Laser-TIG electric arc hybrid welding technology for spaceflight aluminum alloy plate with medium thickness and high strength

An aluminum alloy plate, composite welding technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve high reflectivity, large linear expansion coefficient and thermal conductivity refractory oxide film, energy consumption, material damage and other problems to achieve the effect of reducing metallurgical damage, increasing welding speed and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing the example of the present invention is described in detail, this example implements under the premise of technical method of the present invention, has provided detailed implementation method and concrete operation process, but protection scope of the present invention is not limited to following example.

[0024] This example is used for welding aerospace high-strength aluminum-copper aluminum alloys with dimensions (test plate) of 200mm×150mm×8mm (length×width×thickness). (mm).

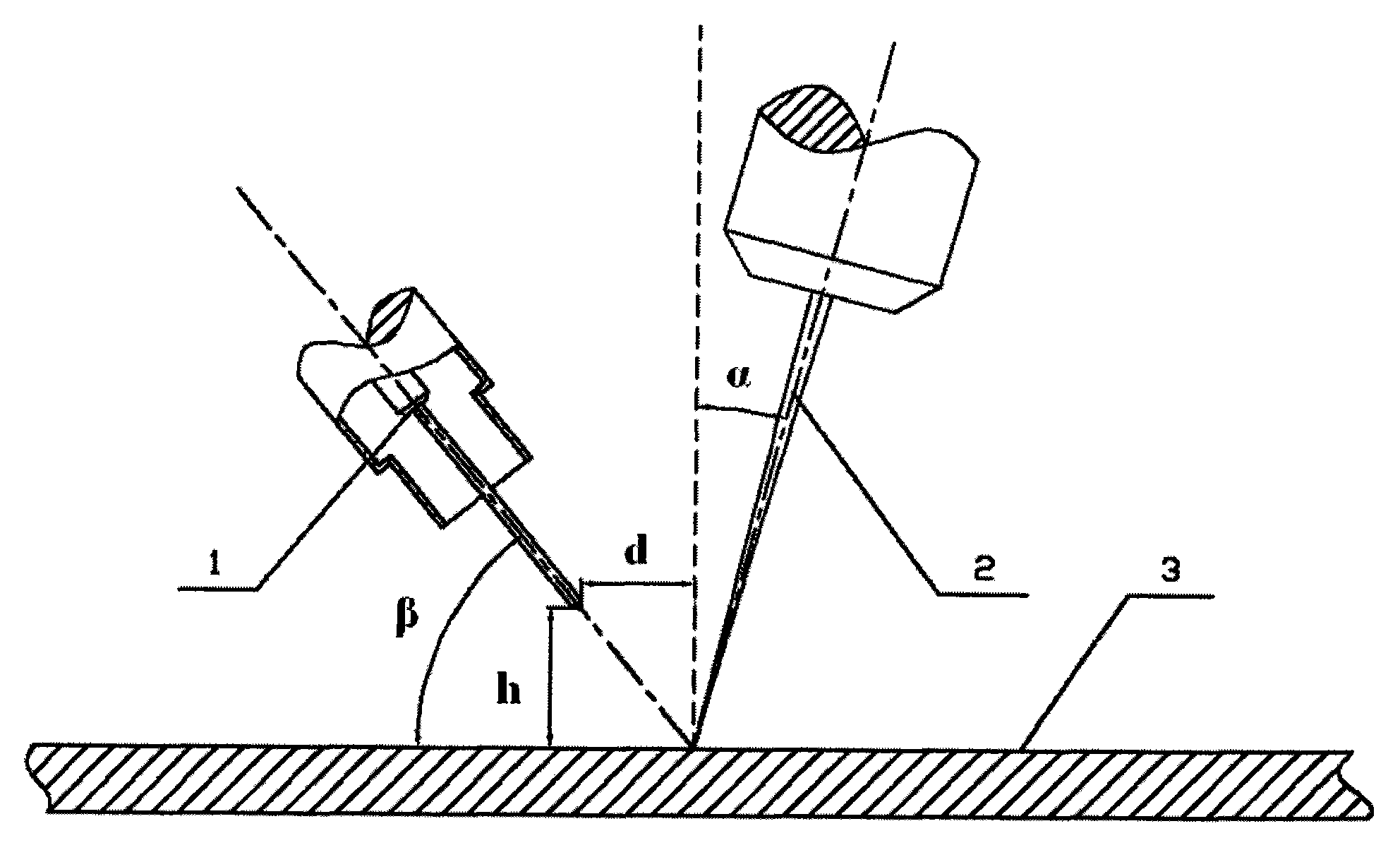

[0025] Such as figure 1 As shown, the non-melting pole TIG arc and the laser beam emitted by the fiber laser are gathered at the same welding position on the workpiece along the welding direction to form a molten pool together, the fiber laser beam 2 is in front, and the non-melting pole TIG arc is behind. The form of the distance between the laser focus and the workpiece is positive defocus, and its defocus amount is +2mm. Among them, the inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com