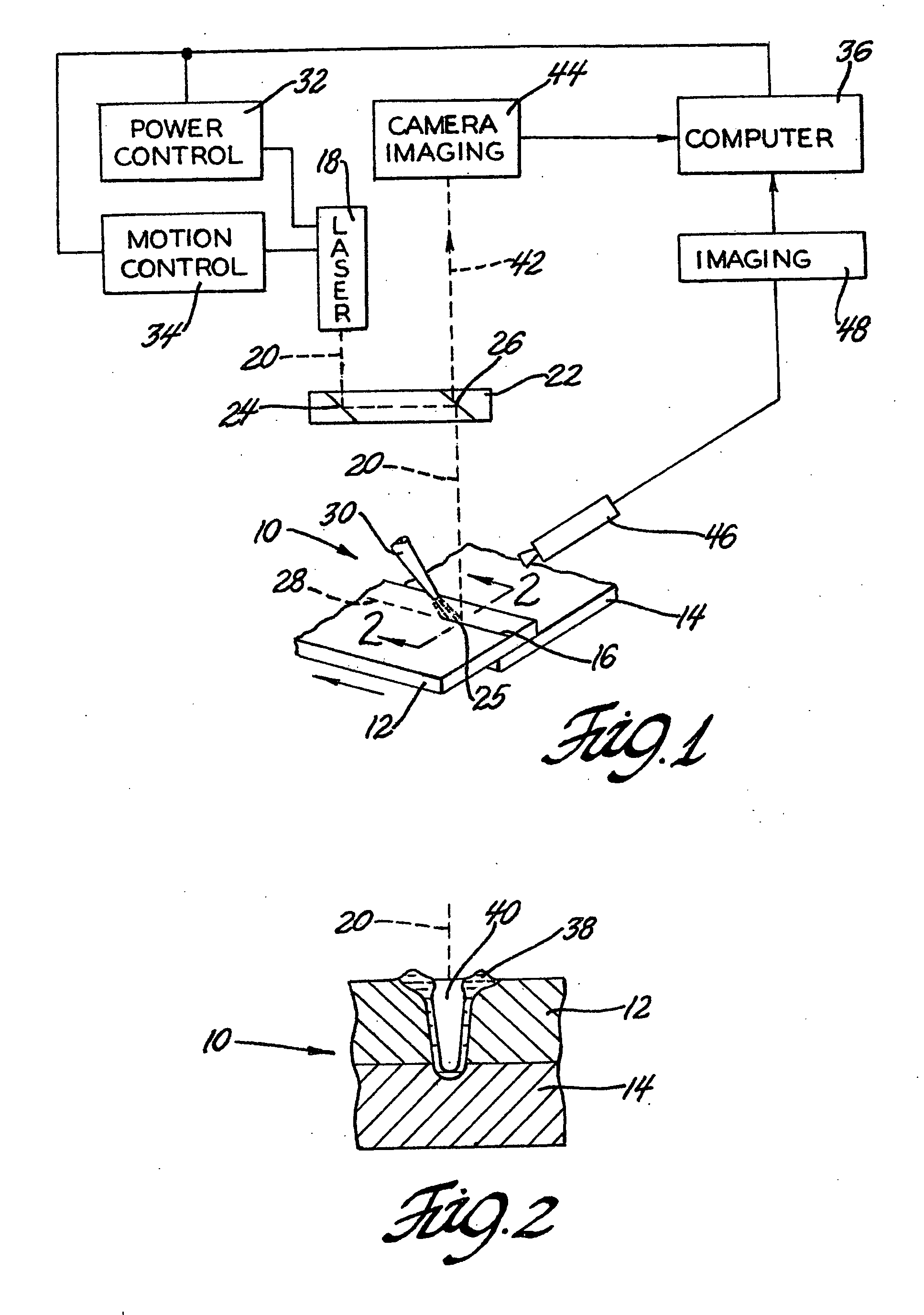

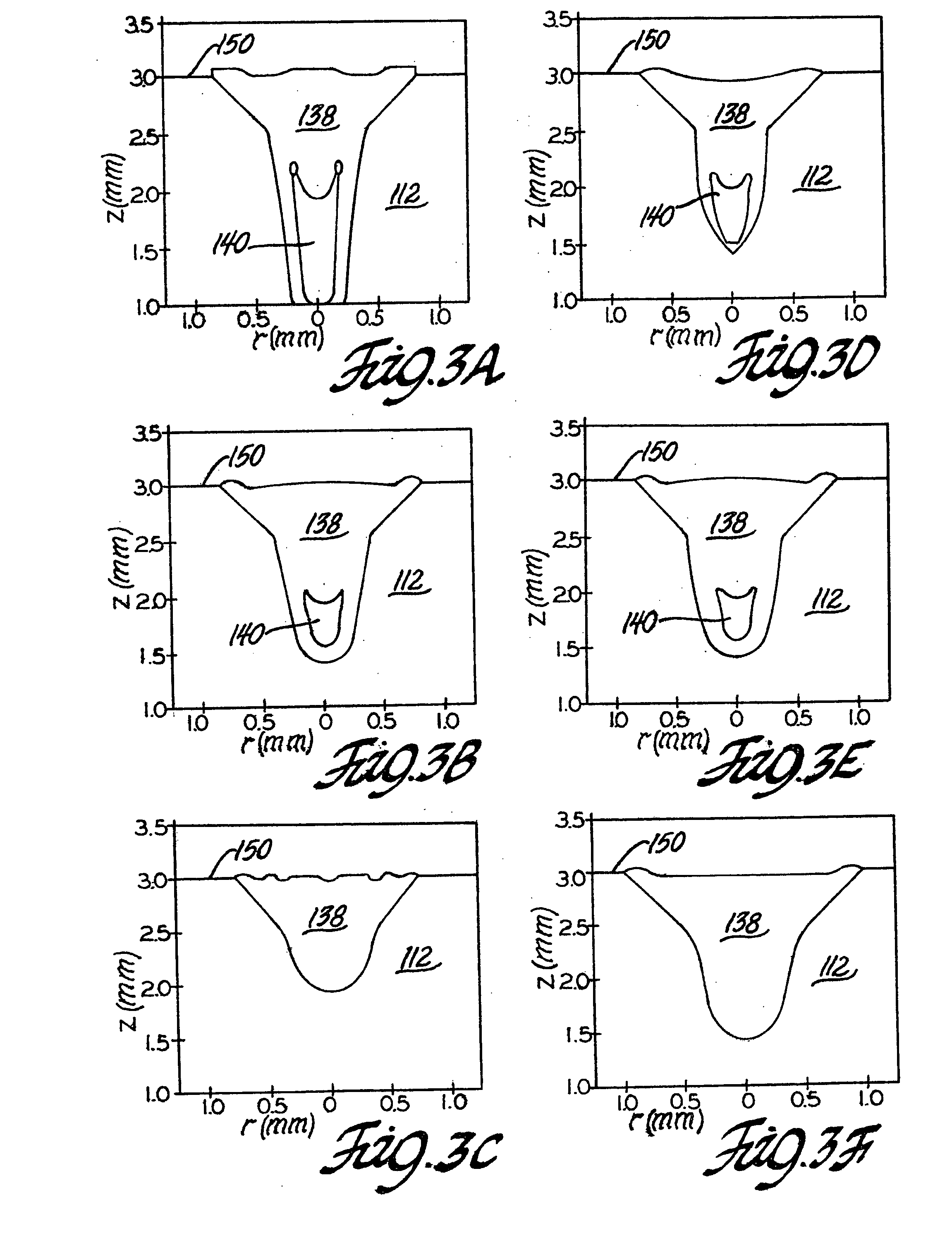

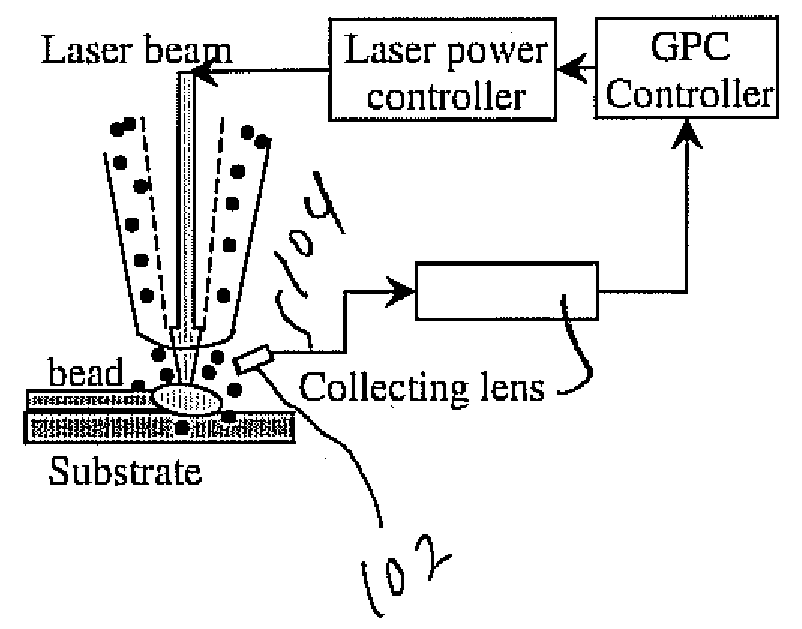

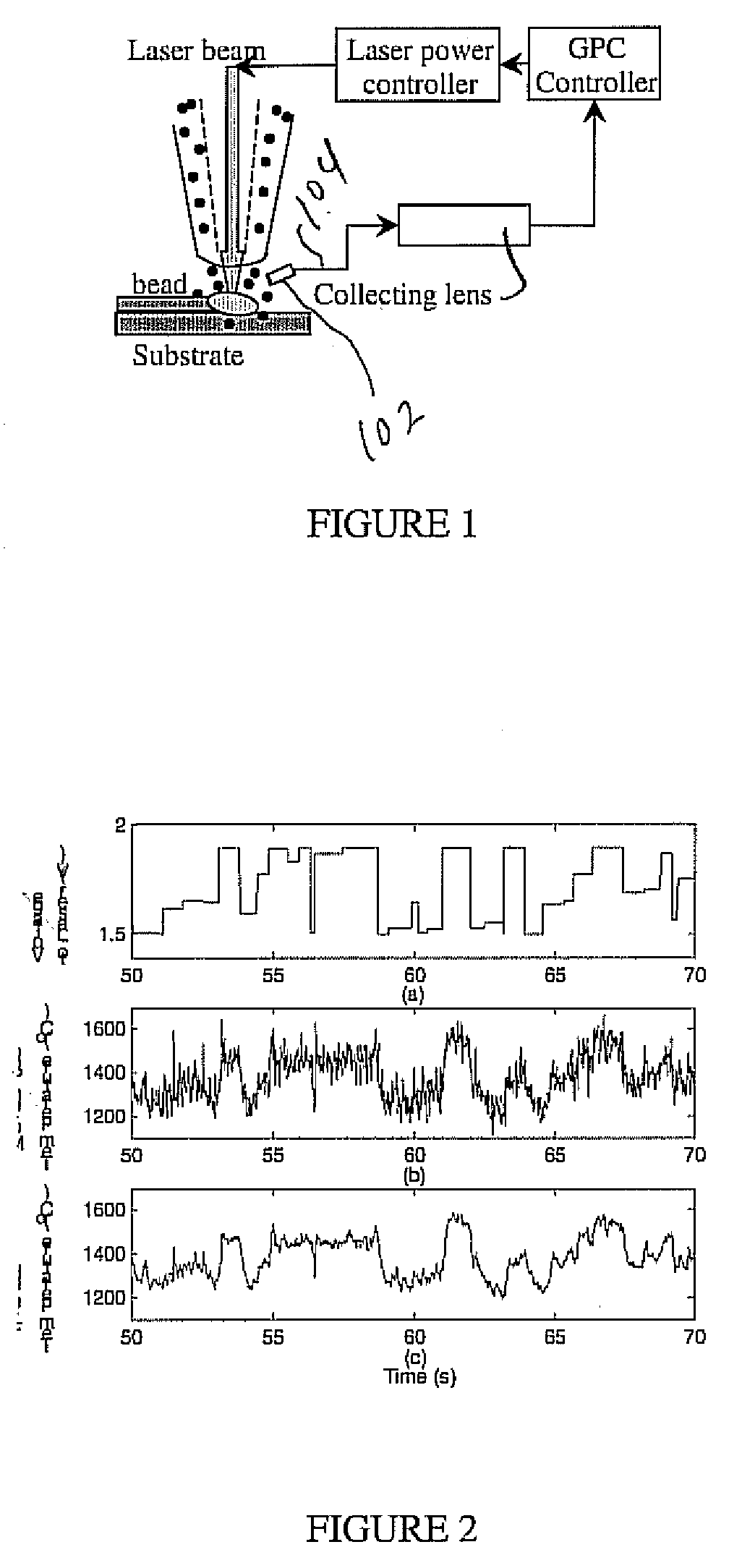

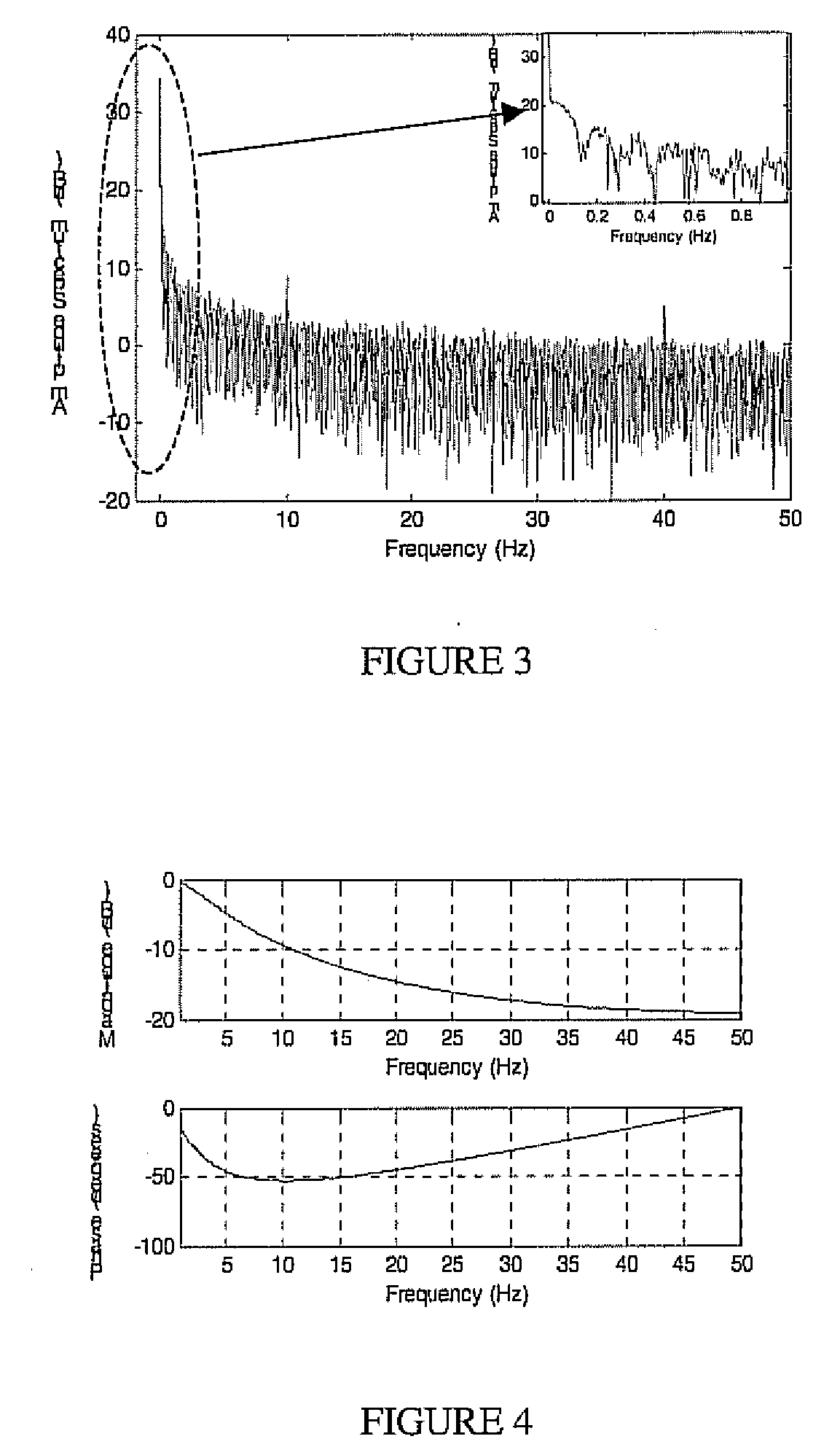

System and method for controlling the size of the molten pool in laser-based additive manufacturing

InactiveUS6995334B1High geometric accuracyEasy to controlAdditive manufacturing apparatusIncreasing energy efficiencyMelting tankLaser Nozzle

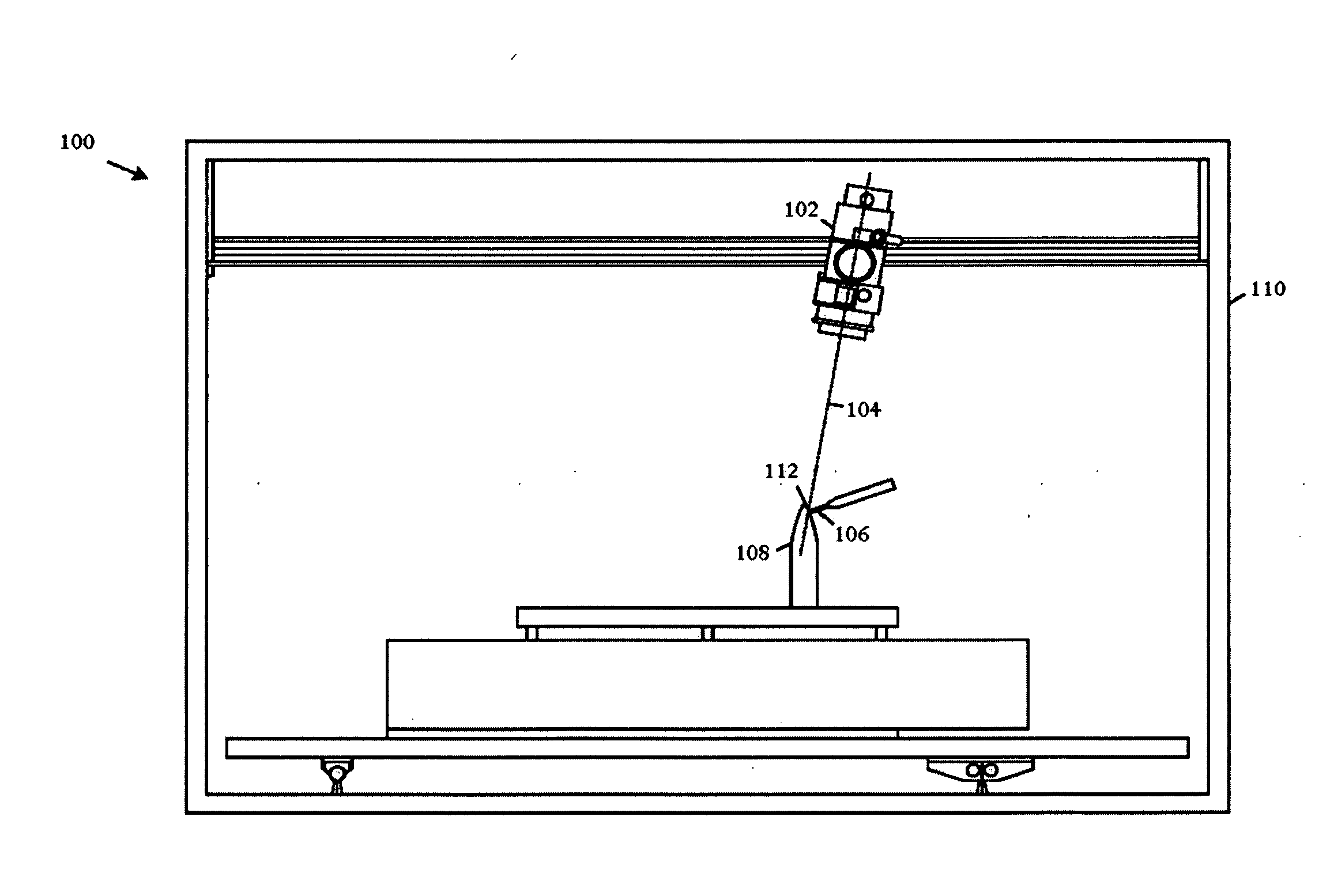

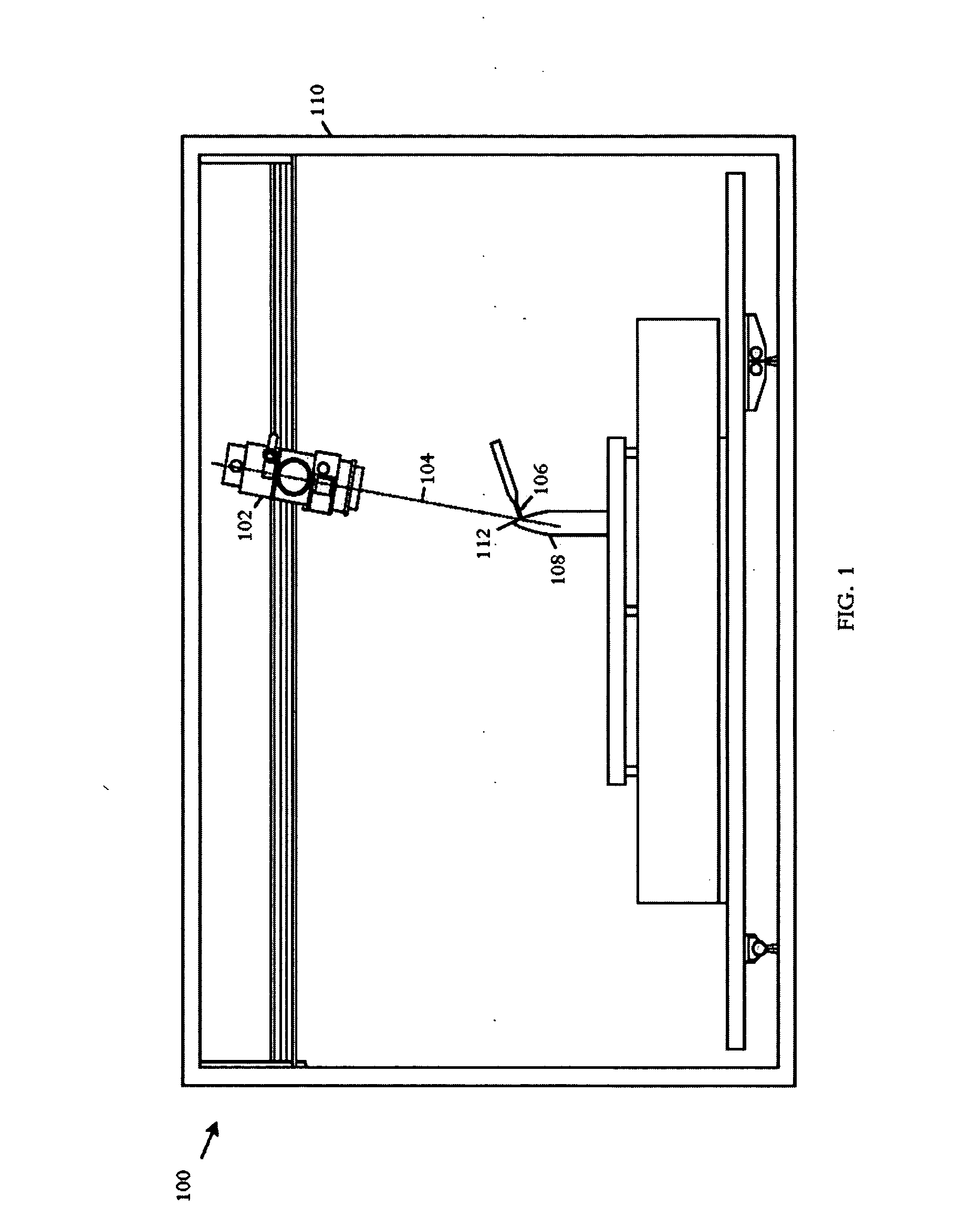

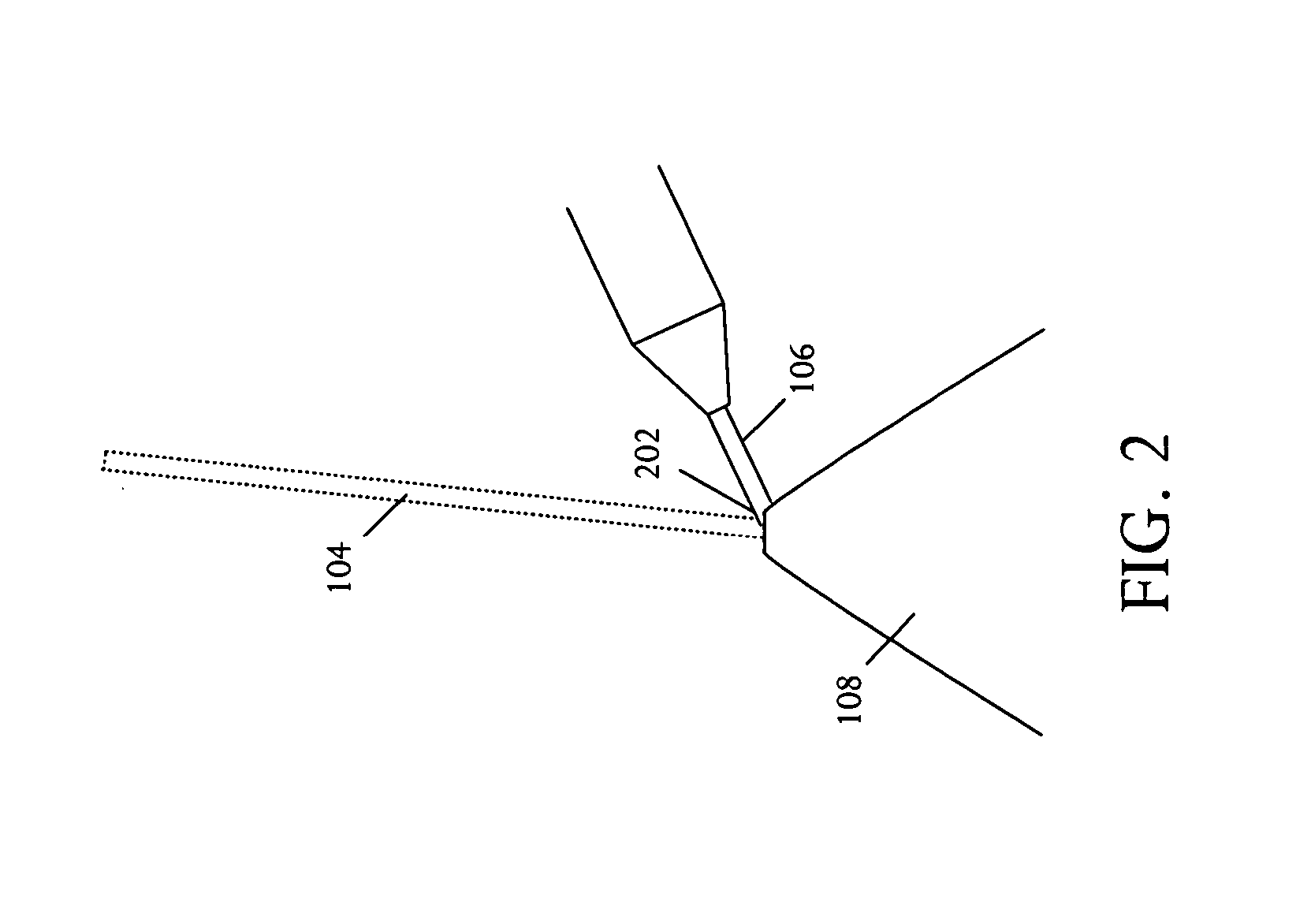

According to one embodiment of the invention, a method for controlling the size of the molten pool in a laser based additive manufacturing process includes coaxially aligning an imaging device with a laser nozzle and imaging a molten pool, created by a laser, on a substrate with the imaging device. The method further includes comparing at least one characteristic of the molten pool with a respective characteristic of a target molten pool, and adjusting, in substantially real-time, a laser power of the laser based on the comparison in order to correlate the characteristic of the molten pool with the respective characteristic of the target molten pool.

Owner:SOUTHERN METHODIST UNIVERSITY

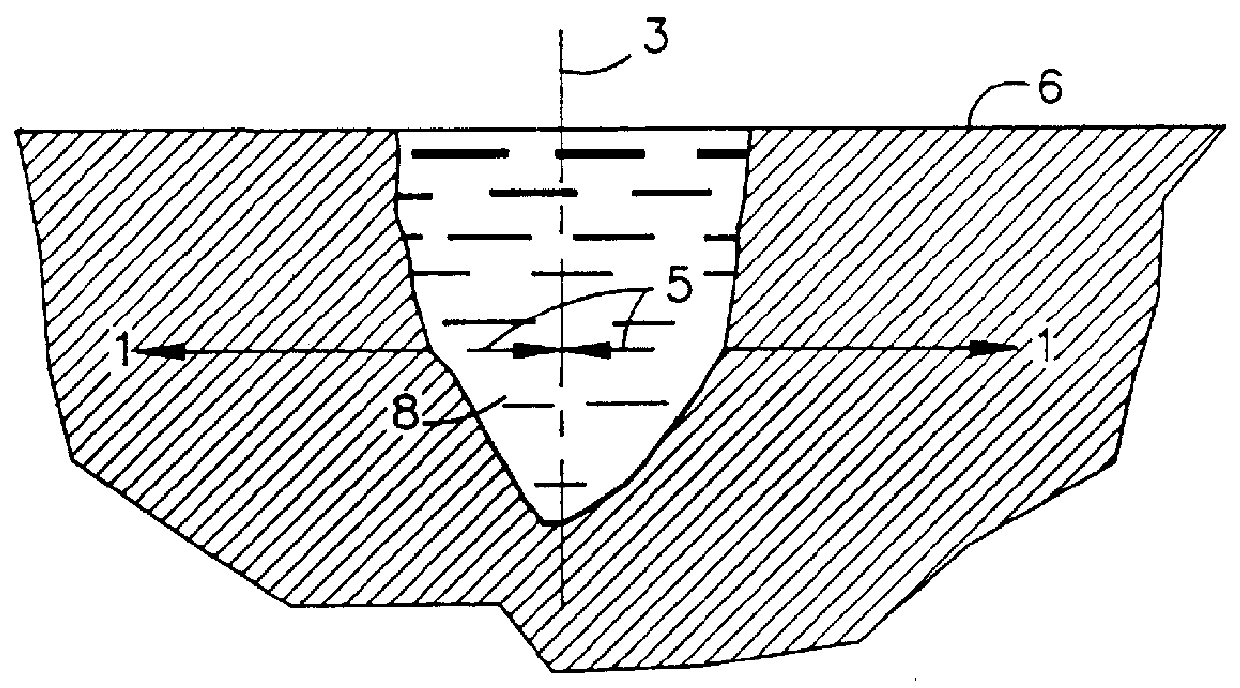

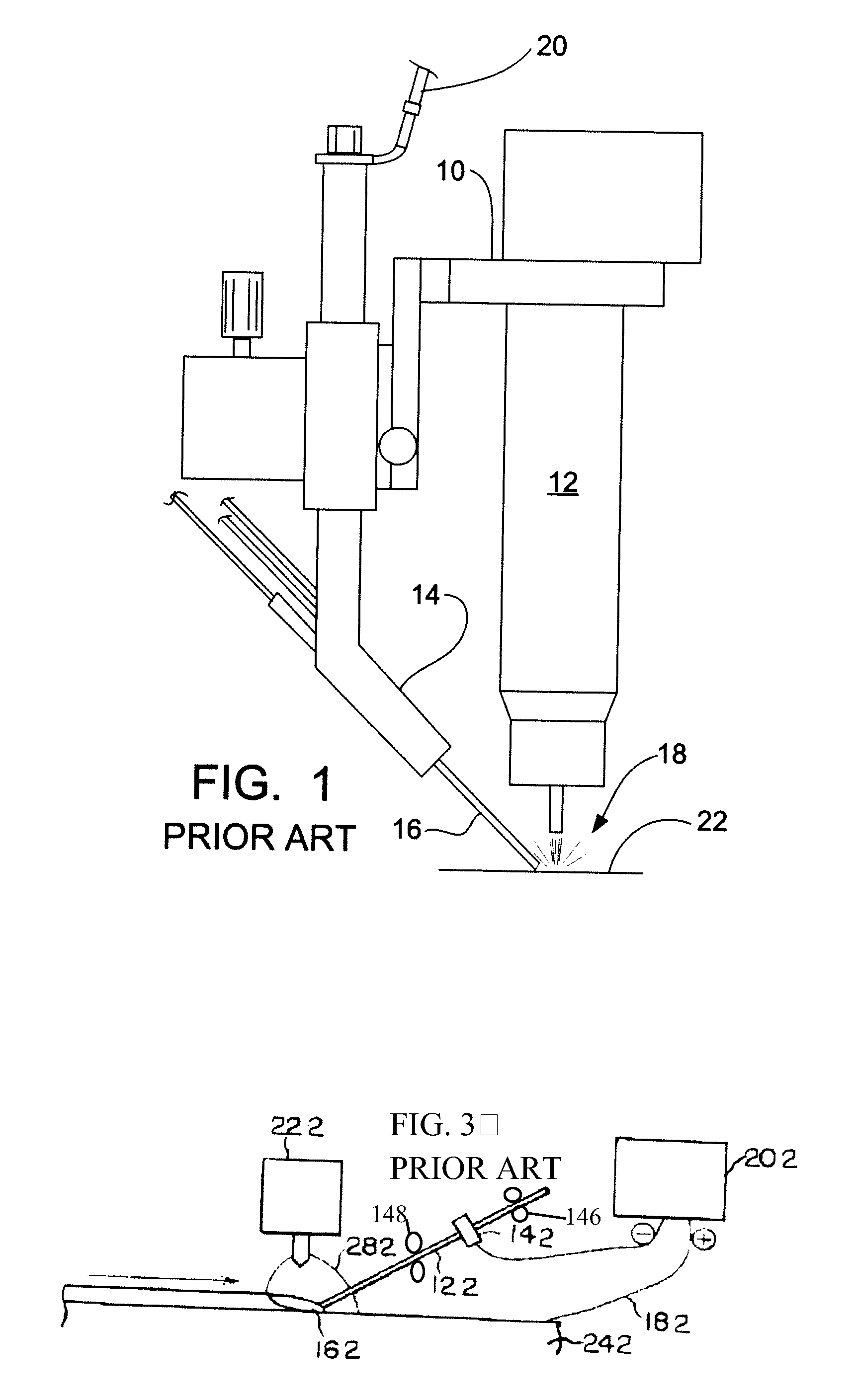

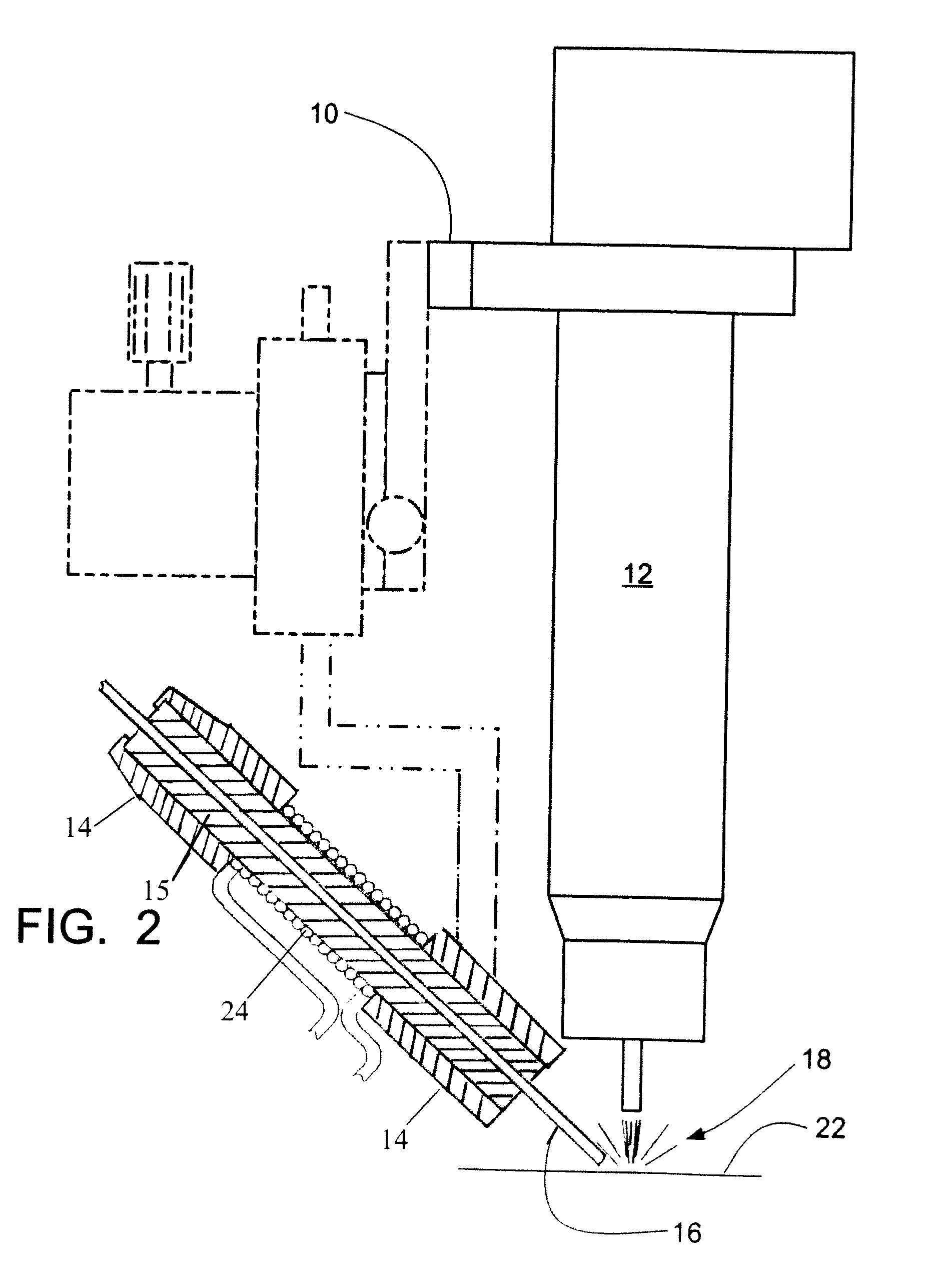

Method and apparatus for electric arc welding

An electric arc welding apparatus for depositing molten metal from an advancing welding wire into a weld puddle in an open root between two juxtapositioned plates where the root extends in a welding path and is formed by converging walls terminating in generally parallel walls spaced to define a gap, which apparatus comprises a contact holder with a wire outlet, a switching power supply directing welding current to the wire as the wire passes from the outlet toward the open root, with the advancing wire defining an electrode stick out between the contact holder and the weld puddle, a circuit for sensing the length of the stick out, and control means for adjusting the welding current as a function of the sensed stick out length.

Owner:LINCOLN GLOBAL INC

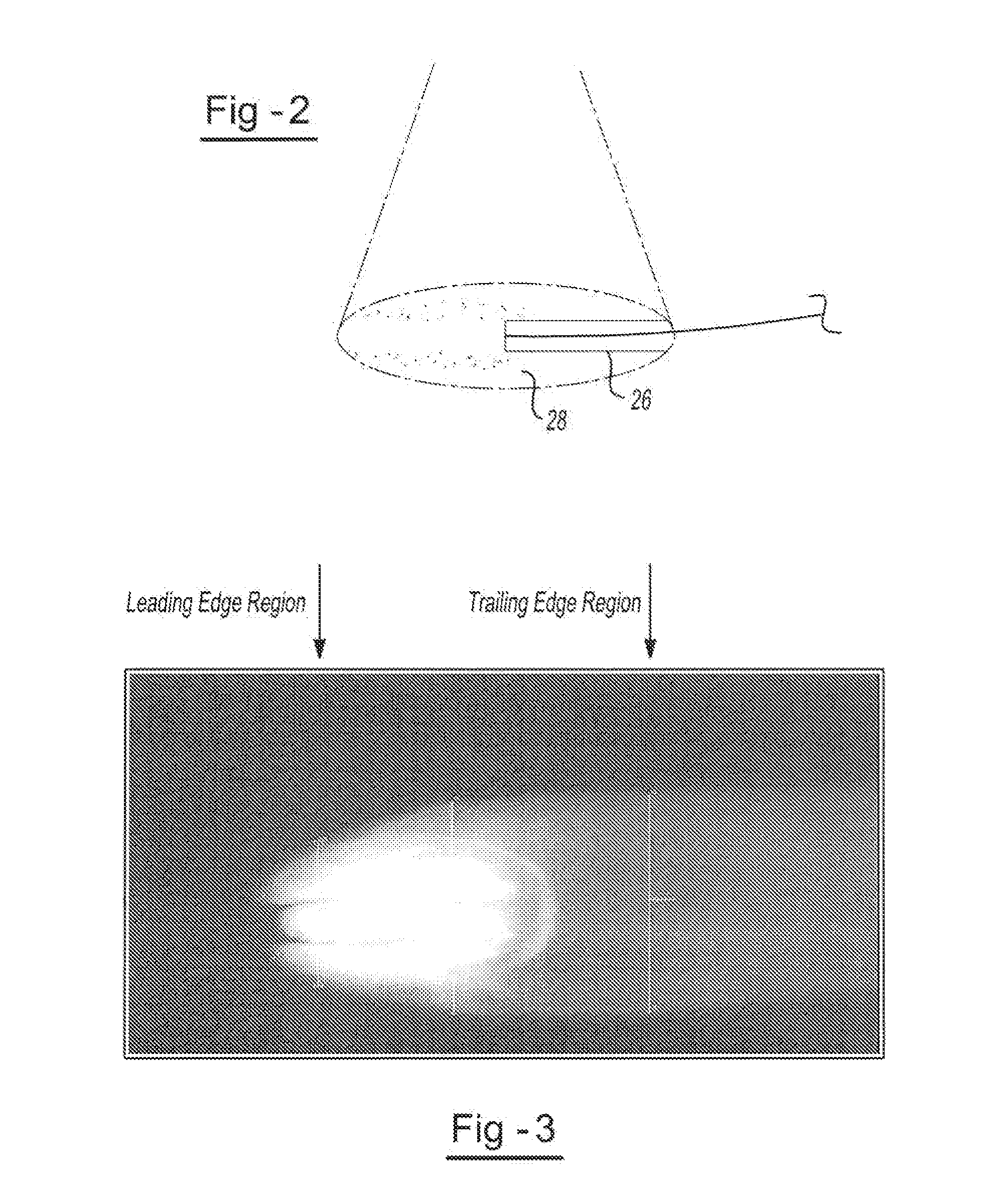

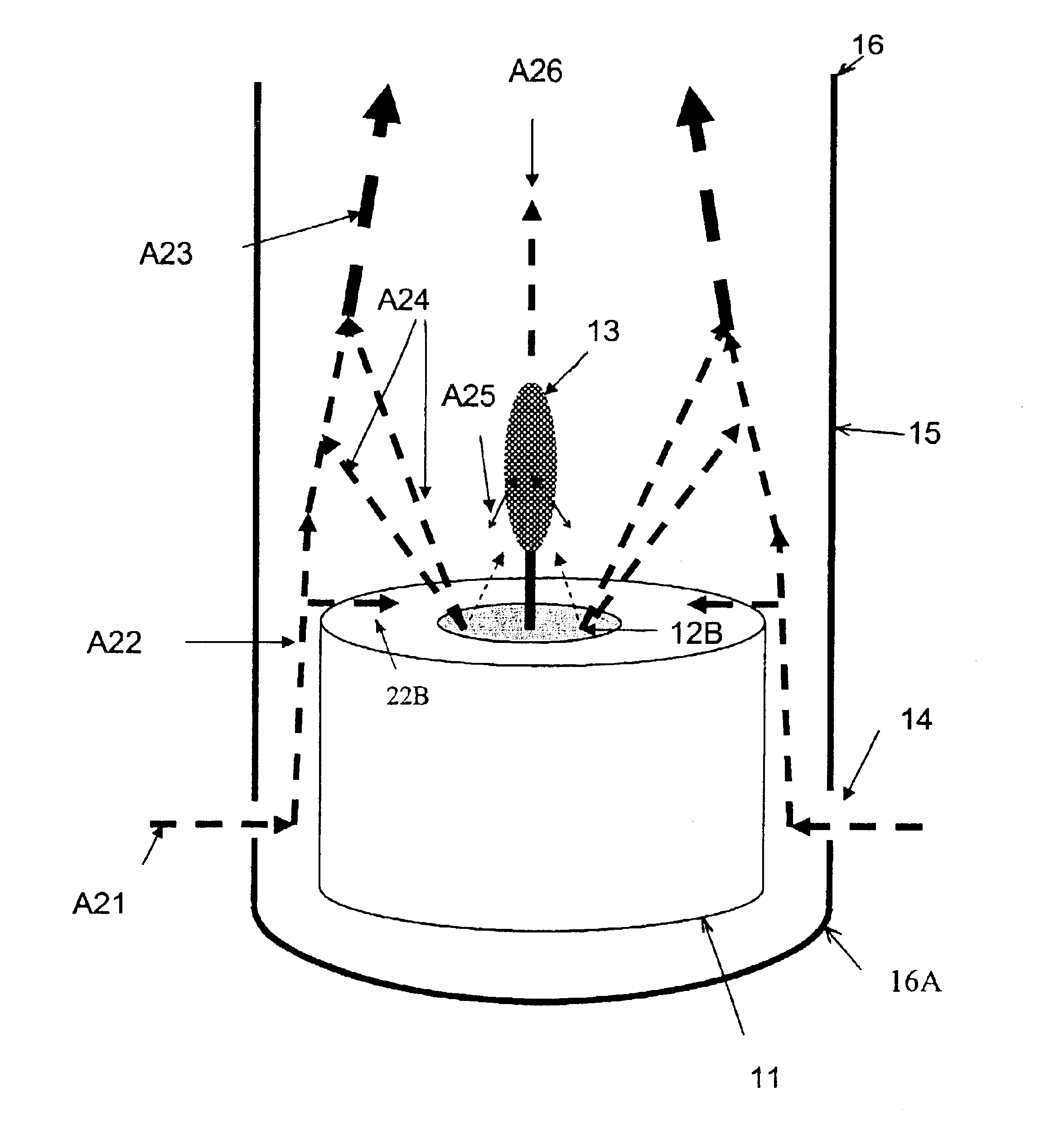

Electron beam layer manufacturing using scanning electron monitored closed loop control

ActiveUS20110114839A1Speed up the processQuick buildAdditive manufacturing apparatusMaterial analysis using wave/particle radiationClosed loopTrailing edge

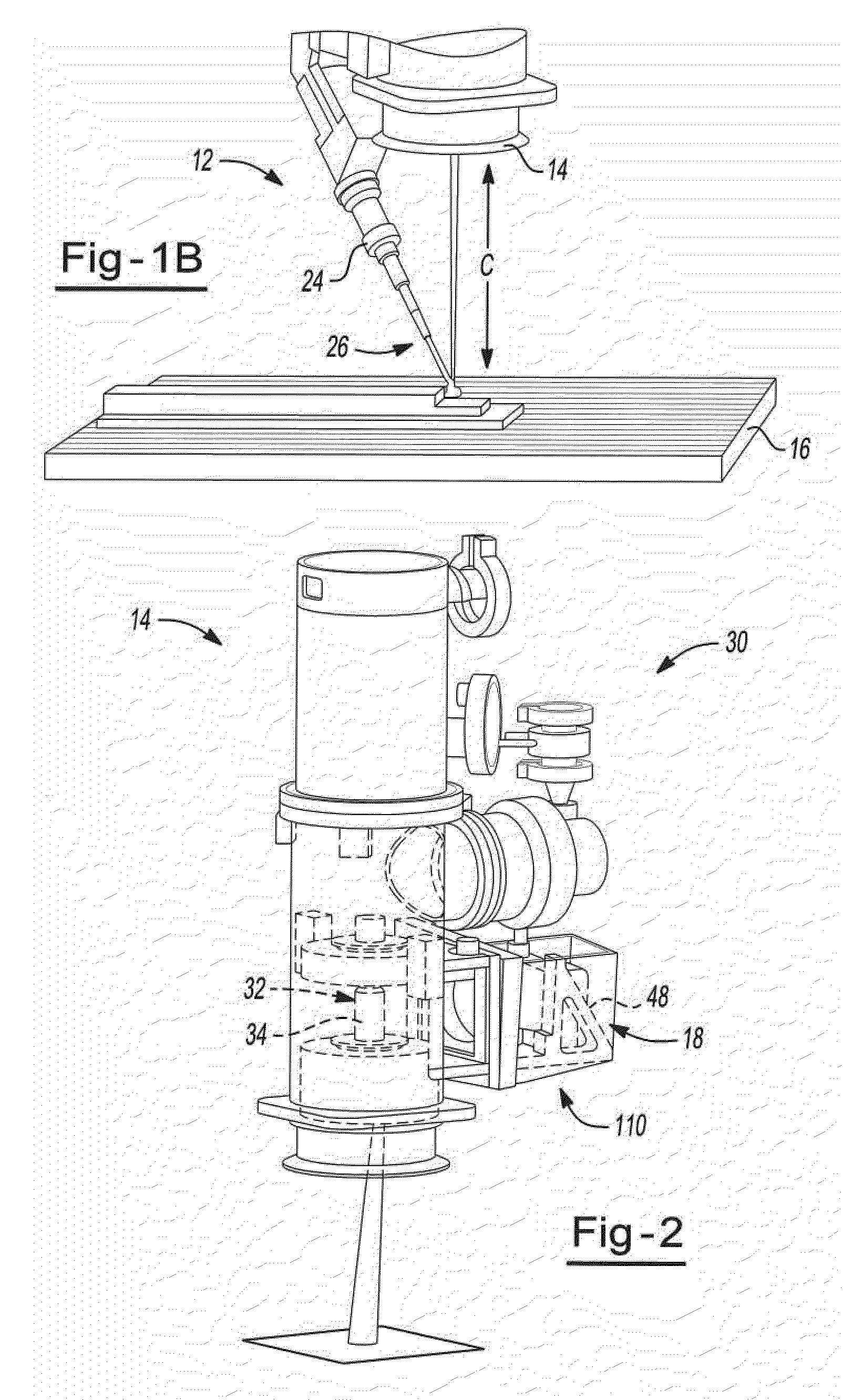

A process (and apparatus for performing the process) for layer manufacturing a three-dimensional work piece comprising the steps of; feeding raw material in a solid state to a first predetermined location; exposing the raw material to an electron beam to liquefy the raw material; depositing the raw material onto a substrate as a molten pool deposit, the deposit having a forward edge region in an x-y plane with a forward edge region width and a trailing edge region in the x-y plane with a trailing edge region width, under at least one first processing condition; monitoring the molten pool deposit for at least one preselected condition using detecting of scatter from a scanning electron beam contemporaneously with the depositing step; solidifying the molten pool deposit; automatically altering the first processing condition to a different processing condition based upon information obtained from the comparing step; and repeating steps at one or more second locations for building up layer by layer, generally along a z-axis that is orthogonal to the x-y plane, a three-dimensional work piece.

Owner:SCIAKY SA

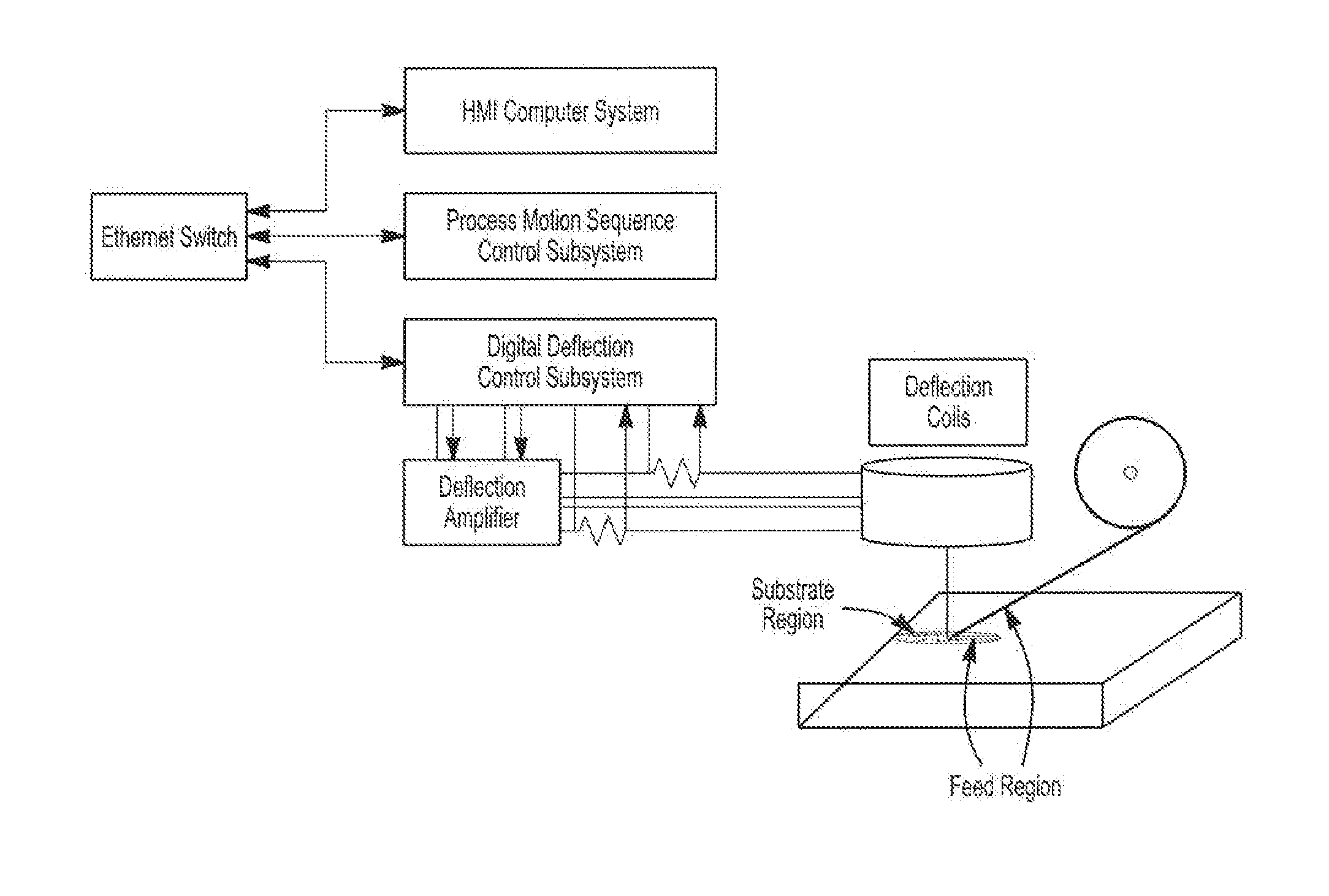

Raster methodology, apparatus and system for electron beam layer manufacturing using closed loop control

ActiveUS20110240607A1Constant feed rateConstant frame rateLiquid surface applicatorsAdditive manufacturing apparatusGratingClosed loop

A method for layer-by-layer manufacturing of a three-dimensional metallic work piece, comprising the steps of: delivering a metallic feed material in a substantially solid state into a feed region; emitting an electron beam having one or more predetermined electrical currents; translating the electron beam through a first predetermined raster pattern frame in an x-y plane that includes: a plurality of points within the feed region sufficient so that the metallic feed material is subjected to a melting beam power density level sufficient to cause melting of the metallic feed material and formation of a molten pool deposit; and a plurality of points in a substrate region that is outside of the feed region, sufficient so that the plurality of points outside the feed region is subjected to a substrate beam power density level that is different from (e.g., lower than) the melting beam power density level; monitoring a condition of one or both of the feed region or the substrate region substantially in real time for the occurrence of any deviation from a predetermined condition; upon detecting of any deviation, translating the electron beam through at least one second predetermined raster pattern frame in the x-y plane that maintains the melting beam power density level substantially the same as the first predetermined raster pattern frame, but alters the substrate beam power density level in a manner so that the monitored condition returns to the predetermined condition; and repeating the above steps at one or more second locations for building up layer by layer, generally along a z-axis that is orthogonal to the x-y plane, a three-dimensional layered metallic work piece. The teachings herein also contemplate an apparatus that includes an electronic control device that performs any of the methods herein, as well as articles made according to such methods.

Owner:SCIAKY SA

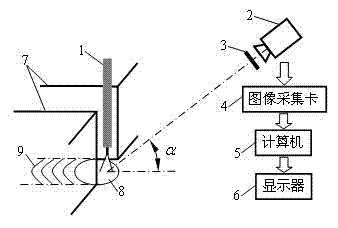

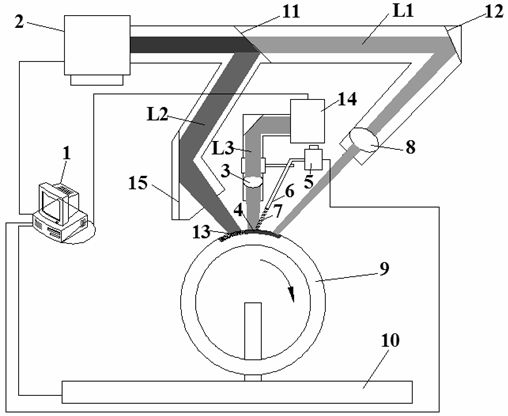

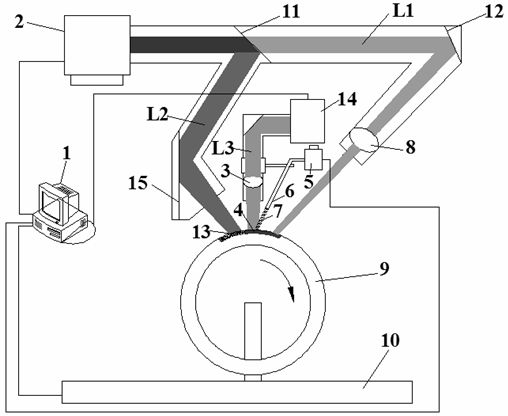

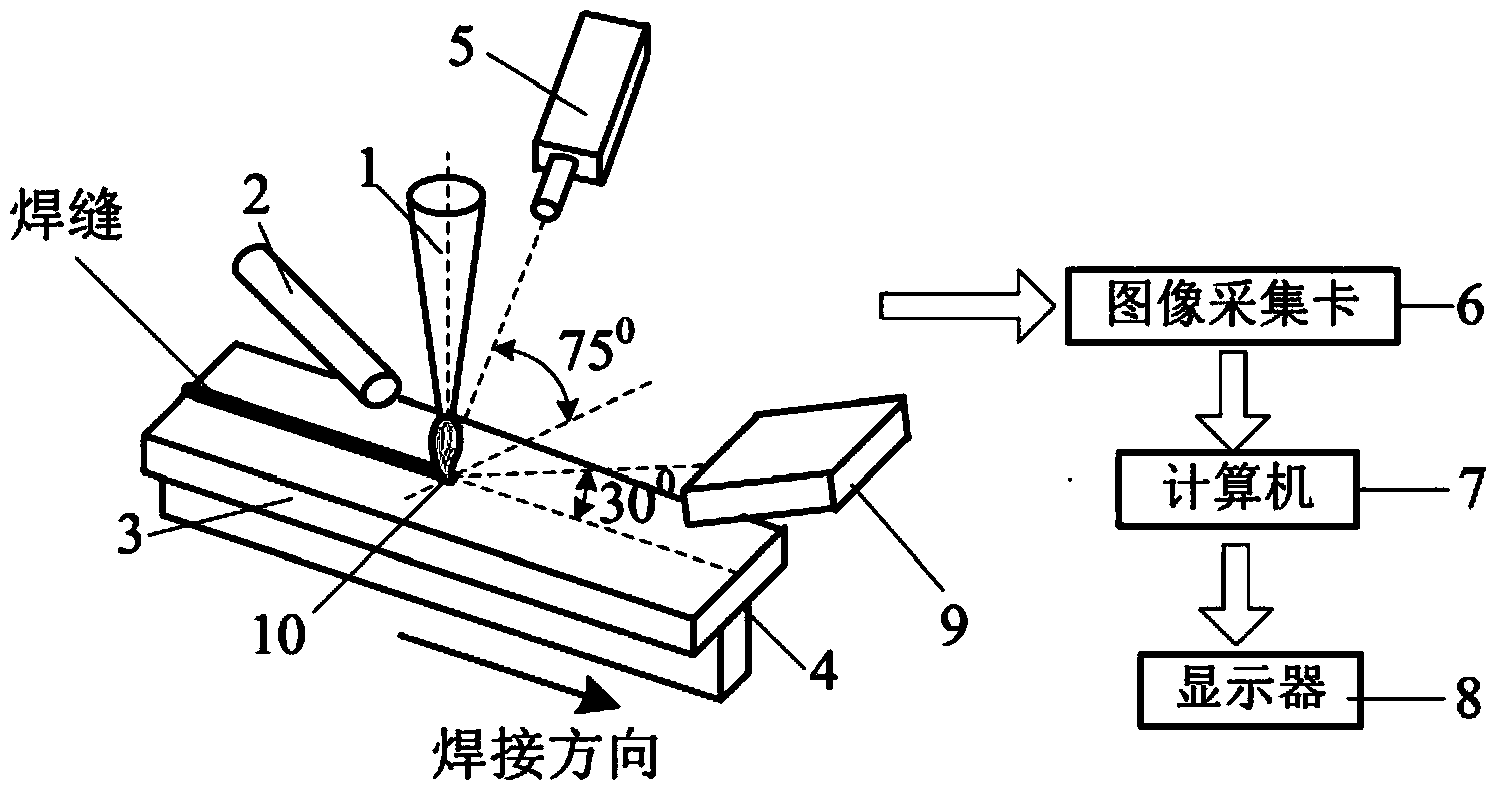

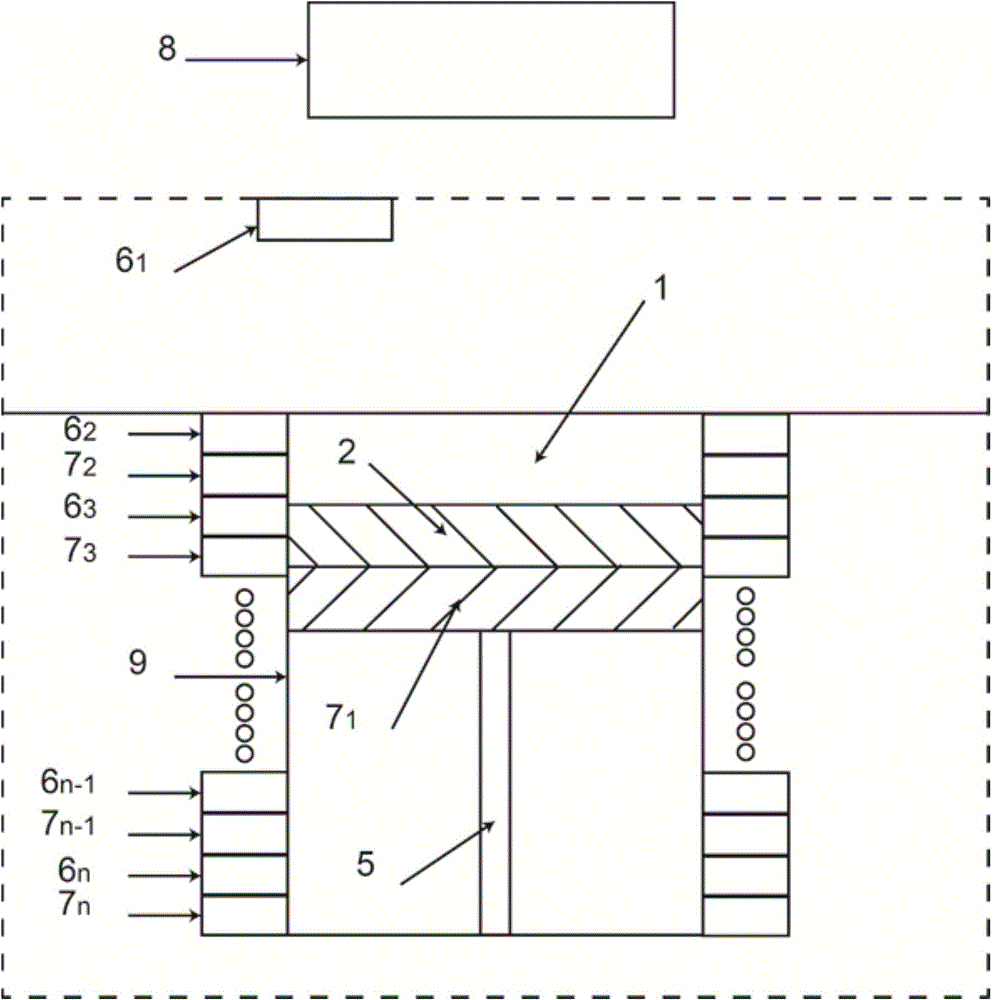

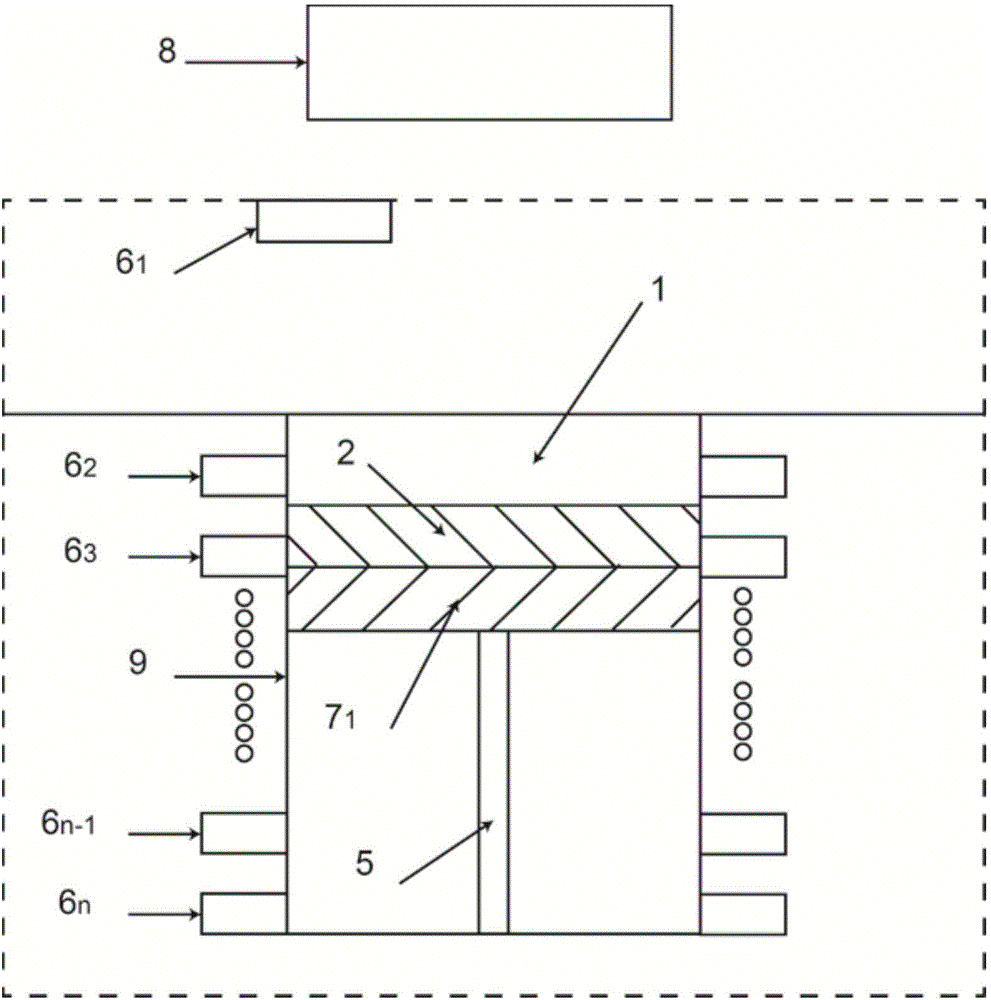

Narrow gap welding monitoring and welding line deviation detecting method based on infrared vision sensing

ActiveCN102814574AReduce volumeReduce power consumptionArc welding apparatusDisplay deviceEngineering

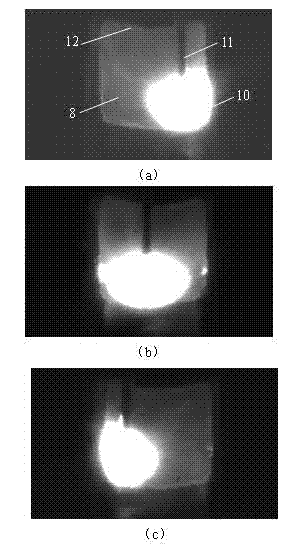

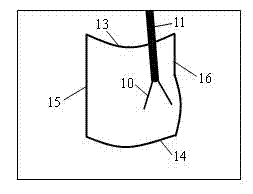

The invention discloses a narrow gap welding monitoring and welding line deviation detecting method based on infrared vision sensing and belongs to the technical field of welding. An infrared vision sensing system comprises an infrared complementary metal oxide semiconductor (CMOS) camera, a filtering system, an image collecting card, a computer, a display and the like. Narrow gap welding arc light and molten pool radiation light are used as a light source, an infrared narrow belt filtering system is used for filtering interference signals and adjusting light intensity, and the computer collects and displays a welding image obtained through the infrared CMOS camera. An image capturing window is used for capturing an image away from an arc side, the image is processed, welding line deviation information is obtained by extracting a groove single-side edge, and a real-time property of welding line deviation detecting is improved while arc noise is effectively avoided. The system is simple in formation, clear in monitored image, high in welding line deviation detecting precision, strong in anti-interference capacity and good in engineering practicality and can achieve the purposes of real-time monitoring of narrow gap welding and synchronous detecting of welding line deviation.

Owner:JIANGSU UNIV OF SCI & TECH

Laser welding control

In laser welding of metallic workpieces, the energetic beam is moved over the workpiece surface to form a pool of molten weld metal that quickly solidifies behind the advance of the laser into a weld nugget. The laser beam produces a keyhole of plasma-containing vapor within the molten pool. Weld nugget porosity, due to entrapment of the vapor, is minimized by continually sensing radiation from the molten metal pool to determine pool depth and width and then controlling laser power and speed to continually produce a weld metal pool wide enough for the liquid to fully expel the vapor and solidify into a pore free nugget.

Owner:GENERAL MOTORS COMPANY

Method with functions of preheating and postheating for forming crack-free coating with high efficiency by three-light-beam laser-cladding technique

InactiveCN102383126ALow and adjustable dilution rateSmall heat affected zoneMetallic material coating processesLaser beam welding apparatusMelting tankHeat-affected zone

The invention discloses a method with functions of preheating and postheating for forming crack-free coating with high efficiency by a three-light-beam laser-cladding technique. The method comprises the following steps of: splitting a laser beam emitted by an Nd: YAG laser into two laser beams by using a laser beam splitter, namely a preheating laser beam for preheating the surface of a base material and a postheating laser beam for postheating the formed coating; then blowing alloy powder into a molten pool which is formed by focusing a laser beam emitted by a CO2 laser and acting the focused laser beam on the surface of the base material by using a powder nozzle, wherein after the CO2 laser beam moves away, a molten layer is cured and crystallized quickly to form the coating; and postheating the formed coating by adopting the postheating laser beam. The method has the advantages that: (1) the dilution rate of the coating is low and adjustable, and the coating is metallurgically combined with the base material, so the base material has a small thermal influence area and is deformation-free and crack-free; (2) residual inner stress in the coating can be eliminated effectively, a tissue can be improved, and the coating has high abrasion resistance, high corrosion resistance, high anti-cracking performance and high thermal shock resistance; and (3) relative to the processing efficiency in the conventional laser cladding technology, the processing efficiency in the method can be improved by 50 times to the maximum extent, so the processing cost is reduced greatly, and a large-scale industrialized application potential is realized.

Owner:NANCHANG HANGKONG UNIVERSITY

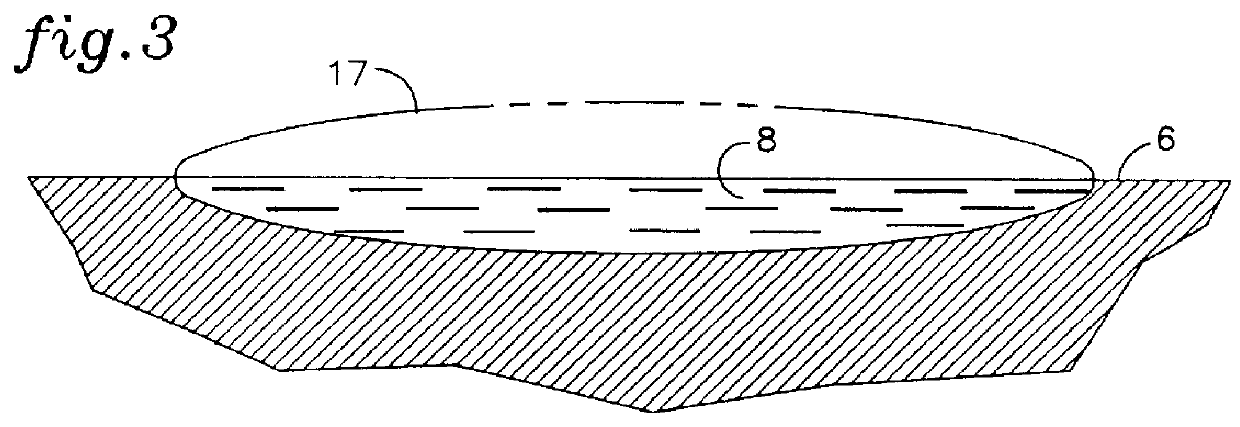

Crack free metallic articles

InactiveUS6103402AReduce material stressReduce solidificationTurbinesBy zone-melting liquidsCrazingClosed loop

A containerless method of producing a crack free metallic article of near-net shape includes melting a filler material into a metallic substrate or seed under conditions chosen to preclude cracking. In a preferred embodiment of the invention, a laser beam is operated at a relatively low power density and at a relatively large beam diameter at the substrate surface for an extended length of time to produce a molten pool with a low aspect ratio. Near-net shape is achieved by applying the process in a closed-loop, multi-axis material deposition system.

Owner:UNITED TECH CORP

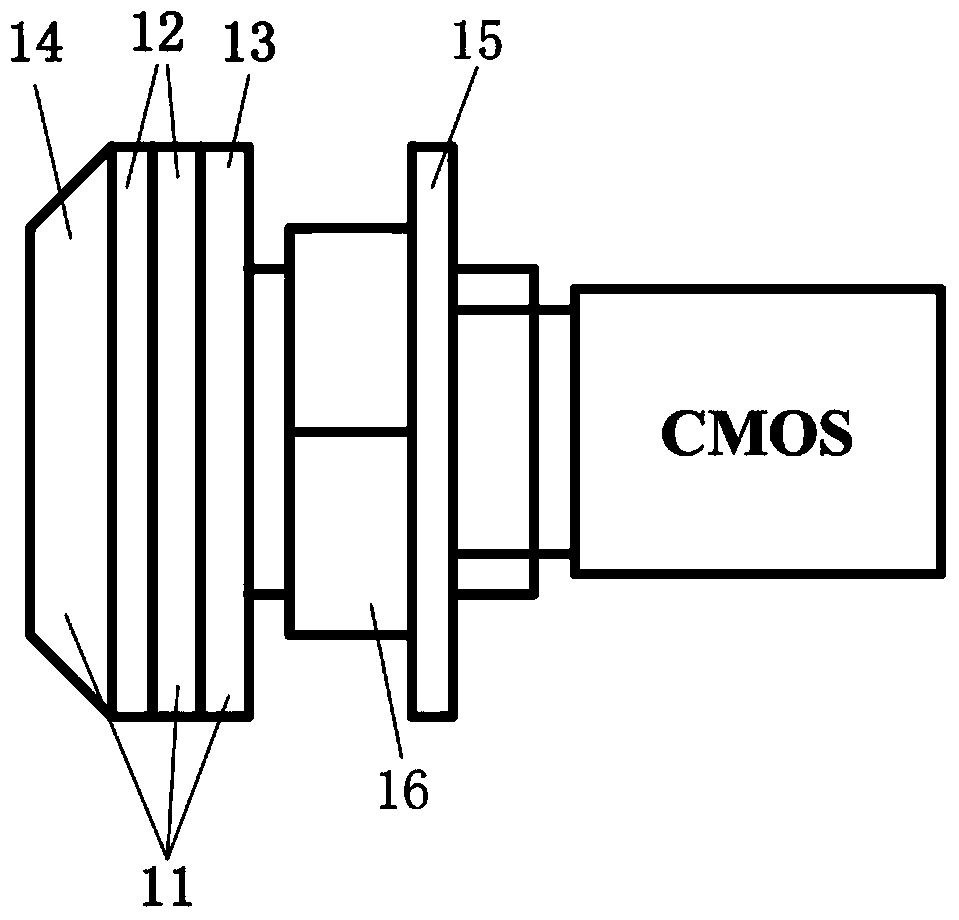

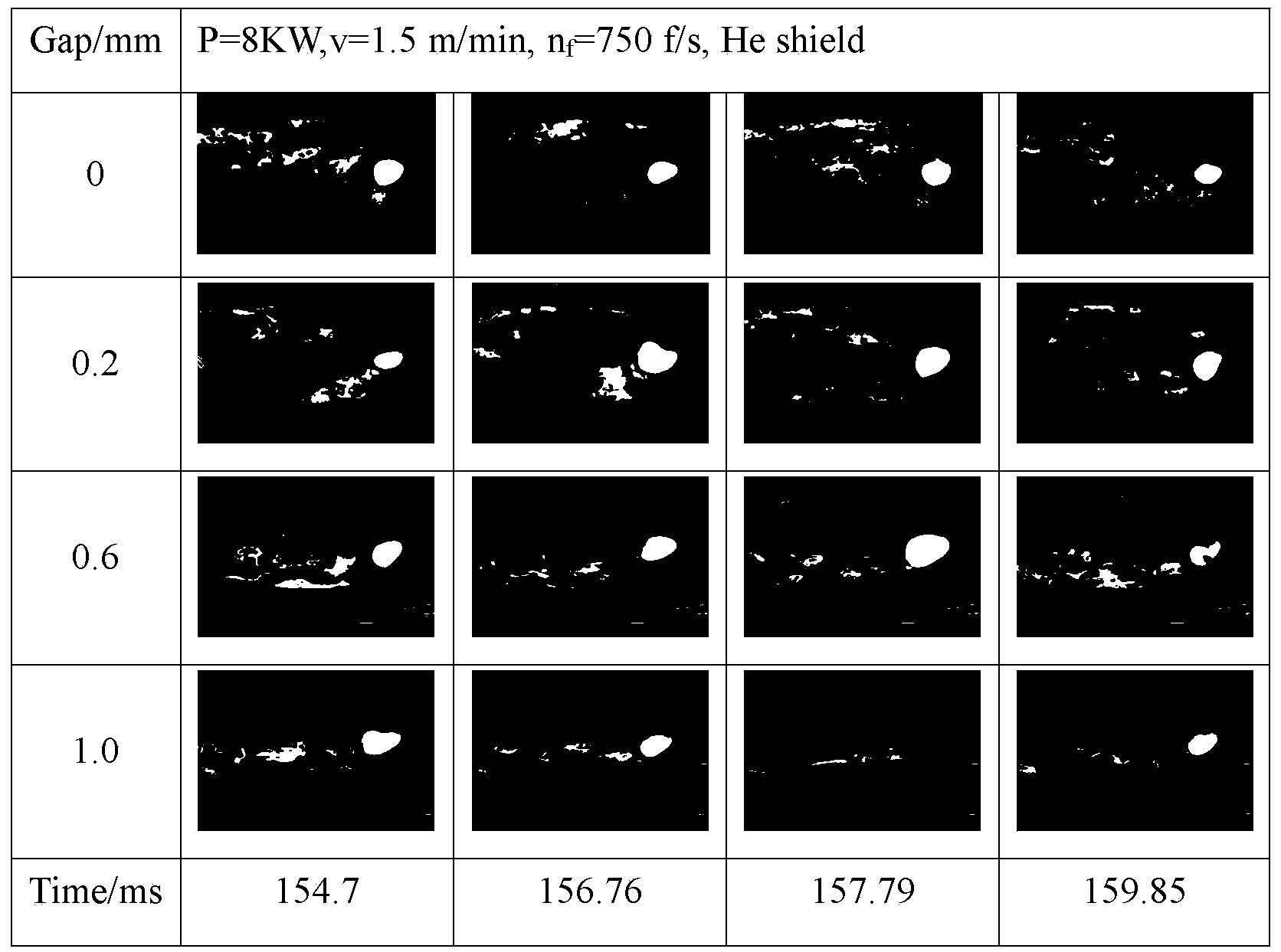

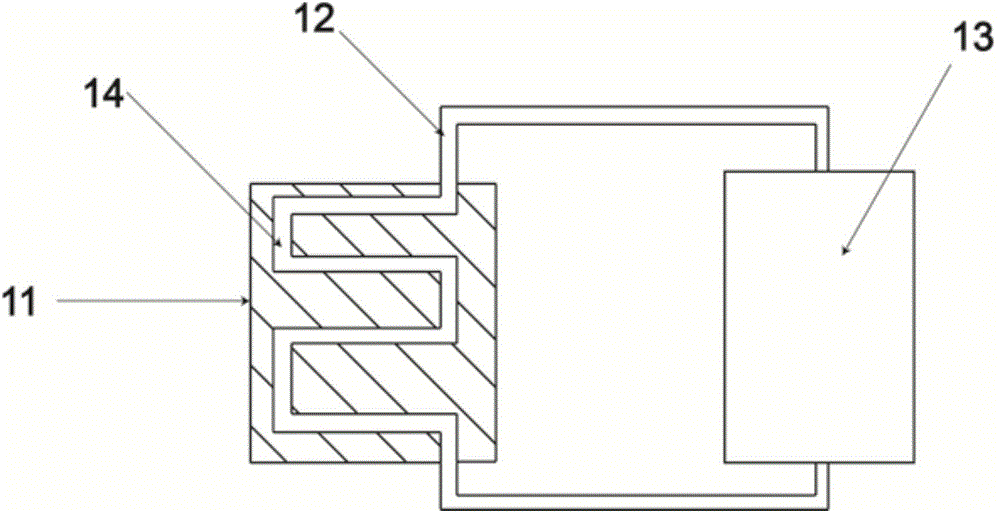

Laser lap welding gap detecting system and laser lap welding gap detecting method based on molten pool image visual sensing

ActiveCN103506756AMeet the requirements of seam trackingImprove quality and efficiencyLaser beam welding apparatusAnti jammingDisplay device

The invention discloses a laser lap welding gap detecting system and a laser lap welding gap detecting method based on molten pool image visual sensing. The detecting system is a visual sensing system and comprises a CMOS camera, a light filtering system, a secondary light source, an image capture card, a computer, a display and the like, wherein the CMOS camera has a LinLog photosensory technology. According to the detecting method, the secondary light source and emitted light of molten pools are used as light sources; plasma is filtered out by utilizing the light filtering system, and light intensity is adjusted; the computer is used for collecting and displaying molten pool images in real time, wherein the molten pool images are obtained by the CMOS camera; molten pool image edges and areas and orifice image edges and areas are extracted and calculated by utilizing a Labview image processing platform, and the quantitative relations between molten pool sizes and orifice areas and between the molten pool sizes and orifice gaps are obtained. The detecting system is simple in structure, clear in monitoring image, high in light signal detecting accuracy, strong in anti-jamming capacity, good in engineering practicability and capable of monitoring laser welding of T-type overlap joint gaps in real time.

Owner:SHANGHAI JIAO TONG UNIV

Induction heated, hot wire welding

InactiveUS20100059493A1Prevent heat lossImprove thermal shock resistanceArc welding apparatusLaser beam welding apparatusEngineeringElectric resistivity

A hot wire welding process. An induction coil is used to preheat the filler metal wire prior to its entering the welding puddle / arc region. An induction coil is placed in close proximity to the welding arc. The filler wire is guided and supported by a delivery guide so that the filler wire passes through the center of, and is insulated from, the induction coil. The induction coil induces a current flow in the filler wire. The current produces heat as a result of the electrical resistivity of the filler wire. The heat produced raises the temperature of the filler wire just before it is fed into the weld arc region, thus reducing the energy required from the welding arc to melt the filler metal wire into the weld puddle.

Owner:BABCOCK & WILCOX TECHNICALSERVICES GRP INC

High energy beam area-selecting fusing method and device capable of controlling temperature gradient in shaping area

ActiveCN104959604AEnsure directional solidification conditionsReal-time monitoring of temperature gradientsAdditive manufacturing apparatusTemperature controlHeat flow

The invention discloses a high energy beam area-selecting fusing method and device capable of controlling temperature gradient in a shaping area, and a temperature measurement module and a temperature control module are added to a shaping assembly of the device. When the device is used for manufacturing high-energy beam additive, the temperature gradient interval in a molten pool can be calculated in real time utilizing the boundary temperature, acquired by the temperature measurement module, of a shaping area, proper hot-fluid conditions can be applied to the shaping area through the temperature control module to control temperature gradient intervals of the molten pool and the shaping area, so the molten pool can always satisfy conditions of directional solidification, high precision and performance directional solidified metal members and monocrystalline metal members having different sizes and structures can be efficiently manufactured. By adopting the high energy beam area-selecting fusing method and device capable of controlling the temperature gradient in a shaping area, not only the temperature gradient of the shaping area can always satisfy directional solidification conditions, but also the temperature gradient distribution in stages of a shaping process can be flexibly changed according to actual process needs, so various of functional / structural gradient members can be manufactured.

Owner:HUAZHONG UNIV OF SCI & TECH

Welding wire sending and pulverized solder sending laser cladding forming method and device

InactiveCN101733550AIncrease peripheral light intensityOvercoming the deficiency of undermeltingLiquid spraying apparatusWelding/cutting media/materialsLight beamLaser beams

The invention discloses a welding wire sending and pulverized solder sending laser cladding forming method. The method is characterized in that a conscope is used to change a solid laser beam transmitted by a laser to an annular light beam through light path transformation, then an annular focus lens is used to focus the annular light beam to an annular conical light beam, a hollow conical aphotic zone is formed in the annular conical light beam, a welding wire sending and pulverized solder sending protective gas composite nozzle is arranged in the aphotic zone and has the same axis of the annular conical light beam, a welding wire sending hole is arranged in the center, parallel pulverized solder sending holes are around the welding wire sending hole, collimating protective gas holes are parallel to and around the pulverized solder sending holes, wire is sent to a molten pool through the welding wire sending hole along the axial direction of the light beam and vertically to a machining face, airborne pulverized solder is sent to the molten pool through the pulverized solder sending holes at the same time, and collimating protective gas surrounds the welding wire and pulverized solder and is blown to the molten pool. The invention adopts the welding wire sending and pulverized solder sending protective gas composite nozzle to realize welding wire, pulverized solder and protective gas composite cladding and solve the defects of the prior art.

Owner:SUZHOU UNIV

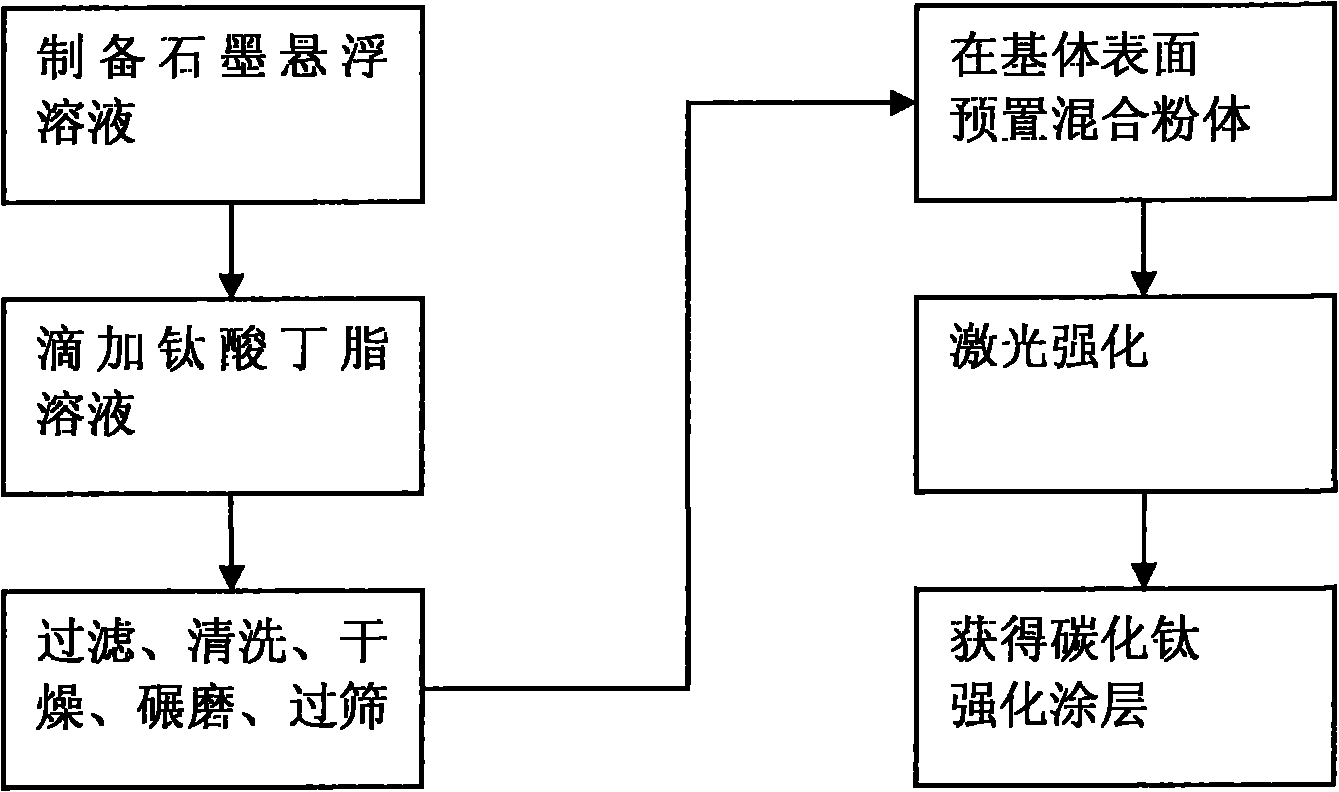

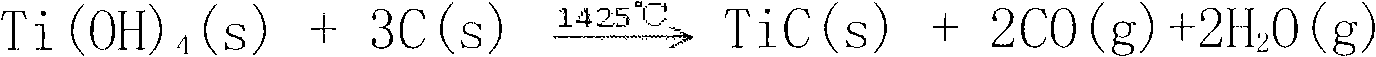

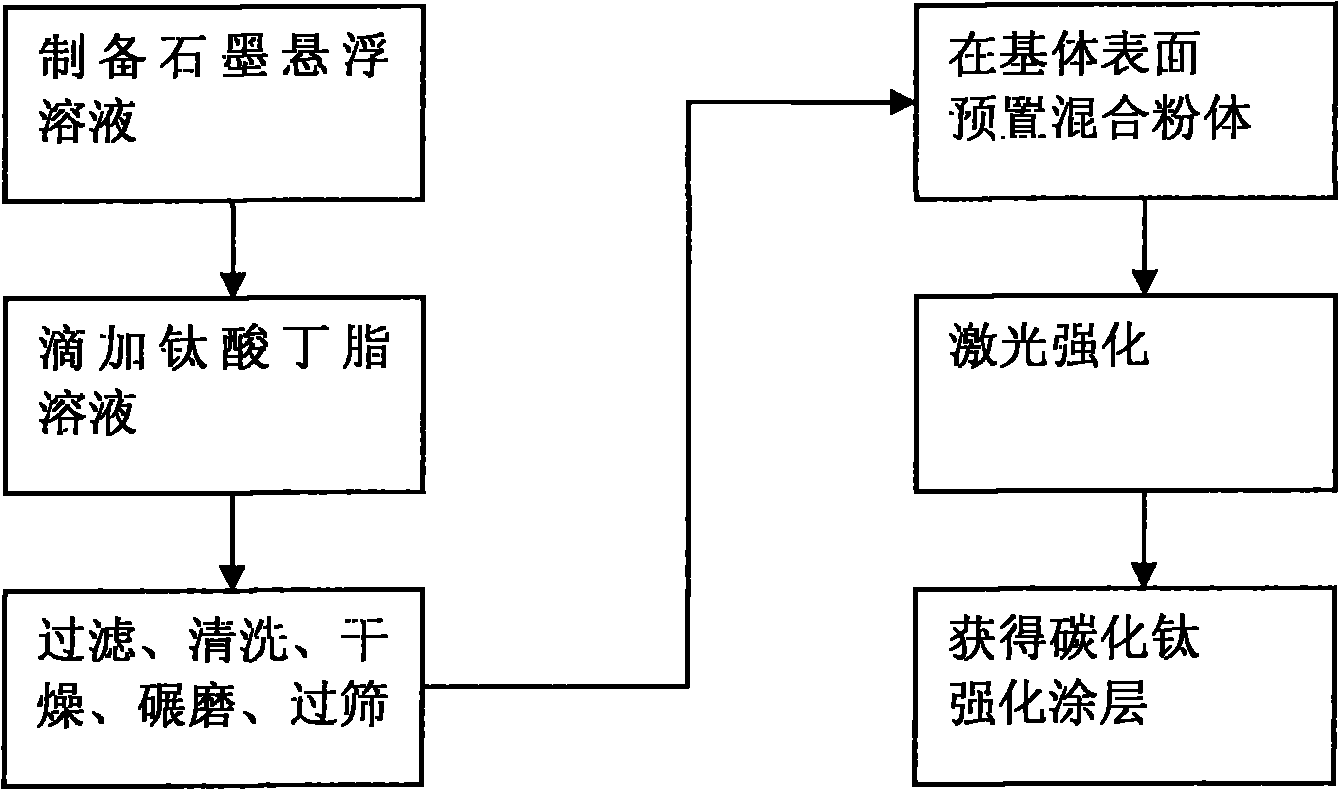

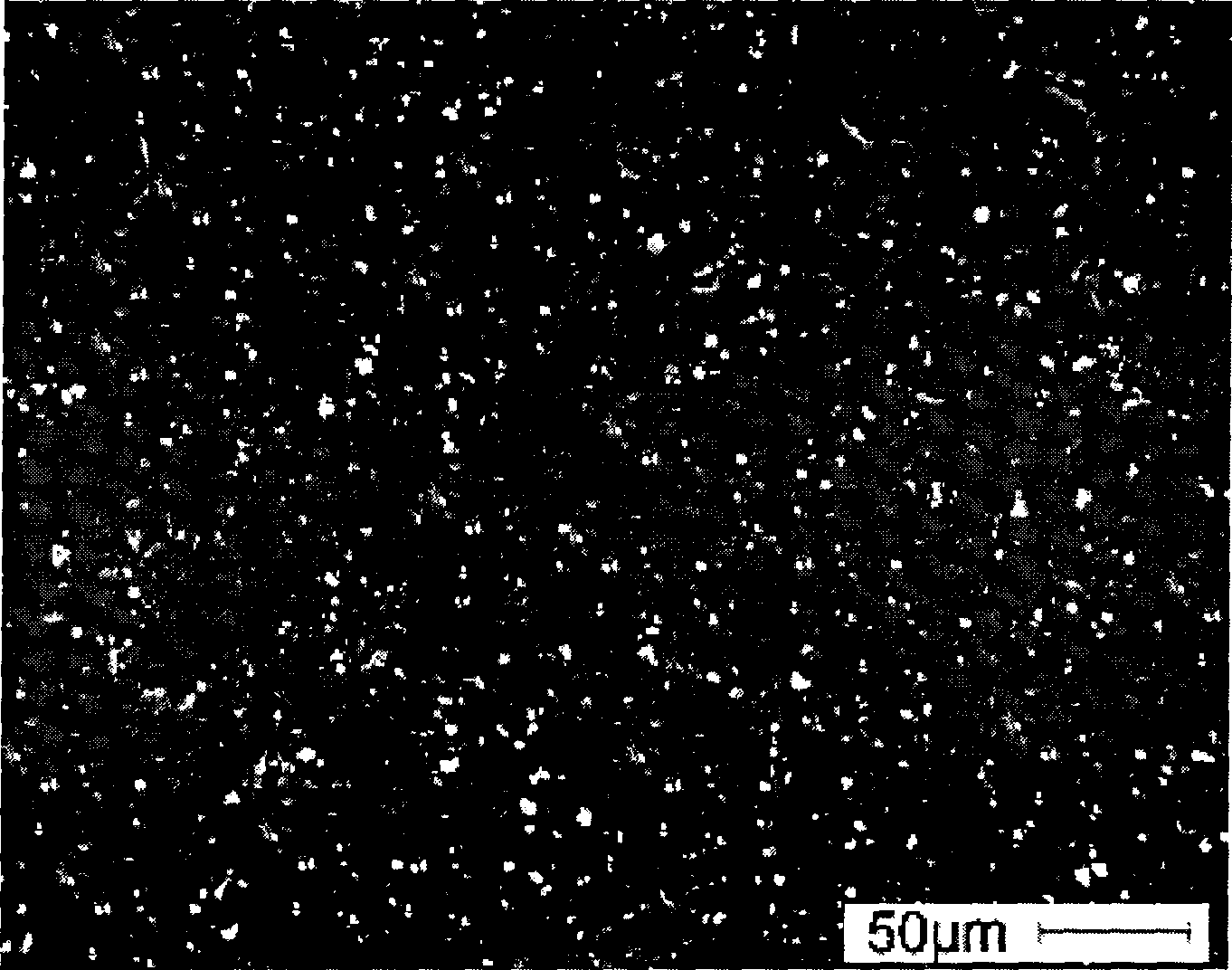

Method for preparing metal surface laser strengthened coat

InactiveCN101812684AIncrease profitImprove the strengthening effectMetallic material coating processesChemical reactionArgon atmosphere

The invention discloses a method for preparing a metal surface laser strengthened coat, which comprises the following steps: preparing uniformly mixed powder of titanium dioxide hydrate and graphite powder by using a wet chemistry method; pre-placing the mixed powder on the surface of a basal body; and irradiating the surface of the basal body by using laser as a heat source under an argon atmosphere to form a molten pool, performing a carbon-thermal chemical reaction on the pre-placed mixed powder under a high-temperature environment to generate titanium carbide, and finally forming a titanium carbide composite coat on the surface of the basal body. In the same way, the method is also suitable for preparing a TiN enhanced composite coat by mixing hydrated oxide thereof and graphite by the wet chemistry method, then mixing the mixture and urea to form pre-placed powder and cladding the pre-placed powder on the basal body by laser. The surface of the enhanced coat prepared by the technical scheme is smooth, and has no cracks or pores; enhancing particles are uniformly distributed in the coat; the enhanced coat and the basal body are metallurgically combined; and the mixed powder prepared by adopting the wet chemistry method is uniformly mixed, ensures complete reaction, and is suitable for industrial popularization and application.

Owner:姚建华

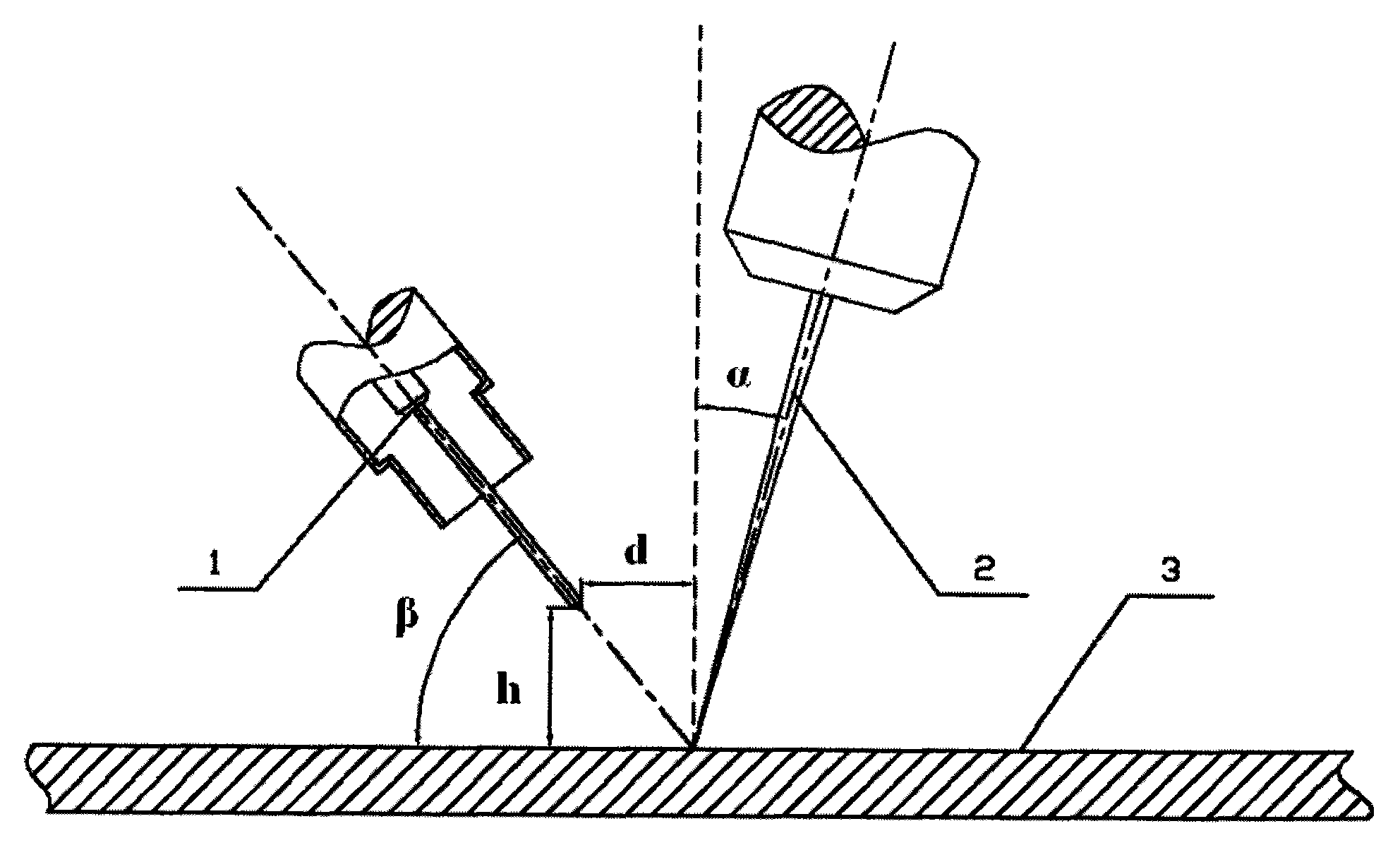

Laser-TIG electric arc hybrid welding technology for spaceflight aluminum alloy plate with medium thickness and high strength

InactiveCN101670495AIncrease profitReduce metallurgical damageLaser beam welding apparatusSpaceflightLaser beams

The invention discloses a laser-TIG electric arc hybrid welding technology for a spaceflight aluminum alloy plate with medium thickness and high strength and belongs to the technical field of weldingengineering. In the hybrid welding technology, a non-consumable TIG electric arc and laser beams emitted by a optical fiber laser are gathered at the same welding position on a workpiece along weldingdirection so as to jointly form a molten pool; when in welding, the laser beams are in the front and the non-consumable TIG electric arc is in the back; the distance form between the focus of the laser beams and the workpiece is sharp defocus, a dip angle between the laser beams and vertical direction is 15-17 degrees, the vertical distance from the tungsten electrode point end of the TIG electric arc to the surface of the workpiece is 3-5mm, the horizontal distances between the tungsten electrode point end of the TIG electric arc and from the laser beams to an action point on the surface ofthe workpiece are 3-5mm, and a dip angle between the tungsten electrode point end of the TIG electric arc and the horizontal direction of the workpiece is 45-55 degrees. The hybrid welding technologynot only improves the utilization ratio of laser energy, but also obviously enhances welding speed, and reduces metallurgical damage of a spaceflight aluminum alloy welding joint with high strength.

Owner:BEIJING UNIV OF TECH

Electron beam layer manufacturing

ActiveUS8546717B2Obstruct passageProgramme controlAdditive manufacturing apparatusFree formClosed loop

A process and apparatus for free form fabrication of a three-dimensional work piece comprising (a) feeding raw material in a solid state to a first predetermined location; (b) depositing the raw material onto a substrate as a molten pool deposit under a first processing condition; (c) monitoring the molten pool deposit for a preselected condition; (d) comparing information about the preselected condition of the monitored molten pool deposit with a predetermined desired value for the preselected condition of the monitored molten pool deposit; (e) solidifying the molten pool deposit; (f) automatically altering the first processing condition to a different processing condition based upon information obtained from the comparing step (d); and repeating steps (a) through (f) at one or more second locations for building up layer by layer a three-dimensional work piece. The apparatus is characterized by a detector that monitors a preselected condition of the deposited material and a closed loop electronic control device for controlling operation of one or more components of the apparatus in response to a detected condition by the detector.

Owner:SCIAKY SA

Warhead with integral, direct-manufactured features

InactiveUS20050235862A1Improve functionalityImprove permeabilityAmmunition projectilesAdditive manufacturing apparatusManufacturing technologyHigh energy

Owner:LOCKHEED MARTIN CORP

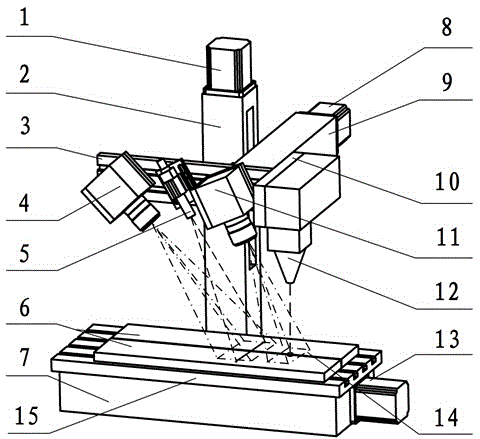

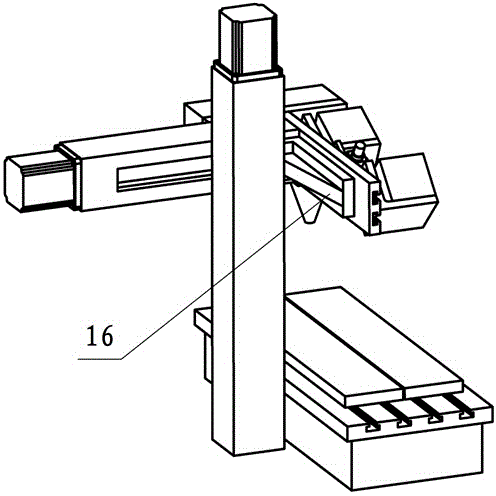

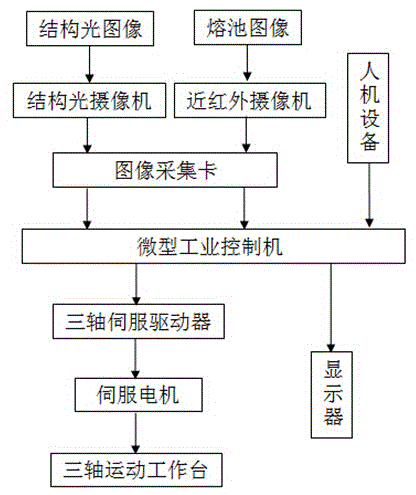

Dual-wavelength binocular vision seam tracking method and tracking system

ActiveCN104942404AAccurate measurementOvercoming strong arcArc welding apparatusReconstruction algorithmVisual perception

The invention discloses a dual-wavelength binocular vision seam tracking method. The method comprises the steps including image acquisition, data processing, seam tracking and the like. The invention further discloses a tracking system for implementing the method. The system adopts a near-infrared and structured light dual-wavelength binocular vision sensing system, images of a molten pool and different wavelengths of seam area images with of seams are measured simultaneously and transmitted to a miniature industrial control computer, and the seam positions are measured accurately with a multi-information fusion algorithm and a seam image three-dimensional reconstruction algorithm; the miniature industrial control computer adopts the Kalman filter algorithm to perform optimal estimation on the seam tracking deviation state according to a seam position detection result, a servo driver drives a servo motor to move so as to control a 3-axis motion workbench to generate corresponding motion, a welding torch or a laser head is controlled for deviation correction, and the seams are tracked accurately. The system can eliminate hard light, splashing and electromagnetic interference on a welding site and improve the seam tracking accuracy and reliability.

Owner:GUANGDONG UNIV OF TECH +1

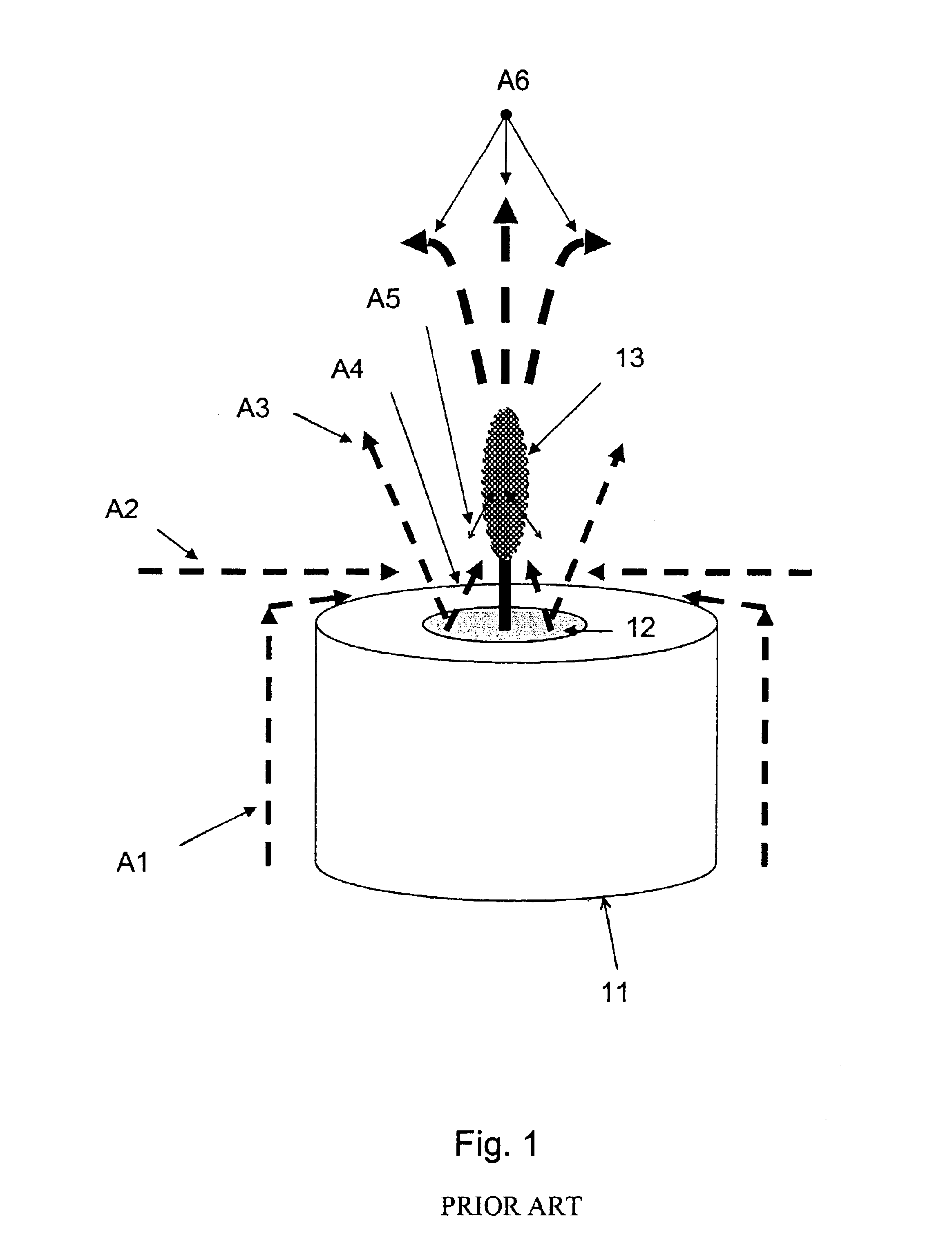

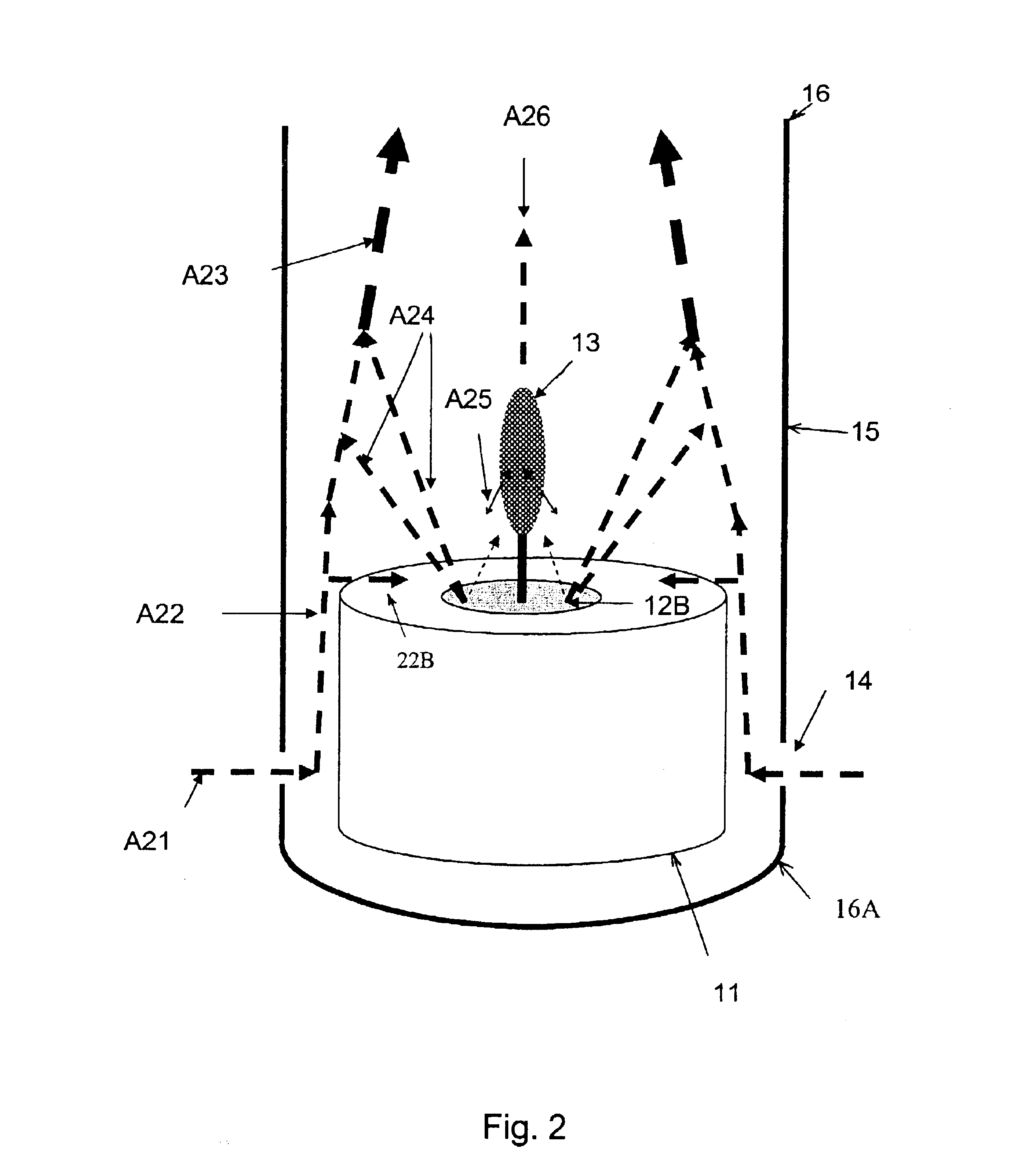

Method for improving the delivery of volatiles from a burning candle and a system for the same

InactiveUS6849240B2Reduce deliveryMinimizing combustionCapillary burnersFire rescueEngineeringAtmosphere

The invention provides a system and a method for improving the delivery of volatiles from a burning candle by providing a stabilized laminar gas flow adjacent a volatile-containing molten pool, ensuring an enlarged molten pool by close regulation of thermal transfer between a monolithic candle mass and the surrounding atmosphere, and minimizing volatile loss through unregulated thermal gradients.

Owner:INT ART & SCI GRP

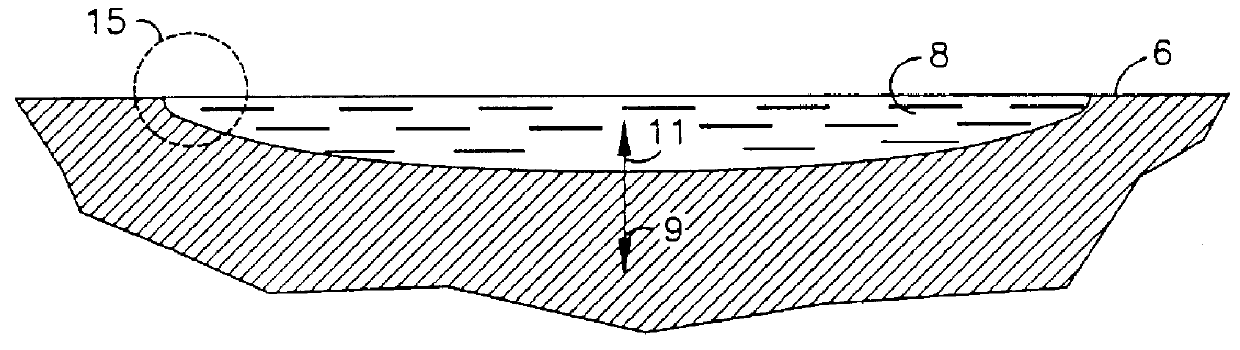

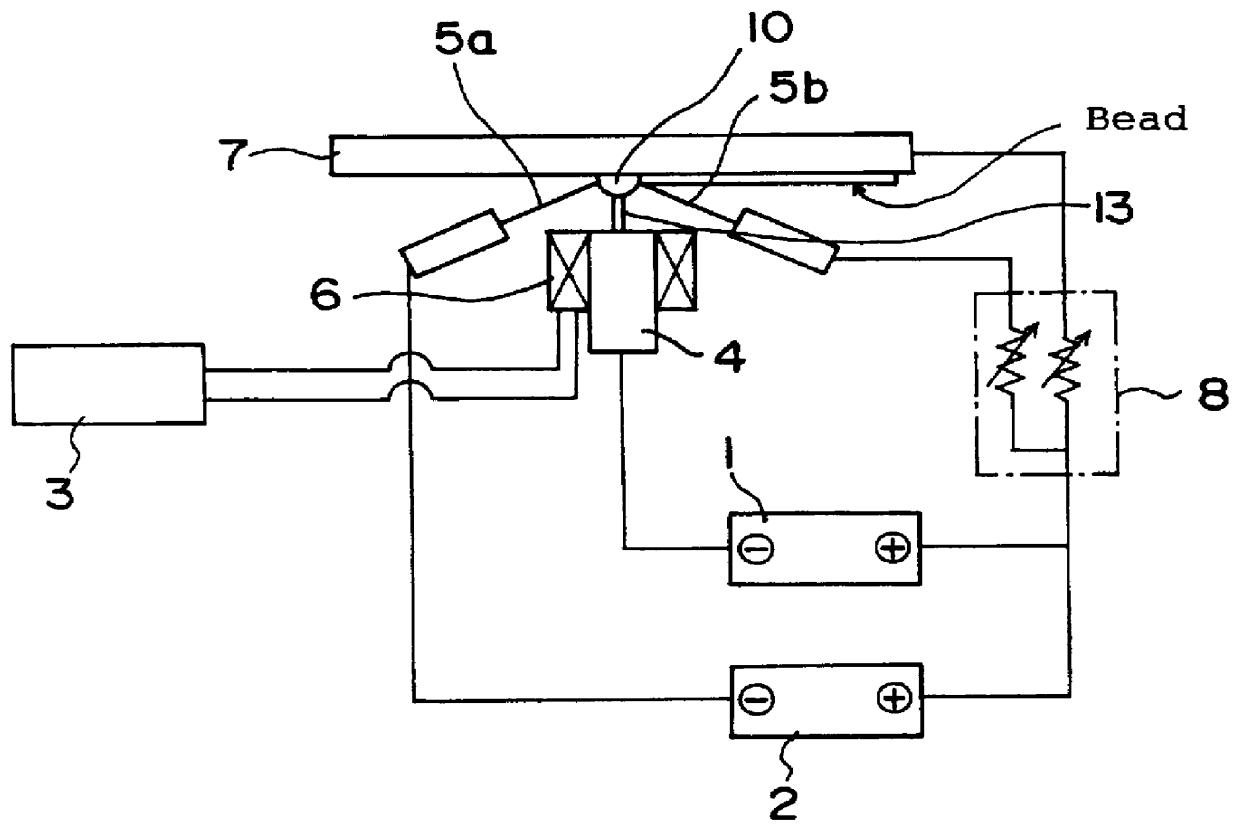

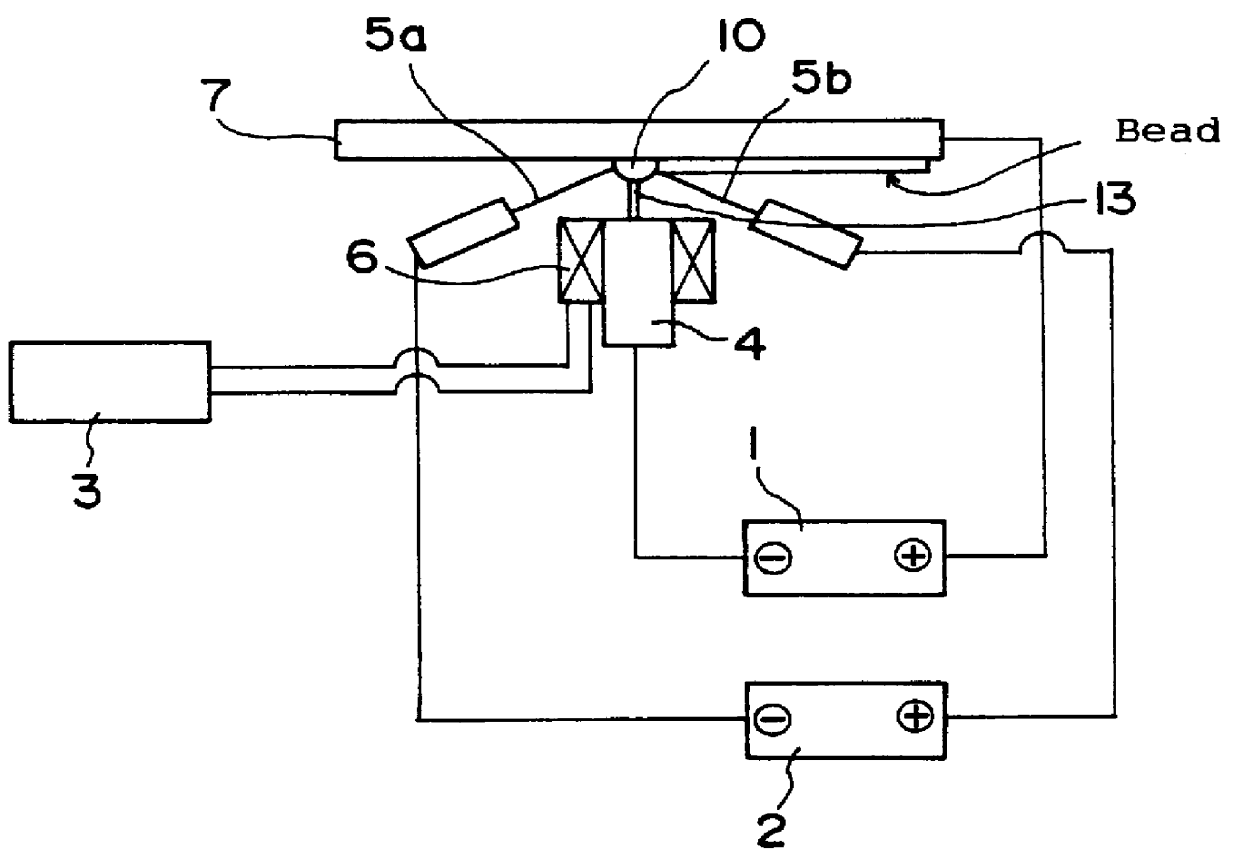

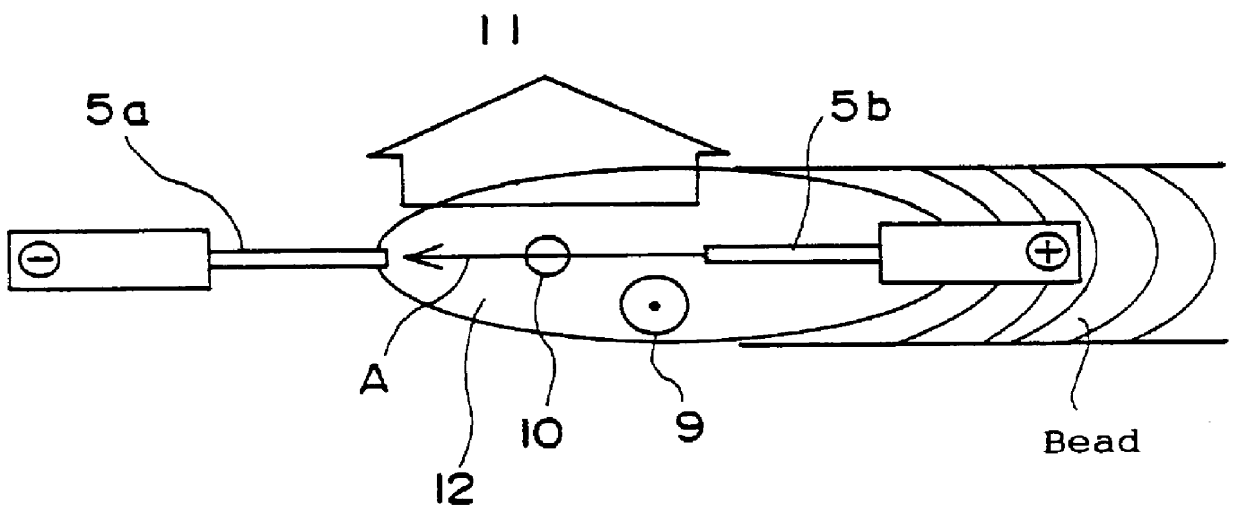

Method of welding in the horizontal position and welding apparatus therefor

InactiveUS6023043ABetter-shaped beadWelding/cutting auxillary devicesArc welding apparatusEngineeringWelding defect

PCT No. PCT / JP97 / 01533 Sec. 371 Date Jan. 12, 1998 Sec. 102(e) Date Jan. 12, 1998 PCT Filed May 7, 1997 PCT Pub. No. WO97 / 43073 PCT Pub. Date Nov. 20, 1997The object of this invention is to prevent the occurrence of welding defects such as undercuts, overlaps and faulty angles of fusion, and to increase the efficiency of welding in the horizontal position. Auxiliary wires 5a and 5b are inserted into molten pool 12, and a unidirectional current is made to flow between them. A magnetic field 9 is induced which is approximately orthogonal to the surface of the parent material so as to generate an upward Lorentz force (opposite the pull of gravity) in molten pool 12. This force supports the molten metal and prevents it from dripping, resulting in a better-shaped bead.

Owner:MITSUBISHI HEAVY IND LTD

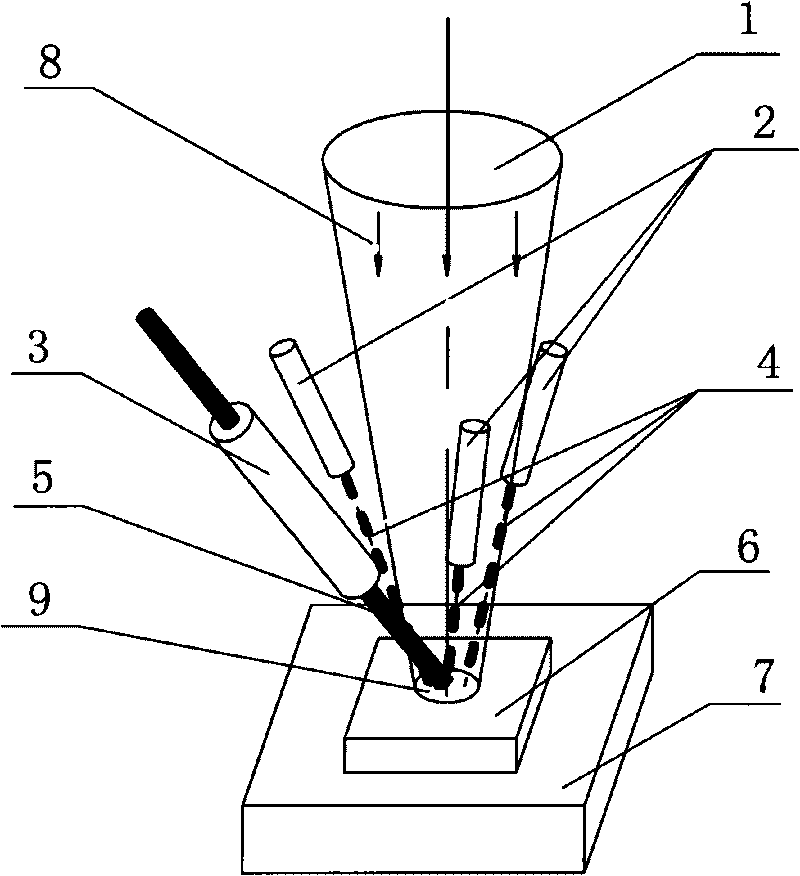

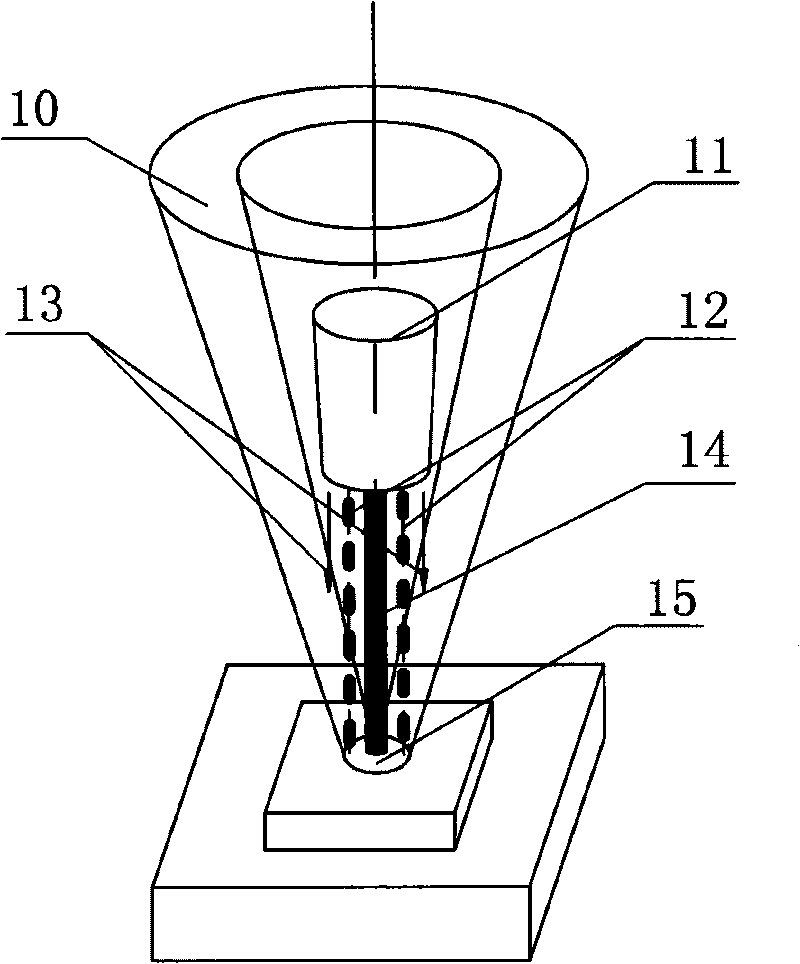

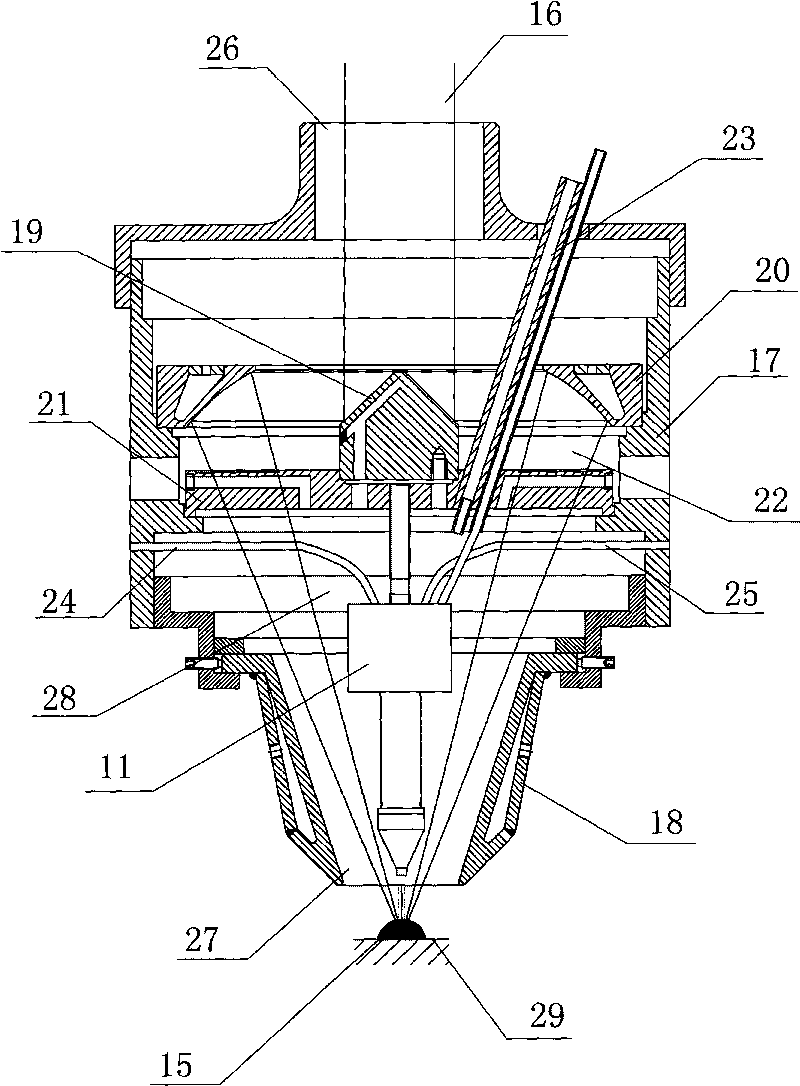

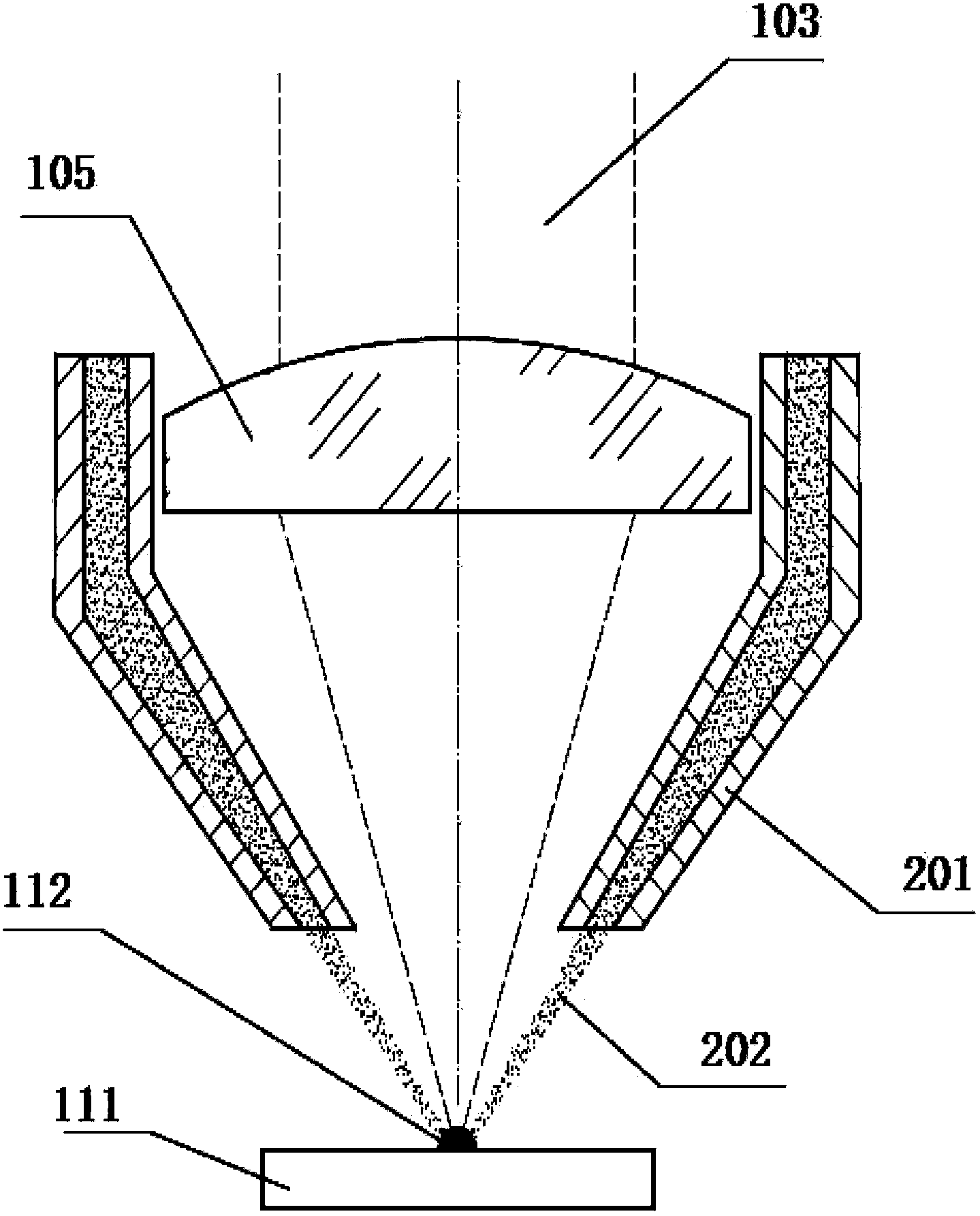

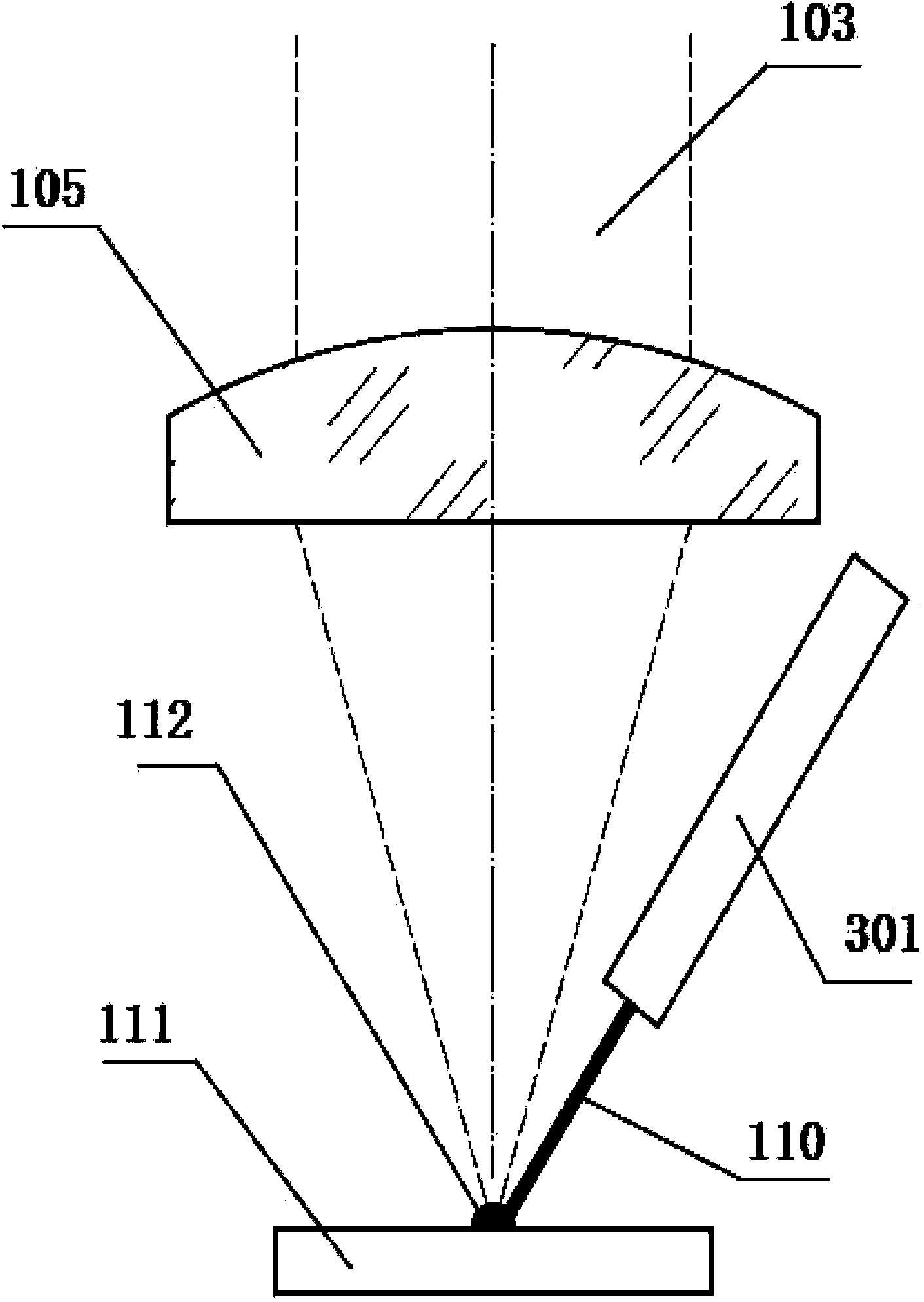

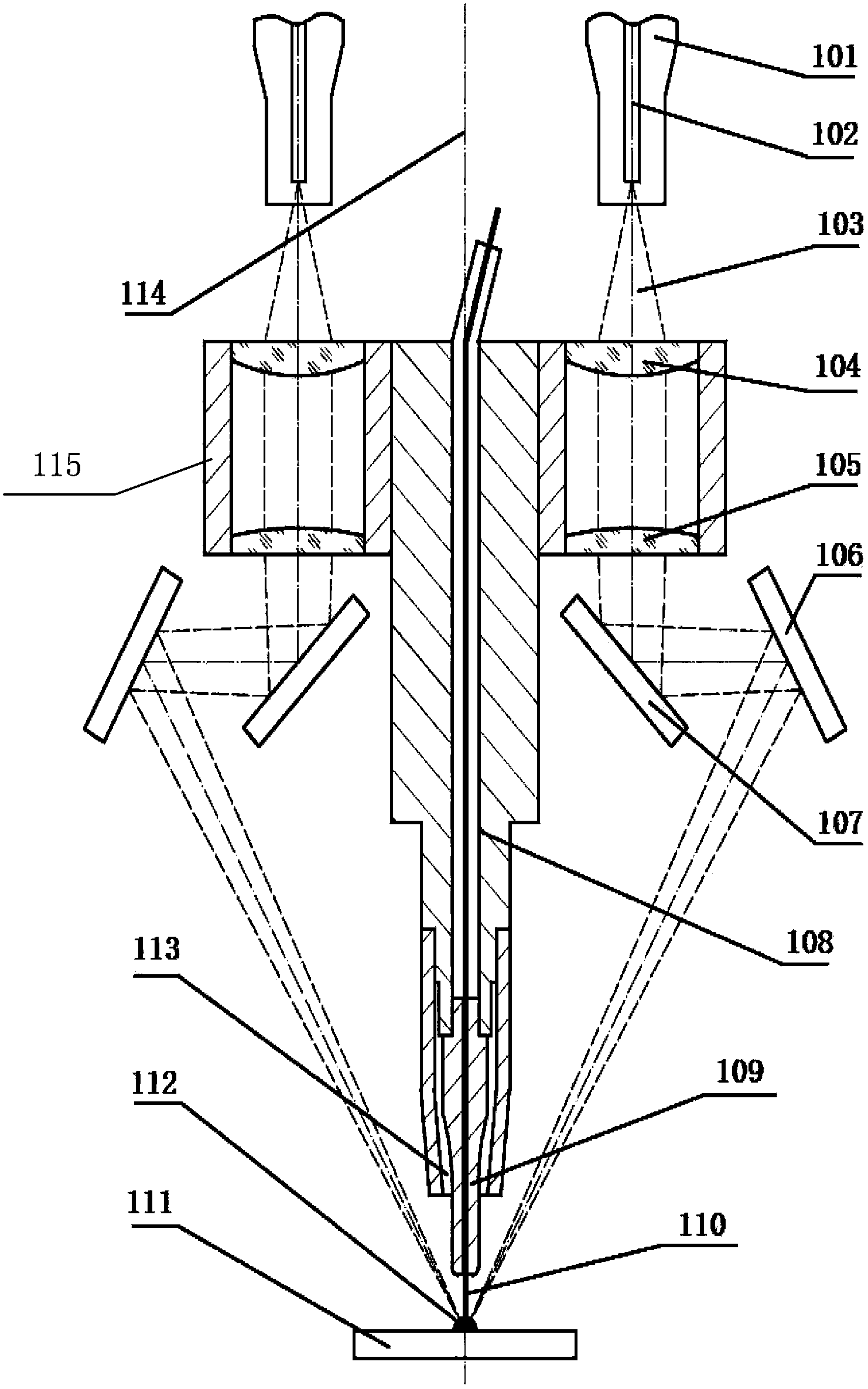

Multi-beam center wire feeding laser processing head and processing method thereof

InactiveCN104289811AEnsure consistencyEvenly heatedLaser beam welding apparatusOptical ModuleLaser processing

The invention belongs to the field of laser processing, in particular to a multi-beam center wire feeding laser processing head and a processing method of the multi-beam center wire feeding laser processing head. The laser processing head comprises a wire feeding tube, a wire feeding nozzle and a plurality of identical optical modules, wherein the wire feeding tube and the wire feeding nozzle are located on the center axis of the laser processing head, the optical modules are rotationally and symmetrically distributed around the center axis, each optical module comprises a collimating lens set, a focusing lens set and a reflecting mirror set, lasers are transmitted to the processing head through a plurality of paths of optical fibers, a plurality of laser beams are focused on one point of the surface of a workpiece to form a molten pool after being collimated, focused and reflected by the optical modules, a metal wire is perpendicularly fed into the molten pool on the surface of the workpiece through the fire feeding nozzle, and the laser processing head moves on the surface of the workpiece according to a certain track so that the center wire feeding laser processing process can be achieved. Through the multi-beam center wire feeding laser processing head, center wire feeding in laser focusing light spots in circular symmetry distribution is achieved, and the processing quality consistency is guaranteed when the laser processing head moves in different directions.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

Electron beam layer manufacturing using scanning electron monitored closed loop control

ActiveUS8598523B2Avoid oversaturationConstant widthAdditive manufacturing apparatusMaterial analysis using wave/particle radiationClosed loopTrailing edge

A process (and apparatus for performing the process) for layer manufacturing a three-dimensional work piece comprising the steps of: feeding raw material in a solid state to a first predetermined location; exposing the raw material to an electron beam to liquefy the raw material; depositing the raw material onto a substrate as a molten pool deposit, the deposit having a forward edge region in an x-y plane with a forward edge region width and a trailing edge region in the x-y plane with a trailing edge region width, under at least one first processing condition; monitoring the molten pool deposit for at least one preselected condition using detecting of scatter from a scanning electron beam contemporaneously with the depositing step; solidifying the molten pool deposit; automatically altering the first processing condition to a different processing condition based upon information obtained from the comparing step; and repeating steps at one or more second locations for building up layer by layer, generally along a z-axis that is orthogonal to the x-y plane, a three-dimensional work piece.

Owner:SCIAKY SA

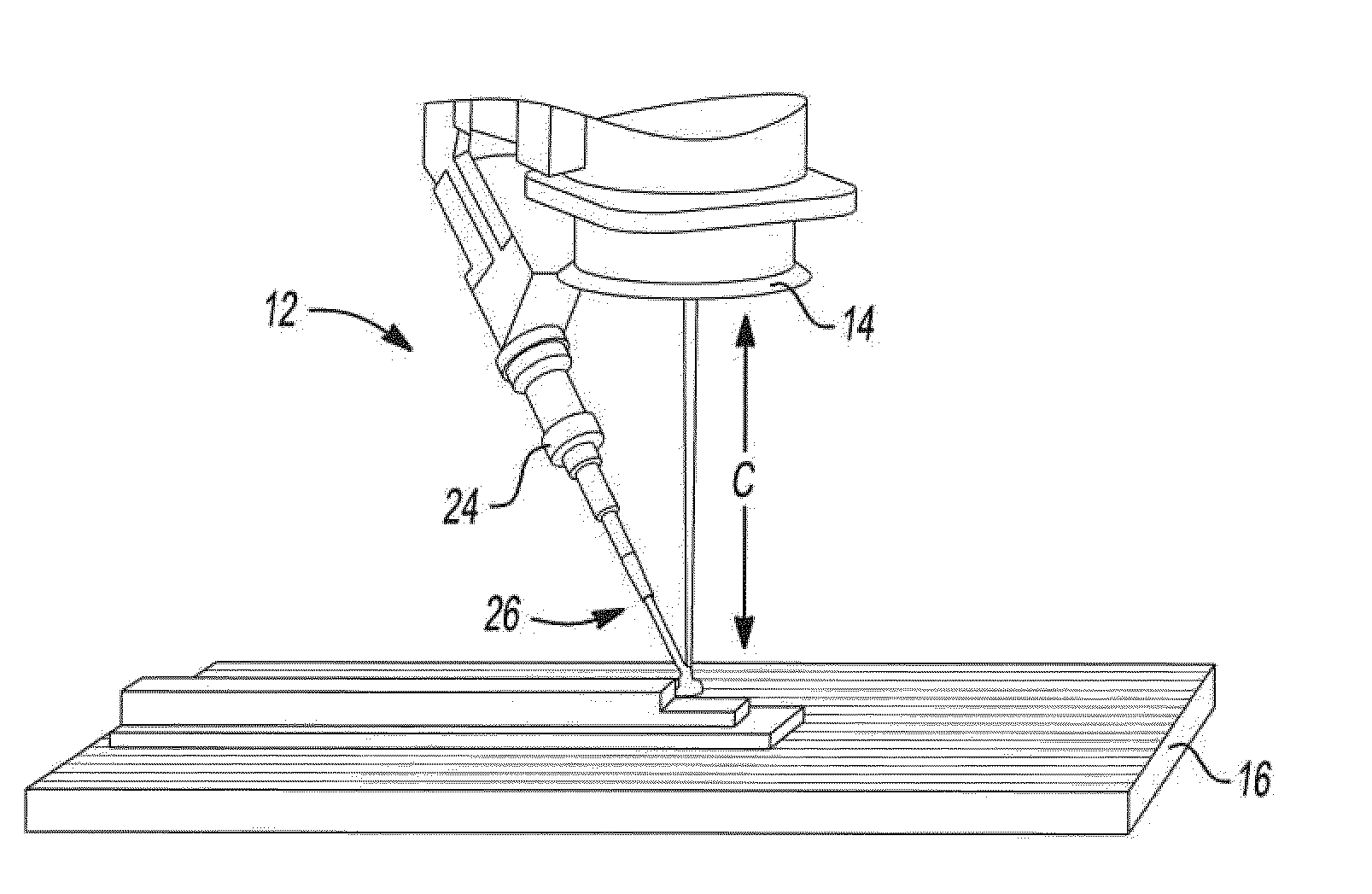

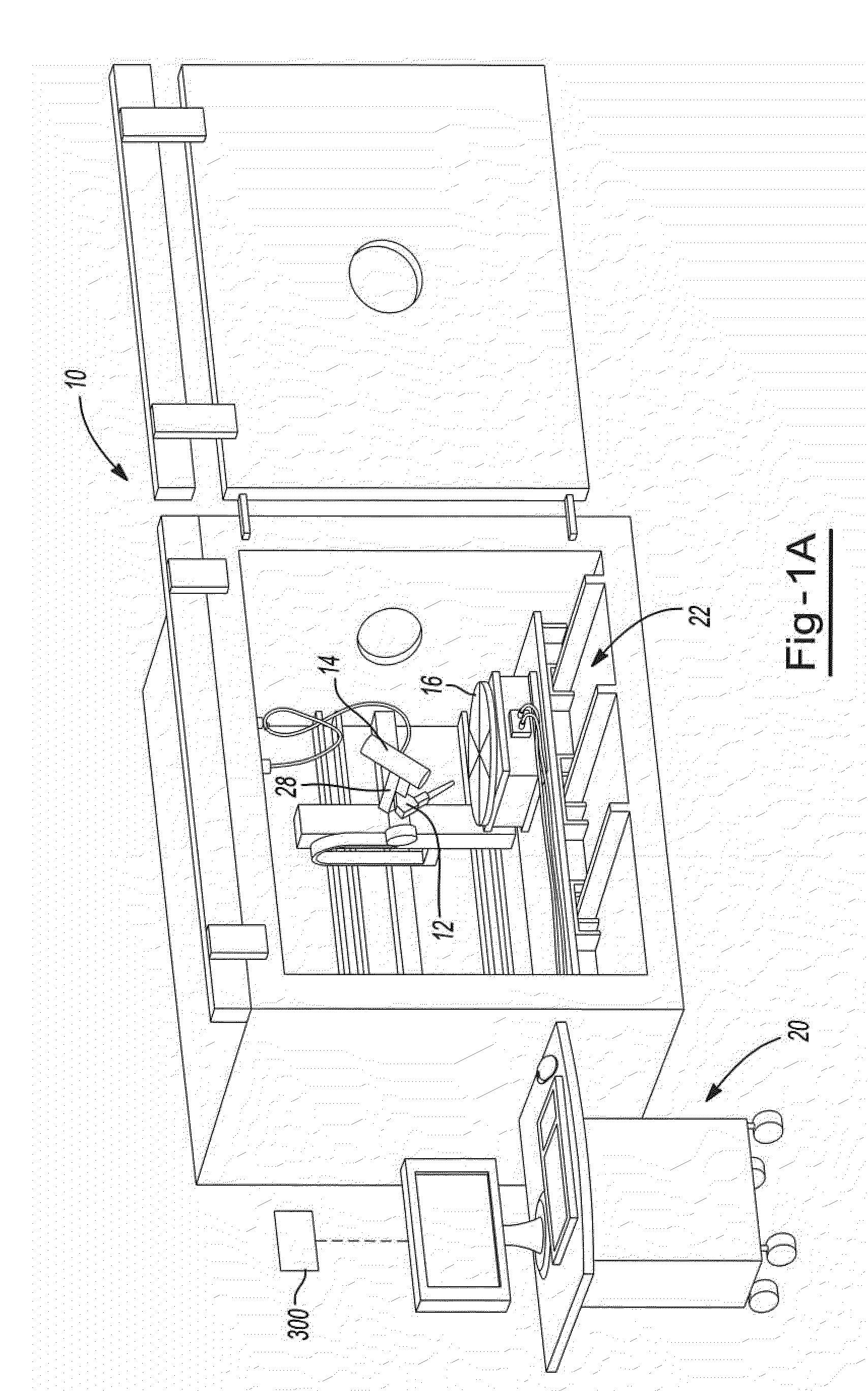

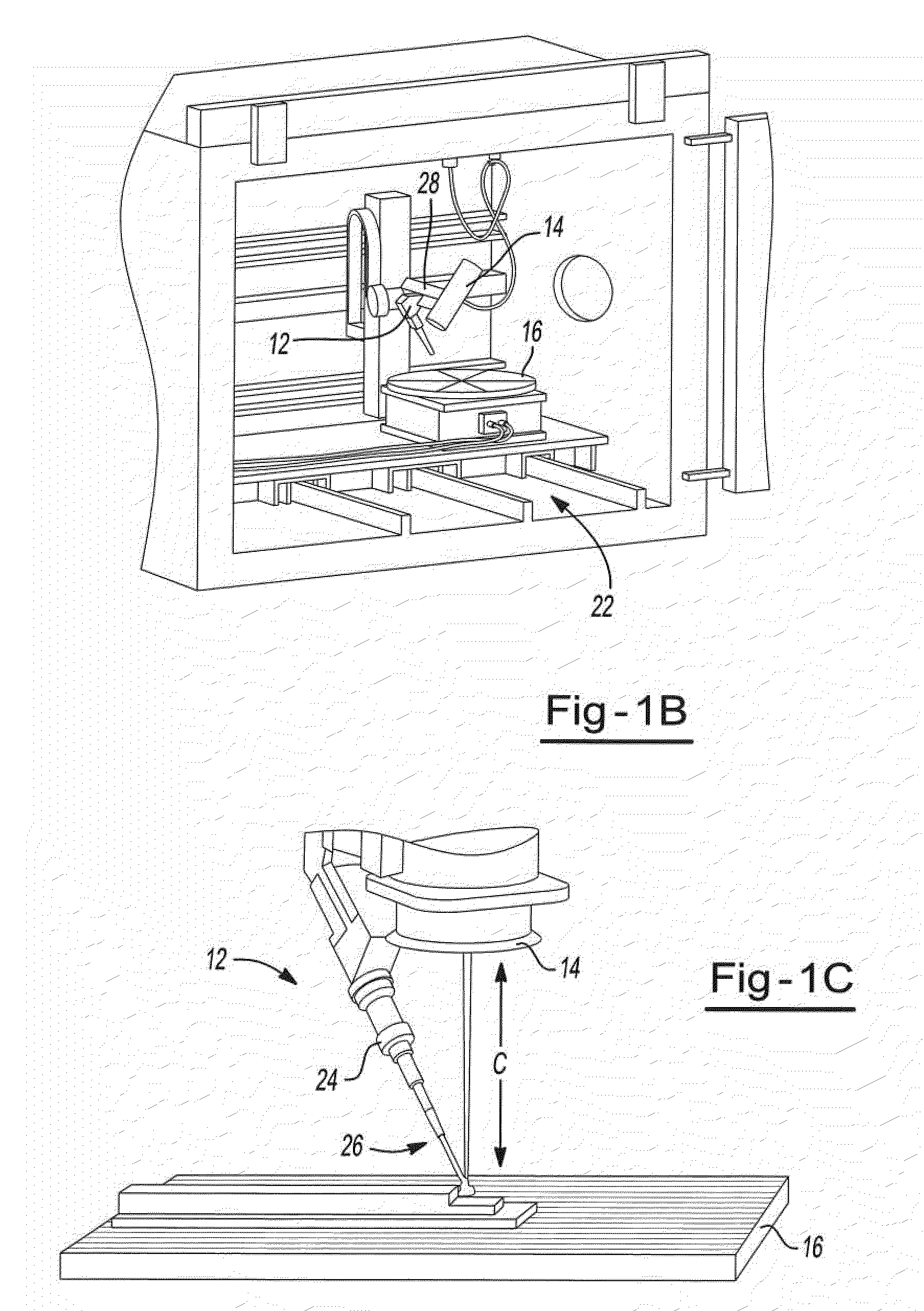

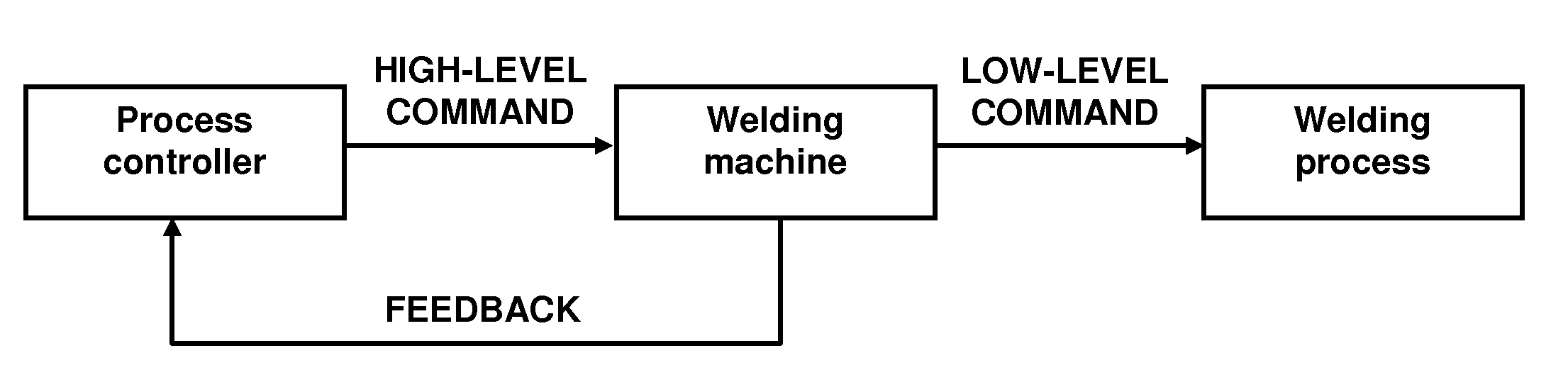

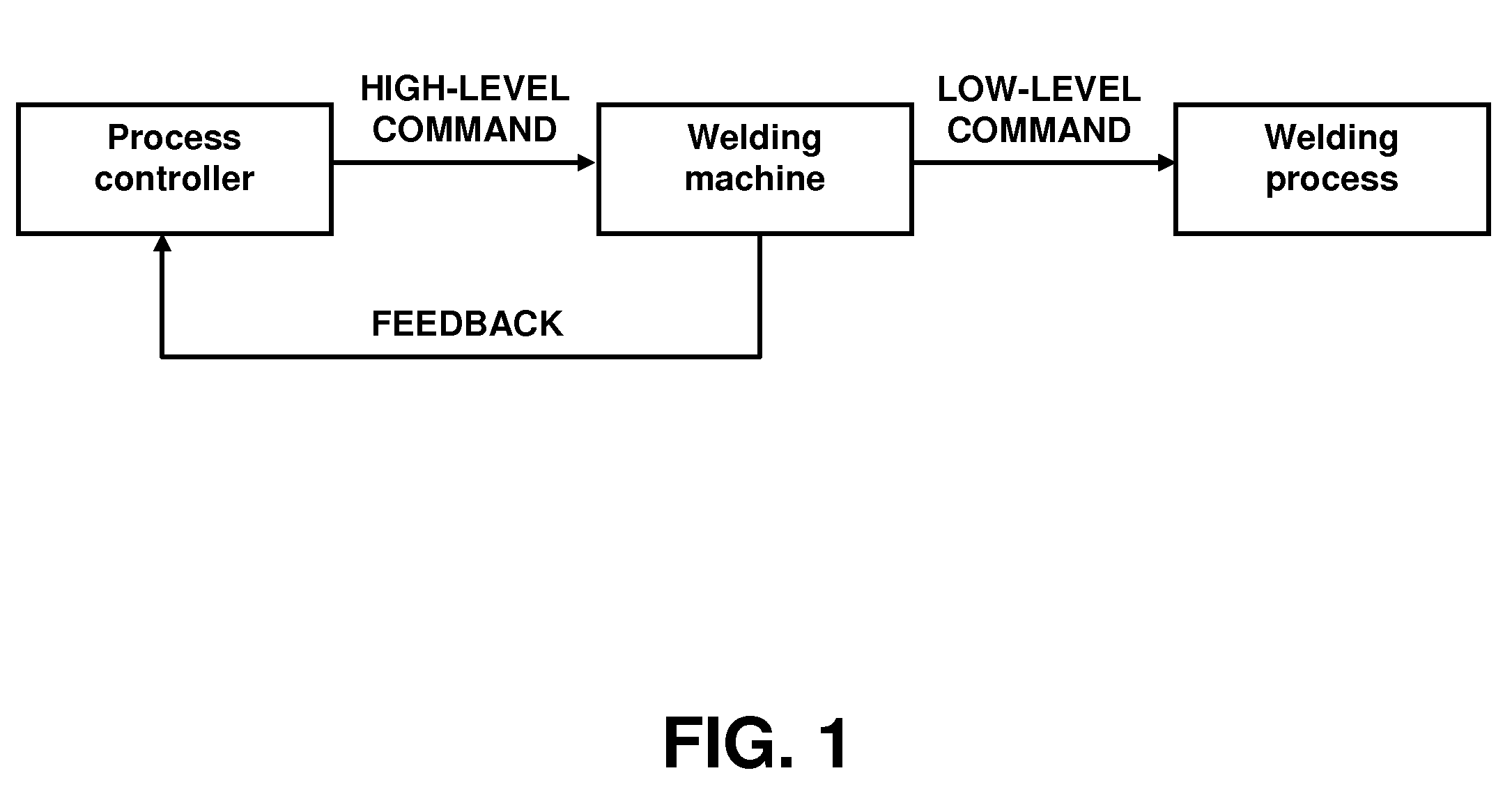

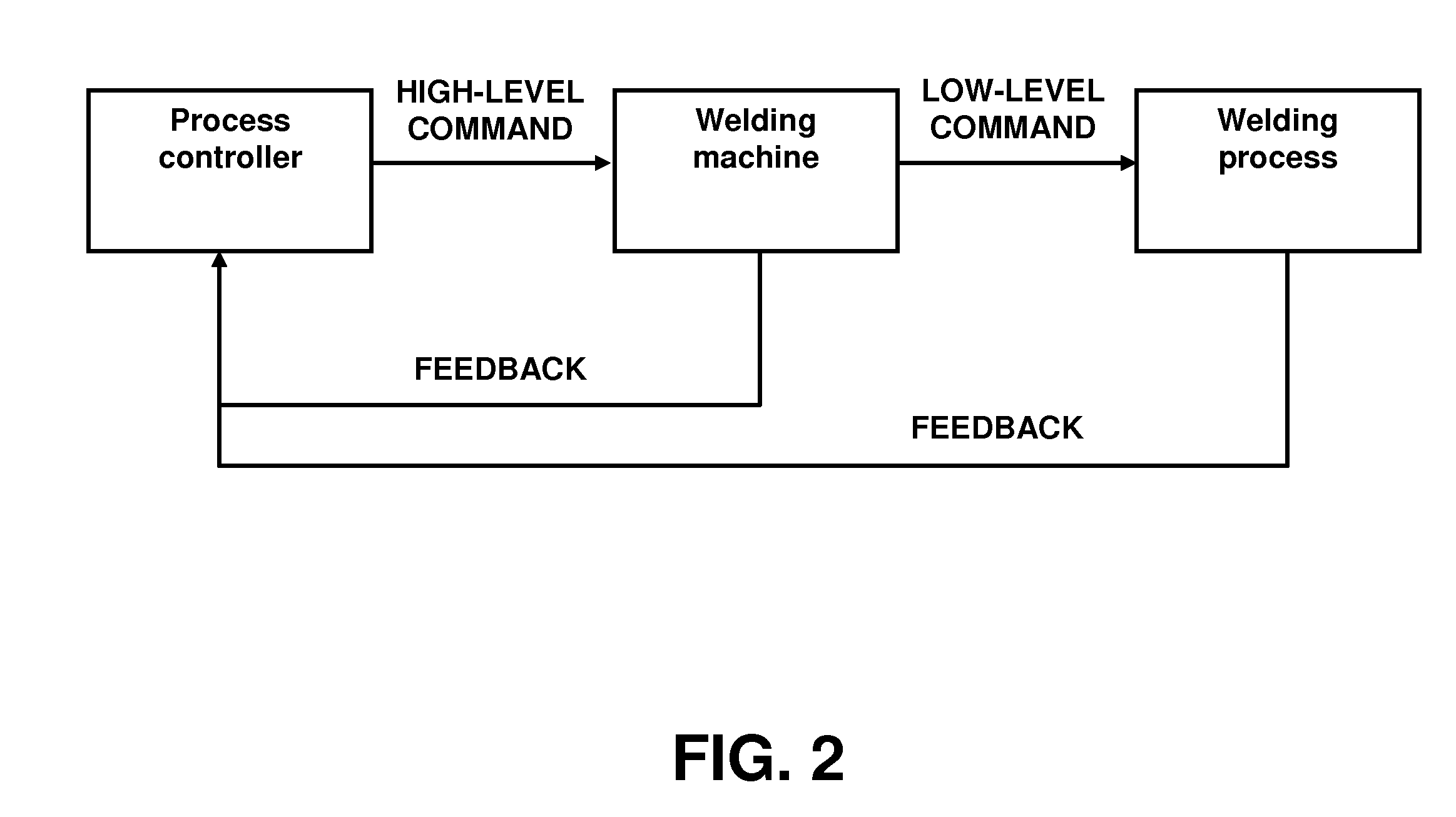

Controlled weld pool volume control of welding processes

ActiveUS20100288734A1Easy to controlAccurate volumeTemperatue controlElectron beam welding apparatusReal-time dataEngineering

A new method of process control for fusion welding maintains a controlled weld pool size or volume, for example in some applications a substantially constant weld pool size or volume. The invention comprises a method of linking machine and process variables to the weld pool size or volume in real time, thereby enabling constant weld pool volume control. The invention further comprises a method of using thermal inverse models to rapidly process real-time data and enable models-based control of welding processes so as to implement constant weld pool volume control.

Owner:SIGMA LAB OF ARIZONA

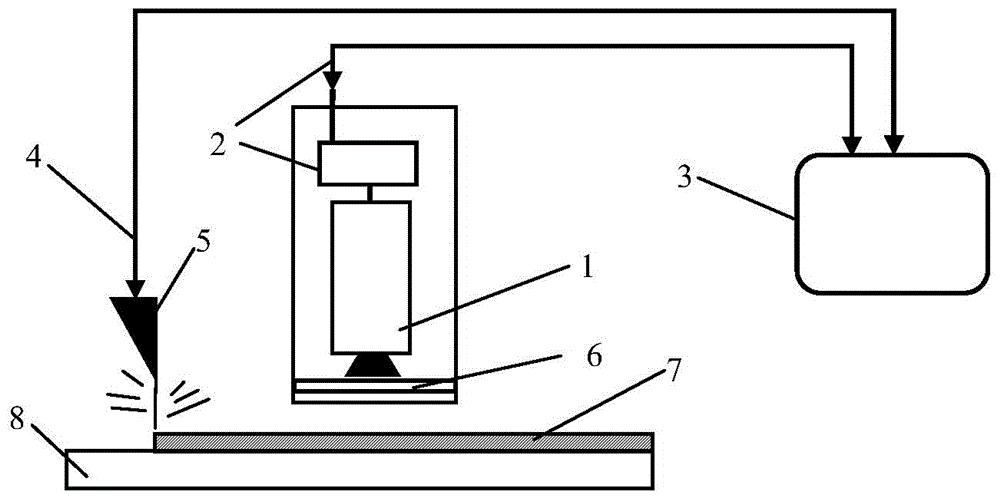

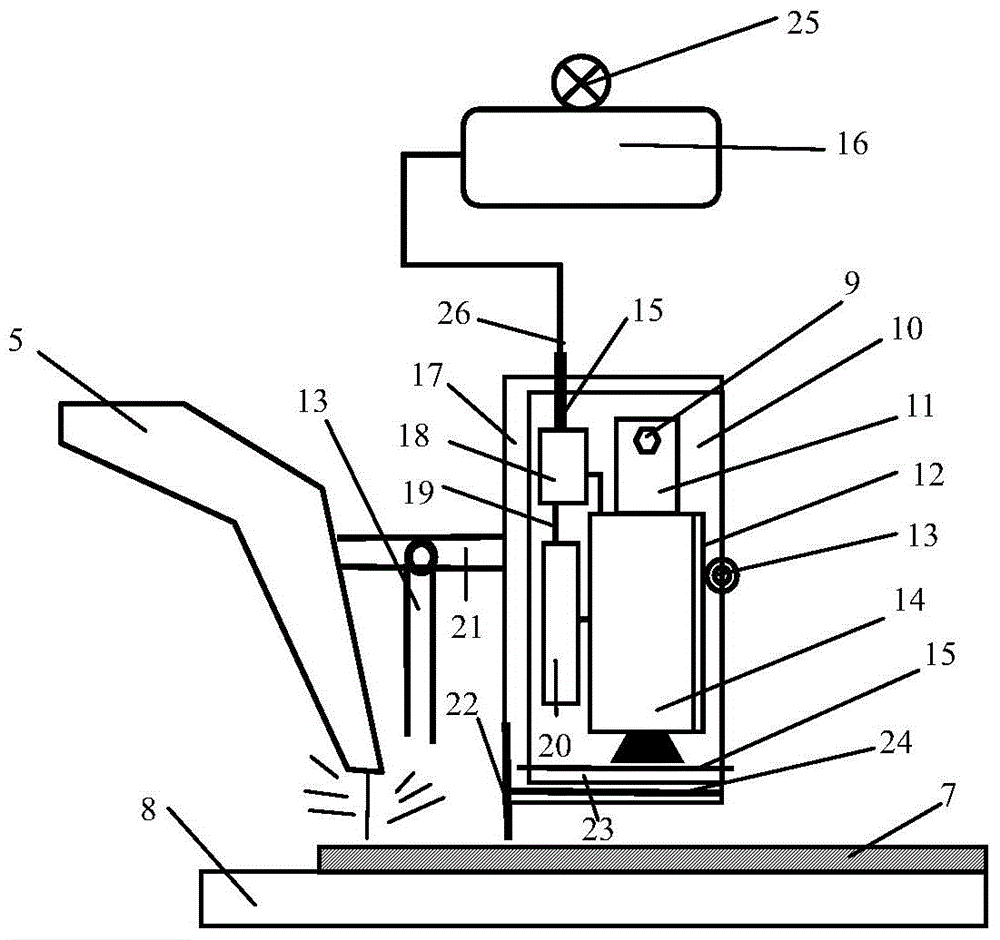

Welding quality analysis device based on infrared vision and analysis method thereof

InactiveCN104977305ALower regenerationIncrease the level of automationWelding/cutting auxillary devicesOptically investigating flaws/contaminationMelting tankVision processing

The invention discloses a welding quality analysis device based on infrared vision and an analysis method thereof. The analysis device comprises an infrared vision collecting system that is adjustably and fixedly connected to a welding facility, a vision processing system, in which welding defect intelligent recognition algorithm is embedded, and a feed control system, which can evaluate the welding quality, give an alarm, and adjust the parameters of the welding facility. The analysis method comprises the following steps: (1) collecting the infrared vision information of a molten pool or an area near a molten pool in real time through infrared sensing; (2) processing the infrared vision information by the welding defect intelligent recognition algorithm so as to obtain the weld seam positions and welding defect characteristics; (3) evaluating the welding quality in real time, and controlling the welding facility and giving an alarm aiming at different welding defects. According to the provided intelligent analysis device and intelligent analysis method, the welding process can be monitored in real time, the welding defects can be recognized, the welding seam position can be traced, the welding quality can be evaluated, the welding loss can be reduced, and the finished product yield rate can be increased.

Owner:HUAZHONG UNIV OF SCI & TECH

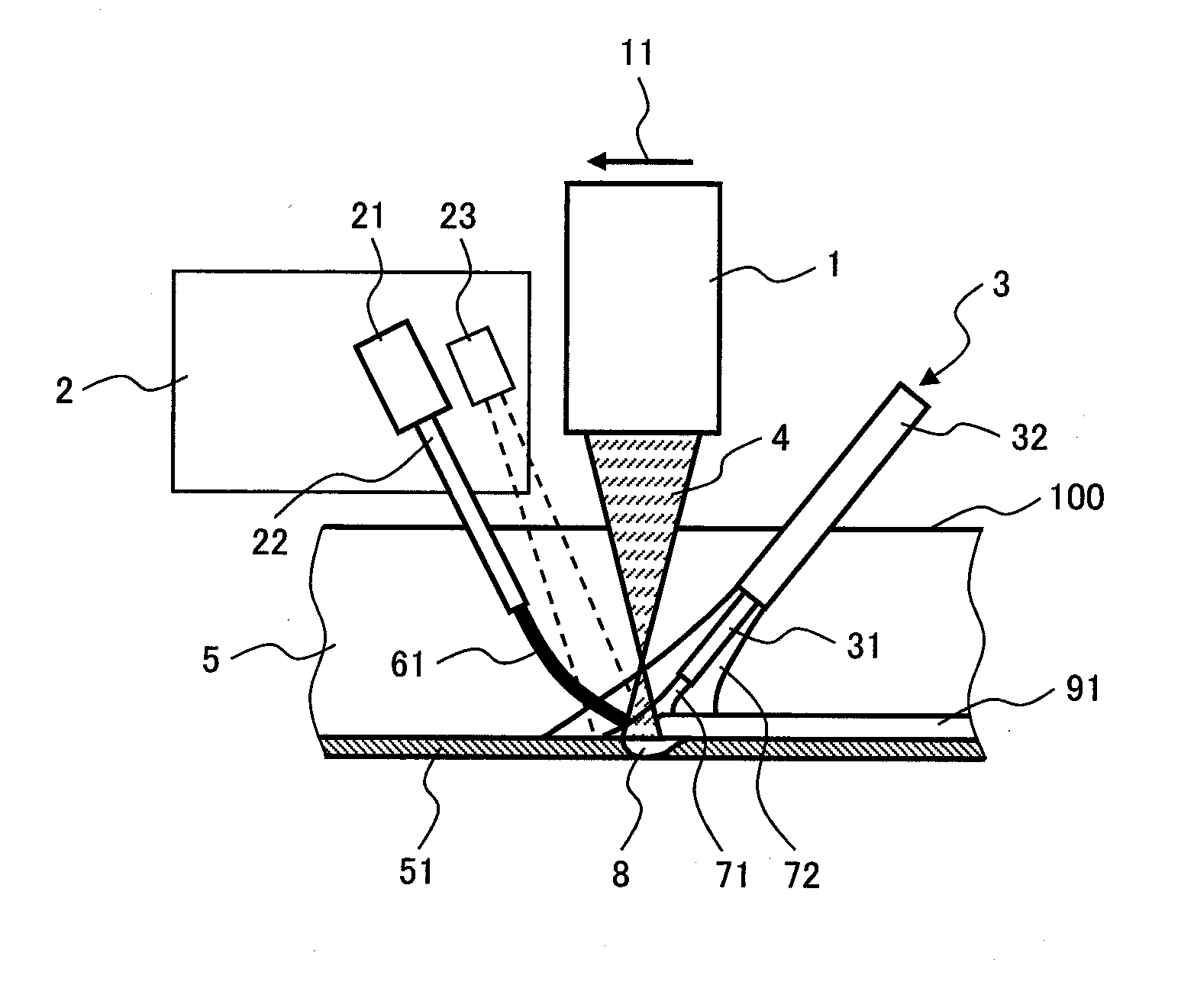

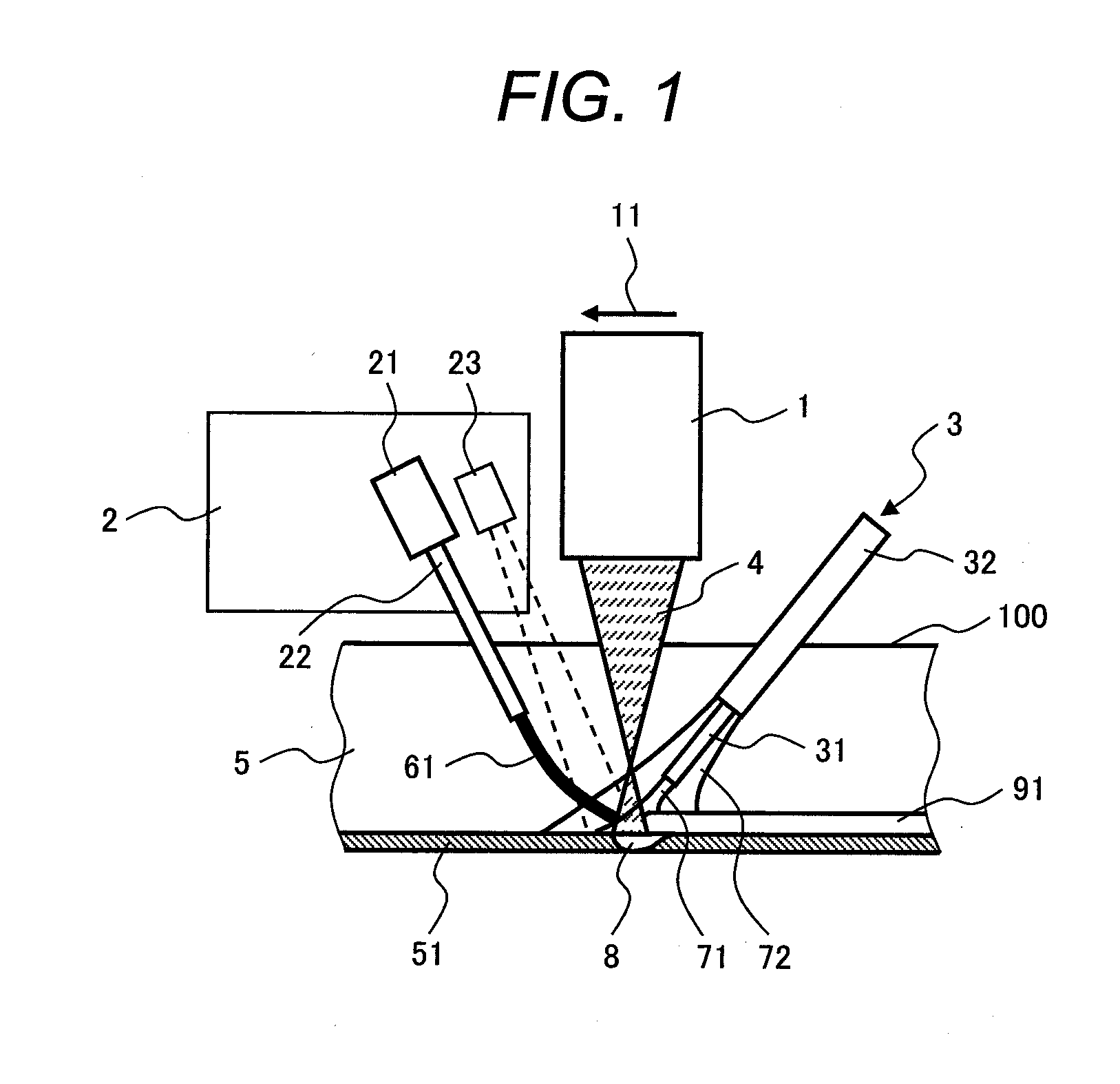

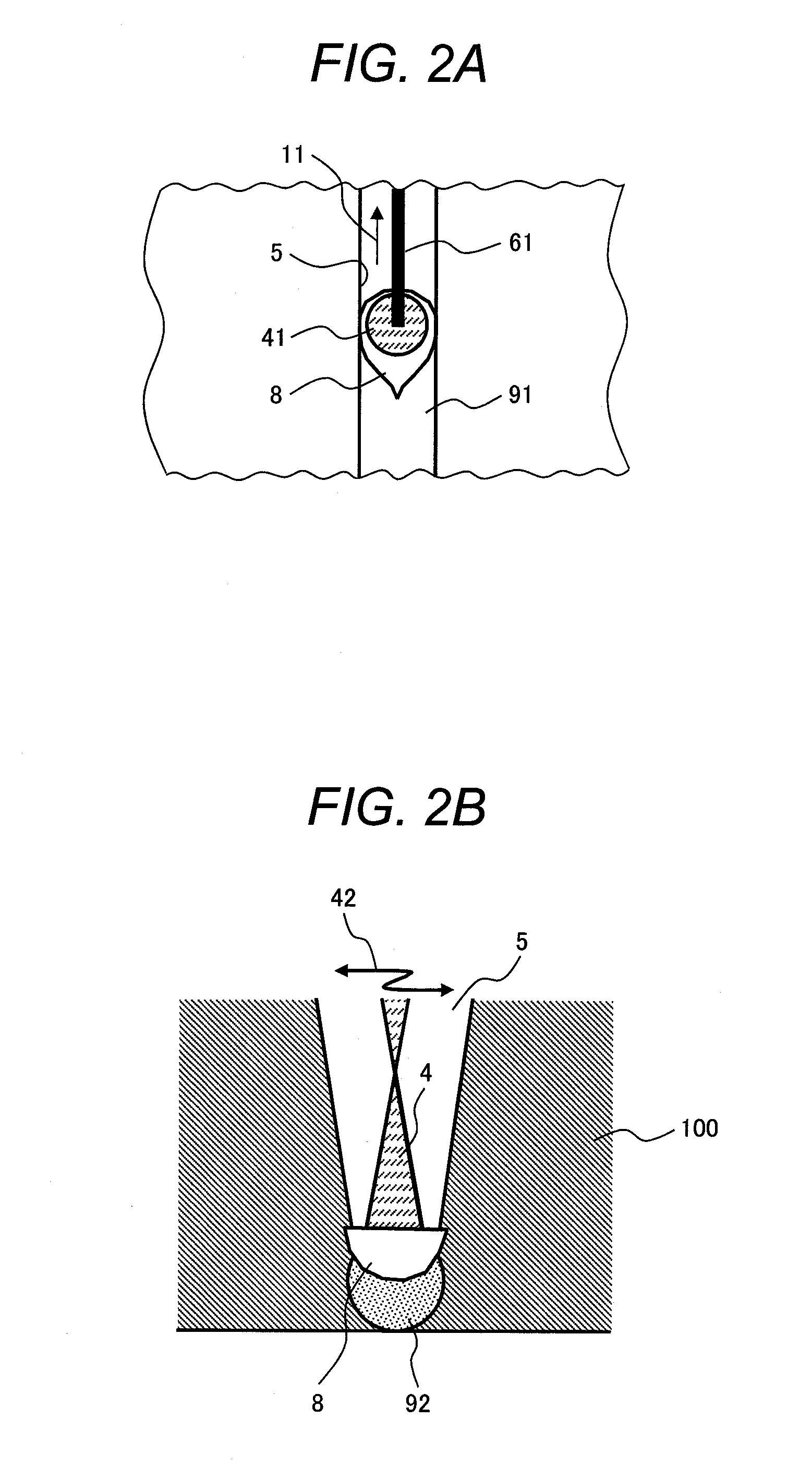

Laser narrow groove welding apparatus and welding method

A welding apparatus and a welding method are employed for laser narrow groove welding which performs welding scanning a laser beam in the welding direction while feeding a solid filler metal into a narrow groove. The welding apparatus includes a laser beam irradiation head having a mechanism periodically oscillating an irradiation point of the laser beam with a predetermined amplitude in the bottom of the groove, and a filler metal control device having a solid filler metal feeder feeding the solid filler metal to the molten pool formed in the bottom of the groove by the laser beam and adjusting the feeding position independent of a motion of the laser beam irradiation head so that the tip position of the solid filler metal detected is constantly positioned in the center of the groove.

Owner:HITACHI LTD

Real time implementation of generalized predictive control algorithm for the control of direct metal deposition (DMD) process

InactiveUS20080223832A1Increasing temperature profileHigh dimensional accuracyDigital computer detailsThermometers using physical/chemical changesControl systemLinear model

A linear model based generalized predictive control system controls the molten pool temperature during a Direct Metal Deposition (DMD) process. The molten pool temperature is monitored by a two-color pyrometer. A single-input single-output linear system that describes the dynamics between the molten pool temperature and the laser power is identified and validated. The incremental generalized predictive control algorithm with Kalman filter estimation is used to control the molten pool temperature.

Owner:P O M GRP THE

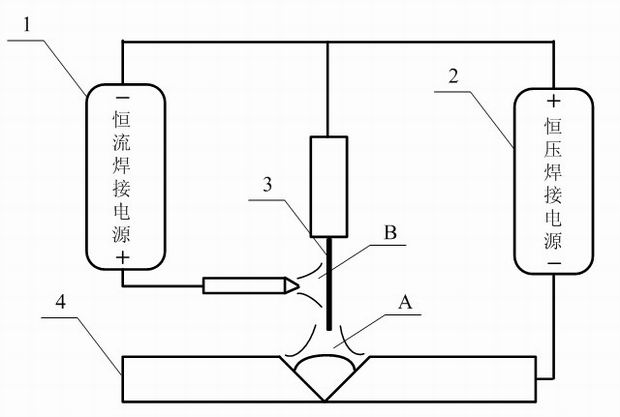

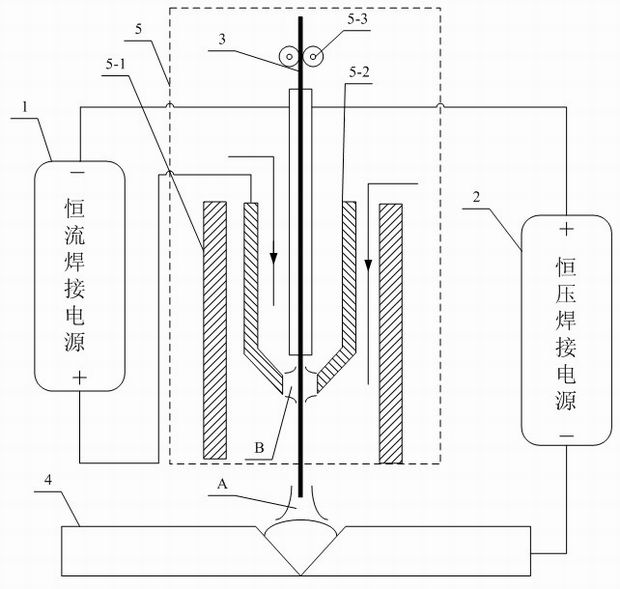

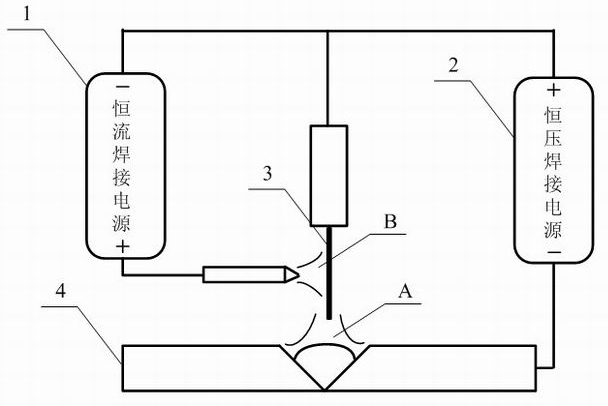

Hot wire consumable electrode gas protection welding method and realization device thereof

InactiveCN101862886AFast meltingIncrease the melting speed, so that the welding deposition speedArc welding apparatusMelting tankWelding power supply

The invention relates to a hot wire consumable electrode gas protection welding method and a realization device thereof, which belong to the technical field of welding. The invention solves the problems of low welding efficiency and low welding quality in the existing consumable electrode gas protection welding method and the device for realizing the welding method caused by incapability of realizing the reasonable distribution of welding wires and hot input of fusing tanks. The welding method comprises the following steps: placing the tail end of the consumable electrode welding wire near a part to be welded of a work piece to be welded; forming a main arc between the tail end of the consumable electrode welding wire and the surface to be welded of the work piece to be welded under the effect of a constant voltage welding power supply for realizing the welding; placing the tail end of a conductive annular sleeve of a welding gun near the side wall of the consumable electrode welding wire in the welding process; and forming a preheating electric arc between the tail end of the conductive annular sleeve of the welding gun and the side wall of the consumable electrode welding wire under the effect of a constant current welding power supply for realizing the preheating on the consumable electrode welding wire. The realization device consists of the constant current power supply, the constant voltage welding power supply and the welding gun. The invention is used for the implementation of the gas protection welding.

Owner:HARBIN INST OF TECH

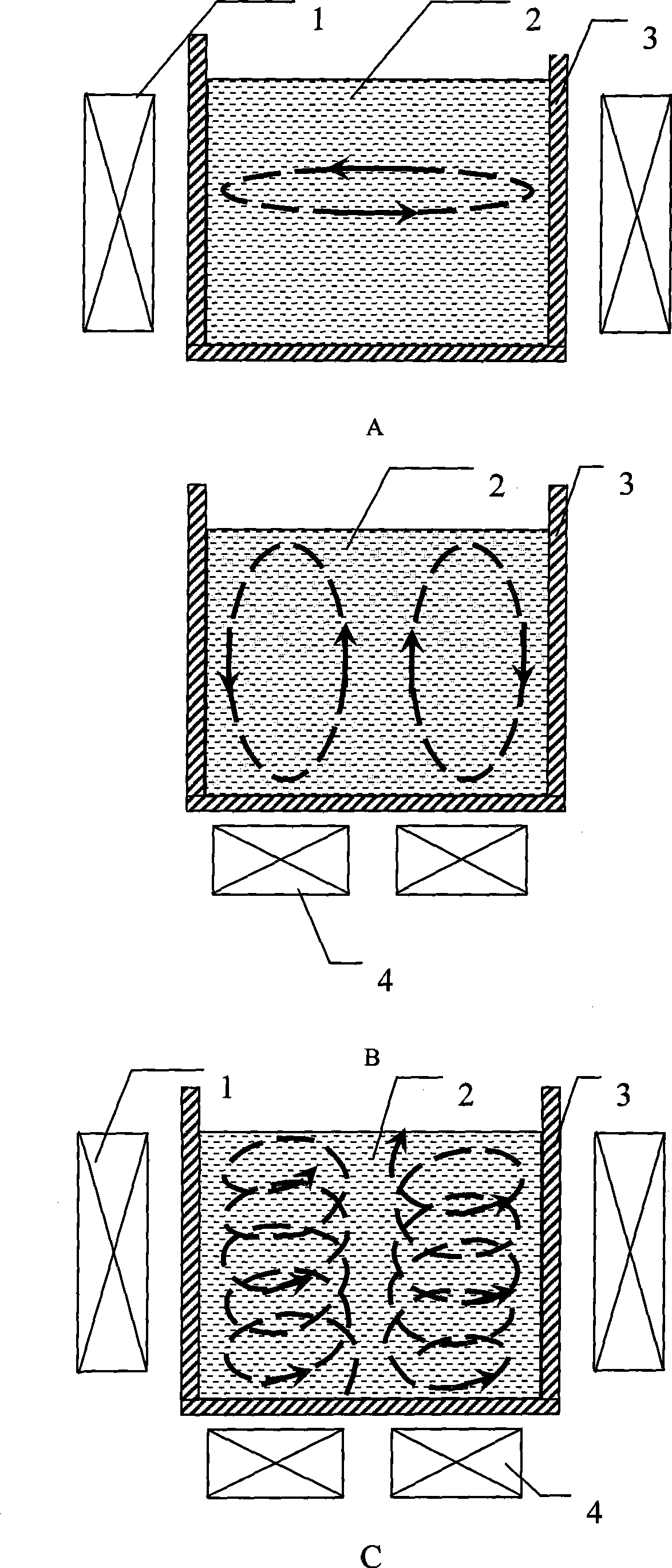

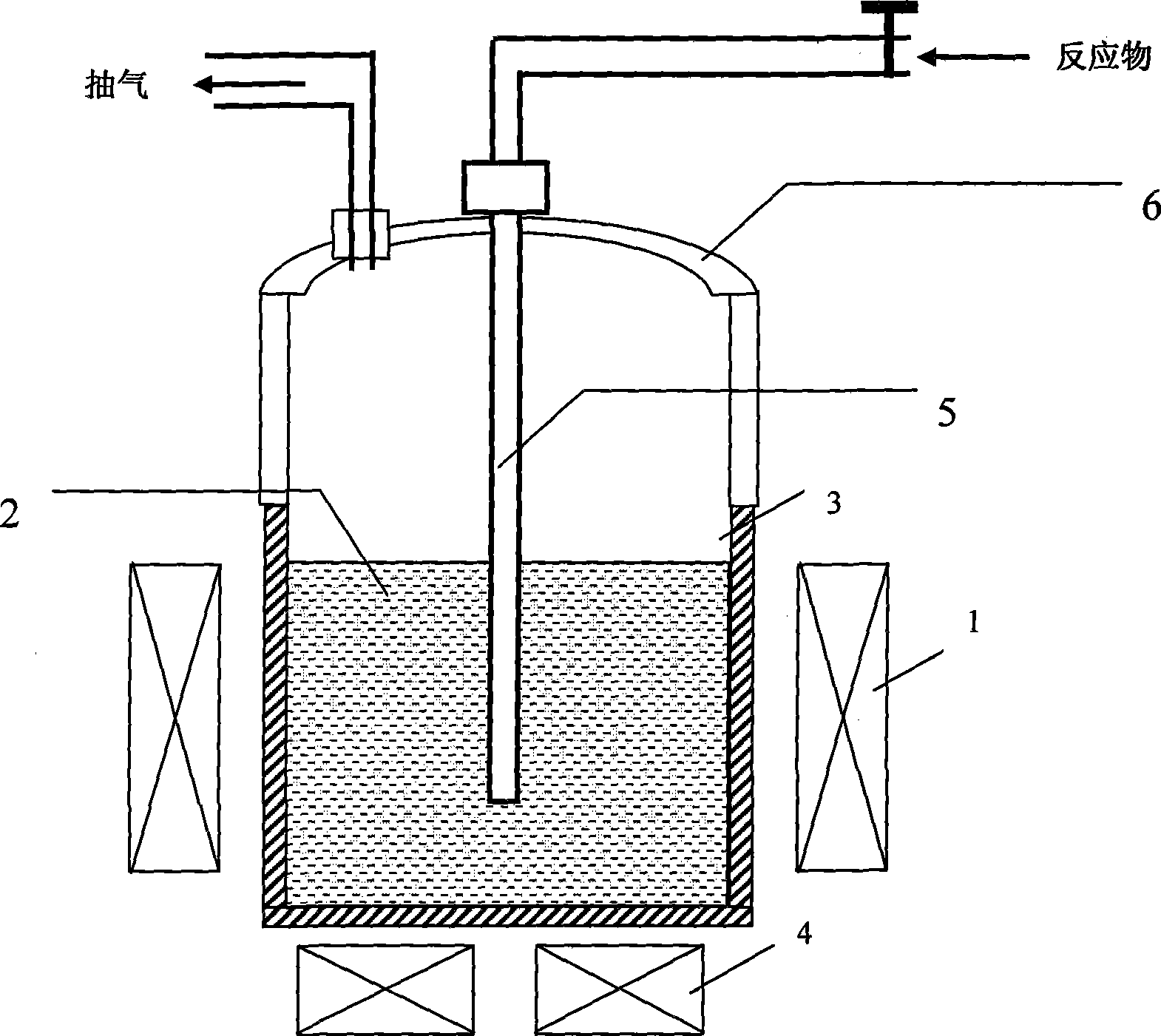

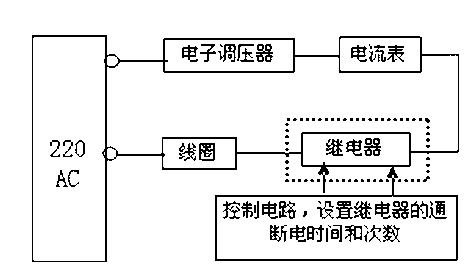

Metal matrix composition home-position synthesizing method in combined electric magnetic field

The invention provides a method for continuously producing particle reinforced metal matrix composites in an industrial scale, which adopts the synthesis of metal matrix composites in a combination magnetic field. The method is characterized in that: the combination of a rotating magnetic field and a travelling wave magnetic field is adopted to synthesize a preparation particle reinforced metal matrix composite fused mass in the in-situ synthesis process of composites. The low frequency rotating magnetic field is placed at the outer side of a composite material molten pool, and the center of a coil of the magnetic field and the center of the fused mass are at the same height; and the travelling wave magnetic field is exerted at the bottom part of the composite material molten pool, and the coil center of the travelling wave magnetic field and the center of the composite material molten pool are at the same position. The composite material particle reinforced phases prepared by the method are distributed evenly and thinned, interior tissues are compact and have no structural defects such as loosening and hole shrinkage, the degree of finish of external surfaces of casting blanks is high, defects are eliminated, and the friction resistance and the abrasion resistance of the composites are obviously improved.

Owner:JIANGSU UNIV

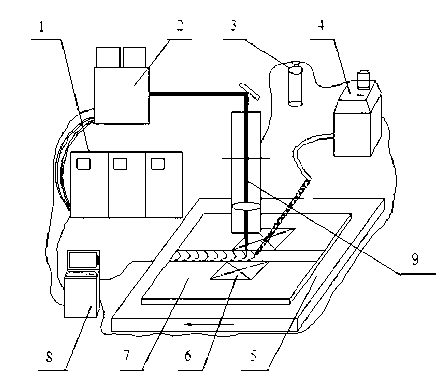

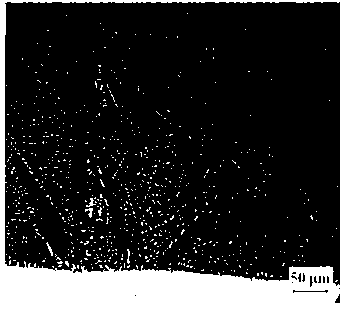

Method for refining solidified structure of laser cladding layer by using alternating magnetic field and device thereof

InactiveCN102703898ARefining solidified tissueChange shapeMetallic material coating processesNumerical controlAlternating current

The invention relates to a method for refining a solidified structure of a laser cladding layer by using an alternating magnetic field and a device thereof, belongs to the technical field of laser processing. A compound coating is prepared on the surface of a substrate in a manner of conventional powder-feed laser cladding; the alternating magnetic field is applied to acting on a laser molten pool during the laser cladding; the powder-feed laser cladding process is carried out under the alternating magnetic field; and the direction of magnetic lines of force generated by the alternating magnetic field is perpendicular to the scanning speed direction of the laser cladding. The device for refining the solidified structure of the laser cladding layer by using the alternating magnetic field comprises a cooler, a CO2 laser, an argon protector, a synchronous powder feeder, a clamping device, an alternating magnetic field, a cladding substrate body and a numerical control operation floor. The method and the device provided by the invention are capable of obviously refining the solidified structure of the cladding layer; when alternating current with certain frequency is introduced into a coil, an alternating magnetic field can be generated between a metal melt and the magnetic field coil; and the intensity of the alternating magnetic field is controlled so as to change a form of the solidified structure of the cladding layer and refine crystalline grains through changing the intensity of an alternating magnetic field. The device provided by the invention is simple, low in investment cost, high in benefit, etc.

Owner:KUNMING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com