Patents

Literature

5879results about How to "Improve absorption rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

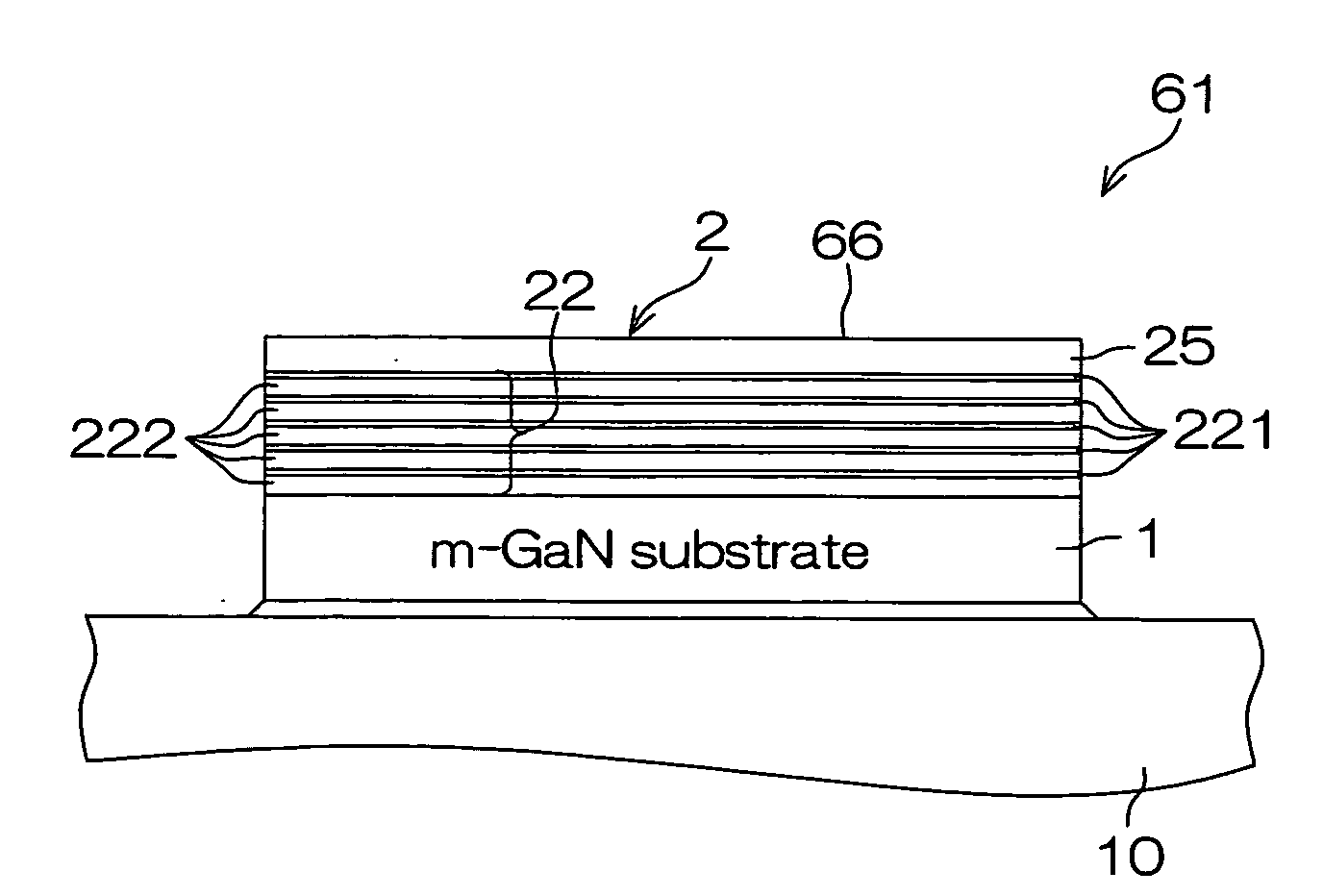

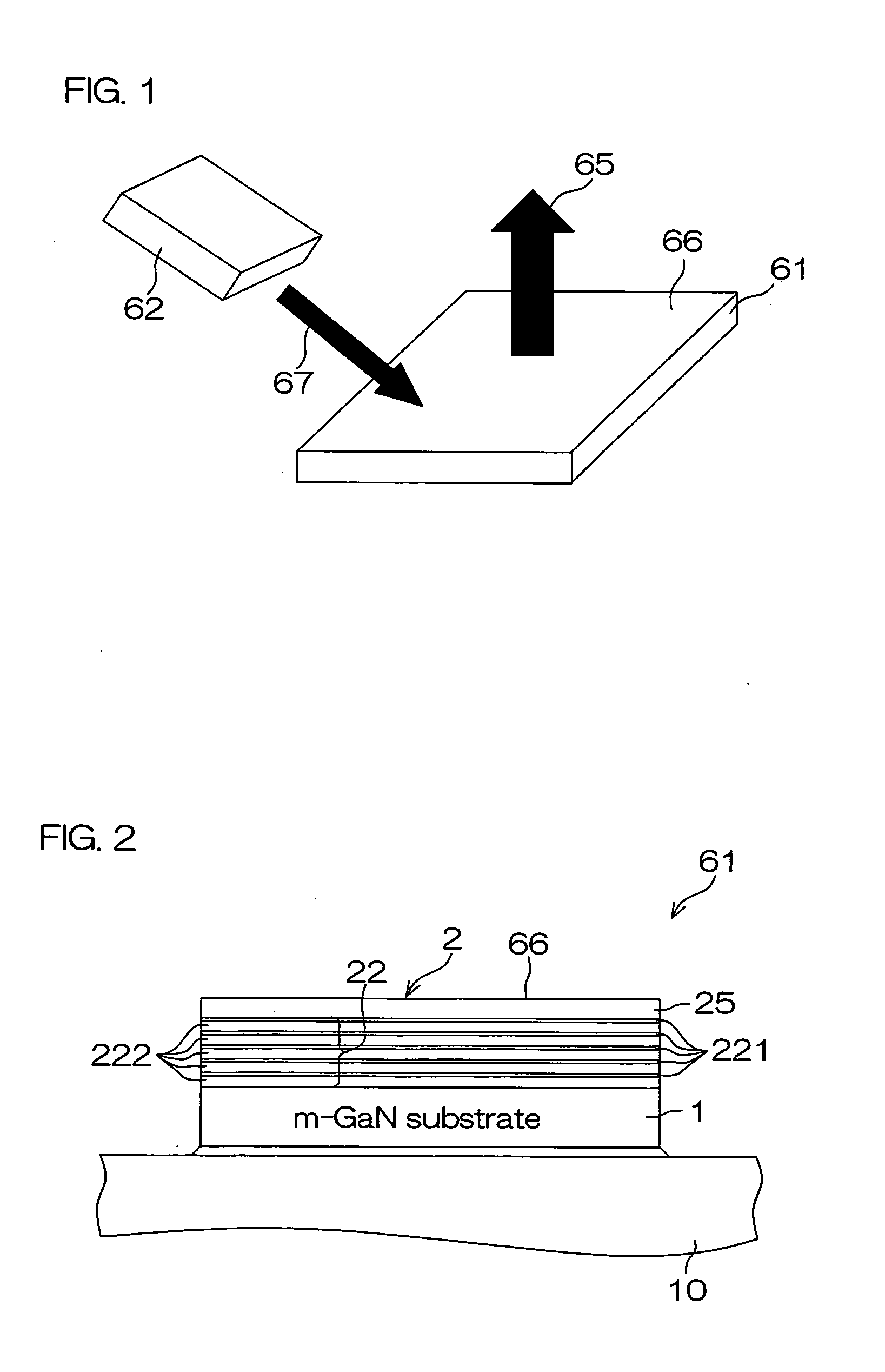

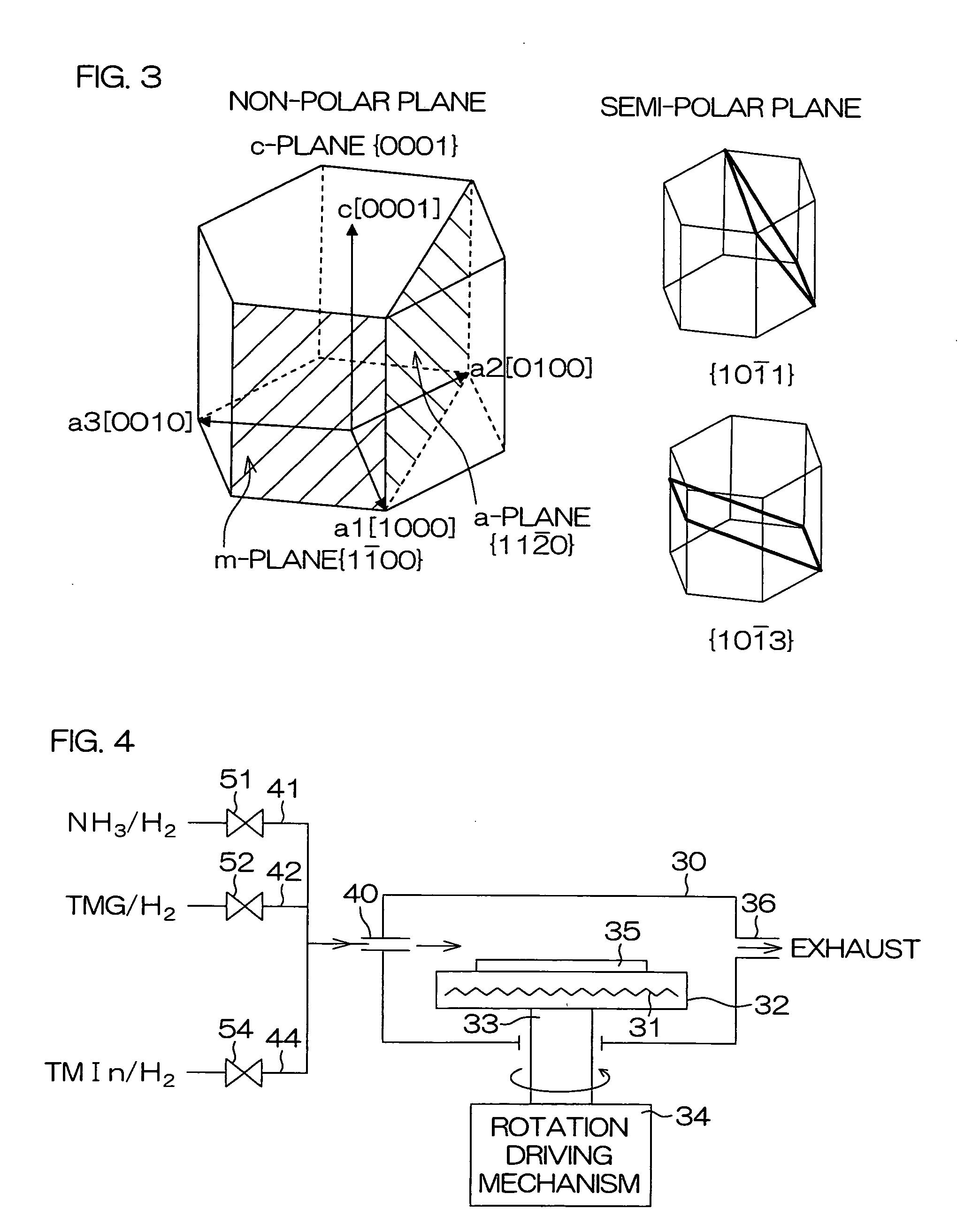

Light emitting device

InactiveUS20080232416A1Improve efficiencyImprove propertiesLaser detailsLaser active region structureLength waveWide band

Owner:ROHM CO LTD

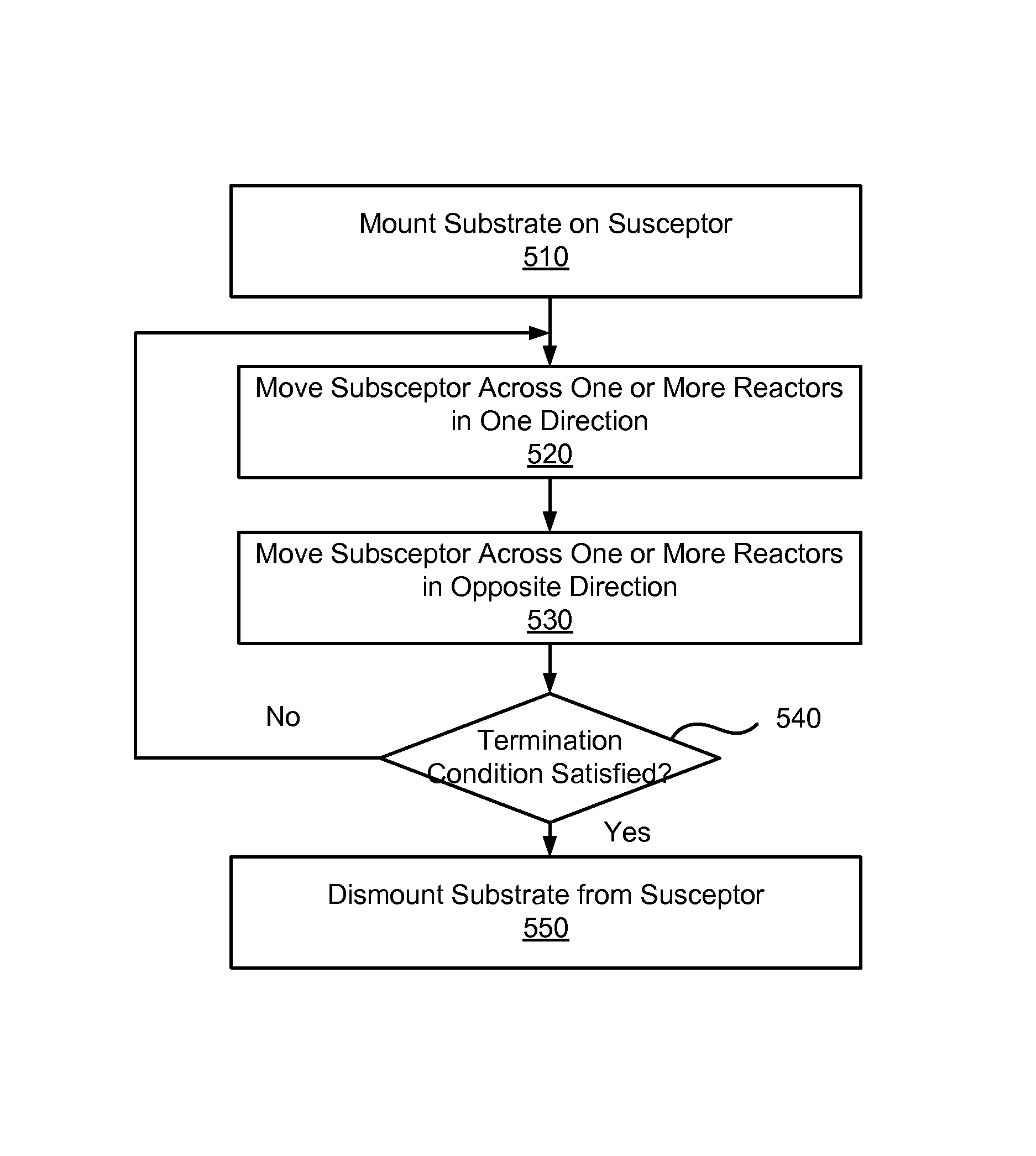

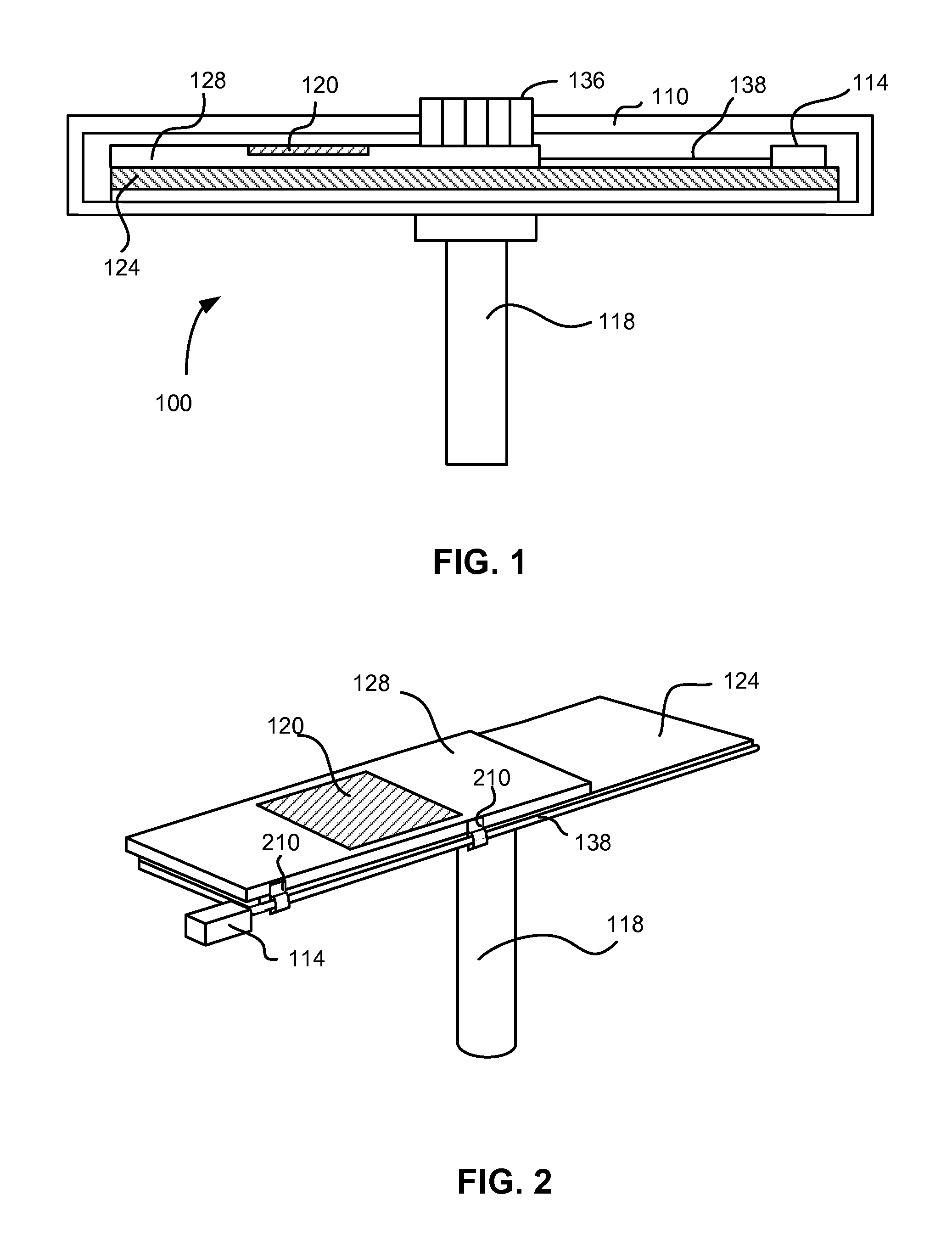

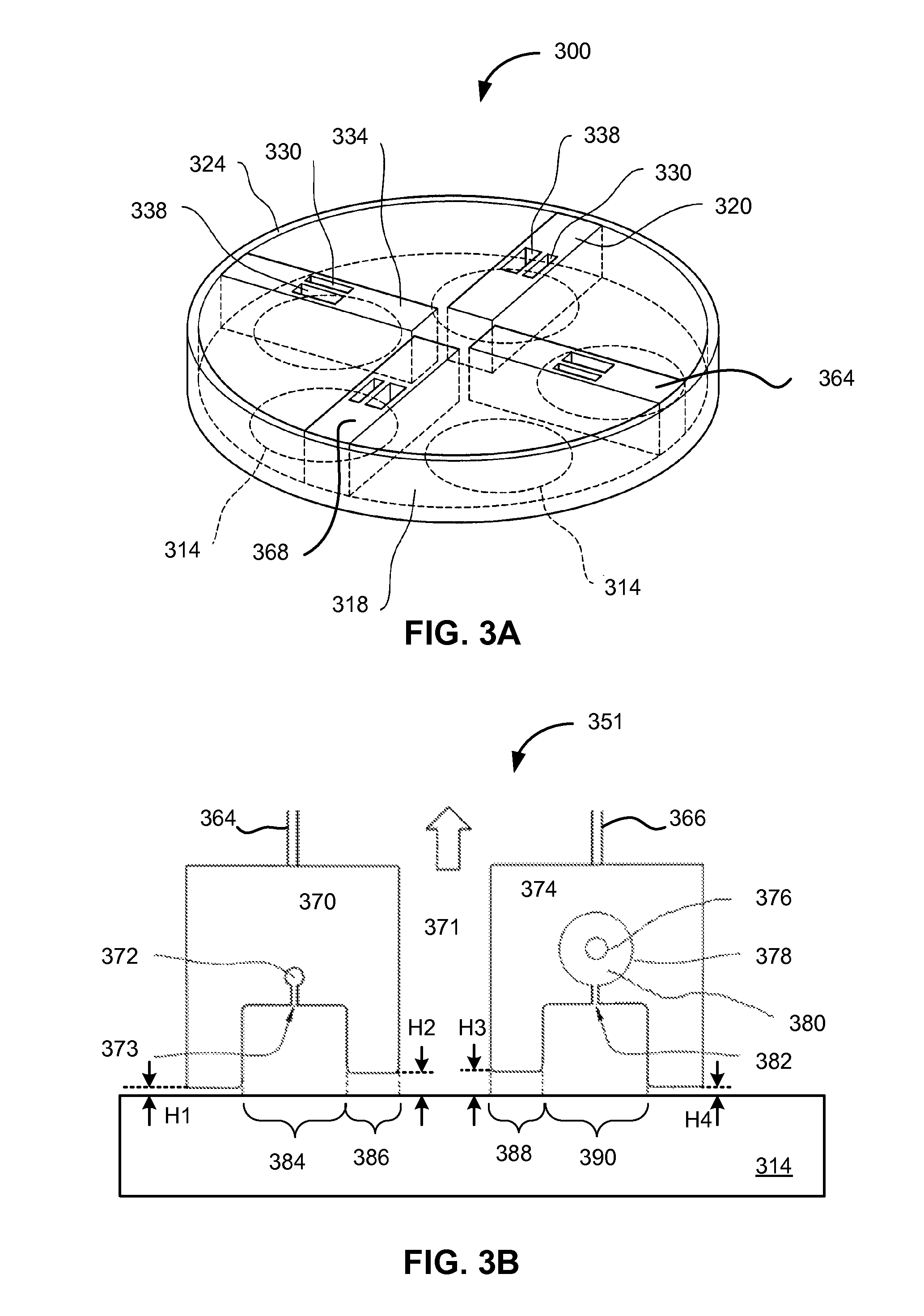

Deposition of layer using depositing apparatus with reciprocating susceptor

InactiveUS8771791B2Improve absorption rateIncrease deposition ratePretreated surfacesNatural mineral layered productsSusceptorReciprocating motion

Atomic layer deposition is performed by reciprocating a susceptor in two directions, subjecting a substrate on the susceptor to two different sequences of processes. By subjecting the susceptor to different sequences of processes, the substrate undergoes different processes that otherwise would have required an additional set of injectors or reactors. The reduced number of injectors or reactors enables a more compact deposition device, and reduces the cost associated with the deposition device.

Owner:VEECO ALD

Silver-containing, sol/gel derived bioglass compositions

Silver-containing, sol-gel derived bioactive glass compositions and methods of preparation and use thereof are disclosed. The compositions can be in the form of particles, fibers and / or coatings, among other possible forms, and can be used, for example, for treating wounds, improving the success of skin grafts, reducing the inflammatory response and providing anti-bacterial treatments to a patient in need thereof. Anti-bacterial properties can be imparted to implanted materials, such as prosthetic implants, sutures, stents, screws, plates, tubes, and the like, by incorporating the compositions into or onto the implanted materials. The compositions can also be used to prepare devices used for in vitro and ex vivo cell culture.

Owner:IMPERIAL INNOVATIONS LTD

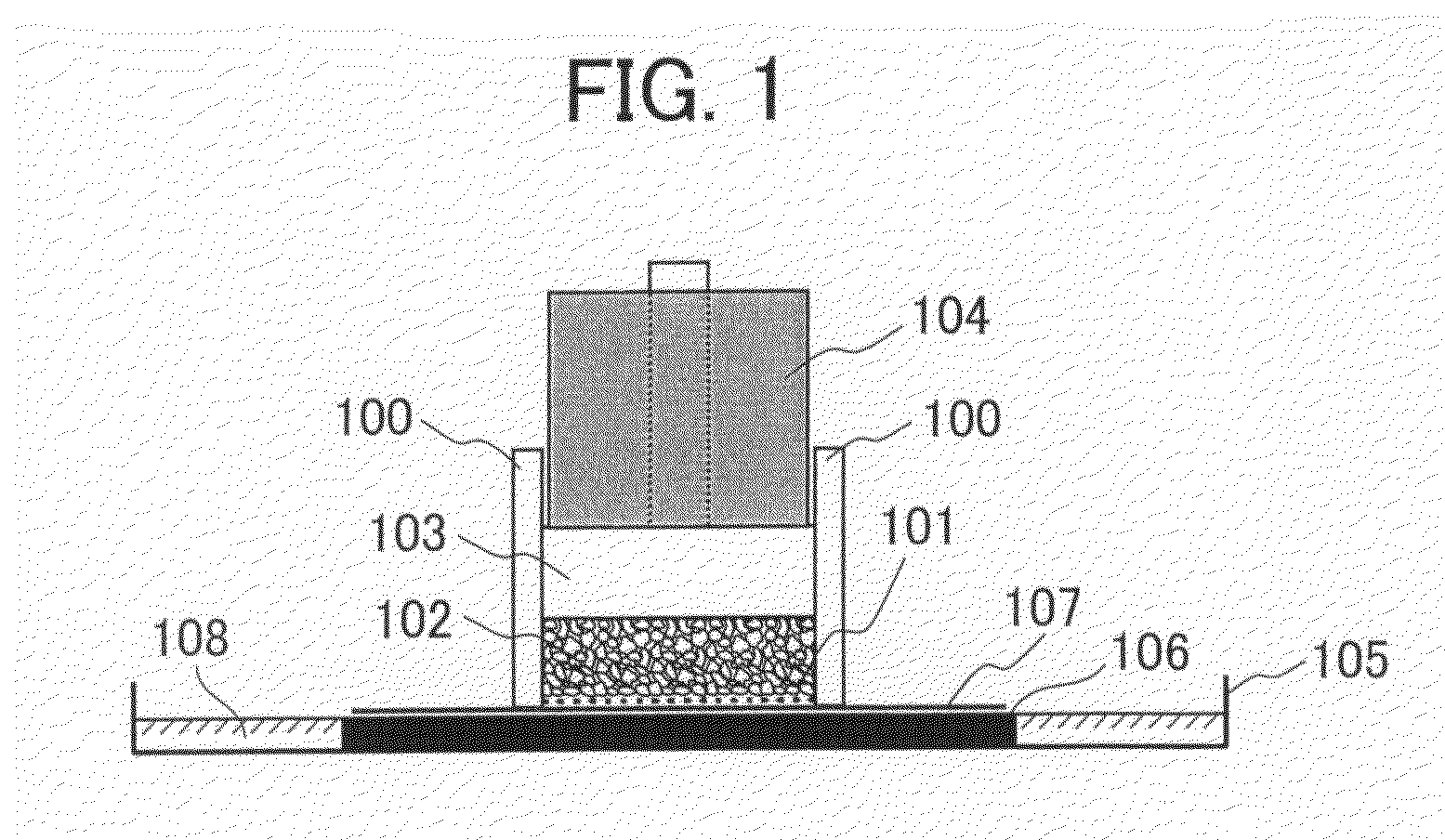

Water-absorbing resin and method for manufacturing the same

The present invention provides a highly productive method for manufacturing a water-absorbing resin, the amounts of fine powder and dust of which are small, the amount of residual monomer of which is small, and whose absorption rate is high. That is, the method for manufacturing the water-absorbing resin of the present invention is a method for crosslinking and polymerizing an aqueous solution of an acid-group containing unsaturated monomer, and is characterized in that stationary polymerization is carried out in such a manner that a solid matter is added to the monomer aqueous solution, and an initiation temperature of the polymerization is adjusted to 40° C. or more or a maximum temperature of the polymerization is adjusted to 100° C. or more.

Owner:NIPPON SHOKUBAI CO LTD

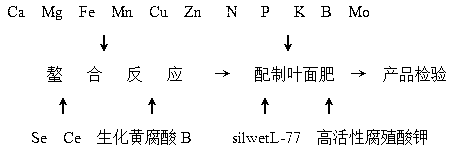

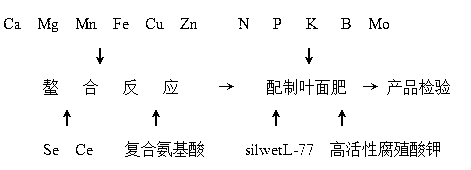

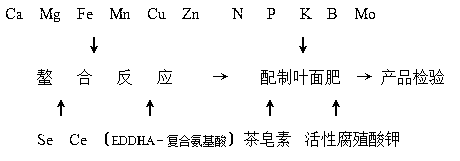

High-efficiency multielement compound foliage selenium fertilizer and preparation technique thereof

ActiveCN102795938AImprove absorption rateChange surface propertiesFertilizer mixturesGrowth regulatorAgricultural crops

The invention discloses a high-efficiency multielement compound foliage selenium fertilizer which aims to increase selenium artificially. The high-efficiency multielement compound foliage selenium fertilizer comprises the following components: macroelements, medium elements, microelements, chelator, selenium, rare-earth elements, active organic substances, growth regulator and surfactant. The high-efficiency multielement compound foliage selenium fertilizer is especially suitable for producing selenium-rich tea, selenium-rich rice, selenium-rich corn and other selenium-rich agricultural products in low-selenium or selenium-deficient regions. The invention has the advantages of favorable raw material compatibility, scientific proportion, scientific technique and diversified and compounded nutrient elements, and can effectively solve the nutrient deficiency symptom of the crop, thereby achieving the goal of sufficiently supplementing insufficient soil nutrients.

Owner:李子先 +1

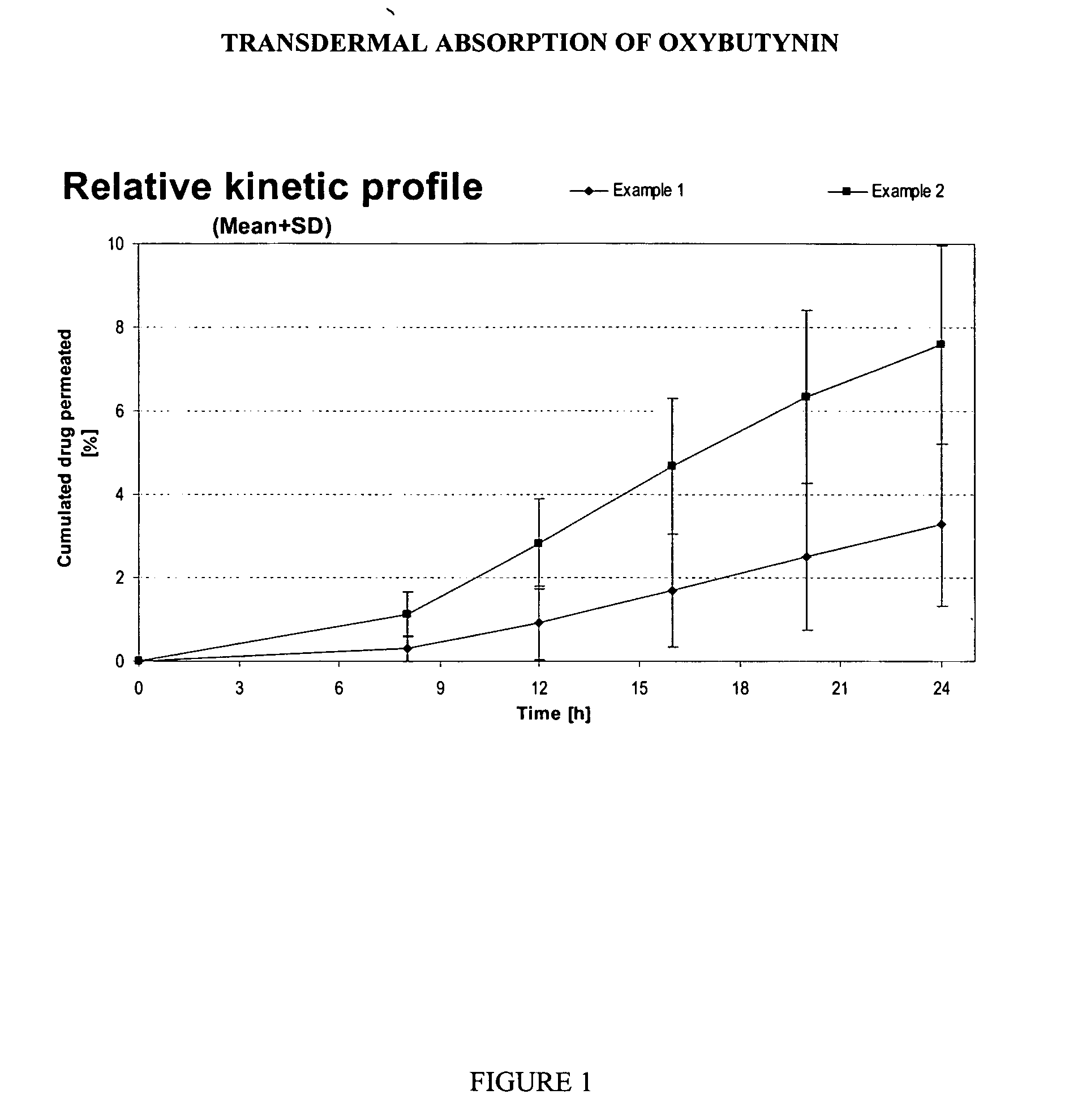

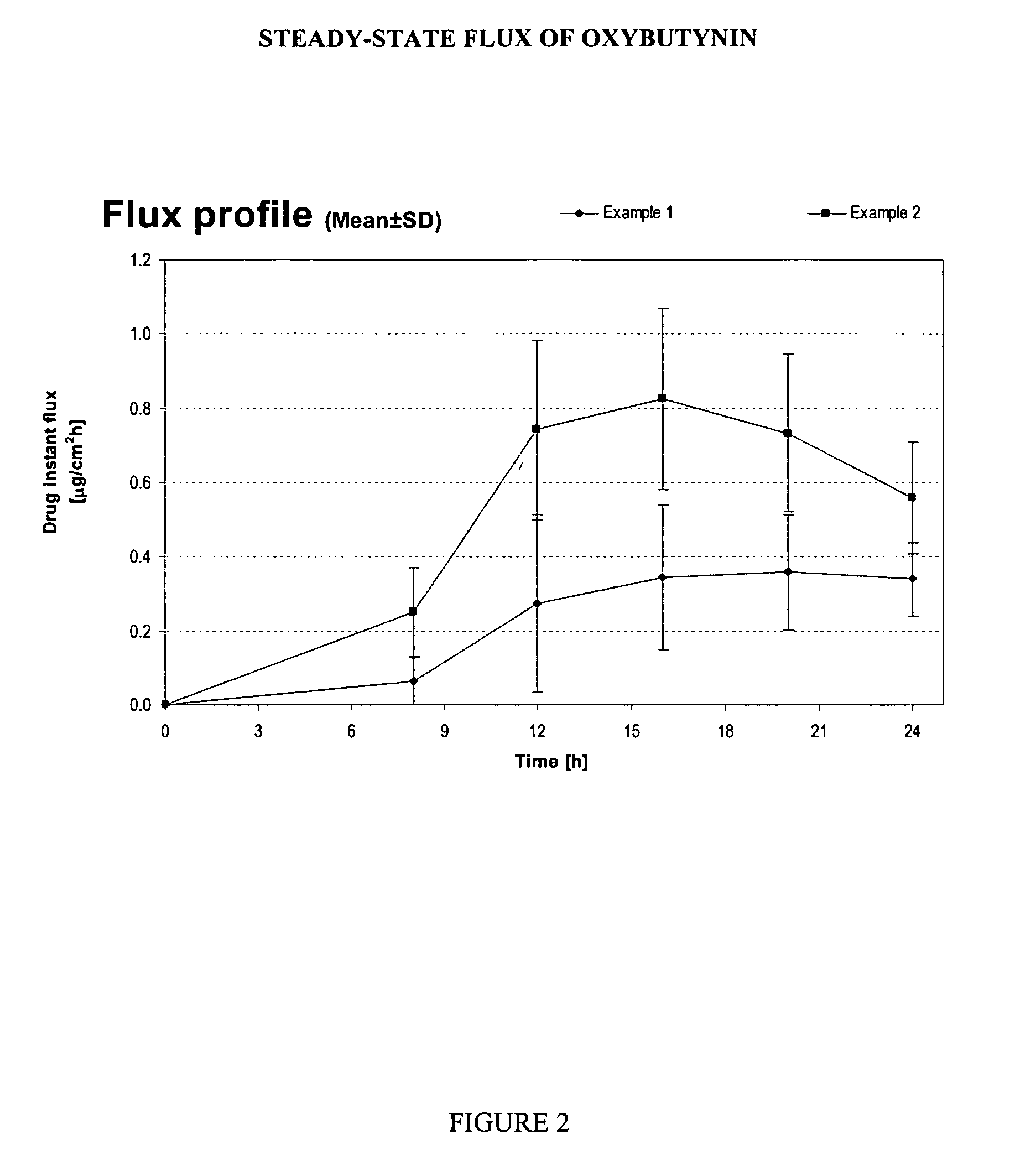

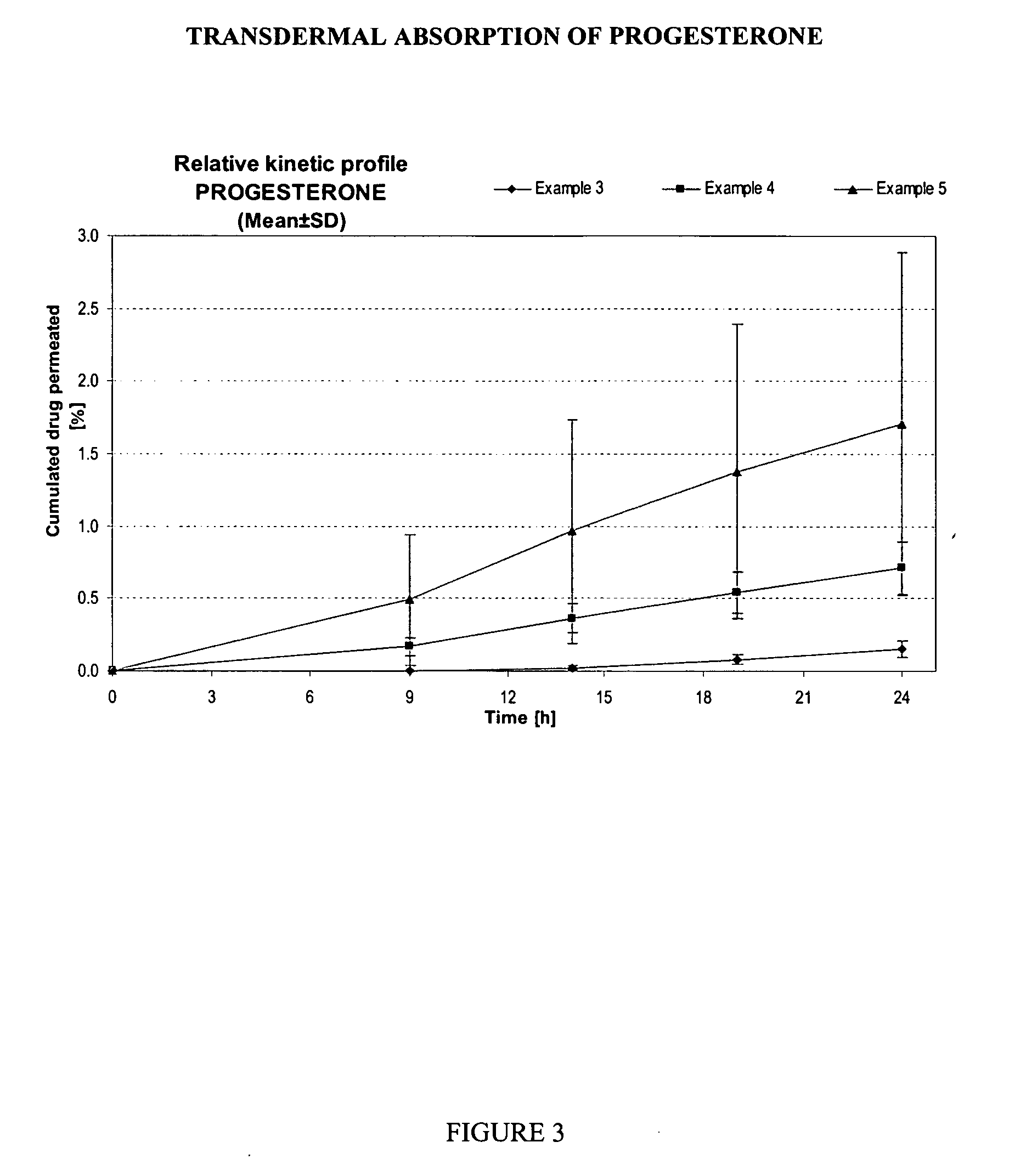

Permeation enhancer comprising genus Curcuma or germacrone for transdermal and topical administration of active agents

InactiveUS20050244522A1Increase permeationImprove permeabilityBiocideOrganic active ingredientsTetraglycolGermacrone

A formulation, method and system for the topical, transdermal or transmucosal administration of a therapeutically effective active agent. Particularly, the invention provides a formulation, system and method for enhancing the permeation or penetration of active agents across the dermal or mucosal surfaces of a mammalian subject. The formulation includes a plant extract of the genus Curcuma of the family Zingiberaceae, a germacrone, or a natural or synthetic constituent thereof, which has been found to increase penetration of the active agent across the dermal or mucosal surface. If desired, a secondary permeation enhancer of a polyalcohol, a monoalkyl ether of diethylene glycol, a tetraglycol, or a mixture thereof can be used for certain active agents for optimal permeation enhancement.

Owner:ANTARES PHARMA IPL

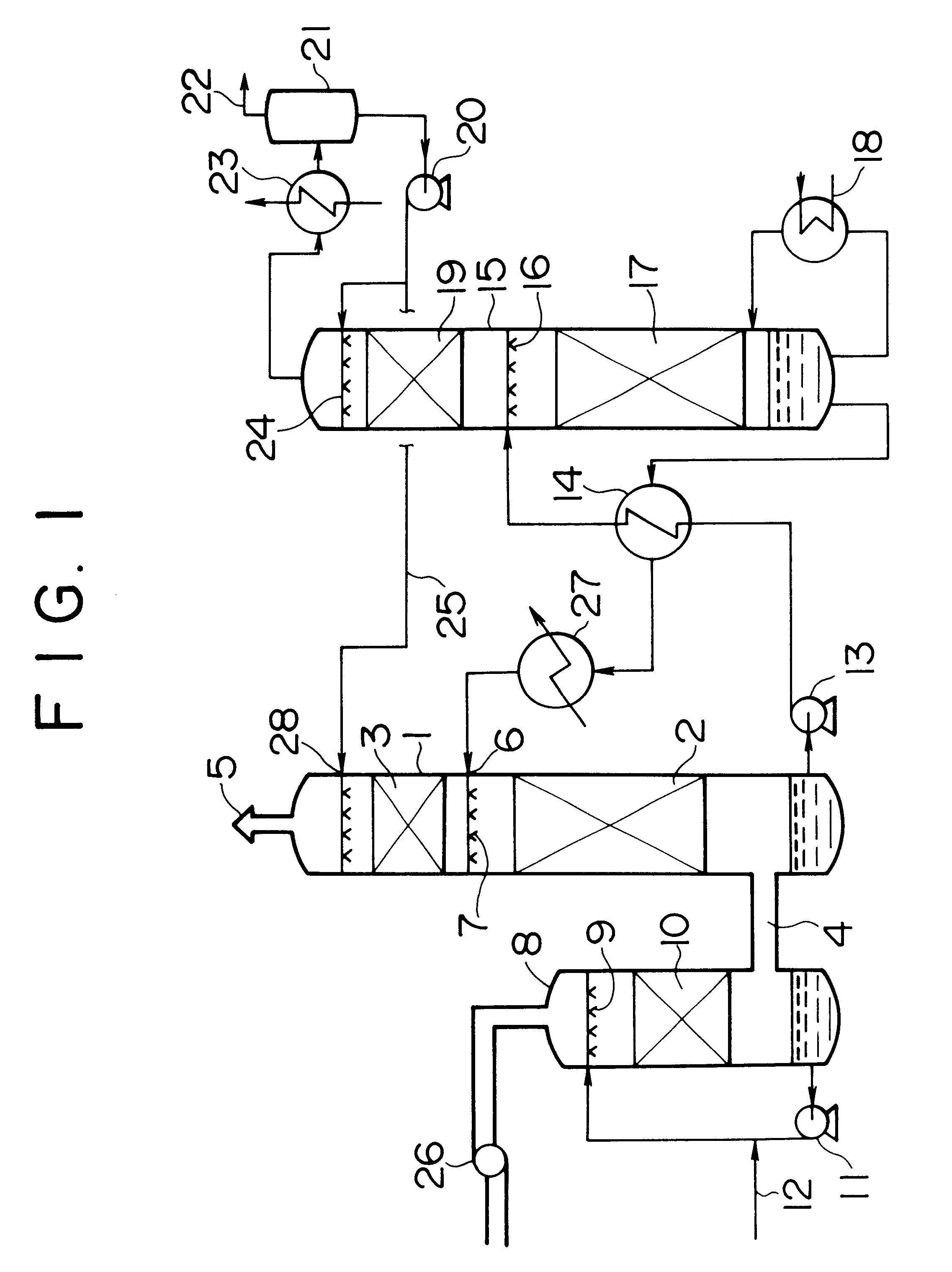

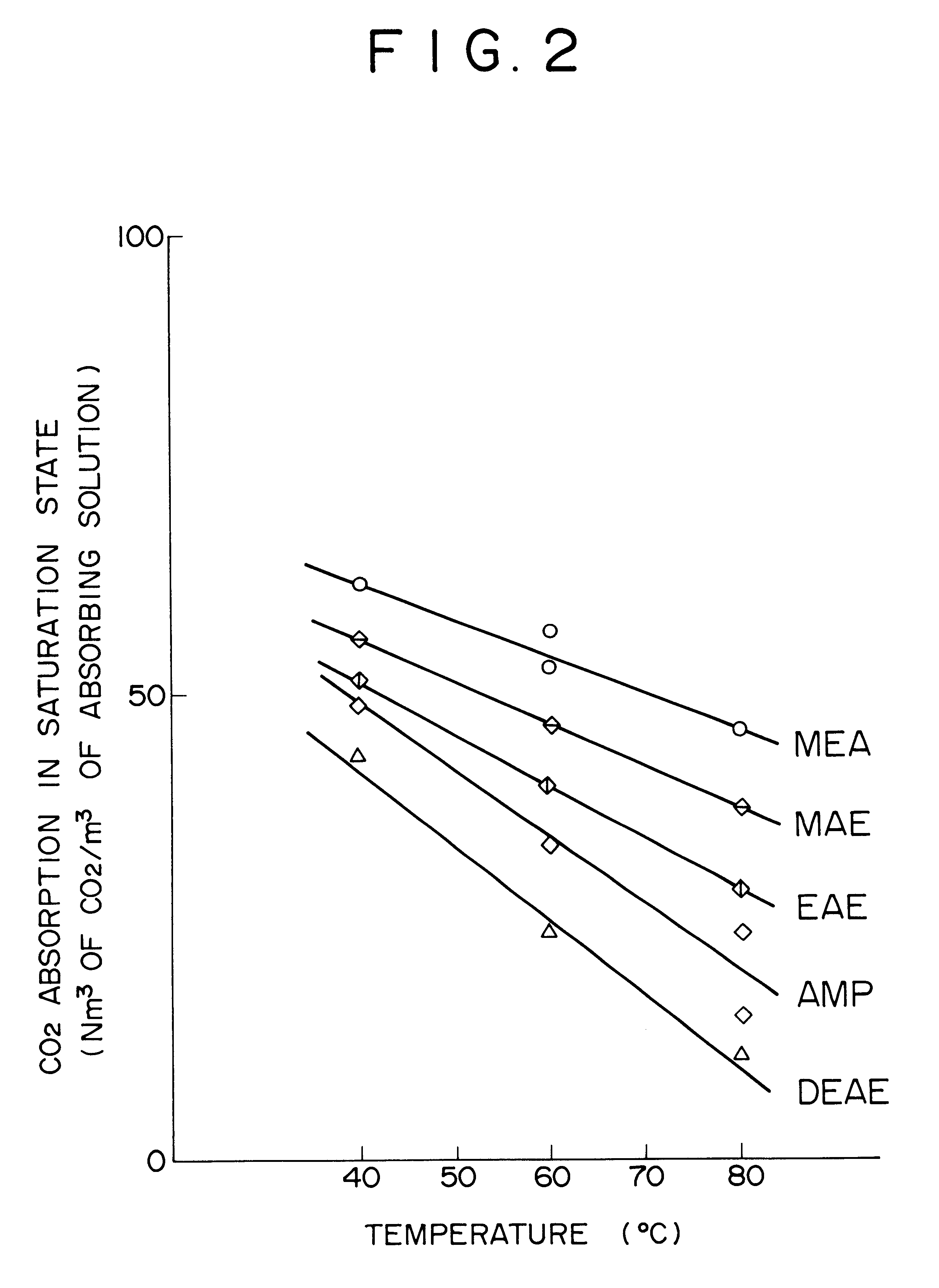

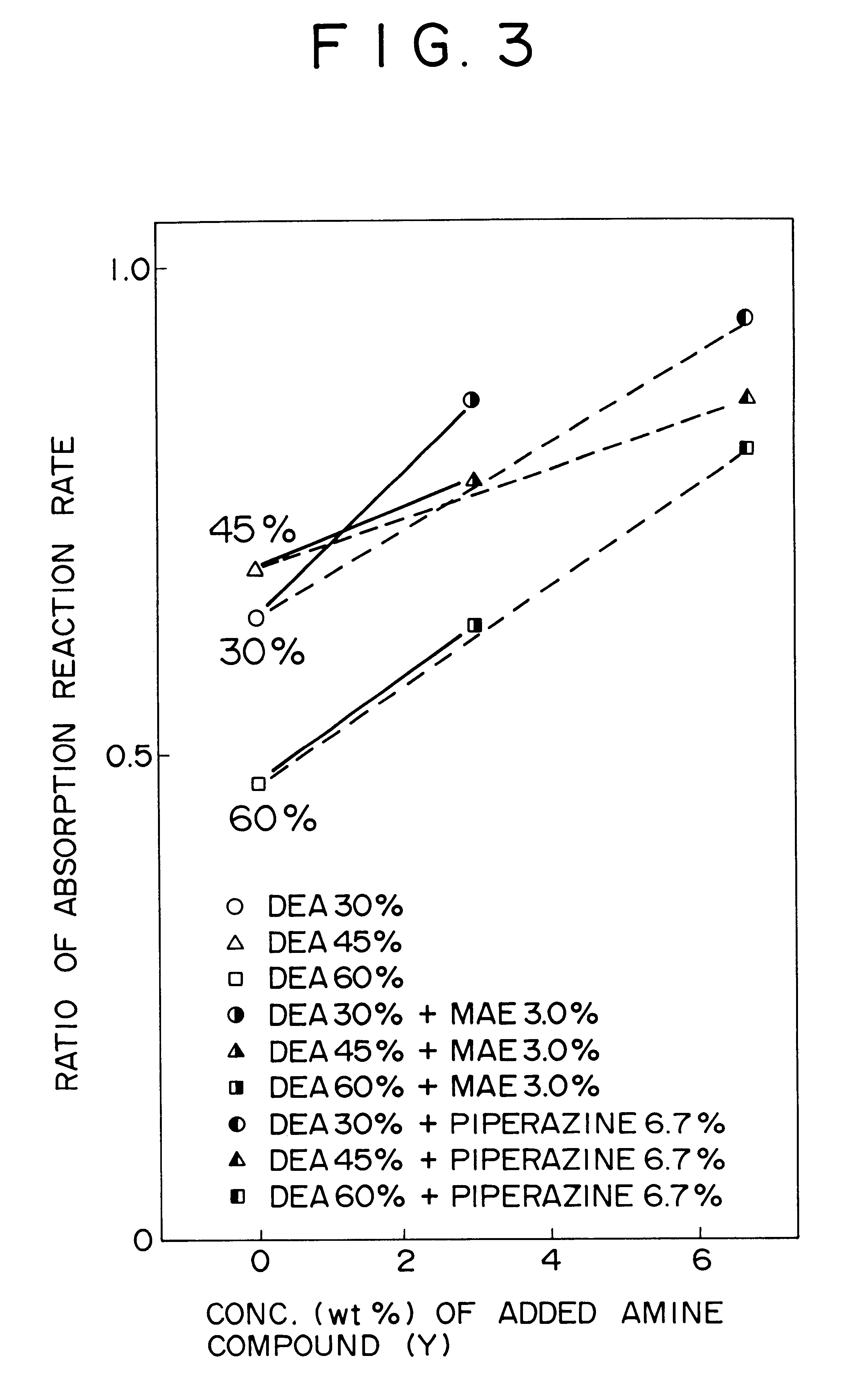

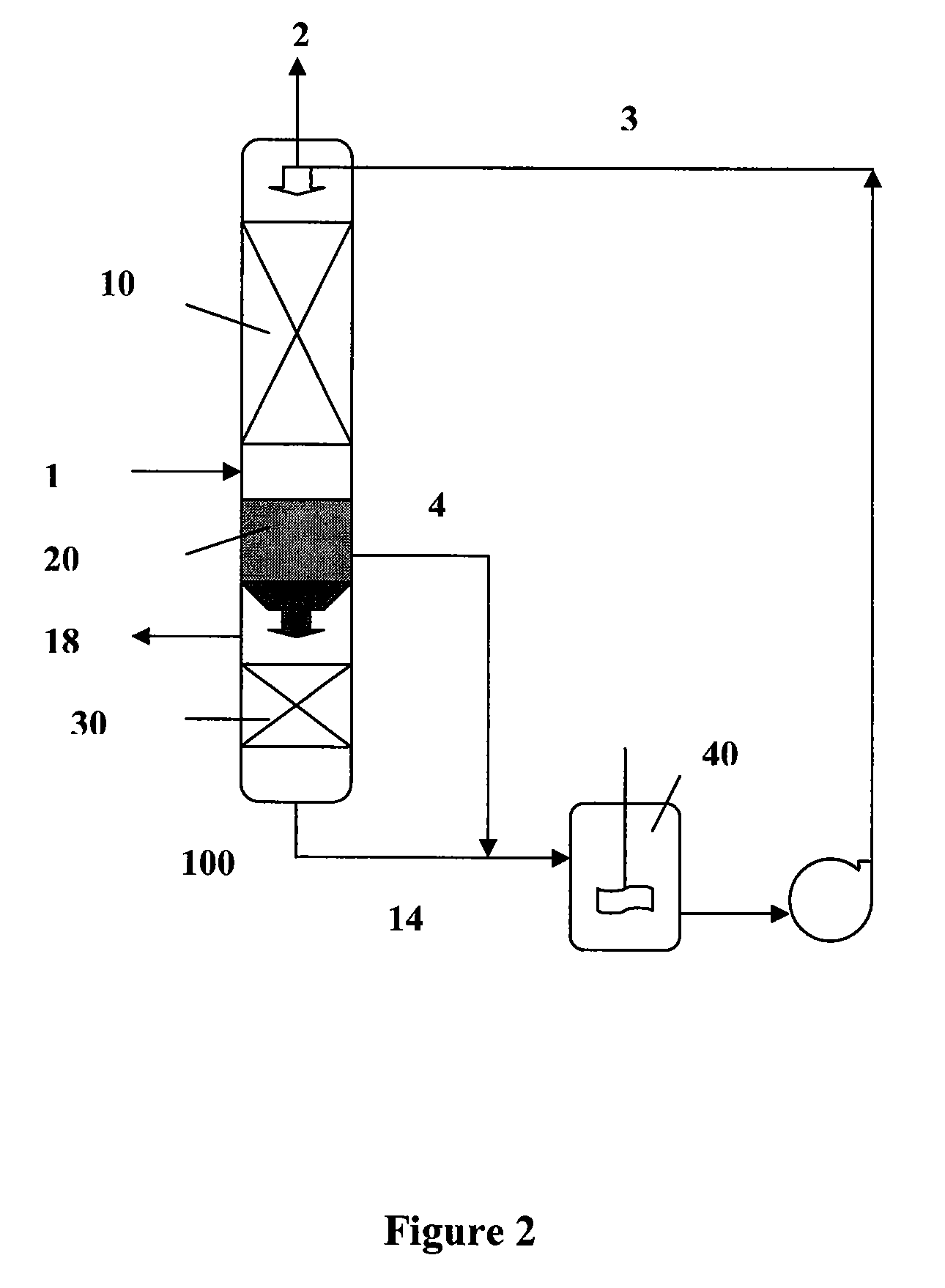

Method for removing carbon dioxide from combustion exhaust gas

InactiveUS6500397B1Improve absorption rateHigh absorption rateHydrogen sulfidesDispersed particle separation2-methylaminoethanolMorpholine

There are disclosed a method for removing CO2 from a combustion exhaust gas which comprises the step of bringing the combustion exhaust gas under atmospheric pressure into contact with an aqueous solution of a hindered amine selected from the group consisting of 2-amino-2-methyl-1-propanol, 2-methylaminoethanol, 2-ethylamino-ethanol and 2-piperidineethanol; and another method for removing carbon dioxide from a combustion exhaust gas which comprises the step of bringing the combustion exhaust gas under atmospheric pressure into contact with a mixed aqueous solution of 100 parts by weight of an amine compound (X) selected from the group consisting of 2-amino-2-methyl-1, 3-propanediol, 2-amino-2-methyl-1-propanol, 2-amino-2-ethyl-1, 3-propanediol, t-butyldiethanolamine and 2-amino-2-hydroxymethyl-1,3-propanediol; and 1-25 parts by weight of an amine compound (Y) selected from the group consisting of piperazine, piperidine, morpholine, glycine, 2-methylamino-ethanol, 2-piperidineethanol and 2-ethylaminoethanol.

Owner:THE KANSAI ELECTRIC POWER CO +1

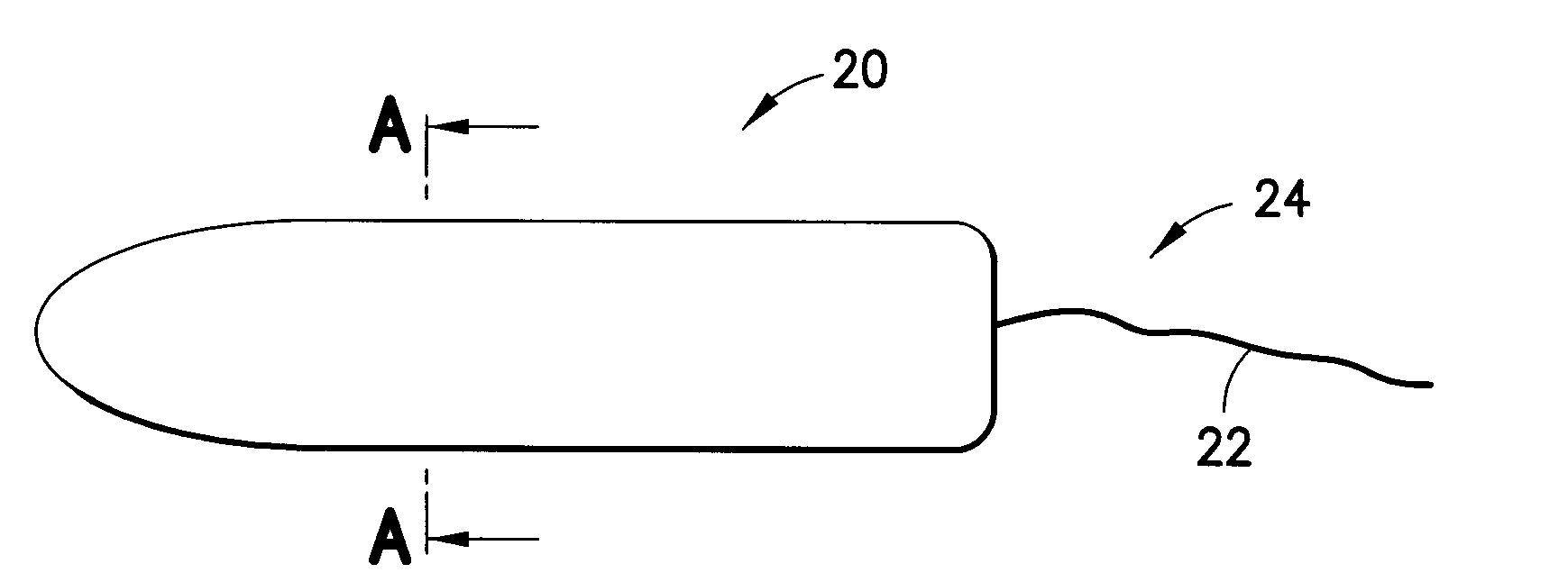

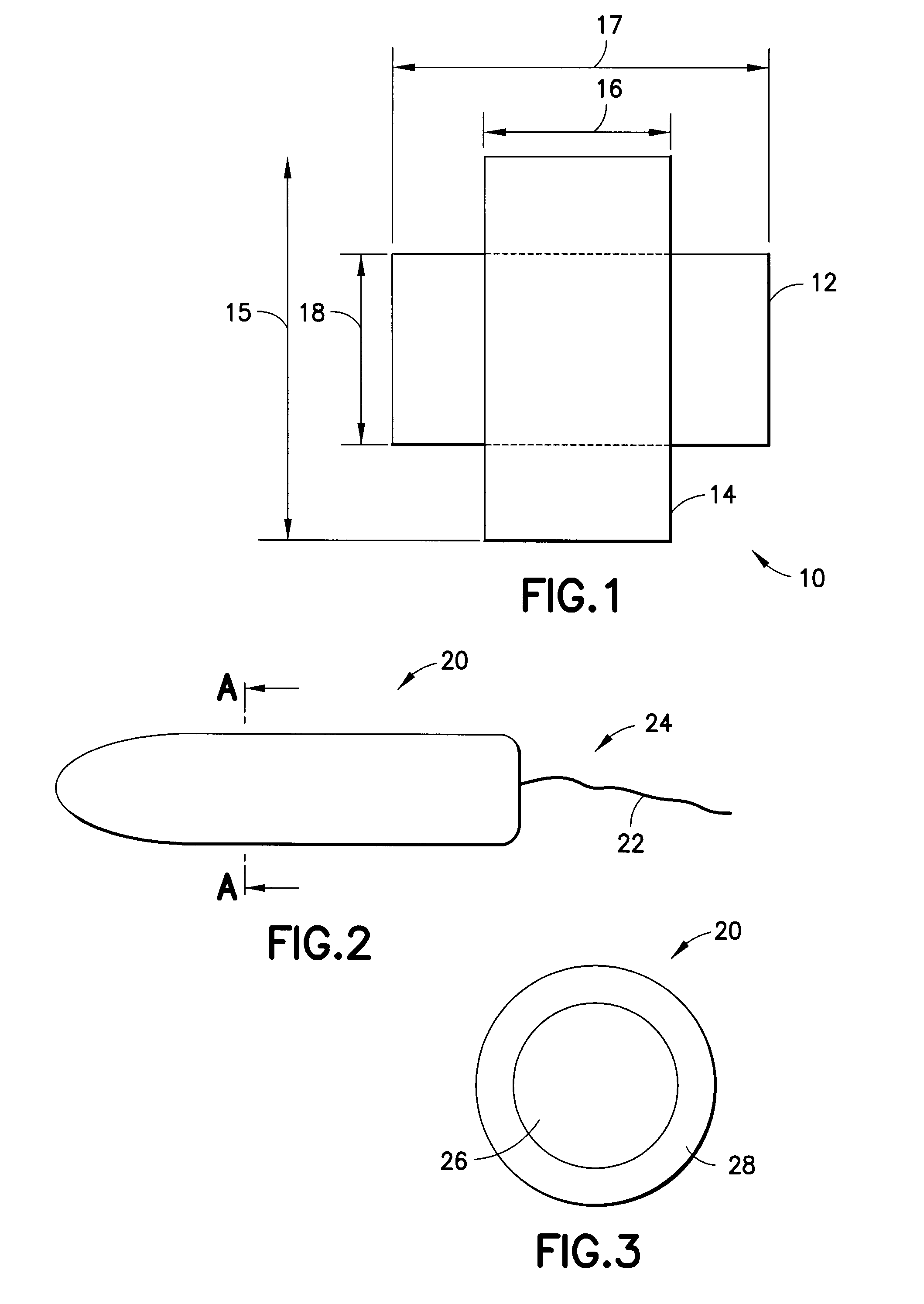

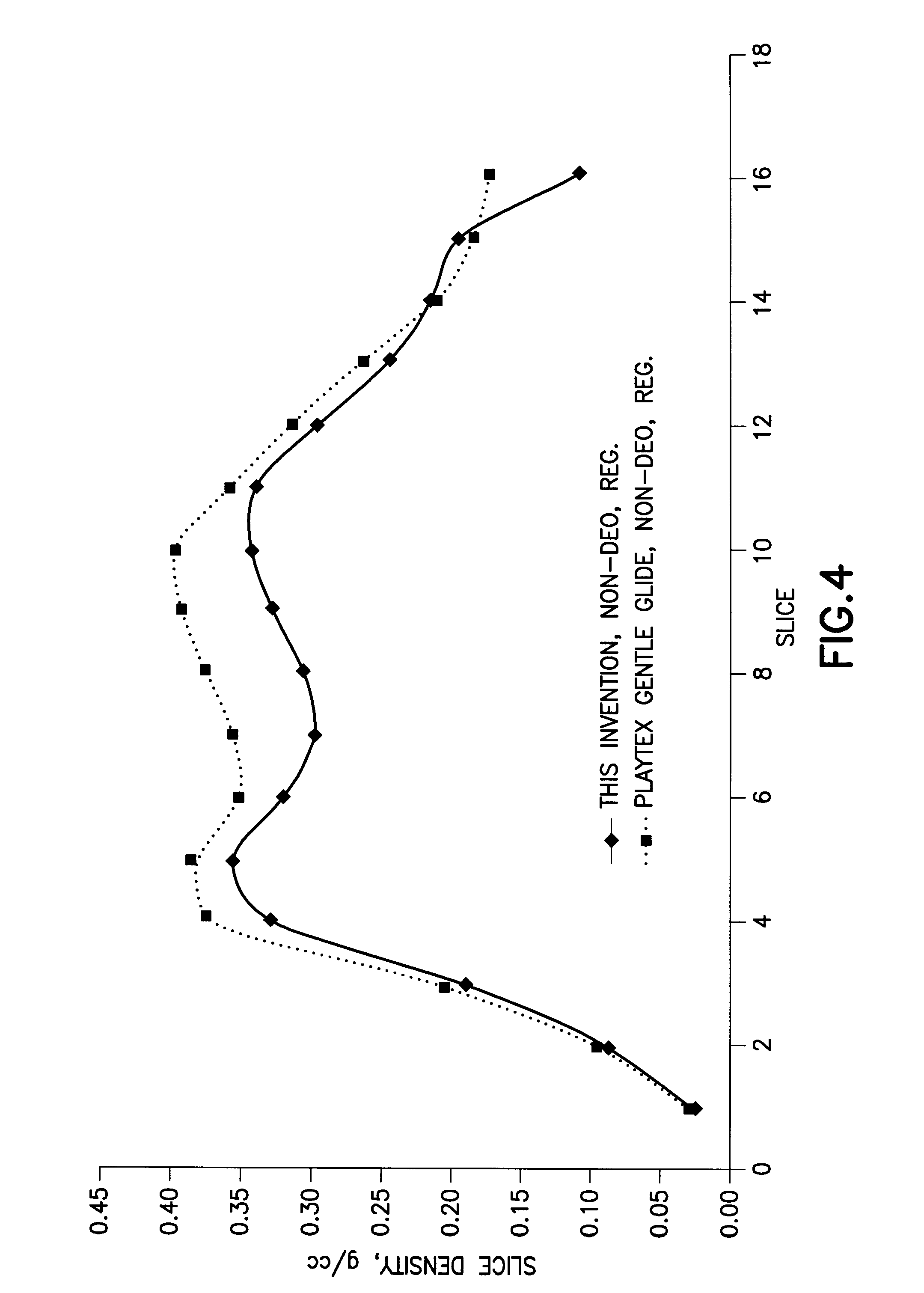

Tampon pledget for increased by-pass leakage protection

InactiveUS20080287902A1Increase in of absorbency capacityIncrease in rate of absorbencyBaby linensTamponsMedicineTamponade

The present invention provides a tampon pledget with one or more of the following properties: increased absorbency rate; high absorbent capacity and fluid retention; rapid expansion potential; and ease of ejection of the pledget from the applicator. Surprisingly, the one or more properties are achieved by using a modified dual cross-pad, folded, compressed tampon pledget design.

Owner:PLAYTEX PROD INC

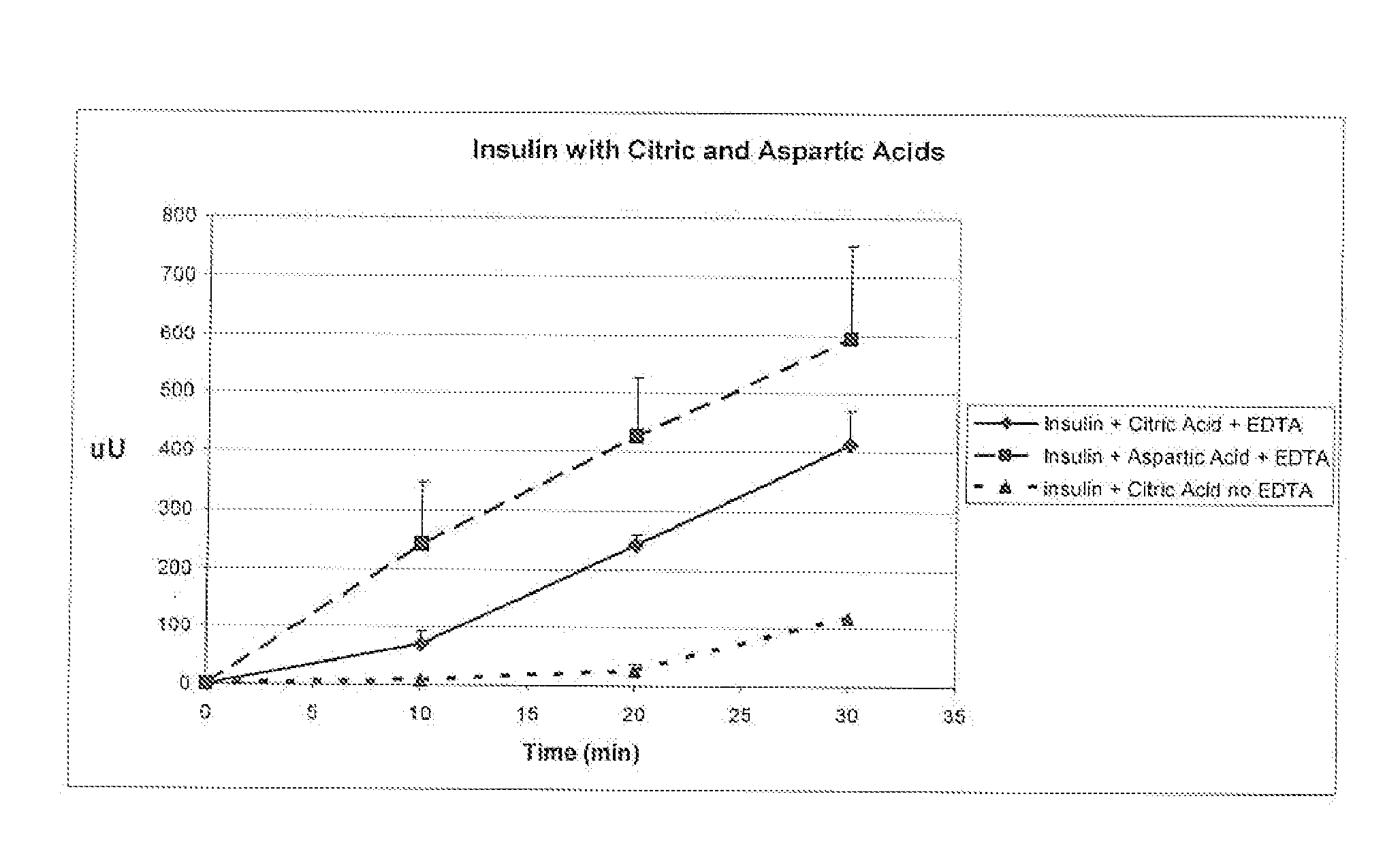

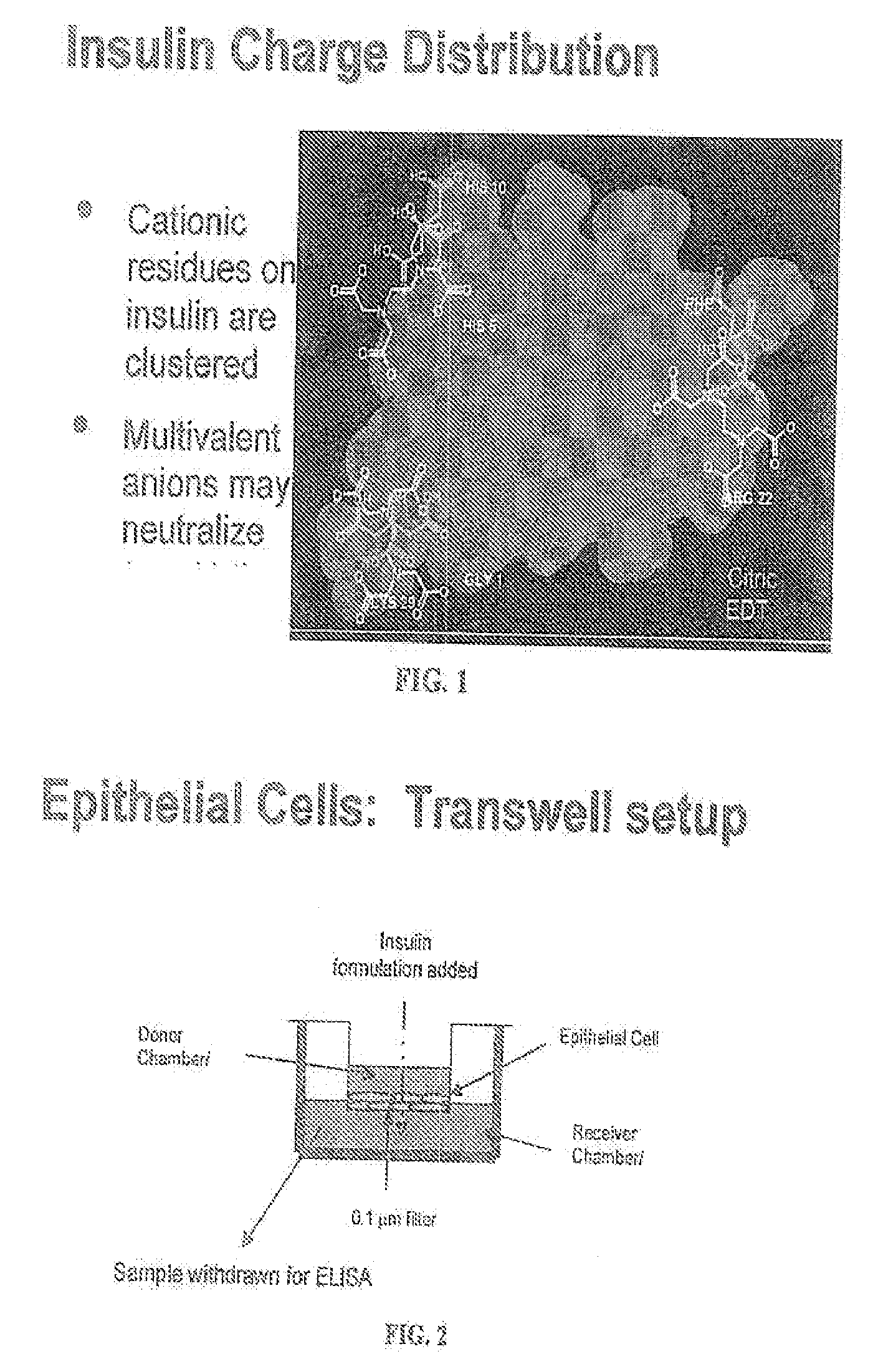

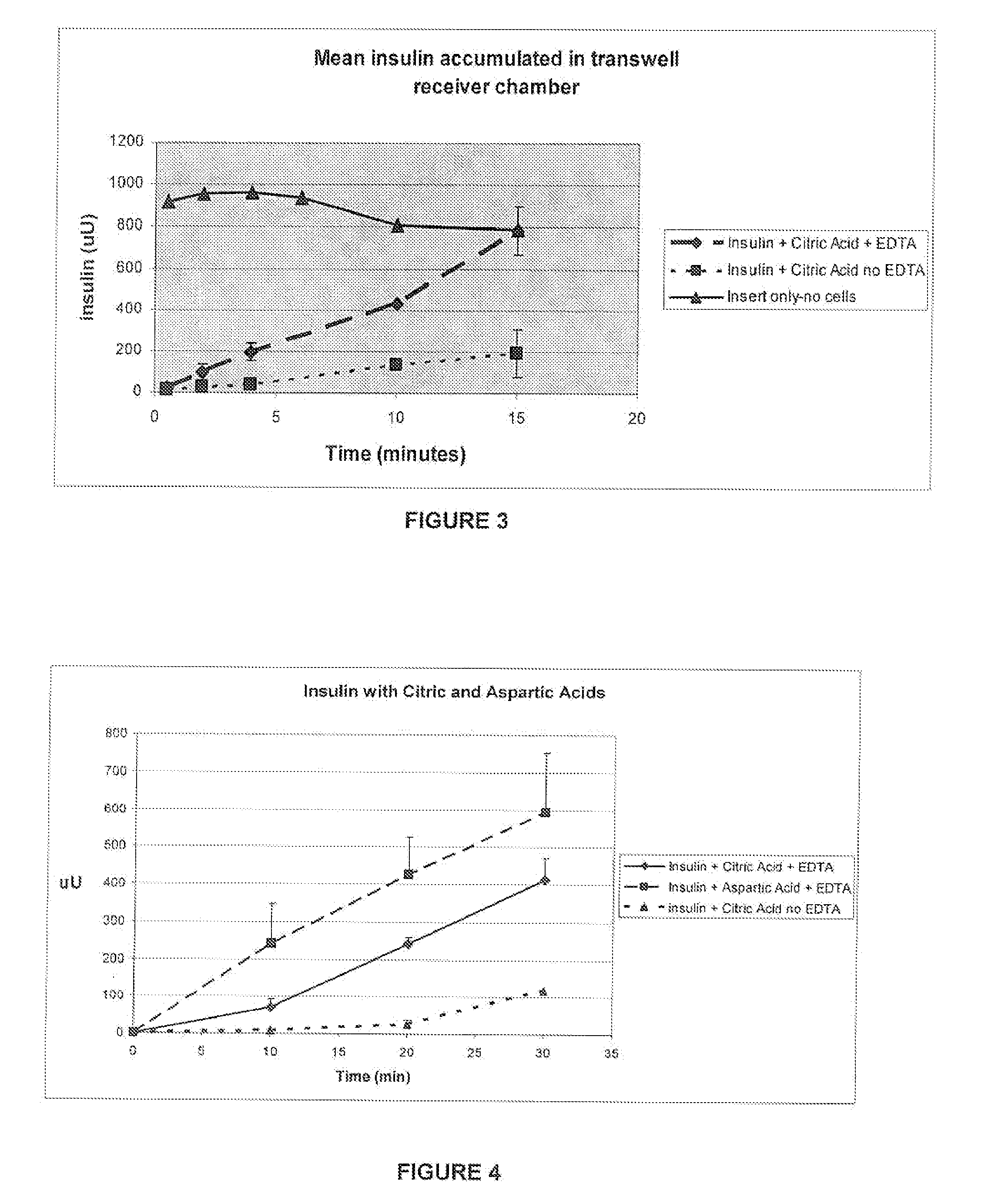

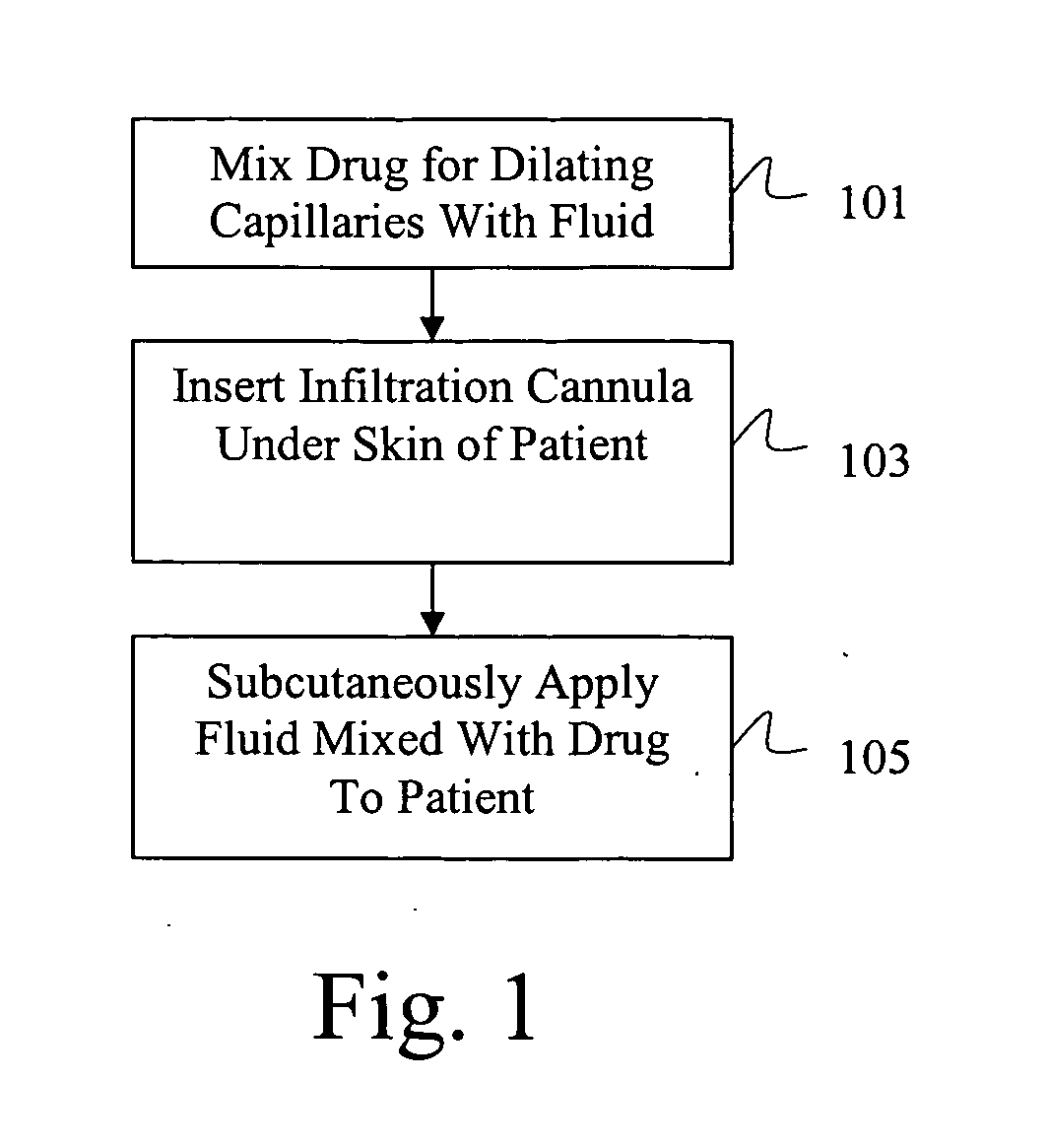

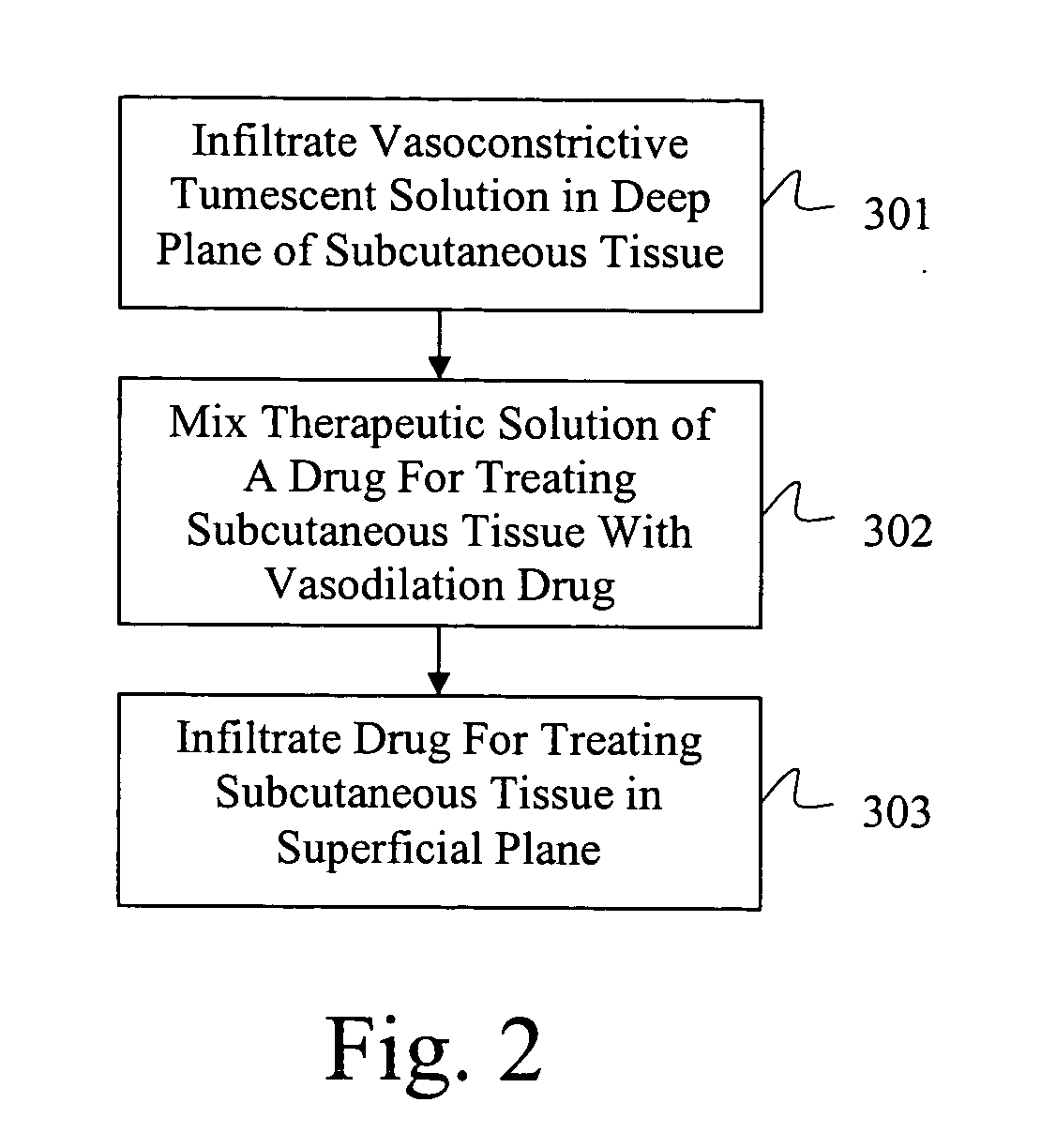

Rapid acting and long acting insulin combination formulations

ActiveUS20080039368A1Increase speedReduce the amount of solutionPeptide/protein ingredientsMetabolism disorderBefore BreakfastIntensive insulinotherapy

A combined rapid acting-long acting insulin formulation has been developed wherein the pH of the rapid acting insulin is adjusted so that the long acting glargine remains soluble when they are mixed together. In the preferred embodiment, this injectable basal bolus insulin is administered before breakfast, provides adequate bolus insulin levels to cover the meal, does not produce hypoglycemia after the meal and provides adequate basal insulin for 24 hours. Lunch and dinner can be covered by two bolus injections of a fast acting, or a rapid acting or a very rapid acting insulin. As a result, a patient using intensive insulin therapy should only inject three, rather than four, times a day. Experiments have been performed to demonstrate, the importance of the addition of specific acids to hexameric insulin to enhance speed and amount of absorption and preserve bioactivity following dissociation into the monomeric form by addition of a chelator such as EDTA. As shown by the examples, the preferred acids are aspartic, maleic, succinic, glutamic and citric acid. These are added in addition to a chelator, preferably ethylenediaminetetraacetic acid (EDTA). The results show that the citric acid formulation was more effective at dropping the blood glucose rapidly than the identical rapid acting formulation prepared with HCl in swine. Charge masking by the polyacid appears to be responsible for rapid insulin absorption. EDTA was not effective when used with adipic acid, oxalic acid or HCl at hastening the absorption of insulin. These results confirm the results seen in clinical subjects and patients with diabetes treated with the rapid acting insulin in combination with citric acid and EDTA.

Owner:ELI LILLY & CO

Drug delivery system for accelerated subcutaneous absorption

ActiveUS20050287134A1Prevent and delay absorptionImprove absorption rateBiocidePeptide/protein ingredientsWhole bodyVascular dilation

A method for accelerating subcutaneous absorption of a fluid or drug into the systemic circulation of a specific targeted tissue. A first drug operative to produce local capillary vasodilatation and / or increase the rate of bulk flow of solution through the interstitial space is mixed with a fluid. The fluid may contain a crystalloid solution or a dilute solution of a pharmacologic drug required for a routine or emergency therapeutic treatment for a patient. The first drug is substantially non-toxic to the patient. The fluid mixed with the first drug is then delivered subcutaneously or into deeper tissues of the patient, by use of a hyperdermic needle or infiltration cannula. As the capillaries are dilated, the fluid is efficiently absorbed and circulated systemically.

Owner:KLEIN JEFFREY A

Intradermal delivery of biological agents

InactiveUS20090012494A1Significant comprehensive benefitsMinimal expertiseBiocidePeptide/protein ingredientsActive agentWhole body

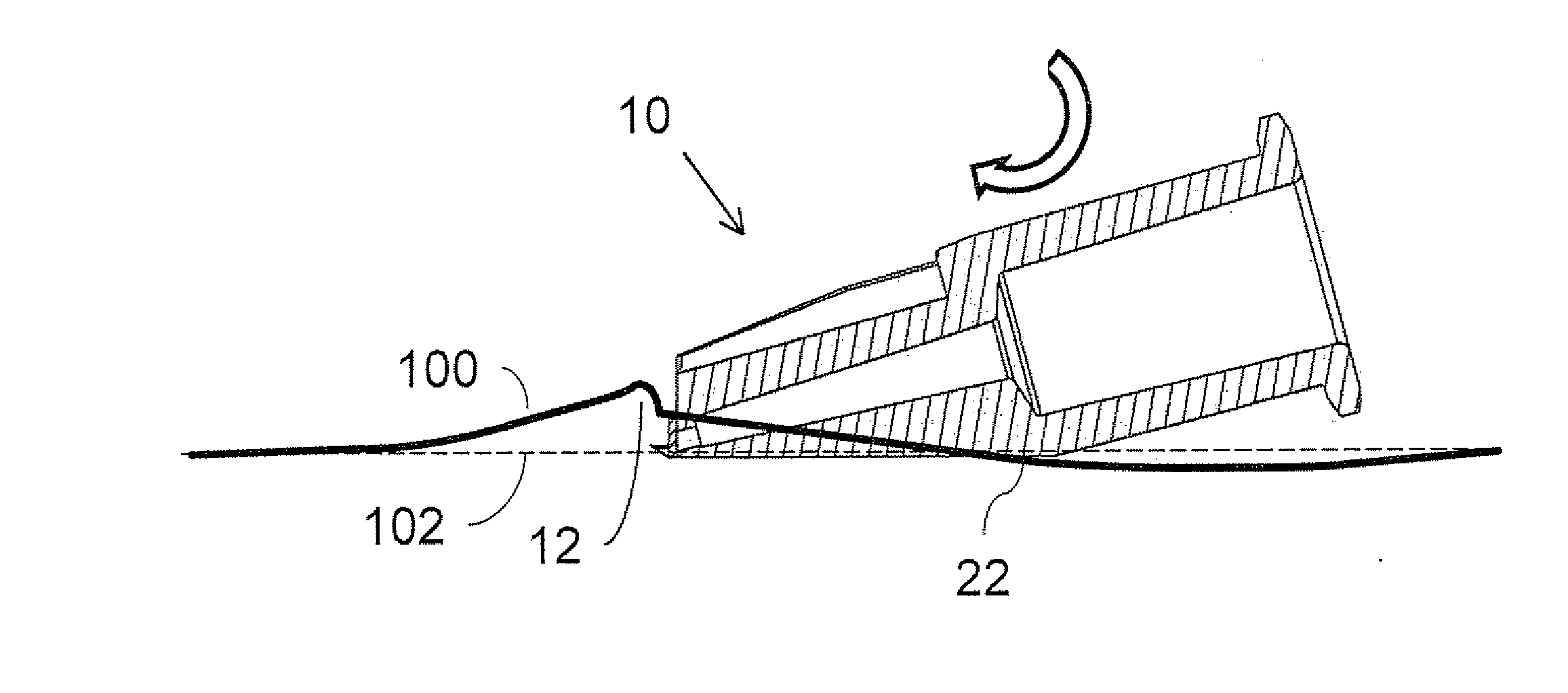

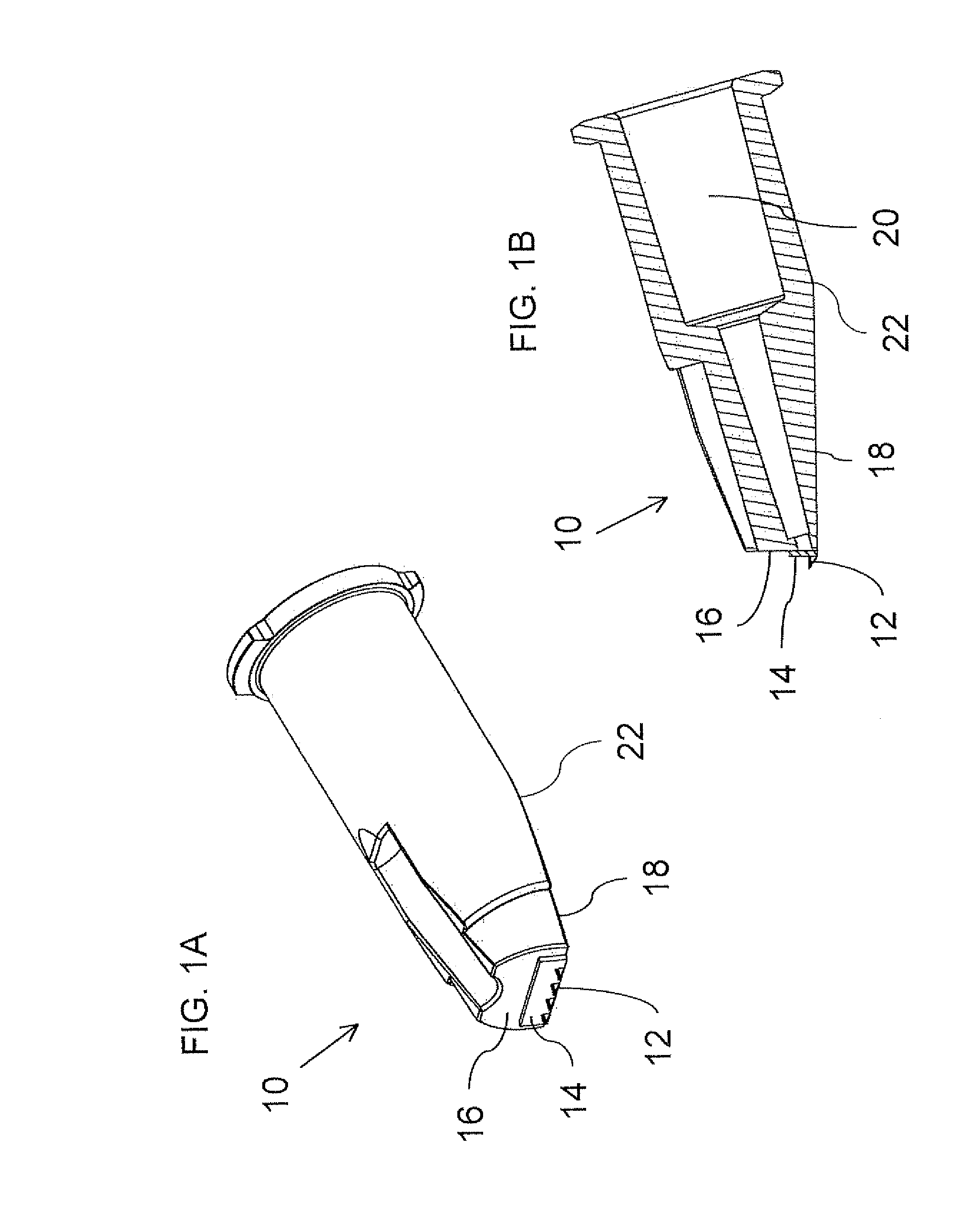

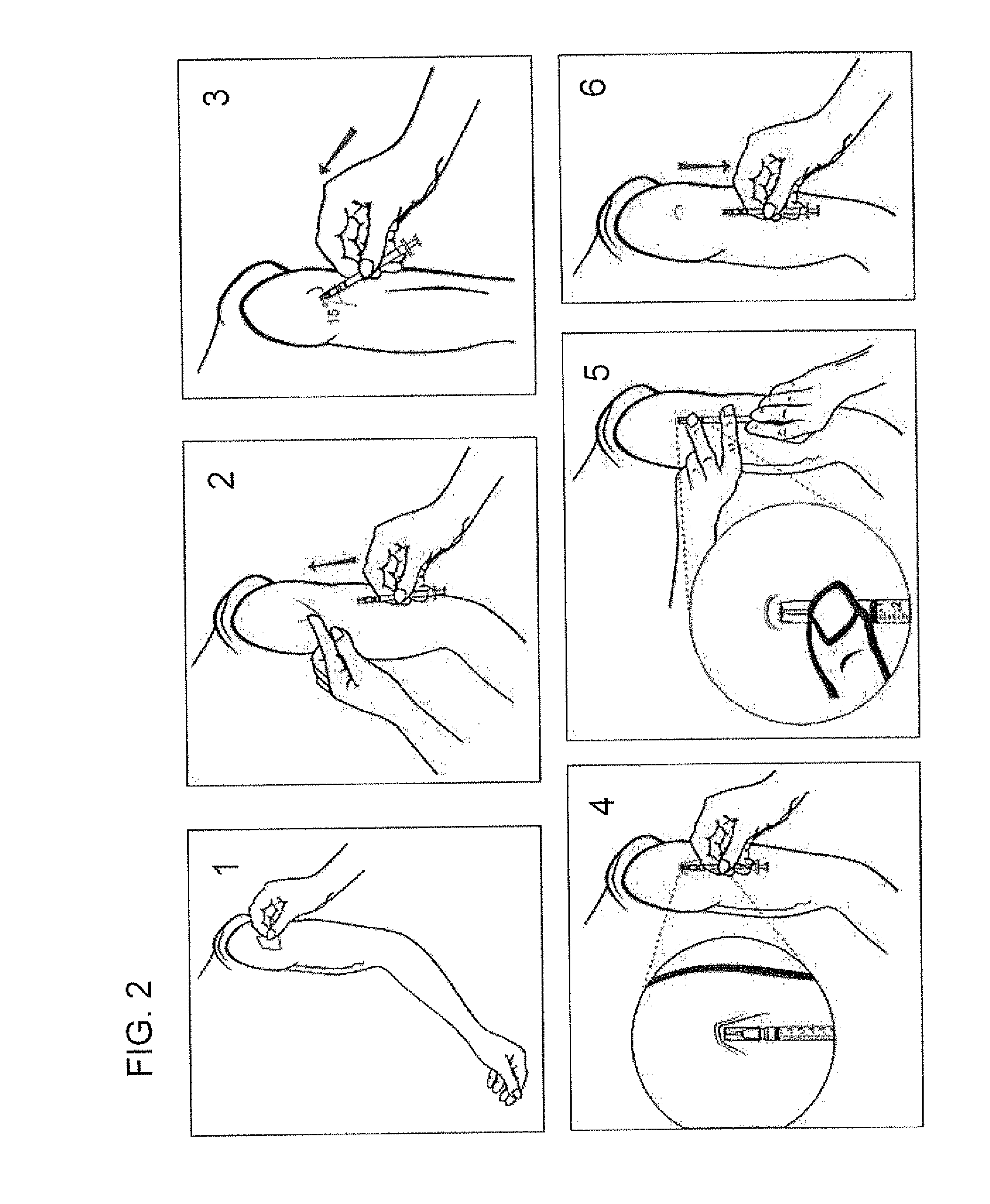

The present invention relates to methods for intradermally delivering one or more biologically active agents such as vaccines and therapeutic agents into the dermis layer of the skin of a subject to obtain systemic delivery or an immune response using a microneedle drug delivery device containing the agent to be delivered. The methods employ a microneedle device with a row of hollow microneedles. The microneedles penetrate the skin of the subject and assume an anchored state in which the microneedles are anchored in the skin and project laterally from the device. A pivotal motion is then performed with the device so that the skin in which the microneedles are engaged is lifted above the initial plane of the surface of the skin while the biologically active agent is delivered. The methods of the invention elicit increased humoral and / or cellular response as compared to conventional vaccine delivery routes, facilitating dose sparing.

Owner:NANOPASS TECH LTD

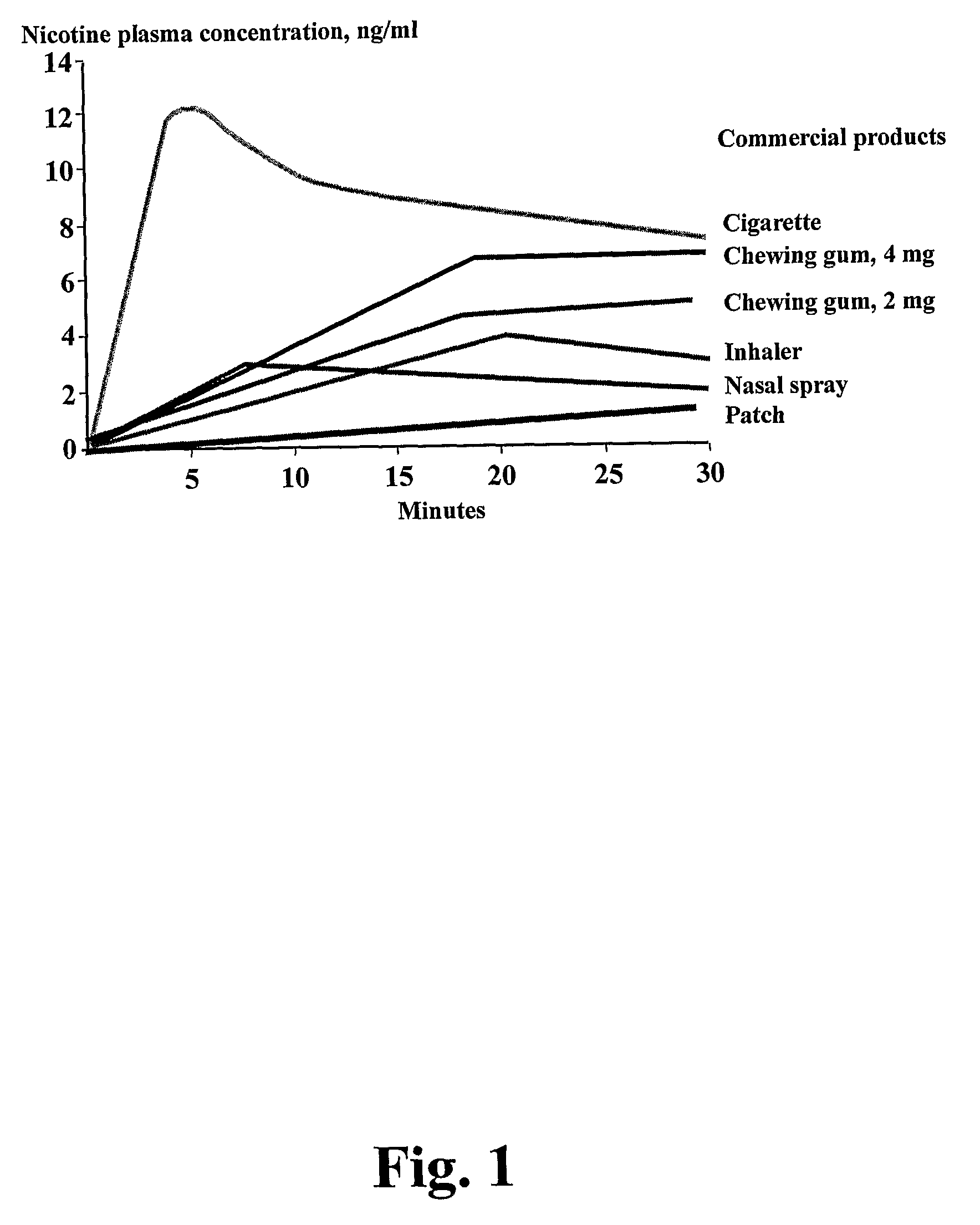

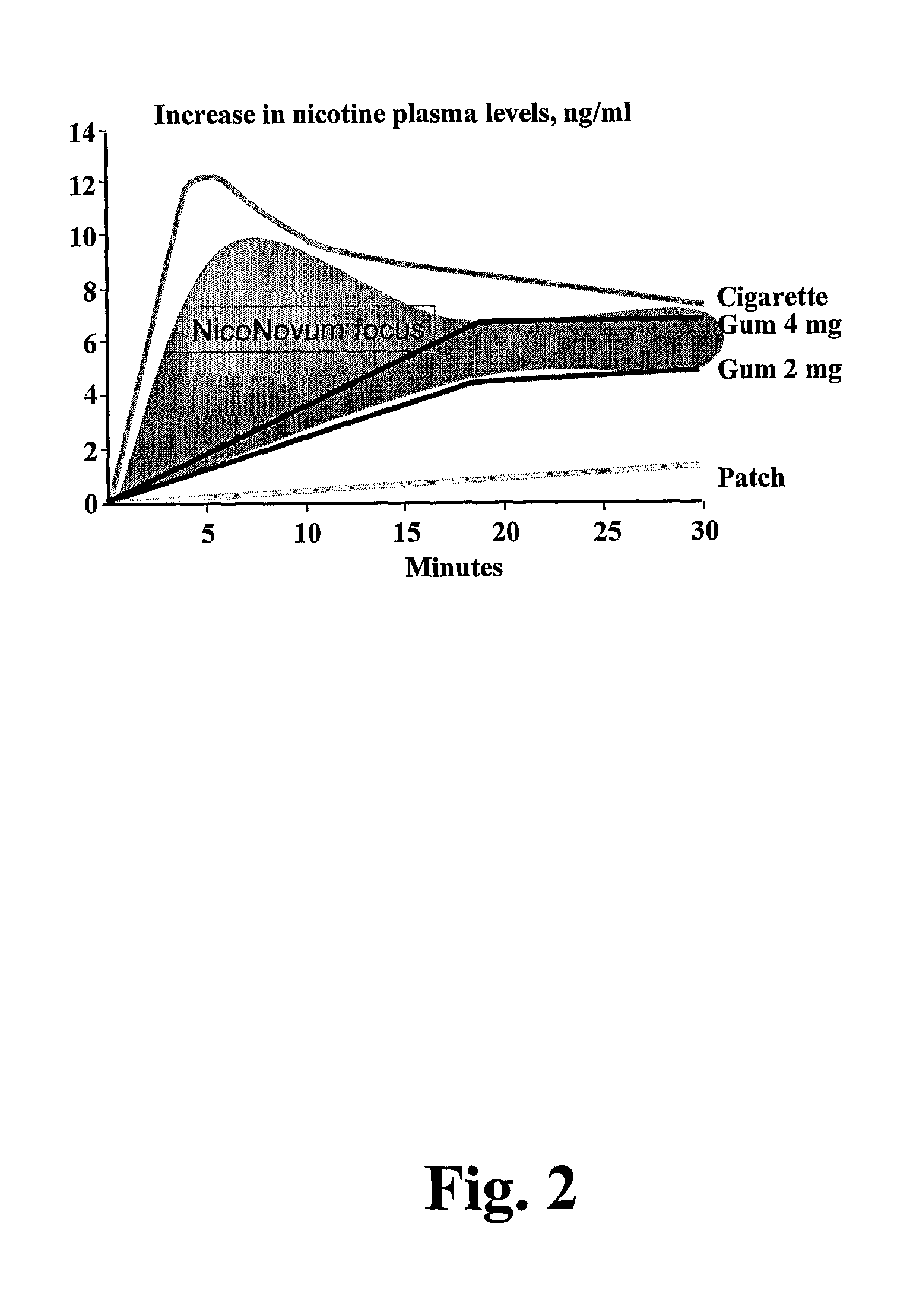

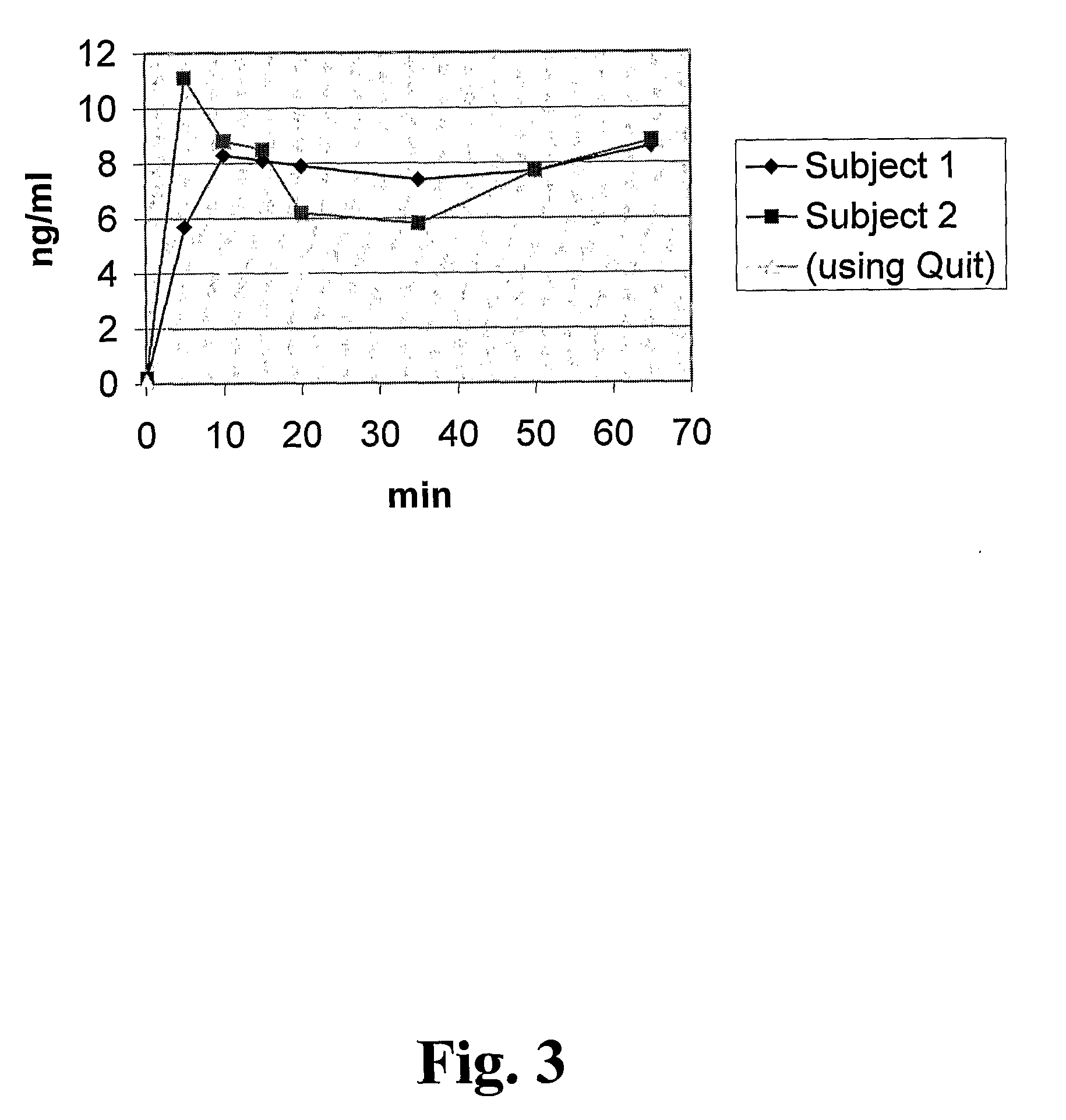

Use of an Artificial Sweetener to Enhance Absorption of Nicotine

The present invention relates to increased absorption of nicotine over the prior art. In particular the absorption of nicotine is enhanced after administration of a composition containing nicotine and a sweetener such as an artificial sweetener like saccharin to the oral mucosa in the form of a spray.

Owner:NICONOVUM AB

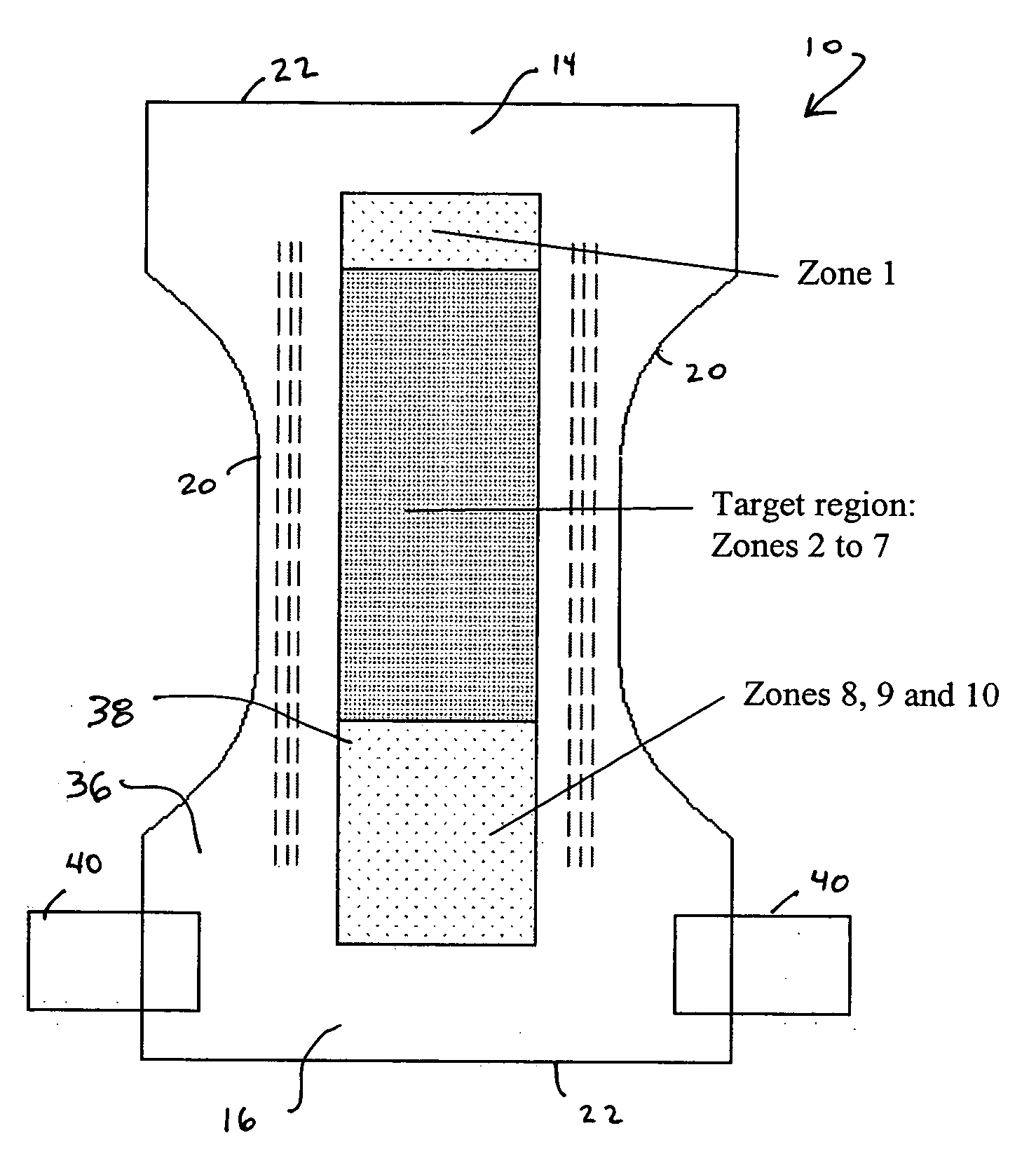

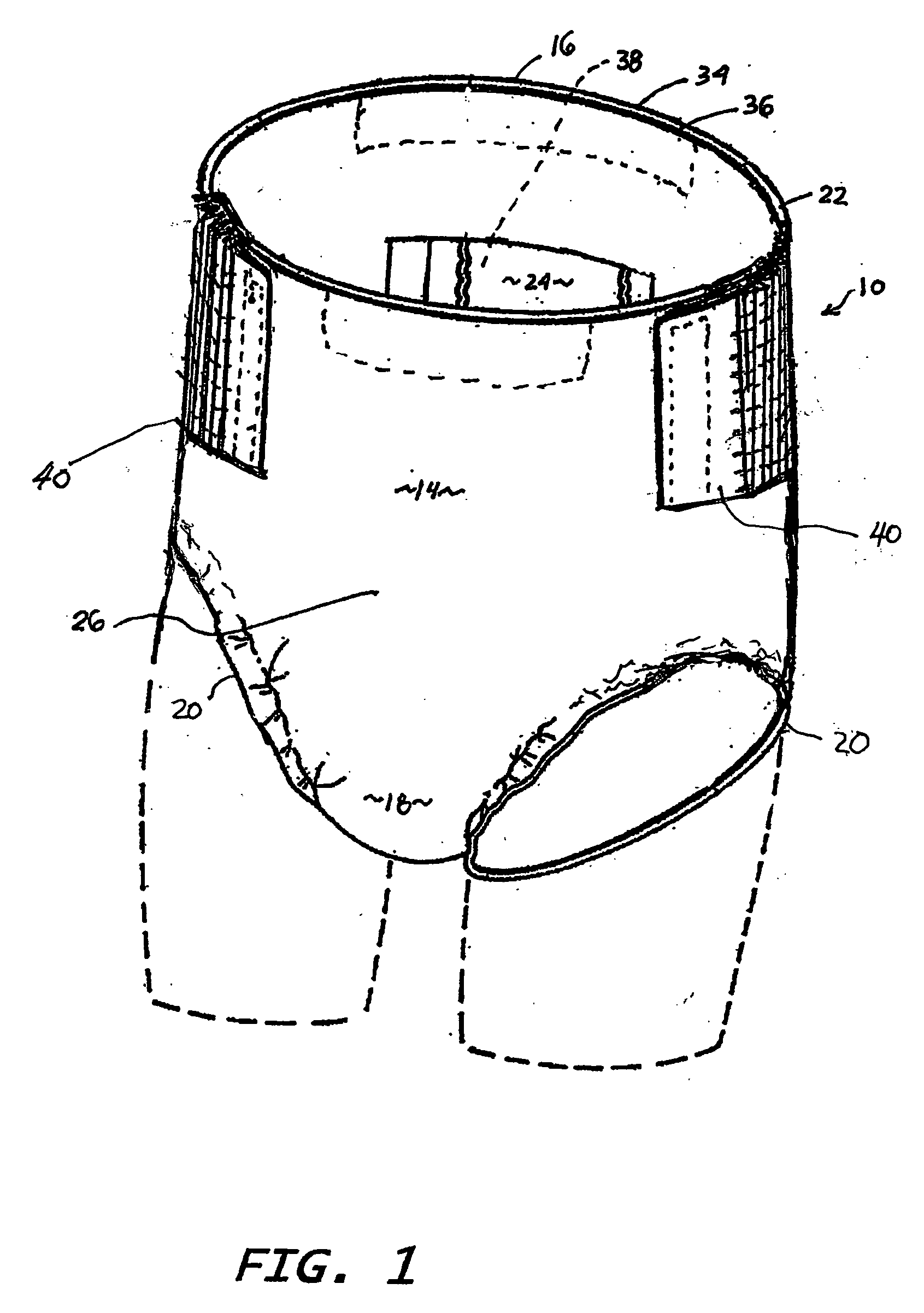

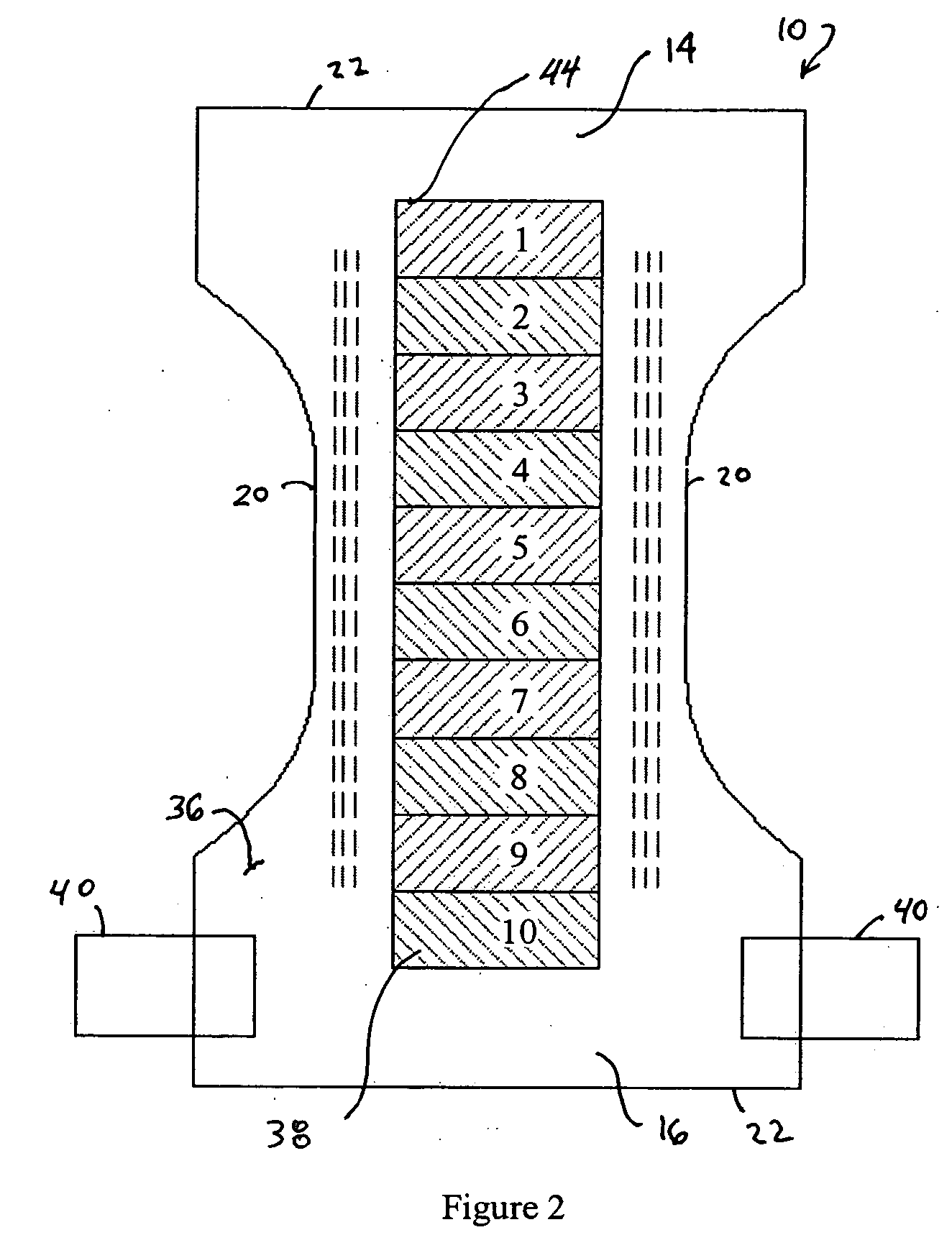

Absorbent article having pulpless absorbent core

A disposable absorbent article comprising a liquid permeable topsheet, a liquid impermeable backsheet, and an absorbent core interposed between the topsheet and the backsheet. The absorbent member is defined by a pulp-less absorbent core having a superabsorbent material providing efficient fluid handling characteristics. The absorbent core may be defined by its fluid handling properties including, but not limited to, greater absorbency rate index (ARI) and greater percentage absorbency rate index (PARI) as compared to absorbent articles of conventional pulp-containing technology.

Owner:DSG TECH HLDG

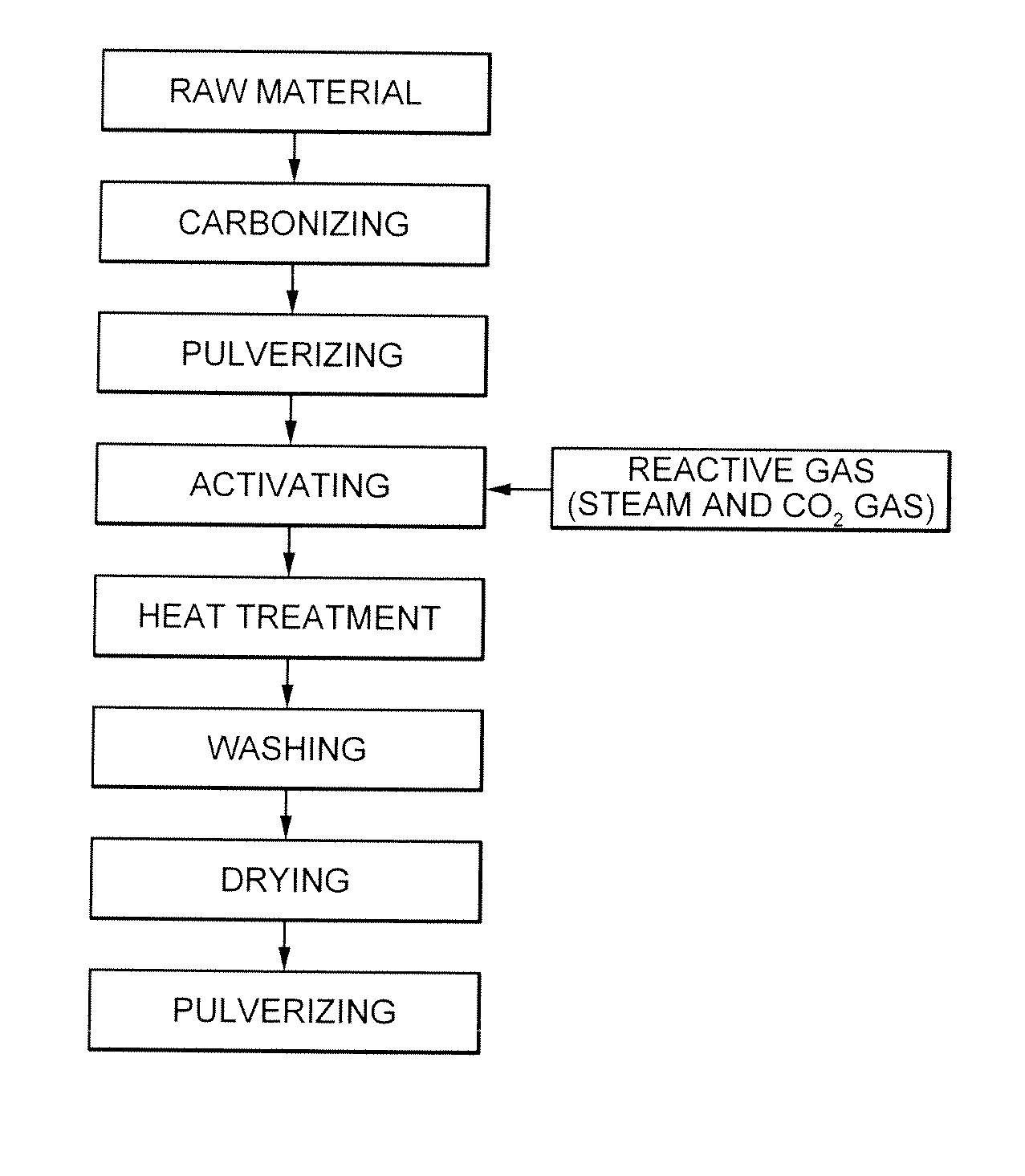

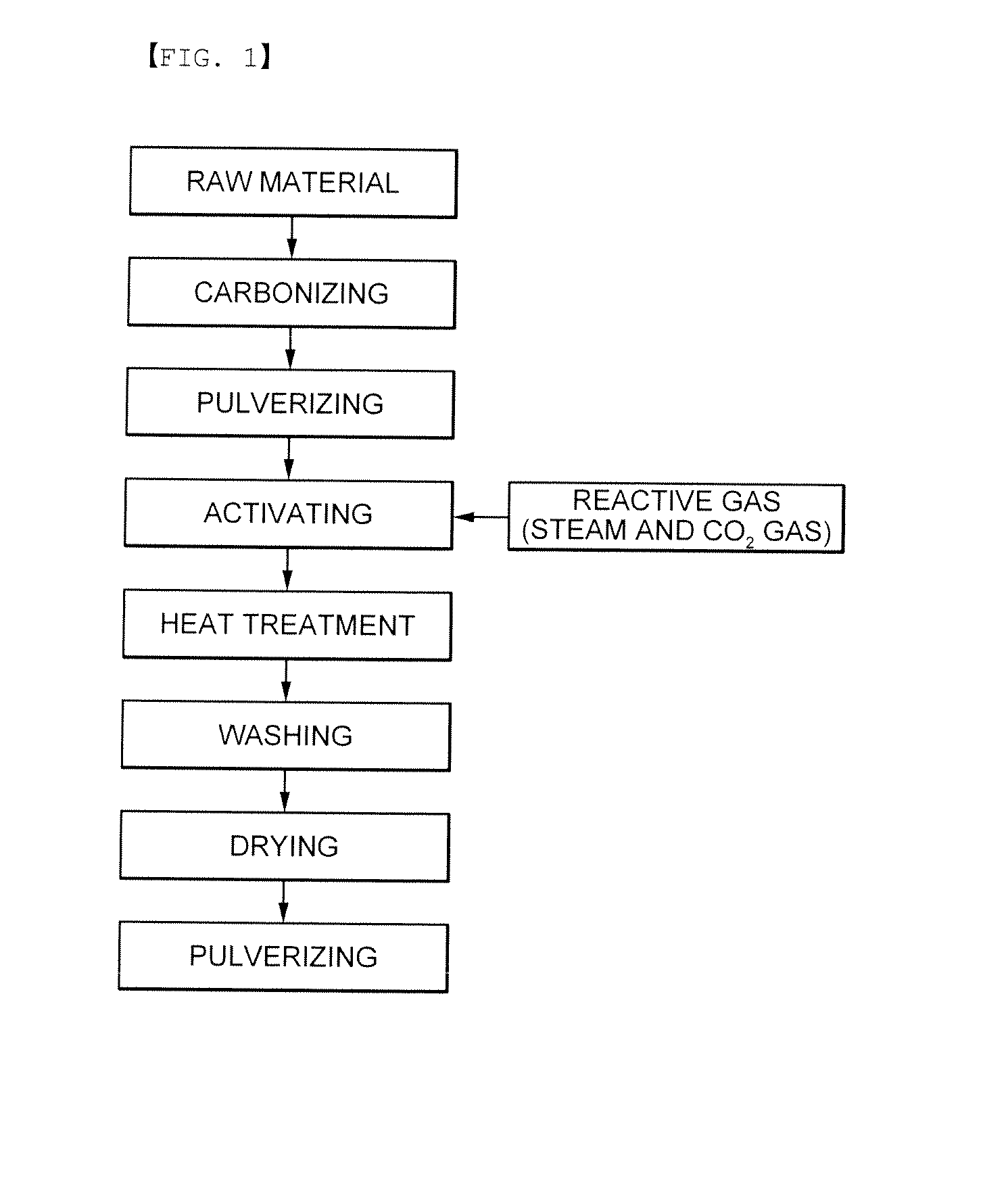

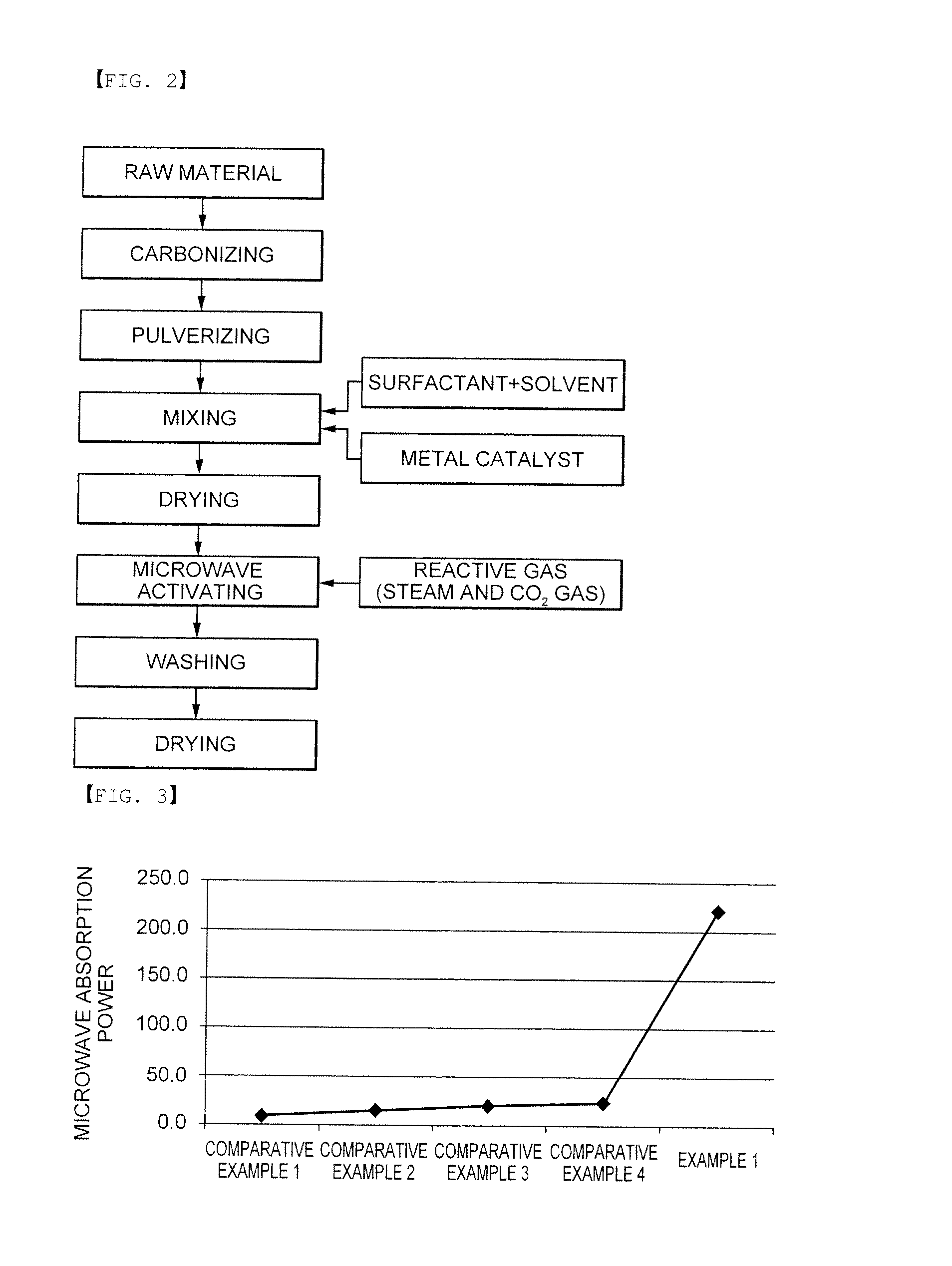

Activated carbon, method for preparing the same, and electrochemical capacitor including the same

InactiveUS20140177136A1Less surface functional groupUniform sizePigmenting treatmentCarbon compoundsActivated carbonHigh rate

Disclosed herein are an activated carbon in which pores with pore sizes of 0.3˜5 nm account for 80% or higher based on an overall pore volume, a method for preparing the activated carbon, and an electrochemical capacitor including the activated carbon, so that, since the activated carbon has uniform sized fine pores, high-rate discharge characteristics, high-rate charging and discharging characteristics, and low-temperature characteristics can be improved; since the content of functional groups on the surface of the activated carbon is low, there can be provided a supercapacitor and a lithium ion capacitor, having improved high voltage and lifespan characteristics; and the time for preparing an active material can be significantly shortened and thus the material cost and the process cost can be remarkably reduced.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

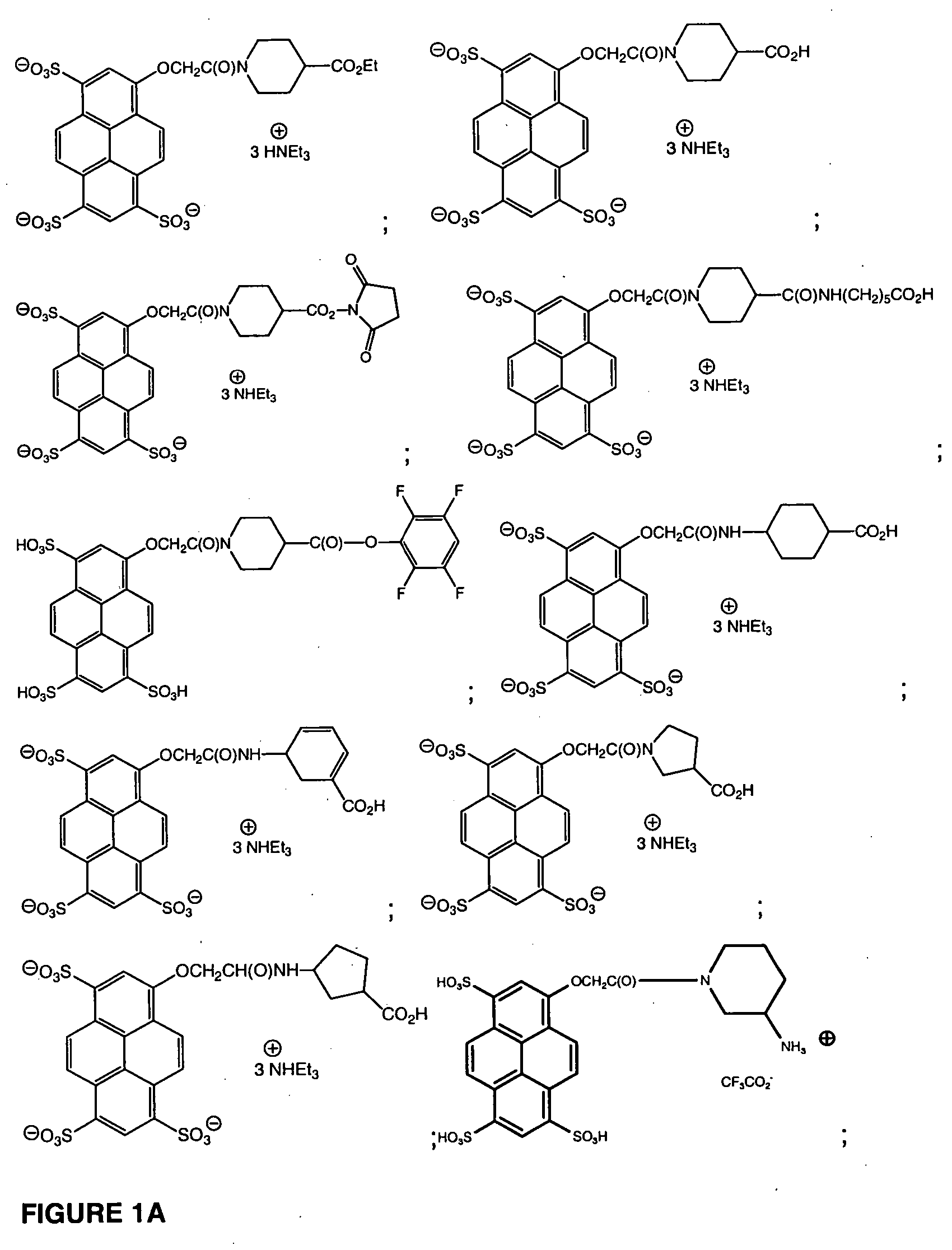

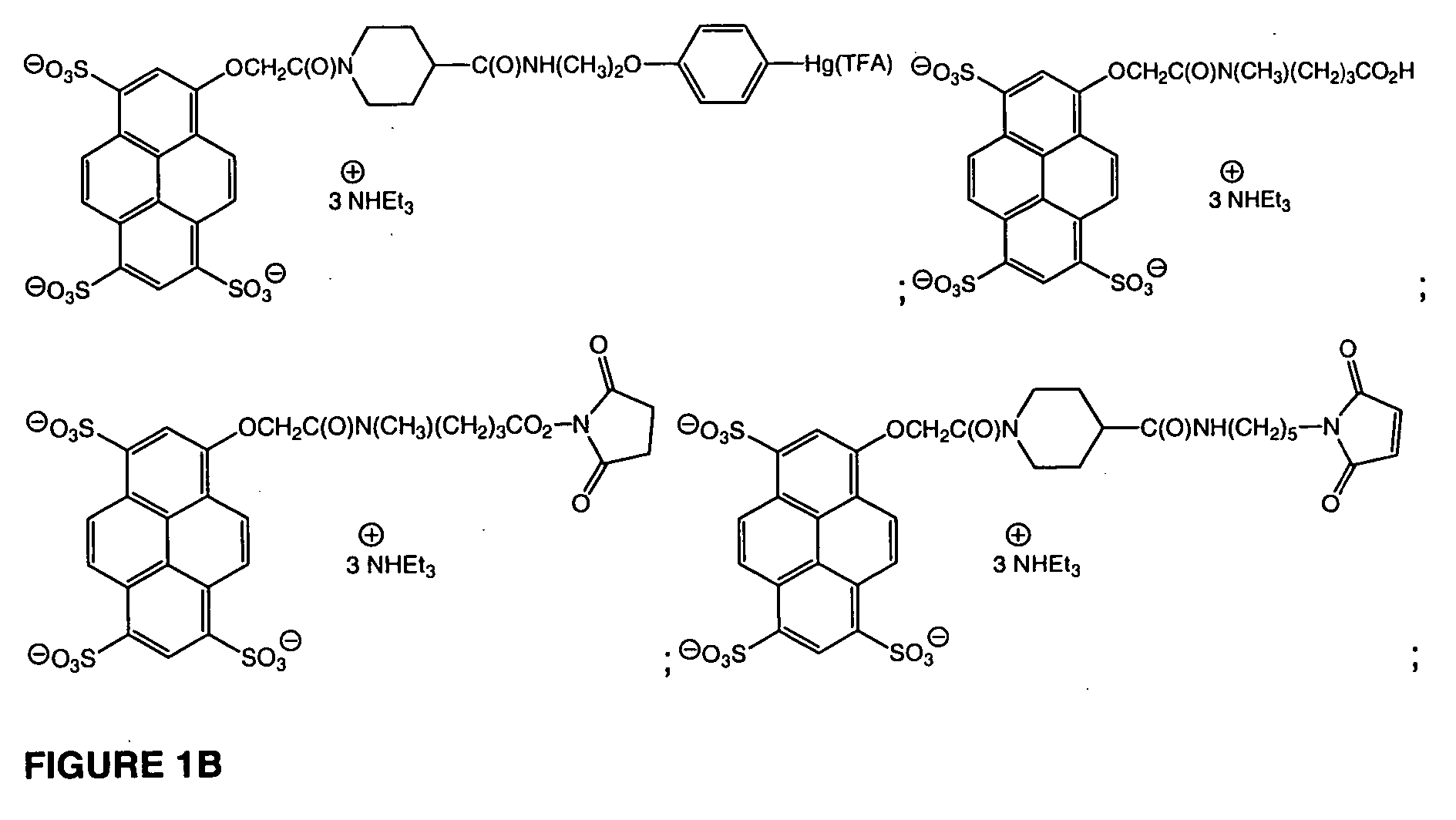

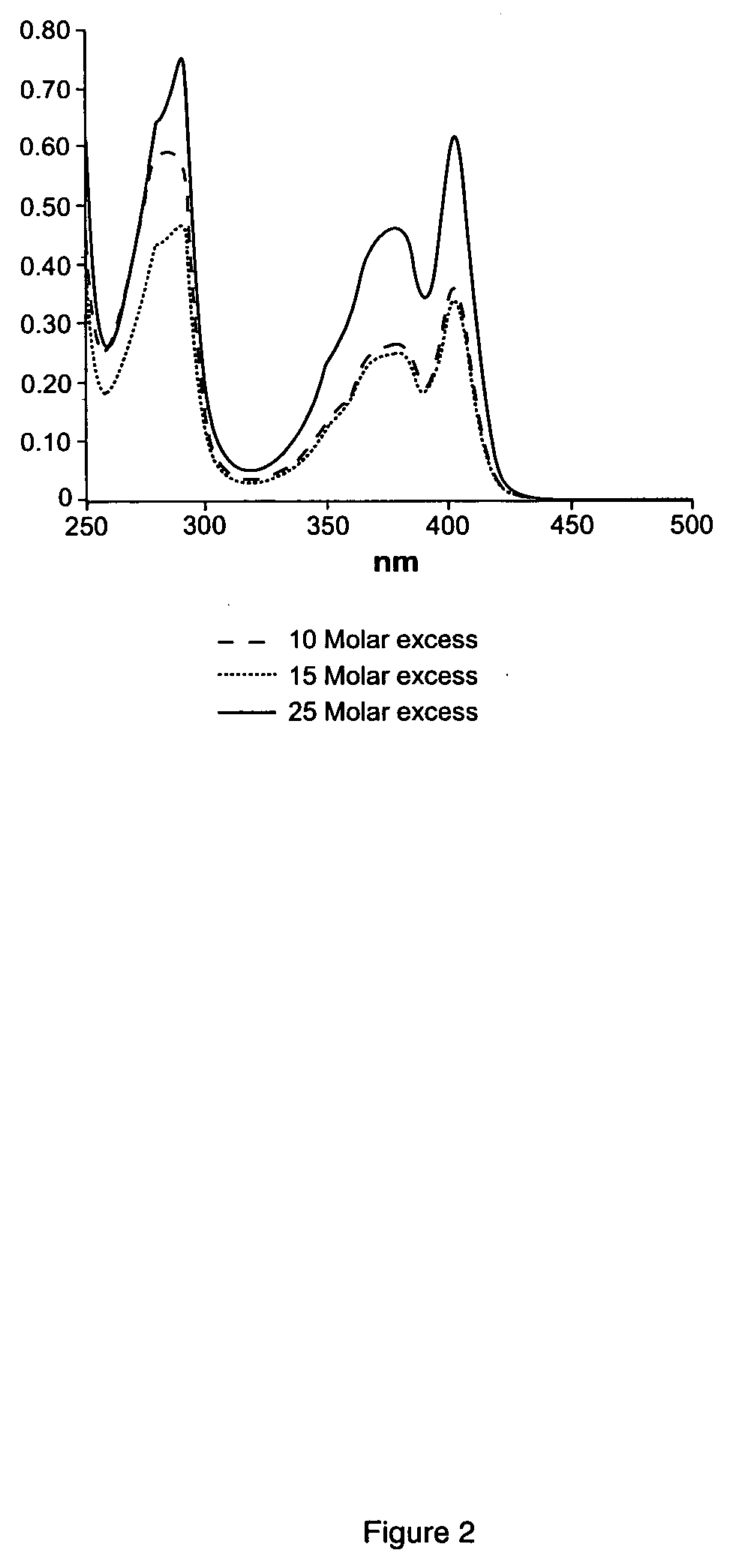

Pyrenyloxysulfonic acid fluorescent agents

InactiveUS20050123935A1Improve absorption rateHigh quantum yieldHybrid immunoglobulinsSugar derivativesAnalyteFluorescence

The invention provides a novel class of reactive fluorescent agents that are based on a pyrene sulfonic acid nucleus. The agents are readily incorporated into conjugates with other species by reacting the reactive group with a group of complementary reactivity on the other species of the conjugate. Also provided are methods of using the compounds of the invention to detect and / or quantify an analyte in a sample. In an exemplary embodiment, the invention provides multi-color assays incorporating the compounds of the invention.

Owner:MOLECULAR PROBES

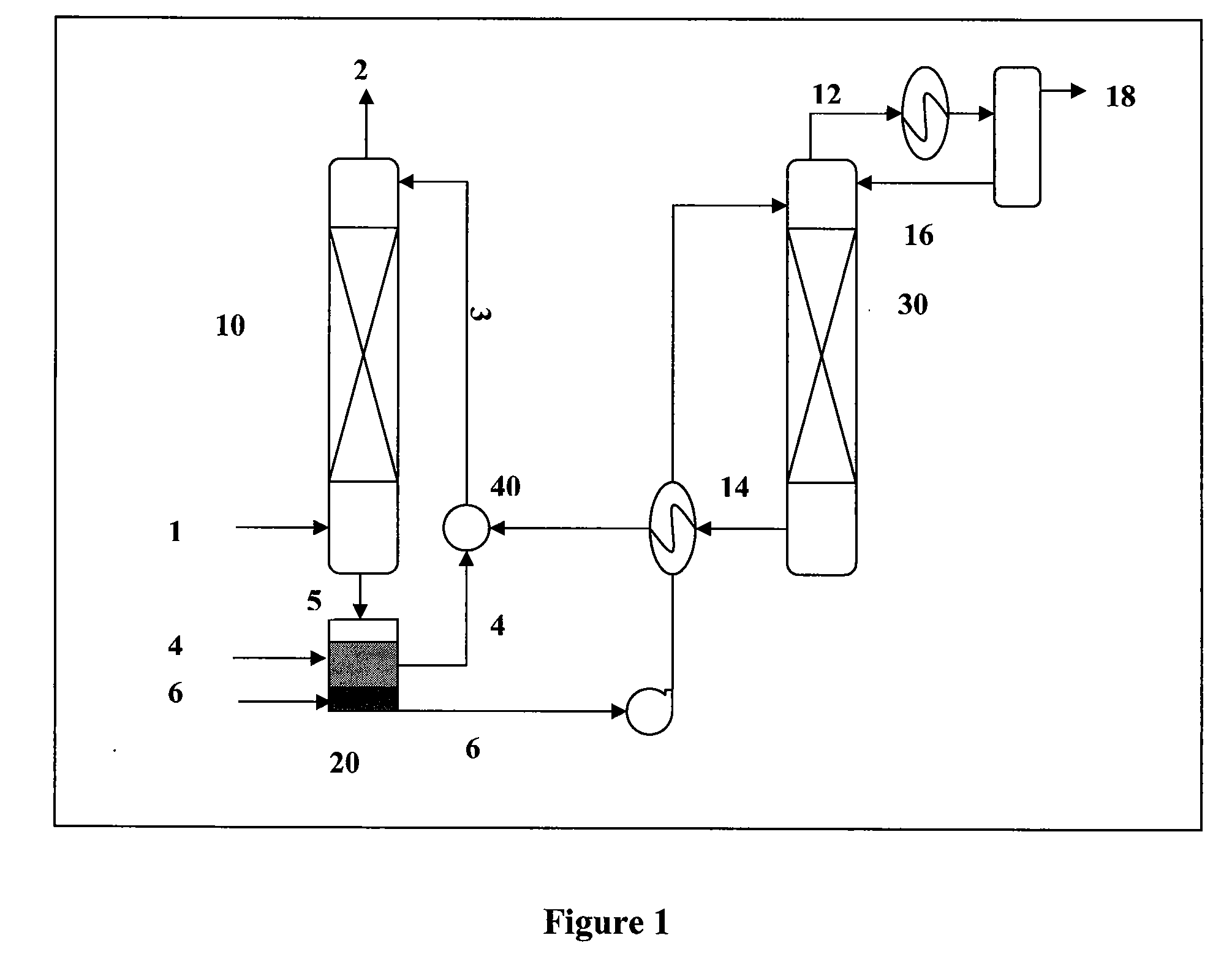

Self-Concentrating Absorbent for Acid Gas Separation

ActiveUS20090263302A1Improve absorption rateReduce energy costsCombination devicesGas treatmentProduct gasChemistry

An process for efficiently deacidizing a gaseous mixture is described. The process utilizes a self-concentrating absorbent that absorbs an acid gas at reduced overall energy costs for the deacidizing operation.

Owner:HU LIANG

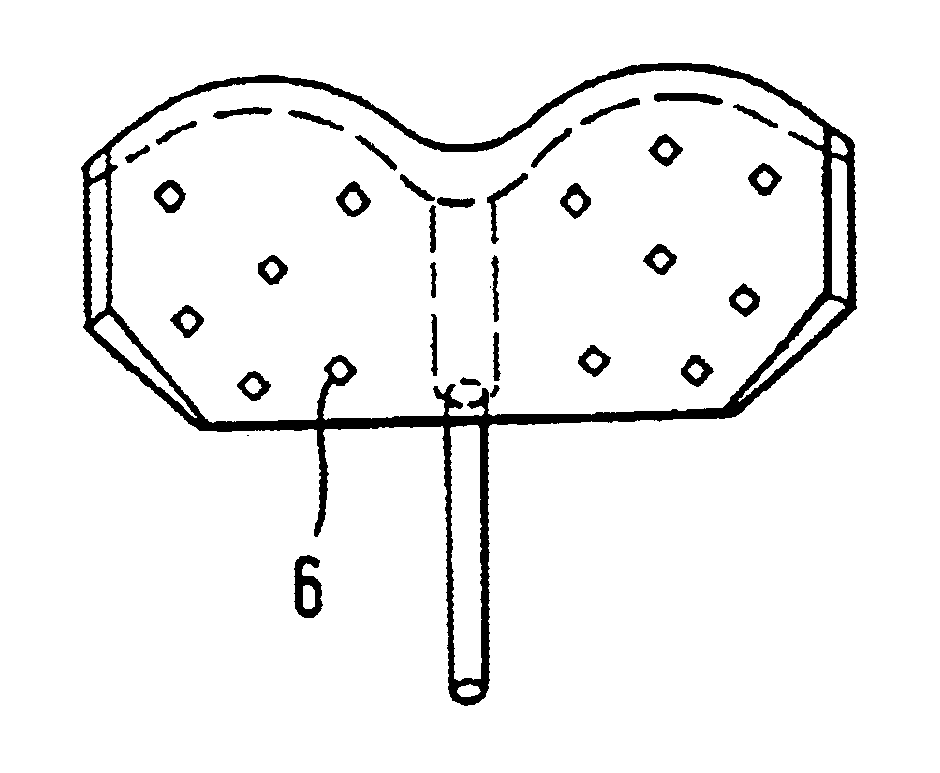

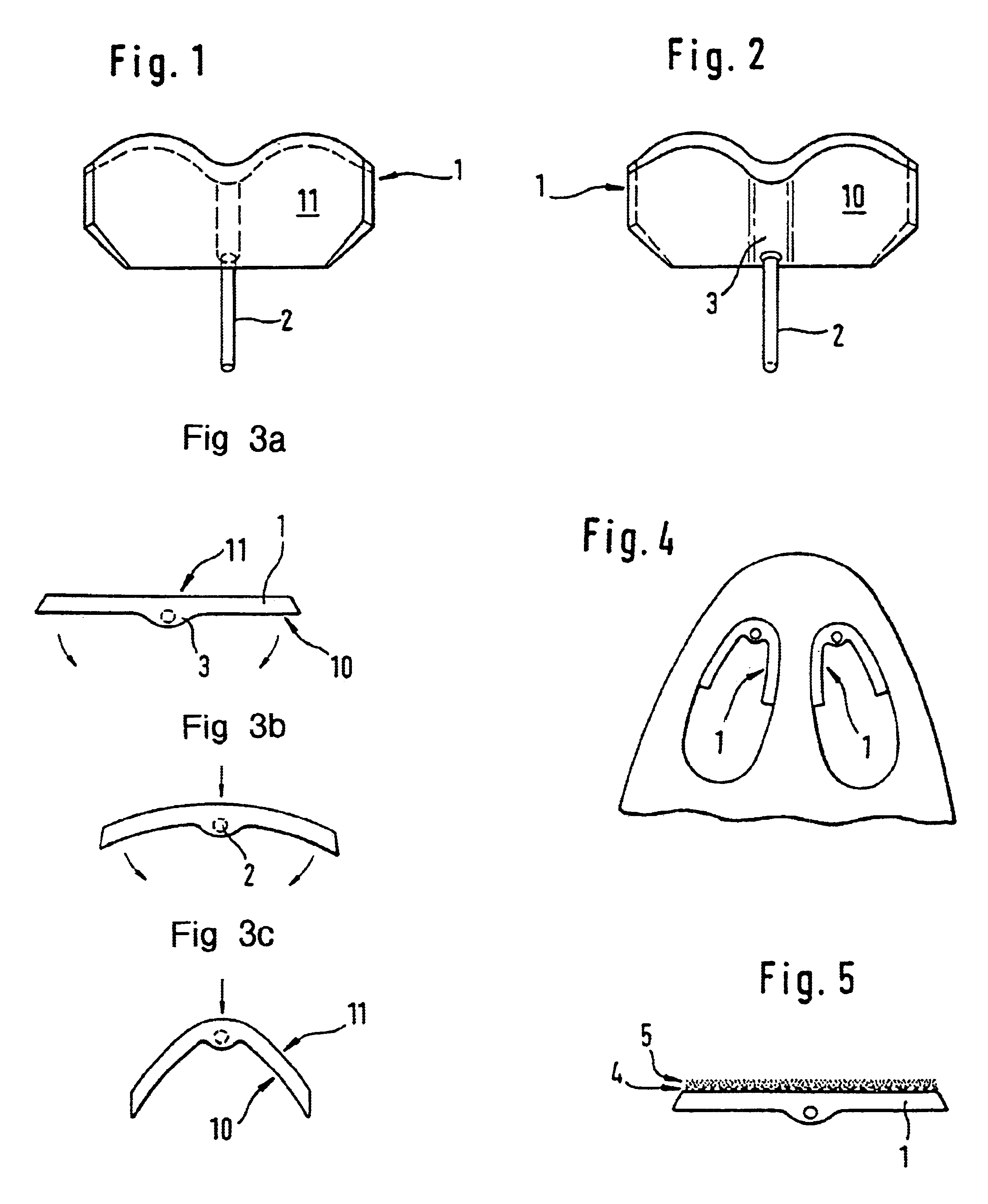

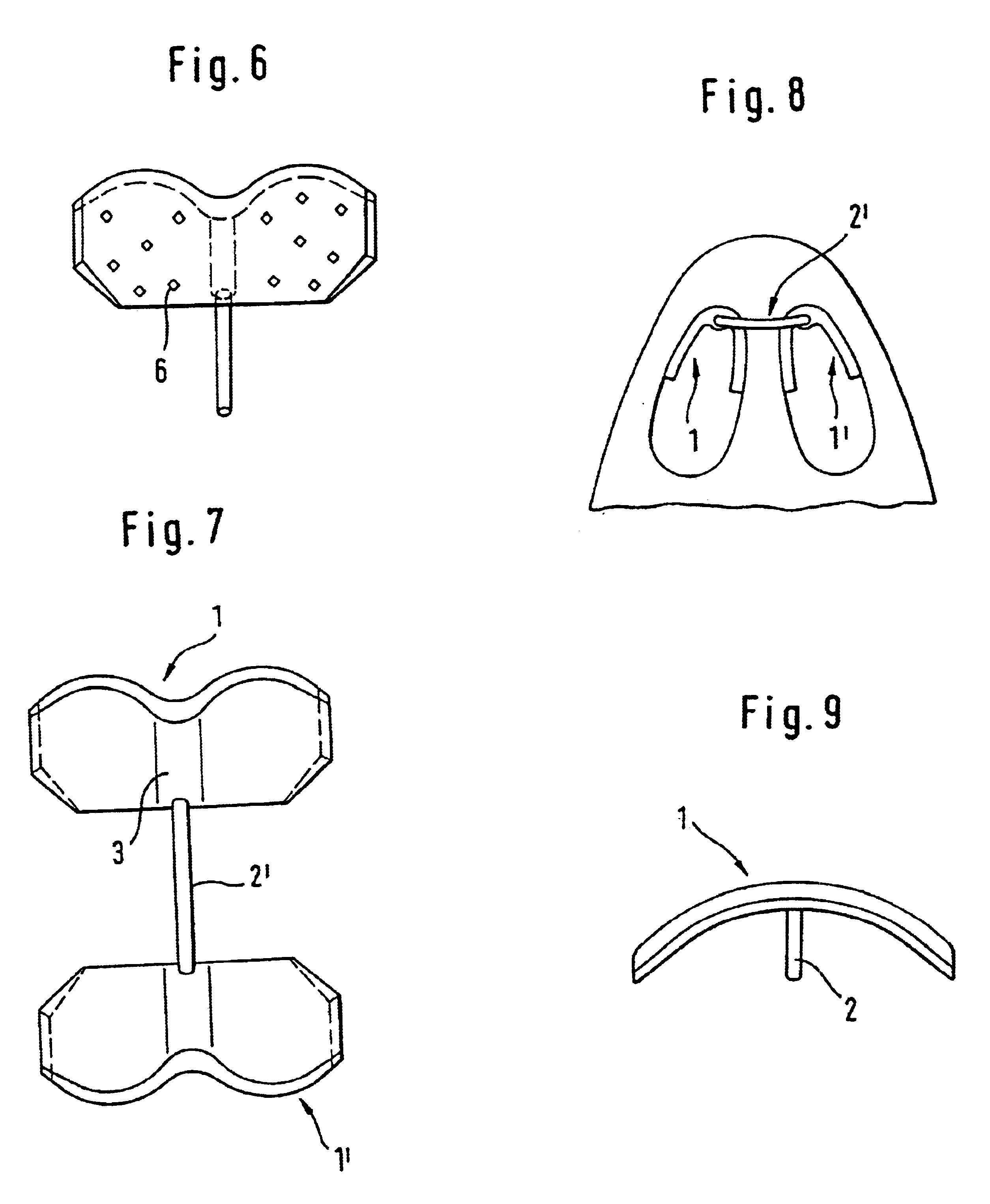

Device for insertion into the human nose

InactiveUS6626172B1Avoid uneven levelsImprove absorption rateRespiratorsBreathing filtersNose partsBiomedical engineering

A device for insertion into the human nose, characterised by having at least one elastically deformable plate-like base element with an inner side and an outer side and with a substantially rectangular shape, said element being substantially flat or slightly arched in its unstressed condition.

Owner:SIEMENS & CO HEILWASSER & QUELLENPROD DES STAATSBADES BAD EMS

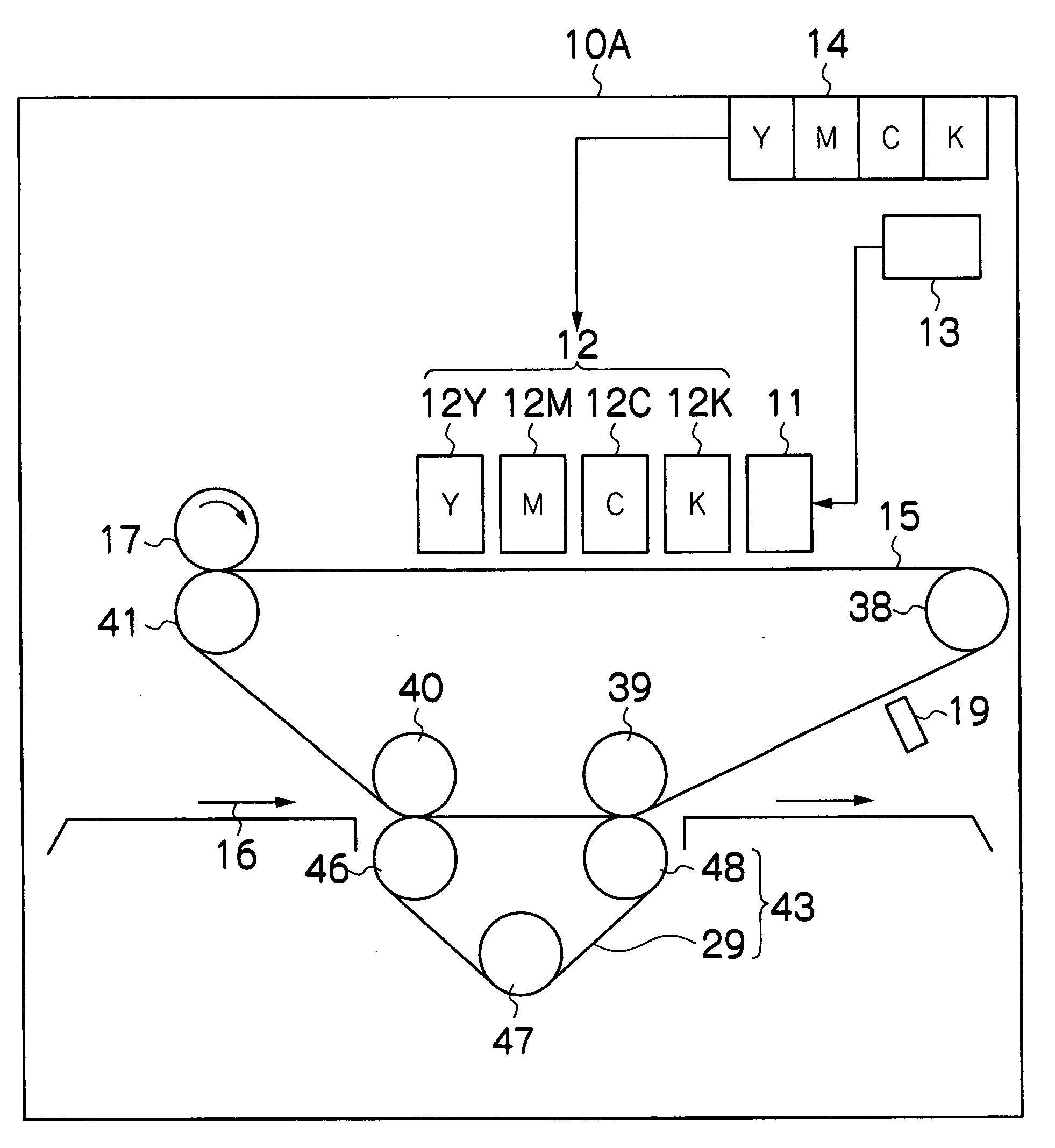

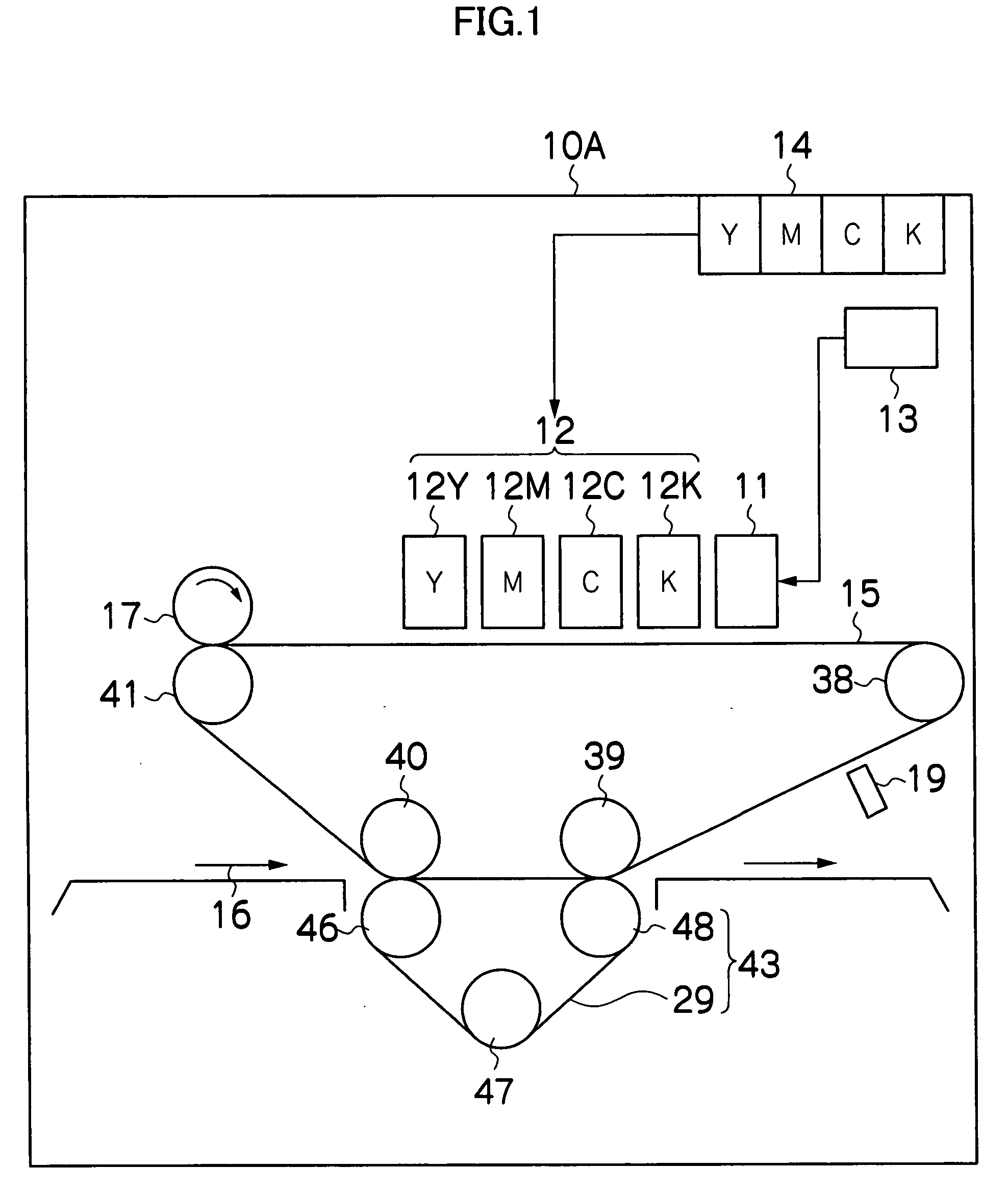

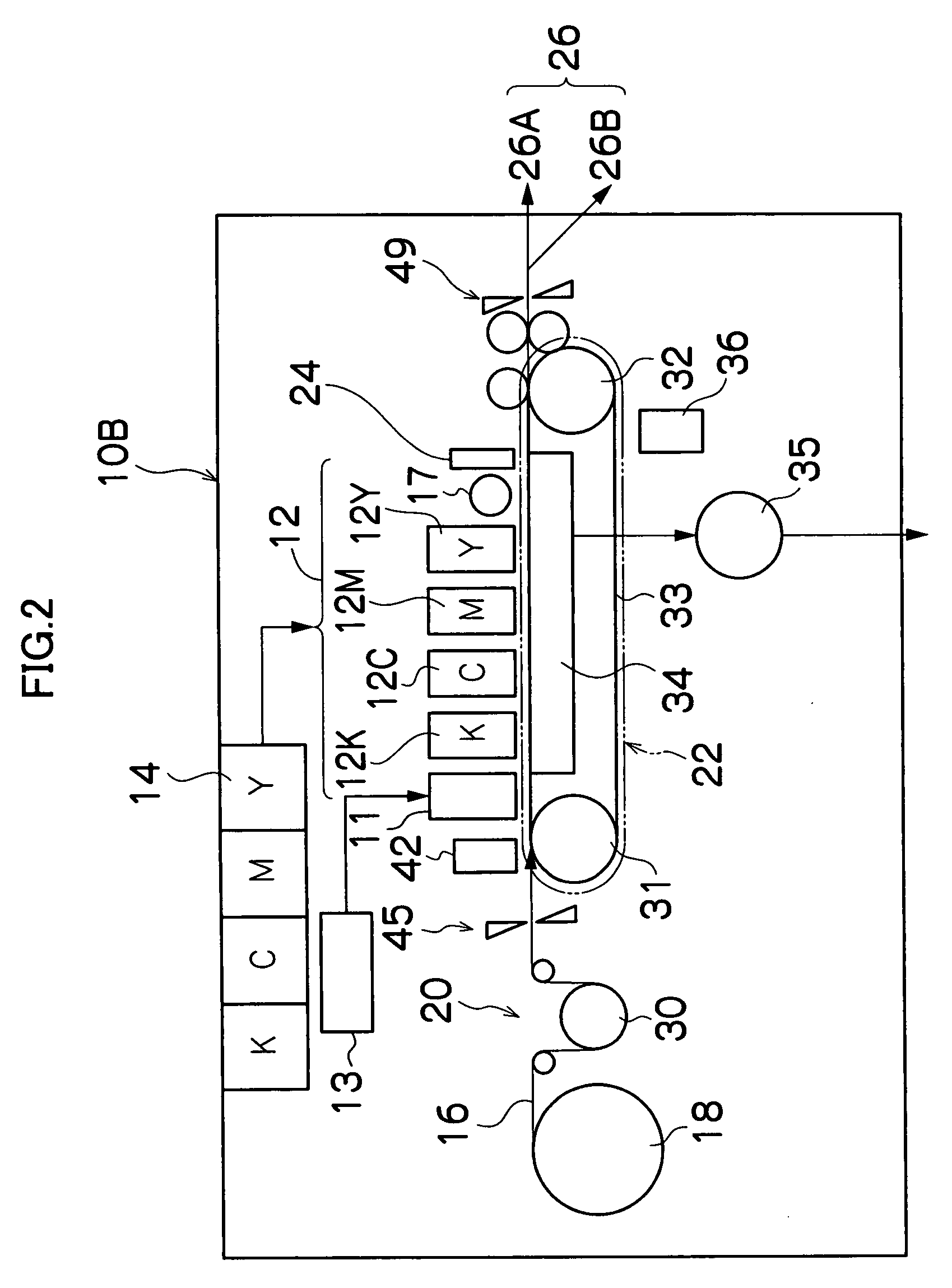

Inkjet recording apparatus and inkjet recording method

InactiveUS20080055356A1High quality printingImprove absorption rateInking apparatusMeasurement apparatus componentsSolventBiomedical engineering

The inkjet recording apparatus has: an ink droplet ejection device which ejects a droplet of an ink containing a coloring material; a treatment liquid deposition device which deposits a treatment liquid that causes the coloring material contained in the ink to aggregate so as to create a coloring material aggregate; and an absorbing body which absorbs a solvent of a mixed liquid including the ink ejected as the droplet by the ink droplet ejection device and the treatment liquid deposited by the treatment liquid deposition device, wherein solvent absorption holes having an opening diameter larger than a spreading width of the coloring material aggregate in the mixed liquid on a surface of a recording body are formed in a surface of the absorbing body.

Owner:FUJIFILM CORP

Electrical, plating and catalytic uses of metal nanomaterial compositions

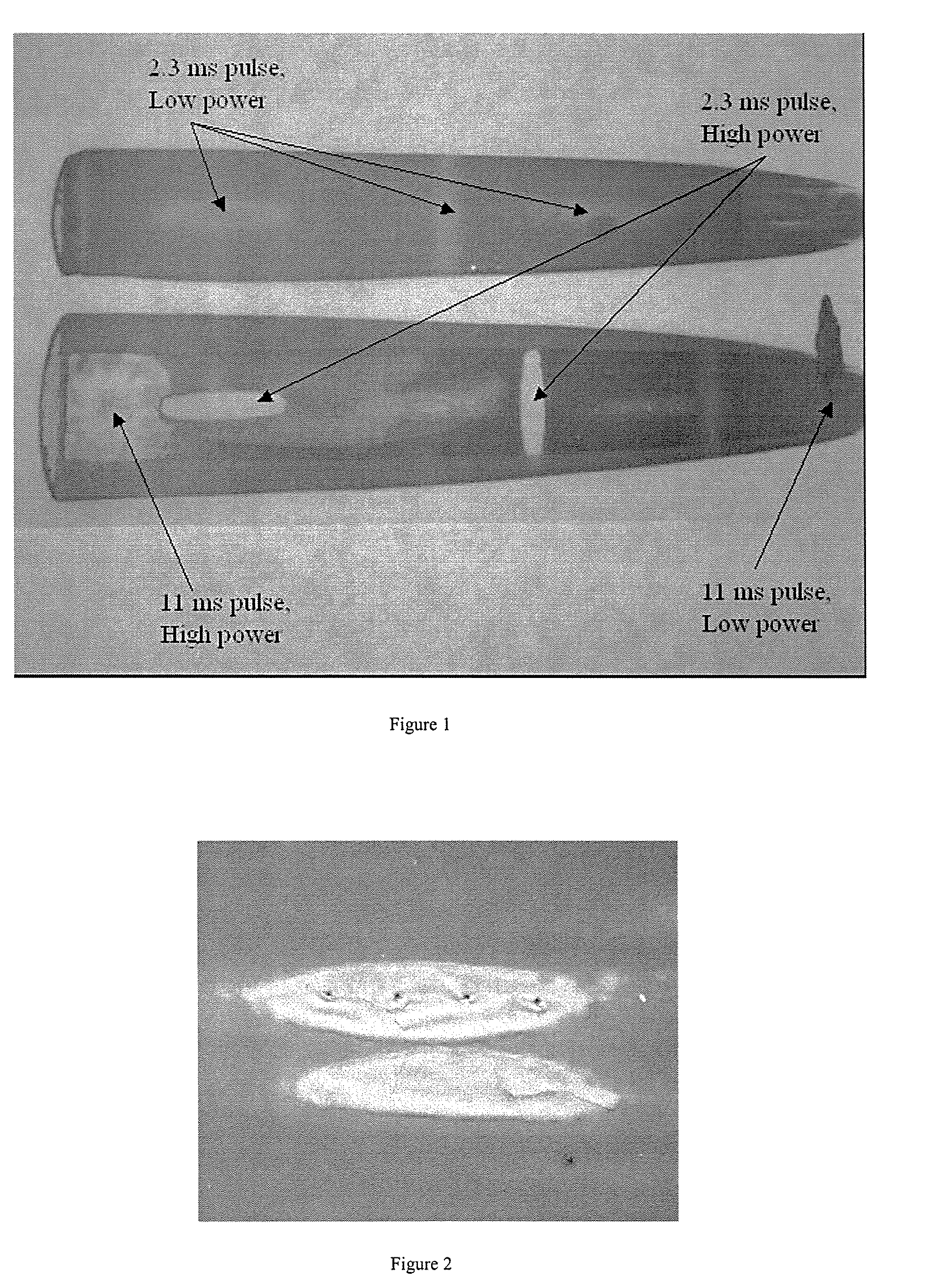

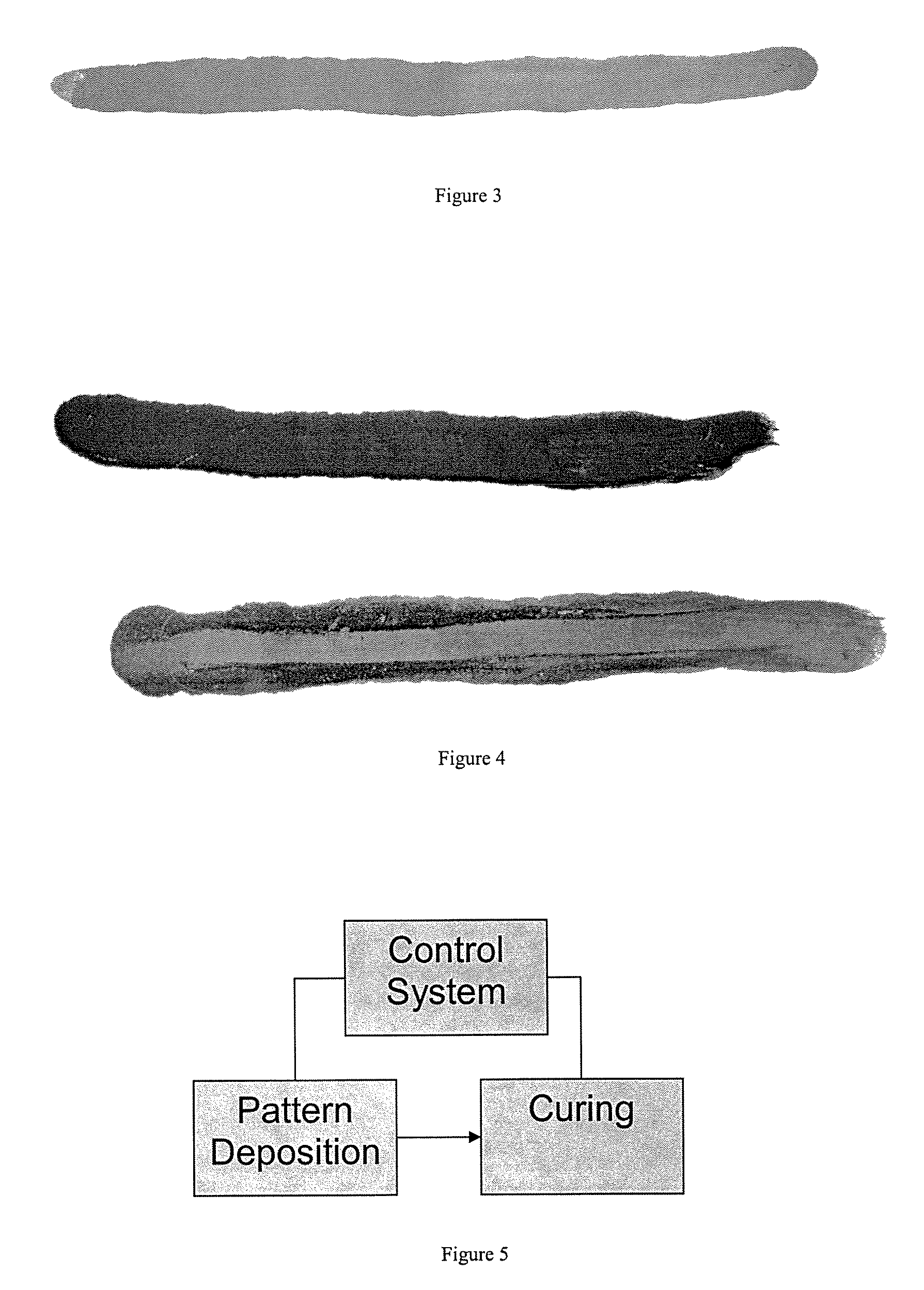

ActiveUS7820097B2Improve absorption rateReduce reflectivityOptical radiation measurementMangetographic processBiological activationElectroplating

Owner:NCC NANO LLC

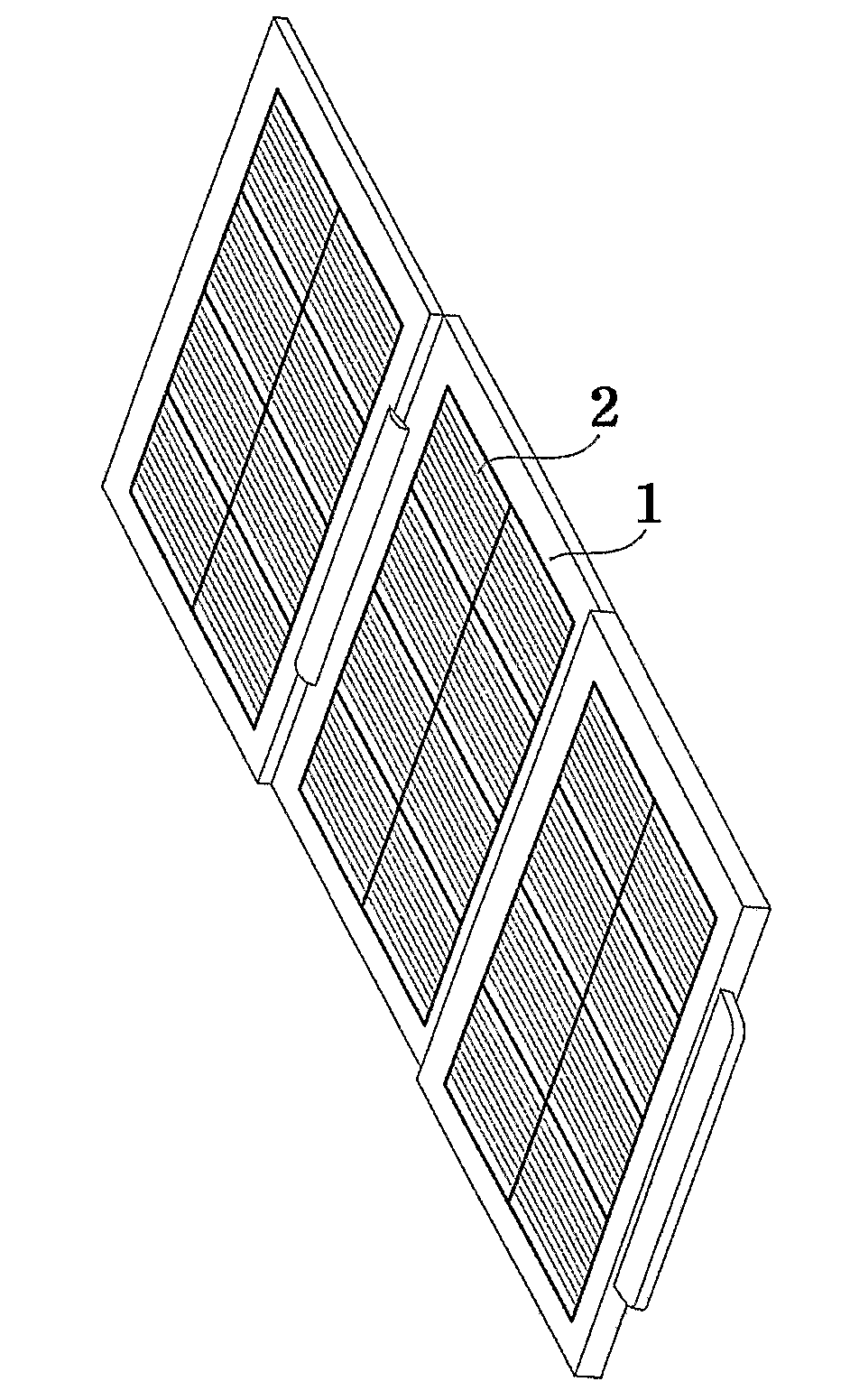

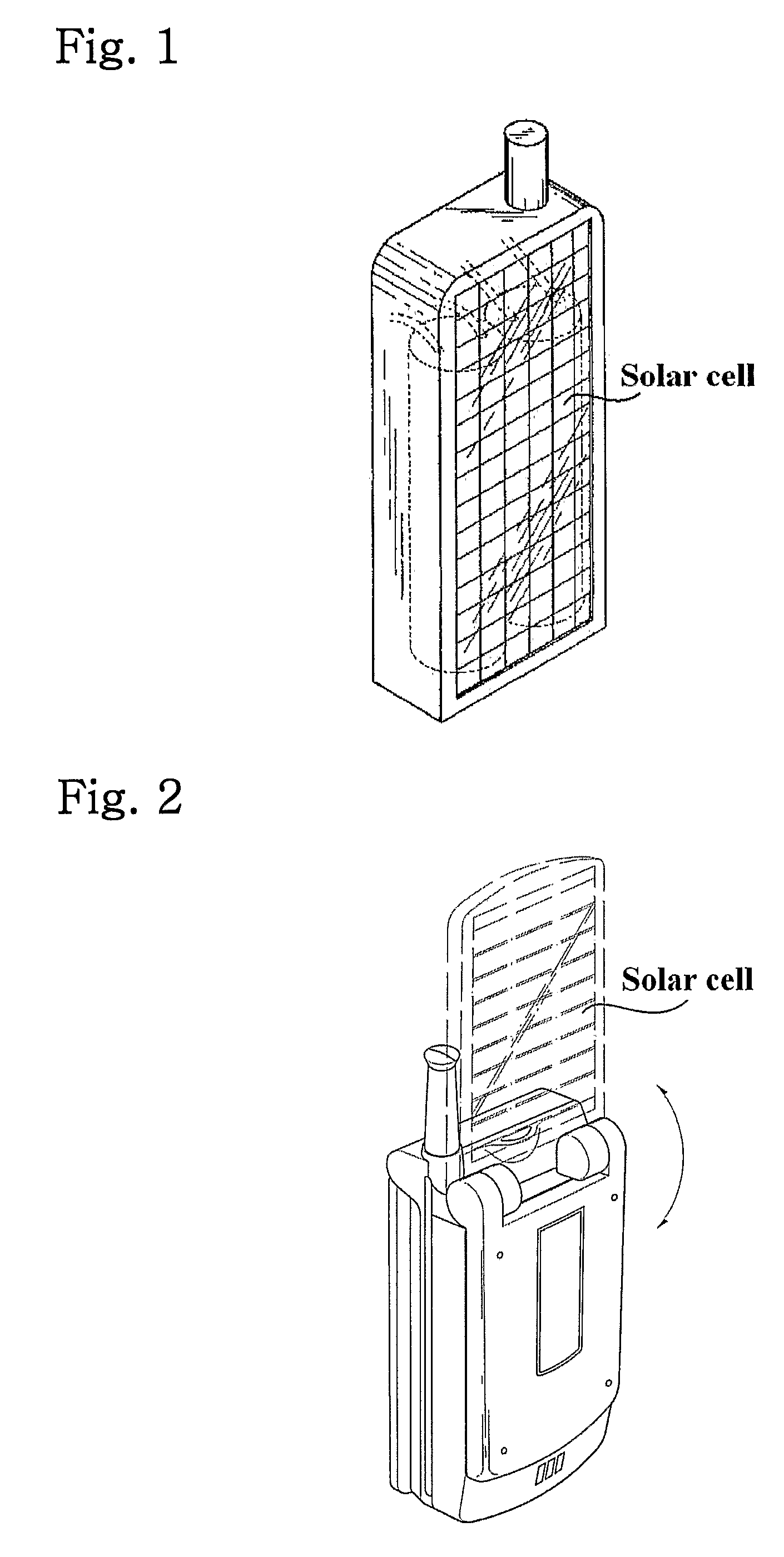

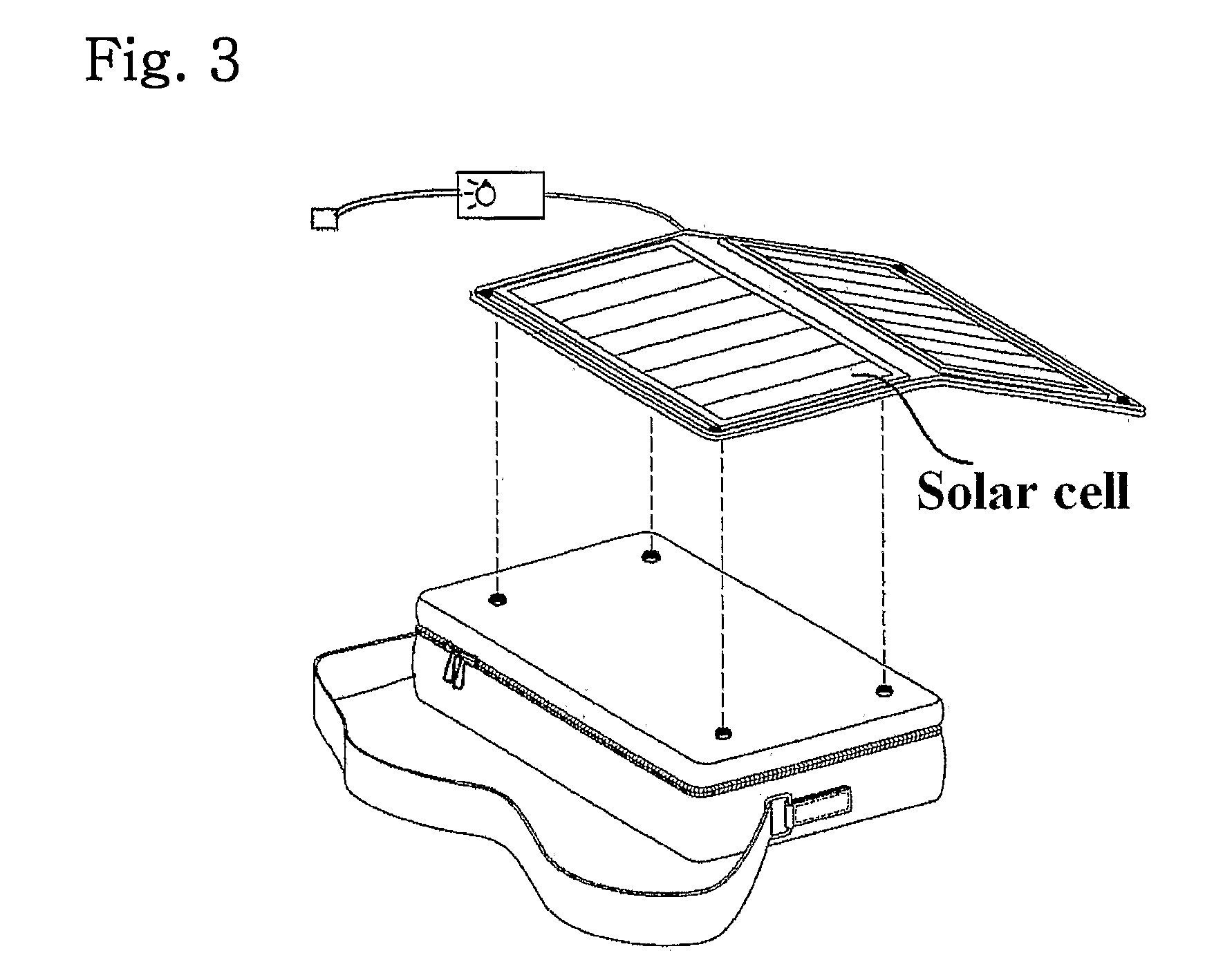

Method and Device for Recharging Using Portable Multi-Voltage Solar Cell

InactiveUS20070222410A1Small sizeConvenient to usePhotovoltaic supportsBatteries circuit arrangementsPower controlEngineering

A portable solar cell charger and methods of charging electronic devices using the same are disclosed. A portable solar cell charger comprises at least one solar cell plate holding a plurality of solar cells; a film with reformed surface formed on the solar cell plate; a power control part supplying a load side with power after perceiving a voltage required from the load side; and a case holding the solar cell plate and the power control part. A method of charging an electronic device using a solar cell charger comprises perceiving a voltage required from a load side using a microprocessor; converting the perceived voltage using D / A converter; comparing the converted voltage with a voltage from a solar cell plate; integrating signals from a comparator and a pulse generator; adjusting the voltage from the solar cell plate; and supplying the voltage from the solar cell plate into the load side.

Owner:SOLEITEC

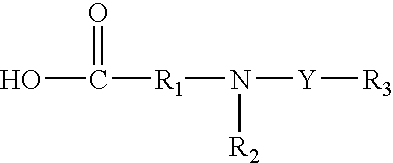

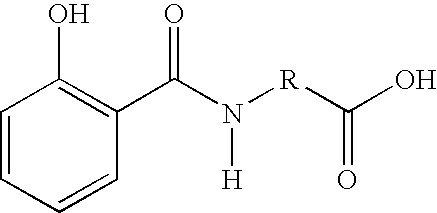

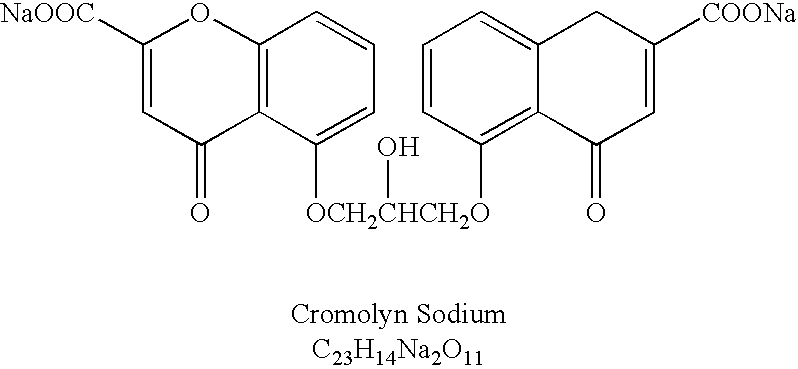

Formulations for oral administration of cromolyn sodium

InactiveUS20040259952A1High activityImprove absorption rateBiocideAntipyreticOral medicationCromolyn Sodium

An oral dosage form comprises cromolyn sodium (sodium or disodium cromoglycate), and an acylated amino acid delivery agent.

Owner:NOVO NORDISK NORTH AMERICA OPERATIONS AS

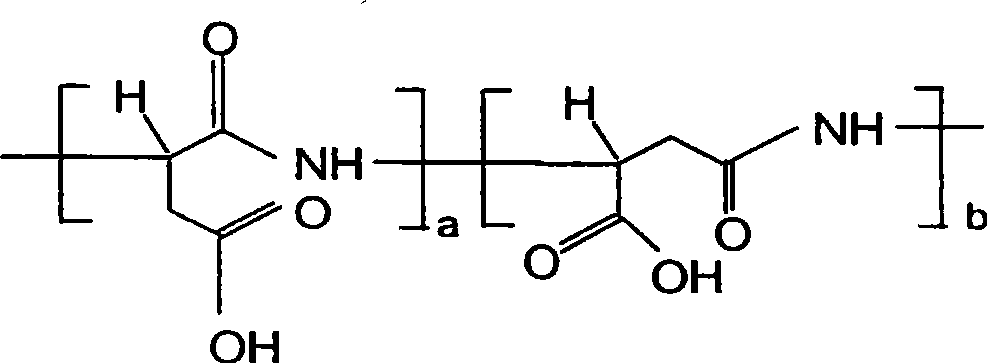

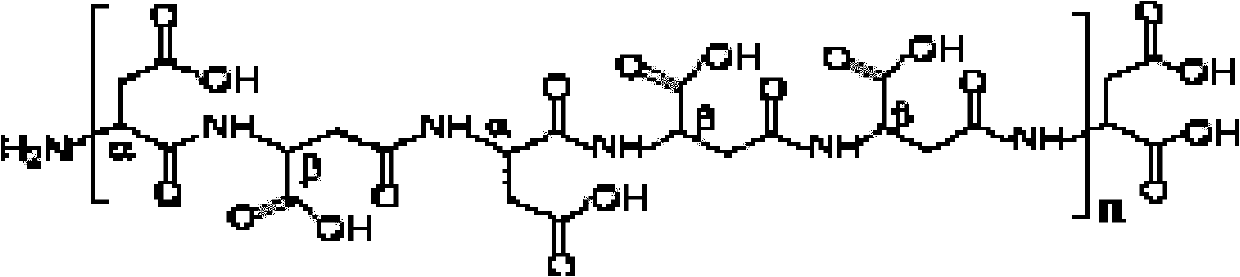

Synergistic slow release nitrogen fertilizer and preparation thereof

ActiveCN101434504AExtend the fertilizer periodIncrease profitAgriculture gas emission reductionUrea compound fertilisersMolten stateUrease Inhibitors

The invention relates to a nitrogen fertilizer, in particular to a synergistic slow-releasing nitrogen fertilizer and a preparation method thereof. The fertilizer comprises: urea nitrogen fertilizer, biochemical inhibitors and a synergist, wherein, the weight portion ratio of the urea nitrogen fertilizer to the biochemical inhibitors to the synergist is equal to 1:0.001 to 0.1:0.0005 to 1; the biochemical inhibitors are a nitrification inhibitor and a urease inhibitor and the synergist is poly (aspartic acid), wherein, the weight portion ratio between the urease inhibitor and the nitrification inhibitor is equal to 0.5 to 2:0.5 to 2. The preparation method is as follows: during the operation process of the nitrogen fertilizer, the biochemical inhibitor and the synergist are added into the fertilizer under the molten state of the fertilizer. The synergistic nitrogen fertilizer of the invention is suitable for various plants and soils. The fertilizer has notable disease-resistant, drought-resistant and lodging resistant effects on crops after being applied in soils, can effectively improve nutrients reserving power of soils and has certain effect on succession crops. Gain production can be increased by 8% to 30%, vegetable production can be increased by 14% to 60% and cash crop production can be increased by more than 30% by using the synergistic slow-releasing nitrogen fertilizer.

Owner:SINOCHEM AGRI LINYI R&D CENT CO LTD

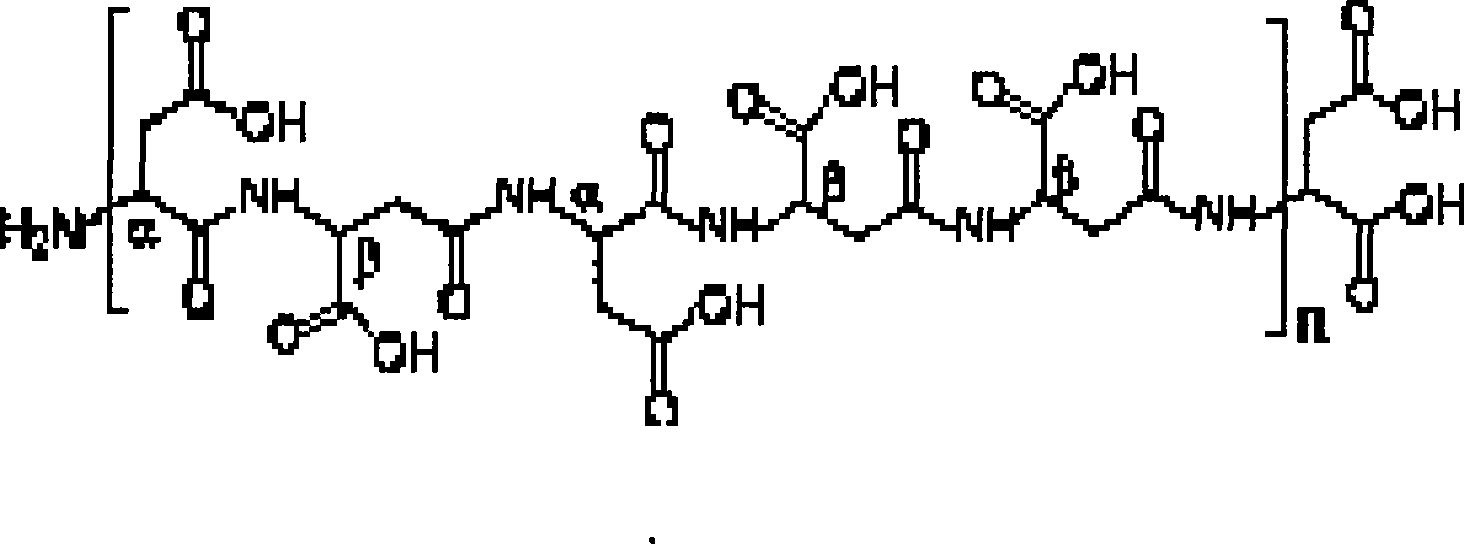

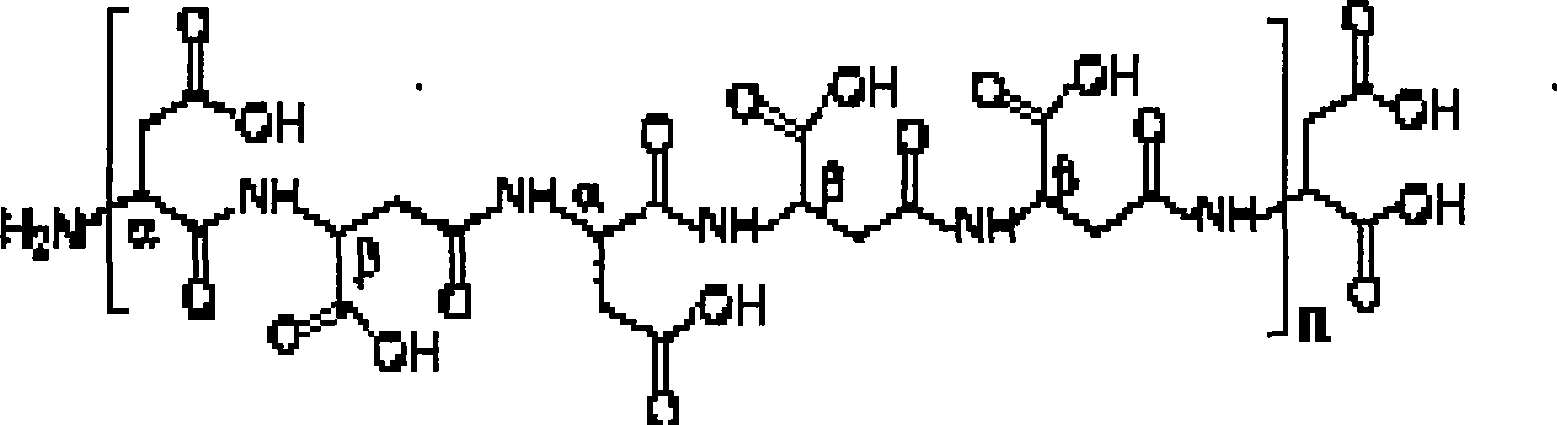

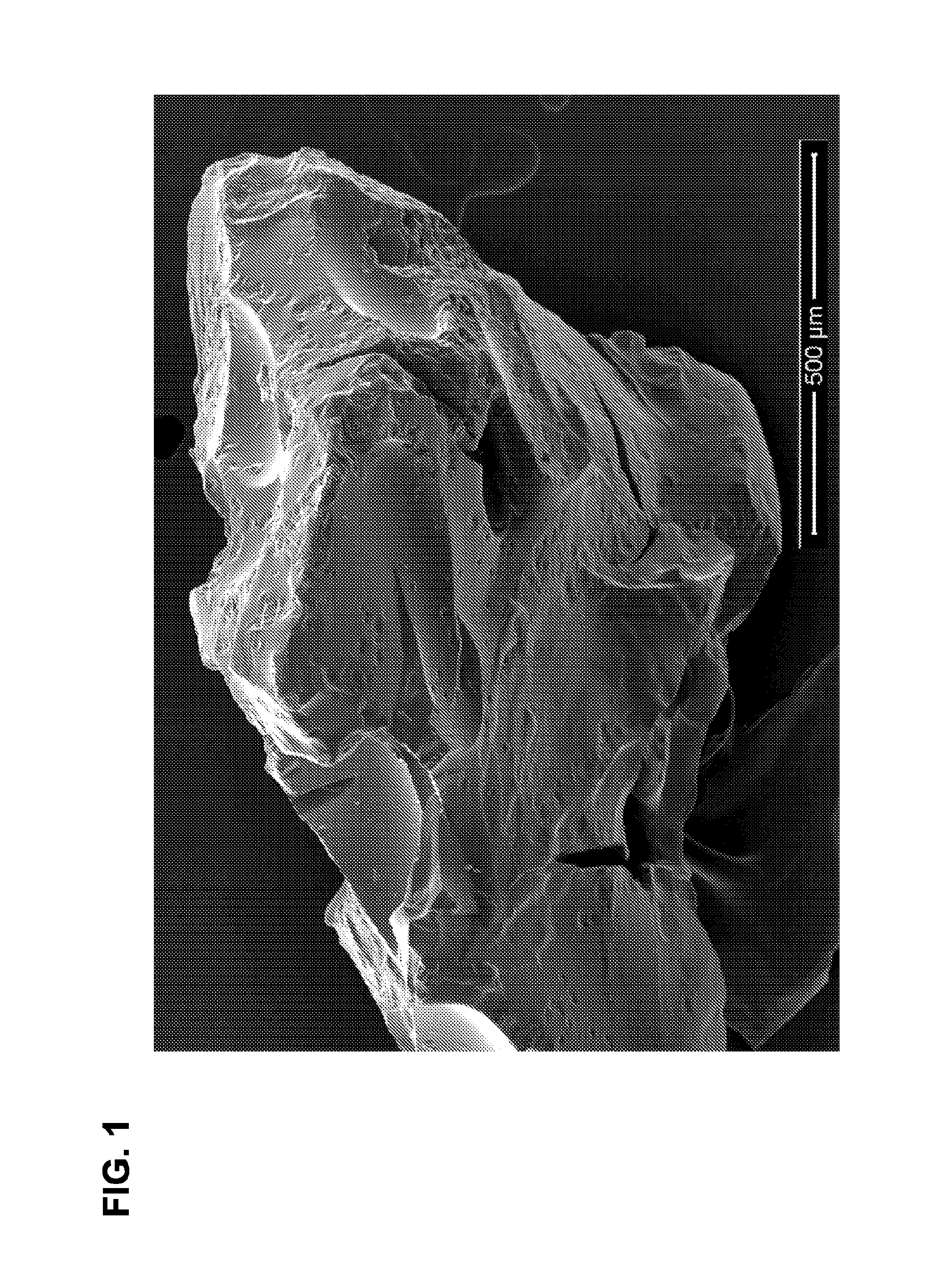

Degradable superabsorbent polymers

InactiveUS20130065765A1Increase demandSufficient amountBiocideGlass/slag layered productsGlyoxylic acidFiber

The present disclosure relates to degradable superabsorbent materials based on acetals of glyoxylic acid and derivatives thereof with polyvinyl alcohol, and methods of making the polymers. The polymers are used to make superabsorbent particles, coatings, sheets, and fibers. Formulations and articles including the superabsorbent polymers, particles, coatings, sheets, and fibers are also disclosed.

Owner:RELUCEO

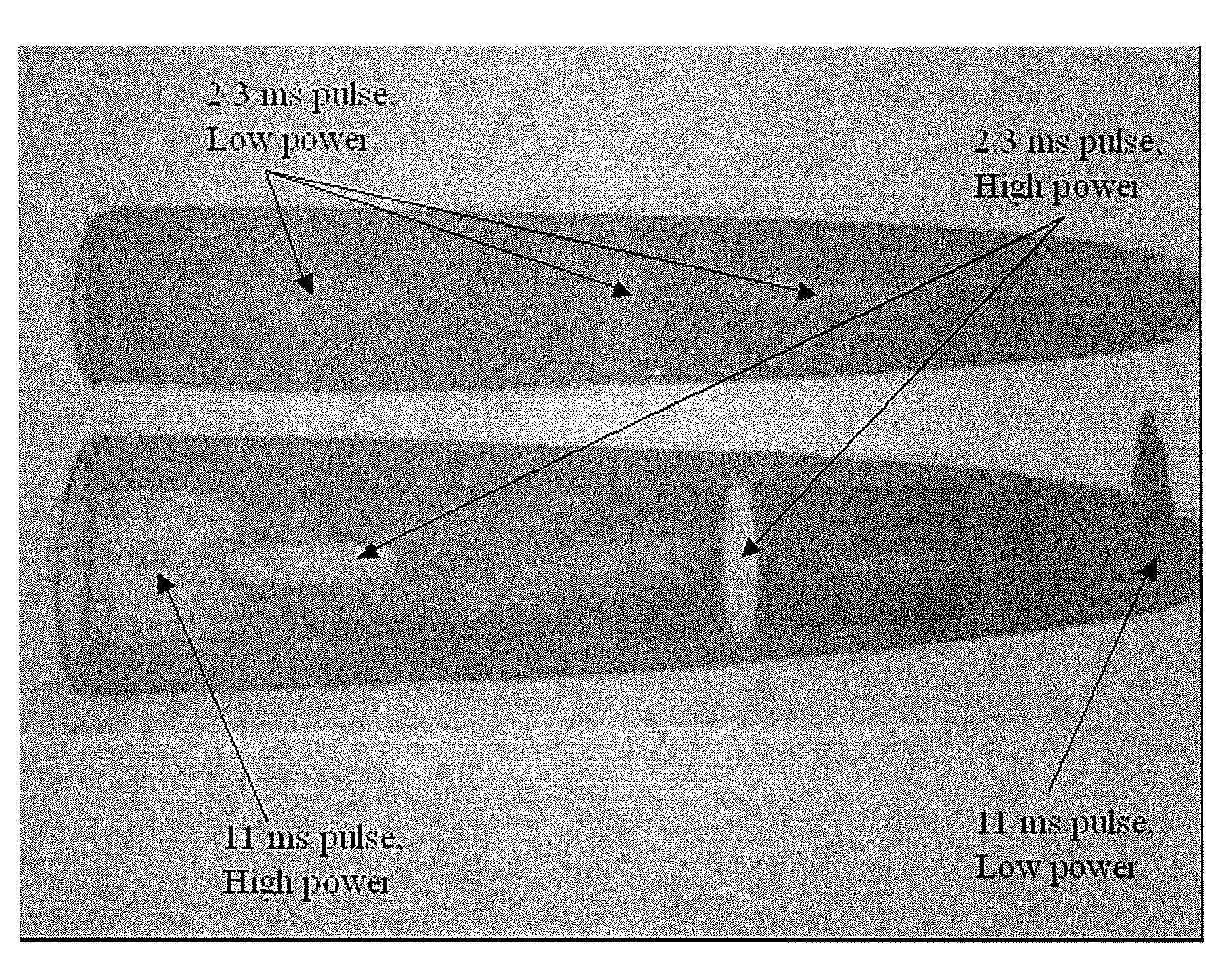

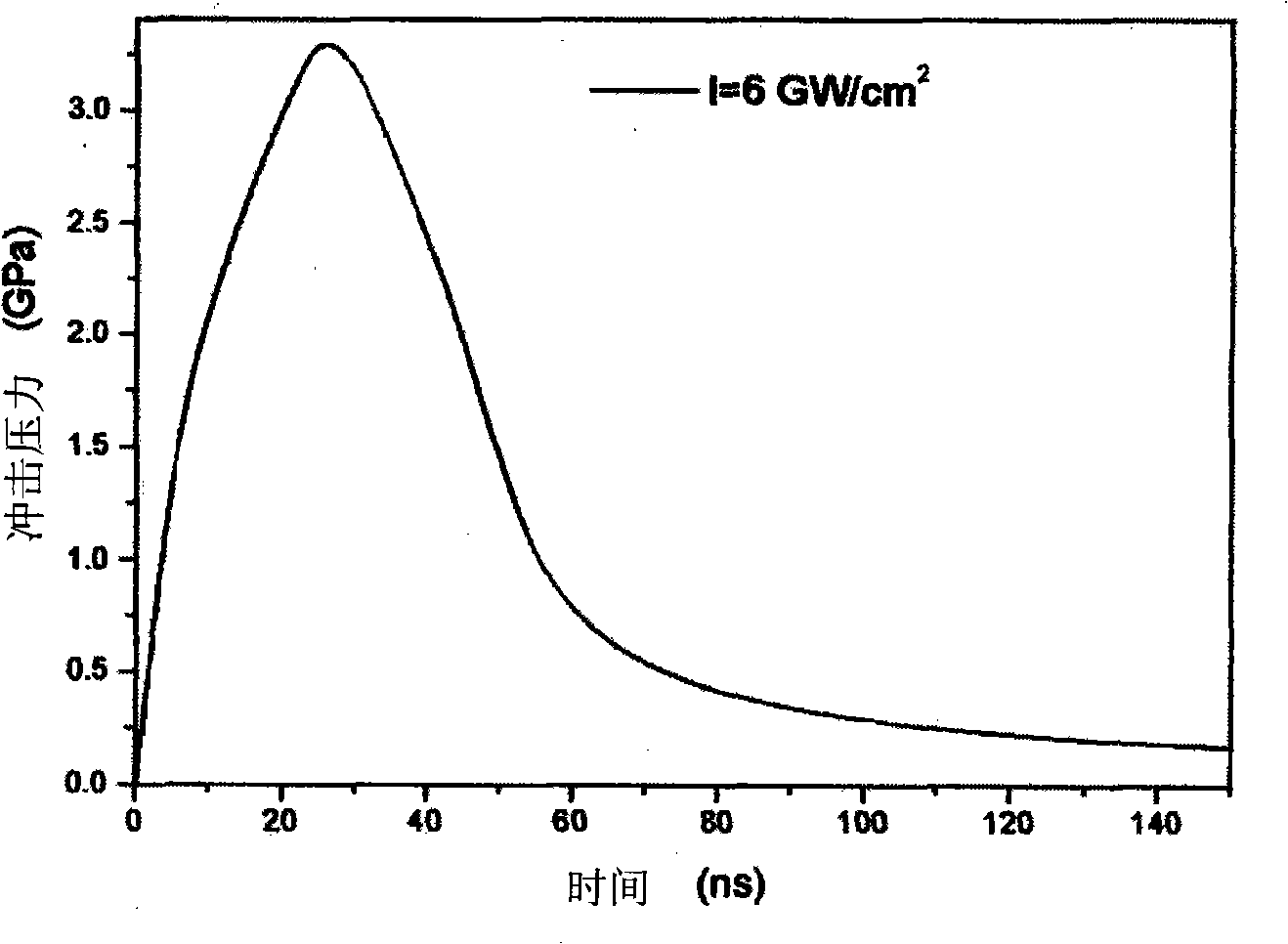

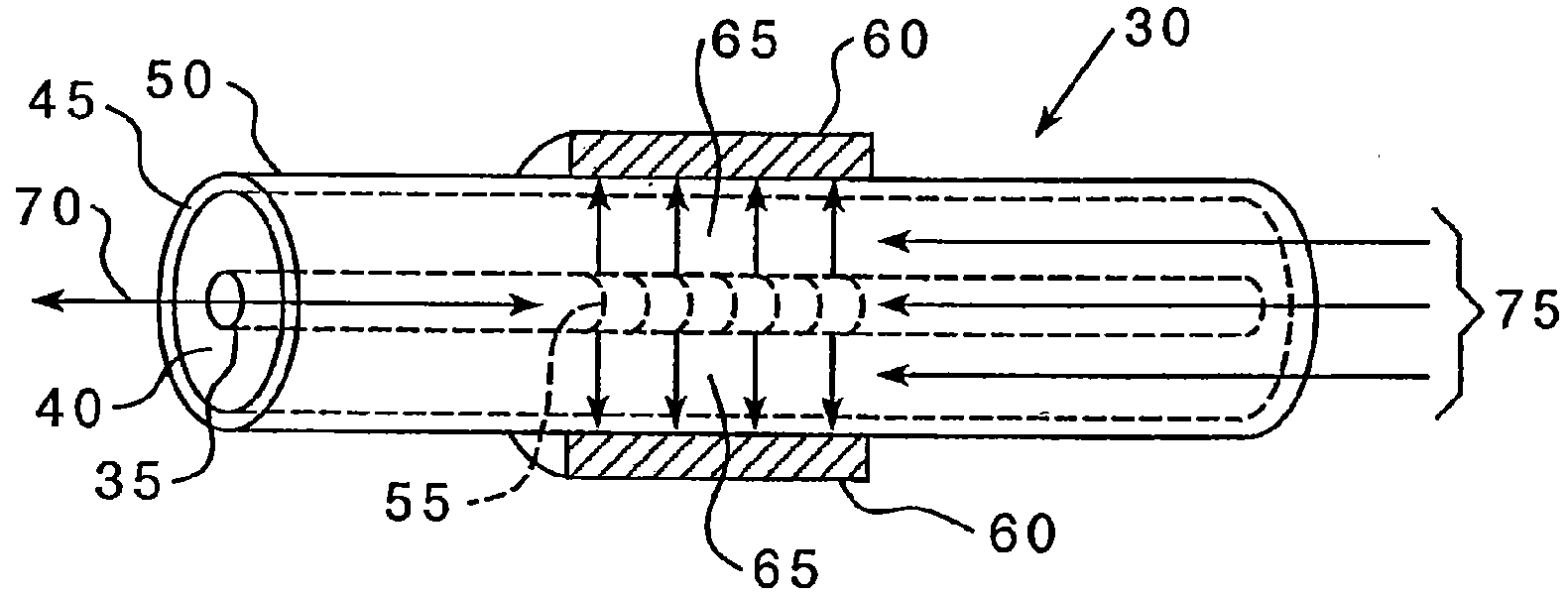

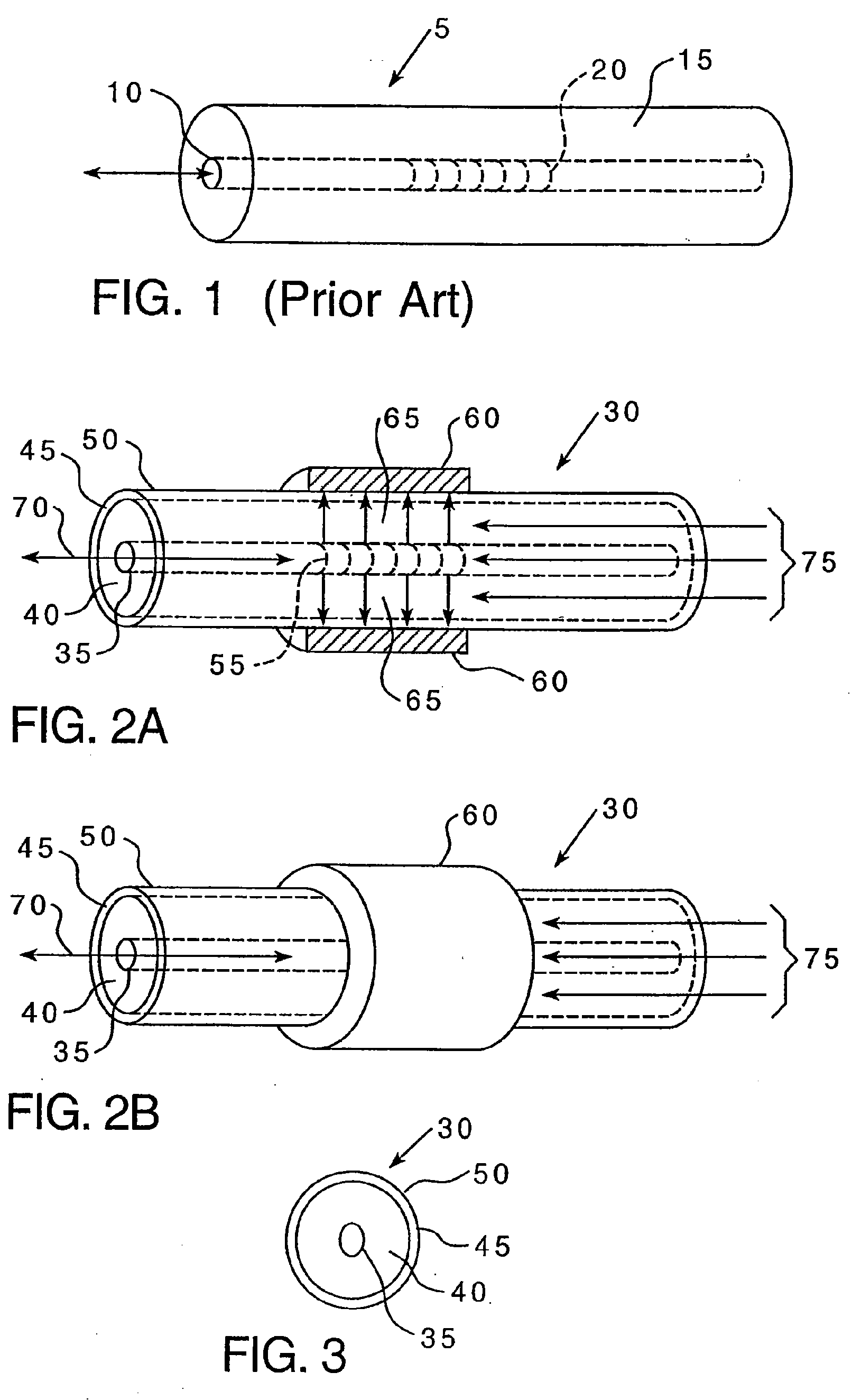

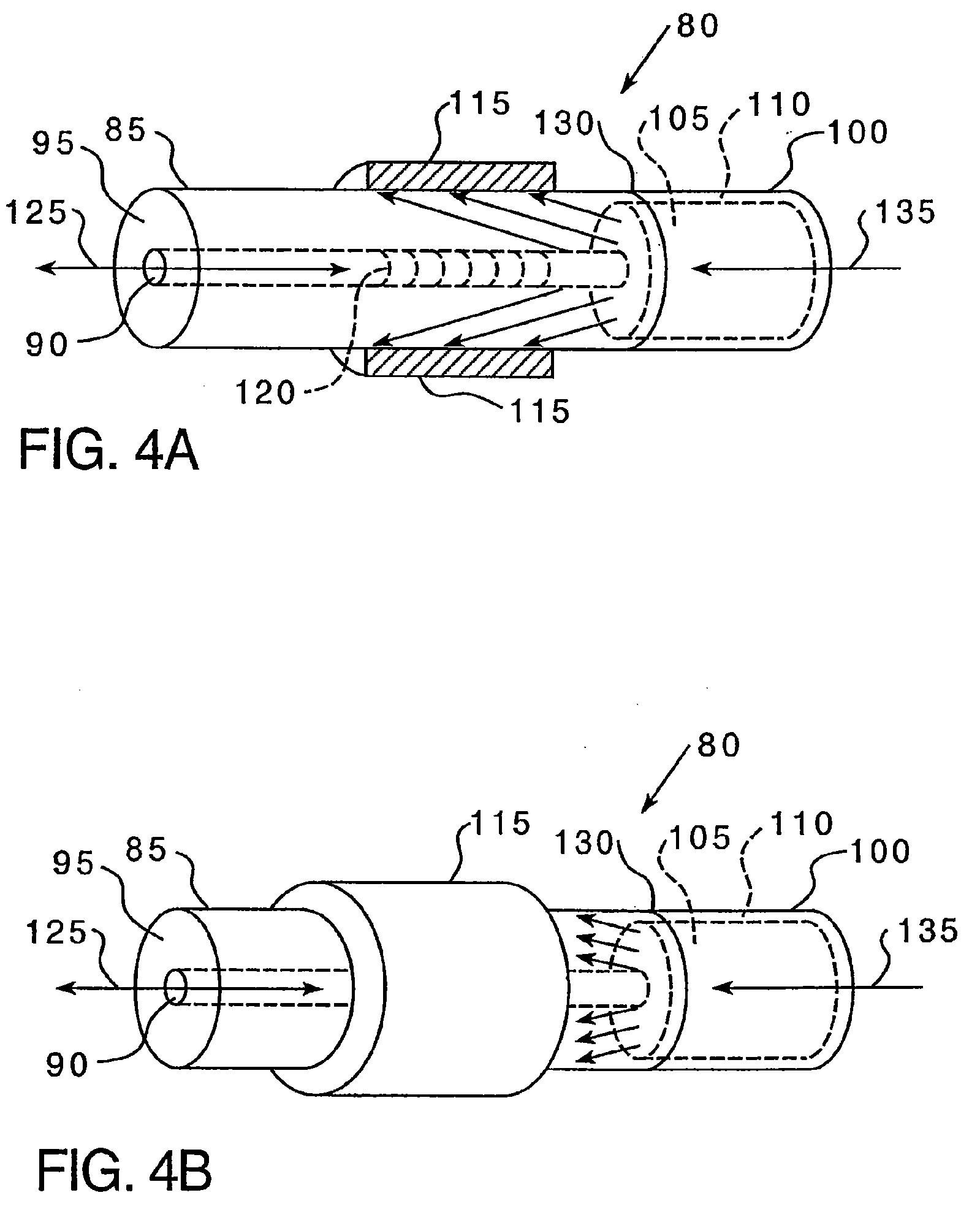

Laser impact tiny bulk forming method and apparatus for tiny apparatus

InactiveCN101269440AEasy to achieve microplastic formingImprove absorption rateLaser beam welding apparatusOptical pathForming force

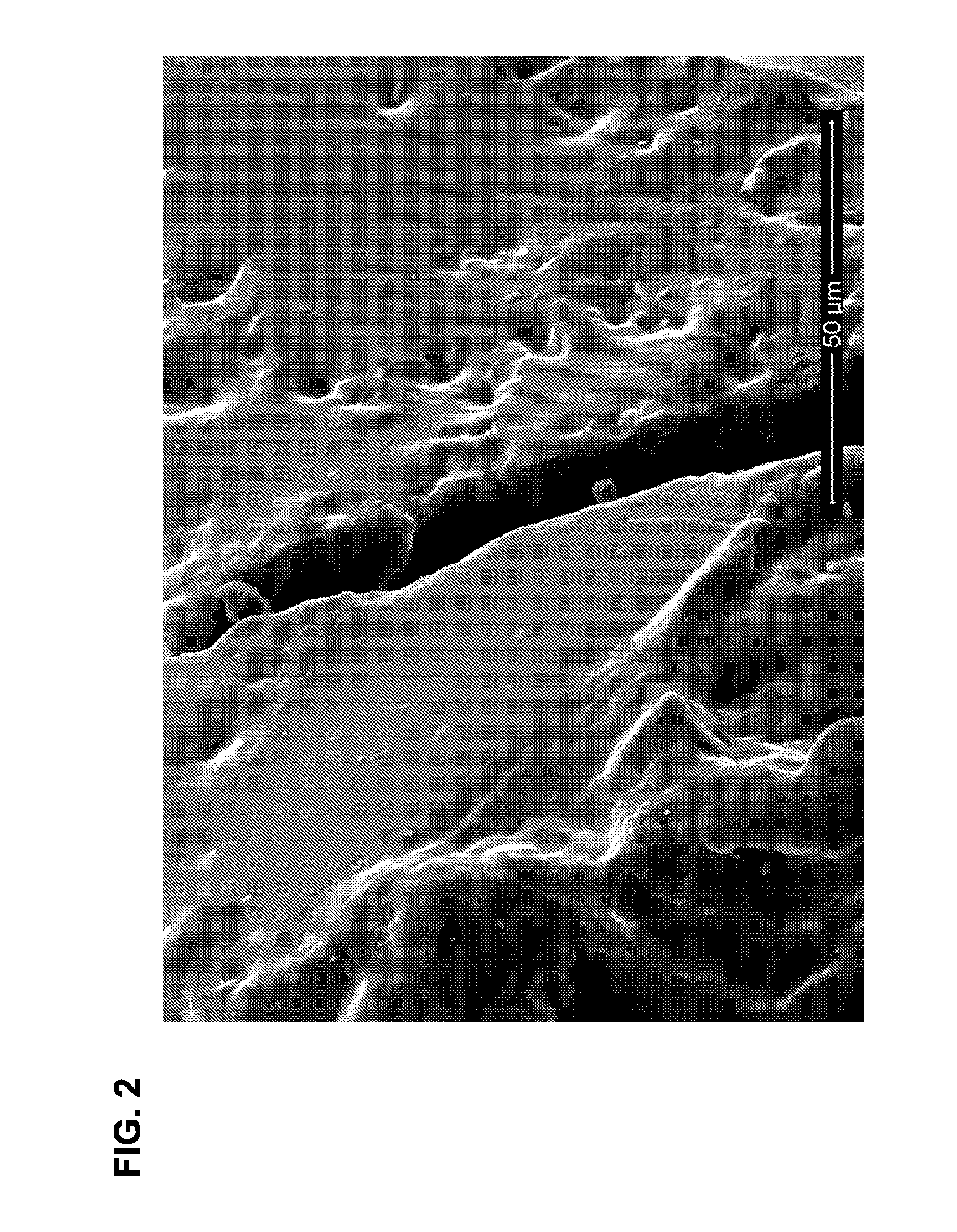

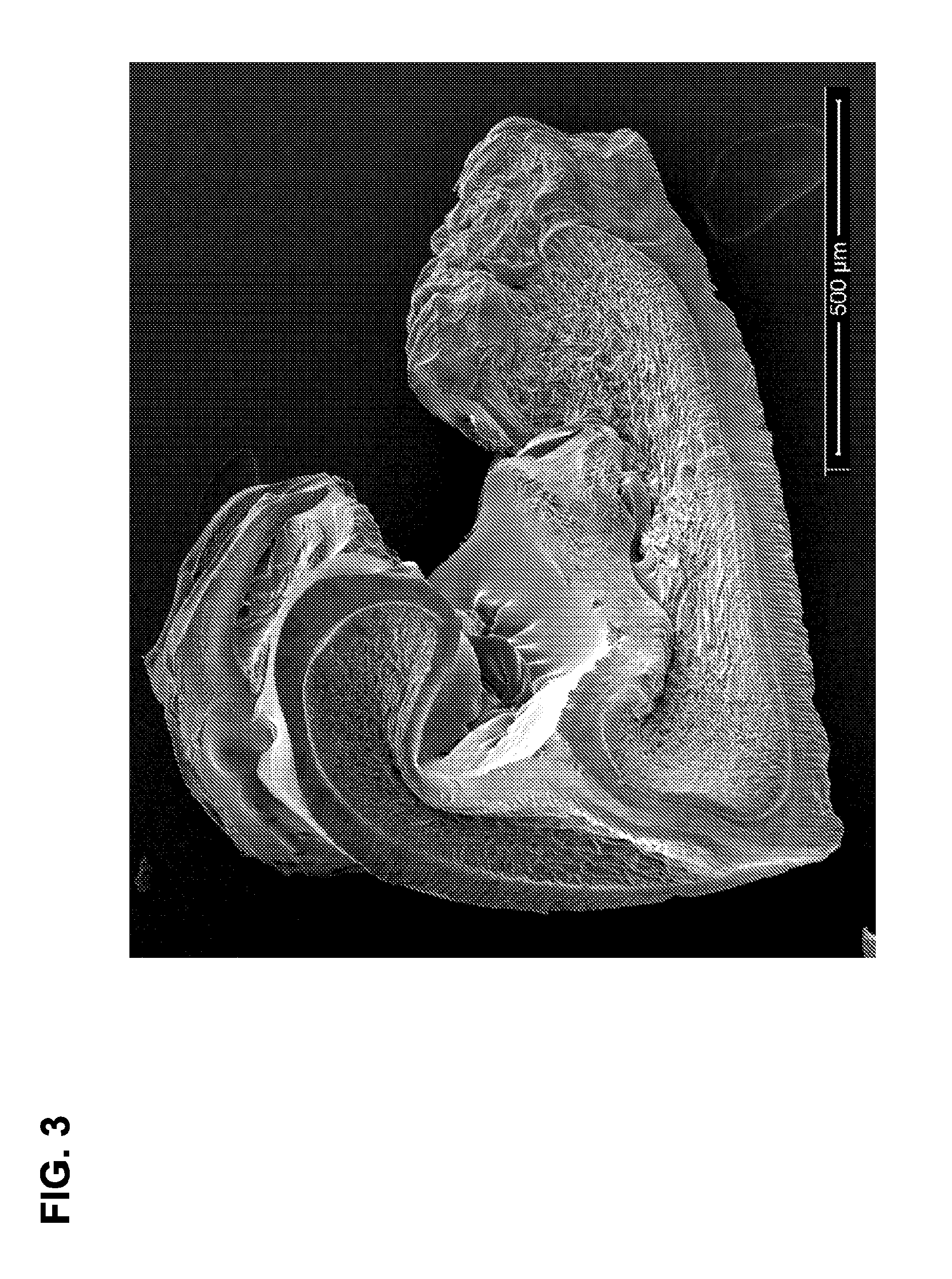

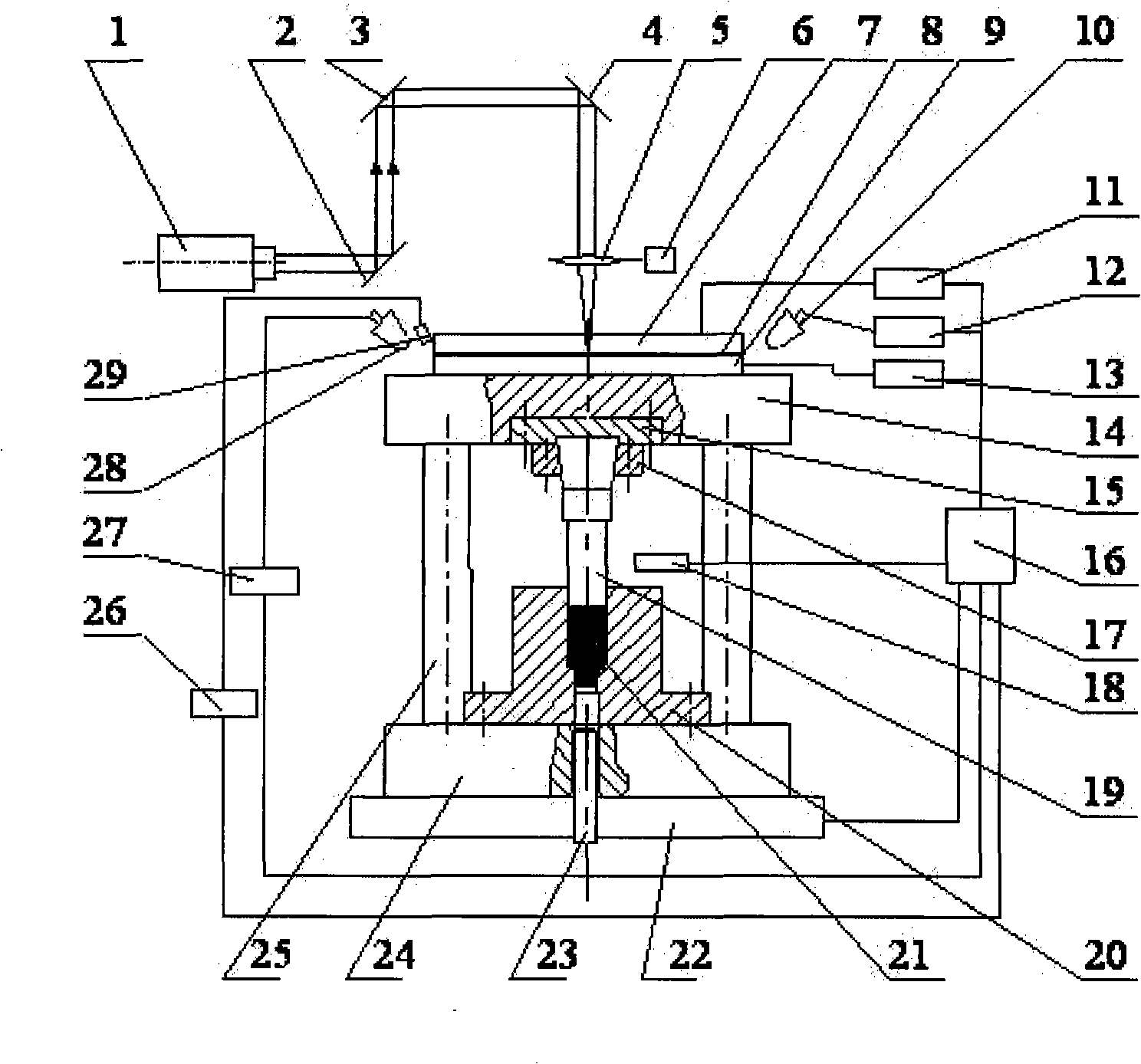

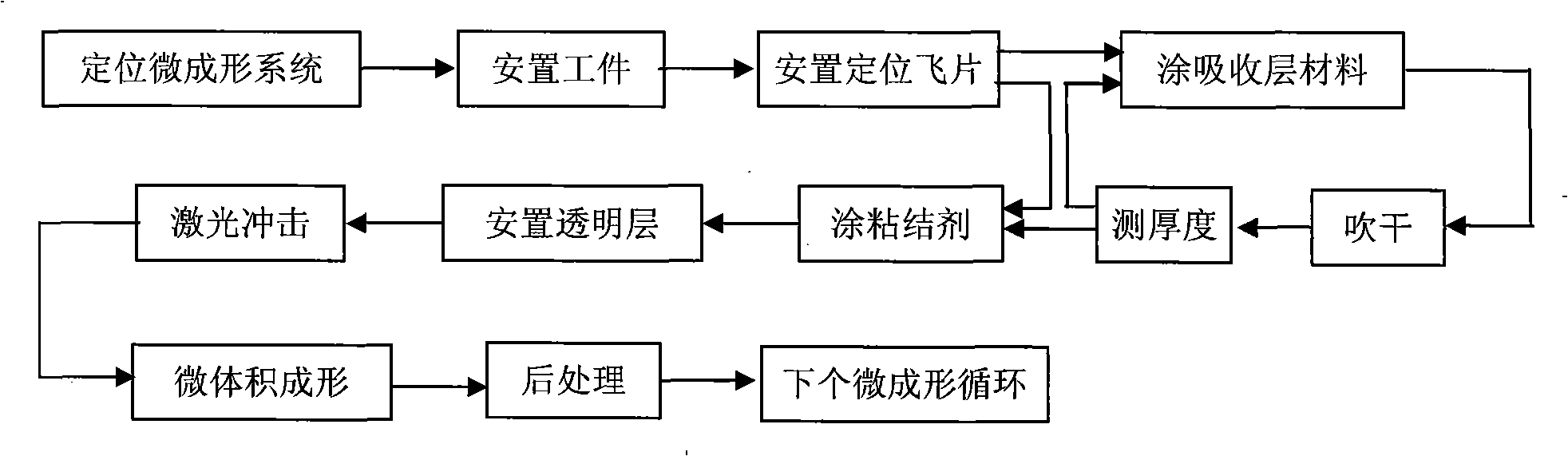

The invention provides a laser impulse micro-bulk forming method and a device thereof, being suitable for the micro-bulk forming of a planchet and belonging to the laser micro-processing field and micro-bulk forming field. The forming method is as follows: impulse wave induced by laser is used as a forming force source for micro-device micro-bulk forming; laser burst generated by a laser generator according to requirements is irradiated at a flying-piece surface layer passing through a transparent restraint layer through an external light path system; a high temperature and high pressure plasma body is generated and the impulse wave is formed; overhigh pressure of the impulse wave is used for driving the flying-piece and a micro-plastic forming system connected with a flying piece; a micro-workpiece is pressed; the micro-bulk forming of the workpiece is finished. The device applied to the method comprises six parts of the laser generator, an external light path system, an induction impulse wave generation system, a micro-plastic forming system, a control system and an operating platform. The laser impulse micro-bulk forming method can be used for realizing the micro-bulk forming of any complex shaped micro-devices, and can be repeatedly impacted and loaded on, and has good repeatability and easy realization of automatic production.

Owner:JIANGSU UNIV

Fiber optic gas sensor

ActiveUS20090129721A1Induce strainImprove absorption rateMaterial analysis by optical meansCoupling light guidesProduct gasSensor materials

A gas sensor includes an in-fiber resonant wavelength device provided in a fiber core at a first location. The fiber propagates a sensing light and a power light. A layer of a material is attached to the fiber at the first location. The material is able to absorb the gas at a temperature dependent gas absorption rate. The power light is used to heat the material and increases the gas absorption rate, thereby increasing sensor performance, especially at low temperatures. Further, a method is described of flash heating the gas sensor to absorb more of the gas, allowing the sensor to cool, thereby locking in the gas content of the sensor material, and taking the difference between the starting and ending resonant wavelengths as an indication of the concentration of the gas in the ambient atmosphere.

Owner:UNIVERSITY OF PITTSBURGH +1

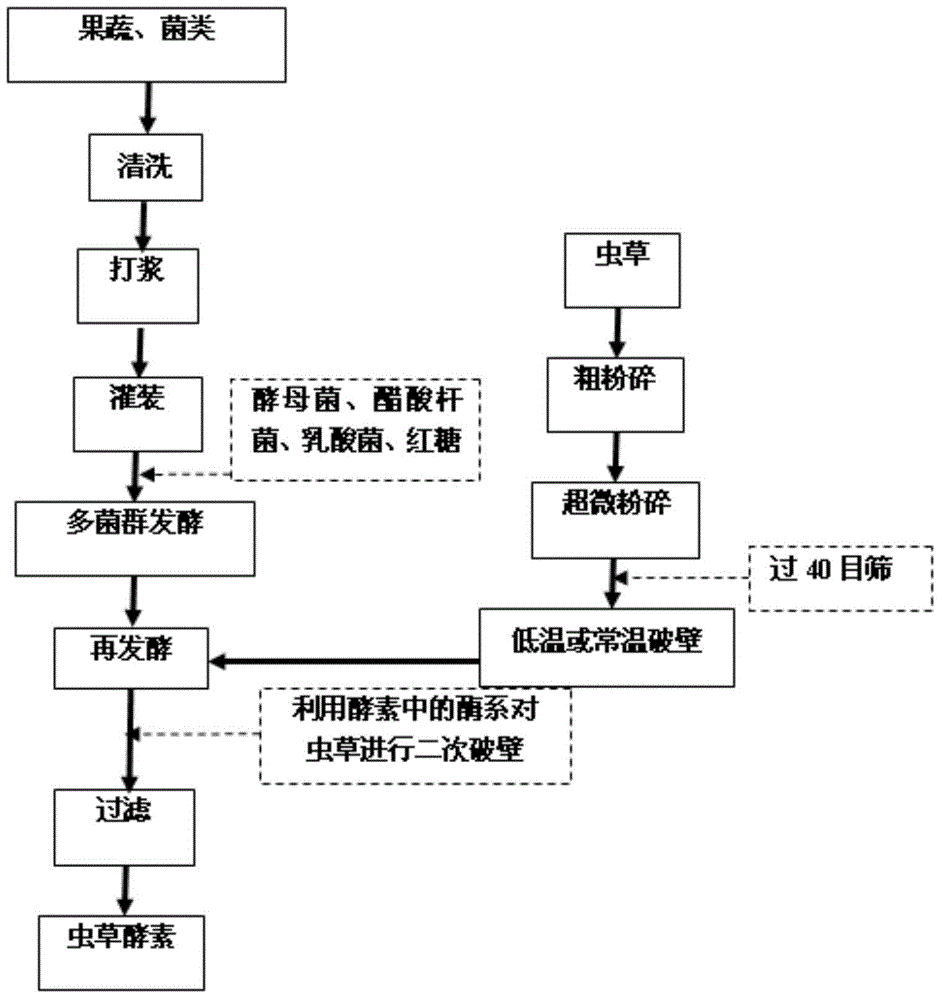

A cordyceps sinensis enzyme and a preparation method thereof

InactiveCN104856015ANo loss of nutritionImprove absorption rateFood preparationEnzyme systemBULK ACTIVE INGREDIENT

The present invention provides a cordyceps sinensis enzyme and a preparation method thereof. The enzyme is prepared by fermenting the following ingredients in parts by weight: fruits and vegetables 55-70 parts, fungi 8-12 parts, cordyceps sinensis 1-2 parts and sugar 15-20 parts with the addition of probiotic 0.2-0.8 part. The preparation method comprises the following steps: preparing cordyceps sinensis sporoderm-broken powder, preparing primary enzyme solution, fermenting the powder and the solution for preparing the cordyceps sinensis enzyme, etc. The enzyme uses ultramicro crushing technology to crush the cordyceps sinensis, and low temperature or room temperature sporoderm-breaking technology to conduct sporoderm-breaking on the cordyceps sinensis so that the nutrition loss of the cordyceps sinensis is prevented and the absorption rate of the cordyceps sinensis is improved; the enzyme utilizes rich enzyme systems of enzymes to conduct additional sporoderm-breaking on the sporoderm-broken powder, which facilitates the release and homogenization of active ingredients in the cordyceps sinensis, and improves the effect of drugs. The prepared enzyme contains proteins, amino acids, vitamins, enzyme substances, etc. essential for human bodies, effectively accumulates functional components of the cordyceps sinensis, and effectively improves various health-care effects of the enzymes.

Owner:西藏月王药诊生态藏药科技有限公司

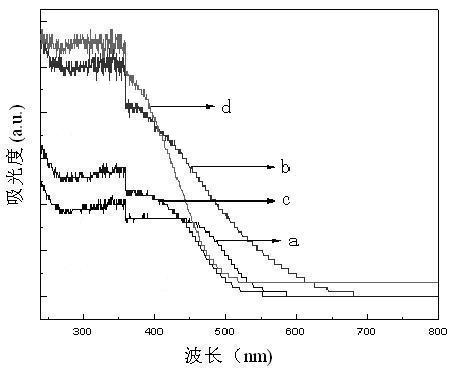

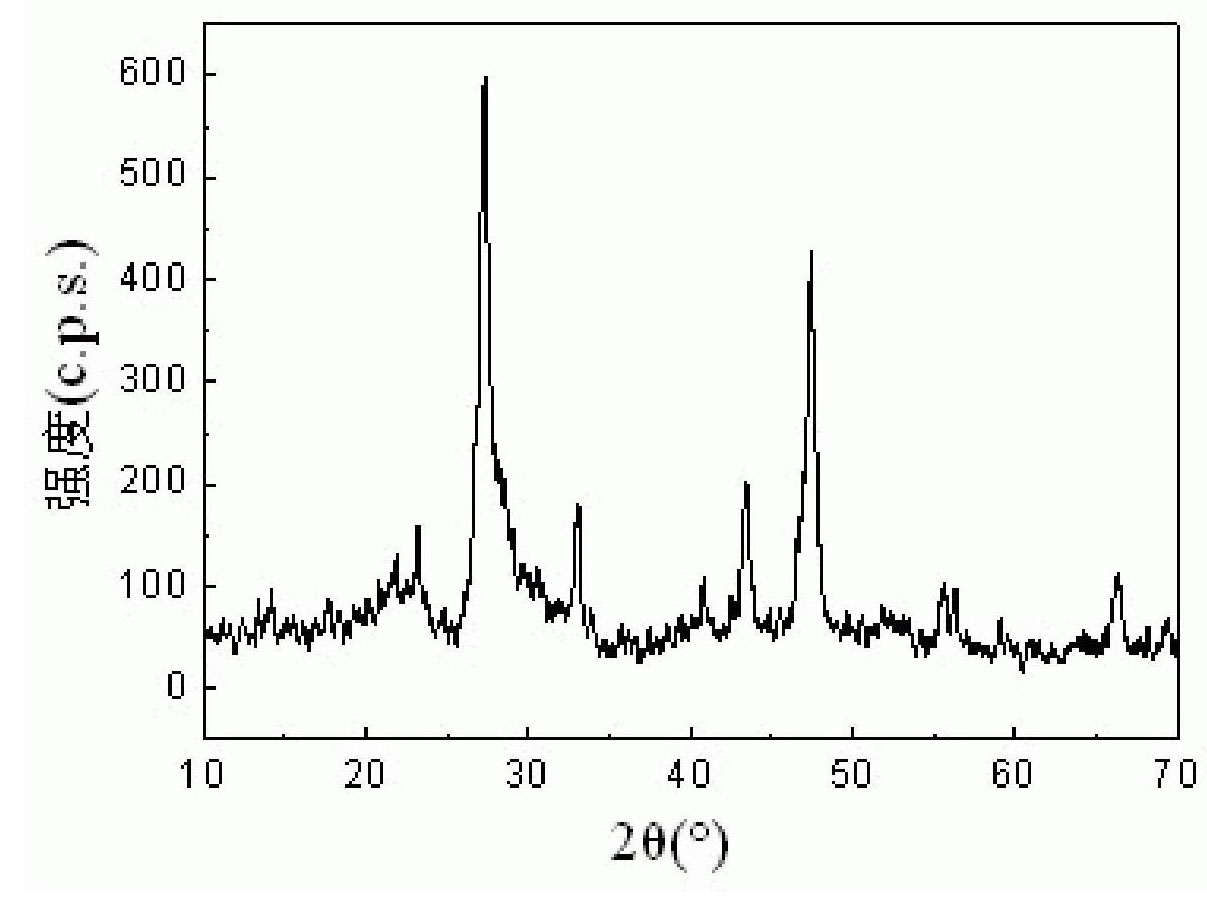

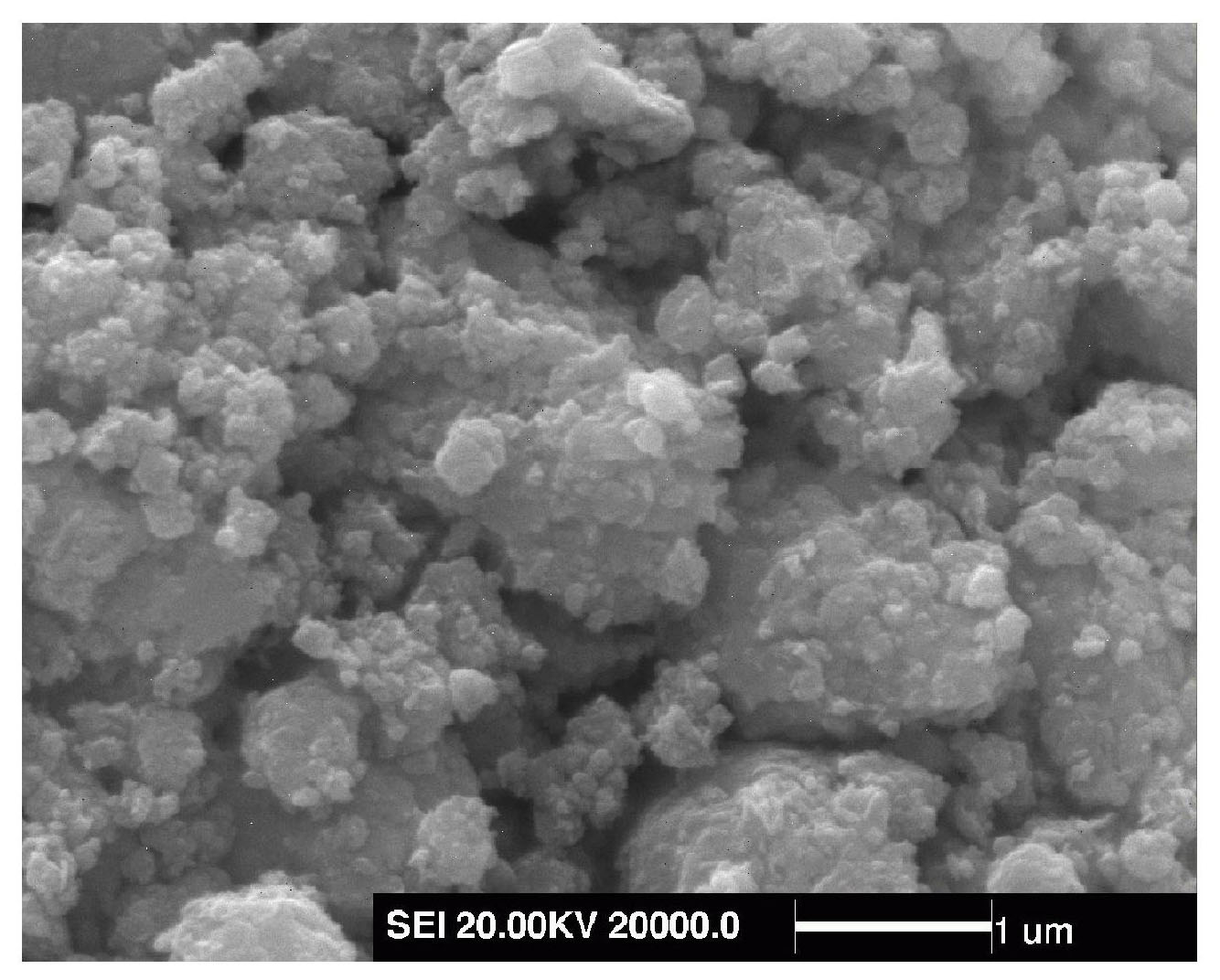

Photocatalyst for preparing hydrogen and sulphur by decomposing hydrogen sulfide and preparation method thereof

InactiveCN101927173AIncrease profitReduce chance of recombinationPhysical/chemical process catalystsDispersed particle separationIndiumHYDROSOL

The invention discloses a photocatalyst for preparing hydrogen and sulphur by decomposing hydrogen sulfide and a preparation method thereof, relating to a photocatalyst and a preparation method thereof. The invention solves the problem that the existing photocatalyst ZnIn2S4-CdIn2S4 the atomic ratio of which is that Zn:Cd=7:3 has low photocatalysis activity. The photocatalyst of the invention is ZnIn2S4-CdIn2S4 doped by transition metal ions. The preparation method comprises: adding sol prepared from transition metal salt, bivalent cadmium salt, bivalent zinc salt, trivalent indium salt and thioacetamide into an autoclave; and carrying out hydrothermal synthesis and vacuum drying to obtain the photocatalyst for preparing the hydrogen and the sulphur by decomposing the hydrogen sulphide. The invention has high catalytic activity; the speed for producing the hydrogen by carrying out photocatalysis on the hydrogen sulphide is 1100-3500 mu mol / h.g which is 1.8-6 times of that obtained by utilizing the ZnIn2S4-CdIn2S4. The photocatalyst of the invention can be used for processing tail gas containing hydrogen sulphide.

Owner:HARBIN 6 RING PETROCHEM TECHN DEVCORP

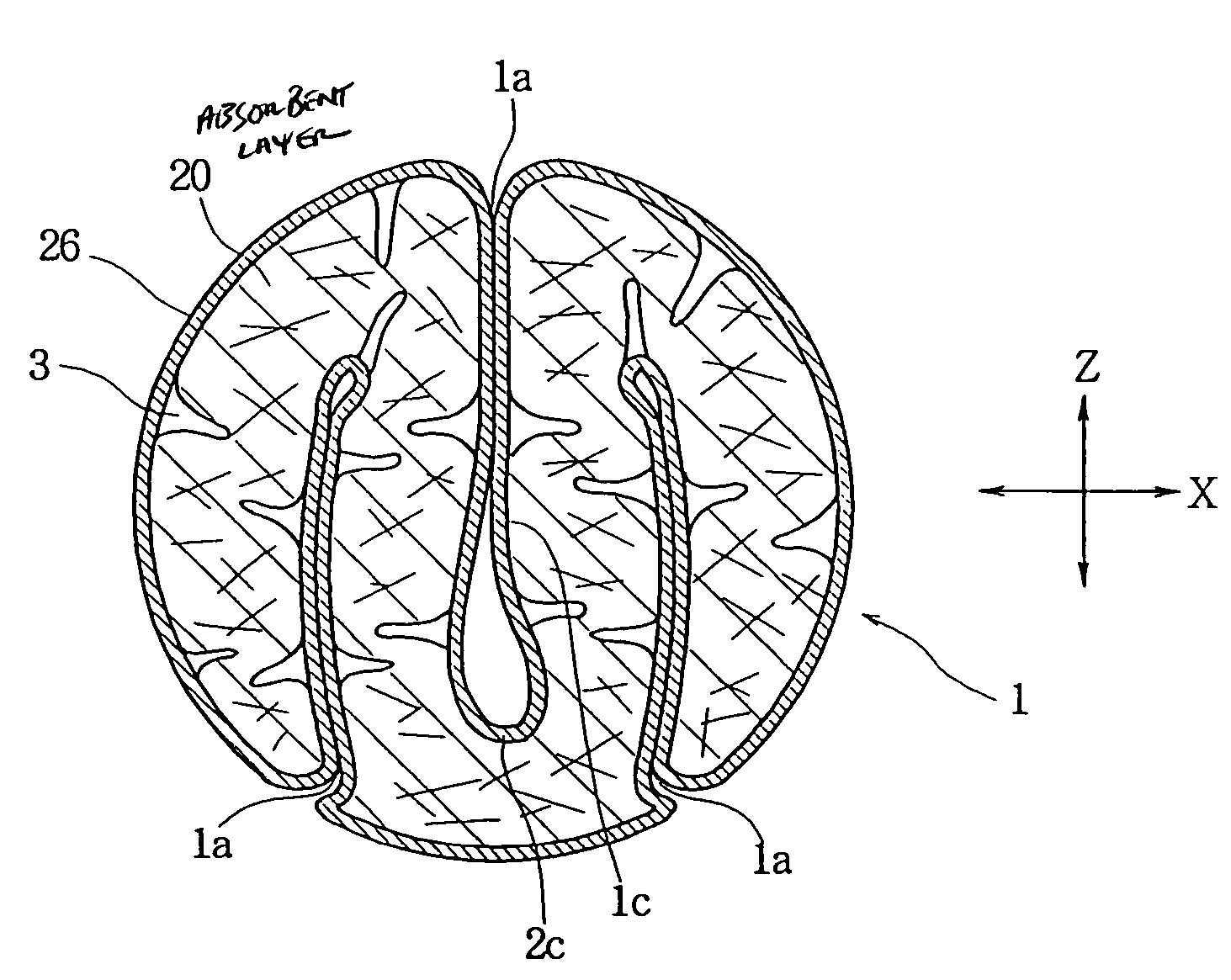

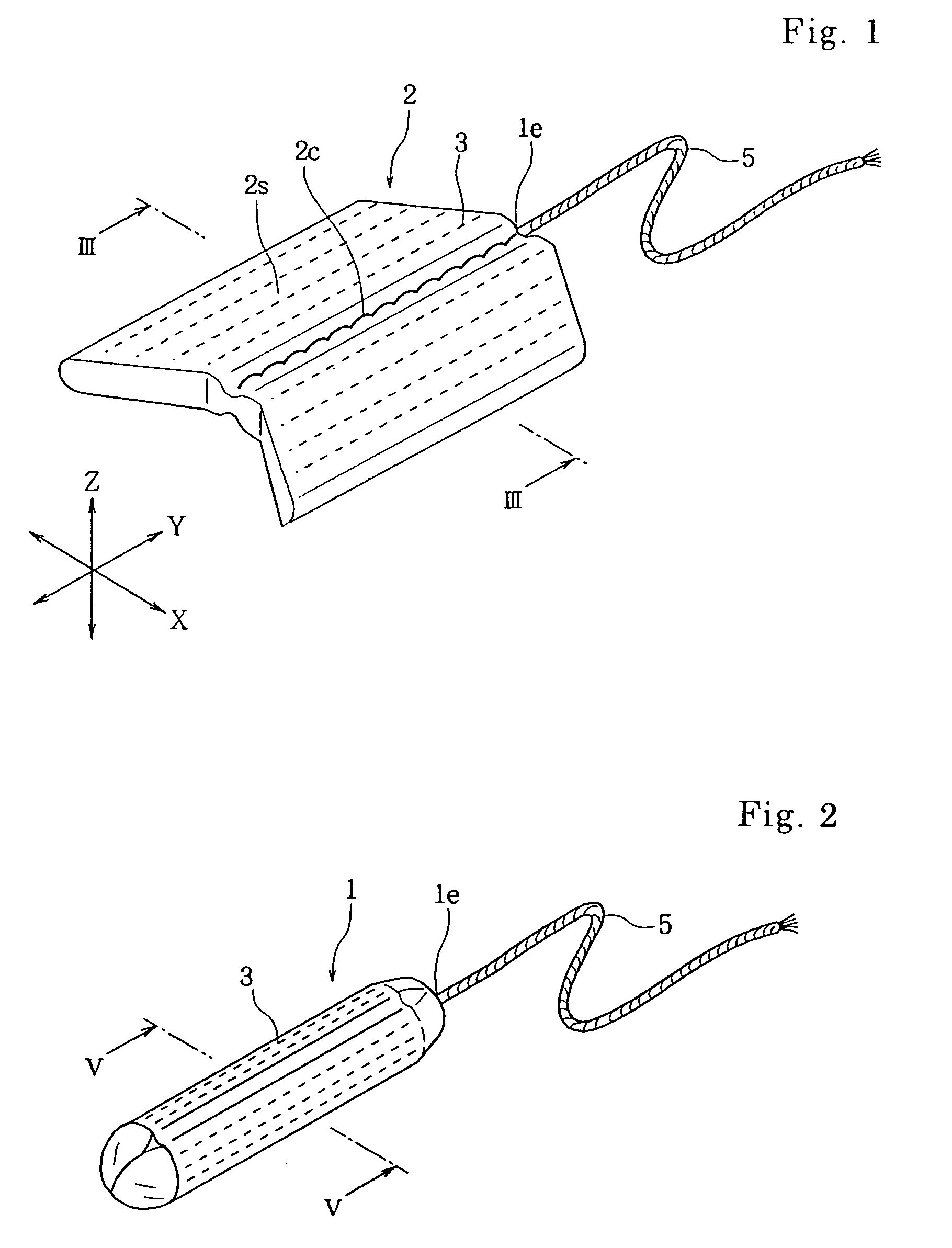

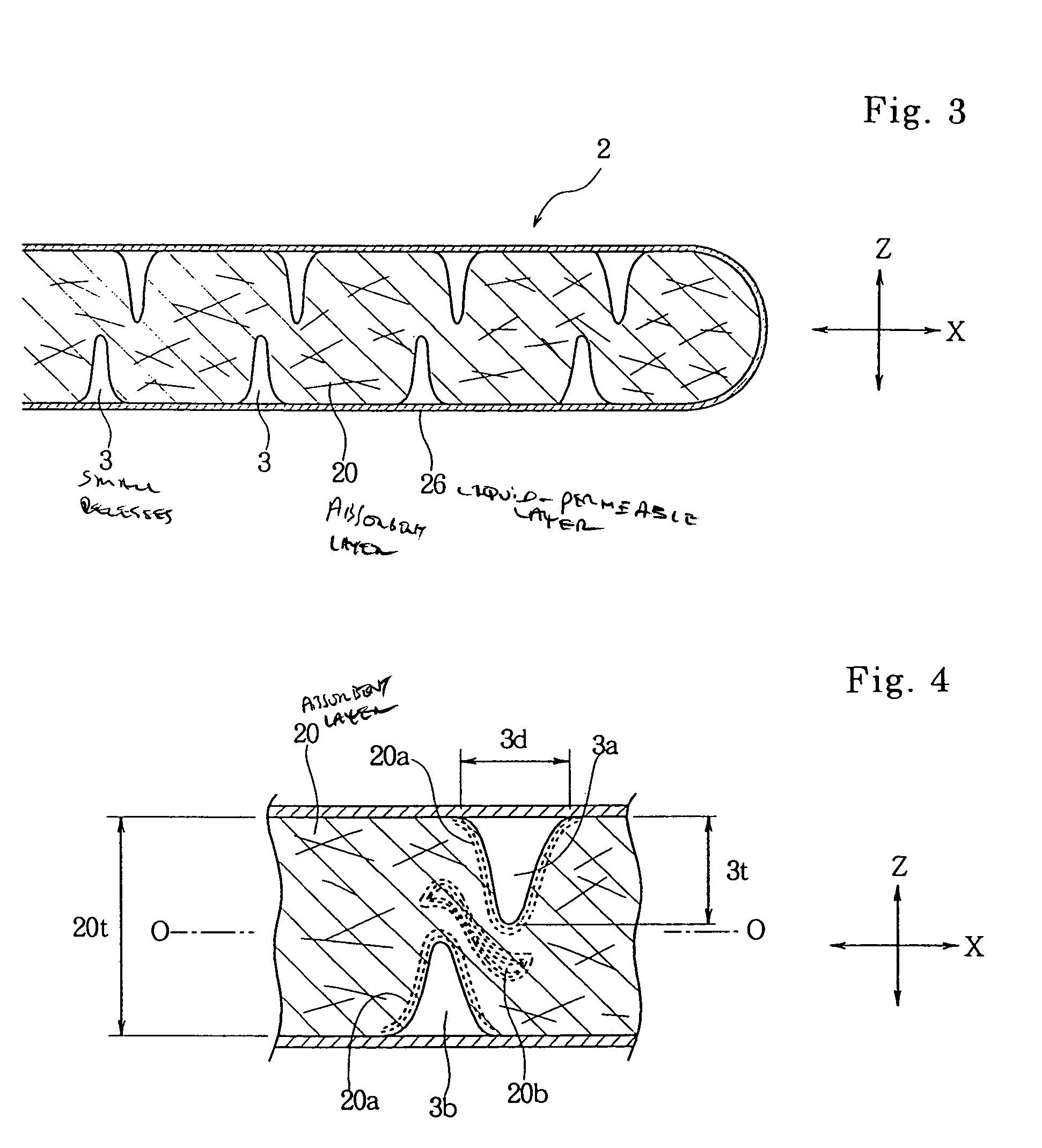

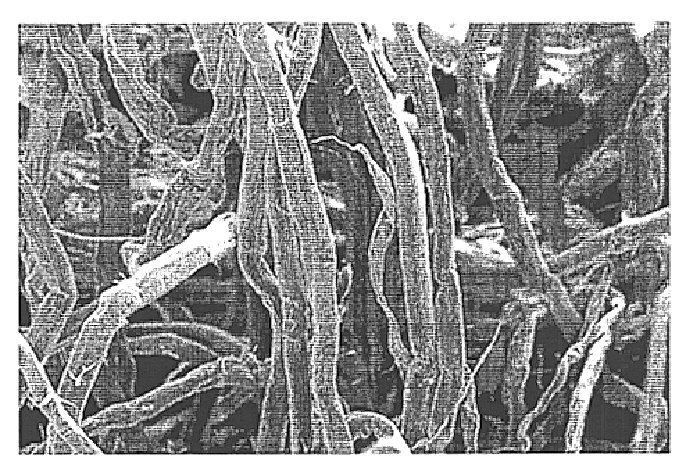

Sanitary tampon

There is disclosed a sanitary tampon including an absorber including: an absorbent layer made of an absorbent fibrous material; and a hydrophobic liquid-permeable layer covering the absorbent layer. The absorber is formed firstly into a flat shape and then into a column shape. The absorbent layer forming the flat absorber is formed with a plurality of small recesses which open in the surface of the absorbent layer and extend into the absorbent layer.

Owner:UNI CHARM CORP

Superabsorbent cellulosic fiber and method of making same

InactiveUS6844066B2Good absorption rateHigher efficient graftingMonocomponent cellulose artificial filamentDisinfectionCellulose fiberUnsaturated monomer

Owner:RAYONIER PERFORMANCE FIBERS

Multi-functional slow-release urea fertilizer and preparation method

InactiveCN102557838AExtend the fertilizer periodStrong chelating functionAgriculture gas emission reductionFertilizer mixturesManganesePlant growth

The invention relates to nitrogen fertilizers, in particular to a multi-functional slow-release urea fertilizer and a preparation method. The fertilizer comprises urea, a biochemical inhibitor, synergist, water-soluble salt ions of secondary and trace elements necessary for plants and / or beneficial elements for plant growth. By weight percentage, the weight percentage of the urea to the biochemical inhibitor to the synergist is equal to 1: 0.001-0.1: 0.0005-0.05, the salt ions of the secondary and trace elements necessary for the plants comprises one kind or a plurality of kinds of calcium, magnesium, sulfur, ferrum, copper, zinc, manganese, boron, molybdenum and chlorine, the weight percentage of the urea to all the secondary and trace elements necessary for the plants is equal to 1: 0-0.1: 0-0.1: 0-0.06: 0.001-0.03: 0.001-0.01: 0.001-0.01: 0.001-0.008: 0.001-0.01: 0.001-0.005: 0-0.006, the beneficial elements for the plant growth comprise silicon and selenium, and the weight percentage of the urea to all beneficial elements for the plant growth is equal to 1: 0-0.1: 0.001-0.08. The multi-functional slow-release urea fertilizer can promote growth of root systems, invigorate plants, enhance disease resistance, drought resistance and lodging resistance, and stimulate prematurity.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com