Patents

Literature

1476 results about "Hydrogen sulphide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

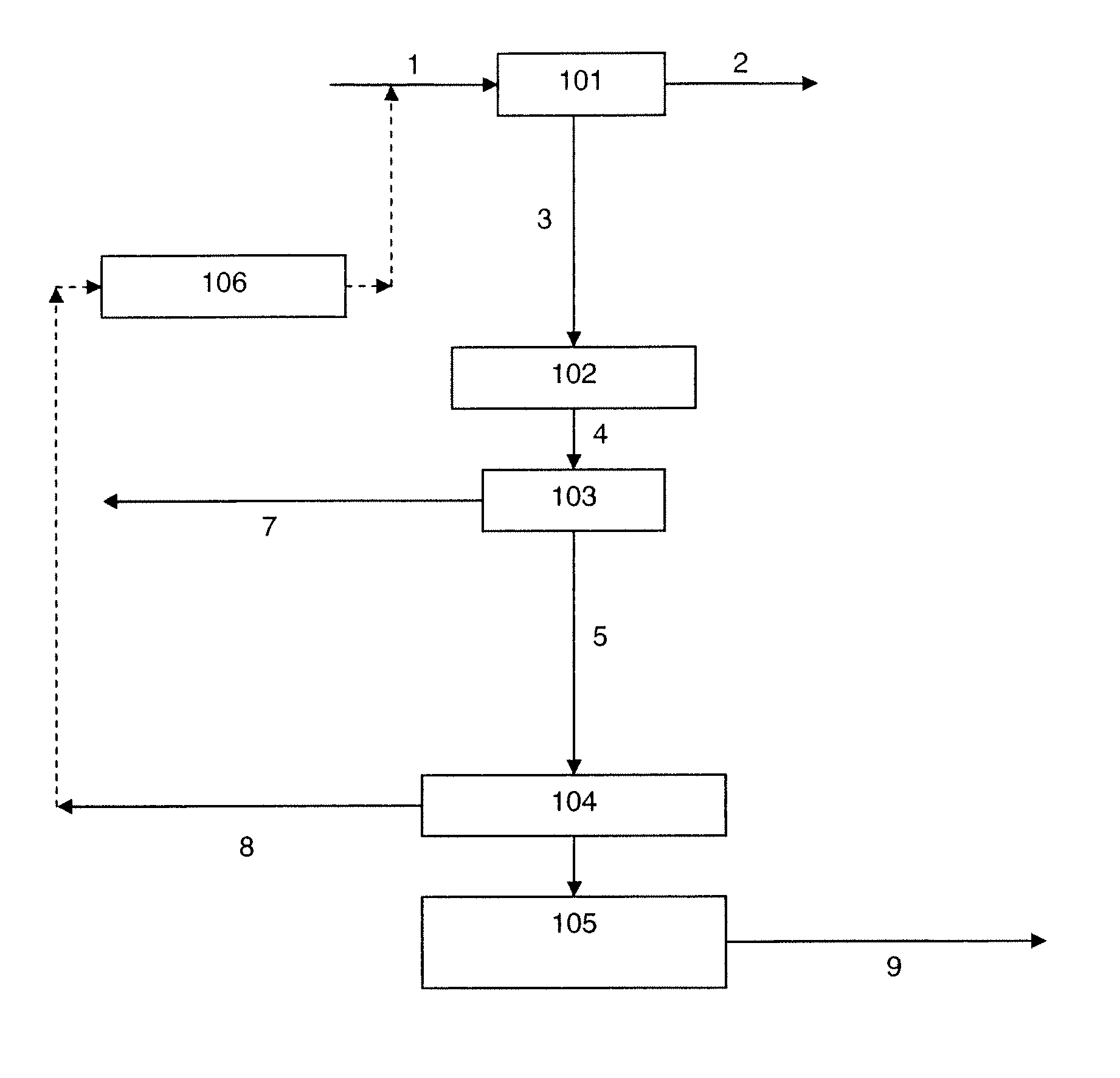

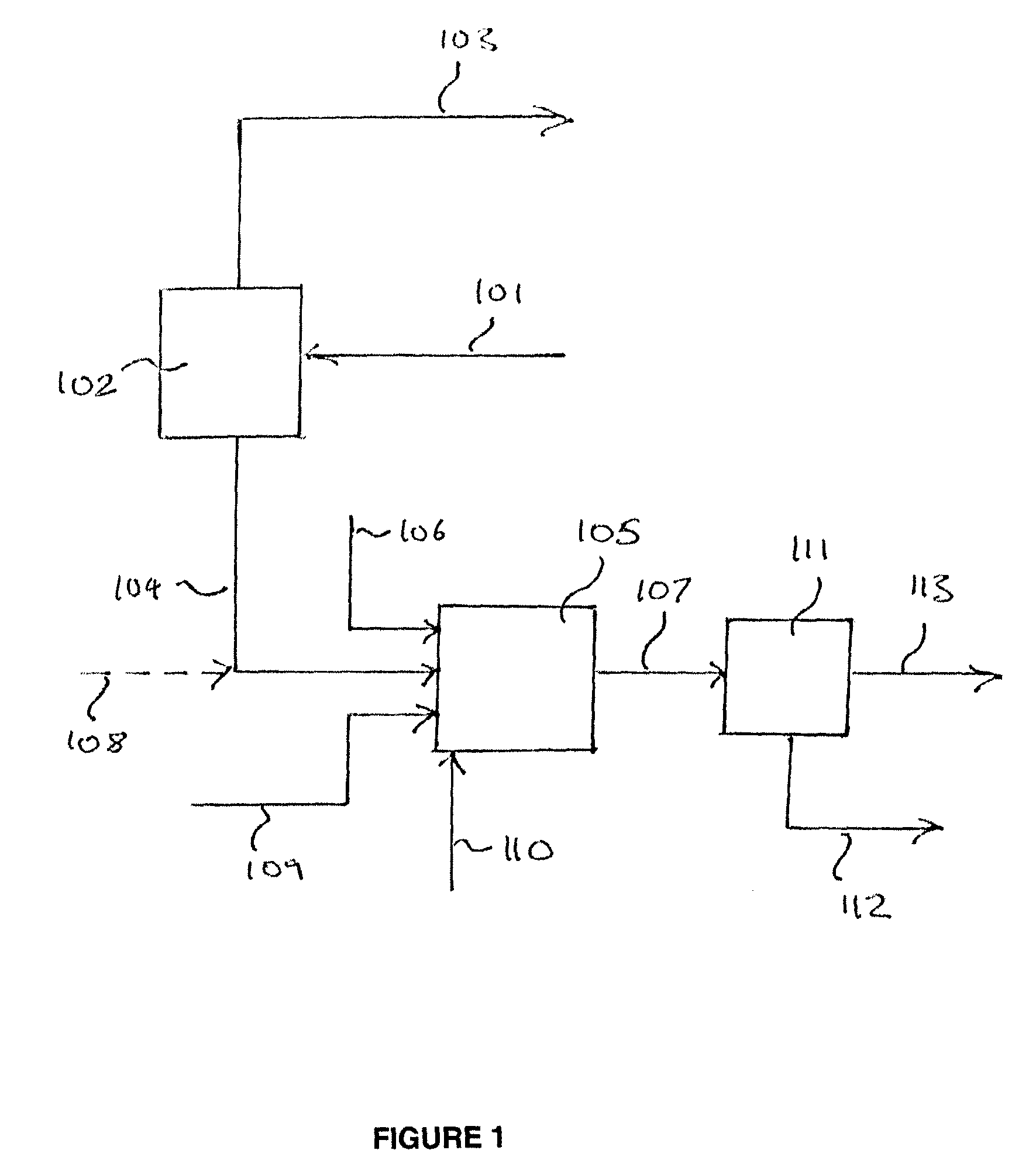

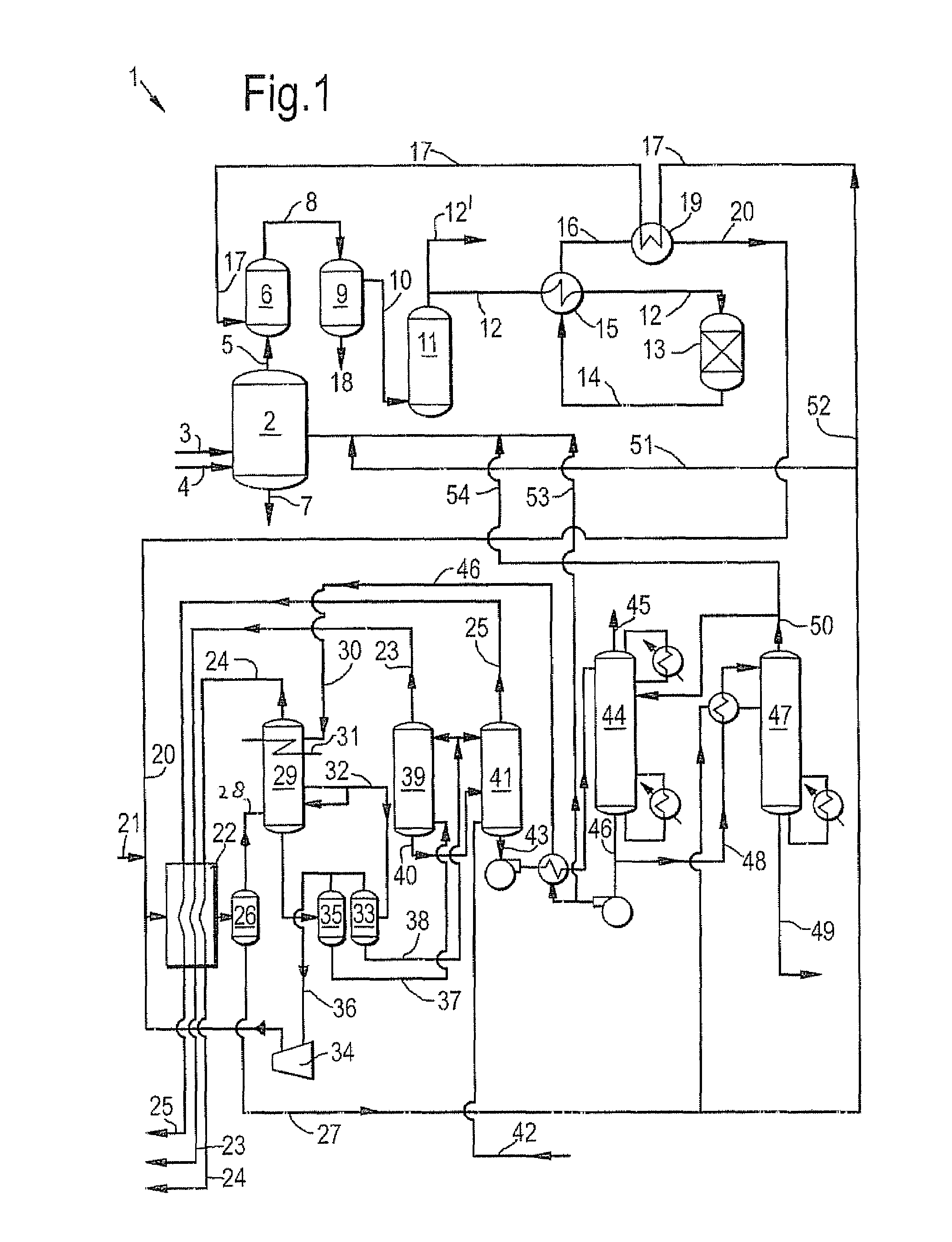

Separation of a sour syngas stream

A feed stream, comprising hydrogen sulphide (H2S), carbon dioxide (CO2), hydrogen (H2) and, optionally, carbon monoxide (CO), is separated into at least a CO2 product stream and an H2 or H2 and CO product stream. The stream is separated using a pressure swing adsorption system, an H2S removal system and a further separation system, which systems are used in series to separate the stream. The method has particular application in the separation of a sour (i.e. sulphur containing) syngas, as for example produced from the gasification of solid or heavy liquid carbonaceous feedstock.

Owner:AIR PROD & CHEM INC

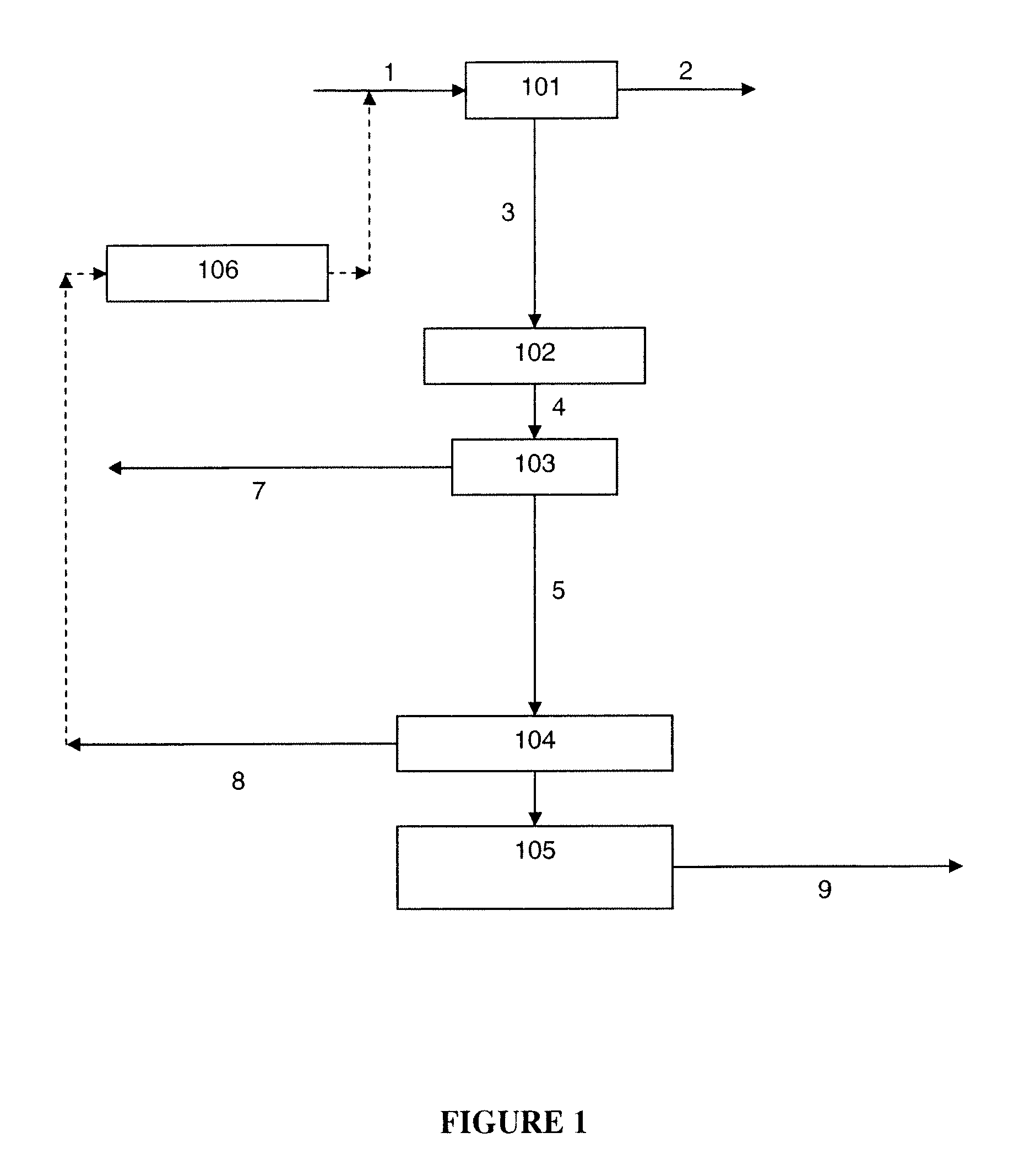

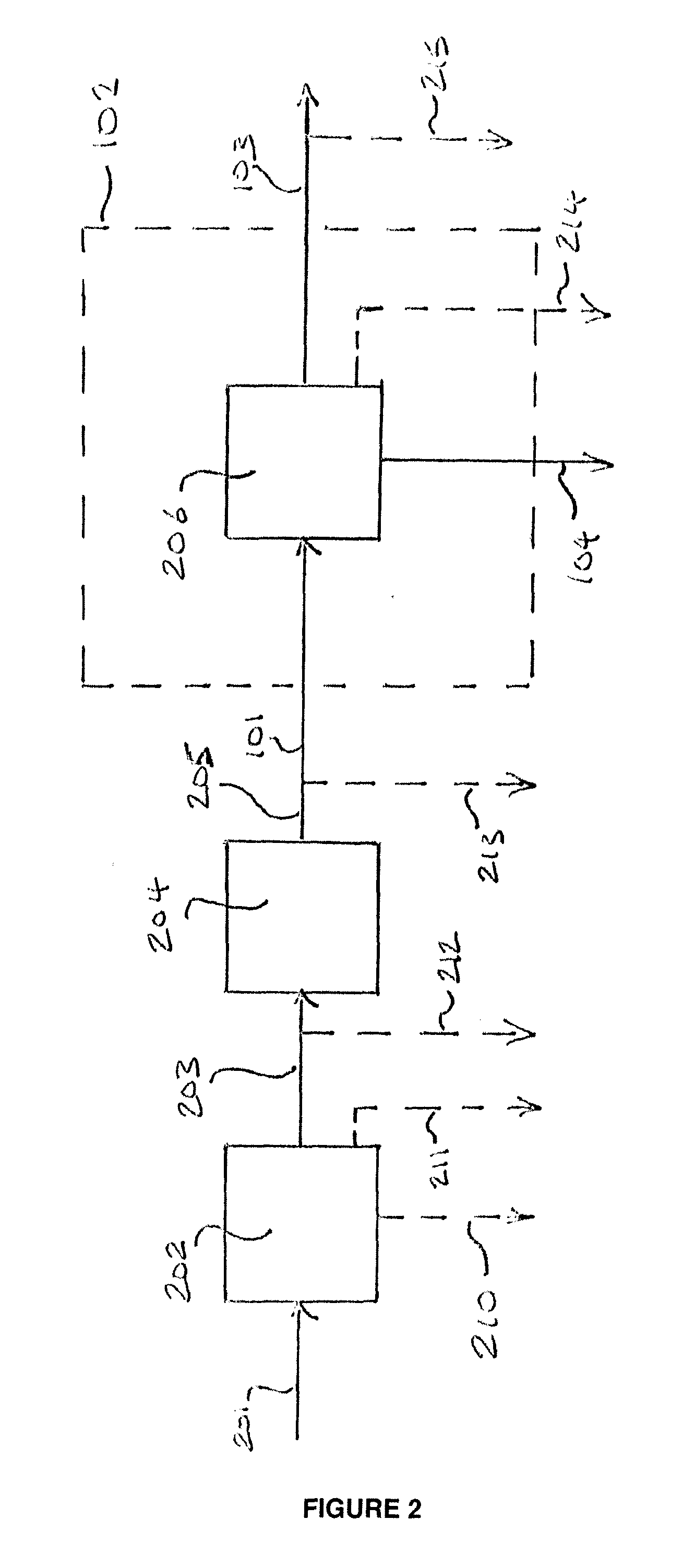

Method of treating a gaseous mixture comprising hydrogen, carbon dioxide and hydrogen sulphide

A gaseous mixture, comprising CO2, H2, H2S and optionally CO, is separated into an H2 or H2 and CO product stream (H2 / CO product stream), and a CO2 enriched stream containing at least one combustible component selected from H2S, H2, CO and any additional combustible components present in the gaseous mixture. A support fuel stream, comprising one or more combustible components, is combusted to form a stable flame, and the CO2 enriched stream and flame are contacted in the presence of sufficient O2 to combust all or substantially all of the combustible component(s) present in said CO2 enriched stream. A CO2 product stream is formed from said combustion effluent. The support fuel stream may be generated from the process of generating or separating the gaseous mixture or from the H2 / CO product stream. Where the CO2 enriched stream contains H2S, the support fuel stream may also be a stream obtained off-site that comprises H2S.

Owner:AIR PROD & CHEM INC

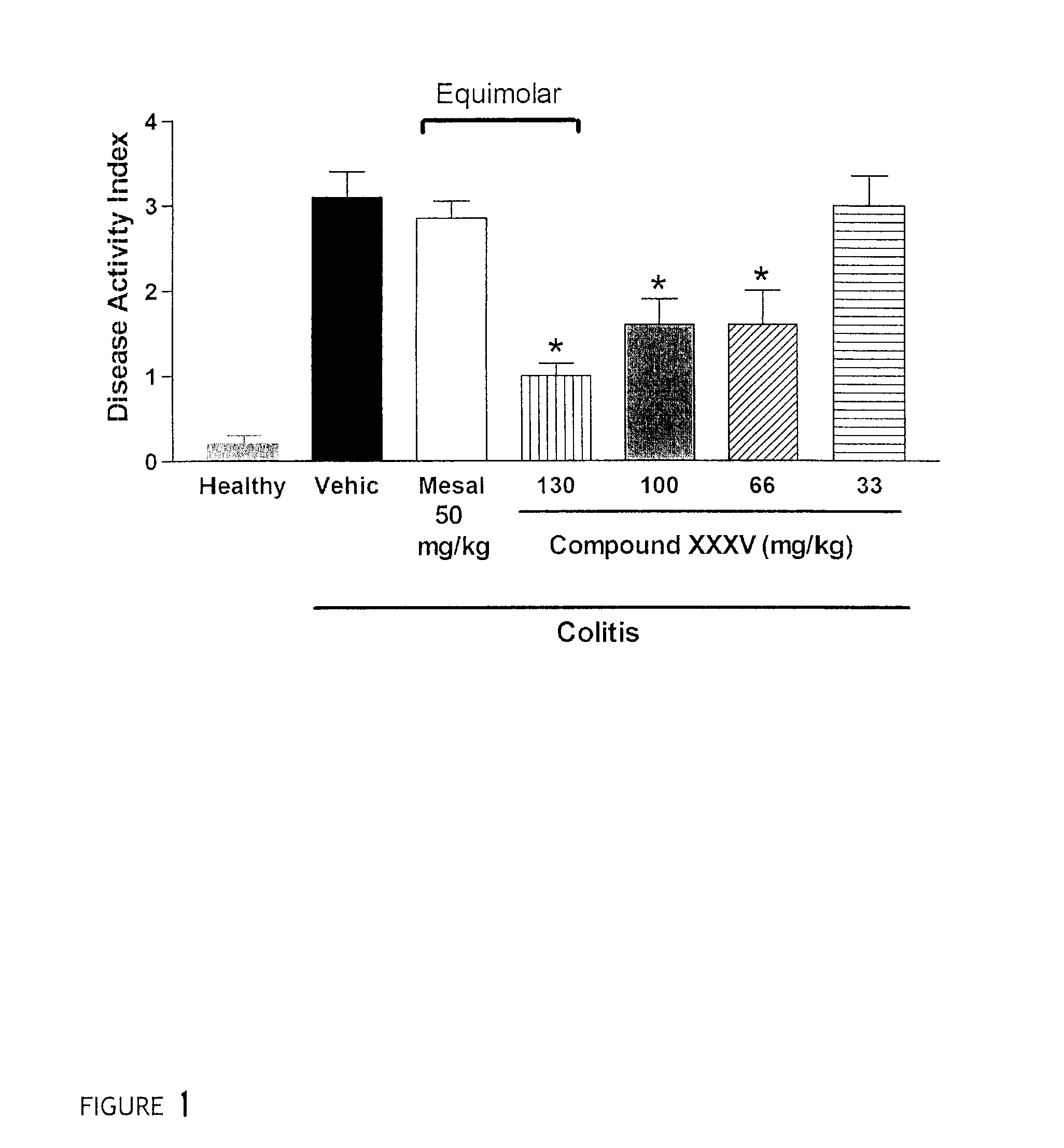

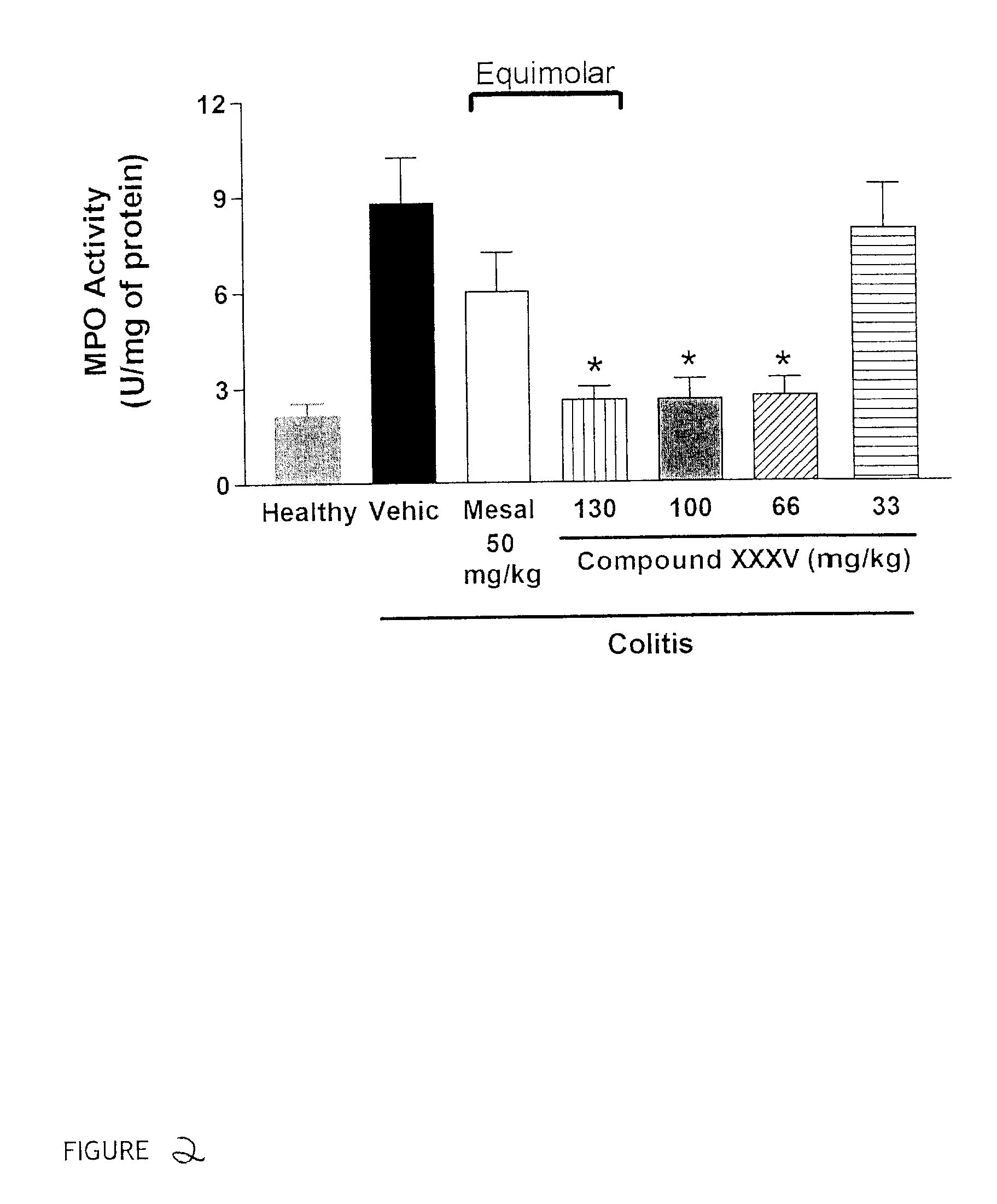

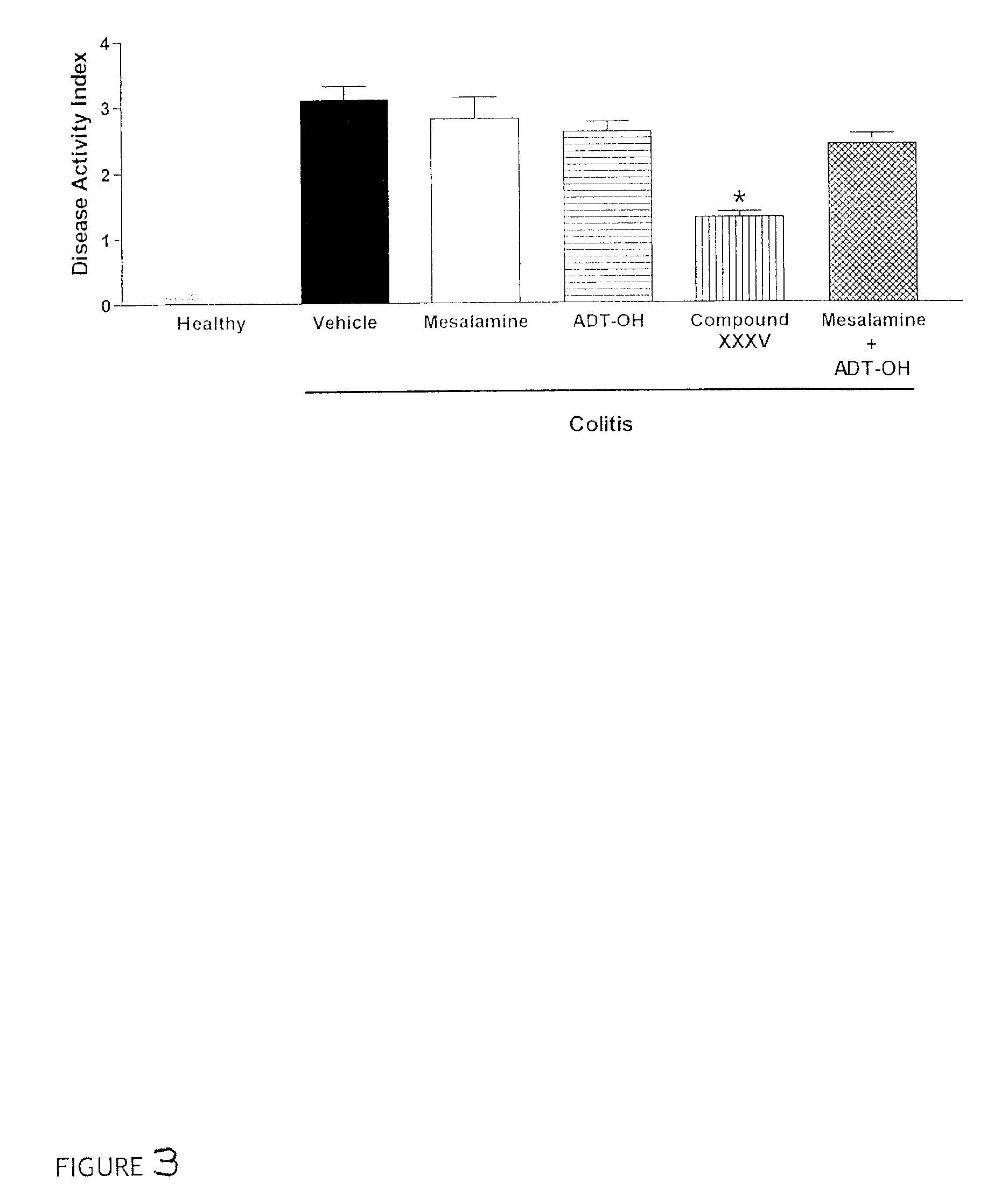

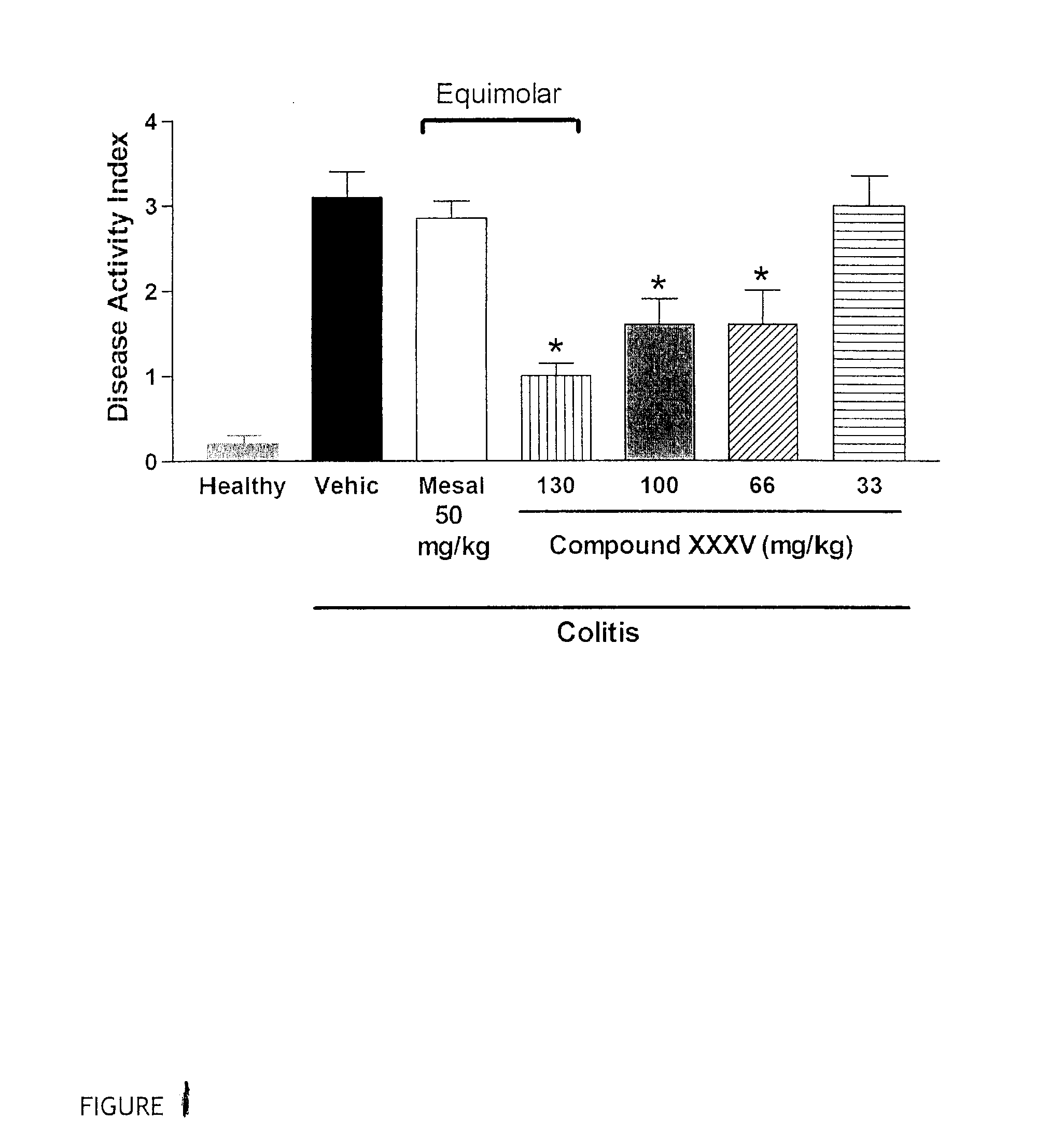

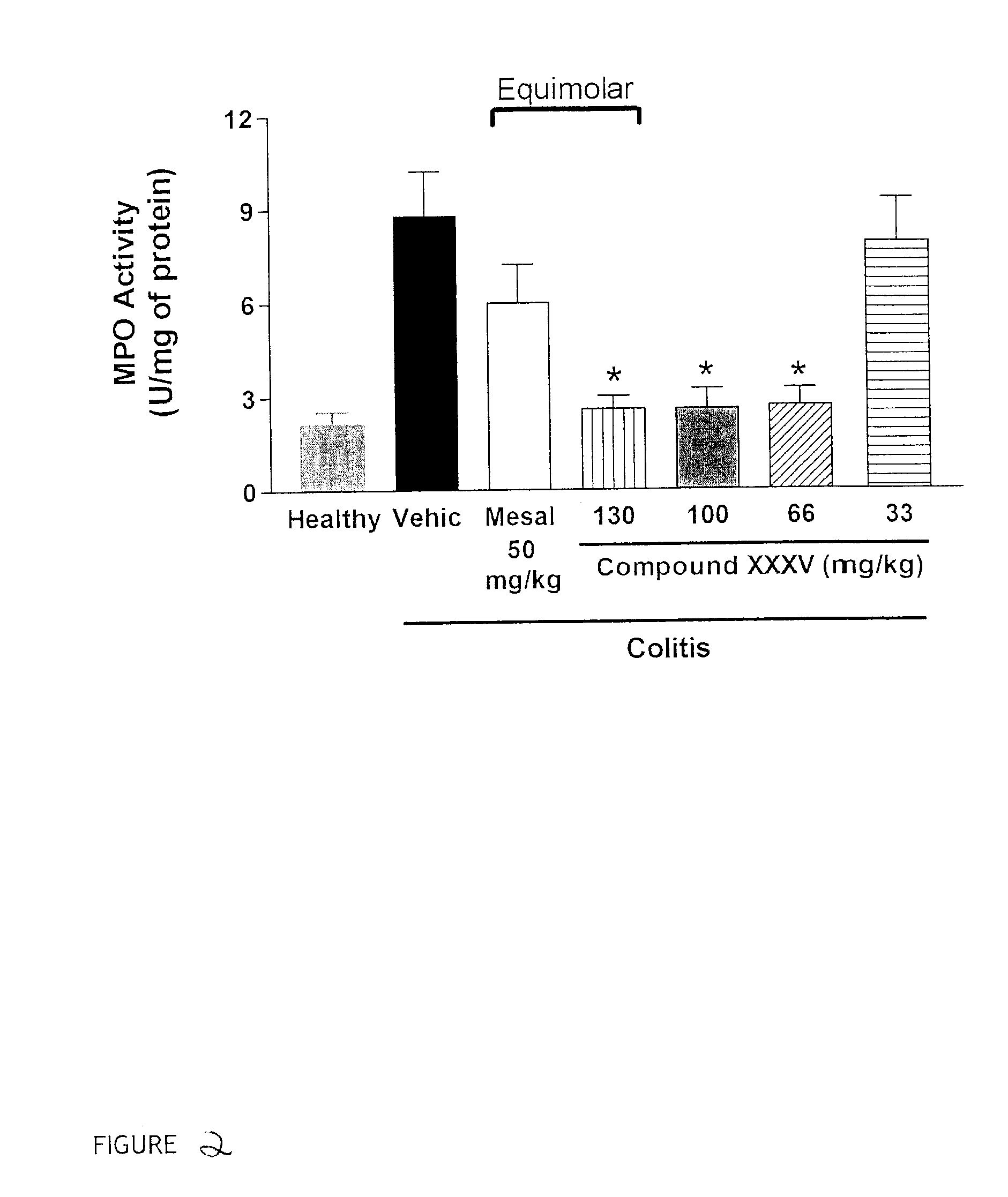

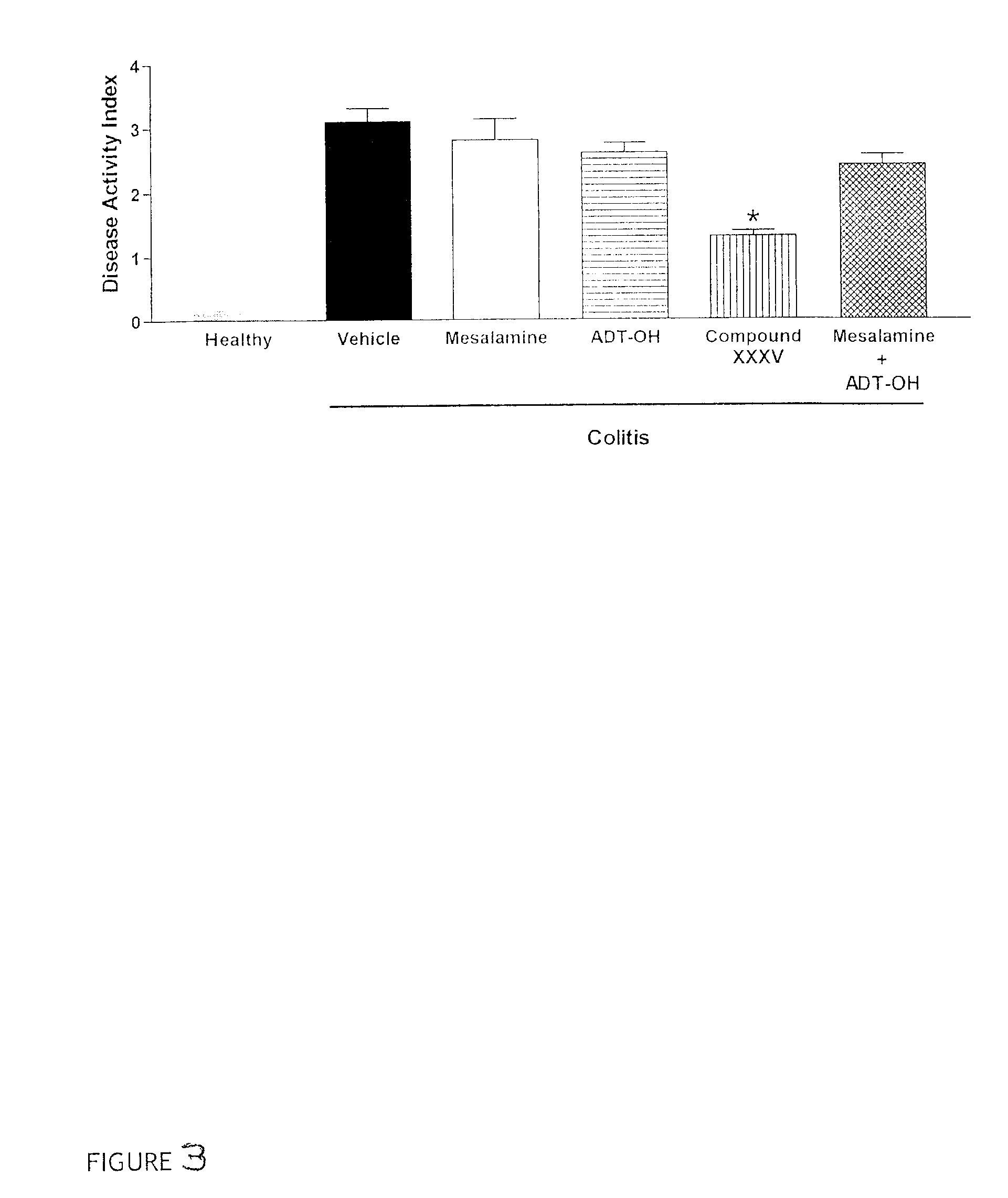

Derivatives of 4- or 5-aminosalicylic acid

InactiveUS7910568B2Easily reach colonPromote absorptionBiocideAntipyreticSalicylic acidBULK ACTIVE INGREDIENT

Owner:ANTIBE THERAPEUTICS INC

Derivaitves of 4-Or 5-Aminosalicylic Acid

InactiveUS20080207564A1Less readily absorbedEasily reach colonBiocideAntipyreticThioester synthesisSalicylic acid

The present invention provides new derivatives of 4- or 5-aminosalicylic acid, and a pharmaceutical composition containing these derivatives of 4- or 5-aminosalicylic acid as active ingredients, useful for the treatment of intestinal diseases such as inflammatory bowel disease (IBD) and irritable bowel syndrome (IBS) and for the prevention / treatment of colon cancer. More particularly, these derivatives comprise a hydrogen sulfide releasing moiety linked via an azo, an ester, an anhydride, a thioester or an amide linkage to a molecule of 4- or 5-aminosalicylic acid. Furthermore, the present invention provides a process for preparing these compounds and their use for treating IBD and IBS and the prevention / treatment of colon cancer.

Owner:ANTIBE THERAPEUTICS INC

Method of preventing hydrogen sulfide odor generation in an aqueous medium

ActiveUS20060006120A1Water treatment compoundsSpecific water treatment objectivesBiotechnologyChemical treatment

The present invention relates to a fast acting chemical treatment for preventing the generation of hydrogen sulfide odor by the microbial metabolic activities of sulfate reducing bacteria. Specifically, the invention relates to a method for preventing hydrogen sulfide odor generation in a sulfur species-containing aqueous medium, which includes adding to the aqueous medium an effective amount for the purpose of a sulfide scavenger treatment selected from the group consisting of glyoxal, triazine, n-chlorosuccinimide, and mixtures thereof.

Owner:BL TECH INC

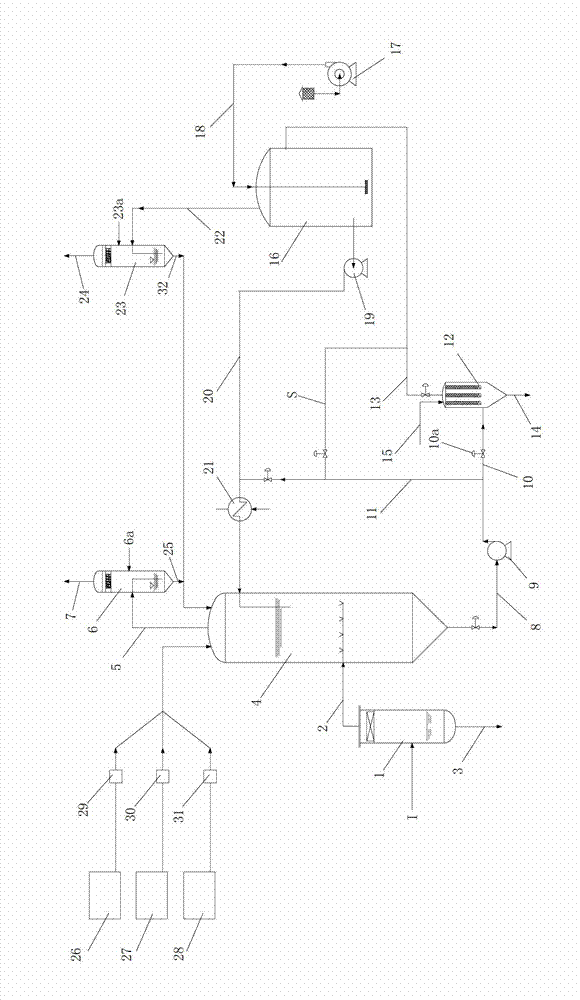

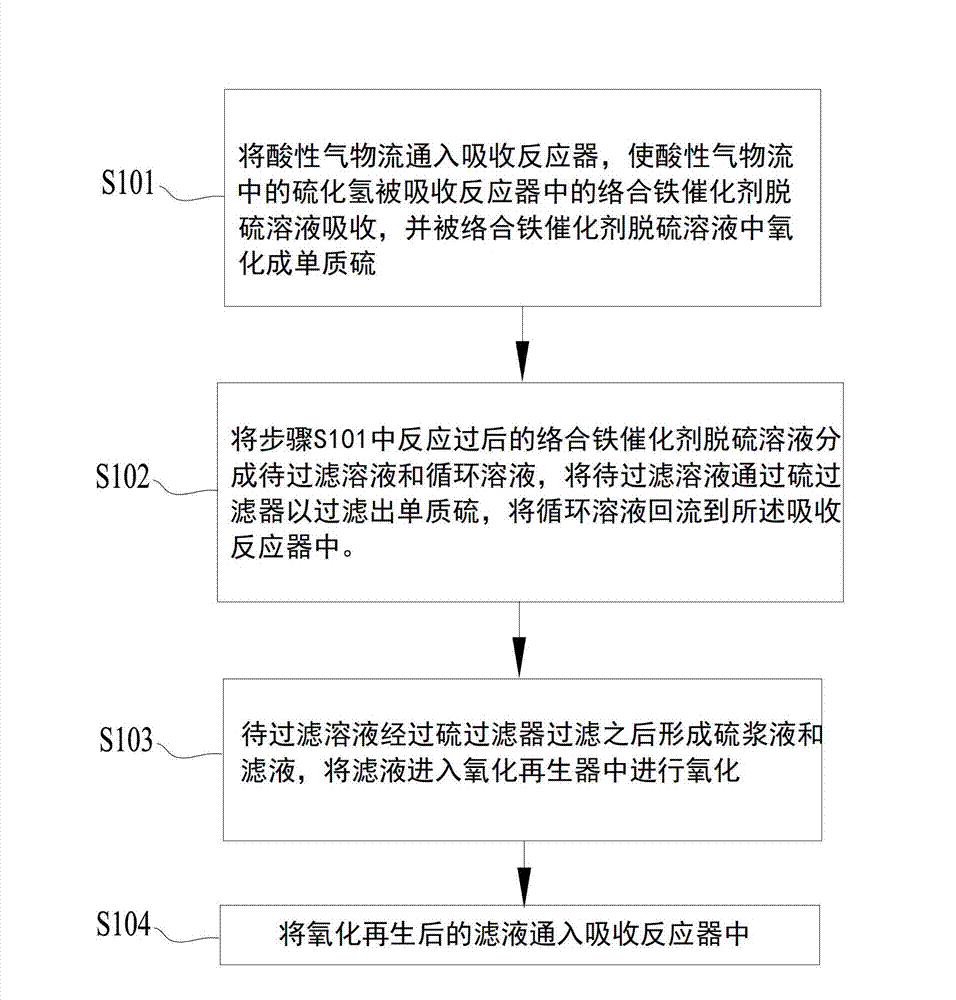

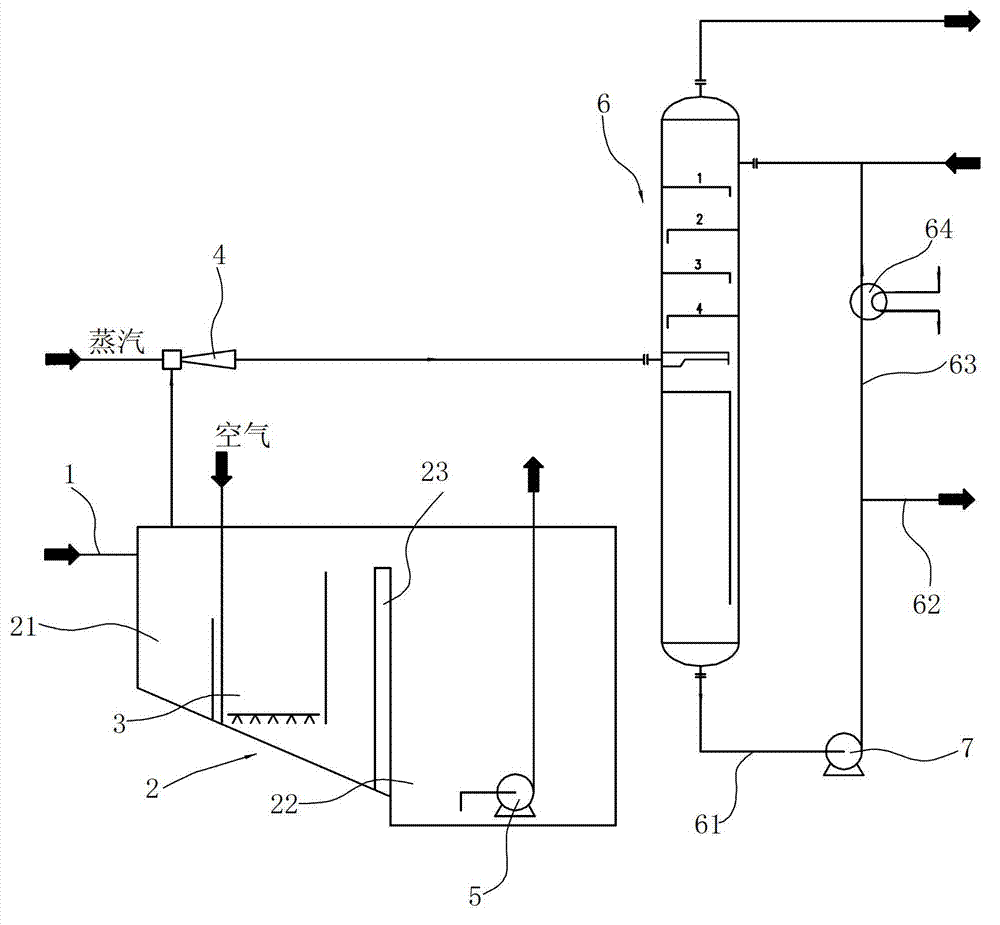

Treatment system and treatment method for removing hydrogen sulfide from acid gas

ActiveCN102895870ALow internal sulfur concentrationReduce the concentration of sulfurDispersed particle separationSulfur preparation/purificationPtru catalystPhysical chemistry

The invention relates to a treatment system and a treatment method for removing hydrogen sulfide from acid gas. The treatment system comprises an absorption reaction unit, a sulphur filtering unit, a solution regeneration unit, a temperature control unit and a medicament deliver unit, wherein the absorption reaction unit has a ferrum-catalyst desulfuration solution, is used for absorbing hydrogen sulfide contained in the acid gas introduced in the ferrum-catalyst desulfuration solution, and oxidizing the hydrogen sulfide into sulphur; the sulphur filtering unit is used for filtering the sulphur; and the solution regeneration unit is used for oxidizing and regenerating the filtered ferrum-catalyst desulfuration solution. The sulphur filtering unit is positioned between the absorption reaction unit and the solution regeneration unit. According to the system and the method, the sulphur is filtered from the solution before the step of oxidation and regeneration, so that the sulphur can not be deposited at the bottom end of an oxidization regenerator, the concentration of the sulphur in the system is low, so that the system can operate stably for a long time, and has good operational flexibility under various work conditions; the structure of equipment can be simplified; the investment is saved; and the construction period is also saved.

Owner:美景(北京)环保科技有限公司

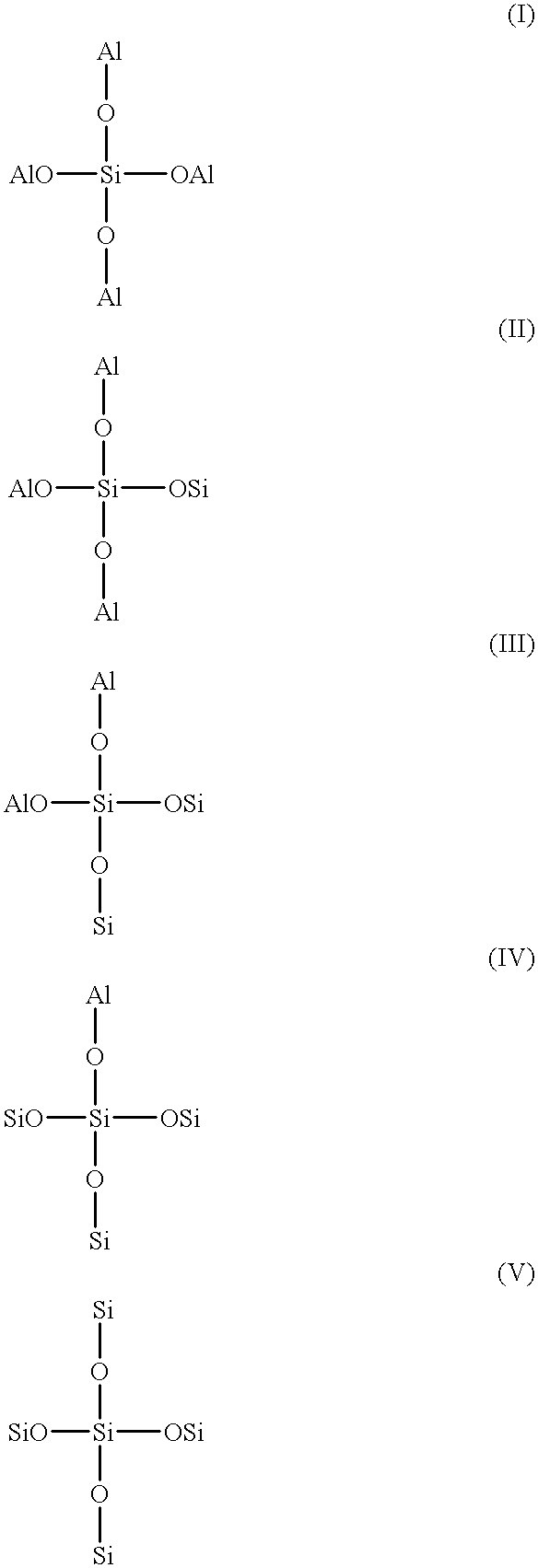

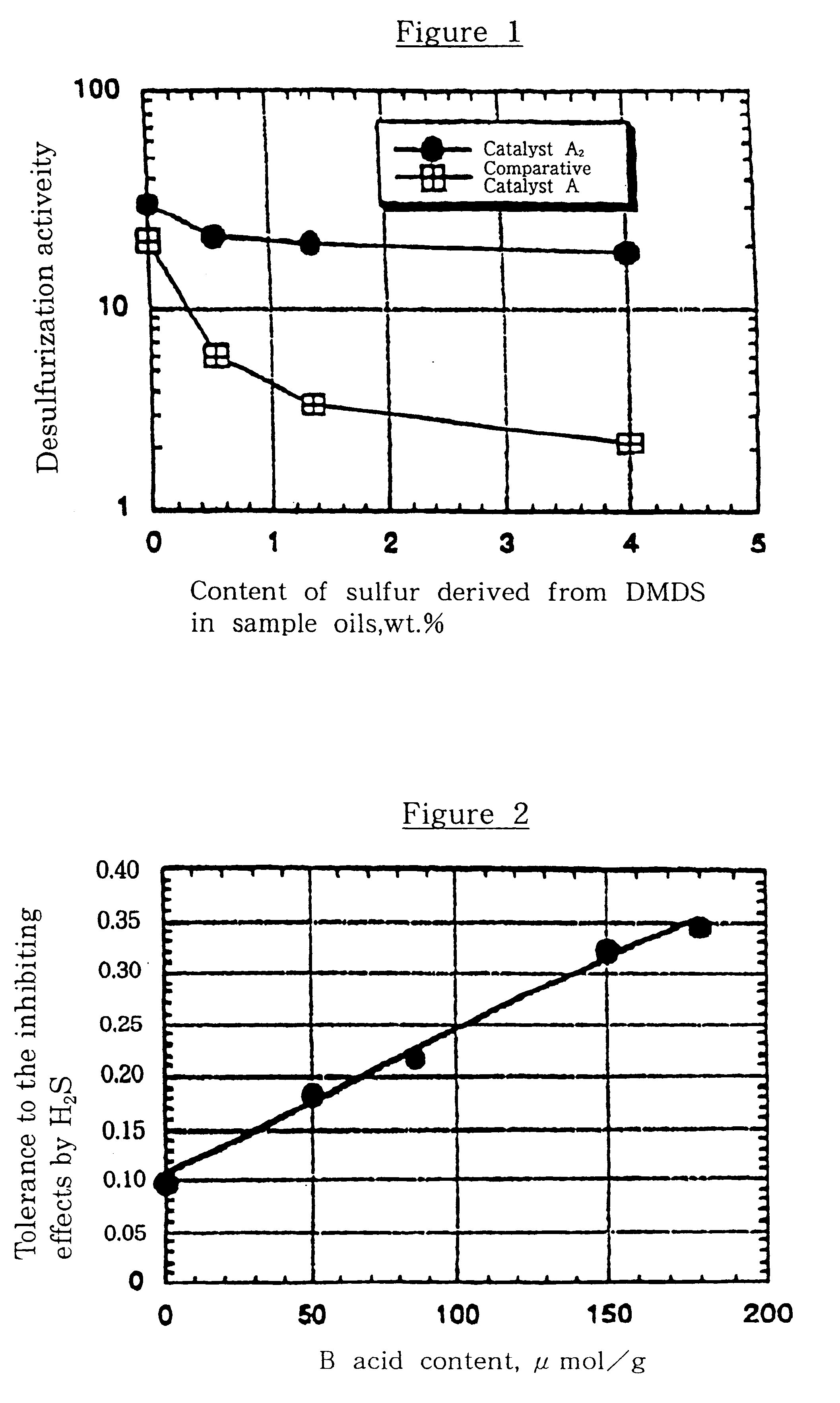

Hydrotreating catalyst and processes for hydrotreating hydrocarbon oil with the same

InactiveUS6267874B1Improve toleranceEfficient removalHydrocarbon oil crackingTreatment with hydrotreatment processesActive componentSilicon dioxide

The present invention relates to a hydrotreating catalyst composed of a carrier having a Brønsted acid content of at least 50 mumol / g such as a silica-alumina carrier or a silica-alumina-third component carrier, in which the silica is dispersed to high degree and a Brønsted acid content is at least 50 mumol / g, and at least one active component (A) selected from the elements of Group 8 of the Periodic Table and at least one active component (B) selected from the elements of Group 6 of the Periodic Table, supported on said carrier. The present invention also relates to a method for hydrotreating hydrocarbon oils using the same. The hydrotreating catalyst of the present invention provides excellent tolerance to the inhibiting effect of hydrogen sulfide, high desulfurization activity, and exhibits notable effects for deep desulfurization of hydrocarbon oils containing high contents of sulfur, in particular gas oil fractions containing difficult-to-remove sulfur compounds. The hydrotreating catalyst of the present invention is also very effective for hydrodenitrogenation, hydrocracking, hydrodearomatization, hydroisomerization, hydrofining and the like of hydrocarbon oils.

Owner:TONENGENERAL SEKIYU

Sulfur removal agent suitable for production of oil-gas well

InactiveCN102698576ASimple recipeAffect normal productionDispersed particle separationPropanolAlcohol

The invention relates to a sulfur removal agent suitable for the production of an oil-gas well. The sulfur removal agent comprises the following components in percentage by mass: 10 to 25 percent of hexahydro-1,3,5-tris(hydroxyethyl)-s-triazine, 5 to 20 percent of alcohol amine, 5 to 20 percent of small molecular alcohol and the balance of water. The alcohol amine is one or a mixture of more thantwo of monoethanolamine, ethyleneglycol amine, diisopropanolamine, methyldiethanolamine and triethanolamine; and the small molecular alcohol is one or a mixture of more than two of methanol, ethanol and propanol. The sulfur removal agent has a simple formula, can be soluble with water, and can effectively reduce the content of hydrogen sulfide in crude oil or natural gas; simultaneously, productsgenerated by the sulfur removal agent and the hydrogen sulfide are water-soluble, and cannot block a mineshaft and influence the normal production of the oil-gas well; and the sulfur removal agent can achieve effects at the temperature of 30 to 120 DEG C and can be quickly reacted with the hydrogen sulfide.

Owner:SOUTHWEST PETROLEUM UNIV

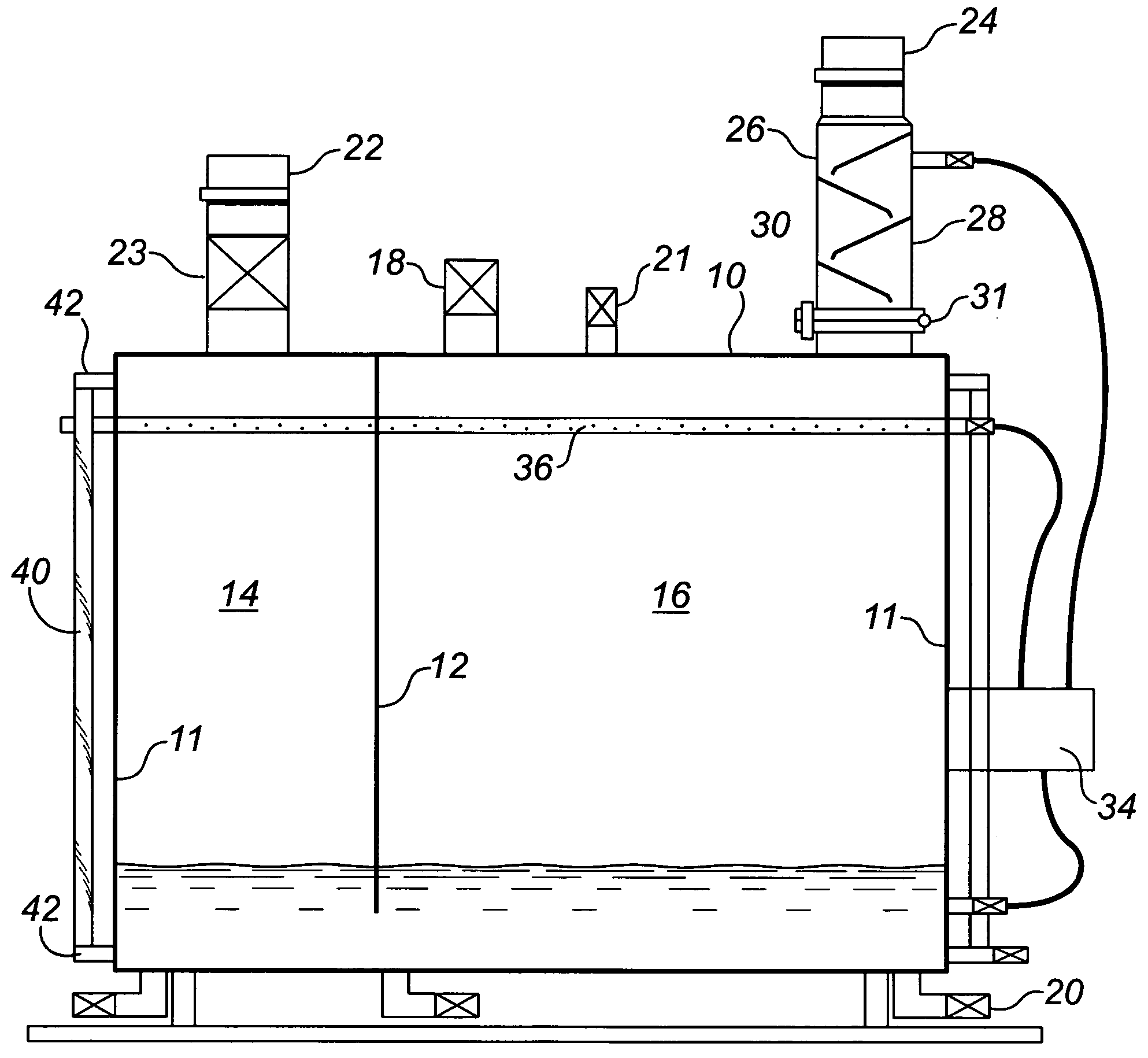

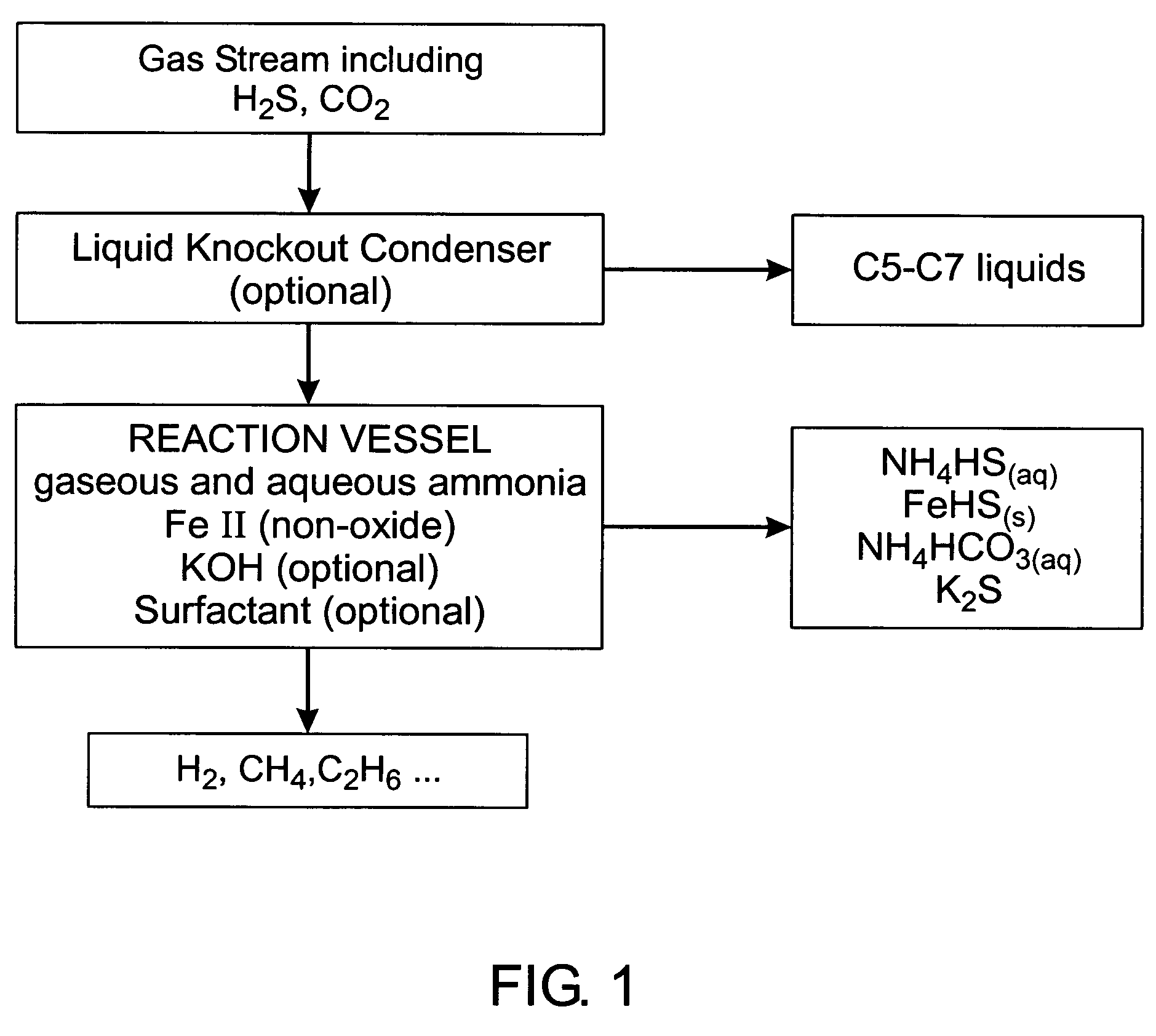

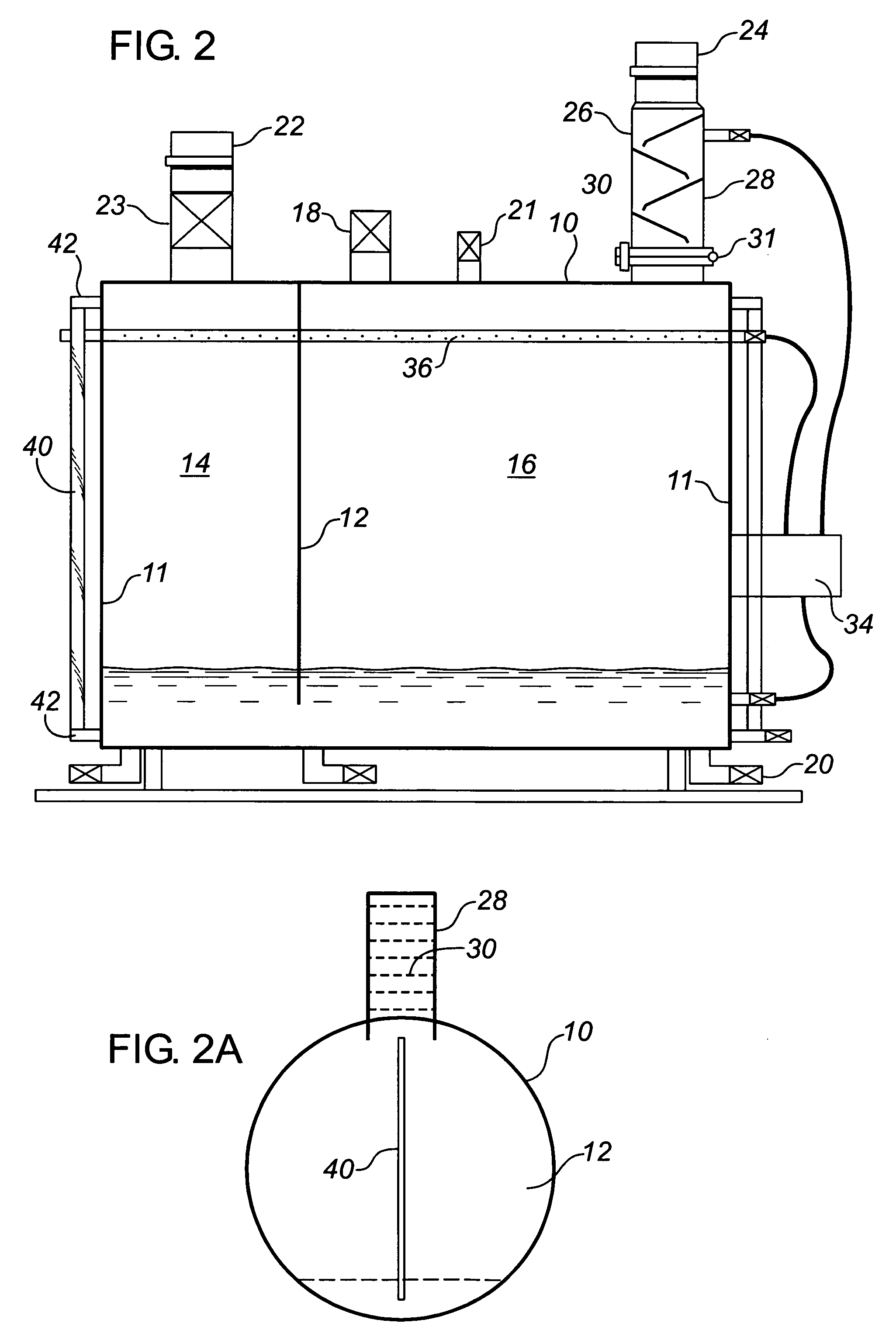

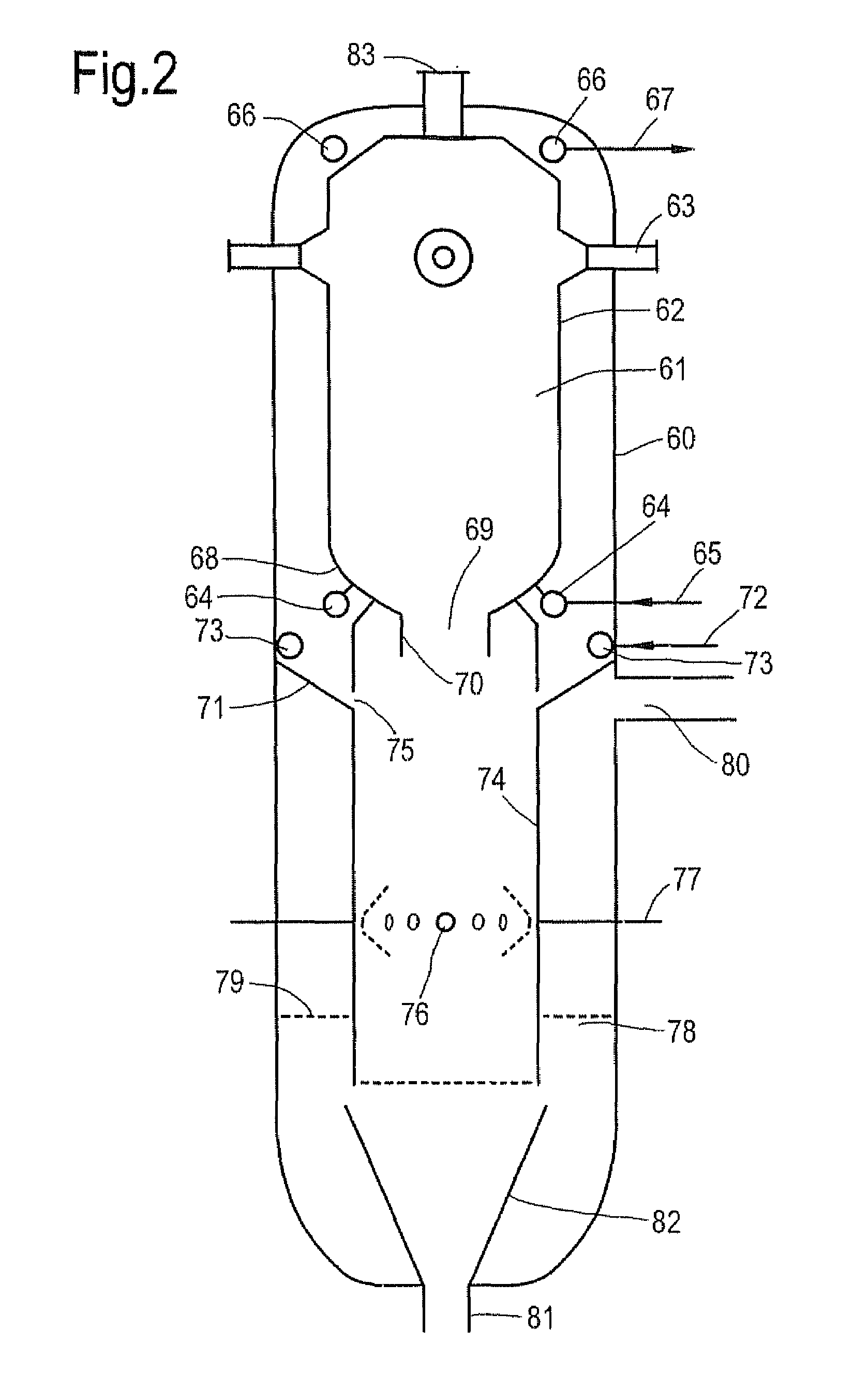

Method and apparatus for hydrogen sulphide removal

InactiveUS7144555B1Efficient and effectiveEfficiently and effectively accomplishedCombination devicesExhaust apparatusGaseous ammoniaFerric

A method for removing hydrogen sulphide and carbon dioxide from a gas stream includes the step of contacting the gas stream with aqueous and gaseous ammonia in a closed vessel in the presence of solid iron. An apparatus for removing hydrogen sulphide and carbon dioxide from a gas stream includes a closed vessel for containing aqueous and gaseous ammonia and an iron source. The vessel is partitioned into inlet and outlet chambers and may itself serve as the iron source.

Owner:WELL TO WIRE EMISSIONS CONTROL

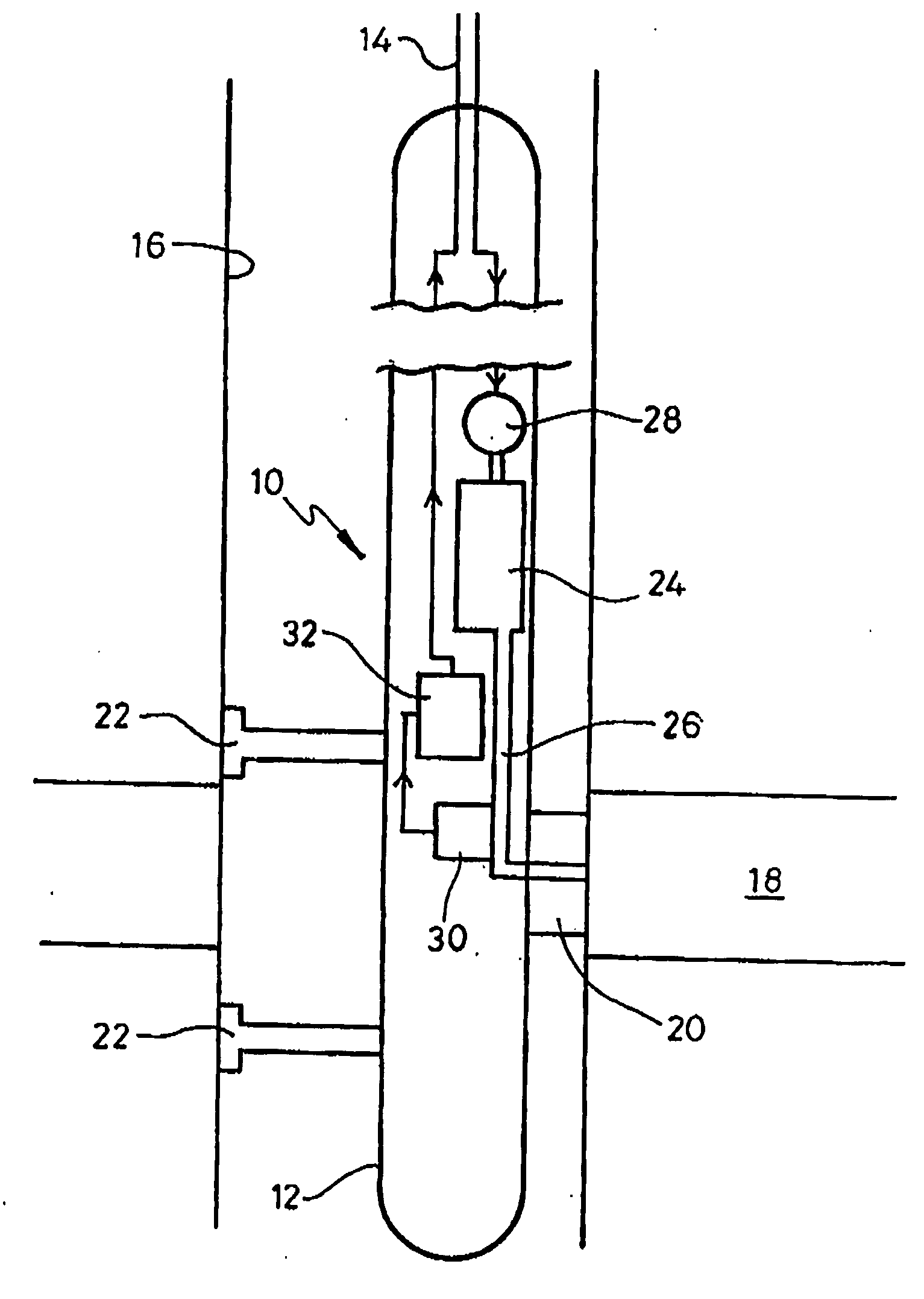

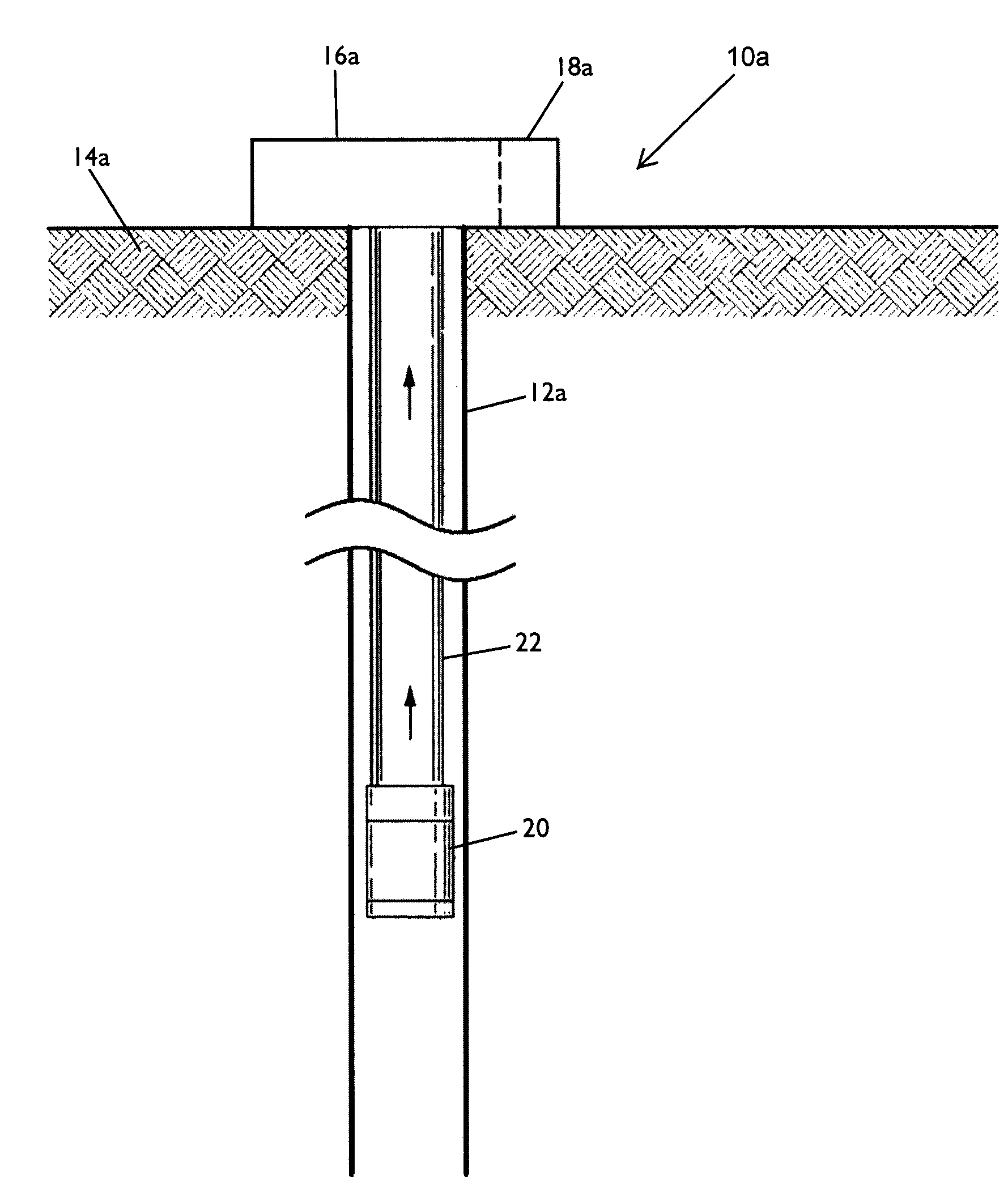

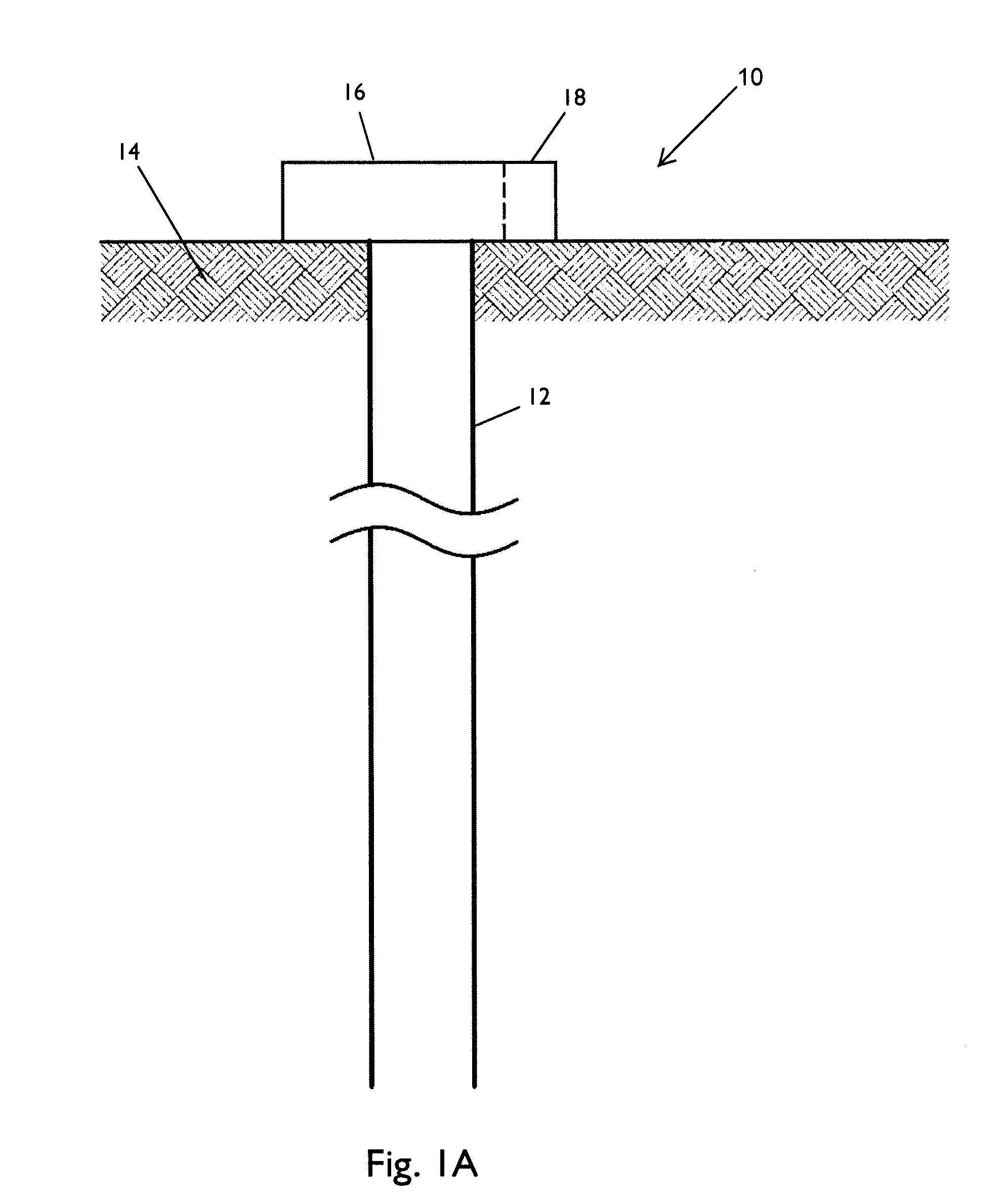

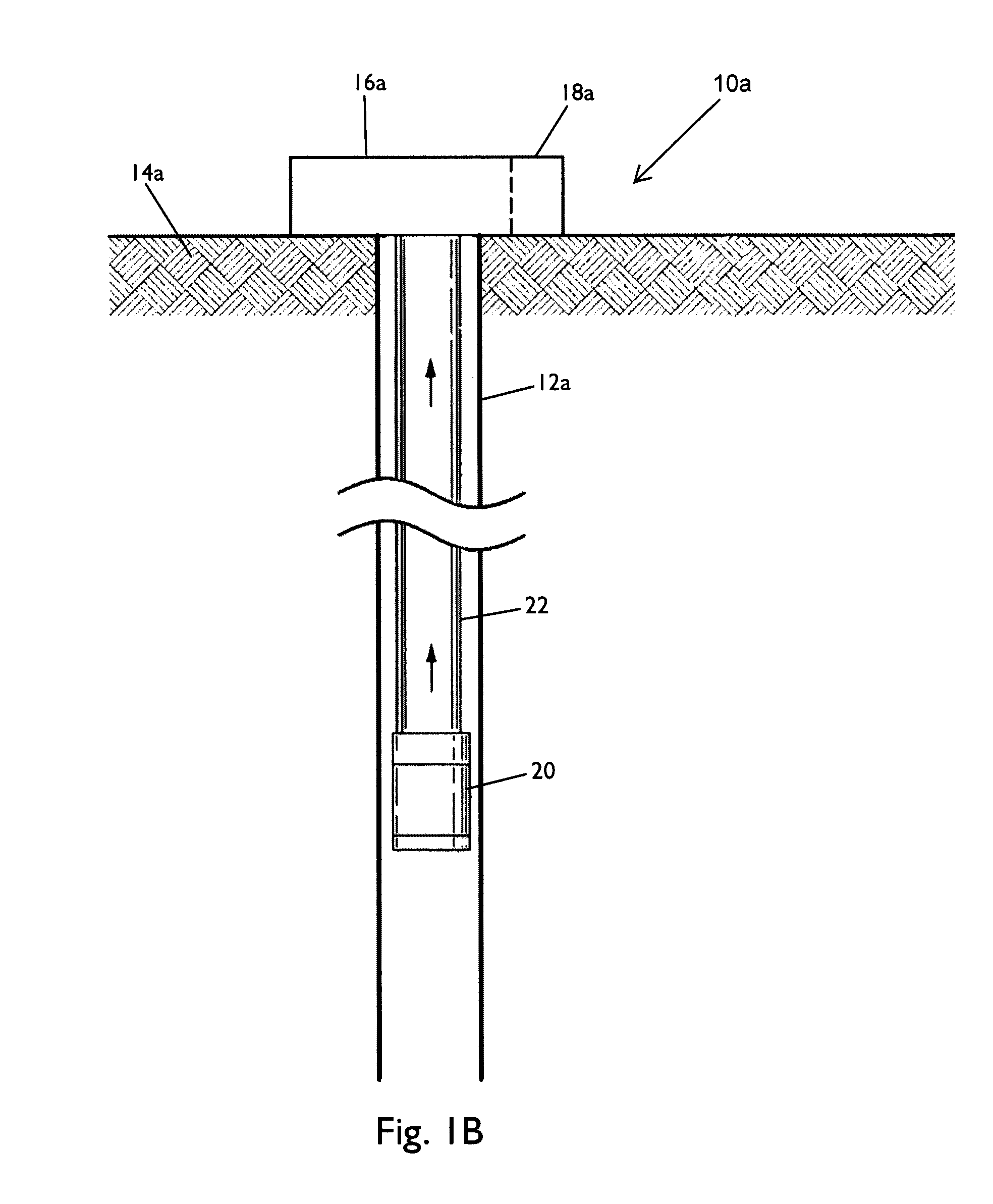

Methods and apparatus for the measurement of hydrogen sulphide and thiols in fluids

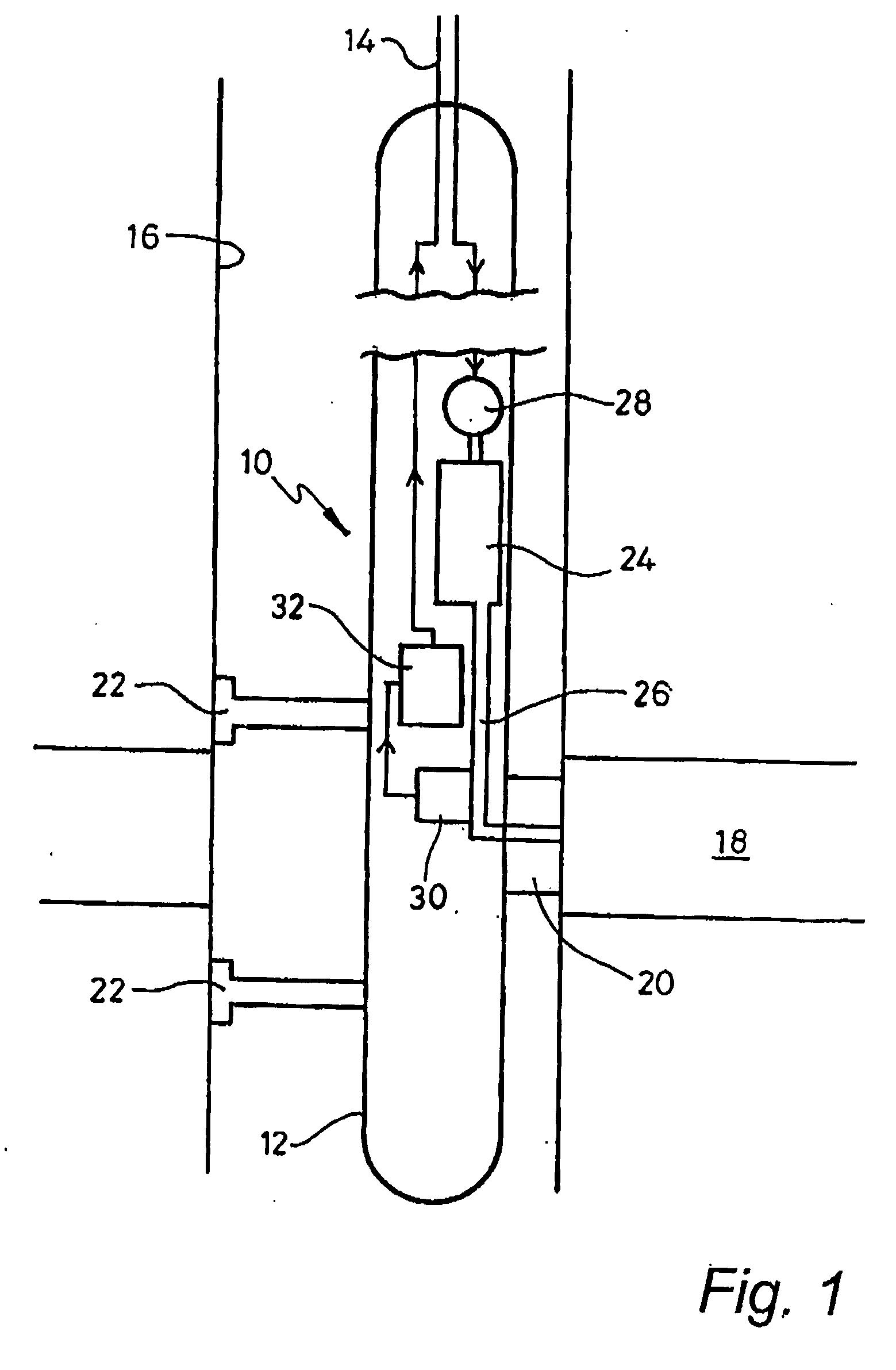

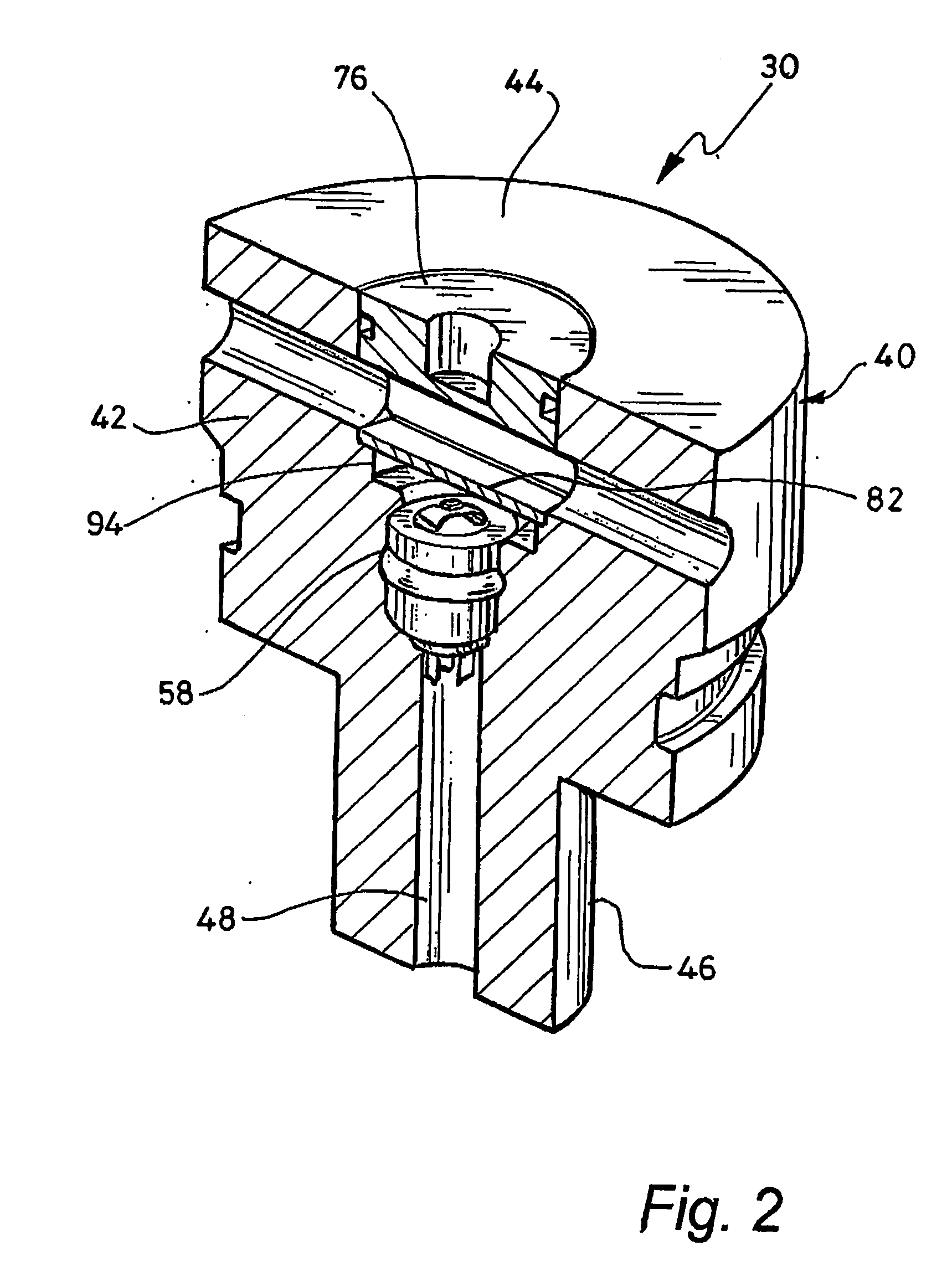

ActiveUS20060243603A1Reduce the differenceRelieve pressureSurveyWeather/light/corrosion resistancePhysical chemistryRedox

An electrochemical sensor for measuring the amount of hydrogen sulphide or thiols in a fluid in a wellbore comprises a temperature- and pressure-resistant housing containing a flow path for the fluids. The fluids flow over one side of a gas permeable membrane made of zeolite or a suitable ceramic material, the other side of the membrane being exposed to a chamber containing a reaction solution which together with the hydrogen sulphide or thiols create a redox reaction resulting in an electrical current dependent upon the amount of hydrogen sulphide or thiols in the fluid.

Owner:SCHLUMBERGER TECH CORP

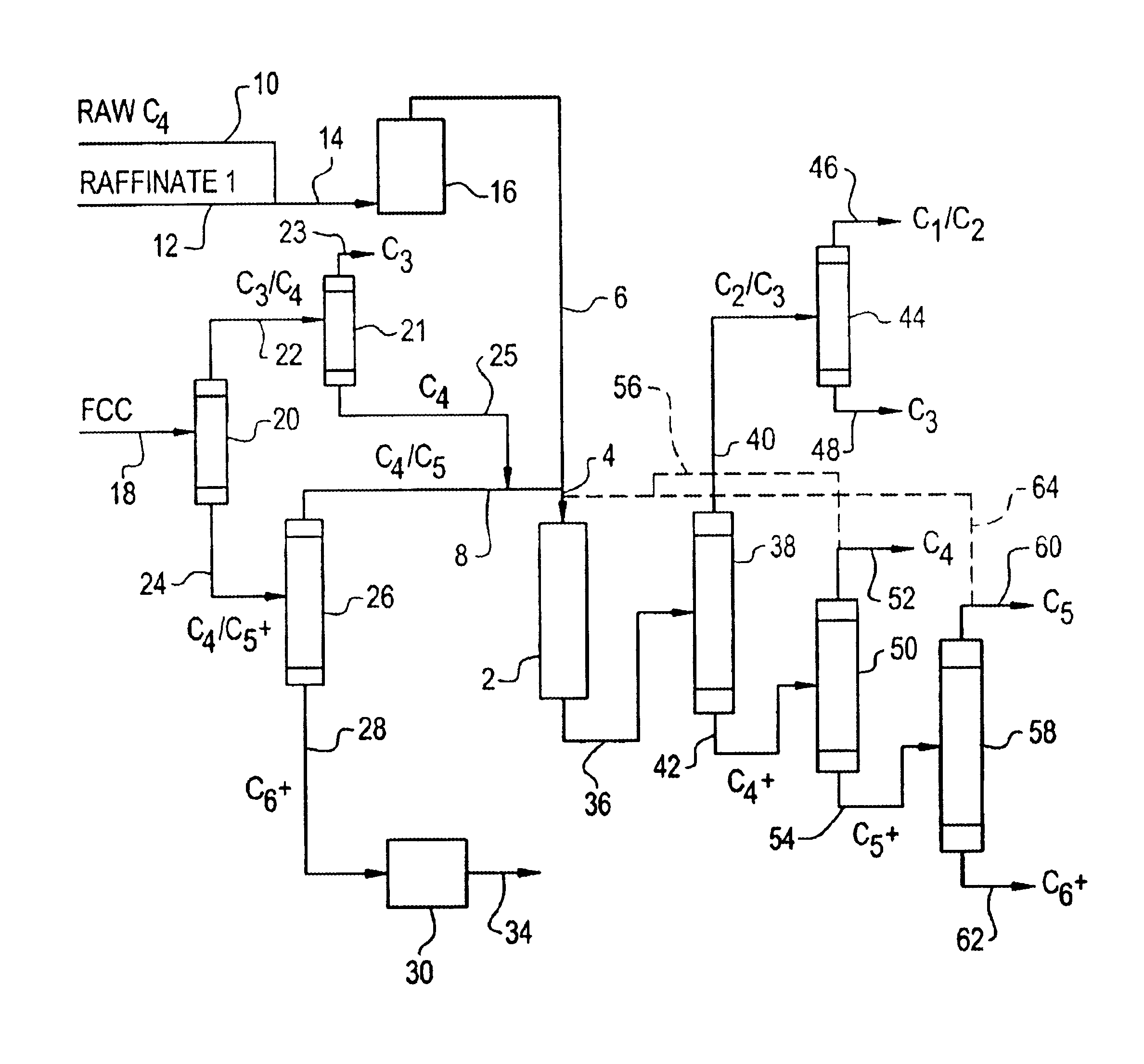

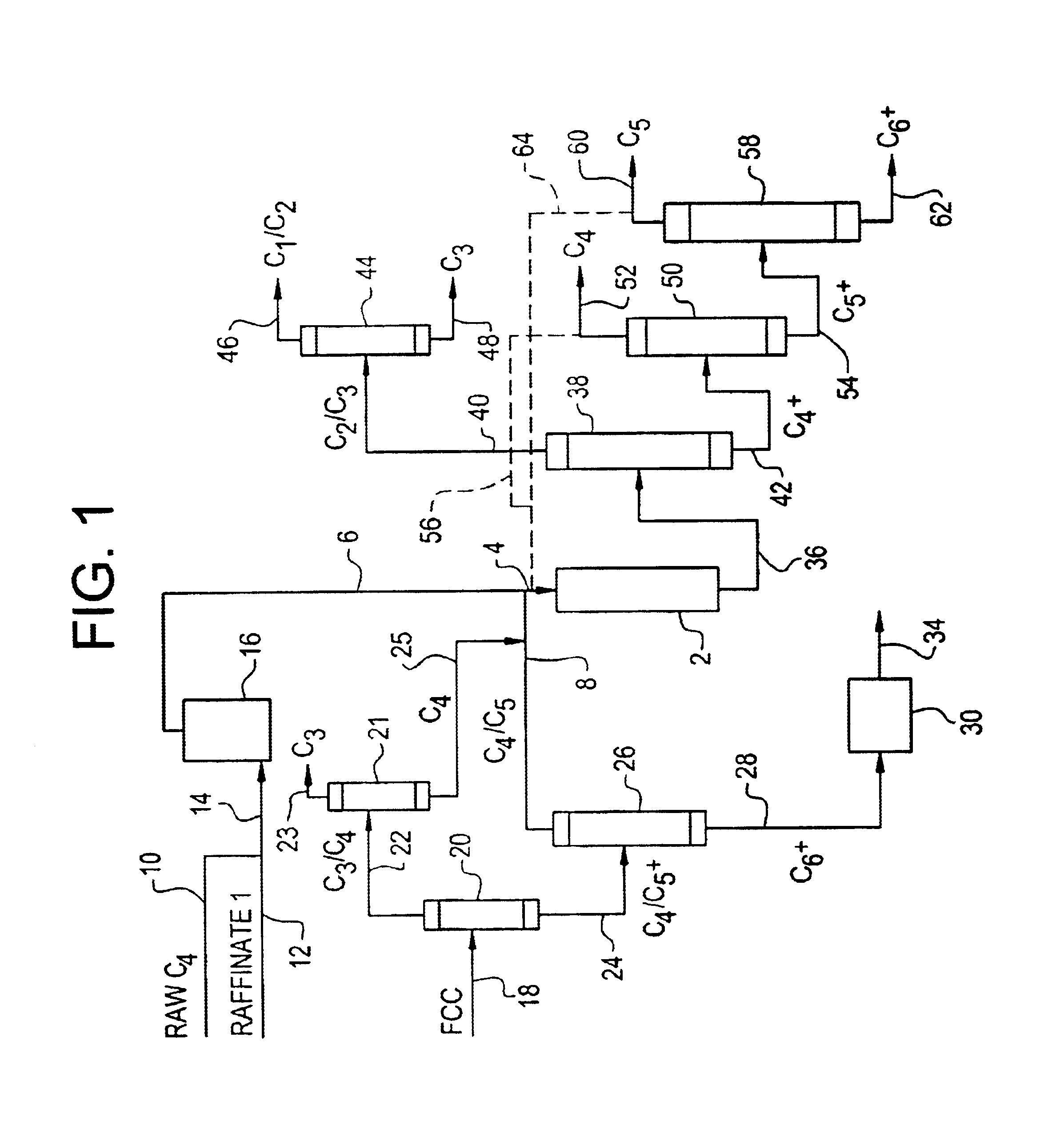

Production of olefins

InactiveUS6858133B2High purityHigh yieldLiquid crystal compositionsCatalytic crackingAlkeneSulfur containing

A process for desulfurising an olefin-containing hydrocarbon feedstock including sulfur-containing hydrocarbon compounds as impurities, the process comprising passing a hydrocarbon feedstock containing one or more olefins through a reactor containing a crystalline silicate selected from the group consisting of an MFI-type crystalline silicate having a silicon / aluminum atomic ratio of at least 180 and an MEL-type crystalline silicate having a silicon / aluminum atomic ratio of from 150 to 800 which has been subjected to a steaming step to produce an effluent with an olefin content of lower molecular weight than that of the feedstock and removing hydrogen sulphide from the effluent.

Owner:ATOFINA RES SA

Combustion catalyst of hydrogen sulfide in gas and its preparation and use method

InactiveCN1410149AHigh selectivityImprove conversion rateDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystSilicon oxide

A combustion catalyst for the hydrogen sulfide in gas is composed of silicon oxide as carrier (75-96 wt.%), vanadium oxide (0.5-15) and iron oxide (0.2-10). Its advantages are high selectivity to hydrogen sulfide, high conversion rate of SO2 and catalytic activity, low operation temp. (250-350 deg.C), and high specific surface area and strength.

Owner:CHINA PETROLEUM & CHEM CORP

Anti-Corrosion Conformal Coating for Metal Conductors Electrically Connecting an Electronic Component

InactiveUS20110189381A1Prolong lifeFinal product manufacturePretreated surfacesElectrical conductorPhosphine

An apparatus includes an electronic component mounted on a substrate and metal conductors electrically connecting the electronic component. A conformal coating overlies the metal conductors and comprises a polymer into which a phosphine compound is impregnated and / or covalently bonded. Accordingly, the conformal coating is able to protect the metal conductors from corrosion caused by sulfur components (e.g., elemental sulfur, hydrogen sulfide, and / or sulfur oxides) in the air. That is, the phosphine compound in the polymer reacts with any corrosion inducing sulfur component in the air and prevents the sulfur component from reacting with the underlying metal conductors. Preferably, the phosphine compound in the polymer does not react with other components in the air (e.g., carbon dioxide) which would otherwise deplete its availability for the target reaction. The phosphine compound may be rendered completely non-volatile by covalently bonding it directly into the polymer backbone.

Owner:IBM CORP

Compositions for improving the organoleptic qualities of cooked foodstuffs

Compositions for generating a cooked flavor in a foodstuff, comprising specified flavor precursors that react on heating to generate the flavor and maintain a reactive association after inclusion in the foodstuff. The compositions may include combination of a sulphur source, e.g. hydrogen sulphide, methane thiol, a sulfur-containing amino acid, thiamine, cystine, sodium sulphide, ammonium sulphide, ammonium polysulphide, onions, garlic, shallots, eggs, methionine, and mixtures thereof, and at least one reductone, e.g. a furanone, a ketone, a pyrone, an aldehyde, a carbonyl compound, isomaltol, maltol, pyruvaldehyde, hydroxyacetone, 3-deoxyglucosone, 5-hydroxy-5,6-dihydromaltol, 2,3-butanedione, 3-hydroxy-2-butanone, a process flavor, cooked vegetable concentrates, soy sauce, and mixtures thereof.

Owner:KERRY INGREDIENTS UK

Liquid sulphur degassing device and liquid sulphur degassing method

The invention relates to a liquid sulphur degassing device and a liquid sulphur degassing method. The liquid sulphur degassing device comprises a liquid sulphur tank communicated with a liquid sulphur pipeline, wherein the liquid sulphur tank is internally provided with gas stripping equipment which can strip hydrogen sulphide gas in liquid sulphur, and the upper part of the liquid sulphur tank is provided with gas pumping equipment which can pump the hydrogen sulphide gas with other gases in the liquid sulphur tank out of the liquid sulphur tank; and the liquid sulphur degassing device is characterized in that the liquid sulphur tank comprises a gas stripping tank and a finished product tank, wherein an overflow dam is arranged between the gas stripping tank and the finished product tank; the liquid sulphur pipeline is communicated with the gas stripping tank; the suction inlet of the liquid sulphur pump is connected with the bottom of the finished product tank; the outlet of the gas pumping equipment is connected with the material inlet of an absorption tower; and the top of the absorption tower is provided with a waste gas outlet, the upper part of the absorption tower is provided with an absorption liquid inlet, a liquid outlet arranged at the bottom of the absorption tower is connected with a main pipeline, and the main pipeline is provided with a pressure pump which pumps out, pressurizes and conveys the liquid in the absorption tower. The liquid sulphur degassing device provided by the invention is simple in process, low in equipment investment and good in degassing effect.

Owner:ZHENHAI PETROCHEMICAL ENG CO LTD

Hydrogenation catalyst precuring method

InactiveCN1994567ALow priceEasy to makeCatalyst activation/preparationRefining to eliminate hetero atomsPtru catalystOxidation state

The invention relates to a method for pre-vulcanizing hydrogen catalyst, wherein it comprises that: immerging the hydrogen catalyst at oxidation state with oxidation state water solution, while the density of solution is 5wt%-55wt%, immerges for 5min-4h at room temperature, and while the density of solution is 55wt%-70wt%, immerges for 5min-4h at 40-90Deg. C; drying the immerged catalyst at room temperature-90Deg. C at vacuum or normal pressure, for 1-10h. The invention has simple process, while the catalyst activity is higher than the catalyst vulcanized by hydrogen sulfide.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

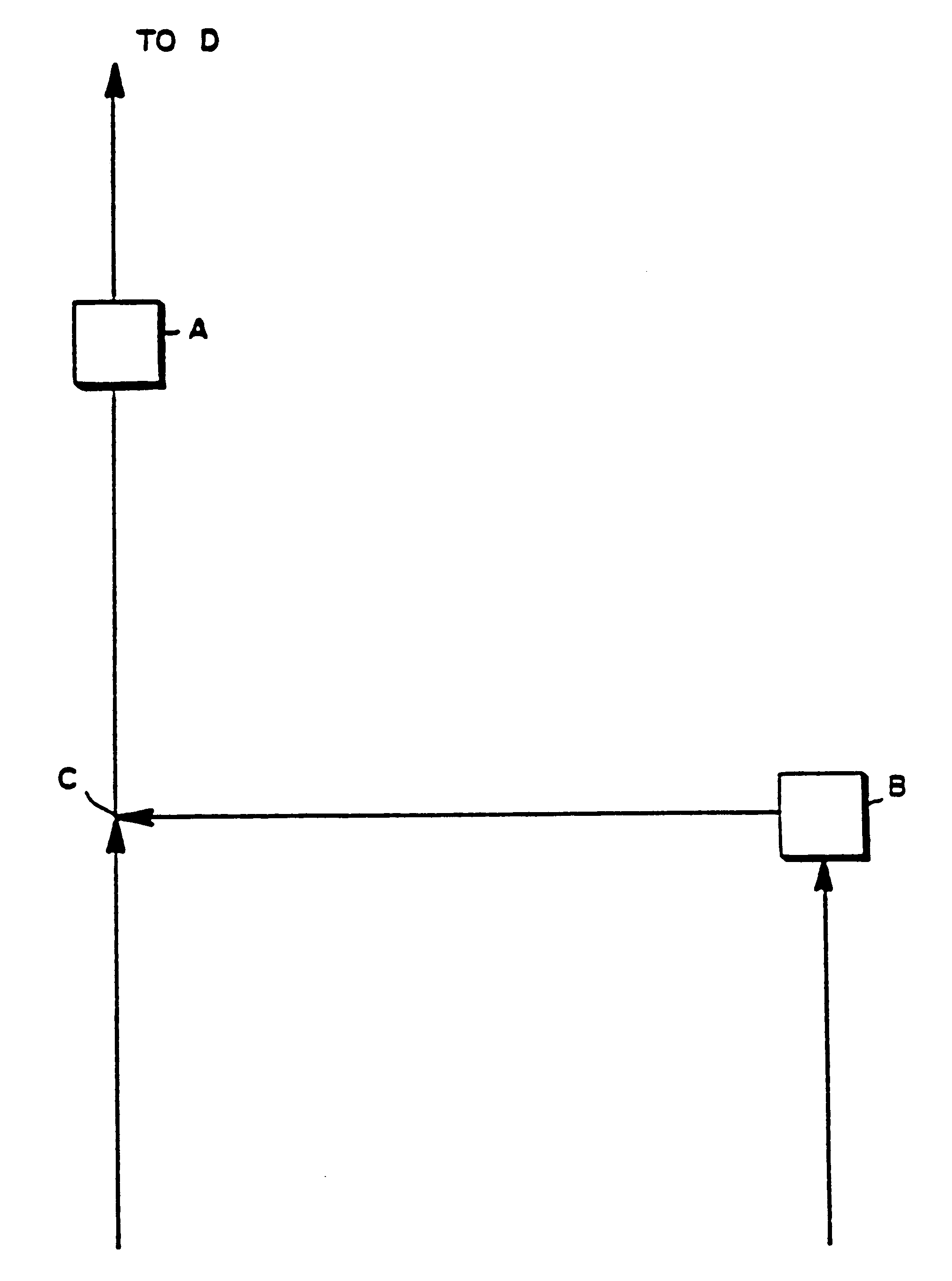

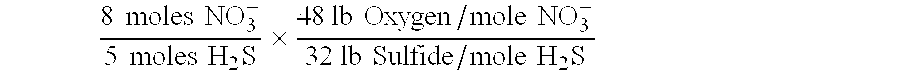

Process for removal of dissolved hydrogen sulfide and reduction of sewage BOD in sewer or other waste systems

InactiveUSRE37181E1Substantial eliminationEliminate the problemTreatment using aerobic processesSpecific water treatment objectivesSulfideSewage

Removal of dissolved hydrogen sulfide and a reduction in BOD is achieved by the addition of nitrate ions to waste systems in an amount sufficient to stimulate growth of bacteria which utilize dissolved hydrogen sulfide in their metabolism. Specifically, about 2.4 lbs. <INS-S DATE="20010522" ID="INS-S-00001">nitrate <INS-E ID="INS-S-00001">oxygen per lb. of sulfide is required.

Owner:UNITED STATES FILTER CORPORATION

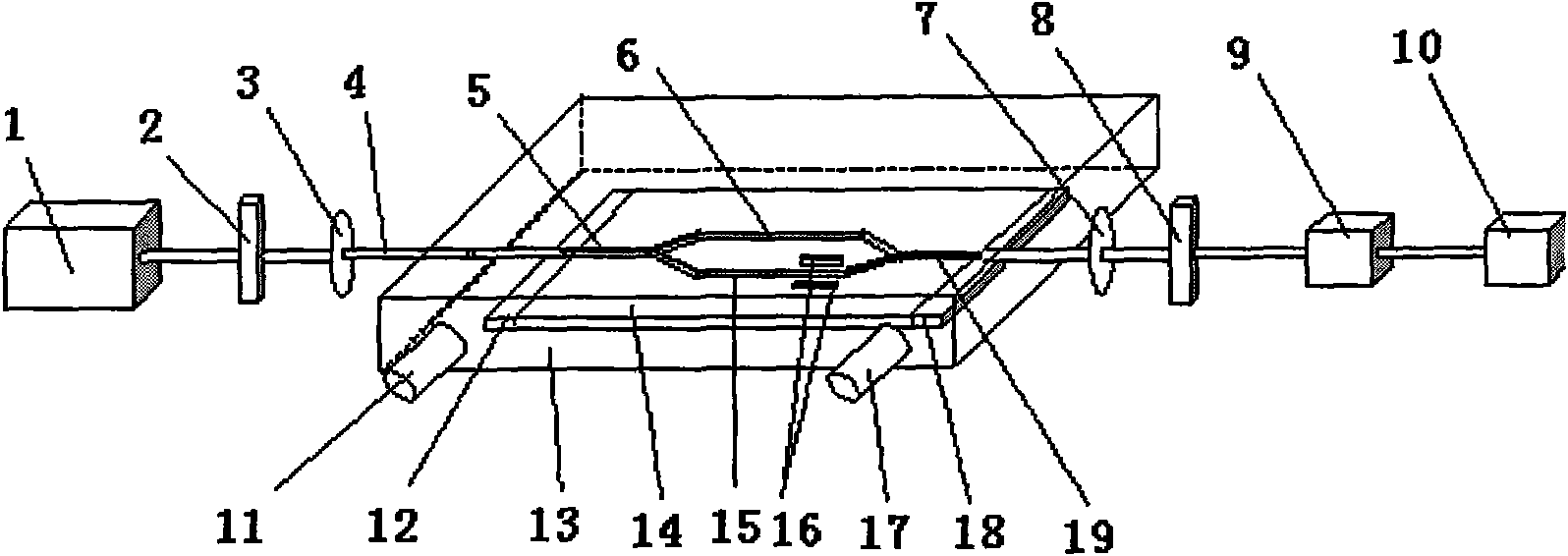

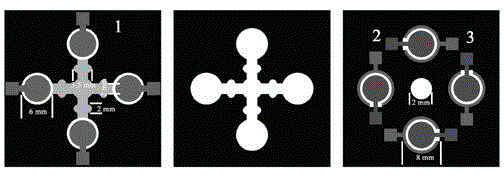

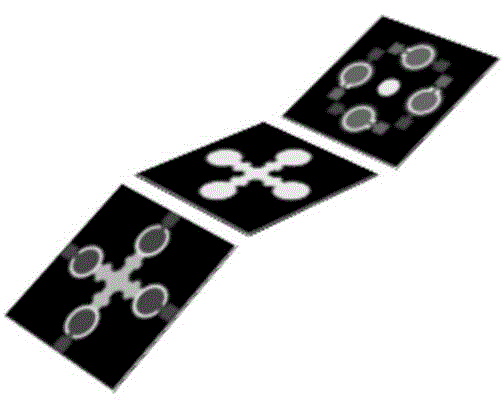

Optoelectronic hybrid integration sensor device of sulfureted hydrogen gas concentration and test method thereof

ActiveCN101576488AHigh detection sensitivityHigh selectivityPhase-affecting property measurementsCoupling lossLaser light

The invention discloses an optoelectronic hybrid integration sensor device of sulfureted hydrogen gas concentration, which has the characteristics: laser light led out from a laser (1) penetrates through a lens (3) via a polarizer (2), an optical fiber (4) transmits focused polarized light into a gas box (13), the coupling of the optical fiber with a wave guide is realized on an input coupling element (12), the coupled light enters a Mach-Zehnder wave guide interferometer (14), branch wave guides (5 and 19) are respectively connected with a reference arm wave guide (15) and a signal arm wave guide (6) in parallel, the end surface sizes of the two wave guides are determined by mode field matching so as to reduce coupling loss and improve coupling efficiency, a wave guide phase modulator (16) adopts a lumped type wave guide phase modulator structure and is arranged between the reference arm wave guide and the signal arm wave guide, the light interfered by the Mach-Zehnder wave guide interferometer is coupled out of the gas box by an output coupling element (18) to enter a photoelectric signal transforming and processing system and then is led into a photoelectric diode (9) by a lens (7) and an analyzer (8) via the optical fiber, after that, the light intensity is transformed into electric signals to be inputted to a micro signal processor (10), and finally the concentration value of the sulfureted hydrogen gas is obtained by calculation.

Owner:克拉玛依市金牛工程建设有限责任公司

Preparation of electrochemical luminescence paper chip and application of chip in hydrogen sulfide detection

InactiveCN104819976ASpeed up the flowReduce volatilityChemiluminescene/bioluminescenceWaxSignalling molecules

The invention discloses a method for preparing an electrochemical luminescence paper chip and a method for measuring content of signal molecule hydrogen sulfide in MCF-7 by using an electrochemical luminescence sensor. The method is characterized by preparing a hydrophobic region, a semi-hydrophobic region, a hydrophilic region and a hollow channel on paper by utilizing a wax printing technology, cutting the hollow channel by virtue of a laser cutting machine, preparing proper printing ink, printing a corresponding reference electrode and a working electrode on the paper, functionalizing the working area, dripping stock solution in a pretreatment region, and fixing cancer cells; and folding the prepared paper chip, forming a three-electrode system, dropwise adding electrolyte solution in a reaction region, connecting an electrochemical workstation, thus realizing high-sensitivity detection of the low-content signal molecules in the cancer cells.

Owner:UNIV OF JINAN

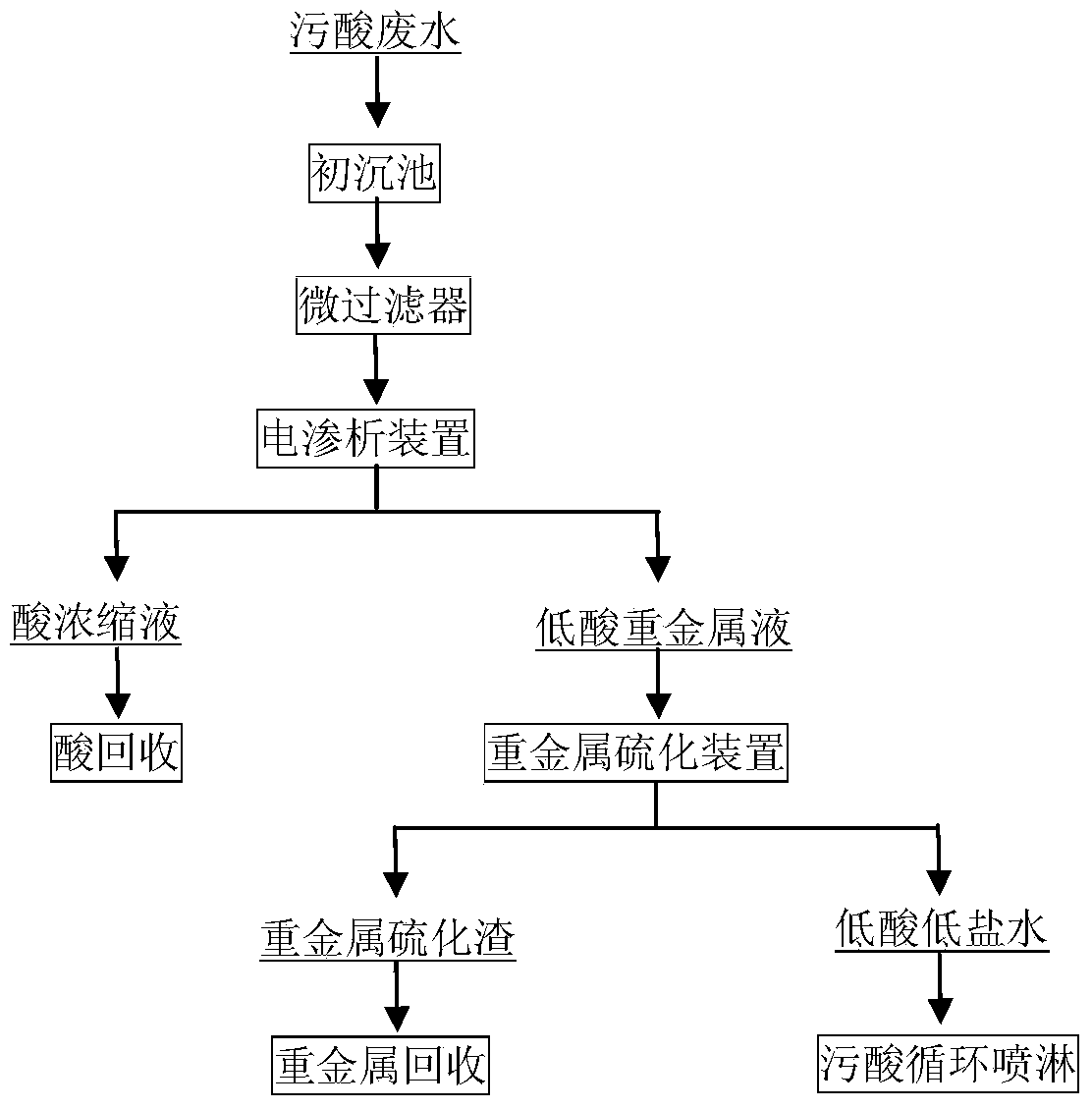

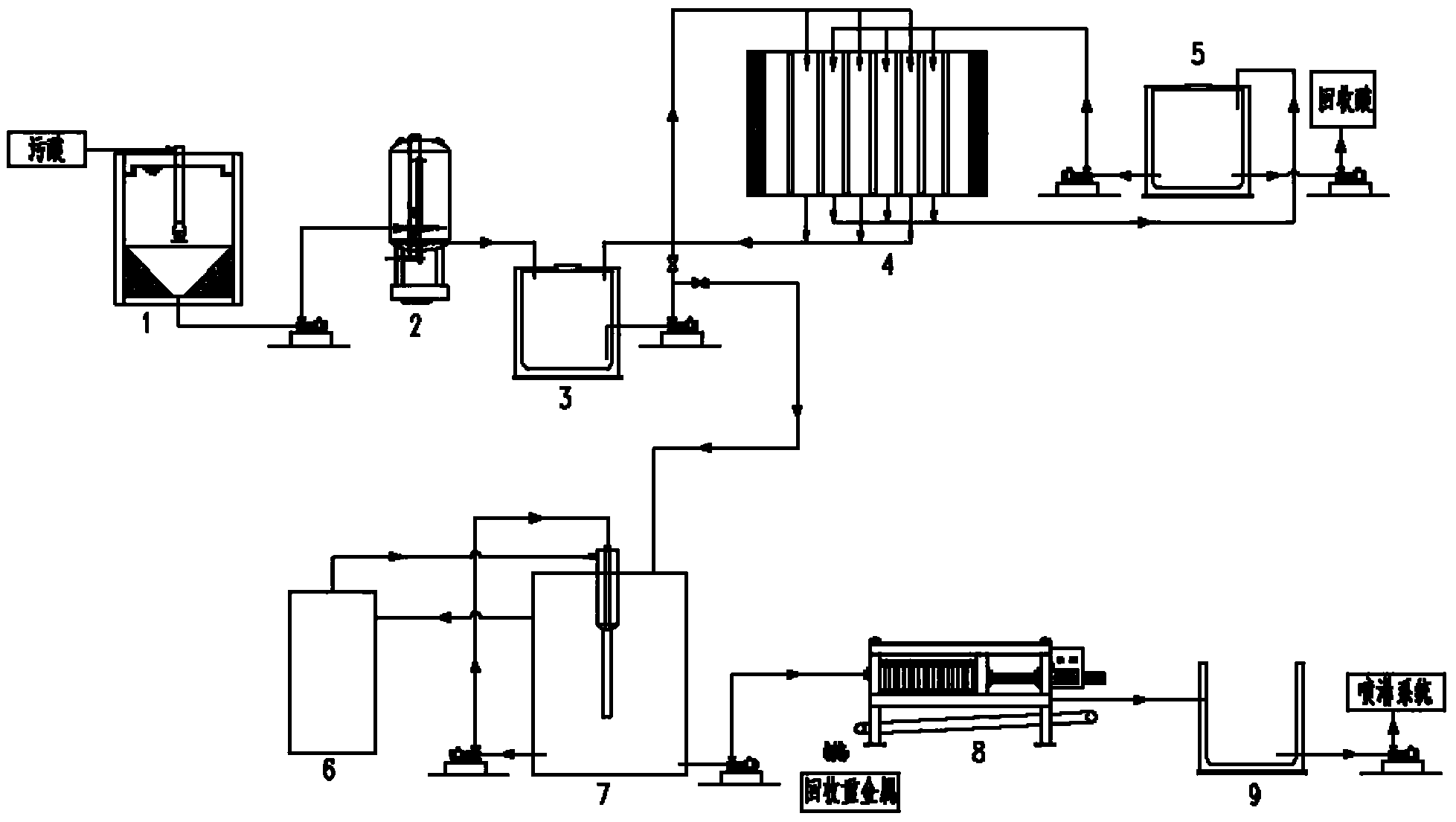

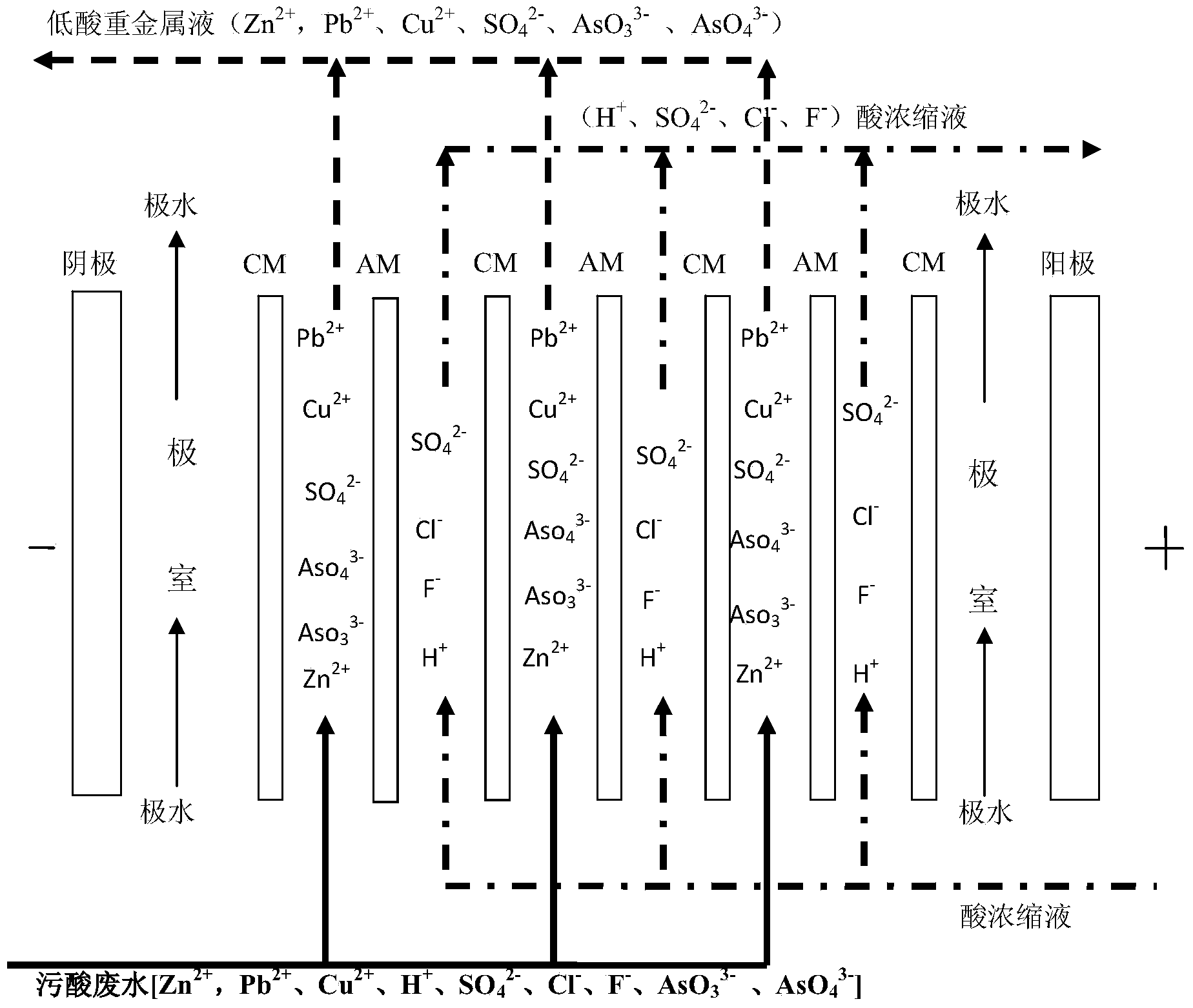

Heavy metal waste acid and wastewater resource recycling method and device

ActiveCN103553248APromote recoveryEfficient recyclingDispersed particle separationMultistage water/sewage treatmentLiquid wasteProcess integration

The invention discloses a heavy metal waste acid and wastewater resource recycling method and device. According to the method, acids in waste acid can be well separated through selection of anionic and cationic membranes in the electrodialysis process, heavy metal ions still remain in a waste acid solution, and the separated acid enters a concentration basin, has the acidity of over 8 percent and can be used for a sulfuric acid preparation process; the acidity of the treated waste acid is reduced to a pH value of over 3, valuable heavy metals in heavy metal-containing low-acidity waste liquor can be rapidly recovered by utilizing a hydrogen sulfide and jet process integration technology, and the recovery rate of the heavy metal ions is over 95 percent; the residual low-acidity low-salt wastewater can be recycled for a spraying system. According to the method, the heavy metal waste acid and wastewater can be treated at high efficiency, the phenomena that neutralization residues which are difficultly treated are generated and secondary pollution is caused in the process of neutralizing by adopting alkalis are avoided, high-quality sulfuric acid and heavy metals can be recovered, and more important, the adopted equipment and device are simple, convenient to operate and good in treatment effect.

Owner:CENT SOUTH UNIV +1

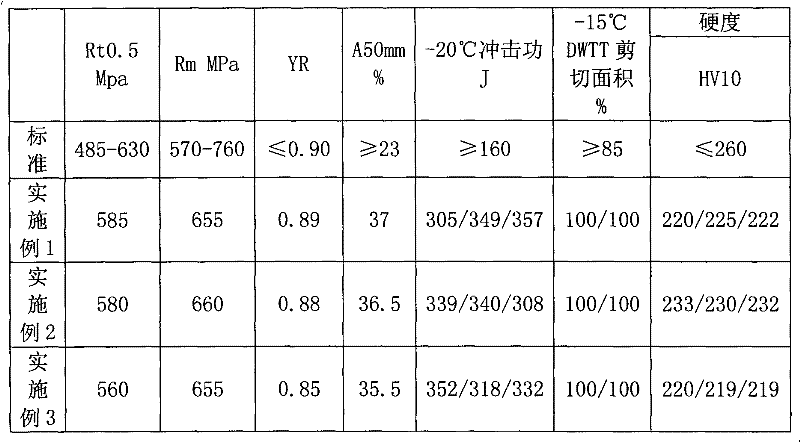

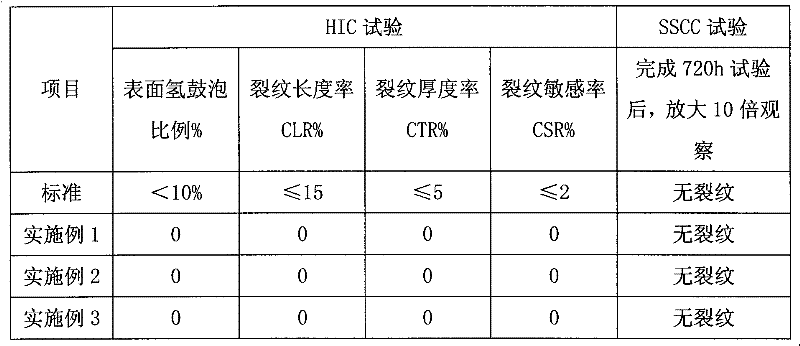

X70 pipeline steel hot rolled coil and manufacture method thereof

The invention relates to an X70 pipeline steel hot rolled coil and a manufacture method thereof. The coil comprises the following ingredients in percentage by weight: 0.02 to 0.05 percent of C, 0.10 to 0.30 percent of Si, 1.00 to 1.40 percent of Mn, at most 0.015 percent of P, at most 0.002 percent of S, 0.015 to 0.05 percent of Alt, 0.05 to 0.08 percent of Nb, 0.02 to 0.035 percent of V, 0.01 to 0.02 percent of Ti, 0.10 to 0.50 percent of Cr, at most 0.006 percent of Ca, 0.10 to 0.30 percent of Ni and 0.10 to 0.30 percent of Cu. The manufacture method is mainly characterized in that a, the laser fused (LF) refining is carried out outside a furnace: desulfurization is carried out until the weight percent of S is less than or equal to 0.0015 percent; b, the RH refining is carried out outside the furnace: Ca-Si lines are added before the vacuum smelting and steel outlet; c, the continuous casting temperature is 1553+ / -15DEG C; d, the continuous casting pulling speed is higher than or equal to 1.0 m / min; e, the plate blank heating temperature is lower than or equal to 1200 DEG C; f, the rough rolling terminating temperature is 930 to 1030 DEG C; g, the finish rolling terminating temperature is 780 to 850 DEG C; h, the steel band coiling temperature is 450 to 580 DEG C; and l, the cooling speed of the layer flow cooling is higher than or equal to 5 DEG C / s. The X70 pipeline steel hot rolled coil simultaneously meets the requirements of high toughness and hydrogen sulphide corrosion resistance of X70 pipeline steel.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

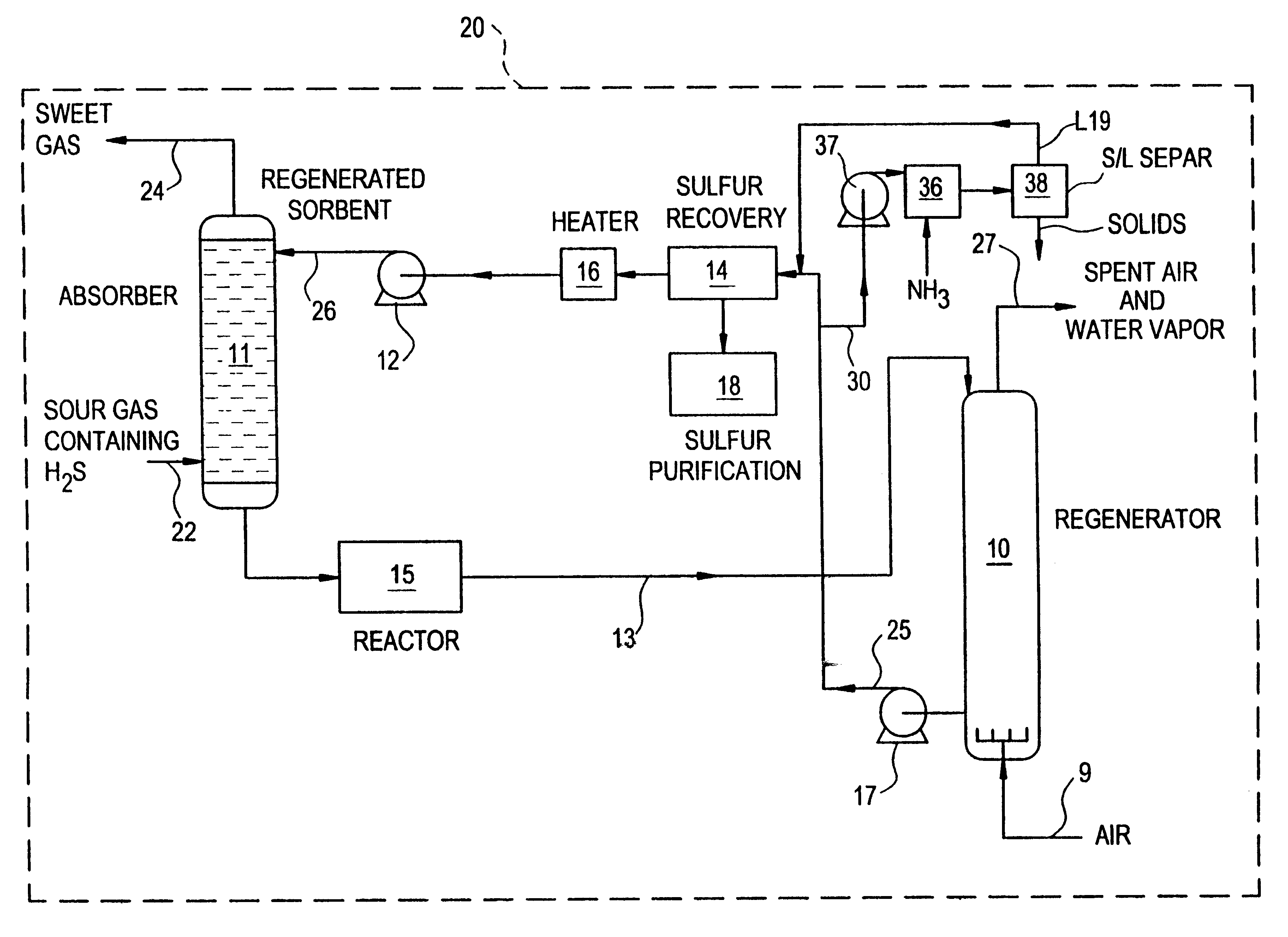

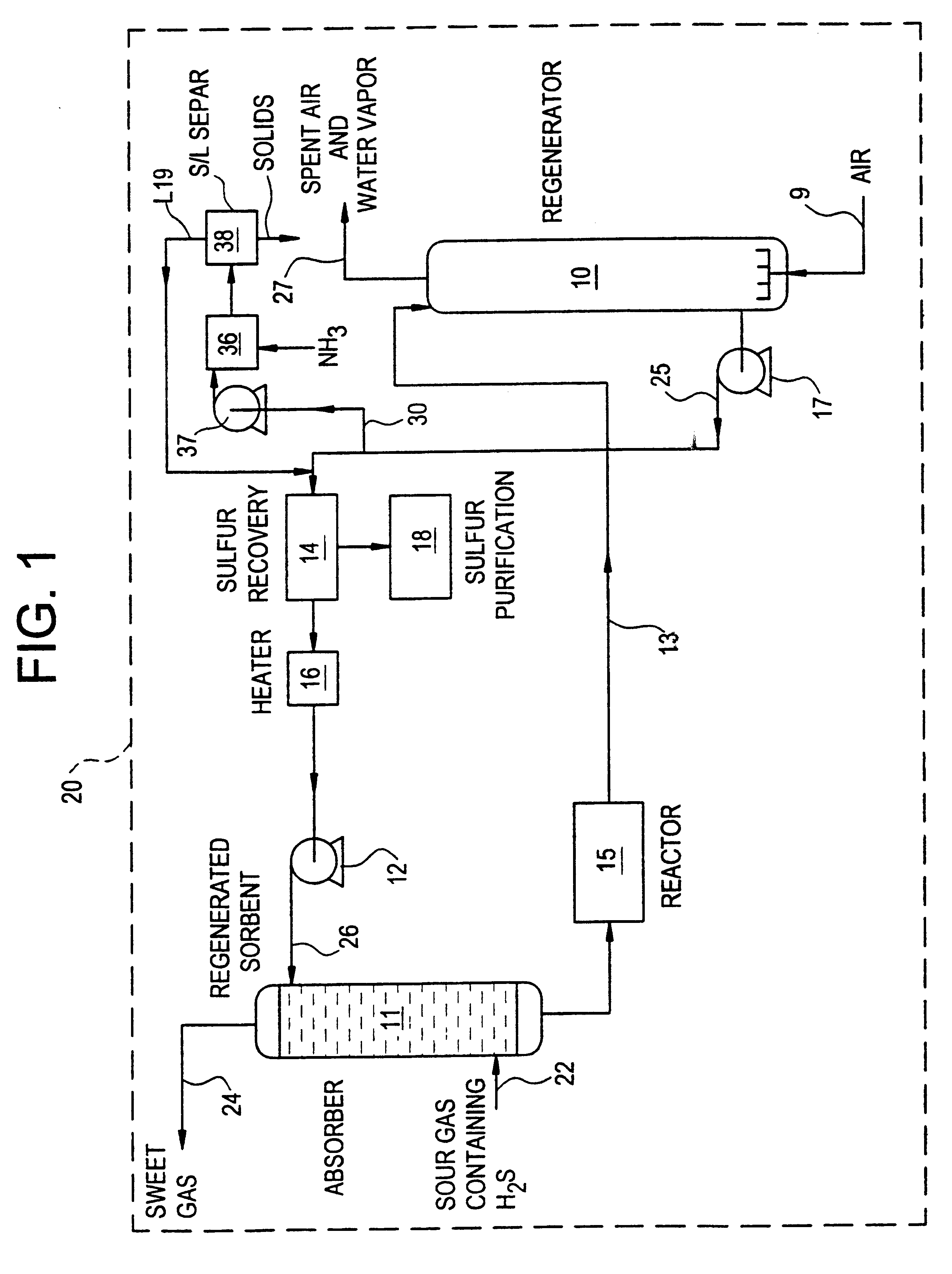

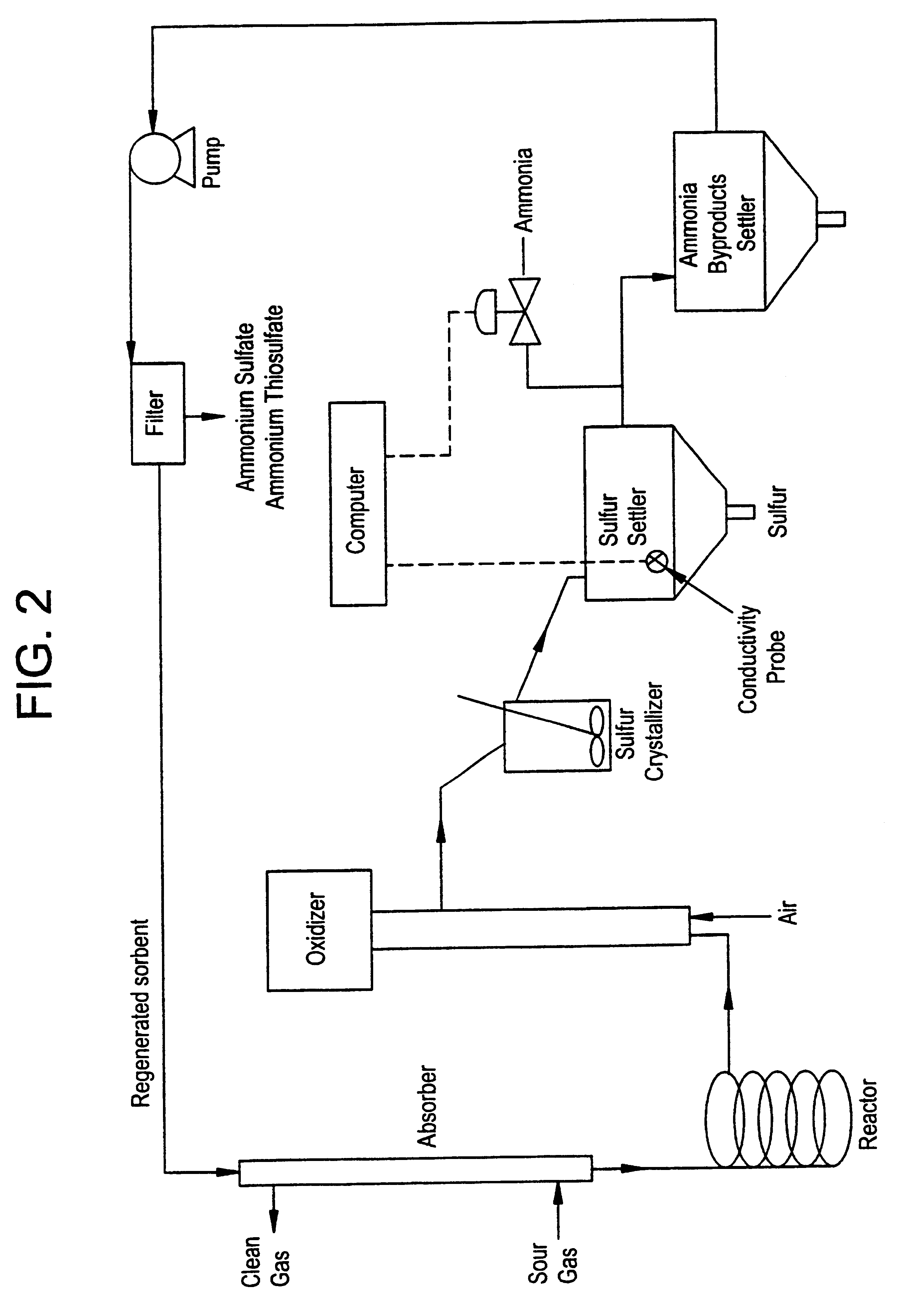

Regeneration method for process which removes hydrogen sulfide from gas streams

InactiveUS6544492B1Removal process is favorableAvoid problemsThiosulfates/dithionites/polythionitesHydrogen sulfidesThio-Sulfide

A process is provided for the removal of hydrogen sulfide out of a gaseous stream (22), such as a natural gas, by contacting the hydrogen sulfide containing gas with a sorbing liquid (26) containing a tertiary amine so that the hydrogen sulfide is sorbed into the liquid in absorber (11) and transferring the sorbing liquid / hydrogen sulfide mixture to a reactor (15) where the tertiary amine promotes the conversion of the hydrogen sulfide into polysulfide via reaction with sulfur; transferring the polysulfide solution from the reactor (15) to a regenerator (10) where polysulfide is converted into elemental sulfur via reaction with air (9); transferring at least a portion of the solution (25) containing elemental sulfur, as well as sulfate and thiosulfate species, into a mixture (36) where it is contacted with gaseous ammonia which reacts with the sulfate and thiosulfate species to produce ammonium sulfate and ammonium thiosulfate which are removed from the solution while the remaining portion of solution (25) is transferred to a sulfur recovery unit (14). That portion of the solution which has been subjected to ammonium sulfate and ammonium thiosulfate removal is rejoined with that portion of the solution (25) being forwarded to sulfur recovery unit (14). The solution from the sulfur recovery unit (14) is recycled back to the absorber (11).

Owner:URS

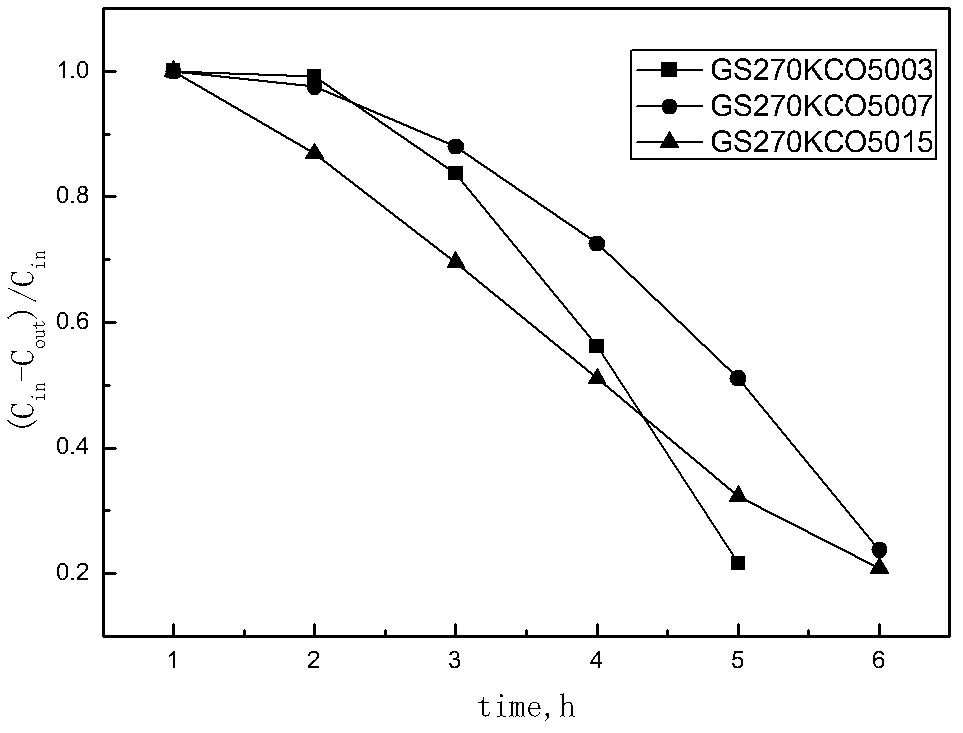

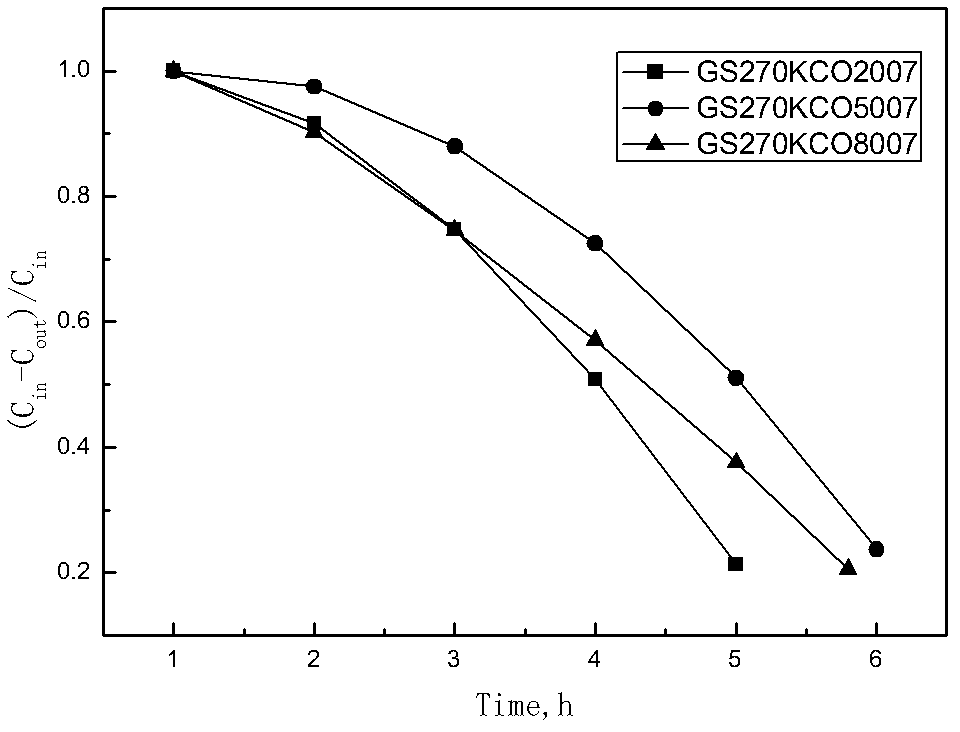

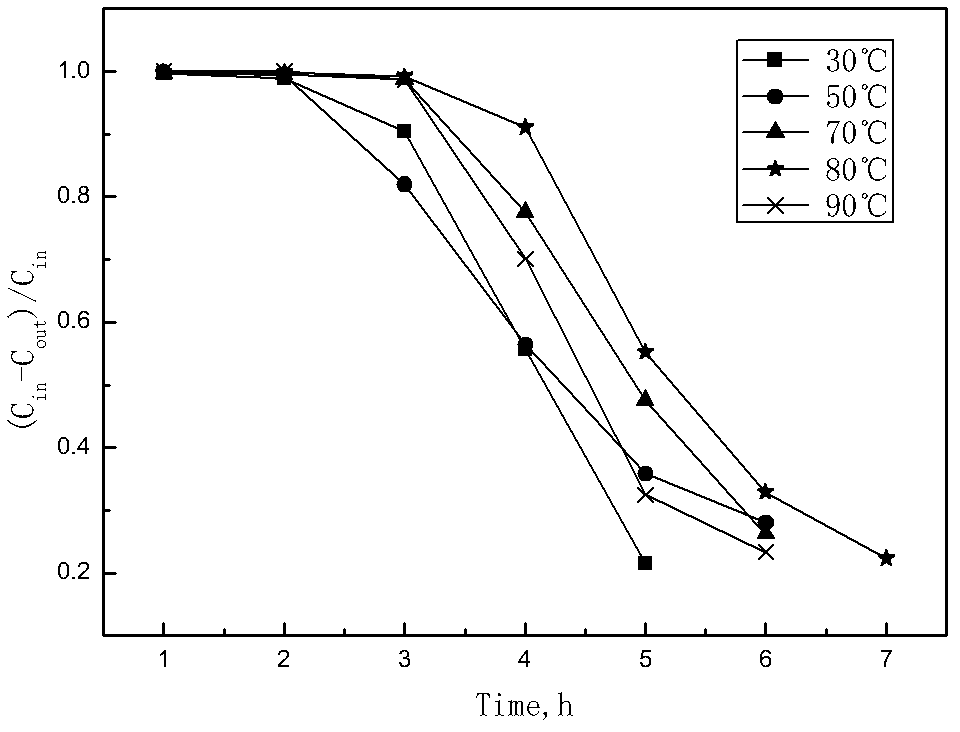

Modified activated carbon, preparation method thereof and method for adsorbing hydrogen sulfide using modified activated carbon

InactiveCN102580675ALarge adsorption capacityHigh ability to absorb hydrogen sulfideOther chemical processesDispersed particle separationActivated carbonPhysical chemistry

The invention relates to modified activated carbon, a preparation method of the modified activated carbon, and a method for adsorbing hydrogen sulfide using the modified activated carbon. The modified activated carbon is prepared by the method comprising the steps of: 1) mixing the raw material activated carbon with water, adding the mixture into a high-temperature reaction kettle for high-temperature modification, and then drying the high-temperature modified activated carbon; 2) then dipping the high-temperature modified activated carbon into KOH solution or CuSO4 solution for solution dipping modification; and 3) washing the activated carbon modified by dipping by distilled water to be neutral, drying again to obtain the combined modified activated carbon. The modified activated carbonhas good adsorptive capacity for hydrogen sulfide and greatly improves the sulfur capacity, thus being used for disposing hydrogen sulfide in a centralization-breeding factory.

Owner:TAIYUAN UNIV OF TECH

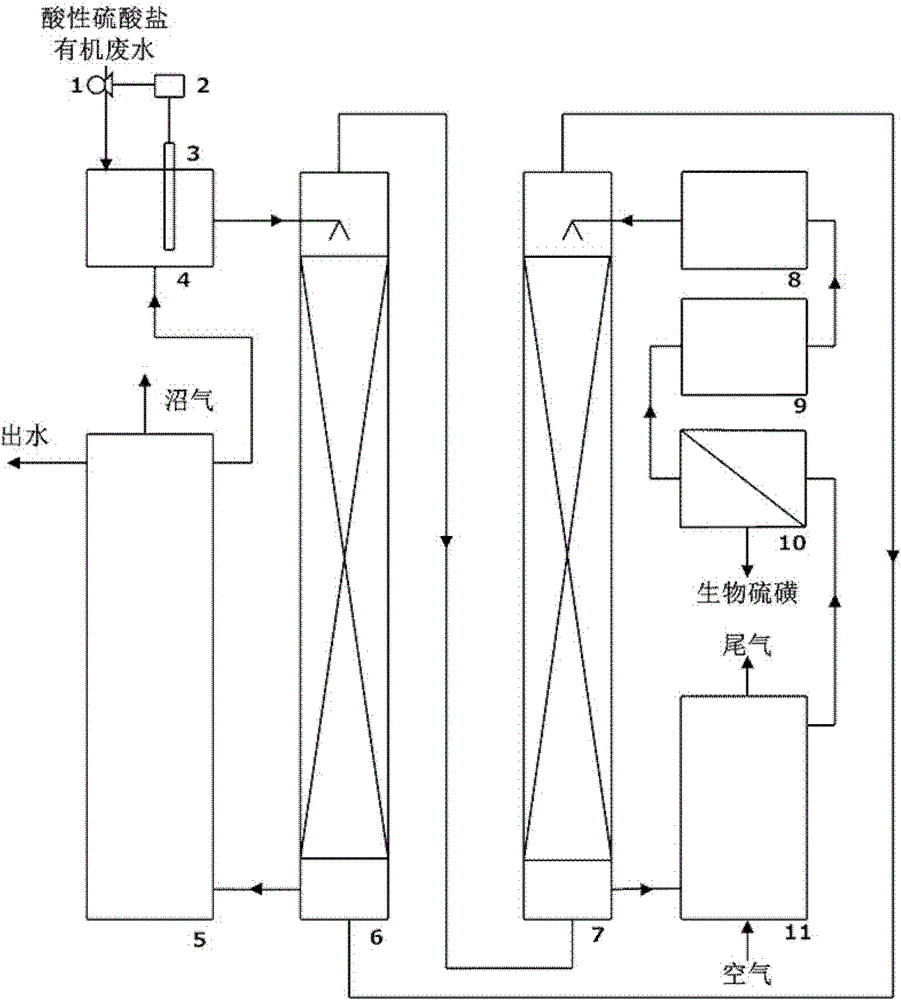

Device and method for comprehensively treating acidic sulfate organic waste water based on biological desulfurization

InactiveCN102795739AAchieving processing powerFacilitate conversion and strippingMultistage water/sewage treatmentWater basedSulfate-reducing bacteria

The invention belongs to the field of environmental engineering, and in particular relates to a device and a method for comprehensively treating acidic sulfate organic waste water based on biological desulfurization. The method comprises the following steps of: 1, reducing sulfate in the organic waste water, blowing hydrogen sulfide off, namely (1-1) mixing the acidic sulfate organic waste water and sulfide-containing recirculation water in an anaerobic digestion reactor, controlling the pH of the mixture to be 5.0 to 6.0, and thus obtaining a hydrogen sulfide-containing acidic mixed solution, and (1-2) introducing inert gas, blowing the hydrogen sulfide off, adding sulfate reducing bacteria, reducing the sulfate to form sulfide, obtaining the sulfide-containing recirculation water and returning to the step (1-1); and 2, absorbing, oxidizing and recycling the hydrogen sulfide, namely (2-1) absorbing the hydrogen sulfide blown off in the step (1-2) by using a weak alkaline solution, adding sulfur-oxidizing bacteria, oxidizing the hydrogen sulfide to form elemental sulfur, separating to obtain the elemental sulfur and effluent, and (2-2) treating the effluent for recycling. By the device and the method, sulfate innocent treatment and resource recovery treatment are realized.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

125ksi anti-hydrogen sulfide stress corrosion high-strength oil casing steel and preparation process thereof

The invention provides 125ksi anti-hydrogen sulfide stress corrosion high-strength oil casing steel and a preparation process thereof. The chemical components (% by mass) of the steel used in the present invention are as follows: 0.08-0.27% of C, 0.1-0.5% of Si, 0.15-1.8% of Mn, 0.3-1.0% of Cr, 0.4-1.0% of Mo, 0.05-0.4% of V, 0.01-0.1% of Ti, 0.1-0.7% of Cu, 0.2-3.0% of Ni, 0.0001-0.002% of B, 0-0.015% of P, 0-0.010% of S, 0-0.06% of O, 0-0.05% of N, 0-0.05% of H and the balance comprising Fe and unavoidable impurities. The yield strength of the steel grade is 862-1034 MPa, thereby meeting theinternational standard for anti-hydrogen sulfide stress corrosion NACE-A test requirements.

Owner:NORTHEASTERN UNIV

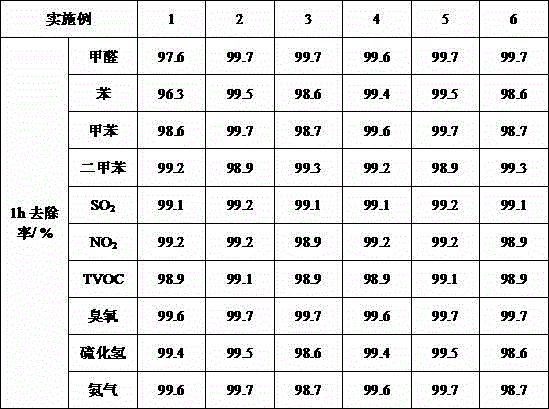

Granular non-noble-metal efficient integrated air purification composite material

InactiveCN105833842AOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystAir decontamination

The invention relates to a formula and preparation technology of a granular non-noble-metal efficient integrated air purification composite material, and belongs to the technical field of adsorption catalysis and air pollution treatment. The composite material is characterized by taking zeolite, meerschaum, a porous active carbon material, iolite or a self-made carrier as a catalyst carrier, taking one or several non-noble-metal oxides as an active component and a nitrogen-containing organic auxiliary agent, and being prepared through an immersion method. The catalyst has a column granular shape, and has the capacity of the non-noble-metal oxides being 12-15 wt% and the content of the nitrogen-containing organic auxiliary agent being 2.0-4.0 wt%. The material can effectively adsorb and purify formaldehyde, TVOC, benzene, toluene, xylene, ozone, sulfur dioxide, nitrogen dioxide, hydrogen sulfide and ammonia gas in air in an integrated manner at normal temperature and humidity, and the overall purification rate is no less than 95%. The material is suitable for places, such as offices, office buildings, living rooms, shopping malls, hospitals and hotels, for integrated air purification.

Owner:江苏瑞丰科技实业有限公司

Preparation method for hydrogenated C9 petroleum resin

The invention relates to a preparation method for a hydrogenated C9 petroleum resin. A technical point of the method is that: the method comprises a desulfurization process and a hydrogenation process. Steps of the desulfurization process comprise: pouring cyclohexane, toluene, and mixed aromatic hydrocarbon into a mixer, and completely mixing; heating the mixed resin solution, and adding the heated resin solution and hydrogen gas to a desulfurization hydrogenation reactor; carrying out a desulfurization reaction under an effect of a desulfurization catalyst; and carrying out high fraction separation, low fraction separation, gas stripping with a gas stripping tower, and hydrogen sulfide removing to obtain a desulfurization resin liquid. Steps of the hydrogenation process comprise: heating the desulfurization resin liquid, and adding the heated desulfurization resin liquid and hydrogen gas to a hydrogenation reactor; carrying out a hydrogenation reaction under an effect of a hydrogenation catalyst; carrying out high fraction separation and low fraction separation to obtain a hydrogenation resin liquid; and carrying out distillation on the hydrogenation resin liquid to obtain the hydrogenated C9 petroleum resin finished product. The desulfurization catalyst adopts cobalt and molybdenum as active ingredients, and the hydrogenation catalyst adopts nickel, tungsten and copper as active ingredients. The method of the present invention has characteristics of simple process, good decolorization effect, stable quality, wide application range, and the like.

Owner:盘锦和运新材料有限公司

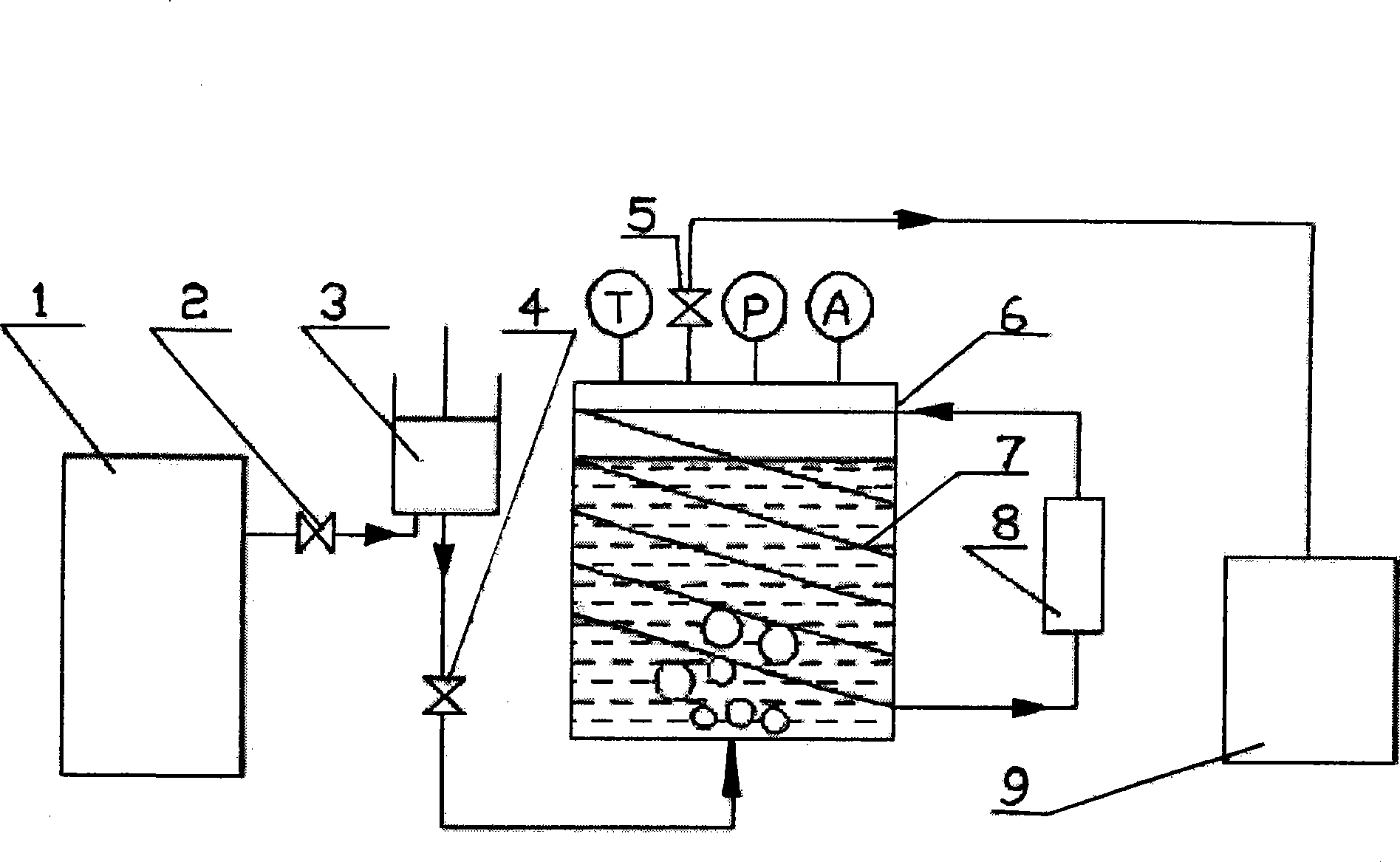

Biogas purification method and system

InactiveCN101428190AHigh purityLow purityPressurized chemical processDispersed particle separationPurification methodsLiquid water

The invention relates to a marsh gas purification method and a system thereof. The method comprises the following steps: keeping pressure below the pressure for the production of methane hydrate for the purpose of enabling carbon dioxide to react with sulfureted hydrogen to produce hydrate, and then separating methane gas from marsh gas. The marsh gas purification system comprises a marsh gas separating tank 6 and a marsh gas storage tank 1; liquid water is stored in the marsh gas separating tank 6; the marsh gas storage tank 1 is communicated with a compressor 2 through a pipeline equipped with a valve; the compressor 2 is communicated with the marsh gas separating tank 6 through a pipeline equipped with a valve; a refrigeration pipe 7 is coiled on the inner wall of the marsh gas separating tank 6; two ends of the refrigeration pipe 7 are mounted respectively on a refrigerator 8 positioned outside the marsh gas separating tank 6; the marsh gas separating tank 6 is communicated with a methane storage tank 9 through a pipeline equipped with a valve; and a marsh gas sampler A, a pressure sensor P, and a temperature sensor T are separately mounted on the marsh gas separating tank 6.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

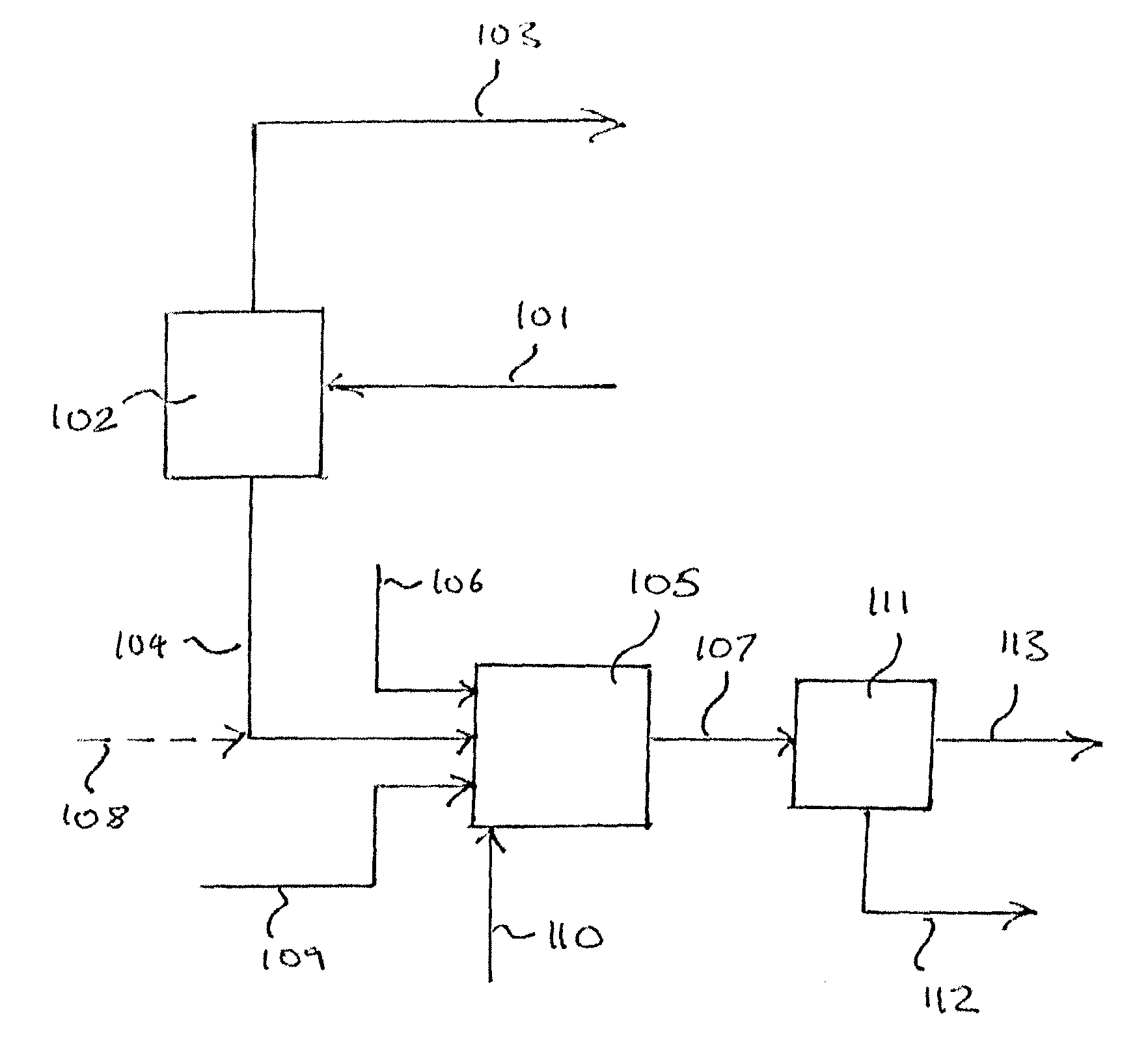

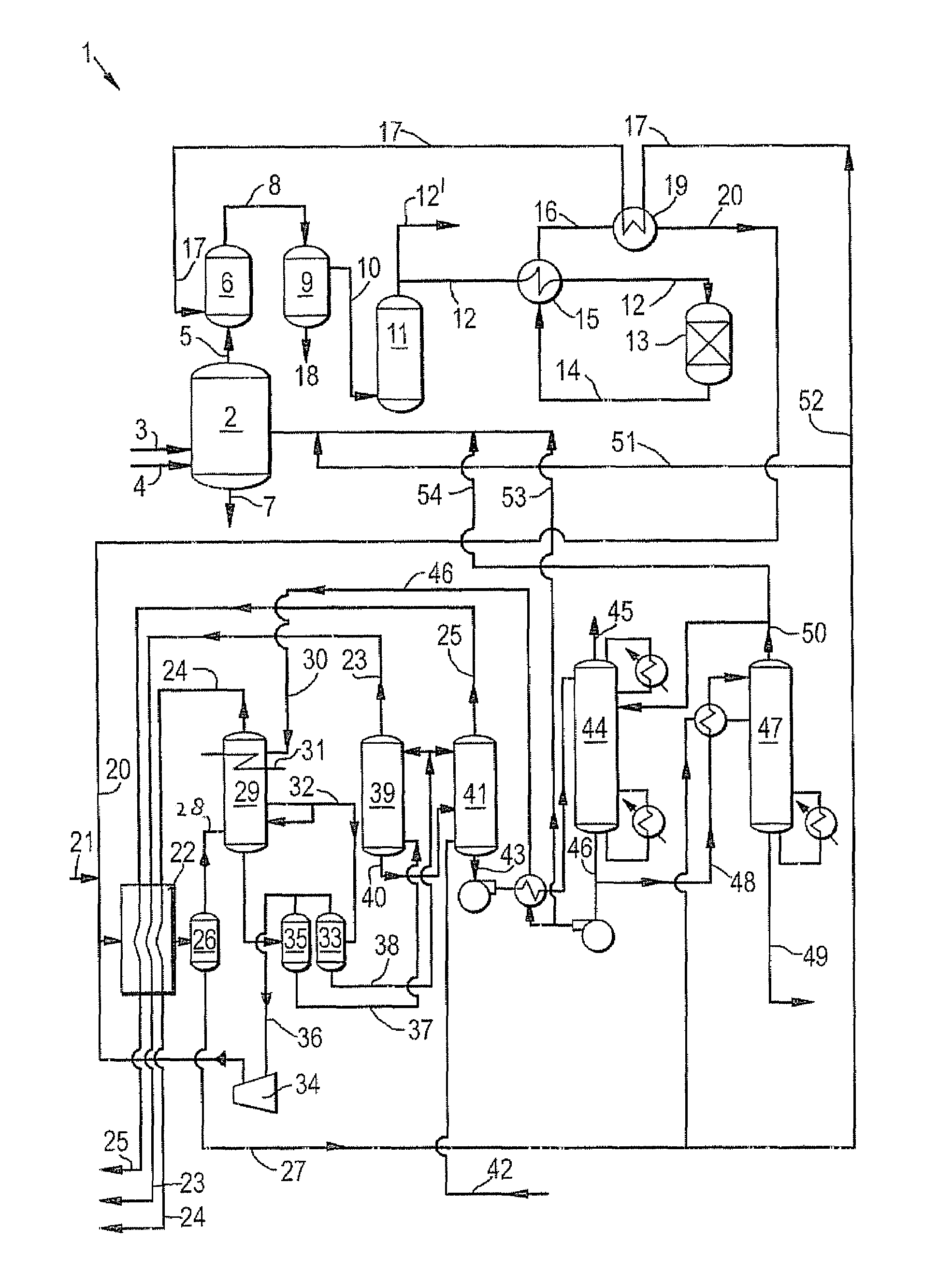

Process for producing a purified synthesis gas stream

InactiveUS20090183431A1Prevent buildupBuildProductsHydrocarbon from carbon oxidesMethanol waterPartial oxidation

A process for producing a purified synthesis gas stream from a carbonaceous feedstock, the process comprising the steps of(a) partial oxidation of the carbonaceous feedstock with a molecular oxygen comprising gas to obtain a synthesis gas comprising water, hydrogen sulphide, and carbon dioxide besides the main constituents carbon monoxide and hydrogen,(b) mixing the synthesis gas and methanol and reducing the temperature of said mixture and separating a liquid methanol-water mixture from a cooled gaseous synthesis gas,(c) contacting the cooled synthesis gas obtained in step (b) with methanol to decrease the content of hydrogen sulphide and carbon dioxide in the synthesis gas, thereby obtaining a rich methanol stream comprising hydrogen sulphide and carbon dioxide and a synthesis gas stream depleted in hydrogen sulphide and carbon dioxide;(d) regenerating the rich methanol stream of step (c) by separating from the rich methanol a carbon dioxide fraction and a hydrogen sulphide fraction to obtain lean methanol, which lean methanol is used as methanol in step (b) and / or (c), and wherein(e) part of the methanol in the methanol-water mixture obtained in step b) is isolated and reused in step (b) and / or (c) and wherein,(f) another part of the methanol in the methanol-water mixture obtained in step (b) is recycled to step (a) under conditions such that methanol is converted into carbon monoxide and hydrogen.

Owner:SHELL OIL CO

Gas chromatograph column with carbon nanotube-bearing channel

A carbon nanostructured micro-fabricated gas chromatography column which is particularly well-suited to the surface well-site and / or the downhole analysis of natural gas in oilfield or gasfield applications (but which may also be used in non-oilfield or non-gasfield situations) is described. This micro-fabricated column integrates a micro-structured substrate such as a silicon substrate with carbon nanotubes as an active nanostructured material in a micro-channel. Benefits of the present invention include enhanced separation of alkanes and isomers, particularly below hexane (i.e., below C6), as well as the separation of carbon dioxide, hydrogen sulfide, and water and other substances present in natural gas. The chromatography column of the present invention is in one embodiment a part of an entire gas chromatograph system that in its simplest form also comprises an injector and a detector. Preferably the injector, separation column, and detector are all micro-fabricated on a substrate.

Owner:SCHLUMBERGER TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com